Patents

Literature

8928results about How to "Improve reaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

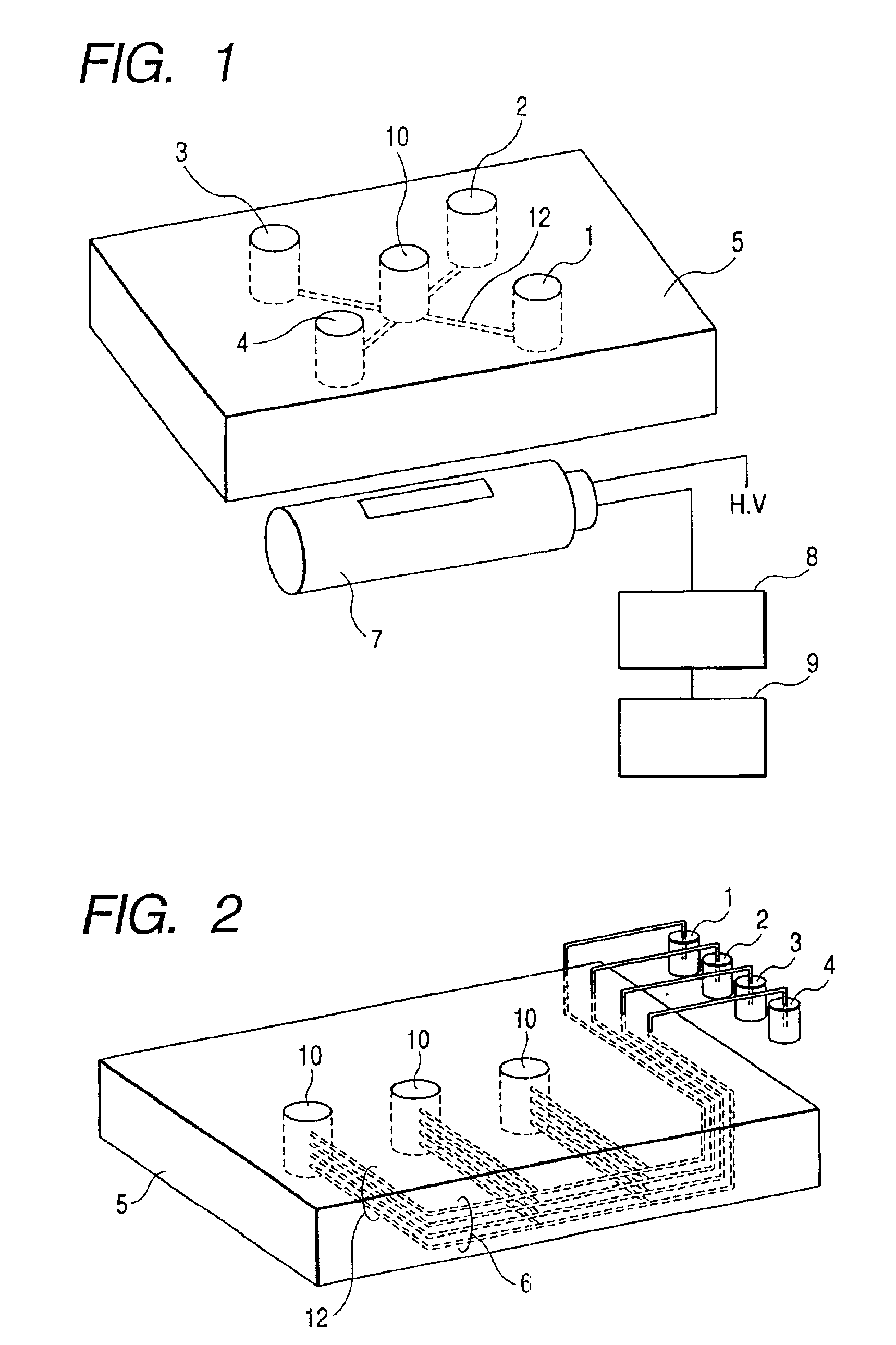

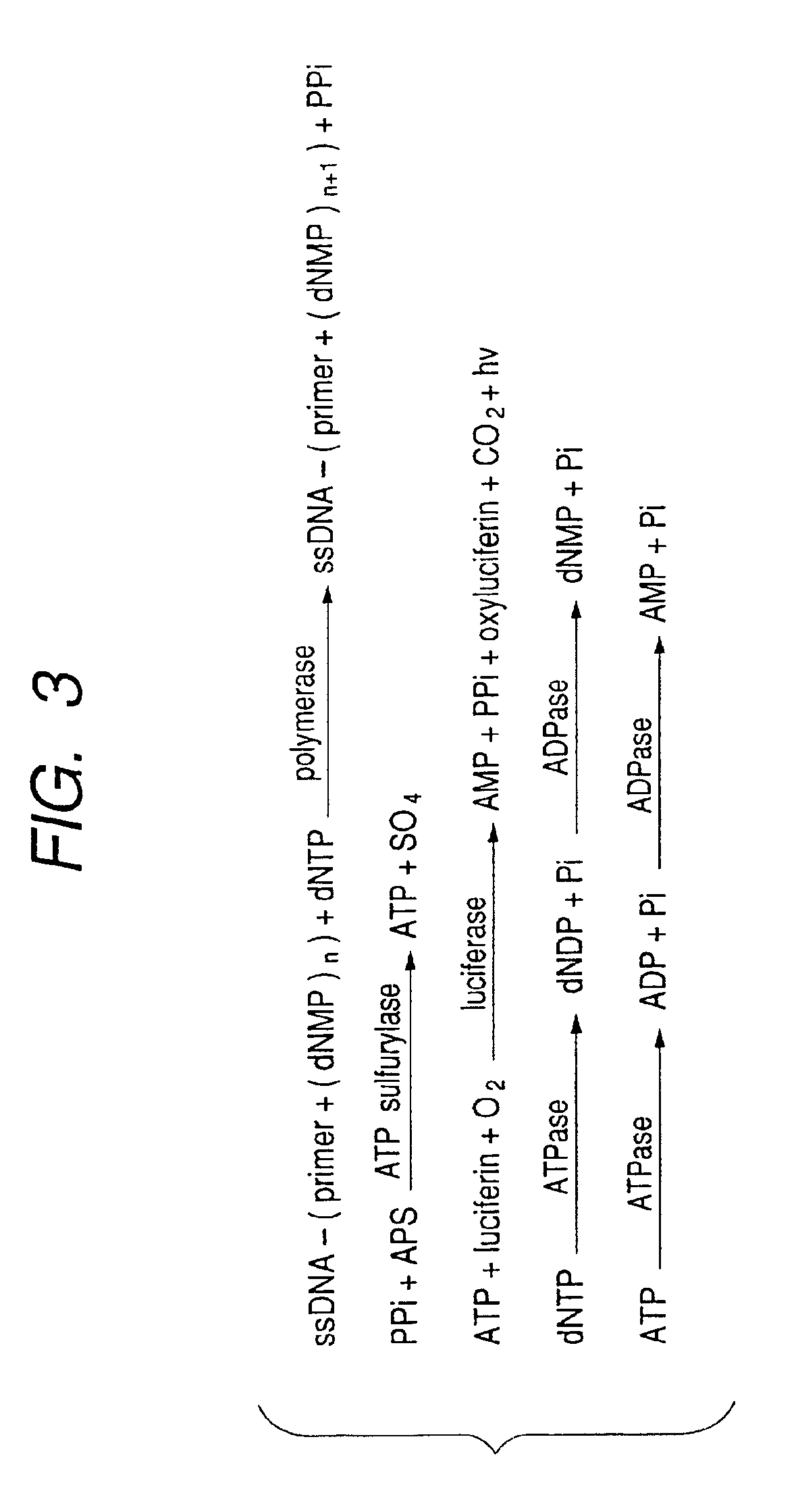

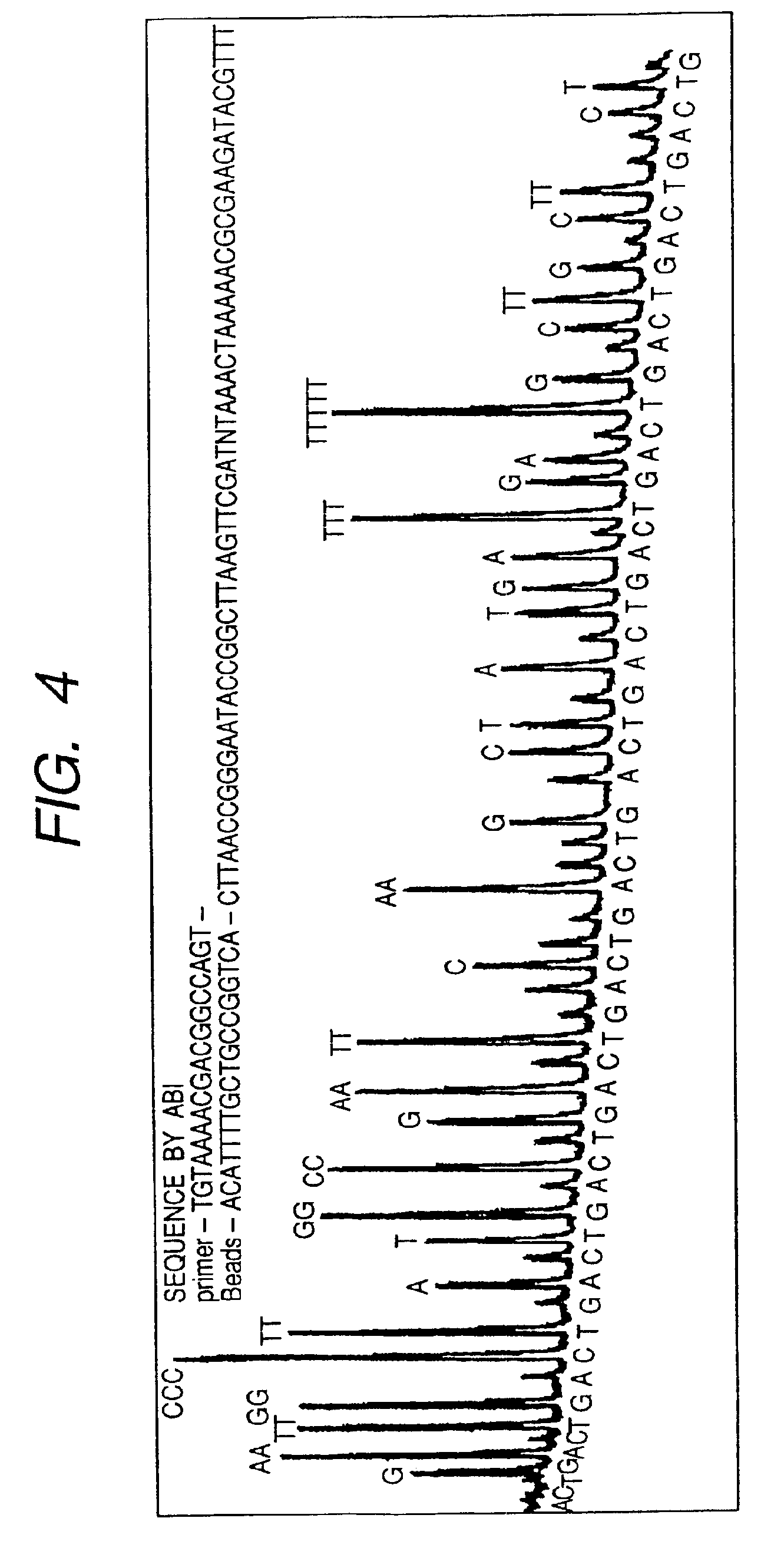

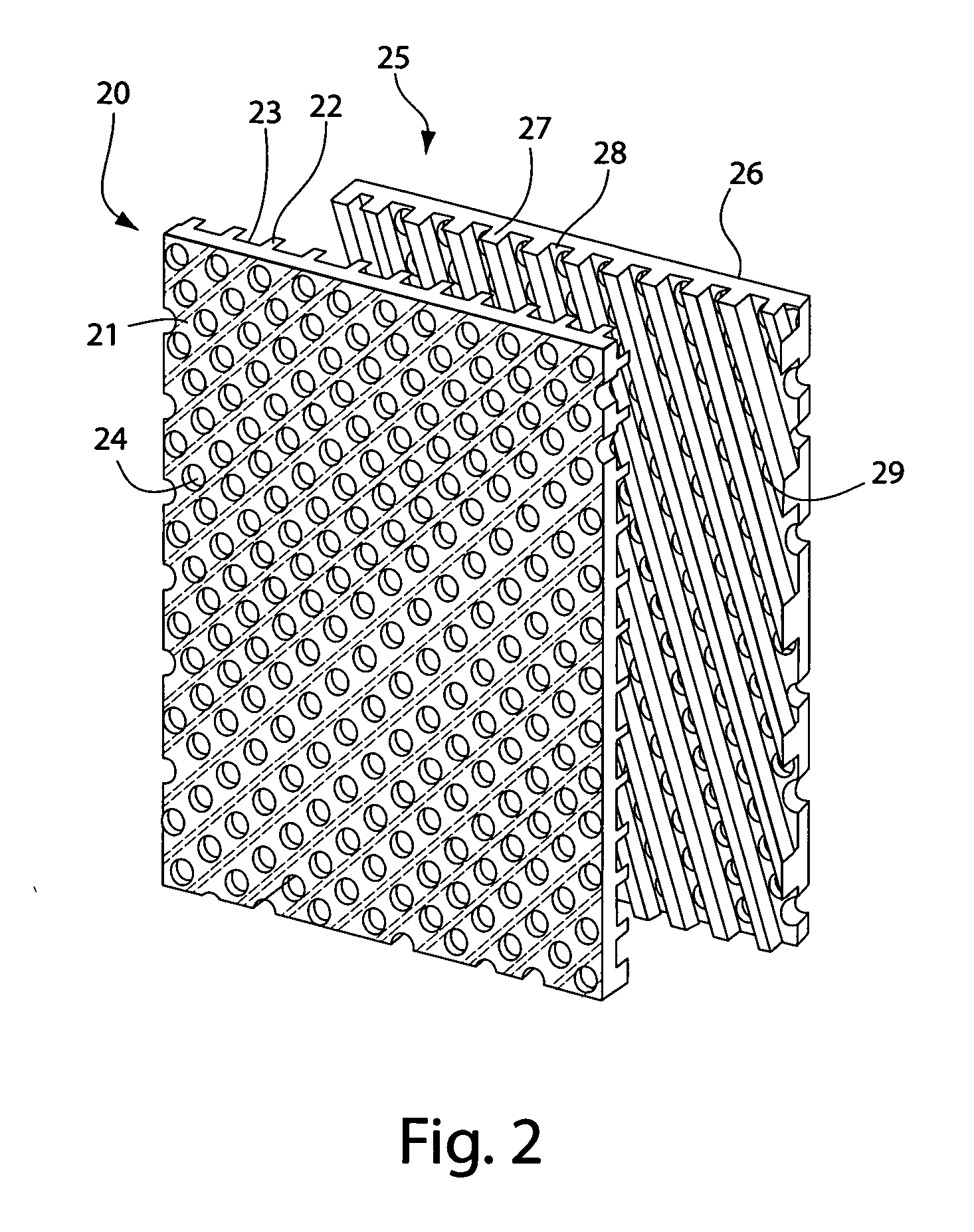

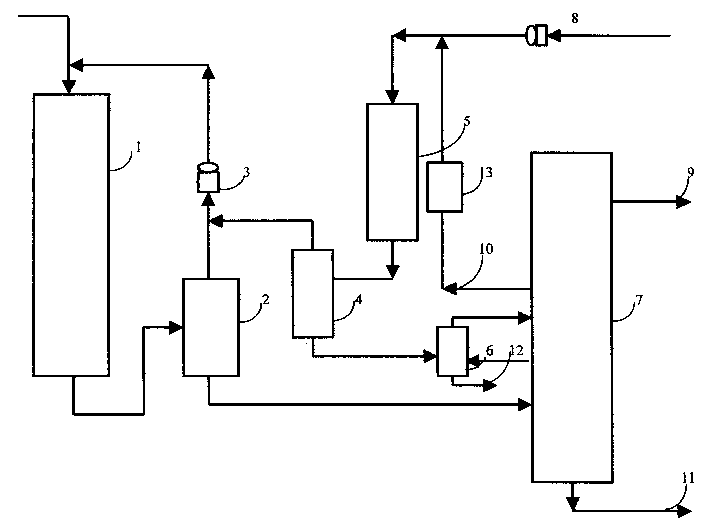

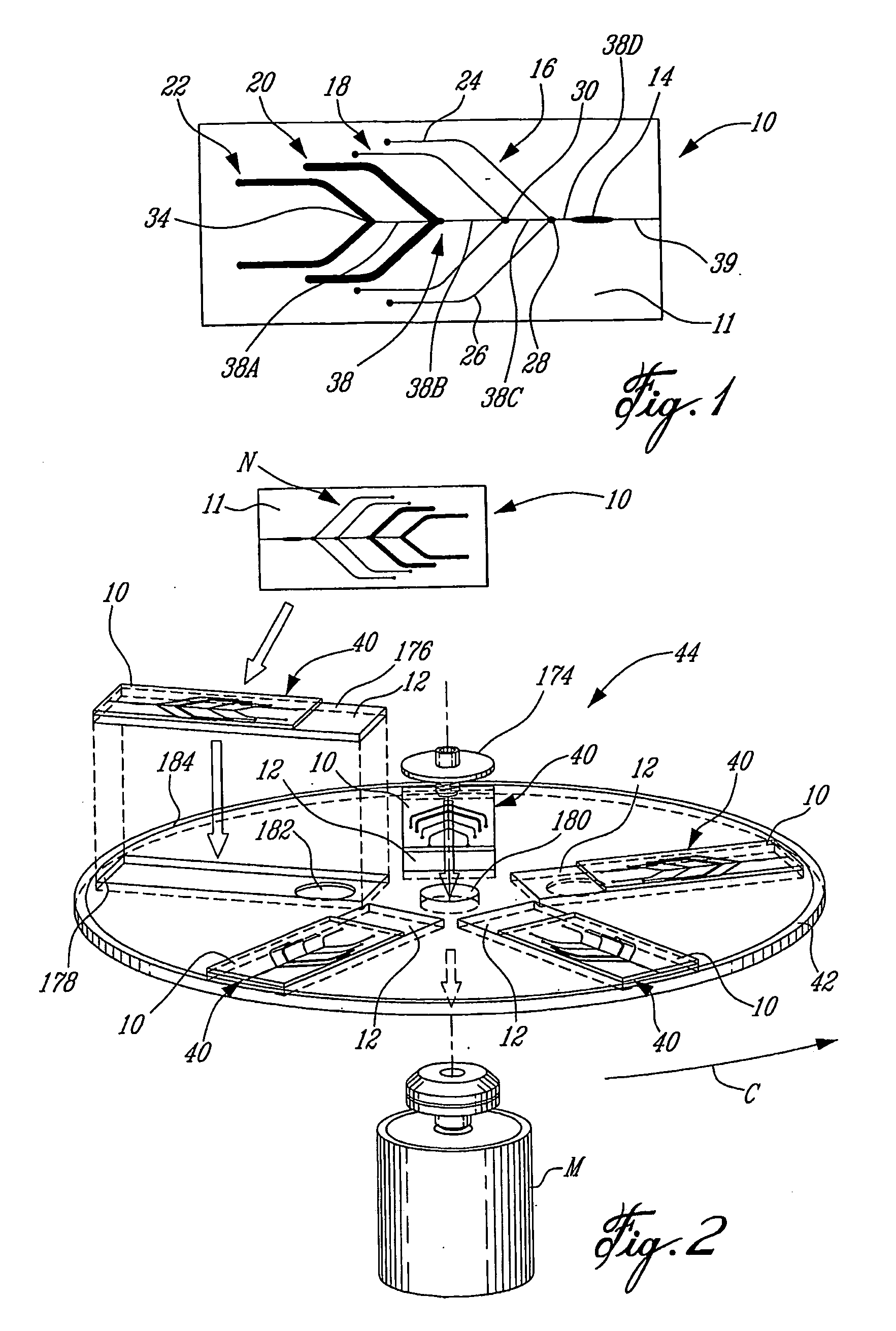

DNA base sequencing system

InactiveUS6841128B2Increase supplySize of apparatus be minimizedBioreactor/fermenter combinationsElectrolysis componentsA-DNAReagent

The present invention provides a DNA base sequencing system having a compact, simple and convenient structure.In one embodiment of the present invention, a reaction chamber module for pyrosequencing in which a multiple number of reaction vessels (reaction chambers) 10 and reagent-introducing narrow tubes 6 are integrated is formed in a device board 5. Reagents held in reagent reservoirs 1, 2, 3 and 4 mounted separately from this reaction chamber module are introduced into the reaction vessels 10 via reagent-introducing narrow tubes (capillaries) 6. The reagent-introducing narrow tubes (capillaries) 6 at the area of 2 cm from the reaction vessels 10 are structured with narrow capillaries having an inner diameter of about 0.1 mm and the conductance of these capillaries for the reagent solution determines the injection speed of the solution.Using the present invention, many kinds of DNAs can be analyzed simultaneously.

