Patents

Literature

2298results about How to "Lower working temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

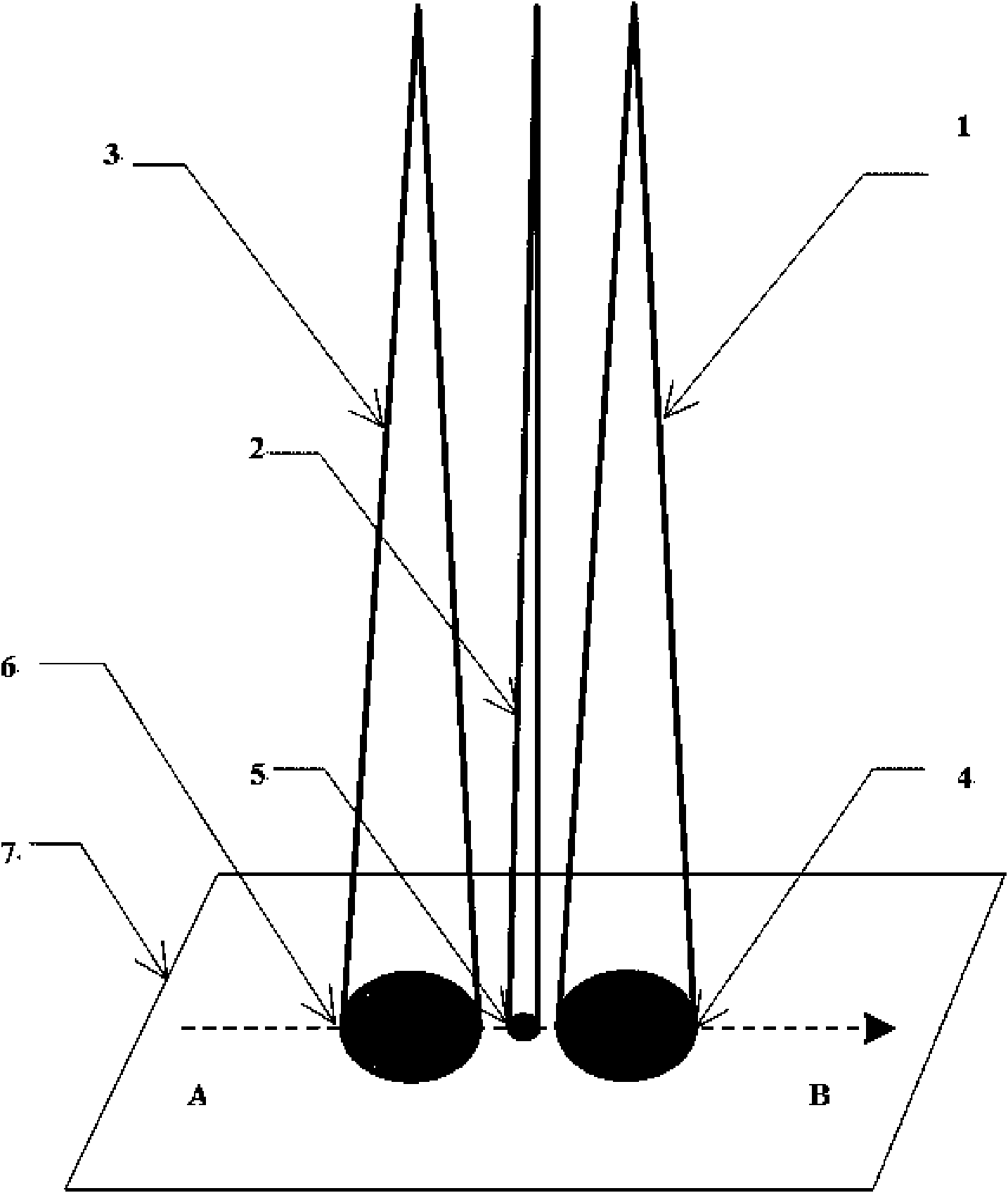

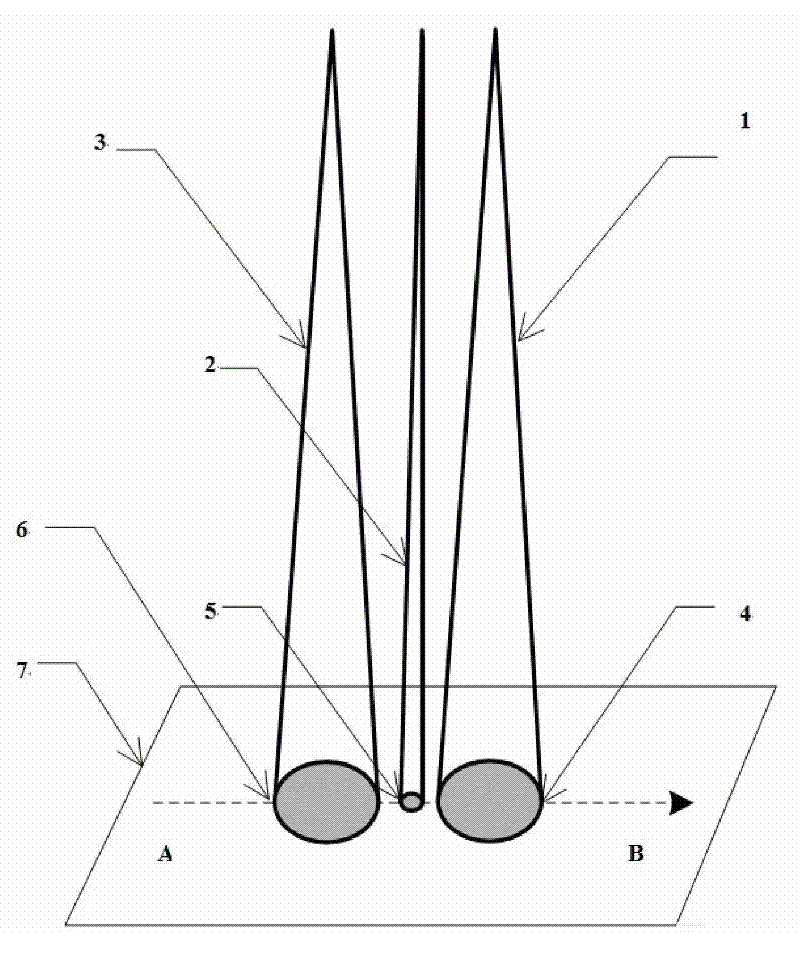

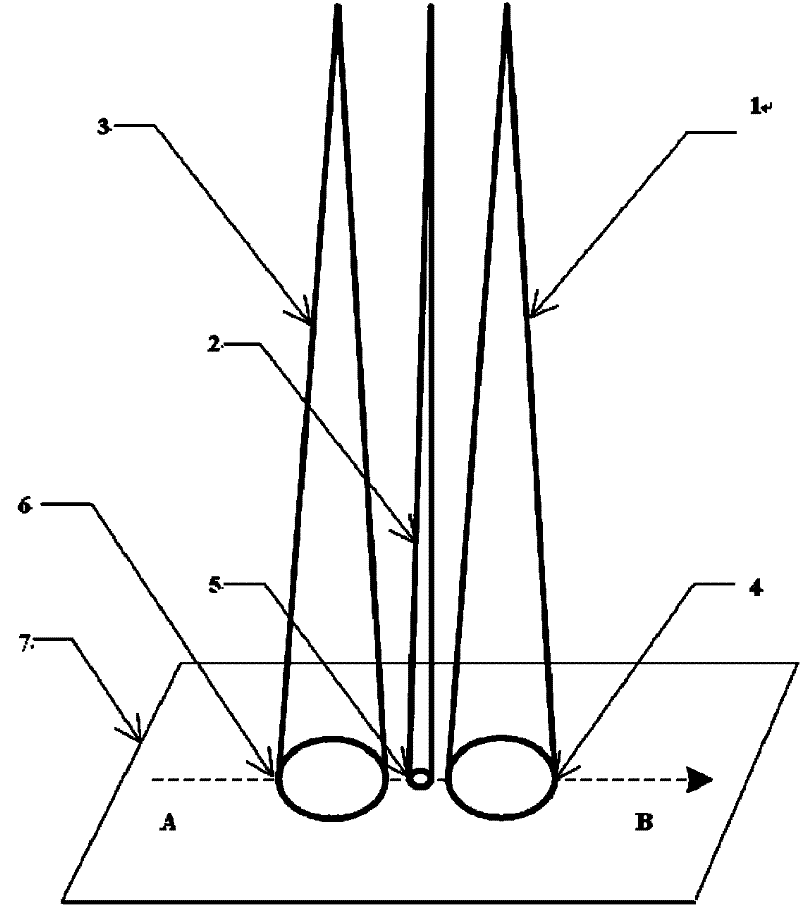

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

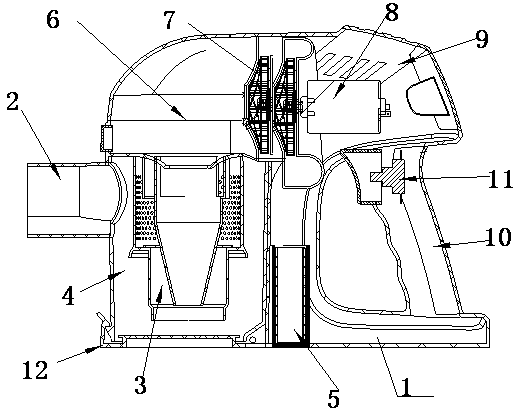

Handheld cleaning equipment

InactiveCN104172986AIncrease vacuumImprove dust removal efficiencySuction filtersHand heldWorking temperature

The invention discloses handheld cleaning equipment. The handheld cleaning equipment comprises an outer casing, a suction pipeline, a separation device, a dust cylinder, a power source, a filtering device, an airflow generator, a motor, an air outlet, a handle and a switch; the rear end of the outer casing is provided with the handle; the center at the front end of the outer casing is provided with the suction pipeline; the separation device is arranged behind the suction pipeline; the dust cylinder is arranged below the separation device; the filtering device is arranged above the separation device; the rear end of the filtering device is provided with the airflow generator; the rear end of the airflow generator is provided with the motor coaxially; the rear end of the motor is provided with the air outlet; the power source is arranged between the handle and the dust cylinder; the handle is provided with the switch. The handheld cleaning equipment has the advantages of being high in reliability, compact in structure, small and exquisite in size, strong in suction, good in filtering performance, low in working temperature, light in weight and convenient to use and having a wide market prospect in a dust collector market.

