Patents

Literature

545 results about "Short life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

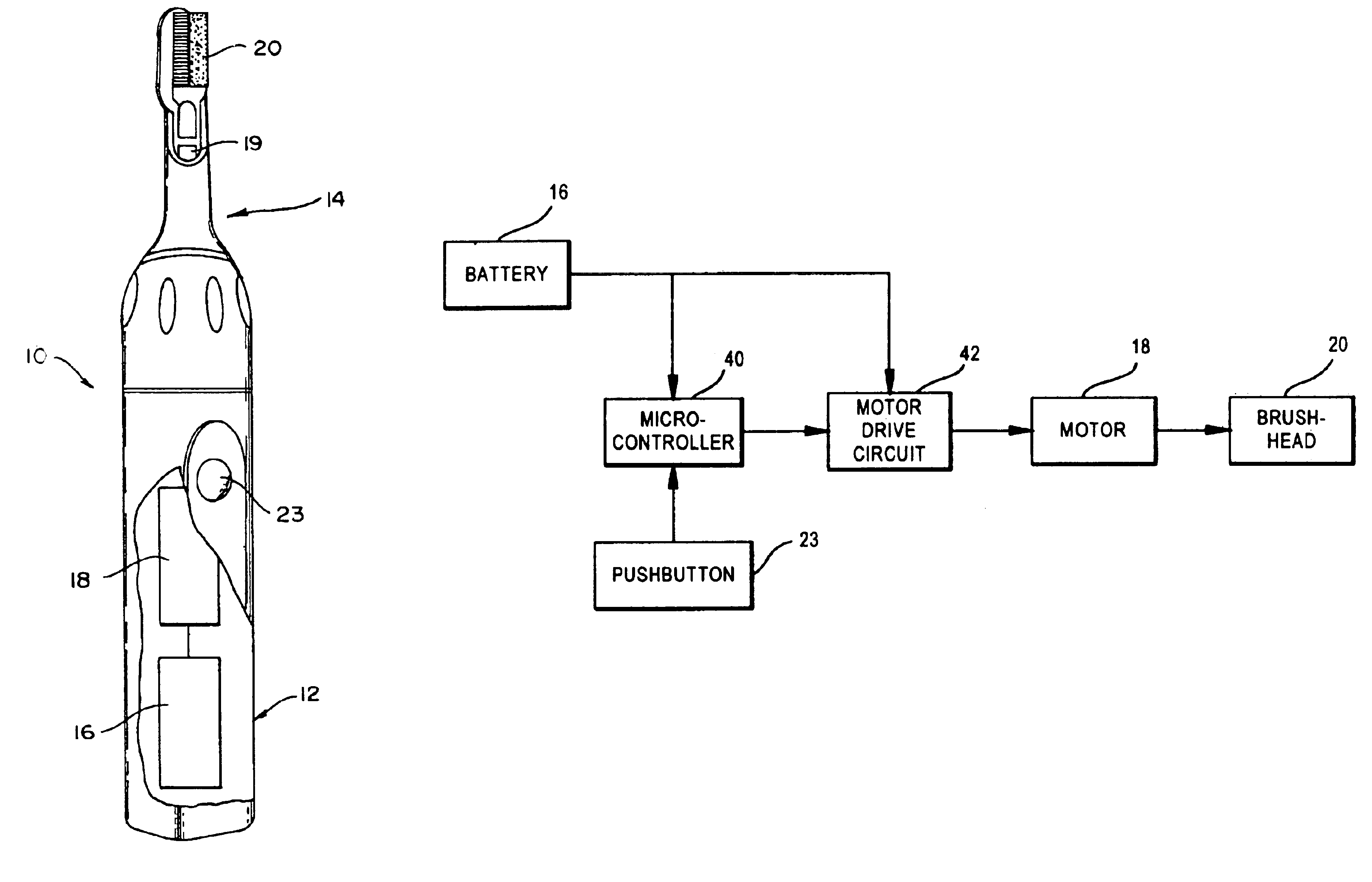

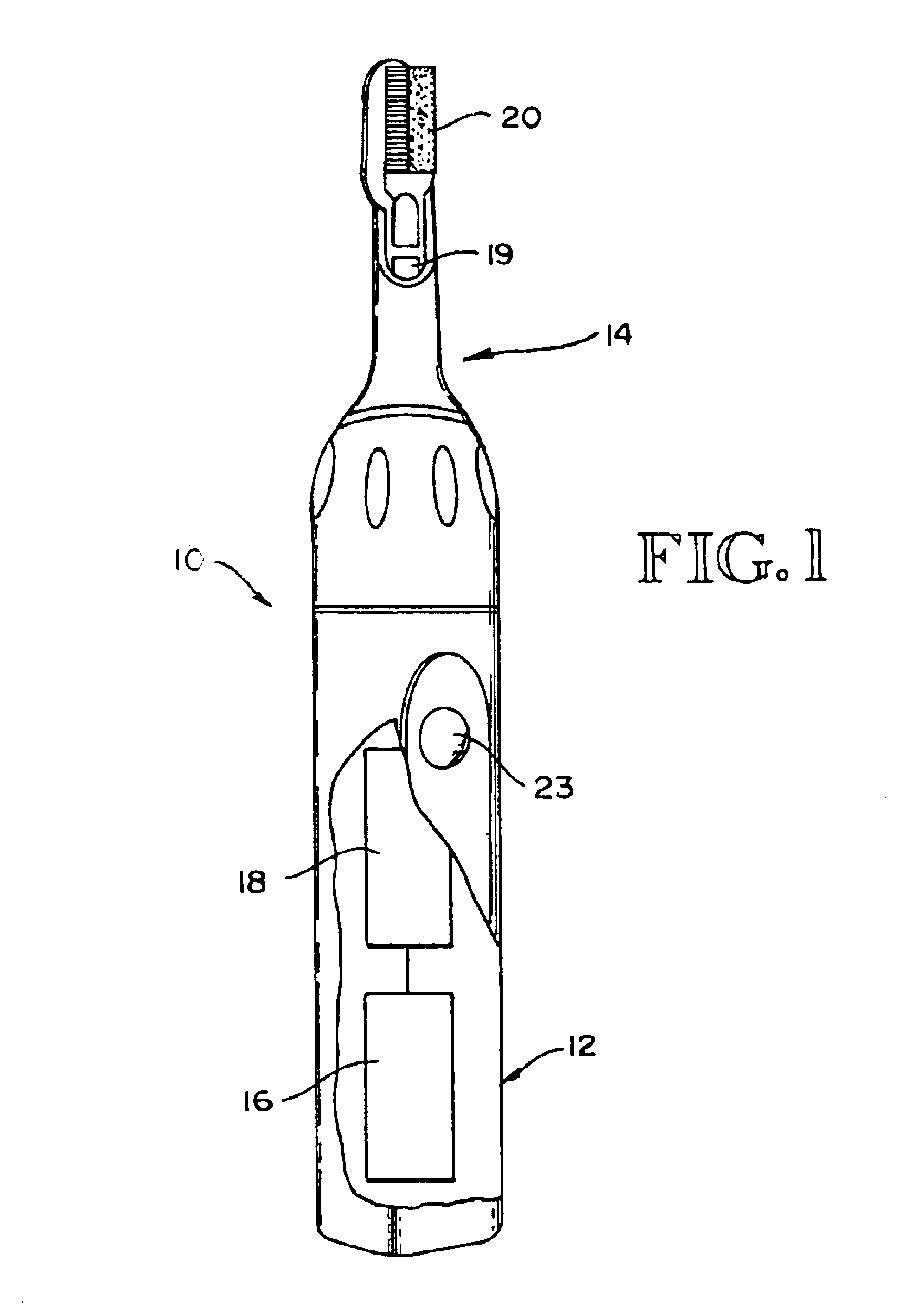

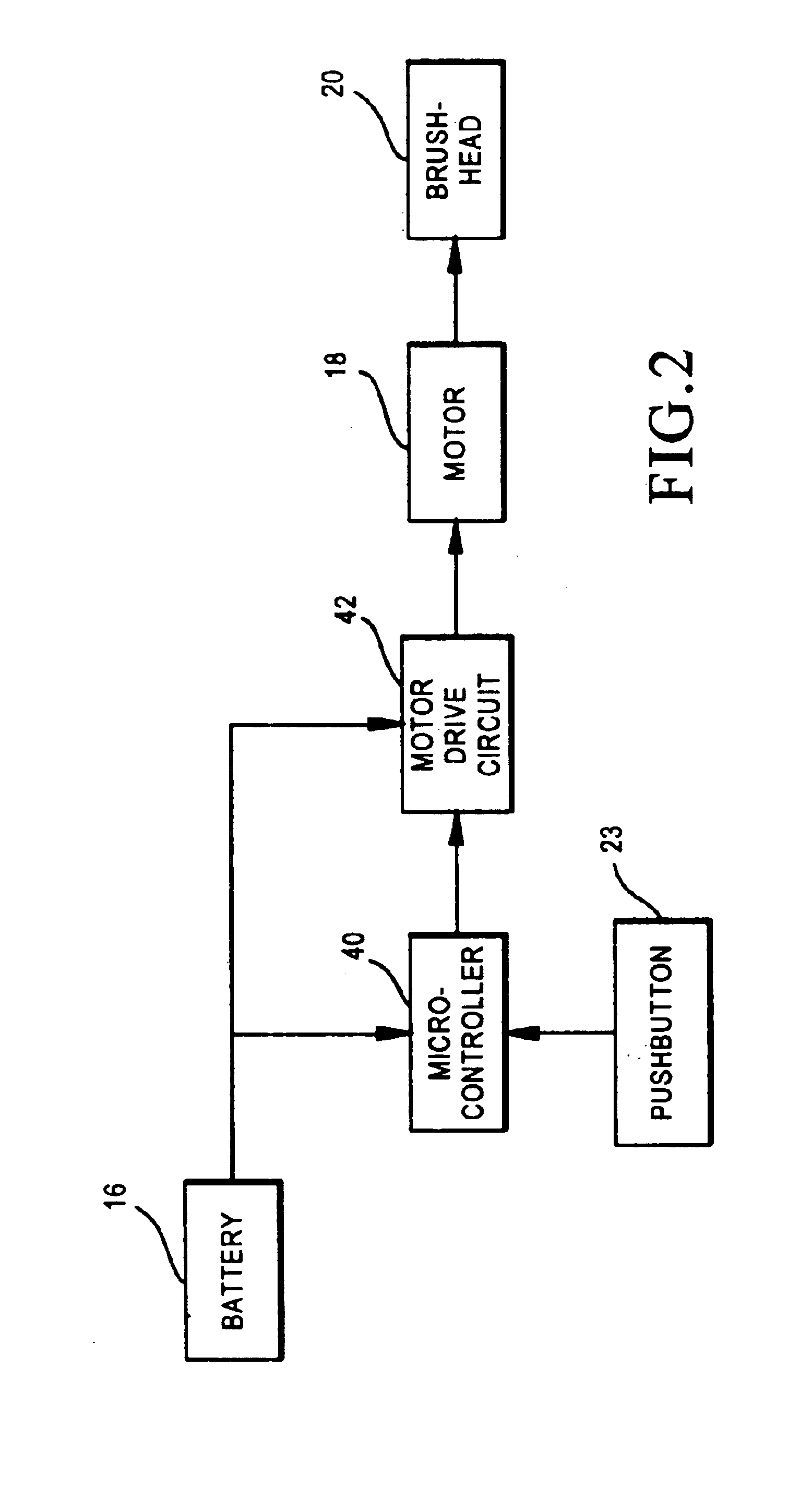

Short-life power toothbrush for trial use

A trial (test) power toothbrush designed to emulate the performance of a corresponding commercial toothbrush, powered by a non-rechargeable battery. The power to drive the toothbrush is controlled by a control circuit which is responsive to the battery to maintain the drive power at approximately the level of the commercial unit and a short “trial use” period, i.e. one month / 30 days, and then to terminate operation of the power toothbrush. The trial toothbrush may then be readily disposed of by the user, including the battery therein.

Owner:PHILIPS ORAL HEALTHCARE

Organic electroluminescent device and display device

ActiveCN109411634AImprove luminous efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingResonanceFluorescence

The invention provides an organic electroluminescent device and a display device. The organic electroluminescent device comprises an organic luminescent layer; the organic luminescent layer comprisesa main body material, a sensitizing agent material and a resonance thermally activated delayed fluorescence (TADF) material; the main body material is a broad-band gap material; the sensitizing agentmaterial is a thermally activated delayed fluorescence material; a singlet-state energy level of the thermally activated delayed fluorescence material is located between a singlet-state energy level of the broad-band gap material and a singlet-state energy level of the resonance thermally activated delayed fluorescence material; and a triplet-state energy level of the thermally activated delayed fluorescence material is located between a triplet-state energy level of the broad-band gap material and a triplet-state energy level of the resonance thermally activated delayed fluorescence material.With the organic electroluminescent device and the display device, the defects of short life time and wide spectrum of the device caused by a condition that the traditional TADF material is adopted to emit light at the present stage can be overcome.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD +1

