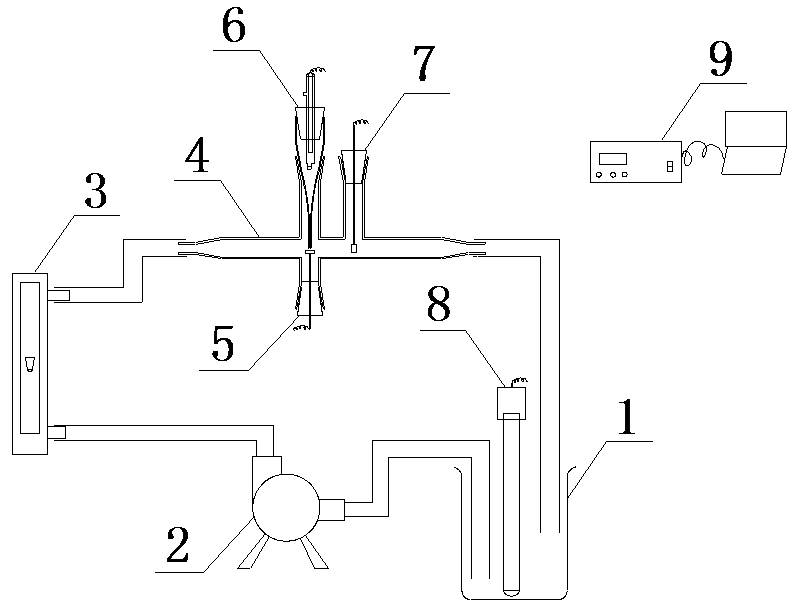

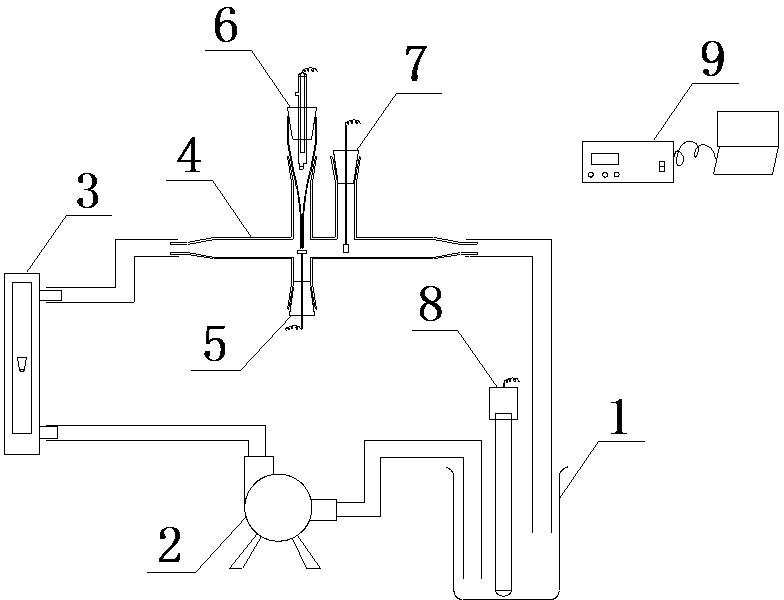

Corrosion inhibitor performance evaluation device and method of circular cooling water system

A technology for circulating cooling water and evaluation devices, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve the problems that electrochemical methods cannot simulate the working conditions of circulating cooling water well, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

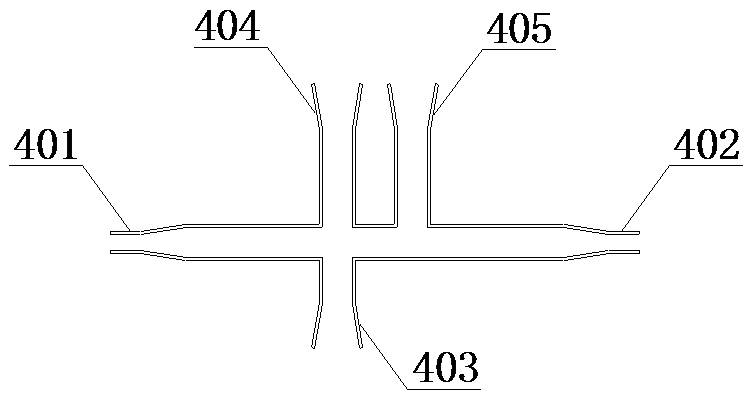

Embodiment 1

[0042] The five-port glass tube 4 in the present embodiment is newly designed and processed, and its structural schematic diagram is as follows figure 2 As shown, the five glass tubes 4 are designed with water inlet 401, water outlet 402, working electrode port 403, reference electrode port 404 and auxiliary electrode port 405, the working electrode port 403, reference electrode port 404 and auxiliary electrode port 405 They are respectively used to install the working electrode 5, the reference electrode 6 and the auxiliary electrode 7. The specifications of the five glass tubes 4 are as follows: the five glass tubes 4 are a glass tube with a diameter of 26 mm and a length of 400 mm. The horizontal ends of the five glass tubes 4 are water inlets 401 and water outlets 402 respectively. The water outlet 402 is tapered to a diameter of 16mm, and its length is 40mm; one side of the five-port glass tube 4 is a reference electrode port 404 and an auxiliary electrode port 405, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com