Owner:SUZHOU CLEANPLUS ELECTRIC APPLIANCE

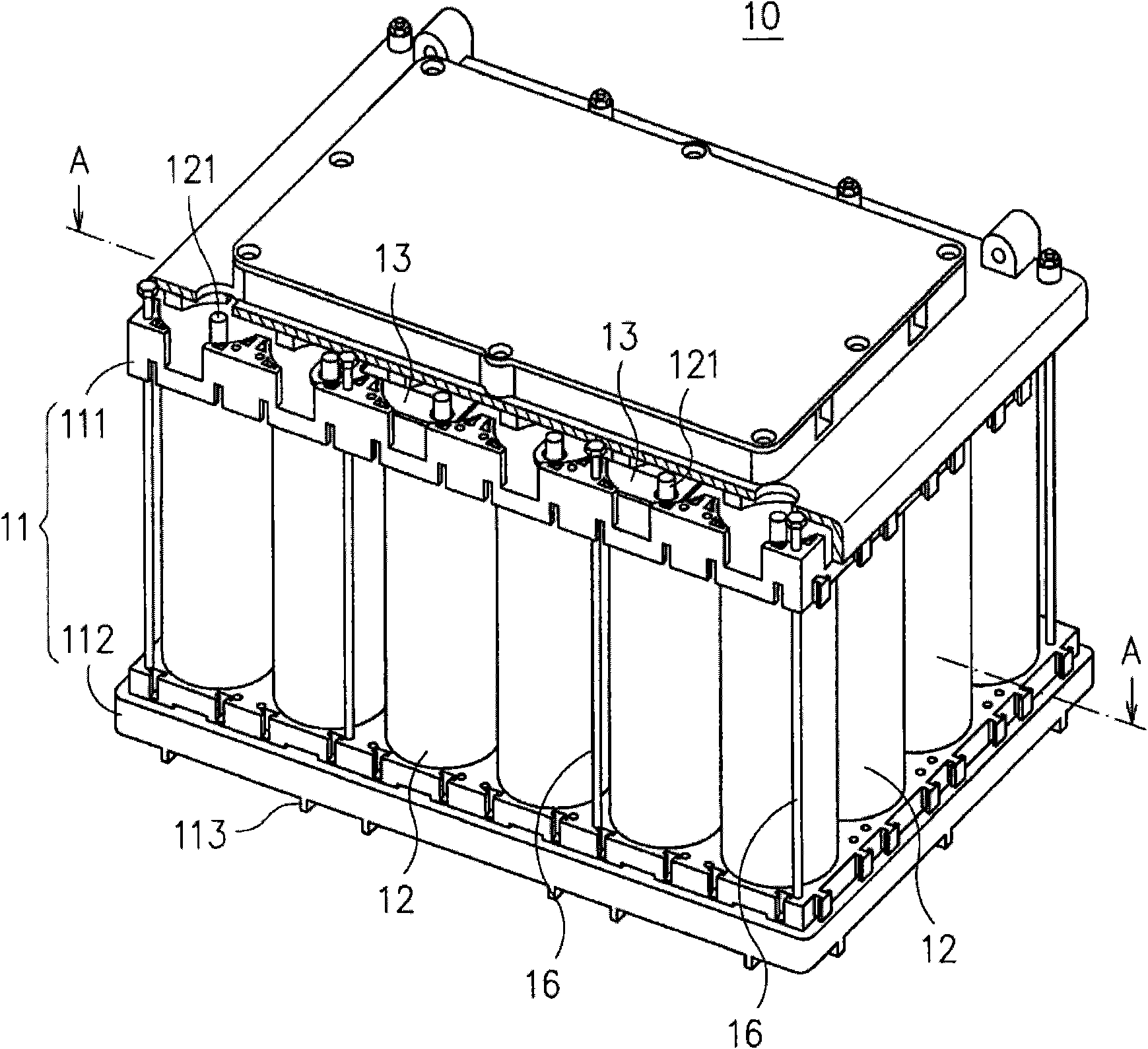

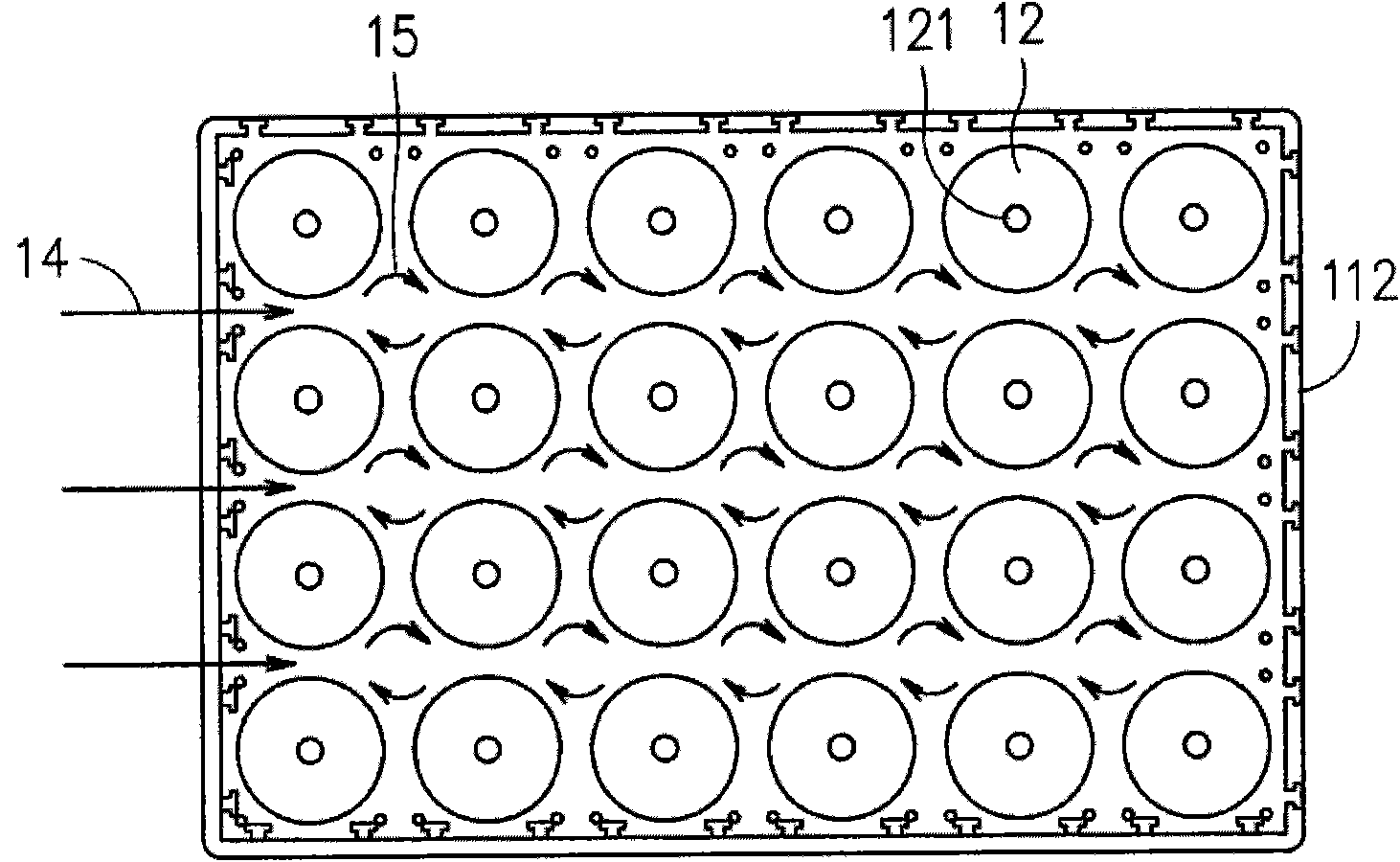

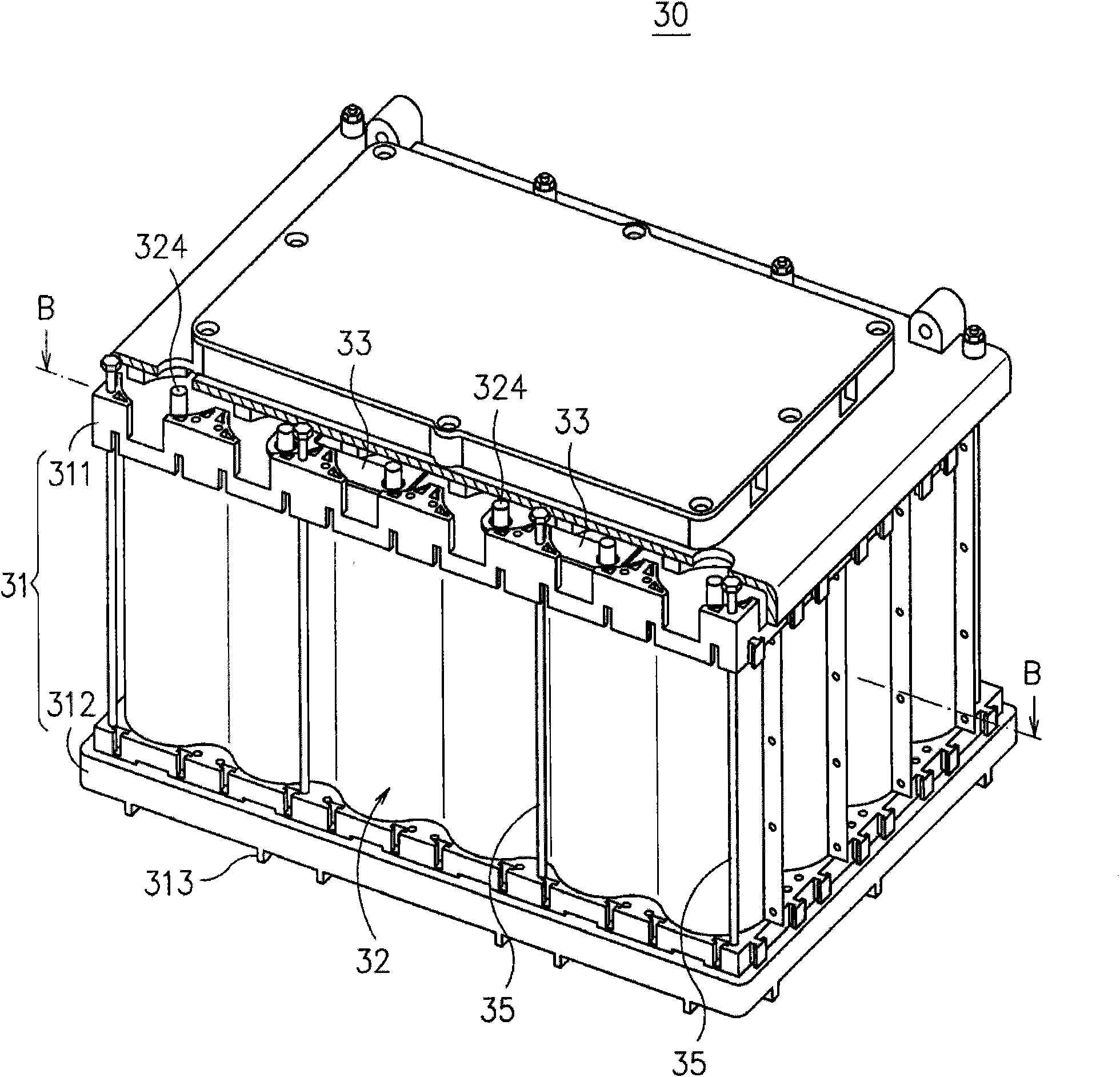

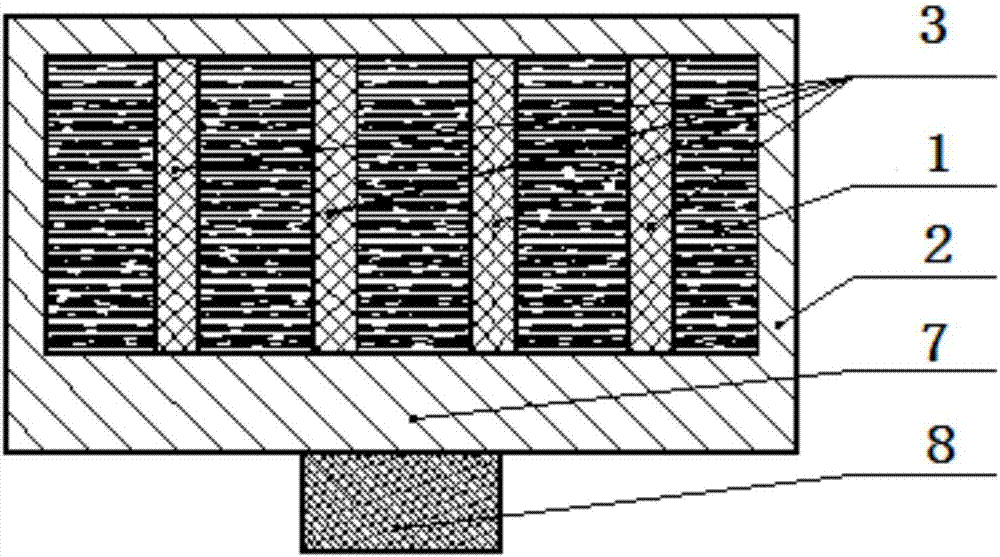

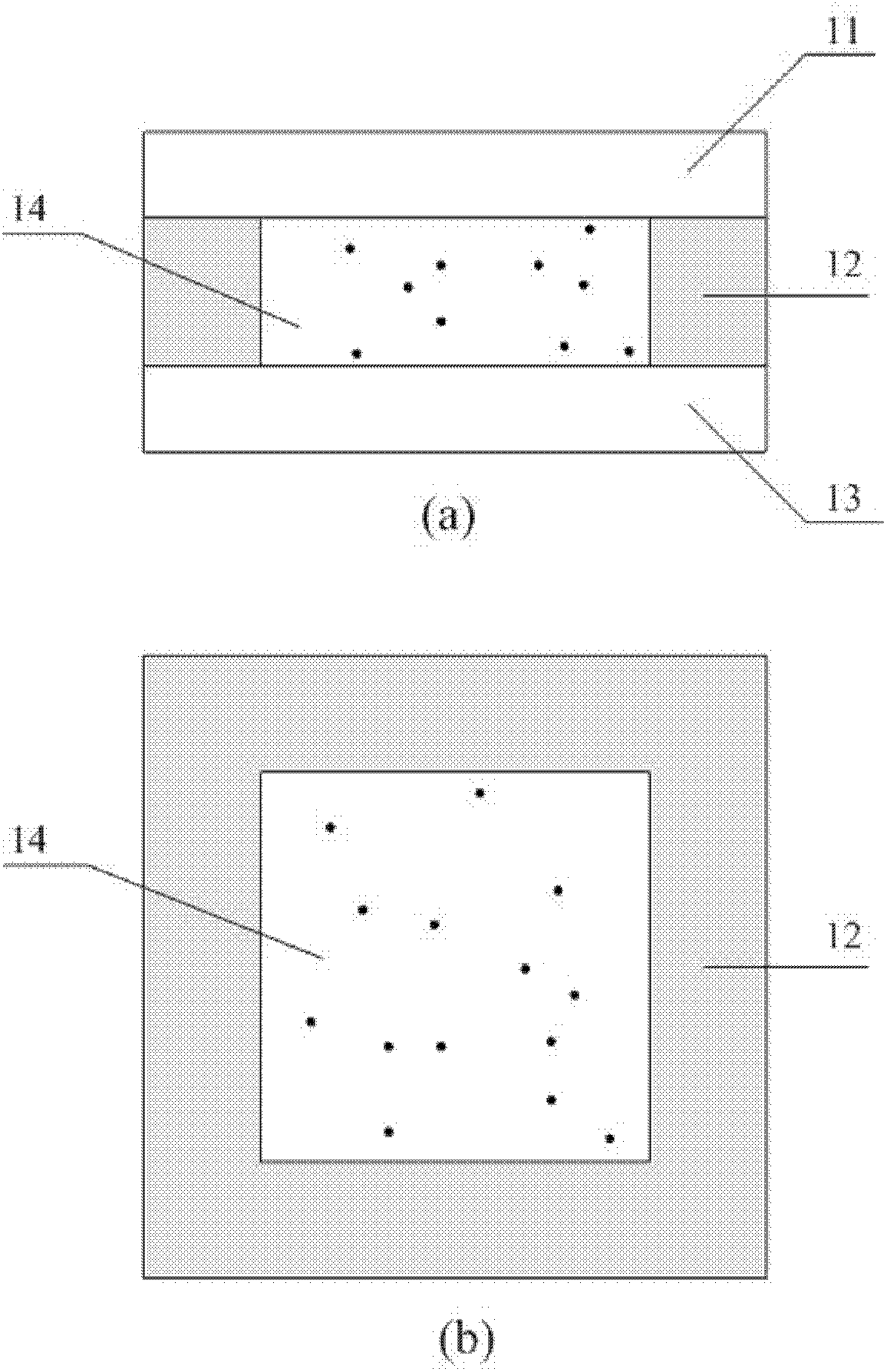

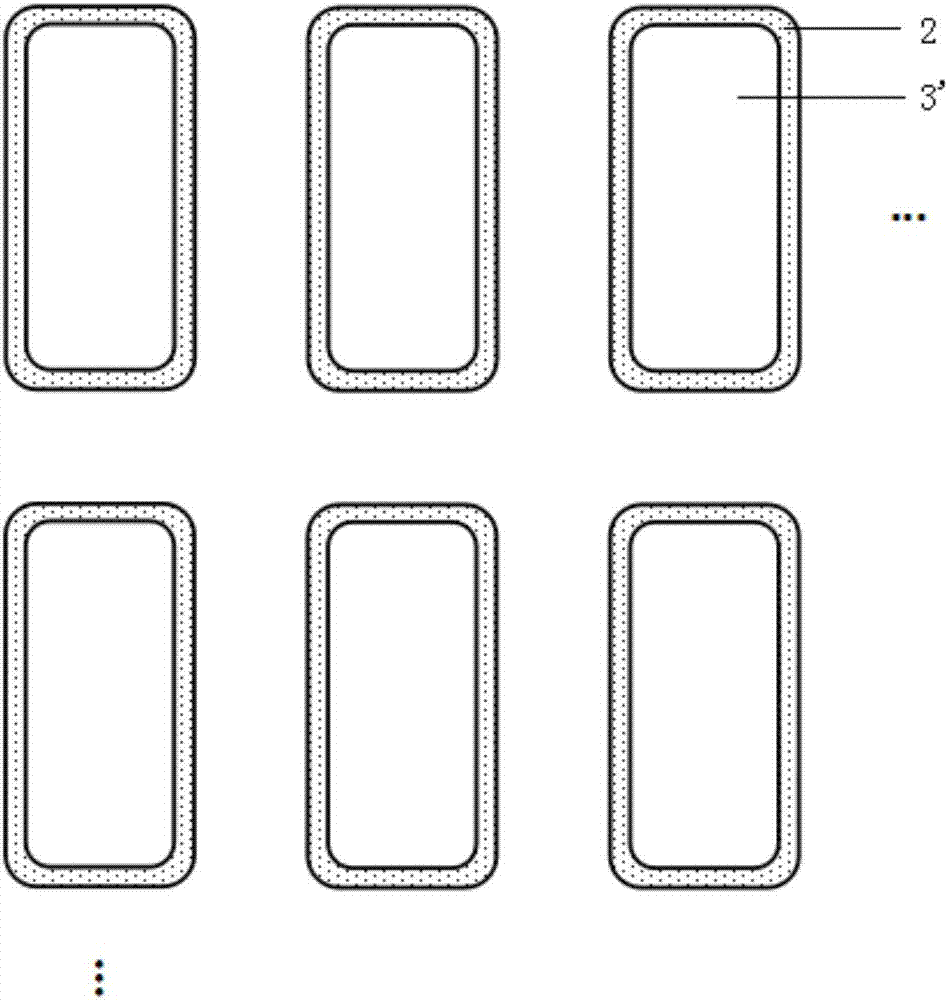

Battery pack with thermal conducting adhesives

InactiveCN102055003ALower working temperatureAverage temperature differencePrimary cell maintainance/servicingNon-aqueous electrolyte cellsElectricityAdhesive

The invention discloses a battery pack with thermal conducting adhesives. The battery pack comprises a shell and a plurality of battery units, wherein the shell is provided with a cooling device, the battery units are arranged in the shell, the thermal conducting adhesives with an electric insulation characteristic and a thermal conducting characteristic are arranged outside the battery units and are in contact with the outer surfaces of the battery units.

Owner:IND TECH RES INST

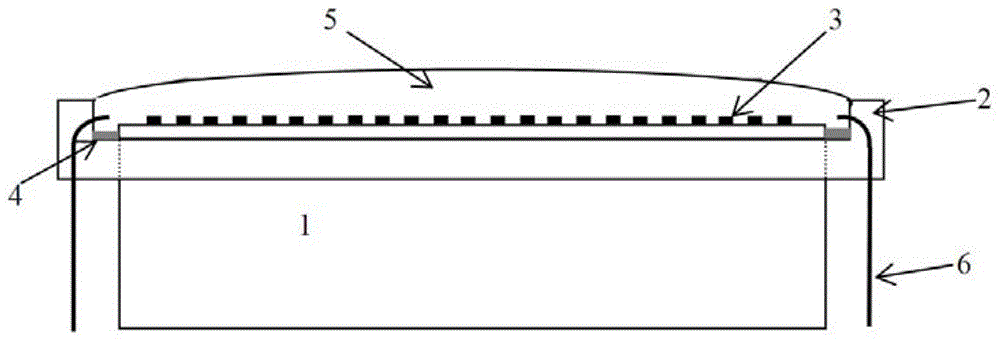

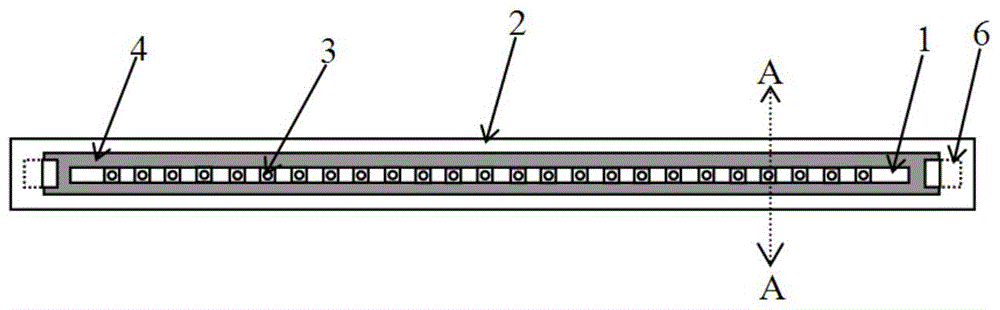

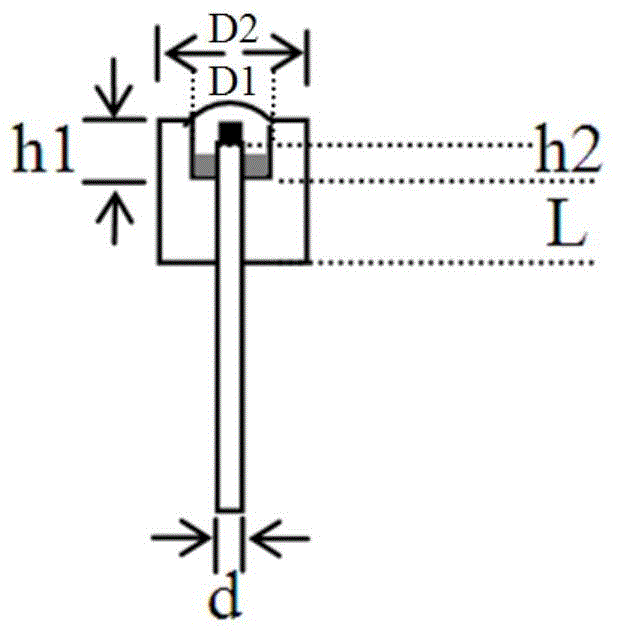

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

Fused quartz tubing for pharmaceutical packaging

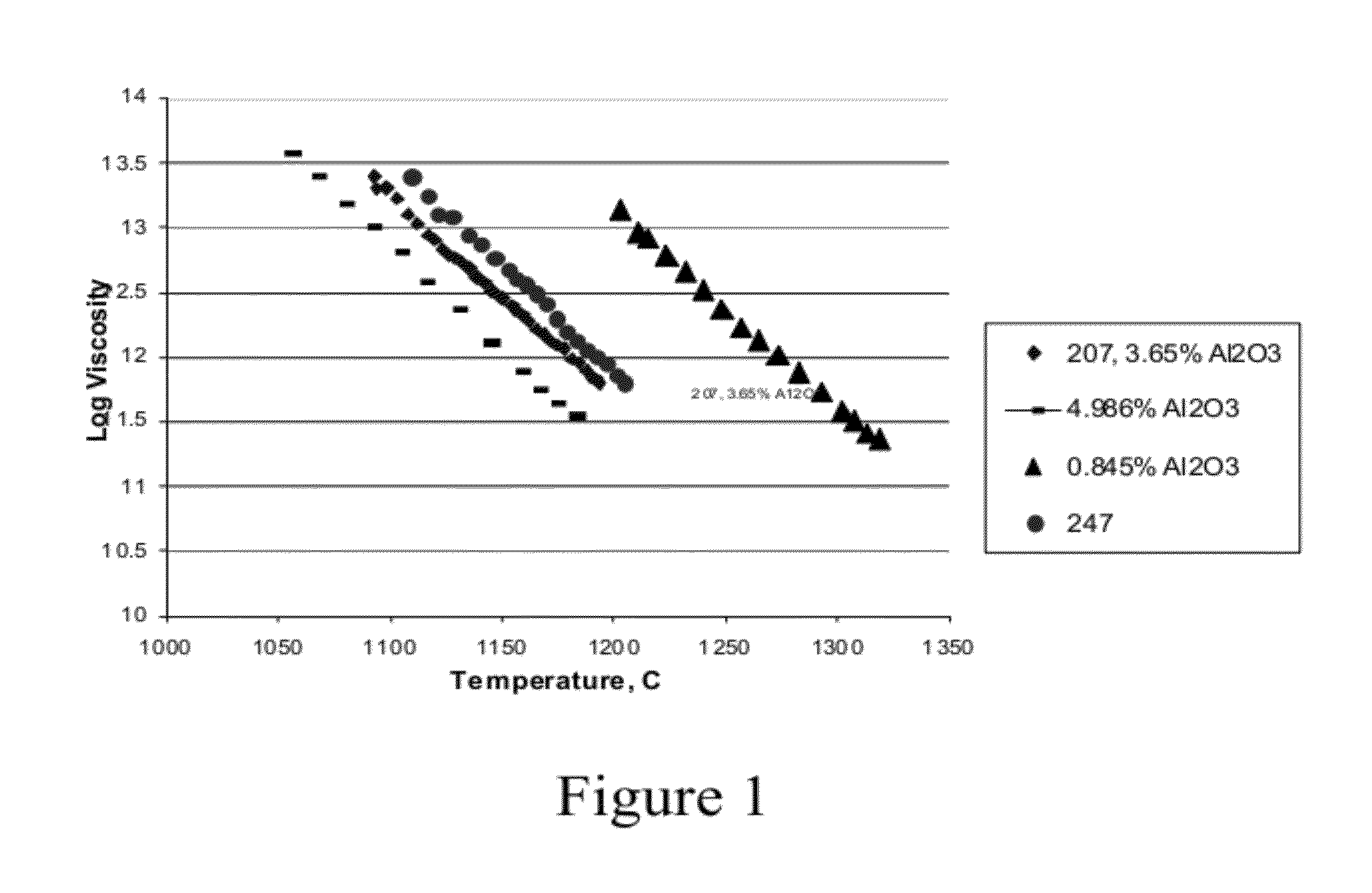

InactiveUS20120148770A1Reduce softeningLow working point temperatureLayered productsPharmaceutical containersRare earthWorking temperature

A high silica glass composition comprising about 82 to about 99.9999 wt. % SiO2 and from about 0.0001 to about 18 wt. % of at least one dopant selected from Al2O3, CeO2, TiO2, La2O3, Y2O3, Nd2O3, other rare earth oxides, and mixtures of two or more thereof. The glass composition has a working point temperature ranging from 600 to 2,000° C. These compositions exhibit stability similar to pure fused quartz, but have a moderate working temperature to enable cost effective fabrication of pharmaceutical packages. The glass is particularly useful as a packaging material for pharmaceutical applications, such as, for example pre-filled syringes, ampoules and vials.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

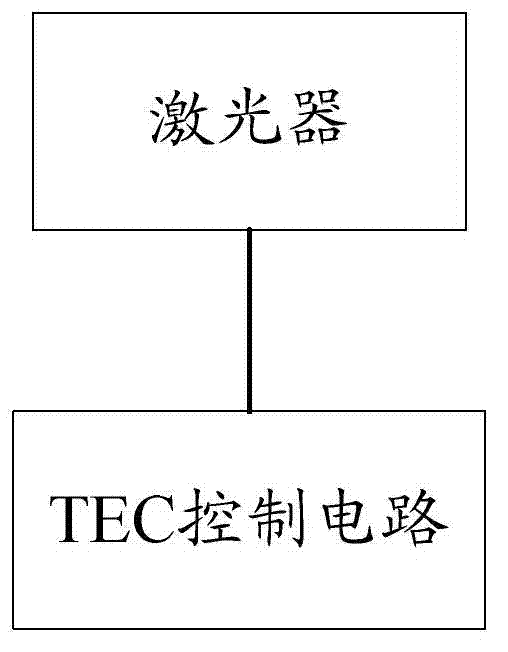

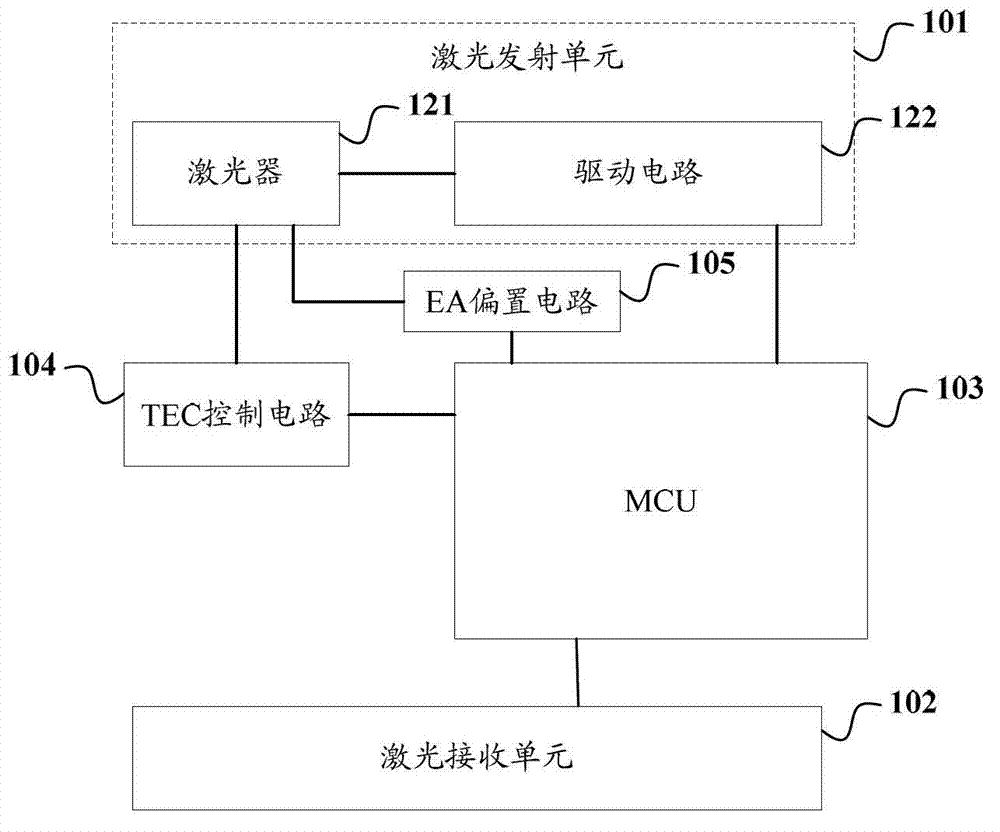

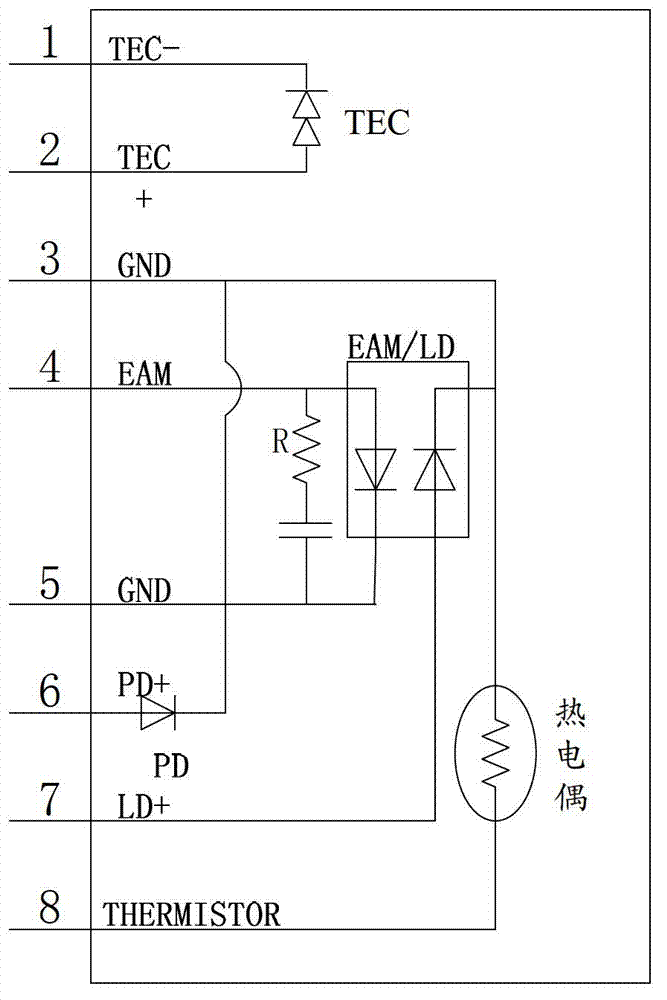

Optical module and adjusting method of working temperature of laser thereof

InactiveCN102970080AReduce power consumptionLower working temperatureLaser detailsElectromagnetic transmissionOptical ModuleOptical power

The invention discloses an optical module and an adjusting method of a working temperature of a laser thereof. The method comprises determining a current environment temperature according to an obtained temperature value after a micro controller unit (MCU) in the optical module obtains the temperature value detected by a temperature sensor; determining a working temperature set value corresponding to the current environment temperature and a BIAS current set value; controlling a driving circuit to output corresponding BIAS current according to the determined working temperature set value; and controlling a thermoelectric cooler (TEC) control circuit to adjust the working temperature of the laser to be a corresponding temperature according to the determined working temperature set value. Due to the facts that the working temperature of the laser is allowed to be changed correspondingly along with the environment temperature within a certain range and BIAS current adjustment is simultaneously adopted to serve as a compensation means to enable optical power and extinction ratio to be constant, the difference between the working temperature of the laser and the environment temperature is reduced, heating or refrigeration current provided for a TEC is reduced, and the goal of reducing power consumption is achieved.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

