Portable gas monitor

a gas monitor and portable technology, applied in the field of portable gas monitors, can solve the problems of one or more components of the prior art portable monitors being prone to sluggishness and even failure, and the portable monitors are not designed to be parts,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

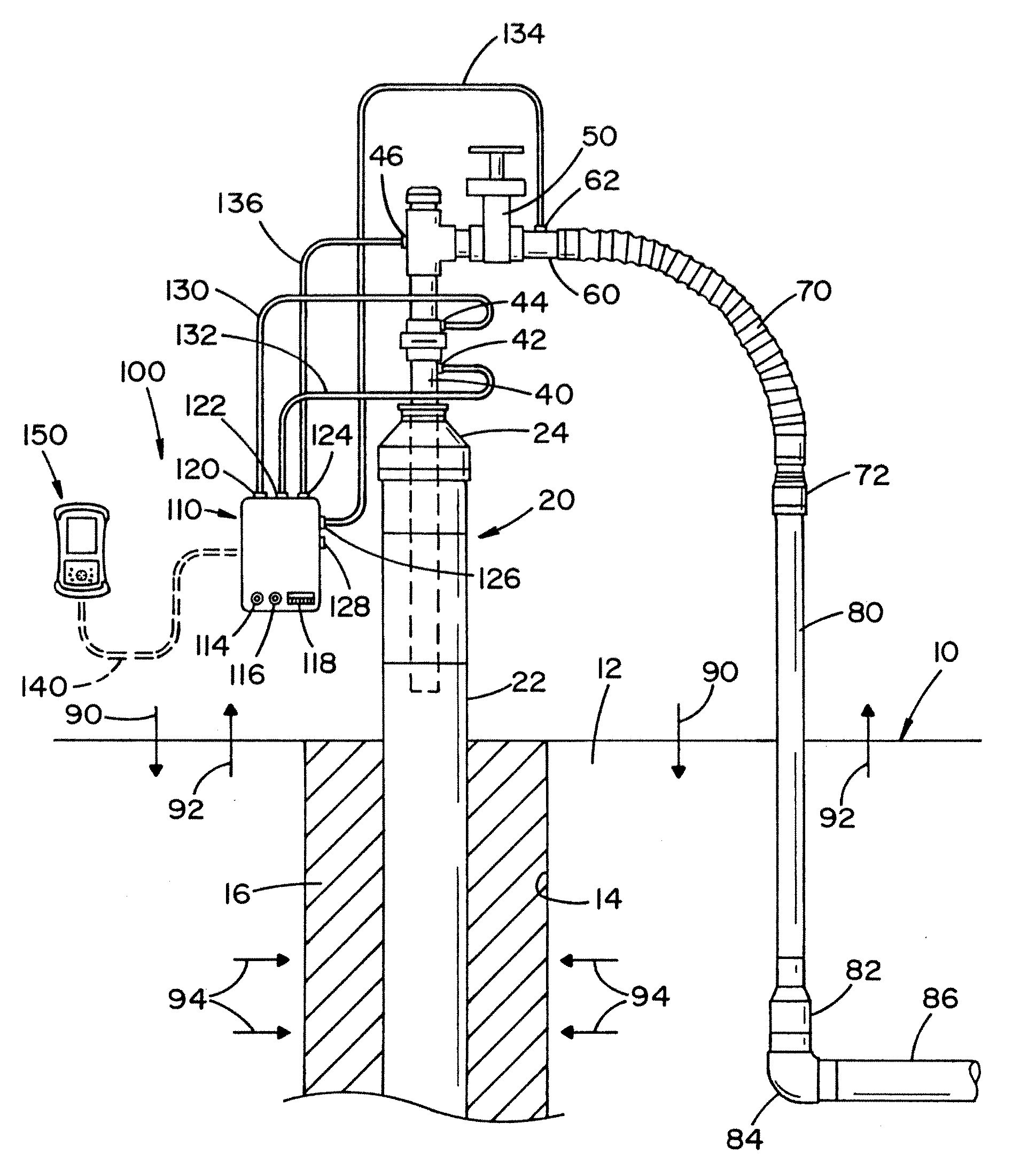

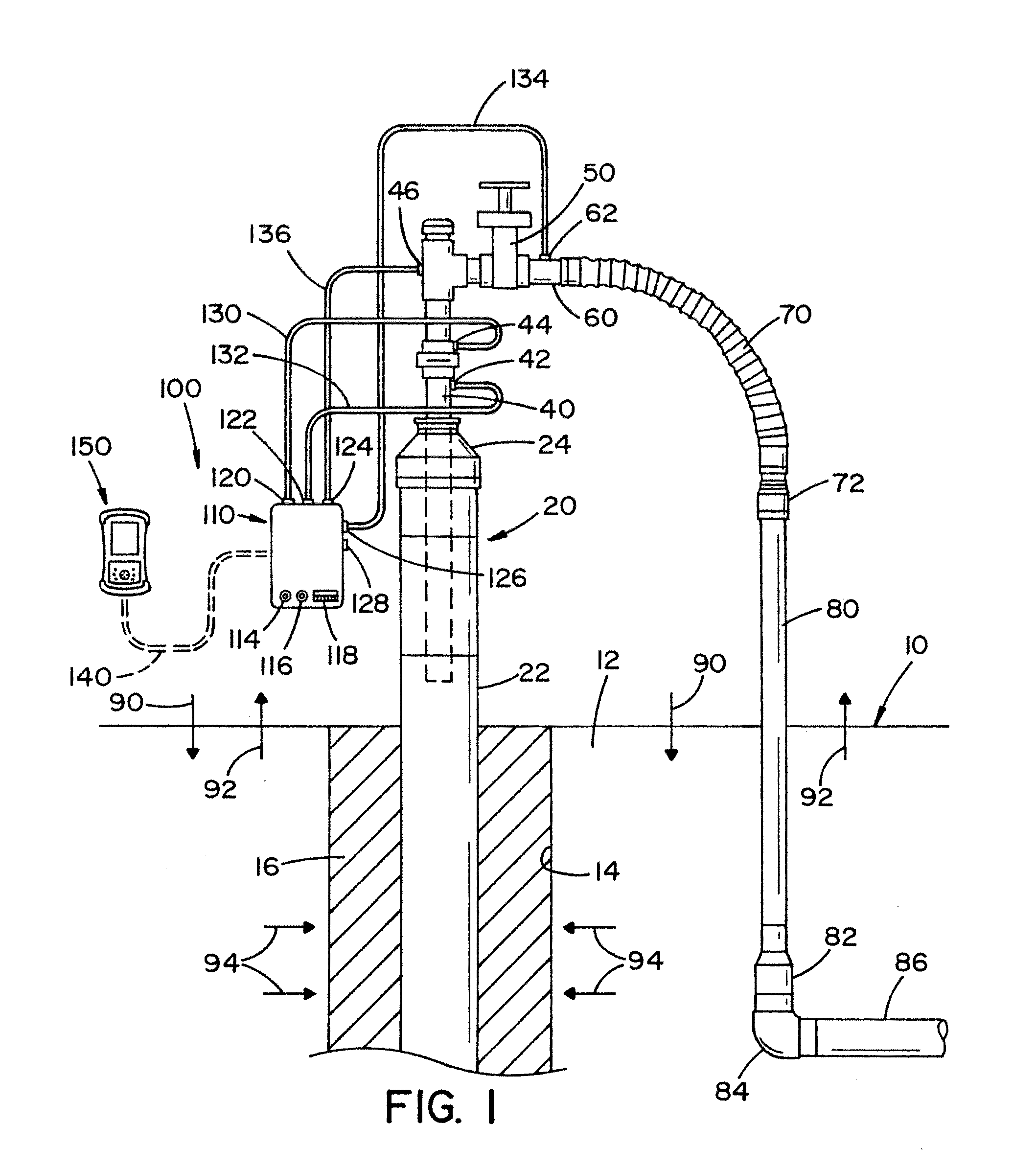

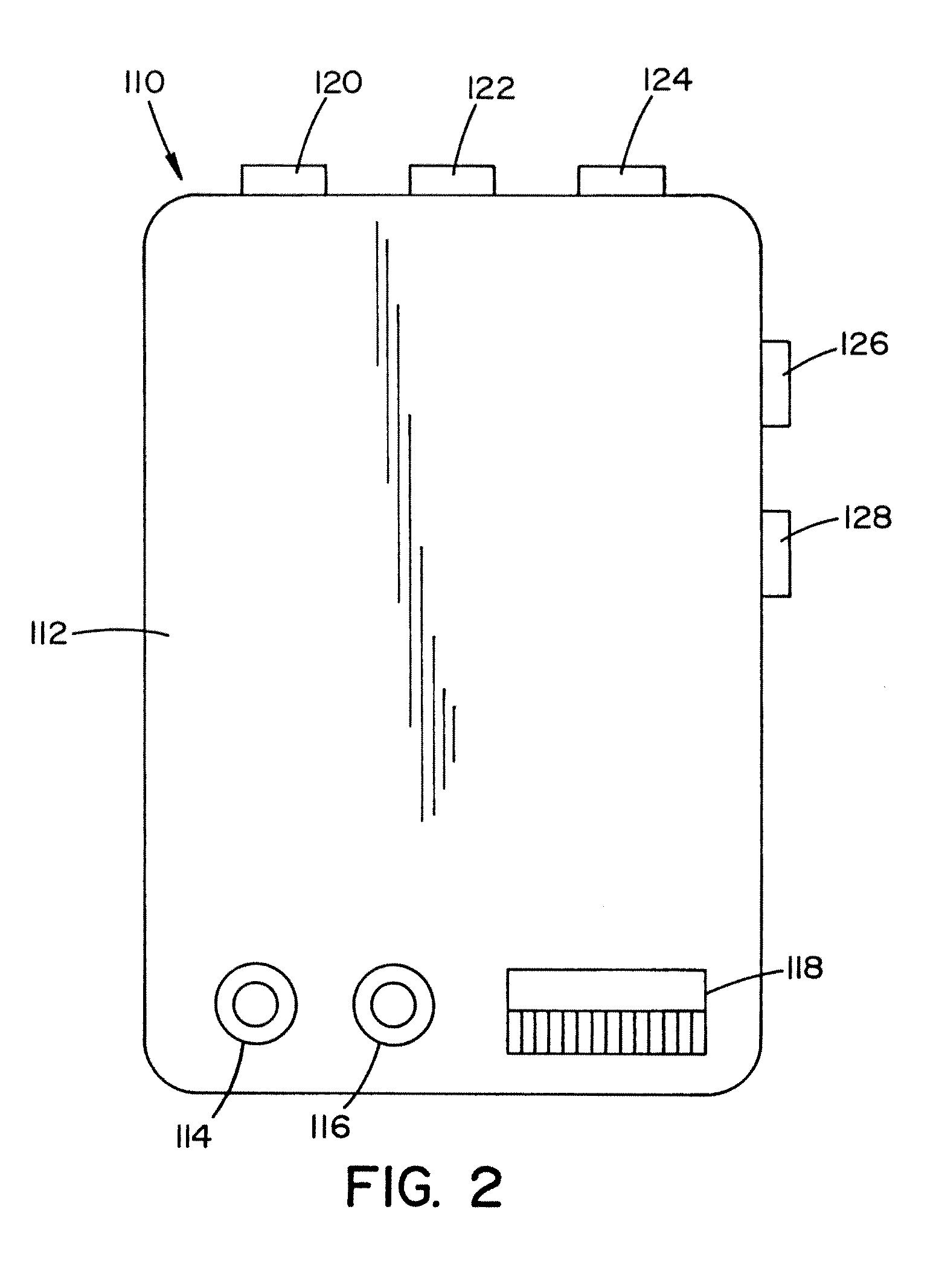

[0043]The solid waste and environmental industry uses field technicians to measure, monitor and store environmental information at particular industrial sites and landfill sites. When measuring gases from a landfill well, information regarding methane, carbon dioxide and oxygen is desirable to determine the environmental impact of the landfill and the potential energy from methane gas that can be obtained from the landfill. The present invention is directed to a portable monitor that can be used by field technicians to obtain gas flow rates and gas composition from landfill wells and will be described with particular reference thereto; however, it will be appreciated that the portable monitor of the present invention can be used in other or additional applications.

[0044]Referring now to the drawings wherein the showing is for the purpose of illustrating a non-limiting preferred embodiment of the invention only and not for the purpose of limiting the same, FIG. 1 illustrates a conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com