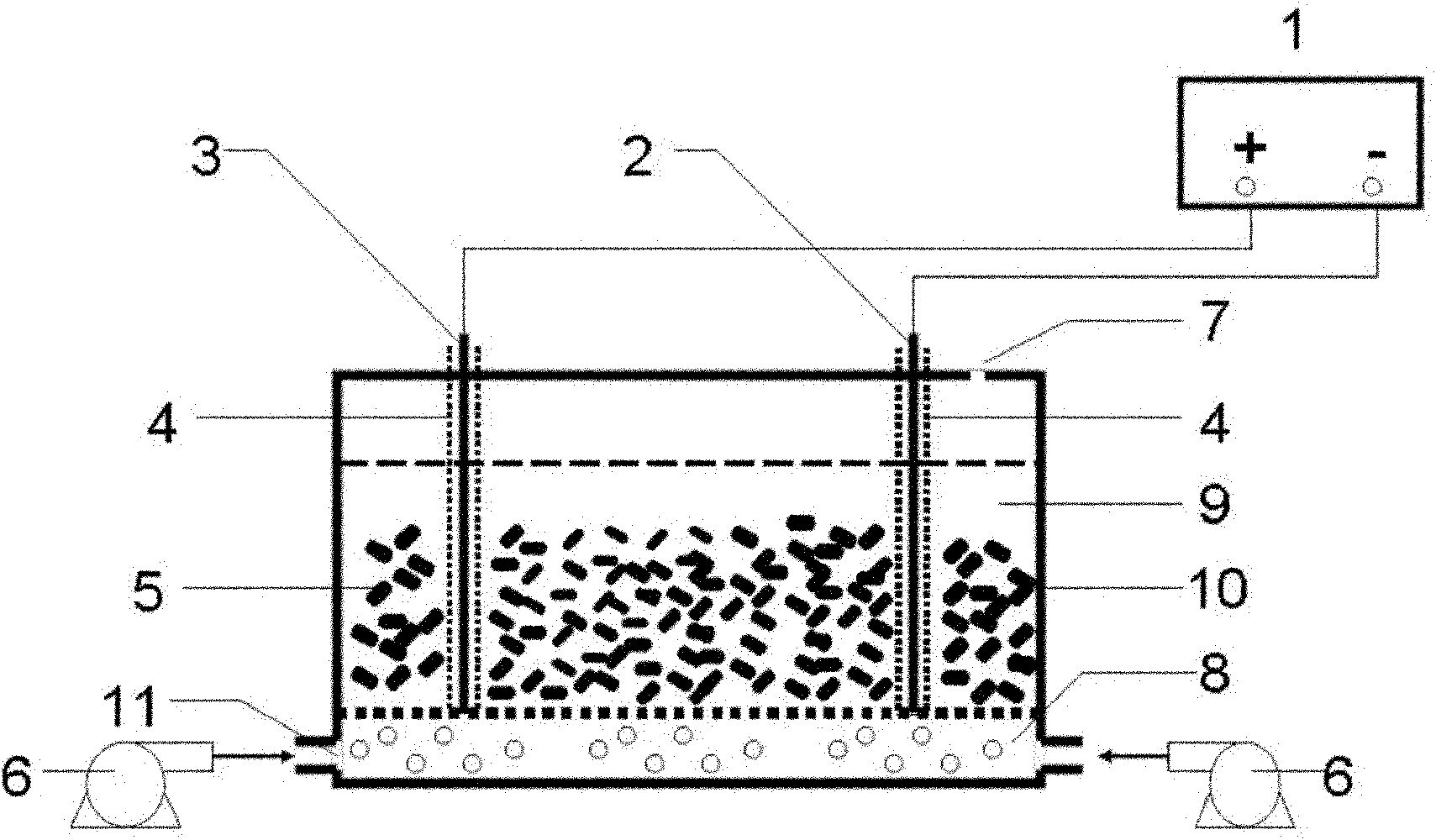

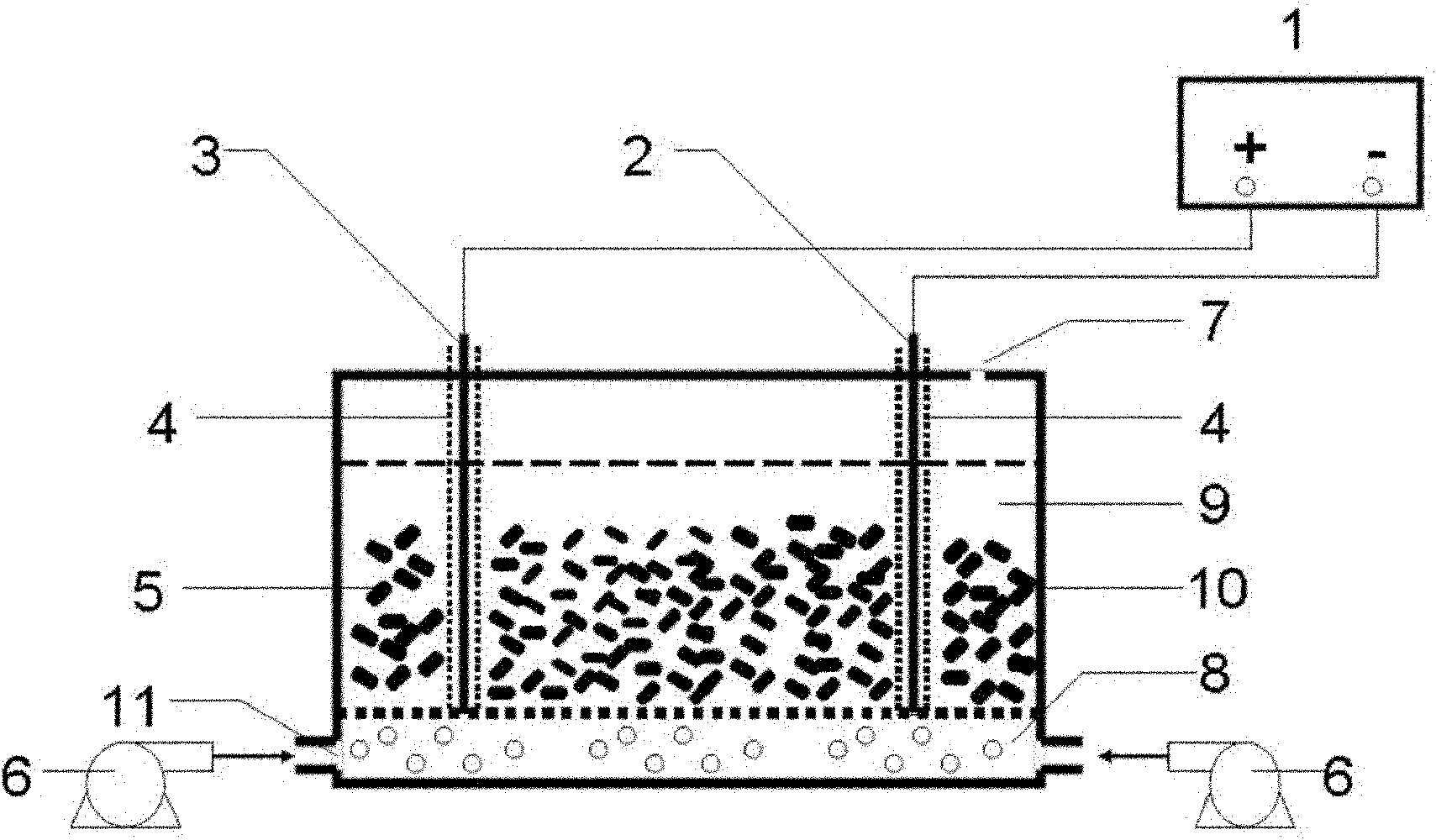

Method for removing organic matters in water by utilizing three-dimensional electrode electro-fenton and device thereof

A three-dimensional electrode, water removal technology, applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., to save operating costs, reduce mass transfer effects, and improve reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Three-dimensional Electrode Fenton Oxidation Treatment of Explosives Wastewater

[0023] Take 400mL of explosive wastewater after flocculation, adjust the pH to 7, add 300g of activated carbon, use carbon fiber (ACF) as the cathode, iron sheet as the anode, and the distance between the plates is 8cm. Actual electrolysis area: 5cm×6cm. Both ends of the reactor were simultaneously aerated (flow rate 3.5 L / min). Constant voltage 9V. Sampling every 1h, the reaction time is 4h. The COD values before and after treatment are shown in Table 1.

[0024]Table 1 embodiment 1 different treatment time COD value

[0025] time

Embodiment 2

[0026] Example 2: Three-dimensional Electrode Fenton Oxidation Treatment of Leather Wastewater

[0027] Take 400mL of leather wastewater, adjust the pH to 2, add 300g of medical stone, use the graphite electrode as the cathode, the iron sheet as the anode, and the distance between the plates is 8cm. Actual electrolysis area: 5cm×6cm. Both ends of the reactor were simultaneously aerated (flow rate 5L / min), and the constant voltage was 12V. Sampling every 1h, the reaction time is 3h. The COD values before and after treatment are shown in Table 2.

[0028] Table 2 embodiment 2 different treatment time COD value

[0029] time

Embodiment 3

[0030] Example 3: Three-dimensional Electrode Electro-Fenton Oxidation Treatment of Printing and Dyeing Wastewater

[0031] Take 400mL of printing and dyeing wastewater, adjust the pH to 5, add 300g of zeolite, use the carbon nanotube composite material as the cathode, and the iron plate as the anode, the distance between the plates is 9cm, the actual electrolysis area: 5cm×6cm. Both ends of the reactor were simultaneously aerated (flow rate 8L / min), and the constant voltage was 15V. Sampling every 1h, the reaction time is 3h. The COD values before and after treatment are shown in Table 3.

[0032] Table 3 embodiment 3 different treatment time COD value

[0033] time

[0034] 3h

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com