Patents

Literature

3363 results about "Heater Rod" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

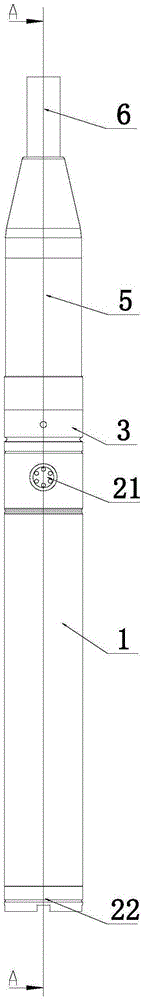

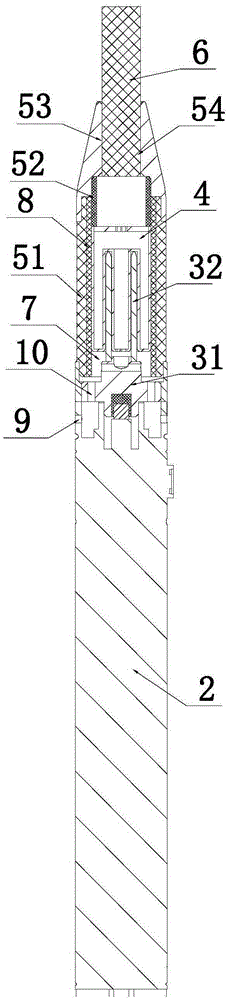

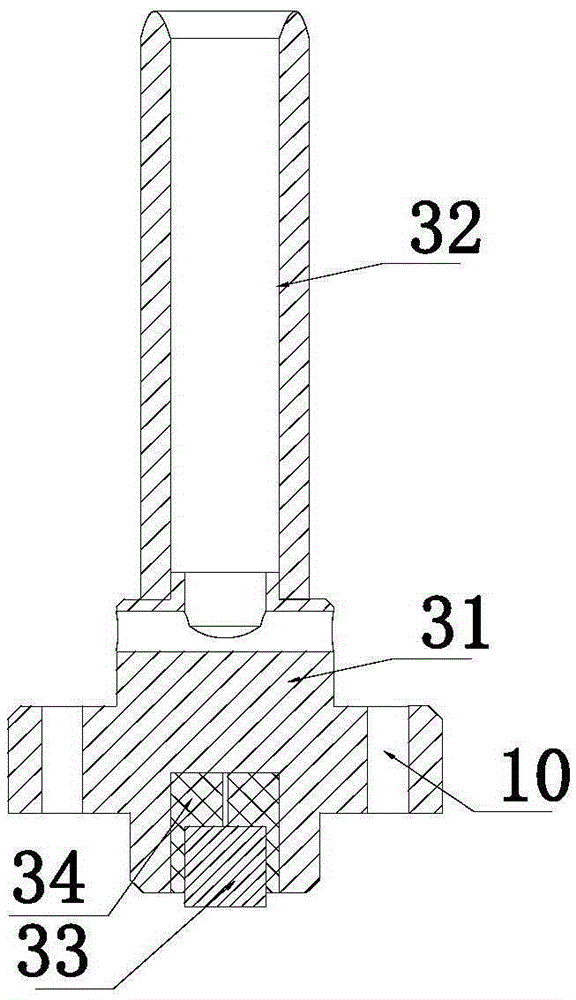

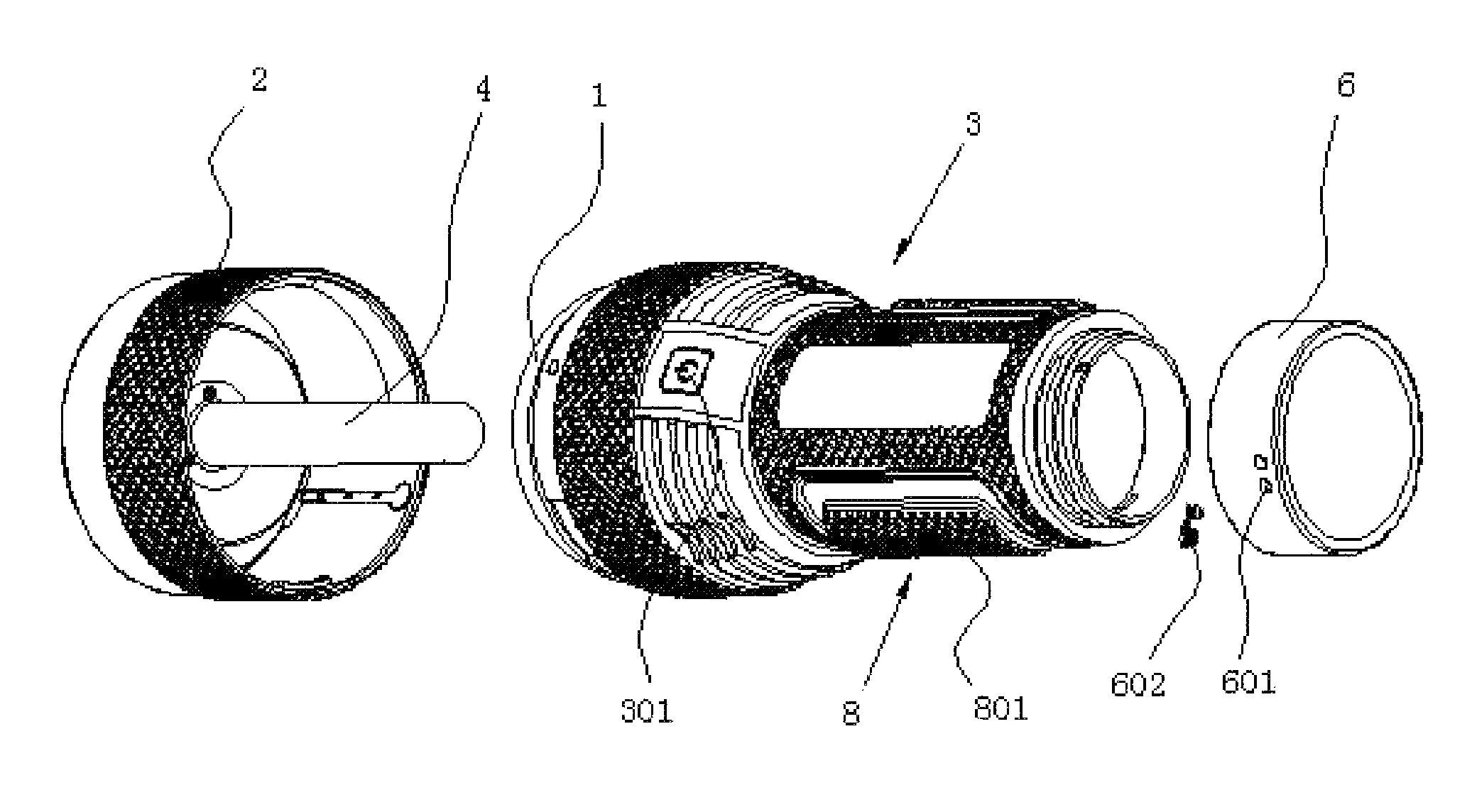

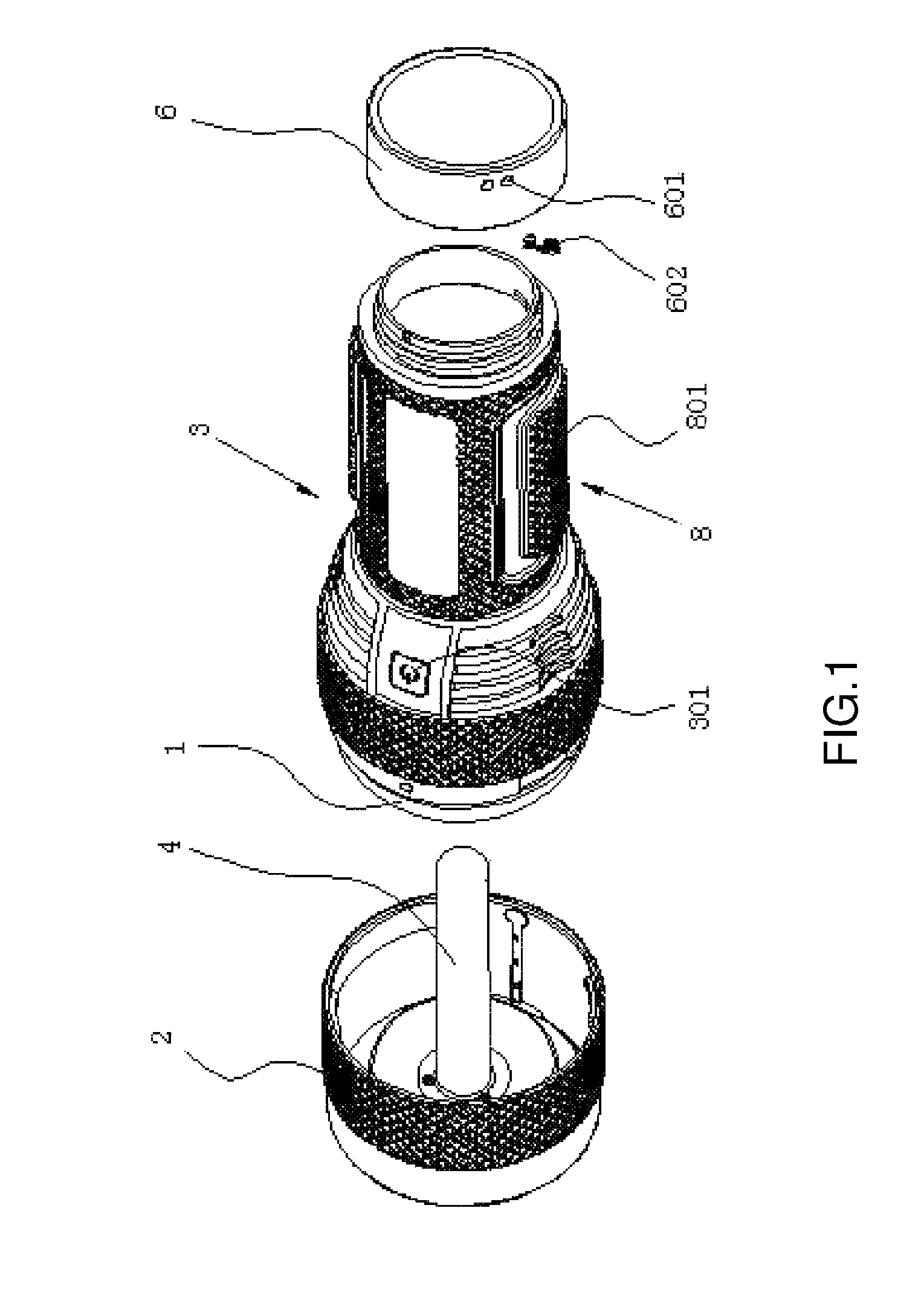

Novel cigarette heating and smoking device with solid smoke cartridge

ActiveCN105342011AAchieve releaseExtended service lifeTobacco pipesTobacco devicesHeater RodEngineering

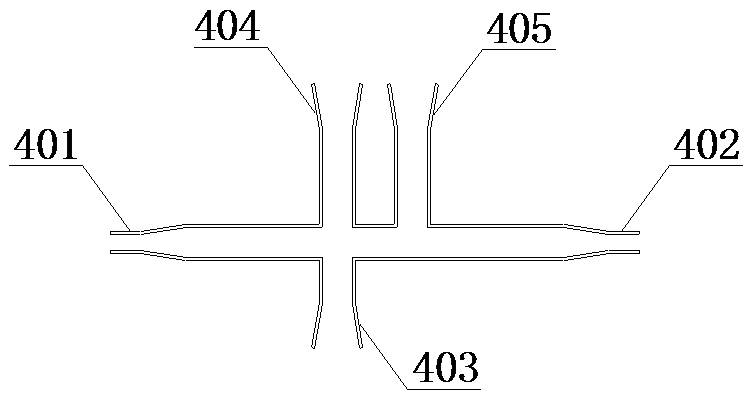

The invention relates to a novel cigarette device, and in particular relates to a novel cigarette heating and smoking device with a solid smoke cartridge. A smoke cartridge fixing assembly of the device comprises a fixing connecting sleeve, a compacting sealing sleeve and a smoking connector, wherein the fixing connecting sleeve is internally provided with a cylinder-shaped cavity, the cylinder-shaped cavity is communicated with an air inlet, a smoke cartridge assembly is arranged in the cylinder-shaped cavity, smoking substances for heating and smoking are arranged in the smoke cartridge assembly, the lower end of the smoke cartridge assembly is provided with a concave hole matched with a heating bar, the heating bar is inserted into the concave hole, air inlet holes are formed in the periphery of the concave hole, the upper end of the smoke cartridge assembly is provided with an air outlet hole, the air outlet hole is in sealed insulation with the cylinder-shaped cavity, and is communicated with an inner ring of the compacting sealing sleeve, the smoking connector is arranged on the upper part of the fixing connecting sleeve, and is provided with a smoking hole, and a smoking assembly is arranged on the smoking hole. With the device, the release of smoke is realized, a heating assembly does not contact directly with a smoke forming substrate, the heating device does not need to be cleaned, and thus the service life is prolonged.

Owner:CHINA TOBACCO ZHEJIANG IND

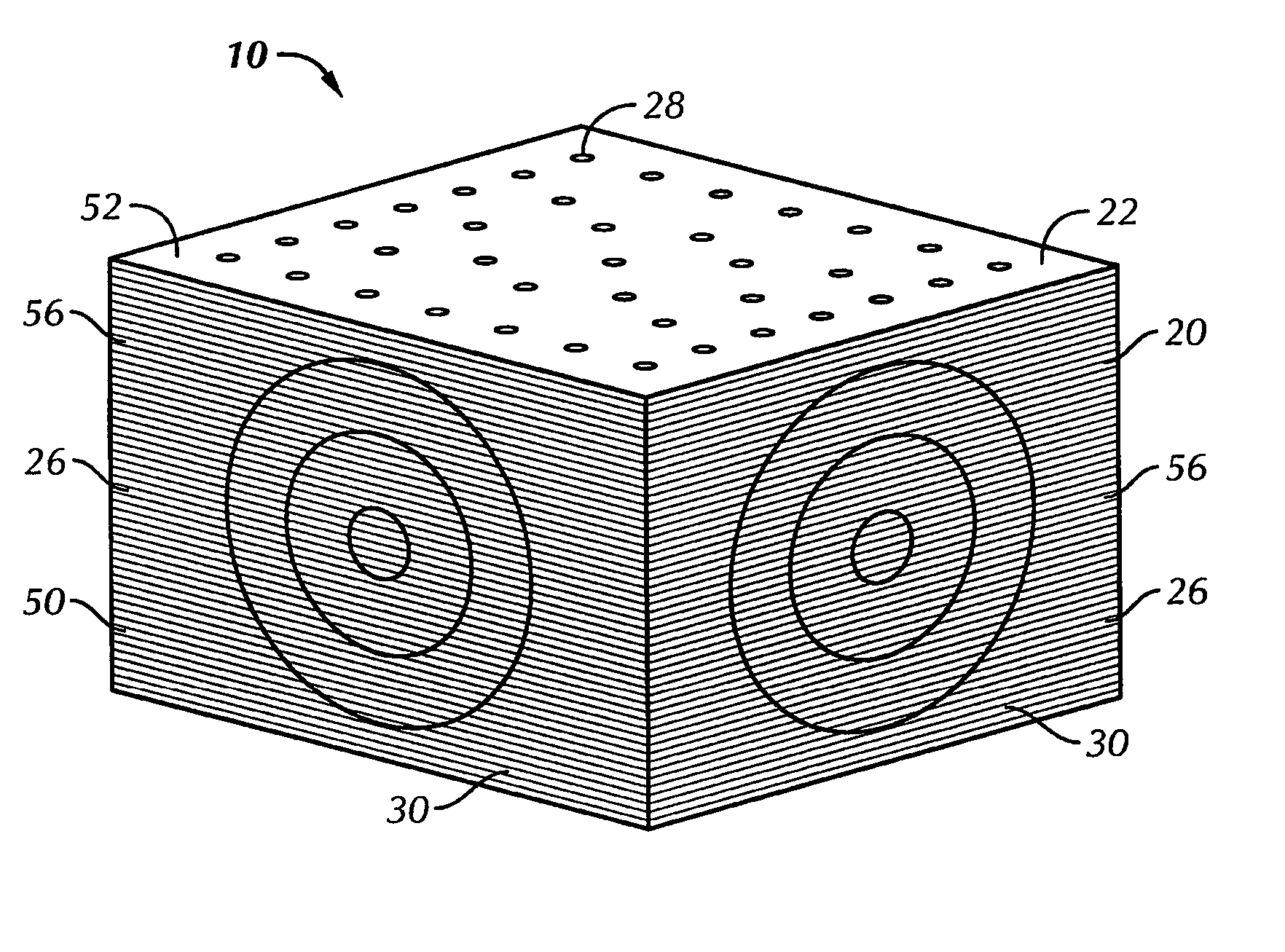

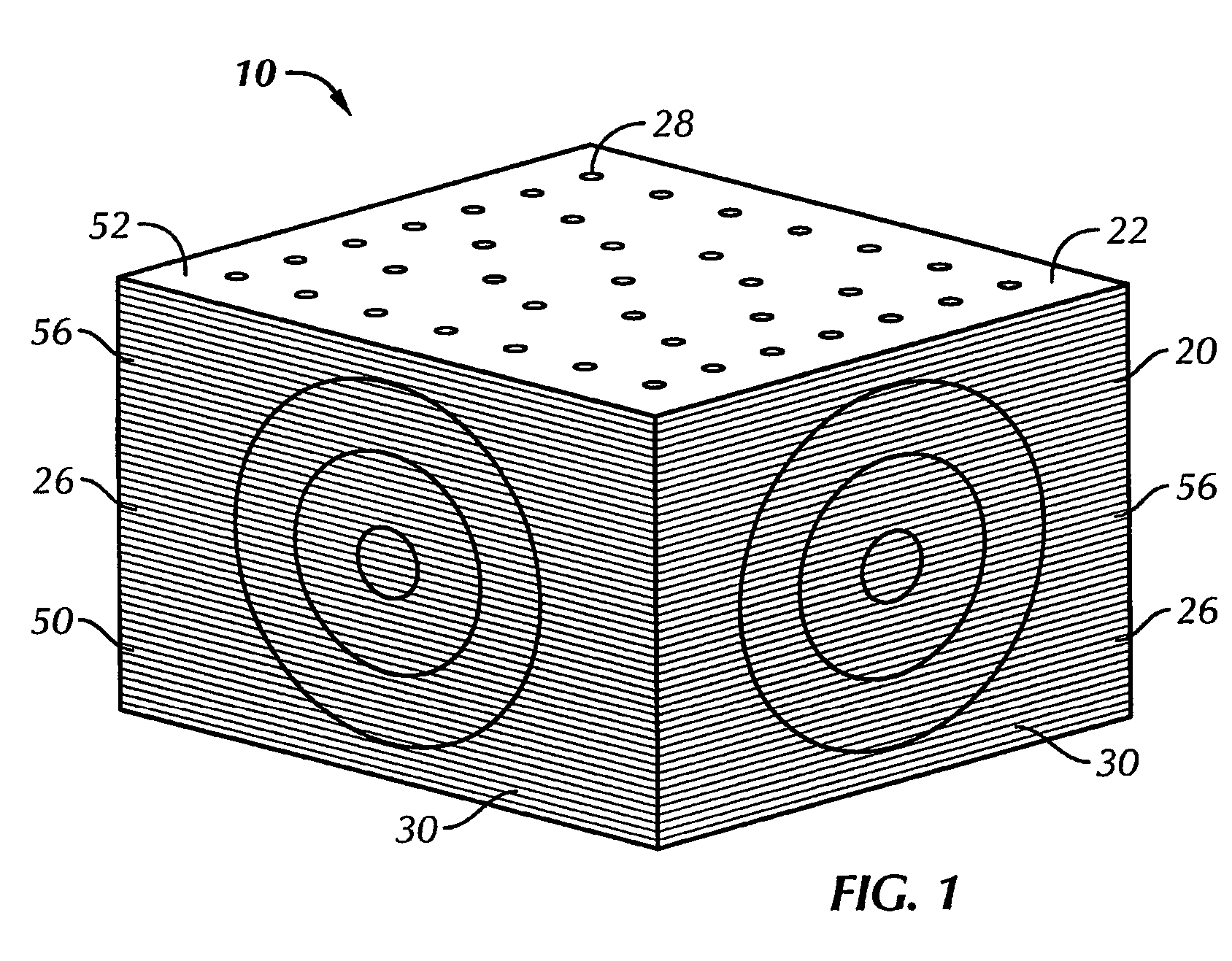

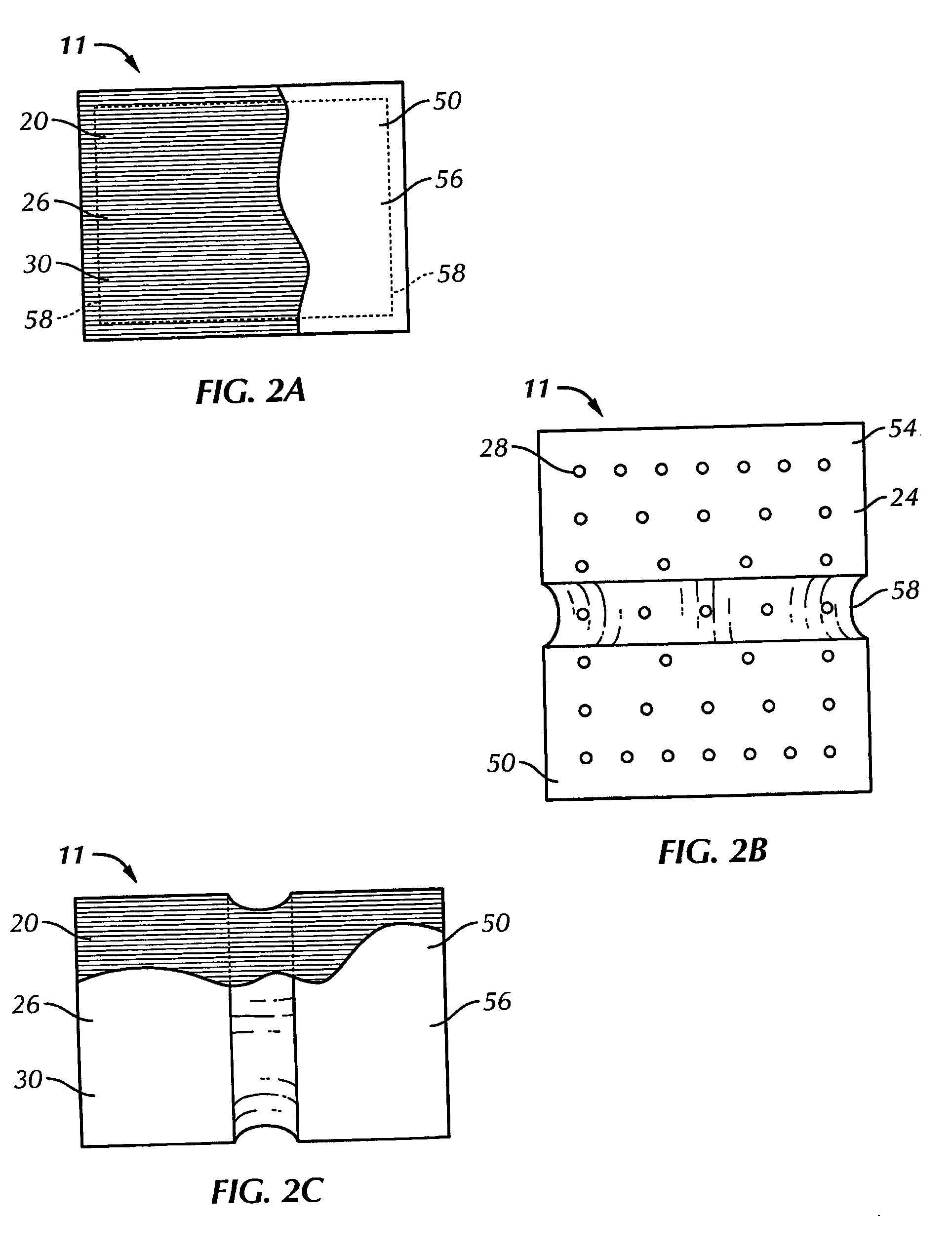

Layered foam target and method of manufacturing the same

An archery target is manufactured by stacking a plurality of layers of foam with the bottom surface of an upper layer engaging the top surface of a lower layer in face-to-face engagement to form a stack having a top surface, a bottom surface and a plurality of side surfaces. The foam layers are compressed and the layers of foam are secured to each other by applying heat to the side surfaces such that a plurality of target faces of at least partially melted foam are formed. The layers of foam are further integrated to one another by applying a heated rod through the entire stack to form at least one hole extending through the layers. The archery target is capable of being used in a stand-alone arrangement having at least four target faces and could be used as an insert for a three-dimensionally shaped target shell.

