Patents

Literature

132results about How to "Guaranteed combustion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

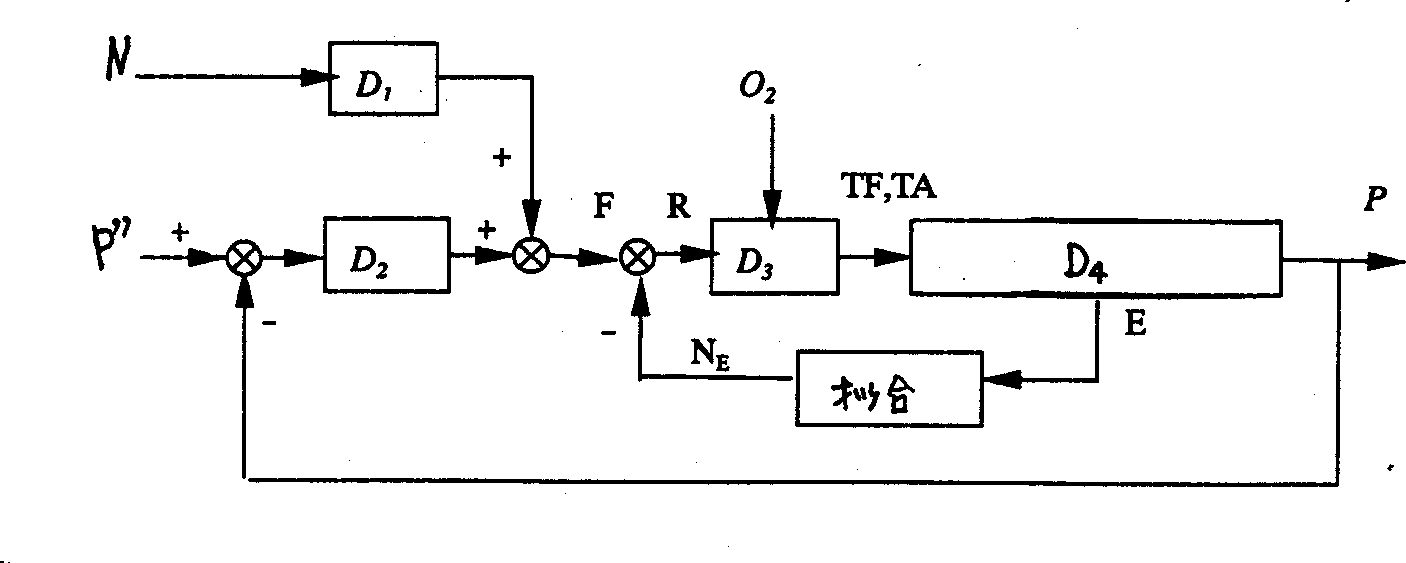

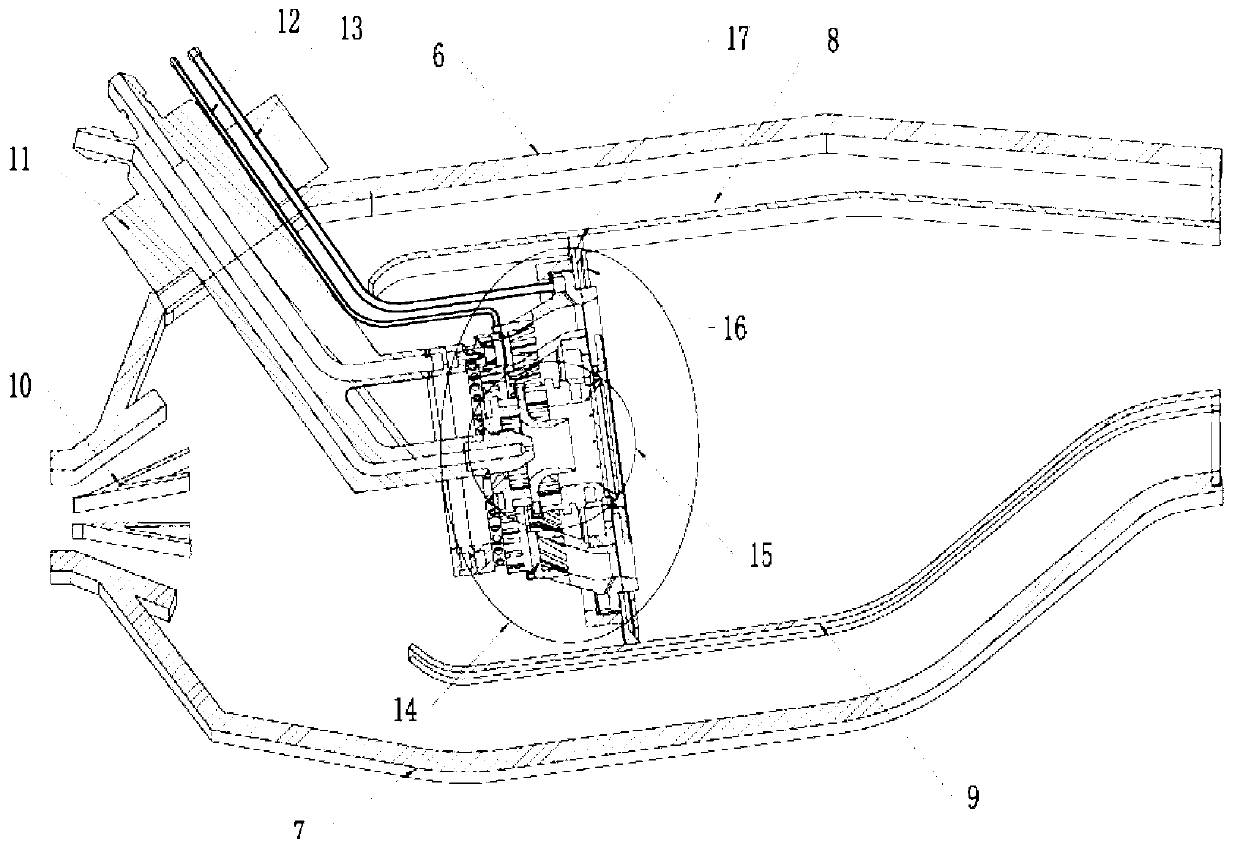

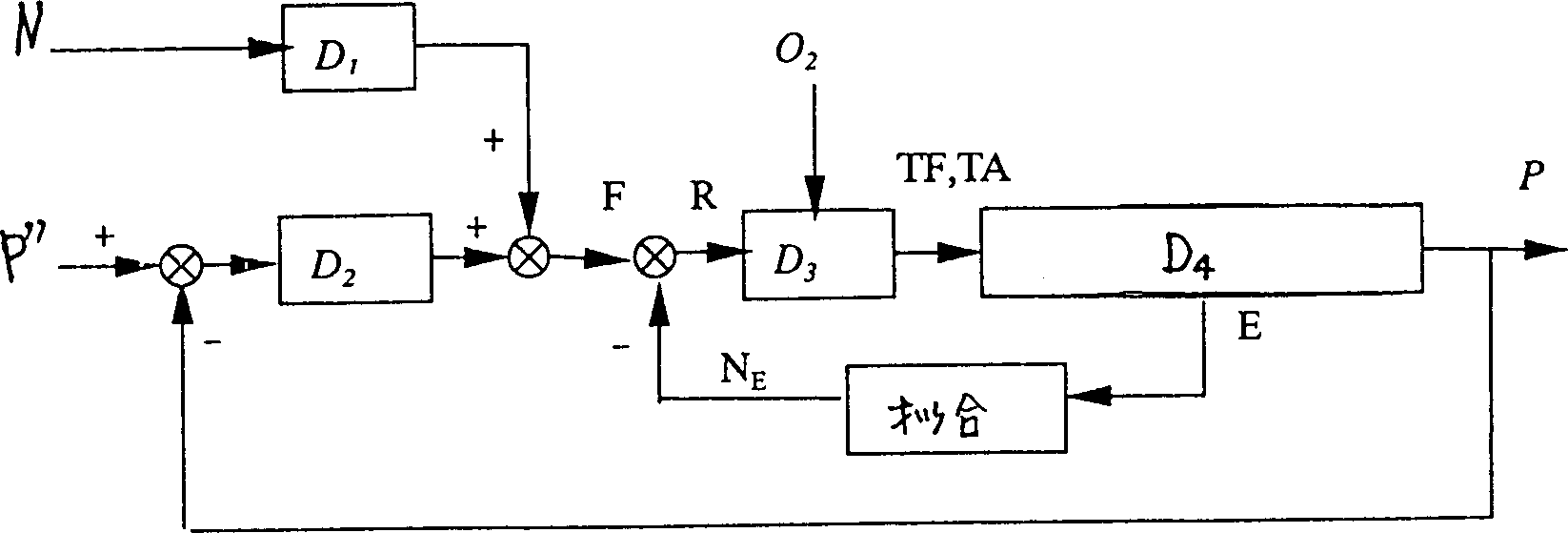

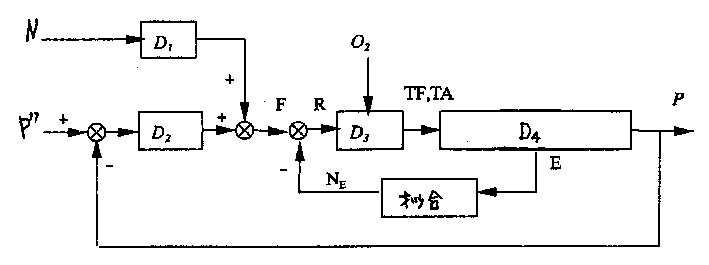

Optimized control method of combustion in multiple fire nozzle hearth of boiler

The present invention belongs to the combustion controlling technology of boiler hearth, especially of multiple fire nozzle hearth, and is suitable for the combustion monitoring of combustion in a four corner-rounded boiler. The present invention relates optimized efficient low nitrogen oxide exhaust control by arranging several flame image detectors to obtain the 3-D temperature distribution in hearth and through fitting the expression between radiation energy E and power generating load NE of the poer set, measuring the flame center height and the change rules of flame section temperature center with fuel amount and blast distribution proportion in different layers and different corners, and giving control command of fuel amount and blast distributino proportion in different layers and different corners according to boiler load, fuel amount and blast amount.

