Patents

Literature

60results about How to "Lower extrusion temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Total-biodegradation plastic film and preparation method thereof

InactiveCN101240086AQuality improvementImprove performanceFlat articlesPlastic filmMechanical property

A full-biodegradable plastic membrane, which uses thermoplastic starch with diameter of 1-9 mu m, biodegradable polymer and auxiliary component as raw material, processed by screw extruding apparatus and membrane producing apparatus. The raw material comprises 30-70 parts by weight of thermoplastic starch with diameter of 1-9 mu m, 10-40 parts by weight of biodegradable polymer, 5-10 parts by weight of compatible modified component, 3-5 parts by weight of complex plasticized component, 10-30 parts by weight of lubricant. These materials are mixed and processed by screw extruding apparatus and membrane producing apparatus, wherein the lubricant is at least adding into other materials for mixture before process by screw extruding apparatus and during melt blending, and the adding amount of lubricant before process by screw extruding apparatus is not more than 1 / 3 of the total amount thereof. By highly increasing dosage of lubricant and changing mixing way, thermoplastic degree of starch is increased, rheological property of the system and processing quality of product are dramatically improved, mechanical property of the product is enhanced.

Owner:上海悦仕生物材料有限公司 +1

Novel 6063 aluminum alloy material and its production technology

The invention discloses a novel 6063 aluminum alloy material. Rare earth elements are added into the original 6063 aluminum alloy. The novel 6063 aluminum alloy material comprises, based on the weight percentage,0.36%- 0.4% of Si, 0.48% - 0.52% of Mg, 0 -0.35% of Fe, 0 -0.1% of Cu, 0 - 0.05% of Mn, 0 - 0.05% of Cr, 0 - 0.05% of Zn, 0 - 0.05% of Ti, 0.18%-0.22% rare earth elements, 0-0.1% of the remaining impurities and the balance of Al. According to the invention, the content of Mg and Si is controlled within a narrow range. At the same time, cerium-based mixed rare earth elements and alloying element boron are added, which keeps alloy material high strength and high electrical and thermal conductivity; improves machining property and plastic extrusion; and improves production efficiency.

Owner:CHENGDU SUNSHINE ALUMINUM

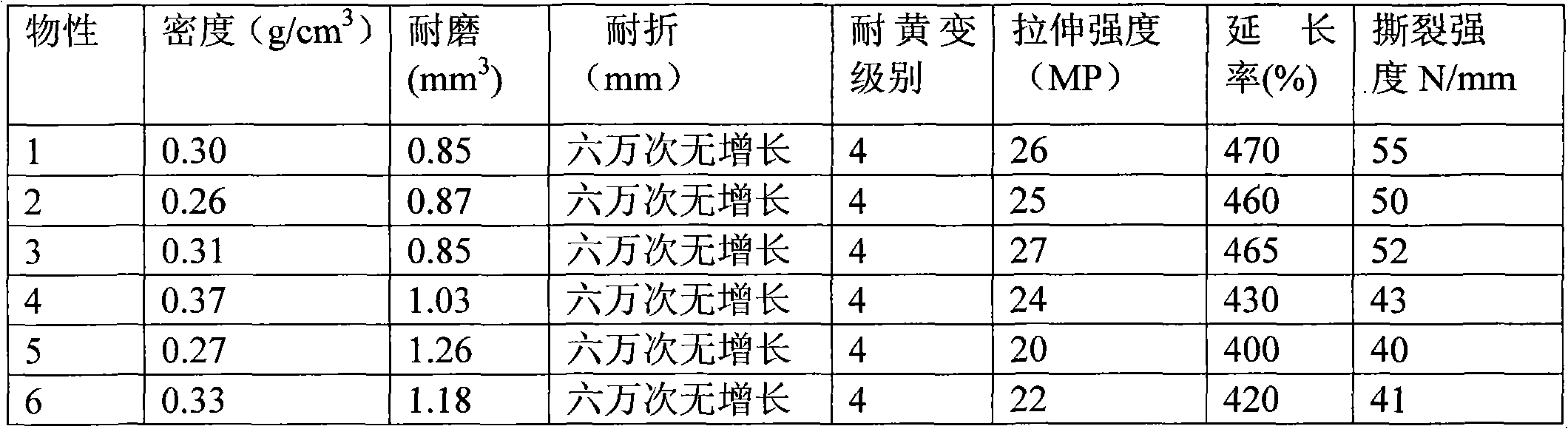

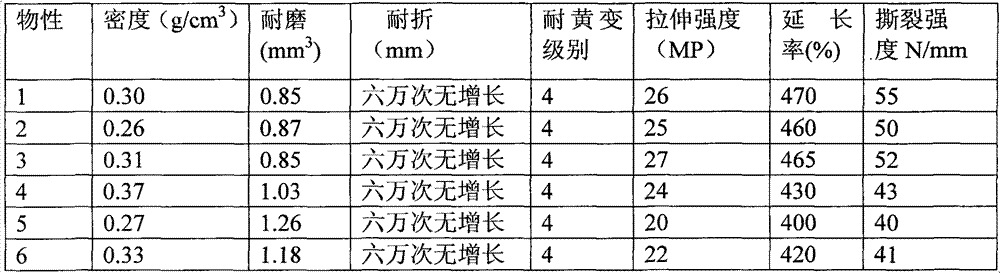

Low-density foamed thermoplastic polyurethane elastomer and its preparation process

The invention relates to a low-density foamed thermoplastic polyurethane elastic body and a preparation process thereof, belonging to the technical fields of polyurethane elastic bodies and preparation processes of the polyurethane elastic bodies. The low-density foamed thermoplastic polyurethane elastic body comprises the following raw materials such as a macromolecular polyol, a chain extender,an isocyanate and an azo foaming agent in a weight ratio of (40-60): (8-11): (32-49): (3.5-6); and a production process comprises the following steps of: 1, metering, transporting and mixing the raw materials; 2, reacting and extruding; 3, underwater pelletizing; 4, vulcanizing; and 5, inspecting. The molecular structure of the low-density foamed thermoplastic polyurethane elastic body provided by the invention is formed by rigid chain segments obtained by reaction of the isocyanate and the chain extender and flexible chain segments obtained by reaction of the isocyanate and the macromolecular polyol in an alternate manner, has unique comprehensive properties, excellent characteristics such as high tension, high tensile force, high toughness and aging resistance and leading wear resistance and is a mature environmentally-friendly material.

Owner:SHANDONG AOBANG POLYURETHANE

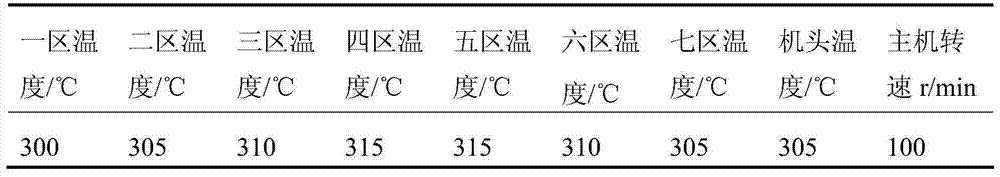

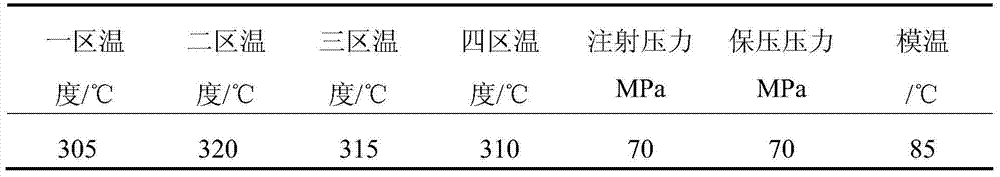

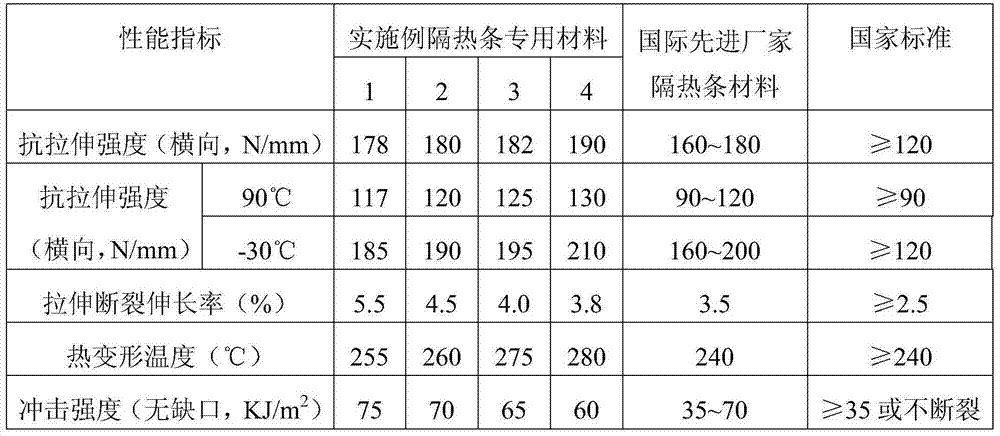

Special material for high-fluidity high-temperature polyamide heat-insulation strip and preparation method of material

The invention discloses a special material for a composite glass fiber heat-insulation strip using high-fluidity high-temperature nylon resin as a matrix. The material comprises the following components: 72-77.5wt% of high-fluidity high-temperature nylon, 22-27.5wt% of glass fiber, 0.05-1wt% of a fiber treating agent, 0.1-2wt% of a coloring agent, 0.1-1wt% of an antioxidant, 0.05-1wt% of a plasticizer, 0.05-1wt% of a coupling agent and 0.1-1wt% of additives. The invention also discloses a polymerization method of high-fluidity high-temperature nylon and a preparation method of the special material for the heat-insulation strip. Since a melt of the high-temperature nylon adopted in the material has good fluidity so that the process is simple, the energy consumption can be reduced, the cost conservation is achieved, the added aid is protected from being decomposed at a high temperature to cause failure and meanwhile, the prepared special material for the heat-insulation strip has excellent performance, high strength and good dimensional stability and the excellent performance can be still maintained at large temperature difference.