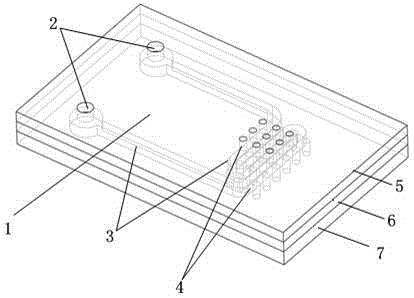

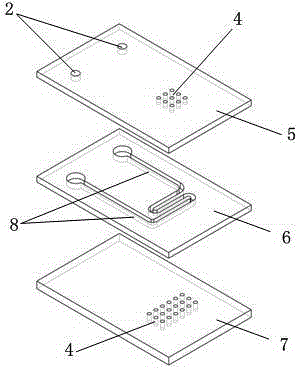

Printed circuit board embedded runner liquid cooling heat exchange device

ActiveCN105188260AImprove heat transfer coefficientLower working temperaturePrinted circuit aspectsCircuit fluid transportPrinted circuit boardConductive materials

The invention discloses a printed circuit board embedded runner liquid cooling heat exchange device. The heat exchange device comprises a top PCB layer, a middle PCB layer and a bottom PCB layer, wherein a runner is laid on the middle PCB layer, and an embedded runner is formed after the runner is sealed by the top PCB layer and the bottom PCB layer. An inlet and an outlet of the runner are formed in the top PCB layer or the bottom PCB layer simultaneously, or positioned in the top PCB layer and the bottom PCB layer respectively. A plurality of metal conduction holes are formed in the top PCB layer or the bottom PCB layer provided with a heating device, the metal conduction holes are positioned under the installation position of the heating device and filled with a conductive material, and the conductive material is a good conductor of heat simultaneously. The printed circuit board embedded runner liquid cooling heat exchange device disclosed by the invention is capable of effectively solving the problem of heat dissipation of a high-power device in a printed circuit board, and is smaller in volume and higher in integration and reliability.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

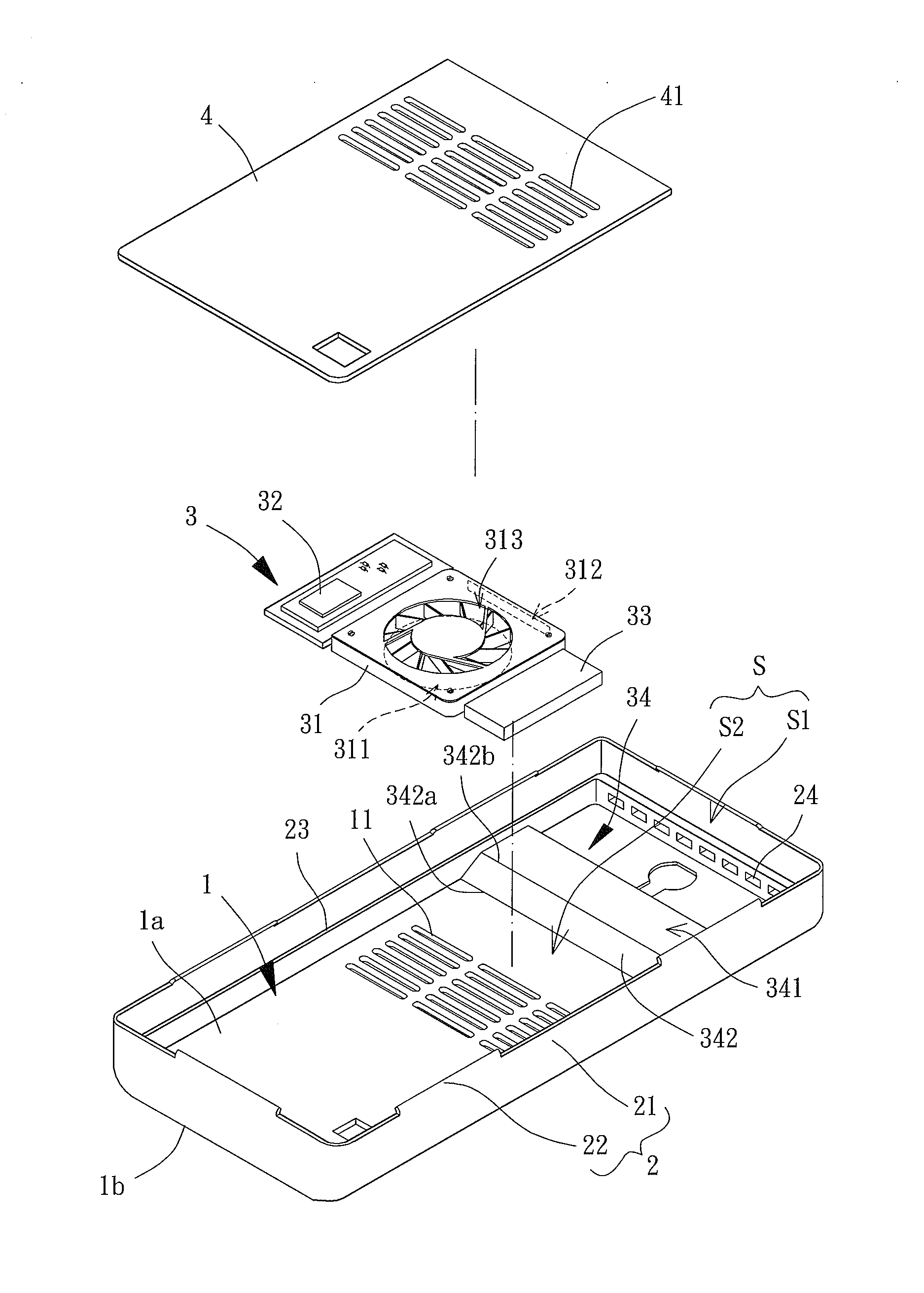

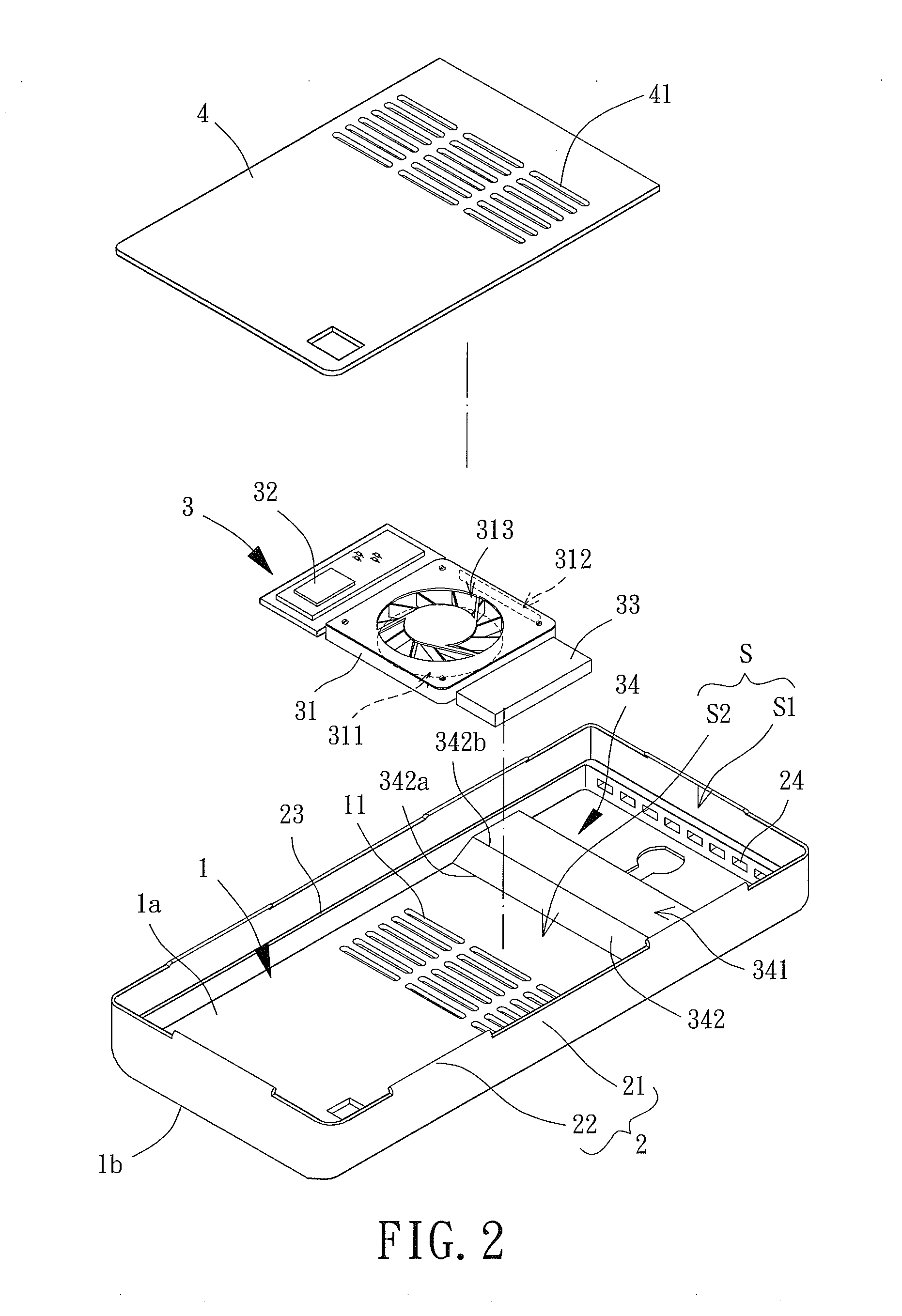

Protective cover for a hand-held electronic device

InactiveUS20150017905A1Cool efficiency be increaseImprove cooling efficiencyDigital data processing detailsOther accessoriesEngineeringHand held

Owner:SUNON ELECTRONICS FOSHAN

Zinc phosphating solution of aluminium and aluminium alloy

InactiveCN101812682ALower working temperatureEnergy savingMetallic material coating processesBuilding materialChromium

The invention belongs to the field of metal surface treatment, relating to a zinc phosphating solution of aluminium and aluminium alloy. The invention is mainly used for zinc phosphating treatment of the aluminium and aluminium alloy in the industries of home appliances, automobiles, hardware, building materials and railway locomotives. The zinc phosphating solution is composed of 8-25g / l of PO4<-3>, 6-16g / l of NO3<-1>, 1.6-8.0g / l of Zn<+2>, 0.12-0.38g / l of F<-1>, 0.6-8.0g / l of Fe<+2>, 0.01-1.5g / l of Ni<+2>, 0.0002-0.0006g / l of accelerating agent, 0.001-1.2g / l of organic complexing agent and the balance of water. When the phosphating solution of the invention is used for processing the aluminium and aluminium alloy, the obtained phosphating film has favourable matching capability with the coating, and the griding test of the paint film can reach 0 grade. The phosphating solution of the invention does not use toxic chromium, and the phosphating film does not contain chromium so as to solve the problems of environment pollution and toxic hazard on the human body when the chromium is used for processing the aluminium and aluminium alloy, and lower treatment cost.

Owner:中化化工科学技术研究总院有限公司

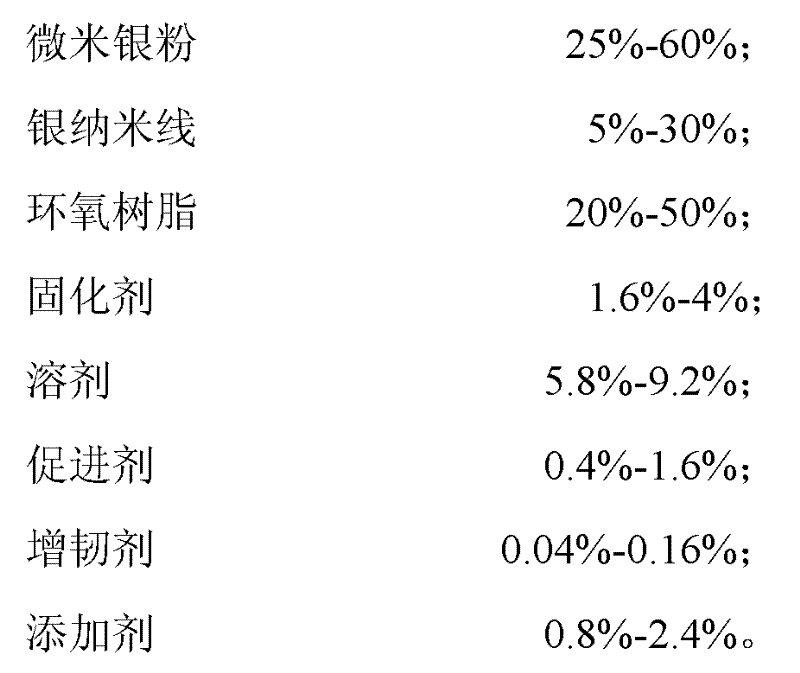

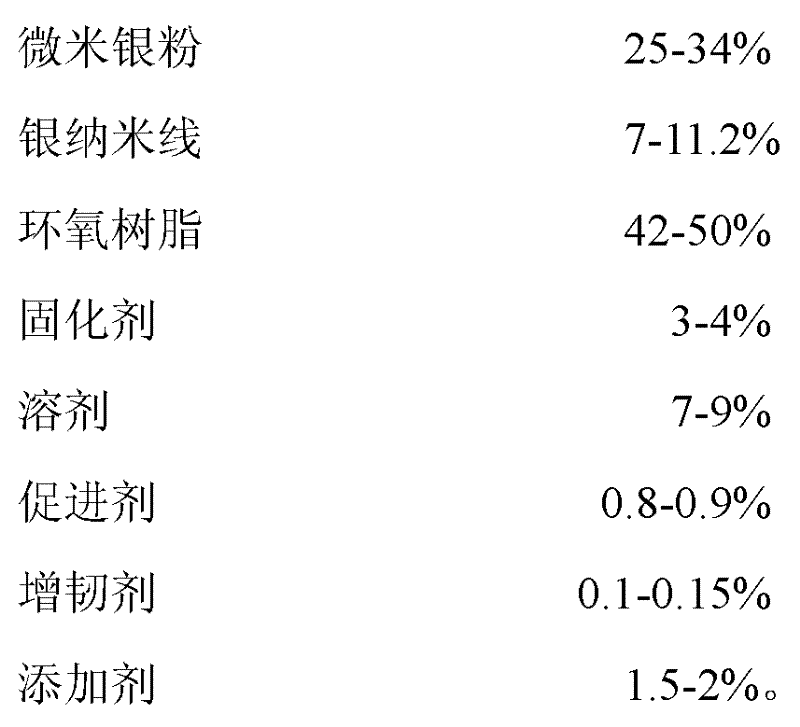

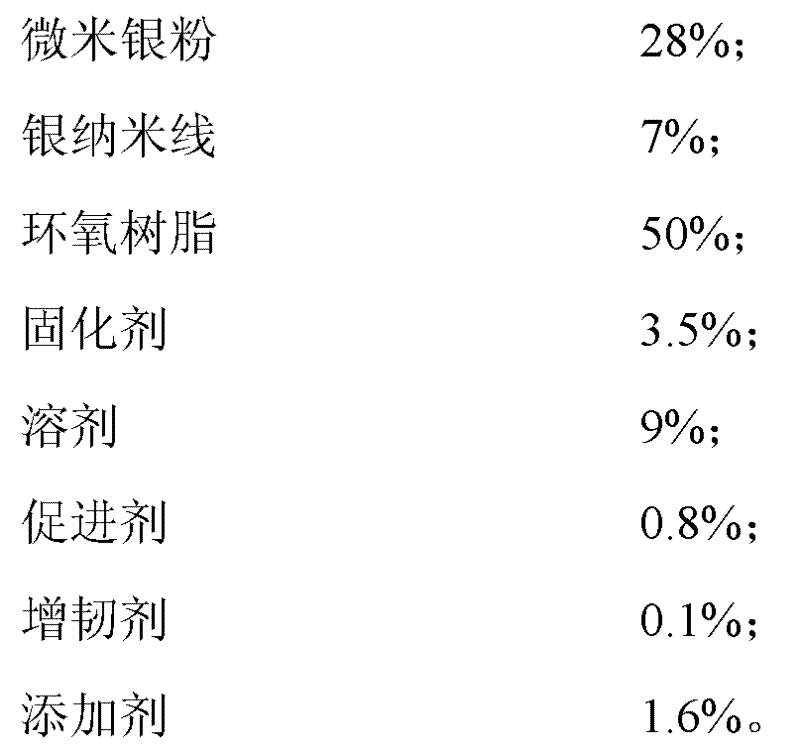

Silver nanowire doped conductive silver colloid and preparation method thereof

InactiveCN102676102AImprove electrical performanceReduce silver contentNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to the field of semiconductor electronic materials, and in particular relates to a silver nanowire doped conductive silver colloid and a preparation method thereof. The raw materials of the silver nanowire doped conductive silver colloid provided by the invention comprise the following components in percentage by weight: 25-60% of micrometer silver powder, 5-30% of silver nanowires, 20-50% of epoxy resin, 1.6-4% of curing agent, 5.8-9.2% of dissolvent, 0.4-1.6% of accelerant, 0.04-0.16% of toughening agent and 0.8-2.4% of additive. The conductive silver colloid is prepared by mixing and doping single-crystal silver nanowires and silver granules, thus, the total silver doping amount is reduced to 35-45%, and the conductive silver colloid has a favorable conductive effect, high shear strength, low working temperature and good ageing-resistant performance, and the cost of the conductive silver colloid is reduced. The silver nanowire doped conductive silver colloid can be widely applied to the fields of solar cell (film, crystal silicon) conductive colloids, conductive colloid LED (Light-Emitting Diode) package and the like.