Owner:HUAZHONG UNIV OF SCI & TECH

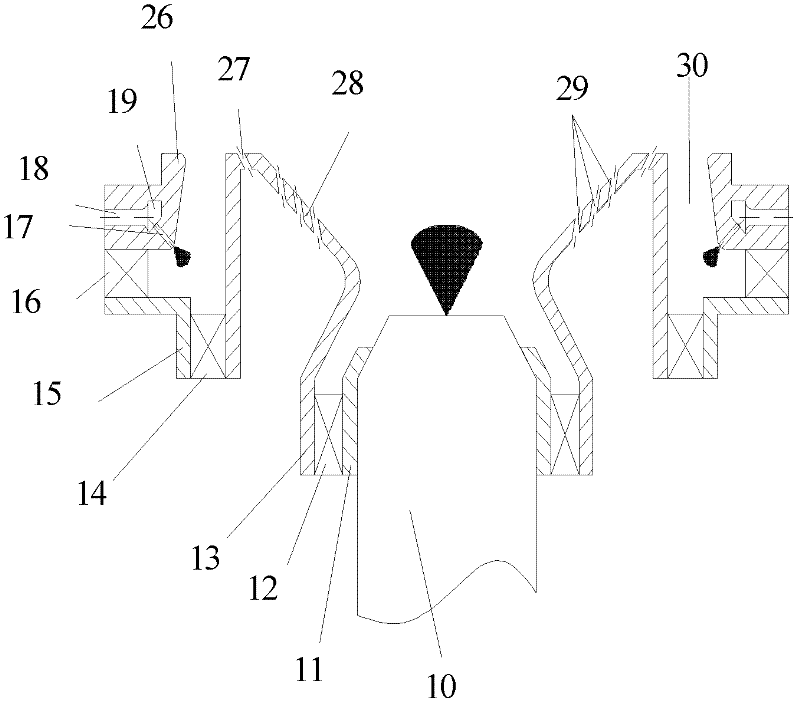

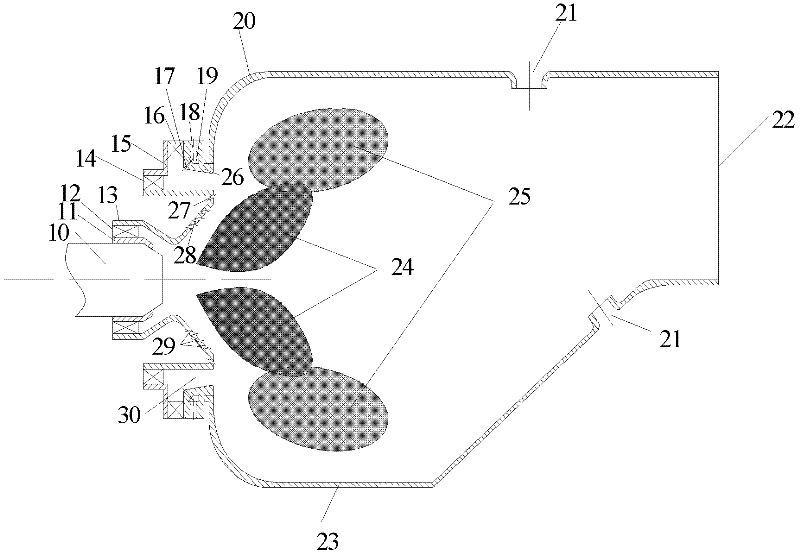

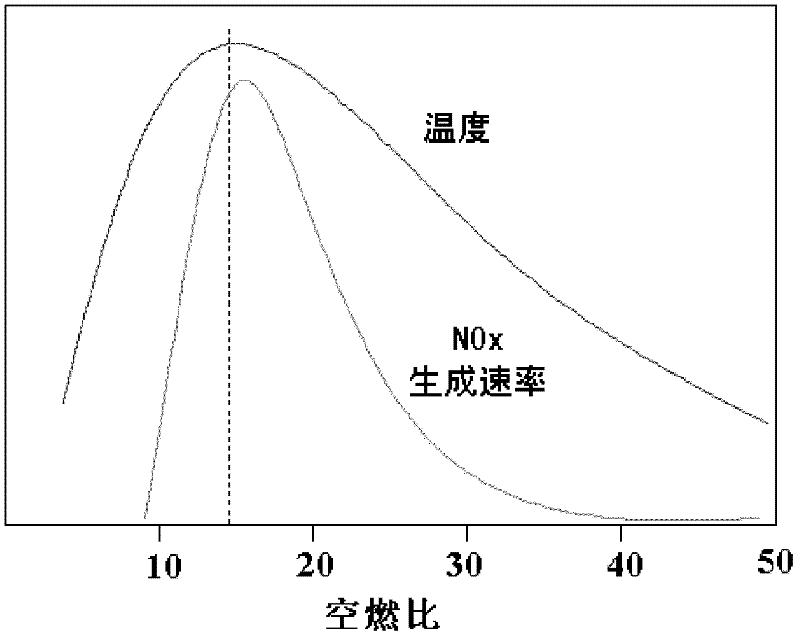

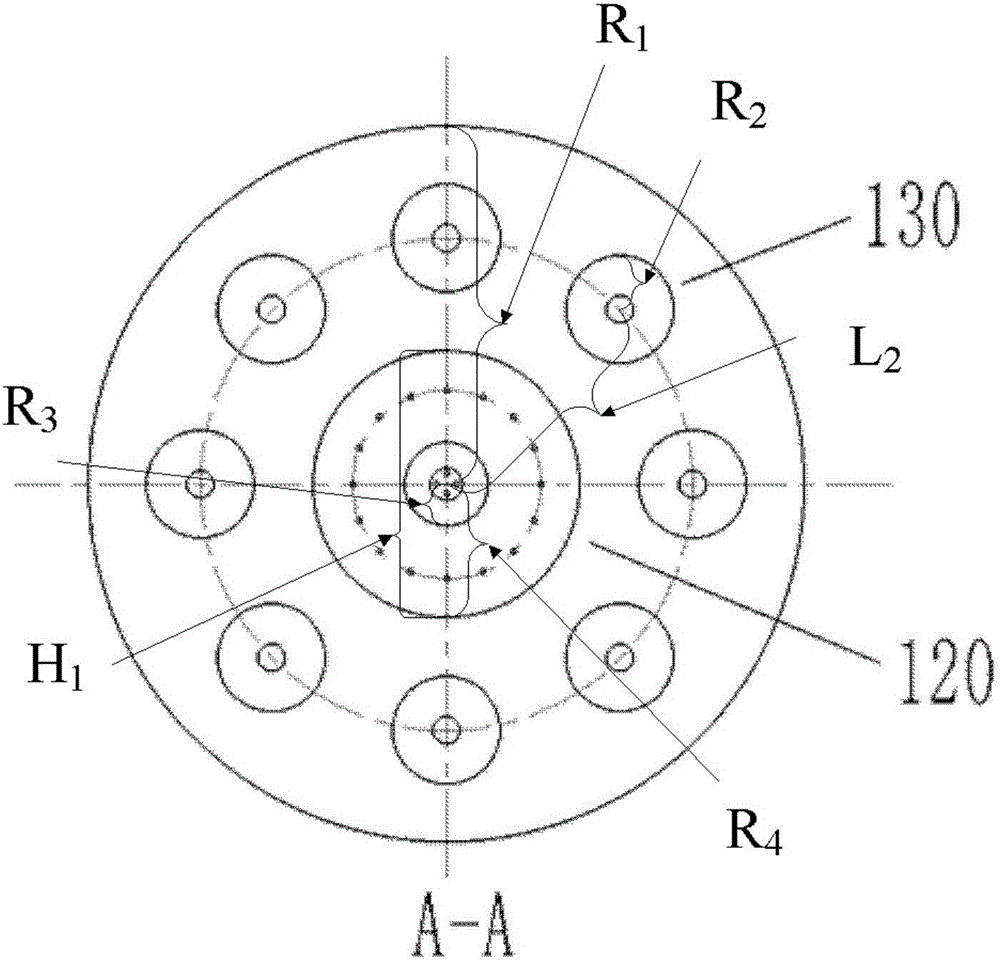

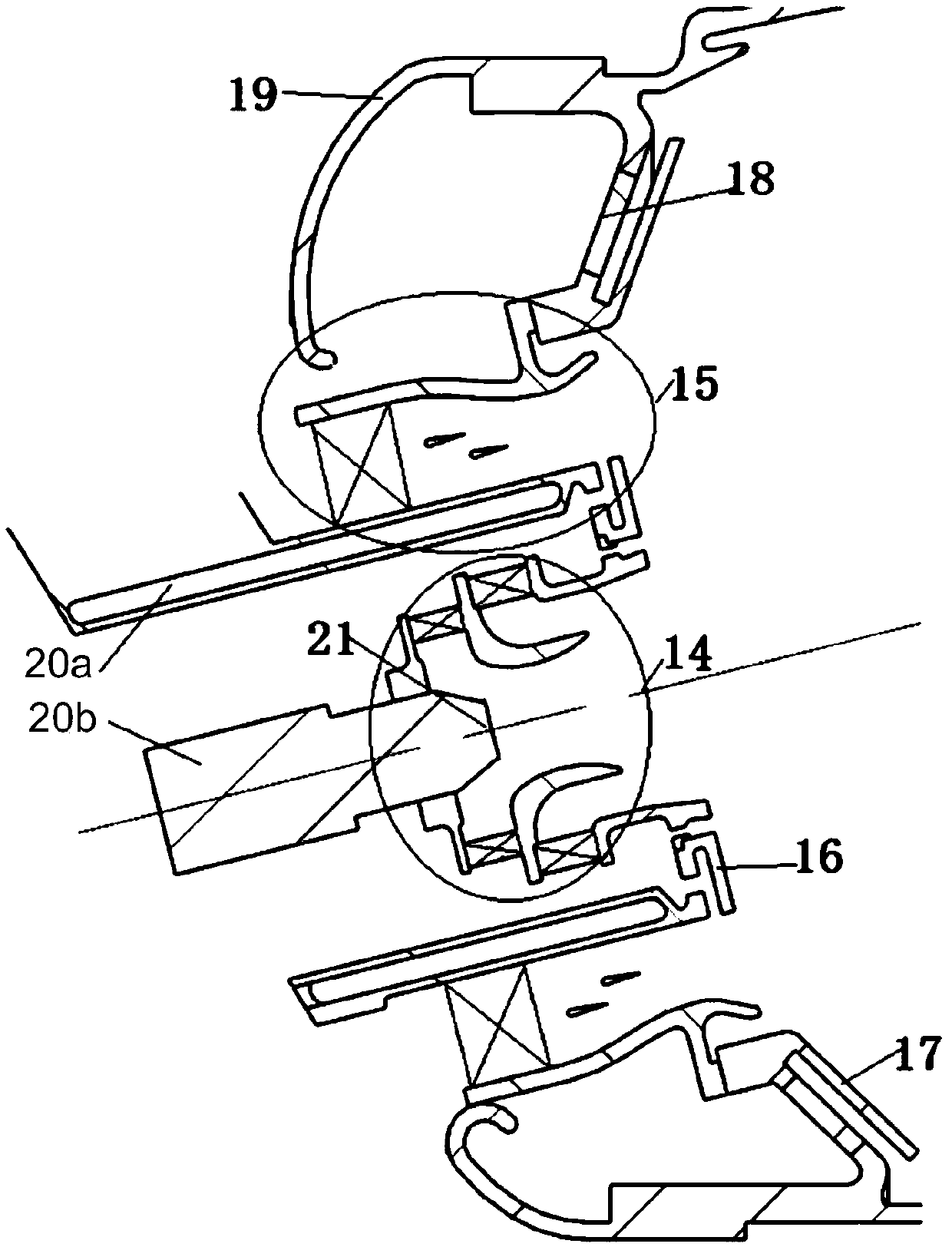

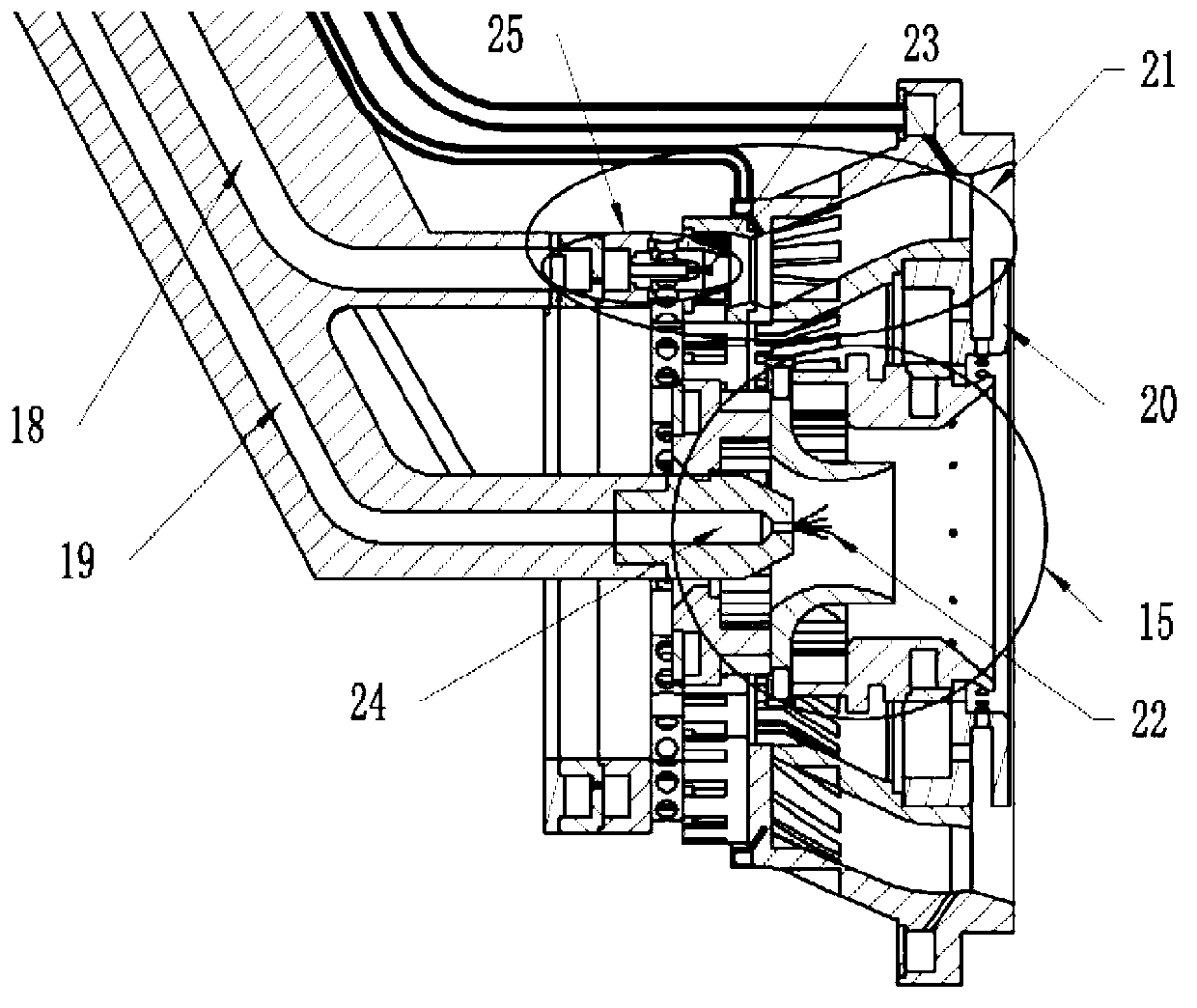

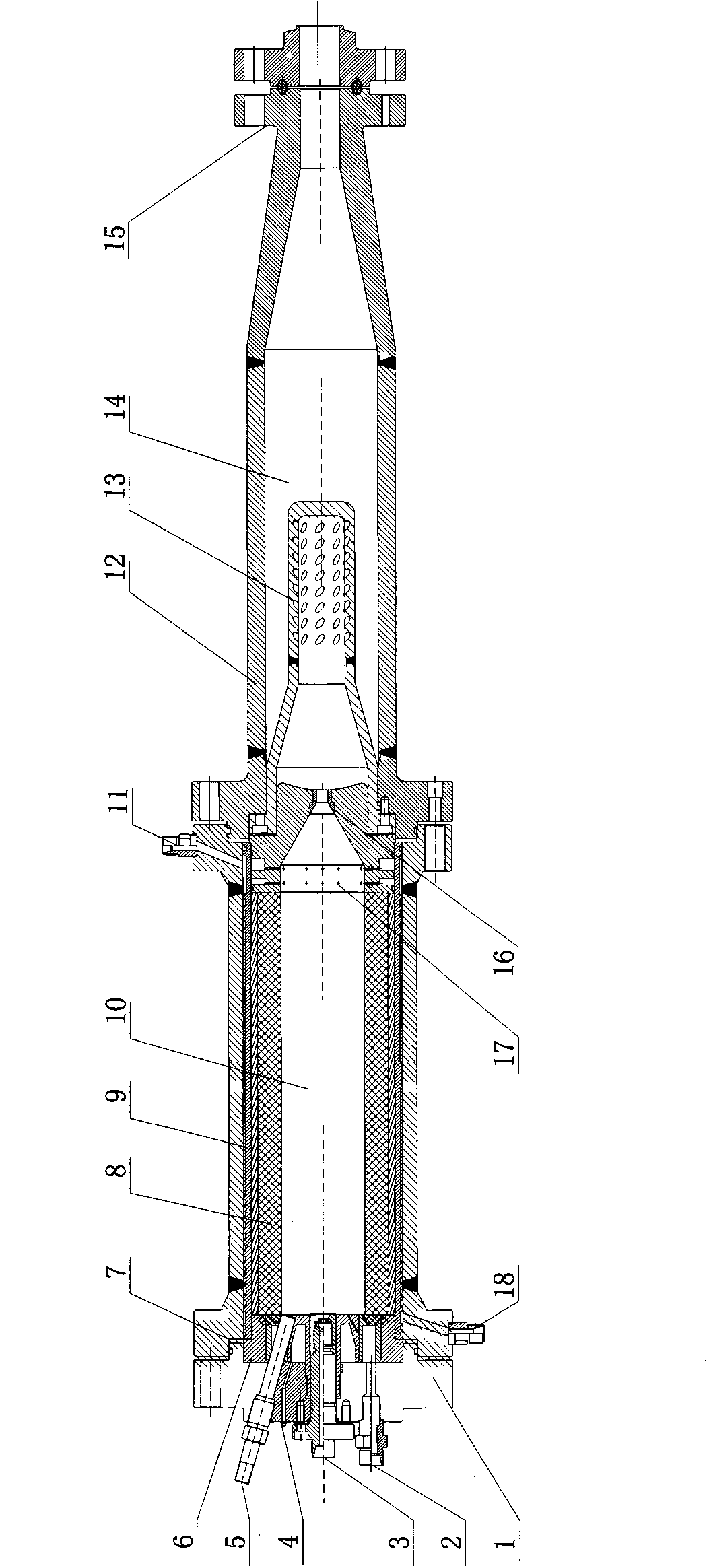

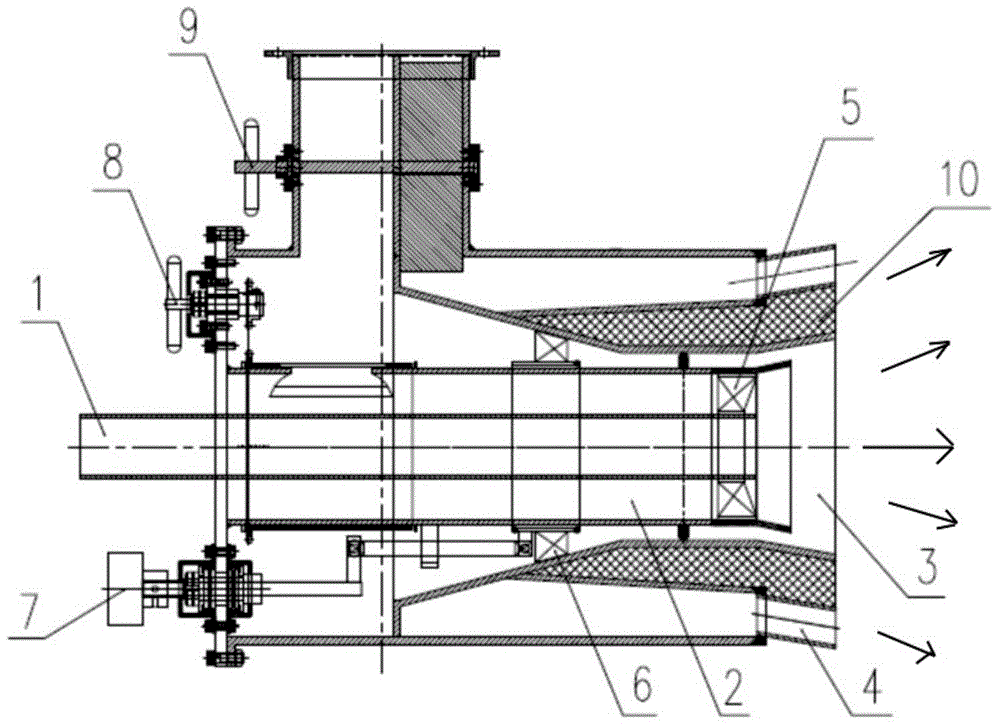

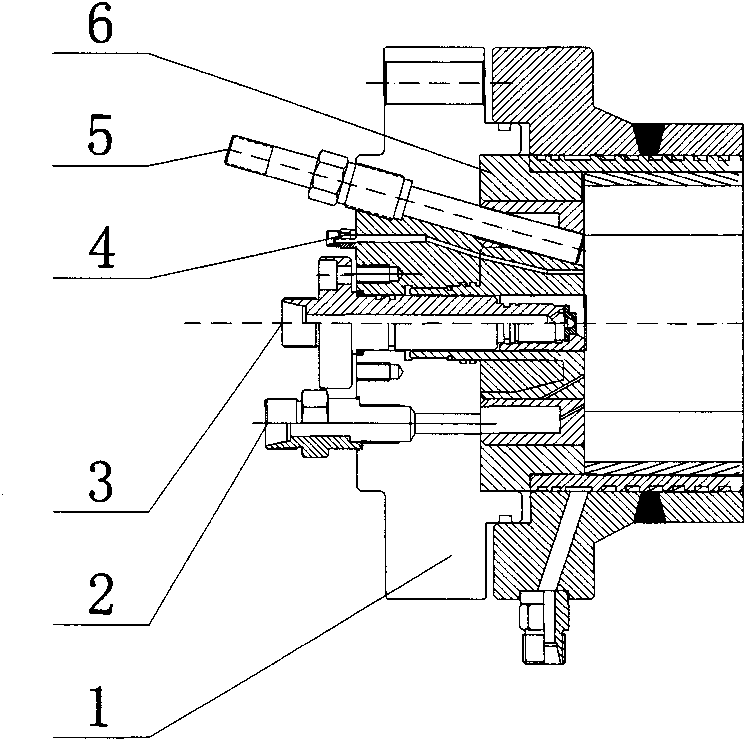

Fuel and air mixing device for low-pollution burning chamber of gas turbine

ActiveCN102506446AFast evaporationQuick blendContinuous combustion chamberIndustrial gasCombustion chamber

The invention discloses a fuel and air mixing device for a low-pollution burning chamber of a gas turbine. Fuel comprises a main burning level and a duty burning level; and air is supplied by a three-stage cyclone. The fuel and air mixing device is characterized in that the central duty level adopts diffusive burning, and the peripheral main burning level adopts premixing or semi-premixing burning. The central duty level consists of a centrifugal atomizing nozzle and first-stage cyclone air; and the rotating directions of the first-stage cyclone air and second-stage cyclone air are opposite. The fuel of the main burning level is supplied by a multipoint direct-injection type nozzle, the air is respectively supplied by the second-stage cyclone air and third-stage cyclone air, and the rotating directions of the second-stage cyclone air and third-stage cyclone air are opposite. The central duty level is used when in low working conditions such as starting and slowing and the like, so that the stable burning range can be widened, the burning efficiency can be improved and the emission of CO and UHC is reduced; and when in large working conditions, the duty level and the main burning level work simultaneously, the duty level provides a stable ignition source for the main burning level, a main burning area is in a lean-oil state, and the temperature is far lower than the temperatureof insulated flame, so that the emission of NOx under the large working conditions can be obviously reduced. The fuel and air mixing device can be used for an aerial gas turbine engine or an industrial gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

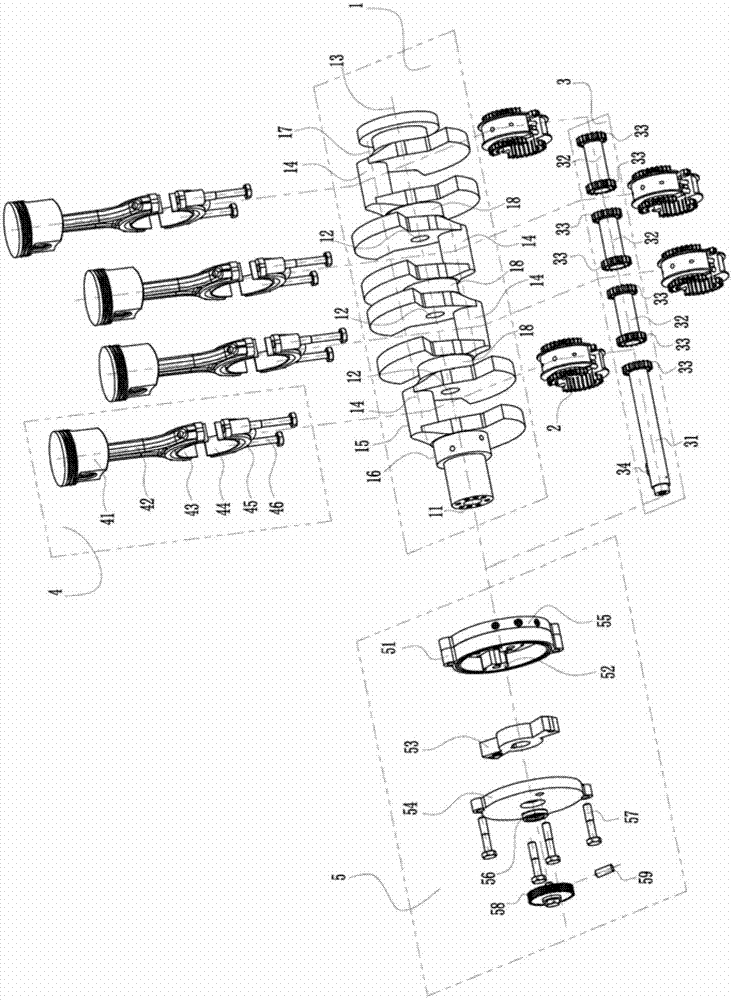

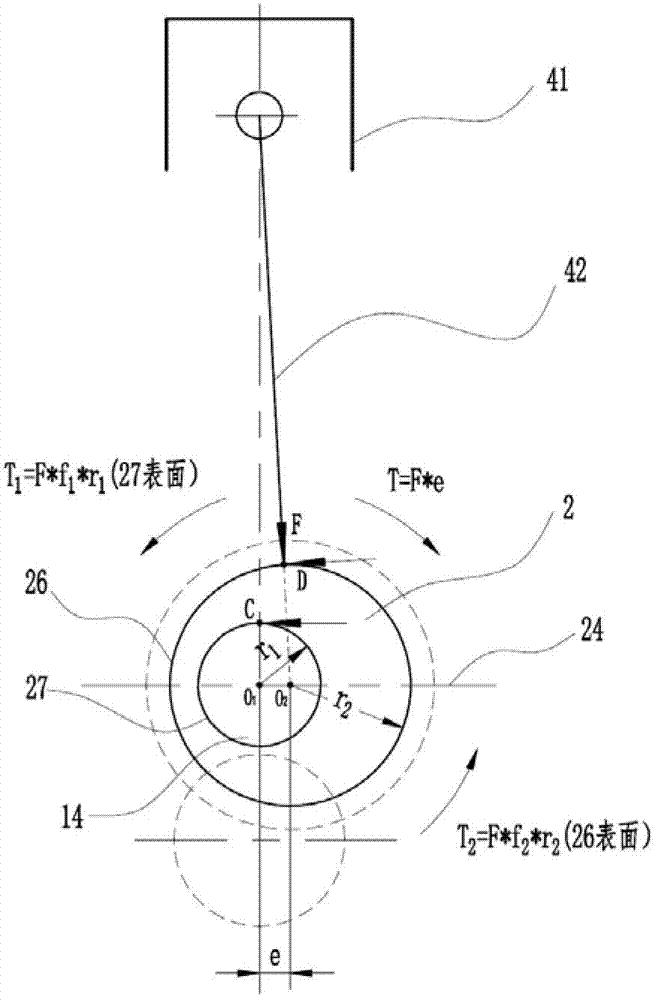

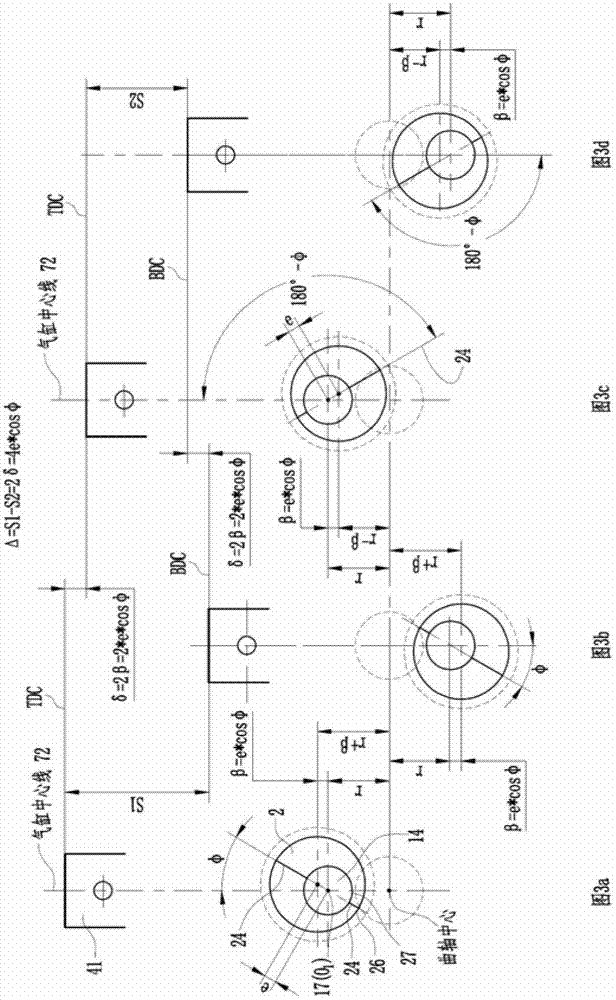

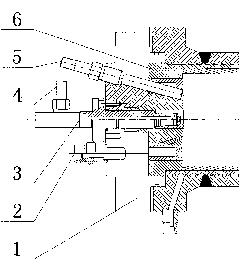

Variable compression ratio device with self-locking structure

InactiveCN102889142AAvoid destructionImprove reliabilityEngine controllersMachines/enginesTransmission systemSelf locking

The invention discloses a variable compression ratio device with a self-locking structure for an engine. The device comprises an eccentric shaft sleeve assembly, a transmission shaft, a gear assembly, a driver assembly and a control valve assembly, and the structure meets the first self-locking condition that f1*r1+f2*r2 is more than or equal to e. The variable compression ratio device has the self-locking capacity in a crank angle area of engine explosion pressure pulse, the huge explosion pressure of the top of a piston can be borne, the pressure is not transmitted to a transmission system, the structural damage is reduced, and the reliability of the device is improved; and the compression ratio of each cylinder can be accurately and synchronously adjusted through low driving torque only outside the crank angle area of explosion pressure pulse, so that the engine always operates at the highest efficiency regardless of conditions of full load or partial load. The variable compression ratio device has the advantages of convenience in adjustment and control, low power consumption, simple structure and low cost and is suitable for various engines.

