Patents

Literature

1927results about How to "Guaranteed liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

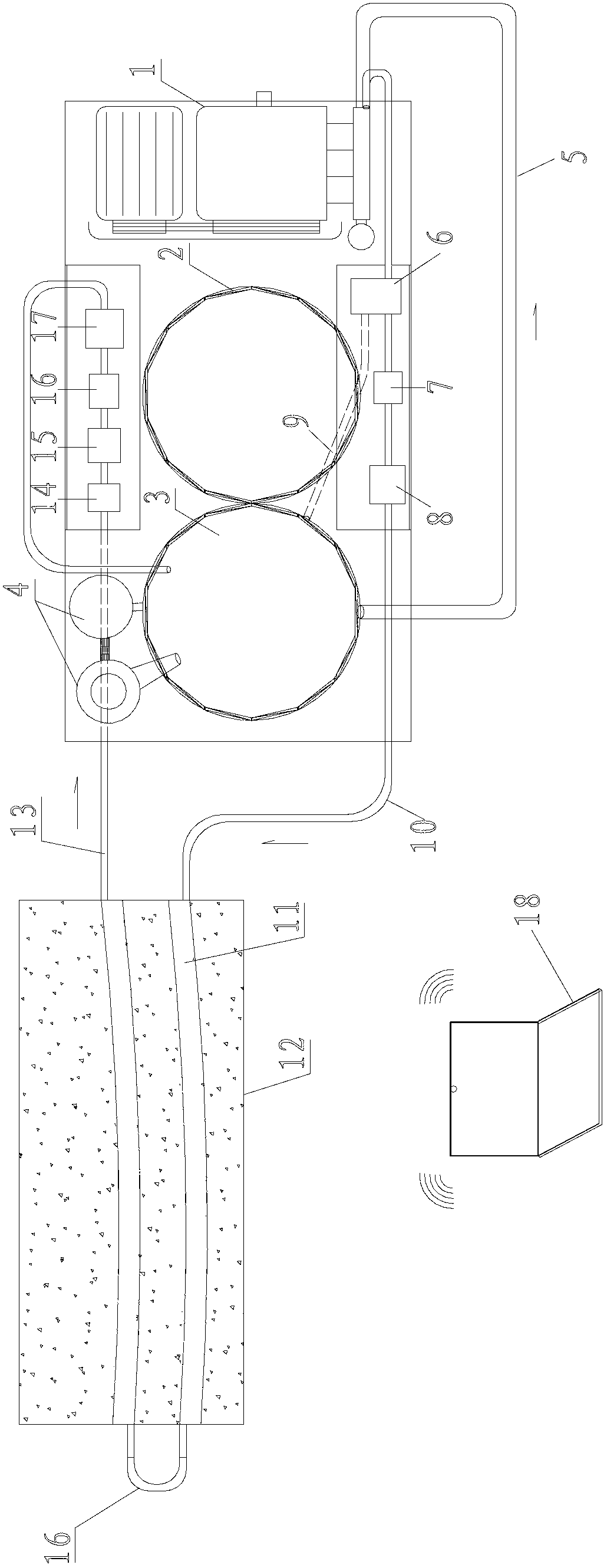

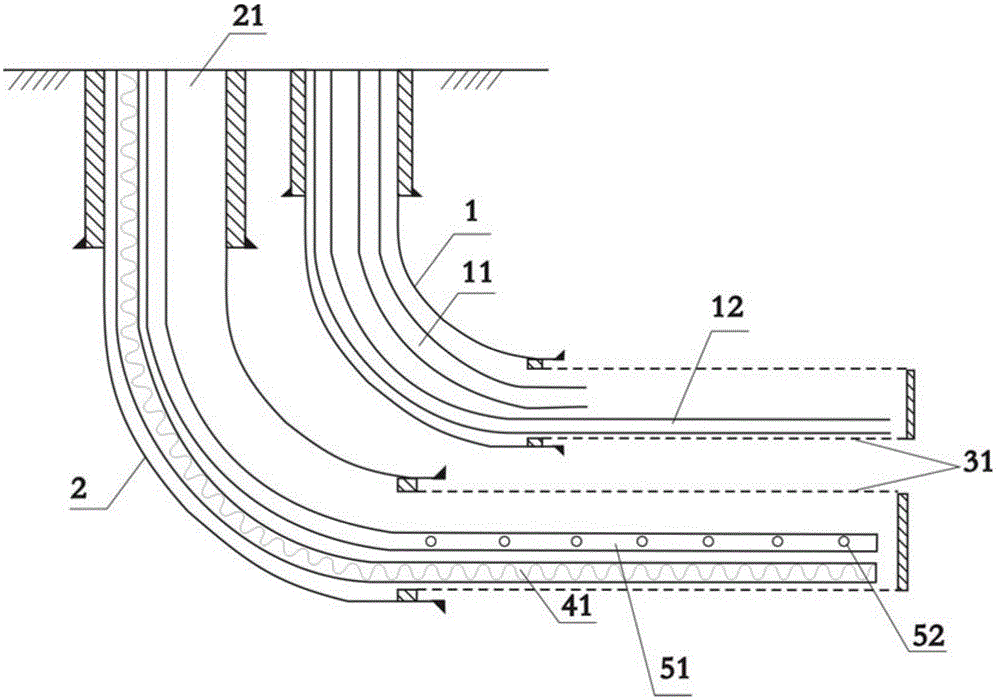

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

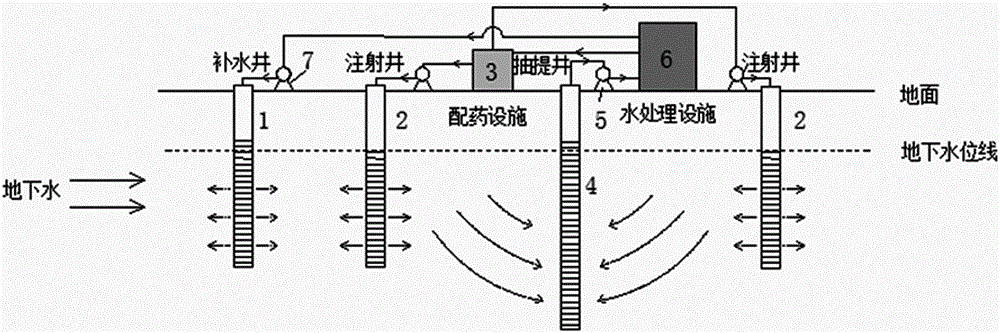

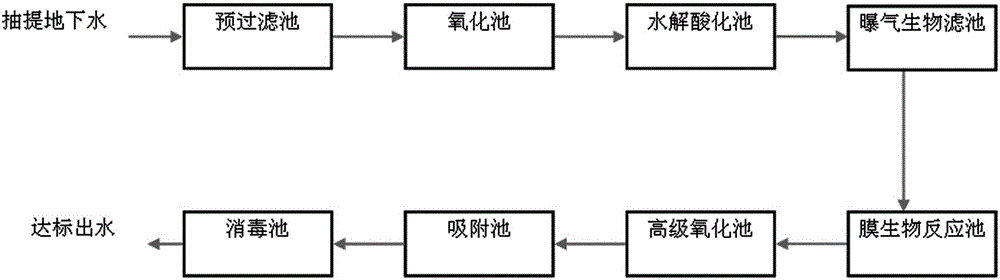

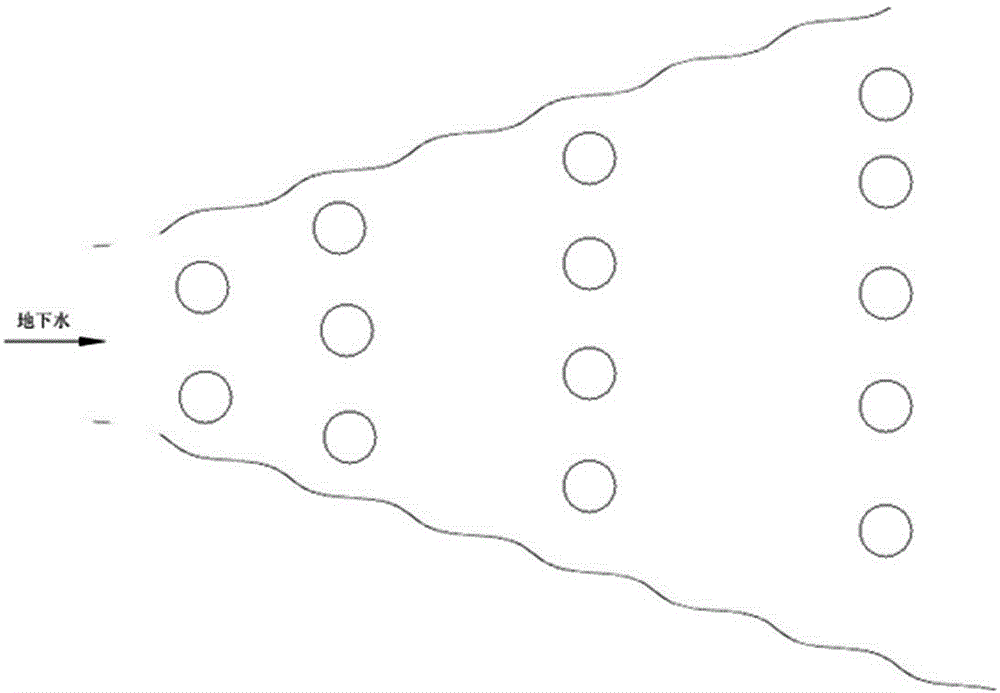

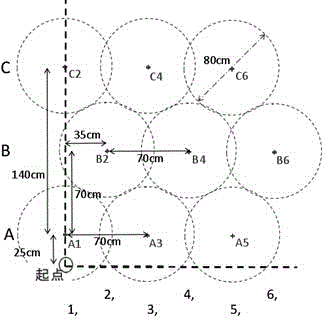

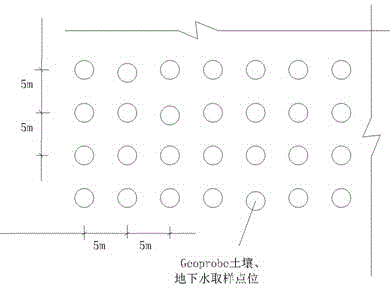

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

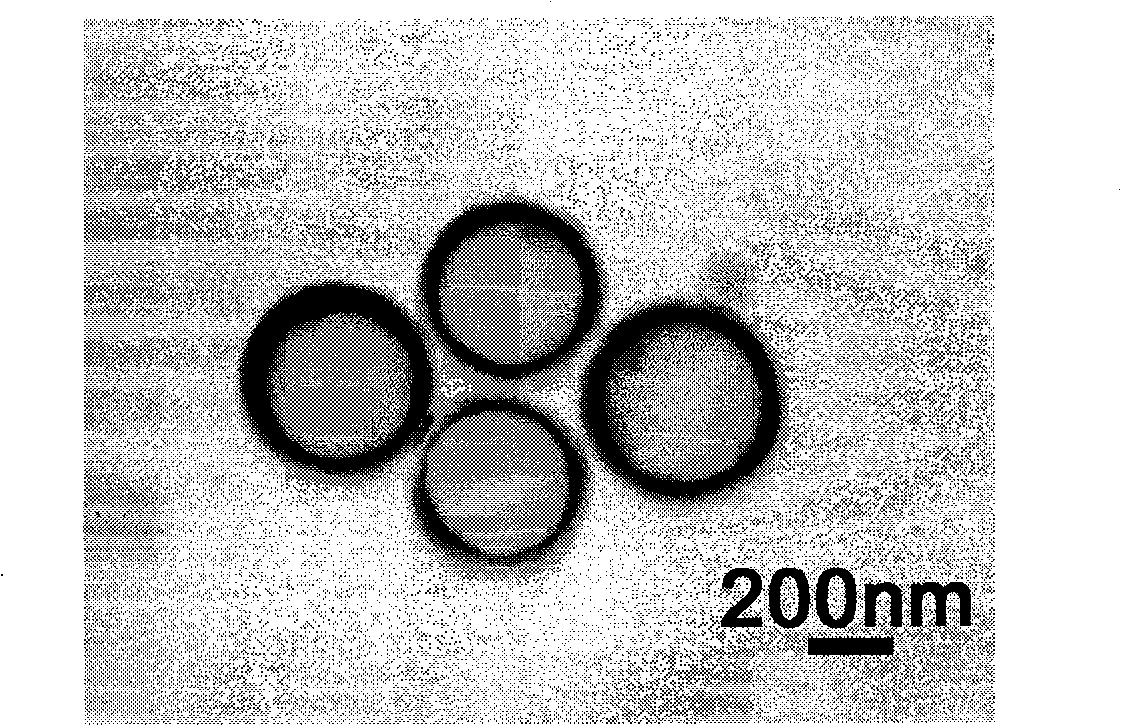

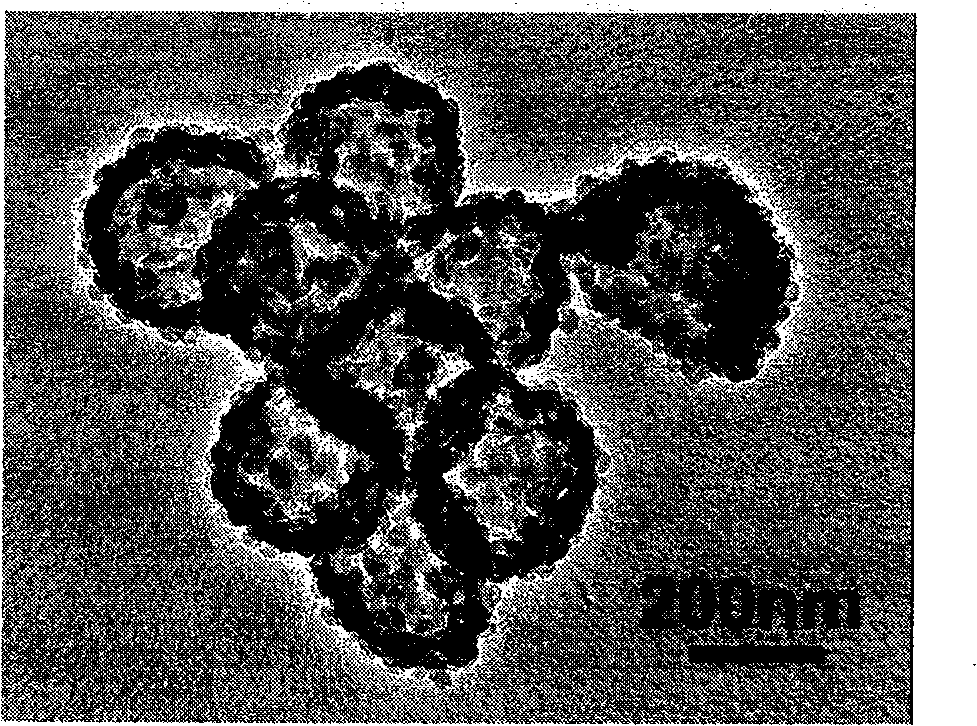

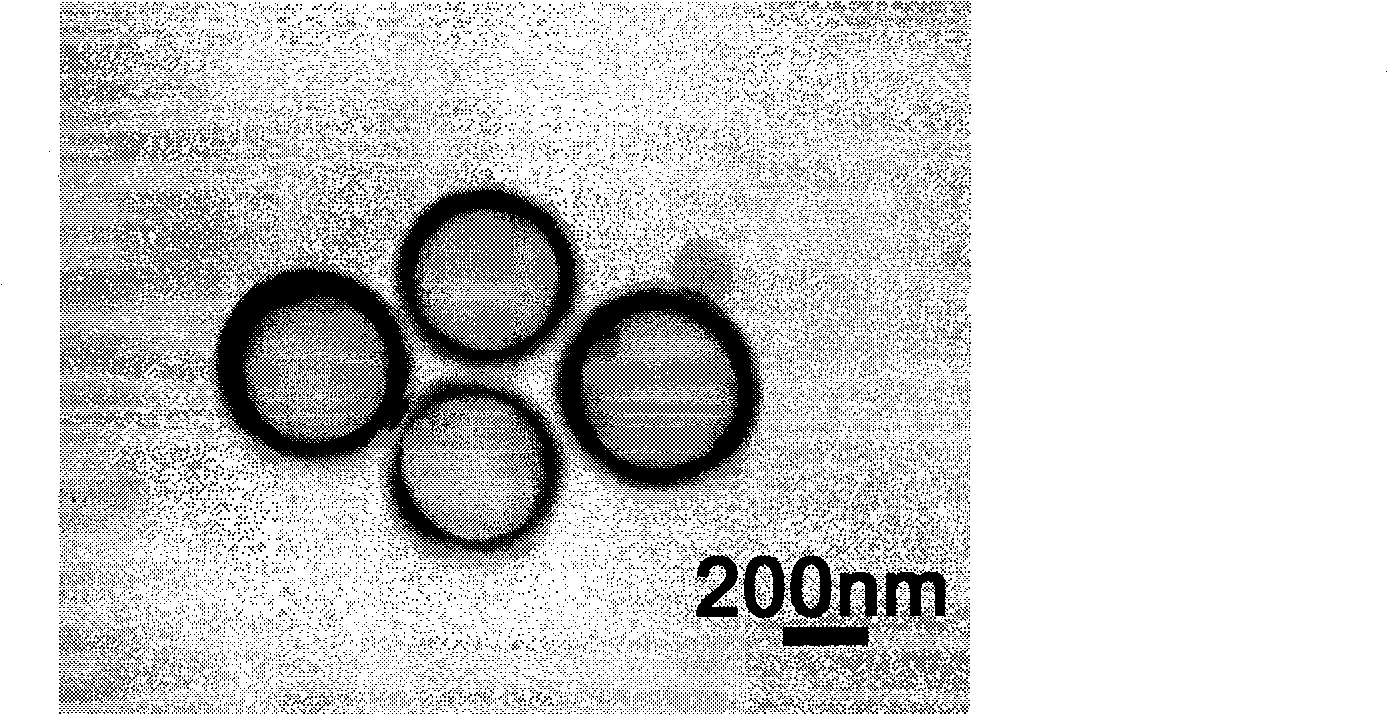

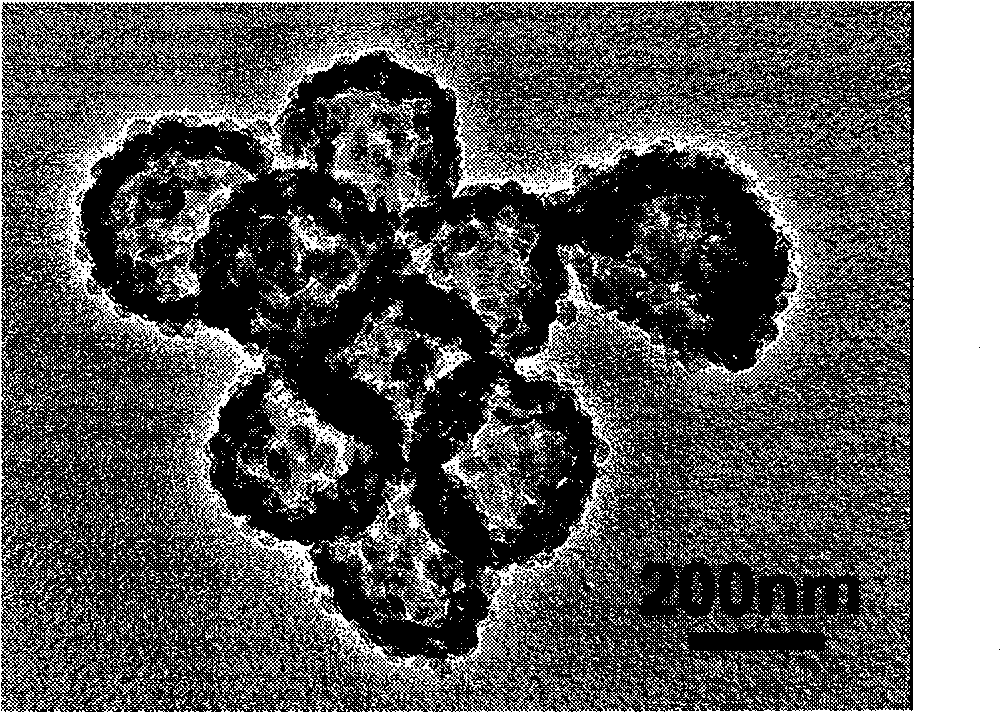

Method for preparing hollow ball with double-layer structure and hollow ball with multi-layer complex structure by template method

ActiveCN101259402AGuaranteed liquidityLarge specific surface areaMicroballoon preparationMicrocapsule preparationSolventMaterials science

The invention belongs to the field of materials with a hollow structure, in particular to a method for preparing double-layer hollow spheres and hollow spheres with multi-layer compound structures by using a template method. The invention prepares the compound hollow sphere by taking a polymer hollow sphere as a template and combining sol-gel, settlement reaction and redox process through the method of forcing interface or surface settlement, removes the template polymer through high sintering or selective extraction of a solvent to obtain the hollow spheres of minerals, metals and organic matters. The structure and the size of the hollow sphere can be controlled through controlling the reagent activity, the feeding mode, the reagent concentration and a circulation reaction method; besides, compounding of various matters can be realized; the hollow sphere of the invention not only has good dispersing performance, but also has excellent strength and size stability. The invention relates to the application of the materials with a hollow structure.

Owner:BEIJING NEW BUILDING MATERIAL

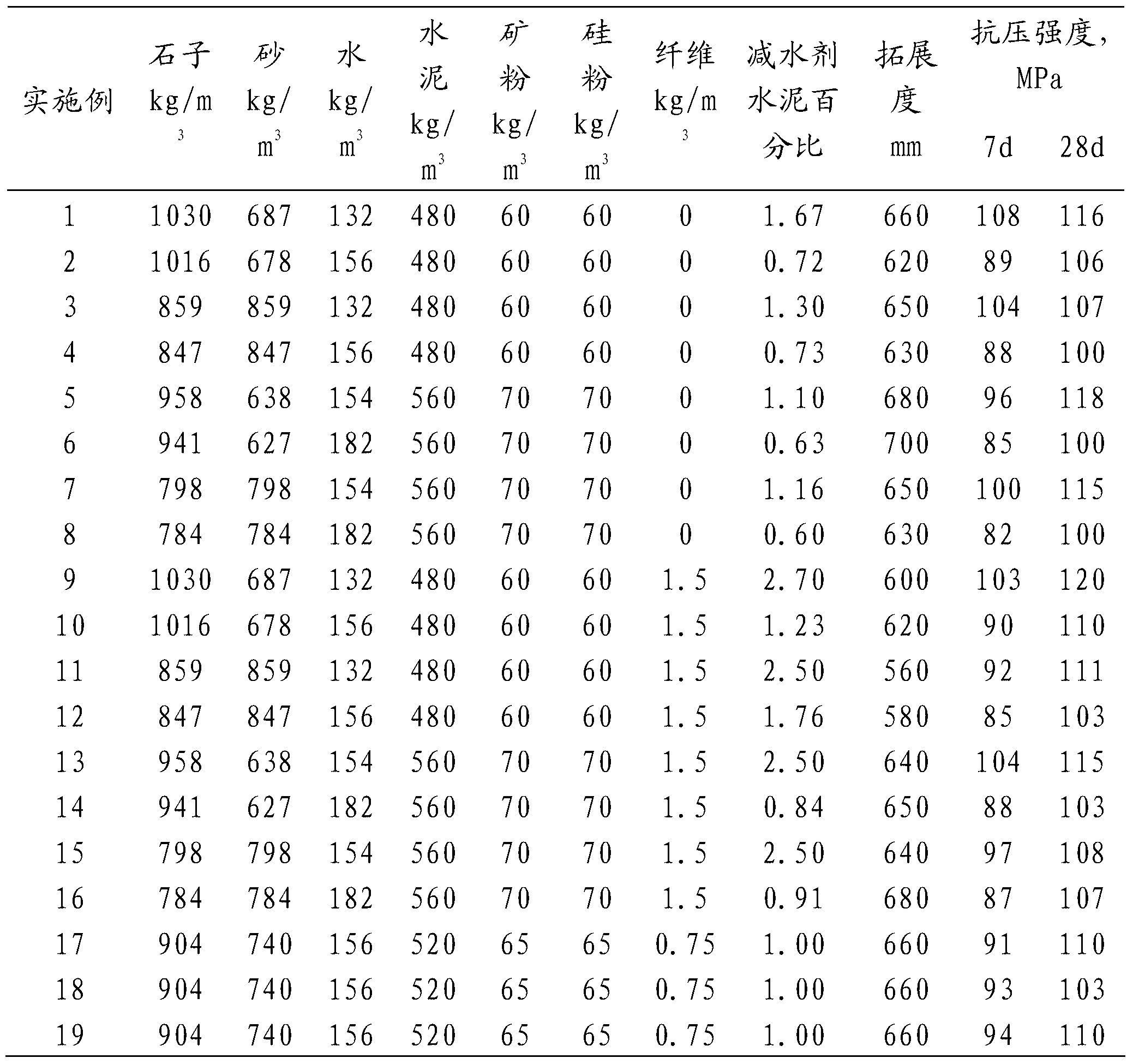

Ultrahigh-toughness concrete and preparation method thereof

ActiveCN104556881AImprove toughnessHigh-efficiency water reducer reduces water-cement ratio and improves toughnessSolid waste managementFiberSlag

The invention discloses an ultrahigh-toughness concrete and a preparation method thereof. The ultrahigh-toughness concrete mainly comprises cement, silica fume, mineral slag, fly ash, quartz powder, quartz sand, steel fiber, nano calcium carbonate, water and a water reducing agent. The weight ratio of the silica fume to the cement is (10-20):100; the weight ratio of the mineral slag to the cement is (1-20):100; the weight ratio of the fly ash to the cement is (5-20):100; the weight ratio of the quartz powder to the cement is (30-38):100; the weight ratio of the quartz sand to the cement is (80-150):100; the steel fiber accounts for 2.0-4 vol% of the concrete; the weight ratio of the calcium carbonate to the cement is (0.1-5):100; the water-binder ratio is 0.16-0.22; and the weight ratio of the water reducing agent to the cement is (0.5-4):100. The concrete has the advantages of high strength, high toughness and favorable workability; the slump is greater than or equal to 180mm; and the concrete is pumpable and can be cast in place.

Owner:GUANGDONG GUANSHENG CIVIL ENG TECH

Method for preparing hollow ball and hollow ball with complex structure by template method

InactiveCN101259401AGuaranteed liquidityLarge specific surface areaMicroballoon preparationMicrocapsule preparationSolventSol-gel