Owner:JIANGMEN YOUJU NEW MATERIALS

High-strength magnesium-lithium alloy and preparation method thereof

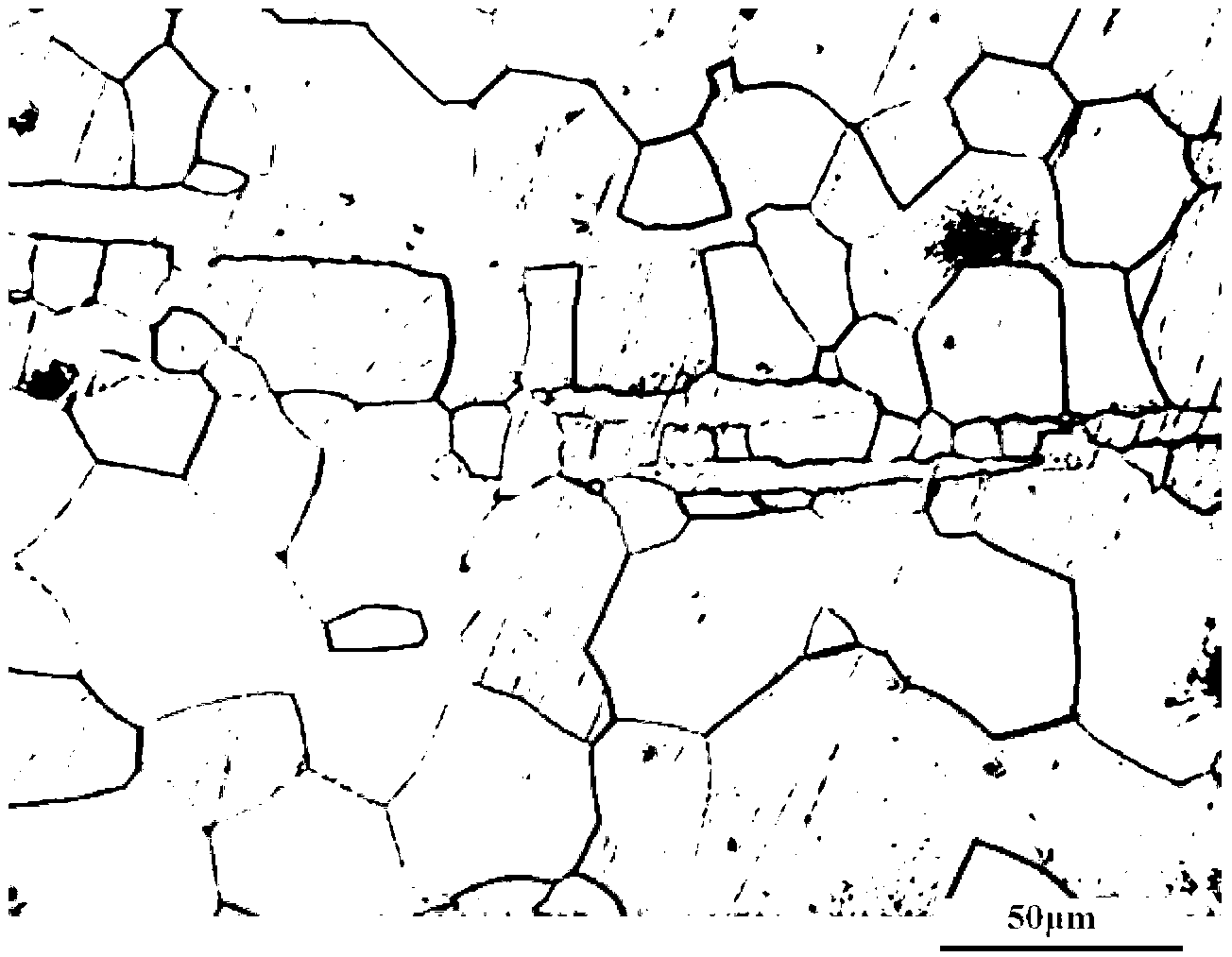

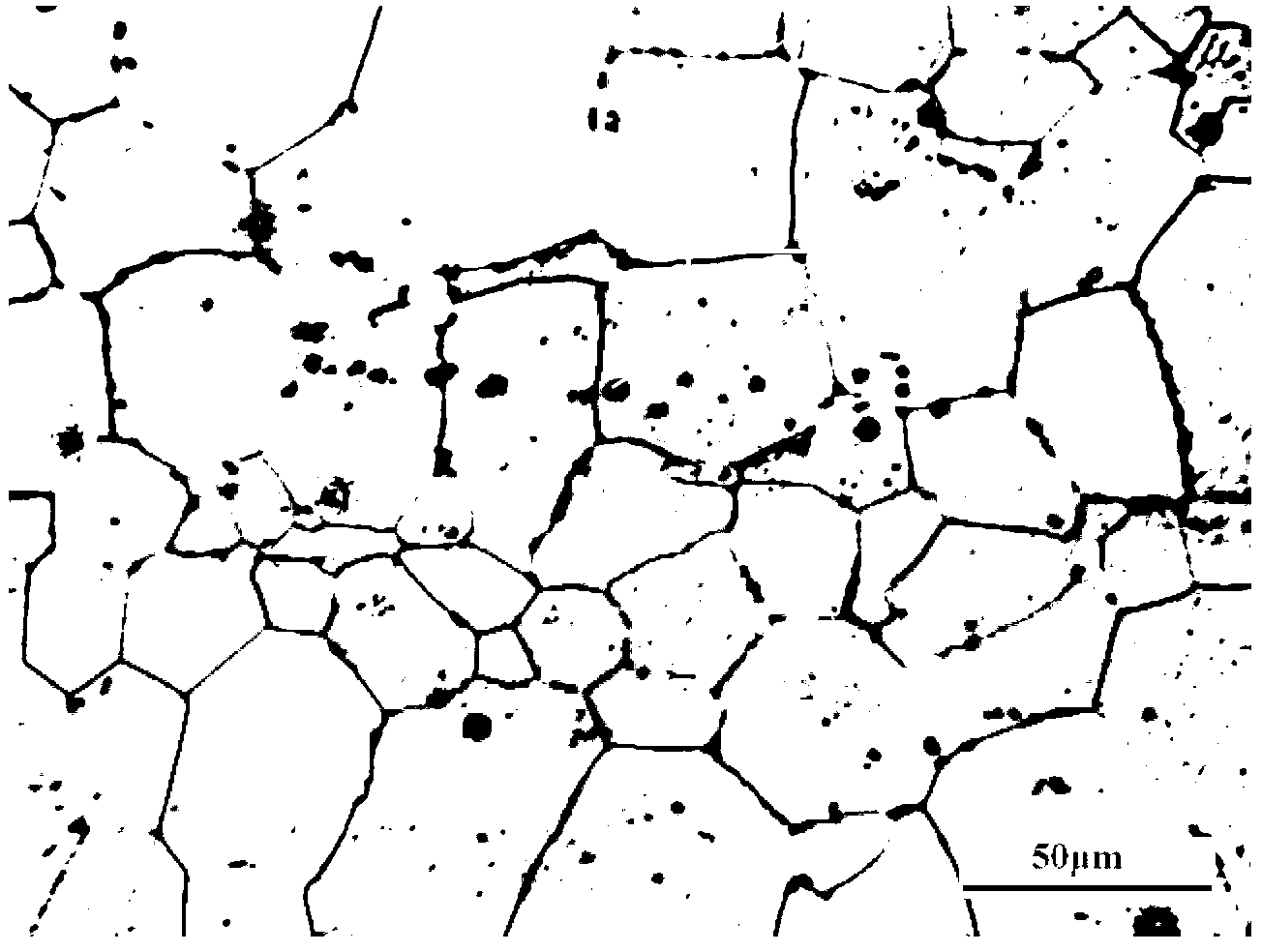

The invention provides high-strength magnesium-lithium alloy and a preparation method thereof. Commercial pure Mg, commercial pure Li, commercial pure Zn, Mg-RY middle alloy are taken as materials; the high-strength magnesium-lithium alloy is prepared from the materials by mass percent: 4.5-5.5% of Li, 2.0-3.8% of RY, 0.2-1.0% of Zn, less than 0.03% of gross of inevitable Fe, Cu, Ni and Si impurities, and the balance of Mg in a mixing manner according to the ratio. The preparation method comprises the steps of: based on commercial pure Mg, commercial pure Li, commercial pure Zn, Mg-RY middle alloy as materials, mixing the following components in percentage by mass: 4.5-5.5% of Li, 2.0-3.8% of RY, 0.2-1.0% of Zn, less than 0.03% of gross of inevitable Fe, Cu, Ni and Si impurities, and the balance of Mg; smelting in a vacuum induction smelting furnace, wherein the inside of the furnace is vacuumized before smelting, and then aerating argon is aerated to protect, the smelting process is carried out under protection of argon atmosphere, and the smelting temperature is 660-750 DEG C; casting the smelted melt into a metal die to obtain as-cast alloy; carrying out hot extrusion for at least twice to obtain the high-strength magnesium-lithium alloy. The obtained alloy disclosed by the invention has high strength and good plasticity; the tensile strength at room temperature is 220-260 MPa; the yield strength is 180-220MPa; the elongation percentage is 15-25%.

Owner:HARBIN ENG UNIV

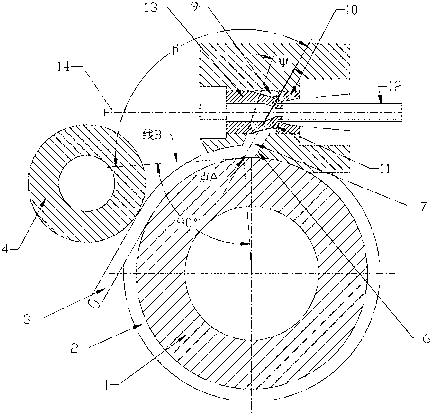

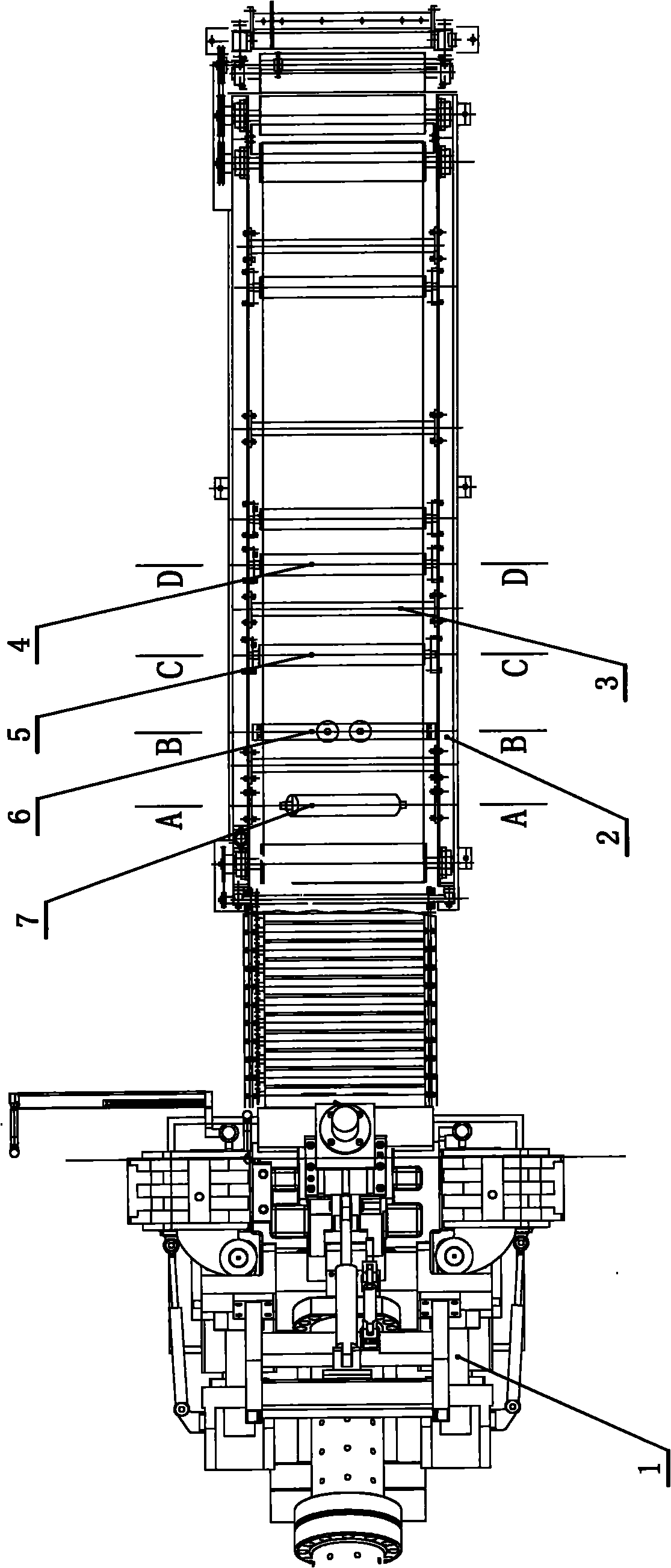

Continuous cladding method and device of obtuse angle flowing channel

The invention discloses a continuous cladding method of an obtuse angle flowing channel. The continuous cladding method comprises the following steps that: a, under the compaction of a compaction wheel, a blank enters an extruding cavity through a friction force between a rotary extruding wheel groove and the blank; b, when the blank advances to a baffle block, the blank enters an extruding cavity feeding hole, wherein the center line of the extruding cavity feeding hole is in a chord line direction of an extruding wheel in a non-radius direction; and c, a metal flowing channel forming the obtuse angle with the cavity feeding hole is arranged at the tail end of the extruding cavity feeding hole, a cladding forming metal containing cavity is arranged at the tail end of the metal flowing channel, a female die and a male die are arranged at the tail end of the cladding forming metal containing cavity, a metal flow velocity splitter is arranged between the female die and the male die, a product is extruded through a circular seam formed by the female die and the male die, a core wire is transferred in through a center circular hole in the male die, and a cladding metal is extruded to form a cladding layer outside the core wire. According to the continuous cladding method, by adopting the blank and through one group of flowing channels with obtuse angles of more than 95 DEG, the metal is extruded to form different cable cladding products through the dies.

Owner:DALIAN JIAOTONG UNIVERSITY

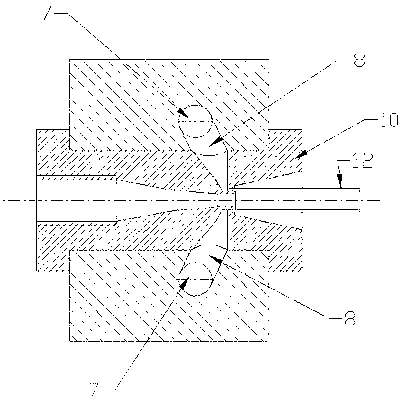

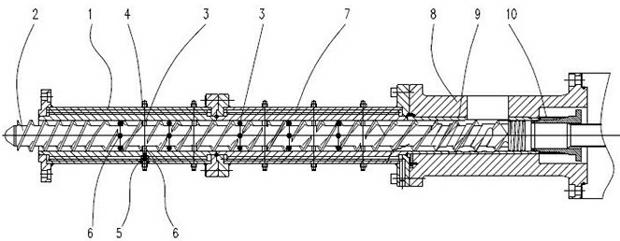

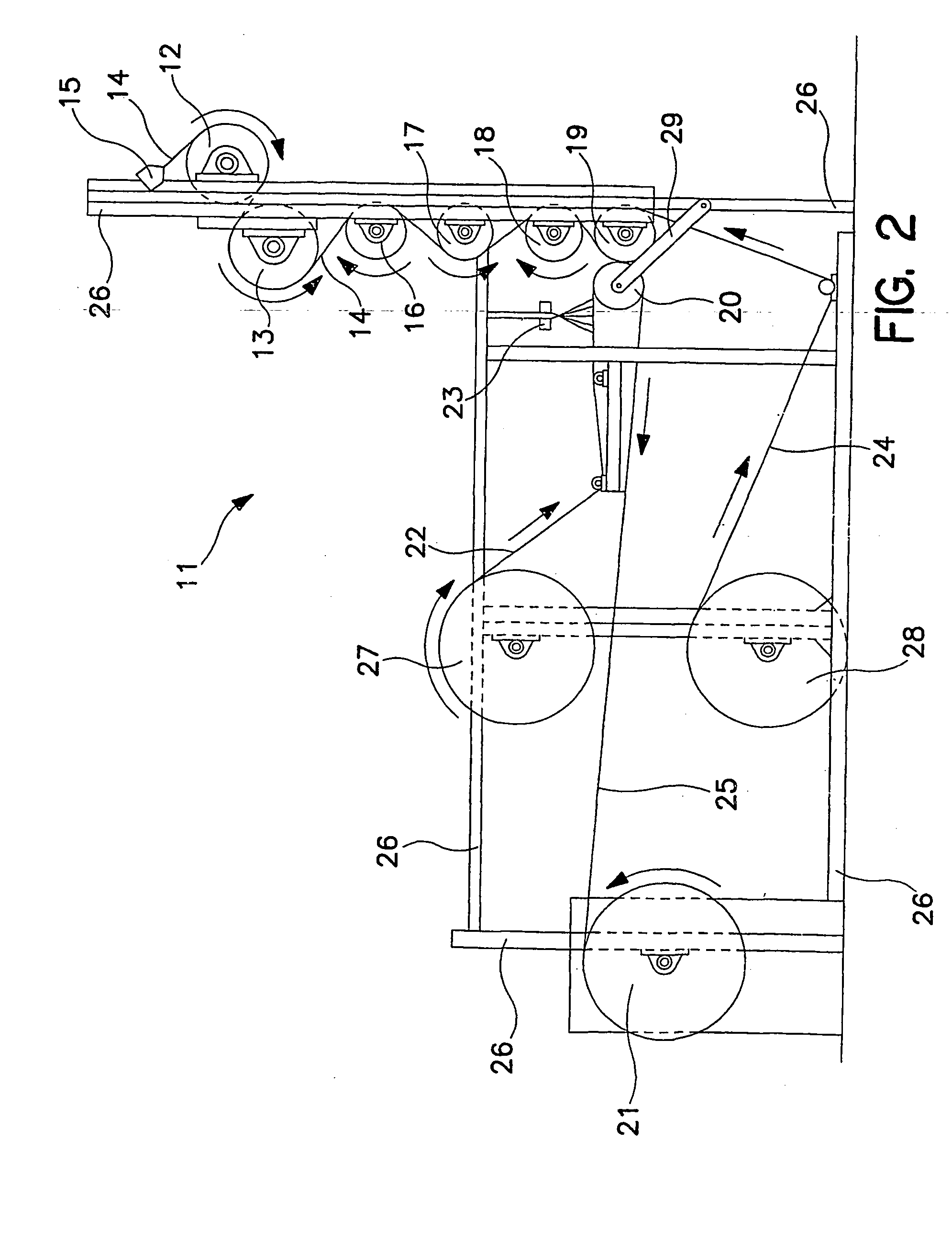

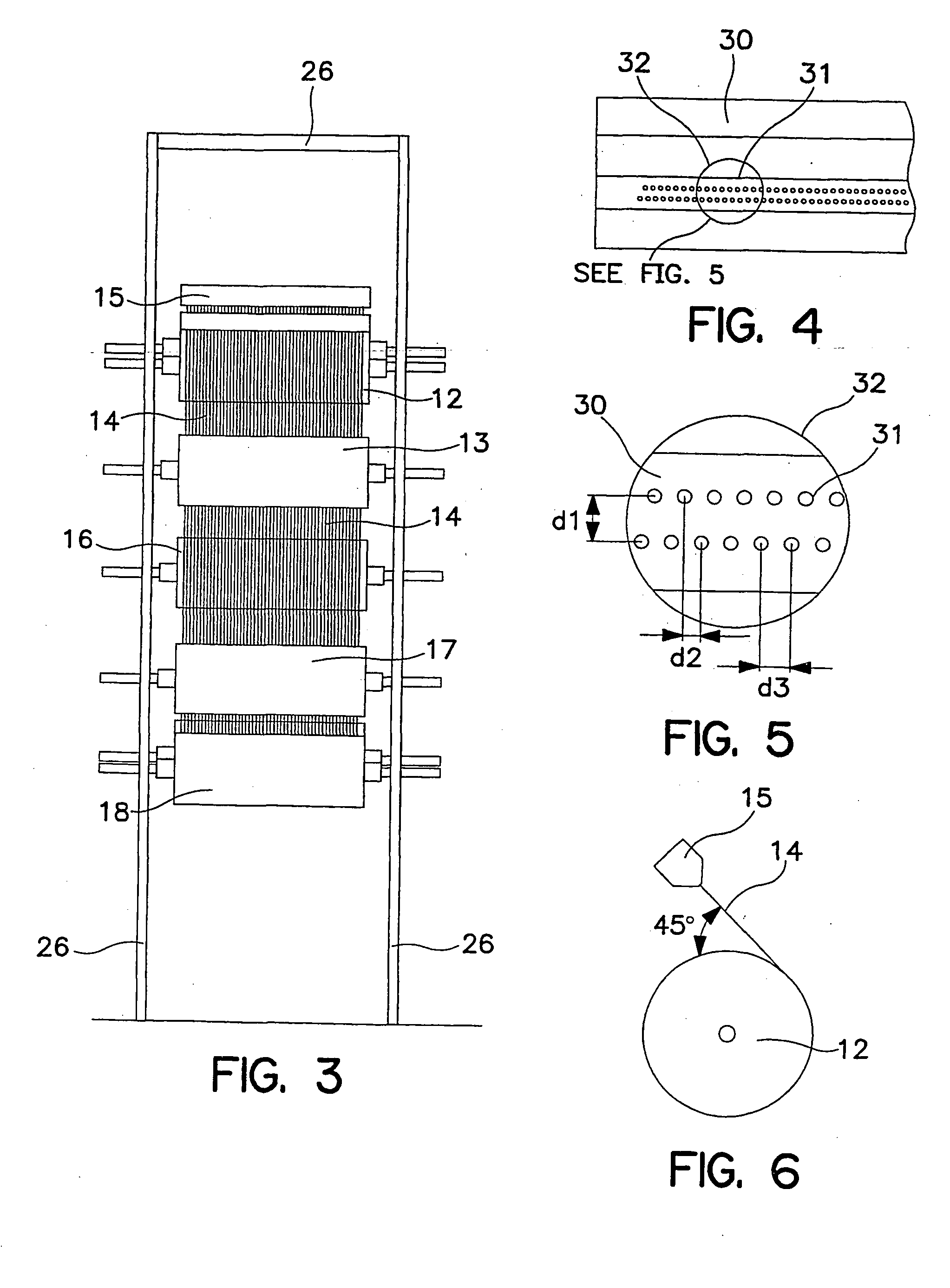

Mixed pin barrel cold feeding extruder

The invention discloses a mixed pin barrel cold feeding extruder which comprises a machine barrel installed on a feeding base body, wherein, a screw bolt is arranged inside the machine barrel; a plurality of rows of radial pins are arranged in the length direction of the machine barrel; the radial pins are fixed on the machine barrel through spiral pressing caps; end sockets of the pins stick into a screw slot of the screw bolt and are close to the root surface of the screw bolt; a circumferential grooving is formed in the corresponding position on a screw edge of the screw bolt, and the pinscan be inserted in the circumferential grooving; a plurality of rows of tangential pins are also arranged on the mixed pin barrel cold feeding extruder; the tangential pins penetrate through pin holes formed on the machine barrel, and penetrate through the screw slot of the screw bolt in the tangential direction of the screw bolt; the circumferential grooving is formed in the corresponding position on the screw edge of the screw bolt, and the pins can penetrate through the circumferential grooving; the two ends of each tangential pin are fixed on the machine barrel by nuts through external threads. The tangential pins adopt hollow structures, and fluid cooling medium can pass through the hollow structures. Compared with a common radial pin barrel cold feeding extruder, the mixed pin barrel cold feeding extruder has the advantages of better plasticization mixing effect, lower extrusion temperature, higher production capacity and wider application range.