Owner:HITACHI LTD

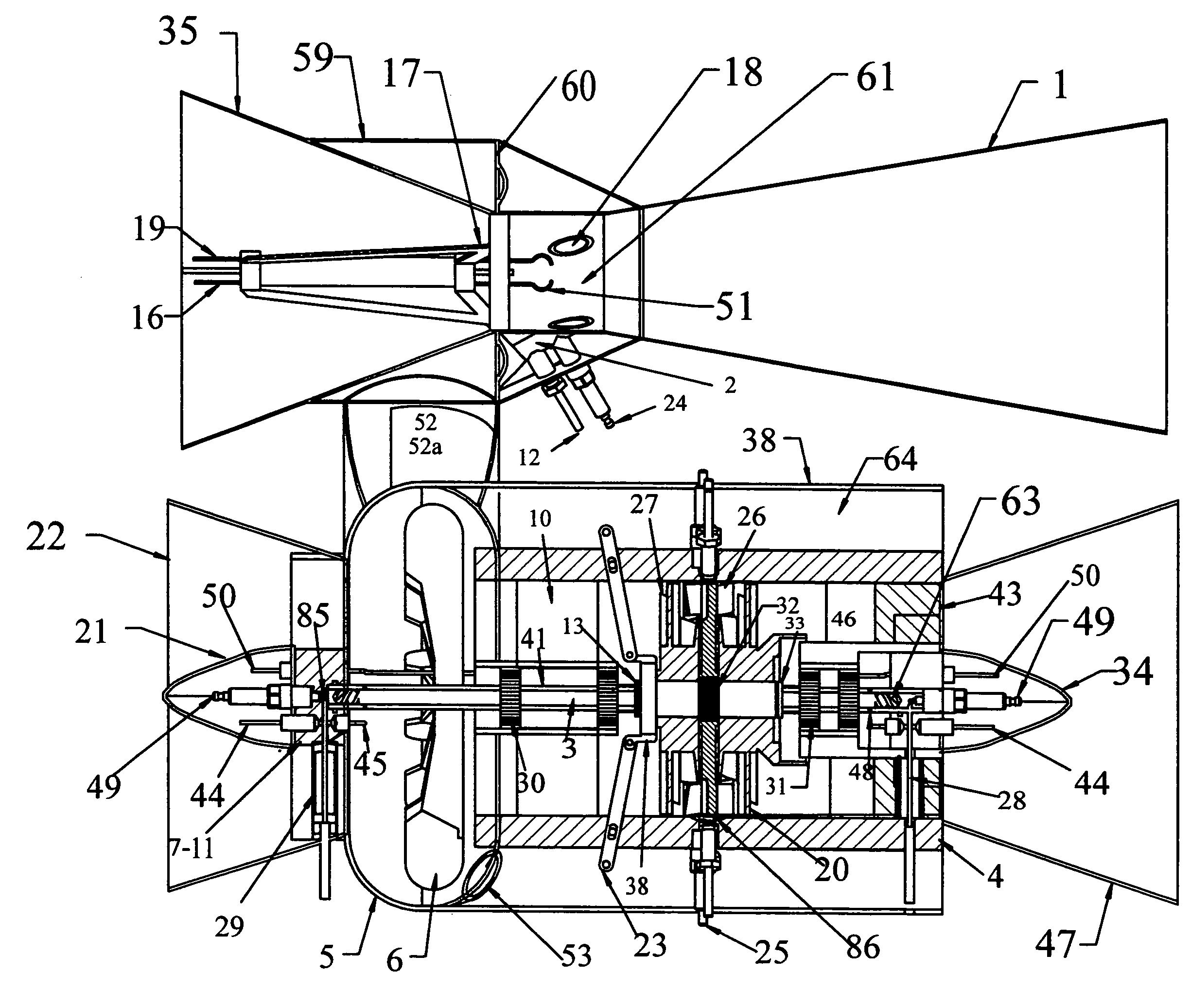

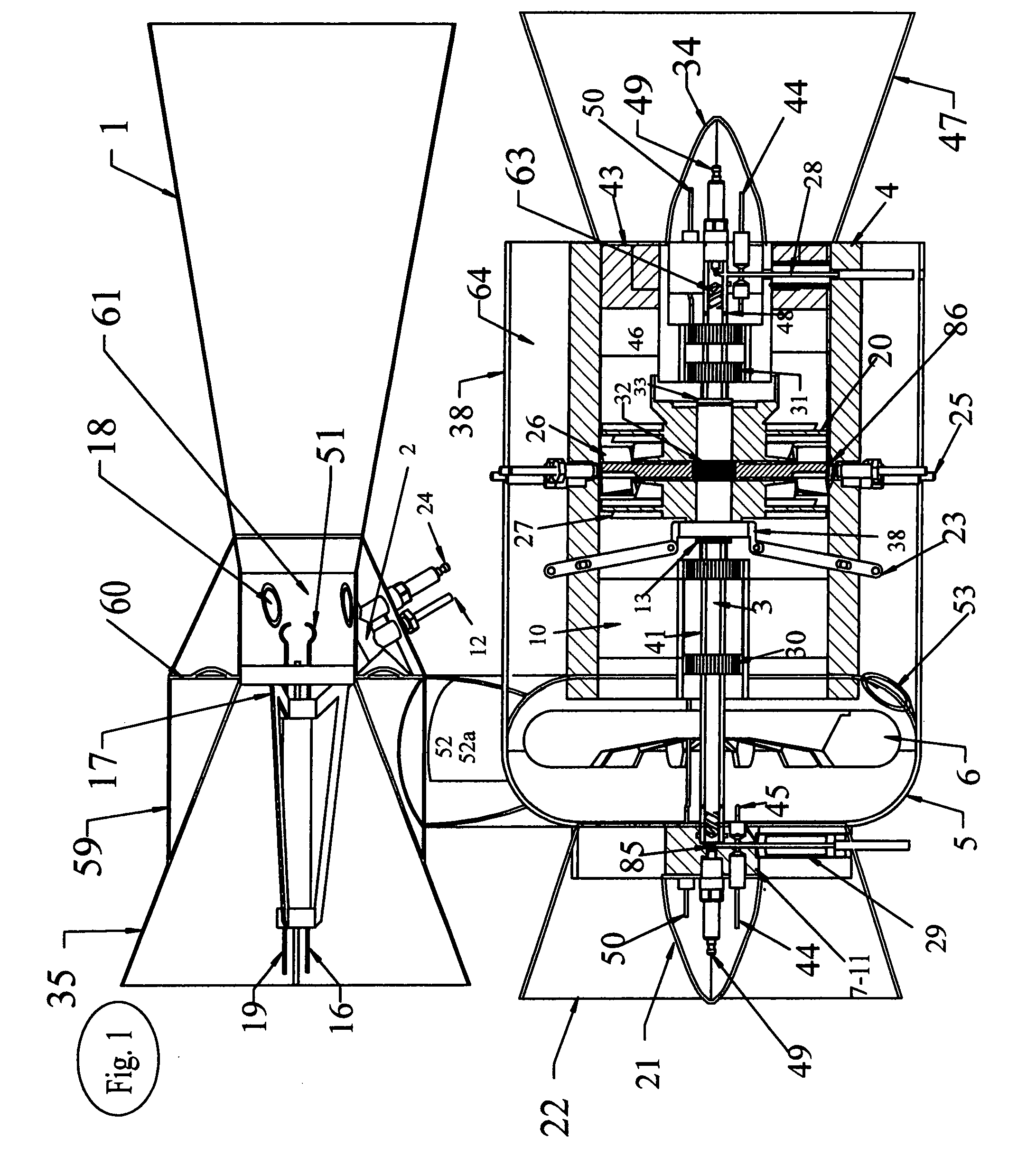

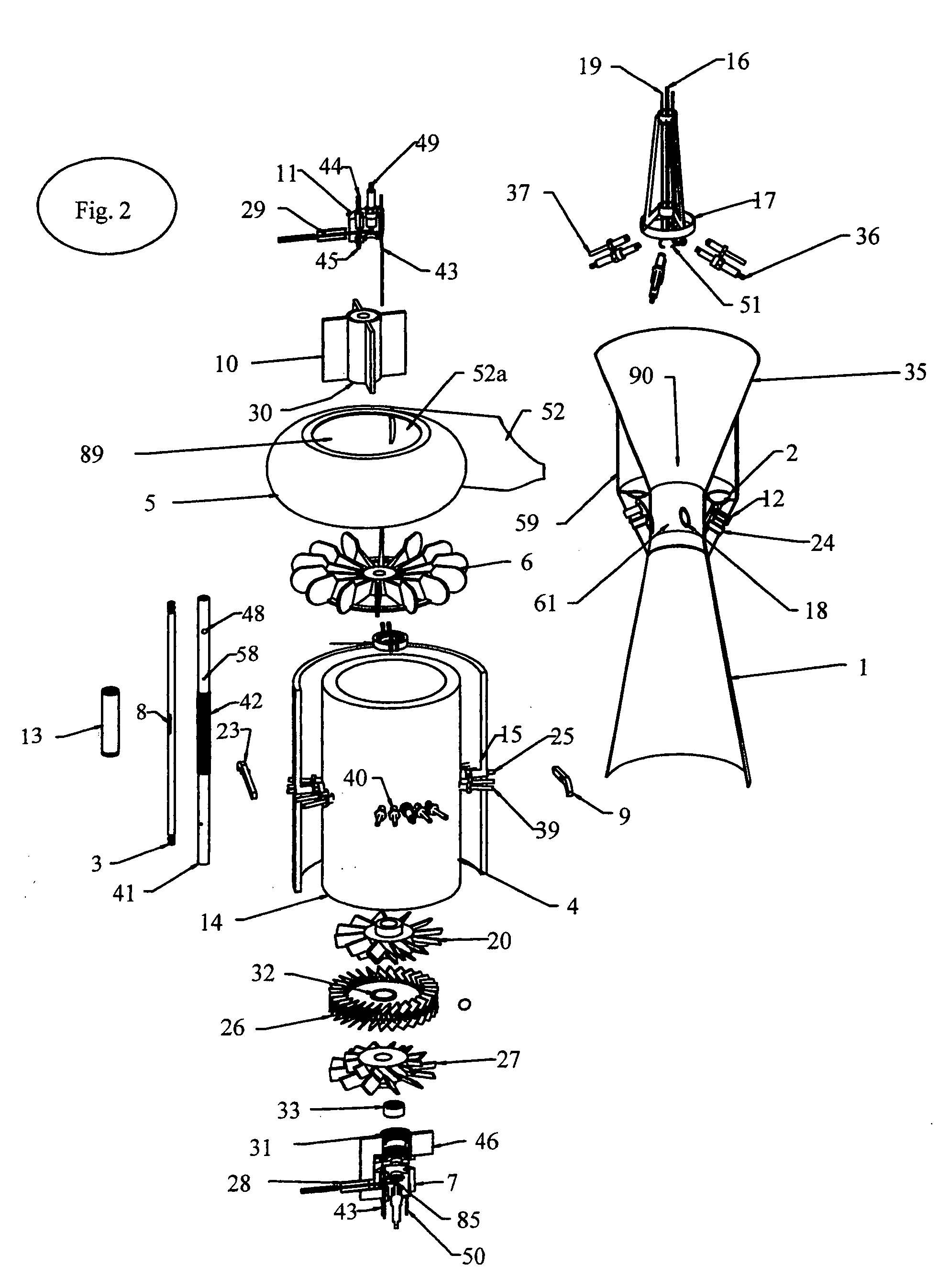

Methods of combining a series of more efficient aircraft engines into a unit, or modular units

InactiveUS20100251692A1More thermal capacityReduce environmental pollutionContinuous jet plantsRocket engine plantsRamjetFree-piston engine

The present invention generally relates to units of engines and more particularly to units containing a unique combined-cycle (combustion-detonation) “counter-rotation, anti-gyration, gyroscopic,” turbine fan-jet / free-piston engine configuration for induced air supercharging and boosting the performance of novel Ramjet engines or Ramjet engine configurations by improving internal air-stream dynamics. These dynamics are the result of co-operative air stream intermixing through convergent, supercharge-attenuated, inducted, compressed, tuned, pre-heated ambient air. Achieved through the varying of the geometric structural form and the utilization of unique engines and air induction and propulsion conformations, aided with supplemental air, fuel, oxygen and optiomal water and electrolyte charging.

Owner:KINDE SR RONALD AUGUST

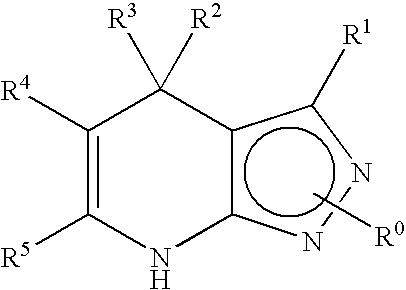

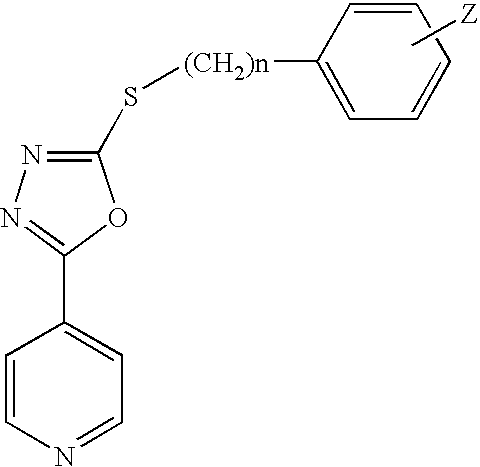

Gsk-3betainhibitor

InactiveUS20100069381A1Superior GSK-3 specific inhibitory activityImprove solubilityAntibacterial agentsBiocideDiseaseDitazole

For the purpose of providing a GSK-3β inhibitor containing an oxadiazole compound or a salt thereof or a prodrug thereof useful as an agent for the prophylaxis or treatment of a GSK-3β-related pathology or disease, the present invention provides a GSK-3β inhibitor containing a compound represented by the formula (I):wherein each symbol is as defined in the specification, or a salt thereof or a prodrug thereof.

Owner:TAKEDA PHARMA CO LTD

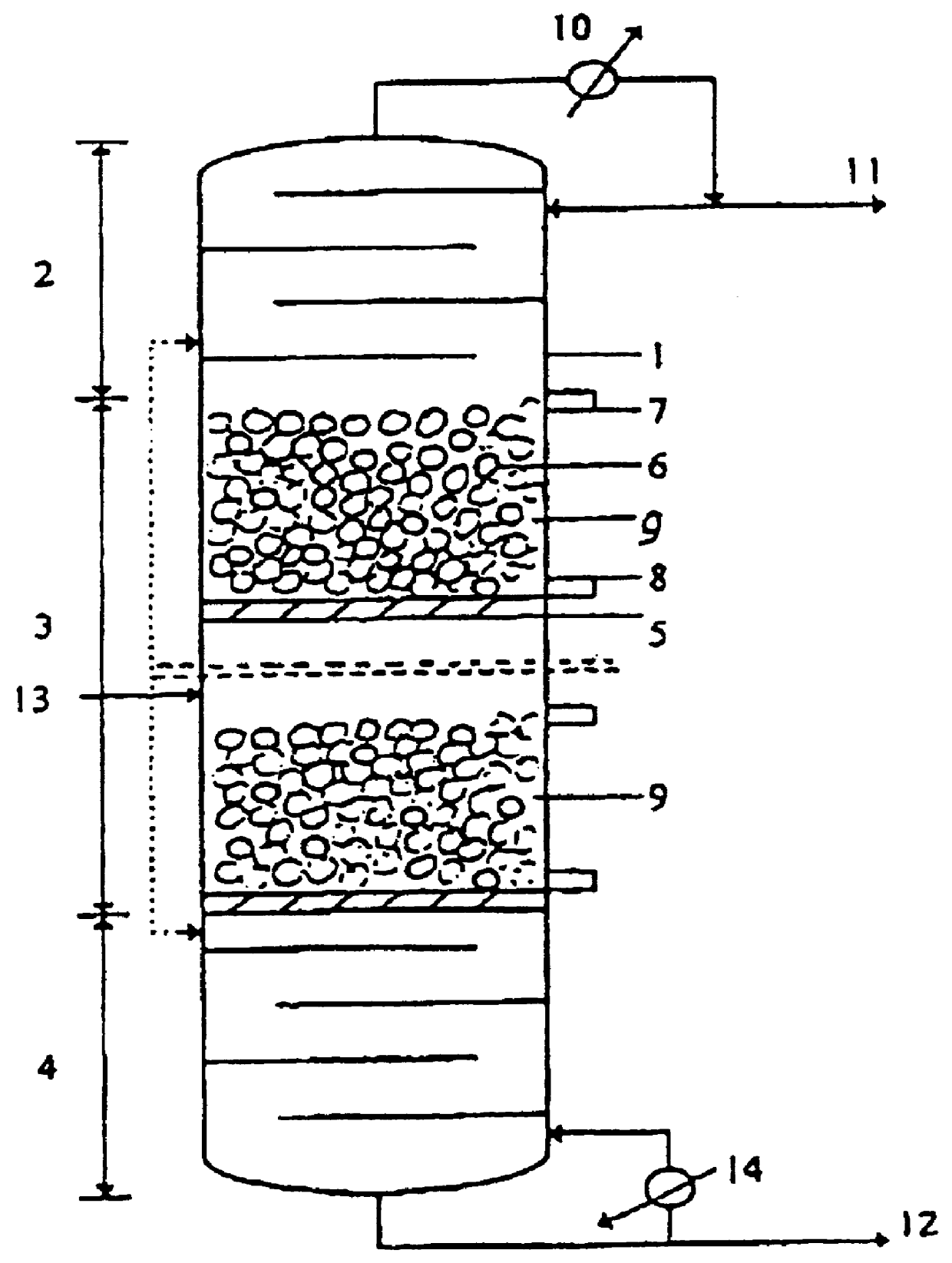

Boiling bed hydrogenation treatment catalyst and its preparing process

ActiveCN101240190AThe reaction equipment is simpleReduce operating costsRefining to eliminate hetero atomsLow speedSpherical shaped

The invention relates to a boiling bed hydrogenation catalyst and a preparation method. The boiling bed hydrogenation catalyst of the invention is spherical shape which diameter is 0.1mm to 0.8mm, and has appropriate amount of additives and hydrogenation of metal components, and has reasonable hole distribution. The catalyst preparation method of the invention is spherical carrier impregnation, the process of spherical carrier preparation is following: making catalyst carrier raw material which is in appropriate temperature into appropriate size grain, then spheroidizing the grain, heating the conglobation and making them into spherical catalyst carrier. The process for making the catalyst carrier raw material into the appropriate size grain is that wet stock passes screen stencil by mechanical action and generates grain. Between the processes of the making grain and nodularization, granular material primely is placed for a period of time or operates in low-speed in nodularization device for a period of time. The catalyst of the invention appropriately conducts the boiling bed hydrogenation for heavy oil, residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

