Patents

Literature

145results about How to "Solve the problem of foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-density foamed thermoplastic polyurethane elastomer and its preparation process

The invention relates to a low-density foamed thermoplastic polyurethane elastic body and a preparation process thereof, belonging to the technical fields of polyurethane elastic bodies and preparation processes of the polyurethane elastic bodies. The low-density foamed thermoplastic polyurethane elastic body comprises the following raw materials such as a macromolecular polyol, a chain extender,an isocyanate and an azo foaming agent in a weight ratio of (40-60): (8-11): (32-49): (3.5-6); and a production process comprises the following steps of: 1, metering, transporting and mixing the raw materials; 2, reacting and extruding; 3, underwater pelletizing; 4, vulcanizing; and 5, inspecting. The molecular structure of the low-density foamed thermoplastic polyurethane elastic body provided by the invention is formed by rigid chain segments obtained by reaction of the isocyanate and the chain extender and flexible chain segments obtained by reaction of the isocyanate and the macromolecular polyol in an alternate manner, has unique comprehensive properties, excellent characteristics such as high tension, high tensile force, high toughness and aging resistance and leading wear resistance and is a mature environmentally-friendly material.

Owner:SHANDONG AOBANG POLYURETHANE

Uncured polyurethane waterproofing coating and preparation method thereof

ActiveCN103923565AGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses an uncured polyurethane waterproofing coating and a preparation method thereof, belonging to the technical field of polyurethane waterproofing coatings. The uncured polyurethane waterproofing coating is prepared from the following raw materials in percentage by weight: 13-20% of prepolymer, 30-65% of asphalt, 1.0-1.5% of latent curing agent, 3-15% of compatilizer, 2-9% of thermoplastic elastomer and 0-3% of powder stuffing, wherein prepolymer is a substance synthesized by reaction between polyether and isocyanate. The uncured polyurethane waterproofing coating mainly aims to improve the material proportion and polymerization process of polyurethane, and the problem that a hot-melted asphalt material is needed to be heated by using a machine is solved; the uncured polyurethane waterproofing coating is convenient in construction and good in flowability; the viscosity of the constructed material can be automatically enhanced, so that the constructed material can become an elastic plastic body and a favorable waterproofing layer without internal stresses; in addition, the uncured polyurethane waterproofing coating can be well bonded with a coiled material and can be compounded to be waterproof so as to form a waterproofing layer capable of overcoming tension fracture caused by basement layer cracking and preventing puncturing; the uncured polyurethane waterproofing coating is simple and convenient in process, rapid in construction, free of maintenance, high in working efficiency and capable of becoming the development direction of building waterproofing in the further.

Owner:浙江鲁班建材科技股份有限公司

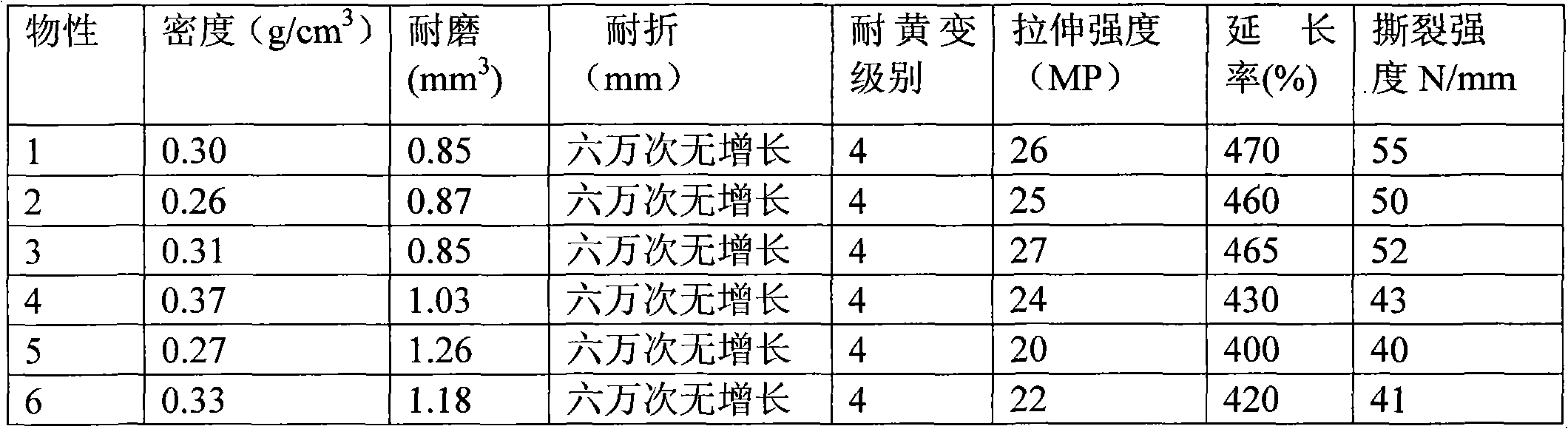

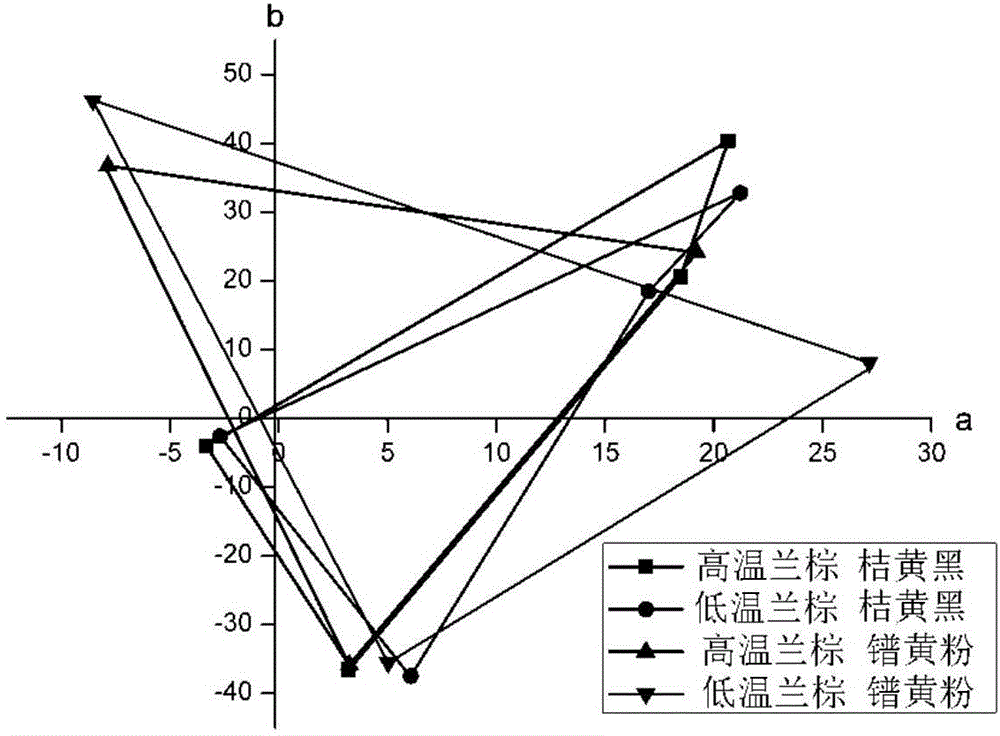

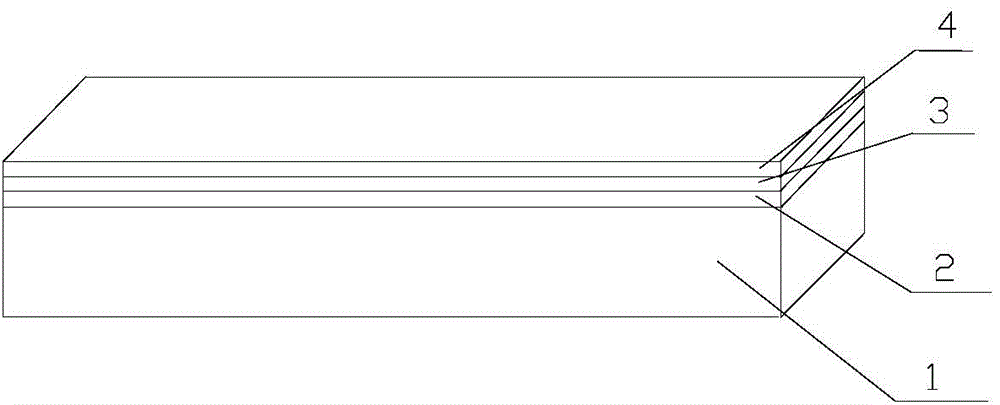

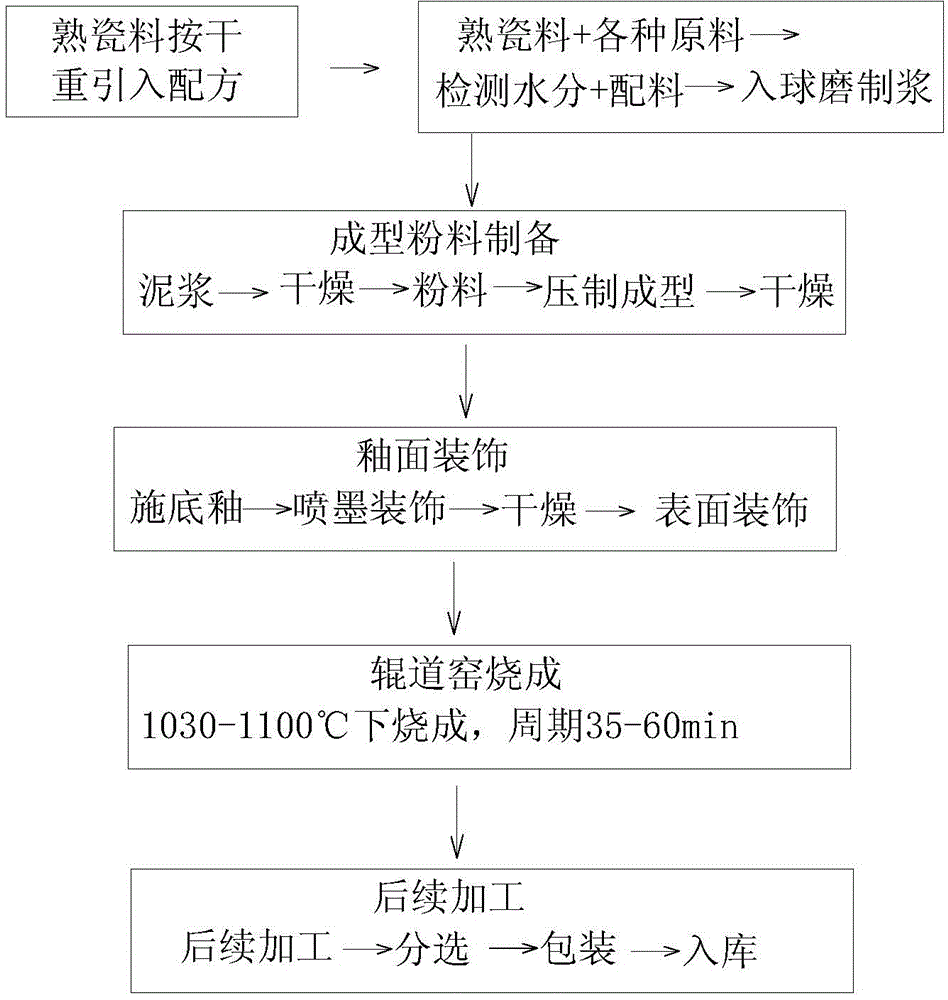

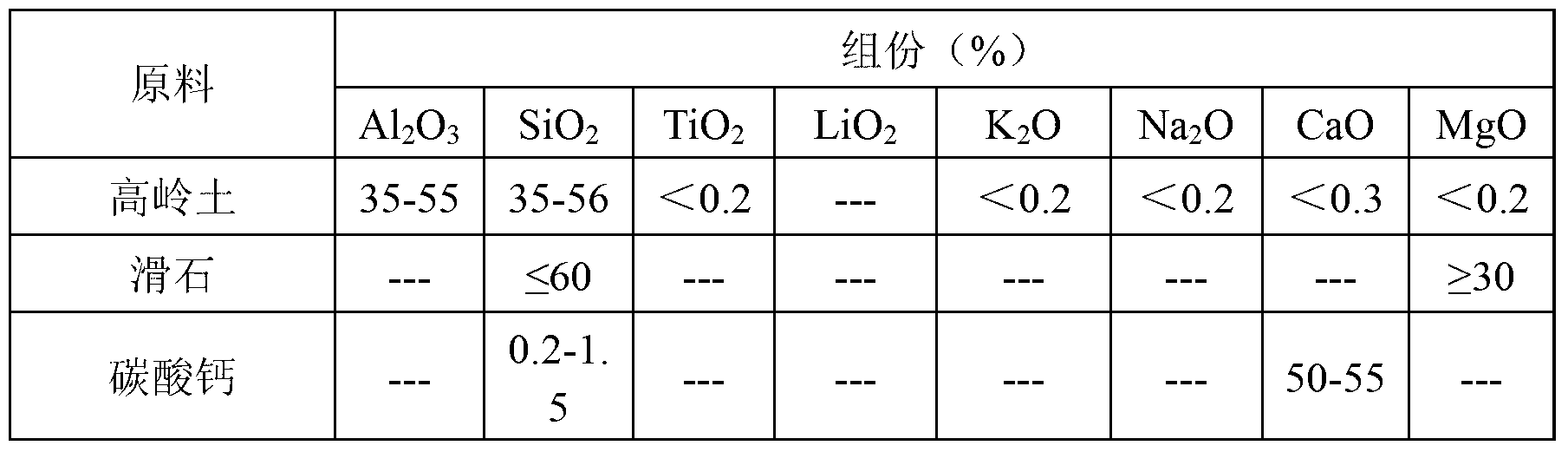

Wide-color-gamut inkjet glaze decorated ceramic floor tile and production process thereof

The invention relates to the technical field of ceramic tiles, and in particular relates to a wide-color-gamut inkjet glaze decorated ceramic floor tile and a production process thereof. A floor tile billet comprises the following components in parts by weight: 40-75 parts of a cooked porcelain material, 0-38 parts of porcelain stone, 20-30 parts of clay and 0-5 parts of a mineralizing agent; and a production method comprises the following steps: firstly performing conventional processes such as wet-process ball-milling, spray drying and dry-pressing molding on architectural ceramics to prepare a billet, by taking titanium series engobe as a ground glaze, combining engobe with a low-temperature ink-jet ink composition of interior wall tiles to perform inkjet decoration, and performing firing in a roller hearth kiln under the conditions that the firing temperature is 1030-1100 DEG C and the firing cycle is 35-60min to prepare a finished product, wherein the water absorption rate of the finished product is 0-3%, and the quality of the product can meet the national standard requirements. The wide-color-gamut inkjet glaze decorated ceramic floor tile disclosed by the invention has the beneficial effects that energy conservation and emission reduction can be achieved, and the firing temperature can be reduced by 50-100 DEG C compared with that of the same category of products; the technology bottleneck that titanium series opacified engobe can be yellowed when being applied in the floor tiles in a conventional high-temperature process can be effectively solved; and the color gamut range of an inkjet decorative layer of a glaze decorated ceramic tile can be significantly broadened.