Owner:沈大兹

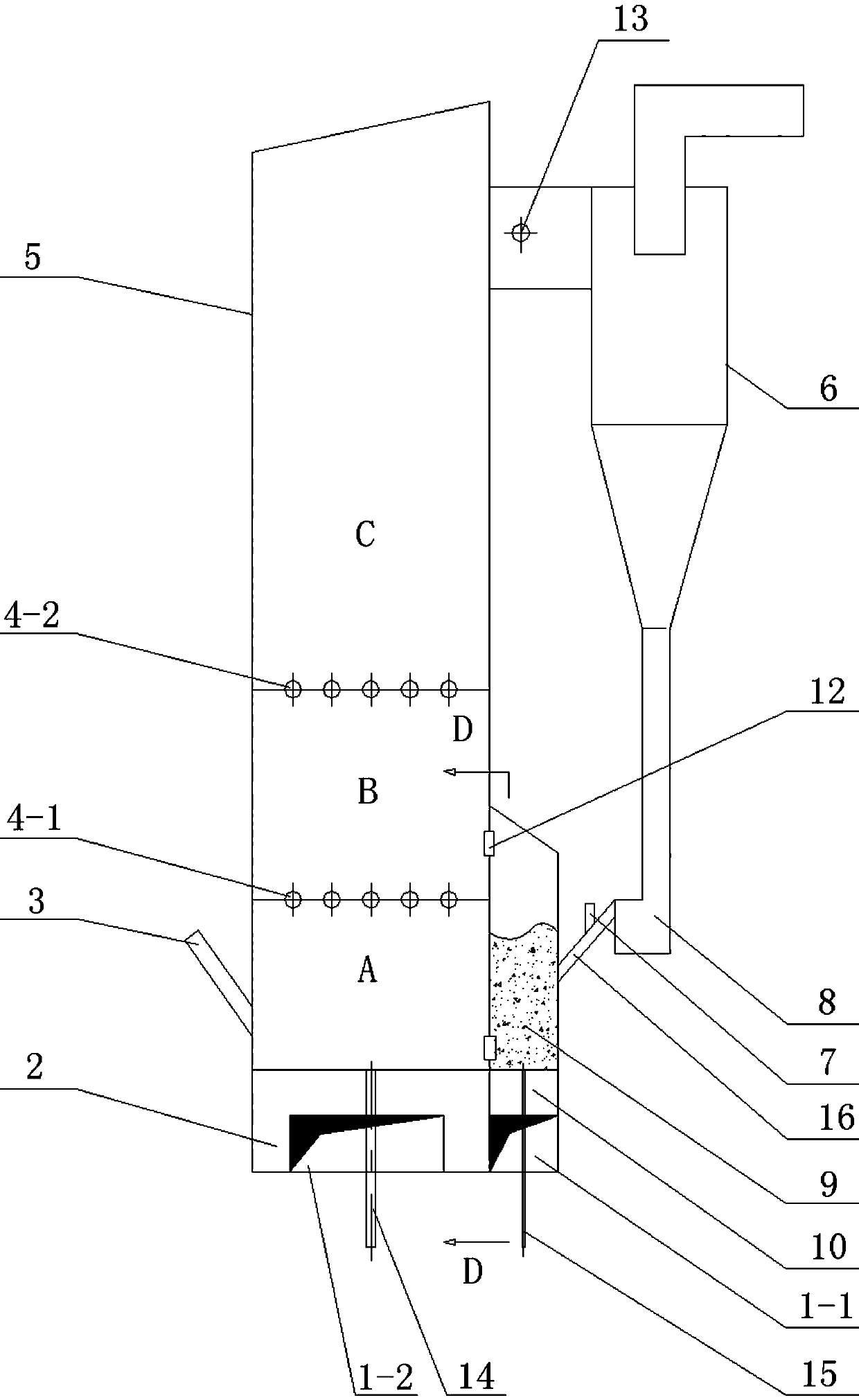

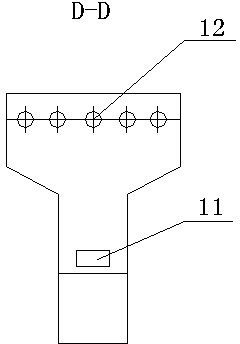

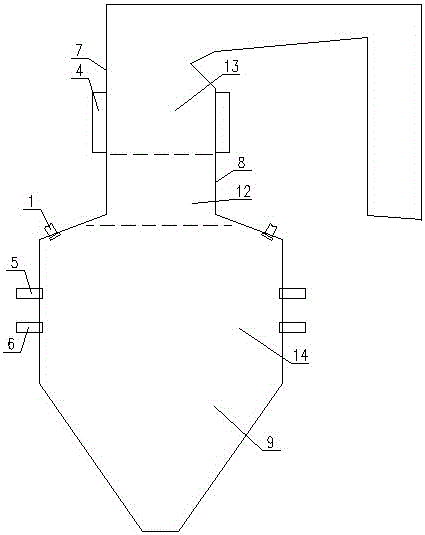

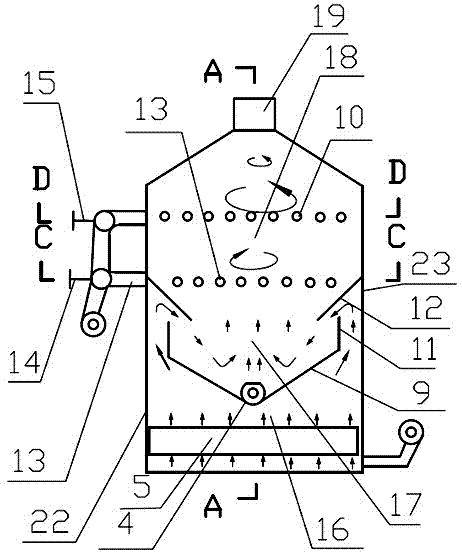

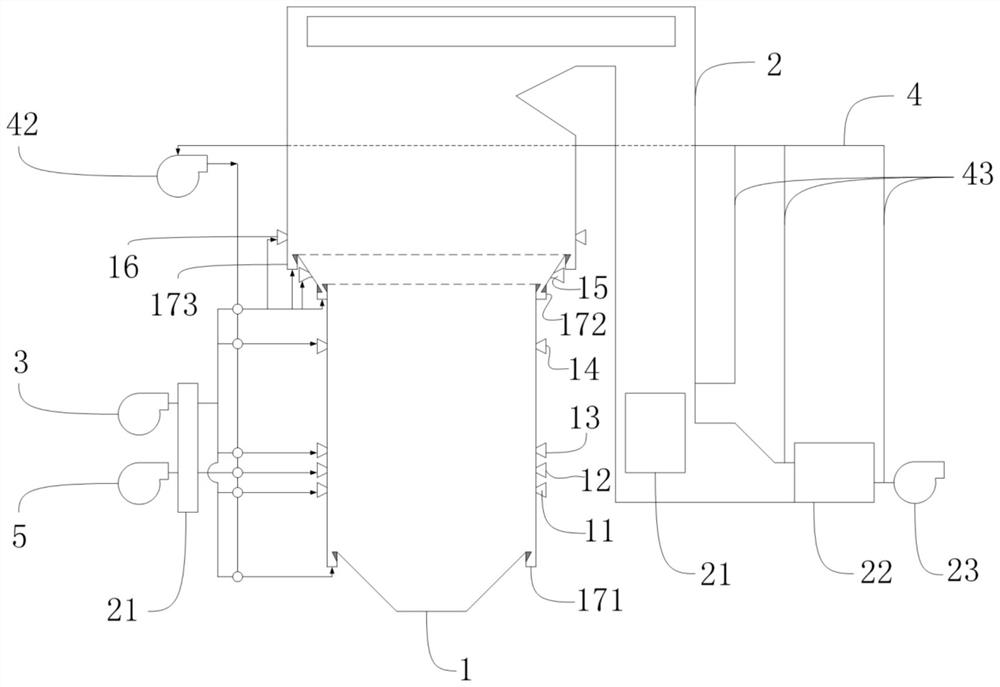

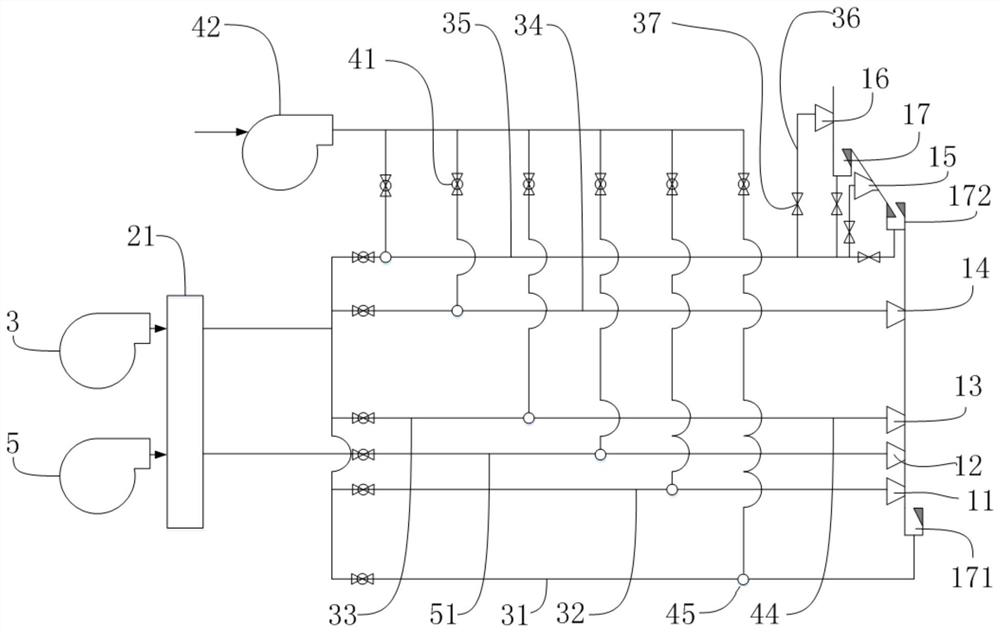

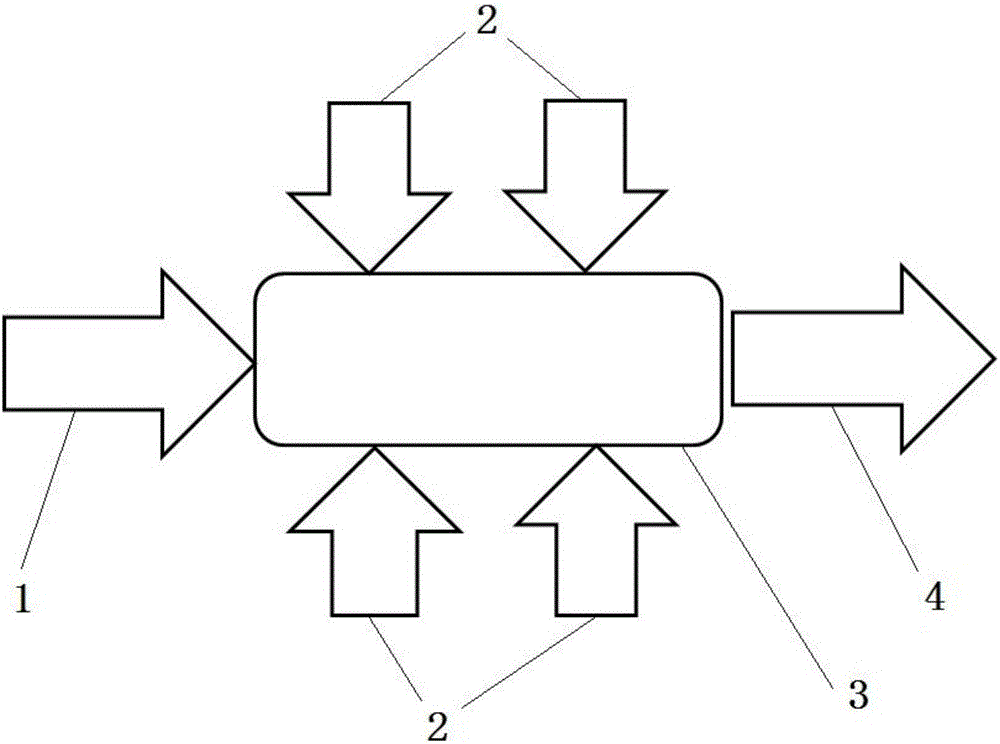

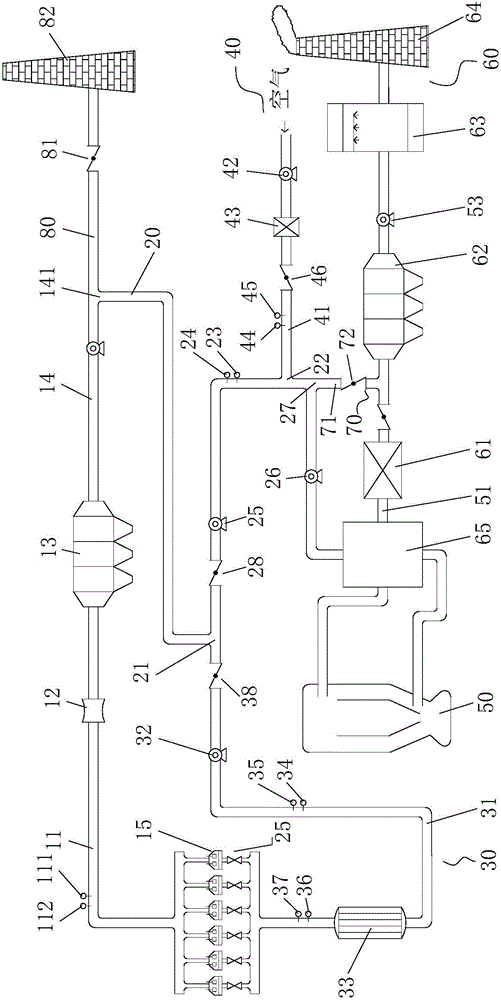

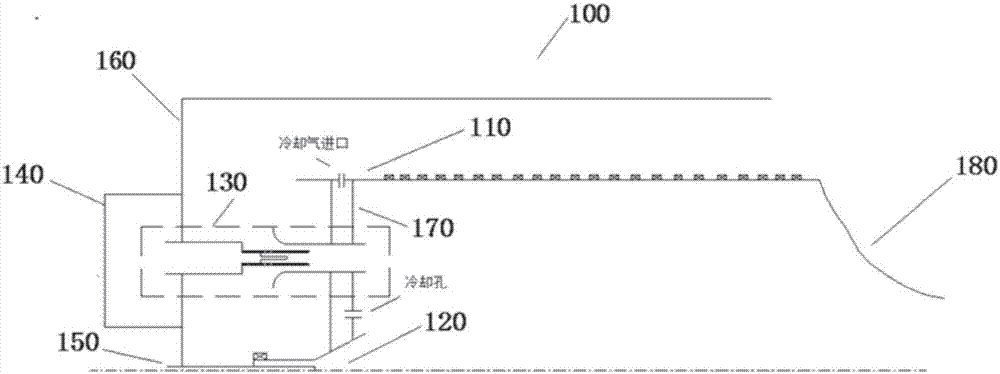

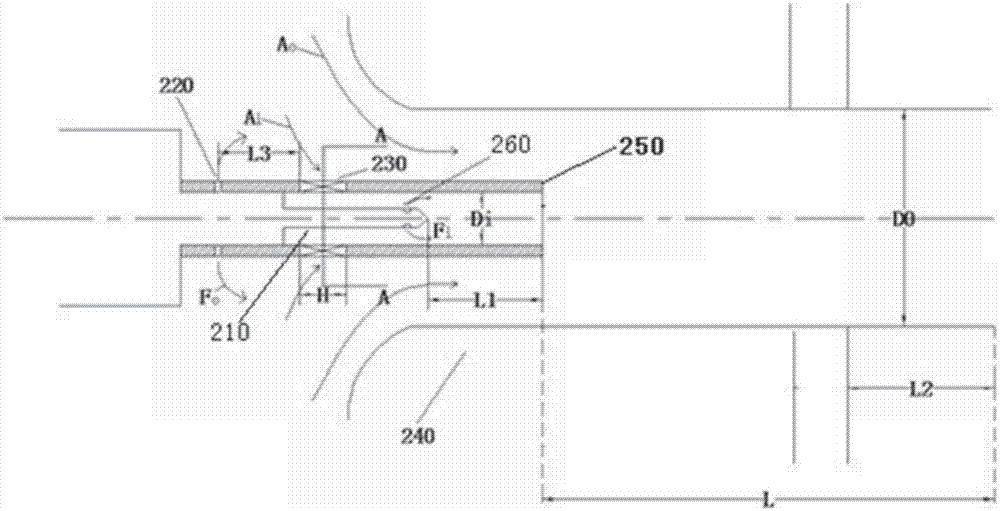

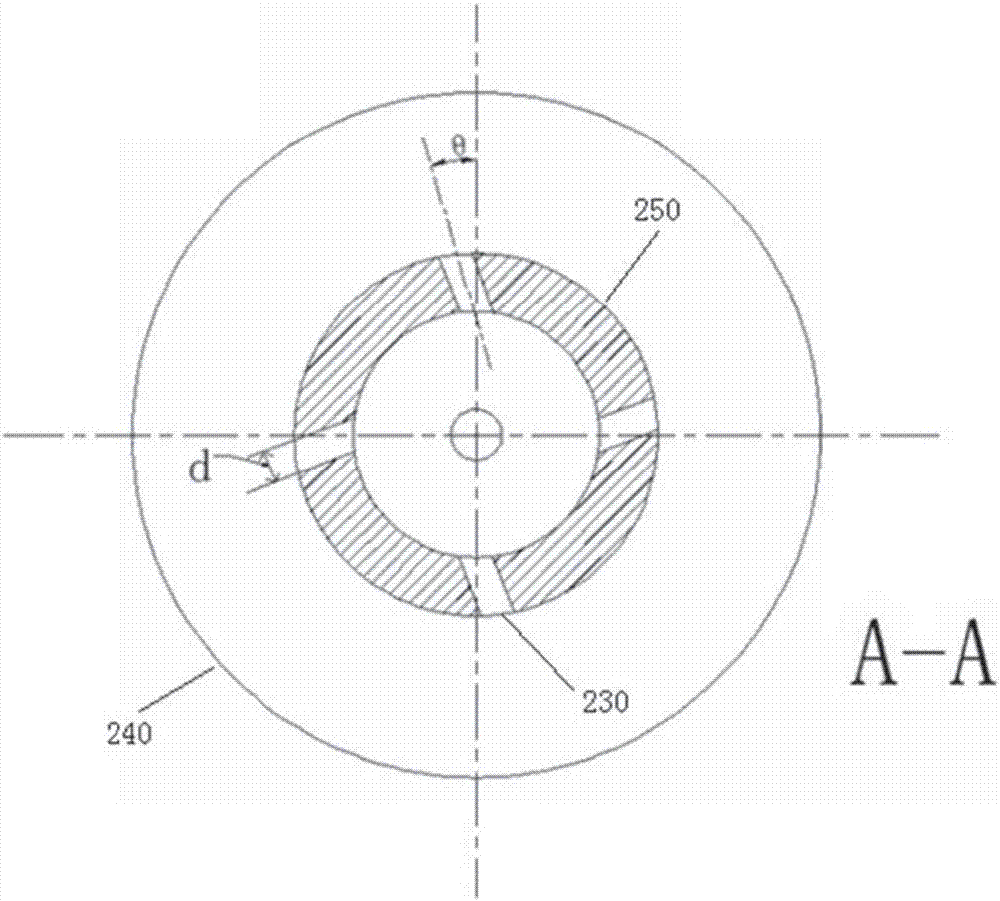

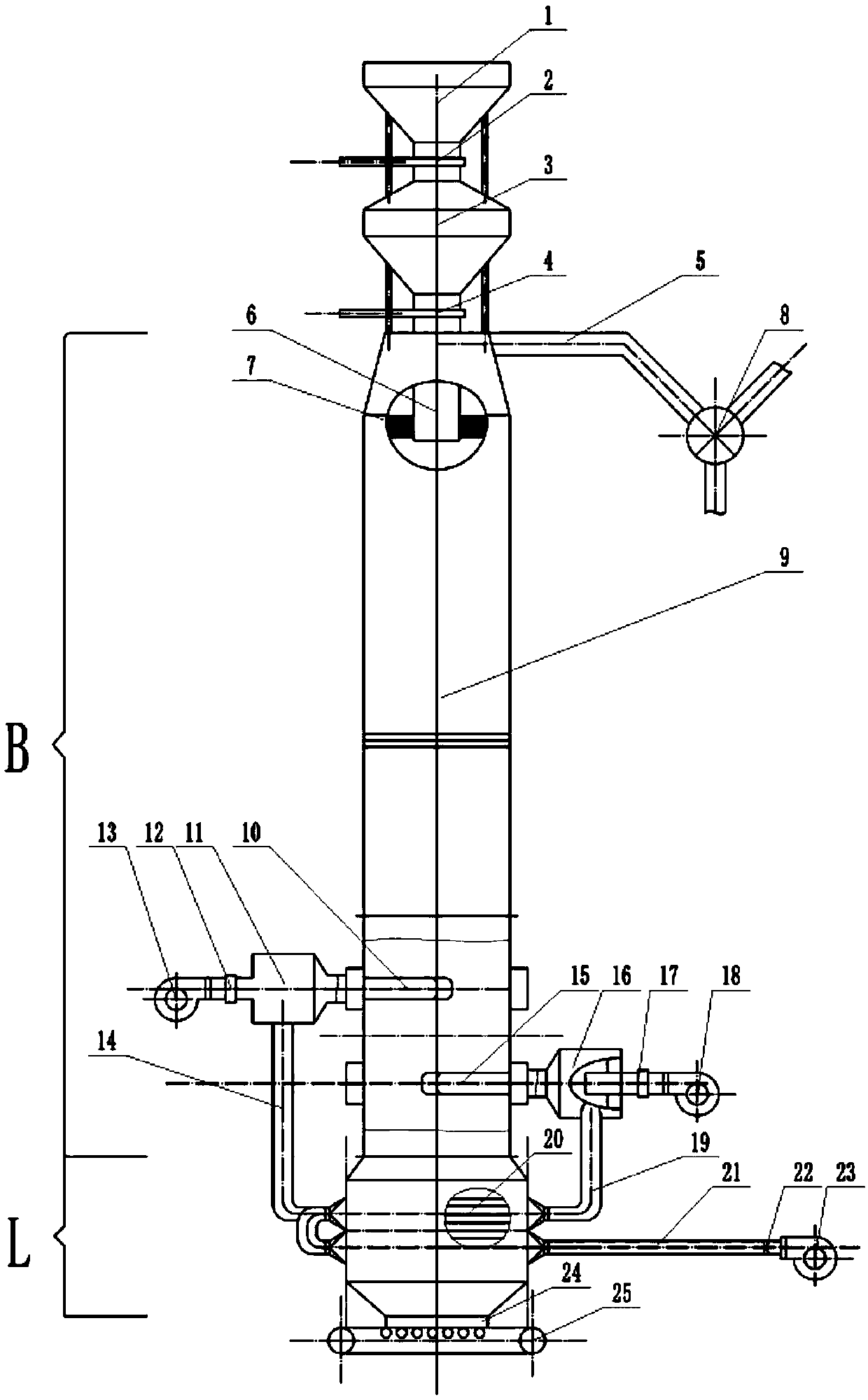

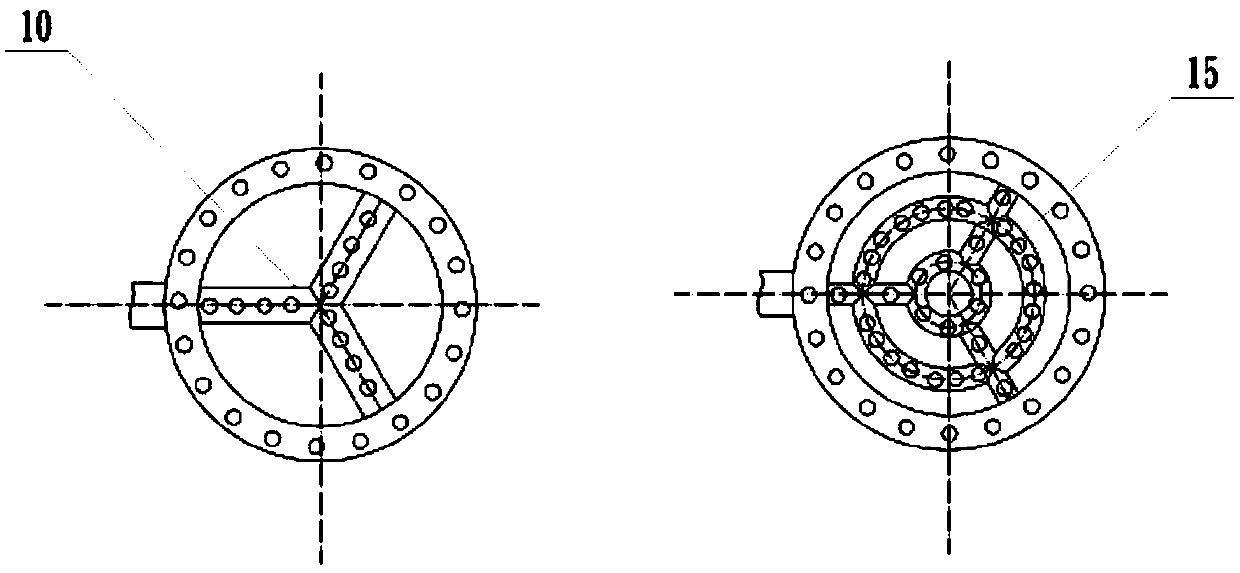

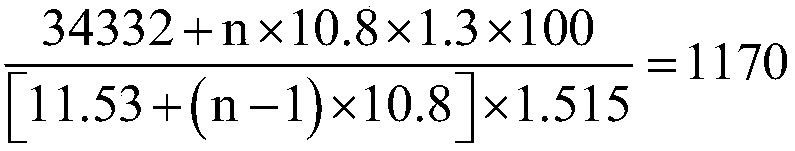

Device and method for controlling NOx of circulating fluidized bed by coupling air staging and fuel staging

ActiveCN104879748AGuaranteed combustion efficiencyReduce emissionsFluidized bed combustionEmission preventionAutomotive engineeringBurning out

The invention relates to a device and a method for controlling NOx discharge of a circulating fluidized bed by coupling air staging and fuel staging, and belongs to the technical field of circulating fluidized beds. According to the device and the method, the fuel staging and the air staging are combined, fuel gas generated by the circulating fluidized bed is taken as reburning gas, so that the cost is low, and the NOx discharge during running process of the circulating fluidized bed is effectively reduced. A vaporizing chamber and an air chamber of the vaporizing chamber are arranged outside the rear wall of a furnace body, a fuel gas inlet communicated with the furnace body and the vaporizing chamber is formed in the rear wall of the furnace body, a burn-out area outlet of the furnace body is communicated with a cyclone separator, the bottom of the cyclone separator is communicated with the vaporizing chamber through a return valve and a connecting pipe. Secondary fuel is added to a material inlet, and is mixed with a high-temperature circulating material in the vaporizing chamber to obtain a mixed material; air is supplied to the vaporizing chamber from the bottom of the vaporizing chamber, the mixed material is fluidized, the generated fuel gas enters the furnace body, a reburning area with a reducing atmosphere is formed at the upper end of a main combustion area, and NOx generated in the main combustion area is reduced into N2. The device and the method are used for controlling the NOx discharge of the coal-fired circulating fluidized beds.