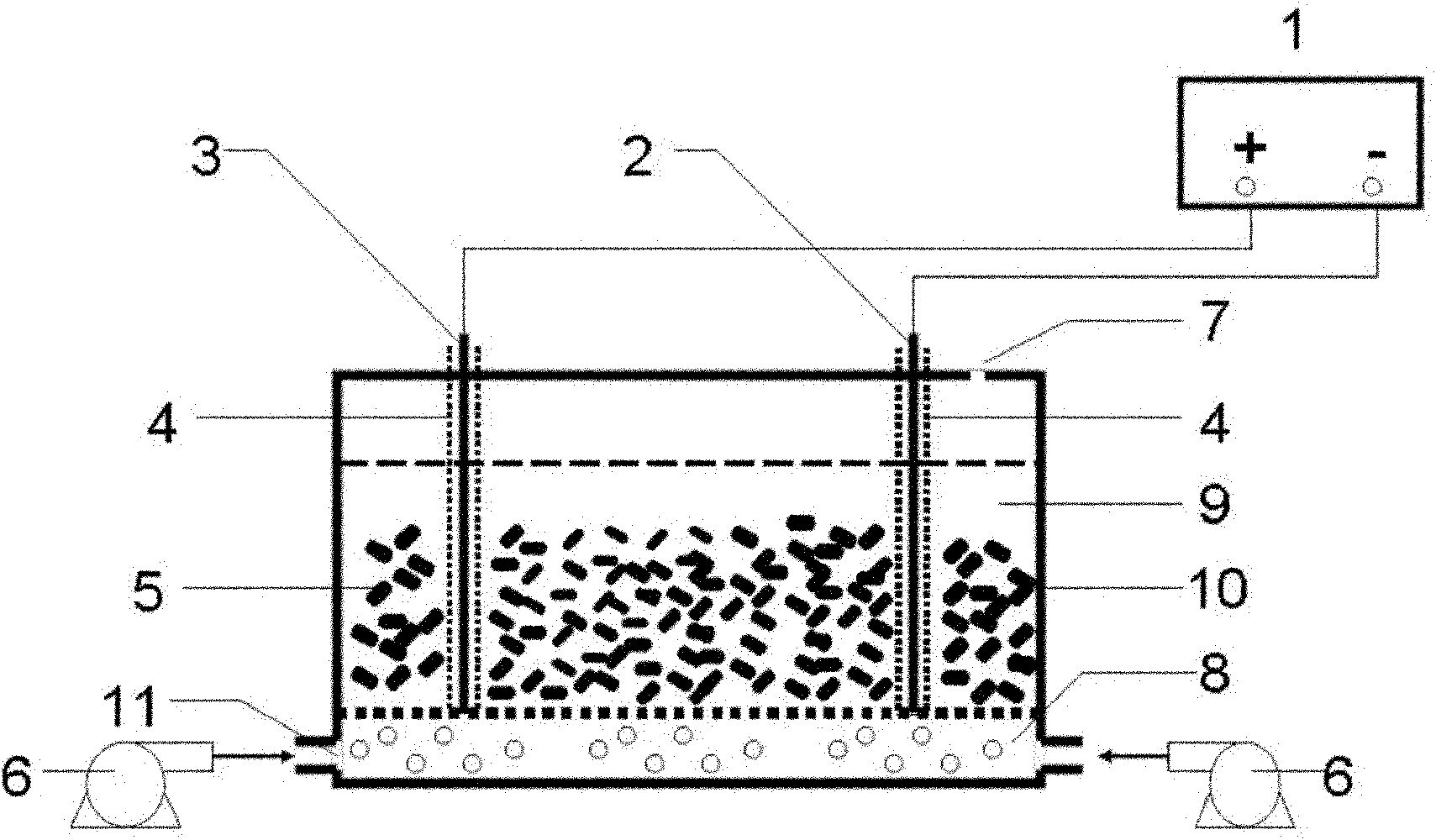

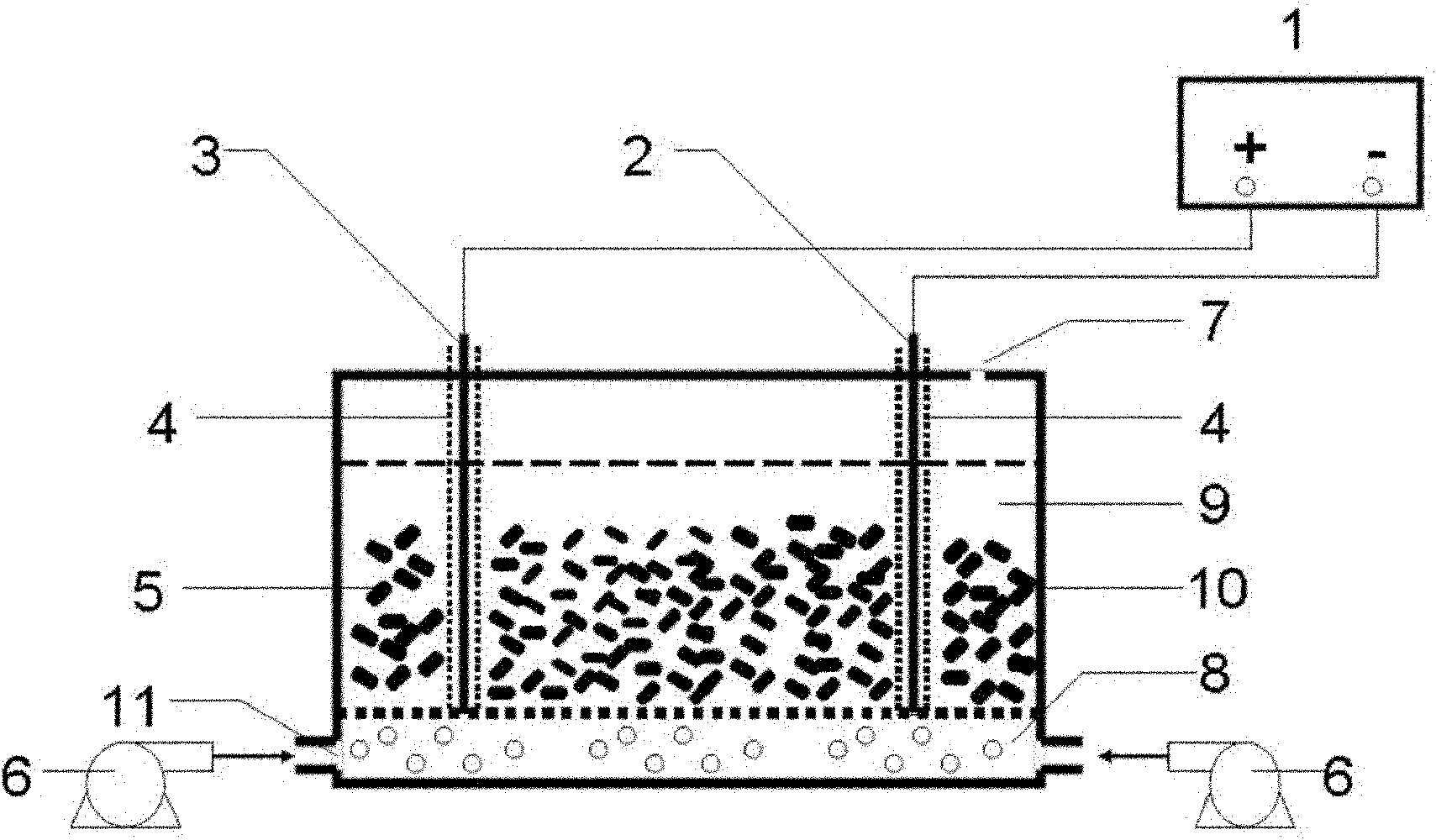

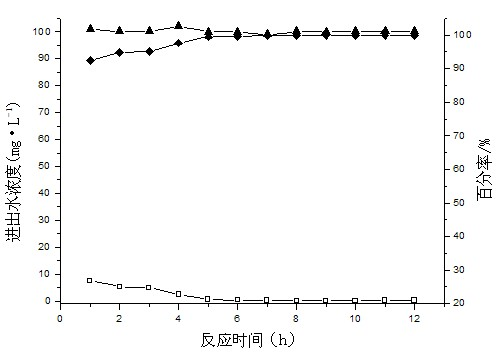

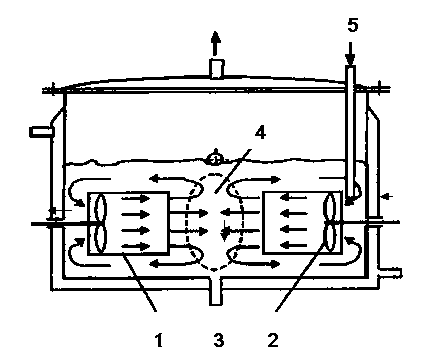

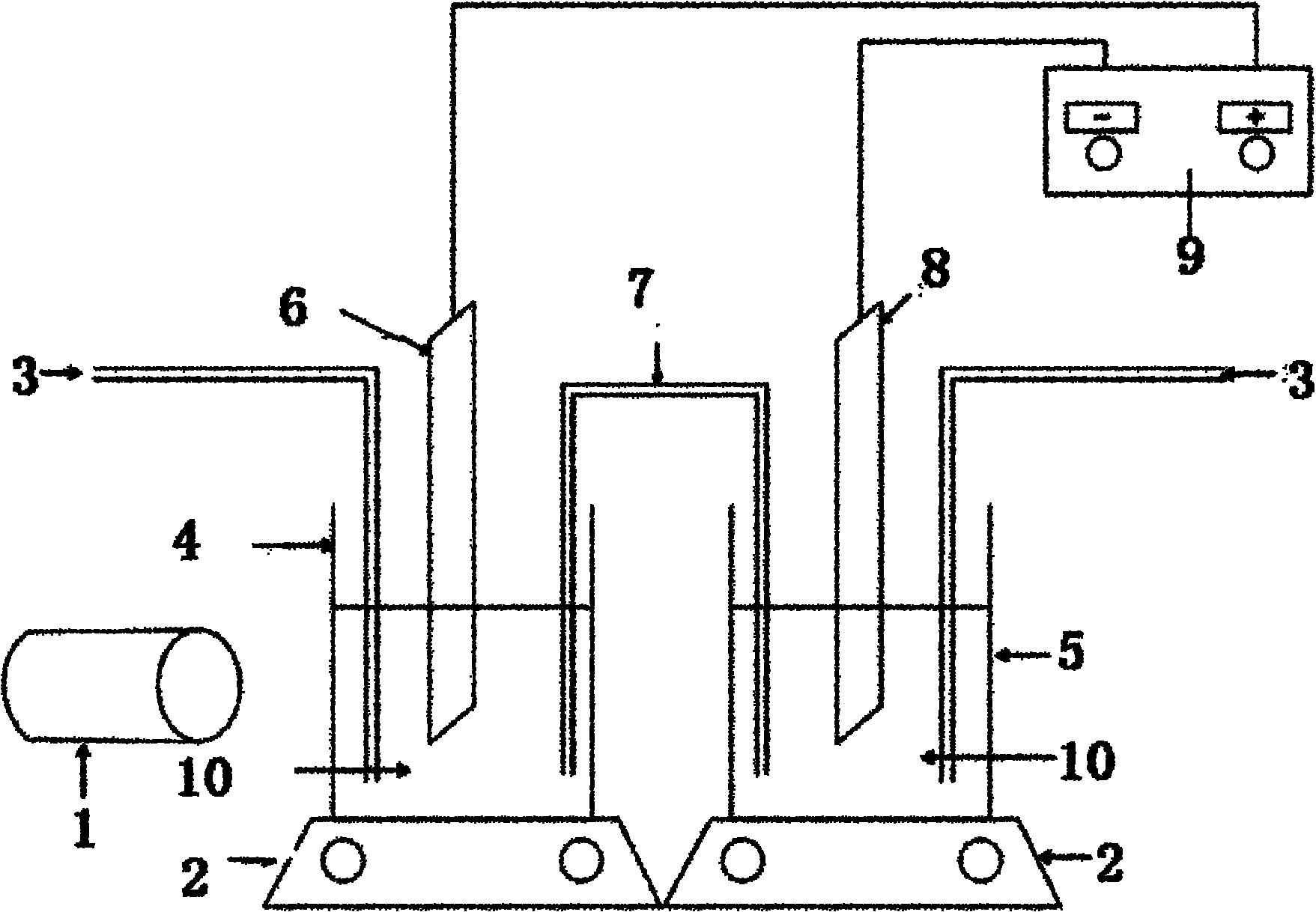

Method for removing organic matters in water by utilizing three-dimensional electrode electro-fenton and device thereof

InactiveCN102070230AIncrease contact areaExtension of timeWater/sewage treatment by oxidationFenton reagentFixed bed

The invention relates to a method for carrying out oxidation treatment on organic waste water by utilizing a three-dimensional electrode electro-fenton and a device thereof. The device comprises a reactor shell, a carbon material cathode, an iron plate anode, a three-dimensional particle electrode of a fixed bed, a direct-current voltage-stabilizing power supply, a microporous aeration plate and an air pump, wherein a reactor consists of a reaction chamber and a gas chamber; the carbon material cathode, the iron plate anode and the particle electrode are positioned in the reaction chamber at the upper part of the reactor; and the gas chamber is formed between the bottom of the reactor and the microporous aeration plate. After direct current is introduced, the iron anode is oxidized to generate iron ions, oxygen in the gas chamber is reduced on the surface of the cathode to generate hydrogen peroxide, and the iron ions and the hydrogen peroxide form a fenton reagent to oxidize and remove organic matters in waste water; and simultaneously, due to the particle electrode, the contact area and the contact time of the waste water and the fenton reagent are increased, and the mass transfer effect of the waste water in the reactor is reduced. The invention is applicable to treatment of various types of organic waste water, the equipment is compact, the operation is easy, the whole reactor is easy to control, and the requirements of an actual water treatment unit are met.

