Patents

Literature

68 results about "Heater type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen sulfide gas sensitive, preparation, and method for making hydrogen sulfide gas sensitive device

InactiveCN101493430AWith quantum effectSelf-catalytic activityTitanium dioxideMaterial resistancePolyethylene glycolPhysical chemistry

The invention relates to a hydrogen sulfide gas-sensing material and preparation thereof as well as a method for manufacturing hydrogen sulfide gas-sensing devices, comprising: SnO2 powder and TiO2 powder are mixed according to the molar ratio of 6-10: 1 for obtaining SnO2-TiO2 nano-composite material; Pb(NO3)2 or AgNO3 is added and then fine grinded; the hydrogen sulfide gas-sensing material is regulated into a paste shape by using anhydrous ethanol and polyethylene glycol, and then evenly coated on the surface of an electrode tube; by annealing processing, a gas-sensing electrode tube is obtained; finally, the gas-sensing electrode tube is welded, electrically aged, and packaged according to a heater type structure traditional technology for manufacturing the hydrogen sulfide gas-sensing device. Compared with the prior art, the invention has the advantages that the hydrogen sulfide gas-sensing material has the quantum effect of the nano material, self-catalytic activity, surface effect, and the like, and also has high sensitivity to the hydrogen sulfide gas, high resolution, good choosing performance, short response time, and low operating temperature as a novel gas-sensing material.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

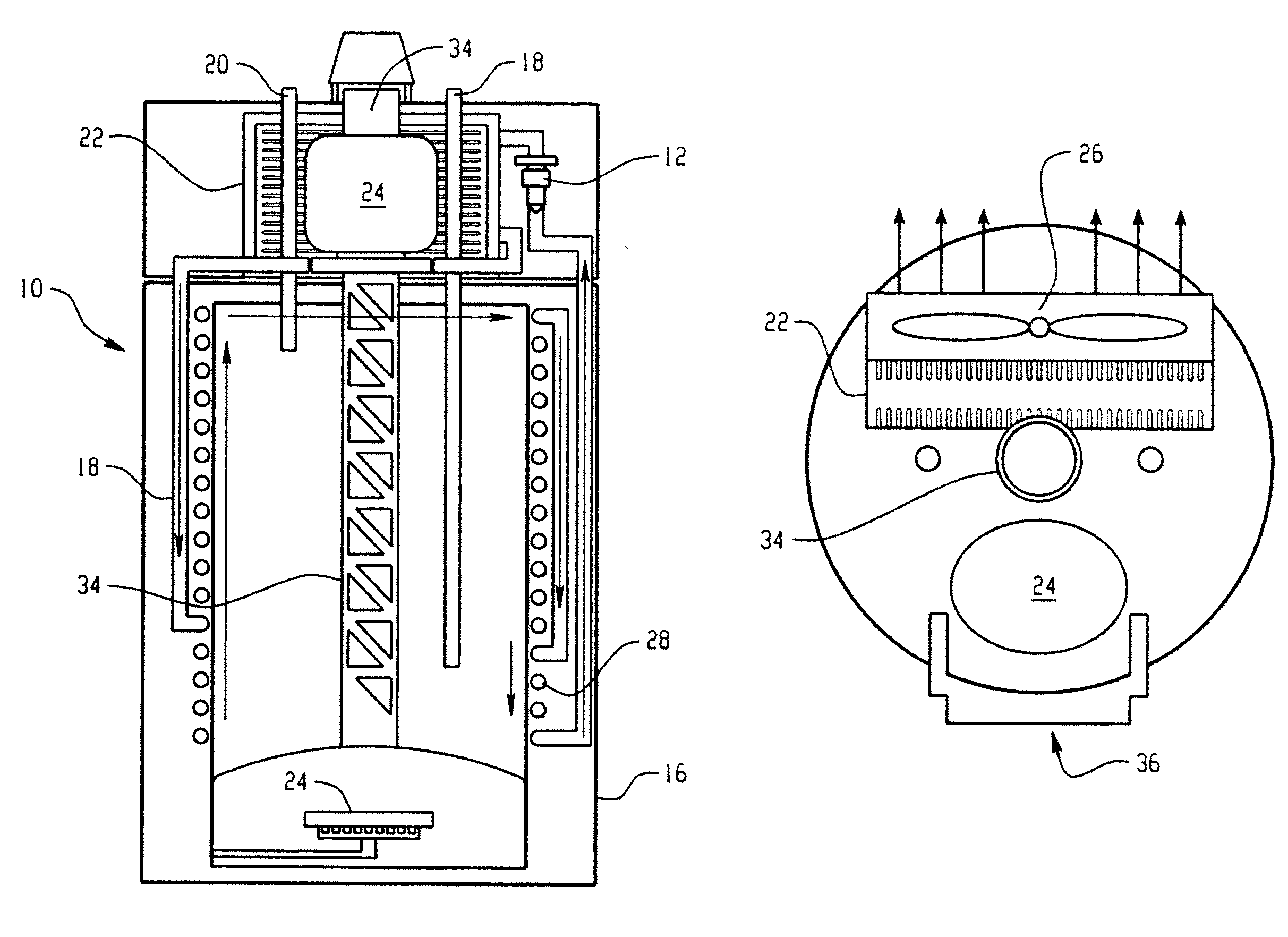

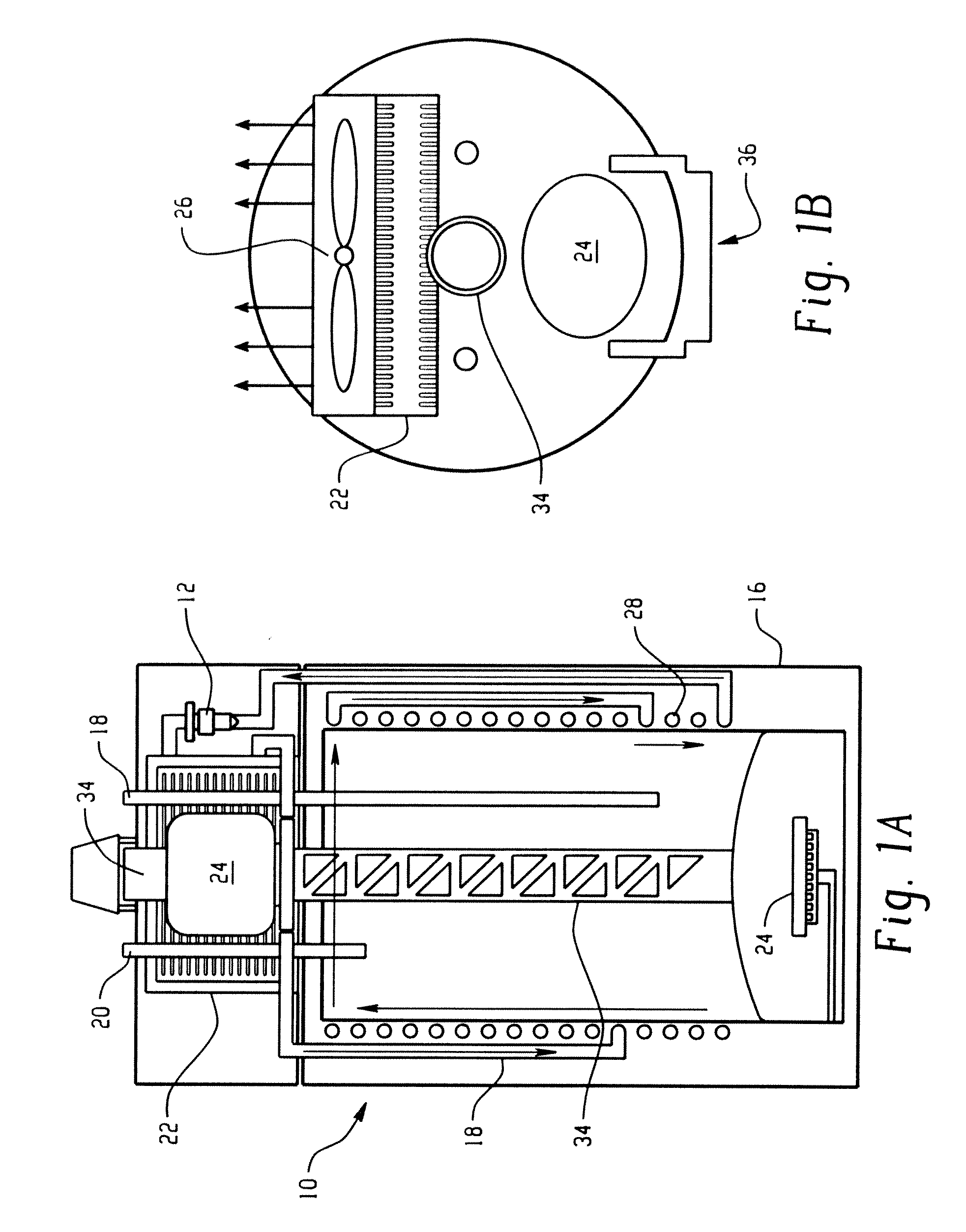

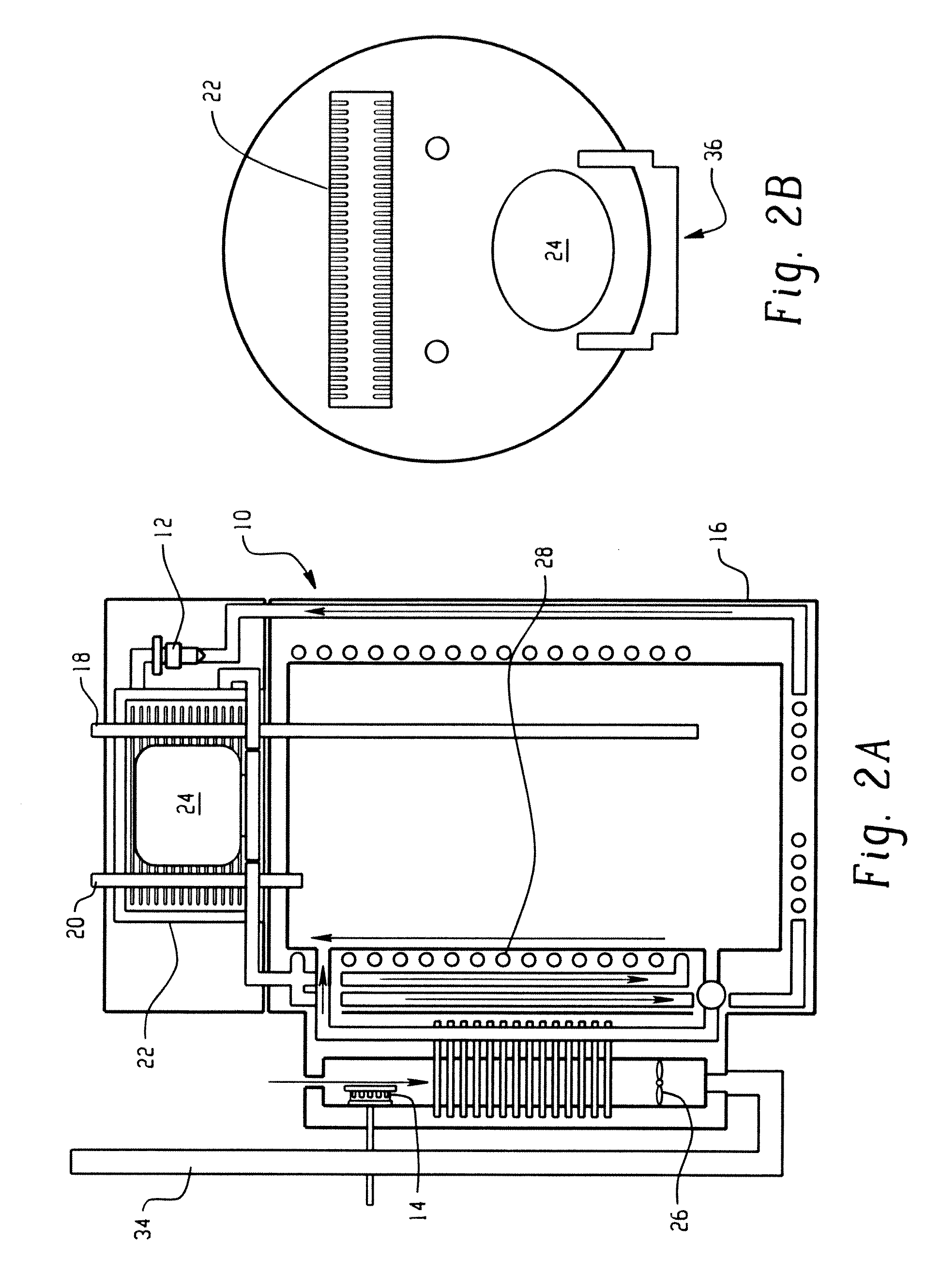

Heat pump water heater in conjunction with gas water heater

InactiveUS20130042635A1Improve energy efficiencyLow costCompression machines with cascade operationWater heatersCombined useEngineering

A method for heating water delivered and stored in a water heater storage tank includes activating at least one of dual fuel heater types in response to various modes of operation. The water heater is preferably a dual fuel or hybrid heat pump gas water heater that includes a heat pump as the first type of heater for heating the water, and a gas burner as the second type of heater that transfer heat to the water. One or more sensors monitor water temperature and communicate with a controller to activate one of, or both of, the first and second types of heaters. If there is an electrical power outage, the hybrid heat pump gas water heater is still able to heat the water.

Owner:GENERAL ELECTRIC CO

Formaldehyde air-sensitive material and its preparation method and preparation method for formaldehyde air-sensitive device

InactiveCN101144789AWith quantum effectSelf-catalytic activityMaterial resistanceGas detectorPolyethylene glycol

The invention relates to a formaldehyde gas sensitive material, the preparation method thereof and a manufacture method of a formaldehyde gas sensitive component. The component of the formaldehyde gas sensitive material takes an SnO2-TiO2 binary nanometer composite material as a substrate, the mol ratio of the Ti / Sn is 0.2 to 0.5, the fractional ratio of the quality adulterated is 2 percent to 5 percent Cd2, the formaldehyde gas sensitive material is adjusted to be pasty after being ground with an appropriate amount absolute ethyl alcohol and 0.2 to 1 portion polyethylene glycol, and is painted on the surface of an electrode pipe evenly, and a formaldehyde gas sensitive electrode pipe is produced through 400 degree annealing processing for two to four hours; finally a formaldehyde gas sensitive component is made through the welding, the electrical ageing and the sealing to the gas sensitive electrode pipe according to the heater type structure traditional process. The gas sensitive sensor made through the invention has low operating temperature, has high sensitivity to the formaldehyde gas, has good antiinterference performance to other indoor pollutant gases, such as benzene, toluene, xylene and ammonia, etc, the response time and the recovery time are short, and the gas sensitive sensor is used for the detection to the indoor decorating formaldehyde gas pollution.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Gas sensitive material for detecting low-concentration formaldehyde

The invention discloses a novel gas sensitive material for detecting low-concentration formaldehyde, and belongs to the technical field of gas sensitive materials. SnO is taken as a base material and In2O3 and graphene are mixed in SnO by virtue of a hydrothermal reaction method or a solvent thermal reaction method (taking alcohol and ethanol as solvents), wherein a molar ratio of SnO to In2O3 is 8-10, and the amount of doped graphene accounts for 0.08-0.15% the sum of the mass of the SnO and the In2O3. A heater-type gas sensitive sensor which is made by taking the material as the gas sensitive material has sensitivity (a ratio of resistance of elements in air to resistance of elements in detected gas) of 1.09-1.1 to 0.001ppm formaldehyde and has sensitivity of 220-240 on 1000ppm formaldehyde at a working temperature of 200 DEG C.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

