Patents

Literature

6359 results about "Automated control system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic control system. An automatic control system (ACS) sustains or improves the functioning of a controlled object. In a number of cases the auxiliary operations for the ACS—starting, stopping, monitoring, adjusting, and so on—can also be automated.

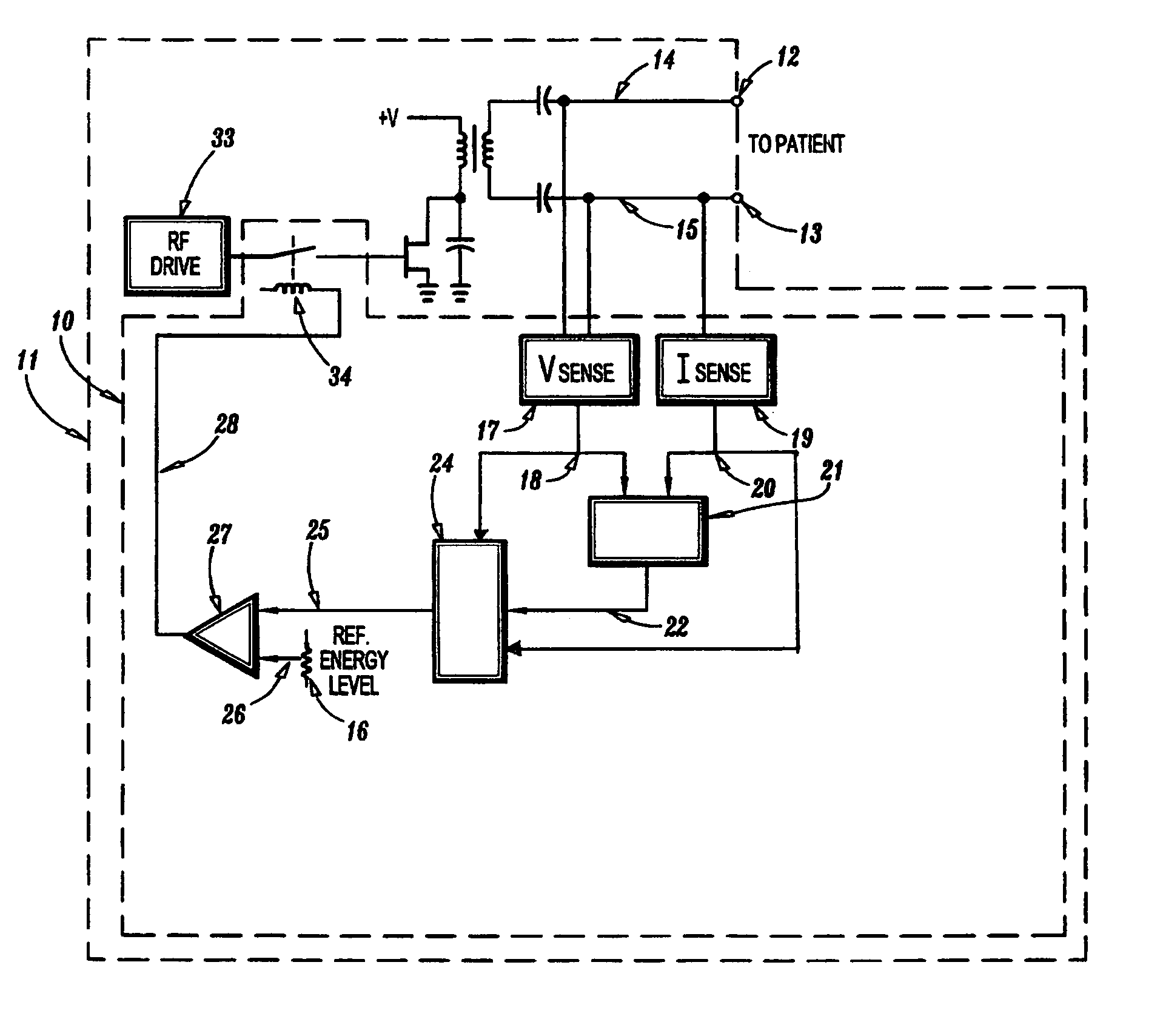

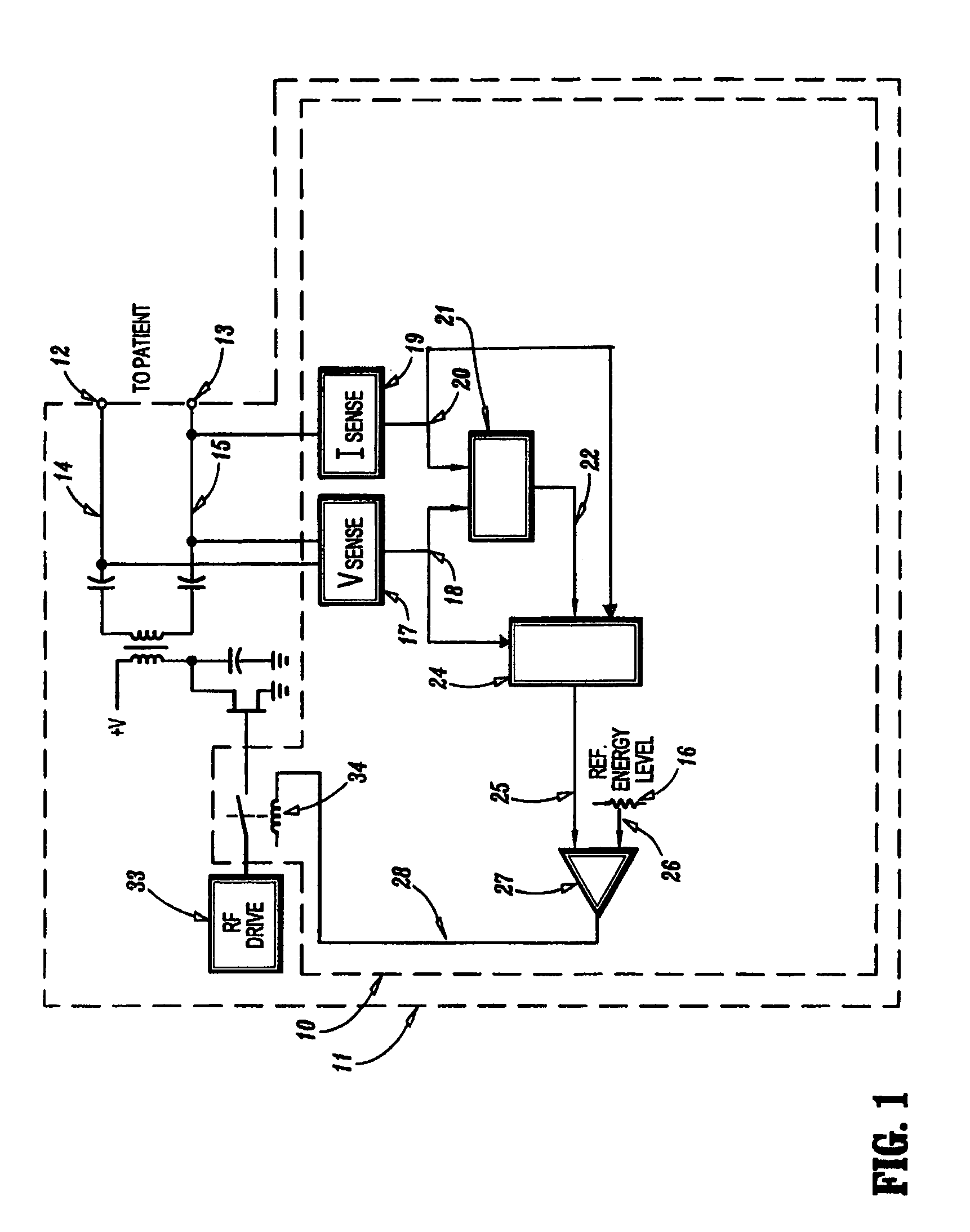

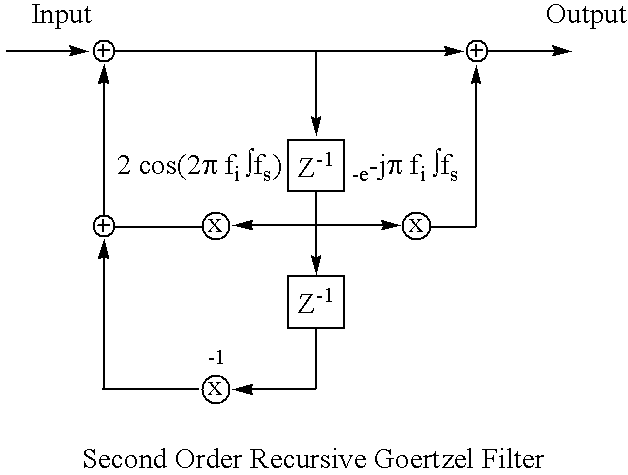

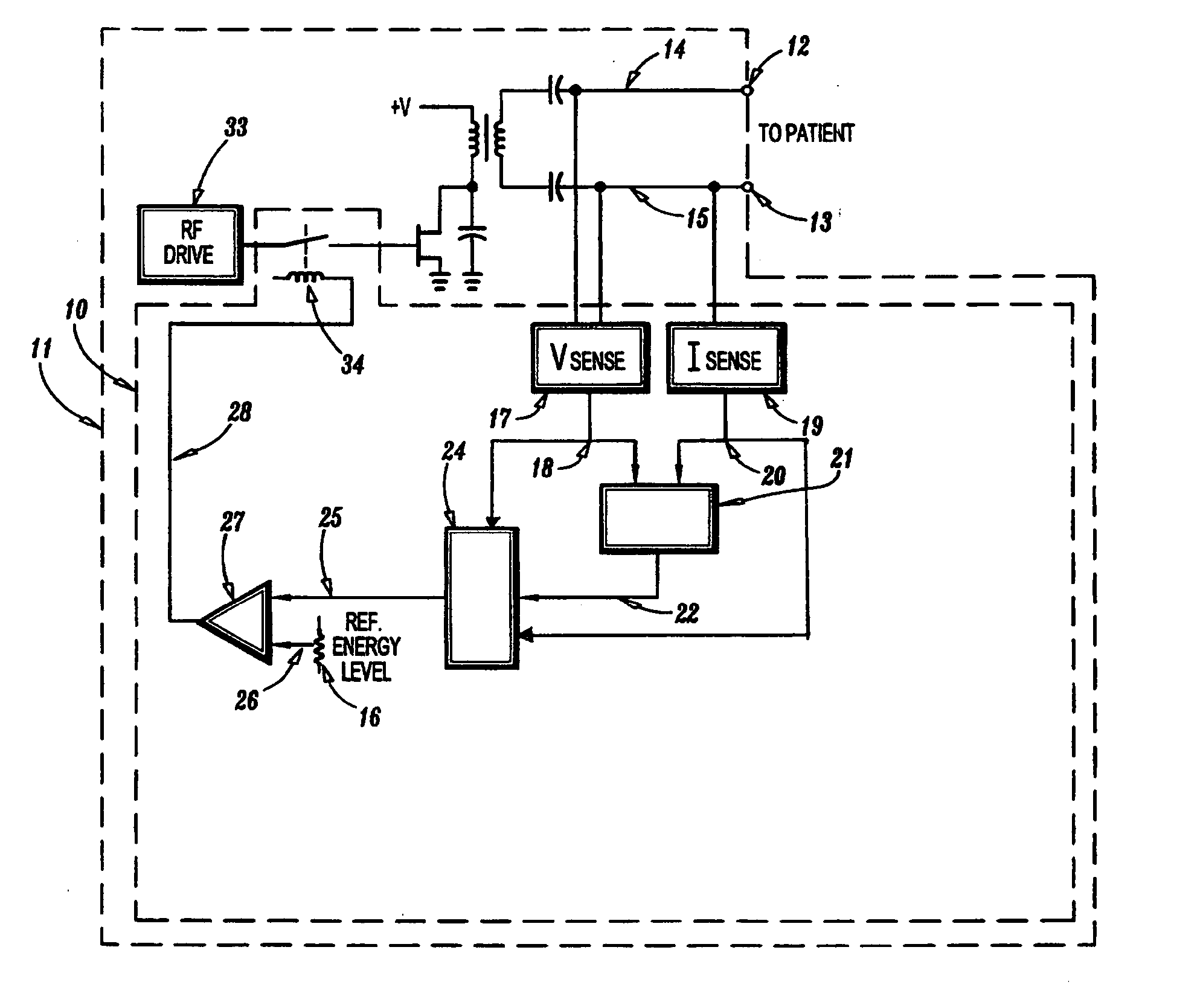

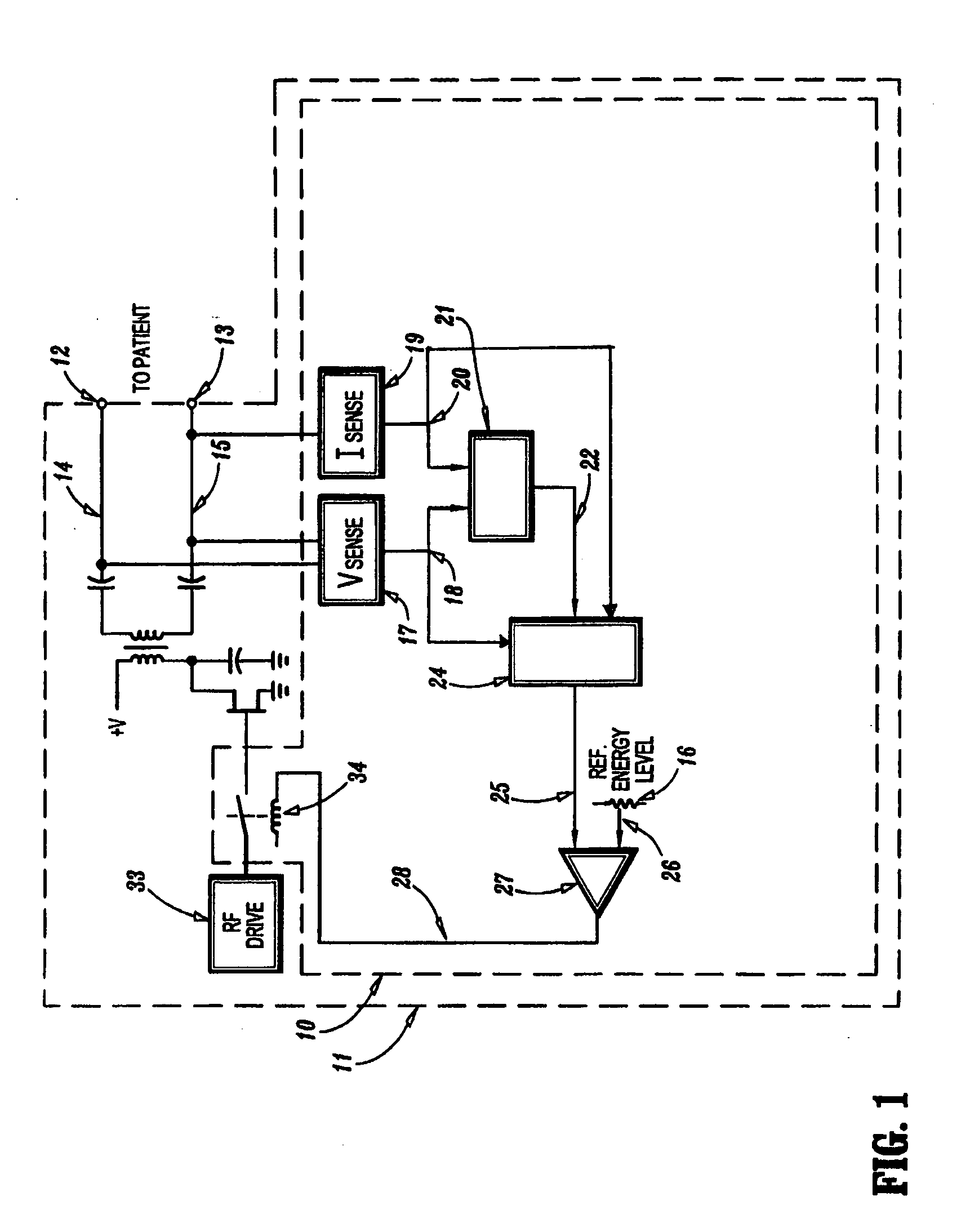

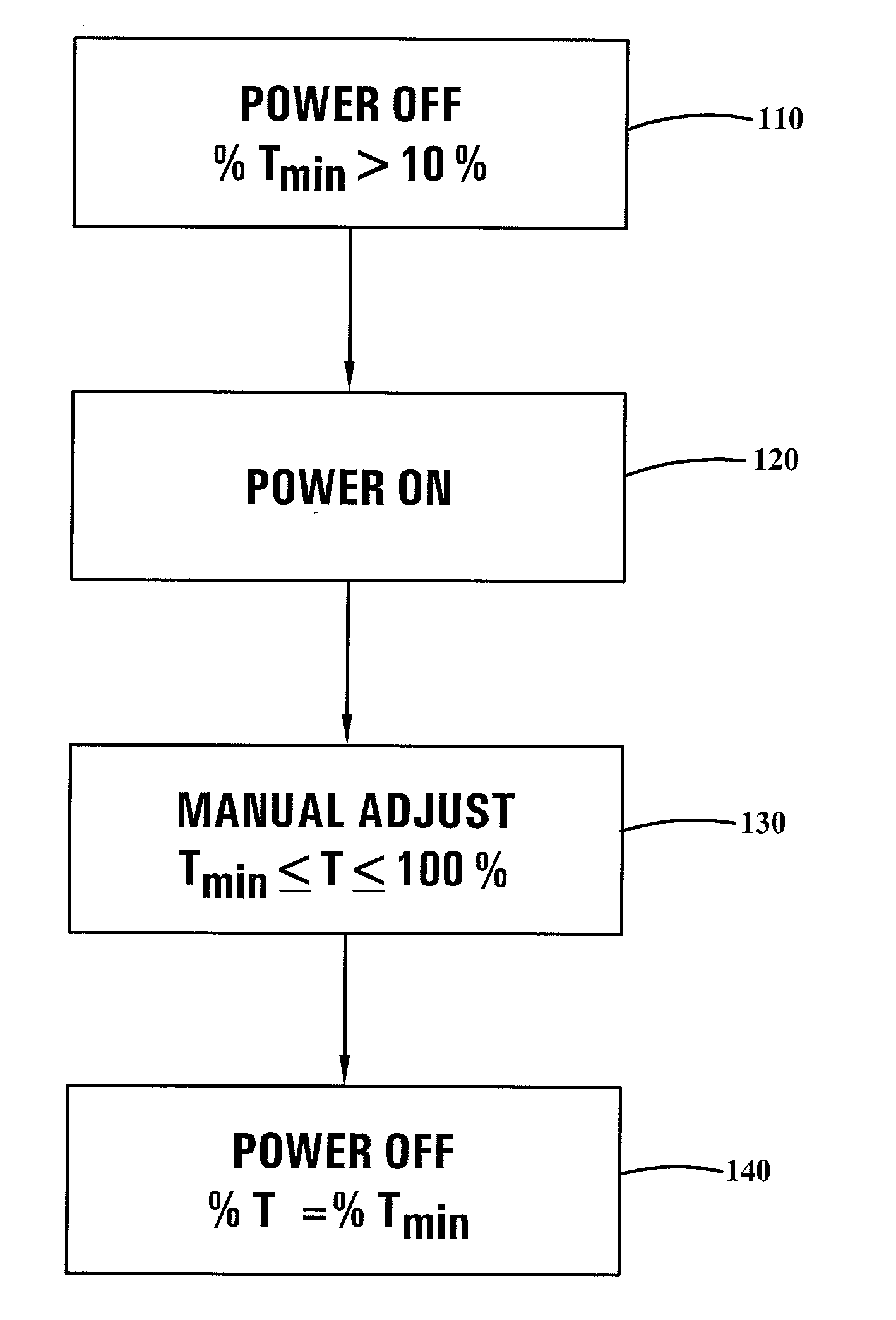

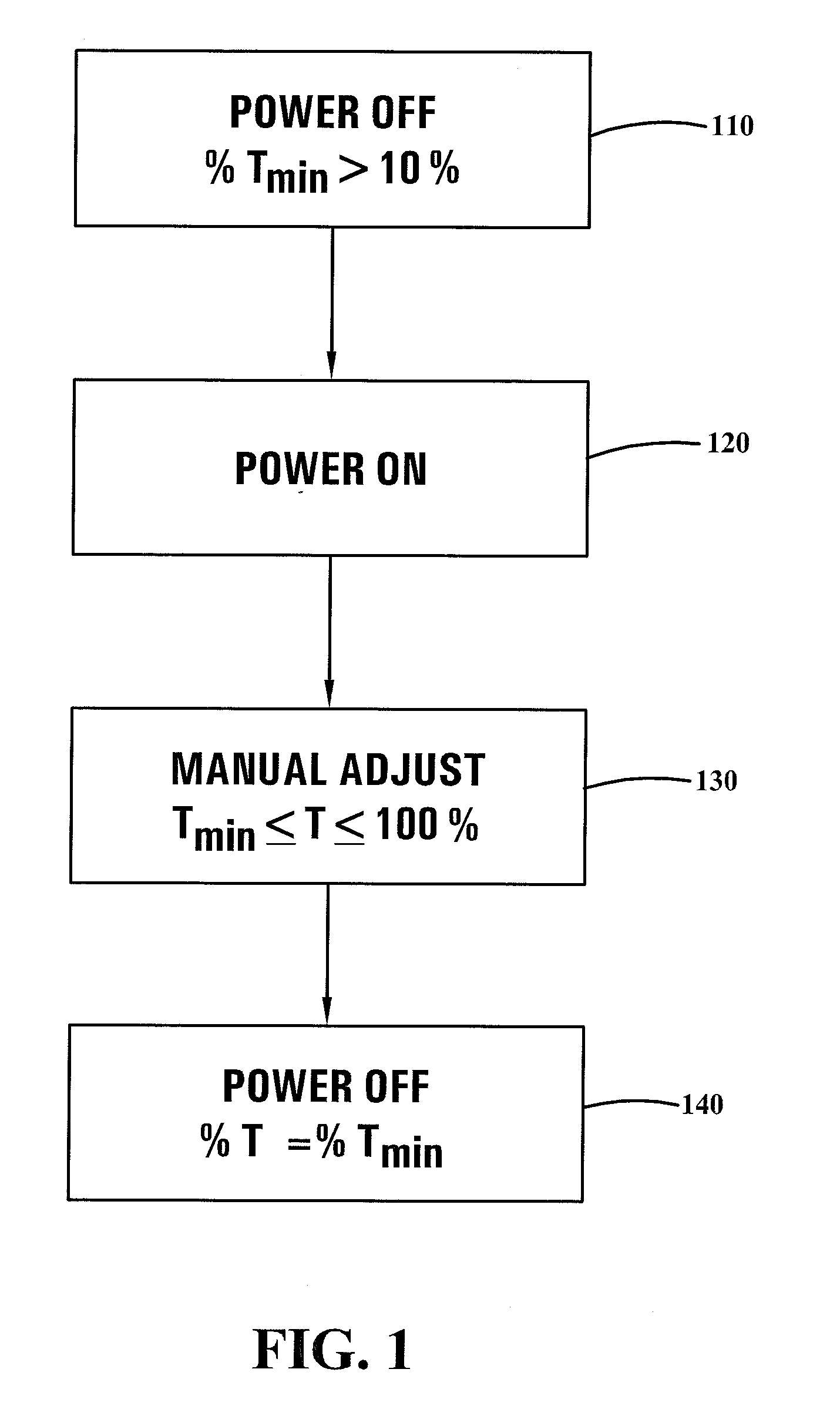

Automatic control system for an electrosurgical generator

An automatic control system for an electrosurgical generator is herein disclosed. The automatic control system includes voltage and current sensing circuits, a processing circuit, an output determining circuit, and a control circuit. Samples of the voltage and current outputs are supplied to the processing circuit and the output determining circuit to generate an output signal. The output signal is compared to a reference signal to generate a feedback signal for controlling a drive circuit.