Owner:HUAZHONG NORMAL UNIV

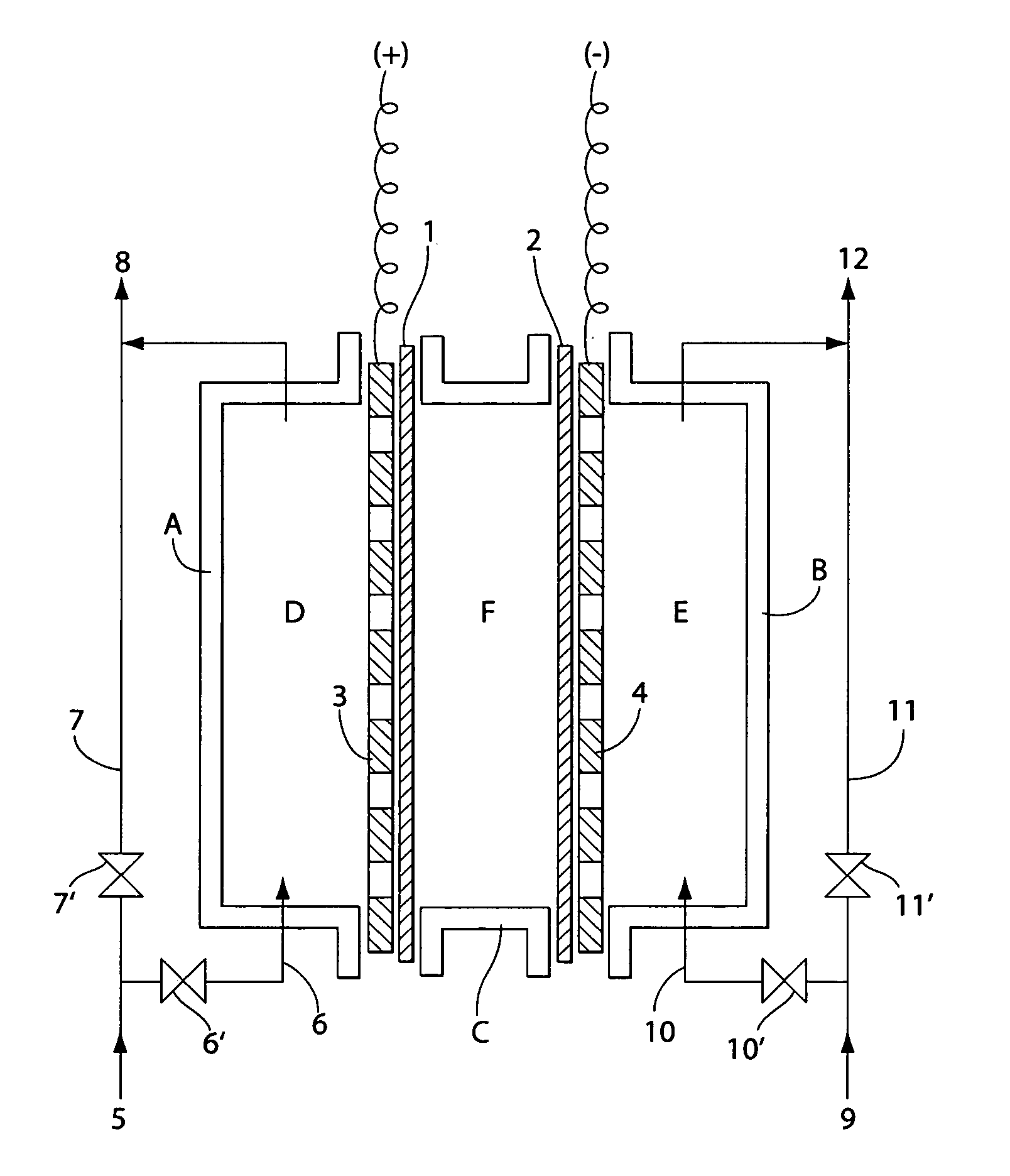

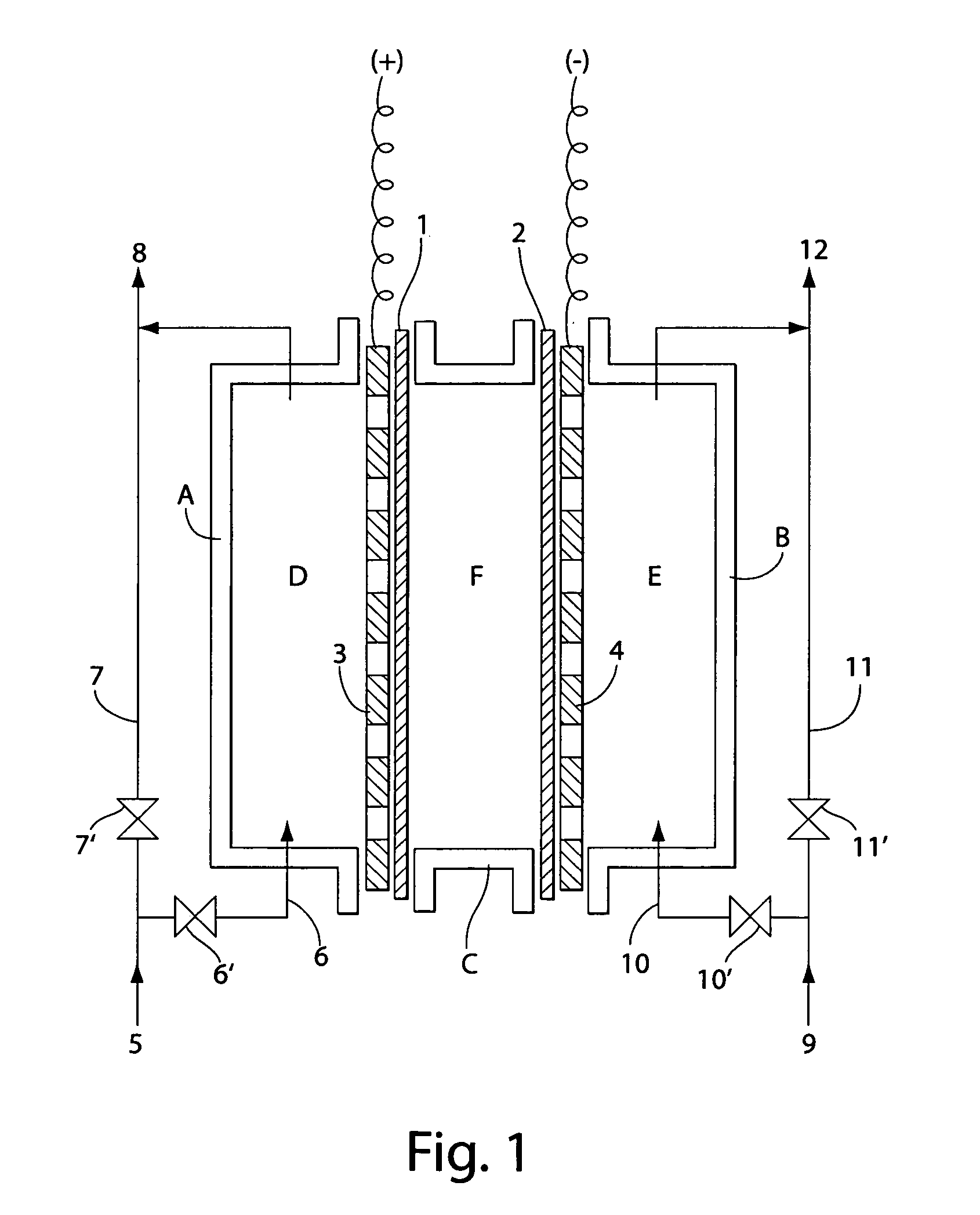

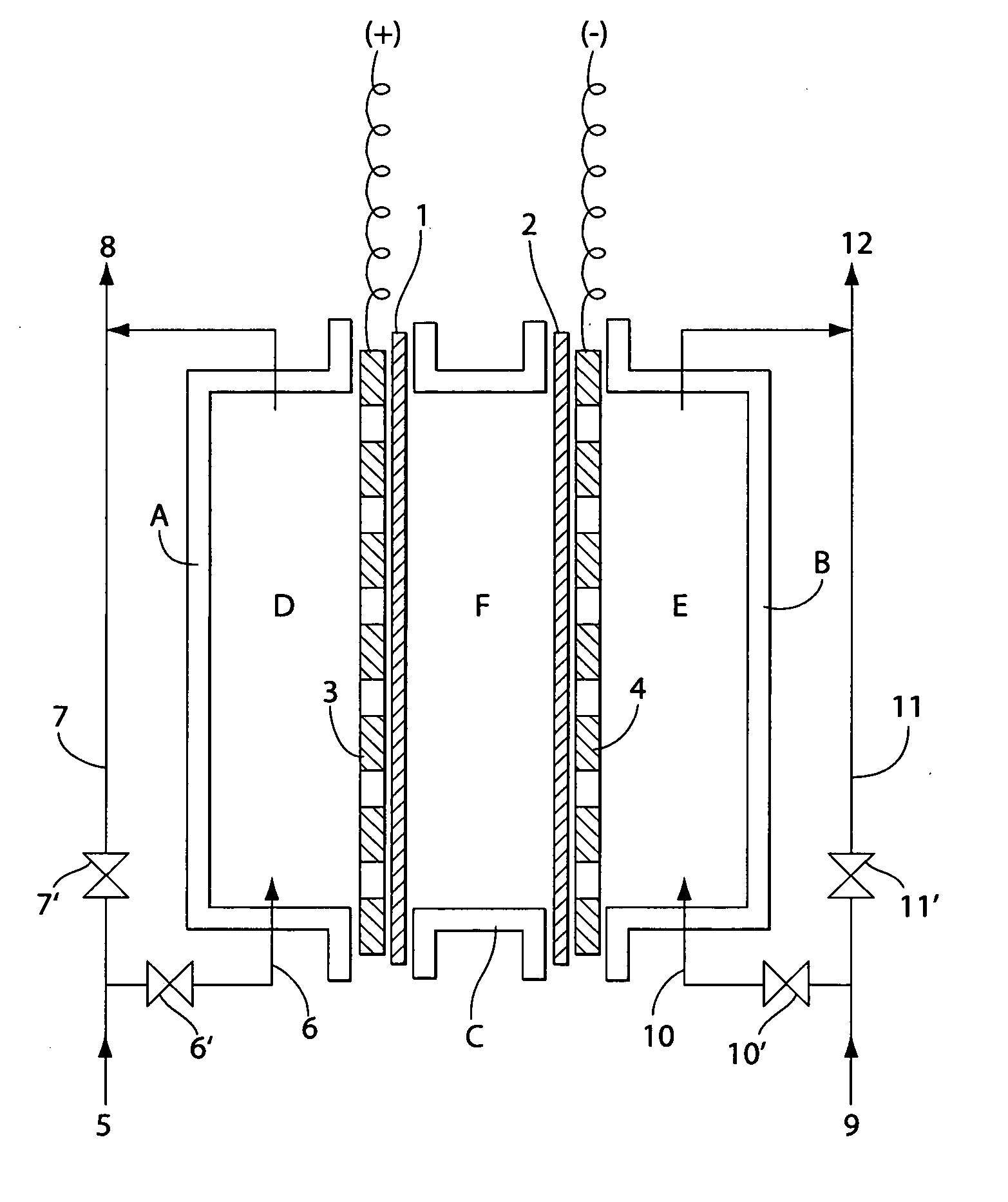

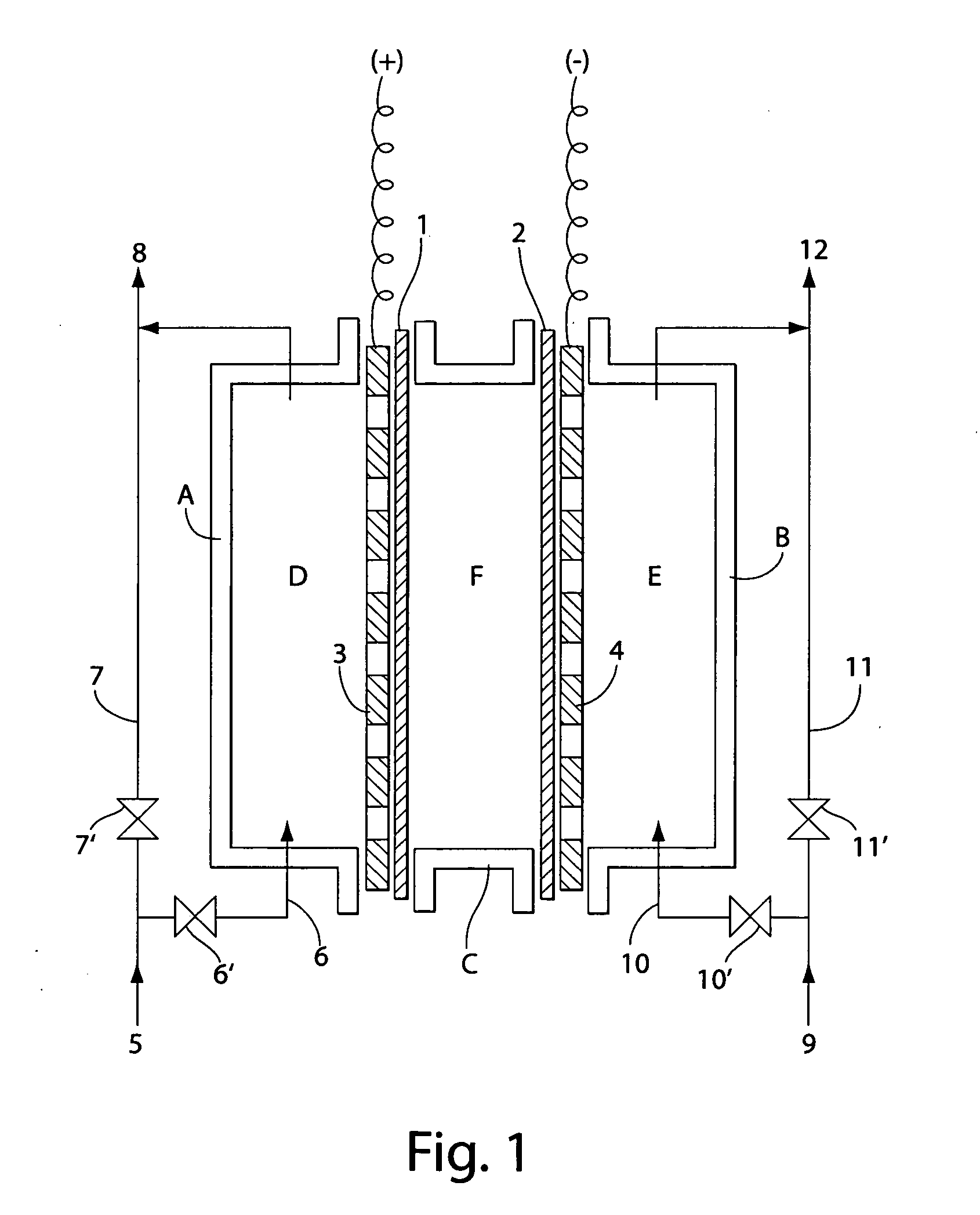

Production of electrolytic water

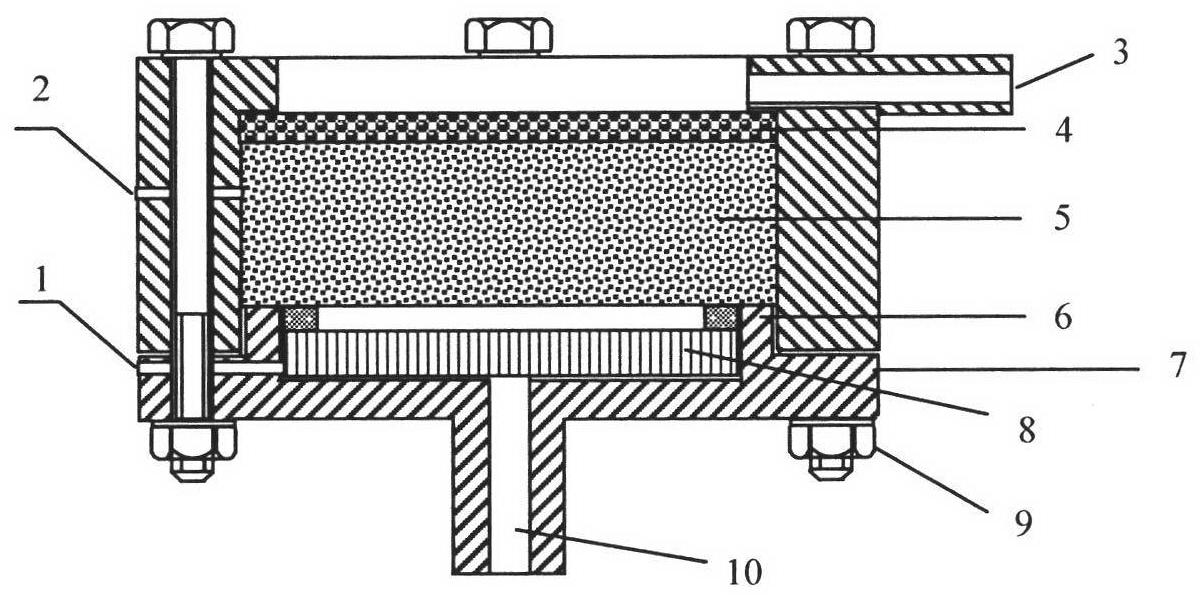

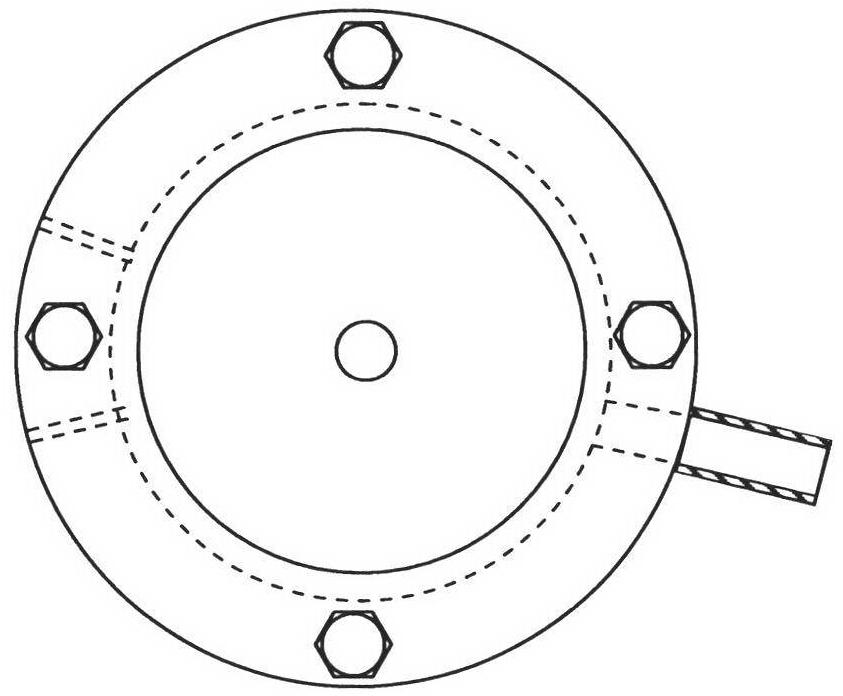

InactiveUS7238272B2Prevent adhesionIncrease productivityCellsLiquid separation by electricityWater useElectrolysed water

Apparatus and methods are provided for producing electrolytic water using three chambers, rigid plates and ion exchange membranes. Benefits include reduced scale production and increased long-term bactericidal effects of the water produced.

Owner:ELECTROLYZER

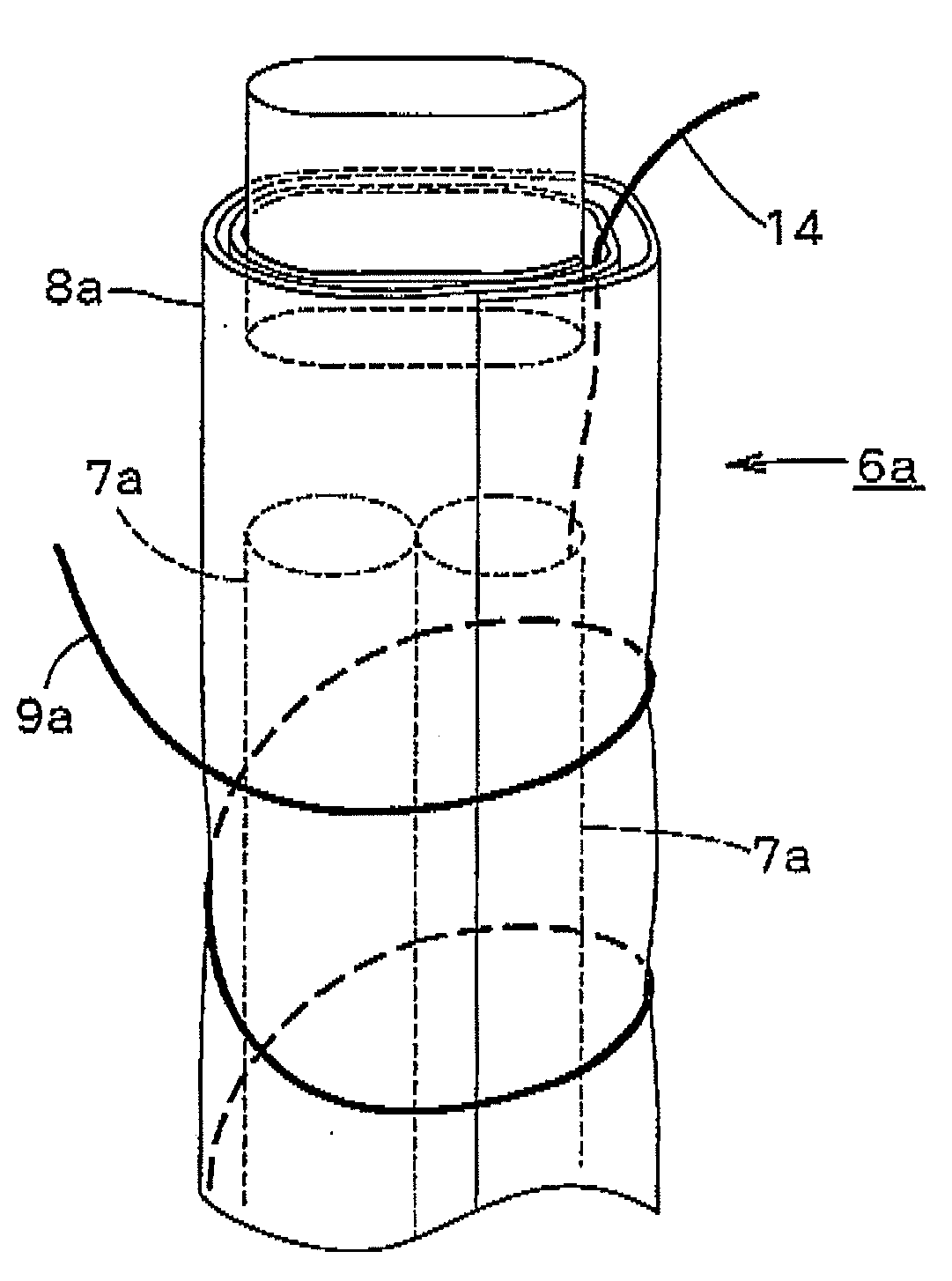

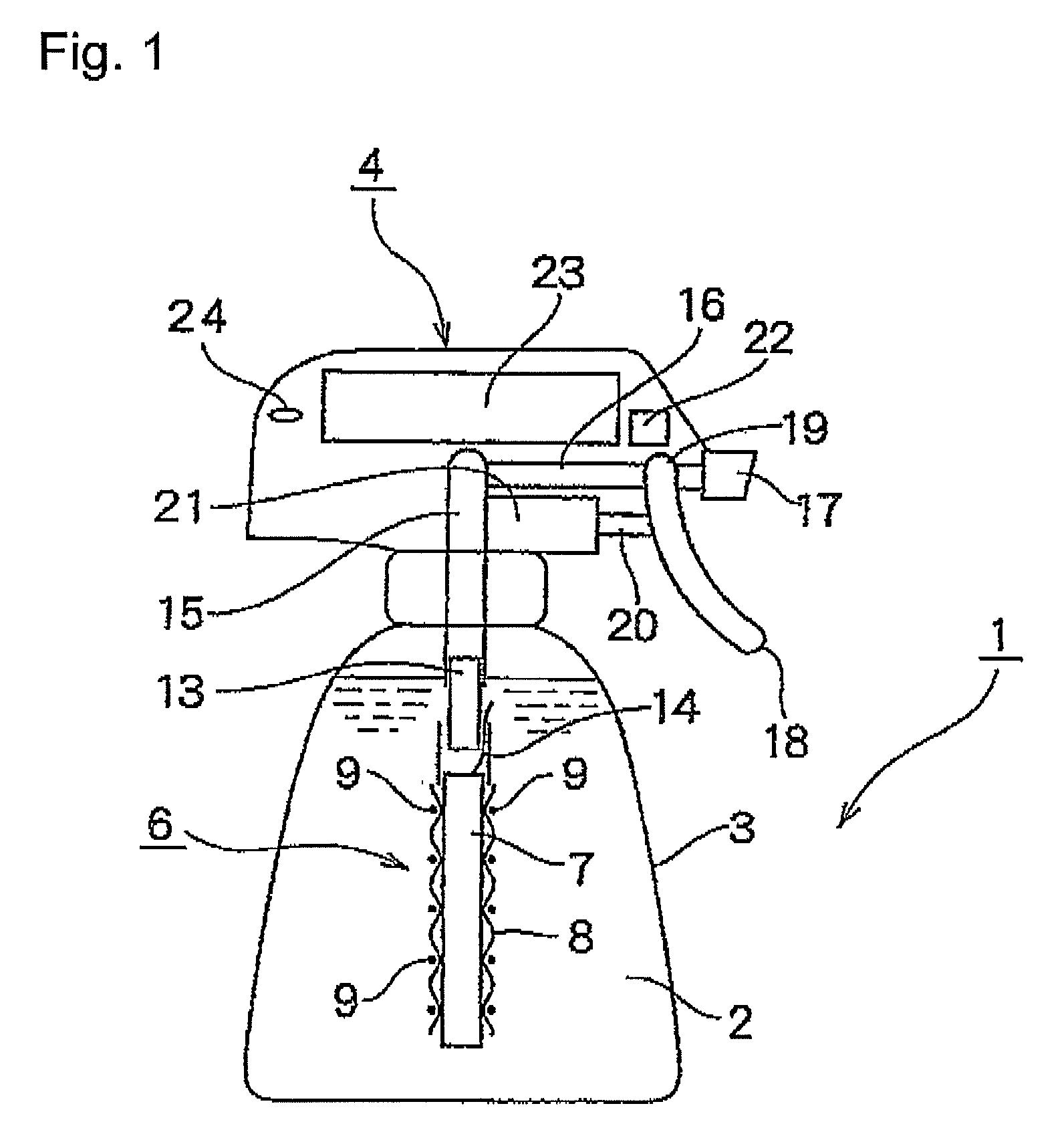

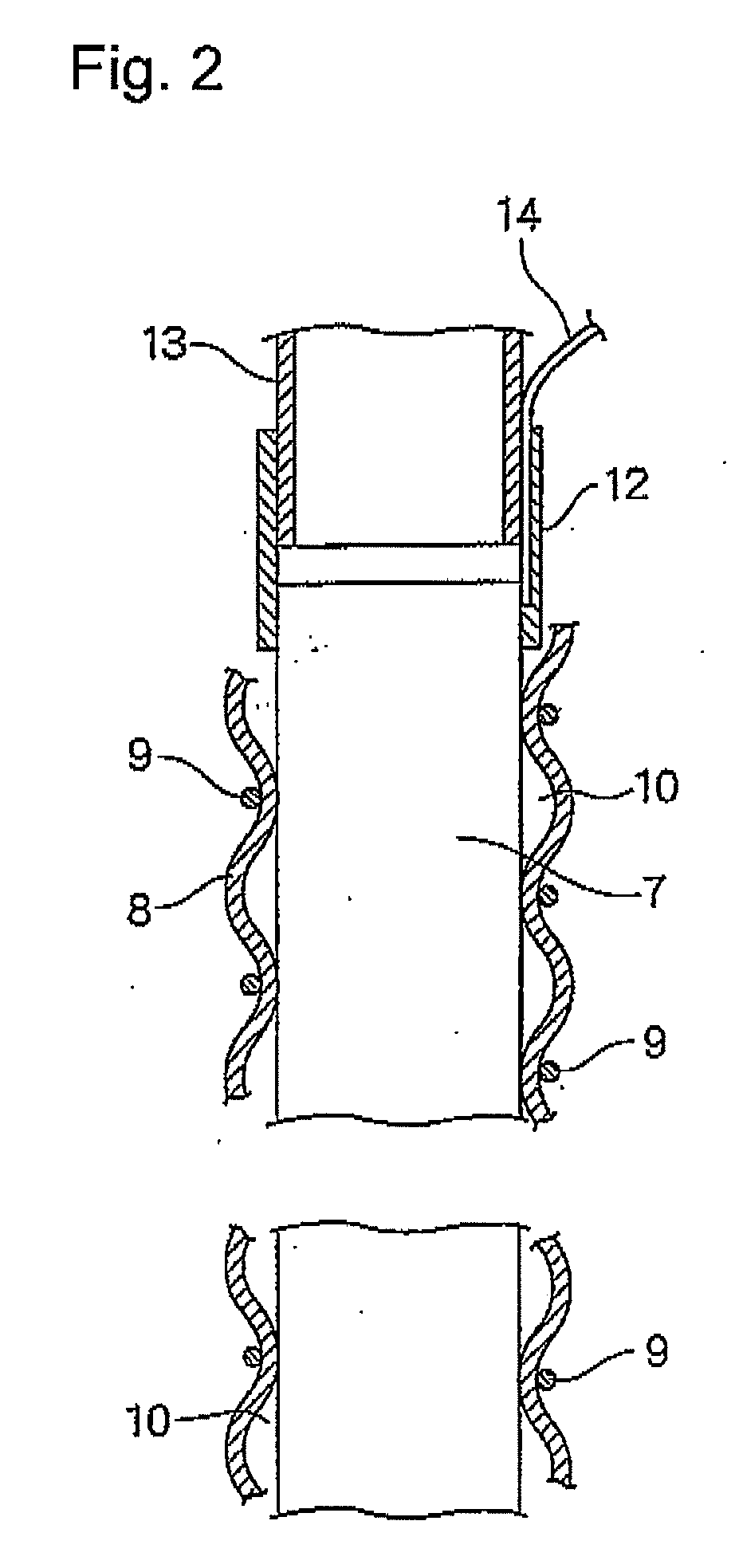

Membrane-electrode assembly, electrolytic cell employing the same, electrolytic-water sprayer, and method of sterilization