The invention belongs to the field of materials with a hollow structure, in particular to a method for preparing hollow spheres of minerals, metals and organic matters and hollow spheres with compound structures as well as hollow spheres with photic, electrical, magnetic and catalytic properties and hollow spheres with compound structures thereof by taking a polymer hollow sphere as a template. The invention prepares the hollow spheres with compound structures by taking the polymer hollow sphere as the template and combining sol-gel, settlement reaction and redox process through the method of forcing interface or surface settlement, removes the template polymer through high sintering or selective extraction of a solvent to obtain the hollow spheres of minerals, metals and organic matters. The structure and the size of the hollow sphere can be controlled through controlling the reagent activity, the feeding mode, the reagent concentration and a circulation reaction method; besides, compounding of various matters can be realized; the hollow sphere of the invention not only has good dispersing performance, but also has excellent strength and size stability. The invention relates to the application of the materials with a hollow structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

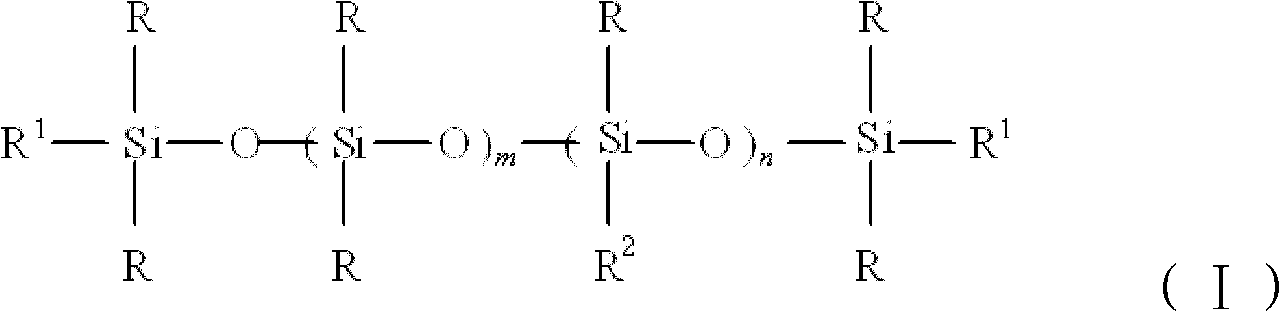

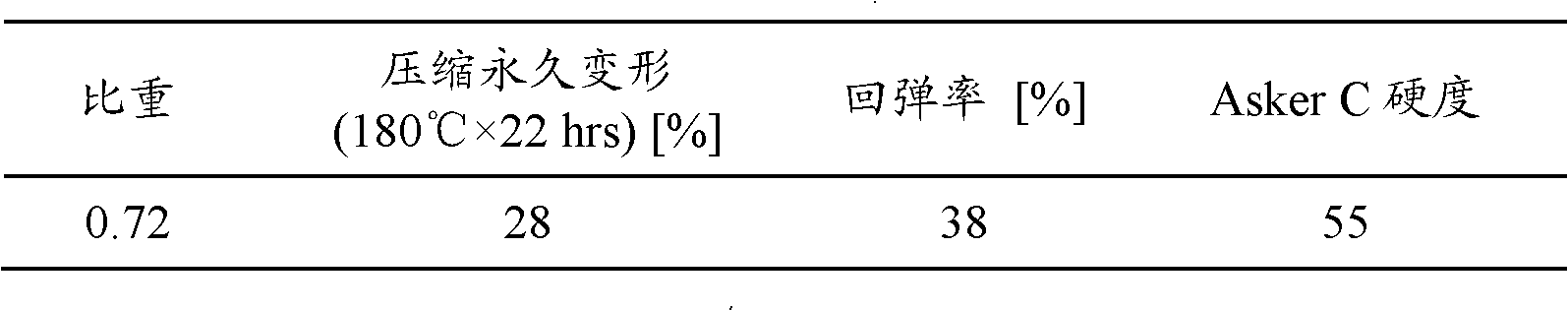

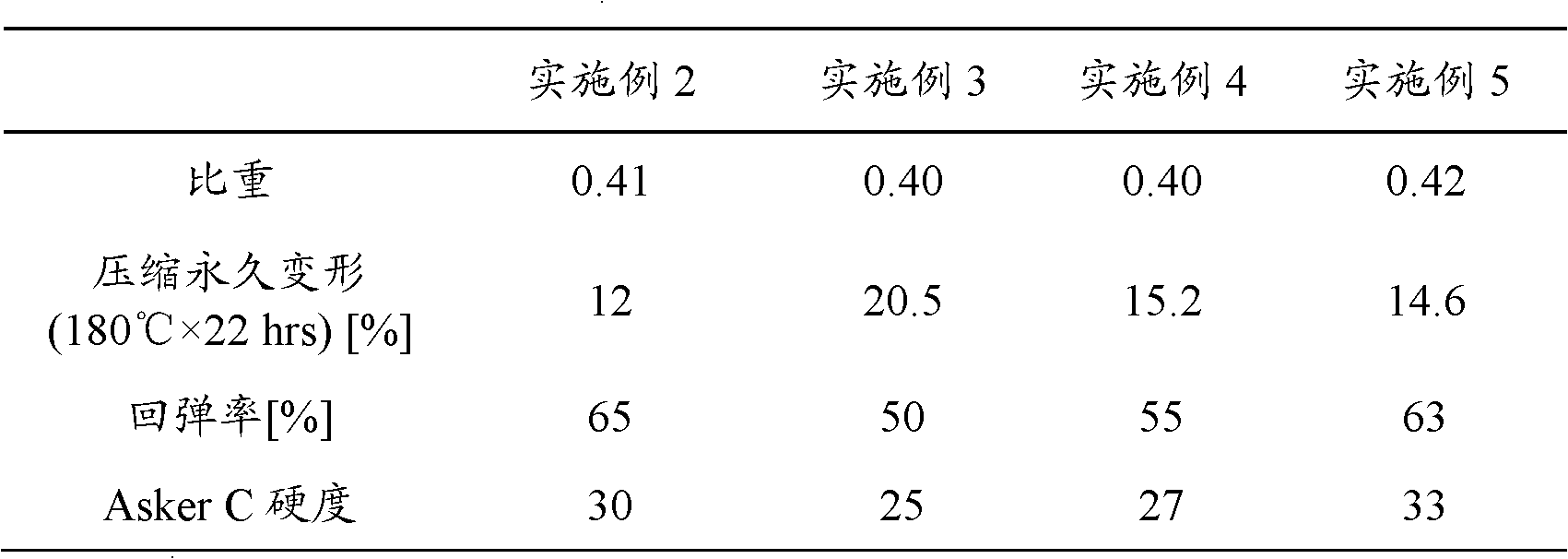

Liquid silicon rubber composition and preparation method thereof

The invention relates to a liquid silicon rubber composition which comprises the following components in parts by mass: 100 parts of polydimethylsiloxane with vinyl as an end group, 1-400 parts of inorganic reinforcing agent, 1-20 parts of low-viscosity polydimethylsiloxane with a vinyl-containing side group, 0.01-10 parts of cross-linking agent, 1-30 parts of polydimethylsiloxane with hydroxyl as an end group, and a platinum catalyst capable of curing the liquid silicon rubber composition. The invention further relates to a preparation method of the liquid silicon rubber composition. The liquid silicon rubber composition has low viscosity and good fluidity before being cured and is applicable to injection molding; and the composition has excellent resilience and low compression deformation ratio after being cured. The liquid silicon rubber composition can be applied to an elastomer, a pressure roll and an image heating and fixing device in a copier and a laser printer as well as certain silicon rubber products in need of the properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Medicinal and edible health care blending oil

InactiveCN103444911AGuaranteed liquidityMaintain normal physiological functionEdible oils/fatsSunflower seedSAFFLOWER SEED

The invention discloses medicinal and edible health care blending oil. The medicinal and edible health care blending oil is composed of the following components in percentage by weight: 2-25% of wheat germ oil, 2-25% of walnut oil, 2-25% of tea seed oil, 2-25% of linseed oil, 2-25% of almond oil, 2-25% of grape seed oil, 2-25% of peanut oil, 2-25% of corn germ oil, 2-25% of sunflower seed oil, 2-20% of pumpkin seed oil, 2-15% of safflower seed oil, 1-10% of perilla oil, 1-10% of barbary wolfberry fruit oil, 1-8% of pomegranate seed oil, 1-8% of seabuckthorn seed oil, 1-6% of fire hemp seed oil, 1-6% of eucommia seed oil, 1-6% of evening primrose seed oil, 1-6% of sesame oil, 1-6% of poppyseed oil and 1-6% of phyllanthus emblica oil. The medicinal and edible health care blending oil has the characteristics of high nutrient content, balanced nutrition and no transgenic ingredient and can meet the nutritional requirement of people.