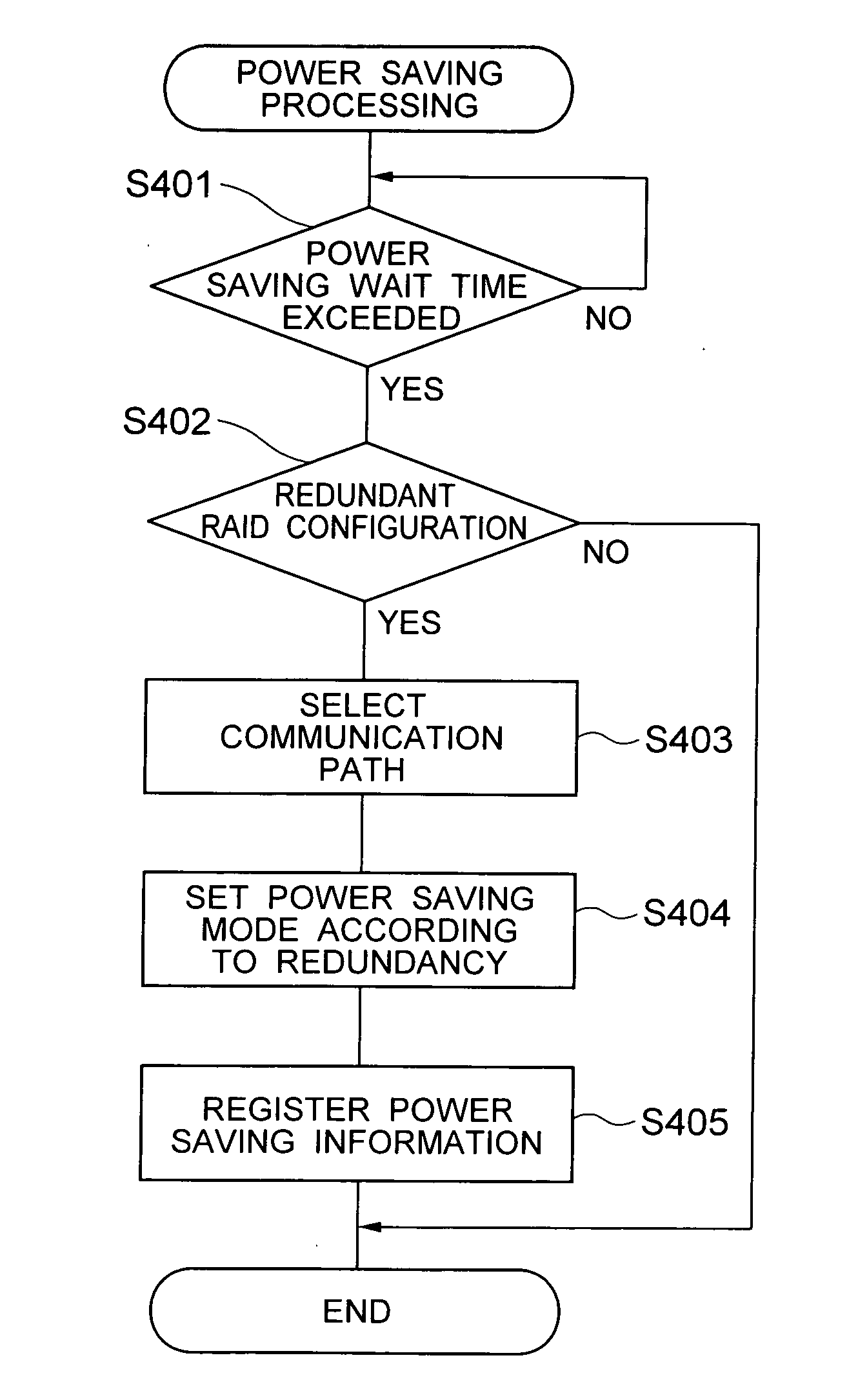

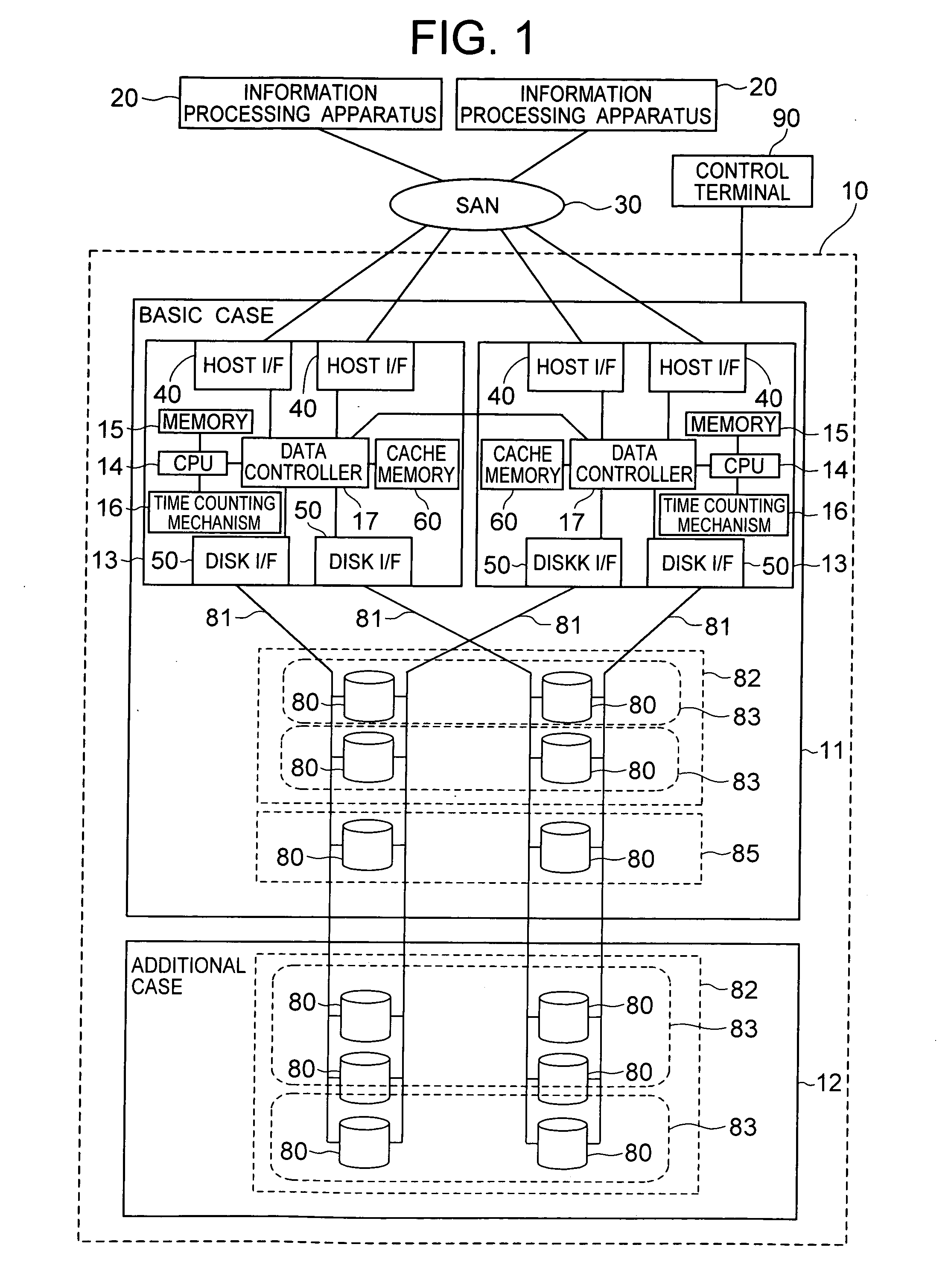

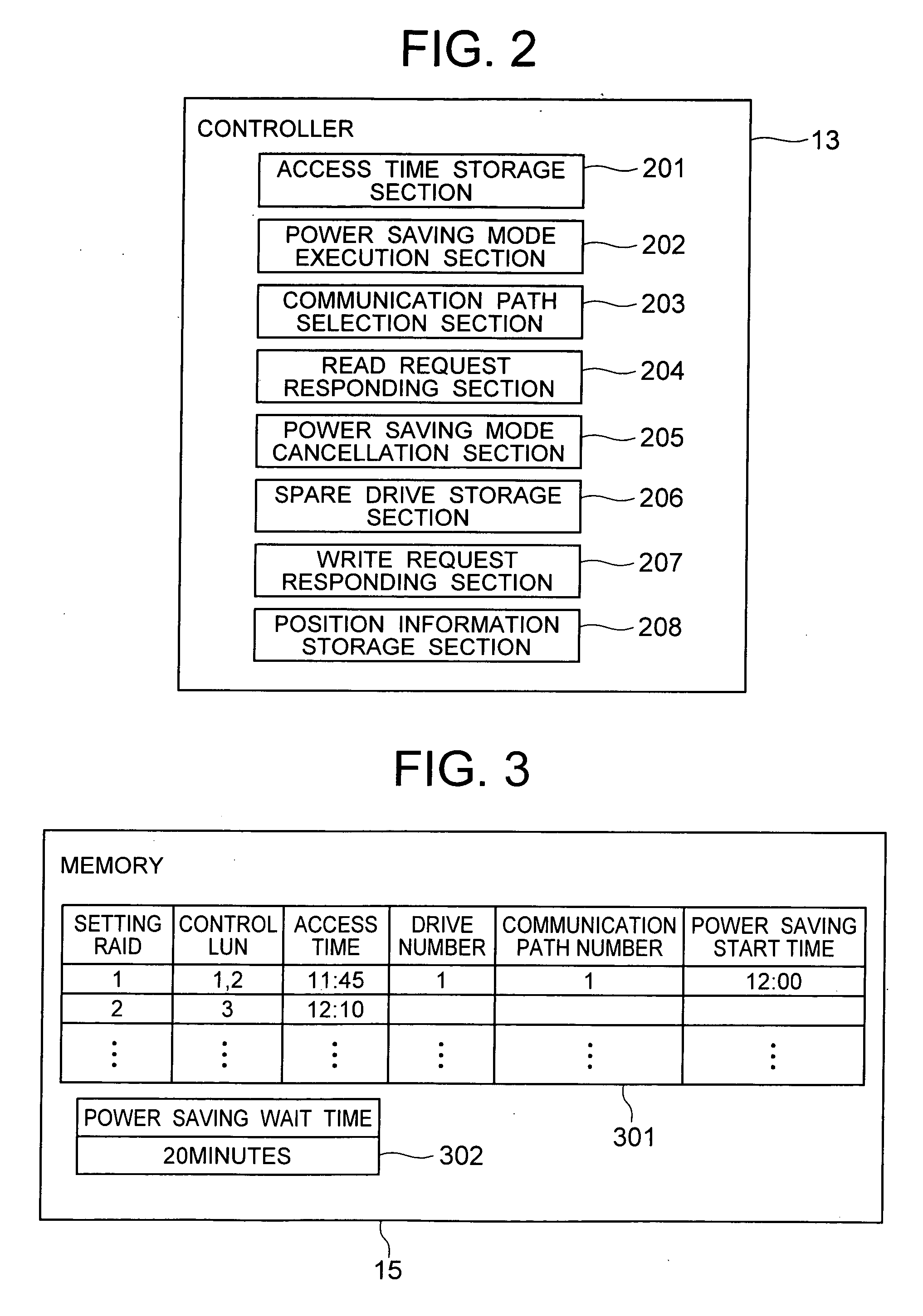

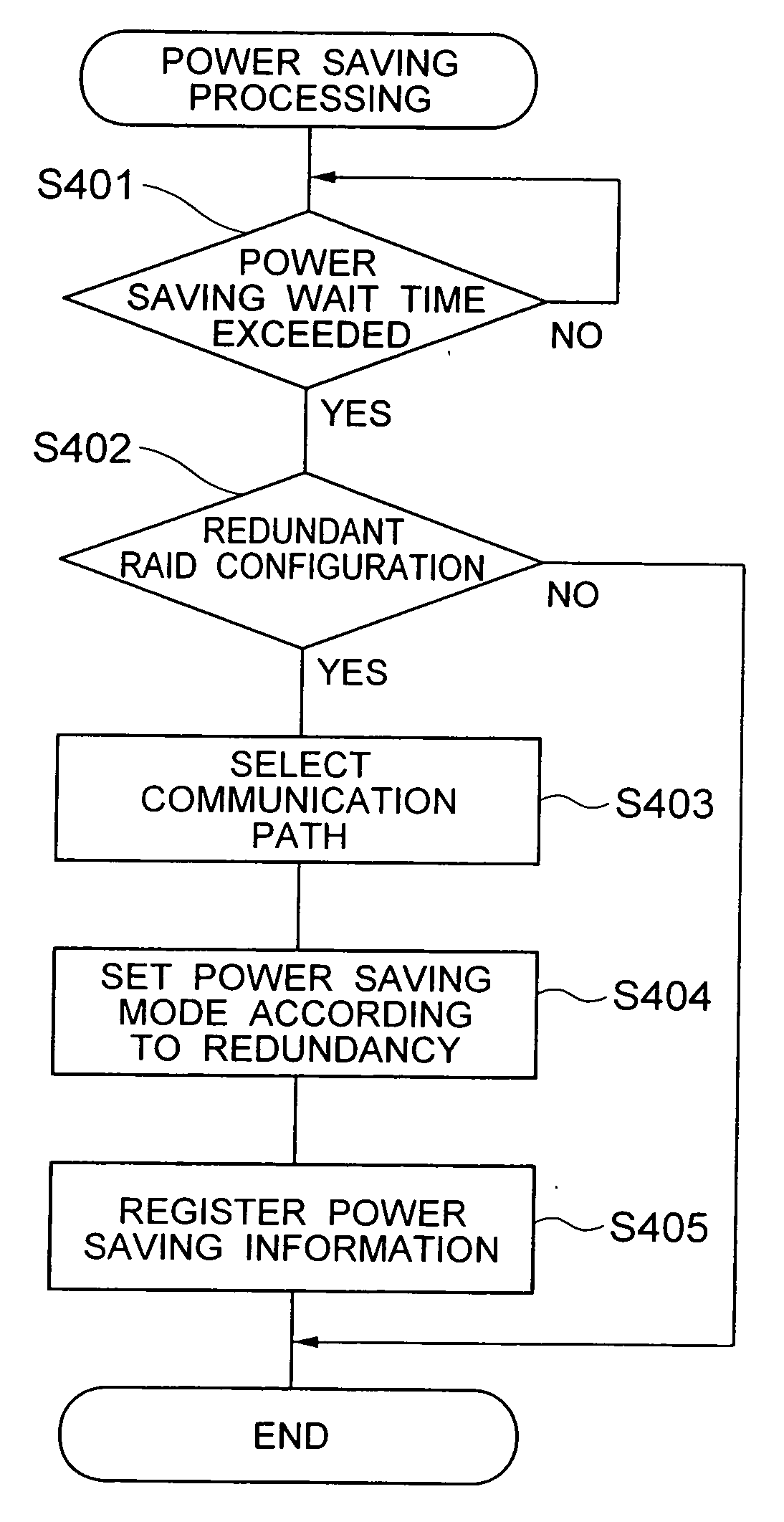

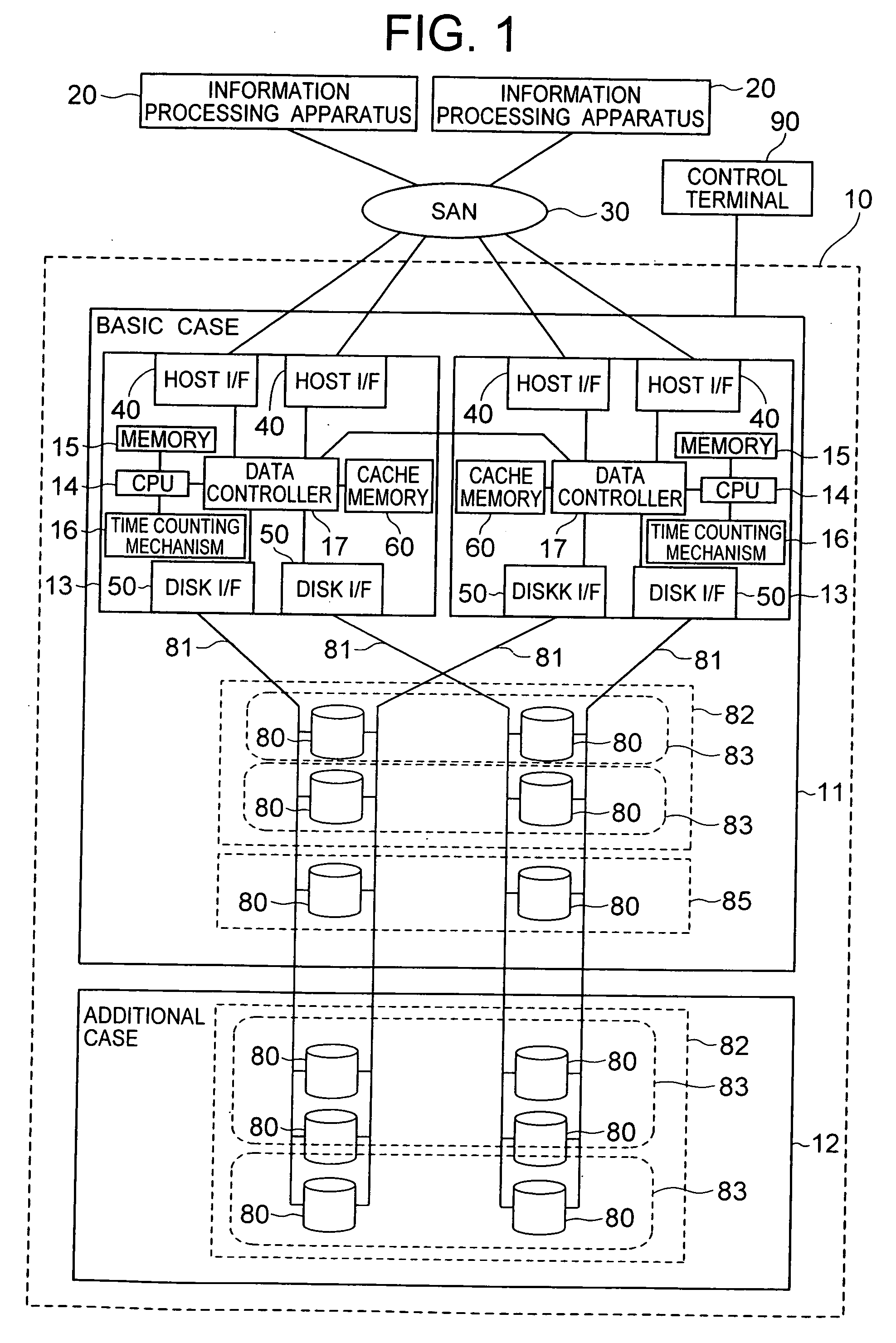

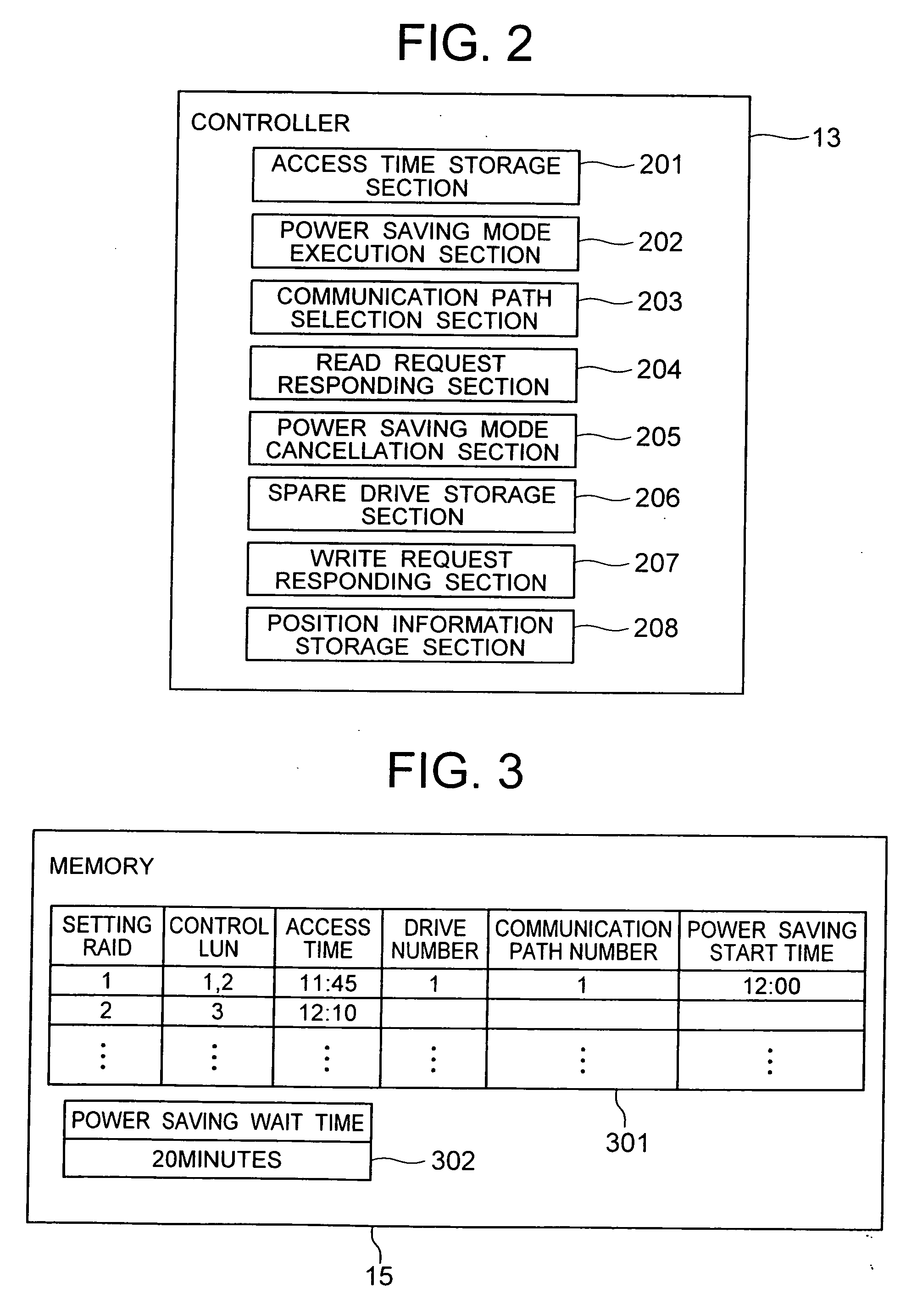

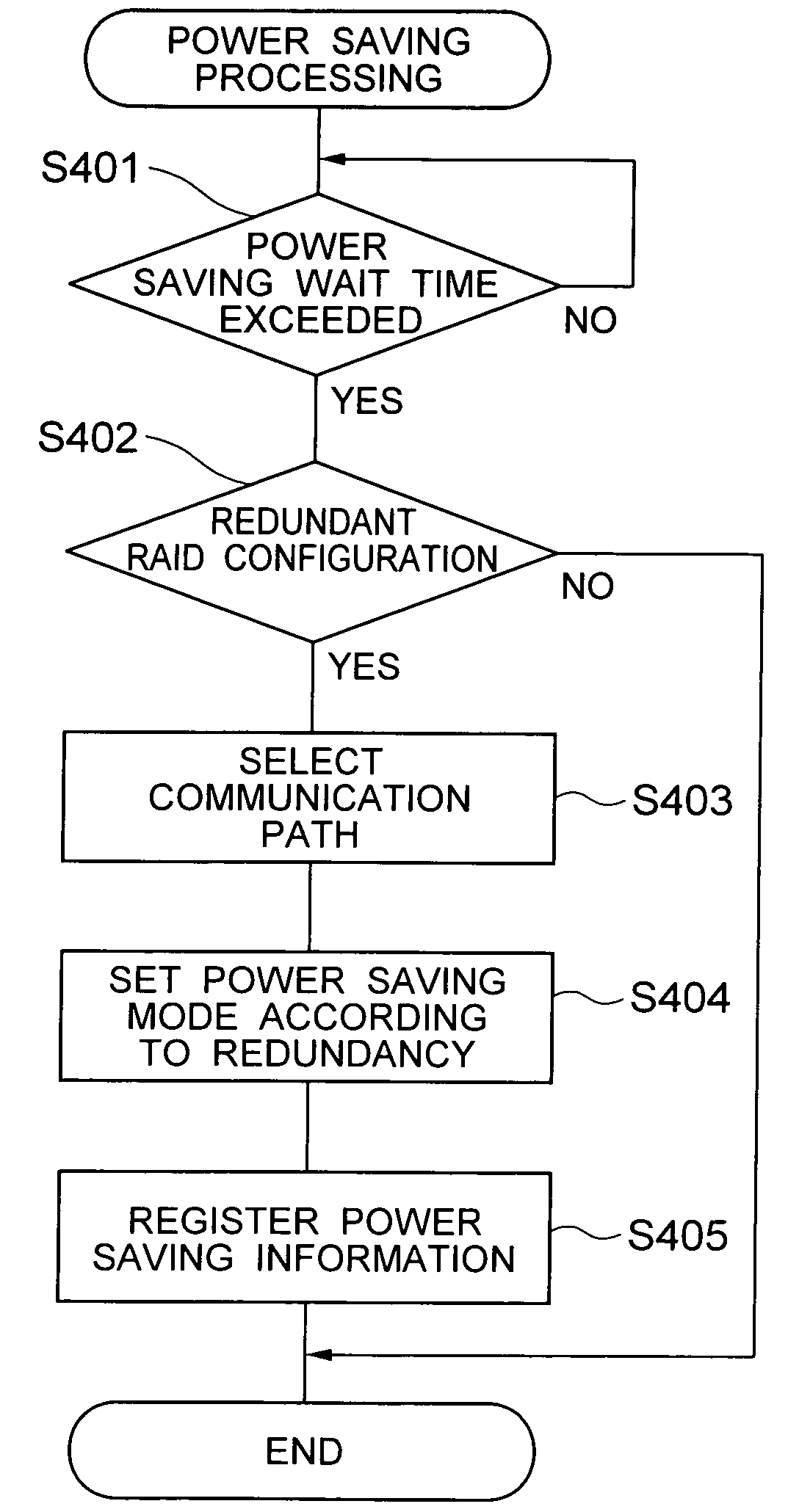

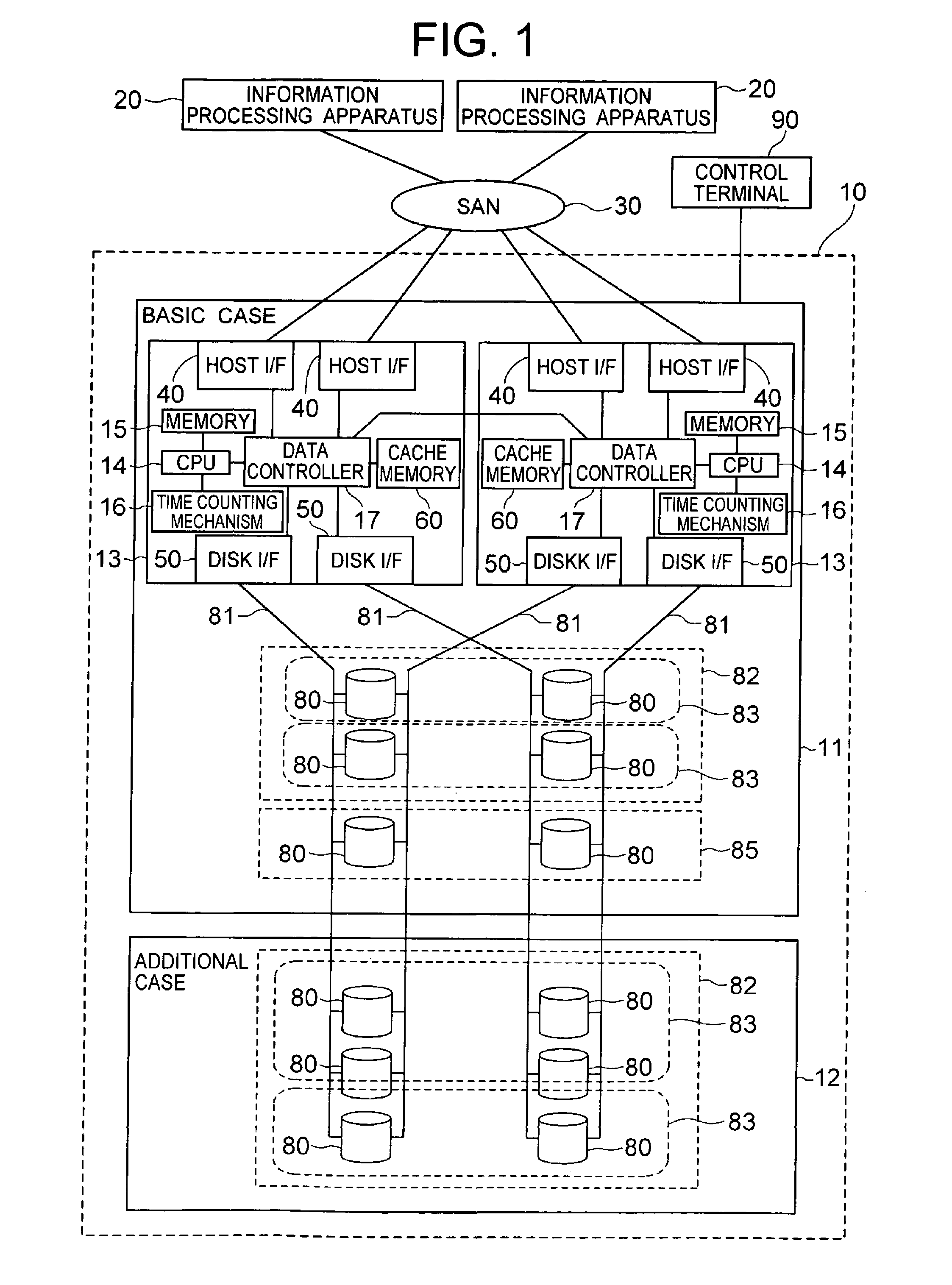

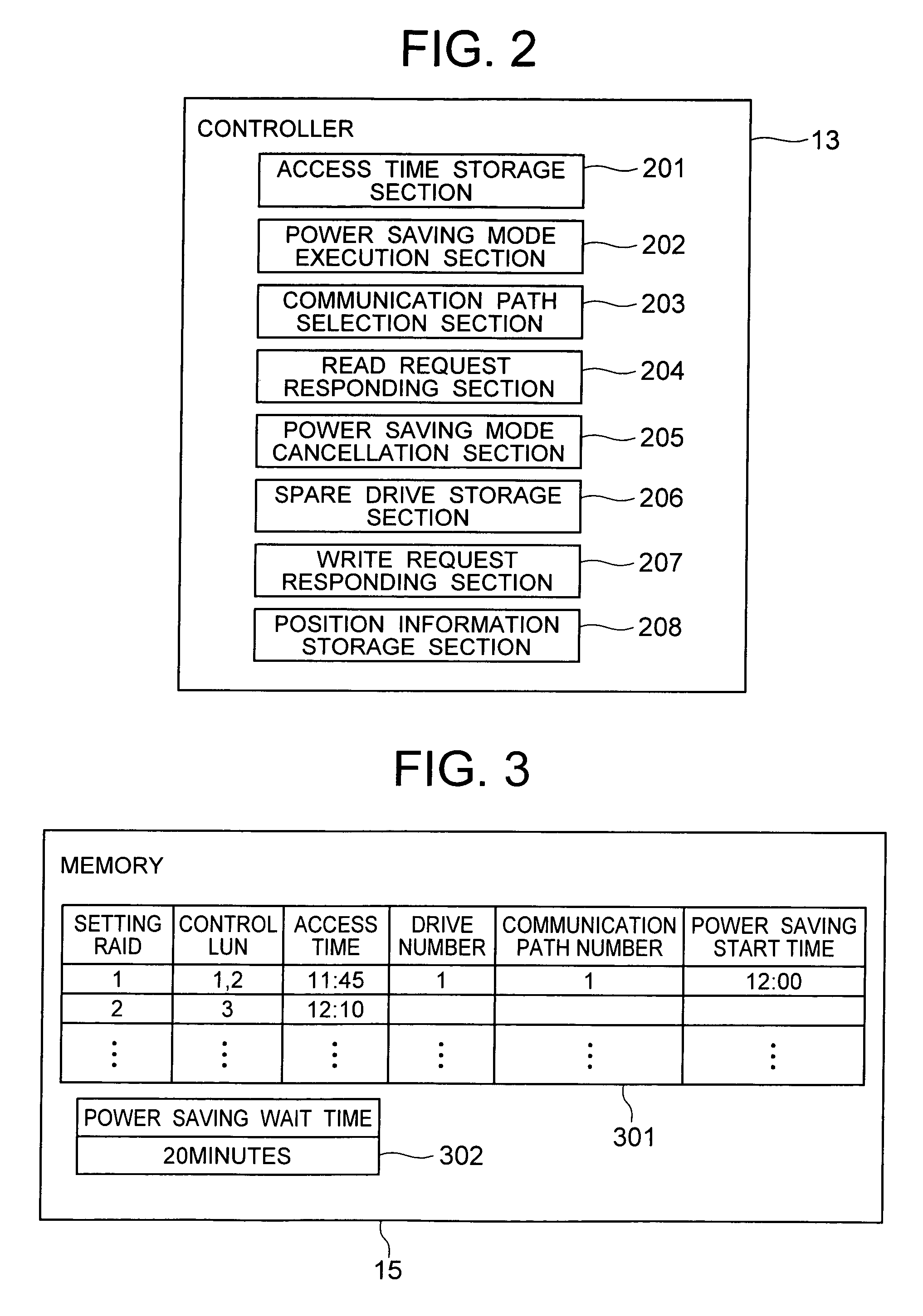

Disk array apparatus and disk array apparatus controlling method

Times at which requests for a data read or data write from / to a logical volume are received are stored in memory as access times of a RAID group making up the logical volume. When a predetermined time has elapsed after the access time, a number of the hard disk drives according to the redundancy of the RAID group are set to a power saving mode. Assume there are first hard disk drives and second hard disk drives having shorter lifes and the RAID group exceeds a predetermined time after the access time. When the RAID group consists of only the first drives, a number of the first drives according to the redundancy of the RAID group are set to a power saving mode and when it consists of only the second drives, an arbitrary number of second drives are set to a power saving mode.

