Patents

Literature

799 results about "Water sorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorption of water is known to change material properties by hydro-plasticization [1] and changes the volume by moisture expansion [2]. The effect of parameters such as initial concentration of dye, amount of bio-sorbent, initial pH, shaking time and speed were investigated to evaluate its sorption capacity.

Water gel containing natural high molecule and its radiation preparing method

InactiveCN1944495AImprove water absorptionGood flexibilityOrganic active ingredientsAntipyreticCross-linkWound dressing

The present invention provides one kind of water gel containing natural high molecular material and its preparation process. The water gel has cross-linking degree of 70-95 % and water absorption of 500-80000 %, and contains natural high molecular material or its derivative selected from chitin, chitin derivative, chitosan, chitosan derivative, carrageenin, etc. The water gel may have synthetic high molecular material, inorganic filler, cross-linking sensitizer, medicine and other assistant added. It is prepared through radiation cross-linking, with the radiation dosage being 10-40 kGy. The water gel of the present invention has high water absorption, high flexibility, good medicine slow releasing performance, and may be used in wound dressing, etc.

Owner:厦门凝赋生物科技有限公司

Water-absorbable polyacrylic acid resin powder, and process for production thereof

ActiveUS20120258851A1Improve water absorptionImprove impact resistanceOther chemical processesCatalyst activation/preparationSolubilityCrosslinked polymers

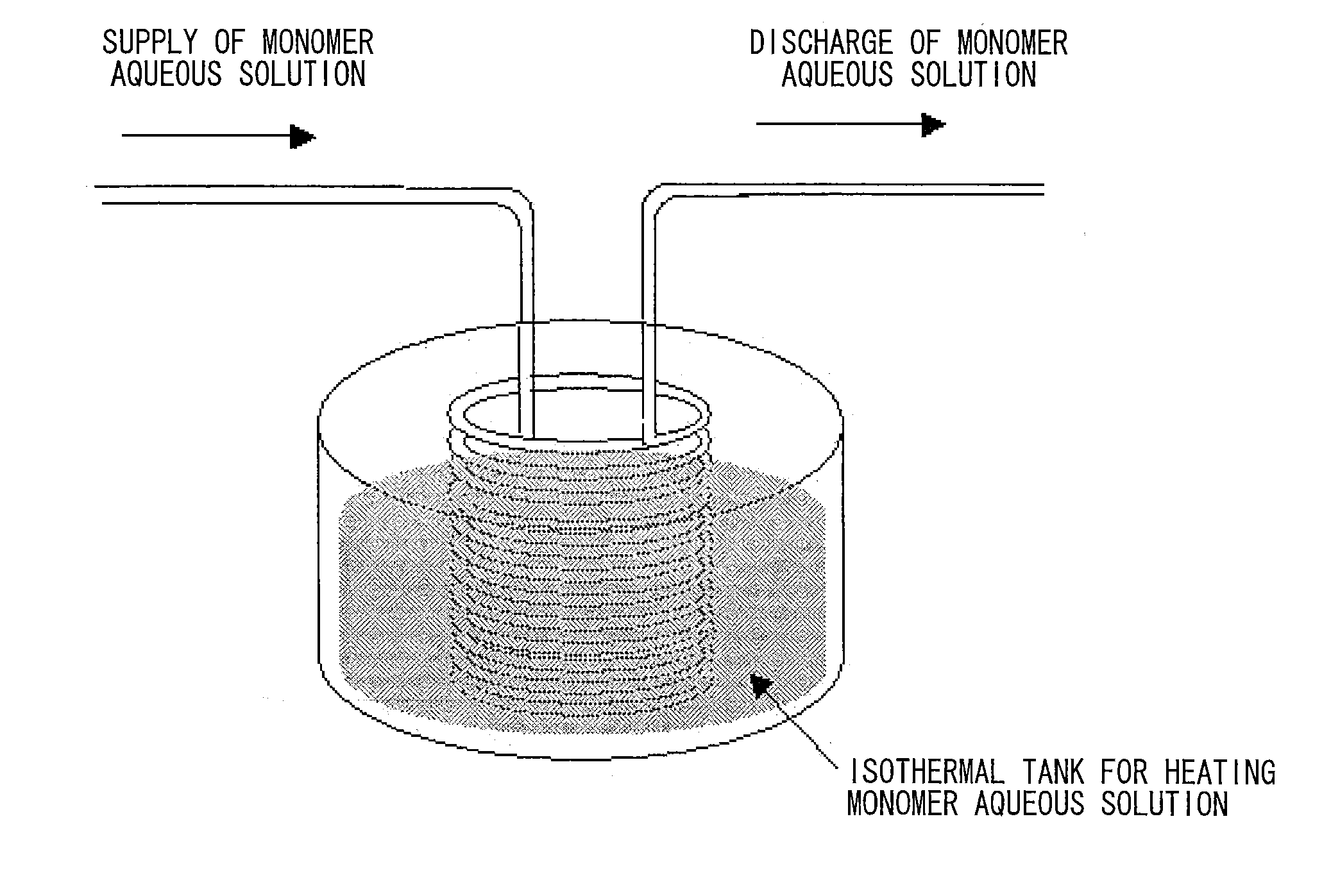

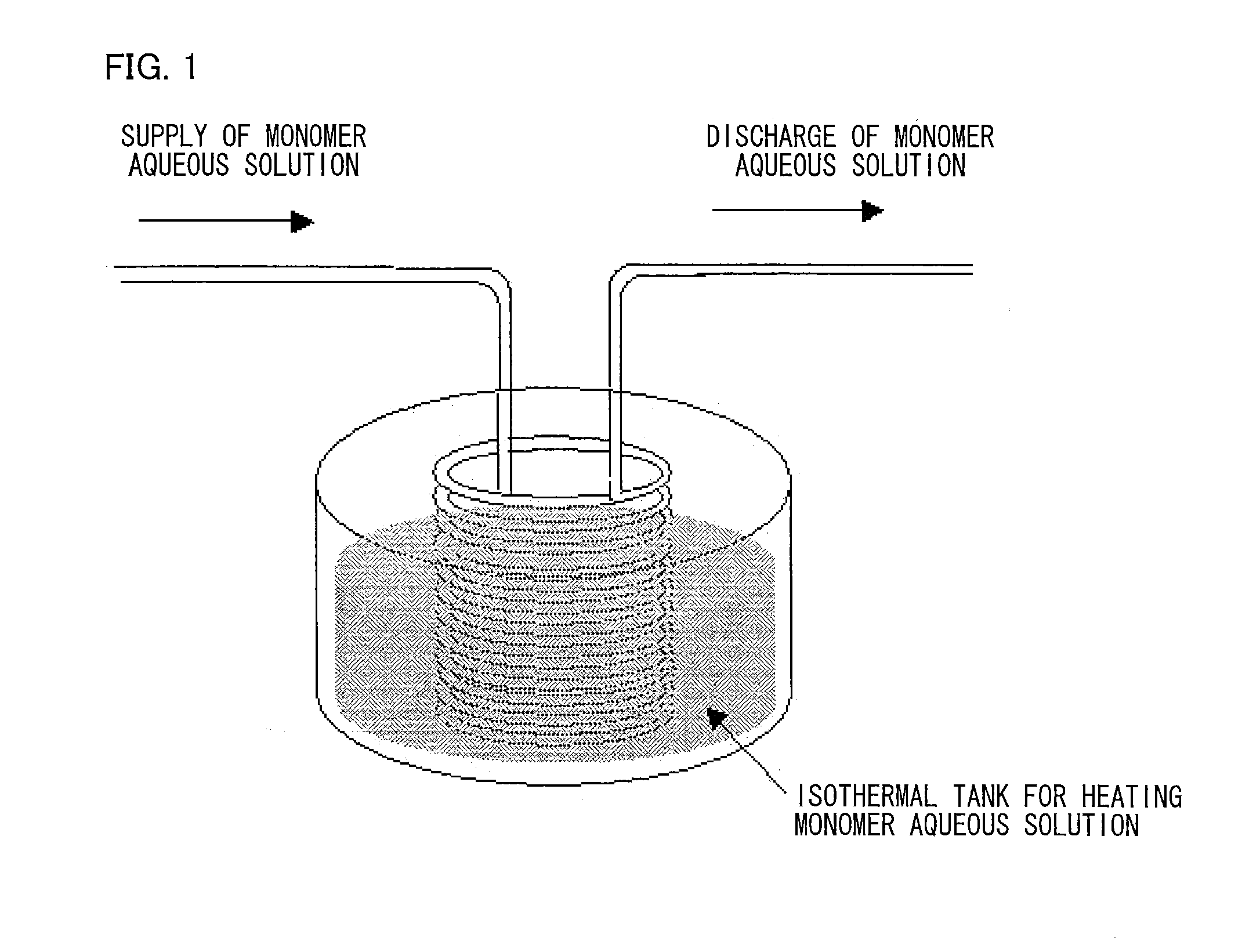

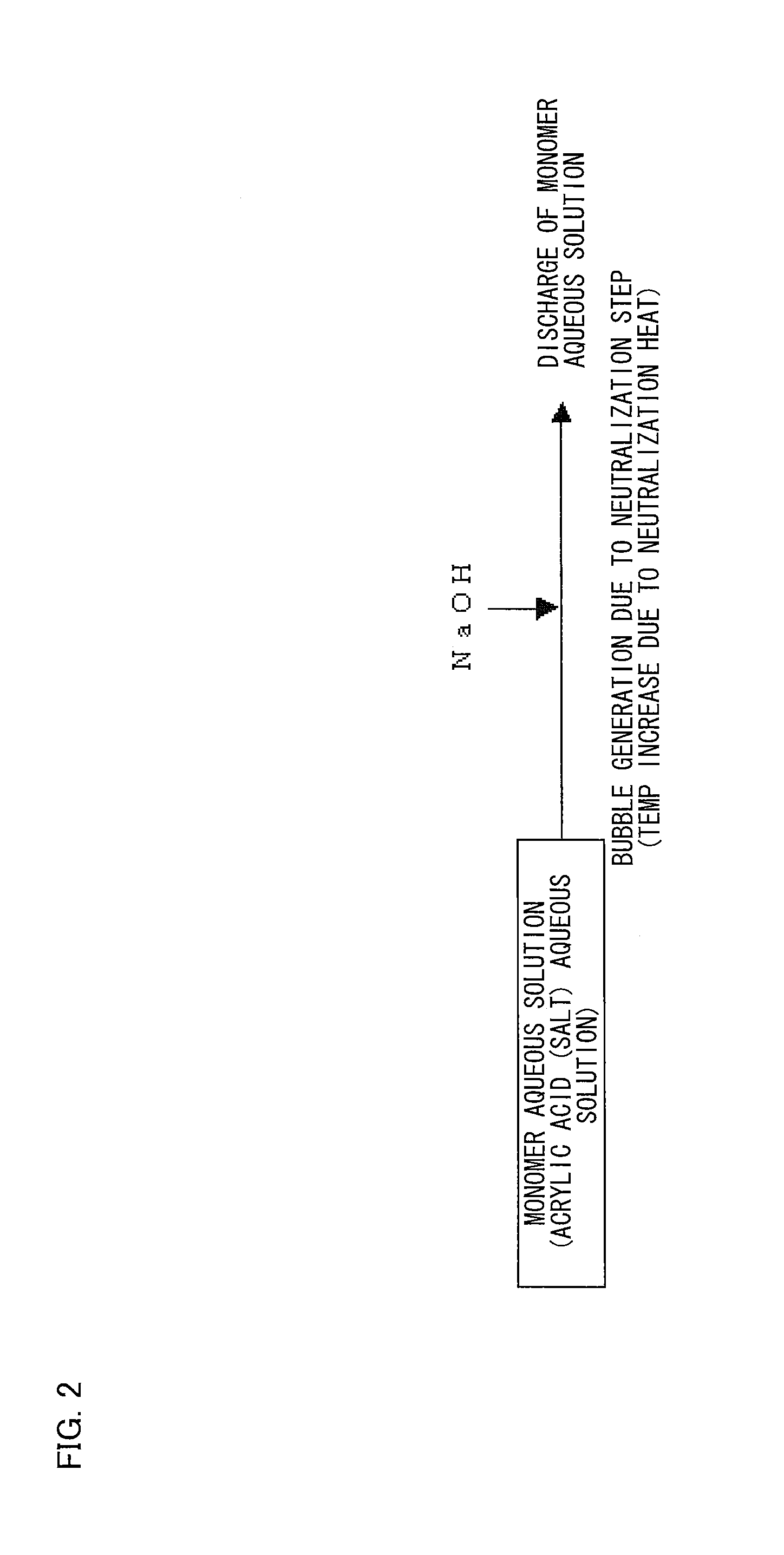

A process according to the present invention for production of water-absorbable polyacrylic acid resin powder, including: (a) polymerizing an acrylic acid-based monomer aqueous solution containing bubbles, and (b) drying a hydrogel crosslinked polymer thus obtained in the step of polymerizing, further includes (c) lowering solubility of dissolved gas in a monomer aqueous solution in the presence of a surfactant and / or a dispersing agent, so as to generate the bubbles in the acrylic acid-based monomer aqueous solution. With this arrangement, it is possible to provide white water-absorbable resin with better water absorbing rate, keeping or without significantly losing the other properties (permeability potential, bulk specific gravity, surface tension, absorbency against pressure, impact resistance, etc.)