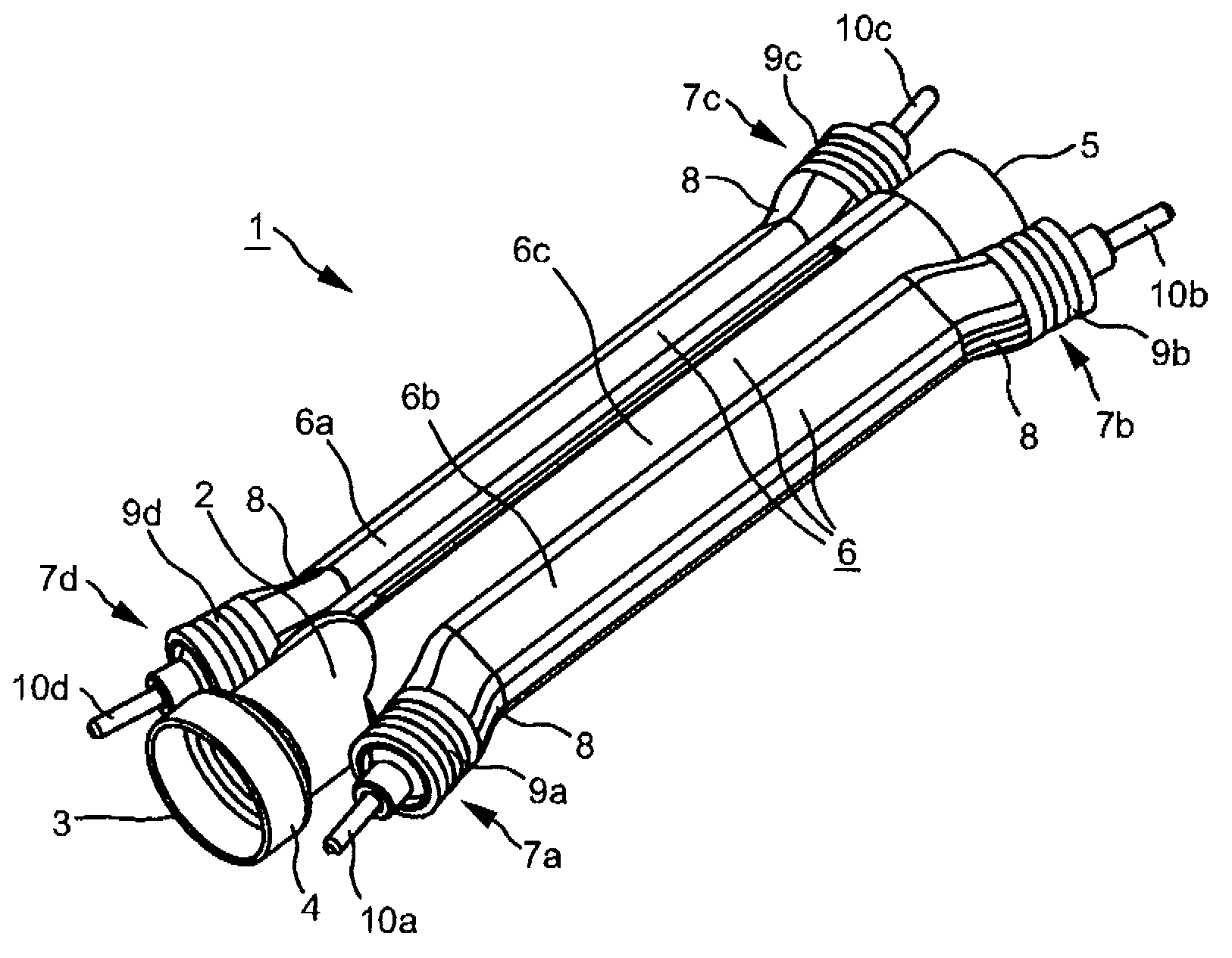

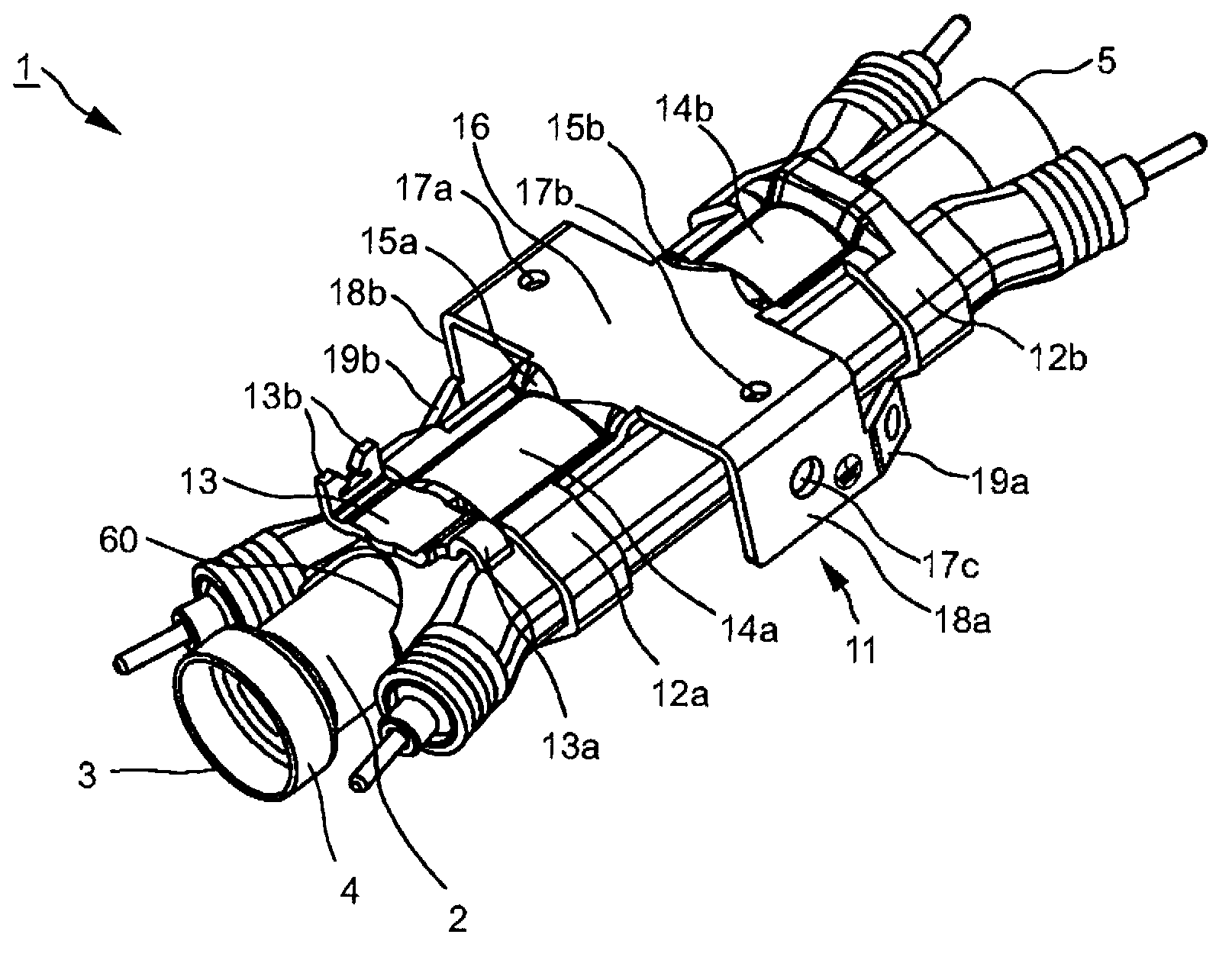

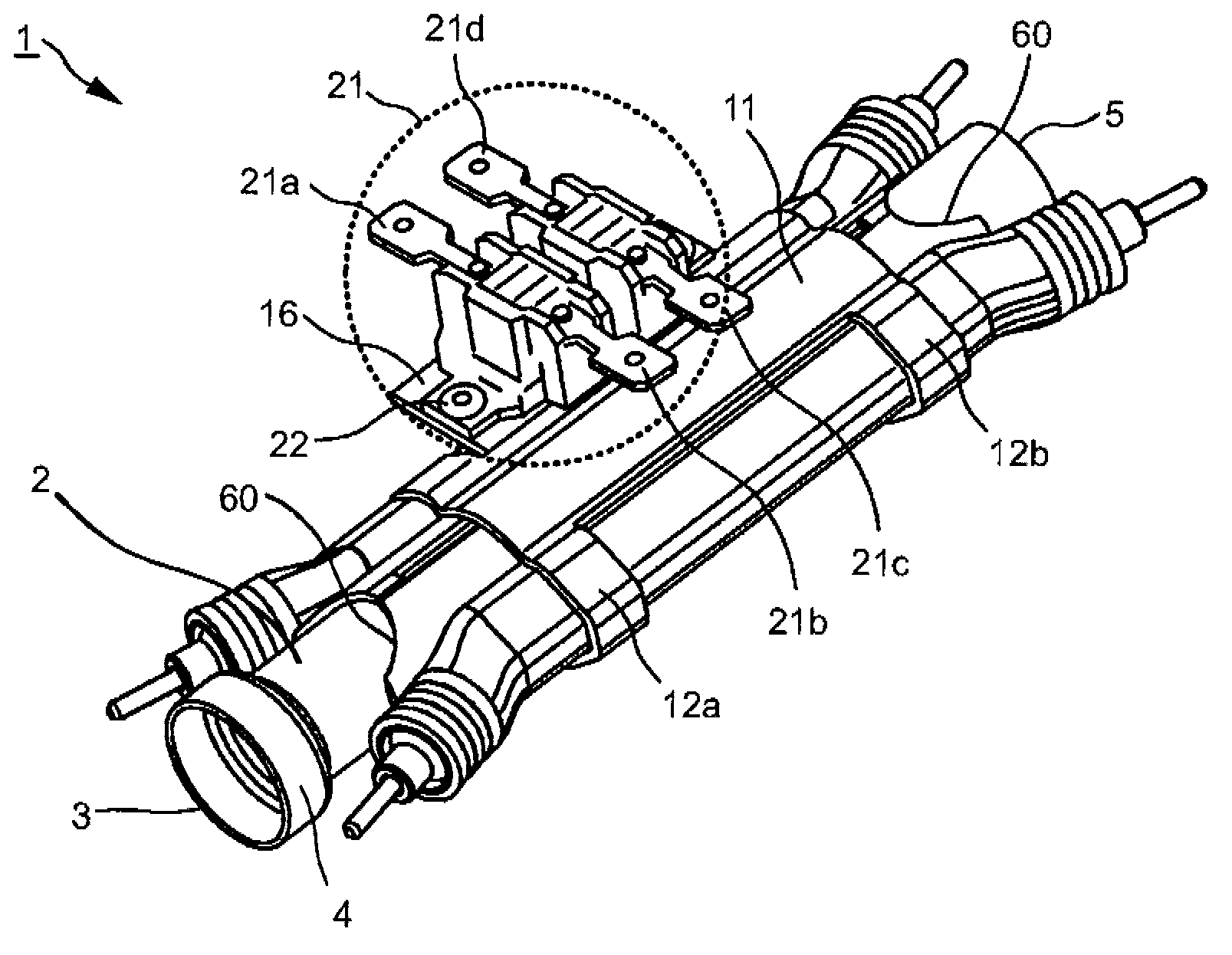

Dynamic flow heater

A fluid heater of the flow-heater type with a fluid channel having a first fluid channel section (35), at least one substantially cylindrical metal pipe (2), a heating device (6) having preferably two tubular heating bodies (6a, 6b) spaced apart from each other over equidistant circumferential sections of the metal pipe, and a heat-conducting means for the heat-conducting connection to the metal pipe (2), wherein a fluid-guiding core (30) which is made from plastic is arranged in the metal pipe (2), the fluid-guiding core forming the first fluid channel section (35) between the metal pipe and the fluid-guiding core (30), wherein the first fluid channel section (35) runs substantially helically in the form of a groove in an outer surface of the fluid-guiding core,; and wherein the fluid channel has a first fluid connection for fluid supply means and a second fluid connection for fluid removal means, wherein the fluid-guiding core (30) furthermore has a second fluid channel section (34) which is arranged, substantially coaxially, in the interior thereof and is connected in series with the first fluid channel section (35). A fluid connection subassembly can be provided in the region of a first end of the metal pipe (2), said fluid connection subassembly having both the first fluid connection (24a) and the second fluid connection (24b), and therefore fluid is supplied and fluid is removed in the region of the same end sides of the metal pipe (2). A closure stopper (50) is then provided in the region of the second end of the metal pipe (2).

Owner:BLECKMANN

Method for manufacturing gas sensor for testing hydrogen

InactiveCN101251508AHigh sensitivityHigh selectivityMaterial analysis by electric/magnetic meansHydrogenCoprecipitation

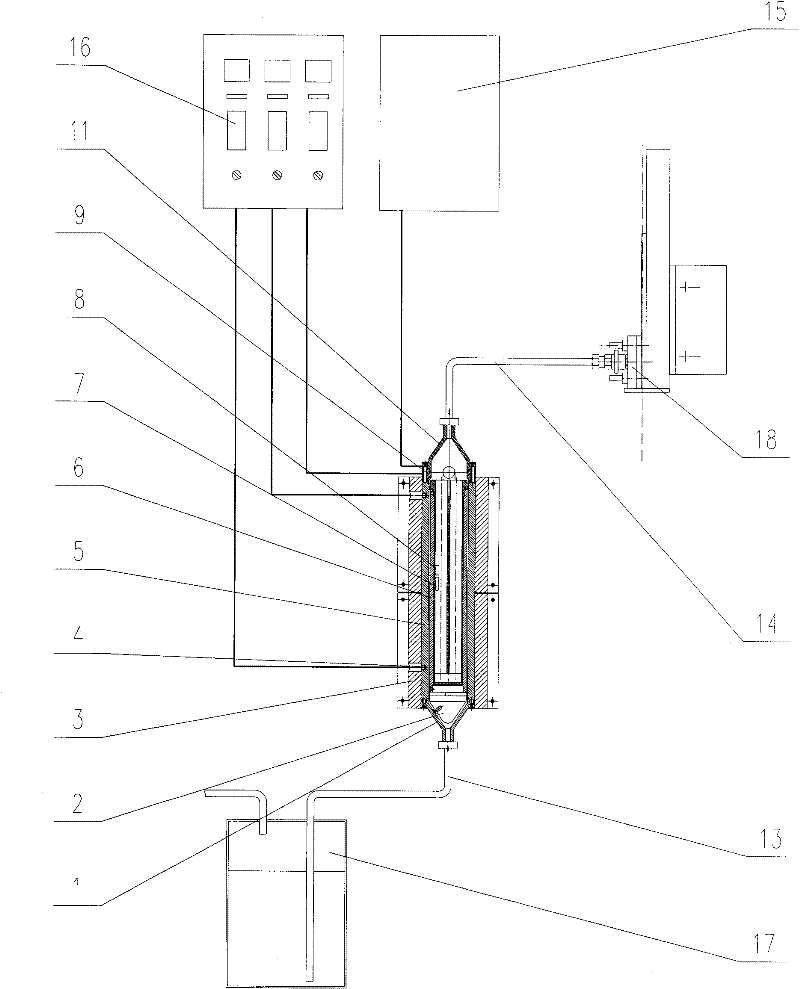

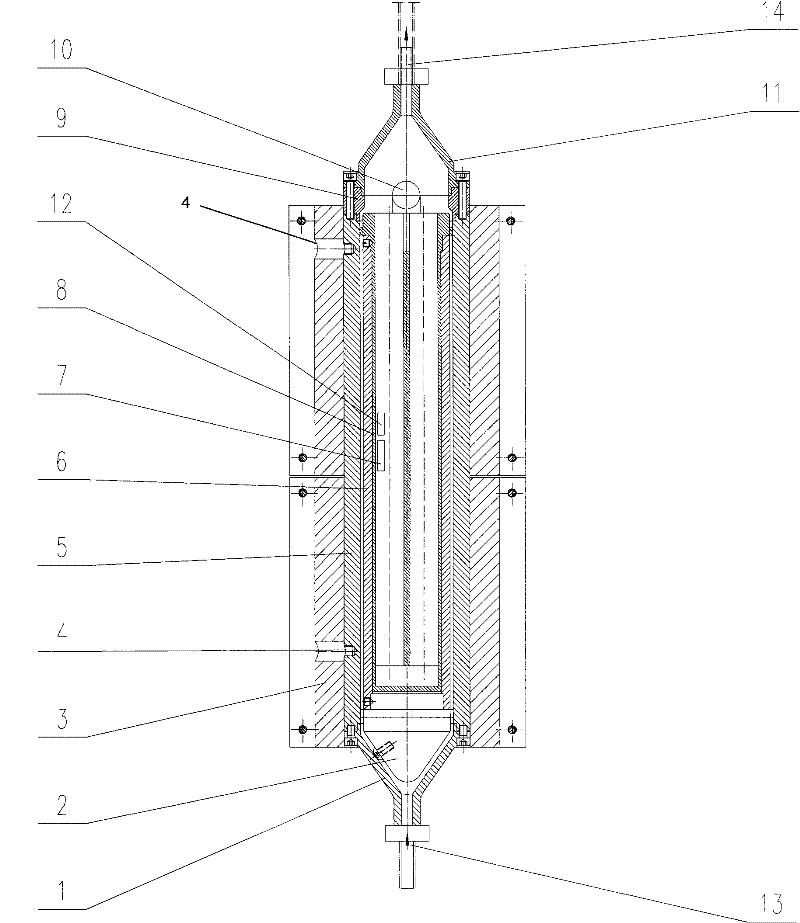

The invention relates to a preparation method for a gas sensor for detecting hydrogen, wherein, ultrasonic wave and low-temperature aging technologies are applied in the complex effect of zinc salts and stannum salts and chemical coprecipitation for preparation of nano ZnSnO3. The invention prepares the novel PdO-ZnSnO3 heater type semiconductor gas sensor by isomerisation of noble metal salts PdCl2, adhesives (ethyl orthosilicate) and deionized water through technologies like grinding, ultrasonic vibration, coating, sintering, etc. on the basis of the nano ZnSnO3, wherein, nano ZnSnO3 bases are prepared by adoption of an improved coprecipitation method. The preparation method for the gas sensor for detecting hydrogen has the advantages of high sensitivity of gas sensitive materials, strong selectivity, low operation temperature, simple preparation technology and so on.

Owner:CHONGQING UNIV

Preparation method and application of aqueous environmentally-friendly type conduction oil

InactiveCN102304351ACompliance with directivesSolve pollutionHeat-exchange elementsHazardous substanceGlycerol

The invention relates to a preparation method and application of aqueous environmentally-friendly type conduction oil in which glycerol is used as a main component, belonging to the field of heat conduction media. According to the invention, the conduction oil contains about 95% by mass of glycerol; the novel conduction oil is extremely environmentally-friendly, can be miscible with water in any proportion and does not contain any toxic and harmful substances, can be discharged without any special treatments, and has the advantages of wide material sources, low price and simple processing technology; and simultaneously, the conduction oil can operate for a long term at high temperature. The novel conduction oil is successfully used on an oil heater type warmer, and can also be popularizedto other related industries at the same time.

Owner:SUN YAT SEN UNIV +1

Composite gas-sensitive material with high sensitivity and high selectivity on acetic acid gas

ActiveCN109001266ALower working temperatureEliminate distractionsMaterial resistanceTin dioxideAcetic acid

The invention discloses a composite gas-sensitive material with high sensitivity and high selectivity on acetic acid gas, and belongs to the technical field of gas-sensitive materials. The composite gas-sensitive material consists of C3N4-SnO2, wherein the mass of C3N4 accounts for 8-12% of the total mass of the material; a heater type gas-sensitive sensor is prepared by taking the material as a sensitive material; when the sensor works at a working temperature of 185 DEG C, the sensitivity to 0.1ppm acetic acid is 1.1-1.3; the sensitivity of an element to 1,000ppm of the acetic acid reaches 35-90, while the sensitivity to 1,000ppm of acetone, formaldehyde, ethanol, acetaldehyde and ammonia gas is 8 or below, thereby proving that sensitivity and the gas sensitivity selectivity of tin dioxide to the acetic acid gas are improved by virtue of C3N4; and in addition, the working temperature of the detection acetic acid gas sensor is reduced, the concentration of acetic acid in air can be rapidly detected, and gas interference such as acetone, formaldehyde, ethanol, acetaldehyde, ammonia gas and the like can be eliminated.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method for acetone gas sensor

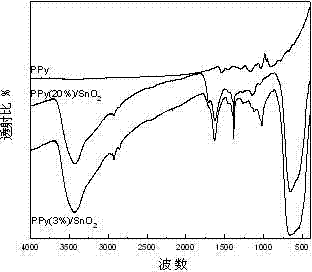

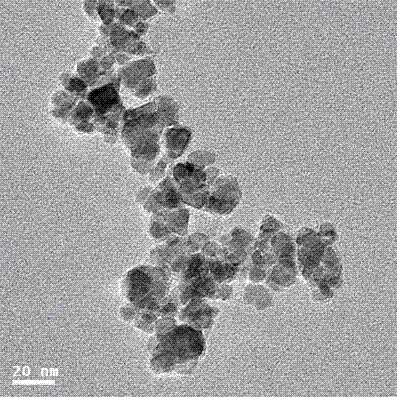

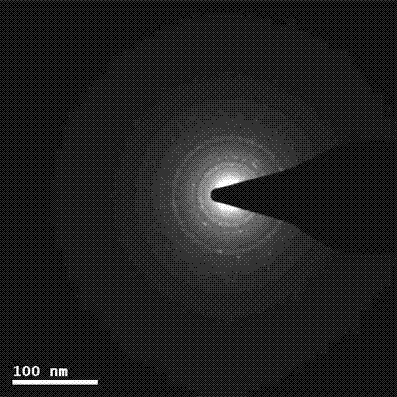

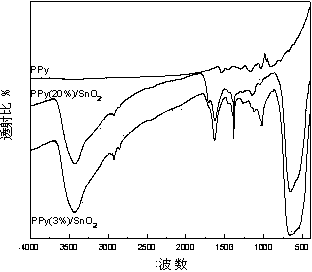

InactiveCN103675078AEasy to purifyImprove gas selectivityMaterial analysis by electric/magnetic meansTin dioxidePolypyrrole

The invention discloses a preparation method for an acetone gas sensor. According to the preparation method, a series of tin dioxide and polypyrrole hybrid materials with different polypyrrole mass percents are prepared by using a simultaneous reaction of a hydrothermal method and a polymer in-situ generation method; the tin dioxide and polypyrrole hybrid materials are used for coating a heater-type device structure and an aluminum oxide ceramic tube is used as a carrier to prepare the acetone gas sensor; a noble metal electrode lead wire is a platinum wire and a sensing element tube core is the aluminum oxide ceramic tube. The method disclosed by the invention is good for finishing a reaction in one step and easily purifying a product. The gas sensor prepared by the method has good gas sensing selectivity on acetone gas under a low working environment; the recovery time can be rapidly responded; meanwhile, the interferences caused by hydrogen, carbon monoxide and ammonia gas can also be eliminated.

