Patents

Literature

29968 results about "Foaming agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A foaming agent is a material that facilitates formation of foam such as a surfactant or a blowing agent. A surfactant, when present in small amounts, reduces surface tension of a liquid (reduces the work needed to create the foam) or increases its colloidal stability by inhibiting coalescence of bubbles. A blowing agent is a gas that forms the gaseous part of the foam.

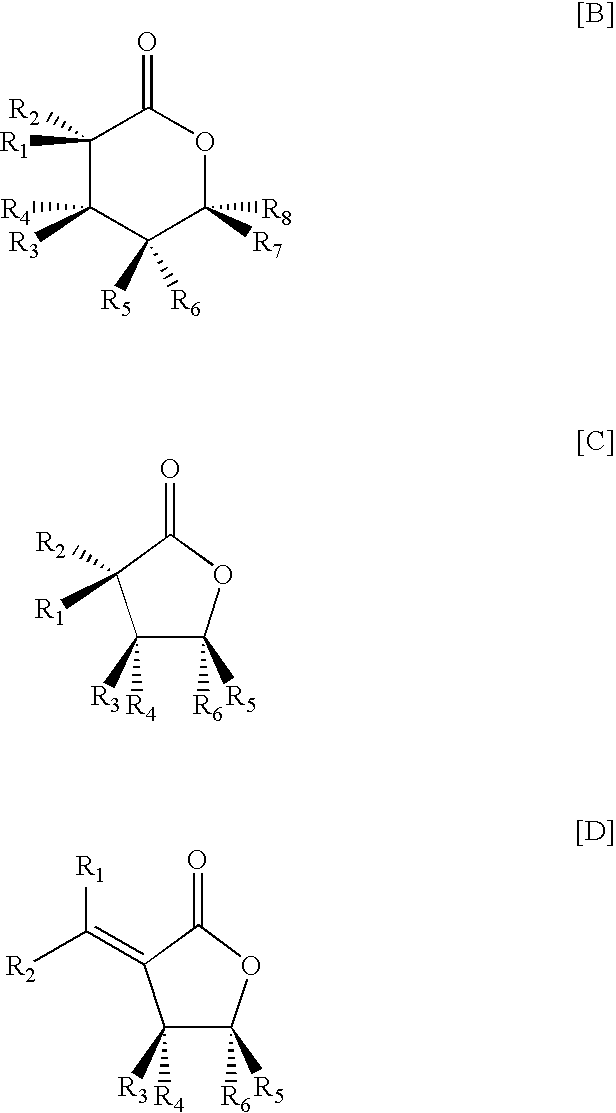

Compositions comprising a fluoroolefin

The present invention relates to compositions for use in refrigeration, air-conditioning, and heat pump systems wherein the composition comprises a fluoroolefin and at least one other component. The compositions of the present invention are useful in processes for producing cooling or heat, as heat transfer fluids, foam blowing agents, aerosol propellants, and fire suppression and fire extinguishing agents.

Owner:EI DU PONT DE NEMOURS & CO

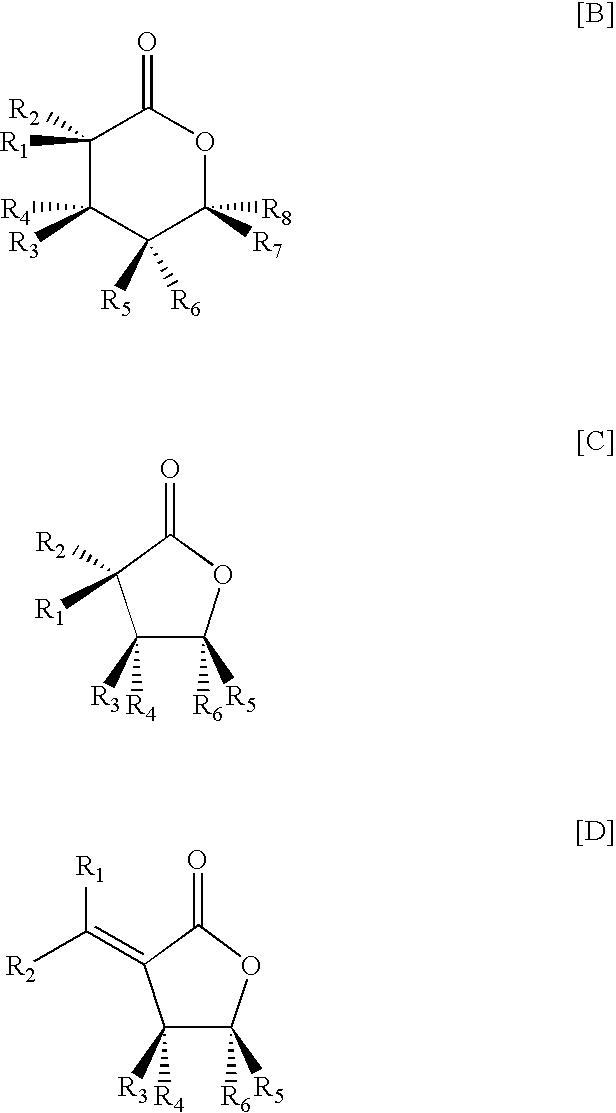

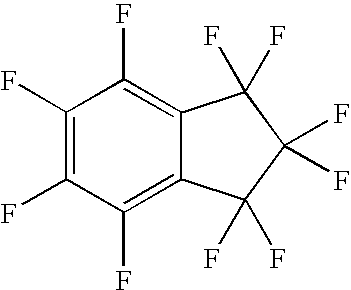

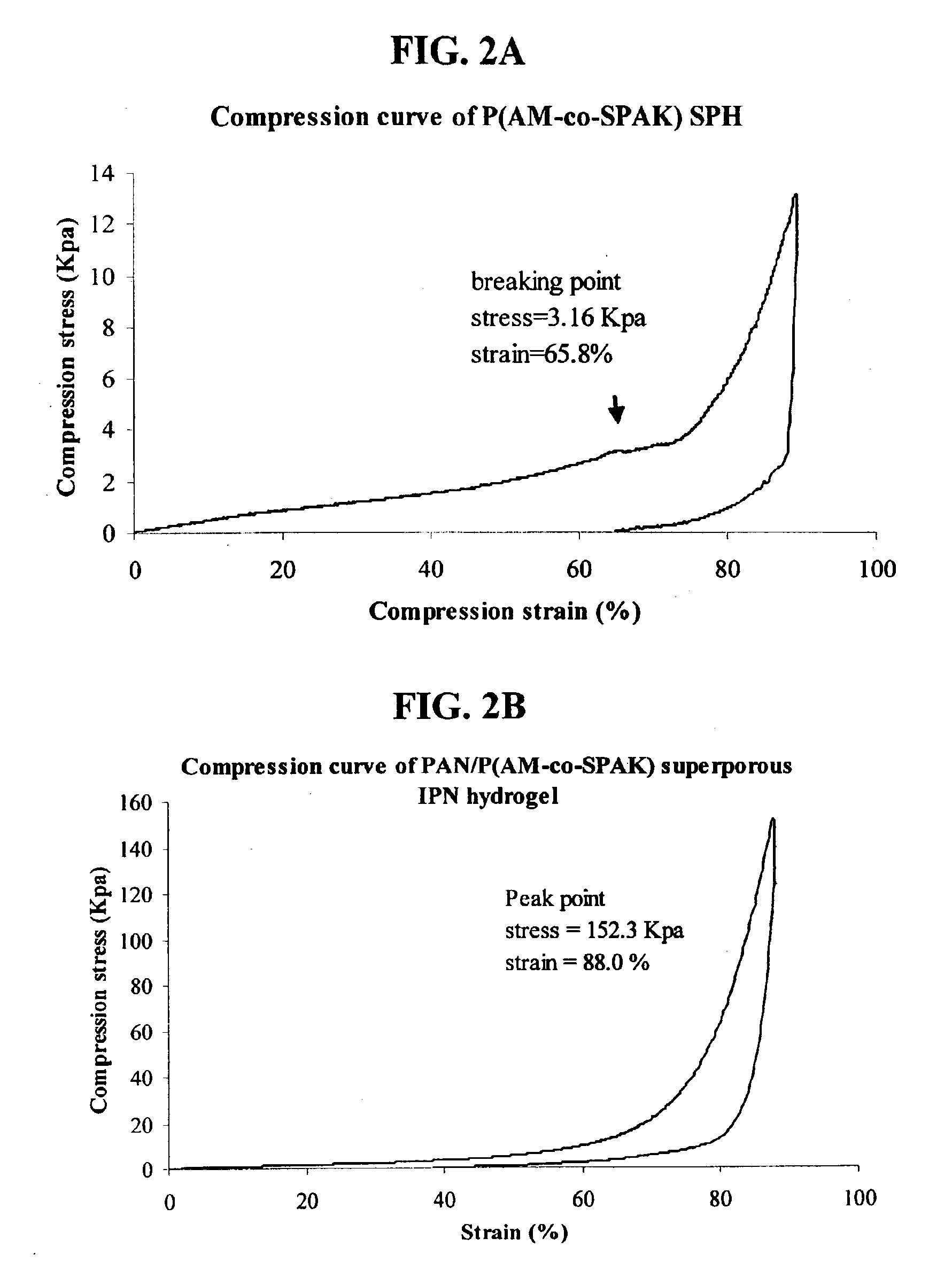

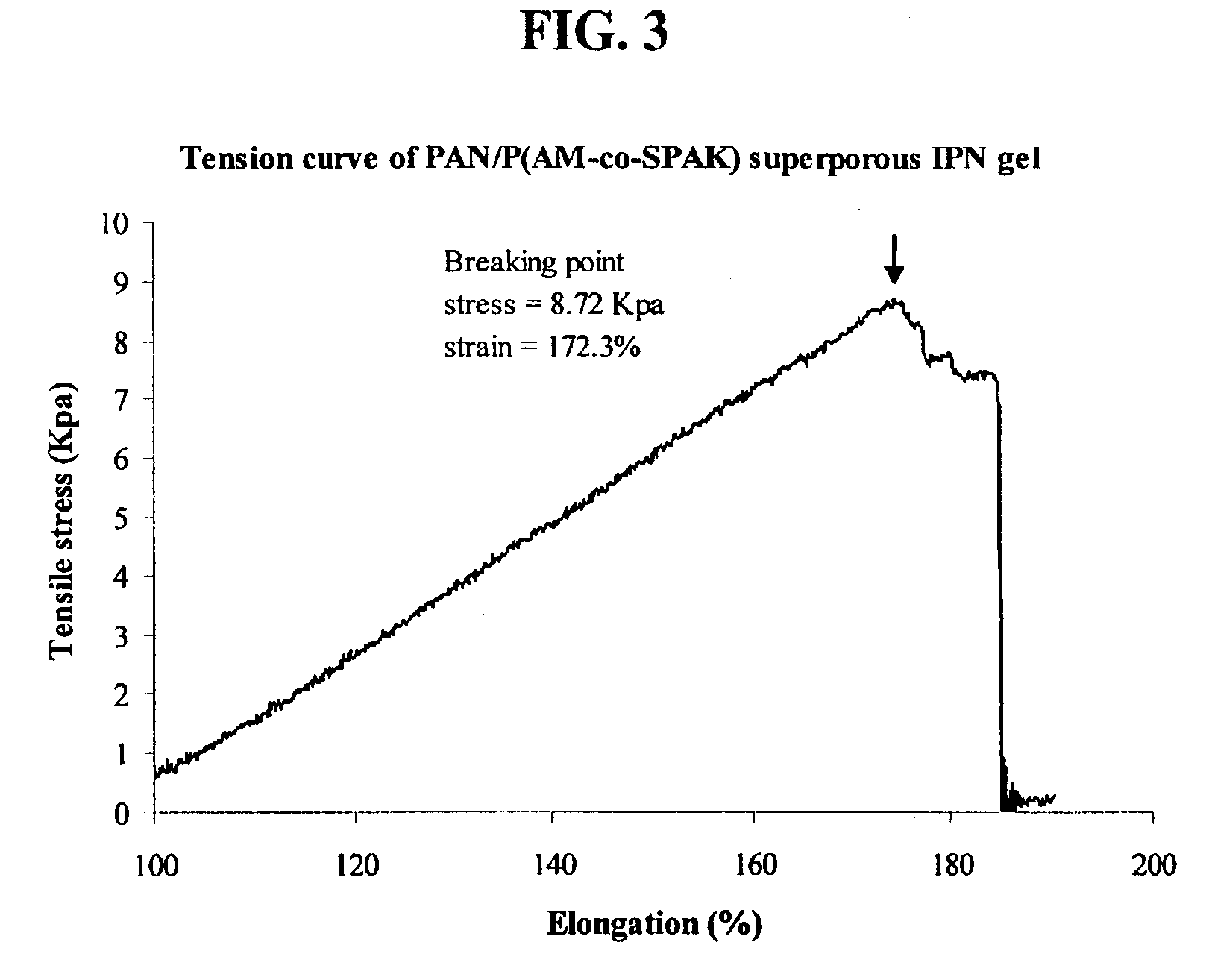

Hydrogels having enhanced elasticity and mechanical strength properties

InactiveUS6960617B2Great compression modulusEnhanced water absorbencePharmaceutical delivery mechanismAbsorbent padsPolyelectrolytePolymer science

