Patents

Literature

931 results about "Clean environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

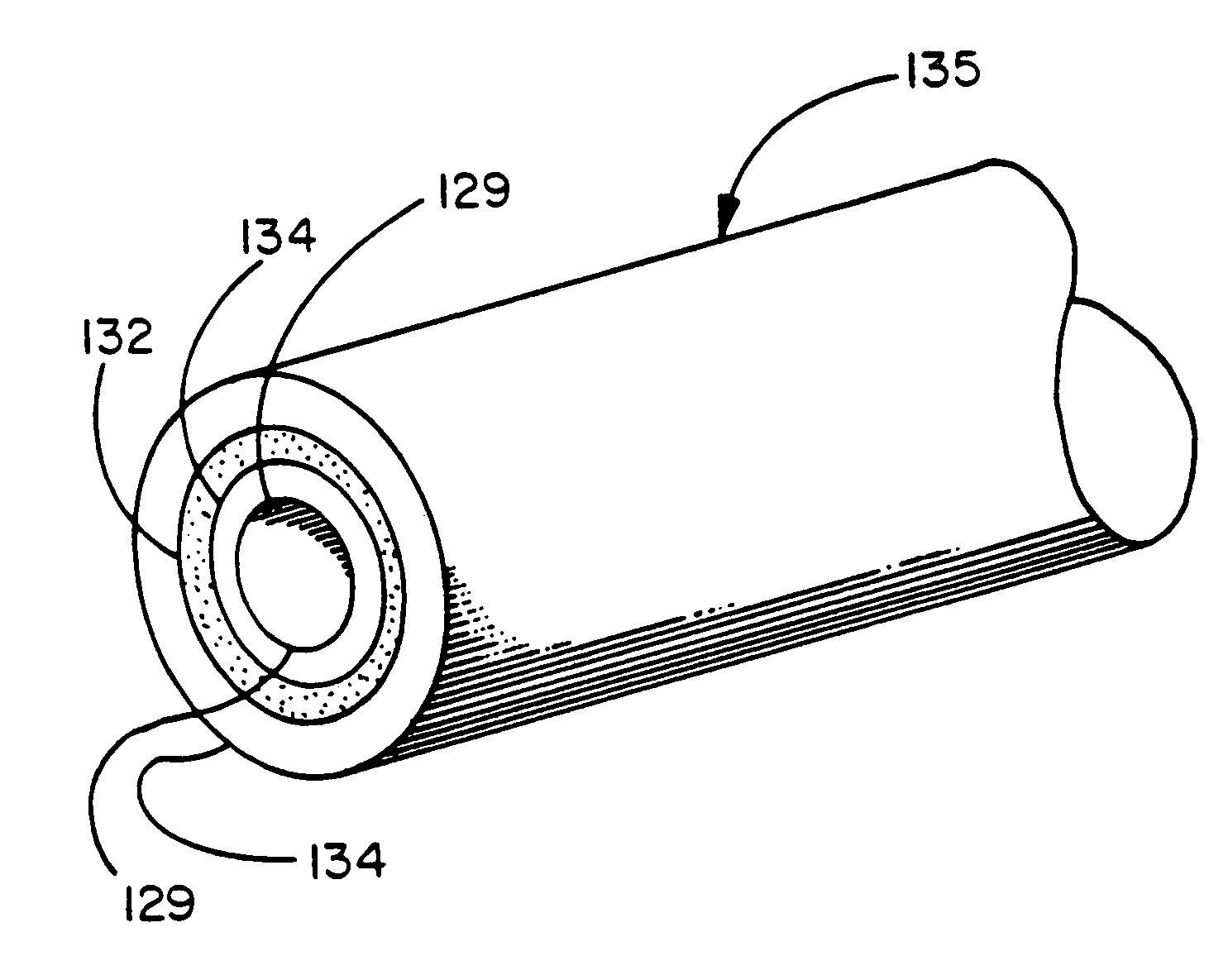

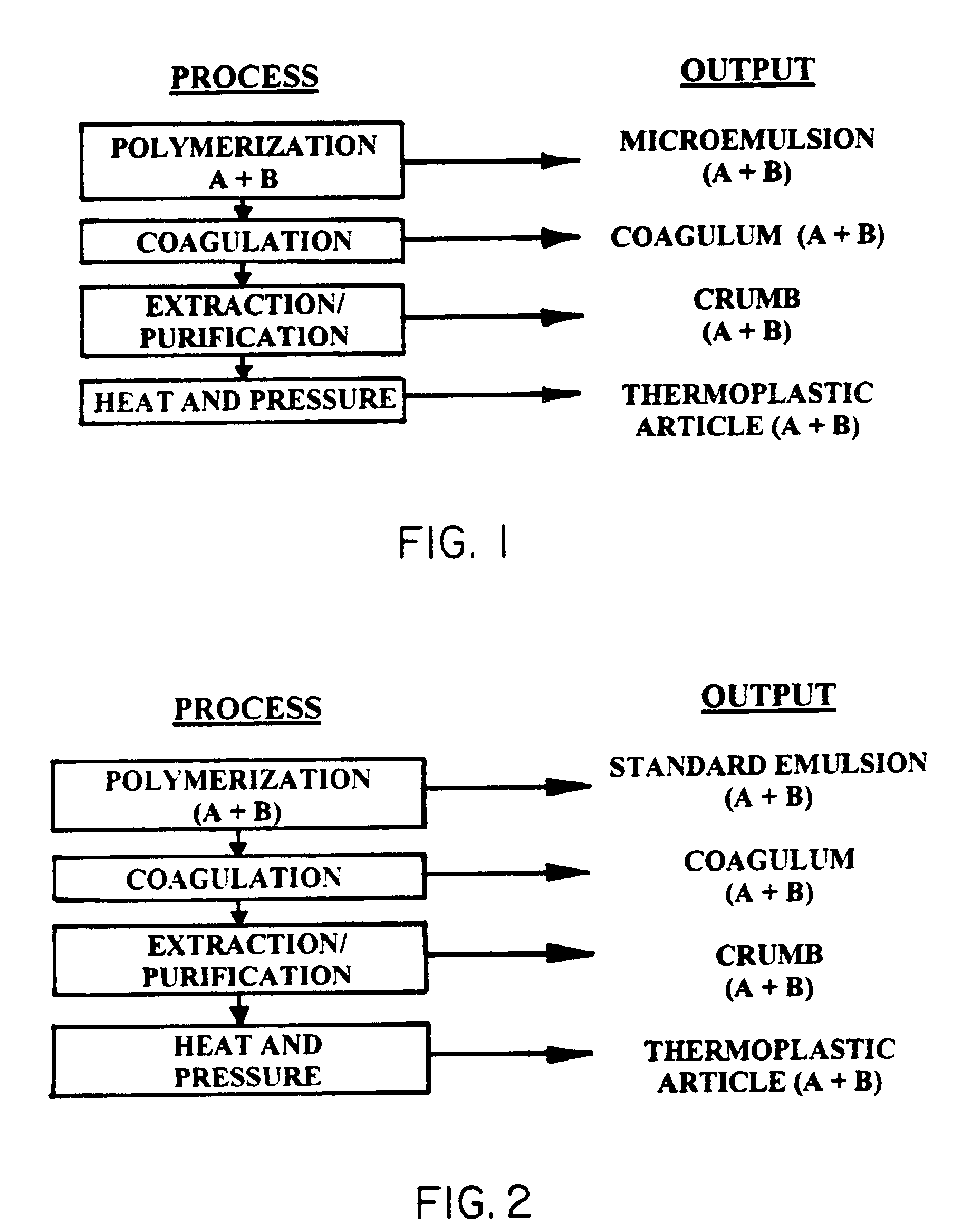

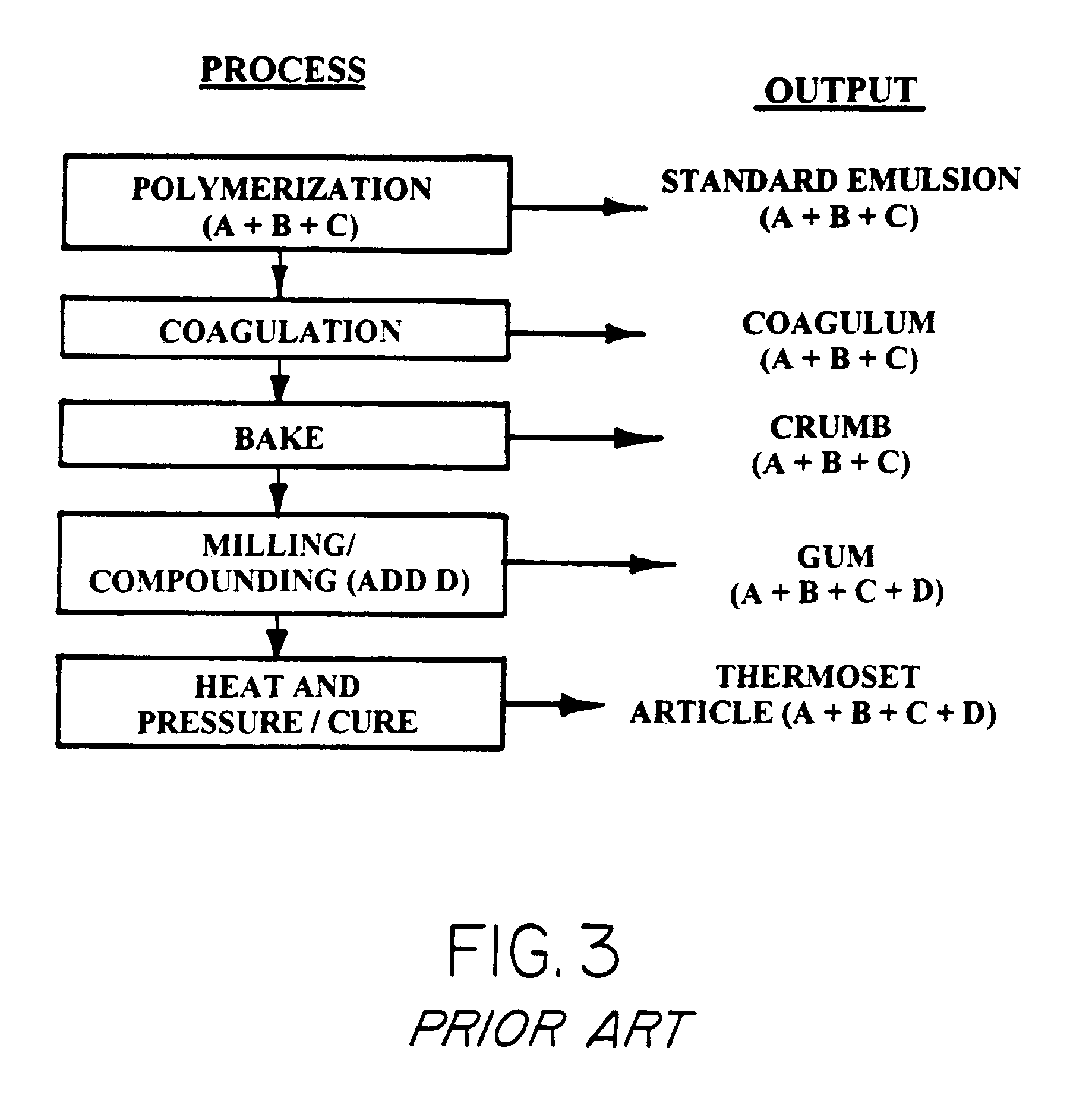

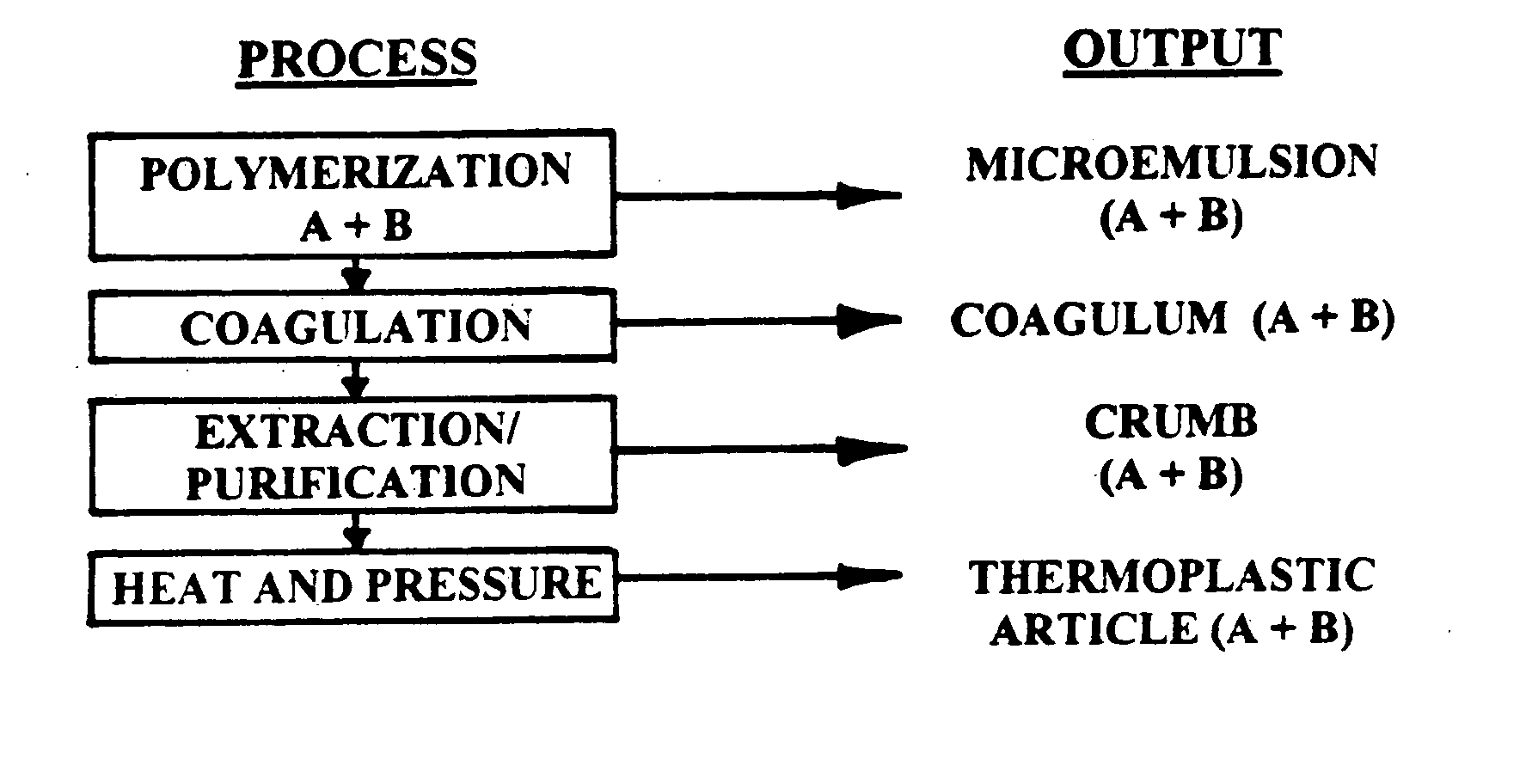

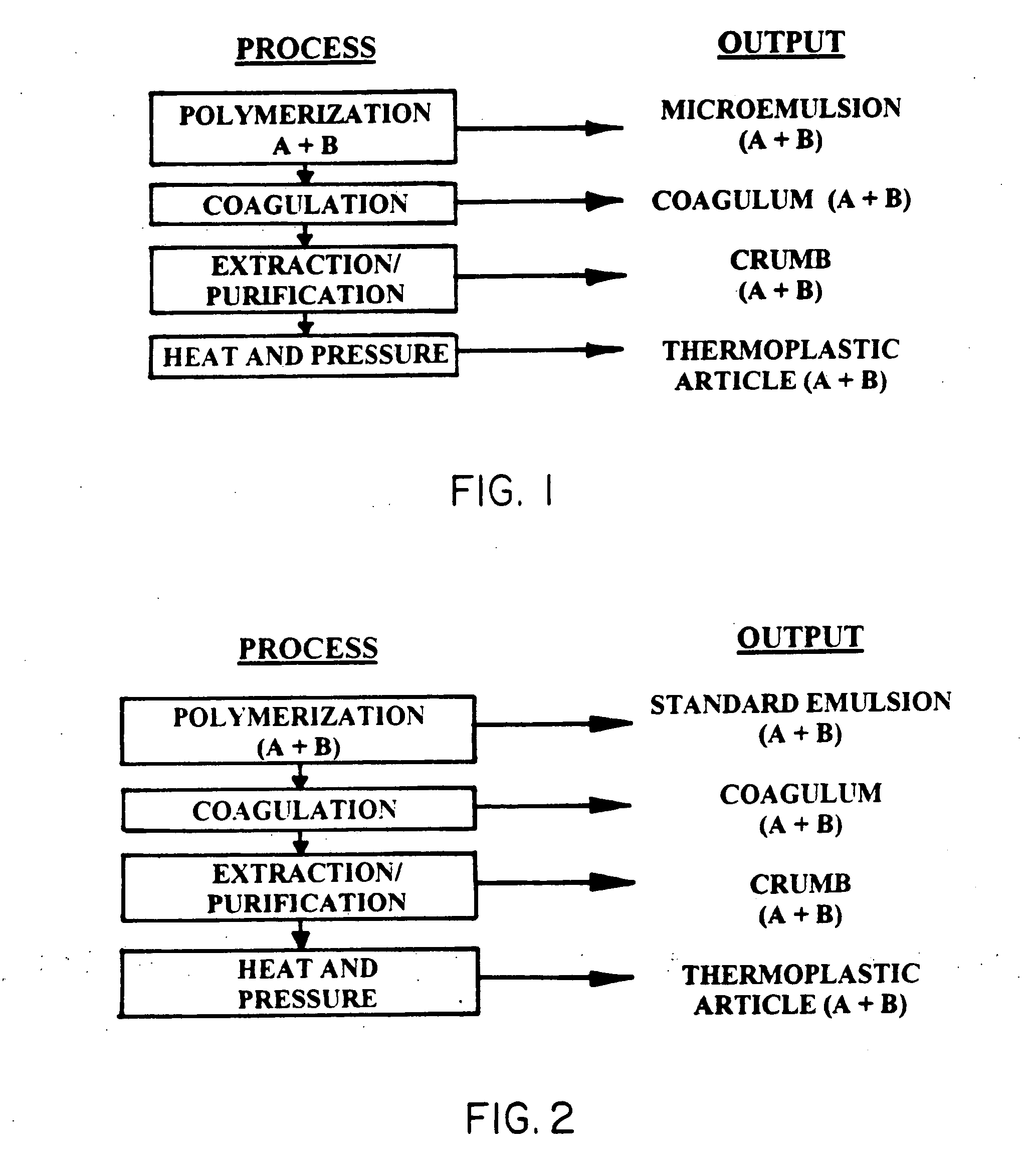

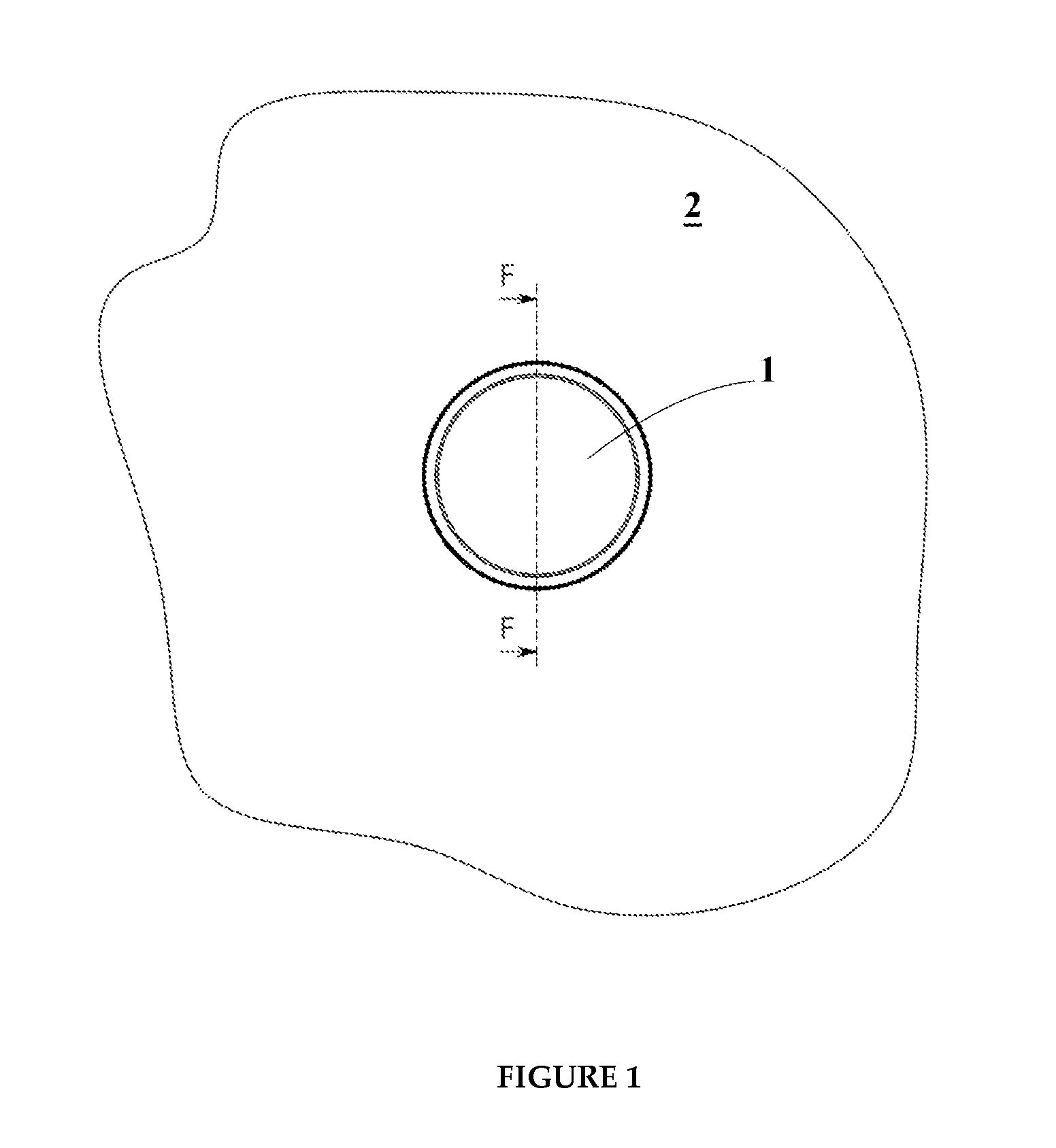

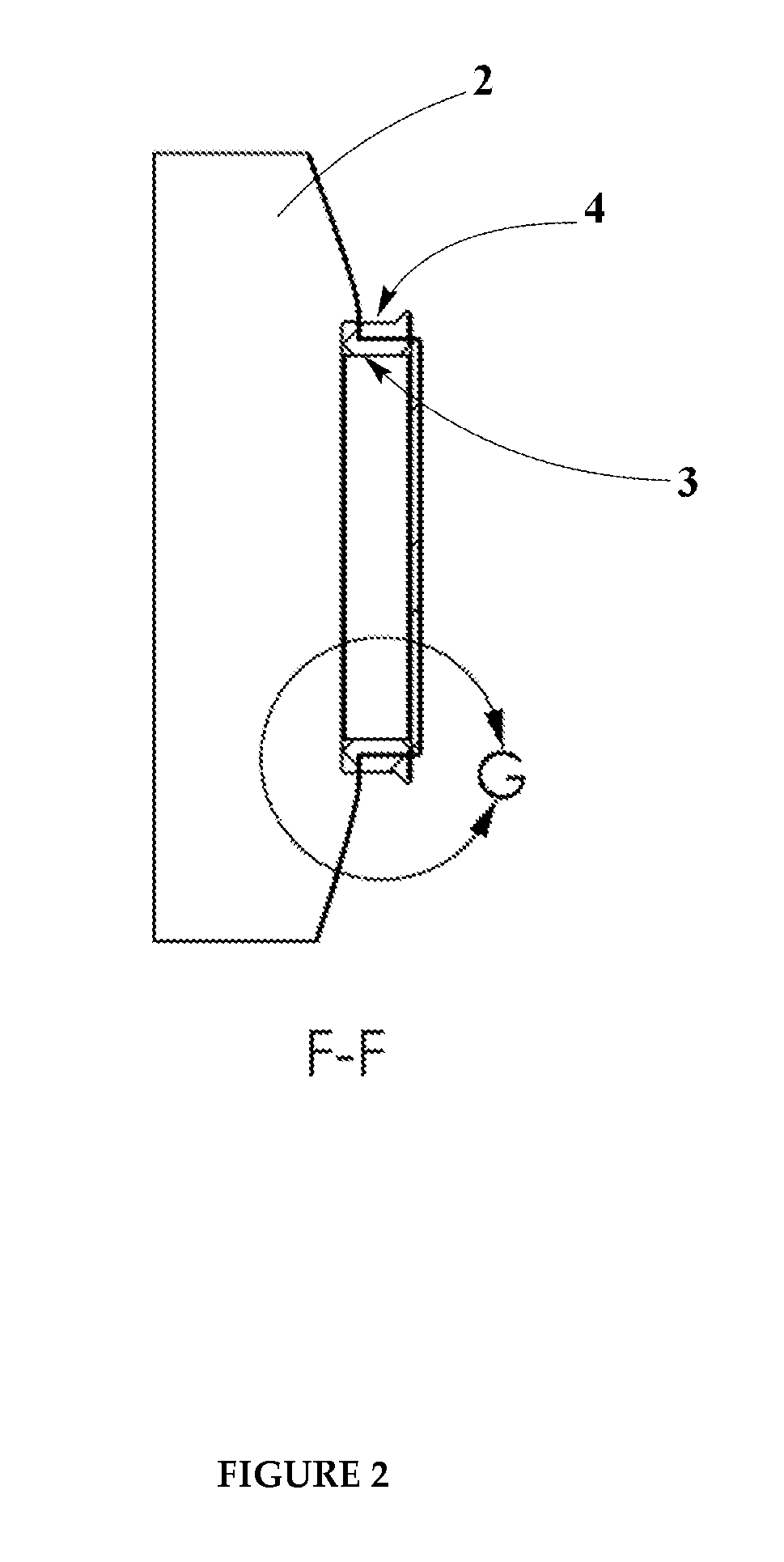

Thermoplastic copolymer of tetrafluoroethylene and perfluoromethyl vinyl ether and medical devices employing the copolymer

An improved elastomeric material is described comprising an essentially noncross-linkable amorphous copolymer of tetrafluoroethylene (TFE) and perfluoromethyl vinyl ether (PMVE) which is both a thermoplastic and exhibits exceptional mechanical properties. This material is particularly suitable for use in ultra-clean environments, and particularly for use in an implantable device, since it does not contain contaminants that previous thermoset TFE / PMVE copolymers have required. Among the improved properties of the present invention are excellent biocompatibility, high matrix tensile strength, high clarity, high abrasion resistance, high purity, adequate elasticity, and ease of processing due to the thermoplastic, and noncross-linkable structure of the copolymer. The material of the present invention is also a high strength bonding agent particularly suited for bonding porous PTFE to itself or to other porous substances at room or elevated temperatures.