Owner:无锡市江南橡塑机械有限公司

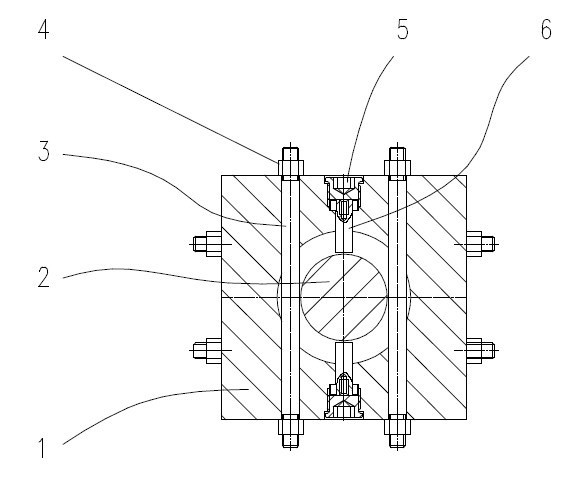

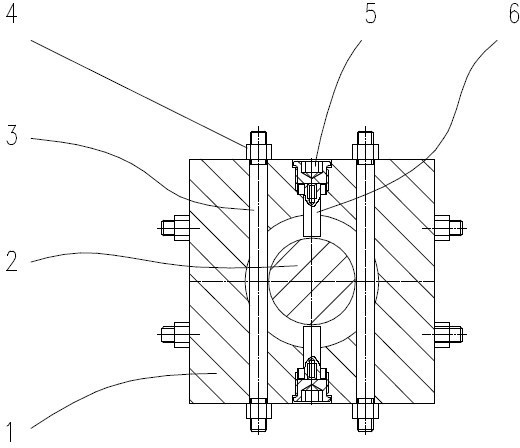

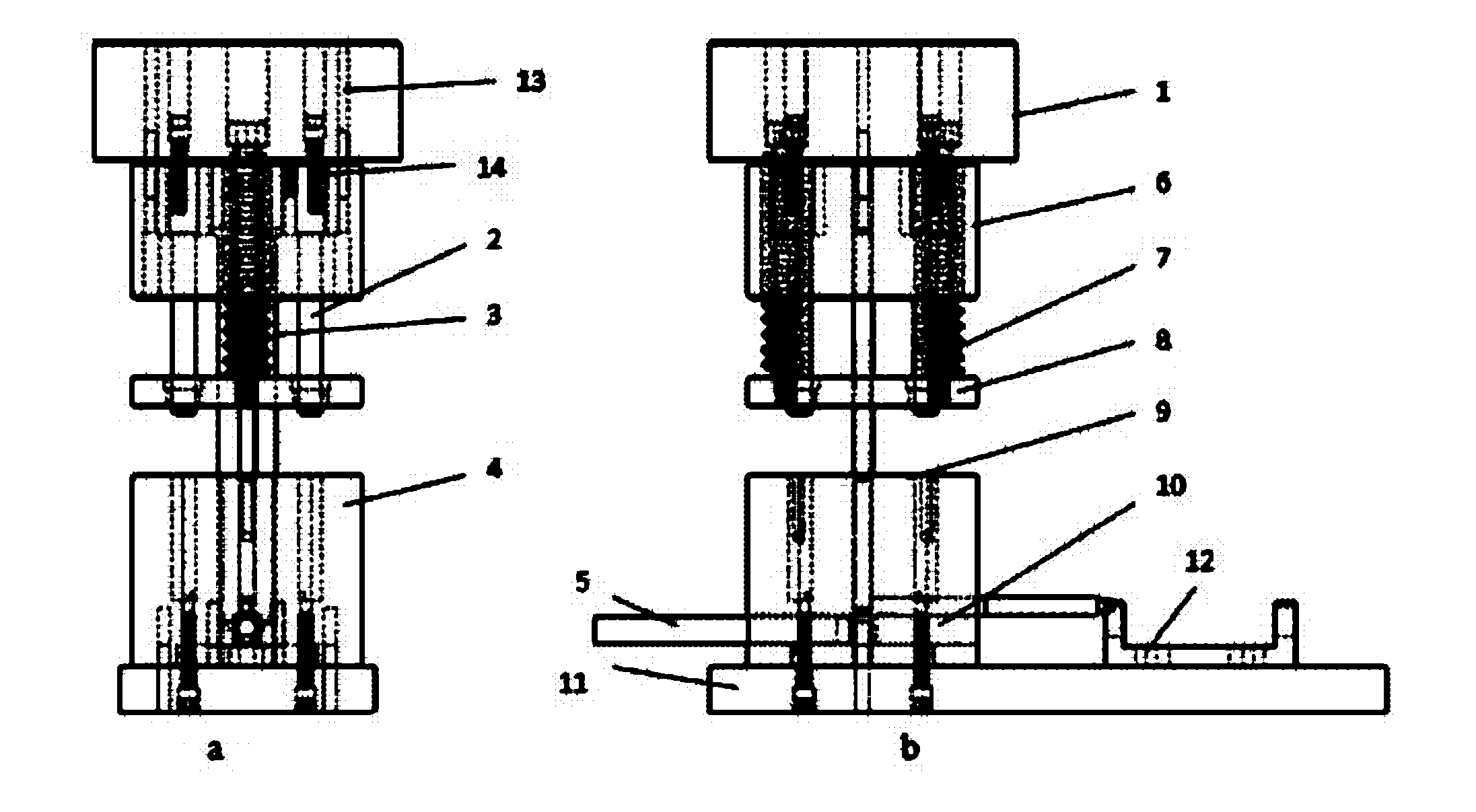

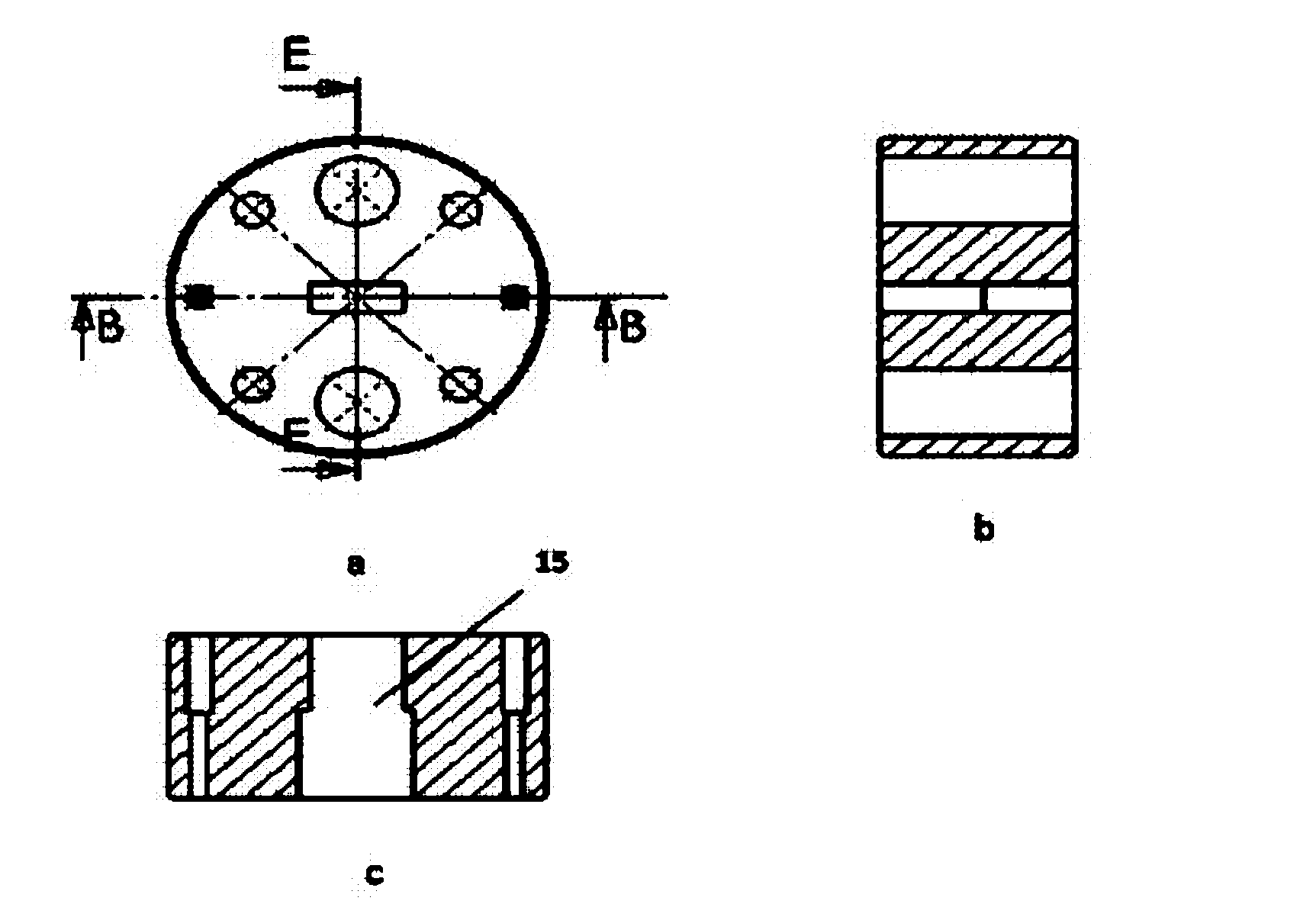

Backpressure equal-channel angular extruding mould

ActiveCN102615133AIncrease the cross-sectional areaIncrease stiffnessExtrusion diesPunchingEngineering

The invention discloses a backpressure equal-channel angular extruding mould which comprises a pressing plate, a guide pillar, a knocking bar, a convex mould, a guide sleeve, a spring, a concave mould, a mould base, a double-fork type punching head, a heating ring, a positioning slide block, a backpressure ejecting rod and an ejecting rod bracket, wherein the rigidity and strength of punching head are increased by the double-fork type punching head; the positioning slide block capable of sliding back and forth is arranged in a horizontal channel, so that the last sample can be conveniently taken out from the horizontal channel; and backpressure is applied to the sample by a backpressure device in an ejecting rod pressurizing form during an extruding process, so that the extruding temperature is efficiently reduced, the grain is refined and the comprehensive mechanical property of magnesium alloy is improved.

