Patents

Literature

473 results about "Landfill gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Landfill gas is a complex mix of different gases created by the action of microorganisms within a landfill. Landfill gas is approximately forty to sixty percent methane, with the remainder being mostly carbon dioxide. Trace amounts of other volatile organic compounds (VOCs) comprise the remainder (<1%). These trace gases include a large array of species, mainly simple hydrocarbons.

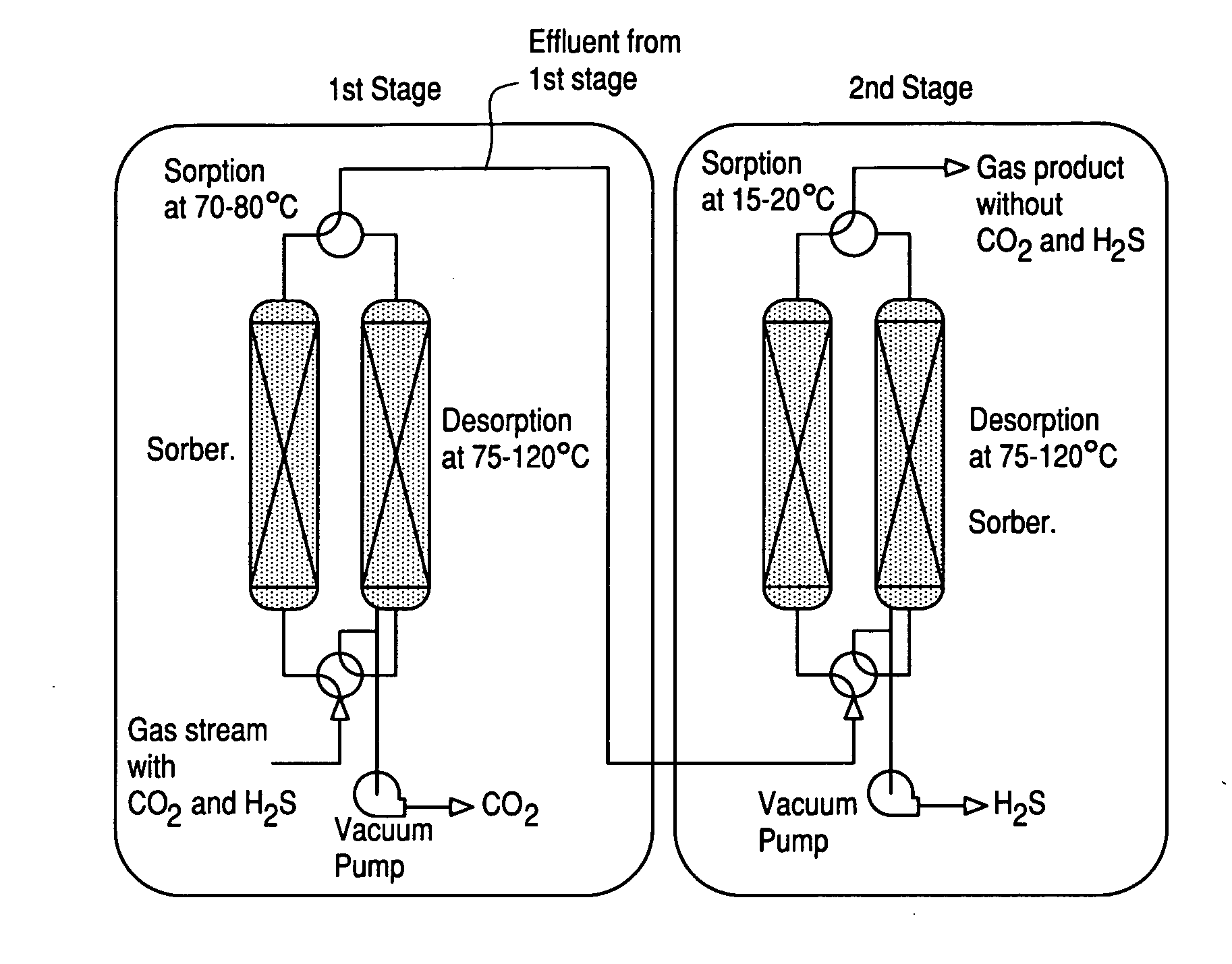

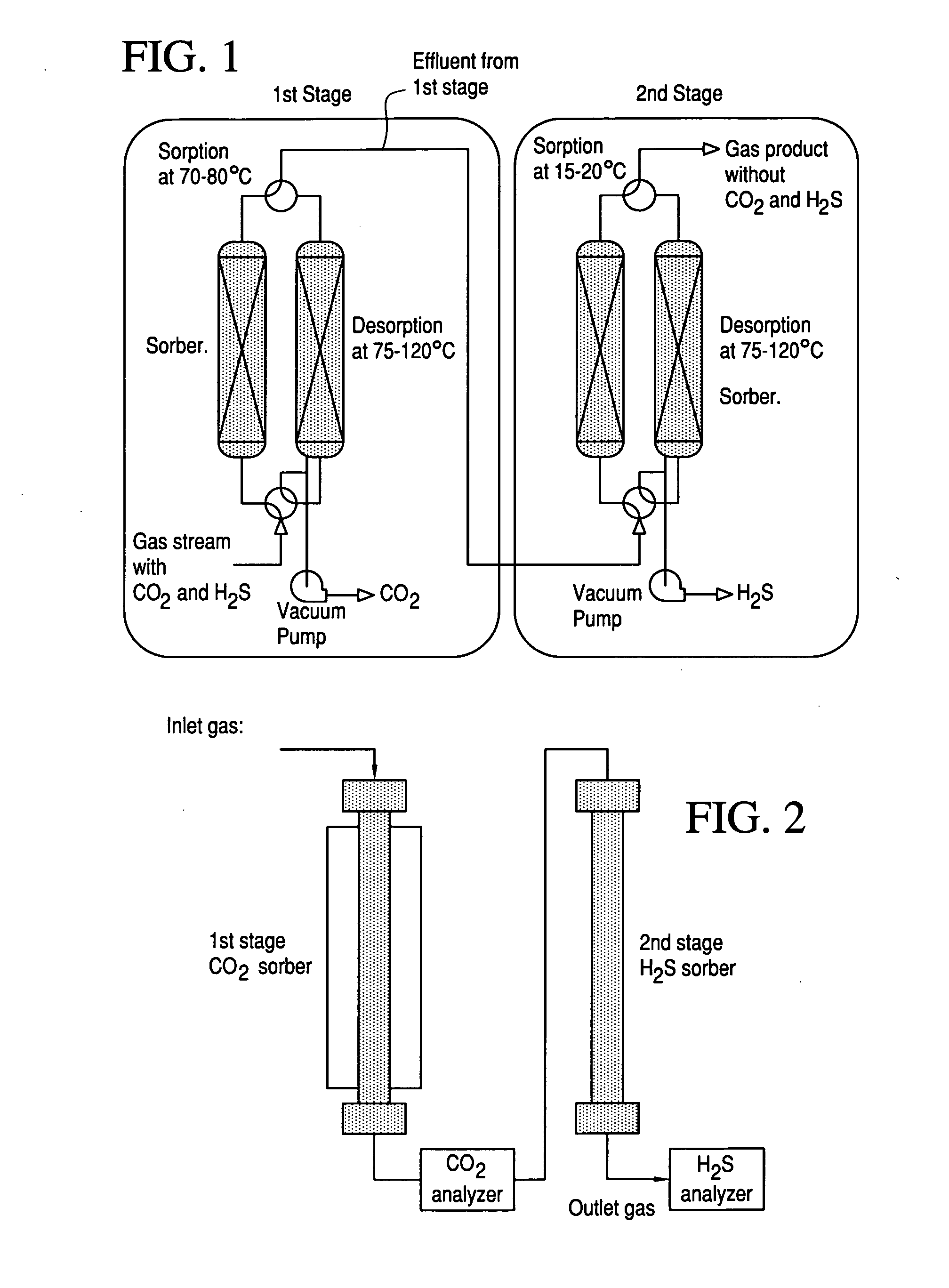

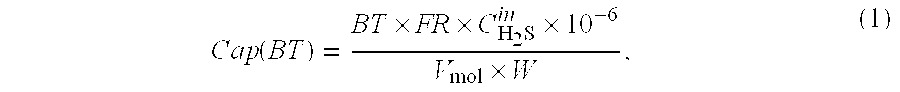

Novel sorbents and purification and bulk separation of gas streams

InactiveUS20080264254A1Large capacityLittle and no corrosive effectNitrous oxide captureGas treatmentSorbentDesorption

Porous-material-supported polymer sorbents and process for removal of undesirable gases such as H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH, and CH3—S—CH3 from various gas streams such as natural gas, coal / biomass gasification gas, biogas, landfill gas, coal mine gas, ammonia syngas, H2 and oxo-syngas, Fe ore reduction gas, reformate gas, refinery process gases, indoor air, fuel cell anode fuel gas and cathode air are disclosed. The sorbents have numerous advantages such as high breakthrough capacity, high sorption / desorption rates, little or no corrosive effect and are easily regenerated. The sorbents may be prepared by loading H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic polymer(s) or mixtures thereof, as well as any one or more of H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic compound(s) or mixtures thereof on to porous materials such as mesoporous, microporous or macroporous materials. The sorbents may be employed in processes such as one-stage and multi-stage processes to remove and recover H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH and CH3—S—CH3 from gas streams by use of, such as, fixed-bed sorbers, fluidized-bed sorbers, moving-bed sorbers, and rotating-bed sorbers.

Owner:PENN STATE RES FOUND +1

Gas purification processes

InactiveUS20110185896A1Reduce and eliminate needEasy to controlGas treatmentGaseous fuelsVacuum levelAir purification

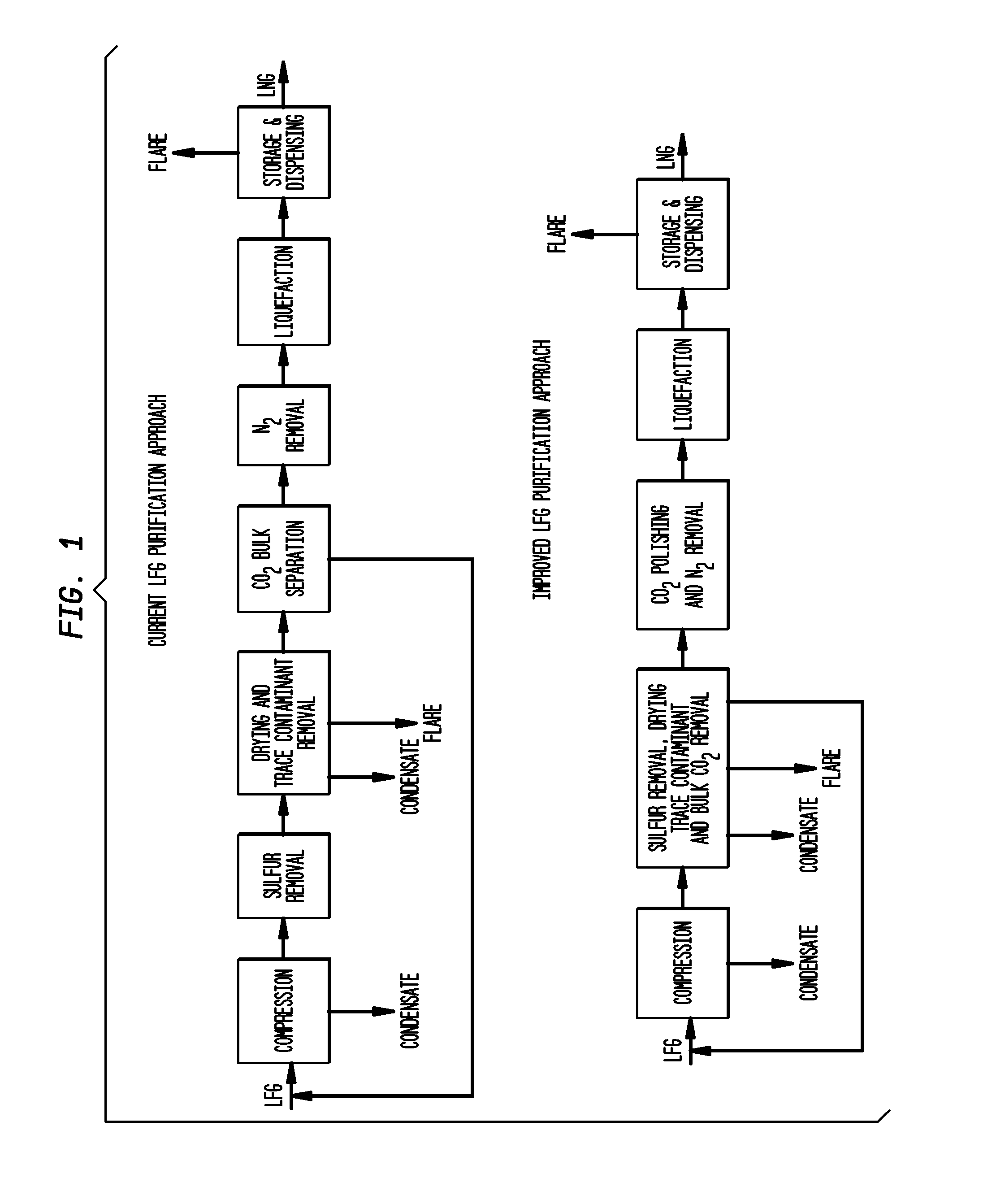

A method for removing contaminants from a natural gas stream such as a biogas / landfill gas stream. The natural gas stream is fed to a first adsorption unit for removal of certain contaminants and then to a second adsorption unit for the removal of additional contaminants. Alternatively, a membrane stage may be employed between the adsorption units. The method utilizes the external purge to enhance pressure swing adsorption working capacity so that the vacuum level required for regeneration is not as high.

Owner:LINDE AG

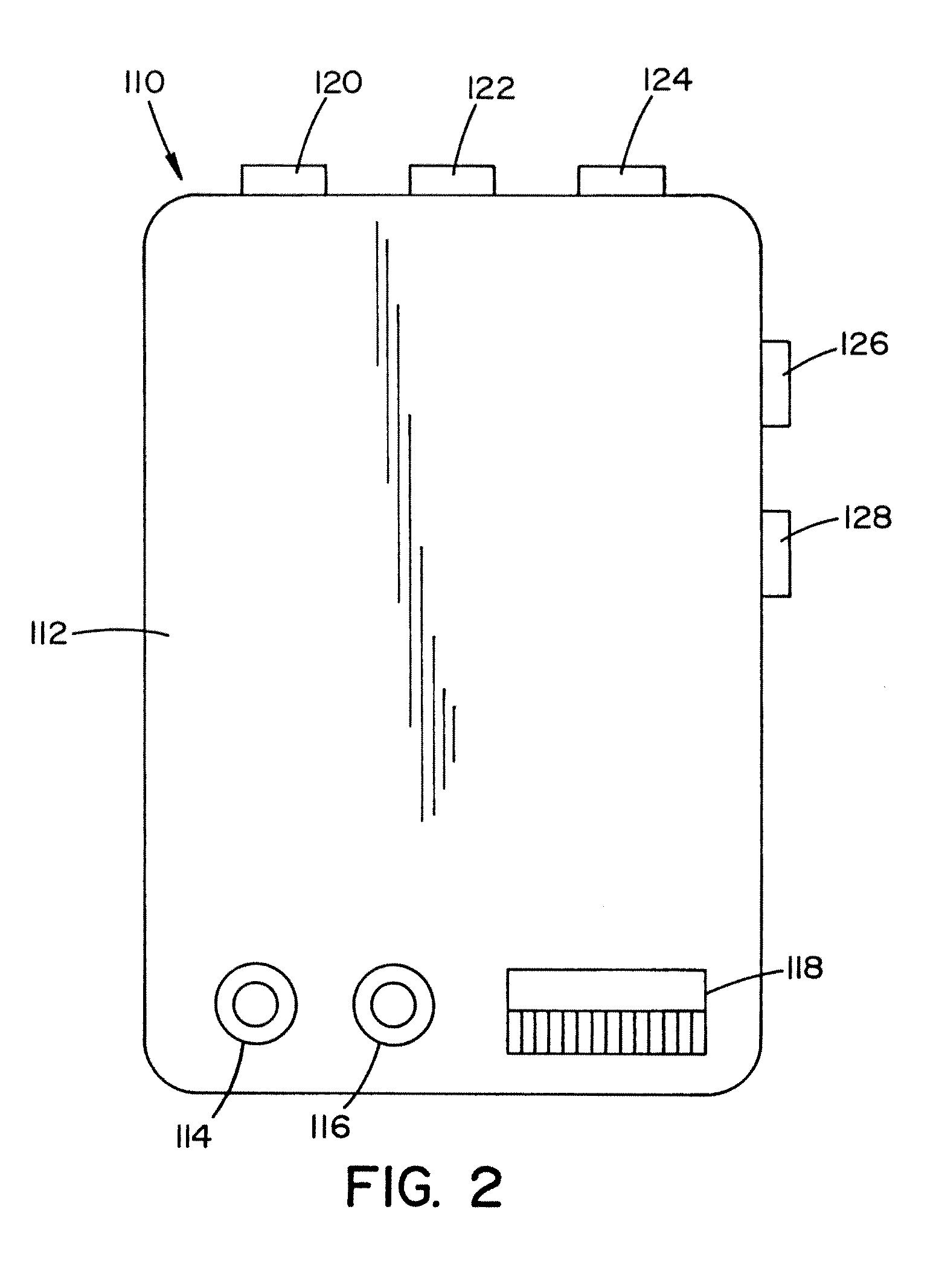

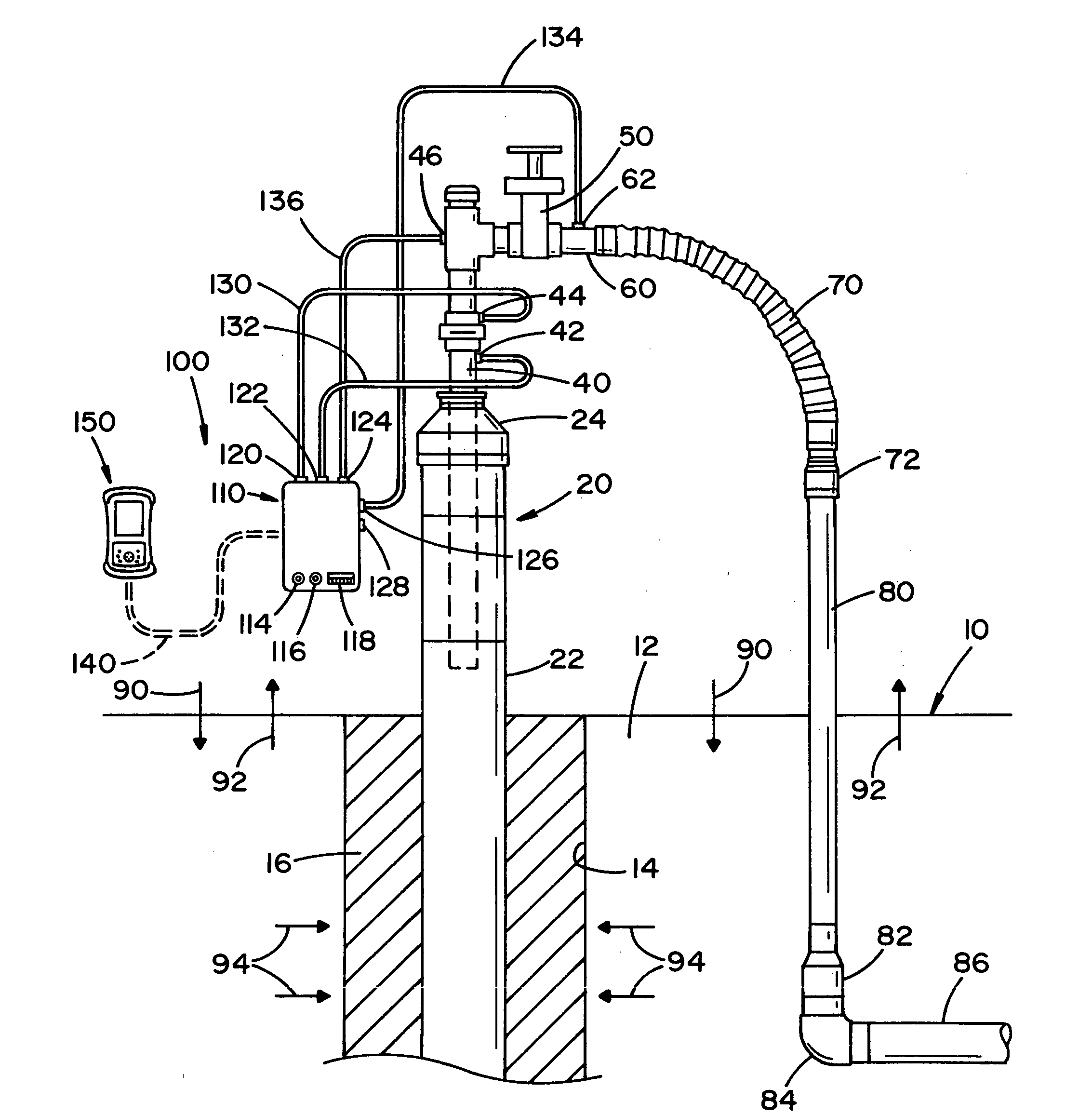

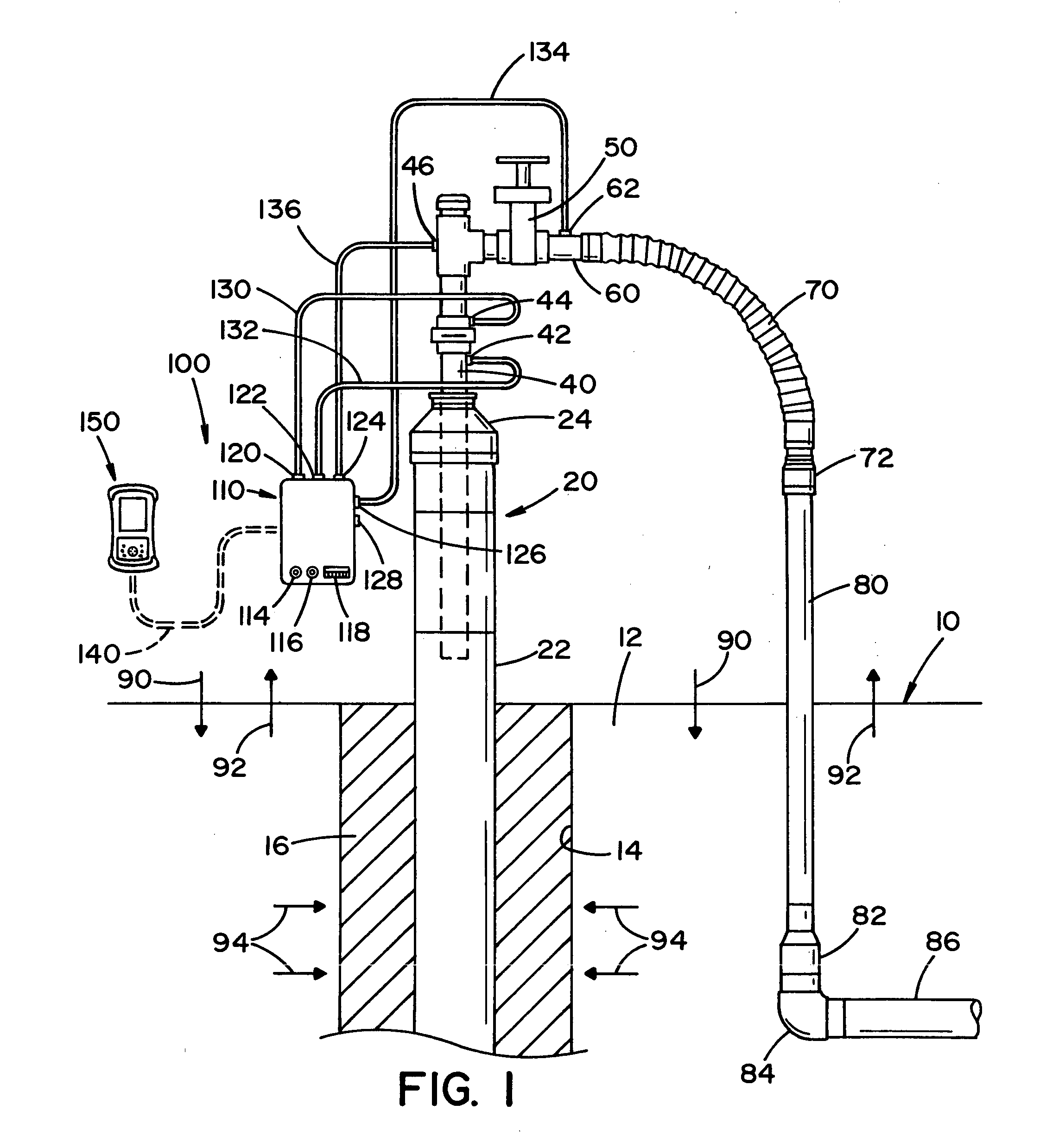

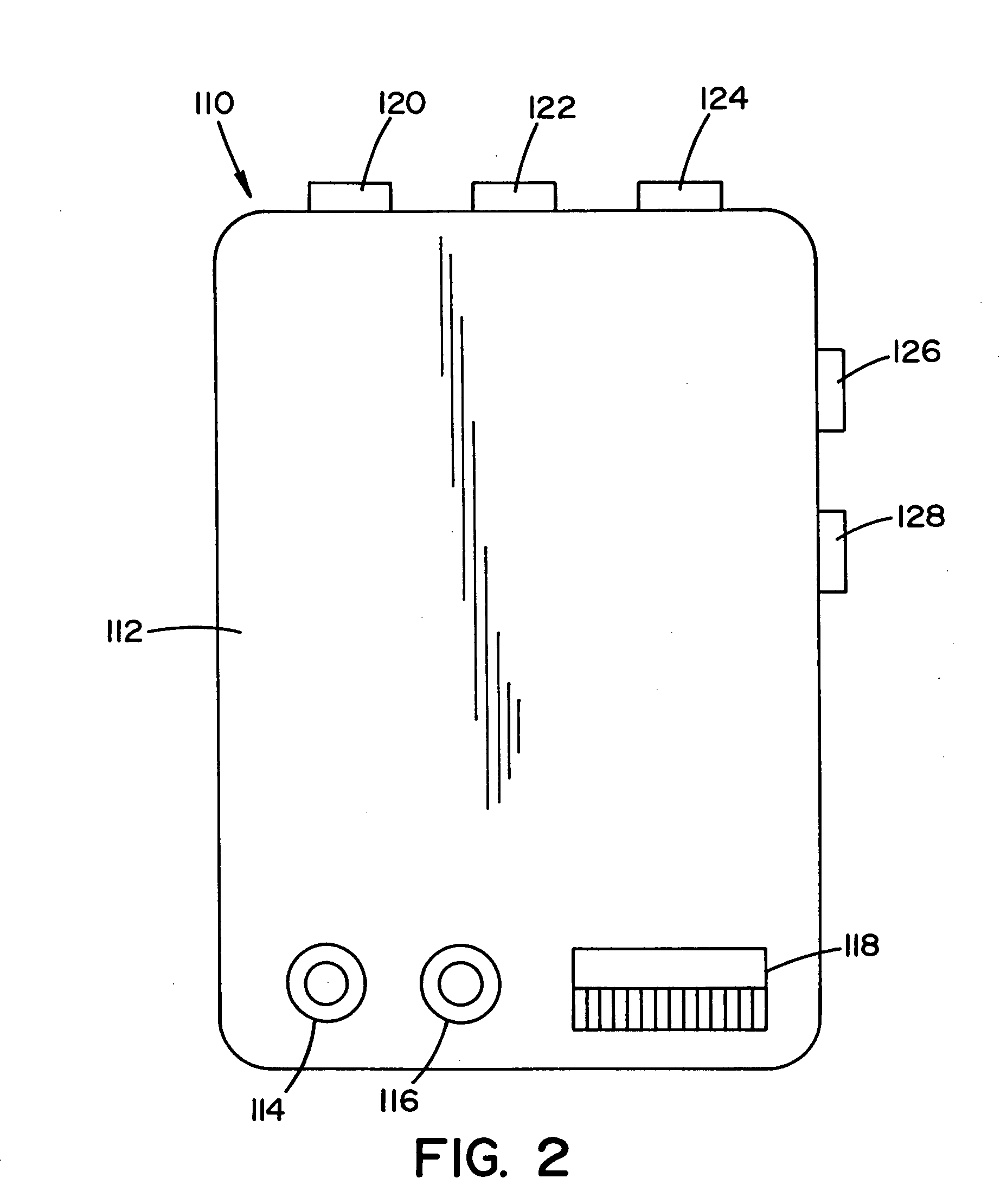

Portable gas monitor

InactiveUS20110231099A1Easy to identifyEasily obtain informationElectric/magnetic detection for well-loggingConstructionsEngineeringControl unit

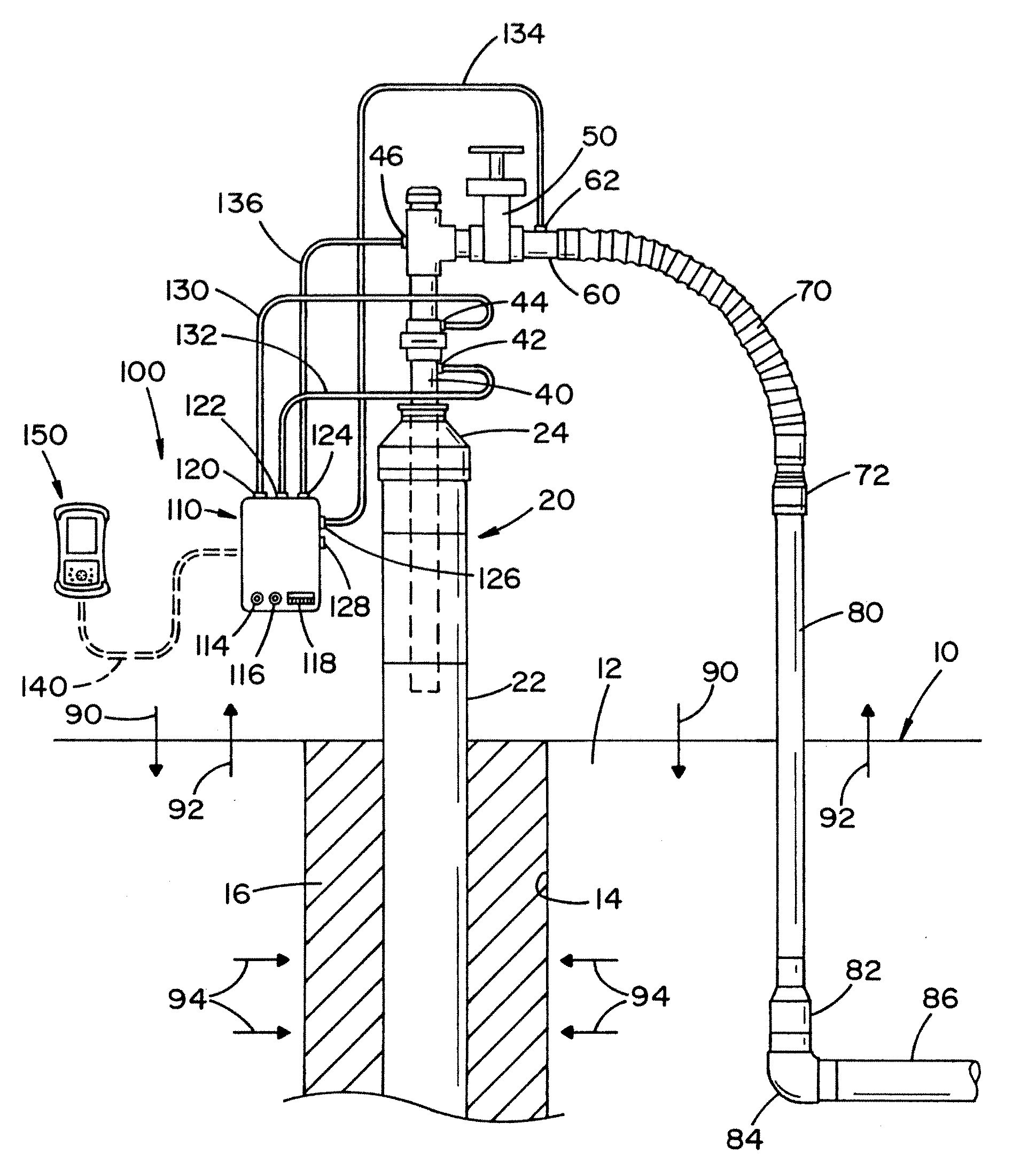

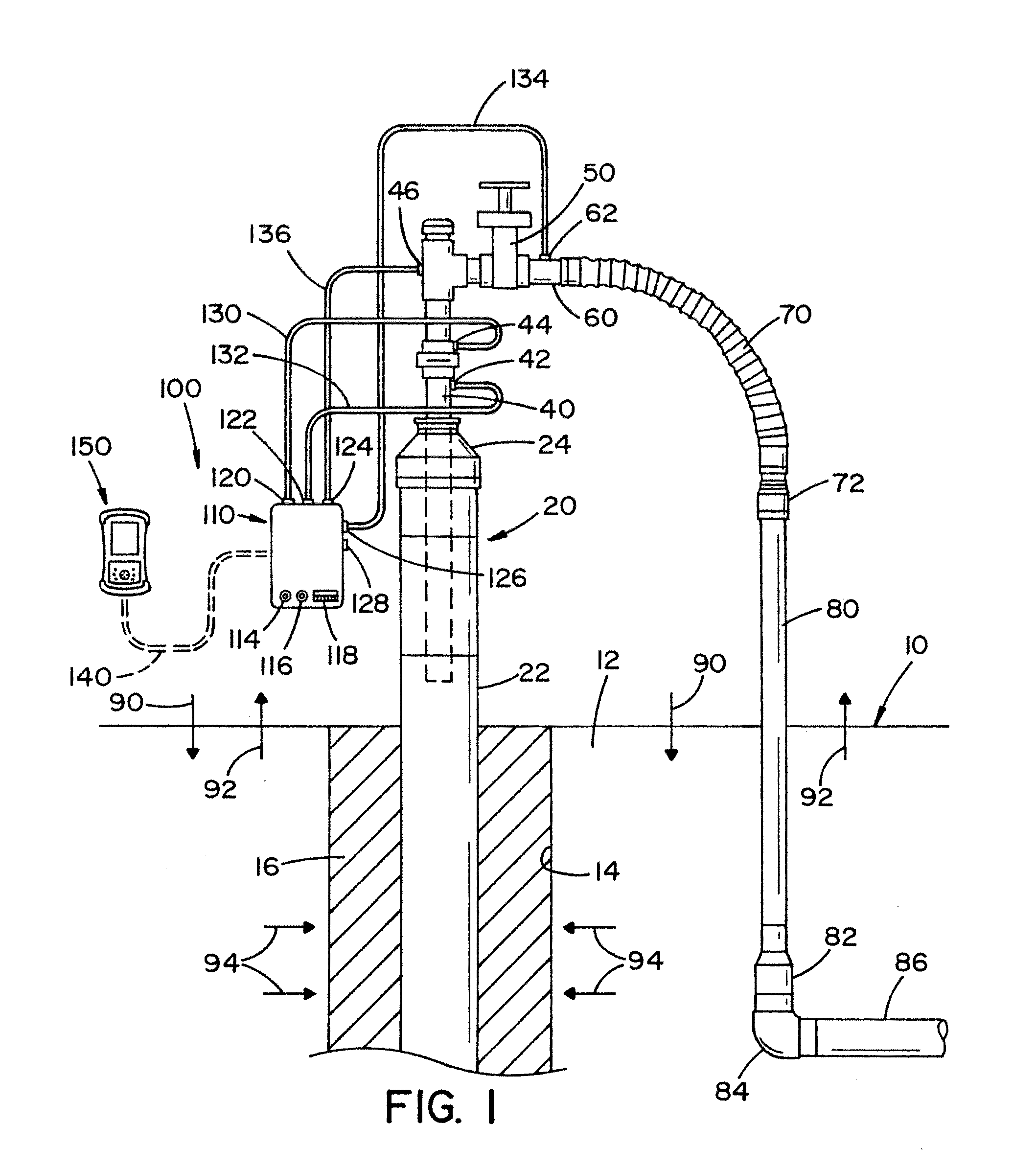

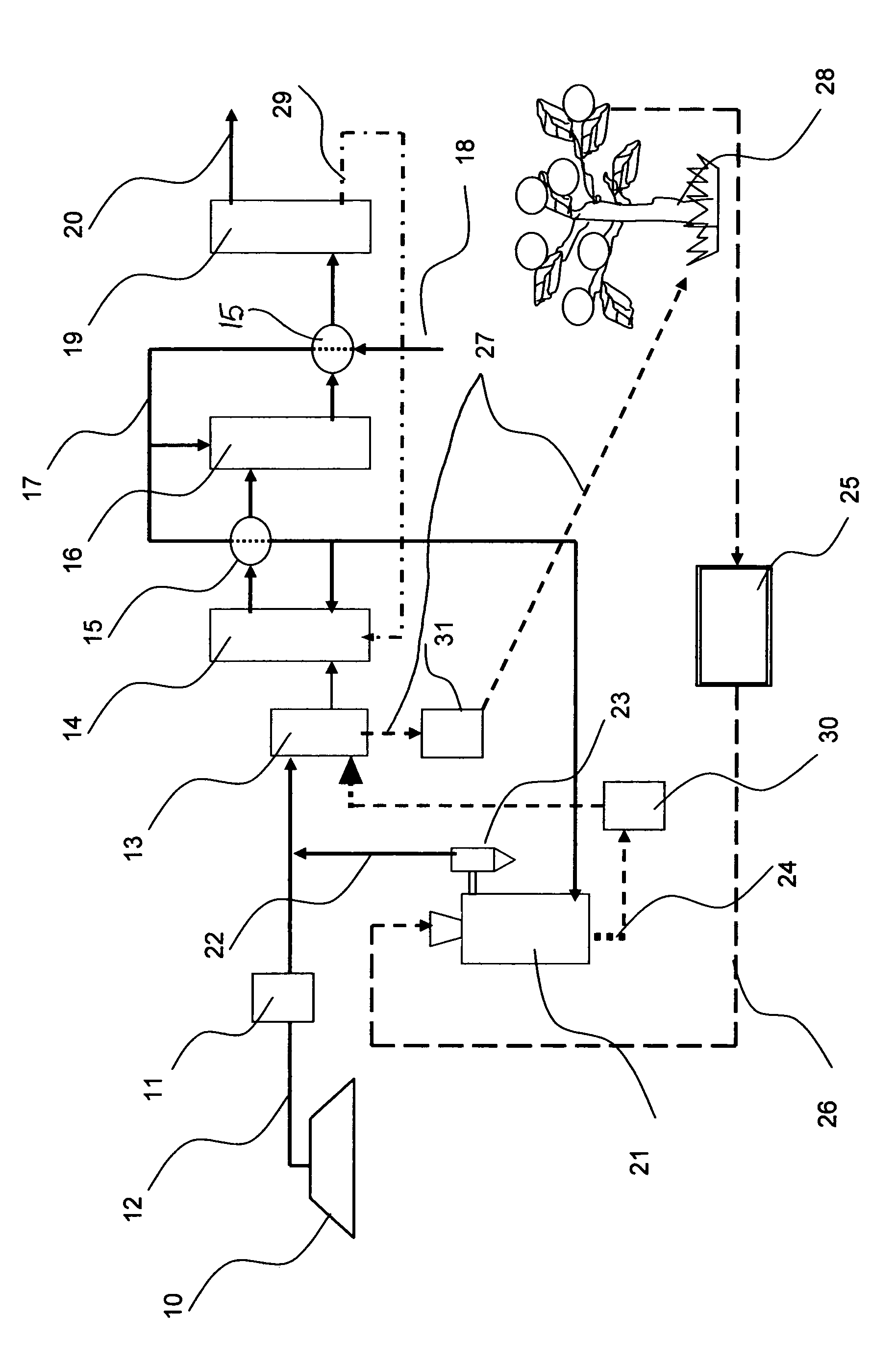

A portable monitor used to measure landfill gas and landfill well parameters. The portable monitor includes a control unit and a measuring unit that can communicate wirelessly with one another. The control unit and / or measuring unit can include a heating arrangement to increase the temperature of one or more components in the control unit and / or measuring unit in cold environments.