InactiveUS20090127128A1Improving bactericidal activityImproving bactericidal activity and feelingCellsWater treatment compoundsBiomedical engineeringElectrolytic cell

The present invention provides a membrane-electrode assembly which comprises: at least one rod-form or tubular electrode; a tubular diaphragm disposed around the periphery of the electrode; and a wire-form counter electrode disposed around the periphery of the diaphragm, the diaphragm being fixed to the rod-form or tubular electrode with the wire-form counter electrode to thereby form an electrode chamber having a gas / liquid passage between the diaphragm and the rod-form or tubular electrode.

Owner:DE NORA PERMELEC LTD +1

Low-temperature SCR catalyst using nitrogen-dopped activated carbon as carrier and preparation technique thereof

InactiveCN101352681AIncrease the degree of oxidationEasy to handleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen

The invention discloses a low-temperature SCR catalyst which takes nitrogen mingled with active carbon as a carrier. The catalyst takes the nitrogen mingled with active carbon prepared by ammonia gas ignition as the carrier and one of the oxides loaded with metallic element of Mn, V, Fe, Co or Cu as an active ingredient. The invention also discloses a specific method for preparing the catalyst. The carrier of nitrogen mingled with active carbon increases the number of base sites on the surface of the active carbon, so as to improve the adsorptive capacity of NO and O2 and lead more NO to be oxidized into NO2. The load of the metal metallic oxides of Mn, V, Fe, Co and Cu forms a large amount of acid sites on the surface of the catalyst, which promotes the absorption capability of the catalyst to NH3. The measures effectively enhances the denitration activity of the low-temperature SCR catalyst which takes the nitrogen mingled with active carbon as the carrier and extends the activity temperature window of the reaction thereof.

Owner:ZHEJIANG UNIV

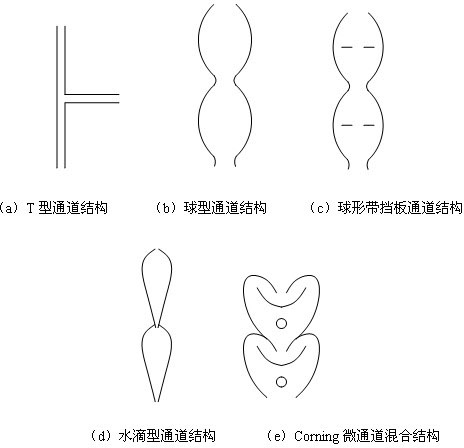

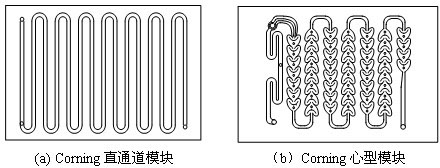

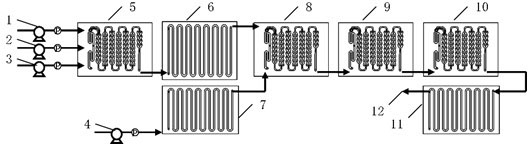

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471APrevent leakageAvoid dangerNitro compound preparationTemperature controlChlorobenzene

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

Sphingomonas strain and application thereof in water treatment

InactiveCN102168054APromote degradationReduce concentrationBacteriaMicroorganism based processesIndustrial waste waterWater source

The invention belongs to the technical fields of environmental engineering and bioengineering and particularly relates to a sphingomonas strain and applications thereof in the aspects of shortcut nitrification-denitrification of nitrogen-containing industrial waste water and domestic sewage and treatment of a polluted water source. The sphingomonas strain is separated from a Taihu water in China,is a local strain and has high safety; and the strain can be grown in a basic medium, wherein in the basic medium, CO2 is used as a carbon source and energy or CO2 and an organism are used as a mixedcarbon source and energy, and ammonia nitrogen or nitrate nitrogen is used as a nitrogen source. The bacterium liquid, the dormancy cell and the immobilized strain of the sphingomonas can decompose ammonia nitrogen into nitrite nitrogen and simultaneously can decompose the ammonia nitrogen into nitrogen, can be used as denitrification microorganism for converting the ammonia nitrogen into the nitrite nitrogen and the nitrogen, thereby achieving the shortcut nitrification-denitrification. The strain can rapidly decompose the ammonia nitrogen and is suitable for treating the nitrogen-containingindustrial waste water and domestic sewage as well as polluted water source.

Owner:NANJING UNIV

Production of electrolytic water

InactiveUS20050189237A1Increase free chlorine production efficiencyPrevent adhesion of scaleCellsLiquid separation by electricityWater useElectrolysed water

Apparatus and methods are provided for producing electrolytic water using three chambers, rigid plates and ion exchange membranes. Benefits include reduced scale production and increased long-term bactericidal effects of the water produced.

Owner:ELECTROLYZER

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201AAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

Formaldehyde scavenging agent with oil solubility and preparation method

InactiveCN103055465AImprove purification efficiencyImprove practicalityPreparation by ester-hydroxy reactionPolyester coatingsSocial benefitsSolubility

The invention relates to the chemical technology field, and concretely relates to a formaldehyde scavenging agent with oil solubility and a preparation method and a usage method. The formaldehyde scavenging agent with oil solubility can be prepared to paint, and can be used for coating on the furniture, floor or other decoration sheet materials, and has good purification efficiency on indoor free formaldehyde, and no secondary pollution can be generated. On the premise of no change of the sheet material application and construction technology in the prior art, and the release of indoor formaldehyde can be fundamentally controlled. The preparation method is simple, the usage is convenient, and the formaldehyde scavenging agent is suitable for large-scale production and business application for enterprises, has good application prospect, and has obvious economy and social benefit.

Owner:上海格伦化学科技有限公司

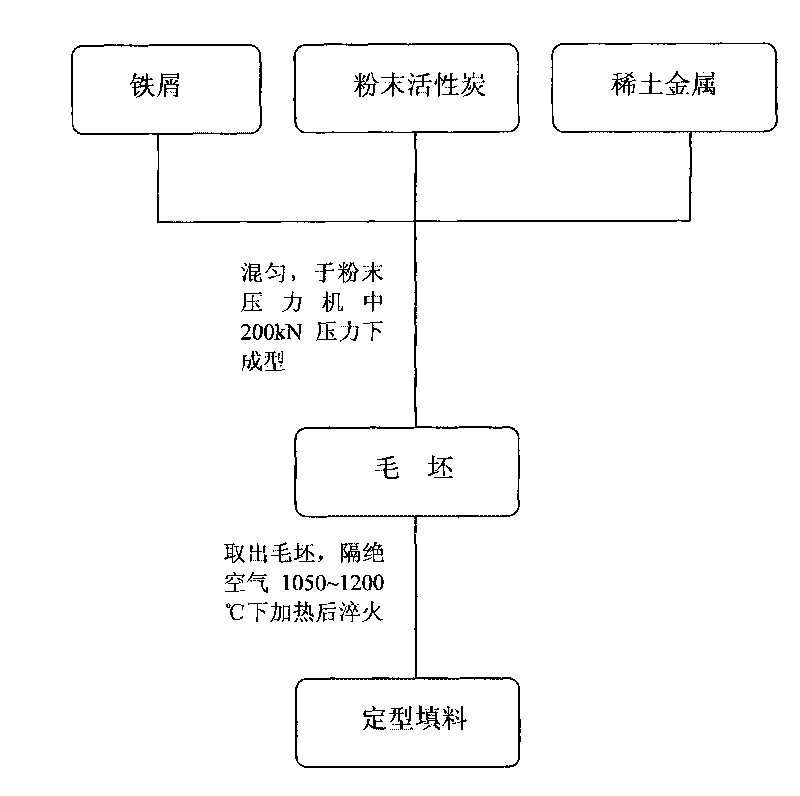

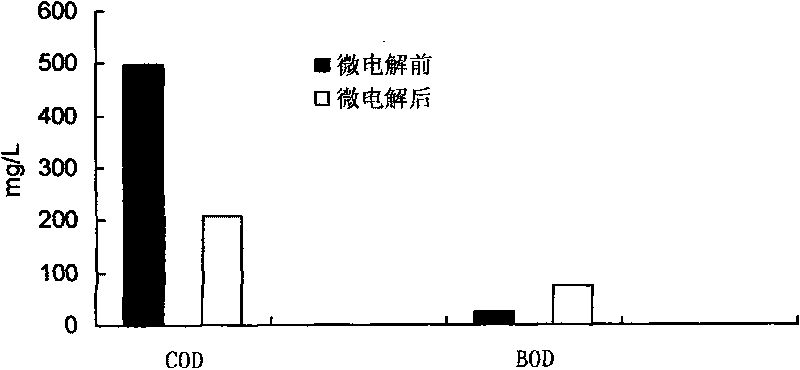

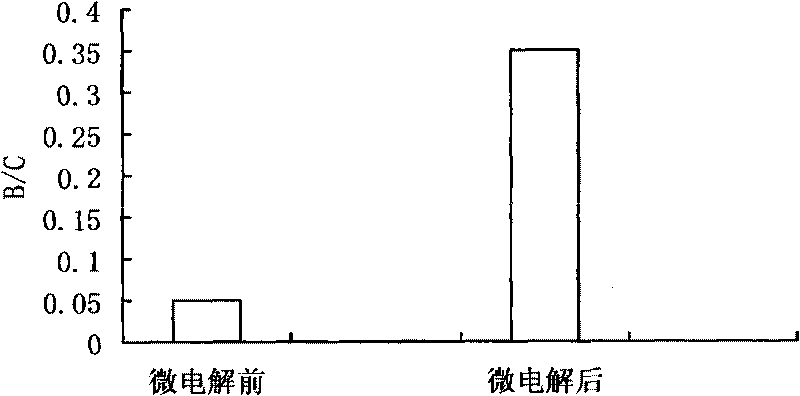

Preparation method of iron-carbon micro-electrolytic filler

InactiveCN101704565ALarge specific surface areaImprove responseWater contaminantsWater/sewage treatmentActivated carbonPowder mixture

A preparation method of iron-carbon micro-electrolytic filler relates to a preparation method of the micro-electrolytic filler for treating wastewater, comprising the following steps: using scrap iron with grain diameter of less than 60 meshes, active carbon powder with grain diameter of less than 100 meshes and rare-earth metal powder as raw materials; using hydrochloric acid solution with mass percentage of 5% for acid washing the scrap iron to activate the scrap iron; mixing the scrap iron with the active carbon powder and the rare-earth metal powder on mass percent of 85%: (14.91-14.00)%: (0.01-0.09)%; using a press machine to add the powder mixture to a Bauer ring-shaped mould for molding at 200 kN; demolding to obtain rough product; heating the rough product for 90-100 min at 1050-1200 DEG C in the absence of air; and then annealing to obtain the iron-carbon micro-electrolytic filler. The iron-carbon micro-electrolytic filler has good specific surface, excellent micro-electrolytic effect and simple technique, and is capable of effectively preventing passivation of the filler surface and hardening of the filler; moreover, the preparation method is easy to promote and suitable for industrial production.

Owner:TONGJI UNIV

Multi-component oxidation micro-electrolytic filler and preparation method thereof

ActiveCN102276021AIncrease contact areaAvoid separationWater/sewage treatment by sorptionActivated carbonIron powder

The invention belongs to the technical field of environmental engineering wastewater treatment, and particularly relates to multi-component oxidized micro-electrolysis filler and a preparation method thereof. The multi-component oxidized micro-electrolysis filler is mainly prepared from the following components in percentage by mass: 50-60% of iron, 20-30% of activated carbon, 12-15% of adhesive and 3-5% of catalyst through mixing, wherein iron is iron scrap or iron powder with particle size not more than 80 mesh; and activated carbon is in a powder and has particle size not more than 100 mesh. The preparation method of the multi-component oxidized micro-electrolysis filler comprises uniformly mixing iron, activated carbon, the adhesive and the catalyst according to the ratio, adding water, stirring and aging, then carrying out extrusion molding to obtain molded filler, demolding to obtain a filler blank, after naturally drying, drying, sintering in the absence of air, and cooling thefiller blank to obtain the multi-component oxidized electrolysis filler. According to the invention, the hardening, dead pool, stoppage and other practical problems existing in the use of the traditional micro-electrolysis fillers are solved.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

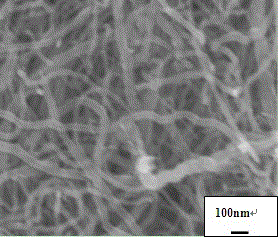

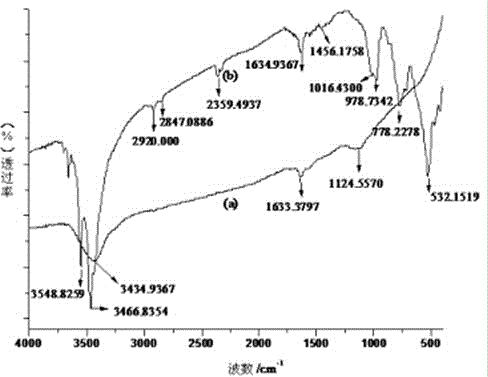

Vanadium-phosphorus-oxygen catalyst, and preparation method thereof

ActiveCN103769181AHigh reactivityEvenly distributedOrganic chemistryPhysical/chemical process catalystsPtru catalystPhysical chemistry

The invention discloses a vanadium-phosphorus-oxygen catalyst, and a preparation method thereof. According to the preparation method, a nano vanadium phosphorus oxide is taken as a precursor, is subjected to activating and then moulding, or is subjected to moulding and then activating so as to obtain the vanadium-phosphorus-oxygen catalyst; grain size of the nano vanadium phosphorus oxide is less than 100nm, and by volume, particles with a grain size of 30 to 50nm accounts for 7 to 14%, particles with a grain size of 50 to 70nm accounts for 54 to 79%, and particles with a grain size more than 70nm accounts for 7 to 39%. According to the vanadium-phosphorus-oxygen catalyst prepared by taking the nano vanadium phosphorus oxide as a precursor, octahedral structure of (VO)2P2O7 is neater, catalyst structure is stable, and catalytic activity and catalyst stability are higher. When the vanadium-phosphorus-oxygen catalyst is used for catalytic preparation of maleic anhydride via oxidation of n-butane, n-butane conversion rate reaches 87 to 95mol%, and maleic anhydride selectivity reaches 72 to 84mol%.