Owner:COVIDIEN AG

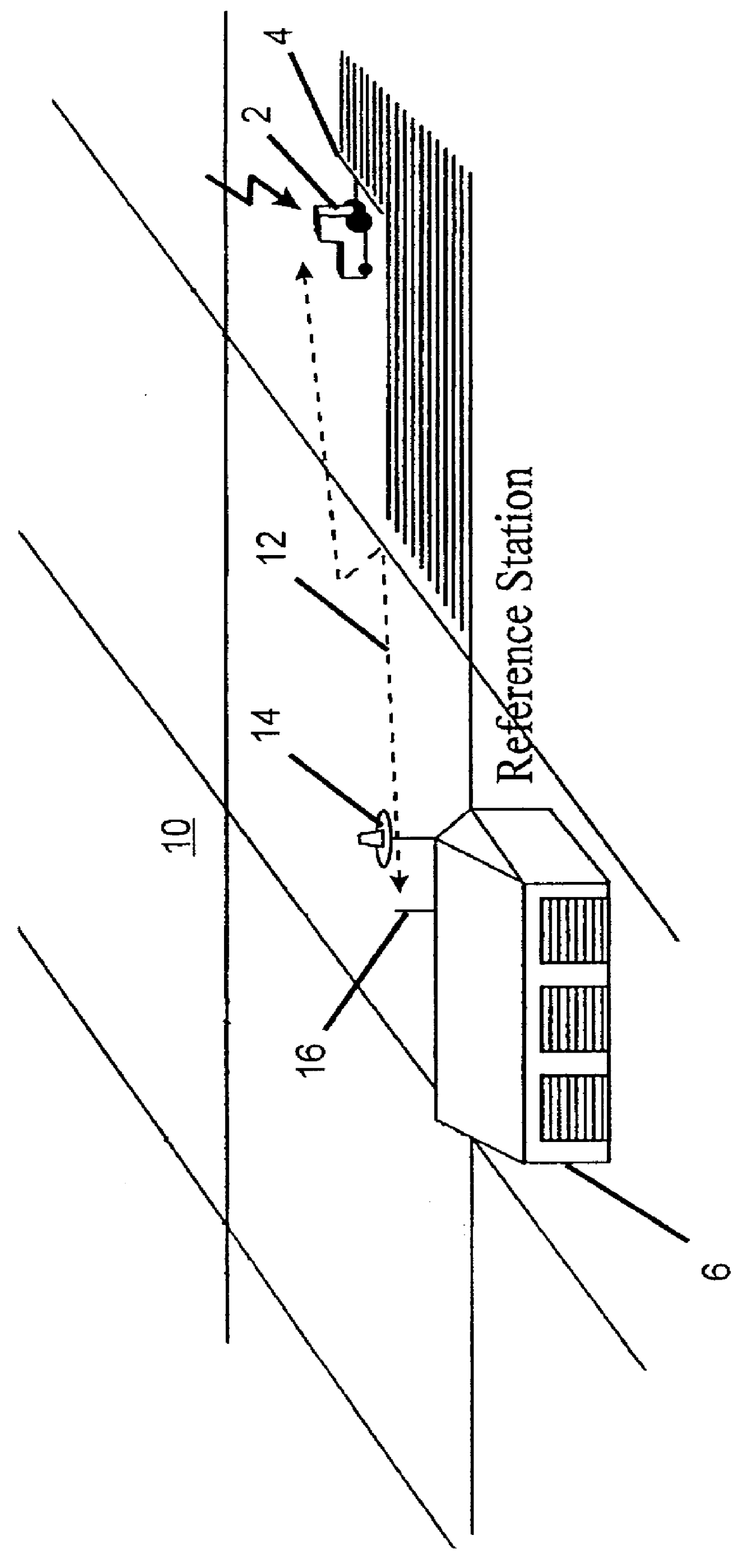

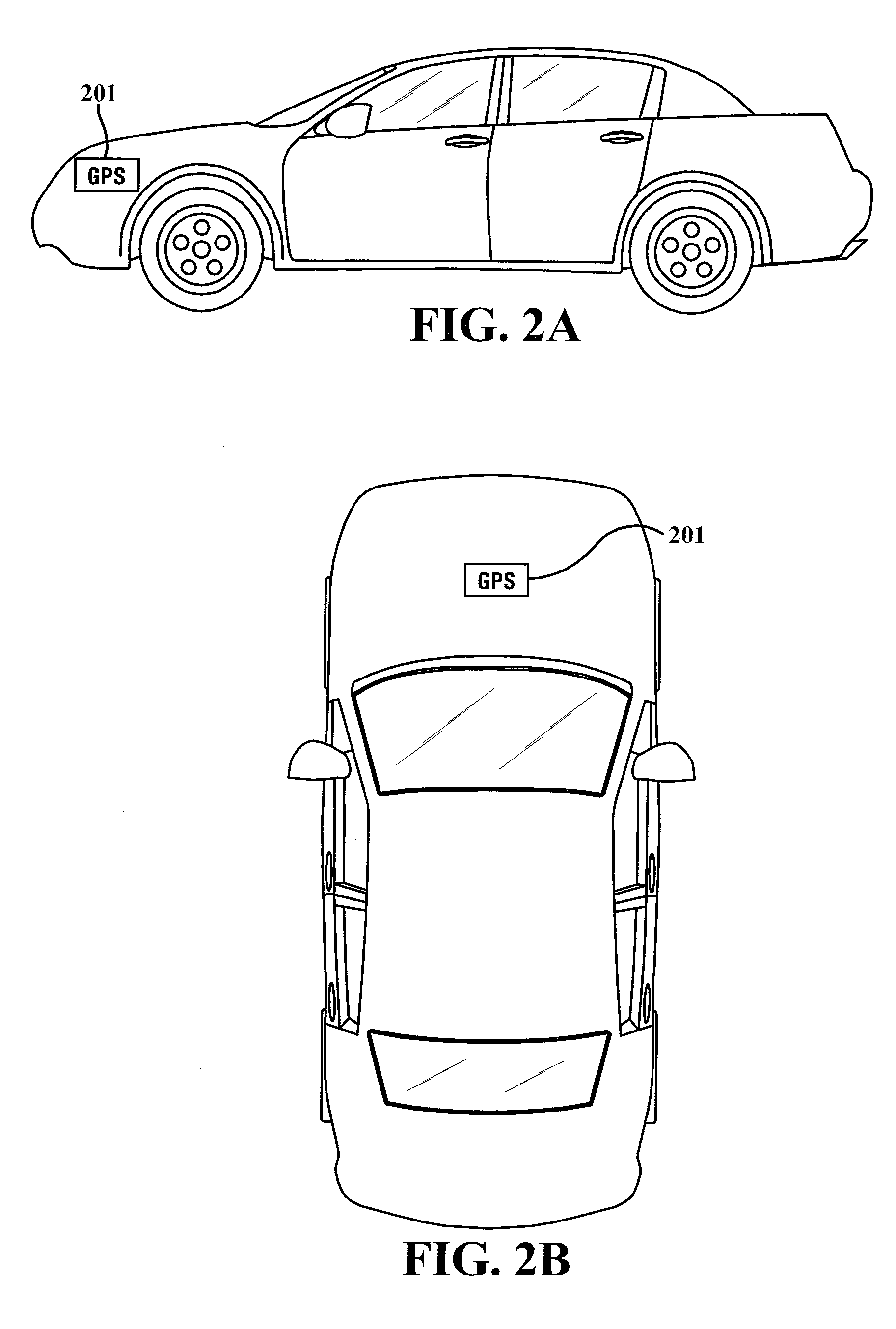

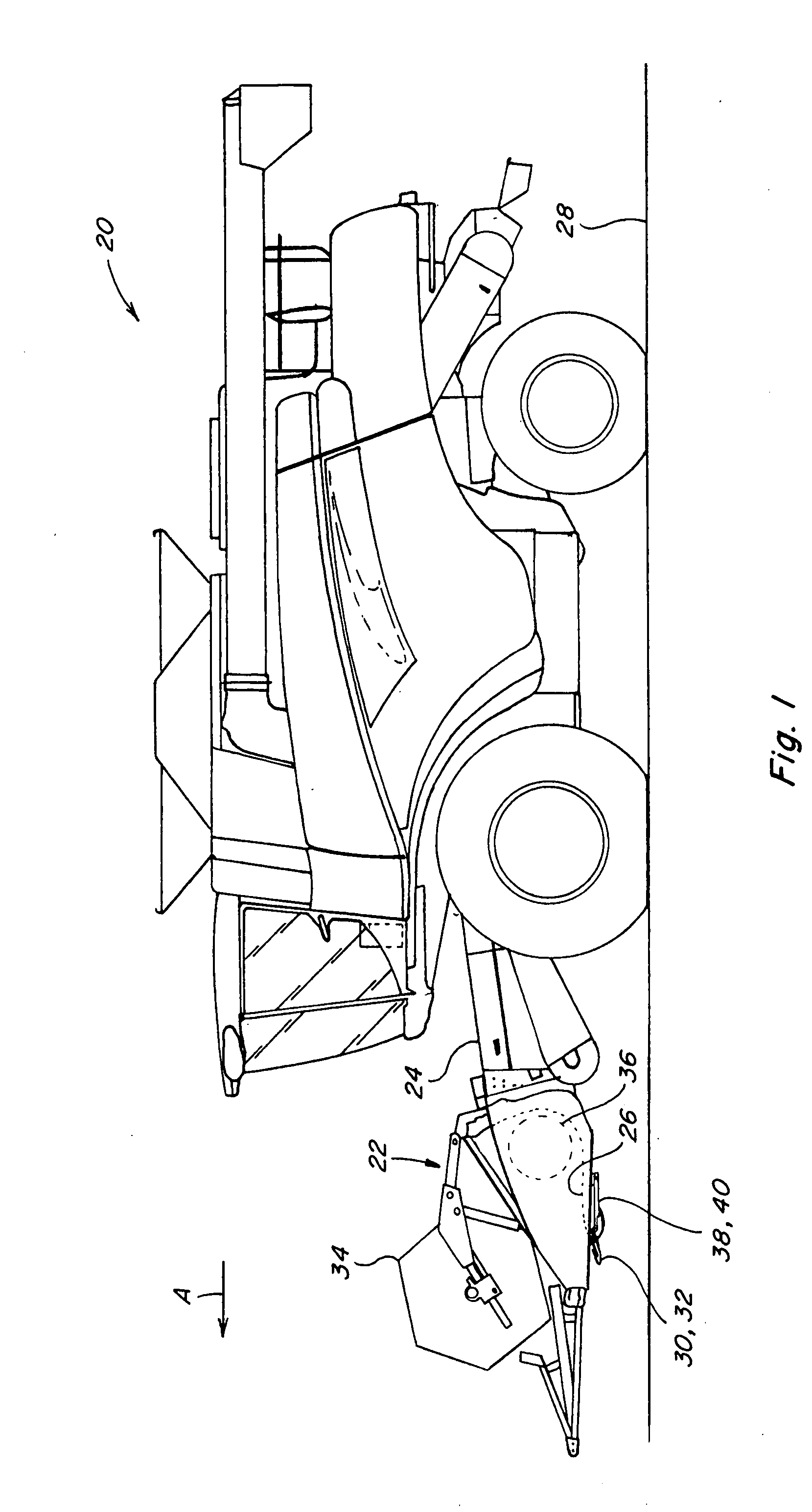

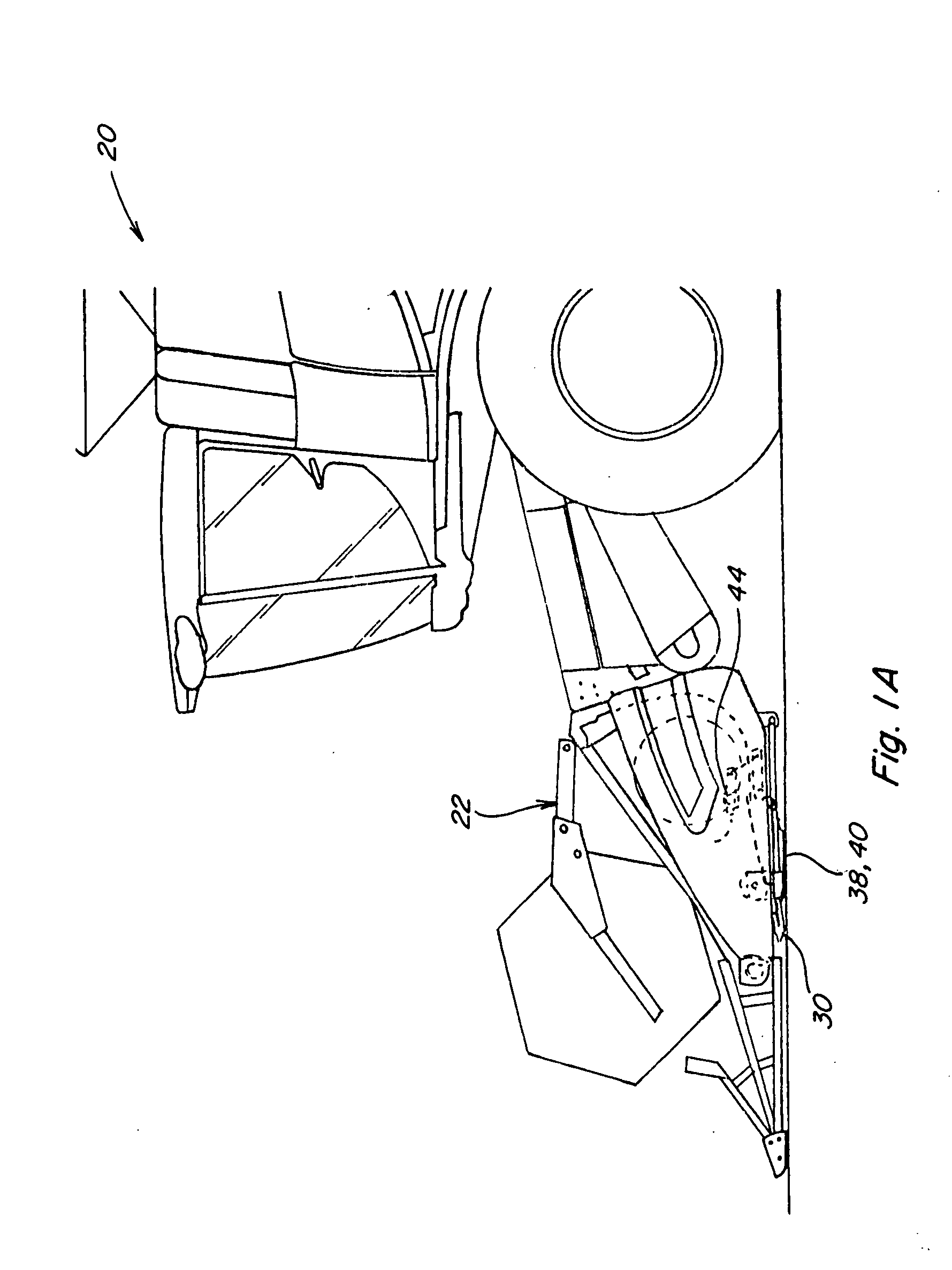

Method and system for automatic control of vehicles based on carrier phase differential GPS

InactiveUS6052647AImprove system stabilitySimple processDigital data processing detailsPosition fixationAutomatic train controlAutomatic control

Described is an automatic control system for land (and possible marine) vehicles based on carrier phase differential GPS (CPGPS). The system relies on CPGPS to determine vehicle position and attitude very precisely (position to within 1 cm and attitude to within 0.1 DEG ). A system incorporates a technique to calculate and compensate for antenna motion due to vehicle roll and pitch. One aspect of the system utilizes an intelligent vehicle controller that recognizes and adapts to changing conditions, such as vehicle speed, implements towed by the vehicle, soil conditions, and disturbance level. The system provides the capability to control the vehicle on various paths, including straight lines and arbitrary curves. Also described is a technique for initialization and vehicle control using only a single pseudolite.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

Automatic control system for an electrosurgical generator

An automatic control system for an electrosurgical generator is herein disclosed. The automatic control system includes voltage and current sensing circuits, a processing circuit, an output determining circuit, and a control circuit. Samples of the voltage and current outputs are supplied to the processing circuit and the output determining circuit to generate an output signal. The output signal is compared to a reference signal to generate a feedback signal for controlling a drive circuit.