Owner:NIPPON SHOKUBAI CO LTD

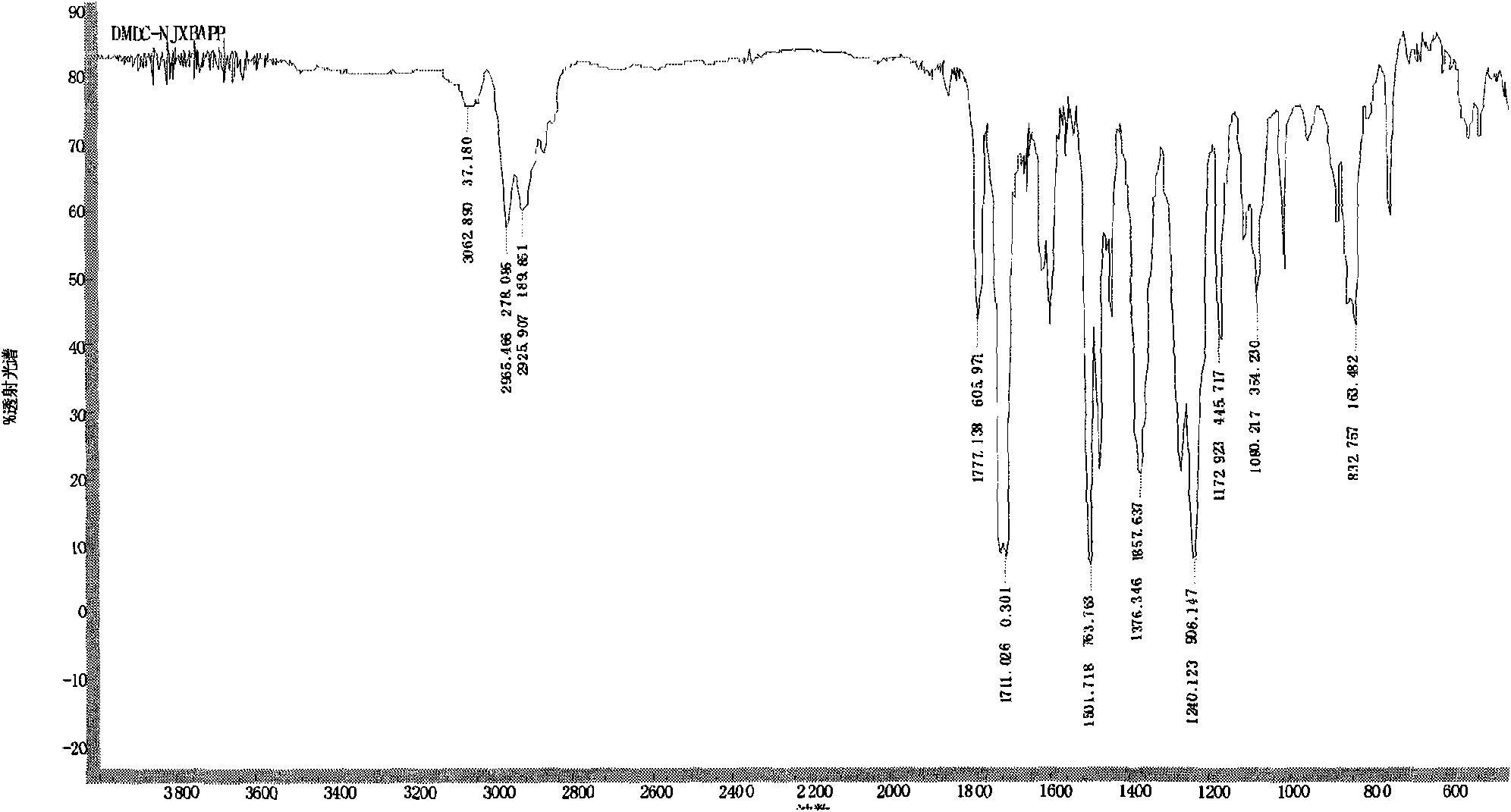

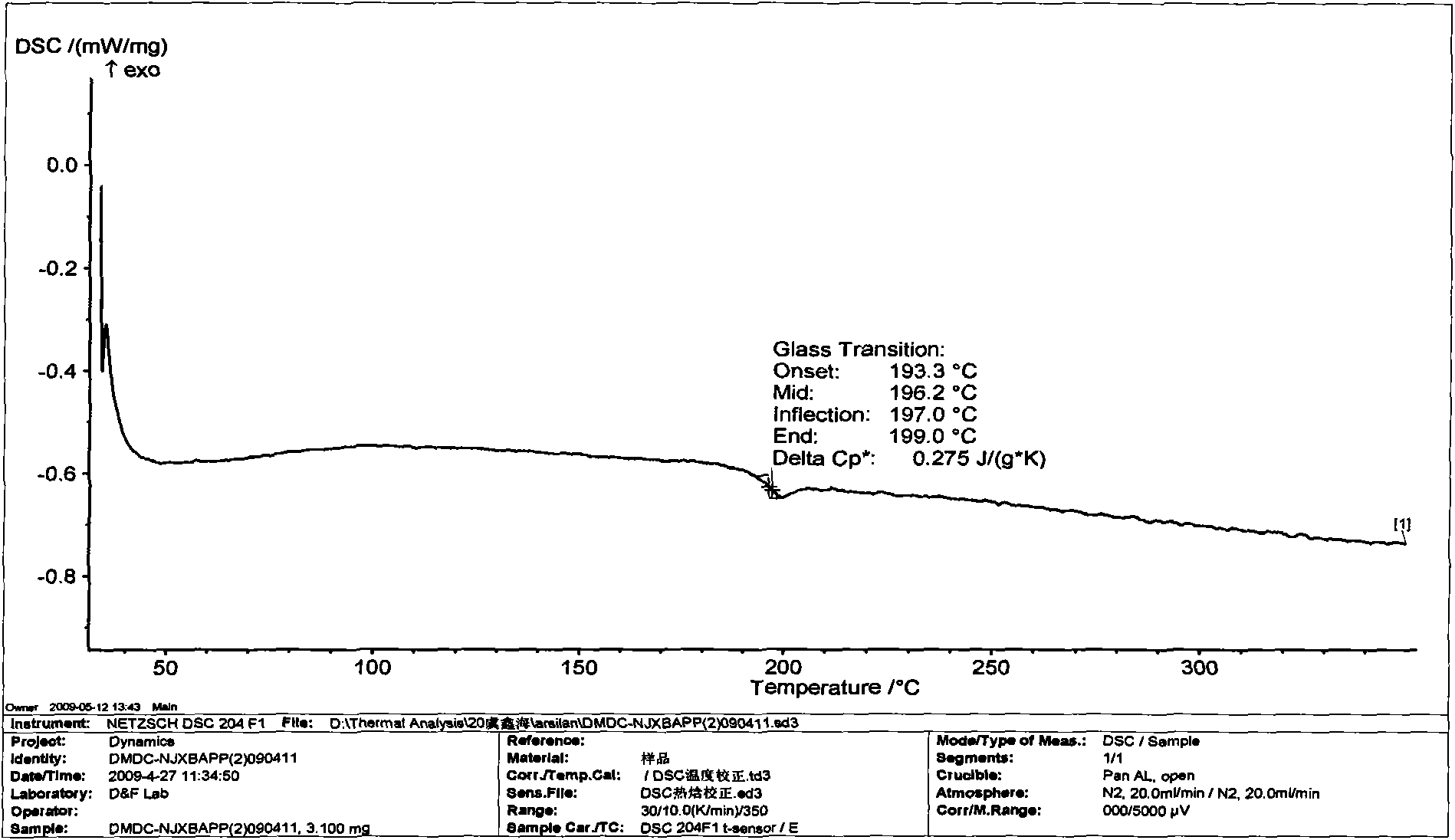

Alicyclic-containing polyimide film and preparation method thereof

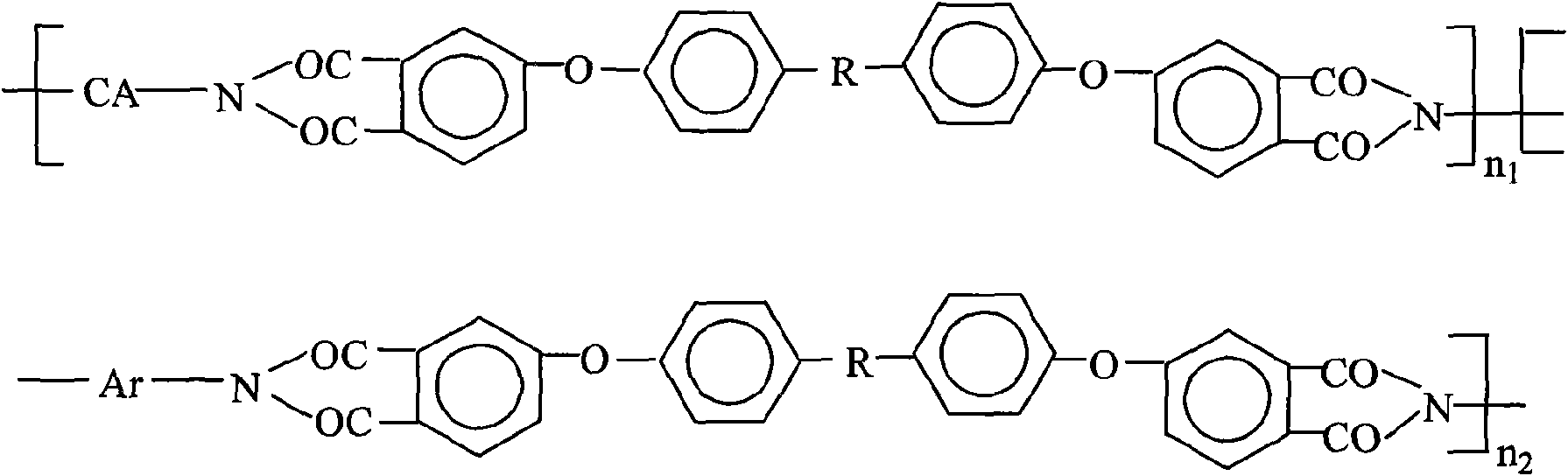

InactiveCN101580637AConvenient sourceLow costTelescopesNon-linear opticsOptical communicationPhotochemistry

The invention relates to an alicyclic-containing polyimide film. The molecular structure general formula of the film is the right formula, wherein, -CA- is a bivalence connection group of an alicyclic dibasic primary amine, -Ar- is a bivalence connection group of an aromatic dibasic primary amine, and -R- is a bivalence connection group of an aromatic dibasic estolide. The preparation thereof includes: the alicyclic dibasic primary amine and the aromatic dibasic primary amine are dissolved in non-proton organic solvent with strong polarity, the aromatic dibasic estolide is added, the non-proton organic solvent with strong polarity is used for regulating the viscosity of the alicyclic-containing polyamic acid resin solution after reaction for 1-3 hours, forming is carried out in a curtain coating machine, and dehydration fever imidization, cooling and demoulding are carried out so as to obtain the film. The preparation method has mild reaction condition and low cost and is environmentally friendly; and meanwhile, the alicyclic-containing polyimide film has excellent mechanic property and heat resistant property and low water absorption, and the visible light transmission thereof is as high as more than 97%. The film has good application prospect in the fields of optical waveguide material, photorefractive material and photoelectric material in optical communication field and direct action membrane material in the liquid crystal display field and the like.