Owner:HITACHI LTD

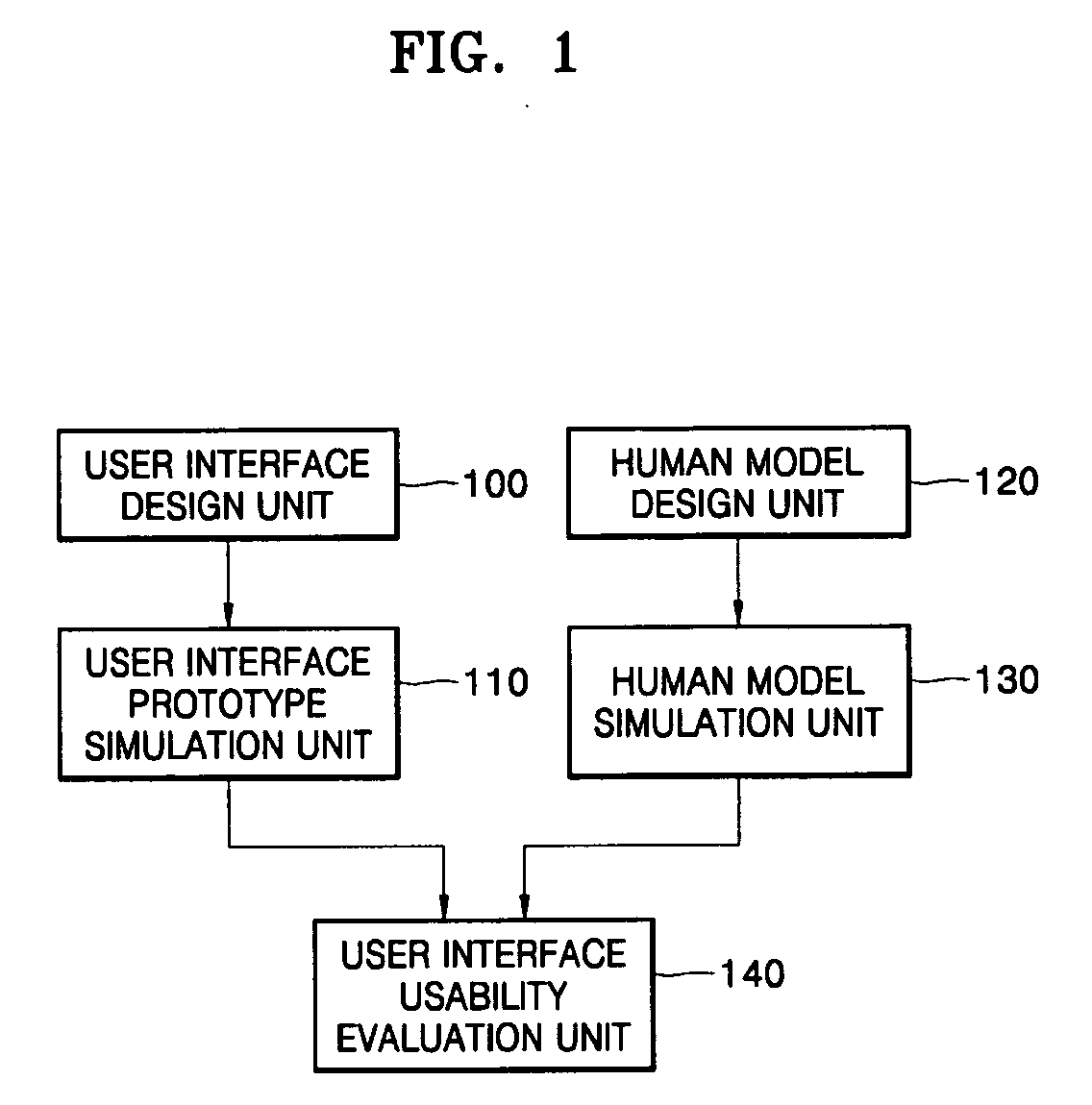

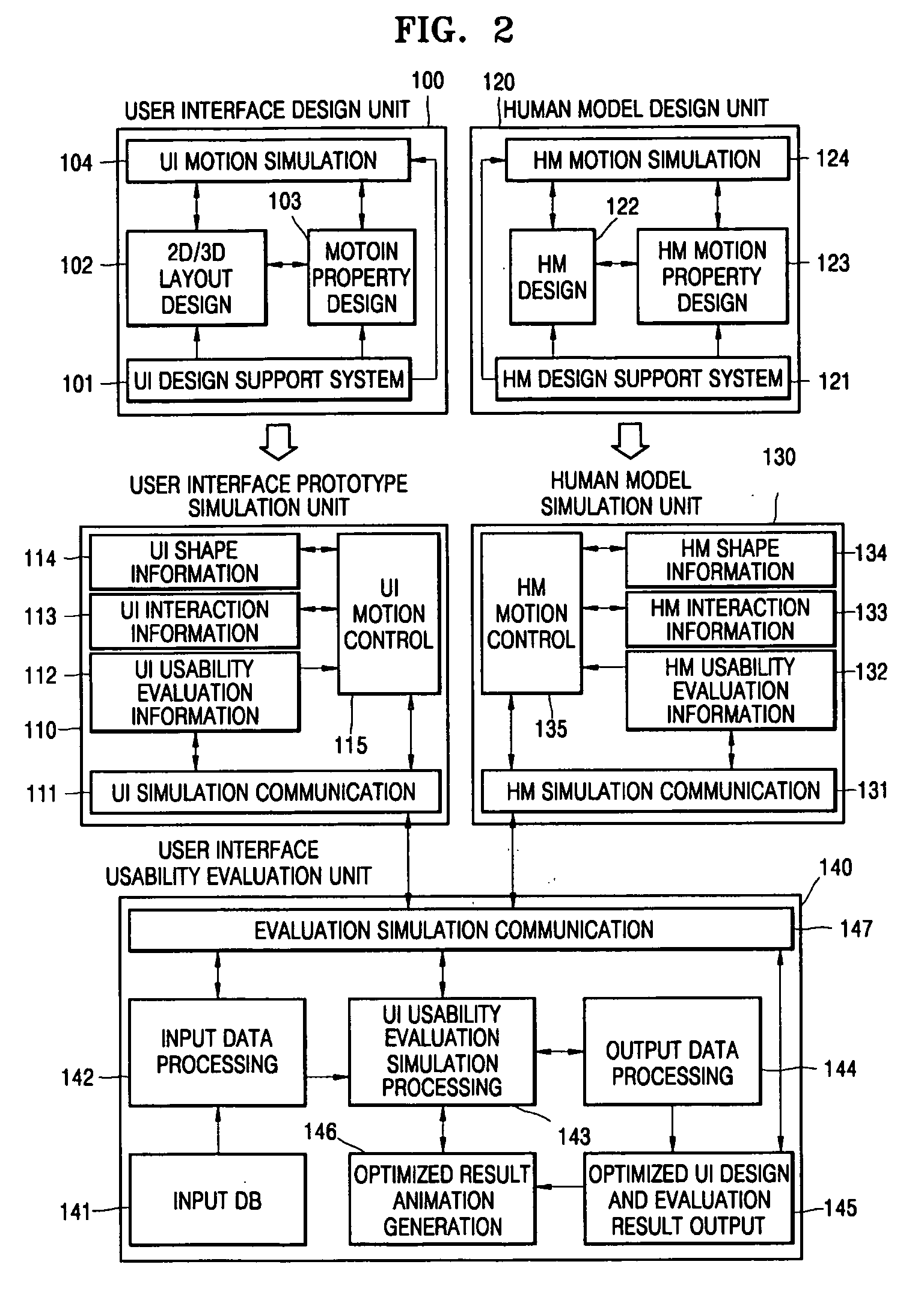

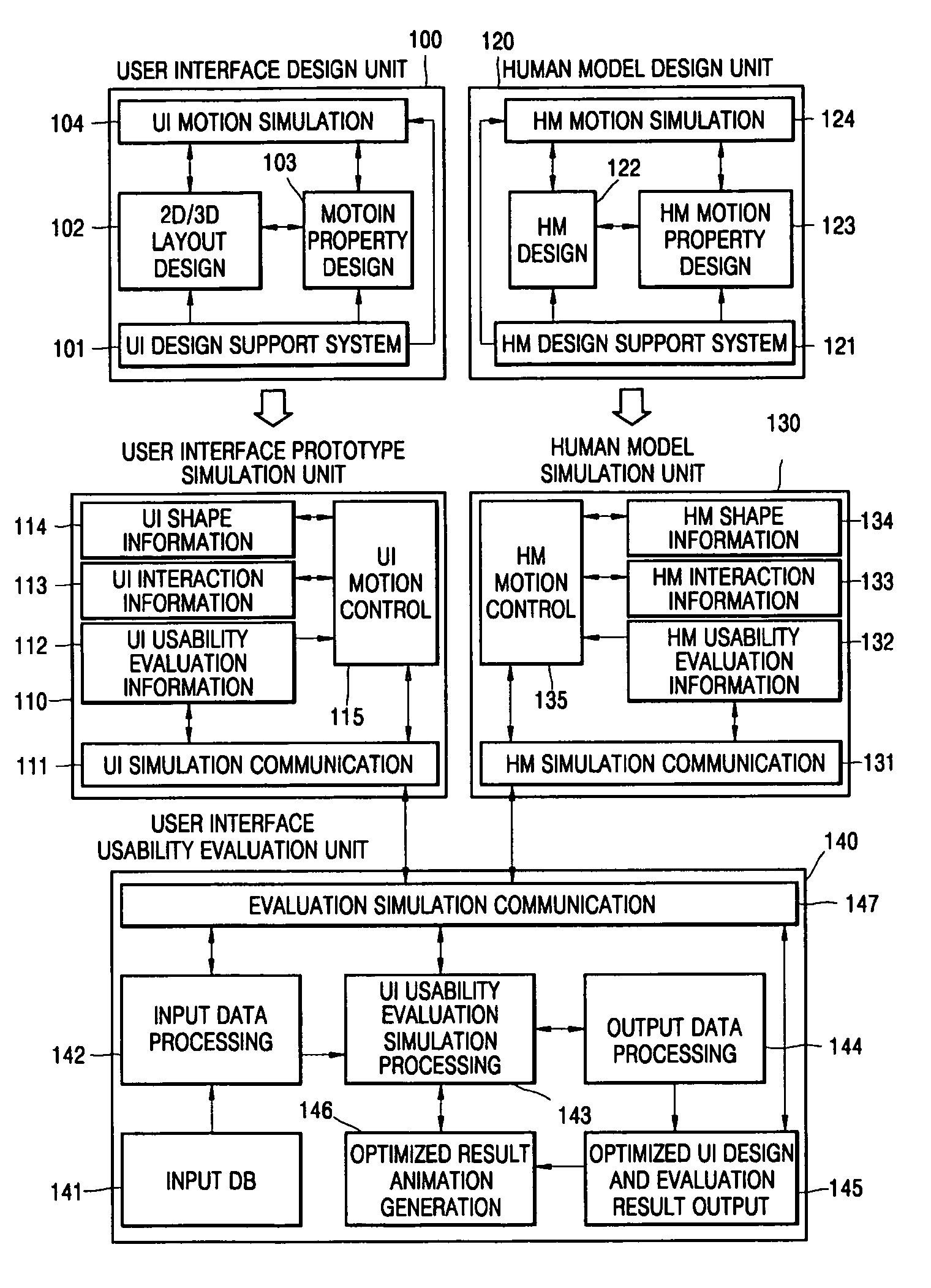

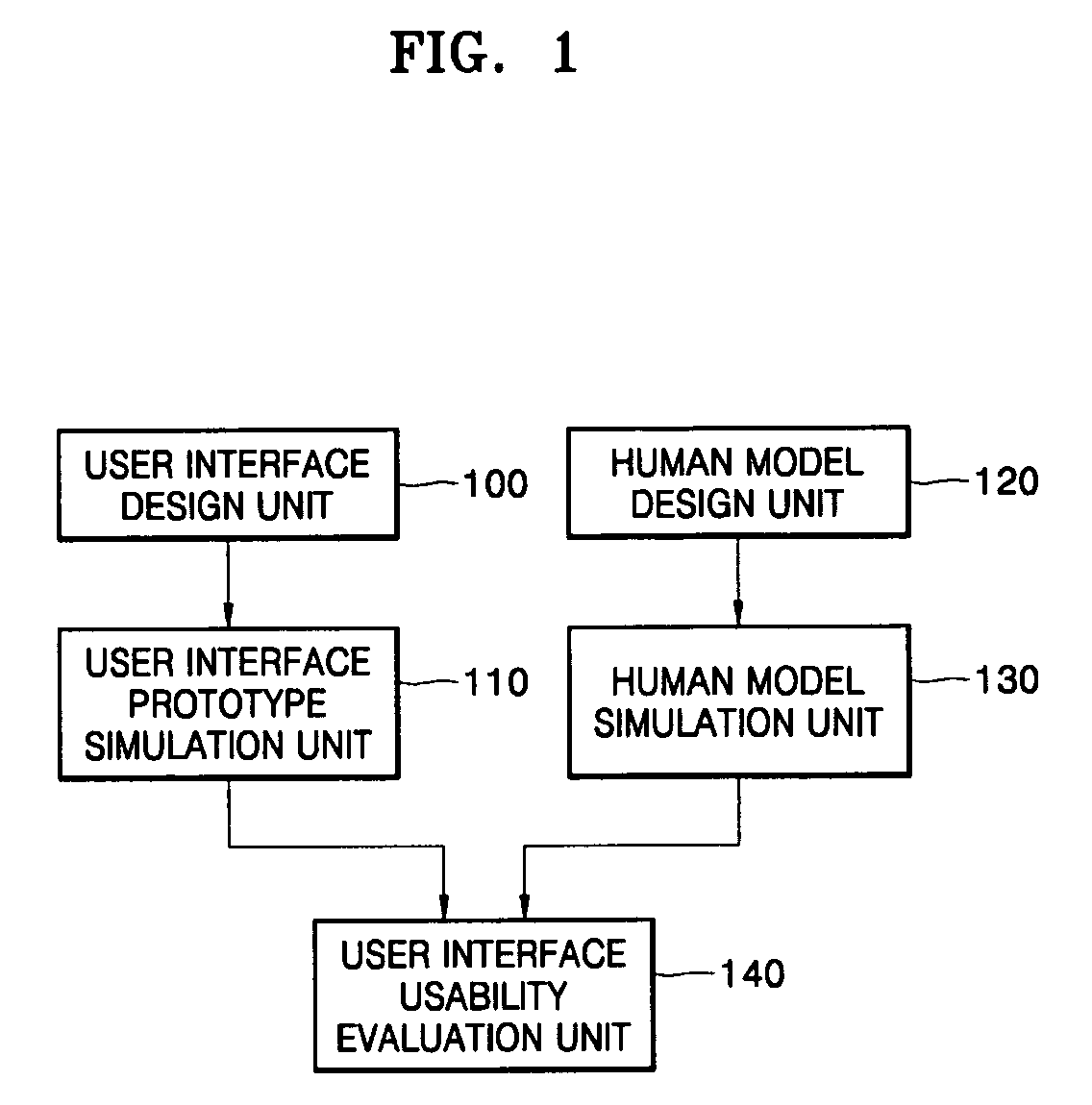

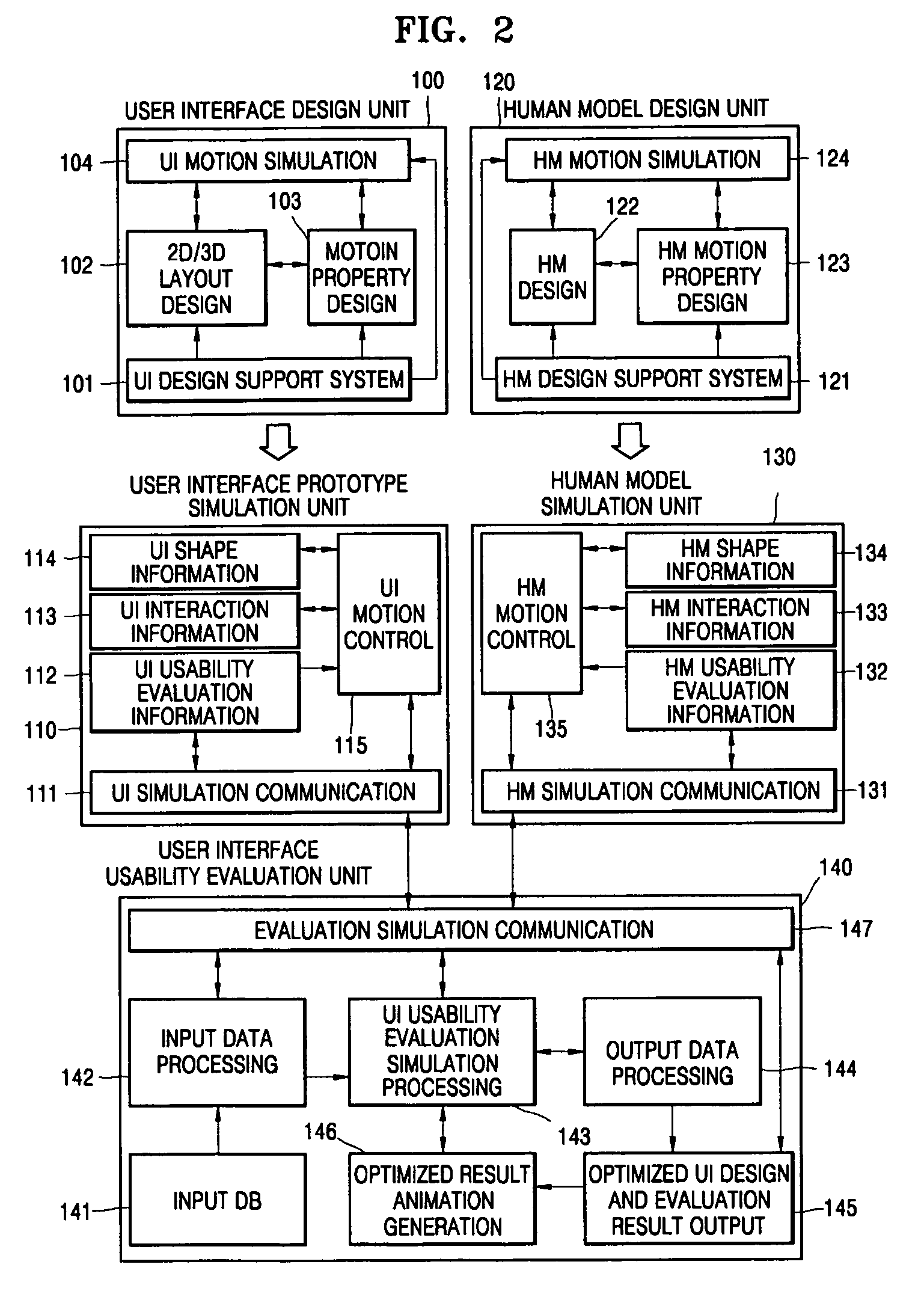

User interface design and evaluation system and hand interaction based user interface design and evaluation system

ActiveUS20060199167A1Cathode-ray tube indicatorsComputation using non-denominational number representationWork performanceInteraction design

A user interface design and evaluation system and a hand-interaction-based user interface design and evaluation system are provided. The user interface design and evaluation system includes: a user interface design unit, a human model interaction design unit, a user interface prototype simulation unit, a human model simulation unit, and a user interface evaluation unit. In order to develop a user interface in consideration of usability of a user, the system provides a usability evaluation feedback system performing optimization of an interface design based on a motion simulation of a body model and user interface model. Through this, an optimum interface design is derived and by reducing the initial usage difficulty of the new interface for a user, the user can easily use the new interface and work performance of the user can be enhanced. In addition, by supporting fast prototyping and evaluation in a new product development stage, efficient production of a product having a short life cycle can be actively implemented.

Owner:ELECTRONICS & TELECOMM RES INST

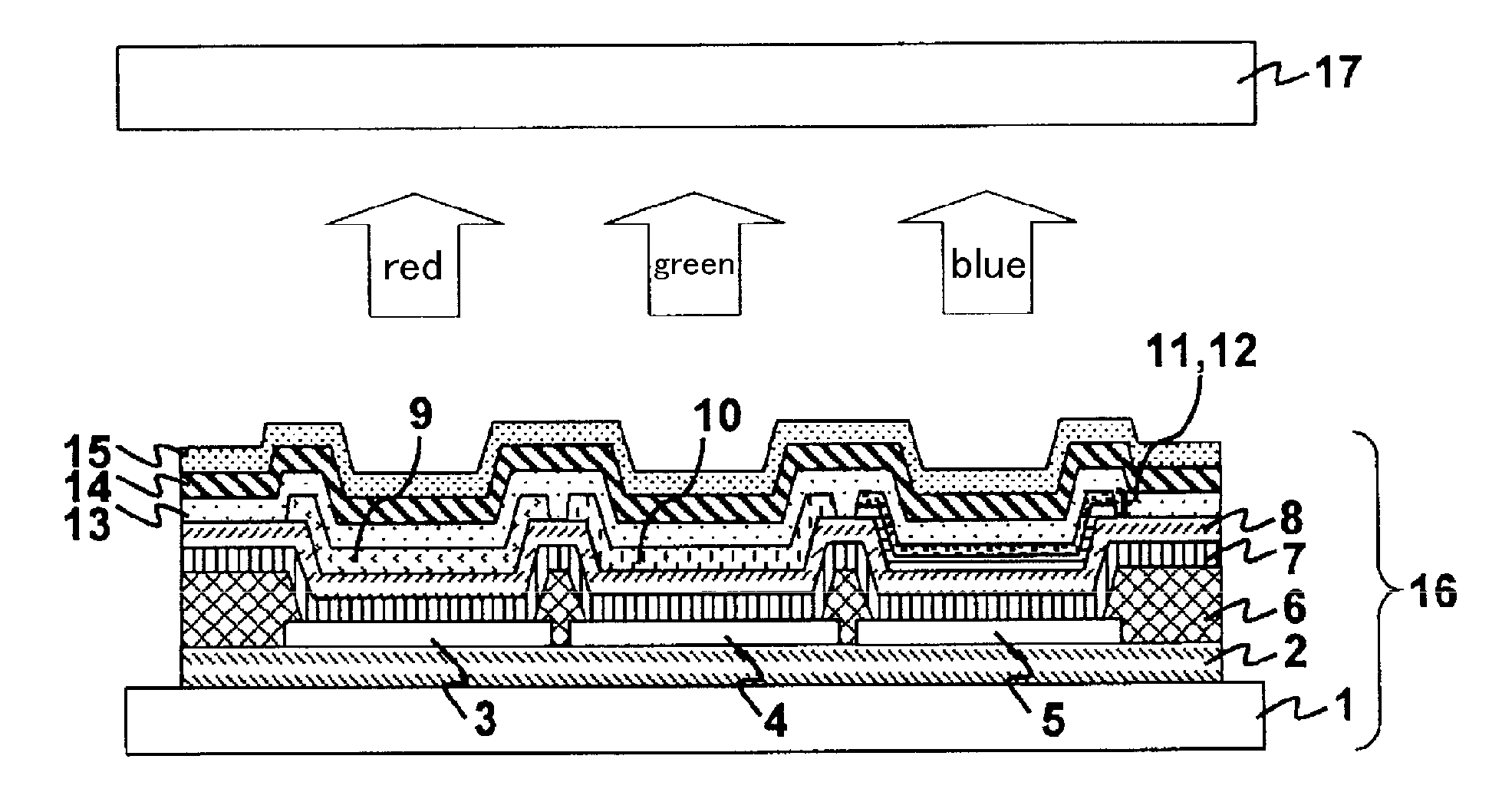

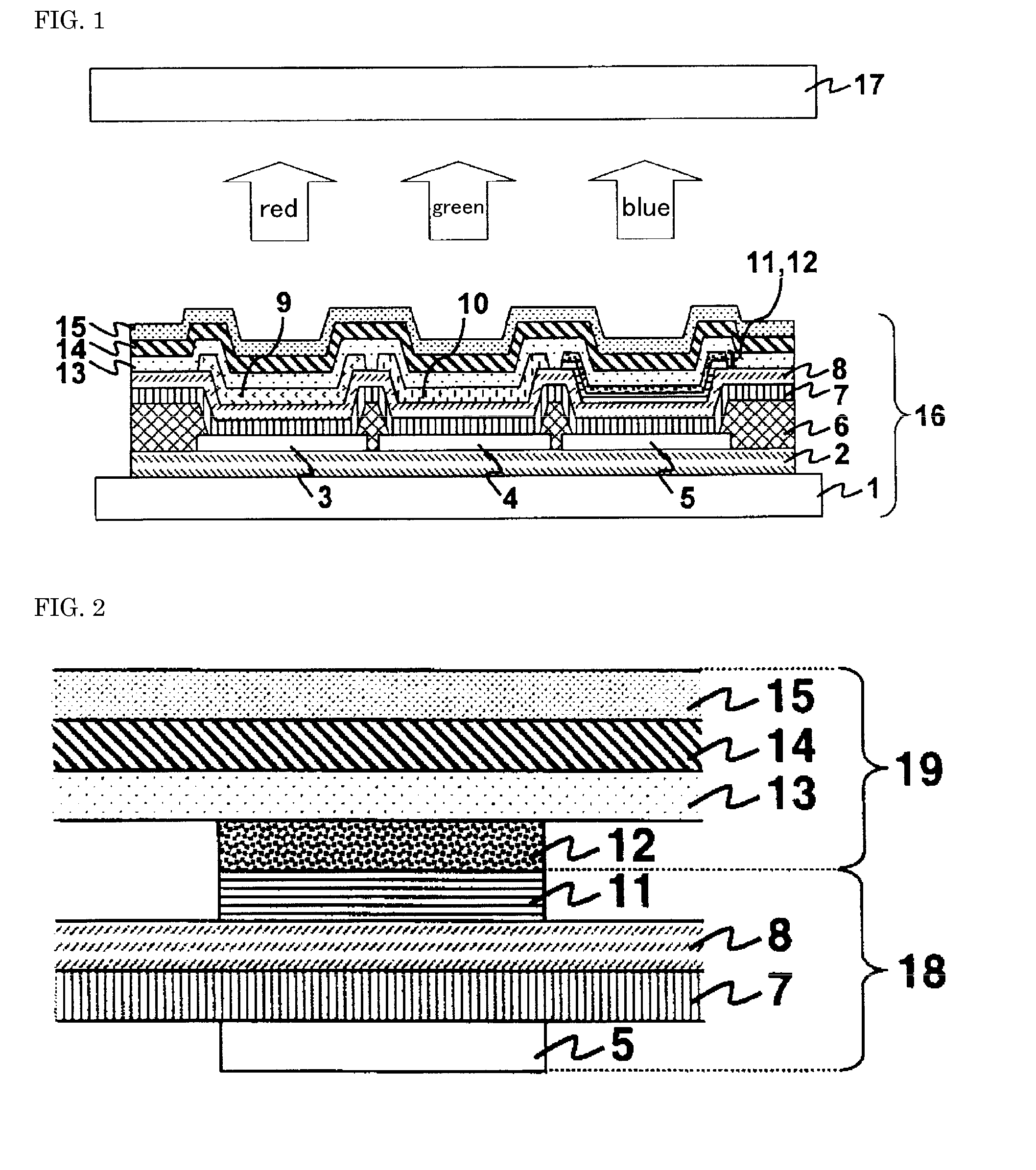

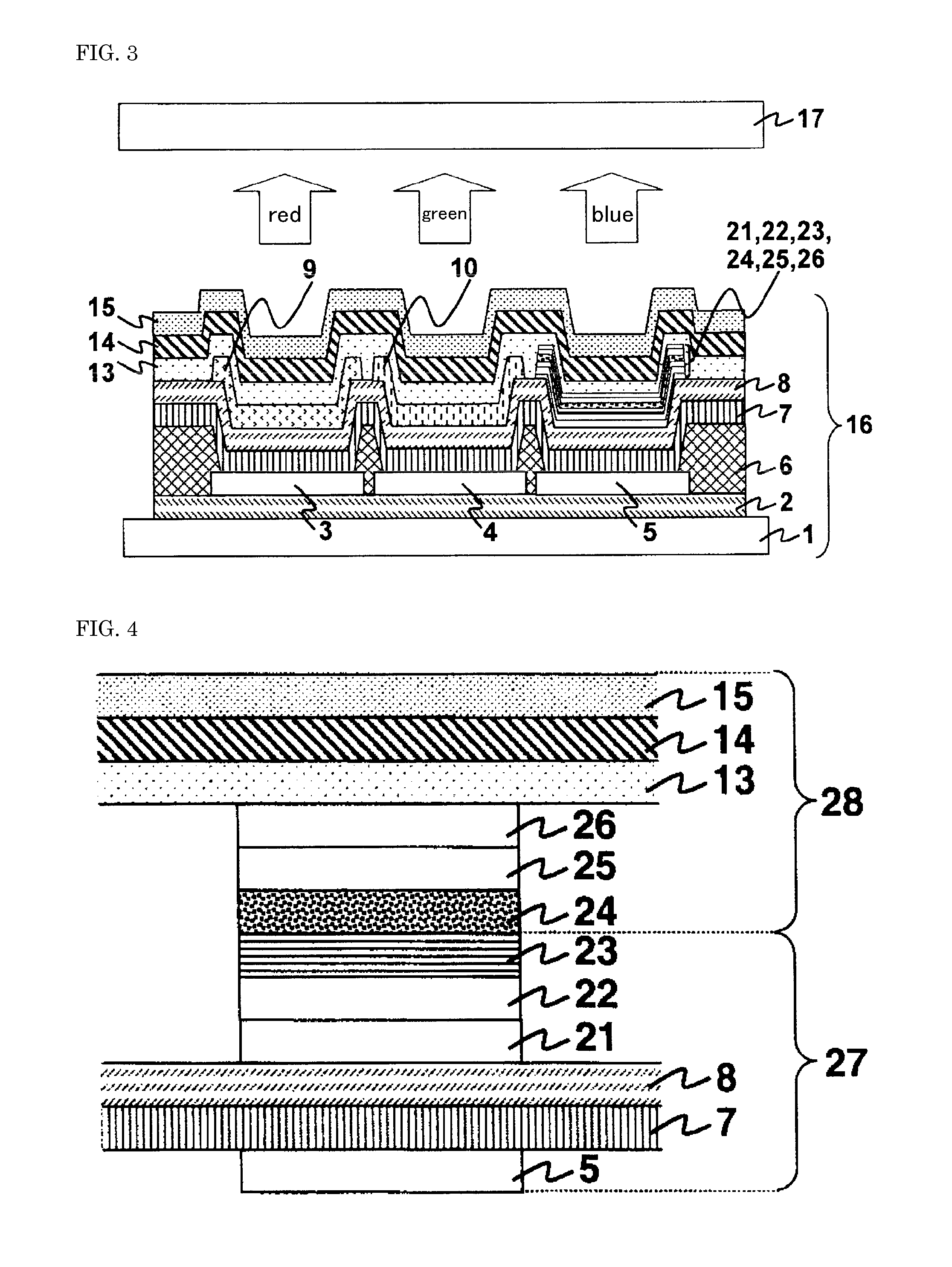

Organic light-emitting display device

InactiveUS20090242911A1Prolong lifeSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionHole injection layer

An object of the present invention is to provide an organic light-emitting display device using a number of organic light-emitting elements that emit lights of different colors, wherein the life of the organic light-emitting elements that emits light of a color having a short life can be prolonged. According to the present invention, a hole injection layer 7, an α-NPD vapor deposited film 8, an n doped electron transportation layer 11 and a p doped hole transportation layer 12, which are patterned to the same size as B sub-pixels, a DNA vapor deposited film 13, an electron injection layer 14 and an upper electrode 15 are formed on a lower electrode 5 in a B sub-pixel. The α-NPD vapor deposited film 8 and the DNA vapor deposited film 13 function as a blue light-emitting layer and exhibit the same properties as when a blue light-emitting element made up of a lower electrode 5, a hole injection layer 7, an α-NPD vapor deposited film 8 and an n doped electron transportation layer 11 and a blue light-emitting element made up of a p doped hole transportation layer 12, a DNA vapor deposited film 13, an electron injection layer 14 and an upper electrode 15 are connected in series. Therefore, it becomes possible to lower the value of a current required for certain brightness, and thus, the life can be prolonged.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Disk array apparatus and disk array apparatus controlling method

Times at which requests for a data read or data write from / to a logical volume are received are stored in memory as access times of a RAID group making up the logical volume. When a predetermined time has elapsed after the access time, a number of the hard disk drives according to the redundancy of the RAID group are set to a power saving mode. Assume there are first hard disk drives and second hard disk drives having shorter lifes and the RAID group exceeds a predetermined time after the access time. When the RAID group consists of only the first drives, a number of the first drives according to the redundancy of the RAID group are set to a power saving mode and when it consists of only the second drives, an arbitrary number of second drives are set to a power saving mode.

Owner:HITACHI LTD

User interface design and evaluation system and hand interaction based user interface design and evaluation system

ActiveUS7464010B2Program control using stored programsHardware monitoringUsability assessmentWork performance

A user interface design and evaluation system and a hand-interaction-based user interface design and evaluation system are provided. The user interface design and evaluation system includes: a user interface design unit, a human model interaction design unit, a user interface prototype simulation unit, a human model simulation unit, and a user interface evaluation unit. In order to develop a user interface in consideration of usability of a user, the system provides a usability evaluation feedback system performing optimization of an interface design based on a motion simulation of a body model and user interface model. Through this, an optimum interface design is derived and by reducing the initial usage difficulty of the new interface for a user, the user can easily use the new interface and work performance of the user can be enhanced. In addition, by supporting fast prototyping and evaluation in a new product development stage, efficient production of a product having a short life cycle can be actively implemented.

Owner:ELECTRONICS & TELECOMM RES INST

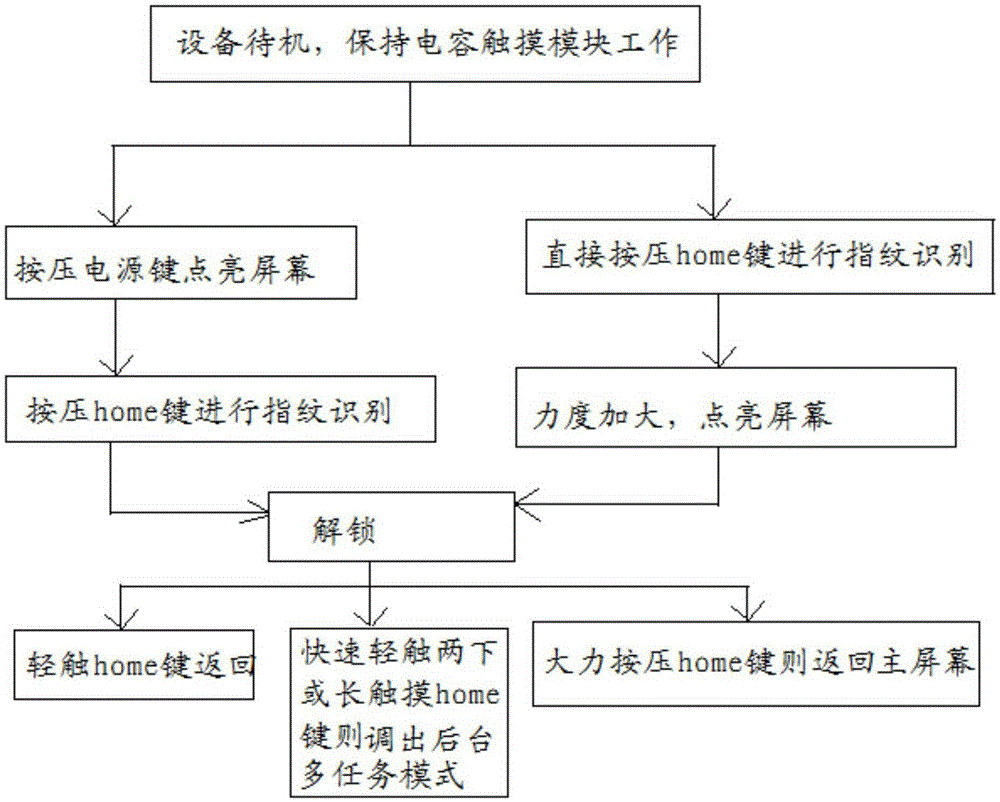

Control method for home key of electronic equipment

InactiveCN105389102AImprove operating experienceExtended service lifeDigital data authenticationSubstation equipmentCapacitanceKey pressing

The invention relates to a control method for a home key of electronic equipment. According to the home key of the electronic equipment, a capacitive touch module, a touch sensor (which can recognize different pressures, and the different pressure recognition is realized through three main parts of generation of pressure by touch, recognition of the pressure and command feedback after recognition), and a finger print recognition module are integrated in the home key, so that not only is better operating experience brought, but also the longer service life is provided. The home key can be arranged alone, and meanwhile, can be hidden below glass of a display panel. Through the adoption of the control method, not only is the problem of short life of a conventional home entity key solved, but also the better integrative concise operation experience is brought; a more compact design is realized while realizing more functions, and the non-entity home key can realize functions of return, fingerprint recognition, main home screen return, and fingerprint unlock.