Owner:COVIDIEN AG

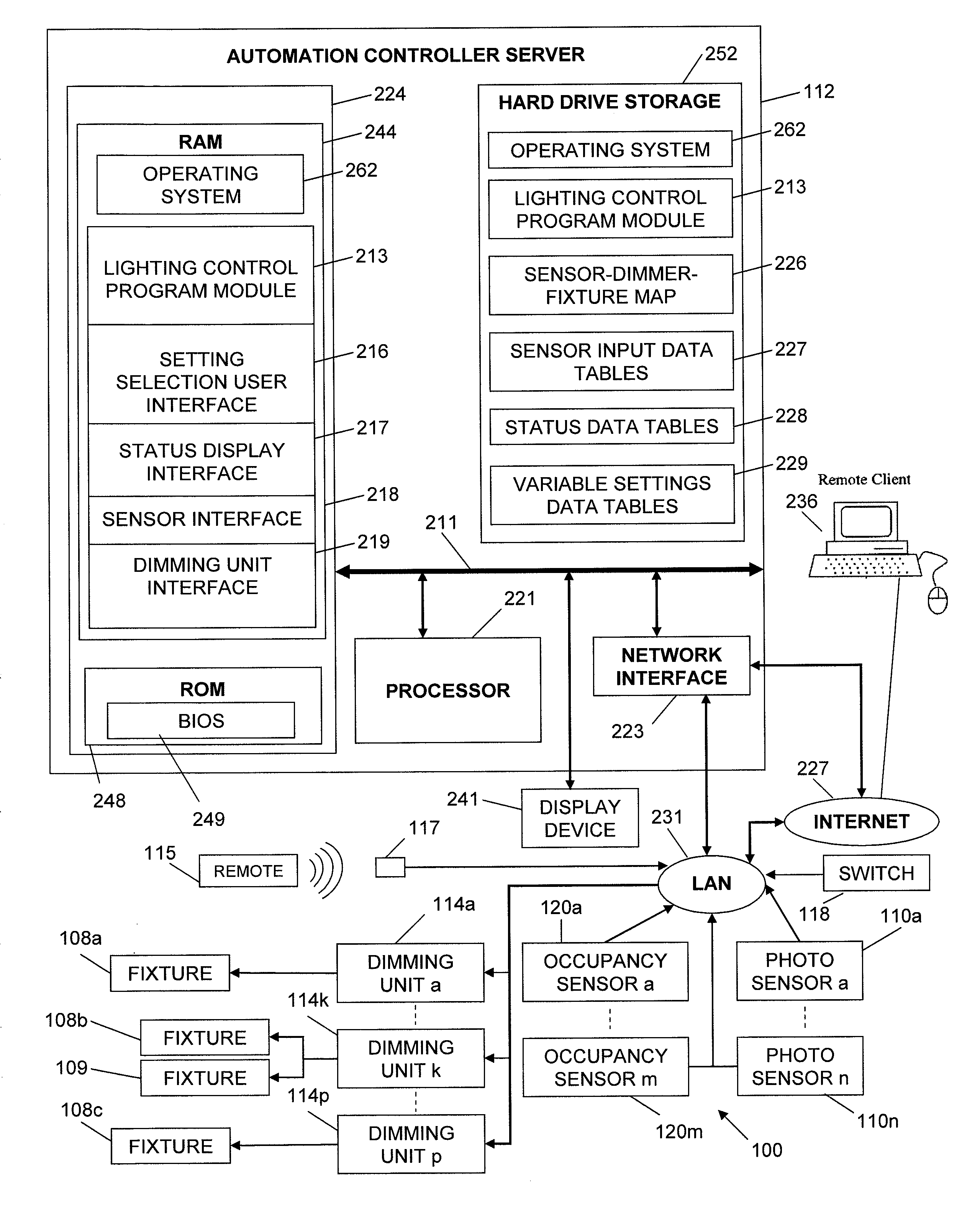

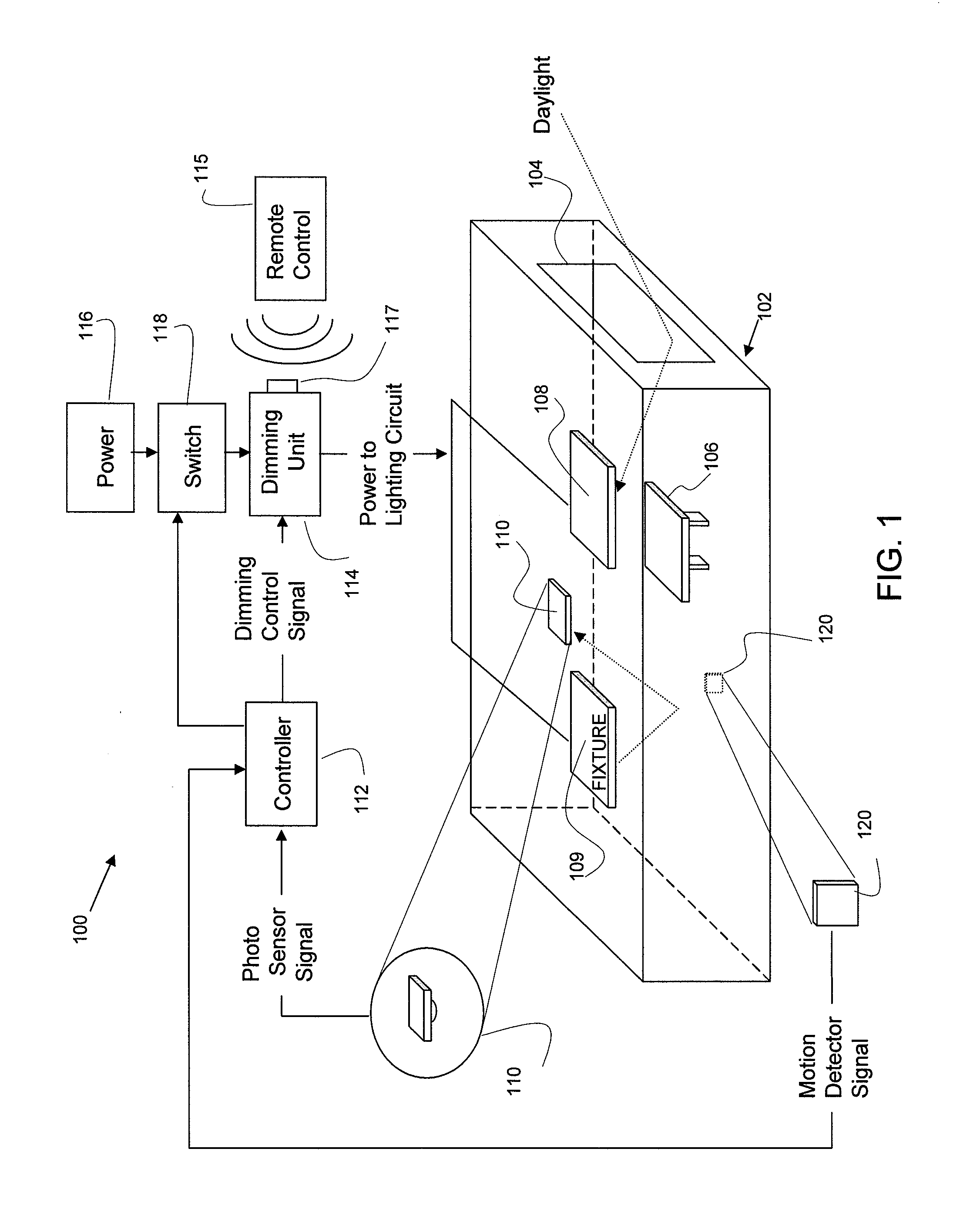

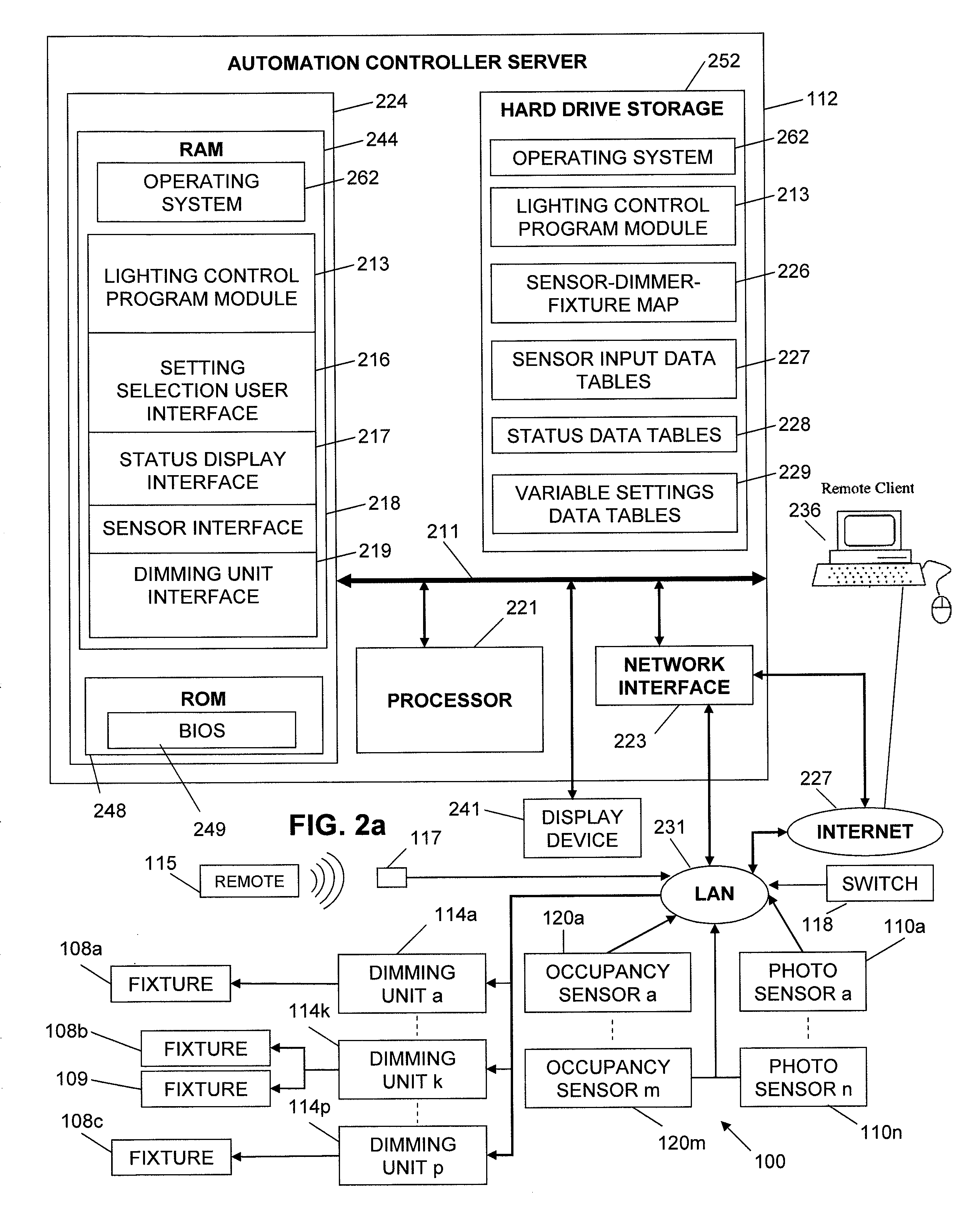

Automated Dimming Methods and Systems For Lighting

InactiveUS20100176733A1High-frequency energyHigh impedanceElectrical apparatusElectric light circuit arrangementAutomatic controlControl system

Automated control systems and methods for lighting systems are described herein. In certain embodiments, the control systems include either an improved dimmable ballast, an improved dimmer circuit, or both. The control systems are suitable for various applications including a light harvesting system and a security lighting system.

Owner:PURESPECTRUM

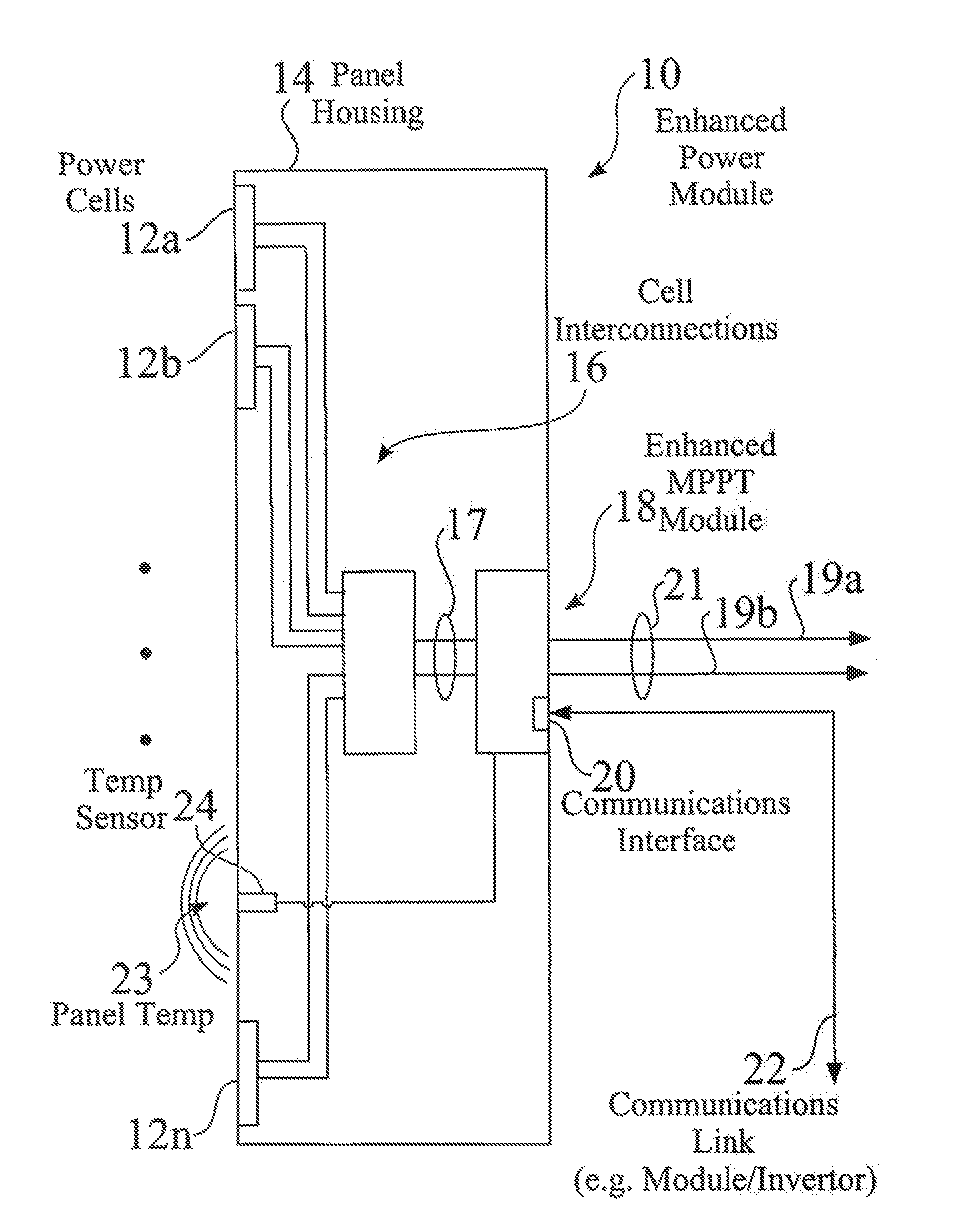

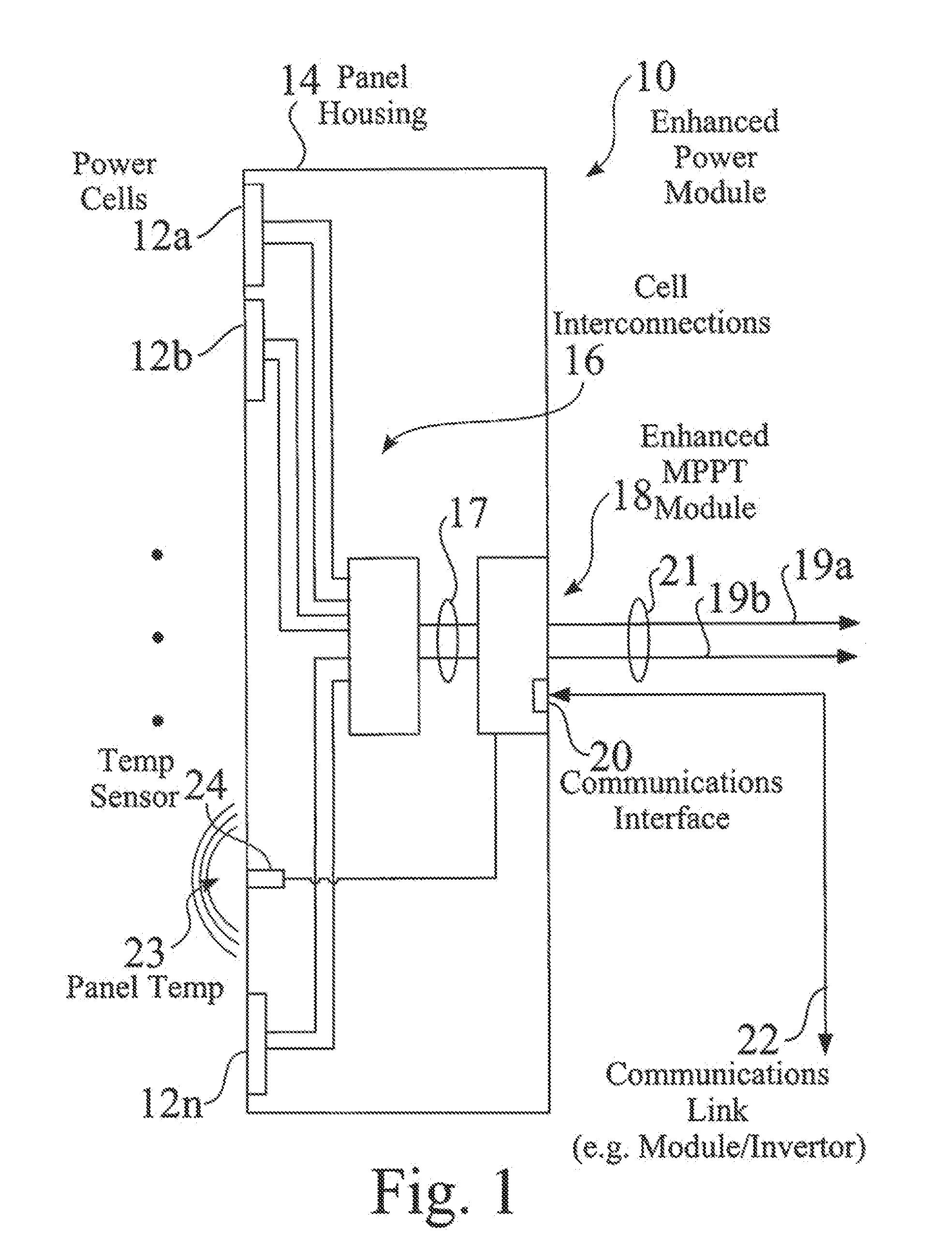

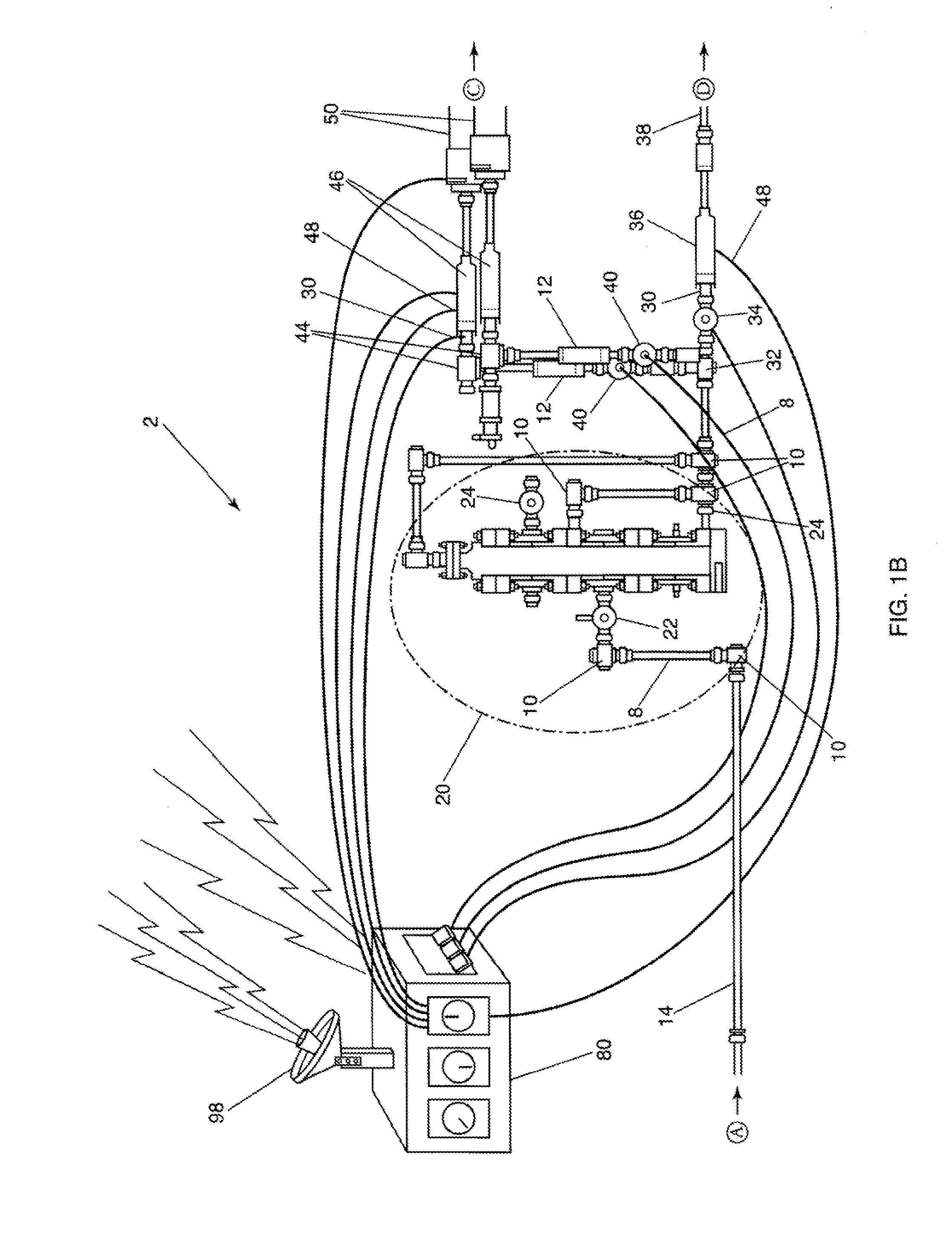

Enhanced solar panels, liquid delivery systems and associated processes for solar energy systems

ActiveUS20120138123A1Avoid accumulationReduce lossesSolar heating energyPhotovoltaic monitoringControl systemFiltration

Fluid delivery systems and related structures and processes are provided, such as for use with water, treated water, and / or a cleaning solution, for any of cleaning, cooling or any combination thereof, for one or more solar panels in a power generation environment. Enhanced coatings are provided for the incident surface of solar panels, such as to avoid build up of dirt, scale, or other contaminants, and / or to improve cleaning performance. Reclamation, filtration, and reuse structures are preferably provided for the delivered fluid, and seal structures may preferably be implemented between adjoining panels, to minimize loss of the delivered water or cleaning solution. The fluid delivery system may preferably be linked to an automated control system, such as but not limited to integrated DMPPT modules and related systems.

