Glue extrusion device for fiber gluing equipment of winding machine

A winding machine and fiber technology, which is used in the processing of textile material equipment configuration, liquid/gas/vapor removal with squeeze rollers, etc., can solve the problem of inability to accurately control the amount of glue, inability to meet production requirements, and decreased glue fluidity, etc. problem, to achieve the effect of not easy to break, improve safety, and maintain fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

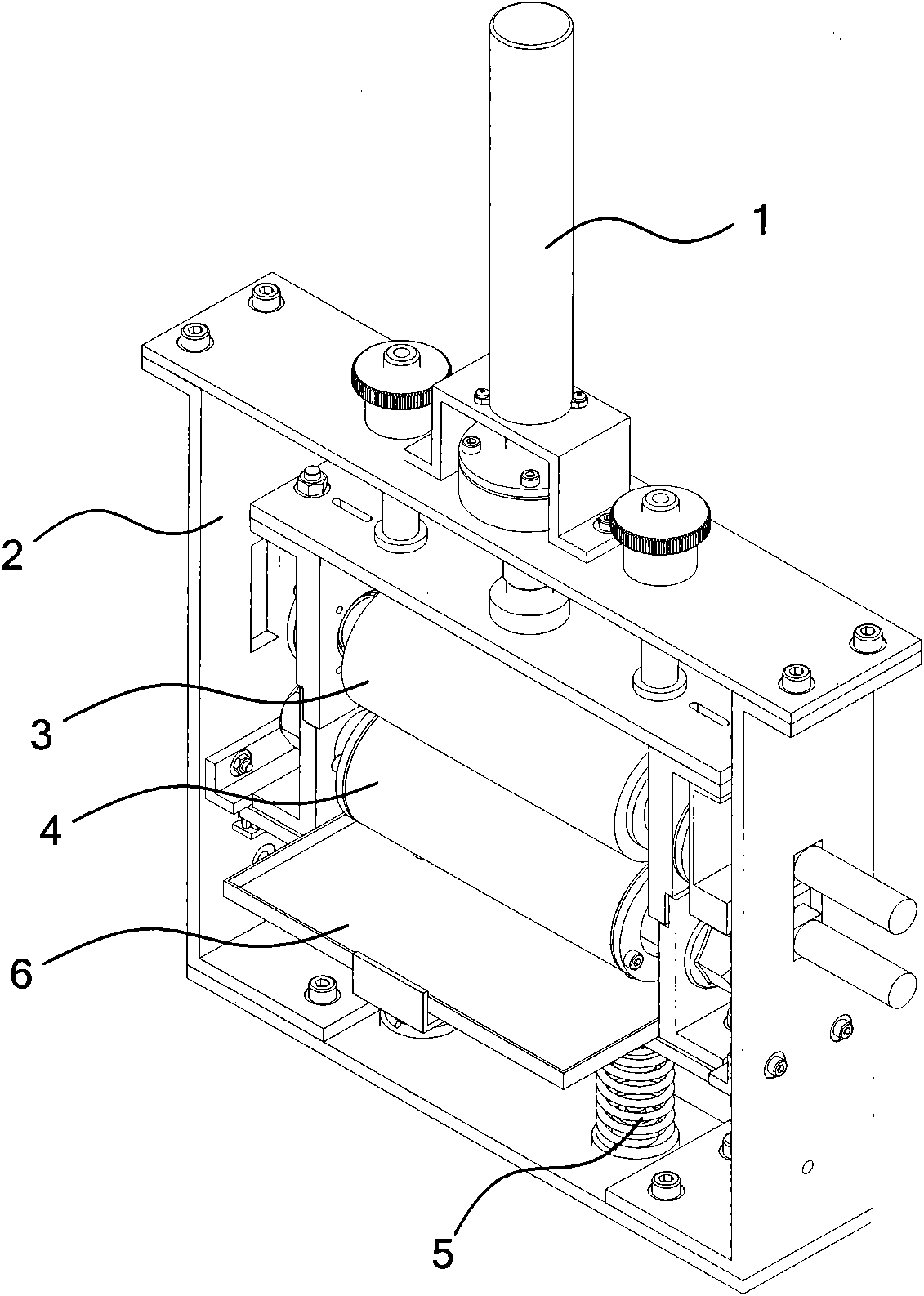

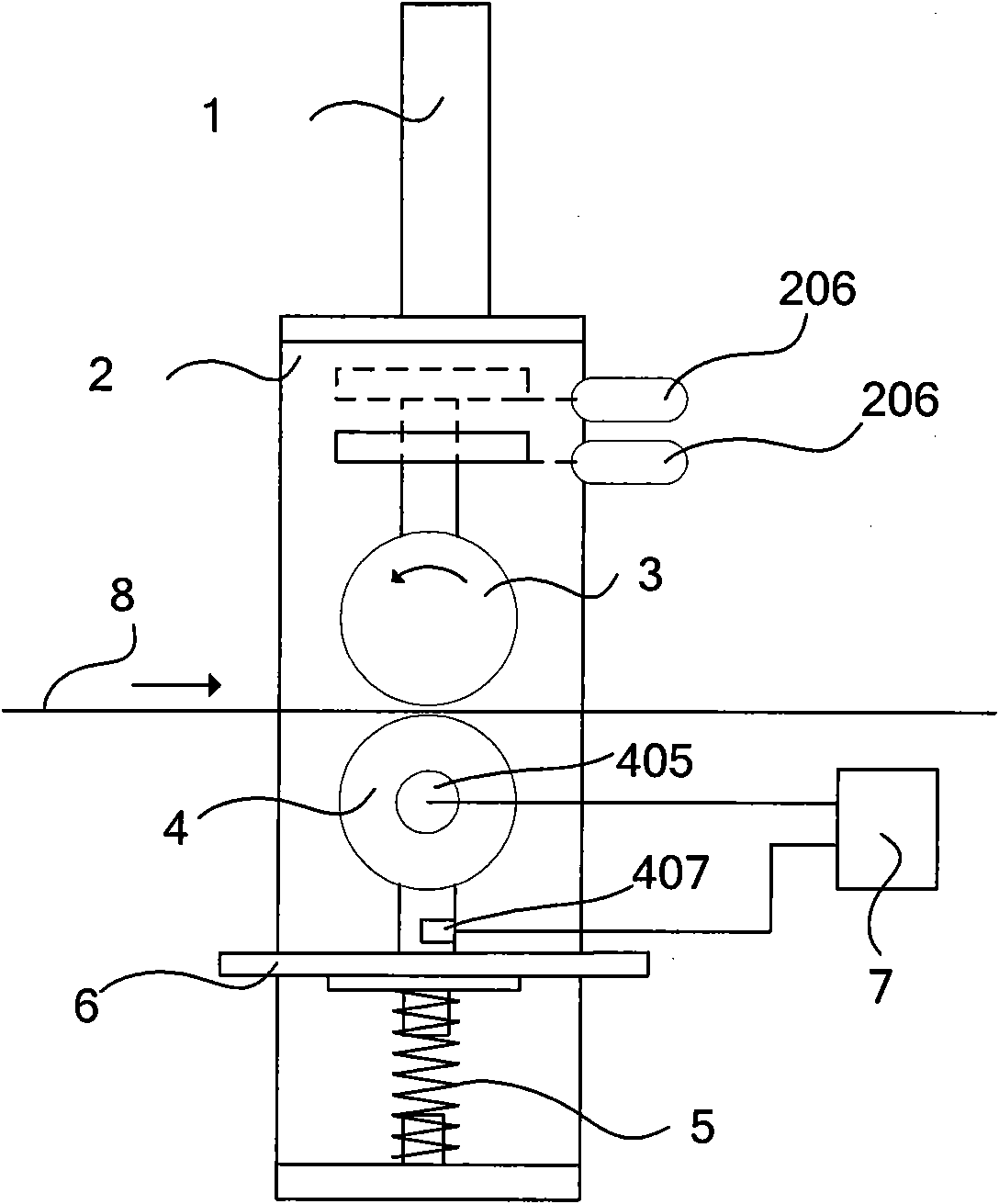

[0029] The present invention is a kind of extruding device of fiber gluing equipment of winding machine, such as figure 1 , figure 2 As shown, it includes servo motor 1, box body 2, upper extrusion rubber roller 3, lower extrusion rubber roller 4, shock absorbing spring 5, adhesive box 6 and temperature control system 7;