Owner:北京用友政务软件股份有限公司

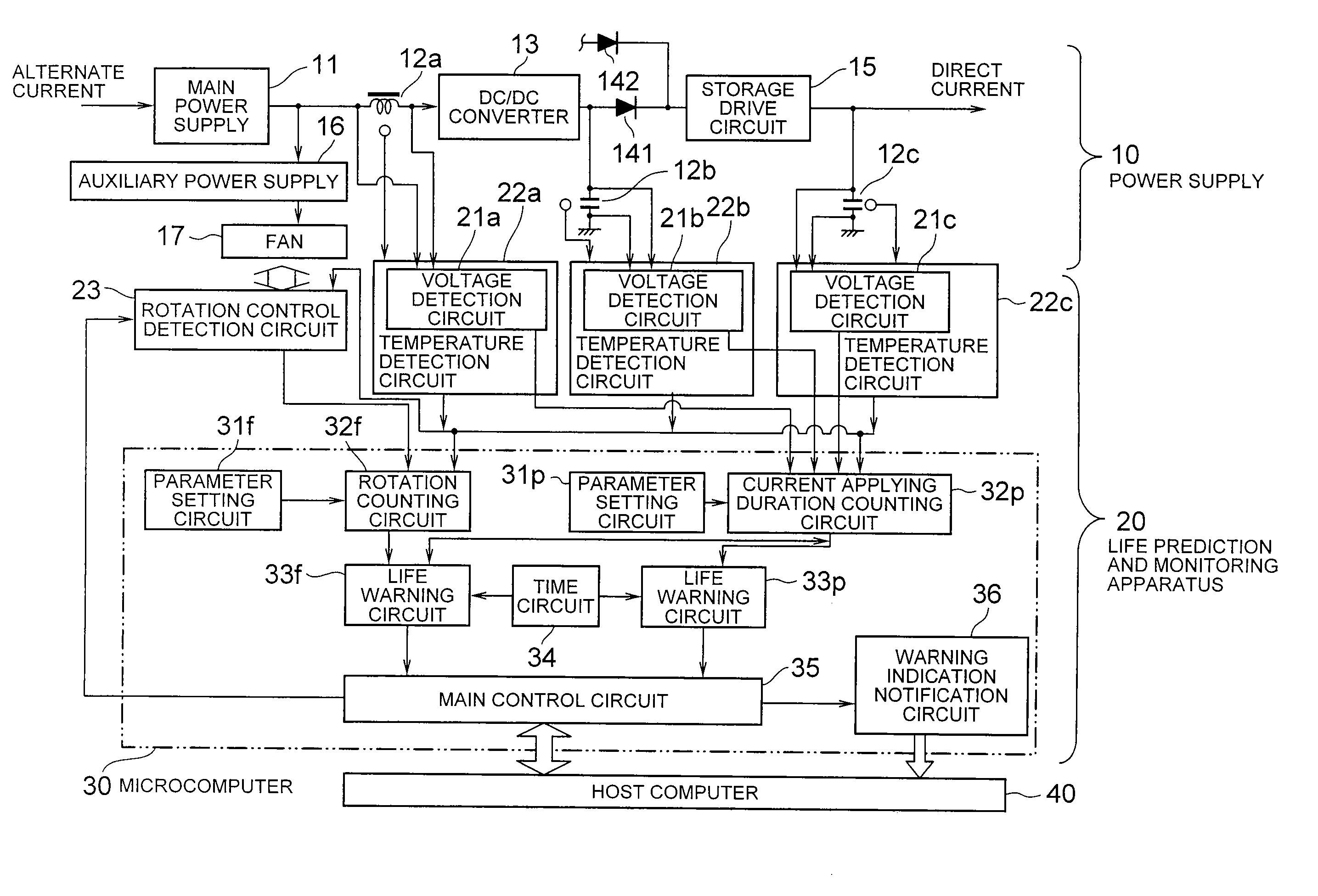

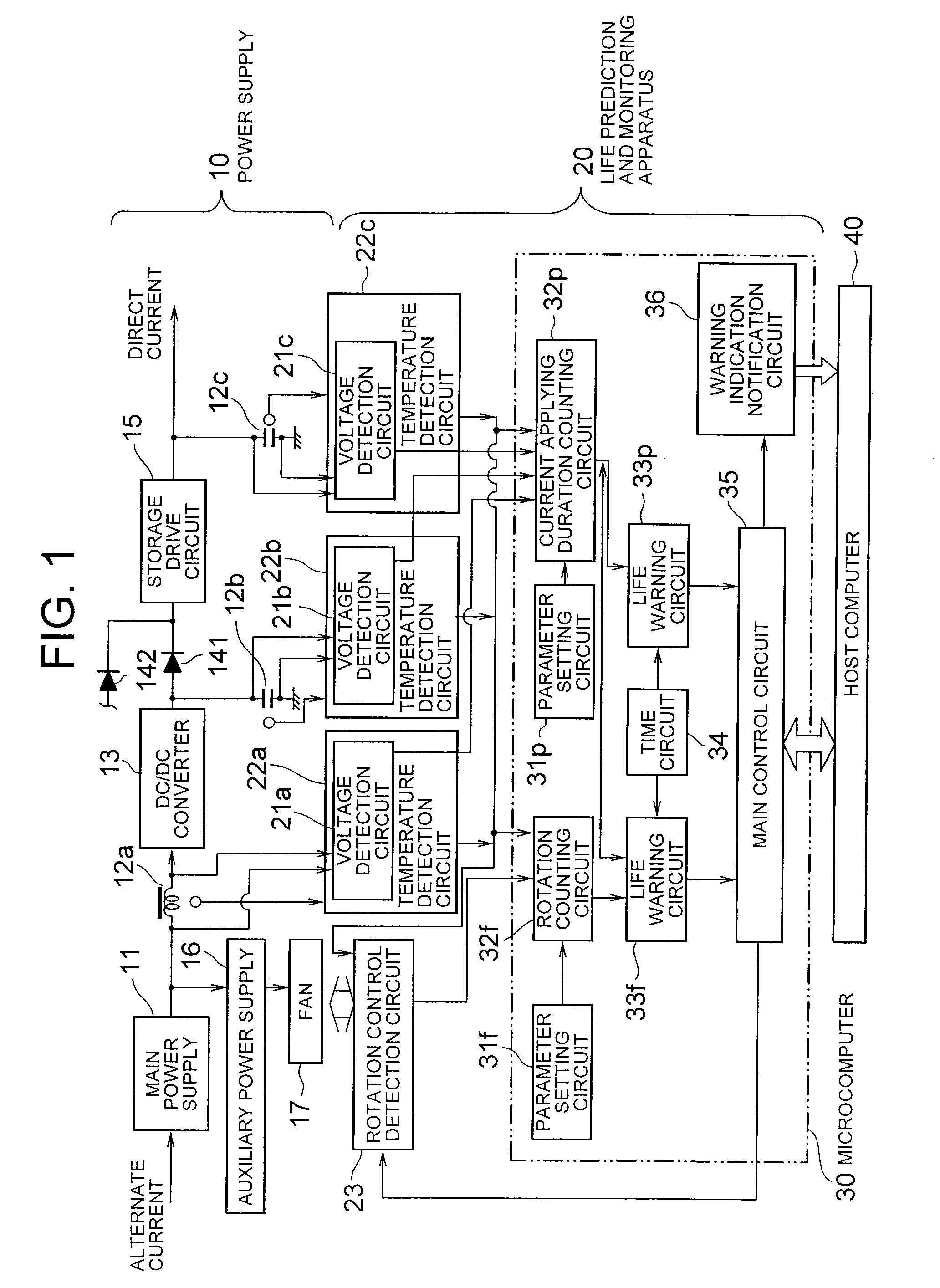

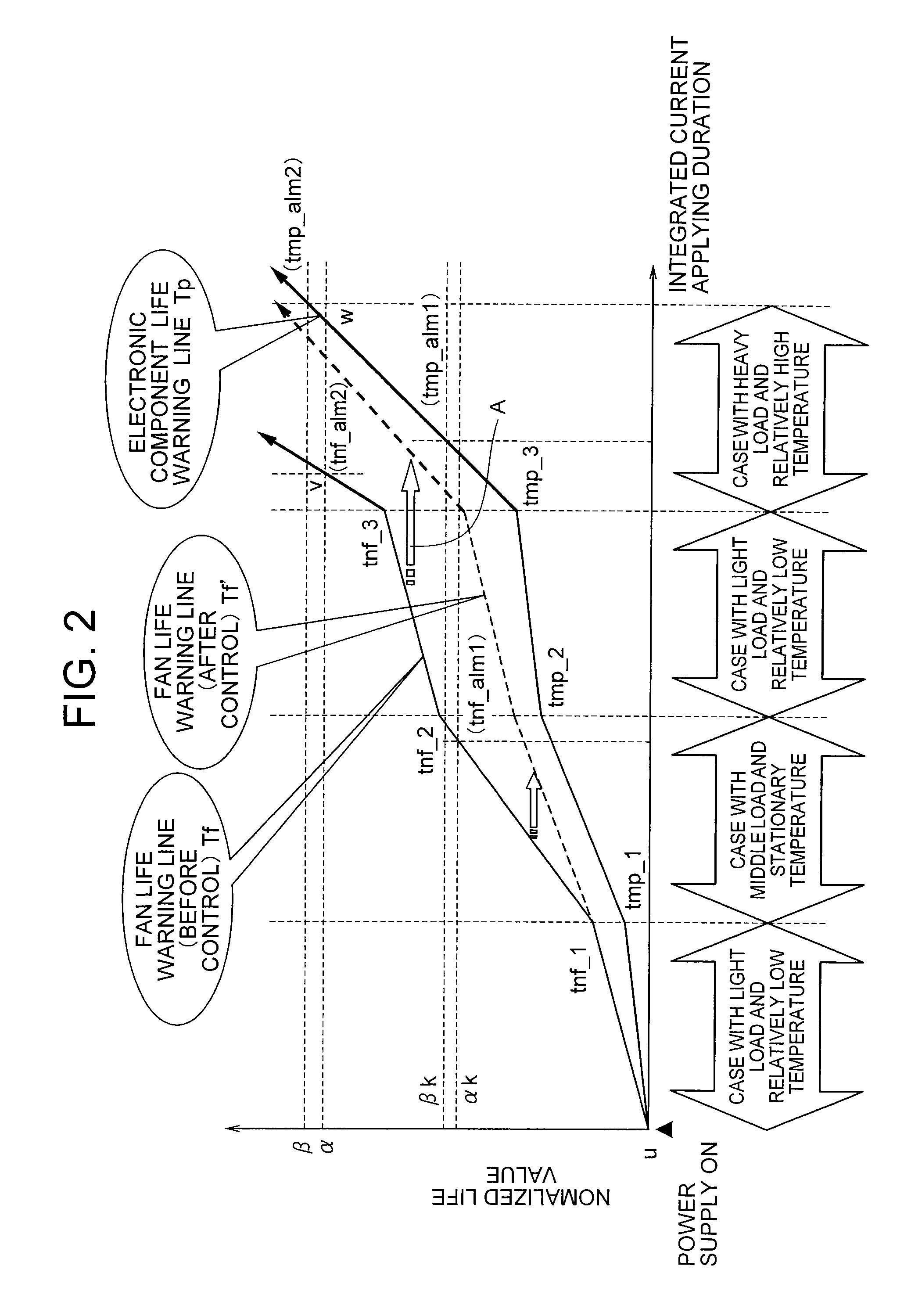

Life prediction and monitoring apparatus, life prediction and monitoring method, and life prediction and monitoring program

InactiveUS20070150236A1Improve reliabilityPlug gaugesNuclear monitoringProcess engineeringMonitoring methods

A counting unit counts a current supplying duration for a component which determines a life of a device. A prediction unit predicts the device life based on an integrated current supplying duration integrated by the counting unit and a lifetime of the component. A monitoring unit monitors an efficient operating condition of the device based on a prediction signal outputted from the life prediction unit. The counting unit and the life prediction unit is provided at a short-life fan and a long-life component respectively, and the life prediction unit predicts the life of the device based on information on the short-life fan and the long-life component.

Owner:NEC CORP

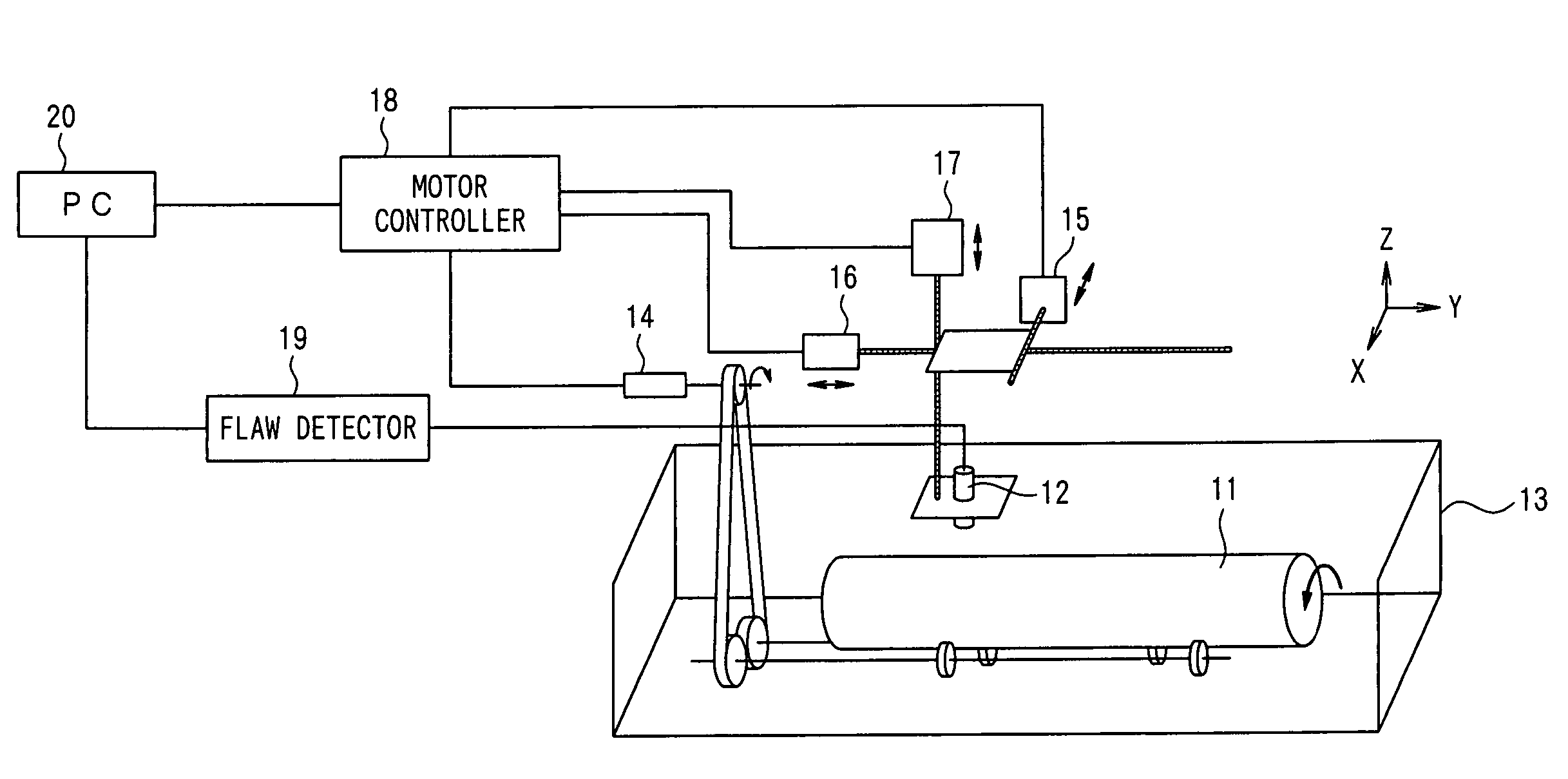

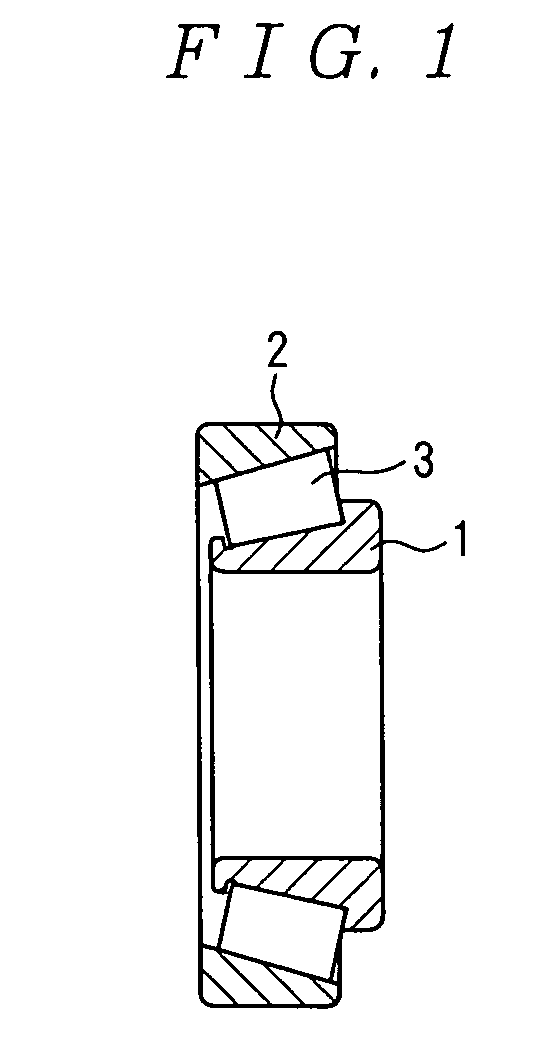

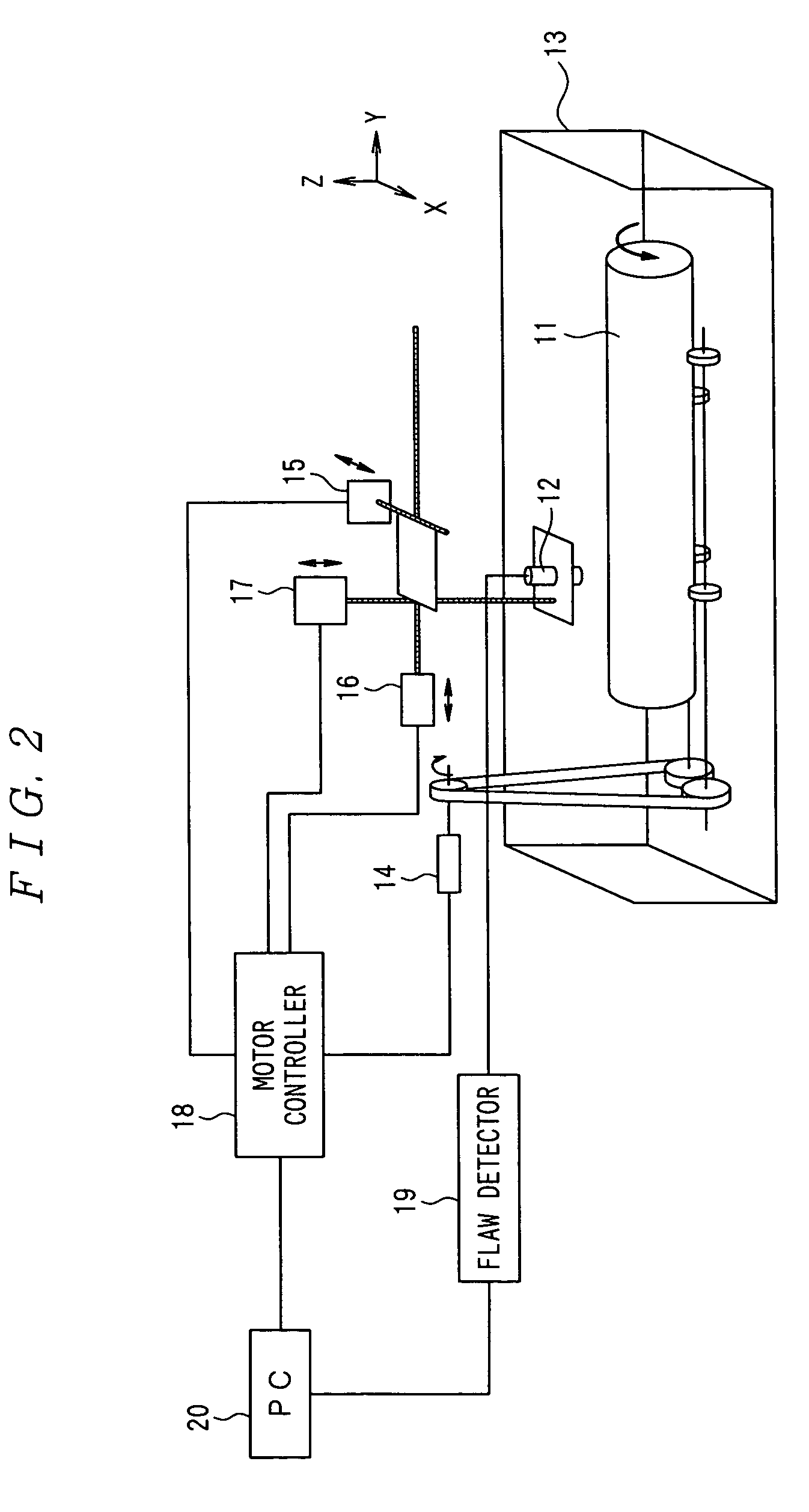

Bearing steel,method for evaluating large-sized inclusions in the steel and rolling bearing

InactiveUS20060048576A1Low costDetection intensity is worsenedVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallurgyRolling-element bearing

A first object is to provide a method for evaluating large-sized inclusions in a bearing steel. The method enables quantitative evaluation of large-sized inclusions even if the steel has a high degree of cleanliness. Further, a second object is to provide an appropriate bearing steel evaluated by the method for evaluating large-sized inclusions. Further, a third object is to provide a rolling bearing capable of eliminating short life products and cracked products and providing longer lifetime for entire bearings. In order to achieve the first object, a round bar formed of a bearing steel to be evaluated and an ultrasonic probe are placed in an ultrasonic transmission medium, and the size and number of large-sized inclusions that are present in the flaw detection volume are measured to estimate the existence probability of large-sized inclusions in the bearing steel to be evaluated. The second object is achieved by specifying large-sized inclusions that are present in the bearing steel in accordance with the method for evaluating large-sized inclusions. Further, to achieve the third object, a rolling bearing is manufactured from a seamless steel tube, as material, having a diameter of 180 mm or less and a wall thickness of 25 mm or less, and ensured that it does not include a defect having a length of 1 mm of more at its material stage.

Owner:NSK LTD

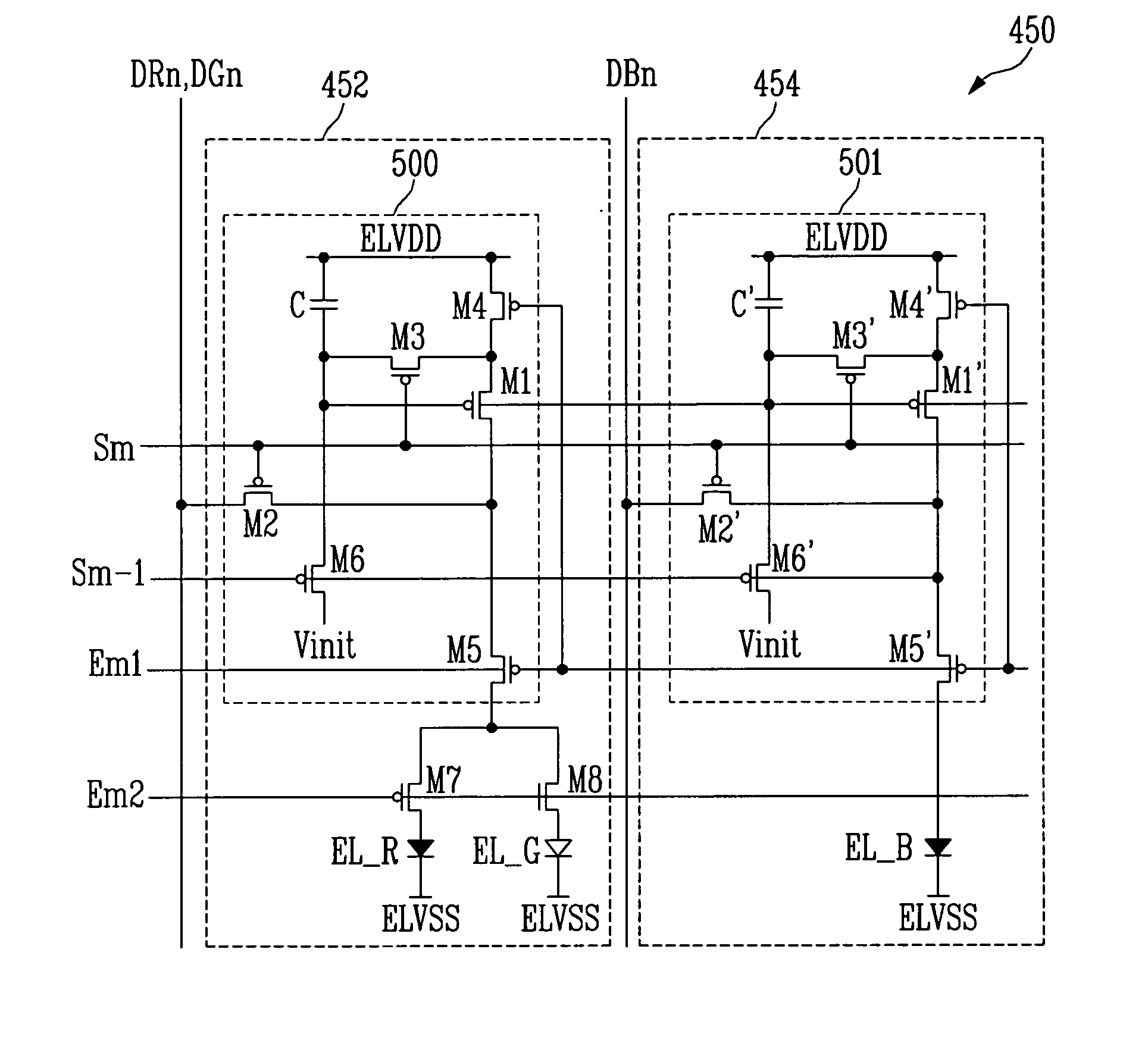

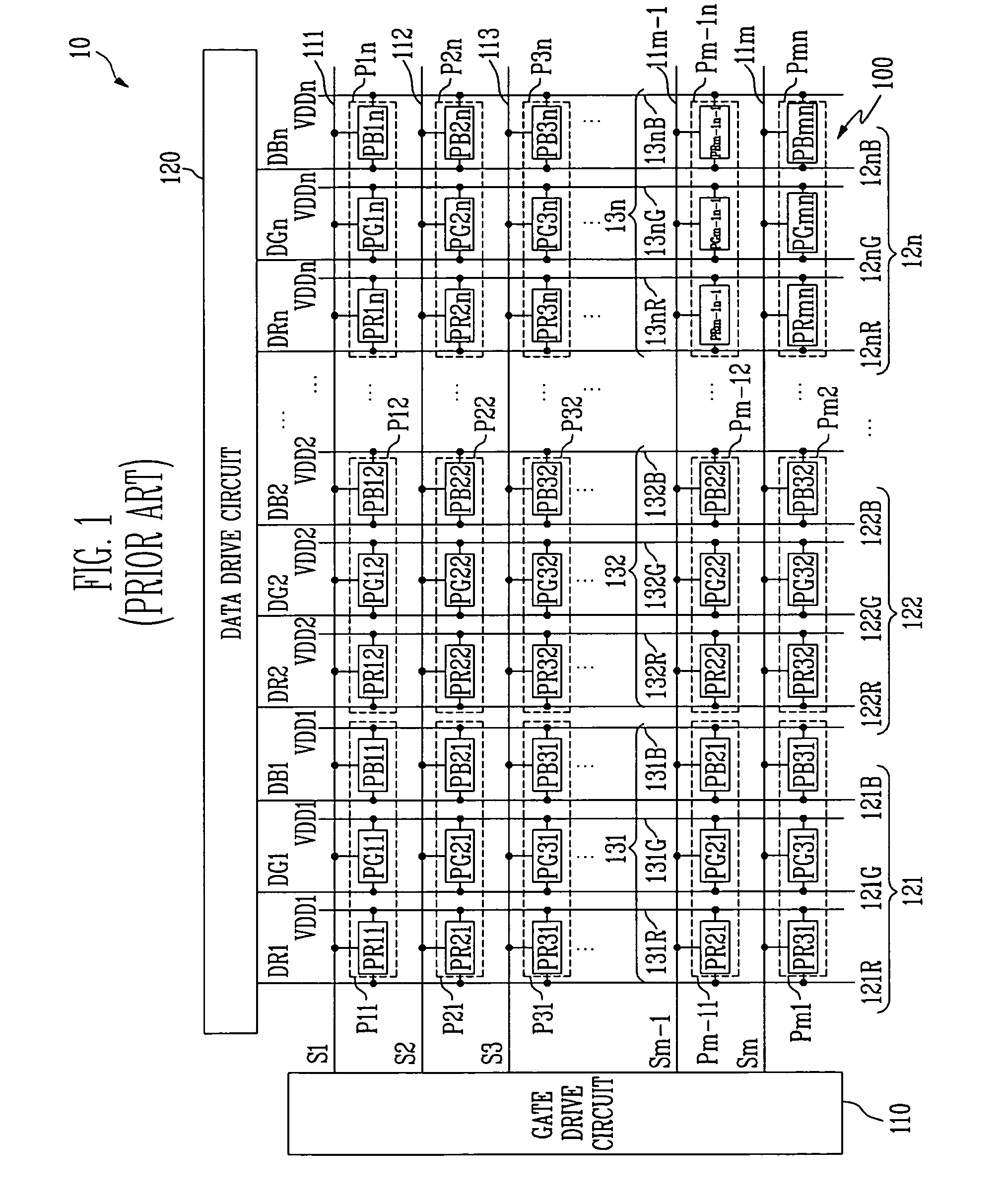

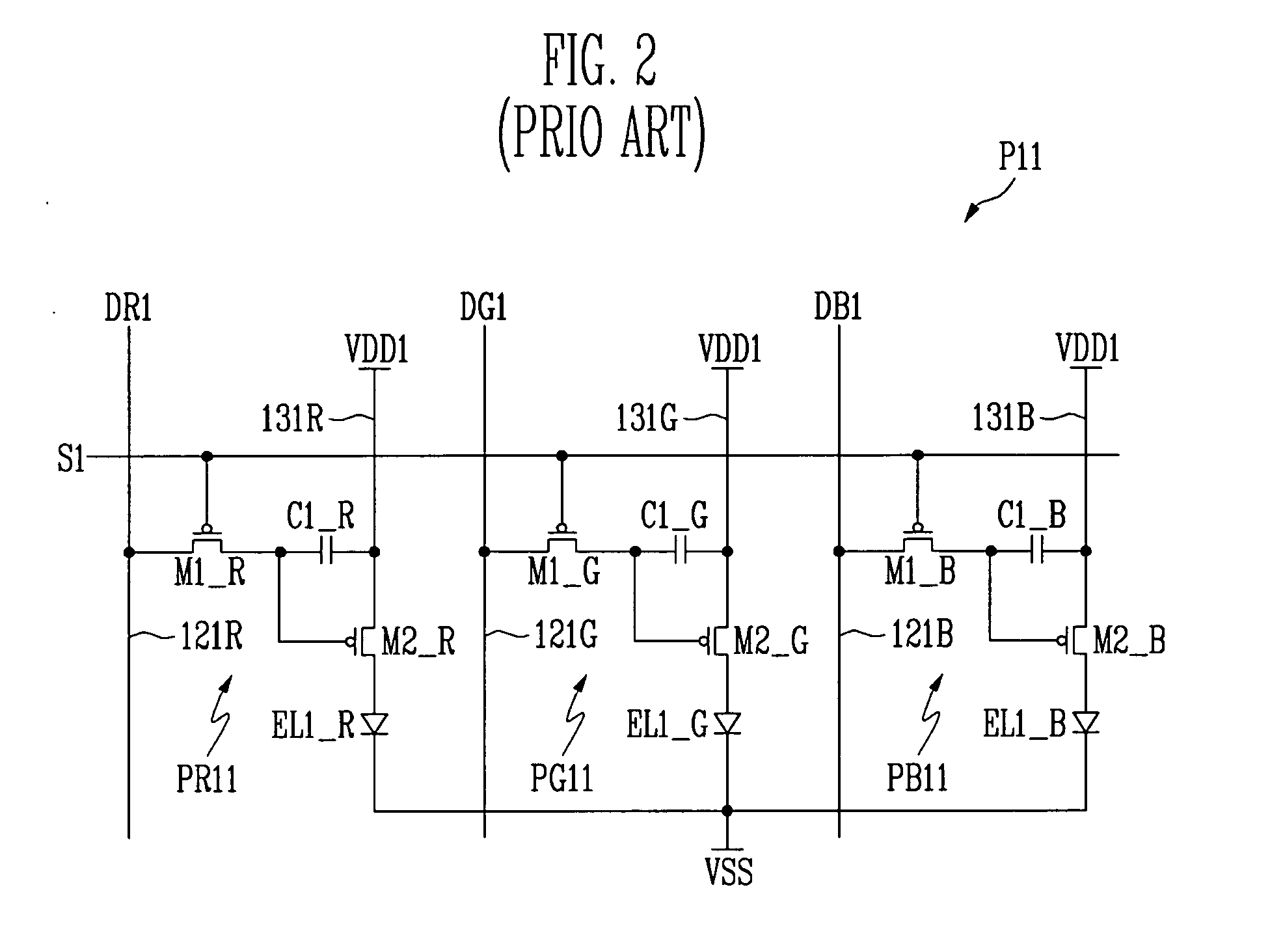

Organic light emitting display device and driving method thereof

ActiveUS20070103405A1Long life-timeShort lifeElectrical apparatusStatic indicating devicesControl signalScan line

An organic light emitting diode (OLED) display device and a driving method using a time division control drive method for OLEDs having a relatively longer life time and a general drive method for OLEDs having a relatively shorter life time. A gate drive circuit provides scan signals in sub-frames to scan lines. A data drive circuit provides a data signal to data lines. An emission control signal generation circuit provides first and second emission control signals to control the OLEDs. A display region includes pixels arranged in a matrix and connected to the scan lines, data lines, emission control lines, and power lines. The pixels include a first and a second unit pixel portion. The first unit pixel portion performs a time division control drive by driving a plurality of organic light emitting diodes by one shared pixel circuit. In the second unit portion one organic light emitting diode is driven by an independent pixel circuit.

