Patents

Literature

7221results about How to "Uniform temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

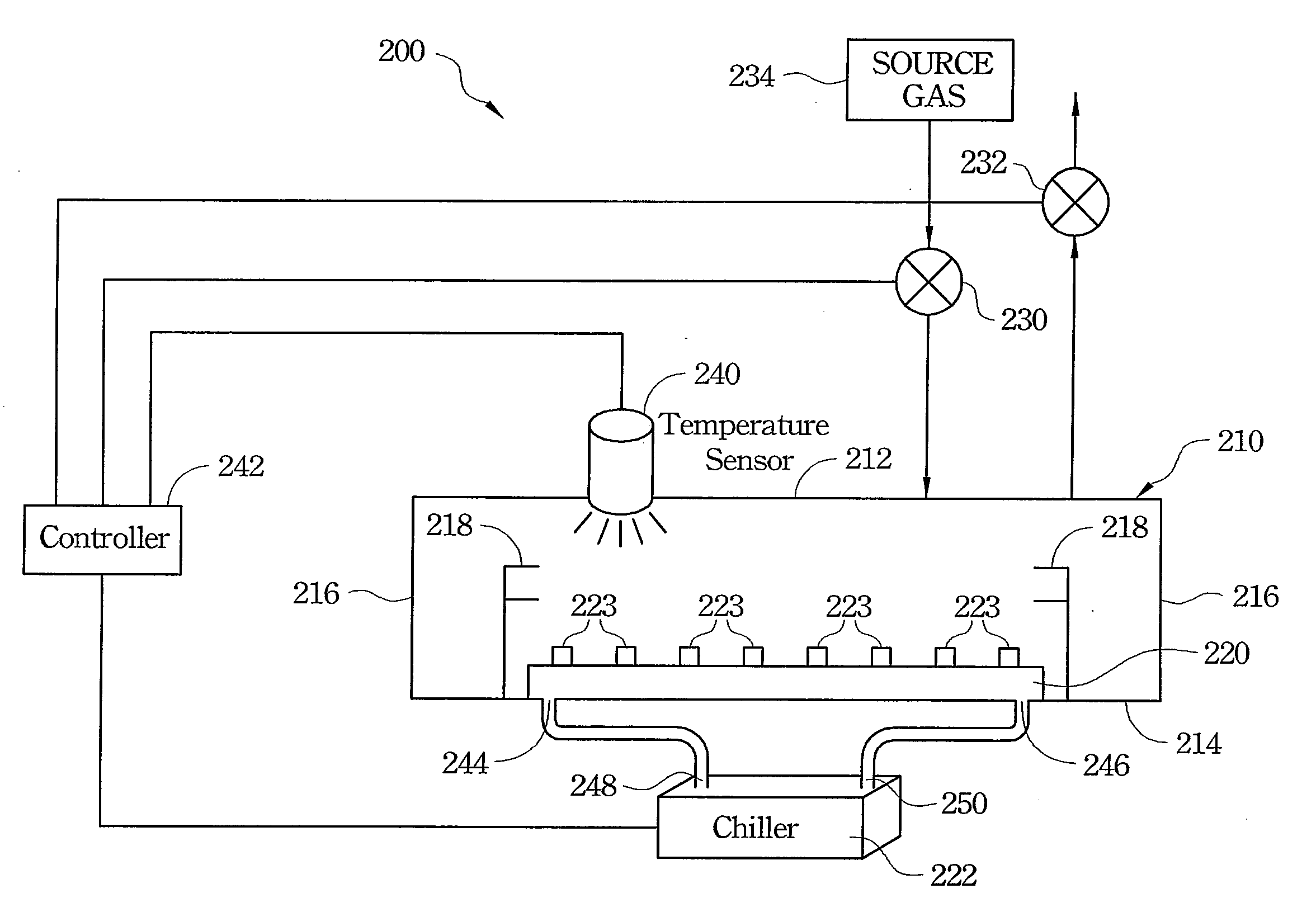

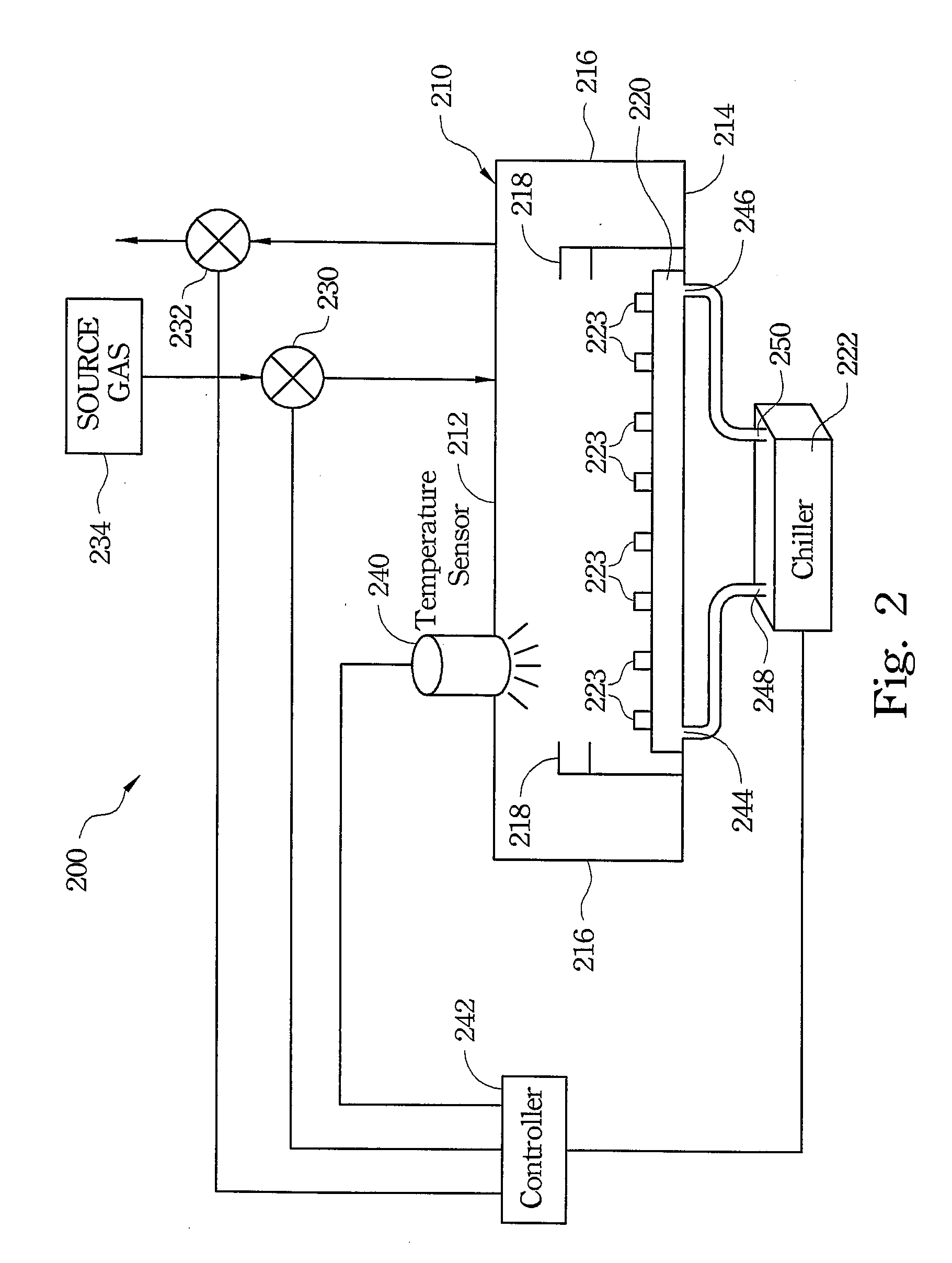

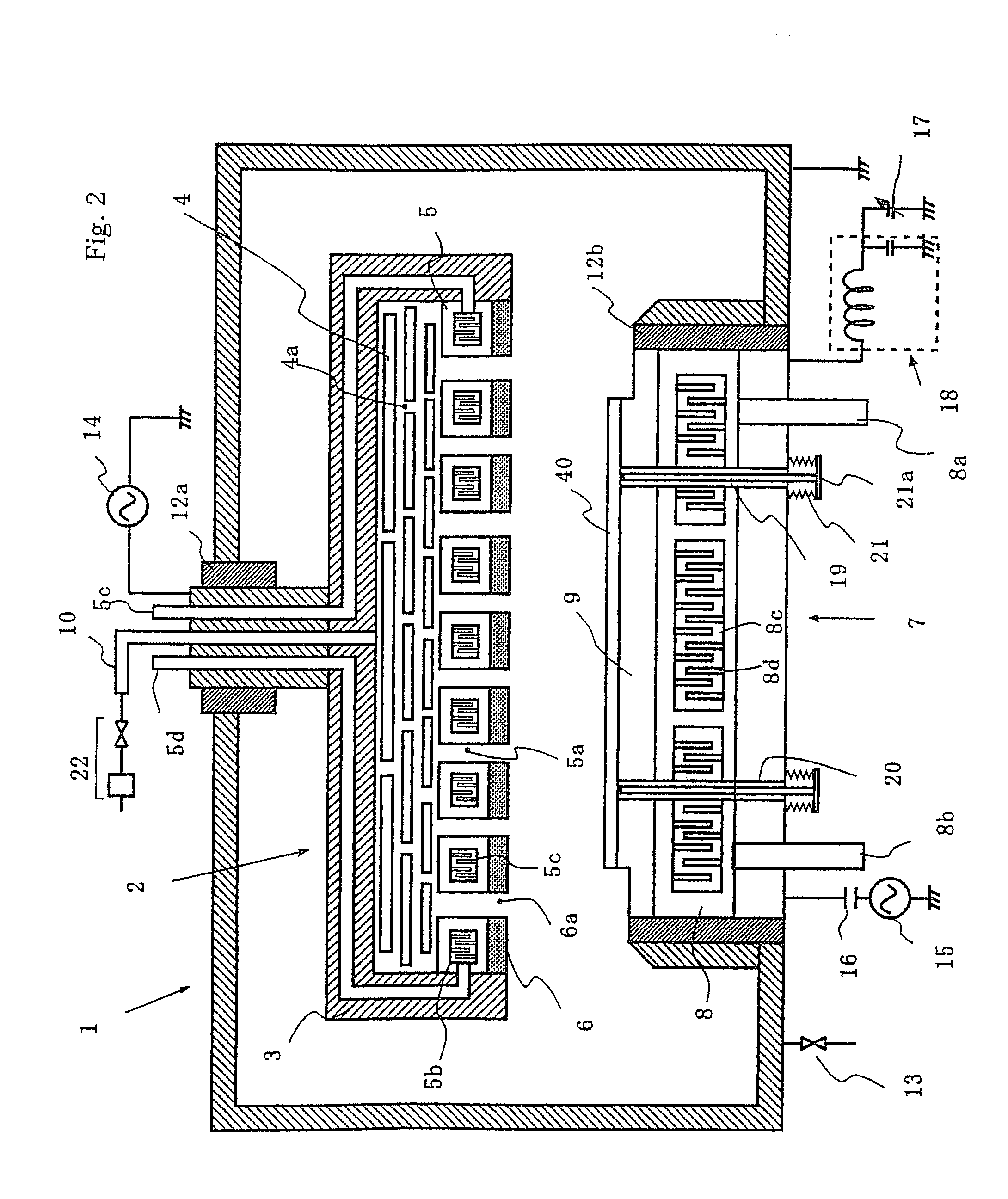

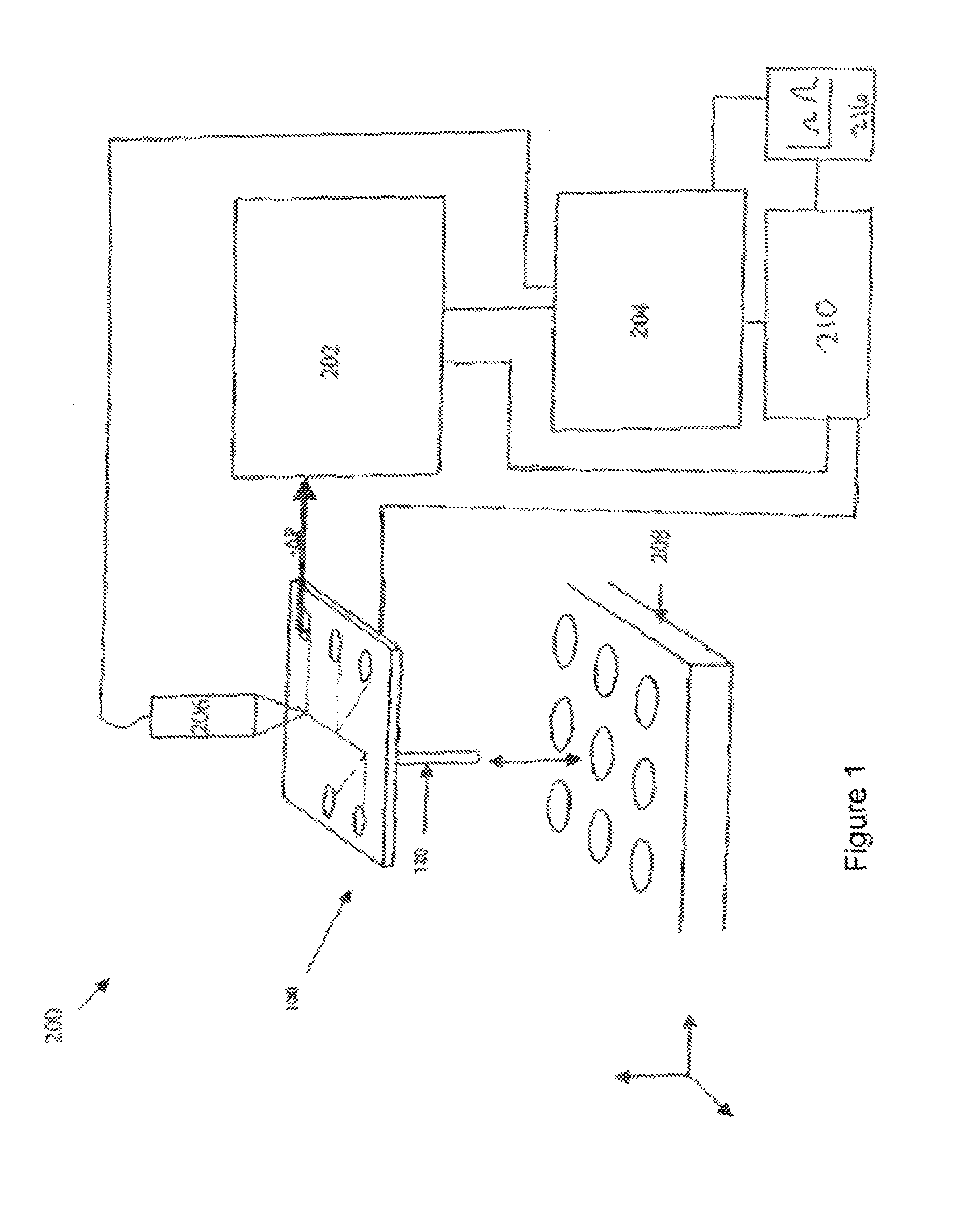

Temperature Controlled Loadlock Chamber

ActiveUS20090000769A1Uniform temperatureUniform processingTemperatue controlSemiconductor/solid-state device manufacturingEngineeringStreamflow

A temperature controlled loadlock chamber for use in semiconductor processing is provided. The temperature controlled loadlock chamber may include one or more of an adjustable fluid pump, mass flow controller, one or more temperature sensors, and a controller. The adjustable fluid pump provides fluid having a predetermined temperature to a temperature-controlled plate. The mass flow controller provides gas flow into the chamber that may also aid in maintaining a desired temperature. Additionally, one or more temperature sensors may be combined with the adjustable fluid pump and / or the mass flow controller to provide feedback and to provide a greater control over the temperature. A controller may be added to control the adjustable fluid pump and the mass flow controller based upon temperature readings from the one or more temperature sensors.

Owner:TAIWAN SEMICON MFG CO LTD

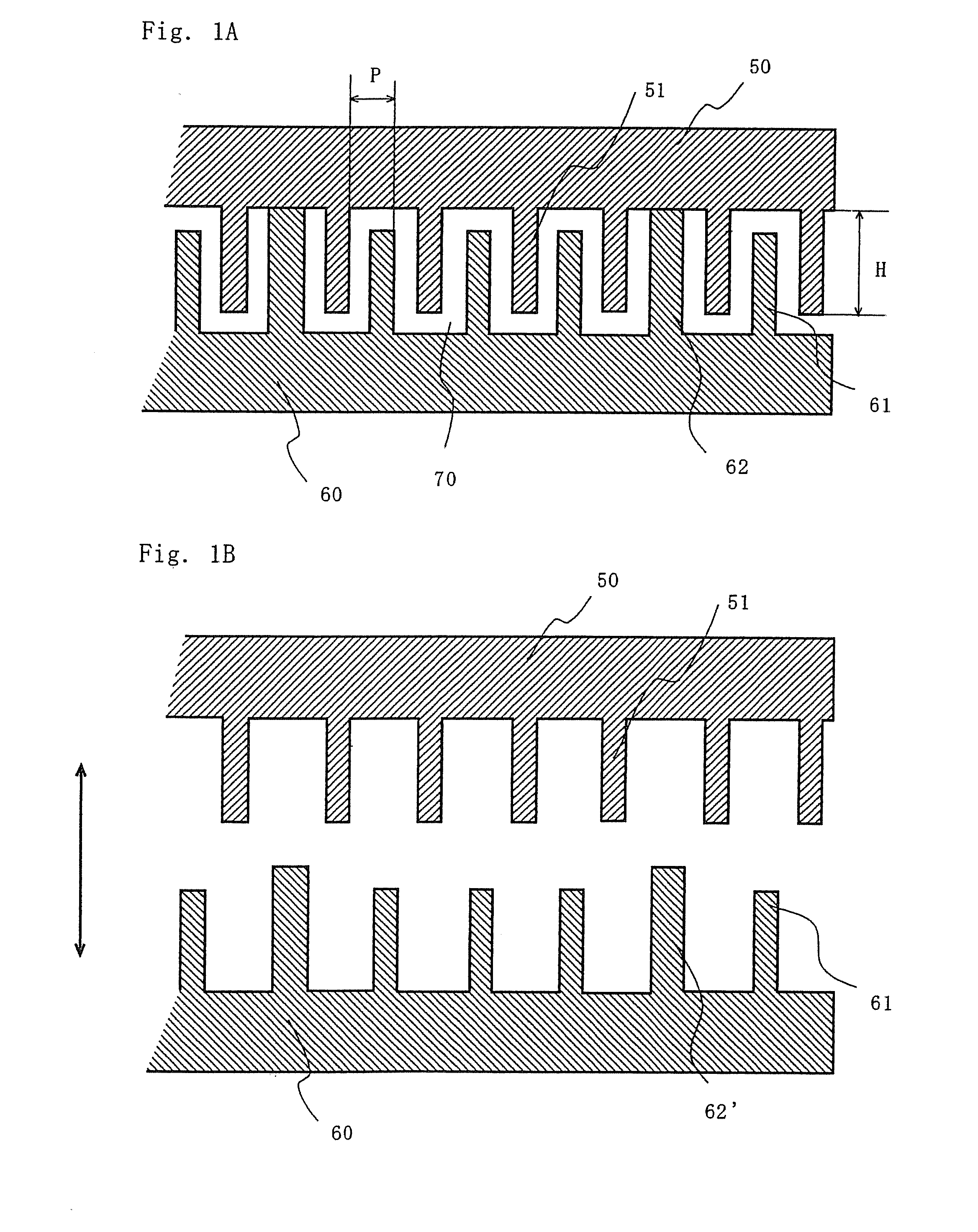

Substrate processing apparatus

ActiveUS20090197418A1Efficiently and uniformly cool and heat portionStable processingDomestic cooling apparatusDecorative surface effectsPlate heat exchangerEngineering

A method of using a heat exchanger efficiently and uniformly to cool or heats portions to be controlled to a prescribed temperature, and then continuously carry out stable processing. The heat exchanger is constructed by arranging partition walls between two plates to form a fluid channel and a fin parallel with the channel or inclined by a prescribed angle on each of the two plates insides the channel so that the plate or a member in contact with the plate is cooled or heated with the fluid flowing through the channel.

Owner:CANON ANELVA CORP

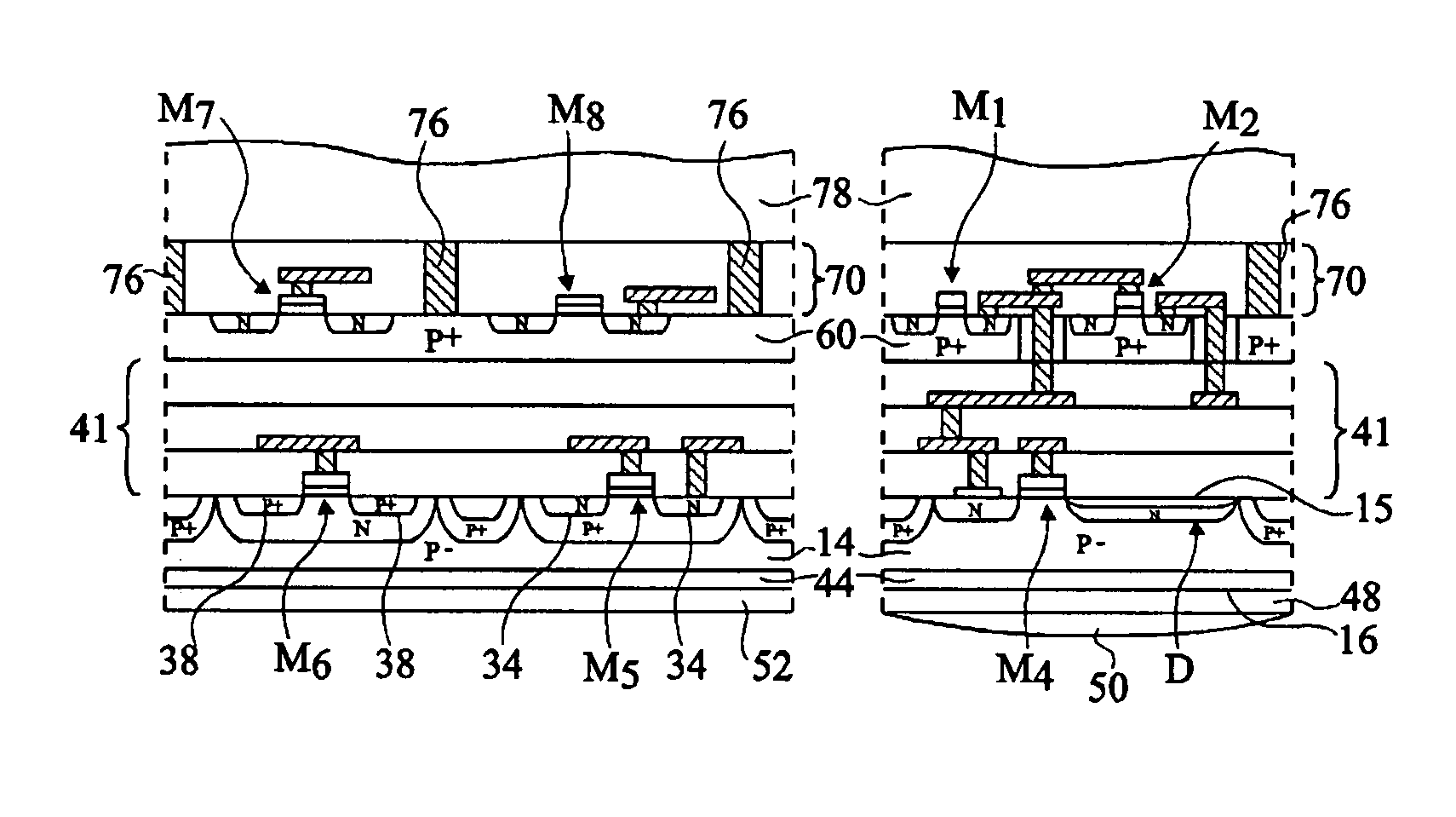

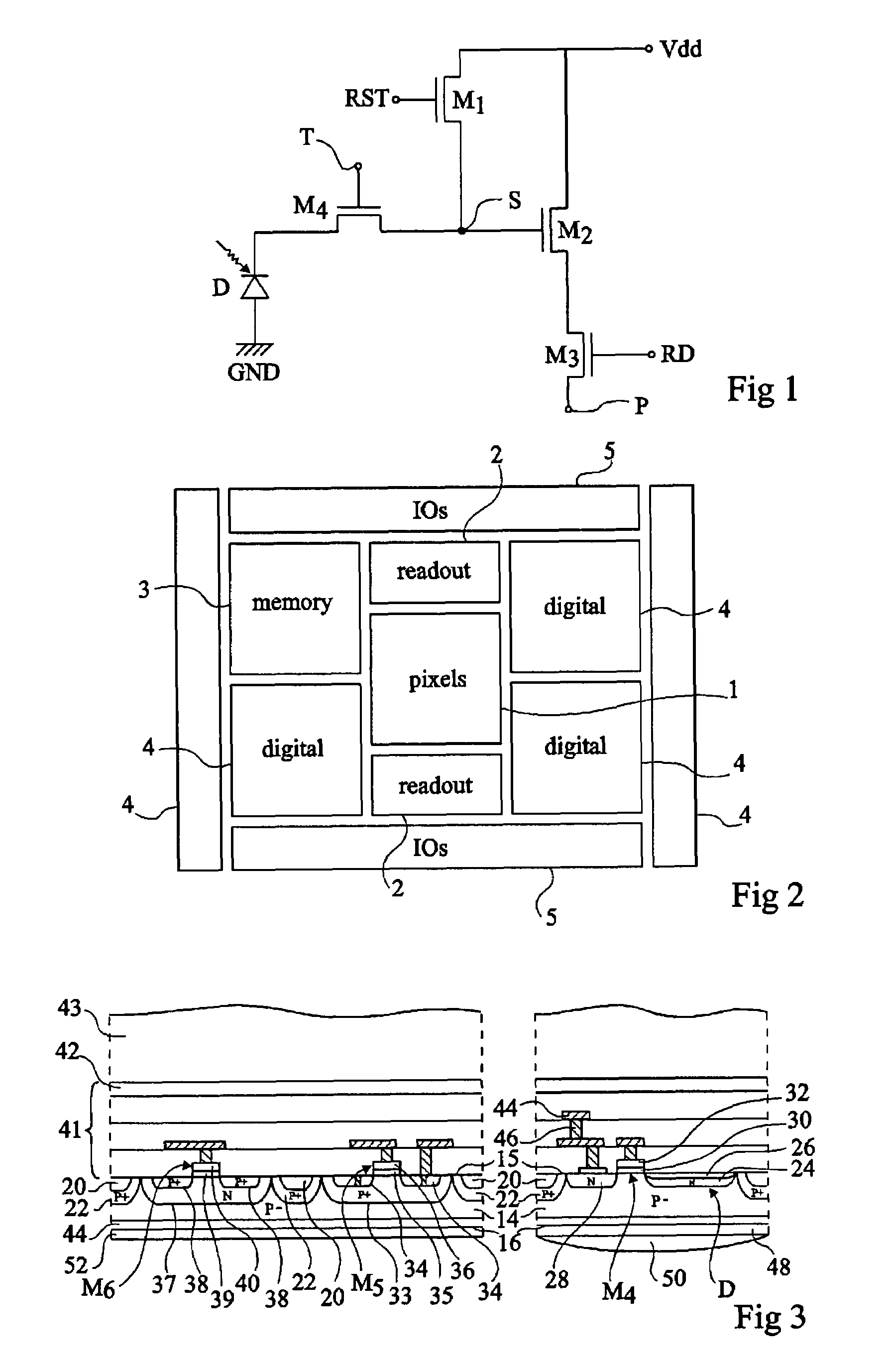

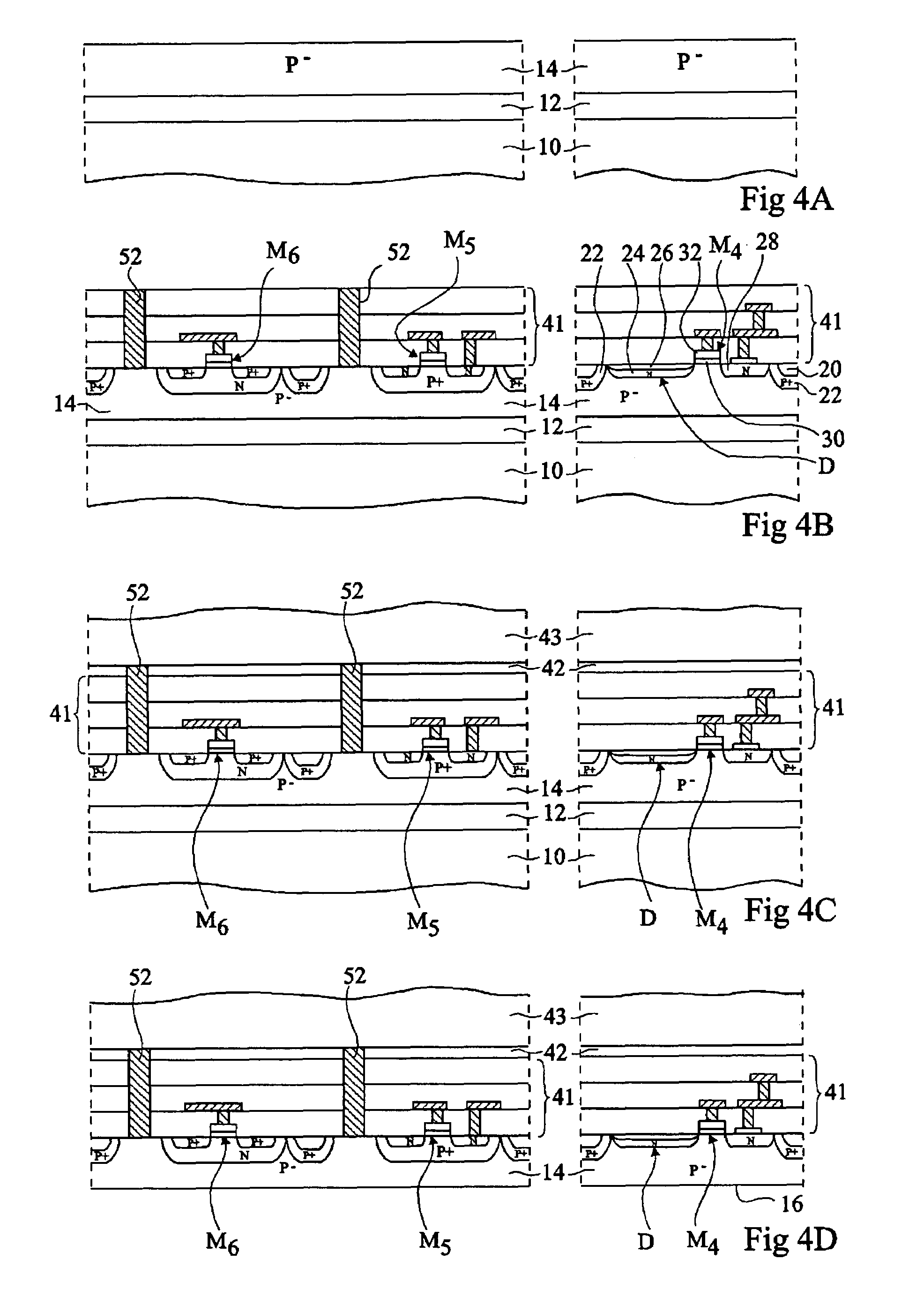

Back-lit image sensor with a uniform substrate temperature

InactiveUS7687872B2Improve cooling effectUniform temperatureSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsEngineering

An image sensor including photosensitive cells including photodiodes and at least one additional circuit with a significant heat dissipation including transistors. The image sensor is made in monolithic form and includes a layer of a semiconductor material having first and second opposite surfaces and including, on the first surface side, first regions corresponding to the power terminals of the transistors, the lighting of the image sensor being intended to be performed on the second surface side; a stack of insulating layers covering the first surface; a thermally conductive reinforcement covering the stack on the side opposite to the layer; and thermally conductive vias connecting the layer to the reinforcement.

Owner:STMICROELECTRONICS SRL +2

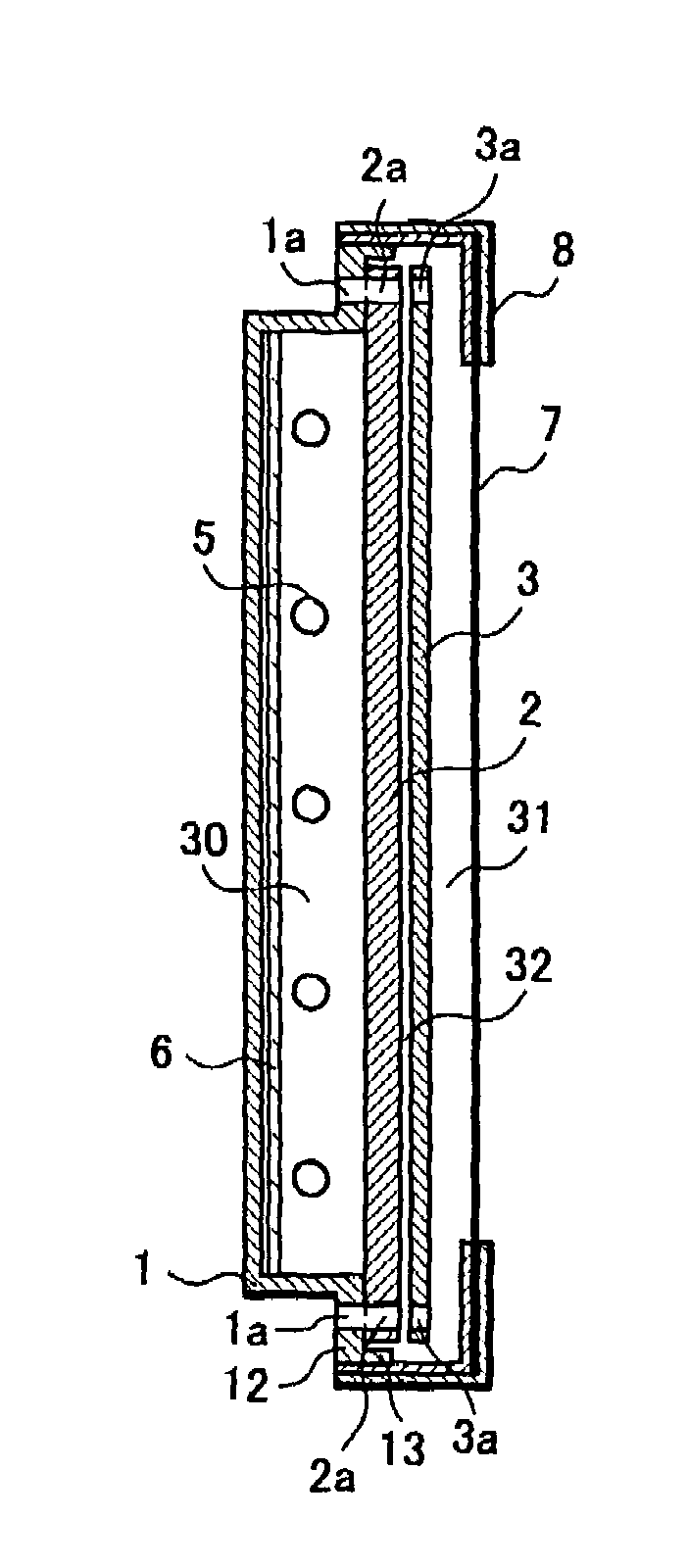

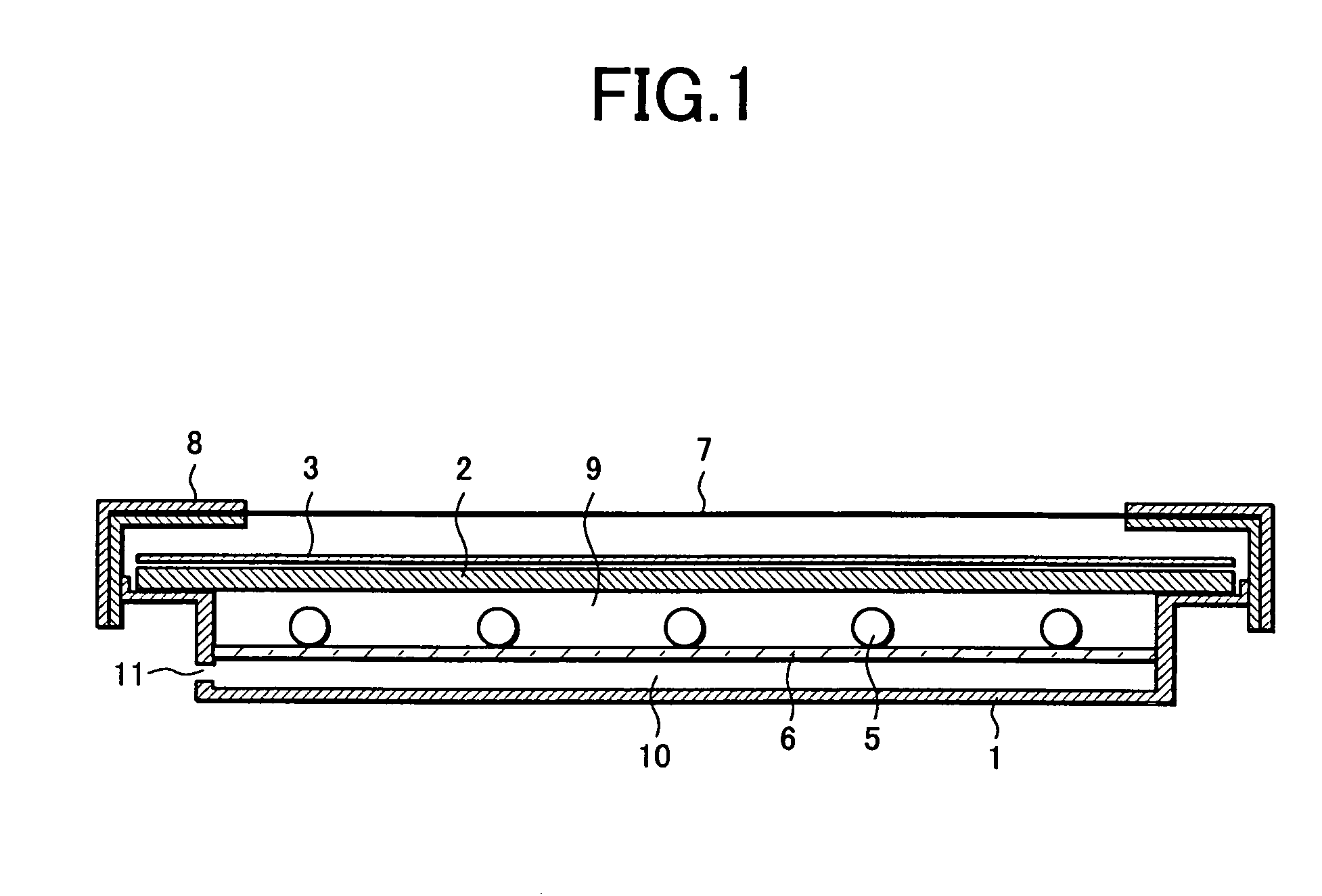

Liquid crystal display device

InactiveUS7059757B2Avoid deformationRule out the possibilityMeasurement apparatus componentsPoint-like light sourceLiquid-crystal displayEngineering

A liquid crystal display device has a plurality of lamps, a light diffusion plate and / or an optical sheet, a shield portion for accommodating the lamps, the light diffusion plate and / or the optical sheet. There is a liquid crystal display panel located opposite to one side of the light diffusion plate and / or the optical sheet opposed each with the other side to the lamps. The light diffusion plate and / or the optical sheet each have a vent, and a lamp chamber formed in the lamp-accommodating side of the light diffusion plate and / or the optical sheet. There is an LCD panel chamber formed in the LCD panel-disposing side of the light diffusion plate and / or an optical sheet that communicate with each other through the vent of the light diffusion plate and / or optical sheet.