Owner:JIANGXI HEMEI CERAMICS +1

Anti-foaming agent for papermaking system

InactiveCN102154939AEliminate effectiveNot affected by performanceDefoamers additionPaper/cardboardFoaming agentPapermaking

The invention provides an anti-foaming agent for a papermaking system. The anti-foaming agent consists of advanced fatty alcohol, advanced fatty alcohol polyether, aliphatic ester, organic silicon composition, emulsifying agent and water. The anti-foaming agent can effectively eliminate the harmful foam in the processes of papermaking, coating, pulp washing, sewage treatment and the like in the industries of coating and starch processing and the like and the papermaking industry, the performance of the anti-foaming agent is not affected by temperature, and the problem of foam elimination under the jointed foam stabilizing condition of multiple surfactants can be well solved.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Temperature-sensitive-type intelligent nano particles used in drilling fluid and preparation method thereof

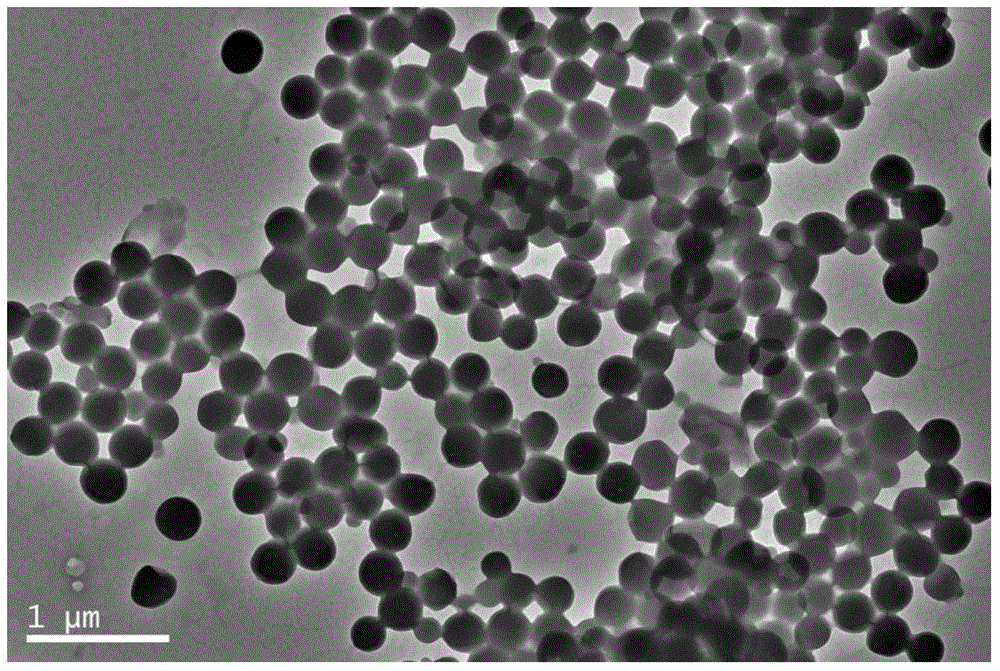

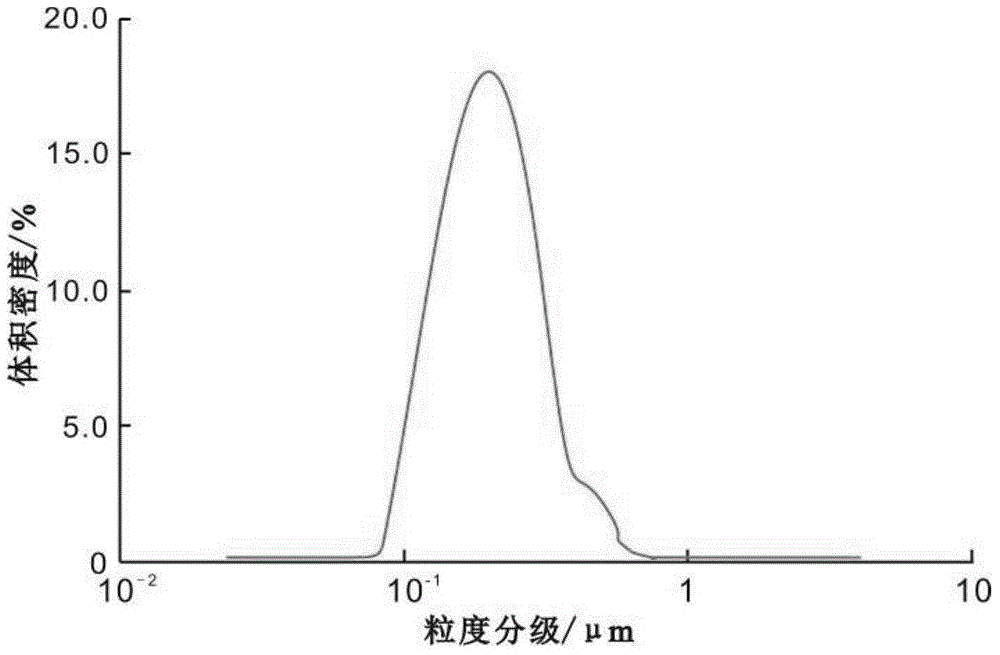

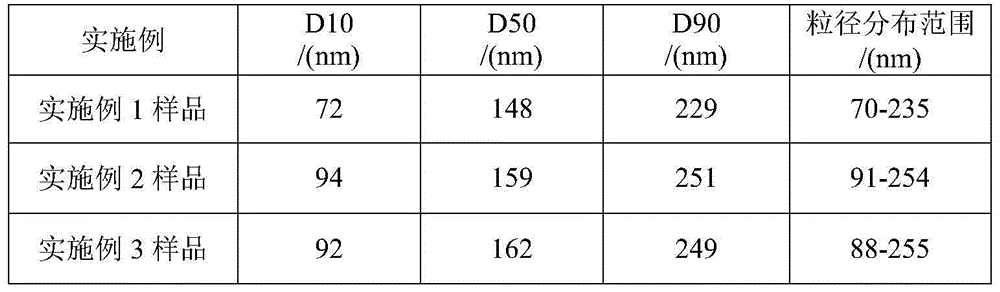

InactiveCN105038728AGood dispersionImprove water resistanceDrilling compositionHydrophilic monomerPressure transmission

The invention relates to a temperature-sensitive-type intelligent nano particles used in a drilling fluid and a preparation method thereof. In the invention, a silane coupling agent is used for performing ultrasound surface modification to nano SiO2 and a vinyl functional group is introduced. With the surface-modified nano SiO2, a temperature-sensitive-type monomer and a hydrophilic monomer are subjected to a polymerization reaction in a water medium with a co-solvent with addition of an initiator, wherein granularity distribution of the temperature-sensitive-type intelligent nano particles is D10 <= 100 nm, D 50 <= 165 nm and D90 <= 260 nm. When the temperature is higher than a sensitive value, the nano particles achieve double functions of both physical blocking and chemical inhibition, so that a continuous compact hydrophobic blocking layer is formed inside shale, thereby achieving effects of preventing and delaying pressure transmission and filtration invasion, and further enhancing stability of a shale well wall.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

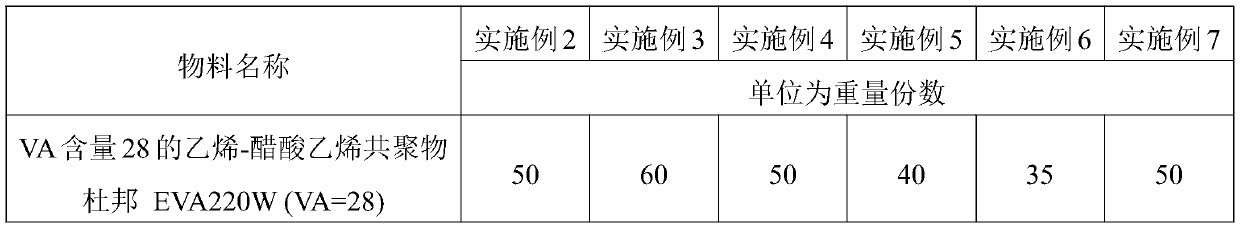

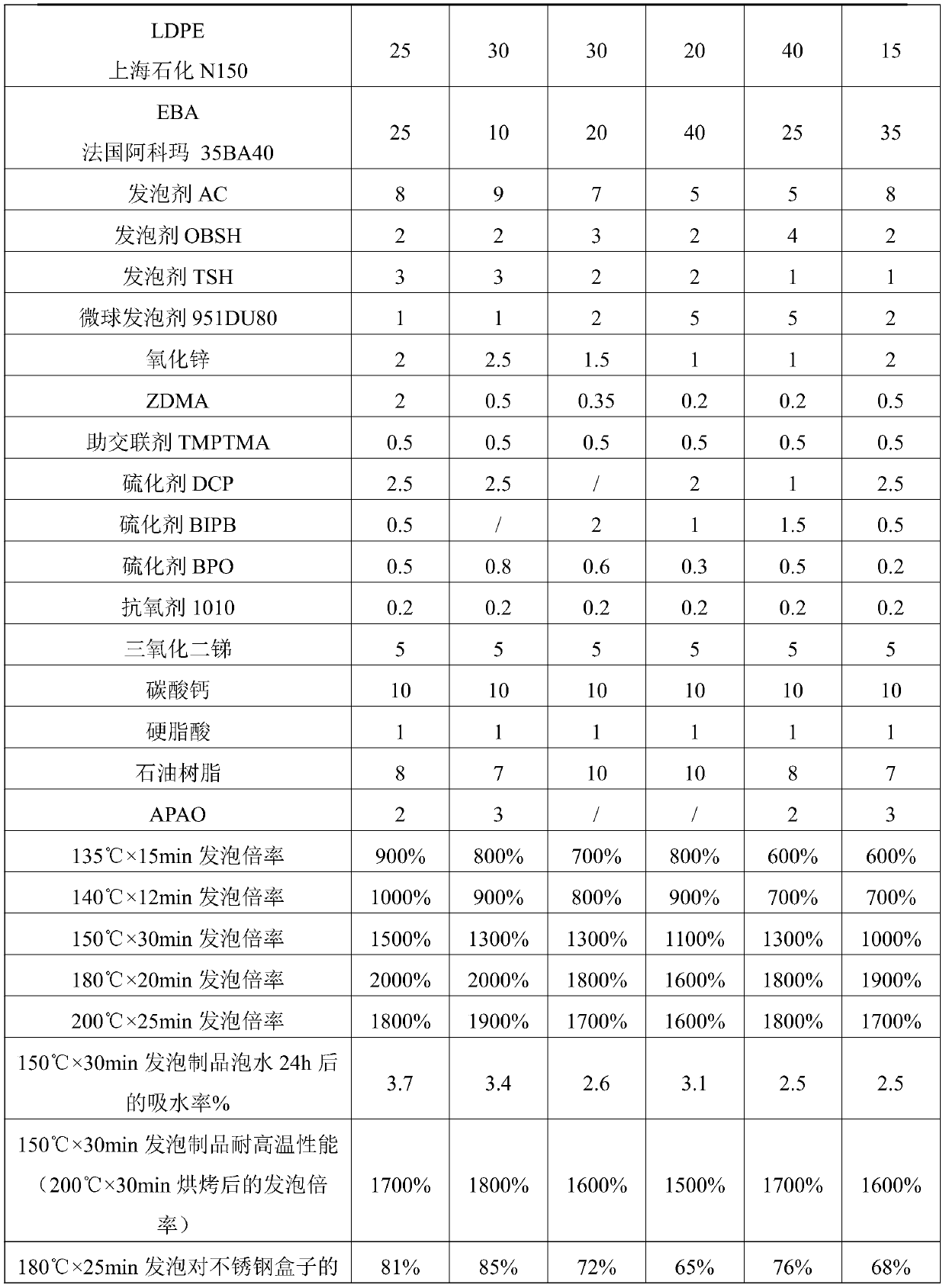

Low-temperature automobile expansion adhesive and preparation method thereof

ActiveCN110684486AHigh foaming ratioNot prone to collapse and shrinkage problemsNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationFoaming agent

The invention discloses a low-temperature automobile expansion adhesive. The low-temperature automobile expansion adhesive is made of the following raw materials in parts by weight: 100 parts of a polymer, 3-5 parts of a peroxide vulcanization agent, 0.5-3 parts of a vulcanization auxiliary agent, 5-15 parts of a foaming agent, 0.5-8 parts of a foaming activator, 1-10 parts of a filler, 2-15 partsof a tackifier, 0.5-3 parts of a lubricant, 0-2 parts of an antioxidant, and 0-10 parts of a flame retardant. According to the low-temperature automobile expansion adhesive, the raw material composition is carefully chosen, the content of each raw material is optimized, and the prepared low-temperature automobile expansion adhesive has high foaming ratio and small product density, and can fill large cavities. The expansion adhesive has high bonding strength with an ABS framework member. The expansion adhesive has good high-temperature baking stability. The expansion adhesive after foaming isnot easy to collapse and shrink. The low-temperature foaming performance and high-temperature foaming ratio are well balanced. The storage stability is good, the product quality is stable, and a storage period is relatively long.

Owner:浙江杰上杰新材料股份有限公司

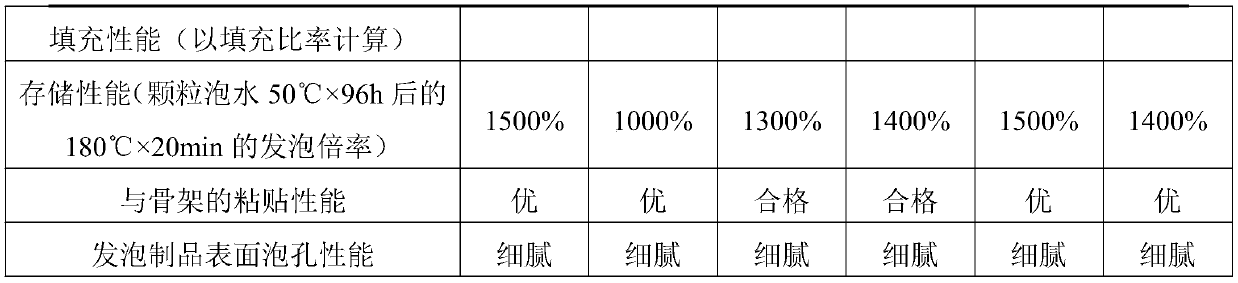

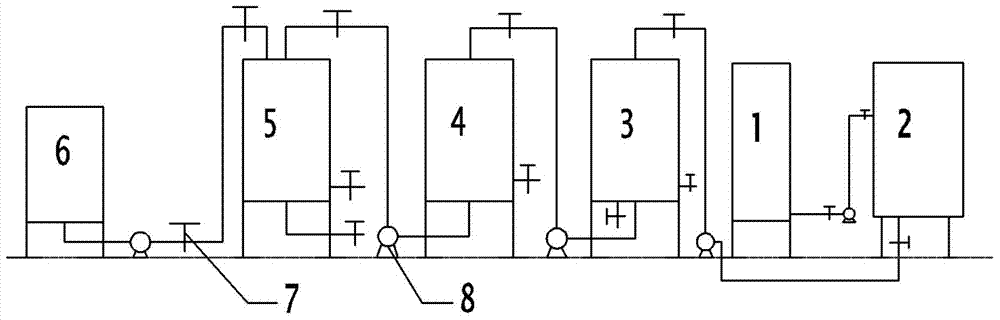

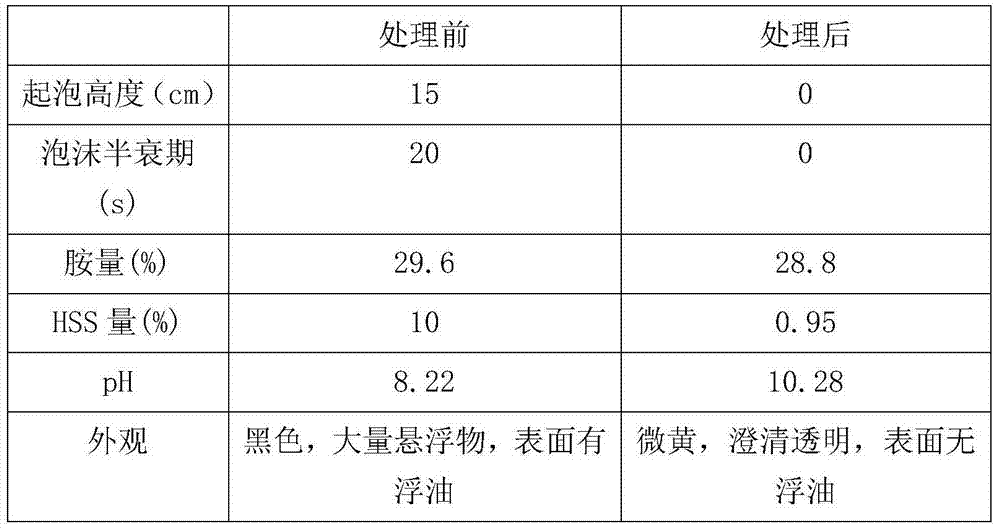

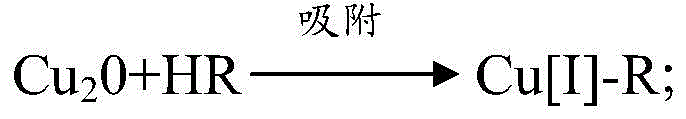

Purification method of amine liquid

ActiveCN103693777AOutstanding FeaturesHighlight significant progressMultistage water/sewage treatmentActivated carbonPurification methods

The invention discloses a purification method of amine liquid, relates to a separation method of processing liquid of taking a separating machine device as characteristics, and in particular relates to an amine liquid purification method based on foam separation. The existing mechanical filtering, activated carbon adsorption and ion exchange devices for purifying the amine liquid are utilized, and a foam separator is added in front of the devices and used for removing a surface active material of causing foaming of the amine liquid. Thus, the cleaning cycle of subsequent mechanical filtering, the replace cycle of activated carbon adsorption, and the regeneration cycle of the ion exchange device are prolonged, the defects that the existing simple mechanical filtering method is poor in amine liquid purification quality, short in equipment utilization cycle, and high in production cost are overcome, and the defects of high price and serious membrane pollution of the existing membrane separation method are also overcome.

Owner:HEBEI UNIV OF TECH

Environment-friendly, sun-resistant and wear-proof water-based ink and preparation method thereof

InactiveCN105482549ASolve the problem of foamingGood environmental protection functionInksPolymer scienceSunscreen agents

The invention discloses environment-friendly, sun-resistant and wear-proof water-based ink and a preparation method thereof. The ink comprises raw materials in percentage by weight as follows: 25%-30% of a waterborne acrylic emulsion, 18%-20% of deionized water, 0.2%-0.5% of a dispersing agent, 0.2%-0.5% of dimethylethanolamine, 0.2%-0.4% of a wetting agent, 1.5%-2% of a slow drying agent, 5%-10% of an anti-wear agent, 10%-15% of an uvioresistant sun-screening agent, 0.2%-0.4% of a leveling agent and 30%-35% of organic pigment. The problems of poor adhesion of water-based ink and foaming of the ink in the printing use process are solved, and the water-based ink has the characteristics of high adhesion, wear resistance and sun screening.