Owner:WL GORE & ASSOC INC

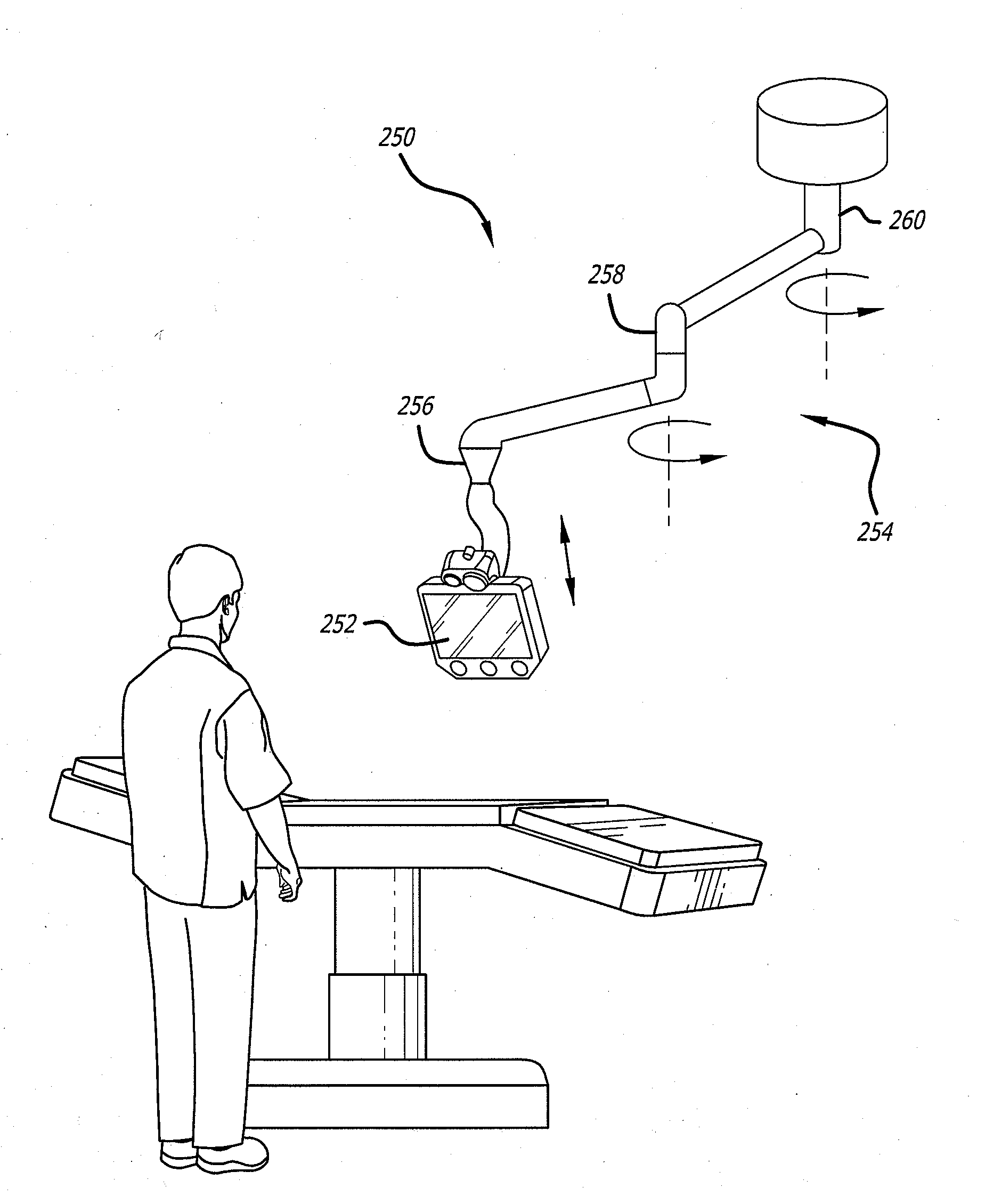

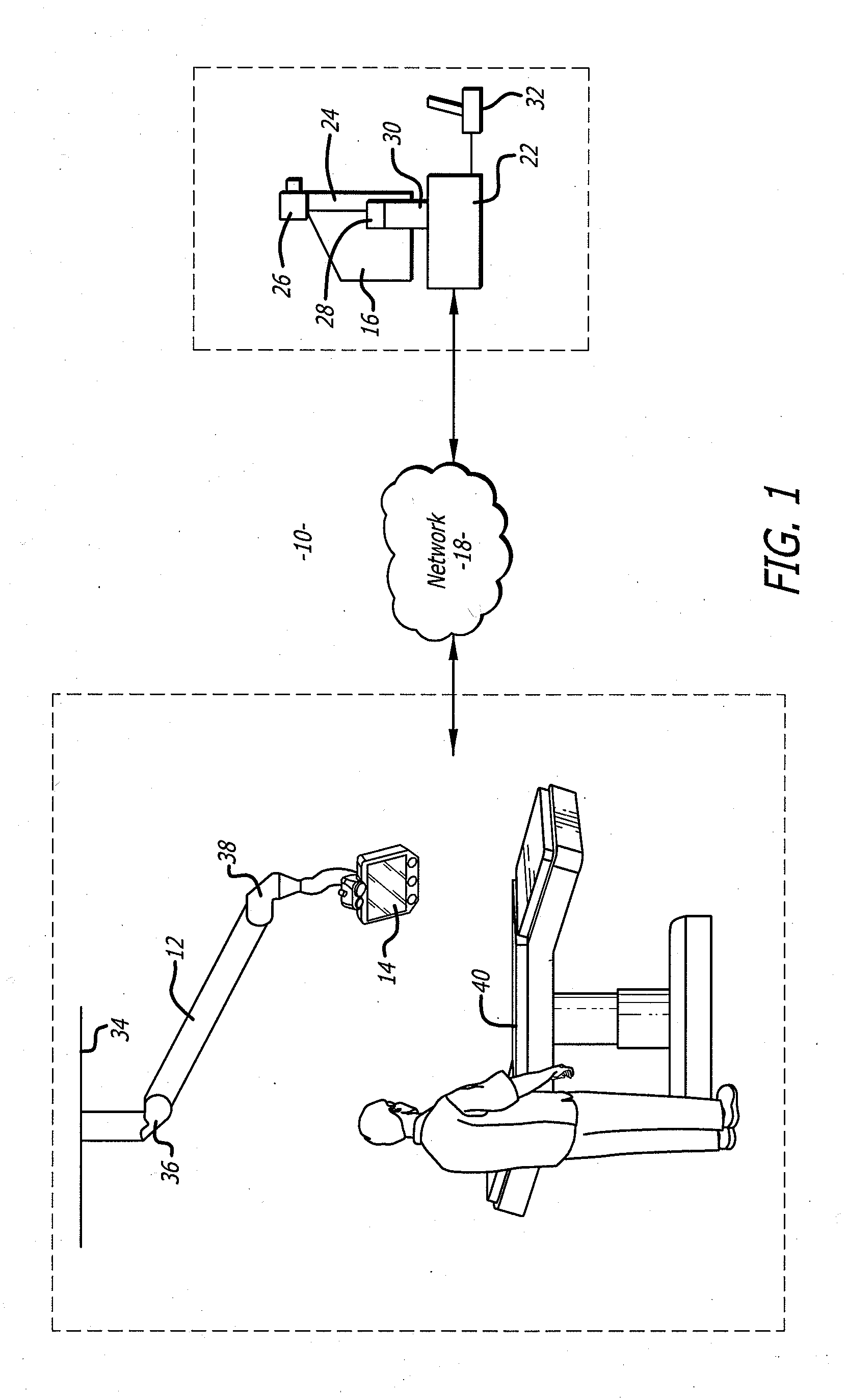

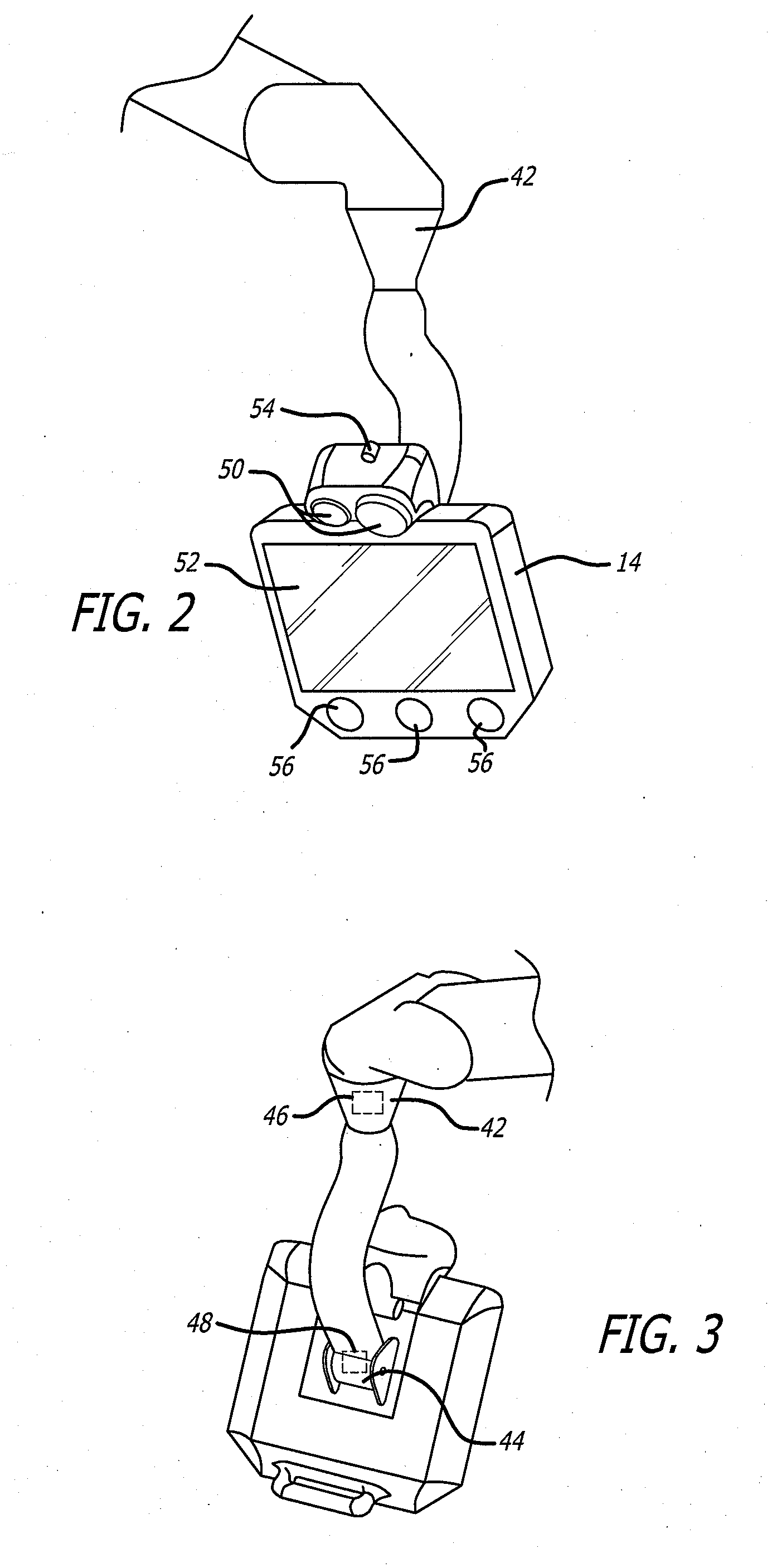

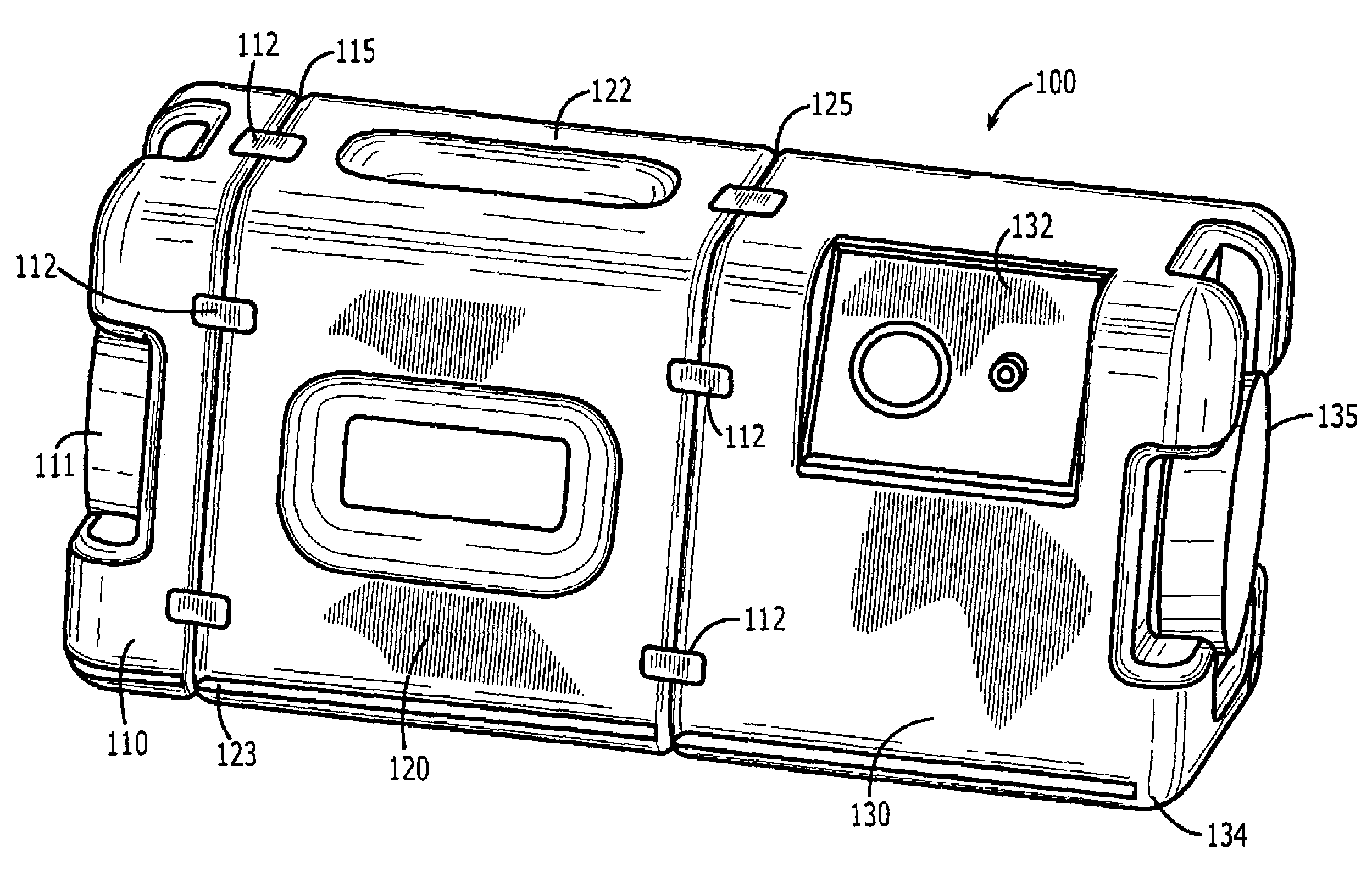

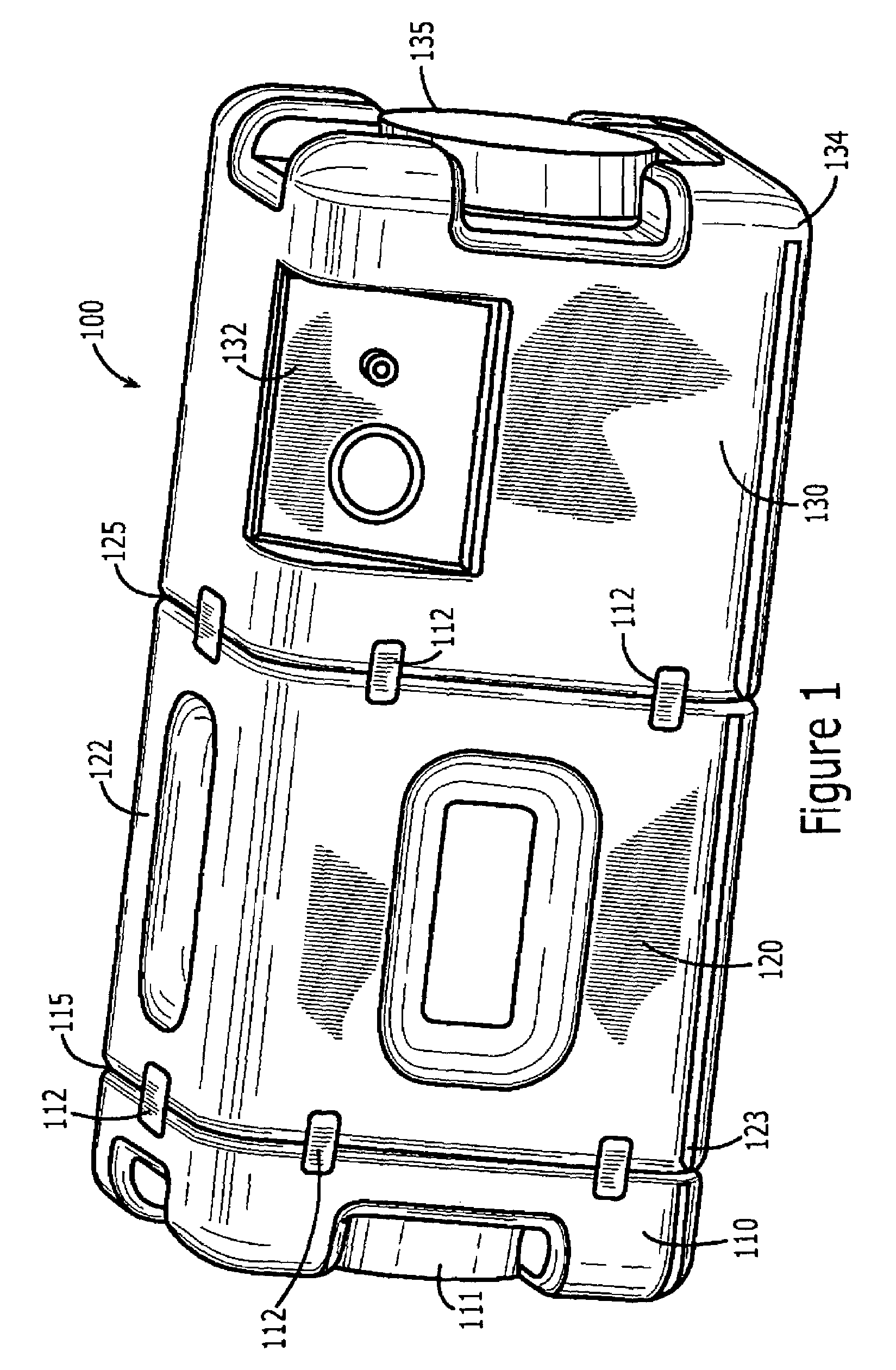

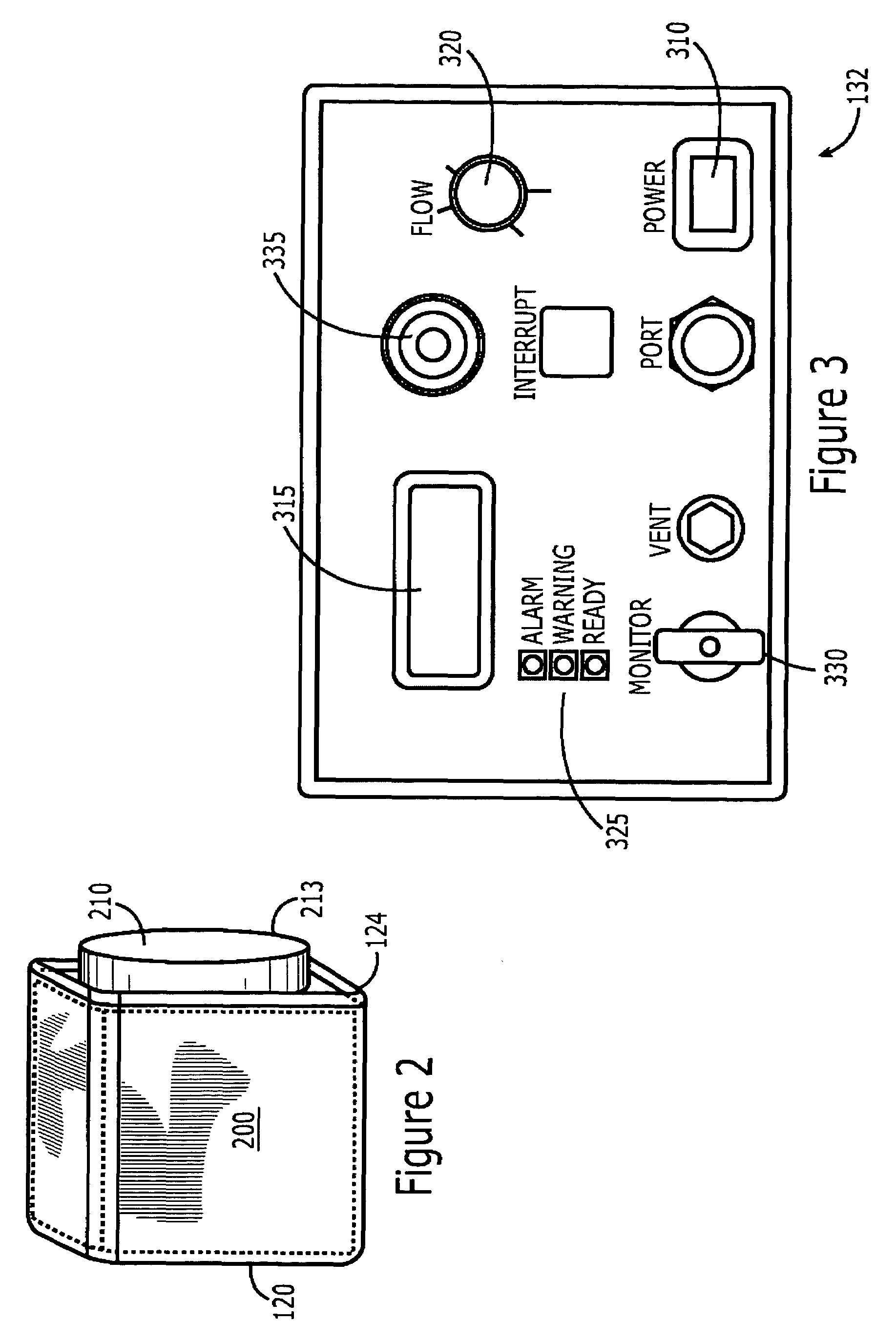

Robot face used in a sterile environment

A robot system that includes a robot face with a monitor, a camera, a speaker and a microphone. The system may include a removable handle attached to the robot face. The robot face may be controlled through a remote controller. The handle can be remove and replaced with another handle. The remote controller can be covered with a sterile drape or sterilized after each use of the system. The handle and remote controller allow the robot to be utilized in a clean environment such as an operating room without requiring the robot face to be sterilized after a medical procedure. The robot face can be attached to a boom with active joints. The robot face may include a user interface that allows a user to individually move the active joints of the boom.

Owner:TELADOC HEALTH INC +1

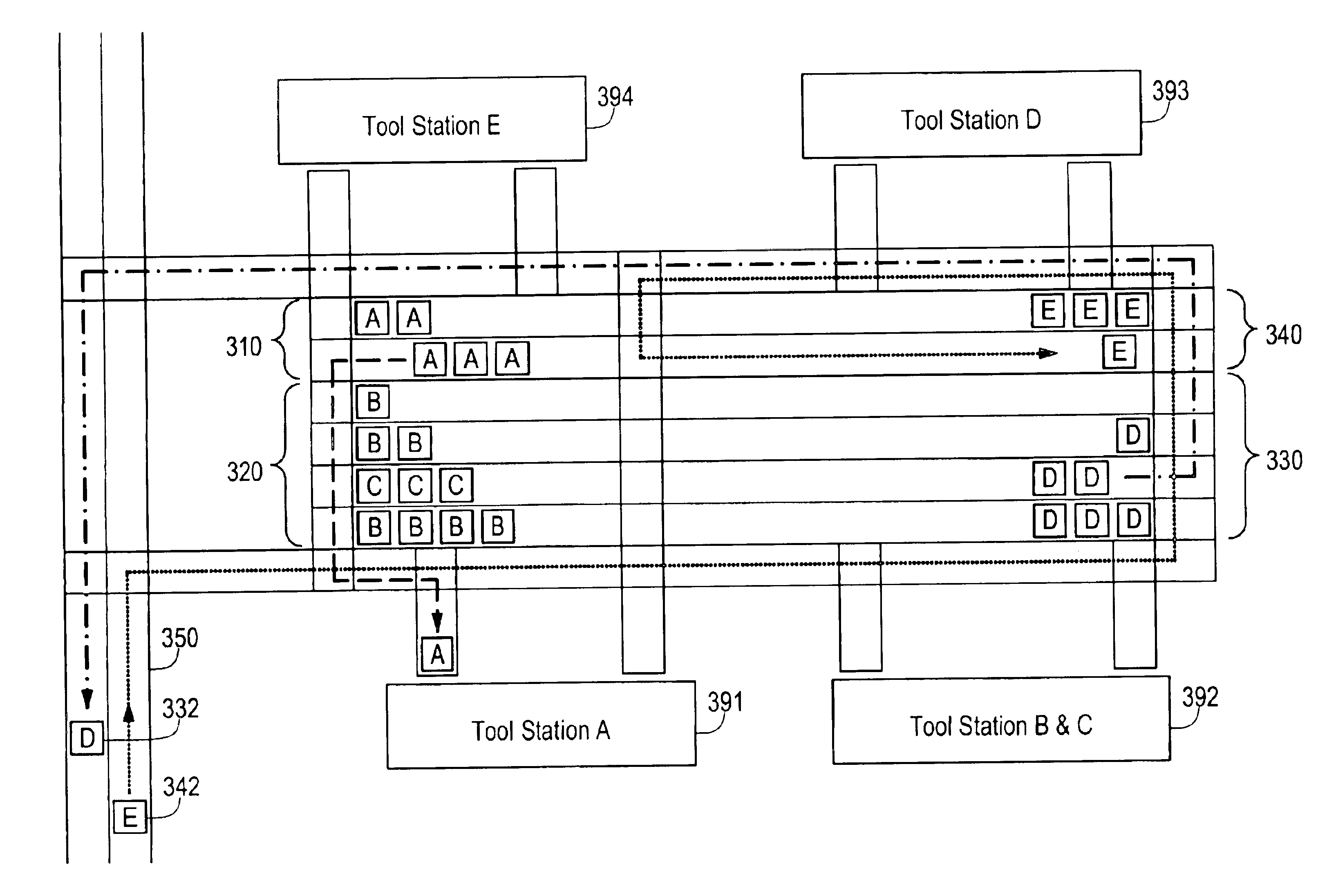

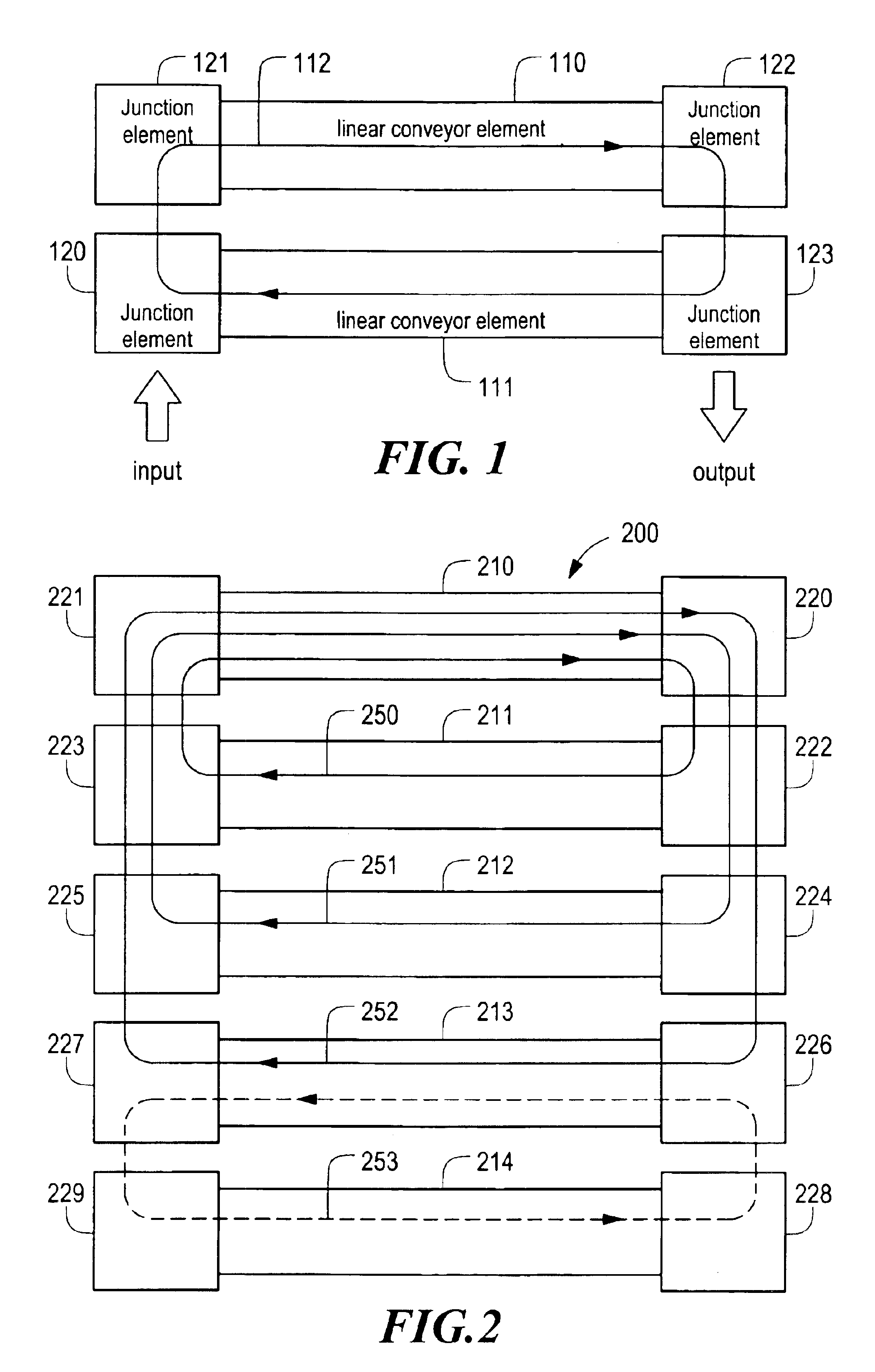

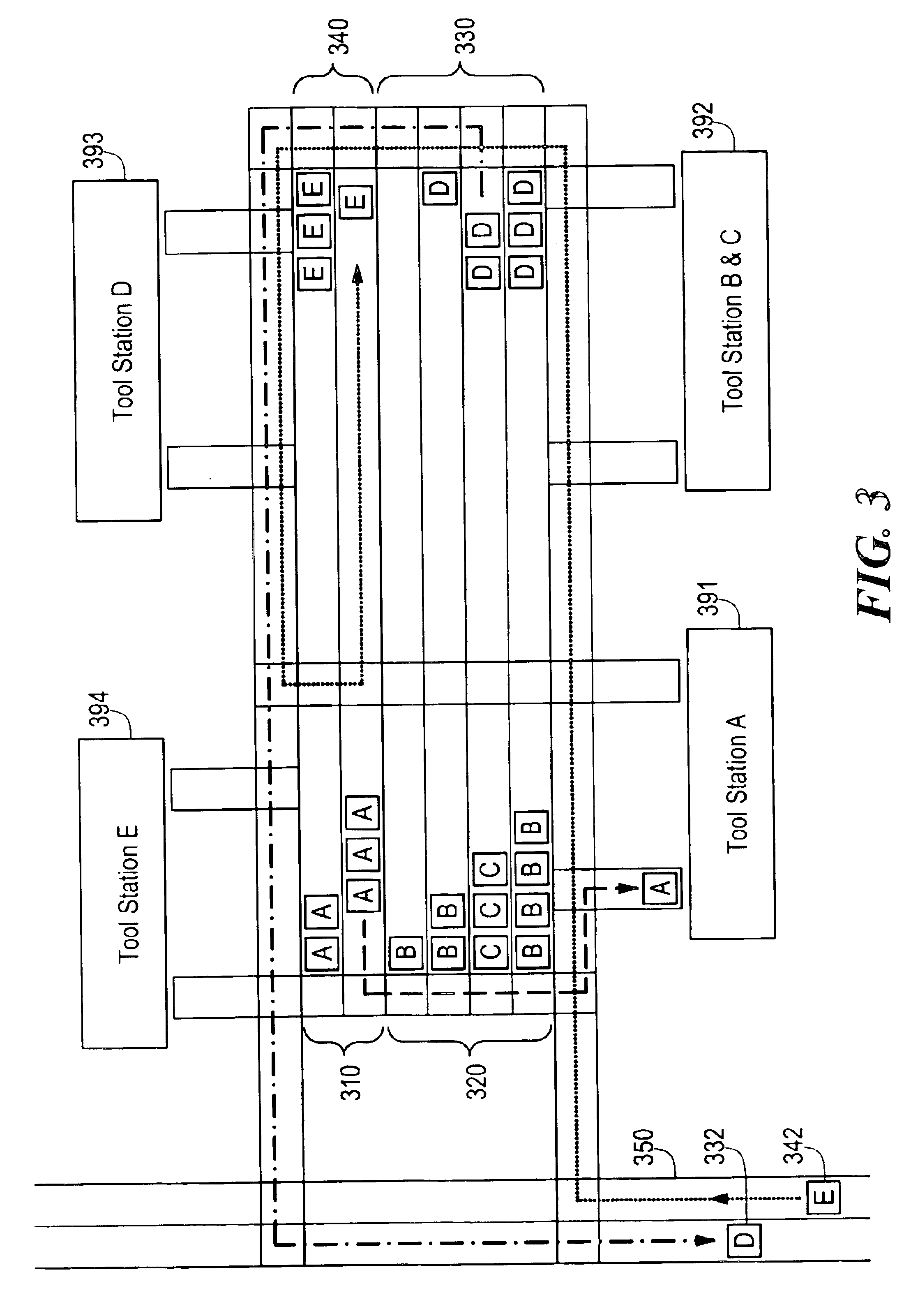

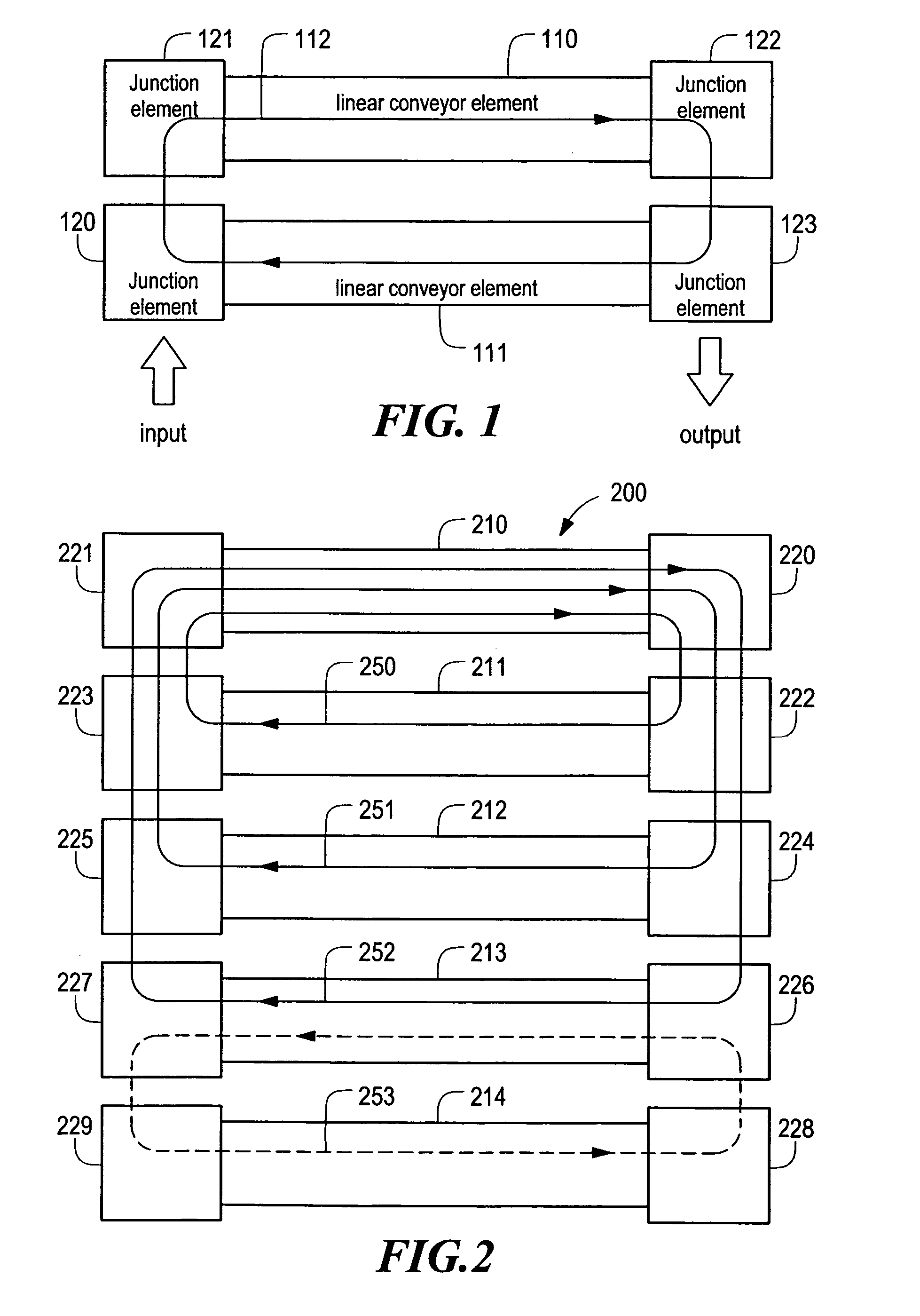

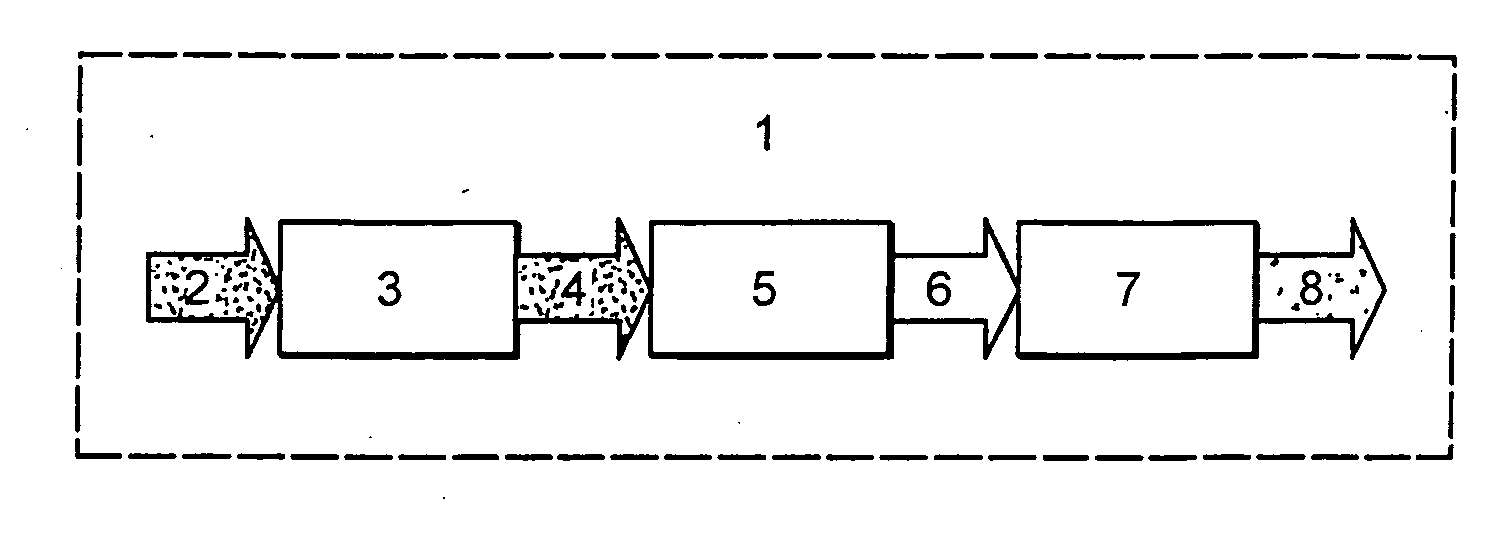

Conveyorized storage and transportation system

InactiveUS6854583B1OptimizationAvoid normal workDigital data processing detailsSemiconductor/solid-state device manufacturingModularityMechanical engineering

A configurable storage system particularly suited for use with clean environment conveyors is disclosed. The storage system includes modular conveyor track elements which may be provided as one way paths which, when provided with plural transfer elements with respect to a conveyor highway, enable the rotation of a workpiece from a storage matrix to a transfer path and back to the storage matrix.