Owner:张伟伟

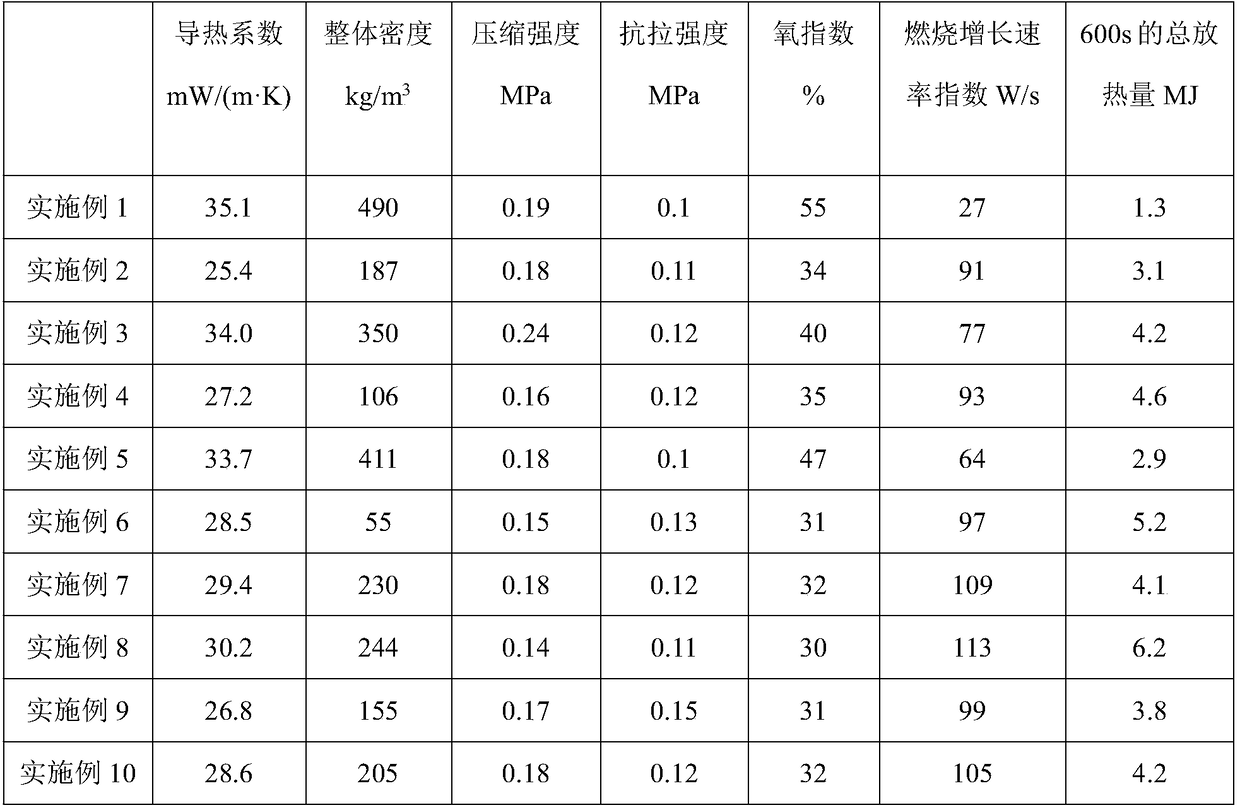

Homogenous low-heat-conductivity inorganic heat insulation board and preparation method thereof

The invention discloses a homogenous low-heat-conductivity inorganic heat insulation board and a preparation method thereof. The homogenous low-heat-conductivity inorganic heat insulation board is prepared from the reaction of an inorganic material, filler and polyurethane hard foam and prepared from the following raw materials in parts by weight: 31 to 85 parts of the inorganic material, 0 to 20parts of the filler, and 15 to 49 parts of the polyurethane hard foam. The heat conduction coefficient of the prepared insulation board is less than 40mW / (m.K), the integral density is 35 to 500 kg / m<3>, and the thermal insulation and heat preservation performance is good. The compressive strength is greater than or equal to 0.1MPa, the tensile strength is greater than or equal to 0.1MPa, the mechanical strength is high, and the durability is good. The oxygen index is greater than or equal to 30 percent, the combustion growth rate index is less than or equal to 120W / s, the total heat release amount in 600s is less than or equal to 7.5MJ, and the homogeneous low-heat-conductivity inorganic insulation board is difficult to combust and high in fireproof grade. The preparation process is simple and suitable for the industrialized production.

Owner:南京红宝丽新材料有限公司

Geo-polymer recycled concrete and preparation method thereof

InactiveCN101570426ADelayed activationImprove liquiditySolid waste managementCement productionRoad engineeringSlag

The invention belongs to the fields of civil engineering and environmental material engineering, and in particular relates to geo-polymer recycled concrete and a preparation method thereof. The geo-polymer recycled concrete is prepared from raw materials of recycled coarse aggregate, recycled fine aggregate, fly ash, slag powder, water, sodium silicate, sodium hydrate, naphthalene sulfonate formaldehyde condensation compound and calcium saccharate according to certain mixing proportion by adopting a special stirring process. The product of the geo-polymer recycled concrete not only has simple preparation process, but also has good working performance, mechanical property, durability and heat-insulating property. Simultaneously, the geo-polymer recycled concrete and the preparation method can efficiently use a great deal of waste concrete and two industrial byproducts of the fly ash and blast furnace slag, are significant in saving resources, saving energy sources and protecting the environment, and accord with the sustainable development strategy of the building industry. The product of the geo-polymer recycled concrete can be widely applicable to road engineering, structural engineering and other various civil engineering constructions.

Owner:TONGJI UNIV

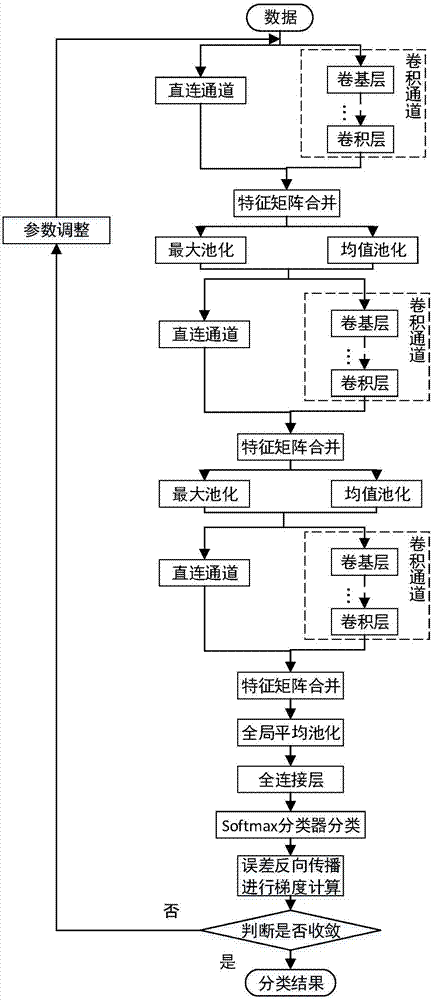

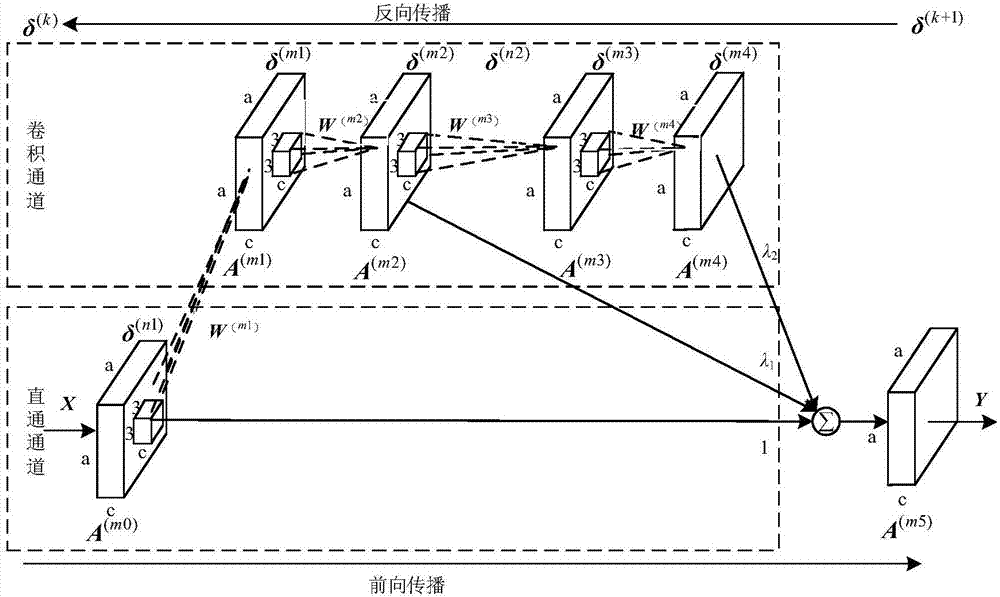

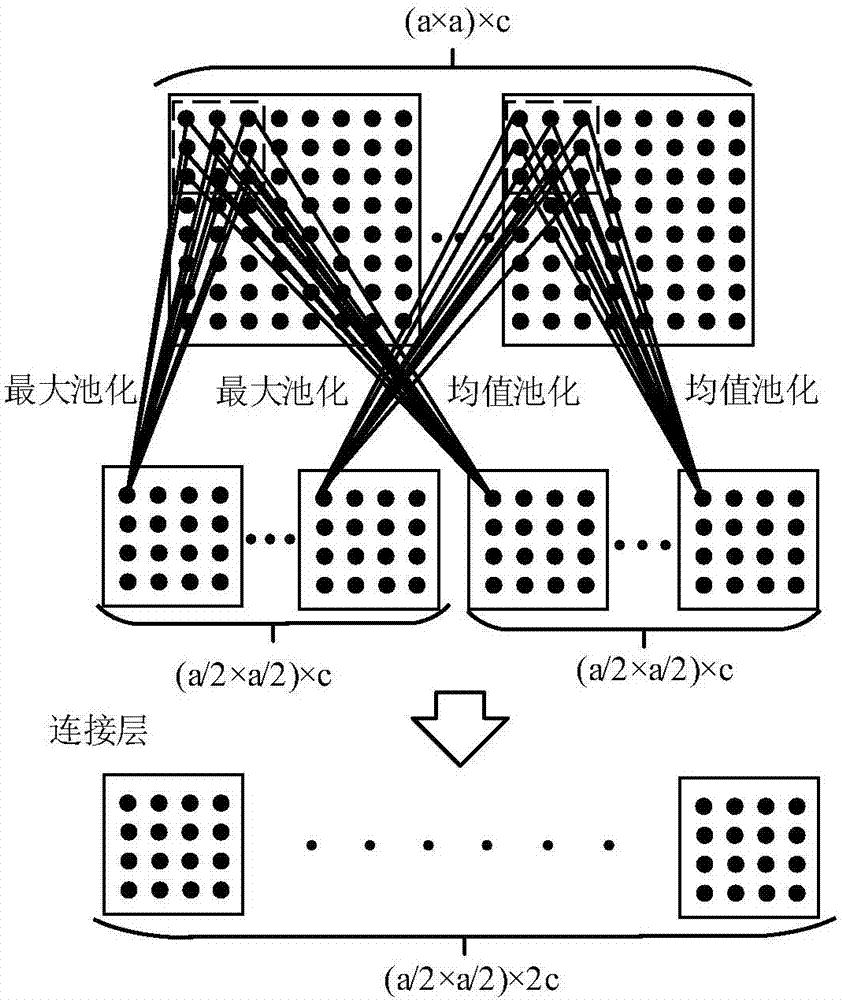

Improved parallel channel convolutional neural network training method

InactiveCN107092960AGuaranteed liquidityOvercoming the difficulty of gradient instabilityNeural architecturesNeural learning methodsAlgorithmEngineering

The invention relates to an improved parallel channel convolutional neural network training method. The improved parallel channel convolutional neural network training method comprises steps that characteristic extraction of data of the convolutional neural network is carried out through utilizing direct connection and convolutional channels to acquire characteristic matrixes; the characteristic matrixes are merged, and data dimension reduction is further carried out; the convolutional neural network is trained, and a loss value of network training at present is calculated; error items and a weight gradient of each layer are calculated; whether the network is in a convergence state is determined according to the loss value, if not, an initialization parameter of the convolutional neural network is adjusted according to the weight gradient, and re-training is further carried out; if yes, the network training result is outputted. The method is advantaged in that data circulation in the network can be guaranteed through introducing the direct connection channel, a problem of gradient instability during deep convolutional neural network training is solved, and deeper networks can be trained; through maximum pooling and mean value pooling, characteristic matrix dimensions of two times of characteristic extraction can be made to be consistent, and advantages of two pooling methods are integrated.

Owner:CIVIL AVIATION UNIV OF CHINA

Melamine decorative veneer and preparation method thereof

ActiveCN101439524AImprove the finishHigh glossWood veneer joiningWood layered productsAdhesiveHeat resistance

The invention discloses a melamine veneer and a preparation method thereof, and belongs to the technical field of decorating materials. The melamine veneer is composed of a substrate and melamine impregnated paper. The melamine impregnated paper is obtained by impregnating paper in a melamine resign adhesive and processing the impregnated paper. The melamine resin adhesive has better activity as the formula thereof is determined by repeated tests. The melamine veneer has a simple processing technology, which causes the melamine resin adhesive to be more evenly and thoroughly immersed into decorating paper. The veneer formed by pressing has a plurality of advantages of the traditional melamine veneer such as high hardness, good abrasion resistance and good heat resistance, good chemical resistance, smooth and clean surface, easy maintenance and cleaning and the like, and further has the advantage of high luminance.

Owner:QUANYOU FURNITURE

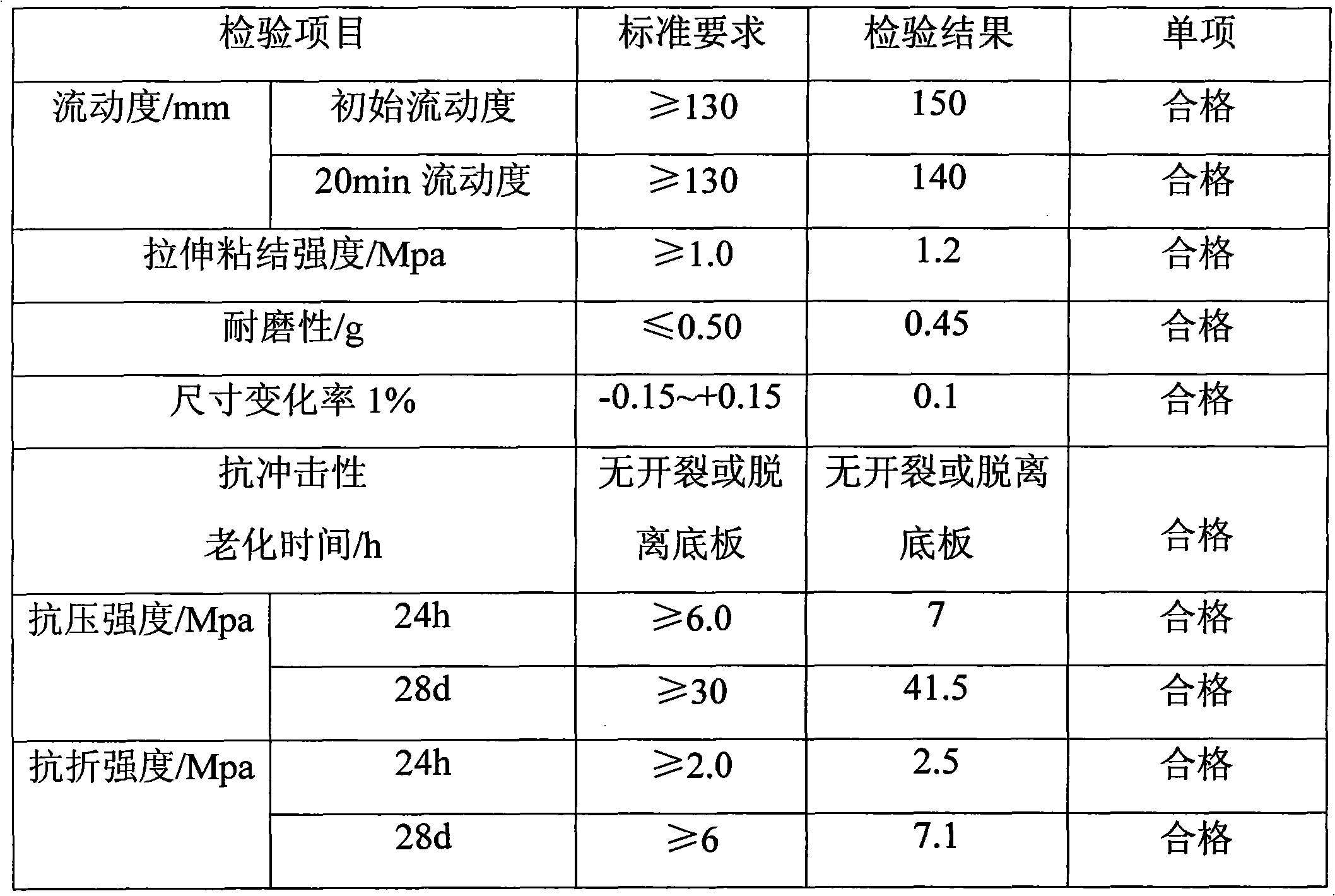

Self-leveling mortar of composite cement

InactiveCN101941824ASelf-leveling is widely usedGuaranteed liquidityPortland cementUltimate tensile strength

The invention belongs to the technical field of building materials, and relates to self-leveling mortar of composite cement, which aims to solve the problem of large-scale construction cracking caused by poor later-stage shrinkage performance under the condition that the strength of the existing self-leveling mortar at home and abroad meets the requirement (is usually more than 20MPa). The main gelled material in the self-leveling mortar of the composite cement provided by the invention is ordinary Portland cement. The technical scheme of the invention can effectively solve the technical problem.

