Organic electroluminescent device and display device

An electroluminescent device and organic light-emitting layer technology, applied in organic light-emitting devices, organic light-emitting device parameters, electro-solid devices, etc., can solve the problems of wide spectrum, short device life, etc. Conducive to the narrowing effect of the spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

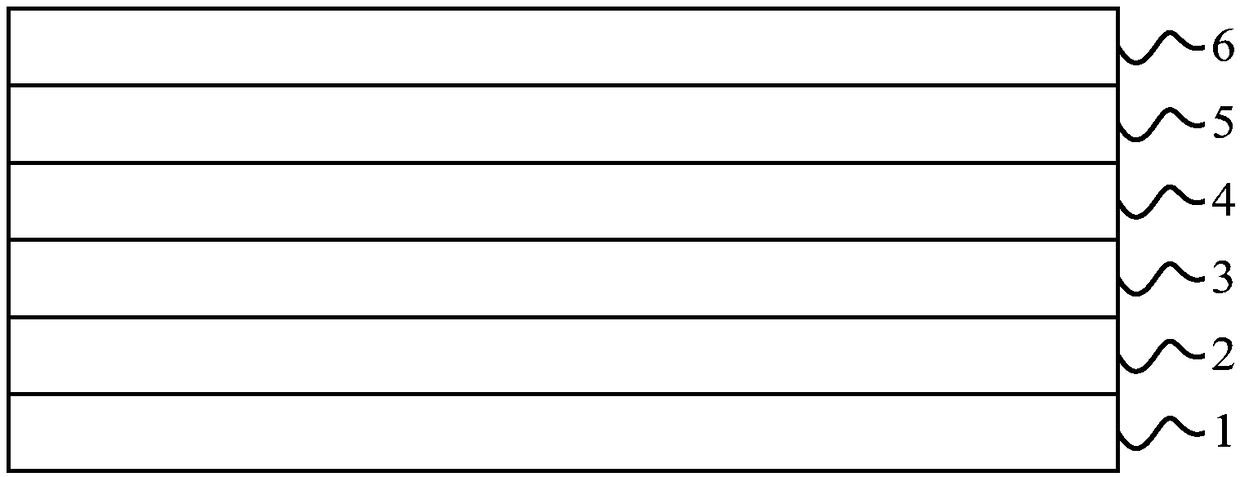

[0101] The present invention also provides a preparation method of the organic electroluminescent device, to figure 1 As an example, it includes sequentially depositing an anode 2 , a hole transport region 3 , an organic light-emitting layer 4 , an electron transport region 5 , and a cathode 6 on a substrate 1 , and then packaging. Wherein, when preparing the organic light-emitting layer 4, the organic light-emitting layer 4 is formed by co-evaporating the wide bandgap material source, the sensitizer material source and the resonant TADF material source.

[0102] Specifically, the preparation method of the organic electroluminescent device of the present invention comprises the following steps:

[0103] 1. Ultrasonically treat the glass plate coated with the anode material in a commercial cleaning agent, rinse in deionized water, ultrasonically degrease in acetone: ethanol mixed solvent, bake in a clean environment until the water is completely removed, and use ultraviolet lig...

Embodiment 1

[0112] The device structure of this embodiment is:

[0113] ITO / HI-2(10nm) / HT-27(40nm) / W-7:20wt%T-37:3wt%M-3(30nm) / ET-53(30nm) / LiF(0.5nm) / Al( 150nm)

[0114] Wherein, the anode is ITO; the material of the hole injection layer is HI-2, and the general total thickness is 5-30nm, which is 10nm in this embodiment; the material of the hole transport layer is HT-27, and the total thickness is generally 5-50nm, The present embodiment is 40nm; the host material of the organic light-emitting layer is wide bandgap material W-7, the sensitizer material is T-37 and the doping concentration is 20wt%, the dye is resonance type TADF material M-3 and the doping concentration is 3wt%, the thickness of the organic light-emitting layer is generally 1-60nm, and this embodiment is 30nm; the material of the electron transport layer is ET-53, and the thickness is generally 5-30nm, and this embodiment is 30nm; electron injection layer and cathode material selection LiF (0.5nm) and metallic aluminum...

Embodiment 2

[0117] The device structure of this embodiment is:

[0118] ITO / HI-2(10nm) / HT-27(40nm) / W-7:15wt%T-37:5wt%M-8(30nm) / ET-53(30nm) / LiF(0.5nm) / Al( 150nm)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com