Owner:JIANGXI TONGBAILI COLOR PRINTING PACKAGING

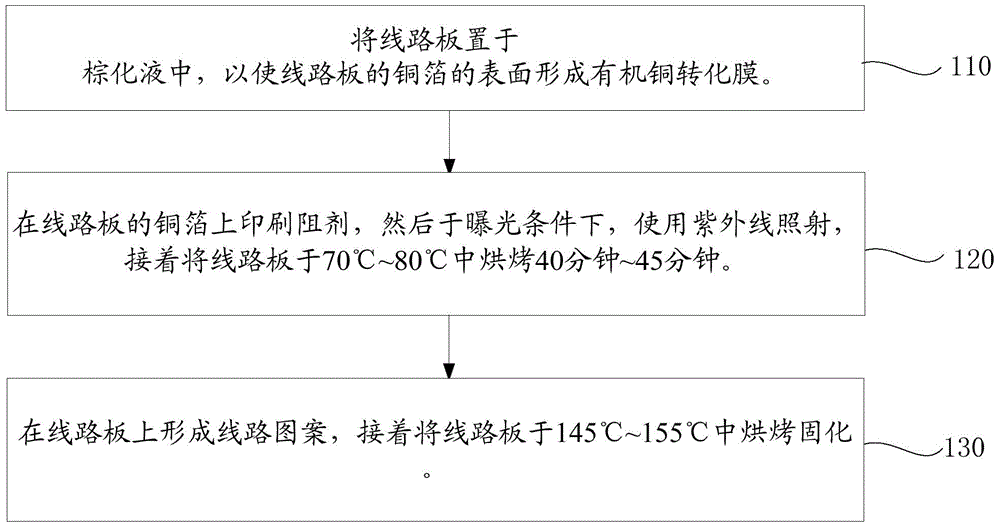

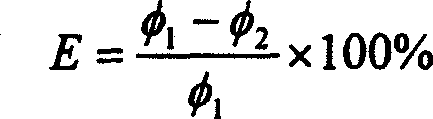

Surface processing method of circuit board

InactiveCN104320926ASolve the problem of foamingSolve sheddingInsulating substrate metal adhesion improvementMetallic material coating processesEpoxyUltraviolet

The invention discloses a surface processing method of a circuit board. The method comprises the following steps: arranging the circuit board in a browning liquid so as to enable an organic copper conversion film to be formed on the surface of the copper foil of the circuit board; printing a resistive agent on the copper foil of the circuit board, then under an exposure condition, performing ultraviolet ray irradiation, and then baking the circuit board for 40 to 45 minutes at a temperature of 70 DEG C to 80 DEG C; and then forming a line pattern on the circuit board, and next, baking the circuit board at a temperature of 145 DEG C to 155 DEG C for solidification, wherein the resistive agent is epoxy resin printing ink. The surface processing method of the circuit board can effectively solve the problems of foaming and falling of the resistive agent on the circuit board.

Owner:深圳华祥荣正电子有限公司

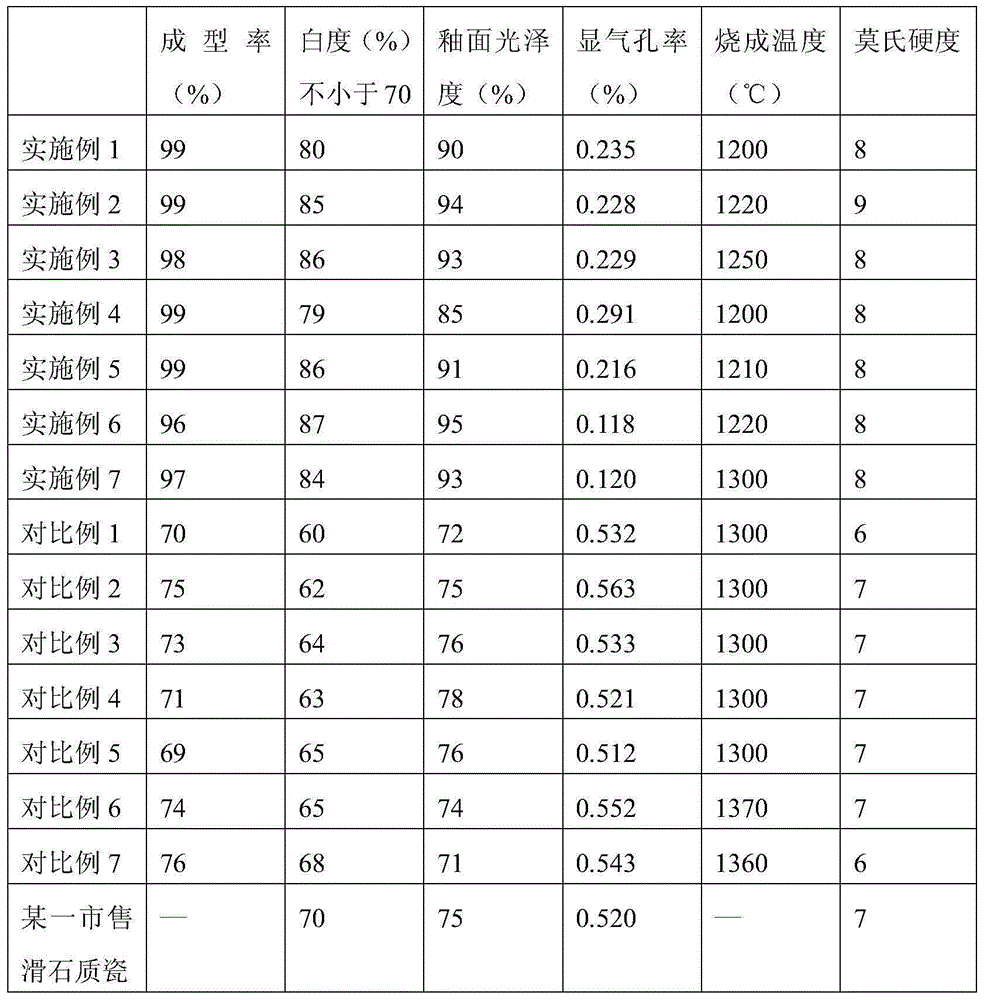

Porcelain formula and manufacturing process

The present invention provides a porcelain formula and a manufacturing process. The porcelain manufacturing process comprises: grinding and mixing raw material components of Longyan clay, bone charcoal, talcum, clay, Mingling mud, sepiolite, Enzhou rare stone powder, feldspar, calcite, flint clay and mineral wool according to a ratio in parts by weight; performing shaping according to a design, trimming a green body, drying the green body, firing the green body in a non-glazing manner at a low temperature of 800 DEG C to 850 DEG C in a reducing atmosphere with 3%-5% CO, and performing polishing for smoothness; and glazing the green body, adding Huiqing, heating and firing the product at 1200 DEG C to 1250 DEG C in a reducing atmosphere with 6%-8% CO. The porcelain provided by the present invention is firm in bonding of raw material components, has an average shaping rate greater than 96%, and is good in whiteness and glaze glossiness. Cracks are effectively prevented, and meanwhile, the blister and deformation phenomena caused by talcum in the porcelain formula are eliminated. In addition, the firing temperature of the porcelain manufacturing process is lowered.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

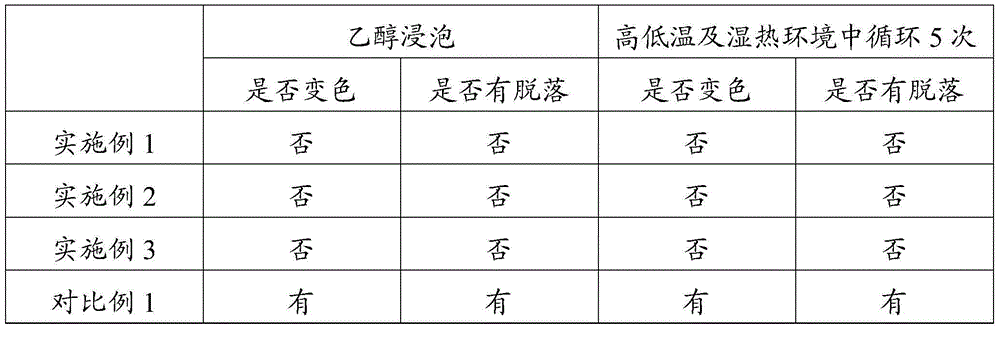

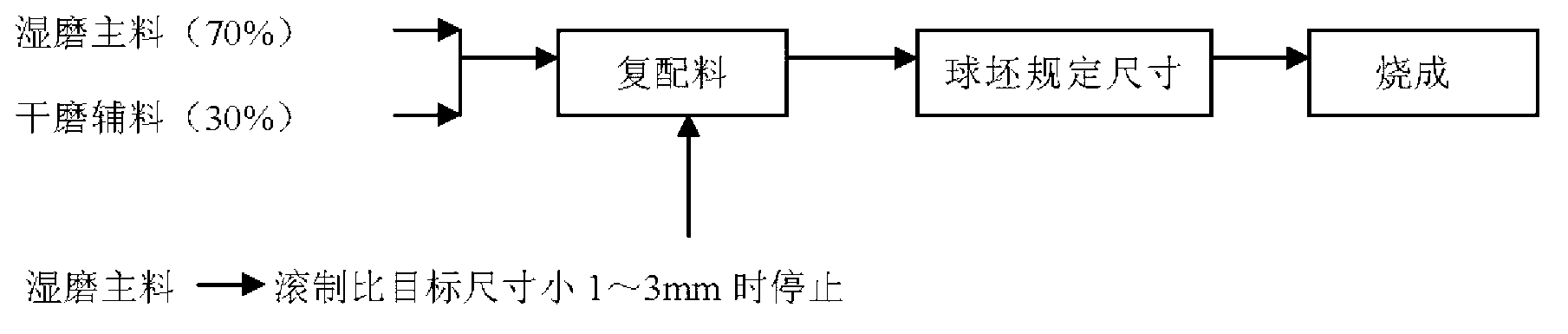

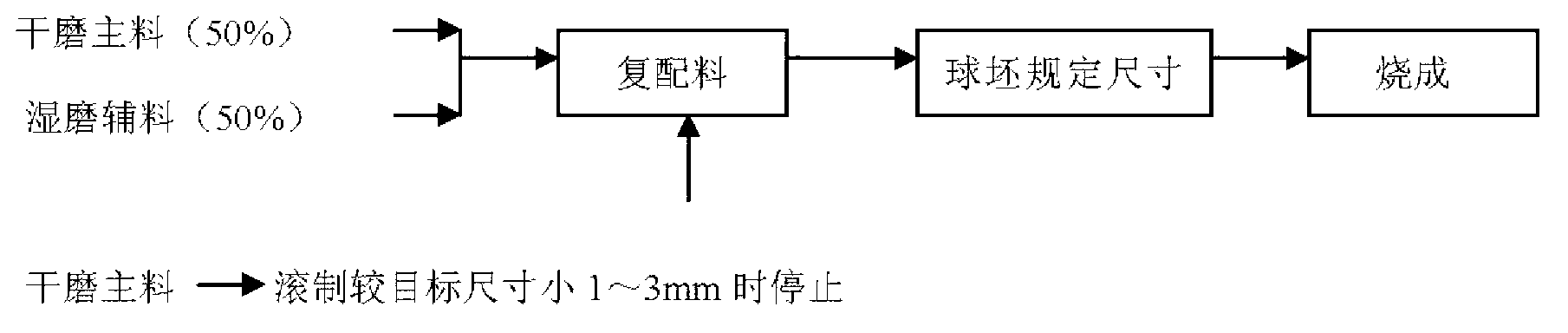

Method for improving appearance quality of inertial porcelain ball

The invention discloses a method for improving appearance quality of an inertial porcelain ball, and belongs to the technical field of novel materials. The method disclosed by the invention divides conventional ball-billet rolling process into two stages, wherein in the first stage, ingredients are grinded by a dry method or a wet method to roll the ball-billet till the size of the ball-billet is 1-3mm smaller than target size; and in the second stage, powder compounded by dry and wet grinding is adopted, and based on the ball-billet formed in the first stage, auxiliary materials are added to prepare compound powder based on the dry or wet grinded powder, and a novel surface wrapping layer is formed by rolling. Practices show that the method can solve the problem of ball layering in production of the inertial ball by the wet method ball-milling process and surface blistering after calcining. The method solves the problem that the degree of sphericity of the product in production of the inertial ball by the wet method ball-milling process is insufficient, and cracks are easy to generate after calcining. In addition, detection shows that the integral physical property of the product is further improved while the appearance quality of the inertial porcelain ball is improved at the same time.