Owner:ELKINS EARTHWORKS

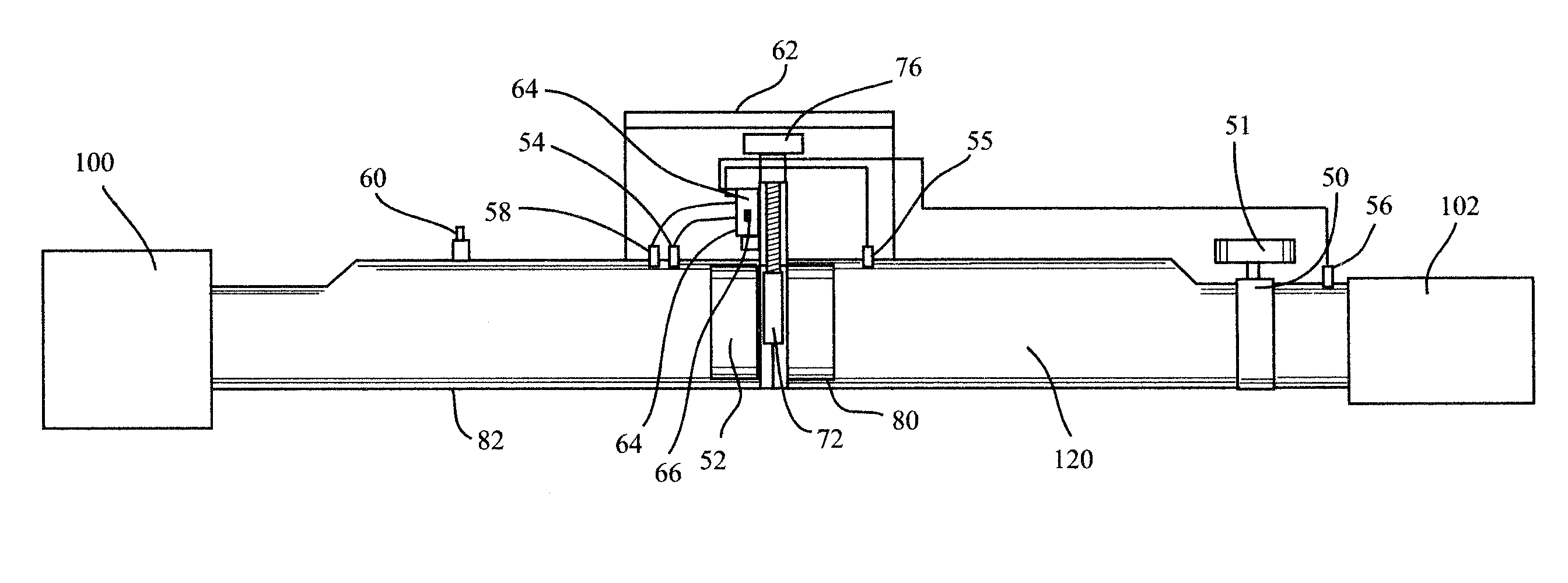

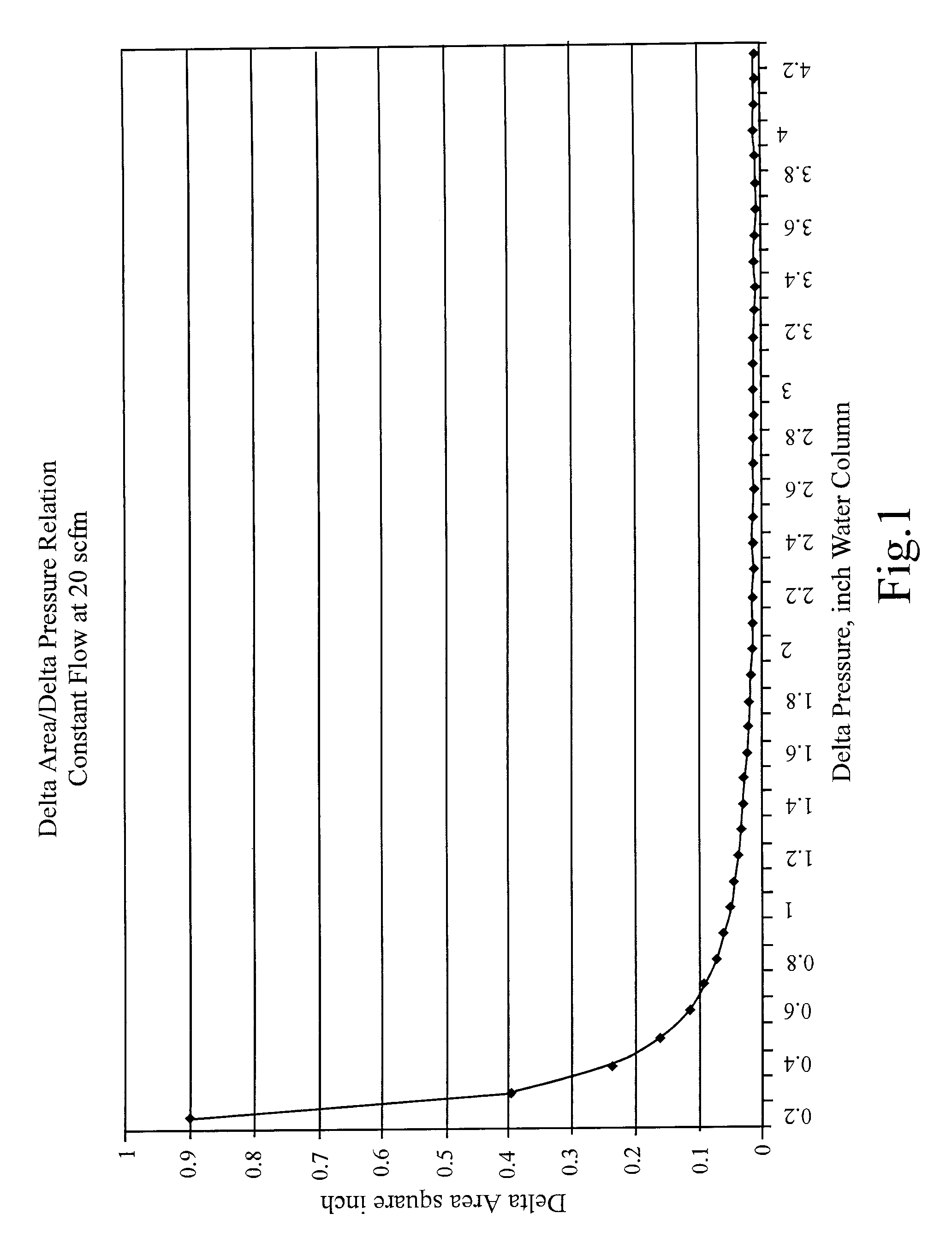

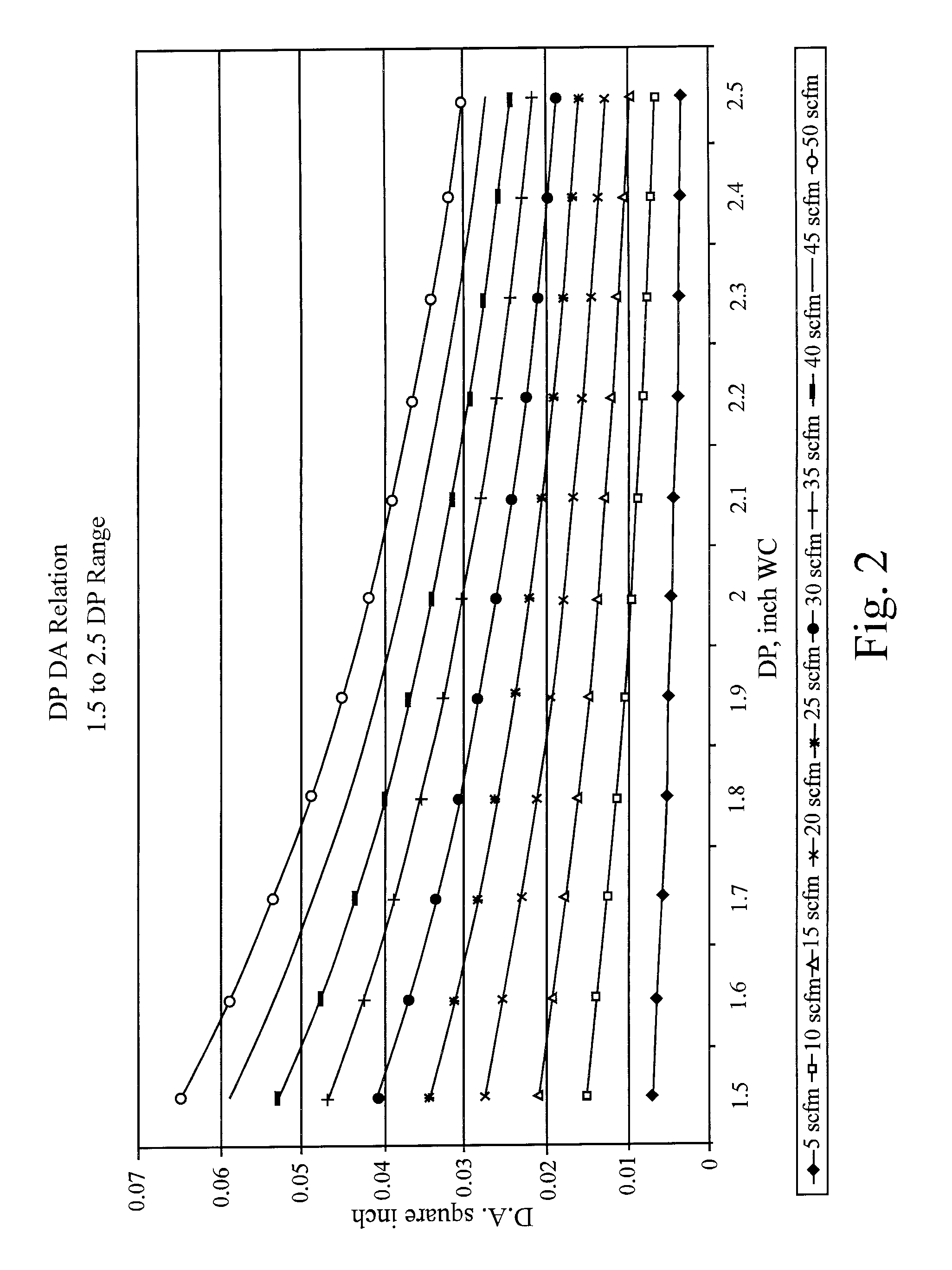

Landfill gas extraction constant flow control method and device

InactiveUS6999883B1Minimal supervisionReduce installation costsSamplingFlow propertiesAutomatic controlDifferential pressure

A control method and apparatus for regulating gas flow from landfill gas wells uses a differential pressure-regulating valve to maintain a set flow through a constant flow wellhead assembly. This wellhead assembly maintains a constant flow from the well despite normal variations in environmental factors affecting gas flow. The wellhead assembly includes a second valve that is used in series with the pressure-regulating valve to adjust the operating conditions of the regulating valve to keep it within its operating range. The pressure-regulating valve configuration allows a simple automatic control to position the valve. Periodic manual sampling of extracted gas and adjustment of the valve conditions is used to adjust for longer-term variations in well conditions.

Owner:MARKS & NOVA BALL MARKS TRUSTEES OR SUCCESSORTRUSTEE OF THE MARKS FAMILY TRUST UAD 5 13 05 ROBIN

CO2 separator method and apparatus

InactiveUS6929680B2Operation efficiency can be improvedLess methane is lostCarbon compoundsLandfill technologiesProduct gasRefrigeration

Owner:CONSORTIUM SERVICES MANAGEMENT GROU

Portable gas monitor

ActiveUS20080127726A1Easy to identifyEasily obtain informationElectric/magnetic detection for well-loggingSolid waste disposalControl unitElectrical and Electronics engineering

A portable monitor used to measure landfill gas and landfill well parameters. The portable monitor includes a control unit and a measuring unit that can communication wirelessly with one another. The control unit and / or measuring unit can includes a heating arrangement to increase the temperature of one or more components in the control unit and / or measuring unit in cold environments.

Owner:ELKINS EARTHWORKS

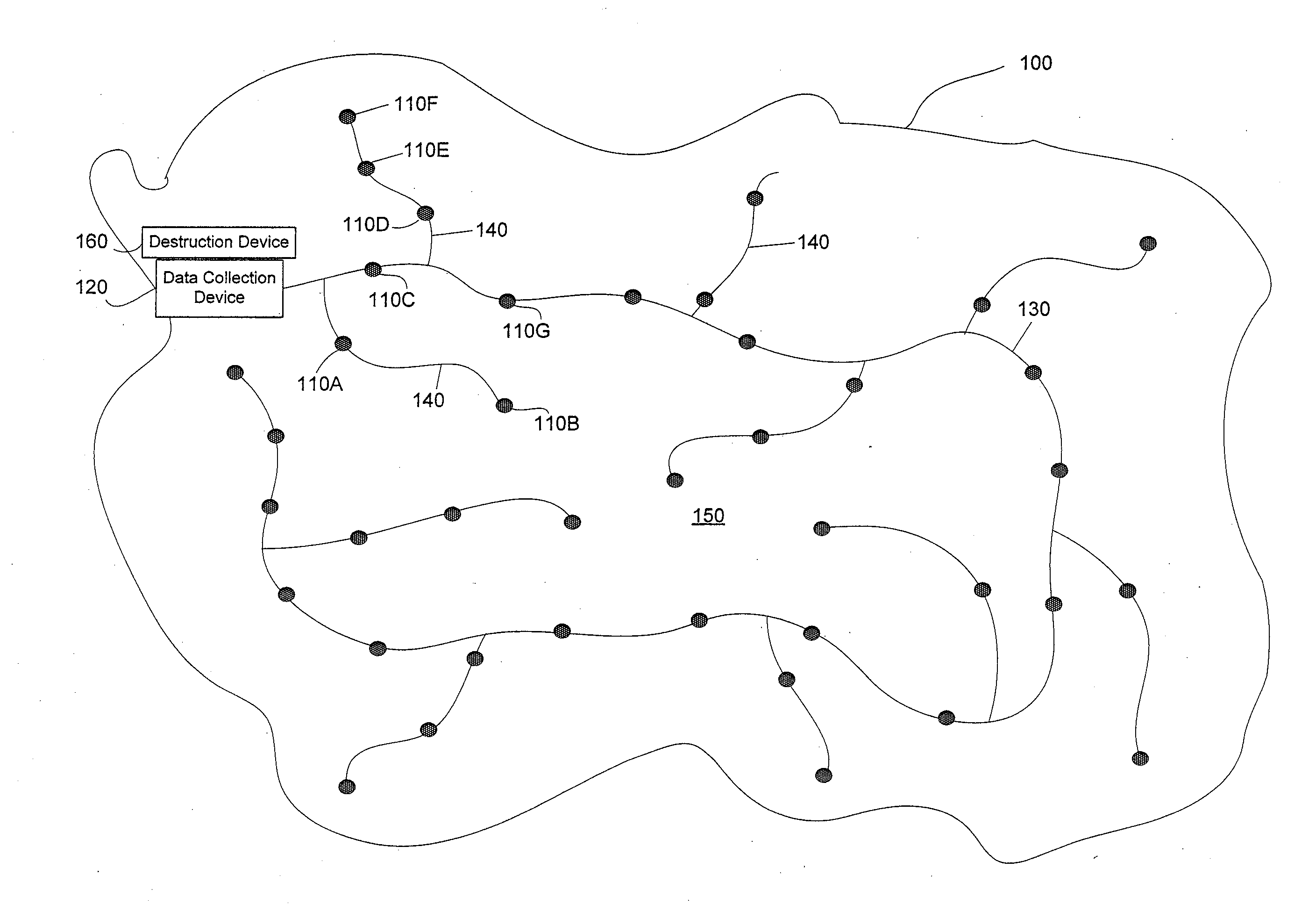

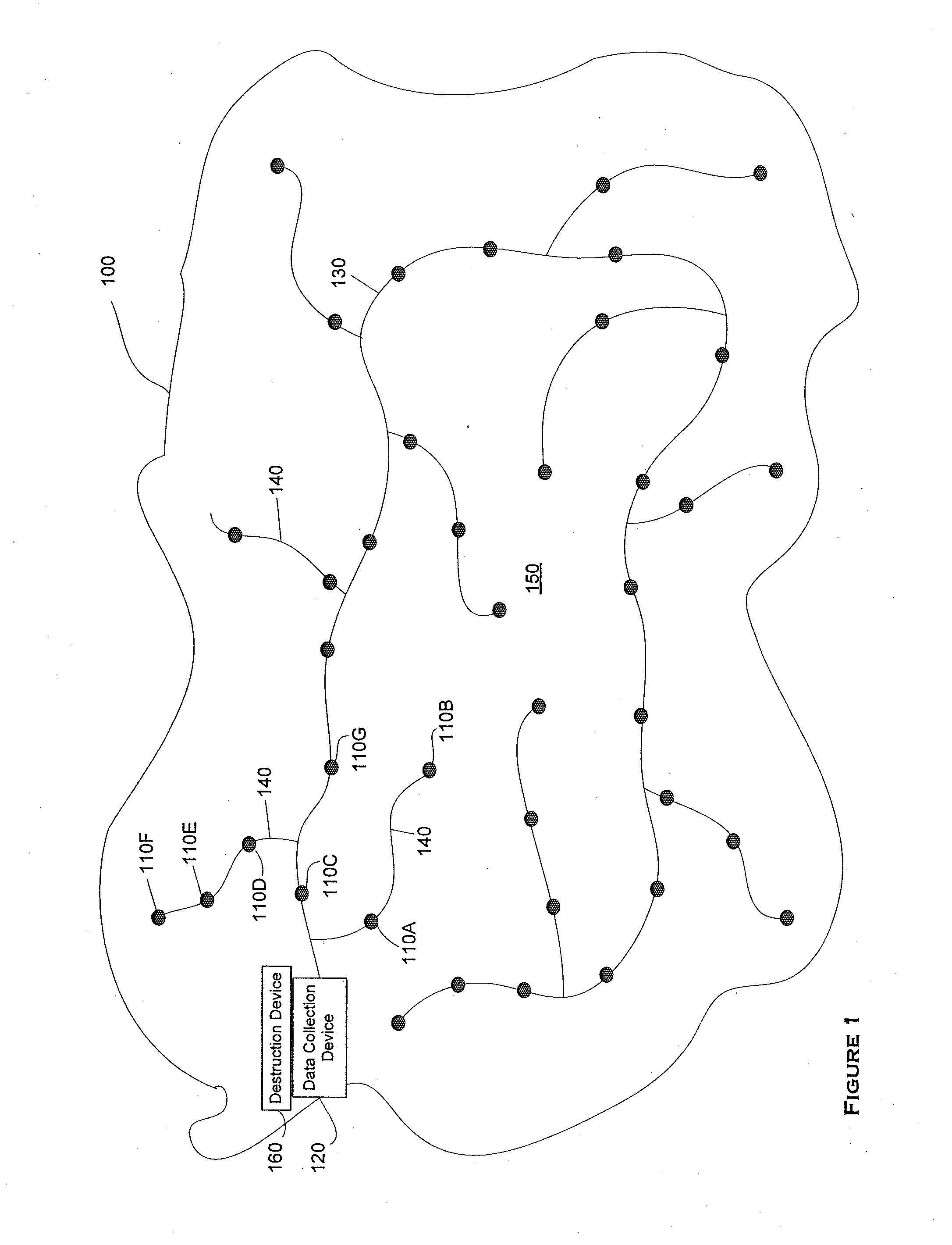

Optimizing energy production of a landfill gas extraction system

InactiveUS20070225923A1Increased energy productionSolid waste disposalVolume/mass flow measurementProduct gasProcess engineering

A computing system determines adjustments for each of a plurality of wellheads in a gas extraction system in order to increase a total energy production of the gas extraction system to at least an expected total energy production. The computing system determines preliminary adjustments for each of the wellheads and then determines further adjustments to certain of the wellheads based at least partly on a current energy production of respective wellheads, data regarding historical energy production of respective wellheads, and an affect the preliminary adjustment for a respective wellhead would have on the total energy production of the gas extraction system.

Owner:TOOLEY JAMIE

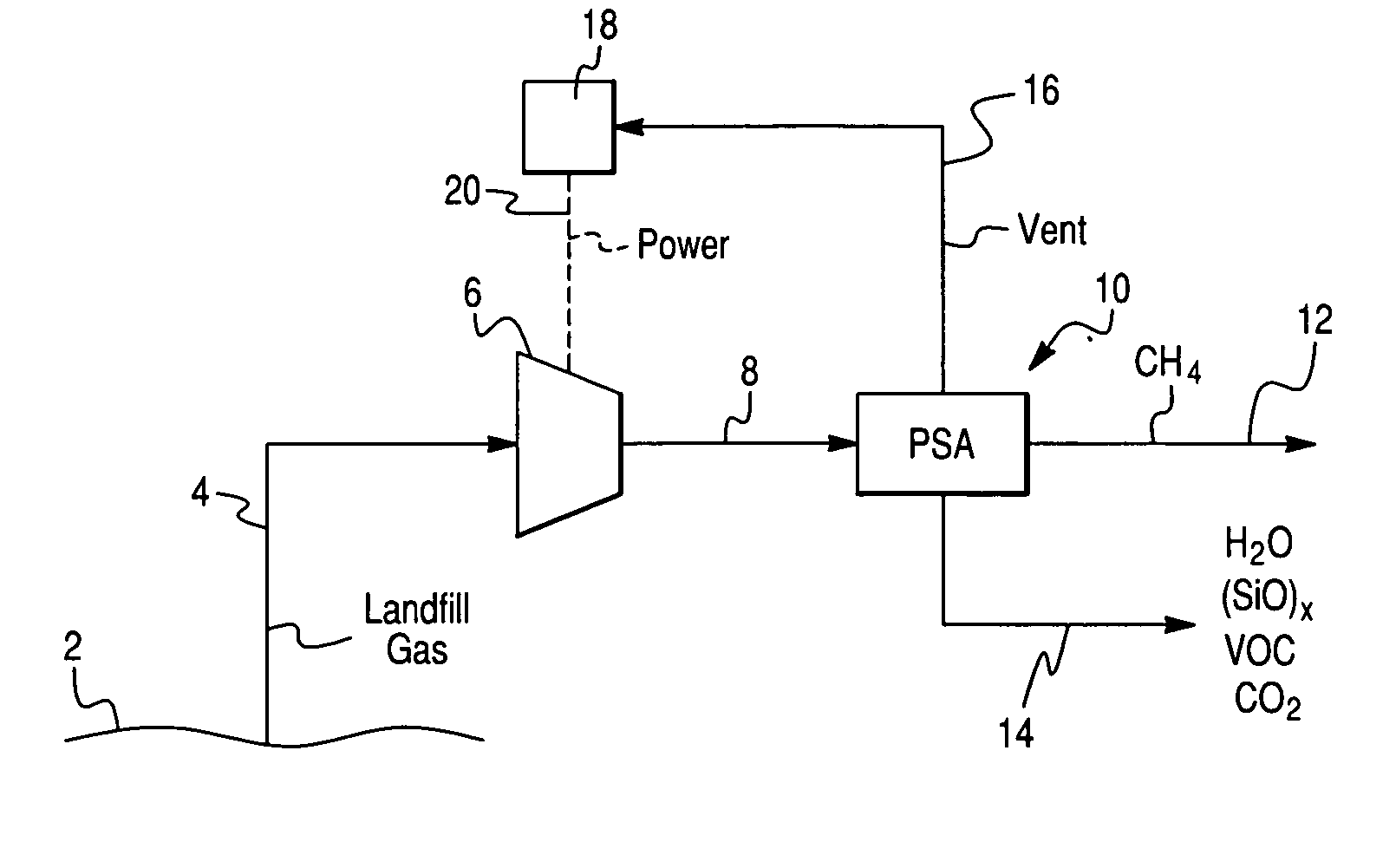

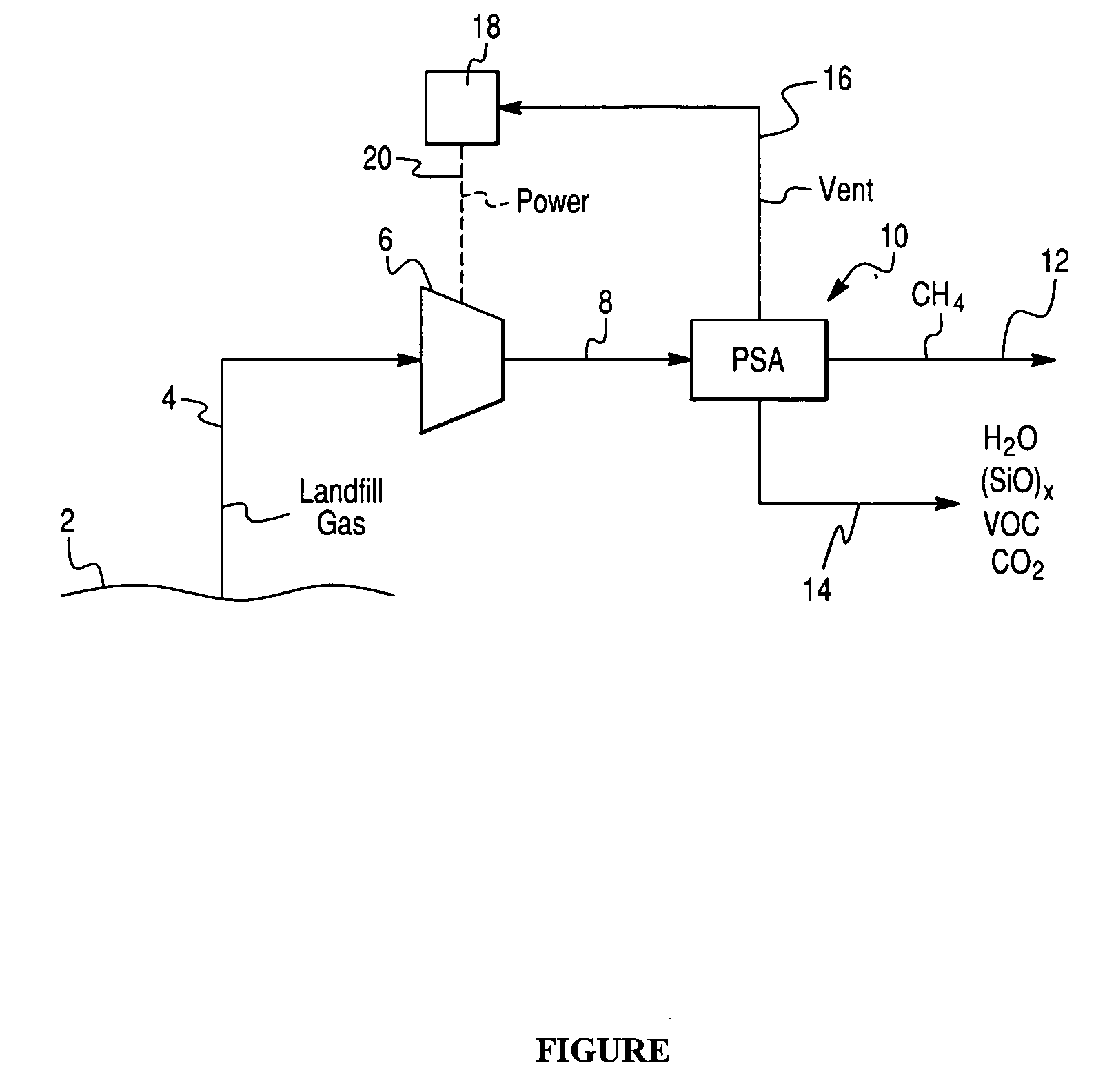

Landfill gas upgrading process

A natural gas stream derived from a landfill and containing impurities including siloxane impurities is purified by a PSA process to produce a methane-rich product stream which is substantially free of siloxane impurities. A methane-rich vent stream having a pressure less than the product stream is formed that is also free of siloxanes and can be used as a fuel stream to run a compressor for the PSA process.