Owner:SHANGHAI JIAO TONG UNIV

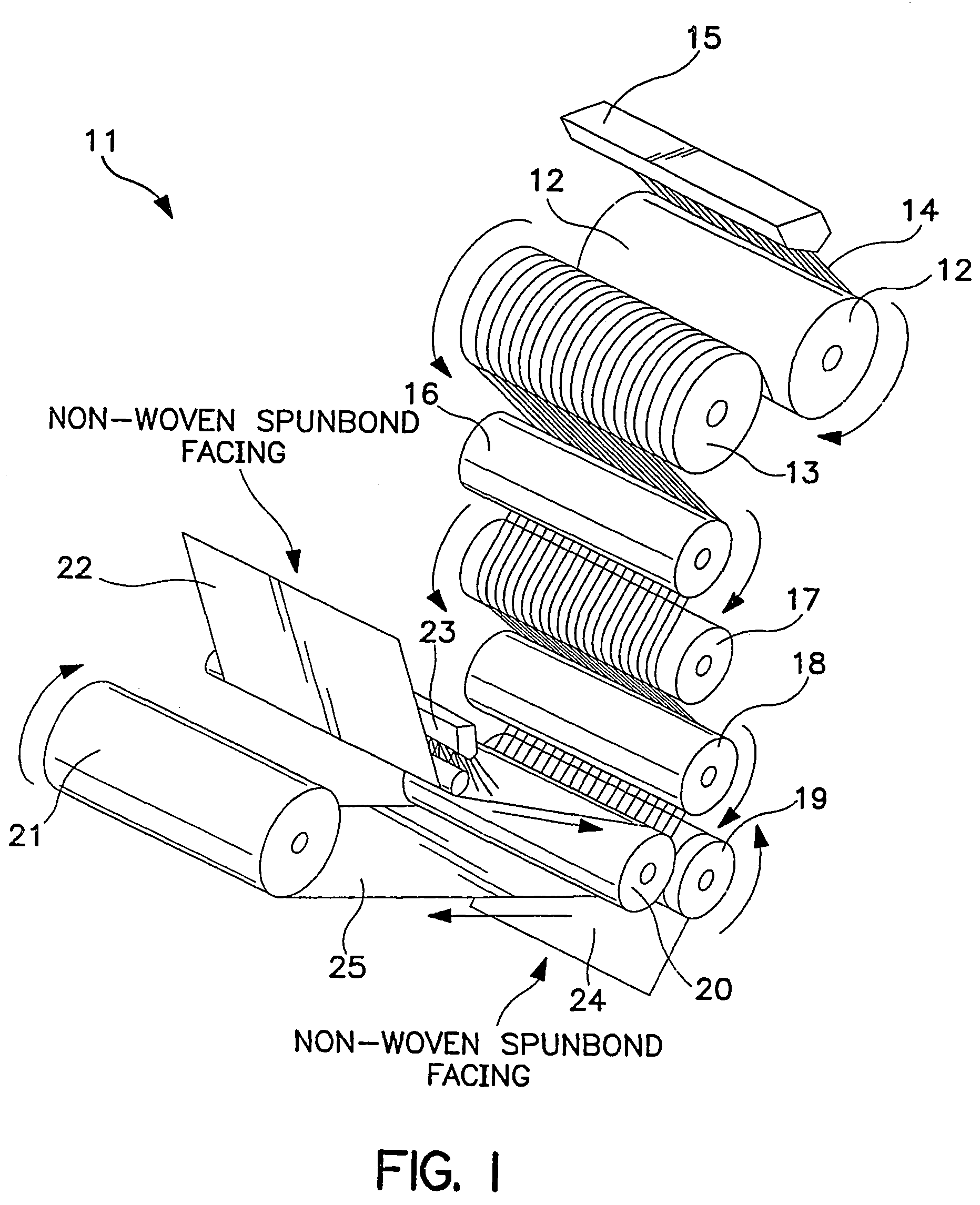

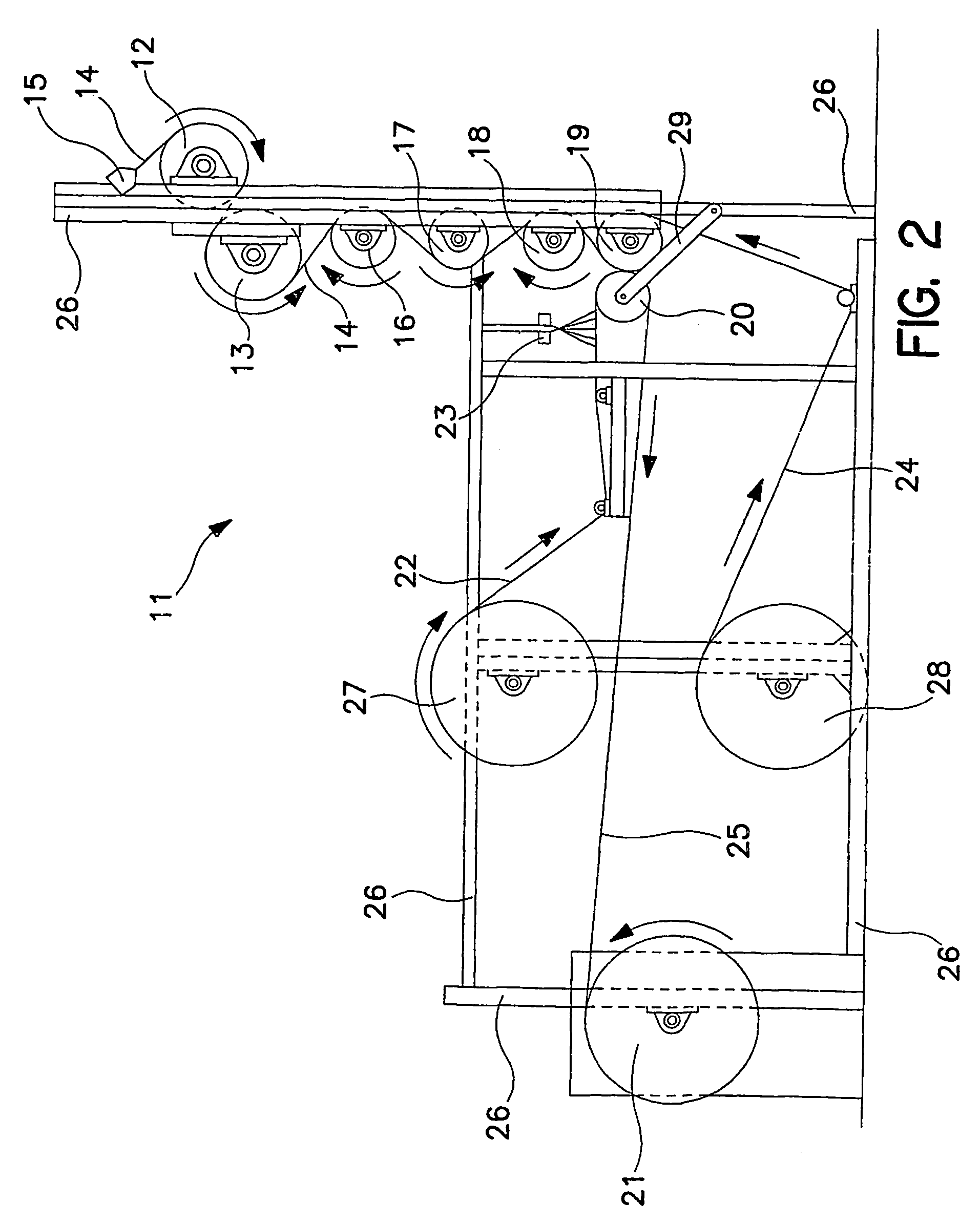

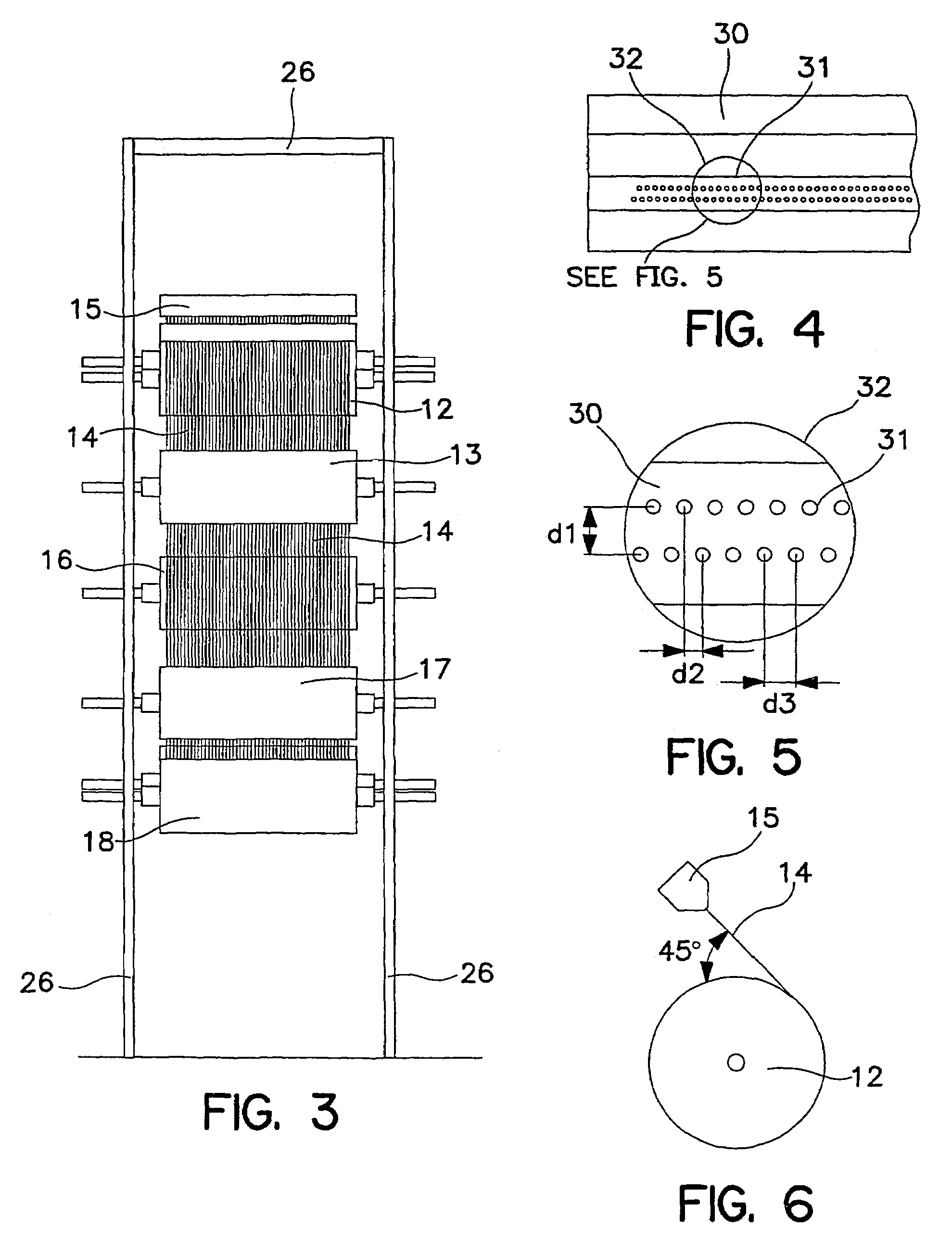

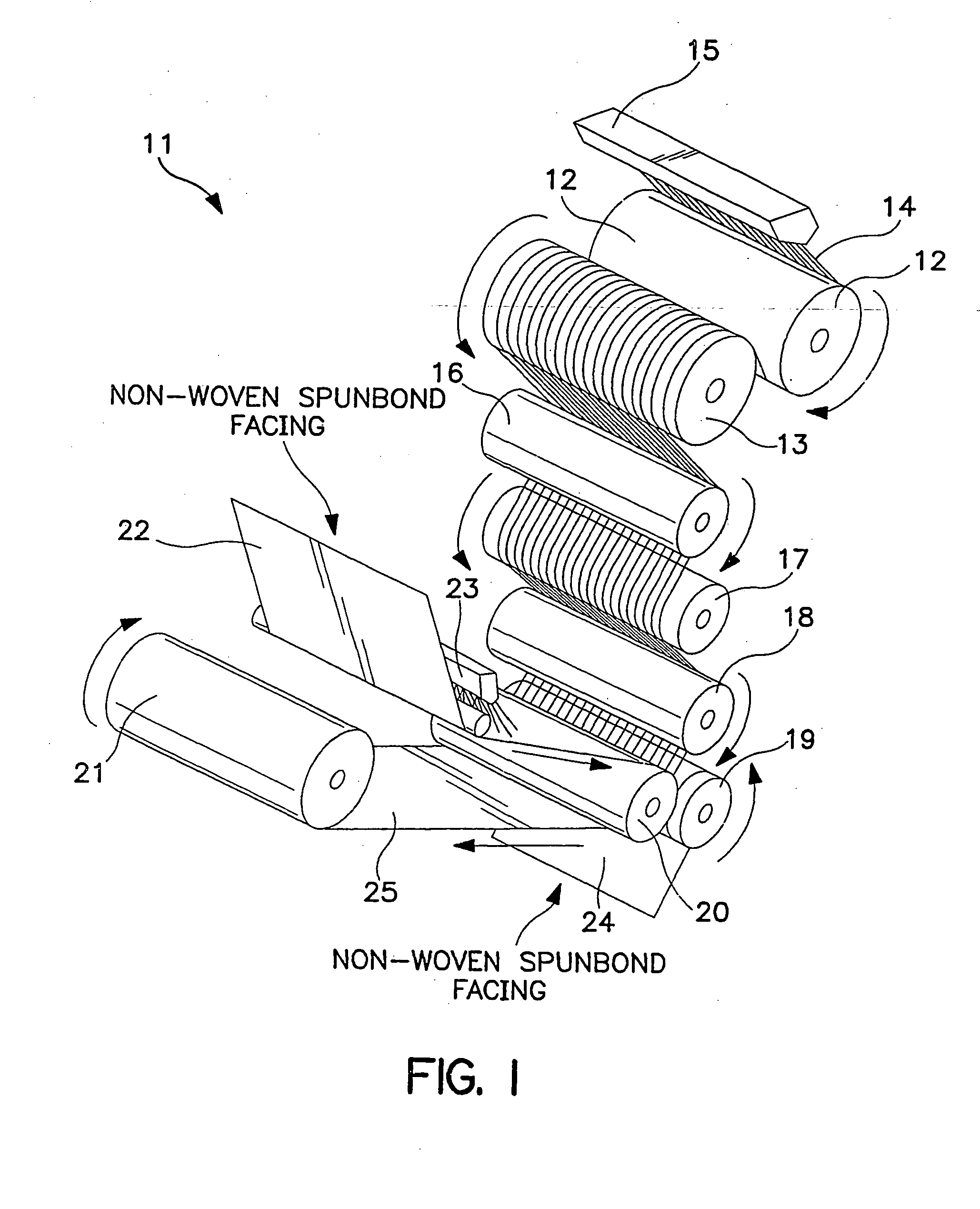

Method of thermally processing elastomeric compositions and elastomeric compositions with improved processability

InactiveUS7326751B2Lower extrusion temperatureEasy to processNon-woven fabricsArtifical filament manufactureElastomerChemistry

Owner:KIMBERLY-CLARK WORLDWIDE INC

High-flame-retardant low-gloss dynamically vulcanized thermoplastic elastomer material and continuous preparation method thereof

The invention discloses a high-flame-retardant low-gloss dynamically vulcanized thermoplastic elastomer material and a continuous preparation method thereof. The material is prepared from an ethylene-butylene elastomer, polypropylene, a cross-linking agent, lipophilic silicon dioxide, polyethylene wax, an assistant cross-linking agent, a halogen-containing flame retardant, a flame retardant aid, an anti-dripping agent, a lubricant and an antioxidant. According to the thermoplastic elastomer material, the impact resistance can be improved in the presence of the flame retardant, the flame retardant property is excellent, the V0 level can still be achieved under the condition that the thickness is 0.8 mm, the special lipophilic silicon dioxide and polyethylene wax are used for reducing the glossiness of the material, and the glossiness can be remarkably reduced. The production process of the dynamically vulcanized thermoplastic elastomer is low in energy consumption, greatly reduces the production cost, and is very suitable for large-scale process production.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

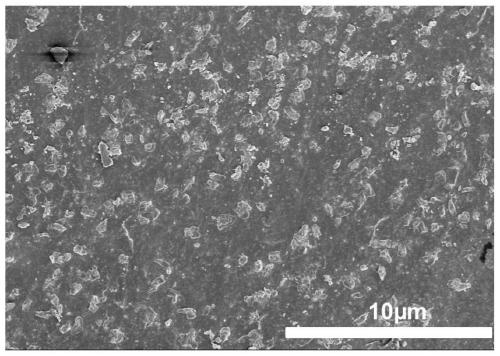

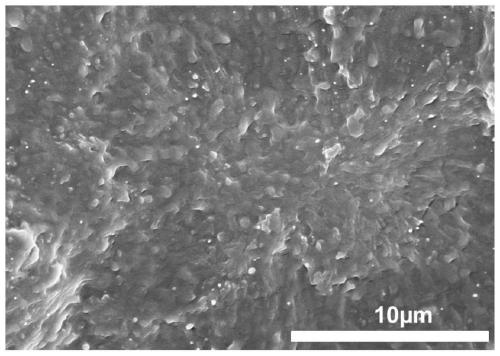

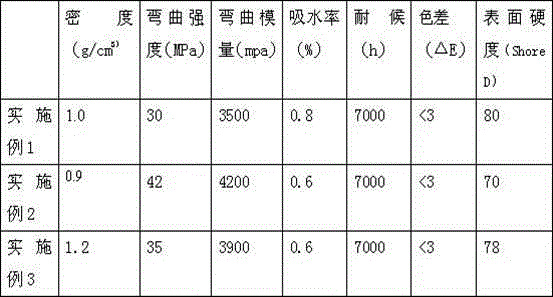

ASA plastic-wood material and preparation method thereof

The invention provided an ASA plastic-wood material. The ASA plastic-wood material comprises the following components in percentage by mass: 70-90% of ASA plastic particles, 0.3-1% of a foaming agent, 10-30% of wood flour, 2-5% of a compatilizer and 1-4% of a lubricant. Because the wood flour used for preparing the ASA plastic-wood material is treated by an additive, the combinability and interface compatibility of the wood four and the ASA can be enhanced, the quality of the product can be improved, and thus the ASA plastic-wood material has great popularization value.