Owner:中国人民解放军白求恩医务士官学校

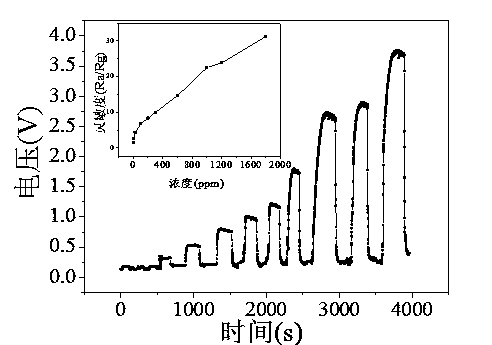

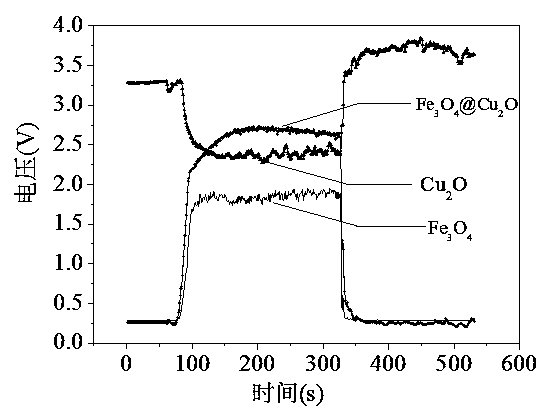

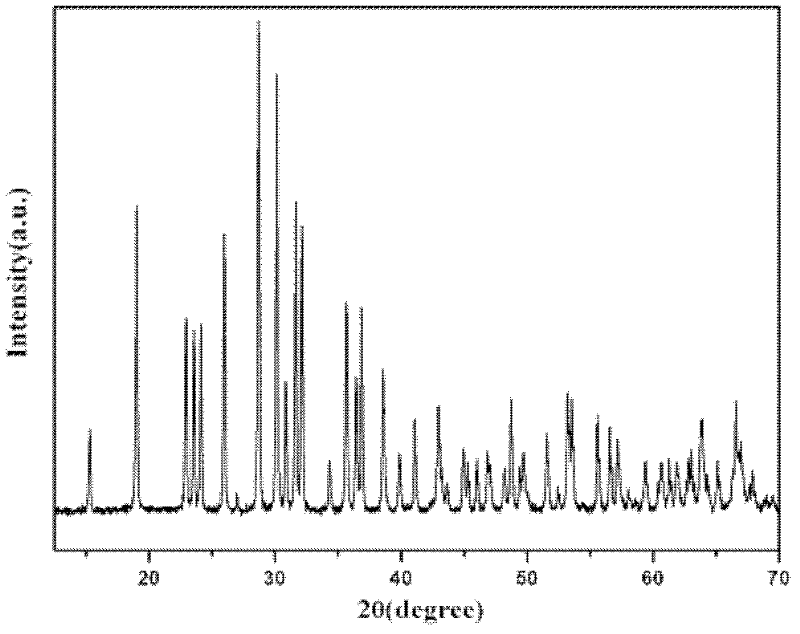

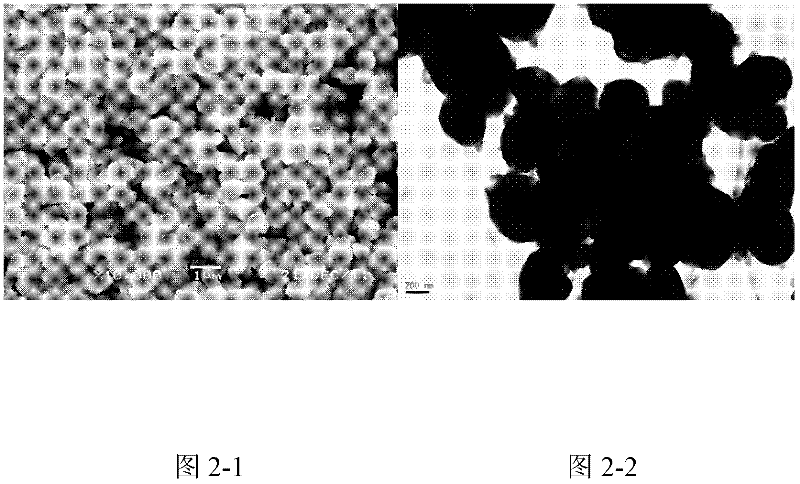

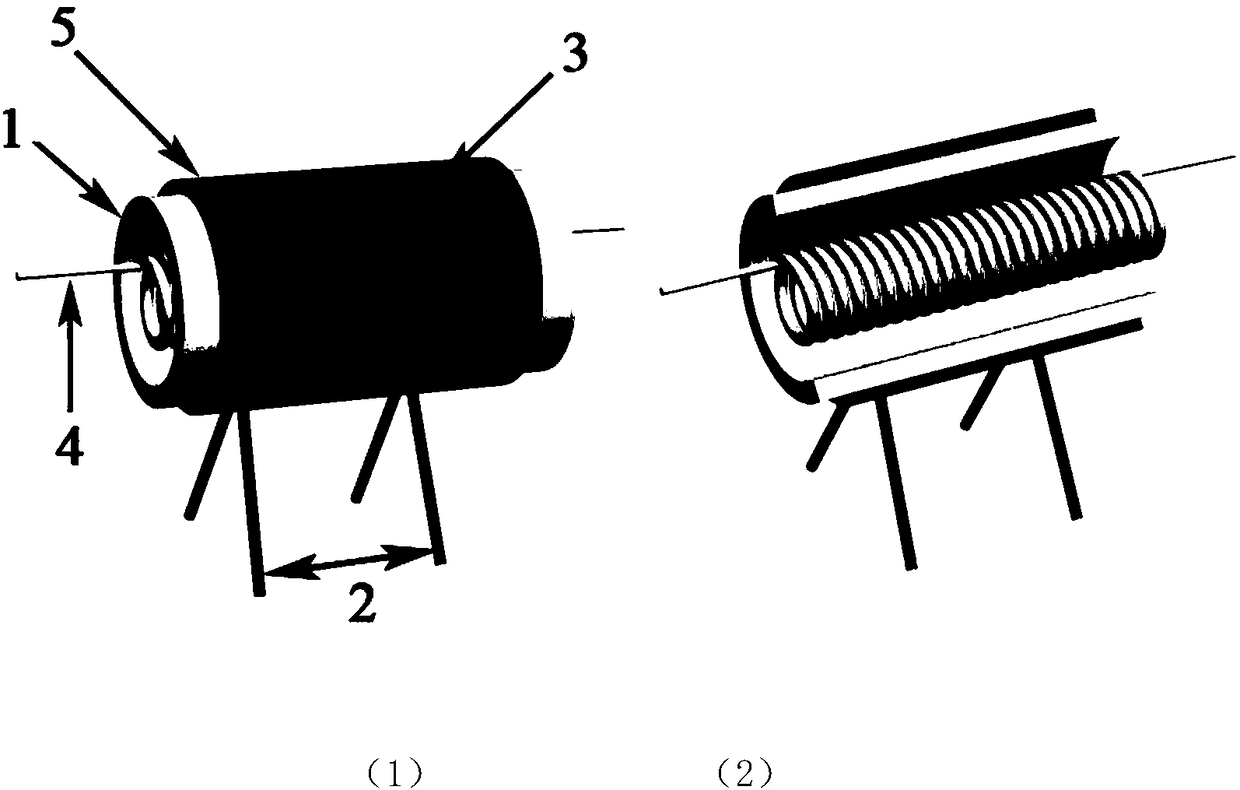

Preparation method and application of n-p junction type ferrum-copper based oxide gas sensitive element

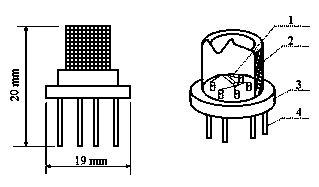

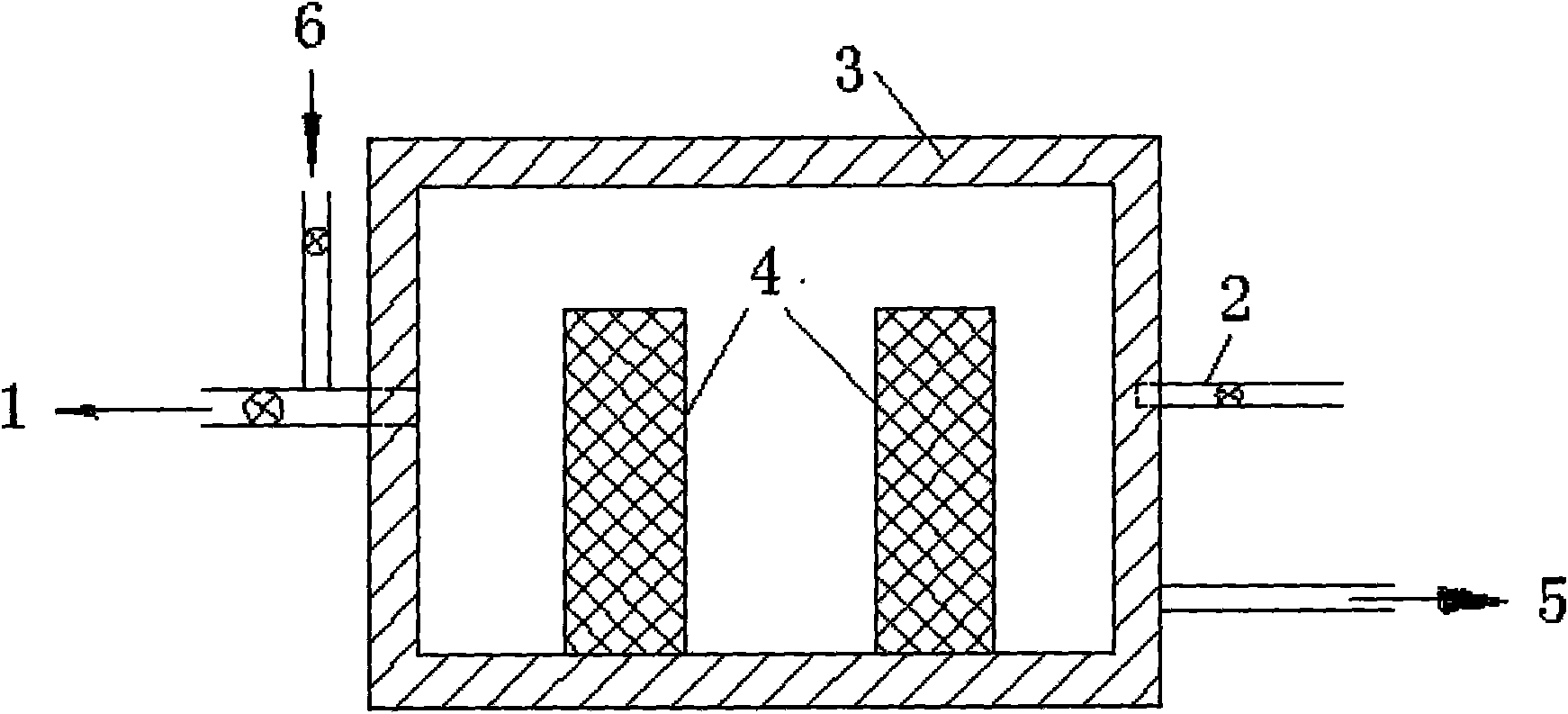

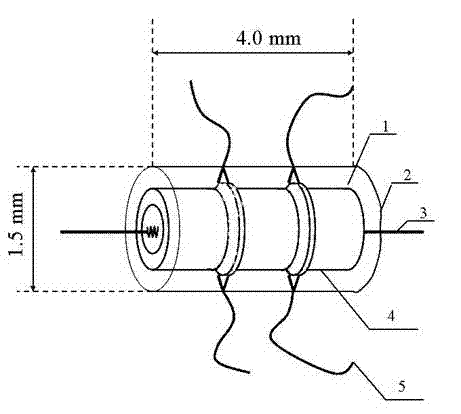

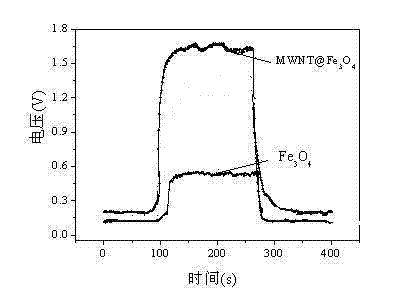

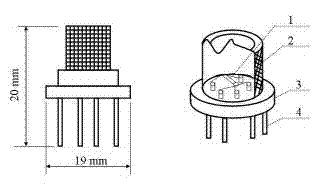

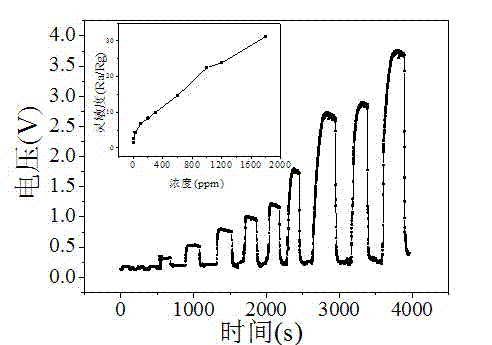

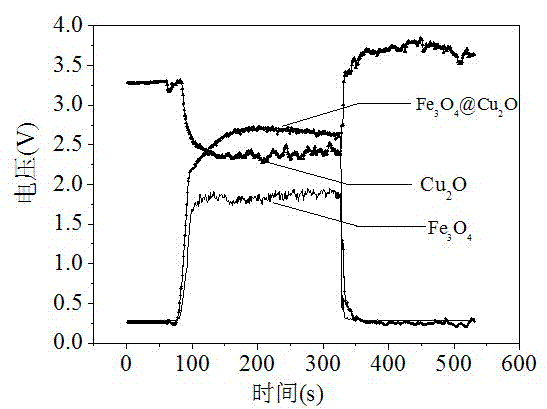

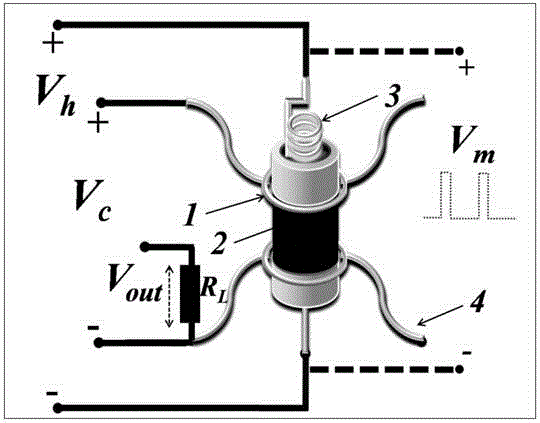

InactiveCN103115946BCapacitive effectGood synergistic sensitizationMaterial analysis by electric/magnetic meansHeater typeSemiconductor

The invention relates to a preparation method and application of an n-p junction type ferrum-copper based oxide gas sensitive element. A gas sensor adopts a heater type device structure and takes an alumina ceramic tube as a carrier. A forked gold electrode is applied to the outer surface of the gas sensor. Platinum extraction electrodes are arranged at the two ends of the gas sensor. A heater strip is arranged in the ceramic tube. A gas sensitive material is coated on the outside the ceramic tube and is an n type semiconductor ferroferric oxide and p type semiconductor cuprous oxide porous compound. The gas sensor is prepared by preparing the alumina ceramic tube on which the material is coated into a tube core and then welding, packaging and electrically aging the tube core according to the conventional process of a heater type device. The preparation method is simple in process, mild in conditions and low in cost and is especially suitable for volume production. The prepared gas sensitive element is used for detecting the ethanol concentration at 200-300 DEG C, has the characteristics of high response sensitivity to 1-1800ppm ethanol, good restorability, quick response and the like and can be used for determining ethanol concentration in industrial and agricultural production and environment detection.

Owner:UNIV OF JINAN

Application of copper tungstate and preparation method of copper tungstate gas sensor

InactiveCN102645453AShort response timeGood choiceMaterial resistanceTungsten compoundsGas detectorTungstate

The invention provides an application of copper tungstate as an ethanol gas sensing element and a preparation method of a copper tungstate gas sensor, belonging to the technical field of preparation of gas sensitive materials and gas sensors. The preparation method comprises the following steps of: mixing copper solution and tungsten solution based on the same molar ratio of the copper to the tungsten, and reacting, after reacting, cooling, washing with deionized water, drying and roasting to obtain CuWO4 powder; fully mixing and grinding the CuWO4 powder with an adhesive to prepare slurry, evenly coating the slurry on the outer surface of an Al2O3 ceramic tube, and annealing for 2-4h at 400 DEG C to prepare a gas sensitive electrode tube; and finally welding, electrically ageing and packaging the gas sensitive electrode tube according to a traditional heater-type process to prepare a CuWO4 gas sensor. The CuWO4 gas sensor prepared by the invention has the advantages of high sensitivity to ethanol, short response time, favorable selectivity and relatively low working temperature, is simple and easy to prepare by only using conventional containers and devices, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

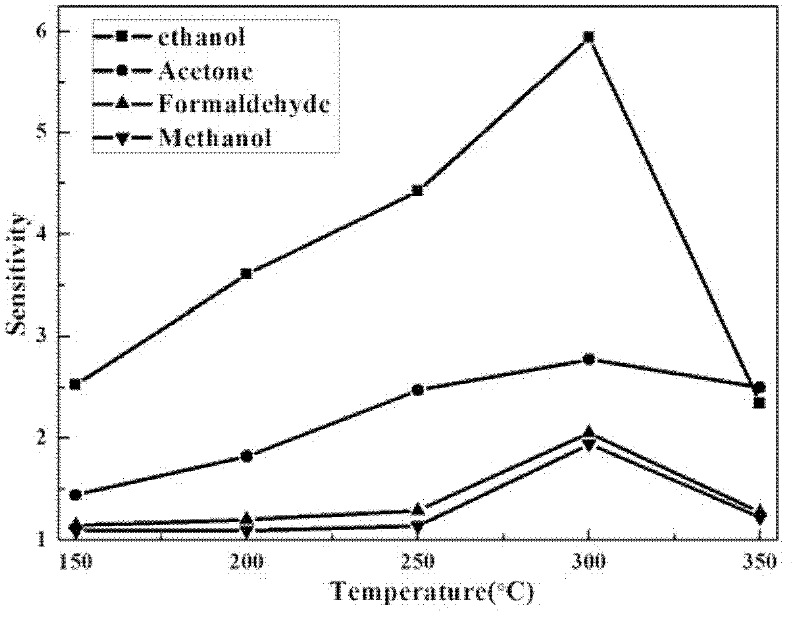

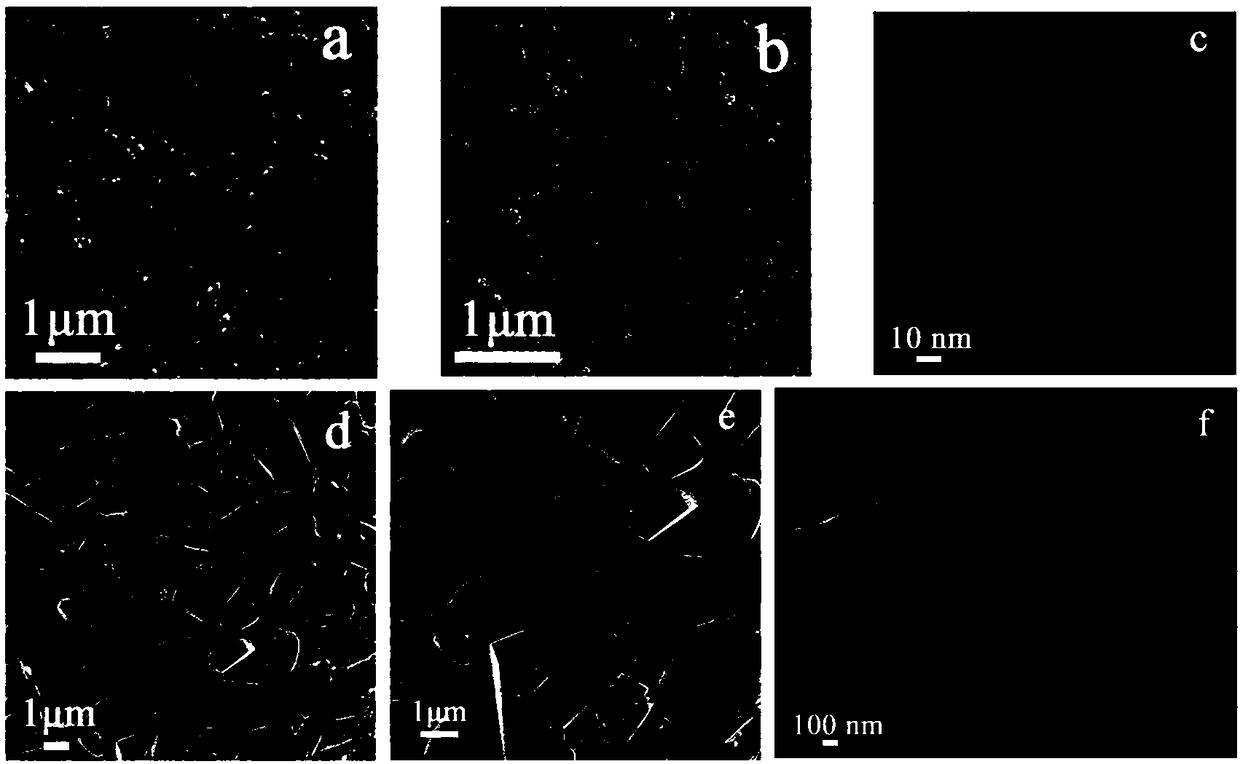

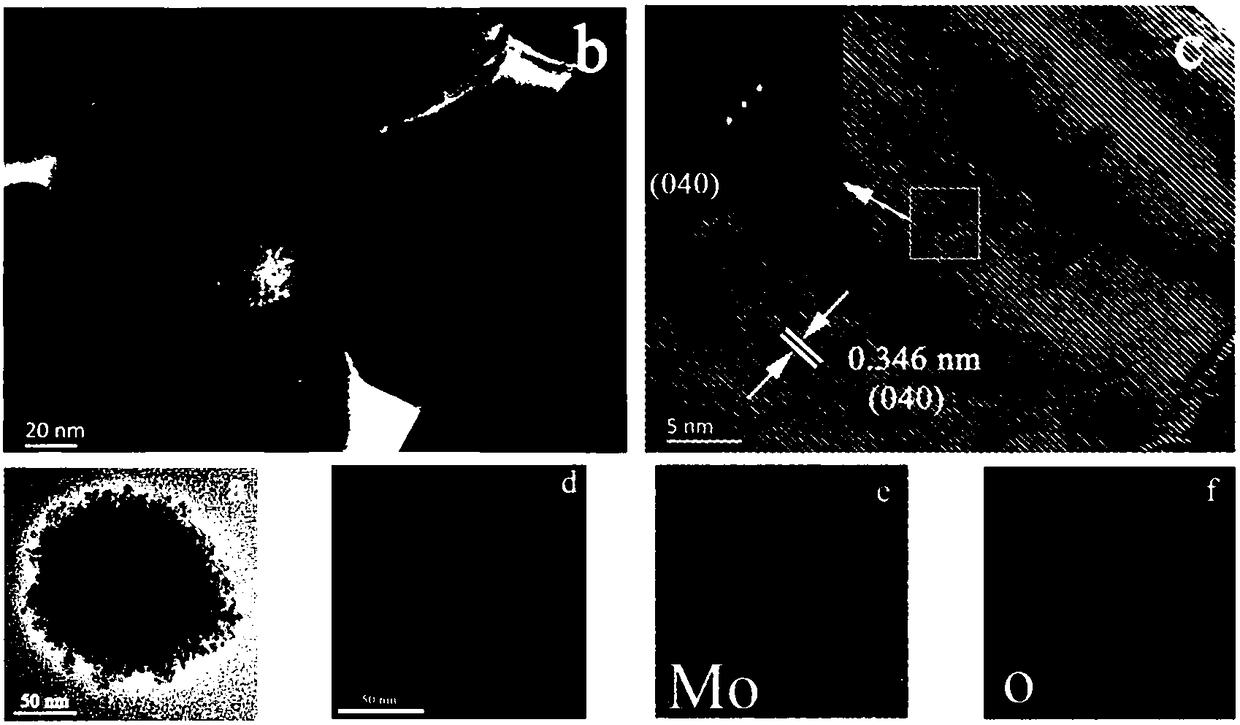

Triethylamine sensor based on MoO3 nano sensitive material as well as preparation method and application thereof

InactiveCN108508062AThe synthesis method is simpleUniform size distributionMaterial resistanceNickel cadmiumHeater type

The invention relates to a triethylamine sensor based on a MoO3 nano sensitive material as well as a preparation method and application thereof in detecting triethylamine gas in a complicated environment, which belongs to the technical field of semiconductor oxide gas sensors. The sensor is of a heater-type structure and consists of a Al2O3 ceramic tube substrate with two parallel annular and independent gold electrodes on the outer surface, a MoO3 nano sensitive material smeared on the outer surface of a ceramic tube and the gold electrodes and a nickel-cadmium heating coil arranged in the ceramic tube. By utilizing the rapid responsive restoration and excellent selectivity of the MoO3 nanosheet sensitive material which is simple in preparation and uniform in size for the triethylamine, the triethylamine sensor with high performance is developed, the detection performance in a complicated environment is good, and the application prospect is good.

