Self-leveling mortar of composite cement

A technology of self-leveling mortar and composite cement, which is applied in the field of building materials, can solve problems such as poor shrinkage performance and construction cracking, and achieve the effect of long service life and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

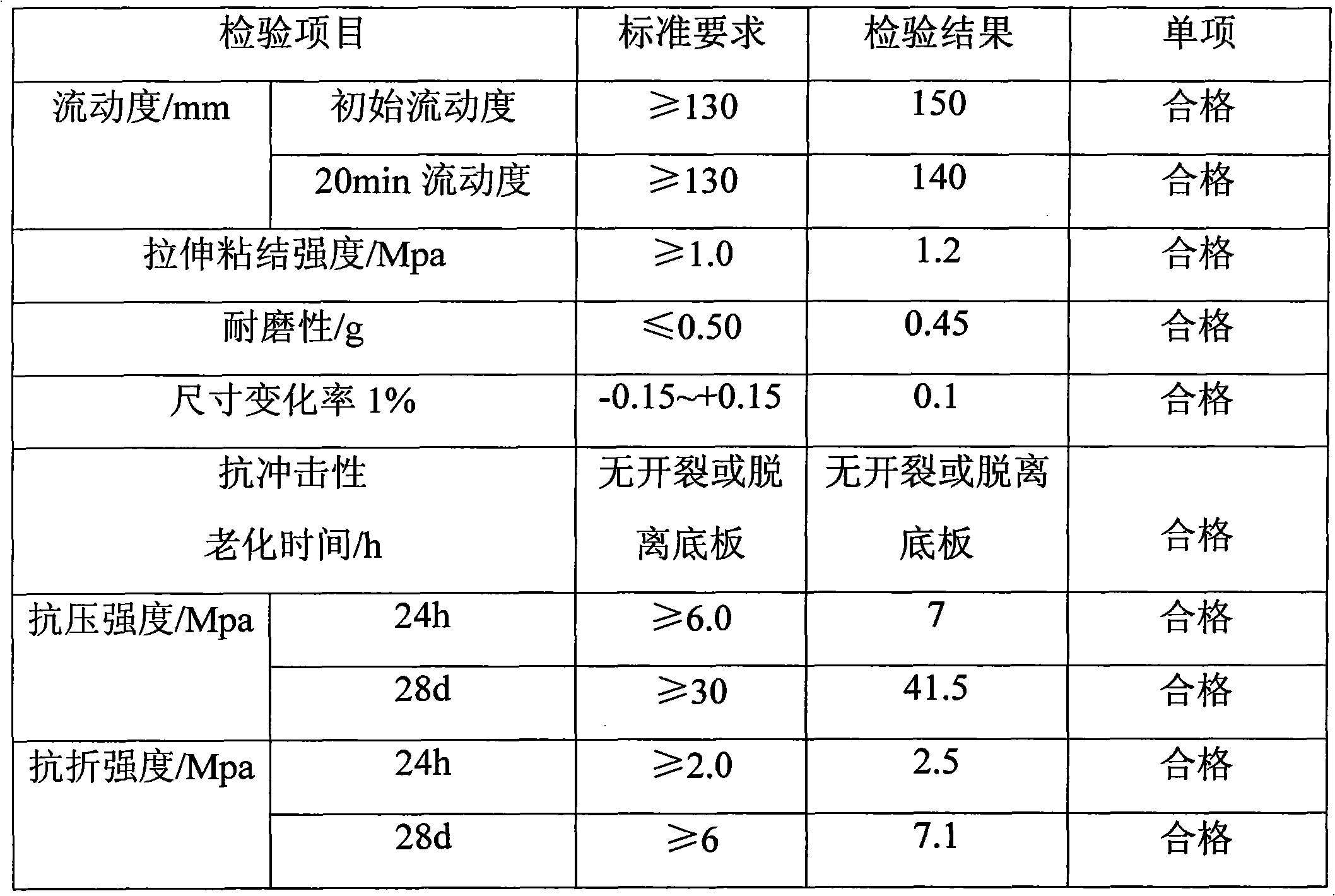

Image

Examples

Embodiment

[0038] A kind of composite cement self-leveling mortar, 100 parts of cement self-leveling mortar includes:

[0039] Portland cement 23 parts;

[0040] 8 parts of sulphoaluminate cement;

[0041] 4.44 parts of 400-700 mesh limestone powder;

[0042] Silica fume (D50≥0.225u) 1 part;

[0043] 5 parts of 200 mesh anhydrite;

[0044] 2 parts of 200 mesh slaked lime;

[0045] Fine sand (50-150 mesh quartz sand without organic matter) 50 parts;

[0046] 0.6 parts of polysulfate-based water reducer;

[0047]1.0 parts of polyethylene glycol shrinkage reducing agent;

[0048] 0.2 parts of industrial grade tartaric acid;

[0049] 0.1 part of industrial grade lithium carbonate;

[0050] 0.5 parts of mineral oil powdery defoamer;

[0051] 1.5 parts of mobile latex powder;

[0052] Alkali-resistant iron oxide pigments Iron orange 2.5 parts;

[0053] 300~600mpa·s 0.06 parts of hydroxypropyl methylcellulose.

[0054] In this embodiment, the water reducer is polycarboxylate water r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com