Owner:SHANGHAI FUXIN NEW ENERGY TECH

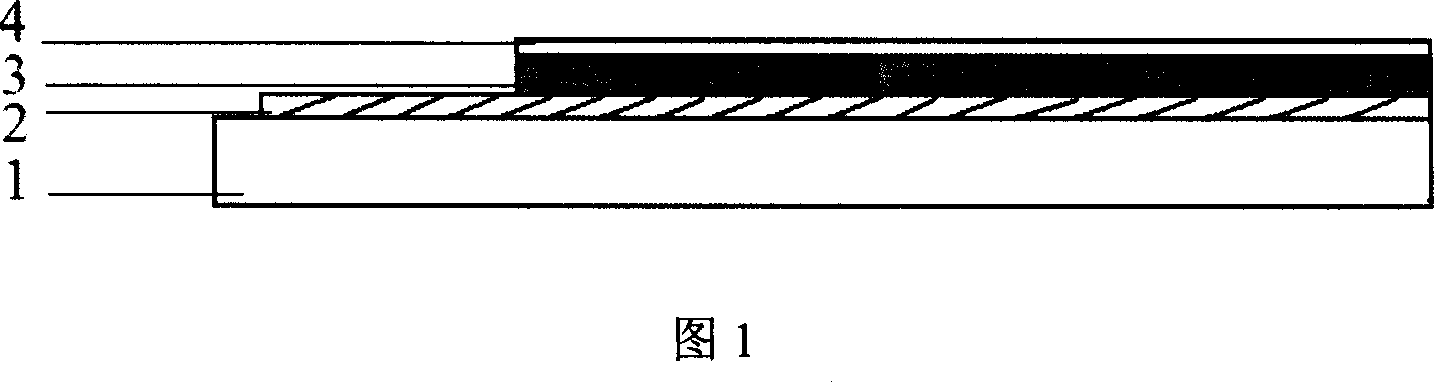

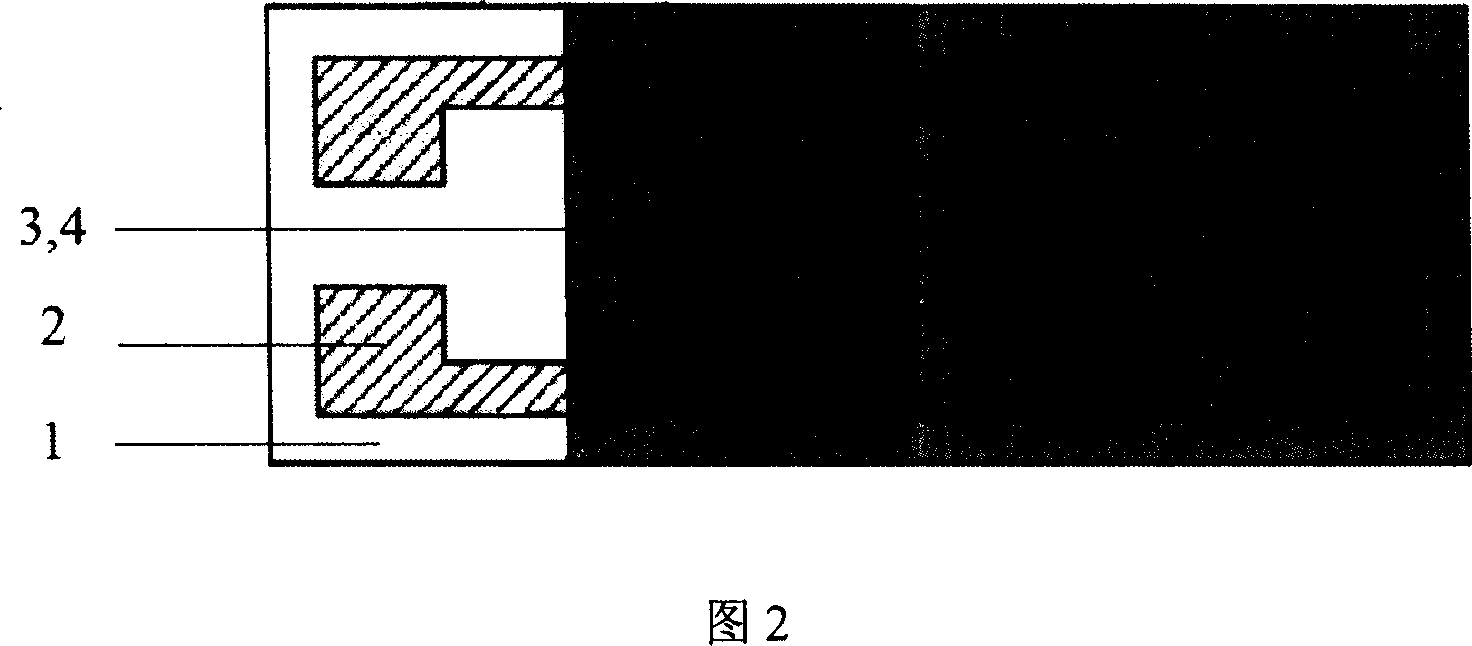

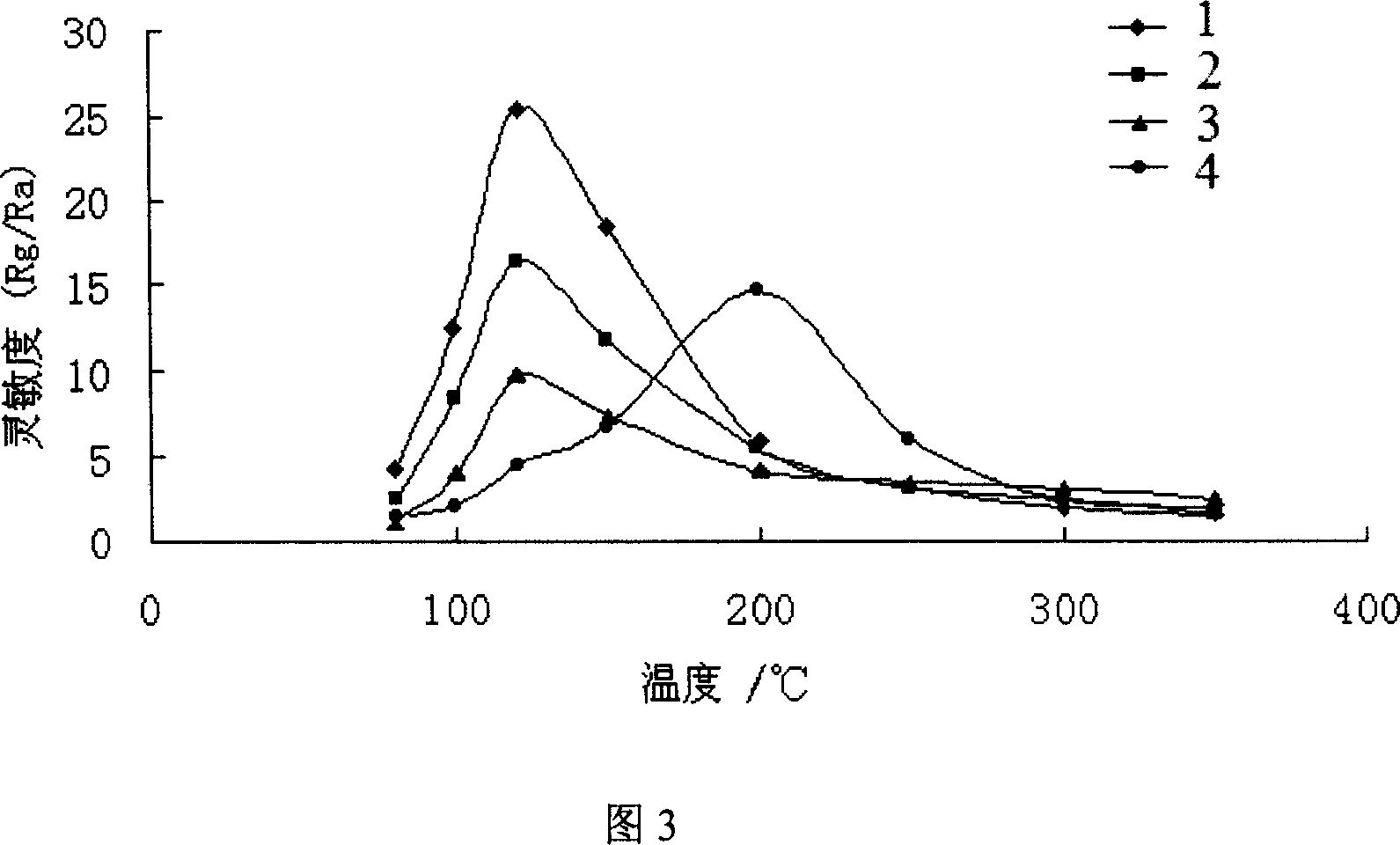

Tungstic acid thin film air-sensitive sensor surface modifying method

The invention discloses a surface modification method of the tungstic oxide film gas sensor. The process includes: cleaning the Al203 base sheet; spurting the interdigital electrode on the base sheet in the magnetron sputtering device using the platinum as the target and the argon gas as the working gas; spurting the tungstic oxide film on the base sheet with the interdigital electrode using the tungsten as the target and the argon, oxygen as the working gas; spurting the metal layer on the film using the Ti, Ni, Mo, Va, Platinum, Aurum or Pd as the target material and the argon gas as the working gas; heat process to the metal layer in air and get the surface modifying gas sensor. The film is uniform and high purity which is good adhesion to the base bottom and the parameter is easy to control. The gas sensor has the low working temperature and good selectivity, also the response and recovery time are shot.

Owner:TIANJIN UNIV

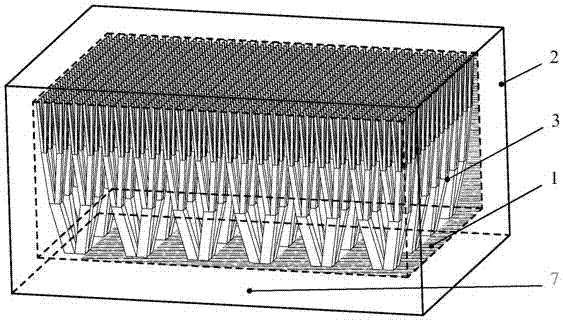

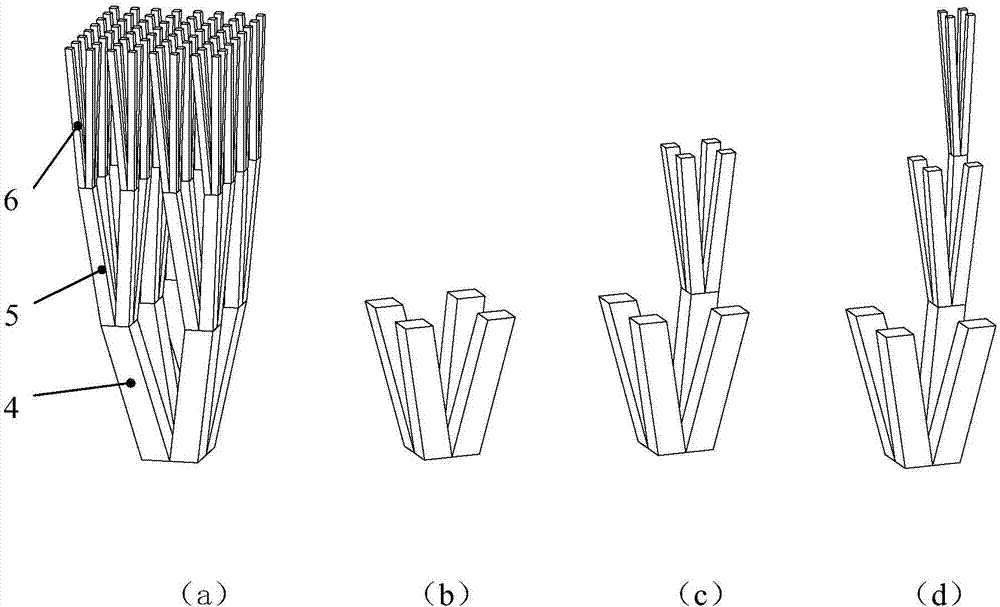

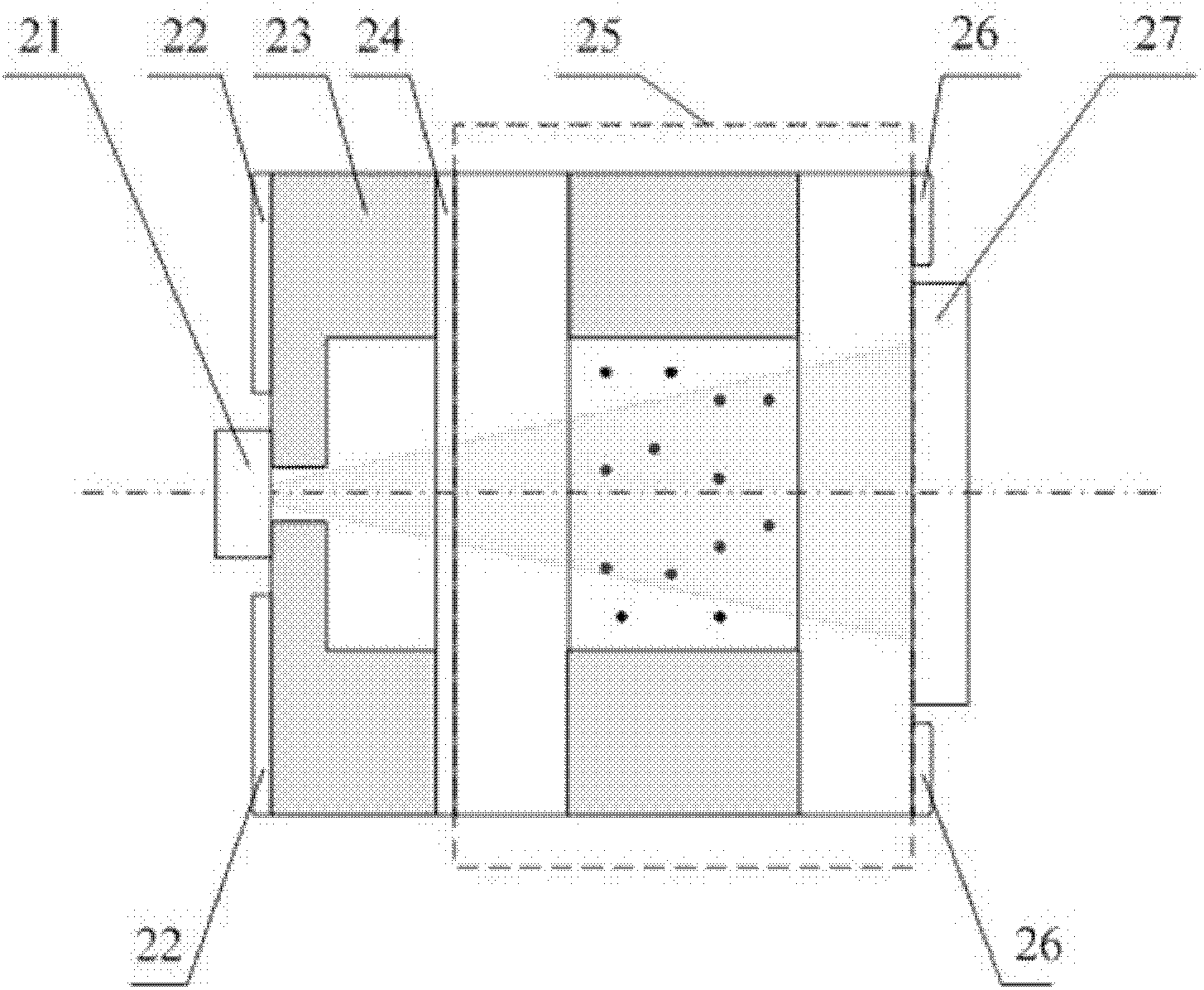

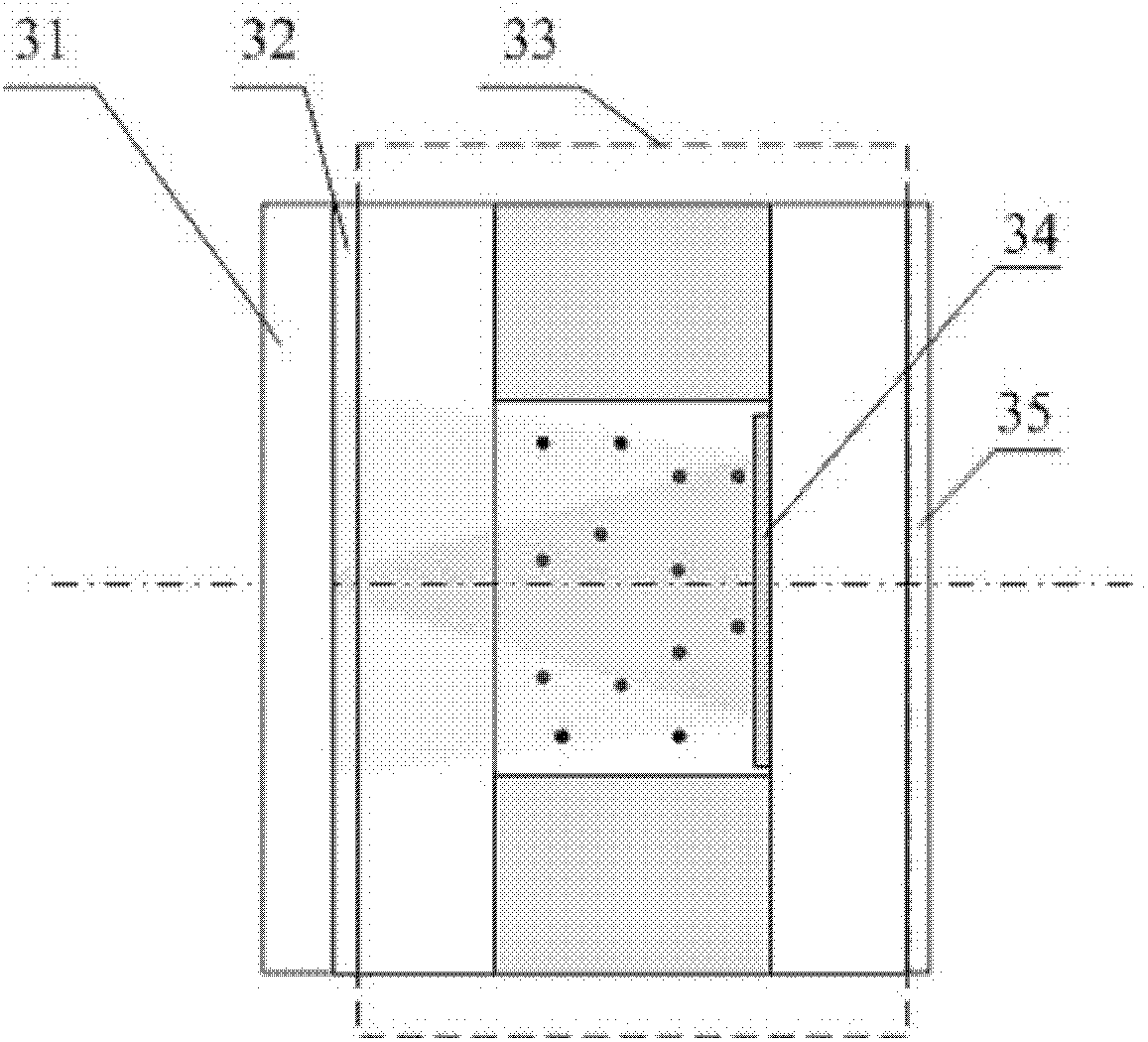

Variable-gradient fractal lattice sandwiched reinforcement phase change heat sink

ActiveCN106940148AUniform absorptionSmooth releaseHeat storage plantsSemiconductor/solid-state device detailsEngineeringHeat sink

The invention discloses a variable-gradient fractal lattice sandwiched reinforcement phase change heat sink and aims to provide an efficient phase change heat sink which is high in heat exchange efficiency, has certain universality and can be developed in a serialization mode. The variable-gradient fractal lattice sandwiched reinforcement phase change heat sink is realized according to the following technical scheme: reinforcement heat transfer structures are distributed in a phase change heat sink shell in an array; each variable-gradient fractal lattice sandwiched unit takes a variable-gradient V structure as a first-stage reinforcement heat transfer structure (4) according to the heat transfer and heat exchange characteristics of the phase change heat sink; on this basis, at variable-gradient V-shaped ends of the first-stage reinforcement heat transfer structures, the variable-gradient V structures in the same shape are gradually increased to form multiple stages of reinforcement heat transfer structures, and the specific surface areas of the multiple stages of reinforcement heat transfer structures are multiplied in sequence; the first-stage reinforcement heat transfer structures can transfer heat to an area far away from a heat radiation bottom plate rapidly in a reinforcement mode, and the second-stage reinforcement heat transfer structures (5) and the third-stage reinforcement heat transfer structures can transfer heat to phase change material far away from the heat radiation bottom plate rapidly to complete heat exchange.

Owner:10TH RES INST OF CETC

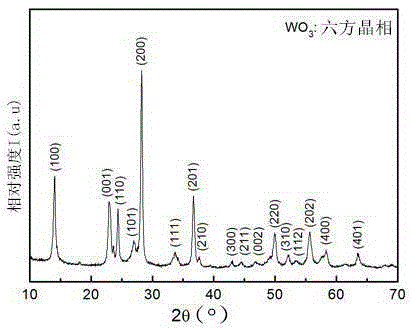

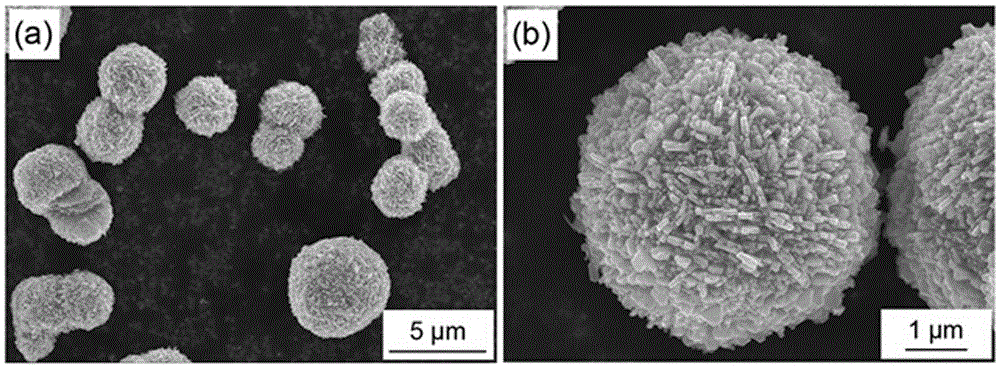

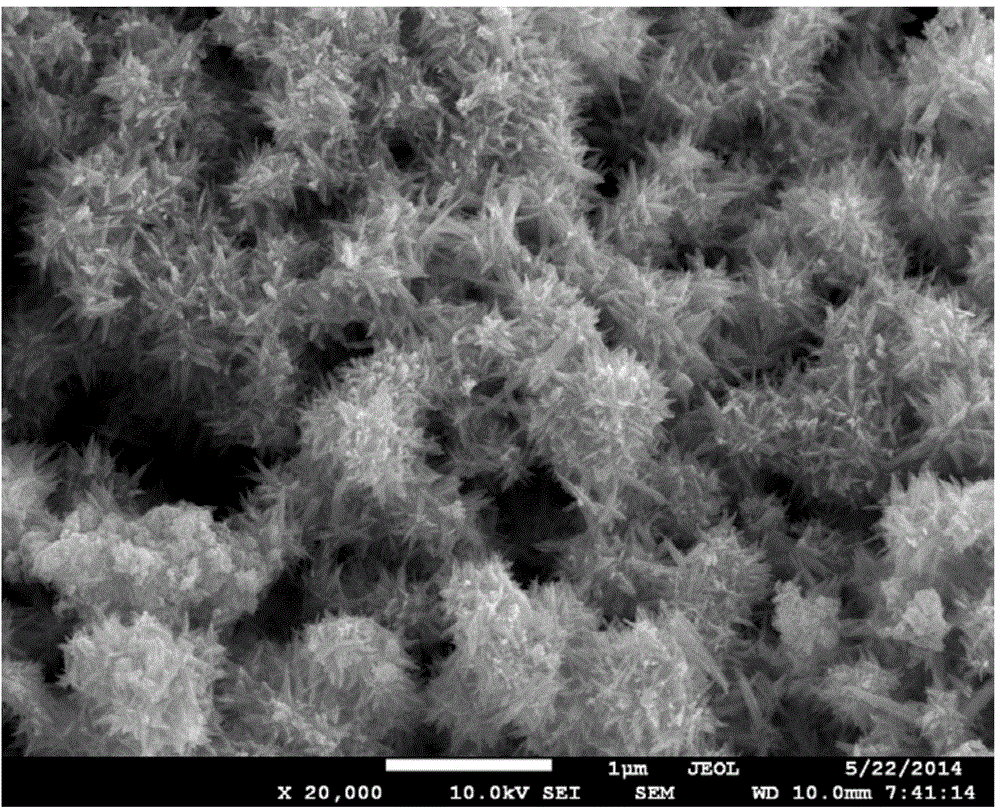

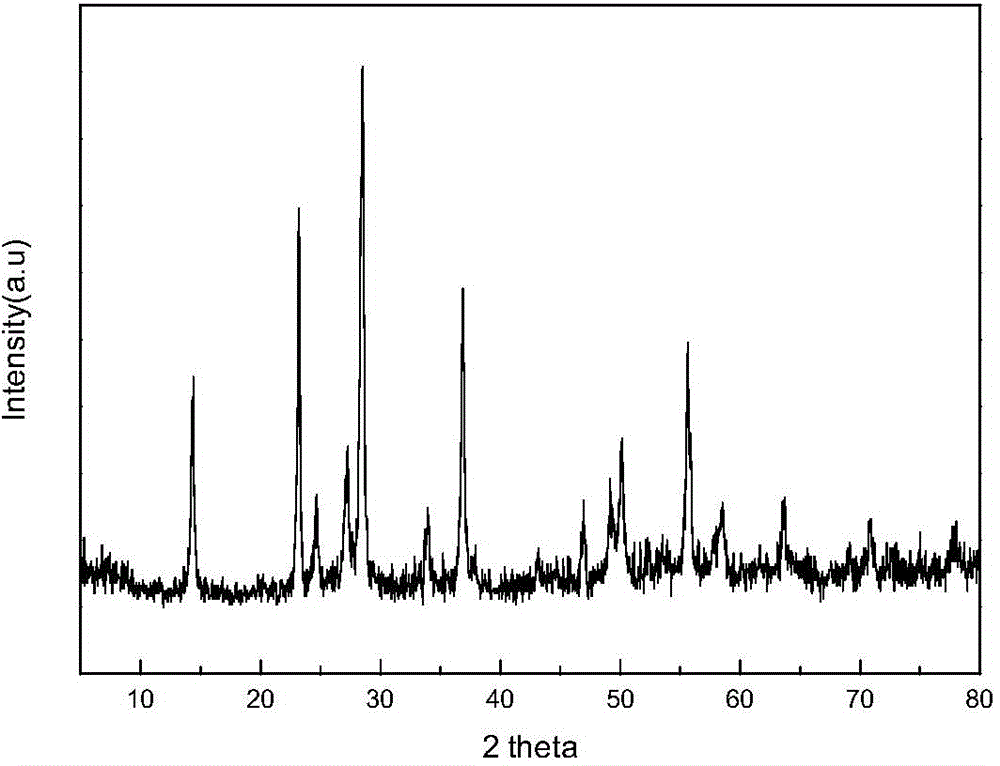

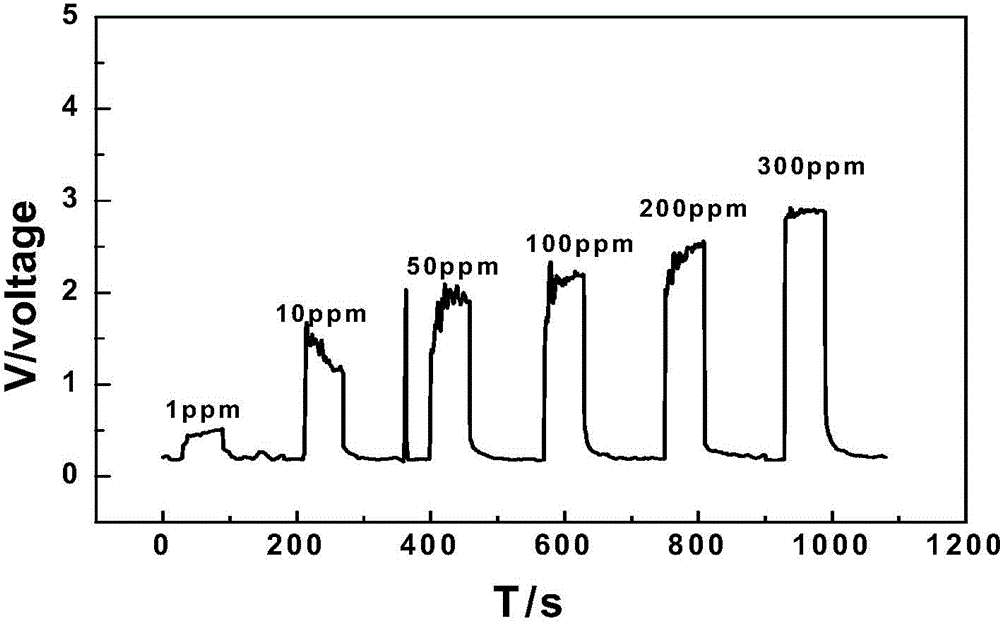

Gas sensor based on graded porous WO3 microspheres and preparation method thereof

ActiveCN105301062AGood reversibilityGood choiceSemi-permeable membranesVolume/mass flow by thermal effectsPorosityDispersity

The invention belongs to the technical field of semiconductor oxide gas sensors, and particularly relates to a gas sensor based on graded porous WO3 microspheres and a preparation method thereof. A gas-sensitive coating in the gas sensor based on the graded porous WO3 microspheres is prepared from the graded porous WO3 microspheres, the graded porous WO3 microspheres have single hexagonal-phase crystal structures and are uniform in body size and good in individual dispersity, the diameter of the graded porous WO3 microspheres is 3-5 micrometers, and each graded porous WO3 microsphere is formed by assembling WO3 nanorods with the diameter being at the nanoscale and has a large specific surface area and high porosity. According to the preparation method, hydro-thermal synthesis is performed in the presence of a mixing assistant, and the graded porous WO3 microspheres are obtained and assembled to form the finished product. The gas sensor based on the graded porous WO3 microspheres has the advantages of being low in working temperature, high in sensitivity, low in energy consumption, high in selectivity and the like.