Owner:DELTA SPORTS PRODS

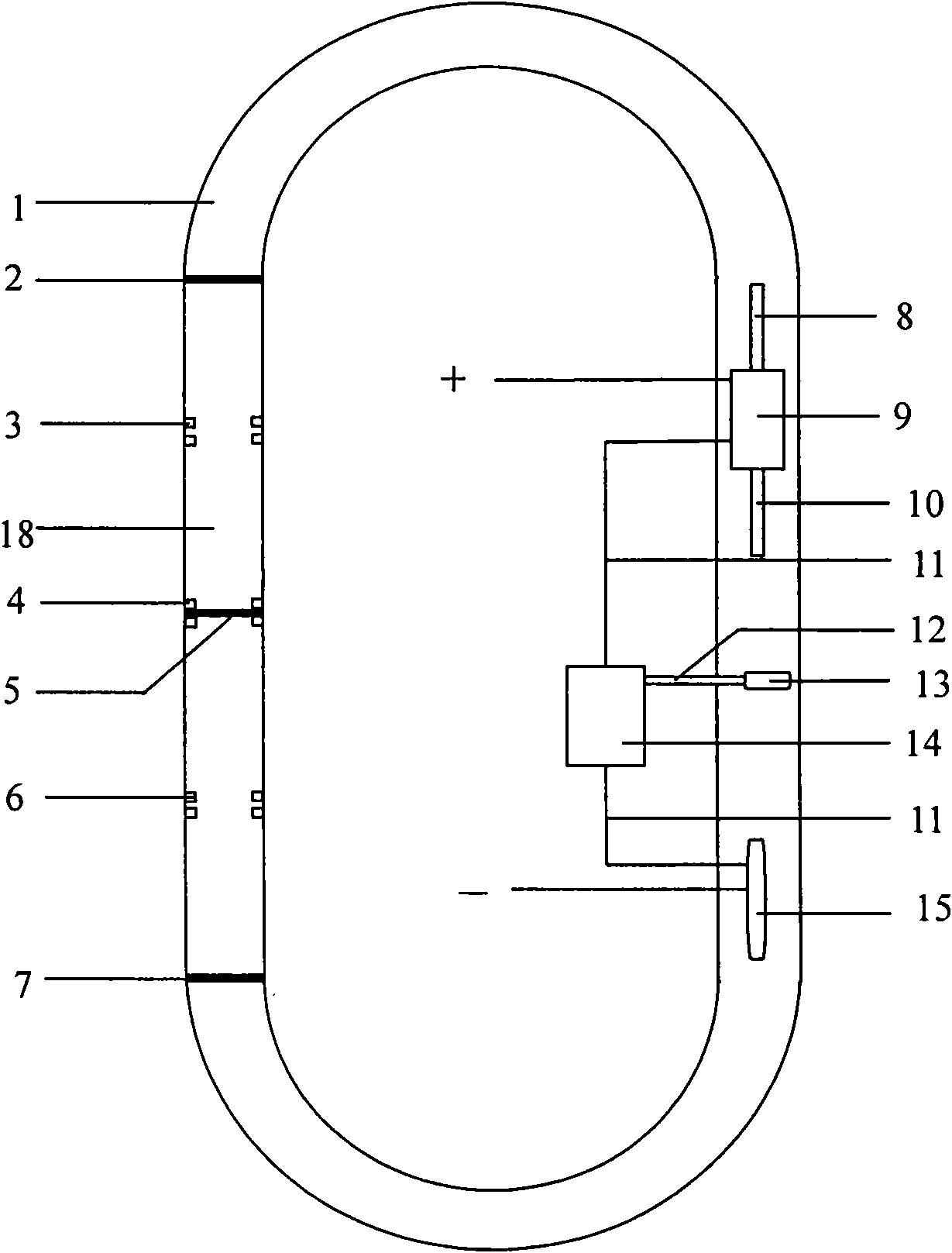

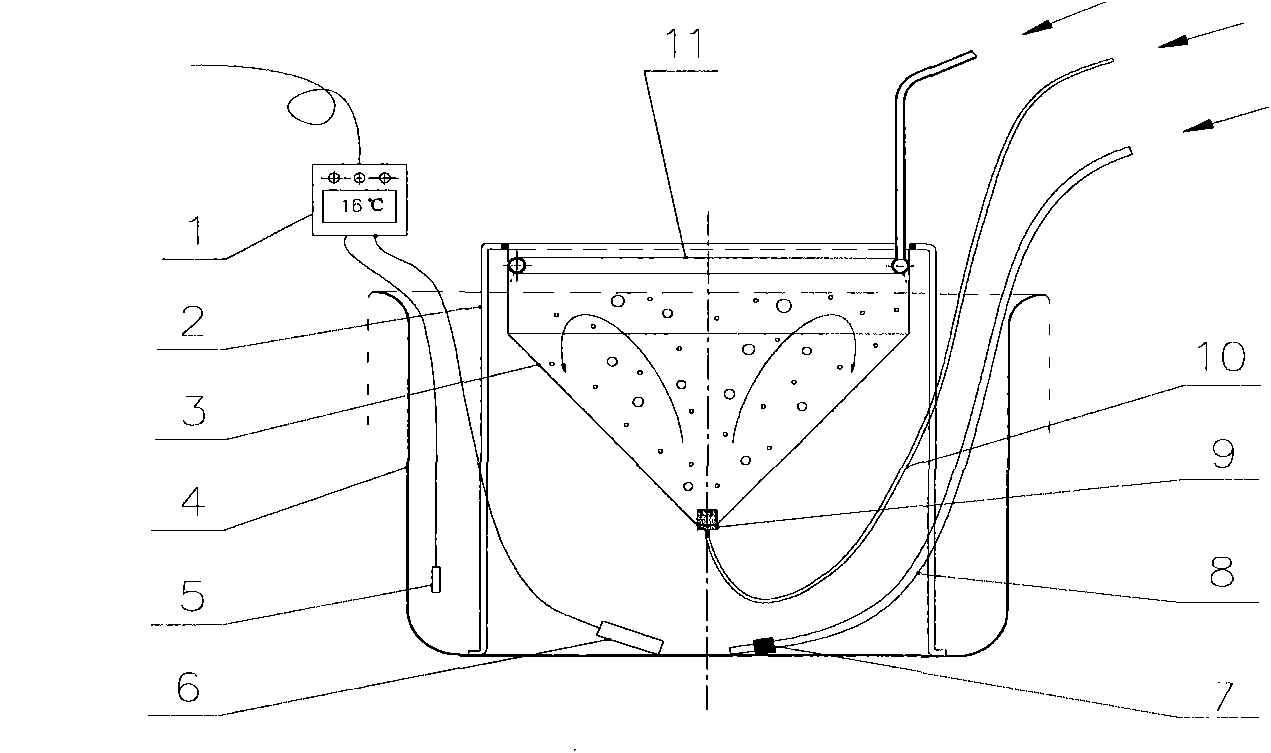

Method for screening and separating high-quality fry and poor-quality fry in batches

InactiveCN101564014ARapid Screening SeparationClimate change adaptationPisciculture and aquariaHeater RodWater flow

The invention discloses a method for screening and separating high-quality fry and poor-quality fry in batches, belonging to the method for screening and separating the fry, which aims to provide a method for screening and separating the high-quality fry and the poor-quality fry. The method is carried out in a circular way and is characterized in that a straight way on the left side of the circular way is respectively provided with a front baffle plate and a rear baffle plate, and three slip grooves are arranged between the front baffle plate and the rear baffle plate; and a diving pump, an inflating head and a heating rod are put in a straight way on the right side of the circular way. When the fry are screened and separated, the speed of the water flow is maintained at about 1cm / s so as to form a clockwise water flow in the circular way. The fry is put in water adjacent to the front baffle plate, and the speed of the water flow is gradually changed so as to ensure that the fry with poor physique swim to the rear baffle plate with the water flow, and the fry with good physique still stay at the front baffle plate. After the fry are steadily distributed on the left straight way, movable baffle plates are rapidly inserted at the three slip grooves. The fry adjacent to the front baffle plate have the best physique, the fry adjacent to the rear baffle plate have the poorest physique, and the high-quality fry are fished out and put in a culture pond for culturing.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

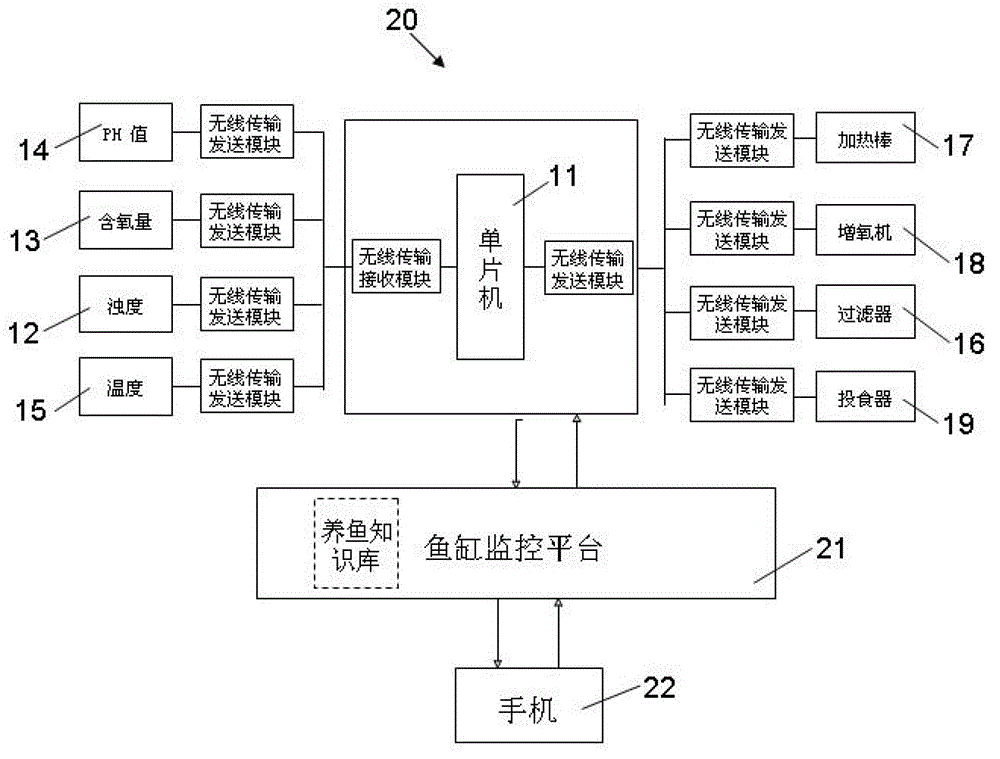

Intelligent monitoring method and system for fish tank

The invention discloses intelligent monitoring method and system for a fish tank. The system comprises a data acquisition and control unit and an upper computer. The data acquisition and control module comprises a single chip microcomputer, a data acquisition unit and a device control unit. The data acquisition unit comprises a turbidity sensor, an oxygen content sensor, a pH sensor and a temperature sensor. The device control unit comprises a filter, a heating bar, an aerator and a feeding device. Monitoring data of water quality in the fish tank is acquired by the turbidity sensor, the oxygen content sensor, the pH sensor and the temperature sensor, and monitoring data signals are sent to the single chip microcomputer through a ZigBee wireless transmission network. The single chip microcomputer sends the monitoring data signals to the upper computer through the ZigBee wireless transmission network. The upper computer receives control signals prior to controlling operation of one or any of the filter, the heating bar, the aerator and the feeding device.

Owner:SHANGHAI OCEAN UNIV

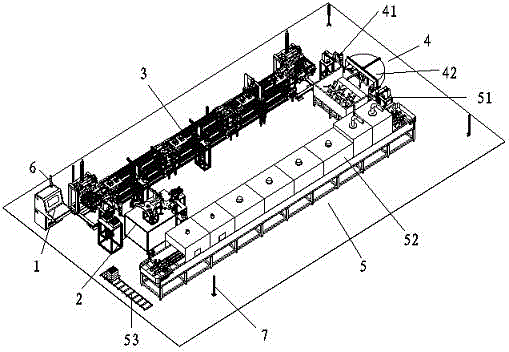

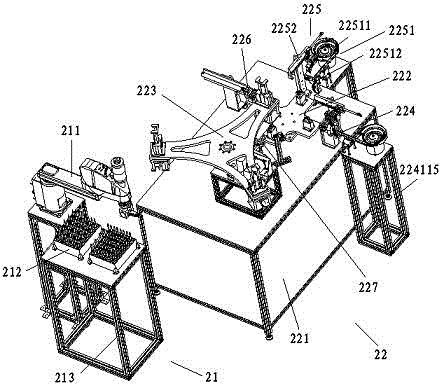

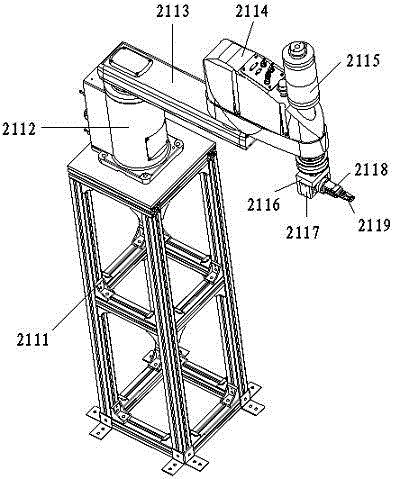

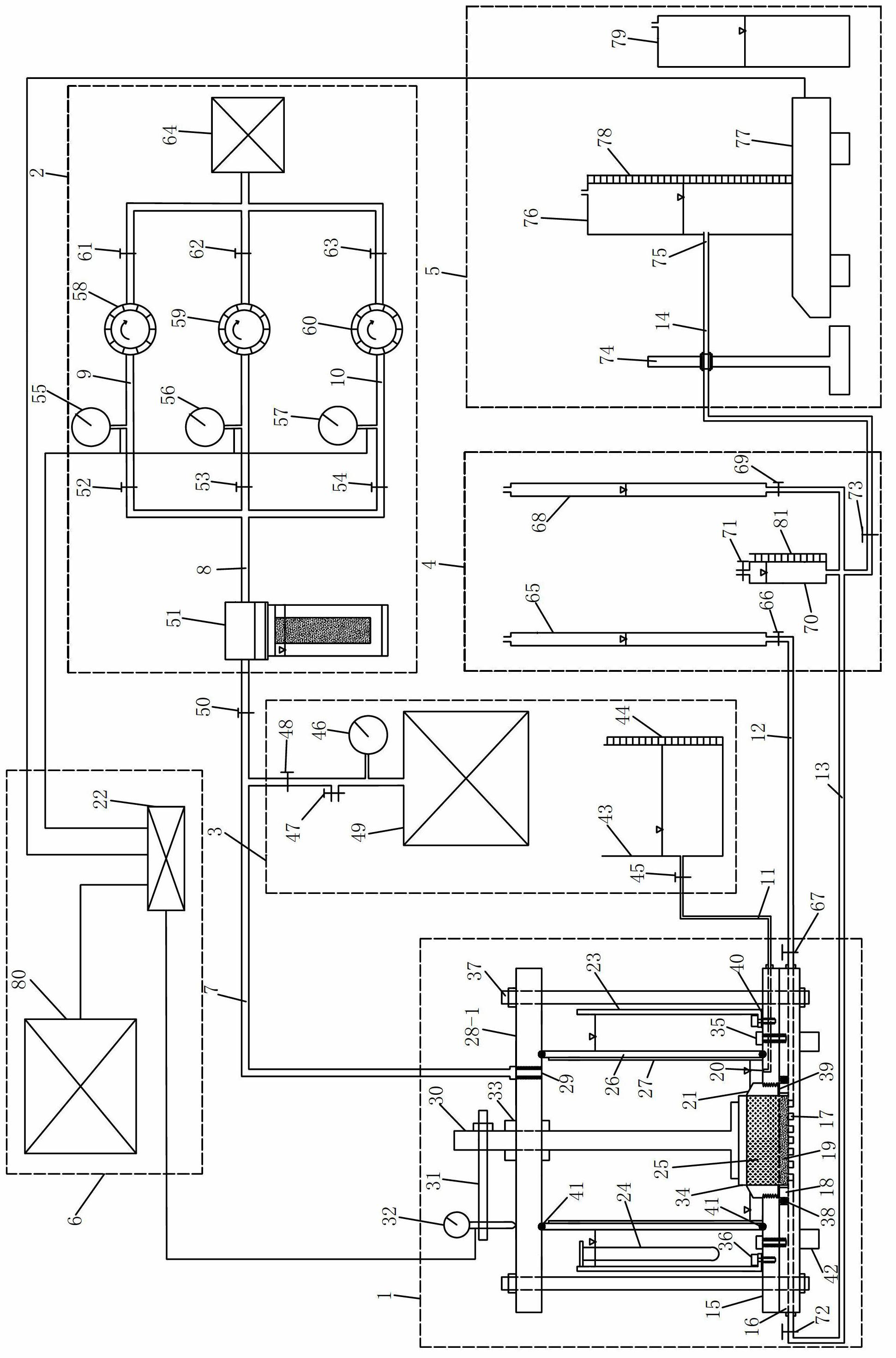

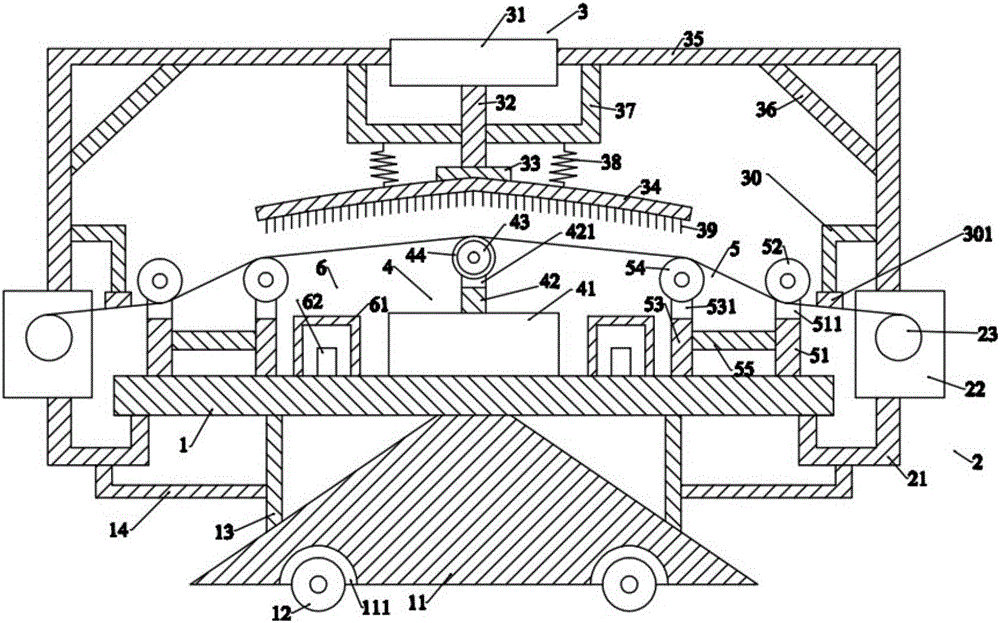

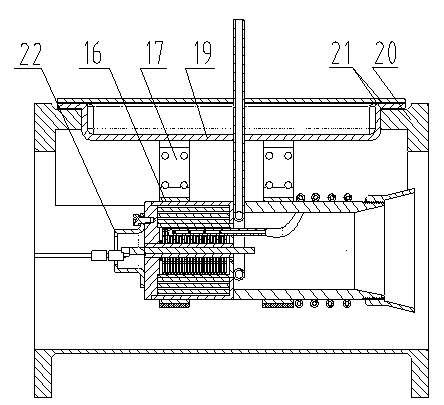

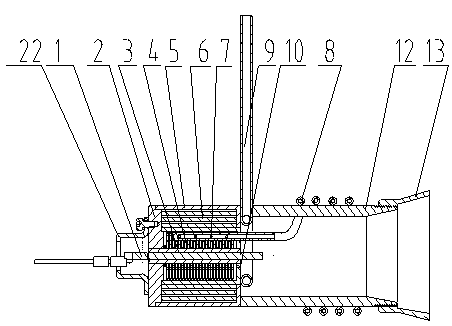

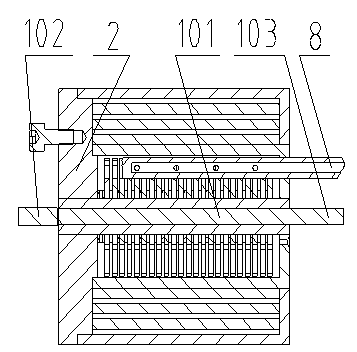

Electric heating rod assembly machine

ActiveCN105855897AImprove assembly and welding efficiencyImprove production stabilityAssembly machinesOther manufacturing equipments/toolsElectricityGrating

The invention discloses an electric heating rod assembly machine. The electric heating rod assembly machine comprises an electric control box, a rotary assembly mechanism, a chain assembly line, a coating mechanism, a drying mechanism, an indicator lamp tower and area safety gratings, wherein the indicator lamp tower is mounted on the top plate of the electric control box; the front side of the electric control box is provided with the rotary assembly mechanism; the rotary assembly mechanism is used for conveying a workpiece assembled for a first time to the chain assembly line at the rear side of the rotary assembly mechanism; the chain assembly line is used for conveying a wokpiece assembled for a second time to the coating mechanism at the front right side of the chain assembly line; the coating mechanism is used for conveying an assembled electric heating rod to the drying mechanism at the front side of the coating mechanism; and the area safety gratings are arranged around in a rectangular manner. In this way, the assembly welding efficiency is high, the production stability is good, the product scrap rate is low, and the overall production efficiency is high.

Owner:南通江海港建设工程有限公司

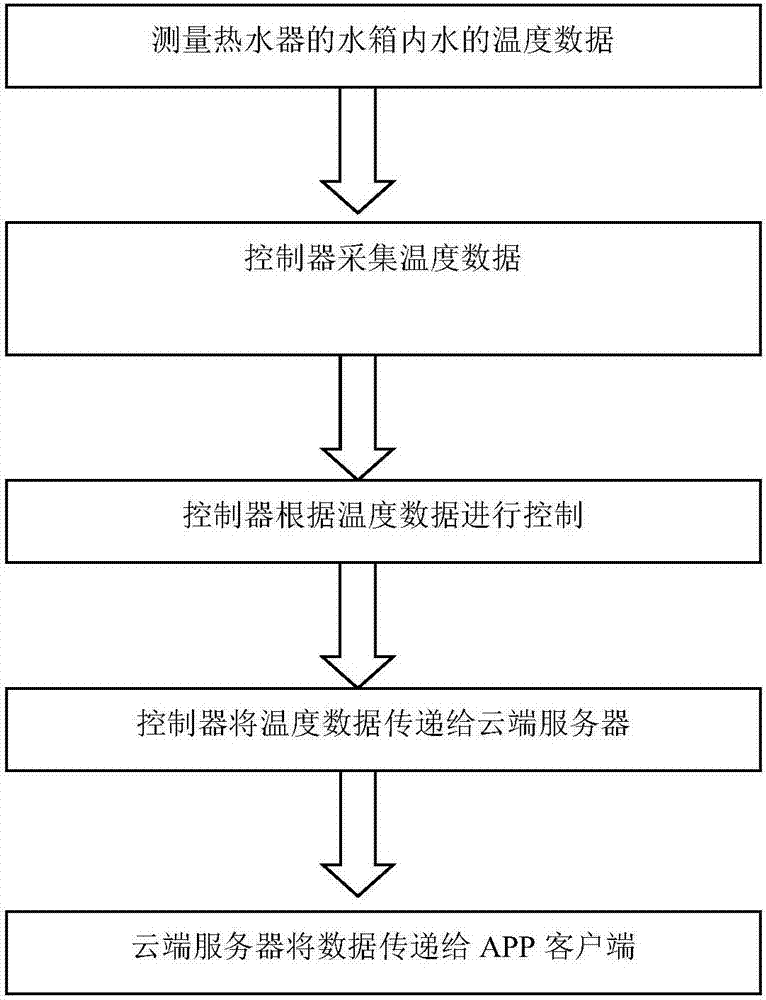

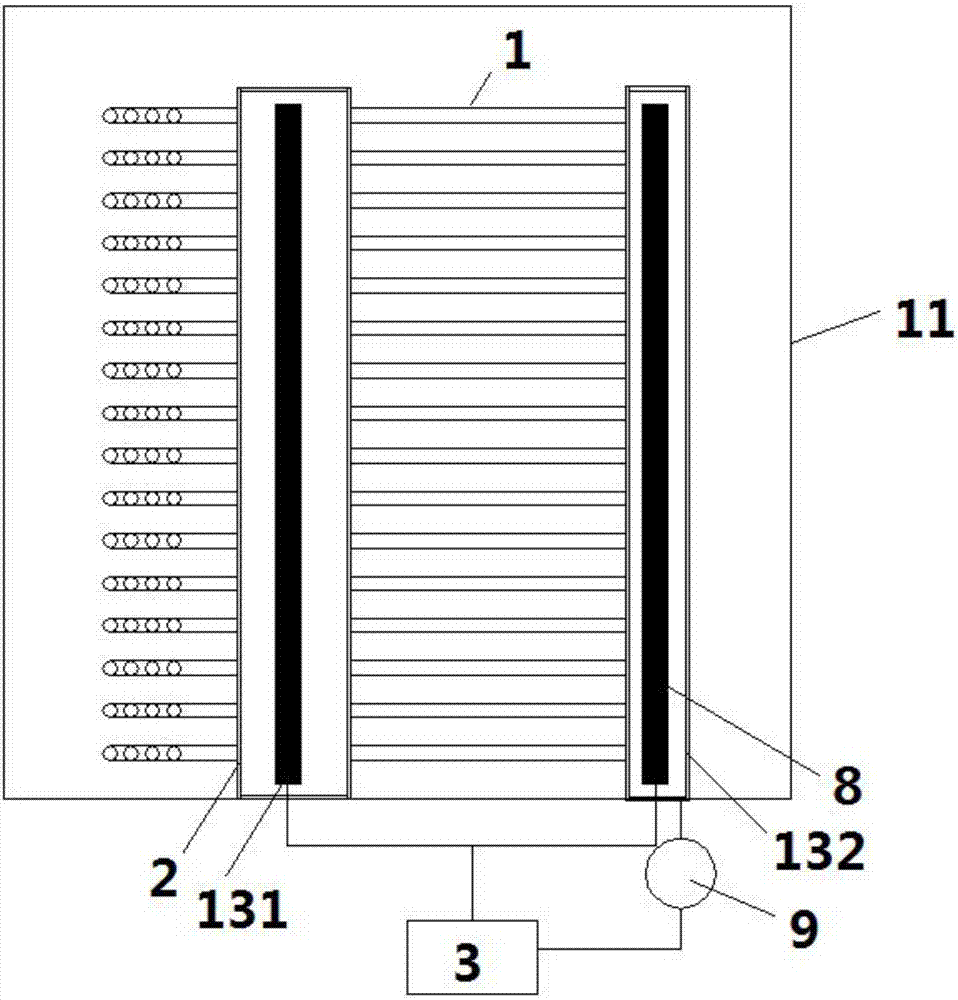

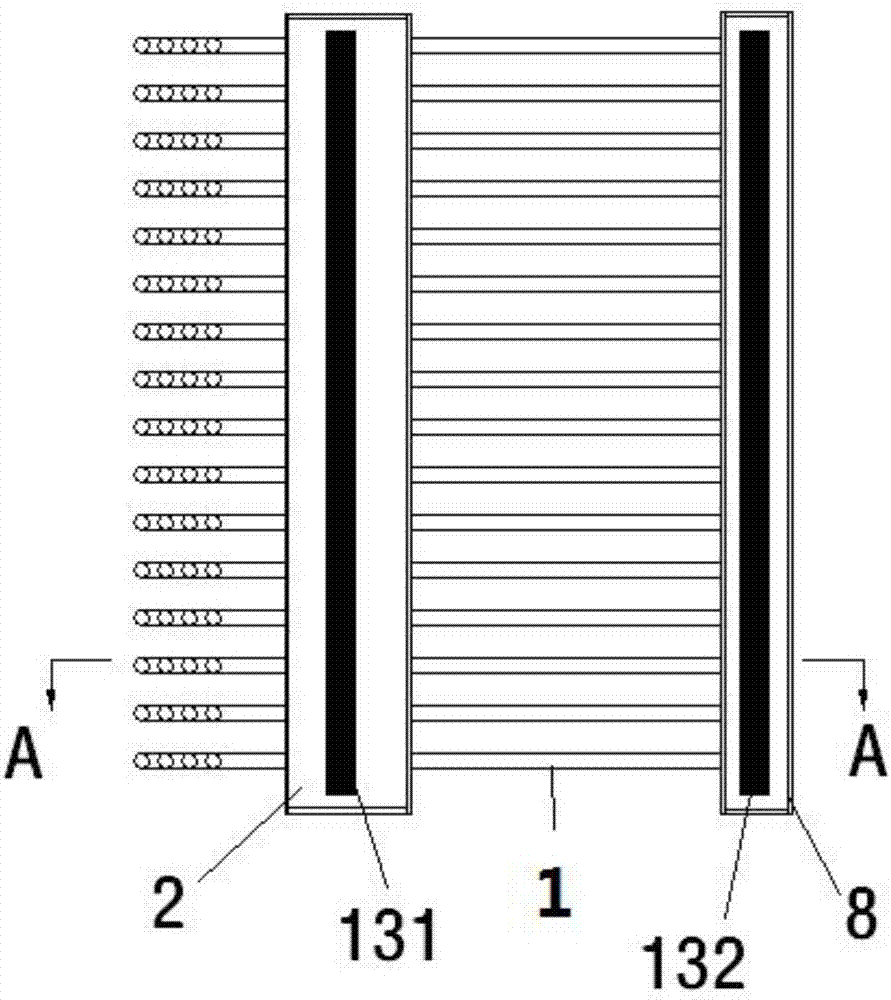

Electric water heater capable of controlling hot water temperature

ActiveCN107367058AImprove intelligenceSave energyStorage heatersWater heatersData connectionAutomatic control

The invention discloses an electric water heater capable of intelligently controlling hot water temperature. The electric water heater comprises a controller, an electric heating device and a water tank; the electric heating device is arranged in the water tank; the water tank comprises a water inlet pipe and a water outlet pipe; a temperature sensor is arranged in the water tank for detecting the temperature of water in the water tank; the temperature sensor, the electric heating device and the controller are in data connection; the controller automatically controls the heating power of the electric heating device according to the detected temperature; the electric heating device comprises a left pipe box, a right pipe box and a floating coil; the floating coil communicates with the left pipe box and the right pipe box to form a heating fluid closed cycle; and electric heating rods are arranged in the left pipe box and the right pipe box. The electric water heater realizes intelligent temperature control through the temperature detection, and realizes remote monitoring.