Owner:ACCURATE SOLAR POWER LLC

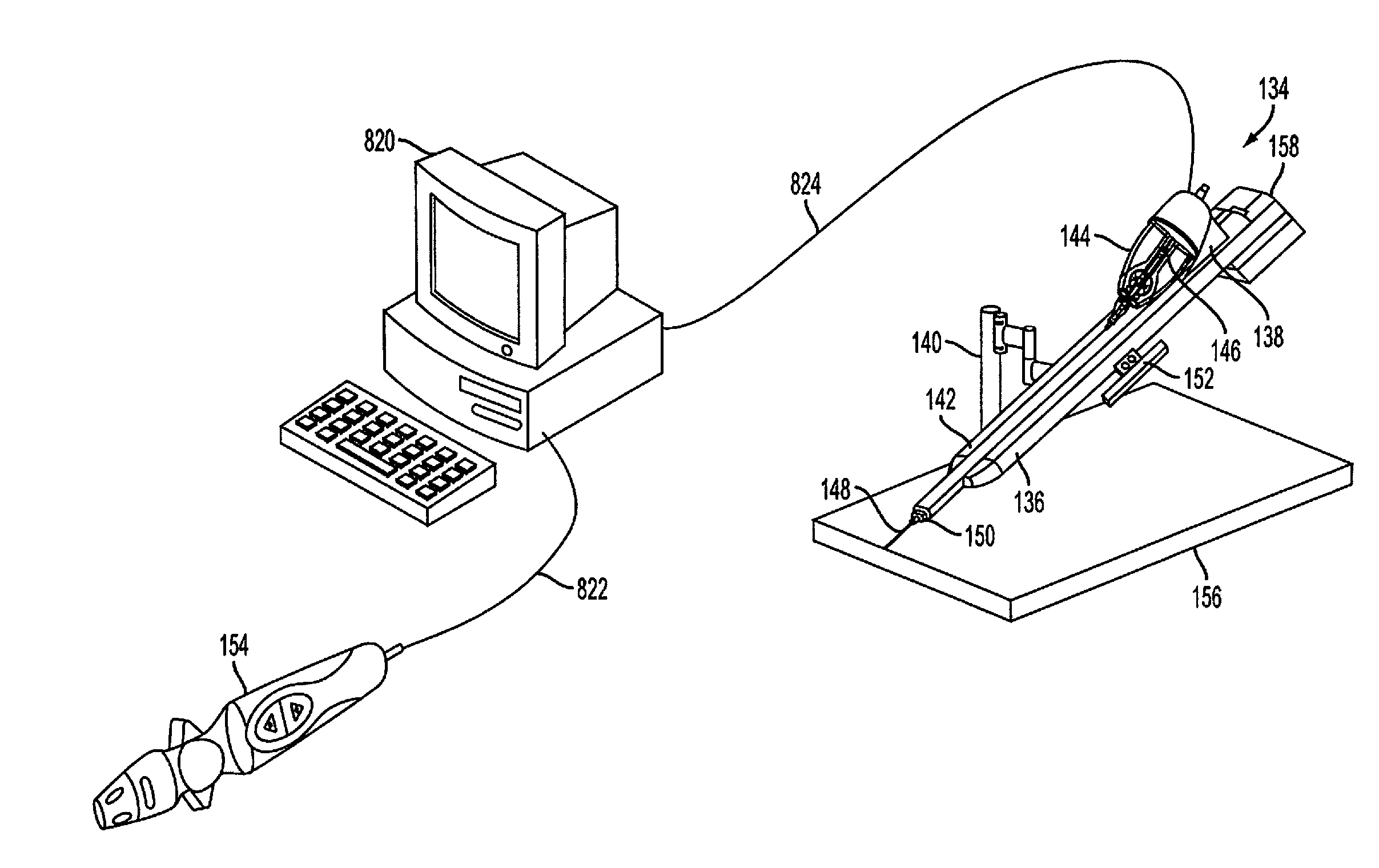

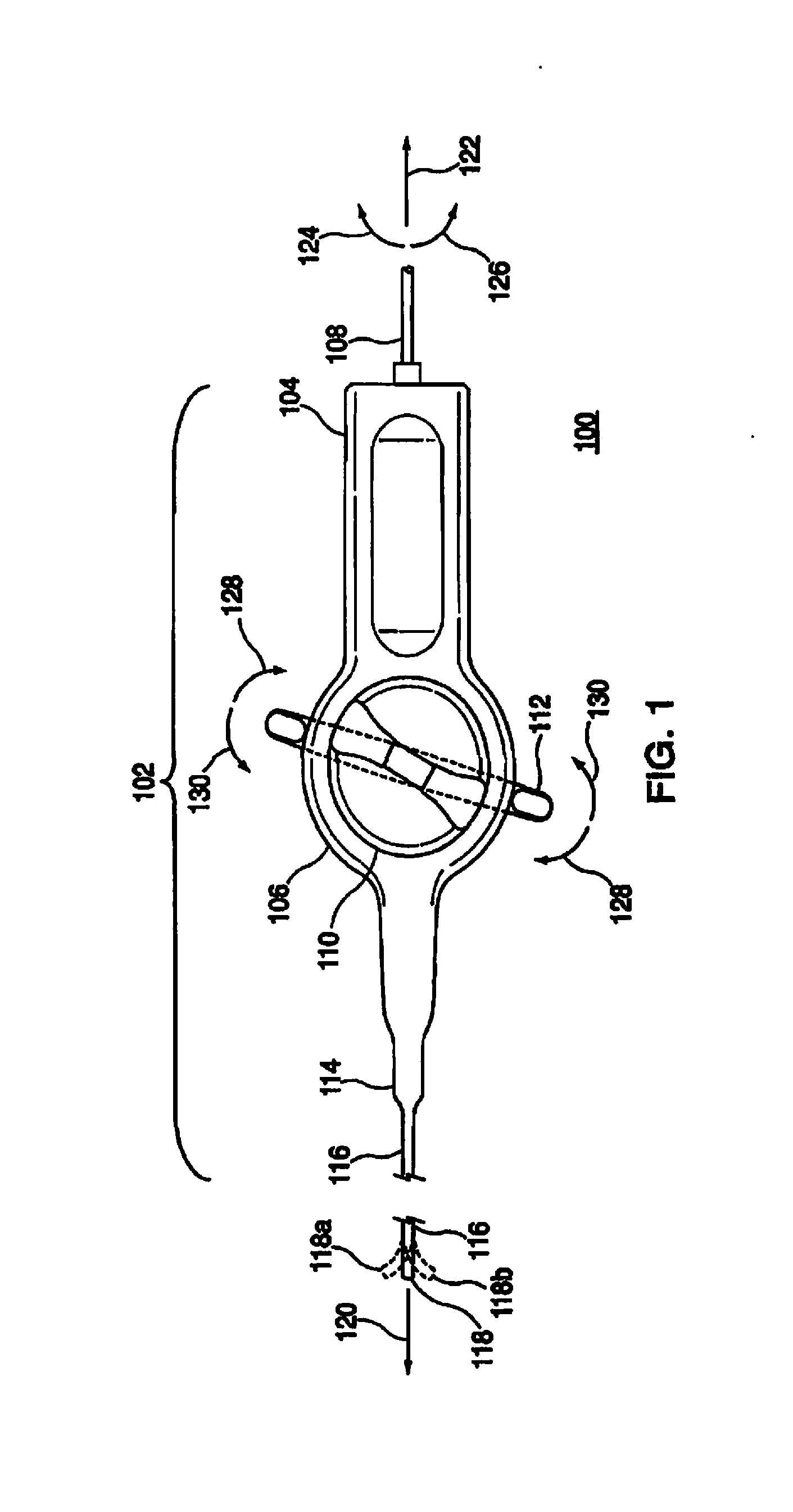

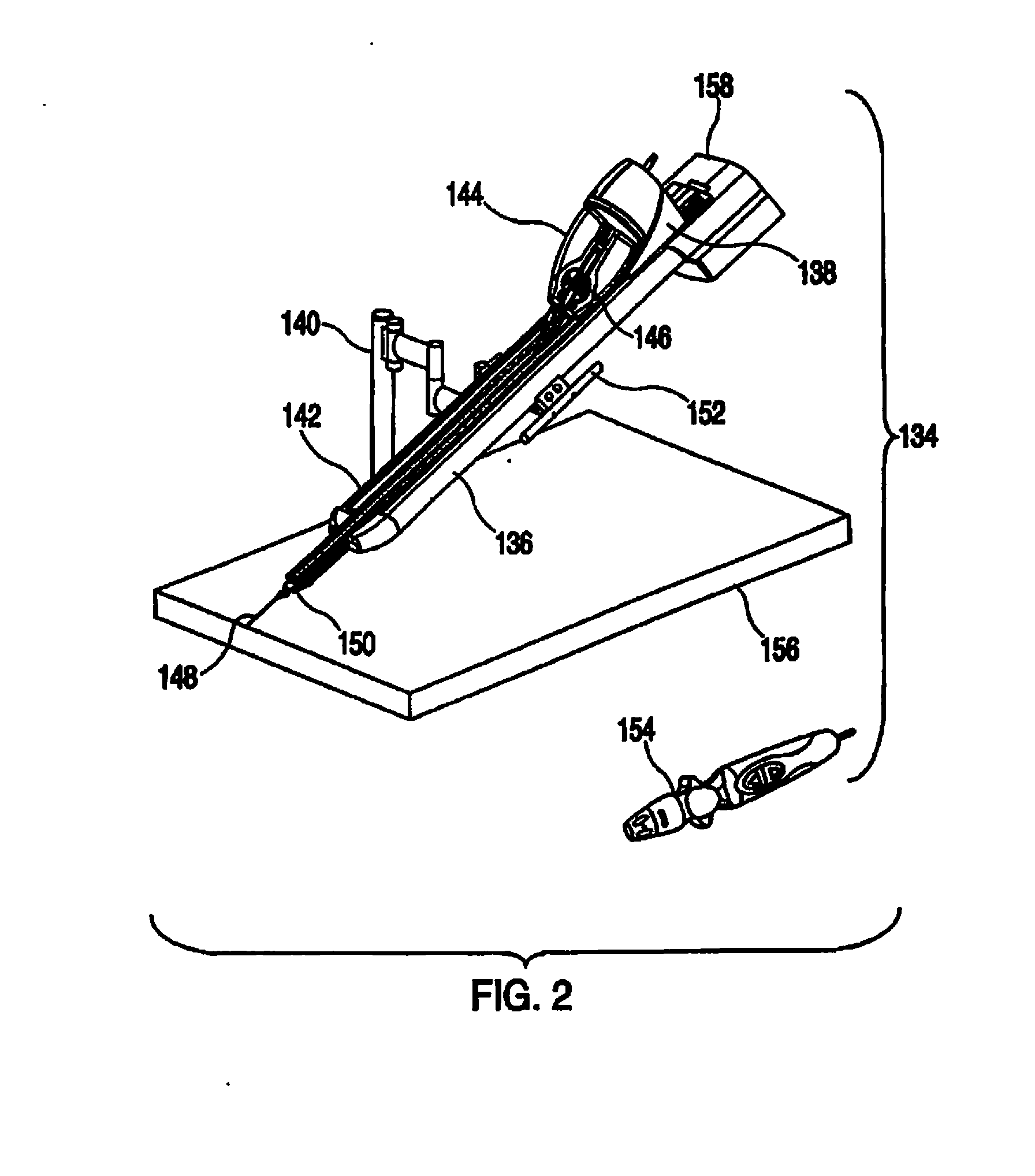

Remotely Controlled Catheter Insertion System with Automatic Control System

ActiveUS20120184955A1Keep sterileAvoid contactDiagnosticsSurgical instrument detailsMotor driveAutomatic control

A system for remotely controlling the positioning within the body of a patient of an elongated medical device optionally having a control handle, comprises a catheter position system and a remote controller configured to control the robotic device. The catheter position system includes a handle controller; a sled member coupled to the handle controller, the sled member being configured to position the medical device within the body of the patient; and a sled base configured to advance the sled member towards the body of a patient, the sled bed being coupled to a sterile barrier effective to maintain sterility inside the sled base. The catheter position system may include a control system configured to issue positioning commands in response to sensor signals received from the catheter. The catheter position system may also include a motor driven rotatable catheter introducer clamp configured to enable rotation of an introducer.

Owner:CATHETER PRECISION INC

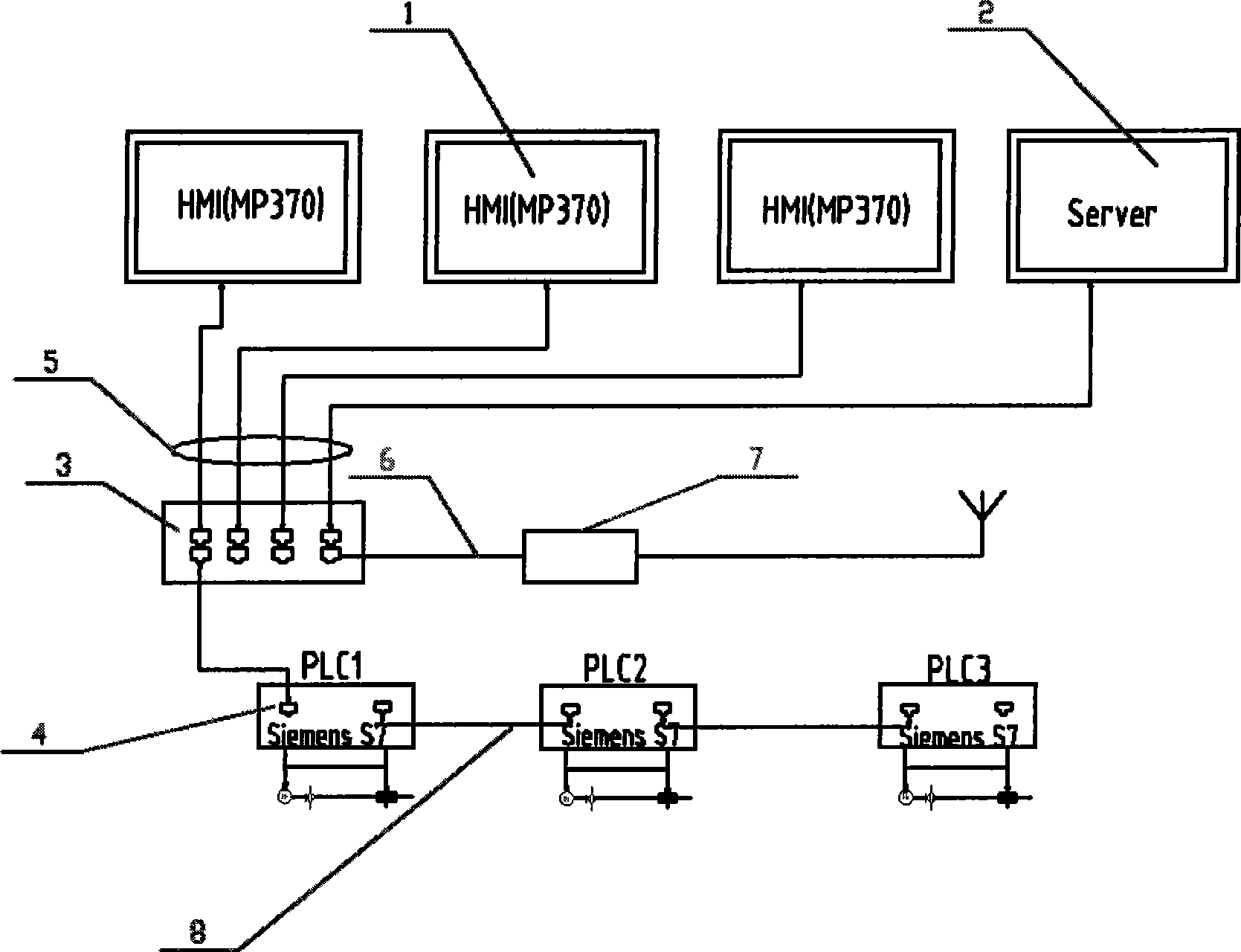

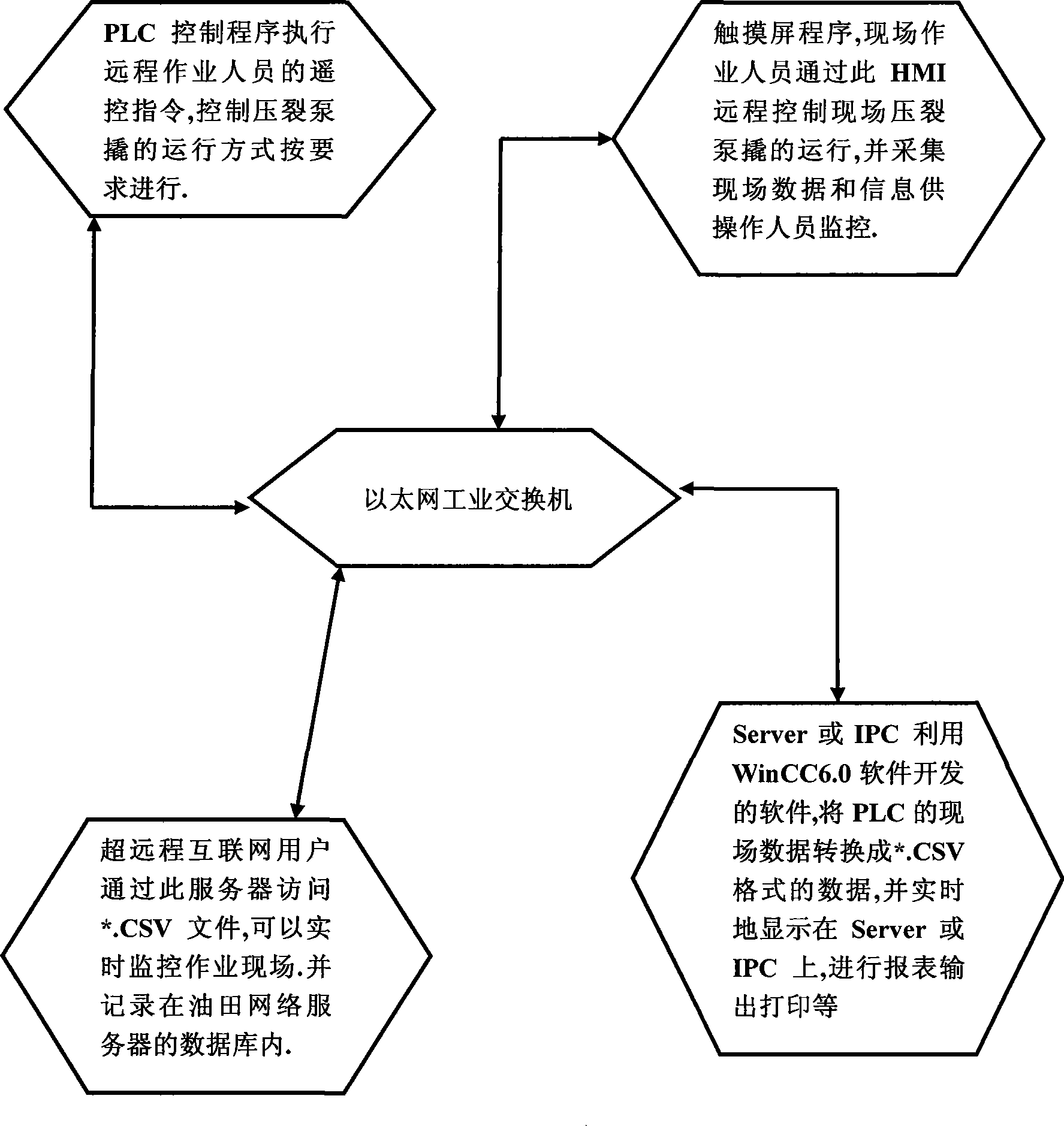

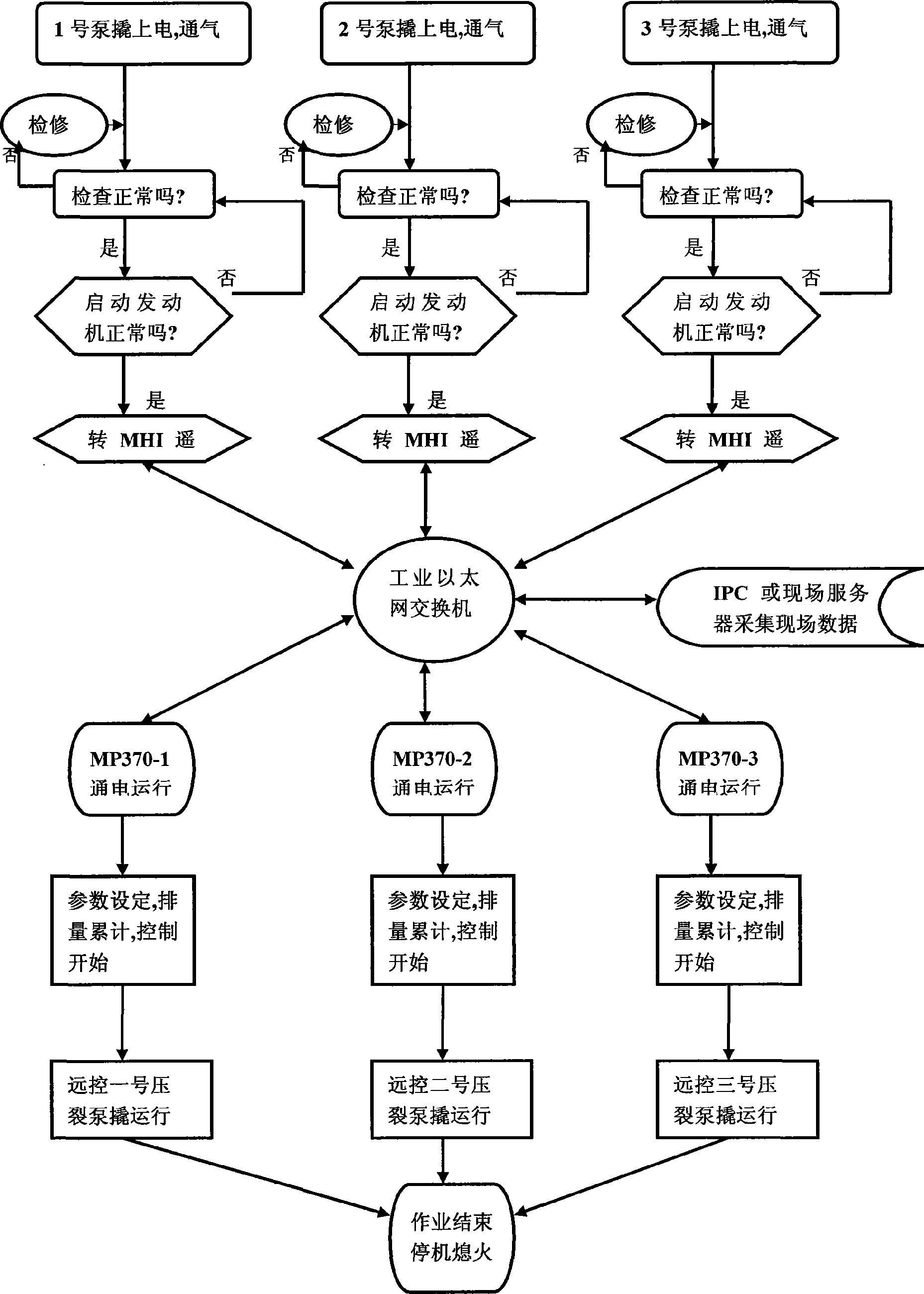

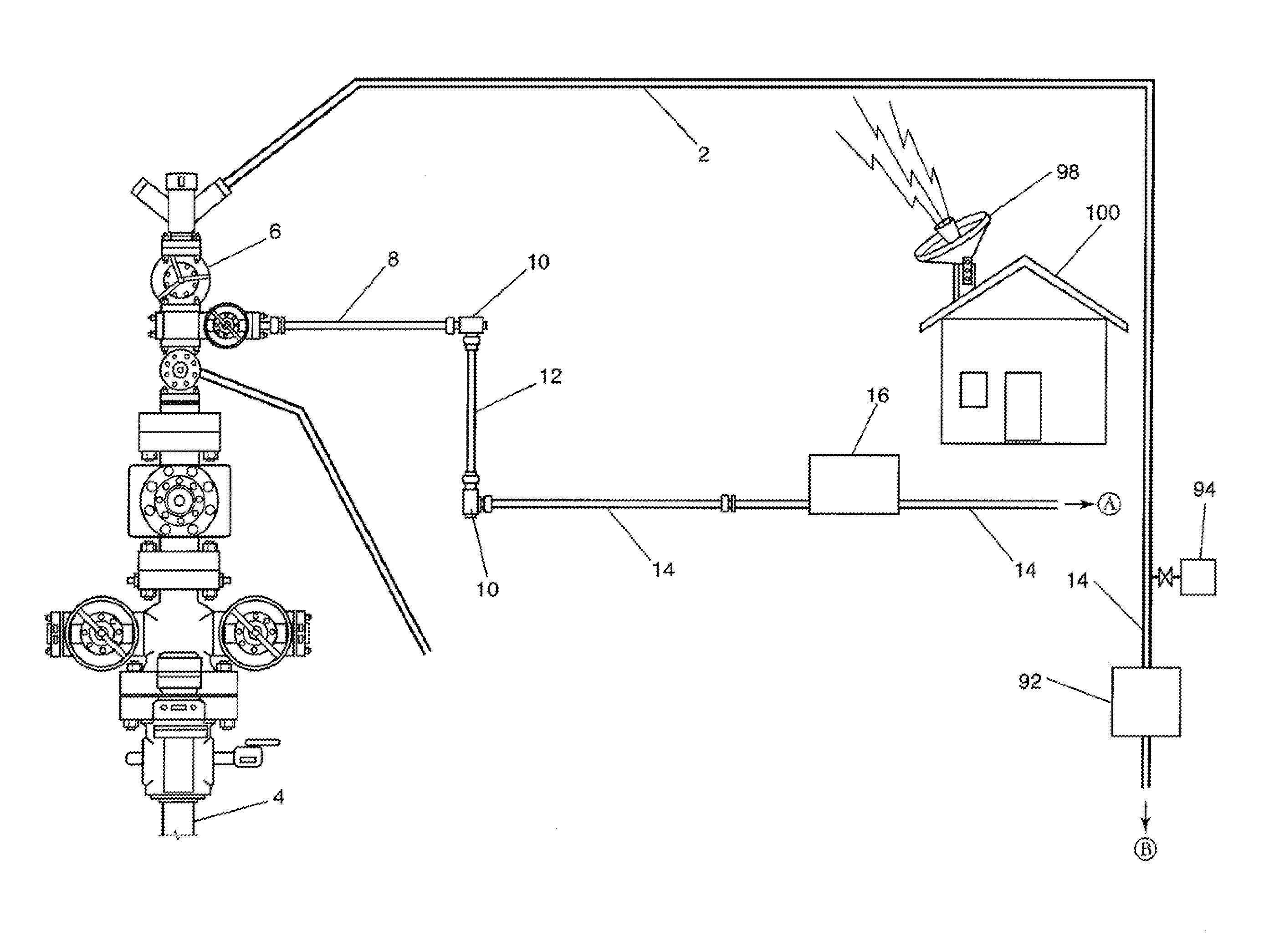

Oil field fracturing pumping remote automatic control system

ActiveCN101414171AMonitor and control operationsOrderly and stable operationTotal factory controlProgramme total factory controlAutomatic controlHuman–machine interface

The invention discloses a remote automatic control system of a fracturing pump skid used in an oil field. The system is used for remote automatic control of a well service pump skid and a truck-mounted skid used in the oil field; the remote automatic control system consists of a field control system which consists of Siemens S7-315 series PLCs which are taken as a core, a Siemens MP370 which is taken as a remote control human-machine interface, and Ethernet which is taken as a transmission media; the system can achieve remote control functions such as start, stop and emergency stop of an engine, gear shifting, braking, turning back to a neutral position and idle speed of a gearbox and the like, and the system can modify field running parameters in a remote manner, thus realizing bidirectional transmission between the pump skid and the human-machine interface (HMI); the Ethernet is taken for communication so that the pump skid can transmit the field data to a remote controller or a server at the speed of 100MB / S; an industrial exchanger is taken to connect the devices such as the PLC, the HMI and the like to achieve more group controls; the exchanger can convert the field data into the data formats such as a standard *.CSV format and the like, and directly transmit the data to the server for data processing.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