Owner:SAMSUNG DISPLAY CO LTD

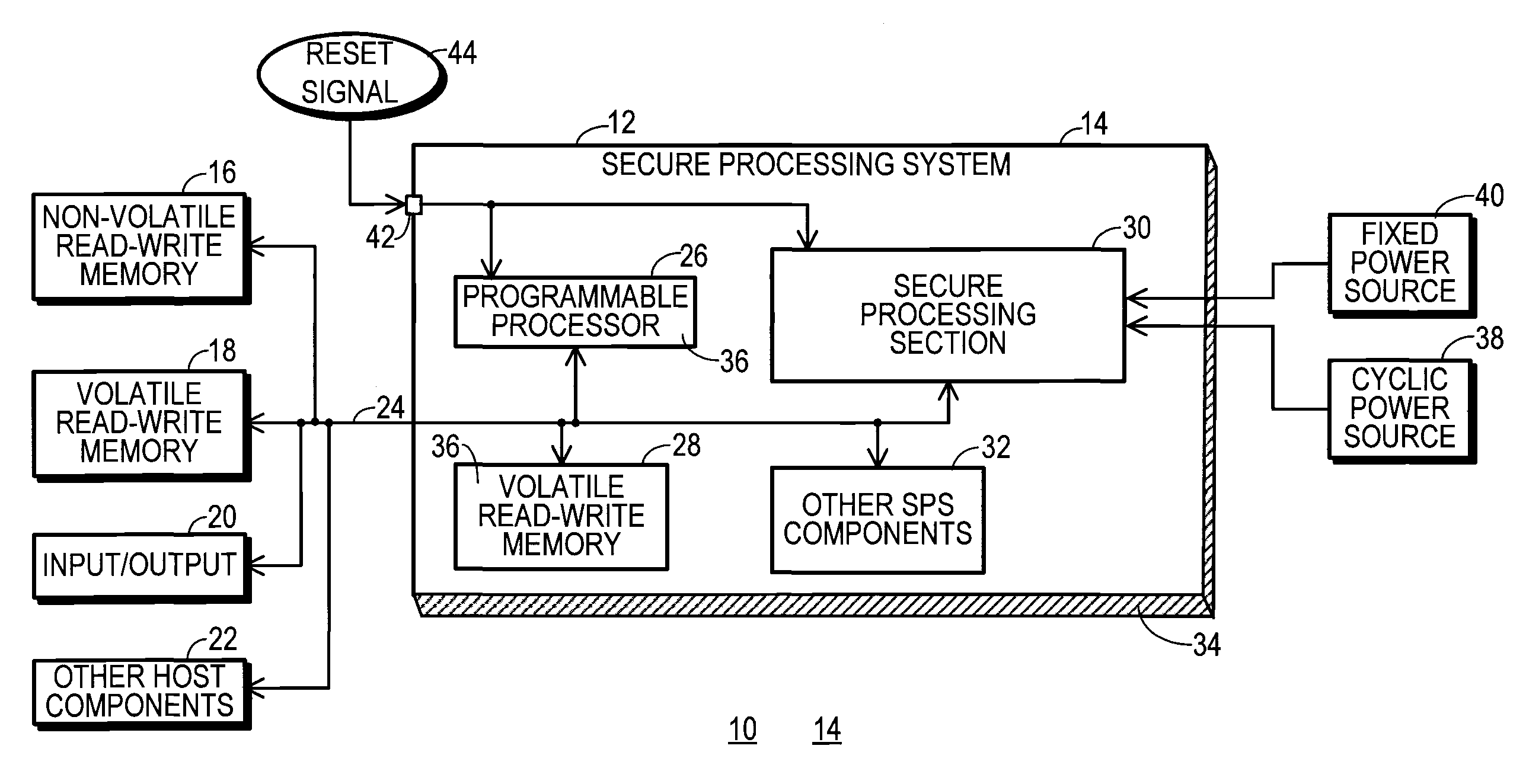

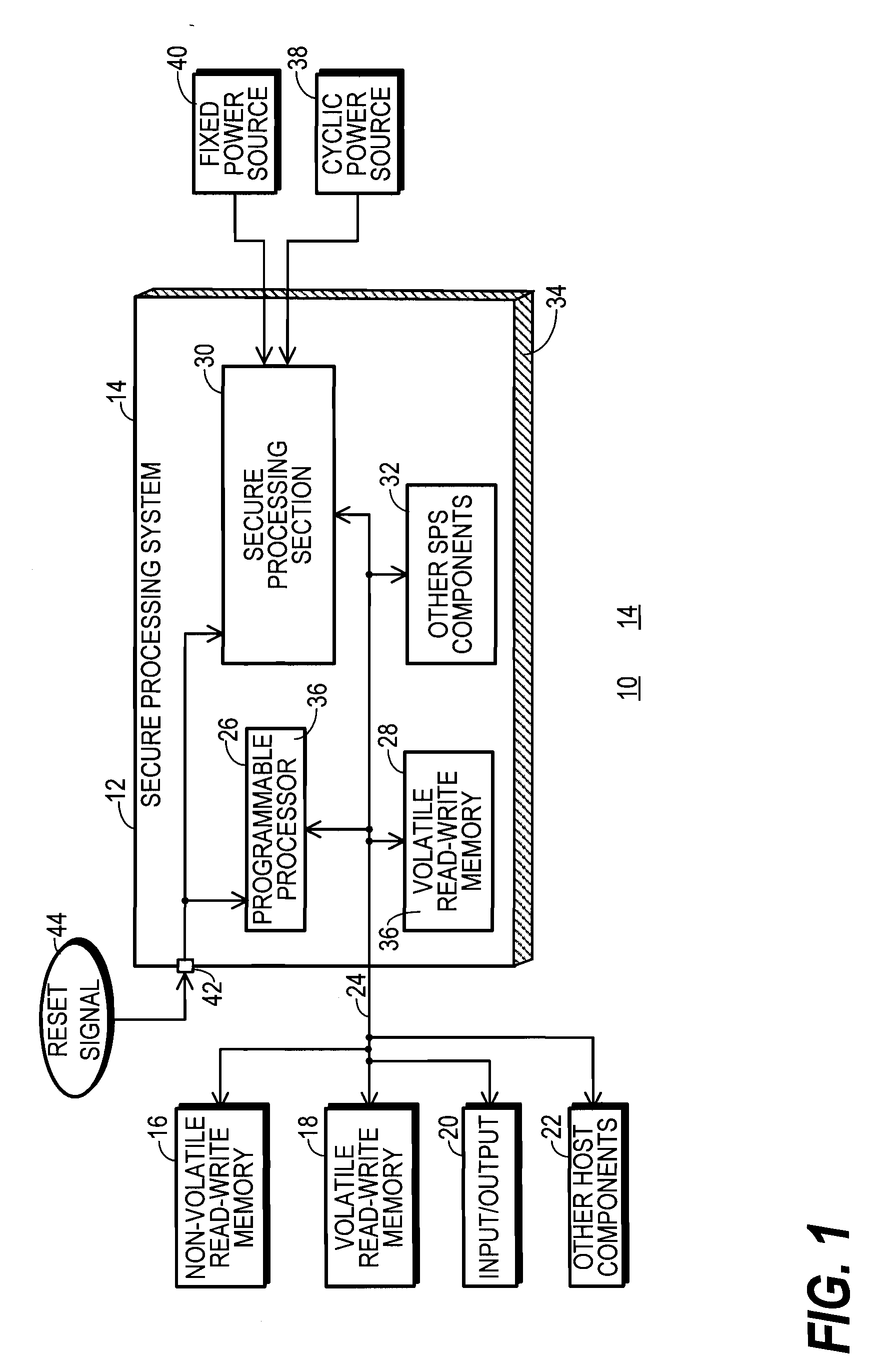

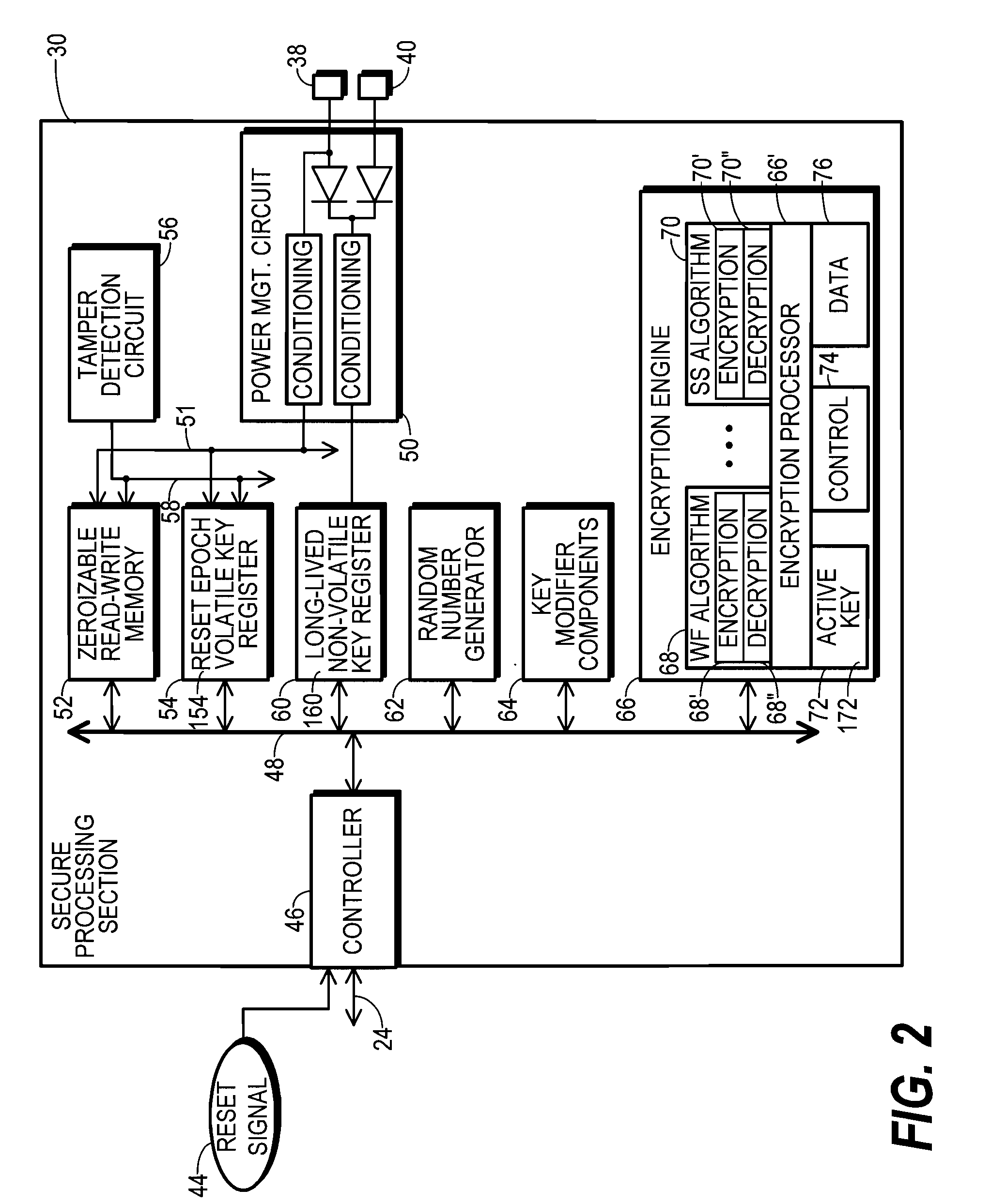

Encryption apparatus and method therefor

InactiveUS20100296651A1Encryption apparatus with shift registers/memoriesSecret communicationComputer hardwareMaster key

An encryption apparatus (14) includes an integrated circuit (34) having a secure processing section (30). A plaintext reset epoch key (154) is stored in the secure processing section (30) and configured to have a short life. A plaintext master key (160) is stored in the secure processing section (30) and configured to have a long life. A multiplicity of active keys (172) are generated, encrypted using a weaker but faster cryptographic algorithm (68) and the reset epoch key (154), then stored in a high-capacity key magazine (86) portion of unsecured memory (16, 18, 28). Some keys and data are also encrypted using a stronger but slower cryptographic algorithm (70) and the master key (160), then stored in unsecured memory (16, 18, 28). Keys (272, 372) may be converted between weaker, faster encryption and stronger, slower encryption.

Owner:NXP USA INC

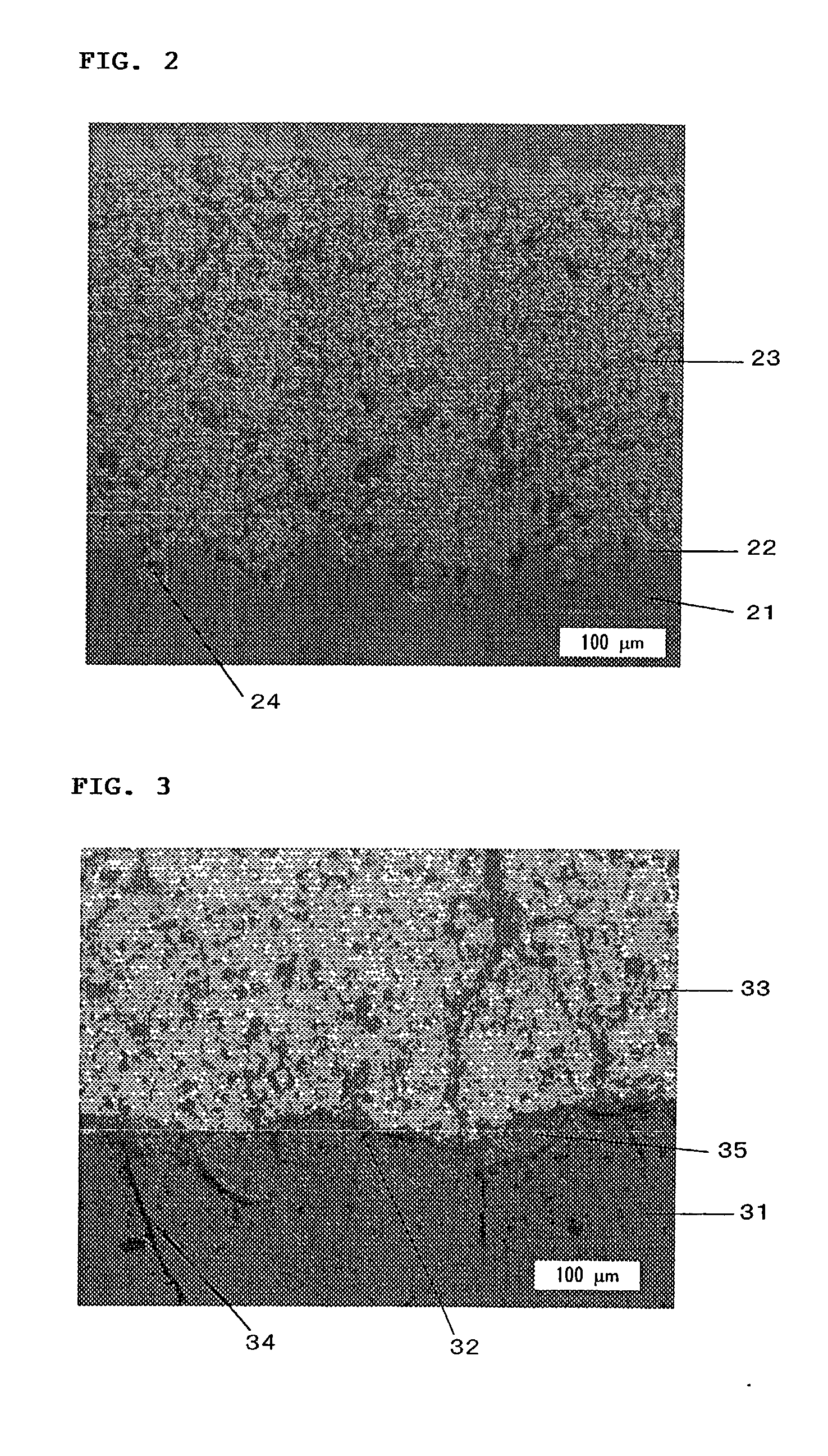

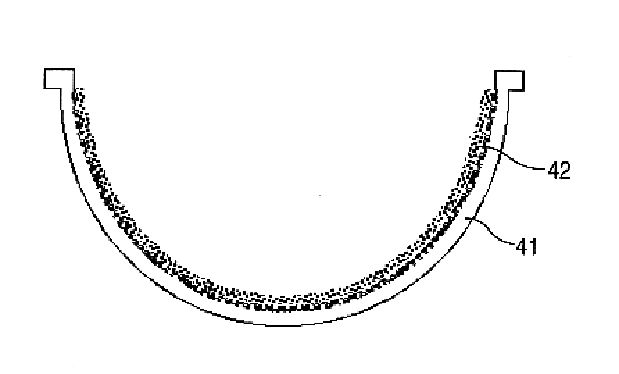

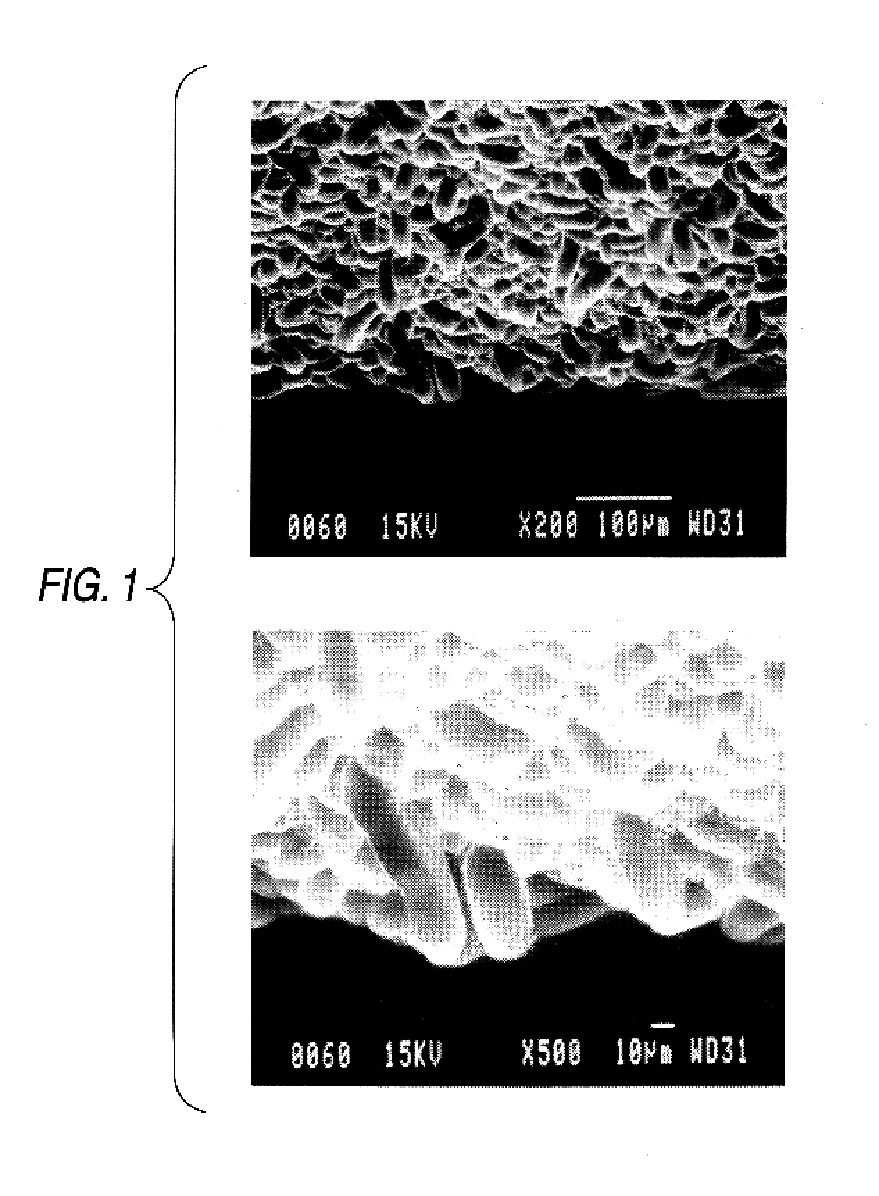

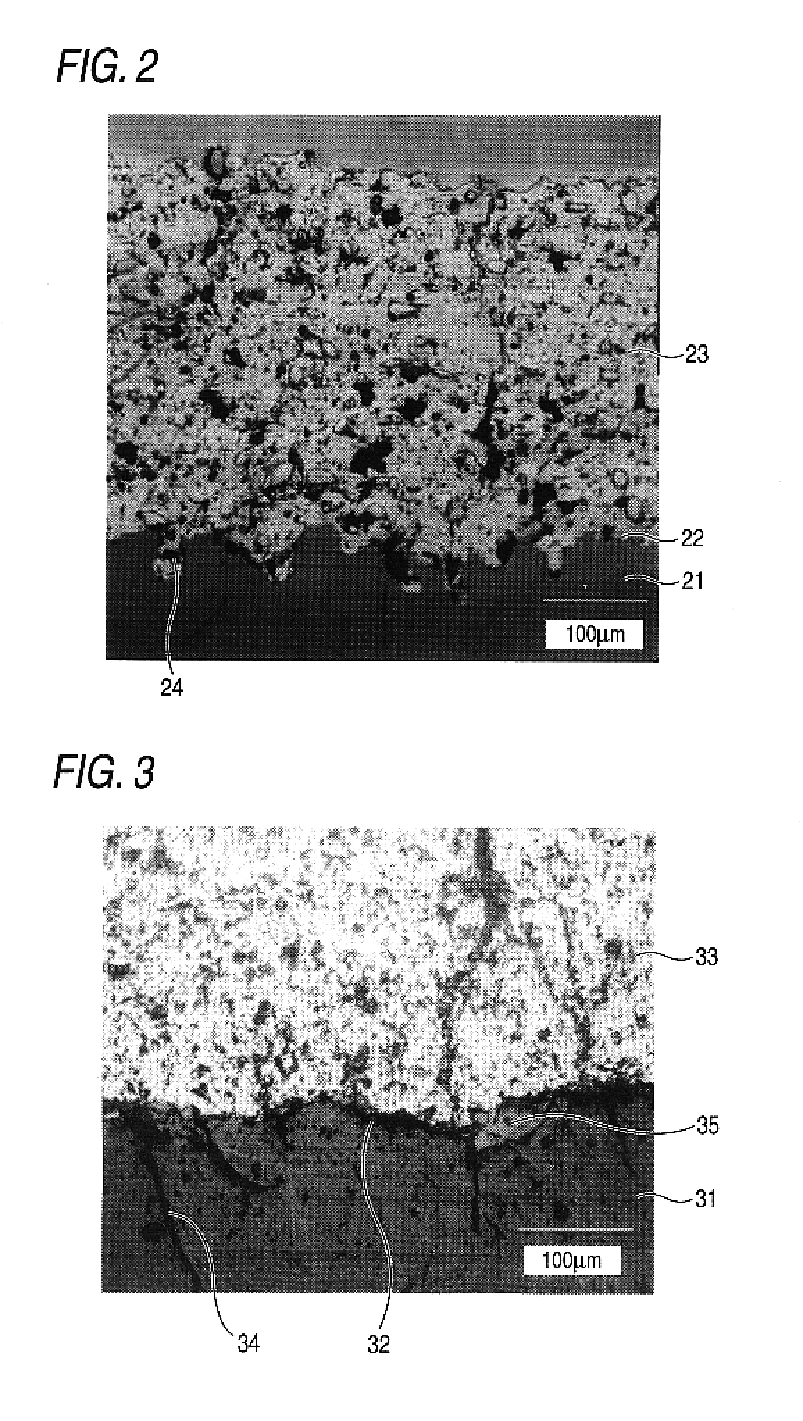

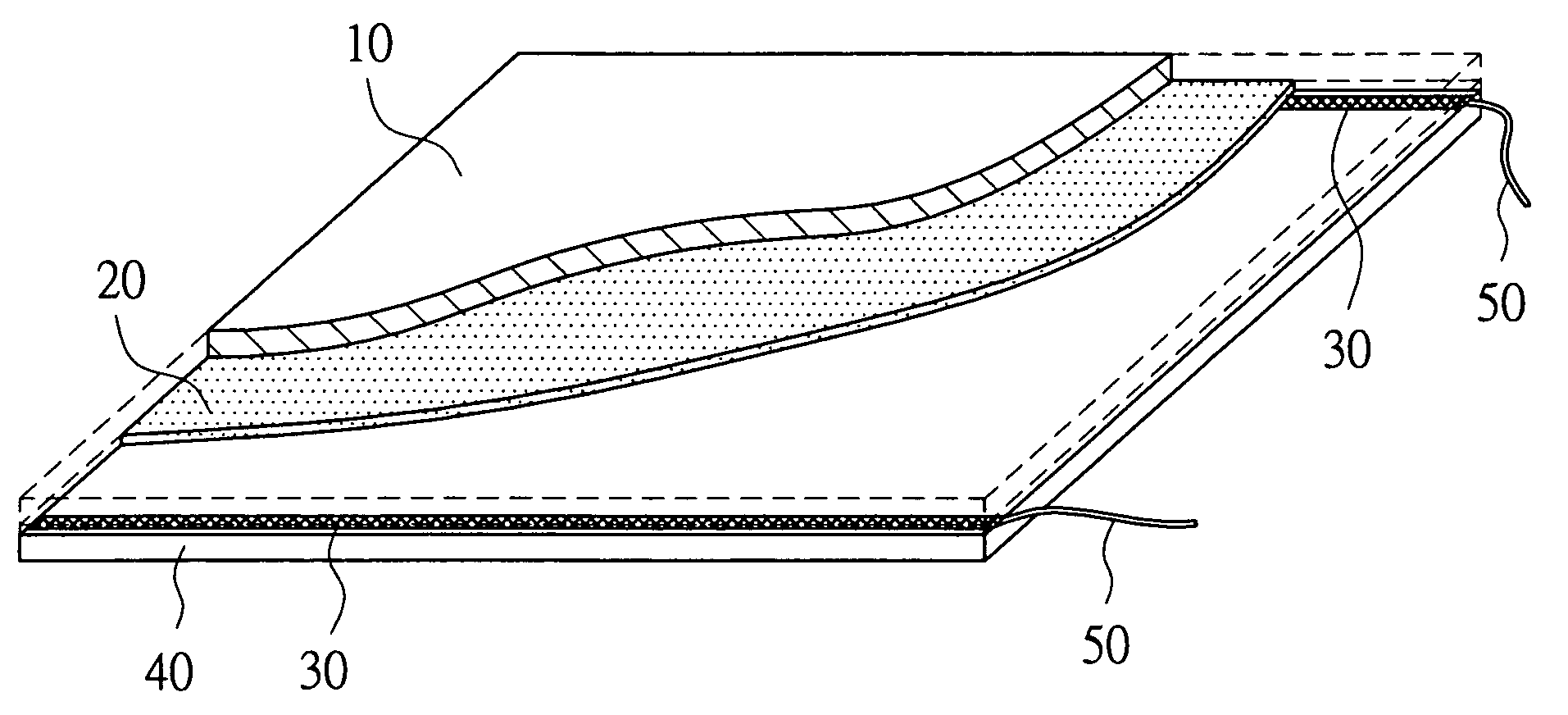

Quartz glass parts, ceramic parts and process of producing those

InactiveUS20030091835A1Improve adhesionImprove plasma resistanceMolten spray coatingFilm/foil adhesivesProduction rateSurface roughness

In quartz glass parts and ceramic parts that are used in film-deposition devices and pre-cleaning devices in the production of semiconductors, etc., there are problems such as peeling off of the parts themselves during the use, peeling off of film-like substances adhered to the part surfaces, contamination of the products and short life time of the parts caused by corrosion of the part surfaces by plasma, and reduction in the productivity by frequent exchange of the parts. In quartz glass parts and ceramic parts that are used in film-deposition devices and pre-cleaning devices in the production of semiconductors, etc., with respect to parts, the surface of which is constituted of a ceramic thermal sprayed coating, ones having the ceramic thermal sprayed coating having a surface roughness Ra of from 5 to 20 mum are high in adherence of a film-like adherence, ones having the ceramic thermal sprayed coating having a surface roughness Ra of from 1 to 5 mum are high in plasma resistance, and ones in which grooves having a large anchor effect to the thermal sprayed coating is formed on a substrate on which the ceramic thermal sprayed coating is formed are free from peeling off of the ceramic thermal sprayed coating from the substrate and are high in durability.