Owner:SHARP KK

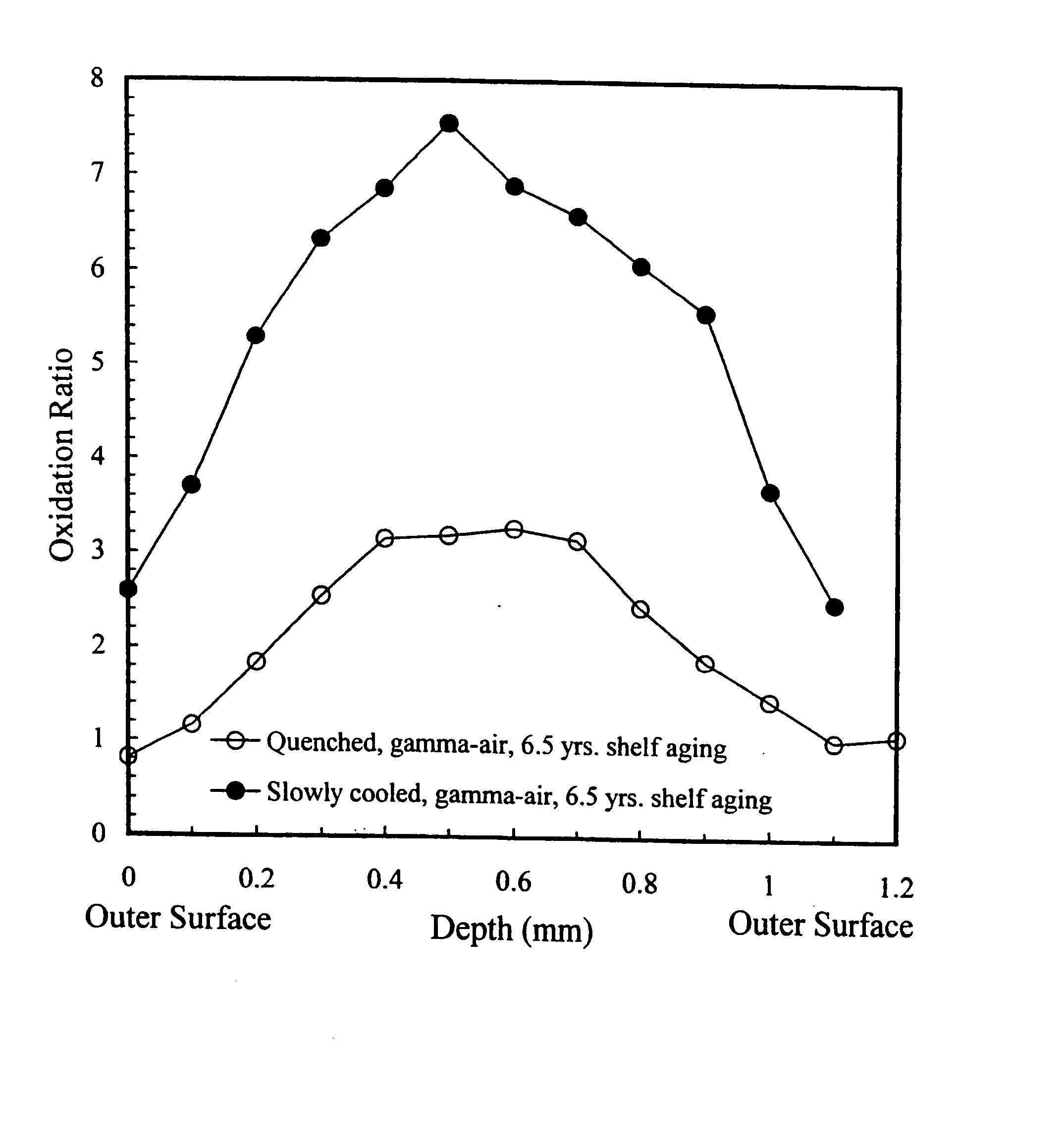

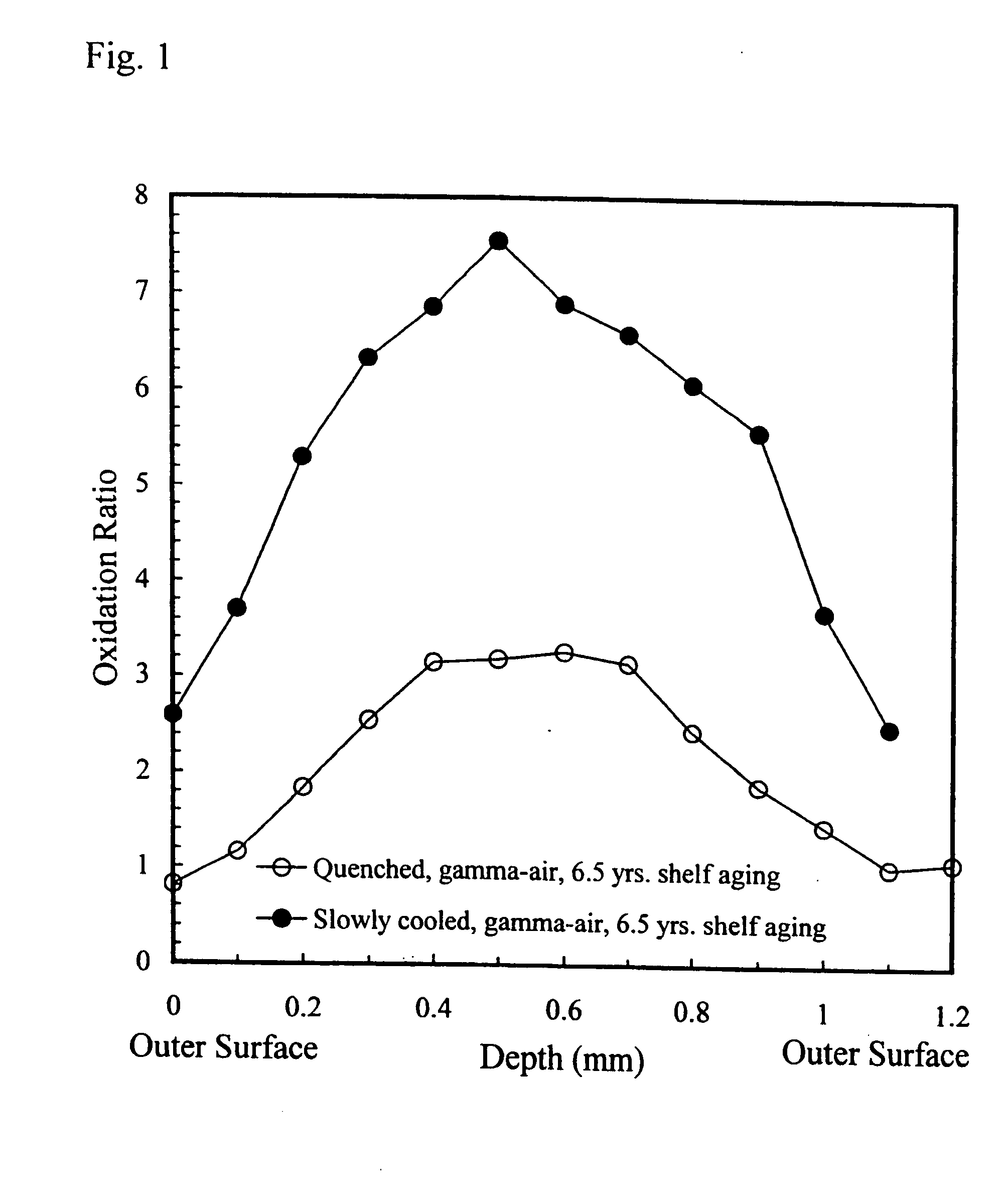

Oxidation-resistant and wear-resistant polyethylenes for human joint replacements and methods for making them

InactiveUS20070293647A1Improve wear resistanceImprove the immunitySurgeryPackage sterilisationPresent methodWear resistant

The present invention presents methods for making oxidation-resistant and wear-resistant polyethylenes and medical implants made therefrom. Preferably, the implants are components of prosthetic joints, e.g., a bearing component of an artificial hip or knee joint. The resulting oxidation-resistant and wear-resistant polyethylenes and implants are also disclosed.

Owner:THE ORTHOPAEDIC HOSPITAL

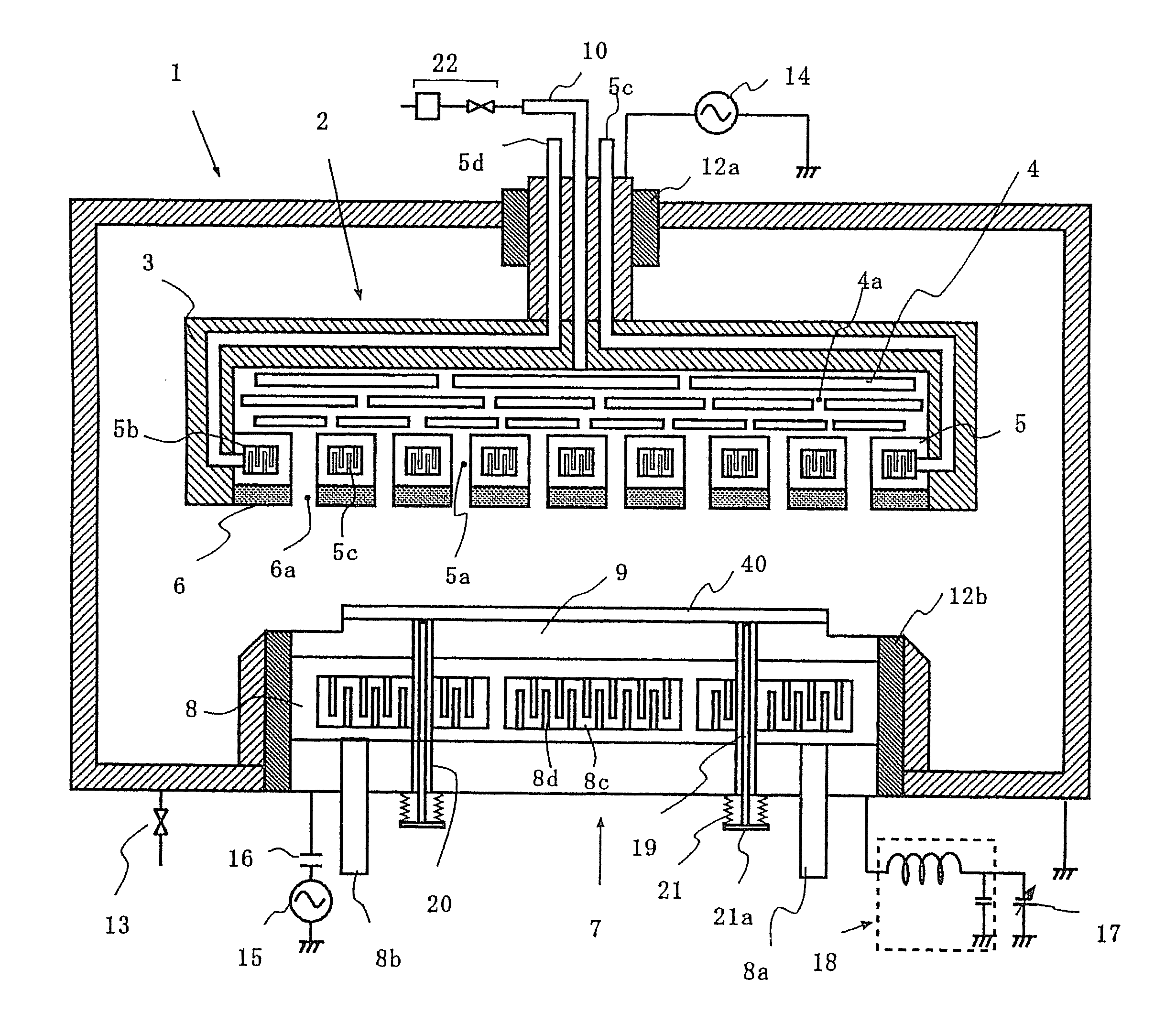

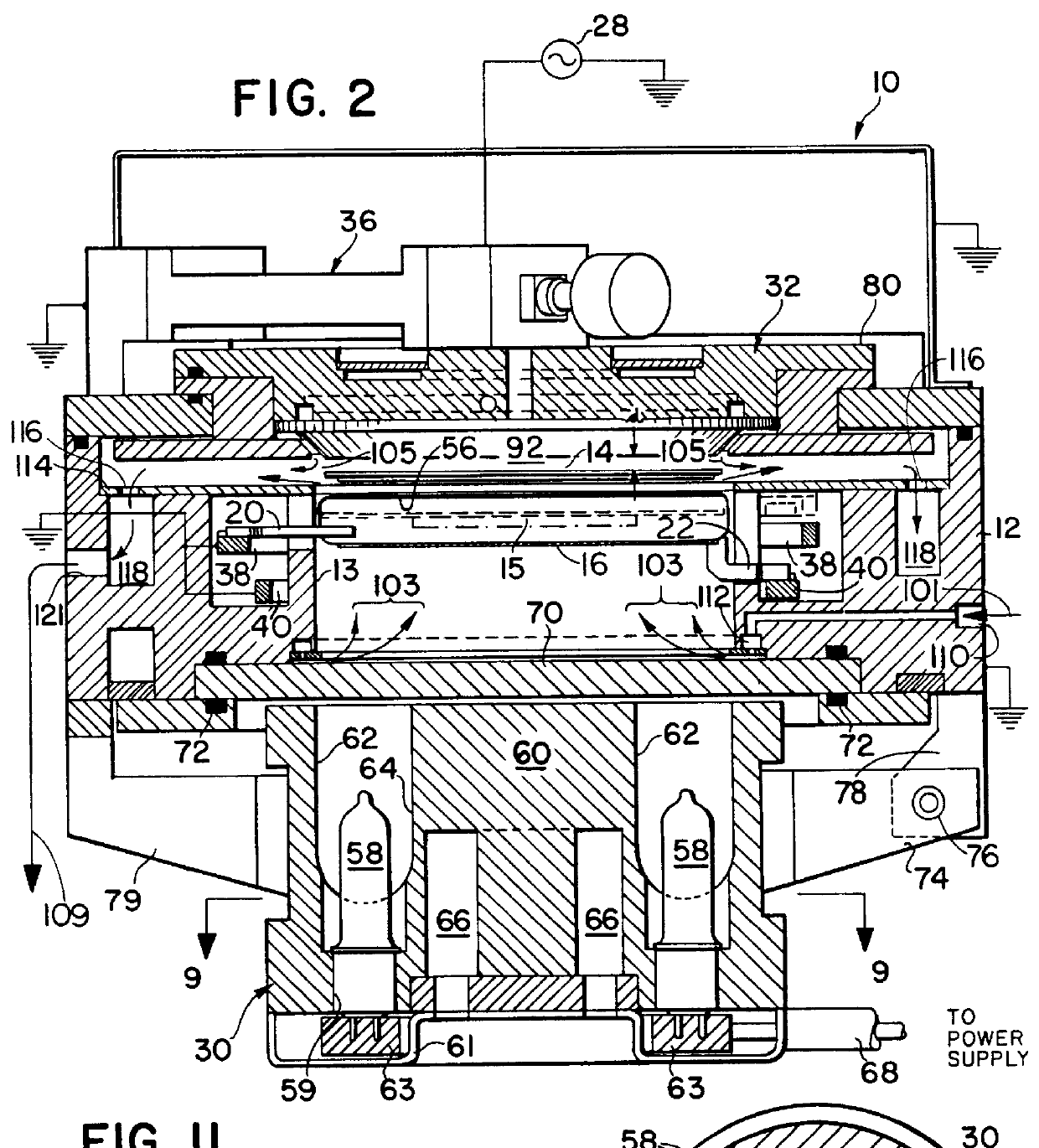

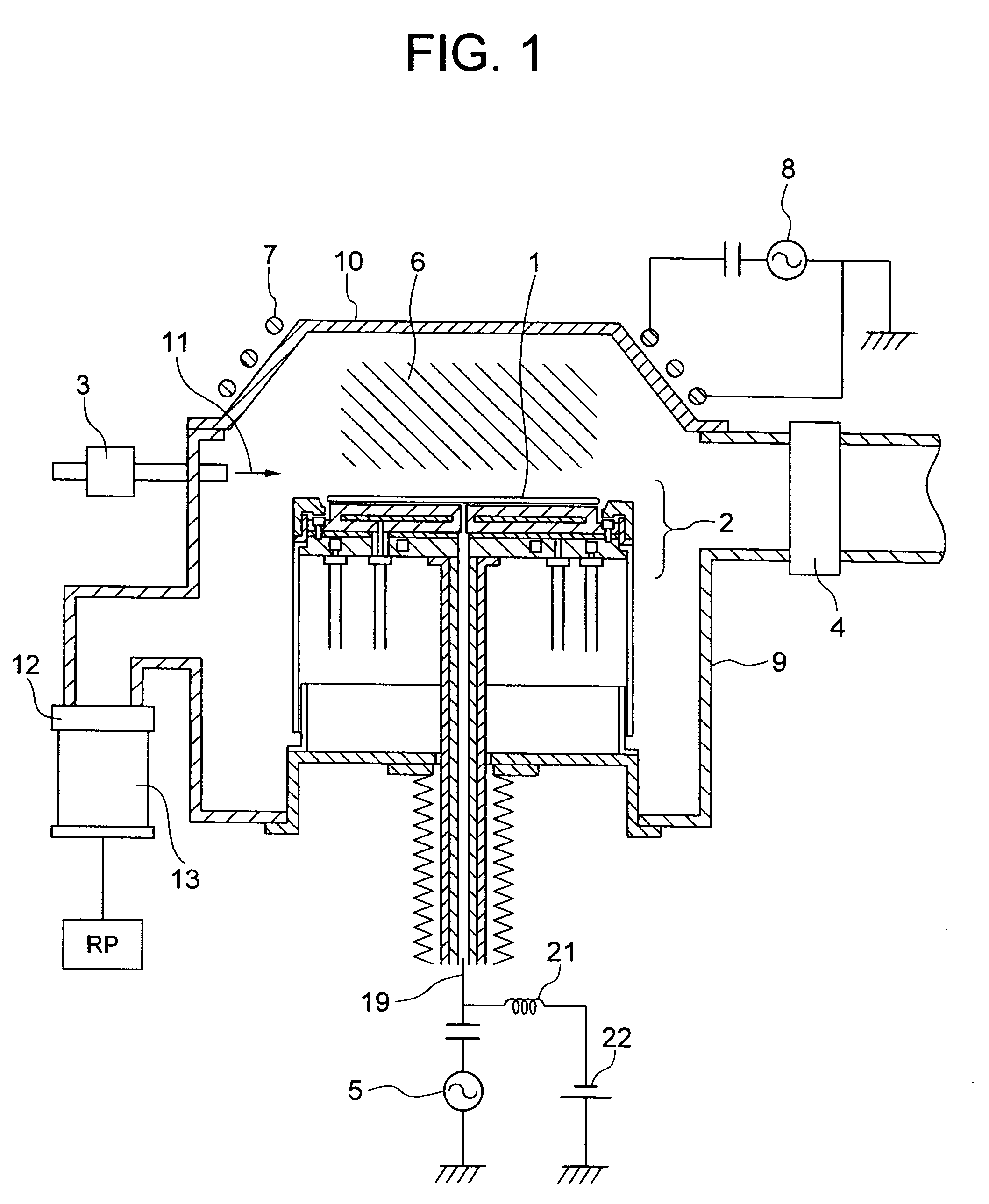

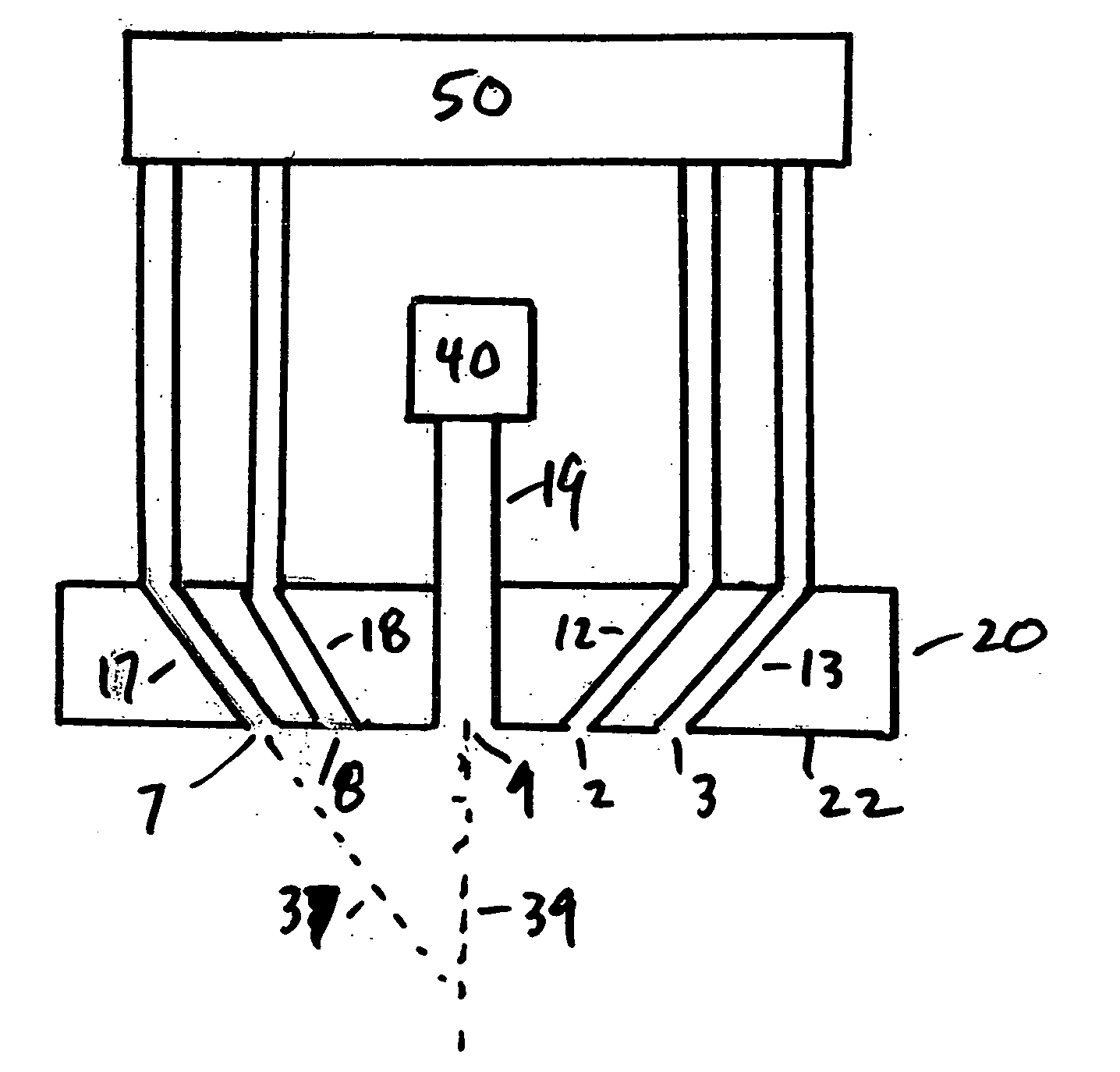

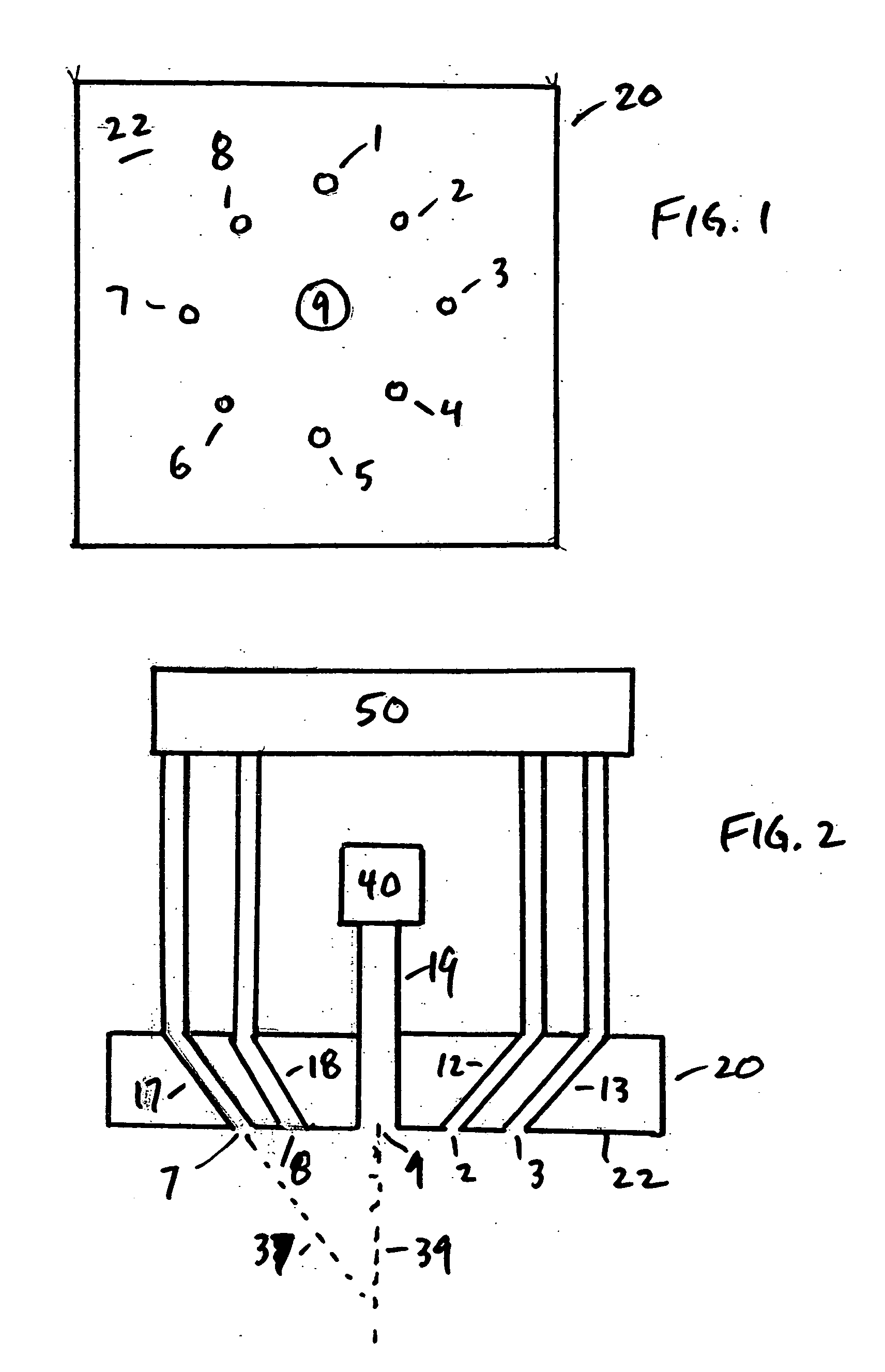

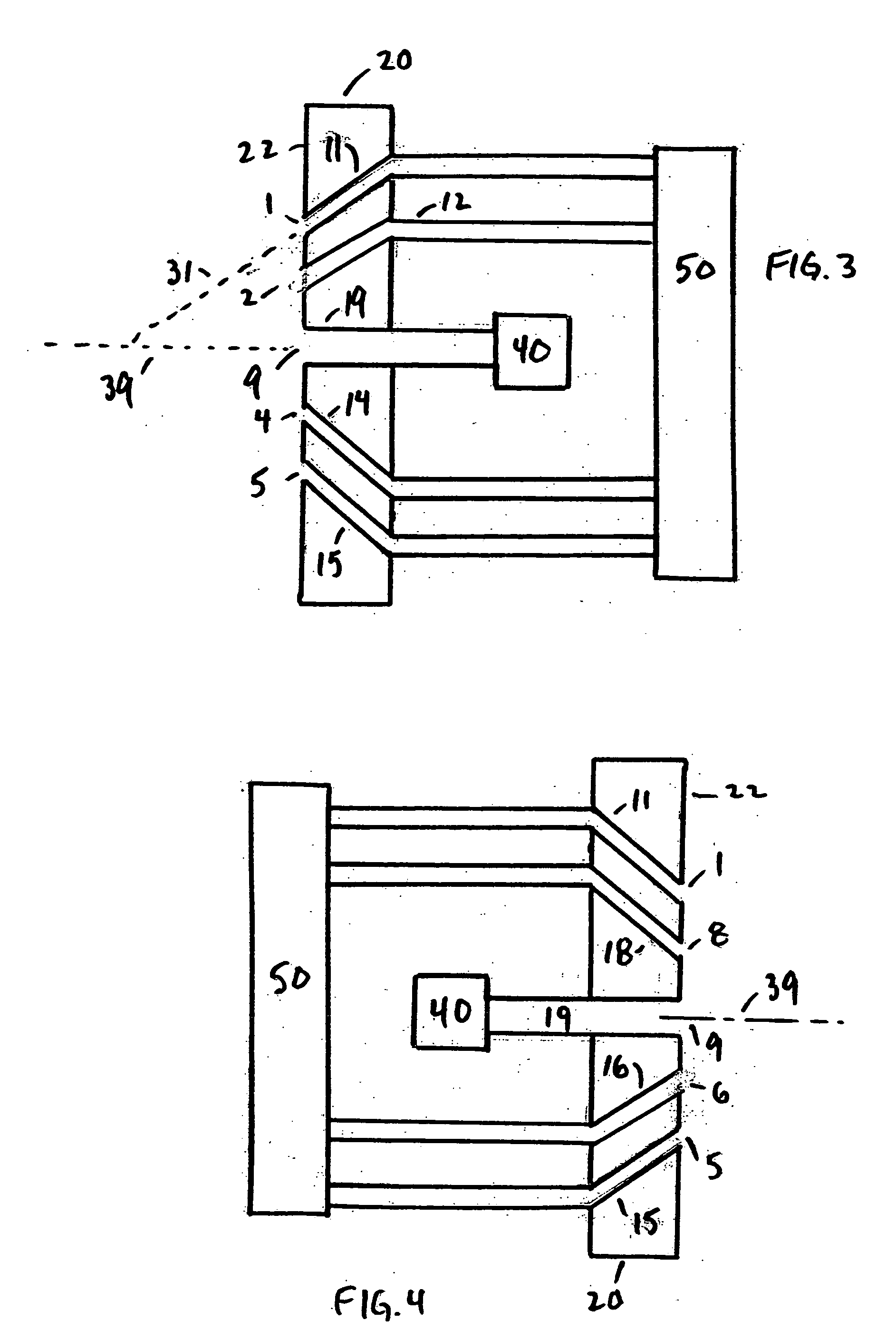

Process for PECVD of silicon oxide using TEOS decomposition

InactiveUSRE36623E1Eliminate depositsAvoid failureElectric discharge tubesPretreated surfacesHigh rateSilicon oxide

A high pressure, high throughput, single wafer, semiconductor processing reactor is disclosed which is capable of thermal CVD, plasma-enhanced CVD, plasma-assisted etchback, plasma self-cleaning, and deposition topography modification by sputtering, either separately or as part of in-situ multiple step processing. The reactor includes cooperating arrays of interdigitated susceptor and wafer support fingers which collectively remove the wafer from a robot transfer blade and position the wafer with variable, controlled, close parallel spacing between the wafer and the chamber gas inlet manifold, then return the wafer to the blade. A combined RF / gas feed-through device protects against process gas leaks and applies RF energy to the gas inlet manifold without internal breakdown or deposition of the gas. The gas inlet manifold is adapted for providing uniform gas flow over the wafer. Temperature-controlled internal and external manifold surfaces suppress condensation, premature reactions and decomposition and deposition on the external surface. The reactor also incorporates a uniform radial pumping gas system which enables uniform reactant gas flow across the wafer and directs purge gas flow downwardly and upwardly toward the periphery of the wafer for sweeping exhaust gases radially away from the wafer to prevent deposition outside the wafer and keep the chamber clean. The reactor provides uniform processing over a wide range of pressures including very high pressures. A low temperature CVD process for forming a highly conformal layer of silicon dioxide is also disclosed. The process uses very high chamber pressure and low temperature, and TEOS and ozone reactants. The low temperature CVD silicon dioxide deposition step is particularly useful for planarizing underlying stepped dielectric layers, either alone or in conjunction with a subsequent isotropic etch. A preferred in-situ multiple-step process for forming a planarized silicon dioxide layer uses (1) high rate silicon dioxide deposition at a low temperature and high pressure followed by (2) the deposition of the conformal silicon dioxide layer also at high pressure and low temperature, followed by (3) a high rate isotropic etch, preferably at low temperature and high pressure in the sane reactor used for the two oxide deposition steps. Various combinations of the steps are disclosed for different applications, as is a preferred reactor self-cleaning step.