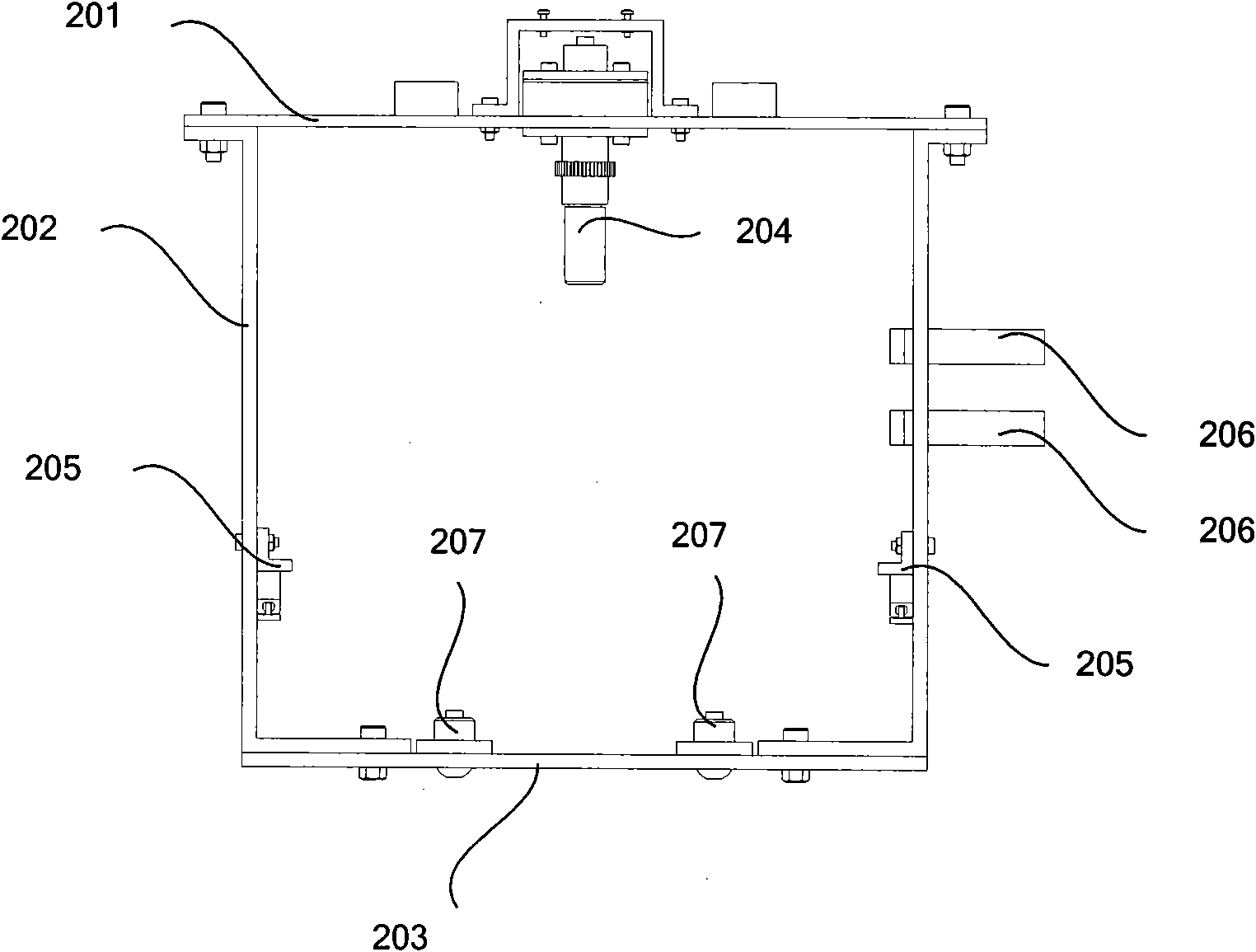

[0030] Box 2 such as image 3 As shown, it includes a box upper plate 201 , a box side plate 202 , a box lower plate 203 , a lead screw 204 , a small baffle 205 , a limit switch 206 and a spring end 207 .

[0031] The upper plate 201 of the box body, the two side plates 202 of the box body and the lower plate 203 of the box body are connected end to end to form a square frame. A lead screw 204 is installed in the middle of the box upper plate 201, and two through holes are punched at both ends of the box body upper plate 201, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com