Owner:上海宝元化学建材有限公司

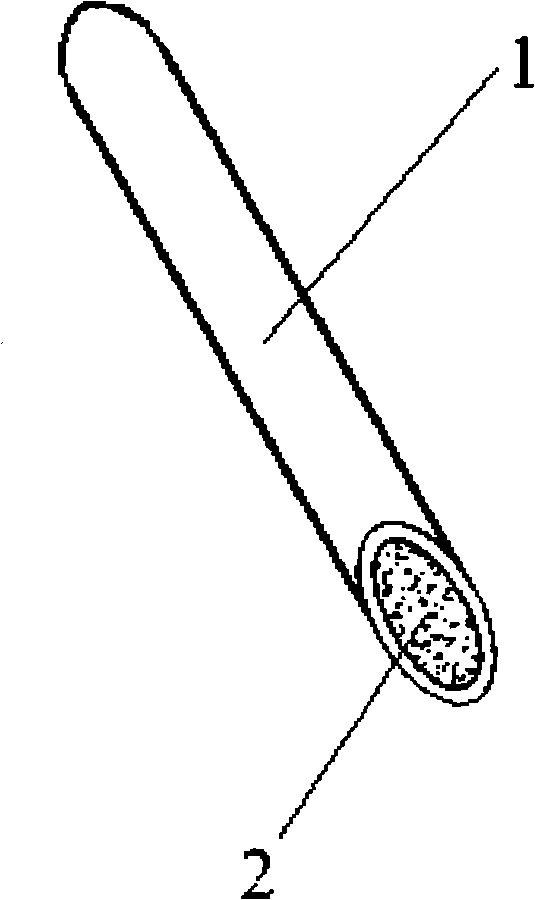

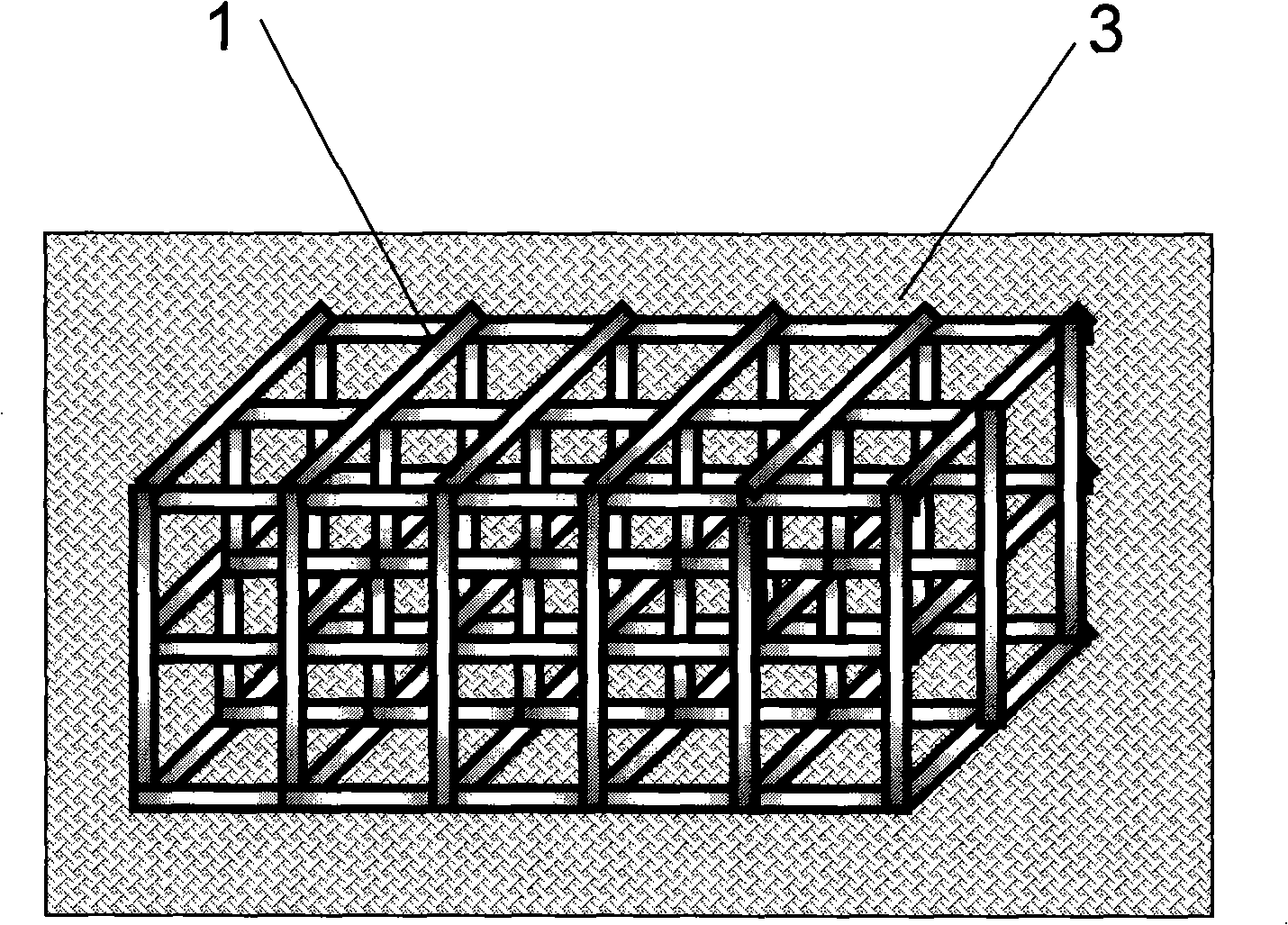

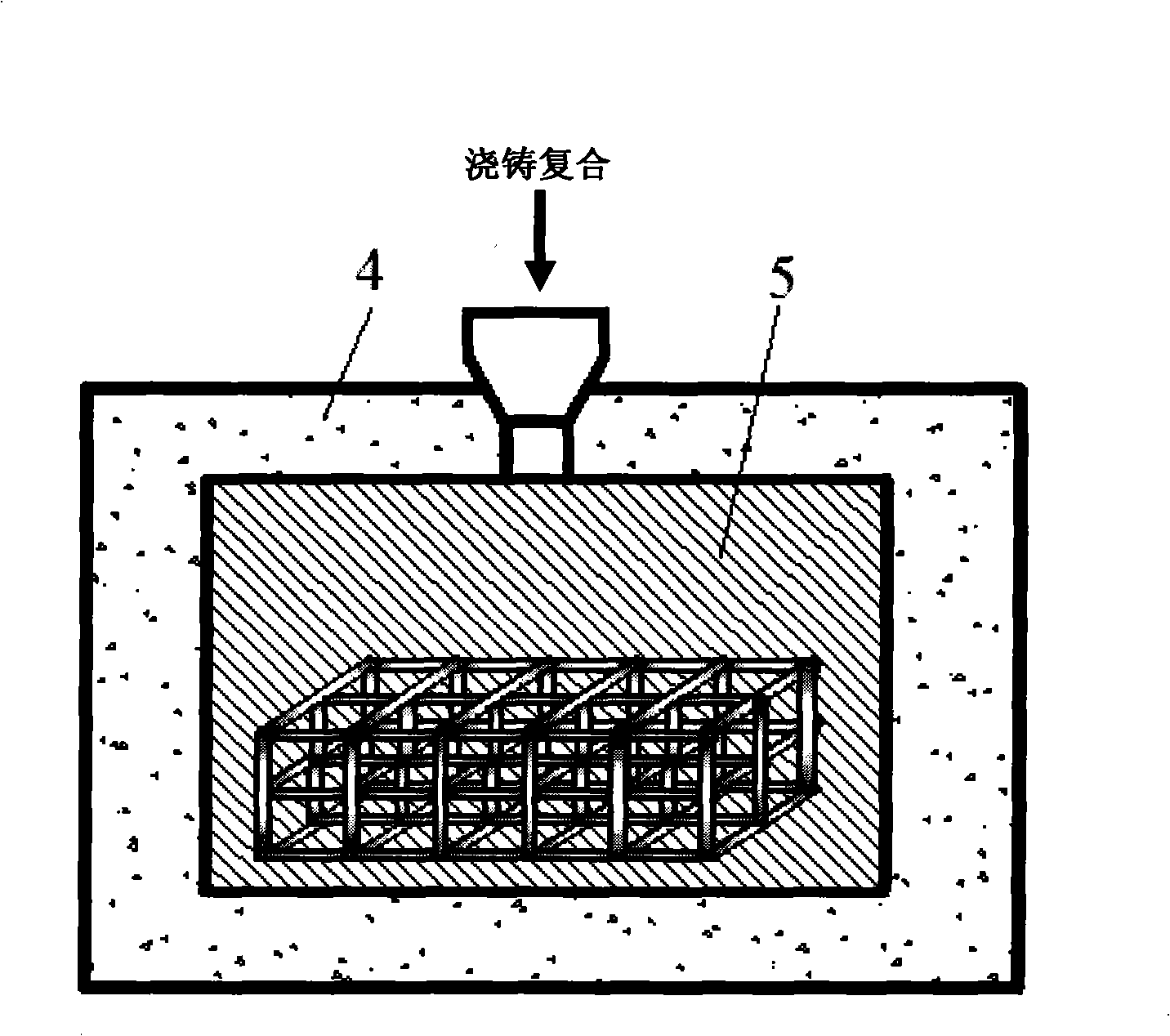

Preparation method of reinforced composite wear-resistant lining board of precast framework

The invention discloses a preparation method of a reinforced composite wear-resistant lining board of a precast framework. The prepared reinforced composite wear-resistant lining board is formed by compounding a framework reinforced body containing hard phases and base body metal. The preparation method comprises the following steps: adopting a framework precast body made of tube wires filled with hard materials, performing the vacuum high-temperature sintering, forming the framework reinforced body containing hard phases, and leading the framework reinforced body to perform the metal casting composite molding with the base body metal, so as to form the lining board formed by compounding the framework reinforced body containing hard phases and the base body metal. The framework reinforced body is performed by the vacuum high-temperature sintering to form a complete metallurgical texture structure, which has order arrangement, uniform distribution, stable performance and strong integrity, can always keep complete framework structure after compounding with the base body metal, thereby developing the high wear-resistance of the hard phases in the framework reinforced body, and keeping better flexibility of the base body metal. The reinforced composite wear-resistant lining board can be compounded locally or gradiently, or integrally, and can be widely applied to wear-resistant fields of mine, electricity, metallurgy, coal, building materials, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

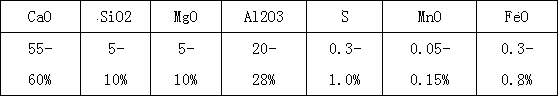

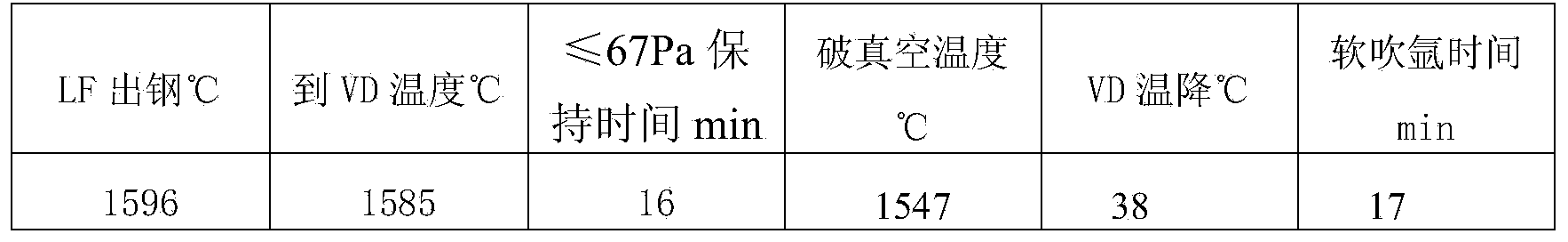

Aluminum-containing cold forging steel smelting process

ActiveCN103469050AEfficient control back to SiGuaranteed liquidityManufacturing convertersAluminateSmelting process

The invention discloses an aluminum-containing cold forging steel smelting process, comprising the steps of blast furnace molten iron making, processing by a converter, refining and continuous casting, wherein requirements of molten iron are as follows: P is not more than 0.10%, Si is not more than 0.50% and not less than 0.30%, S is not more than 0.030%; requirements in converter refining are as follows: CaO is not less than 85%, activity degree is not less than 280 and SiO2 in fluorite is not more than 6%; low-Si pre-melted slag or refining agent replaces partial CaO and fluorite in a converter steel discharging process for rapid slag making, a refining furnace deoxidizing agent is applicable to slag deoxidization after stirring calcium carbide and aluminum particles, and Si-containing material is prohibited; during continuous casting, pure Ca lines are applicable between a medium packet impact zone and various flows, so that calcium aluminate which is low in melting point and is from reaction of Al2O3 generated from medium packet through secondary oxidation and Ca floats and is removed. The process can reduce the content of Si in steel, improve Al content and guarantee continuous pouring of molten steel.

Owner:ZENITH STEEL GROUP CORP

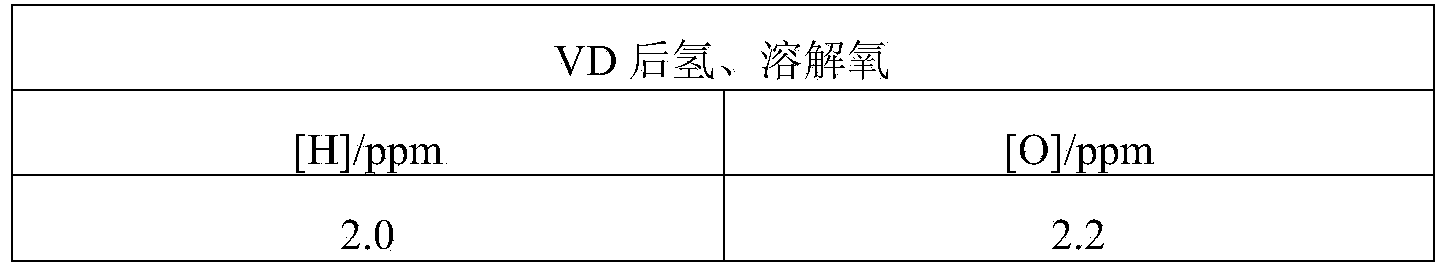

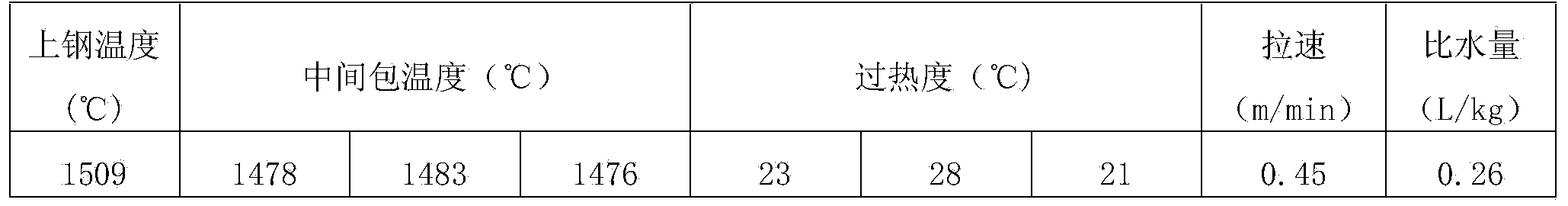

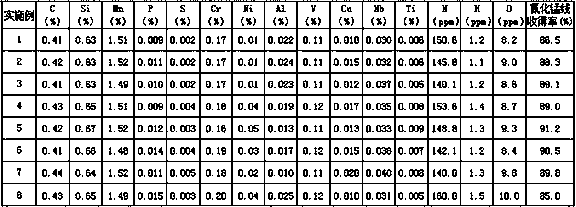

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

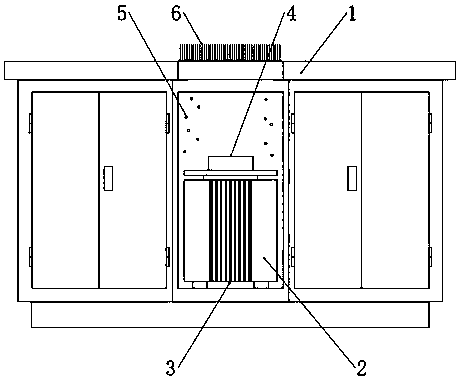

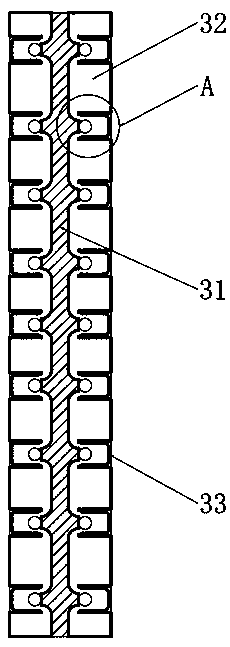

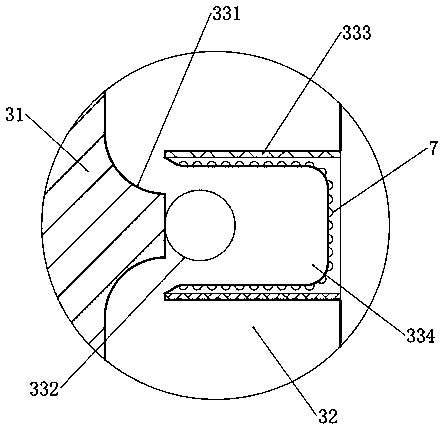

Transformer cabinet based on self-feedback uniform heat dissipation

ActiveCN111540570AImprove job stabilityIncrease job securityTransformers/inductances coolingTransformers/inductances casingsEngineeringTransformer oil

The invention discloses a transformer cabinet based on self-feedback uniform heat dissipation. The invention belongs to the field of transformer equipment, a special composite heat dissipation sheet can be additionally arranged on a surface of an existing transformer oil tank, matched lifting heat-absorbing balloons are introduced while the heat dissipation of the oil tank is greatly improved, a self-feedback heat dissipation mechanism arranged on the composite heat dissipation sheet is used for sensing the heat distribution condition on the transformer oil tank; phase expansion is carried outaccording to heat distribution; more lifting heat-absorbing balloons are attracted through the magnetic attraction effect to be in contact for heat transfer; the transfer of heat to the lifting heat-absorbing balloons is accelerated; after absorbing enough heat, the lifting heat-absorbing balloons automatically rise to a cup-shaped outer heat dissipation shell to transfer the heat to the outside;the lifting heat-absorbing balloons serve as intermediate media to play a role in temporary heat storage, a heat conduction bridge between the transformer oil tank and the outside is built, the uniform and efficient heat dissipation and cooling of the transformer oil tank are achieved, and, therefore, the working stability and safety of a transformer are improved.