Owner:JILIN UNIV

Method for compactly sintering chromium oxide aggregate

The invention discloses a method for compactly sintering a chromium oxide aggregate. The method comprises the following steps: after pressing and forming pure Cr2O3 micro powder or Cr2O3 compound micro powder, putting into an electric heating kiln or a heater type kiln, keeping the total pressure in the kiln, controlling CO differential pressure in the kiln and reducing and sintering a Cr2O3 material in a CO atmosphere maintained by carbon; firstly, vacuumizing when sintering, then filling Ar gas or Ar+CO gas of a protective gas, sintering at the temperature of 1400-1600 DEG C, keeping the temperature for 2 hours at the temperature and obtaining the pure Cr2O3 aggregate which is compactly sintered. The method has low labor strength, convenient and controllable sintering, low sintering temperature, environmental protection and energy saving, is safer than a method adopting an H2 atmosphere for sintering and is a good method for compactly sintering the aggregate with high chromium.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

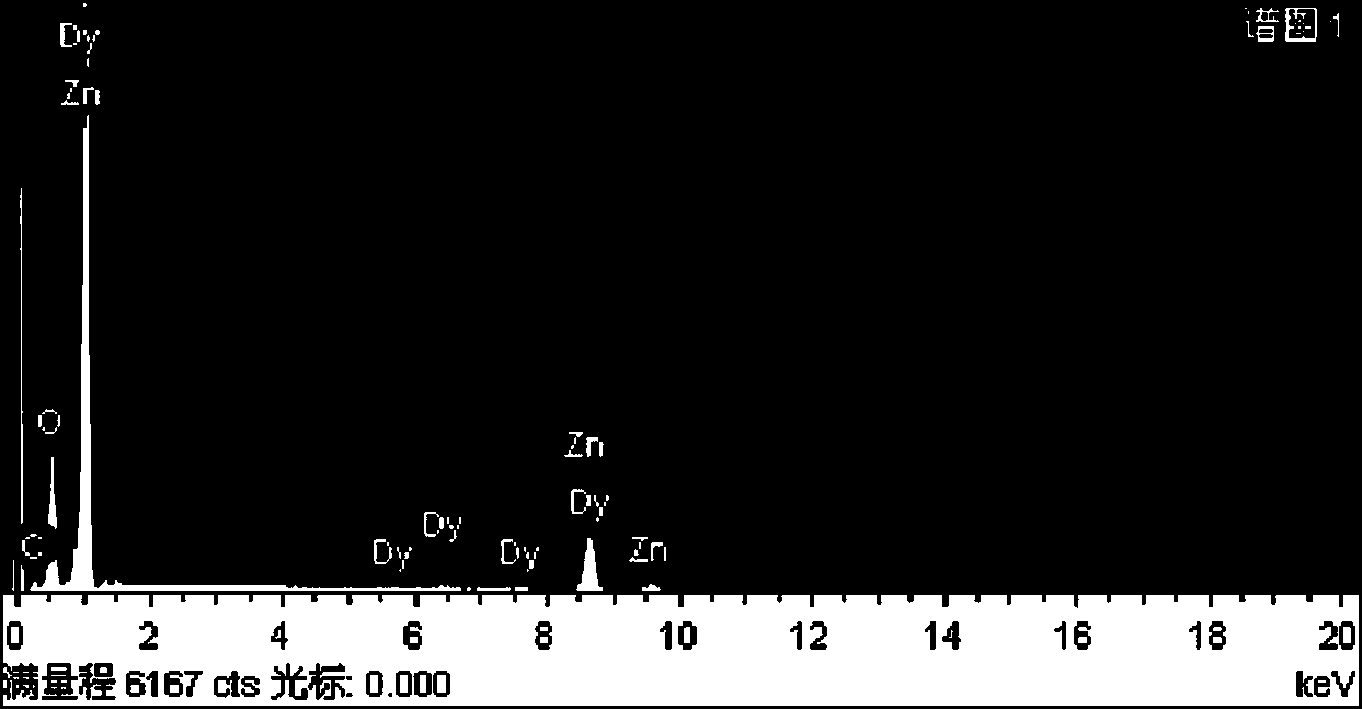

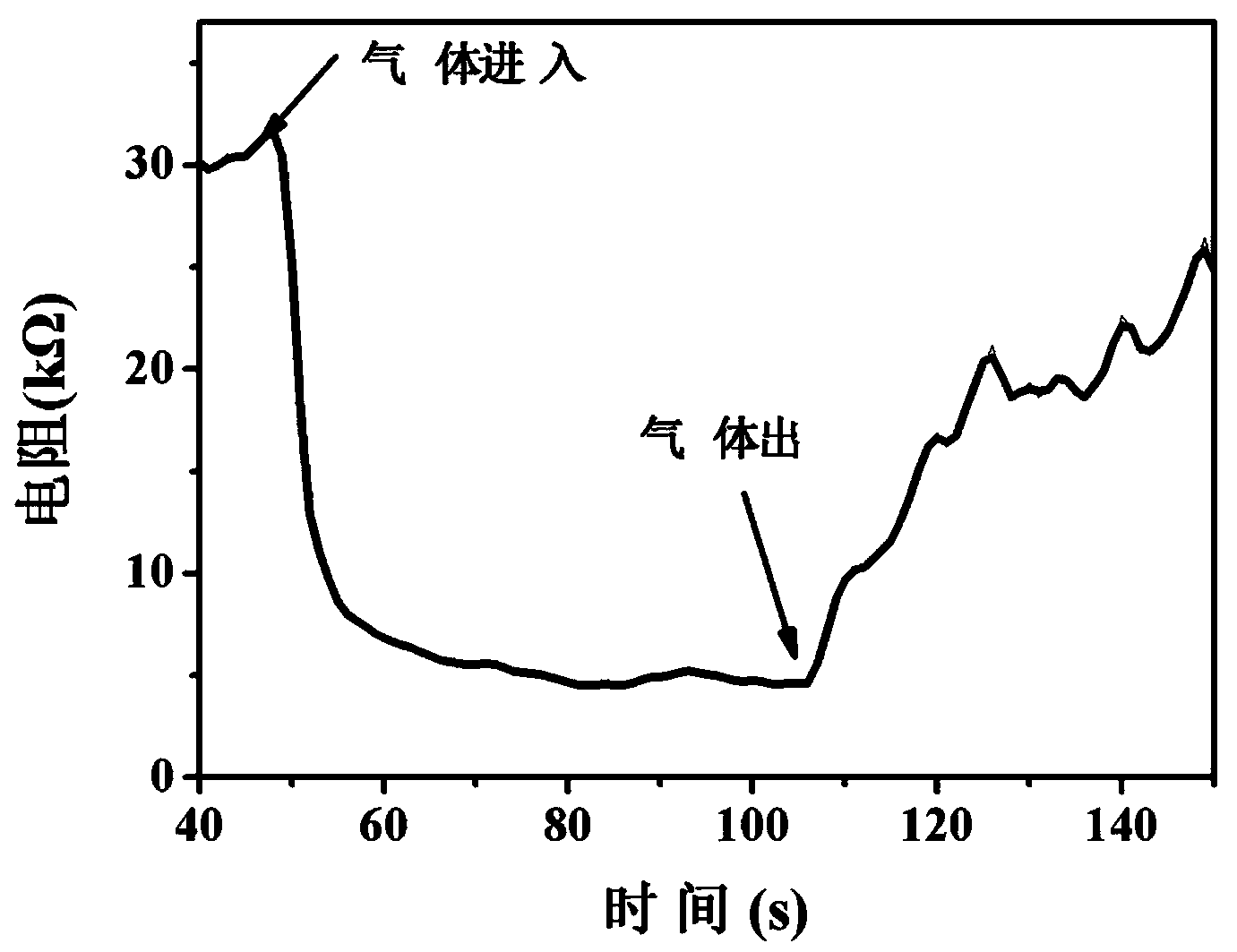

Preparation method of rare earth doped zinc oxide nanowire for gas sensor

InactiveCN103364446ASmall diameterLarge specific surface areaMaterial nanotechnologyMaterial analysis by electric/magnetic meansChemical solutionGas detector

The invention discloses a preparation method of a rare earth doped zinc oxide nanowire for a gas sensor. The zinc oxide nanowire is synthesized under a strong alkali condition by using a chemical solution method; the gas sensor is of a heater-type device structure; an aluminum oxide ceramic tube is used as a carrier and internally provided with a heating wire; a gas sensitive material of the rare earth doped zinc oxide nanowire is coated outside the ceramic tube. The gas sensor can be used for detecting ethanol within different working temperature ranges and is high in response ratio and short in response time. The preparation method of the rare earth doped zinc oxide nanowire is simple; the rare earth doping variety and concentration are easy to control; the obtained rare earth doped zinc oxide nanowire has the advantages such as uniformity in diameter distribution, good stability and the like; the rare earth doped zinc oxide nanowire prepared by the invention can be used for the gas sensor, a solar cell photoanode and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

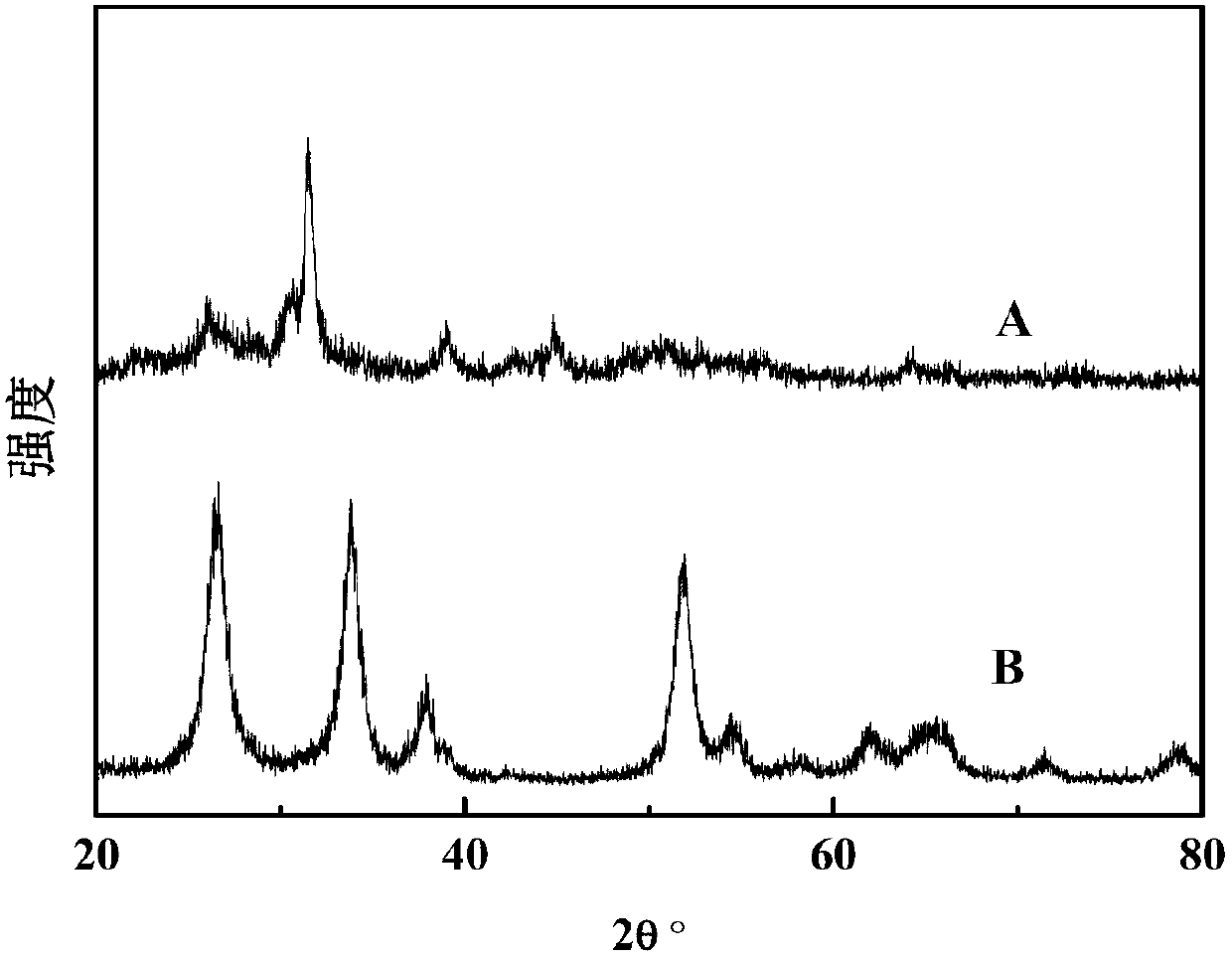

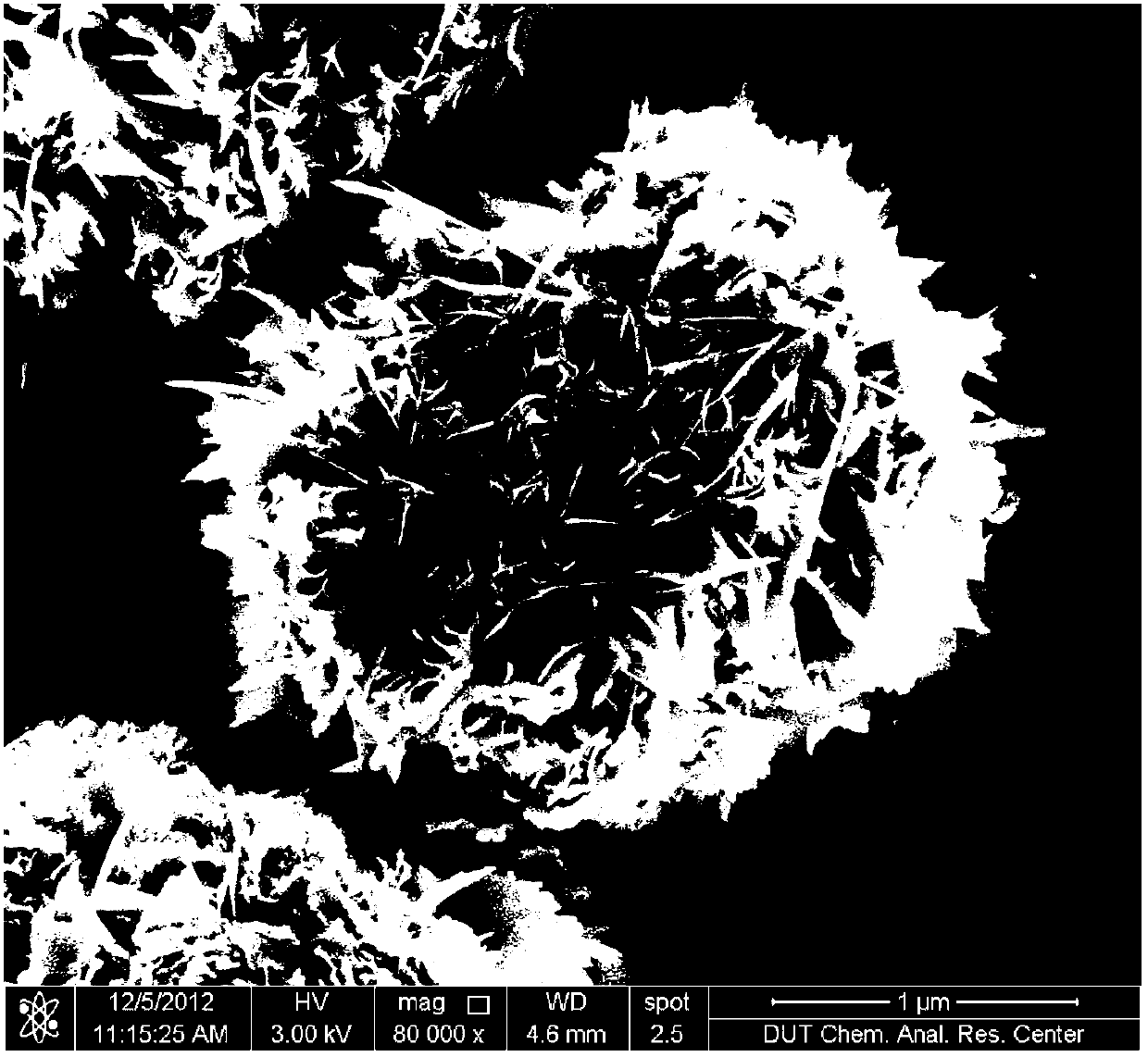

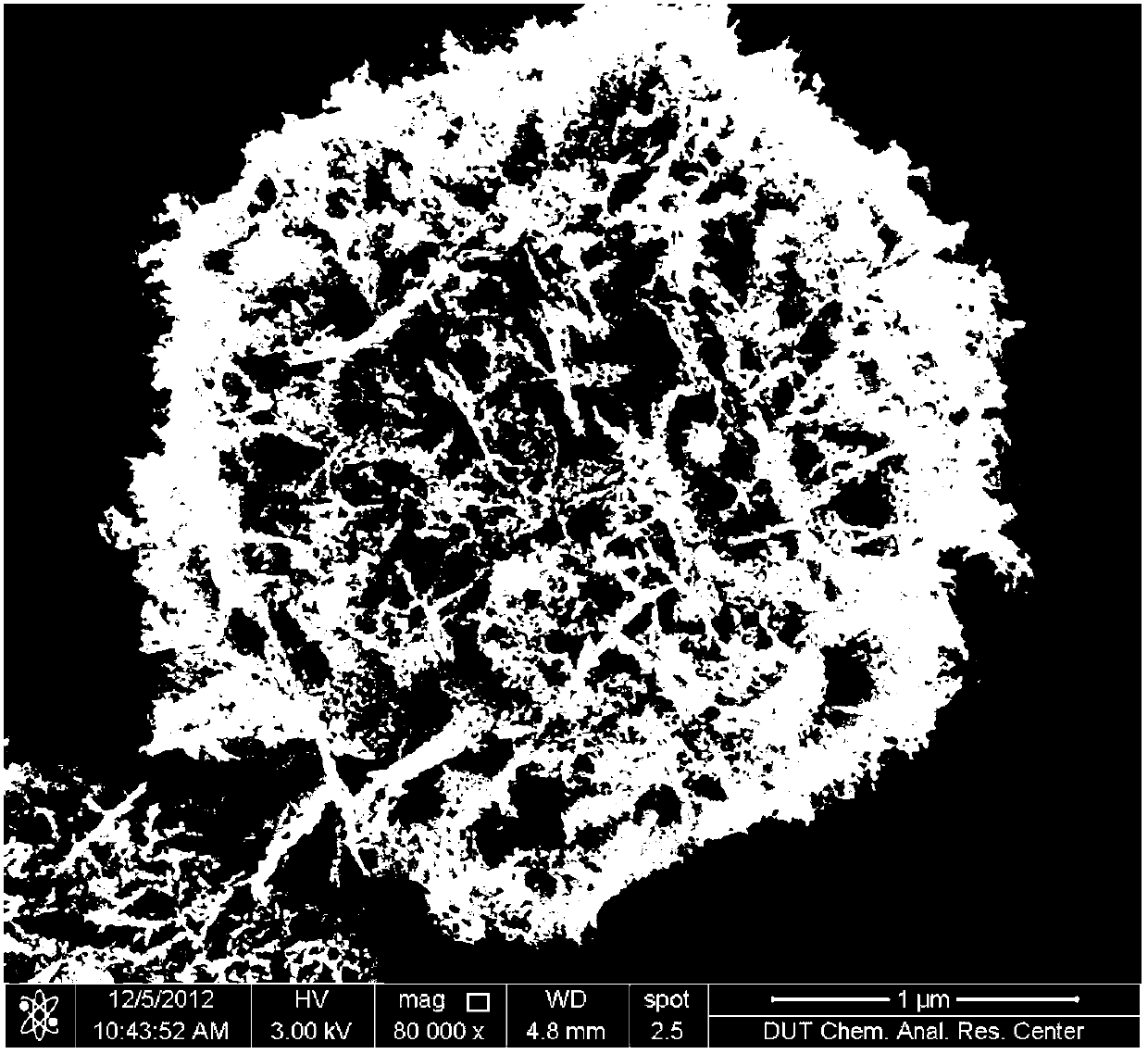

Porous tin dioxide material as well as preparation method and application thereof

InactiveCN103121708ANoveltyStable structureMaterial nanotechnologyTin oxidesTin dioxideSensor materials

The invention relates to a porous tin dioxide material as well as a preparation method and application thereof, and belongs to the technical field of preparation process of metal oxide semiconductor sensor materials. The preparation method of the porous tin dioxide material comprises the following steps of: obtaining a hierarchical patterned structure stannous sulfide by utilizing a solvothermal method; and obtaining a patterned ball shaped porous tin dioxide material by utilizing an oxygen-ventilating and calcining method. According to the preparation method of the porous tin dioxide material disclosed by the invention, the patterned ball shaped porous tin dioxide, which has clear petals consisting of nanometer particles and has a stable structure, is obtained by utilizing the simple solvothermal method and the oxygen-ventilating and calcining method. Meanwhile, a heater-type gas sensor, which is manufactured by the porous tin dioxide material, has better and more sensitive sensitivity to the acetone.