Owner:APPLIED MATERIALS INC

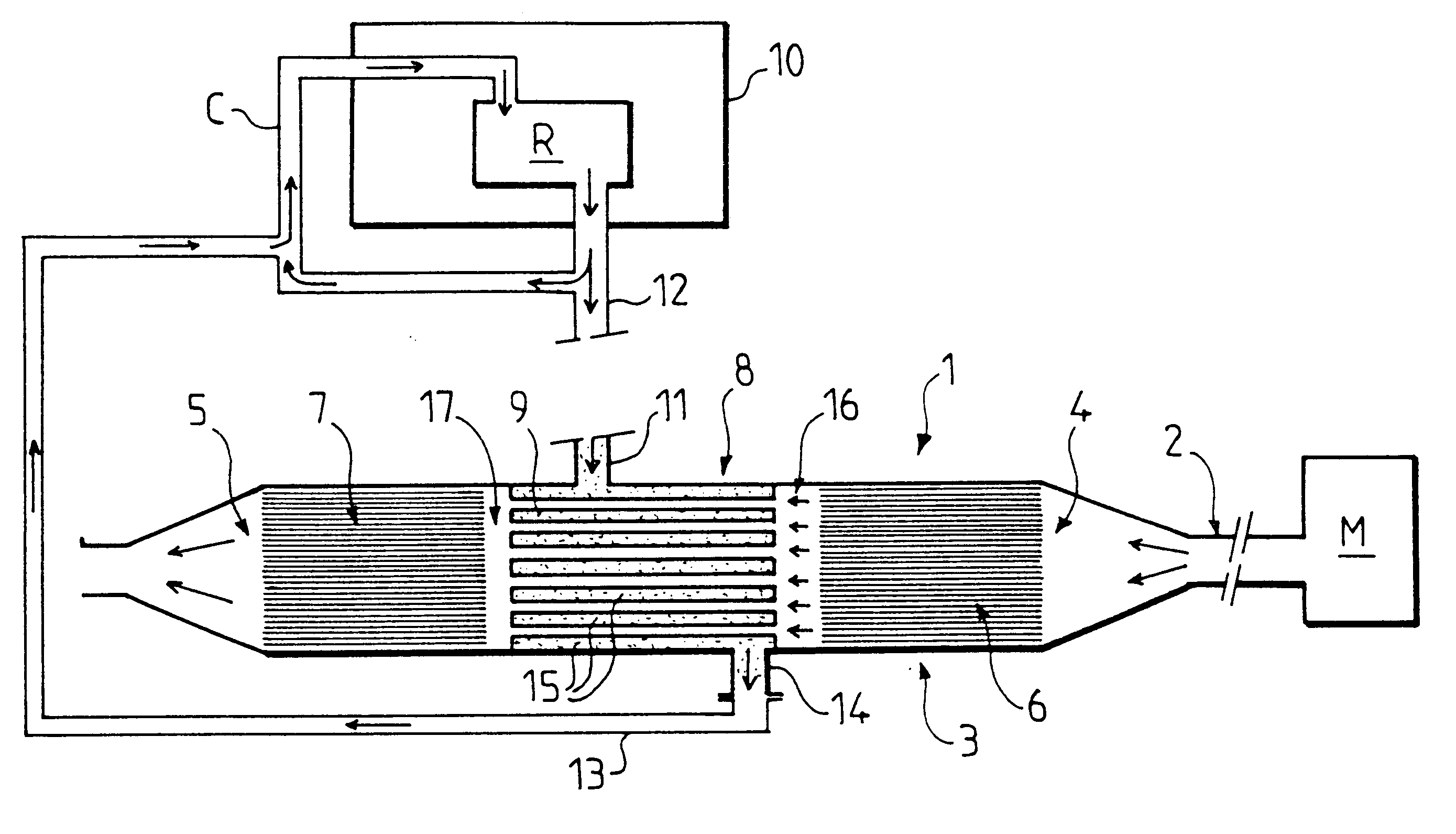

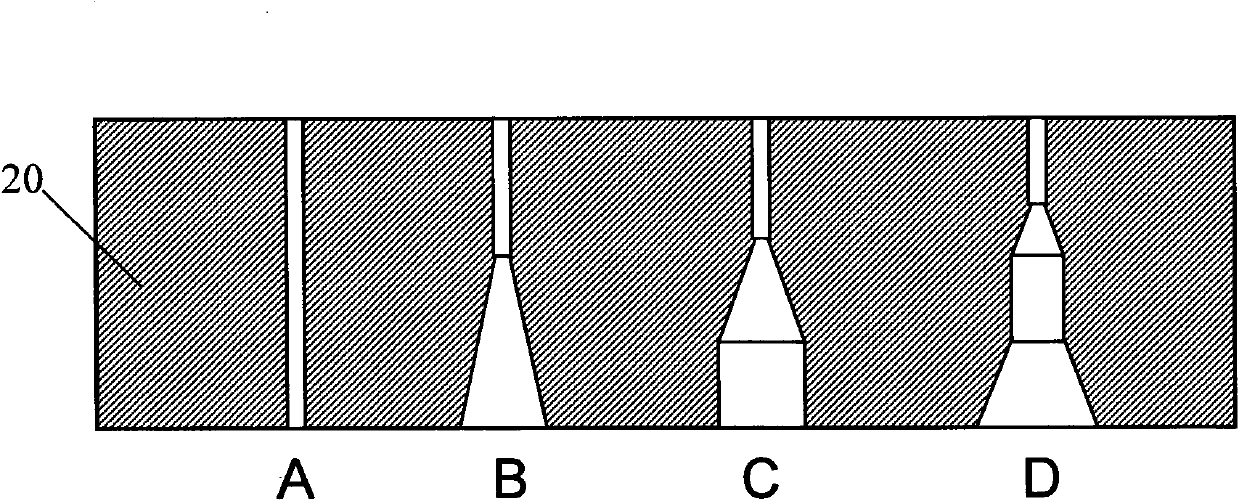

Controlled temperature catalytic converter, in particular for a motor vehicle

InactiveUS6178744B1Uniform temperatureImprove distributionInternal combustion piston enginesExhaust apparatusMobile vehicleExhaust fumes

A catalytic converter includes a casing connected to the output from an exhaust gas and residue manifold of an engine, in particular an engine of a motor vehicle. The casing contains arrangements for oxidizing the exhaust gases and residues and for trapping the oxidized gases and residues. A central part of the casing houses cooling arrangements for reducing the temperature of the gases and residues upstream of the trapping arrangements below a predetermined threshold.

Owner:VALEO THERMIQUE MOTEUR

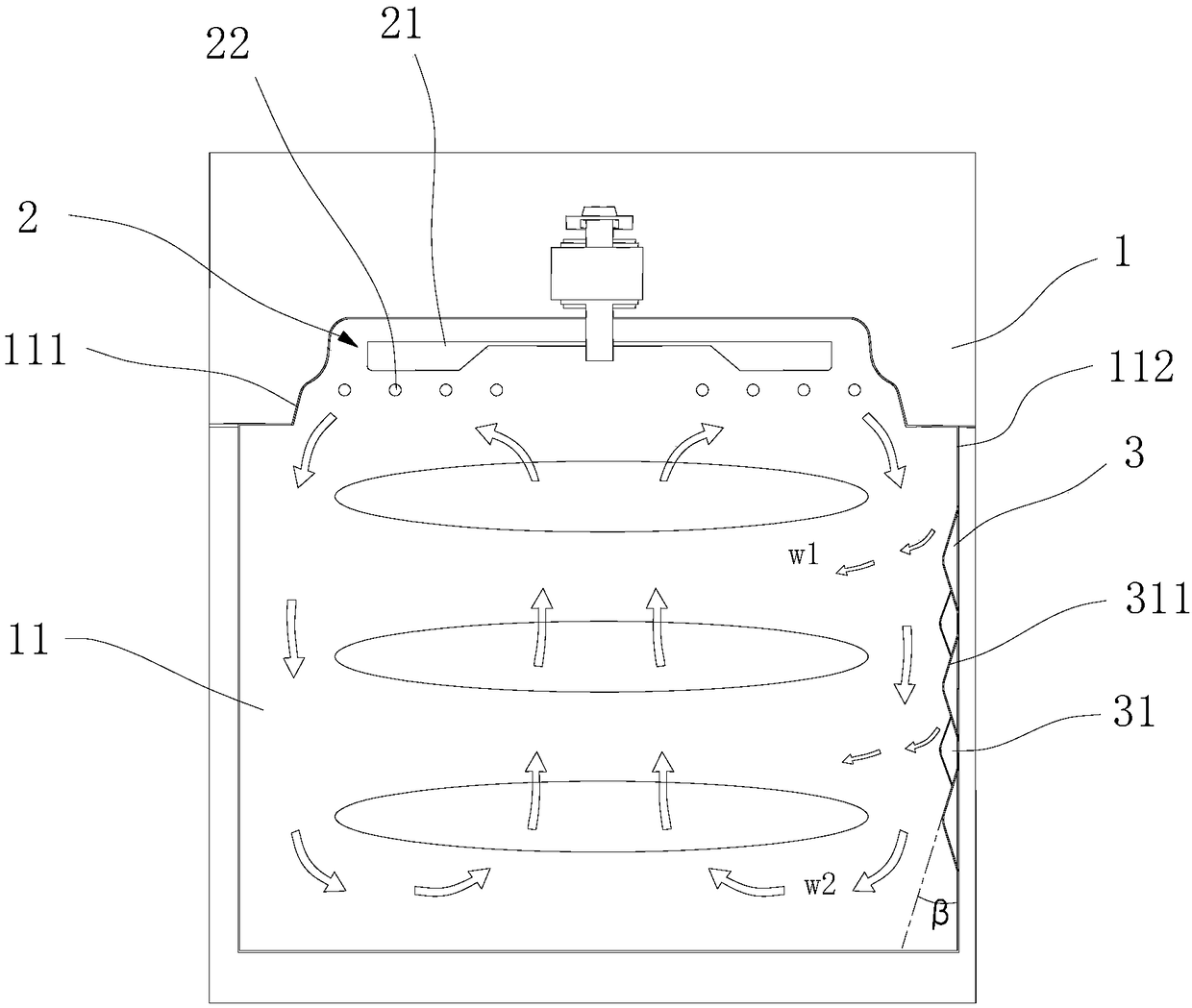

Cooking device

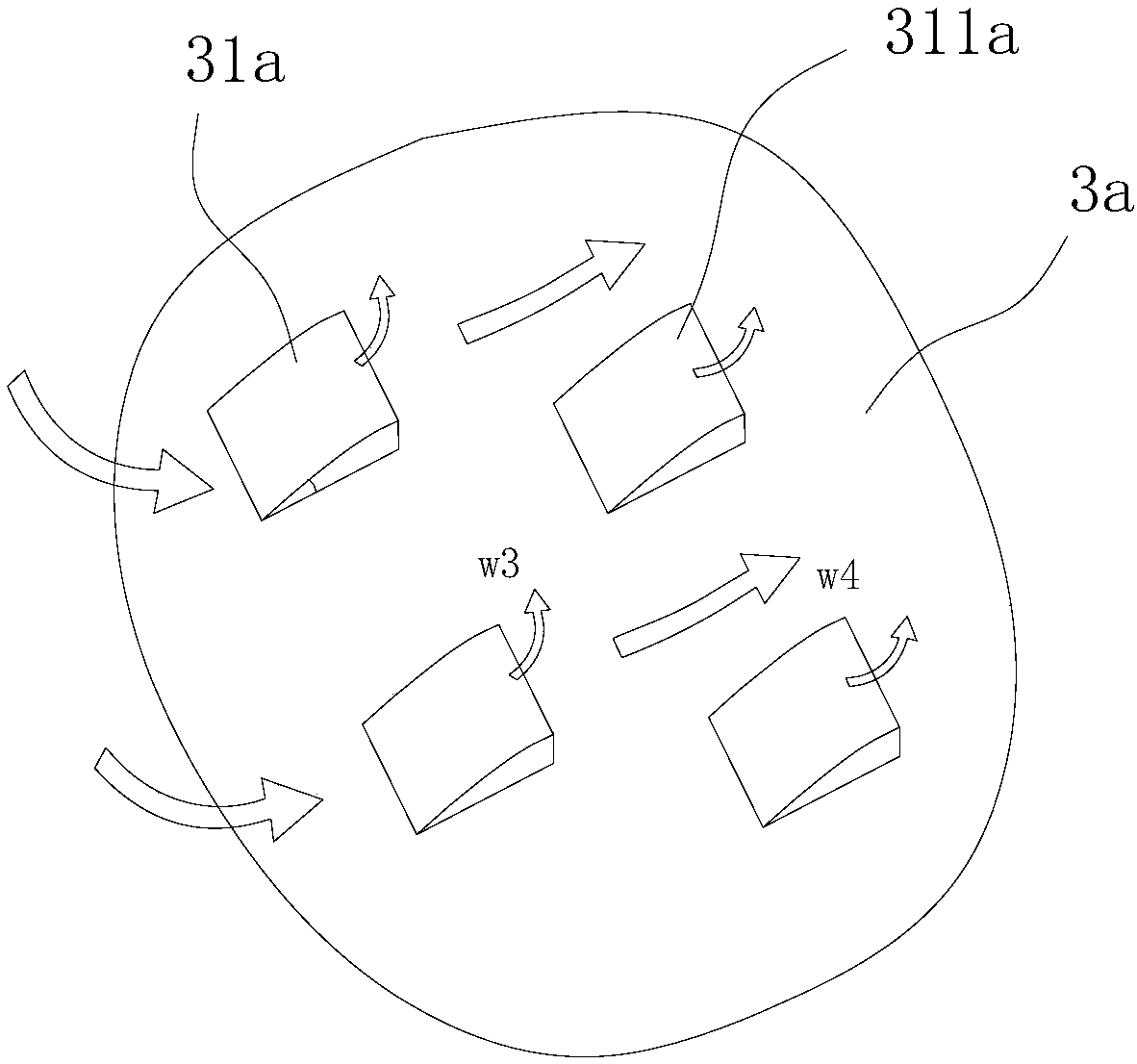

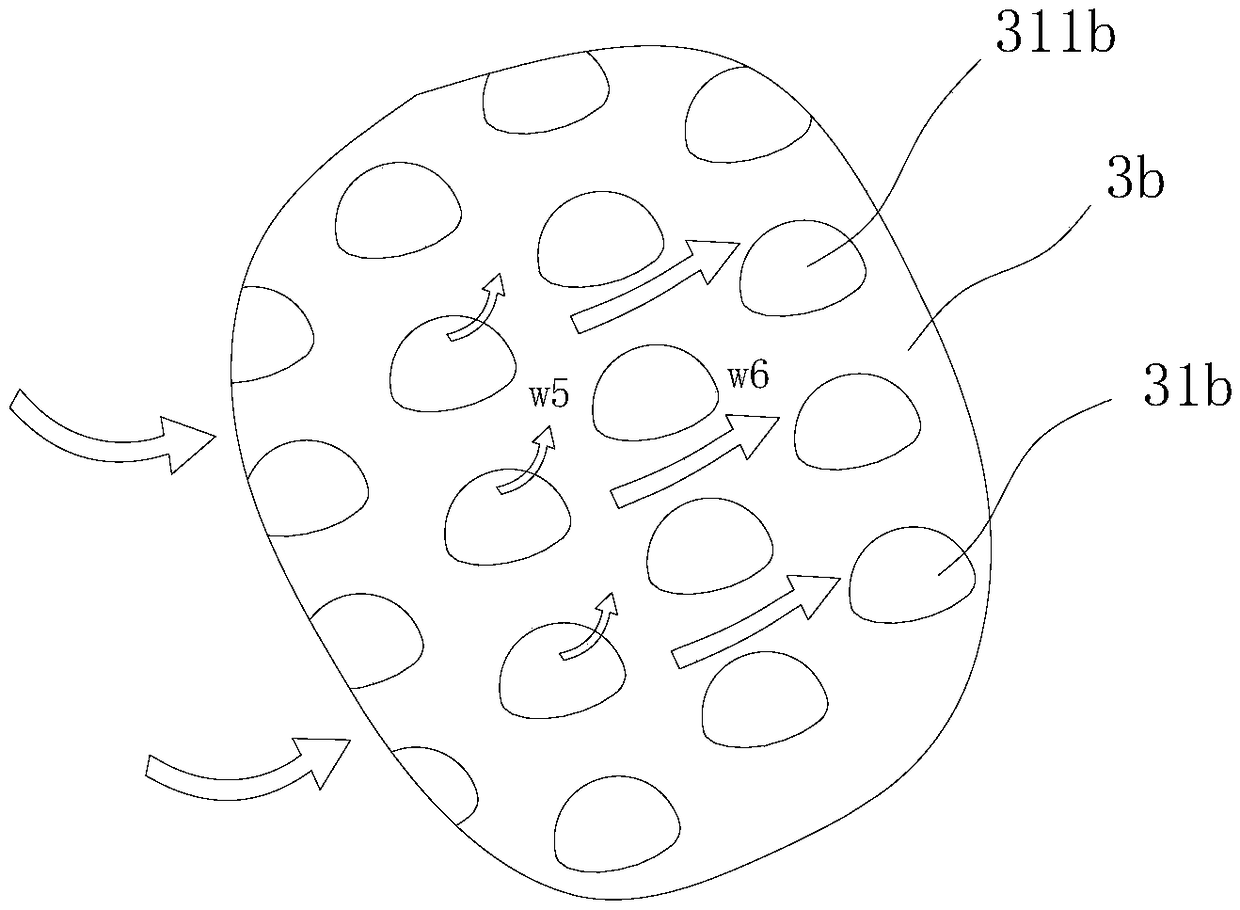

PendingCN108703675AFully heatedImprove cooking resultsRoasting apparatusRoasters/grillsProcess engineeringAirflow

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

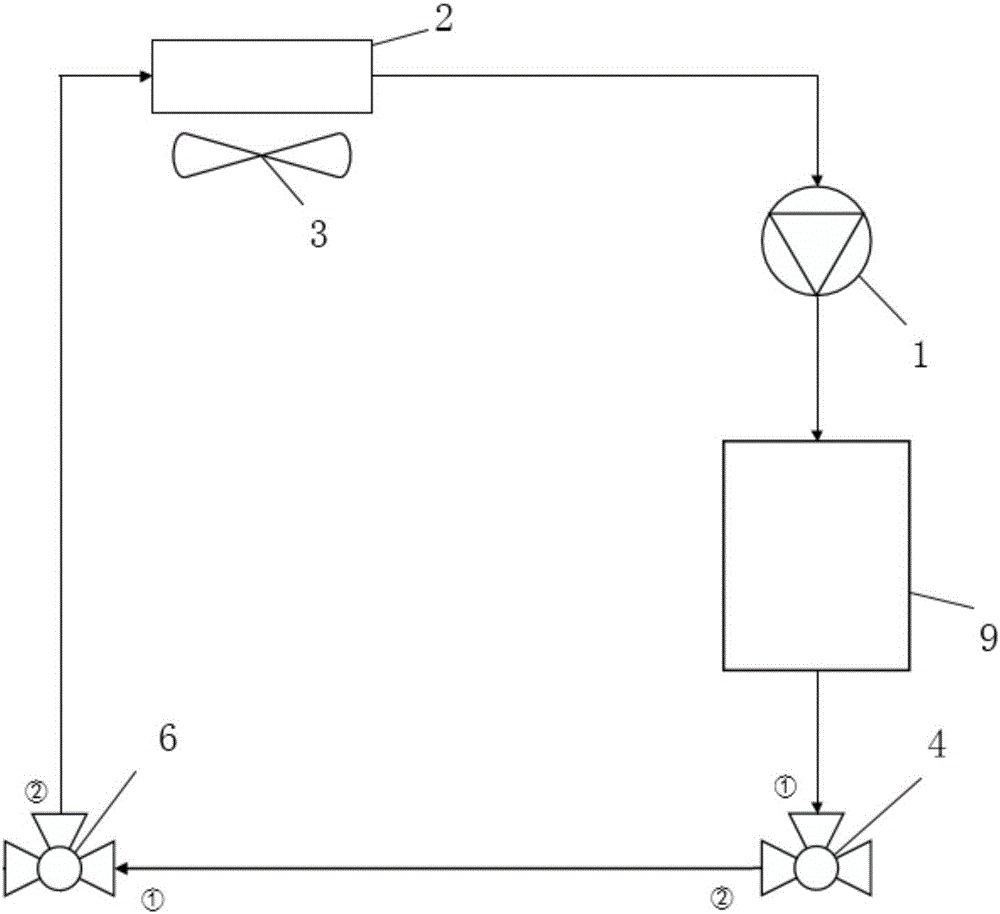

Intelligent multi-loop electric automobile cooling system

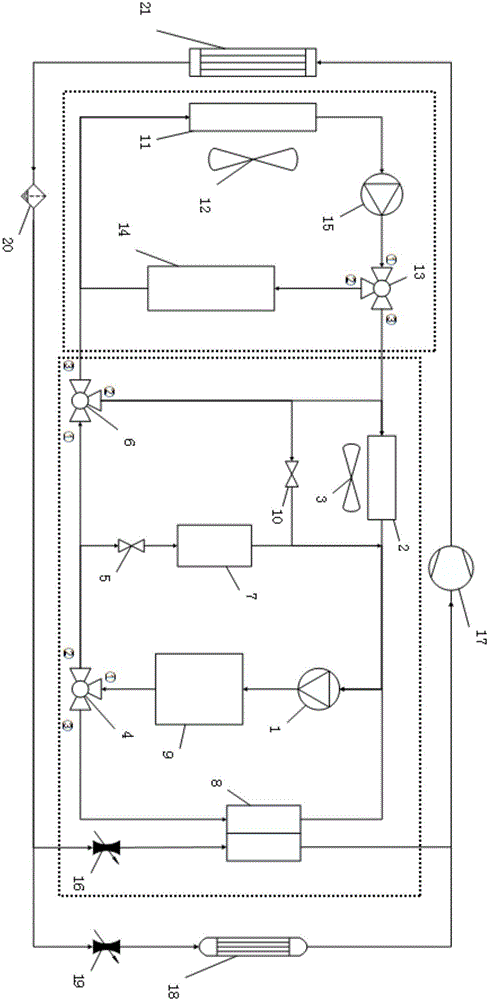

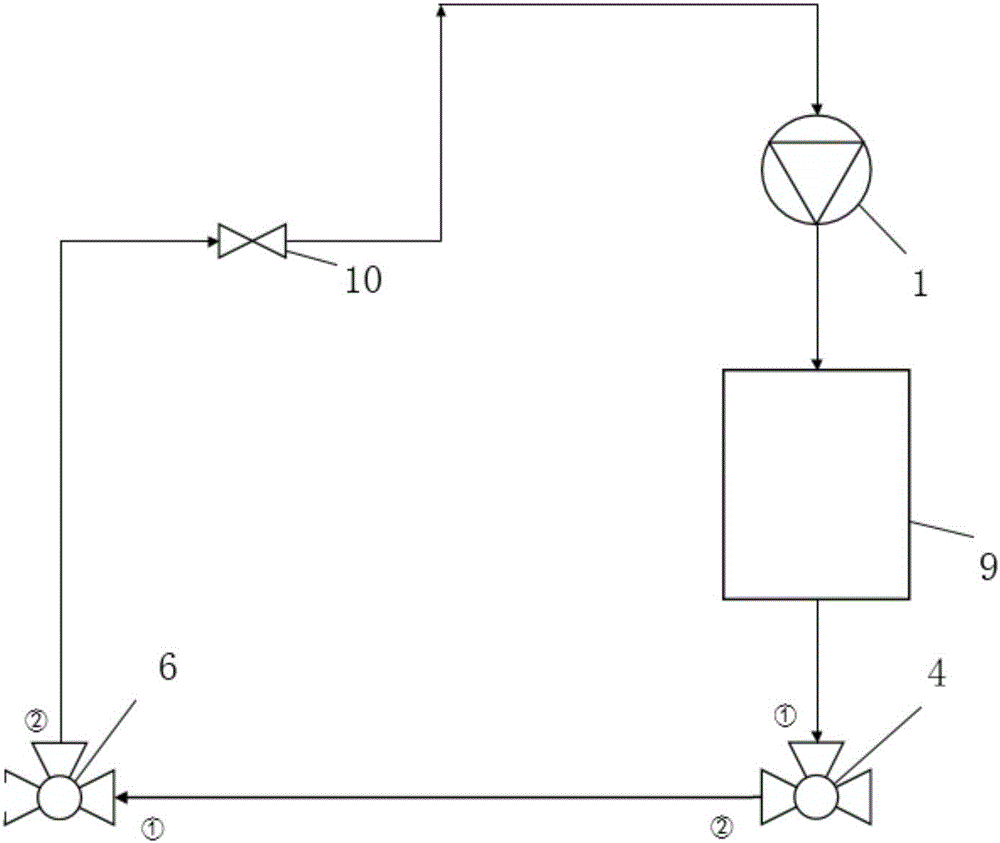

ActiveCN106585414AUniform temperatureGuaranteed uptimePower to auxillary motorsPropulsion by batteries/cellsIntelligent lightingPower battery

The invention relates to an intelligent multi-loop electric automobile cooling system. The intelligent multi-loop electric automobile cooling system comprises a power battery pack, an armature module, a battery radiator, an armature radiator, electric water pumps, straightway valves, three-way valves, a PTC heater and a heat exchanger. The cooling system is provided with the two electric water pumps, the two straightway valves and the three three-way valves, and a plurality of loops are formed through pipeline connection. Compared with the prior art, the intelligent multi-loop electric automobile cooling system is provided with the multiple three-way valves and the straightway valves, pipelines are connected to form the loops meeting different cooling or heating needs, the loops are selectively opened or closed according to the characteristics and working states of the electric automobile power battery pack and the armature module, thus temperature balance of an electric automobile is ensured, efficient operation of the electric automobile is ensured, and system energy conservation is significant. Power battery pack cooling and armature module cooling are associated with each other, thus automobile endurance mileage becomes longer, and the power performance and economy of the automobile become better.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

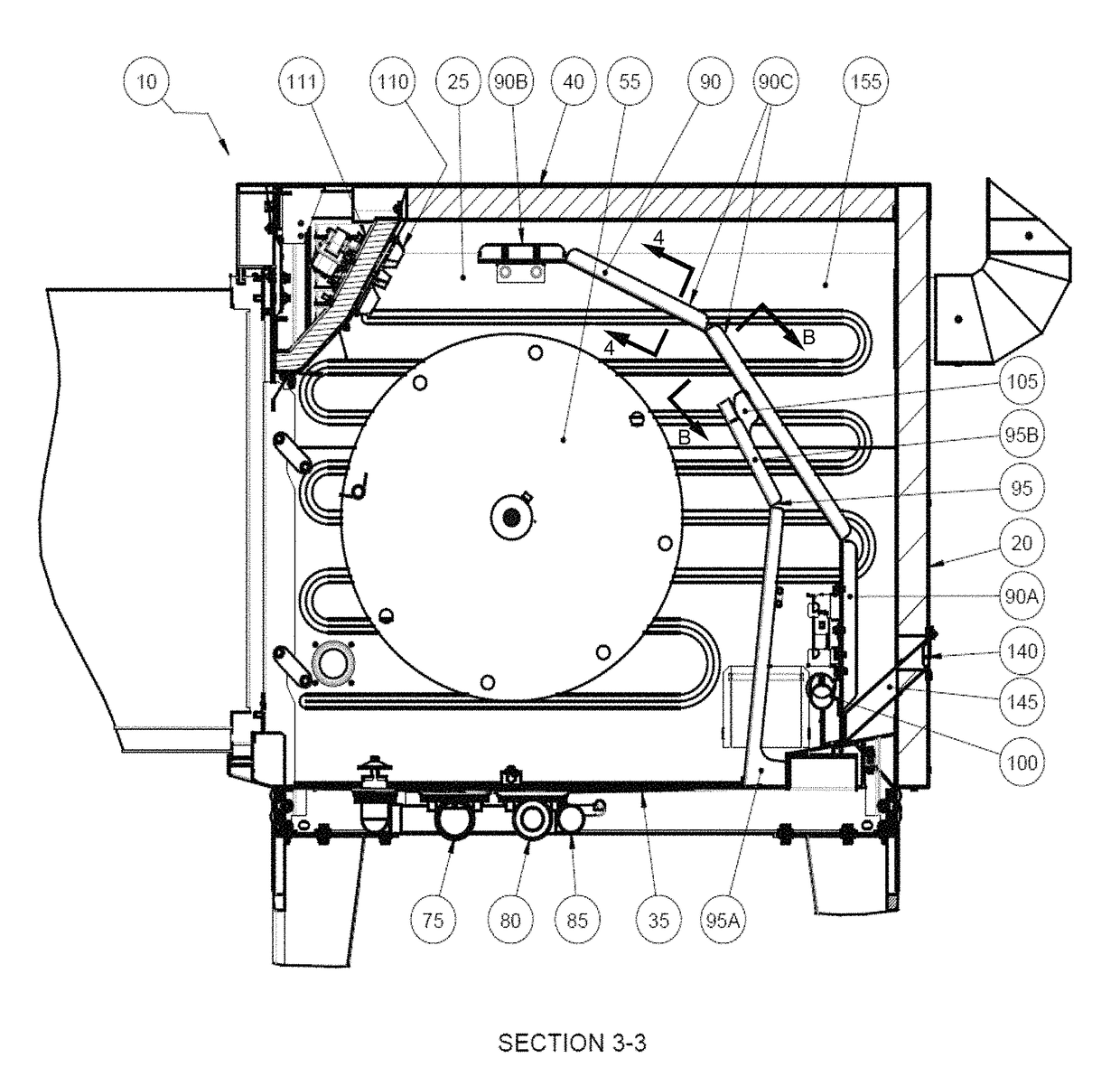

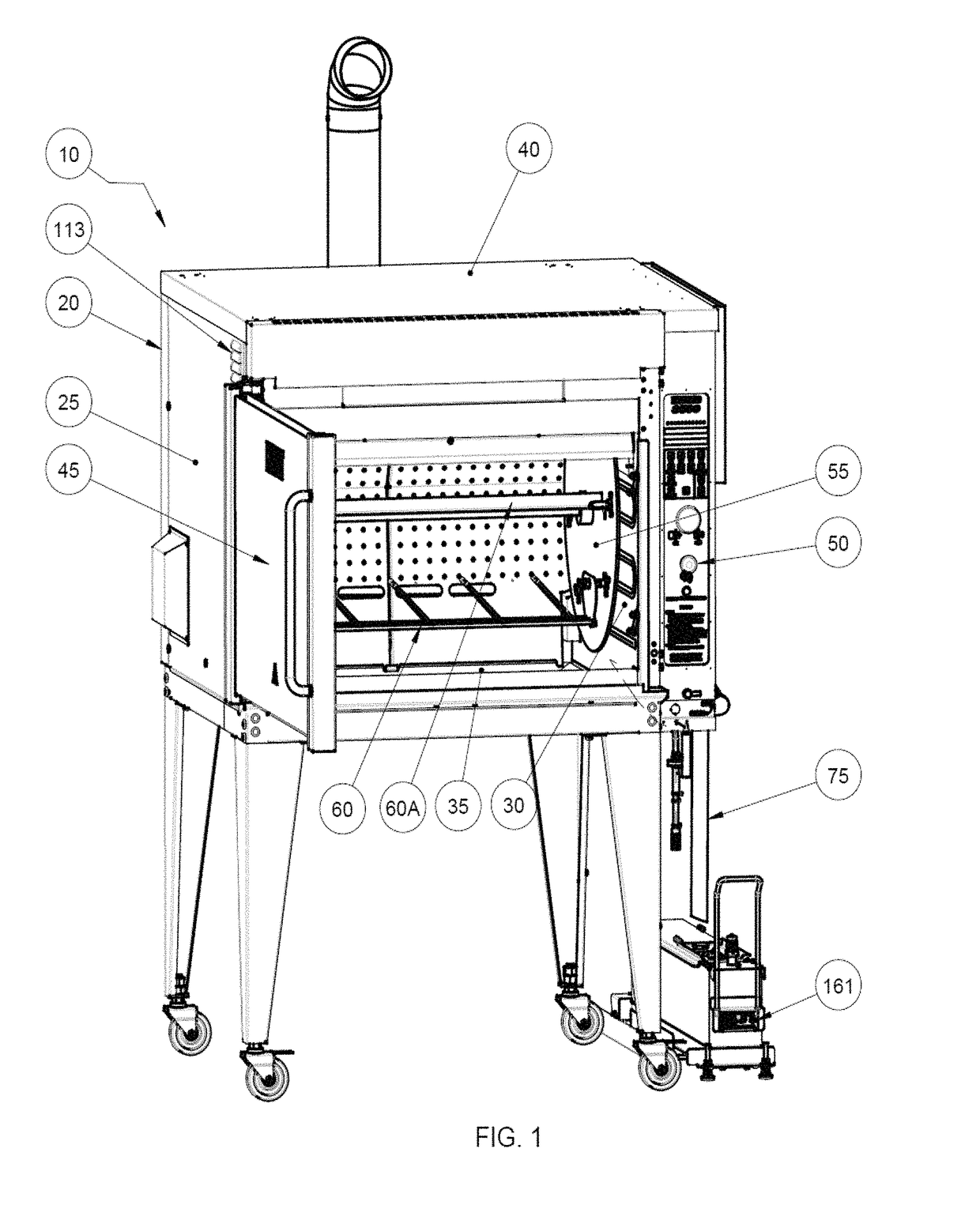

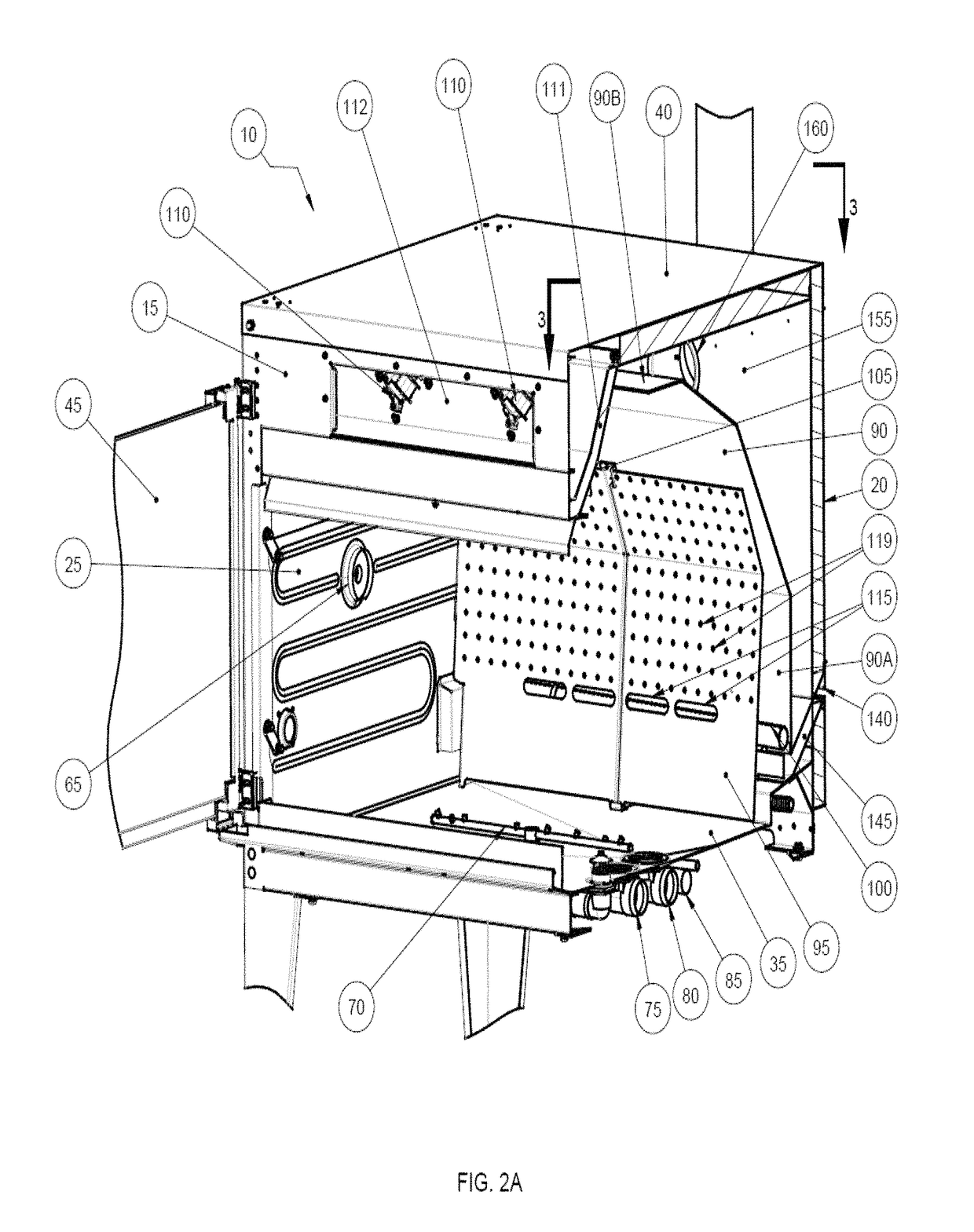

Atmospheric rotisserie burner with convection heating

ActiveUS10051995B2Utility and advantagePreventing situationRoasting apparatusRoasters/grillsAir movementEngineering

The present invention provides a device for cooking food that has a cooking cavity defined by a front wall, a back wall that opposes the front wall, two opposing side walls, a ceiling, and a floor that opposes the ceiling; a substrate for supporting a food item, the substrate substantially enclosed by the cavity; a first plenum spanning between the two opposing side walls, said plenum comprising a first segment proximal to the back wall, a second segment proximal to the ceiling, and at least one third segment that joins the first segment and the second segment; a second plenum positioned proximal to but medially displaced from the first plenum; a flame heating element located between the first plenum and the second plenum; and at least one air movement device located proximal to a region in which the front wall and ceiling intersect.