Owner:TOSOH CORP

Quartz glass parts, ceramic parts and process of producing those

InactiveUS6902814B2Improve adhesionImprove plasma resistanceMolten spray coatingFilm/foil adhesivesProduction rateSurface roughness

In quartz glass parts and ceramic parts that are used in film-deposition devices and pre-cleaning devices in the production of semiconductors, etc., there are problems such as peeling off of the parts themselves during the use, peeling off of film-like substances adhered to the part surfaces, contamination of the products and short life time of the parts caused by corrosion of the part surfaces by plasma, and reduction in the productivity by frequent exchange of the parts. In quartz glass parts and ceramic parts that are used in film-deposition devices and pre-cleaning devices in the production of semiconductors, etc., with respect to parts, the surface of which is constituted of a ceramic thermal sprayed coating, ones having the ceramic thermal sprayed coating having a surface roughness Ra of from 5 to 20 μm are high in adherence of a film-like adherence, ones having the ceramic thermal sprayed coating having a surface roughness Ra of from 1 to 5 μm are high in plasma resistance, and ones in which grooves having a large anchor effect to the thermal sprayed coating is formed on a substrate on which the ceramic thermal sprayed coating is formed are free from peeling off of the ceramic thermal sprayed coating from the substrate and are high in durability.

Owner:TOSOH CORP

Activated carbon fiber soft electric heating product and manufacturing method thereof

InactiveUS20100062667A1Light weightUniform electric heating performanceEnvelope/housing resistor manufactureMedical devicesFiberEpoxy

An activated carbon fiber soft electric heating product and its manufacturing method for overcoming existing problems including uneven temperature rise and heat dissipation at surfaces of the product, unbendable feature, short life and poor safety. An activated carbon fiber cloth and a woven fiber cloth of the activated carbon fiber soft electric heating product are fixed by an epoxy resin layer, and a conducting copper net is disposed between the activated carbon fiber cloth and the epoxy resin layer and coupled to a power input wire. The manufacturing method includes the steps of: (1) spraying an epoxy resin on a surface of the woven fiber cloth, and bake-drying and hot pressing the woven fiber cloth; and (2) connecting the conducting copper net and the power input wire, laying the activated carbon fiber cloth, and performing a second-time hot pressing. Meanwhile, carbon fiber constitutes a heat generating surface with the advantages of a light weight, a soft texture, a bendable feature, a uniform electric heating performance, a fast temperature rise, a highly safe, reliable and long life feature. In addition, the method of the invention involves a simple technical skill and an easy operation.

Owner:PAN

Disk array apparatus and disk array apparatus controlling method

Times at which requests for a data read or data write from / to a logical volume are received are stored in memory as access times of a RAID group making up the logical volume. When a predetermined time has elapsed after the access time, a number of the hard disk drives according to the redundancy of the RAID group are set to a power saving mode. Assume there are first hard disk drives and second hard disk drives having shorter lifes and the RAID group exceeds a predetermined time after the access time. When the RAID group consists of only the first drives, a number of the first drives according to the redundancy of the RAID group are set to a power saving mode and when it consists of only the second drives, an arbitrary number of second drives are set to a power saving mode.

Owner:HITACHI LTD

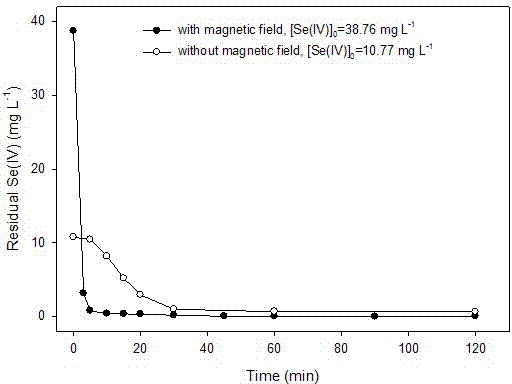

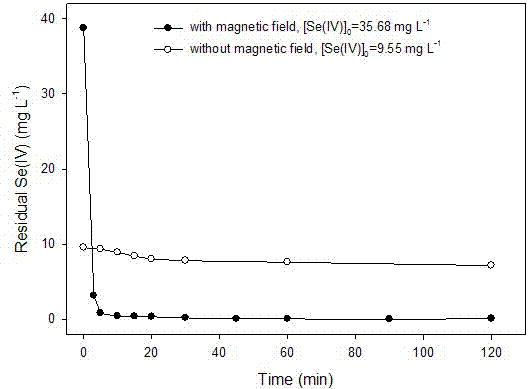

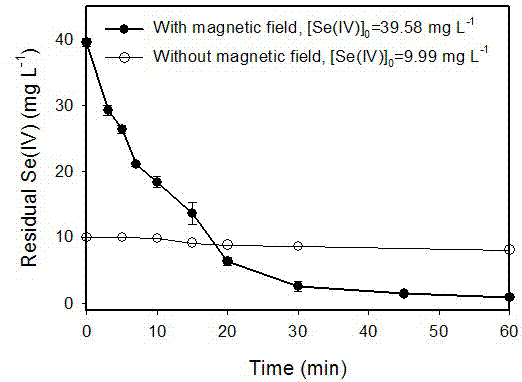

Method for removing Se(IV)/Se(VI) from water by magnetic field enhanced zero-valent iron

ActiveCN102807272ASmall volumeExtended service lifeWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by reductionMagnetic tension forceWastewater

The invention relates to a method for removing Se(IV) / Se(VI) from water by magnetic field enhanced zero-valent iron and relates to a water and waste water treatment method. The method solves the problems of low reaction speed of the conventional micron-sized zero-valent iron / iron scrap and the Se(IV) / Se(VI), low removal efficiency, narrow pH application range and short life of the zero-valent iron. The method adopts the following modes: (1) a stationary bed mode: applying magnetic field at the periphery of the zero-valent iron stationary bed and allowing the Se(IV) / Se(VI)-containing water to pass through the zero-valent iron stationary bed to be purified; and 2) a completely mixed reactor mode: adding a certain amount of zero-valent iron in the Se(IV) / Se(VI)-containing water, magneticallystirring or externally applying the magnetic field to realize quick reaction of the micron-sized zero-valent iron / iron scrap and the Se(IV) / Se(VI) so as to purify the water. According to the method, the magnetic field can inhibit generation of a zero-valent iron passivation film, the mass transfer speed of the Se(IV) / Se(VI) and the micron-sized zero-valent iron / iron scrap is increased and the removal efficiency of the micron-sized zero-valent iron / iron scrap on the Se(IV) / Se(VI) is greatly improved.

Owner:TONGJI UNIV +1

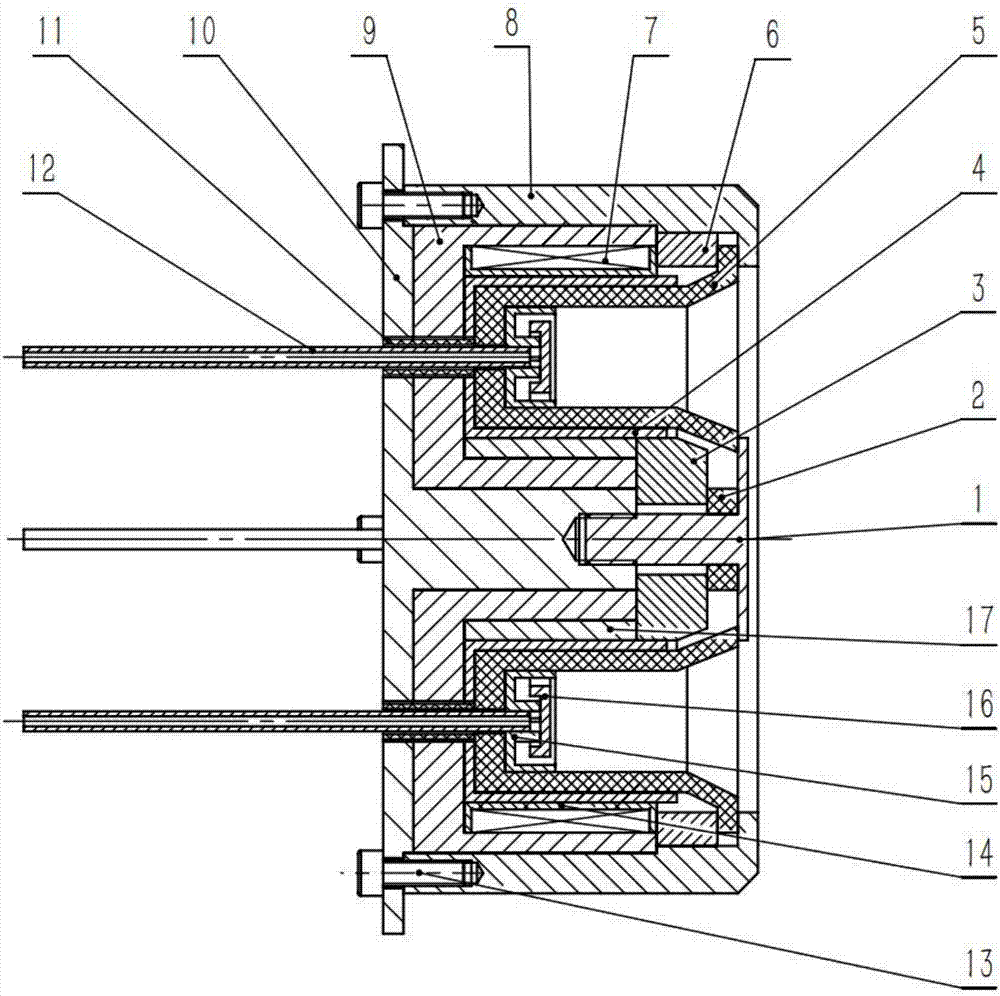

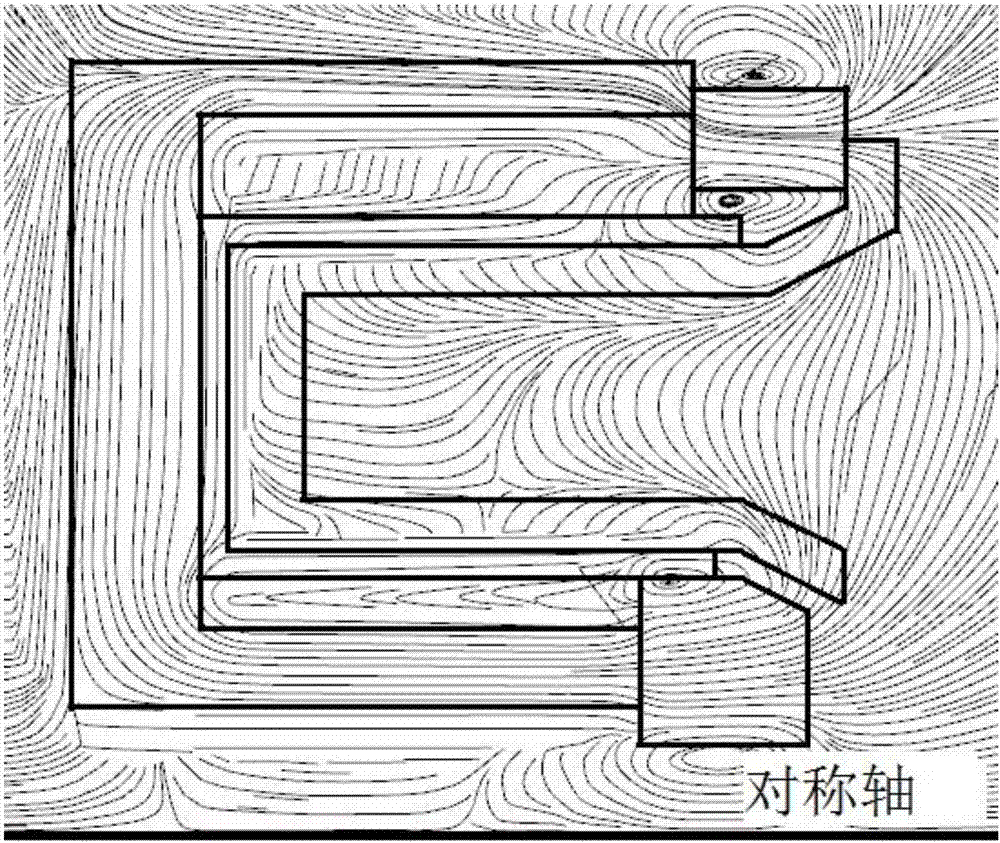

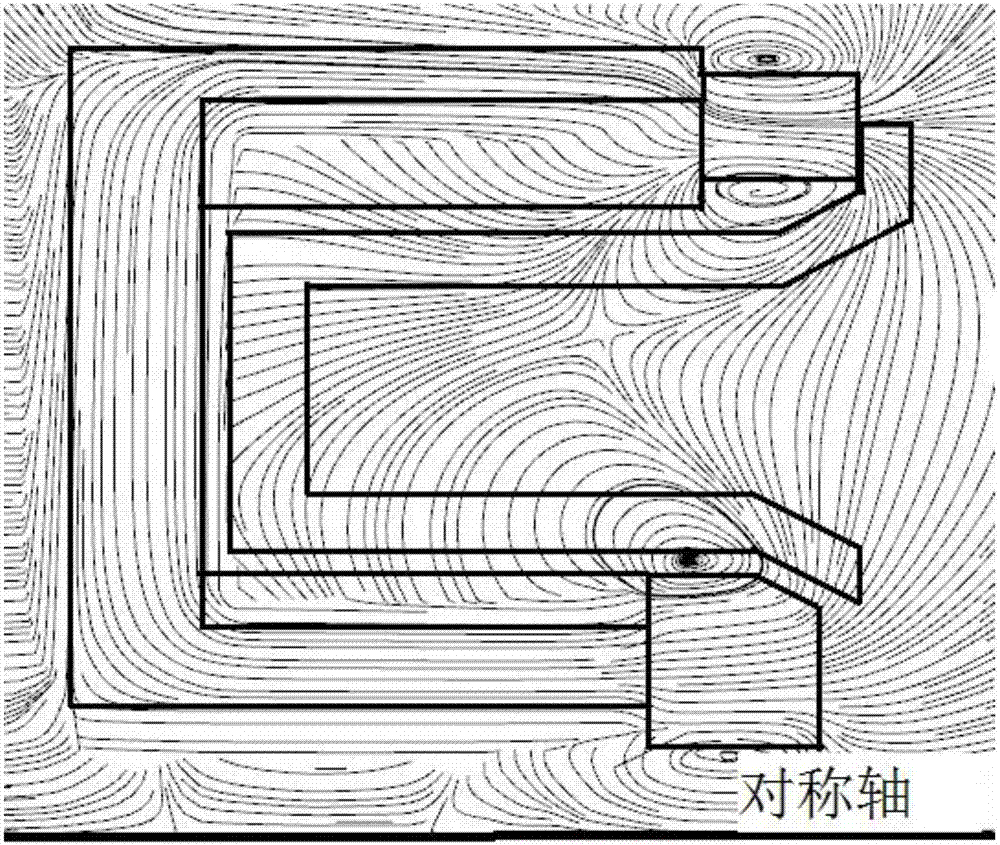

Magnetic field-adjustable low-power Hall thruster with magnetic shielding effect

ActiveCN107165794AReduce corrosionExtend your lifeMachines/enginesUsing plasmaElectricityMagnetic shield

The invention discloses a magnetic field-adjustable low-power Hall thruster with a magnetic shielding effect, and belongs to the technical field of electric propulsion. Along with diversification of spaceflight task demands, more attention is paid to the low-power Hall thruster; but low power of the Hall thruster causes the problems of short life and low efficiency; and the problems are related to the geometric size of a discharge channel of the Hall thruster, the magnetic field configuration and strength and the like. The magnetic shielding theory is introduced in the design of the low-power Hall thruster; a permanent magnet is used for generating a high magnetic field; a double-magnetic-screen structure is used for forming a magnetic shielding magnetic field in the discharge channel to limit the plasma movement, so that the wall surface corrosion is weakened, and the life is prolonged; meanwhile, the power consumption of the Hall thruster is greatly reduced through use of the permanent magnet, and is not higher than 100 W; and in addition, the invention further designs a heat conduction structure in the thruster for preventing influence on the performance of the permanent magnet due to too high thermal load.

Owner:BEIHANG UNIV

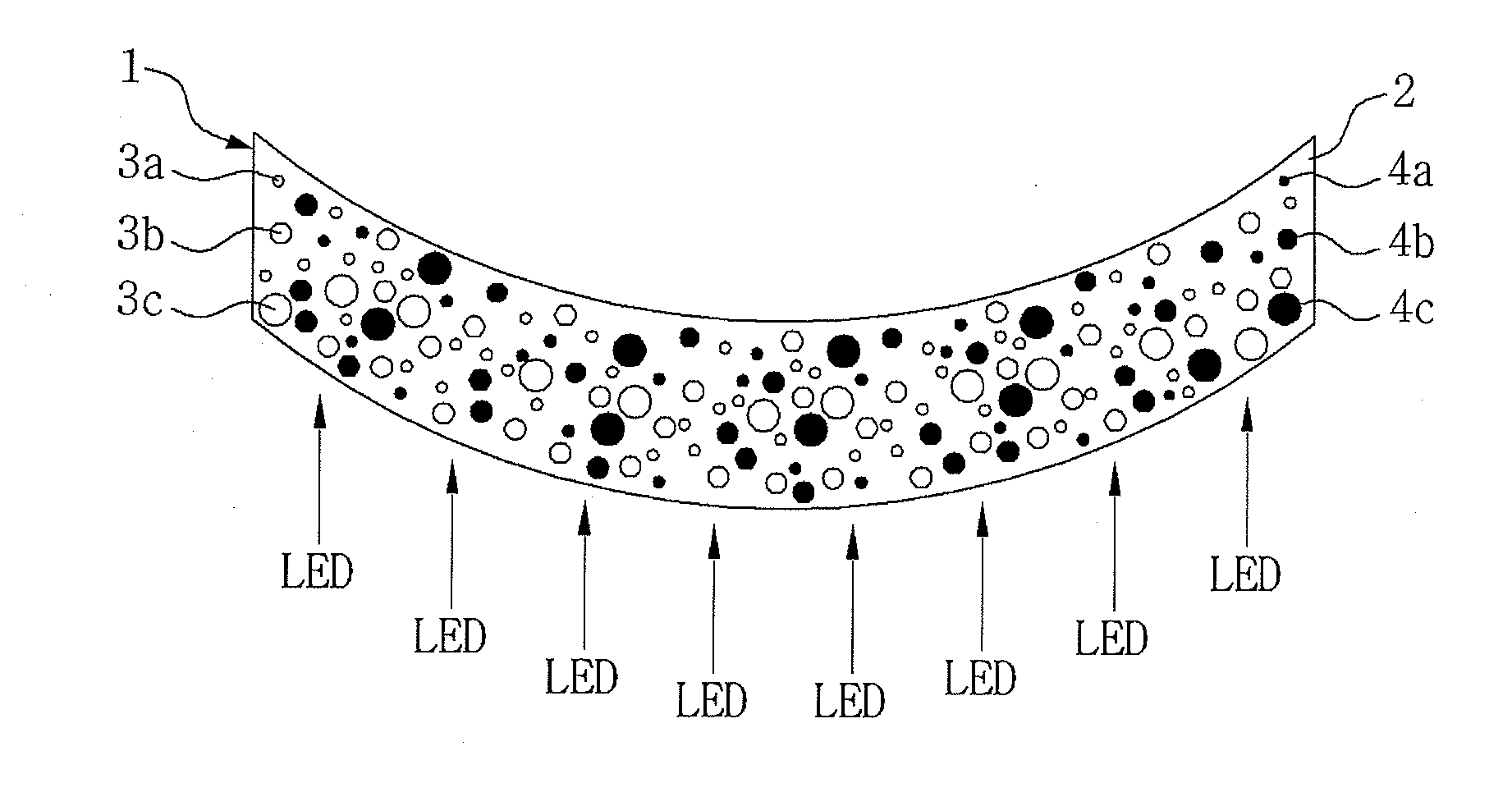

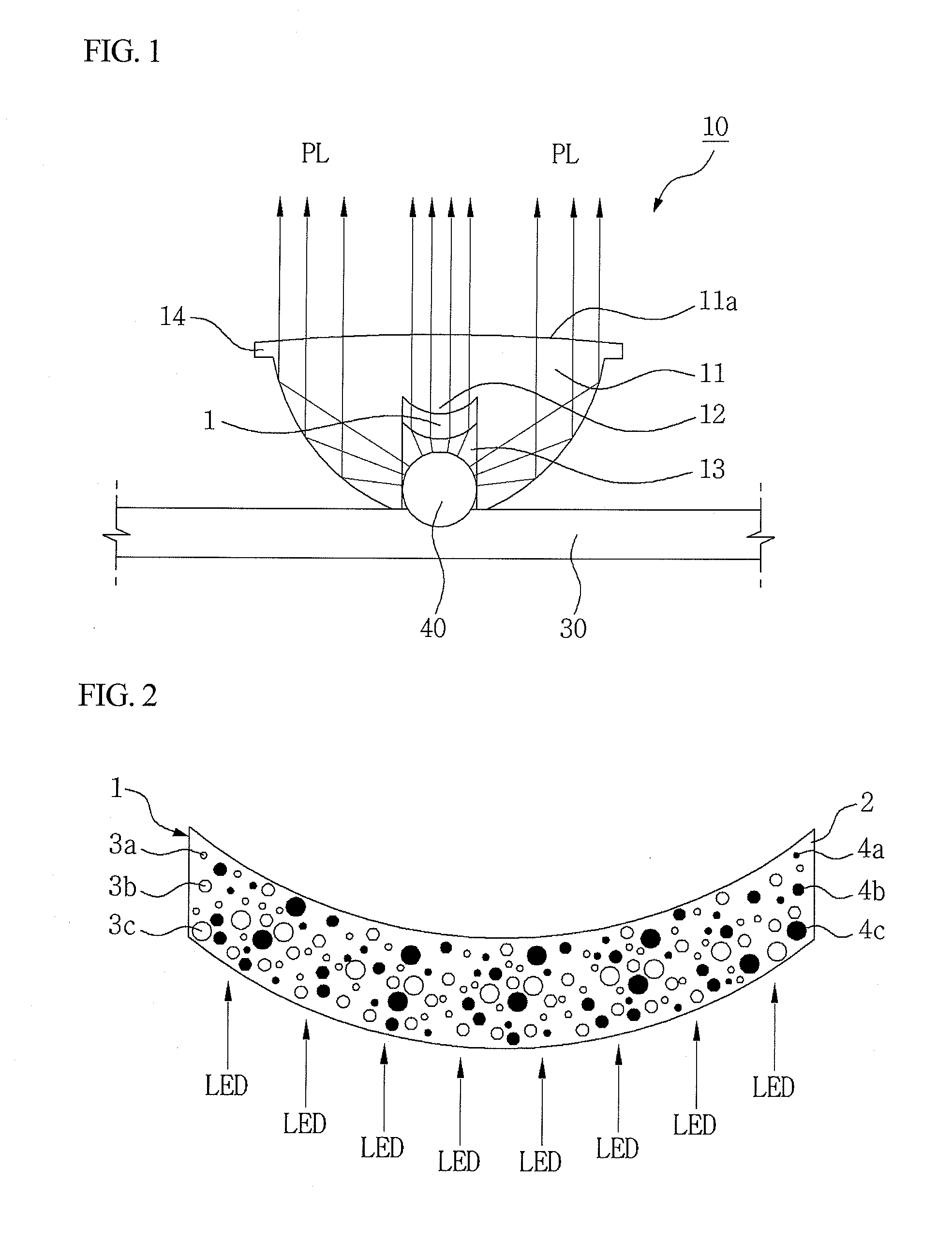

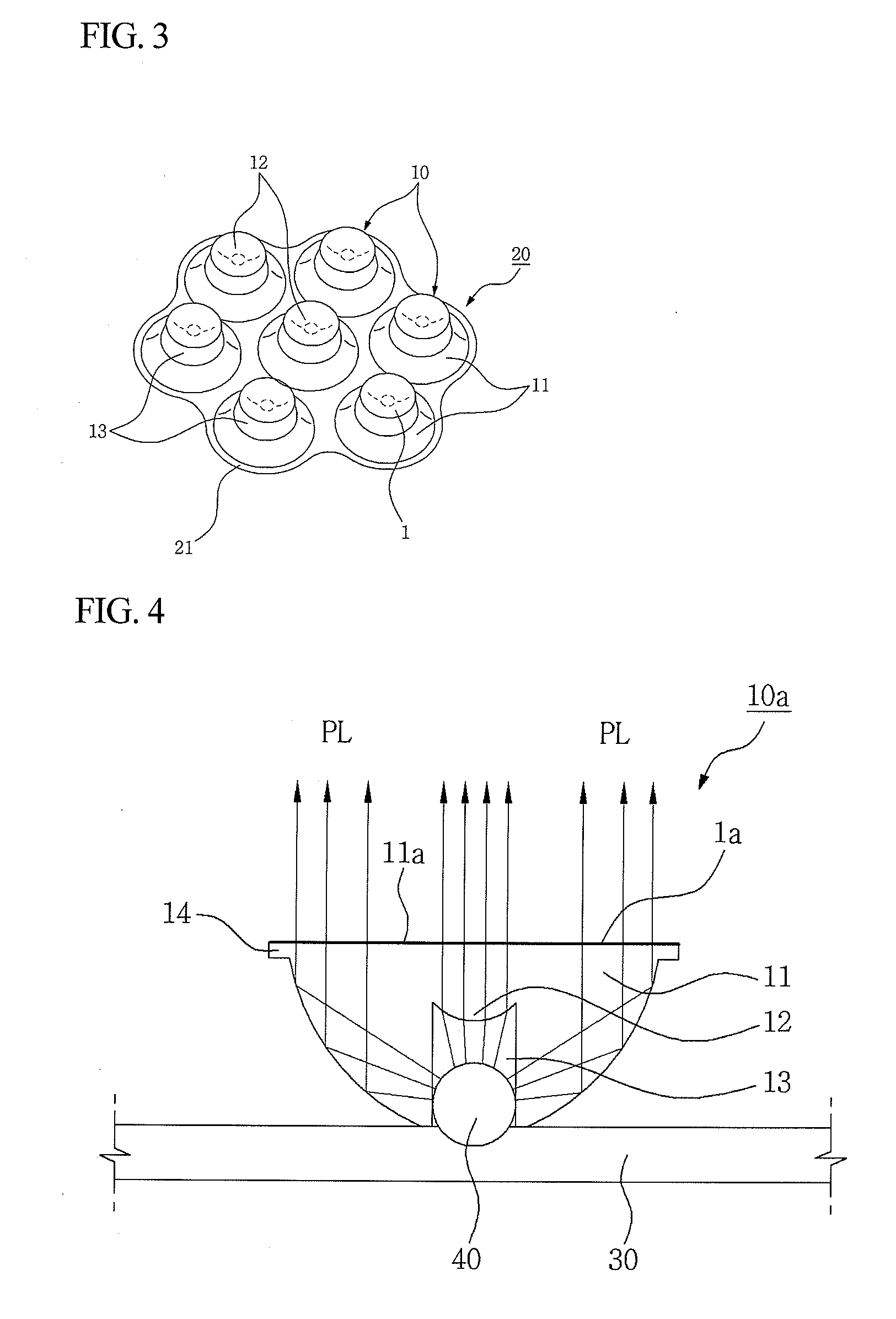

LED light converting resin composition and LED member using the same

ActiveUS20110317283A1Simply and easily replacingImprove comfortDischarge tube luminescnet screensLamp detailsFluorescenceHeat resistance

Disclosed are an LED light converting resin composition, and an LED member using the same. The LED light converting resin composition comprises 20˜99 wt % of transparent resin, 0.8˜60 wt % of a lighting color converting fluorescent substance, and 0.2˜20 wt % of a light diffusing bead with an average particle diameter of 0.2˜30 μm. It is possible to emit a white or yellowish white light, like a conventional white light LED, only by independently using a white light emitting LED lens with no change in a blue, violet, or UV LED. There is no need to use a white LED which is relatively expensive and has a short life. Instead, as required, it is possible to easily replace a conventional LED lens with the disclosed LED lens by a user or an operator, thereby obtaining a mild white light with a required luminance. Thus, glaring, caused by a high-luminance white LED lighting, can be effectively reduced, thereby providing a milder lighting with improved comfort. Furthermore, the concern about the deterioration of a lighting device can be reduced due to a high heat-resistance, which increases economical efficiency.

Owner:STCUBE +1

Chinese medicine for treating chronic renal failure

InactiveCN101502619APromote absorptionAvoid absorptionMammal material medical ingredientsUrinary disorderLife qualityPinellia

The invention discloses a traditional Chinese medicine for treating chronic renal failure and aims at solving the problems that the prior art supports the life by dialysis so as to result in short life cycle of patients and high cost and the like. The traditional Chinese medicine comprises the following raw materials: 30g of raidx astragali, 10g of white ginseng, 20g of rhizoma atractylodis macrocephalae, 20g of honey-fried licorice root, 20g of poria, 10g of Chinese angelica, 20g of rehmannia glutinosa, 20g of white paeony root, 10g of wrinkled gianthyssop herb, 15g of pinellia tuber and the like. The prescription is used for treating chronic uremia, can invigorate vigour, strengthening the spleen, replenishing blood, nourishing the blood, excreting water, expel toxin, strengthening the kidney and expel toxin, can reduce dialysis gradually by combining the modern medical method, finally separate the dialysis and transfusion, relieve economic burden of the patients, improve disease process fundamentally, improve life quality and courage and prolong life cycle.