Owner:ENGELHARD CORP

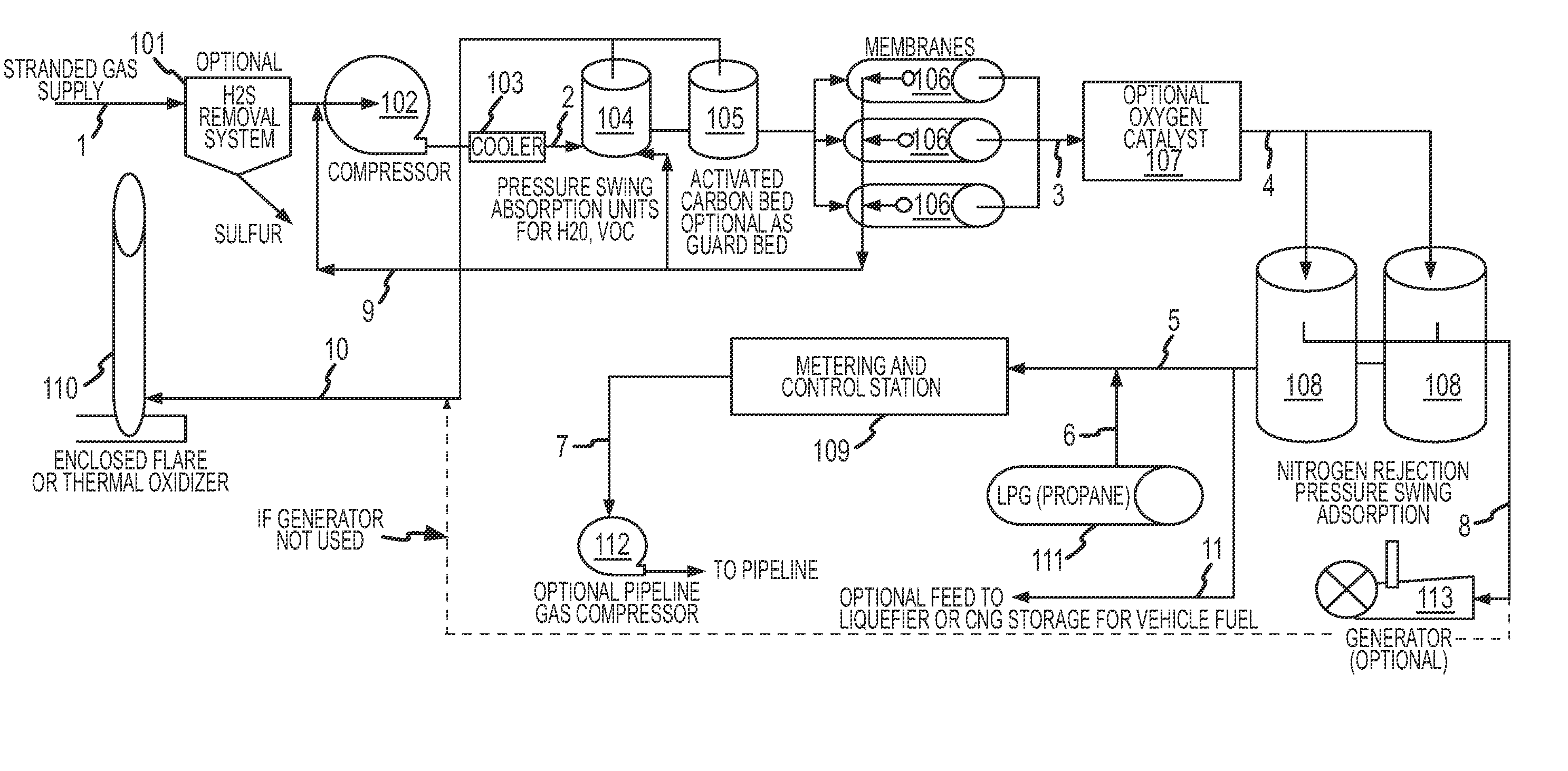

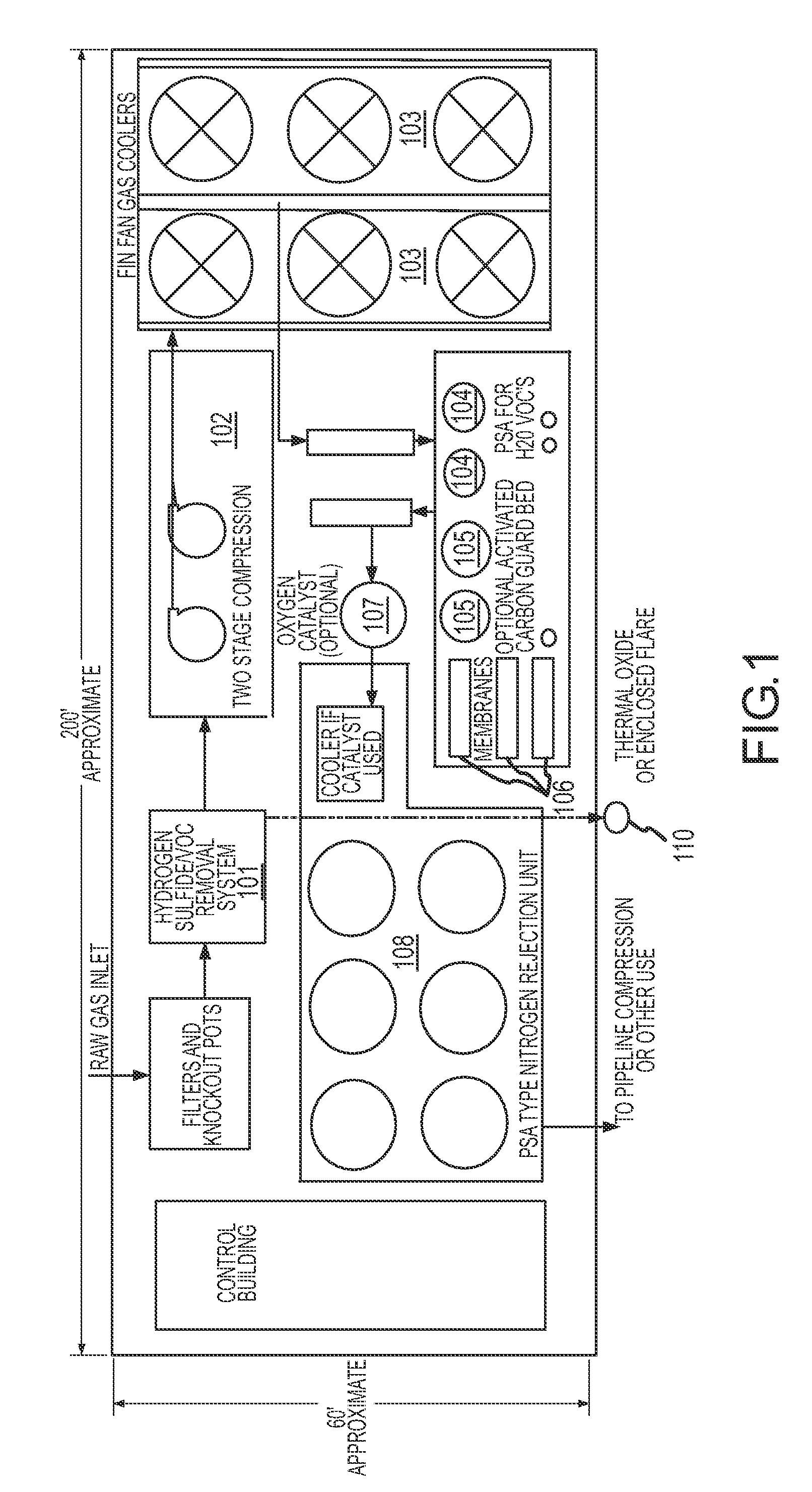

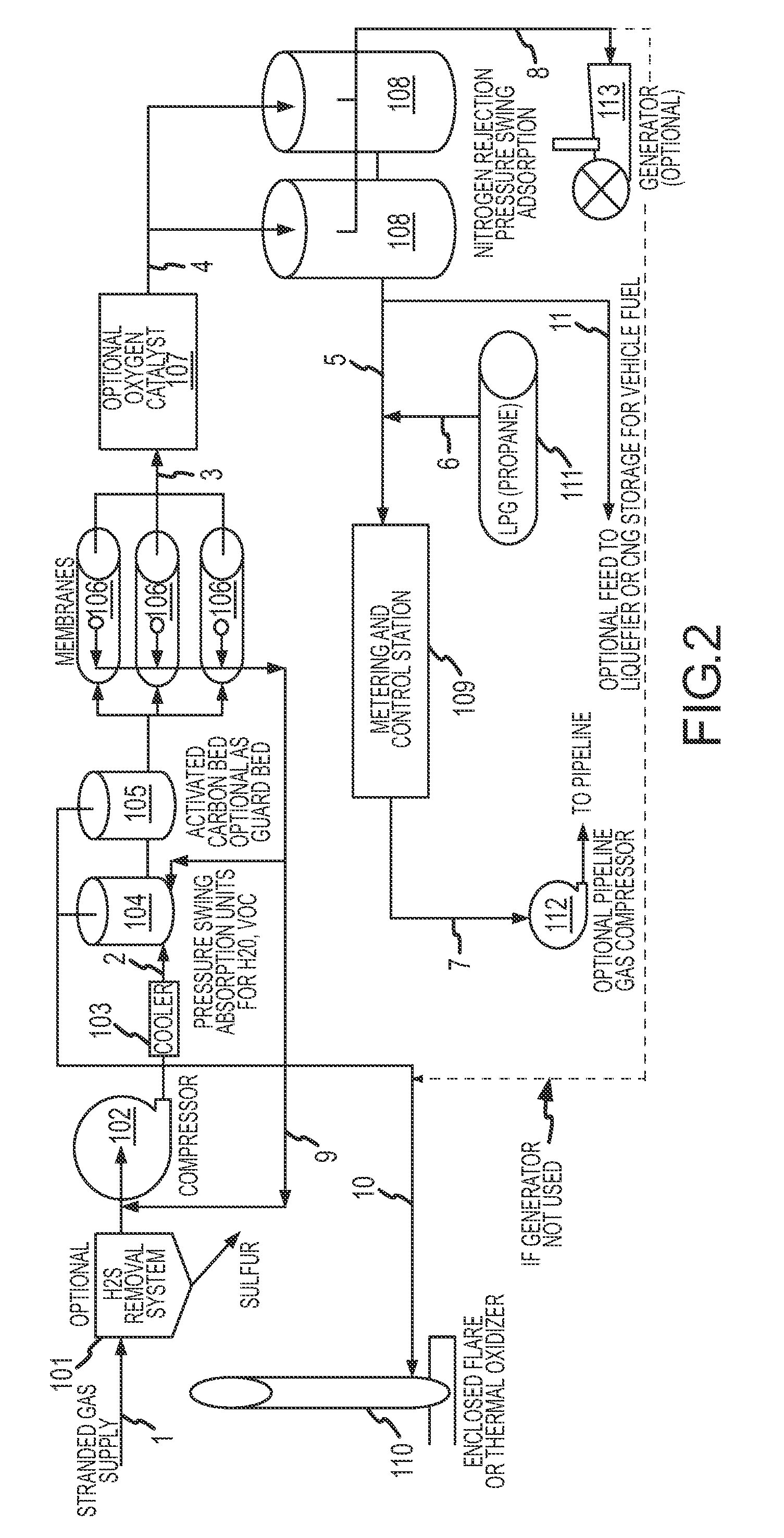

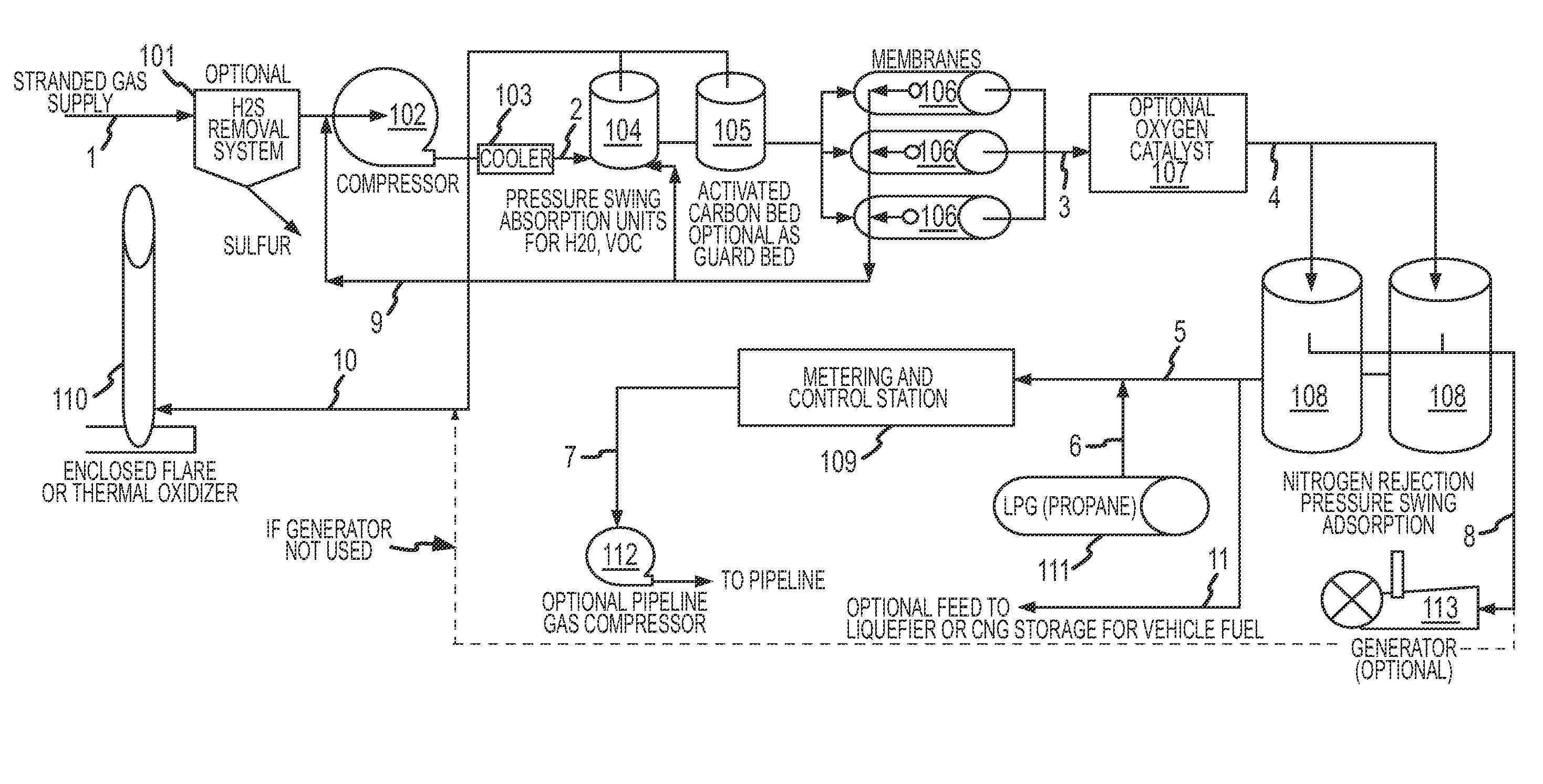

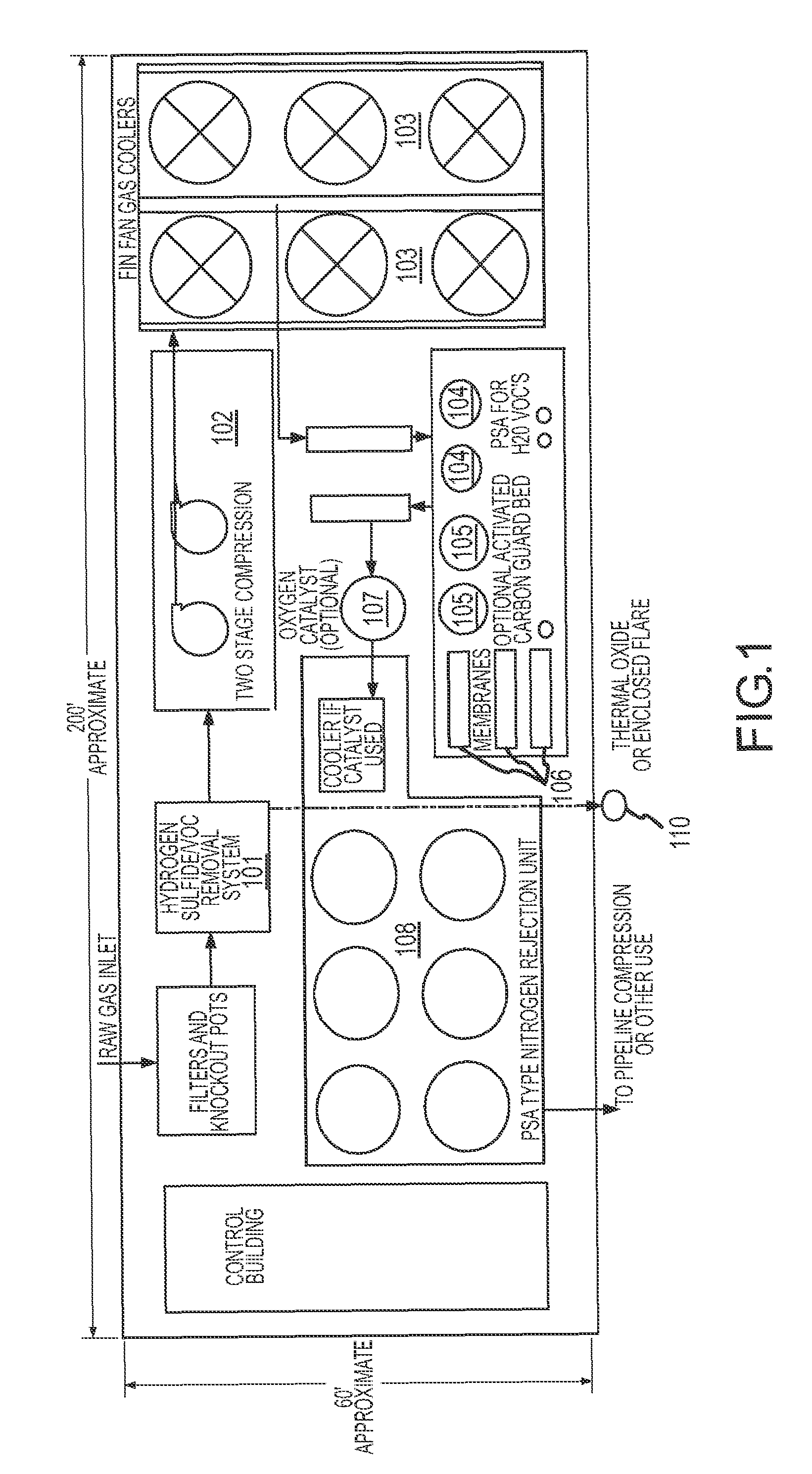

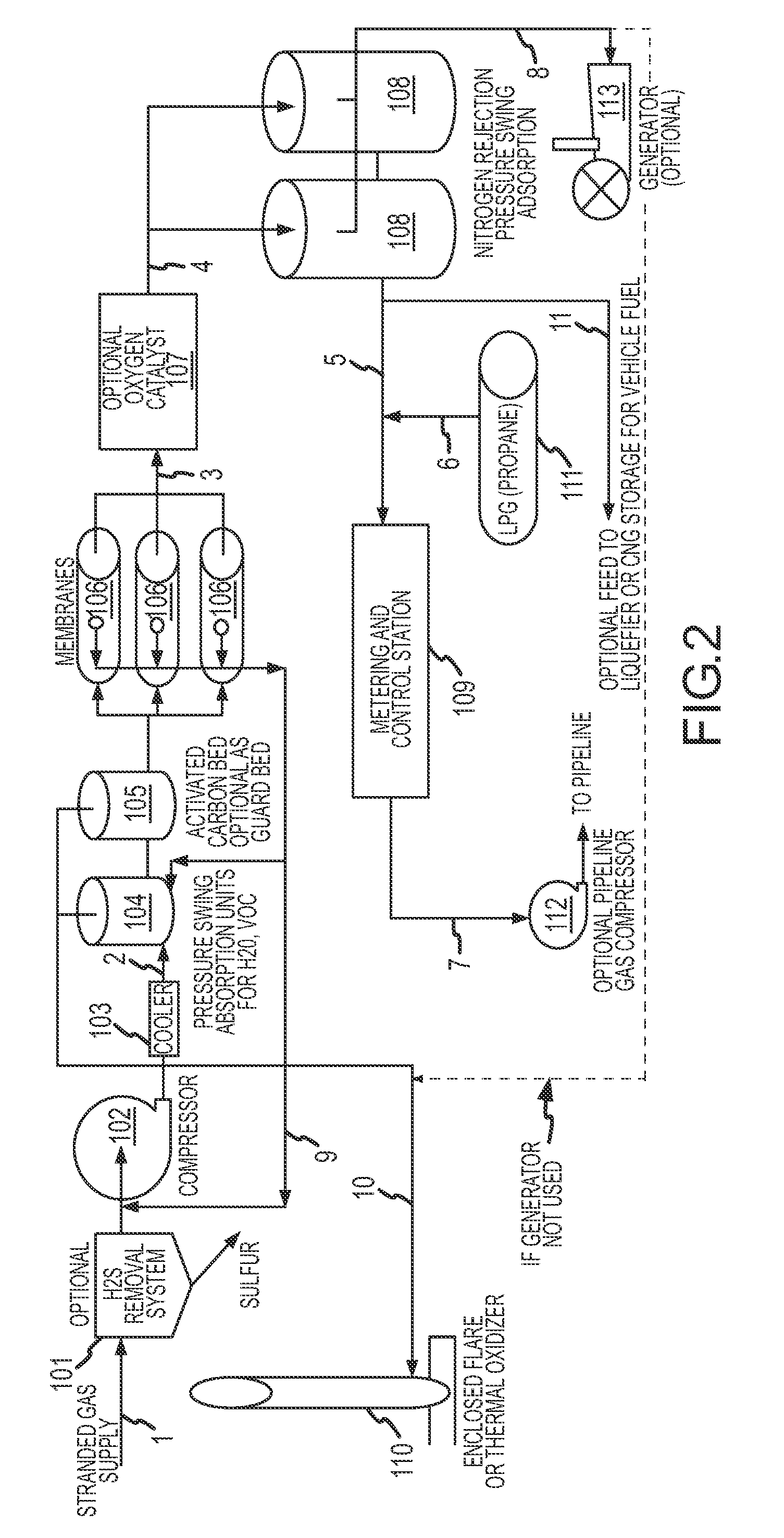

Method for processing landfill and other stranded gas containing commercial quantities of methane and contaminated by carbon dioxide, nitrogen and oxygen into a pipeline or vehicle quality natural gas product

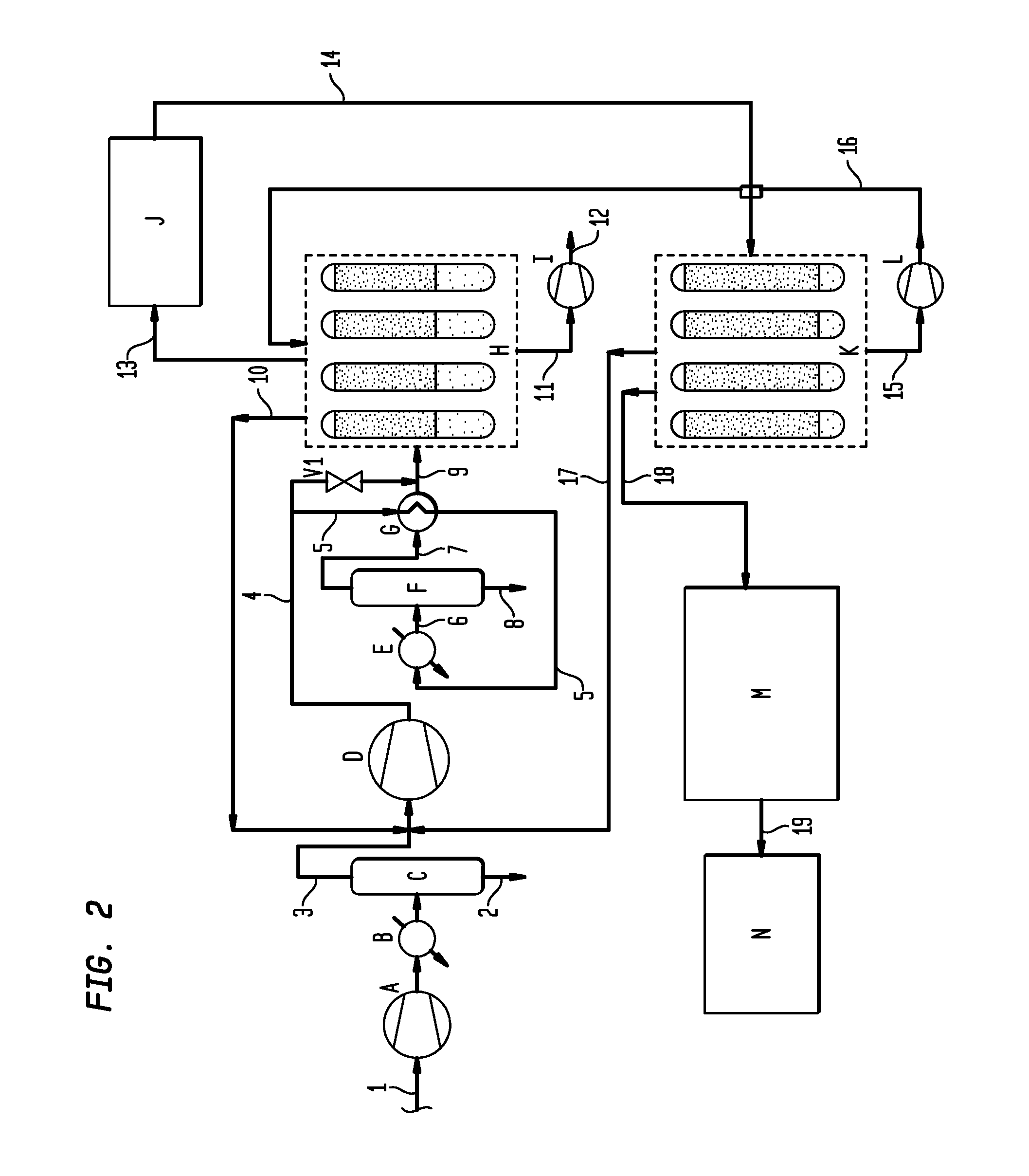

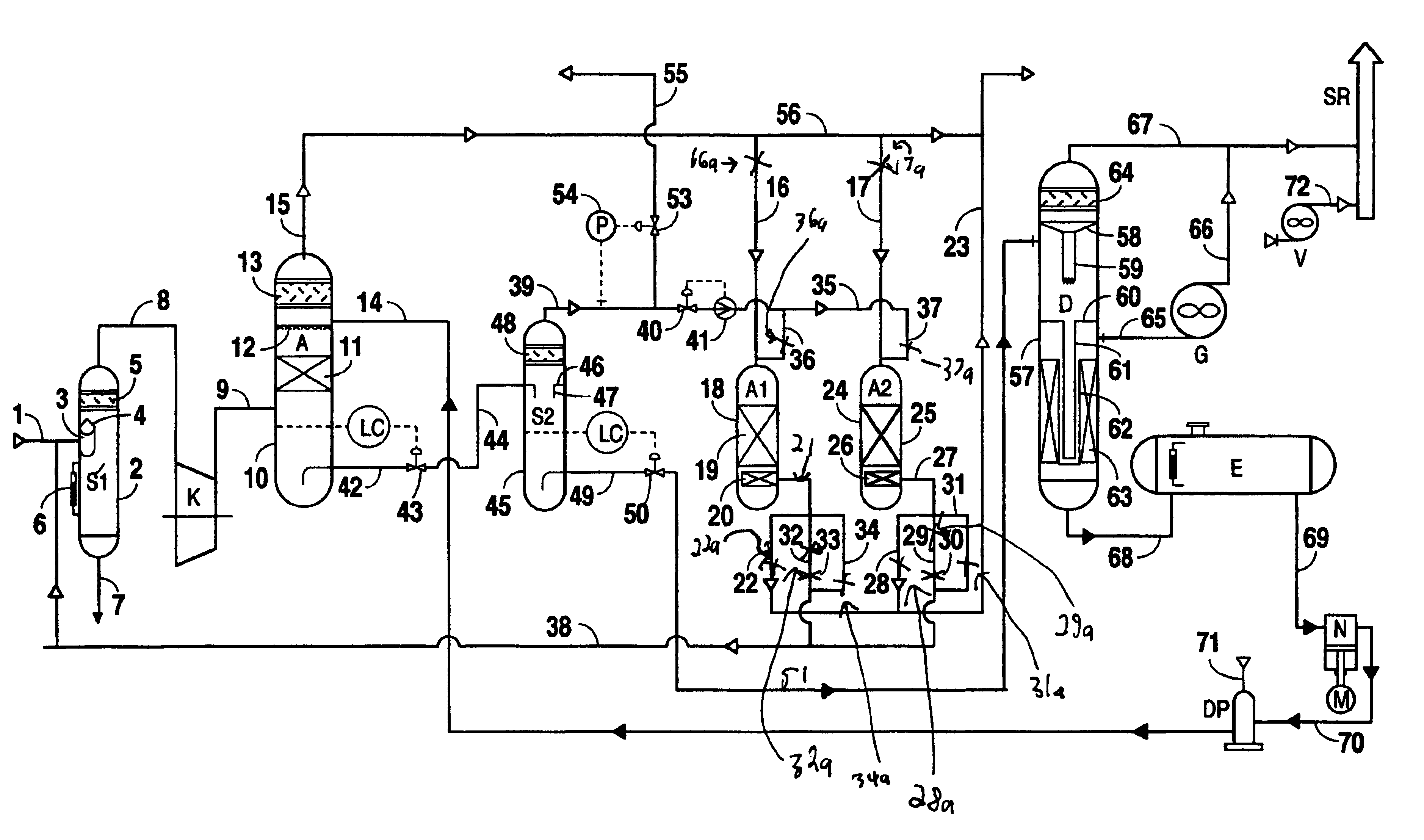

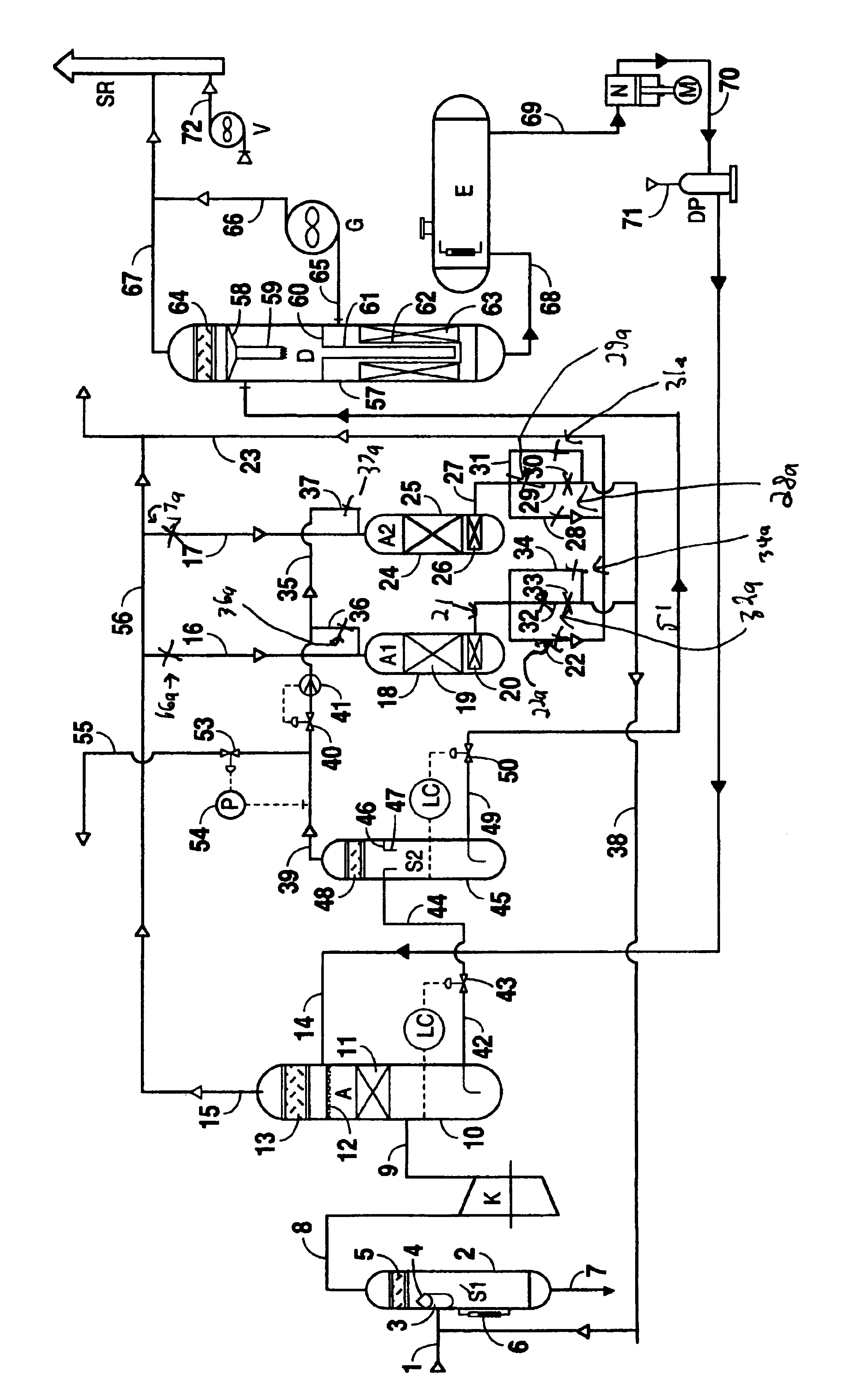

Stranded natural gas, when contaminated by difficult to remove constituents such as Nitrogen and Oxygen, has long been considered uneconomical to process into pipeline quality gas and is abandoned or utilized in other energy applications where economically viable. Landfill Gas (LFG) is often considered a stranded gas although in many instances it is available at reasonable distances to natural gas pipelines, and has only rarely been processed for injection into natural gas pipelines. Other stranded contaminated gases, such as gases vented from remote oil wells or coal beds where access to transportation pipelines is not feasible are also candidates for collection. In many instances, billions of cubic feet of methane rich LFG has been vented or flared into the atmosphere. The present invention utilizes a variety of components and provides a product gas that will meet all known pipeline requirements and / or vehicle fuel specifications without the need for blending with pipeline gas and without using cryogenic separation techniques or partial cryogenic processes. The invention also provides a product gas suitable for further processing into Liquefied Natural Gas.

Owner:INGENCO HLDG LLC

Method for processing landfill and other stranded gas containing commercial quantities of methane and contaminated by carbon dioxide, nitrogen and oxygen into a pipeline or vehicle quality natural gas product

Stranded natural gas, when contaminated by difficult to remove constituents such as Nitrogen and Oxygen, has long been considered uneconomical to process into pipeline quality gas and is abandoned or utilized in other energy applications where economically viable. Landfill Gas (LFG) is often considered a stranded gas although in many instances it is available at reasonable distances to natural gas pipelines, and has only rarely been processed for injection into natural gas pipelines. Other stranded contaminated gases, such as gases vented from remote oil wells or coal beds where access to transportation pipelines is not feasible are also candidates for collection. In many instances, billions of cubic feet of methane rich LFG has been vented or flared into the atmosphere. The present invention utilizes a variety of components and provides a product gas that will meet all known pipeline requirements and / or vehicle fuel specifications without the need for blending with pipeline gas and without using cryogenic separation techniques or partial cryogenic processes. The invention also provides a product gas suitable for further processing into Liquefied Natural Gas.