Owner:济宁鲁星电气科技有限公司

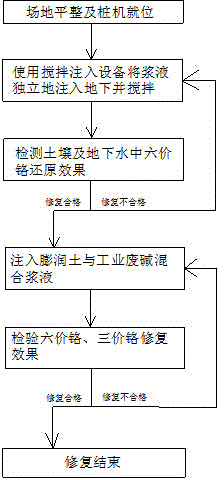

Remediation method for hexavalent chromium polluted soil and underground water

ActiveCN104624632AComplete restorationEfficient removalWater contaminantsContaminated soil reclamationSodium BentoniteInjection equipment

The invention discloses a remediation method for hexavalent chromium polluted soil and underground water. The remediation method comprises the following steps: step (10): putting a pile machine in place; step (20): independently injecting acidified bentonite slurry loaded with active carbon powder and bentonite slurry loaded with zero-valent iron powder into the ground by using stirring and injection equipment and stirring; step (30): detecting the reduction effect of hexavalent chromium in the soil and the underground water; step (40): injecting bentonite and industrial waste alkali mixed slurry; and step (50): detecting the remediation effect of hexavalent chromium and trivalent chromium. By virtue of the remediation method, remediation chemicals can be in direct and sufficient contact with the soil and the underground water to react, so that the hexavalent chromium in the soil and the underground water can be completely reduced; meanwhile, an indissolvable stable compound is formed by the trivalent chromium and the useless loss of the remediation chemicals can be reduced; the potential of hydrogen of a stratum is balanced; and the remediation method is suitable for the large-area hexavalent chromium polluted stratums different in potential of hydrogen and moisture content.

Owner:SOUTHEAST UNIV

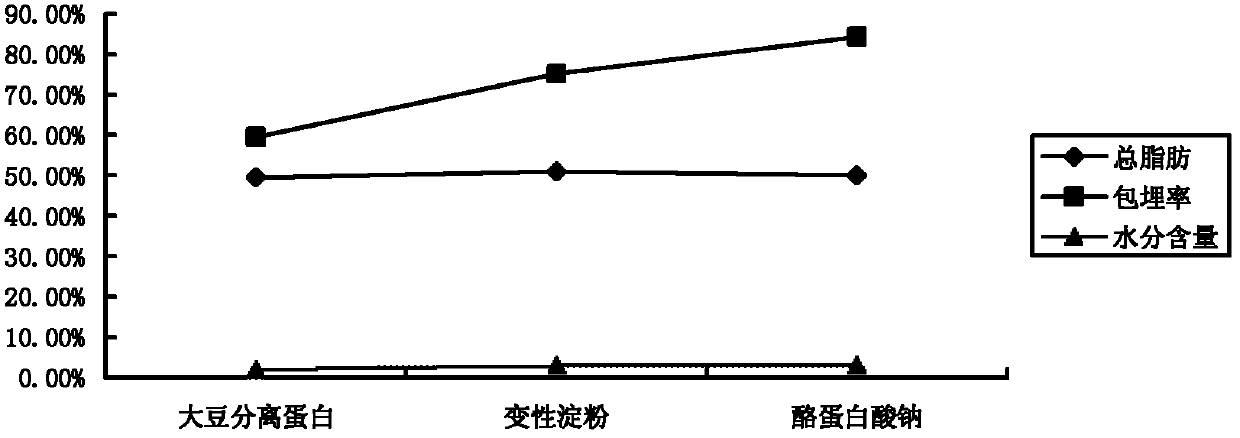

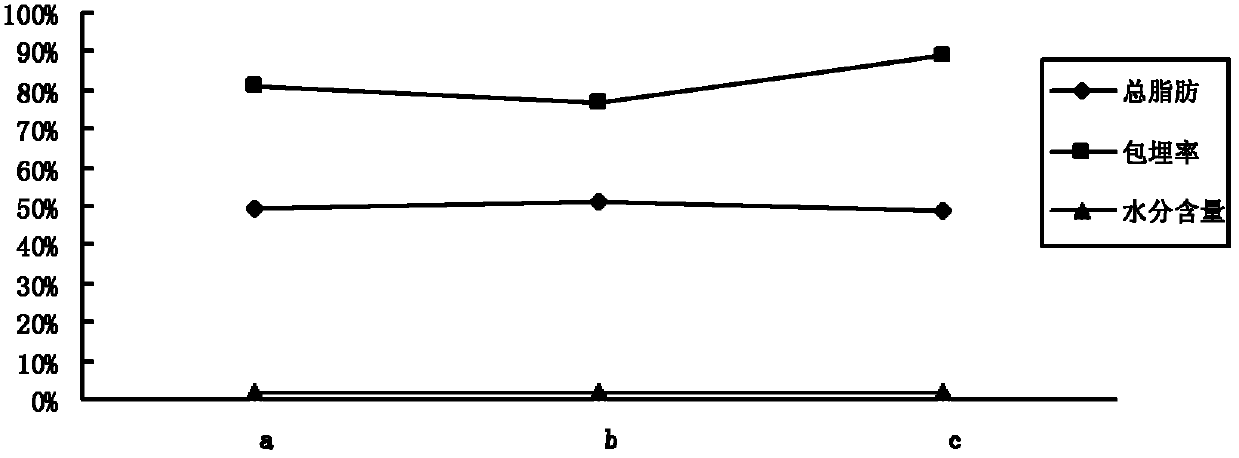

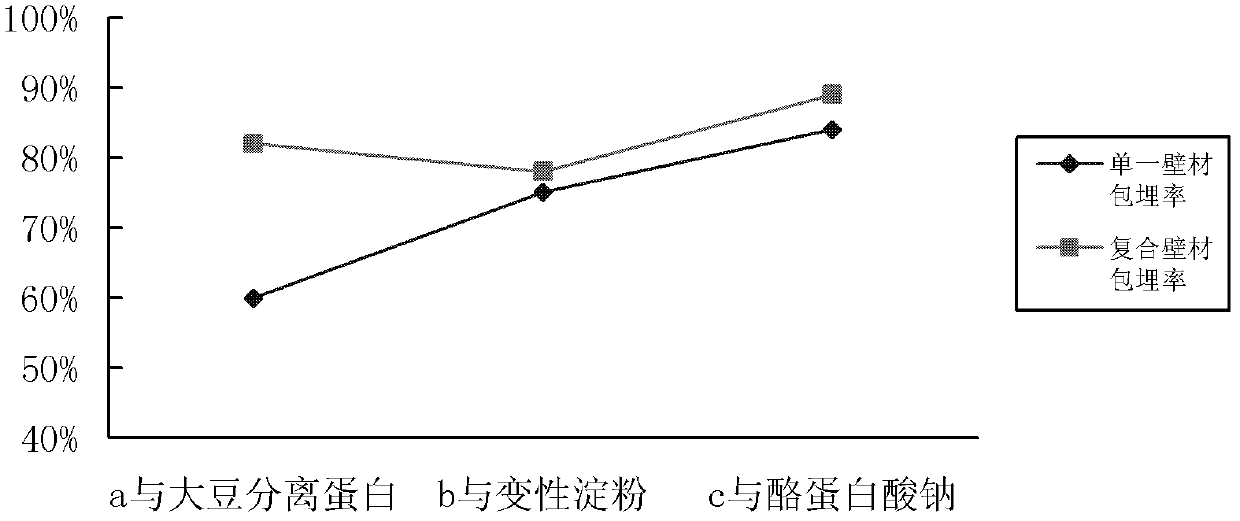

Soybean oil powder grease and preparation method thereof

ActiveCN102599261AReduce generationGuaranteed liquidityEdible oils/fats production/working-upSolubilityOil and grease

The invention relates to soybean oil powder grease and a preparation method thereof. Concretely, soybean first-grade oil is used as a raw material to be used as core materials, a microencapsulation embedding technology is adopted, and a novel series soybean oil powder grease product with excellent processing characteristics and rich and mass nutrients is developed through the selection of an embedding agent, a filling agent and an emulsifying agent and the optimization of process conditions. The improvement is carried out on the trial test study, an industrialized production and test recipe is obtained. During the proportioning, the soybean oil powder grease comprises the following ingredients in percentage by weight: 9.25 percent to 27.25 percent of core material, 1.35 percent to 2.7 percent of embedding agent, 13.925 percent to 33.8375 percent of filling agent, 0.5625 percent to 1.125 percent of emulsifying agent and 55 percent of water. Compared with ordinary liquid-stage grease products, the product has various advantages that the quality guarantee period of the product is prolonged, the product functionality is improved, the product water solubility is improved, and the product application range is enlarged.

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

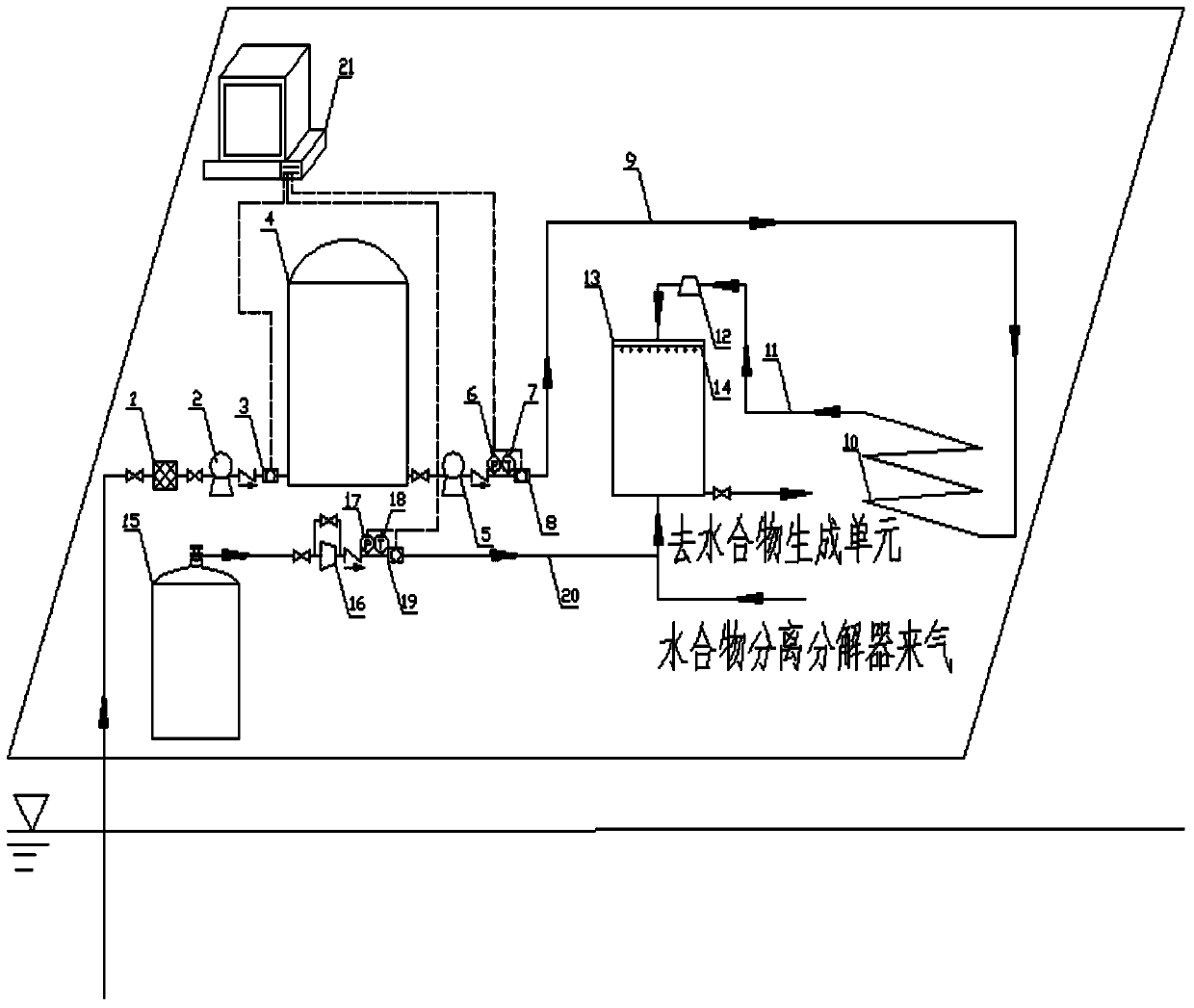

Prestressed mud jacking trolley and circulating mud jacking method

ActiveCN102704403AGuaranteed compactnessGuaranteed liquidityBridge erection/assemblyBridge materialsLow speedPre stress

The invention provides a prestressed mud jacking trolley and a circulating mud jacking method. The prestressed mud jacking trolley comprises a mortar pump, a high-speed pulping machine, a low-speed pulp storage barrel, a water-binder ratio test instrument, a pressure sensor, an electromagnetic flow-meter, a pulp inlet-overflow valve, a pulp return valve, a pressure regulating valve and a computer, wherein the low-speed pulp storage barrel is connected with the water-binder ratio test instrument, and is connected with the mortar pump through a pulp suction pipe; the mortar pump is connected with a prestressed pipeline of a constructed object through a pulp inlet pipe; the prestressed pipeline is connected with the low-speed pulp storage barrel through a pulp return pipe; the pressure sensor, the electromagnetic flow-meter, the pulp inlet-overflow valve, the pulp return valve and the pressure regulating valve are arranged on the pulp inlet pipe and the pulp return pipe; and the computer receives measurement data and controls the power-on and power-off of the pulp inlet-overflow valve, the pulp return valve and the pressure regulating valve through signals. The prestressed mud jacking trolley and the circulating mud jacking method have the advantages as follows: the prestressed mud jacking trolley achieves high integration and is convenient to use; the mud jacking pressure and the pulp performance can be controlled accurately; the pulp amount can be metered accurately; and the technical problem that the mud jacking in the prestressed pipeline is not full and not compact can be solved by exhausting air in the pipeline in a circulating manner.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