Owner:刘云

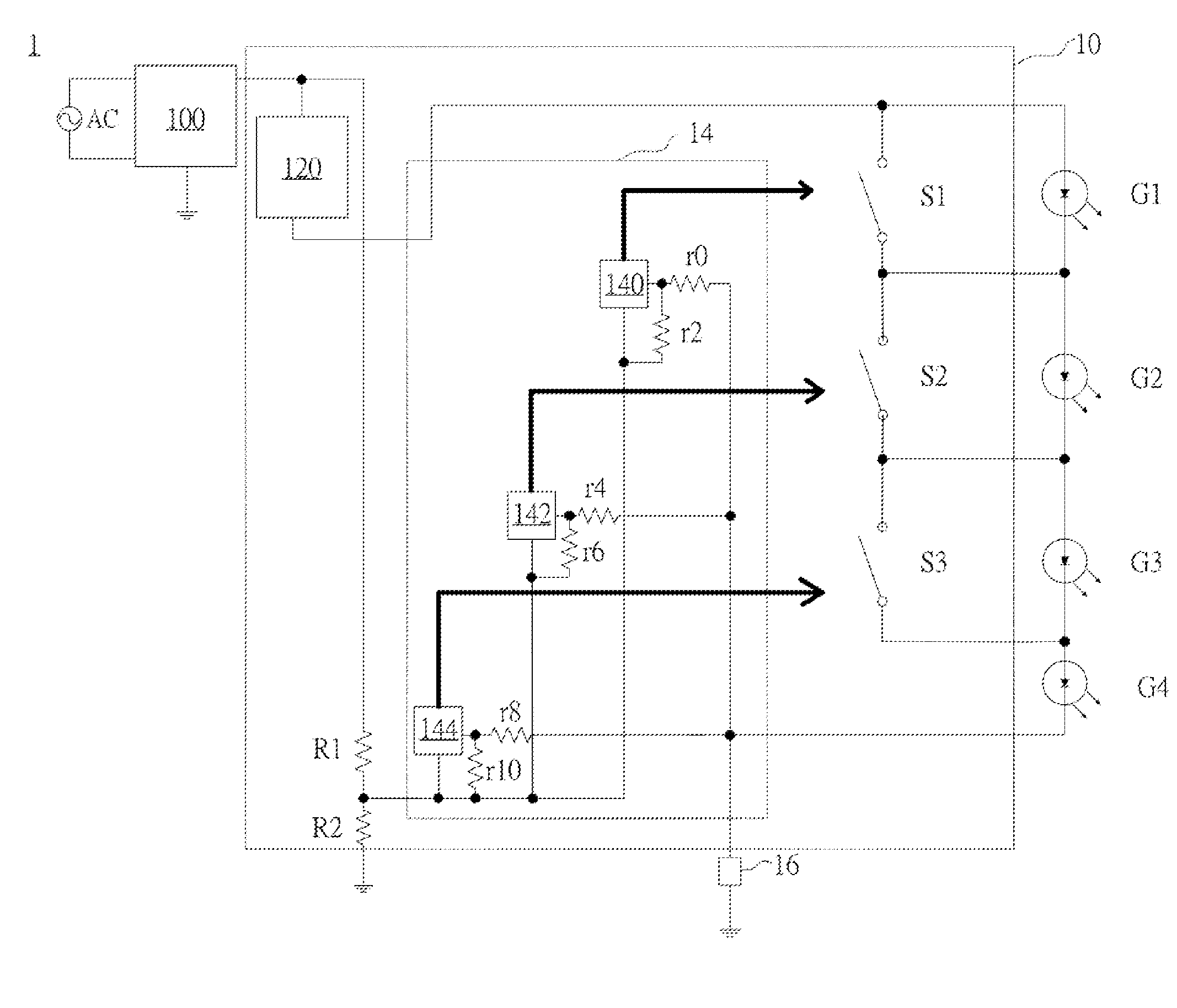

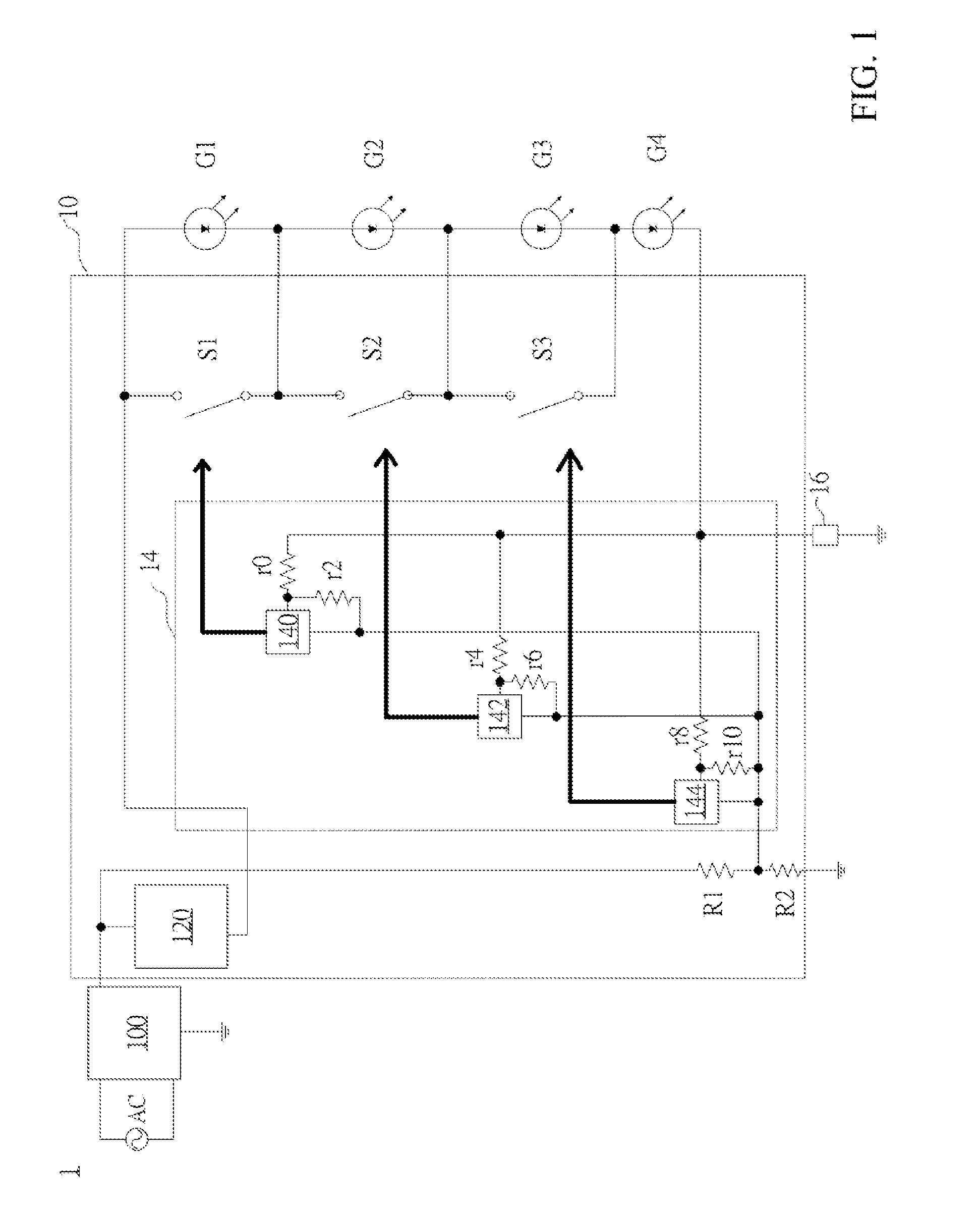

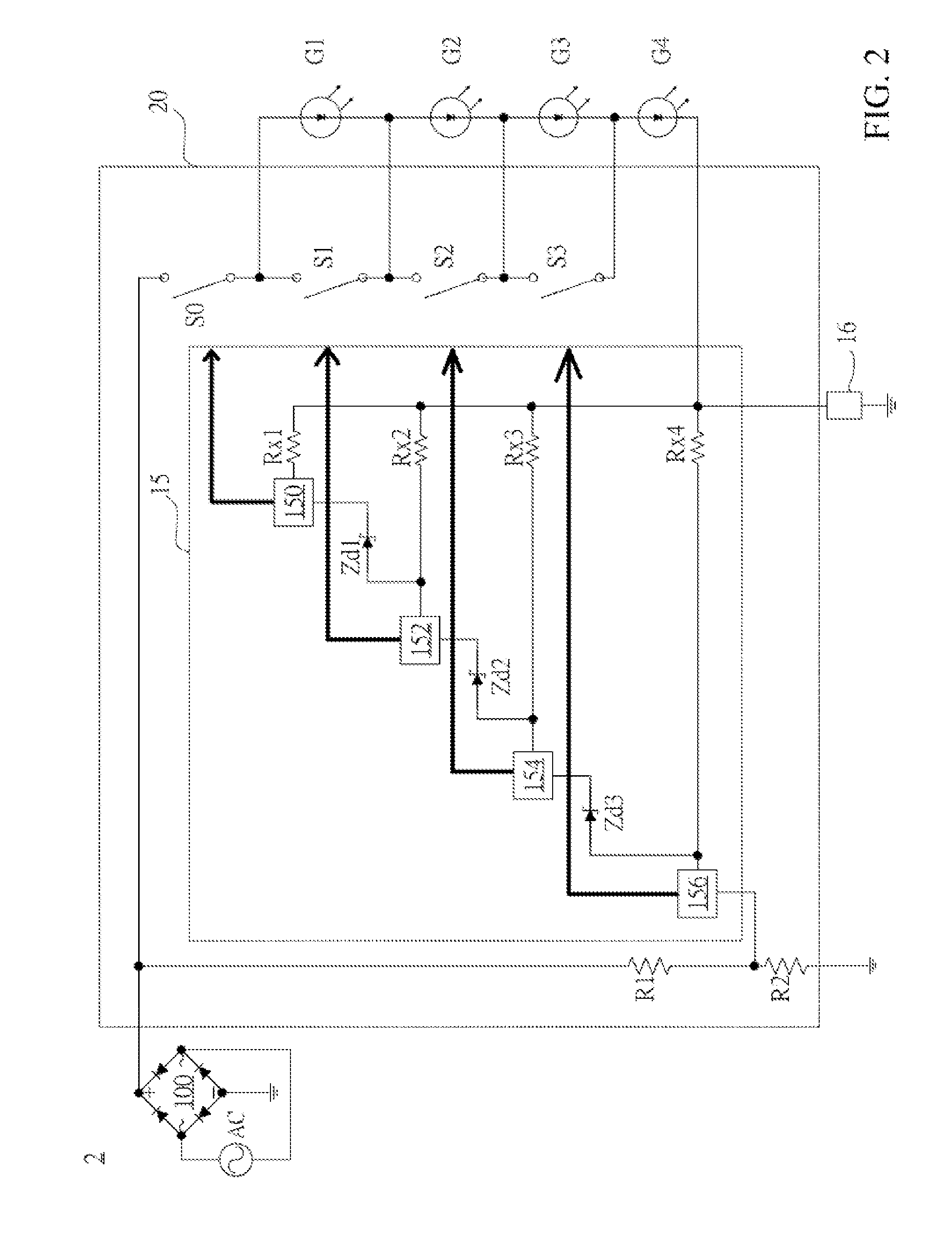

Ac-powered LED light engines, integrated circuits and illuminating apparatuses having the same

InactiveUS20150257225A1Without deteriorationReduce countElectrical apparatusElectroluminescent light sourcesCapacitanceOn board

Disclosed are novel AC-powered LED light engines for Solid State Lighting (SSL) able to achieve a high PF and a low THD without a traditional PFC. Getting rid of bulky, and costly magnetic components, short-life electrolytic capacitor, and EMI-causing fast switching, the disclosed AC-powered LED light engines ushers in a cost-effective, and energy-efficient LED driver design while eliminating the short-life electrolytic capacitor in an LED driver and reducing the Total Cost of Ownership (TOC). Thanks to no bulky components, the disclosed AC-powered LED light engines in a discrete or an integrated circuit form could be applied to the increasingly popular Driver-on-Board (DoB) design. Aside from being TRIAC-dimmable via legacy phase-cut dimmers, the disclosed LED light engines could also be made PWM-, analog-, or rheostat-dimmable with the incorporation of an appropriate dimming circuit to modulate the average LED current, adding more flexibility and versatility to dimming applications.

Owner:GRP TECH

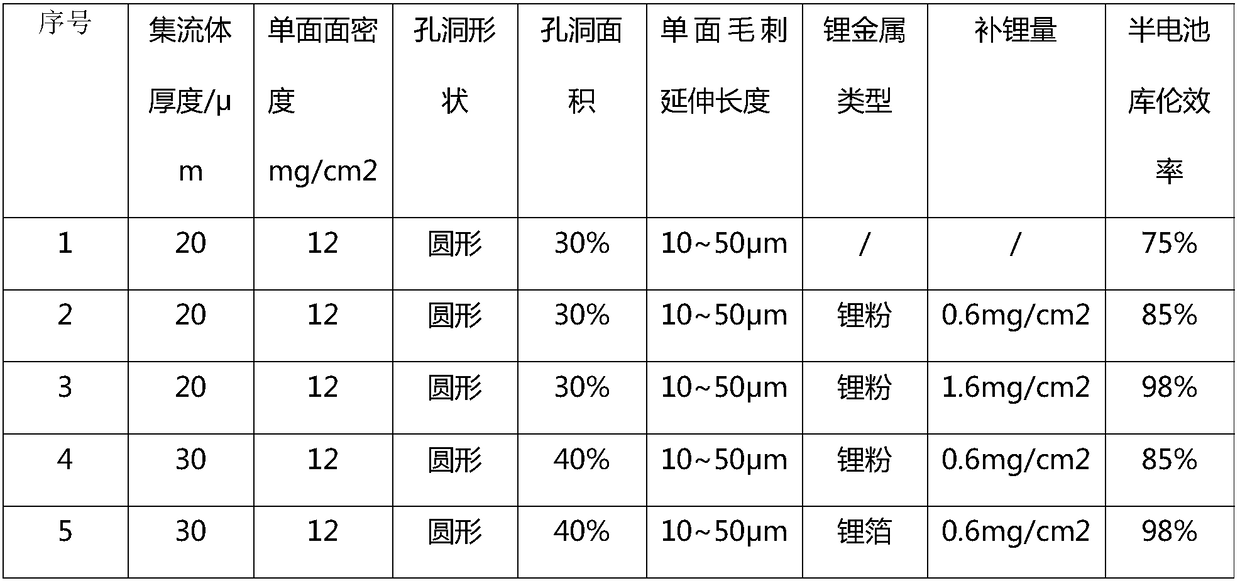

Lithium ion battery negative electrode single-side pre-lithiation method using three-dimensional foil

InactiveCN108550780AStrengthens the conductive networkIncrease gram capacityElectrode carriers/collectorsManufacture by sprayingGraphite electrodeLithium metal

The invention provides a lithium ion battery negative electrode single-side pre-lithiation method using a three-dimensional foil. The method comprises the following steps: 1, coating a three-dimensional current collector with a negative electrode slurry, and performing rolling to obtain a rolled electrode sheet; 2, performing pre-lithiation compounding on the electrode sheet: carrying the following two pre-lithiation processes according to the difference of lithium metal raw materials: uniformly spraying or coating one side of the rolled electrode sheet with lithium metal powder through a lithium metal powder pre-lithiation process or bonding and compounding one side of the rolled electrode sheet with a lithium foil under a certain pressure by adopting a lithium foil pre-lithiation process; and 3, assembling a positive electrode, a diaphragm and the negative electrode obtained after the pre-lithiation compounding is completed in order to form a battery cell, and performing electrolyteinjection and formation on the battery cell. The lithium ion battery negative electrode single-side pre-lithiation method using the three-dimensional foil solves the problems of swelling peeling, short life and low capacity of a silicon carbide / graphite electrode; and two-side pre-lithiation is simplified into single-side pre-lithiation, so the pre-lithiation efficiency is improved.

Owner:TIANJIN ENERGIES

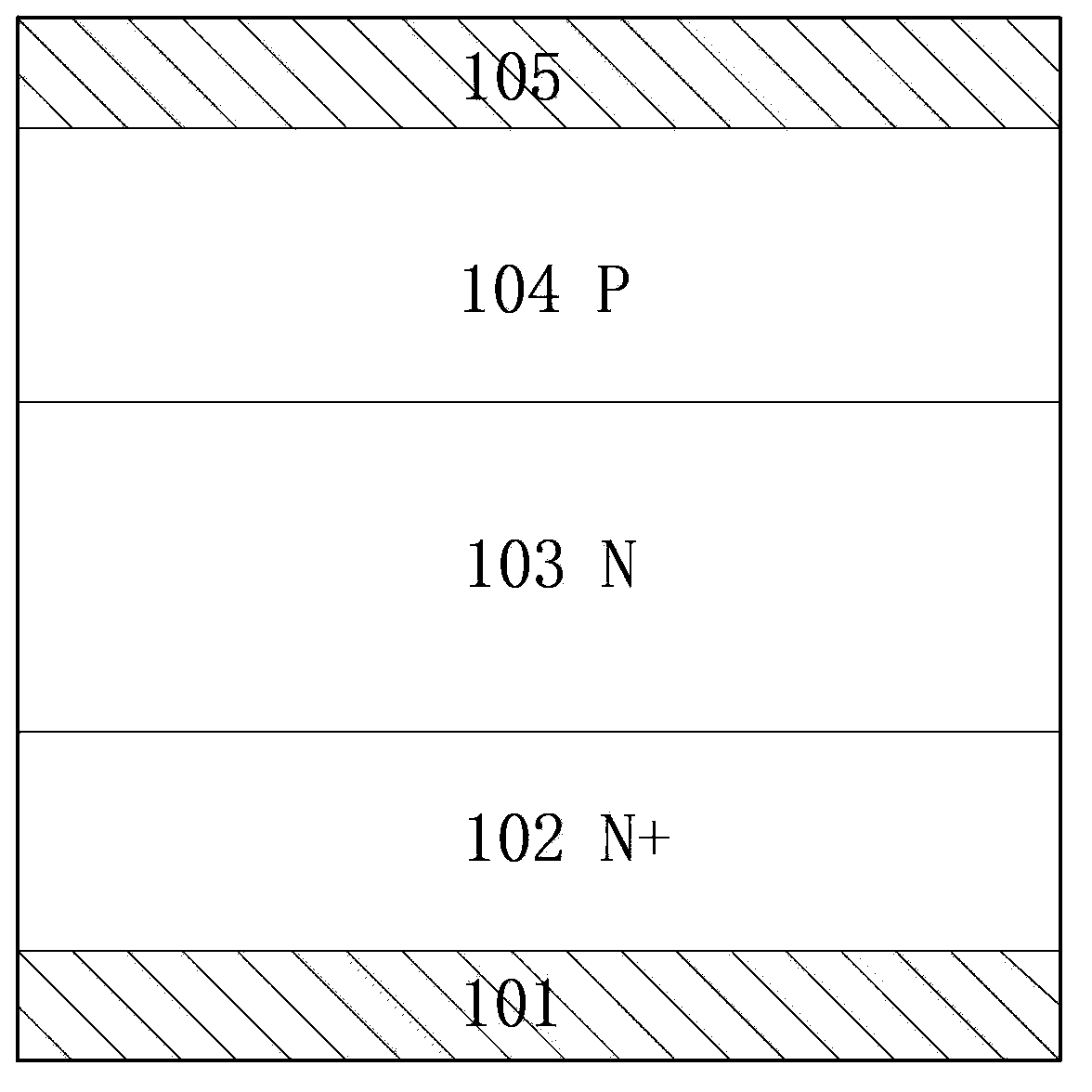

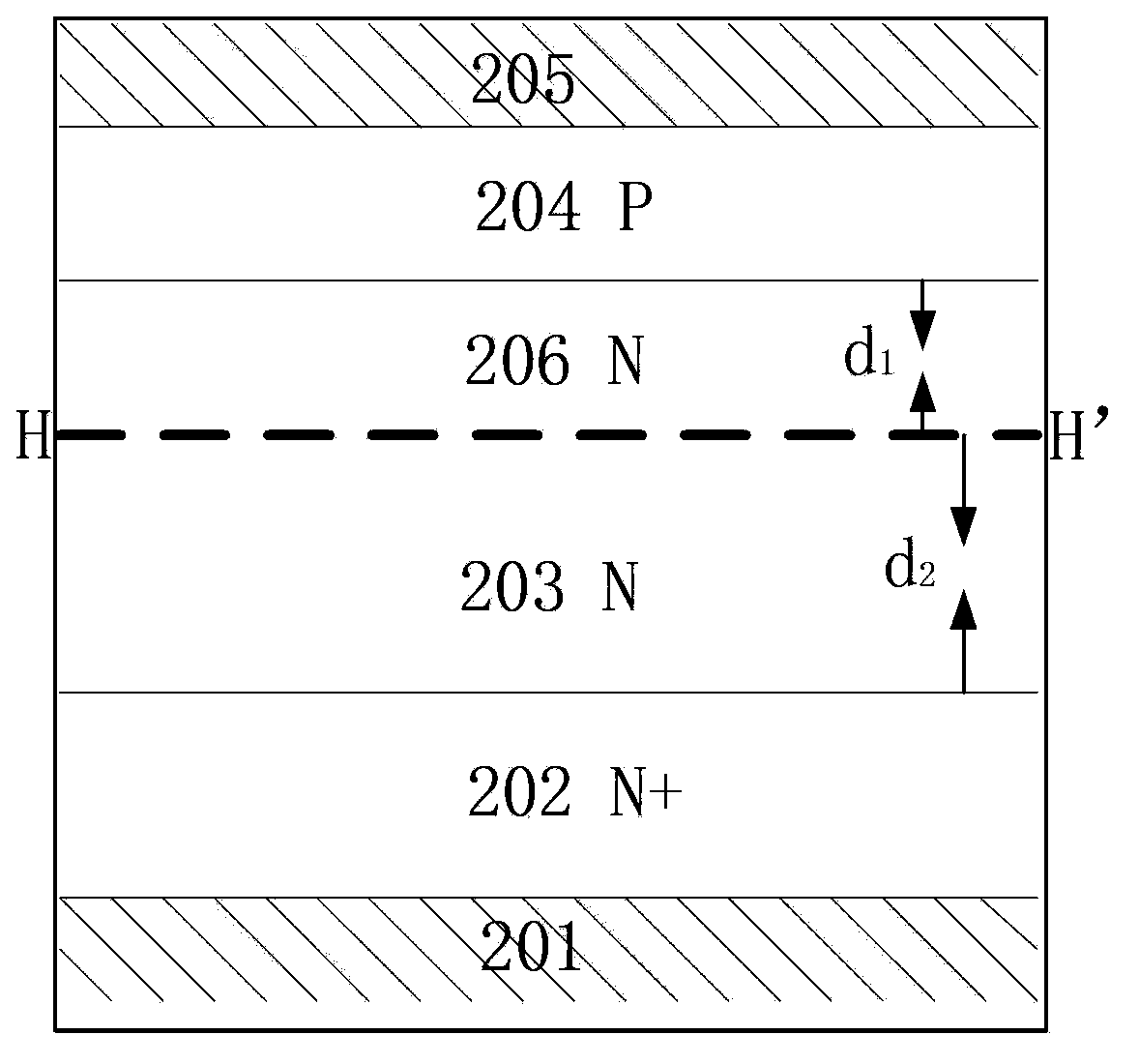

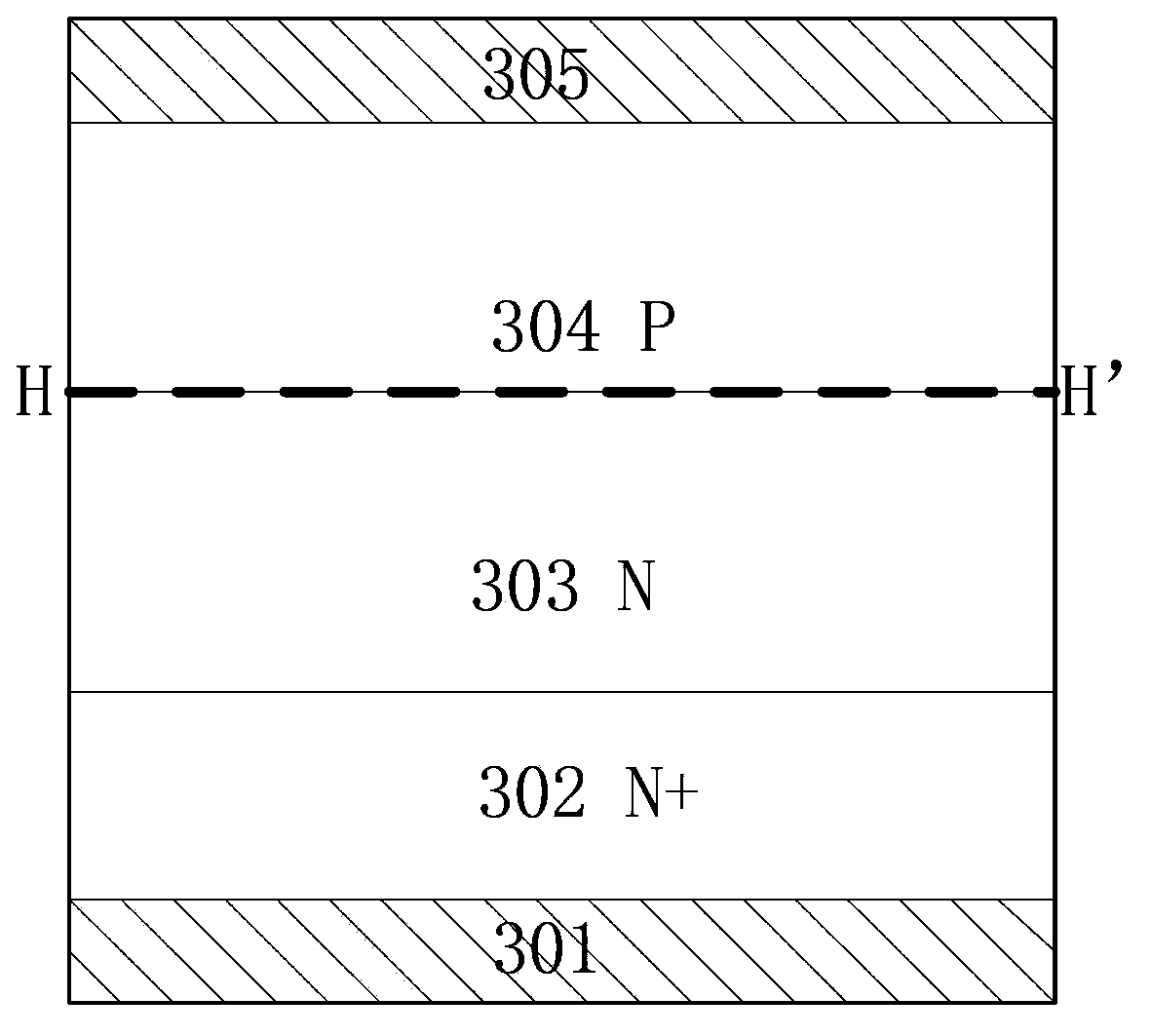

Structure of fast recovery diode (FRD) and manufacturing method thereof

ActiveCN103700712AIncrease the switching frequencyShort lifeSemiconductor/solid-state device manufacturingDiodeCharge carrierBody area

The invention provides a structure of a fast recovery diode and a manufacturing method of the fast recovery diode. The structure comprises a cathode metal layer, a cathode area located on the cathode metal layer and comprising a first conduction type, a drift area located on the cathode area and having the first conduction type, an anode area located on the drift area and having a second conduction type, and an anode metal layer located on the anode area, wherein a PN (North Pole) junction is formed at an interface of the drift area and the anode area, and bonding interfaces are formed at the PN junction and / or in a drift area and / or the anode area. The bonding interfaces are introduced, thereby forming a short life area in a fast recovery diode body area, and the position of the bonding interface is precisely controlled to accurately control the life distribution of a carrier in the fast recovery diode body area, and effectively improve the switching speed of the fast recovery diode, and simultaneously ensure the switch softness.

Owner:BYD SEMICON CO LTD

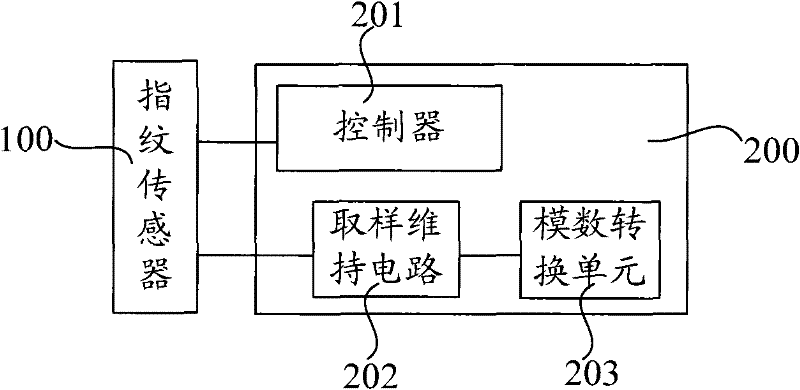

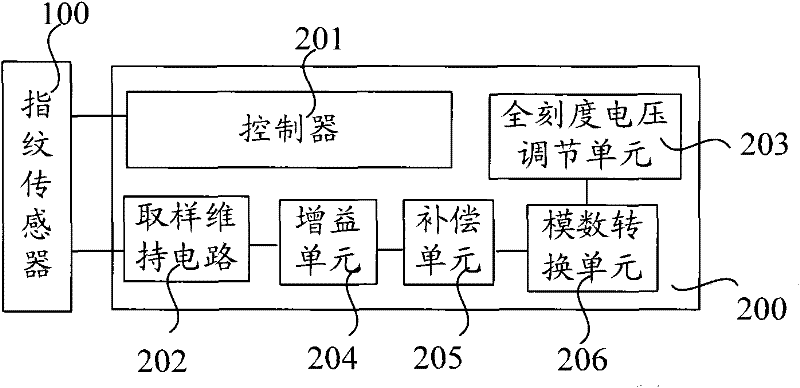

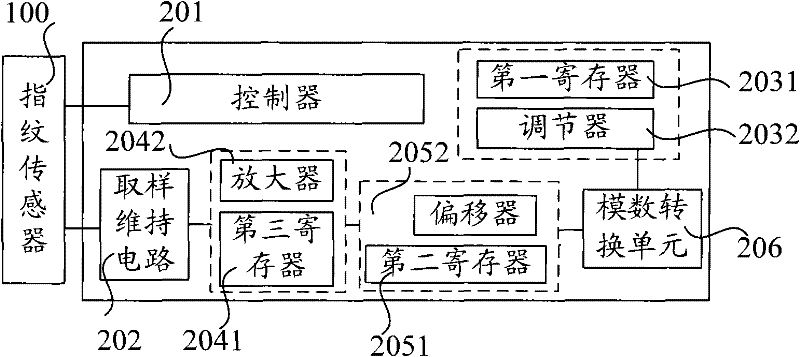

Fingerprint identification system and test device

InactiveCN102279924AImprove performanceExtended input voltage rangeCharacter and pattern recognitionEngineeringFull scale

A fingerprint identification system and a test device including the fingerprint identification system, the fingerprint identification system includes: a fingerprint sensor for detecting a fingerprint pattern and converting the fingerprint pattern into a discrete analog signal about fingerprint information; a drive circuit The unit is used to perform data processing on the discrete analog signal detected by the fingerprint sensor, and the drive circuit unit includes: a controller used to drive the fingerprint sensor; a sampling and holding circuit used to collect and maintain the instantaneous voltage of the discrete analog signal , forming a continuous analog signal; an analog-to-digital conversion unit, used to convert the continuous analog signal into a digital signal; a full-scale voltage adjustment unit, used to adjust the full-scale voltage of the analog-to-digital conversion unit, and the full-scale voltage is the analog-to-digital conversion unit Maximum input voltage for analog-to-digital conversion. The fingerprint identification system has excellent performance, high yield rate, and overcomes the problem of short service life caused by aging.