Owner:DONGGUAN CHNV TECH CO LTD

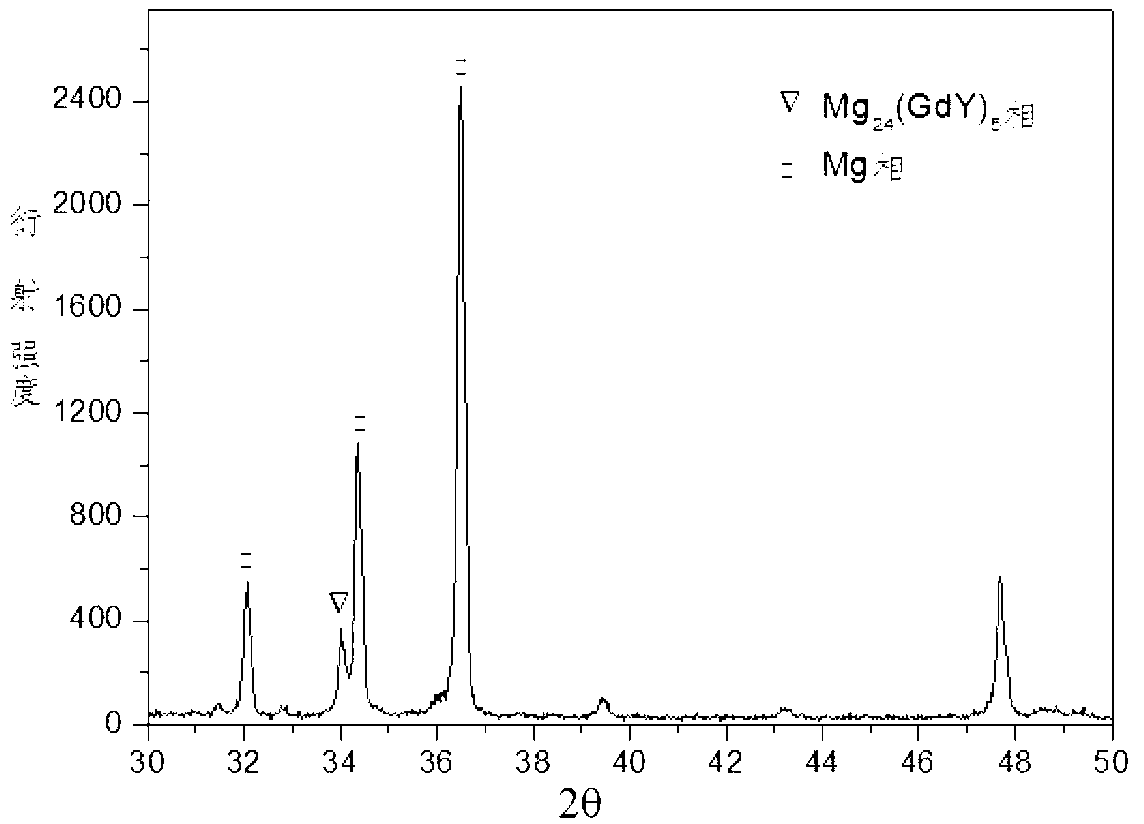

Extrusion process for preparing high-strength and high-plasticity rare earth-magnesium alloy

The invention discloses an extrusion method for preparing a high-strength and high-plasticity rare earth-magnesium alloy, which comprises the following steps: using an equal-channel extrusion mold as the extrusion mold, wherein the included angle between a horizontal channel and a vertical channel is 90 degrees; respectively heating the mold and a sample to be extruded, wherein the heating temperature of the sample is different from the heating temperature of the mold, and the heating temperature of the sample is lower than the heating temperature of the mold; performing fast extrusion on the heated sample in the heated mold; and shortening the extrusion process time as much as possible, and applying a back pressure to the direction in which the sample is extruded to ensure that the sample is under a three-dimensional stress. Thus, crystal grains of the rare earth-magnesium alloy prepared by the method are greatly refined, and second phases are precipitated less.

Owner:SHANGHAI JIAO TONG UNIV

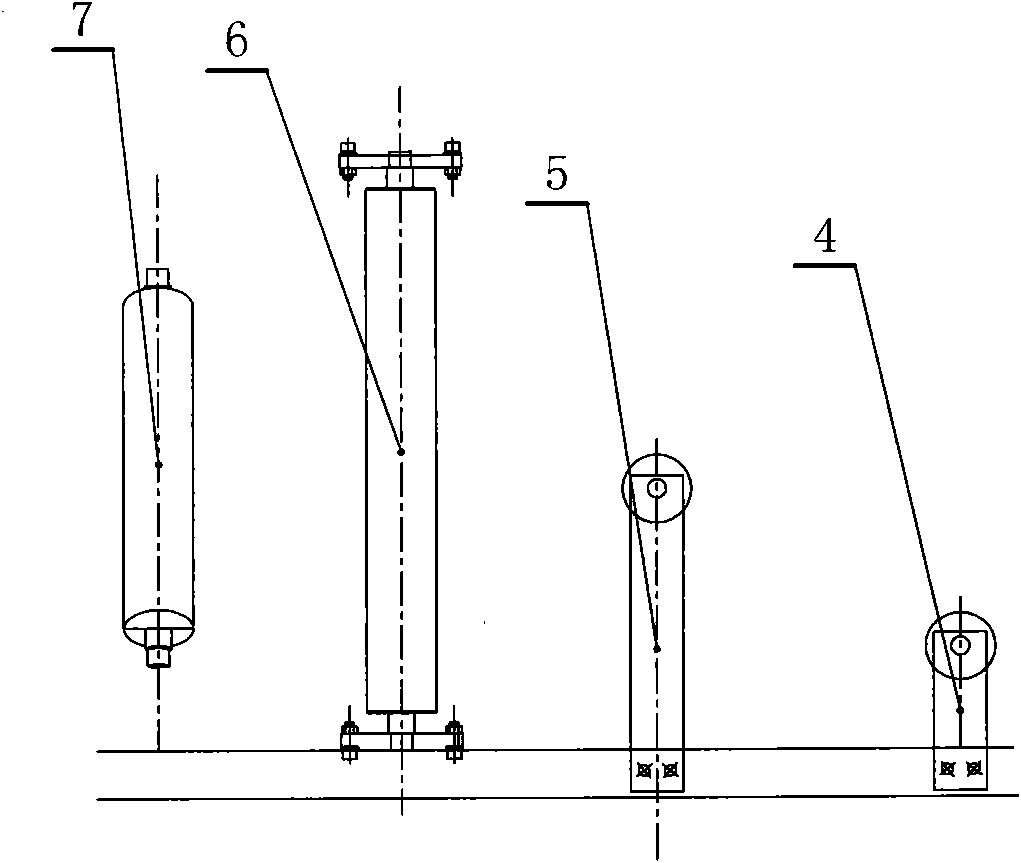

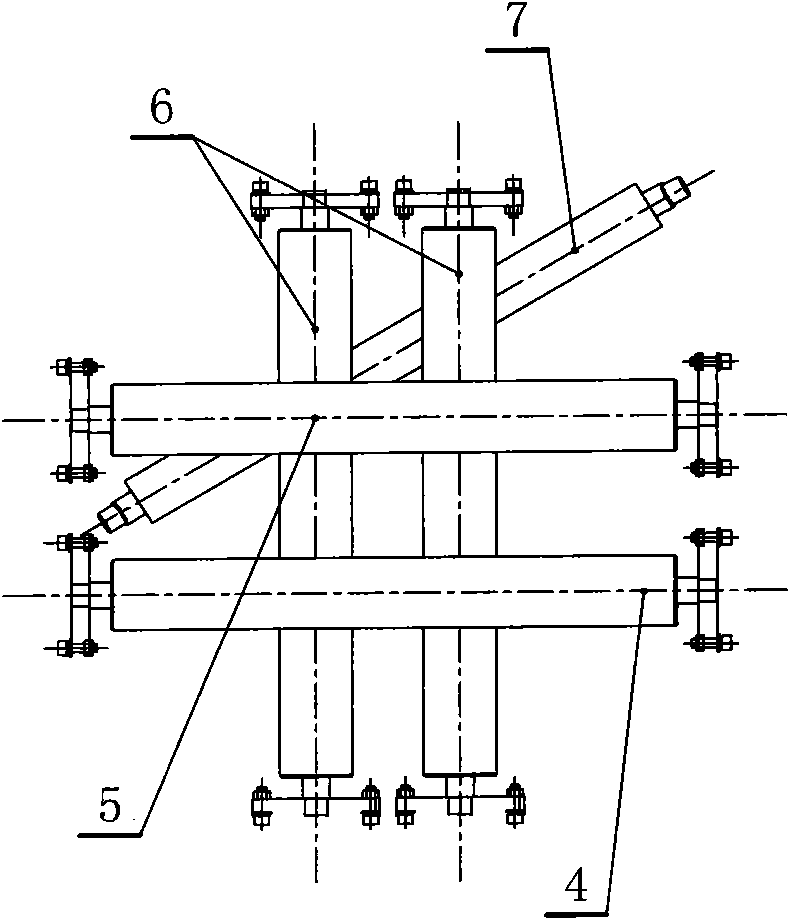

Double-plex extrusion linkage production line with turnover device

The invention discloses a double-plex extrusion linkage production line with a turnover device, which has good product quality and high production efficiency. The double-plex extrusion linkage production line comprises a double-plex extruder unit which comprises a first extruder, a second extruder and a complex head, the back side of the complex head is provided with a track which is connected with a receiving roll in a relative rotation way, the tract at the back side of the complex head is sequentially provided with a pre-turnover roll, a turnover roll, a leveling roll and a belt pressing roll in a relative rotation way, the pre-turnover roll, the turnover roll, the leveling roll and the belt pressing roll are all positioned above the receiving roll, the pre-turnover roll is slantly arranged, the turnover roll is vertically arranged, the leveling roll and the belt pressing roll are horizontally arranged, and the horizontal position of the leveling roll is higher than that of the belt pressing roll. The pre-turnover roll is arranged on the tract through a pre-turnover roll connecting seat which is provided with a plurality of pre-turnover roll regulation holes. The turnover roll is arranged on the tract through the turnover roll connecting seat which is provided with a carrier roll in a relative rotation way.

Owner:八亿橡胶有限责任公司

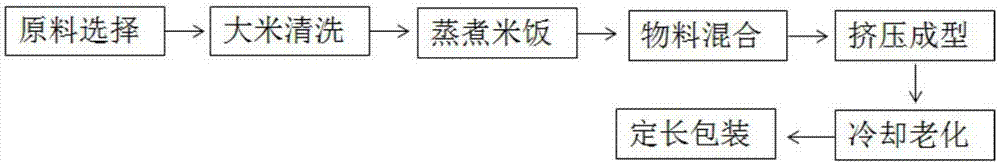

Method for preparing fresh wet rice noodles from extruding cooked rice

The invention discloses a method for preparing fresh wet rice noodles from extruding cooked rice. The method comprises the following steps of (1) selecting raw materials; (2) performing cooking to obtain the cooked rice; (3) mixing materials; (4) performing extrusion and shaping; and (5) performing cooling and packaging. Through the adoption of the method disclosed by the invention, the problems of long production cycle, high cost, high investment, high energy consumption, microbial contamination, poor product quality and the like existing during conventional rice noodle processing are solved.

Owner:JIANGNAN UNIV

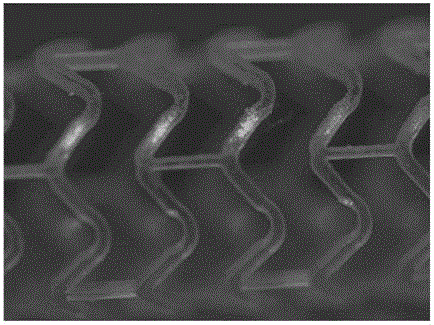

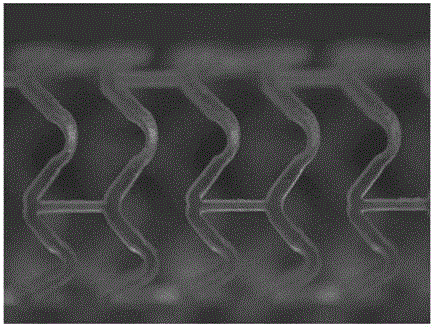

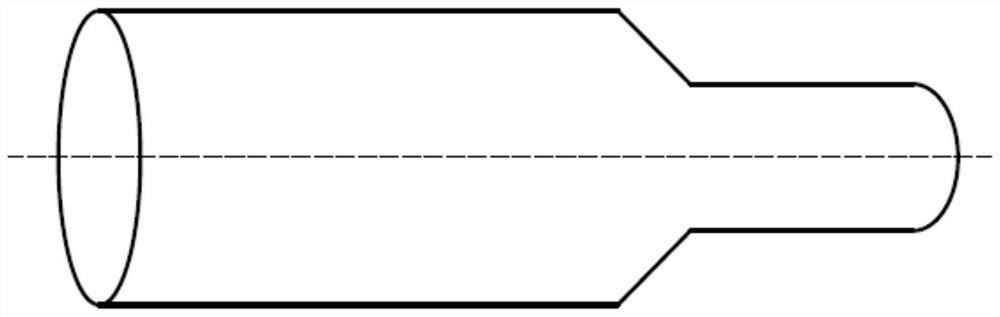

Machining method for degradable polymer intravascular stent

InactiveCN105149888ASegment stabilizationCompact structureSurgeryPharmaceutical delivery mechanismMelting Point TemperatureSlow cooling

The invention provides a machining method for a degradable polymer intravascular stent. The machining method comprises the following steps that firstly, a pipe is formed; secondly, a stent base body is formed through laser engraving; thirdly, the surface of the stent base body is polished. In the first step, the pipe is formed through the extrusion technology that cold pressurization is carried out on a plastic pipe, wherein polymer raw materials for the stent base body are heated in a plastic extruder to the temperature higher than the corresponding melting point temperature Tm and lower than the extruding temperature in the normal pressure extruding technology by 5-15 DEG C, 5-20 MPa pressure is applied at the same time, the raw materials are extruded out of a mold of the extruder with the temperature and the pressure maintained, and slow cooling is carried out. Compared with the prior art, by means of the machining method for the degradable polymer intravascular stent, the strength of the obtained intravascular stent is higher, the overall radial supporting force is higher, and the surface of the stent is smoother and free of flaws.