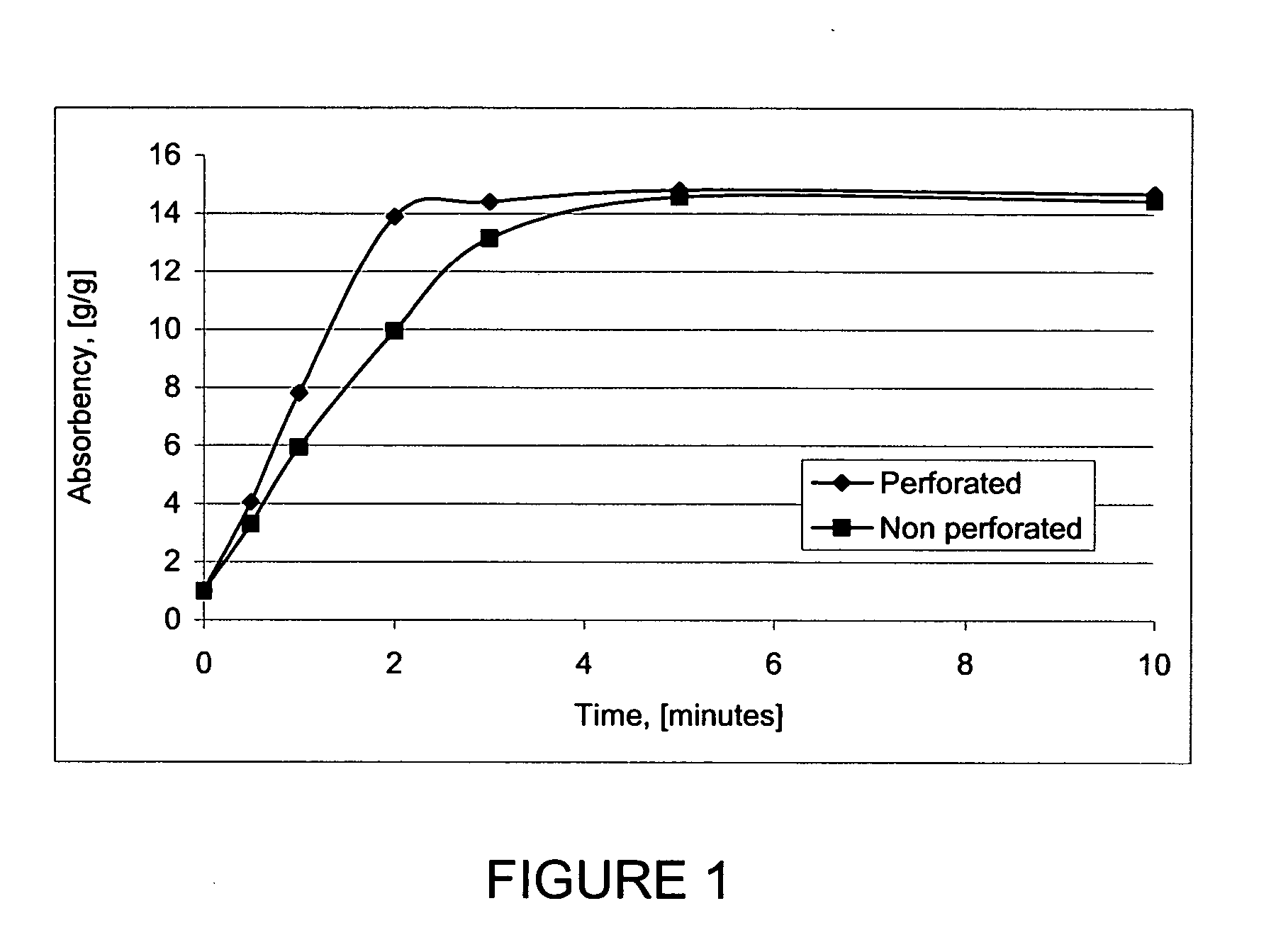

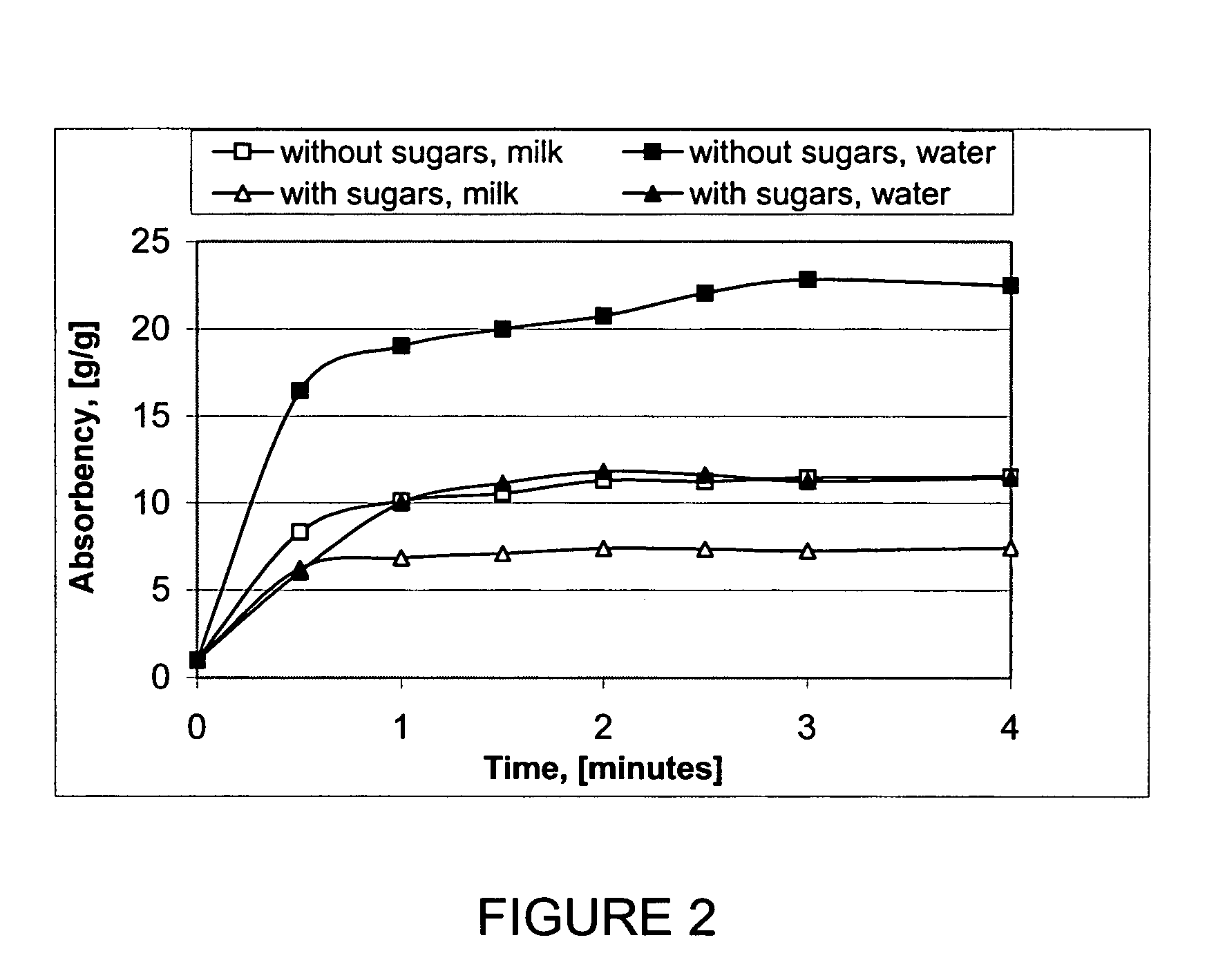

Hydrogels having improved elasticity and mechanical strength properties are obtained by subjecting a hydrogel formulation containing a strengthening agent to chemical or physical crosslinking conditions subsequent to initial gel formation. Superporous hydrogels having improved elasticity and mechanical strength properties are similarly obtained whenever the hydrogel formulation is provided with a foaming agent. Interpenetrating networks of polymer chains comprised of primary polymer(s) and strengthening polymer(s) are thereby formed. The primary polymer affords capillary-based water sorption properties while the strengthening polymer imparts significantly enhanced mechanical strength and elasticity to the hydrogel or superporous hydrogel. Suitable strengthening agents can be natural or synthetic polymers, polyelectrolytes, or neutral, hydrophilic polymers.