Owner:DALIAN UNIV OF TECH

Preparation method and application of carbon-doped mesoporous metal oxide acetone sensor

InactiveCN103115947AHigh sensitivityAvoid interactionDecorative surface effectsMaterial analysis by electric/magnetic meansPlatinumMultiwalled carbon

The invention relates to a preparation method and application of a carbon-doped mesoporous metal oxide acetone sensor. A gas sensor adopts a heater type device structure and takes an alumina ceramic tube as a carrier. A forked gold electrode is applied to the outer surface of the gas sensor. Platinum extraction electrodes are arranged at the two ends of the gas sensor. A heater strip is arranged in the ceramic tube. A gas sensitive material is coated on the outside of the ceramic tube and is multiwalled carbon nanotube doped monodisperse mesoporous ferroferric oxide. The gas sensor is prepared by preparing the alumina ceramic tube on which the material is coated into a tube core and then welding, packaging and aging the tube core. The preparation method is simple in process, mild in conditions and low in cost and is especially suitable for volume production. The prepared gas sensitive element is used for detecting the acetone concentration at 270-290 DEG C, has the characteristics of high sensitivity to 1-5400ppm acetone, good restorability, quick response and the like and can be used for determining acetone concentration in cosmetic and industrial production and environment detection.

Owner:UNIV OF JINAN

Graphene quantum dot-ZnO composite gas-sensitive material with high sensitivity to acetic acid gas

The invention discloses a graphene quantum dot-ZnO composite gas-sensitive material with high sensitivity to acetic acid gas and belongs to the technical field of gas-sensitive materials. The gas-sensitive material is prepared from ZnO and graphene quantum dots, wherein the mass of the graphene quantum dots accounts for 10% to 20% the total mass of the gas-sensitive material. A heater type gas sensor made by using the material as a sensitive material has the sensitivity (the ratio of element resistance in air to element resistance in detected gas) of 2 to 2.6 to 0.01ppm acetic acid at the working temperature of 300 DEG C and the sensitivity of 590 to 620 to 1,000ppm acetic acid, has the average response recovery time shorter than 45 seconds and can achieve rapid detection on concentration of the acetic acid in the air.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

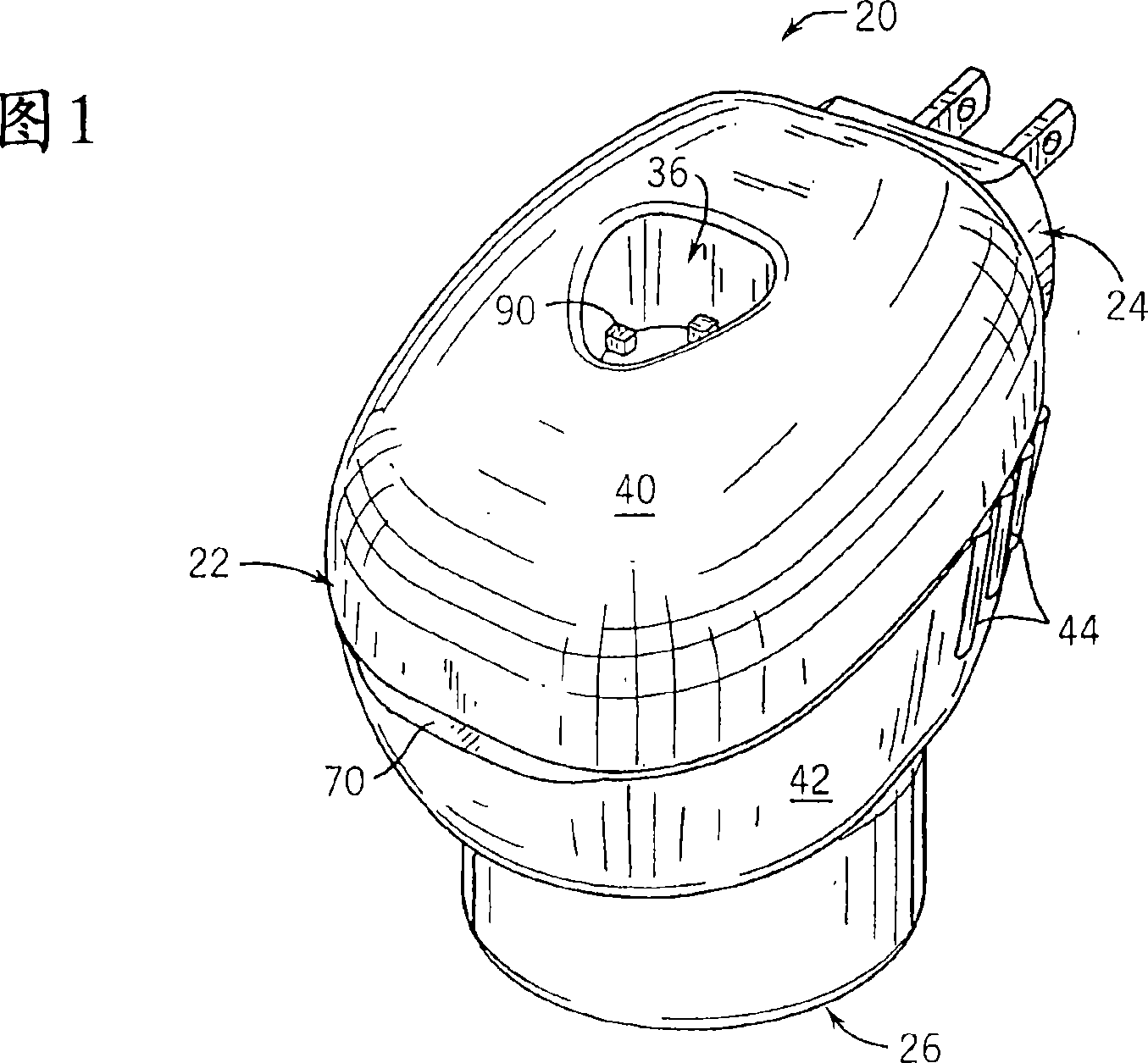

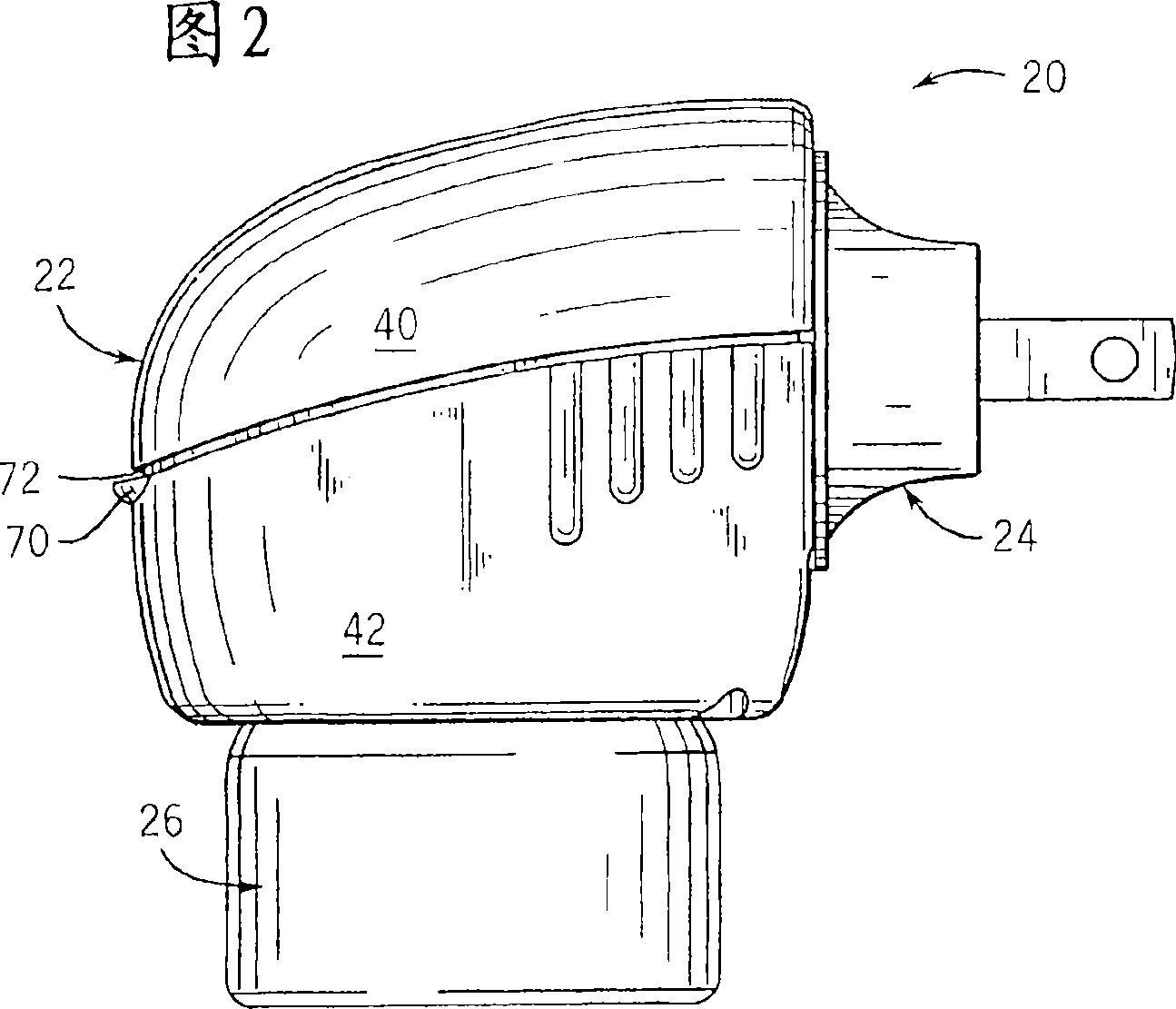

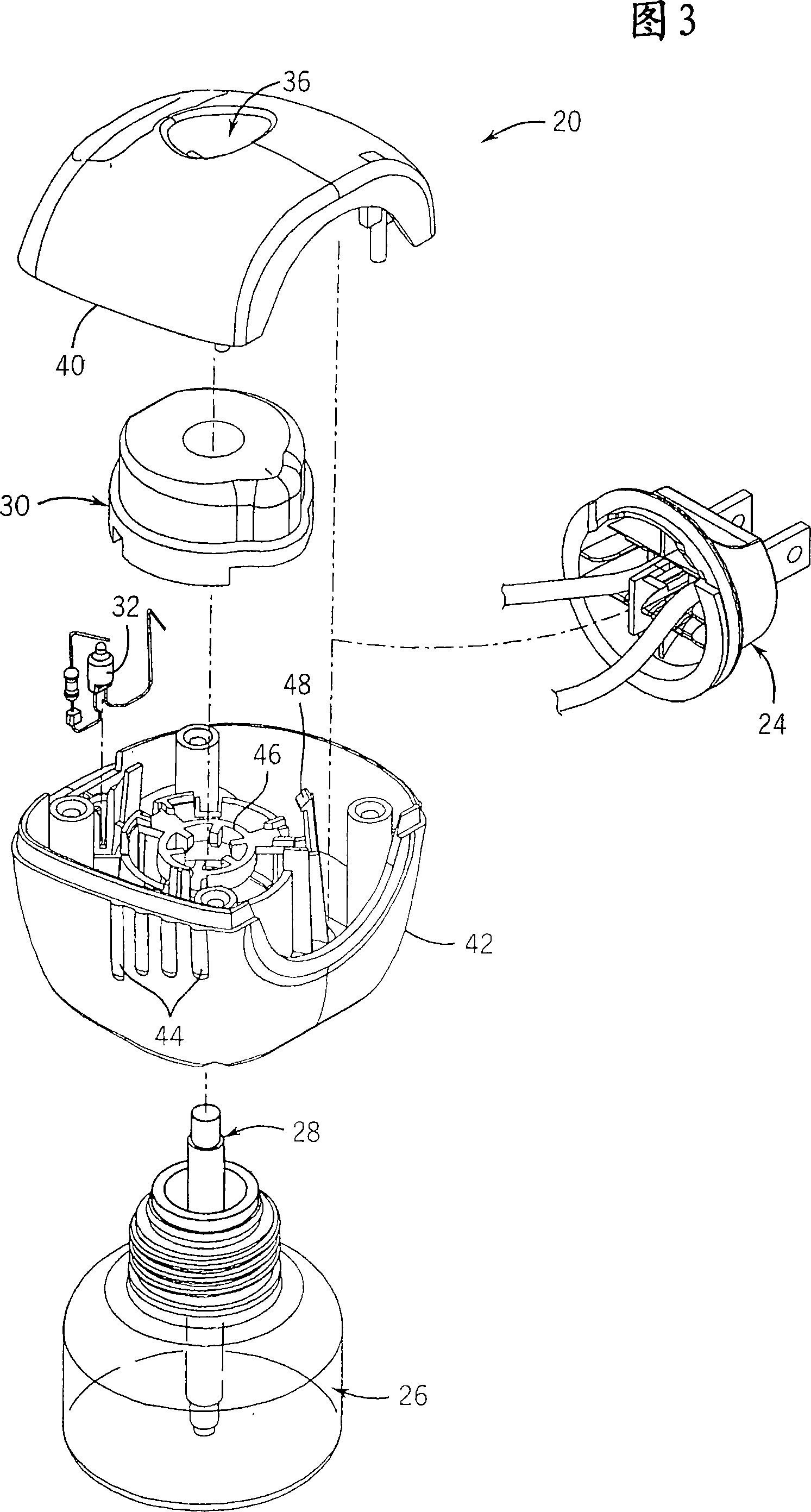

Electric liquid volatile dispenser

Owner:SC JOHNSON & SON INC

Toluene and xylene gas sensitive material and preparation thereof as well as preparation method of toluene and xylene gas sensitive device

InactiveCN105259214AHigh sensitivityWide detection rangeMaterial analysis by electric/magnetic meansAlcoholNanometre

The invention relates to a toluene and xylene gas sensitive material and a preparation method thereof as well as a preparation method of a gas sensitive device. The toluene and xylene gas sensitive material is prepared from the following components: (I) base material layered flower-shaped ZnO nano powder; (II) Rh2O3, wherein the doping amount of the Rh2O3 is 0.1% to 5% of the mass of the base material layered flower-shaped ZnO nano powder. The toluene and xylene gas sensitive material is blended into paste by using a proper amount of absolute ethyl alcohol; then the paste is uniformly coated on the surface of an aluminum oxide ceramic electrode tube and is naturally aired; then the aluminum oxide ceramic electrode tube is subjected to annealing treatment to obtain a gas sensitive electrode tube; finally, the gas sensitive electrode tube is welded, electrically aged and packaged according to a heater-type structure traditional process to prepare the toluene and xylene gas sensitive device. The toluene and xylene gas sensitive material provided by the invention has high sensitivity on toluene and xylene, good selectivity and short responding time, and meets the requirements of the gas sensitive device.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Graphene-ZnGa2O4 compound gas-sensitive material with high selectivity on formaldehyde gas

InactiveCN109490376AImprove gas selectivityReduce sensitivityMaterial resistanceGas detectorWorking temperature

The invention discloses a graphene-ZnGa2O4 compound gas-sensitive material with high selectivity on a formaldehyde gas, and belongs to the technical field of gas-sensitive materials. The gas-sensitivematerial is prepared from graphene-ZnGa2O4, wherein the graphene is 0.08-0.20 percent of total mass of the material. A heater type gas-sensitive sensor prepared by using the material as a sensitive material has the lowest detection limit on formaldehyde being 1ppm, the sensitivity on 1ppm formaldehyde be 1.1-1.2, the sensitivity on 1000ppm formaldehyde being 29-33 and the response time and recovery time on 1-1000ppm formaldehyde being not more than 21 seconds and 25 seconds ; and the material has high gas-sensitive selectivity since the sensitivity on 1000ppm acetone, 1000ppm trimethylamine,1000ppm acetaldehyde, 1000ppm ammonia and the like is respectively less than 2.5 at the same working temperature.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method and application of n-p junction type ferrum-copper based oxide gas sensitive element

InactiveCN103115946ACapacitive effectGood synergistic sensitizationMaterial analysis by electric/magnetic meansHeater typeSemiconductor

The invention relates to a preparation method and application of an n-p junction type ferrum-copper based oxide gas sensitive element. A gas sensor adopts a heater type device structure and takes an alumina ceramic tube as a carrier. A forked gold electrode is applied to the outer surface of the gas sensor. Platinum extraction electrodes are arranged at the two ends of the gas sensor. A heater strip is arranged in the ceramic tube. A gas sensitive material is coated on the outside the ceramic tube and is an n type semiconductor ferroferric oxide and p type semiconductor cuprous oxide porous compound. The gas sensor is prepared by preparing the alumina ceramic tube on which the material is coated into a tube core and then welding, packaging and electrically aging the tube core according to the conventional process of a heater type device. The preparation method is simple in process, mild in conditions and low in cost and is especially suitable for volume production. The prepared gas sensitive element is used for detecting the ethanol concentration at 200-300 DEG C, has the characteristics of high response sensitivity to 1-1800ppm ethanol, good restorability, quick response and the like and can be used for determining ethanol concentration in industrial and agricultural production and environment detection.