Owner:INGENCO HLDG LLC

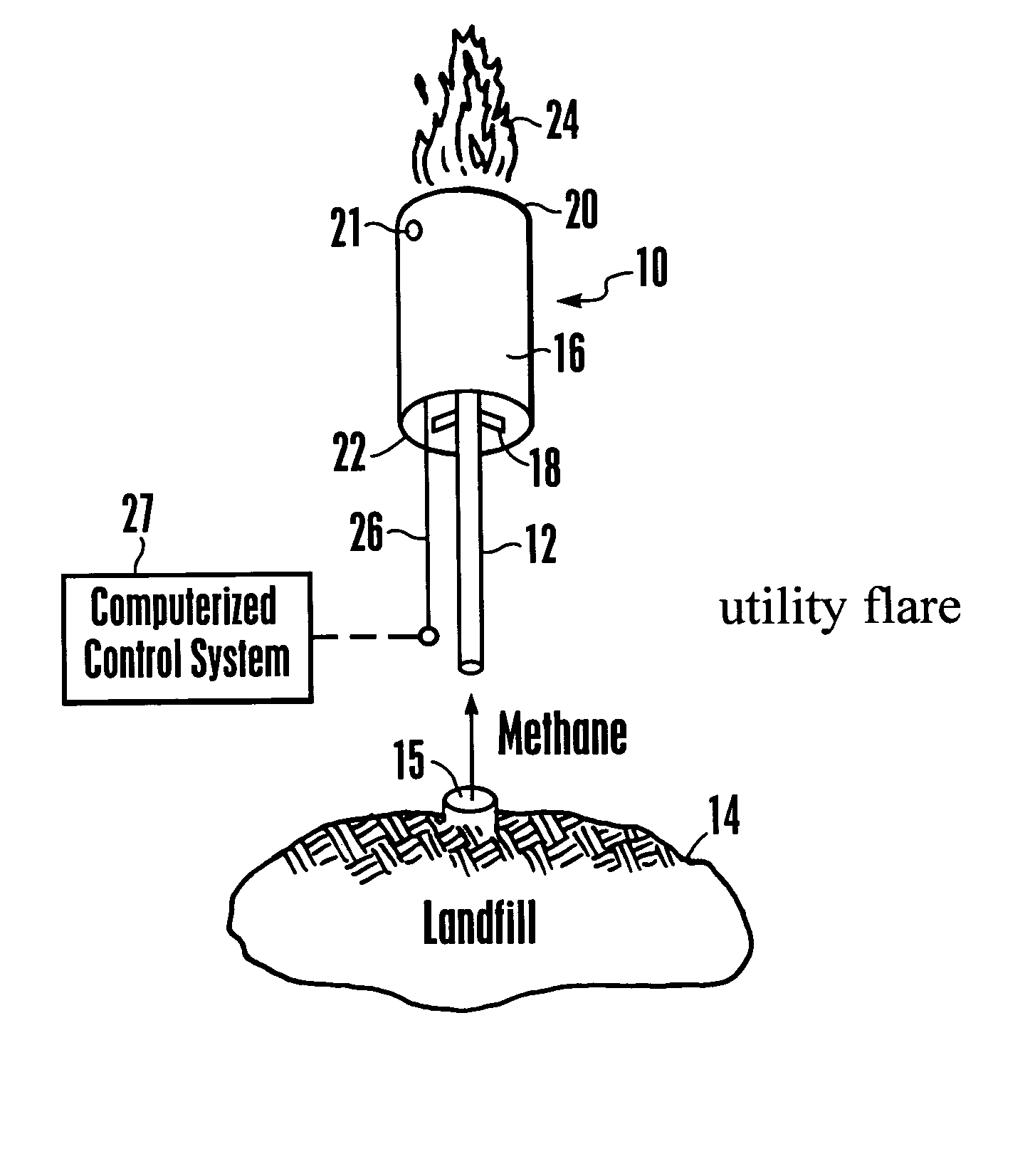

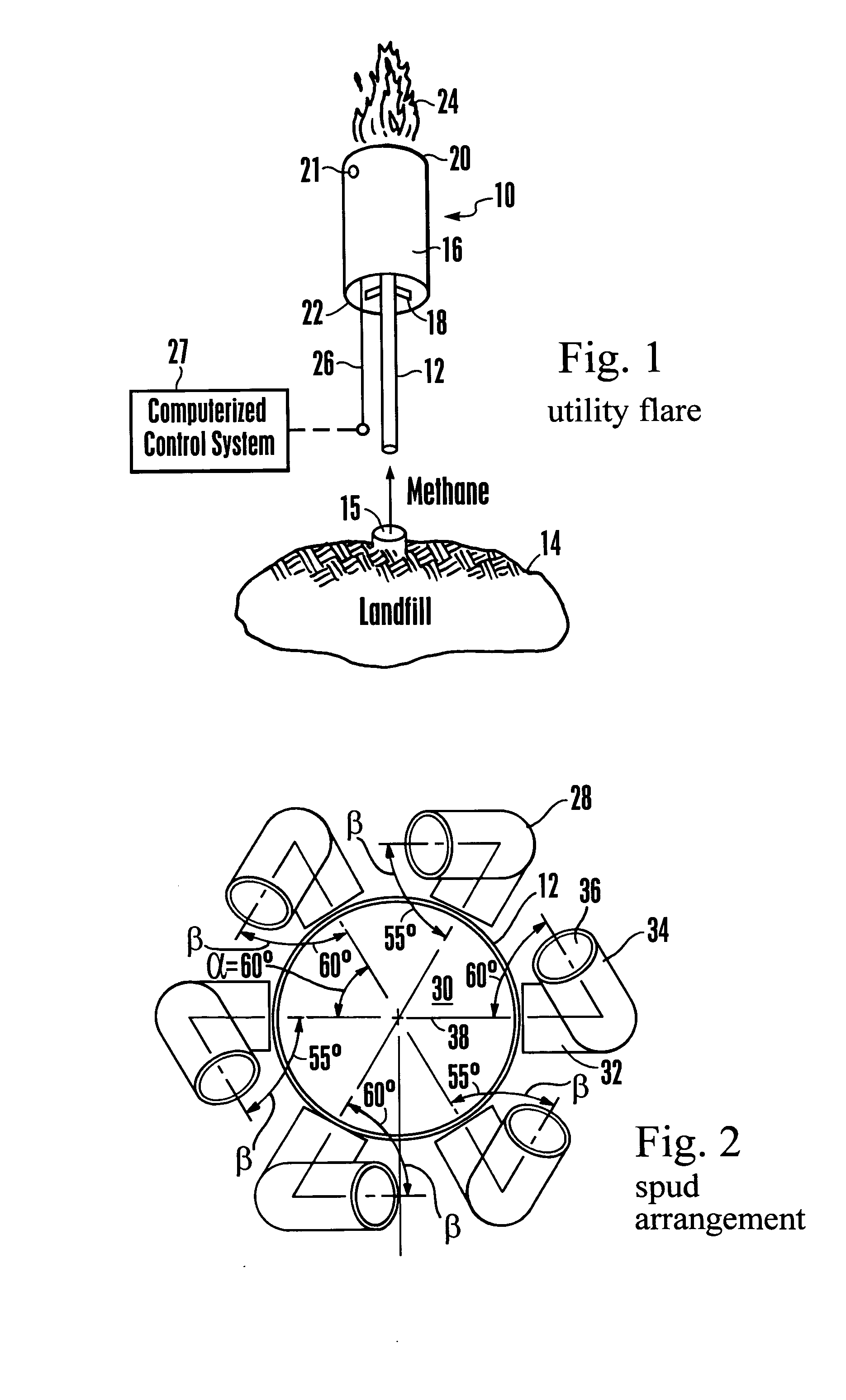

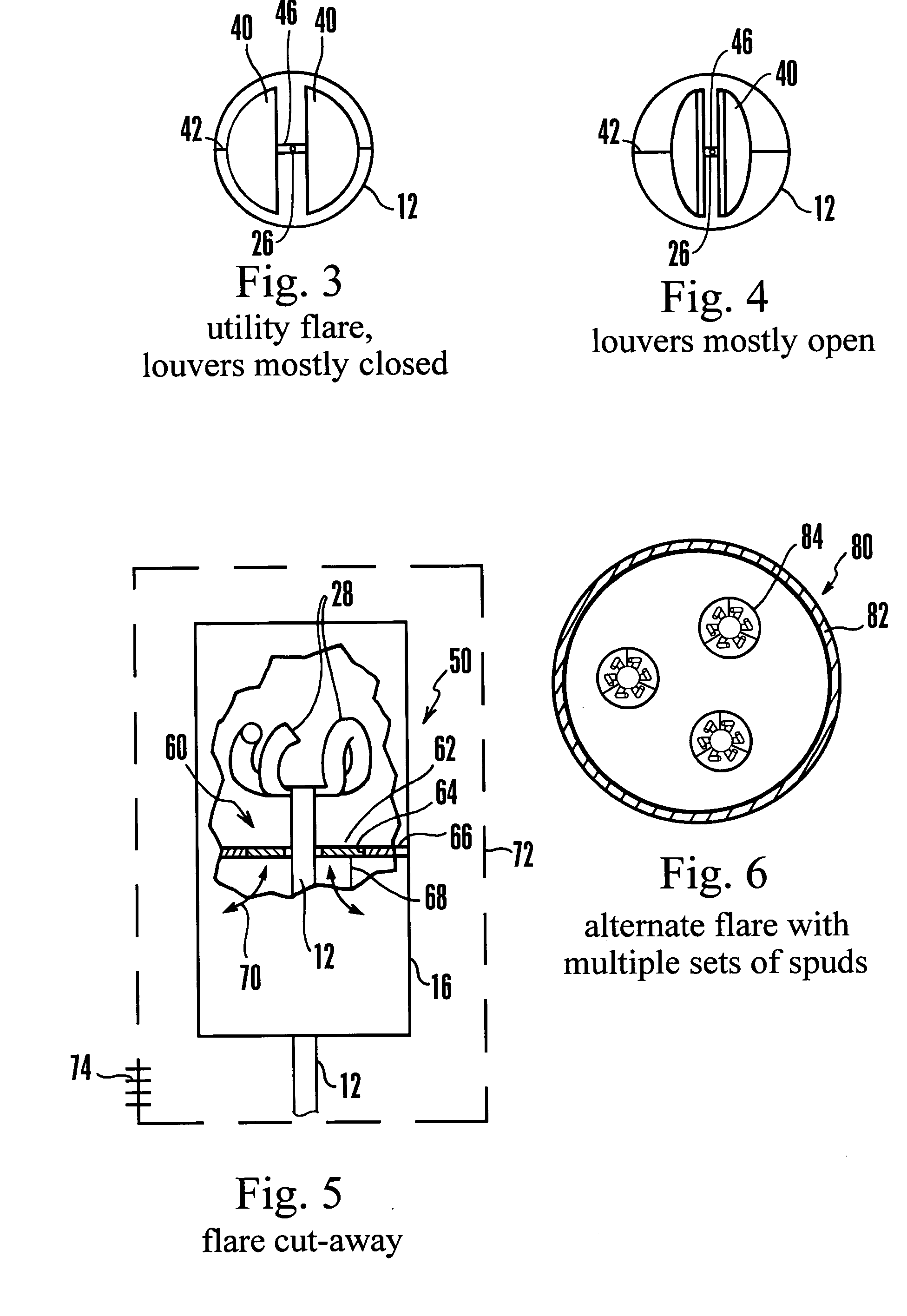

Landfill gas extraction flare

A landfill methane burner flare has a methane riser within a shroud. The methane riser terminates in a series of spuds that are bent to promote turbulence and mixing in methane passing through and out of the spuds. Louvers can be positioned in the riser to selectively establish a methane gas pressure within the riser, and / or louvers can be positioned between the methane riser and shroud to selectively establish combustion air flow in the flare.

Owner:LFG & E INT

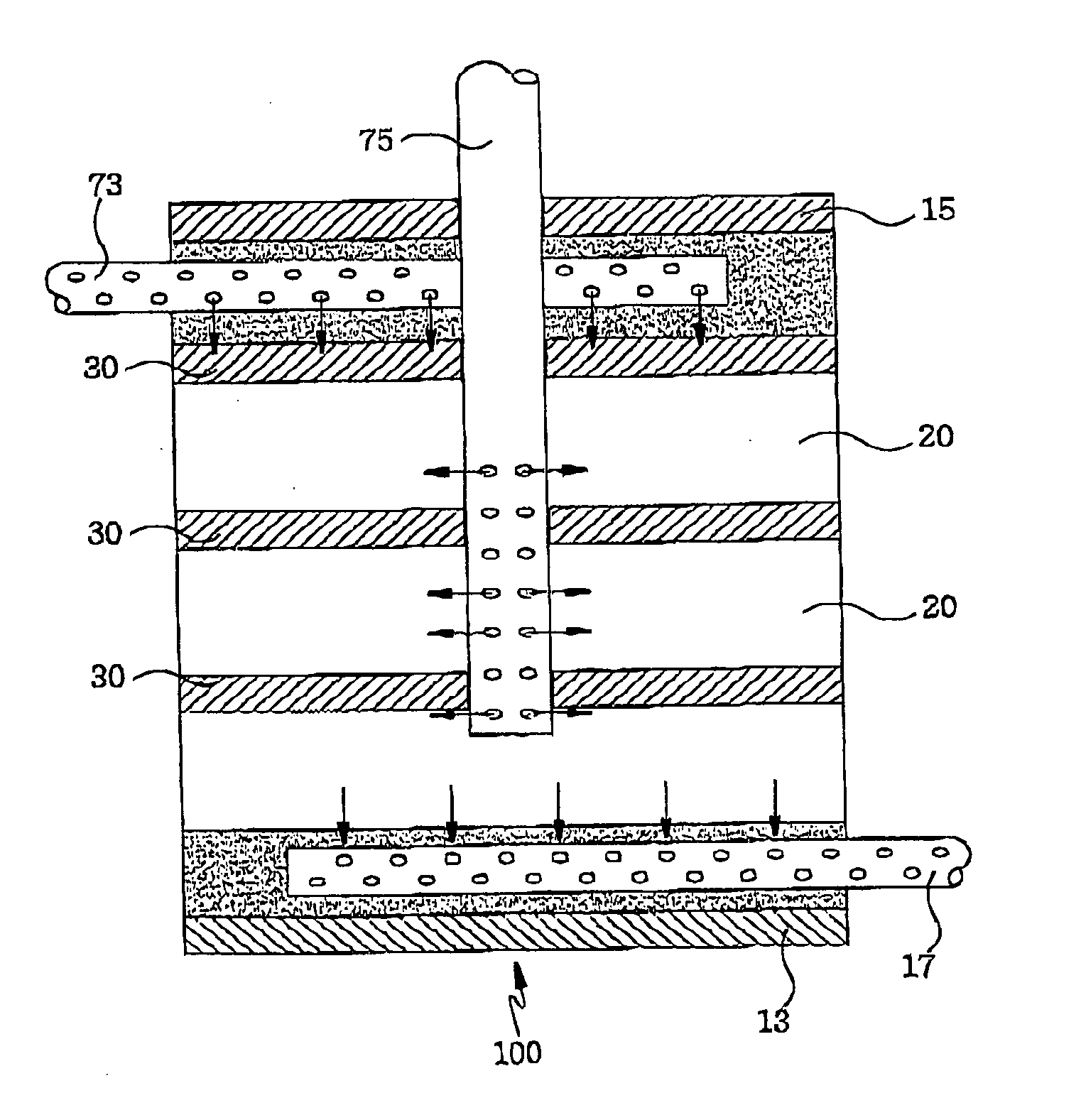

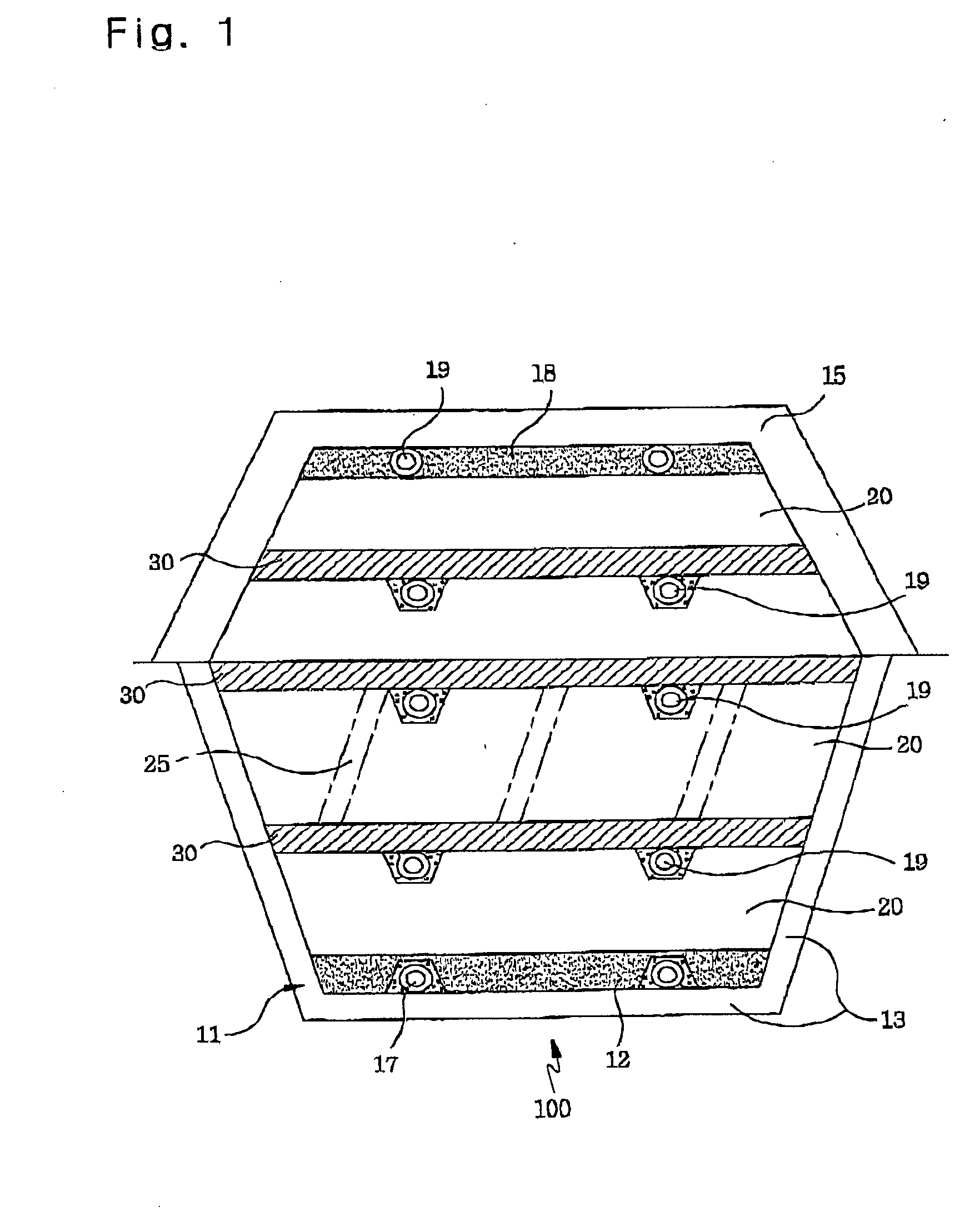

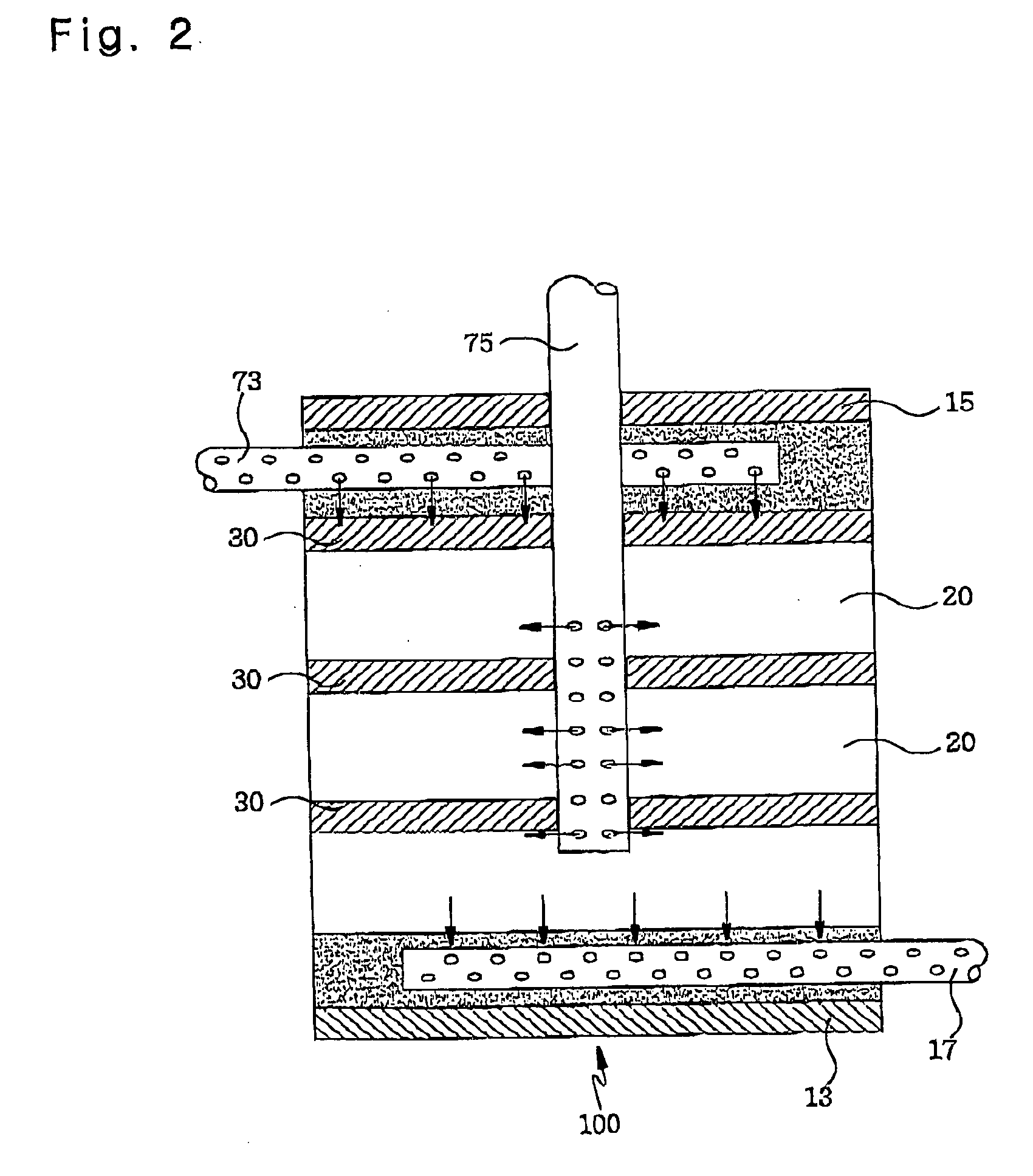

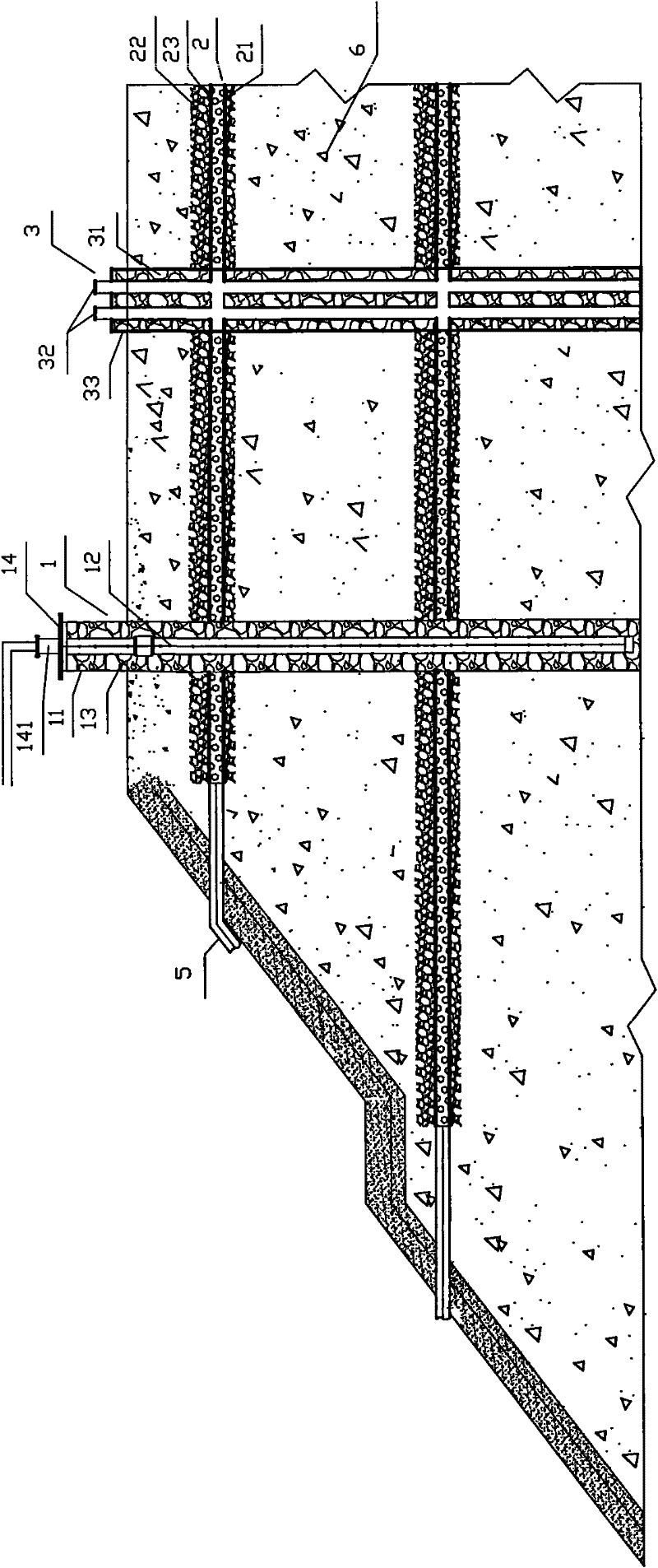

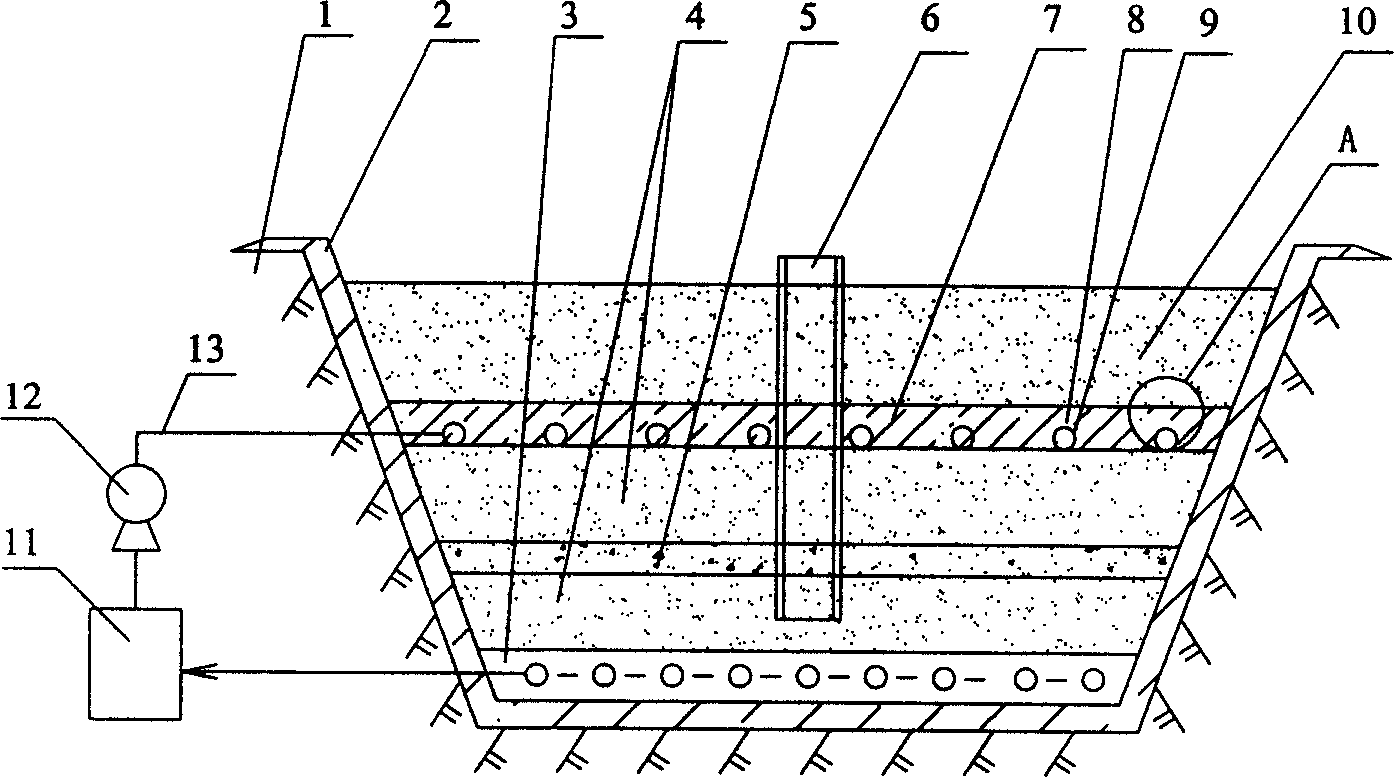

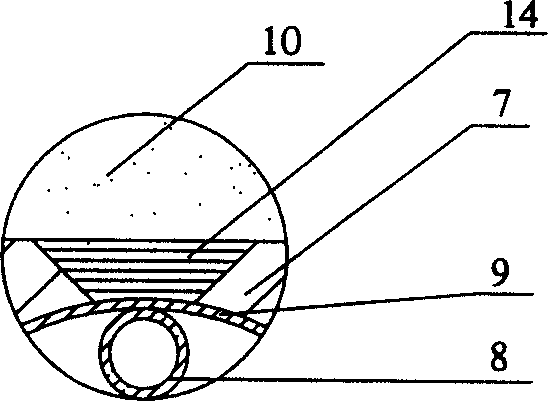

Landfill structure using concept of multi-layered reactors and method for operating the same

InactiveUS20050201831A1Easy to controlReduce the environmentLandfill technologiesSolid waste disposalEnvironmental engineeringLandfill gas

The invention relates to a landfill structure and a method for operating the same and, more particularly, to a landfill structure using a concept of multi-layered reactors, a method for making efficient use of landfill gas generated from the landfill, a method for early stabilizing the landfill and a method for reducing environmental contaminants generated from the landfill.

Owner:ENV21

In-situ landfill gas well perforation method and apparatus

The present invention relates to a method and apparatus for perforating a landfill gas well in situ. The invention allows for improved recovery of gas from a gas well without the danger of explosion.

Owner:WASTE MANAGEMENT INC

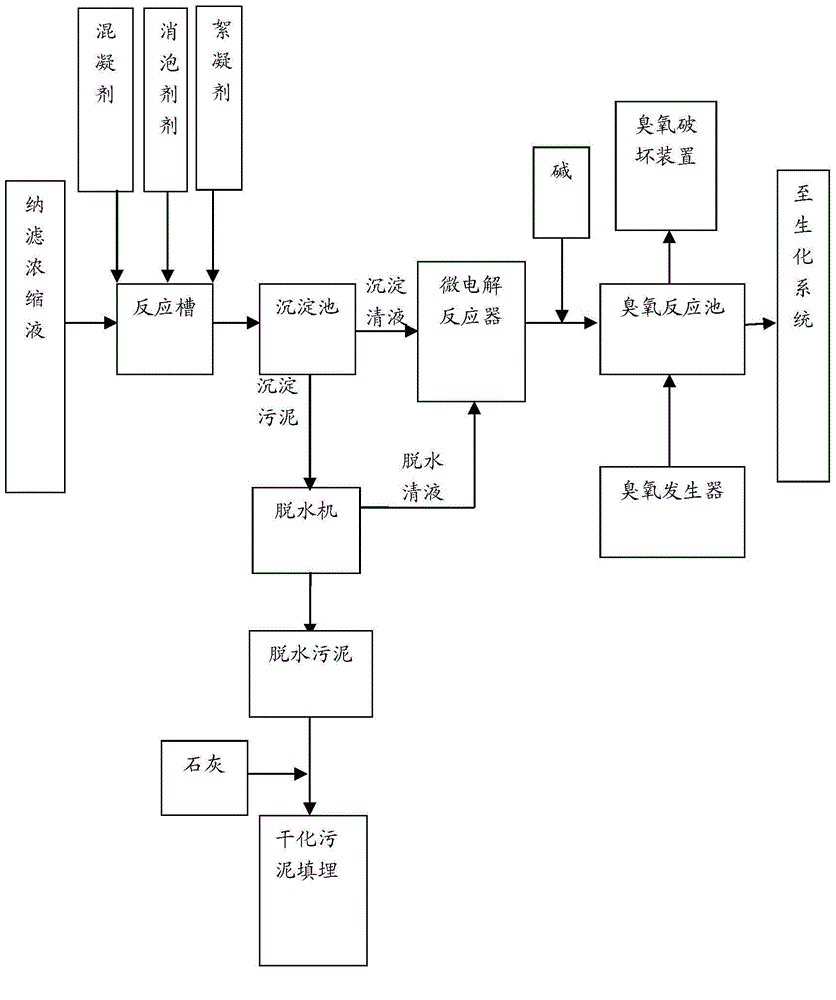

Landfill leachate nanofiltration concentrate treatment method

ActiveCN104478157AHigh removal rateImprove economyWater contaminantsMultistage water/sewage treatmentOzone generatorChemical reaction

The invention provides a landfill leachate nanofiltration concentrate treatment method. The method comprises the following steps: pumping a landfill leachate nanofiltration concentrate into a reaction tank, adding a coagulant, an antifoaming agent and a flocculating agent into the reaction tank, and reacting; allowing the obtained concentrate to go through a pipeline and flow into a precipitation pool, and carrying out solid-liquid separation to obtain precipitated sludge and a precipitated clear liquid; pumping the precipitated sludge into a dehydrator for separation, sending the generated dehydrated clear liquid and the precipitated clear liquid to a microelectrolysis reactor, and oxidizing; adding an alkali to oxidized water to adjust the pH value to 7-9, sending the obtained water to an ozone reaction tank for further oxidation, and introducing ozone generated by an ozone generator into an ozone reaction tank for aeration; and returning the treated nanofiltration concentrate to a biochemical system. The method ingeniously combining a physical and chemical reaction with a biochemical technology has the advantages of stable running, easy operation and maintenance, low running cost and high treatment efficiency, and partially solves the carbon source insufficiency problem of landfill leachate.