Owner:NORTHEASTERN UNIV

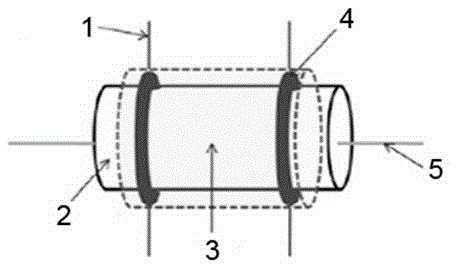

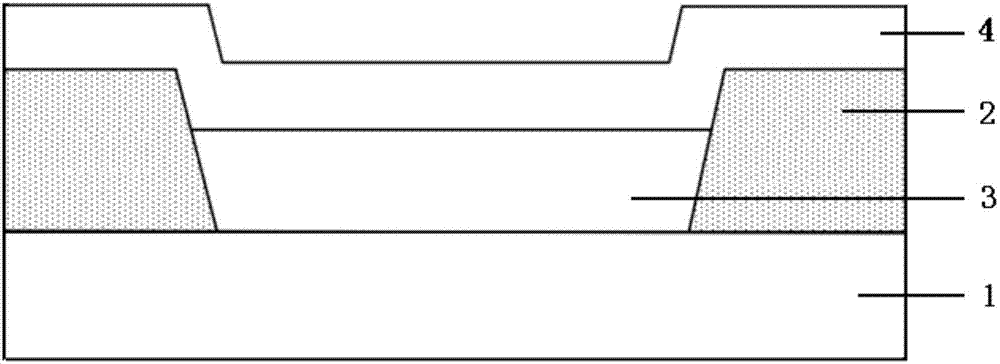

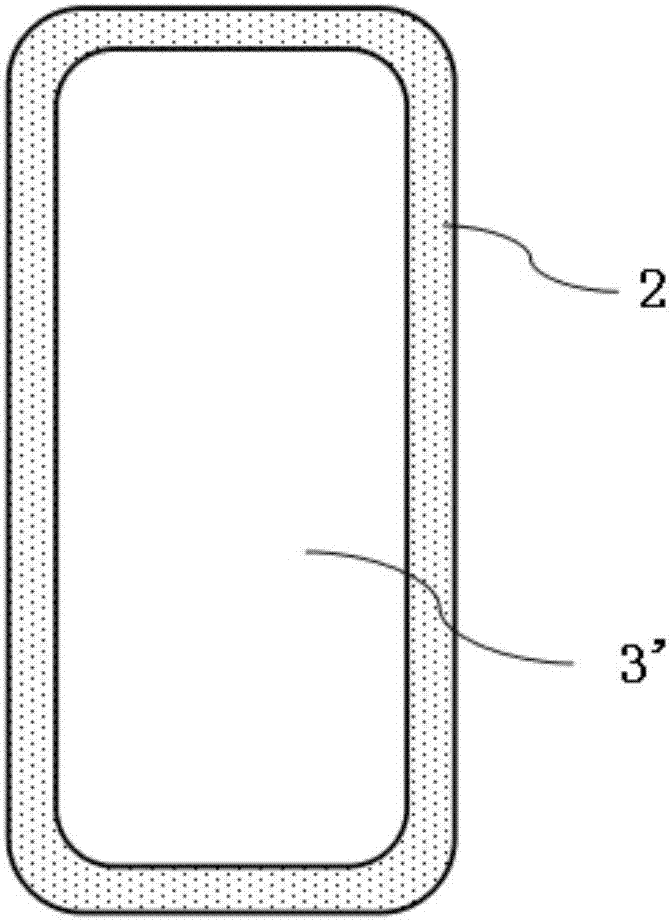

Groove type atomic gas cavity and atomic clock physical system formed by same

ActiveCN102323738ALower working temperatureUnlimited thicknessApparatus using atomic clocksCrystal planeParticle physics

The invention relates to a groove type atomic gas cavity produced by applying MEMS technology and an atomic clock physical system formed by the same. The cavity is characterized in that the cavity is formed in such a manner that a silicon wafer with a groove and Pyrex glass sheets define a cavity structure through bonding; the cavity structure is used for alkali metal atom vapor and buffer gases to fill in; the cross section of the groove is in a shape of inverted trapezoid; and the groove comprises a bottom surface and side walls forming included angles with the bottom surface. The cavity is manufactured based on MEMS (micro-electro-mechanical system) technology. The silicon groove is formed through anisotropic etching of the (100) monocrystalline wafer. The groove type cavity is manufactured through silicon-glass anode bonding. The side walls of the cavity are {111} crystal planes of the silicon wafer. The cavity and the system have the following beneficial effects: by utilizing the cavity, the distance between two reflectors in the cavity is easy to enlarge through atomic cavity dimension design, thus increasing the length of the interaction space between laser and atomic gas, enhancing the signal to noise ratio of the CPT (coherent population trapping) signal and being beneficial to improvement of the frequency stability of the micro CPT atomic clock.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

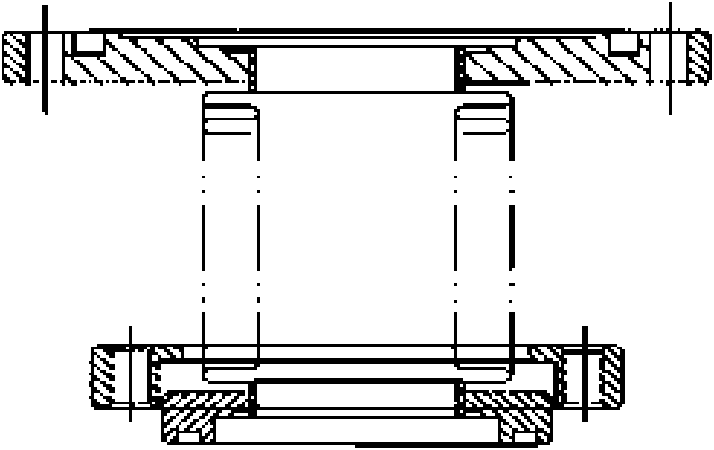

Process for growing phi 8'' solar-grade Czochralski silicon by using 18-inch thermal field

ActiveCN101798704AOptimize parameter conditionsImprove insulation effectBy pulling from meltSlagEvaporation

The invention discloses a process for growing phi 8'' solar-grade Czochralski silicon monocrystalline by using an 18-inch thermal field. By adopting the 18-inch thermal-shielding thermal field and an upper-shaft magnetic fluid sealing device with a cooling system and combining the optimized parameter conditions of crystal-pulling processes, the invention enables the thermal field to have good heat preservation and obviously reduced energy consumption, enables gas to smoothly flow to be beneficial for the exhaustion of volatile matter, stabilizes crystallization, prolongs the service life of equipment and reduces the production cost; and in addition, the invention reduces magnet demagnetization and the evaporation of a magnetic fluid to avoid the air leakage and the slag dropping of the sealing of the magnetic fluid affecting the growth of the Czochralski silicon monocrystalline, improves the sealing performance and prolongs the service life, thereby ensuring the crystal-pulling processes of crystal leading, diameter equalization, shoulder rotation and the like to be stable and improving production efficiency and yield.

Owner:峨嵋半导体材料研究所

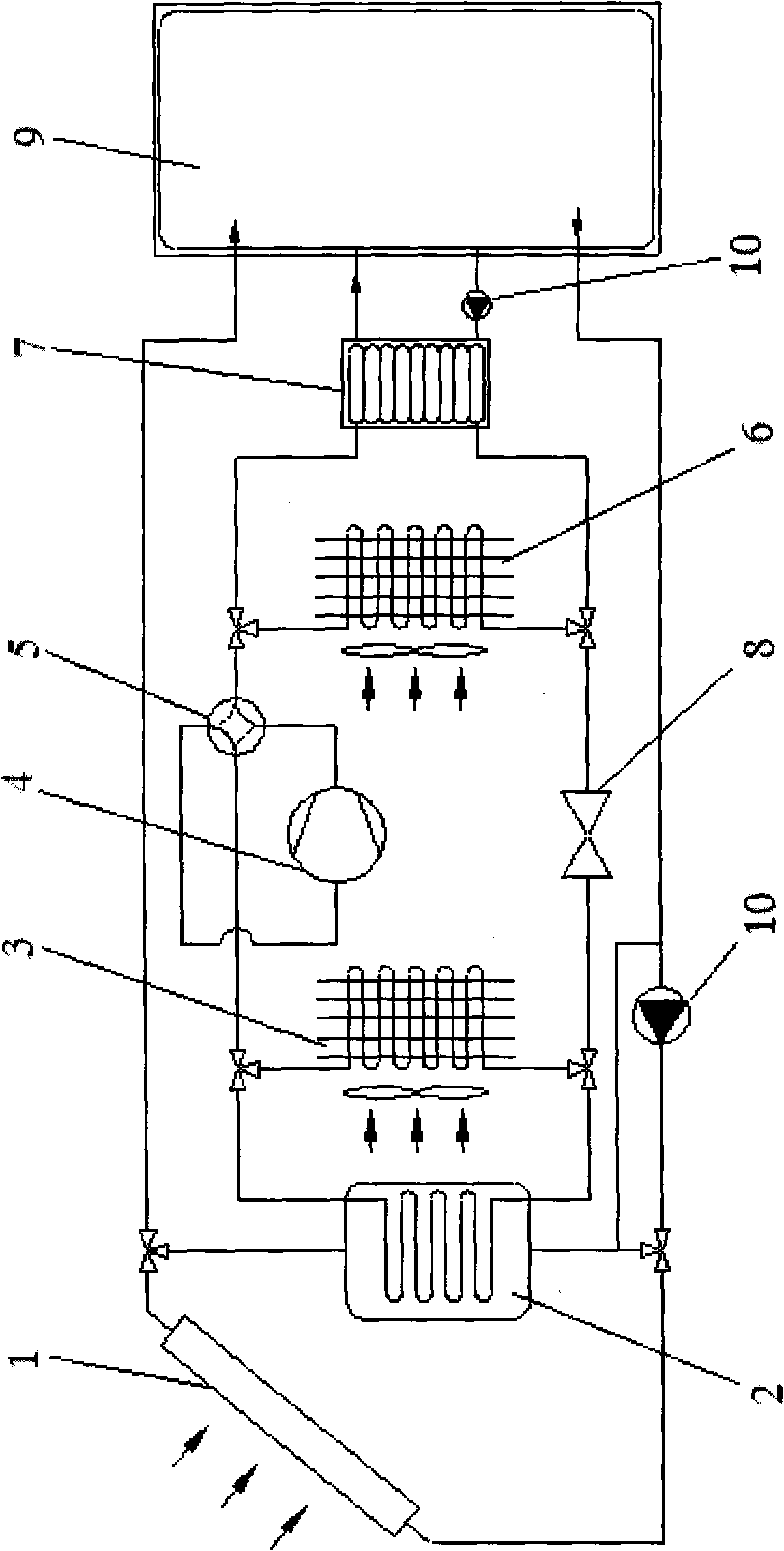

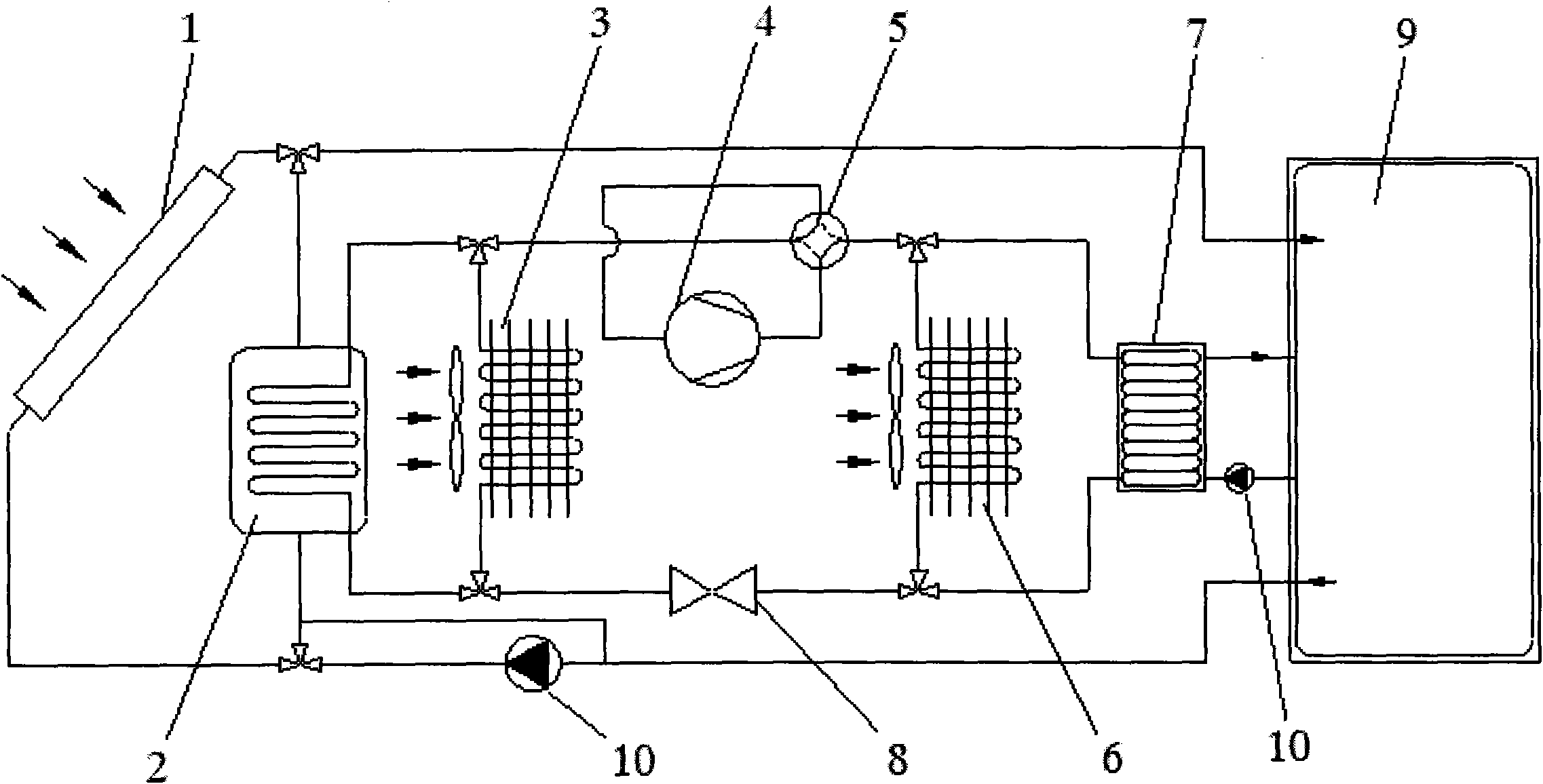

Phase change thermal storage type auxiliary solar hot-water device of air source heat pump

InactiveCN101943481AReduce energy consumptionReduce lossFluid heatersSolar heating energyThermal energy storageEngineering

The invention discloses a phase change thermal storage type auxiliary solar hot-water device of an air source heat pump, comprising an indoor air cooled heat exchanger, an outdoor air cooled heat exchanger and a rotator compressor, wherein the outdoor air cooled heat exchanger is connected with the indoor air cooled heat exchanger respectively through a four-way reversing valve and an expansion valve; the rotator compressor is connected with the four-way reversing valve in parallel; the indoor air cooled heat exchanger is connected with a water cool tube heat exchanger; and the outdoor air cooled heat exchanger is connected with a phase change thermal accumulator in parallel. The device of the invention can carry out phase change energy storage when solar radiation is overmuch in summer, thereby avoiding over high water temperature to exceed use requirement, sever water tank heat dissipation and other drawbacks, and when the solar radiation is in short, heat supplement is carried out through phase change to release energy, and an air source heat pump is used to assist heating in necessity.

Owner:SOUTHEAST UNIV

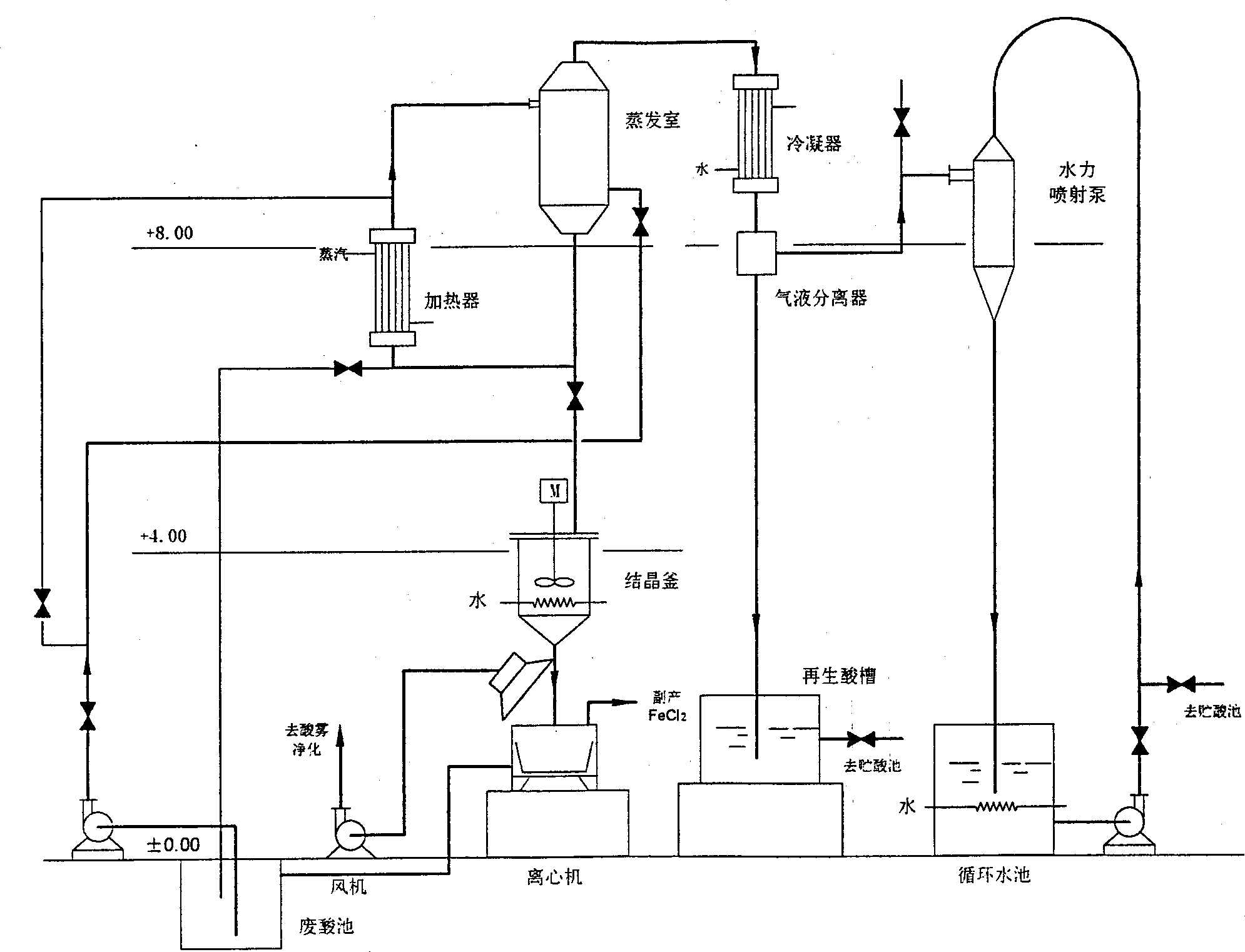

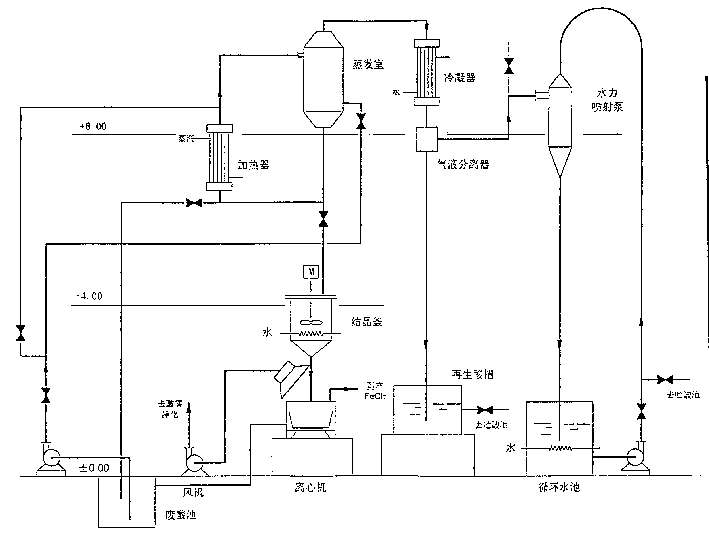

Process for treating waste pickling liquid of hydrochloric acid by negative-pressure external-circulation evaporation-concentrating crystallization method

InactiveCN1373243ALow boiling pointReduce leakageWater/sewage treatment by heatingLiquid wasteEvaporation

A process for treating used pickling liquid of hydrochloric acid includes pumping said waste liquid into evaporating chamber, heating it by steam heater while circulating the waste liquid between heater and evaporating chamber, evaporation concentrating to generate ferrous chloride crystal, centrifugal separation to obtain solid ferrous chloride crystal, and returning mother liquid back to waste acid pool. Its advantages are long service life and less leakage of hydrogen chloride.