Owner:天津索玛科技有限公司

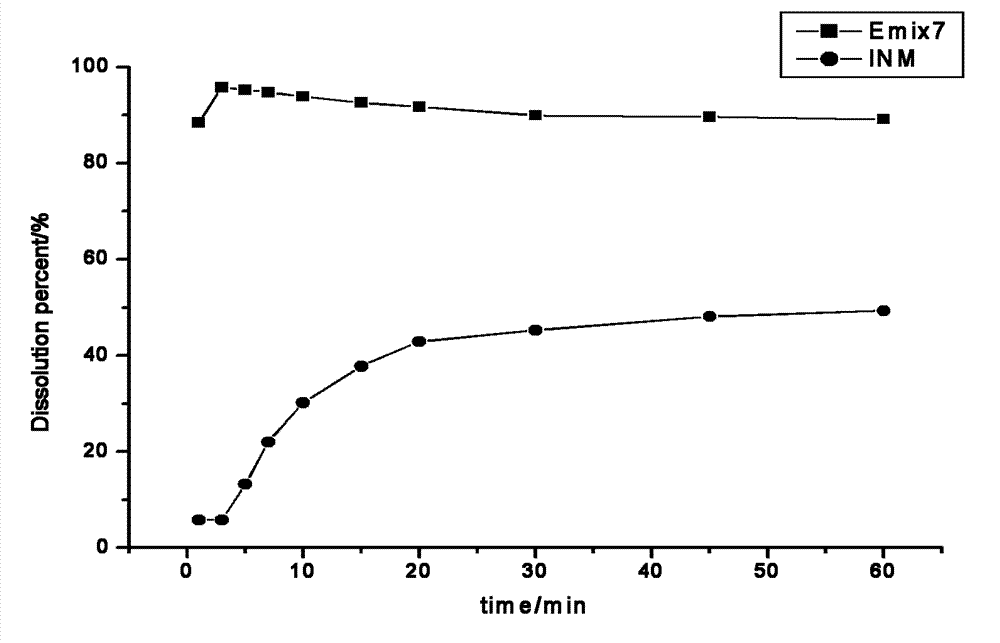

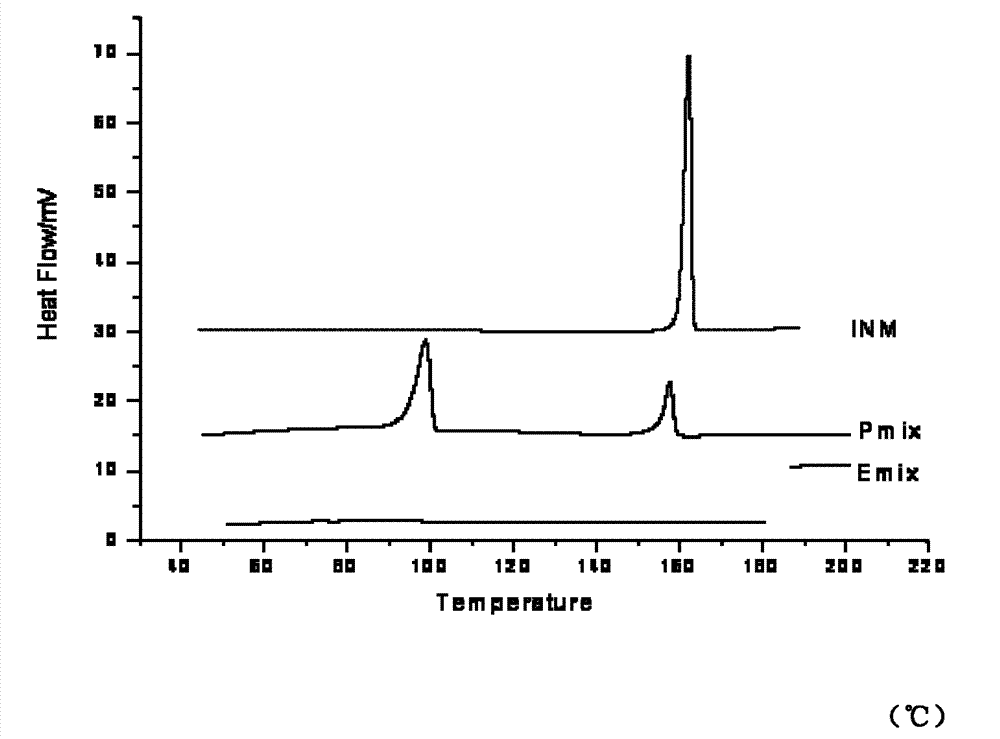

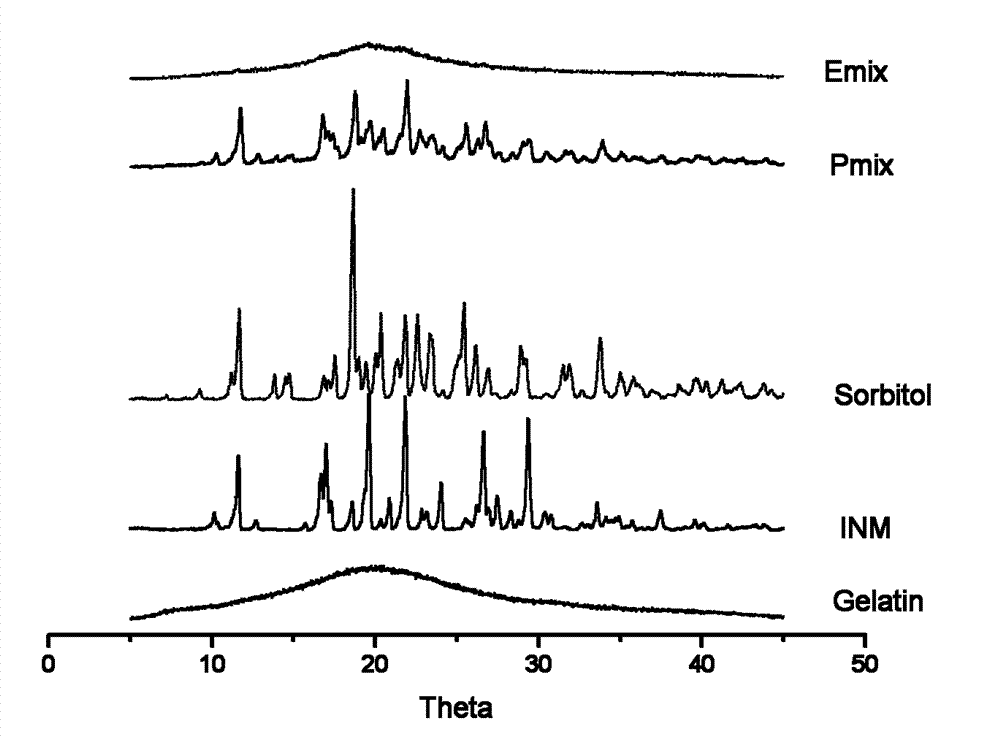

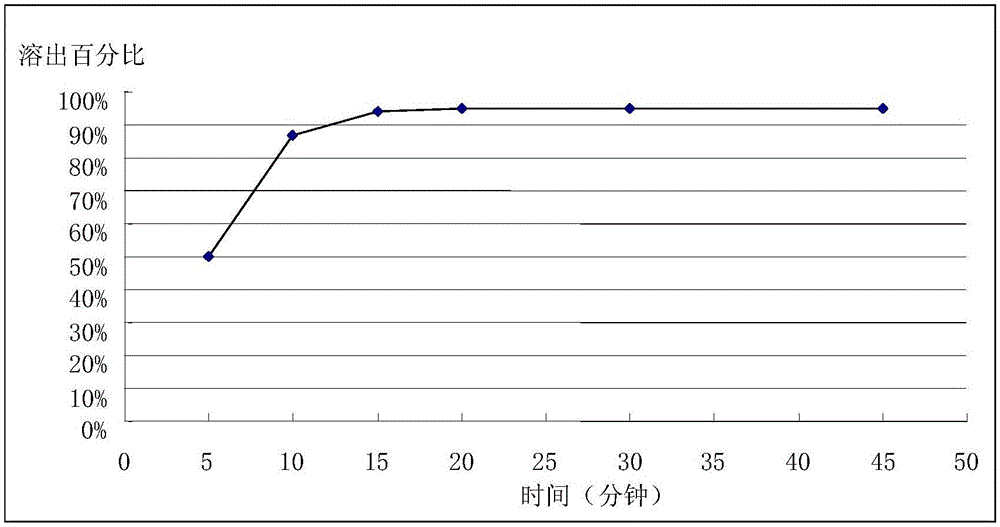

Hot-melt extrusion process for preparing indometacin quick release preparation from multi-element auxiliary materials

InactiveCN102204868BLower extrusion temperatureFacilitate the extrusion processPowder deliveryOrganic active ingredientsIndometacinPolymer science

The invention discloses a hot-melt extrusion process for preparing an indometacin quick release preparation from multi-element auxiliary materials and belongs to the field of pharmacy. The method comprises the following steps of: crushing indometacin and medicinal auxiliary materials, and after screening the powder with a 60 to 120-mesh sieve, uniformly mixing the powder into a physical mixture; according to the melting points or the glass transition temperatures of the medicament and the auxiliary materials, setting the extrusion temperature of a double-screw hot melt extruder to be between 50 and 150 DEG C, after the extrusion temperature reaches the preset temperature, starting a screw, adding the prepared physical mixture into the extruder, and extruding the physical mixture into strips through the screw; and after crushing the strips, screening the powder with a 20 to 80-mesh sieve to obtain medicinal solid dispersoid particles or powder. The auxiliary materials comprise the following components in percentage by weight: 10 to 90 percent of polymer, 5 to 50 percent of plasticizer, 0 to 10 percent of lubricant, 0 to 5 percent of surfactant and 0 to 20 percent of disintegrant. A sugar alcohol with a relatively low softening point or melting point, and the like, serving as the plasticizer, is added into the polymer with a relatively high softening point or melting point so as to reduce the extrusion temperature and make the extrusion process easy. The prepared indometacin solid dispersoid has the characteristic of quickly dissolving out.

Owner:BEIJING UNIV OF CHEM TECH

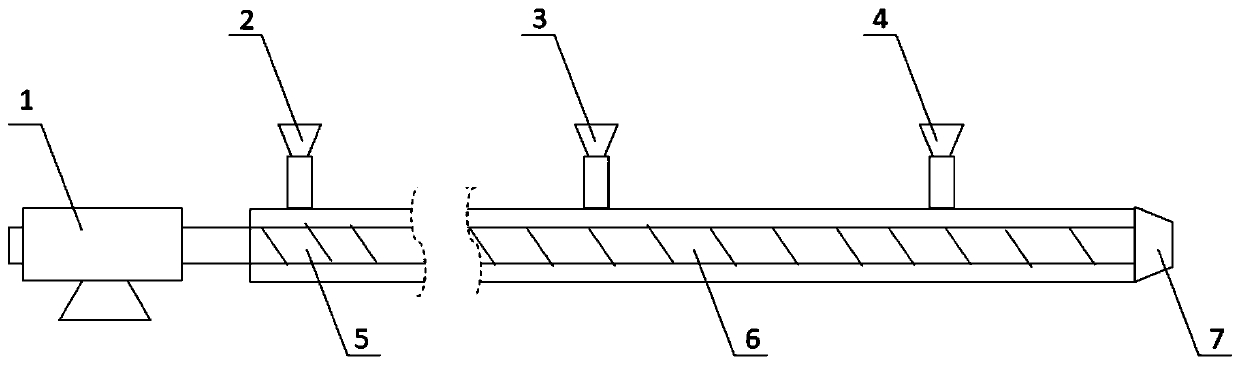

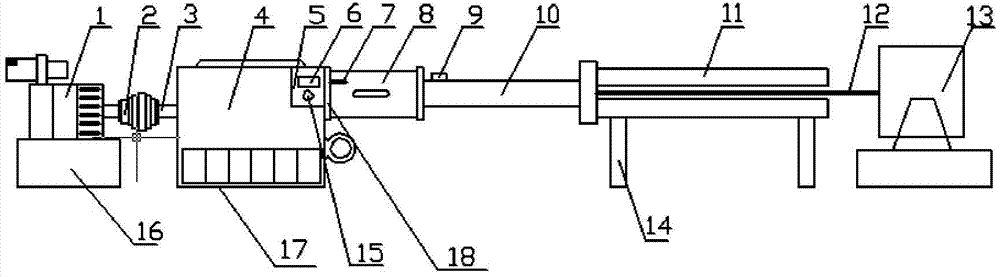

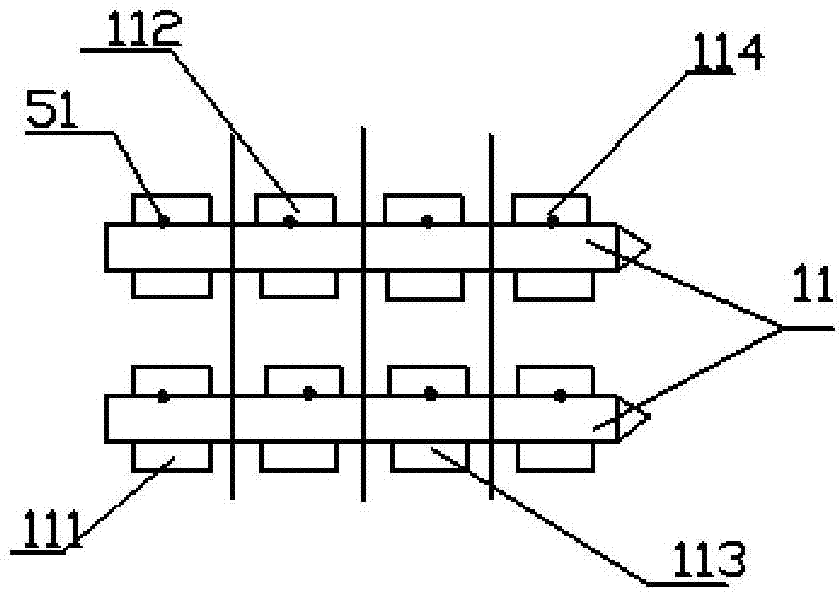

Post-grafting device used for silane crosslinking cable production line

InactiveCN105448433ALower extrusion temperatureAvoid technical pitfalls of pre-crosslinkingInsulating conductors/cablesElectricityTemperature control

A post-grafting device used for a silane crosslinking cable production line is composed of an extruder, an electric heating post-grafting device and a cabling machine. The extruder is composed of a motor, a shaft coupling, a reduction box, a gearbox, a shaft sleeve and a screw which are arranged from left to right in sequence. The extruder is connected with the electric heating post-grafting device and the cabling machine. The outer surface of the reduction box is provided with a temperature control operation panel. The operation panel is provided with a temperature display screen and a switch. The inner surface of the shaft sleeve is provided with a temperature detector. The screw is externally covered by a cylinder body. The cylinder body is provided with a heating device. The electric heating post-grafting device is a screw extruder. The screw of the extruder is 150-200 mm in diameter and 3-5 m in length and comprises 4-5 heating segments.

Owner:安正(天津)新材料股份有限公司

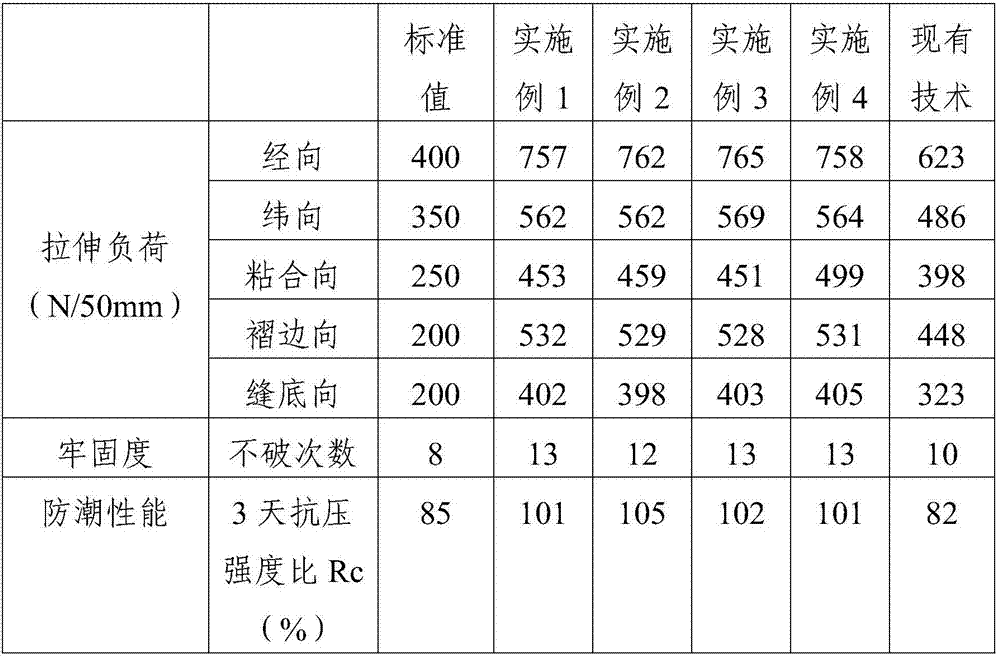

Film-coated cement package bag

The invention provides a composite film cement packaging bag, which relates to the field of cement bags; it includes a plastic woven bag and a film, and the plastic woven bag is composed of the following raw materials in parts by weight: 50-70 parts of modified polypropylene, 30-30 parts of polyethylene 40 parts, 15-25 parts of polyester fiber, 10-18 parts of ABS resin, 5-10 parts of asbestos powder, 8-15 parts of urea-formaldehyde melamine resin, 12-16 parts of aluminum oxide, 13-17 parts of dicumyl peroxide , 6-10 parts of recycled material, 2-4 parts of color masterbatch, 3-5 parts of whitening agent; the film is composed of the following raw materials in parts by weight: polyethylene 40-55 parts, polypropylene 10-15 parts, carbon fiber 2- 5 parts, 15-20 parts of fatty acid polyoxyethylene resin, and 10-13 parts of furfural resin; the cement packaging bag prepared by the invention has high strength, good firmness, and improved moisture-proof performance.