Owner:HARBIN INST OF TECH

Method for reducing nitrogen oxide of powder coal boiler mixed burning gas fuel

InactiveCN101050853AGuaranteed combustion efficiencyEmission reductionCombustion using gaseous and pulverulent fuelBurnersOxygenMixed gas

A method for decreasing nitrogen oxide of mixed gas fuel used on pulverized-coal boiler includes dividing gas fuel to be two grades then leading them into pulverized-coal furnace tank, leading in primary gas fuel as combustion-assistant fuel at bottom of master burner at master combustion region to burn it by utilizing gradation air-combustion technique with low air overdose parameter, leading in secondary gas fuel at top of master combustion region to form reducing atmosphere of re-combustion region and leading in burn out air at top of re-combustion region.

Owner:HARBIN INST OF TECH

Face-fired boiler advanced denitration burning method

ActiveCN106247320AReduce concentrationLower emission valueCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlue gasHearth

The invention discloses a face-fired boiler advanced denitration burning method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of turbulent burners in each of layers of turbulent burners arranged on a front wall and a rear wall and is burnt, secondary air is introduced through secondary air nozzles of the turbulent burners, over fire air is introduced through one or more layers of over fire air nozzles on the front wall and the rear wall, the primary air and the secondary air on the front wall and the rear wall are oppositely introduced, the excess air coefficient range of the main burning area of the turbulent burners is 0.5-1.05, and the fire coal undergoes low oxygen burning; the excess air coefficient range of the over fire area of the over fire air nozzles is 1.05-1.3, and oxygen rich burning is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over fire layer to reduce nitrogen oxides in flue gas in high temperature environment in the hearth and inhibit generation of new nitrogen oxides. The face-fired boiler advanced denitration burning method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

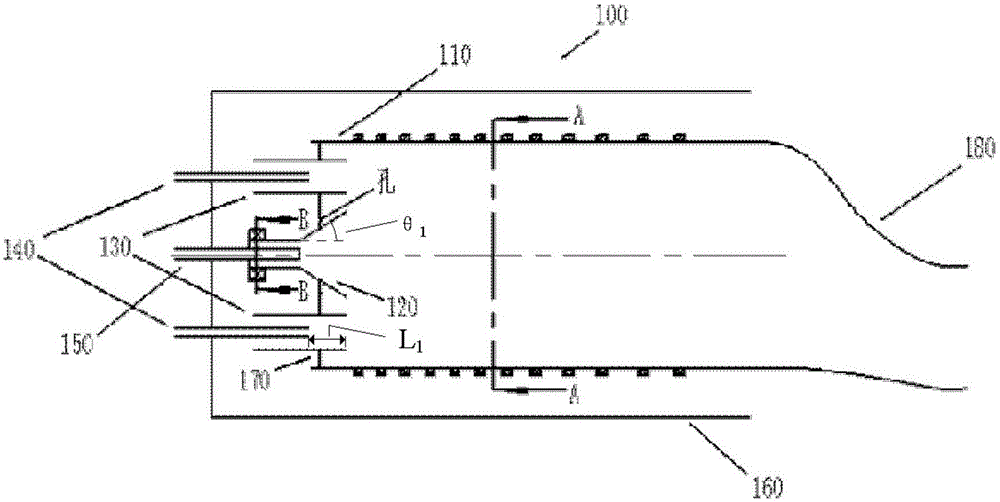

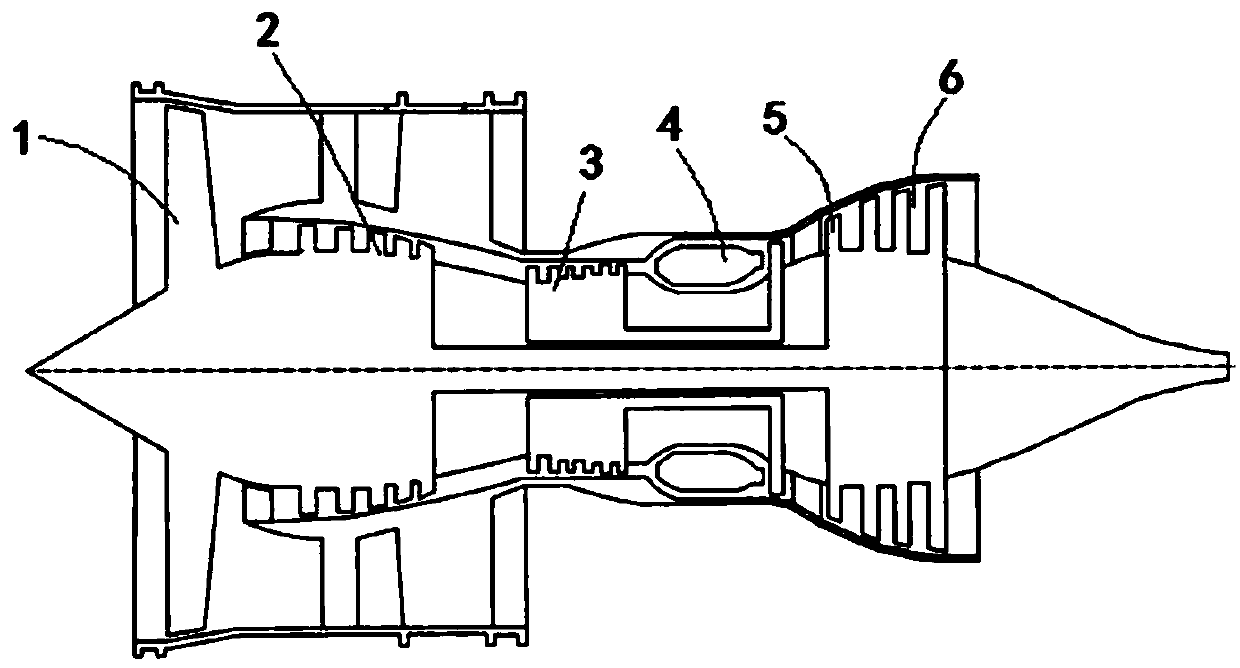

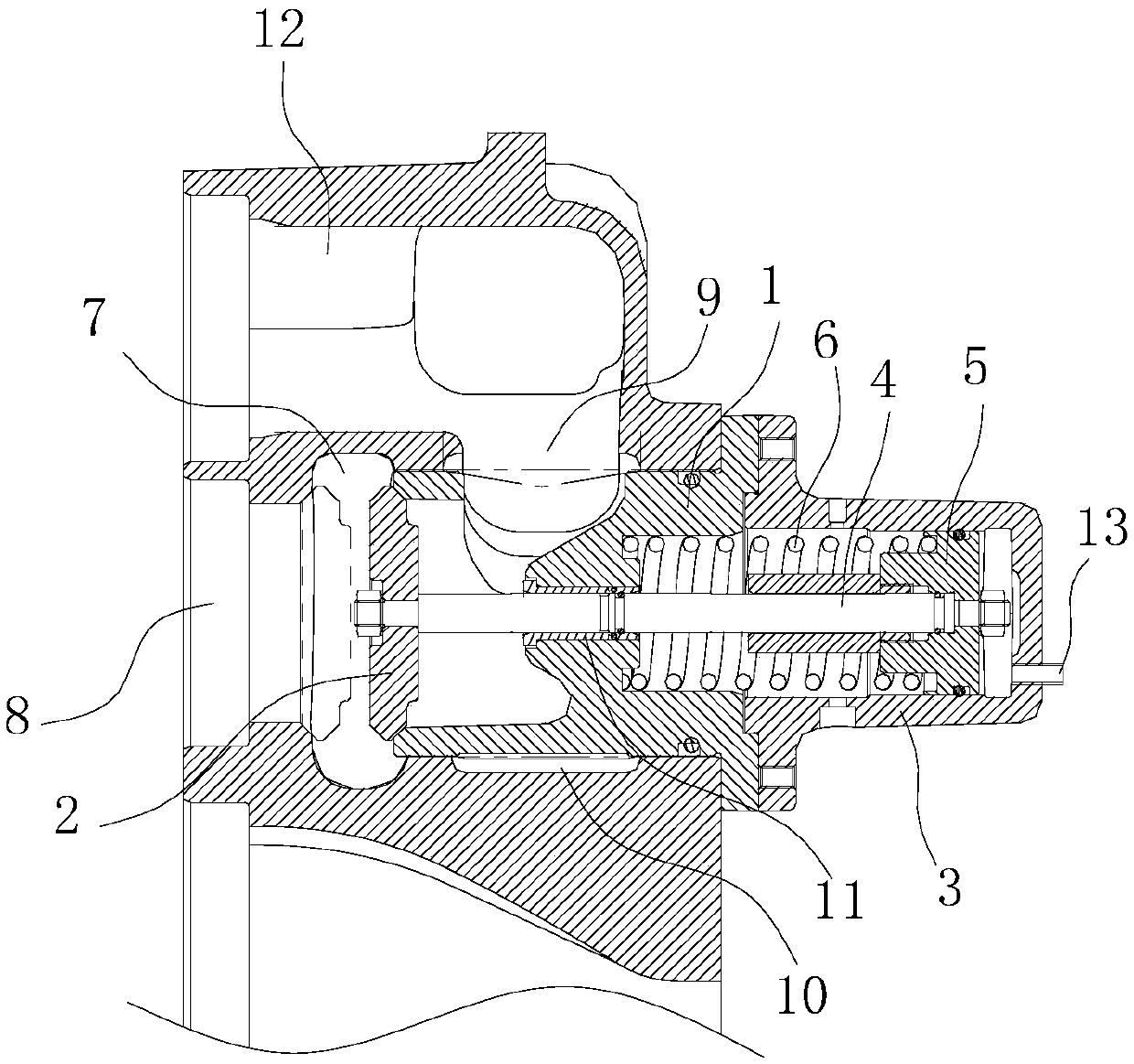

Gas turbine engine mild combustor and control method thereof

ActiveCN106016362AAchieve emissionsGuaranteed combustion efficiencyContinuous combustion chamberCombustion chamberCombustor

The invention provides a mild combustor. The mild combustor comprises a combustor flame tube, a combustor casing and a combustor head baffle; the combustor head baffle and the front wall of the combustor casing form the head of the combustor, and an on-duty nozzle assembly is arranged in the center of the head of the combustor; a jet flow nozzle assembly is arranged on the circumference of the head of the combustor, and the center of the head of the combustor serves as the circle center of the circumference; a first return flow zone formed by the on-duty nozzle assembly is located in the downstream position of the outlet end of the on-duty nozzle assembly, a second return flow zone formed by the jet flow nozzle assembly is located in the downstream position of the first return flow zone, mild combustion in the combustor flame tube is achieved, and ultra-low nitrogen oxide emission in a wide load range can be achieved; and moreover, high-temperature flue gas is mixed with air / fuel mixed gas, and accordingly the combustion efficiency is improved. The mild combustor is compact in structure, is a cylindrical combustor and can directly replace a gas turbine engine combustor of the similar structure.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

W-firing boiler advanced denitration combustion method

ActiveCN106247321AReduce concentrationLower emission valueFluegas recirculationIndirect carbon-dioxide mitigationHearthEngineering

The invention discloses a W-firing boiler advanced denitration combustion method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of main combustors on boiler arches of a front wall and a rear wall and is combusted, secondary air and under-arch secondary air are respectively introduced through secondary air nozzles and under-arch secondary air nozzles, exhaust gas wind is introduced through exhaust gas wind nozzles on the front wall and the rear wall, one or two layers of over-fire air are introduced through over-fire air nozzles, the excess air coefficient range of a main combustion area is 0.7-1.05, and the fire coal undergoes low oxygen combustion; the excess air coefficient range of an over-fire area is 1.05-1.3, and oxygen rich combustion is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over-fire air layer to reduce nitrogen oxides in flue gas and inhibit generation of new nitrogen oxides. The W-firing boiler advanced denitration combustion method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

Vehicle fuel and preparation method thereof

ActiveCN105885970AImprove stabilityGuaranteed combustion efficiencyLiquid carbonaceous fuelsFuel additivesDetonatorCombustion

The invention provides a vehicle fuel and a preparation method thereof. The vehicle fuel comprises the following components in parts by weight: 5-10 parts of diesel oil, 30-80 parts of polymethoxy dimethyl ether, 1-5 parts of an alcohol combustion improver, 1-5 parts of a corrosion inhibitor, 1-10 parts of an anti-detonator, 1-5 parts of a catalysis combustion improver, 1-10 parts of a stabilizer, 1-5 parts of an anti-oxidant, 0.1-5 parts of a dispersing agent and 5-10 parts of solvent oil. The preparation method comprises the following steps: sufficiently stirring and mixing the diesel oil, the polymethoxy dimethyl ether and the solvent oil at normal temperature to obtain a first mixture; under the stirring state, adding the alcohol combustion improver, the corrosion inhibitor and the catalysis combustion improver into the first mixture to obtain a second mixture; under a stirring and 35-60 DEG C constant-temperature condition, adding the stabilizer, the anti-detonator, the anti-oxidant and the dispersing agent into the second mixture, wherein the time interval of addition between adjacent substances is 1-2 hours; and preserving the heat and standing for 3-5 hours after stirring for 1-2 hours. The vehicle fuel provided by the invention is good in stability, and the utilization rate of the polymethoxy dimethyl ether is high.

Owner:SHANDONG CHENXIN NEW ENERGY

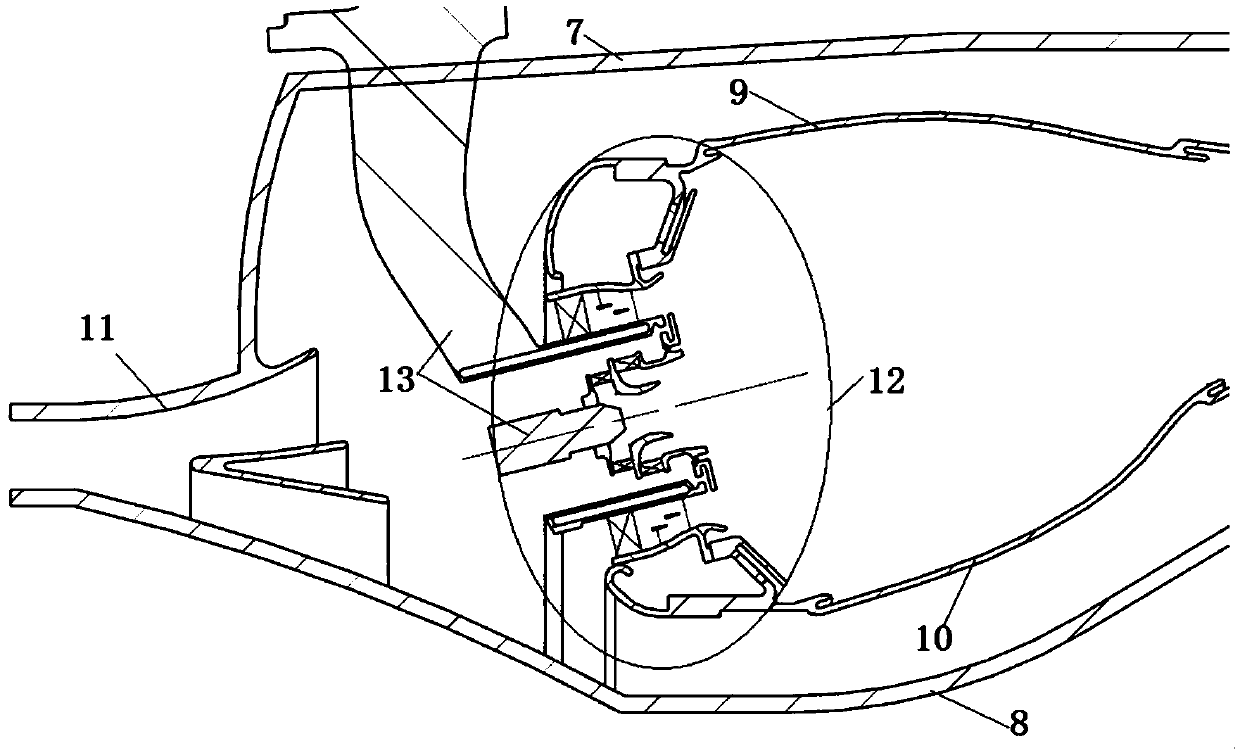

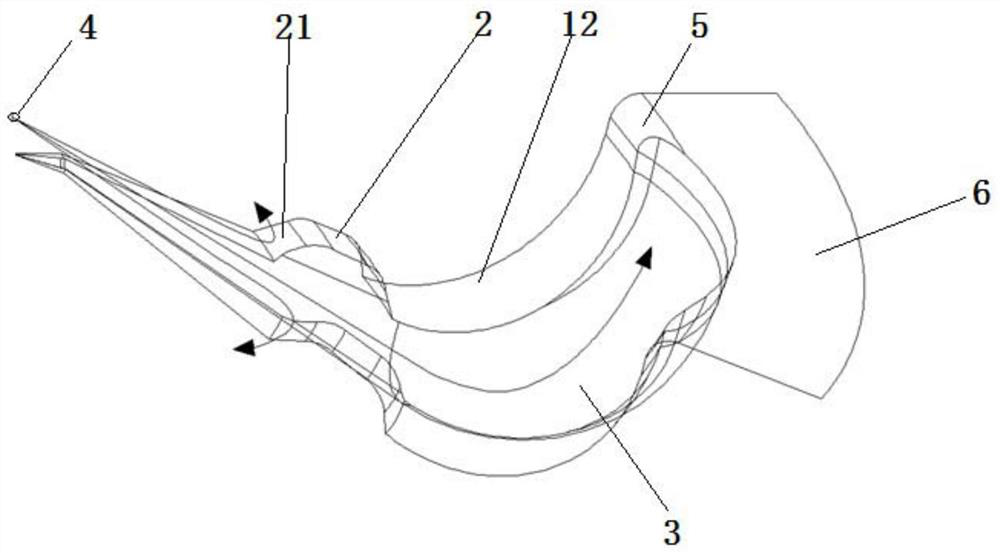

Low-pollution combustion chamber and combustion control method thereof

ActiveCN110657452ASmall penetration depthEvenly distributedBurnersContinuous combustion chamberCombustion chamberEngineering

The invention relates to a low-pollution combustion chamber and a combustion control method thereof. The low-pollution combustion chamber comprise a combustion chamber head, the combustion chamber head comprises a primary combustion stage and a pre-combustion stage, and the primary combustion stage comprises a primary combustion stage channel and a primary combustion stage swirler arranged in theprimary combustion stage channel. The low-pollution combustion chamber is characterized in that the primary combustion stage further comprises a pre-mold plate arranged in the primary combustion stagechannel, the pre-mold plate is divided into an outer-layer pre-mold plate and an inner-layer pre-mold plate in the radial direction, wherein the spraying point position and the spraying direction offuel oil of the primary combustion stage are arranged to control the primary combustion stage fuel oil to be sprayed into the primary combustion stage channel through a primary combustion stage fuel oil spray hole, the primary combustion stage direct-injection oil mist is partially formed, and the other part of the the primary combustion stage fuel oil is sprayed on the pre-mold plate close to theinner side of the primary combustion stage channel or sprayed on the two layers of pre-mold plates. Through cooperation of the double-layer pre-mold plate and the spraying point position and the spraying direction, and the combustible mixed gas is distributed more uniformly in a flame tube under different working conditions.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

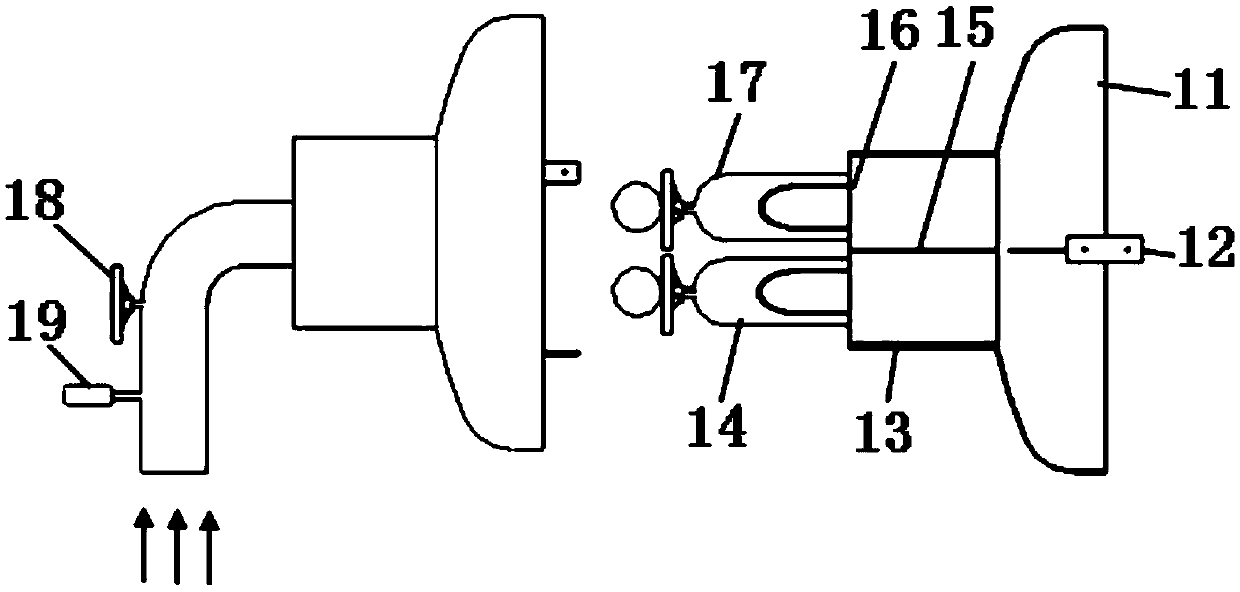

Low-pollution combustor for emission reduction through hydrogenation during aviation fuel combustion

ActiveCN103277813APromote oxidationPromote disseminationContinuous combustion chamberCombustion chamberHydrogen

The invention relates to a low-pollution combustor for emission reduction through hydrogenation during aviation fuel combustion. As a whole, the combustor adopts a premixed lean combustion mode, wherein the head portion of the combustor adopts the mode that a preliminary combustion stage center and a main combustion stage center are in staged combustion, and the overall structure of a flame tube is a single-ring cavity. A preliminary combustion stage adopts a diffusive combustion mode to guarantee stable combustion. A main combustion stage adopts a premixed combustion to lower pollutant discharge of large working conditions. The preliminary combustion stage and the main combustion stage can adopt a hydrogenation auxiliary combustion mode respectively or simultaneously, therefore, the efficiency and the stability of extremely lean combustion are guaranteed, the limit of the lean combustion is expanded, the temperature and the combustion pulsation in a combustion zone are reduced, and the purpose of reducing the pollutant discharge of nitric oxides NOx is achieved. According to the low-pollution combustor for the emission reduction through the hydrogenation during the aviation fuel combustion, hydrogenation assistance is conducted on the aviation fuel combustion, the pollutant discharge of NOx is lowered substantially through the extremely lean consumption, the fuel is mainly aviation fuel, the hydrogenation only plays a role in assisting combustion, the total consumption of hydrogen is low, and the requirement for the improvement of an engine and aircraft hardware is low. The low-pollution combustor has the advantage of fuel flexibility.