Owner:DONGHUA UNIV

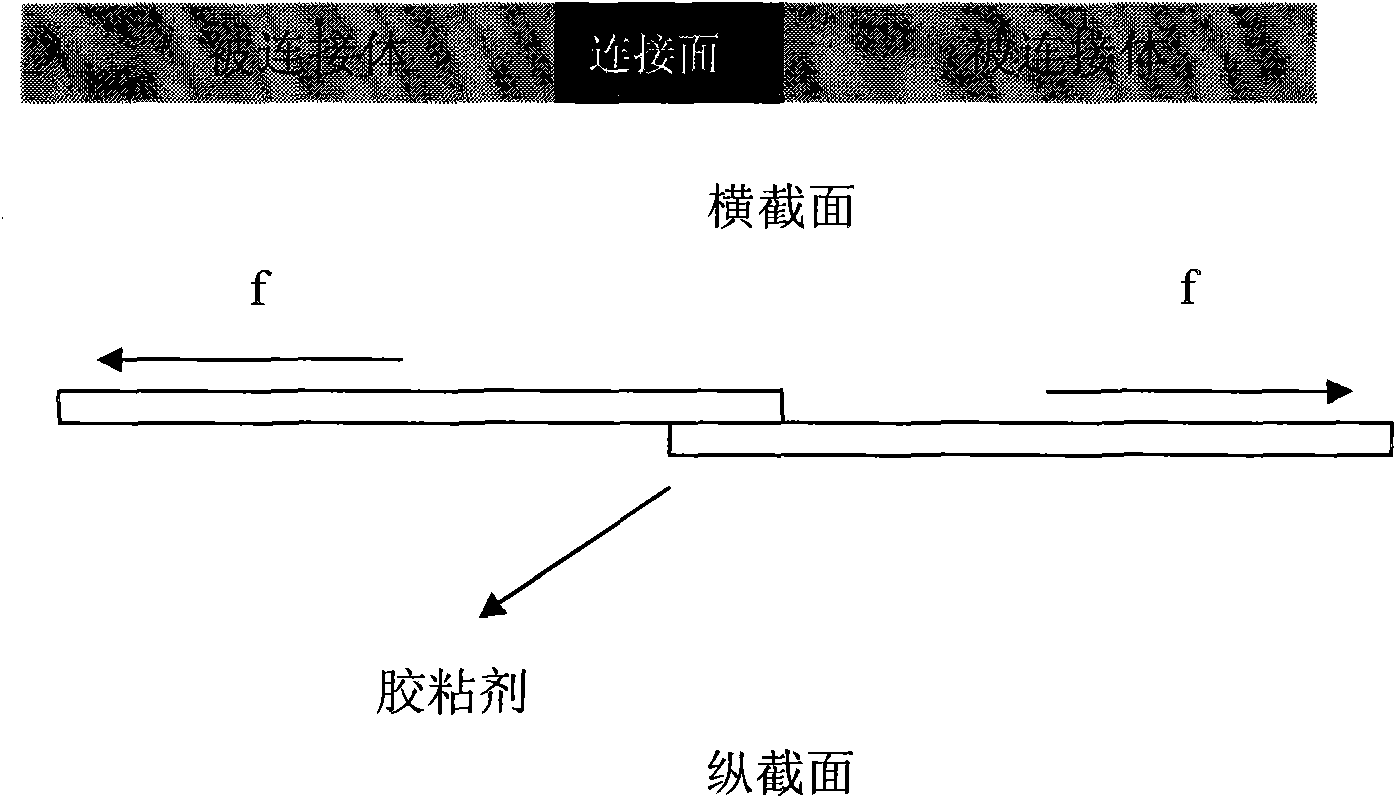

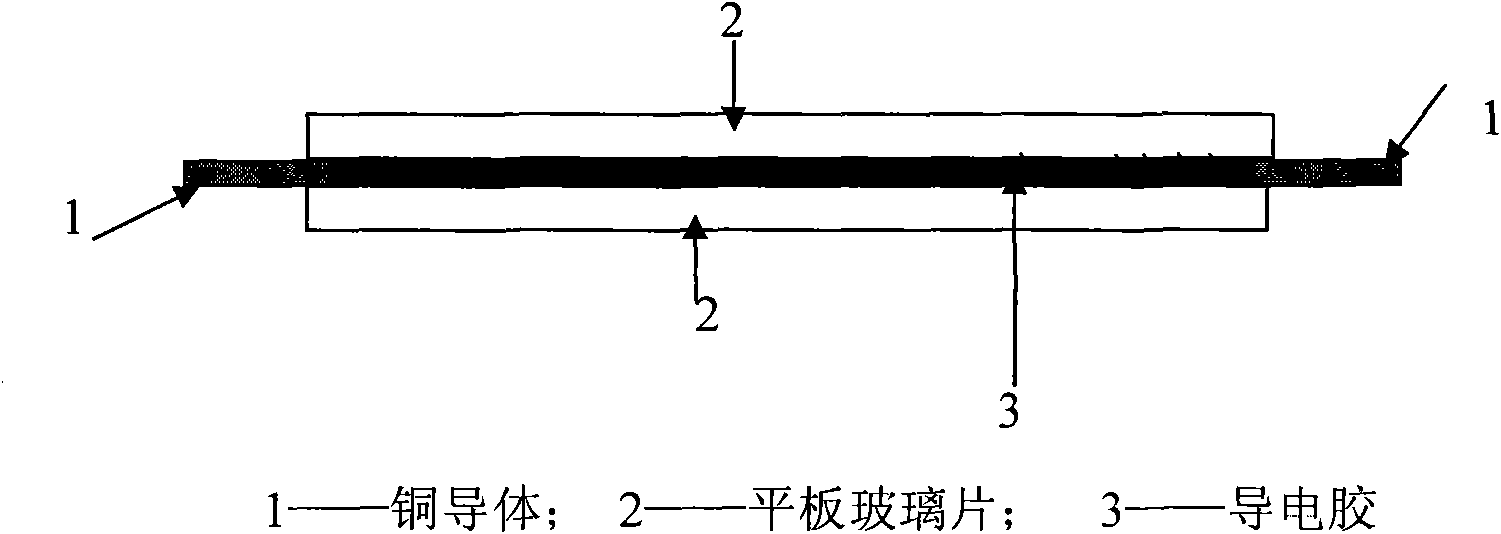

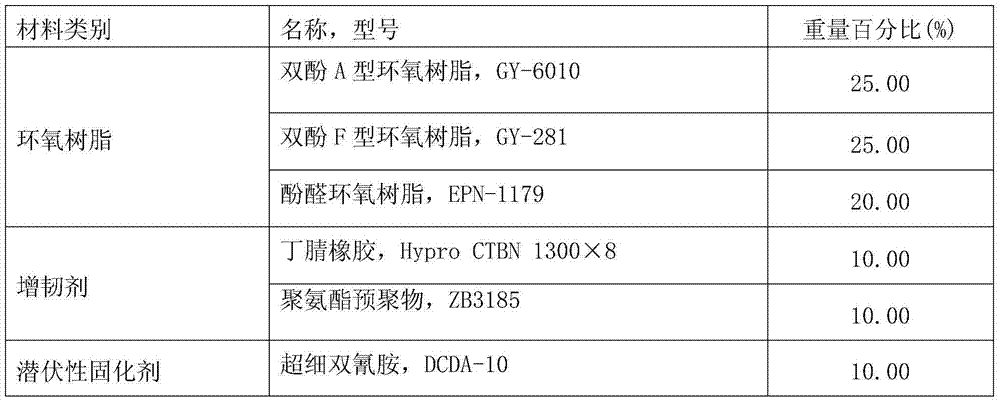

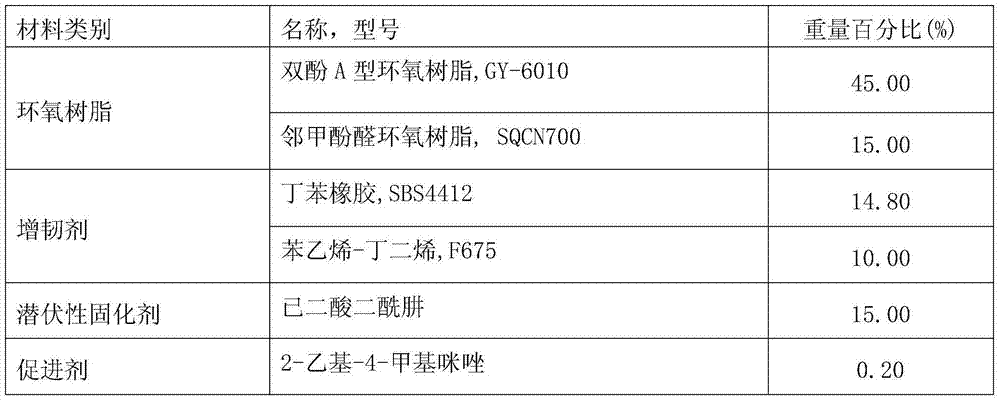

High-performance conducting resin and preparation method thereof

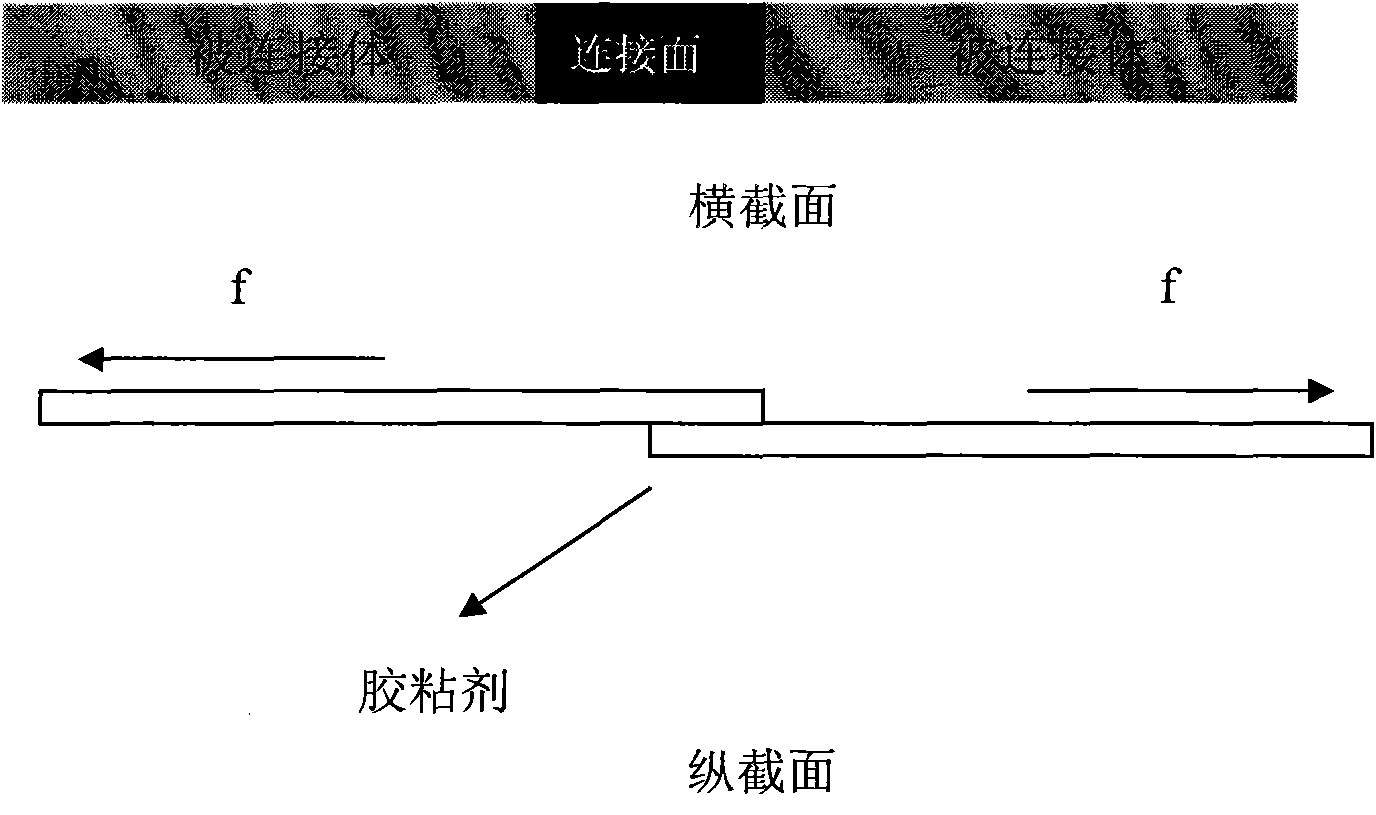

InactiveCN101781540AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyRoom temperature

The invention relates to a high-performance conducting resin, comprising the following components: epoxy, latent curing agent, active toughener and conducting particles. The preparation method comprises the following steps: adding the epoxy and the active toughener in a reaction bulb to react, then adding the latent curing agent, uniformly stirring, adding the surface-treated conducting particles, uniformly stirring, and defoaming in vacuum to obtain the high-performance conducting resin. The conducting resin in characterized in that the bonding strength reaches up to 24.1 MPa; the volume resistivity is 4.30*10<-5>-2.12*10<-4> ohm.cm; the Tonset thermal decomposition temperature reaches up to 398.7 DEG C; the water absorption is only 0.2%; and storage life at the room-temperature is as long as more than 3 months. The invention has the advantages of simple preparation process, low cost, convenient operation and convenient reaction material source, can complete the preparation process in universal devices, is beneficial to realizing industrial production, and has wide application prospects in the fields of electronic components, resonators, relays, electronic capacitors and the like.