Owner:安徽天元塑业有限公司

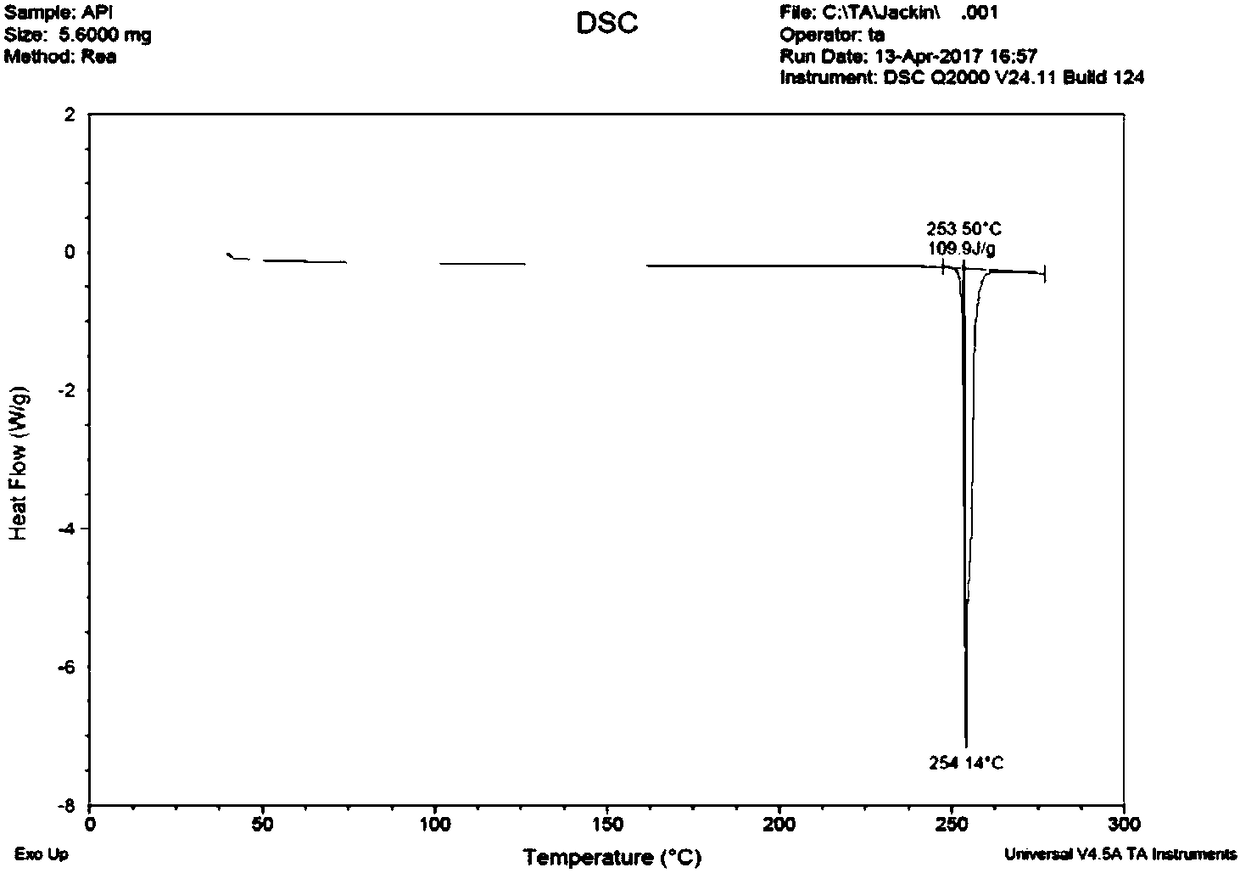

Aprepitant medicine composition and method for improving bioavailability of Aprepitant medicine composition

ActiveCN108324720ALess materialImprove solubilityOrganic active ingredientsDigestive systemCelluloseActive agent

The invention discloses an Aprepitant medicine composition, which comprises Aprepitant, at least one kind of intestine soluble carrier material and at least one kind of nonionic surfactant. The carrier is preferably hydroxypropyl methylcellulose succinate acetate, is favorably for dispersing the Aprepitant medicine to the inside in the molten state; in addition, after the addition of the nonionicsurfactant span, the consumption of the carrier is further reduced; the extrusion temperature is lowered. The invention provides a method for preparing the medicine composition using the Aprepitant asactive ingredients; the problems that in the preparation process of a conventional Aprepitant medicine composition by using an HME technology, the auxiliary material consumption of the Aprepitant isgreat; the storage is difficult, the metastable solid dispersion body has instable physical performance; recrystallization can easily occur; the solubility and dissolving-out speed reduction can be caused, and the like are solved.

Owner:NANJING HERON PHARMA SCI & TECH CO LTD

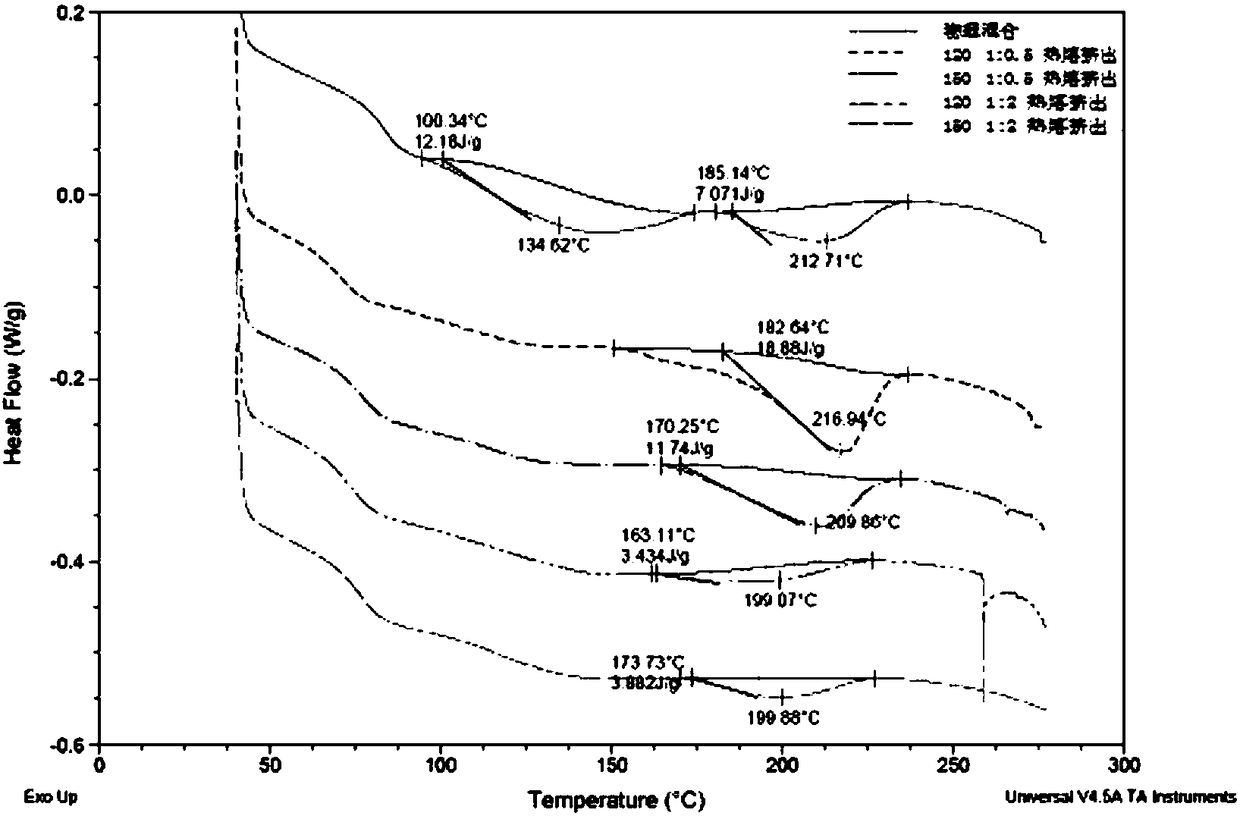

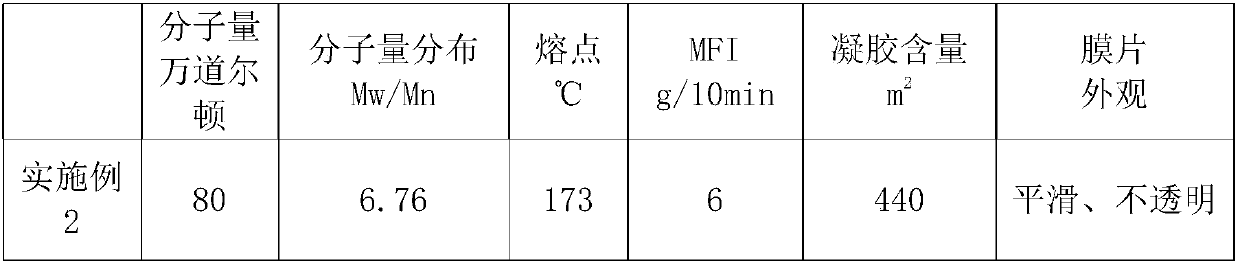

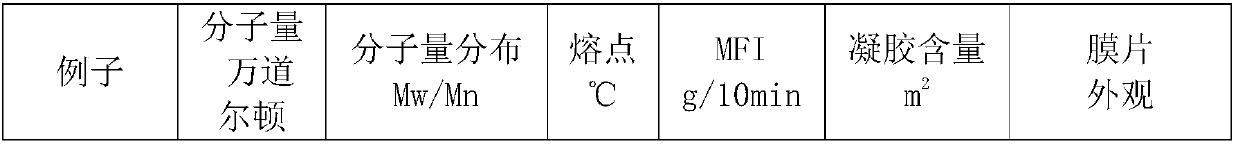

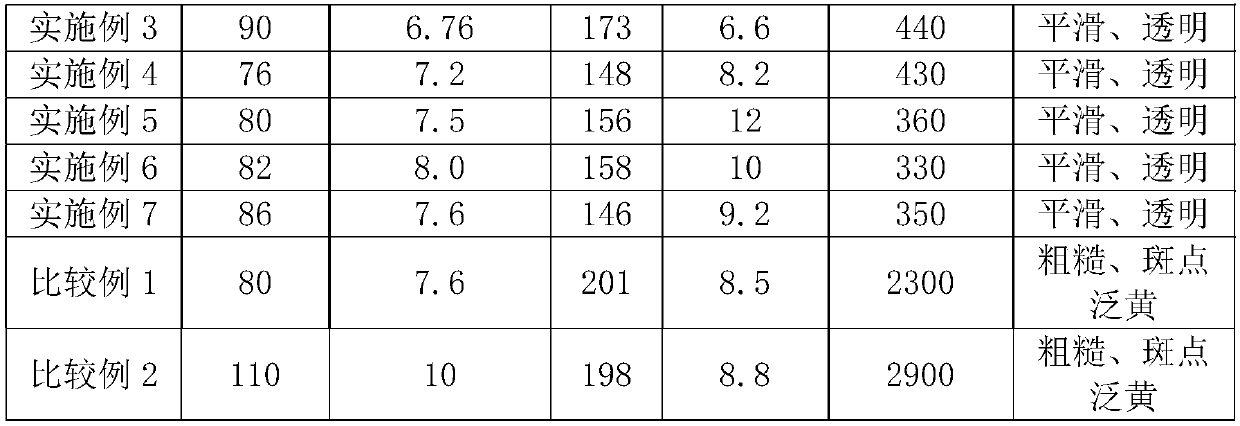

Low gel content vinylidene fluoride thermoplastic resin, preparation method and applications thereof

The invention relates to the field of organic chemical materials, particularly to a low gel content vinylidene fluoride thermoplastic resin, wherein the raw materials comprise two different fluorine-containing polymers A and B, the fluorine-containing polymer A is the homopolymer or copolymer of vinylidene fluoride having a melting point of 100-175 DEG C, and the fluorine-containing polymer B is an elastomer material or a plastic material having a melting point of less than 210 DEG C. According to the present invention, during the processing of the low gel content vinylidene fluoride thermoplastic resin, the adhesion is improved, and the good processing fluidity is achieved; and the properties of the original polymer are retained, the processing defects between the polymers are compensated, the production cost is low, the thermal stability at a high temperature is good, the gel content is low, the product defects are less, and the applications of the vinylidene fluoride resin are broadened.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

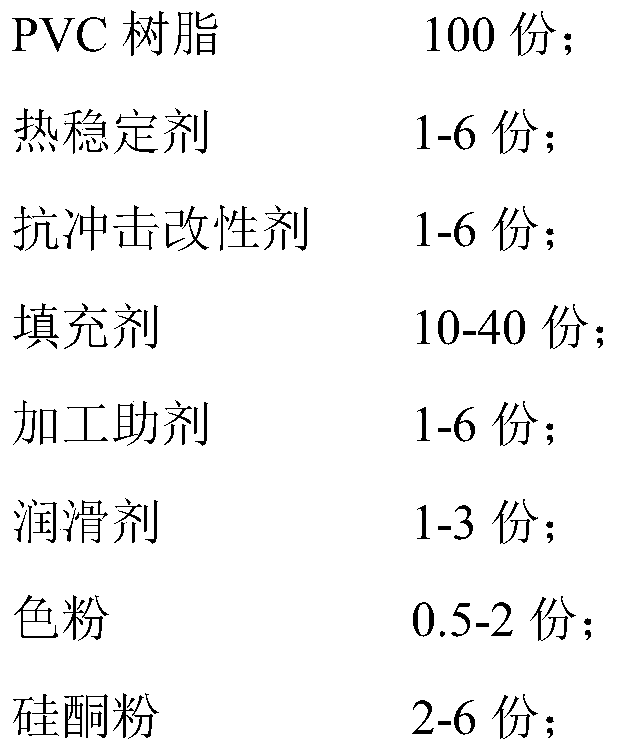

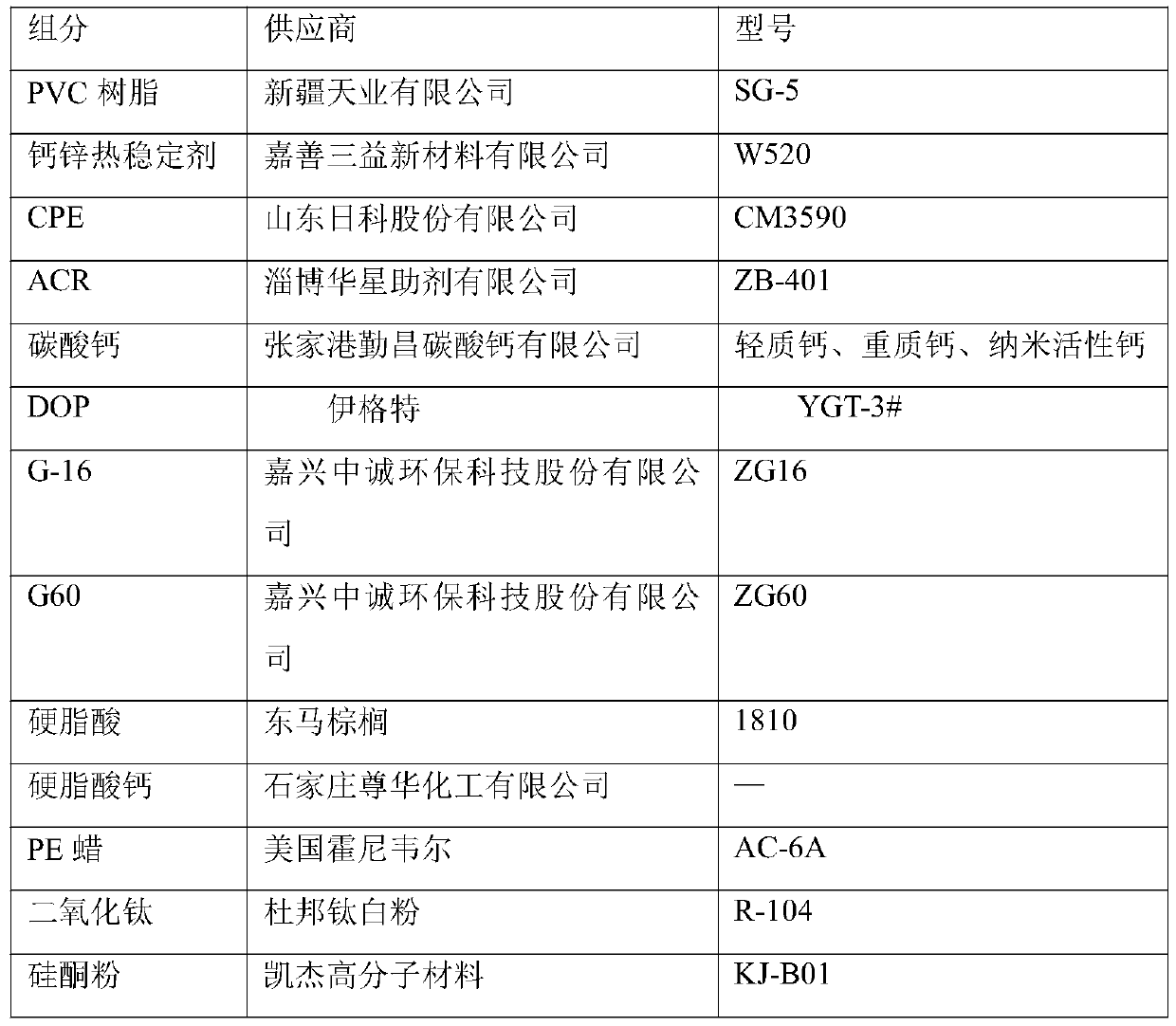

Rigid polyvinyl chloride pipe material and preparation method thereof

InactiveCN111171475AImprove surface smoothnessReduce coefficient of frictionPolymer sciencePolyvinyl chloride

The invention discloses a rigid polyvinyl chloride pipe material and a preparation method thereof, and relates to the field of high polymer materials. The rigid polyvinyl chloride pipe material provided by the invention comprises the following components in parts by weight: 100 parts of PVC resin; 1-6 parts by weight of a stabilizer; 1-6 parts by weight of an impact modifier; 10-40 parts by weightof a filler; 1-6 parts by weight of a processing aid; 1-3 parts by weight of a lubricant; 0.5 to 2 parts by weight of toner; and 2-6 parts by weight of silicone powder. The silicone powder with highsilica content and high molecular weight is added into the polyvinyl chloride resin, so that the polyvinyl chloride resin can be used as a wear-resistant agent, and thereby the friction coefficient between silicone is relatively small, the dispersity is uniform, the lubricating property is good, and the surface smoothness of polyvinyl chloride can be remarkably improved.