Owner:JINGANG NEW MATERIALS

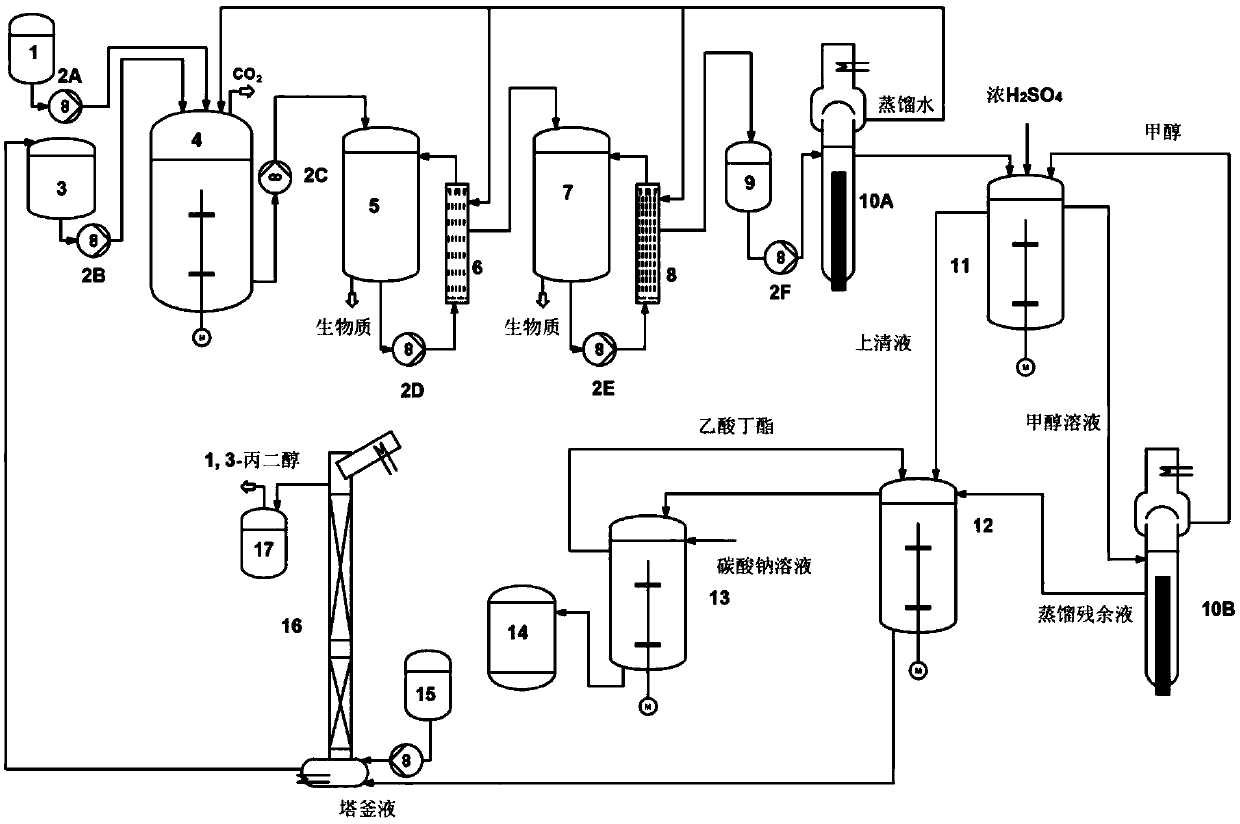

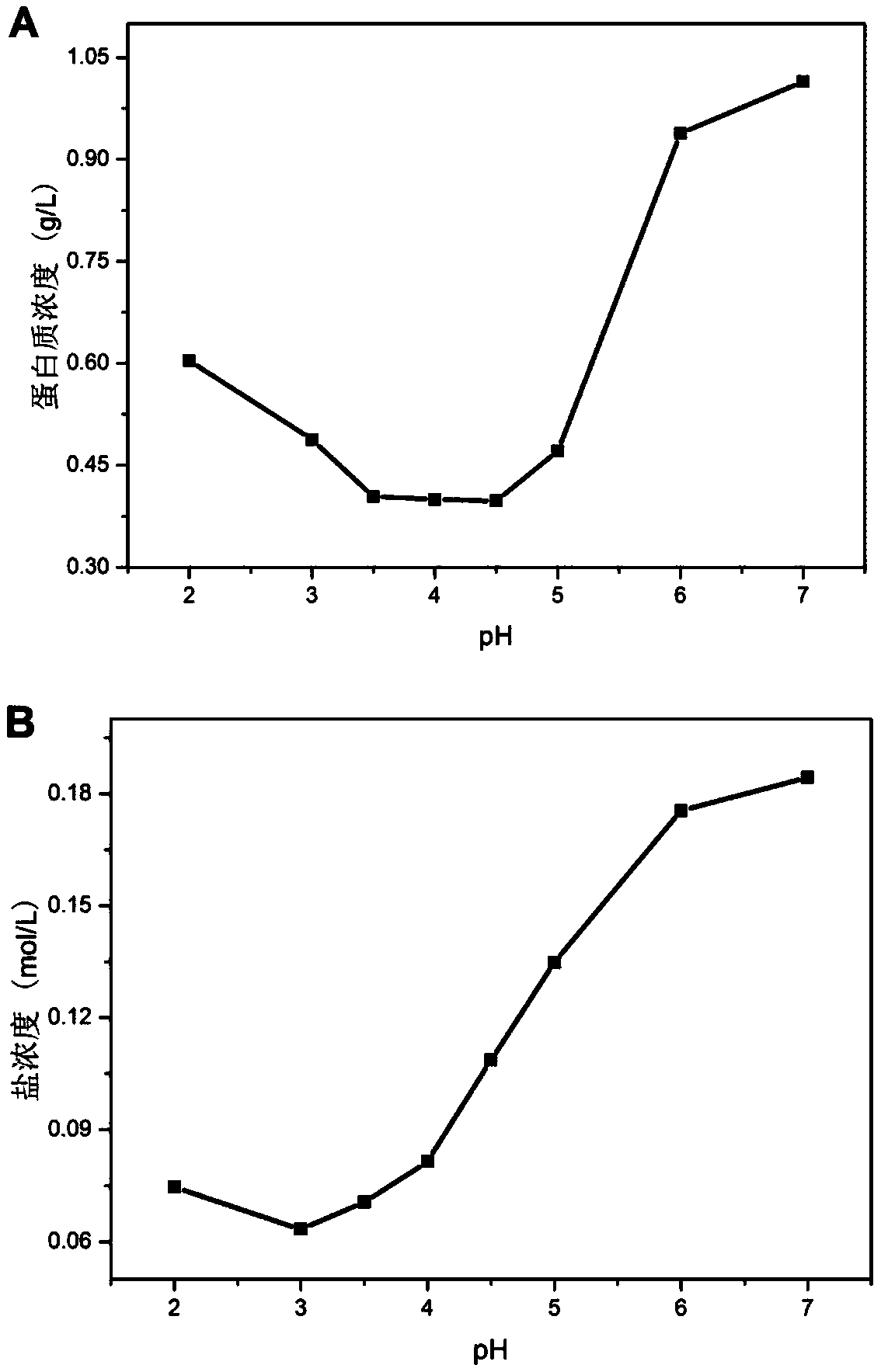

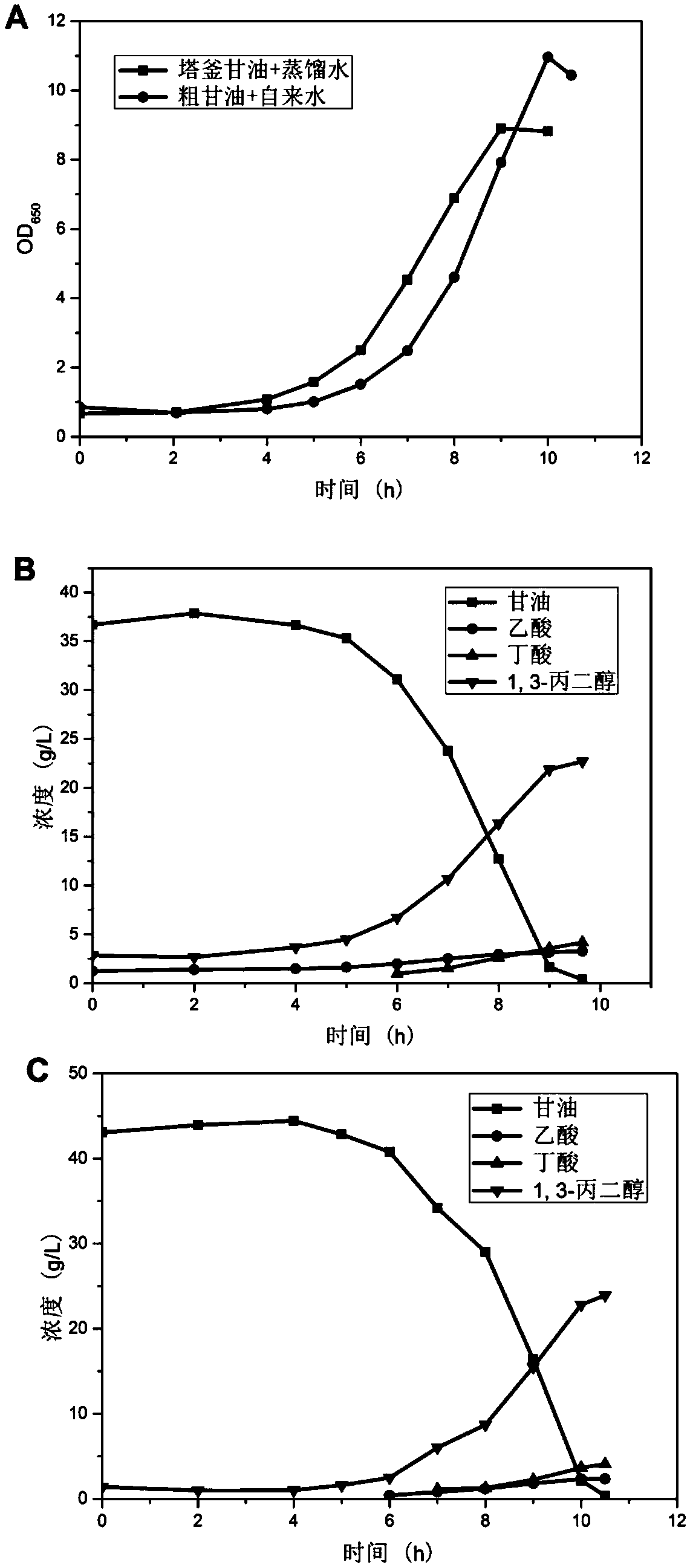

Method of isolating 1,3-propanediol, acetic acid and butyric acid from fermentation liquor

ActiveCN109574802ASolve the problem of foamingSolve the problem of viscous material precipitationOrganic compound preparationHydroxy compound separation/purificationOrganic acidAcetic acid

The invention belongs to the technical field of bioengineering and provides a method of isolating 1,3-propanediol, acetic acid and butyric acid from a fermentation liquor. The method includes: performing micro-filtering and ultrafiltering on the fermentation liquor to obtain a fermentation supernatant, and removing nearly all bacteria and most miscellaneous proteins; concentrating the fermentationsupernatant, and removing part of water; using an acid to adjust the concentrate to acidity, and filtering to remove precipitate; using a hydrophobic organic solvent to extract acetic acid and butyric acid from the supernatant, using an alkali or an alkaline inorganic salt solution to back-extract the organic acid from the extract, and rectifying raffinate to recycle 1,3-propanediol. The method herein is simple to perform and has high recovery rate; the problems that 1,3-propanediol and byproducts are difficult to separate and the cost is high are solved; the method is a separation method having a promising industrial application prospect.

Owner:DALIAN UNIV OF TECH

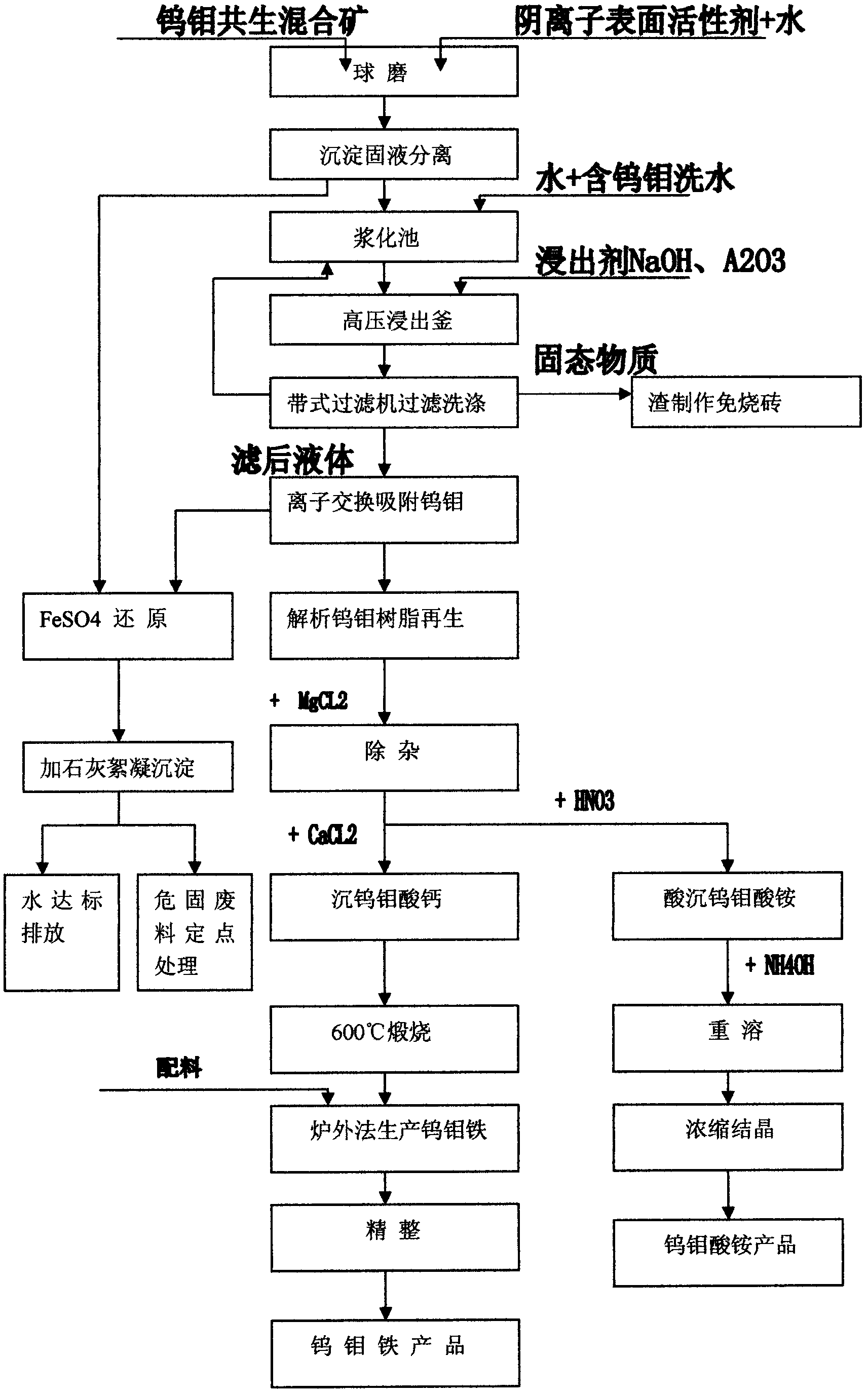

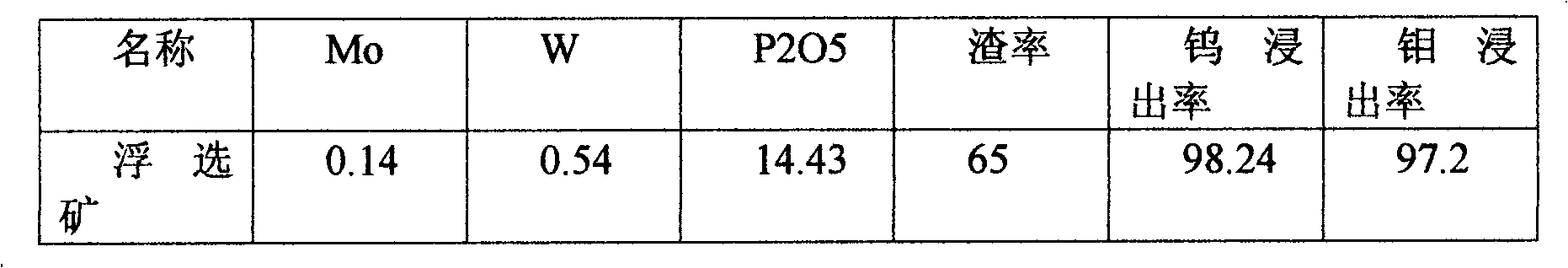

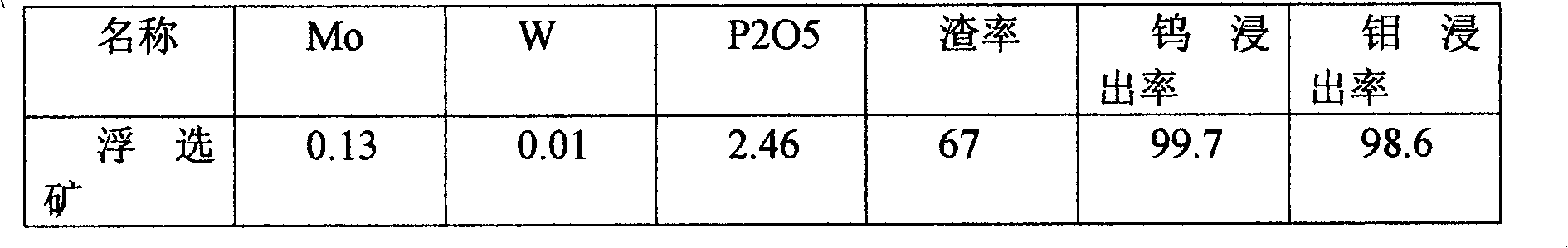

Method for producing tungsten and molybdenum products by processing tungsten and molybdenum symbiotic mixed ore

ActiveCN102296179ASolve the problem of foamingEliminate resin poisoningProcess efficiency improvementTungstenMagnesium

The invention discloses a method for producing a tungsten-molybdenum product by processing tungsten-molybdenum symbiotic mixed ore. The method comprises the following steps of: 1) adding anionic surfactant into the tungsten-molybdenum symbiotic mixed ore in a solid-liquid volume ratio of 1:3; 2) performing solid-liquid separation after ball milling; 3) treating the filtered liquid in a wastewater treatment tank, and pumping the solid into a slurrying tank; 4) adding sodium hydroxide serving as a leaching agent and bauxite A2O3 serving as an oxidant into the slurrying tank in a solid-liquid system, regulating the pH value to 12.5, stirring and slurrying; 5) pumping the slurry mixture into a high-pressure leaching kettle, heating, reacting, filtering, washing, leaching filtrate, diluting the filtrate by adding water, and regulating the PH value to 2.5 by using acid; 6) adsorbing tungsten and molybdenum by using weak alkali macroporous anion resin D314; 7) resolving the resin by using aqueous ammonia; 8) adding magnesium chloride into the resolved solution to remove phosphorus, silicon and arsenic, and obtaining filtered solution by filtering; and 9) obtaining the tungsten-molybdenum product by using the filtered solution. The method has the advantages of low investment, low production cost, short process flow, high leaching and recovery rate, low impurity leaching rate, environment friendliness and energy conservation.

Owner:HESHAN WODE TUNGSTEN & MOLYBDENUM

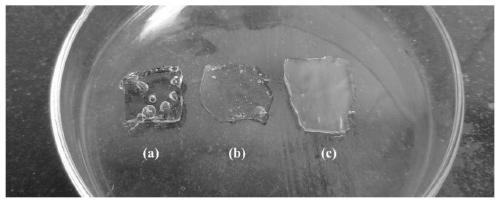

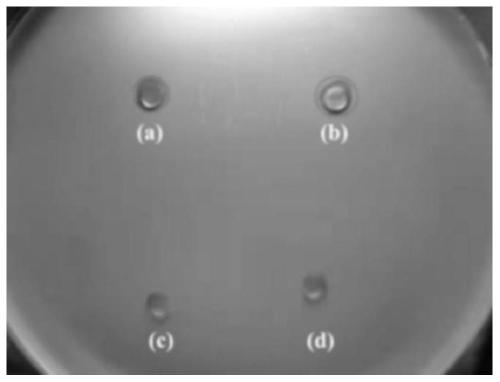

Preparation method of chitosan/polyvinyl alcohol hydrogel dressing

The invention discloses a preparation method of a chitosan / polyvinyl alcohol hydrogel dressing, and belongs to the technical field of polymer materials. The preparation method comprises the followingsteps: (1) obtaining a chitosan / polyvinyl alcohol solution; and (2) carrying out freeze thawing and an irradiation treatment in sequence to obtain the chitosan / polyvinyl alcohol hydrogel dressing. Thesynthesized chitosan / polyvinyl alcohol hydrogel can obviously improve the appearance and mechanical properties of hydrogel, the prepared dressing does not need a cross-linking agent or an initiator,the forming and sterilization of the hydrogel dressing are completed at the same time, and the hydrogel has a good application prospect.