Owner:DONGHUA UNIV +1

Washing machine and control method thereof

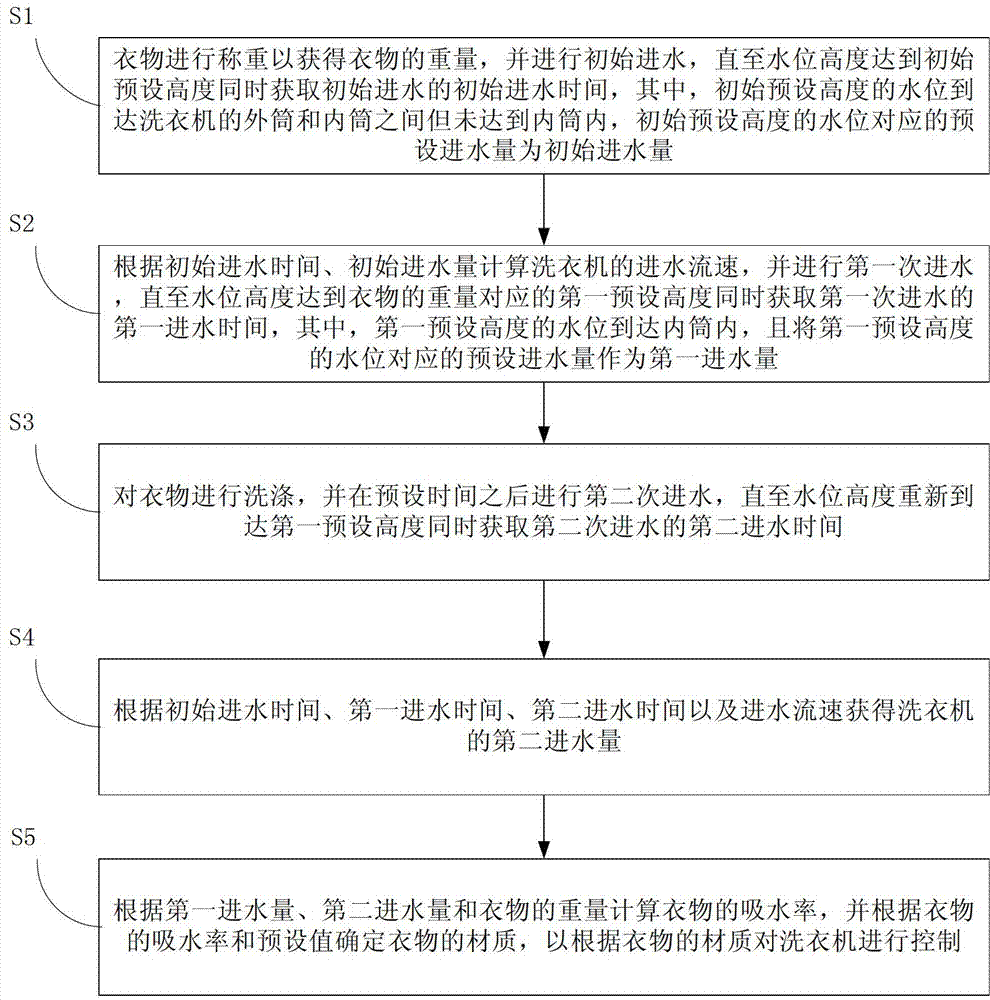

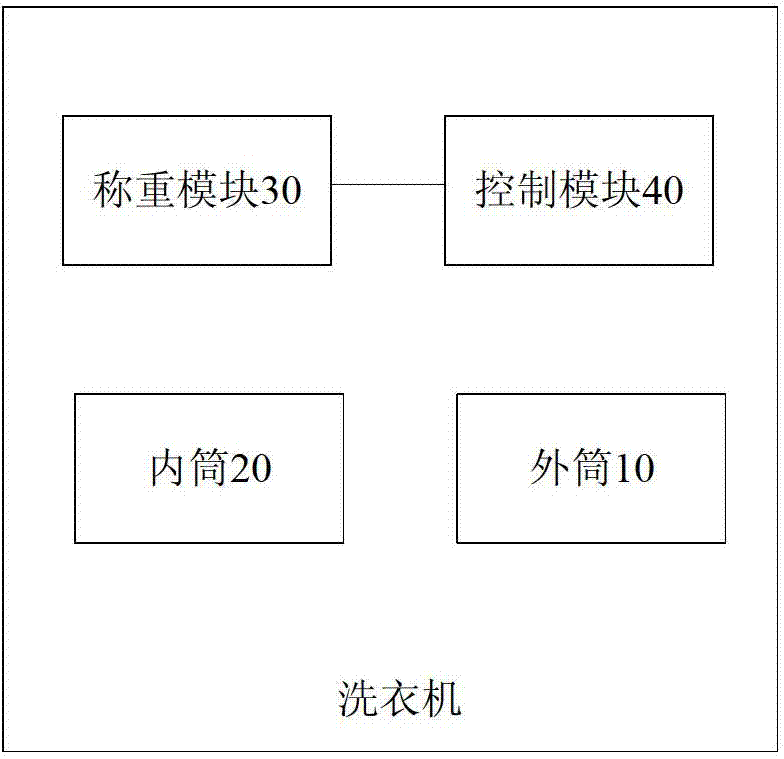

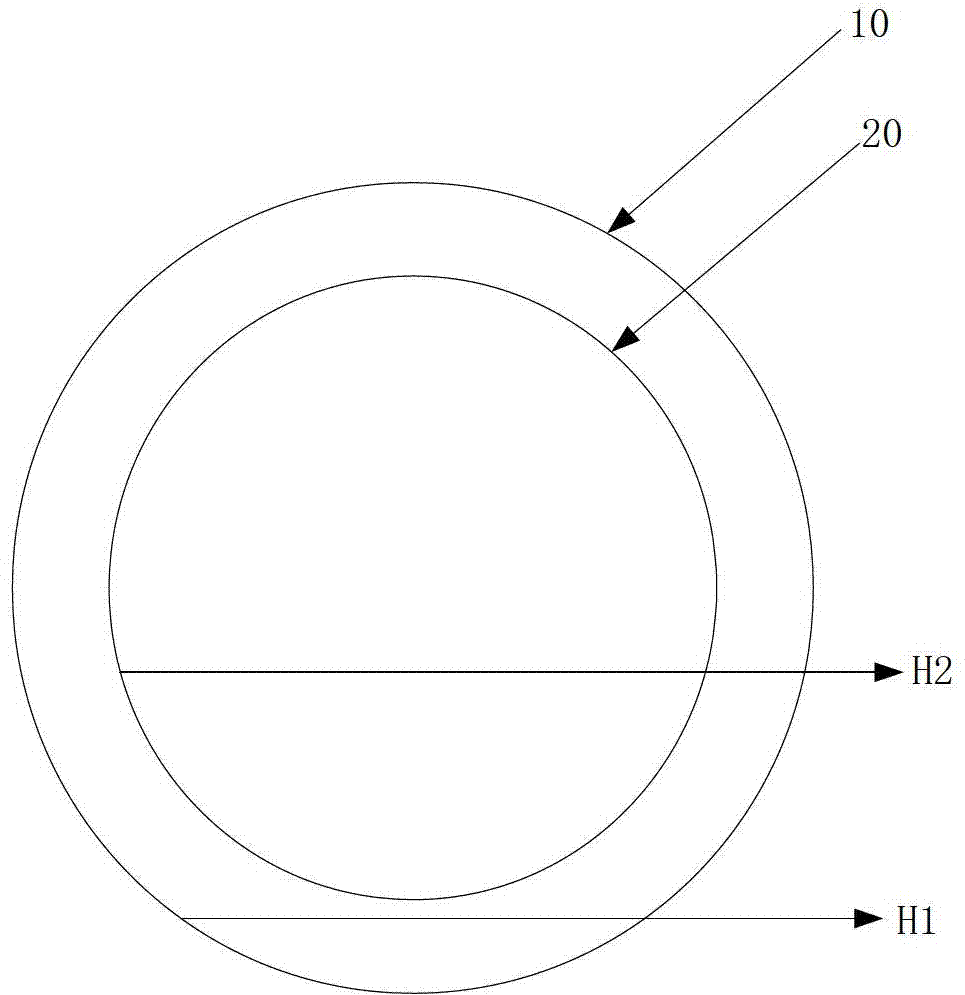

ActiveCN103485121AImprove satisfactionGuaranteed washing effectOther washing machinesControl devices for washing apparatusEngineeringWater intake

The invention discloses a washing machine and a control method thereof. The control method comprises the following steps of: weighing clothes to obtain the weight of the clothes, carrying out initial water filling until the height of water reaches an initial preset height, and acquiring initial water filling time, wherein a water intake quantity corresponding to the initial preset height represents an initial water intake quantity; calculating a water intake flow rate, carrying out primary water filling until the height of the water reaches a first preset height, and acquiring first water filling time, wherein a water intake quantity corresponding to the first preset height represents a first water intake quantity; after washing the clothes for preset time, carrying out secondary water filling until the height of the water reaches a second preset height, and acquiring second water filling time; according to the initial water filling time, the first water filling time, the second water filling time and the water intake flow rate, acquiring a second water intake quantity; and according to the first water intake quantity, the second water intake quantity and the weight of the clothes, calculating water absorption of the clothes, and determining the material of the clothes according to the water absorption of the clothes and a preset value so as to control the washing machine according to the material of the clothes. According to the invention, the material of the clothes can be identified so as to implement reasonable control on the washing machine and improve use experience of a user.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Light glazed ceramic tile with anion function and low water absorption and production method thereof

The invention discloses a light glazed ceramic tile with anion function and low water absorption and a production method thereof. The formula of the glazed ceramic tile is as follows: fancy glaze containing 0.1-90 portions of stamp powder, 0.0-190 portions of pigments, 100-200 portions of stamp-pad ink and 0.01-15 portions of anion material; a green body containing 10-45 portions of ceramic shraff, 15-20 portions of clay, 10-20 portions of feldspar, 30-50 portions of sandstone, 30-50 portions of water, 0.0-0.3 portion of lignin, and 0.0-1.0 portion of sodium tripolyphosphate; and conventionalcover glaze. The production method comprises the following steps: stirring and screening the fancy glaze materials to obtain the fancy glaze; conducting ball-milling, screening and pelleting after materials of the green body are mixed, and then conducting compression moulding and drying, glazing, embossing, and sintering for 50-55 minutes at the temperature of 1195-1205 DEG C, thus obtaining the product. The ceramic tile has the characteristics of being light, low in water absorption, high in mechanical strength, small in coefficient of thermal conductivity, strong in antifouling capability and the like, can continuously release anions with the number of more than 500 / cm3 in space, and can be widely applied to decoration of building outer walls and home furnishing spaces.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

Preparation of porous sericin sponge material

Preparation of sponge-like porous materials of silk protein is carried out by converting its conformation with denaturant at low temperature to have frozen phase separation to obtain the product. Its parameters can be regulated by controlling concentration of the silk protein, amount of denaturant or its characteristics, freezing time or post-treatment in porosity, pore size, and mechanical performance. Neither cross-linker nor pore-generating agent nor surfactant nor organic solvent with strong toxicity is used. It is produced in a simple process, and has a uniform texture, high porosity up to 98%, good toughness and elasticity and reliability, water absorbing rate up to 5000%, elastic recovery rate 100% and press deformation >90%.

Owner:FUDAN UNIV

Special haydite for cultivating flowering plants

The invention relates to special haydite for cultivating flowering plants, belonging to life decoration appliances. The method of the haydite cultivation for the flowering plants is a novel cultivation method which rises in recent years, which is sanitary, environmental-friendly and beautiful, can be matched with elegant interior decoration, is simple and convenient in cultivation management and is popular with the people. The existing haydite in the market is divided into three types some of which has excessively high price, the low-cost substitute, i.e. building haydite is bad to phytostabilization due to low water absorption, light weight and smoothness, thereby being limited to indoor parts of foliage plant water planting and basin soil capping and having narrow usable range of outdoor cultivation. The haydite of the invention is developed and manufactured for indoor and outdoor flowering plant cultivation in elegant environments. The haydite has high water absorption up to 30-35%, suitable volume-weight and surface character, contains a plurality of nutrient elements, is beneficial to stabilization and growth of the plants, can be used separately, can be mixed with other matrixes to change performances in accordance with different proportions, and can be repeatedly used for years.

Owner:周良型

Foaming latex cement energy-saving material for self anti-crack building enclosure

InactiveCN101497532ASolve the contradiction of high strength and high thermal conductivityShorten the construction periodSolid waste managementCeramicwareBuilding energyUltimate tensile strength

The invention relates to a building material, in particular to an energy-saving material of foaming latex cement for a self anti-cracking building enclosure. The energy-saving material of the foaming latex cement for the self anti-cracking building enclosure effectively seals air (of which heat conductivity coefficient is 0.023) with low heat conductivity coefficient in a system, and forms a building material with obvious energy-saving effect with a lightweight insulating material; simultaneously, in the system, the brittleness of an inorganic gelling material is improved by using elastic latex so as to obtain a new material with the advantages of low water absorption, high safety, self anti-cracking, no need of a special anti-cracking protective layer, simple construction technology, high system strength, short construction period and low comprehensive manufacturing cost, and effectively overcome the defects of complex construction technology, high water absorption, poor system safety, long construction period, high manufacturing cost and the like because the prior building energy-saving material system needs the special anti-cracking protective layer.

Owner:武汉沃尔浦科技有限公司

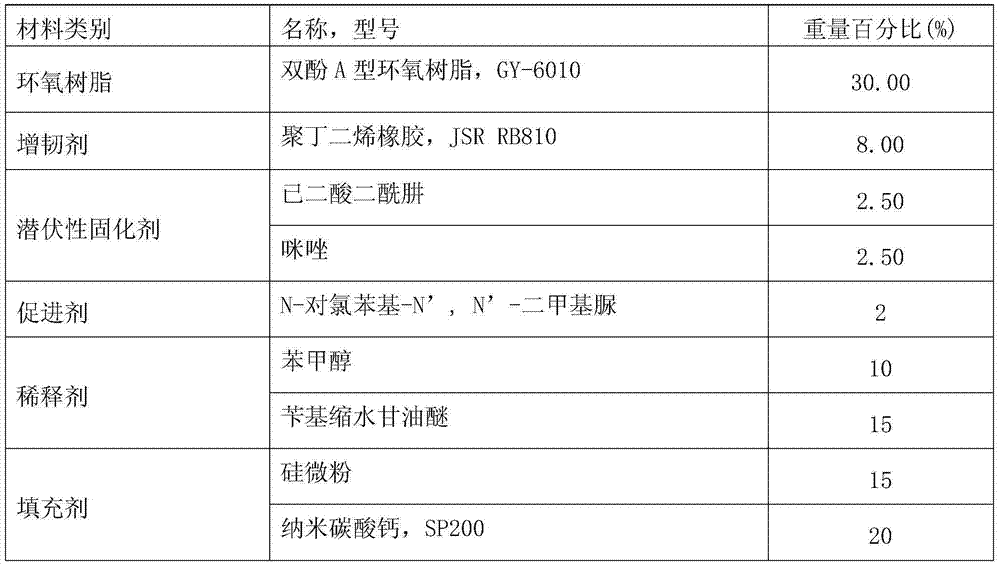

Sealant

InactiveCN103937432AReduce brittlenessLow curing temperatureNon-macromolecular adhesive additivesOther chemical processesEpoxyLiquid-crystal display

Owner:上海禧合应用材料有限公司

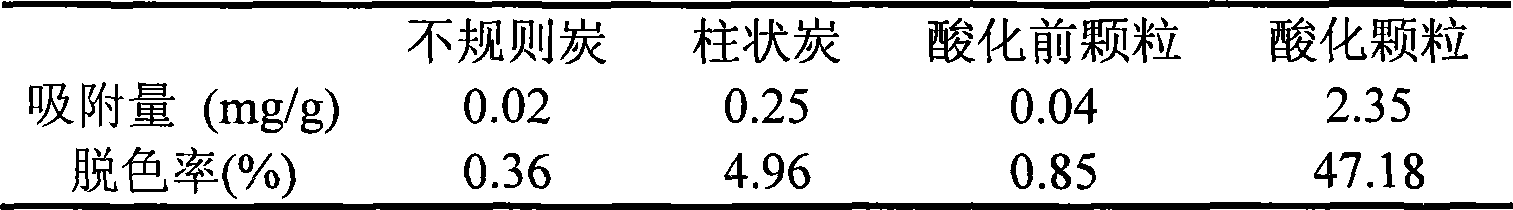

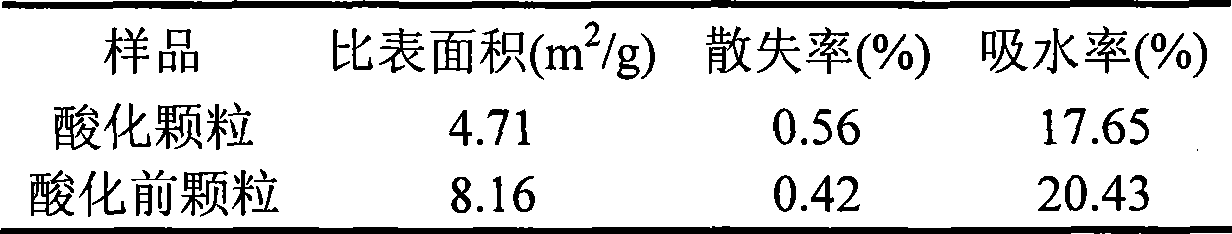

Preparation method of acidification sludge bentonite granules

InactiveCN101362073AReasonable designSimple processOther chemical processesGranulation by material expressionSodium BentoniteSludge

The invention relates to a preparation method of acidified sludge bentonite particles, pertaining to the technical field of environmental protection. Sludge and nano-bentonite powder are mixed together according to a certain ration, porous sludge bentonite particles are prepared by roasting under high temperature and the activity of the porous sludge bentonite particles is further modified by sulphuric acid to prepare the acidified sludge bentonite particles. The acidified sludge bentonite particles is yellow solid particles, with organic substance content reaching 165.788mg / g, specified surface area being 4.71m<2> / g, lost ratio being 0.56 percent and water absorptivity being 17.65 percent. The preparation method has the advantages of simple technology, economic efficiency, low cost, and the like, and the prepared acidified sludge bentonite particles have stable quality, uniform appearance and good absorptivity, thereby not only realizing the utilization of sludge as resource and the reduction of the pollution caused by the sludge, but also having wide application value in the aspect of decoloring processing of waste water produced in printing and dyeing, and realizing the purpose of treating waste by utilizing waste.