Owner:UNIV OF JINAN

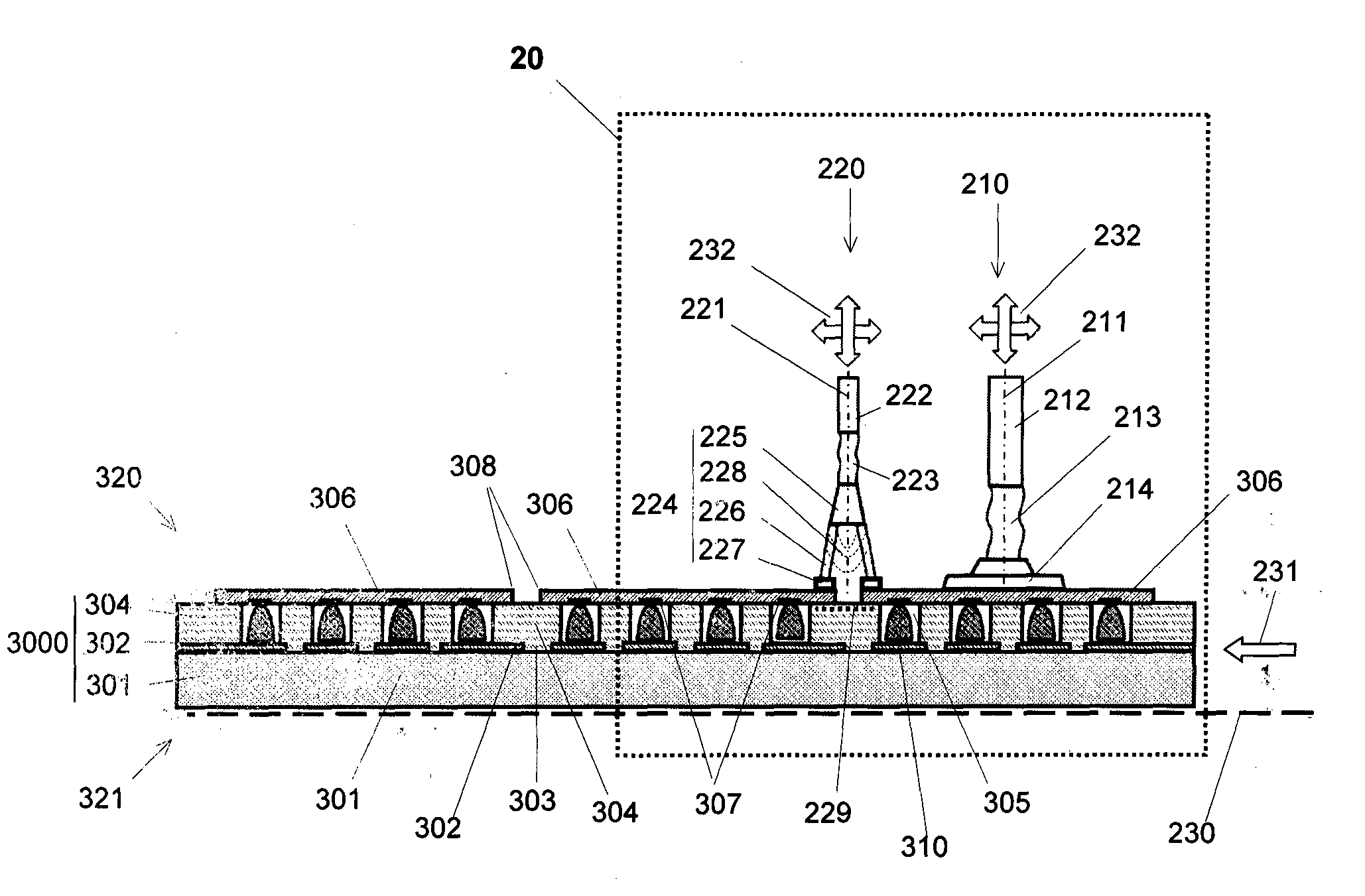

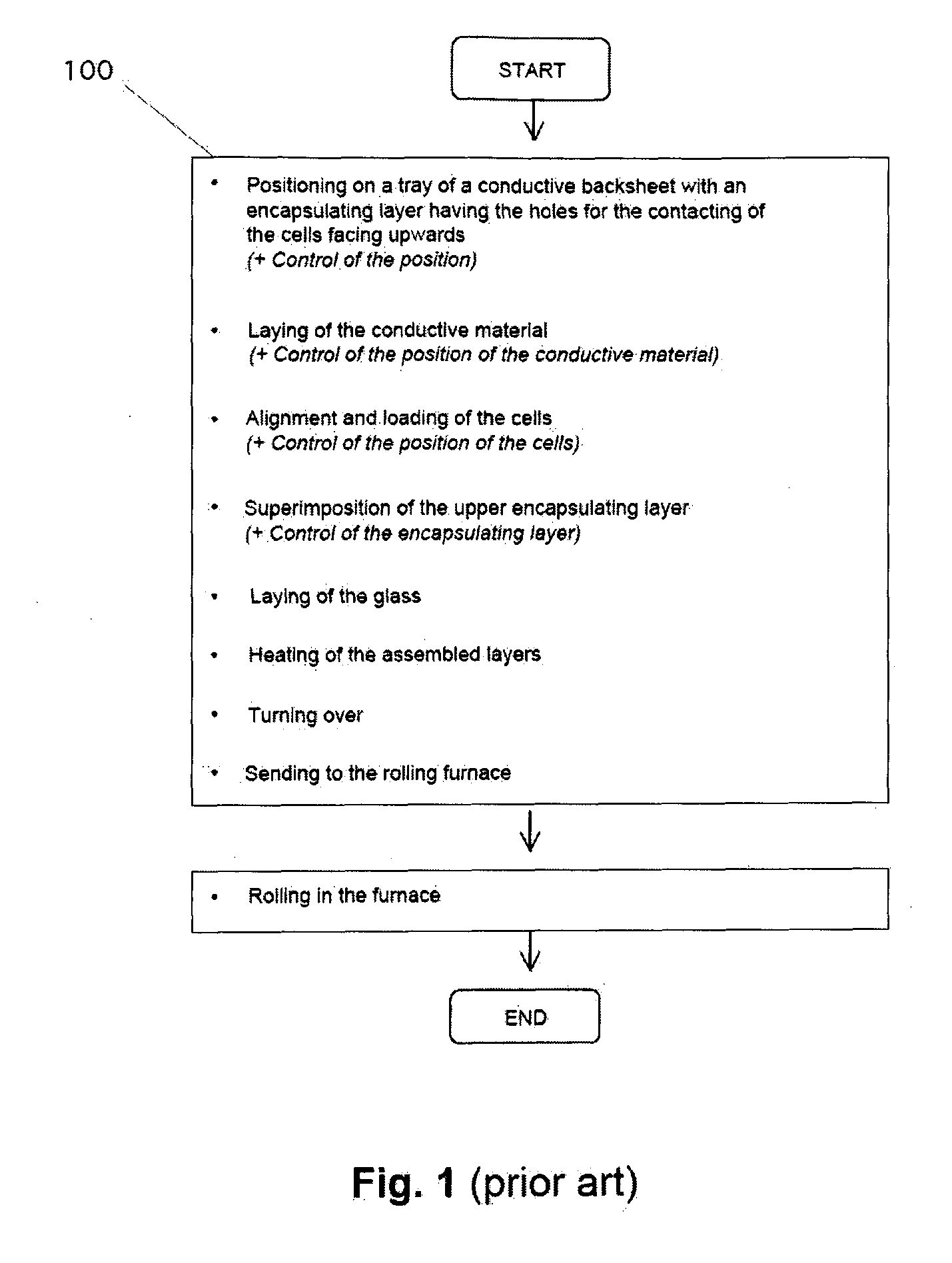

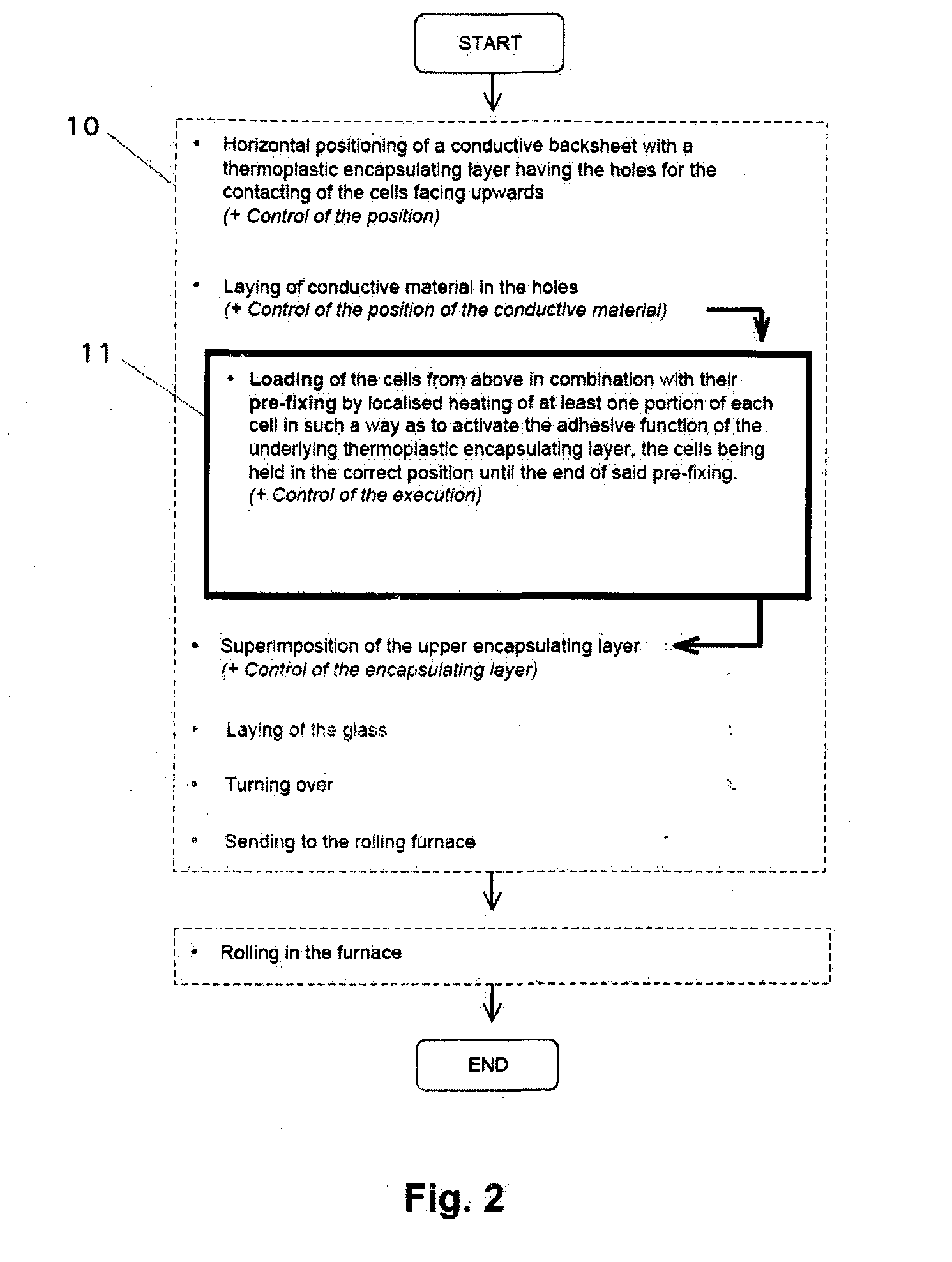

Assembly method of a photovoltaic panel of the back-contact type with pre-fixing of the cells, and combined loading and pre-fixing station

ActiveUS20160300976A1Waste is causedMore robust, repeatableFinal product manufacturePhotovoltaic energy generationAdhesiveSuperimposition

Automatic assembly method of a photovoltaic panel with cells of the back-contact type provided with a conductive backsheet with a thermoplastic encapsulating layer; the loading of the cells occurs in combination with their pre-fixing in a combined station sequentially placed before the superimposition of the upper encapsulating layer and after the laying of the conductive adhesive. The loading is carried out with a first device of the automatic mechanical hand type which takes a group of cells, aligns them with the back contacts in correspondence of the holes and lays them vertically from above. Furthermore, a second device of the presser-heater type carries out the pre-fixing of the cells holding them in the final position also with localised heating on at least one portion of each cell in such a way as to activate the adhesive function of the underlying thermoplastic encapsulating layer. A combined loading and pre-fixing station is also disclosed.

Owner:VISMUNDA

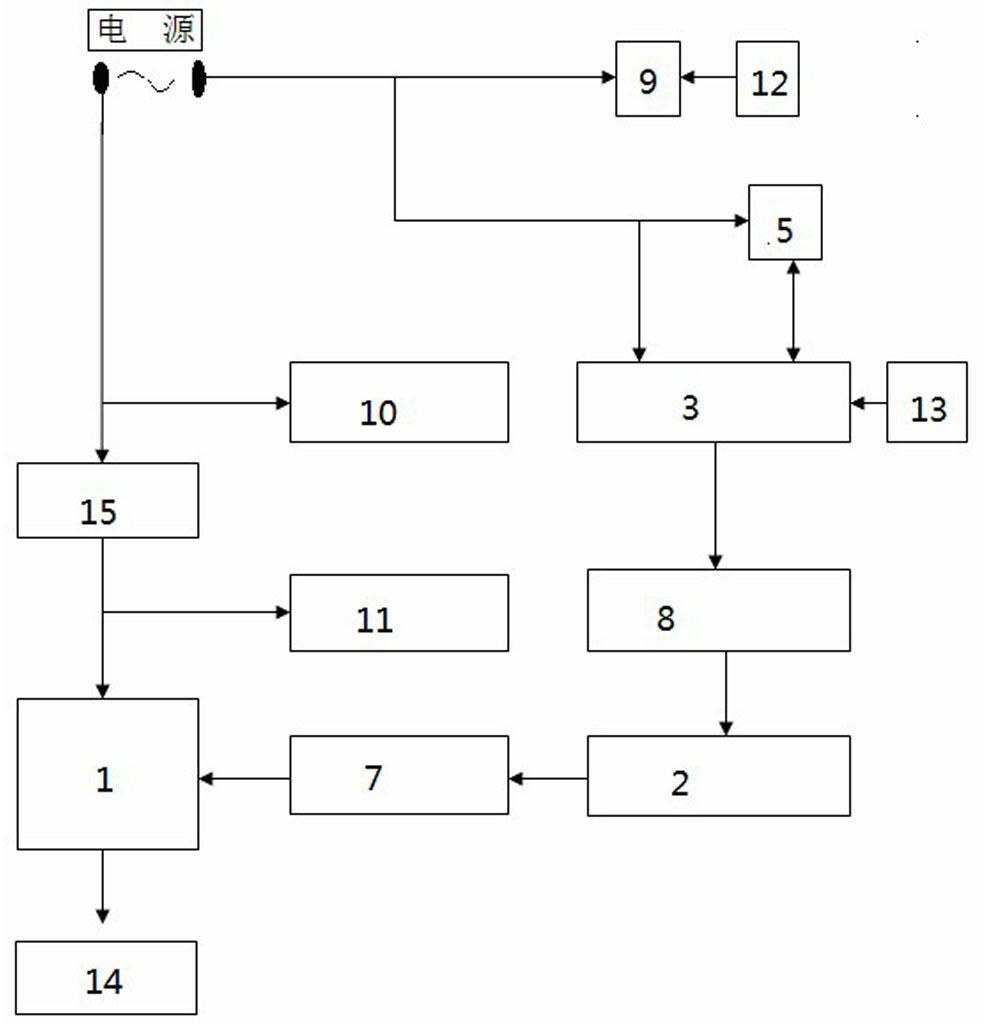

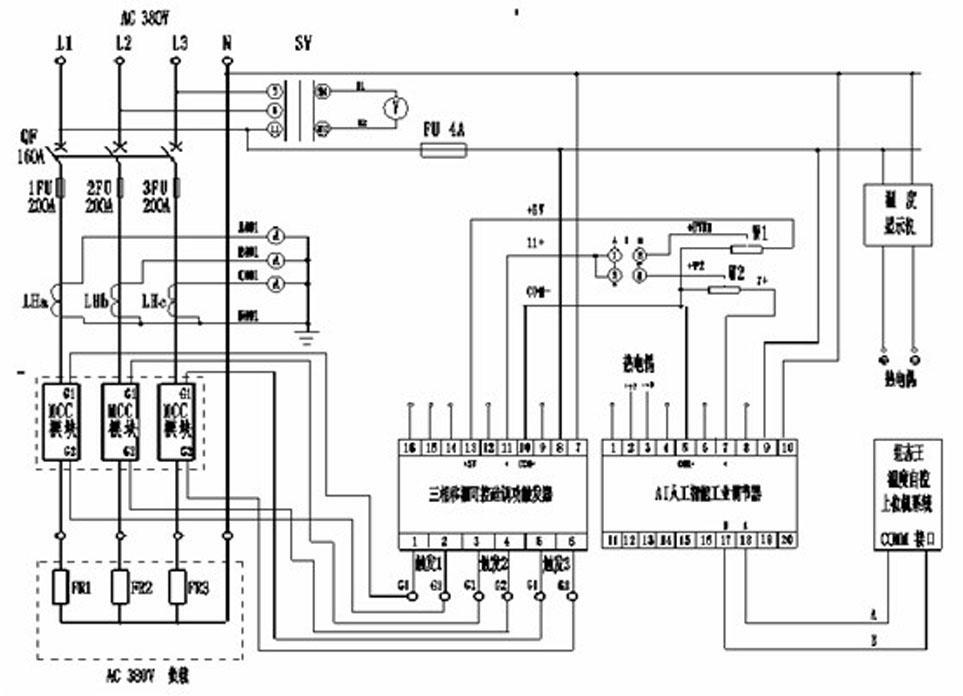

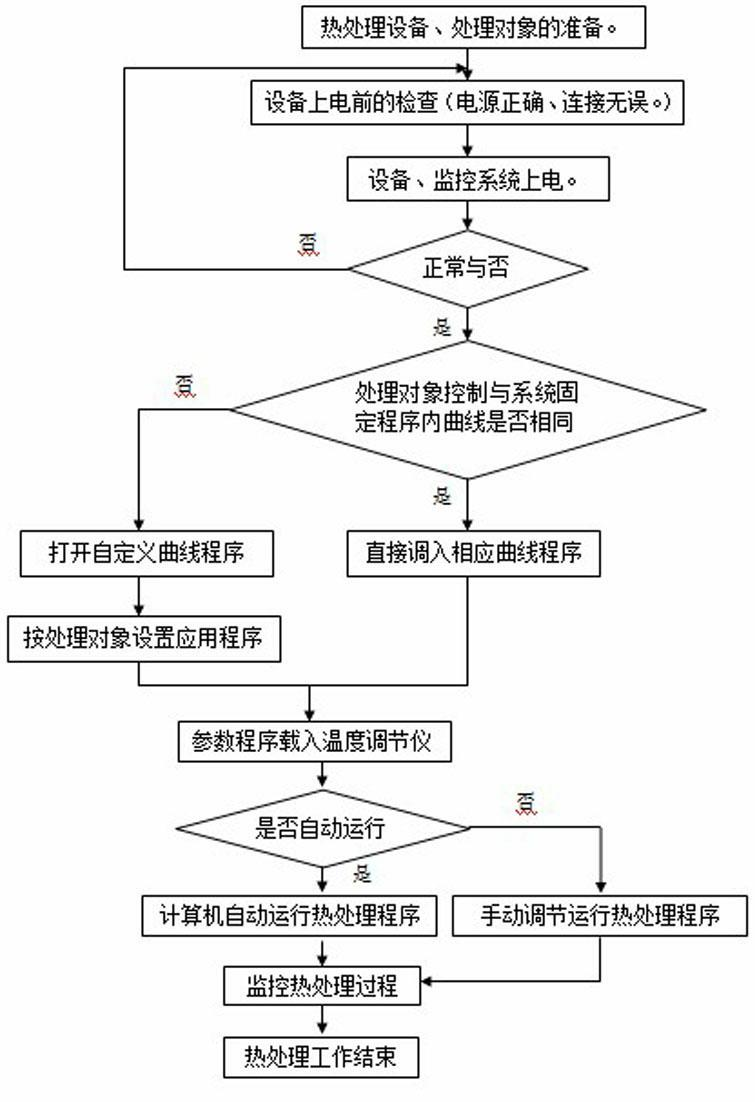

Automatic temperature control system for heat treatment and using method thereof

InactiveCN102676794ALarge capacityRich typeHumidity controlHeat treatment process controlSoftware systemBidirectional communication

The invention relates to an automatic temperature control system for heat treatment and a using method thereof, and belongs to the technical field of automation control. A K graduation thermocouple I and a K graduation thermocouple II of the automatic temperature control system are fixed on a heating surface of a to-be-heated workpiece; the K graduation thermocouple I is connected with a temperature display instrument; the K graduation thermocouple II is connected with an artificial intelligent temperature regulating instrument; an upper monitoring system is in bidirectional communication connection with the artificial intelligent temperature regulating instrument; the artificial intelligent temperature regulating instrument is connected with an AIJK series three-phase phase-shift trigger through a control device; the AIJK series three-phase phase-shift trigger is connected with a high-power MCC series alternating current silicon controller rectifier (SCR) pressure regulating module through a pulse distribution device; the high-power MCC series alternating current SCR pressure regulating module is connected with a load; and the load is fixed at a position required to be heated. According to the system, heat treatment equipment has high capacity, heater types are multiple, and residual stress generated in the welding process is convenient to eliminate; meanwhile, a heat treatment software system can record the whole treatment process; and in addition, the system overcomes defects of the traditional stress relieving equipment.