Owner:安徽省皖晨电子科技有限公司

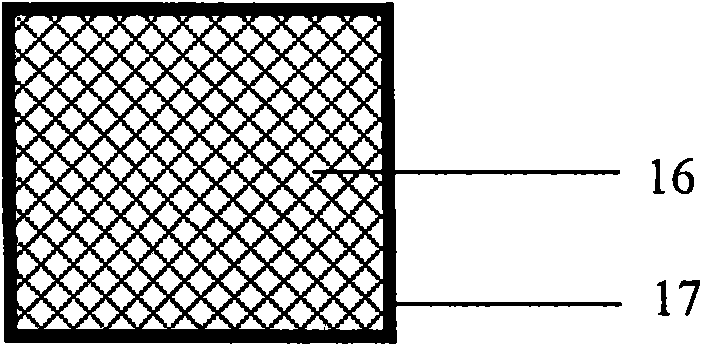

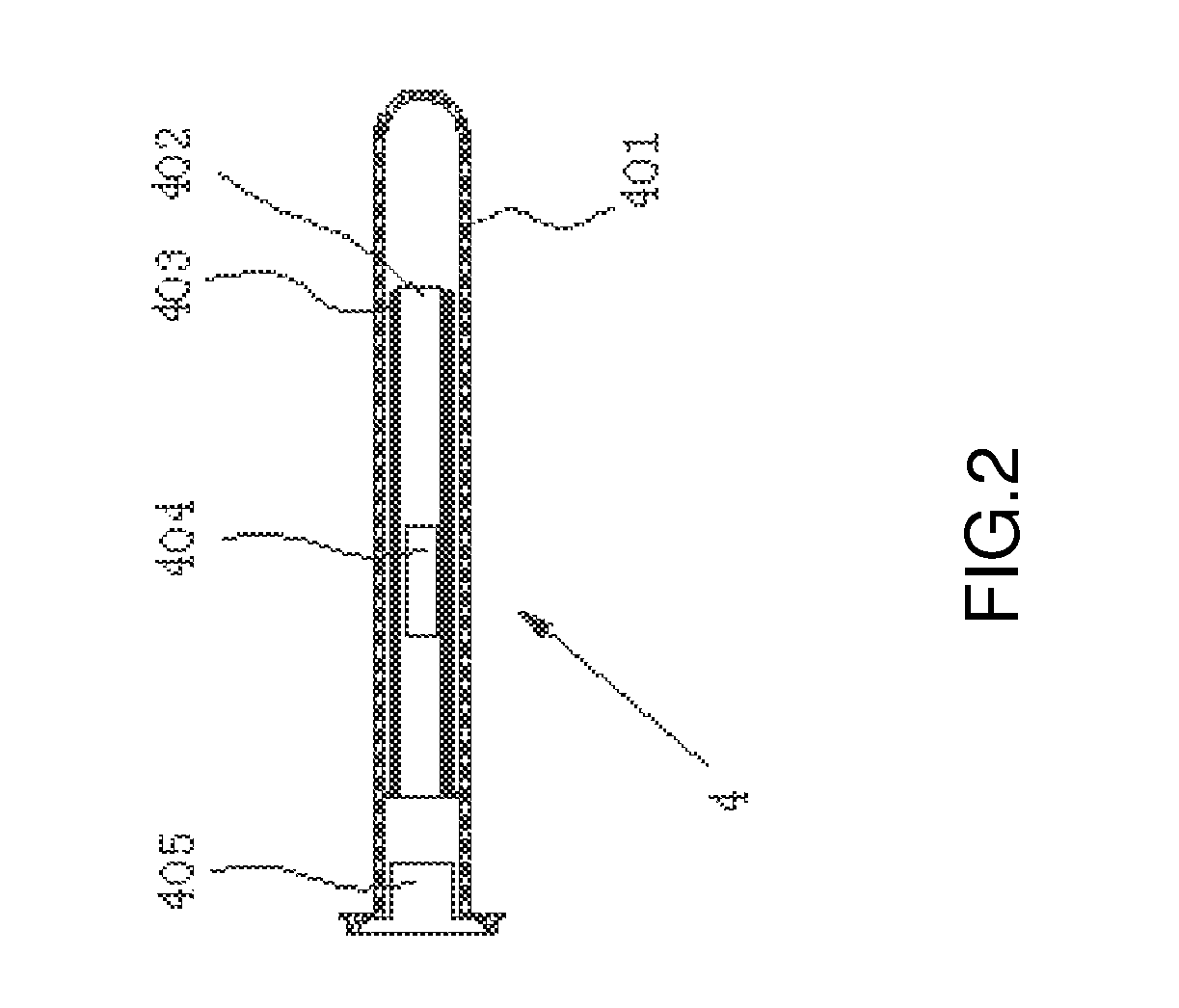

Novel solid-state cigarette core of electronic cigarette and preparation method for novel solid-state cigarette core

InactiveCN104223366AIncrease contact areaIncrease the heating areaTobacco devicesHeater RodEngineering

The invention relates to a novel solid-state cigarette core of an electronic cigarette and a preparation method for the novel solid-state cigarette core, belongs to the technical field of electronic cigarettes, and particularly relates to a solid-state cigarette core of the electronic cigarette and a preparation method thereof. The solid-state cigarette core of the electronic cigarette is prepared by heating an aroma carrier material and has a filtering effect. Through a design of a hollow cigarette core, a contact area between the cigarette core and a heating rod is increased, and a heating area and the heating efficiency of an atomizer are increased; a fibrous material is taken as a carrier to fully adsorb the aroma carrier material, and by indirectly heating the thermosensitive solid aroma carrier material, smoke which can be inhaled by a consumer is formed, and the consumer is endowed with the natural tobacco feel. Meanwhile, through reasonable combination of the paper hollow cigarette core and a filter element, the aroma carrier function and the filtration function of the material are perfectly combined, the smoke which has certain resistance to suction and which can be inhaled by the consumer is formed, the contents of tar and harmful granular matters in the smoke of the electronic cigarette are reduced, the smoking feel similar to the conventional cigarettes is endowed, and the electronic cigarette smoking pleasure is greatly improved.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

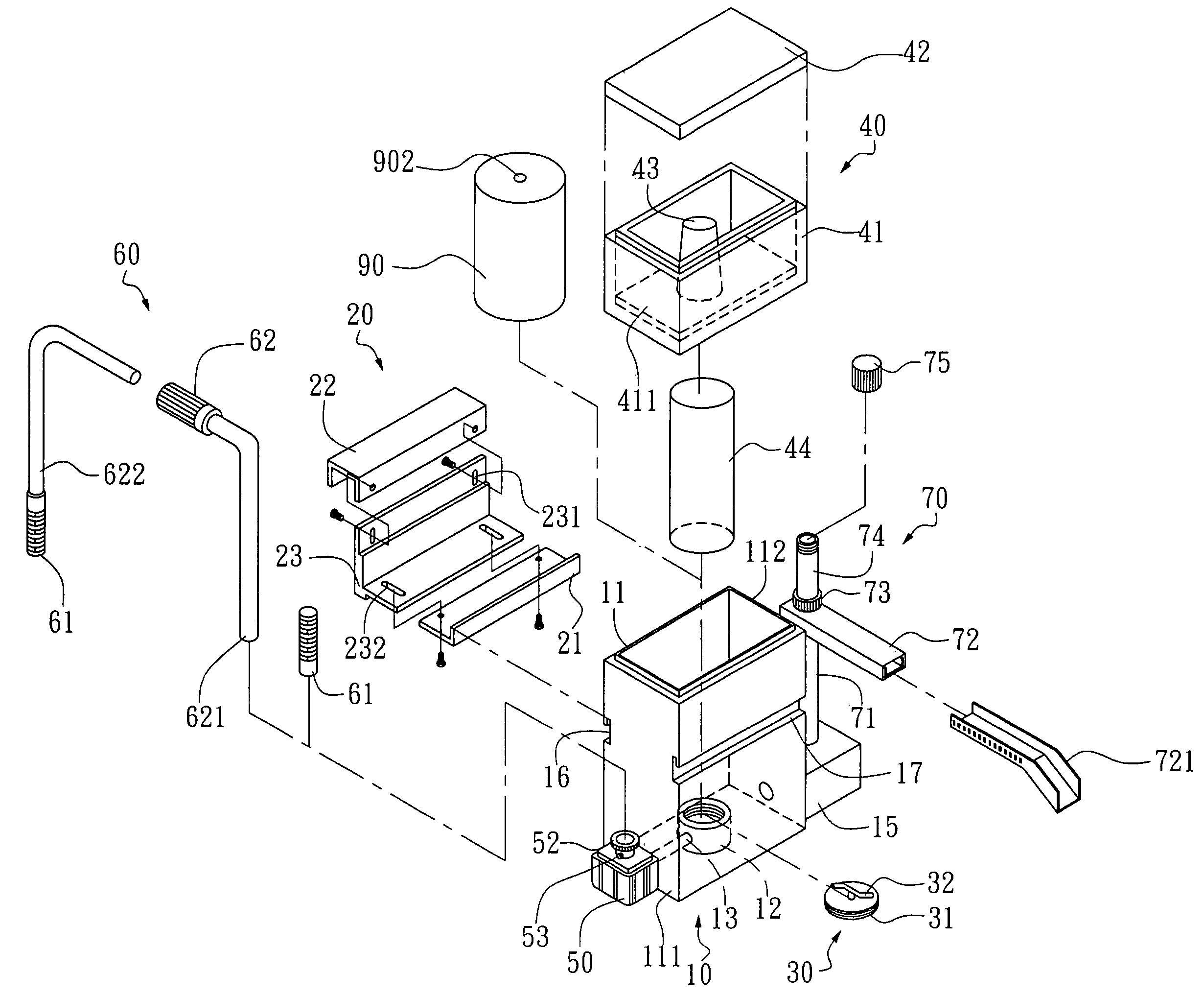

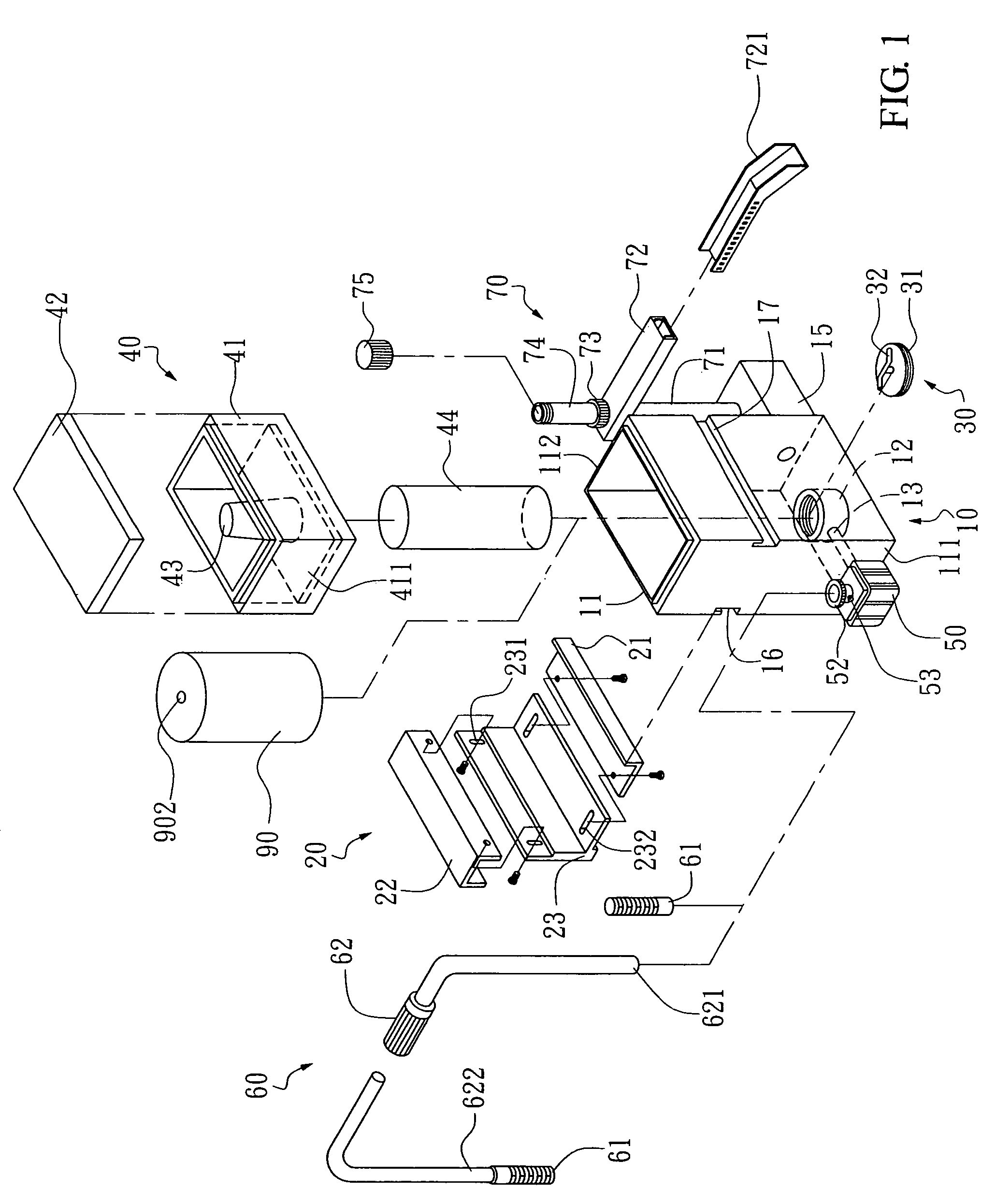

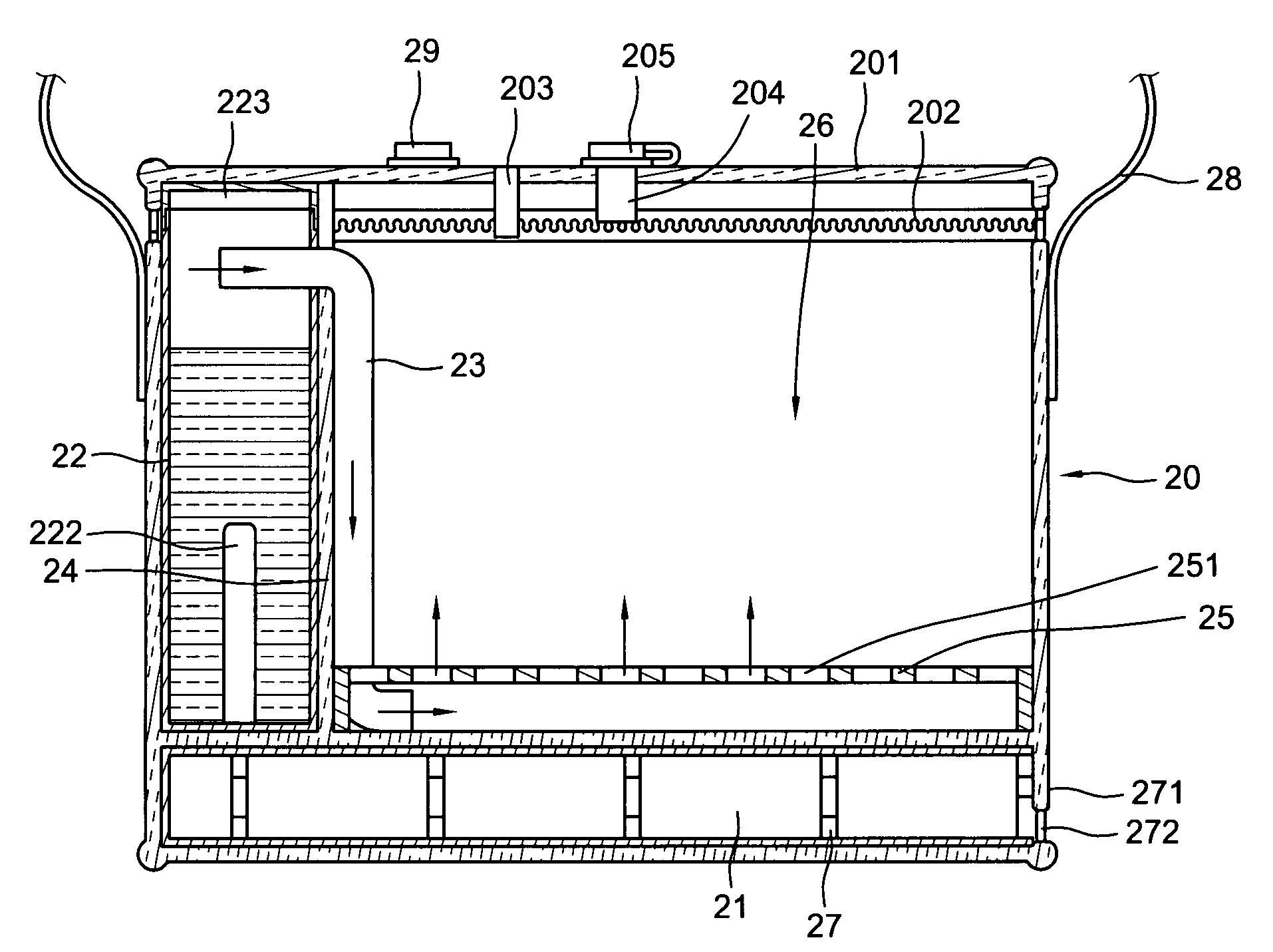

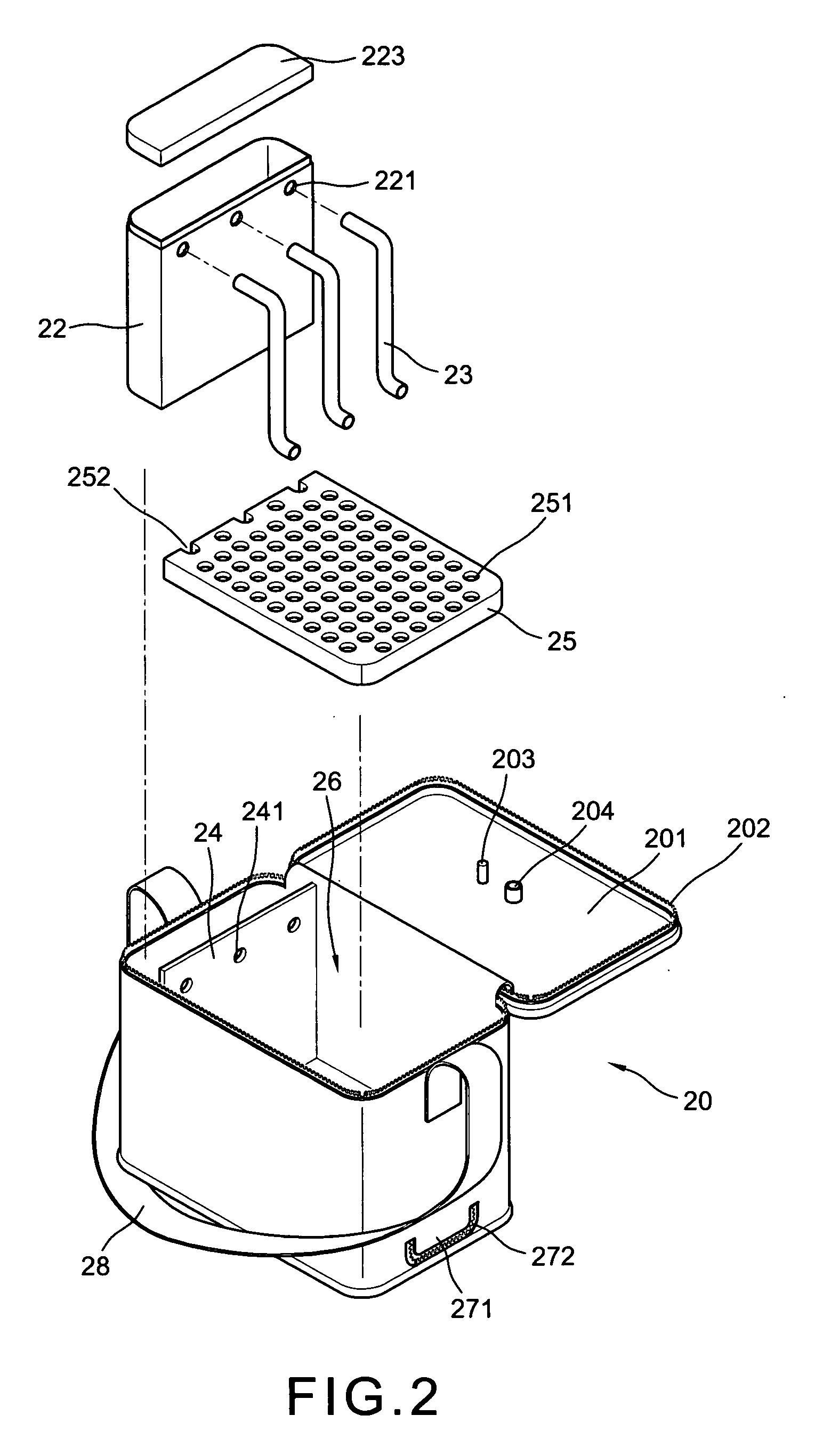

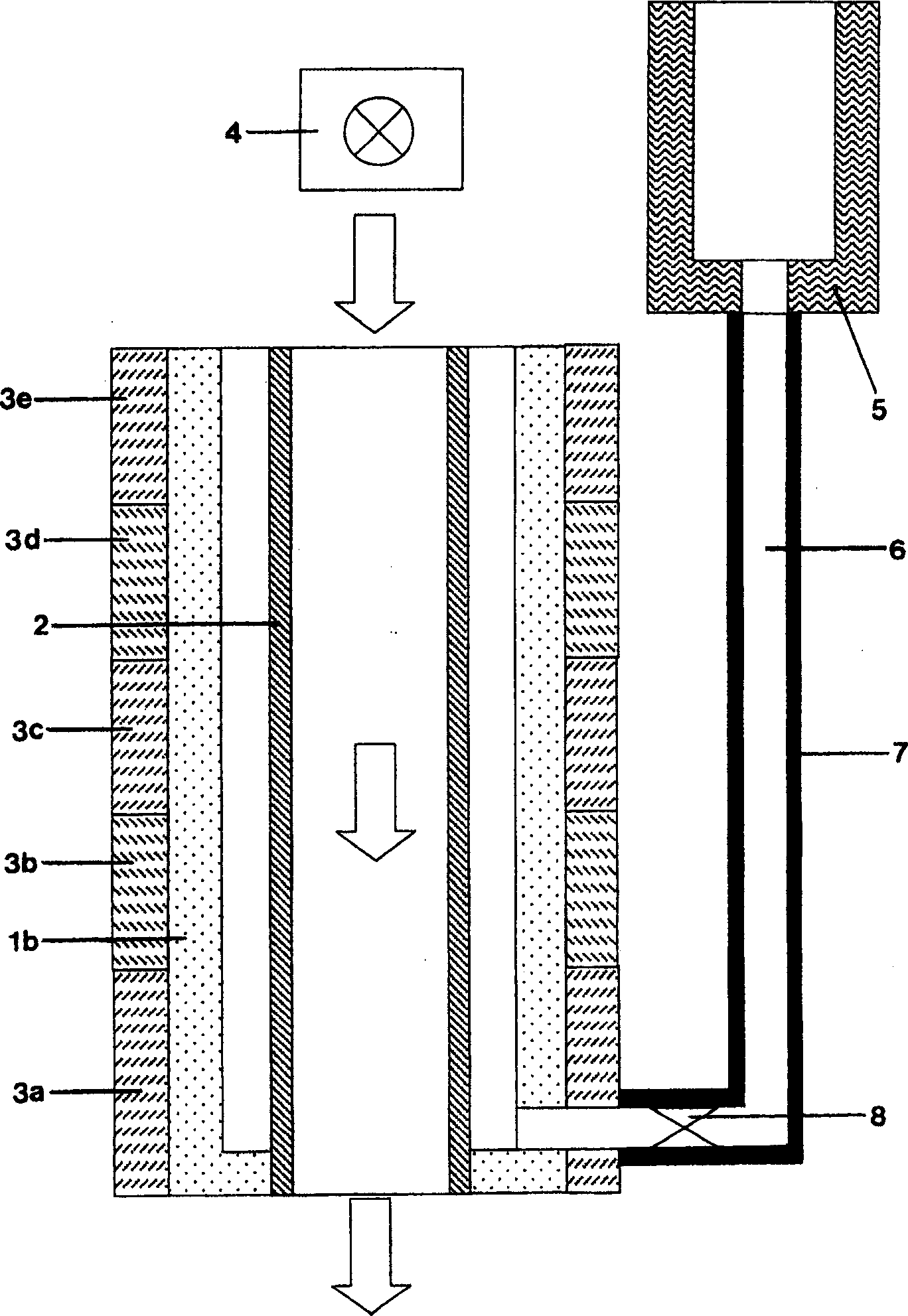

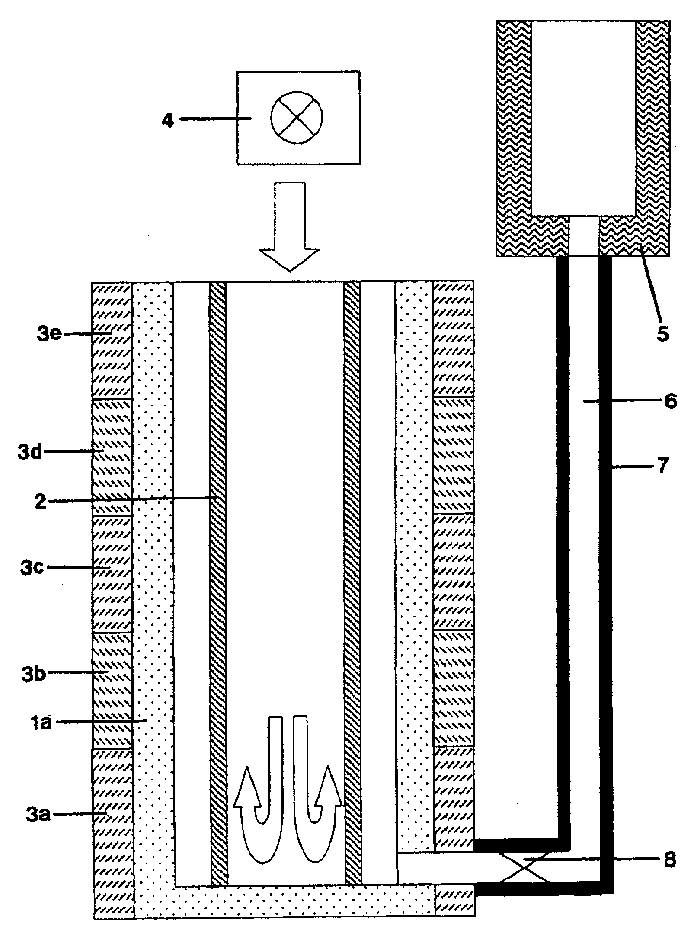

Multifunctional filtering device for an aquarium

InactiveUS7022227B1Avoiding the aquarium from disarrayingEfficient receptionTreatment involving filtrationSolid sorbent liquid separationUltravioletHeater Rod