Owner:河南省科学院同位素研究所有限责任公司

Solvent-free polyurethane paint and manufacture method thereof

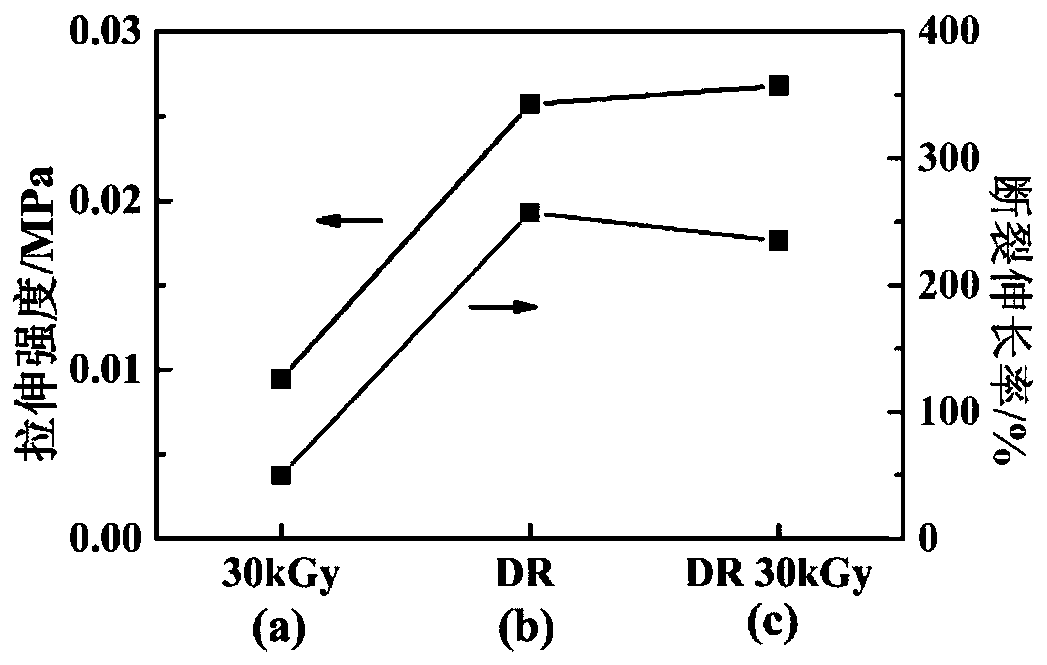

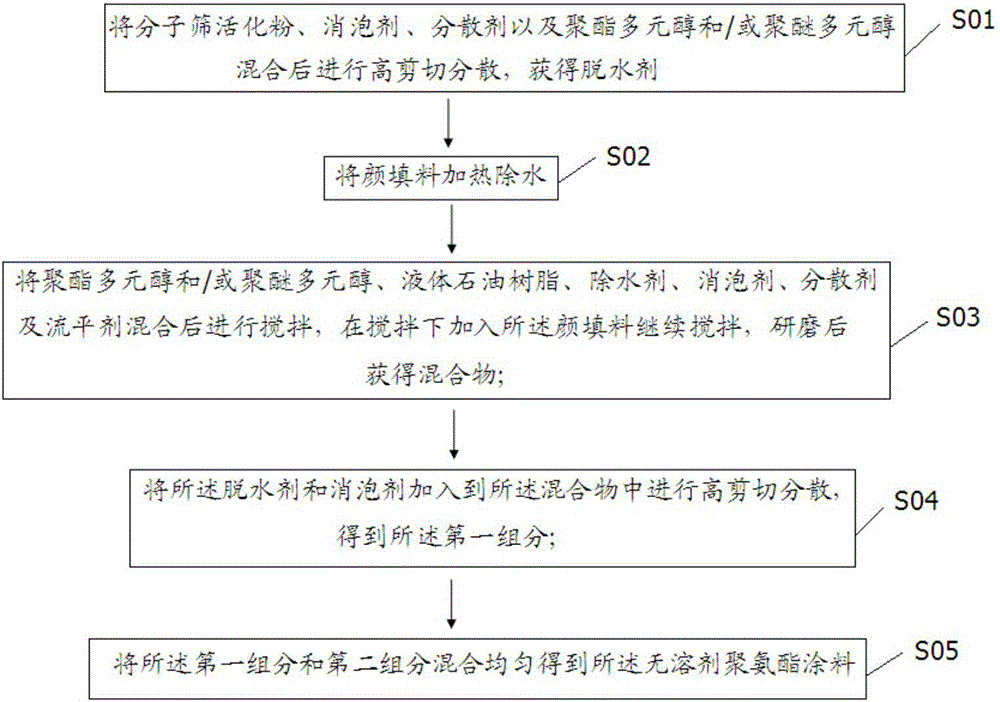

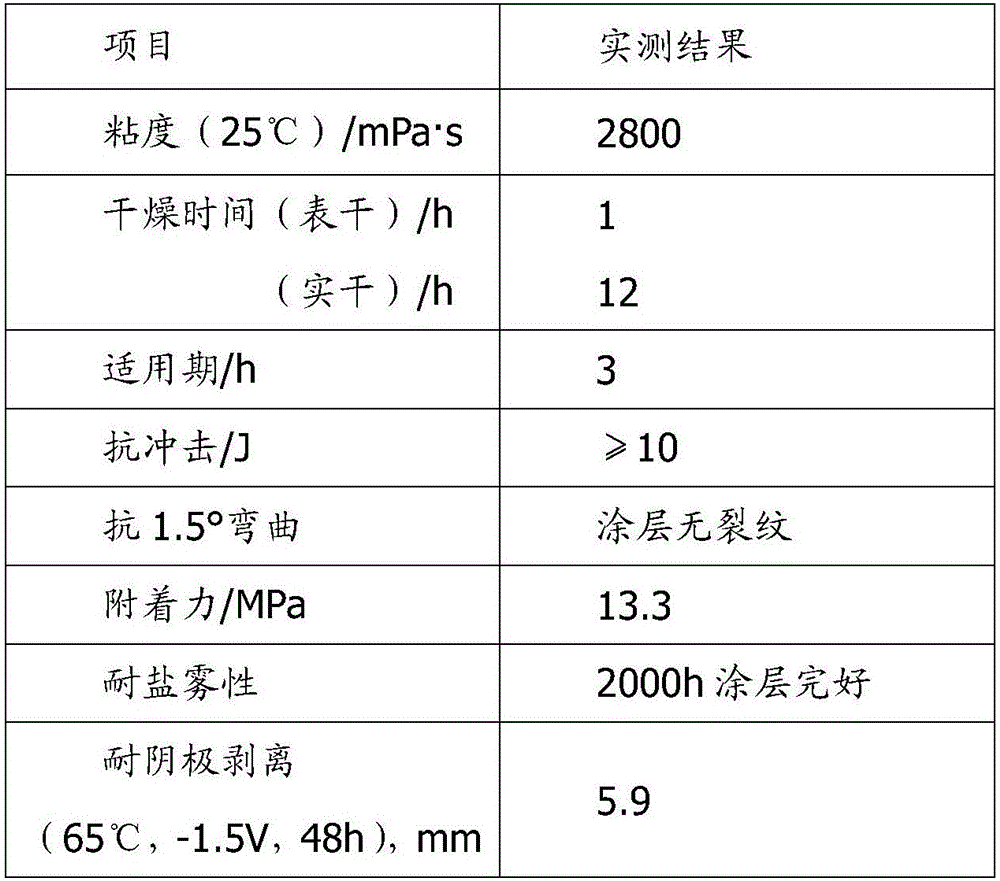

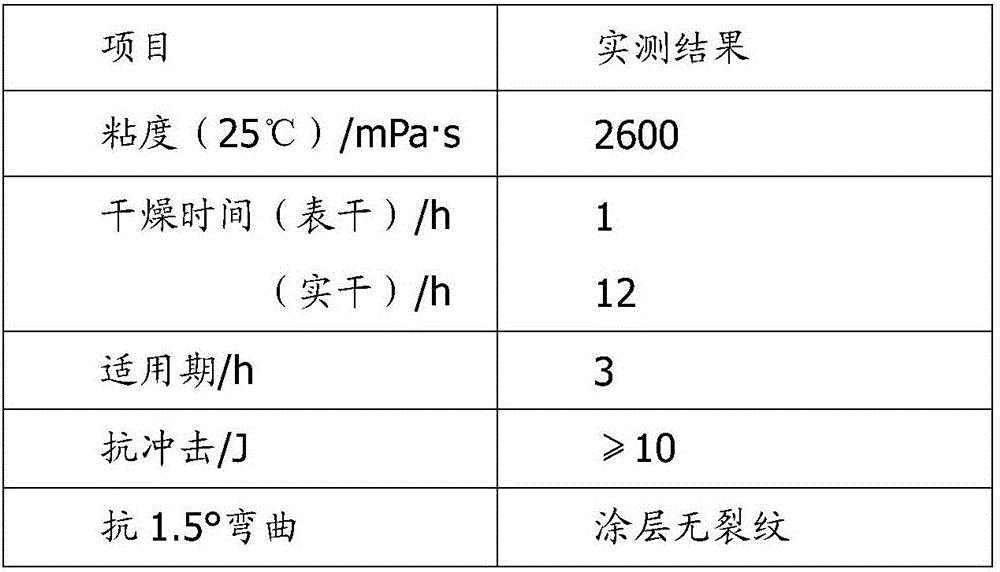

ActiveCN106336793AModerate viscositySolve problems such as inconvenience caused by constructionAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterSolvent free

The invention provides a solvent-free polyurethane paint and a manufacture method thereof. The solvent-free polyurethane paint comprises a first component and a second component; the component A comprises the following raw materials: 1.6-1.7 parts of polyester polyol and / or polyether polyol, 0.1-0.2 parts of liquid petroleum resin, 1.55-1.96 parts of pigments and fillers, 0.12-0.16 parts of molecular sieve activated powder, 0.015-0.02 parts of a water-removal additive, 0.03-0.04 parts of an antifoaming agent, 0.015-0.02 parts of a dispersant, and 0.015-0.02 parts of a levelling agent; and the component B comprises polyisocyanate. The paint has proper viscosity, the working life can reach 3h, the good construction performance can be guaranteed, the paint can be used for coating construction at normal temperature. the coating has good physical and chemical properties, the impact resistance is greater than 10 J, anti-15 DEG bending coating cannot generate cracks, the salt spray-resistant coating with 2000 h is undamaged, and the cathode stripping resistant performance is less than 6 mm. the paint can be used for anticorrosion of structures such as anticorrosion in large-scale crude oil storage tanks, anticorrosion outside the underground pipelines, and normal temperature coating construction of sea port concrete surface.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Soluble L-calcium lactate preparation and preparing method

InactiveCN1422614ASolve the problem of foamingHigh yieldMetabolism disorderAnhydride/acid/halide active ingredientsDairy foodsNutrition

The present invention discloses a souble L-calcium lactate preparation and its preparation method. Said invention uses the ocean waste shell as raw material and adopts direct acidification process after cleaned without high-temp. calcination to get the invented product which can be extensively used in the fields of milk product, beverage, health-care food and pharmaceutical industry. Said preparation possesses high biological utilization rate, it is up to 64%, its solubility is 2400 times that of calcium carbonate and 67 times that of calcium citrate, so that it can promote growth of bone effectively.

Owner:HUAHONG BIOLOGICAL PROD SHANGHAI

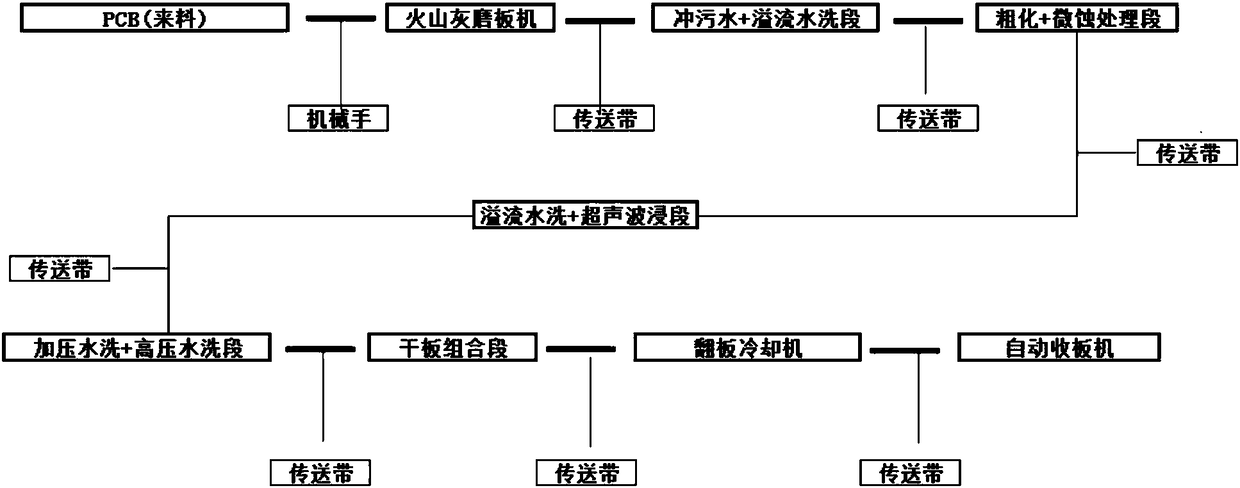

PCB (printed circuit board) resistance welding pretreatment process

ActiveCN108282966AReduce scratchesReduce the probability of scratchesProcessing steps orderNon-metallic protective coating applicationSolder maskSurface cleaning

The invention discloses a PCB (printed circuit board) resistance welding pretreatment process. The PCB resistance welding pretreatment process includes the steps of automatic feeding, volcanic-ash board grinding, roughening, microetching, surface cleaning, board drying, cooling and automatic board collecting. The process is high in automation degree, feeding and receiving are operated automatically, the step of carrying boards manually is omitted, processing efficiency is improved, and labor cost is lowered; in the steps of roughening and microetching, copper surfaces and holes of the PCBs aretreated by adopting a roughening solution and a microetching solution, the copper surface roughening effect is controlled by controlling of copper surface roughness and cleanliness, the roughness anduniformity of the copper surfaces can be optimized by roughening and microetching treatment, the binding force of the copper surfaces and the holes of the PCBs with resistance welding ink is improved, problems of bubbling and ink coming off the resistance welding layer are solved, and in addition, automatic board collecting operation also reduces the probability of friction on the board surfaces.

Owner:江西景旺精密电路有限公司

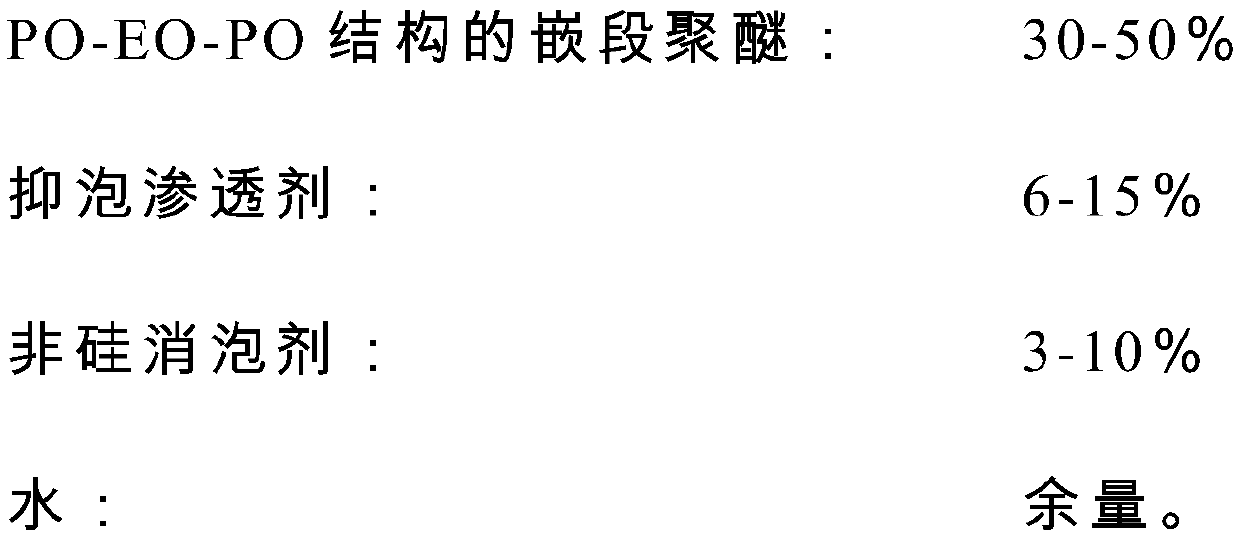

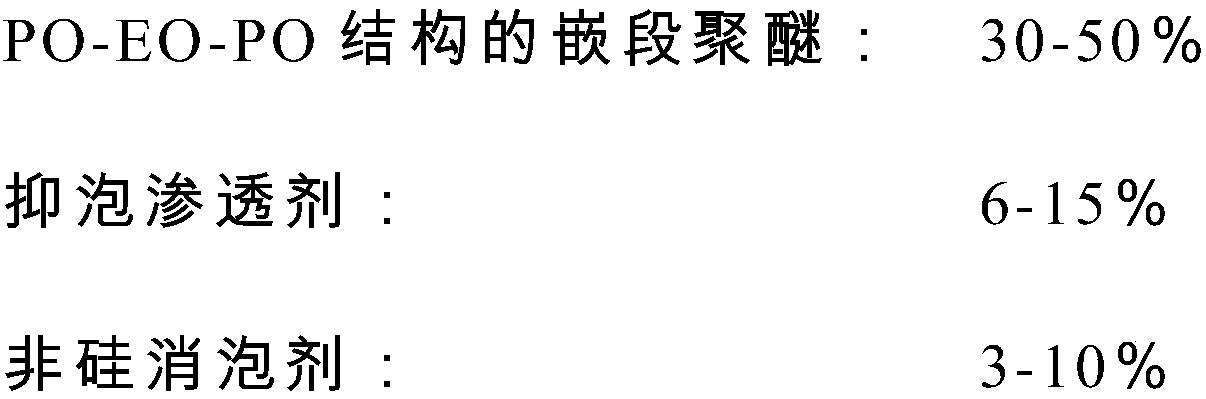

Single-ingredient diamond wire cutting fluid for silicon chip

InactiveCN109777588AImprove permeabilityEliminate generationLubricant compositionFoaming agentWire cutting

The invention discloses a preparation method of single-ingredient diamond wire cutting fluid for a silicon chip. The cutting fluid is prepared from the following ingredients in percentage by weight: 30 to 50 percent of block polyethers of PO-EO-PO structures, 6 to 15 percent of anti-foaming penetrants, 3 to 10 percent of non-silicon anti-foaming agents and the balance water. In the use process, the cutting fluid has the advantages of low foam, fast wetting, good silicon powder dispersion effect, few silicon chip line marks, low broken chip proportion, capability of easy discharged chip cleaning and the like; the qualification rate is greatly improved; the cutting qualification rate can reach 95 percent or higher.