Owner:YUNNAN CONSTR & INSTALLATION JOINT STOCK

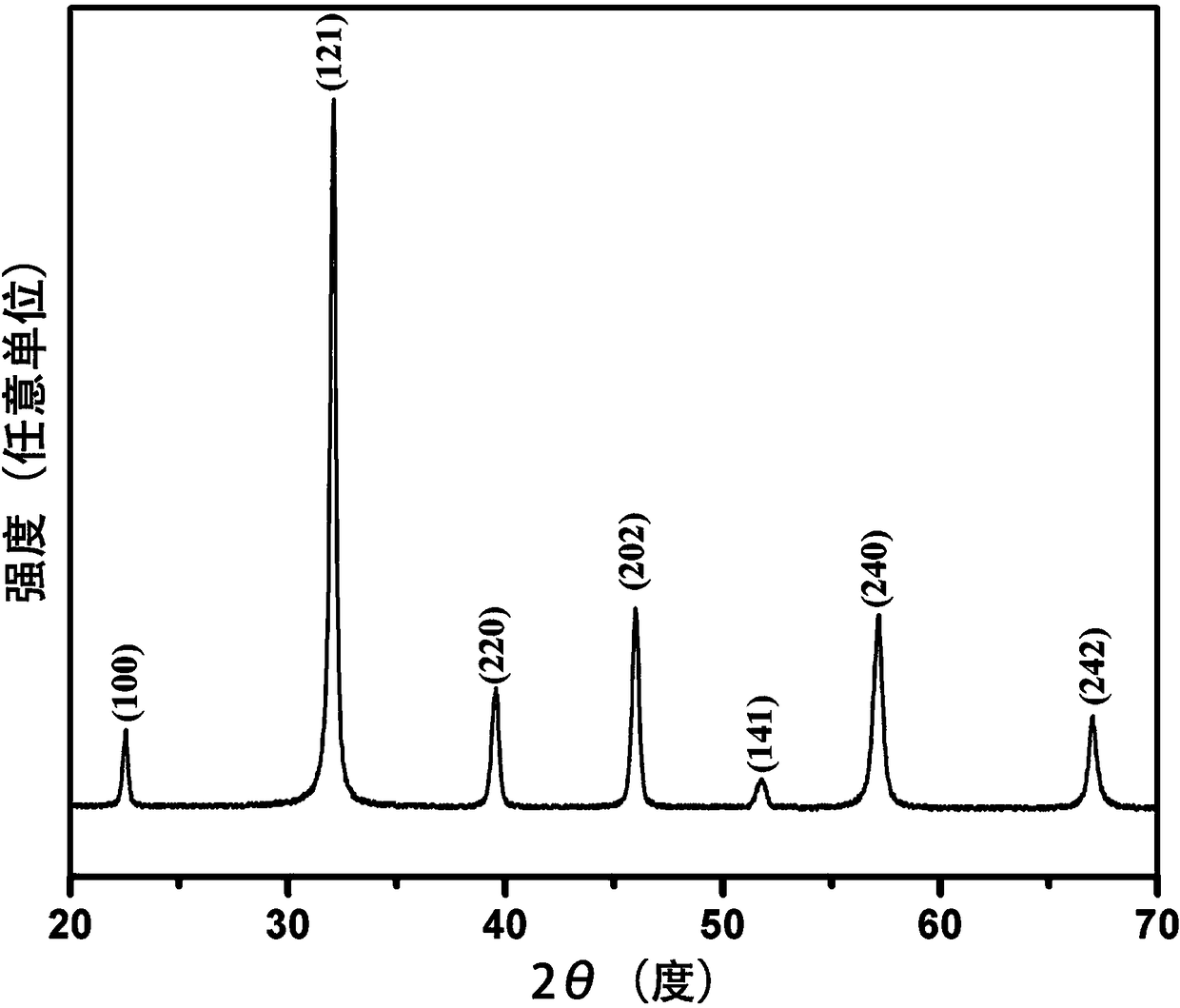

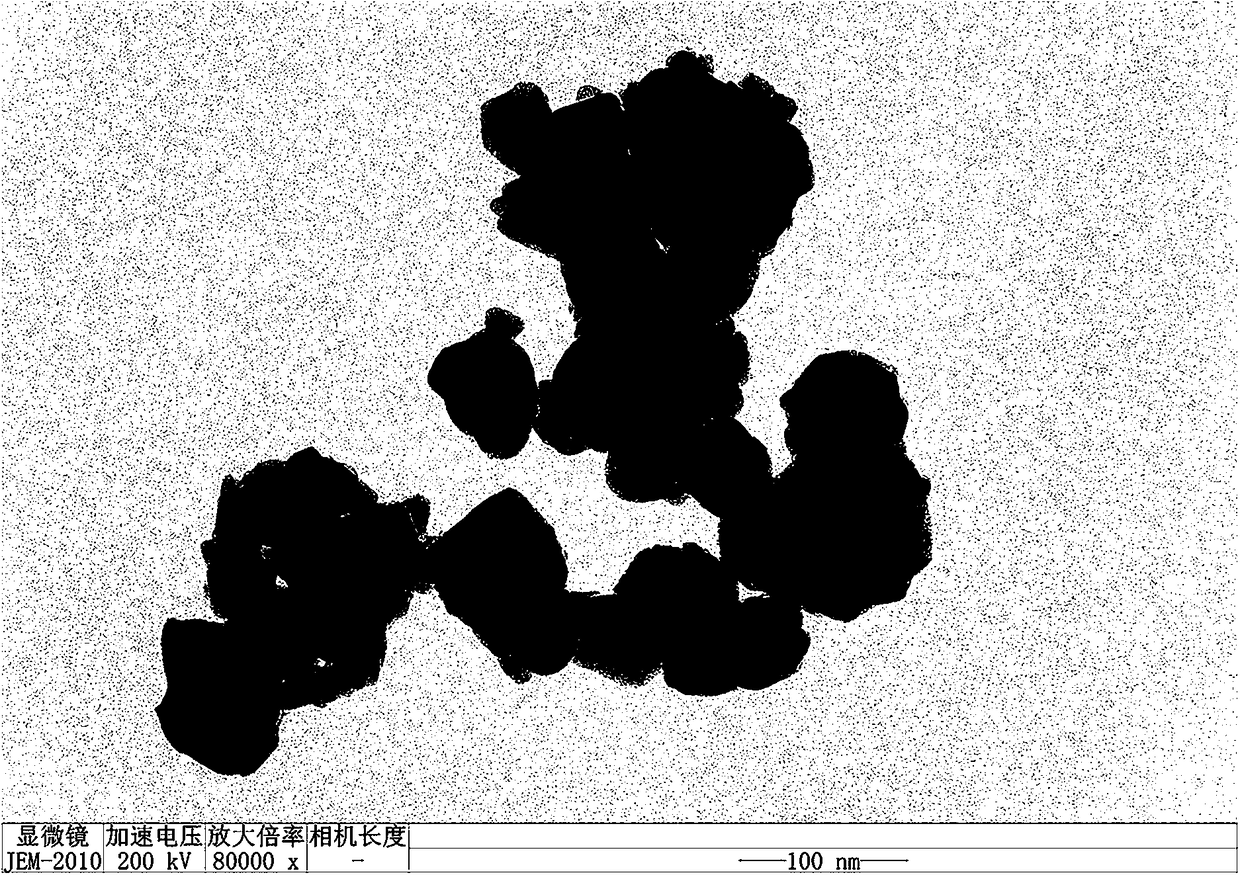

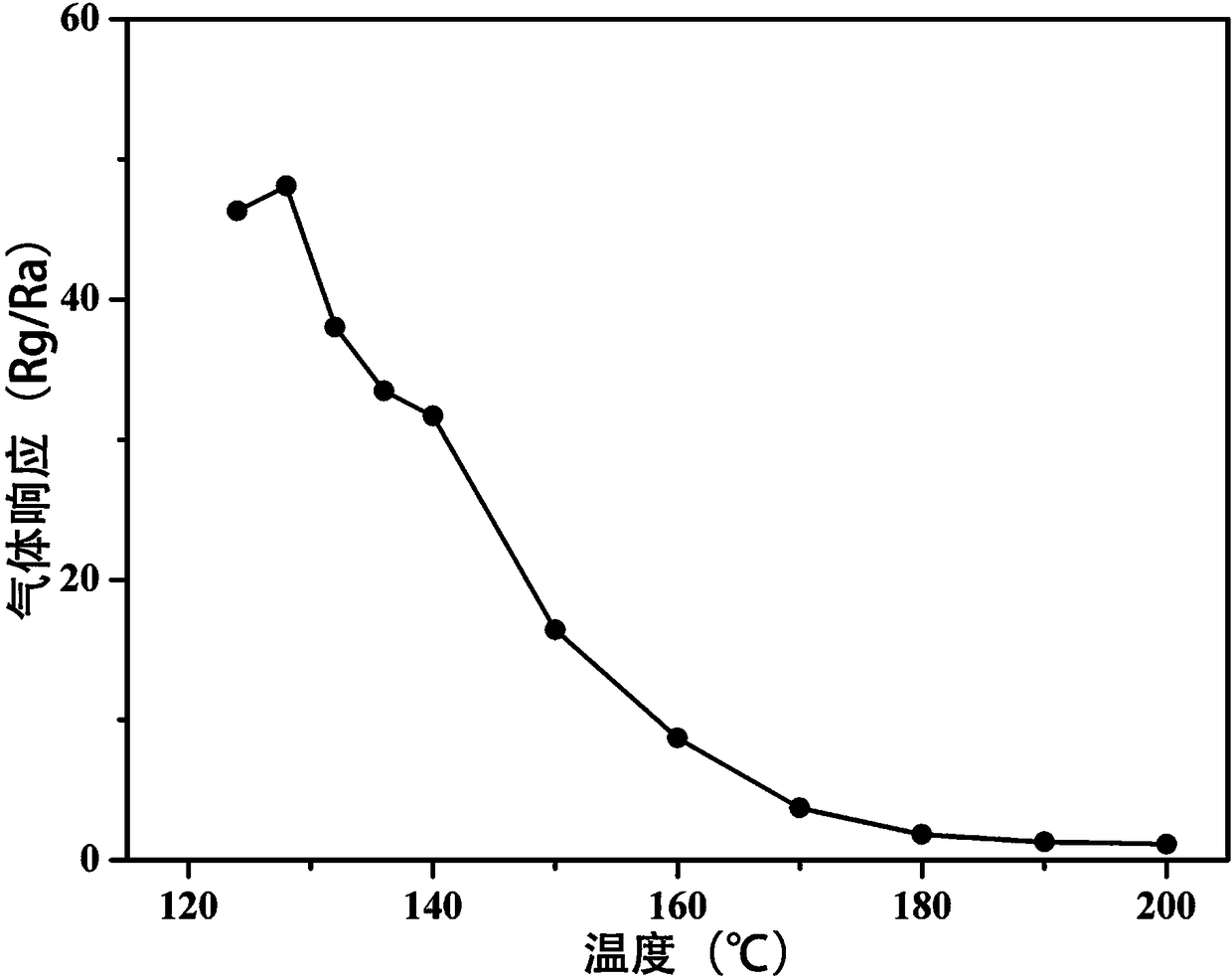

LaFeO3-based ethanol gas sensor with high gas-sensitive property and preparation method thereof

ActiveCN108152337AIncrease the ability to absorb oxygenLower working temperatureMaterial resistanceRare earthWorking temperature

The invention belongs to the technical field of preparation of gas sensors, and provides a LaFeO3-based ethanol gas sensor with high gas-sensitive property and a preparation method thereof. La2 / 3Ba1 / 3Fe2 / 3Ti1 / 3O3 nano-powder prepared with a sol-gel method is taken as a working mediumsubstance for preparing a nindirectly-heated heater-type ceramic tube constructed gas sensor element. In a LaFeO3 lattice, an equivalent quantity of Ba elements and Ti elements with an equivalent quantity are introduced at a La bit and an Fe bit, so that the surface oxygen adsorption performance of the nano-powderis improved, the ethanol gas sensor element is lower in working temperature under the condition of not adding heavy metals or rare earth precious metals, and is higher in gas response and selectivity.The high gas-sensitive property LaFeO3-based ethanol gas sensor with high gas-sensitive property is 128 DEG C in best working temperature specific to the ethanol, is 48.1 in gas response specific to100ppm ethanol at the best working temperature, is below 22.4 and below in gas response specific to 100ppm acetone, DMF (Dimethyl Fformamide), dichloromethane, n-hexane, carbon dioxide and hydrogen gas response, and is up to 15.1 in gas response specific to 20ppm ethanol.

Owner:TAIYUAN UNIV OF TECH

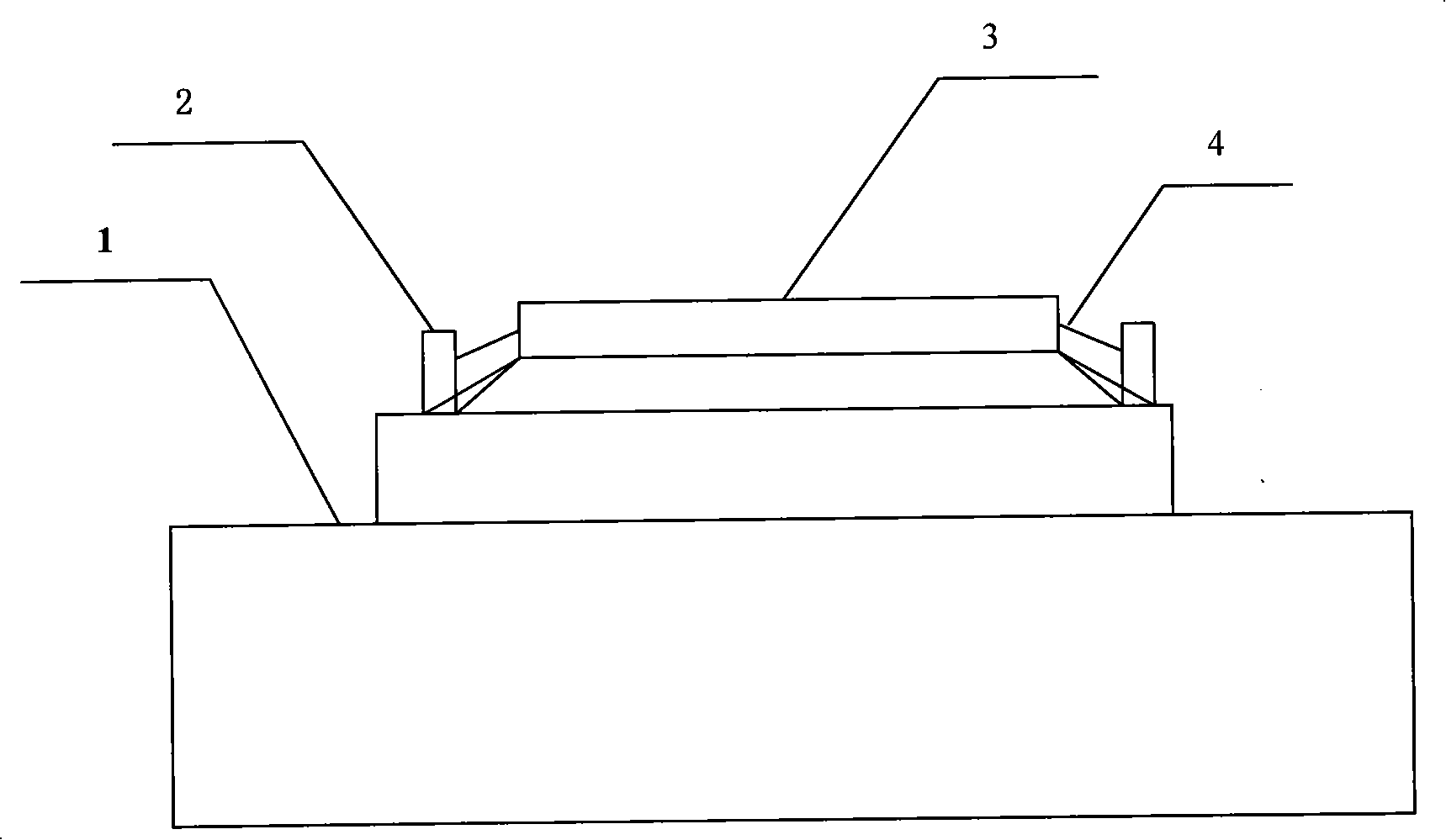

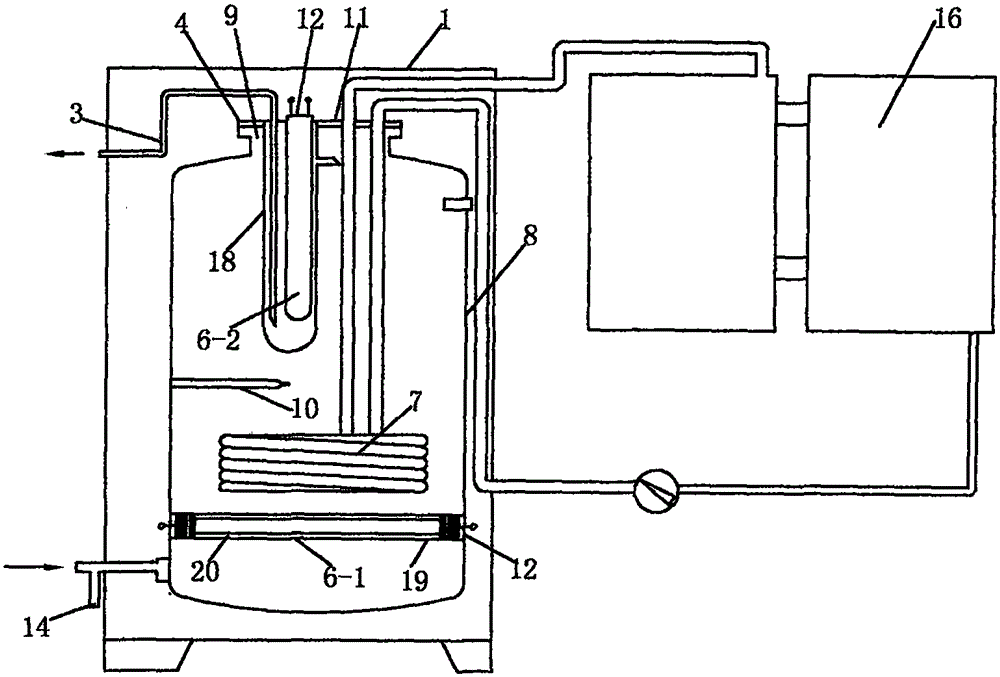

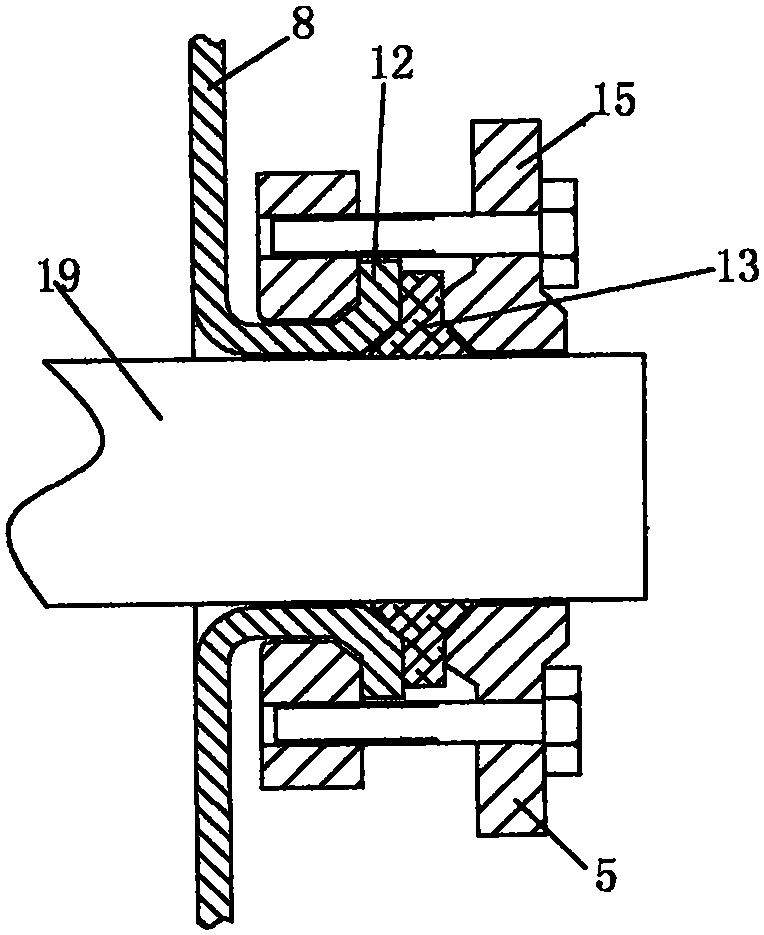

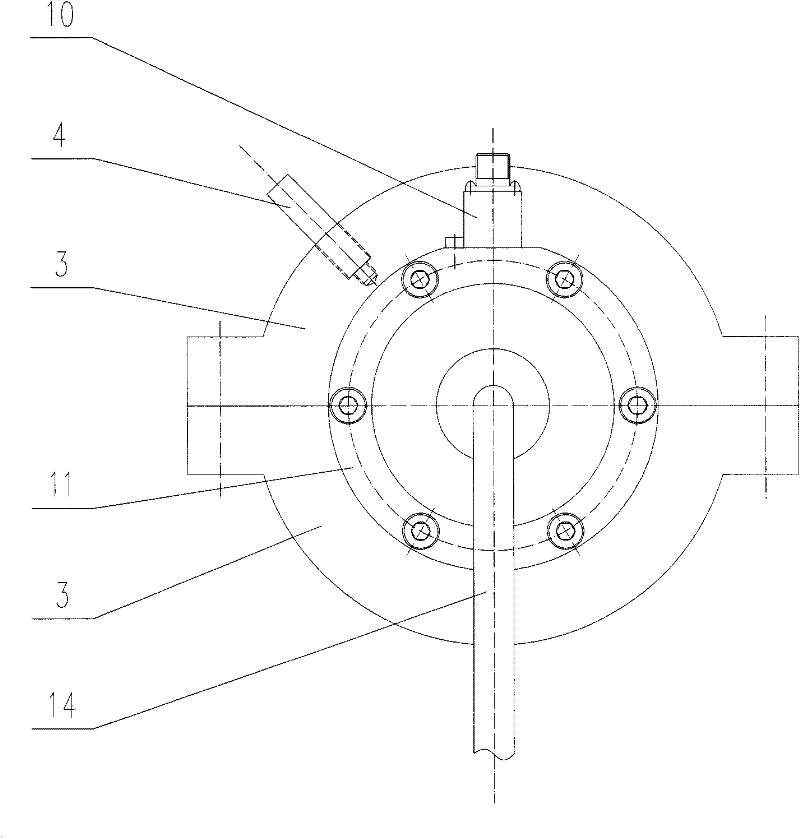

Heater-type light-wave electric heating tube installing structure in solar water heater nonmetal water tank

Disclosed is a heater-type light-wave electric heating tube installing structure in a solar water heater nonmetal water tank. A hole 9 is formed in a semicircular end face of the upper part of the water tank, a flange cover 11 is arranged above the hole, and the flange cover 11 is provided with a heat exchanger 7 and an injection-type 18 which is used for heating water when the water flows past. Connectors 12 with threads or connectors 12 with flanges are coaxially welded at two sides of the lower part of the water tank 8, a metal casing pipe 19 or a non-metal casing pipe 19 is installed in the inner hole of the connectors 12, a straight-shape electric heating tube 6 or a blind-hole-shape 6 is installed on an inner hole air 20 of the casing pipe 19.