A multifunctional filtering device for an aquarium mainly includes a filter box for being suspended at an aquarium. The filter box includes a pump motor for producing mixture of water and air and a vortex flow generator disposed at the center of the inner side of the bottom thereof and in communication with a water outlet disposed at the pump motor. A bubble collector is disposed at the top of the vortex flow generator. The filter box may be suspended inside or outside the aquarium. The filter box includes a water input pipe unit and a water output pipe unit which may be differently configured in accordance with the suspension position of the filter box. The water output pipe unit may be further disposed with a heating rod or ultraviolet sterilization lamp for heating or sterilizing breeding water in the aquarium.

Owner:LIAO SHIH HUI

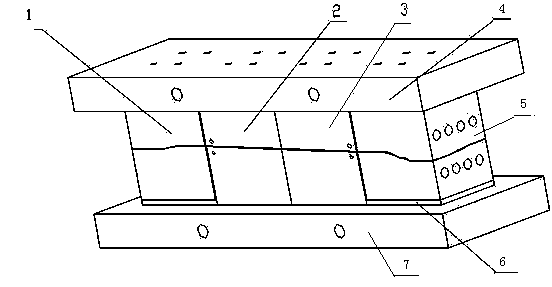

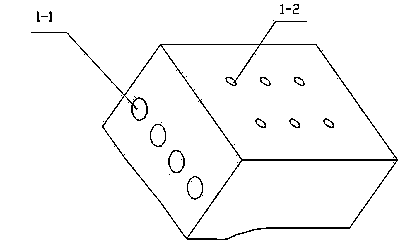

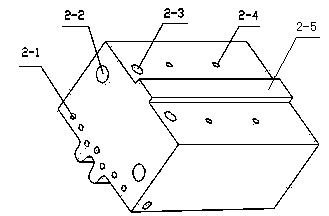

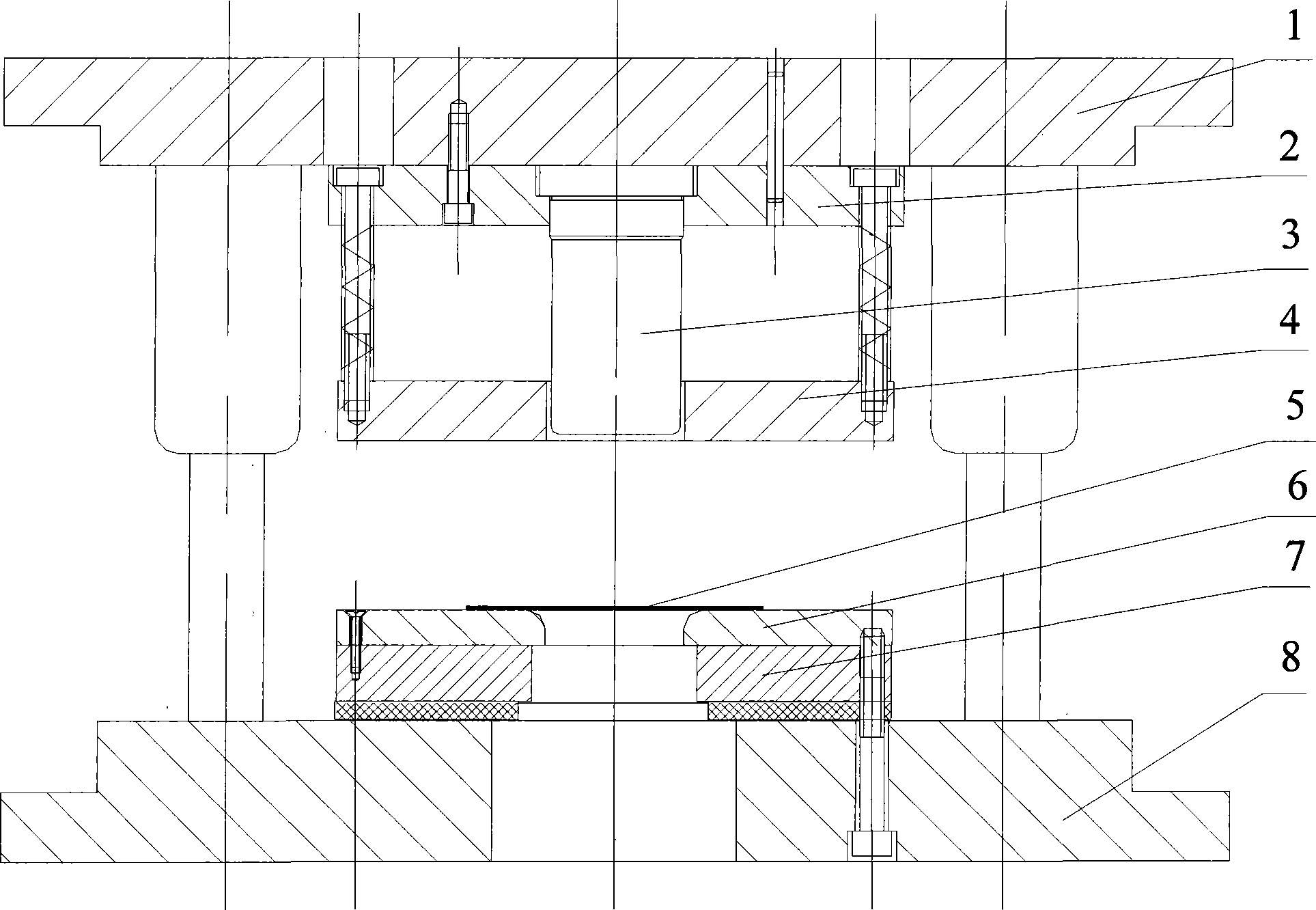

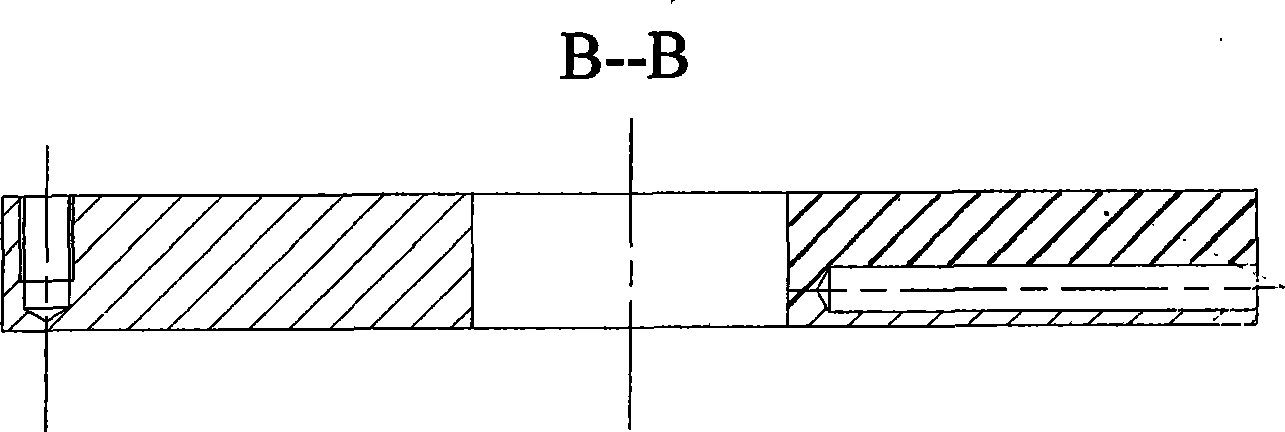

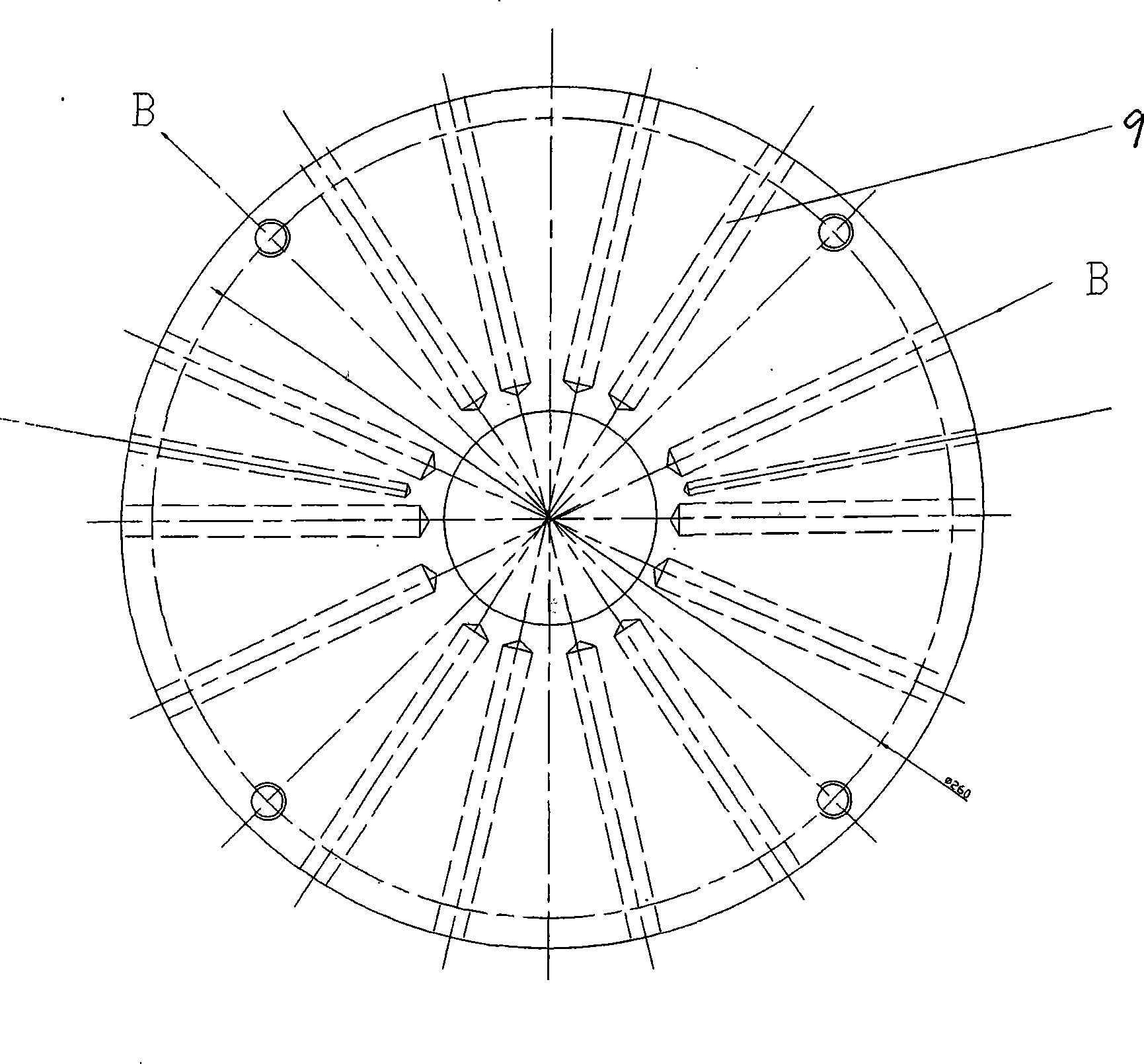

Modularized differential temperature forming hot punching mold

InactiveCN103464607APrevent transmission toRealize the purpose of partition coolingShaping toolsSurface coolingPunching

The invention relates to a modularized differential temperature forming hot punching mold, which comprises a template, heating modules and cooling modules, wherein the heating modules are respectively and fixedly arranged at the two sides of the template through screw bolts, the cooling modules are respectively and fixedly arranged in the middle of the template, heating rods are arranged in the heating modules, the uniform heating is carried out through the heating rods, water inlet and outlet holes are formed in the contact surfaces of the cooling modules and the template in a longitudinal direction, a plurality of surface cooling pipelines are arranged inside the cooling modules along the shape of the work surface, water inlet and outlet openings are correspondingly formed in the template, and the cooling modules are cooled through circulation water. A part of module is heated, and the other part of module is cooled, so the goal of regional cooling is reached, and the hot punching part with the performance gradient is obtained. The modularized differential temperature forming hot punching mold has the advantages that the structure is reasonable, the cooling speed of different positions is controlled, and the temperature gradient can be generated on the same hot punching part so that the hot punching part has good integral mechanical property.

Owner:HARBIN INST OF TECH AT WEIHAI

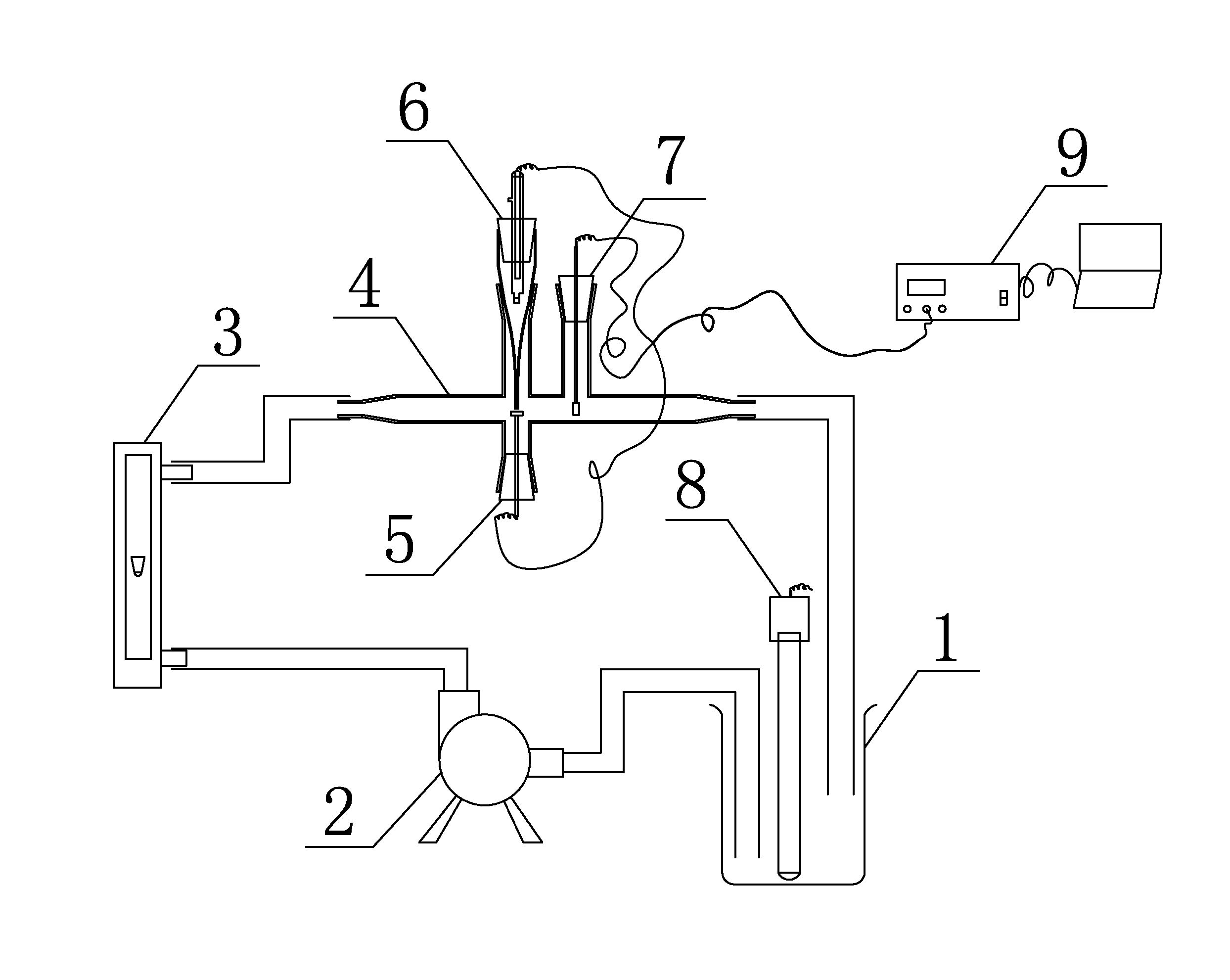

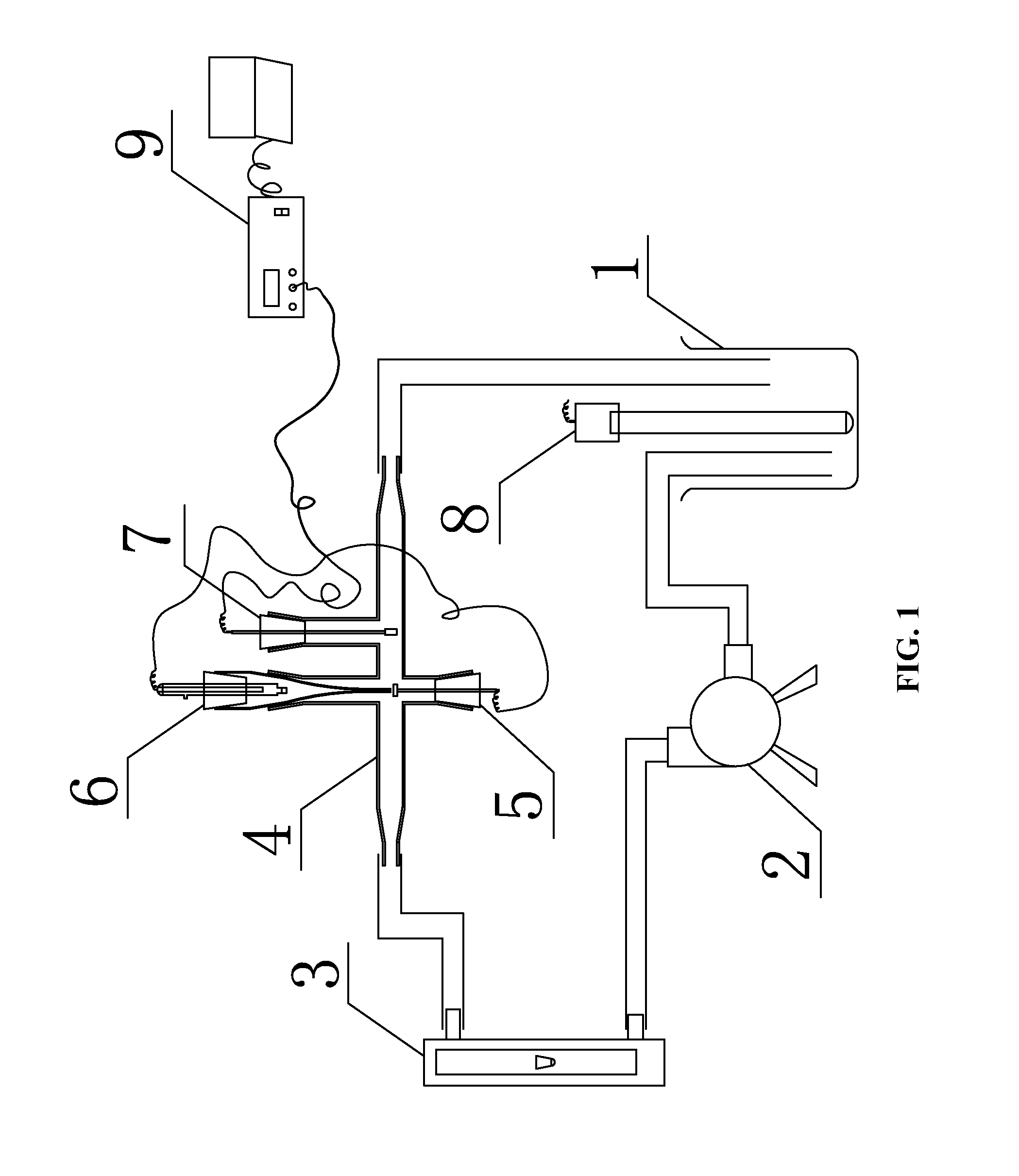

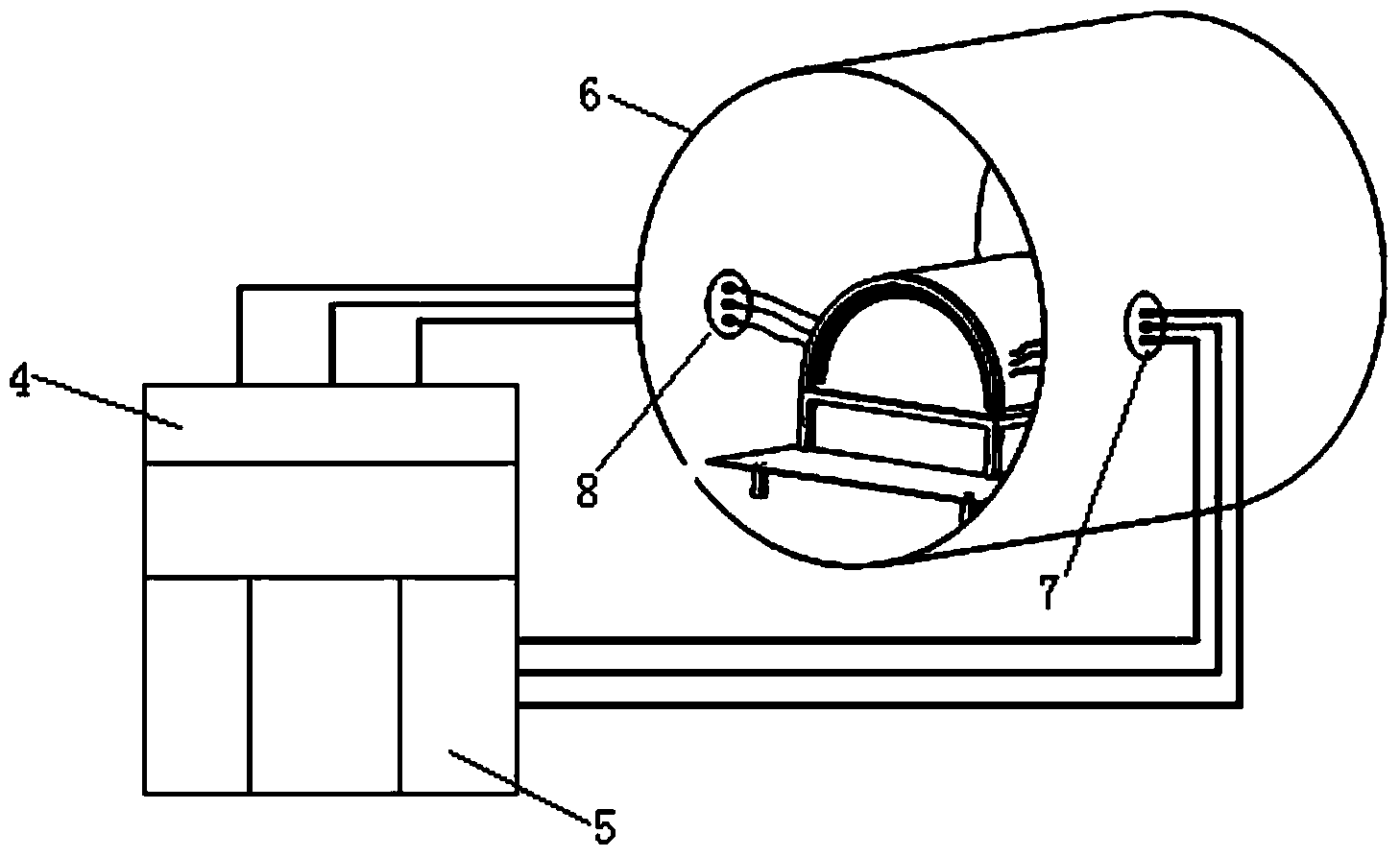

Device and method for testing corrosion inhibitor

ActiveUS20130284597A1Rapid assessmentEasy to collectWeather/light/corrosion resistanceAuxiliary electrodeEngineering

A device for testing a corrosion inhibitor, the device including: a circulating cooling water tank; a circulating water pump; a flowmeter; a five-port glass tube; a working electrode; a reference electrode; an auxiliary electrode; a heating rod; and an electrochemical workstation. The circulating water pump is connected to the circulating cooling water tank. The heating rod is fixed inside the circulating cooling water tank. The water inlet of the flowmeter is connected to the circulating water pump. The water outlet of the flowmeter is connected to the water inlet of the five-port glass tube. The water outlet of the five-port glass tube is connected to the circulating cooling water tank. The working electrode the reference electrode, and the auxiliary electrode are connected to the electrochemical workstation; and the electrochemical workstation is connected to a host computer.