Owner:苏州禾川化学技术服务有限公司

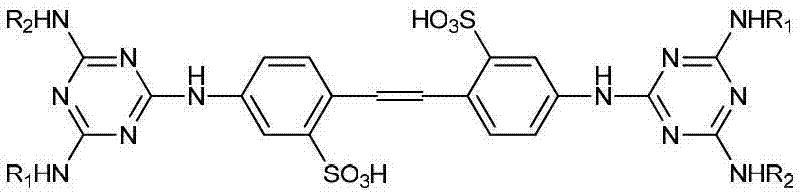

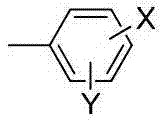

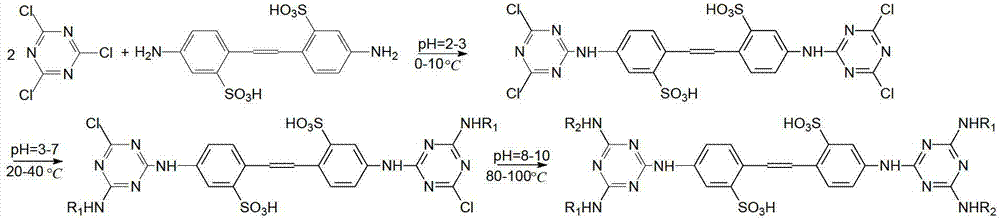

Method for synthesizing DSD (4, 4'-diaminostilbene-2, 2'-disulfonic) acid-triazine fluorescent brightening agents

ActiveCN103205134ASolve stickyIncrease profitStyryl dyesLuminescent compositionsChemical oxygen demandOrganic solvent

The invention discloses a method for synthesizing DSD (4, 4'-diaminostilbene-2, 2'-disulfonic) acid-triazine fluorescent brightening agents. A DSD acid-triazine fluorescent brightening agent reaction system is improved to a certain degree by an existing method, and on the basis of comprehensive consideration in various aspects such as the reaction cost, expanded production is carried out but only can be implemented by means of simply expanding reaction equipment. The method is characterized by comprising salifying all organic amine NH<2>R<2> and DSD acid of raw materials for tertiary condensation reaction or parts of the organic amine NH<2>R<2> and DSD acid to obtain DSD acid organic ammonium salt aqueous solution; and sequentially enabling the DSD acid organic ammonium salt aqueous solution to perform primary condensation reaction, secondary condensation reaction and tertiary condensation reaction to obtain the DSD acid-triazine fluorescent brightening agents. The method has the advantages that optional compounds or auxiliaries except for reactants are omitted in reaction procedures; the burden of desalination in an aftertreatment procedure caused by addition of extra salt in an existing method for manufacturing DSD acid-triazine fluorescent brightening agents is relieved, and the problem of foaming due to additional surfactants is solved; the COD (chemical oxygen demand) of waste liquor and the total quantity of the waste liquor are reduced; and problems of increase of cost and pollution due to organic solvents utilized in primary condensation reaction in the existing method are solved.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM +1

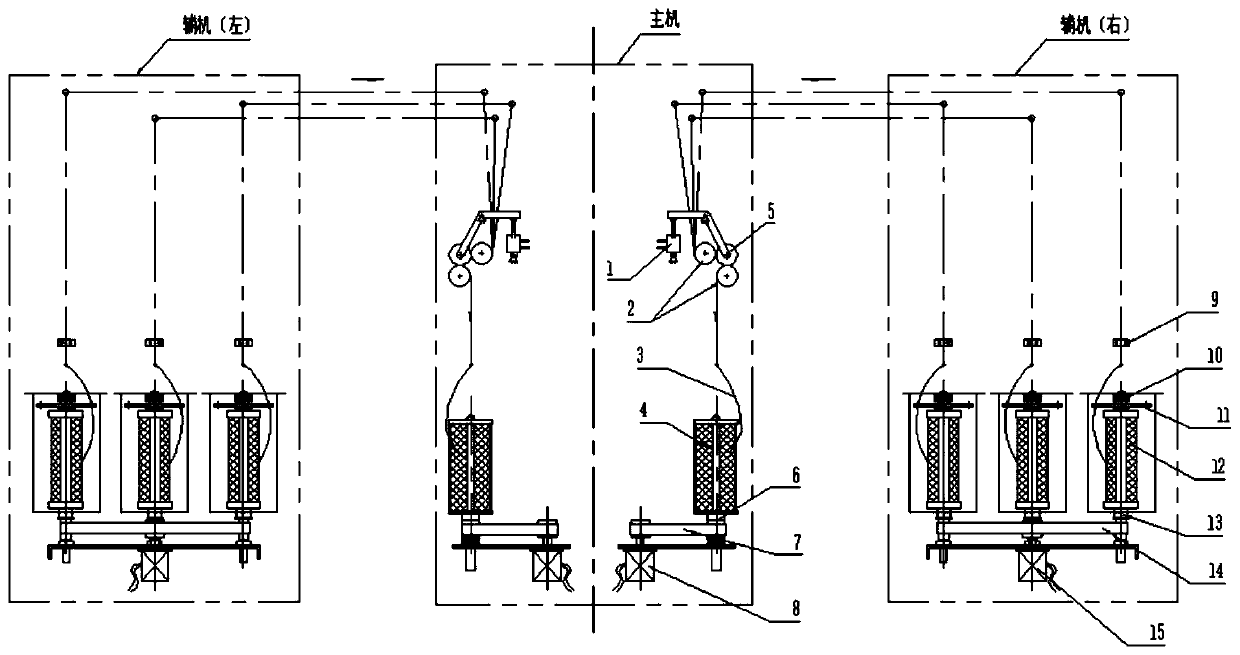

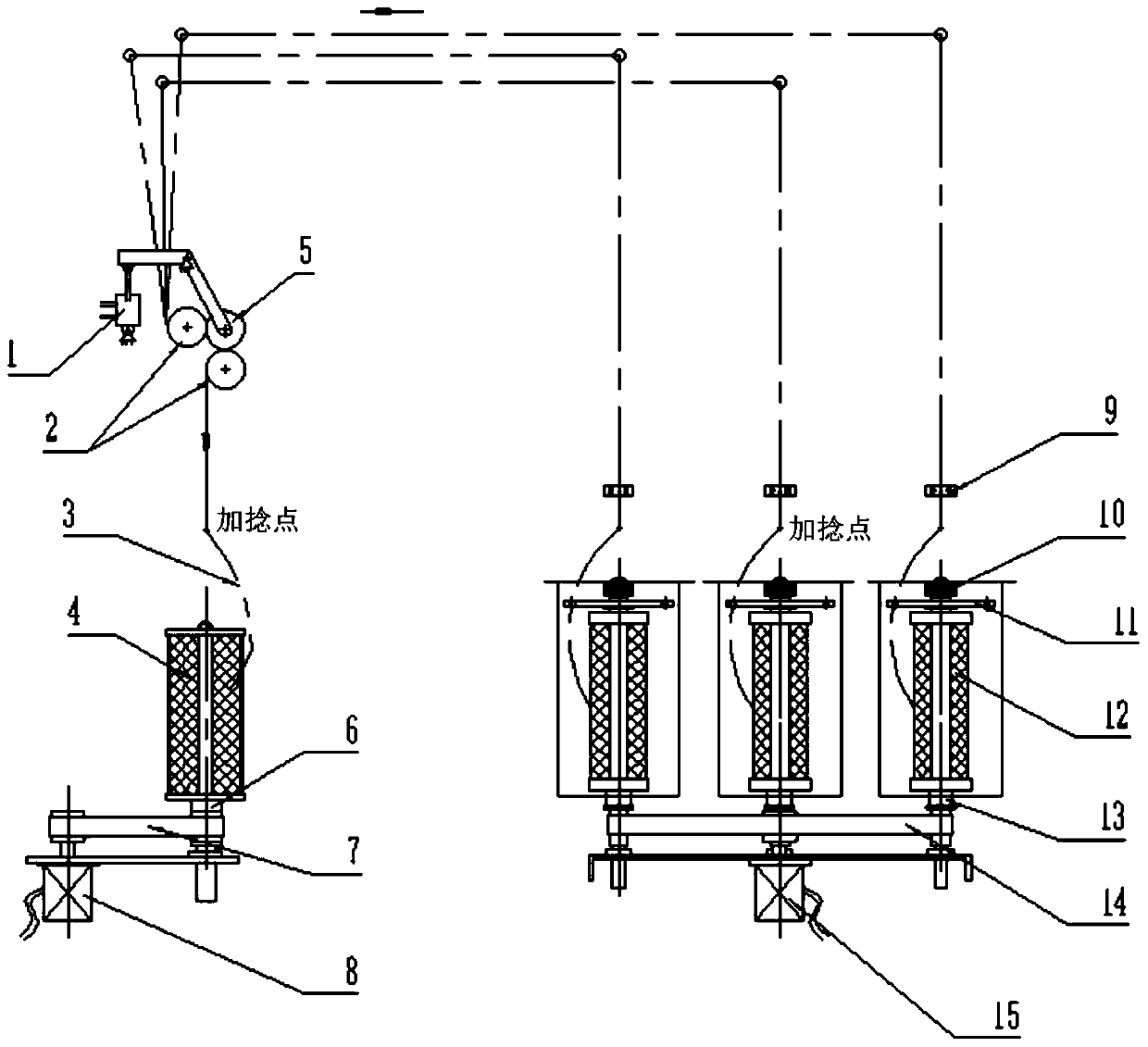

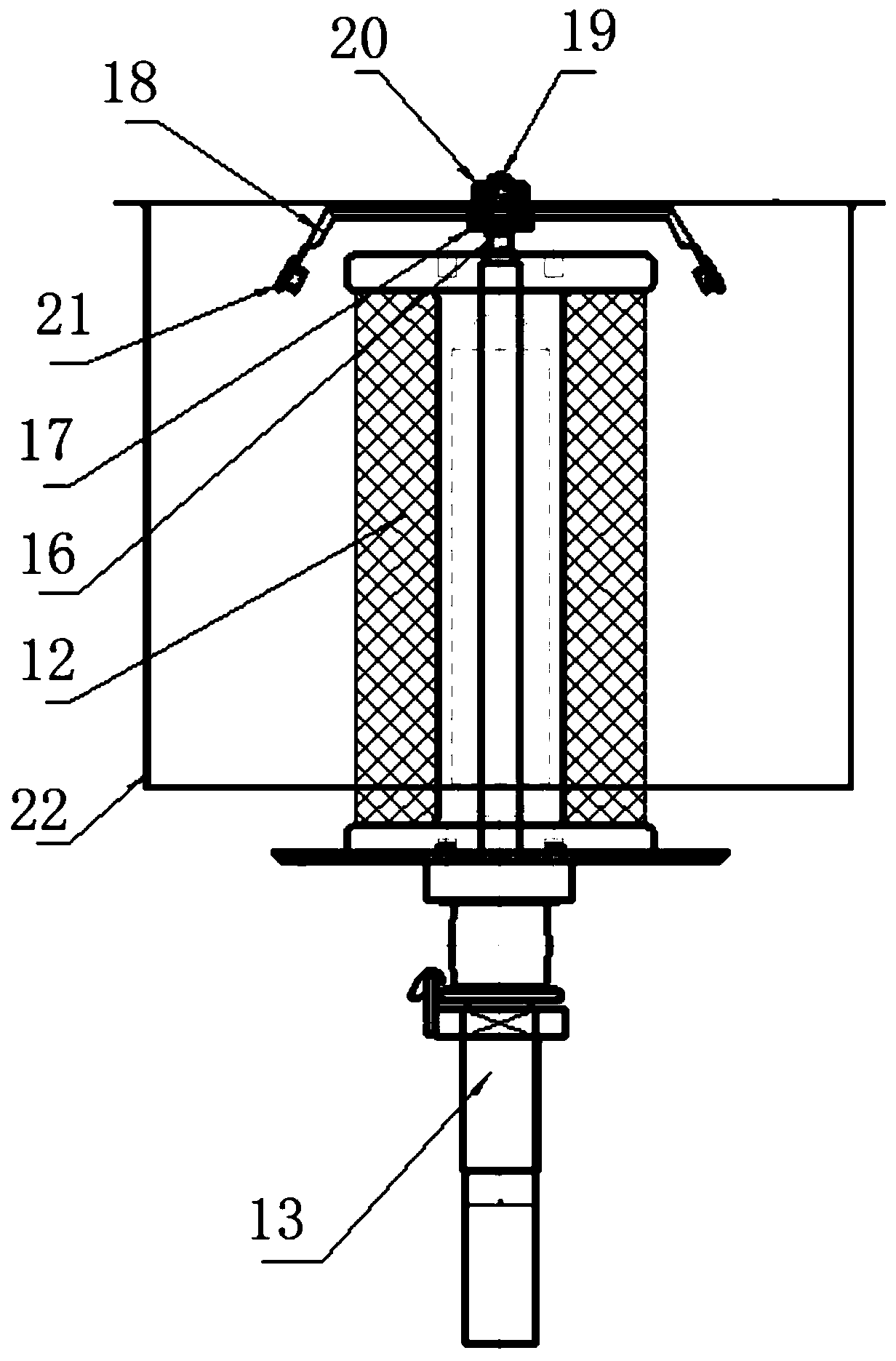

One-step composite twisting frame

The invention provides a one-step composite twisting frame, and belongs to the technical field of textile machinery. By arranging an unwinding device on the top of a first twist spindle, the problemsthat in the yarn twisting process, uneven yarn twist, fuzzing, bubbling and the like are caused by unstable balloon tension can be effectively solved. The one-step composite twisting frame comprises afirst twisting mechanism, a roller transmission structure and the a second twisting mechanism; in the first twisting mechanism, single twisting is conducted through the first twisting spindle, and two or more yarns completing single twisting enter the roller transmission structure for monofilament stranding to form a twisted yarn; the second twisting mechanism is used for second twisting of the twisted yarn; the unwinding device is arranged on the top of the first twist spindle, that is to say, a bracket is additionally arranged in the middle of a twisting zone of the yarns, the size of a balloon formed through high-speed rotation of the yarns in the twisting zone is fixed, the balloon size is basically the same, and the yarn quality problem generated by colliding with other parts cannotbe caused; the problems of yarn fuzzing, bubbling, more white dots, more broken ends and the like of a traditional one-step twisting frame can be effectively solved.

Owner:HANGZHOU CHANGYI TEXTILE MACHINE

Method for preparing alkyl ketene dimer emulsion without surfactants

ActiveCN105908567AStabilizer lastingImprove sizing effectWater-repelling agents additionPaper/cardboardPhotochemistryAmino acid

The invention relates to a method for preparing alkyl ketene dimer emulsion without surfactants. The method includes steps of (1), preparing emulsifier water phases, to be more specific, wetting hectorite, uniformly mixing the hectorite and aqueous solution of water-soluble sodium amino acid salt with each other and regulating pH (potential of hydrogen) values of the hectorite and the aqueous solution by the aid of diluted acid; (2), pasting cationic starch to prepare stabilizer water phases; (3), preparing the alkyl ketene dimer emulsion, to be more specific, mixing the emulsifier water phases and AKD (alkyl ketene dimer) melted liquid with one another to obtain mixtures, stirring the mixtures, adding the stabilizer water phases into the mixtures and continuing to stir the mixtures and the stabilizer water phases to obtain the stable O / W (oil-in-water) type AKD emulsion. The method has the advantages that the water-soluble sodium amino acid salt and the nanometer solid granular hectorite are used as emulsifiers, the cationic starch is used as a stabilizer, the emulsifiers and the stabilizer are added in a sectional manner to prepare the alkyl ketene dimer emulsion, processes for preparing the alkyl ketene dimer emulsion are simple, the surfactants are omitted, accordingly, the problem of foam due to the surfactants can be solved, the alkyl ketene dimer emulsion is durable in stability, liquid drop has a small diameter, and good adhesive application effects can be realized.

Owner:山东熙来淀粉有限公司

Non-curing polyurethane waterproof coating and preparation method thereof

ActiveCN103923565BGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention relates to a non-curing polyurethane waterproof coating and a preparation method thereof, belonging to the technical field of polyurethane waterproof coating. It consists of the following raw materials in percentage by weight: prepolymer 13-20%, asphalt 30-65%, latent curing agent 1.0-1.5%, compatibilizer 3-15%, thermoplastic elastomer 2-9%, powder Sexual filler 0-30%, the prepolymer is a reaction composition of polyether and isocyanate. The core of the invention improves the material ratio and polymerization process of polyurethane, which overcomes the problems that hot-melt asphalt materials need to be heated by machines, etc. It is convenient for construction and has good fluidity. The waterproof layer without internal stress can also have good adhesion with the coiled material. It can be composited waterproof to form a waterproof layer that overcomes the cracking of the base layer and prevents puncture. The process is simple and can be quickly constructed. It needs maintenance and has fast work efficiency, which can become the development direction of building waterproofing in the future.