Owner:NANCHANG UNIV

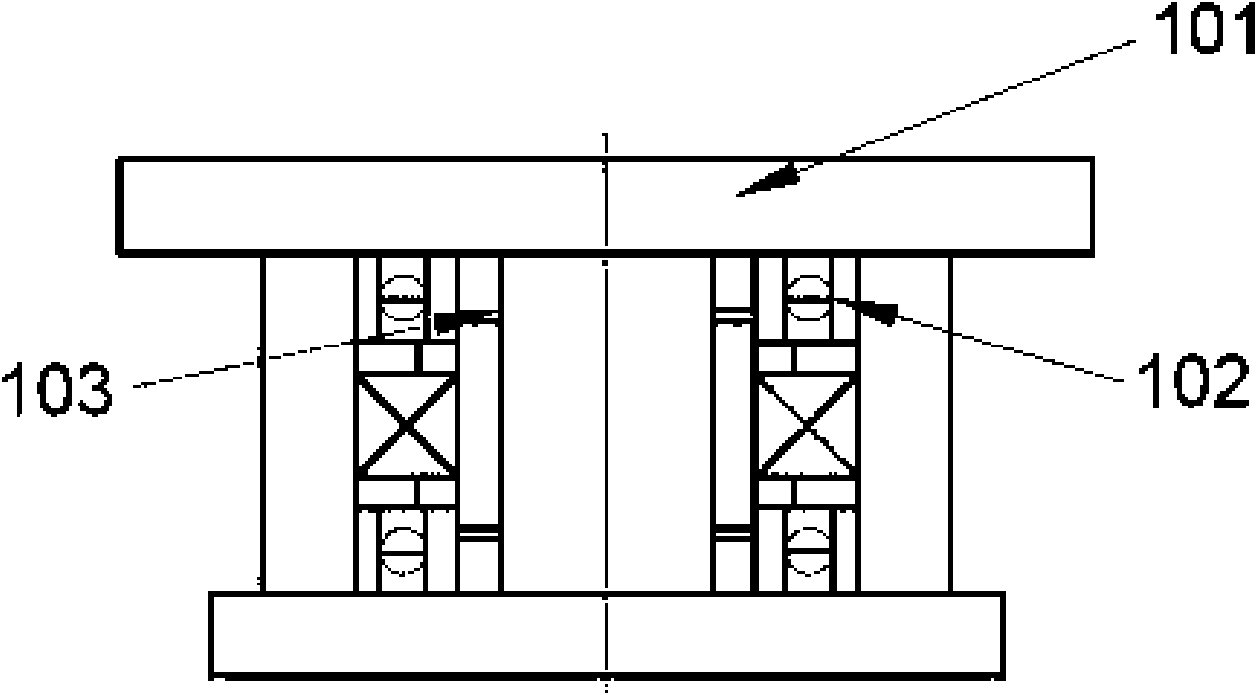

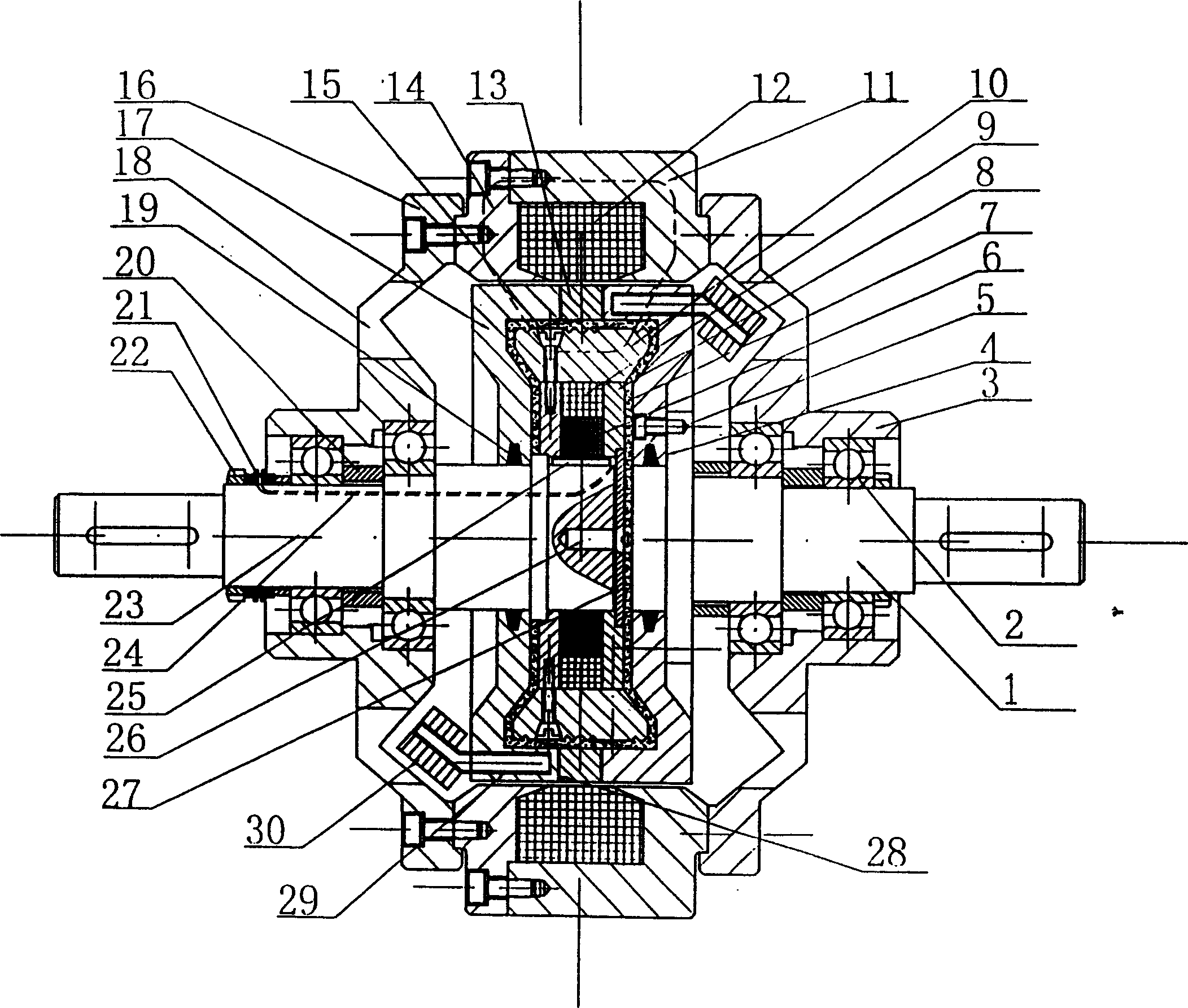

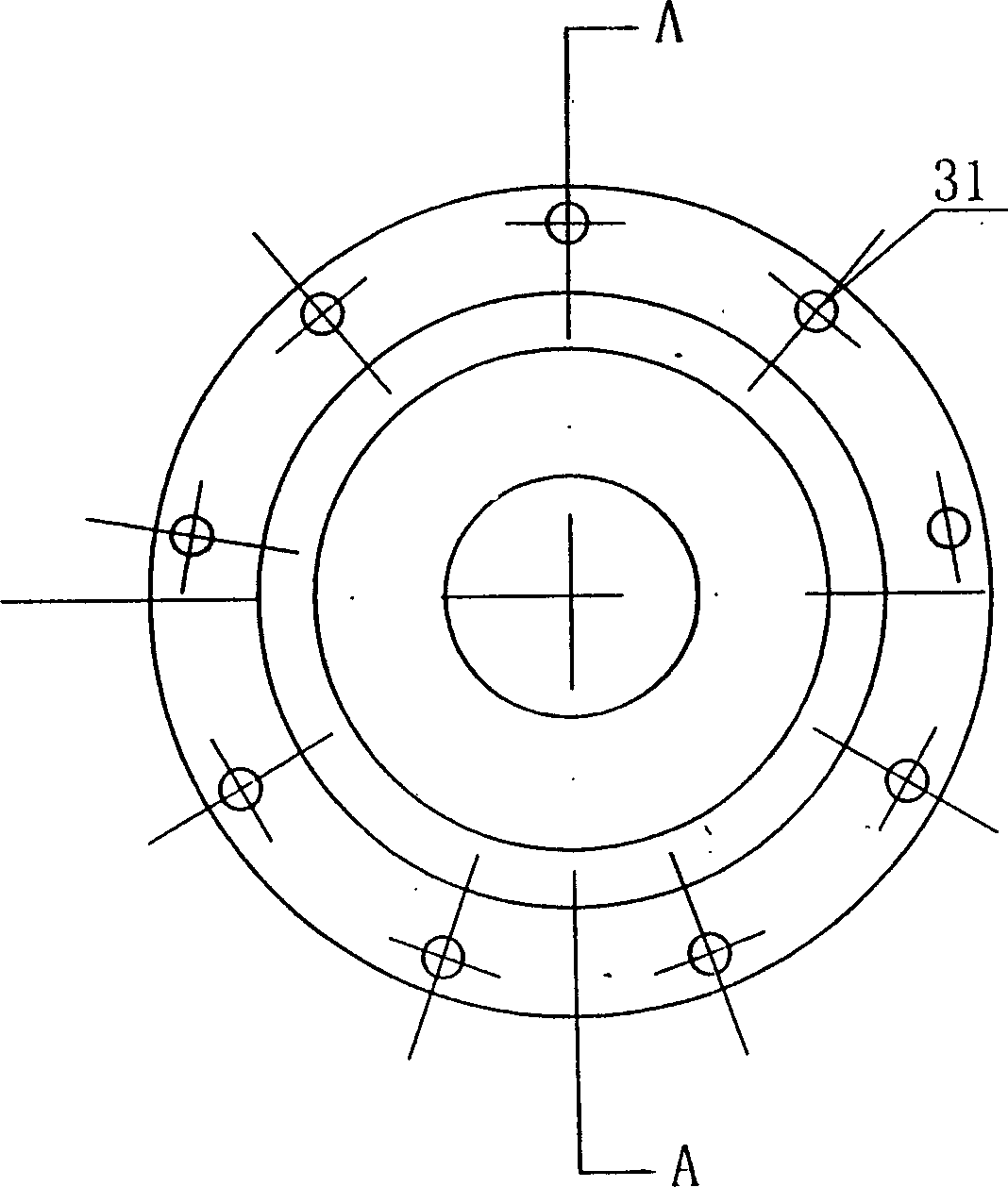

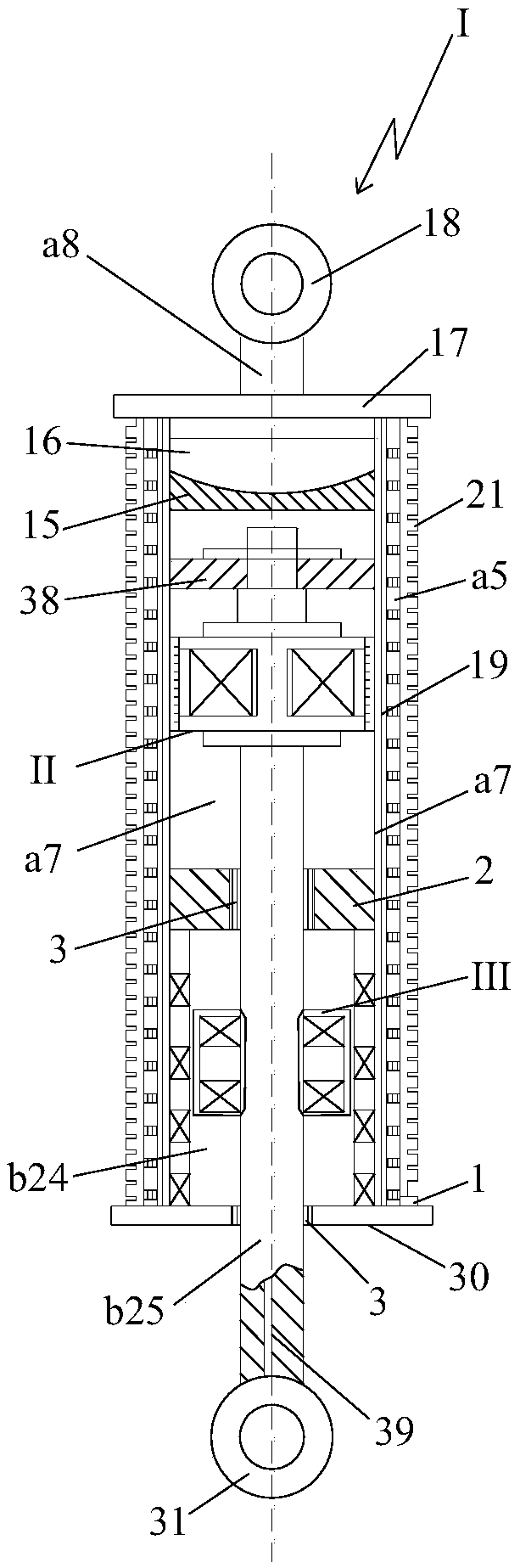

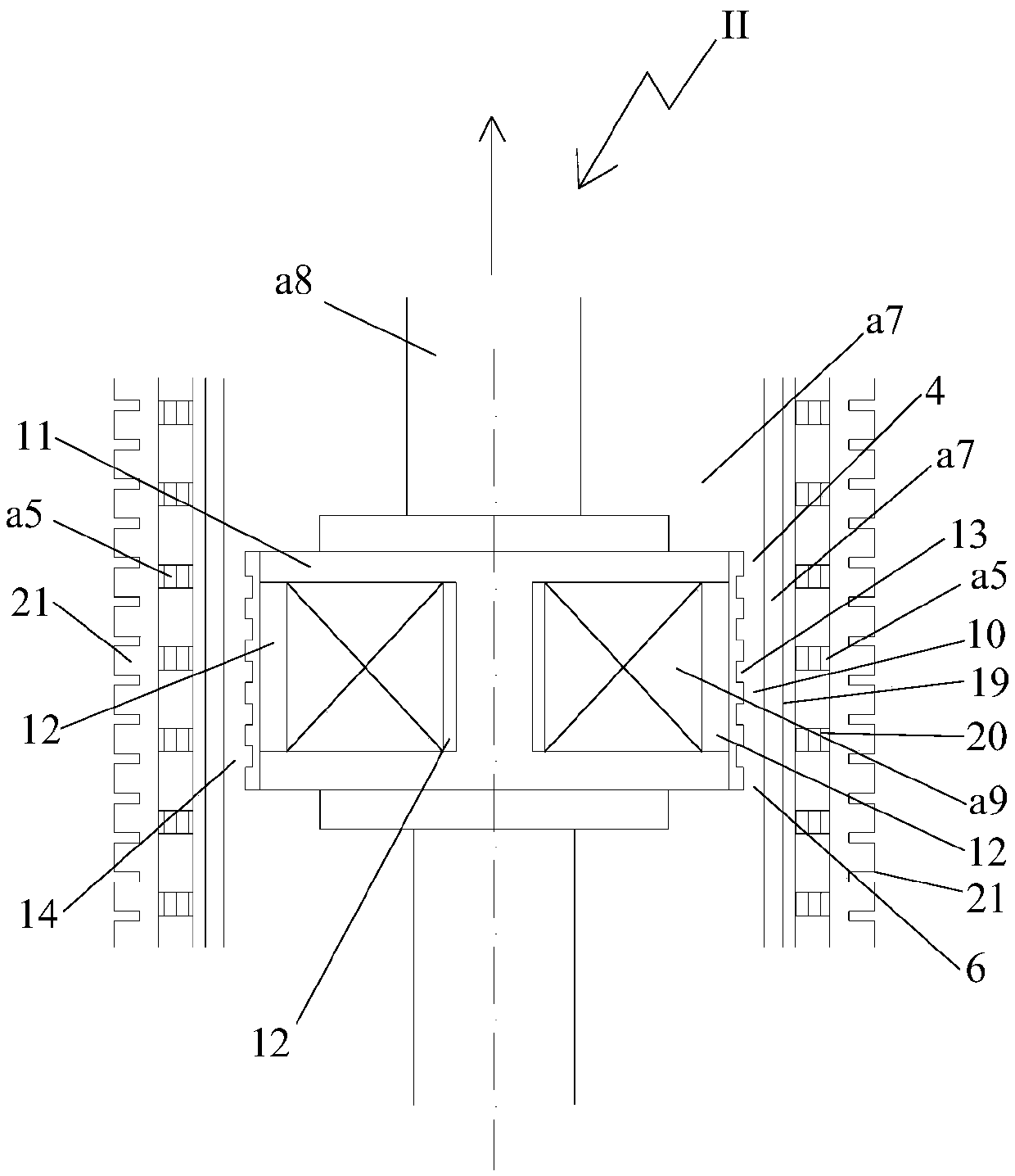

Magnetic rheological soft startor

A magnetic rheological soft starter is used in mechanical transmission. In order to eliminate impact of clutch during starting, new material magnetic rheological fluid (MRF) is introduced as the power transmission medium, and magnetic field electromagnetic winding produces is used in altering the rheological characteristic and controlling transmitted torque to reach the aim of smooth starting. For small structure, great torque and reduced heat produced during operation, the present invention makes driving part in cavity holding driven part, adopts two electromagnetic windings to control the rheological characteristic of MRF in radial and axial work gap, and mounts heat pipe to the end cap of the driving part to lower its temperature. The present invention is used mainly in soft starting of mechanical unit, power transmission, speed regulation and overload protection.

Owner:CHONGQING UNIV

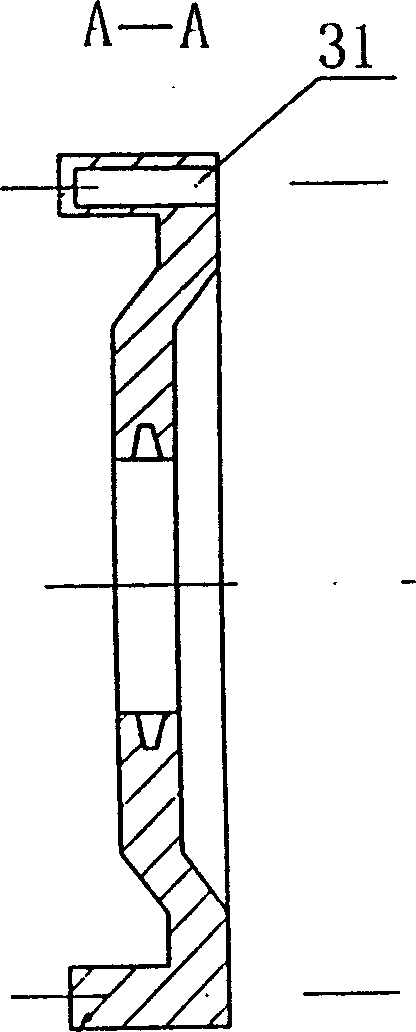

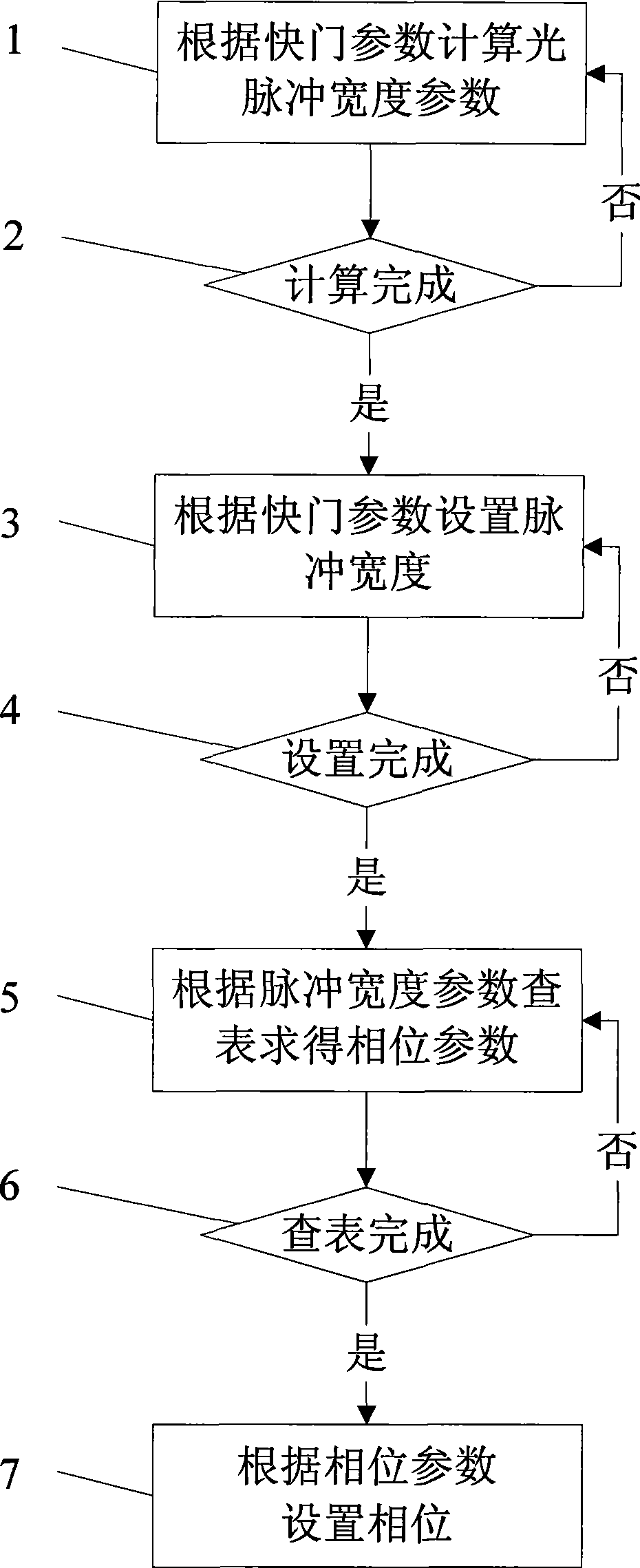

Control method of video camera synchronous LED flash light compensation

ActiveCN101414095AReduce brightnessLower working temperatureTelevision system detailsColor television detailsImaging qualityWorking temperature

The invention relates to a control method for a camera synchronous LED flash and fill-in light, which comprises the following steps: a width parameter of an optical pulse is calculated according to a shutter parameter; whether the calculation is completed or not is detected; if yes, the pulse width is set up according to the shutter parameter; whether the setting is finished is detected; if yes, a phase position parameter is obtained by searching a table according to the pulse width; whether the table search is finished is detected; if yes, the phase position is set up according to the phase parameter. Compare with the prior art, in the invention, LED light source flash pulse and shutter are synchronous, thus providing light source with high speed flash for a camera and reducing the energy consumption in the premise of guaranteeing light filling; by this means, the working temperature of the LED is reduced and the service life of the LED is prolonged. When a person faces the camera and feels the illumination of the light source is lower in the premise of guaranteeing image quality, the person to be shot has no lighting glaring sense, thus behaving natural in the shooting process.

