Special material for high-fluidity high-temperature polyamide heat-insulation strip and preparation method of material

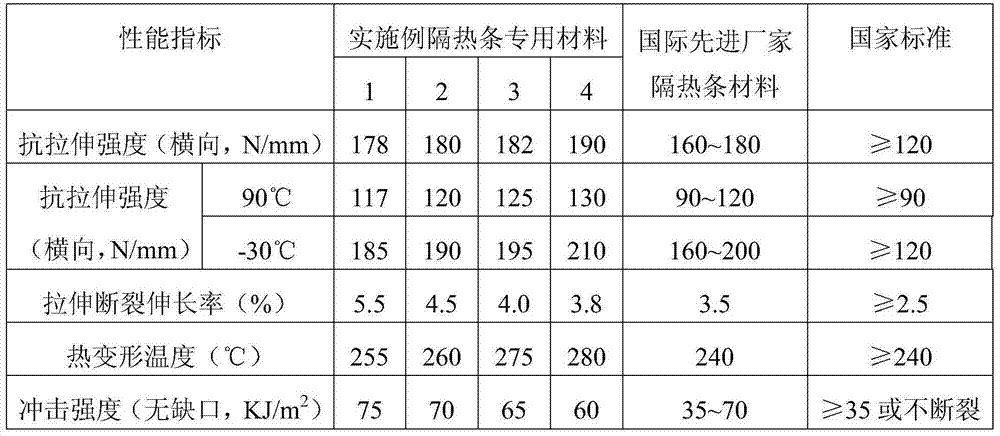

A technology of high-temperature polyamide and high fluidity, applied in the field of heat-insulating strip materials, can solve the problems of poor dimensional stability of heat-insulating strip materials, poor high-temperature resistance of additives, poor melt flow, etc., and achieve dimensional stability Good, good chemical corrosion resistance, the effect of optimizing the extrusion process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Synthesis of high fluidity high temperature nylon resin

[0024] Add 35 parts of nylon 6T salt, 30 parts of nylon 66 salt, and 1 part of diethylenetriamine into deionized water, and then add 2 parts of end-capping agent. After purging with nitrogen, increase the pressure of the reaction system to 3.2 MPa, raise the temperature to 240°C, and then Keep it for 10 hours, carry out copolymerization, and obtain a prepolymer; then, under a nitrogen atmosphere, at a temperature of 240°C, react for 5 hours, and perform a solid-state reaction to increase viscosity, thereby obtaining a high-fluidity high-temperature nylon with a relative viscosity of 2.6 and a melting point of 270°C .

[0025] (2) Preparation of special materials for heat insulation strips

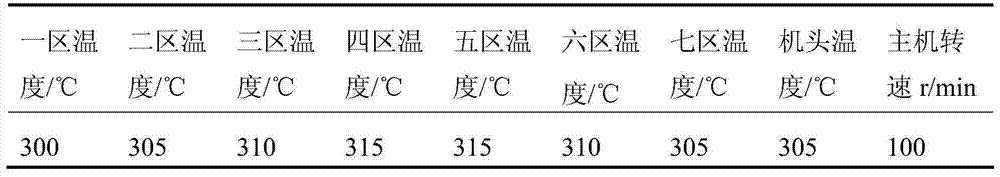

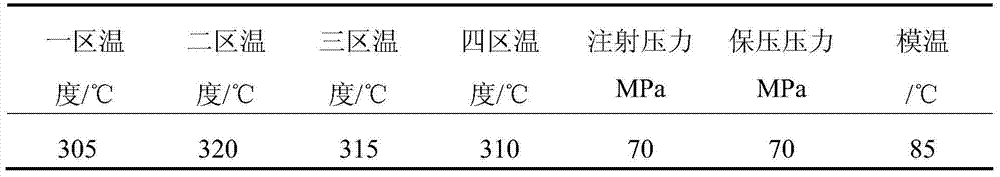

[0026] Dry 74wt% high-fluidity high-temperature nylon and 1wt% black high-temperature nylon masterbatch in a blast oven at 100°C for 12 hours, and dry 23.5wt% glass fiber pretreated with 0.5wt% fiber treatment agent at 80...

Embodiment 2

[0028] (1) Synthesis of high fluidity high temperature nylon resin

[0029] Add 40 parts of nylon 6T salt, 5 parts of nylon 9T salt, 30 parts of nylon 66 salt, and 2 parts of triaminotriphenylmethane into deionized water, then add 2 parts of end-capping agent, and after purging with nitrogen, increase the pressure of the reaction system to 3.0MPa, raise the temperature to 235°C, and then keep it for 5h to carry out copolymerization to obtain a prepolymer; then under vacuum conditions, the temperature is 180°C, react for 15h, and carry out solid phase reaction to increase viscosity, thereby obtaining high-fluidity high-temperature nylon, which is relatively The viscosity is 2.8 and the melting point is 285°C.

[0030] (2) Preparation of special materials for heat insulation strips

[0031] Dry 72wt% high-fluidity high-temperature nylon and 2wt% black high-temperature nylon masterbatch in a blast oven at 100°C for 12 hours, and dry 23wt% glass fiber pretreated with 1wt% fiber t...

Embodiment 3

[0033] (1) Synthesis of high fluidity high temperature nylon resin

[0034] Add 30 parts of nylon 6T salt, 30 parts of nylon 66 salt, and 0.5 part of triethylenetetramine into deionized water, then add 2 parts of catalyst, after purging with nitrogen, increase the pressure of the reaction system to 4.0 MPa, raise the temperature to 250°C, and then keep it for 8 hours , to carry out copolymerization to obtain a prepolymer; then under vacuum conditions, the temperature is 200 ° C, react for 8 hours, and carry out solid phase reaction to increase viscosity, thereby obtaining high-fluidity high-temperature nylon with a relative viscosity of 2.5 and a melting point of 300 ° C.

[0035] (2) Preparation of special materials for heat insulation strips

[0036] Dry 77.5wt% high-fluidity high-temperature nylon and 0.1wt% black high-temperature nylon masterbatch in a blast oven at 100°C for 12 hours, and dry 22wt% glass fiber pretreated with 0.05wt% fiber treatment agent at 80°C After d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com