Owner:CHINA PETROLEUM & CHEM CORP +1

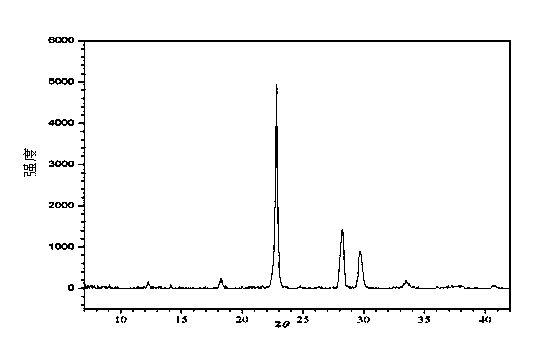

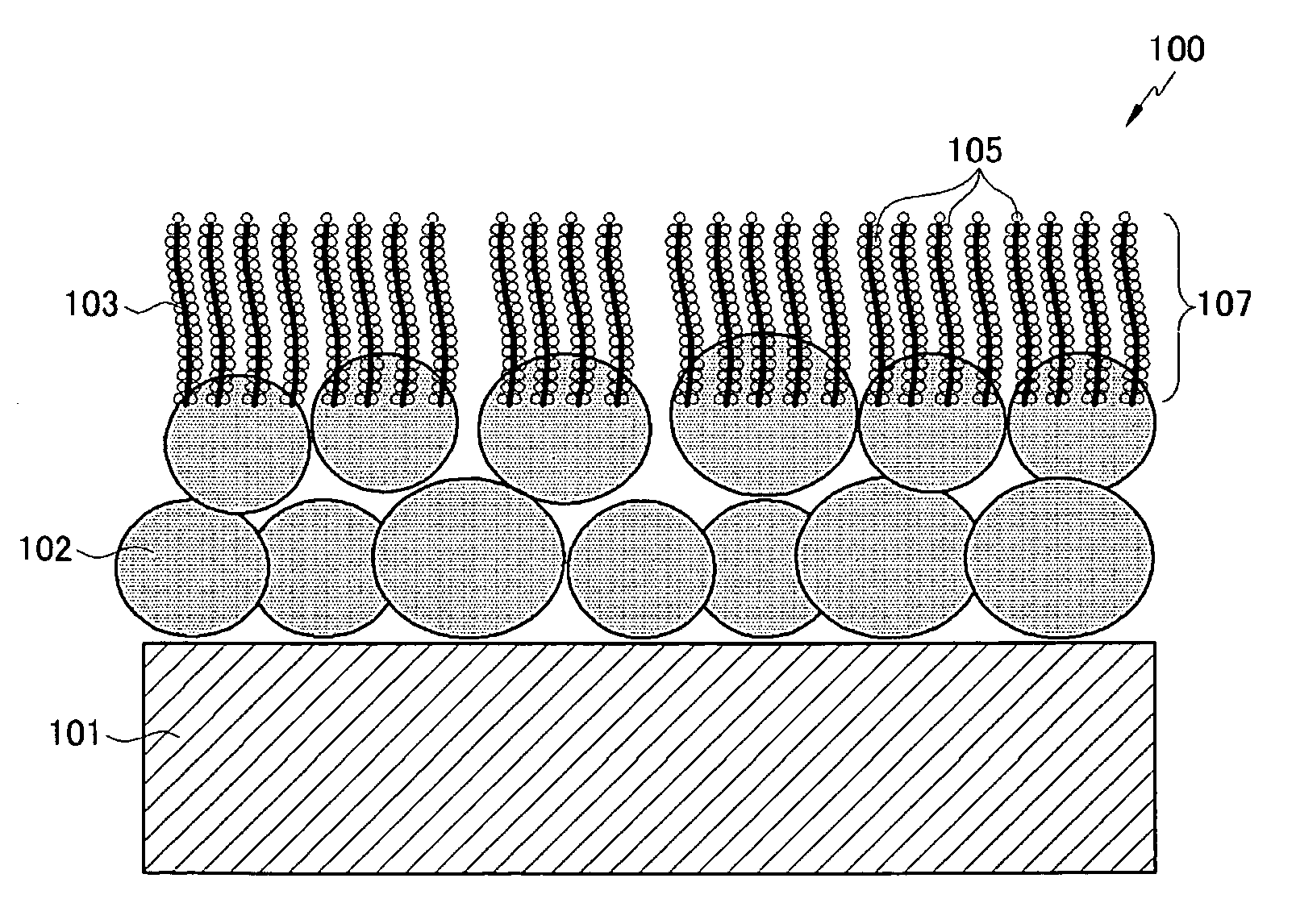

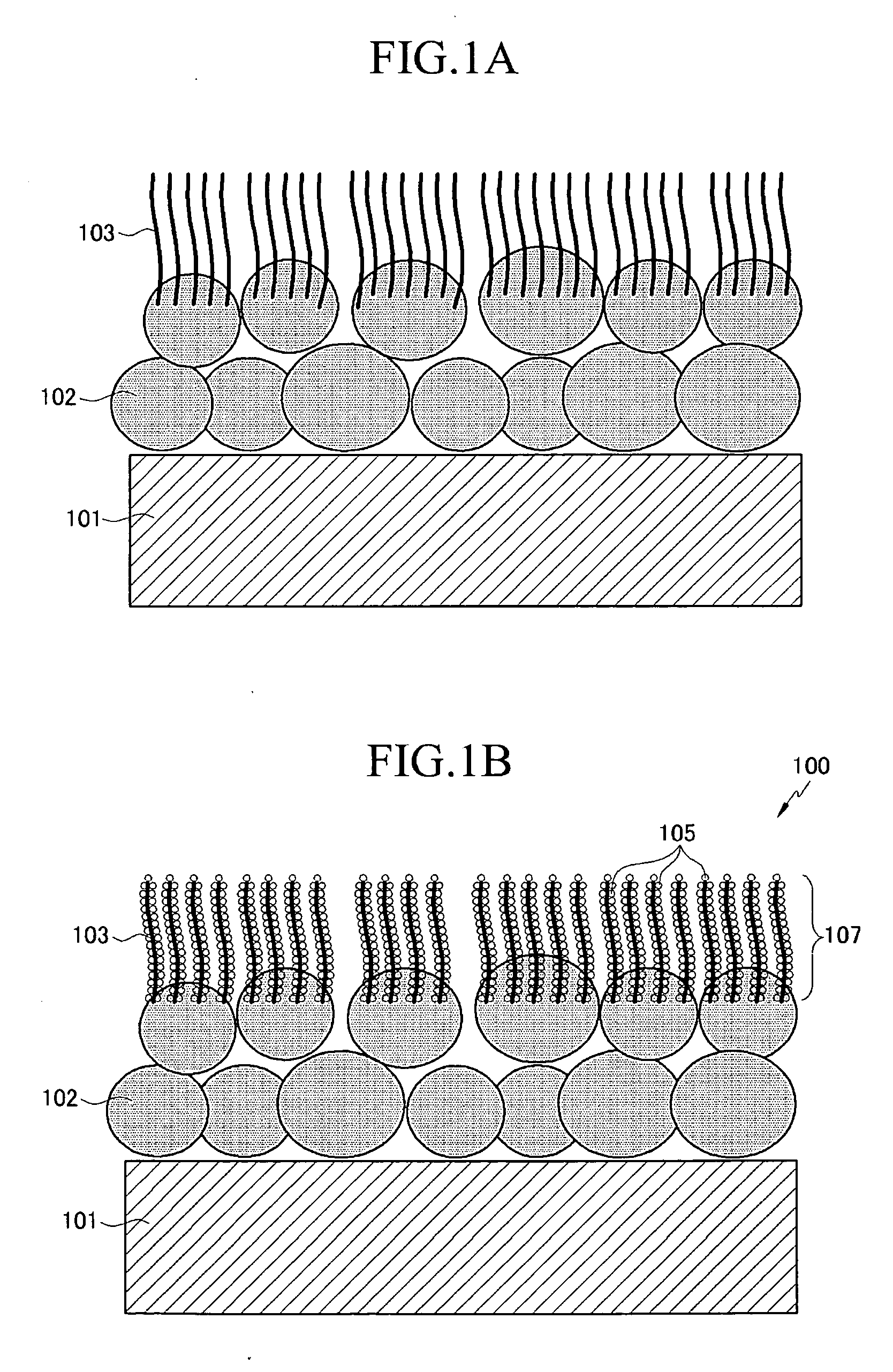

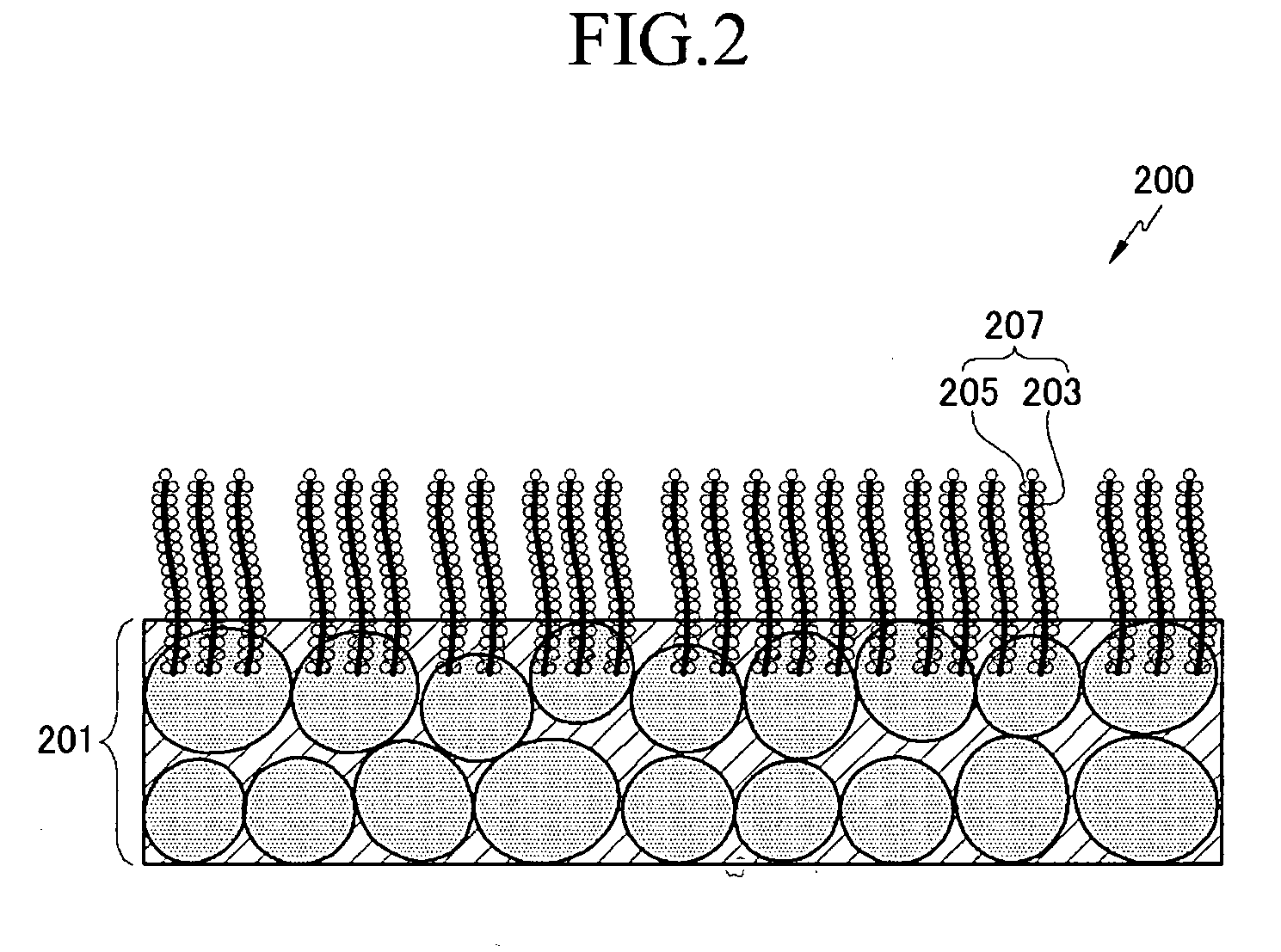

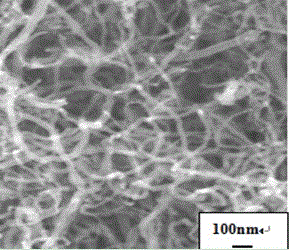

Electrode for fuel cell, fuel cell comprising the same, and method for preparing the same

InactiveUS20060115711A1Increase surface areaImprove reaction efficiencyMaterial nanotechnologyFuel cell auxillariesFuel cellsEngineering

An electrode for a fuel cell of the present invention includes an electrode substrate, a microporous layer formed on the surface of the electrode substrate, and a nano-carbon layer formed on the surface of the microporous layer with a catalyst layer coated on the surface of the nano-carbon layer. Alternatively, an electrode for a fuel cell includes an electrode substrate in which carbon particles are dispersed, a nano-carbon layer on the electrode substrate, and a catalyst layer on the nano-carbon layer.

Owner:SAMSUNG SDI CO LTD

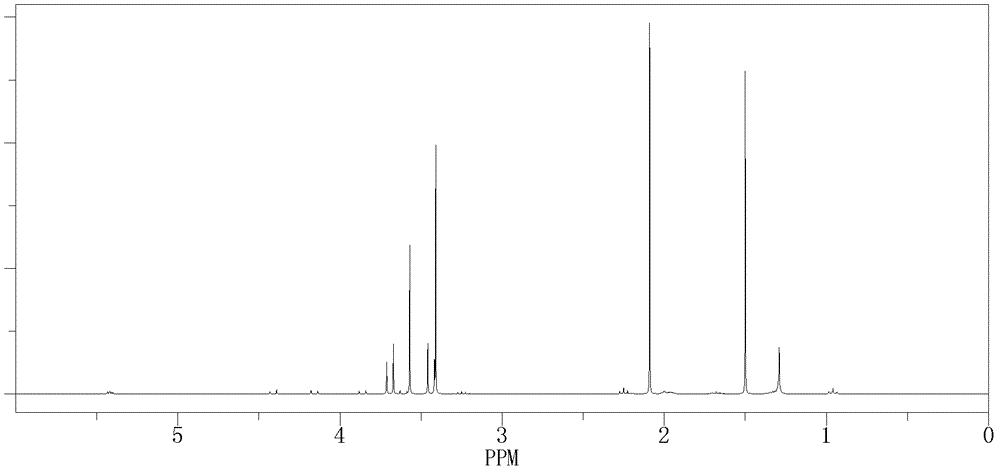

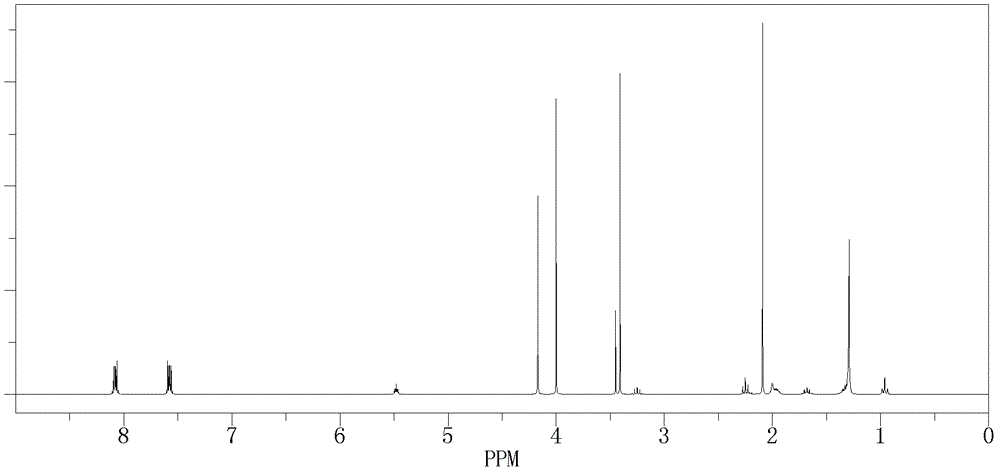

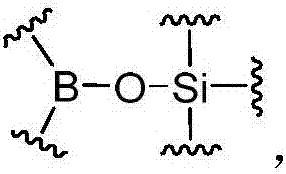

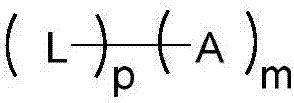

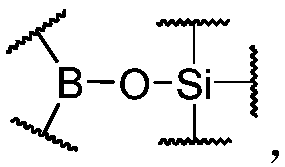

Dynamic polymer with dynamic cross-linked structure

The invention discloses a dynamic polymer with a dynamic cross-linked structure. Organic boric acid silicon ester bonds are contained on polymer chain skeletons of a cross-linked network and / or on cross-linked link skeletons between polymer chains, wherein the organic boric acid silicon ester bonds are necessary for forming / maintaining a dynamic polymer structure. The dynamic polymer is rich in structure and diverse in properties. By regulating and controlling the structure of a reactant, the dynamic polymers with different properties can be prepared. In addition, due to strong dynamic reversibility of the organic boric acid silicon ester bonds in the polymer, the polymer can exhibit functional characteristics of stimulus responsiveness, self-healing property, recoverability and the like; and besides, due to the presence of the organic boric acid silicon ester bonds, the polymer can also have the energy absorbing effects, and polymer materials can be toughened in a given structure. The dynamic polymer can be used for making shock-absorption cushioning materials, impact-resistance protection materials, self-healing materials, ductile materials and the like.

Owner:厦门天策材料科技有限公司

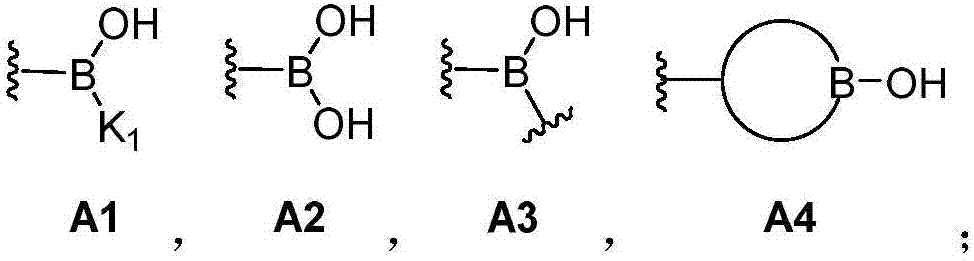

Preparation method of nanometer zinc oxide

A process for preparing nano-zinc oxide includes such steps as dissolving soluble Zn salt and urea in water, microwave radiating while reacting by homogenizing-depositing method to obtain the deposit of alkaline zinc carbonate, vacuum drying, ball grinding, calcining to obtain the crystal grains of nano-zinc oxide, mixing with surface modifier, organic solvent and disperser, ball grinding, and microwave radiating which surface modifying.

Owner:SUZHOU UNIV

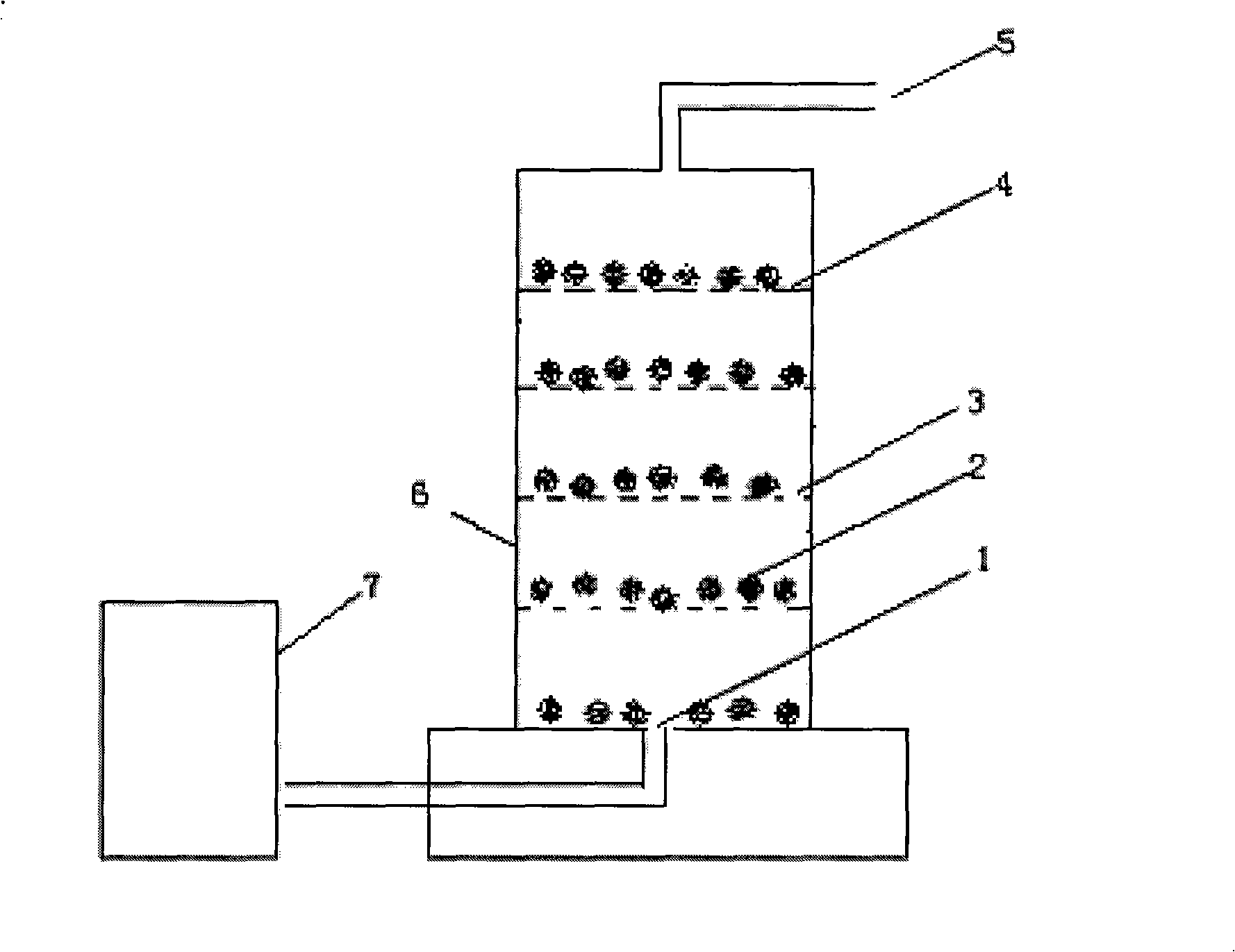

Method for producing MnO2 supported catalyst as well as method of using the same and apparatus for treating waste water

InactiveCN101406831AGood granularityEasy to recycleMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATESesquioxide

The invention discloses a method for preparing MnO2 supported catalysts, an application method thereof and a wastewater treatment device. The preparation method comprises the following steps: manganese acetate is prepared into a solution; one of activated carbon, active aluminium sesquioxide, white silica gel, a molecular sieve, zeolite or diatomite is taken as a carrier and dipped in the solution; and supported solid catalysts are prepared through dipping, evaporation, concentration, drying and roasting. A reactor of the wastewater treatment device is divided into a plurality of reaction spaces by baffles, and the catalysts exist as fluidized beds on every baffle. When the MnO2 supported catalysts prepared by the method are used in the reaction of degrading refractory organic matter through ozone catalytic oxidation, the contact time among the MnO2 supported catalysts, wastewater and ozone is between10 and 120 minutes, and the mass ratio of the adding amount of the catalysts to the wastewater in the reaction is between 1 to 200 and 1 to 20. The MnO2 supported catalysts prepared by the method have the characteristics of easy recovery, high repeat utilization property and high efficiency of catalyzing and degrading refractory organic matters.