Owner:JIANGSU BOILN PLASTICS CO LTD

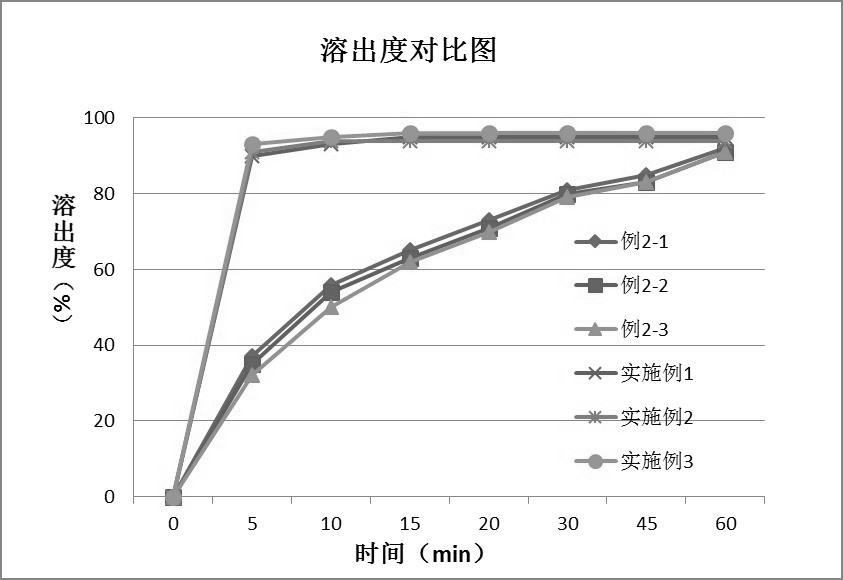

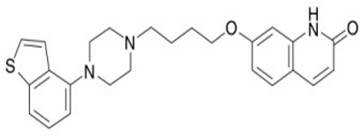

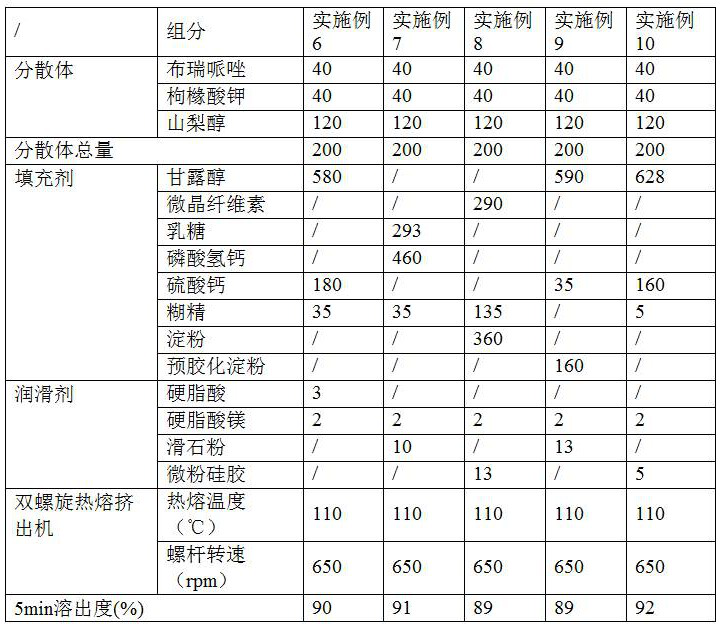

Preparation method of brexpiprazole tablets

PendingCN112168794AInhibition of high temperature degradationLower requirementOrganic active ingredientsNervous disorderHot meltPharmaceutical Aids

The present invention discloses a preparation method of brexpiprazole tablets and belongs to the field of pharmaceutical preparations. The brexpiprazole tablets are prepared by directly tabletting brexpiprazole solid dispersion particles and auxiliary materials, and the brexpiprazole solid dispersion particles are prepared by the following method: heating and melting potassium citrate, sorbitol and brexpiprazole in a hot melt extruder, and extruding and granulating the melt materials, wherein a weight ratio of brexpiprazole to potassium citrate is 1:(0.5-2) and a weight ratio of the brexpiprazole to the sorbitol is 1:(1-5). An in-vitro dissolution rate of the brexpiprazole is increased.

Owner:浙江诺得药业有限公司 +1

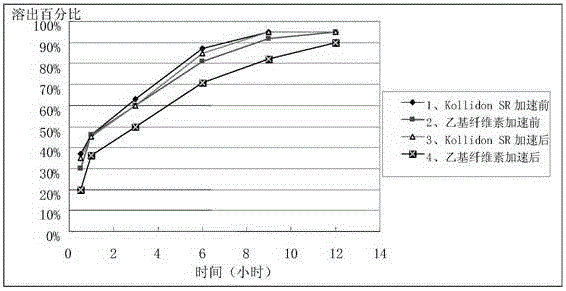

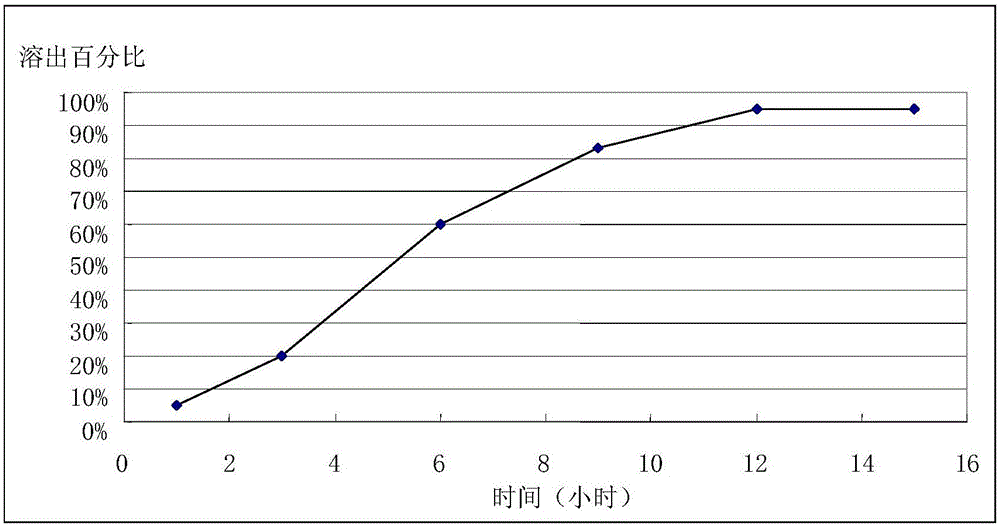

Multi-unit release pharmaceutical composition of amlodipine maleate and preparation method of pharmaceutical composition

ActiveCN106580924AReach therapeutic concentrationsActions and effects are long-lasting and long-lastingOrganic active ingredientsPharmaceutical non-active ingredientsAdjuvantDissolution

The invention belongs to the technical field of pharmaceutical preparations, and relates to a multi-unit release pharmaceutical composition of amlodipine maleate and a preparation method of the pharmaceutical composition. The pharmaceutical composition consists of the following components in percentage by weight: 10-95% of sustained-release particles containing the amlodipine maleate, 5-90% of quick-release particles containing the amlodipine maleate and 0-5% of other adjuvants. The sustained-release particles are prepared by virtue of hot-melt extrusion and the quick-release particles are prepared by virtue of dry granulation, the sustained-release particles and the quick-release particles are mixed according to a certain proportion and a lubricant is added in accordance with a formulated amount, so that the pharmaceutical composition is prepared. The pharmaceutical composition and a preparation method thereof have the advantages that the rapid dissolution of drugs can be promoted to achieve a treatment concentration and the drugs can take lasting effects, the bioavailability of the amlodipine maleate is high, the stability of the finished product (the composition) is good, and the preparation process is simple and easy to operate, low in energy consumption, free from residue of organic solvents and easy for implementation of large-scale continuous production.

Owner:NORTHEAST PHARMA GRP

Low-density foamed thermoplastic polyurethane elastic body and preparation process thereof

Owner:SHANDONG AOBANG POLYURETHANE

Melt processable thermoplastic polymer composition

The present invention relates to a melt processable polymer composition and a method of improving the melt processability of the host polymer. Said melt processable polymer composition comprises a thermoplastic non-aliphatic host polymer and a minor but effective amount of a fluoropolymer processing aid.

Owner:德弘公司

High-strength magnesium-lithium alloy and preparation method thereof

The invention provides high-strength magnesium-lithium alloy and a preparation method thereof. Commercial pure Mg, commercial pure Li, commercial pure Zn, Mg-RY middle alloy are taken as materials; the high-strength magnesium-lithium alloy is prepared from the materials by mass percent: 4.5-5.5% of Li, 2.0-3.8% of RY, 0.2-1.0% of Zn, less than 0.03% of gross of inevitable Fe, Cu, Ni and Si impurities, and the balance of Mg in a mixing manner according to the ratio. The preparation method comprises the steps of: based on commercial pure Mg, commercial pure Li, commercial pure Zn, Mg-RY middle alloy as materials, mixing the following components in percentage by mass: 4.5-5.5% of Li, 2.0-3.8% of RY, 0.2-1.0% of Zn, less than 0.03% of gross of inevitable Fe, Cu, Ni and Si impurities, and the balance of Mg; smelting in a vacuum induction smelting furnace, wherein the inside of the furnace is vacuumized before smelting, and then aerating argon is aerated to protect, the smelting process is carried out under protection of argon atmosphere, and the smelting temperature is 660-750 DEG C; casting the smelted melt into a metal die to obtain as-cast alloy; carrying out hot extrusion for at least twice to obtain the high-strength magnesium-lithium alloy. The obtained alloy disclosed by the invention has high strength and good plasticity; the tensile strength at room temperature is 220-260 MPa; the yield strength is 180-220MPa; the elongation percentage is 15-25%.

Owner:HARBIN ENG UNIV

Method of thermally processing elastomeric compositions and elastomeric compositions with improved processability

ActiveUS20050119410A1Improve processabilityLower extrusion temperatureArtifical filament manufactureNon-woven fabricsElastomer

Owner:KIMBERLY-CLARK WORLDWIDE INC

Instant whole-wheat crisp chips and making method thereof

PendingCN109090474ALower extrusion temperatureReduce energy consumptionFood preservationBakery productsMicrowaveEngineering

Provided is instant whole-wheat crisp chips. A making method of the instant whole-wheat crisp chips comprises the steps that complete wheat grains are used as raw materials, full soaking is performedto make wheat to have saturated water absorption amount, and then cooking, extrusion, tableting and microwave vacuum drying are performed to prepare the instant whole-wheat crisp chips. No man-made additive is added during processing, extrusion and drying are performed under the low-temperature condition, the current trend to 'clean label' foods is conformed, meanwhile the complete wheat grains are processed into crisp chips, the crisp chips are a true sense of whole-wheat food, and the current whole-wheat trend is conformed.

Owner:JIANGNAN UNIV

High-thermal-stability Al alloy and preparation process thereof

The invention discloses a high-thermal-stability Al alloy and a preparation process thereof. The Al alloy comprises the following components by weight ratio: 1-2% of Mg, 0.2-1% of Zr, 2-4% of Cu, 0.2-1% of Si, 0.01-0.1% of B, 0.5-1% of Fe, 0.1-2% of Ni, 0.5-1% of Ti, 0.1-2% of Mo, no more than 0.02% of Cr, 0.2-1% of a rare-earth element, and the balance Al. The Al alloy prepared through the preparation process disclosed by the invention has the beneficial effects that a conventional Al alloy preparation process is improved; the thermal stability is high; and the stable mechanical properties can still be kept in a high-temperature environment.

Owner:山东创新精密科技有限公司

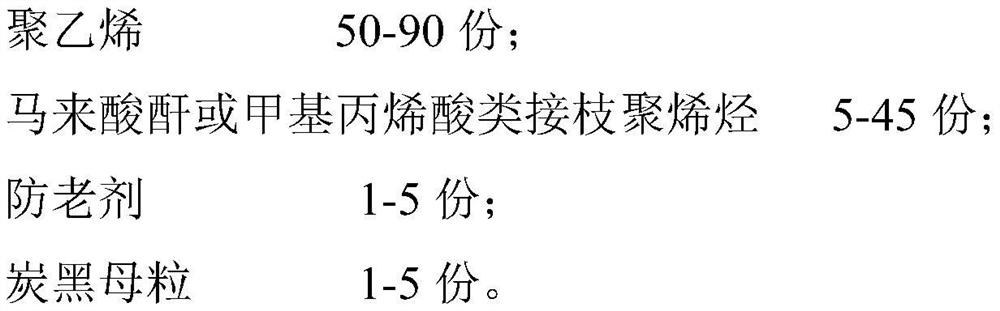

Formula, preparation method and application of heat-shrinkable sleeve

InactiveCN112111097AHigh strengthHigh application strengthSynthetic resin layered productsLaminationPhosphoric Acid EstersPolymer science

The invention discloses a formula of a heat-shrinkable sleeve. The formula of the heat-shrinkable sleeve comprises the following components in parts by mass: 50-90 parts of polyethylene; 5-45 parts ofmaleic anhydride or methacrylic acid grafted polyolefin; 1-5 parts of an anti-aging agent; and 1-5 parts of carbon black master batch, wherein the melt index of the polyethylene is 2-10 g / 10 min; inthe maleic anhydride or methacrylic acid grafted polyolefin, the content of a comonomer is 1-5 wt%; the anti-aging agent is any one of a compound combination of more than one selected from amines, phenols, heterocycles, thioesters and phosphite esters; and the carbon black master batch comprises carbon black and polyolefin. Meanwhile, the invention further provides a preparation method and application of the heat-shrinkable sleeve according to the formula. Therefore, through the formula of the heat-shrinkable sleeve which is convenient to process and produce and relatively low in cost, the prepared heat-shrinkable sleeve can wrap metal or non-metal parts such as a rubber pipe, a wiring harness or a metal pipeline and the like; and meanwhile, the sleeve has good mechanical properties, is wrapped more densely and shows good sealing performance.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com