Owner:GARDEN ENVIRONMENTAL PROTECTION

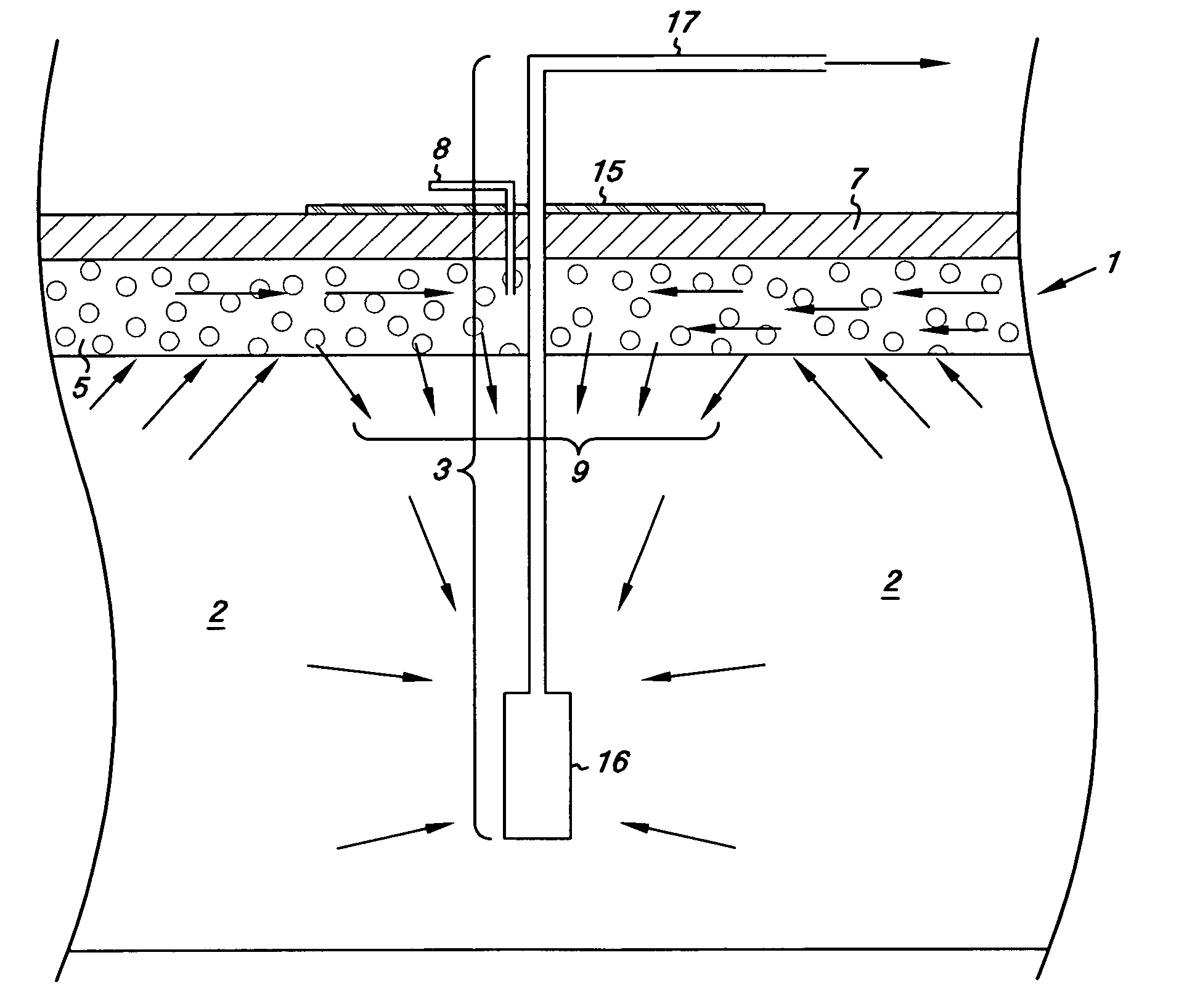

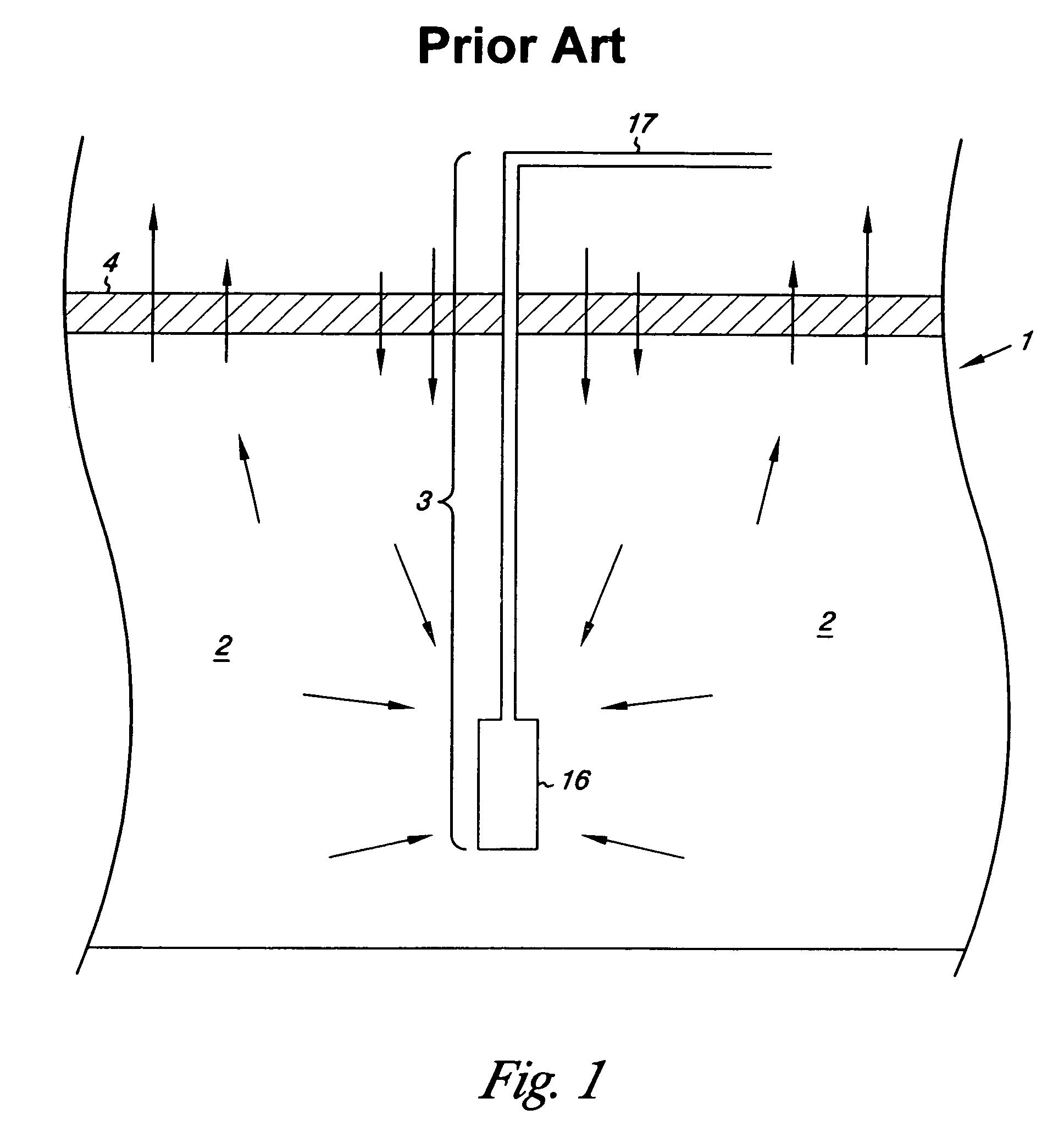

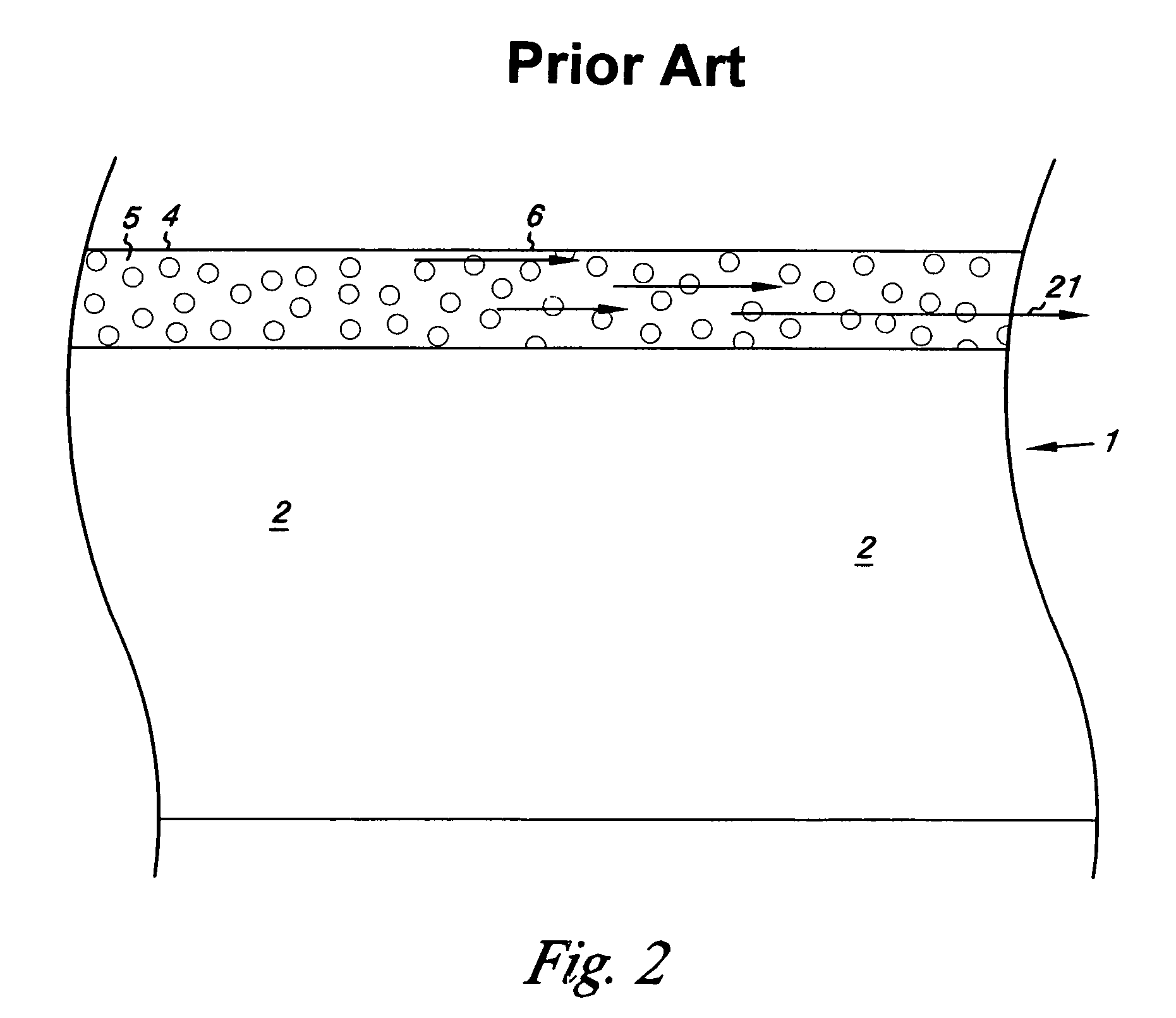

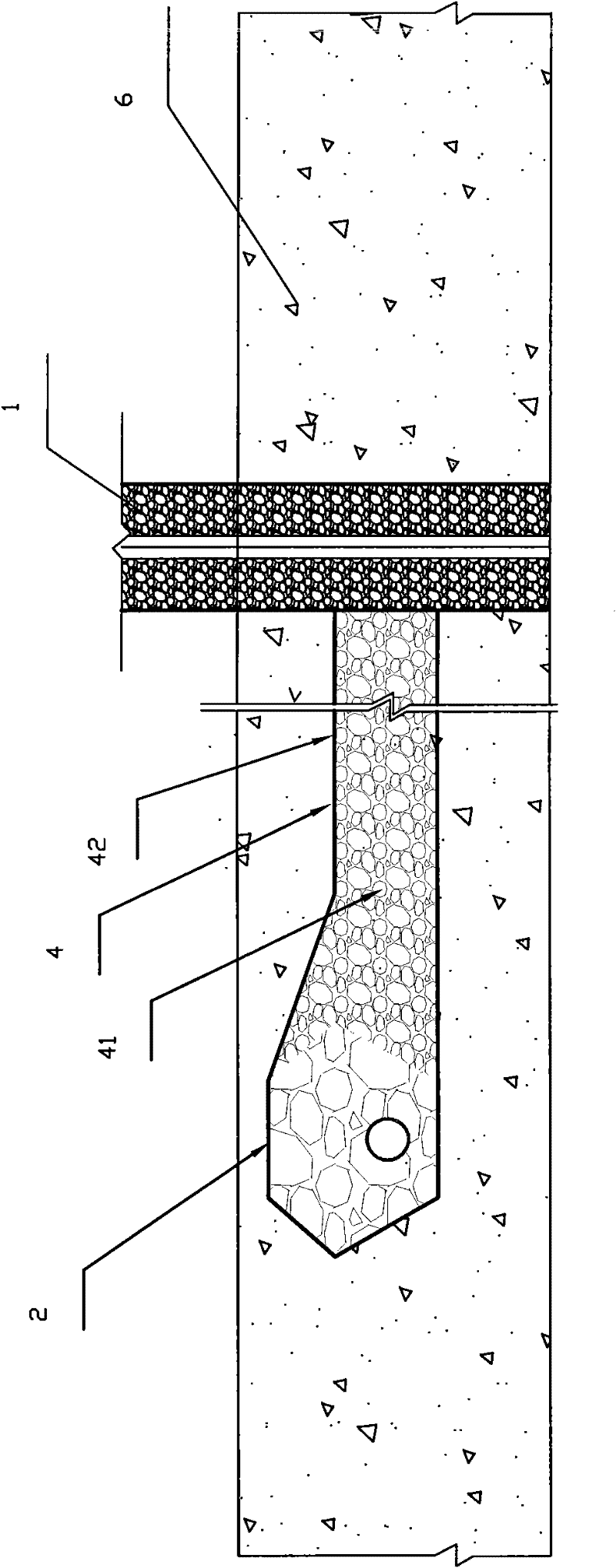

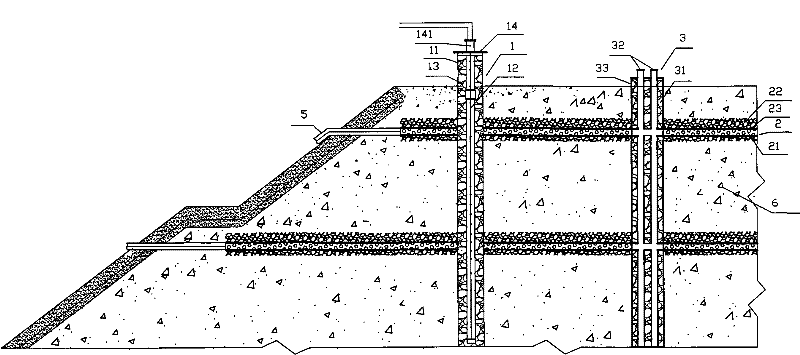

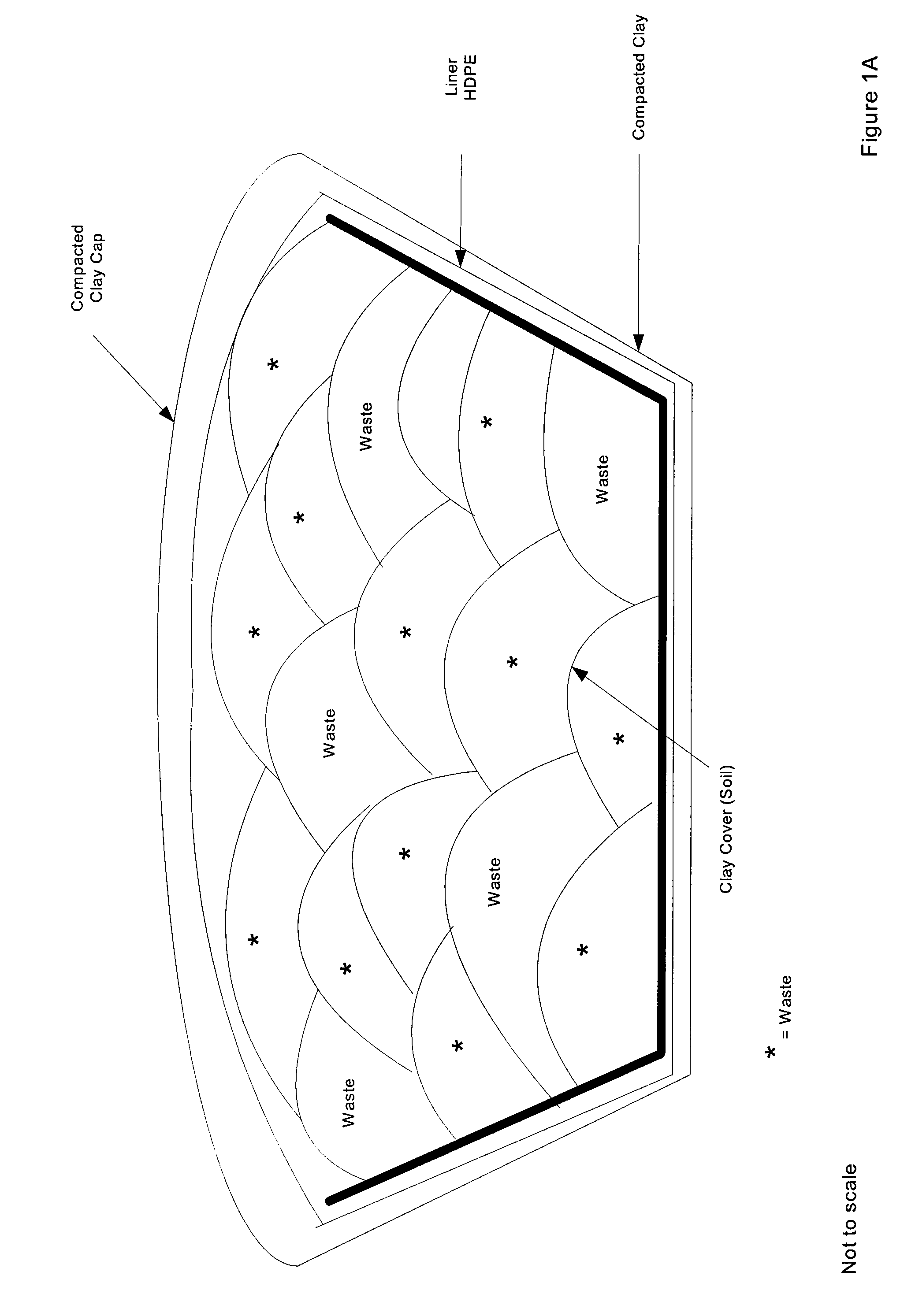

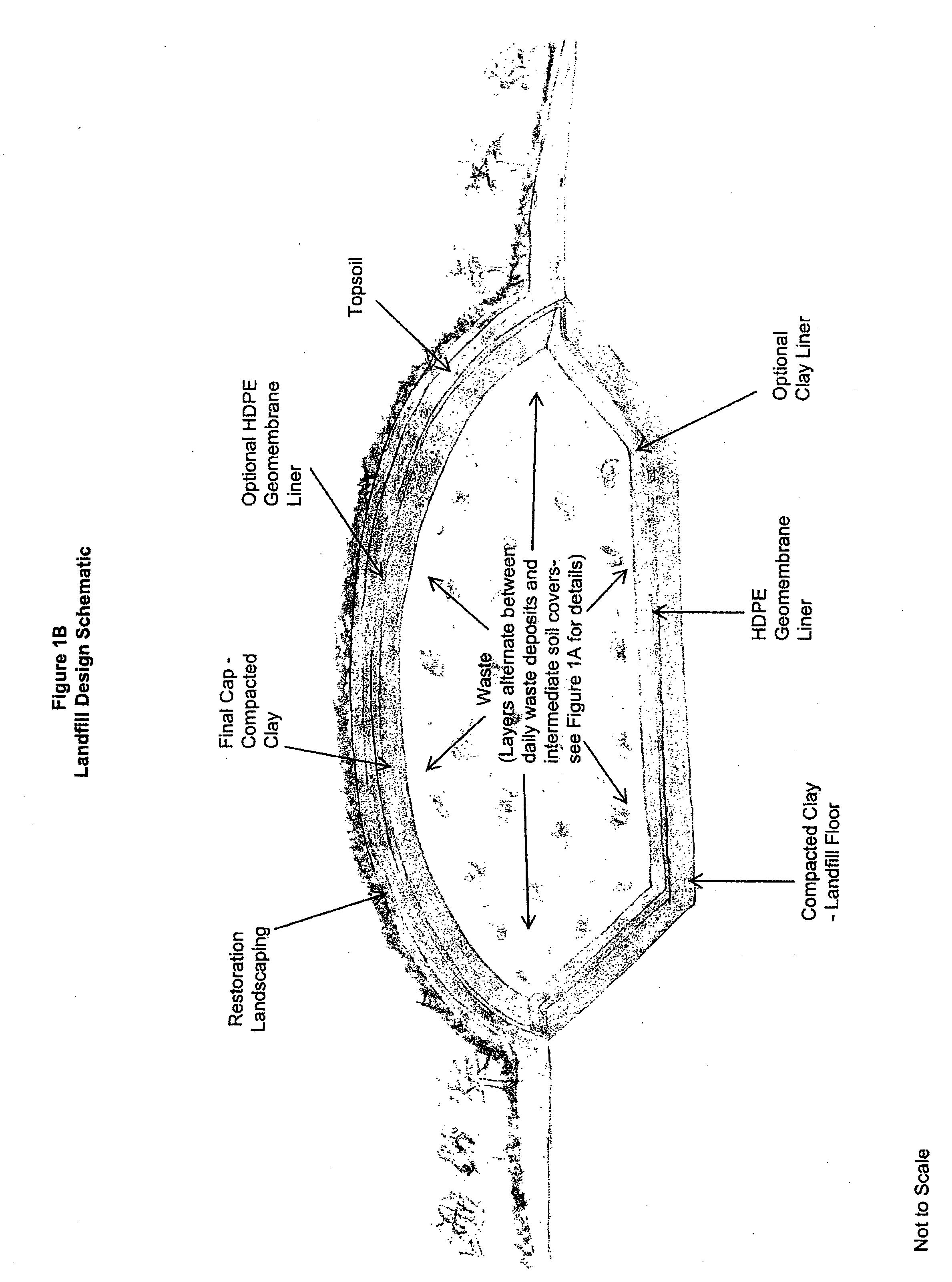

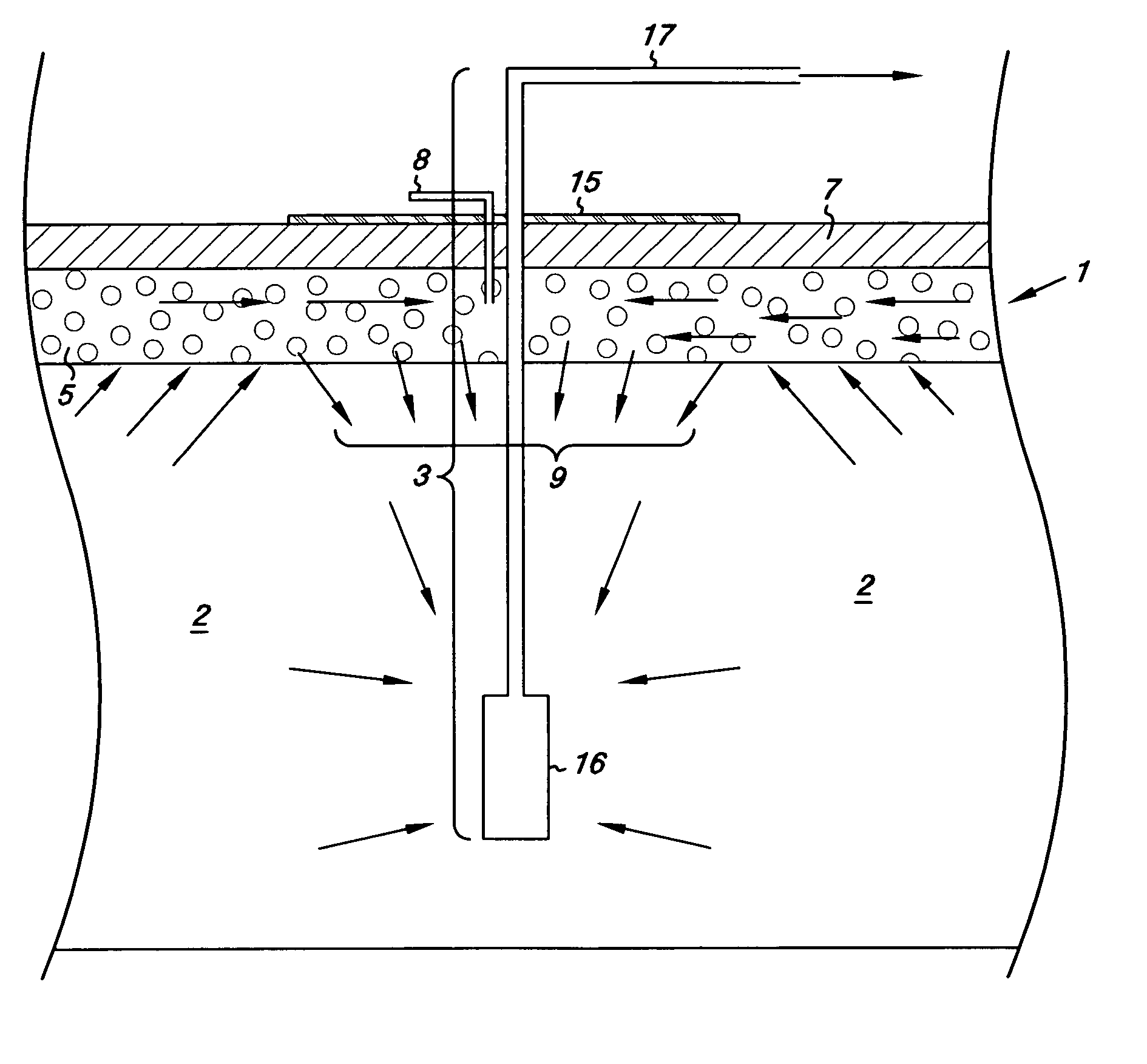

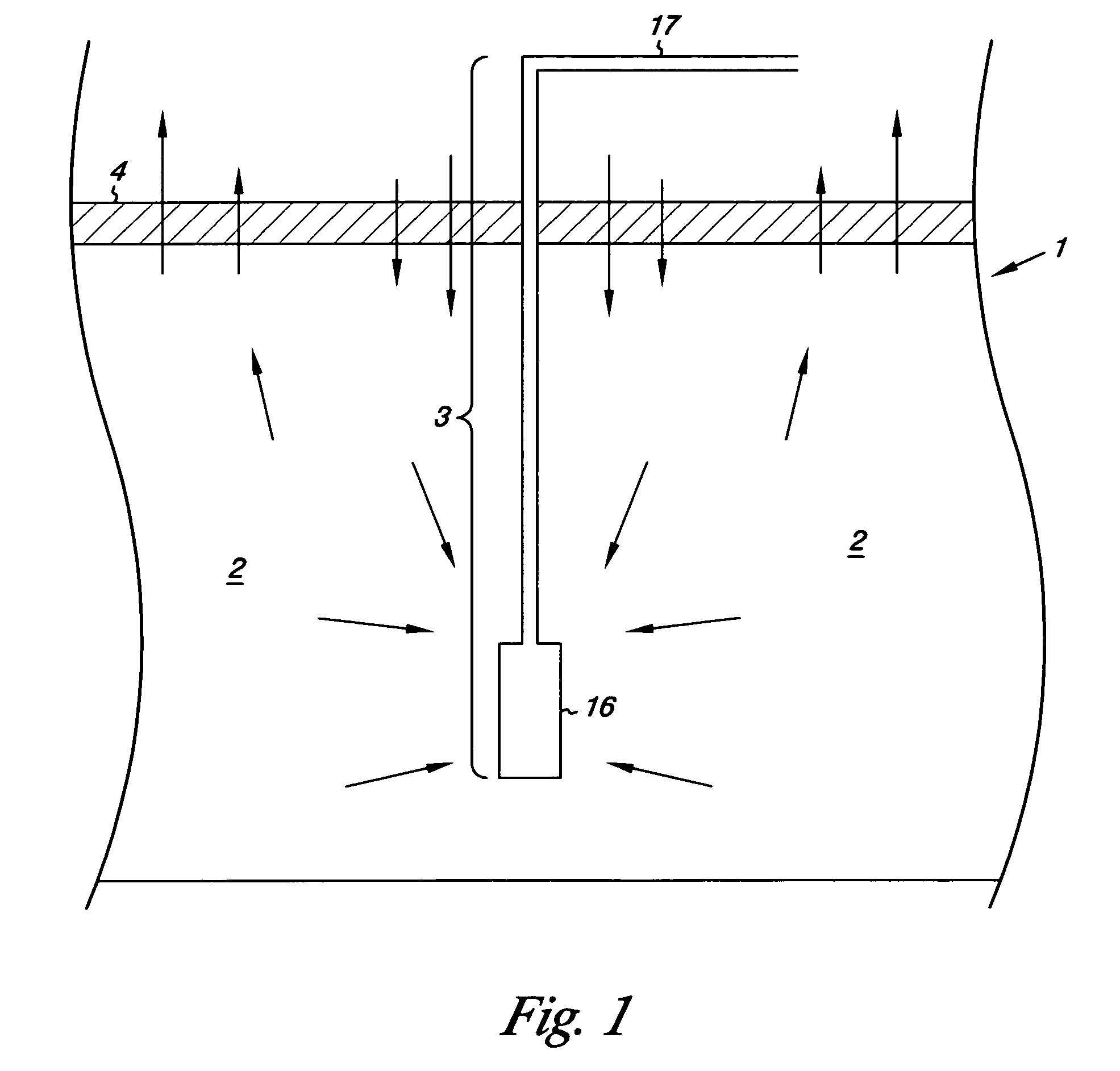

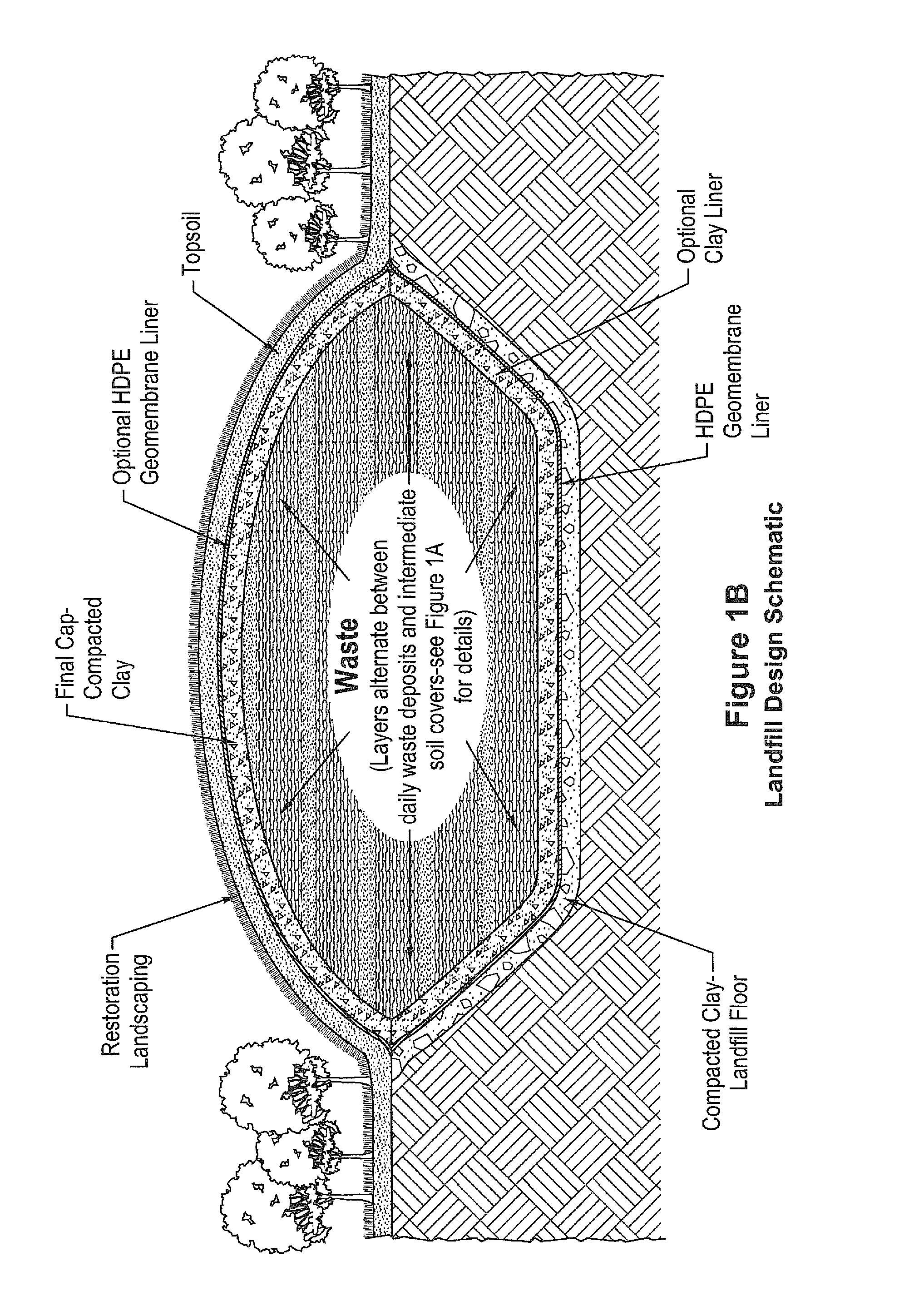

Landfill design and method for improved landfill gas capture

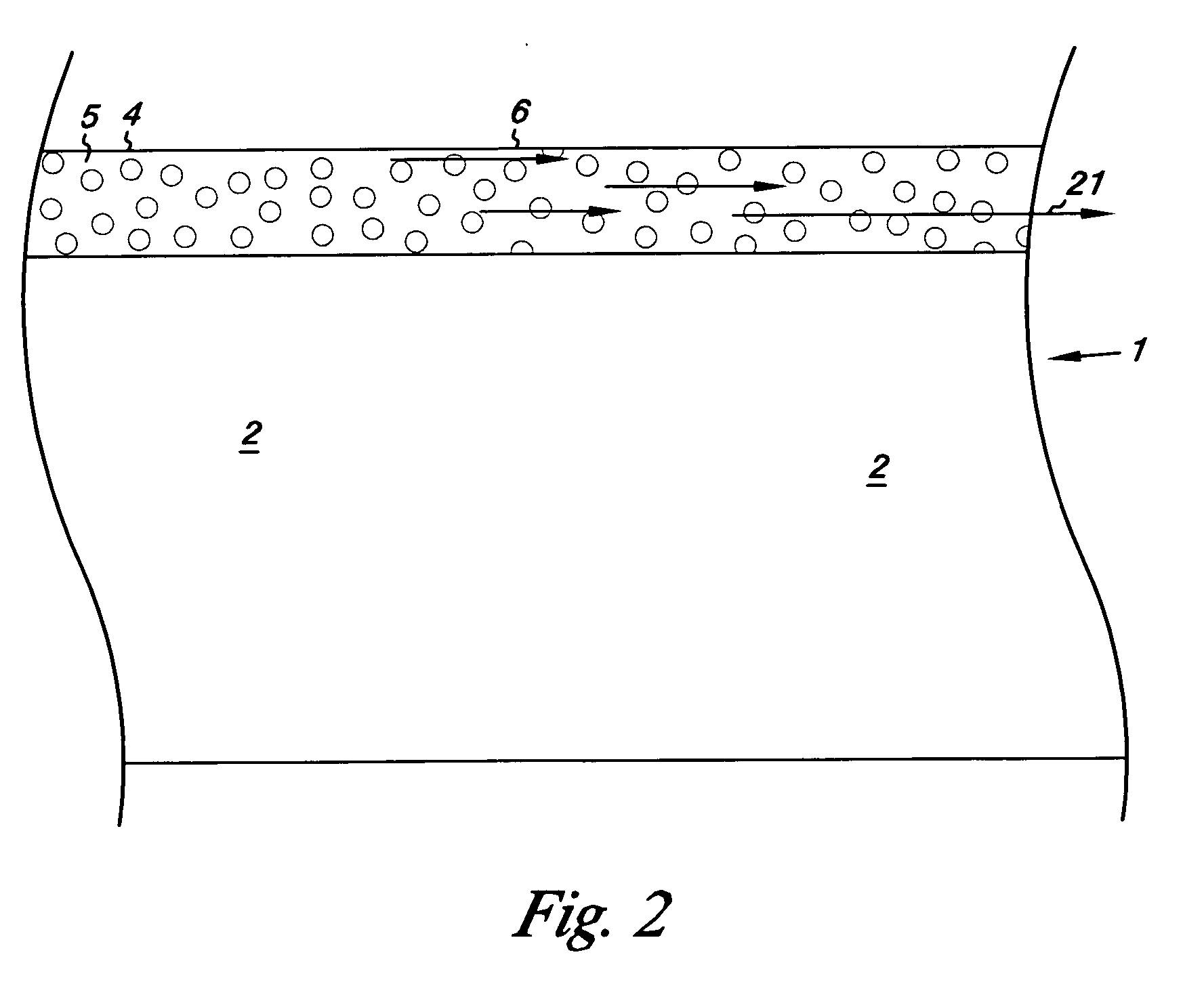

InactiveUS7198433B2Efficient collectionFacilitate methodMethane captureSolid waste disposalGas compositionAir entrainment

The invention provides an improved method of collecting biogas from a landfill that results in more complete collection of biogas produced in the landfill, and with less contamination with air. The method involves providing the landfill with an upper gas containment layer near the surface of the landfill to retard biogas escape and air entrainment into the landfill. Underneath the gas containment layer is provided a gas-permeable conductive layer. Underneath the conductive layer, a well withdraws biogas from the landfill. Withdrawal of biogas from the well creates a partial vacuum that draws gas from the gas-permeable conductive layer down through the waste mass to the well. If the rate of gas withdrawal from the well is too rapid, air will be entrained from the atmosphere into the gas-permeable conductive layer. But if the rate of gas withdrawal from the well is too slow, biogas may percolate through the gas-containment layer and the surface of the landfill to escape. Monitoring the gas composition of the gas-permeable layer allows one to determine quickly and continuously whether the rate of gas withdrawal from the well is too fast or too slow.