Owner:NANJING UNIV

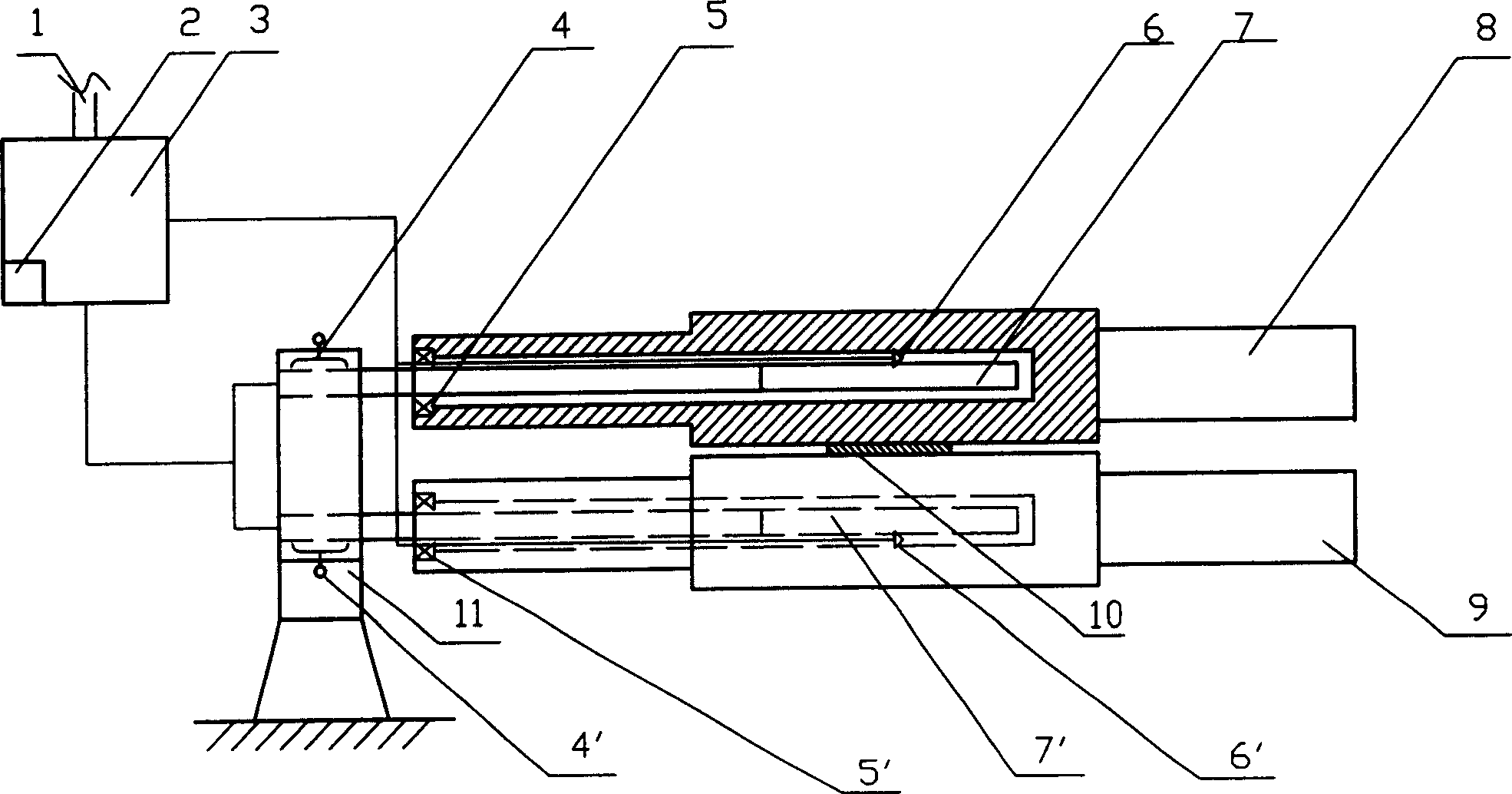

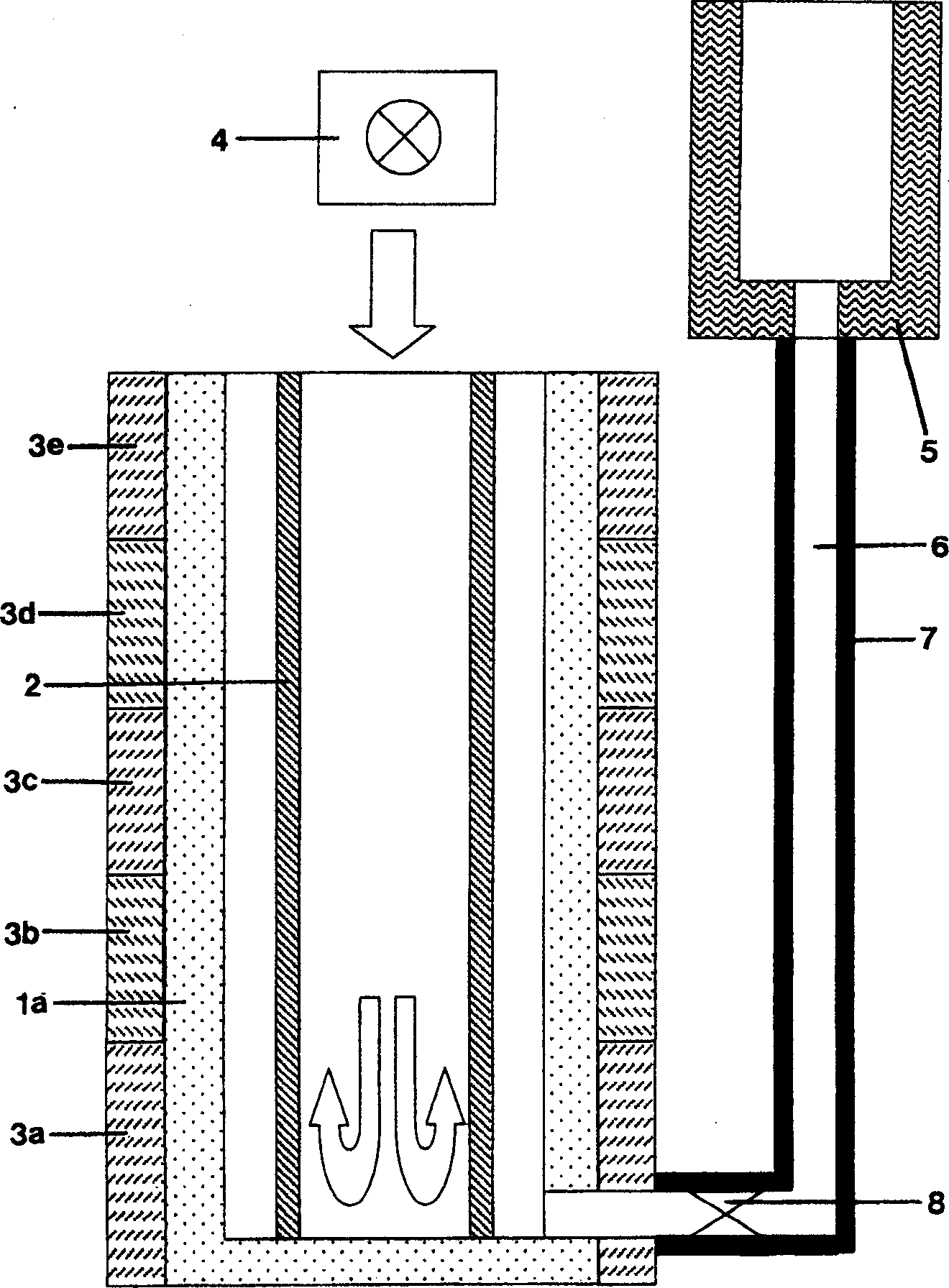

Roller center heater of magnesium alloy board

InactiveCN1745920AImprove performanceTemperature Accuracy ControlRollsMetal rolling arrangementsTemperature controlControl system

A core heater unit for the roller used for afterheat rolling of Mg-alloy plate is composed of the mechanical system consisting of a pair of hollow rollers, supporting frame and bearings and the temp control system comprising power supply, transformer, temp controller box, a pair of metallic heating rods arranged in said hollow rollers, and electro-thermal couple. Its advantages are high temp accuracy and high productivity.

Owner:UNIV OF SCI & TECH BEIJING

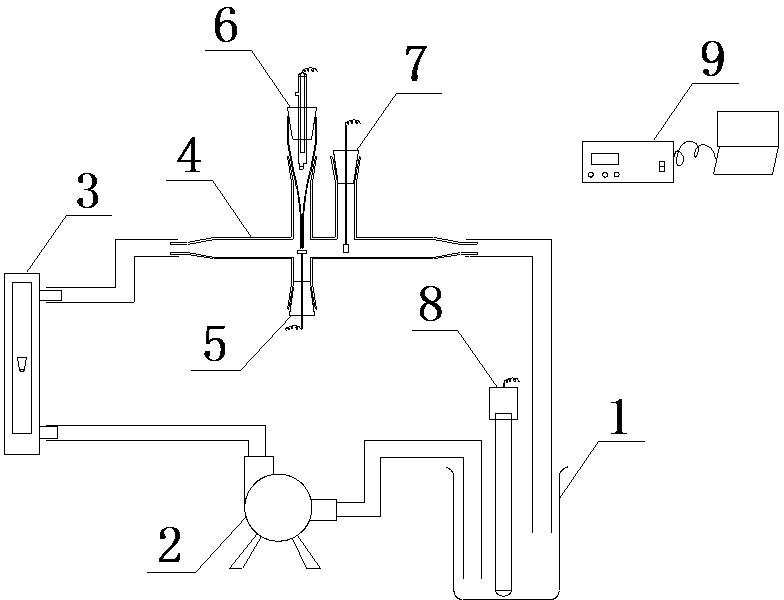

Corrosion inhibitor performance evaluation device and method of circular cooling water system

InactiveCN102636528AEasy to operateShort timeWeather/light/corrosion resistanceMaterial electrochemical variablesHeater RodAuxiliary electrode

The invention discloses a corrosion inhibitor performance evaluation device and method of a circular cooling water system and belongs to the technical field of corrosion inhibitor performance evaluation. In the invention, a circulating water pump is connected with a circular cooling water tank through a pipeline, a heating bar is arranged in the circular cooling water tank, the water inlet of a flow meter is connected with the circulating water pump through a pipeline, the water outlet of the flow meter is connected with the water inlet of a five-opening glass tube through a pipeline, a working electrode, a reference electrode and an auxiliary electrode are respectively arranged on a working electrode opening, a reference electrode opening and an auxiliary electrode opening, the water outlet of the five-opening glass tube is connected with the circular cooling water tank through a pipeline, and the working electrode, the reference electrode and the auxiliary electrode are connected with an electrochemical working station. The device provided by the invention can simulate the flow speed and temperature condition of the circular cooling water under actual working condition, perform AC impedance spectroscopy test on the testing system at the operation state of a testing device, and calculate according to the electrochemical total reaction charge transfer resistance under corrosion inhibitor / non-corrosion inhibitor condition to obtain the corrosion inhibition efficiency of the corrosion inhibitor.

Owner:NANJING UNIV

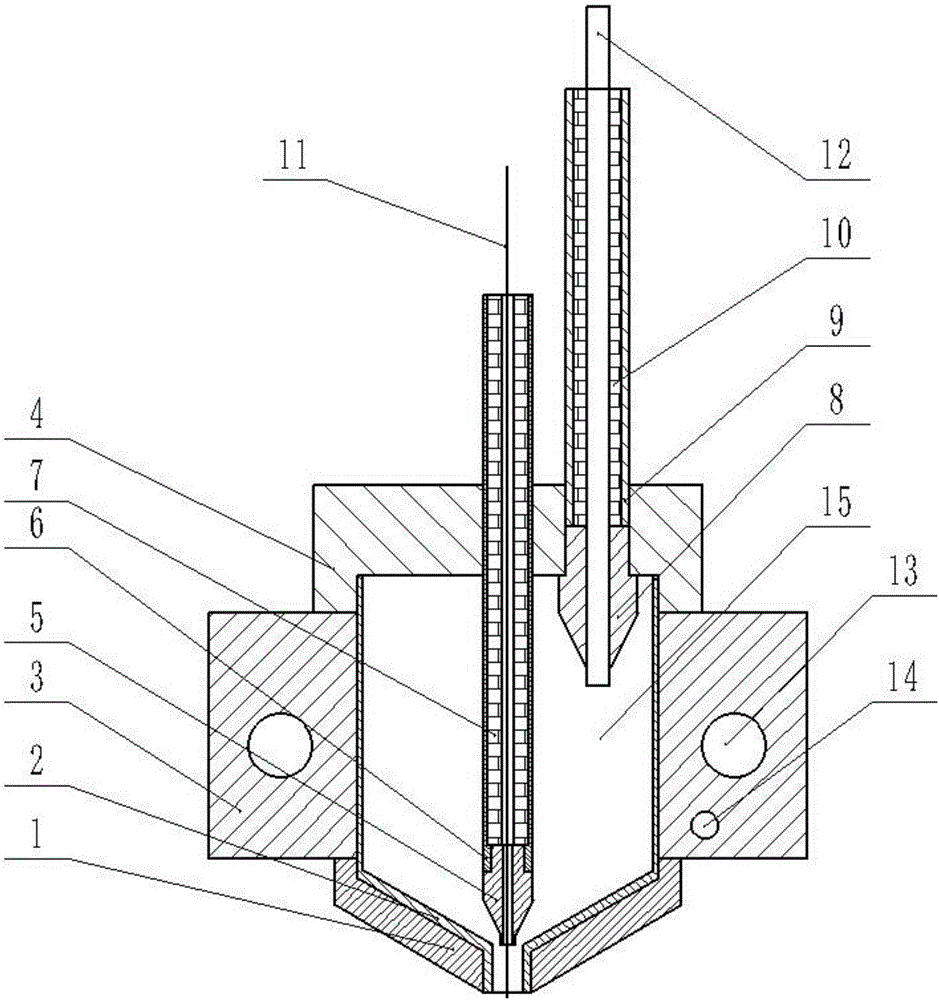

Spray head applicable to continuous fiber reinforced composite material additive manufacturing

ActiveCN106493946AImprove adhesionImprove printing qualityManufacturing heating elements3D object support structuresHeater RodFiber-reinforced composite

The invention belongs to the field of additive manufacturing, and relates to a spray head applicable to continuous fiber reinforced composite material additive manufacturing, which comprises a spray head body, an inner cavity, heat conduction blocks, a cover cap, a fiber spray head, a fiber throat pipe, a polytetrafluoroethylene pipe I, a resin spray head, a resin throat pipe, a polytetrafluoroethylene pipe II, heating rods and temperature sensors. A bonding effect of rein and fiber can be improved, and the spray heads can be prevented from being blocked and can be cleaned conveniently. The spray heads are detachably connected to the lower end of the inner cavity; the heat conduction blocks are sleeved on the spray heads; the heating rods and the temperature sensors are nested on the heat conduction blocks; the cover cap is detachably connected to the upper end of the inner cavity; the fiber throat pipe and the resin throat pipe are detachably connected onto through holes of the cover cap; the resin spray head is also detachably connected onto the through hole connected with the resin throat pipe; the polytetrafluoroethylene pipe I is sleeved in the fiber throat pipe; the fiber spray head is detachably connected to the lower end of the fiber throat pipe; the polytetrafluoroethylene pipe II is sleeved in the resin throat pipe; and the inner cavity and the cover cap are connected to form a cavity.