Owner:SHANDONG UNIV

Energy-saving consumption-reducing technique for preparing haydite by co-disposing polluted soil and desilting sediment

ActiveCN102173850APromote healthy developmentLow running costCeramicwareExpanded clay aggregateWater content

The invention relates to an energy-saving consumption-reducing environment-friendly method for preparing haydite by co-disposing municipal massive solid wastes, which comprises the following steps: directly mixing polluted soil and polluted desilting sediment (without energy-consuming drying), adding a conditioner, granulating, and firing at 900-1200 DEG C for 15-40 minutes. The test indicates that the prepared haydite product has the following properties: the bulk density is 500-900 kg / m<3>, the cylindrical compressive strength is 5.0-10.0 Mpa, and the water absorptivity is 4.8-9.2%; and the leaching toxicities of typical heavy metals are as follows: Cu<0.26 mg / L, As<0.03 mg / L, Cd<0.0002 mg / L, and Hg<0.0001 mg / L. The method provided by the invention fully utilizes the water-content complementarity of the polluted soil and sewage reservoir sediment as well as the characteristic of mutual catalytic degradation of heavy metal pollutants and organic pollutants, implements energy saving and consumption reduction in the technical field of traditional techniques for preparing haydite from solid wastes, lowers the cost and secondary pollution in solid waste disposal industry, enhances the properties of the solid waste haydite, and widens the application field of the solid waste haydite.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

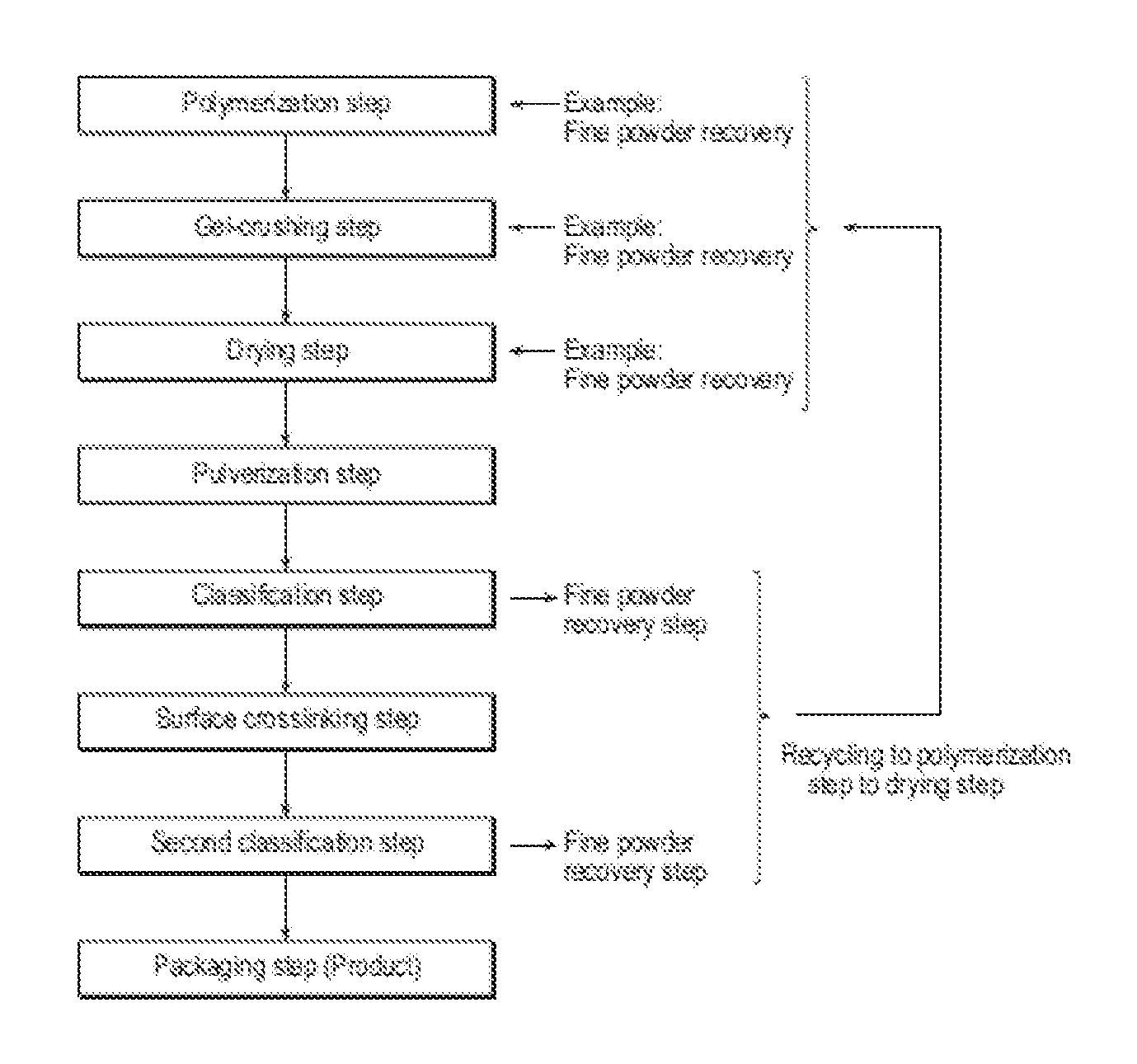

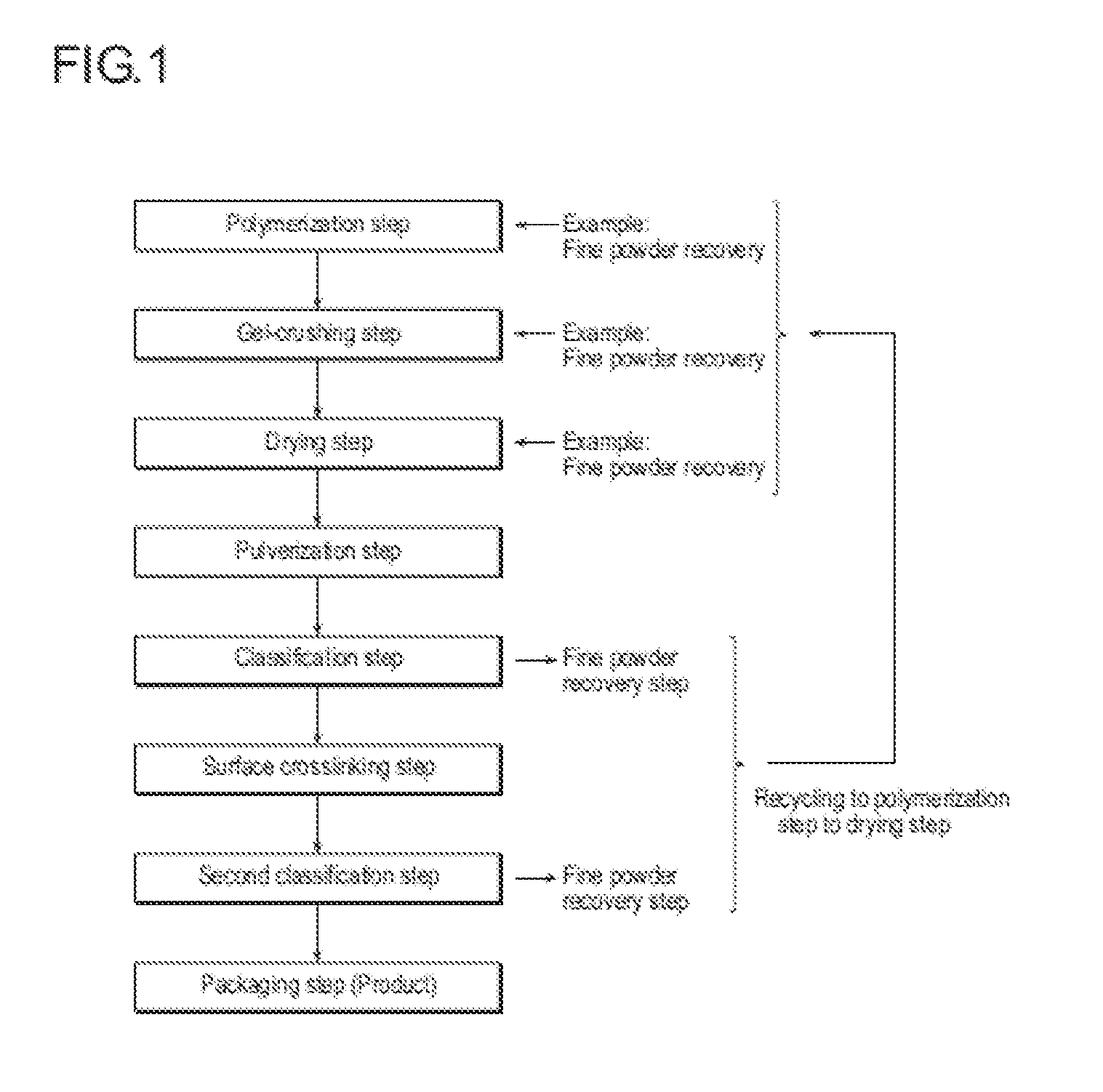

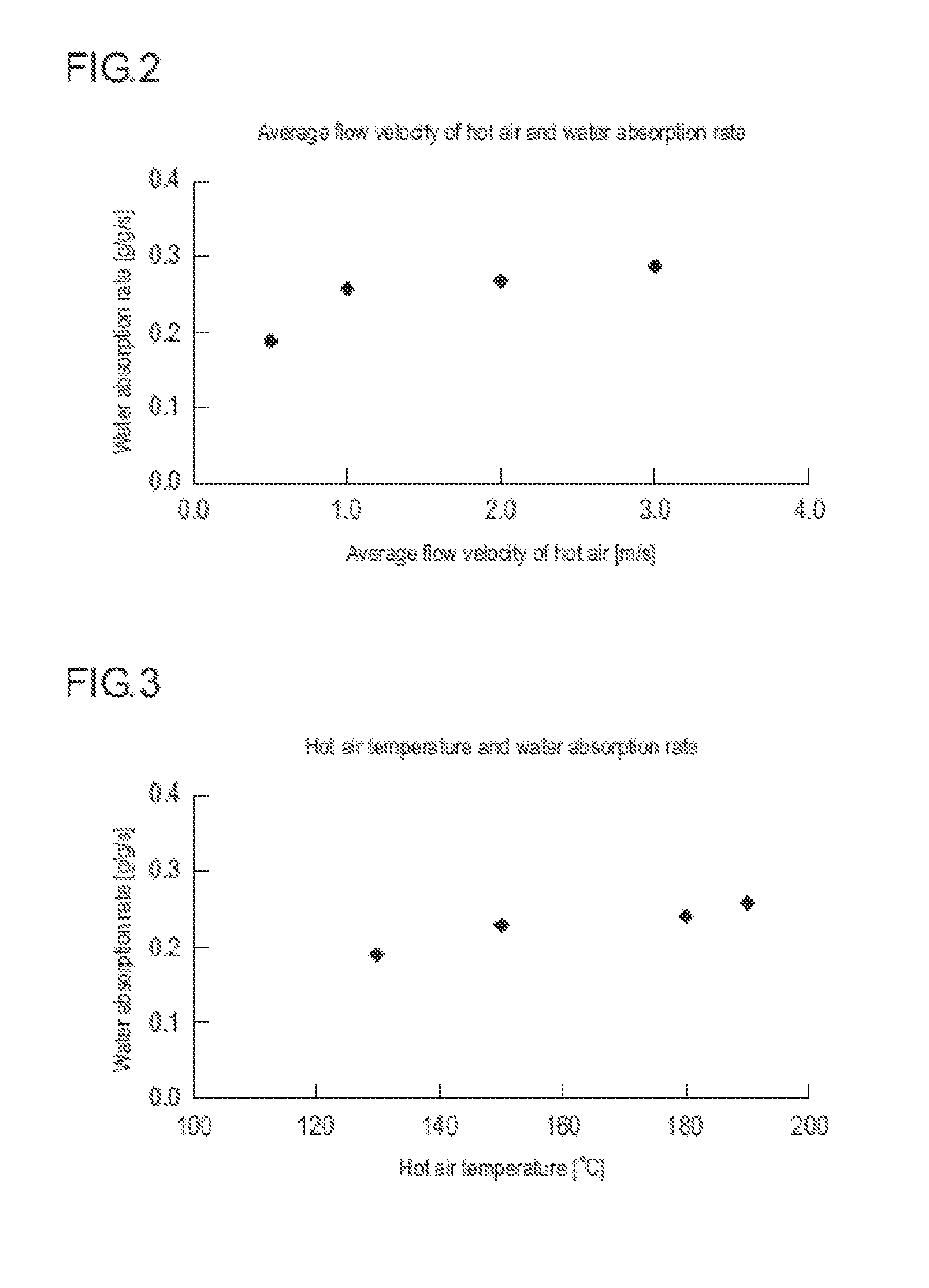

Method for producing polyacrylic acid (SALT)-based water absorbent resin powder

ActiveUS20130102750A1Good physical propertiesMaintain stable propertiesPolymer scienceAbsorption rate

A water absorbent resin having less fine powder or powdery dust and a controlled particle size is provided, and the water absorption rate of the water absorbent resin is increased by a simple method at low cost, while maintaining or improving other physical properties such as liquid permeability. Disclosed is a method for producing a polyacrylic acid (salt)-type water absorbent resin powder, which includes, in sequence, a step of polymerizing an aqueous solution of acrylic acid (salt)-type monomer; a step of gel-crushing a gel of a water-containing gel-like crosslinked polymer during polymerization or after polymerization; a step of drying the water-containing gel-like crosslinked polymer; and a step of pulverizing and classifying the dried polymer, wherein water absorbent resin fine particles having a particle size of less than 150 μm or a hydrated-particles thereof is added to a step prior to the drying step, and in the drying step, hot air drying is carried out with a hot air having an average flow velocity of 1.0 to 3.0 [m / s], a dew point of 30° C. to 100° C., and a hot air temperature of 140° C. to 235° C.

