Roller center heater of magnesium alloy board

A technology of magnesium alloy plate and heating device, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of large surface temperature change of roll, unable to meet production requirements, uneven heating temperature of roll, etc. The effect of uniform surface temperature, improving production efficiency and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

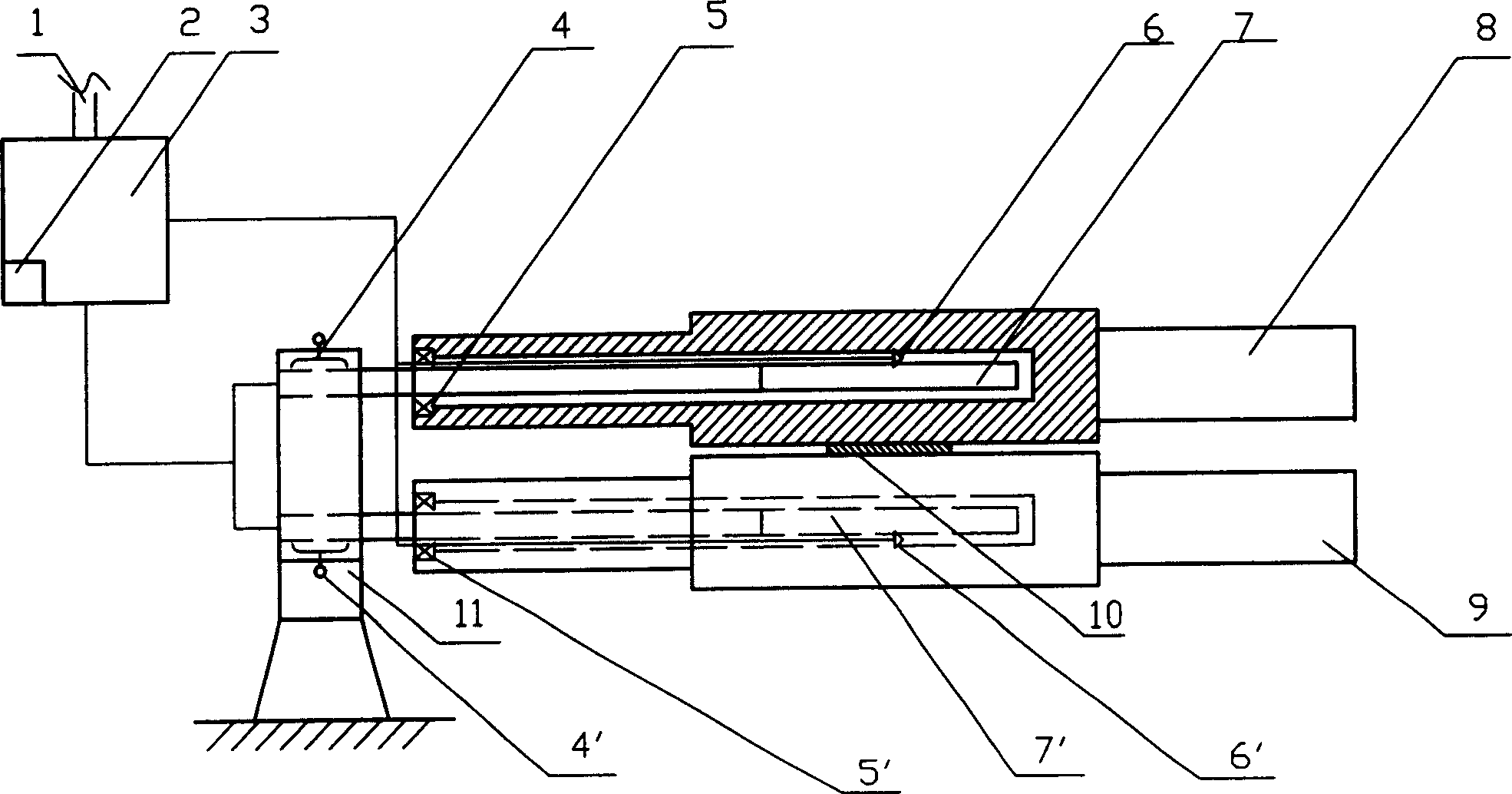

[0015] The power supply 1 is connected to the temperature control box 3, and one end of the heating rod 7, 7' is fixed, and the heating end is supported by a cantilever in the core of the upper and lower work rolls. When the heating rod needs to be heated, the transformer in the temperature control box 3 controls the heating of the heating rod The required voltage is connected by a wire between the heating rod and the transformer. Since there is a relationship curve between the temperature in the core of the upper and lower work rolls 8 and 9 and the surface temperature, the temperature of the thermocouples 6 and 6' inside the core can reflect the surface temperature of the roll. When the surface temperature of the roll reaches the required temperature , the heating rod stops heating, and the magnesium alloy raw material 11 heated in advance is rolled. During rolling, the upper and lower work rolls rotate by themselves under the action of the transmission device at the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com