Owner:MIDDLESEX GEN INDS MESNE

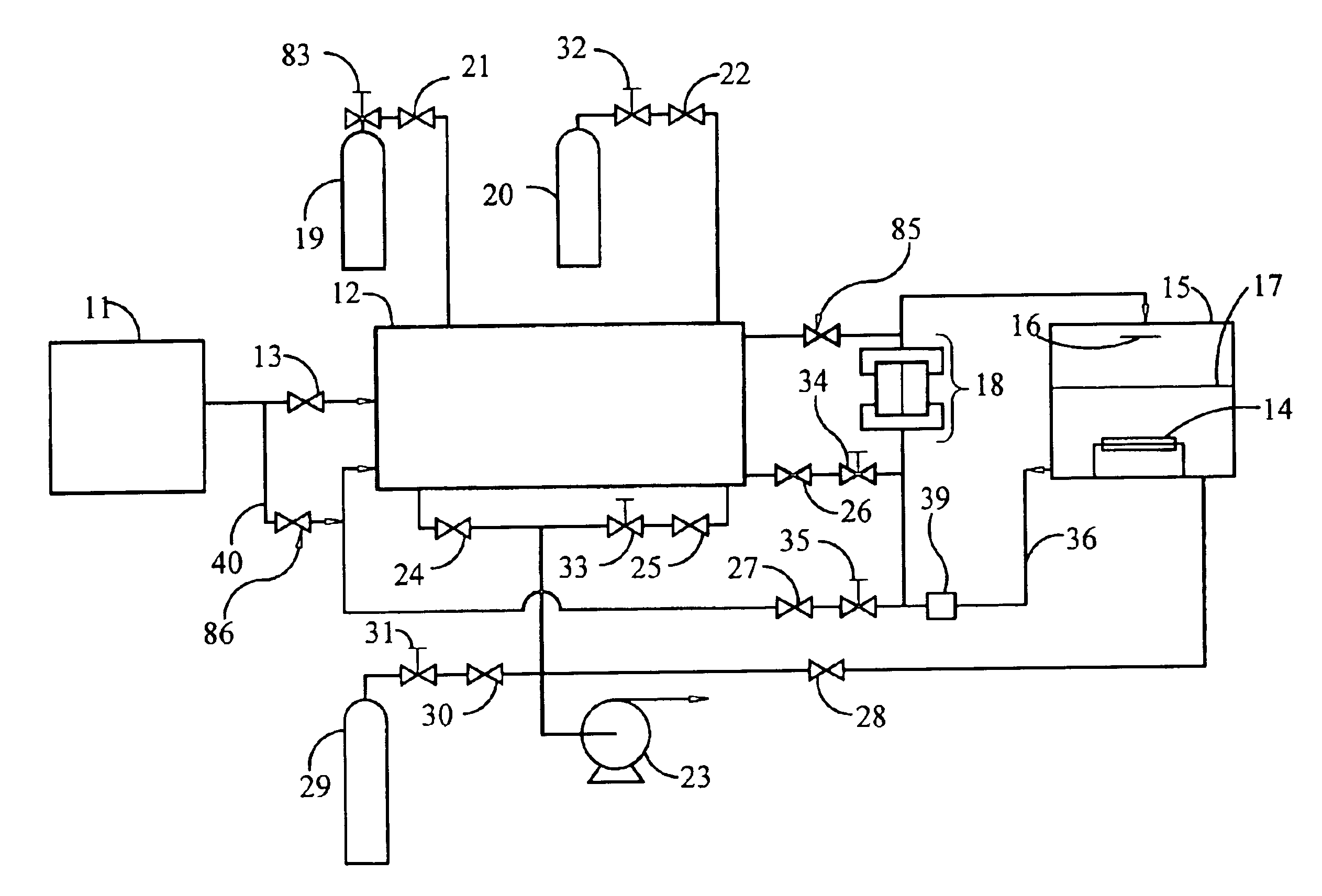

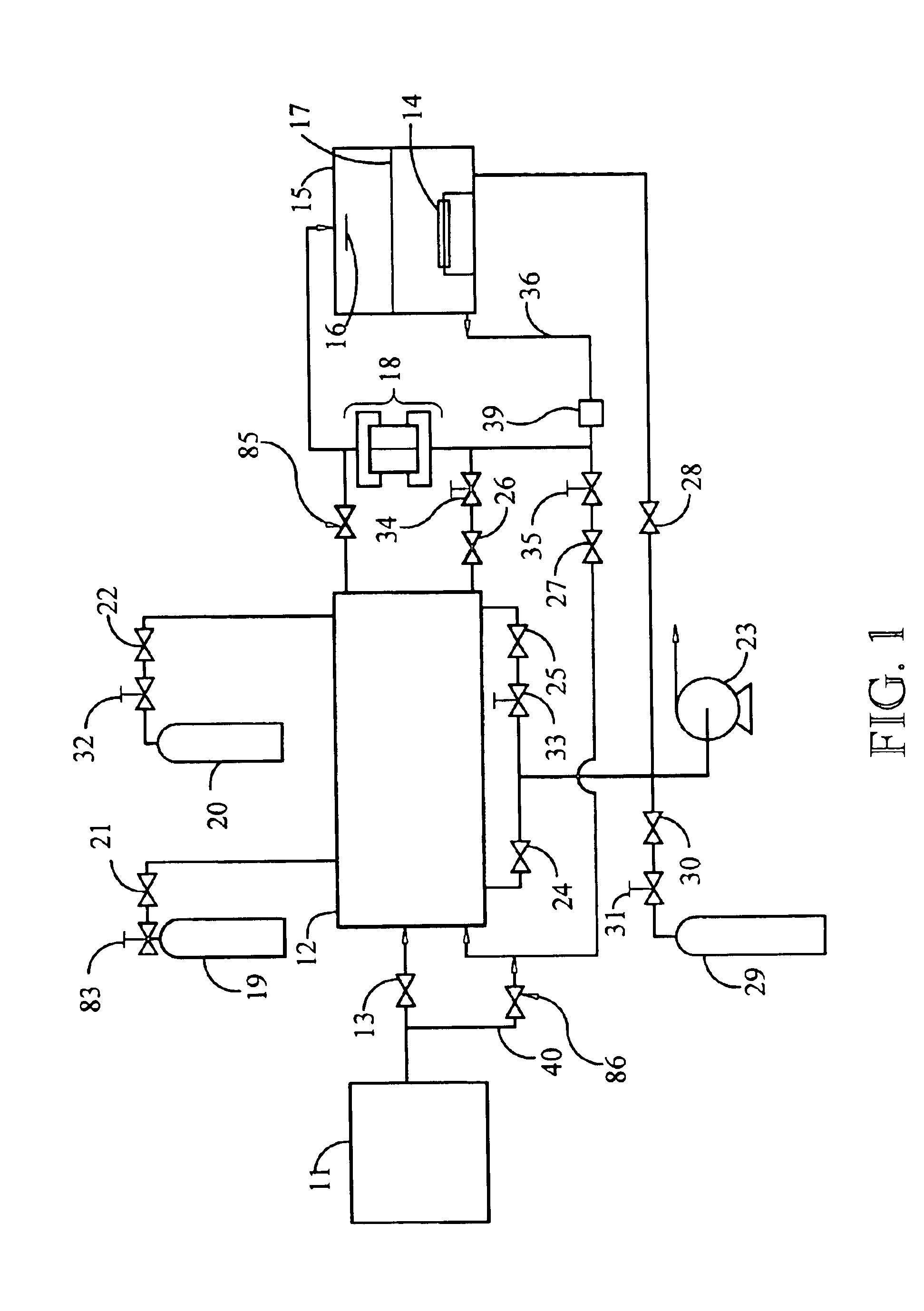

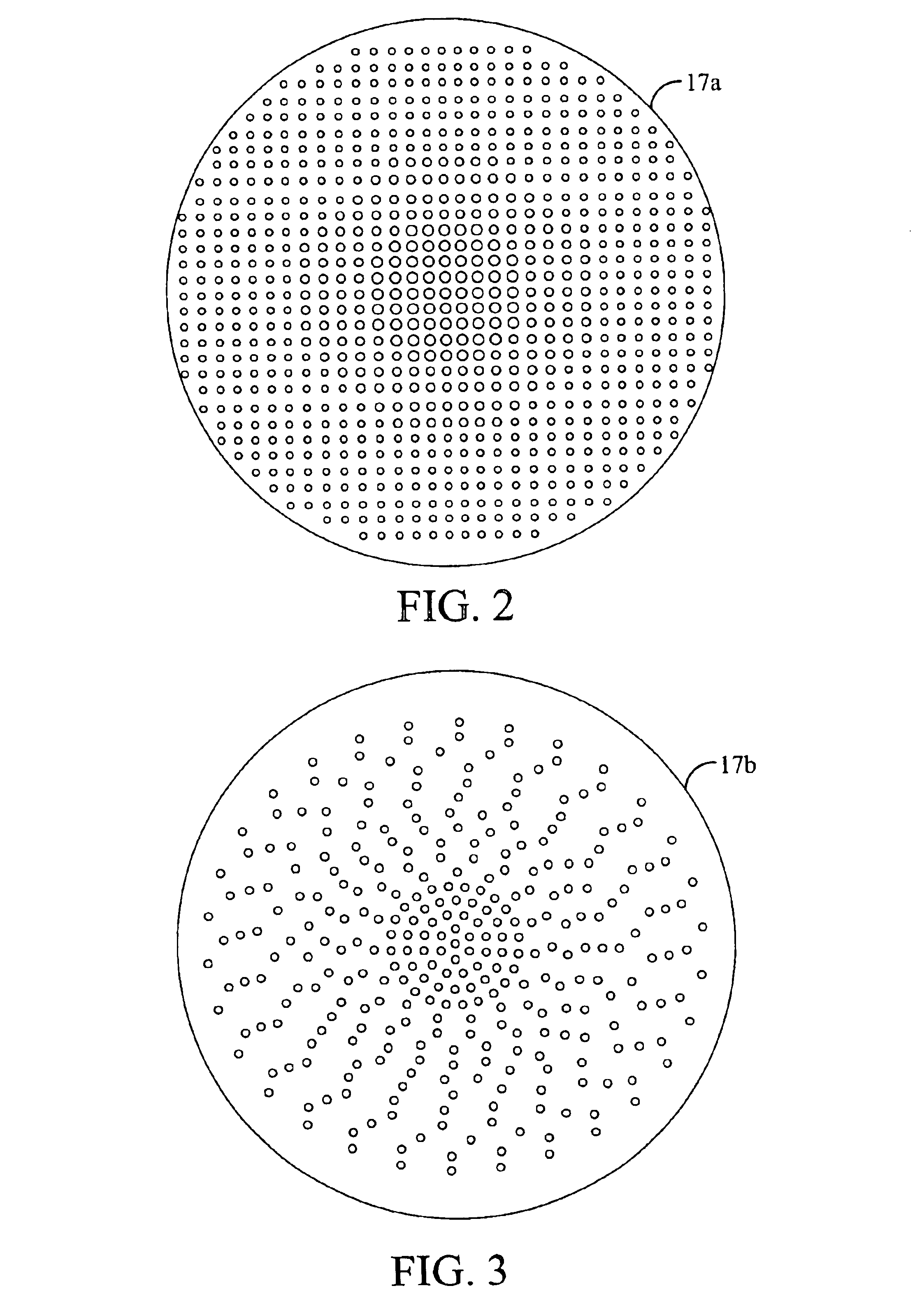

Apparatus and method for flow of process gas in an ultra-clean environment

InactiveUS6949202B1Improve effectivenessImprove processing efficiencyMaterial nanotechnologyDecorative surface effectsProduct gasProcess engineering

Processes for the addition or removal of a layer or region from a workpiece material by contact with a process gas in the manufacture of a microstructure are enhanced by the use of recirculation of the process gas. Recirculation is effected by a pump that has no sliding or abrading parts that contact the process gas, nor any wet (such as oil) seals or purge gas in the pump. Improved processing can be achieved by a process chamber that contains a baffle, a perforated plate, or both, appropriately situated in the chamber to deflect the incoming process gas and distribute it over the workpiece surface. In certain embodiments, a diluent gas is added to the recirculation loop and continuously circulated therein, followed by the bleeding of the process gas (such as an etchant gas) into the recirculation loop. Also, cooling of the process gas, etching chamber and / or sample platen can aid the etching process. The method is particularly useful for adding to or removing material from a sample of microscopic dimensions.

Owner:TEXAS INSTR INC +1

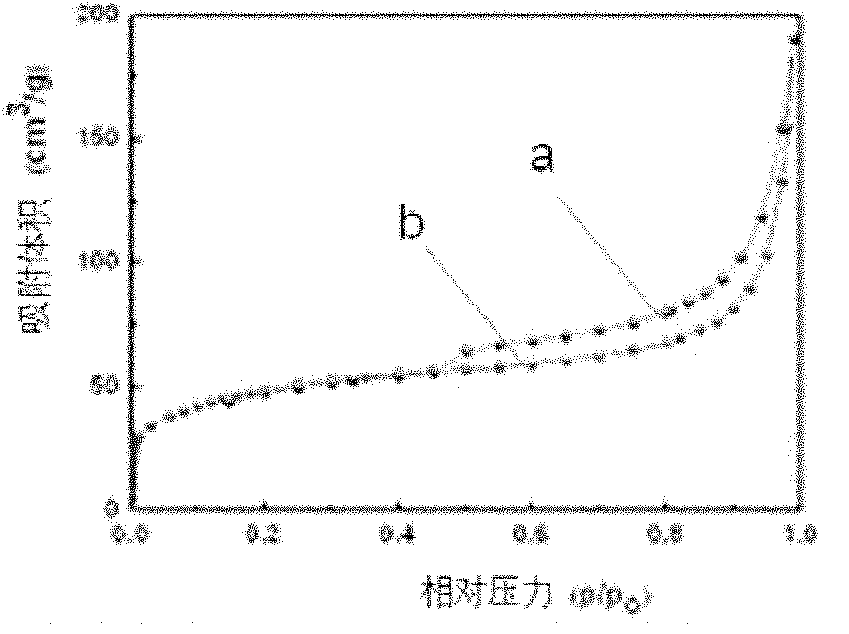

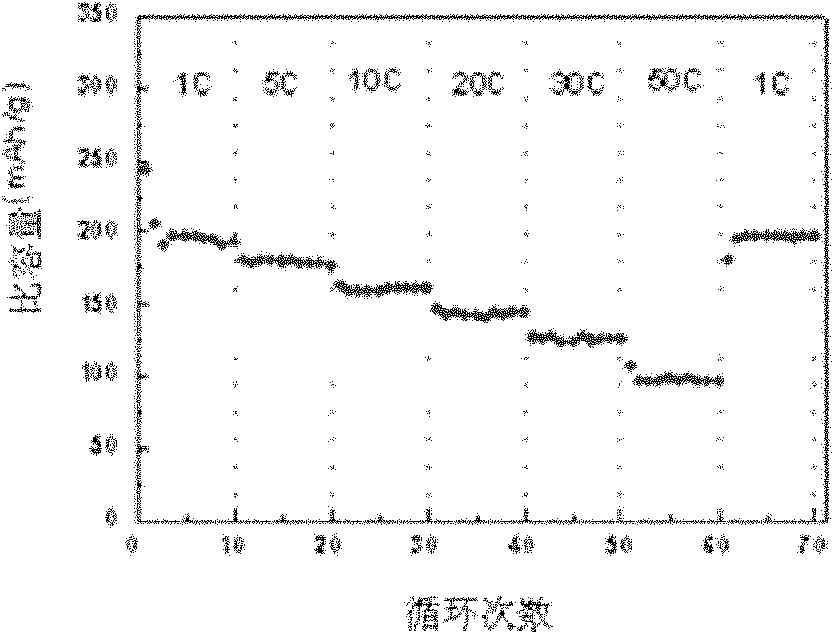

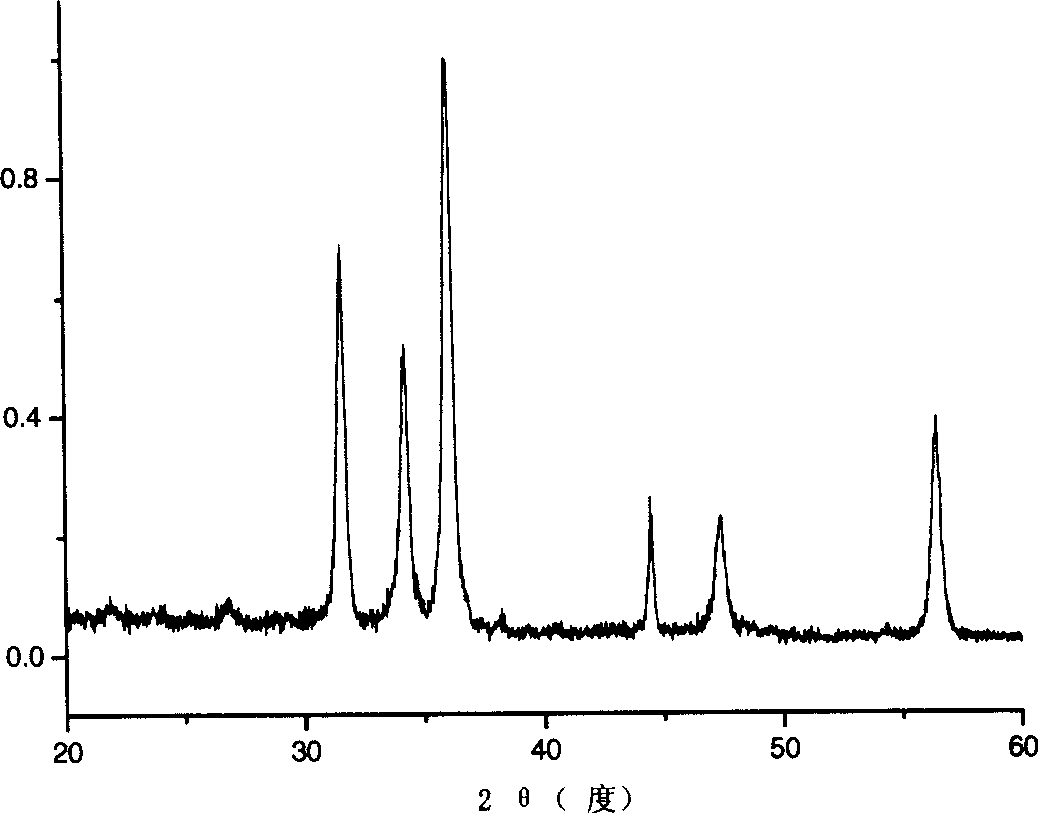

Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

InactiveCN102569761AShape is easy to controlControllable surface structureCell electrodesGraphene nanocompositesHigh energy

The invention relates to a titanium dioxide / graphene nanocomposite material, a preparation method of the nanocomposite material and application of the nanocomposite material in the field of energy source and cleaning environment. The graphene accounts for 1-25wt% and the balance is titanium dioxide. Morphology of the titanium dioxide is a mesoporous structure or a structure with a dominant high energy surface, and titanium dioxide is scattered uniformly on the surface of graphene. According to the invention, by adopting a titanium source and graphene as initial materials, and water or organic solvents as reaction solvents, the nanocomposite material with titanium dioxide with the mesoporous structure or a titanium dioxide nano sheet with the dominant high energy surface compounded with graphene can be obtained through hydrothermal synthesis or a hydrolysis reaction. The invention can be carried out in an aqueous solution system and the crystallinity of the product is high. The composite material can be applied to a cathode material of a power ion battery, has a higher charge-discharge capacity, is excellent in high current charge and discharge, stable in circulating performance, has very good photocatalytic performance and can be used to light degradation of organic pollutants and water photolysis for preparing hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Water-removable coatings for LCD glass

InactiveUS6715316B2Same and smoothnessMaterial nanotechnologyNanostructure manufactureMegasonic cleaningAqueous solution

Owner:CORNING INC

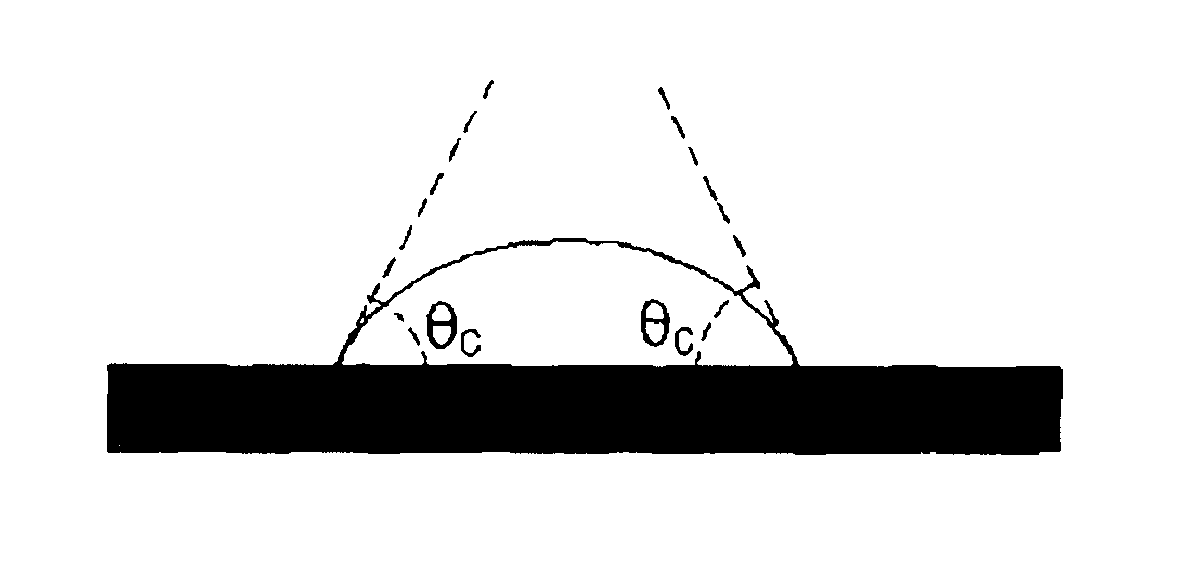

High-water-flux forward-osmosis composite membrane and preparation method thereof

ActiveCN103977718AHigh selectivityImprove hydrophilicitySemi-permeable membranesConcentration polarizationPolysulfone membrane

The invention relates to a high-water-flux forward-osmosis composite membrane and a preparation method thereof. The forward-osmosis composite membrane is a polysulfone-sulfonated polysulfone-inorganic filler blended / polyamide composite membrane. A traditional osmosis membrane is generally applied to a reverse-osmosis system, and if the traditional osmosis membrane is used in a forward-osmosis process, the water flux of osmosis is far lower than a theoretical value since the traditional osmosis composite membrane is large in thickness, the hydrophilicity of a supporting layer of a polyamide layer is poor so as to cause serious inner concentration polarization. The preparation method comprises the following steps: blending a polymer with a modifier to form film casting liquid; after scraping or leveling, performing non-solvent coagulating bath with water; by a phase-inversion method, preparing a polysulfone ultrafiltration membrane with good hydrophilicity, high porosity, uniform surface pore structure and narrow pore diameter distribution; and in a clean environment and at room temperature, airing the polysulfone membrane till the surface is dry, and growing a polyamide active layer on the surface of the polysulfone membrane by an interfacial polymerization method, thereby obtaining the forward-osmosis composite membrane with good hydrophilicity, high porosity, low thickness and high mechanical strength. The high-water-flux forward-osmosis composite membrane disclosed by the invention has the advantages that not only the osmosis flux is high, but also the reverse leakage of an extraction medium is low, and the selective permeability is good.

Owner:UNIV OF SCI & TECH OF CHINA

Waste lubricating oil hydrogenation reproducing method

InactiveCN101041789AImprove qualityAchieve hydrogenation saturationLubricant compositionRefining to eliminate hetero atomsColloidBase oil

The invention discloses a waste fluid oil hydrogenation reclaiming method, which comprises the following steps: choosing the waste fluid oil as raw material; dewatering; filtering; proceeding adsorption procession; stripping moisture, mechanical impurity, colloid, asphaltene and most of heavy metal impurities; proceeding pre-hydrofining in the reactor with preservative; further-stripping impurity; leading the waste fluid oil into hydrogenation primary reactor; realizing hydrofining under the function of hydrogenation catalyst; making the non-ideal component of raw oil hydrogenation saturation; getting product yield; proceeding fractional distillation and cutting. This invention possesses merits of convenient operation and clean environment, which can make the reclaiming ratio reach above 90%.

Owner:京福马(北京)石油化工高新技术有限公司

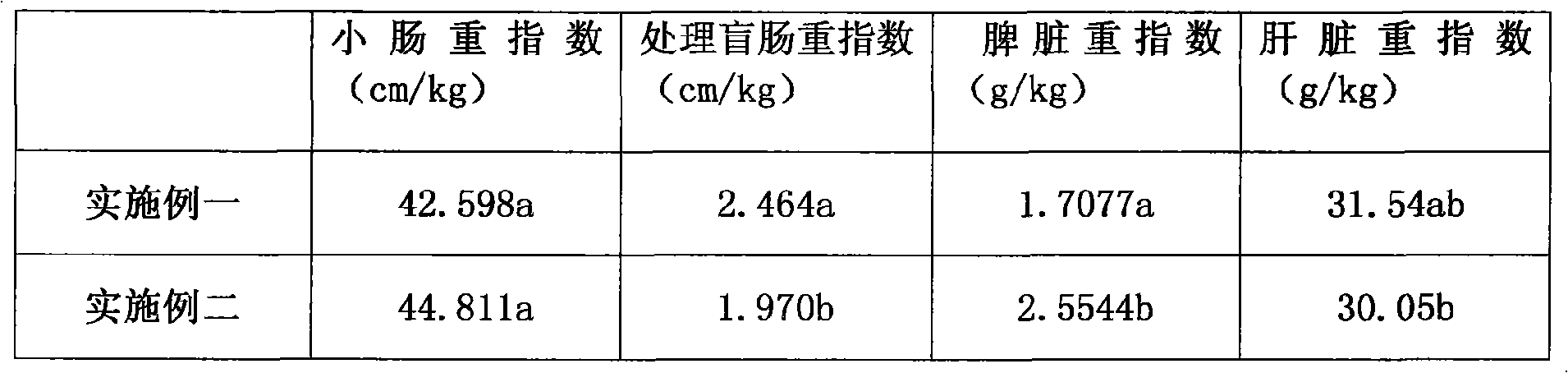

Segregated early weaning method of piglet

ActiveCN101406166AReduce feeding costsIncrease the number of births per yearFood processingAnimal feeding stuffPig farmsMaternal antibody

The invention discloses a method for segregated early weaning of piglets, which comprises the steps of medicine adding, segregation, early transfer and the feeding of early weaning by piglet feed, wherein the medicine adding is performed before and after the delivery of a sow, the advanced medicine adding is used to kill off microorganisms which is expected to be killed, and the medicine adding is also performed from the birth of a suckling piglet to the weaning; the segregation adopts that the parturient sow is transferred into a clean farrowing house for delivery from the pregnancy, and the piglet at the age of between 10 and 14 days is transferred into a clean and comfortable breeding house from the farrowing house; when the level of a maternal antibody of the piglet at the age of between 10 and 14 days is in higher state, the piglet is moved away from the sow and is transferred into a cleaner environment; and the piglet feed for segregated early weaning adopts four stages to feed. The piglet has early weaning segregation time, high survival rate, and quick growth speed, the segregated early weaning of the piglet can save feeding cost of the sow, improve the yearly parity number of the sow, improve the utilization rate of the farrowing house, and reduce the probability that the piglet is infected with sow diseases, and a segregated early weaning technology of the piglet is suitable for the application of modern pig farms.