Owner:HARBIN INST OF TECH

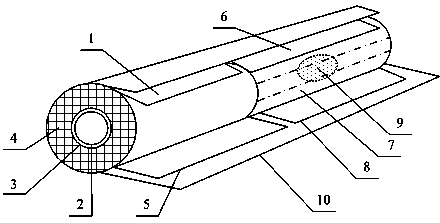

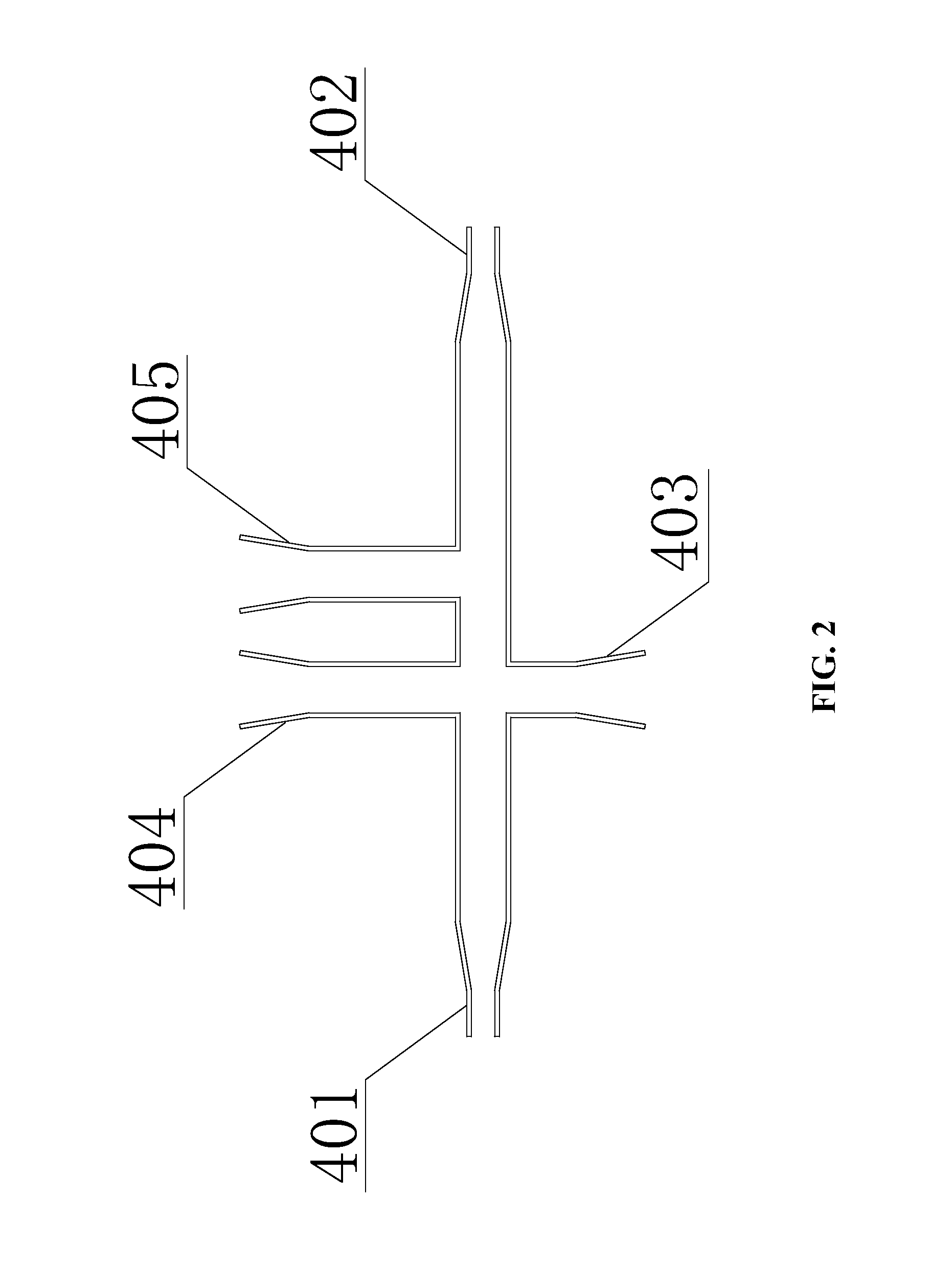

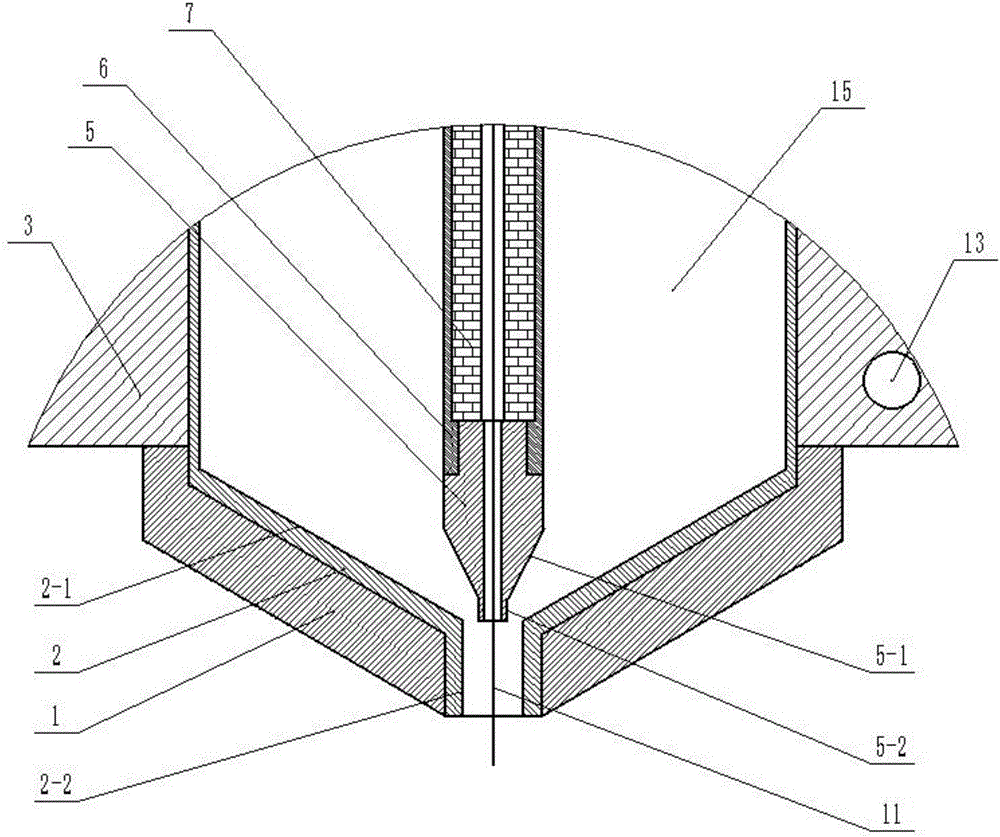

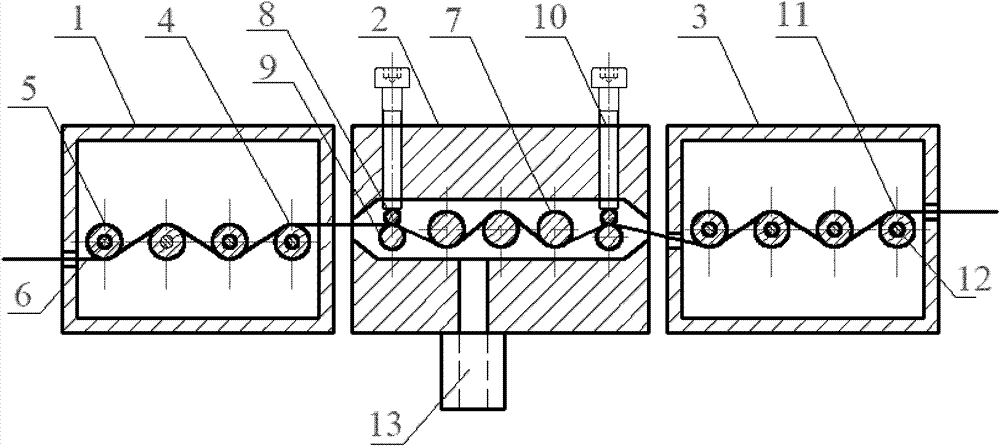

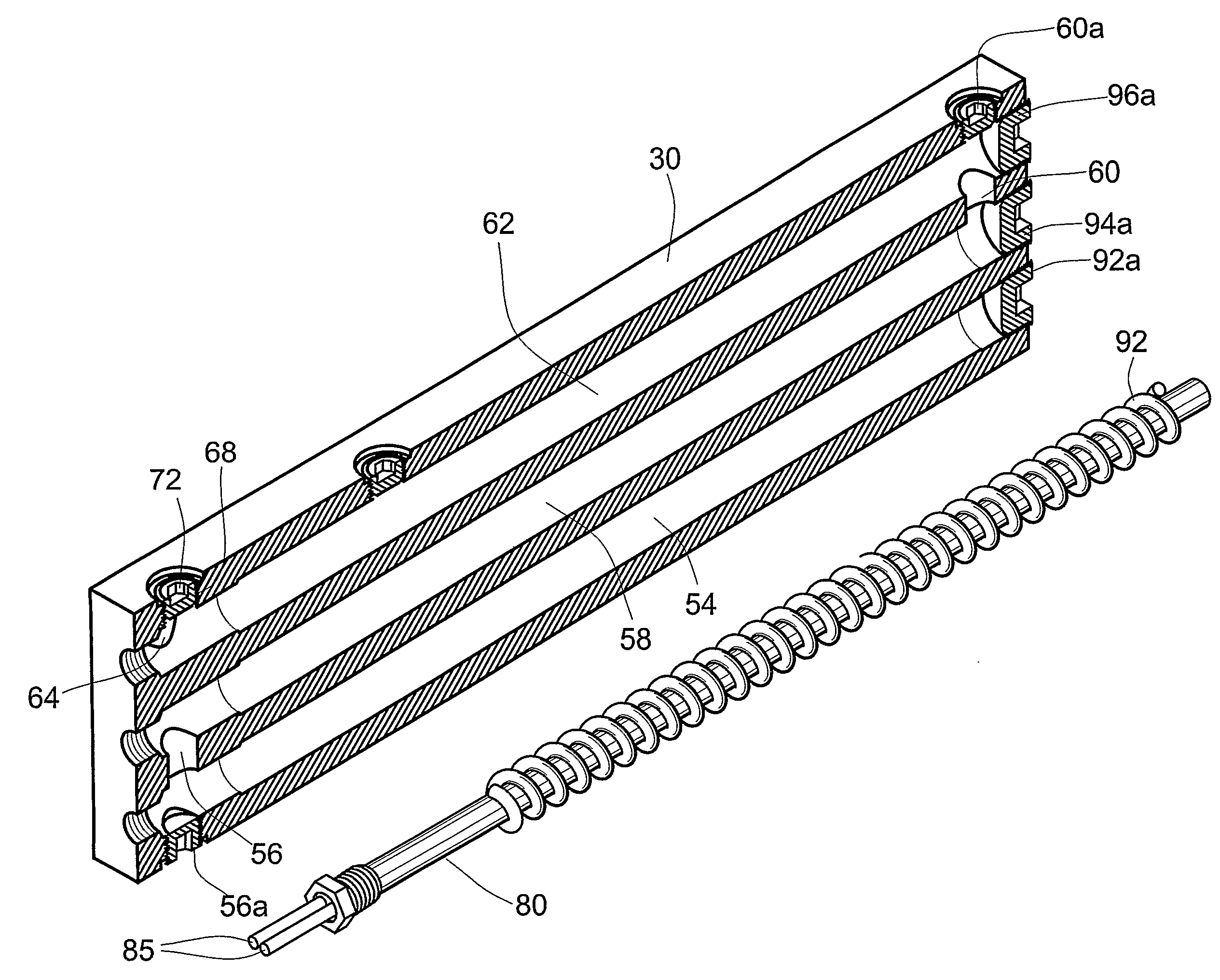

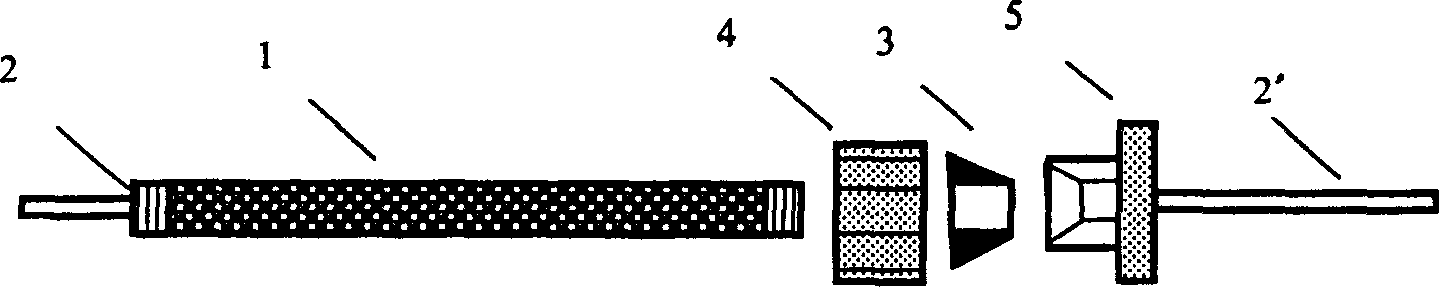

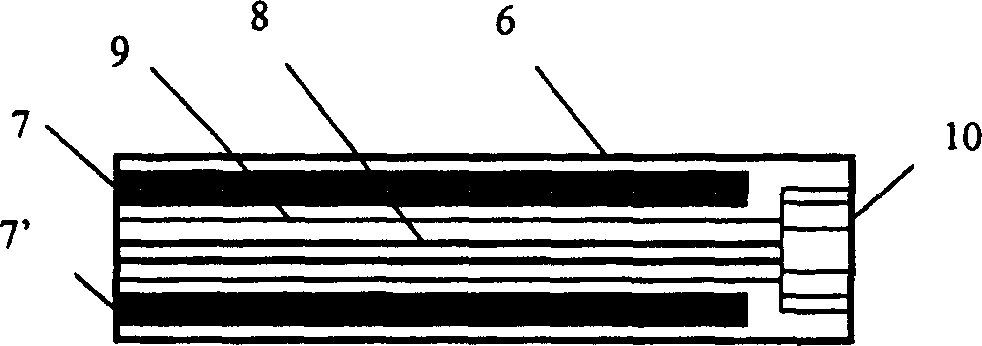

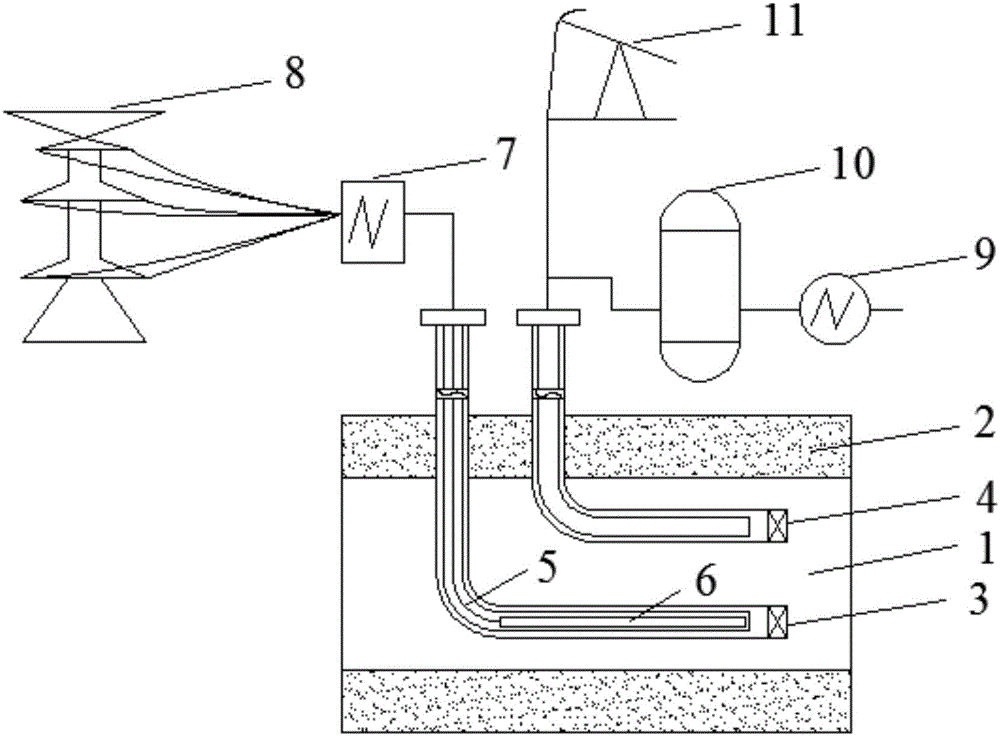

Continuous long fiber-reinforced thermoplastic resin and its preparation method and molding equipment

InactiveCN102729483ARaise the contact temperatureImprove impregnation effectLong-fiber-reinforced thermoplasticFibre reinforcement

The invention discloses a continuous long fiber-reinforced thermoplastic resin and its preparation method and molding equipment. The molding equipment comprises a fiber preheating device 1, a melt impregnation mold 2 and a secondary rolling device 3. The preparation method comprises the following steps of 1, alternately bypassing dispersion rollers (4) with continuous long fibers, and simultaneously heating dispersion roller electrically-heating rods (5) so that preliminary dispersion of the continuous long fibers is realized, 2, alternately bypassing tension rollers (7) with the treated continuous long fibers, and simultaneously feeding thermoplastic resin melt into the melt impregnation mold 2 from an extruder connection device (13) so that the continuous long fibers and the thermoplastic resin melt are subjected to melt impregnation, and 3, alternately bypassing rollers (11) with the continuous long fibers and the thermoplastic resin melt treated by the step 2, and carrying out rolling to obtain the continuous long fiber-reinforced thermoplastic resin. The continuous long fiber-reinforced thermoplastic resin prepared by the molding equipment has the advantages of good impregnation effects, high impregnation efficiency and excellent performances.

Owner:CHINA NAT OFFSHORE OIL CORP +2

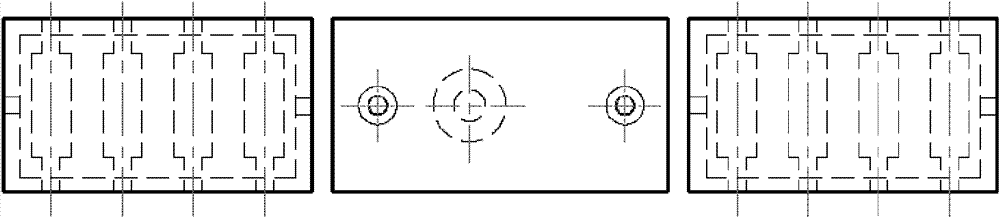

Ultrahigh-temperature thermal current simulation system used for spacecraft vacuum thermal test

InactiveCN104015942ASolve the technical problems of ultra-high temperature and extremely high heat flow simulationSolve temperature problemsCosmonautic condition simulationsThermal insulationHeater Rod

The invention discloses an ultrahigh-temperature thermal current simulation system used for a spacecraft vacuum thermal test in a vacuum container. The ultrahigh-temperature thermal current simulation system mainly comprises a semi-cylindrical graphite heating array, high-reflectivity high-temperature thermal insulation assembly units, a graphite heating array installing support, an ultrahigh temperature measuring unit and a power-regulator power control unit. A plurality of graphite heating rods are arranged and combined into the semi-cylindrical graphite heating array according to the requirements for the density and uniformity of thermal currents. Each graphite heating rod is composed of a graphite heating body and a graphite electrode, alternating-current electricity supply is adopted, and wiring electrode leads penetrate through a high-current cabin-penetrating electricity supply flange arranged on a container wall of the vacuum low-temperature environment simulation container and are electrically connected with the temperature measuring unit and the power-regulator power control unit respectively. Through the unique design of the graphite heating array, the high-reflectivity high-temperature thermal insulation assembly units and the ultrahigh temperature measuring unit, measurement of and control over temperatures over 1800 DEG C in the space environment simulation container are achieved, and the ultrahigh-temperature thermal current simulation system is also suitable for high-temperature and high-thermal-current environment simulation requirements in vacuum thermal tests of all types of spacecraft.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

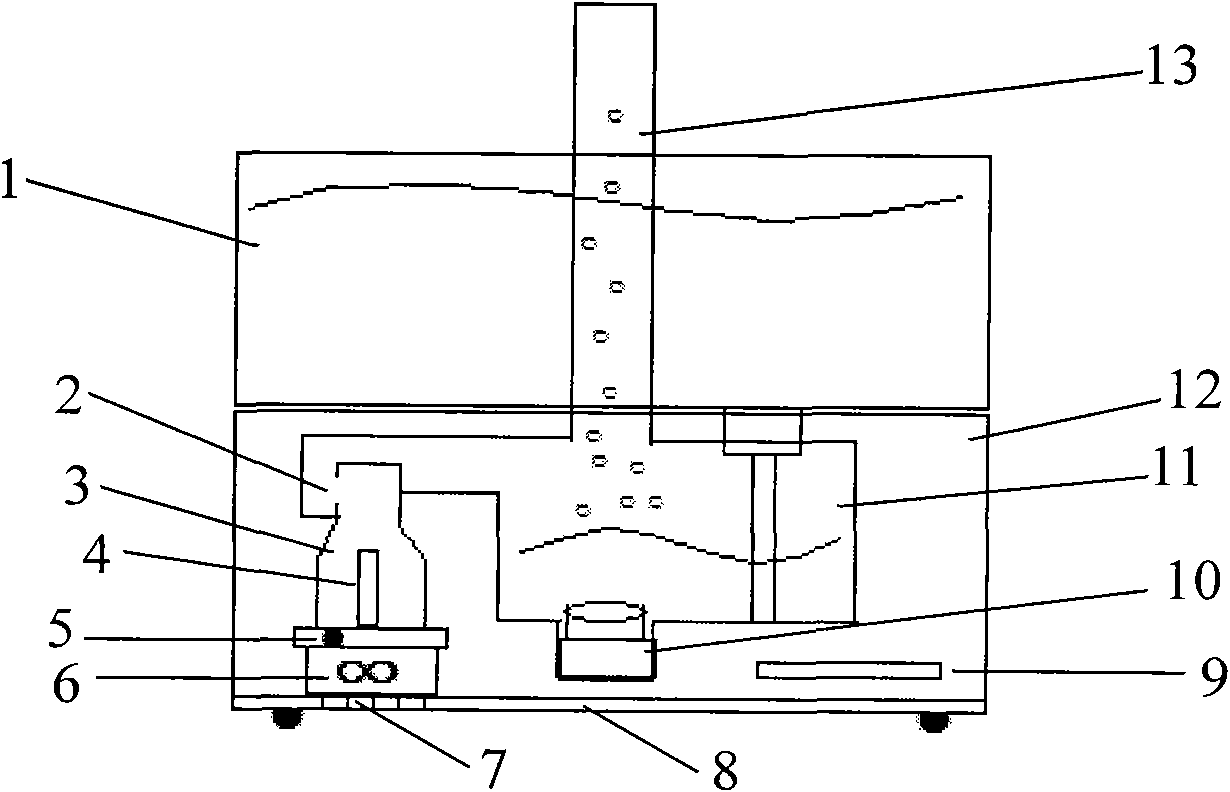

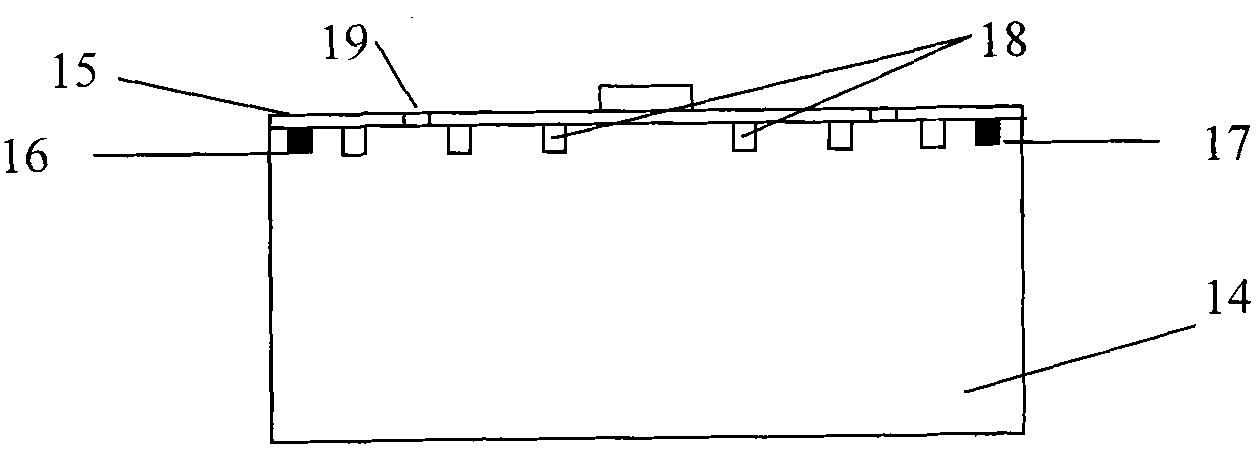

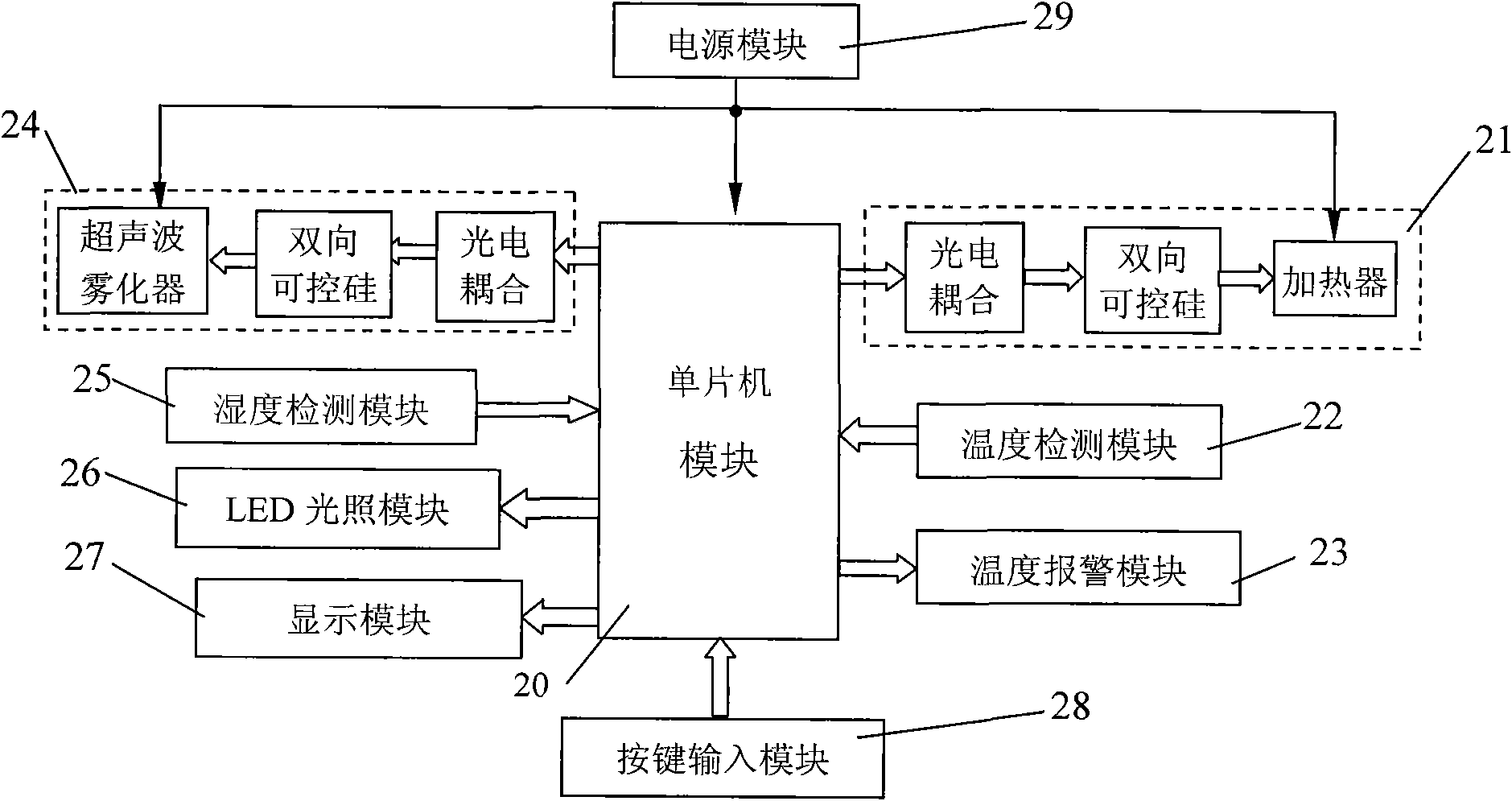

Intelligent cultivation method and device for producing bean sprouts

InactiveCN101926279AGuaranteed uniformitySufficient oxygenAgriculture gas emission reductionCultivating equipmentsHigh energyControl signal

The invention discloses an intelligent cultivation method for bean sprouts. An incubator, a water tank, a base and a control system are provided, and the method comprises the following steps of control on heating, humidification and illumination. For the heating and humidification control, PID closed-loop control is adopted; a temperature and humidity sensor is installed in the incubator; a single chip processes a detected temperature and humidity signal and outputs a corresponding control signal; and a temperature and humidity control module realizes accurate control on the temperature and humidity in the incubator. The heating method is characterized in that air is directly heated by a heating rod, water is atomized by an ultrasonic atomizer, and then the hot air and the water mist are mixed by a fan at the bottom of a heating room and delivered mixture to the incubator. The illumination control is realized by using an LED lamp. The invention solves the problems of non-uniform spraying, excessive waste water, slow heating, high energy consumption, inaccurate temperature and humidity control and the like in the existing bean sprout cultivation device, and is applied to the devices such as a bean sprout incubator, a seed incubator, a household bean sprout growing machine, etc.

Owner:HUAZHONG AGRI UNIV

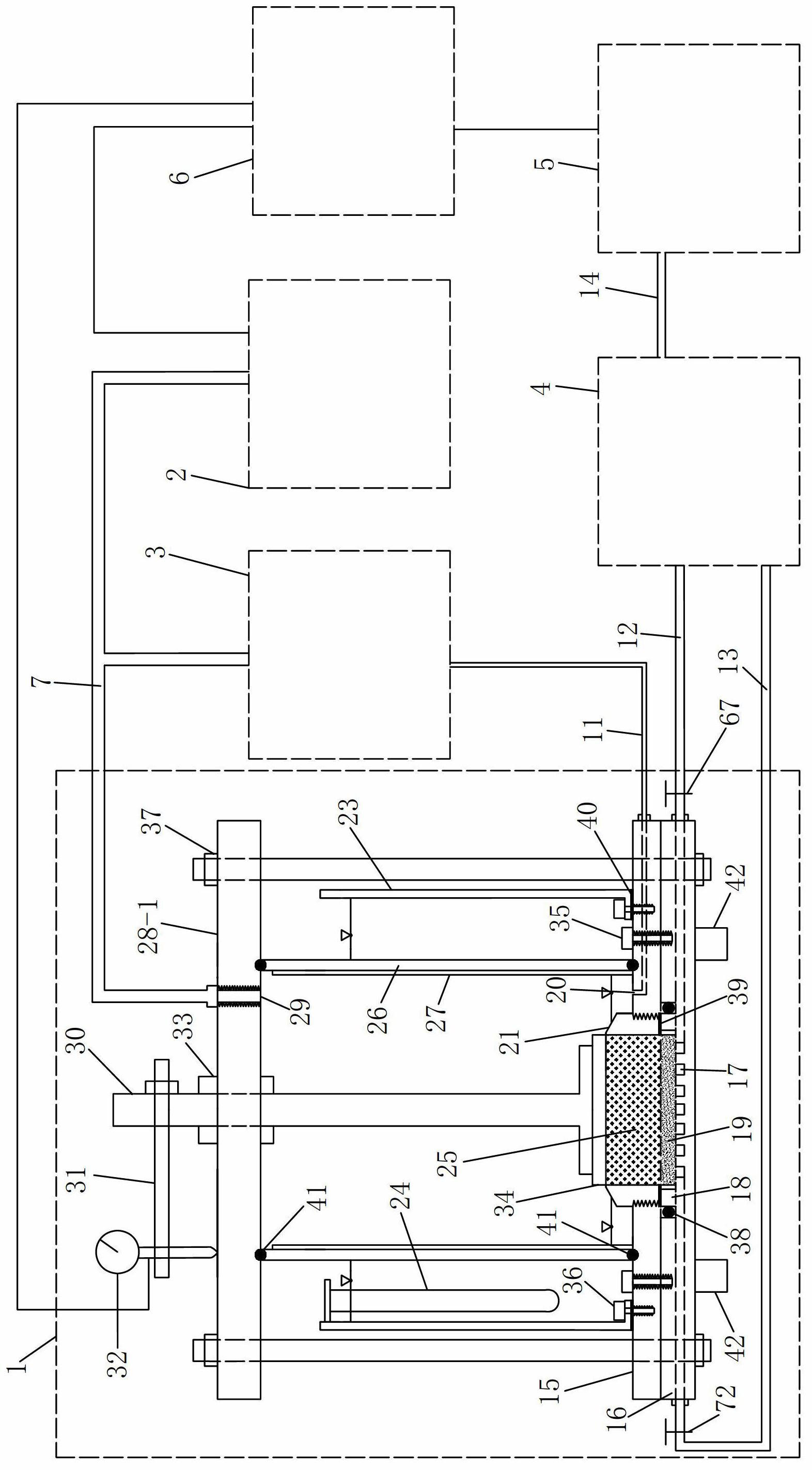

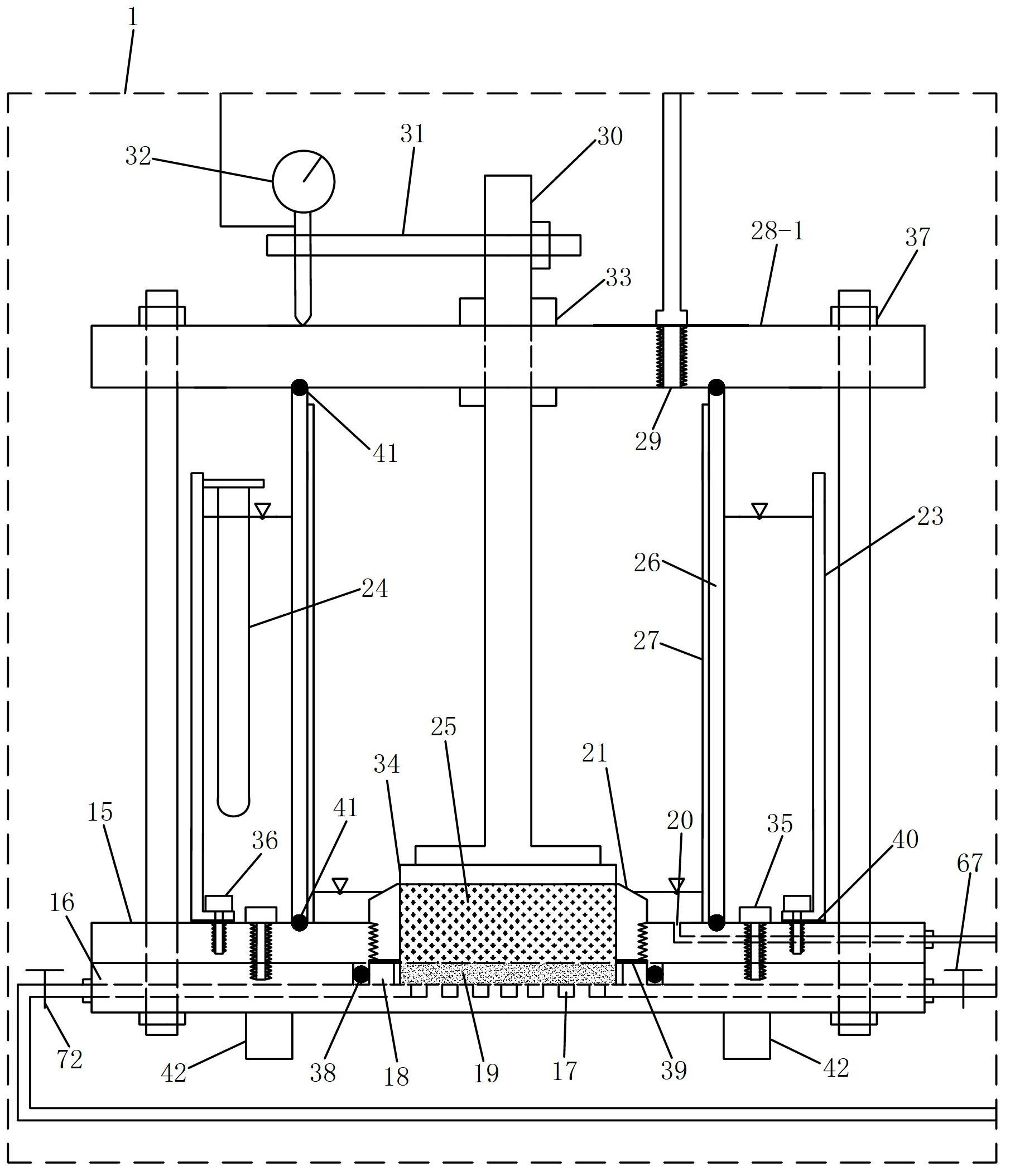

Suction accurately controlled pressure plate instrument capable of directly saturating soil sample

InactiveCN102680665AReasonable designThe measurement result is accurateEarth material testingWater storage tankData acquisition

The invention discloses a suction accurately controlled pressure plate instrument capable of directly saturating a soil sample. The instrument mainly comprises a pressure chamber system, a suction control system, a soil sample air exhaust saturation system, a scouring system, a water quality measuring system, an automatic data acquisition system and the like, and is characterized in that a sample preparation device is tightly contacted with a clay plate through threads, so that the sealing performance of the sample preparation device and the clay plate is ensured; the changes of suction and the water content of the soil sample are monitored and controlled in real time by combining a high-accuracy electronic pressure gauge with an electronic balance; a water storage outer chamber with an upper opening is formed, and a temperature control heating rod ensures that the temperature of an inner chamber is basically constant; water is stored in the inner chamber, and filter paper is soaked in the water, so that the air humidity of the inner chamber is basically saturated; and the inner chamber is improved and matched with a vacuum pump and a water storage tank, so that a new function of performing air exhaust saturation on the soil sample is realized. A measuring result of a soil-water characteristic curve is accurate, particularly test accuracy under the condition of low suction is improved, and a measuring method is convenient.