Owner:7794754 CANADA

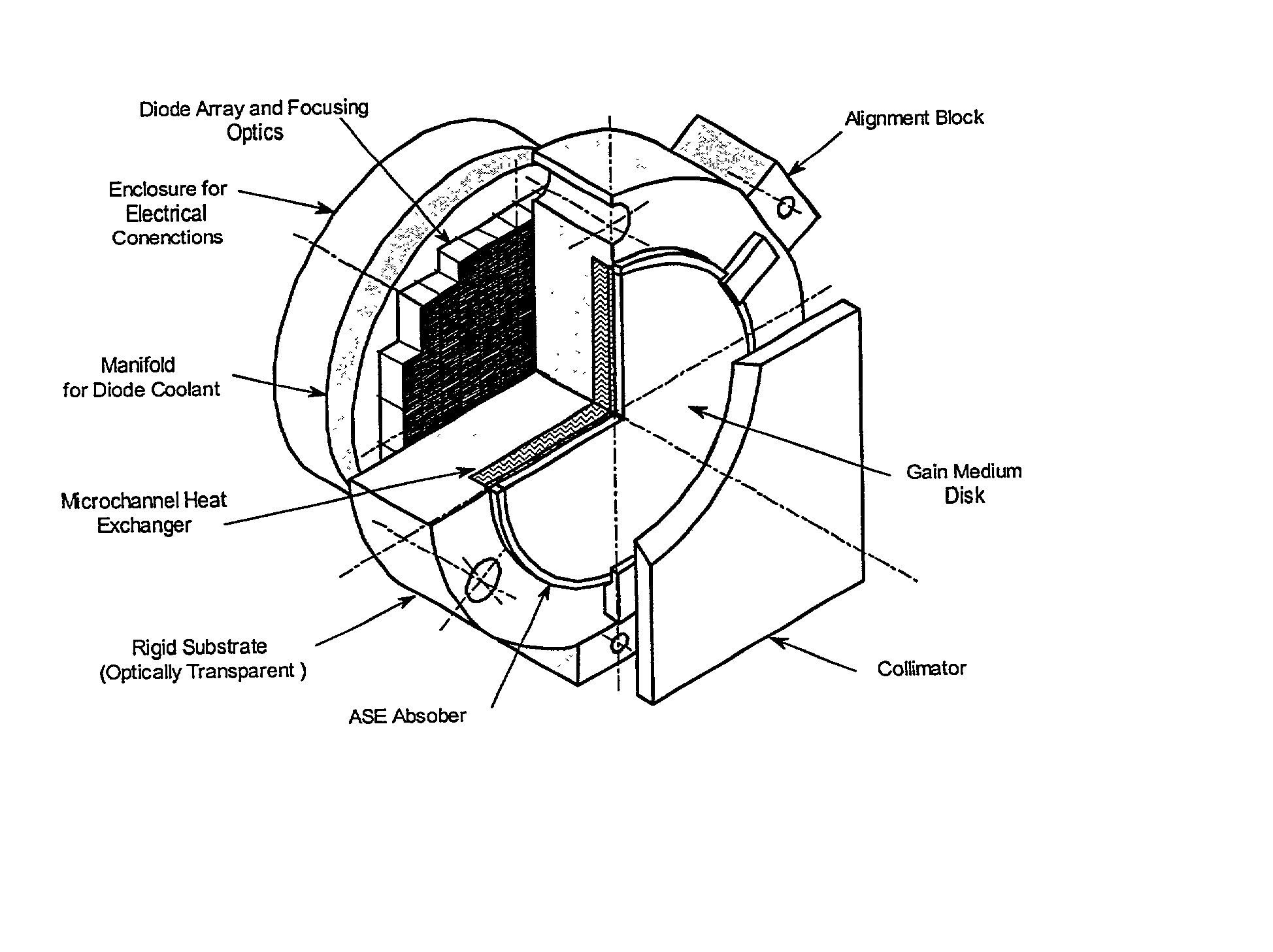

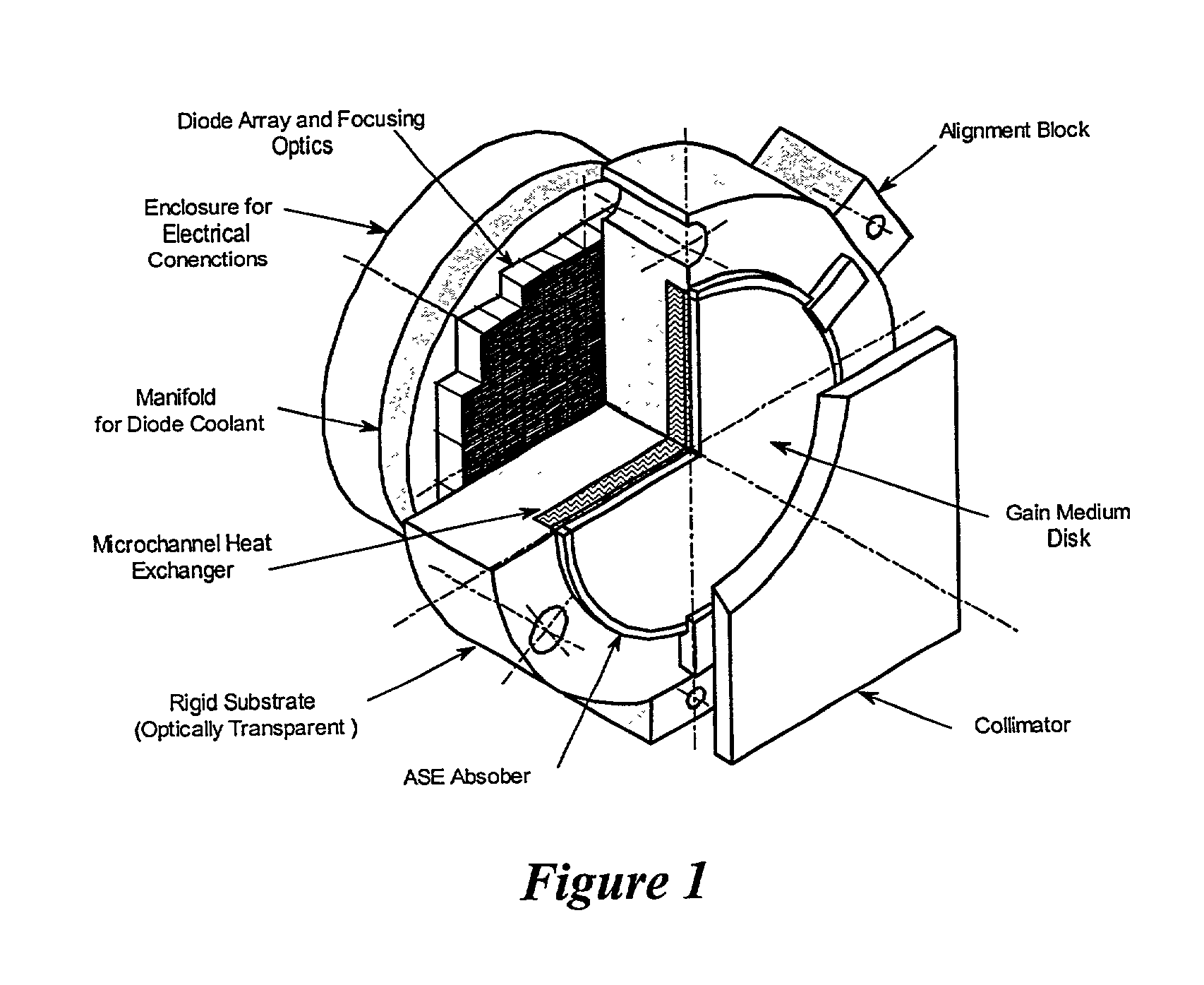

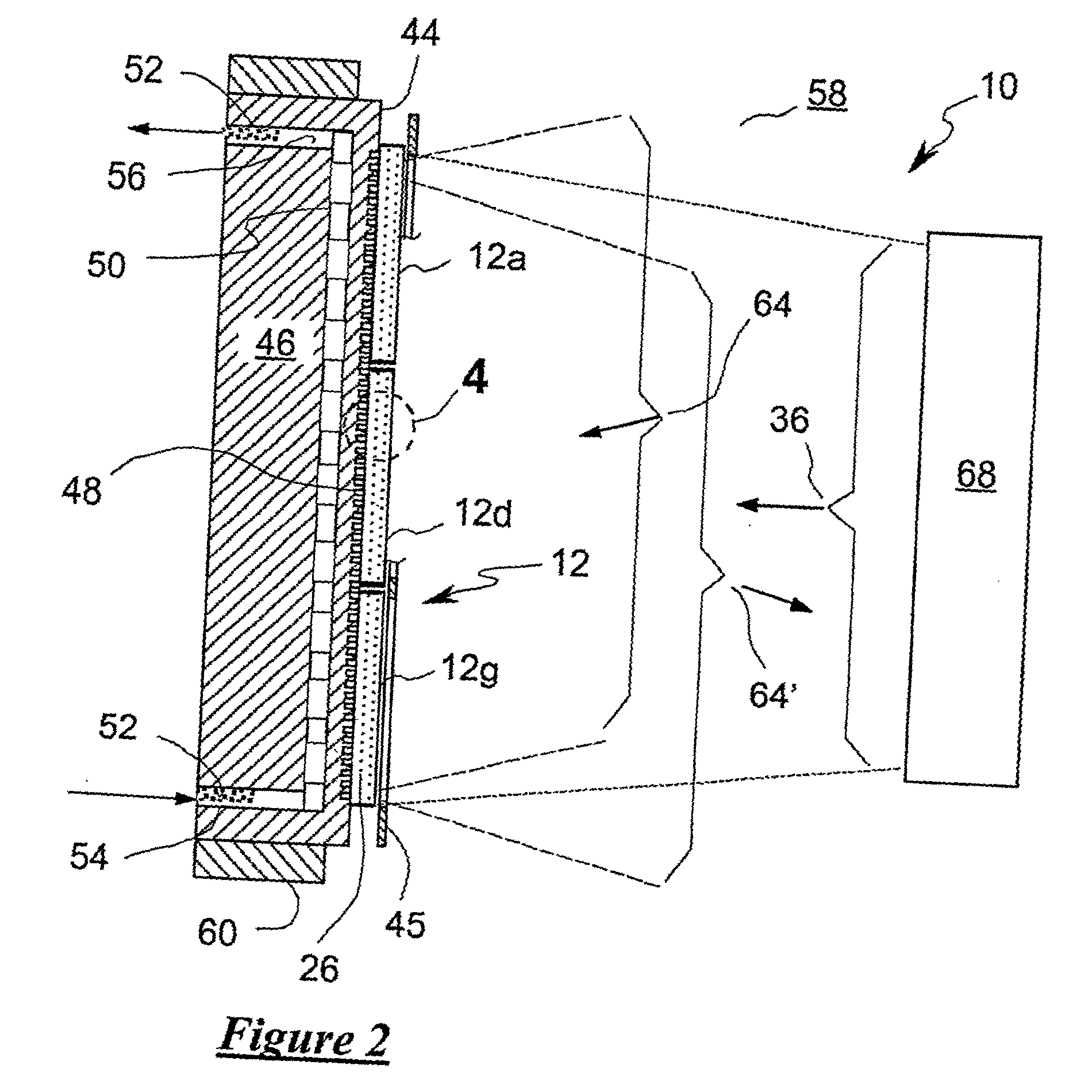

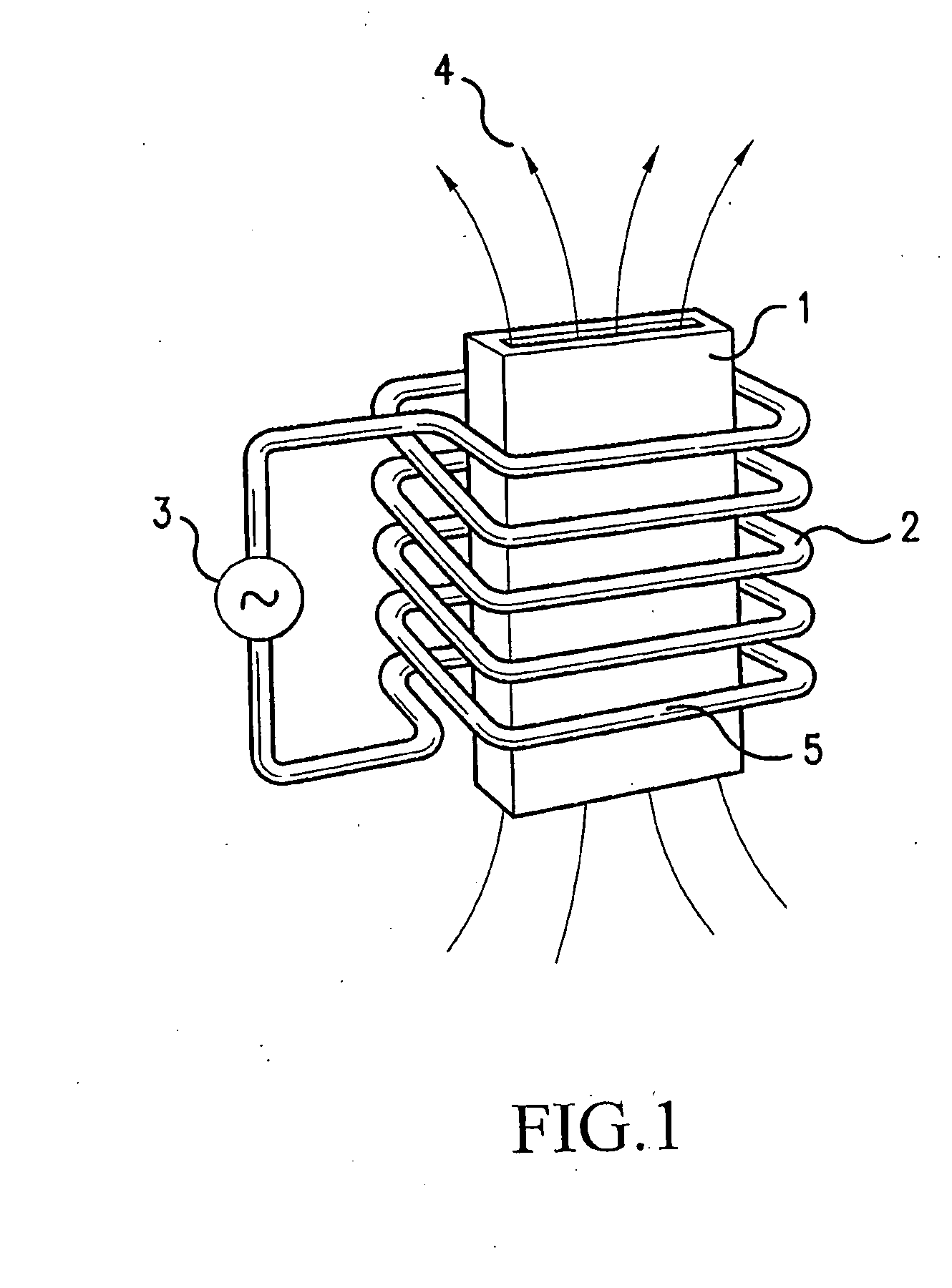

High-average power active mirror solid-state laser with multiple subapertures

InactiveUS20020110164A1Precise positioningRelieve pressureActive medium materialActive medium shape and constructionOptical coatingHydrostatic pressure

An apparatus and method for achieving ultrahigh-power output from a solid-state laser. The solid-state laser of the subject invention uses multiple disk-shaped laser gain media (subapertures) placed adjacent to each other to fill an optical aperture of an AMA module. In one preferred embodiment each of the laser gain media is provided with optical coatings for operation in the active mirror configuration. Furthermore, each of the laser gain media is hydrostatic pressure-clamped to a rigid, cooled substrate, which allows it to maintain a prescribed shape even when experiencing significant thermal load. A cooling medium can be provided to a heat exchanger internal to the substrate and / or flowed through the passages on the substrate surface, thereby directly cooling the laser gain medium.

Owner:THE BOEING CO

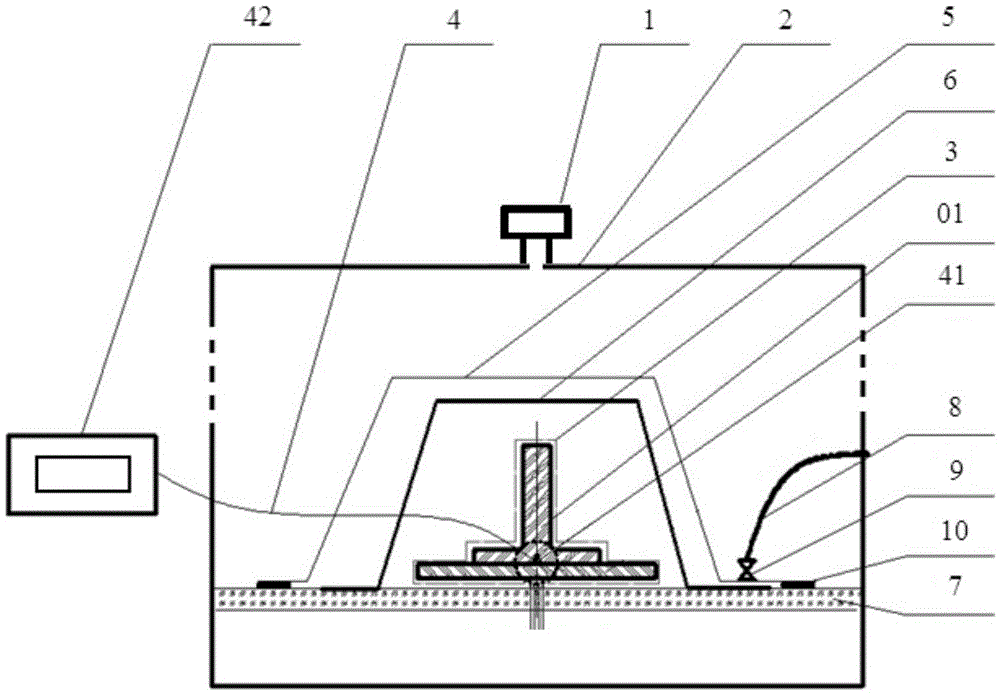

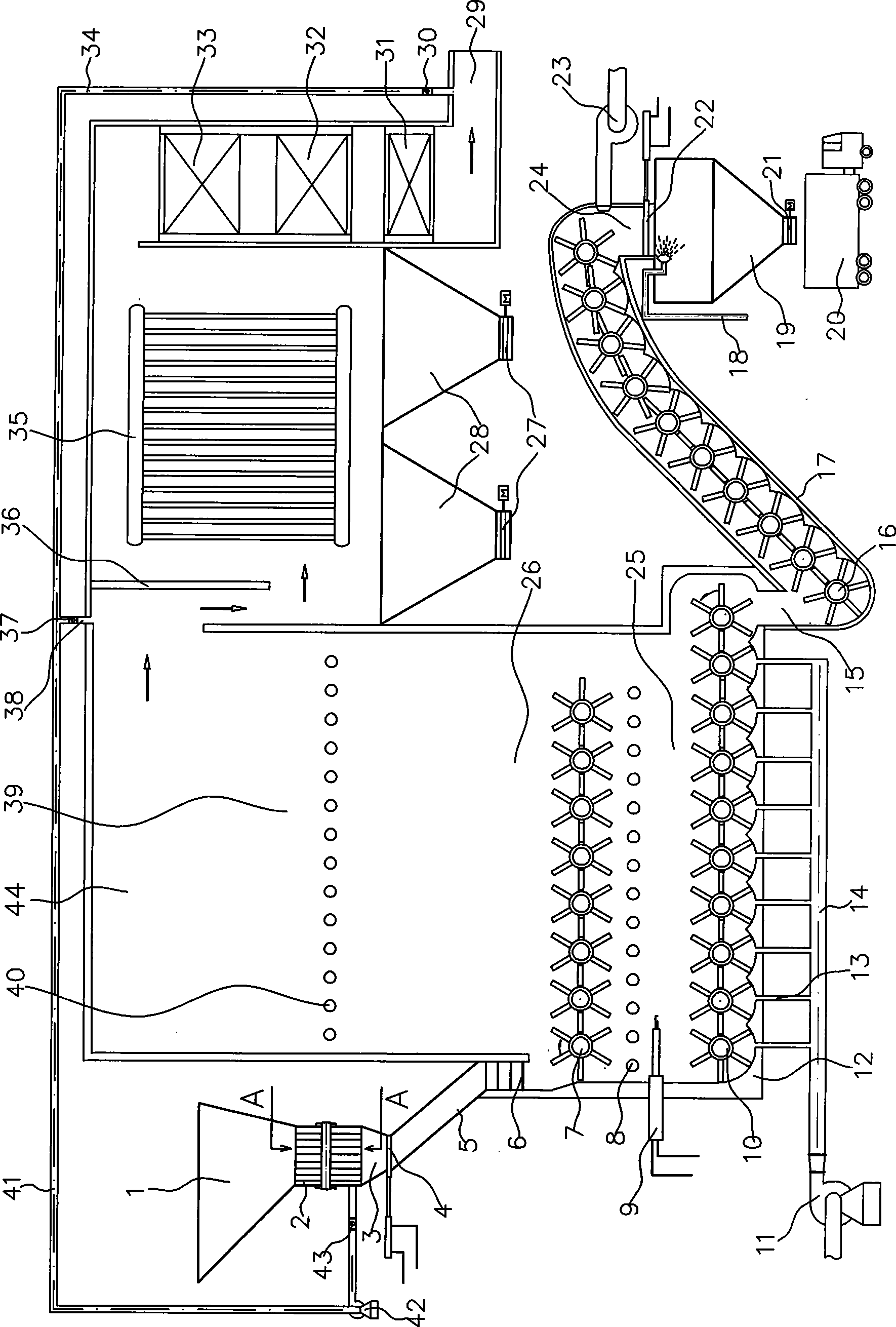

Large multifunctional environmental simulator for electrical test

ActiveCN101799515AUniform temperatureUniform air flowTesting dielectric strengthUltra high voltageHigh pressure

The invention relates to a large multifunctional environmental simulator for electrical tests, which comprises an environmental stimulation chamber and is characterized in that an air heat-exchange circulation system and an ice-melting system are arranged in the environmental stimulation chamber; and the environmental stimulation chamber further comprises an ice-coating, rain-exposing and ultrasonic-atomizing system, a water treatment system, a heat-fogging system, a cooling water circulation system, a refrigeration system, a vacuuming and defogging system, a measurement and control system and an ultra-high voltage power supply system for providing a high-voltage charging state for test-pieces. By achieving the skillful coordination among the systems and the uniform operation control by the measurement and control system, the large multifunctional environmental simulator integrates various testing functions of environmental simulations, such as high-altitude, ice-coating, contamination, rain-exposing and other simulations into a whole. Therefore, the invention is widely suitable for the testing process for large multi-parameter environmental simulations.

Owner:BEIHANG UNIV +1

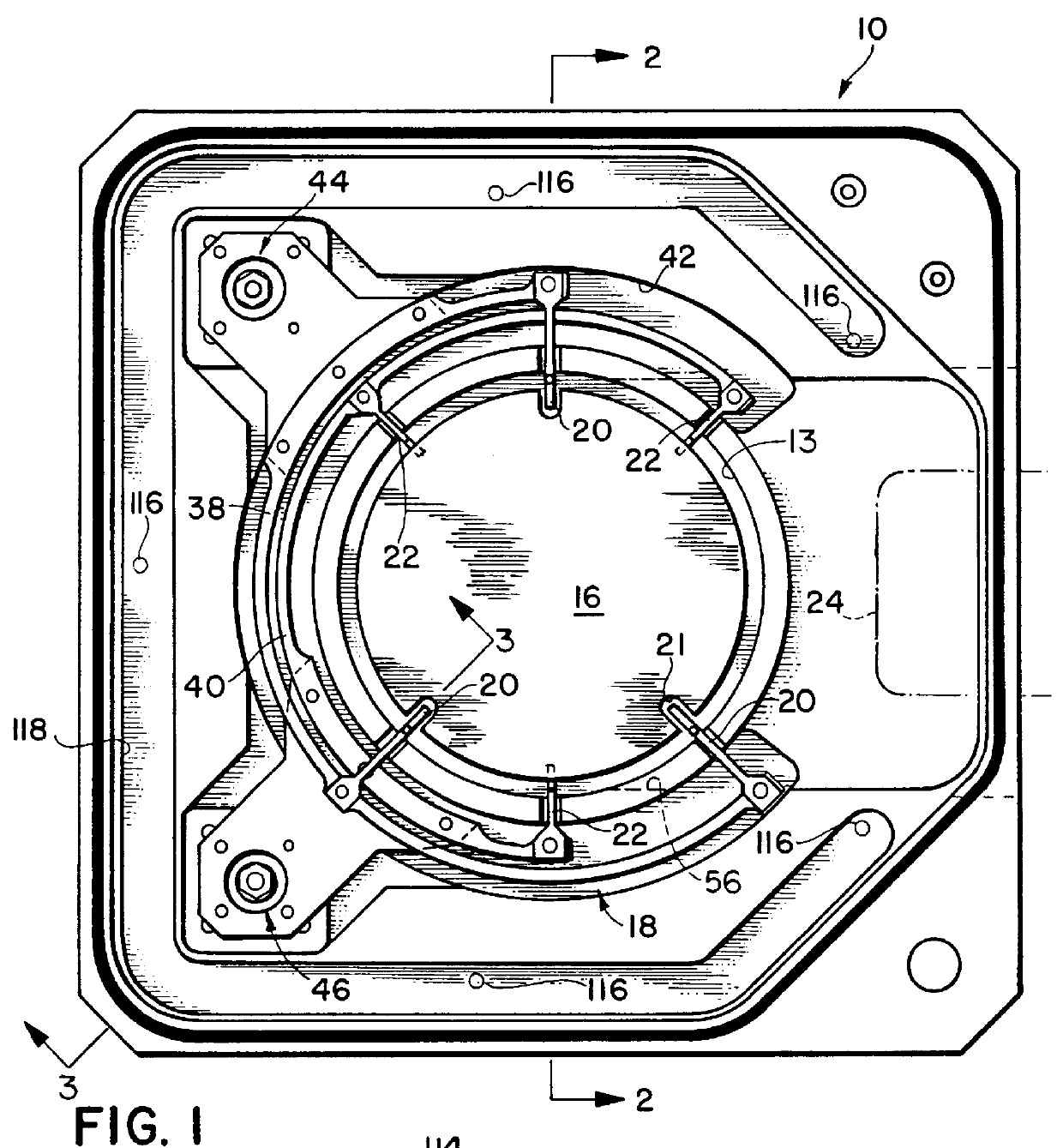

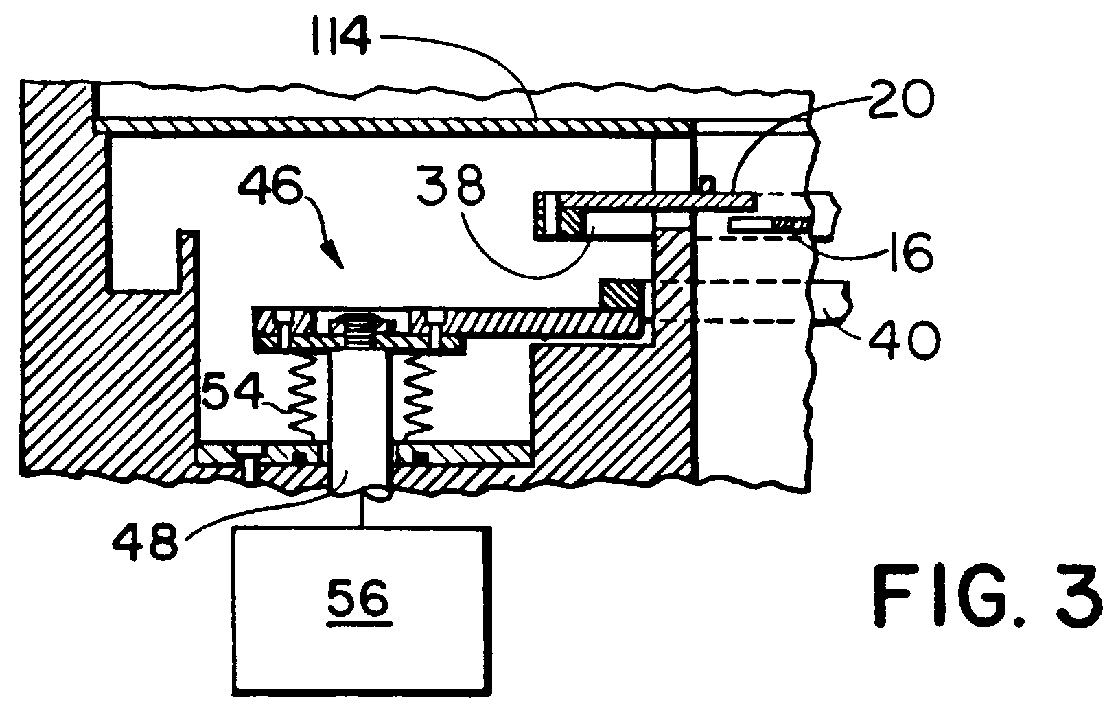

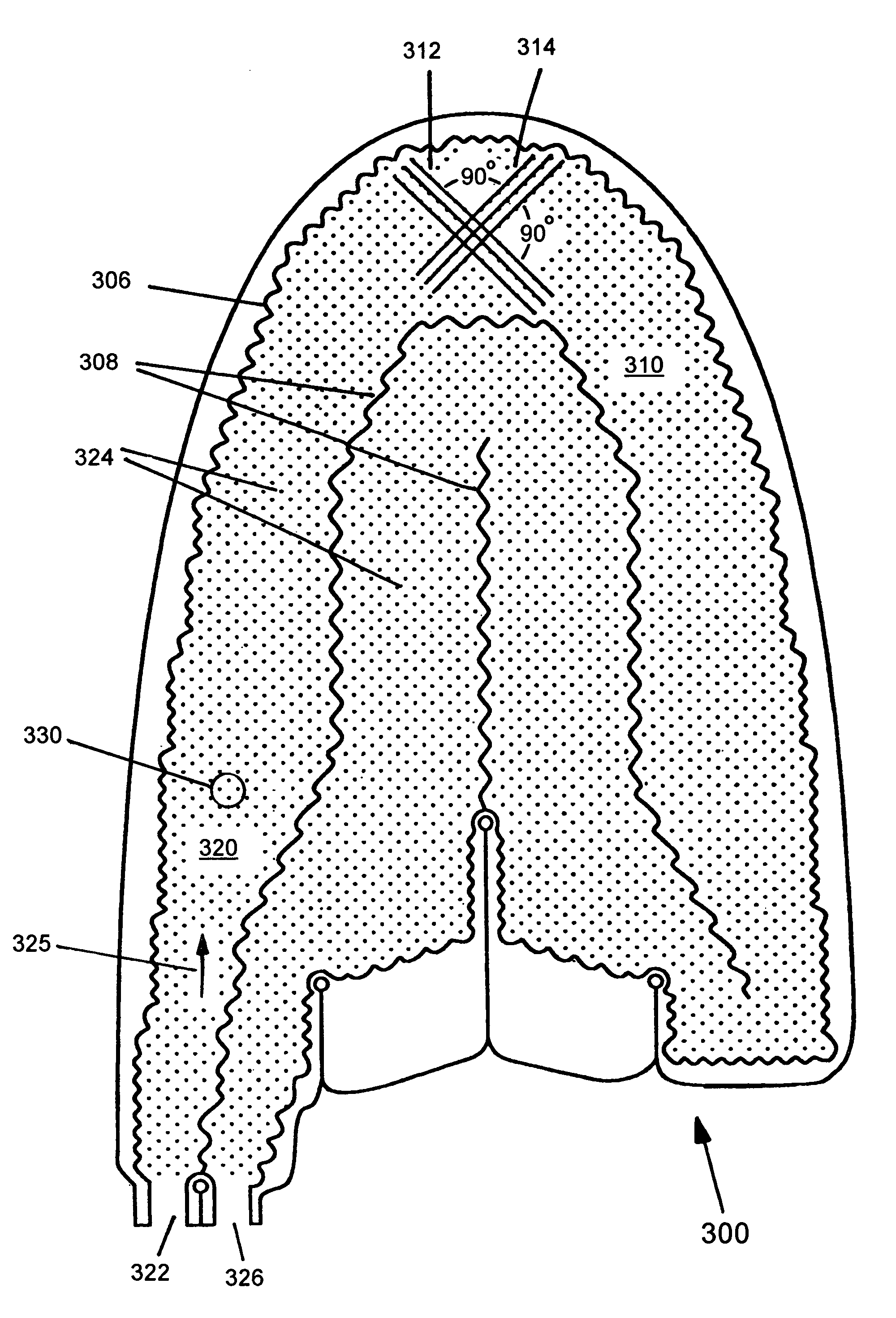

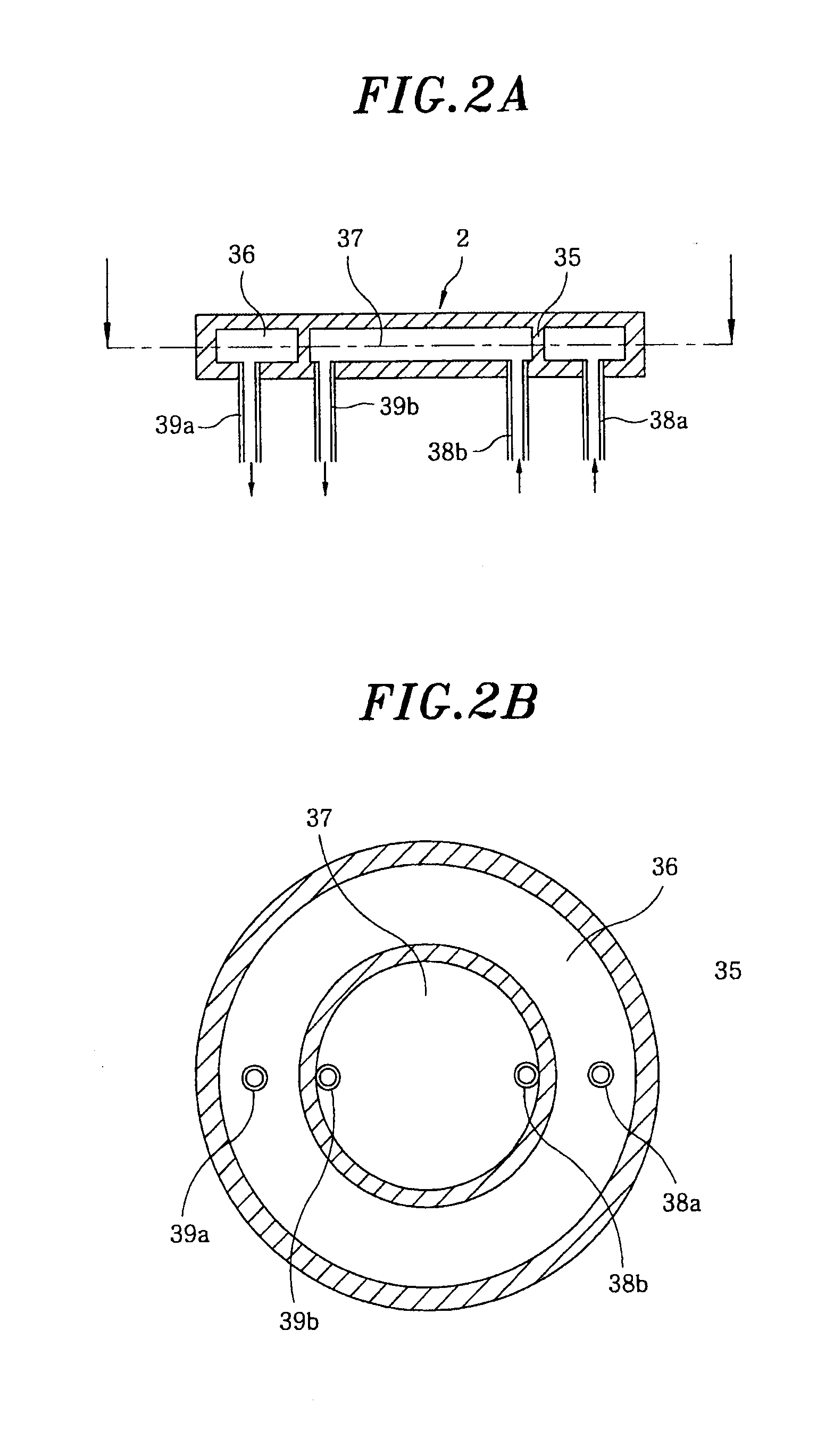

Compliant heat exchange panel

InactiveUS7198093B1Uniform temperatureComplex shapeMetal-working apparatusTherapeutic coolingDot matrixVia fence

A heat exchange panel for use in an active heat exchange system. The heat exchange panel includes first and second layers having seals between the layers at a common border, at fences, and at dots of a dot matrix. The dot matrix is organized into first parallel lines and second parallel lines where the first and second parallel line cross at a 90° angle. The seals at the border and the fences are rippled with smooth ripples.