Owner:PURDUE RES FOUND INC

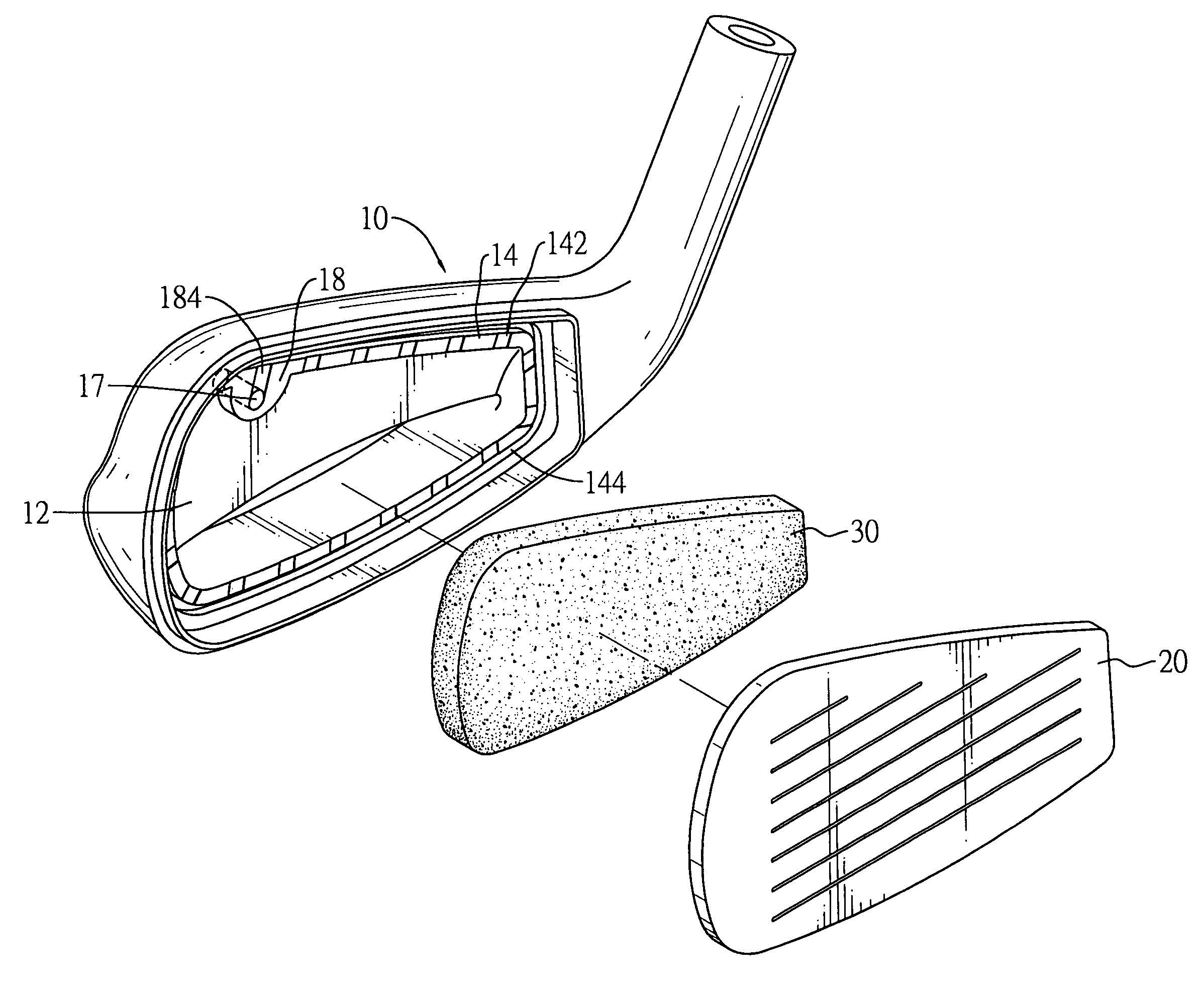

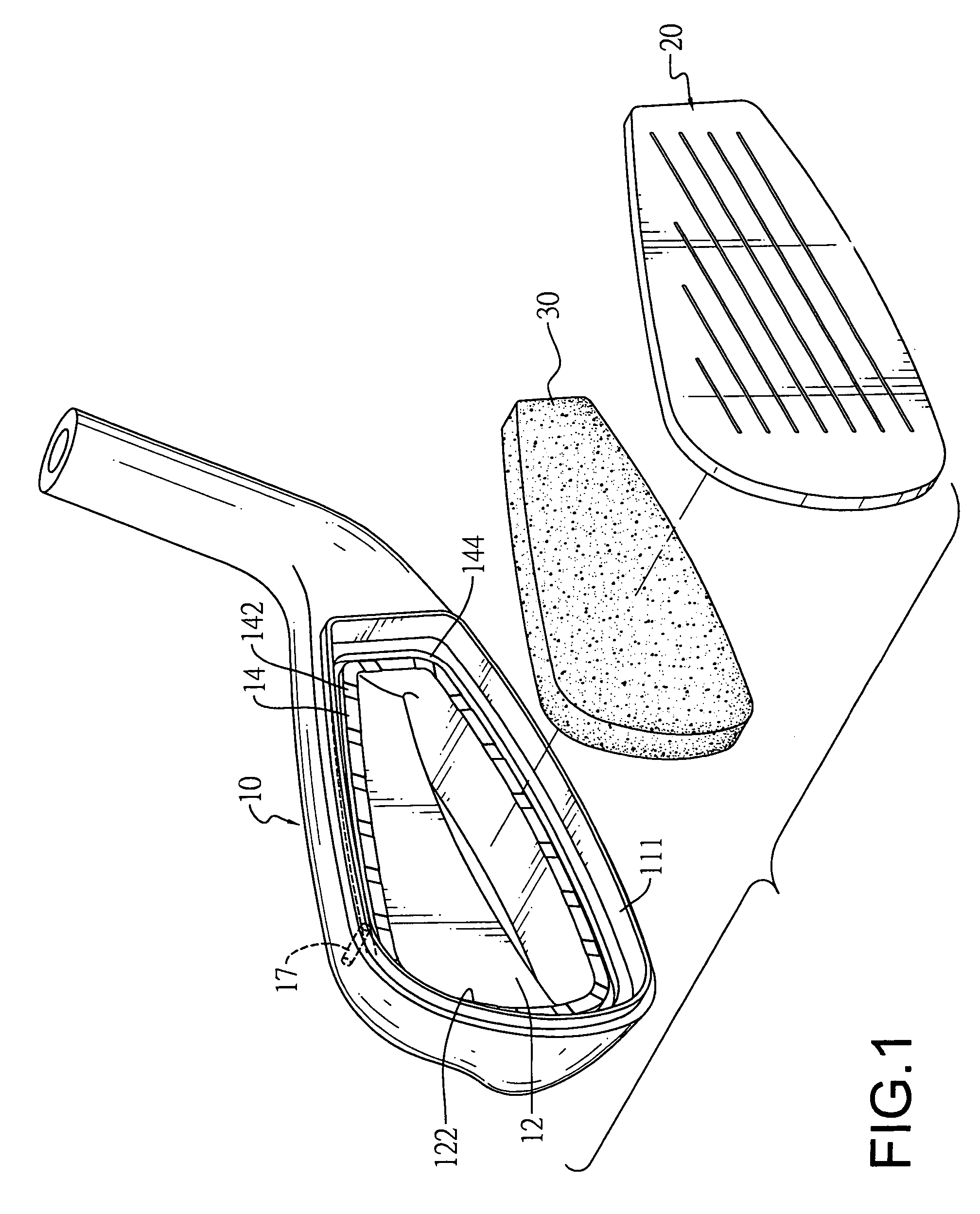

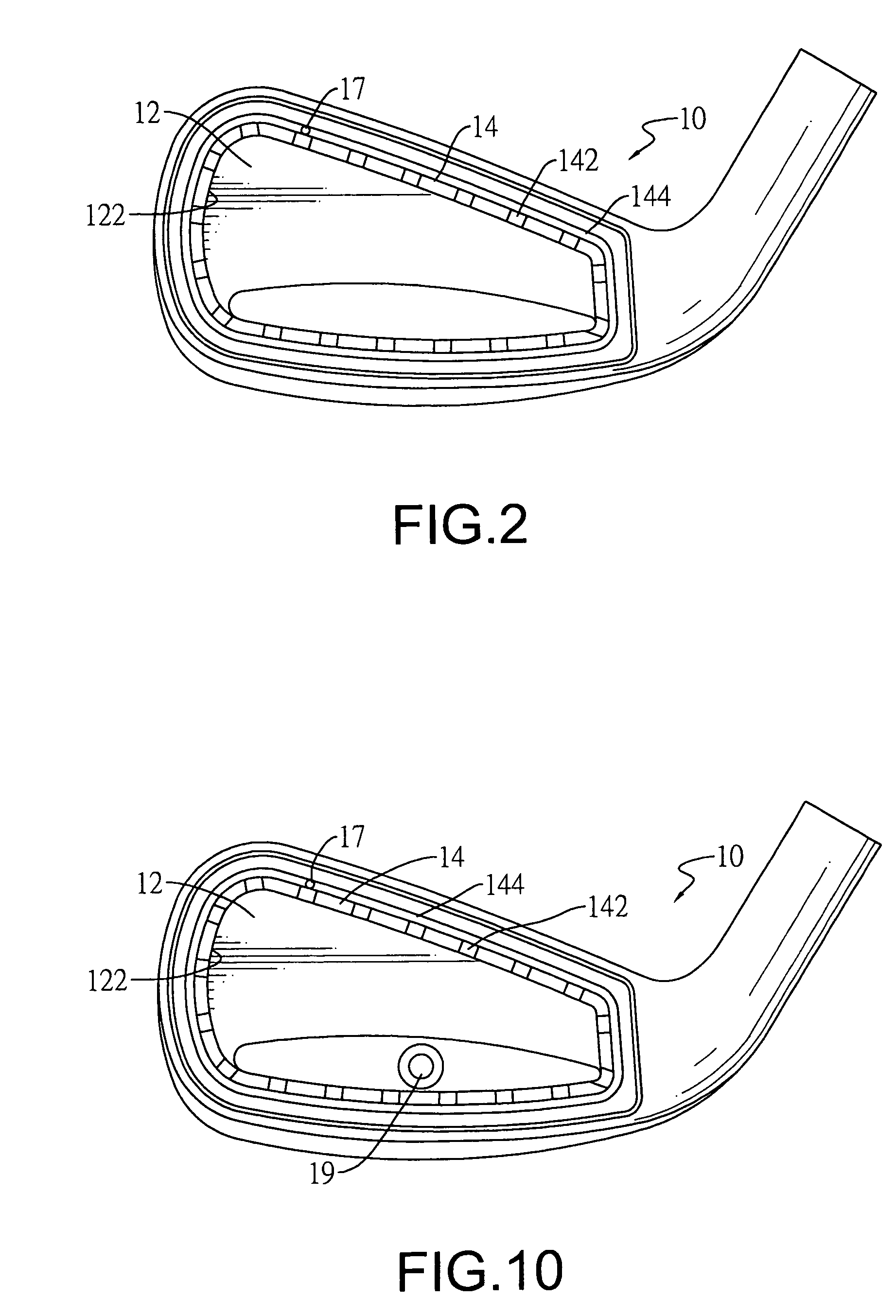

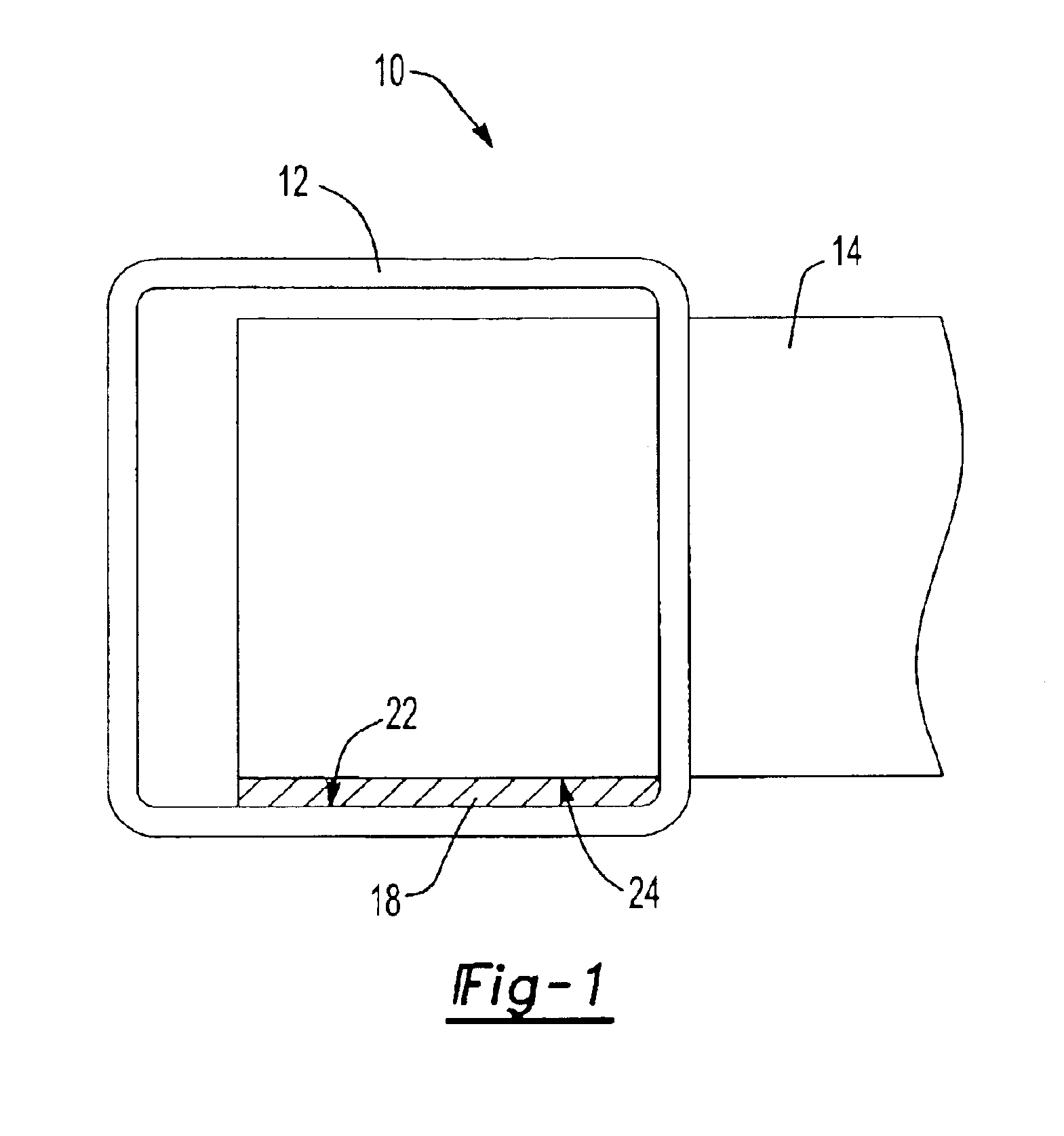

Shock-absorbing golf club head

A shock-absorbing golf club head has a head body, a faceplate and a shock-absorbing core. The head body has a crown, a sole, a toe, a shank, a rear, an open front, a core cavity and an air outlet. The open front has an inner shoulder. The core cavity is defined in the head body and communicates with the open front. The air outlet is defined through the head body, and communicates with the core cavity. The faceplate is mounted securely on the inner shoulder of the open front of the head body. The shock-absorbing core is mounted in the core cavity. The air in the core cavity is discharged to the ambient atmosphere through the air outlet when a foaming agent serving as the shock-absorbing core foams inside the core cavity.

Owner:TSENG WEN CHENG +2

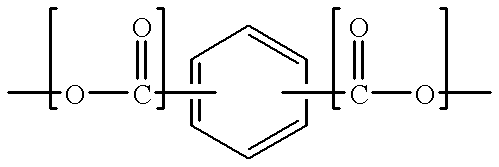

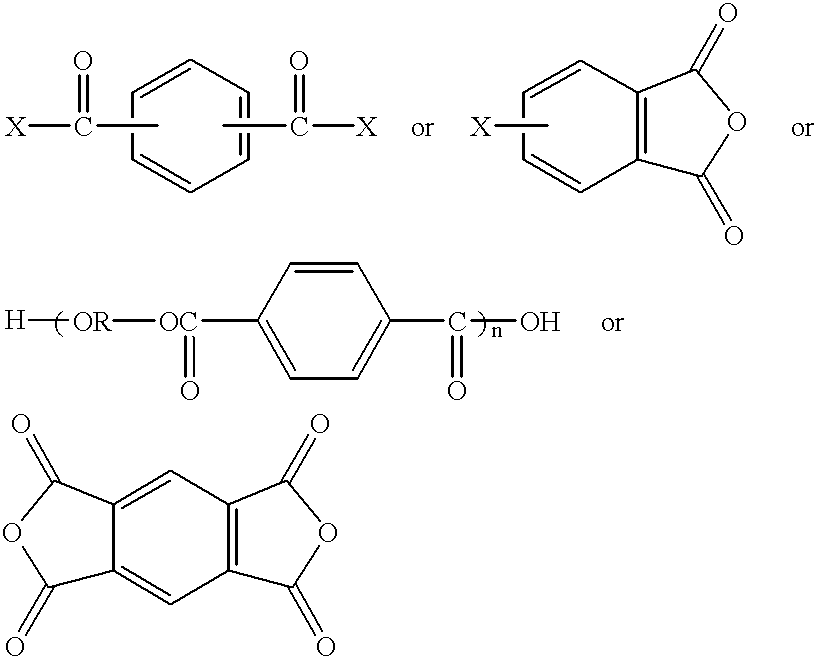

Pentane compatible polyester polyols

InactiveUS6359022B1Increase valueImprove flame retardant performanceOther chemical processesPolyesterDolichol

Disclosed are aromatic polyester polyols, polyol based resin blends, and rigid closed-cell polyisocyanate-based foams made using the polyol based resin blends. The resin blends generally comprise:(a) an aromatic polyester polyol reaction product formed by inter-esterification of a phthalic acid based material; a hydroxylated material having a functionality of at least 2; and a hydrophobic material; and(b) a C4-C7 hydrocarbon blowing agent. Also disclosed is a method for preparing rigid closed-cell polyisocyanate-based foams comprising reacting a polyisocyanate and a polyol based resin blend.

Owner:STEPAN COMPANY

Methods and topical formulations comprising colloidal metal for treating or preventing skin conditions

In preferred embodiments, the present invention relates to compositions comprising colloidal metals and / or metals for the treatment and prevention of skin conditions and / or diseases. More specifically, the disclosed metal containing compositions are useful as antioxidants, anti-aging agents, anti-wrinkle agents, anti-peroxidation agents, antimicrobial agents, anti-inflammatory agents, pain-relieving agents, wound recovery agents, sun-screens, sunblocks, and integument and skin-supporting agents when applied to the skin / integument, or administered generally to an animal or human body.