Owner:MUYUAN FOODS CO LTD

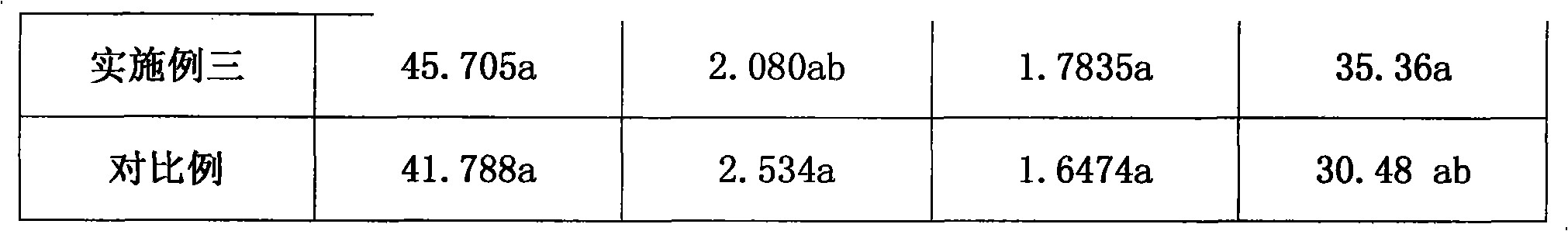

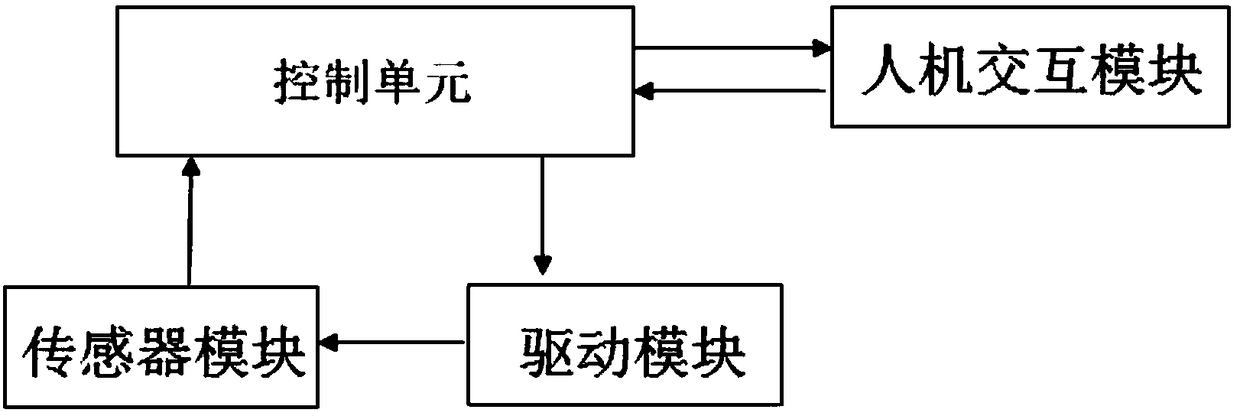

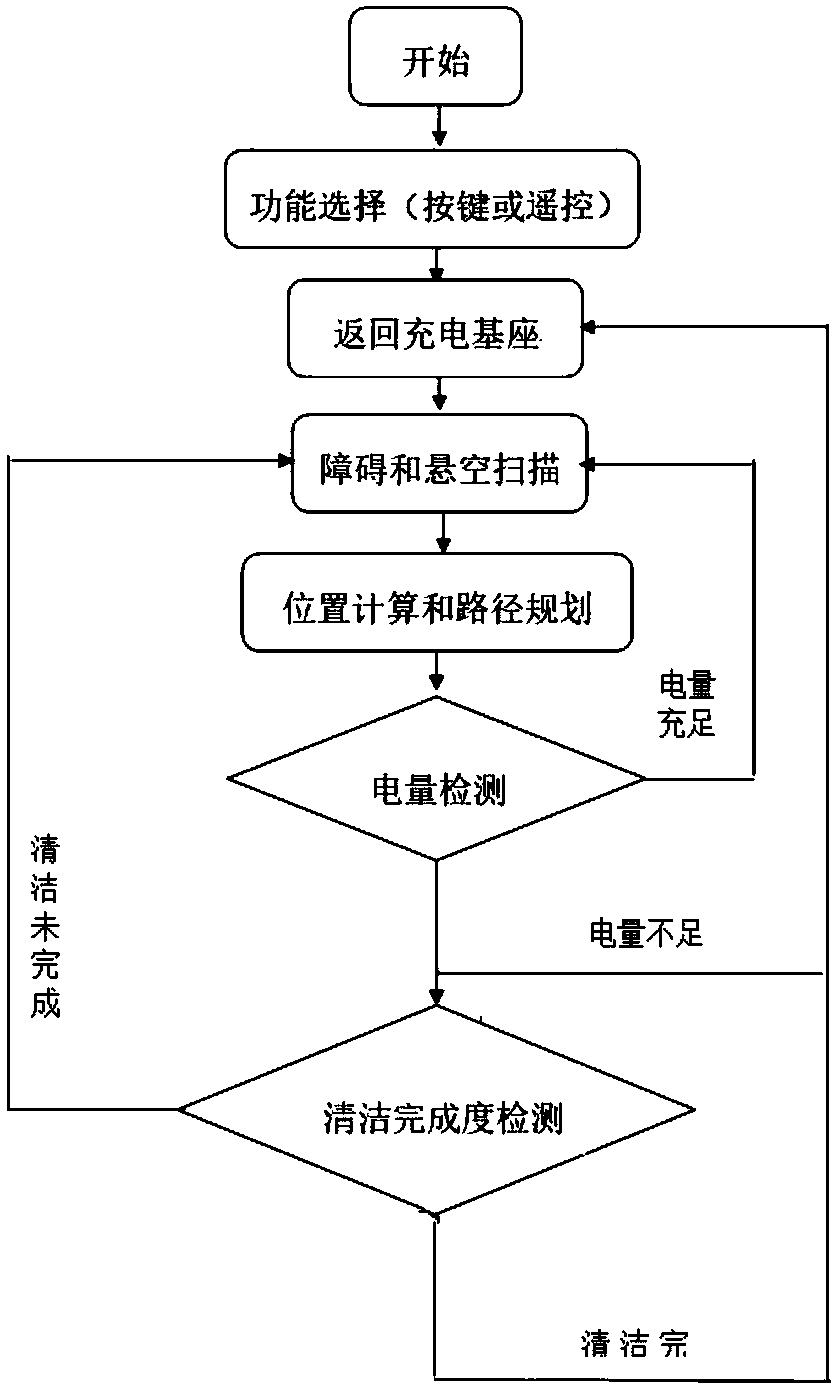

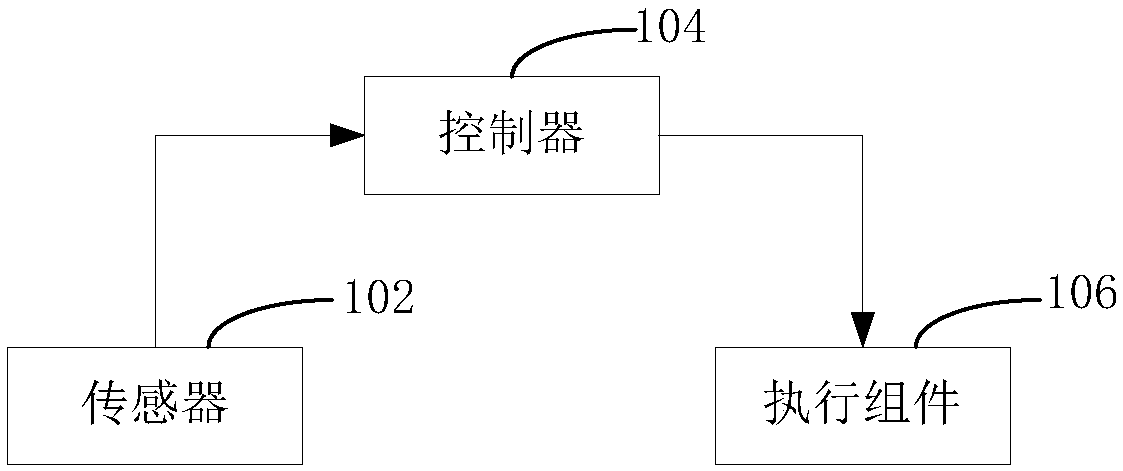

Intelligent cleaning robot and path planning method thereof

ActiveCN109144067AAchieve maximum coverageAchieving cleanlinessPosition/course control in two dimensionsVehiclesReal time analysisRemote control

The invention discloses an intelligent cleaning robot and a path planning method thereof. A sensor module is used for analyzing and feeding back real-time cleaning environment information; an accuratepositioning module is used for acquiring the position of the current intelligent cleaning robot on the environment map which is established through a geometric-topological hybrid map technology, andthe environment map and the real-time position are combined, the optimal sweeping path is planned by using an advanced path planning algorithm, and the data is uploaded to a cloud platform for realizing the real-time analysis, recording, and control; a driving module is used for driving the intelligent cleaning robot to run according to the planned optimal path and carrying out cleaning operation;a man-machine interaction module can be used for displaying the working state and performance of the intelligent cleaning robot by combining the temperature and humidity sensor with the camera, and the remote control and reservation functions of the intelligent cleaning robot can be completed through wifi / Bluetooth technology. According to the invention, the labor intensity is reduced, the laborefficiency is improved, and the robot is suitable for hotels, libraries, office places and public families.

Owner:CHECC DATA CO LTD +1

Porous carbon adsorbing agent containing nano zinc oxide micropartical and its preparation process and application

InactiveCN1724138AImprove adsorption capacityAvoid breedingOther chemical processesSorbentPorous carbon

A porous charcoal adsorbent for cleaning environment is composed of porous charcoal as carrier and zinc oxide nano-particles as active component. Its preparing process includes such steps as reaction between zinc nitrate micro-emulsion and sodium hydroxide to obtain zinc oxide nano-particles, carrying them by porous charcoal and heat treating. Its advantages are high absorptive power and high photo-catalytic and antibacterial activities.

Owner:SUN YAT SEN UNIV

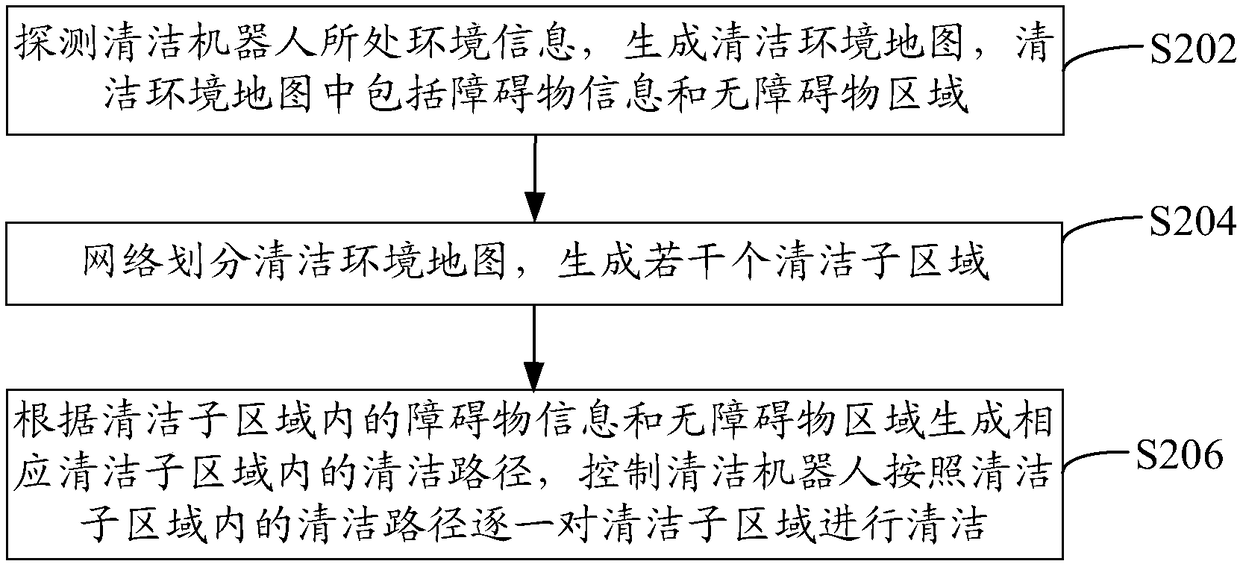

Cleaning robot control method and cleaning robot

ActiveCN108209741AEasy to cleanIncrease coverageCleaning action controlMachine detailsRobot controlControl theory

The invention relates to a cleaning robot control method. The method comprises the steps that information of an environment where a cleaning robot is located is detected, and a cleaning environment map is generated, wherein the cleaning environment map comprises obstacle information and an obstacle-free region; the cleaning environment map is subjected to meshing to generate multiple cleaning subregions; cleaning paths in the corresponding cleaning subregions are generated according to the obstacle information and the obstacle-free region in the cleaning subregions, and the cleaning robot is controlled to clean the cleaning subregions one by one according to the cleaning paths in the cleaning subregions. According to the method, the cleaning coverage degree of the cleaning robot can be larger, and the cleaning efficiency of the cleaning robot can be higher.

Owner:SHENZHEN LDROBOT CO LTD

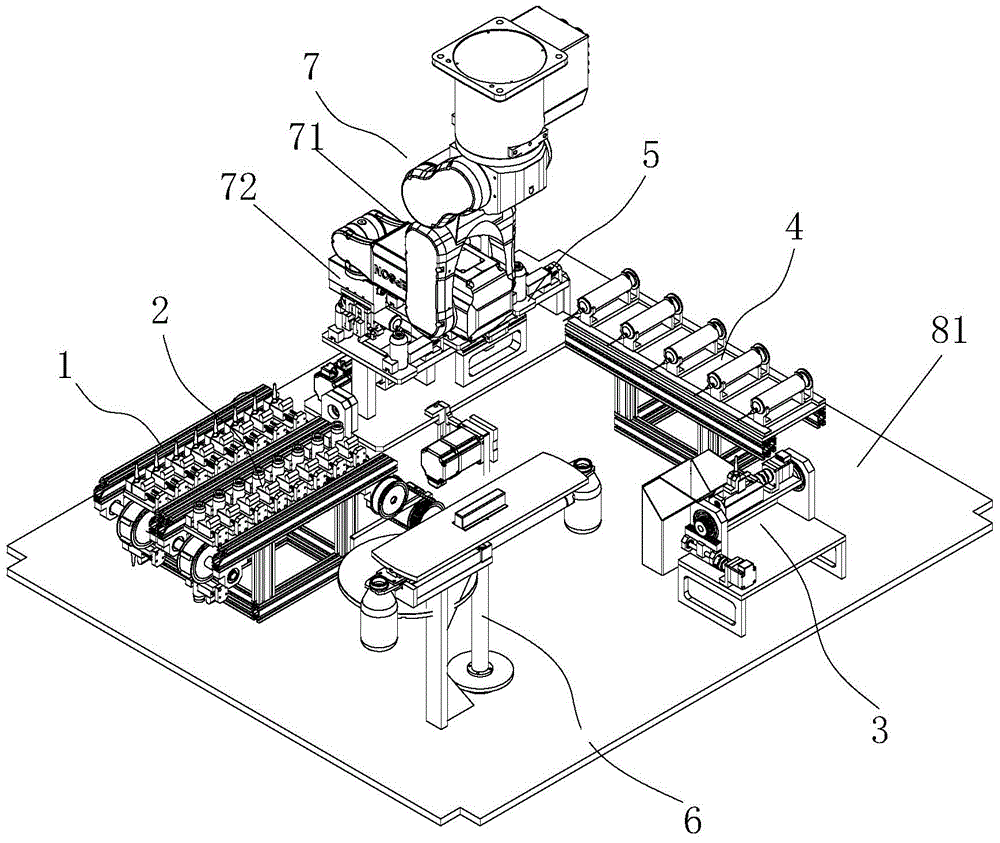

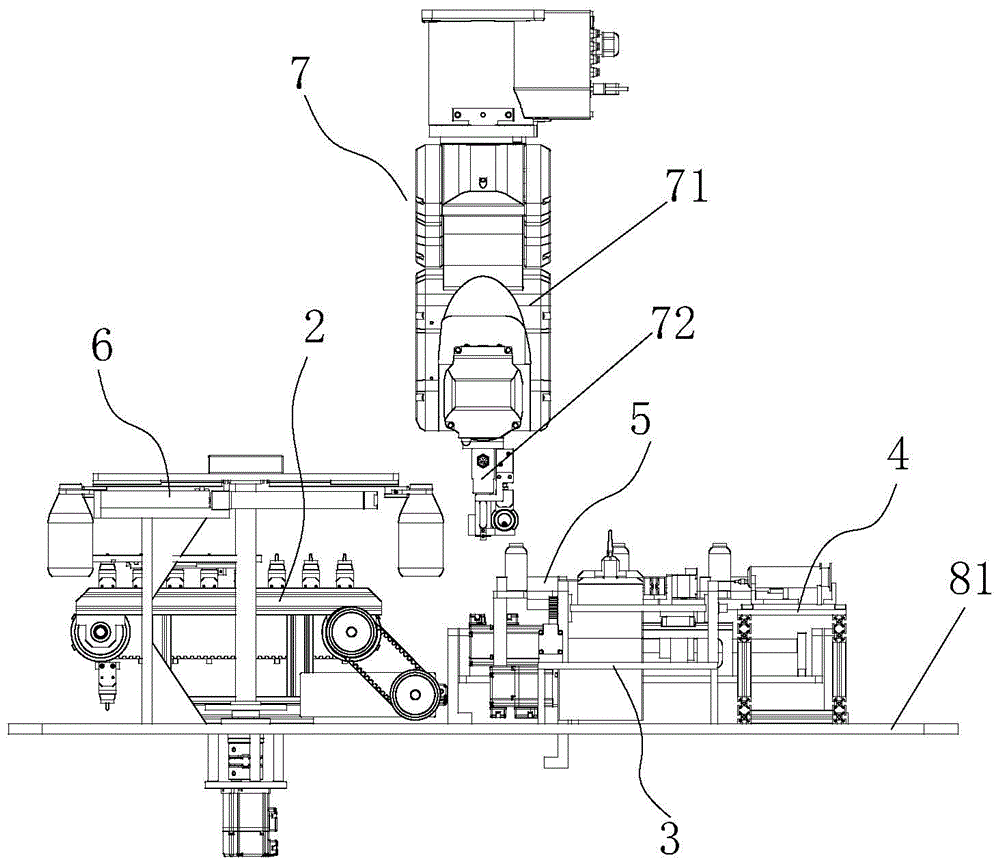

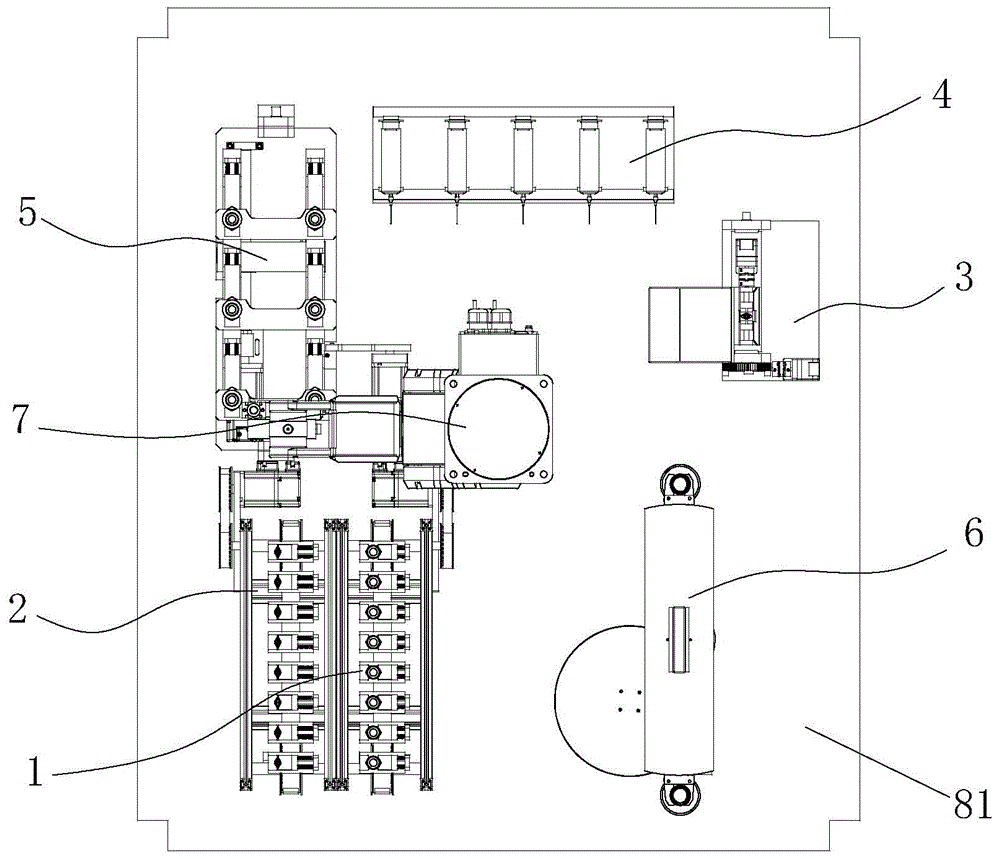

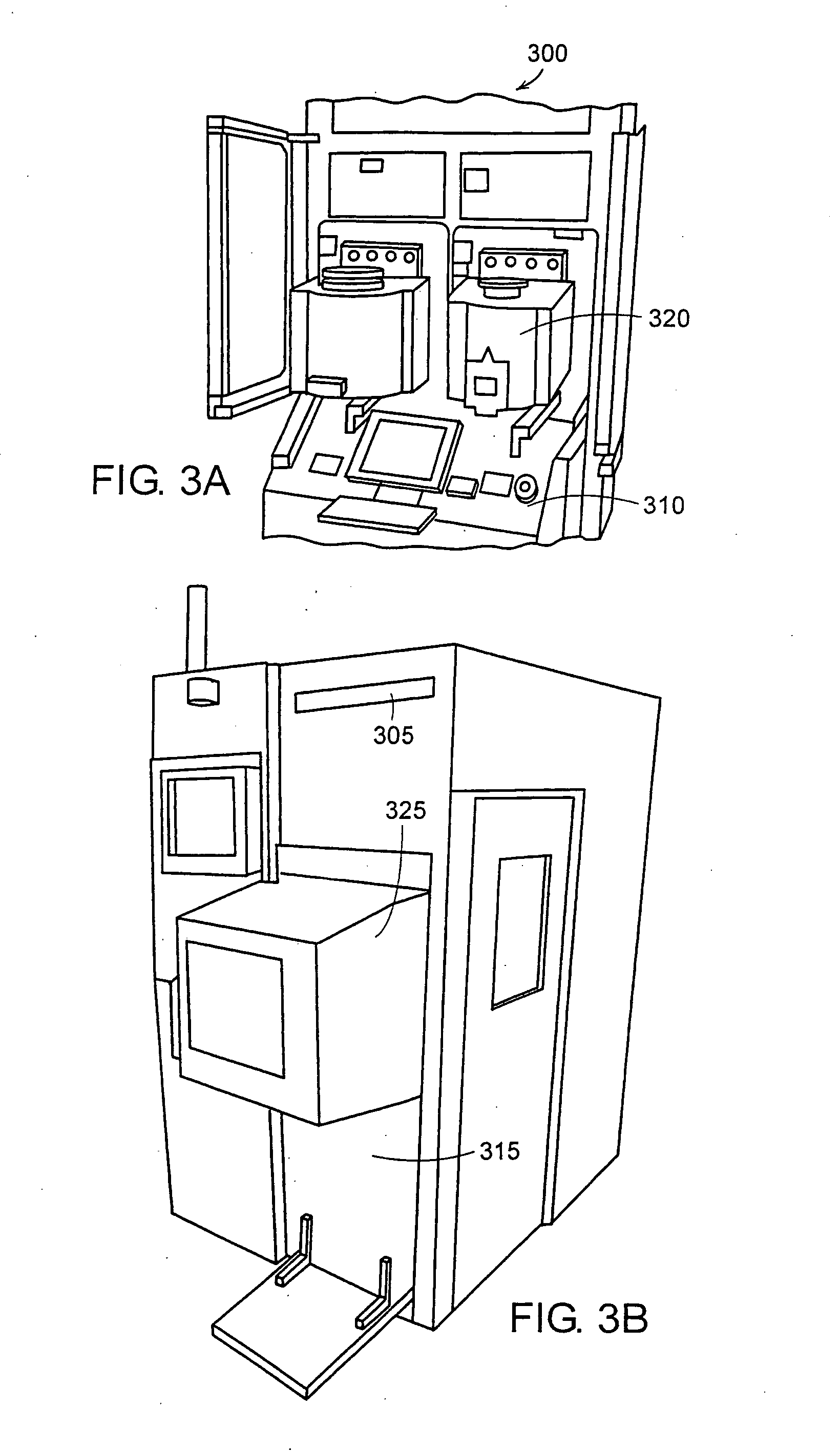

Automatic fluid preparation system and automatic fluid preparation machine used for preparing intravenous fluids

ActiveCN104436354AAvoid cross infectionNo manual operationInfusion devicesPharmaceutical containersSterile environmentShake up

The invention relates to an automatic fluid preparation system and an automatic fluid preparation machine used for preparing intravenous fluids. The automatic fluid preparation system comprises an ampoule bottle conveying device, a penicillin bottle conveying device, an ampoule bottle breaking device, an injector arrangement device, a shaking up device, an infusion bottle conveying device and a multifunctional manipulator. Through the organic combination of the above devices, the fluid preparation is automatically completed in class 100 clean sterile environment without manual operations, so that safety and convenience are increased. In addition, after medical staff inputs an instruction sheet for fluid preparation, the automatic fluid preparation system can automatically check the types of configured medicine bottles, if differences occur, a dispensing action is stopped and an alarm is generated. The automatic fluid preparation system carries out a dispensing program after the medicine staff arranges the medicine which needs to be prepared, the whole process is carried out in a clean environment, so that manual intervention is reduced and the purpose of clean and safe production is achieved.

Owner:DONGGUAN CHANGYUAN SPRAYING TECH

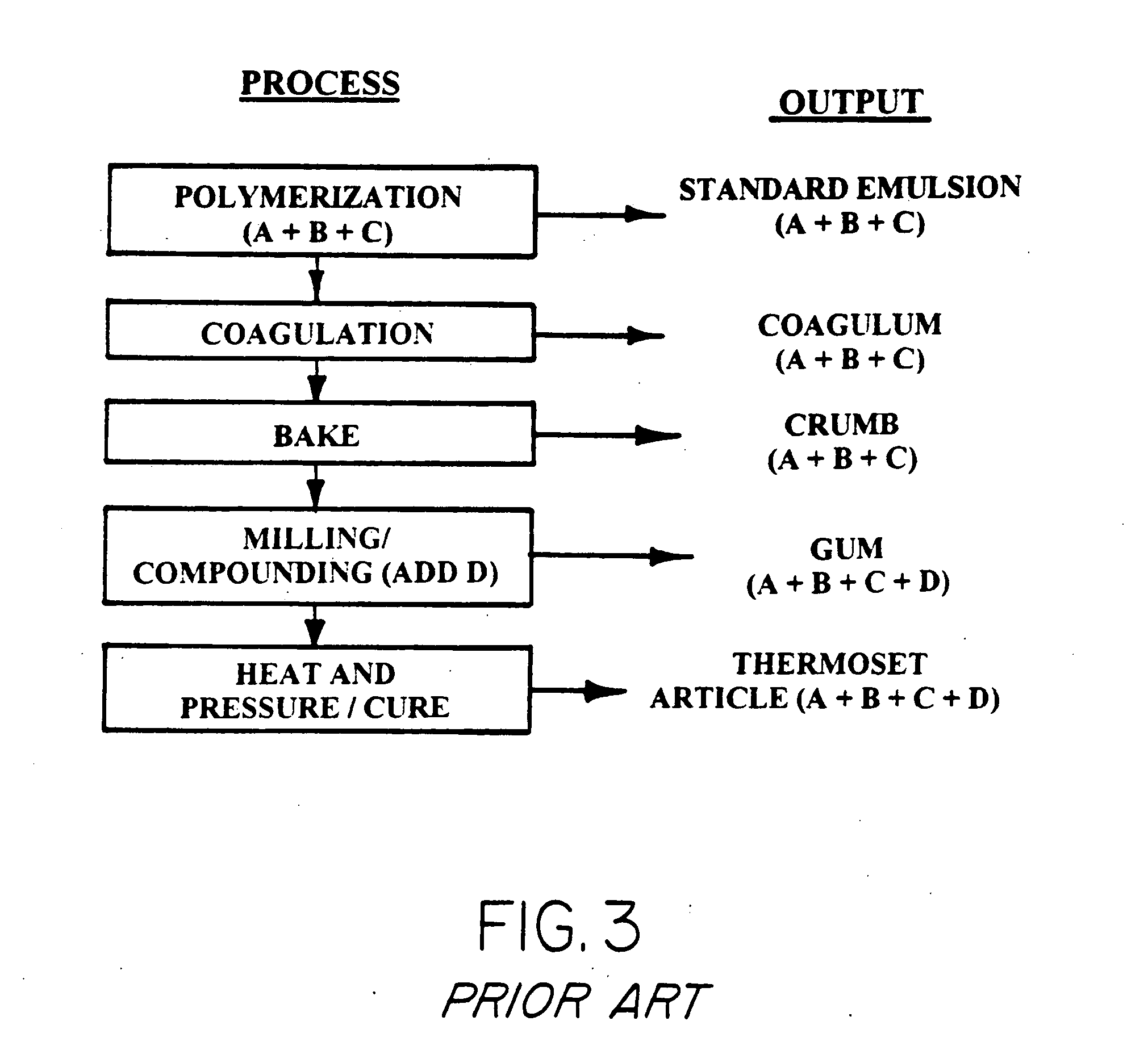

Thermoplastic copolymer of tetrafluoroethylene and perfluoromethyl vinyl ether and medical devices employing the copolymer

InactiveUS20060041091A1Improve mechanical propertiesSolving the Insufficiency of ElasticityVinyl etherElastomer

An improved elastomeric material is described comprising an essentially noncross-linkable amorphous copolymer of tetrafluoroethylene (TFE) and perfluoromethyl vinyl ether (PMVE) which is both a thermoplastic and exhibits exceptional mechanical properties. This material is particularly suitable for use in ultra-clean environments, and particularly for use in an implantable device, since it does not contain contaminants that previous thermoset TFE / PMVE copolymers have required. Among the improved properties of the present invention are excellent biocompatibility, high matrix tensile strength, high clarity, high abrasion resistance, high purity, adequate elasticity, and ease of processing due to the thermoplastic, and noncross-linkable structure of the copolymer. The material of the present invention is also a high strength bonding agent particularly suited for bonding porous PTFE to itself or to other porous substances at room or elevated temperatures.