Owner:AVENT INC

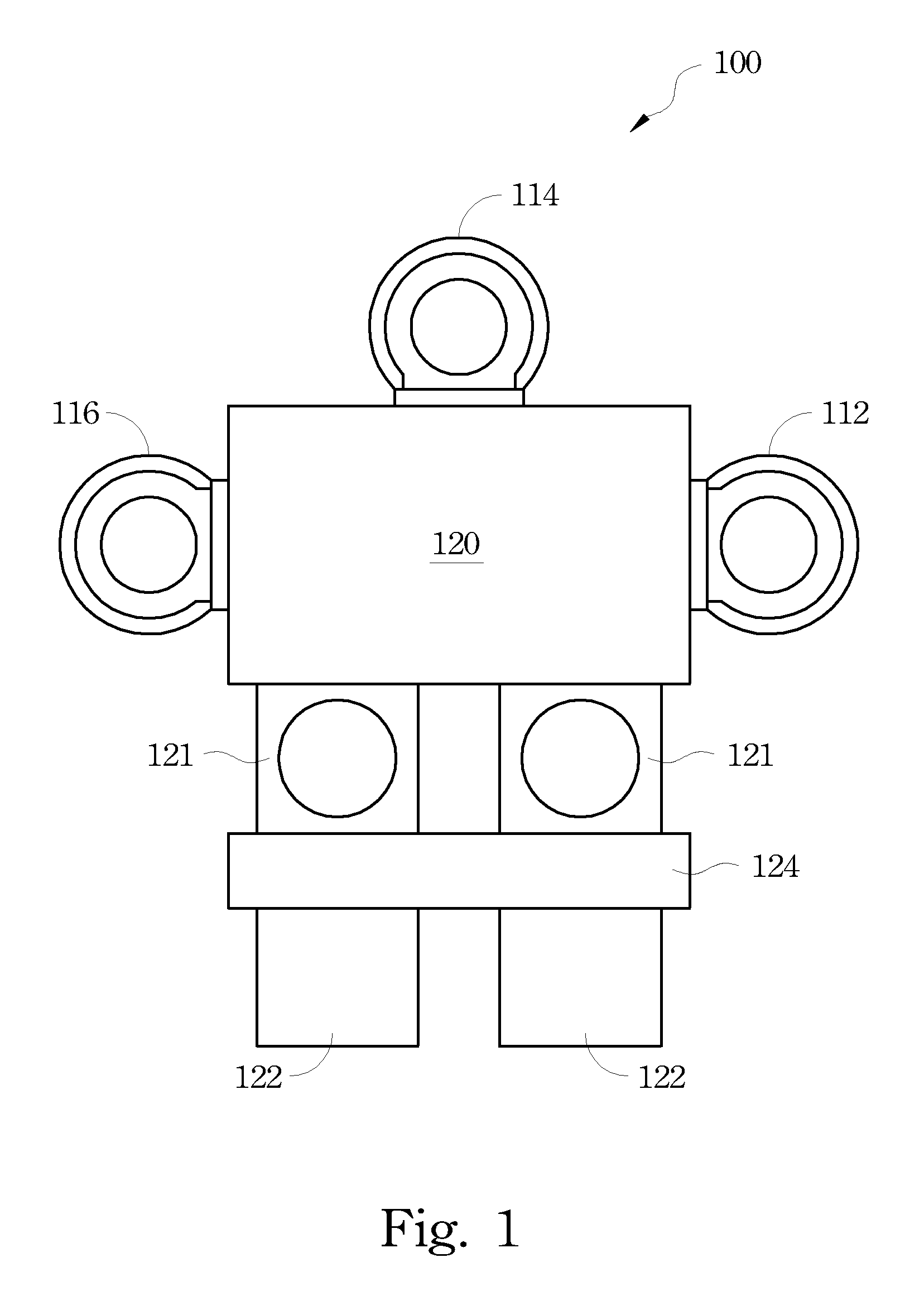

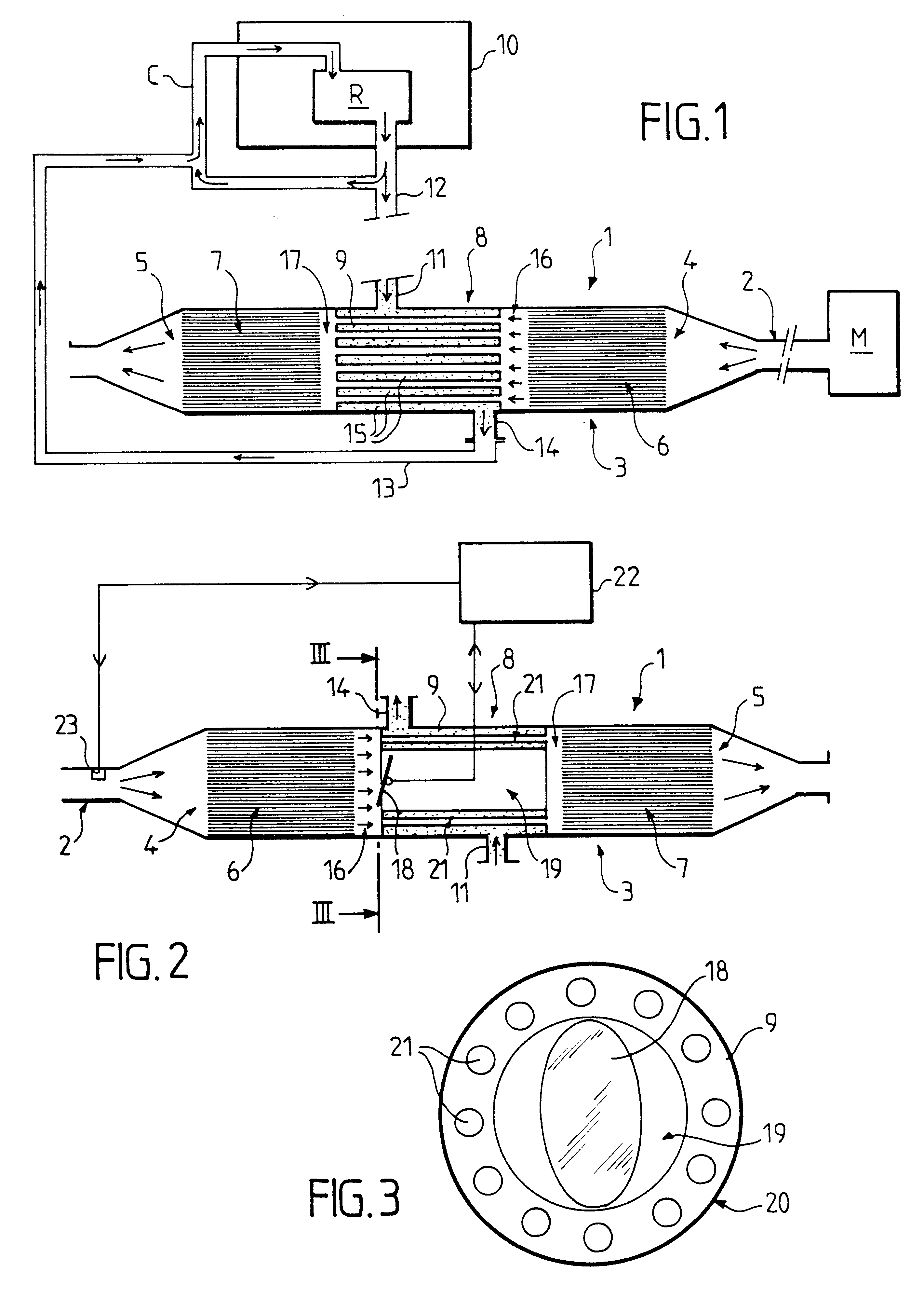

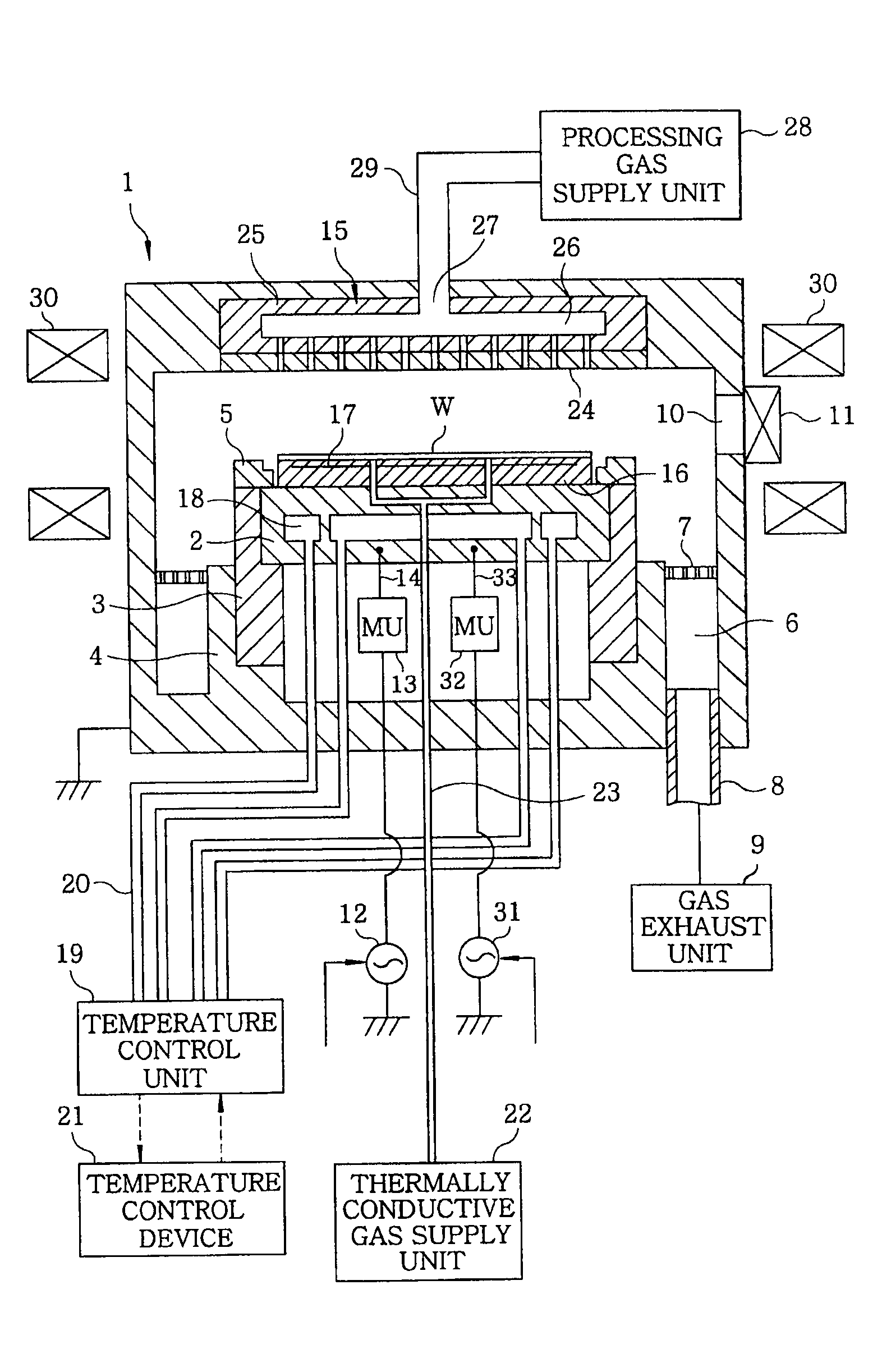

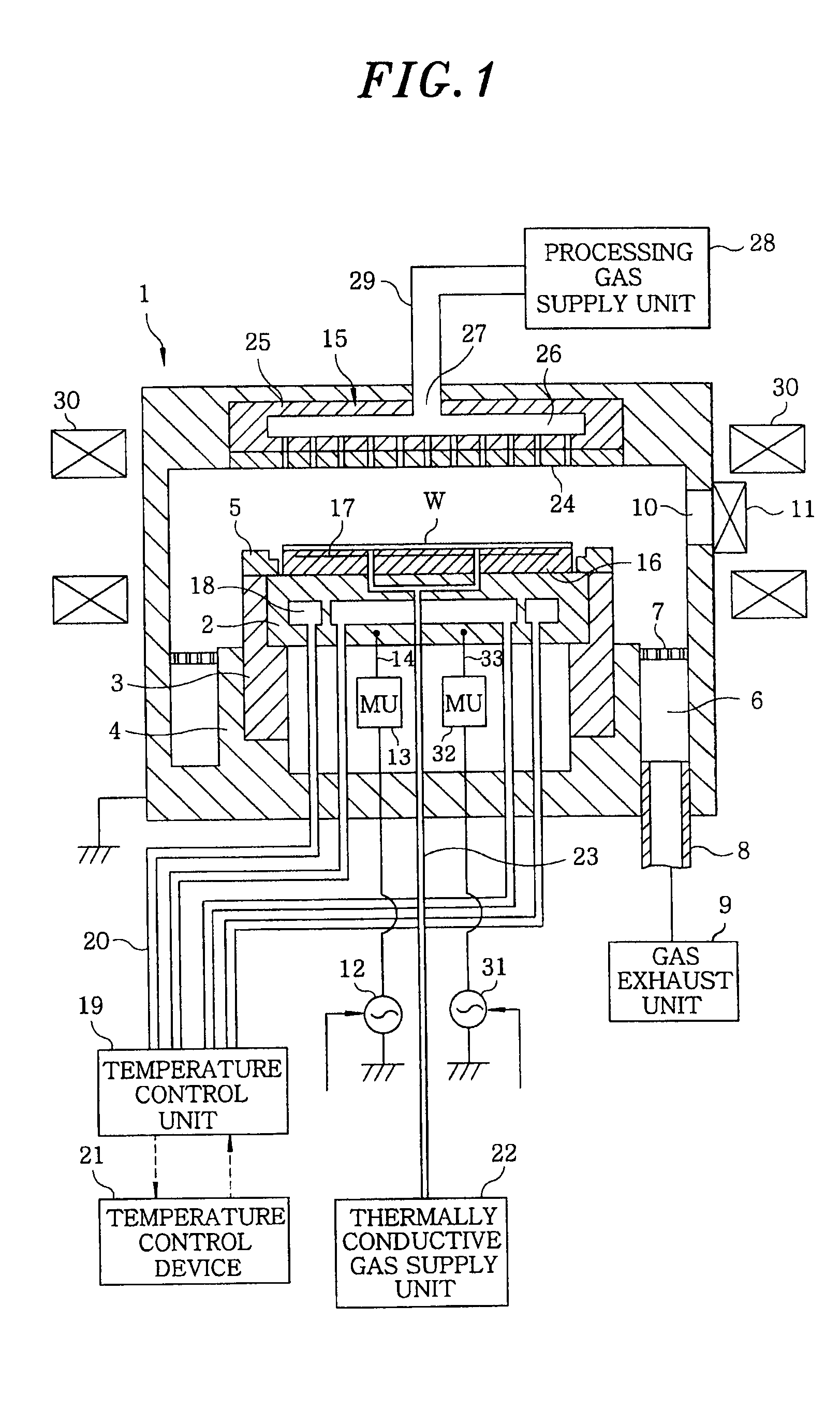

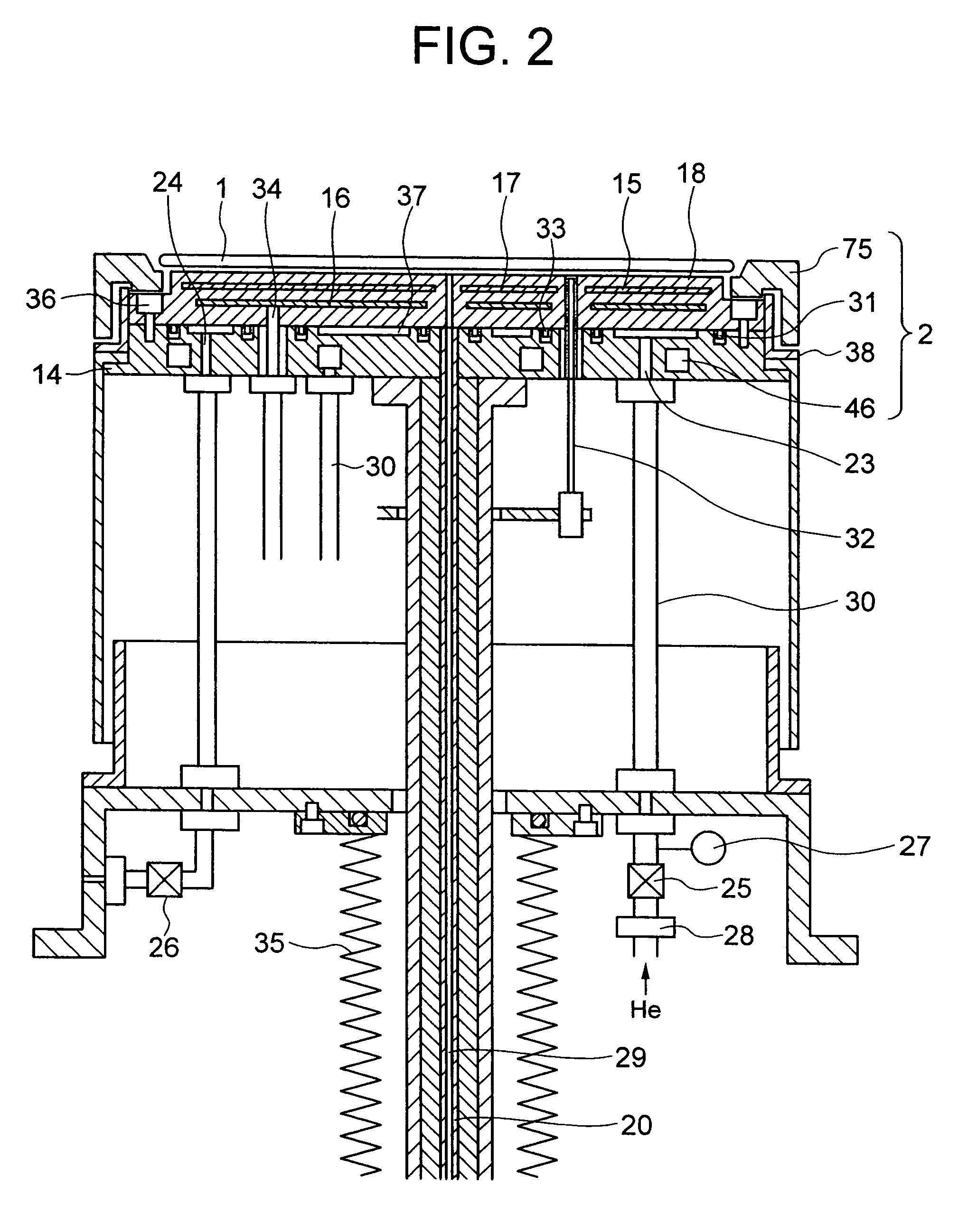

Temperature control device for target substrate, temperature control method and plasma processing apparatus including same

ActiveUS20090118872A1Shorten the time limitUniform temperatureControlling ratio of multiple fluid flowsTemperatue controlPlasma processingCooling channel

A temperature control device for a target substrate includes a mounting table having temperature control members respectively provided in temperature systems to control temperatures of regions of the target substrate to respective predetermined temperature levels; circulation channels through which fluids passing through the temperature control members flow; and heating channels each for flowing therein a heated fluid having a higher temperature compared to the fluids circulating in the circulation channels. The device further includes cooling channels each for flowing therein a cooled fluid having a lower temperature compared to the fluids circulating in the circulation channels; and joining units that join the circulation channels to build the respective temperature control systems, the joining units having flow rate control units that controls flow rate ratios of the fluids supplied from the respective channels to the temperature control members.

Owner:TOKYO ELECTRON LTD

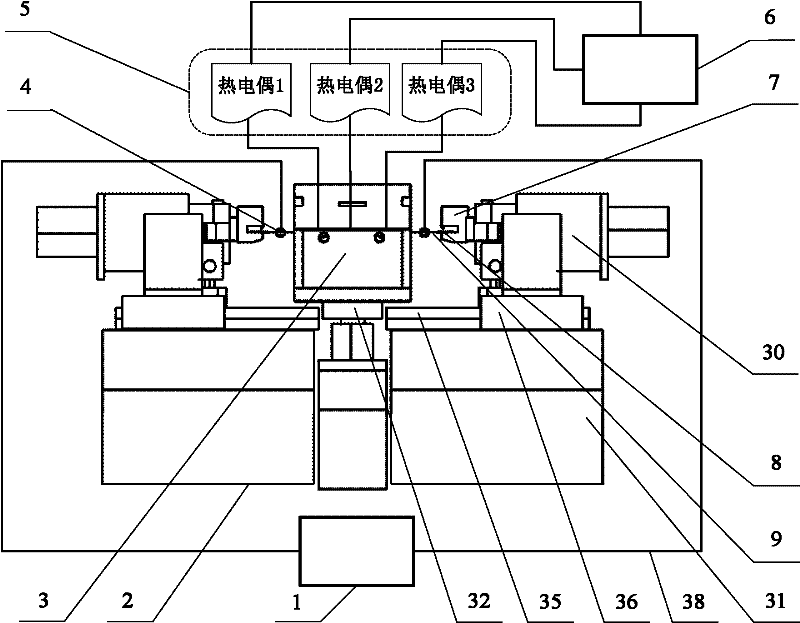

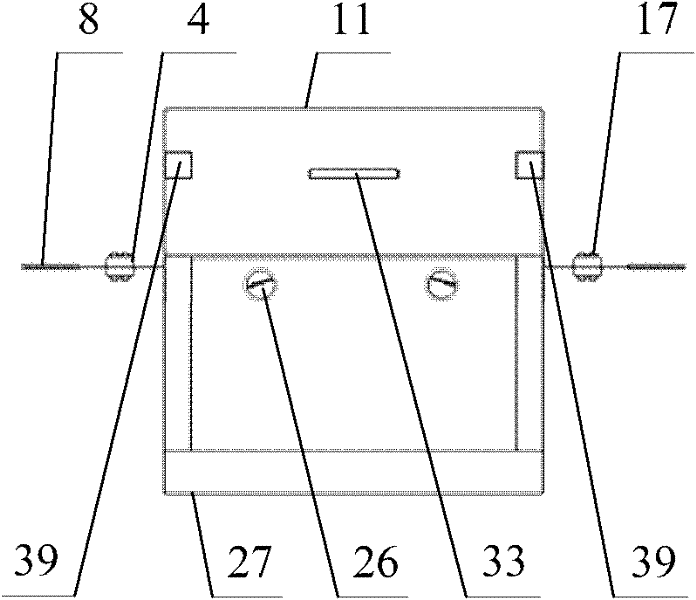

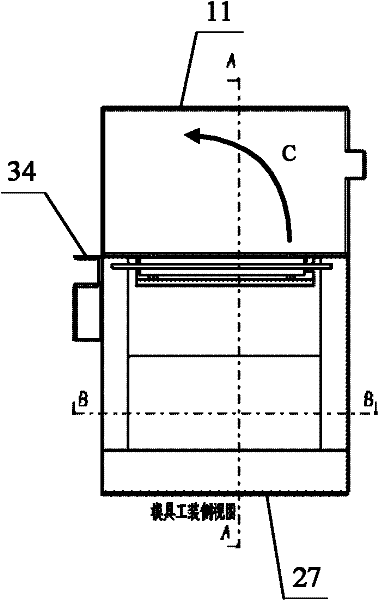

Hot forming tool of titanium alloy thin-wall part and machining method of hot forming tool

ActiveCN102500675AViscoplastic deformation facilitatesAvoid lostShaping toolsTemperature controlProcess integration

The invention provides a hot forming tool of a titanium alloy thin-wall part, comprising five parts, namely stretching equipment, a mould device, a blank, a power supply system and a temperature control system, wherein the mould device is arranged on a central worktable of the stretching equipment; the blank passes through a side wall crack of the mould device; an insulating and heat-insulation cushion layer is used for insulating the blank, a clamp of the stretching equipment, the surface of a mould and a tool of the mould; the power supply system is switched on to electrify an electrode clamping plate and generate a current in the blank; the blank is heated and the temperature of the blank is measured and controlled by the temperature control system; and after the temperature of the blank reaches a target temperature, the part is formed on the surface on the mould by the blank in an adhered manner through carrying out hot forming processes successively including stretching, covering, stretching, heat preservation and creep deformation and the like on the stretching equipment. A machining method of the hot forming tool of the titanium alloy thin-wall part comprises eight steps. According to the invention, the heating efficiency, the process integration, the material formation and the formation precision of the titanium alloy thin-wall part in manufacture are greatly improved, so that the hot forming tool of the titanium alloy thin-wall part and the machining method of the hot forming tool have a practical value and a popularization value.

Owner:BEIHANG UNIV

Wafer processing method

InactiveUS7138606B2Improve temperature distributionUniform temperatureDrying solid materials with heatMuffle furnacesEngineeringLiquid circulation

A wafer processing method for use with a wafer processing apparatus having a liquid cooling jacket with a built-in coolant liquid circulation path and a ceramic plate as attached onto the liquid cooling jacket and having therein a heater and an electrode for an electrostatic chuck. The method enables performance of wafer processing while letting a wafer be mounted on the ceramic plate by a wafer transport. The method includes causing the wafer transport to transport the wafer onto the ceramic plate, pre-heating the wafer while the wafer is held on the ceramic plate for a predetermined length of time, and mounting the preheated wafer on the ceramic plate.

Owner:HITACHI HIGH-TECH CORP

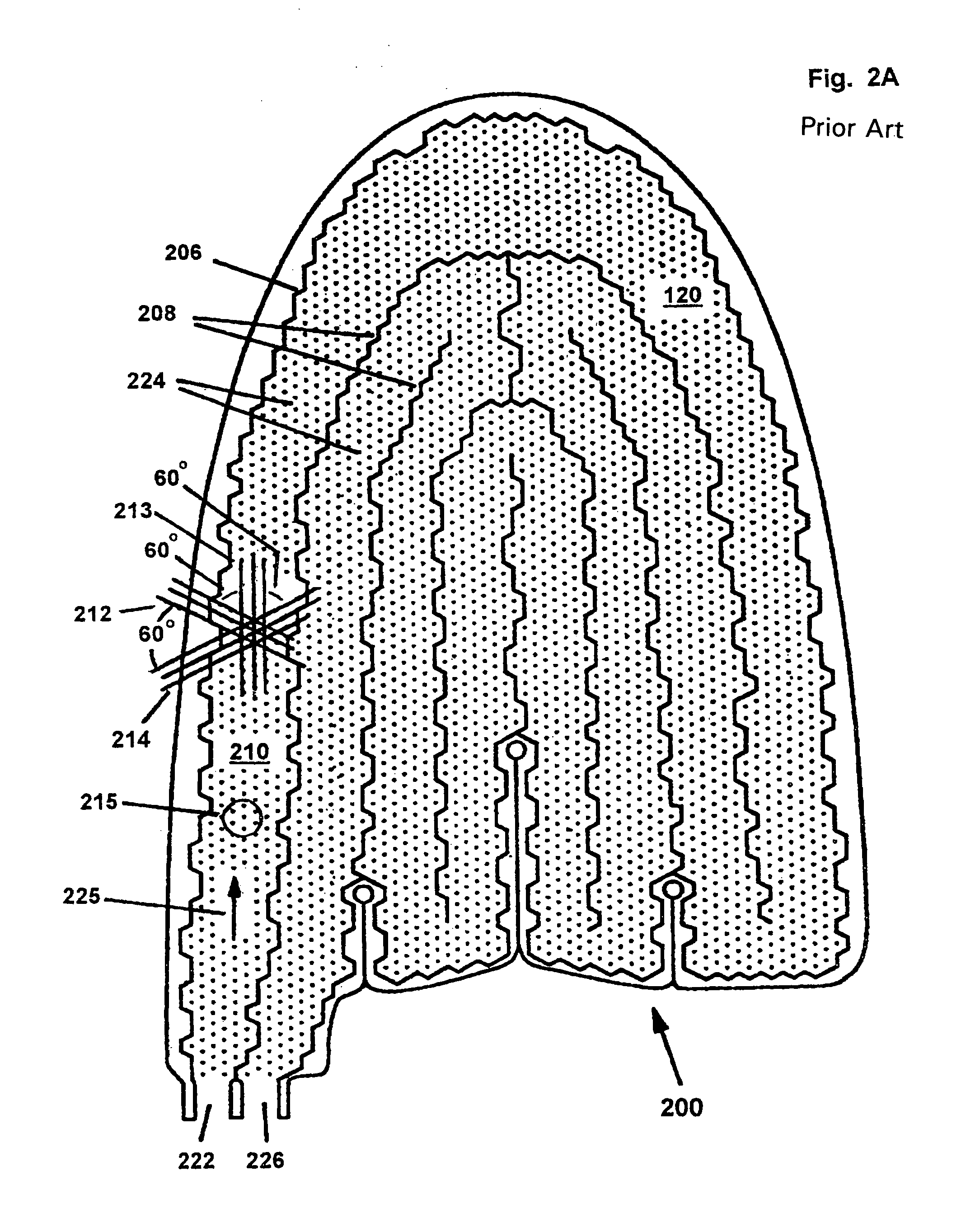

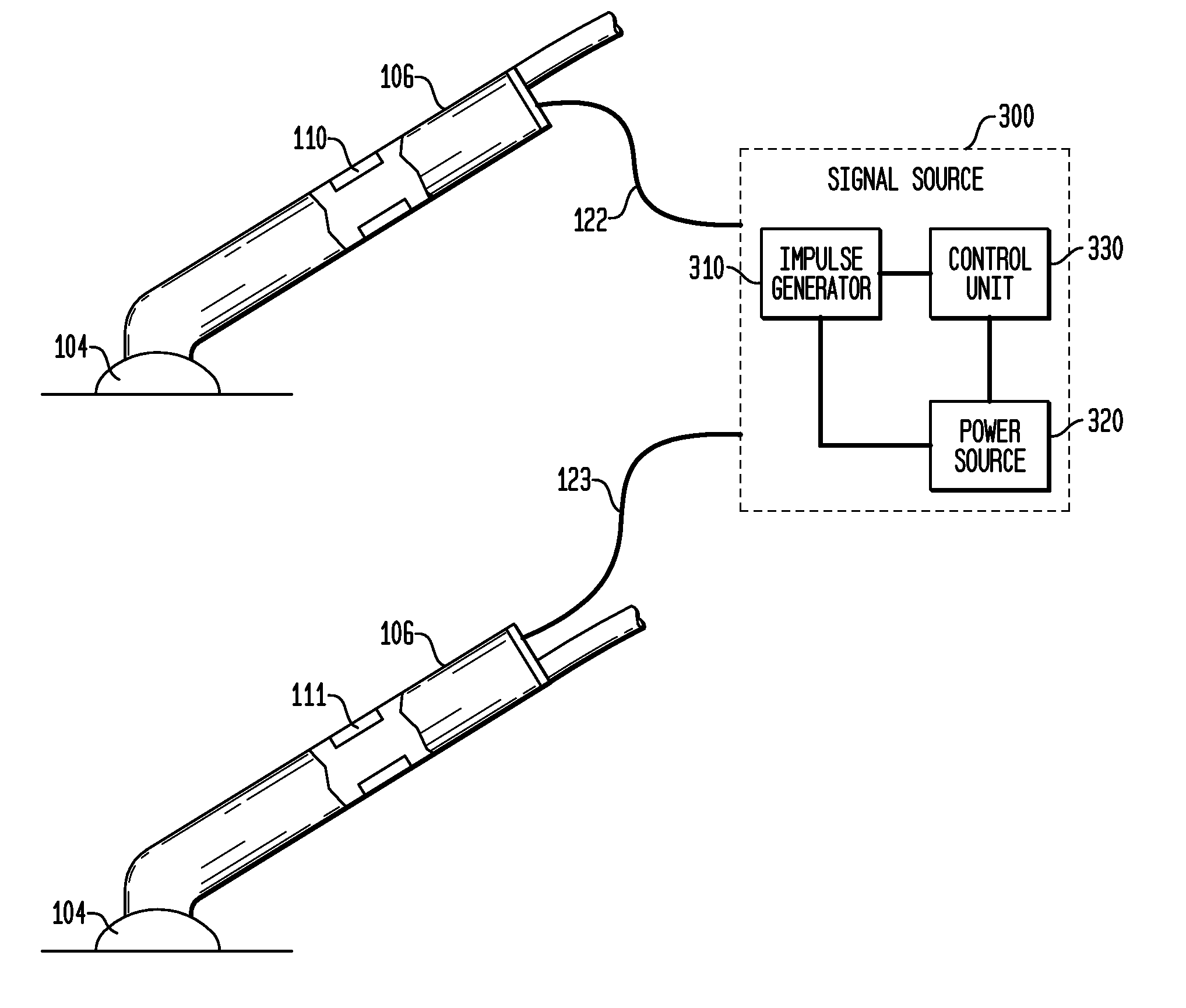

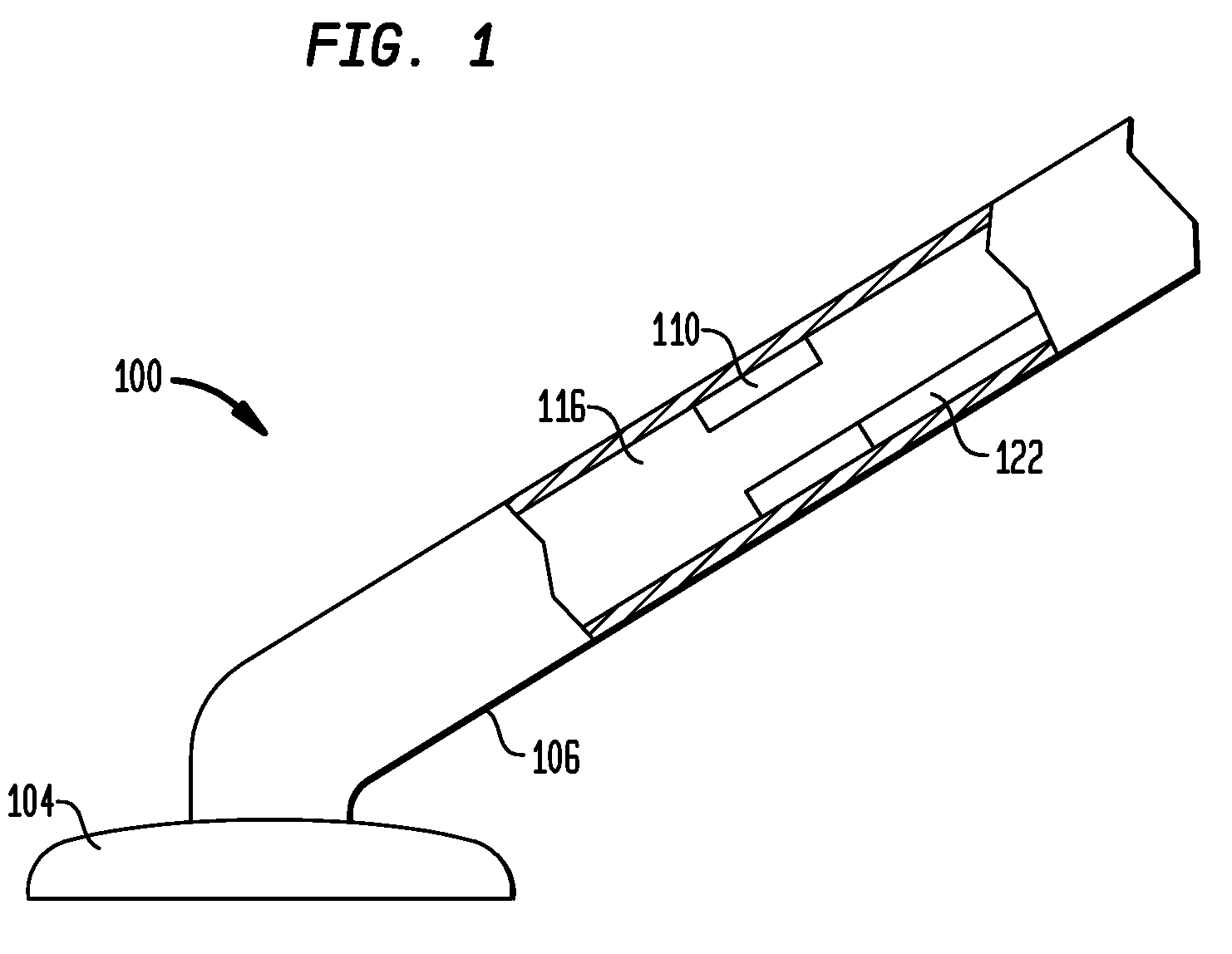

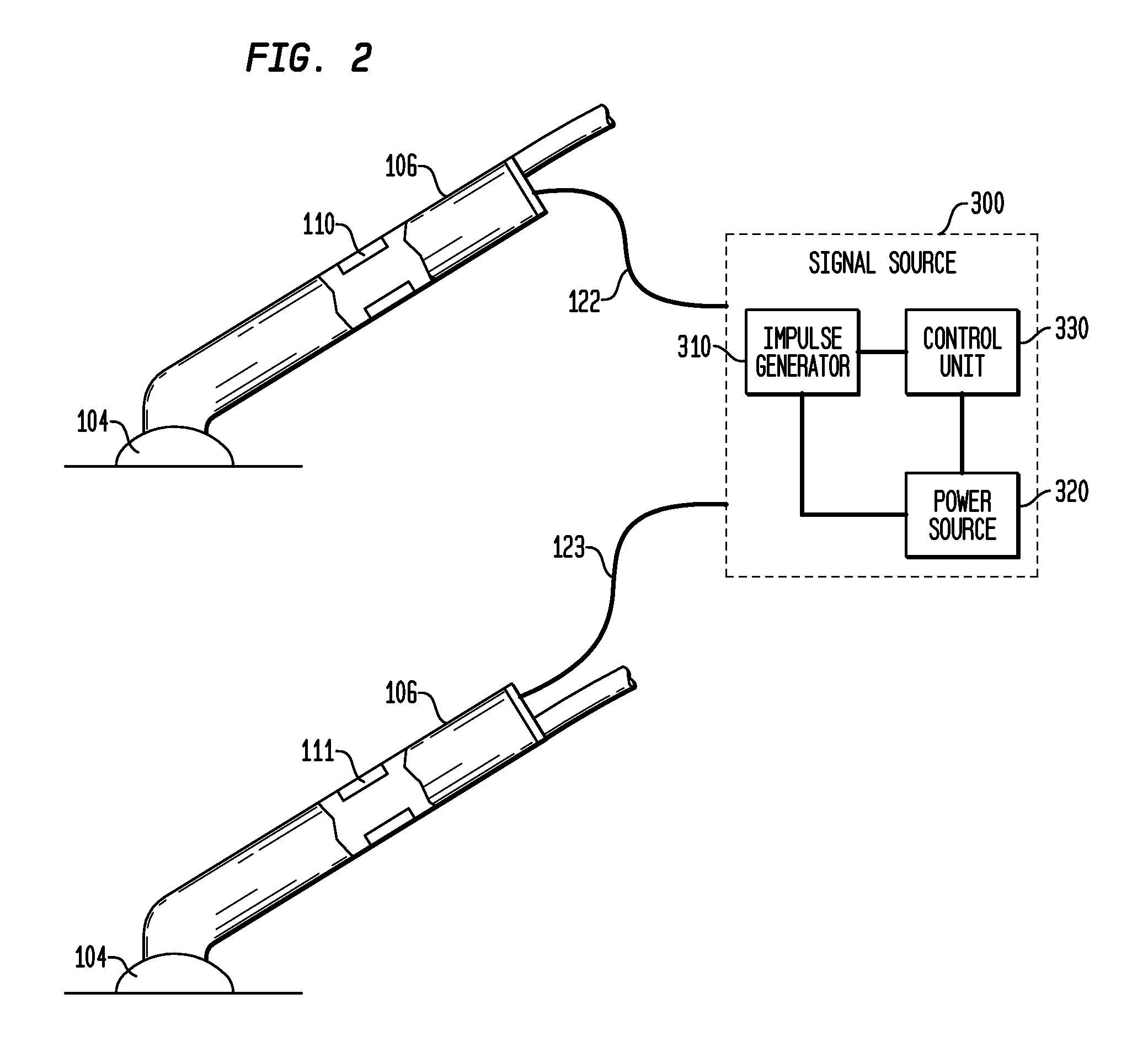

Methods and apparatus for transcranial stimulation

ActiveUS20090319002A1Improve motor performanceAccelerate recoveryElectrotherapyArtificial respirationTissue damageNeuron

The present invention provides systems, apparatus and methods for applying electric current to neurons in the brain to treat disorders and to improve motor and / or memory functions in a patient. In a method according to the invention, an electrode is positioned adjacent to and spaced from the skin surface of the patient's head and an electric current is applied through the electrode to a target region in the brain to modulate one or more neurons in the target region. The electrode is housed within an enclosure and spaced from the skin surface so that the electrode does not directly contact the patient's tissue, which reduces the potential for collateral tissue damage or necrosis and shields the electrode from the patient's tissue which substantially inhibits Faradic products (e.g., H+, OH−, H2O2) of the electrode from reaching the target site.

