LED (Light Emitting Diode) bulb lamp with driving power supply integrated in bulb shell

A technology of LED bulb lamp and driving power supply, applied in electric light source, light source, point light source, etc., can solve the problems of the decline of the appearance of the LED lamp, the limited size of the lamp head, and the inability to install it, so as to prevent the chip from blue or red light. The effect of spillage, lower production costs, and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the implementation of the present invention is not limited to the following content.

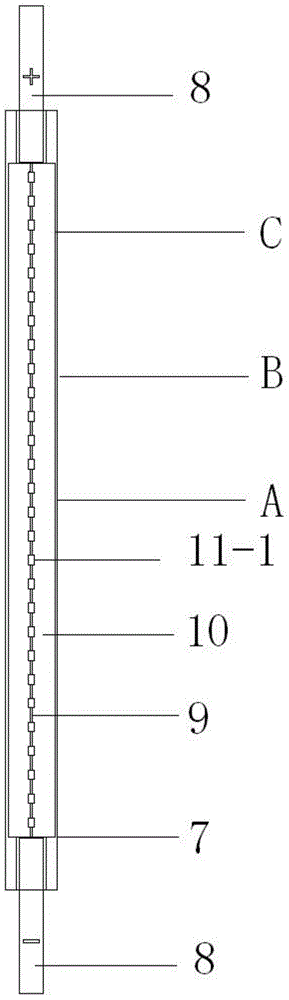

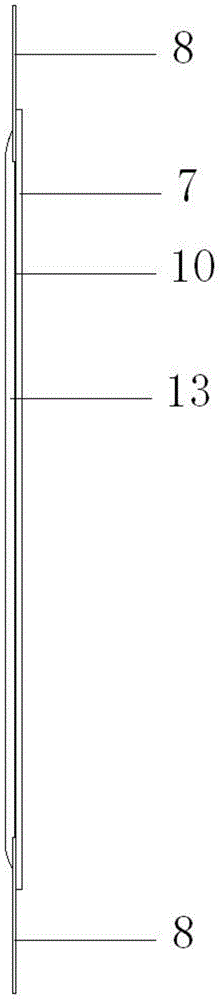

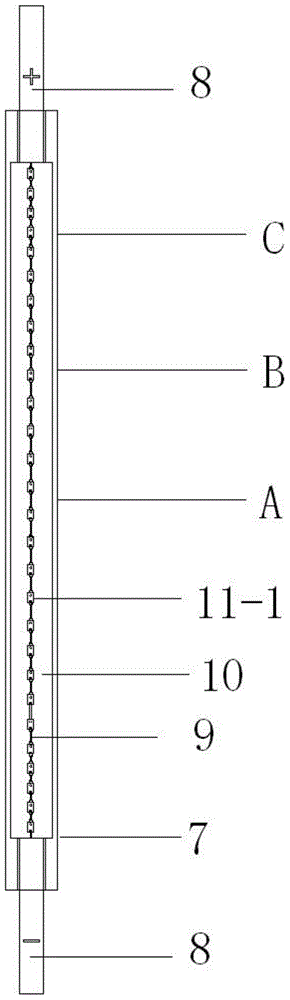

[0042] Such as Figure 1 to Figure 7As shown, an LED light-emitting filament provided by the embodiment of the present invention includes: a substrate 7, metal pins 8 arranged at both ends of the substrate 7, metal lines 9 applied on the surface of the substrate 7, applied on the The primer layer 10 on the surface of the substrate 7 , the LED light-emitting unit 11 fixed on the primer layer 10 , and the sealant layer 13 covering the LED light-emitting unit 11 . A, B, and C are three temperature test points of the glass substrate.

[0043] Such as Figure 8 As shown, an LED power driver provided by an embodiment of the present invention includes: a PCB circuit board 14, a resistor 15, a capacitor 16, an inductor 17, a diode 18, a control chip 19, an outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com