Owner:NIPPON SHOKUBAI CO LTD

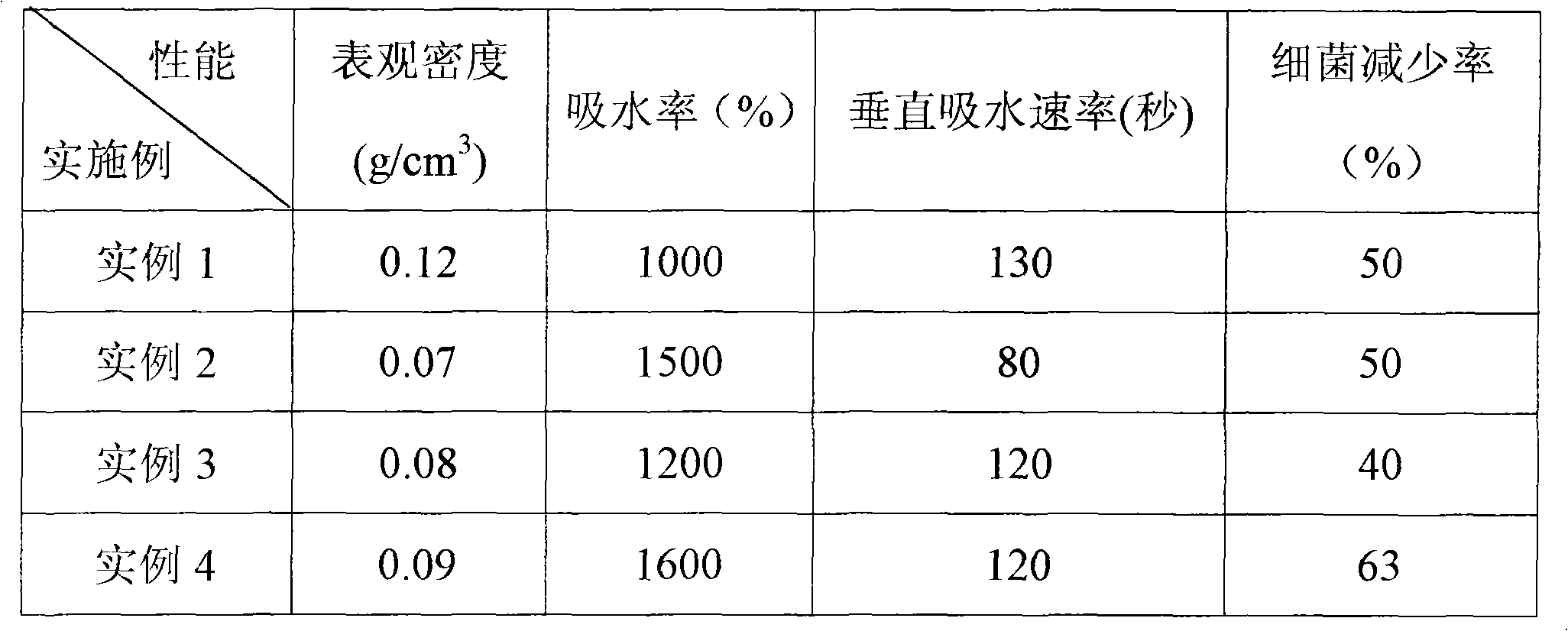

Rapid-imbibing foamed material with antibacterial property and preparation method thereof

ActiveCN101613512AStrong liquid absorptionFast water absorptionAbsorbent padsBandagesFiberPolyvinyl alcohol

The invention provides a rapid-imbibing foamed material with antibacterial property and a preparation method thereof. The material is a porous foamed material with antibacterial property prepared by using polyvinyl alcohol and chitosan as raw materials, formaldehyde as cross linking, and sulfuric acid, surface active agent and water as auxiliary materials; the material has good air permeability, the water absorption rate is more than 1000%, the time with water absorption height being 50mm is less than 150sec, and after imbibing, the material become soft, resilient and flexible sponge. The material has excellent characteristics of bacteria inhabiting, the percentage of reduced bacteria is more than 40% in experimental conditions, resists heat and ultraviolet rays, can be sterilized by a plurality of ways. The material not only can be used as surgical dressing, but also can be used as hemostatic materials, filling materials and the like for surgery. As the material has the advantages of no fiber loss and high imbibing speed, the material has uniqueness in the applications of surgeries in ophthalmology, ear-nose-throat department and other microsurgeries.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Natural multifunctional mineral compound fertilizer

InactiveCN101353285AReduce the amount of applicationIncrease profitAgriculture gas emission reductionOrganic fertilisersAbsorption ratePhysical property

A natural multi-function mineral complex fertilizer is characterized in that the fertilizer is made from the raw materials with the following weight percentages: 28-33% of urea, 15-25% of monoammonium, 12-17% of potassium fertilizer, 30-45% of attapulgite powder and 5-10% of humic acid by the preparation method of the conventional fertilizer. The attapulgite powder is a nano-grade porous nonmetallic mineral substance with physical properties of strong adsorbability, cation exchange property, large specific surface area, and the like, wherein, the water absorption rate is equal to or more than 60%, the cation exchange capacity is equal to or more than 20mmol / 100g, and the specific surface area is equal to or more than 120m<2> / g; meanwhile, the attapulgite powder is rich in various nutrient elements of potassium, phosphor, calcium, magnesium, sulfur, iron, copper, zinc, molybdenum, manganese, boron, iodine, selenium, and the like; the humic acid can inhibit the activities of urase, and slow down the decomposition of the urea, and the complex compound produced can gradually decompose and release nitrogen, thus prolonging the fertilizer efficiency. The natural multi-function mineral complex fertilizer has the advantages of being applicable to all crops, and realizes the aims of reducing the fertilizer consumption, enhancing the utilization ratio of the chemical fertilizer, reducing agricultural production cost, increasing the yield and quality of farm products, and improving the soil.

Owner:薛立成

Aquagel with high water absorbing capacity and preparation method thereof

The invention discloses aquagel with high water absorbing capacity. The aquagel is prepared from the following raw materials in percentage by weight: 4-12 percent of polyvinyl alcohol, 70-90 percent of water, 5-20 percent of water-soluble monomers, 0.04-0.4 percent of an initiator and 0.03-0.3 percent of a crosslinking agent. The aquagel with high water absorbing capacity has the appearance characteristics of colorlessness and transparency, has high water absorbing capacity, and is easy for film forming. The invention further discloses a preparation method of the aquagel with high water absorbing capacity. The method comprises the following steps of: dissolving polyvinyl alcohol into a part of water under the conditions of mechanical stirring and nitrogen protection; adding a first water-soluble monomer and a part of the initiator; reacting at the temperature of 70-80 DEG C for 1-2 hours; adding the remaining water, a second water-soluble monomer, the remaining initiator and the crosslinking agent; polymerizing for 2-4 hours, and raising the temperature to 85-95 DEG C; and preserving heat for 0.5-1.5 hours, and cooling to the room temperature to obtain aquagel with high water absorbing capacity. The aquagel has the advantages of high operability, high controllability, easiness for industrial implementation, and the like.

Owner:ZHEJIANG UNIV +1

Method for baking ceramsite by using town sludge, river mud and bentonite

InactiveCN102173746ASolving difficult and costly problemsIncrease productionCeramic materials productionClaywaresSodium BentoniteSludge

The invention discloses a method for baking ceramsite by using town sludge, river mud and bentonite. The method comprises the following steps of: milling 30 to 35 weight percent of original sludge, 45 to 50 weight percent of river sludge, and 17 to 23 weight percent of bentonite by wheels, mixing and stirring to homogenize the materials; and aging, pelleting, screening, sintering and expanding, and performing air cooling. The bulk density of the obtained ceramsite is 400 to 500Kg / m<3>, the compression strength is 1 to 3.5Mpa, one-hour water absorption is 8 to 10 percent, and the grain size of the product is 1 to 26mm; and the original sludge, the river sludge and the bentonite are used as the raw materials, the ceramsite is directly baked by taking cavings as fuel, the treatment capacity of the sludge is large, the production cost is low, secondary pollution in the production process is avoided, and the performance of the obtained ceramsite product meets the standard requirement of GB / T17431.1-1998.

Owner:常州市金坛博大陶粒制品有限公司

Low-temperature foam glass thermal insulation material and preparation method thereof

InactiveCN102795781ALow water absorptionHigh mechanical strengthThermal insulationAlkali metal oxide

The invention relates to a low-temperature foam glass thermal insulation material and a preparation method thereof, and the foam glass thermal insulation material comprises the following components by mass fraction: 40-80% of SiO2, 0-16% of B2O3, 0-10% of Al2O3, and 10-40% of R2O, wherein R2O is alkali metal oxide; the preparation method comprises the following steps: (1) well mixing water glass with one or more than one of boron-containing raw materials, aluminium-containing raw materials, and an alkali of ROH under stirring so as to obtain a sol system without gelation; (2) drying the sol system to obtain an intermediate material with a water content of 25-50%; (3) performing fragmentation processing of the obtained intermediate material, and then performing foaming heat treatment under a closed condition. The low-temperature foam glass of the invention has good mechanical strength, low water absorption, and a small coefficient of heat conductivity, and can be used as an excellent thermal insulation material; the preparation technology of the invention is simple in process, low in cost, energy saving and environment-friendly, and applicable to industrial production.