Owner:BEIHANG UNIV

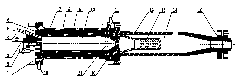

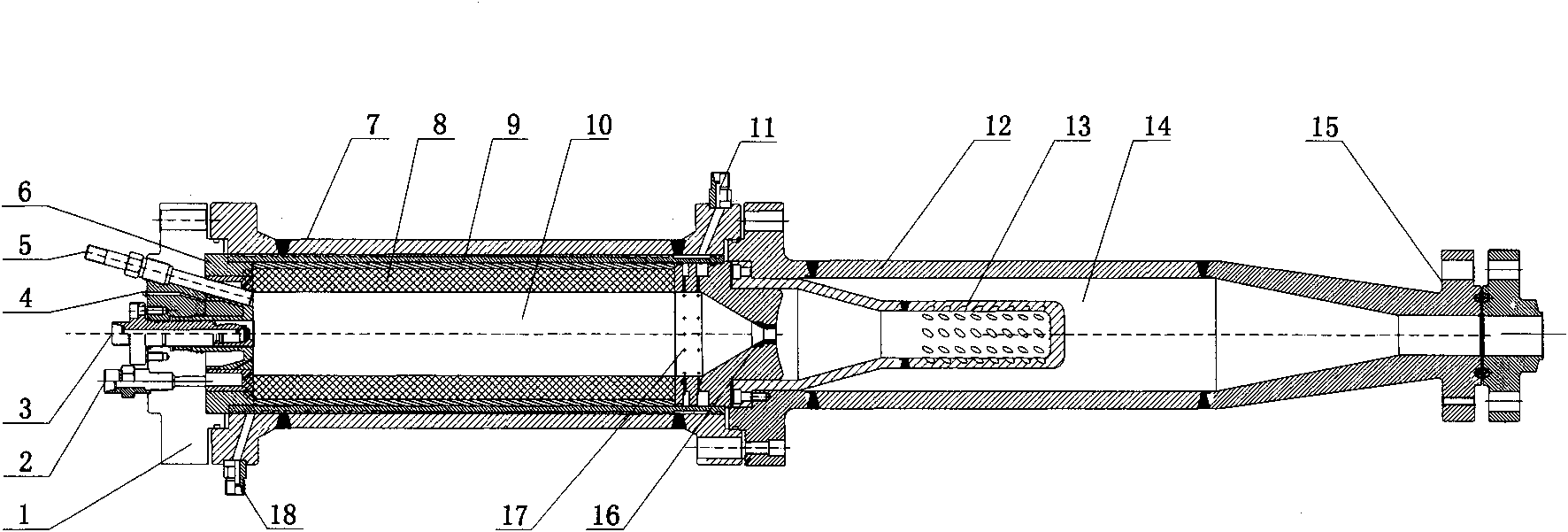

Method for achieving water-injecting high-pressure combustion through pipeline of fuel nozzle

InactiveCN101825279ALower working temperatureImprove job stabilityBurnersFluid removalCombustion chamberFlue gas

The invention relates to a method for achieving the water-injecting high-pressure combustion through the pipeline of a fuel nozzle. Fuel is allowed to enter a combustion chamber (10) from a fuel nozzle (3); compressed air is allowed to enter the combustion chamber (10) from an air distributor (2); a certain amount of water from a water injection hole (4) is injected into the combustion chamber (10) from the fuel nozzle (3) via the pipeline of the fuel nozzle, so that the operating temperature in the combustion chamber (10) can be reduced from approximate 2,000 DEG C to 1,500-1,600 DEG C; the operating end of an igniter (5) is led to the combustion chamber (10), so that the fuel and air can be ignited by the igniter (5) after the fuel and air entering the combustion chamber (10) are atomized and mixed; and high-temperature and high-pressure flue gas can be generated after the complete combustion. By injecting a certain amount of water into the water injection hole (4) on the pipeline of fuel, part of combustion heat can be absorbed by the water, thus stabilizing the operating temperature in the combustion chamber (10) at 1,500 to 1,600 DEG C. Therefore, the method of the invention has the advantages of high reliability and easy operation and significantly prolongs the service life of the equipment.

Owner:SOUTHEAST UNIV

Water injection type high-pressure combustion method

InactiveCN101832553ALower working temperatureImprove job stabilityBurnersFluid removalCombustion chamberFuel oil

The invention relates to a water injection type high-pressure combustion method. The method comprises the following steps of: arranging a water injection hole (4) at one end of a combustion section (7) close to a head part (1); injecting a certain quantity of water to a combustion chamber (10) from the water injection hole (4); enabling fuel oil to enter the combustion chamber (10) from an oil nozzle (3) and compressed air to enter the combustion chamber (10) from an air distributor (2); communicating a working end of an igniter (5) to the combustion chamber (10); igniting a mixture of the fuel oil and air by using an igniter (5); and injecting a certain quantity of water into the combustion chamber (10) from the water injection hole (4). The method has strong reliability and easy operation, and the service life of equipment is obviously prolonged.

Owner:SOUTHEAST UNIV

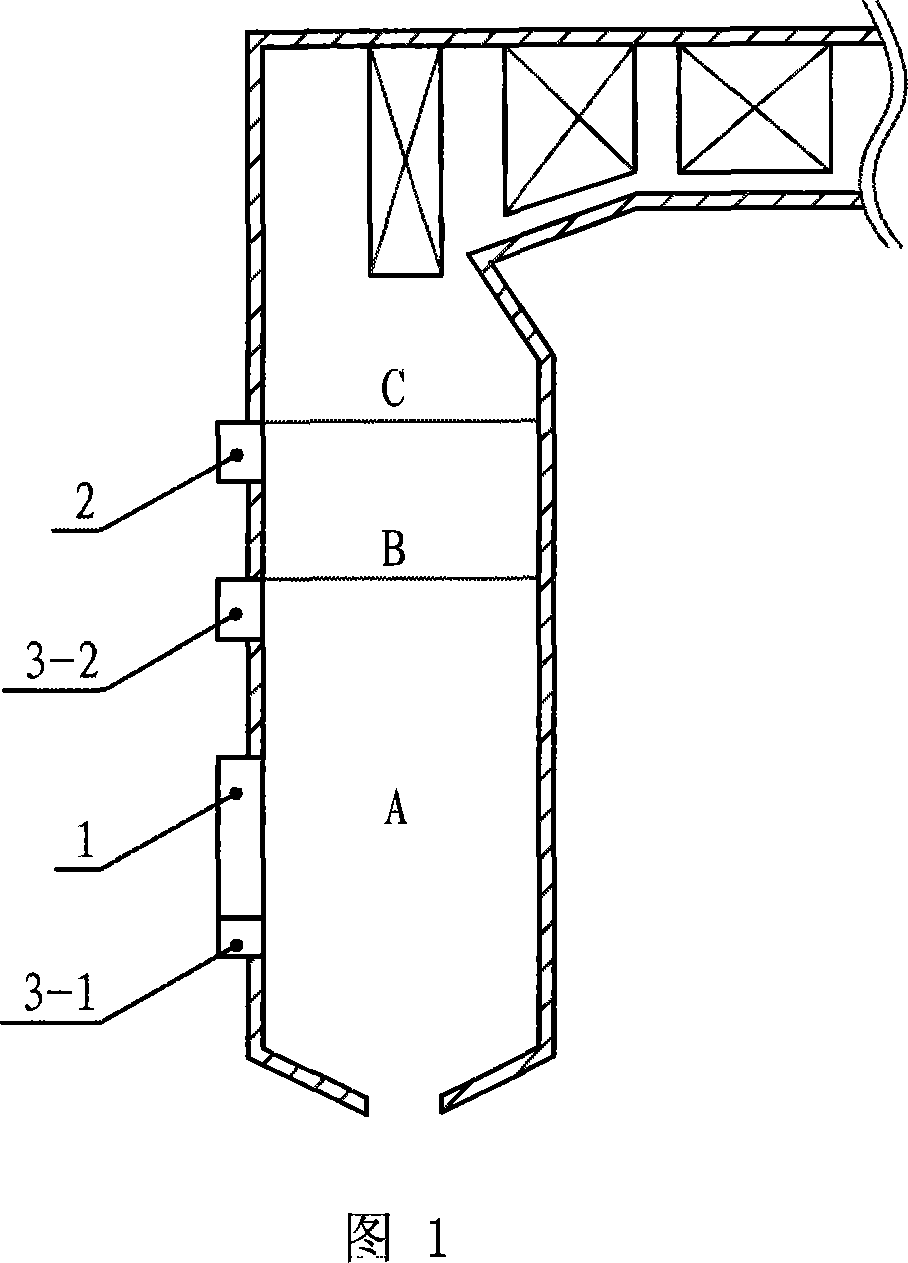

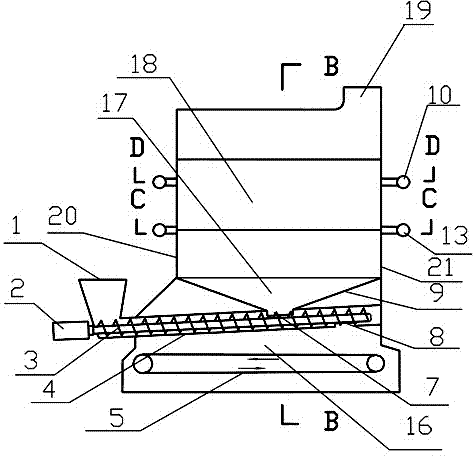

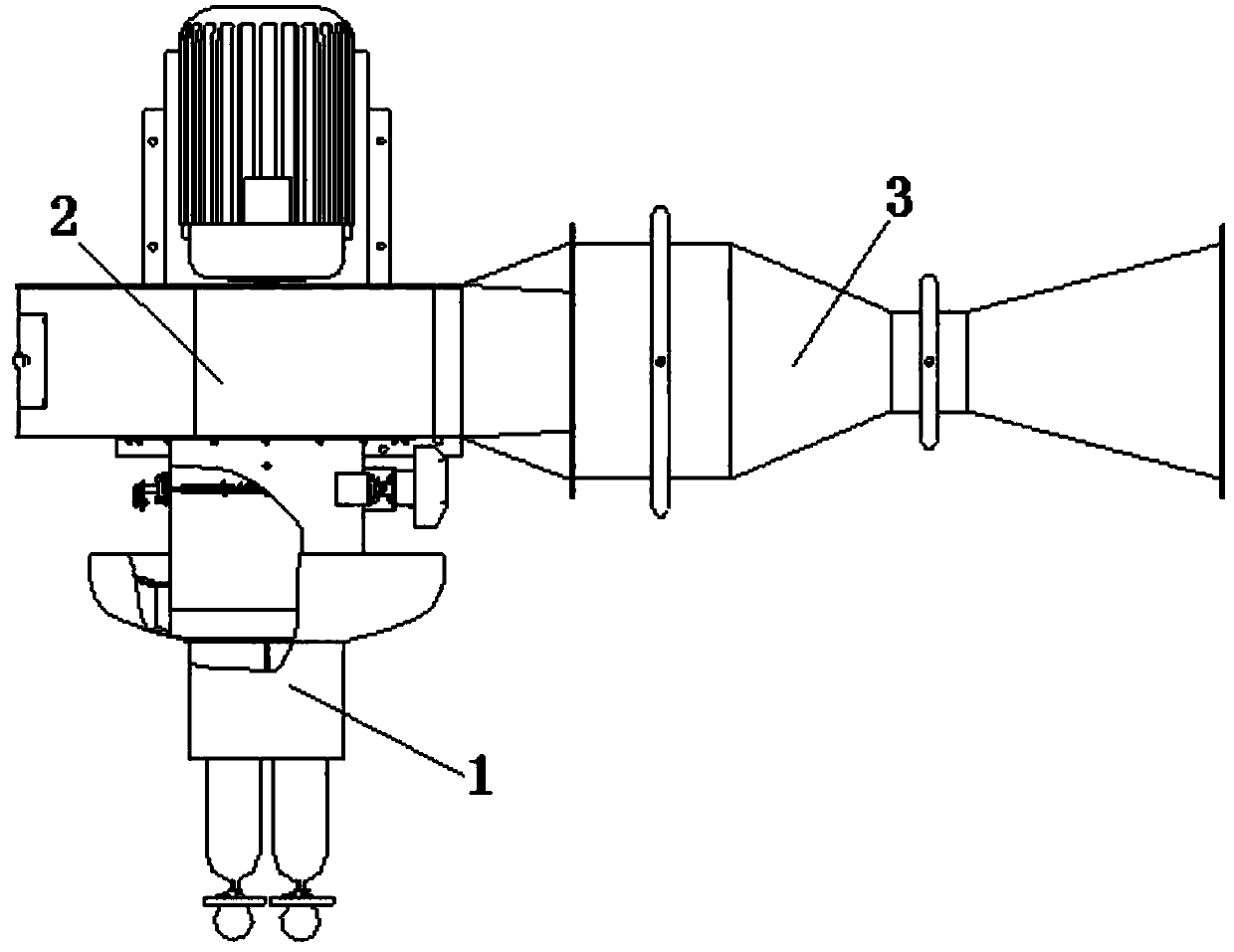

Gas-solid separation and re-coupling type biomass clean combustion device and combustion method

ActiveCN104713078AAchieve separationAchieve combustionSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidCombustion chamber

A gas-solid separation and re-coupling type biomass clean combustion device comprises a spiral feeding system, a chain furnace grate, a solid combustion chamber, a reduction reaction chamber, a gas combustion chamber, a solid combustion air supply system, a primary gas combustion air supply system, a secondary gas combustion air supply system and a cuboid hearth. The spiral feeding system comprises an open hopper, a drive motor, a feeding shaft with a spiral fin and a spiral pipe. The device is provided with the independent reduction reaction chamber, the independent solid combustion chamber and the independent gas combustion chamber. A combustion method of the gas-solid separation and re-coupling type biomass clean combustion device includes the steps that biomass is firstly dissolved into gas and solid through self heat supply, dust of smoke generated after solid combustion is removed, a reduction reaction is conducted on the smoke and gas generated after thermolysis, and NOx is reduced; primary combustion and secondary combustion are conducted, generation of NOx is controlled, and combustion is thorough.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI +1

Combustor air distribution device and air distribution method

ActiveCN109539248AAchieve recyclingFully stable combustionBurnersAir supply regulationCombustorAir volume

The invention discloses a combustor air distribution device and an air distribution method. The combustor air distribution device comprises an air inlet device, an air blower and an air blower outputair volume detection device, wherein an outlet of the air inlet device communicates with the air blower, air blown by the air blower is conveyed to a combustor, a flow detection sensor is arranged onthe air inlet device, and is used for carrying out real-time detection on the flow of gas entering the air blower through the air inlet device, an air inlet is formed in the air blower and used for sucking fresh air, the air blower output air volume detection device is used for detecting the output air volume of the air blower in real time, namely the total air supply volume of the air distribution device, the air blower is provided with an air blower output air volume adjusting device, and is used for adjusting the output air volume of the air blower, the air inlet device comprises a combustible waste gas pipeline and / or a recycled smoke gas pipeline, and the air blower output air volume detection device is a venturi tube device. Thus, accurate air distribution is achieved, and the combustion efficiency and the stability are guaranteed.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