Owner:CHANGAN UNIV

Portable warm bag having steam heating device

A portable warm bag having steam heating device includes a rectangular bag having a pressure sensor, a pressure releasing valve, a switch bottom and a valve cover on both sides of the upper lid, a partition vertically disposed in the bag adjacent a lateral side thereof to define a gap therebetween to receive a vapor creater therein which supplies the vapor into the food containing space via a hose and through a perforated plate above the bottom of the bag, a power source compartment under the bottom of the bag containing a plurality of rechargeable batteries therein for heating a heating bar in the vapor creater to boil the water to create vapor to into the bag to establish a heating circulation into the food which is kept at constant temperature eatable to the user.

Owner:YEH YIN TING

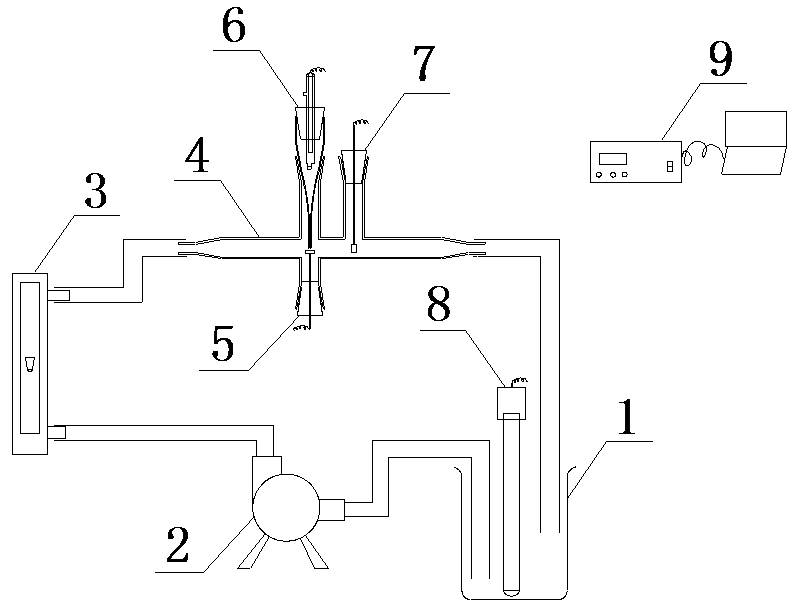

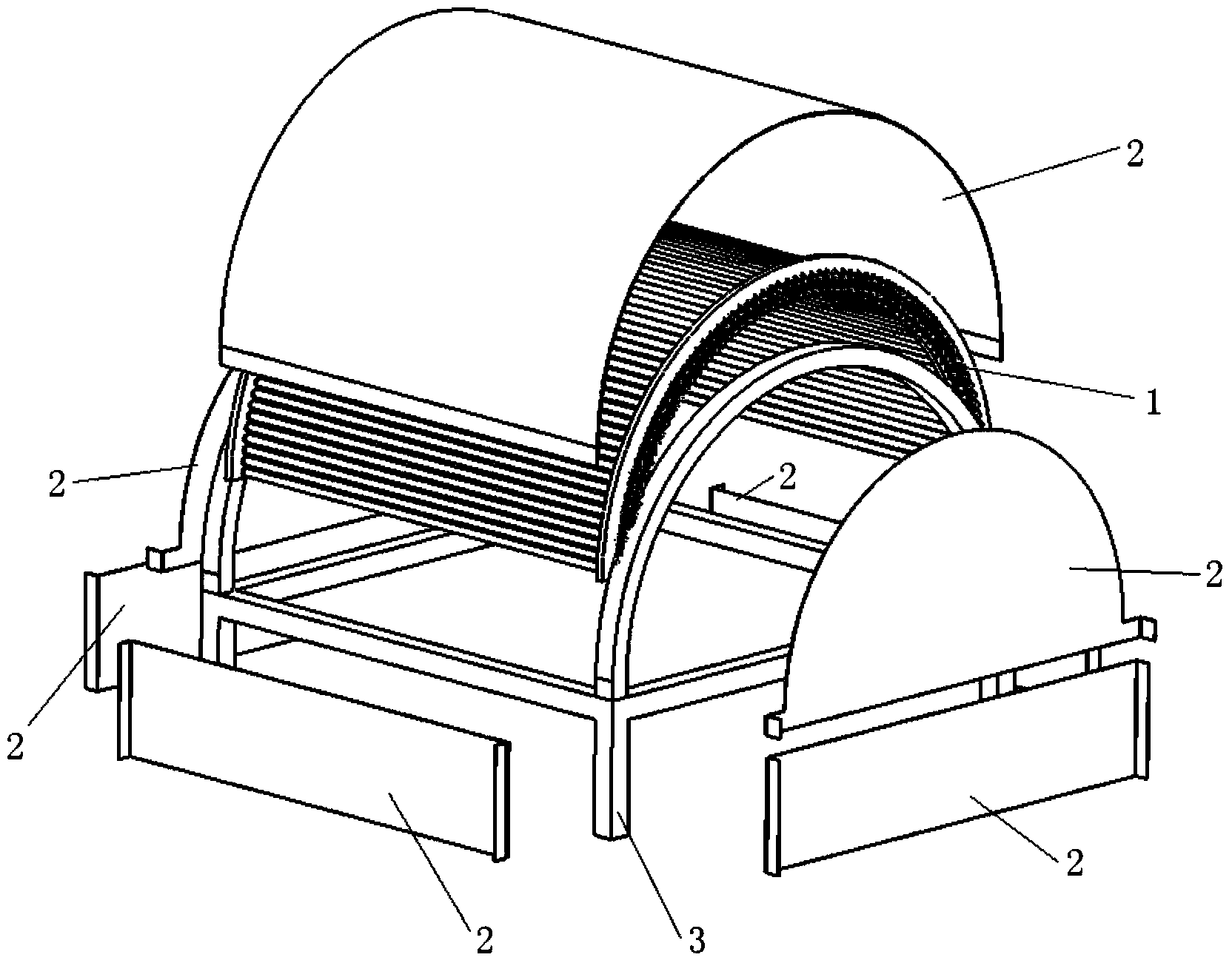

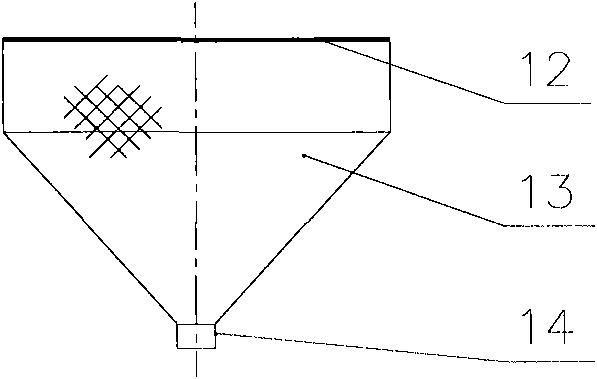

Hatching device and method for demersal spawns of marine fishes

InactiveCN102144597AAvoid damageFlush at any timeClimate change adaptationPisciculture and aquariaHeater RodWater quality

The invention relates to a hatching device and method for demersal spawns of marine fishes. The hatching device comprises a net cage, a water channel, a bracket, a temperature controller indicator, a probe, a heating rod, a water inlet hose, a sinker, an air inlet hose, an air stone and an annular water injector, wherein the net cage and the bracket are located in the water channel; the net cage is bound on the bracket; the water inlet hose and the air inlet hose are located in the water channel outside the net cage; the upside of the net cage is provided with the annular water injector; and the probe and the heating rod are arranged in the water channel. The hatching method comprises the following steps of: controlling a hatching condition; hatching; carrying out microscopic examination observation; carrying out secondary water temperature controlling; managing routinely; collecting larva fish and the like. The hatching method has the advantages that spawn deposition is avoided because of conical point inflation; spawns adhered on net cage edges are washed at any time by the annular water injector; the net cage is conveniently replaced; the water temperature is stably controlled by an electric temperature controller; and the fresh water quality can be ensured due to water feeding and drainage modes of water feeding of the annular water injector at the upside and water feeding of the water channel at the bottom and overflowing of the periphery of the water channel. Therefore, by means of the hatching device and method, a hatching rate of the demersal spawns of the marine fishes in the industrial fry breeding is improved.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Sperm collector with squeezing function

InactiveUS8475422B2Good effectFast and convenient insertionVaccination/ovulation diagnosticsNon-surgical orthopedic devicesPenisHeater Rod

The present invention is a sperm collector with squeezing function. It includes a soft rubber body provided with a penis insertion passage and a container body provided with at least a top end cover and receives the soft rubber body. When the top end cover and the container body are engaged, the soft rubber body is confined within a cavity formed by the top end cover and the container body. When the top end cover is disengaged, a front end portion of the soft rubber body protrudes out of an opening of the container body. A pressing means is provided at a middle lower portion of the container body. When using the present invention, the user could press the pressing means to squeeze the penis insertion passage of the sperm collector. Accordingly, stimulation to penis is increased and better effect of sperm collection is achieved. In particular, since the present invention is also provided with a heating rod, lubricant pockets and electrical vibrators, which enable the user to reach a climax as quick as possible, thereby further enhancing the effect of sperm collection.

Owner:AILV HEALTH TECH

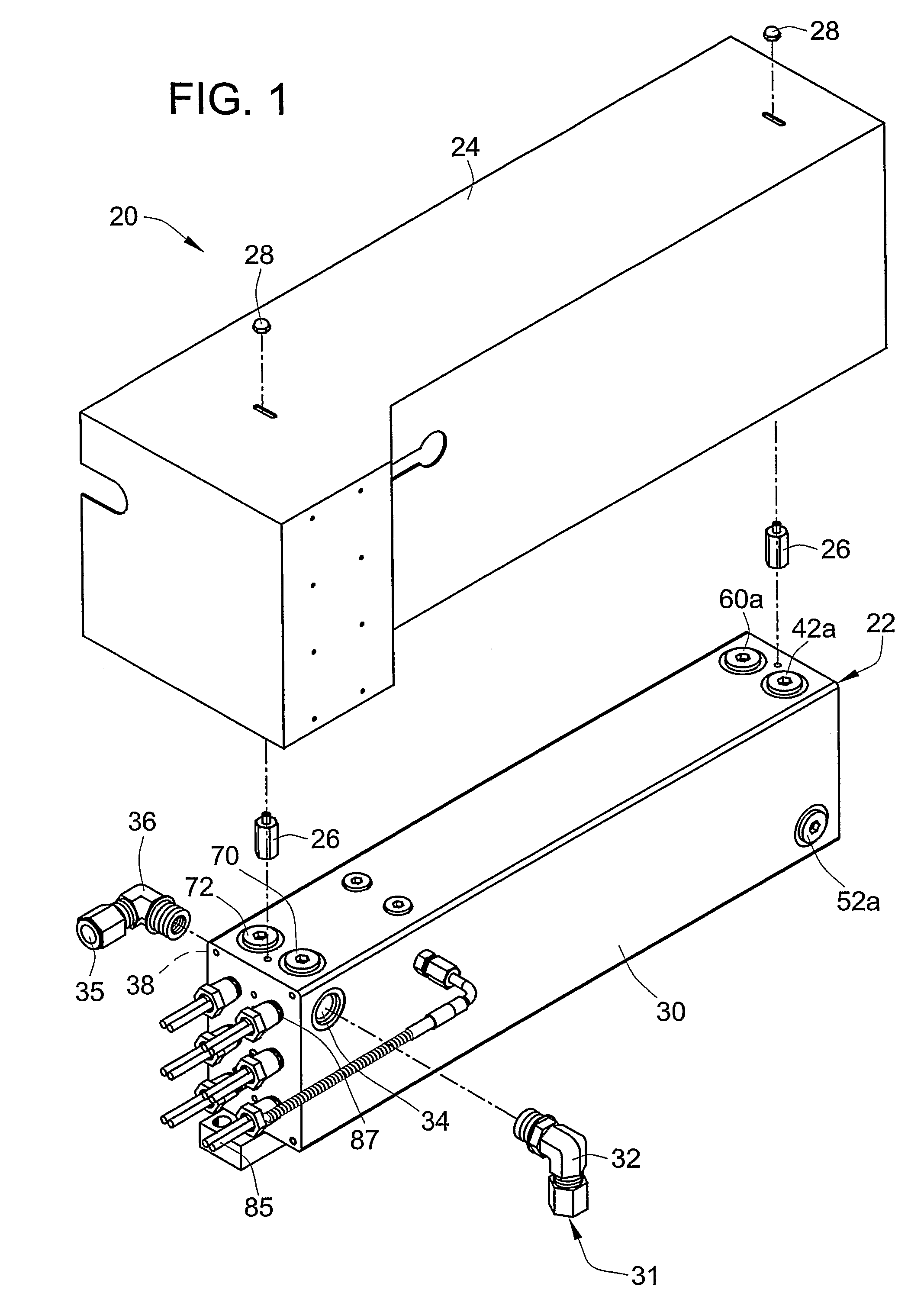

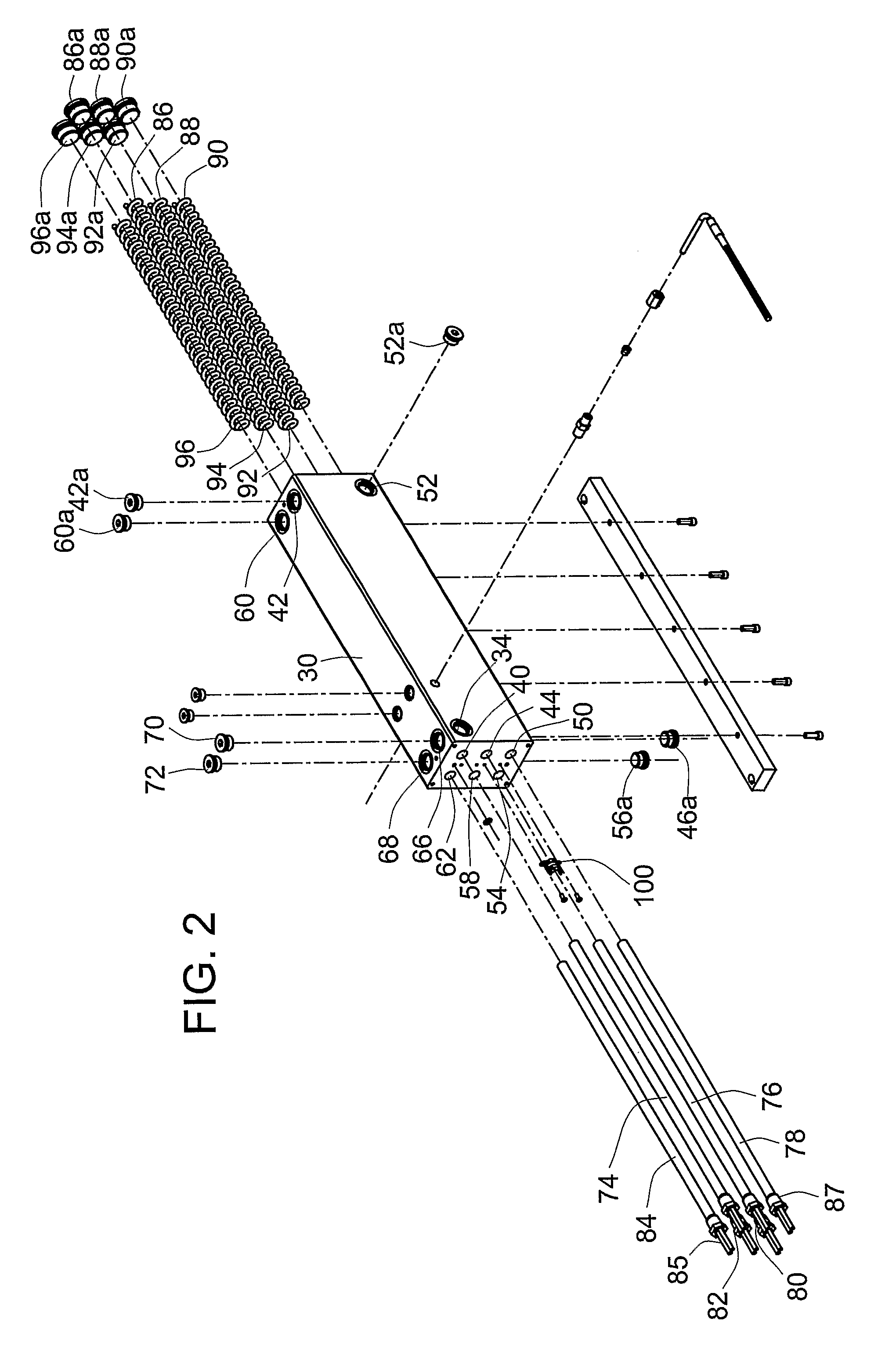

Hybrid heater

ActiveUS7822326B2Minimizing and eliminating associated disadvantageRapid warm up cycleImmersion heating arrangementsBeverage vesselsCoil springHeater Rod

A hybrid heater that includes a structural mass into which passages are provided to create a labyrinth for chemical flow through the structural mass, the passages being sized and disposed to receive a plurality of heater rods such that the chemical is traversed through the passages in direct contact with the heater rods. A coiled spring may be disposed or other spiral arrangement provided in the space between and against the walls of the passages and the heater rod to facilitate flow uniformity around the rods. A temperature sensor may be provided in direct contact with the heating element and may be fitted with a mass sleeve to draw off any excess heat on the sensor during transitions.

Owner:GRACO INC

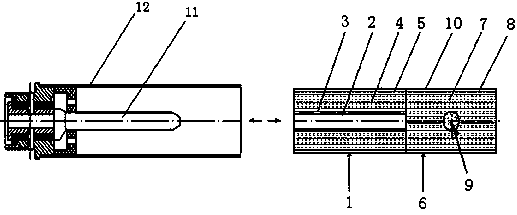

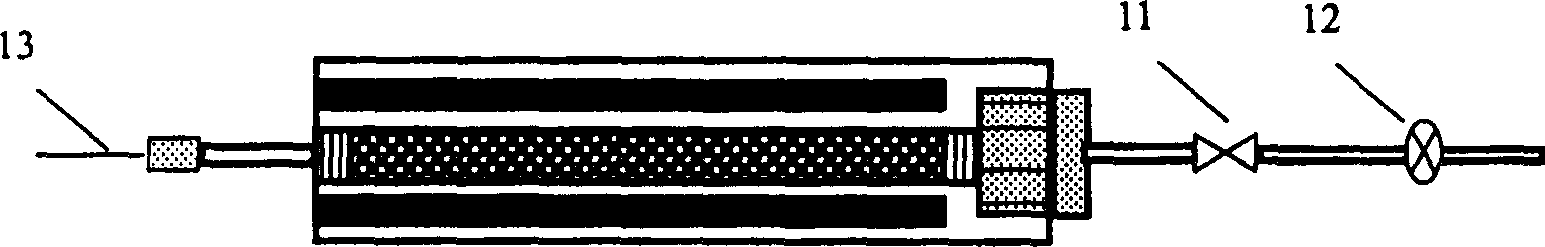

Sample-taking adsorption tube and its hydrolyzed adsorption device

InactiveCN1803252AImprove desorption efficiencyHigh quantitative repeatabilityDispersed particle separationGas phaseHeater Rod

The invention discloses a sampling adsorption pipe and heat desorber, wherein the sampling adsorption pipe is composed of reducing steel pipe with middle displaying thick diameter pipe; the adsorbent is filled with the thick diameter pipe with glass or quartz hair filling with two ends of adsorbent; two ends of sampling adsorption pipe is thin diameter pipe separately; one end of thin diameter pipe is an outlet pipe, which connects the thick diameter pipe stickly; the other end of thin diameter pipe is inlet pipe, which connects the thick diameter pipe through cap; the heat desorber is a metal block of internal heating bar with a cavity in the middle of metal block to contain the sampling adsorption pipe; the other end of heat desorber contains groove position to allocate the sampling adsorption pipe; when desorbed, the heat desorber is heated to preset temperature, which contains the thick diameter pipe of sampling adsorption pipe in the cavity to heat; the nut is inserted in the groove position of heat desorber, which takes the desorbed sample in the gas chromatograph analysis column.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

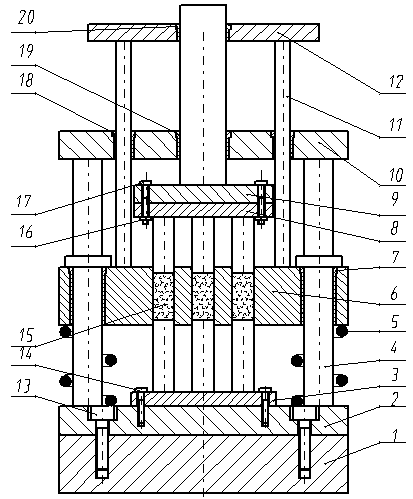

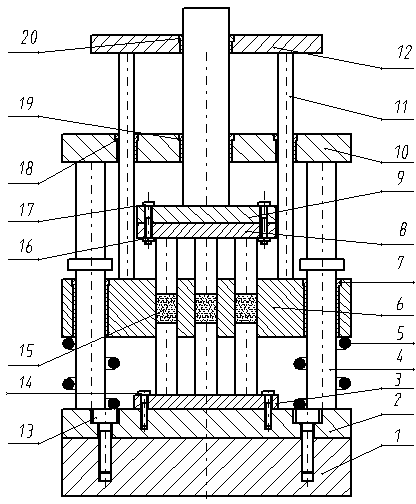

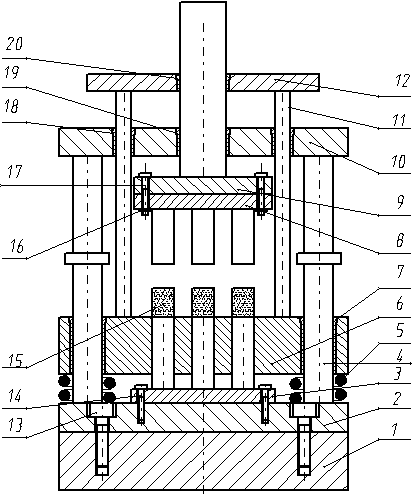

Bi-directional powder pressing forming device capable of demoulding automatically

InactiveCN103273678AImprove density distributionIncrease production speedShaping pressHydraulic cylinderDensity distribution

The invention discloses a bi-directional powder pressing forming device capable of demoulding automatically. An upper mould frame is connected with a lower mould frame through guide columns; and the lower mould frame is fixed on the base board. An upper mould stamping is connected with an upper mould connecting rod which is connected with a first hydraulic cylinder. A lower mould stamping is fixed on the lower mould frame. Female moulds are mounted on the corresponding guide columns through four holes on two sides. Springs are sleeved on the corresponding guide columns of the lower faces of the females moulds and the upper face of the lower mould frame. The female moulds can float on the springs, and each is provided with a heating bar and a thermoelectric couple internally. One ends of four ejection rods are fixed on an ejection rod fixing plate, and the other ends of the ejection rods penetrate the upper mould frame and is located above the female mould. The ejection rod fixing plate is connected with a second hydraulic cylinder. By the aid of the spring floating female mould and the ejection rod structure, bi-directional pressing and automatic demoulding are achieved accurately, density distribution of a workpiece is improved, and production speed is increased. With a multi-punch and multiple-moulding-chamber structure, multiple workpieces can be produced by pressing at one time, mass production can be realized, and device utilization rate and working efficiency are increased.