Owner:ELECTROCORE

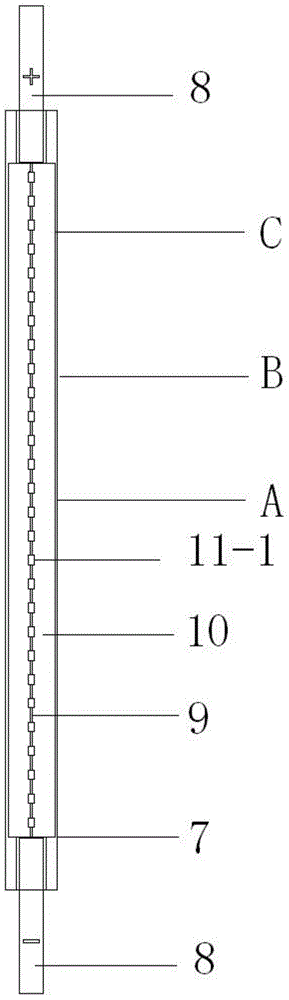

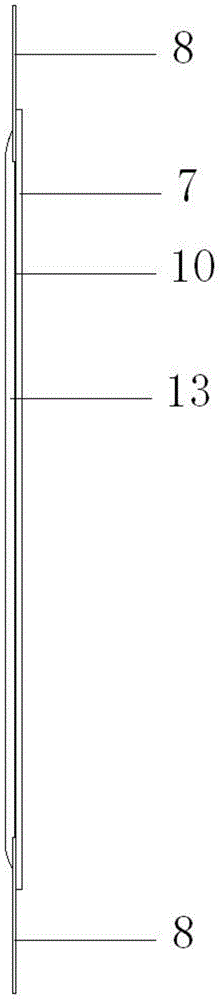

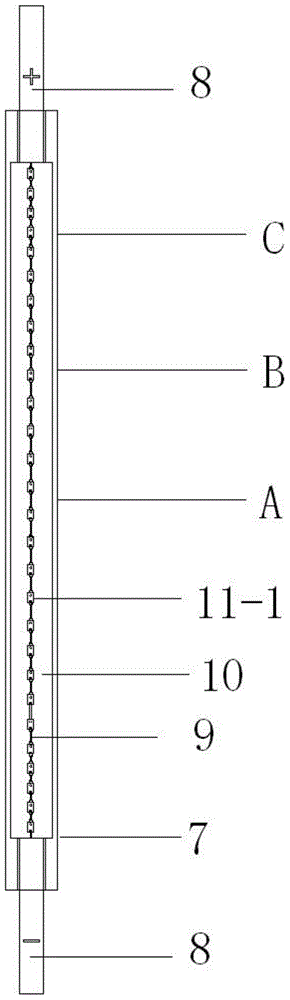

LED (Light Emitting Diode) bulb lamp with driving power supply integrated in bulb shell

InactiveCN104913217ALow costUniform temperaturePoint-like light sourceElectric circuit arrangementsLuminous fluxEngineering

The invention discloses an LED (Light Emitting Diode) bulb lamp with a driving power supply integrated in a bulb shell. The LED bulb lamp comprises the bulb shell, a core column, a power supply drive, multiple LED luminous lamp filaments, heat conduction gas and a lamp holder, wherein the power supply drive is fixedly arranged on the core column; the LED luminous lamp filaments are connected with the power supply drive; the bulb shell is filled with the heat conduction gas; the lamp holder is connected with the bulb shell; each LED luminous lamp filament comprises a substrate; the surface of each substrate is provided with a metal circuit and a bottom adhesive layer; two ends of each substrate are provided with metal pins; each substrate is fixedly provided with an LED luminous unit; each LED luminous unit is provided with a sealing adhesive layer. According to the LED bulb lamp disclosed by the invention, the power supply drive is arranged in the bulb shell, an existing manual assembling link is avoided, large-scale automatic production can be realized, and the production cost is substantially reduced; the lamp filaments adopt an optimized chip arranging type, the temperature of each substrate in different positions is nearly uniform, the luminous flux maintenance rate and the long-term reliability of the whole LED bulb lamp are increased, and the service life of the LED bulb lamp is prolonged.

Owner:HANGZHOU HANGKE OPTOELECTRONICS

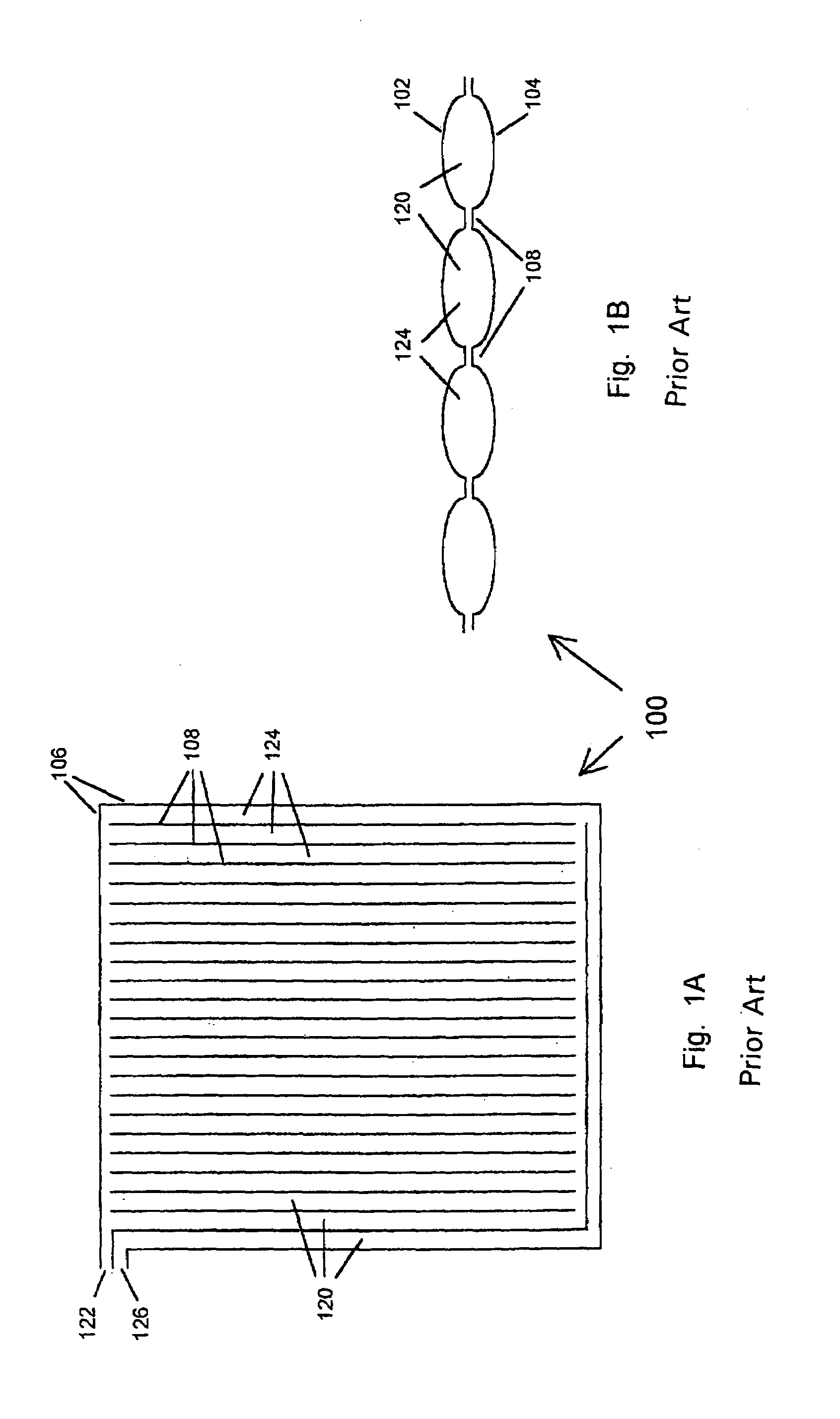

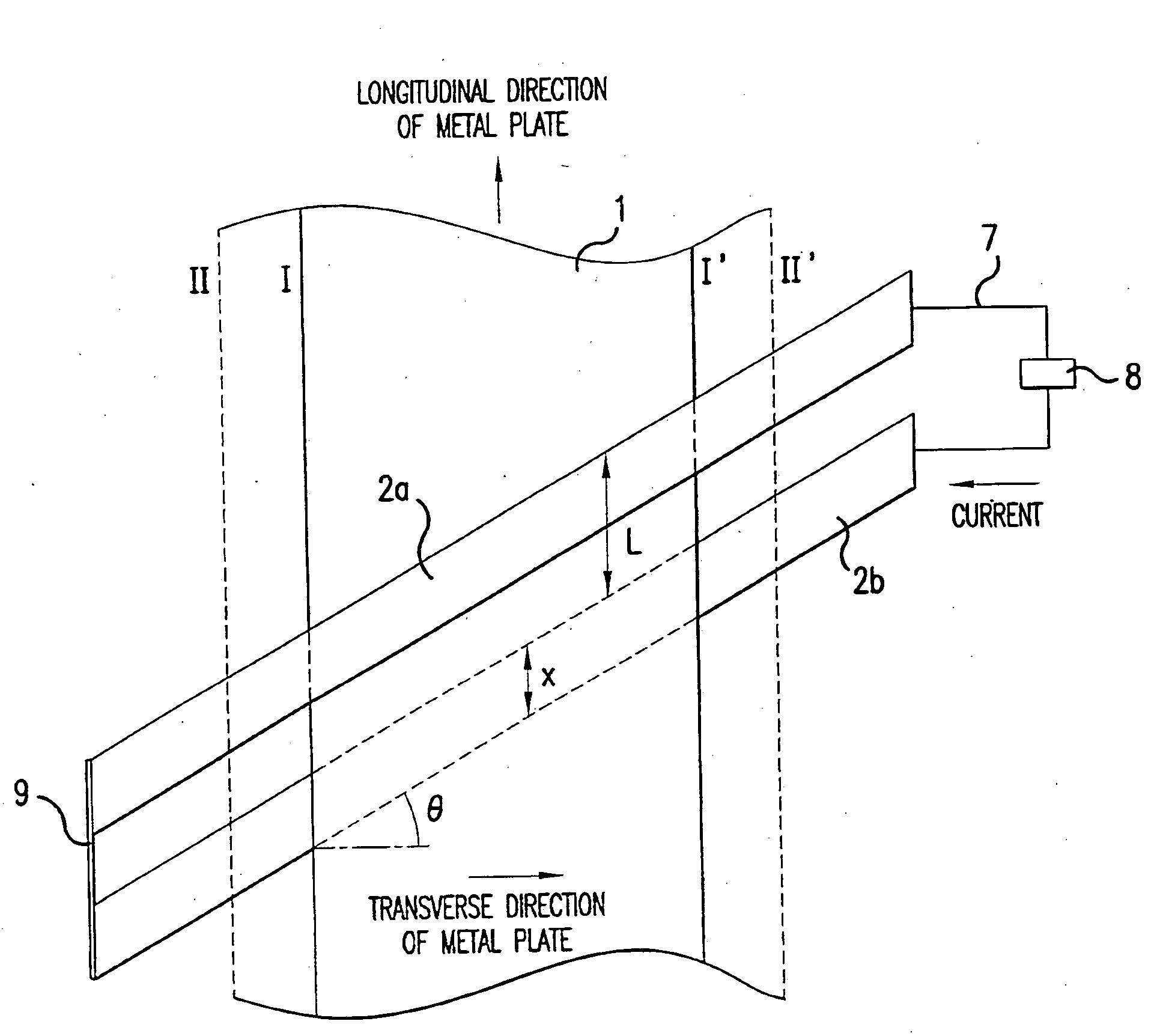

Induction Heating Device for a Metal Plate

ActiveUS20080264932A1Avoid overall overheatingEasy to realize desired temperature distributionLiquid surface applicatorsCoil arrangementsOblique angleMetal

An induction heating apparatus for heating a traveling metal plate includes an induction coil for surrounding the metal plate. The induction coil includes an upper induction coil for being located above the metal plate and a lower induction coil for being located below the metal plate. The upper and lower induction coils are spaced from each other in a longitudinal direction of the metal plate a constant distance across a transverse direction of the metal plate. Each of the upper induction coil and the lower induction coil is arranged obliquely at an edge area of the metal plate so as to form an oblique angle with the transverse direction of the metal plate.

Owner:NIPPON STEEL CORP

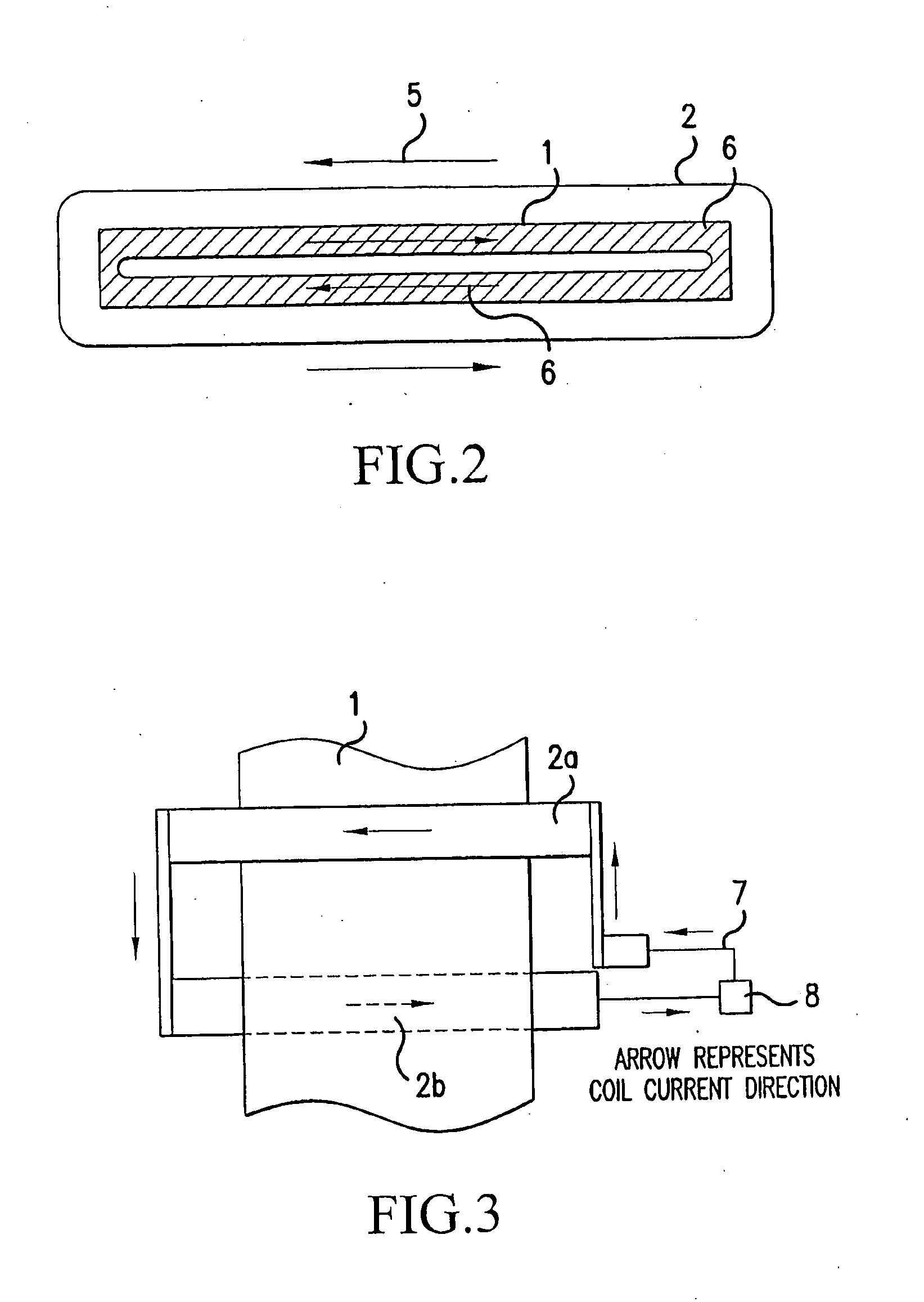

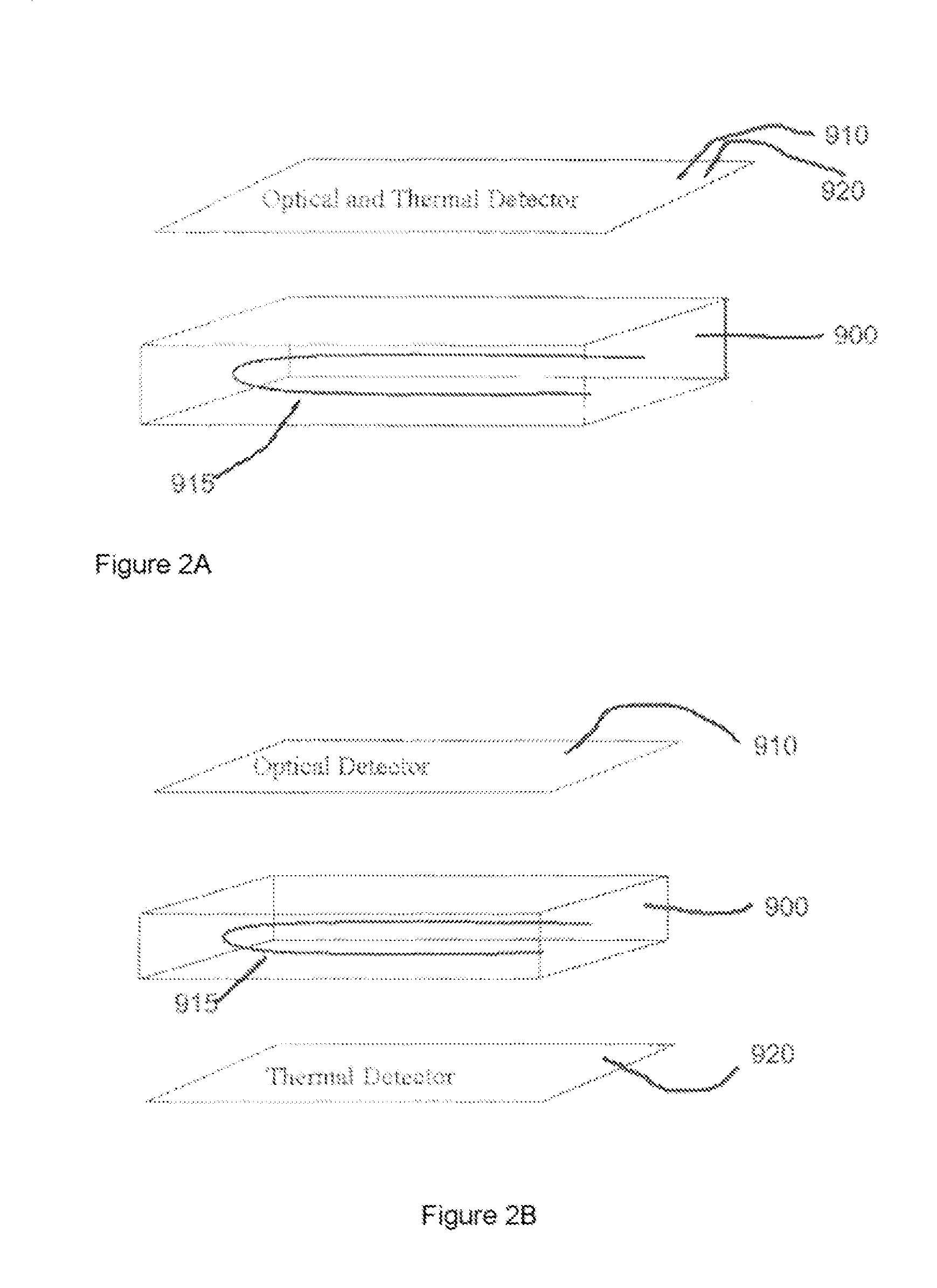

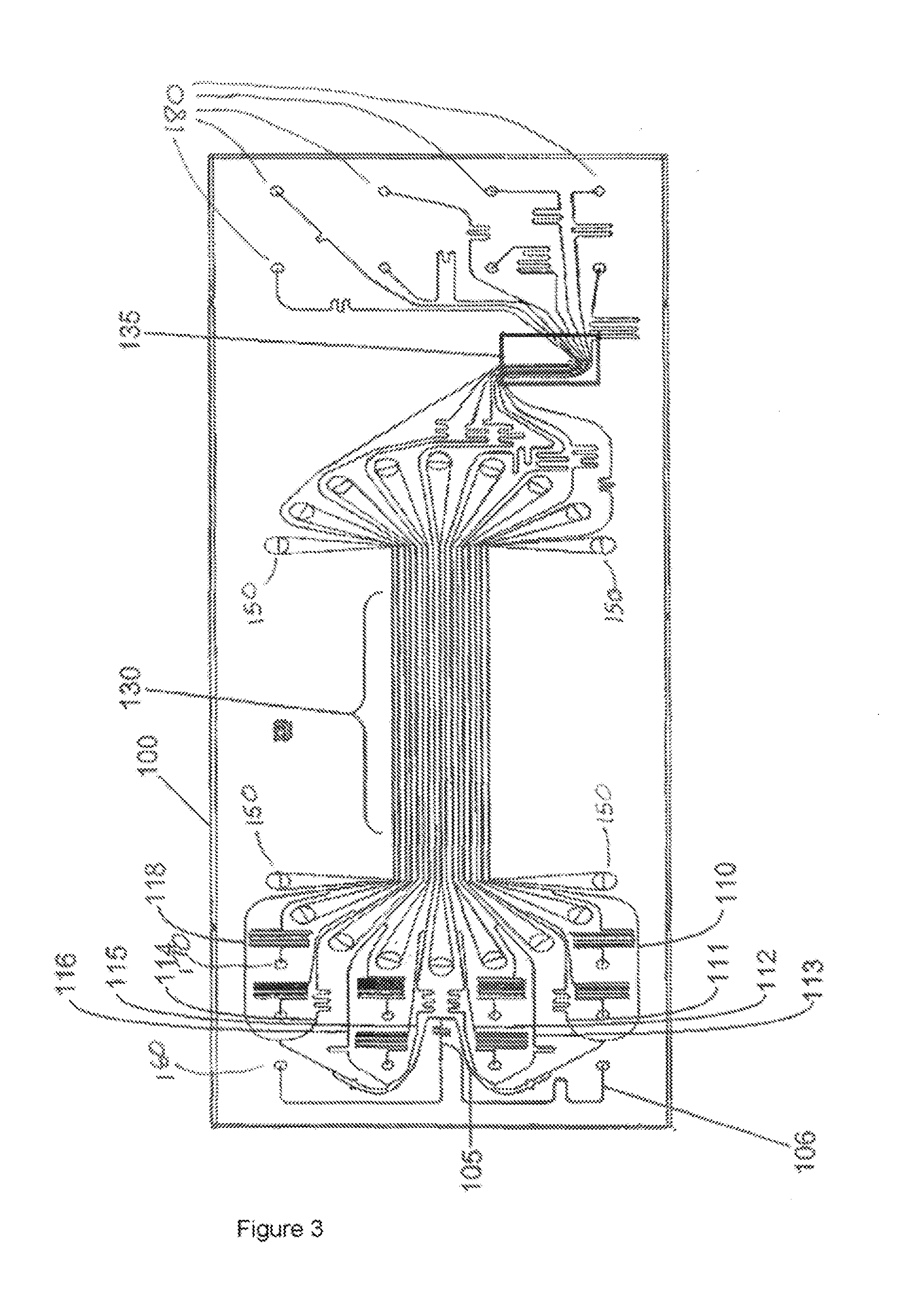

Method and apparatus for applying continuous flow and uniform temperature to generate thermal melting curves in a microfluidic device

InactiveUS20070231799A1Increase temperatureUniform applicationHeating or cooling apparatusMicrobiological testing/measurementEngineeringContinuous flow

The present invention provides a method for performing thermal melt analysis using a microfluidic device, the method comprising providing a microfluidic device having at least one microfluidic channel, introducing fluid comprising into the at least one microfluidic channel, continuously flowing the fluid through the at least one microfluidic channel while varying the temperature of the entire fluid stream as it moves through the at least one microfluidic channel by uniformly heating the entire fluid stream, and measuring, while continuously flowing the fluid through the at least one microfluidic channel, a detectable property emanating from the fluid,

Owner:CANON US LIFE SCIENCES INC

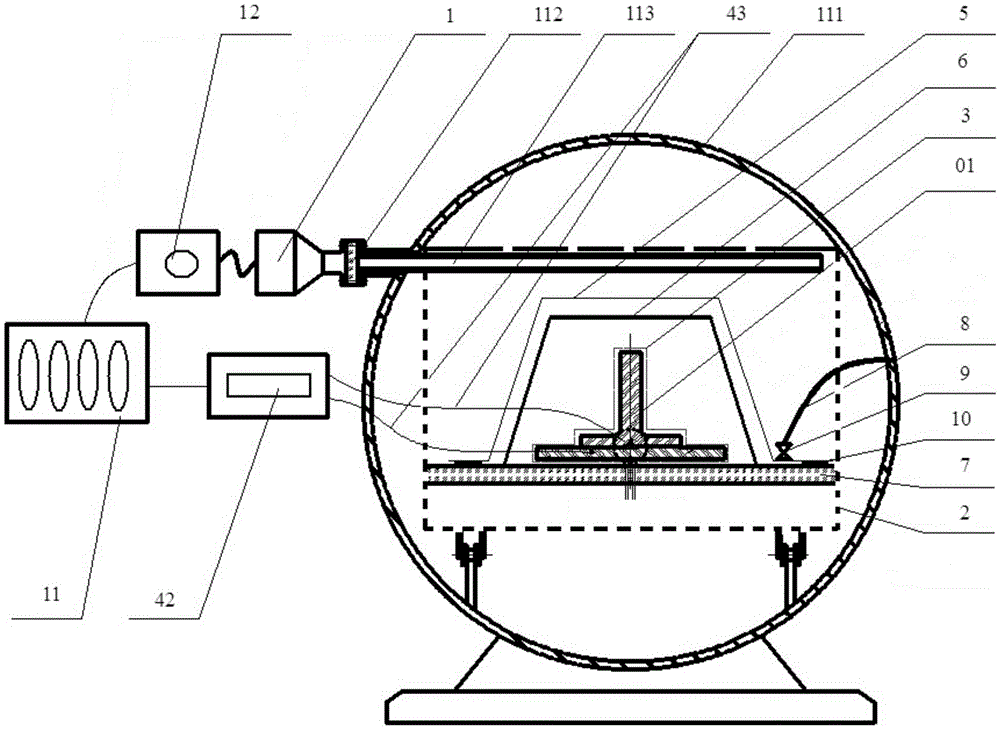

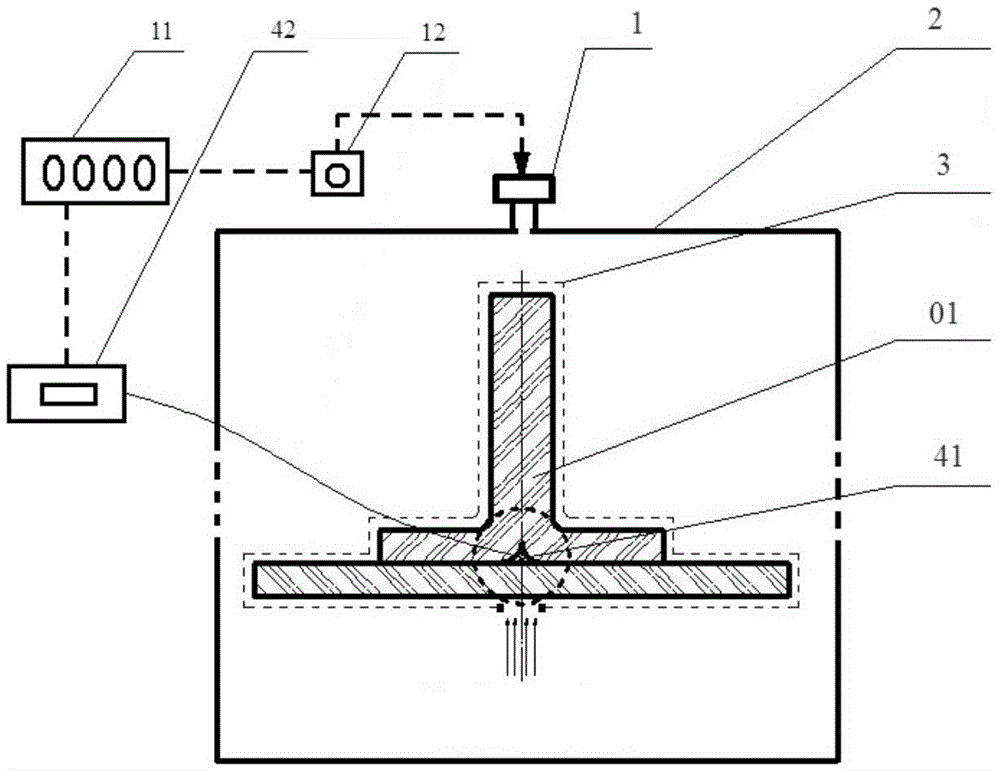

Composite energy field heating device

ActiveCN105666895AImprove performanceUniform and controllable heating and curing processMicrowave cavityAviation

The invention provides a composite energy field heating device. The composite energy field heating device comprises a microwave heating device and a hot-pressing tank, wherein the microwave heating device comprises a microwave generator, a microwave cavity and a microwave local shielding part; the microwave generator is used for sending microwaves into the microwave cavity; a wave absorbing material is arranged in the microwave cavity; the microwave local shielding part is positioned in the microwave cavity, and is used for covering the outer surface of the wave absorbing material; the microwave local shielding part is composed of a shielding microwave region and a transmission microwave region; the transmission microwave region comprises one or more seams, so that microwaves in the microwave cavity can enter the wave absorbing material through the seams for being absorbed; the microwave cavity is integrally arranged in the hot-pressing tank; a ventilating window or a ventilating wall which consists of one or more metal honeycomb plates is arranged on the microwave cavity; and the ventilating window or the ventilating wall can be used for enabling smooth air flow inside and outside the microwave cavity in the hot-pressing tank while shielding the microwaves. The composite energy field heating device can truly realize consistent temperature on all parts in the wave absorbing material, so that high-quality cured products are provided for the aviation and aerospace fields.