Owner:GUANGDONG SHUNDE GUANGSHENG ELECTRICAL APPLIANCE

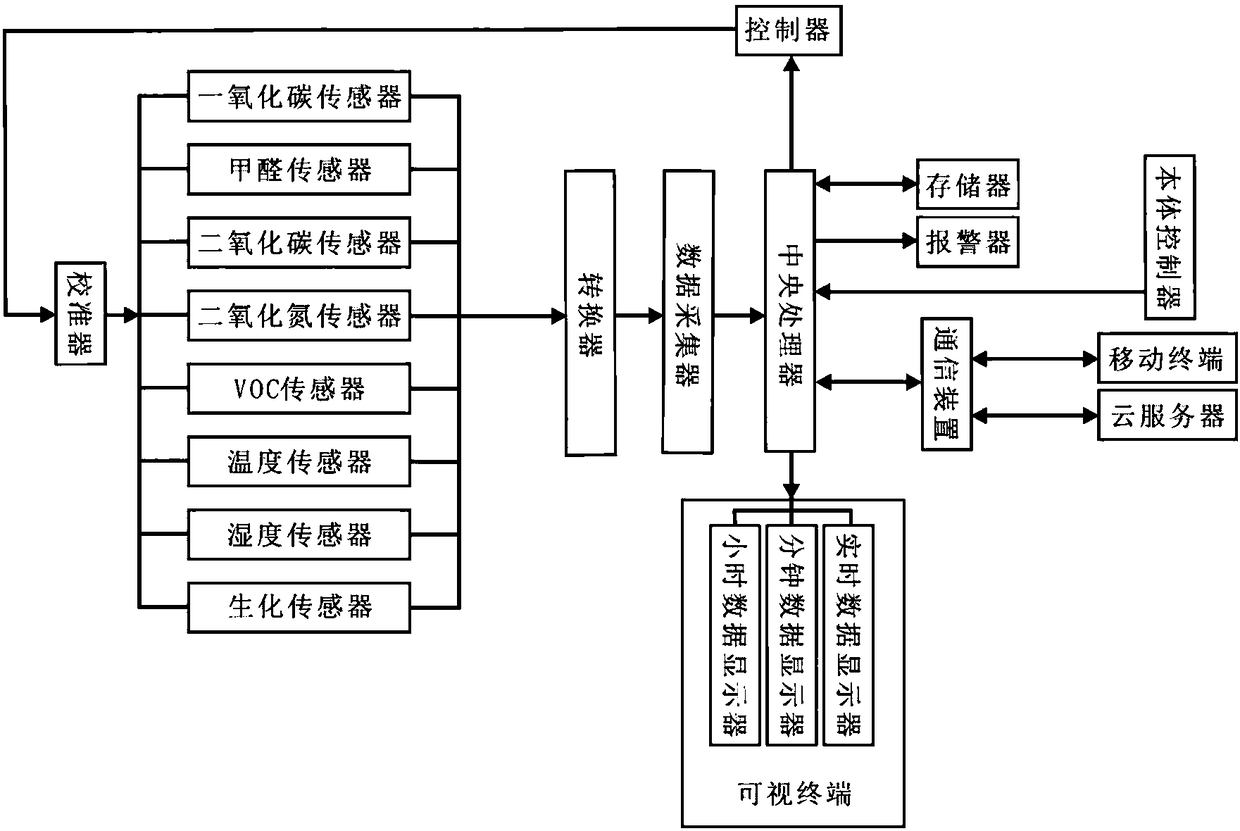

Indoor air monitoring system with sensor group

InactiveCN108061779AComprehensive air dataMany active sitesGas analyser construction detailsMaterial resistancePotassiumData acquisition

The invention relates to an indoor air monitoring system with a sensor group. The monitoring system comprises a central processor, wherein the input end of the central processor is electrically connected with a data acquirer and a body controller through a serial port line; the input end of the data acquirer is electrically connected with a converter; the input end of the converter is electricallyconnected with the output ends of a carbonic oxide sensor, a formaldehyde sensor, a carbon dioxide sensor, a nitrogen dioxide sensor, a VOC sensor, a temperature sensor, a humidity sensor and a biochemical sensor respectively; the nitrogen dioxide sensor is of a heater-type structure, and a sensitive material thereof is a composite metal oxide which is specifically a potassium granule-loaded In2O3 nanosphere and ZnO nanoflower mixture.

Owner:朱明君

Semiconductor sensor and testing circuit of hydrogen sulfide gas

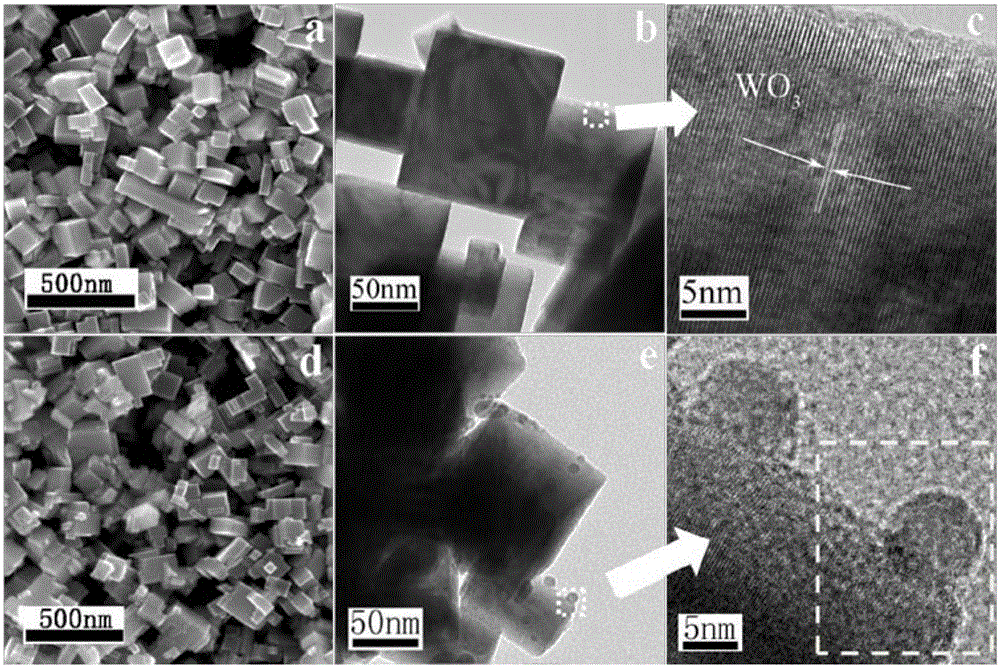

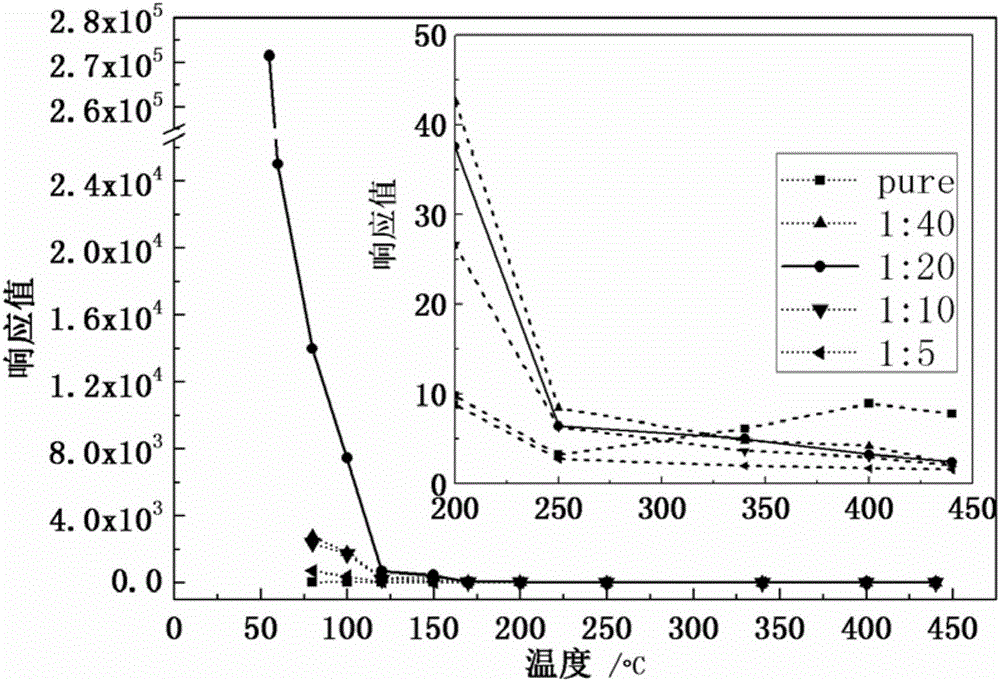

InactiveCN105758894AQuick responsePromote recoveryMaterial resistanceCopper oxide nanoparticlesTungsten trioxide

The invention discloses a semiconductor sensor and a testing circuit of hydrogen sulfide gas.A tungsten trioxide nano material prepared by a chemical method is adopted as a precursor of the semiconductor sensor, and a composite structure of copper oxide nanoparticles is modified on the surface of the precursor.a gas-sensitive element is of a heater-type structure, sensitivity of the semiconductor sensor is 105 at 55 DEG C, and the semiconductor sensor has high selectivity.Through single phase to modulate voltage, response restoration time can be controlled within 65 seconds.The semiconductor sensor has high sensitivity, high selectivity and capability of realizing quick response and restoration at low temperature.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Preparation method for acetone gas sensor

InactiveCN103675078BEasy to purifyImprove gas selectivityMaterial analysis by electric/magnetic meansTin dioxidePolypyrrole

The invention discloses a preparation method for an acetone gas sensor. According to the preparation method, a series of tin dioxide and polypyrrole hybrid materials with different polypyrrole mass percents are prepared by using a simultaneous reaction of a hydrothermal method and a polymer in-situ generation method; the tin dioxide and polypyrrole hybrid materials are used for coating a heater-type device structure and an aluminum oxide ceramic tube is used as a carrier to prepare the acetone gas sensor; a noble metal electrode lead wire is a platinum wire and a sensing element tube core is the aluminum oxide ceramic tube. The method disclosed by the invention is good for finishing a reaction in one step and easily purifying a product. The gas sensor prepared by the method has good gas sensing selectivity on acetone gas under a low working environment; the recovery time can be rapidly responded; meanwhile, the interferences caused by hydrogen, carbon monoxide and ammonia gas can also be eliminated.

Owner:中国人民解放军白求恩医务士官学校

Optical fiber with coating resin preheating device

InactiveCN102259400ACompact structureEasy to operateOptical articlesCoatingsEffective solutionEngineering

The invention provides a preheating device for optical fiber with coating resin, the inlet end extends into the resin bucket through the input pipeline, and the outlet end is connected with the coating Hafur mold through the output pipeline. The preheating device includes: a A hollow cylindrical outer tube for conveying resin; an annular outer layer electric heater, which is close to the outside of the hollow cylindrical outer tube; several outer layer temperature sensors connected with the outer tube; an annular guide installed in the center of the outer tube Flow sleeve; an internal heating electric heater, set in the annular flow guide sleeve; a built-in temperature sensor, close to the internal heating electric heater; a heating power supply, providing electric energy for the outer layer electric heater and the internal heating electric heater; several A digital temperature controller whose interface is connected with the outer layer temperature sensor and the built-in temperature sensor. The invention has simple and compact structure, convenient operation and maintenance; effectively solves the problem of rapid dynamic and uniform heating of resin materials, precise temperature measurement and temperature control, improves the quality of production technology, and reduces the material cost of resin delivery system components in equipment manufacturing.

Owner:上海欧达电气成套设备工程有限公司 +1

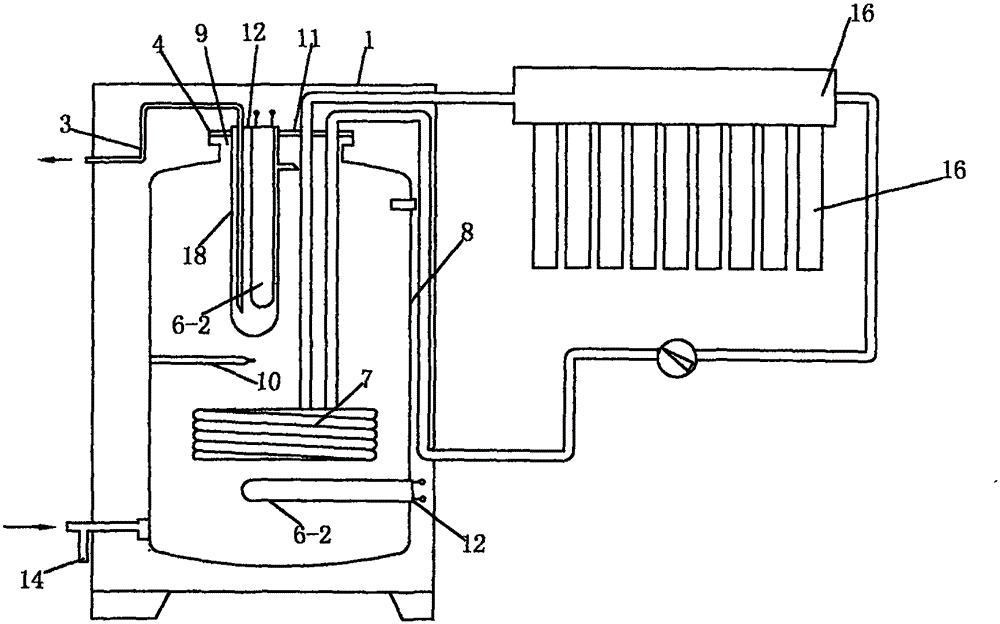

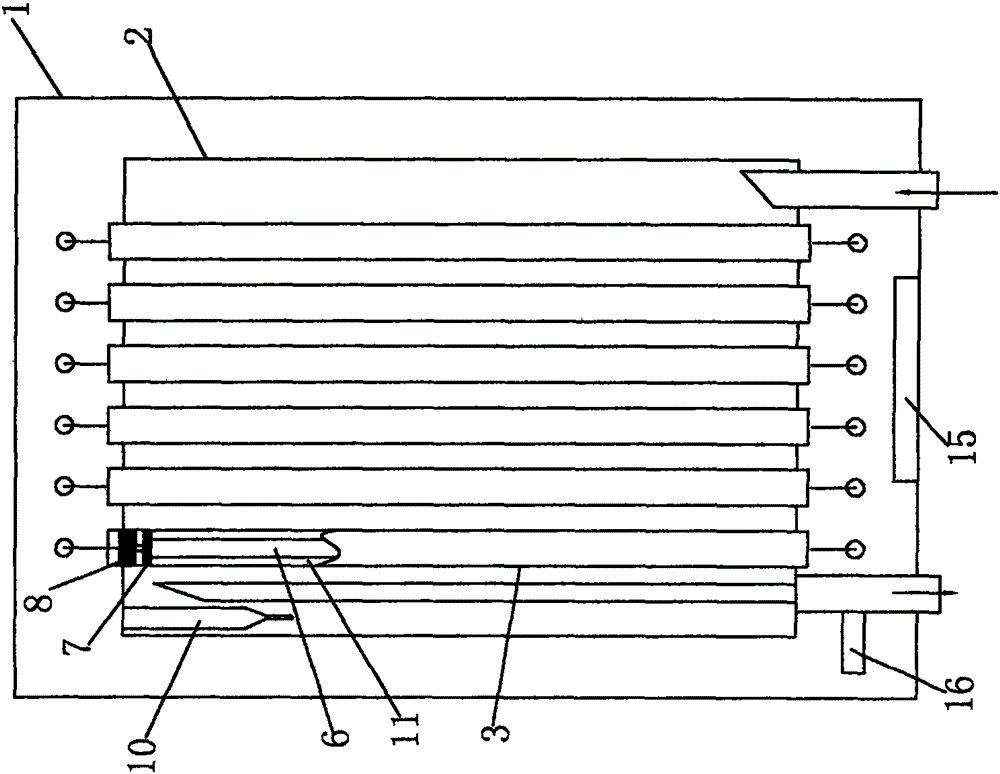

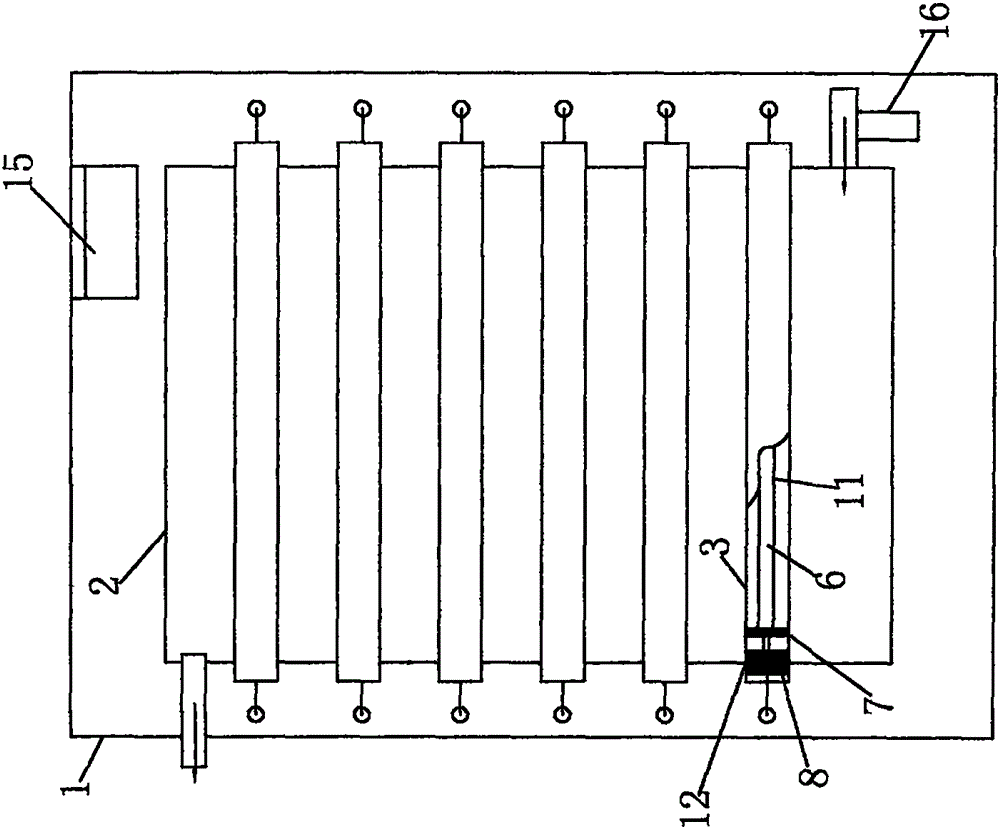

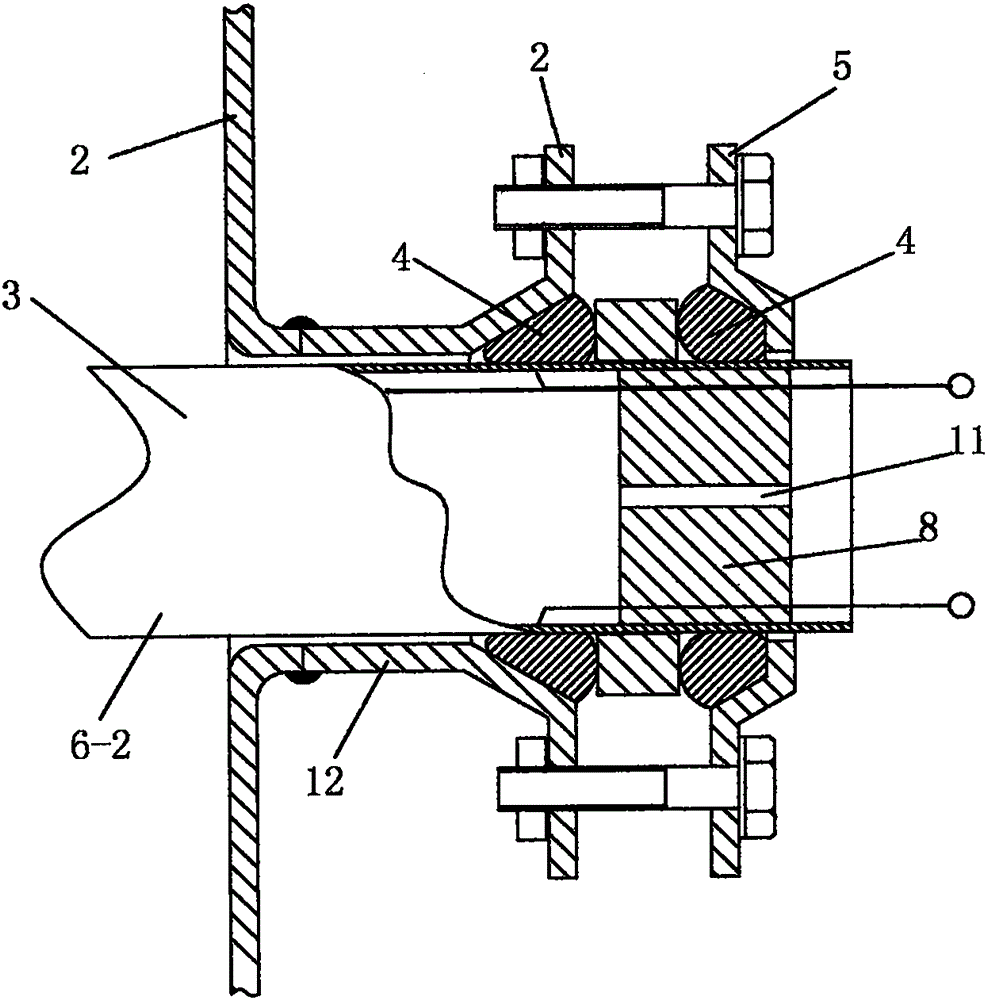

Wall mounting type and floor type electric heating warming stove heater-type light wave electrical heating tube installation structure

The invention relates to a wall mounting type and floor type electric heating warming stove heater-type light wave electrical heating tube installation structure. An electrical heating tube is characterized in that metal sleeves or connectors (12) with threads are welded to the two sides or the upper and lower portions of a water tank (2), a meal or non-metal sleeve (3) is installed in holes of the coaxial connectors, the two ends are provided with sealing pieces (4) and compressed through nuts (5), and the two ends of the electrical heating tube (6) are each provided with a mica plate (7) and a non-metal support (8); and the electrical heating tube is installed in air in the meal or non-metal sleeve (3), and a hole or gap is reserved between the mica plate (7) and the non-metal support (8) at each of the two ends of the electrical heating tube, and therefore the electrical heating tube is communicated with external air.

Owner:GUANGDONG SHUNDE GUANGSHENG ELECTRICAL APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com