Owner:SHANGHAI YAO WEI GROUP IND

Fast forming method of fusion of metal powder of three beams of laser compound scanning

ActiveCN101607311BSlow down drastic changesUniform temperature fieldIncreasing energy efficiencyLength waveMetal powder

Owner:HUAZHONG UNIV OF SCI & TECH

Hydrogen sulfide gas sensitive, preparation, and method for making hydrogen sulfide gas sensitive device

InactiveCN101493430AWith quantum effectSelf-catalytic activityTitanium dioxideMaterial resistancePolyethylene glycolPhysical chemistry

The invention relates to a hydrogen sulfide gas-sensing material and preparation thereof as well as a method for manufacturing hydrogen sulfide gas-sensing devices, comprising: SnO2 powder and TiO2 powder are mixed according to the molar ratio of 6-10: 1 for obtaining SnO2-TiO2 nano-composite material; Pb(NO3)2 or AgNO3 is added and then fine grinded; the hydrogen sulfide gas-sensing material is regulated into a paste shape by using anhydrous ethanol and polyethylene glycol, and then evenly coated on the surface of an electrode tube; by annealing processing, a gas-sensing electrode tube is obtained; finally, the gas-sensing electrode tube is welded, electrically aged, and packaged according to a heater type structure traditional technology for manufacturing the hydrogen sulfide gas-sensing device. Compared with the prior art, the invention has the advantages that the hydrogen sulfide gas-sensing material has the quantum effect of the nano material, self-catalytic activity, surface effect, and the like, and also has high sensitivity to the hydrogen sulfide gas, high resolution, good choosing performance, short response time, and low operating temperature as a novel gas-sensing material.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Formaldehyde air-sensitive material and its preparation method and preparation method for formaldehyde air-sensitive device

InactiveCN101144789AWith quantum effectSelf-catalytic activityMaterial resistanceGas detectorPolyethylene glycol

The invention relates to a formaldehyde gas sensitive material, the preparation method thereof and a manufacture method of a formaldehyde gas sensitive component. The component of the formaldehyde gas sensitive material takes an SnO2-TiO2 binary nanometer composite material as a substrate, the mol ratio of the Ti / Sn is 0.2 to 0.5, the fractional ratio of the quality adulterated is 2 percent to 5 percent Cd2, the formaldehyde gas sensitive material is adjusted to be pasty after being ground with an appropriate amount absolute ethyl alcohol and 0.2 to 1 portion polyethylene glycol, and is painted on the surface of an electrode pipe evenly, and a formaldehyde gas sensitive electrode pipe is produced through 400 degree annealing processing for two to four hours; finally a formaldehyde gas sensitive component is made through the welding, the electrical ageing and the sealing to the gas sensitive electrode pipe according to the heater type structure traditional process. The gas sensitive sensor made through the invention has low operating temperature, has high sensitivity to the formaldehyde gas, has good antiinterference performance to other indoor pollutant gases, such as benzene, toluene, xylene and ammonia, etc, the response time and the recovery time are short, and the gas sensitive sensor is used for the detection to the indoor decorating formaldehyde gas pollution.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

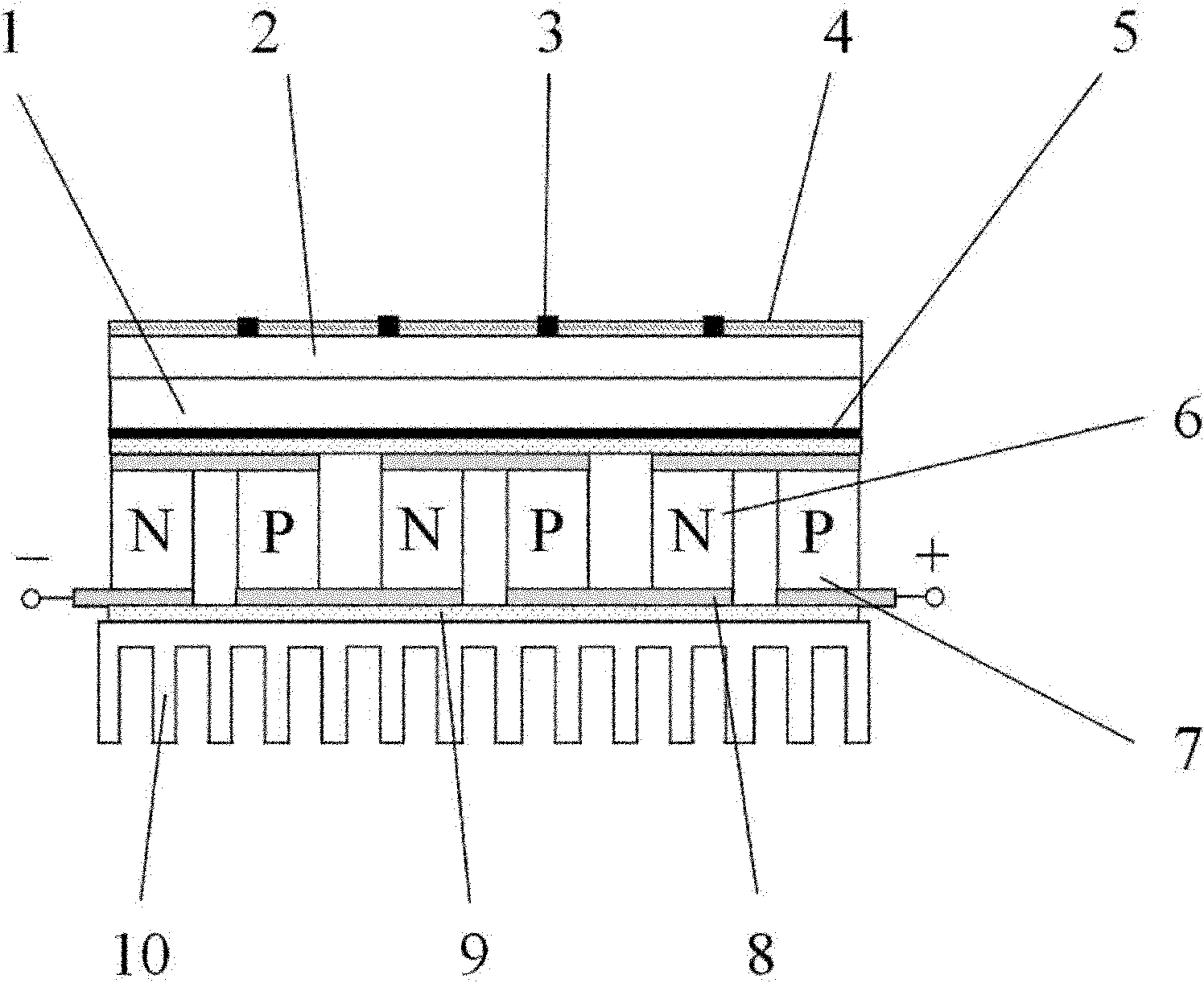

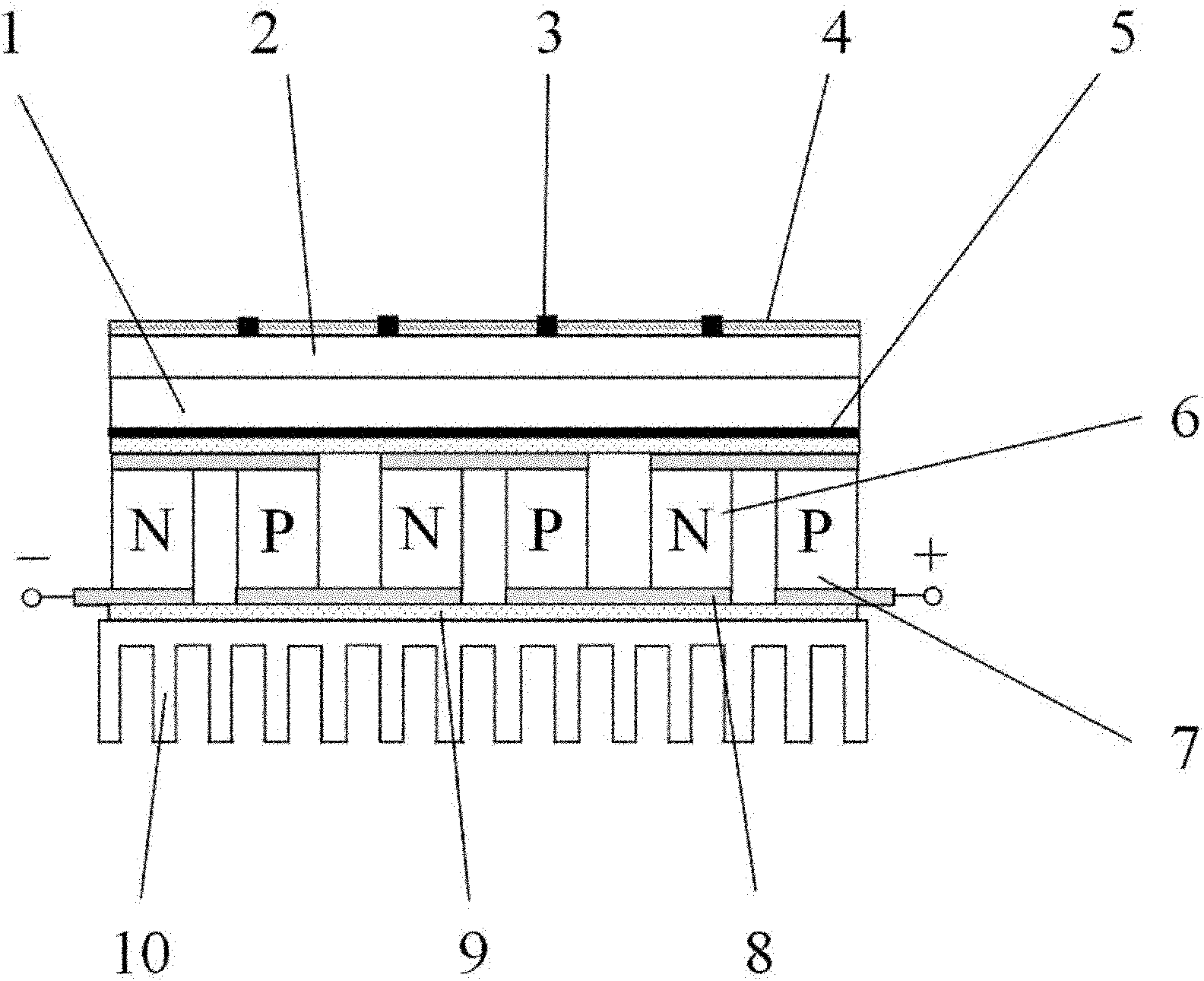

Solar cell capable of simultaneously performing photoelectric conversion and thermoelectric conversion

InactiveCN102130106ALower working temperatureImprove photoelectric conversion efficiencySolid-state devicesPhotovoltaic energy generationWorking temperatureEngineering

The invention relates to a solar cell capable of simultaneously performing photoelectric conversion and thermoelectric conversion, belonging to the technical field of solar photovoltaic power generation and thermoelectric power generation. The solar cell capable of simultaneously performing the photoelectric conversion and the thermoelectric conversion comprises a photoelectric conversion battery, a thermoelectric conversion battery and a heat sink, wherein the photoelectric conversion battery is stuck at the hot end of the thermoelectric conversion battery, and the heat sink is stuck at the cold end of the thermoelectric conversion battery. The solar cell can utilize the thermoelectric conversion battery and the heat sink to continuously absorb working waste heat in the photoelectric conversion battery while utilizing solar energy for performing the photoelectric conversion, thereby not only reducing the working temperature of the photoelectric conversion battery, but also improving the photoelectric conversion efficiency of the photoelectric conversion battery, and further enabling the solar cell to have higher conversion efficiency.

Owner:UNISPLENDOUR CO LTD

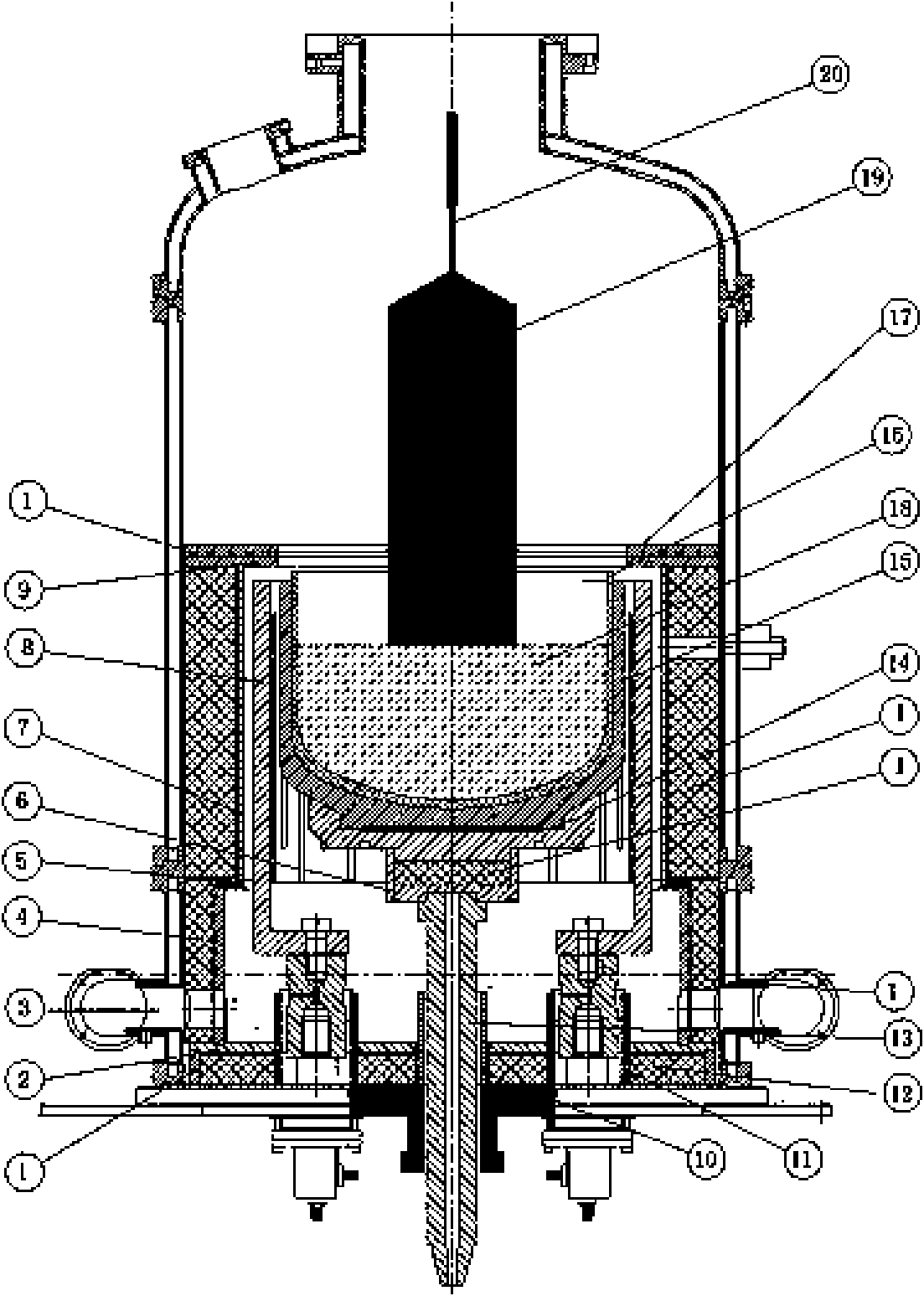

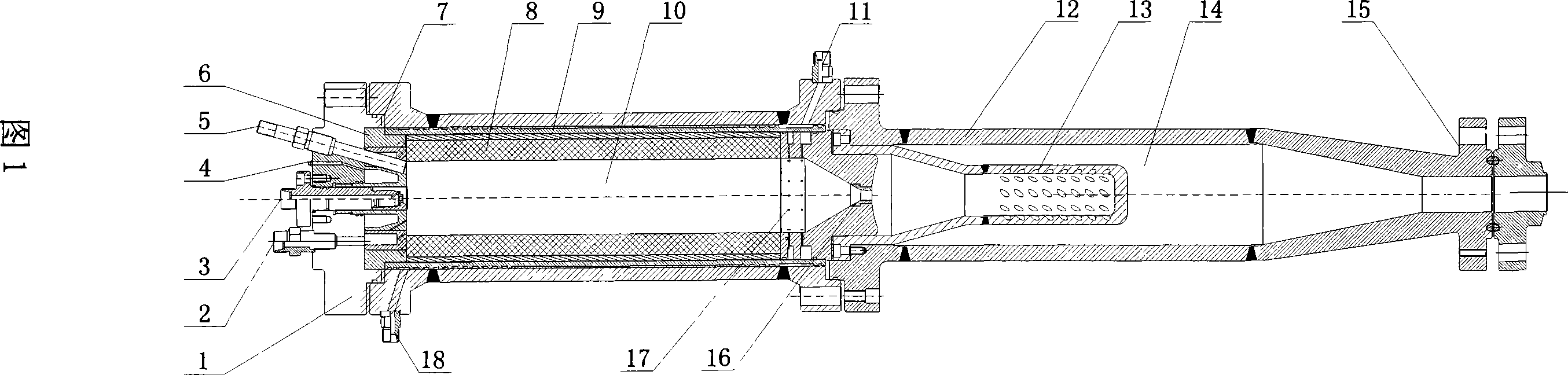

High-pressure mixed gas generator used for petroleum thermal recovery gas injection machine

ActiveCN101067372ALower working temperatureImprove job stabilityFluid removalCombustion chamberWater vapor

The present invention relates to one kind of mixed gas generator for thermal petroleum extraction. The mixed gas generator consists of a head, a combustion section and a mixing section. It features the spiral cooling chamber structure inside the cooling water cap to cool the head effectively, the heat isolating cover and the cooling water jacket with multiple functions of heat insulating, preheating and cooling the combustion section, and the necked bush of the temperature regulator capable of ensuring the sufficient pressure field in the combustor to raise the combustion reaction speed. The mixed gas generator is for burning diesel oil with compressed air as the oxidant to produce high temperature and high pressure fume and spraying water to regulate temperature so as to generate mixed gas of N2, CO2 and water vapor injected into well for thermal petroleum extraction. The present invention is used in oil field to replace steam petroleum extraction.