Owner:INST FOR ENVIRONMENTAL MANAGEMENT

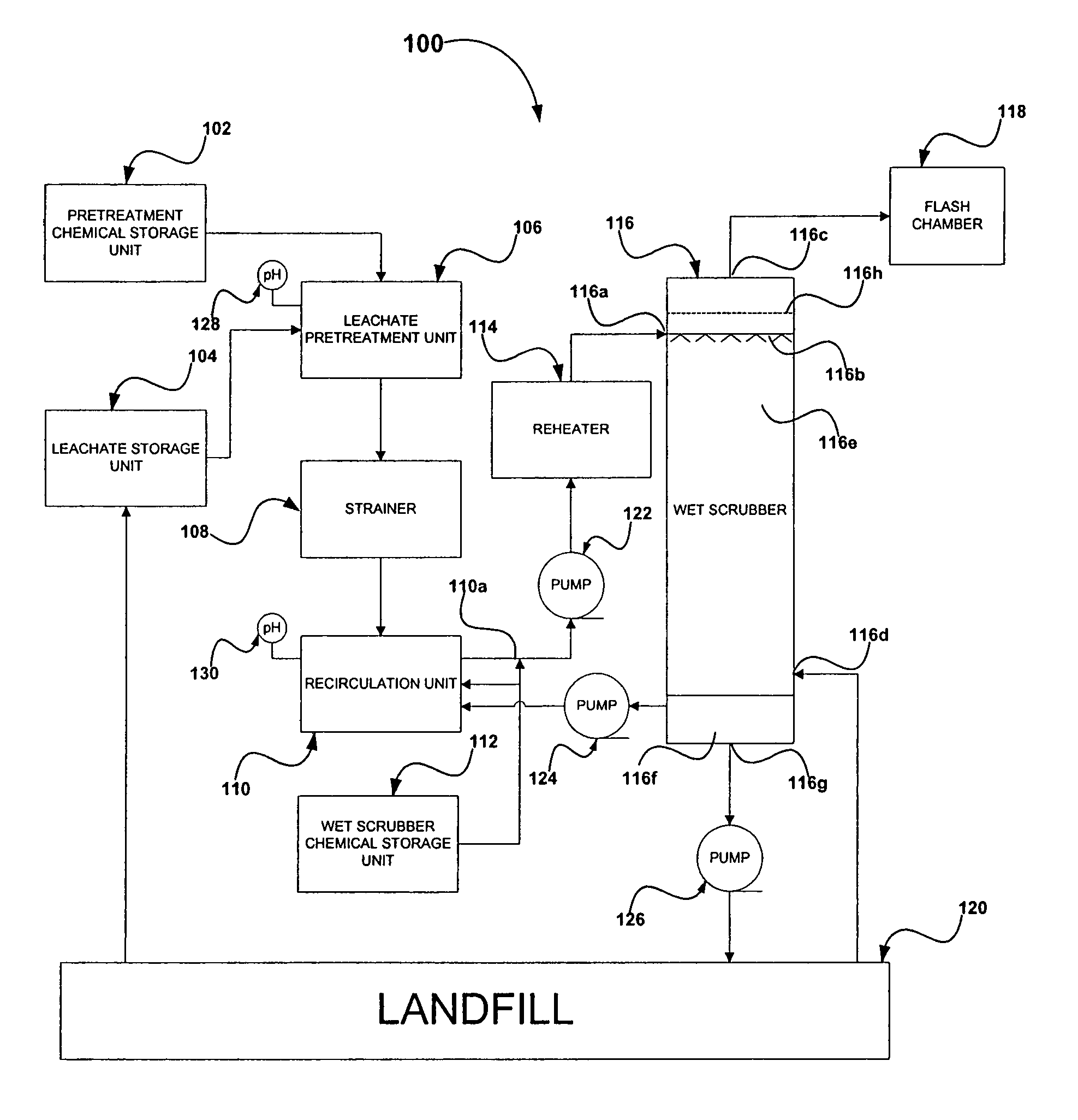

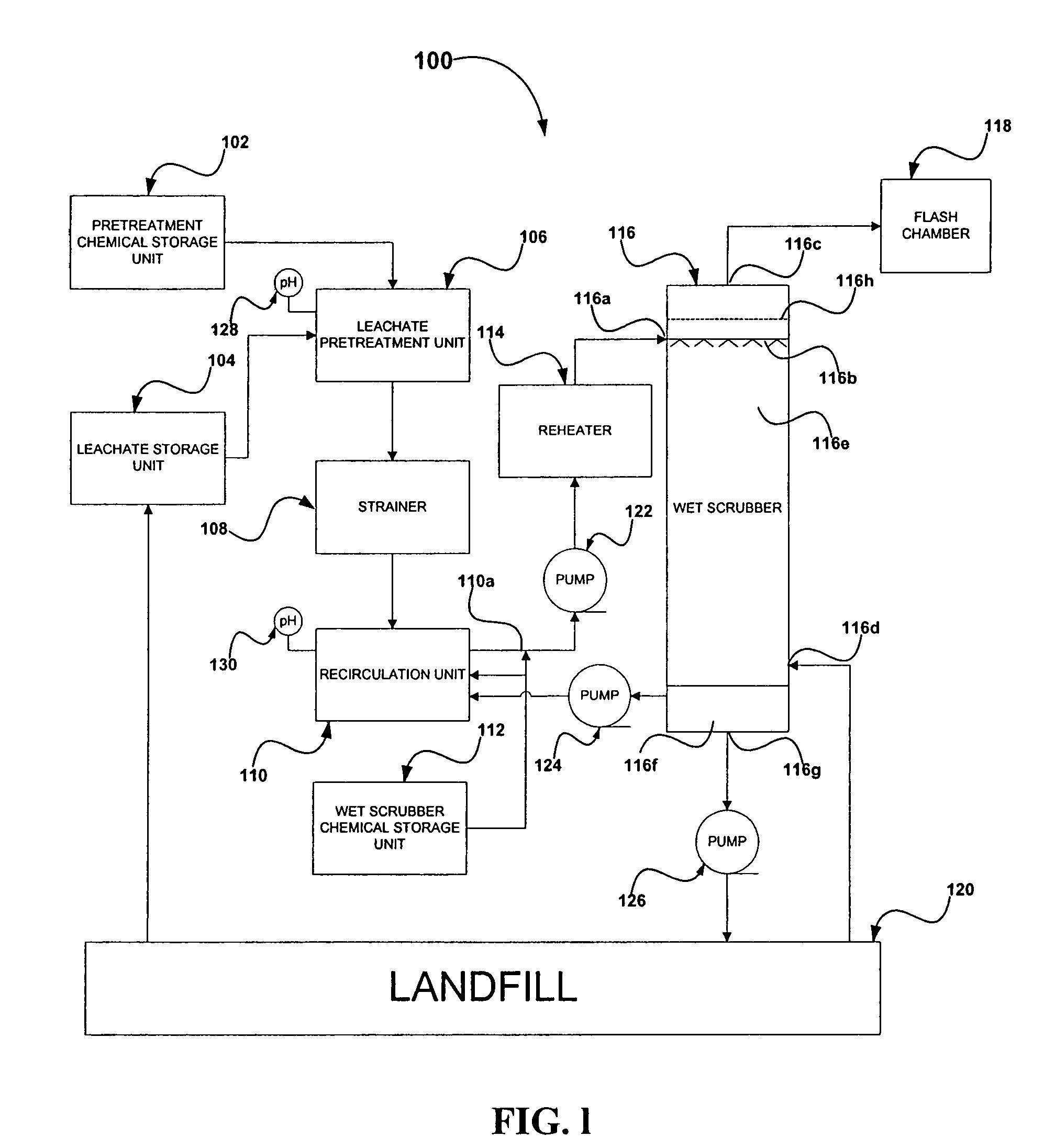

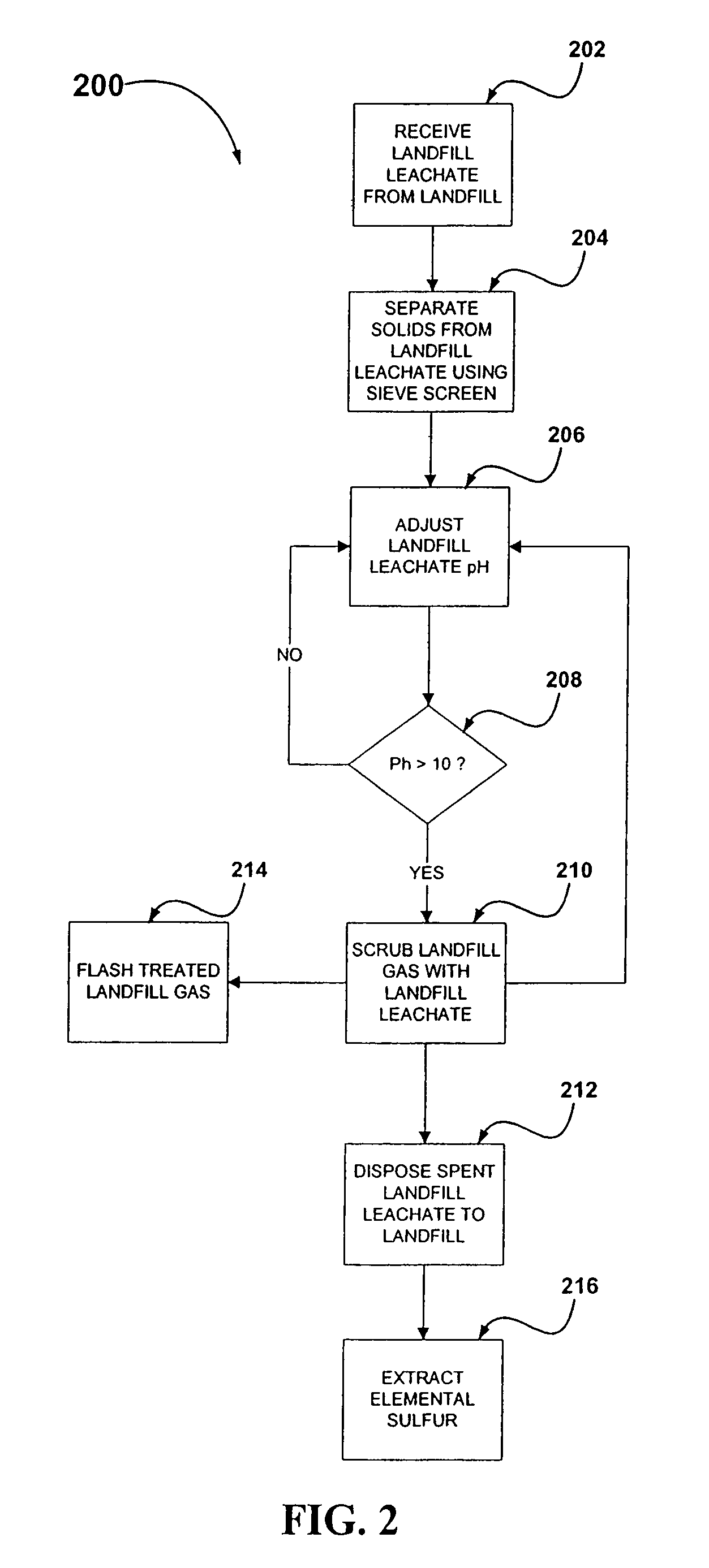

System and method for treating landfill gas using landfill leachate

Embodiments of the present invention are directed to systems and methods for treating landfill gas using landfill leachate. In one embodiment of the present invention, a method includes receiving landfill leachate from at least one of a plurality of sources, and pretreating the landfill leachate to adjust at least one chemical property of at least one component of the landfill leachate. The leachate contacts landfill gas, so that at least one component of the landfill gas chemically reacts with at least one component of the landfill leachate to form a spent landfill leachate and a treated landfill gas. The method also includes recycling a first portion of the spent landfill leachate, recirculating a second portion of the spent landfill leachate to at least one of the plurality of sources, and subjecting the treated landfill gas to flare.

Owner:CASELLA WASTE SYSTEMS

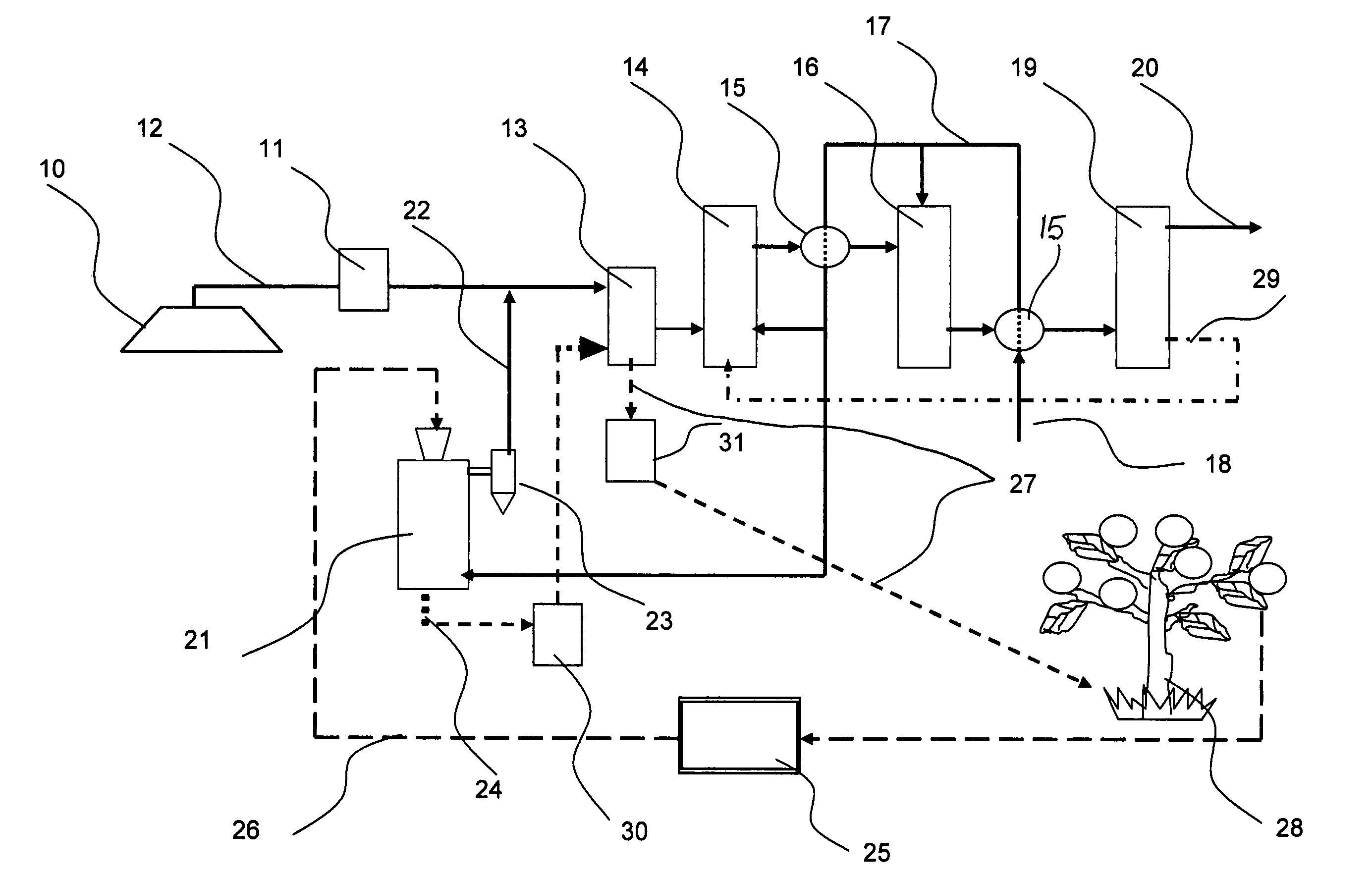

Process for hydrogen production via integrated processing of landfill gas and biomass

InactiveUS7691182B1Simplify technological chainEfficient use ofCombination devicesMethane captureClosed loopHigh surface area

Hydrogen production is provided via integrated closed-loop processing of landfill gas (LFG) and solid biomass feedstocks such as various agricultural wastes with minimal environmental impact. LFG is purified of harmful contaminants over a bed of activated charcoal (AC) and is catalytically reformed to synthesis gas, which is further processed to pure hydrogen via CO-shift and pressure-swing adsorption stages. Biomass is gasified in the presence of steam with production of a producer gas and AC. The producer gas is mixed with LFG and is processed to hydrogen as described above. High-surface area AC produced in the gasifier is used for the purification of both LFG and producer gas. An integrated processing of LFG and biomass offers a number of advantages such as a high overall energy efficiency, feedstock flexibility, substantial reduction in greenhouse gas emissions and production of value-added product-biocarbon that can be used as a soil enhancer.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

System and method for guiding discharge and collection of landfill gas

The invention relates to a system and a method for guiding discharge and collection of landfill gas. In the invention, landfill gas is collected through a gas collecting shaft which can be drawn upward with the increase of a height of a rubbish body and percolated liquid of the rubbish body is led through a way of combining internal three-dimensional discharge and surface collection. The system comprises water guiding blind drains, a gabion, the gas collecting shaft, master pipes for surface collection, gas gathering pipes and percolated liquid processing device. The water guiding blind drains are arranged respectively in different levels of the rubbish body. The two water guiding blind drains in neighboring levels of the rubbish body are communicated with each other through the gabion installed vertically. The gas collecting shaft is communicated with the water guiding blind drains in all levels of the rubbish body through connection canals and can be drawn upward with the increase of a height of the rubbish body. The top of the gas collecting shaft is provided with an outlet for landfill gas. The outlet of landfill gas is communicated with the gas gathering pipes for landfill gas. An outside surface of the rubbish body is provided with the master pipes for surface collection. The master pipes for surface collection are communicated respectively with water guiding blind drains in the different levels of the rubbish body. The lower portions of the master pipes for surface collection are connected to the percolated liquid processing device. The system utilizing the method of the invention has the advantages of safe operation, stable system structure, effective guiding discharge for excess water in a rubbish body, and high landfill gas collection efficiency.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD +1