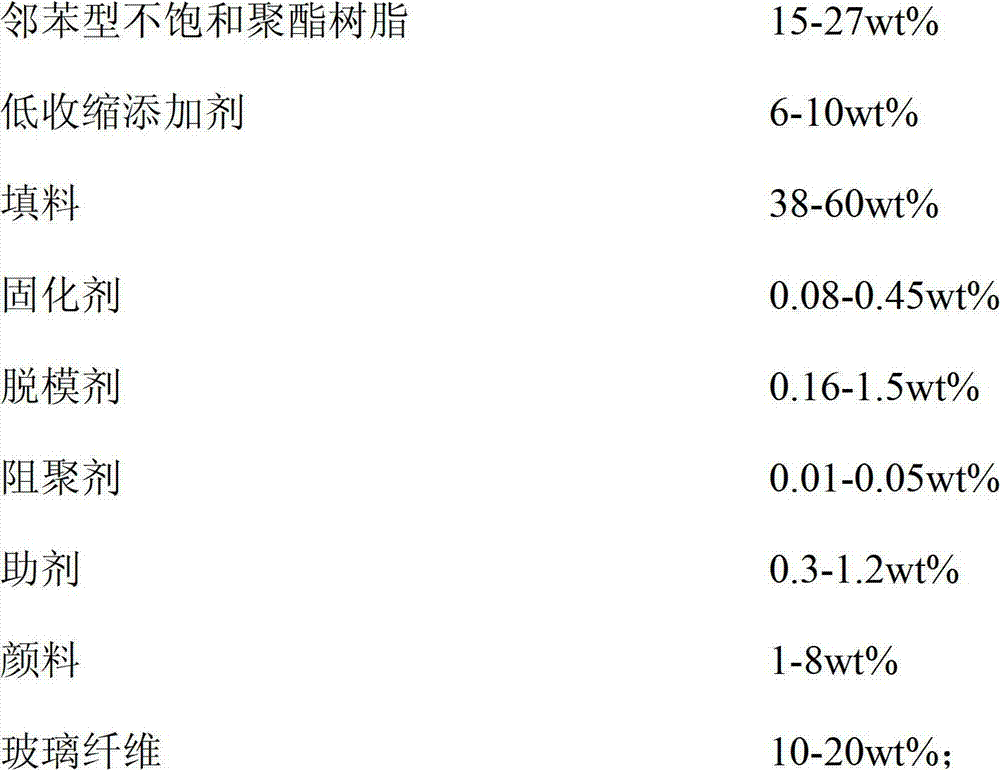

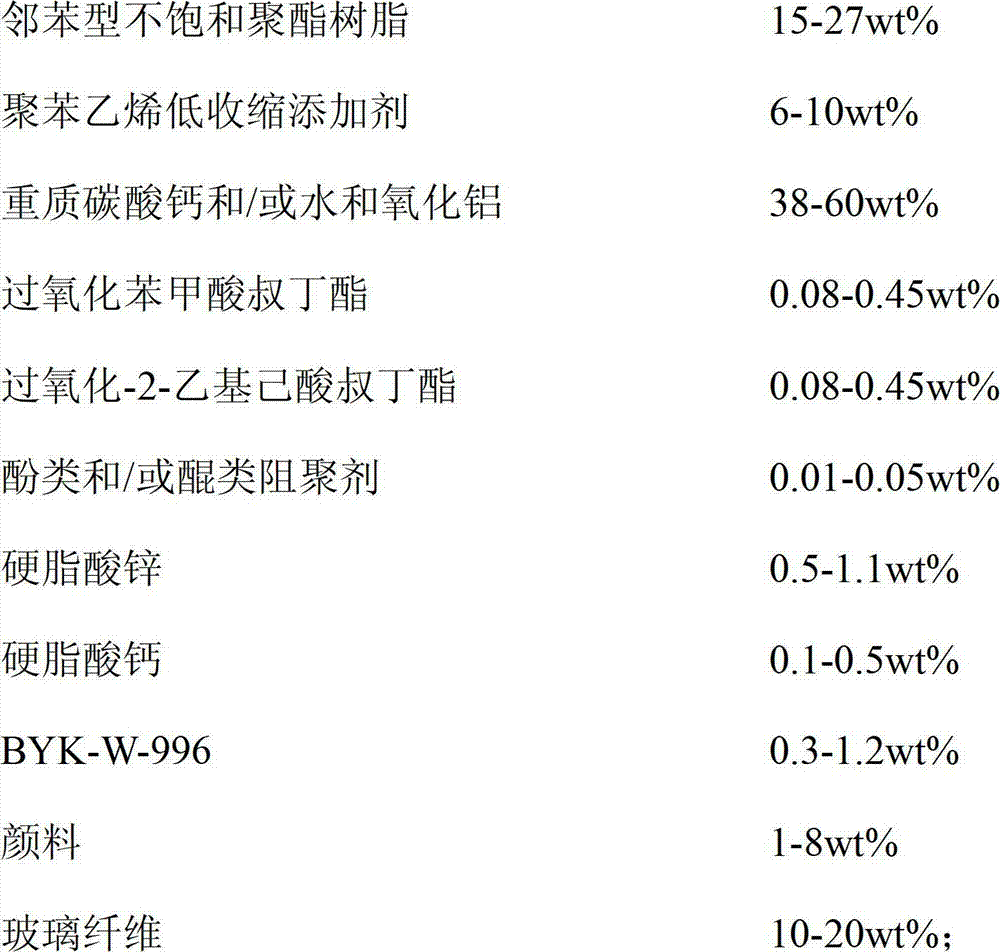

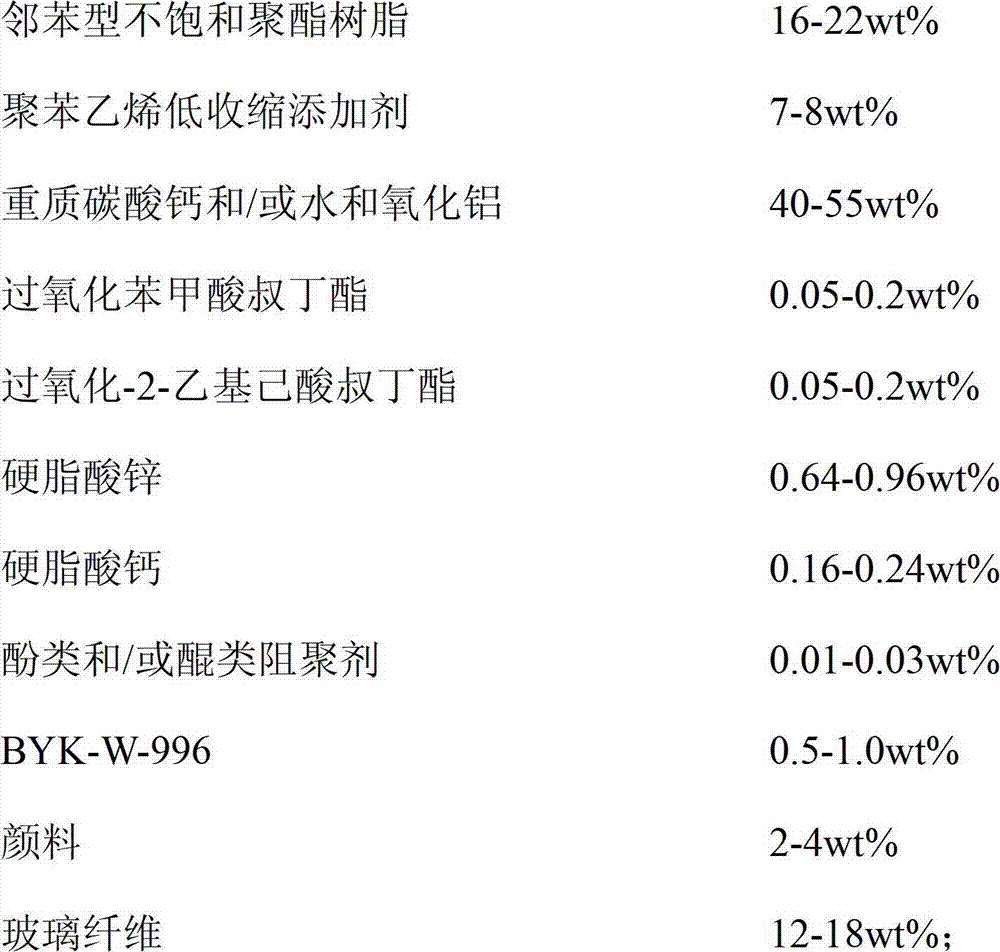

Low temperature and low pressure BMC (Bulk Molding Compound) material, preparation method thereof and purpose thereof

The invention relates to a low temperature and low pressure BMC (Bulk Molding Compound) material. The low temperature and low pressure BMC material comprises unsaturation resin, a low shrinkage additive, a filler, a curing agent, a mold release agent, a polymerization inhibitor, an auxiliary and glass fiber, wherein the mold release agent is a mixture of zinc stearate and calcium stearate. The molding temperature of the low temperature and low pressure BMC material provided by the invention is only 110-130 DEG C and is reduced by about 30% when compared with the molding temperature of the traditional BMC molding material; and the molding pressure of the low temperature and low pressure BMC material provided by the invention is only 70-100 kg / cm2 and is reduced by about 50% when compared with the molding pressure of the traditional BMC molding material.

Owner:WUXI XINHONGTAI ELECTRIC TECH CO LTD

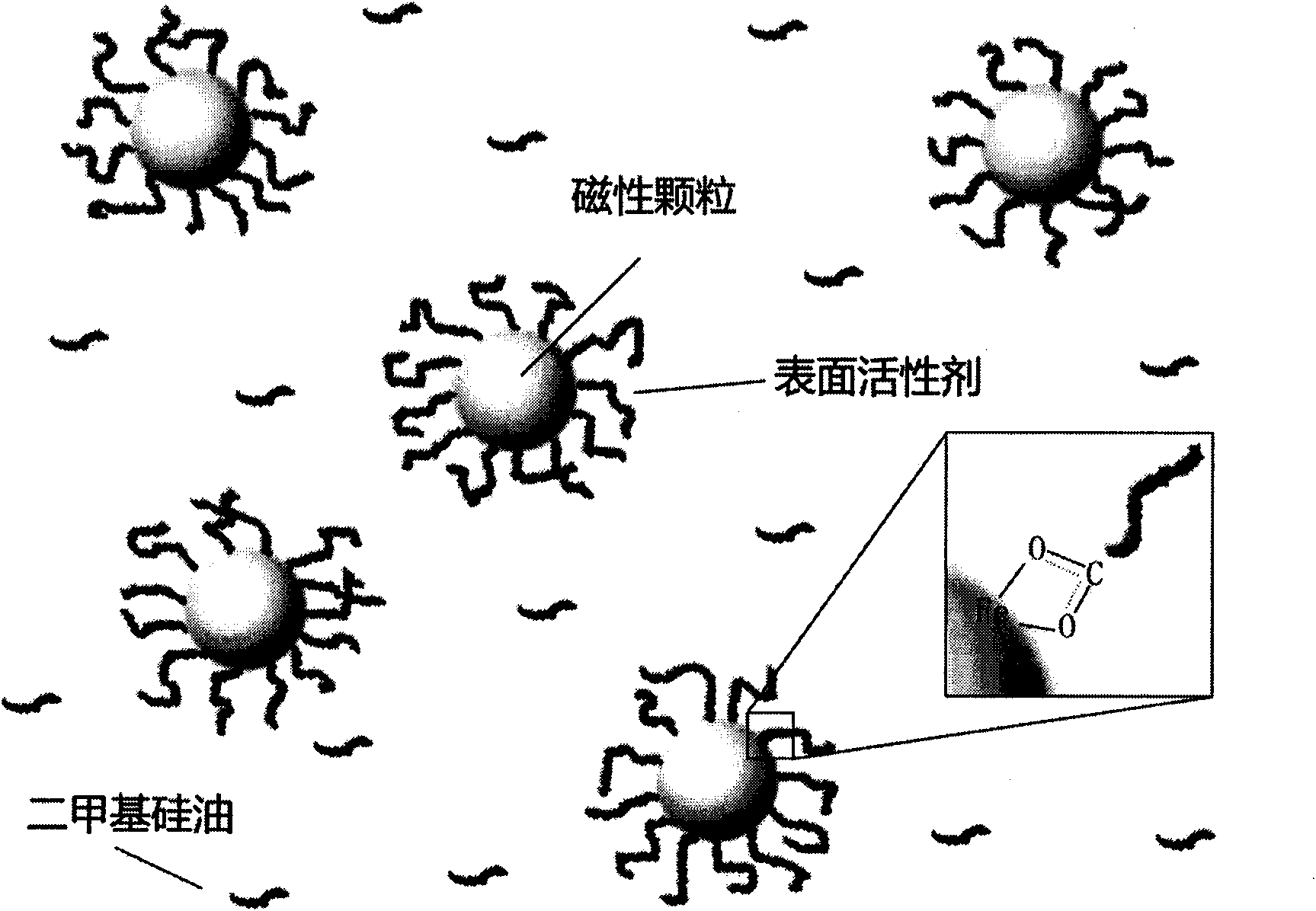

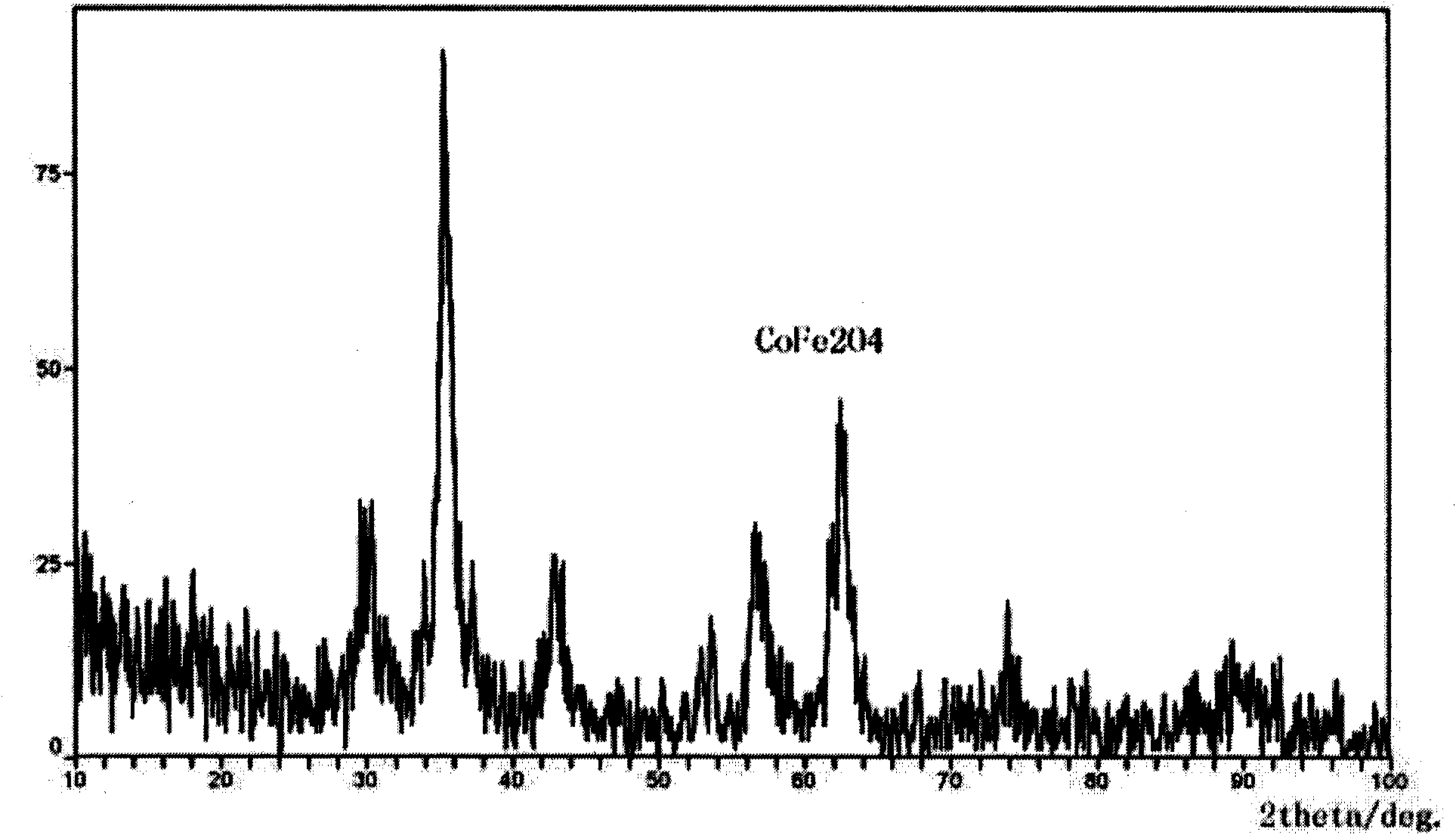

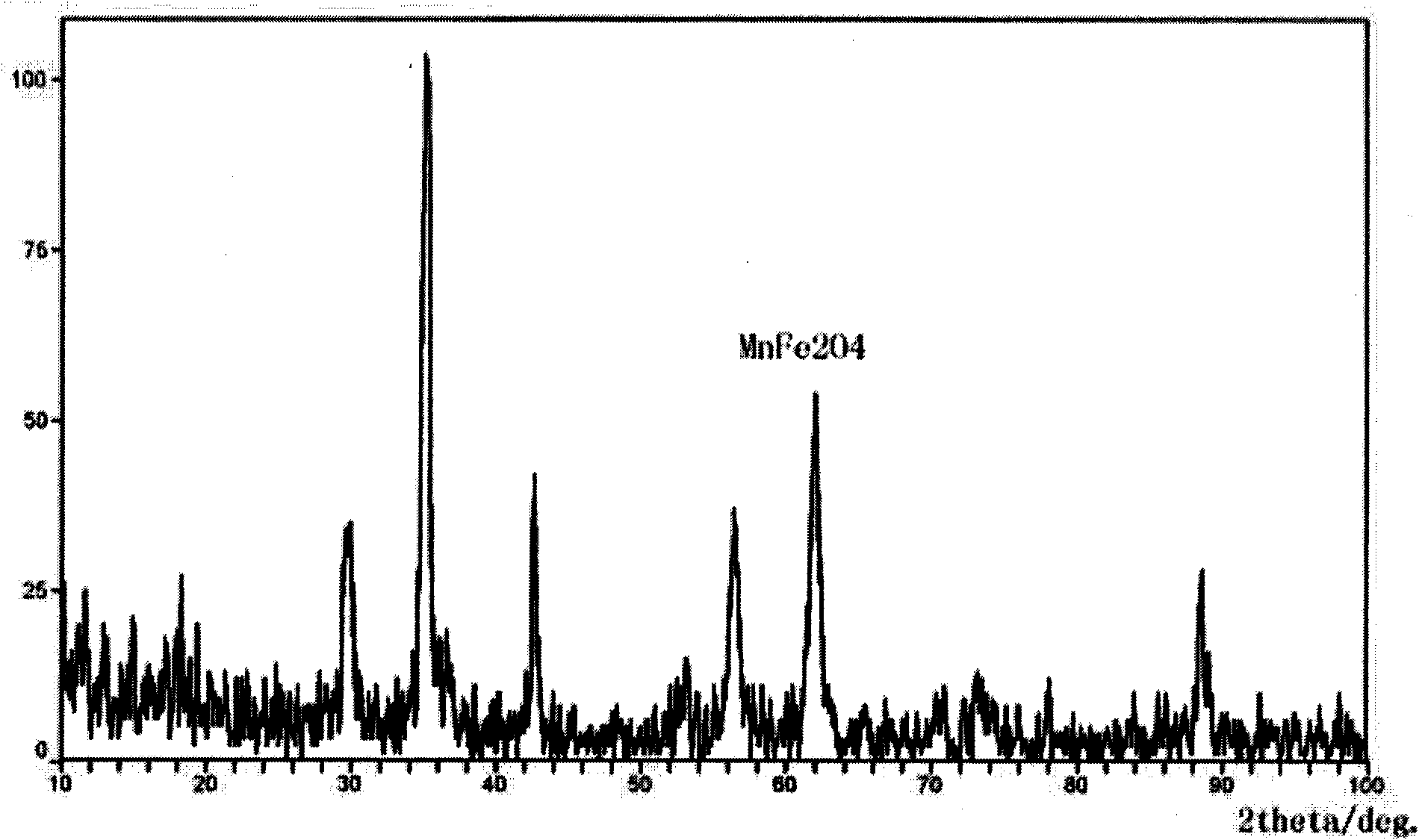

Oxidation resistant dimethyl silicon oil based magnetic fluid and preparation method thereof

InactiveCN101599335ASmall viscosity-temperature coefficientLow compression resistanceMagnetic liquidsOrganic/organic-metallic materials magnetismMethylene DichlorideMagnetic liquids

The invention provides oxidation resistant dimethyl silicon oil based magnetic fluid and a preparation method thereof; the dimethyl silicon oil based magnetic fluid is prepared by nano-magnetic particles, a surface modifier and carrier fluid, and the carrier fluid is the dimethyl silicon oil. The preparation method of the dimethyl silicon oil based magnetic fluid comprises the following steps: preparing the nano-magnetic particles; treating the nano-magnetic particles in an activated way; preparing the nano-magnetic particles which are modified by the surface modifier; adding the modified nano-magnetic particles which are purified into methylene dichloride, dispersing and filtering the mixture to obtain the methylene dichloride based magnetic fluid; adding the magnetic fluid into the dimethyl silicon oil to be stirred and dispersed, heating the mixture and maintaining the temperature between 50 and 90 DEG C, separating and precipitating the mixture to obtain the dimethyl silicon oil based magnetic fluid. The dimethyl silicon oil based magnetic fluid in the invention has the advantages of high stability, low temperature resistance and high temperature resistance. The preparation method is simple, high in efficiency and low in requirement on equipments, thus being easy to be applied in various fields and having wide application prospect.