Owner:MARGULIES JOEL +1

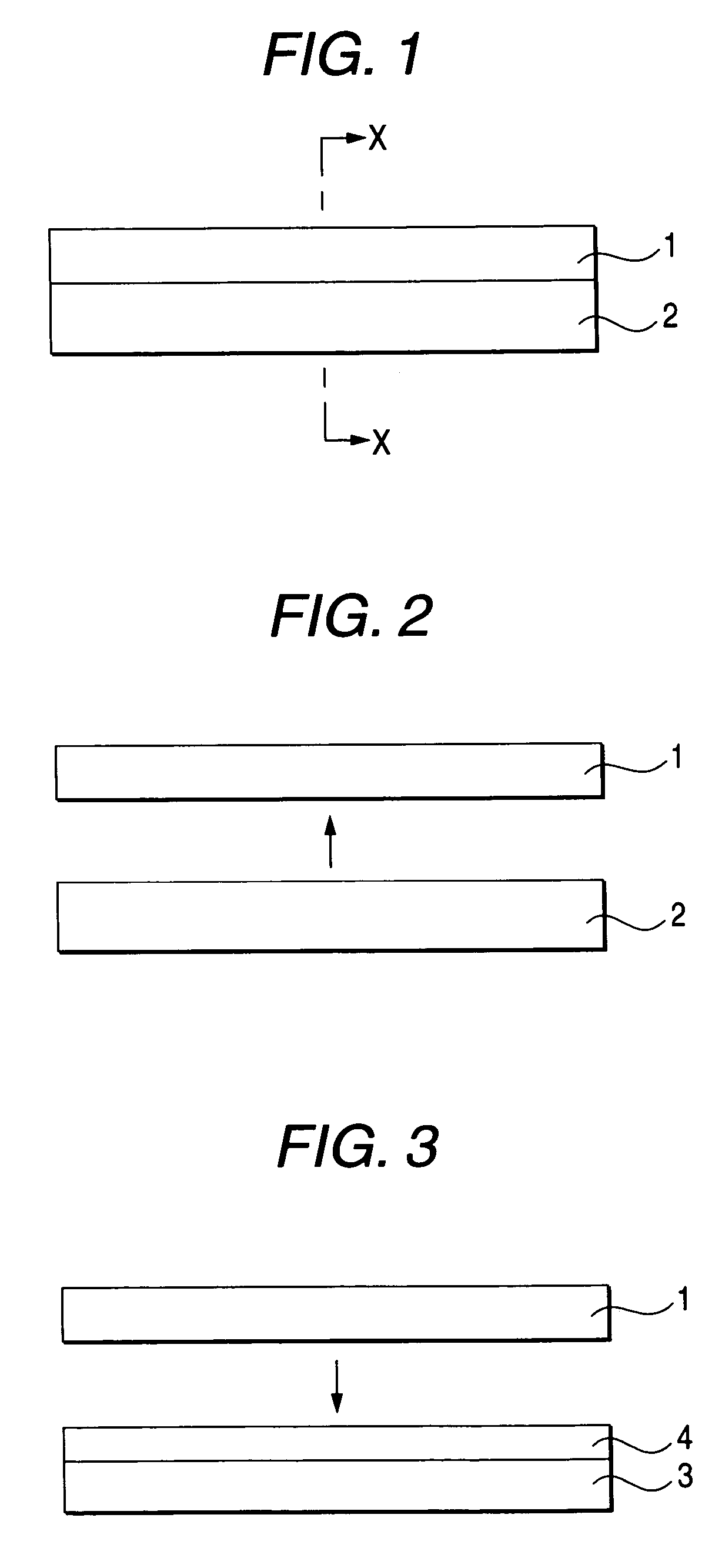

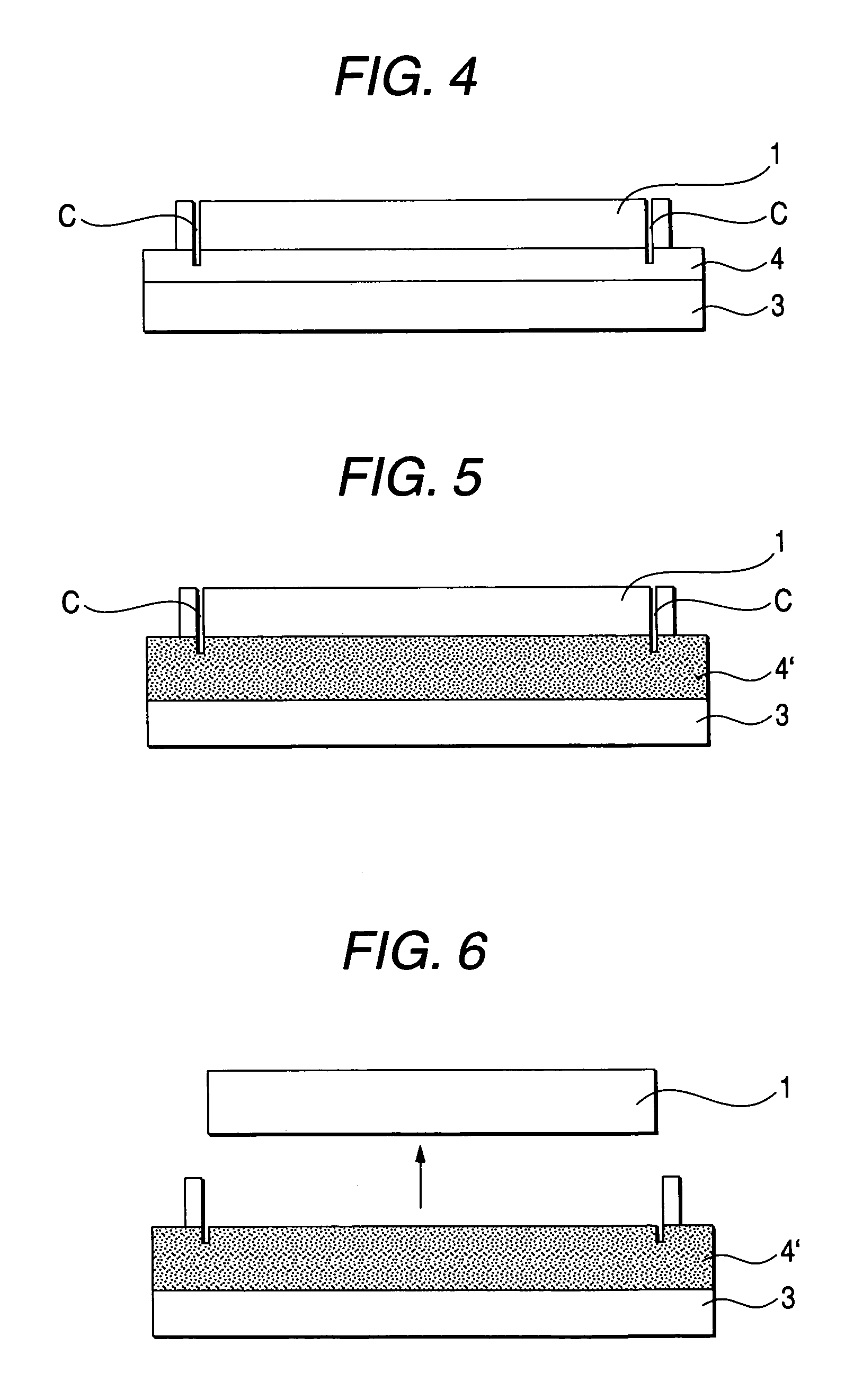

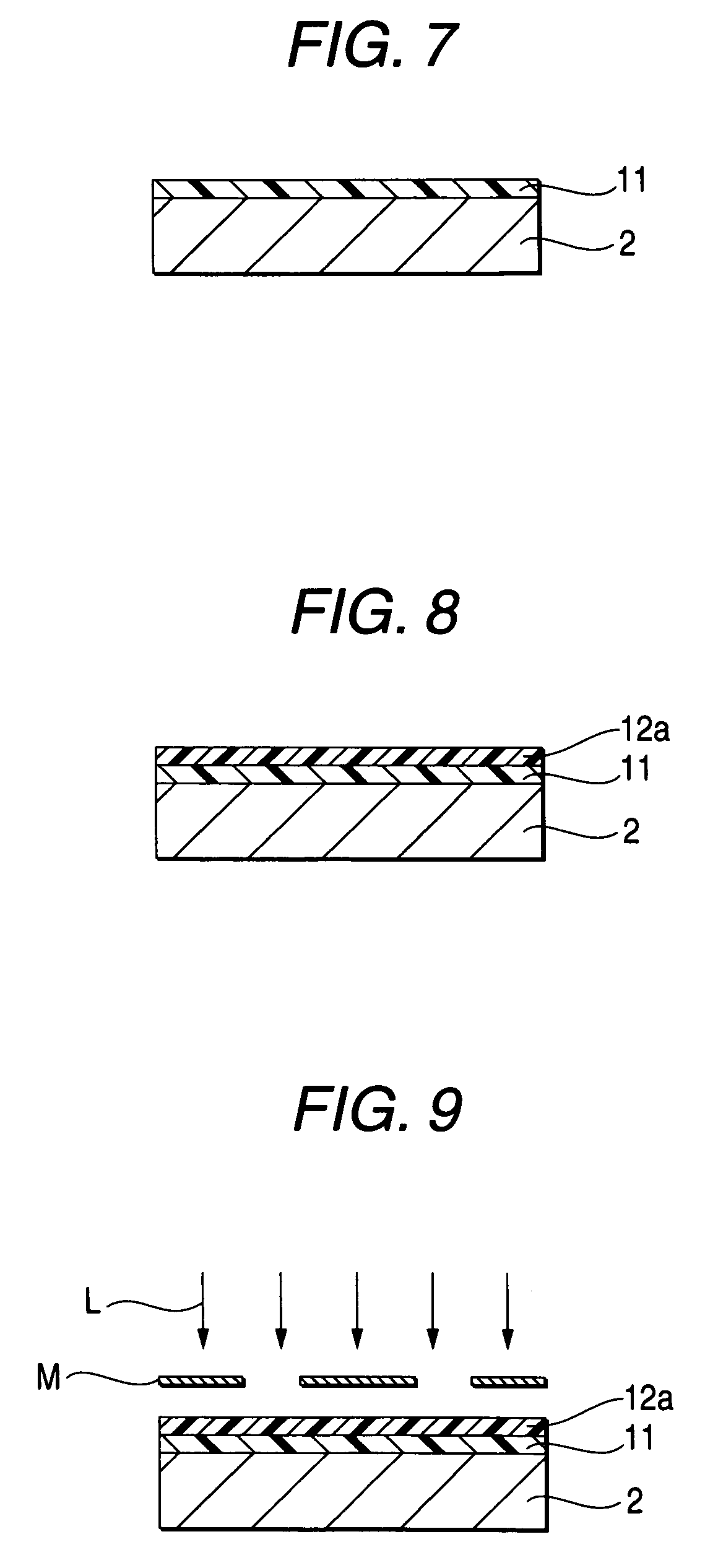

Process for producing flexible optical waveguide

InactiveUS7120345B2Peeling can be safelyReduce adhesionCoupling light guidesOptical waveguide light guideFoaming agentWaveguide

Owner:NITTO DENKO CORP

Activatable material

InactiveUS6846559B2Assist in flow controlPreventing fatigue crack growthSynthetic resin layered productsRecord information storageEpoxyElastomer

An activatable (e.g., heat expandable) material and articles incorporating the same is disclosed. The material includes an epoxy resin; an epoxy / elastomer hybrid or reaction product; a blowing agent; a curing agent; and optionally, a filler. In preferred embodiments, the material includes aramid fiber, nanoclay or both.