Owner:CENT SOUTH UNIV

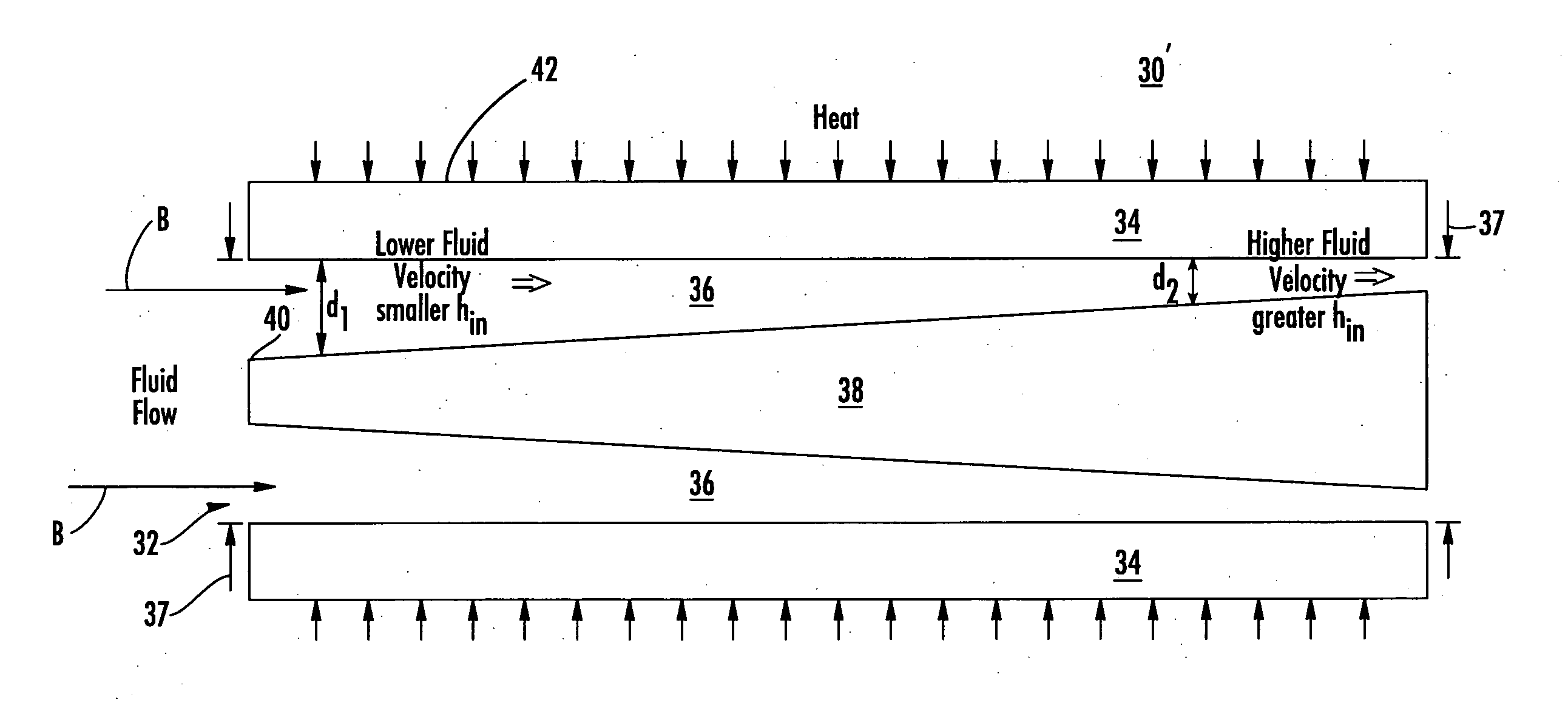

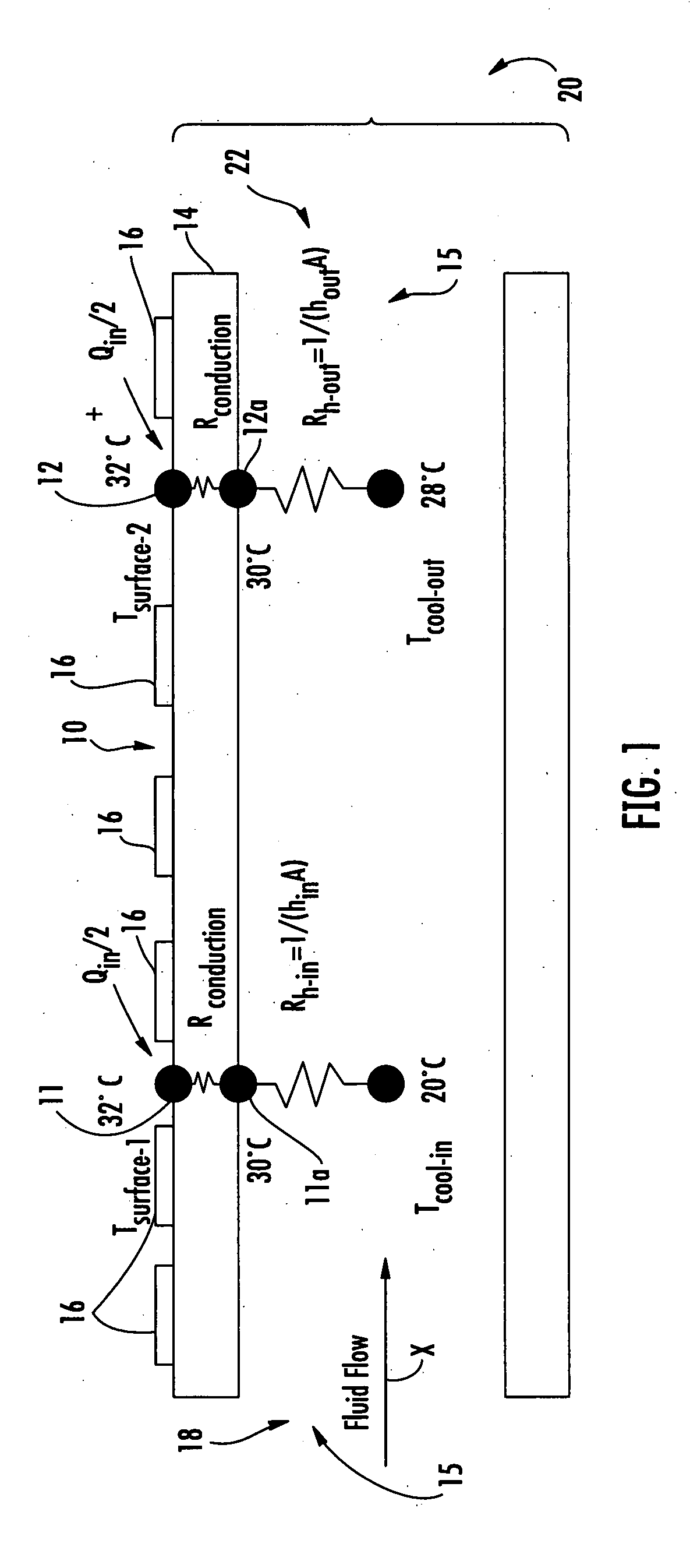

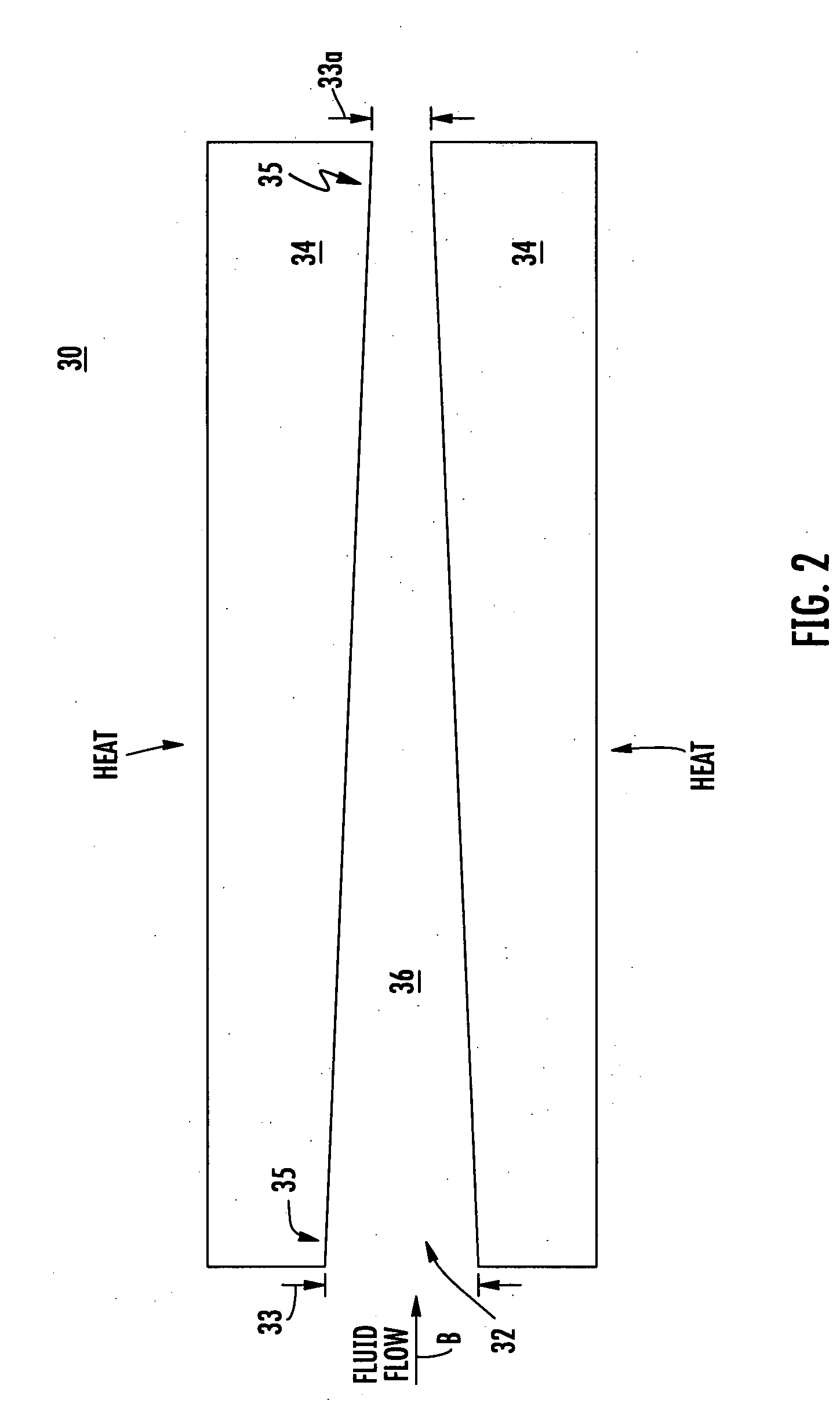

Heat sink and method of making same

ActiveUS20070289718A1Less complexReduce riskIndirect heat exchangersHeat transfer modificationCoolant flowEngineering

A heat sink includes a fluid channel and a cooling wall in contact with coolant flowing in the fluid channel. The channel is configured to vary the velocity of coolant along the length of the fluid channel to vary the coolant's heat transfer coefficient and thereby compensate for the coolant's temperature rise along the length of the fluid channel. The result is a heat sink that is isothermal along its length.

Owner:RAYTHEON CO

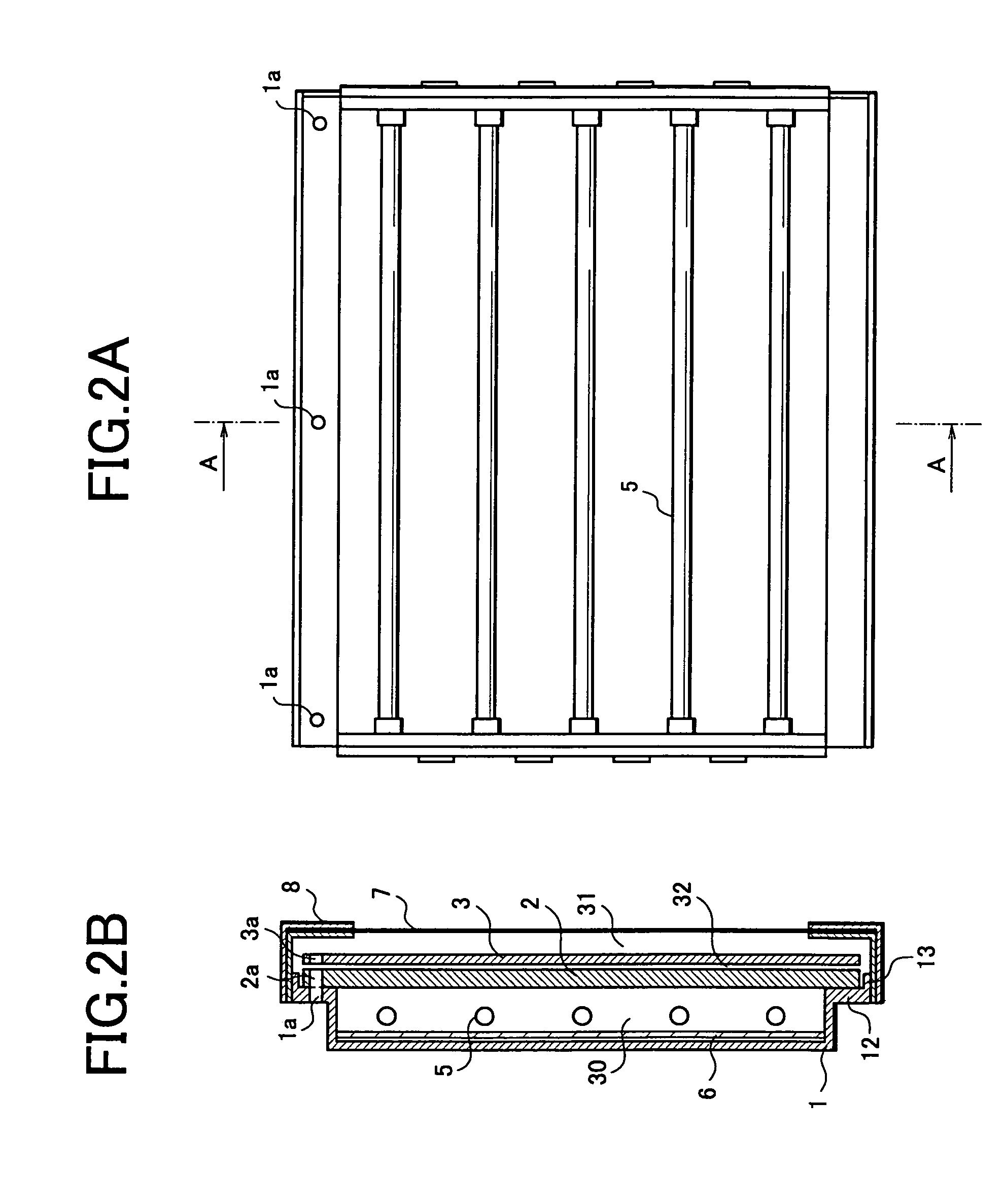

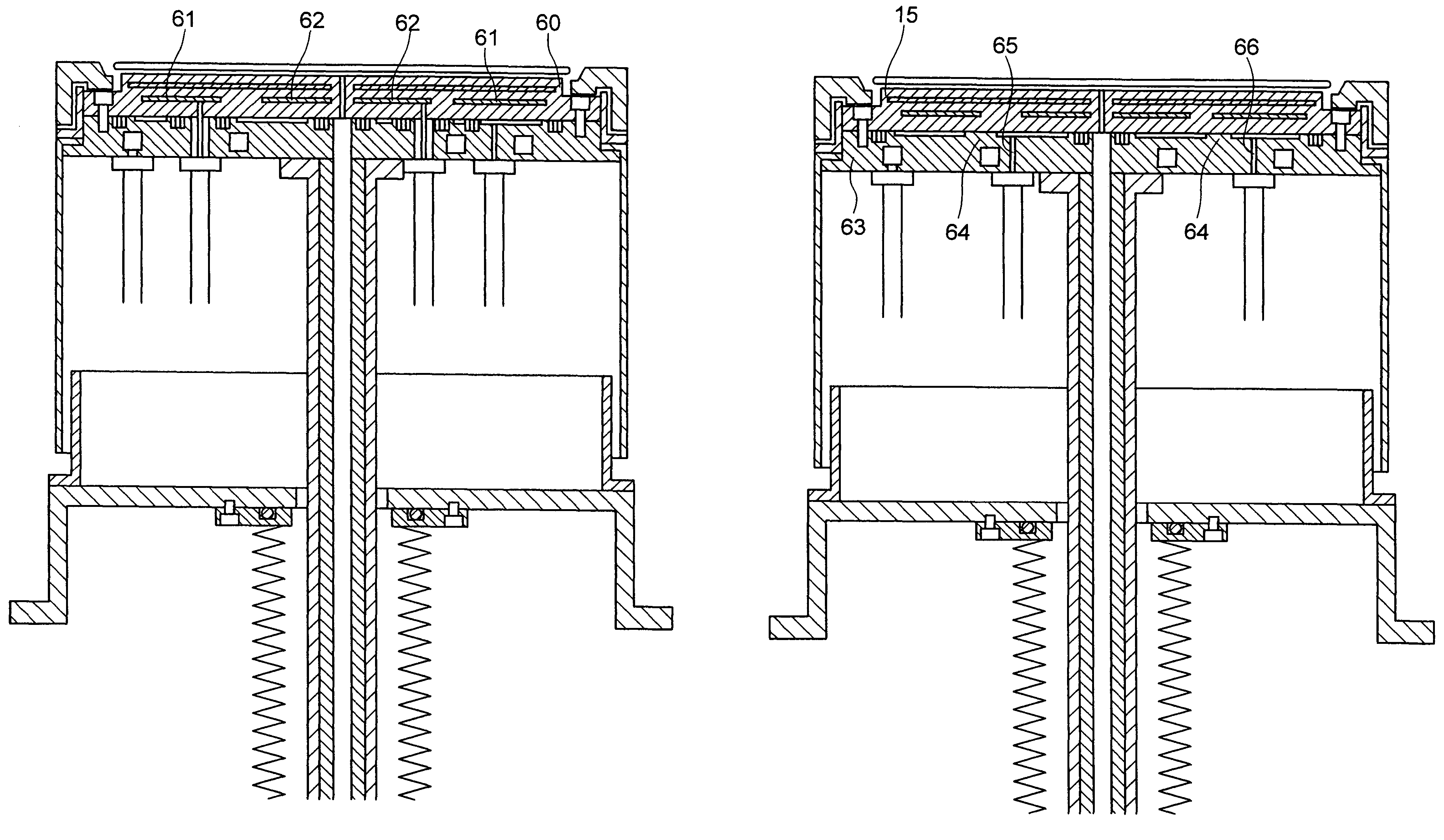

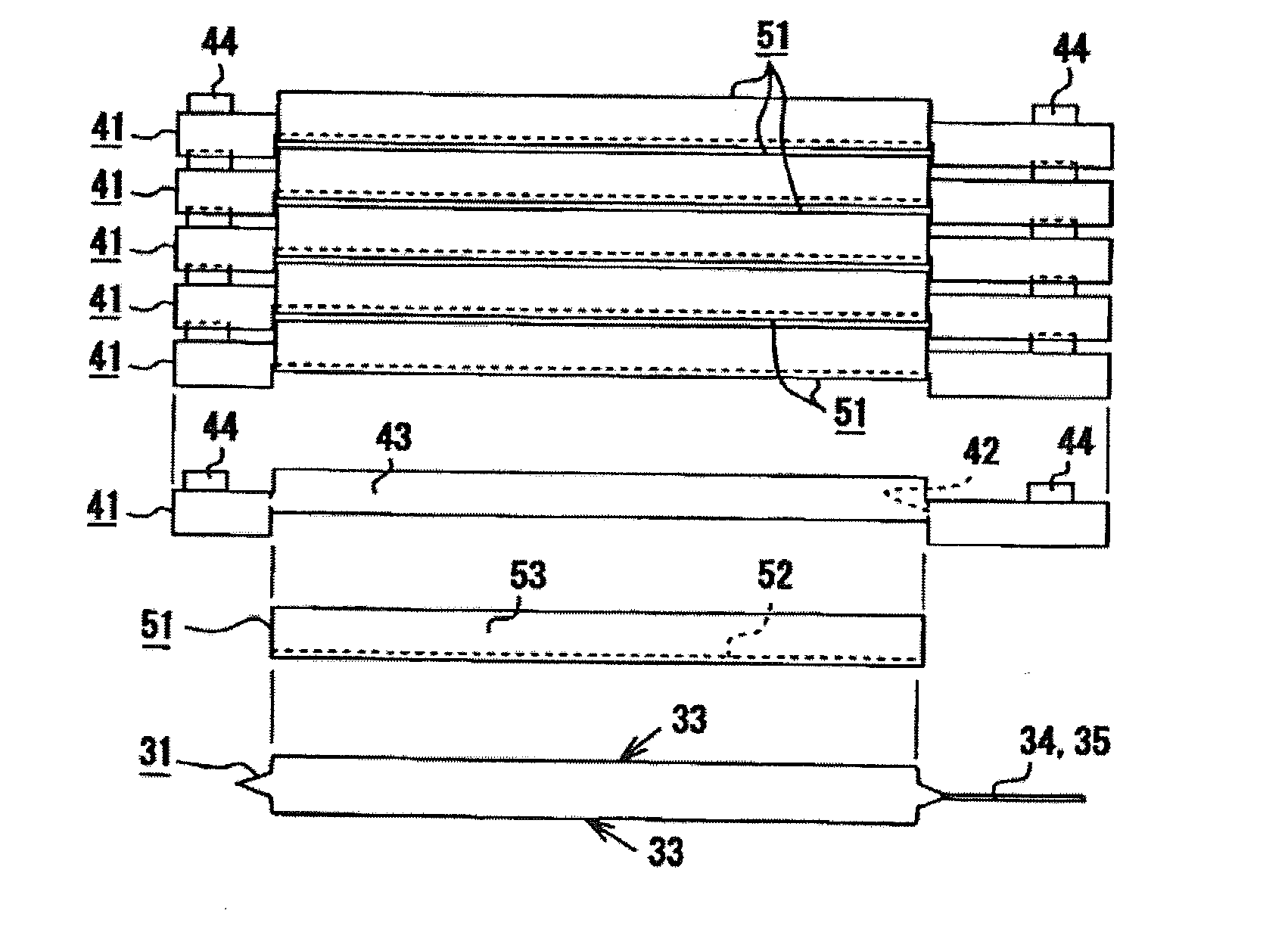

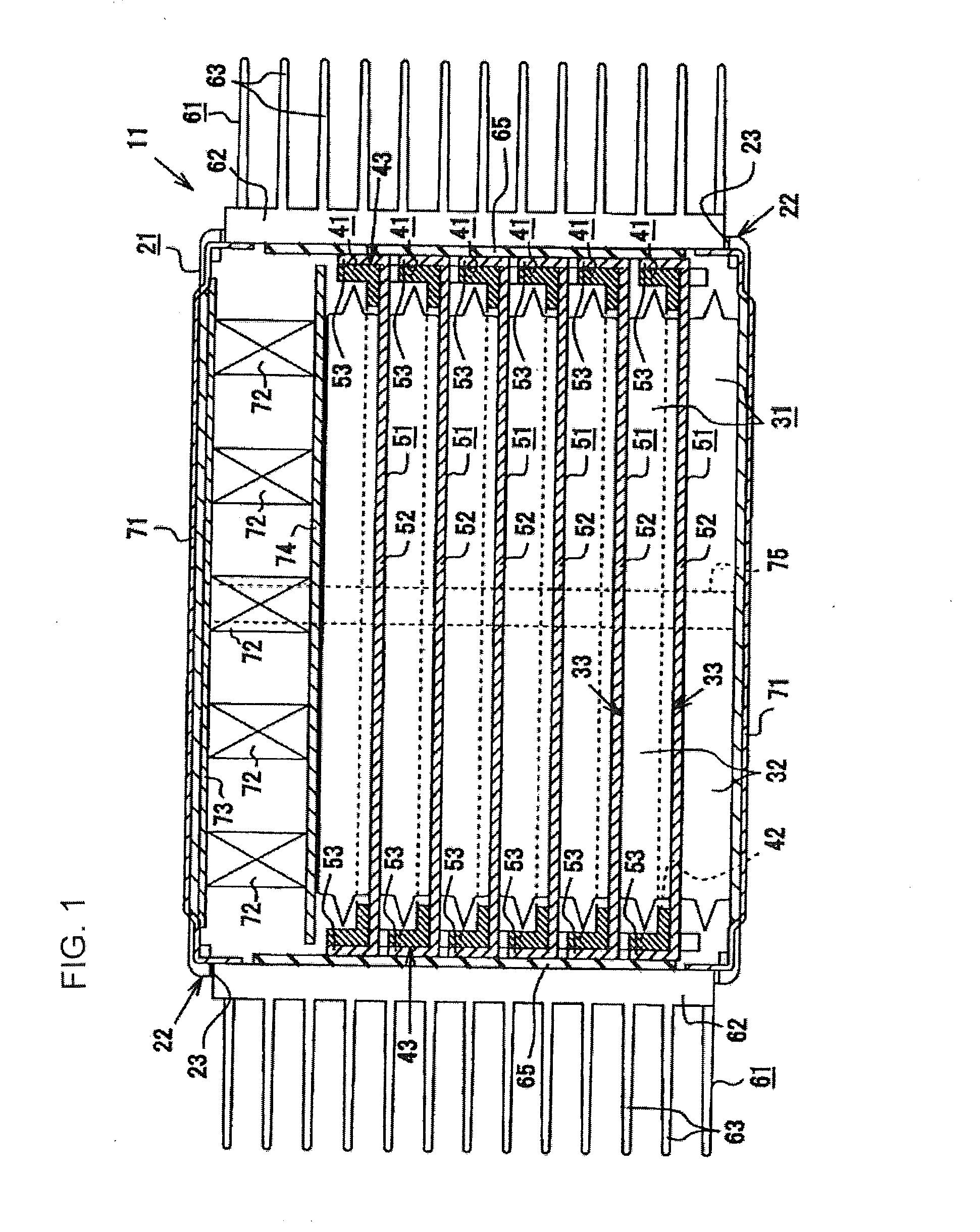

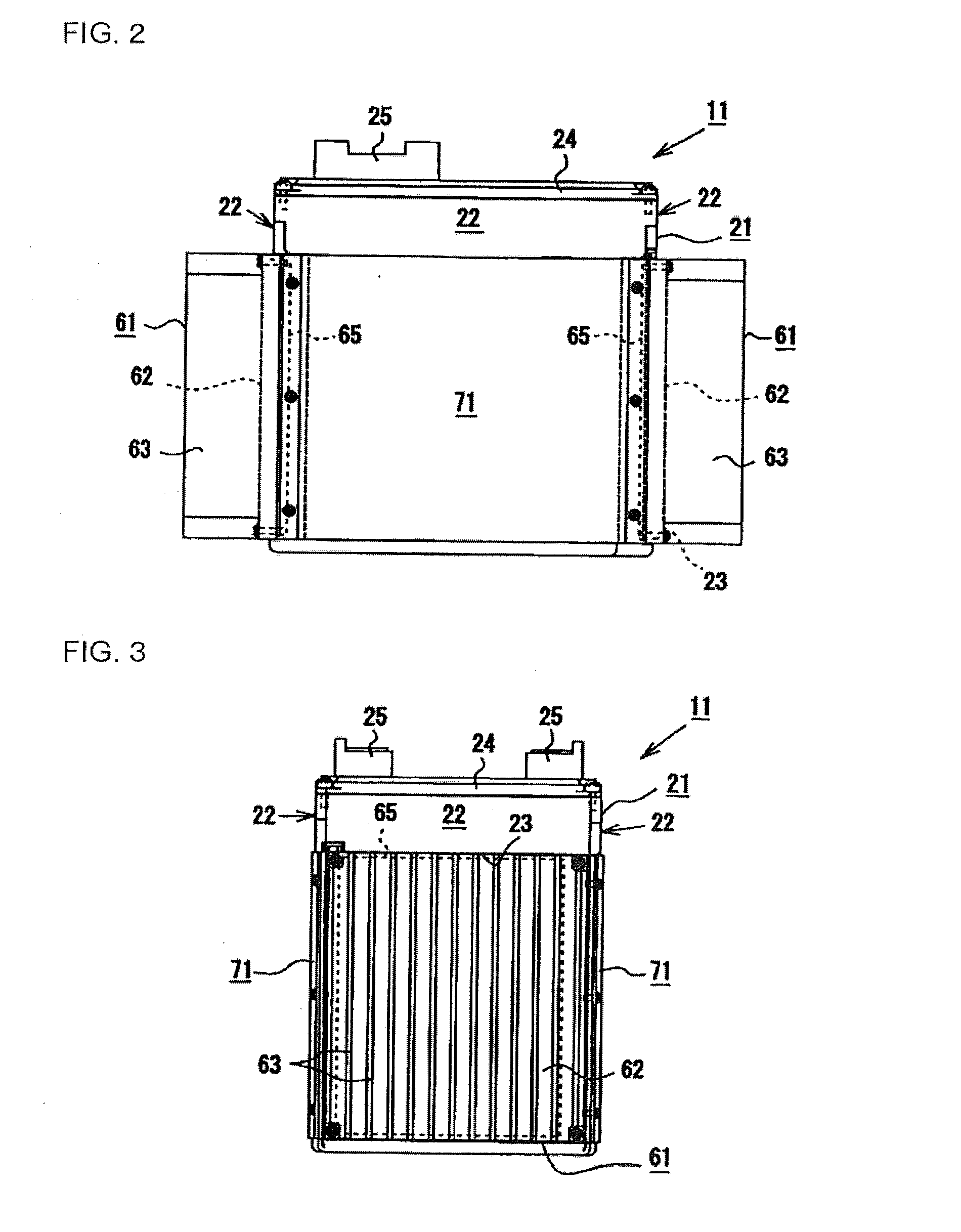

Power storage module

ActiveUS20130120910A1Uniform temperatureEnsure uniform temperatureProtecting/adjusting hybrid/EDL capacitorDouble layer capacitorsComputer moduleEngineering

An energy storage module 11 comprises a case 21, a plurality of stacking plates 41, a heat-transferring metal plate 51 and a heat-releasing fin 61. An exposure outlet 23 is provided on the side 21 of the case 22 containing a plurality of energy storage cells 31. The stacking plate 41 having an aperture 42 is located between the plurality of energy storage cells 31 and is latched to another stacking plate 41 to position said plate. The heat-transferring metal plate 51 having a flat plate portion 52 and a bent portion 53 is provided in face-to-face contact with the main face 33 of each cell of the energy storage cells 31. The heat-releasing fin 61 projects from the exposure outlet 23 to the outside of the case 21 and is thermally face-to-face bonded to the bent portion 53 of the heat-transferring metal plate 51 by the insulation sheet 65.

Owner:FDK CORP

Efficient burning furnace with rotary fluidization grate

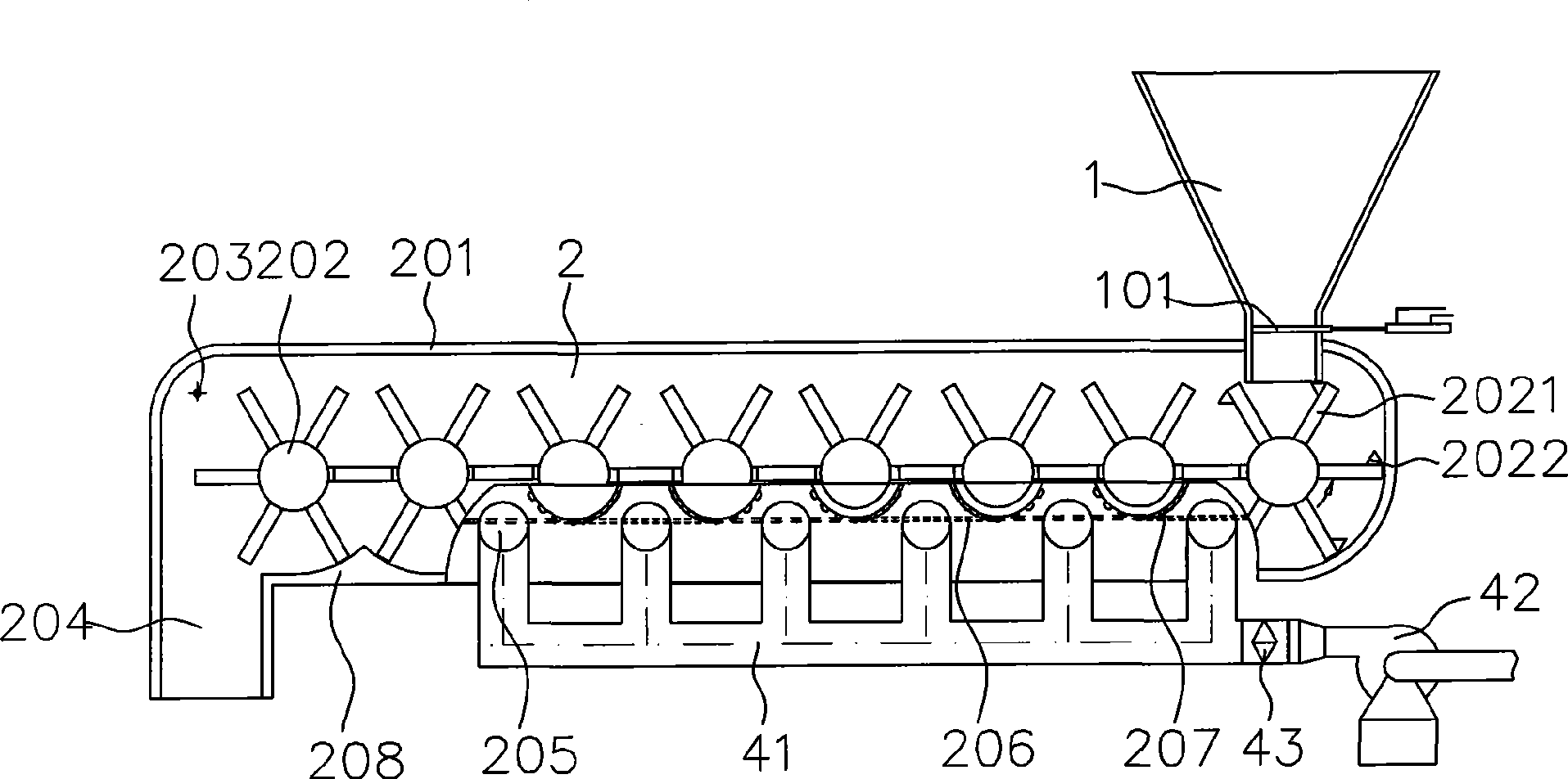

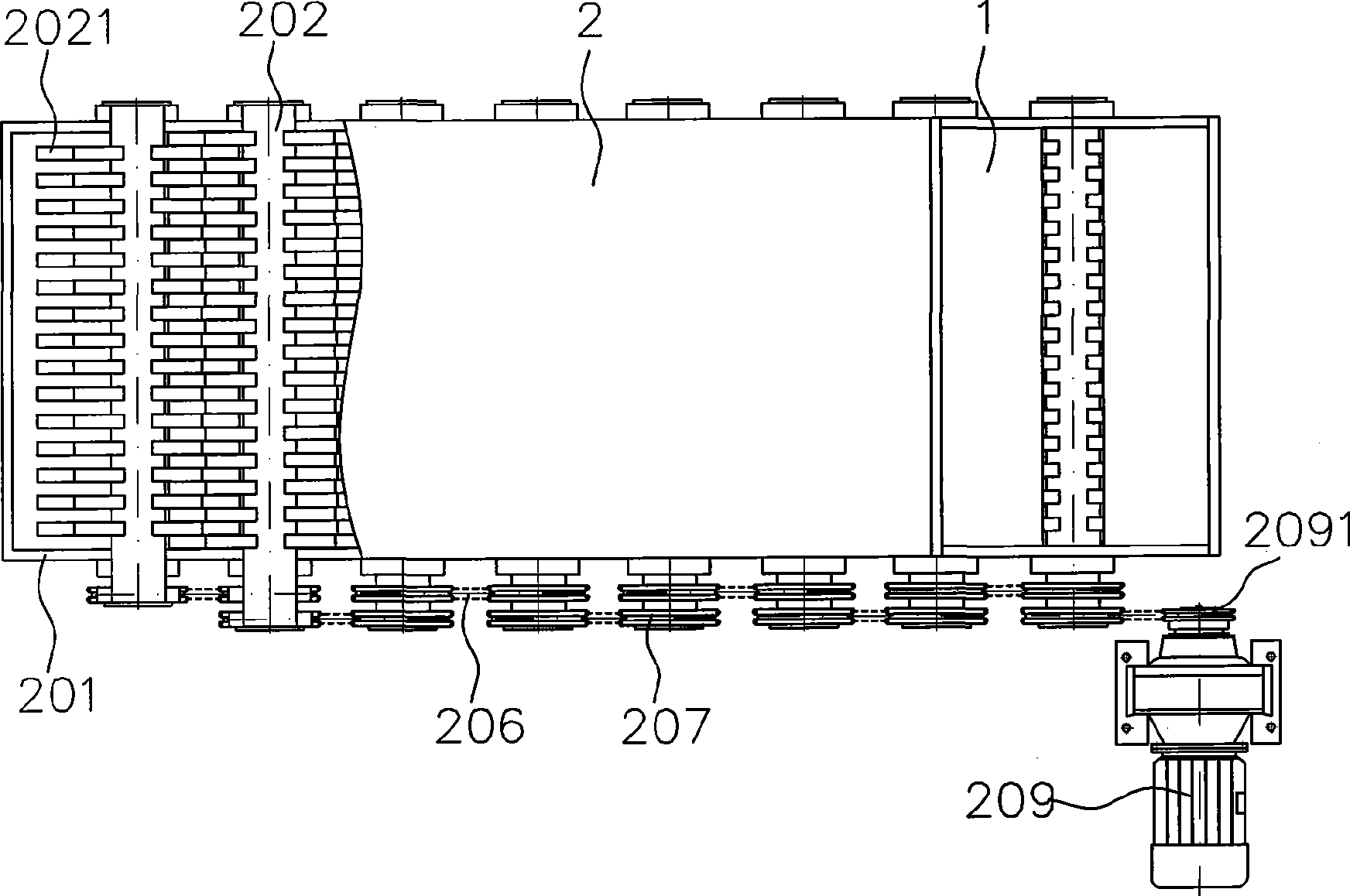

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

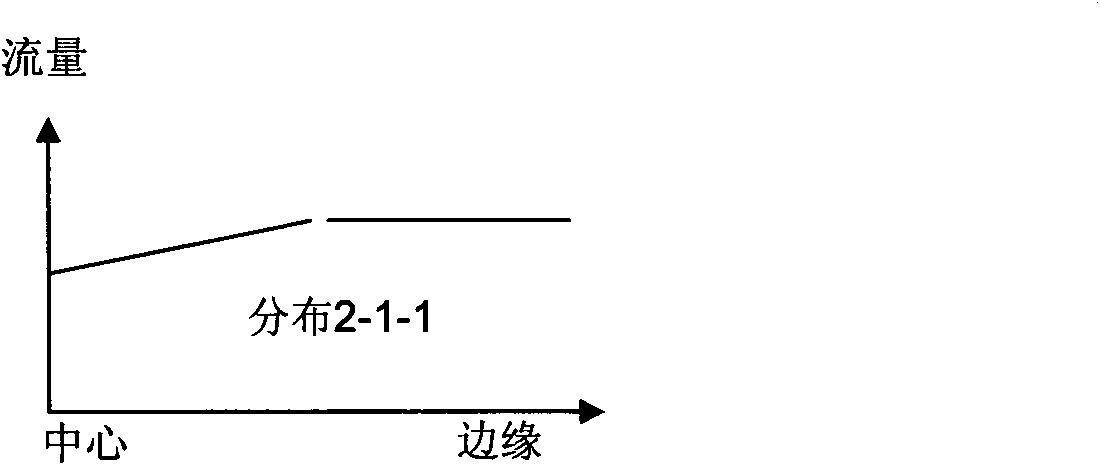

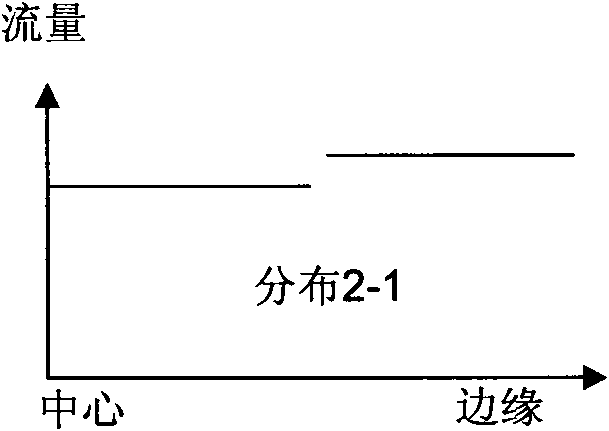

Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

ActiveCN101914761AReduce manufacturing costControl consumptionChemical vapor deposition coatingSystem capacityEngineering