Owner:SUN YAT SEN UNIV

Stuffing for roasted food and its prepn process

InactiveCN101088345APrevent agingGuaranteed liquidityBakery productsFood preparationMonoglycerideColloid

The present invention relates to one kind of stuffing for roasted food and its preparation process. The stuffing consists of sugar 10-30 wt%, modified starch 0-11 wt%, hydrophilic colloid 0.1-0.6 wt%, steamed monoglyceride 1-5 wt%, potassium sorbate 0.01-0.1 wt%, food water preserver 5-30 wt%, edible essence and / or edible color 0.2-0.5 wt%, and water for the rest, with water content being less than wt%. The stuffing has the synergistic effect of colloid and modified starch, high flowability, high water preserving capacity, high freezing resistance and stable quality, and the roasted food with the stuffing has good taste.

Owner:MASSON GROUP

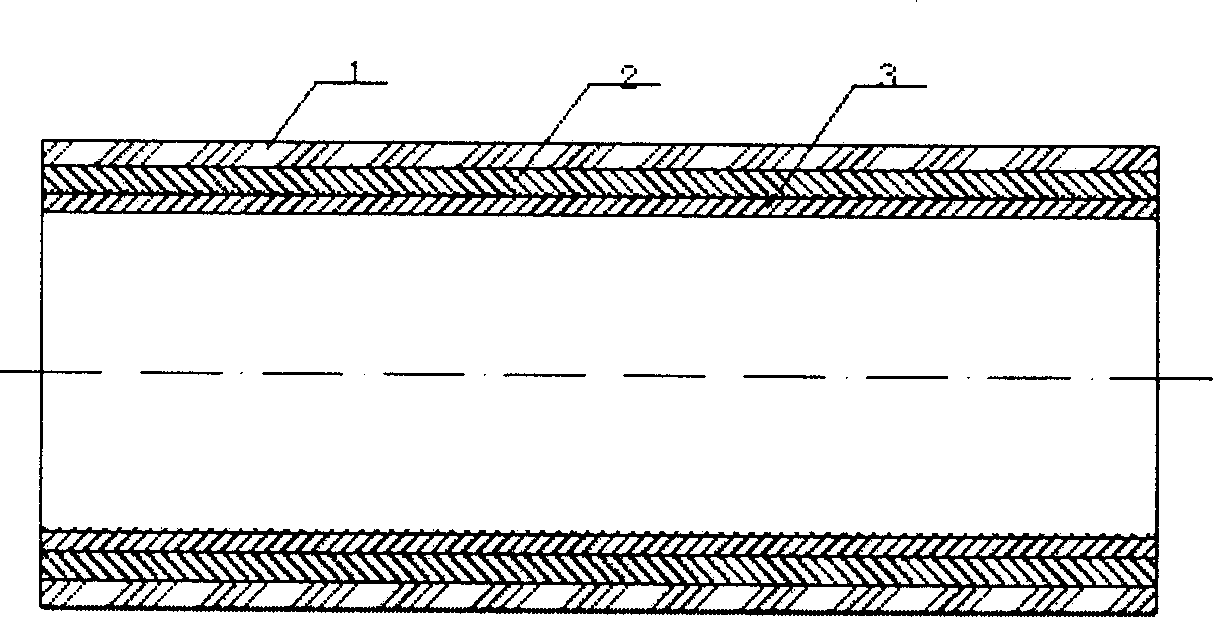

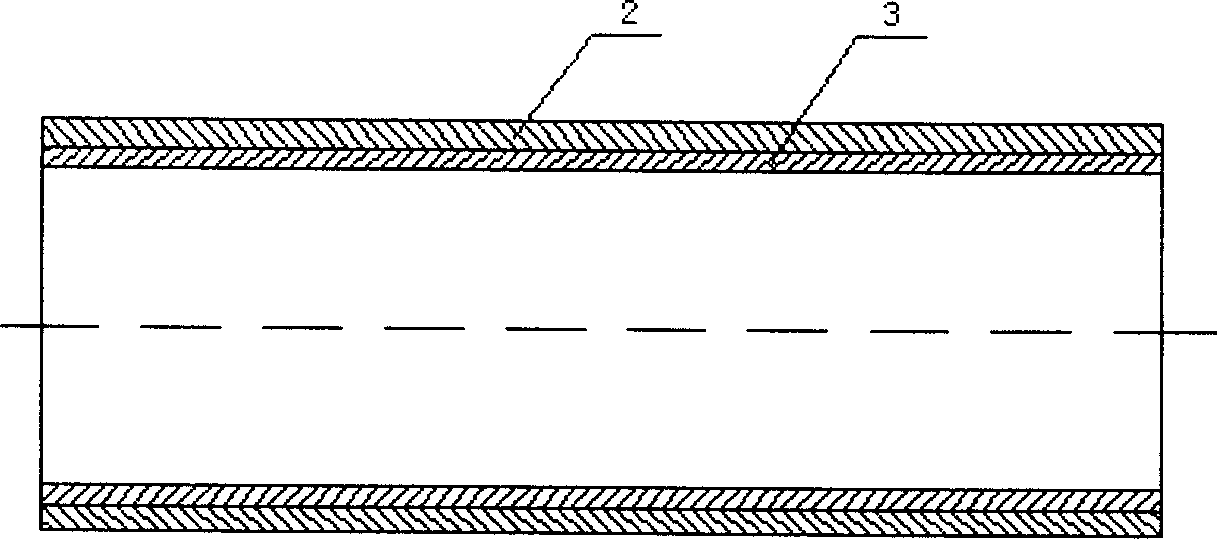

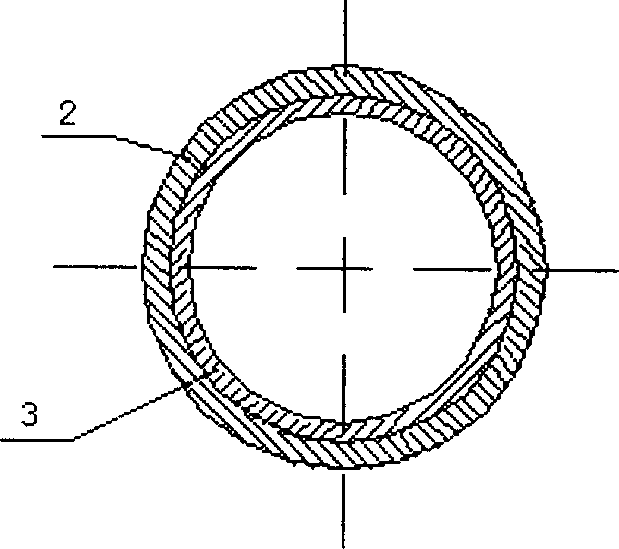

Method for manufacturing bimetal composite wear resistant tube through centrifugal molding double fluids

A technology for manufacturing the antiwear bimetal tube by dual-liquid casting includes such steps as spraying graphite paint onto inner surface of a moulding pipe on centrifugal machine, baking, closing, high speed rotating while pouring molten steel, solidifying to become external steel tube, pouring molten antiwear alloy, solidifying, cooling and cleaning.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Well structure and method for underground modified mining of heavy oil and super heavy oil reservoir

ActiveCN104563981AFully exposed to the effect of modificationAchieve high temperature in-situ modificationFluid removalDrilling compositionElectrical resistance and conductanceMicrowave

The invention provides a well structure and a method for underground modified mining of a heavy oil and super heavy oil reservoir. The well structure comprises oil tubes, a catalyst injection tube and a heating device; injection holes unevenly distributed are formed in the horizontal section of the catalyst injection tube; the heating device comprises a high-energy fused salt heating tube, an electric heating tube, an electric resistance wire heating device, an electromagnetic heating device, a radio-frequency heating device or a microwave heating device; the oil tubes comprise parallel dual oil tubes, concentric dual oil tubes or single continuous punched oil tubes; the invention also provides the method for performing the modified mining on the heavy oil reservoir by utilizing the well structure. According to the well structure and the method for the underground modified mining of the heavy oil and super heavy oil reservoir, provided by the invention, oil can be rapidly dissolved and the viscosity of crude oil is greatly reduced, so the fluidity of mined fluid is further increased, and long-time continuous modification of the oil reservoir can be realized.

Owner:PETROCHINA CO LTD

Coated sand and preparation method thereof

InactiveCN104325065AEasy to prepareGuaranteed liquidityFoundry mouldsFoundry coresParaffin waxPhosphate

The present invention discloses coated sand and a preparation method thereof. The coated sand is prepared from the following raw materials: raw sand, a binder, a curing agent, an additive and a lubricant, wherein the raw sand is prepared by mixing quartz sand and pearl sand according to a weight ratio of 3:1, the binder is a mixture of a furan resin, isocyanate and paraffin wax, the curing agent is a mixture of fatty amine, acetic acid and sodium silicate, the additive is a mixture of expanded graphite, silicon carbide and sodium methyl silanolate, and the lubricant is a mixture of silicone oil, phosphate ester and calcium stearate. The preparation method comprises: (1) preparing a binder; (2) preparing a curing agent; (3) preparing an additive; and (5) mixing, wherein phosphate ester is added to raw sand, the additive is added, complete mixing is performed, silicone oil is added after mixing, the binder is added to mix, calcium stearate and the curing agent are sequentially added after uniformly mixing, and mixing is performed to obtain the coated sand.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

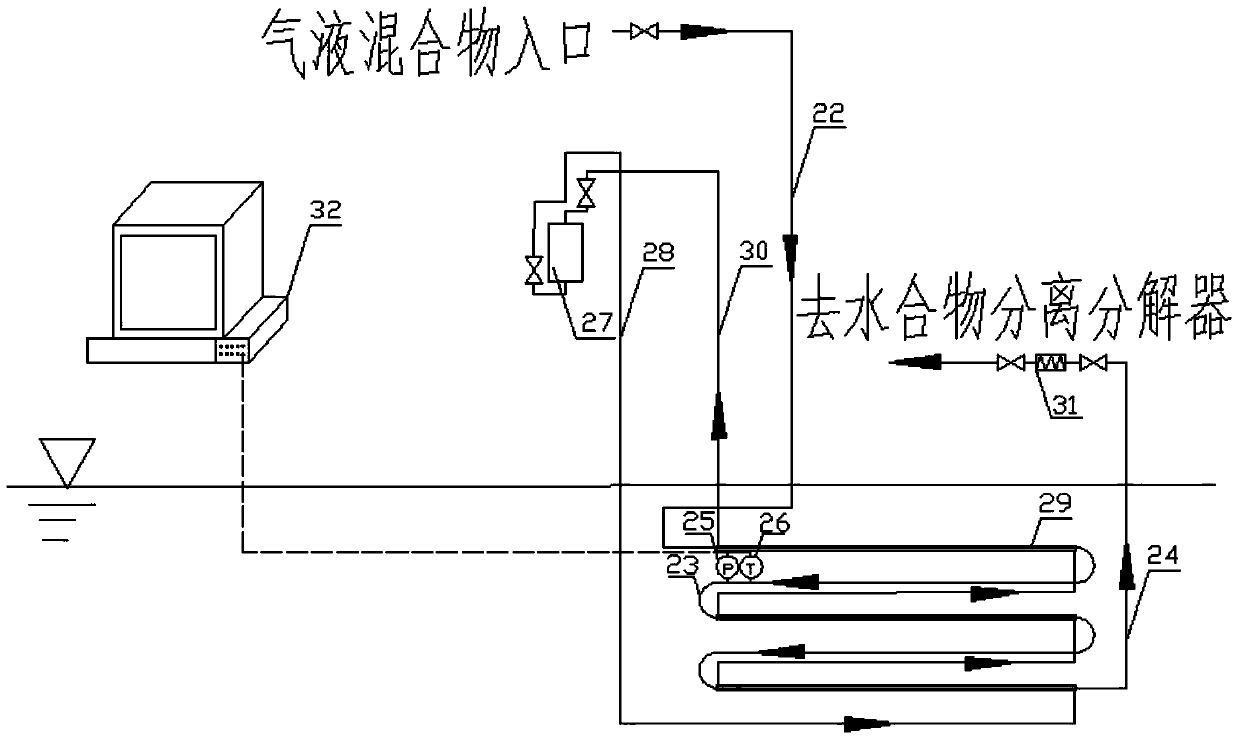

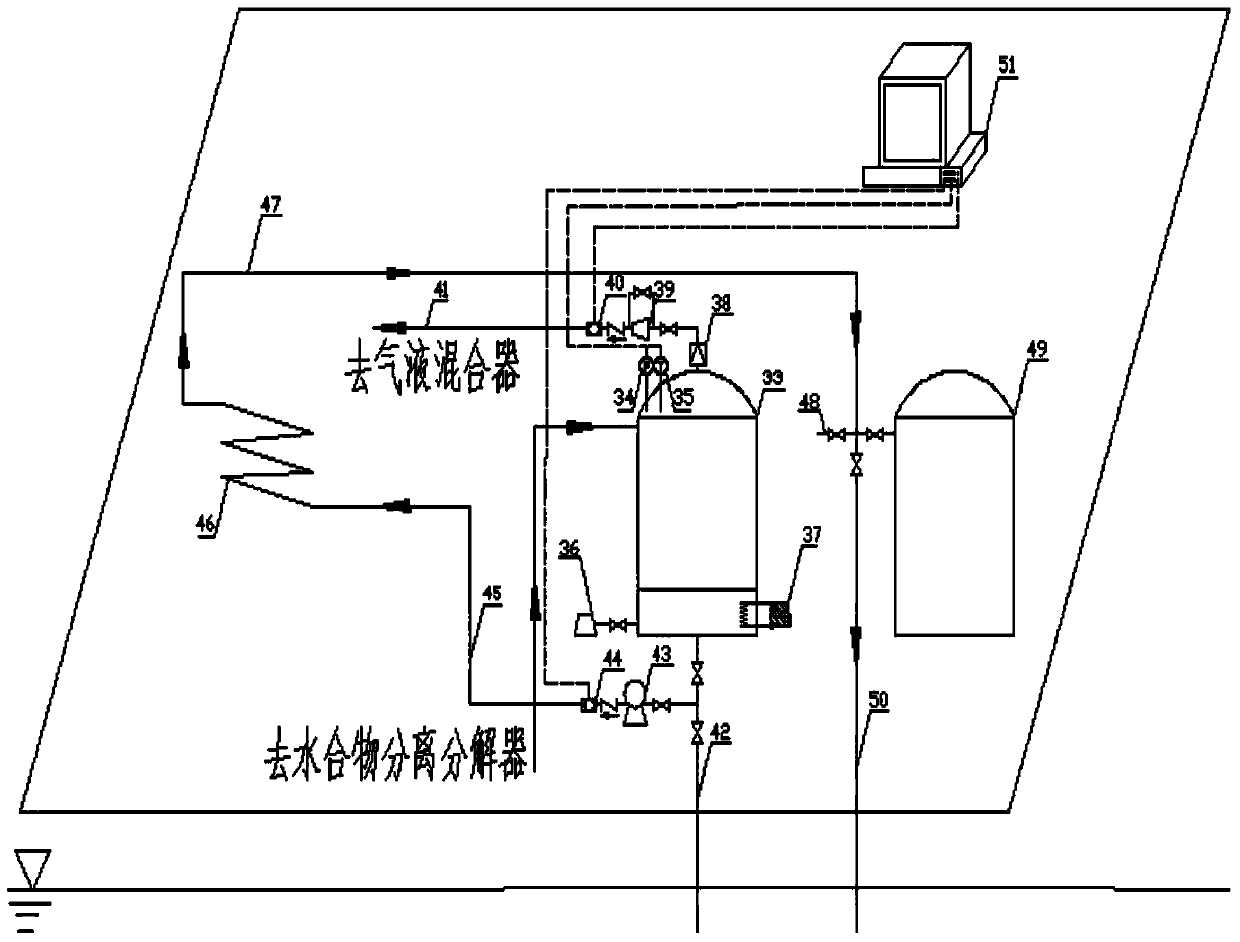

Two-stage sea water desalination method based on hydration and two-stage sea water desalination device based on hydration

ActiveCN103864243AWell mixedContinuous generation boostSeawater treatmentEnergy based wastewater treatmentWater desalinationDihydrogen oxide

The invention belongs to the field of gas hydrate technology application and particularly relates to a sea water desalination method and a two-stage sea water desalination device. The method comprises the following steps: generating a carbon dioxide hydrate from carbon dioxide and sea water by a first-stage sea water desalination system and then resolving the carbon dioxide hydrate so as to obtain fresh water; generating a propane hydrate from propane and sea water by a second-stage sea water desalination system and then resolving the propane hydrate so as to obtain fresh water. The Two-stage sea water desalination device comprises a first-stage sea water desalination device and a second-stage sea water desalination device which are connected in series; each stage of sea water desalination device comprises a gas-liquid supplying and mixing unit, a gas hydrate generating and conveying unit, and a gas hydrate dissociating and resolving unit. The device and the method are high in efficiency, low in energy consumption and easy to achieve.