Owner:GUANGDONG UNIV OF TECH

Process for coking full fraction oil hydrogenation refining

InactiveCN1458233AImprove product propertiesDiesel properties improvedHydrocarbon oils refiningProcess engineeringHeating energy

The present invention is one process of hydrofining coked full fraction oil. Based on available process of hydrofining coked full fraction oil, new hydrogen of the system is used in further refining of diesel oil, so that diesel oil is refined under ideal thermodynamic and dynamic conditions. This results in high product quality, flexible, economic and practical technological process, less investment increment, fully utilization of heat energy and low operation cost. The present invention is suitable for reforming and constructing coked full fraction oil hydrofining apapratus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Surface modification method for carbon nano tube

InactiveCN102942810AGood for secondary modificationImprove thermal stabilityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPtru catalystModified carbon

The invention provides a surface modification method for a carbon nano tube and belongs to the field of nanotechnology. The method includes step one, uniformly mixing a carbon nano tube which is subjected to acidification by a strong oxidizing acid with a silane coupling agent and deionized water, reacting under a certain condition, filtering, washing, and drying to obtain a primary modified carbon nano tube; step two, uniformly mixing the primary modified carbon nano tube with polyhydric alcohols and a concentrated sulfuric acid, reacting under a certain condition, filtering, washing to neutral, and drying to obtain a secondary modified carbon nano tube; uniformly mixing the secondary modified carbon nano tube with an organic carboxylic acid, an esterification reaction catalyst and N,N-dimethylformamide, reacting under a certain condition by the aid of the protection of inert gases, cooling to the room temperature, filtering, washing, and drying to obtain the surface modification carbon nano tube. When the prepared modified carbon nano tube which is provided with ester groups on the surface is mixed with a polyester resin, the interface-free mixing is achieved, and the heat stability and the mechanical property of the modified polyester resin can be improved.

Owner:TAIYUAN UNIV OF TECH

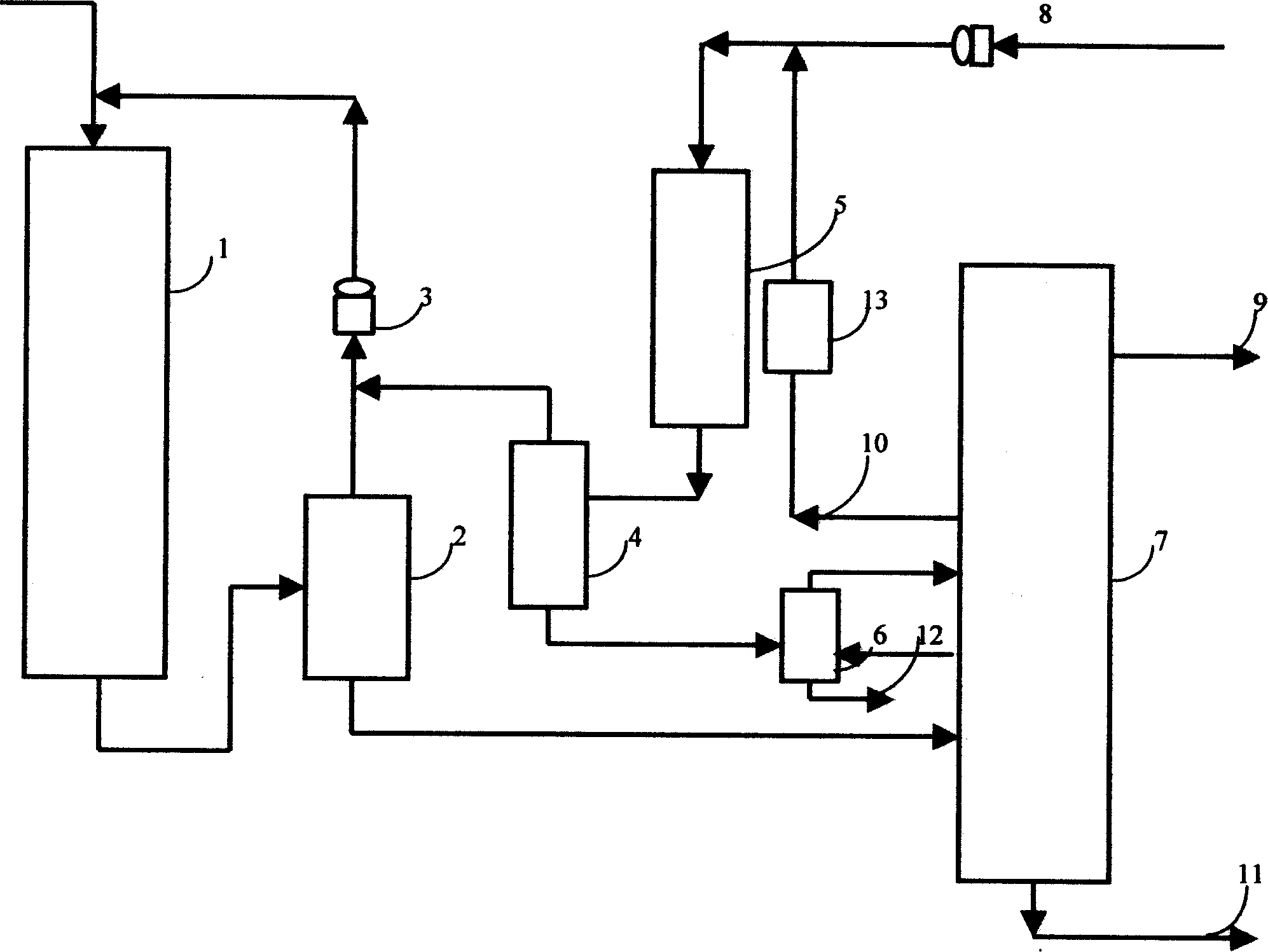

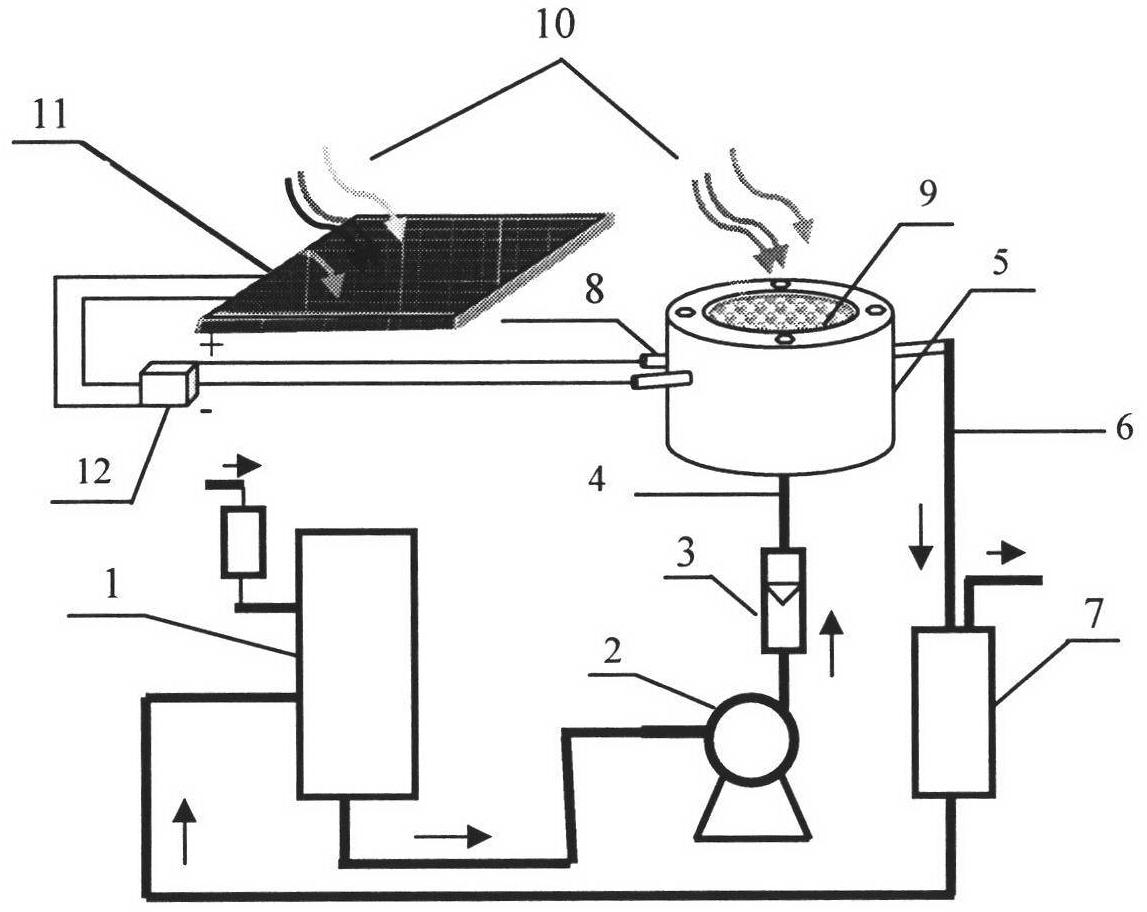

Organic wastewater treatment film reactor utilizing sunlight-assisted electro-catalysis

InactiveCN102603037AAccelerated adsorption/desorption rateThe actual user interface increasesWater/sewage treatment by irradiationEnergy based wastewater treatmentPhoto assistedPorous channel

The invention relates to an organic wastewater treatment film reactor utilizing solar energy photo-assisted electro-catalysis, which comprises a storage tank of water to be processed, a flow controllable constant flow pump, a photoelectric chemical reactor, a clear water storage tank and a solar battery component, wherein a photo anode and a cathode are correspondingly arranged in the reactor; the photo anode takes a porous metal membrane as a base body, and a TiO2 nano tube or a TiO2 mesoporous membrane is formed on the surface of a porous titanium membrane (net) by an electrochemical anisotropic etching technology; a porous channel film is used as the base body; a metal oxide coating electrode with high electrochemical catalytic activity and high electrical conductivity is prepared by a dipping film-forming method, simultaneously, by doping and modifying operations, the electrode material has photo catalytic activity and the reaction efficiency is improved. The reactor integrates electrochemistry, photocatalysis and film separation technologies; the three technologies are coupled to enhance a synergistic effect; the wastewater treatment efficiency can be improved; a solar component is adopted as a power supply; the clean solar energy is utilized to the maximal degree, and the organic wastewater treatment film reactor has social benefits of reducing environment load and economic benefits of reducing cost.

Owner:NANJING UNIV OF TECH

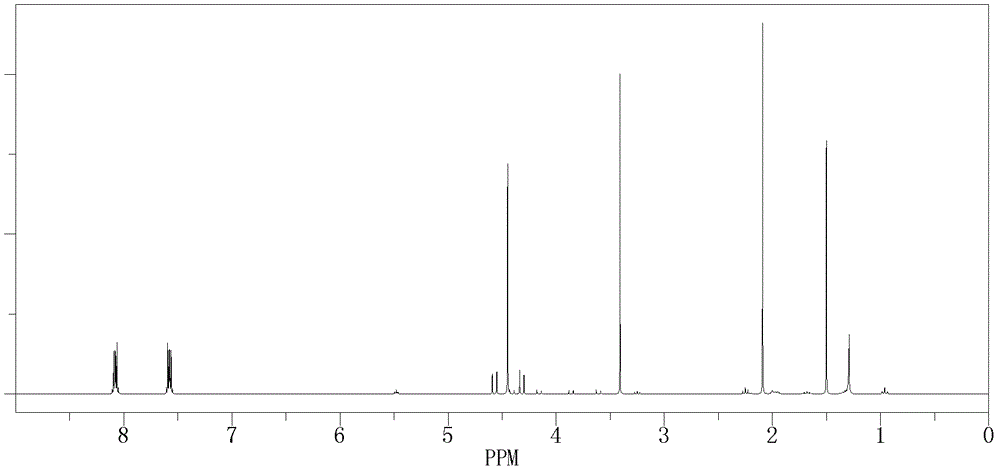

Cationic polymerization initiation system and cationic polymerization method

The invention discloses a cationic polymerization initiation system and a cationic polymerization method. The cationic polymerization initiation system comprises at least one initiator, at least one Lewis acid and at least one additive. The initiator is a compound capable of providing protons or carbocations, wherein a mole ratio of the initiator to monomers is (5.0*10<-5> to 1.2*10<-2>): 1. The Lewis acid is a metal halide or an organic metal halide, wherein a mole ratio of the Lewis acid to the monomers is (5.0*10<-4> to 4.0*10<-1>): 1. The at least one additive is selected from sulfur-containing organic compounds, phosphorus-containing organic compounds and organic compounds containing sulfur and phosphorus, wherein a mole ratio of the at least one additive to the monomers is (1.0*10<-3> to 5.0*10<-2>): 1. The cationic polymerization initiation system has high activity, a low price and stable properties, is convenient for use, has high polymerization efficiency, and can greatly improve polymerization product molecular weight, wherein weight-average molecular weight of polymerization products obtained at a temperature of -60 DEG C is 1*10<6>.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalyst for treating high-concentration organic wastewater through catalytic oxidation

InactiveCN101601998AChange adsorptionIncrease the number ofWater contaminantsCatalyst activation/preparationHigh concentrationActivated carbon

The invention discloses a method for preparing a catalyst for treating high-concentration organic wastewater through catalytic oxidation, which comprises the following steps: 1) drying a cocoanut active charcoal at a temperature of between 100 and 120 DEG C for 8 to 15 hours, taking out and adding the cocoanut active charcoal into 2 to 10 percent sulfuric acid solution to perform soakage for 12 to 36 hours, adding the cocoanut active charcoal into a 1 to 10 percent oxydol solution to perform soakage for 12 to 36 hours, taking the cocoanut active charcoal out, and draying the cocoanut active charcoal in shade to obtain an activated charcoal for standby; and 2) soaking constant volume of the activated charcoal into transition metal salt solution for 12 to 36 hours, drying the activated charcoal at a temperature of between 100 and 120 DEG C for 8 to 15 hours, and calcining the activated charcoal at a temperature of between 300 and 650 DEG C for 3 to 8 hours to obtain the catalyst for treating the high-concentration organic wastewater through the catalytic oxidation. The service life of an active charcoal catalyst bed prepared by the method can reach over 0.5 to 1 year. After the treatment of the wastewater, compared with a Fenton reagent, the treatment efficiency of the catalyst is improved obviously, and the treatment cost is reduced by about 20 percent.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

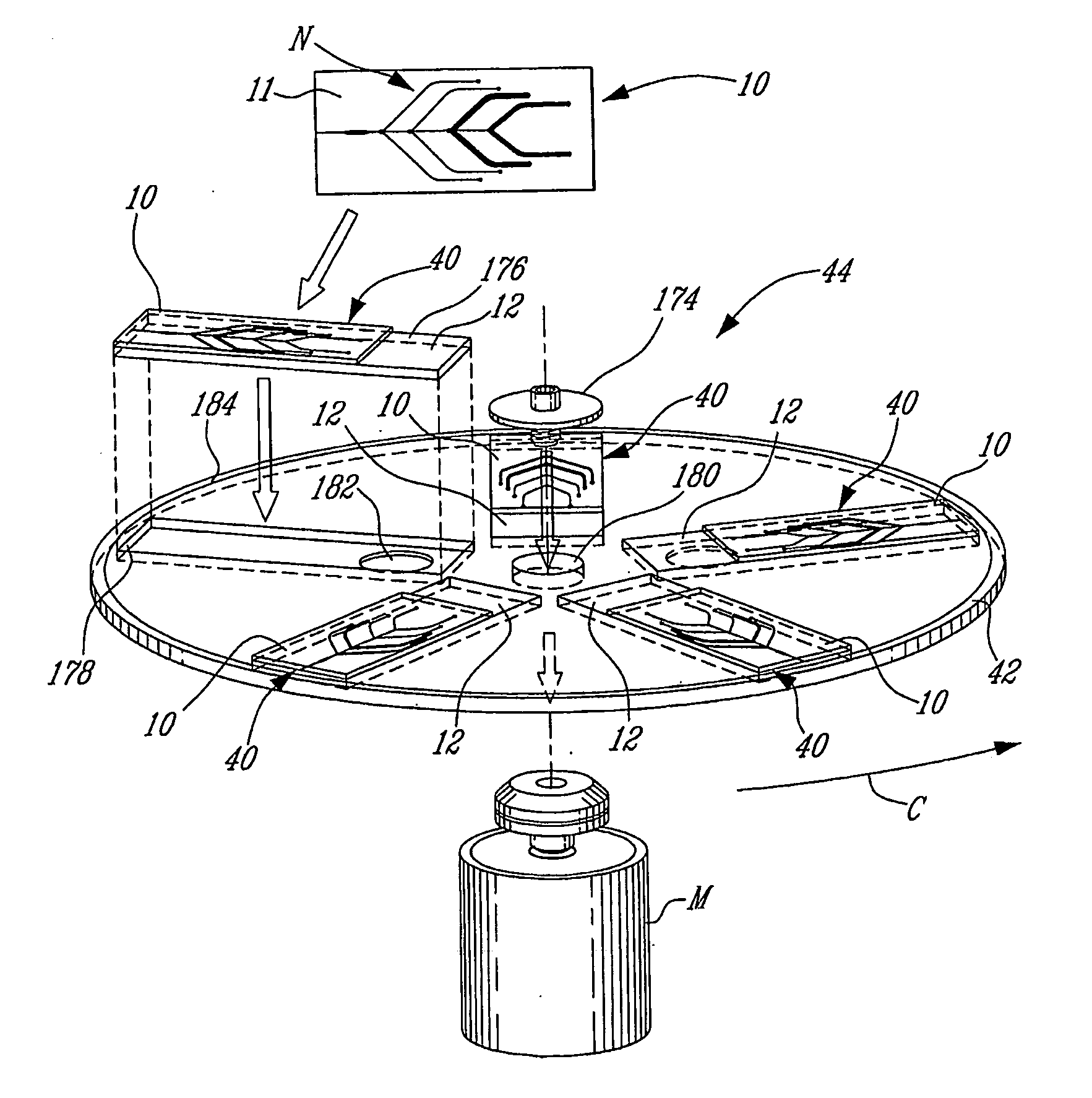

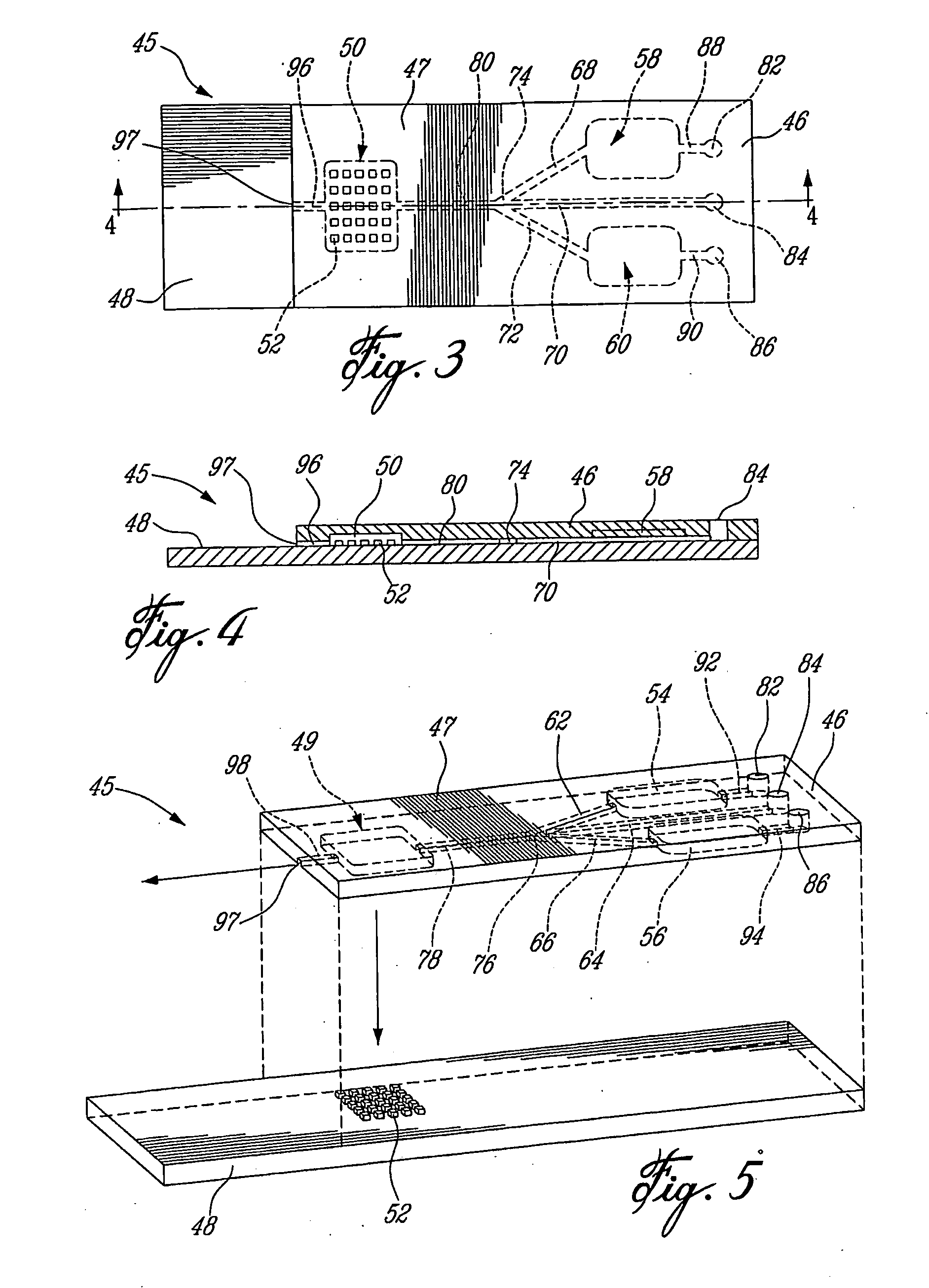

Removable microfluidic cell

InactiveUS20090023610A1Increase reaction reproducibilityImprove reaction efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsFlow cellChemical physics

A microfluidic flow cell for removably interfacing with a removable-member for performing a reaction therebetween. The microfluidic flow cell device comprises at least one reaction portion defining with the removable-member a reaction chamber when in an interfaced position thereof. The microfluidic flow cell comprises at least one fluid-receiving portion for receiving a fluid therein and being in fluid communication with the reaction chamber. When the microfluidic flow cell and the removable-member are in the interfaced position, the cell is adapted to allow for the fluid in the fluid-receiving portion to flow to the reaction chamber. Devices, systems and methods comprising this microfluidic flow cell are also disclosed.