Owner:WL GORE & ASSOC INC

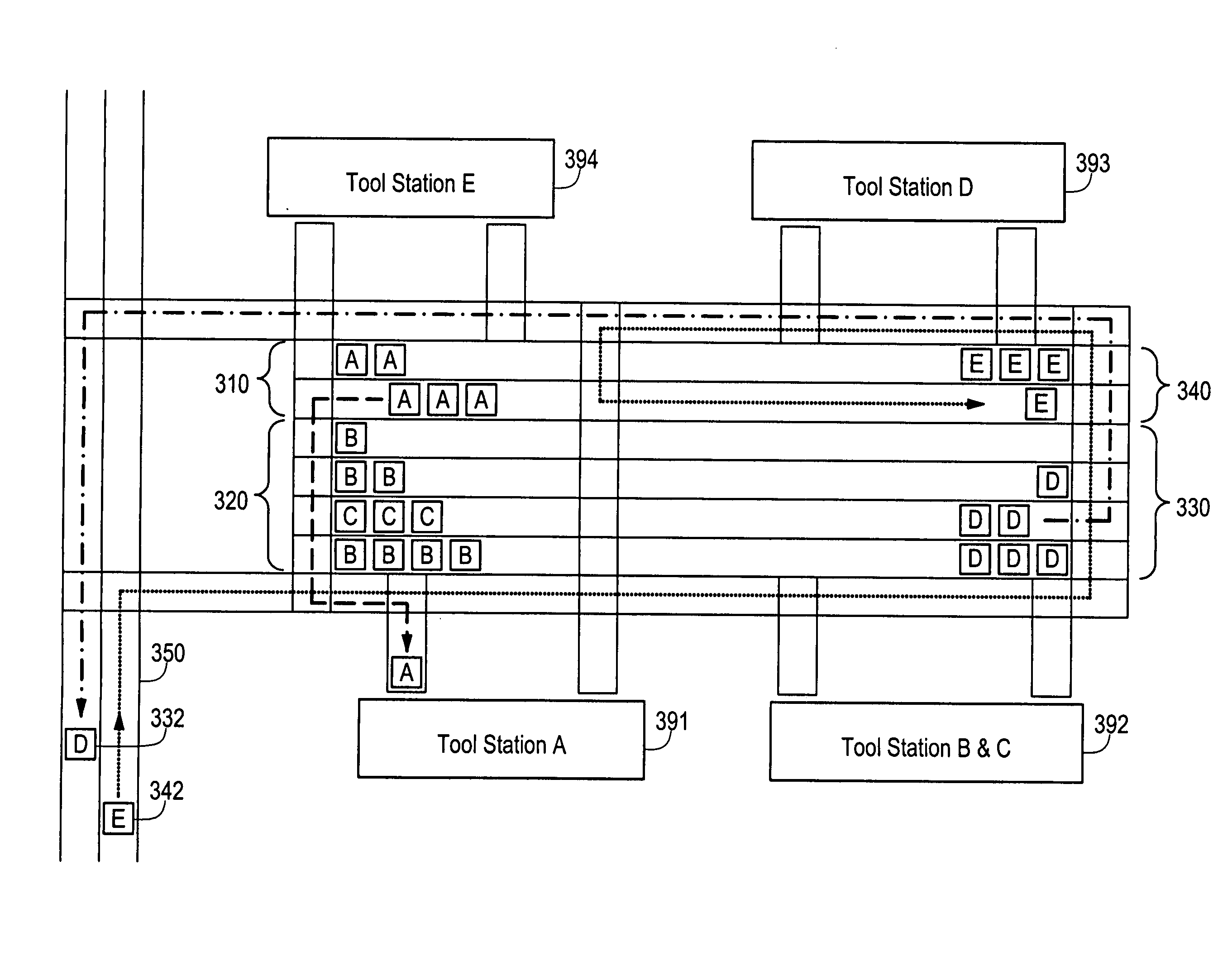

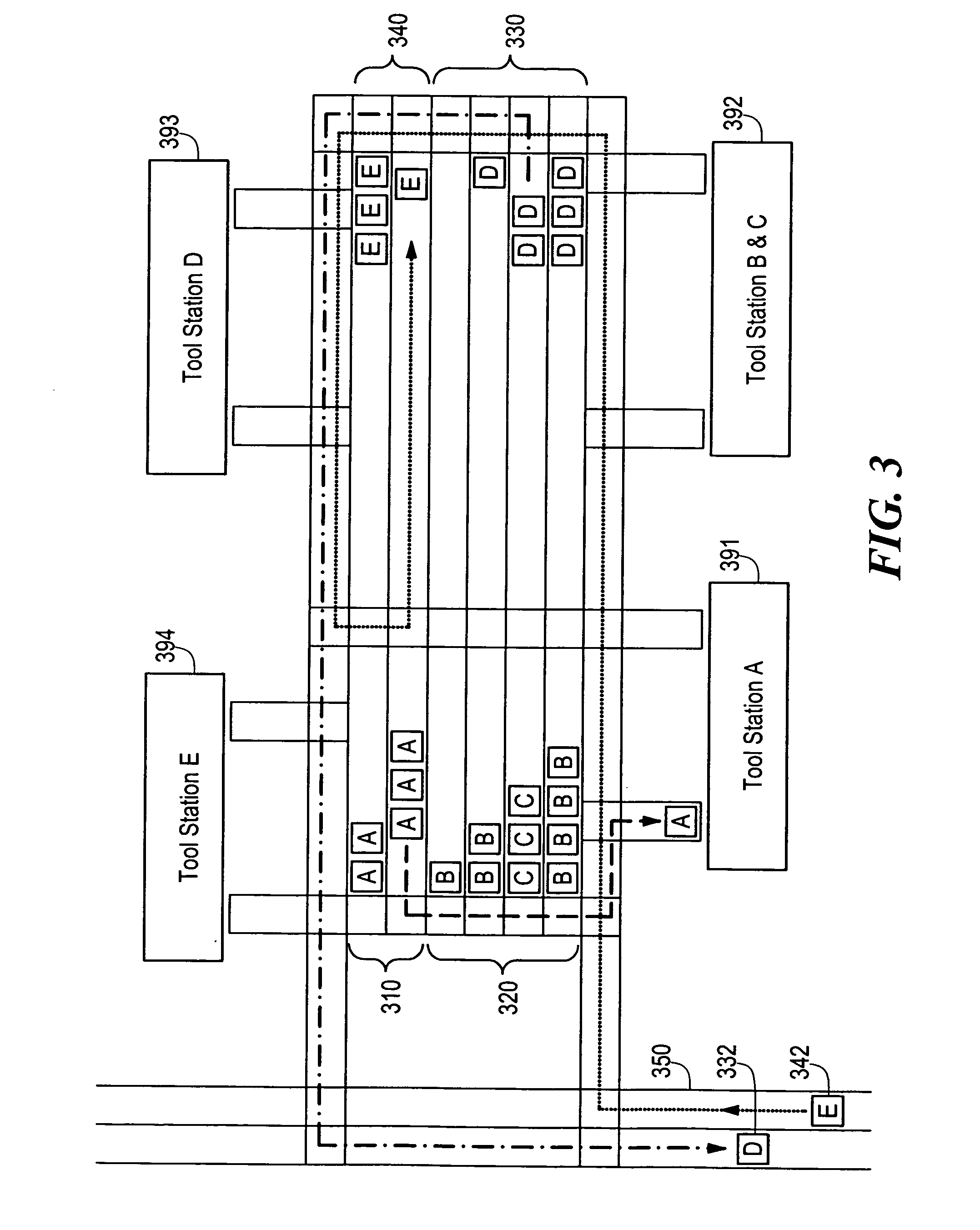

Conveyorized storage and transportation system

InactiveUS20050133340A1Easy to storeAvoid normal workDigital data processing detailsSemiconductor/solid-state device manufacturingTransit systemModularity

A configurable storage system particularly suited for use with clean-environment conveyors is disclosed. The storage system includes modular conveyor track elements which may be provided parallel to and adjacent a ceiling mounted conveyor highway. Conveyor elements may be provided as one-way paths which, when provided with plural transfer elements with respect to a conveyor highway, enable the rotation of a work-piece from a storage matrix to a transfer path and back to the storage matrix. Adjacent storage conveyor elements may be used to realize loops of storage elements. A single storage conveyor element may be shared by multiple loops of storage elements. The modularity of the present system enables the realization of plural, nested loops of storage elements. Control over such systems may be provided locally, centrally or some combination of both, and may adjust the behavior of individual storage conveyor elements based on a variety of factors.

Owner:MIDDLESEX GEN INDS MESNE

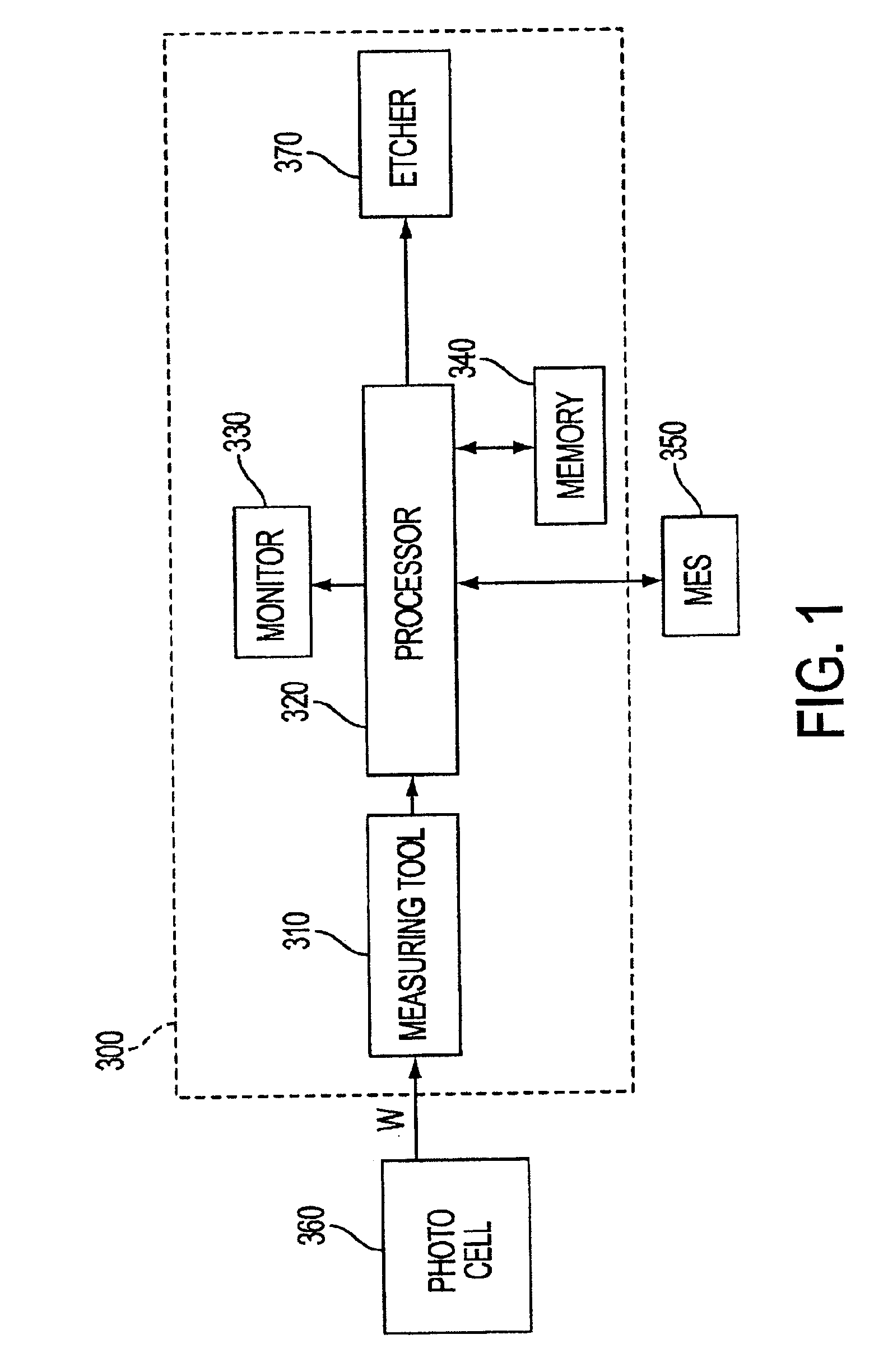

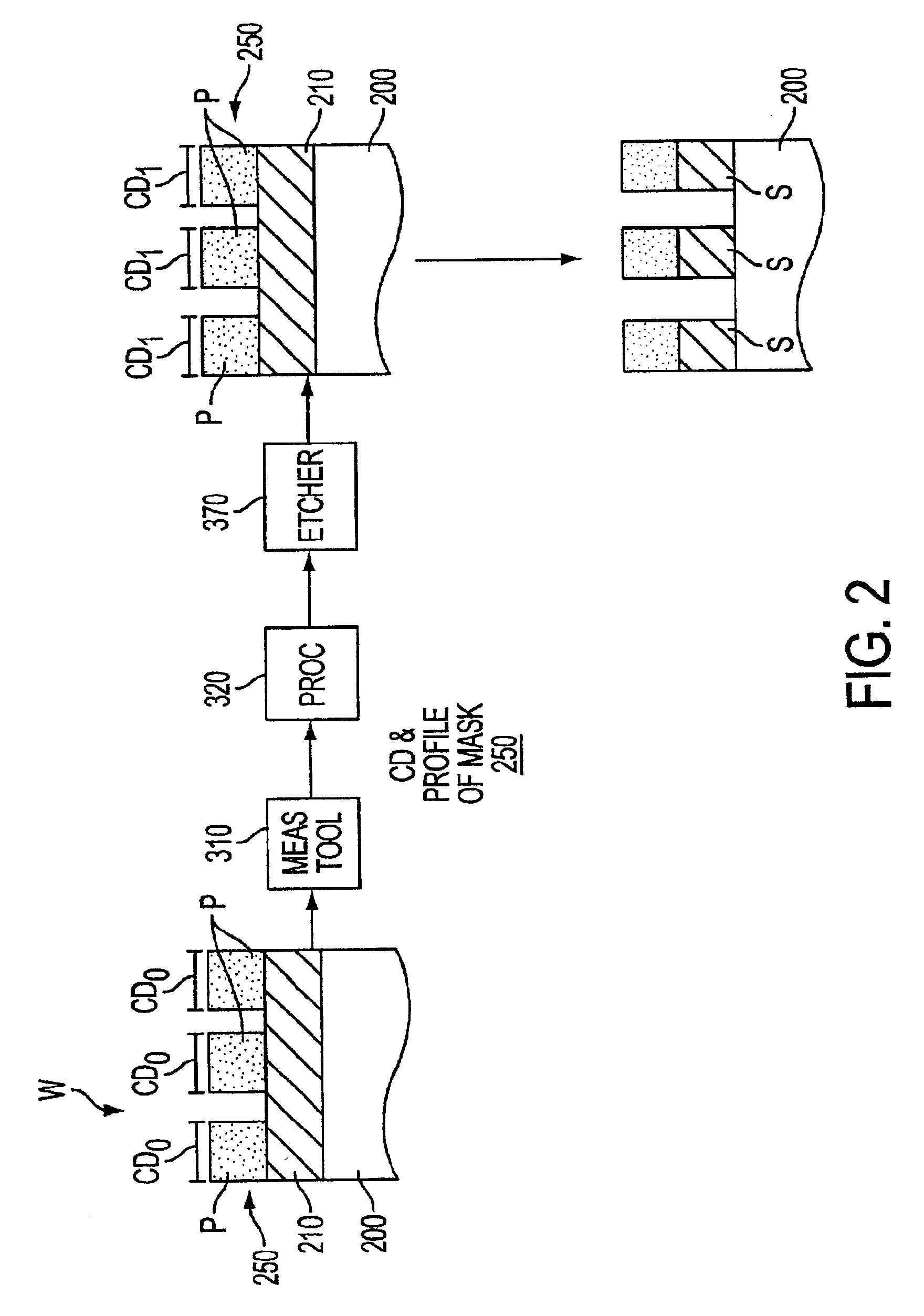

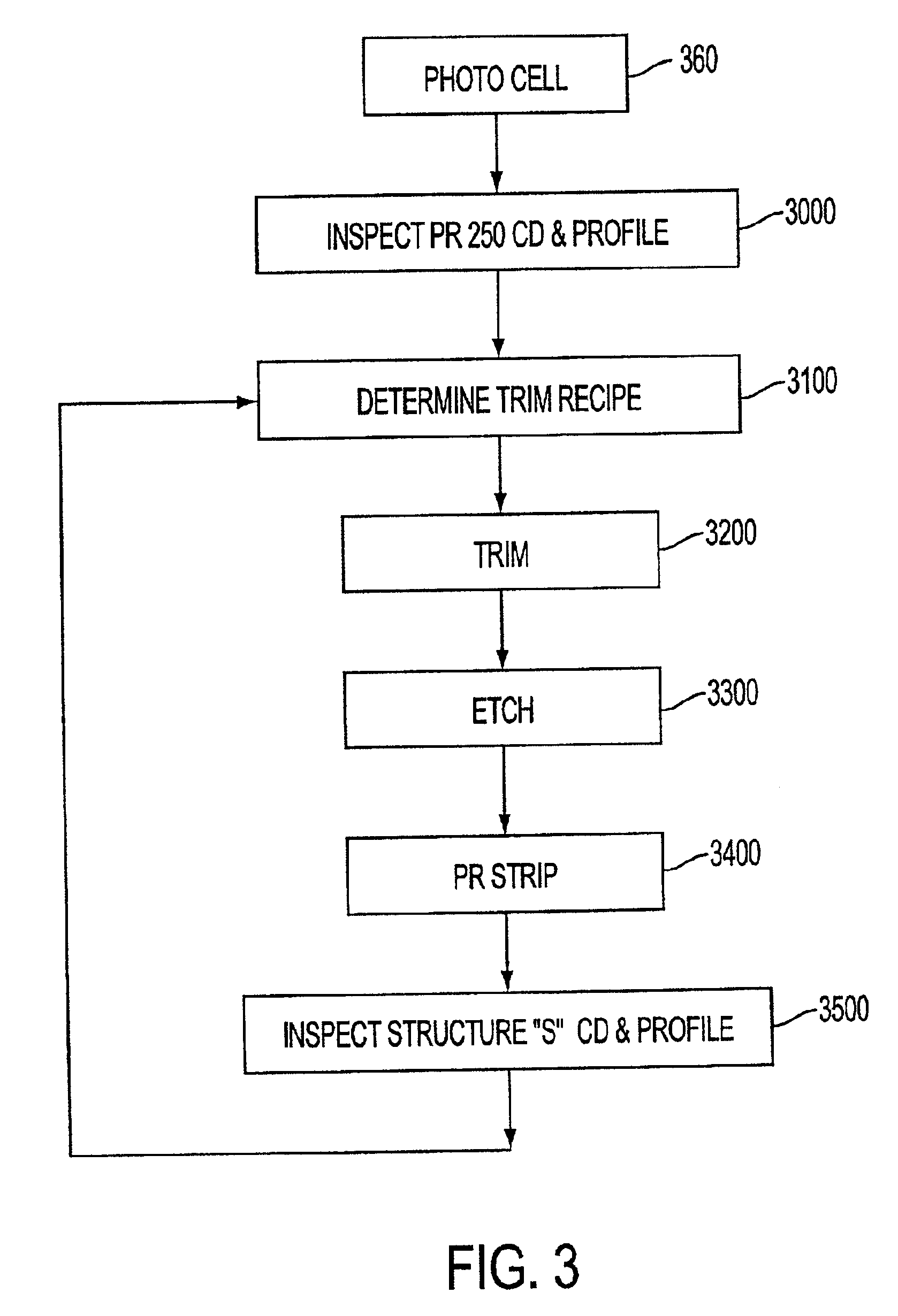

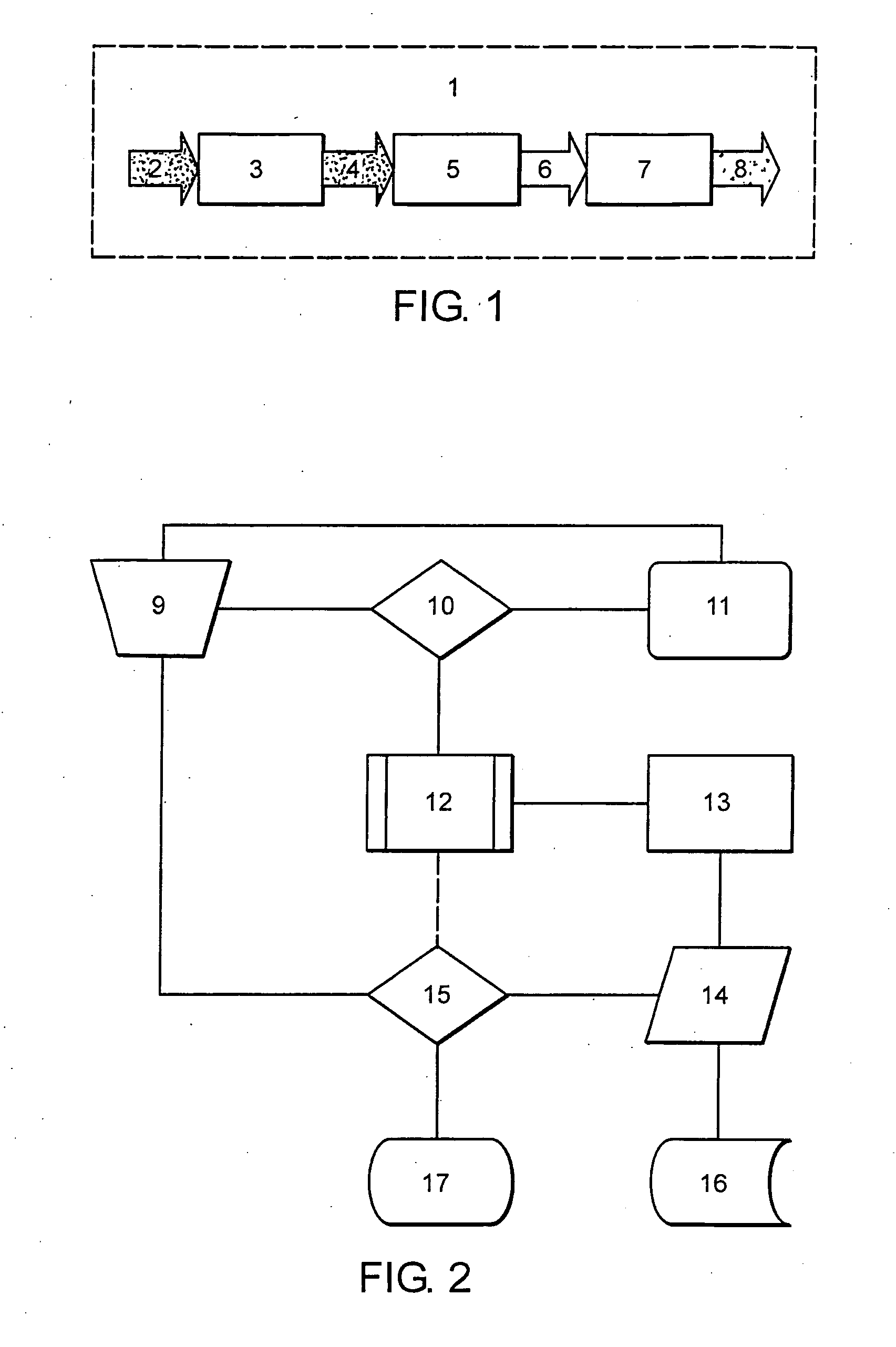

Methodology for repeatable post etch CD in a production tool

InactiveUS6858361B2Reduce CD and profile variationReducing production throughput and yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingResistEngineering

A method and apparatus for processing a semiconductor wafer is provided for reducing dimensional variation by feeding forward information relating to photoresist mask CD and profile to adjust the next process the inspected wafer will undergo (e.g., a photoresist trim process). After the processing step, dimensions of a structure formed by the process, such as the CD of a gate formed by the process, are measured, and this information is fed back to the process tool to adjust the process for the next wafer to further reduce dimensional variation. By taking into account photoresist CD and profile variation when choosing a resist trim recipe, post-etch CD is decoupled from pre-etch CD and profile. With automatic compensation for pre-etch CD, a very tight distribution of post-etch CD is achieved. In certain embodiments, the CD and profile measurements, trim, etch processing and post-etch cleaning are performed at a single module in a controlled environment. All of the transfer and processing steps performed by the module are performed in a clean environment, thereby increasing yield by avoiding exposing the wafer to the atmosphere and possible contamination between steps.

Owner:APPLIED MATERIALS INC

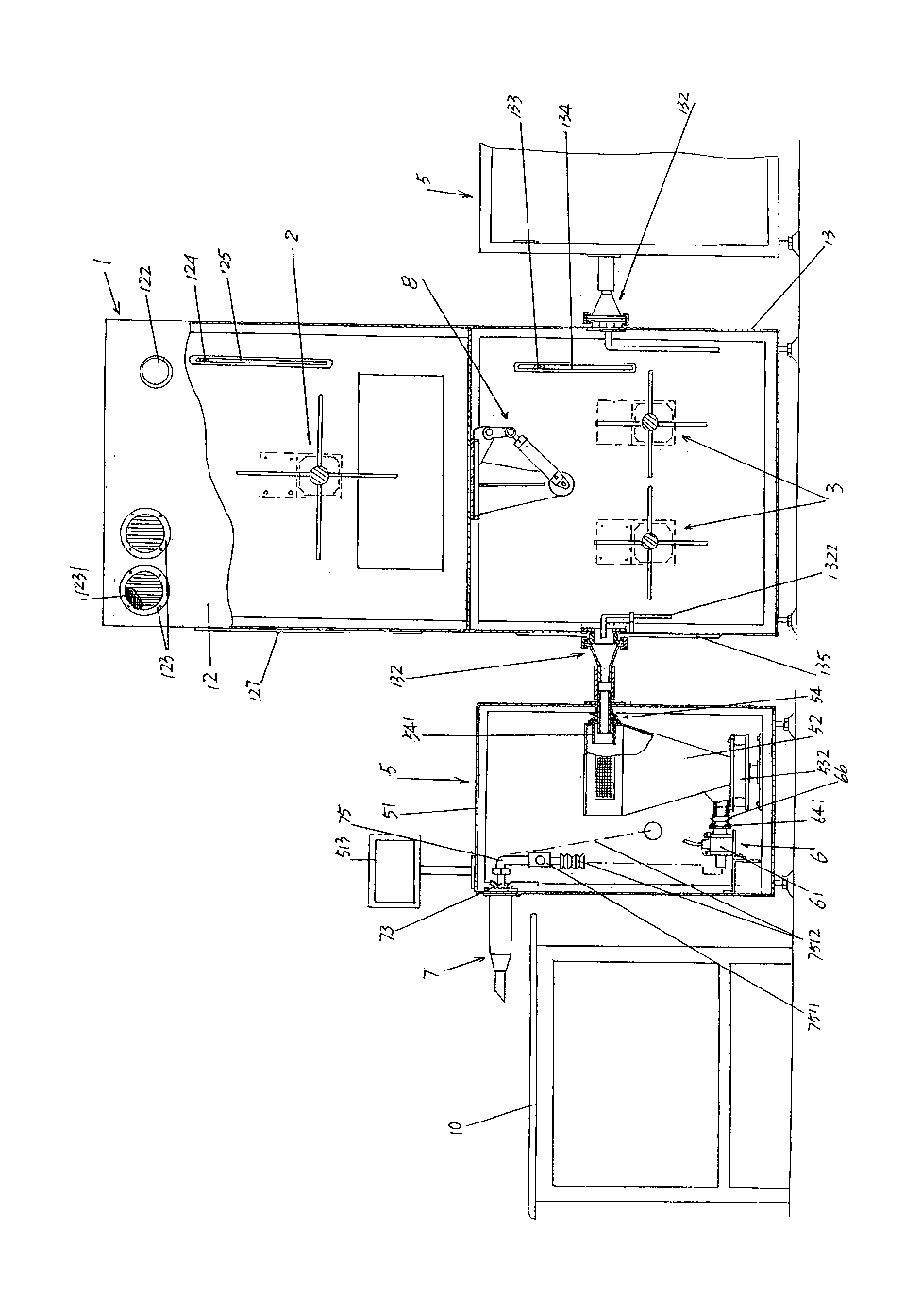

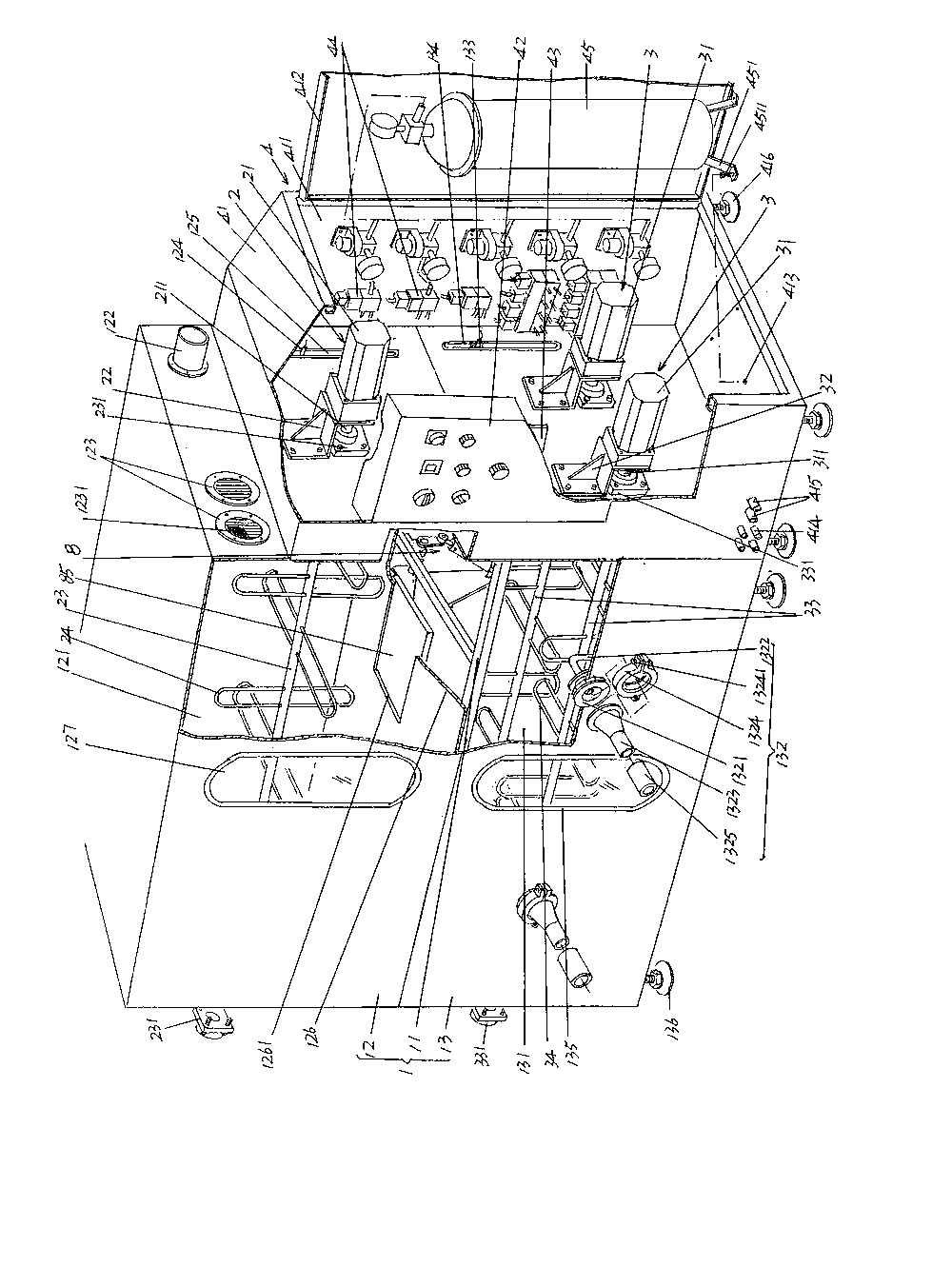

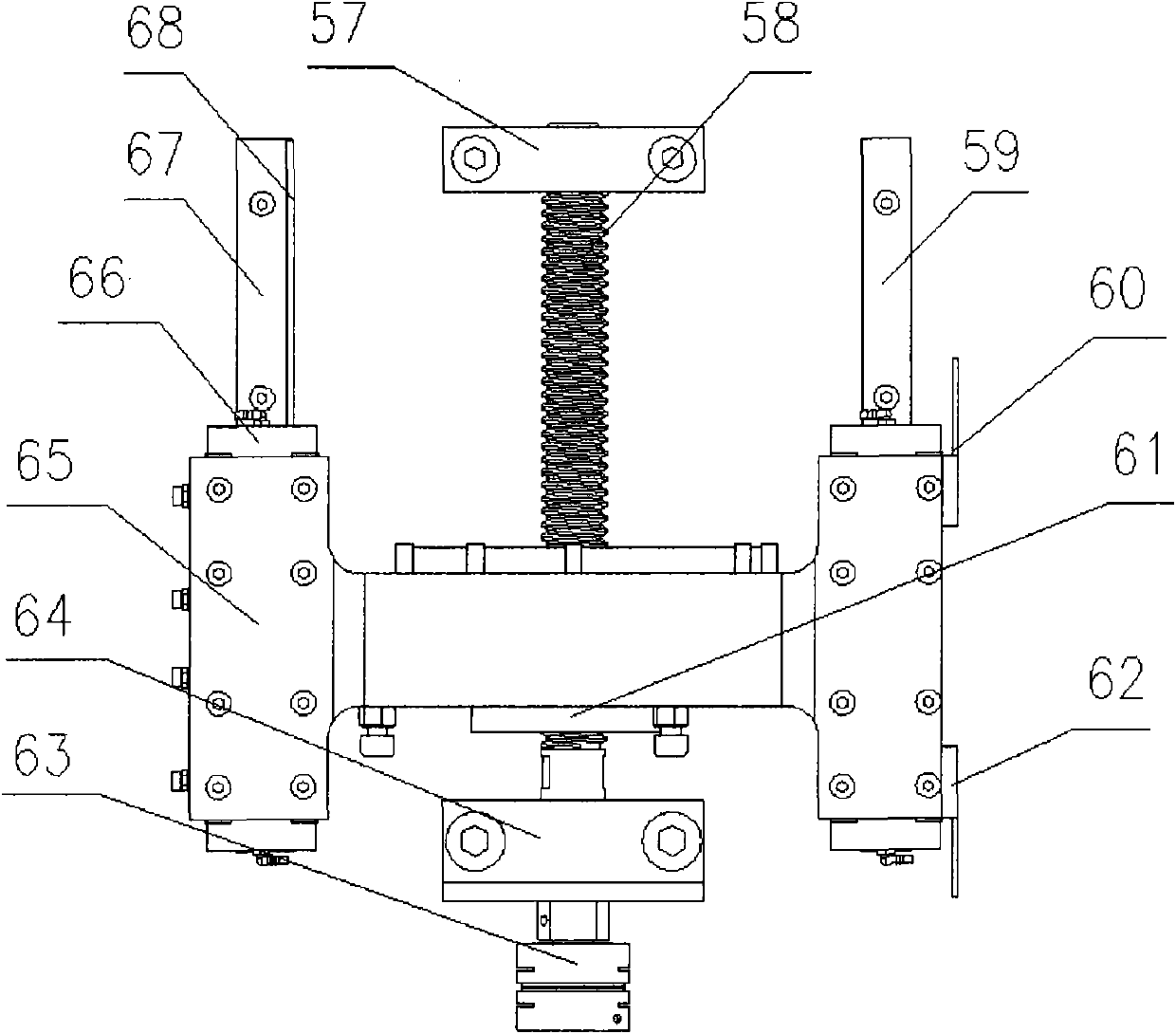

Automatically quantitative down filling machine

ActiveCN103101873AQuantity GuaranteeGuaranteed cleanlinessUpholstery manufactureClothes making applicancesAutomatic controlClean environment