Owner:ZEPHYROS INC

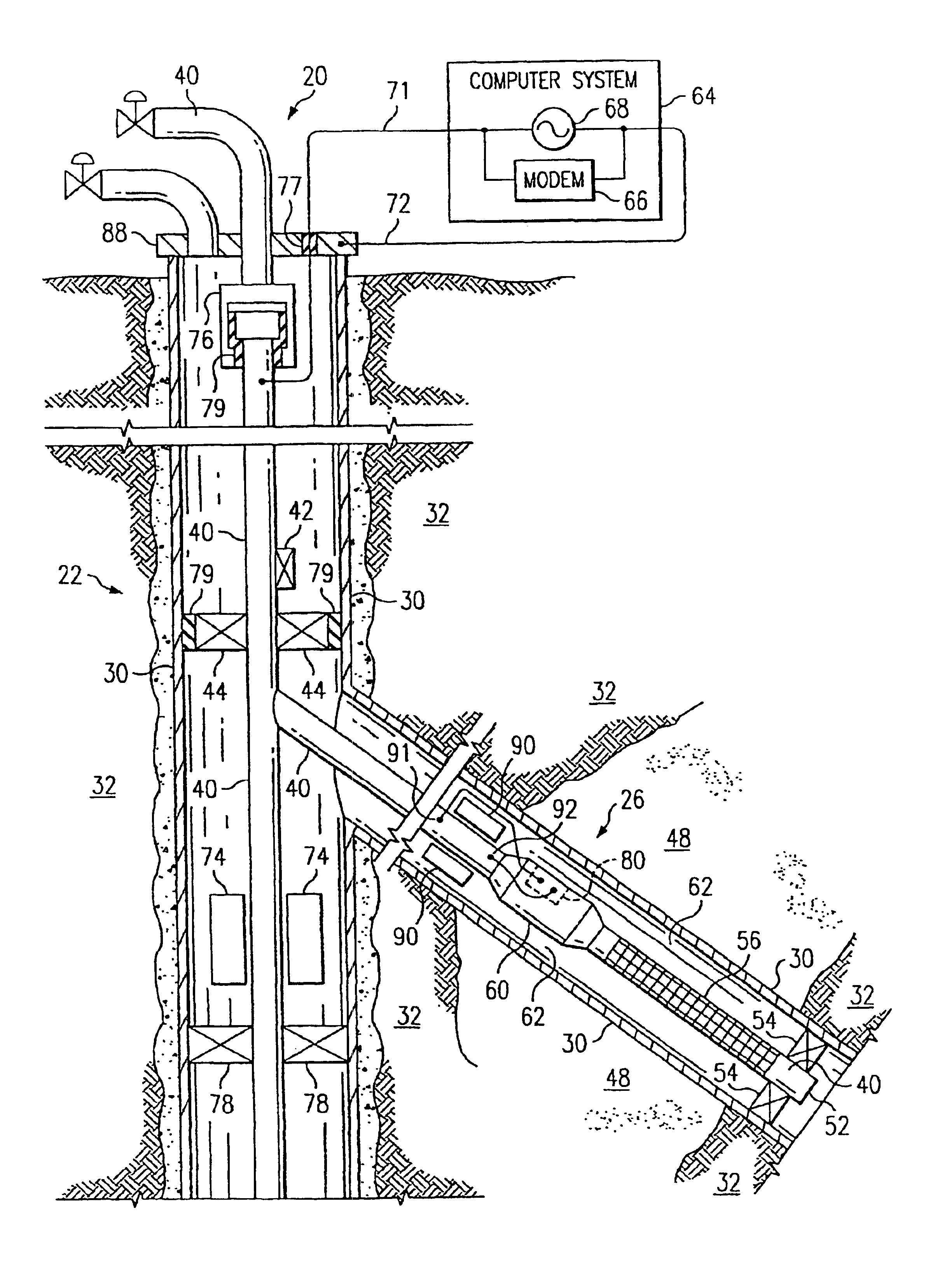

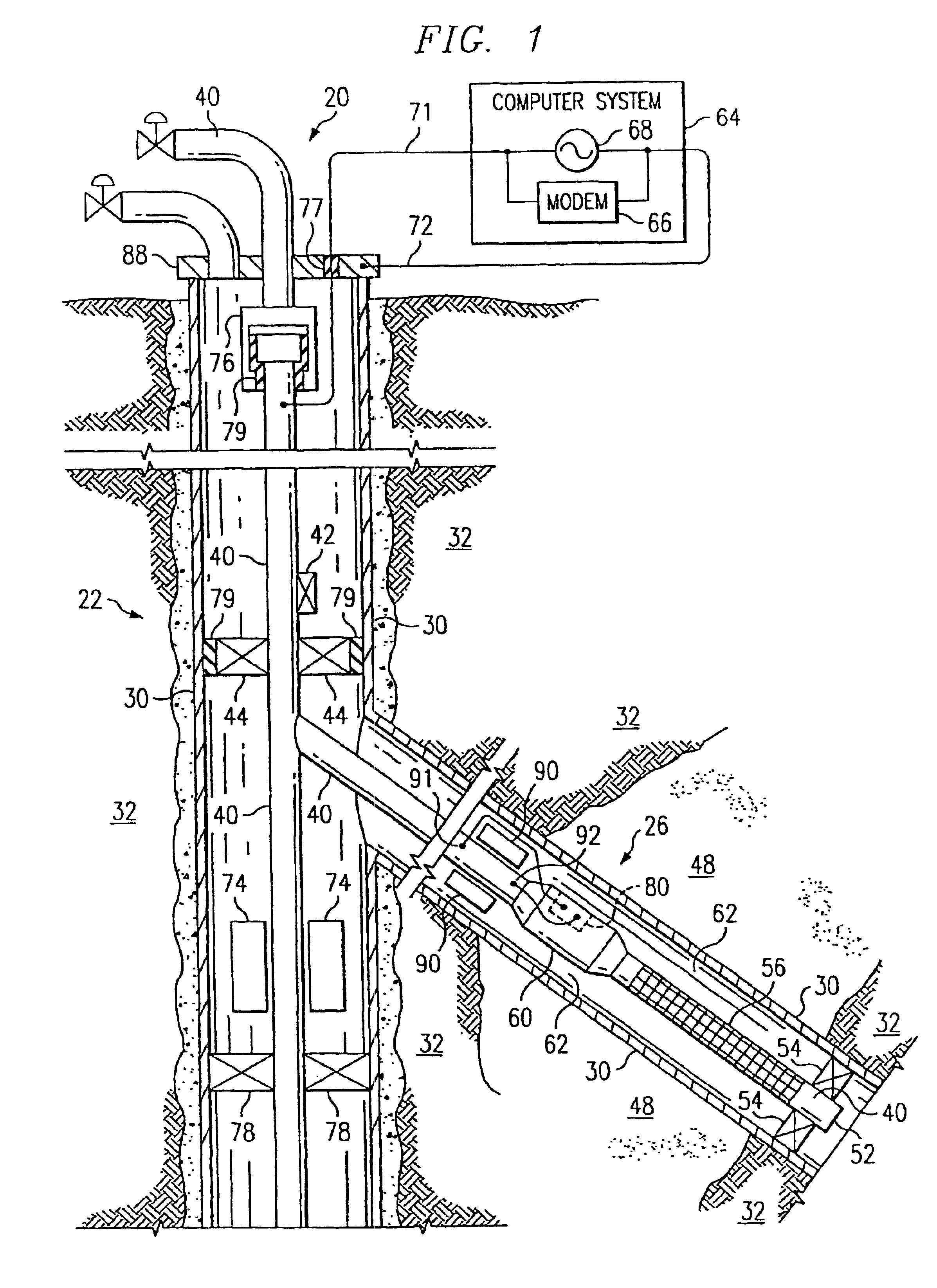

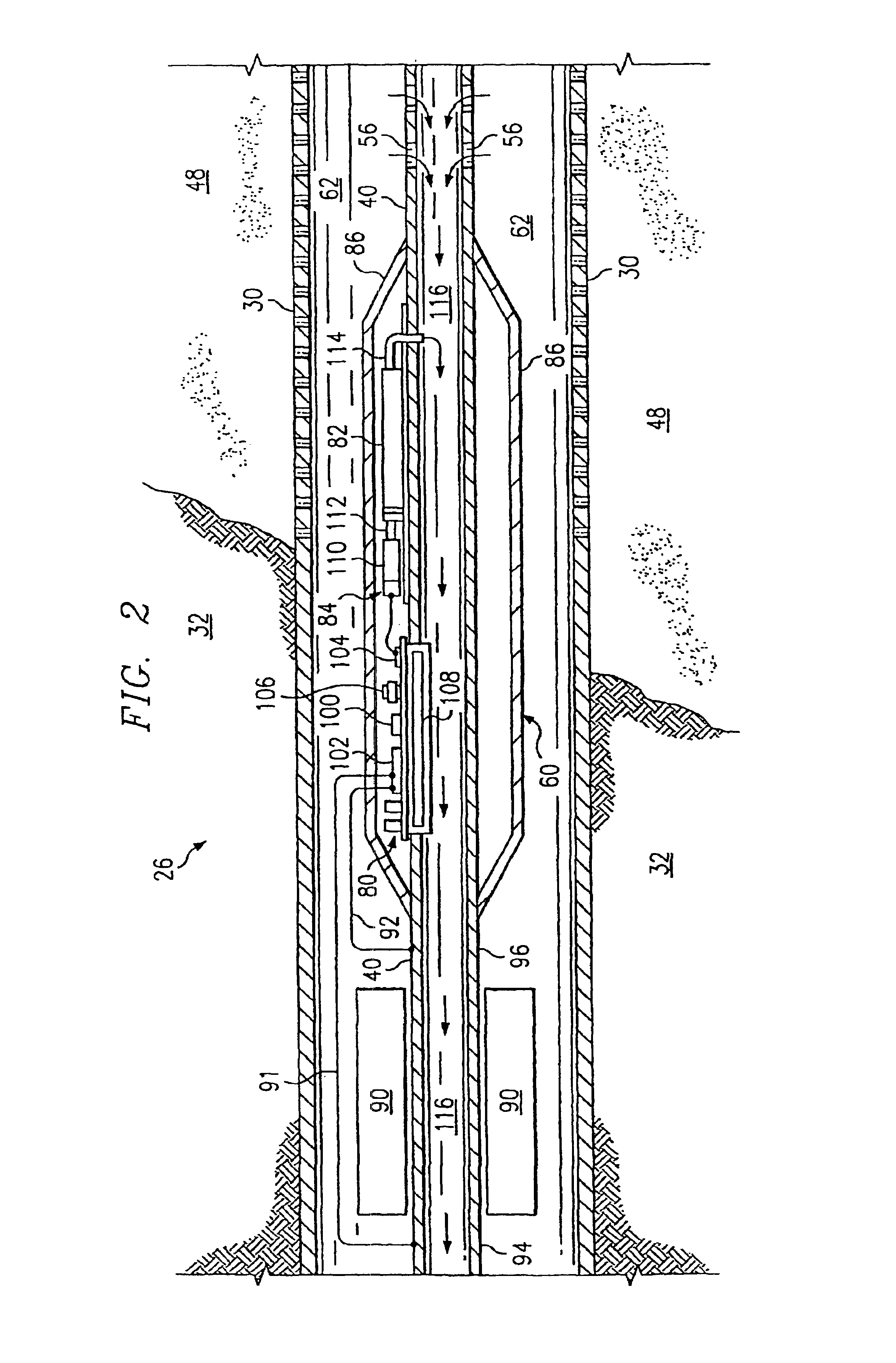

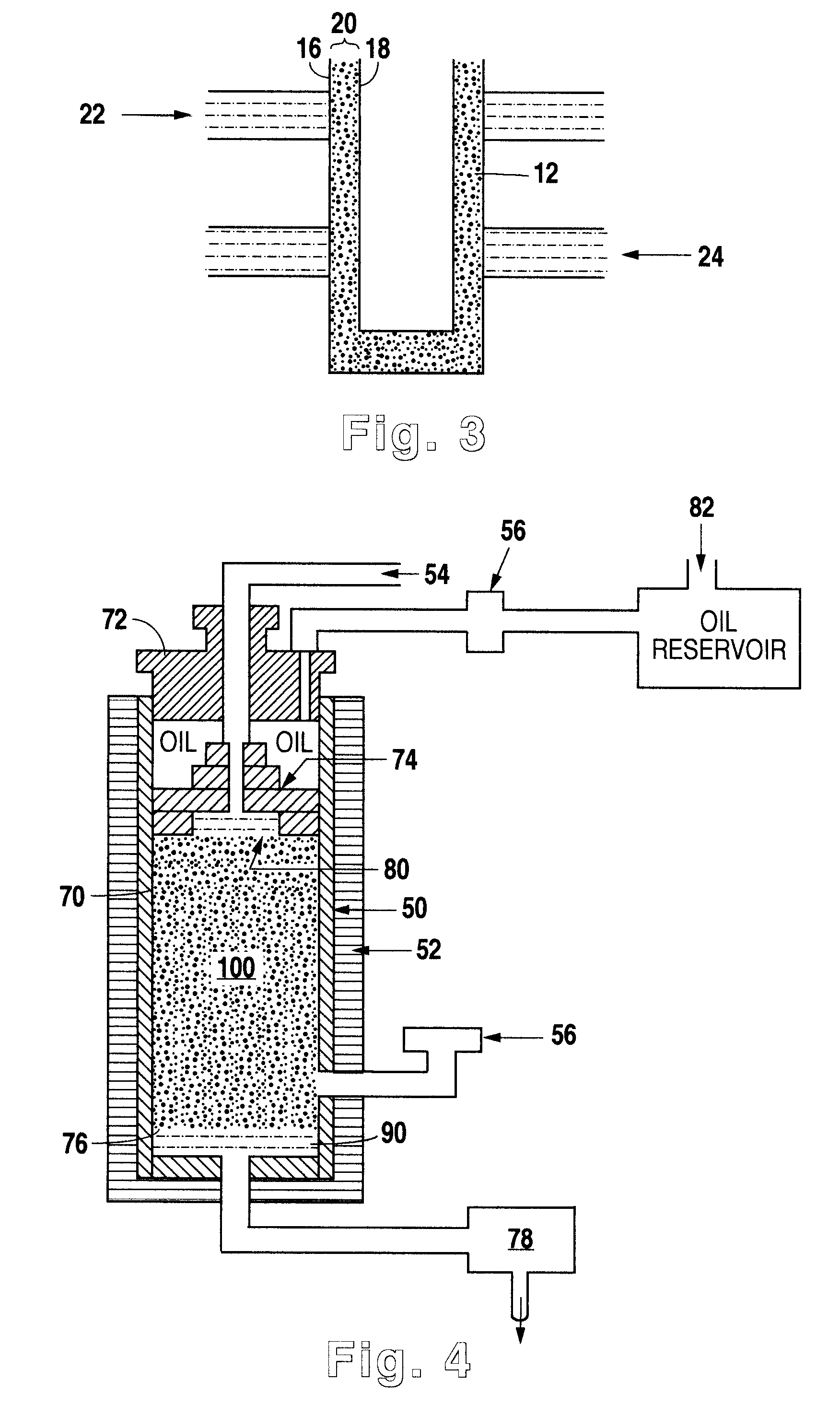

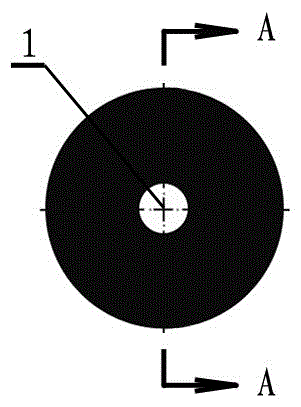

Controlled downhole chemical injection

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

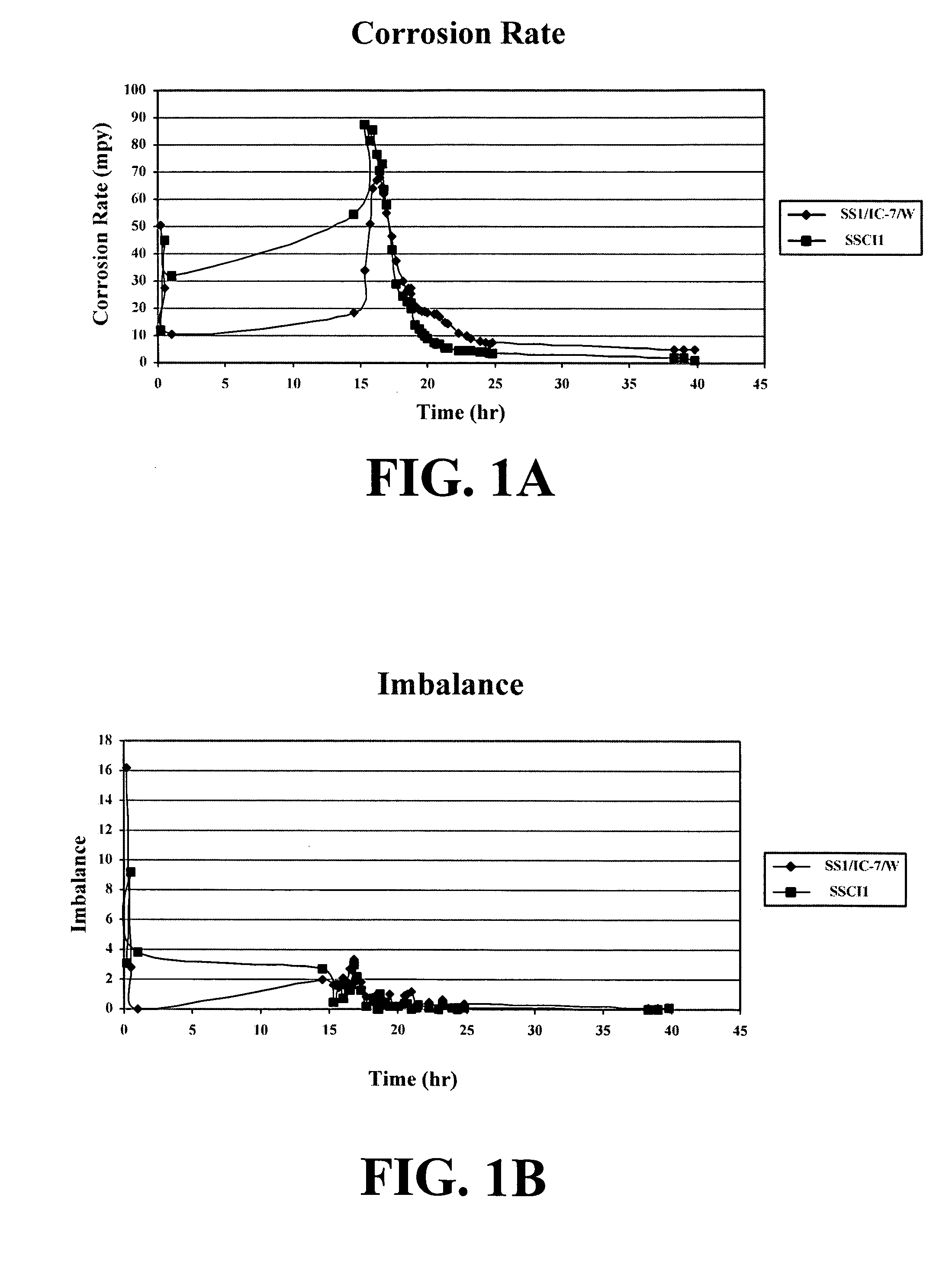

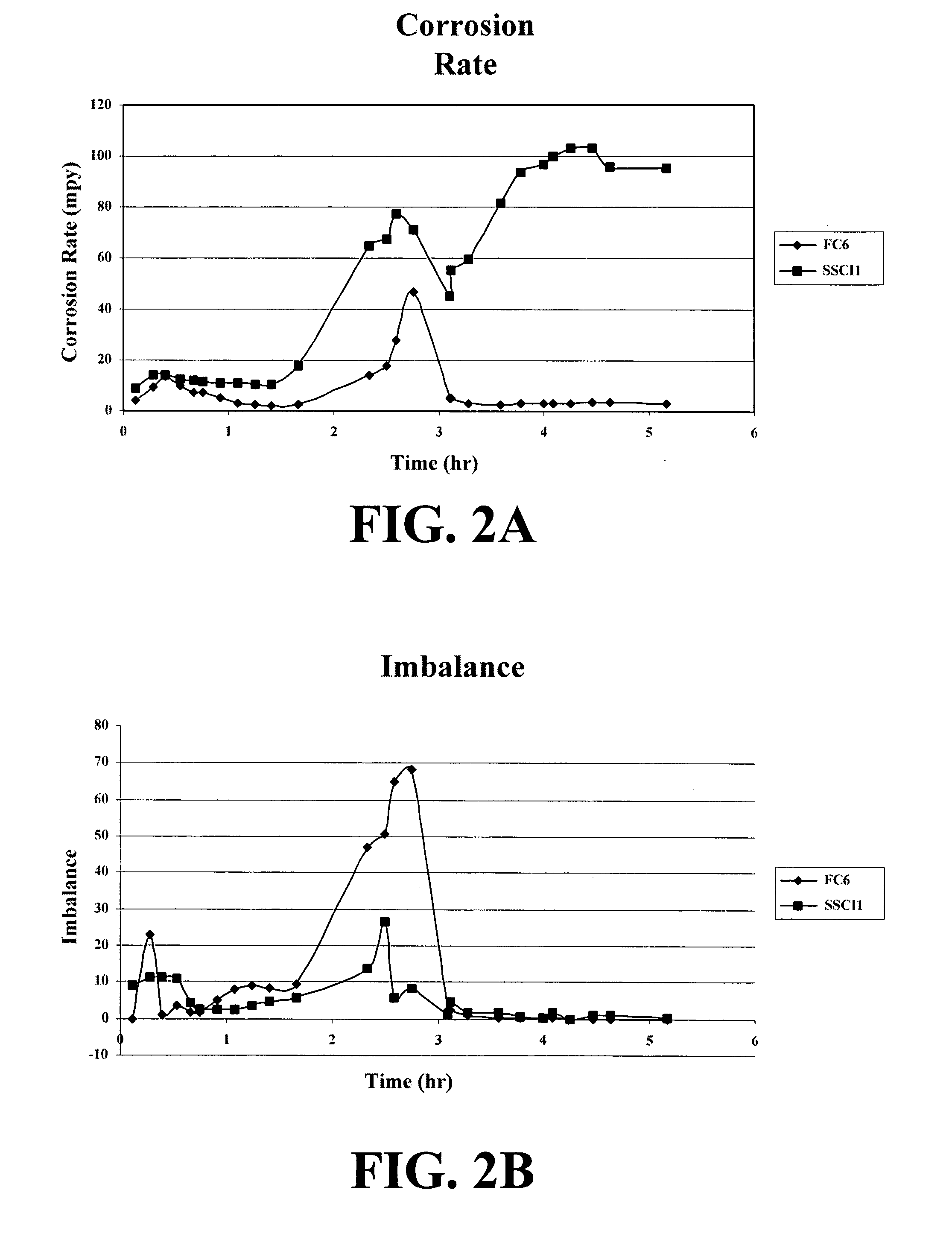

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

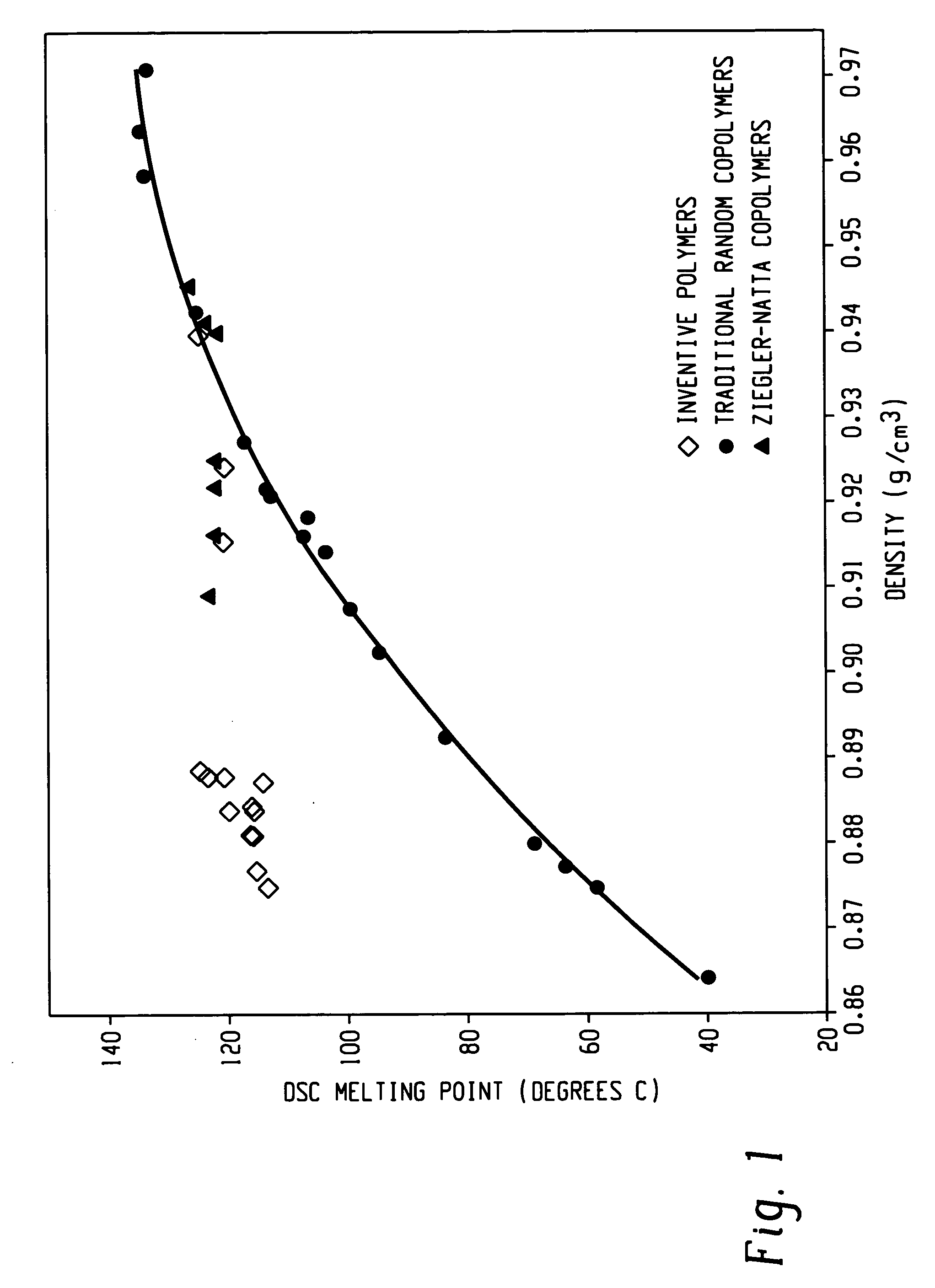

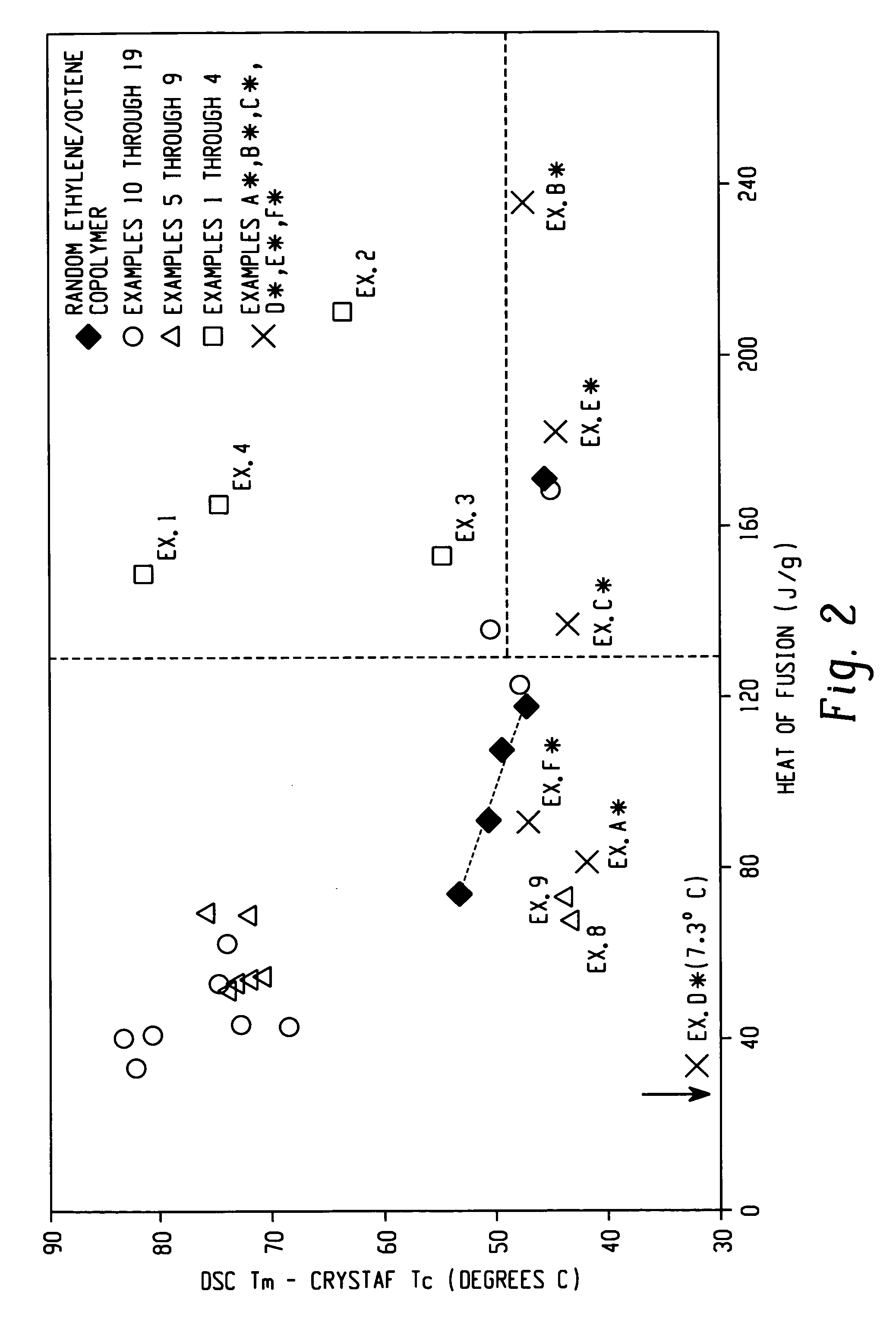

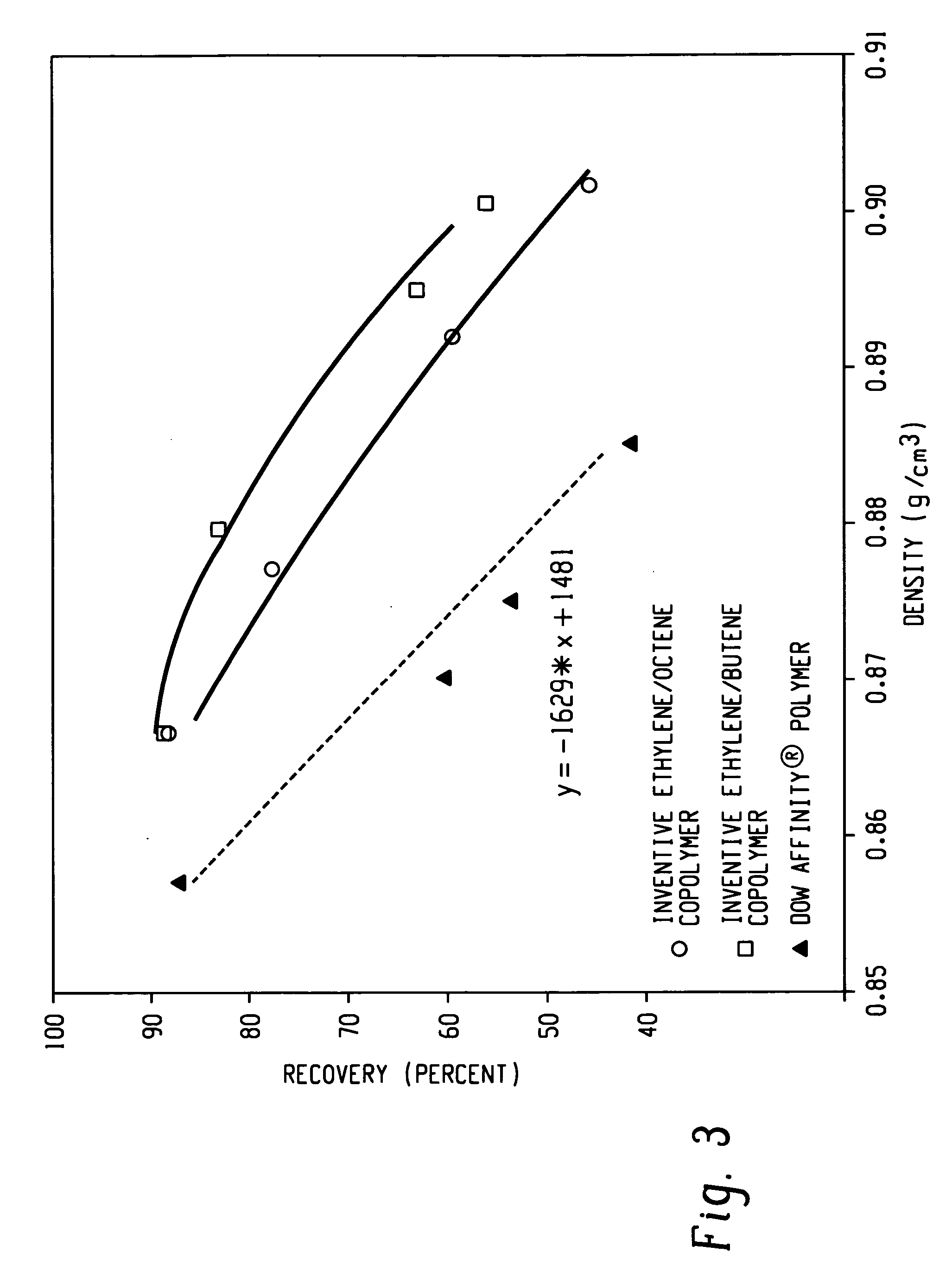

Foams made from interpolymers of ethylene/alpha-olefins

Foamable compositions and foams comprise at least an ethylene / α-olefin interpolymer. The foam has a density from greater than 150 to about 500 kg / m3. The foamable compositions further comprise a blowing agent and a crosslinking agent. The ethylene / α-olefin interpolymers are a multi-block copolymer comprising at least one soft block and at least one hard block. Methods of making the foamable compositions and foams; and foamed articles made from the foams are also described.

Owner:DOW GLOBAL TECH LLC

Methods and compositions for use in cementing in cold environments

Cement compositions for cementing wellbores in cold environments. The cement compositions may include a mixture of a reactive aluminum silicate, aluminum sulfate and hydraulic cement, and may include one or more other additives. The cement compositions may be formulated to have reduced heat of hydration as compared to conventional cements, making them suited for cementing in permafrost environments. The cement slurries may optionally be foamed using a foaming agent and energizing phase.

Owner:AMERICAN CEMENTING LLC

Gelled biopolymer based foam

InactiveUS20050137272A1Improve water absorptionWet strengthCosmetic preparationsToilet preparationsPersonal careCross-link

Gelled biopolymer based foams are disclosed. The gelled foams comprise a cross-linked biopolymer, preferably alginate; optionally, a foaming agent such as hydroxy propyl methyl cellulose; and a plasticizer, preferably glycerin sorbitol, or a mixture thereof, that forms the predominant portion of the gelled foam. The foams are soft and pliable and have high absorbency. They are used as wound dressing materials, controlled release delivery systems, cell culture, barrier media for preventing tissue adherence, and bioabsorbable implants. They also have various personal care applications, especially in oral hygiene, and can be used in food applications.