Owner:金鹏科技有限公司

Material for making piston rubber-rup of slurry pump

The invention is a material to make piston leather bowl of slurry pump, solving the problem of short life. Its characters: the components according to weight shares: natural glue 60-70, butyronitrile glue 30-40, zinc oxide 2-5, stearic acid 2-4, pine tar 4-6, anti-aging agent 2-4, accelerant DM 1.5-2.0, accelerant D 1.0-1.5, high-wearable carbon blacnk 50-90, sulphur 2-5, coumarone 4-9, dibutyl ester 2-10 and short fiber 5-20.

Owner:焦学明

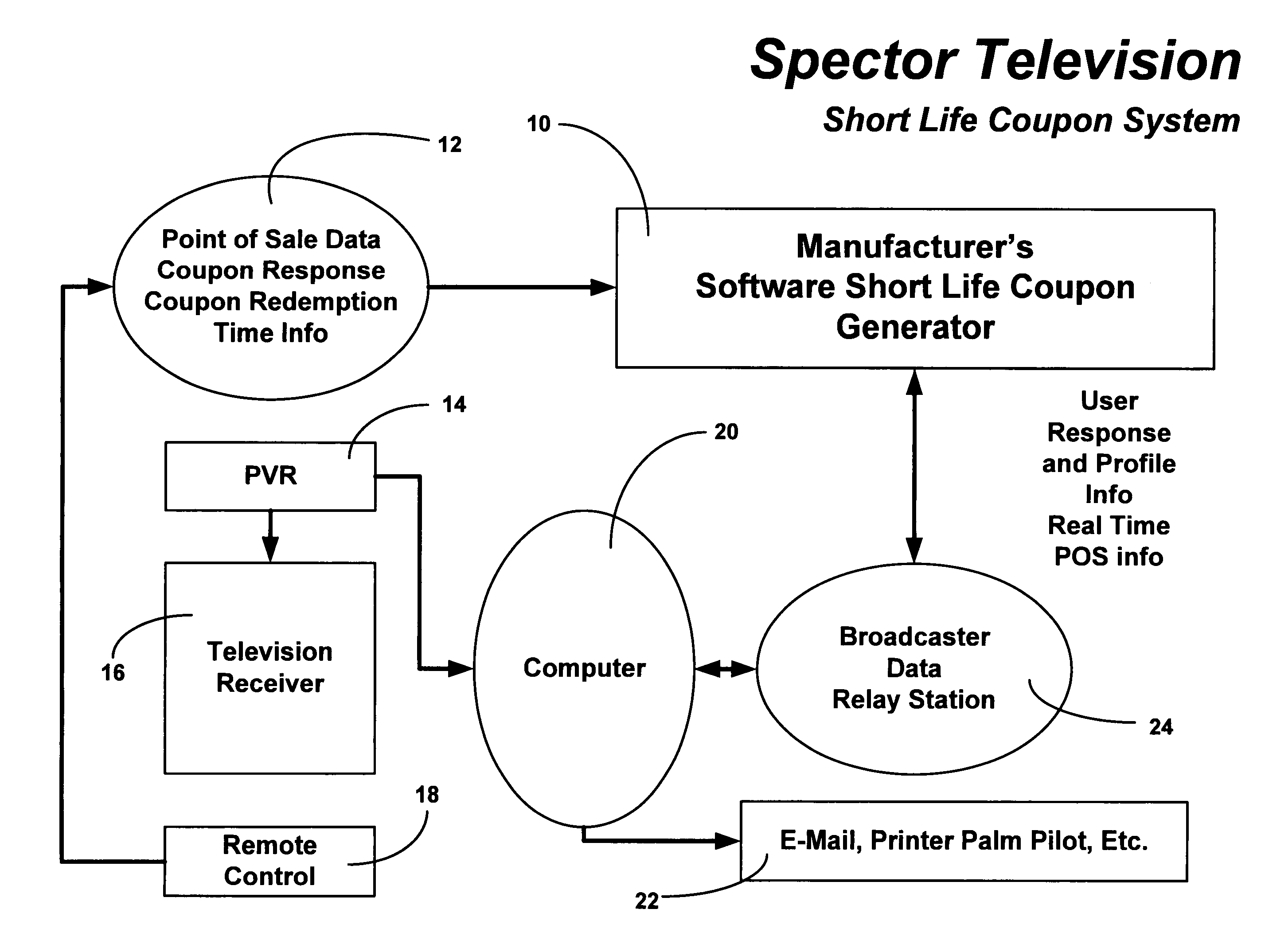

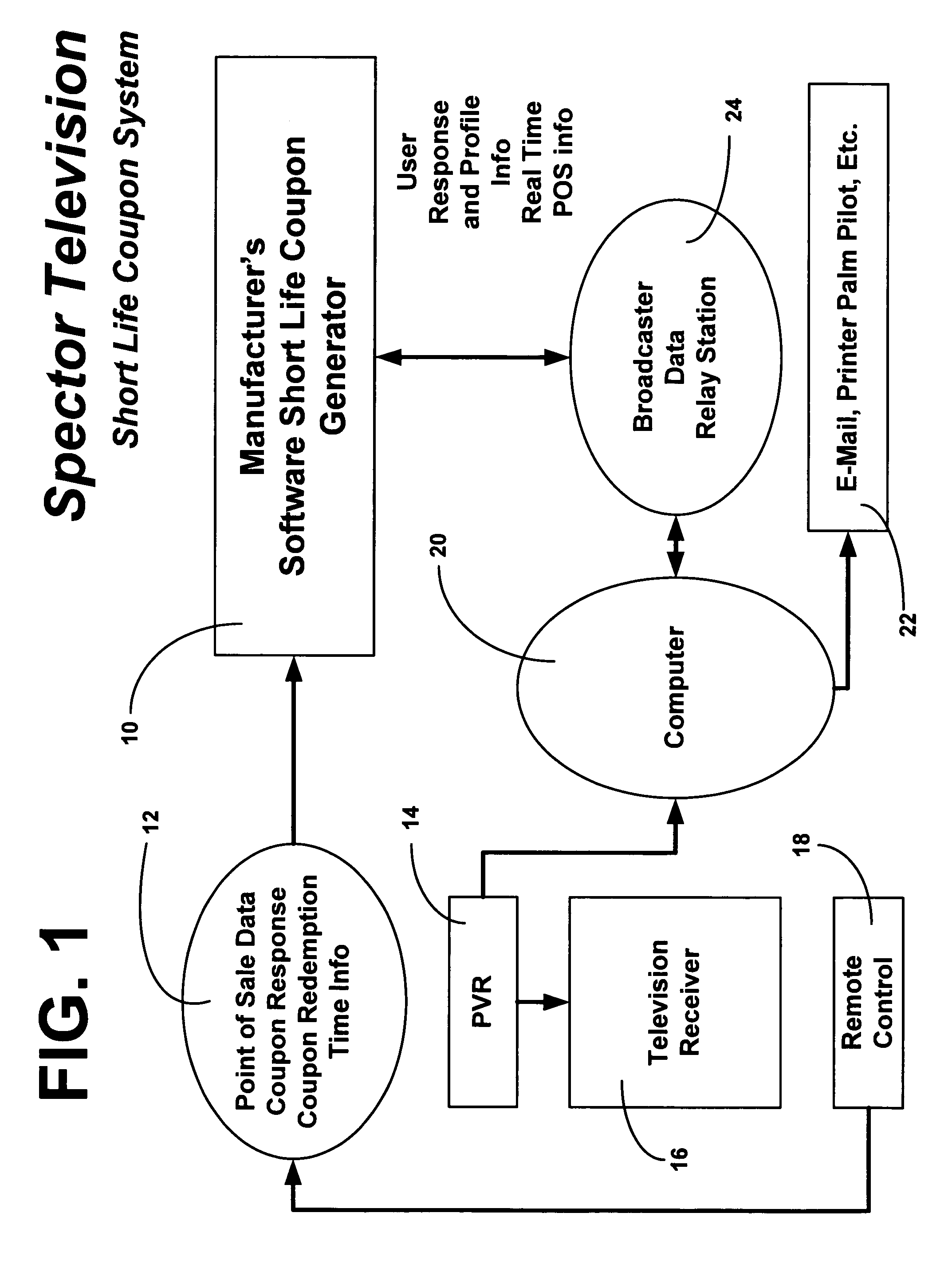

System for issuing short life coupons or other promotional devices

An improved short life coupon system which allows a television viewer to select discount or promotional coupons while viewing a television commercial. Coupon information relating to the commercial is sent to a central station which also contains up-to-date point-of-sale information. This information is analyzed by the central station so that the coupon can be specifically designed to satisfy the viewer and maximize sales.

Owner:OL SECURITY LIABILITY CO

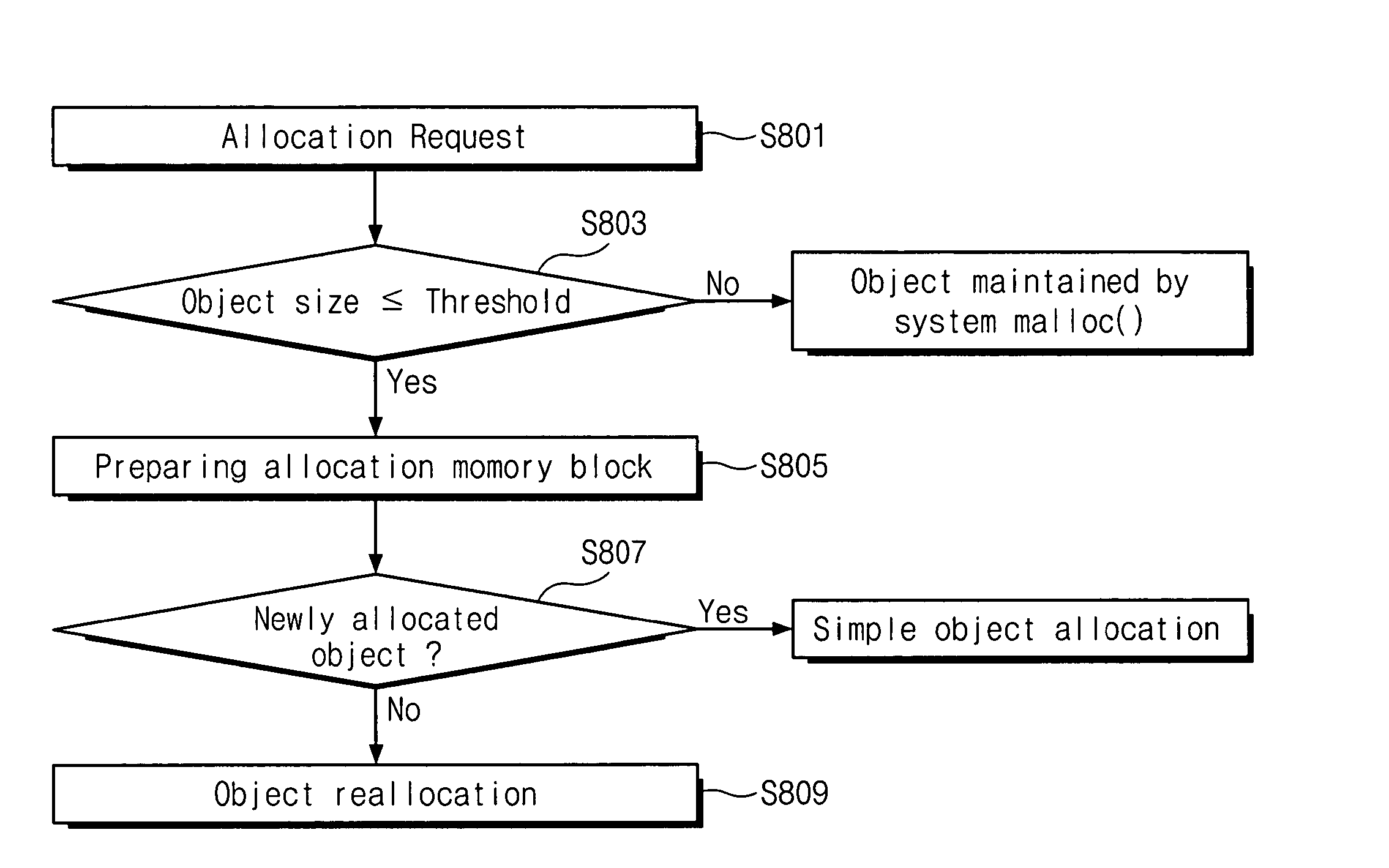

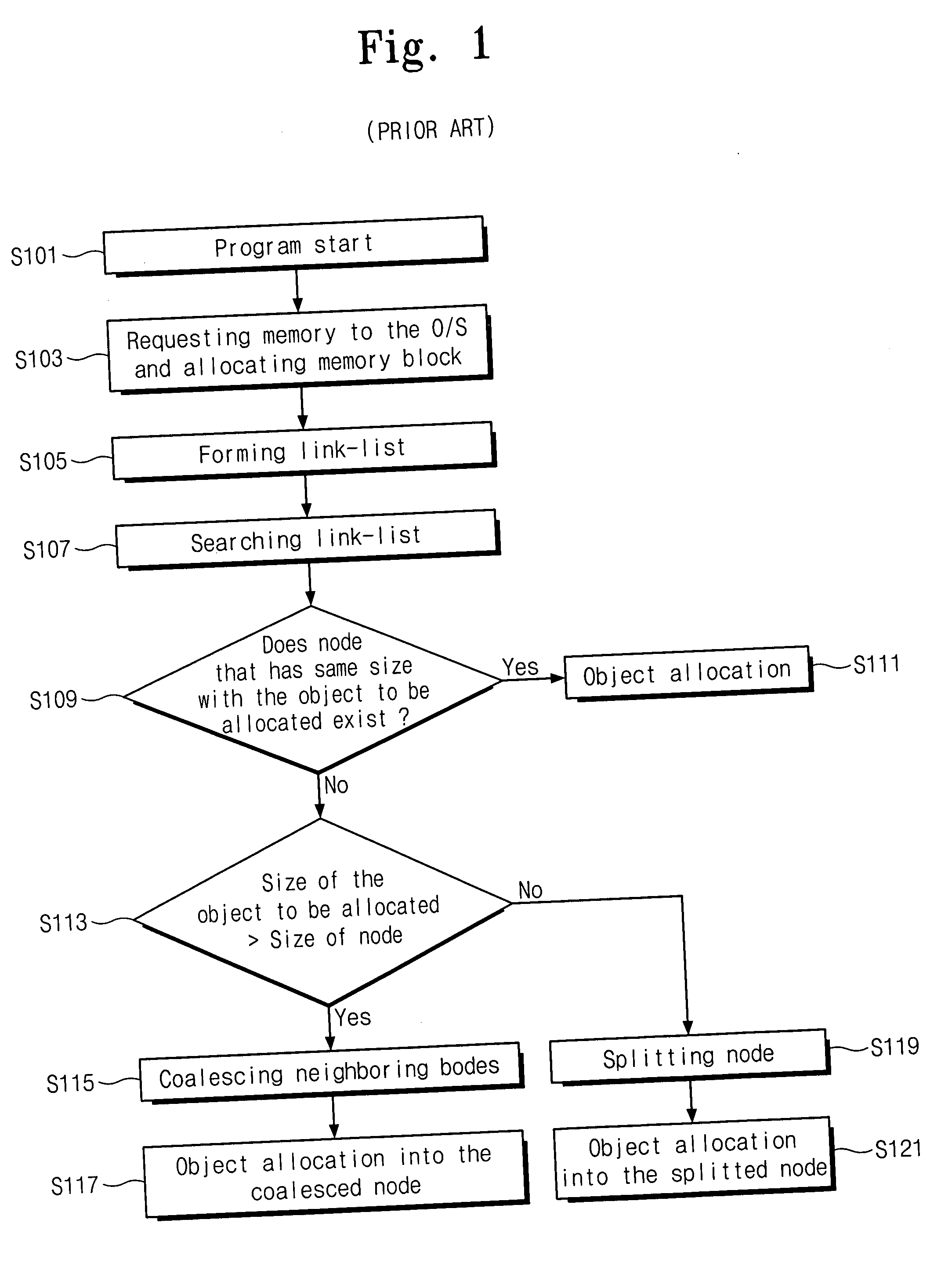

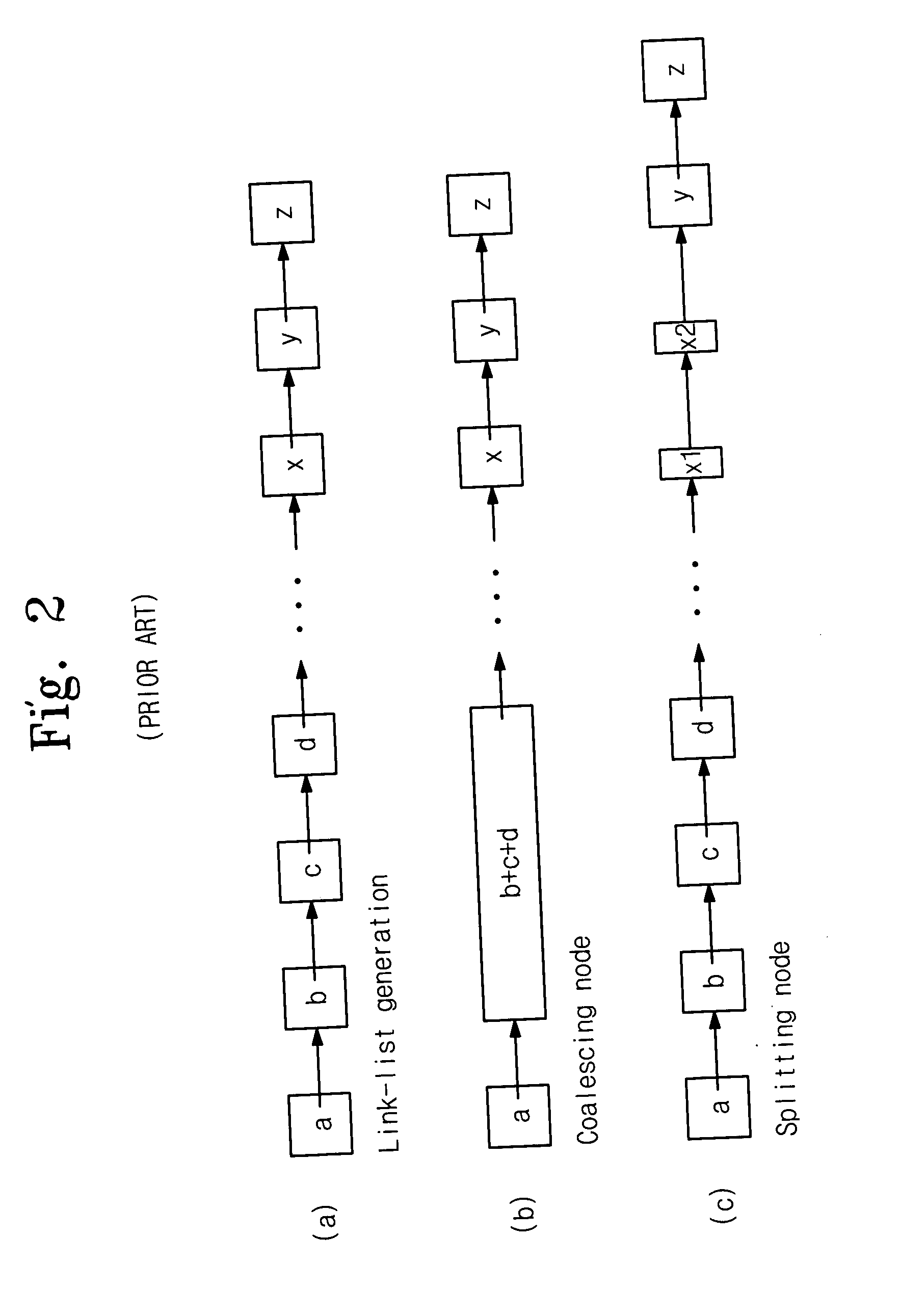

Method and apparatus for executing dynamic memory management with object-oriented program

ActiveUS20050071597A1Improve performanceShort operating timeData processing applicationsMemory adressing/allocation/relocationParallel computingUnit memory

The disclosure is a method and apparatus for operating dynamic memory management with an object-oriented program, by which objects with frequent creation and short life spans are allocated to a unit memory block in sequence. After released from the unit memory block, the objects are added on a free re-use list so as to be reused when there is an invocation of allocation for the same object size. It is advantageous to enhancing system performance.

Owner:SAMSUNG ELECTRONICS CO LTD

Abrasive synthetic rubber material and its production

An abrasive-resisting synthetic rubber material and its production are disclosed. The rubber material consists of natural rubber sheet, cis-1,4-polybutadiene rubber, styrene-butadiene rubber, chlorinated polypropylene rubber, greaseDOP, polytef, nanometer-magnesium hydroxide, oligomer ester, improver, fortifier, sulfur-resisting reducer, vulcanizing agent and filling agent. The process is carried out by plastication milling and milling to obtain abrasive-resisting synthetic rubber material, which has Schau's hardness 60, stretch strength 23, elongation 23 and elasticity 53%. It has better abrasive-resisting and anticorrosive performances and short life.

Owner:河北九星橡塑制品有限公司

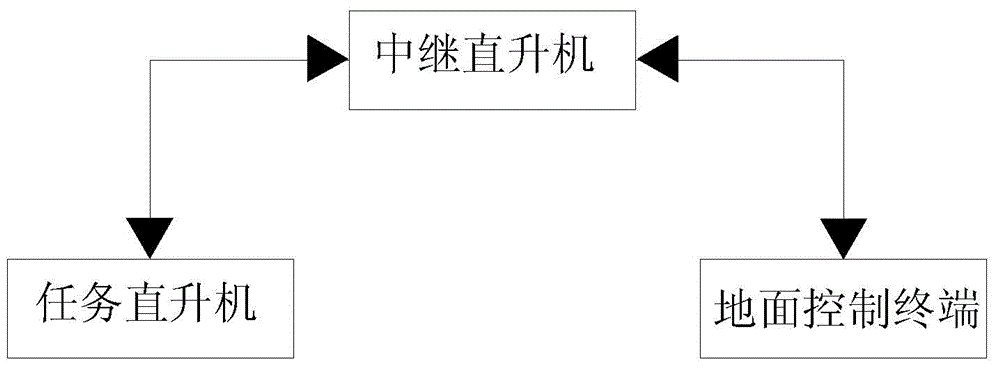

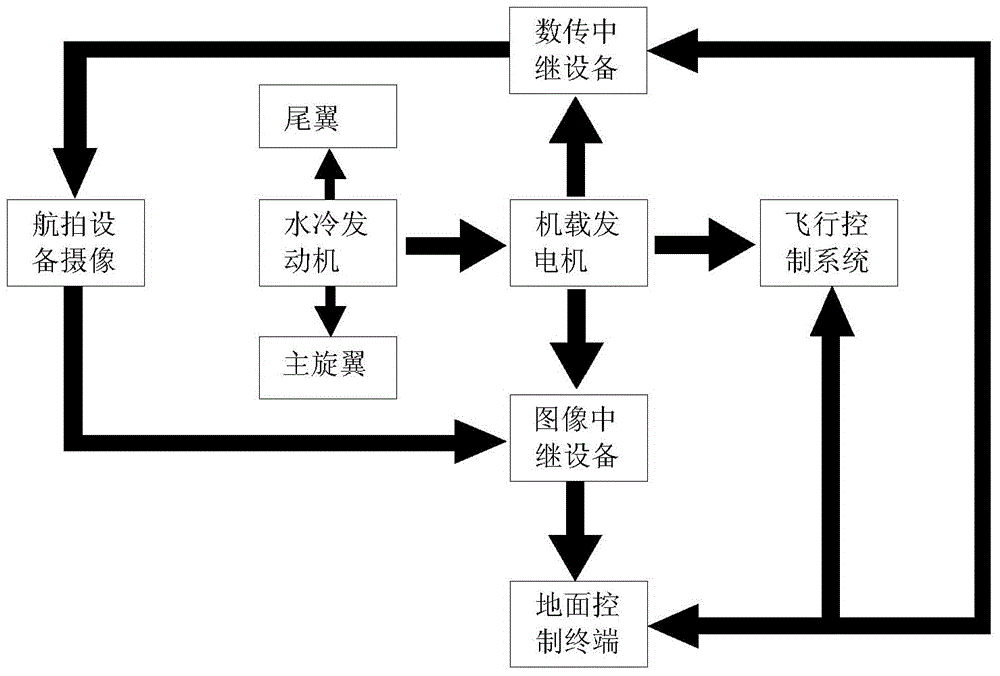

UAV inspection system

InactiveCN104898693AImprove flight control distanceAddress lack of motivationPosition/course control in three dimensionsFly controlEngineering

The present invention relates to the field of UAV operation maintenance, and particularly relates to a UAV inspection system. A ground control terminal can carry out two-way communication with a task helicopter which carries out an inspection task through a relay helicopter, thus the functions of image data transmission and the fly control of the task helicopter are realized, and the fly control distance of an UAV is greatly improved. At the same time, according to the technical scheme, a 126cc water-cooled engine is used to the defects of insufficient power, small load capacity and short life of an 80cc engine, a 200W engine and a rectifier filter module are installed according to a vehicle generation principle, the problem of power supply needed by airborne equipment is solved to a certain extent, and on the whole, the UAV inspection system has the advantages of long fly time, long distance operation across mountains and high adaptability.

Owner:NANTONG XINCHENG ELECTRIC POWER TECH

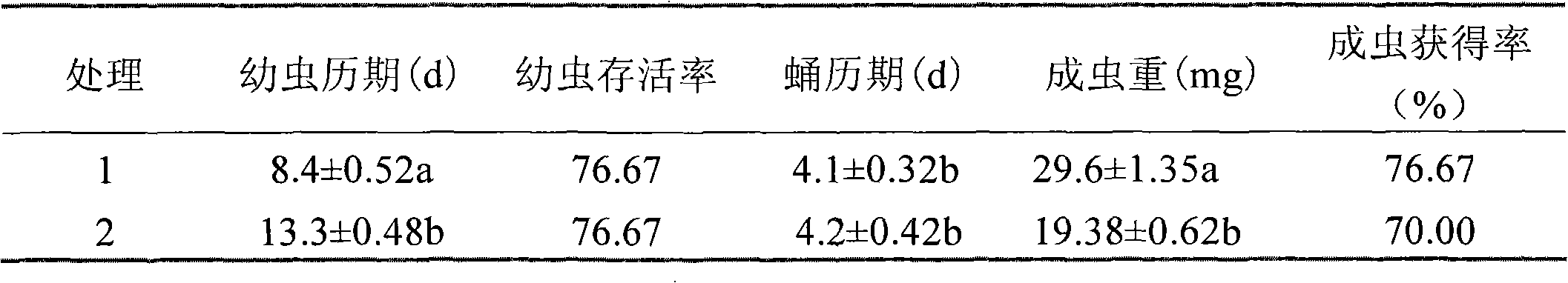

Artificial feed for natural enemy insects

InactiveCN101940270AEasy to prepareReduce manufacturing costAnimal feeding stuffAccessory food factorsArtificial rearingHousefly

The invention discloses an artificial feed for natural enemy insects. The basic component of the artificial feed is defatted powder of yellow mealworm pupae. The artificial feed also comprises at least one of yeast extracts, cane sugar and bee pollens. The mass fraction ratio of defatted powder of yellow mealworm pupae, yeast extracts, cane sugar and bee pollens is 2.0:2.0:1.5:0.6. The natural enemy insects can be Harmonia axyridis Pallas, specifically Harmonia axyridis Pallas larvae. The house flies have short life cycle and strong reproductive capability, development duration of 12d and average female offspring number of 1500. The reproduction number of a couple of house flies in four months (from April to August) can reach 2*1020 if all the reproduced house flies survive; therefore, a great quantity of house flies can be obtained in a short period. The artificial feed has simple preparation method, wide sources, low investment and low production cost.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com