The invention discloses an automatically quantitative down filling machine, and belongs to the technical field of stowage equipment for down and feather filled products. The automatically quantitative down filling machine comprises a box body, a first down stirring mechanism, a second down stirring mechanisms, an electrical automatic control mechanism, a weighing metering mechanism, a down output mechanism, a down filling head and a box cavity channel start-and-stop mechanism. The box body comprises a box frame, a down storage box and a down delivering box. A down lead-in connector, an air window and a down storage quantity signal collector are placed on the down storage box in a matched mode, and a down lead-out connector and a down quantity signal collector are placed on the down delivering box in a matched mode. The first stirring mechanism is used for stirring down inside a down storage box cavity, and the second stirring mechanism is used for stirring down inside a down delivering box cavity. The electrical automatic control mechanism is placed on one side of the box body in a matched mode. The weighing metering mechanism is connected with a down lead-out connector pipeline of the down delivering box, the down output mechanism is connected with the weighing metering mechanism, the down filling head is connected with the down output mechanism in a matched mode, and the box cavity channel start-and-stop mechanism is matched with a bottom plate of the down storage box. The automatically quantitative down filling machine has the advantages of showing rhythmic continuity of down supplying, being capable of providing guarantee for subsequent continuously weighing and down filling, being good in down filling efficiency and light in operation intensity, guaranteeing a clean environment of operation site and eradicating down wasting.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

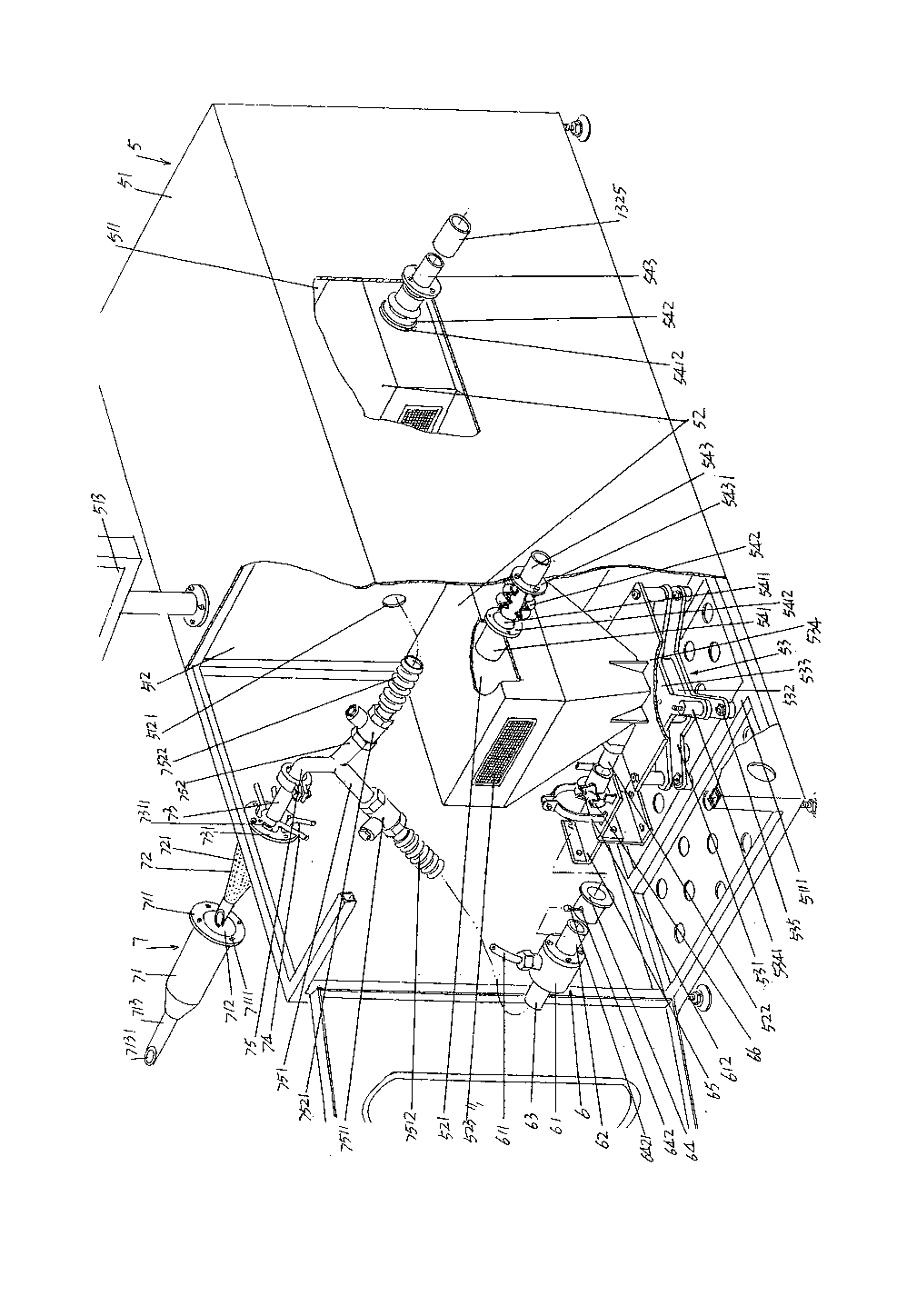

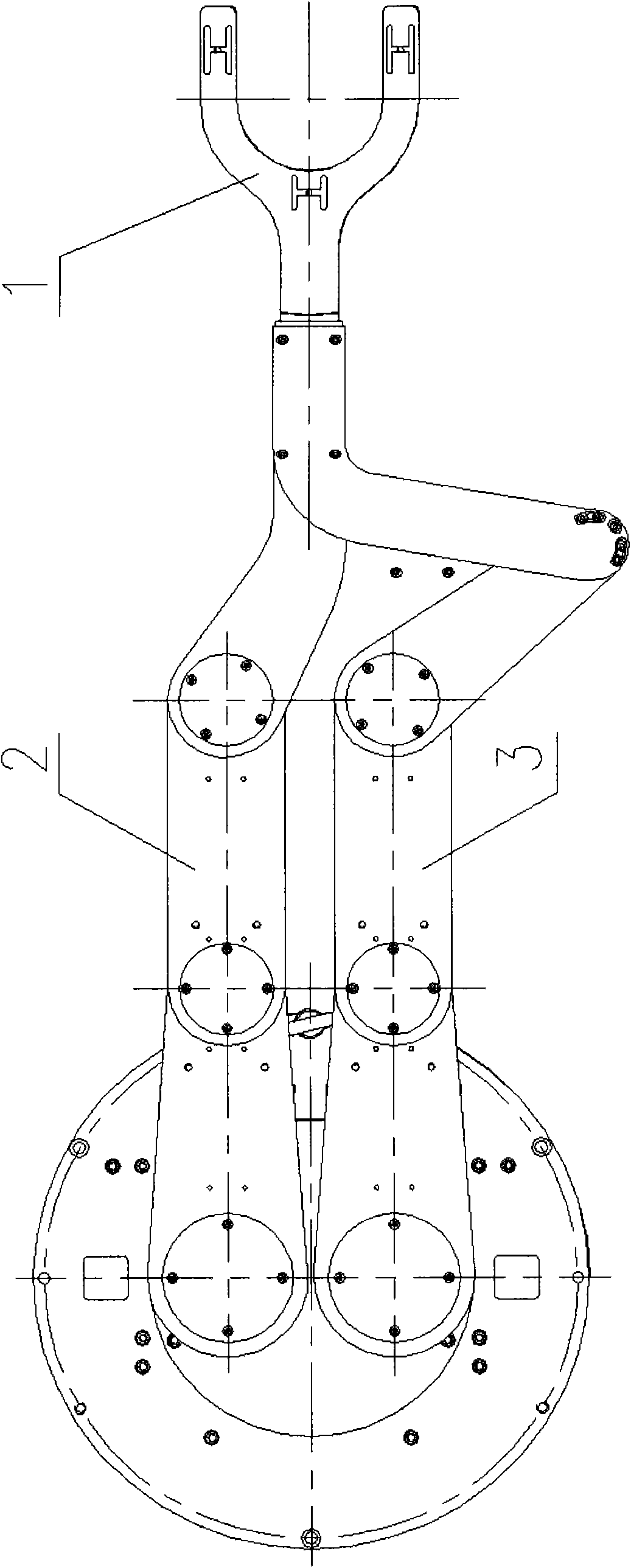

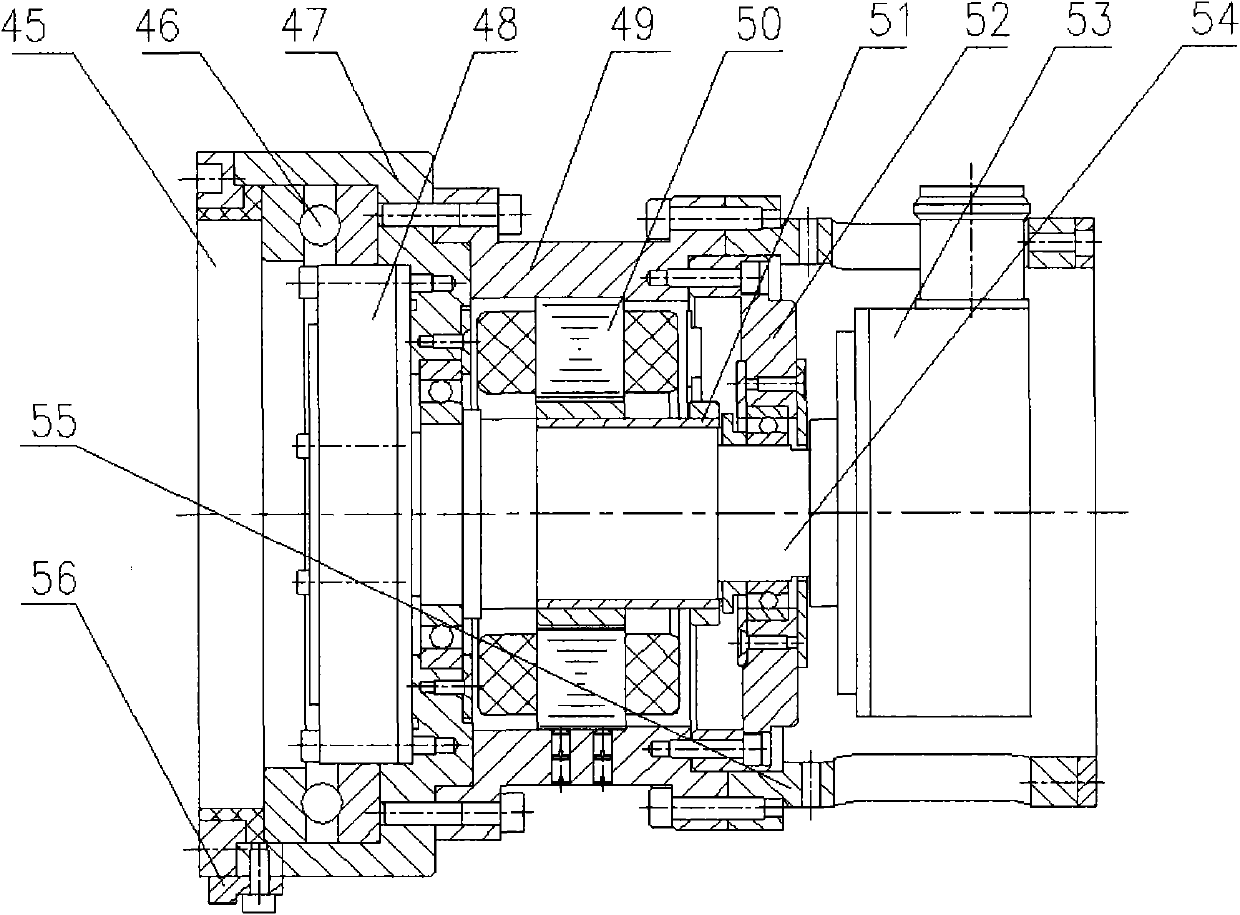

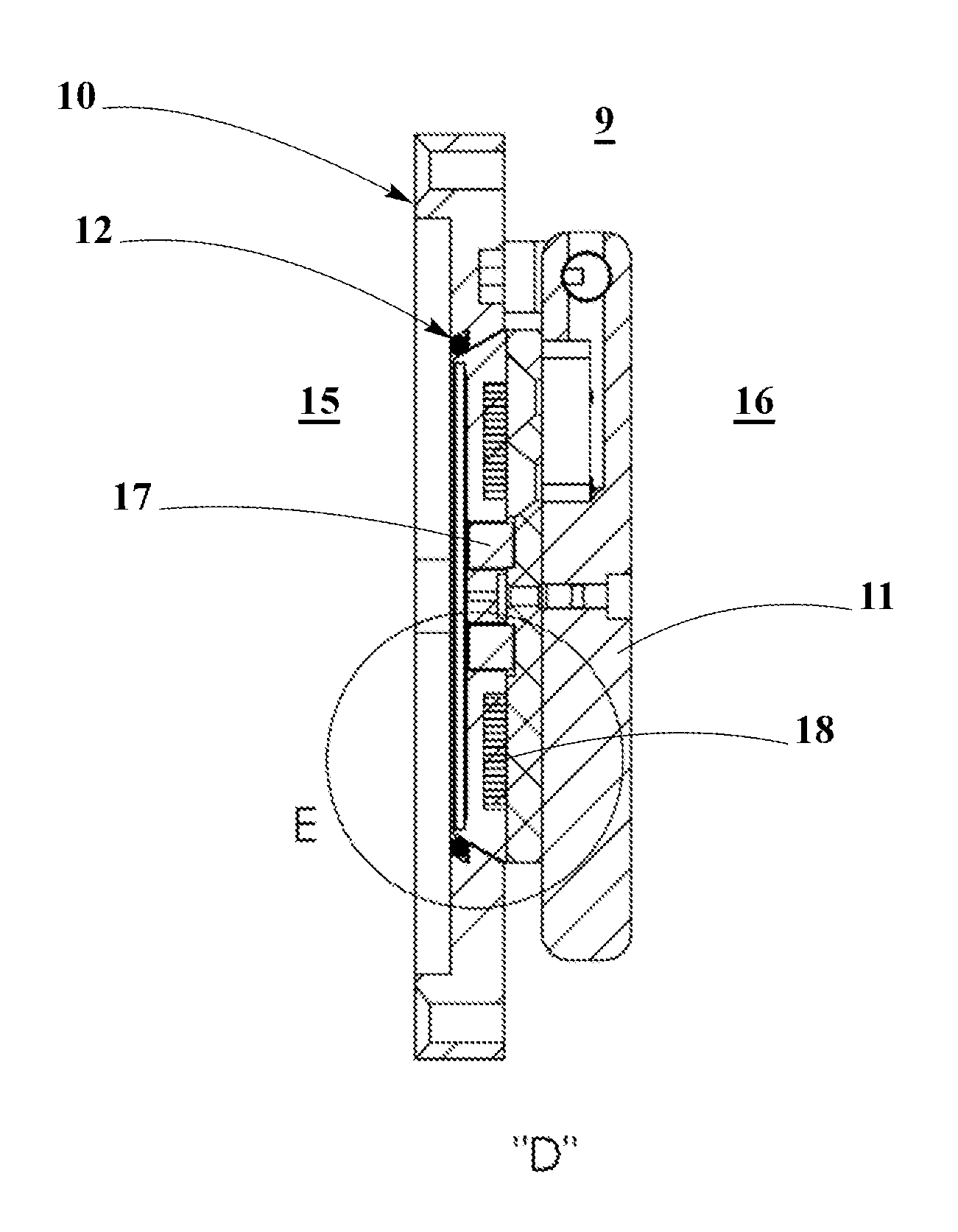

Double-arm transmission robot applied to high-cleanliness environment

InactiveCN101908497AHigh efficiency requirementsMeet cleanliness requirementsProgramme-controlled manipulatorConveyor partsSpatial structureMechanical engineering

The invention relates to a double-arm transmission robot applied to a clean environment, which is used for the transmission and high-precision positioning placement of a large-diameter semiconductor silicon wafer in a high-cleanliness environment. The double-arm transmission robot is in the structural form of R-theta type and has the working principle of a space structure based on a cylindrical coordinate system and the characteristic of independent control of all motion shafts. The double-arm transmission robot mainly comprises an R-axis left arm mechanism, an R-axis right arm mechanism, a T-axis rotating mechanism, a Z-axis lifting mechanism, and the like and seals the pollution of a drive mechanism on an external environment by adopting a special seal device so as to be suitable for the high-cleanliness production environment requirement.

Owner:HARBIN INST OF TECH

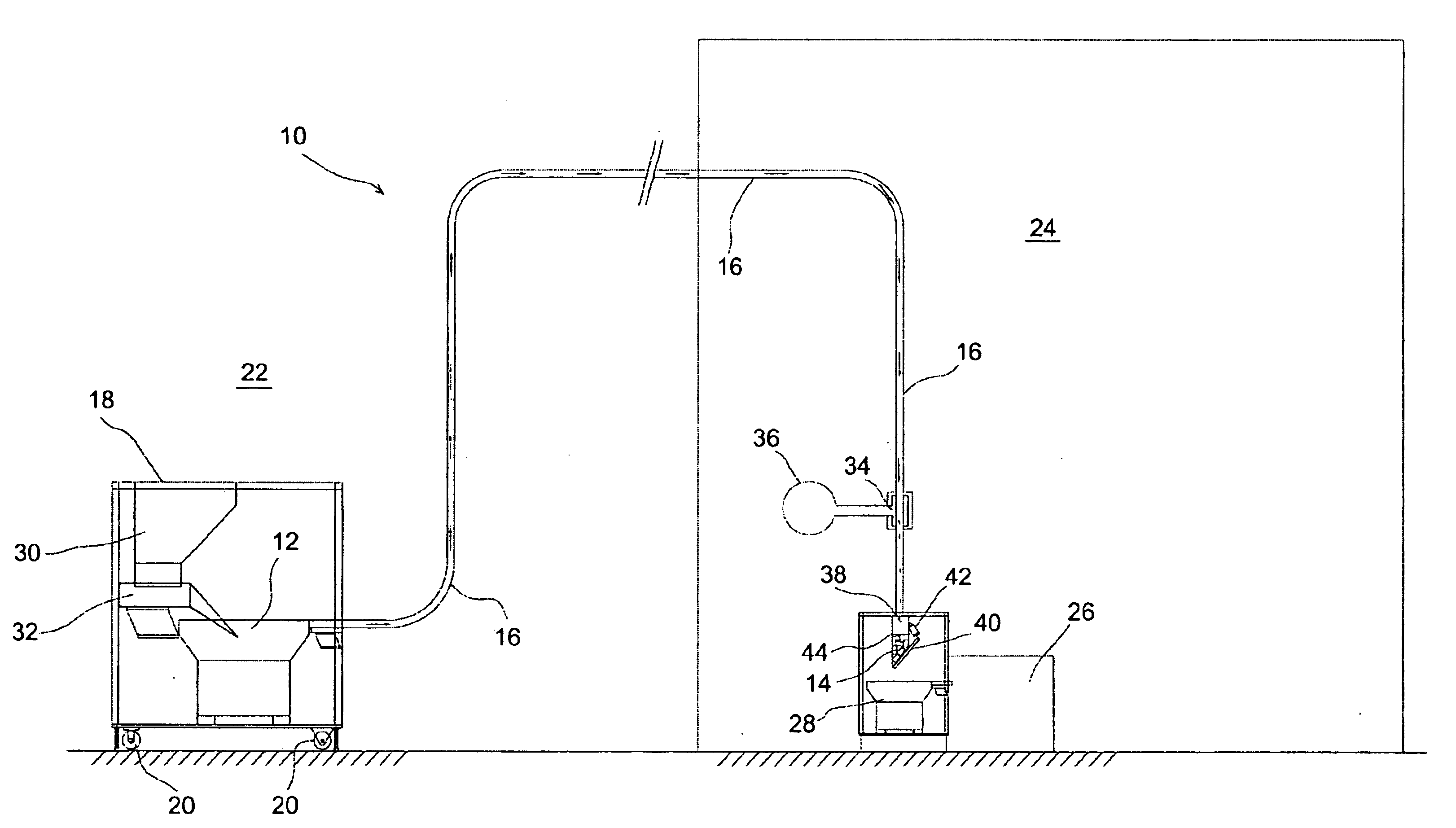

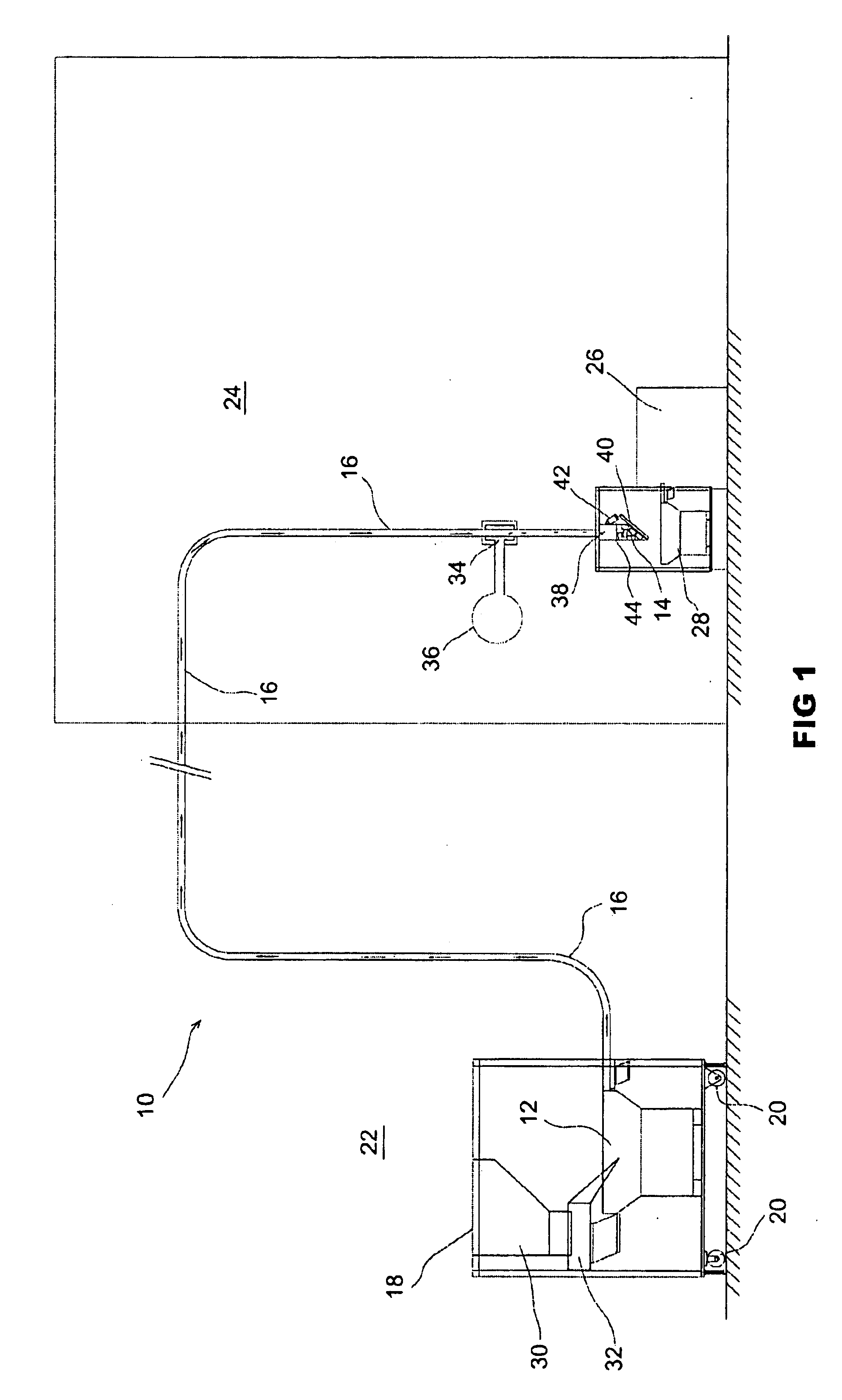

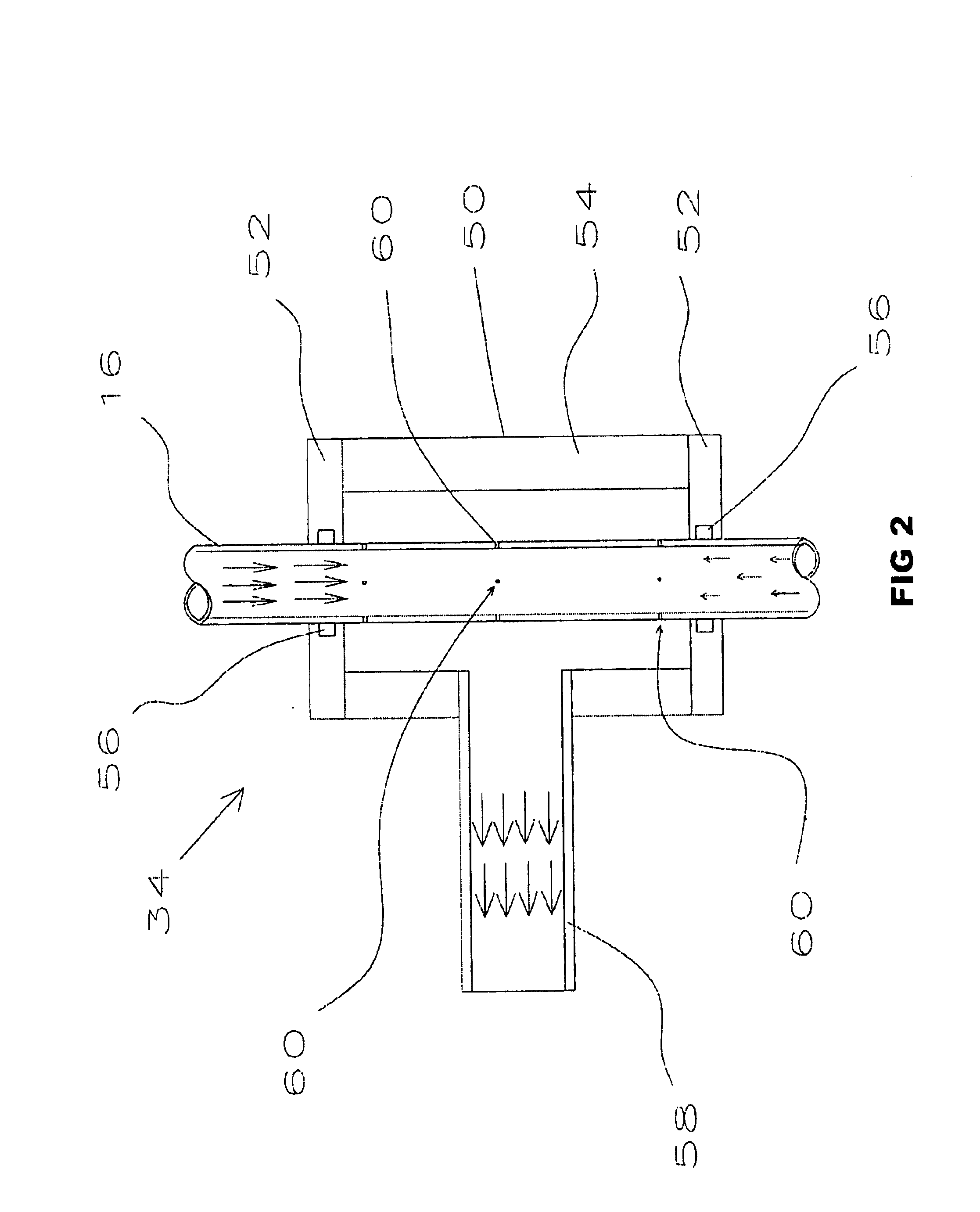

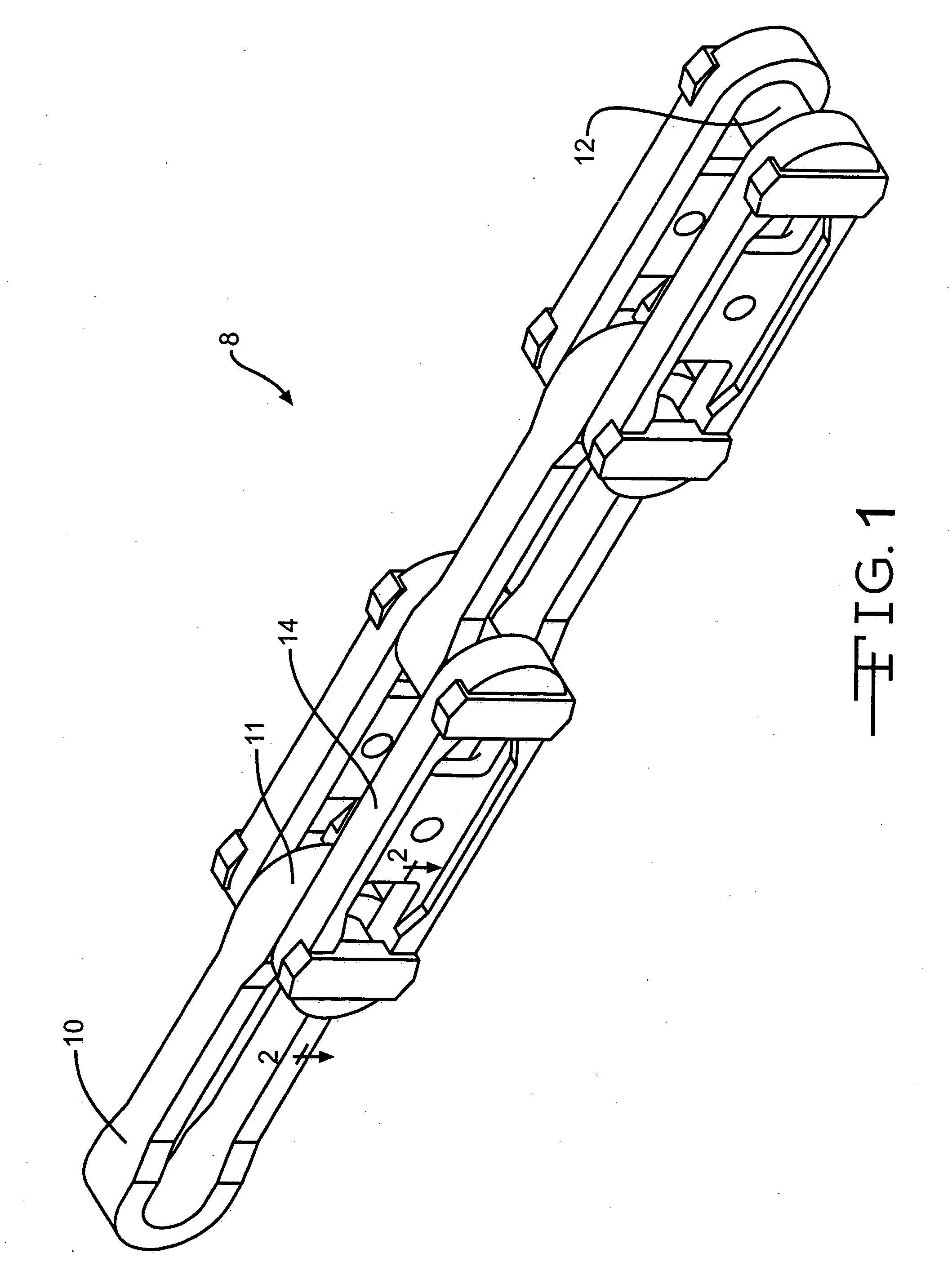

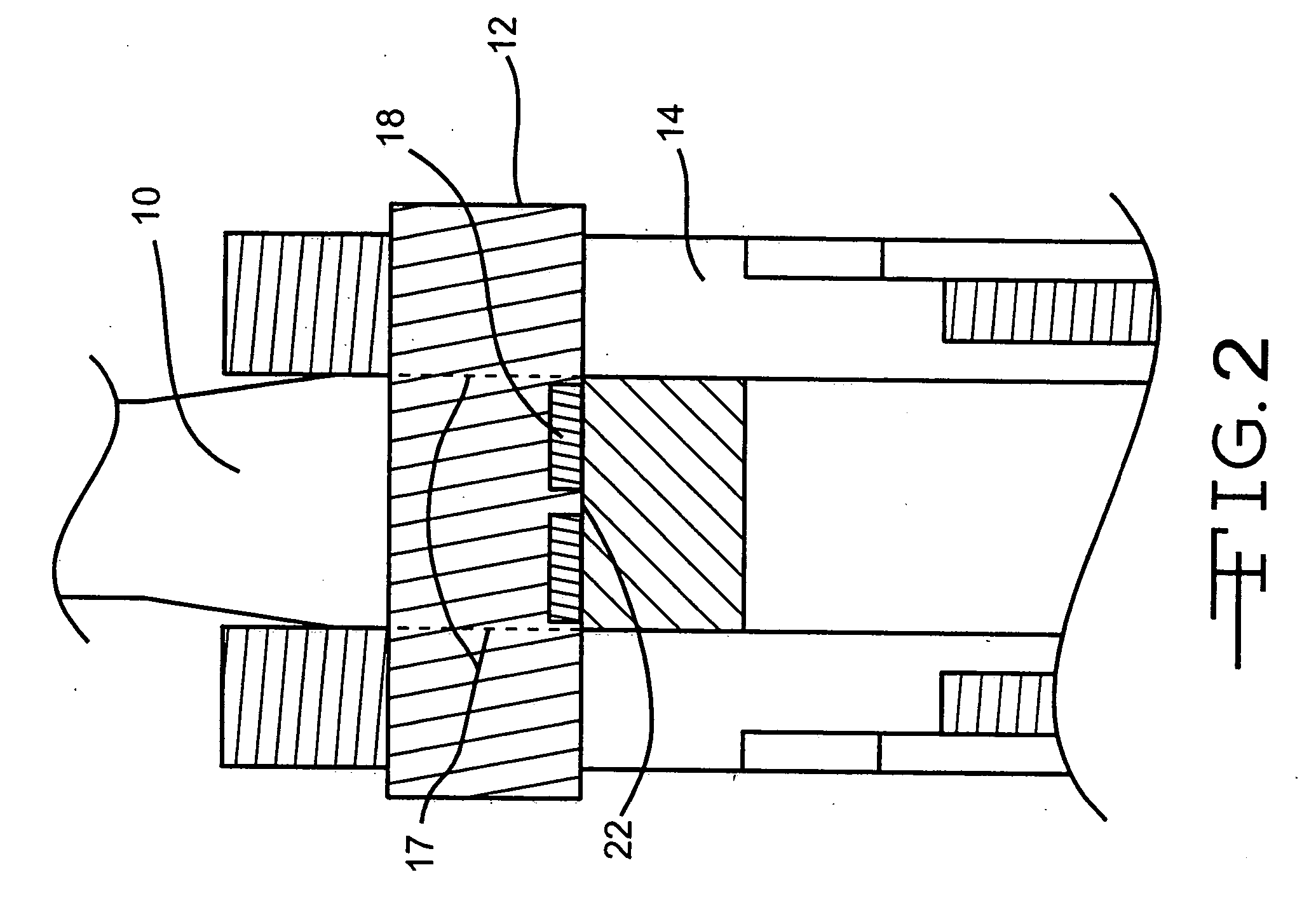

Pellet feeding system for a molding machine

InactiveUS6877933B2Reduce the amount requiredEasy to moveBulk conveyorsFood shapingProduction rateEpoxy

A feeding system (10) for epoxy mould compound (EMC) pellets which has a supply bowl (12) situated outside the clean environment (24) of a conventional automatic moulding machine (26). A tube (16) extends from the supply bowl (12) to a buffer hopper (14) within the clean environment and which is located above the feeder bowl (28) of the automatic moulding machine (26). EMC pellets are transported through the tube (16) from the supply bowl (12) into the buffer hopper (14) via a vacuum suction system (34), (36) which is connected to the tube (16) in proximity to the buffer hopper (14). A counter air flow may be provided to slow the speed of the pellets as they enter the buffer hopper. Batches of the pellets accumulated in the buffer hopper (14) are periodically released into the feeder bowl (28) of the automatic moulding machine (26). The vacuum transportation system reduces dust from the pellets. Also productivity is increased compared to conventional use of the automatic moulding machine (26) by providing for the supply bowl (12) to have a significantly larger capacity compared to the feeder bowl (28) of the automatic moulding machine (28).