Owner:FMC BIOPOLYMER AS

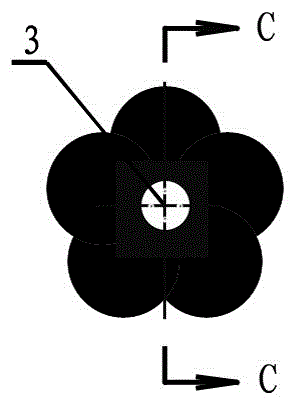

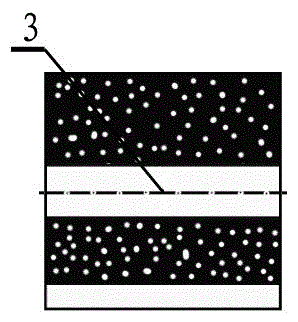

Methods for controlling migration of particulates in a subterranean formation

Method of treating a portion of a subterranean formation comprising: placing a pre-pad fluid into a portion of a subterranean formation wherein the pre-pad fluid comprises a low-viscosity aqueous tackifying composition that comprises an aqueous tackifier compound and an aqueous fluid; placing a fracturing fluid into the portion of the subterranean formation at a pressure sufficient to create or extend at least one fracture therein; and, activating the aqueous tackifier compound with an activator so as to consolidate the unconsolidated particulates. Method of consolidating unconsolidated particulates within a portion of a subterranean formation comprising: placing a foamed low-viscosity aqueous tackifying composition into a portion of a subterranean formation comprising unconsolidated particulates wherein the aqueous tackifying composition comprises an aqueous fluid, a foaming agent, and an aqueous tackifier compound; and, activating the aqueous tackifier compound with an activator so as to consolidate the unconsolidated particulates.

Owner:HALLIBURTON ENERGY SERVICES INC

Expandable material

An expandable material and articles incorporating the same are disclosed. The material includes a polymeric admixture; a blowing agent; a curing agent; a tackifier; and optionally, a filler or fiber.

Owner:ZEPHYROS INC

Foamer/sulfur scavenger composition and methods for making and using same

InactiveUS20050250666A1High activityImprove featuresOrganic chemistryConstructionsFoaming agentDisposal waste

A new multi-purpose foaming composition having applications in oil field application, industrial applications, waste management applications, or other applications that can be benefitted by a foam, is disclosed, where the composition includes a surfactant, a sulfur scavenger and optionally an additive, where the sulfur scavenger and / or additive improve foam characteristics and / or the foam improves an activity of the sulfur scavenger and / or the additives. Method for using and making the foaming compositions are also disclosed, especially, coiled and capillary coiled tubing downhole applications.

Owner:LUBRIZOL OILFIELD SOLUTIONS

Blowing agents for forming foam comprising unsaturated fluorocarbons

Owner:EI DU PONT DE NEMOURS & CO

Storage stable isocyanate-reactive component containing vegetable oil-based polyol

The present invention provides an isocyanate-reactive component containing at least 10 wt. %, based on the weight of the isocyanate-reactive component, of a vegetable oil-based polyol, a nonionic emulsifier containing one of an aliphatic alcohol ethoxylate and an aliphatic phenol ethoxylate having a polymerized ethylene oxide content of at least 25 moles per equivalent of alcohol or phenol and a HLB value greater than 17, one or more non-vegetable oil-based polyols, one or more silicone surfactants, and optionally, water or other blowing agents, catalysts, pigments and fillers, wherein the isocyanate-reactive component is storage stable at temperatures of from −10° C. to 60° C. for at least three days. The inventive isocyanate-reactive component can be shipped and stored at normal shipping and storage temperatures and still produce acceptable foam on a daily basis whilst helping to satisfy polyurethane foam and elastomer producers' “green” requirements.

Owner:BAYER MATERIALSCIENCE AG

Process for mitigation of wellbore contaminants

InactiveUS6942037B1Lessened potential hazardSimple treatmentCleaning apparatusFluid removalFoaming agentWater flow

A method is disclosed for intermittently mitigating hazardous sulfur compounds, such as hydrogen sulfide, mercaptans and sulfur oxides, from a fluid in the head space of a wellbore. The method comprises contacting the fluid with a foamed aqueous stream comprising an active scavenging agent, such as a triazine, and a stiff foaming agent. The scavenging agent reacts with hazardous sulfur compounds to eliminate the compounds from the fluid stream in the vapor space of the wellbore without withdrawing the hydrocarbon from the wellbore and without releasing hazardous sulfur compounds to the environment.

Owner:CLARIANT INT LTD

Expandable microspheres for foam insulation and methods

InactiveUS20050079352A1Use in some applicationHigh of encapsulationLiquid surface applicatorsGlass/slag layered productsPolymer scienceFoaming agent

Hollow thermoexpandable particles or microspheres are provided that contain hydrocarbon blowing agents and have a shell polymer that can be softened at the onset of the expansion temperature and solidified at a higher temperature (thermoset) in an expanded state. Preferably, the microspheres have a shell of thermally expandable and thermally crosslinkable polymer and a hollow interior that contains a hydrocarbon liquid that boils at a temperature below the heat activated crosslinking temperature of the polymer shell. The crosslinking of the shell polymer during or after expansion, which is heat activated at an elevated temperature, can solidify the shell polymer and, then, maintain the expanded volume of the microspheres. The thermoexpandable thermoset polymer particles are useful in insulation, packaging, for making foam materials such as polyurethane or polyisocyanurate rigid foams. The invented thermoset microspheres can substantially improve the close cell percentage and compressive strength of the foam materials and make the foam manufacturing less hazardous.

Owner:IP RIGHTS +1

Wood plastic foamed material and machine-shaping process thereof

The foamed wood-plastic material is produced with plastic, wood dust, mineral stuffing, assistant, modifier, foaming agent, etc. in certain proportion and through mixing, heating to fusion, foaming and forming in a heat forming apparatus. It has continuous homogeneous pores, and is light, high in specific strength, waterproof, anticorrosive and heat insulating, and may be nailed, sawn and planed, so that it may be used widely in building, transportation, packing, household decoration and daily use articles.