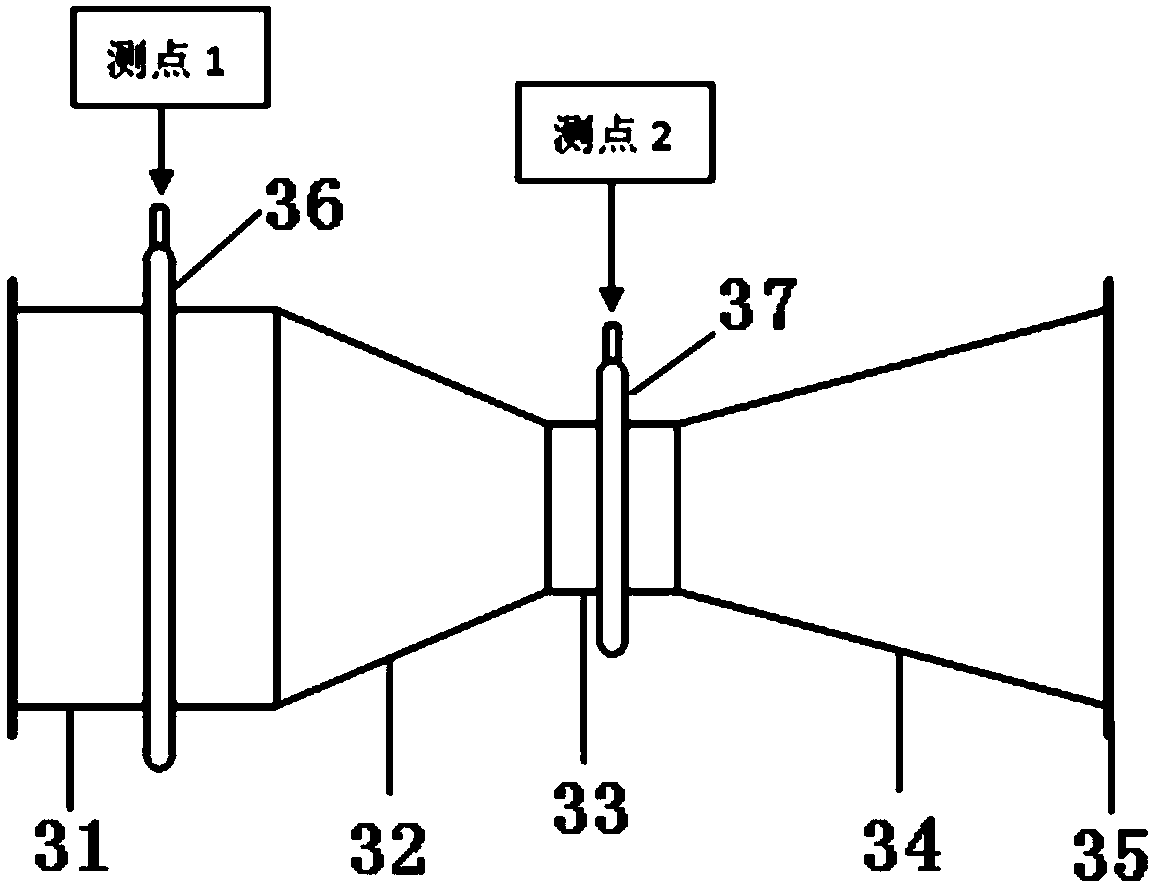

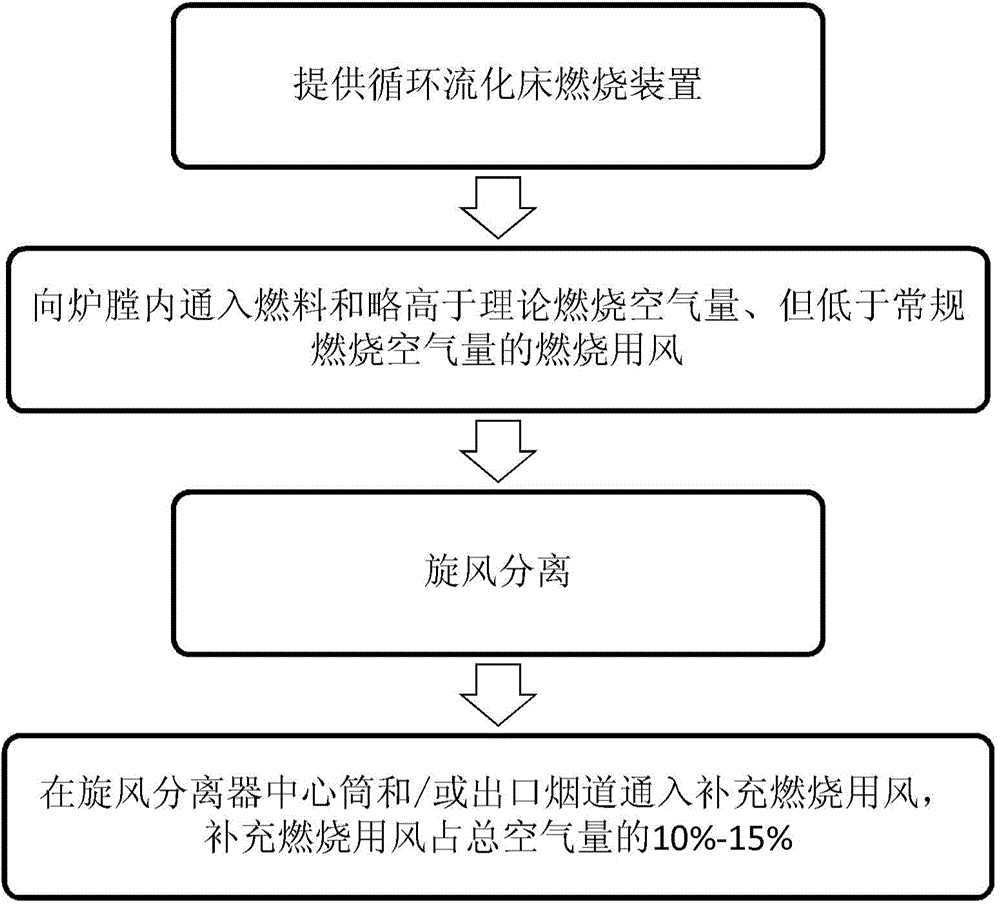

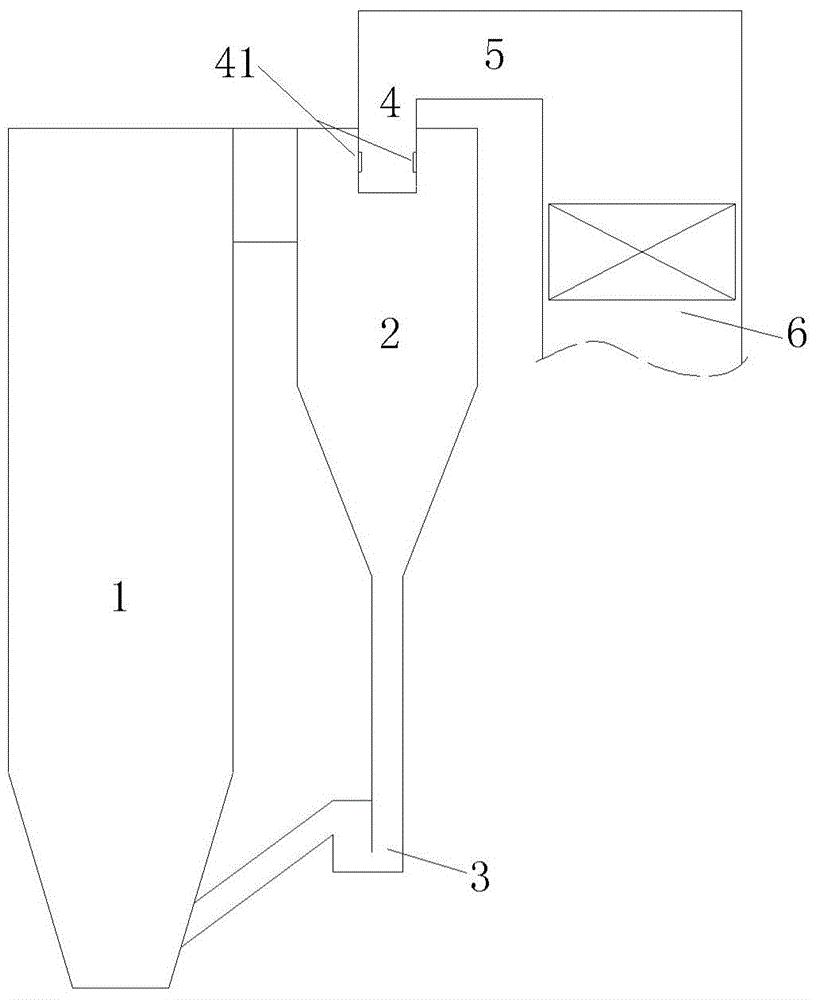

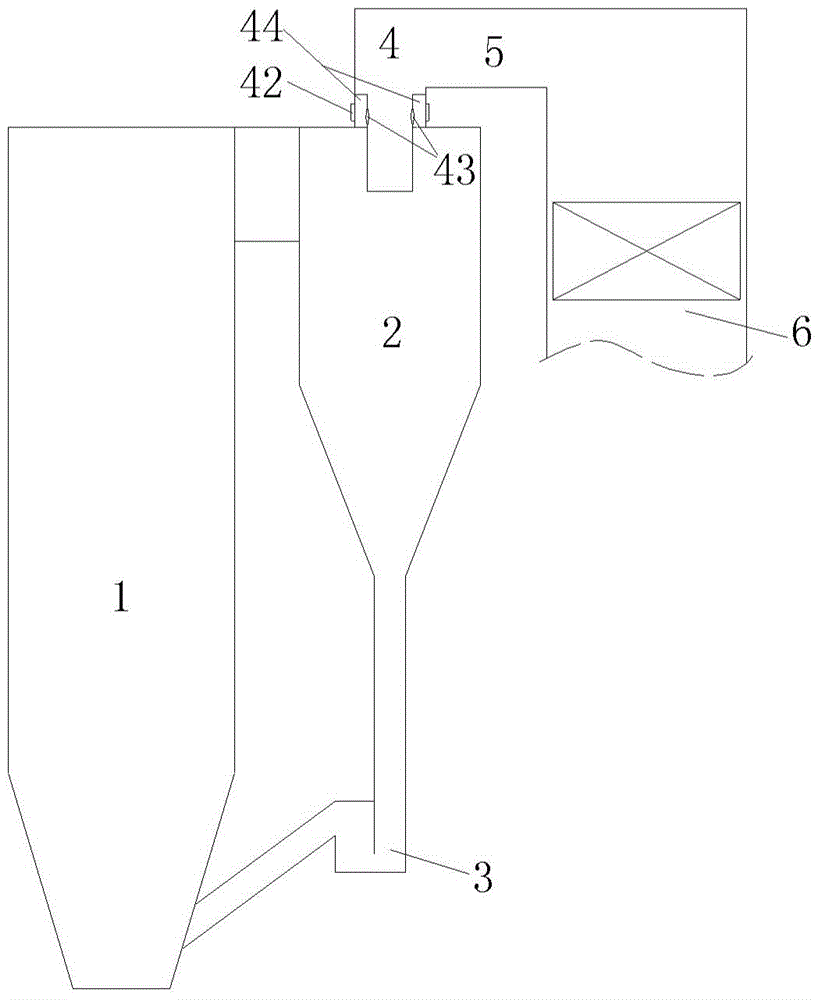

Combustion method capable of reducing nitrogen oxide discharge of circulating fluidized bed

ActiveCN105180158AEmission reductionInhibitionFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberEngineering

A combustion method capable of reducing nitrogen oxide discharge of a circulating fluidized bed comprises the following steps: a combustion device provided; fuel and combustion air, the amount of which is higher than theoretical combustion air amount and lower than conventional combustion air amount is introduced into a combustion chamber of the circulating fluidized bed, so that atmosphere in the combustion chamber of the circulating fluidized bed is kept to be reducing atmosphere; gas-solid mixtures generated by the combustion chamber of the circulating fluidized bed are enabled to enter a cyclone separator, most particles in the gas-solid mixtures are separated and returned to the combustion chamber of the circulating fluidized bed again through a back-feeder, flue gas in the gas-solid mixtures flows into a tail flue through a center cylinder and an outlet flue; and afterflaming air is introduced into the center cylinder and / or the outlet flue, so that carbon monoxide and other combustible components in the flue gas are combusted completely. By adopting the method provided by the invention, the emission concentration of nitrogen oxide in the flue gas can be reduced, and meanwhile, the combustion efficiency of the circulating fluidized bed combustion device is ensured.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

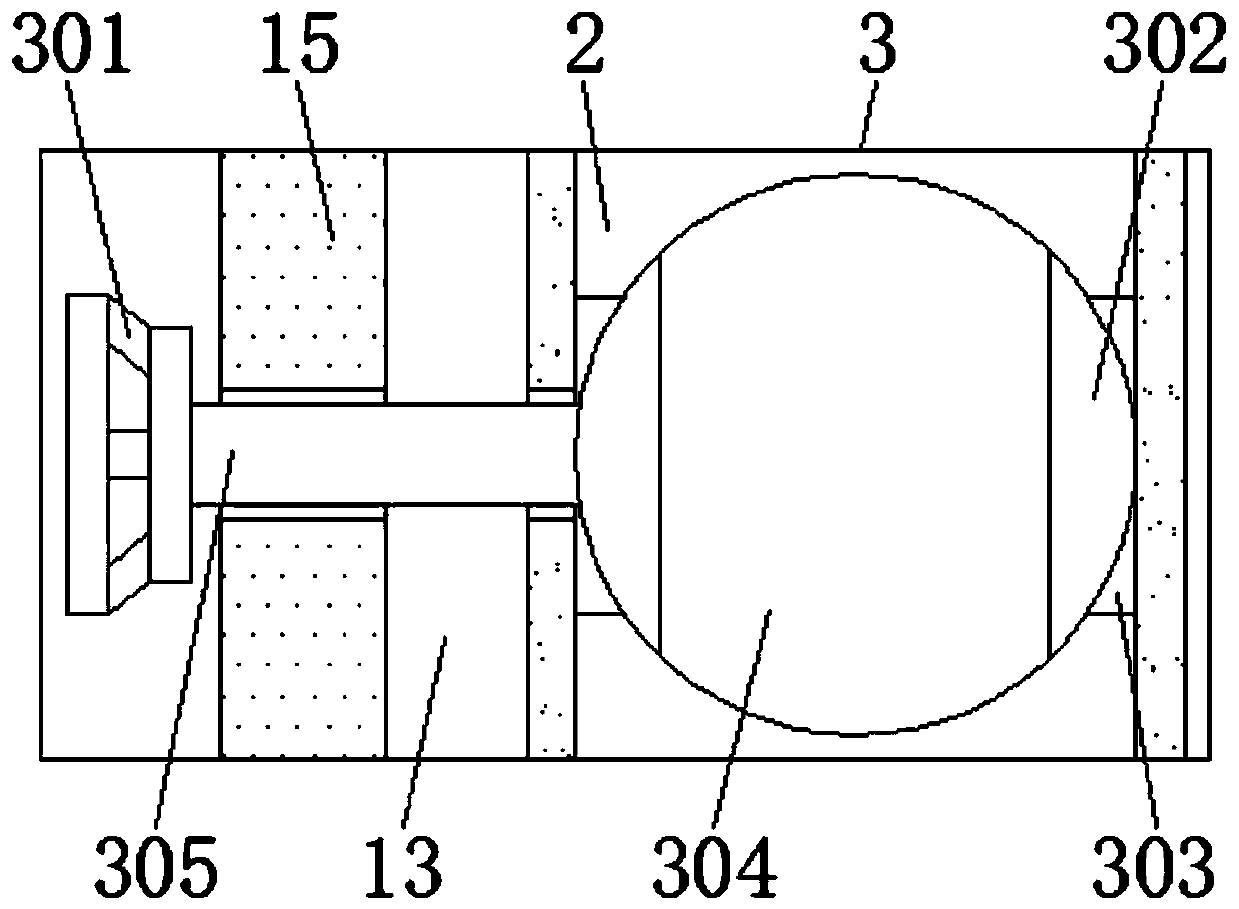

Supercritical carbon dioxide coal-fired boiler system and smoke-air coupling three-dimensional circulation process thereof

ActiveCN111664444AAlleviate wall overheatingLess quantityAir supply regulationStaged combustionFlueAir volume

The invention discloses a supercritical carbon dioxide coal-fired boiler system and a smoke-air coupling three-dimensional circulation process thereof. The coal-fired boiler system comprises a hearth,a flue, a secondary fan and a recirculation flue, wherein combined air nozzles are arranged on the peripheral wall surface of the hearth; one end of the flue communicates with the upper end of the hearth; an air outlet of the secondary fan communicates with the combined air nozzles through an air volume control valve; the air inlet end of the recirculation flue communicates with the flue; the airoutlet end of the recirculation flue communicates with the combined air nozzles through a smoke volume control valve; and a recirculation fan is arranged on the recirculation flue and is used for extracting smoke from the flue. The supercritical carbon dioxide coal-fired boiler system can guarantee the combustion efficiency of a coal-fired boiler and effectively relieves high-temperature corrosion and coking and slagging of the wall surface of the coal-fired boiler.

Owner:HUAZHONG UNIV OF SCI & TECH

Deep denitration combustion method for tangential boiler

ActiveCN106287674ALower emission valueReduce concentrationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelNitric oxideEngineering

The invention discloses a deep denitration combustion method for a tangential boiler. The hearth of the tangential boiler comprises a main combustion zone, a reduction zone and a burning-out zone; fuel coal is fed into the main combustion zone of the hearth for combustion through primary air in one or more layers of primary air nozzles; one or more layers of secondary air is introduced through secondary air nozzles in the main combustion zone; and one or more layers of burning-out air is introduced through burning-out air nozzles in the burning-out zone. The deep denitration combustion method is characterized in that an excess air coefficient in the main combustion zone ranges from 0.5 to 1.05, and the fuel coal is subjected to low oxygen combustion; an excess air coefficient in the burning-out zone ranges from 1.05 to 1.3, and the fuel coal is subjected to oxygen-enriched combustion; an amidogen reduction inhibitor is sprayed in through one or more layers of reduction inhibitor nozzles in the hearth below the burning-out air on the uppermost layer; the reduction inhibitor nozzles on the same layer are located on the same plane; and nitric oxides in smoke are reduced in a high-temperature environment in the furnace, and generation of new nitric oxides is inhibited. By adopting the deep denitration combustion method, a nitric oxide emission value at the outlet of the hearth can be obviously lowered, and ultra-low emission is realized; strict temperature windows and analysts are not needed; denitration cost is greatly lowered; combustion efficiency can also be ensured; economic benefit is obvious; and the deep denitration combustion method has wide applicability.

Owner:SHANGHAI JIAO TONG UNIV +1

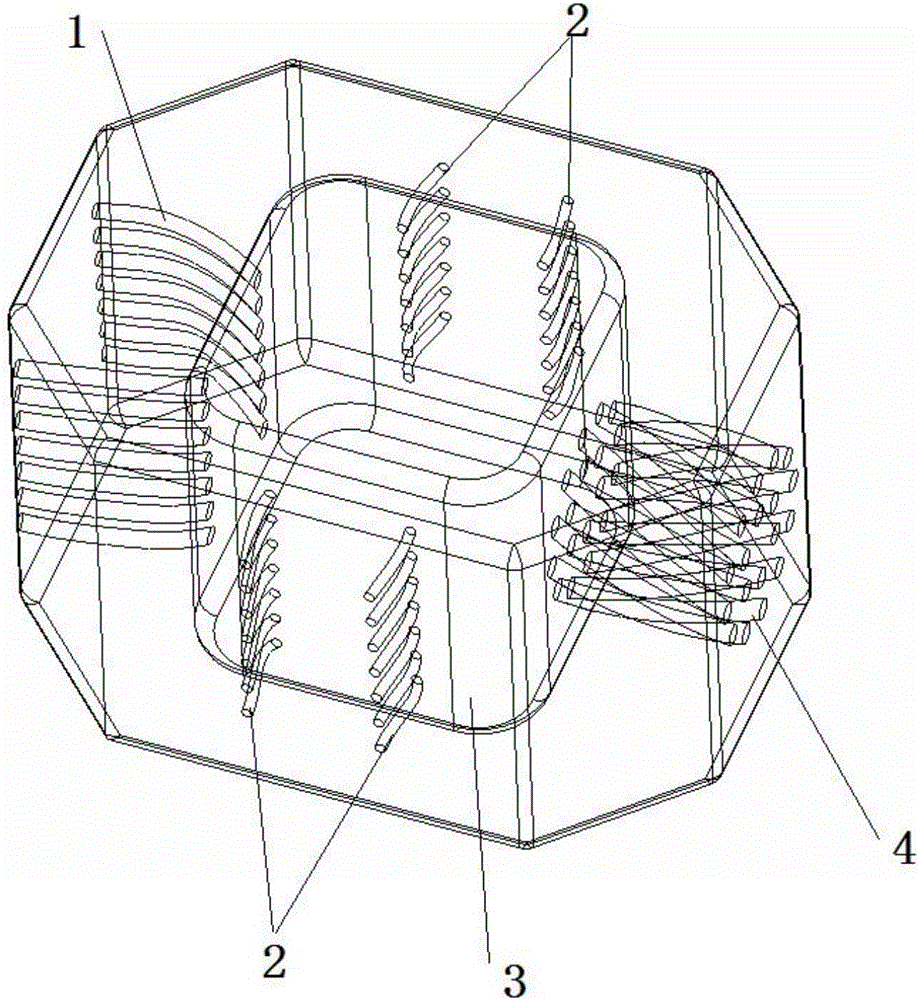

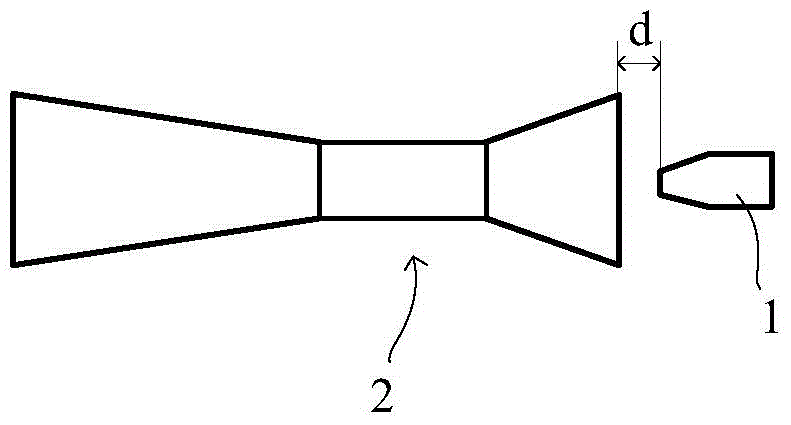

Fuel oil nozzle

The invention provides a fuel oil nozzle. The fuel oil nozzle comprises a fuel pipe, air pipes, a mixing area and a mixed gas spraying pipe. The output ends of the fuel pipe and the air pipes communicate with the input end of the mixing area, and the output end of the mixing area communicates with the input end of the mixed gas spraying pipe. The fuel oil nozzle has the beneficial effects that adequate premixing of fuel gas and air can be achieved, and discharging of NOx, CO and the like is effectively reduced while burning efficiency is guaranteed.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

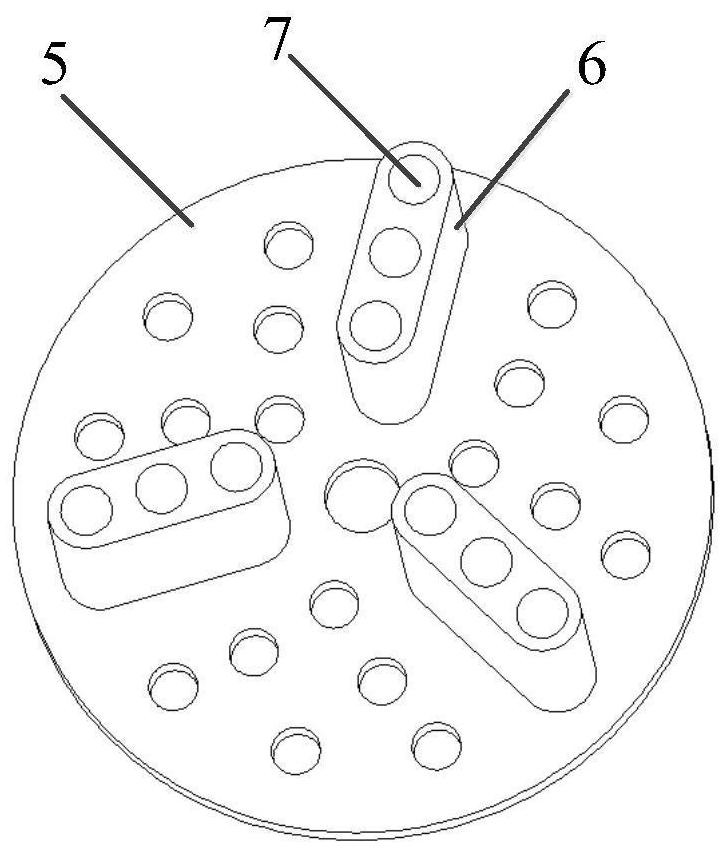

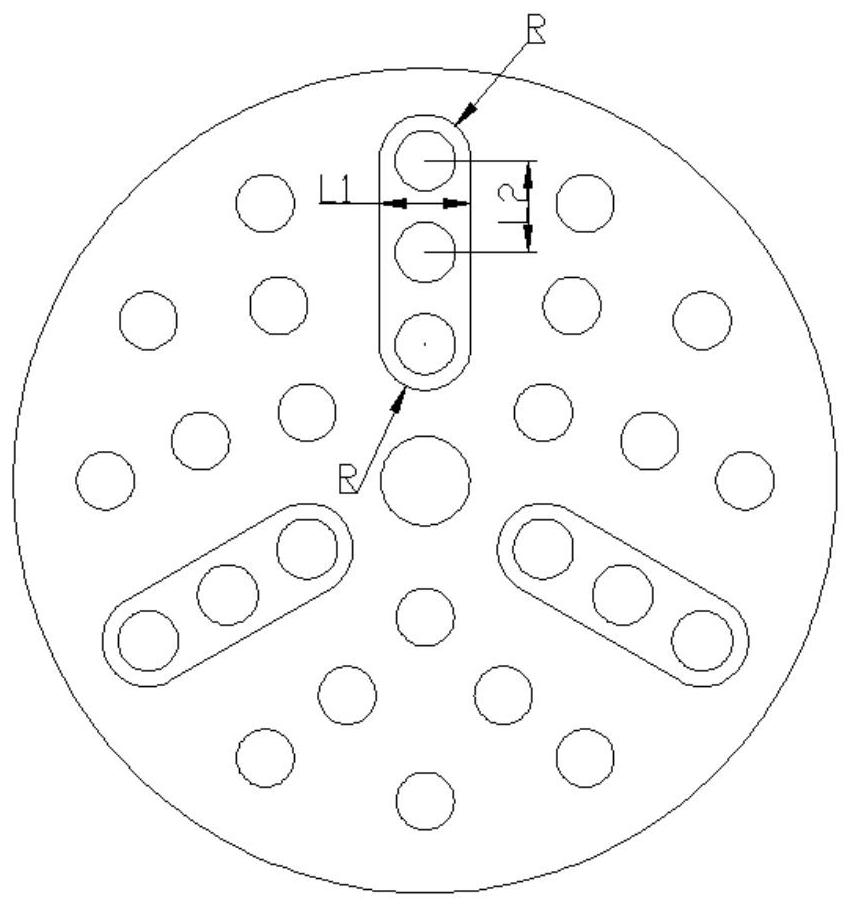

Partition plate nozzle structure of pre-combustion chamber

ActiveCN114165358AImprove stable working rangeSuppression of tangentially unstable combustionInternal combustion piston enginesRocket engine plantsThermodynamicsCombustion chamber

A pre-combustion chamber partition plate nozzle comprises an oxidizing agent nozzle, a fuel nozzle and a bottom. One end of the oxidant nozzle extends into the fuel nozzle and forms an annular gap with the fuel nozzle; a plurality of columns of partition plate sleeves are uniformly distributed on the panel along the circumferential direction; the panel and the partition plate sleeve are integrally formed to form a bottom; a fuel nozzle is mounted at the position, provided with the partition plate sleeve, of one bottom; longitudinal partition plate through holes are formed in the partition plate sleeve, and the partition plate through holes and the fuel nozzles are in one-to-one correspondence and are communicated with each other; a rotational flow hole is formed in the end head of one end of the fuel nozzle installed at the bottom and enables two end faces of the end head to be communicated, and a radial hole is formed in the end, connected with the oxidizing agent nozzle, of the fuel nozzle. By means of the reasonable design of the partition plate nozzle structure, unstable combustion is effectively restrained, and meanwhile high combustion efficiency and good outlet gas temperature uniformity are guaranteed.