Owner:浙江鲁班建材科技股份有限公司

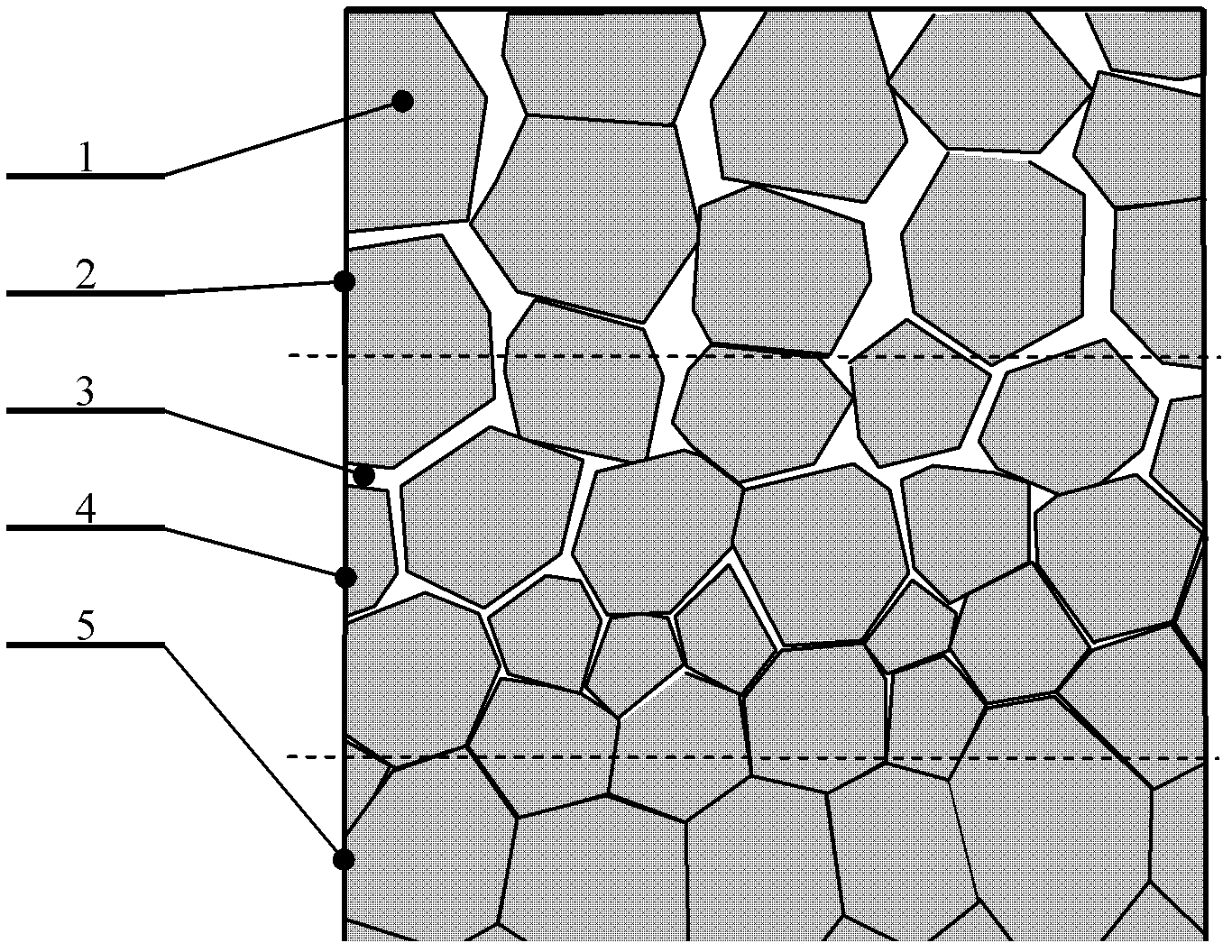

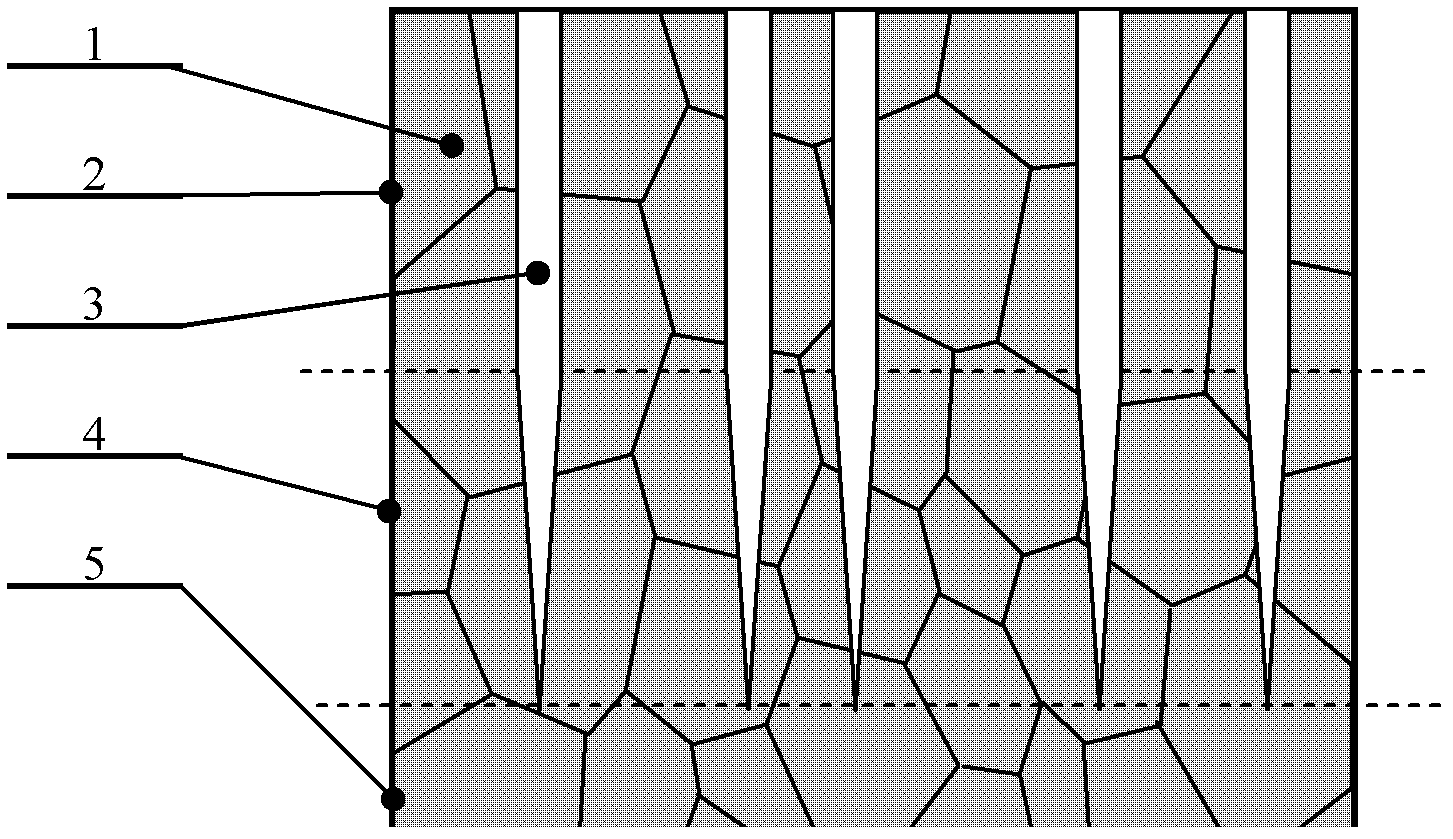

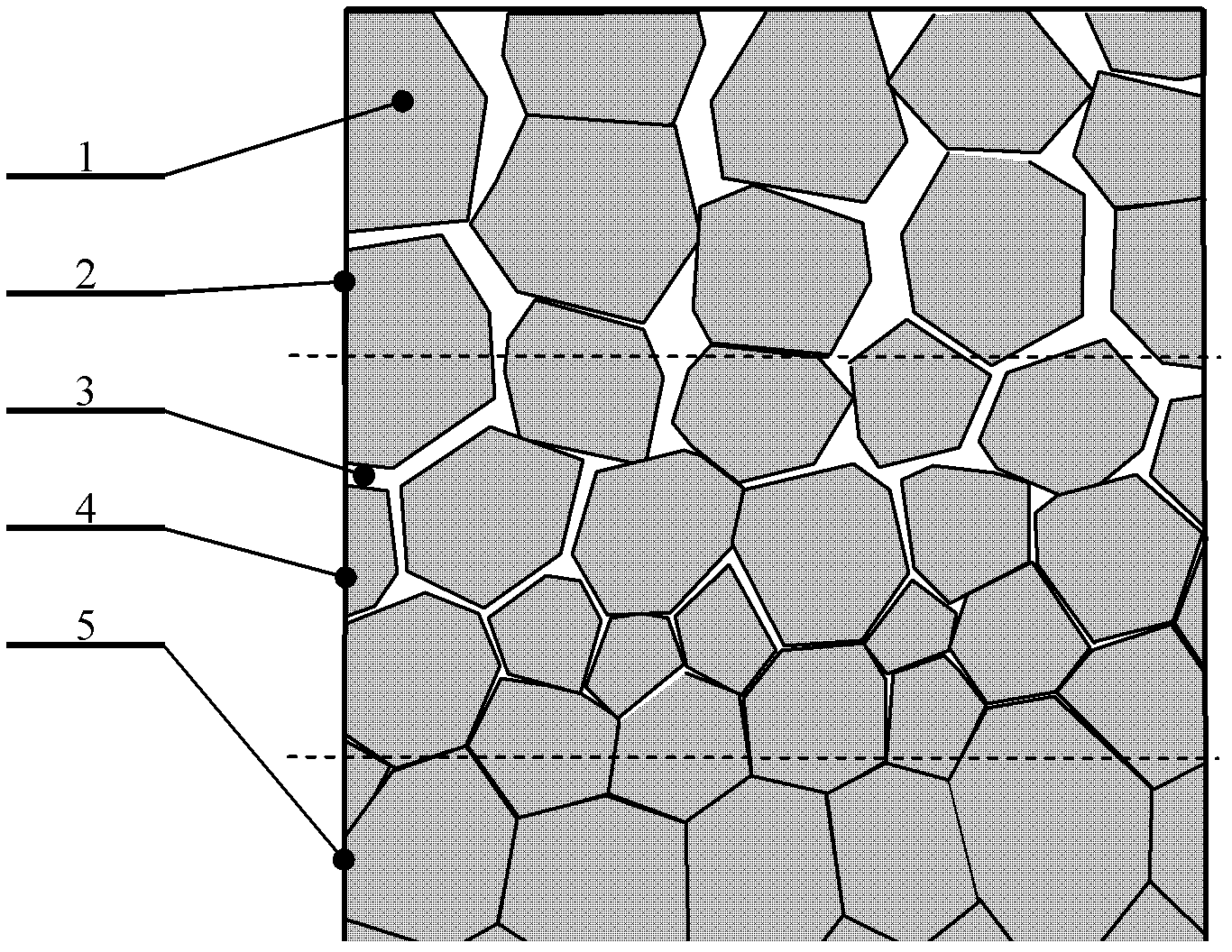

Antifoaming gradient porous structure in plasma-facing material

The invention belongs to the field of nuclear fusion energy application, and discloses an antifoaming gradient porous structure in a plasma-facing material. According to the variation of the porosity, on a thickness direction, the tungsten-based plasma-facing material with the gradient porous structure is composed of three layers of components, which are a surface porous layer, a gradient transition layer, and a substrate. The porosity of the gradient transition layer is gradually reduced from the porosity at the place of the surface porous layer along a depth direction, such that a gradient change is formed. Finally, the porosity of the gradient transition layer is the same with that of the substrate. According to the invention, with the pores communicating with the surface, hydrogen andhelium entering the plasma-facing material are delivered back to the surface, such that the formation of inner foam in the plasma-facing material is avoided, and a phenomenon of foaming is eliminated.

Owner:BEIHANG UNIV

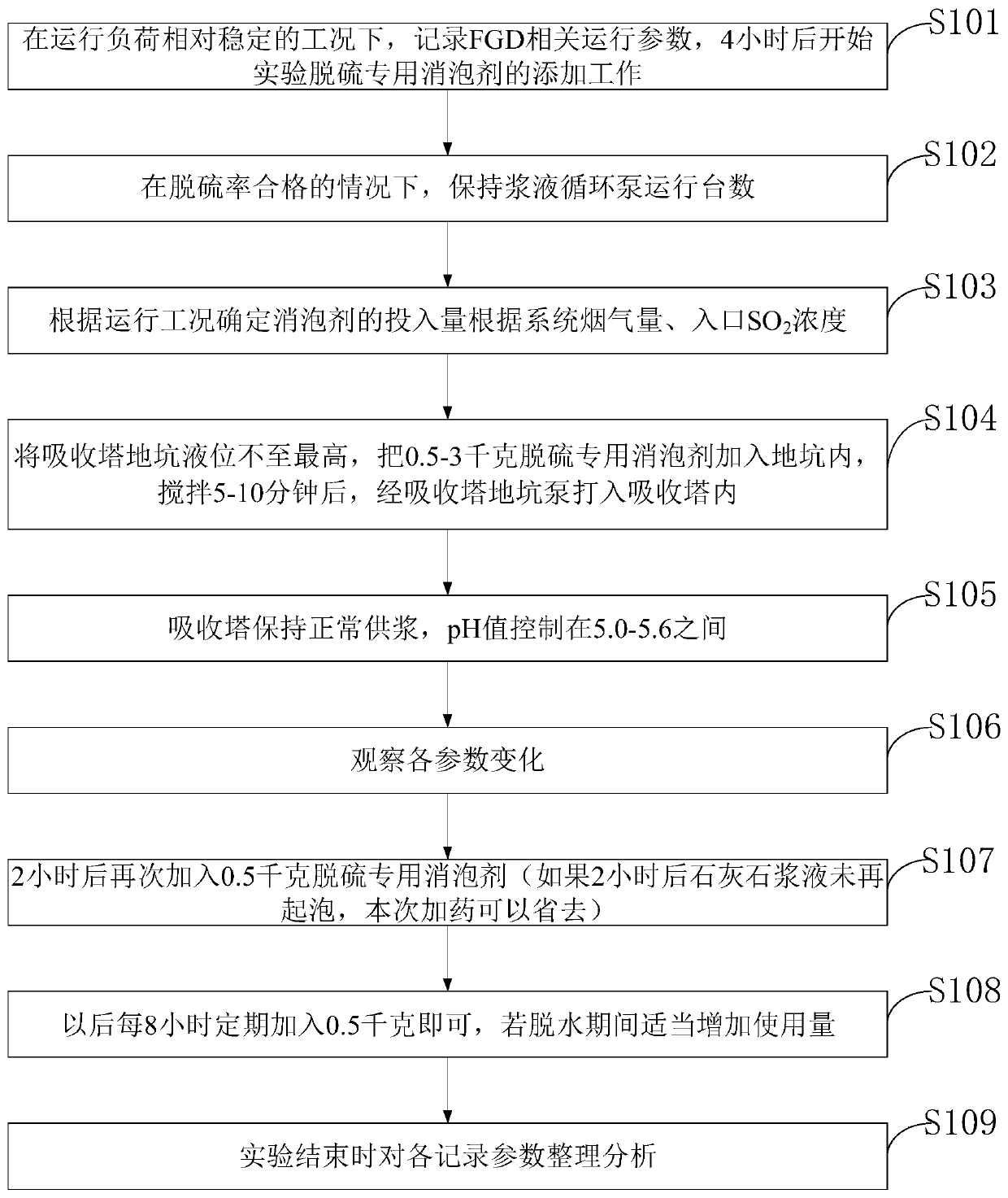

Limestone-wet flue gas desulfurization defoaming method for thermal power plant based on desulfurization defoaming agent

PendingCN111330316ASolve the problem of foamingResolve downtimeGas treatmentDispersed particle separationSlurryCoking plant

The invention belongs to the technical field of flue gas desulfurization, and discloses a limestone-wet flue gas desulfurization defoaming method for a thermal power plant based on a desulfurization defoaming agent. The method comprises the following steps: recording FGD related operation parameters under the working condition of relatively stable operation load, and starting the addition work ofa special defoaming agent for experimental desulfurization after 4 hours; under the conditions that the desulfurization rate is qualified and the PH value is 5.0-5.6, the running number of the slurrycirculating pumps is kept; determining the feeding amount of the defoaming agent according to the operation conditions such as the inlet flue gas amount, the flue gas dust content, the boiler oil feeding amount, the inlet SO2 concentration and the like of the desulfurization system; and adding 0.5-3kg of the special defoaming agent for desulfurization into the pit, stirring for 5-10 minutes, and pumping into an absorption tower through an absorption tower pit pump. The defoaming agent is mainly applied to defoaming of limestone slurry in limestone-wet flue gas desulfurization absorption towersof thermal power plants, municipal coal-fired heat supply units, steel mills and coking plants.