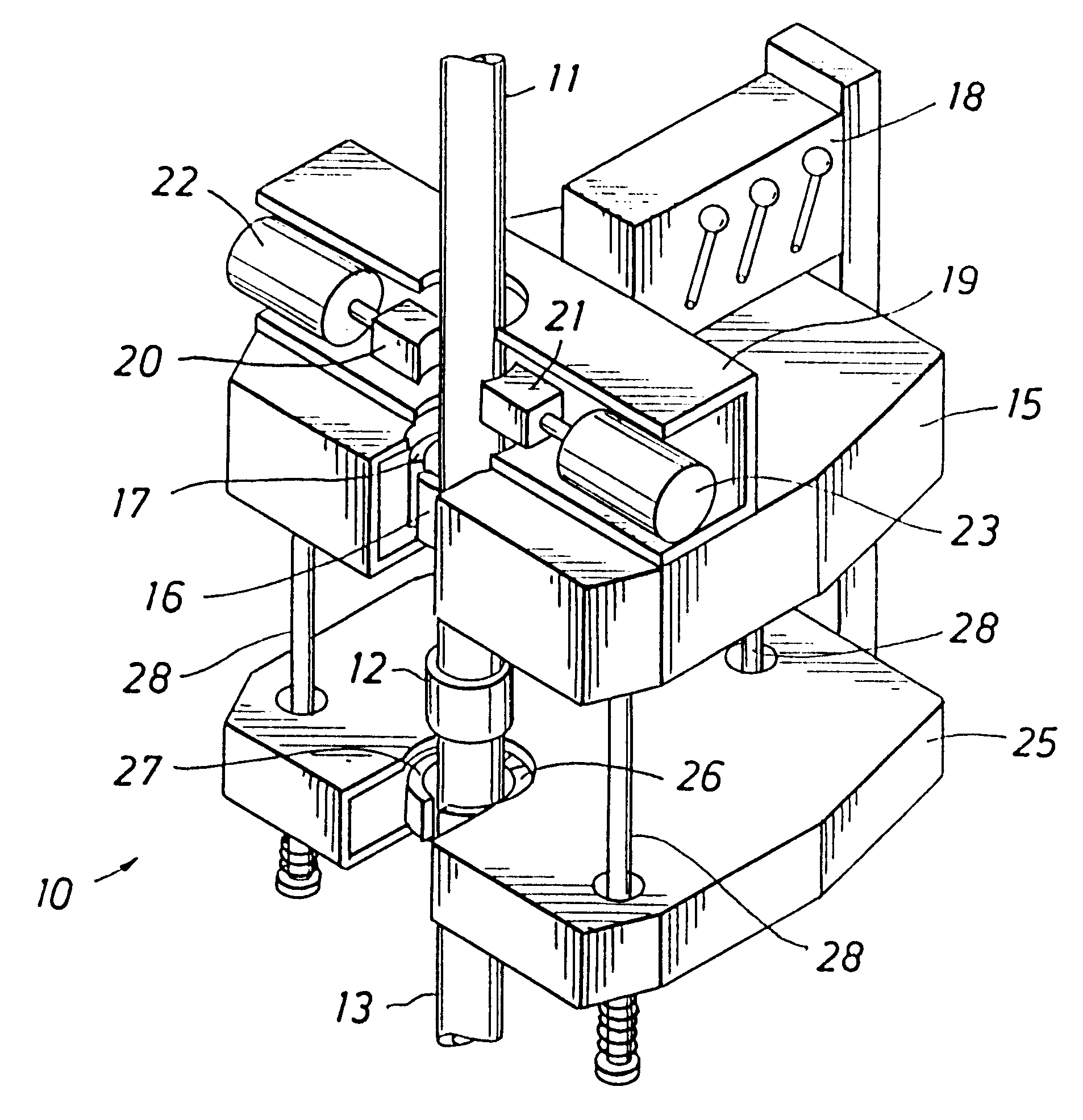

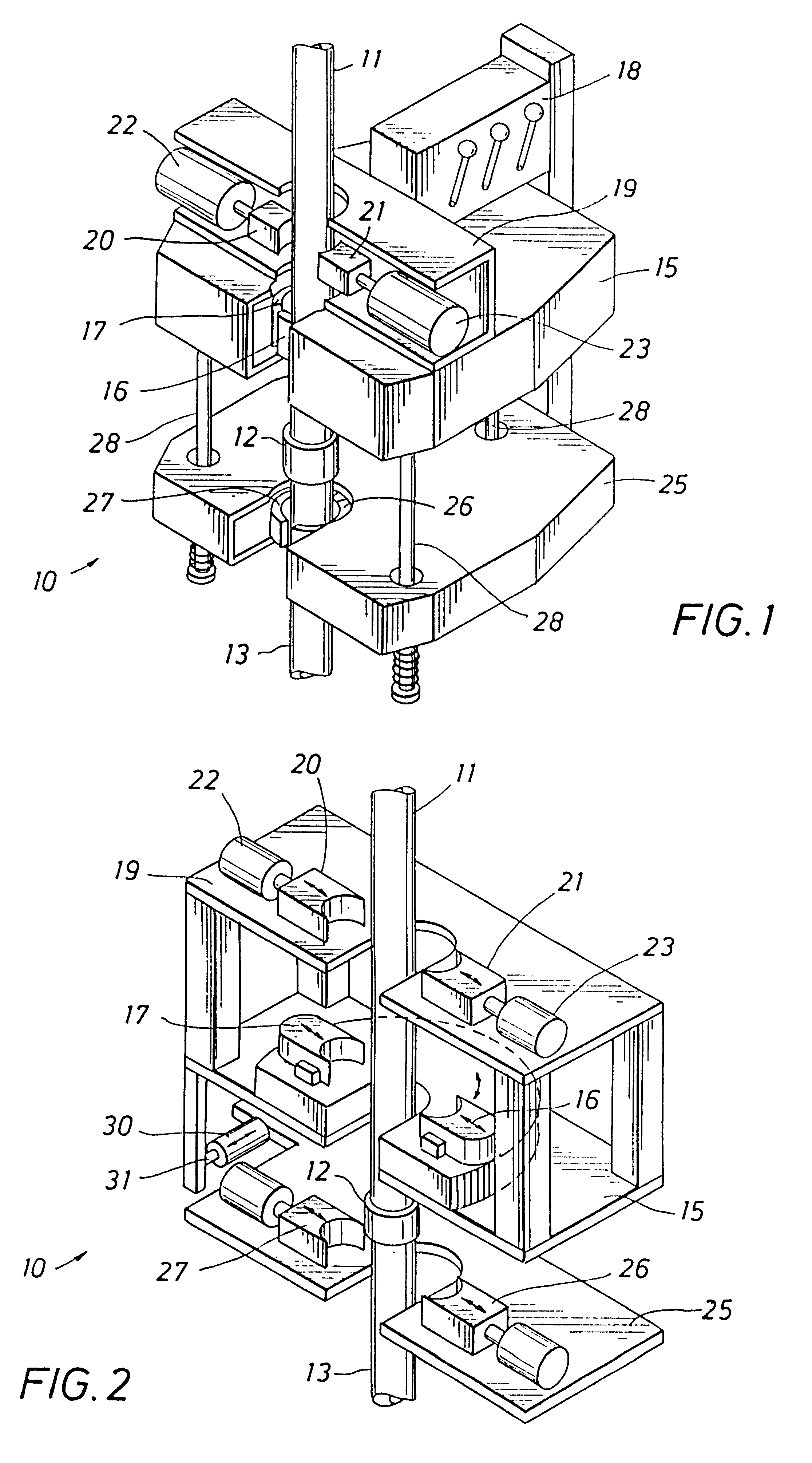

Mechanical torque amplifier

A power tong system is used to make up and break out threaded pipe connections. Rotary power tongs are connected to an integral backup tong through an extendable hydraulic cylinder and rod. A brake is secured to the rotary tong to selectively hold the pipe stationary relative to the rotary tong. When rotation of the pipe by the rotary tong ceases, the brake is applied, and the cylinder and rod are actuated to angularly displace the power tongs and the backup tong to apply a torque force to the pipe connection disposed between the power tongs and the backup. A resulting torque force is obtained that is greater than the maximum torque that can be exerted by the rotary tong acting alone. The system may also be deployed to apply and hold precise torque forces on the pipe connections. When used to obtain a makeup torque below the maximum rated rotary tong output, the rotary tong is regulated to limit its torque output. When the limited torque is reached, the brake is applied and the cylinder and rod are actuated to apply a smooth, closely controlled increase in torque to the connection. The final torque level may be held constant for a desired length of time. In both the high and low torque applications, the brake prevents the rotary tong from being turned backwardly by the increased torque force applied by actuation of the rod and cylinder assembly. Operation of the system may be manually or automatically controlled.

Owner:TESCO HLDG I

Remote ultra-low-density automatic control system

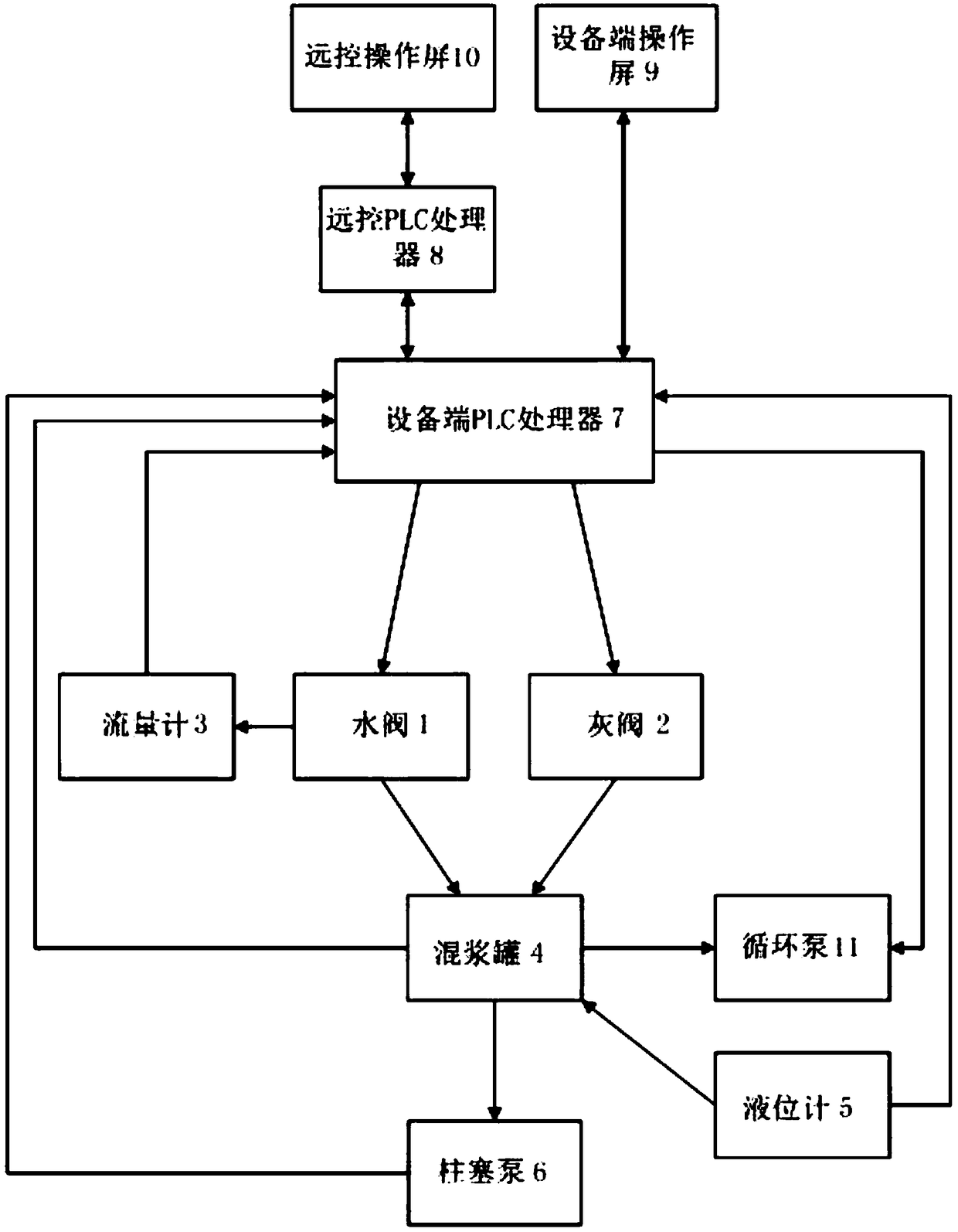

PendingCN109491318AIncreased level of process automationProgramme control in sequence/logic controllersAutomatic controlSlurry

The invention discloses a remote ultra-low-density automatic control system. The system comprises a control unit, a water valve, a flow meter, a cement valve, a slurry mixing tank, a liquid level meter, a circulation pump and a plunger pump; the cement valve, the water valve, the circulation pump and the plunger pump are connected with the slurry mixing tank separately, the flow meter feeds the water supply amount monitored in real time back to the control unit, the liquid level meter is arranged in the slurry mixing tank, the control unit controls the number of revolutions and preset displacement of the plunger pump to achieve automatic displacement as required, the water demand amount and the cement demand amount are calculated by presetting the water-cement ratio and liquid level valuein the control unit, and therefore the opening degrees of the water valve and the cement valve are controlled; the control unit comprises a remote control unit and an equipment end control unit whichare connected with each other. The remote ultra-low-density automatic control system has the advantage of remote cementing equipment monitoring, remote liquid level automatic control, remote automaticwater supply, remote automatic cement supply, remote automatic premixing, remote automatic density control and remote automatic displacement.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

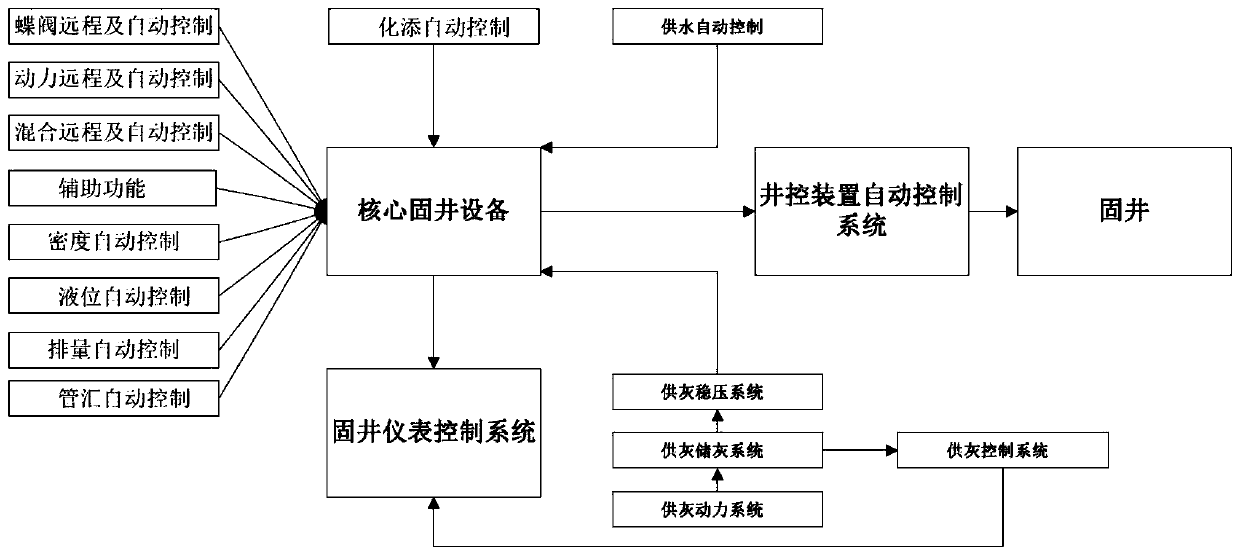

Full-automatic cementing complete set control method

InactiveCN110159225ARaise the advanced levelSolve labor shortageSealing/packingTotal factory controlAutomatic controlControl system

The invention discloses a full-automatic cementing complete set control method, and relates to the related technical field of petroleum equipment. The method comprises the steps of intelligent full-automatic cementing key control, matching control, an automatic power control system, a slurry mixing control system, an automatic premixing function, automatic liquid level control, automatic manifoldcontrol, a hydraulic pneumatic control system, a lime supply automatic control system, a chemical additive automatic control system, a water supply automatic control system and a well control device automatic control system. According to the operating method, intelligent full-automatic control over cementing operation is achieved, and breakthrough of the automatic manifold control technology is achieved successfully; through the lime supply automatic control technology and the full-automatic control technology, the advanced level of equipment and technologies of the company is improved greatly; a new mode of future cementing operation is created, and a new era of a smart oil field is started; through achievement of the intelligent full-automatic cementing operation technology, the problems, that customers face at present, of shortage of labor forces and labor resources can be solved; and the intelligent operation is achieved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

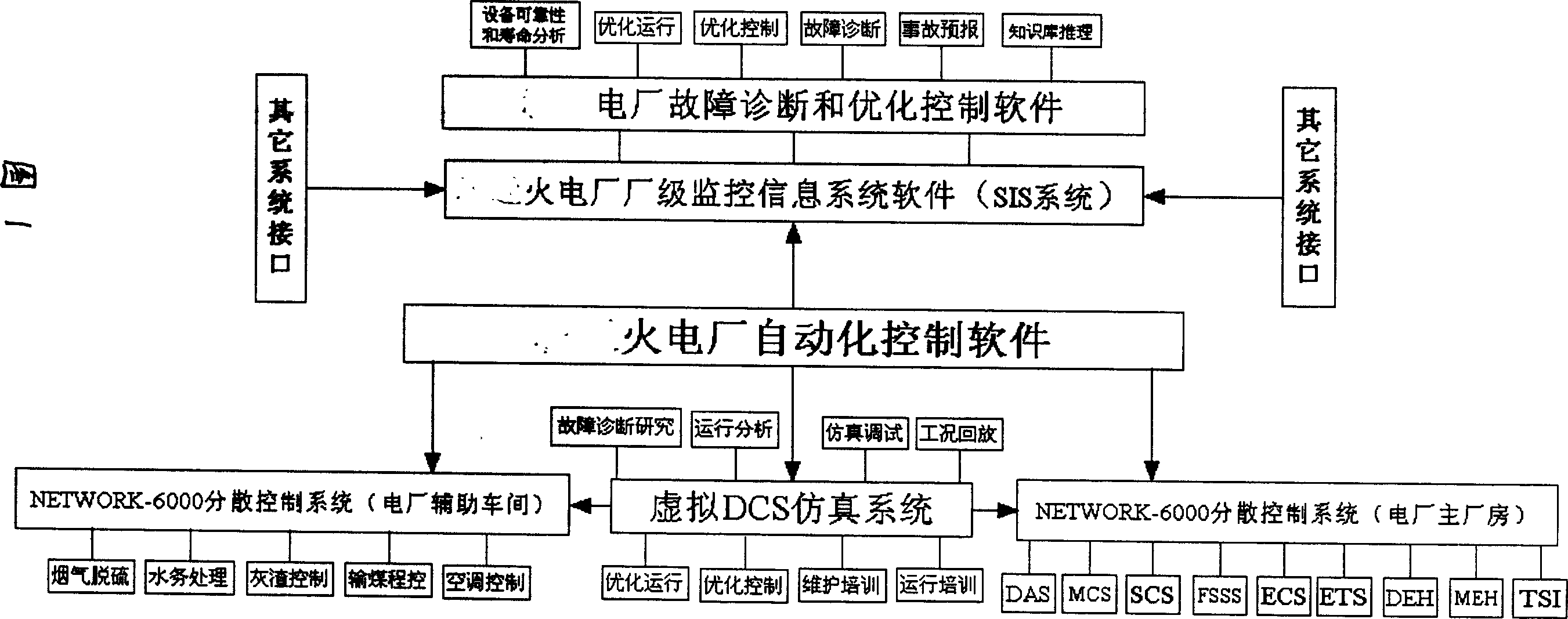

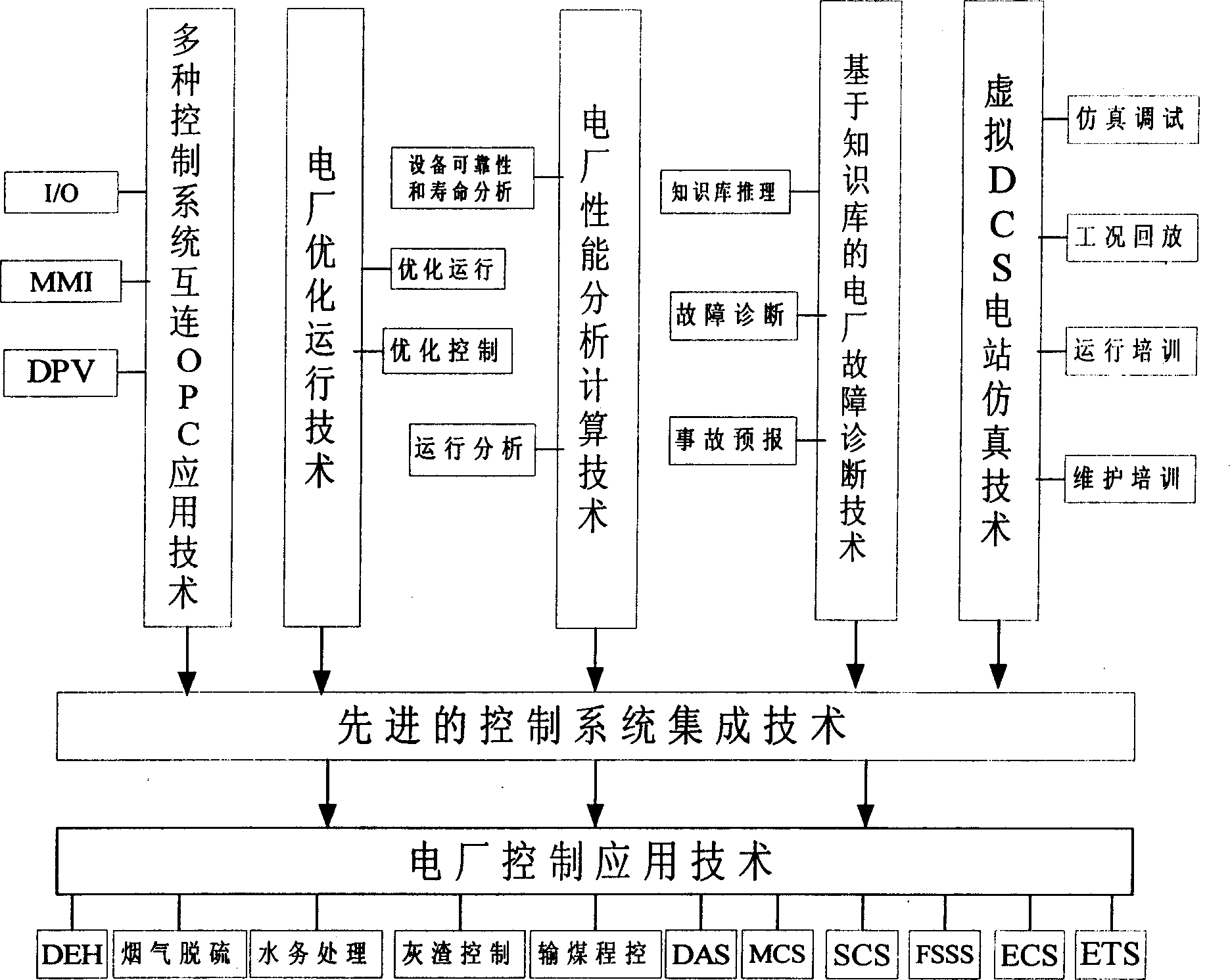

Automatic control system based on artificial intelligence for heat-engine plant

ActiveCN1694025ATake into account maturityGuaranteed growthComputer controlEnergy industryAutomatic controlPower station

The invention discloses a thermoelectric power station automatic control system based on artificial intelligence. It includes dispersible control system, virtual DCS simulation system, program controlling system, monitoring information system and malfunction diagnosing and optimizing controlling system; the dispersible control system is connected with the virtual DCS simulation system and program controlling system; the program controlling system process the operating parameters of every machine group transmitted by dispersible control system, and at the same time transmits data to monitoring information system to display, then transmits malfunction diagnosing and optimizing controlling system to have equipment state monitoring, malfunction diagnosing and forewarns. The invention gathers automatic control, optimizing operation, security monitoring and malfunction diagnosing and forecast. It can improves the automated management level of the thermoelectric power station operation, and enhances enterprises' benefit. It has great economic and applied value in the producing process automatic control of the thermoelectric power station.