Owner:BEIJING AEROSPACE PROPULSION INST

Electrolytic aluminum flue gas quantity and contaminant zero-deviation emission system

ActiveCN106545870AHigher smoke temperatureReduce shockGas treatmentDispersed particle filtrationCombustionFlue gas

The invention provides an electrolytic aluminum flue gas quantity and contaminant zero-deviation emission system, which comprises an electrolytic aluminum flue gas defluorination and dust-removal unit and combustion equipment, and further comprises a zero-deviation emission flue and a flue gas circulation unit. An inlet of the zero-deviation emission flue is connected with an emission outlet of a purification unit; an outlet of the zero-deviation emission flue is connected with a combustion-supporting gas inlet of the combustion equipment; a circulation port is formed in the zero-deviation emission flue; a flue gas inlet of the flue gas circulation unit is connected with the circulation port; and a flue gas outlet of the flue gas circulation unit is connected into an electrolytic cell, so that part of the flue gas is circulated into the electrolytic cell for replacing part of air, and the rest of flue gas is fed into the combustion equipment so as to be used as combustion-supporting gas. The electrolytic aluminum flue gas quantity and contaminant zero-deviation emission system further comprises a combustion-supporting gas compensating unit and a combustion-supporting gas distributing unit for supplementing or distributing the flue gas fed into the combustion equipment so as to ensure the flue gas to be matched with the combustion-supporting gas quantity. A control unit is additionally arranged, so that the flow quantity of circulation flue gas is matched with the required cooled flue gas quantity, the temperature of the circulation flue gas is reduced to a required cooling temperature value, and the flue gas quantity fed into the combustion equipment is matched with the combustion-supporting gas quantity.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

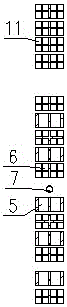

Top-mounted turbulent burner with low NOx emission for water-coal-slurry steam-injection boiler

A top-mounted turbulent burner with low NOx emission for a water-coal-slurry steam-injection boiler is characterized by comprising a water-coal-slurry gun sleeve, a primary airpipe and an inner secondary airpipe, wherein the water-coal-slurry gun sleeve, the primary airpipe and the inner secondary airpipe are coaxially distributed in sequence from the inside to the outside; the outer layer of the inner secondary airpipe is composed of a plurality of outer secondary airpipes, wherein the multiple outer secondary airpipes are annularly distributed at intervals; gaps are reserved between the inner secondary airpipe and the outer secondary airpipes; the gaps are provided with an injection layers; and a high energy igniter sleeve and a fuel gas gun sleeve are installed in the primary airpipe. The top-mounted turbulent burner with low NOx emission for the water-coal-slurry steam-injection boiler reduces emission of the NOx in the water-coal-slurry combusting process.

Owner:SICHUAN TIANFA TECH

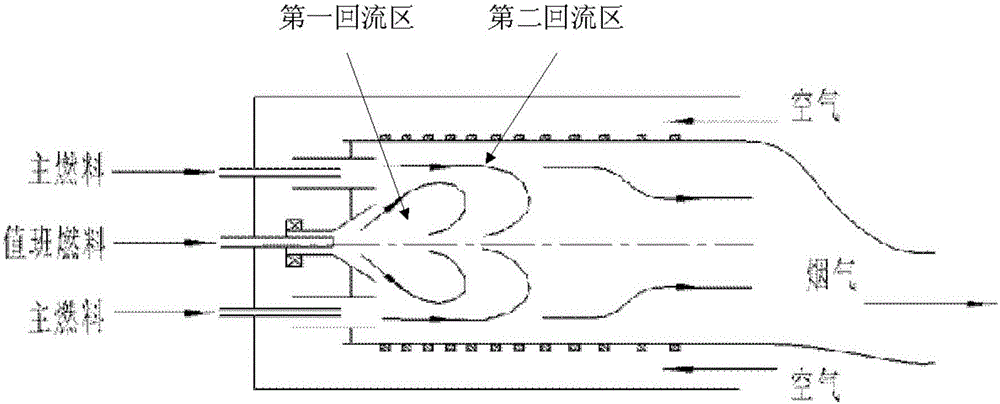

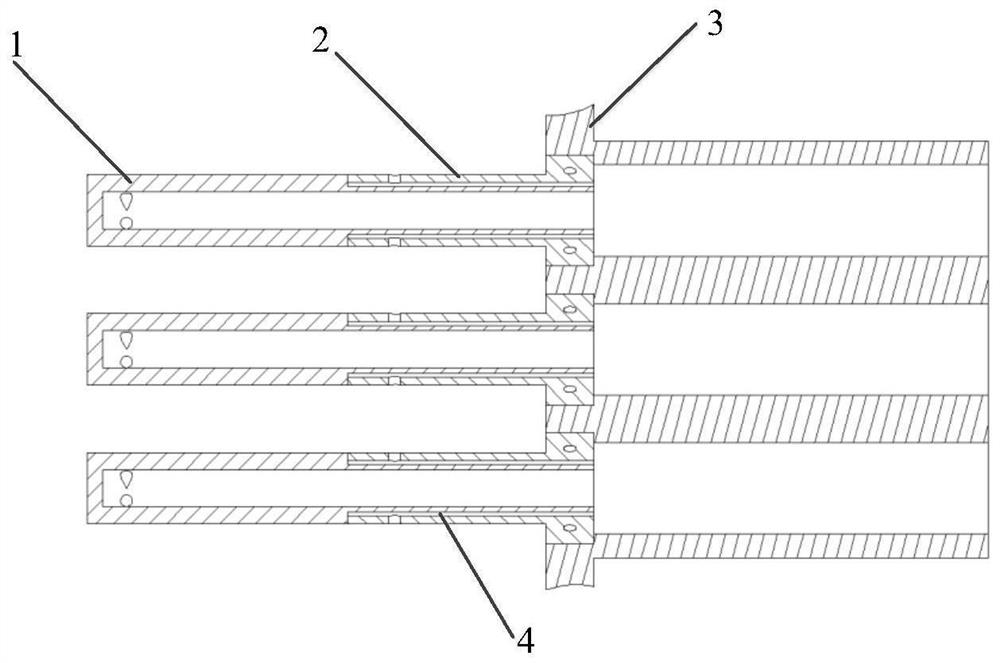

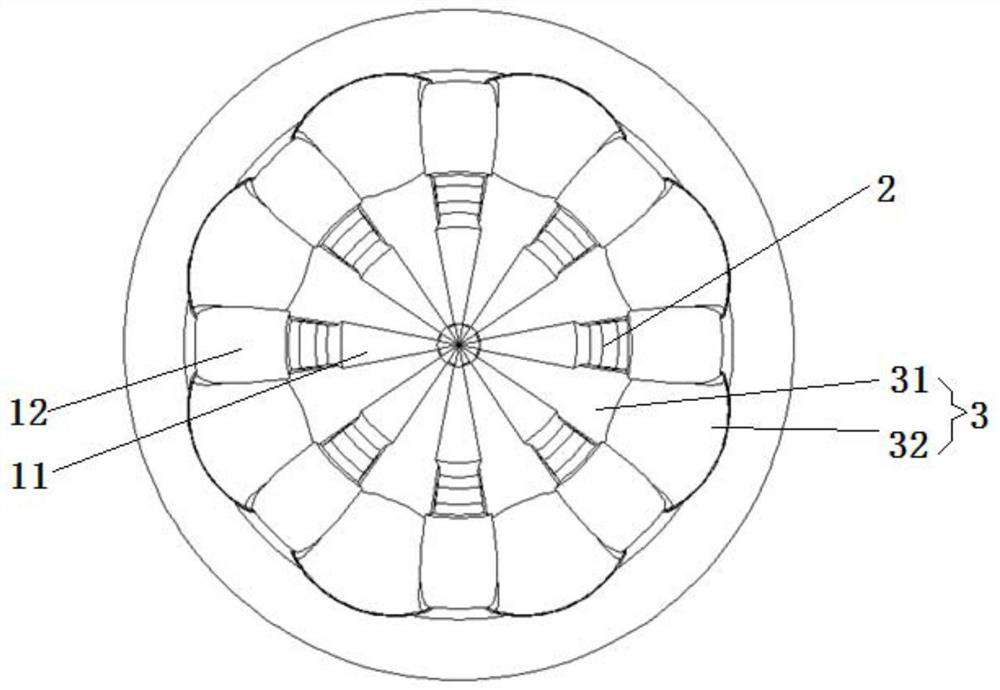

Jet nozzle of mild combustion chamber of gas turbine

ActiveCN107990353AGuaranteed combustion efficiencyAvoid shockContinuous combustion chamberRefluxUltrasound attenuation

A jet nozzle of a mild combustion chamber of a gas turbine comprises a fuel inside nozzle, a fuel outside spray hole, multiple rotational flow groove channels, an outside pipeline and an inside pipeline. The mixing uniformity of fuel and air at a jet nozzle outlet is improved, the outside fuel-air equivalence ratio is relatively low, flame root lifting is facilitated, too-early ignition does not occur easily, jets of the jet nozzle belong to weak rotational flows, the overall pressure loss is relatively low, the axial speed is not prone to attenuation, and increase of the smoke reflux ratio ofthe combustion chamber is facilitated.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

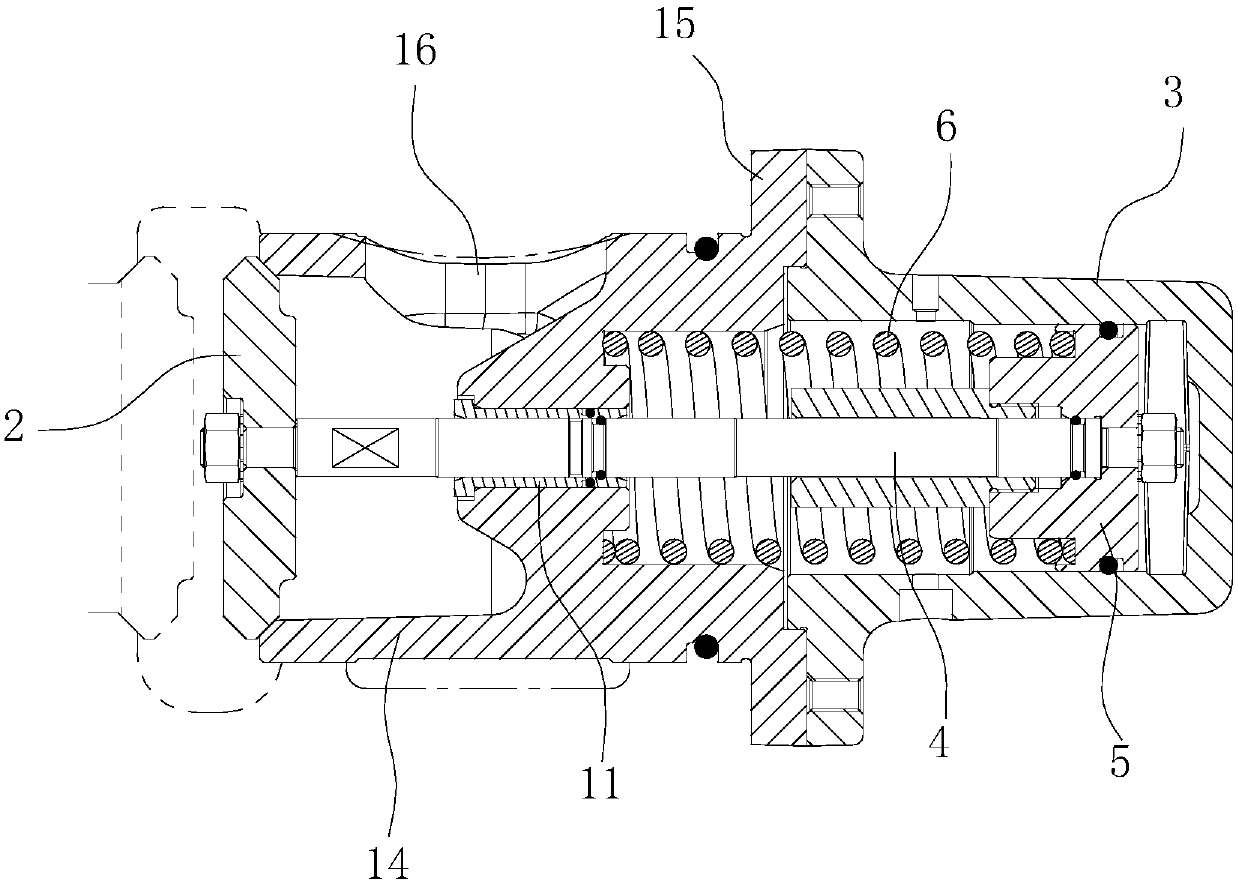

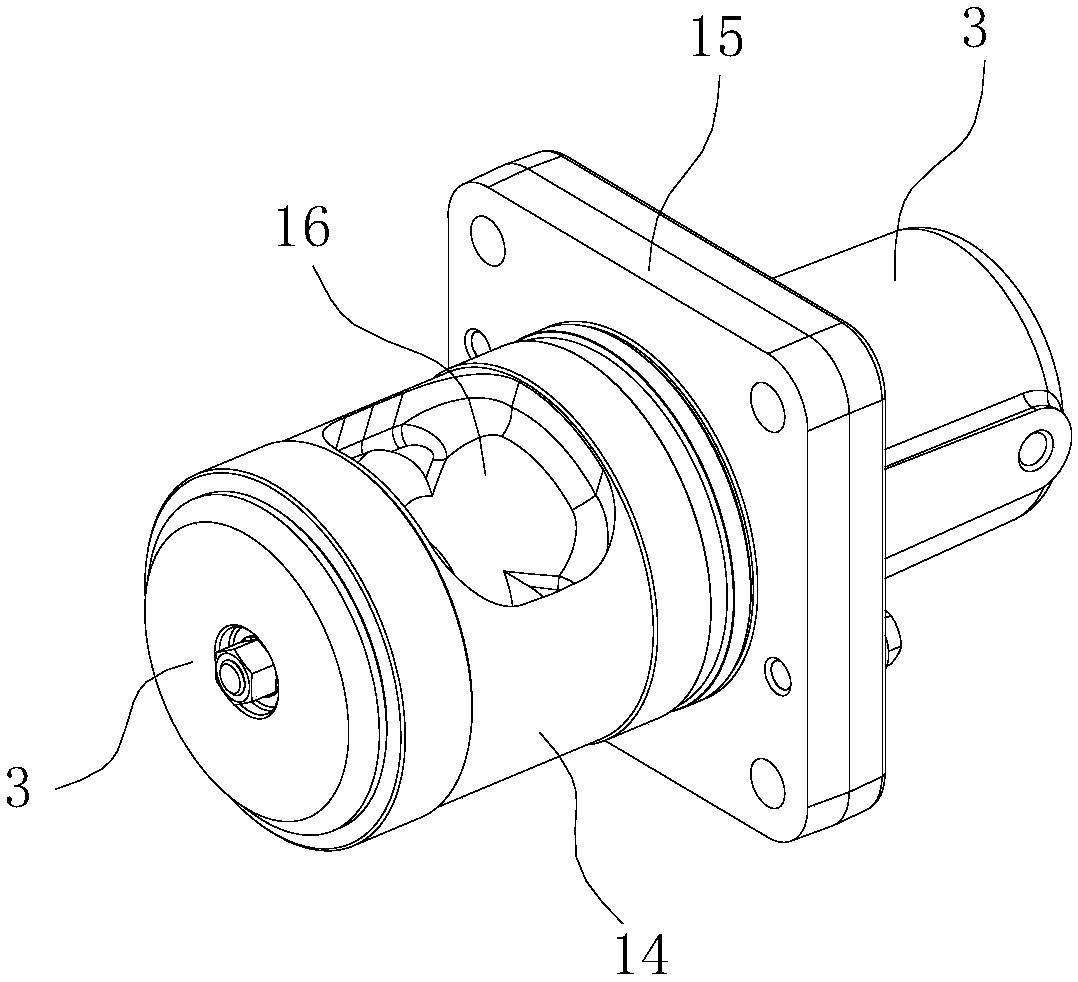

Cooling water bypass valve of engine

PendingCN107725823AGuaranteed combustion efficiencyMultiple way valvesValve housingsEngineeringIntercooler

The invention belongs to the technical field of ship engine producing and manufacturing, and particularly relates to a cooling water bypass valve of an engine. The cooling water bypass valve comprisesa valve cavity. The valve cavity is provided with a water inlet for cooling water inflow and two water outlets for cooling water outflow, wherein the water outlets include the first water outlet andthe second water outlet. A valve element is arranged in the valve cavity and movably arranged in the valve cavity. The valve element moves in the valve cavity and can control the water inlet to selectively communicate with the first water outlet or the second water outlet. The first water outlet communicates with a water inlet of an engine intercooler, the second water outlet communicates with anengine body cooling water cavity, and the water inlet communicates with a water outlet of an engine cooling water pump. The bypass valve can selectively control the low-temperature water to flow intothe intercooler according to needs, the intercooler can cool air to the adaptive temperature according to needs of various work conditions, and the combustion efficiency of the engine is ensured.

Owner:ANQING CSSC DIESEL ENGINE

Optimized control method of combustion in multiple fire nozzle hearth of boiler

The present invention belongs to the combustion controlling technology of boiler hearth, especially of multiple fire nozzle hearth, and is suitable for the combustion monitoring of combustion in a four corner-rounded boiler. The present invention relates optimized efficient low nitrogen oxide exhaust control by arranging several flame image detectors to obtain the 3-D temperature distribution in hearth and through fitting the expression between radiation energy E and power generating load NE of the poer set, measuring the flame center height and the change rules of flame section temperature center with fuel amount and blast distribution proportion in different layers and different corners, and giving control command of fuel amount and blast distributino proportion in different layers and different corners according to boiler load, fuel amount and blast amount.

Owner:HUAZHONG UNIV OF SCI & TECH

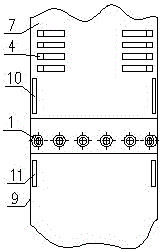

Novel aluminium oxide vertical activation roasting device and roasting method

ActiveCN109654874AReduce energy consumptionQuality improvementCharge composition/stateIncreasing energy efficiencyCombustion chamberFlue gas

The invention relates to the technical field of activated aluminium oxide prepared by non-ferrous metal, specifically a novel aluminium oxide vertical activation roasting device and a roasting method.Aluminium oxide pellets move from top to bottom in a vertical roasting furnace, and are discharged from a discharging valve at the bottom of the furnace body after pre-storage, roasting and cooling processes. Flue gas generated by natural gas combustion roasts aluminium oxide pellets from bottom to top, and then is discharged after primary and secondary dust removal from the top of the furnace body. A cooling heat exchange pipe is arranged at the lower part of the furnace body, cooling gas is introduced into the pipe, the roasted high-temperature aluminium oxide pellets are cooled when flowing outside the pipe; after being heated, the cooling gas in the heat exchange pipe is sent into a combustion chamber through an air pipe to be used as combustion-supporting gas of natural gas, therefore, the waste heat recovery of the aluminium oxide pellets is realized. The roasting device provided by the invention has higher waste heat recovery utilization rate, full heat exchange between combustion flue gas and aluminium oxide pellets, and effectively reduces the natural gas energy consumption; and the method is reasonable, efficient, simple and easy to operate.