Owner:ZHEJIANG UNIV

Deep drawing method of magnesium alloy tailor welded blanks

InactiveCN101380654AUniform Yield Stress DistributionUniform deformationShaping toolsTemperature controlHeater Rod

The invention discloses a deepening and shaping method for a Mg-alloy tailor-welded blank which includes the following technique flows: 1) preparing a blank material: a lubricant is coated on the blank material of the Mg-alloy tailor-welded blank; 2) preheating a die: the die is heated to a preset temperature and the blank material is put in the die after the temperature detected by a thermoelectric couple reaches a preset value; the blank material is heated together with the die; 3) heating the blank material: after the blank material and the die are heated together for 5 to 10 minutes, deepening and shaping is prepared; 4) deepening and shaping: the deepening and shaping speed is controlled in a preset range and deepening and shaping is carried out; 5) finishing the deepening and shaping, after the deepening and shaping is finished, a workpiece is taken out. The method realizes the uniform deformation during the deepening and shaping process of the Mg-alloy tailor-welded blank, avoids the defects of cracking or serious deviation of a welding line and improves the product quality; a deepening and shaping device for the Mg-alloy tailor-welded blank can lead the blank material to realize grads temperature field distribution; besides, the temperature control method is simple which can realize different temperature grads fields only by changing the number and distribution of heating rods.

Owner:SHENYANG LIGONG UNIV

Manufacture of tubular targets

InactiveCN1363716APrevent solidificationAvoid inhomogeneityVacuum evaporation coatingIngot casting plantsMolten stateHeater Rod

A process for producing a tube target for cathode sputtering plants, in which the tube target is formed from a metallic inner tube made of a first material with a first melting point of Ts1>=900 K and a metallic outer tube that concentrically surrounds the inner tube and that is made of a second material with a second melting point of Ts2<=800 K. The inside diameter of the outer tube and the outside diameter of the inner tube are proportioned in such a way that the two tubes fit together tightly and are mechanically firmly joined. The outer tube is formed by casting the second material in a molten state in a heated, vertical, A cylindrical permanent mold, which has a heated mandrel that constitutes the inner tube. After a space between the mold and the inner tube has been filled with the molten second material, a first thermal gradient develops between the inner tube and the mold, a second thermal gradient develops between the bottom and the top of the mold, and the outer tube is simultaneously cooled from the inside to the outside and from the bottom to the top.

Owner:MATERION ADVANCED MATERIALS GERMANY GMBH

Cable surface cleaning device

ActiveCN105689298ASimple structureImprove efficiencyCleaning using toolsDrying machines with progressive movementsBristleSurface cleaning

The invention discloses a cable surface cleaning device. The cable surface cleaning device comprises a supporting plate, motor units, an air cylinder unit, a jacking unit, rolling wheel units and heating units. A supporting block, first rolling wheels, first supporting rods and first supports are arranged on the supporting plate. Each motor unit comprises a second support, a motor and an output shaft. The air cylinder unit comprises a first air cylinder, a first push rod, a connecting block, a curved plate, third supports, first oblique rods, a fourth support, springs, brush bristles and fifth supports. The jacking unit comprises a second air cylinder, a second push rod, a second rolling wheel and a sponge layer. Each rolling wheel unit comprises a second supporting rod, a third rolling wheel, a third supporting rod, a fourth rolling wheel and a transverse rod. Each heating unit comprises a radiating frame and a heating rod. According to the cable surface cleaning device, impurities on the cable surface can be cleared away, and the efficiency is high; in addition, water stains on the cable surface is wiped away, rubber aging caused by damp is prevented, the service life of cables is prolonged, and the using cost is reduced.

Owner:廊坊精联科技有限公司

Air injection-assisted super heavy oil underground cracking improvement technology based on shaft heating modes

InactiveCN106499376AEmission reductionAchieve emissionsConstructionsFluid removalReaction rateHeater Rod

The invention provides a technology method for comprehensive oil production and in-situ improvement of super heavy oil, oil shale, kerogen and medium and low-maturity shale oil reservoirs. The technology method is characterized in that a novel shaft electric heating in-situ cracking improvement technology is adopted, and is assisted by an air injection technology; by drilling a production well group into an oil bearing reservoir or adjusting the existing well network, a heating well, an air injection well and a production well are reasonably arranged; air is injected into the reservoir, and a heating cable in a heating well shaft is connected with an electric heating bar to heat the oil bearing reservoir, so as to realize the improvement of underground cracking of crude oil. The technology method has the advantages that by combining the advantages of shaft electric heating and air injection technologies, the problems of single heat transfer type, insufficient driving energy and the like in a single shaft electric heating mode are solved; by utilizing the heat effect of crude oil and oil oxidizing reaction, the stratum temperature is increased, the cracking temperature of the crude oil is decreased, the reaction rate of in-situ cracking is accelerated, the recovery efficient of the crude oil is improved, and the consumption of water resources and carbon emission are decreased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Pre-heating warmer of diesel engine exhaust aftertreatment device and warming method

ActiveCN103104314AAvoid interferenceAvoid influenceExhaust apparatusSilencing apparatusHeater RodDiesel engine

The invention relates to a pre-heating warmer of a diesel engine exhaust aftertreatment device and a warming method which are capable of raising the exhaust temperature of a diesel vehicle and regenerating a diesel engine exhaust aftertreatment device in ultralow temperature below zero under the condition that an ignition system is not needed. A core rod is sleeved on a heating rod, and one end of the heating rod is exposed out of the core rod to form a high-temperature ignition head. Two ends of the core rod are connected with end covers at two ends of a diesel gasification cavity in a sealed mode, and a heat accumulator is sleeved on the core rod and is placed in the diesel gasification cavity. One end of an ignition cavity is connected with the diesel gasification cavity and is covered on the high-temperature ignition head. An oil delivery pipe is placed outside a wall of the ignition cavity, and an oil spraying pipe part in the oil delivery pipe penetrates through the end covers of the diesel gasification cavity and is placed in the diesel gasification cavity. An oil gas nozzle is formed in an end cover, at one end of the heating rod, of the diesel gasification cavity.

Owner:GUIZHOU HUANGDI DIESEL ENGINE CLEANER

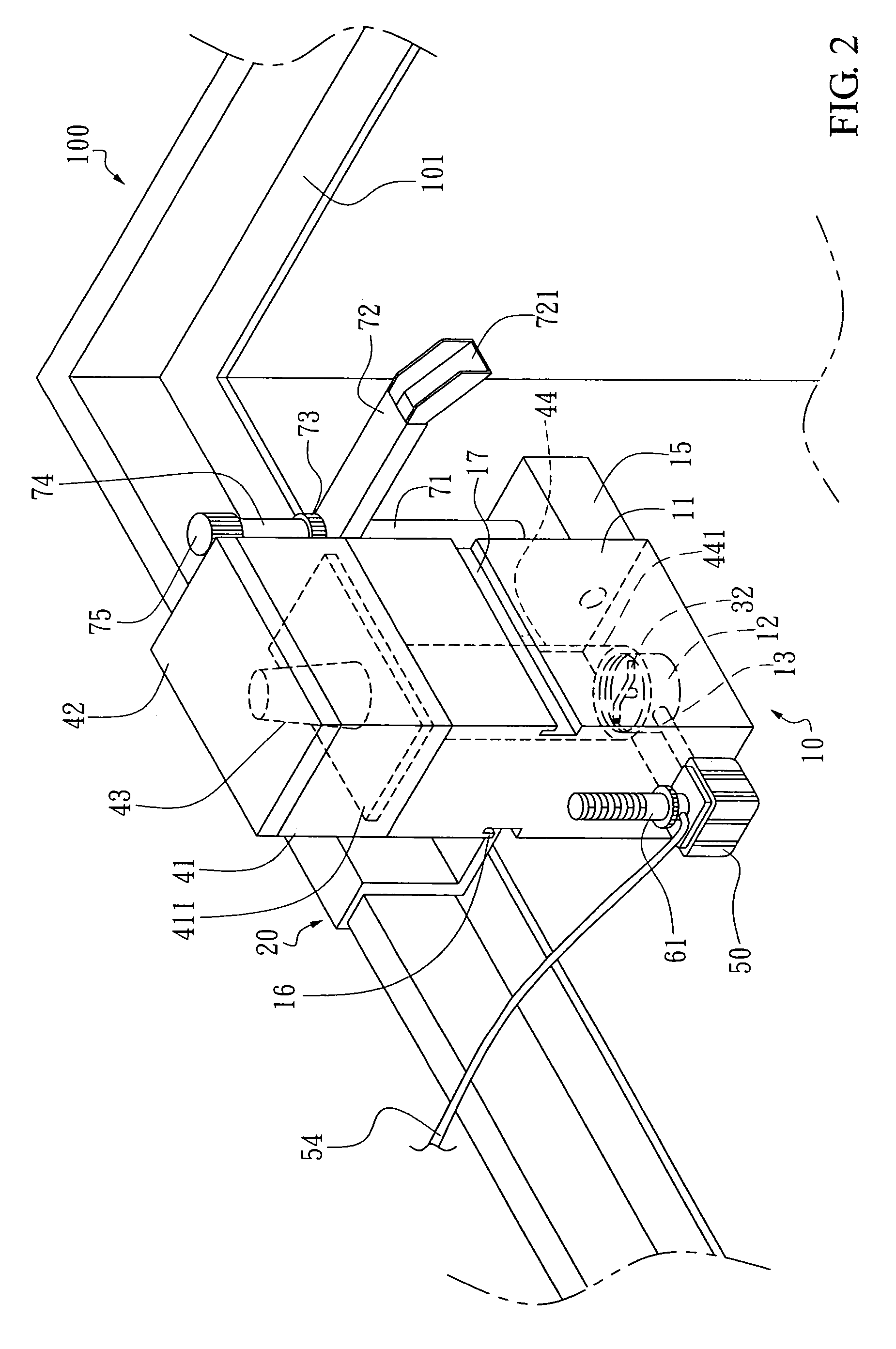

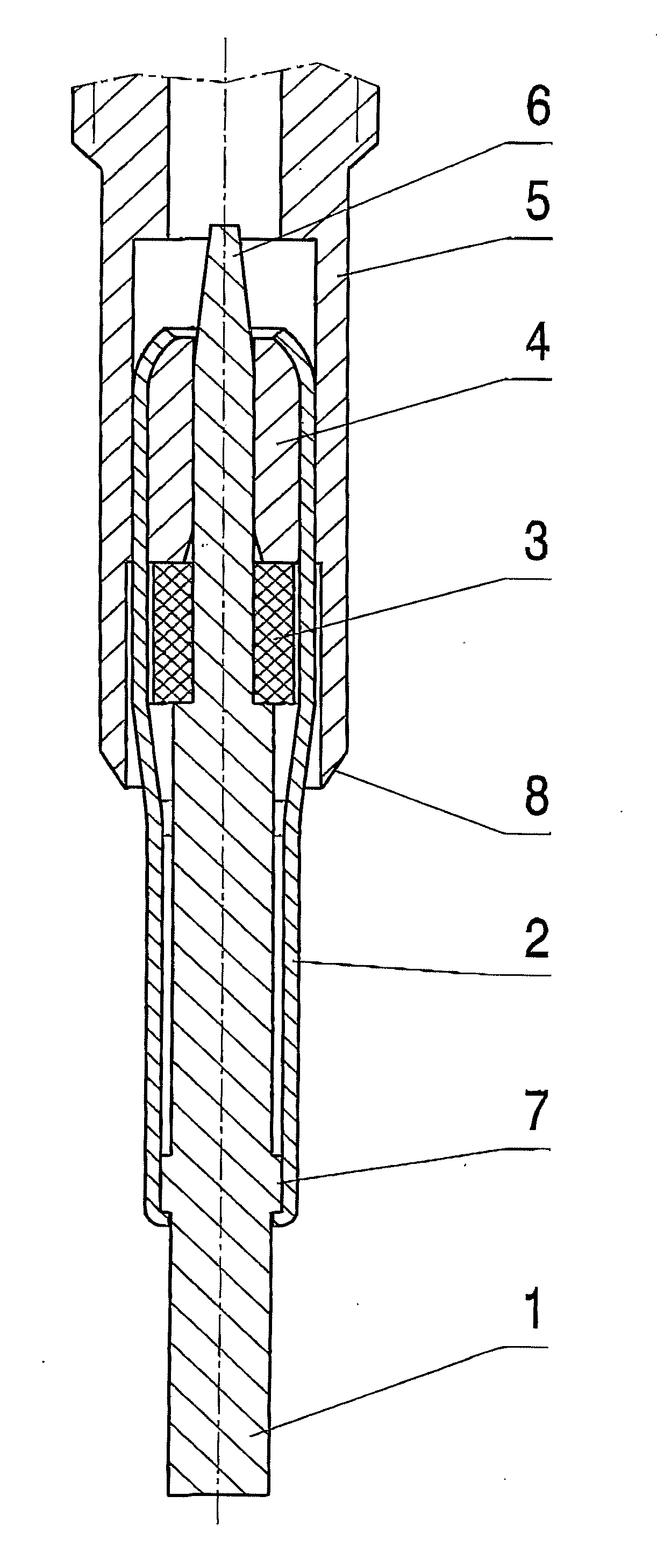

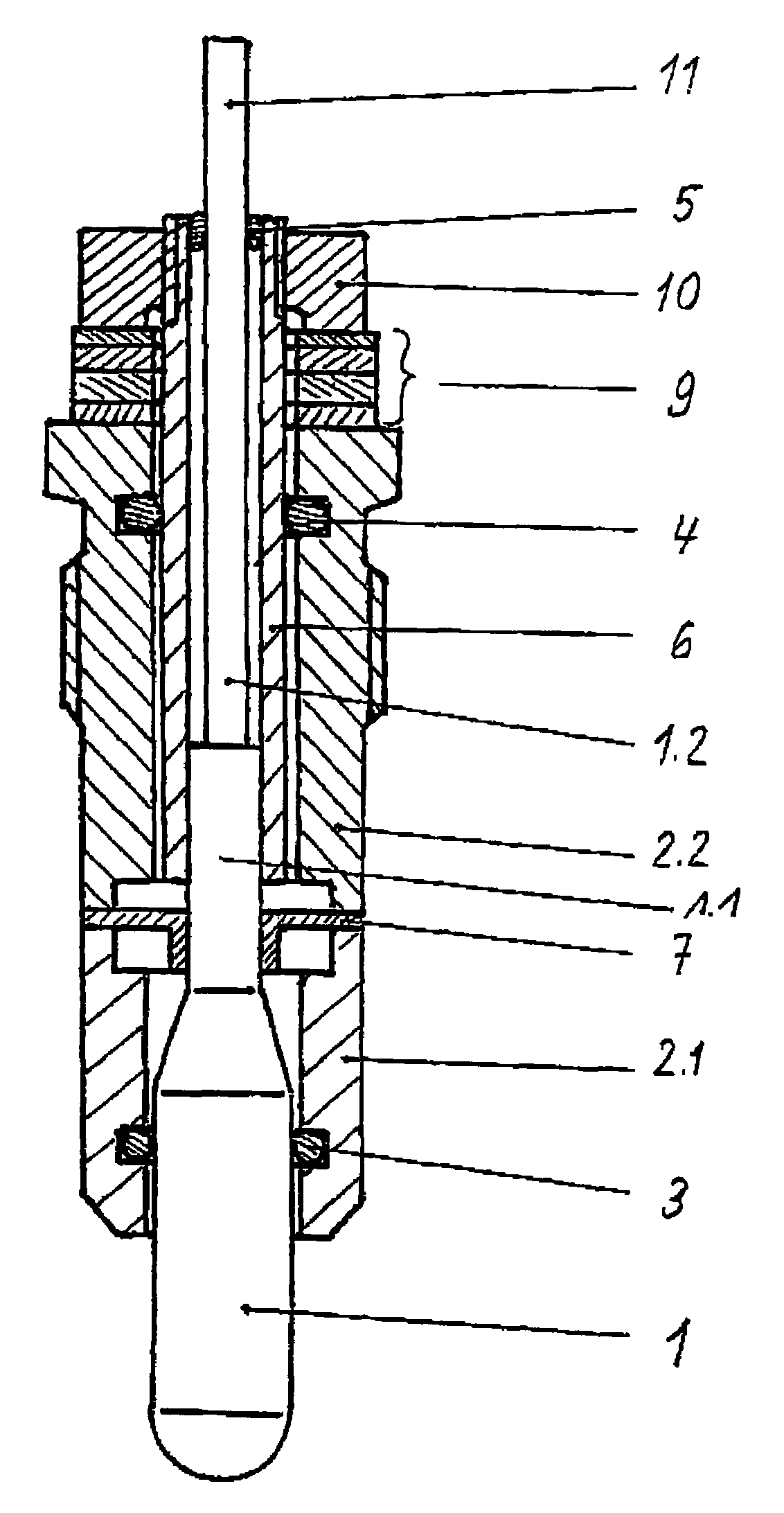

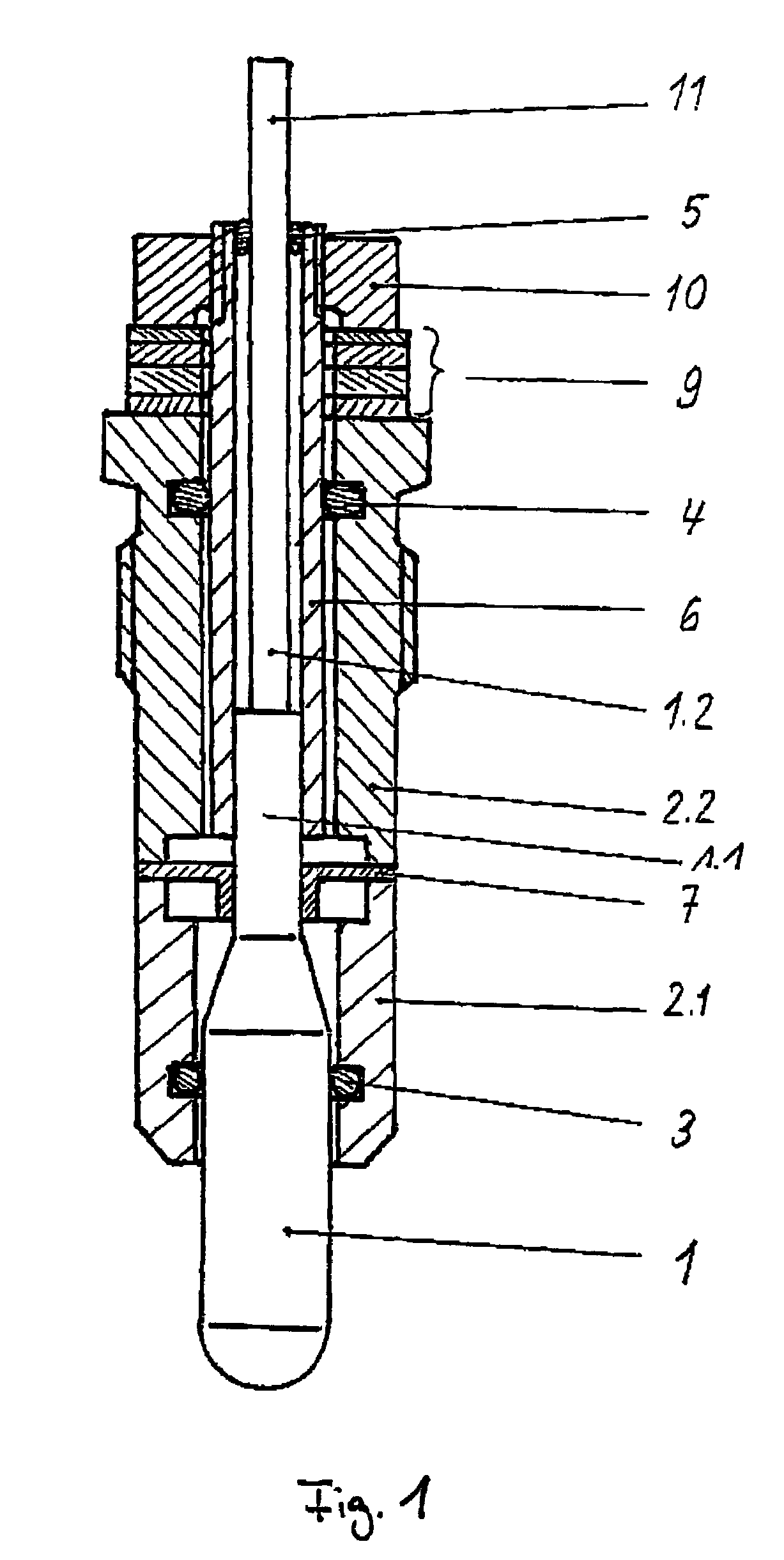

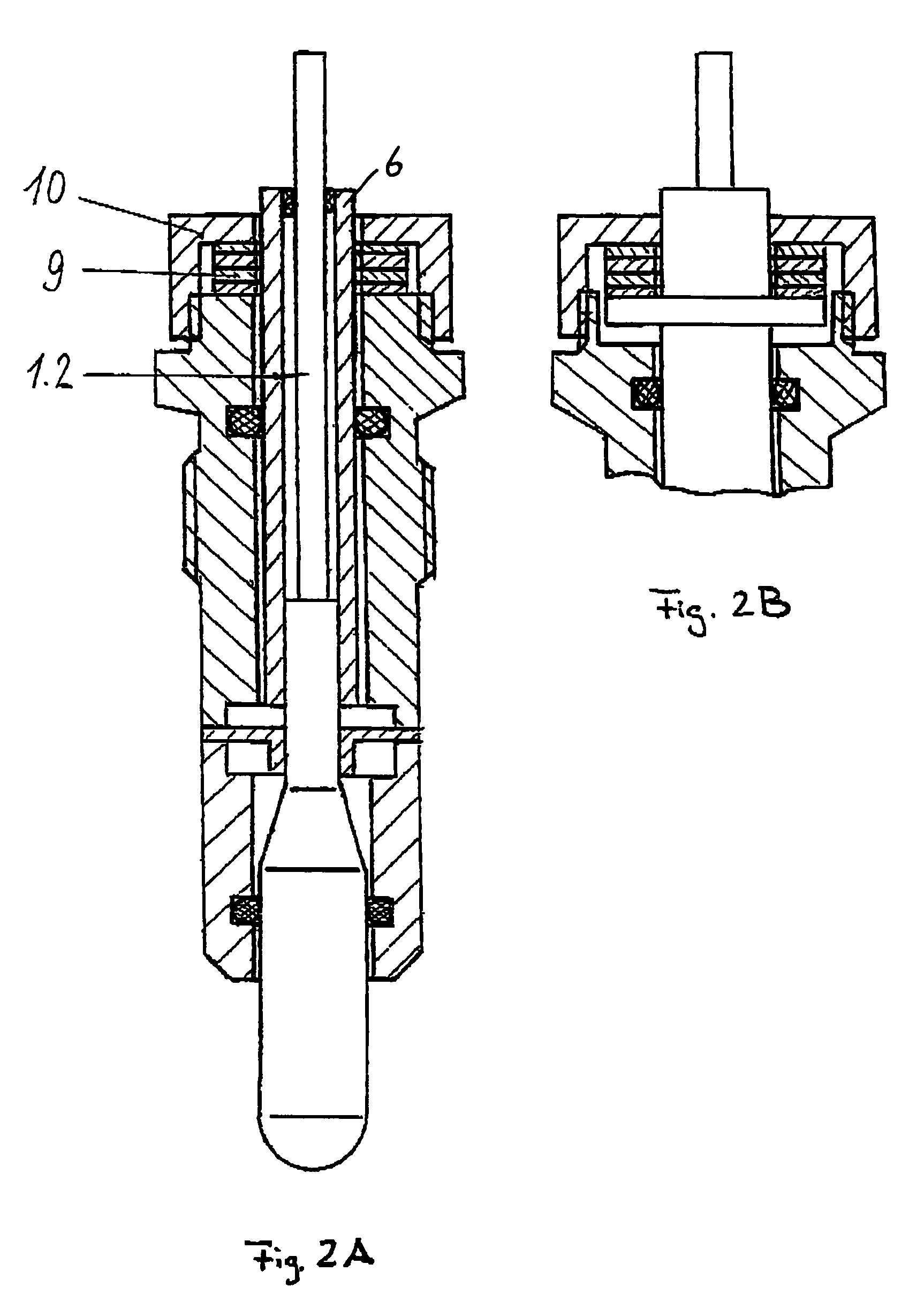

Pressure pickup heating bar, in particular for a pressure pickup glow plug

InactiveUS20070095811A1Simple designLow costIncandescent ignitionMachines/enginesHeater RodEngineering

A pressure pickup heating bar, in particular for a pressure pickup glow plug, having an electrical heating element ( 1 ) and a pressure sensor ( 3 ) onto which the pressure present at the heating bar ( 1 ) is transmitted. The heating bar has a support tube ( 2 ) which encompasses the heating element ( 1 ) on the outside with an axial pretension. A pressure sensor ( 3 ) is arranged between the heating element ( 1 ) and the support tube ( 2 ) and is subjected to pressure that is present on the heating bar.

Owner:BERU AG DE

Pressure glow plug for a diesel engine

ActiveUS7337657B2Reduce or optimize emission values, consumption valuesIncrease powerIncandescent ignitionEngine testingHeater RodGlowplug

A pressure glow plug for a diesel engine has a glow plug body 2 for being inserted into a cylinder of the diesel engine, a heating rod 1 that is arranged in the glow plug body 2 and a pressure sensor 9 that is arranged between the heating rod 1 and the glow plug body 2 in such a way that the pressure in the combustion chamber of the cylinder that is transmitted by the heating rod 1 influences the pressure sensor 9. The heating rod 1 is arranged in the glow plug body 2 such that it can be displaced in an axially sliding fashion, namely by a corresponding sliding element, for example, a membrane 7 or seals 3.

Owner:SENSATA TECH HOLLAND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com