Owner:南京科远智慧能源投资有限公司

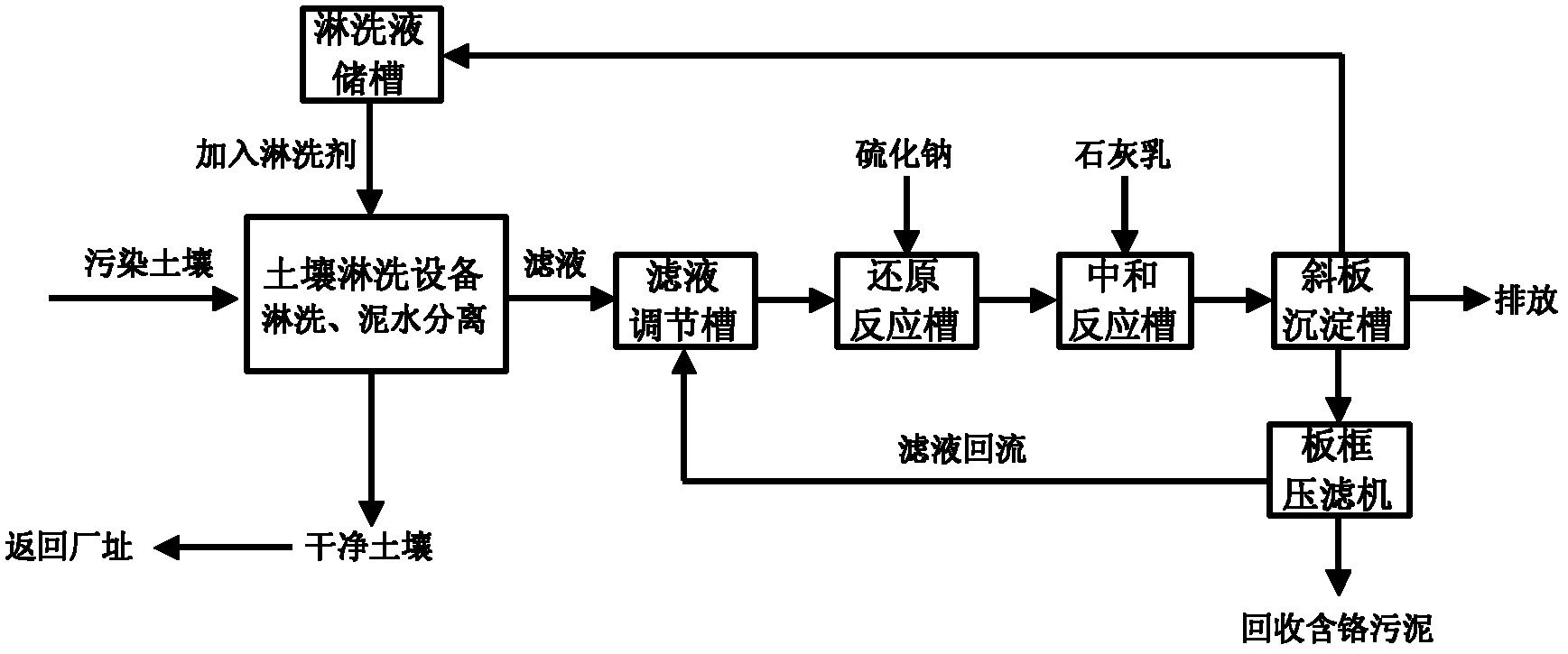

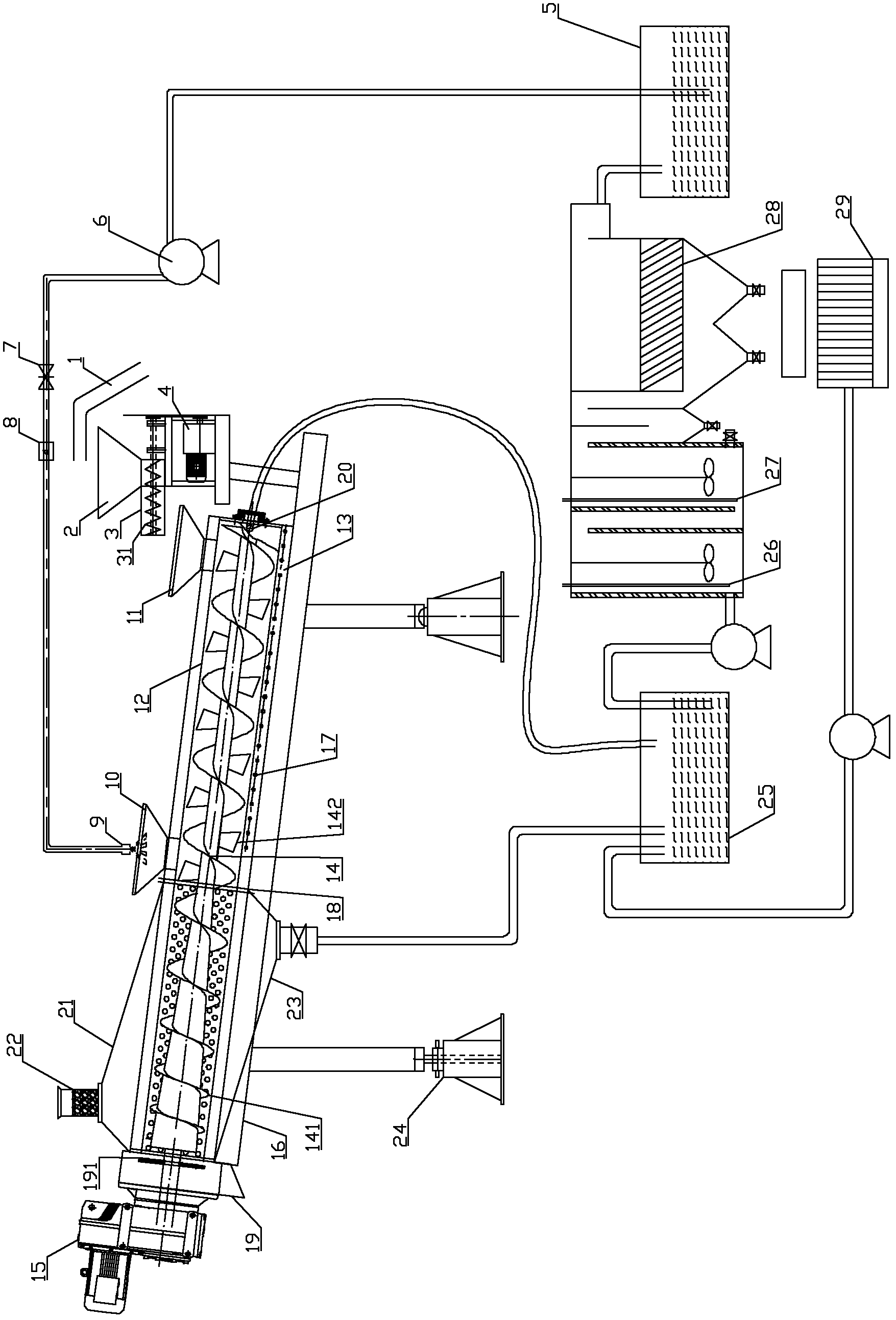

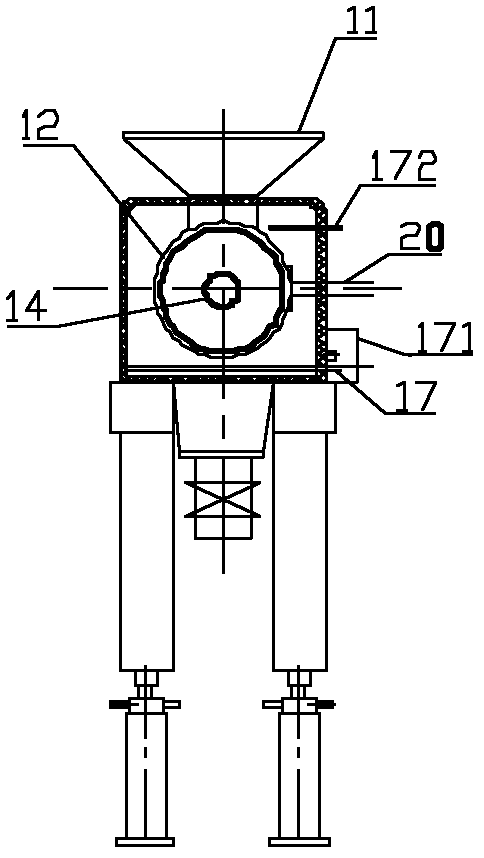

Ectopic leaching restoring device and restoring method for chromic slag polluted soil

ActiveCN102601106AContinuous operationRealize emergency handlingContaminated soil reclamationAutomatic controlSlag

The invention relates to an ectopic leaching restoring device and a restoring method for chromic slag polluted soil. The device is provided with an integrated soil leaching and dewatering system and mainly comprises a feeding system, a soil leaching-dewatering system, a waste gas treating system, an elution collecting treating system and an automatics control system. The chromic slag polluted soil firstly enters a reaction tank leaching section through the feeding system; a chrome-containing component in the soil is transferred into a liquid phase of a leaching agent; the liquid phase is rotated following a spiral stirring thruster; a muddy water mixture is conveyed into a reaction tank dewatering section; the filtrate is discharged through a tank wall with a water-permeable filtering function; the remained soil is conveyed to a mud discharging device following the rotating of the spiral stirring thruster; and lastly, the soil after being leached and dewatered is discharged. The device provided by the invention has the advantages that a power source is utilized to realize the soil leaching and muddy water separating, the energy consumption is low, the structure is simple, the use is convenient, the treating efficiency is high, and the purified degree of the polluted soil after being treated by using the device is above 85%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Variable attenuated transmittance device control system

InactiveUS20100245972A1Lighting circuitsMaterial analysis by optical meansSuspended particlesAutomatic control

Some embodiments include an automotive variable attenuated transmittance device having a predetermined minimum transmittance. Such devices can include a suspended particle device, liquid crystal device, polymer dispersed liquid crystal device, or electrochromic device. Some embodiments also include a manual and / or automatic control system for varying transmittance according to any of a variety of data including, without limitation, position, orientation, transmitted power, and / or the position of an occupant's head.

Owner:HONDA MOTOR CO LTD

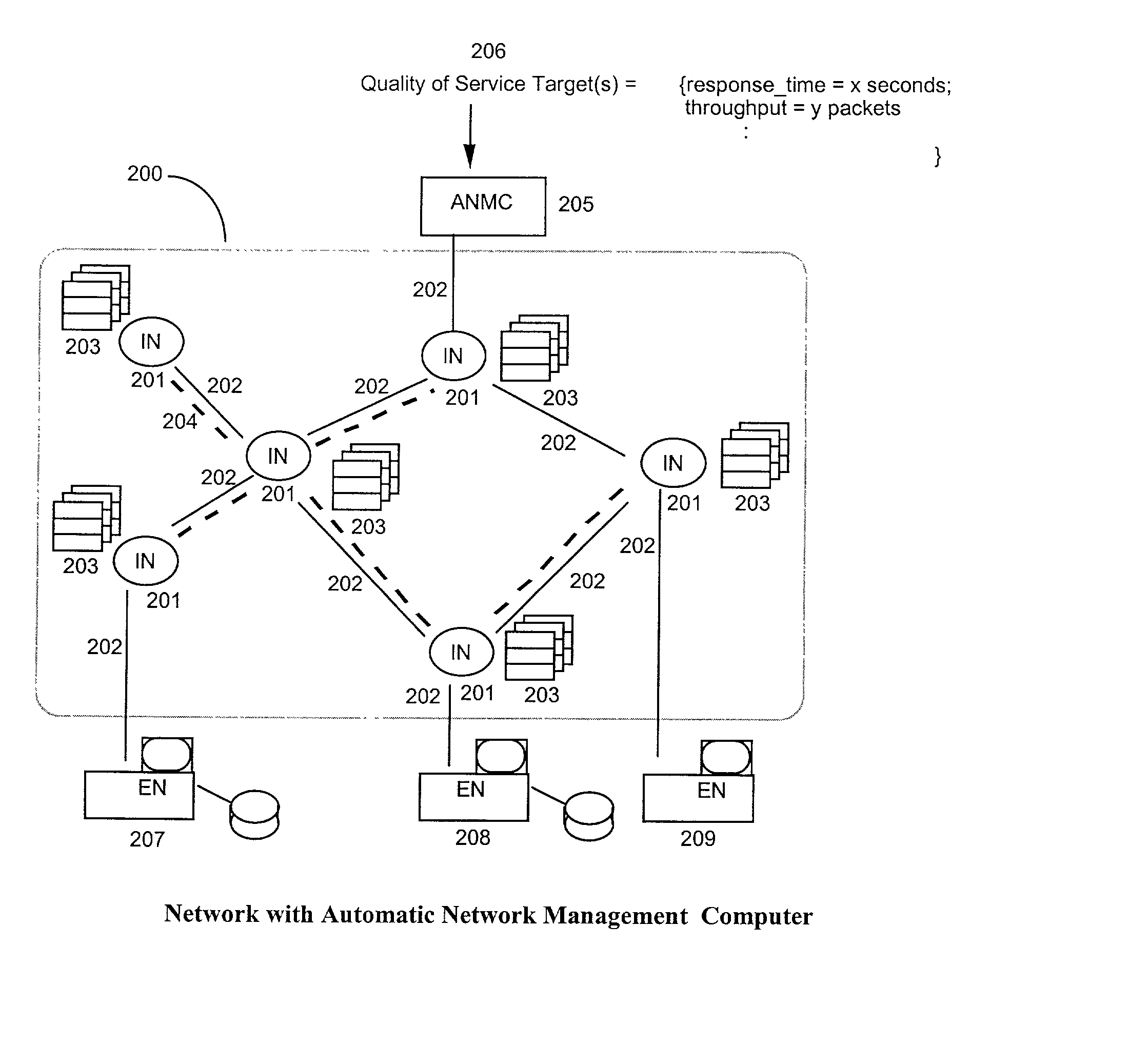

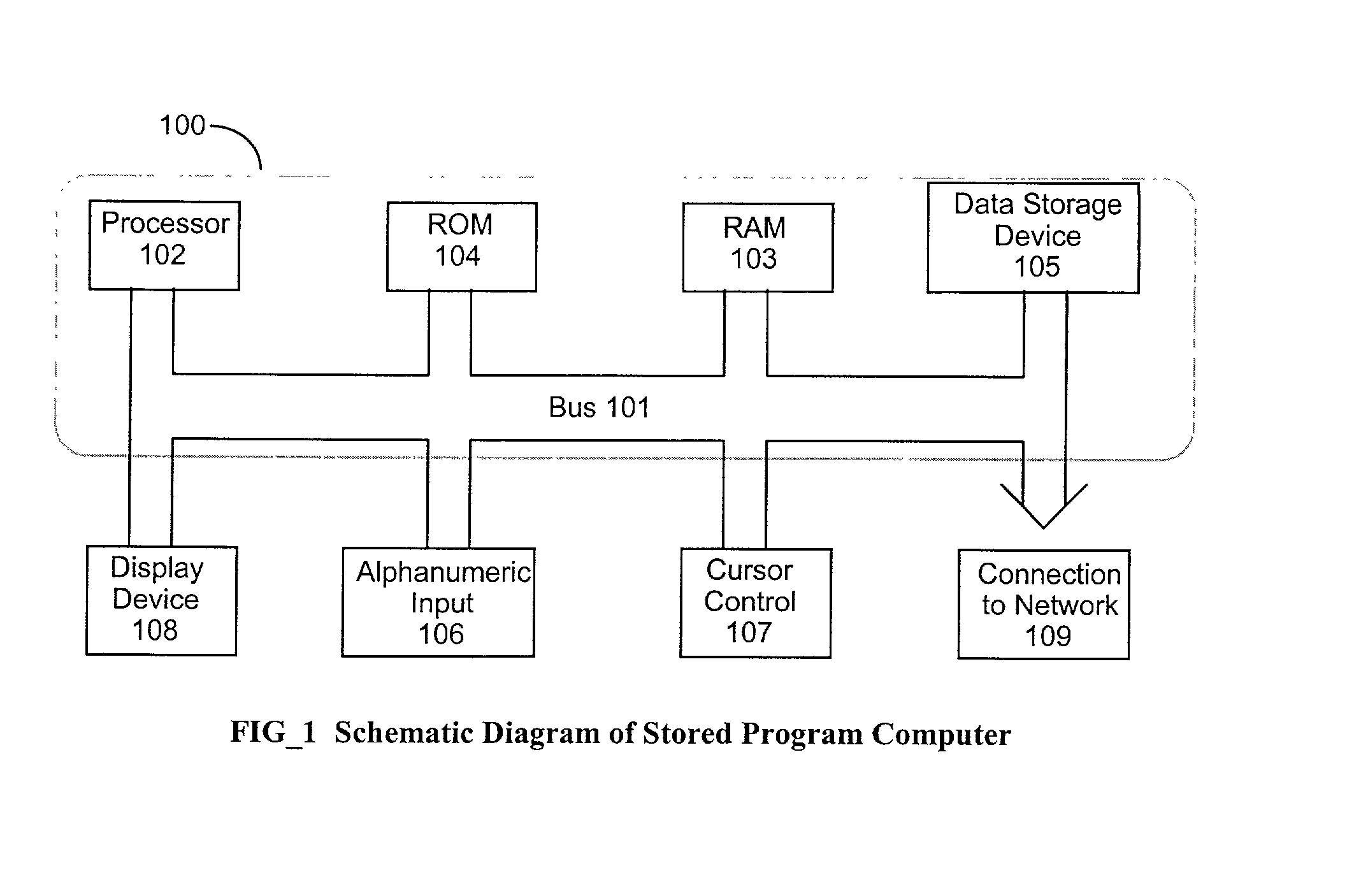

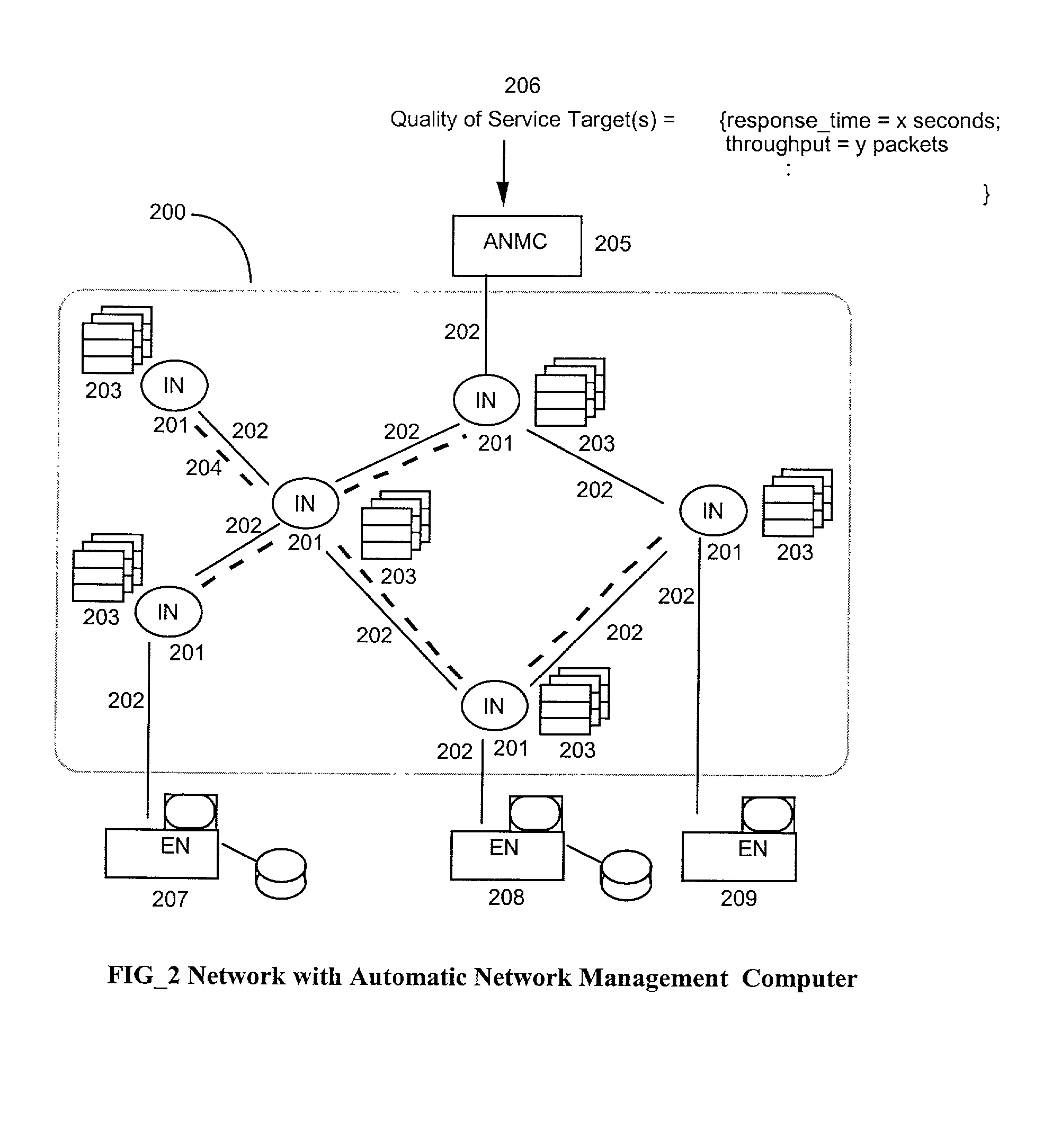

Automatic management systemfor communications networks

InactiveUS20020087696A1Digital computer detailsData switching networksAutomatic controlControl system

An automatic control system for monitoring and controlling bandwidth and workload in a communications network.

