Porous carbon adsorbing agent containing nano zinc oxide micropartical and its preparation process and application

A nano-zinc oxide, porous carbon technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of secondary pollution of microorganisms, and achieve the effect of preventing secondary pollution and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

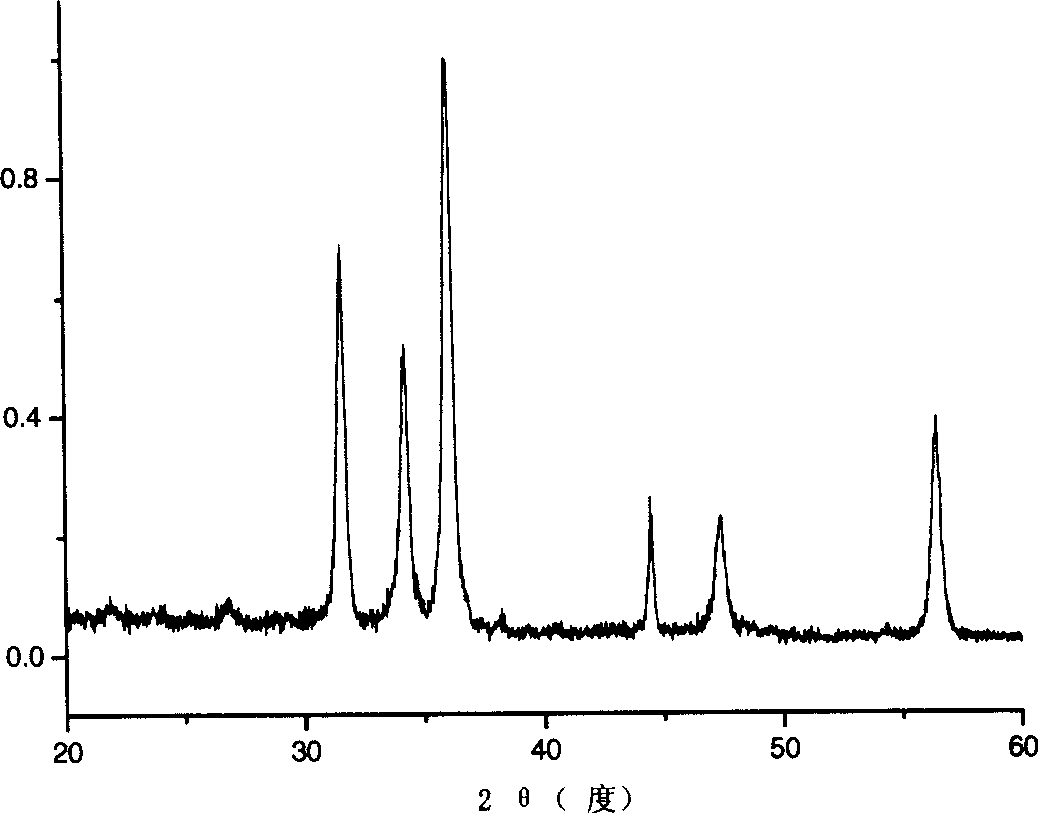

[0024] By ethanol: water: zinc nitrate: surfactant: active carbon fiber=30ml: 100ml: 5g: 15g: 5g ratio, ethanol, water and zinc nitrate are mixed, add surfactant sodium dodecylbenzenesulfonate again, Make a microemulsion; then add activated carbon fiber; add sodium hydroxide solution (concentration 1 mole / liter) under stirring according to the molar ratio of zinc nitrate: sodium hydroxide = 1: 1, to form zinc hydroxide precipitation. The solution was filtered off, washed and dried; the resulting solid mixture was burned at 600° C. for 1 hour to obtain activated carbon fibers containing nano-zinc oxide particles. The loading of zinc oxide in the product is 40%wt. The product is analyzed by a scanning electron microscope, and its surface is loaded with dense particles, which are in an agglomerated state, and the particle size of the aggregate is about 1 μm. Agglomerates are composed of many finer nanoscale particles. The particles were analyzed by X-ray diffraction and proved ...

Embodiment 2

[0026] By ethanol: water: zinc nitrate: surfactant: activated carbon fiber=20ml: 120ml: 5g: 20g: 5g ratio, ethanol, water and zinc nitrate are mixed, add surfactant sodium dodecylbenzenesulfonate again, Make a microemulsion; then add activated carbon fiber; add sodium hydroxide solution (concentration 2 mol / liter) under stirring according to the molar ratio of zinc nitrate: sodium hydroxide = 1: 3, to form zinc hydroxide precipitation. The solution was filtered off, washed and dried; the resulting solid mixture was burned at 600° C. for 1 hour to obtain activated carbon fibers containing nano-zinc oxide particles. The loading of zinc oxide in the product is 20%. The product is analyzed by a scanning electron microscope, and its surface is loaded with dispersed particles with a particle size of about 10-20nm. The particles were analyzed by X-ray diffraction and proved to be hexagonal zinc oxide crystals. The crystal grain size calculated from X-ray diffraction was 10 nm.

Embodiment 3

[0028] According to the ratio of ethanol: water: zinc nitrate: surfactant: activated carbon=30ml: 100ml: 8g: 20g: 5g, ethanol, water and zinc nitrate are mixed, then add surfactant sodium dodecylsulfonate, be made into Microemulsion; then add active carbon; add sodium hydroxide solution (concentration 1 mole / liter) by the molar ratio of zinc nitrate: sodium hydroxide=1:1 under stirring to form zinc hydroxide precipitate. The solution was filtered off, washed and dried; the resulting solid mixture was burned at 600°C for 1 hour to obtain the product activated carbon containing nano zinc oxide particles. The loading of zinc oxide in the product is 65%wt. The product is analyzed by a scanning electron microscope, and its surface is loaded with dense strip-shaped hexagonal columnar crystals, with a crystal diameter of about 20nm and a length of about 300nm. The particles were analyzed by X-ray diffraction and proved to be hexagonal zinc oxide crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com