Wide-color-gamut inkjet glaze decorated ceramic floor tile and production process thereof

A production process and a wide color gamut technology, applied in the field of architectural ceramics, can solve the problems of increasing the performance requirements of molding equipment, reducing the firing temperature of ceramic tiles, and reducing the fineness of formula ball milling, so as to improve the inkjet color development intensity and reduce burning. Reduce energy consumption and reduce glaze defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

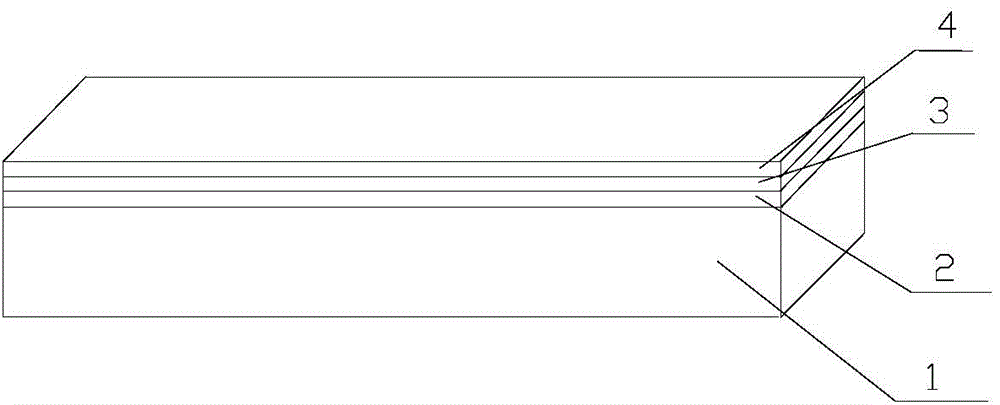

[0038] refer to figure 1 , the wide-color-gamut ink-jet glazed floor tile of the present invention comprises: a body layer 1 , an underglaze layer 2 , an ink-jet decoration layer 3 and a surface decoration layer 4 sequentially from the bottom to the surface. Wherein green body layer 1 comprises the formula (parts by weight) described in Table 1:

[0039] Table 1 Composition of adobe

[0040] Cooked porcelain 40

Porcelain stone 38

clay 28

Mineralizer 2

[0041] The calcined porcelain material adopts a vitrified clinker whose particle size is less than 5 mm and has been sintered at a high temperature of 1180 to 1300° C., and its water absorption rate is less than 0.5%. The calcined porcelain material includes the formula (parts by weight) described in Table 2:

[0042] Table 2 Composition of cooked porcelain

[0043] other ingredients

SiO 2

Al 2 o 3

CaO+MgO

KNaO

1.5

71

19

4

4.5

[004...

Embodiment 2

[0061] This embodiment provides a wide color gamut inkjet glazed floor tile, which is different from Embodiment 1, wherein the body layer 1 includes the formula (parts by weight) described in Table 6:

[0062] Table 6 Adobe Components

[0063] Cooked Porcelain 75

Porcelain stone 0

clay 20

Mineralizer 5

[0064] The calcined porcelain material wherein adopts a kind of particle size to be less than 5mm, through 1180~1300 ℃ of high-temperature sintered vitrified clinker, and its water absorption rate is less than 0.5%, comprises the formula described in Table 7 (parts by weight):

[0065] Table 7 Composition of Cooked Porcelain

[0066] other ingredients

SiO 2

Al 2 o 3

CaO+MgO

KNaO

1.5

72

16

1.5

8.5

[0067] Among them, the sources of cooked porcelain materials can be the following ways: ① waste bricks or low-grade finished products produced in the post-firing process of building ceramic...

Embodiment 3

[0084] This embodiment provides a wide-color-gamut inkjet glazed floor tile. The difference from Embodiment 1 is that the body layer 1 includes the formula (parts by weight) described in Table 11:

[0085] Table 11 Composition of adobe

[0086] Cooked porcelain 50

Porcelain stone 20

clay 30

Mineralizer 0

[0087] The calcined porcelain material wherein adopts a kind of particle diameter to be less than 5mm, through 1180~1300 ℃ high-temperature sintered vitrified clinker, and its water absorption rate is less than 0.5%, comprises the formula described in Table 12 (parts by weight):

[0088] Table 12 Composition of Cooked Porcelain

[0089] other ingredients

SiO 2

Al 2 o 3

CaO+MgO

KNaO

1.5

74

20

1

3.5

[0090] Among them, the sources of cooked porcelain materials can be the following ways: ① waste bricks or low-grade finished products produced in the post-firing process of building cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com