Owner:宁波荣山新型材料有限公司

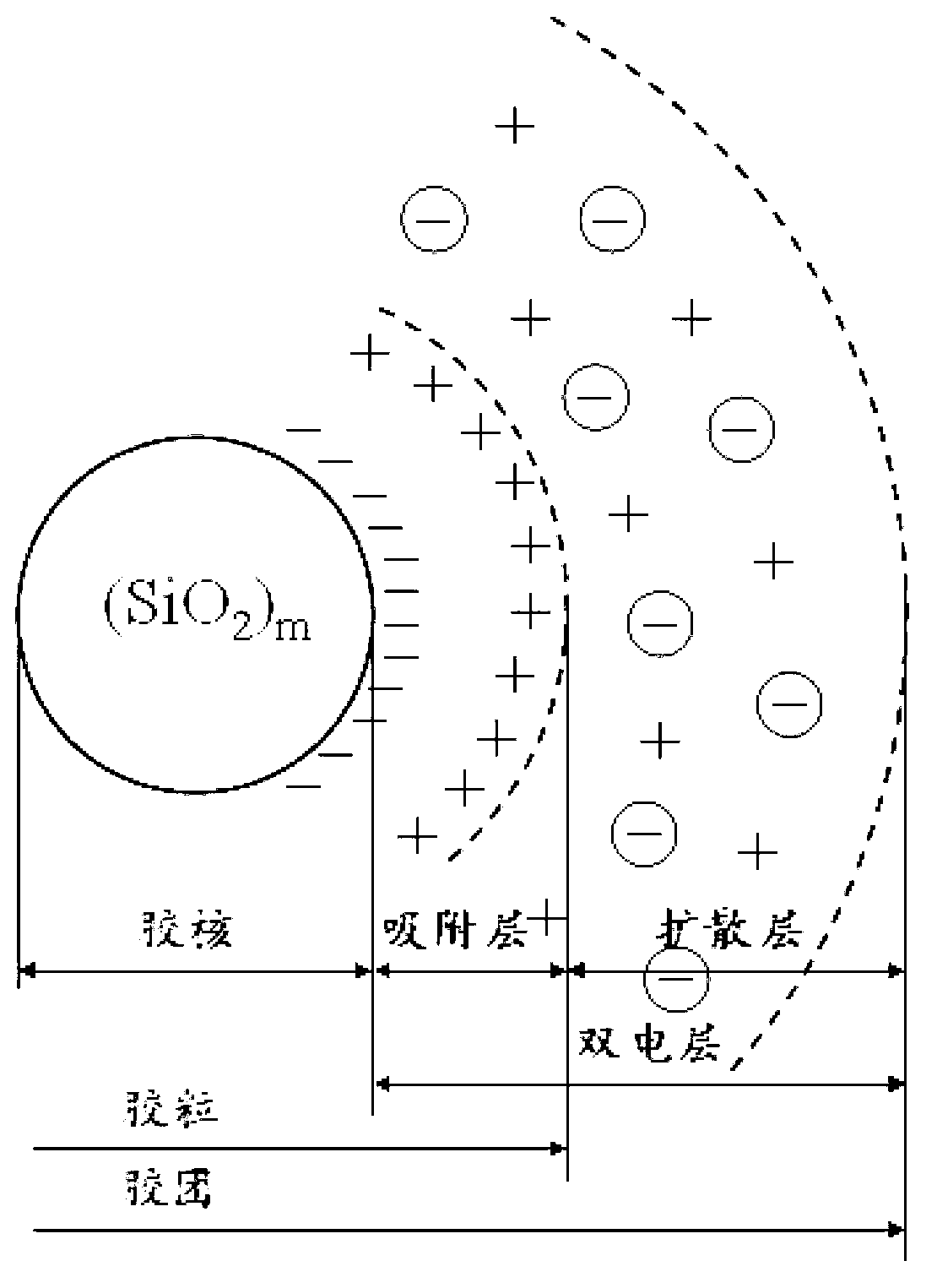

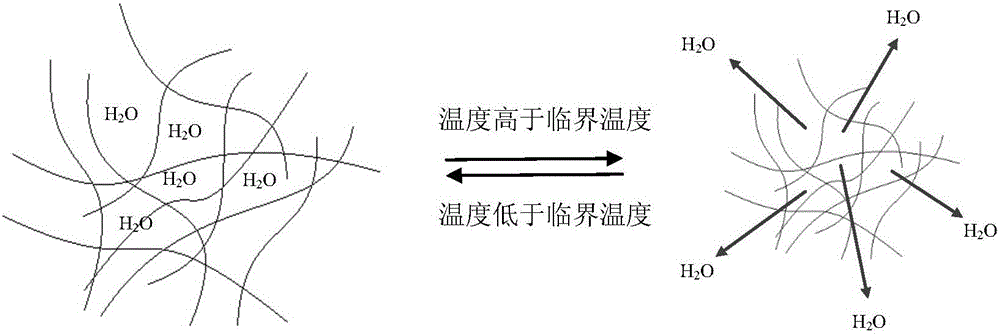

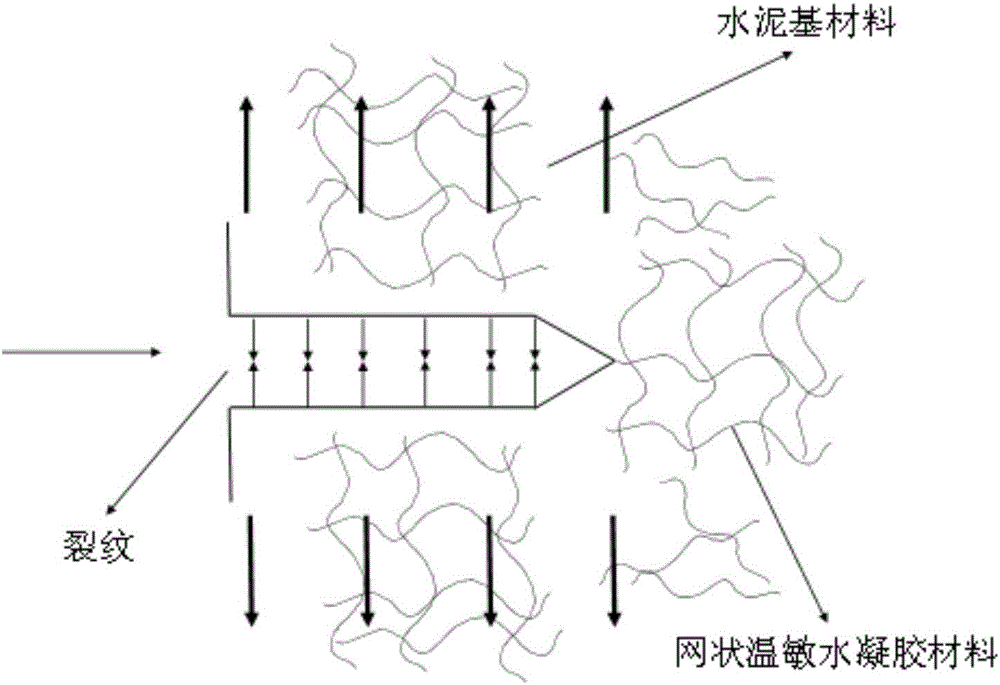

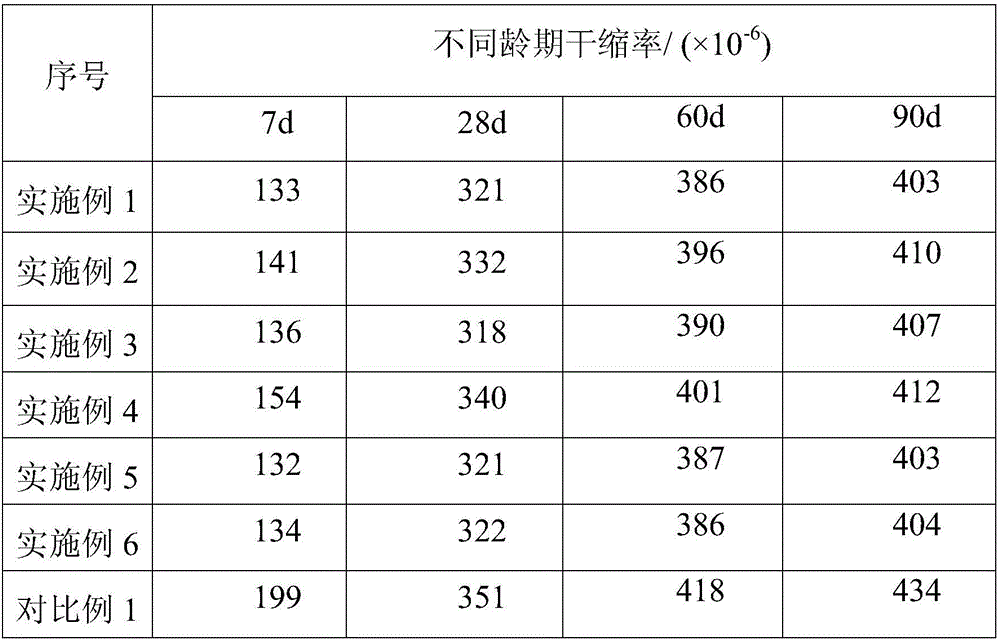

Application of temperature-sensitive hydrogel in improvement of anti-dry-shrinkage cracking property of concrete

The invention provides application of temperature-sensitive hydrogel in improvement of the anti-dry-shrinkage cracking property of concrete. The concrete is prepared from the temperature-sensitive hydrogel, cement, aggregates and water. A preparation method of the concrete comprises the steps that firstly, the temperature-sensitive hydrogel is prepared; secondly, the aggregates and the water are blended to be uniform; lastly, the temperature-sensitive hydrogel and the water are added, the materials are blended to be uniform, and then the concrete can be prepared. The adopted homemade temperature-sensitive hydrogel is lightly-crosslinked macromolecules which can be polymerized to form a film after releasing water, no hole can be reserved in the cement concrete, and other properties of the cement concrete are not affected while the anti-cracking property of the concrete is improved. The initial volume water content of the concrete is increased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the water storage capacity of the concrete is enhanced by mixing the temperature-sensitive hydrogel; the water absorption rate of the concrete is decreased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the connectivity of capillary pores in the concrete is reduced by mixing the temperature-sensitive hydrogel.

Owner:CHANGAN UNIV

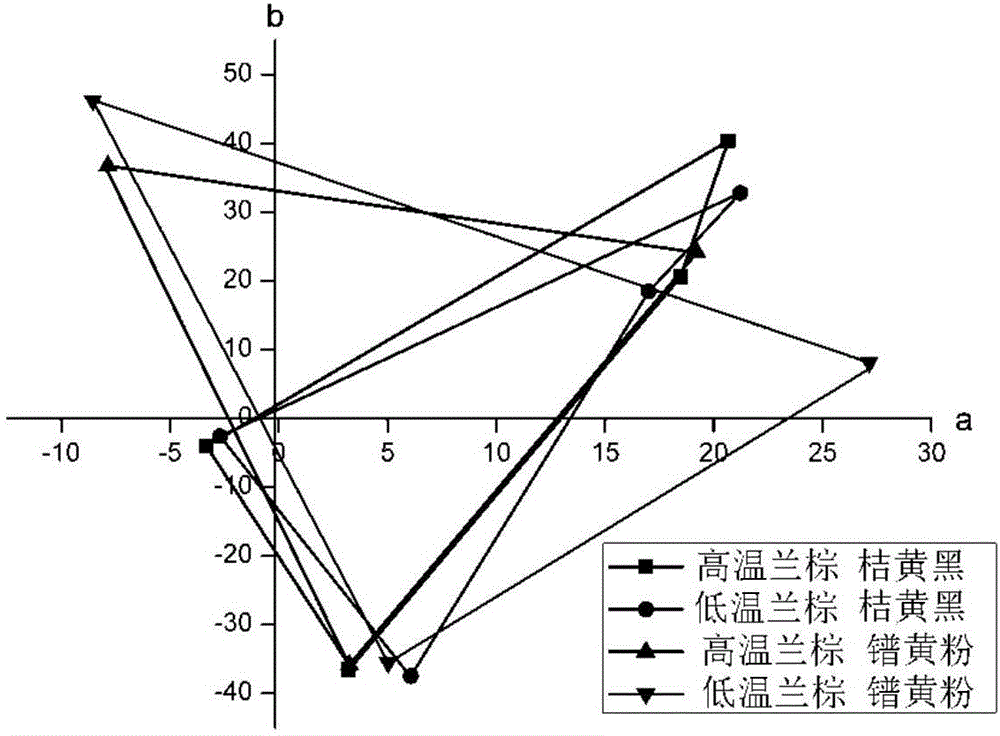

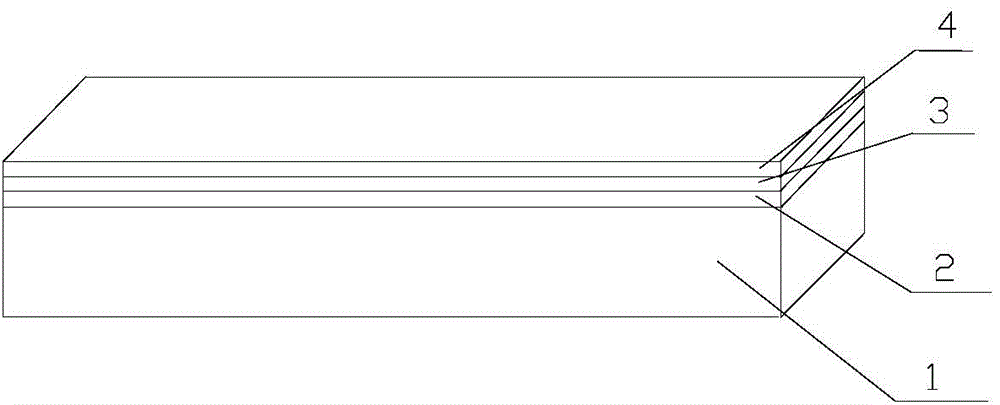

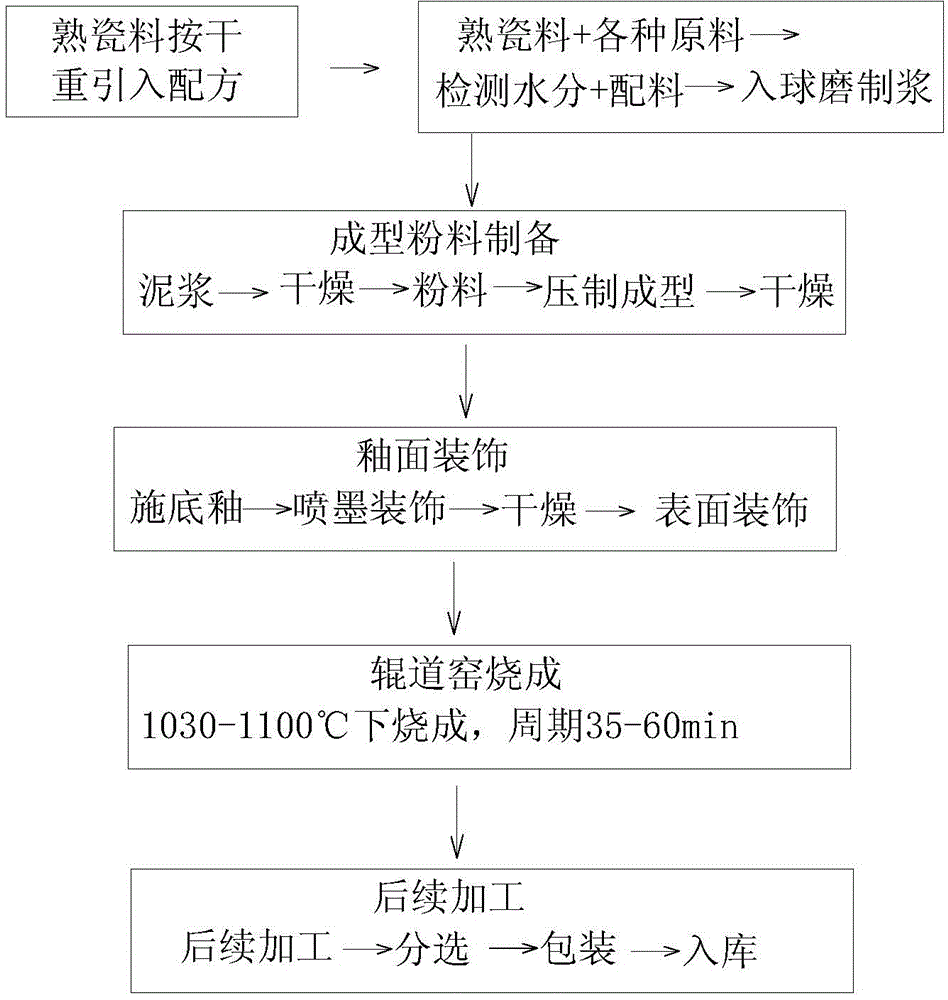

Wide-color-gamut inkjet glaze decorated ceramic floor tile and production process thereof

The invention relates to the technical field of ceramic tiles, and in particular relates to a wide-color-gamut inkjet glaze decorated ceramic floor tile and a production process thereof. A floor tile billet comprises the following components in parts by weight: 40-75 parts of a cooked porcelain material, 0-38 parts of porcelain stone, 20-30 parts of clay and 0-5 parts of a mineralizing agent; and a production method comprises the following steps: firstly performing conventional processes such as wet-process ball-milling, spray drying and dry-pressing molding on architectural ceramics to prepare a billet, by taking titanium series engobe as a ground glaze, combining engobe with a low-temperature ink-jet ink composition of interior wall tiles to perform inkjet decoration, and performing firing in a roller hearth kiln under the conditions that the firing temperature is 1030-1100 DEG C and the firing cycle is 35-60min to prepare a finished product, wherein the water absorption rate of the finished product is 0-3%, and the quality of the product can meet the national standard requirements. The wide-color-gamut inkjet glaze decorated ceramic floor tile disclosed by the invention has the beneficial effects that energy conservation and emission reduction can be achieved, and the firing temperature can be reduced by 50-100 DEG C compared with that of the same category of products; the technology bottleneck that titanium series opacified engobe can be yellowed when being applied in the floor tiles in a conventional high-temperature process can be effectively solved; and the color gamut range of an inkjet decorative layer of a glaze decorated ceramic tile can be significantly broadened.

Owner:JIANGXI HEMEI CERAMICS +1

Hydrophobic silicon oxide aerogel insulation material and preparation method thereof

The present invention provides a hydrophobic silicon oxide aerogel insulation material with low thermal conductivity, low water absorption and low density and preparation method thereof. The hydrophobic silica aerogel insulation material provided by the invention includes the following components: 80g of cement, 0-30g of fly ash, 0-4g of glue powder, 0-2g of HPMC, 0-2g of lignin, 0.1-1g of PP fiber, 40-120g of hydrophobic aerogel particles and 600ml of water. According to the hydrophobic silica aerogel insulation material and the preparation method thereof provided by the present invention, the hydrophobic aerogel is made into thermal insulation mortar, which maintains the traditional advantages and gains increased thermal conductivity coefficient, reduced unit weight and reduced water absorption, so as to better meet the needs of exterior wall external insulation.

Owner:ZHUO DA NEW MATERIAL TECH GRP

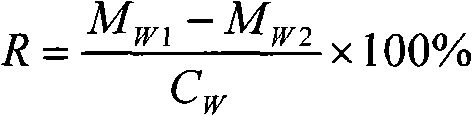

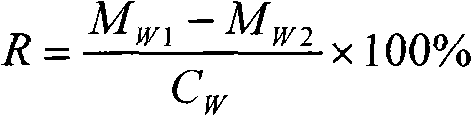

Method for measuring pressure water absorption rate of lightweight aggregate concrete

The invention provides a method for measuring pressure water absorption rate of lightweight aggregate concrete, comprising the steps of: evenly mixing concrete and lightweight aggregate; weighing CW g of evenly mixed concrete and lightweight aggregate and placing in a square hole sieve of 4.75mm, sieving out cement slurry, then weighing MW1 g of the sieved out cement slurry; putting the evenly mixed concrete and lightweight aggregate into a container provided with an air content meter, smashing and sealing tightly, then pumping air into the lightweight aggregate concrete by the air content meter for pressurizing until the pressure can not descend; re-weighing certain amount of pressurized CW g of lightweight aggregate concrete and placing in the square hole sieve of 4.75mm, sieving out cement slurry, then weighing MW2 g of the sieved out cement slurry; and calculating the water absorption rate R of the lightweight aggregate concrete by using the formula R=[(MW1-MW2) / CW]*100%. The technical scheme leads the lightweight aggregate to be in a saturate state before pumping, and can not appear thickening and drying of concrete to lose liquidity and plug pump tubes under the state of pumping.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Deep-sea solid buoyancy material and manufacture method thereof

The invention discloses a deep-sea solid buoyancy material and a manufacture method thereof. The deep-sea solid buoyancy material is characterized by including the following raw materials in parts by weight: 100 parts of epoxy resin, 0-20 parts of a toughening modified agent, 10-80 parts of a curing agent, 0.5-5 parts of a catalyst, 0.2-10 parts of a dispersing agent, 20-300 parts of hollow glass beads, 0-10 parts of chipped fibers and 0.2-5 parts of a coupling agent. Based on the contradiction between the pressure-bearing performance and density of the solid buoyancy material, a method of mixing the hollow glass beads with bigger density and higher pressure-bearing performance with the hollow glass beads with lower density and poorer pressure-bearing performance and appropriately adding the chipped fibers and / or aramid fibers used as reinforcing materials of the solid buoyancy material to prepare the solid buoyancy material is provided; the deep-sea solid buoyancy material formed through adopting the method is low in water absorption, has the density lower than 0.73 g / cm <3>, bears pressure higher than 110 MPa, and meets a requirement for the application in full deep sea areas.