Owner:BYRNES PHILIPPE C

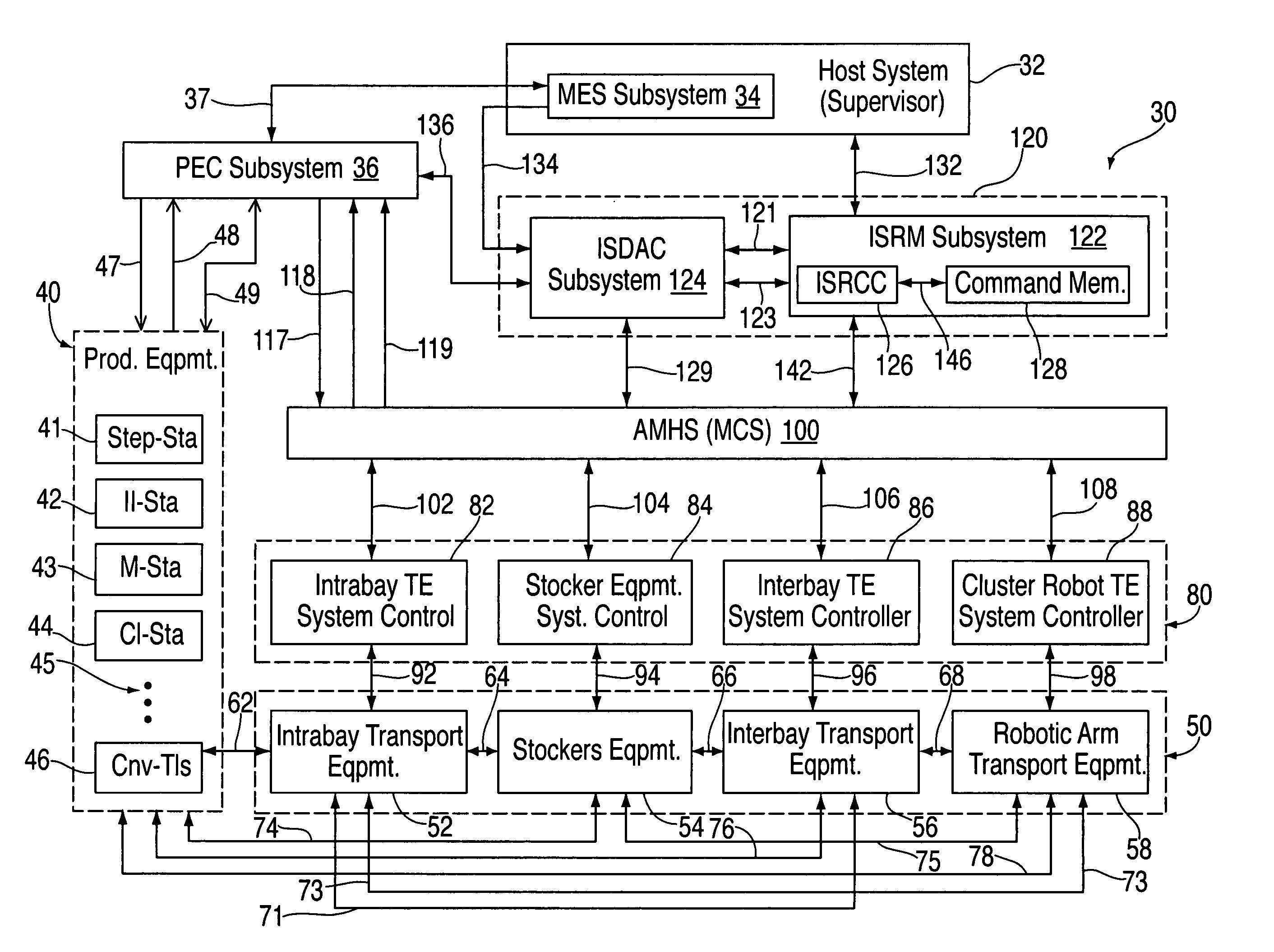

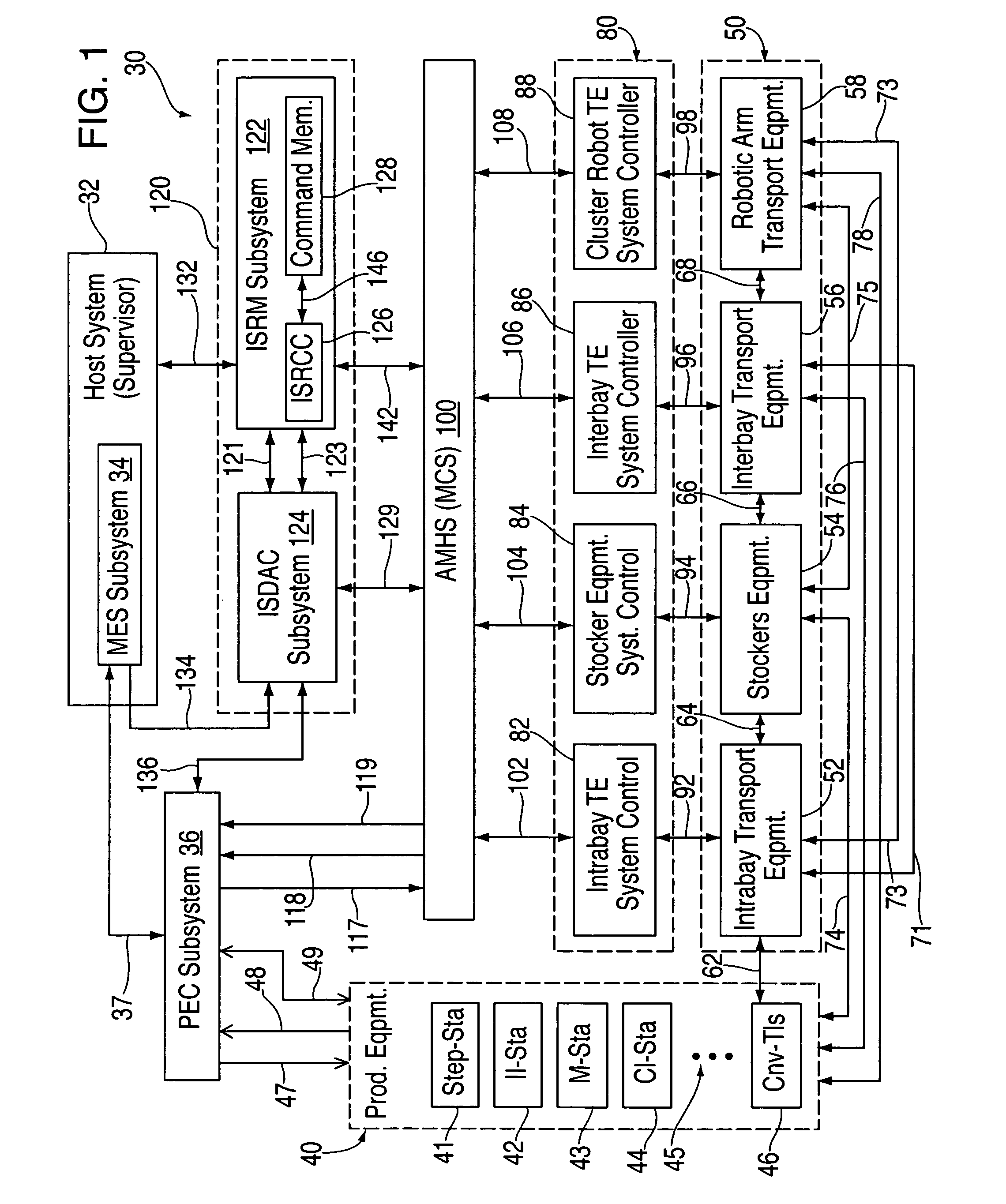

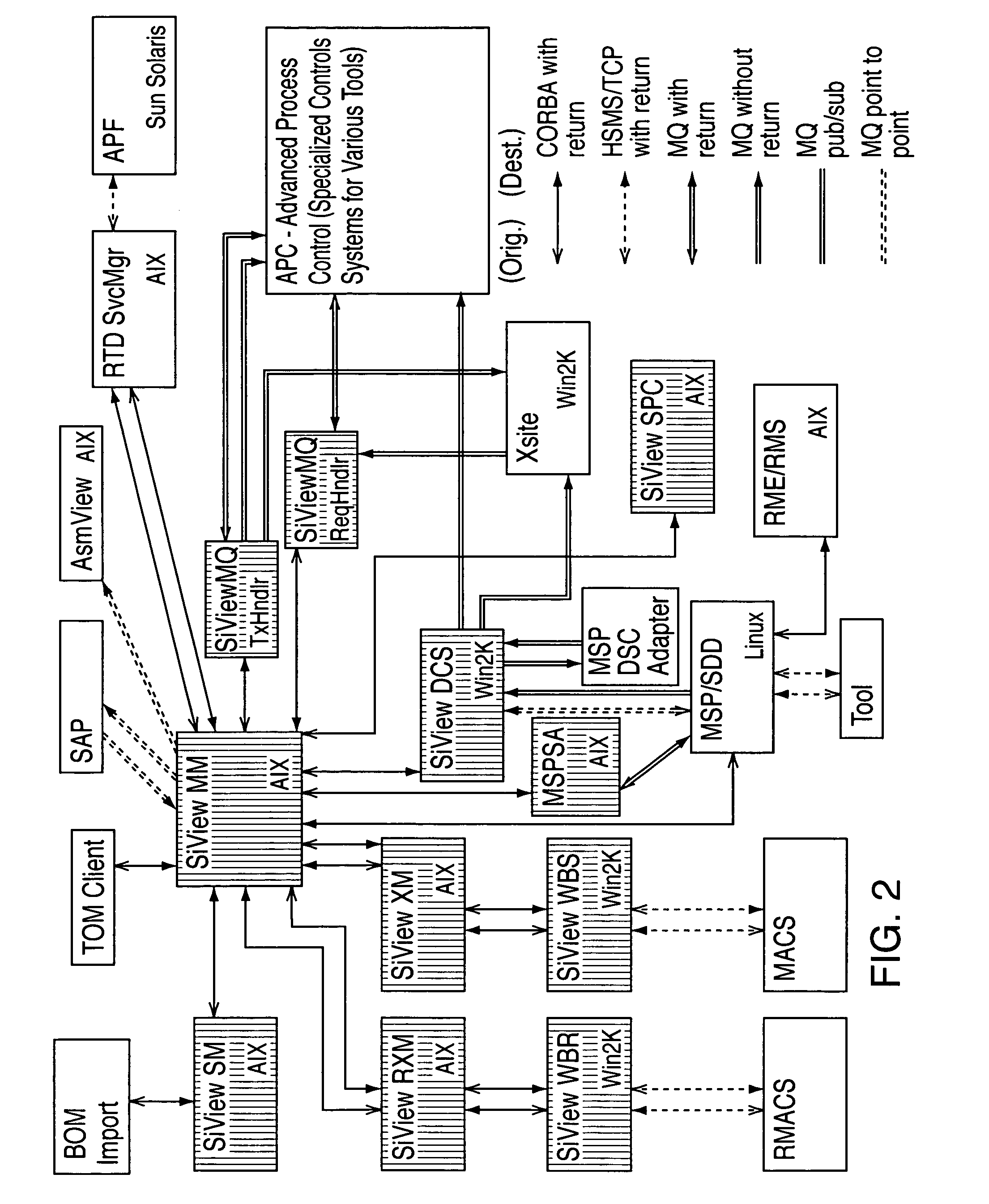

Method and system for automating issue resolution in manufacturing execution and material control systems

InactiveUS20050075748A1Decrease productivityImprove productivitySafety arrangmentsTesting/monitoring control systemsProduction rateImage resolution

Automatic error recovery systems and methods for automated manufacturing plants and factories are disclosed. Such facilities normally have multiple automated control systems, including an automated material handling system (AMHS), all of which run automatically, typically under the control of a computerized manufacturing execution system (MES). The disclosed issue resolution (ISR) systems and methods involve providing components, which may be supervised and operated by an issue resolution management (ISRM) system, if desired, that interfaces with the MES, AMHS, and / or production control system(s) which operate the tools and other stations within the automated factory. The components, which may be considered customized logic cells, may each be written for handling a specific kind of incoming error condition, problem or other issue that might occur and which is amenable to automatic resolution or recovery. These errors often occur between or across the boundaries of the various interactive systems and automated equipment. Each cell may cycle through a sequence of possible error resolution or recovery steps until the specific issue is resolved or until the sequence of steps is exhausted. Other components of the ISR system may provide results-oriented messages and / or facilitate the collection of data as to whether and which corrective commands from the ISR system resolved the reported error conditions automatically. The disclosed ISR systems and methods for resolving errors and other issues automatically helps improve the overall productivity of automated factories by reducing downtime and the need for human intervention to correct problems, thereby increasing factory throughput.

Owner:IBM CORP

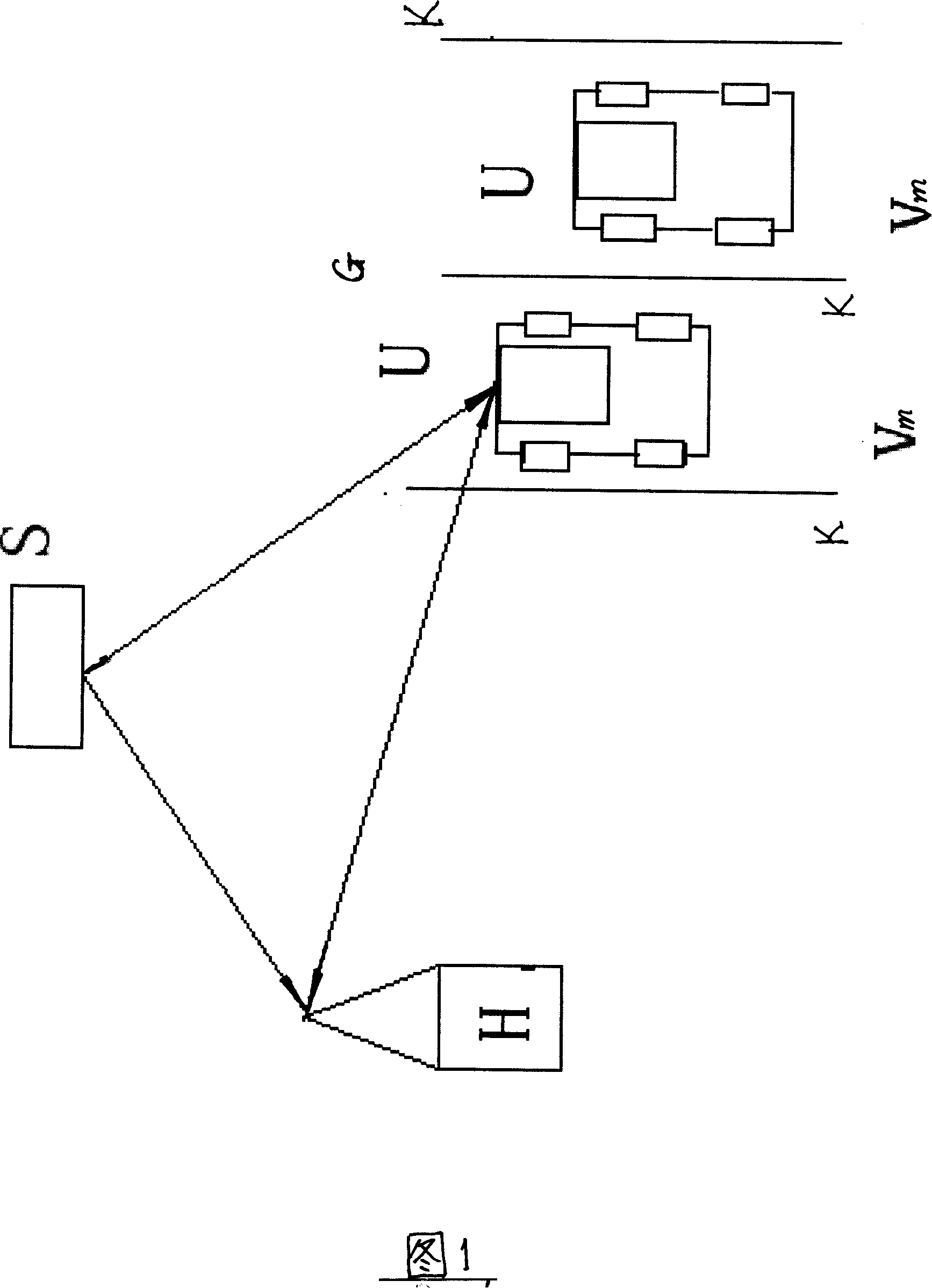

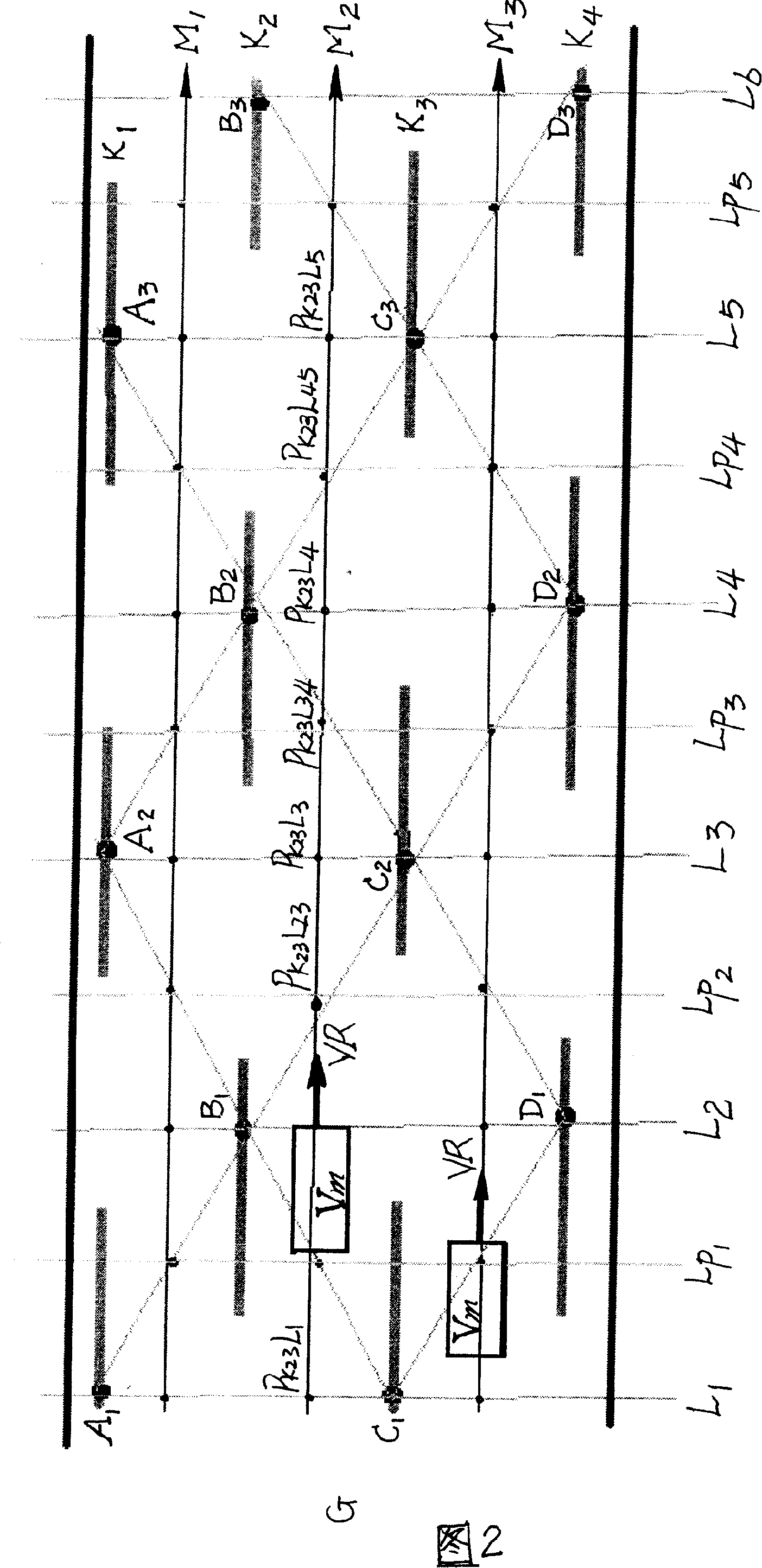

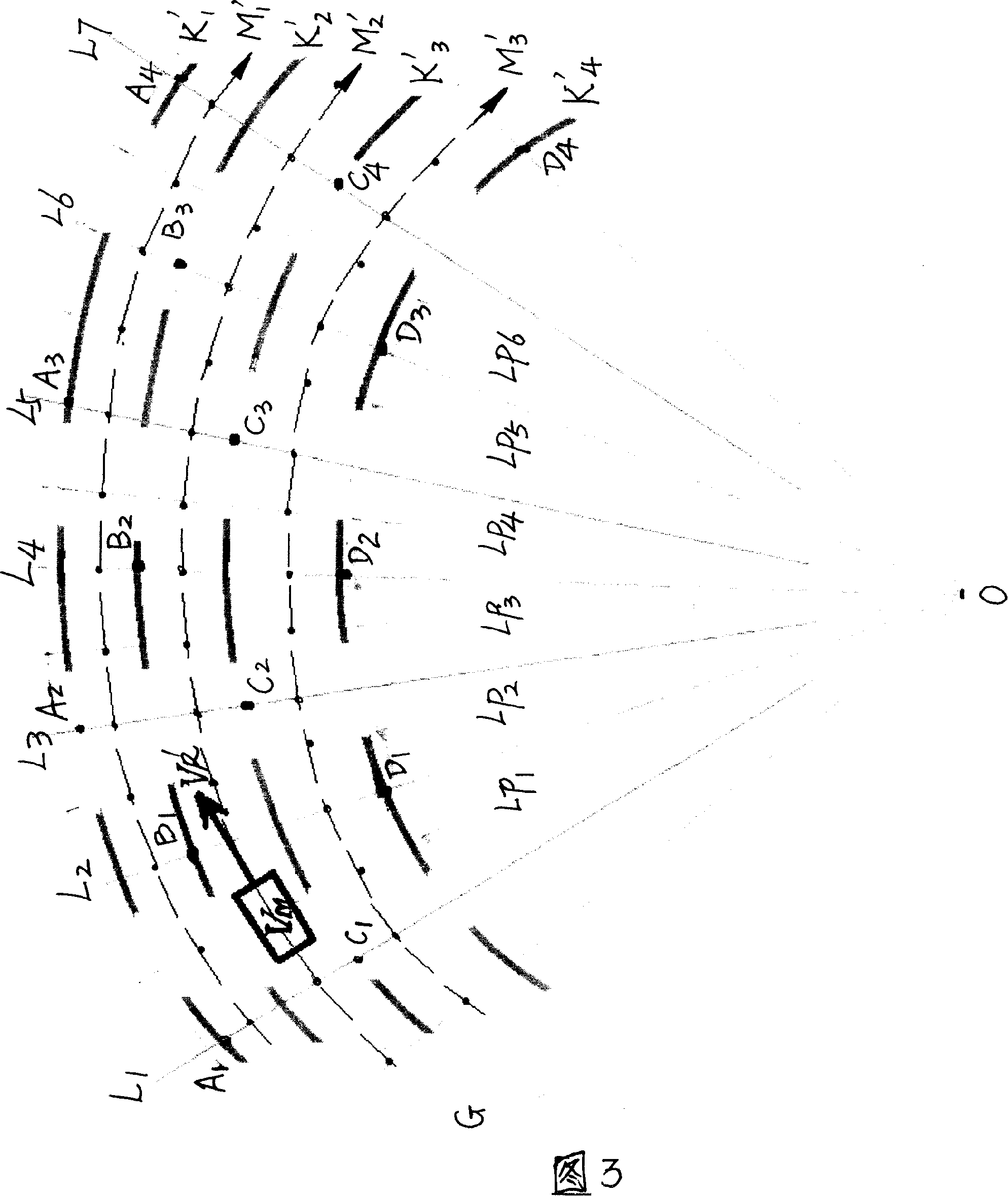

Automatic pilot system for road vehicle

InactiveCN101131588ARealize autonomous drivingPracticalPosition/course control in two dimensionsPilot systemAutomatic control

This invention relates to an automatic driving system of a road vehicle, especially to a system which providing automatic driving information indication for traveling vehicles and realizing vehicle automatic driving through the vehicle automatic control system, which is characterized by comprising: fixing markers at interval along a road travelling line, receiving information feedback by the fixed markers through a set relay information station and forming the vehicle and road information on the road, and constantly supplying the road and vehicle information of the road where the vehicle is to a vehicle automatic receiving processor after the received GPS(Global Position System) information and the vehicle and road information on the road are overall treated, installing an automatic driving software in a vehicle-mounted computer which can receive and treat relevant information of the relay information station at any time, constantly sending operation instructions to a vehicle automatic controller so as to keep the vehicle travelling information direction line consistent with the vehicle driving speed direction line, and sending instructions to the vehicle automatic controller according to the selected mode by a driver so as to realize vehicle automatic driving.