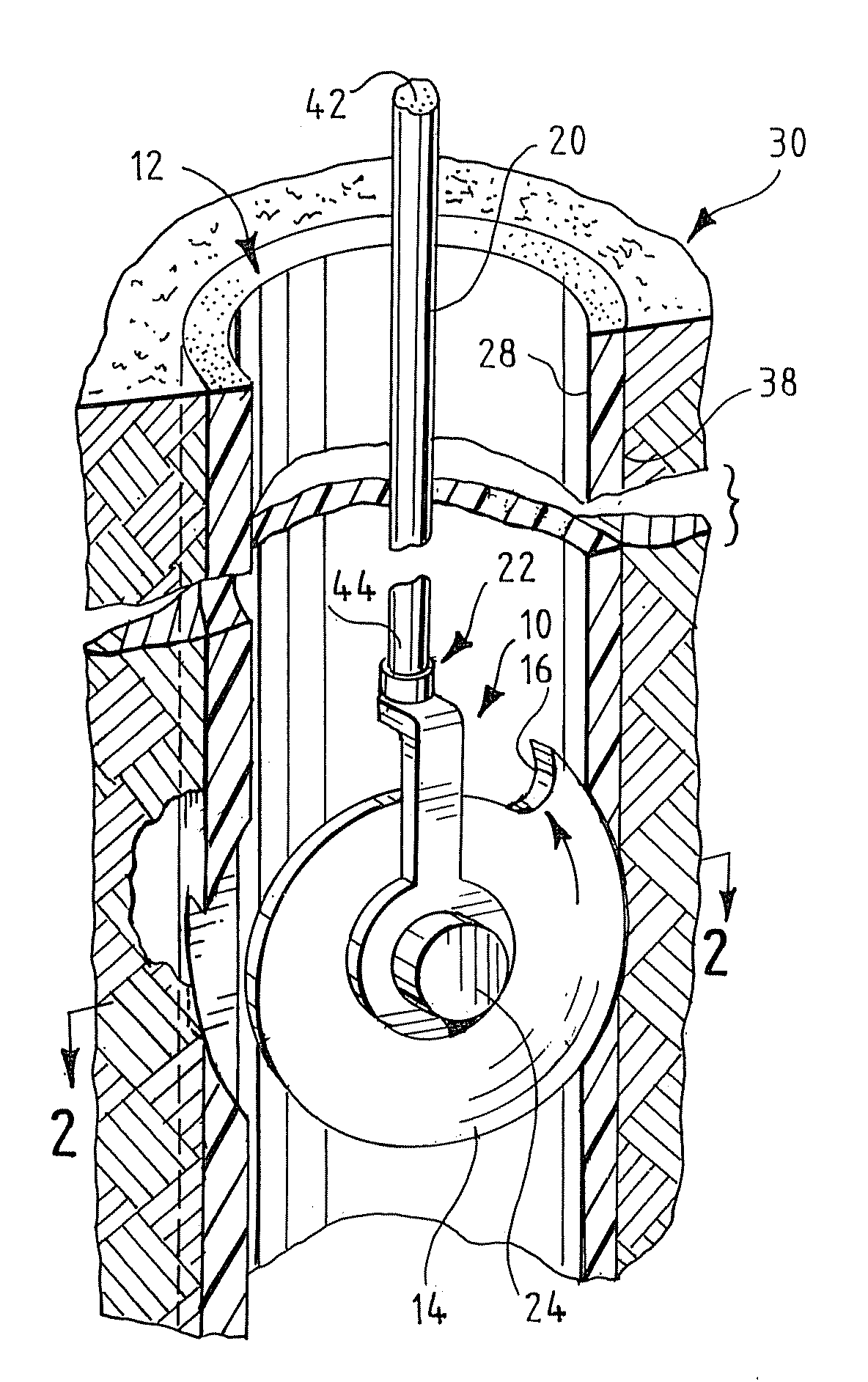

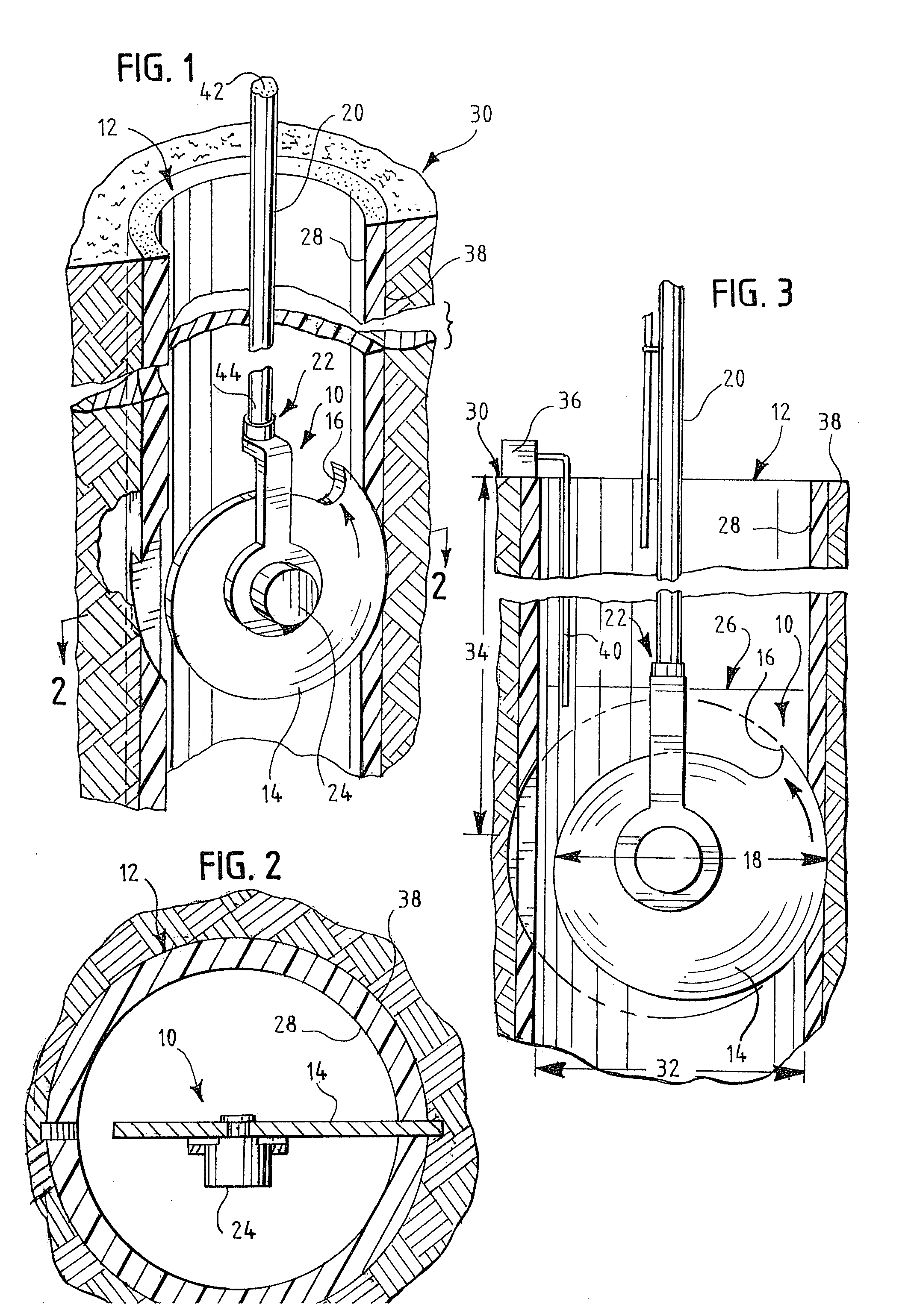

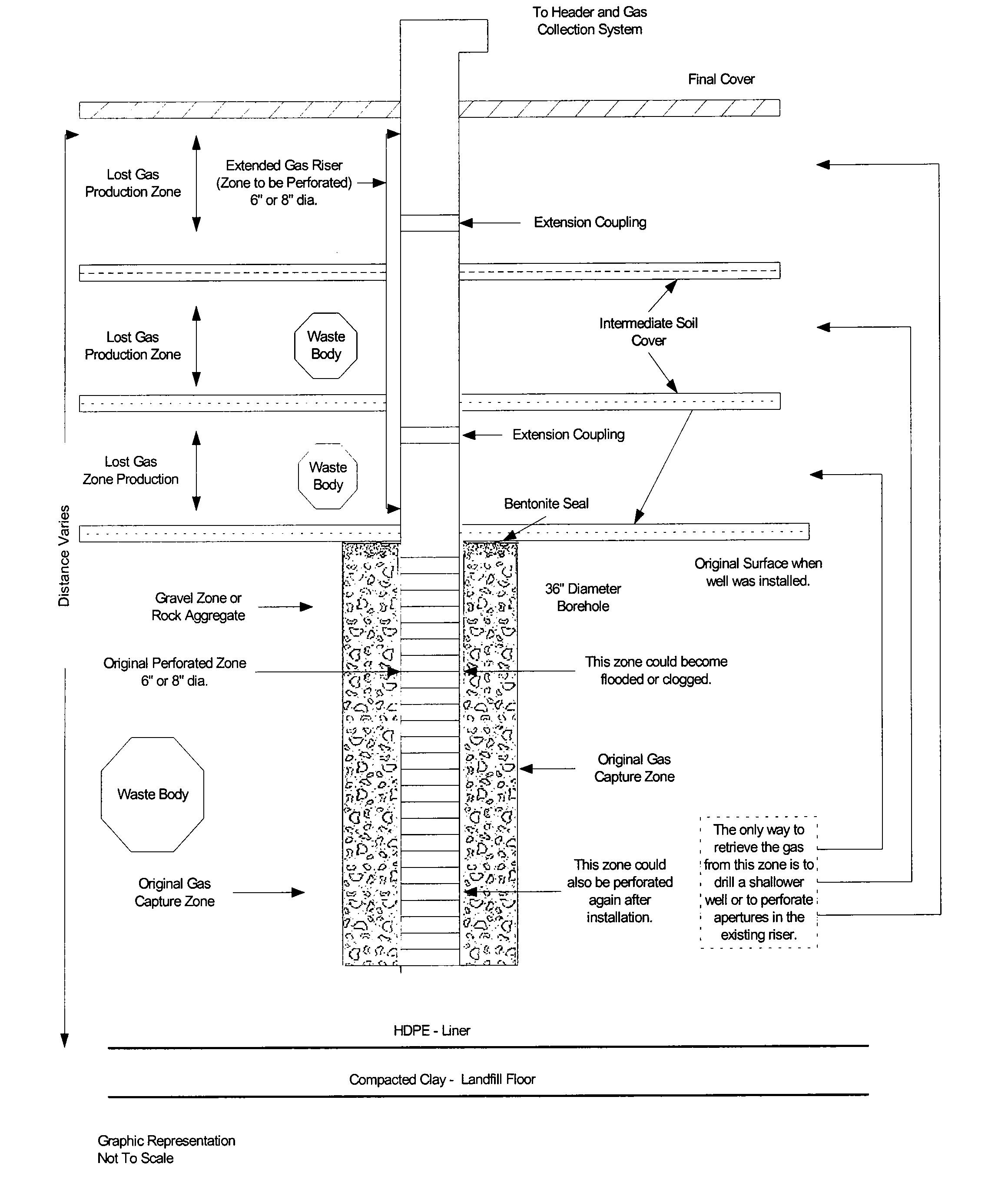

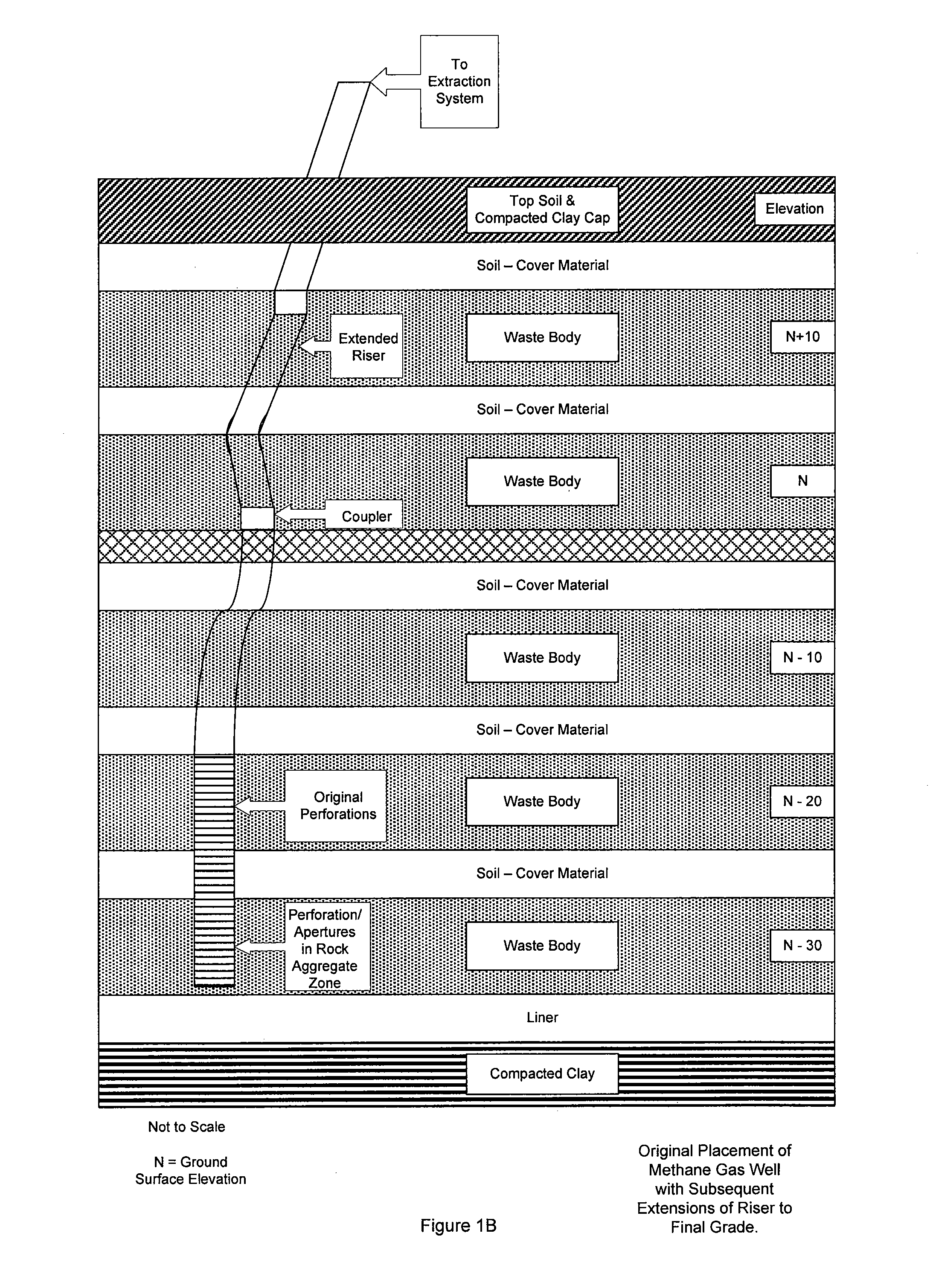

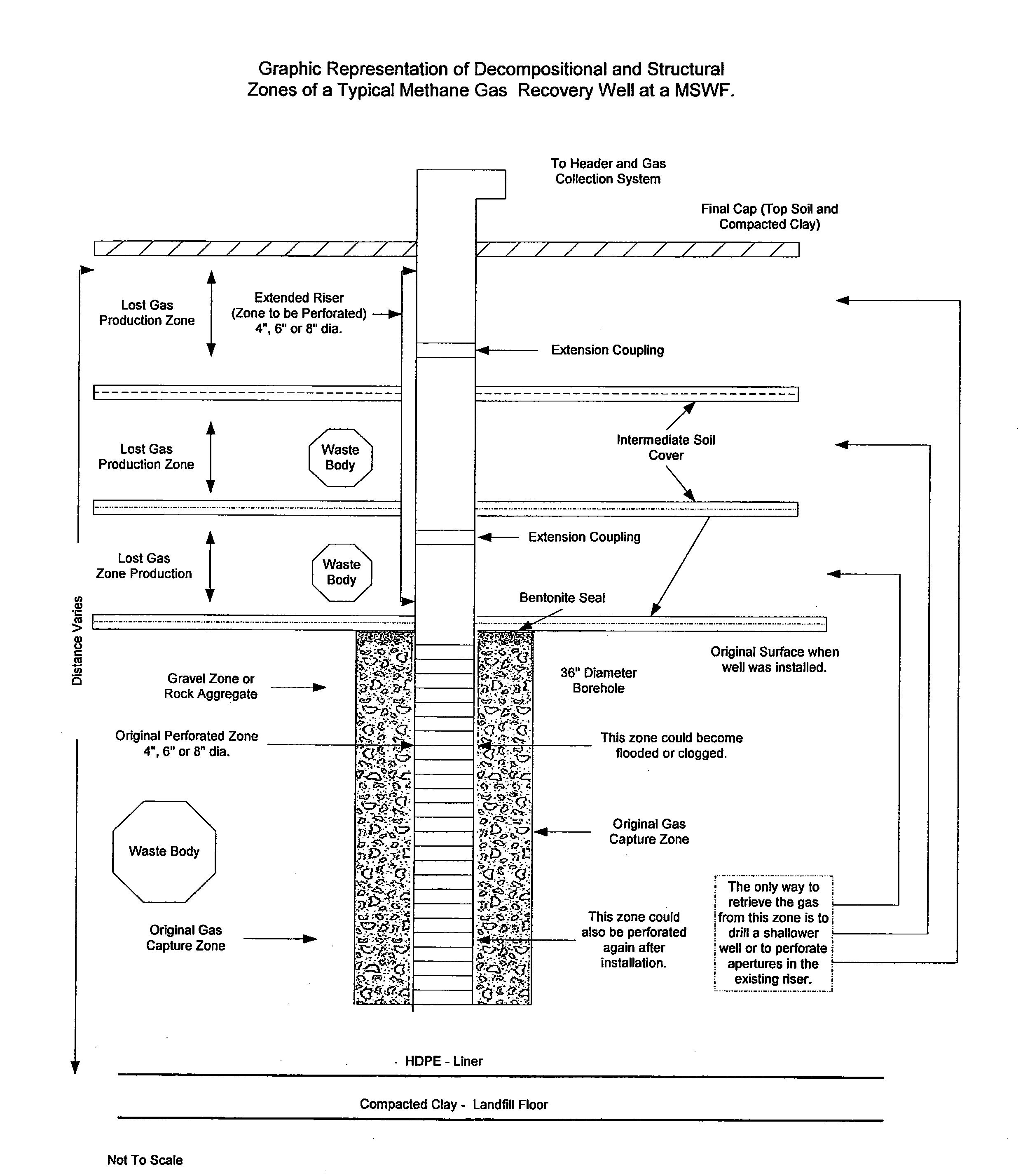

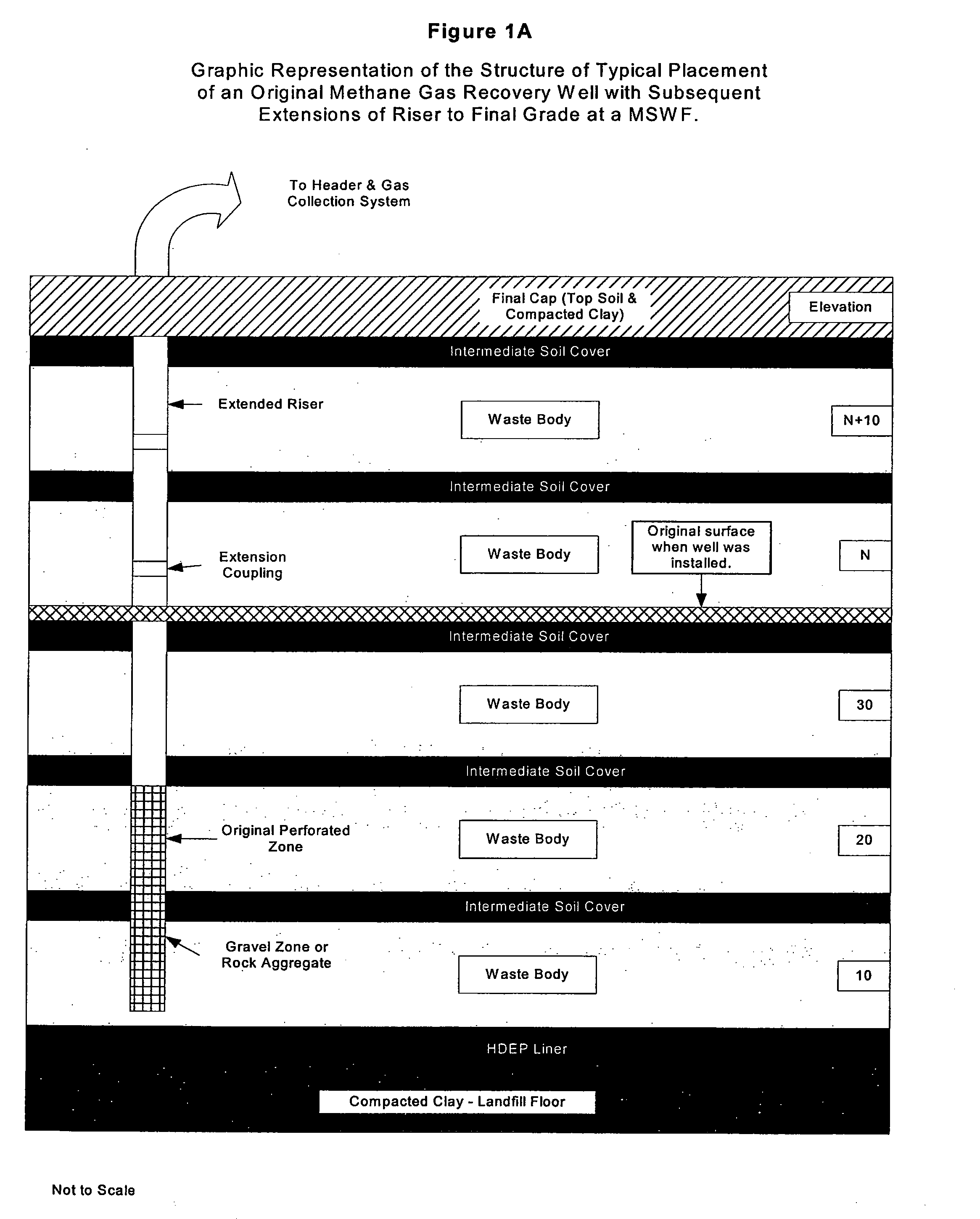

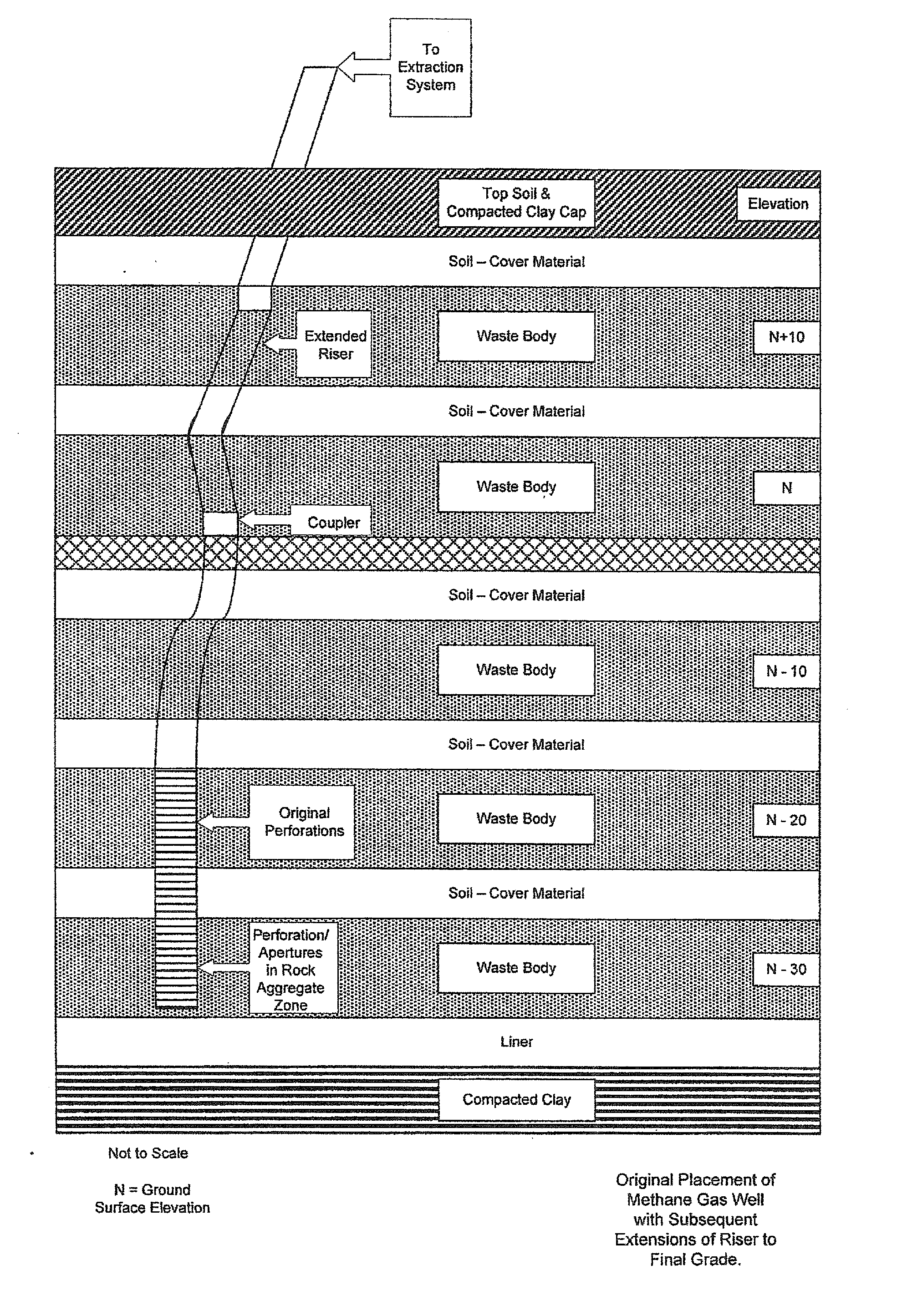

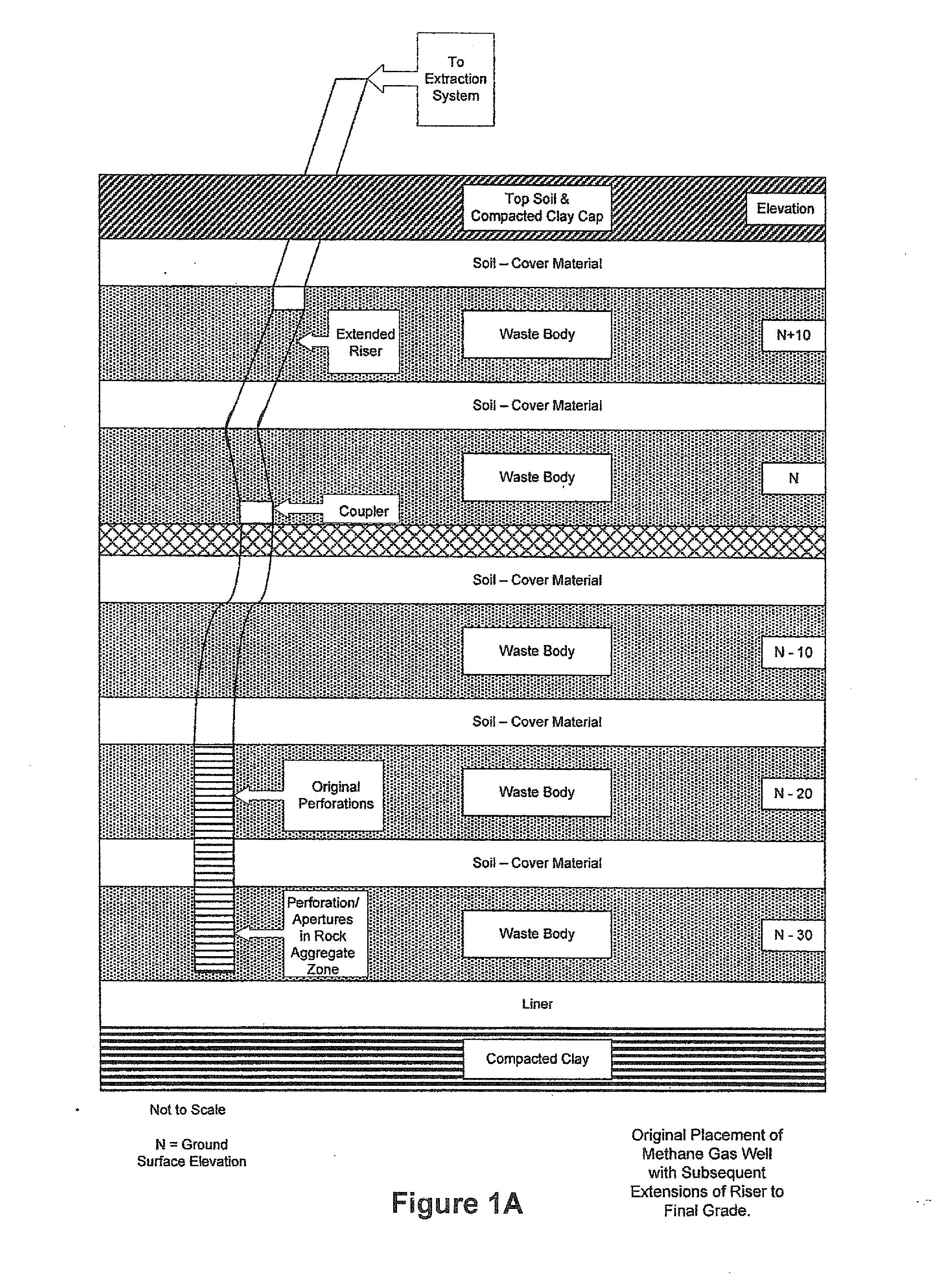

Tool and method for extracting landfill gas

An apparatus and method to internally provide apertures inside PVC, HDPE, or plastic pipe-riser (blank casing) in existing methane gas recovery wells (extraction wells) that have been installed at Municipal Solid Waste Facilities are described. Apertures in methane well risers allow methane gas, LFG derived from the decomposition of waste, to enter the existing riser and extraction system. This process saves time and cost associated with drilling additional wells to retrieve methane gas from subsequent layers of the waste body. The process assists in maintaining regulatory compliance by capturing LFG and preventing it from being emitted into the atmosphere.

Owner:PROSPECTOR DRILLING & TOOL

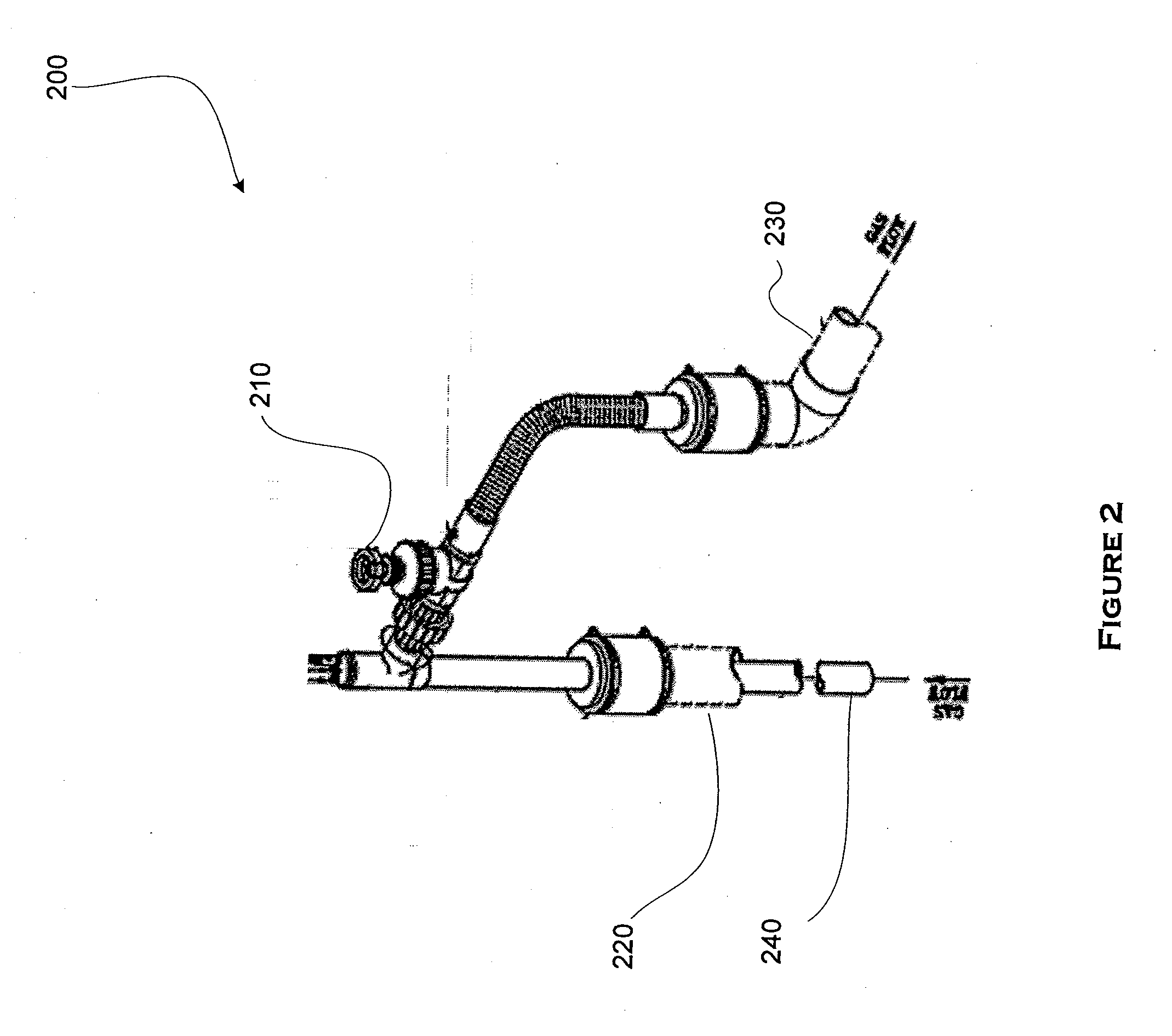

Tool and method for enhancing the extraction of landfill gas

ActiveUS20110061874A1Promote recoveryEfficient and effective recoveryFluid removalGas removalDecompositionPolyvinyl chloride

An apparatus and method to internally provide apertures inside polyvinyl chloride (PVC), high density polyethylene (HDPE), or any polymeric pie, plastic pipe-riser (blank casing) in existing landfill gas recovery wells (extraction wells) that have been installed at Municipal Solid Waste Facilities are described. By creating additional apertures in landfill gas recovery well risers, landfill gas derived from the decomposition of waste is allowed to enter the existing riser and extraction / recovery system. This process saves time and cost associated with drilling additional wells to capture landfill gas from subsequent layers of the waste body. The process assists in maintaining regulatory compliance by capturing landfill gas and preventing it from being emitted into the atmosphere.

Owner:PROSPECTOR DRILLING & TOOL

Landfill design and method for improved landfill gas capture

InactiveUS20060034664A1Efficient collectionFacilitate methodMethane captureSolid waste disposalGas compositionAir entrainment

The invention provides an improved method of collecting biogas from a landfill that results in more complete collection of biogas produced in the landfill, and with less contamination with air. The method involves providing the landfill with an upper gas containment layer near the surface of the landfill to retard biogas escape and air entrainment into the landfill. Underneath the gas containment layer is provided a gas-permeable conductive layer. Underneath the conductive layer, a well withdraws biogas from the landfill. Withdrawal of biogas from the well creates a partial vacuum that draws gas from the gas-permeable conductive layer down through the waste mass to the well. If the rate of gas withdrawal from the well is too rapid, air will be entrained from the atmosphere into the gas-permeable conductive layer. But if the rate of gas withdrawal from the well is too slow, biogas may percolate through the gas-containment layer and the surface of the landfill to escape. Monitoring the gas composition of the gas-permeable layer allows one to determine quickly and continuously whether the rate of gas withdrawal from the well is too fast or too slow.

Owner:INST FOR ENVIRONMENTAL MANAGEMENT

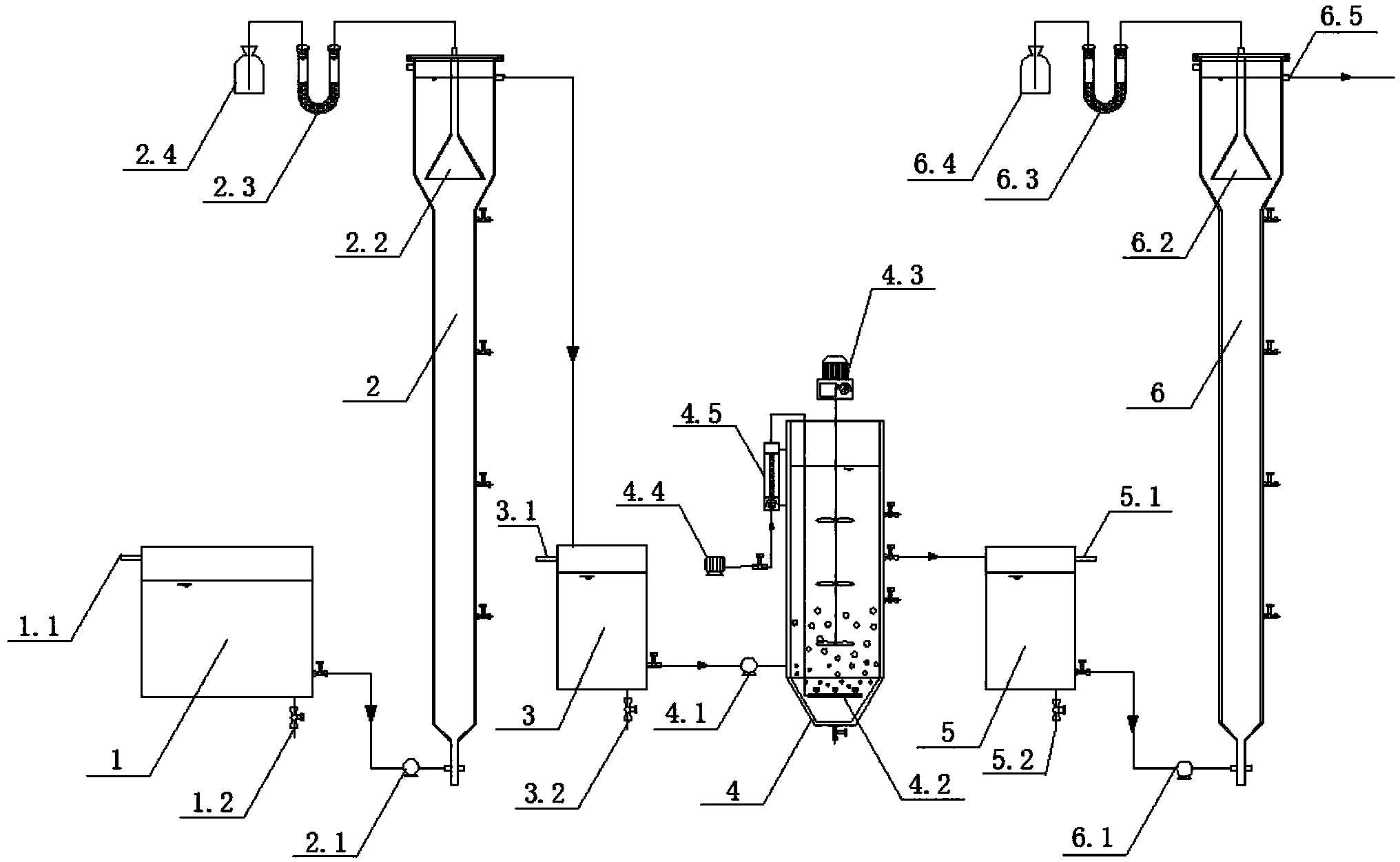

Energy recovery-based landfill leachate autotrophic nitrogen removal method

ActiveCN103833185AAvoid active inhibitionReduce consumptionMultistage water/sewage treatmentEnergy recoveryLow oxygen

The invention discloses an energy recovery-based landfill leachate autotrophic nitrogen removal method belonging to the field of sewage treatment. A device mainly comprises three parts of respectively an anaerobic methane-generating reactor, a partial nitrification reactor and an anaerobic ammonia oxidation reactor, wherein landfill leachate firstly enters the anaerobic methane-generating reactor, anaerobic methanogens can convert organic matters in the landfill leachate into an energy gas methane and the energy gas methane is recovered, then the water quantity is adjusted through a middle water tank, the landfill leachate enters the partial nitrification reactor, and the partial nitrification reactor runs in a low-oxygen aeration manner, and a partial nitrification process is realized through controlling the aeration time; and finally, after the water quantity is adjusted through the middle water tank, the landfill leachate enters the anaerobic ammonia oxidation reactor, and an autotrophic nitrogen removal process of the landfill leachate is completed under the assistance of anaerobic ammonium oxidation bacteria. According to the energy recovery-based landfill leachate autotrophic nitrogen removal method, energy resources in the landfill leachate can be fully recovered, and the operation cost and the energy consumption of treating the landfill leachate are reduced.

Owner:BEIJING UNIV OF TECH

Method for extracting landfill gas

An apparatus and method to internally provide apertures inside polyvinyl chloride (PVC), high density polyethylene (HDPE), or any polymeric pie, plastic pipe-riser (blank casing) in existing landfill gas recovery wells (extraction wells) that have been installed at Municipal Solid Waste Facilities are described. By creating additional apertures in landfill gas recovery well risers, landfill gas derived from the decomposition of waste is allowed to enter the existing riser and extraction / recovery system. This process saves time and cost associated with drilling additional wells to capture landfill gas from subsequent layers of the waste body. The process assists in maintaining regulatory compliance by capturing landfill gas and preventing it from being emitted into the atmosphere.

Owner:STAMOULIS STEFAN

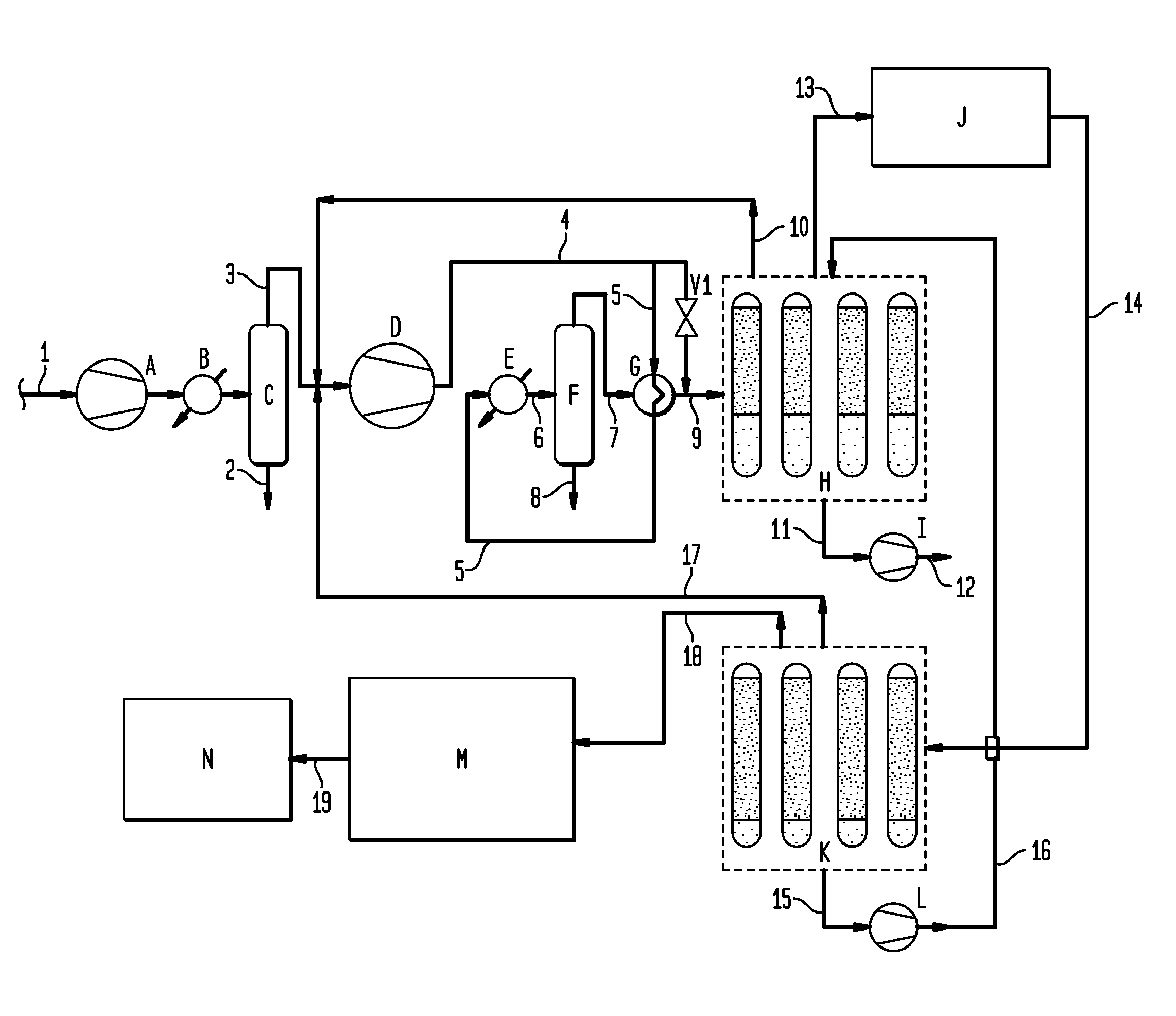

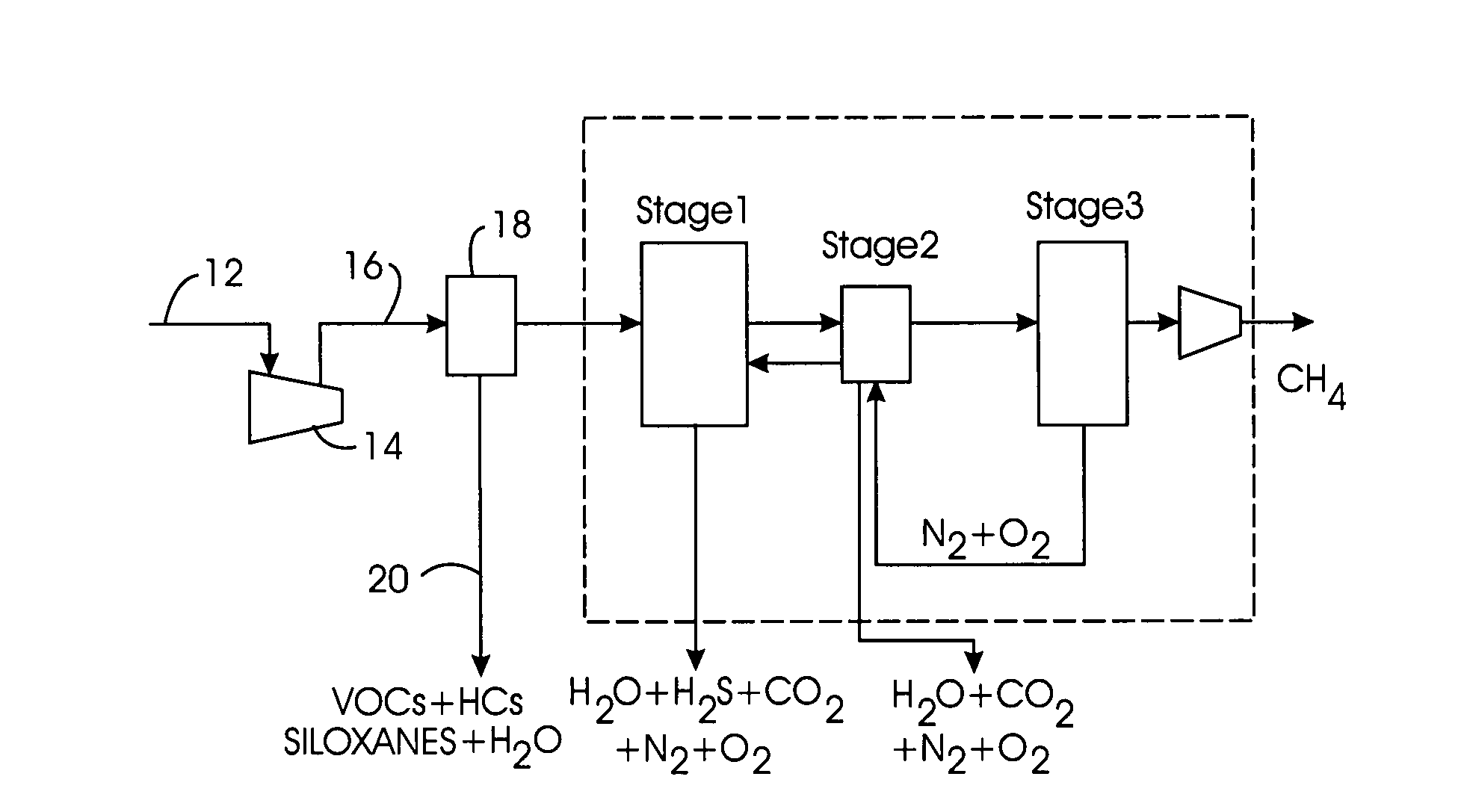

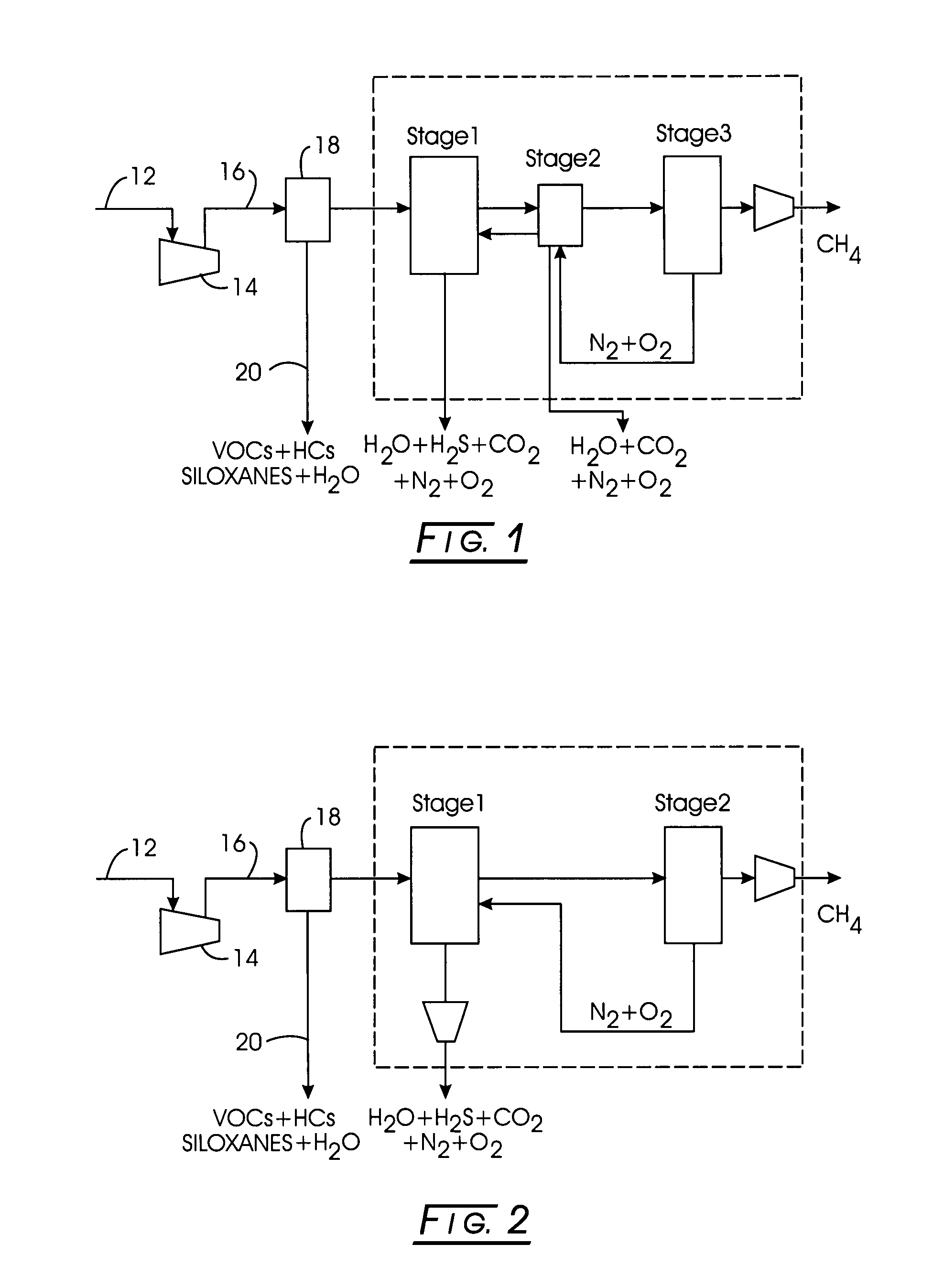

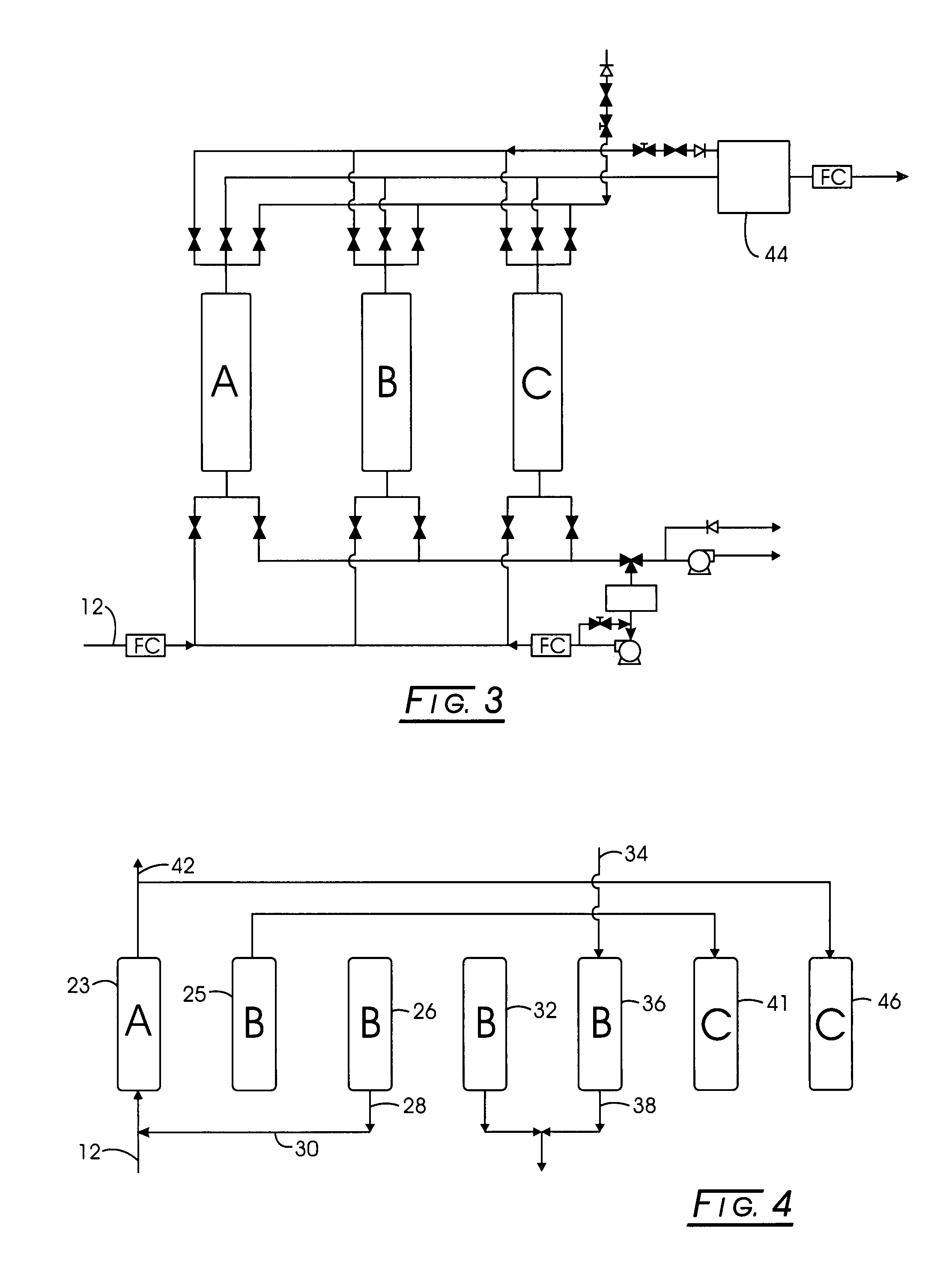

Multi-stage adsorption system for gas mixture separation

ActiveUS8211211B1Safer and more cost-effectiveAvoid problemsHydrogenGas treatmentThree stageProduct gas

Methane product gas is produced from landfill gas and gob gas either by a three-stage process of PSA-TSA-PSA or PSA-PSA-PSA, or a two-stage process of PSA-PSA.