Owner:滕州市华海新型保温材料有限公司

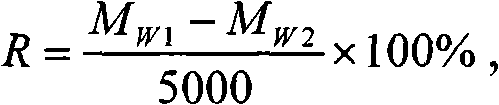

Phase-change-energy-storage phase change concrete and preparation method

The invention provides phase-change-energy-storage phase change concrete and a preparation method. The phase change concrete comprises the following components according to part by weight: 90 parts of ordinary silicate cement, 10 parts of rapid hardening sulphoaluminate cement, 1-1.5 parts of water reducer, 0.5-1 part of accelerating agent, 0.5-1 part of early strength agent, 50-70 parts of water and 10-20 parts of phase change energy storage materials, and the volume (liter) of foam accounts for 300%-500% that of the added water. In the preparation process, cement slurry is stirred uniformly and then stands for 20min-30min, and then the foam is added in the cement slurry. A wall body made by the concrete has high heat insulation performance and electric insulation performance, low unit weight and water absorption, and also has automatic temperature adjusting function under the premise of ensuring the strength.

Owner:SHENYANG JIANZHU UNIVERSITY

Novel wall lightweight heat-insulating material and method for preparing same

InactiveCN101139200AImprove insulation effectLow thermal conductivitySolid waste managementFiberOXALIC ACID DIHYDRATE

The present invention discloses a new type wall body light heat-preservation material, which is characterized in that: the present invention comprises the following raw materials according to the weight ratio: 10-15 percent of magnesia or magnesium hydrate, 3- 7 percent of magnesium chloride, 4-8 percent of perlite, 1-5 percent of alkali resisting fibre, 6-12 percent of powder coal ash or calcium carbonate and 0.3-1 percent of modifier, wherein, the modifier is made of the following components according to weight ratio: 6-10 percent of ferrous sulfate, 1-3 percent of oxalic acid, 1-3 percent of tertiary sodium phosphate, 0.5-2 percent of hexametaphosphate and 12-18 percent of aluminium sulphate. Compared with the original heat-preservation system, the material is with much better heat-preservation performance, much lower heat-conductivity coefficient, much lower density, and much lower water content and water absorption ability. The present invention is with much better performance in heat-preservation, heat-insulation as well as sound absorption and sound insulation and so on. The present is able to bear or endure acid, alkali and corrupted. The manufacturing cost is much lower and the construction process is much more convenient. The present is easy to be popularized.

Owner:成都市圣欧实业有限公司

Bacteriostatic porous polyelectrolyte material and its prepn process

InactiveCN1810298AStrong initial bactericidal abilityReduce usageAbsorbent padsBandagesPvp iodineFreeze-drying

One kind of porous bacteriostatic polyelectrolyte material suitable for stopping bleeding and dressing wound is disclosed. The material features that it is prepared with chitosan solution in 1-5 wt% concentration and sodium alginate solution 1-5 wt% concentration in the weight ratio of 0.25-4 as material and through mixing and freeze drying. The chitosan solution is prepared through dissolving chitosan in water solution of acetic acid. The material includes also sulfadizine silver or PVP-iodine bacteriostatic agent in the amount of 3-10 wt% of chitosan and sodium alginate. The porous material has no toxicity, relatively great pores, high water absorption rate and short bleeding stopping period.

Owner:WUHAN UNIV OF TECH

Agricultural water-loss reducer and production process

ActiveCN101508895AHigh strengthSolution to short lifeOrganic fertilisersSoil conditioning compositionsAlkaneFiber

The invention discloses an agricultural water retention agent which comprises the following components according to parts by weight: 70-100 parts of acrylic acid, 30-40 parts of sodium hydroxide, 18-30 parts of acrylamide, 10-22 parts of starch, 5-15 parts of polyvinyl alcohol, 0.15-0.5 part of cross linker, 10-20 parts of clay, 6-15 parts of fiber, 0.5-2.5 part of evocating agent, 2-6 parts of alkane and surface active agent and 3-8 parts of rest components. The invention also discloses a production process of the agricultural water retention agent. The water absorbing coefficient of the agricultural water retention agent reaches 3000 times and the water absorption of 0.5min reaches 1500 times. The invention has good saline and alkaline resisting performance and long service life, integrates the advantages of two sorts of super water absorbent of a starch graft system and a synthetic polymerization system and can be biodegraded, and matters after treating are organic nutrient substances which can be absorbed by plants. The invention has simple protection process, low cost and stable performance and can be widely applied to the technical field of the water saving and moisture preservation, and the like of agricultural and forestry soils in dry lands.

Owner:北京鸿森鹏程生态农业科技股份有限公司

Completely biodegradable food packing material and preparation method thereof

The invention discloses a completely biodegradable food packing material and a preparation method thereof. The completely biodegradable material of plant fiber and starch is a product obtained by melting, blending and extruding potato starch, bamboo fiber, polycaprolactone, a plasticizer, an inorganic filling agent and a cross linker through a double-screw extruder; and the molten blend comprises the following components in parts by weight: 40 to 60 parts of potato starch, 10 to 30 parts of bamboo fiber, 5 to 10 parts of polycaprolactone, 2 to 10 parts of inorganic filling agent, 2 to 8 parts of cross linker, 5 to 20 parts of plasticizer and 2 to 10 parts of solubilizing agent. Compared with the traditional starch-based plastic degradable material, the tensile strength of the completely biodegradable material is improved by 20 to 40 percent; the stiffness is improved by 20 to 40 percent; the water absorption is reduced by 10 to 20 percent; and the completely biodegradable material has excellent properties of low cost, complete biodegradability and environmental friendliness, and can be widely used for packing food, particularly disposable instant snack boxes.

Owner:HUNAN UNIV OF TECH

Super absorbent degradable colorful crystal soil containing nano-clay and preparation method thereof

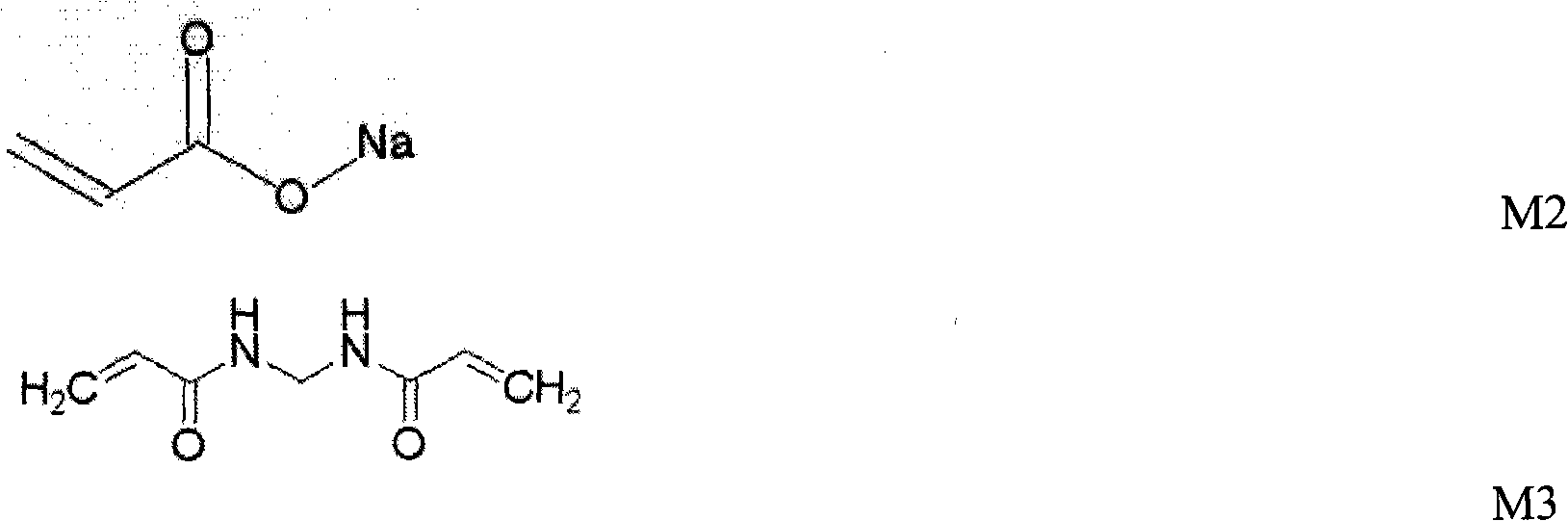

The invention relates to a super absorbent degradable colorful crystal soil containing nano-clay and a preparation method thereof. The polymerization of acrylamide monomer M1, sodium acrylate M2, N, N'-methylene-bisacrylamide M3, inorganic nano-clay M4, water soluble biomacromolecule M5 and water soluble pigment M6 are dissolved in water and are synthesized to prepare the crystal soil in redox initiator system. The crystal soil not only processes high water absorption and color absorption, but also has certain mechanical property and biodegradability. The preparation method is simple and has controllable condition without polluting the environment. The water-absorbing capacity and the biodegradation time of the prepared crystal soil can be adjusted by parameters of temperature, PH value, degree of cross linking, dosage and type of water soluble biomacromolecule and nano-clay and reactant proportion, and the appearance color can be adjusted by the pigment type. The crystal soil of the invention is used for environment decoration of household, flower market and gardening, etc, and engineering field of nursery stock breeding, garden greening, agricultural producing, environment improving, revegetating, etc.

Owner:天津市志润德科技有限公司

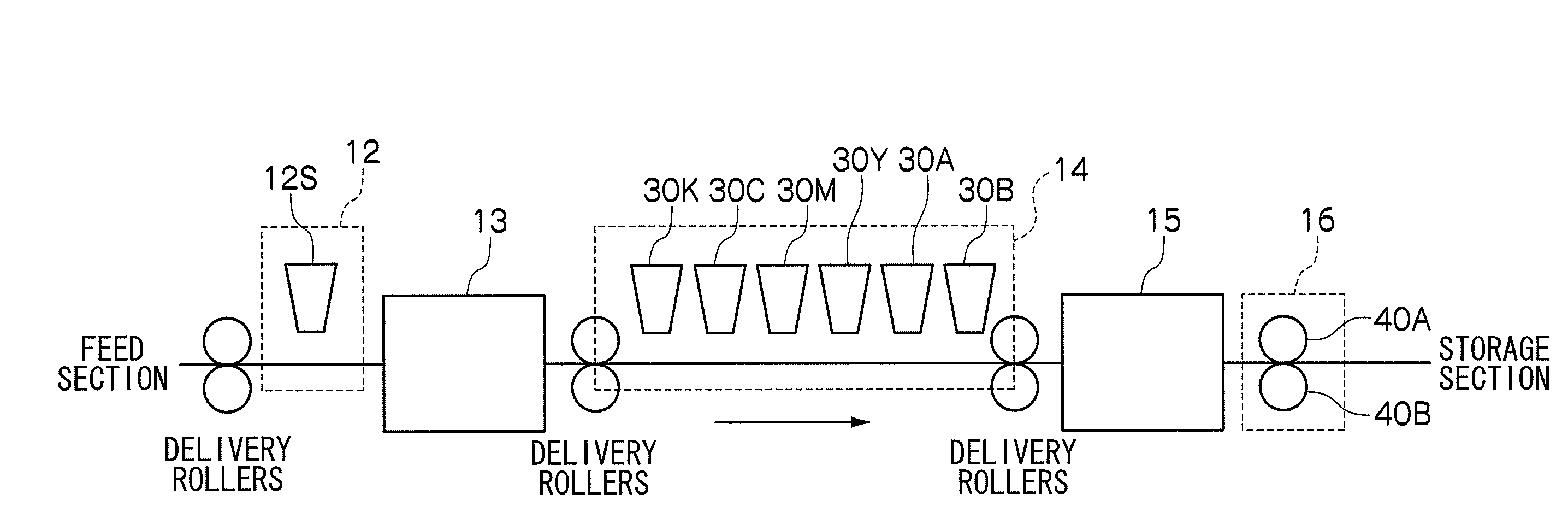

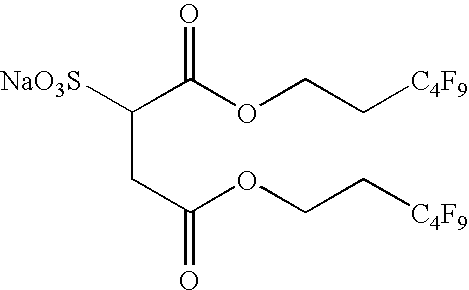

Image recording method, ink set, recorded material

InactiveUS20090233068A1Measurement apparatus componentsDecorative surface effectsSolubilityOrganic solvent

An image recording method including: applying an aqueous pretreatment composition to a recording medium having a water absorption of 14 ml / m2 or less at a contact time of 900 msec in accordance with the Bristow method, the aqueous pretreatment composition containing 10 mass % or more of a water-soluble organic solvent having a solubility parameter value of 13 or less, 1.5 mass % or more of resin particles, and water; forming a blocking layer on the recording medium by drying the aqueous pretreatment composition so that 70 mass % or more of water contained in the aqueous pretreatment composition evaporates within 900 msec from the initiation of the application of the aqueous pretreatment composition; and recording an image by jetting an aqueous ink on the blocking layer, the aqueous ink containing a pigment, resin particles, a water-soluble organic solvent, and water.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com