Owner:江苏溢坤医疗科技有限公司

Smelting method of non-quenched and tempered steel

ActiveCN110055450AImprove purityReduced activityManufacturing convertersProcess efficiency improvementSmelting processCalcium cyanamide

The invention discloses a smelting method of non-quenched and tempered steel. The smelting method comprises the working procedures of converter smelting, LF refining, VD vacuum treatment and continuous casting, and comprises the specific technological steps that (1) nitrogen is blown at the bottom in the whole converter smelting process, and converter high-carbon drawing and tapping is carried out; (2) diffusion deoxidation is carried out in the LF refining process, good deoxidation and desulfurization effects are guaranteed, and the N content of molten steel after LF finishing is 75-90ppm; (3) VD vacuum treatment is carried out, wherein the content of N in the molten steel after hollow breaking is 50-60 ppm, after hollow breaking, soft blowing time is larger than or equal to 30 min, and argon flow is smaller than or equal to 25 L / min; and (4) continuous casting adopts crystallizer stirring and tail-end stirring, medium-high carbon tundish covering agent and medium-carbon crystallizercovering slag are used, and continuous casting billets are cooled slowly in an off-line mode. According to the smelting method of the non-quenched and tempered steel, the nitrogen content yield is stable, the performance of the non-quenched and tempered steel is good, calcium cyanamide (CaCN2) is not adopted, environmental pollution is small, the feeding amount of the manganese nitride wire is small, and the production cost is low.

Owner:石钢京诚装备技术有限公司

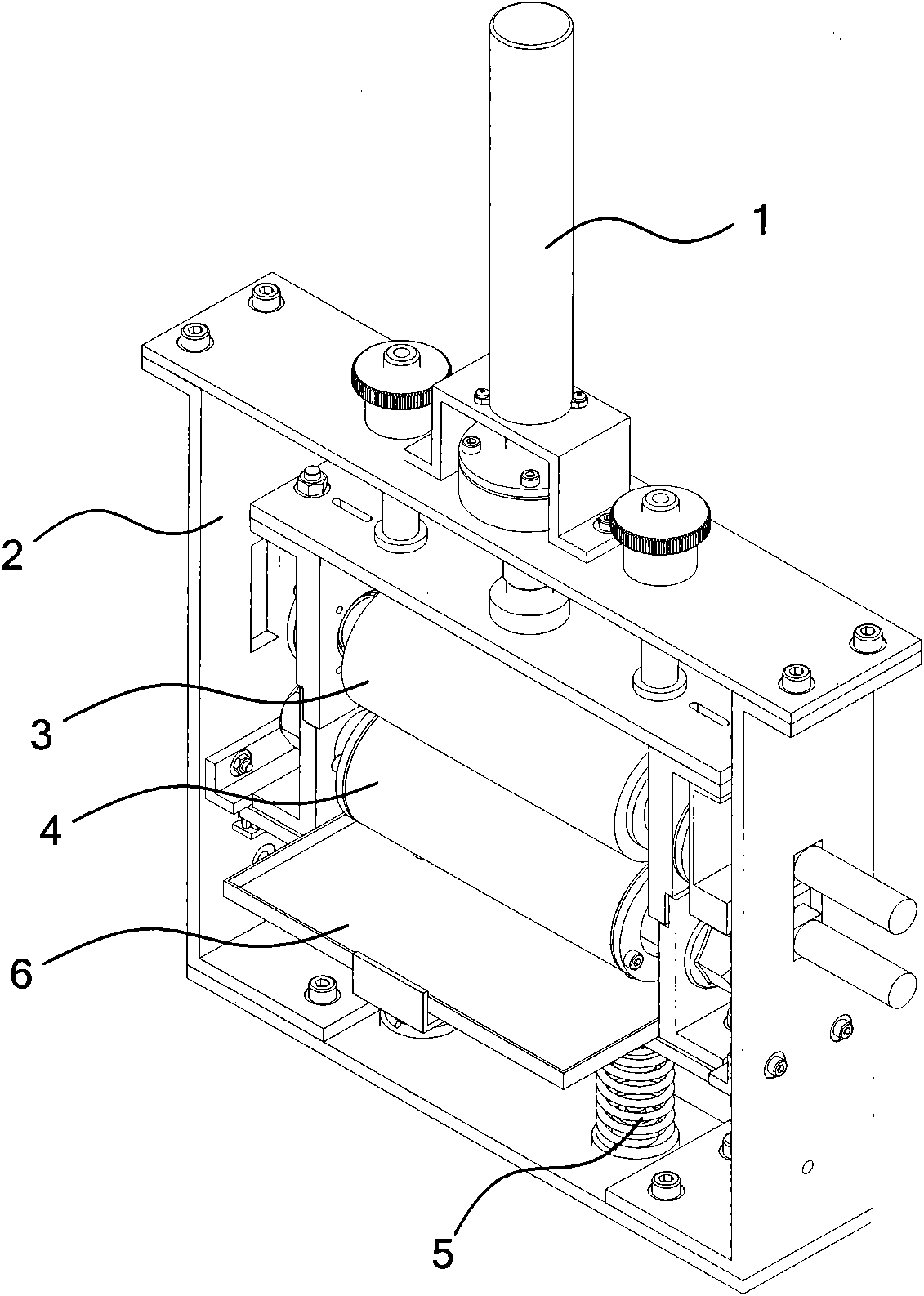

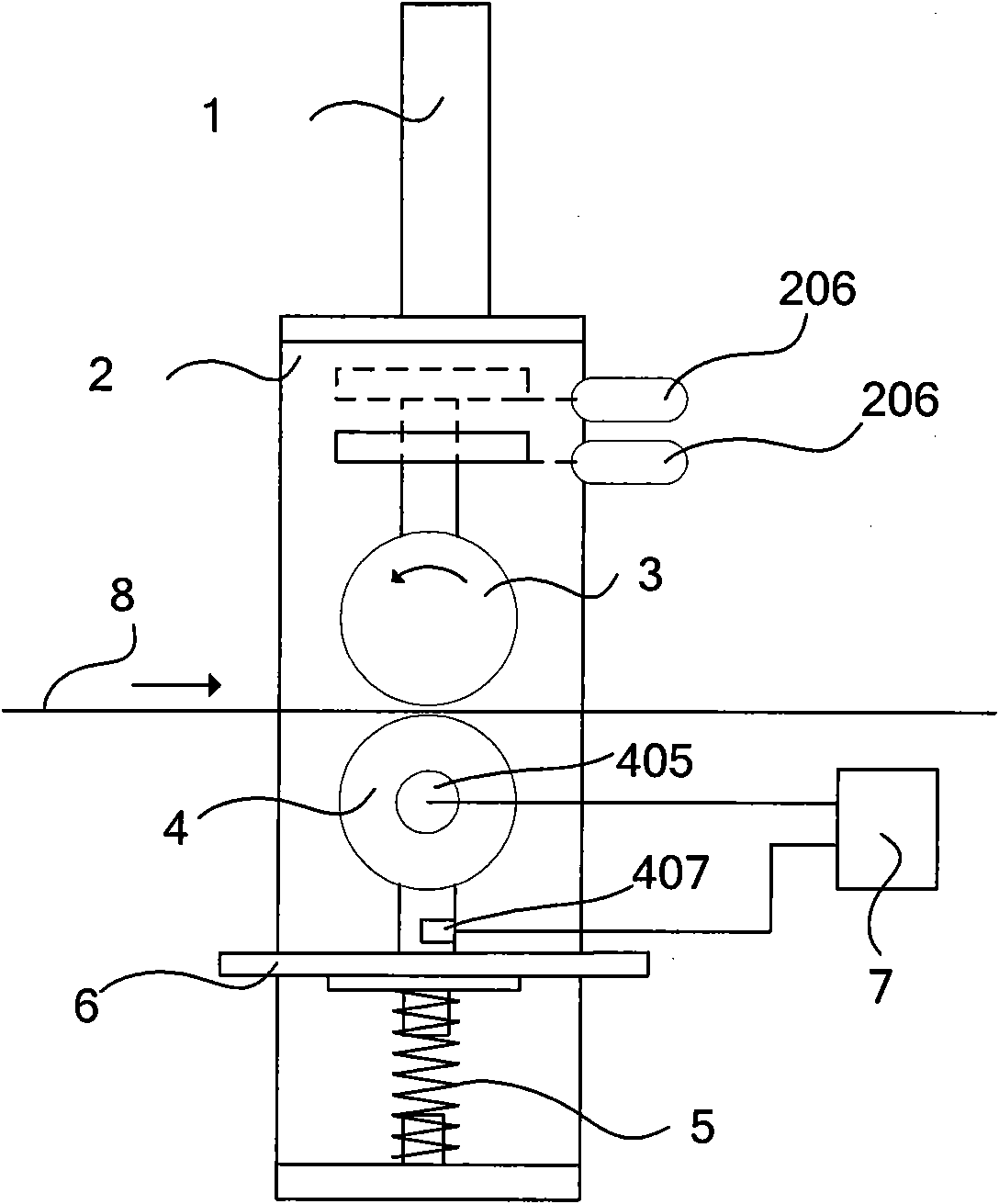

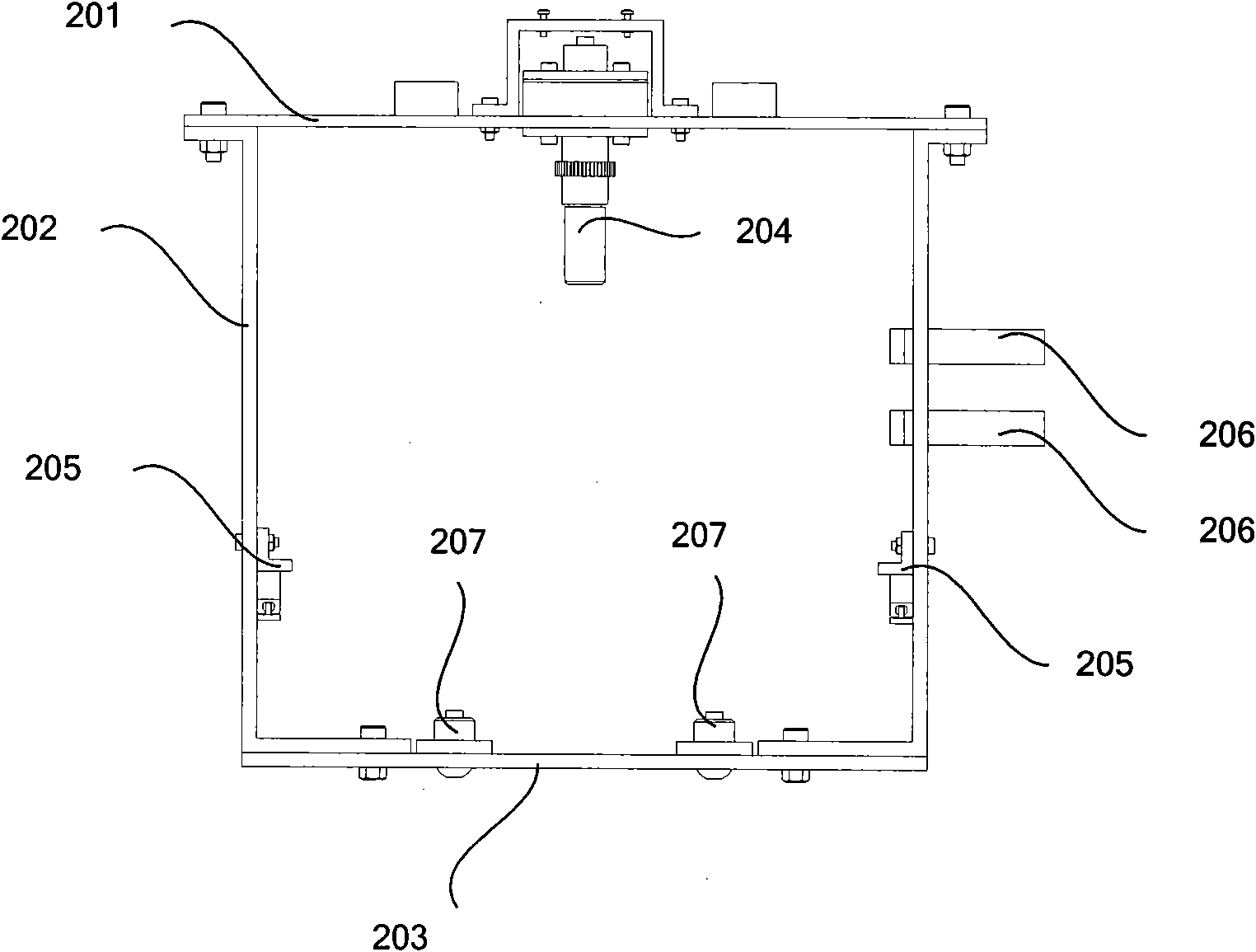

Glue extrusion device for fiber gluing equipment of winding machine

InactiveCN101775724AGuaranteed liquidityFully maceratedLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberTemperature control

The invention discloses a glue extrusion device for fiber gluing equipment of a winding machine, comprising a servo motor, a box body, an upper glue extrusion roller, a lower glue extrusion roller, a damping spring, a glue receiving box and a temperature control system, wherein the servo motor is installed on the box body, two ends of the upper glue extrusion roller and the lower glue extrusion roller are respectively fixed at two sides of the box body and can move freely, the damping spring is fixed between the lower glue extrusion roller and the bottom of the box body, the glue receiving box is arranged below the lower glue extrusion roller, a heating rod and a temperature sensor are arranged in the lower glue extrusion roller, the temperature control system forms a temperature control circuit with the heating rod and the temperature sensor, fiber passes through the place between the upper glue extrusion roller and the lower glue extrusion roller to be subjected to the extrusion of two rollers, and redundant glue solution on the fiber is extruded out and then flows onto the glue receiving box along the two rollers. The device can continuously adjust and control the gluing amount on fiber to control the temperature of the fiber and keep the flowability of the glue solution, the roller type extrusion ensure the glue solution to be more completely macerated on the fiber, the device has stronger adaptability to the fiber, and the fiber is not easy to fracture.

Owner:BEIHANG UNIV

Ultrahigh-strength self-compacting concrete and preparation method thereof

InactiveCN103304206AImprove microscopic propertiesImprove the interface transition areaFiberPolyvinyl alcohol

The invention discloses an ultrahigh-strength self-compacting concrete and a preparation method thereof. The ultrahigh strength self-compacting concrete is mainly composed of a cementing material, an efficient water reducer, a fine aggregate, a coarse aggregate, water and PVA (Polyvinyl Alcohol) fibers, wherein the cementing material is composed of 70%-80% of common silicate cement, 10%-20% of mineral slag and 5%-10% of silicon powder by weight percentage; the fine aggregate is medium sand; the coarse aggregate is granite macadam. The ultrahigh-strength self-compacting concrete has the beneficial effects that the advanced techniques of the ultrahigh-strength concrete and the self-compacting concrete in the field of the concrete materials at present are studied, the advantages of the two concrete techniques are combined so that the dosage of the cement is reduced while ultrahigh performance of the concrete is realized, and furthermore, the purposes of emission reduction of CO2, materials saving and environmental protection as well as green construction are achieved.

Owner:SHENZHEN UNIV

High flux environment-friendly tin wire and preparation method thereof

InactiveCN105772979AImprove plasticityImprove insulation performanceWelding/cutting media/materialsSoldering mediaHigh fluxBenzotriazole

The invention discloses a high flux environment-friendly tin wire and a preparation method thereof. The tin wire consists of a solder and a flux, wherein the content of the solder is 94.2-96.7 mass%, and the content of the flux is 3.3-5.8 mass%; the solder comprises the following alloy components in percentage by mass: 95.0-99.2% of tin, 0.1-3.0% of silver, 0.3-2.2% of copper and 0.01-0.1% of nickel; the flux comprises the following components in percentage by mass: 72-85% of rosin, 1.8-4.5% of solvent, 5-10% of synthetic resins, 0.7-1.2% of benzotriazole, 5-10% of activating agents and 1-5% of surface active agents; and the diameter of the tin wire is preferably 0.1-2 mm. The high flux environment-friendly tin wire is uniform and smooth in surface, is excellent in fluidity after melting, is excellent in wettability, is less in splash during welding, is free of corrosion in residues after welding, is green and environment-friendly, and is low in cost.

Owner:SUZHOU YIFEITE ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com