Owner:陕西页川电力科技有限公司

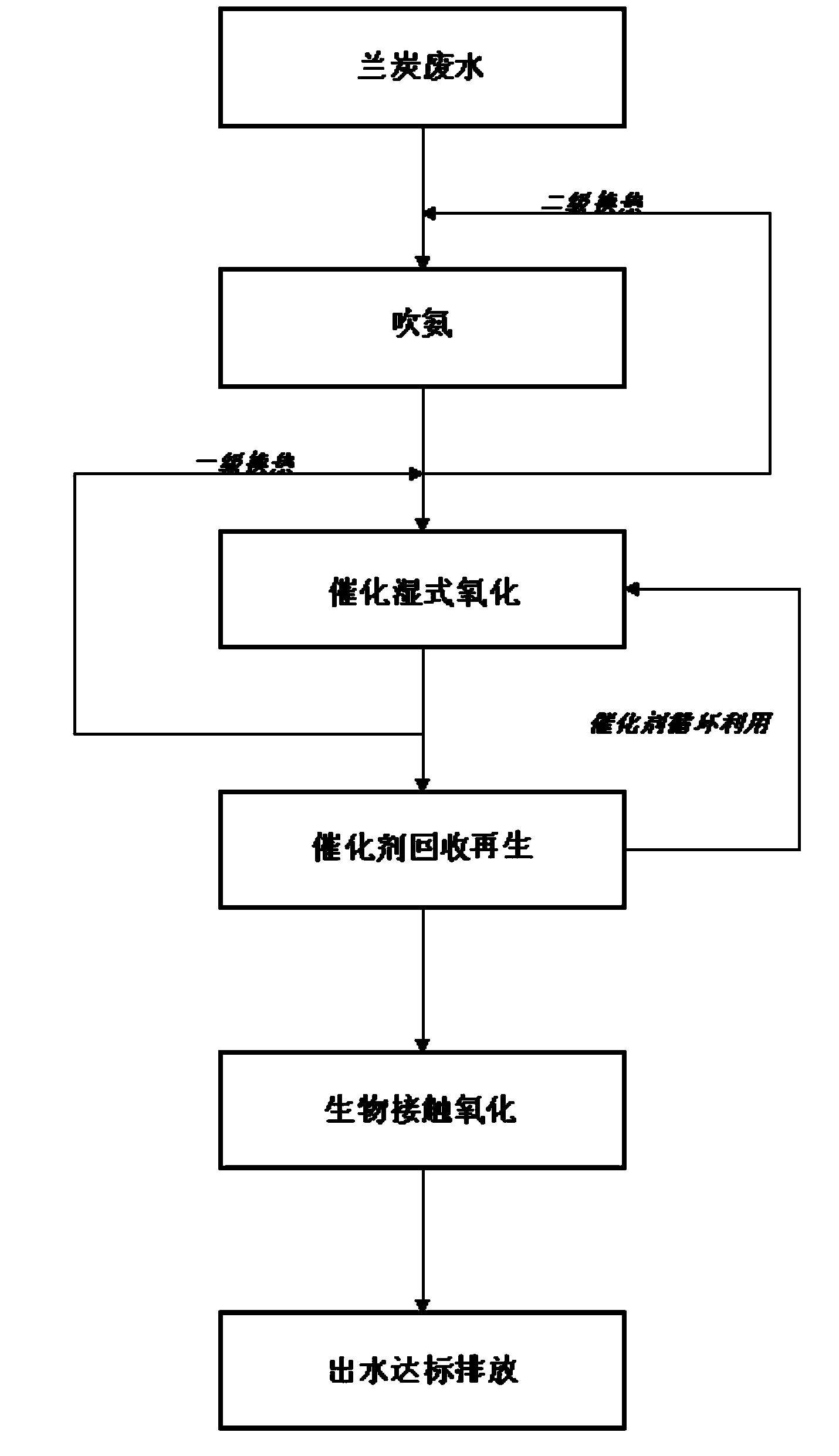

Comprehensive treatment process for semi-coking wastewater

ActiveCN103449679AReduce dosageSolve the problem of foamingMultistage water/sewage treatmentWater/sewage treatment by degassingChemical oxygen demandWater quality

The invention relates to the field of wastewater treatment technologies in environmental protection and particularly relates to a comprehensive treatment process for semi-coking wastewater. The process is characterized by comprising the processing procedures of ammonia blowing, catalytic wet oxidation, catalyst recycling and biological contact oxidation, wherein the procedures are sequentially carried out; both the ammonia blowing procedure and the catalytic wet oxidation procedure are assisted by a gas-liquid mixer, so as to pre-treat the semi-coking wastewater, on one hand, the concentration of pollutants is lowered, and on the other hand, toxic and harmful pollutants in the wastewater are transformed into readily-biodegradable low-toxicity micromolecular pollutants and the biodegradability of the wastewater is improved; then, the biological contact oxidation treatment is carried out, so that the treated water can reach emission requirements. Compared with the prior art, the process has the beneficial effects that the energy consumption is reduced, the requirements for pH values are relatively low, and the usage amount of industrial base is reduced; the temperature and pressure required for reaction are lowered greatly on the premise that a relatively high COD (Chemical Oxygen Demand) removal rate is guaranteed, so that the process has an important significance in sustainable development.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

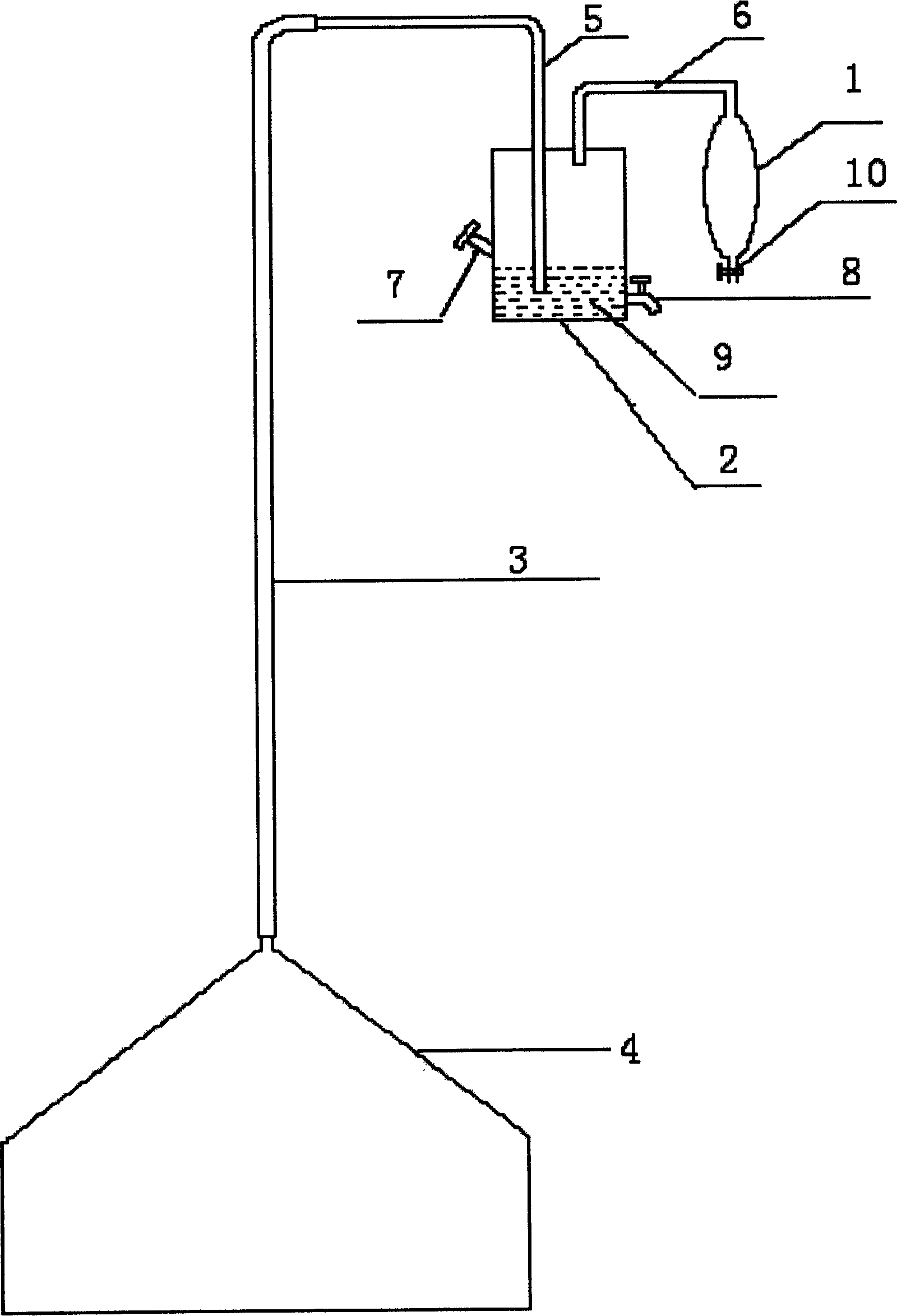

Oxygen availability gas-phase chromatography detecting method and apparatus for aerating tank

InactiveCN1645133AEasy to makeFlexible useComponent separationWithdrawing sample devicesSludgeGas phase

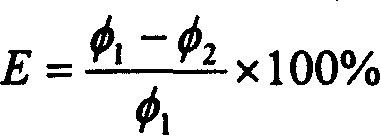

A detection method includes utilizing gas collection device to collect gas overflowed from aeration basin of polluted water and then defoaming the collected gas, measuring out content of oxygen and nitrogen in inlet air and overflowed air at aeration basin by gas chromatograph, calculating out utilization rate of biological oxygen in aeration basin by utilizing content ratio of oxygen to nitrogen in inlet air and overflowed air.

Owner:DALIAN JIAOTONG UNIVERSITY

Preparation method of AKD emulsion free of surface active agent

ActiveCN105696417ASimple preparation processAvoid Bubble ProblemsWater-repelling agents additionPaper/cardboardIonEmulsion

The invention relates to a preparation method of an AKD emulsion free of surface active agent. The method includes the following steps of firstly, preparing an emulsifier water phase, wherein hectorite is wetted by water and mixed with aluminium polychlorid hydrosol; secondly, preparing a stabilizer water phase, wherein positive ion starch is pasted; thirdly, preparing the emulsion, wherein the emulsifier water phase and AKD molten liquid are mixed and stirred, then the stabilizer water phase is added to continue to be stirred, and then the stable O / W type AKD emulsion is obtained. Aluminium polychlorid and nanometer solid particles hectorite serve as the emulsifier, positive ion starch serves as the stabilizer, the emulsifier and the stabilizer are added separately to prepare the emulsion, the preparation process is simple, no surface active agent is added, the foaming problem caused by the surface active agent is avoided, and the emulsion is high in stability, small in drop diameter and good in sizing effect.

Owner:山东熙来淀粉有限公司

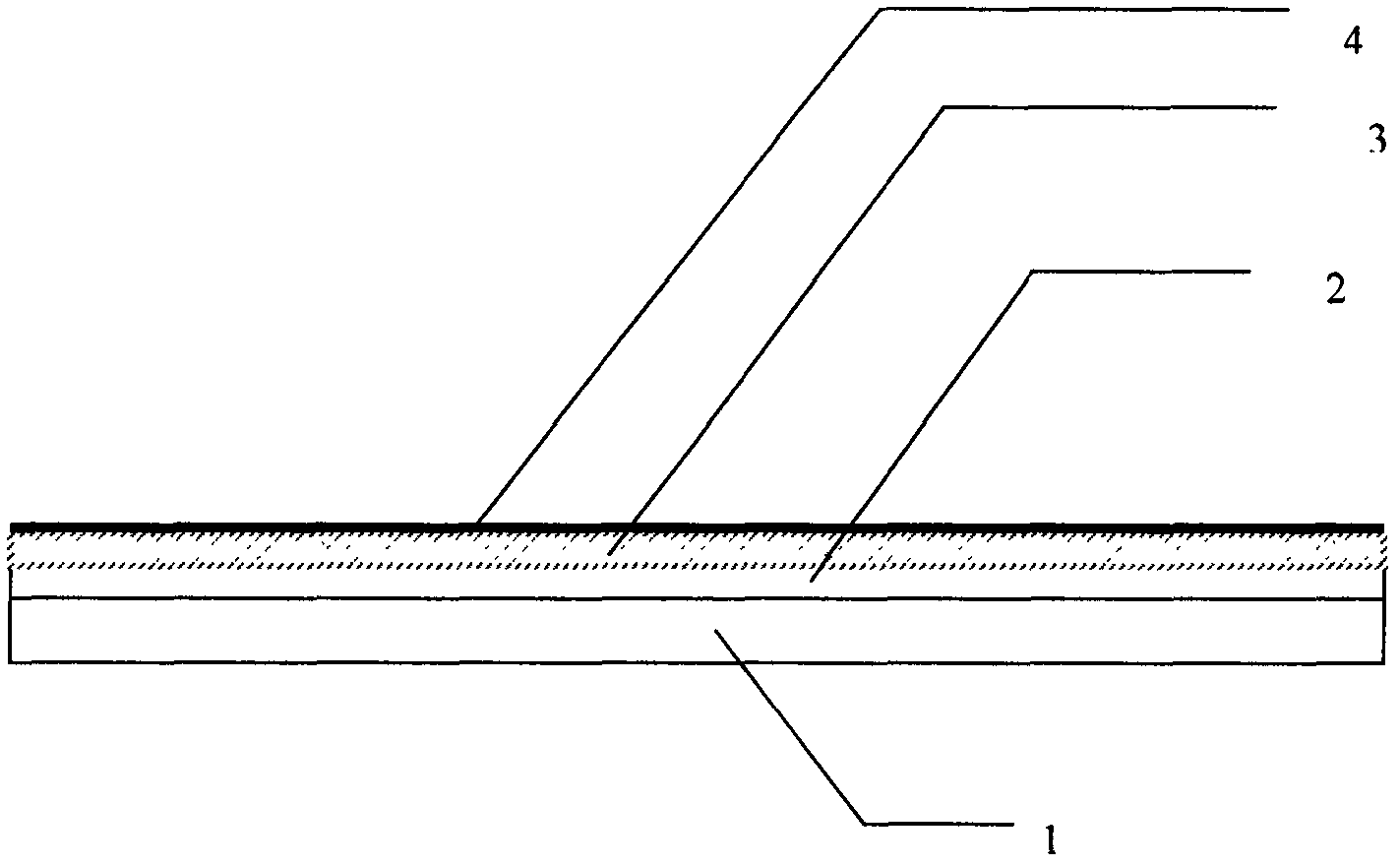

Decorative chromium plating method of aluminum and aluminum alloy parts

InactiveCN102220613ASolve the problem of foamingSolve quality problemsLiquid/solution decomposition chemical coatingZincElectroplating

The invention belongs to field of protection decoration of aluminum and aluminum alloy parts, in particular relates to a chromium plating method. The decorative chromium plating method of the aluminum and aluminum alloy part comprises the steps of: pre-treating before plating, dipping zinc chemically, pre-plating nickel and plating chromium, wherein the step of dipping zinc chemically comprises two times of zinc dipping, dipping zinc, removing zinc and dipping zinc once again; and the method of pre-plating nickel comprises plating and polishing the nickel. In the invention, the processes of dipping zinc chemically and pre-plating zinc are improved, such that the problems that the aluminum alloy which is plated with chromium can be foamed and peeled and the bonding force is poor are solved.

Owner:HARBIN

Preparation method of alginate-coated calcium carbonate particle stable papermaking sizing agent emulsion

ActiveCN110004766AImprove sizing effectSolve the problem of foamingWater-repelling agents additionInorganic compound additionPapermakingOil phase

The invention discloses a preparation method of an alginate-coated calcium carbonate particle stable papermaking sizing agent emulsion. The method comprises the steps of (1), preparation of alginate-coated calcium carbonate particles, wherein a sodium alga acid solution and a calcium carbonate dispersion liquid are mixed uniformly, under stirring, an appropriate amount of gluconolactone is added,a full reaction is performed, and the alginate-coated calcium carbonate particles are prepared; (2) preparation of a papermaking sizing agent emulsion, the prepared alginate-coated calcium carbonate particles are mixed with a papermaking sizing agent liquid oil phase, stirring is performed for a certain period of time under mechanical action, and the stable O / W type papermaking emulsion is obtained. The prepared alginate-coated calcium carbonate particles can be used for the preparation of the papermaking sizing agent emulsion. No surfactant is added during the preparation of the sizing agentemulsion, the foam problem brought by the surfactant is avoided, the prepared emulsion is stable, and the sizing effect is good.

Owner:QILU UNIV OF TECH

Instant noodles with indentations

ActiveCN101836710AIncrease the areaIncrease the outlet channelFood preparationInstant noodleEasily Full

The invention relates to instant noodles with indentations, which can solve the problem of surface yeasting and poor gluten strength of instant lasagna in a frying process. Each instant noodle with indentations comprises a noodle body and is characterized in that indentations are pressed on the noodle body in the extending direction of the noodle body for solving the problems of surface yeasting and poor gluten strength of the noodle in the frying process and enhancing the full-bodied capability of the noodle. After the indentations are made, the boiling noodles are more easily full-bodied, taste daintier, and have improved organoleptic effect and novel and more attractive appearance.

Owner:HENAN ZHENGLONG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com