Heater-type light-wave electric heating tube installing structure in solar water heater nonmetal water tank

A technology for solar water heaters and installation structures, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve problems such as poor electric auxiliary heating, pinhole water leakage, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

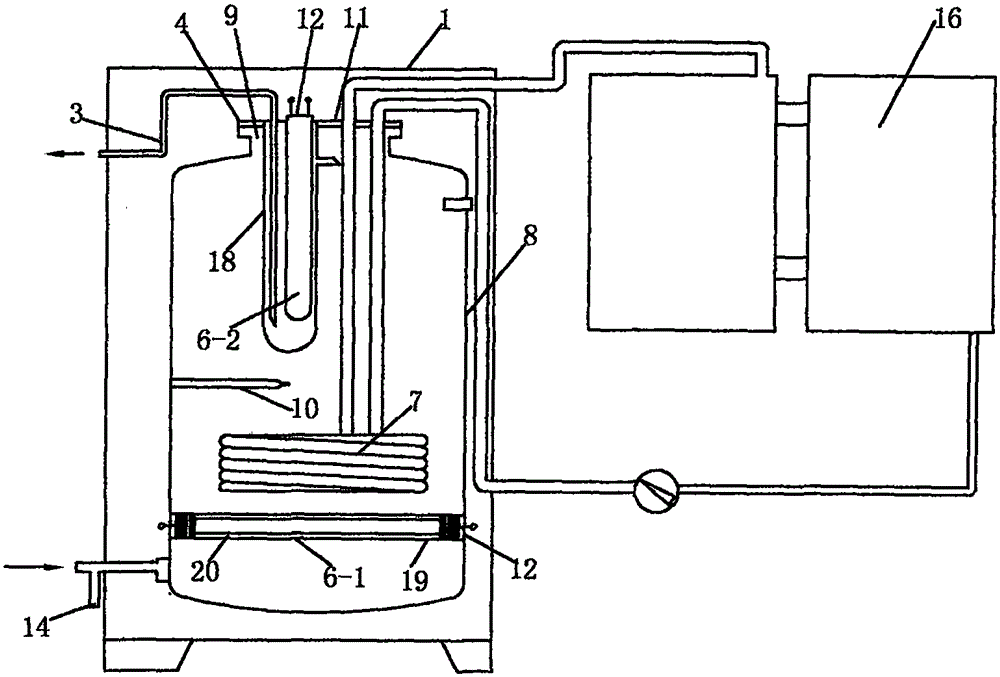

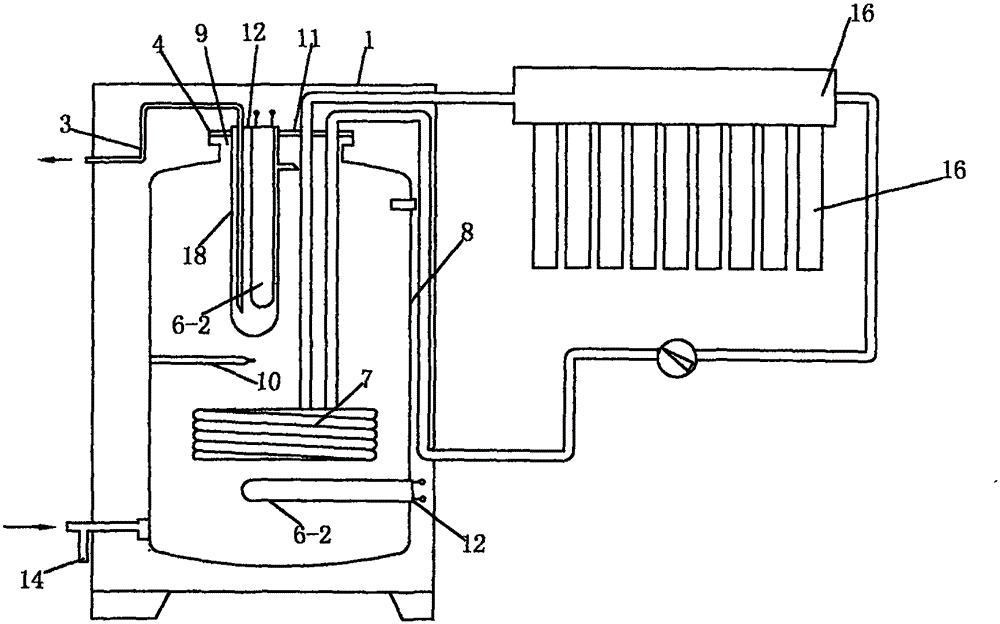

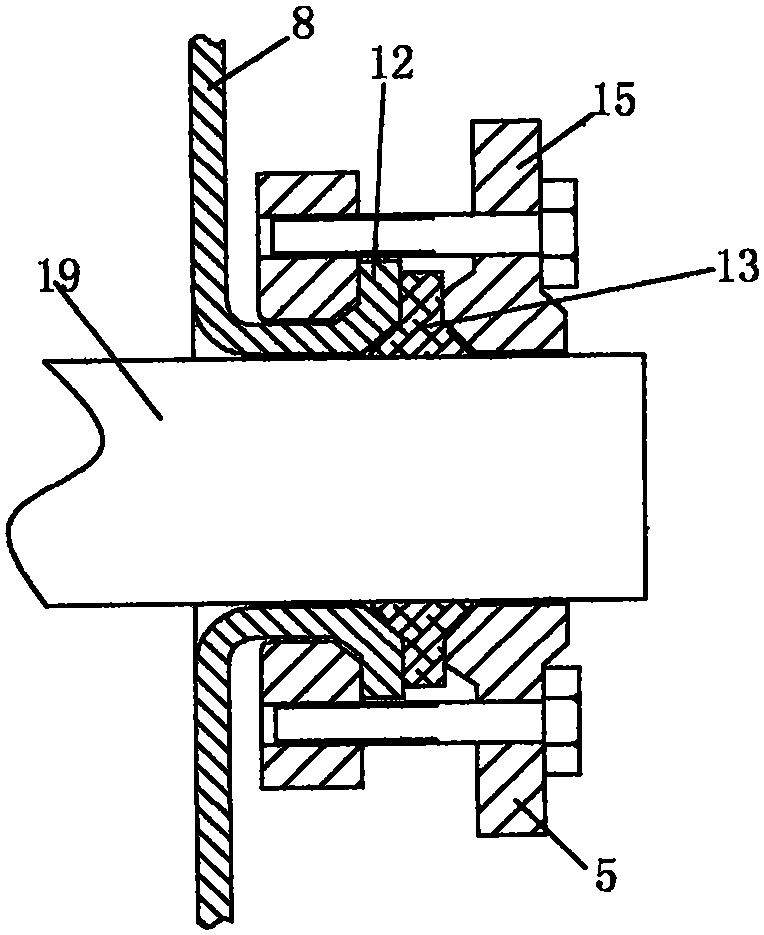

[0009] The following will be explained in conjunction with the accompanying drawings. In the accompanying drawings: shell 1, cold water inlet pipe 2, hot water outlet pipe 3, flange cover seal 4, controller 5, electric heating tube 6 (straight through light wave electric heating tube 6-1, blind hole Light wave electric heating tube 6-2, metal electric heating tube 6-3), heat exchanger 7, water tank 8, hole 9 on the semicircular end face of the upper part of the water tank, temperature measuring or temperature limiter installation tube 10, flange cover 11, threaded joints or flanged joints 12, seals 13, pressure relief valves 14, screw caps or covers 15, solar collector panels or collectors 16, appliances that heat water as it flows through it 18, metal or non-metallic sleeves 19. Air 20.

[0010] figure 1 figure 2 Among them, 2 liquid inlet and outlet pipes of the heat exchanger 7 are installed on the flange cover 11, and the utensil 18 that heats the water when the water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com