Owner:KENT S KNAEBAL & ASSOC

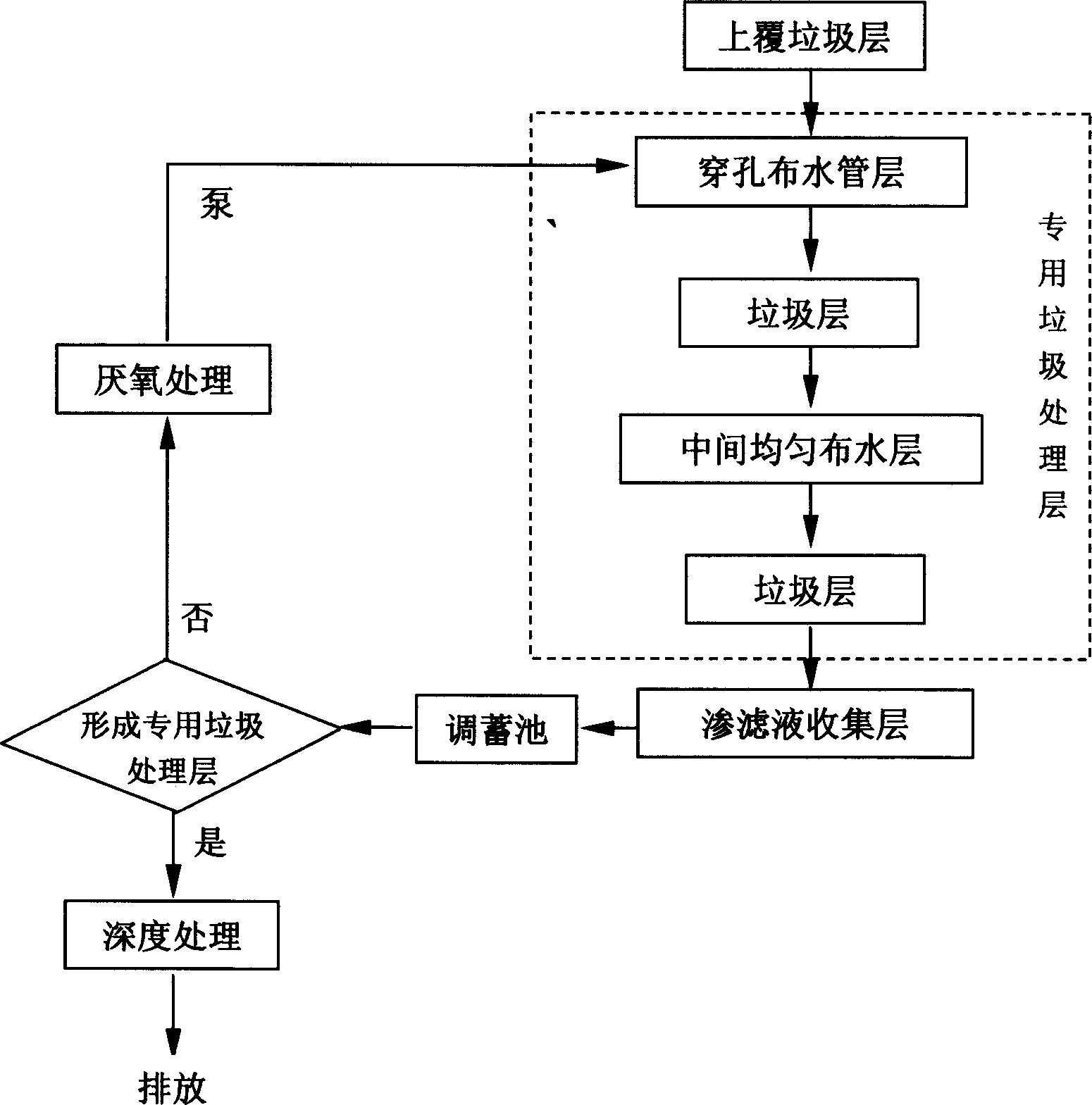

Treatment method for infiltration liquid in domestic refuse burying field

The present invention is in-situ percolate treating process in life garbage landfill. Special garbage treating layer to generate methane is first obtained with biological treating apparatus outside the landfill; and the garbage treating layer with anaerobic microbe, middle water distributing layer and surface water distributing layer is utilized for percolate to contact homogeneously with the anaerobic microbe to convert organic pollutant in percolate into landfill gas capable of being further utilized. The present invention has homogeneous flow of percolate, stable and high percolate treating effect, low power consumption and low cost, and may be used in various kinds of garbage landfill to treat and utilize percolate.

Owner:TONGJI UNIV

Preparation and application of municipal dewatering sludge based coating material for seal of landfill site

ActiveCN102690085AWide variety of sourcesRealize resource utilizationSludge treatmentSolid waste disposalVegetationLand resources

The present invention relates to preparation of a municipal dewatering sludge based coating material for seal of landfill site, is mainly used for seal covering of the landfill site, and belongs to the field of environmental geotechnical engineering. The municipal dewatering sludge is employed as a basis material and modified to be used in seal covering of the landfill site. An air-out layer of the coating material for seal of landfill site has good gas guide performance; an impervious layer is not easily cracking and has low permeability; and a vegetation nutrient layer has rich nutrients and good hydrophobicity. The covering material of the present invention realizes resource utilization of municipal dewatering sludge and saves land resource; the covering material can be produced by industrialized production, has a simple construction for application to seal covering of the landfill site, and has advantages of simpleness, fastness, strong operability, high survival ratio of plants, so as to guarantee quality of seal covering of the landfill site, meet various technological indexes of seal of the landfill site, and greatly improve the landfill environment.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

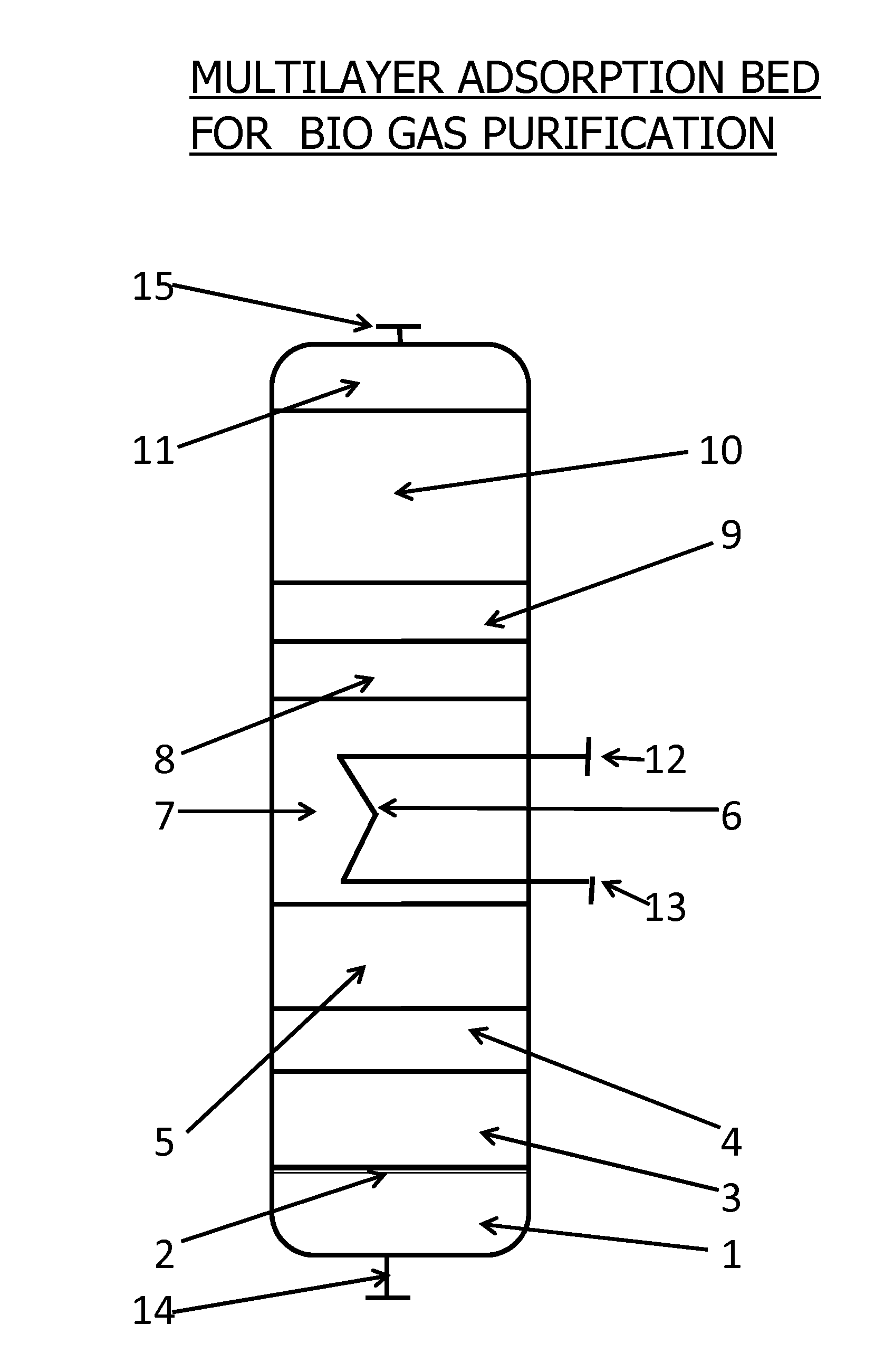

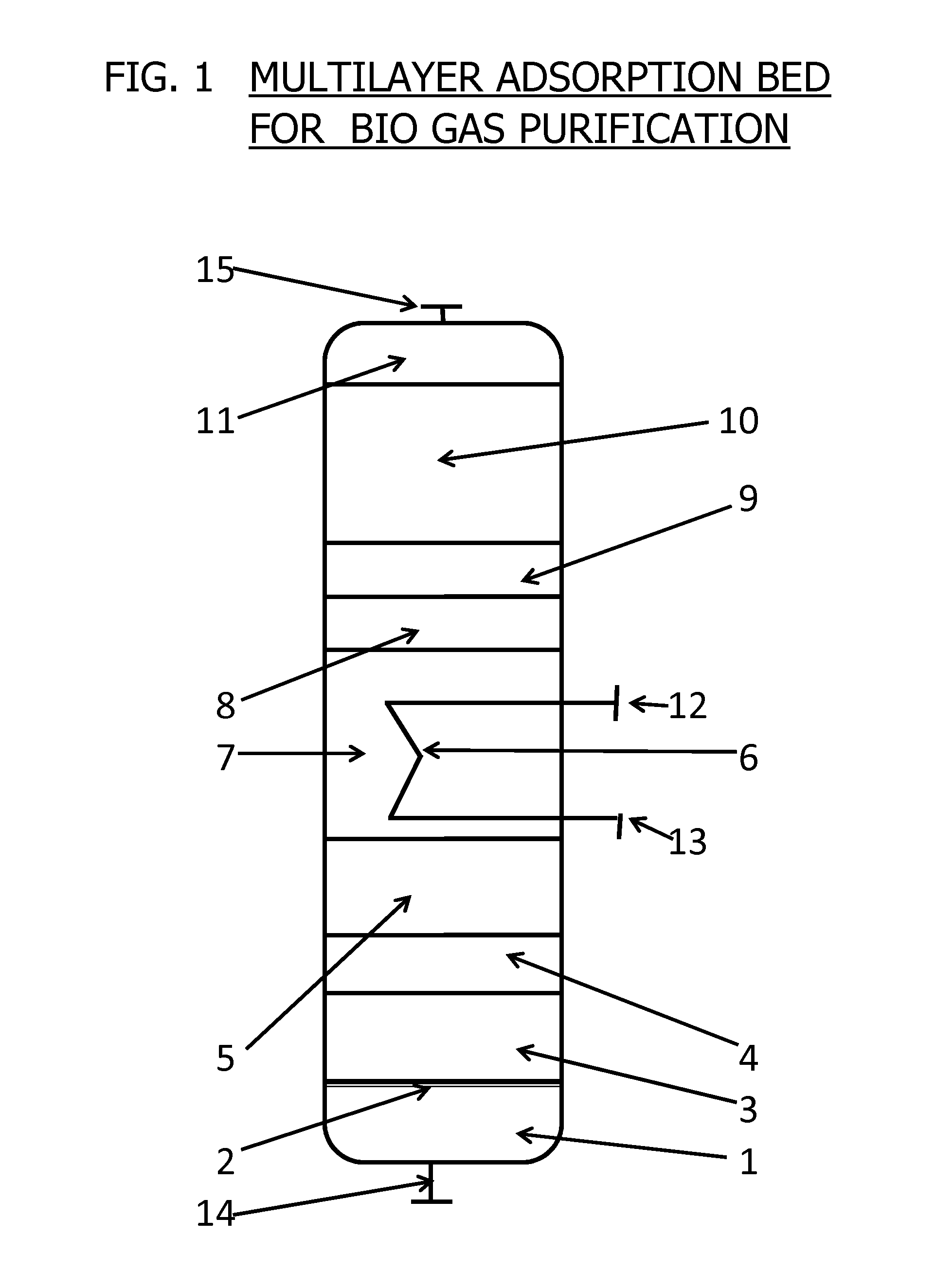

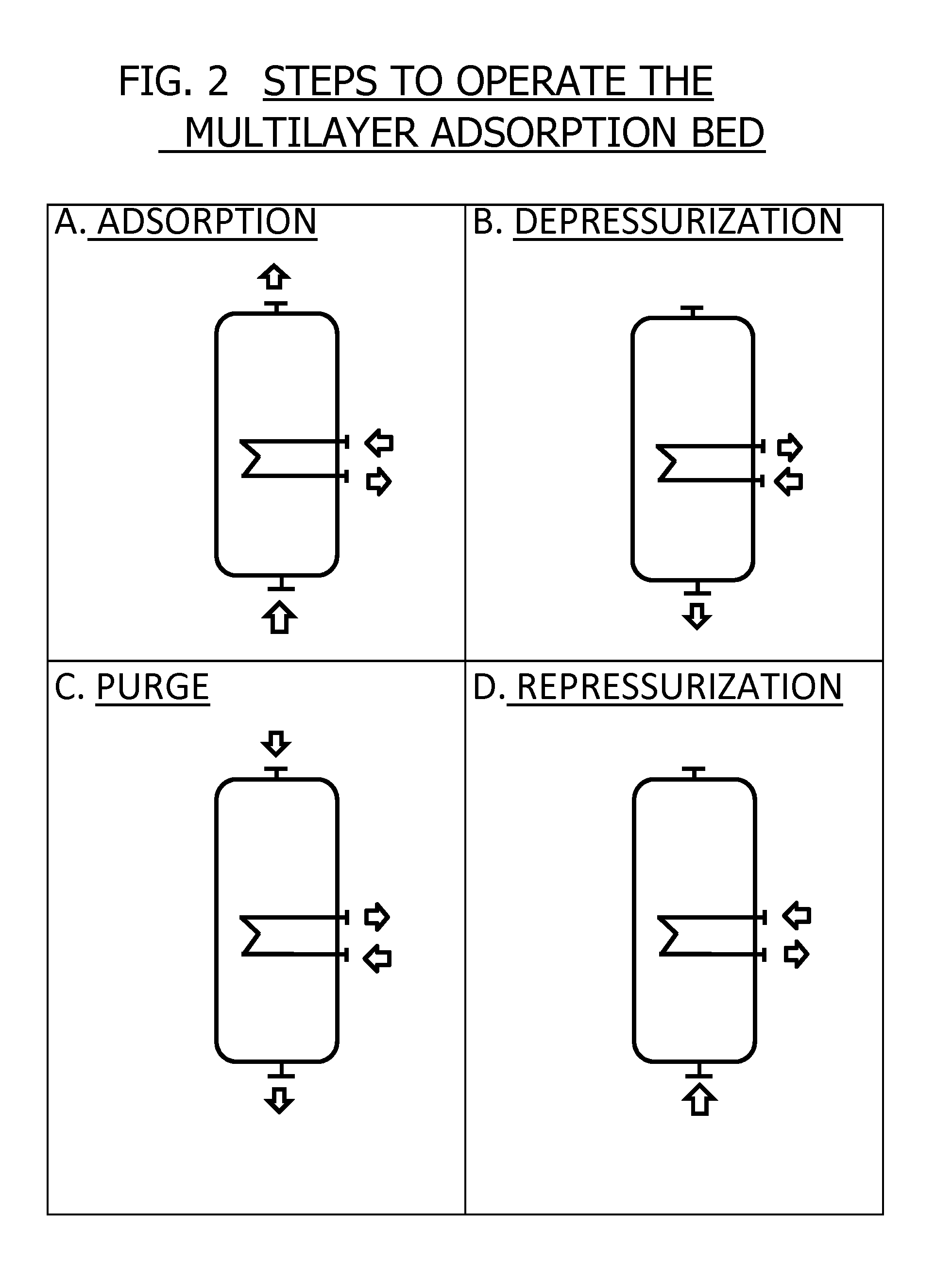

Method to clean impurities from bio-gas using adsorption

The present invention provides for a method to make a multiple layered adsorber bed to adsorb and remove water, siloxanes, hydrogen sulfide, mercaptans, and carbon-dioxide from Biogas sources such as landfill gas. This bed can be operated by a pressure swing or vacuum swing adsorption process.

Owner:ADSORPTECH

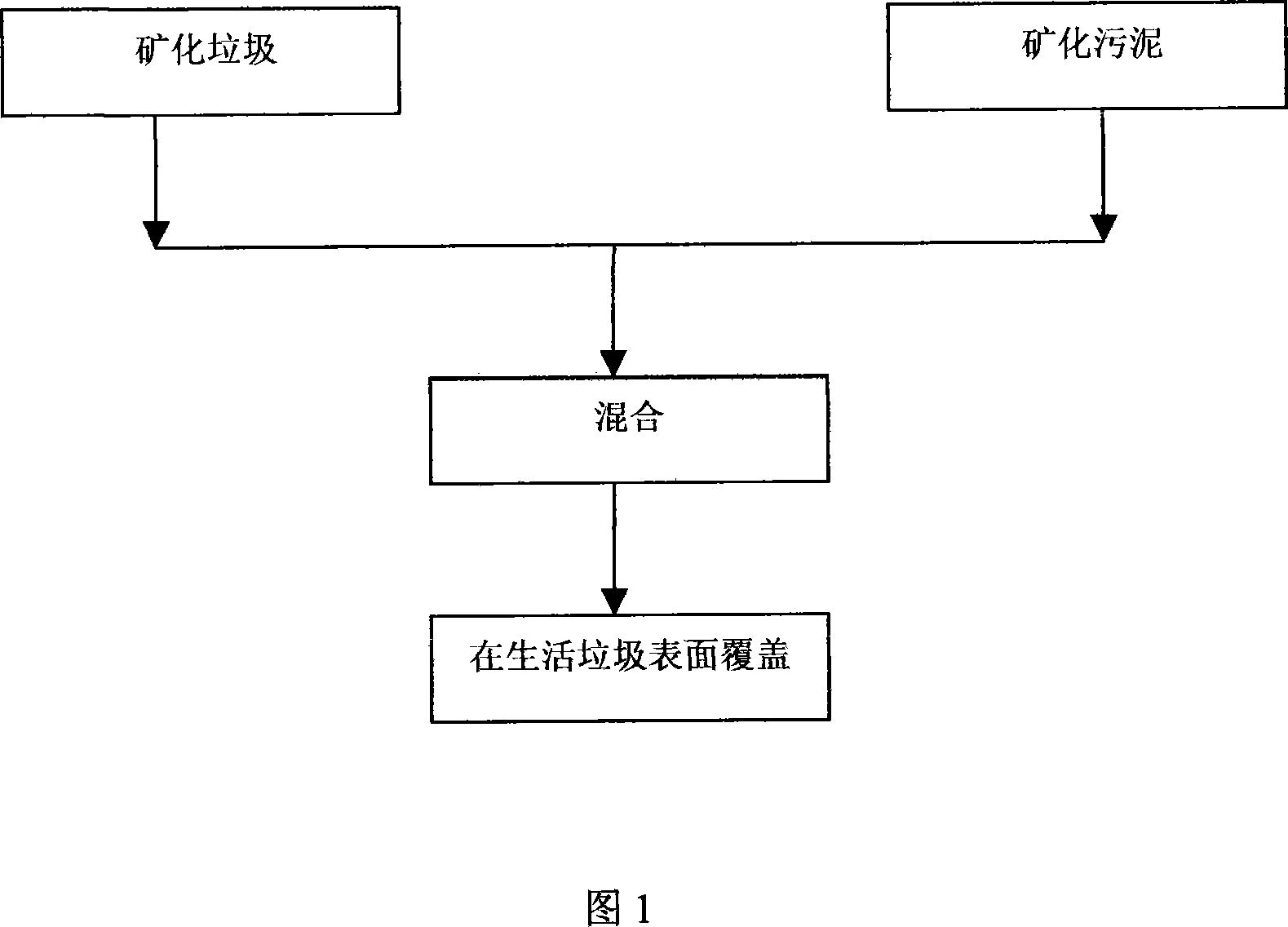

Methane oxidation covering material for life refuse landfill

InactiveCN101062848AAchieve emission reductionReduce manufacturing costSolid waste managementOther chemical processesSocial benefitsSludge

The invention discloses a methane-oxidizing covering material of landfill life waste site, which comprises the following steps: allocating mass percent (dry group) of mineralizing garbage and mineralizing sludge as 20-100% : 0-80%; choosing the mineralizing garbage with grain size at 0. 5mm-4cm and buried above 8 years; choosing the mineralizing sludge with moisture percentage at 50%-70% sludge and buried above 5 years. This invention possesses explicit social benefit and economic benefit and low cost, which can be fit for landfill life waste site widely.

Owner:TONGJI UNIV

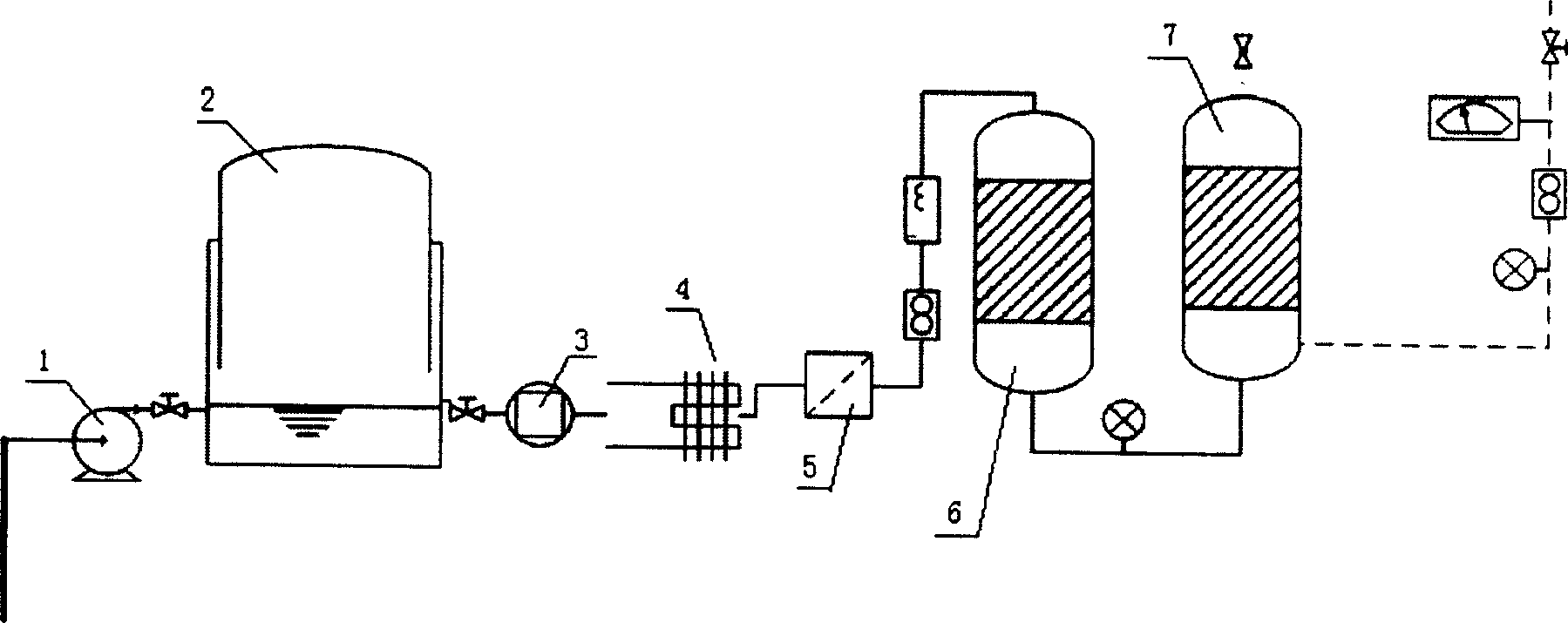

Production and apparatus for producing methane from refuse embedded gas

ActiveCN1680222ASimple and fast operationLess investmentSolid waste disposalAdsorption purification/separationCompressed natural gasFreeze-drying

Production of methane from land-filled garbage gas and its apparatus are disclosed. It is carried out by pressing the abstracted land-filled garbage gas, freezing drying, multi-stage filtering, pretreatment process of adsorption drying, high-pressure adsorbing, co-current pressure equalizing, constant-pressure recovering, and pressure varied adsorption circulating. The apparatus consists of compressors connected orderly, freezing direr, filter, drying tower and pressure varied adsorption circulating system with 2-6 parallel adsorbing columns. Its advantages include simple apparatus and operation, low cost and good flexibility.

Owner:TSINGHUA UNIV

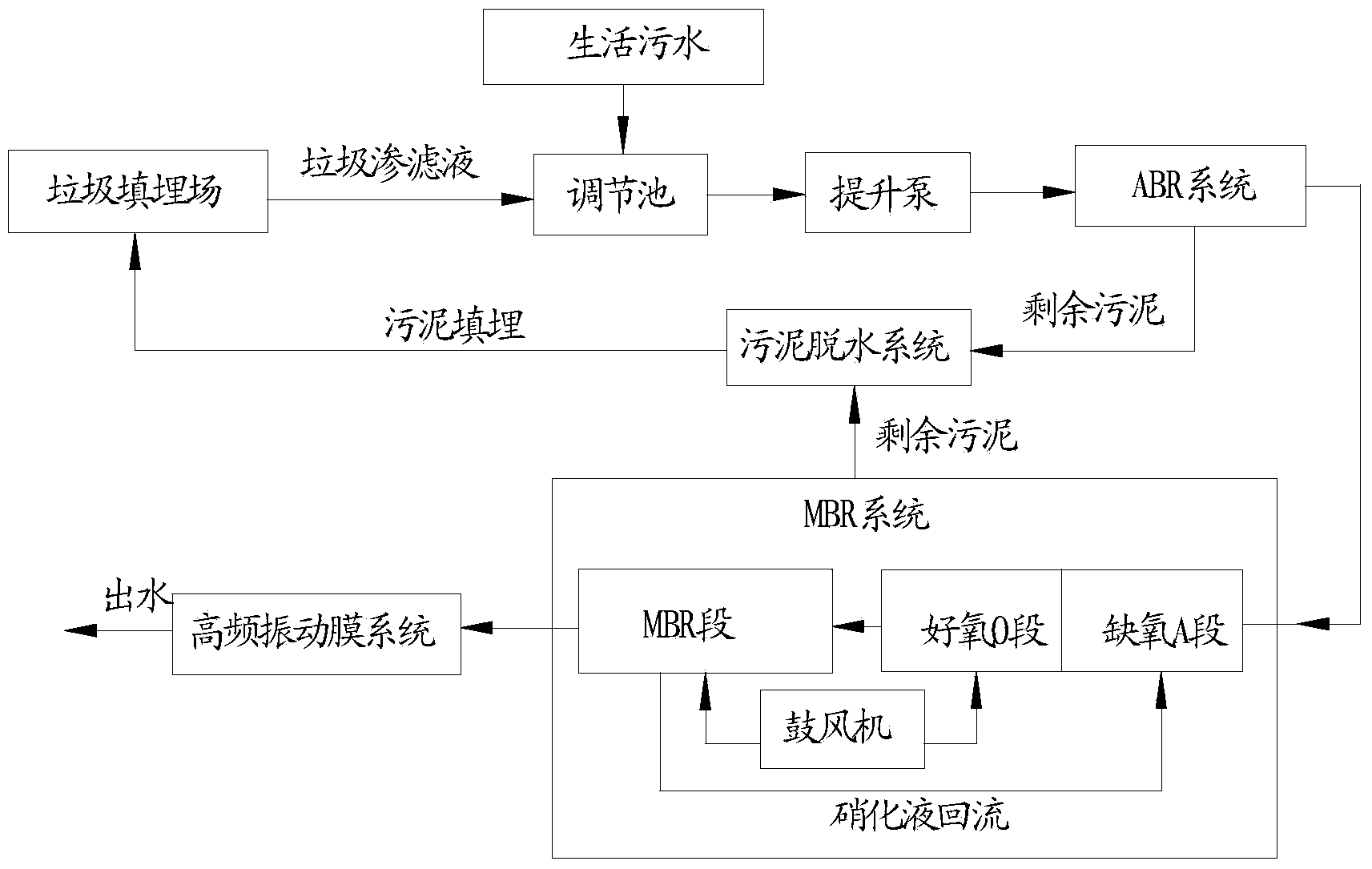

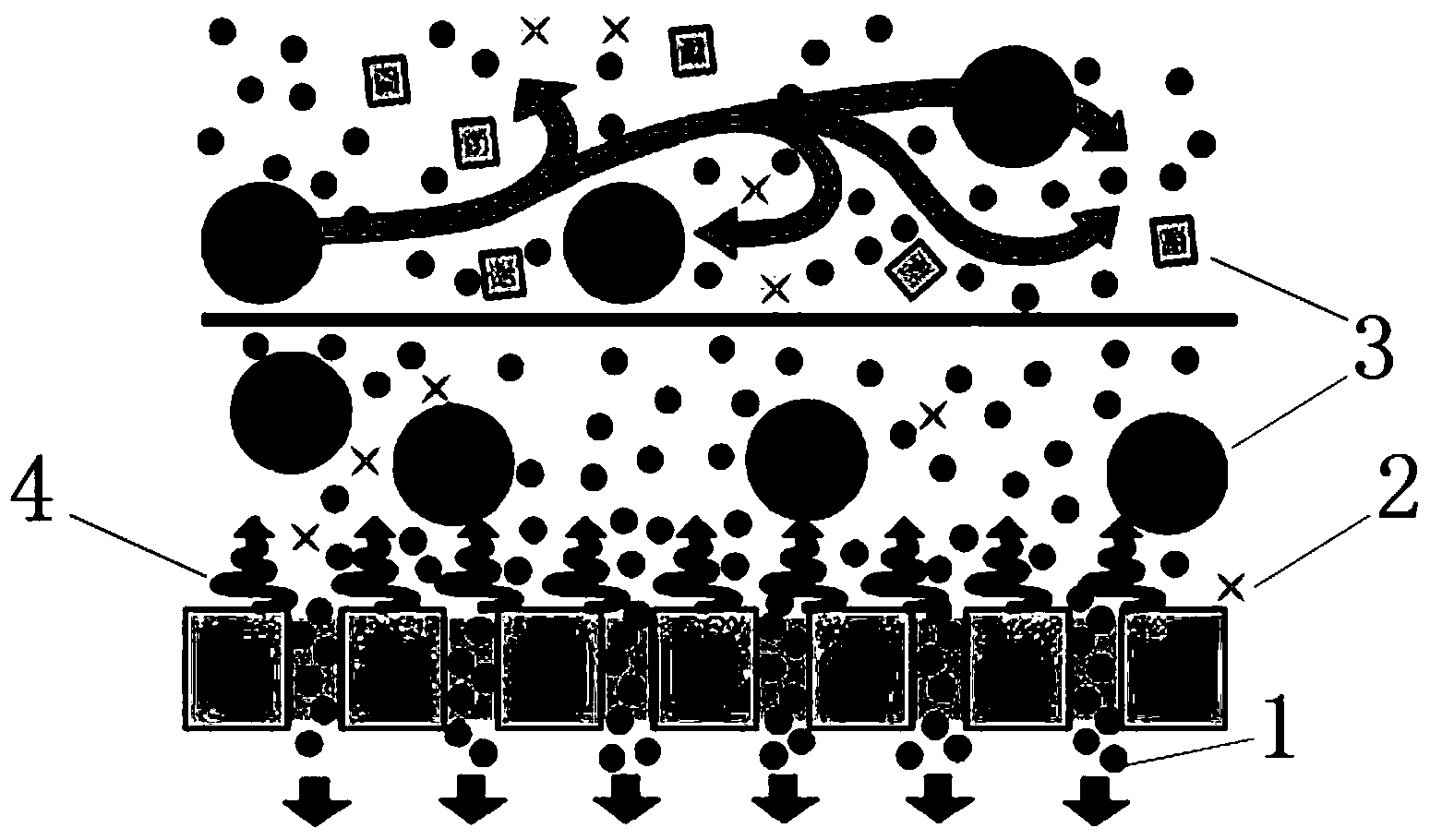

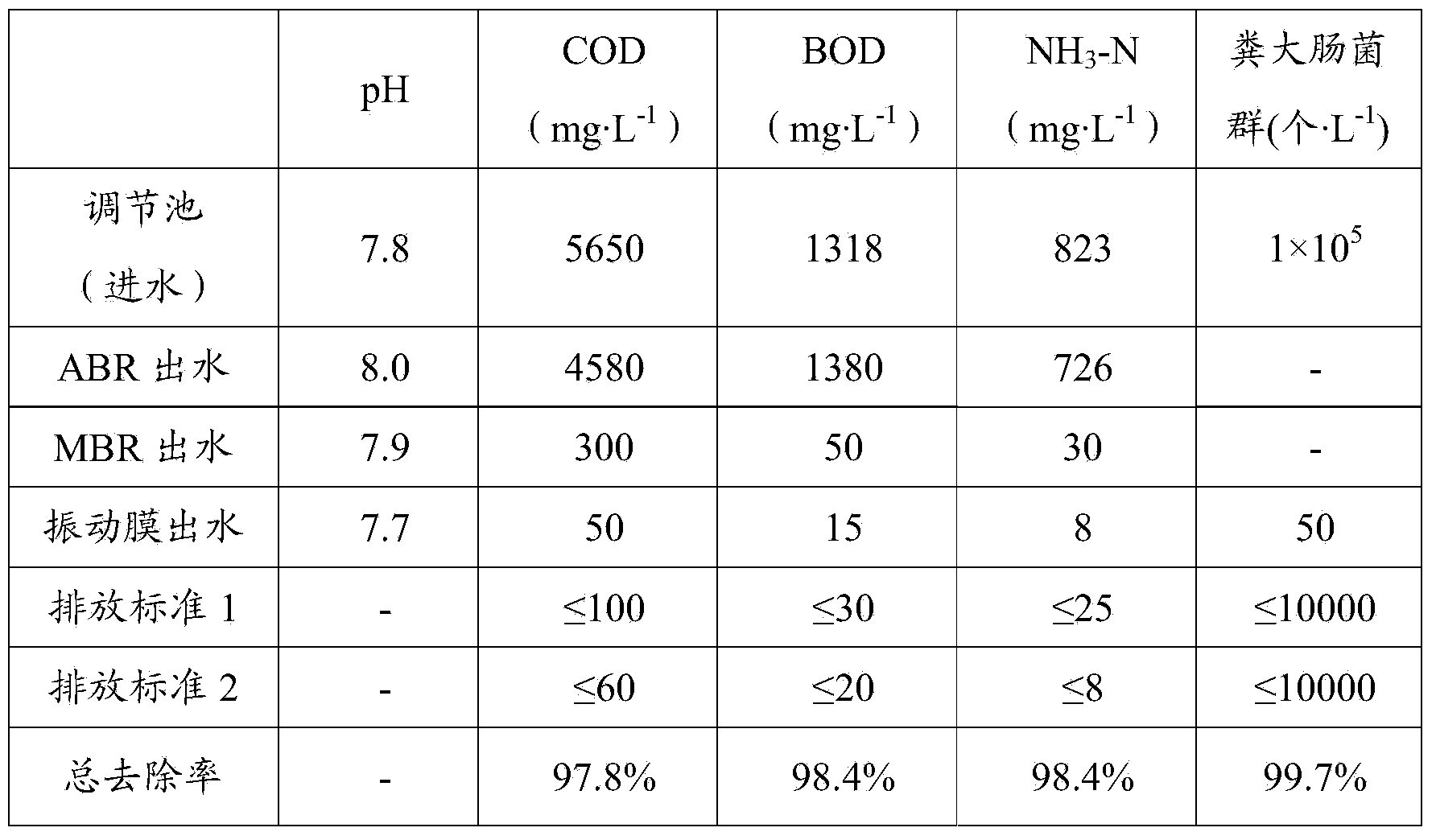

Landfill leachate treatment method based on high-frequency vibration membrane

ActiveCN103708675AEasy to handleImprove denitrification effectMultistage water/sewage treatmentWater qualityAnaerobic reactor

The invention discloses a landfill leachate treatment method based on a high-frequency vibration membrane. The landfill leachate treatment method comprises the following steps: (1) regulating water flow, balancing water quality and precipitating a part of SS for landfill leachate through a regulating tank; (2) feeding sewage into a zigzag anaerobic reactor for treatment; (3) sequentially feeding the sewage into an anoxic tank for denitrification treatment, and an aerobic tank for nitrification treatment; and feeding the sewage into an MBR (Membrane Bio-reactor) for intercepting sludge, bacteria and organic matter; and (4) feeding the sewage into a high-frequency vibration membrane system for deep treatment; filtering the sewage by using a hollow filter membrane assembly, and controlling amplitude of vibration to be 0.1-4cm, and vibration frequency to be 10-60Hz by using a high-frequency vibration driving system. The landfill leachate treatment method disclosed by the invention is stable and reliable in operation and good in effluent quality, COD (Chemical Oxygen Demand) is less than or equal to 60mg / L, BOD (Biochemical Oxygen Demand) 5 is less than or equal to 20mg / L, chromaticity is less than or equal to 30 times, meanwhile the landfill leachate treatment method also solves the problems that the membrane is easy to jam, and high in replacement frequency.

Owner:GUANGDONG PROVINCIAL ACADEMY OF ENVIRONMENTAL SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com