Owner:ASM TECH SINGAPORE PTE LTD

Purging of a wafer conveyance container

InactiveUS20070144118A1Combination devicesSemiconductor/solid-state device manufacturingEngineeringClean environment

Embodiments of the invention are directed to methods and systems of purging of transfer containers, such as standardized mechanical interface (SMIF) pods. In particular, purified purge gases can purify front operated unified pods (FOUPs) and other non hermetically sealed transfer containers, such that the containers can be interfaced with a sealed chamber (e.g., a semiconductor processing tool) without detrimentally contaminating the environment of the sealed chamber with organics and other harmful contaminants. The methods and systems may be used to transfer objects, such as wafers, semiconductor components, and other materials requiring exposure to extremely clean environments, during electronic materials manufacturing and processing. Transfer containers specifically configured to promote purging of the container's enclosure are also described.

Owner:ENTEGRIS INC

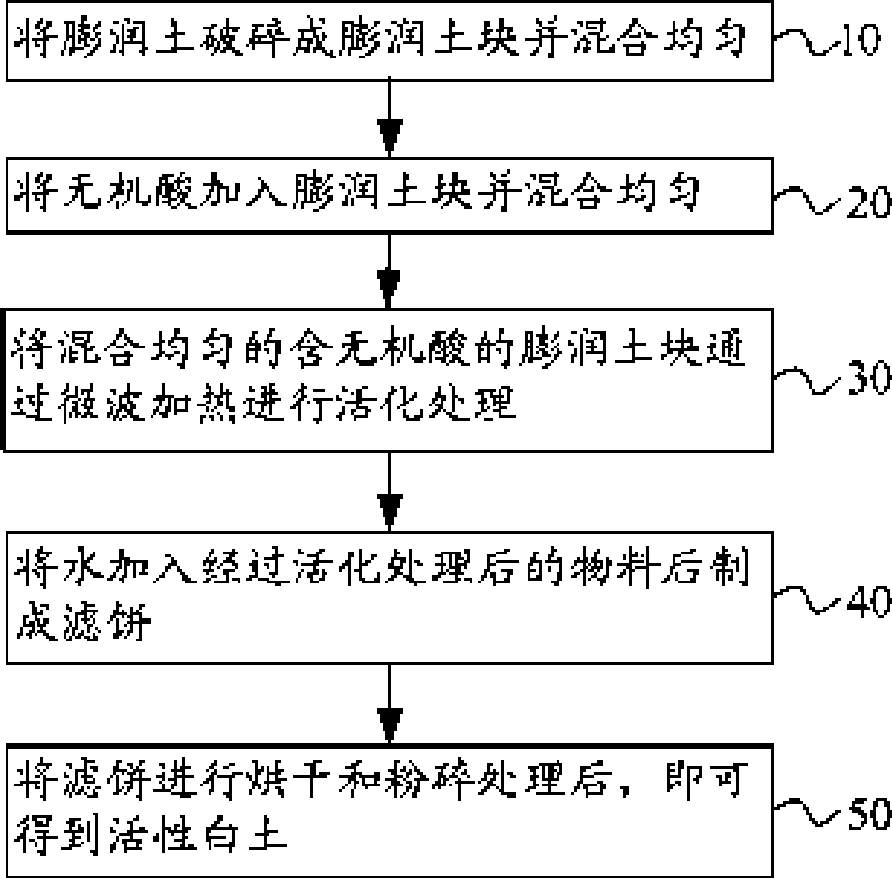

Active clay and preparation thereof

The invention relates to a method for preparing activated clay, which comprises the following steps that: bentonite is crushed into bentonite blocks and is well mixed; inorganic acid is added to the bentonite blocks and well mixed; the well mixed bentonite blocks containing inorganic acid is activated through microwave heating; the activated material is added with water and made into a filter cake; and the activated clay can be obtained after the filter cake is dried and ground. The invention also relates to activated clay prepared by the activated clay preparation method. The method utilizes the principles and characteristics of microwaves to improve the prior activation process of activated clay production, changes activation mechanism and mode so as to achieve optimum activation effects, reduces energy consumption, realizes the automation of activated clay production, reduces production cost, and simultaneously realizes clean environment.

Owner:ANHUI PENGRUN MINING TECH

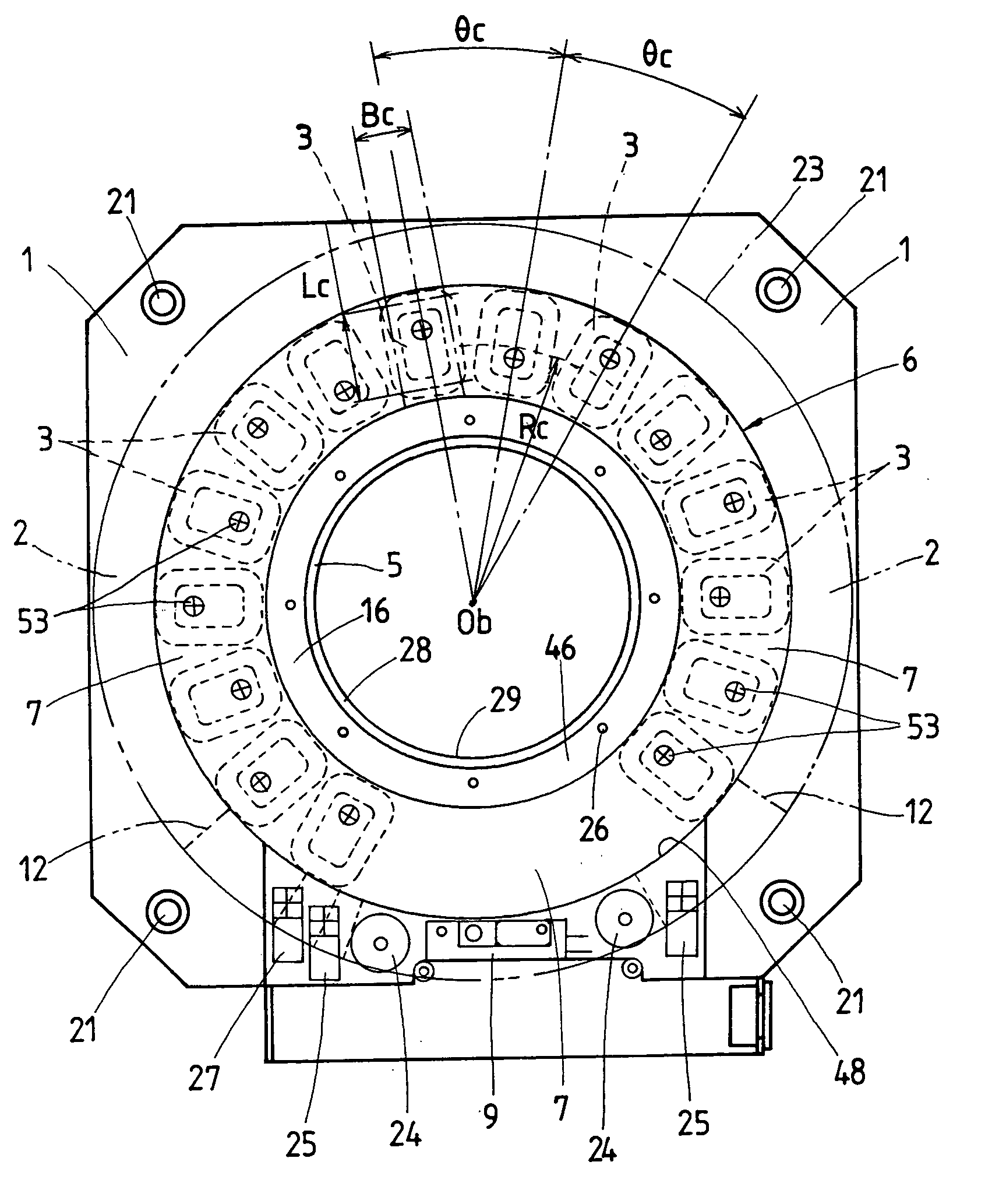

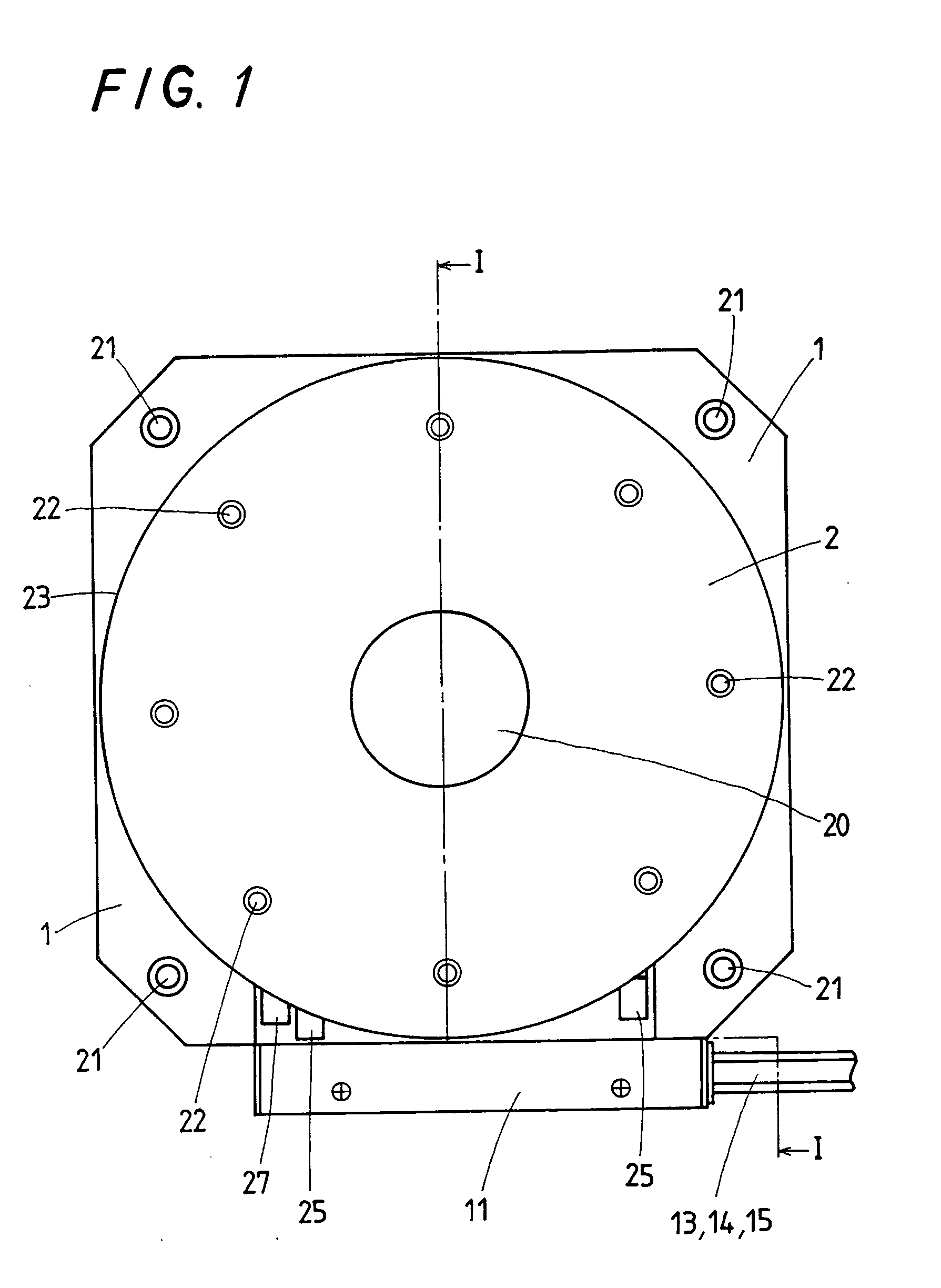

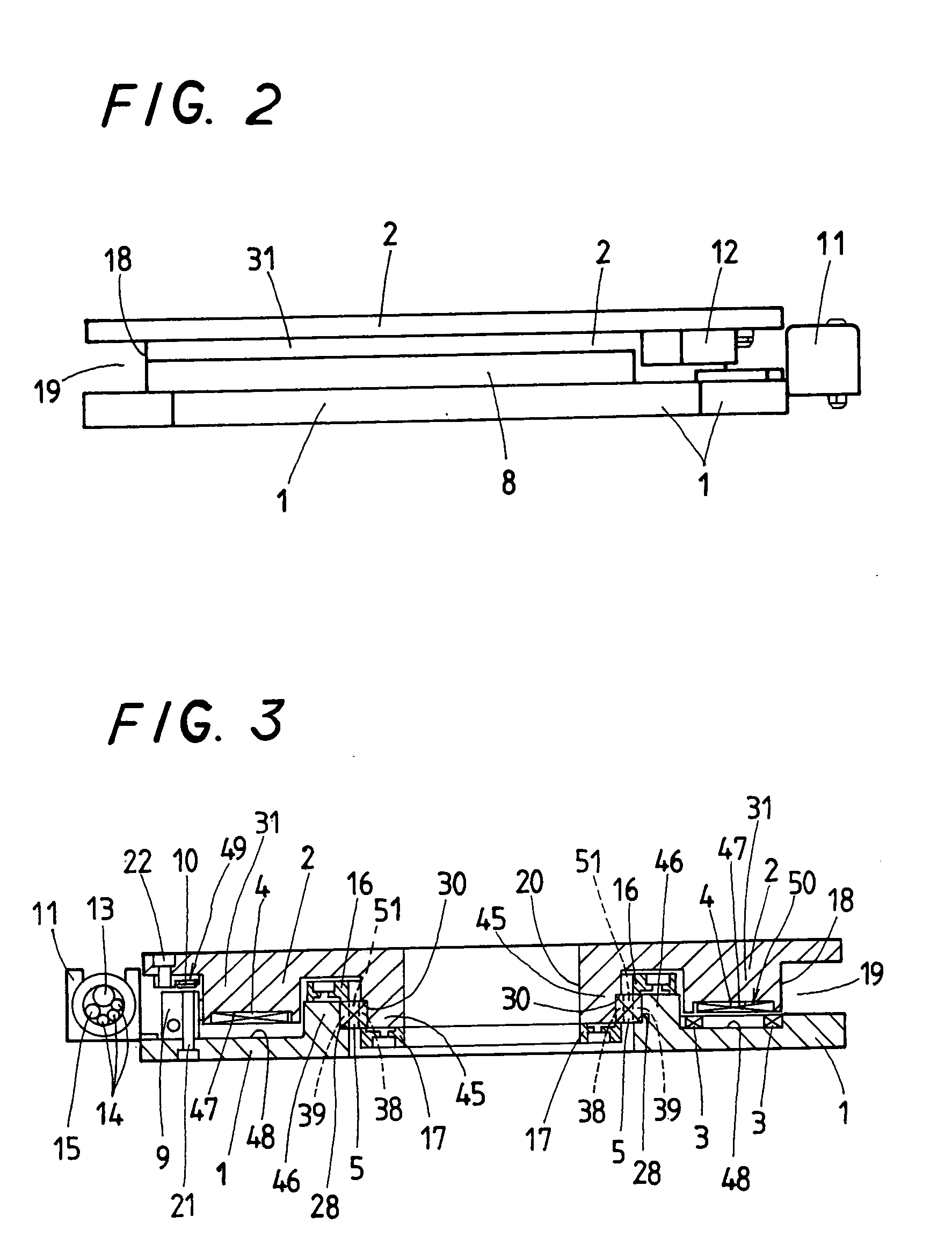

Position-control stage with onboard linear motor

A position-control stage is disclosed which makes it possible to extend largely an angular movement in circular direction for position control, rendering the stage itself compact in construction, allowing to work with high precision in clean environment and further produce the stage with inexpensive cost. The position-control stage has an onboard linear motor composed of armature windings of primary side and field magnets of secondary side. The armature windings are each made in a hollow rectangle where winding turns are wound in the form of flat loop, and are circularly arranged on a disc surface of the bed along a preselected curvature in such a way lying in radial juxtaposition in circumferential direction. The field magnets are made in a flat shape and arranged underneath the turntable in such a pattern lying radially on a disc surface of the preselected curvature in opposition to the armature windings, with their unlike poles alternating in polarity along a circular direction.

Owner:NIPPON THOMPSON

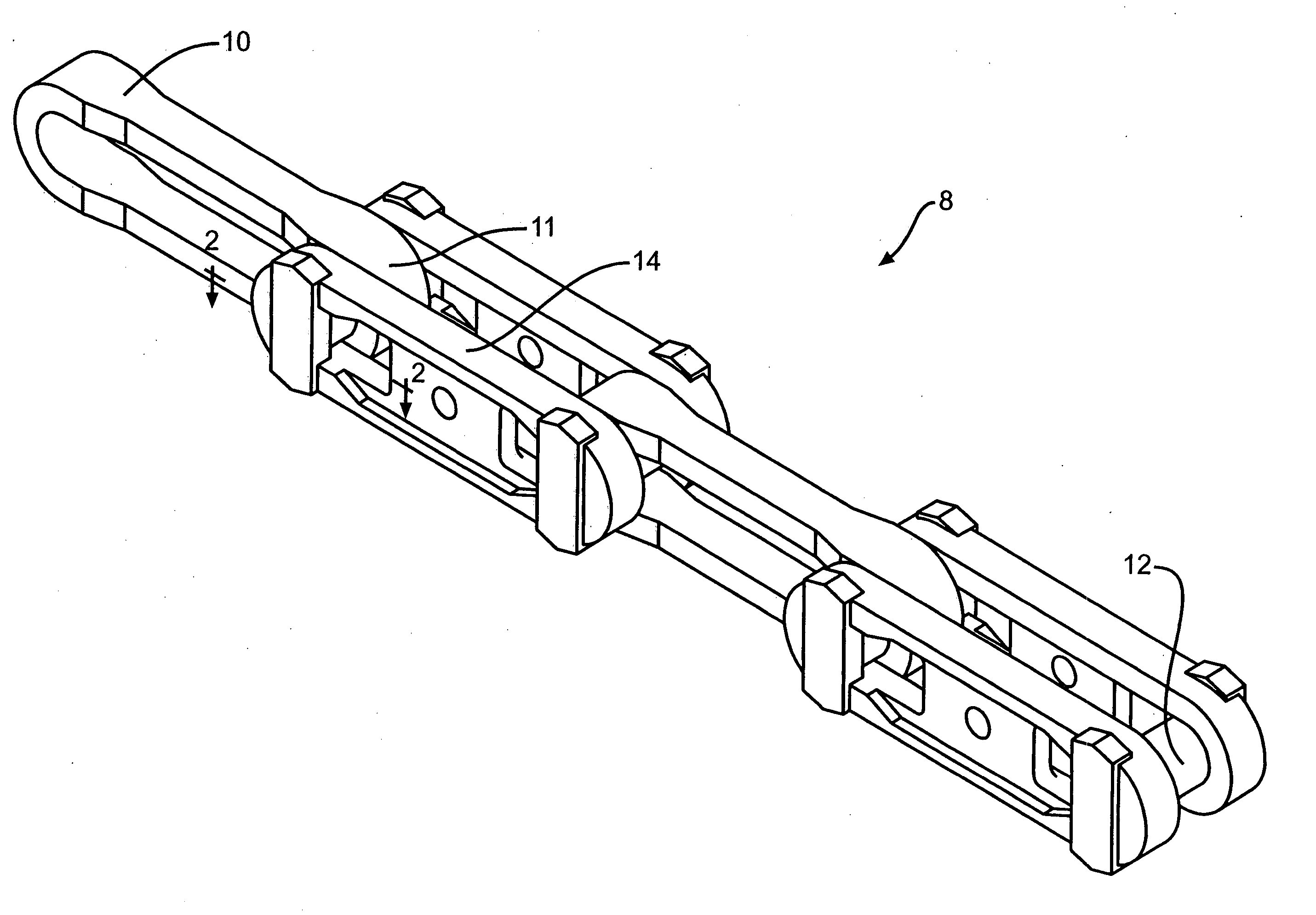

System for lubricating a rivetless chain

The pin and center link of the invention is used in a rivetless chain. It is manufactured to contain a reservoir to receive a lubricant. The reservoir may be in the form of a hole or a groove of various configurations. The lubricant is inserted into the pin or center link to provide lubrication to the center link / pin interface for extending the life of the chain. The size and location of the reservoir are selected to optimize the overall balance between load bearing strength and lubricant surface area at the center link / pin interface. The lubrication system of the present invention will also prevent leakage of lubricant onto the product and provide a clean environment.

Owner:LACERDA MARIO

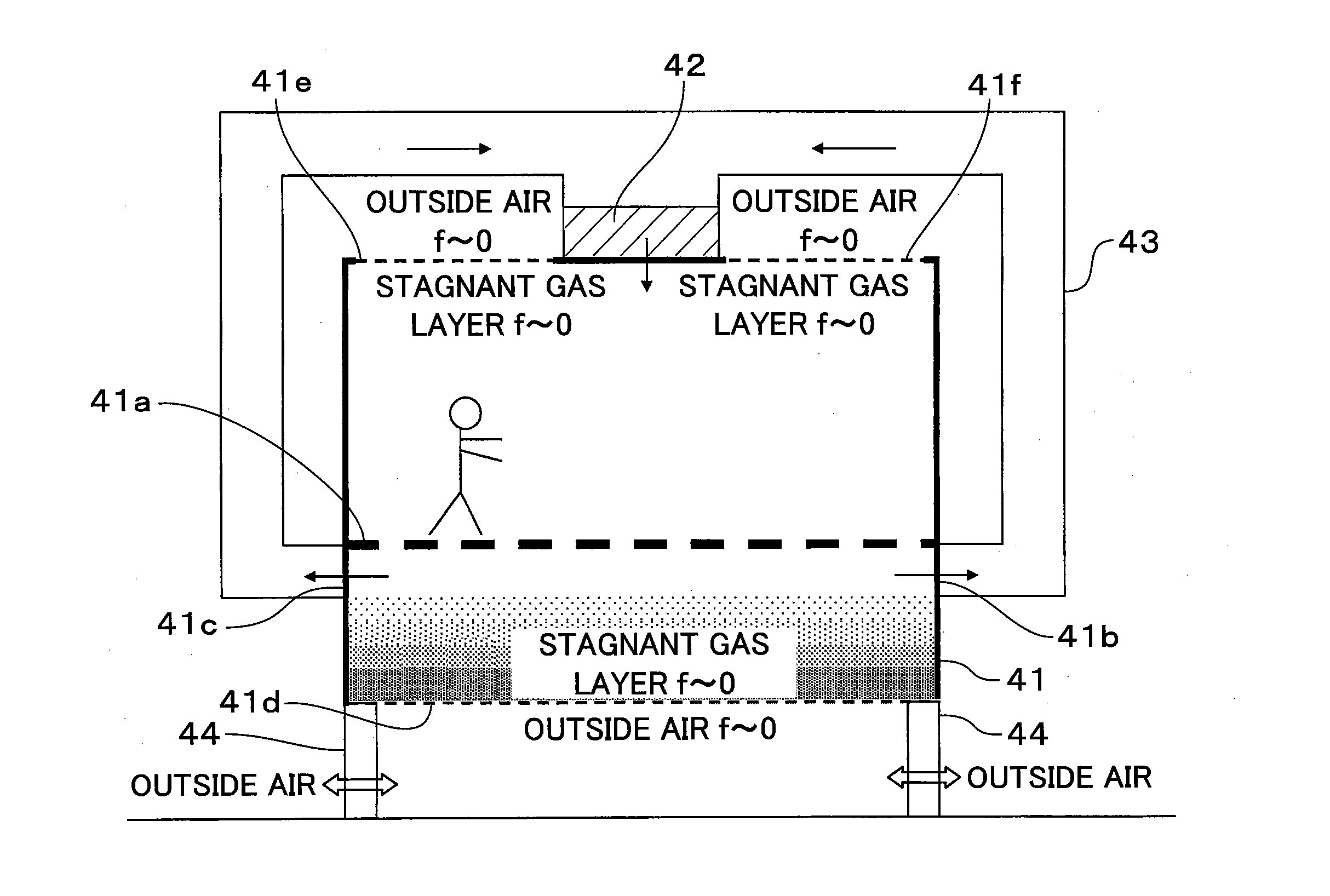

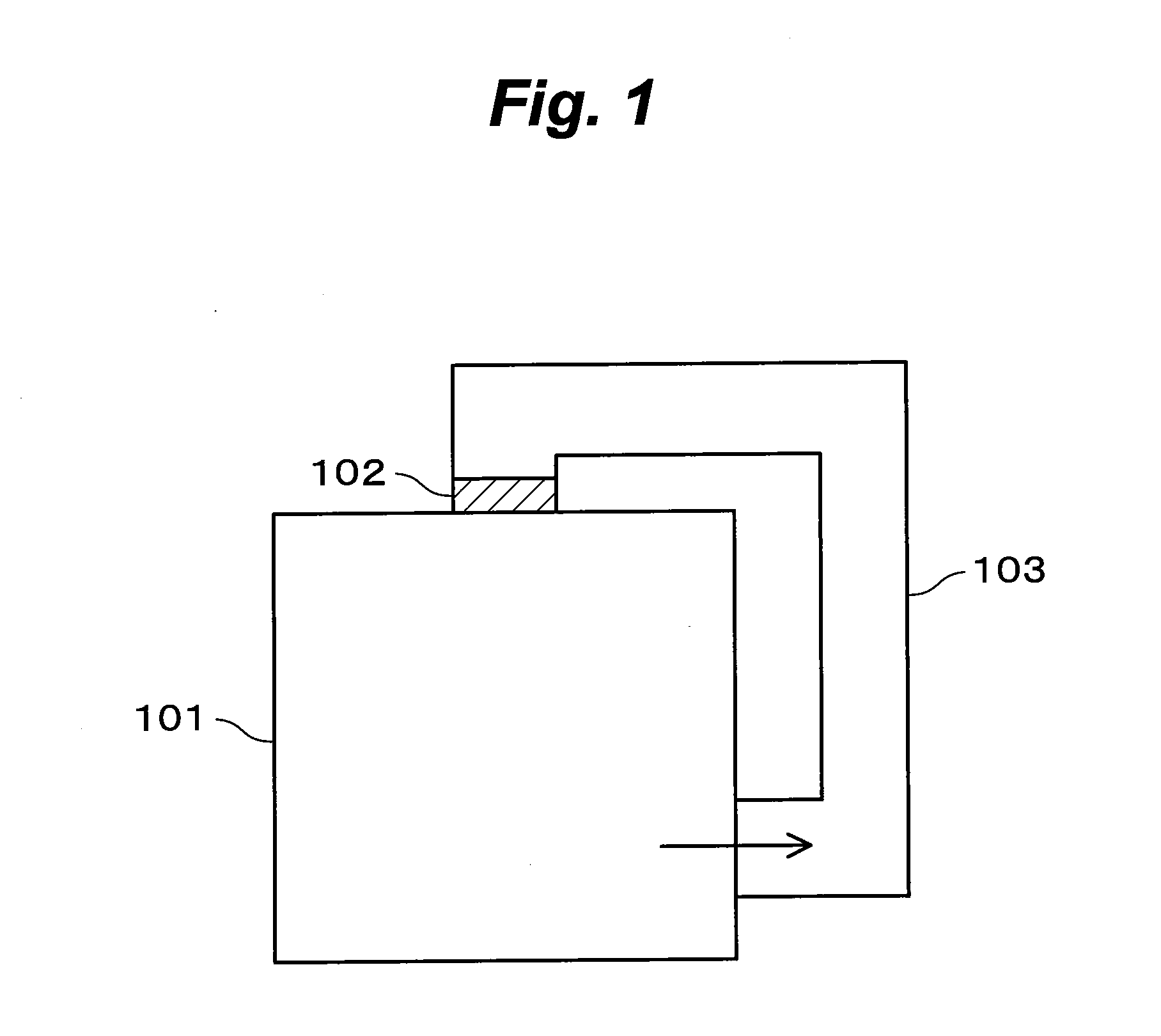

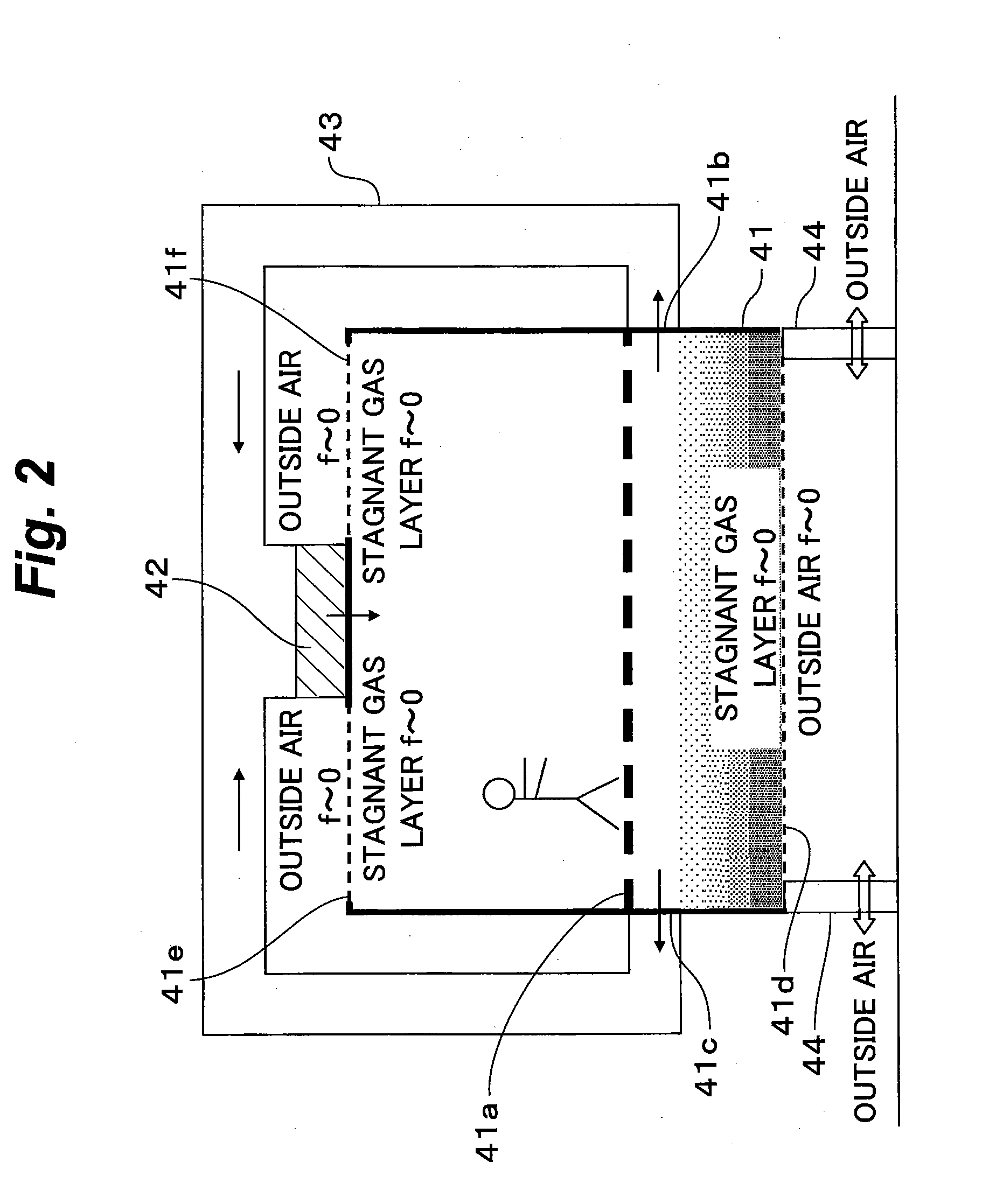

Clean unit, method of operating clean unit, and connected clean unit

InactiveUS20100105309A1Low costIncrease flexibilityMechanical apparatusLiquid surface applicatorsEngineeringDust particles

In a clean unit which has a dust filter with a blowing power source on the upper surface of a working chamber and which can maintain a clean environment, an external gas flow passage is directly connected or connected through a partition wall, through which dust particles cannot pass but gas molecules can pass, to a feedback gas flow passage for connecting air-tightly a ventilation hole formed in the wall of the working chamber and the inlet of the dust filter to each other. On both sides of the partition wall, the flow velocity vector of a gas flowing in the feedback gas flow passage is made to be equal to the flow velocity vector of the gas flowing in an external gas flow passage.