Owner:NORTHEASTERN UNIV

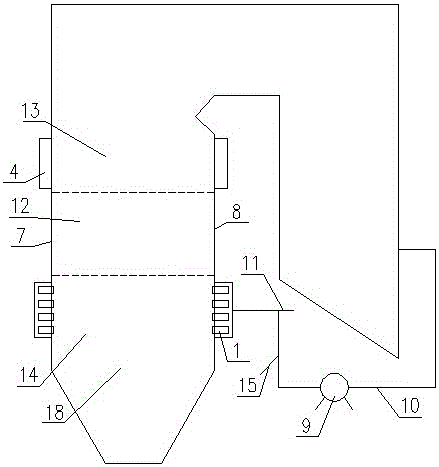

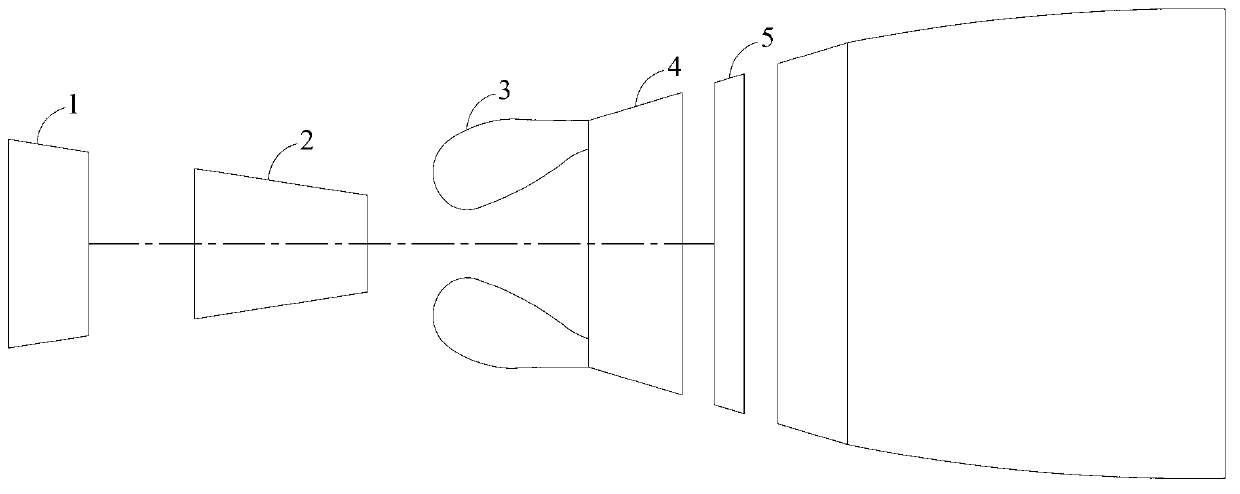

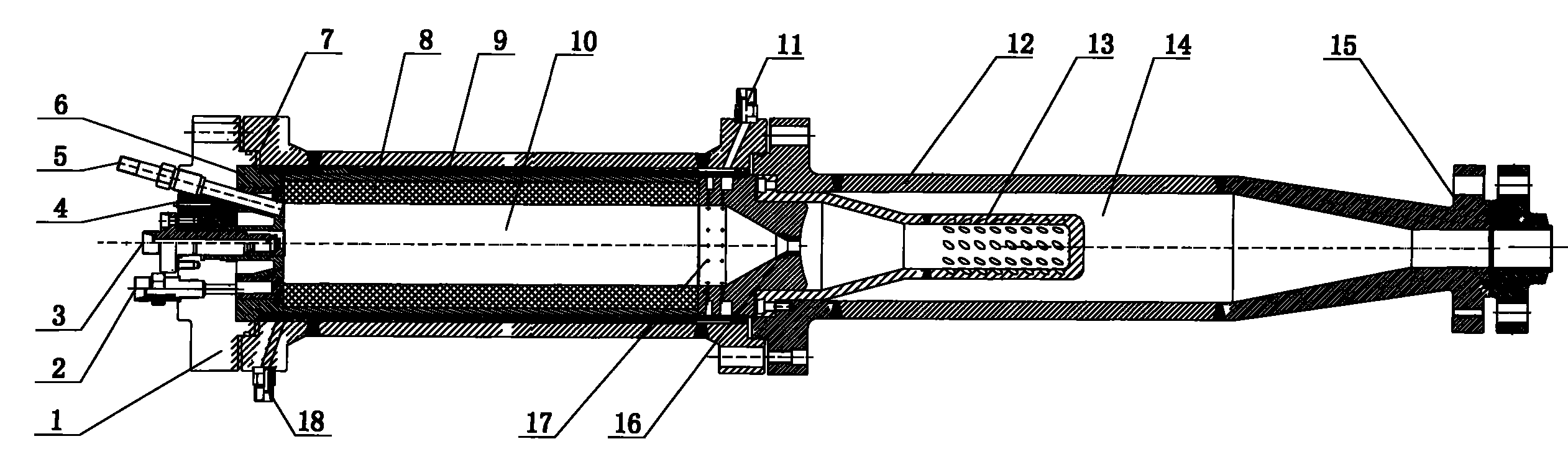

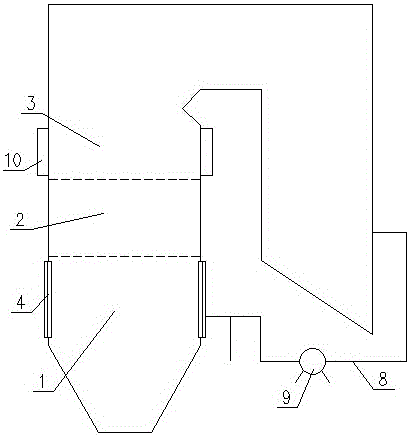

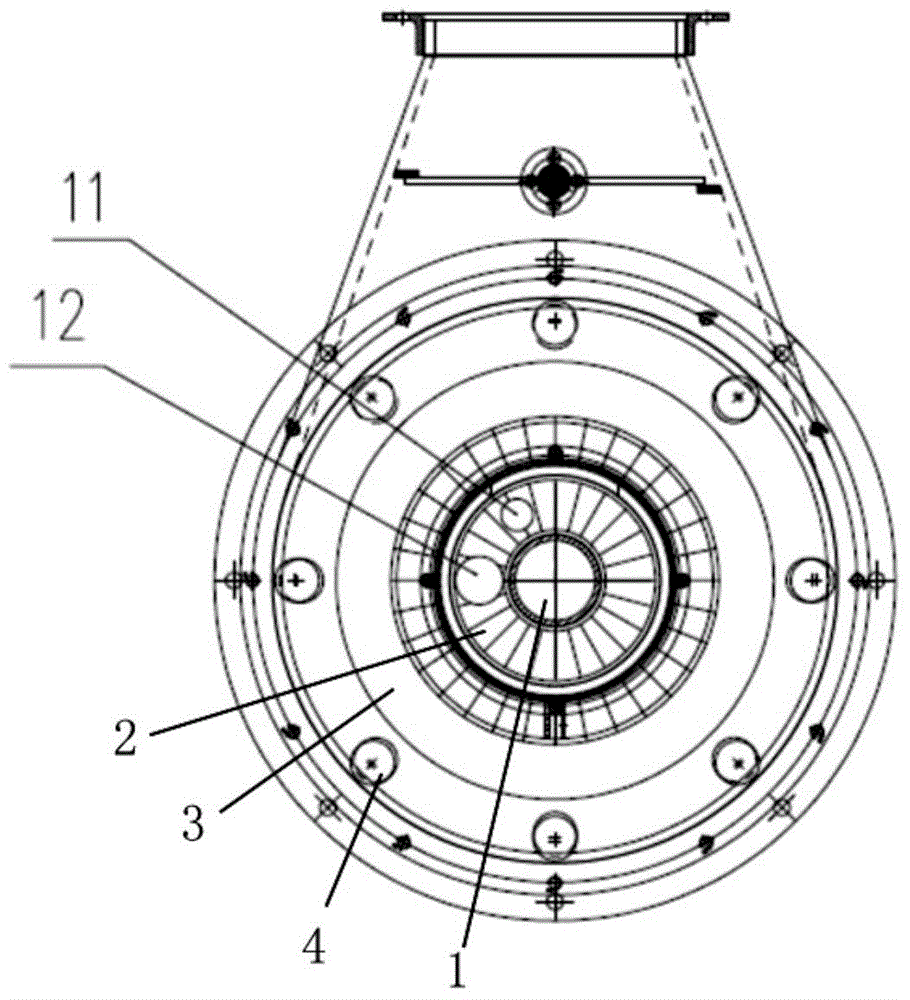

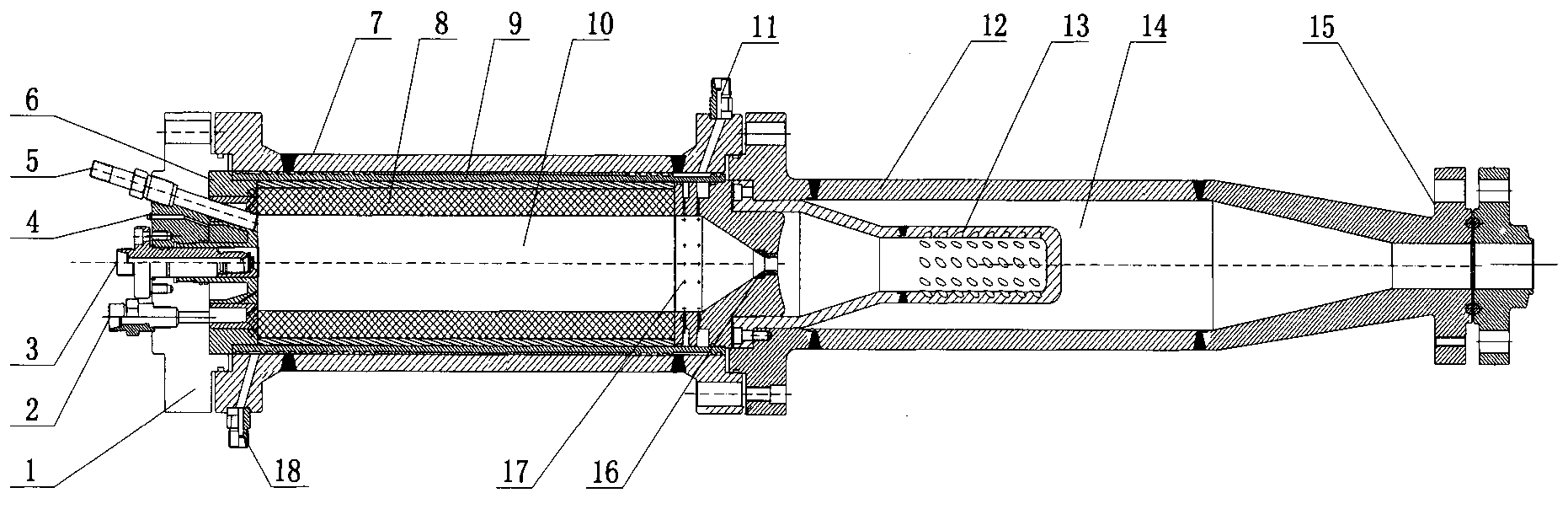

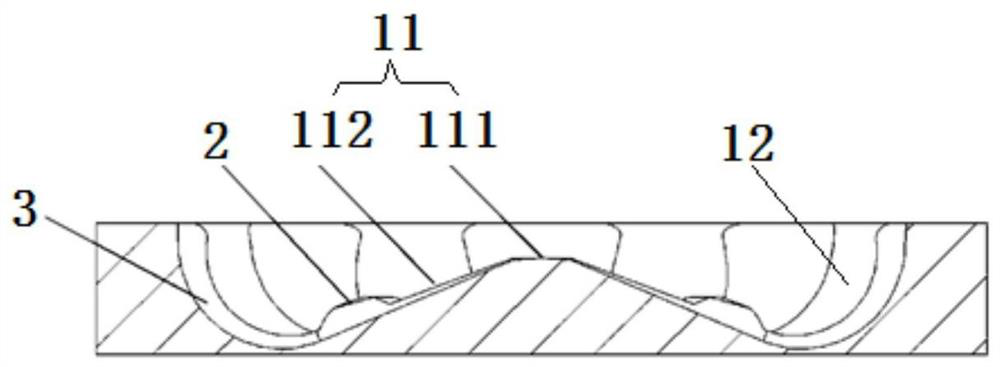

Water injection type high-pressure combustor

InactiveCN101832552ALower working temperatureImprove job stabilityFluid removalGaseous fuel burnerCombustion chamberCombustor

The invention belongs to the technical field of oil exploitation equipment and provides a water injection type high-pressure combustor. The water injection type high-pressure combustor comprises a head part (1), a combustion section (7) and a mixing section (12), wherein the combustion section (7) is arranged in the middle of the water injection type high-pressure combustor, and one end of the combustion section (7) is connected with the head part (1), while the other end is connected with the mixing section (12); the head part (1) is internally provided with an air distributor (2), an oil nozzle (3), a water injection hole (4), an igniter (5) and an air cap (6); the combustion section (7) is a cylindrical structure, and the middle of the combustion section (7) is provided with a combustion chamber (10); the outer side of the combustion chamber (10) is provided with a heat insulation sleeve (8), the outer side of the heat insulation sleeve (8) is provided with a cooling water jacket (9), and a cooling water jacket inlet joint (18) is arranged on the cooling water jacket (9). The water injection type high-pressure combustor has strong reliability and easy operation, and the service life of the equipment is obviously prolonged.

Owner:SOUTHEAST UNIV

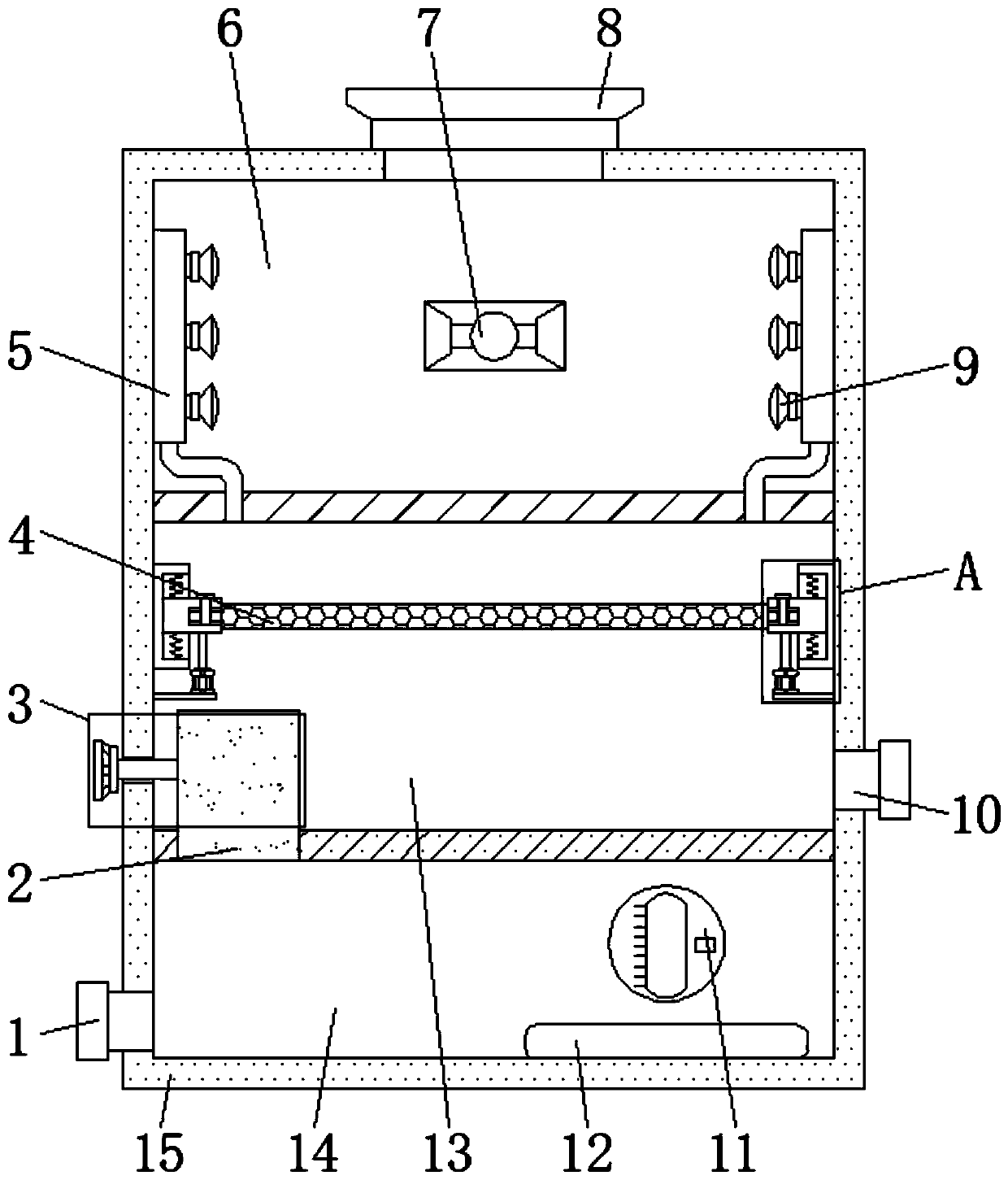

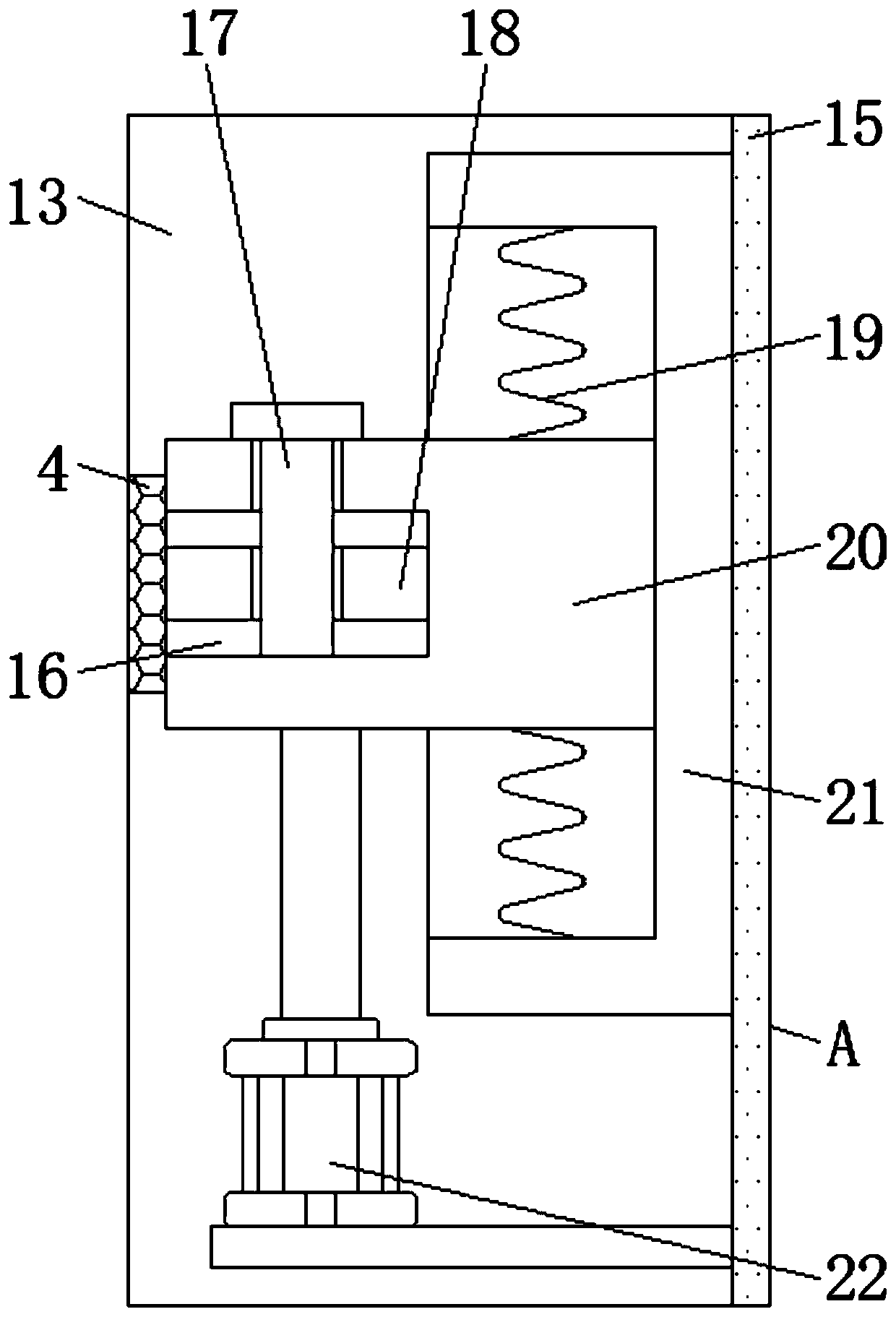

Low-oxygen flameless heat storage type combustion device

ActiveCN110986030AGuaranteed combustion efficiencyImprove convenienceFluegas recirculationIndirect carbon-dioxide mitigationCombustion chamberEngineering

The invention discloses a low-oxygen flameless heat storage type combustion device. The device comprises a first air inlet, a combustion chamber, a preheating cavity, a shell and a control panel. Thepreheating cavity is formed in the bottom end of the interior of the shell, a heating pipe is mounted on one side of the bottom of the preheating cavity, a temperature sensor is mounted at the position, above the heating pipe, of the inner wall of the preheating cavity, a dust filter cavity is formed in the position, above the preheating cavity, in the shell, a circulation groove is formed in oneside of the bottom of the dust filter cavity, the bottom end of the circulation groove extends into the preheating cavity, a flow limiting structure is arranged in the circulation groove, a combustionchamber is arranged at the position, above the dust filter cavity, in the shell, air storage grooves are fixed to the two inner side walls of the combustion chamber, and nozzles are formed in the outer wall of one side of each air storage groove at equal intervals. The combustion efficiency during use of the combustion device is ensured, the application range of the combustion device is widened,and the portability during use of the combustion device is improved.

Owner:HUNAN HENGSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Piston, engine and vehicle

PendingCN111720235AImprove powerImprove emission effectInternal combustion piston enginesPistonsThermodynamicsCombustion chamber

The invention relates to the technical field of pistons, in particular to a piston, an engine and a vehicle. The piston is provided with a combustion chamber with an omega-shape, the inner wall of thecombustion chamber comprises a conical table surface located in the center, and an arc-shaped surface connected to the periphery of the conical table surface, in the circumferential direction, a plurality of dividing bumps are arranged on the conical table surface at intervals, oil injection channels are formed between any two adjacent dividing bumps, a plurality of oil injecting holes of an oilinjector can inject the oil into the multiple oil injection channels one by one, the oil liquid can be atomized into oil mist in the combustion chamber, part of the oil mist can pass through the oil injection channels and impact on the arc-shaped surface to form upward curling flow, so as to utilize the air outside the combustion chamber for combustion, the other part of oil mist can collide on the two adjacent dividing bumps and form lateral curling flow movement, so as to utilize the air inside the combustion chamber for combustion, the air in the combustion chamber can be fully utilized toensure the combustion efficiency, and thus the overall dynamic performance and emission performance of the engine are improved.

Owner:WEICHAI POWER CO LTD

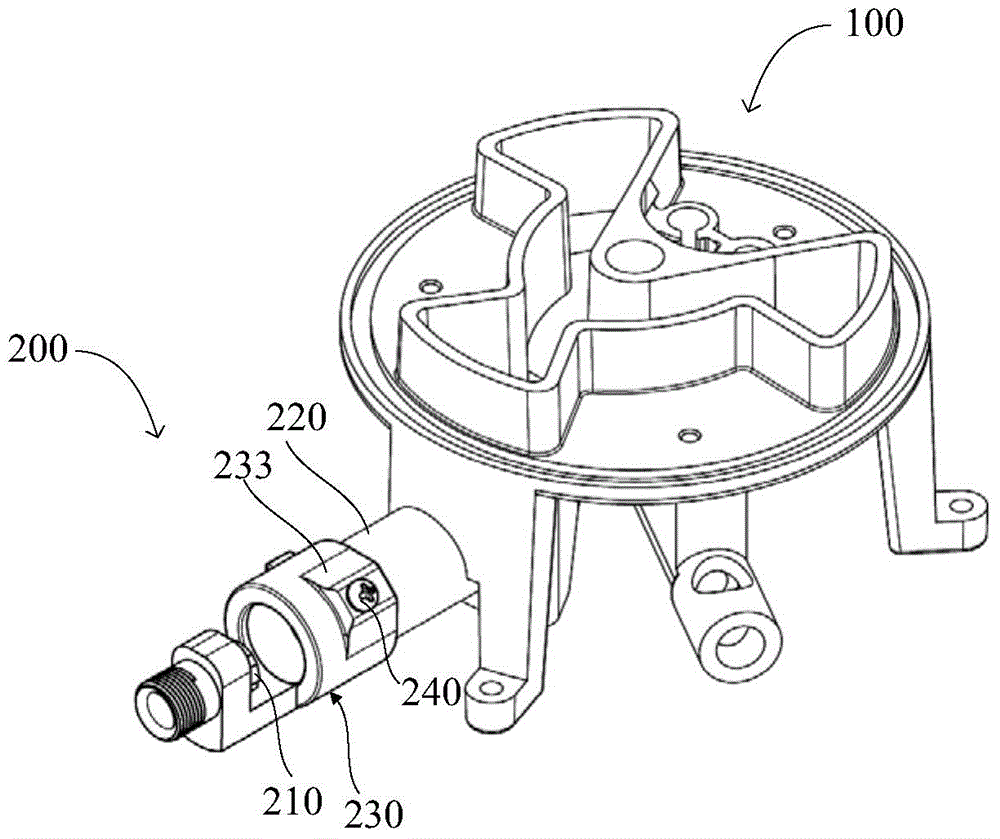

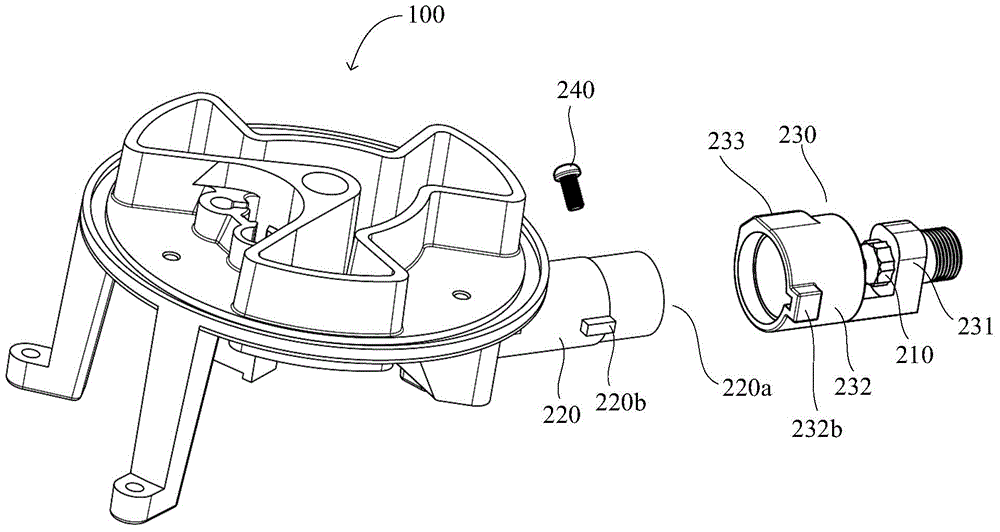

Burner for gas stove and gas stove

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com