Owner:北京欧尼克新型材料有限公司

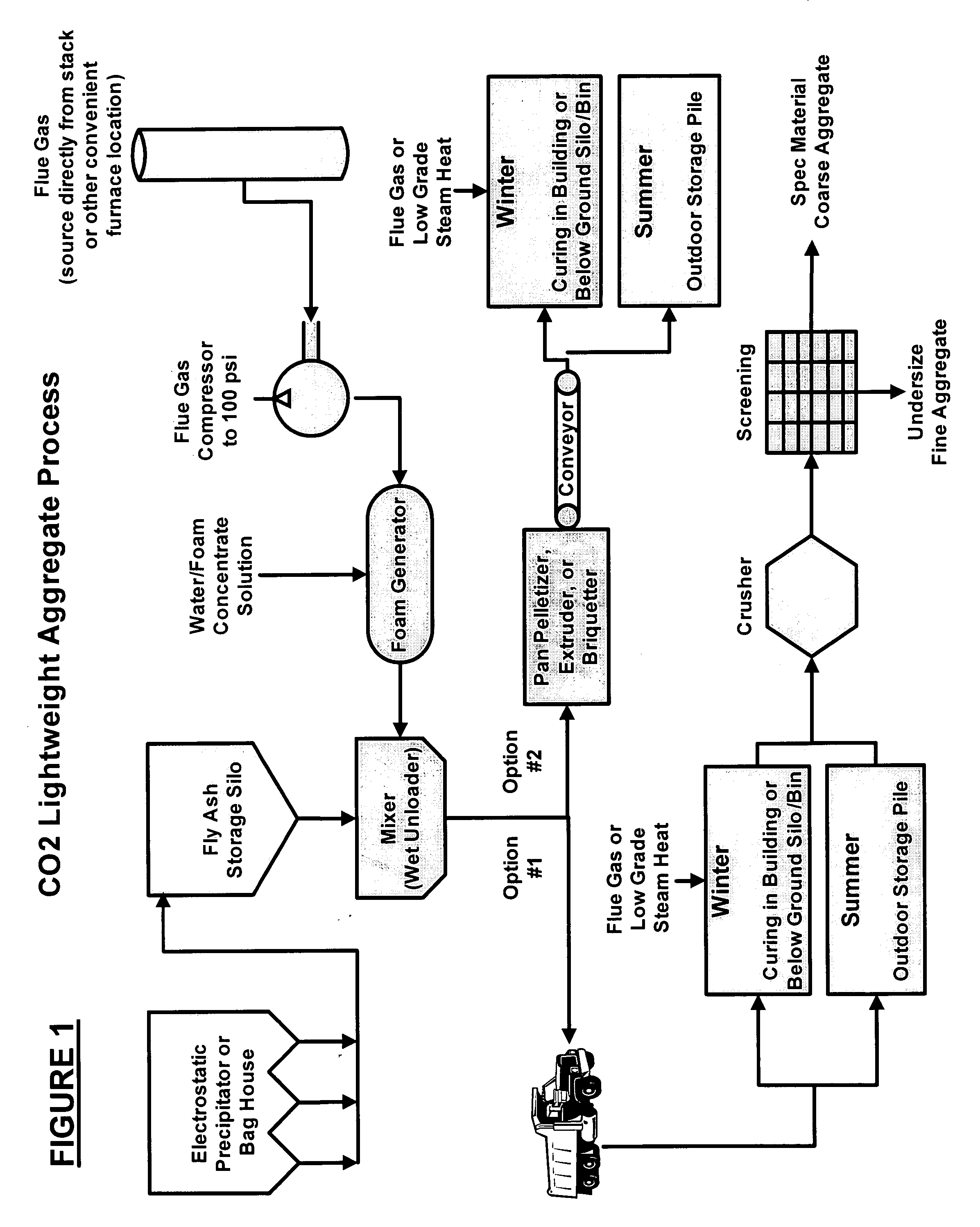

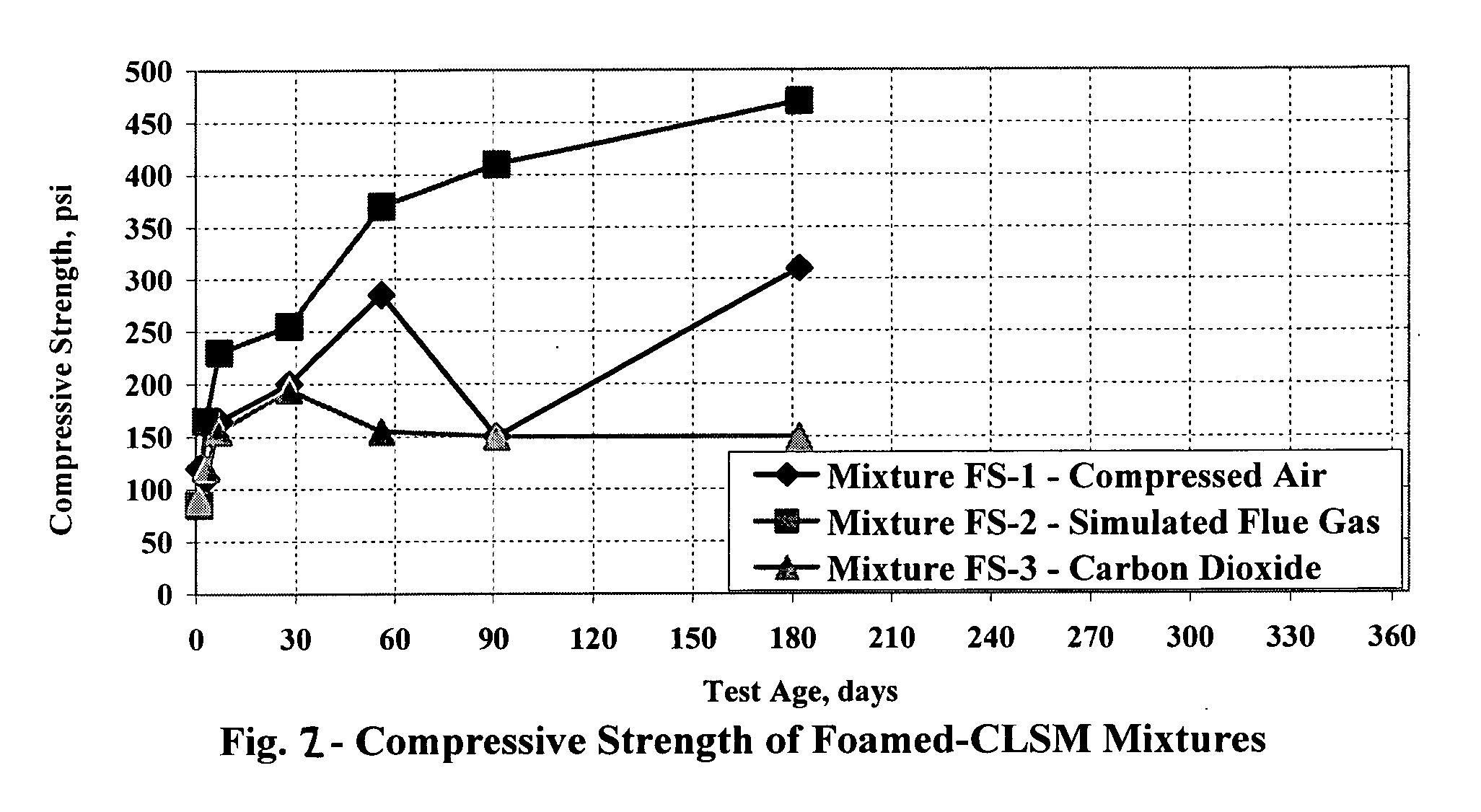

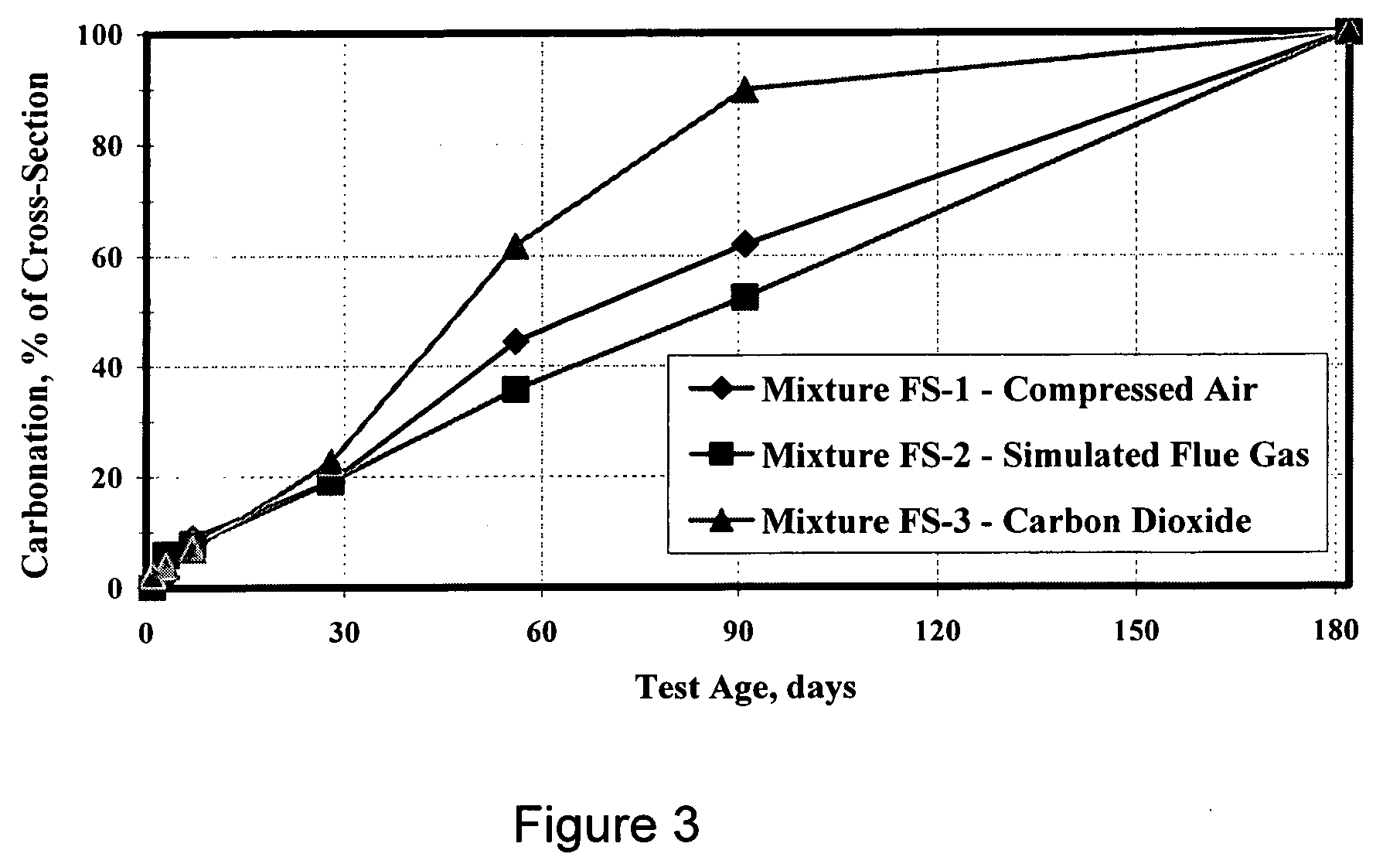

Carbon dioxide sequestration in foamed controlled low strength materials

InactiveUS20060185560A1Improve the environmentEasy to useProductsReagentsCombustion chamberMaterials science

A process for sequestering carbon dioxide from the flue gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the flue gas is formed, and the foam is added to a mixture including a cementitious material (e.g., fly ash) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the flue gas and waste heat reacts with hydration products in the controlled low-strength material to increase strength. In this process, the carbon dioxide is sequestered. The CLSM can be crushed or pelletized to form a lightweight aggregate with properties similar to the naturally occurring mineral, pumice.

Owner:WISCONSIN ELECTRIC POWER

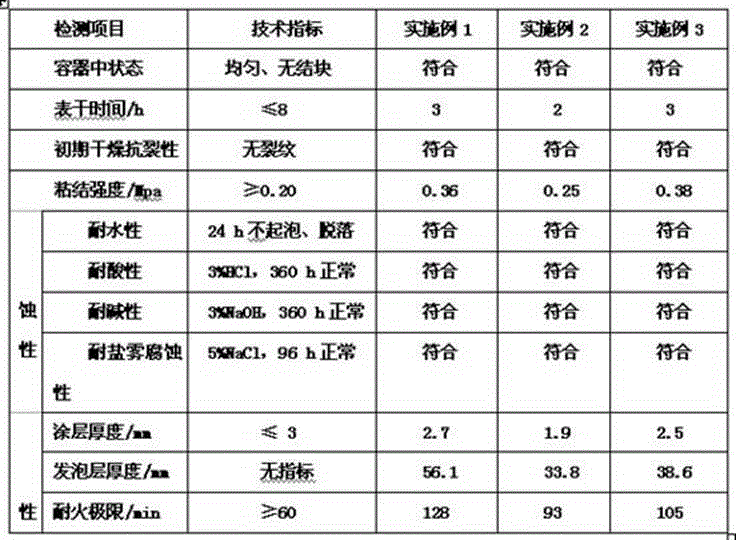

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

Corticosteroid-containing pharmaceutical composition

InactiveUS7078058B2Improve permeabilityEasy to handleOrganic active ingredientsBiocideScalp psoriasisDisease

A foamable pharmaceutical composition comprising a corticosteroid, a quick-break foaming agent, a propellant and a buffering agent, sufficient to buffer the composition to within the range of pH 3.0 to 6.0 is disclosed. The quick-break foaming agent typically comprises an aliphatic alcohol, water, a fatty alcohol and a surface active agent. Due to the nature of the compositions of the invention, they are especially well-suited for use in the treatment of various skin diseases, and in particular, in the treatment of scalp psoriasis.

Owner:STIEFEL WEST COAST

Methods for making foams using blowing agents comprising unsaturated fluorocarbons

Owner:THE CHEMOURS CO FC LLC

Coal gangue lightweight through-hole ceramsite

The invention discloses coal gangue lightweight through-hole ceramsite. The technical scheme has the essentials that the coal gangue lightweight through-hole ceramsite is composed of coal gangues, attapulgite clay, a powdery coal gangue foaming agent, active carclazyte waste dreg, hollow microspheres, lightweight magnesium oxide, expanded perlite, expanded vermiculite, ferrous sulfate and quick lime. The materials of the coal gangue lightweight through-hole ceramsite are stirred and mixed, extruded and granulated, dried, roasted, subjected to heat insulation, sieved, sealed and packaged to prepare the coal gangue lightweight through-hole ceramsite. The coal gangue lightweight through-hole ceramsite has the characteristics of large specific surface area, small bulk density, high water absorption rate, excellent ventilation performance, beautiful appearance and shape and no odors, no harmful bacteria, good lightweight strength, and consistent micro-pores and macro-pores. When the coal gangue lightweight through-hole ceramsite is used for culturing or planting various types of nursery stocks, flowers and vegetables, the roots of the plants can absorb nutrition constituents of water or a liquid fertilizer from the coal gangue lightweight through-hole ceramsite, so that good growth and development and the survival rate of the plants are ensured and the coal gangue lightweight through-hole ceramsite is suitable for preparing a soilless culture substrate and nutrient soil.

Owner:平凉华晨非金属应用科技有限公司

Expanding fire-proof paint

InactiveCN1380368AGood fire and heat insulationGood adhesionFireproof paintsFoaming agentAcrylic resin

The expansive fire-resisting paint contains the components of acrylic resin, catalyst, carbon-forming agent, foaming agent, fire-resisting agent, reinforcing agent, pigment filling material, adjuvantand smoke inhibiting agent, and is characterized by that it utilizes the modification of acrylic resin, surface treatment of catalyst and addition of smoke inhibiting agent to raise comprehensive property of paint. When the paint film is heated and expanded, it can be formed into fire-resistant carbonized layer with three-D space structure, and can release fire-resisting gas to prevent flame fromspreading. Said paint is suitable for steel structure, and material and electric cable, etc.

Owner:MARINE CHEM RES INST

High temperature foamer formulations for downhole injection

ActiveUS7122509B2Increase heightReduce pointsOrganic detergent compounding agentsAnionic surface-active compoundsFoaming agentDecomposition

Owner:WHITEBOX ADVISORS +1

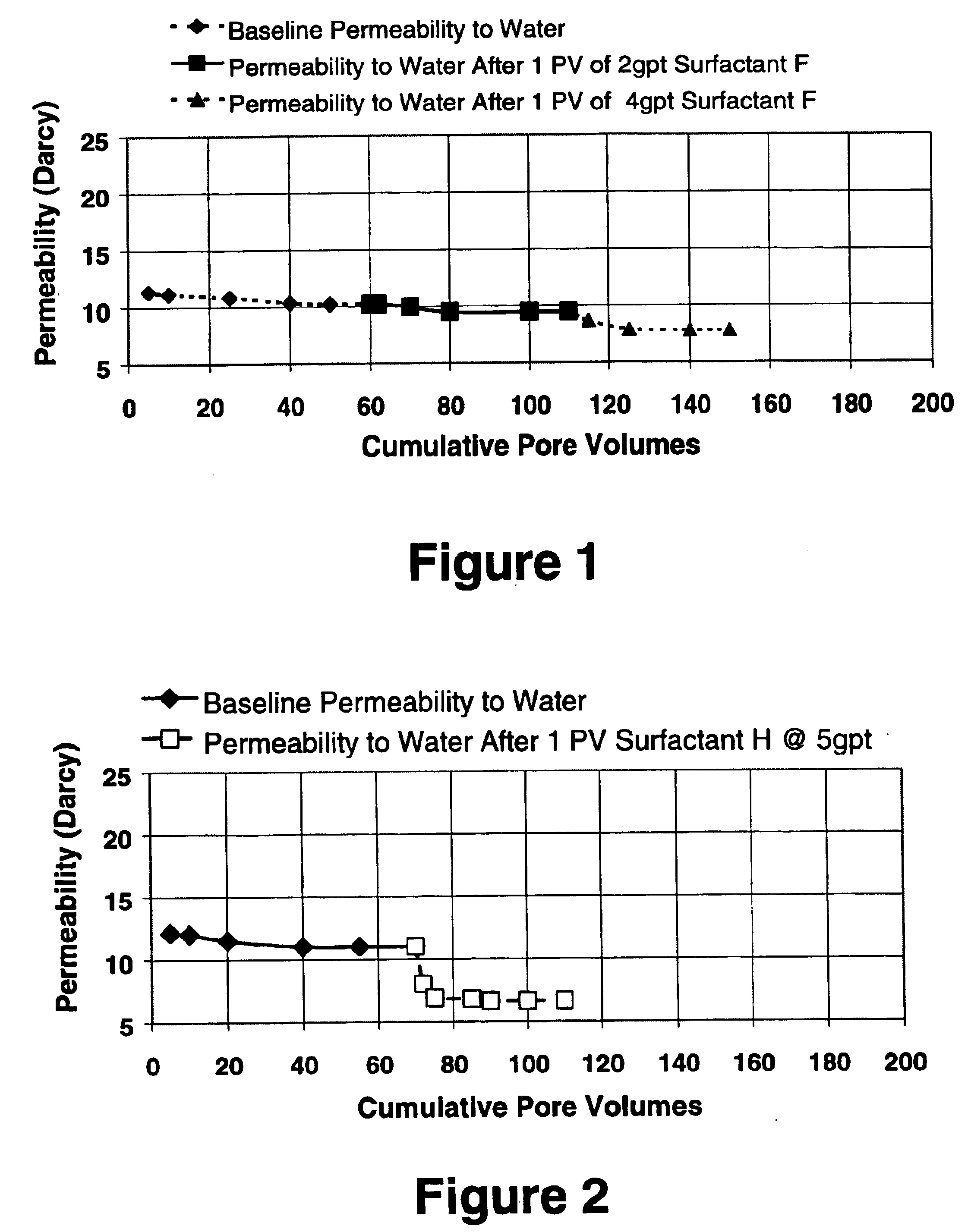

Foaming agents for use in coal seam reservoirs

InactiveUS6915854B2Increase productionGood oil wetting characteristicOther chemical processesFluid removalFoaming agentHydrogen

A well treatment fluid composition that comprises a carrier fluid and an amphoteric surfactant, and optionally a viscosifying agent and proppant, is well suited for use in fracturing coal beds to stimulate methane production. The composition preferably is a foam that comprises a gas such as nitrogen or air. Preferably, the surfactant has the formulaR—NH2—(CH2)n—C(O)OXwherein R is a saturated or unsaturated alkyl group having from 6-20 carbon atoms, n is from 2-6, and X is hydrogen or a salt forming cation.

Owner:SCHLUMBERGER TECH CORP

Topical formulations and delivery systems

InactiveUS7060253B1Improves effervescenceGood removal effectBiocideAerosol deliveryFoaming agentActive agent

A system for delivering a chemical agent in the form of a spray or foam, which in a preferred embodiment involves the use of an aerosol dispenser to deliver a formulation containing both an anionic surface active agent such as sodium lauryl sulfate as a foaming agent and a chemical agent such as either hydrogen peroxide as a disinfecting chemical agent or natural sea water.

Owner:PHYLOMED CORP

Two component thermosettable compositions useful for producing structural reinforcing adhesives

InactiveUS6451876B1Uniform cell structureExcessive heat dissipationEpoxy resin adhesivesEpoxyPartial system

A two part system for producing structural reinforcing adhesives is provided wherein one component containing epoxy resin is combined with a second component containing a specified curative system. An aliphatic polyamine, an amidoamine, an alcohol and an adduct of a polyamine and an epoxide are present in the curative system. When a thermally activated blowing agent is utilized, the resulting foam is remarkably uniform in cell structure and has improved strength and modulus. Hollow inorganic microspheres are employed to reduce the density of the thermoset produced from the two part system.

Owner:HENKEL KGAA

Complex foam extinguishing agent for coal mine

InactiveCN102614615AHigh bonding strengthReduce the drainage rateFire extinguisherSodium bicarbonateMass ratio

The invention discloses a complex foam extinguishing agent for a coal mine and belongs to the technical field of fire prevention and extinguishing. The extinguishing agent is prepared from the following raw materials: main materials are 40 to 60 percent aqueous solution of ammonium bicarbonate or sodium bicarbonate and concentrated sulfuric acid in a solute mass ratio of 2:1-3:1, and auxiliary materials are a stabilizer and a foamer, wherein the auxiliary materials are 0.1 to 2 percent of the total weight of the main materials. Through a test, the extinguishing agent has the foaming coefficient of 20-200 and the foam stabilizing time of more than or equal to 2.5 hours. According to the foam extinguishing agent, the foam of inert gas carbon dioxide is applied to fire prevention and extinguishing of the coal mine, and the foam is diffused in a fire area and fills a fire space, so that the oxygen concentration in the fire area is rapidly reduced, fire is extinguished due to oxygen deficiency in the fire area, temperature is reduced and a fire extinguishing effect is good. The technology also can be applied to coal bed transformation, CO2 foam is easily absorbed by coal to displace partial methane, the recovery ratio of coal seam gas is improved, and CO2 is acid to reduce the generation of secondary precipitates, so that a gas drainage effect is improved. The complex foam extinguishing agent is simple and feasible, and low in cost.

Owner:抚顺正工矿业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com