Water injection type high-pressure combustor

A burner, high-pressure technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problem of shortened service life (sometimes less than one working day of gas injection, easy to burst, denudation, easy to be burned (such as The problems of the fire end face, the igniter ignition head, the oil nozzle atomizer, etc., can improve the working stability and prolong the continuous working cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

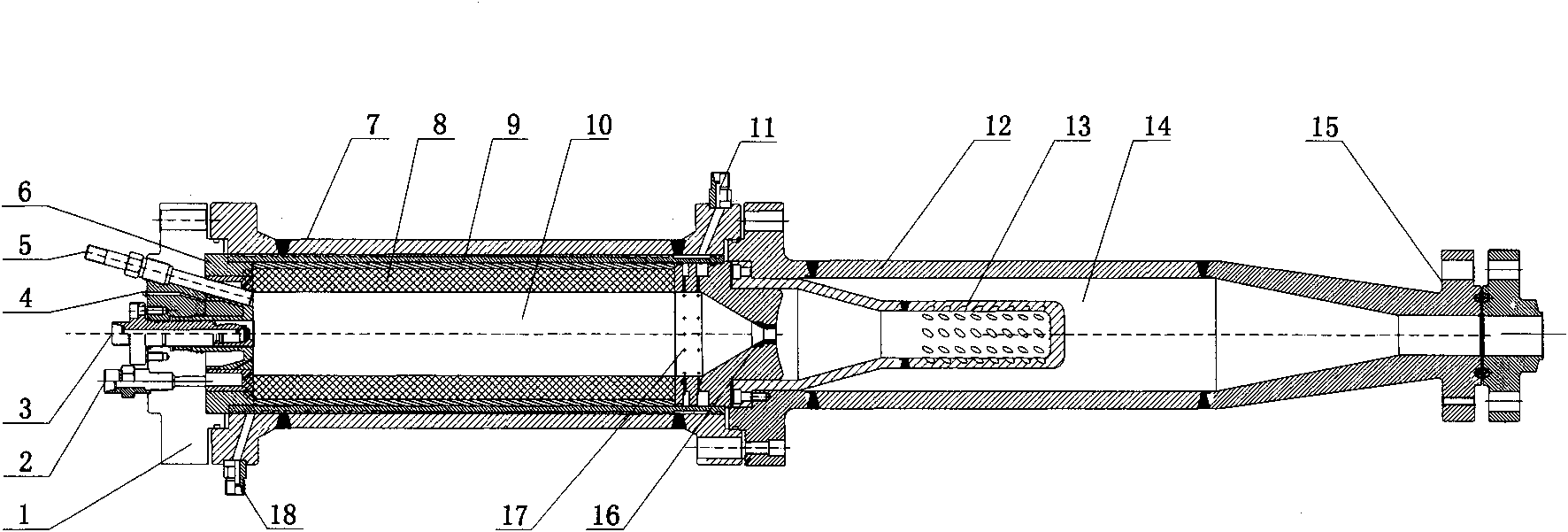

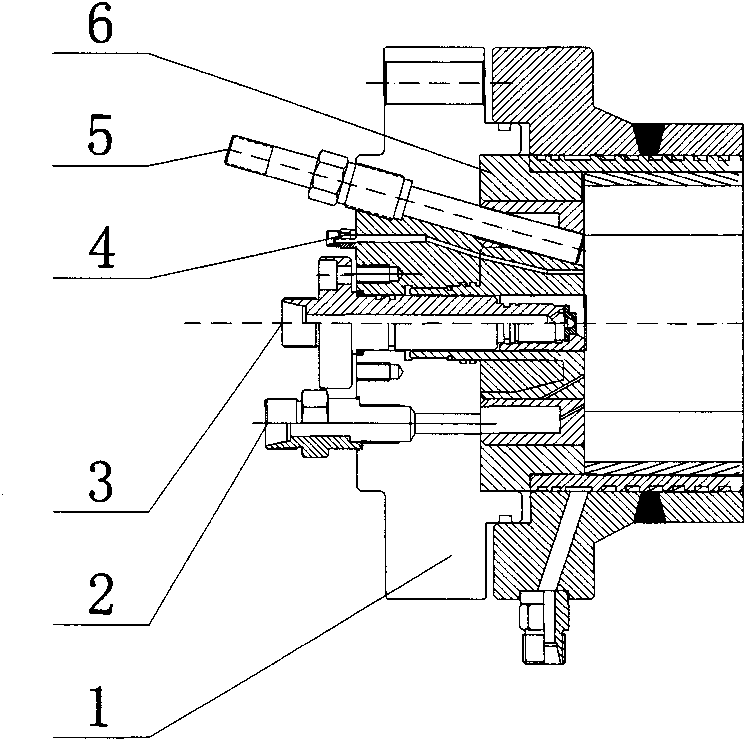

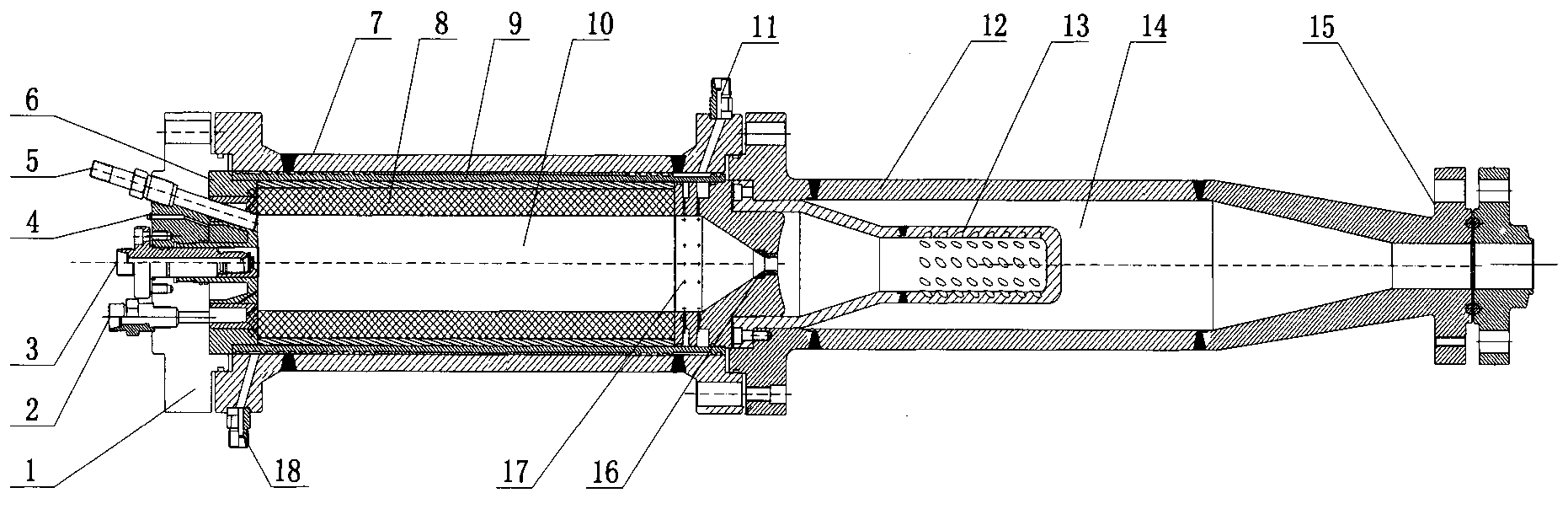

[0023] Example: such as figure 1 , figure 2 As shown, the head 1 of the high-pressure burner is set at the end of the combustion section 7, a wind cap 6 is provided between the head 1 and the combustion chamber 10, and an air distributor 2, oil Nozzle 3, water injection hole 4, igniter 5; Wherein, the outer end of water injection hole 4 is connected with water inlet pipe, and the inner end of water injection hole 4 connects combustion chamber 10 through head 1; Inject water into combustion chamber 10 through this hole.

[0024] Fuel enters the combustion chamber 10 from the oil nozzle 3 , compressed air enters the combustion chamber 10 from the air distributor 2 , and the working end of the igniter 5 also leads to the combustion chamber 10 . A certain amount of water is injected into the combustion chamber 10 from the water injection hole 4 .

[0025] When the present embodiment is working, the fuel and air enter the combustion chamber 10 and are atomized and mixed, ignited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com