High-efficiency intelligent aerobic fermentation reaction system and method

A technology of aerobic fermentation and reaction system, applied in application, preparation of organic fertilizer, organic fertilizer, etc., can solve the problems of fermentation speed drop, environmental pollution, stop, etc., and achieve the effect of avoiding temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

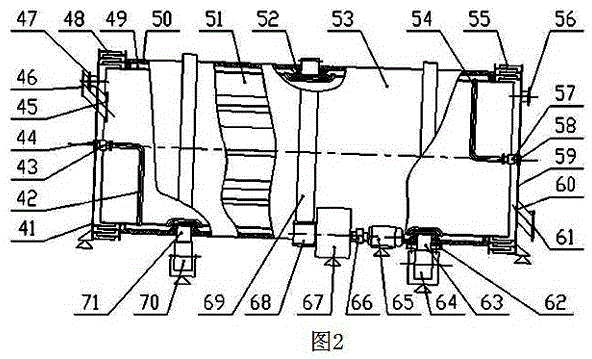

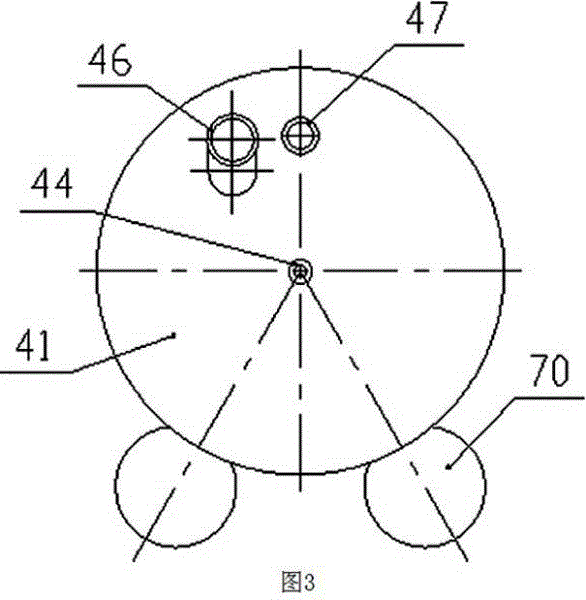

[0094] See figure 2 , The horizontal roller 53 is placed on the feeding side supporting roller group 70 and the discharging side supporting roller group 64. The two supporting roller groups support the feeding side rolling ring 71 and the discharging side rolling ring 63 to adjust the feeding side The supporting wheel group 70 makes the feed side of the aerobic fermentation reactor higher than the discharge side, so that the angle between the axis and the horizontal plane is adjustable between 0 and 5°. The discharging side supporting roller group 64 is provided with a stop wheel 62, and the function of the stop wheel 62 is to prevent the roller from moving along the axis.

[0095] The motor 65 is connected to the coupling 66 and the reducer 67, and drives the horizontal roller 53 to rotate around its axis through the pinion 68 on the output shaft of the reducer 67 and the outer gear ring 69 meshing with it.

[0096] Both ends of the horizontal drum 53 are respectively provided wi...

Embodiment 2

[0106] See Figure 7 The difference between Example 2 and Example 1 of the aerobic fermentation reactor is mainly in the rotary drive device of the horizontal drum.

[0107] The horizontal roller 53 is placed on the feed-side active roller set 83 and the discharge-side active roller set 81. The two sets of roller sets support the feed-side roller 71 and the discharge-side roller 63 to adjust the feed The side supporting wheel group makes the feed side of the aerobic fermentation reactor higher than the discharge side, and the angle between the axis and the horizontal plane is adjustable between 0 and 5°. The discharging side supporting wheel group is provided with a stop wheel 62. Among them, two supporting wheels with coaxial axes form a group, which are respectively connected with sprocket A84 and sprocket B85 through a transmission shaft 82.

[0108] The motor 89 is connected to the reducer 87 through the coupling 88, and the output shaft of the reducer 87 is equipped with a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com