Owner:CSTEC CORP +1

Aseptic transfer port

Rapid transfer port (RTP) systems for transferring articles between two environments (e.g., an isolator barrier system and a transfer container) are provided. Such systems may be adapted to be mated to one another by a docking operation. More particularly, such systems may provide a container assembly for use with an RTP of the type that does not require the transfer container port (beta port) which mates, for example, with the isolator barrier system port (alpha port) to breach the integrity of the container until attachment to the isolator barrier system port (alpha port 9). The container assembly may have an enclosure that, during docking, is not required to be exposed to the clean environment such as an isolator barrier system.

Owner:STTPHARMA

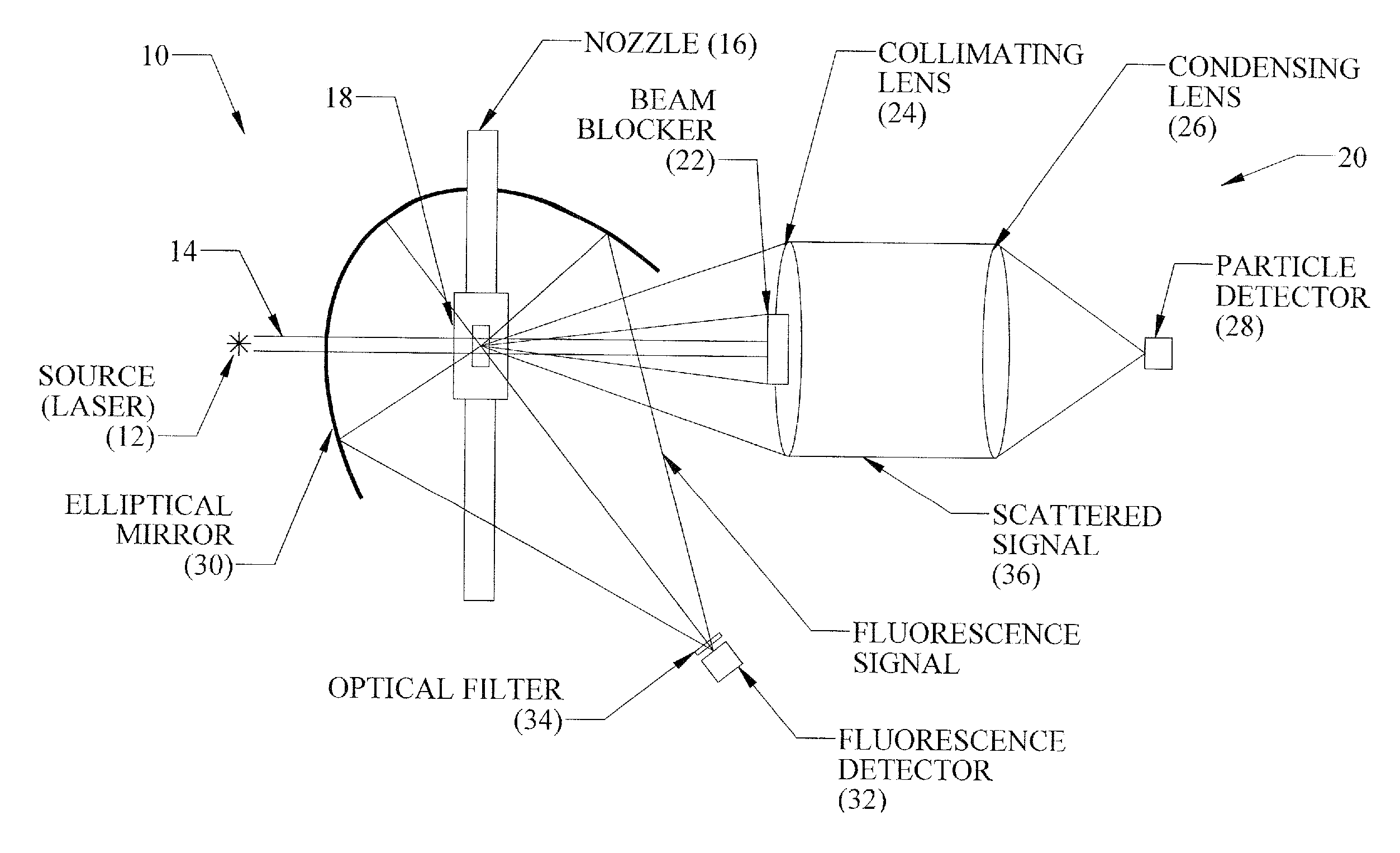

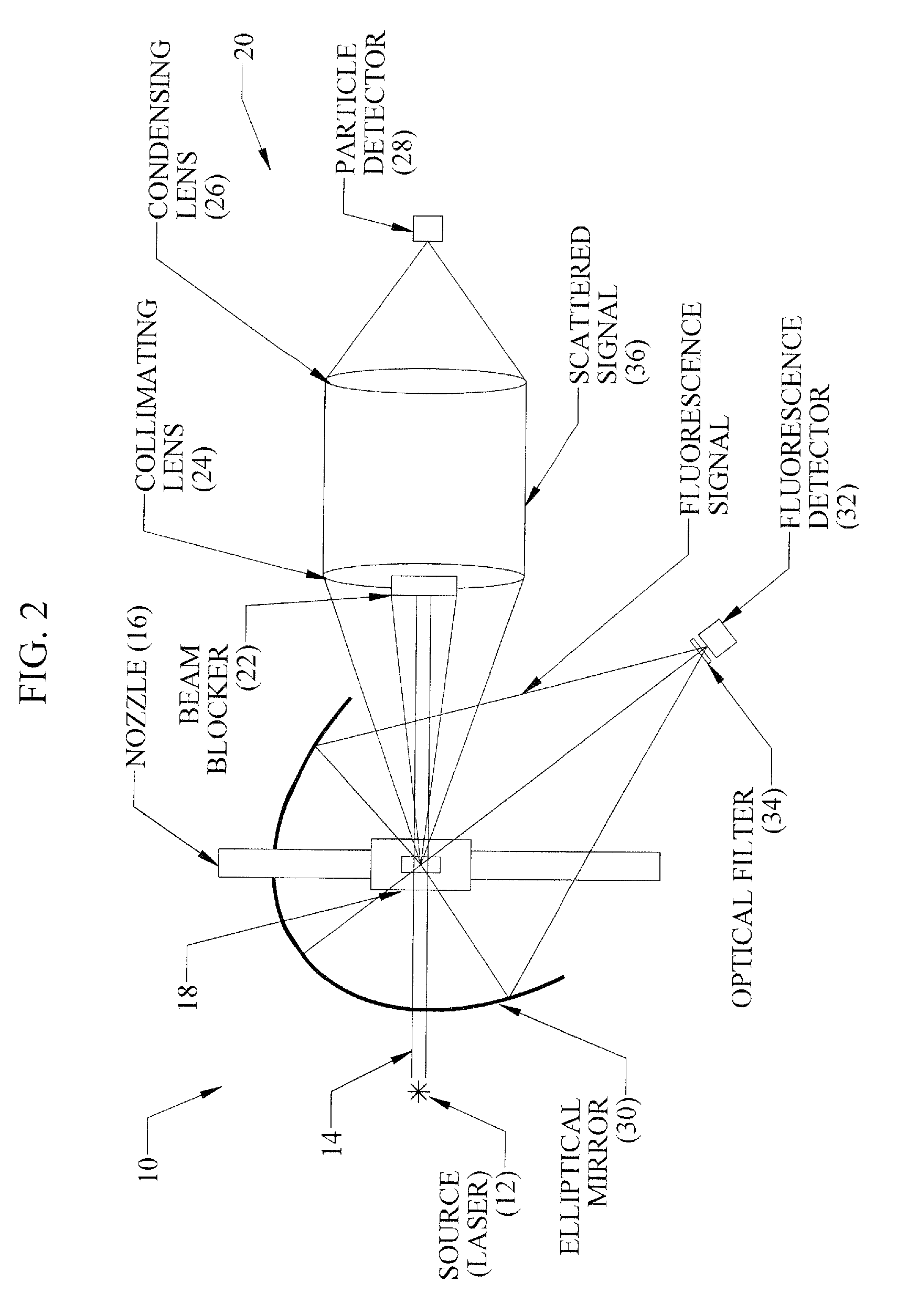

Method for the detection of biologic particle contamination

ActiveUS20090242799A1Avoid cleaningReduce dependencePhotometryLuminescent dosimetersClean environmentImaging data

Methods for detecting particles in a fluid, including determining particle size and intrinsic fluorescence of a particle, and time correlating the particle detection data with image data in the vicinity of the detector or detector inlet to identify contamination sources in clean environments are described.

Owner:YAMATAKE HONEYWELL CO LTD

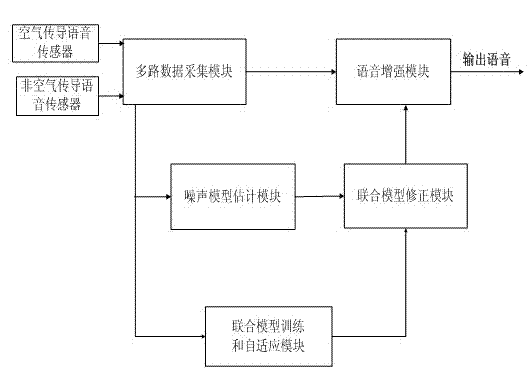

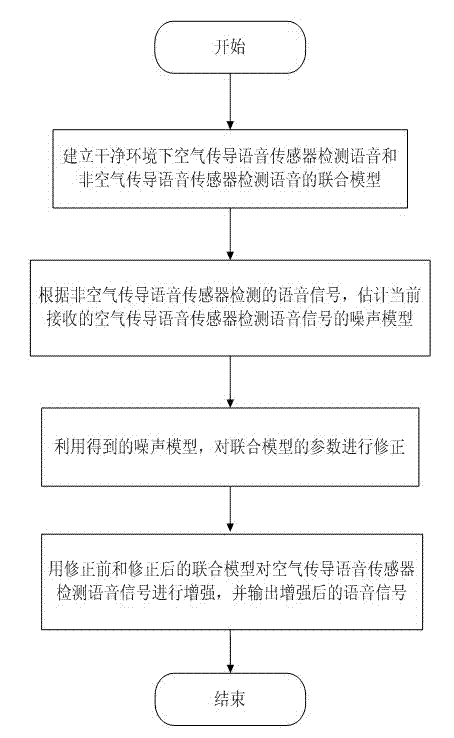

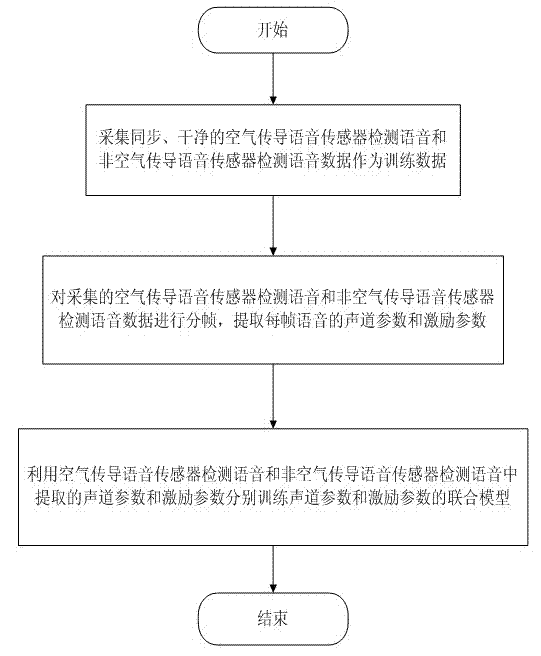

Speech enhancement method and device applicable to strong noise environments

InactiveCN103208291AStrong anti-noise abilityImprove voice qualitySpeech analysisSelf adaptiveData acquisition module

The invention discloses a speech enhancement method and device applicable to strong noise environments. The method comprises establishing an air conduction speech sensor speech detection and non-air conduction speech sensor speech detection combined model under a clean environment; estimating a noise model of a currently received air conduction speech sensor speech detection signal according to a speech signal detected by a non-air conduction speech sensor; correcting parameters of the combined model by using the obtained noise model; and enhancing the air conduction speech sensor speech detection signal through the combined model before and after correction, and outputting enhanced speech signals. The device comprises an air conduction speech sensor, the non-air conduction speech sensor, a multi-channel data acquisition module, a noise model estimation module, a combined model correction module, a speech enhancing module and a training and self-adaptive module for the combined model. Compared with the prior art, the speech enhancement method and device have the advantages of being strong in noise immunity, good in speech quality and the like.

Owner:SOUTH CHINA UNIV OF TECH

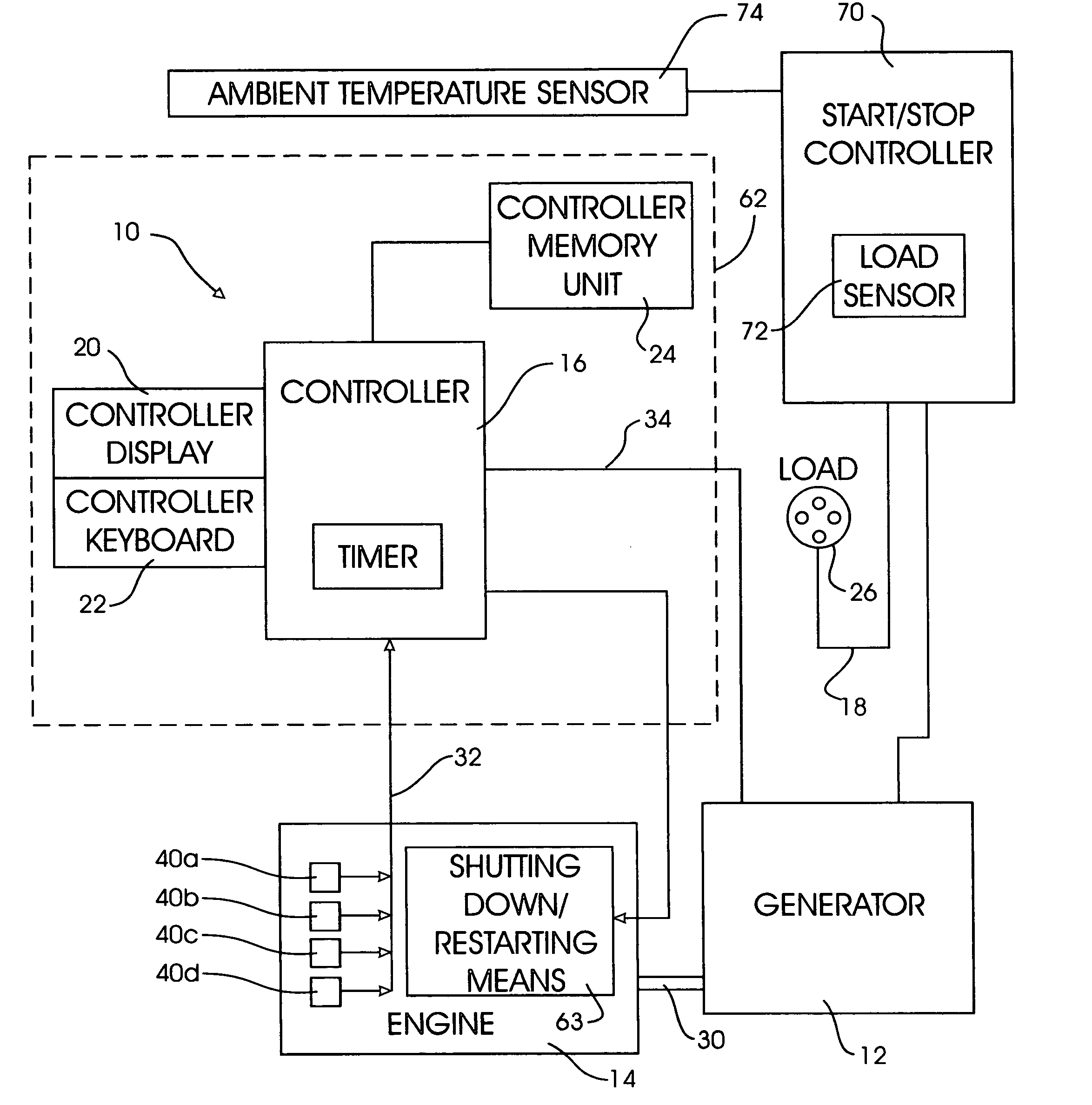

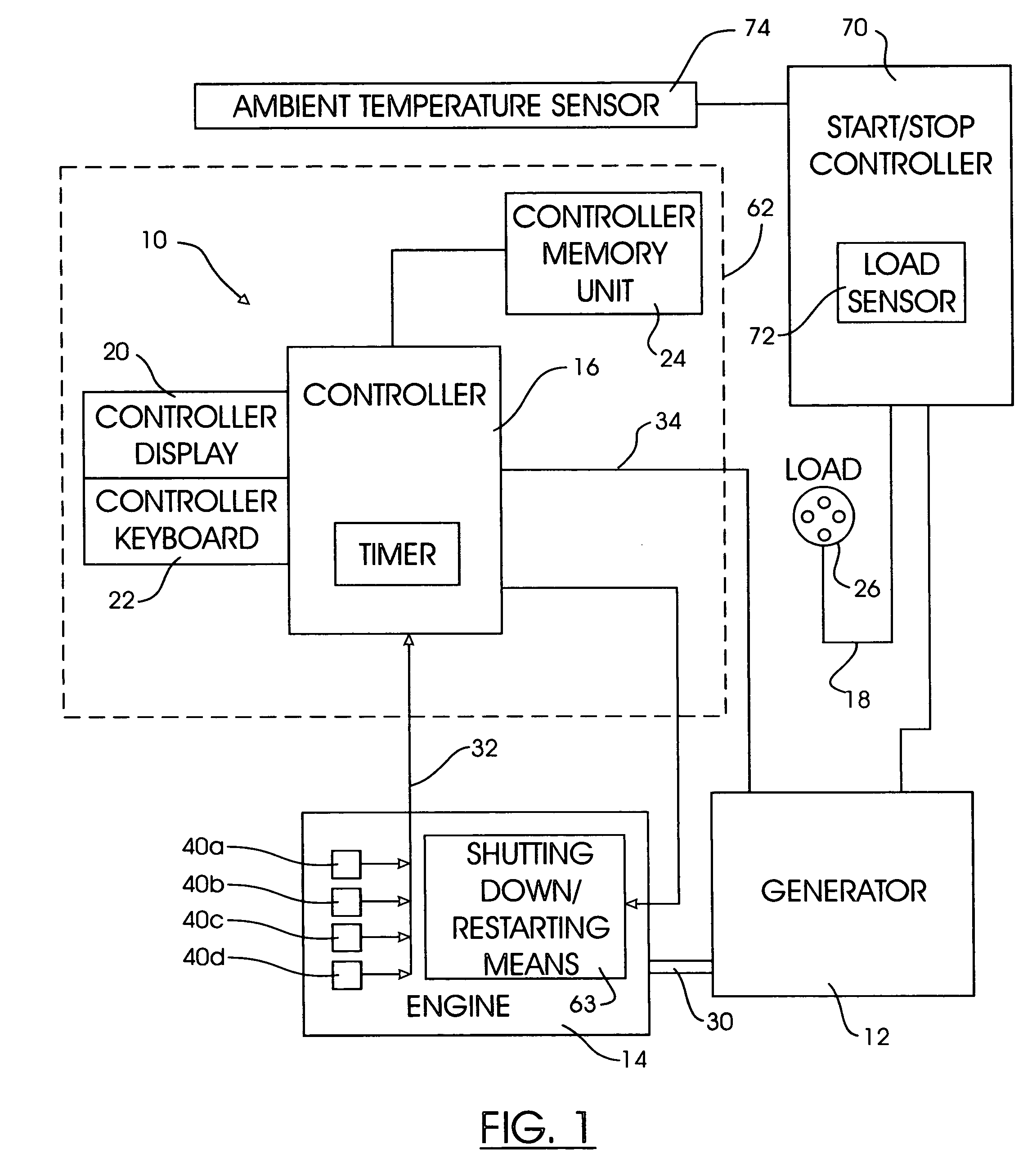

Generator start/stop controller

ActiveUS20070296379A1Clean environmentLow costMotor/generator/converter stoppersEmergency protective circuit arrangementsRefrigerationClean environment

A method and apparatus is disclosed for starting and stopping a generator set that supplies power to a refrigeration system. An ambient temperature sensor is used rather than an in-box sensor in addition to a programmed microprocessor to regulate the operation of the generator. Unnecessary use of the generator is, thereby, limited which contributes to cost, energy and equipment savings and a cleaner environment while ensuring the required in-box temperature is maintained and the quality of perishable goods are not compromised.

Owner:GENDRON JACK DELBERT

Modular air purification unit

InactiveUS7520910B2Easy to disassembleCombination devicesLiquid degasificationAir filtrationAir purification

A modular air filtration unit having a disposable filter section separable from an inlet cap and a blower section. The modular air filtration unit is of rugged, lightweight construction and eases the interchange of used filter assemblies without jeopardizing leakage that might cause contamination of the intended clean environment.

Owner:IMMEDIATE RESPONSE TECH +1

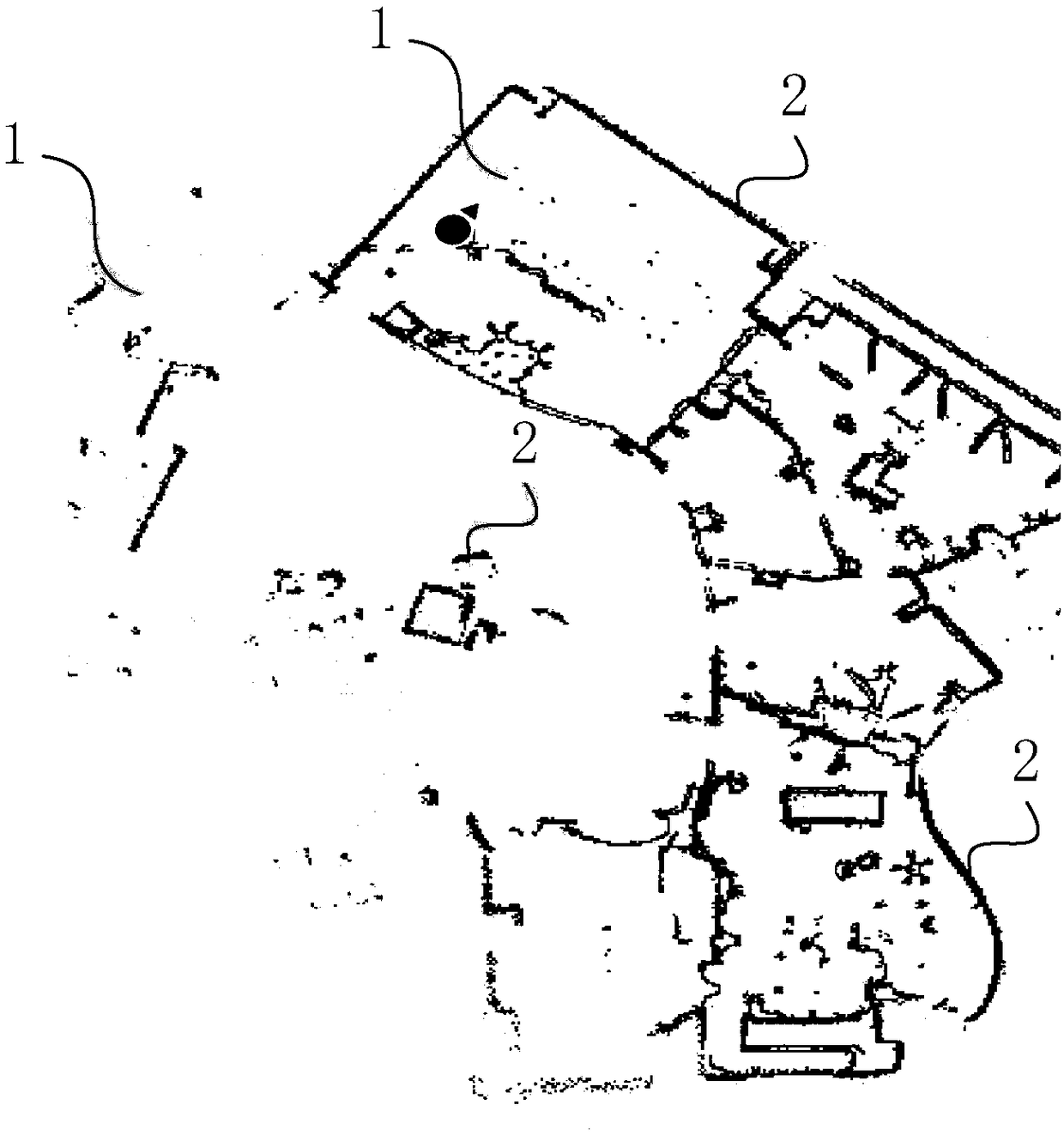

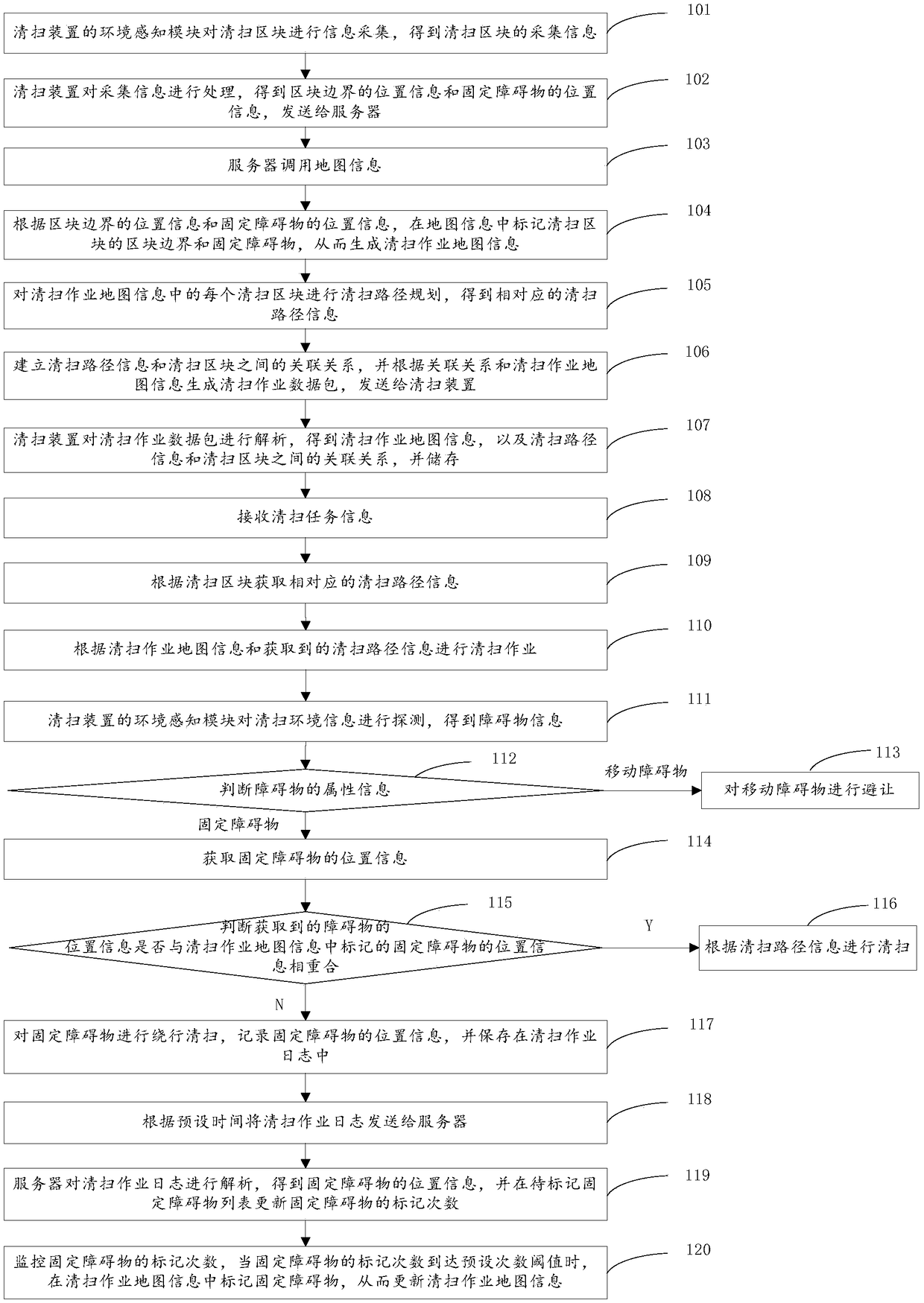

Processing method of operation map information

InactiveCN108733060AAccurately plan the work pathGuaranteed accuracyPosition/course control in two dimensionsVehiclesPath planComputer science

An embodiment of the invention relates to a processing method of operation map information. The method comprises the steps of making a block boundary and a fixed obstacle of a cleaning block in map information, thereby generating cleaning operation map information; performing cleaning path planning on each cleaning block, and obtaining corresponding cleaning path information; performing a cleaningoperation according to the cleaning operation map information and the cleaning path information; detecting the cleaning environment information and obtaining obstacle information; when attribute information of the obstacle is fixed obstacle, acquiring the position information of the fixed obstacle; and the number of marking times of the fixed obstacle reaches a preset number-of-times threshold, updating the cleaning operation map information. According to the processing method, an accurate cleaning operation map is generated based on the map information and the cleaning block information, thereby accurately planning an operation path; furthermore the cleaning operation map information can be updated according to a detecting result, thereby ensuring high accuracy of the cleaning operationmap, and saving electric quantity and cleaning time of a cleaning device in a cleaning process.

Owner:BEIJING ZHIXINGZHE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com