Owner:江苏神速石油装备有限公司

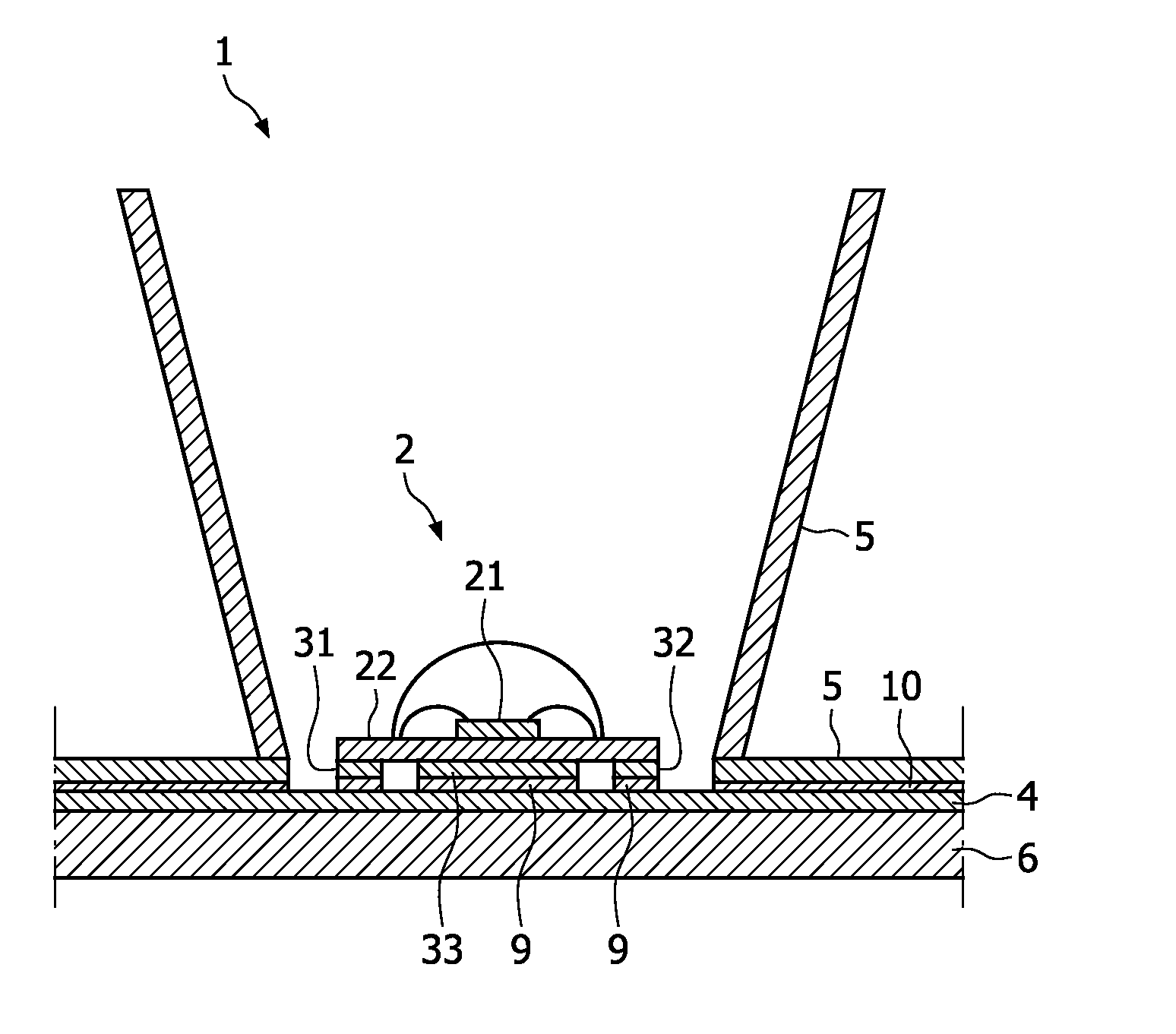

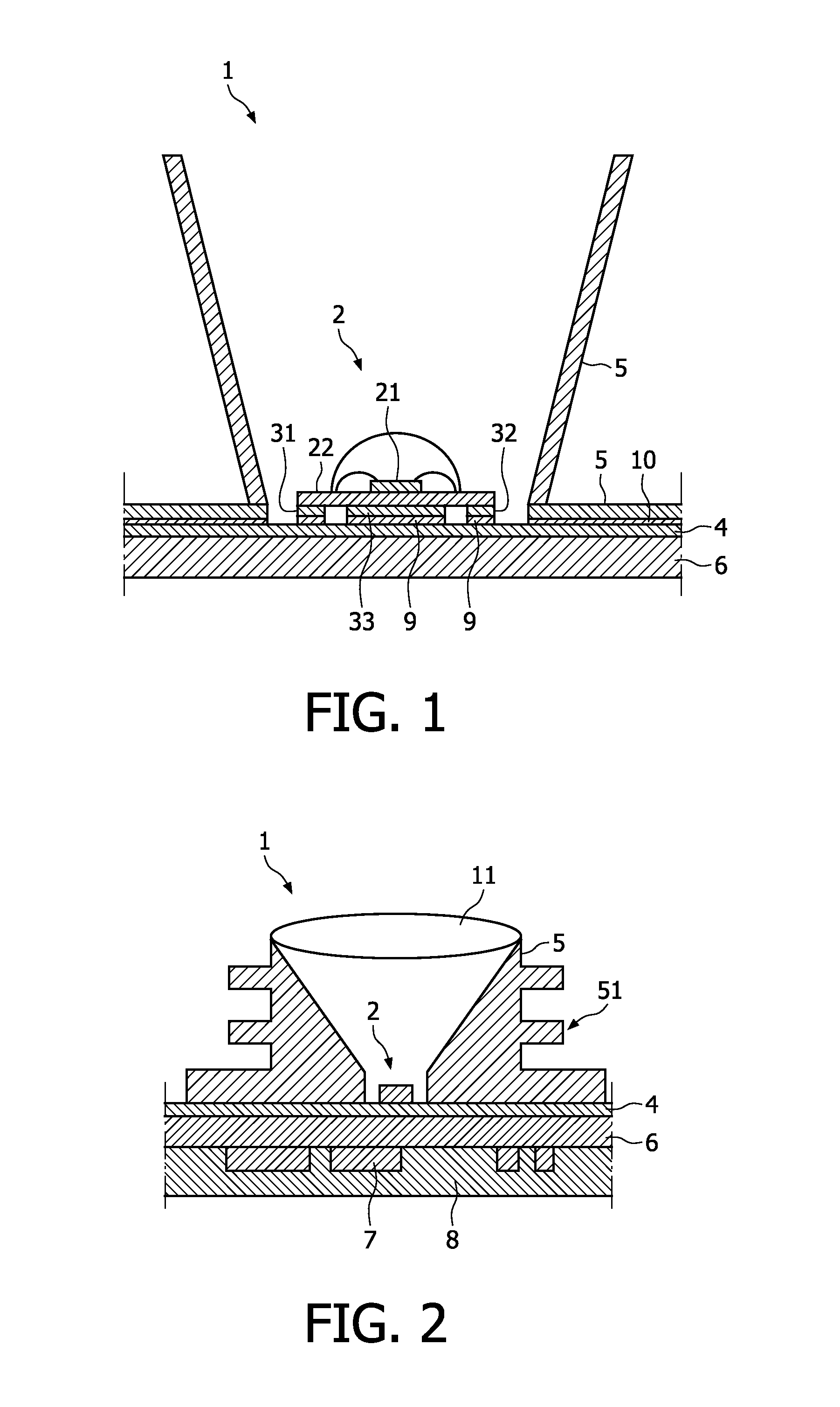

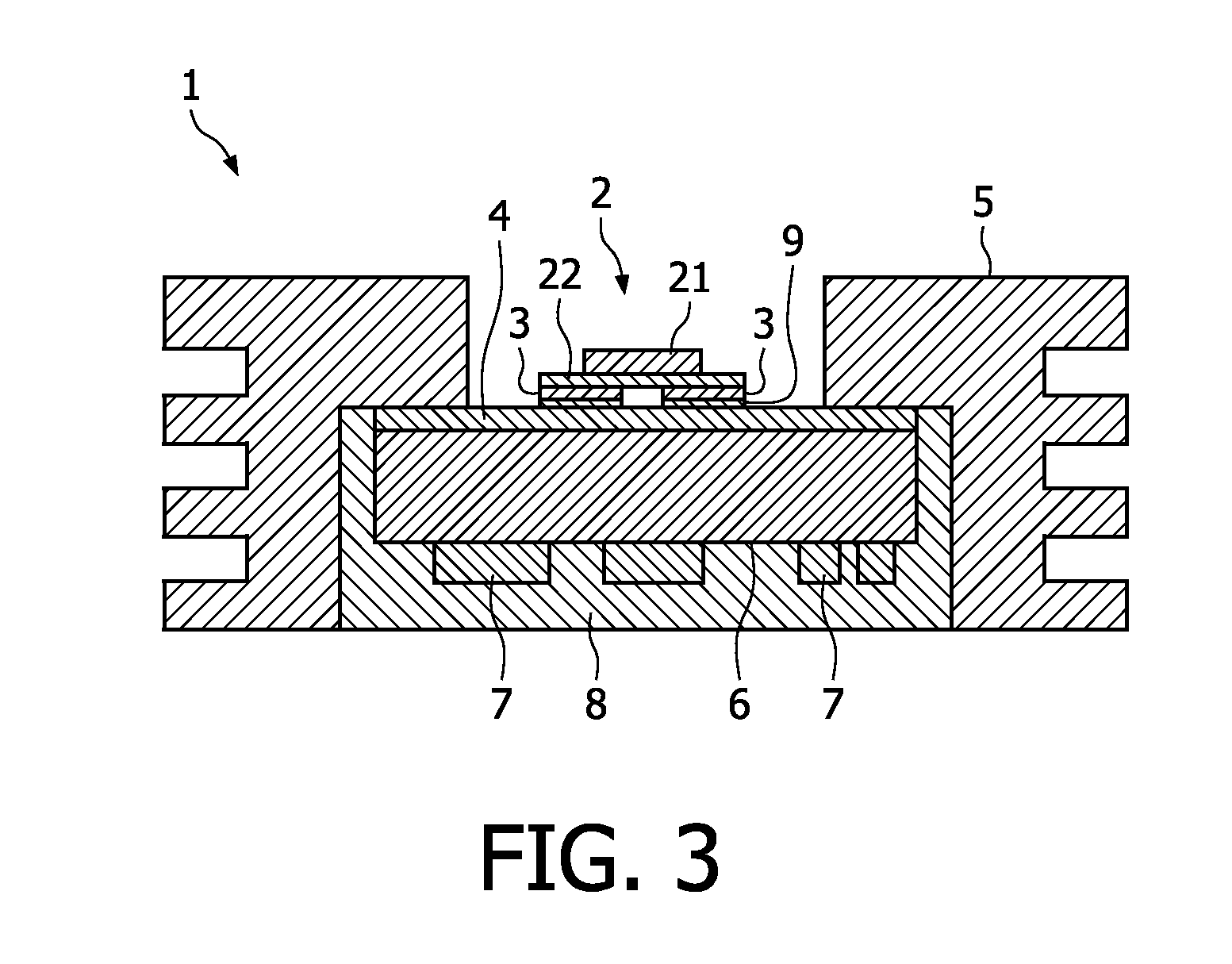

Light-emitting arrangement

InactiveUS20110180819A1Save spaceSimple manufacturing processLighting heating/cooling arrangementsPrinted circuit aspectsEngineeringLight emitting device

The invention relates to a light-emitting arrangement comprising a printed circuit board, PCB, having at least one electrically and thermally conductive portion, a light-emitting diode, LED, being thermally connected to the at least one electrically and thermally conductive portion by at least one contact of the LED, and a heat release member for dissipating heat generated by the LED, the heat release member being thermally connected to the at least one electrically and thermally conductive portion, wherein the heat generated by the LED is transferred along a heat transfer path extending from the LED via the at least one contact and the at least one electrically and thermally conductive portion to the heat release member.The light-emitting arrangement according to the invention provides greatly improved heat removal from the LED while using a low-cost glass-epoxy material for the PCB.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Flower-like nano-WO3/graphene composite gas-sensitive material and preparation method and application thereof

The invention discloses a flower-like nano-WO3 / graphene composite gas-sensitive material and a preparation method and an application thereof. According to the invention, oxidized graphene and soluble tungsten salt are compounded by a microwave-stirring hydrothermal method so as to prepare the flower-like nano-WO3 / graphene composite gas-sensitive material. The content of graphene in the nano-WO3 / graphene composite gas-sensitive material is 0.1-1.0%. The nano-WO3 / graphene composite gas-sensitive material provided by the invention has unique and uniform morphology, has high sensitivity to aniline gas and has good selectivity. Operating temperature is as low as 80 DEG C. The preparation method adopts microwave heating and stirring. The technology is advanced, reaction time is short and cost is low.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

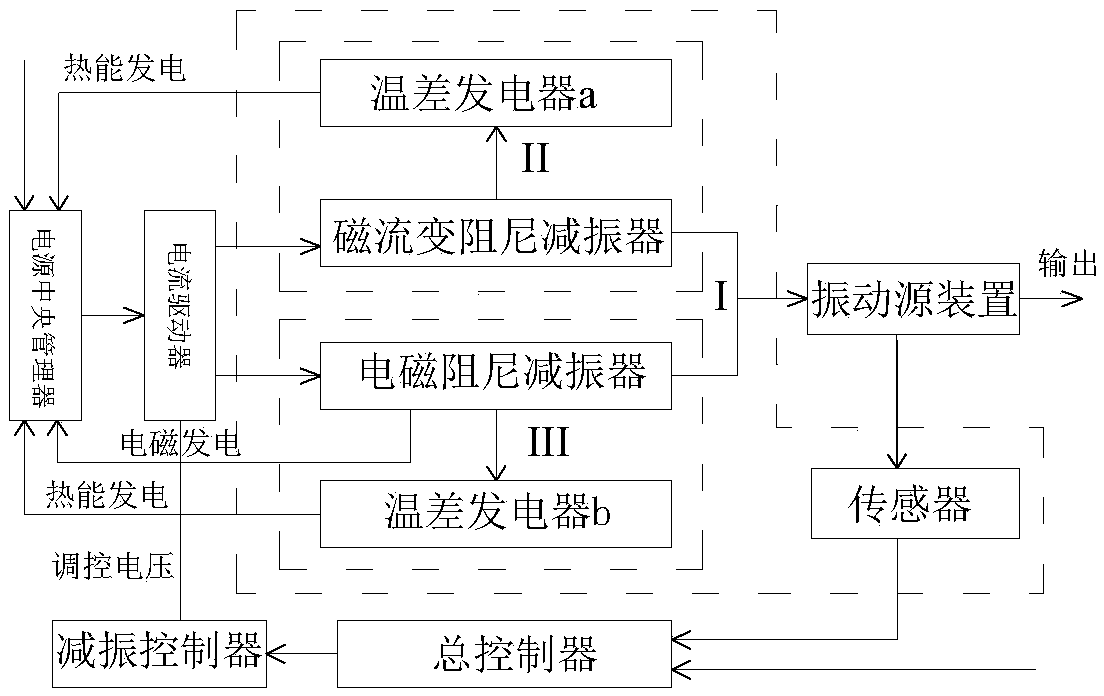

Dual-damping and dual-power-generating combined damping device

InactiveCN105508487ADisturbing forceEfficient recovery and storageBatteries circuit arrangementsNon-rotating vibration suppressionTemperature differenceControl theory

The invention relates to a dual-damping and dual-power-generating combined damping device comprising a magnetorheological damping temperature difference power generating type damper and an electromagnetic damping temperature difference power generating type damper which are spaced by a magnetic isolating material and a sealing material to form working spaces independent from each other. The magnetorheological damping temperature difference power generating type damper and an electromagnetic damping temperature difference power generating type damper form a synergistic dual-damping damping and synergistic dual-power-generating working mode. The device is of a novel device structure formed by integration, the objective of optimizing and improving comprehensive performance of the device is achieved, and the device is applicable to damping of automobiles, trains, ships, tanks, airplanes, machinery, projects and bridges and vibrating energy recycling for power generation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Quantum-dot light emitting diode (QLED) device and fabrication method thereof

ActiveCN106876566AExtend your lifeLower working temperatureSemiconductor devicesQuantum dotComputational physics

The invention provides a quantum-dot light emitting diode (QLED) device. The QLED device comprises a first electrode, an isolation bank, an optical layer and a second electrode, wherein the isolation bank is used for defining a pixel region, the optical layer is arranged in the pixel region, the second electrode covers the isolation bank and the optical layer, the isolation bank contains a high thermal conduction material, and the thermal conductivity of the high thermal conduction material is more than or equal to 10WK<-1>m<-1>. A fabrication method of the QLED device comprises the following steps of providing the first electrode; depositing a bank material layer on a surface of the first electrode, wherein the bank material layer contains the high thermal conduction material, and the thermal conductivity of the high thermal conduction material is more than or equal to 10WK<-1>m<-1>; sequentially performing photoetching, polishing and surface processing on the bank material layer to obtain the isolation bank for defining the pixel region; and depositing the optical layer in the pixel region, wherein the second electrode covers the surfaces of the isolation bank and the optical layer.

Owner:TCL CORPORATION

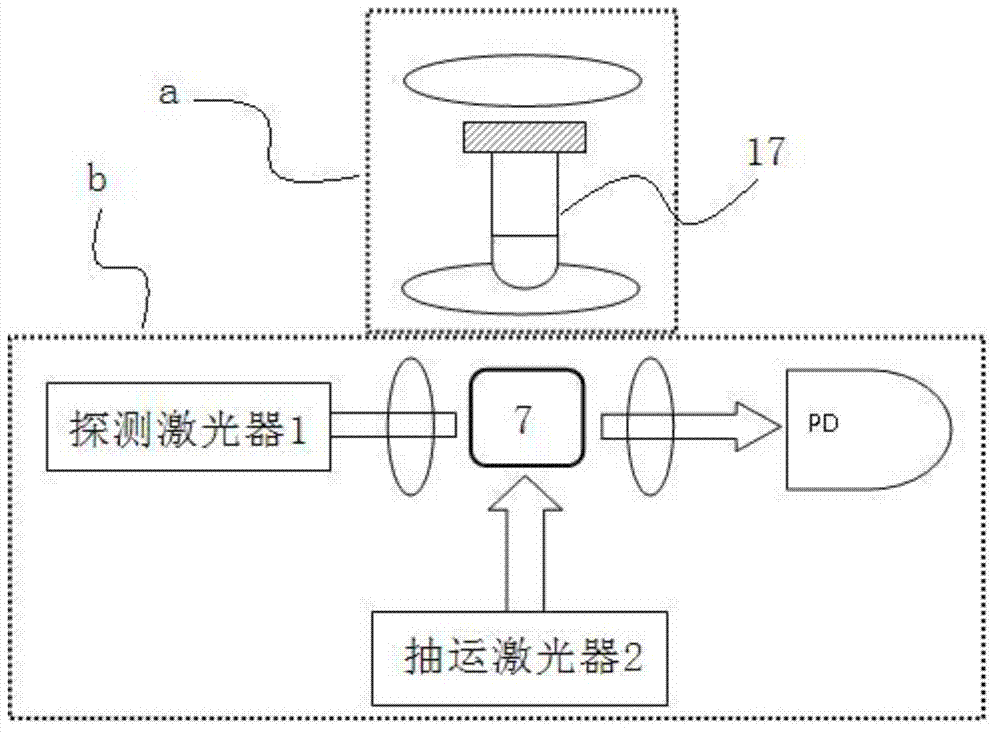

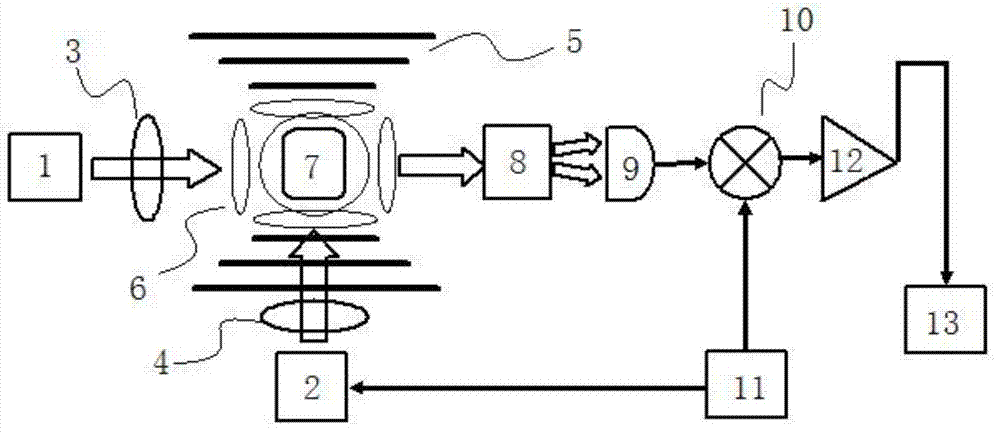

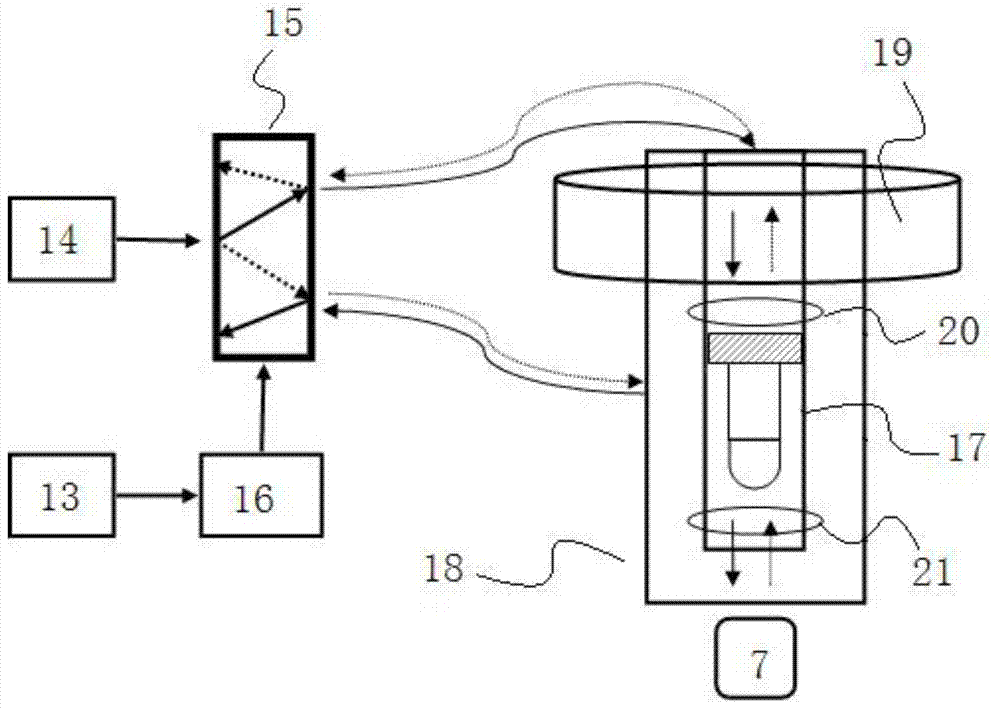

Nuclear magnetic resonance (NMR) device and measurement method based on laser atomic magnetometer

ActiveCN102830381AHigh detection sensitivityLow running costMeasurements using NMRHelmholtz coilProton NMR

The invention discloses a nuclear magnetic resonance (NMR) device based on a laser atomic magnetometer, and the NMR device comprises a cesium atom vapor bubble, a magnetic shielding bushing which is sleeved on the cesium atom vapor bubble, three groups of Helmholtz coils which are arranged inside the magnetic shielding bushing, a polarization device which is used for polarizing cesium atoms inside the cesium atom vapor bubble, a laser transmitting device which is used for transmitting detection laser to the cesium atom vapor bubble, a detection device which is used for detecting an NMR signal of the detection laser penetrating the cesium atom vapor bubble and a pneumatic sample feeding device which is used for pre-polarizing a sample to be detected and can place the pre-polarized sample on the cesium atom vapor bubble. The invention also discloses a measurement method of an NMR based on the laser atomic magnetometer. The device and the method are high in detection sensitivity, free from needing low-temperature refrigeration, low in running cost and lower in working temperature.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

Low-temperature halogen-free lead-free solder paste

InactiveCN102990242AStir wellLow melting pointWelding/cutting media/materialsSoldering mediaRare-earth elementSlag (welding)

The invention relates to a low-temperature halogen-free lead-free solder paste. The solder paste is mixed by Sn-Ag-Bi-based lead-free solder powder added with P or rare earth elements and a rosin-based soldering flux. The soldering flux is basically composed of, by weight, 30-45% of rosin resin, 2-10% of an organic acid activator, 3-5% of a thixotropic agent, 2-5% of a corrosion inhibitor, 3-5% of a surfactant and the balance solvents. The solder paste has the advantages that the welding temperature is low, slag is reduced, and the solder paste is suitable for manual welding and printing welding with poor thermal shock resistance.

Owner:郴州金箭焊料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com