The invention discloses a device for controlling the delivery and the uniform distribution of reaction gas in a MOCVD reaction chamber. By respectively controlling the flow of gas passages non-uniformly distributed radially on a front gas homogenizing plate and input passages at different positions, at least two reaction gases are respectively introduced into two paths which are radially and axially crossed on a spray header, and can be secondarily distributed by nozzles in different shapes, so the uniformly distributed boundary layer concentration, speed and temperature required are achieved on the surface of a rotary epitaxial wafer, the quality of massively produced epitaxial films and the finished product ratio of massively produced epitaxial wafers are improved, the consumption of expensive reaction gases can be effectively controlled and the epitaxial production cost is reduced. By properly increasing the distance between the surface of the spray header and the epitaxial wafer, deposits generated on the surface of the spray header and the nozzles in the epitaxial growth are reduced, the cleaning period is prolonged, and the production efficiency and system capacity are improved. The device also can reduce the processing difficulty and manufacturing cost of the nozzles of the spray header and cooling medium passages.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

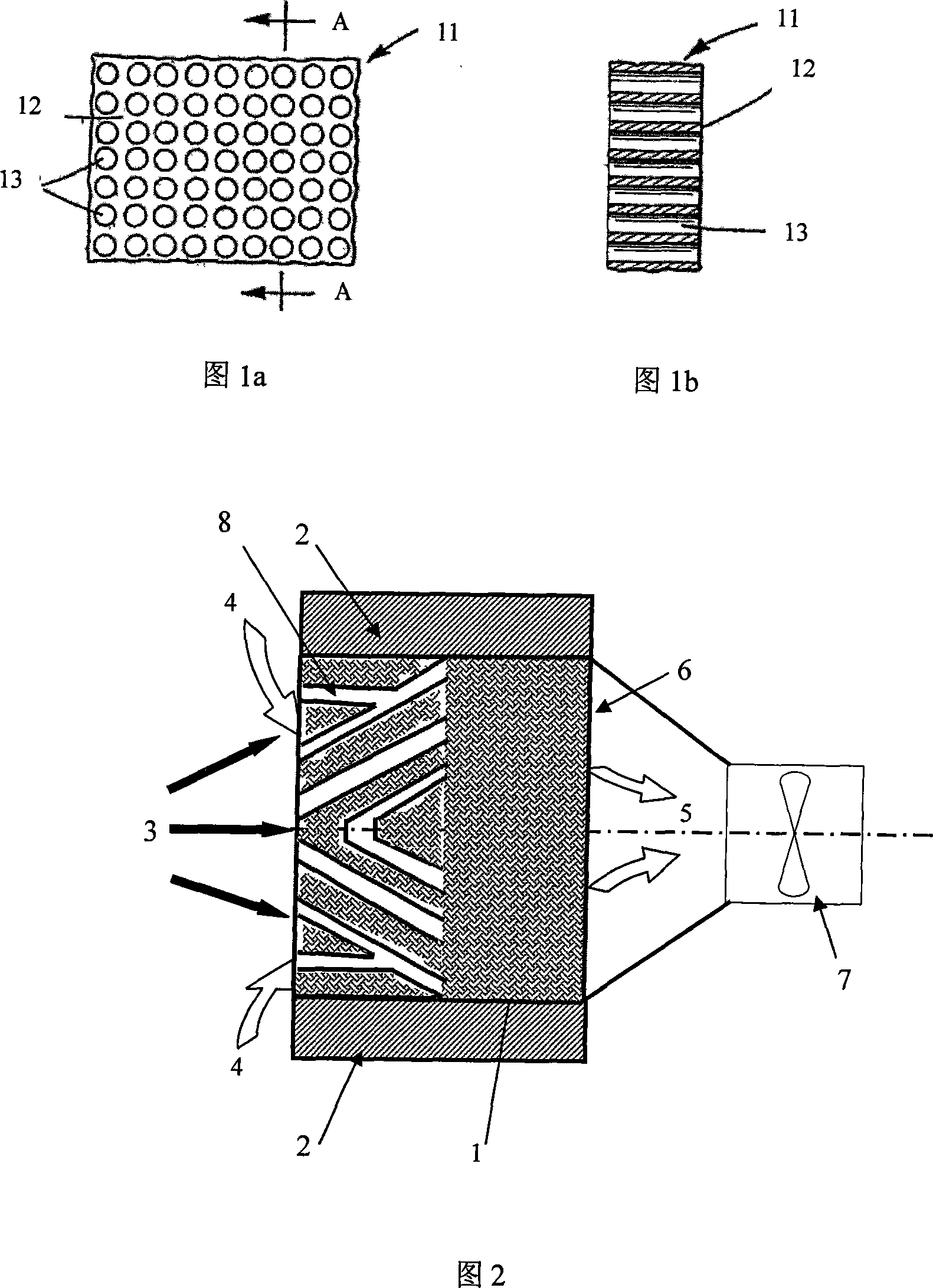

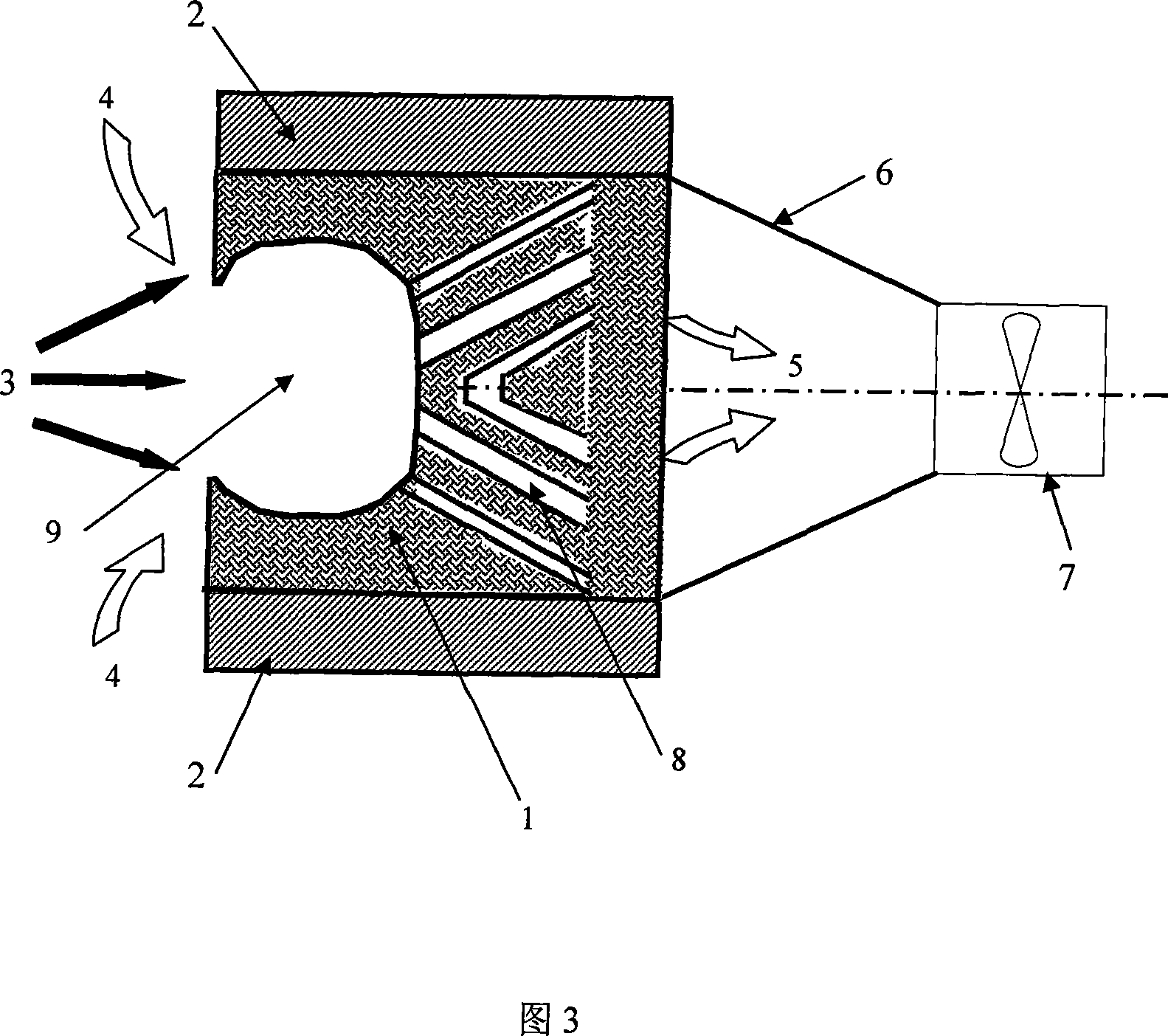

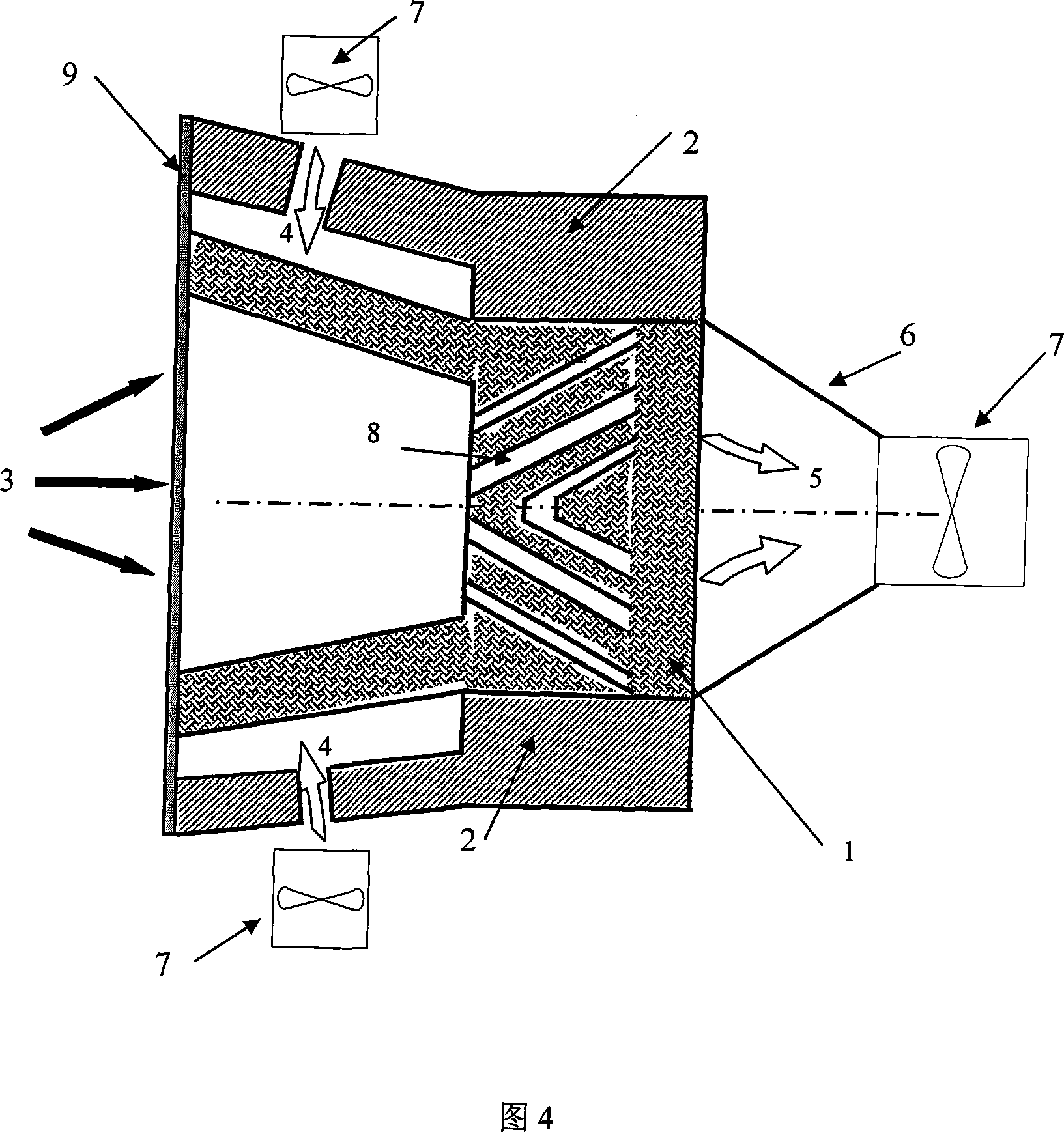

Silicon carbide foam ceramic solar energy air heat-absorbing device

InactiveCN101122425AImprove thermal conductivityFacilitate conductionSolar heating energySolar heat devicesCold airBlackbody cavity

A silicon carbide ceramic foam solar energy air heat absorber uses silicon carbide ceramic foam materials as solar energy absorber. The silicon carbide ceramic foam absorber is wrapped with an insulating layer (2). A radiant heat flux (3) projects onto the surface of the silicon carbide ceramic foam absorber (1) or into an artificial blackbody cavity (9) and is received by the silicon carbide ceramic foam absorber (1). Cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3). Hot air (5) is obtained through heat exchange of thecold air and the radiant heat flux. Or the cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3) or back to the radiant heat flux (3). The hot air (5) of 700 to 1300 DEG C is obtained through the heat exchange of the cold air and the radiant heat flux through a quartz window (10). The silicon carbide ceramic foam absorber (1) buries an air diversion channel (8) beforehand. The invention can effectively receive radiant heat and emit heat to the air and take advantage of self-sensible heat to store heat at the same time.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method and apparatus to promote non-stationary flame

InactiveUS20070037106A1Uniform temperatureWide coverageCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorMomentum

A burner has a central port and 3 or more outer ports whose axes are angled toward or away from the central port axis. Sequentially varying the outer port(s) from which material is injected at a high enough momentum to deflect the flame from the axis of the central port changes the orientation of the flame with respect to the central port axis.

Owner:PRAXAIR TECH INC

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

InactiveCN1483521ASmall temperature differenceImprove surface qualityMetal rolling arrangementsAutomatic controlThin slab

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

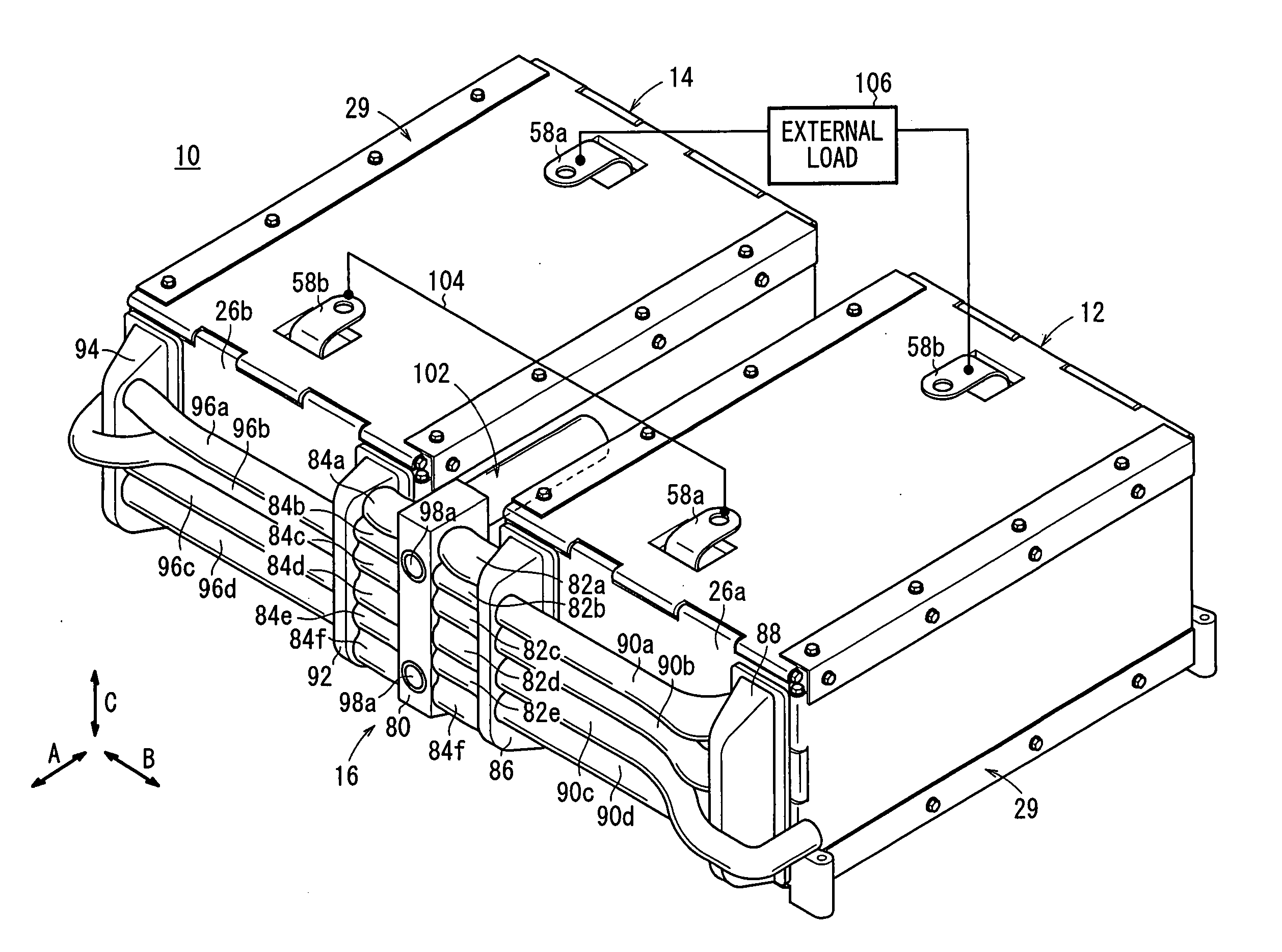

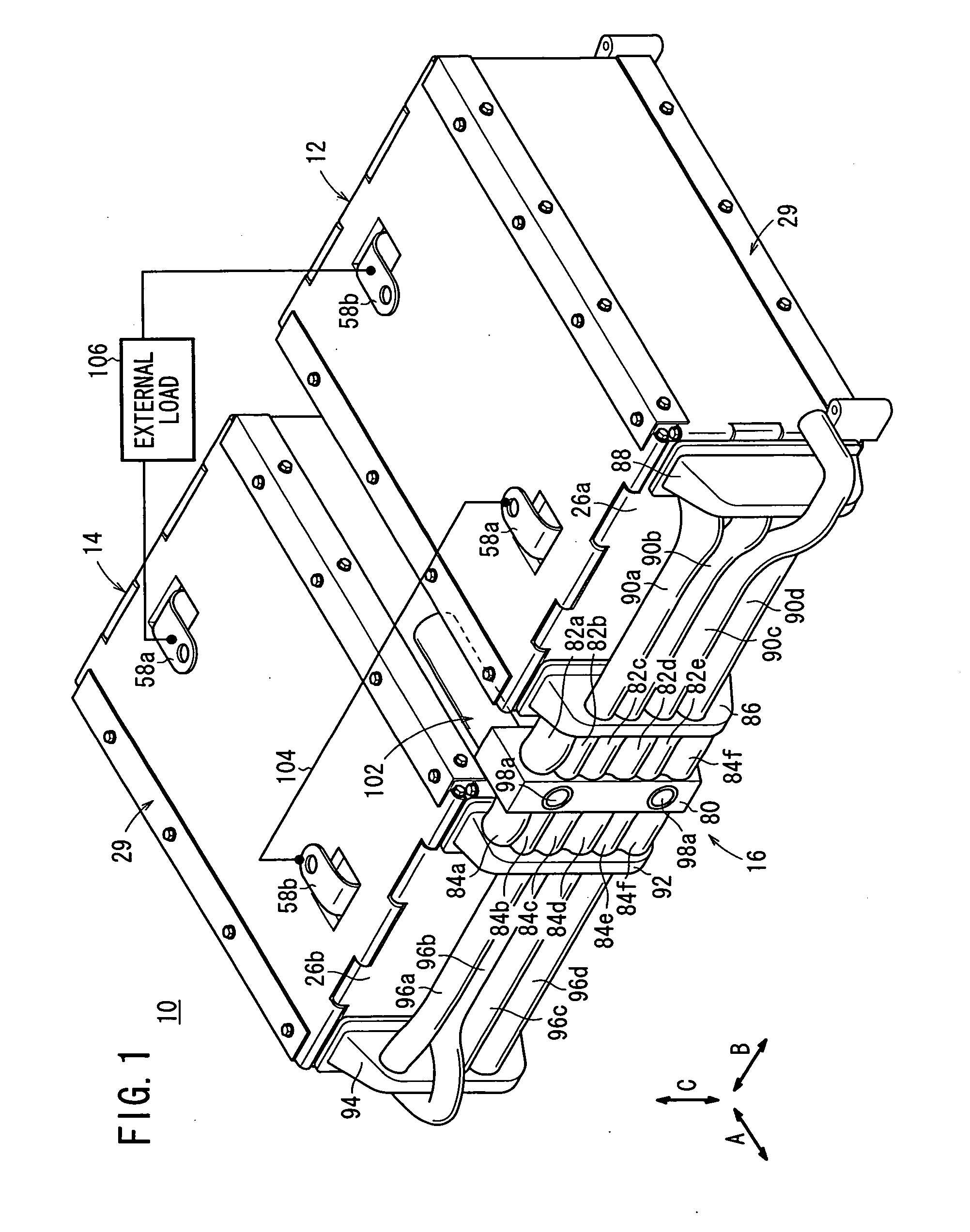

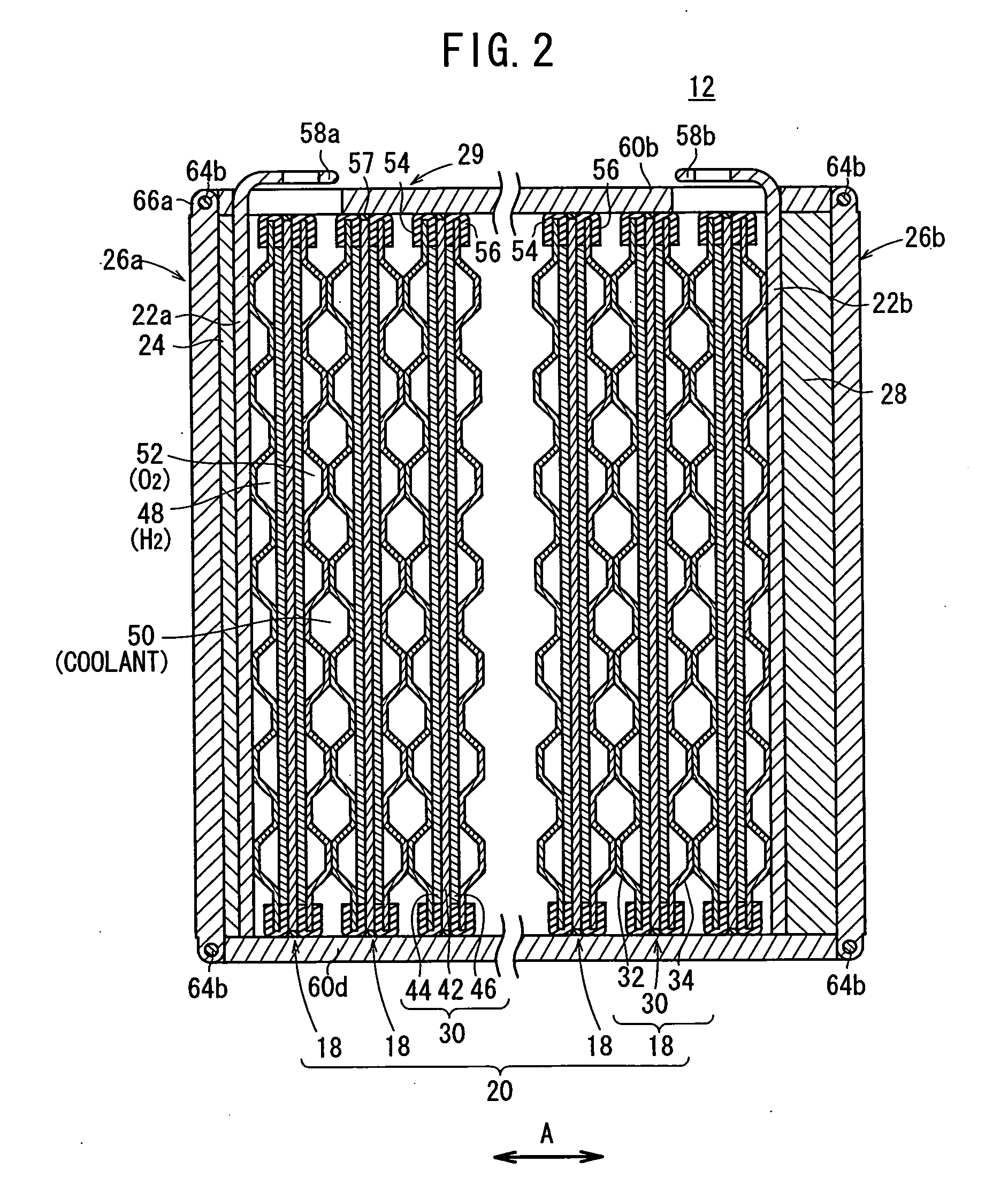

Fuel cell system

ActiveUS20050106446A1Simplification and downsizing of structureReduce in quantityFuel cells groupingFuel cell auxillariesEngineeringElectrical and Electronics engineering

A fuel cell system includes first and second fuel cell stacks which are juxtaposed to each other. An assembly manifold is attached to the first and second fuel cell stacks. A connection block is provided at a central position of the assembly manifold. A fuel gas supply port and a fuel gas discharge port are provided on a front surface of the connection block, and an oxygen-containing gas supply port and an oxygen-containing gas discharge port are provided on a back surface of the connection block. A fuel gas and an oxygen-containing gas are equally supplied to each of the first and second fuel cell stacks.

Owner:HONDA MOTOR CO LTD

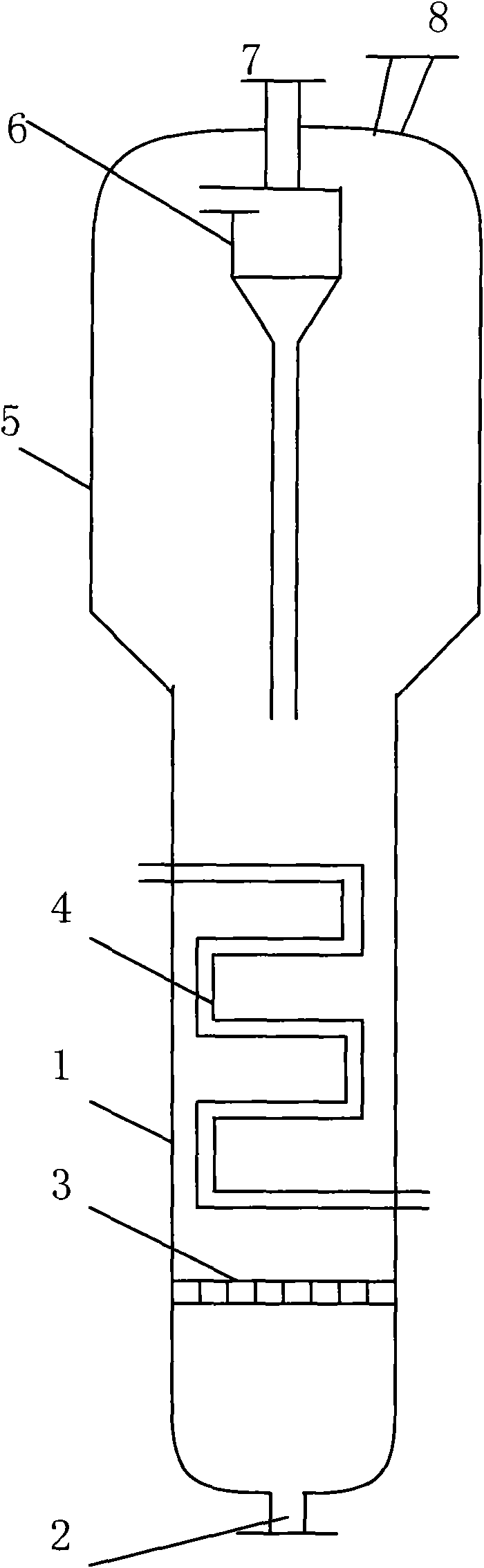

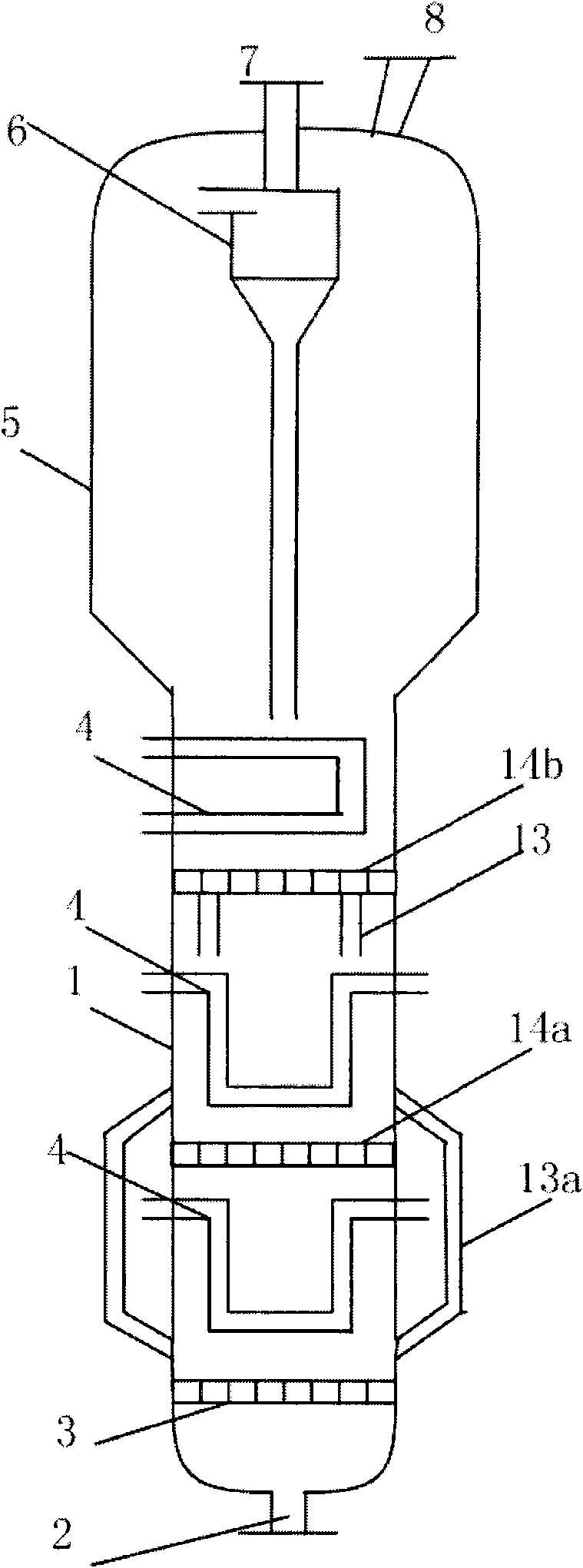

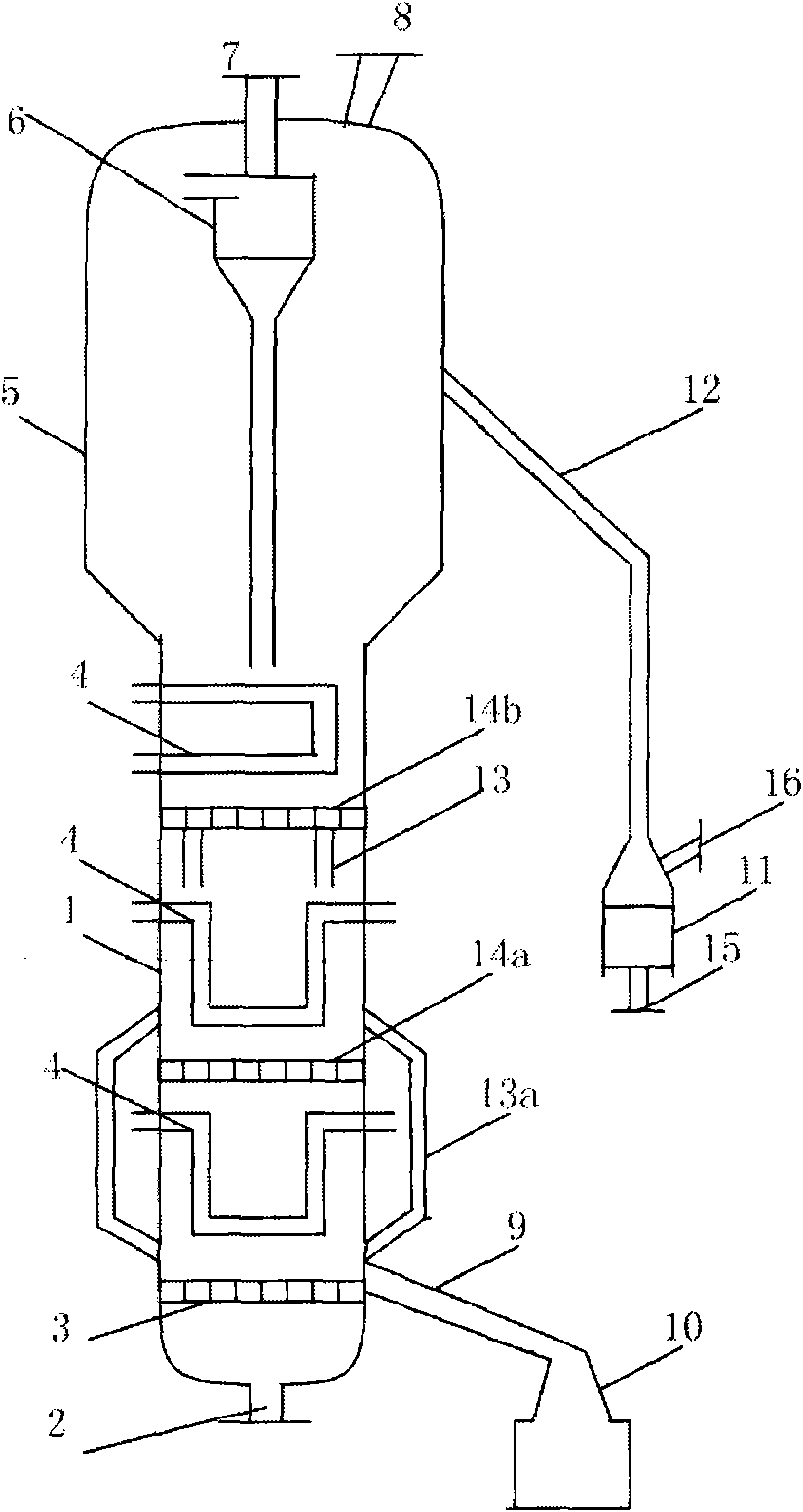

Fluidized bed process and device for preparing methane by synthetic gas

InactiveCN101665395AExpand technical routeRemarkable ability to remove heatHydrocarbon from carbon oxidesChemical/physical processesChemical industryFluidized bed

The invention relates to fluidized bed process and device for preparing methane by a synthetic gas, belonging to the field of chemical industry technologies and equipment. The process comprises the following steps: adding catalyst and diluent into a fluidized bed reaction vessel; heating and reducing the catalyst; charging the synthetic gas into the fluidized bed reaction vessel; charging a cooling medium into a reaction vessel heat exchange component to remove reaction heat; separating to obtain a methane product; and selectively containing the online replacement of the catalyst according tothe service life of the catalyst. The fluidized bed device comprises a reaction vessel simplified body, a raw gas inlet, a gas distributor, a heat exchange component, an expanding section, a cyclone separator, a catalyst feed opening and a gas outlet and selectively comprises a catalyst recovering machine and a gas stripping machine, and the reaction vessel can be divided into at least two stages.The invention has the advantages of good heat removing ability, uniform bed layer temperature, online replacement of the catalyst, high conversion rate and selectivity, long continuous running time of the catalyst, and the like.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com