Owner:UNIV LAVAL

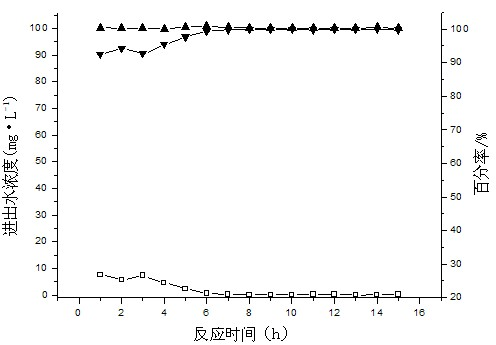

Method and device for removing organic matters from water by using double-pool double-effect visible light in response to photo-electro-Fenton reaction

InactiveCN102092820AImprove stabilityIncrease concentrationWater/sewage treatment by oxidationSalt bridgePotassium

The invention discloses a method and a device for removing organic matters from water by using double-pool double-effect visible light in response to a photo-electro-Fenton reaction. The device comprises a cathode pool, an anode pool, a saturated potassium chloride (KCl) salt bridge, a visible light response semiconductor membrane material anode, a carbon-iron composite material oxygen negative electrode, an air pump, a magnetic stirrer, a direct current stabilized voltage power supply and a visible light source, wherein an anode performs photoelectrocatalysis under the actions of visible light and anode bias voltage to remove organic pollutants from water; the carbon-iron composite material oxygen negative electrode performs cathode potential reduction on O2 under the conditions of external voltage and introduced air to produce hydrogen peroxide which is subjected to an electric Fenton reaction to generate active substances such as hydroxyl radicals and the like capable of effectively removing the organic matters from the water; electrons produced by a photoanode migrate towards an oxygen cathode under the action of anode bias voltage; the O2 is reduced by the electrons on the cathode to generate more H2O2; and the H2O2 produced on the cathode cannot migrate to the anode pool for consumption, so that higher H2O2 concentration is ensured, and the oxidation reaction of the organic matters by electric Fenton is ensured. The method and the device are suitable for treating various types of organic waste water.

Owner:HUAZHONG NORMAL UNIV

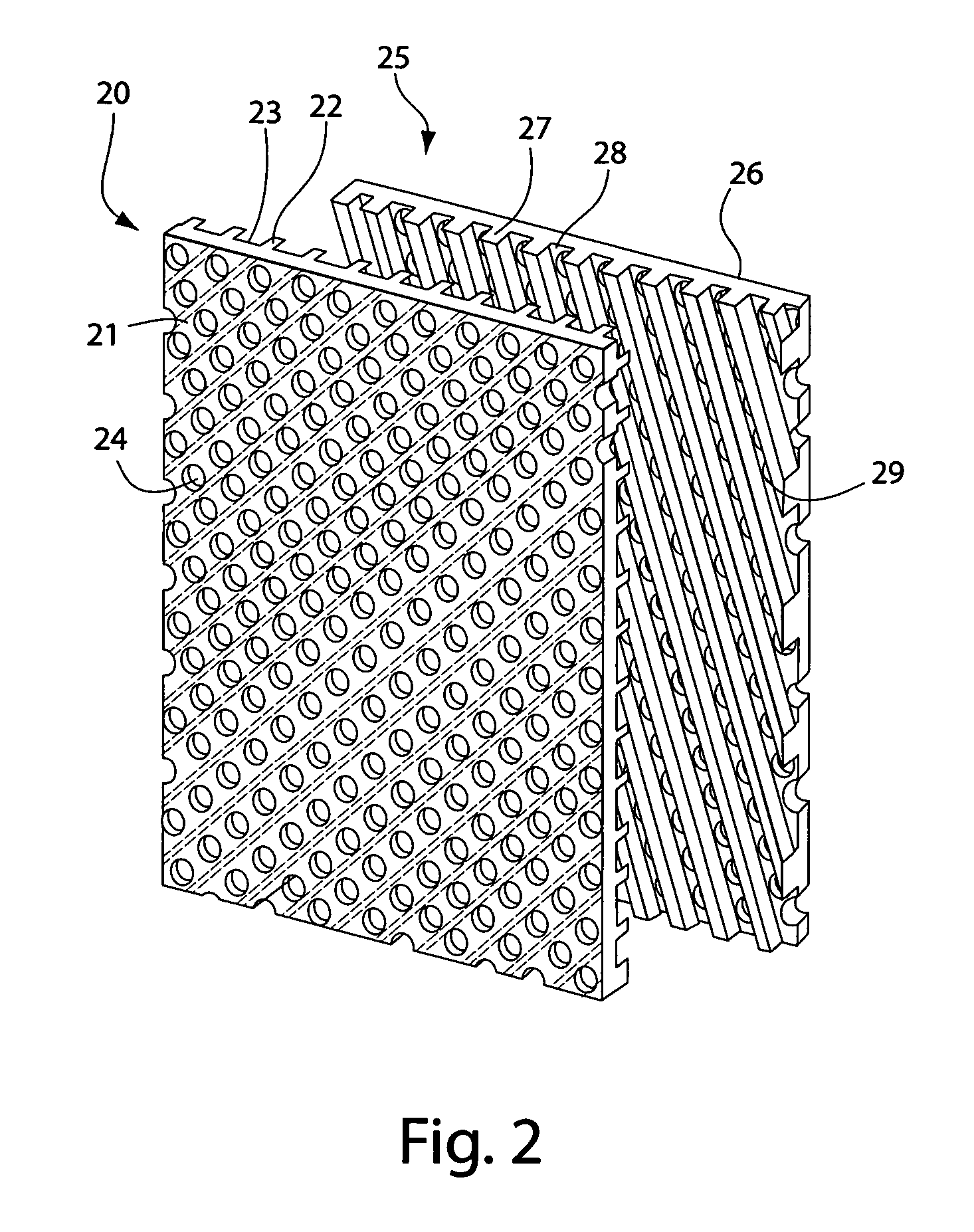

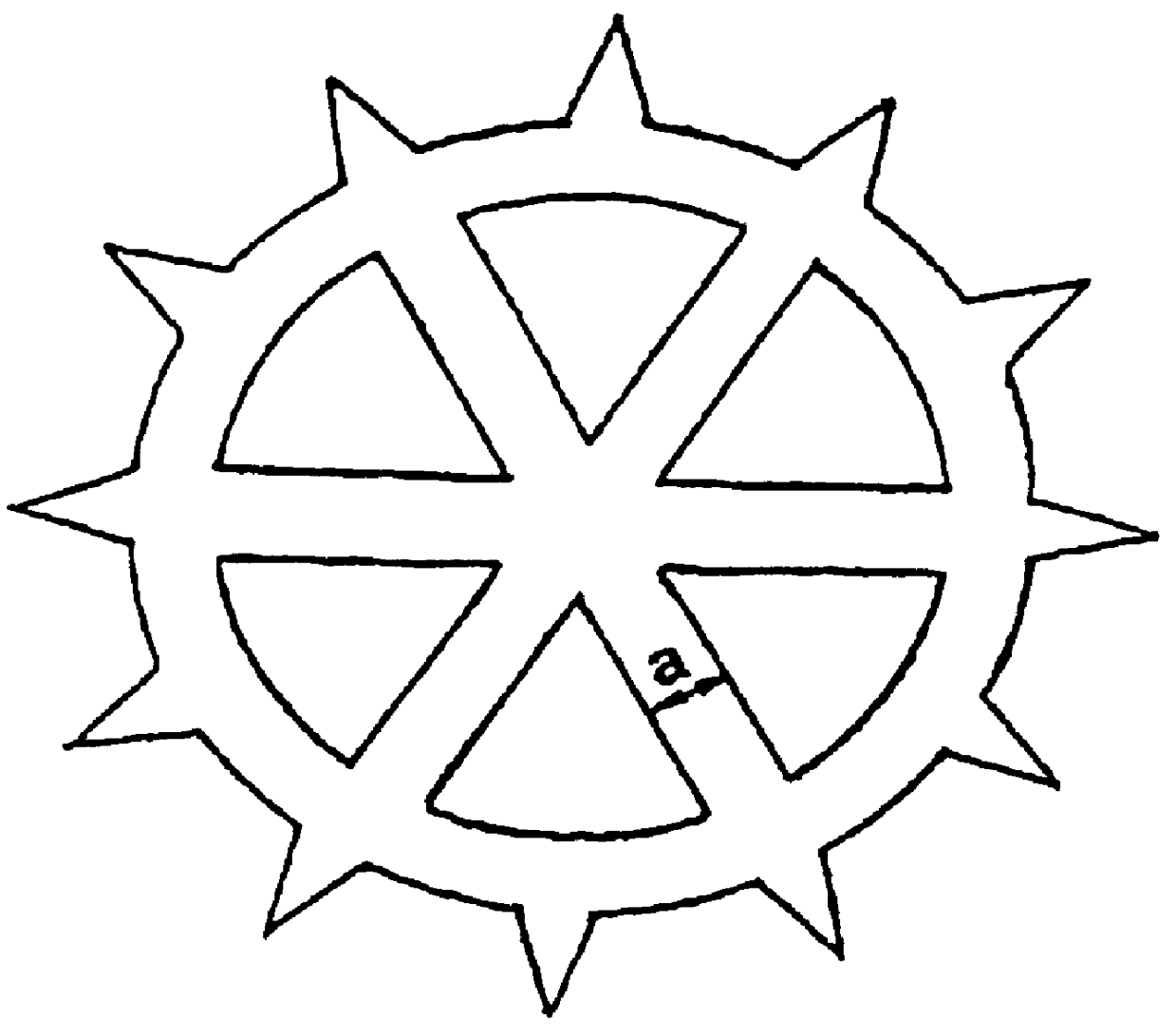

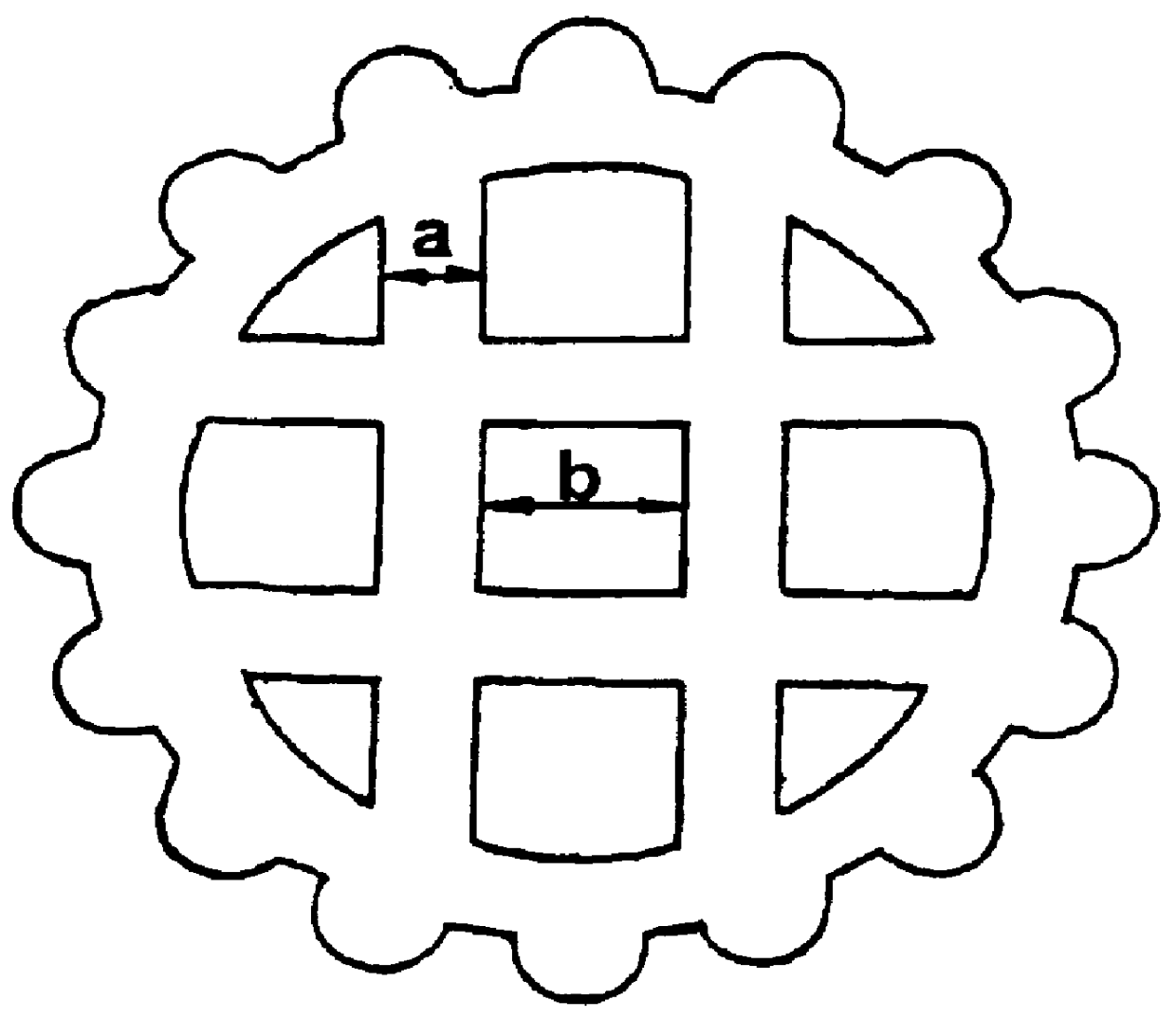

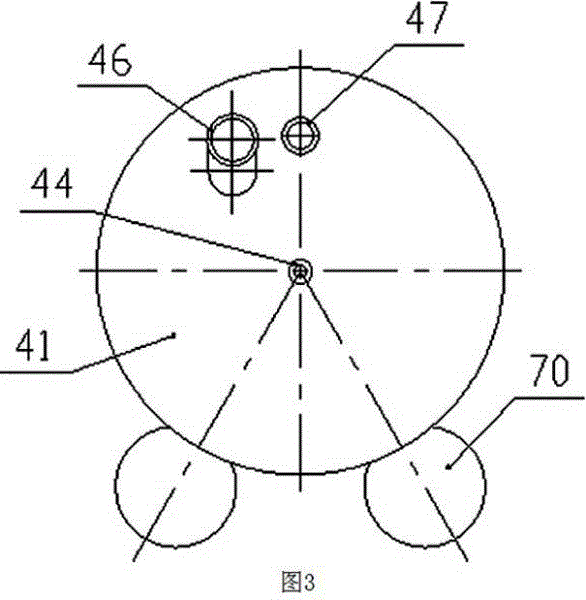

Dual functional catalyst of packing type and the catalytic distillation equipment

InactiveUS6117812AIncrease counter current flow fluxLarge external surface areaMolecular sieve catalystsOther chemical processesFractionationCatalytic distillation

The present invention relates to a dual functional catalyst having both the catalytic reaction function and fractionation function and a catalytic distillation equipment for packing the catalyst therein. Said catalyst has a special shape and can be packed at random into the reaction section of said equipment. So, there exist adequate free spaces inside pellet and between pellets, enabling the vapor and liquid streams to pass through the catalyst beds directly and countercurrently, and contact with the dual functional catalyst directly. The reaction between the reactants and fractionation of products can be carried out simultaneously. Thus a high reaction efficiency is achieved. No special inner part is needed in the reaction section to pack the catalysts, so the structure of the equipment is simple and easy to operate, and the investment and cost of operation are low.

Owner:CHINA PETROCHEMICAL CORP +1

Dynamic polymer having non-covalent crosslinking structure and application thereof

ActiveCN107805309AFast self-healingAchieve synthesisPolyureas/polyurethane adhesivesFibre treatmentBoric acidBiomimetic materials

The invention discloses a dynamic polymer having a non-covalent crosslinking structure. The dynamic polymer contains organic boric acid silicon ester bonds on polymer chain backbone; wherein the organic boric acid silicon ester bonds are existed as polymeric chain contacts of the dynamic polymer, and are the necessary condition for forming or maintaining a dynamic polymer structure. The dynamic polymer has energy dissipation performance by means of the organic boric acid silicon ester bonds having strong dynamic reversibility, embodies functional characteristics of stimulation responsiveness and self-repairability, and has a wide application prospect in the fields of sport protection, a functional coating, and a bionic material.

Owner:厦门天策材料科技有限公司

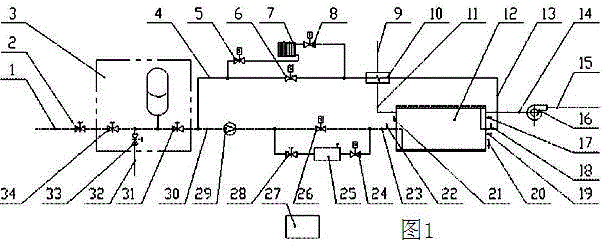

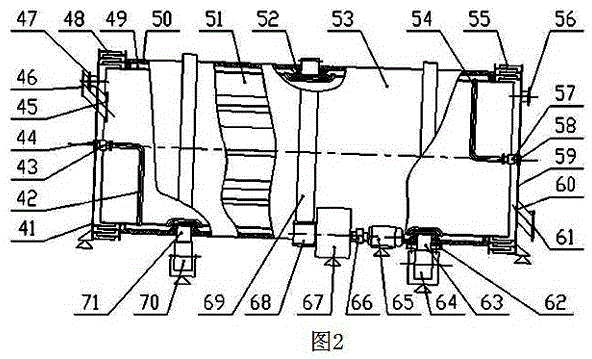

High-efficiency intelligent aerobic fermentation reaction system and method

ActiveCN102617204AFacilitate domestication and mass reproductionImprove reaction efficiencyBio-organic fraction processingOrganic fertiliser preparationControl systemProcess engineering

The invention discloses an aerobic fermentation reaction system and method. The high-efficiency intelligent aerobic fermentation reaction system comprises an aerobic fermentation reactor, a circular water system, a gas intake and exhaust system, a detection system and a control system, wherein a water jacket is arranged outside a horizontal roller of the aerobic fermentation reactor; a material feeding and discharging hole and a gas intake and exhaust hole are respectively formed in sealing covers at two sides of the horizontal roller; the circular water system is connected and communicated with the water jacket on the horizontal roller; the gas intake and exhaust system is connected and communicated with the gas intake and exhaust hole in the sealing cover of the horizontal roller; a sensor of the detection system is arranged in the aerobic fermentation reactor and on a water passing pipe of the aerobic fermentation reactor; a signal output by the sensor is respectively connected with the control system; and the control system is used for controlling the circular water system, the gas intake and exhaust system, the aerobic fermentation reactor and external feeding and discharging conveying equipment. According to the high-efficiency intelligent aerobic fermentation reaction system and method disclosed by the invention, the occupied area is smaller and the fermentation efficiency is higher; no secondary pollution occurs; and the reduction, harmlessness and resourceful treatment of organic wastes can be quickly realized.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com