Owner:吴体福

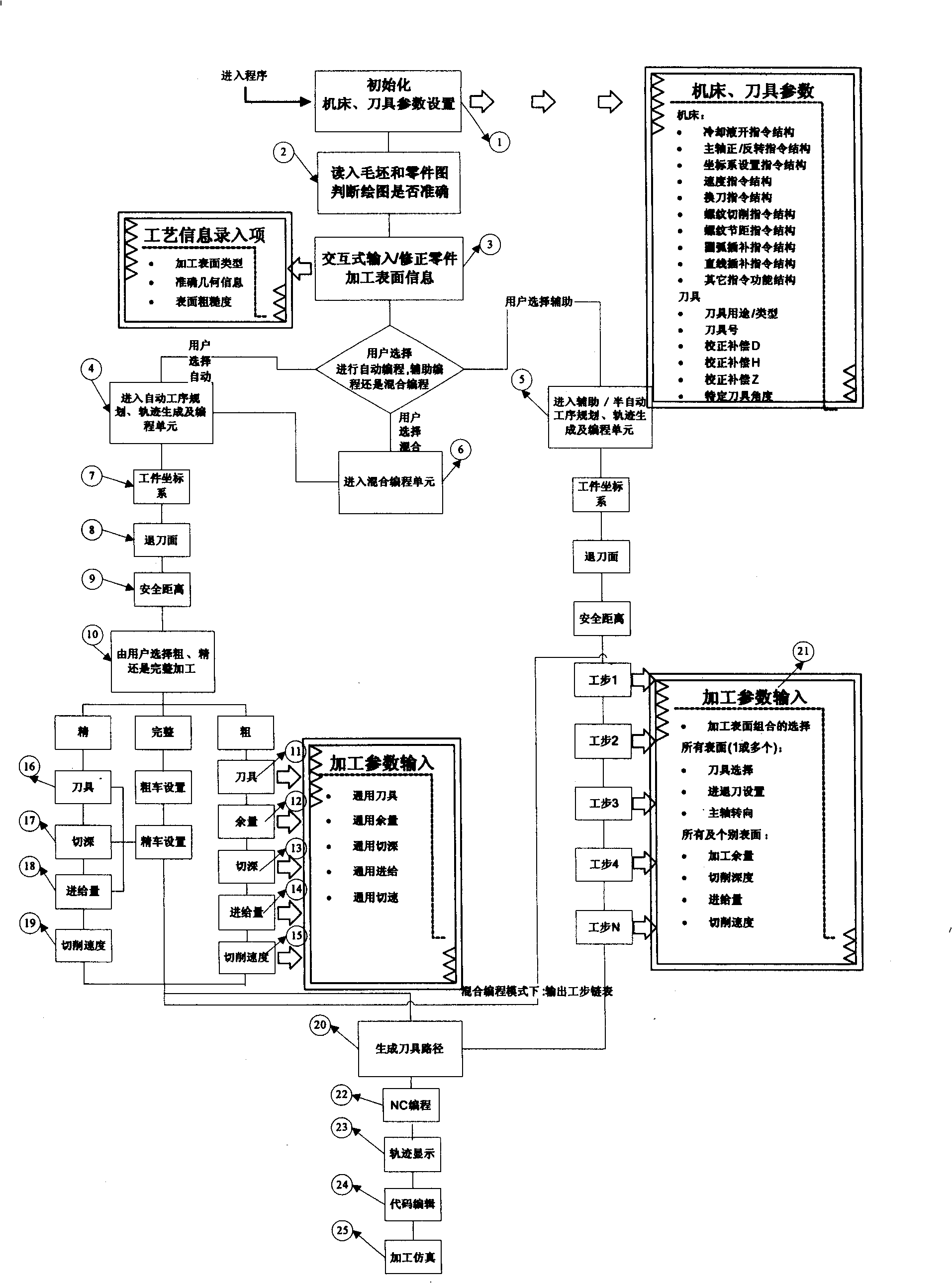

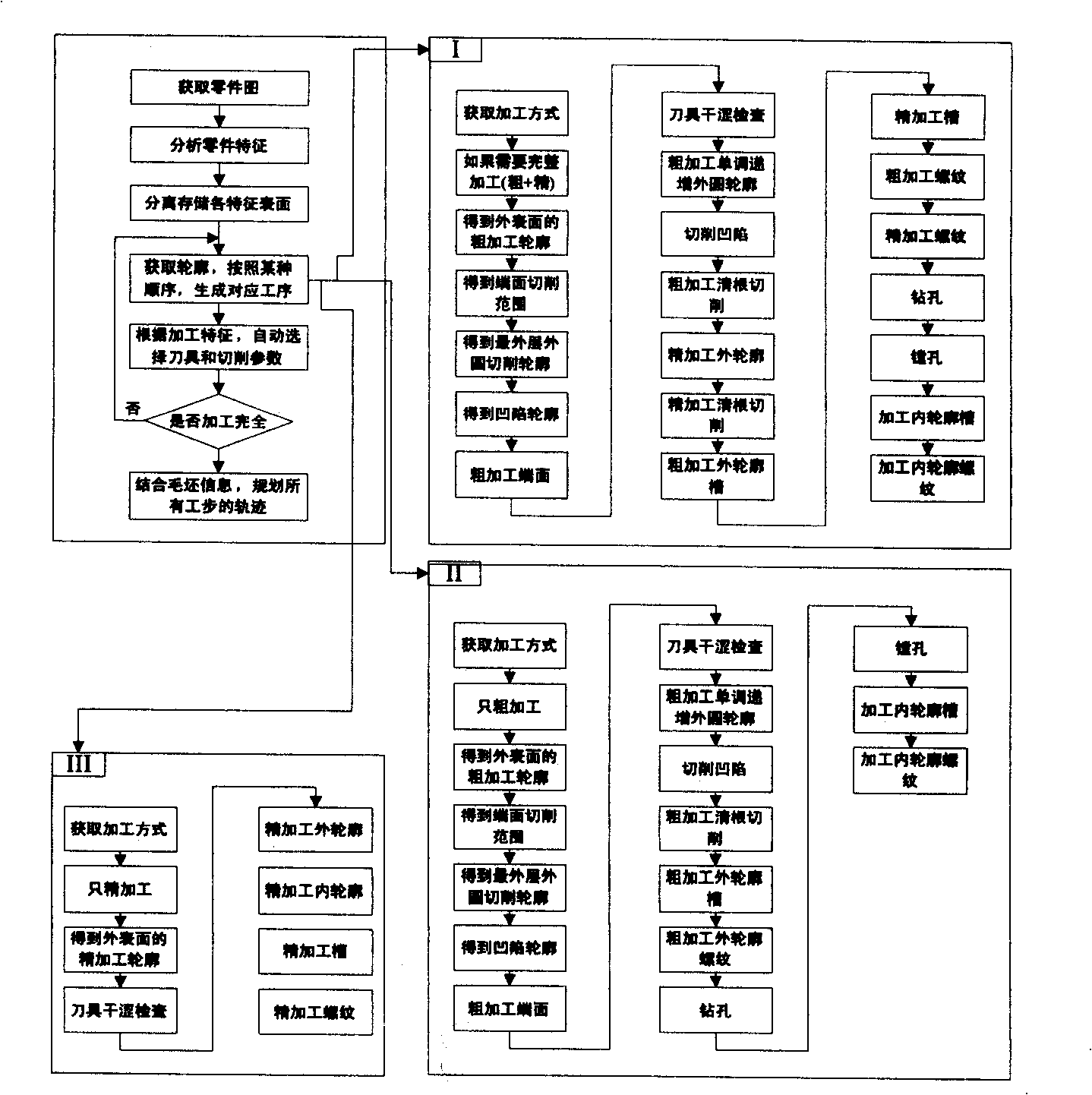

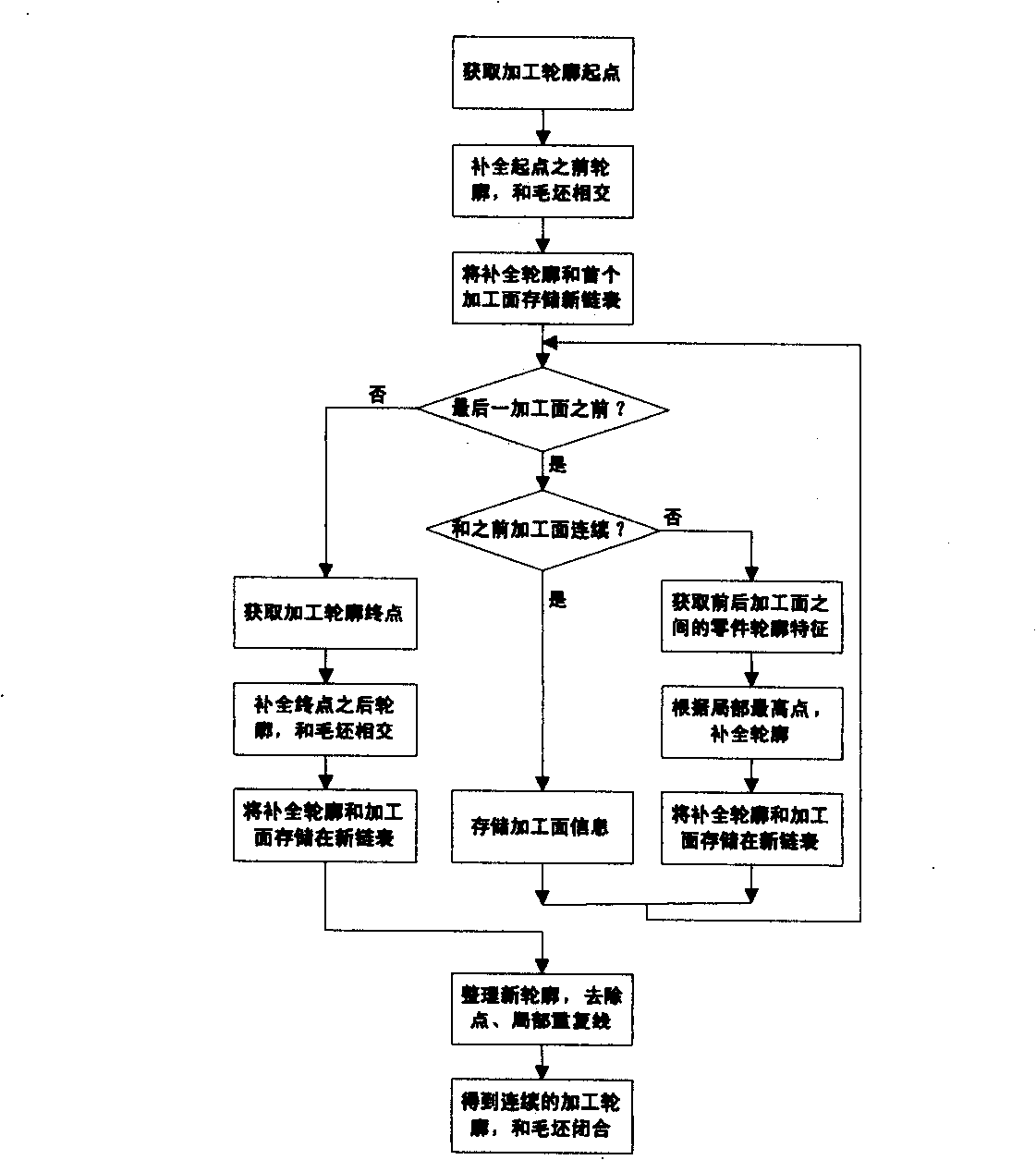

Imaging interactive numerical control turning automatic programming method and system

The invention provides an automatic graphical interaction-typed numerical control (NC) turning programming method and system used for improving programming efficiency and NC code quality, prompting quick product process realization (RPPR) and integrated product process development (IPPD). The technical proposal of the invention is that the automatic graphical interaction-typed numerical control turning programming method is characterized in that the method comprises the steps of: reading in blank and part drawing, removing redundant information, and judging whether the graphics are exact; leading the graphics to have real-time interaction function and be capable of correcting the information of the part processing surface, including processing surface type, exact geometrical information and surface roughness; determining whether to execute the corresponding system function modules by carrying out automatic programming or auxiliary programming or mixed programming according to the selection of the user. The automatic graphical interaction-typed numerical control turning control system is characterized in that the automatic graphical interaction-typed NC turning control system comprises a CAD data reading-in module which is respectively connected with an automatic programming module, an auxiliary programming module and a mixed programming module which are respectively connected with an automatic track layout module which is connected with an NC code generation module.

Owner:TSINGHUA UNIV

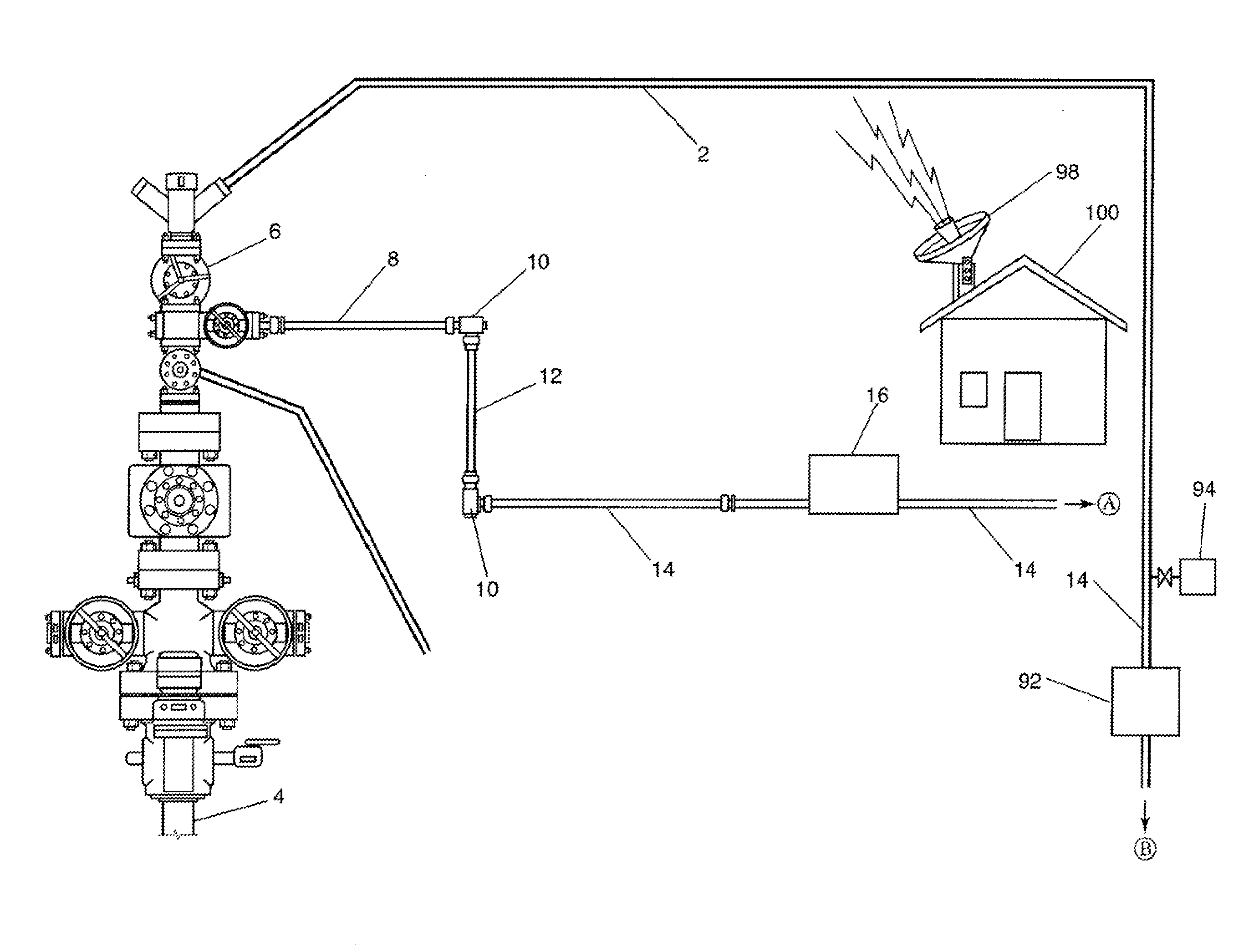

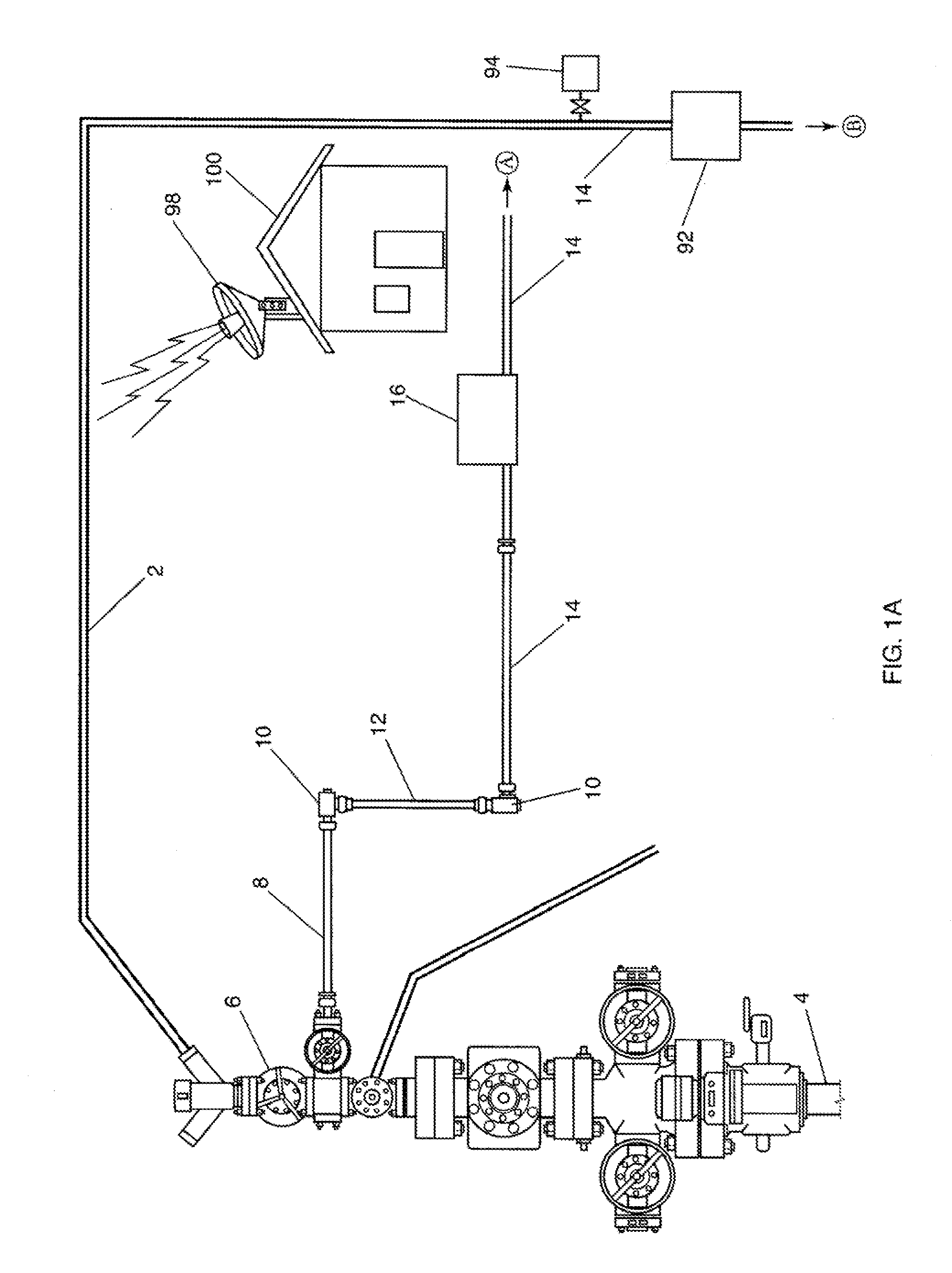

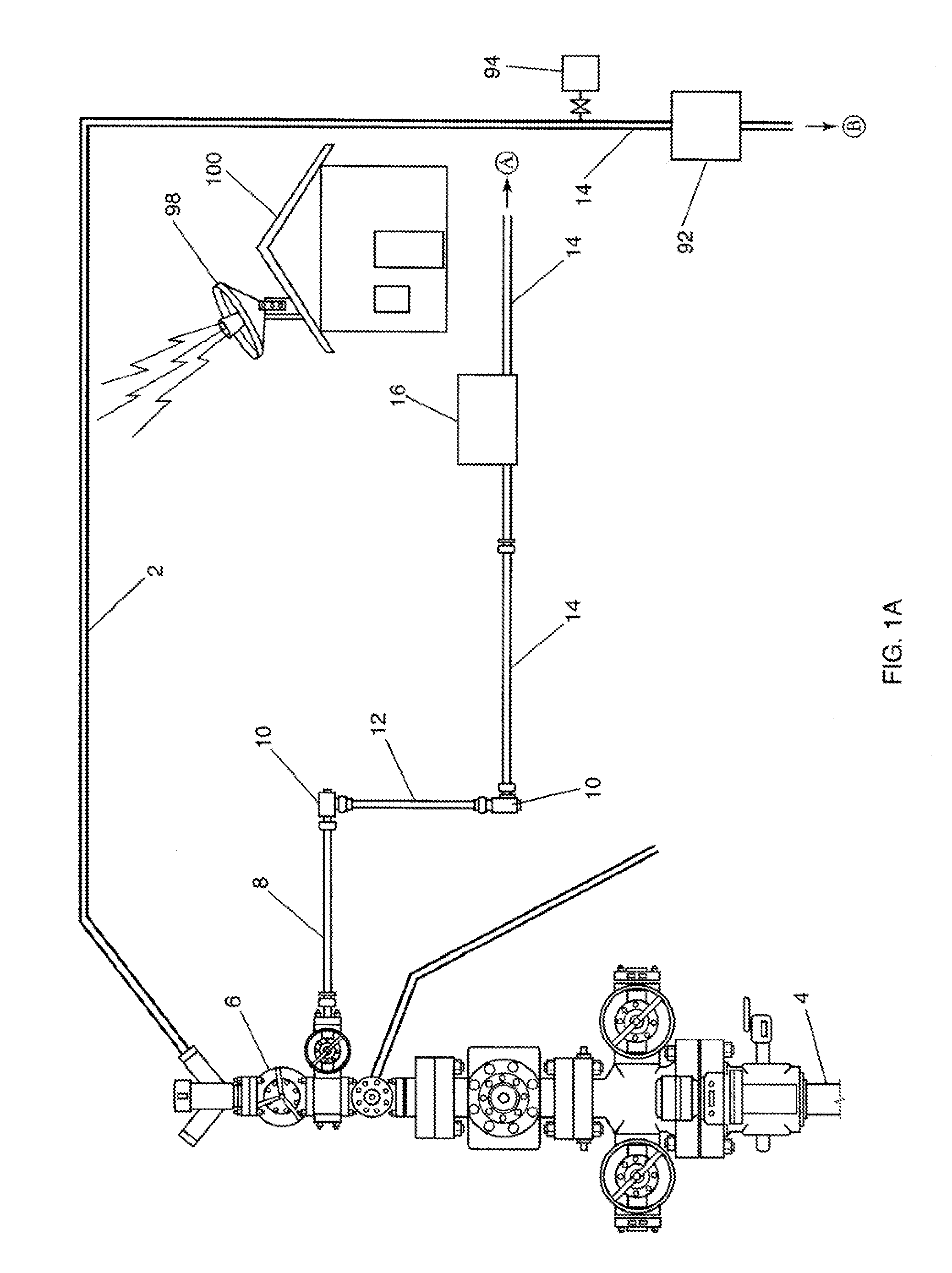

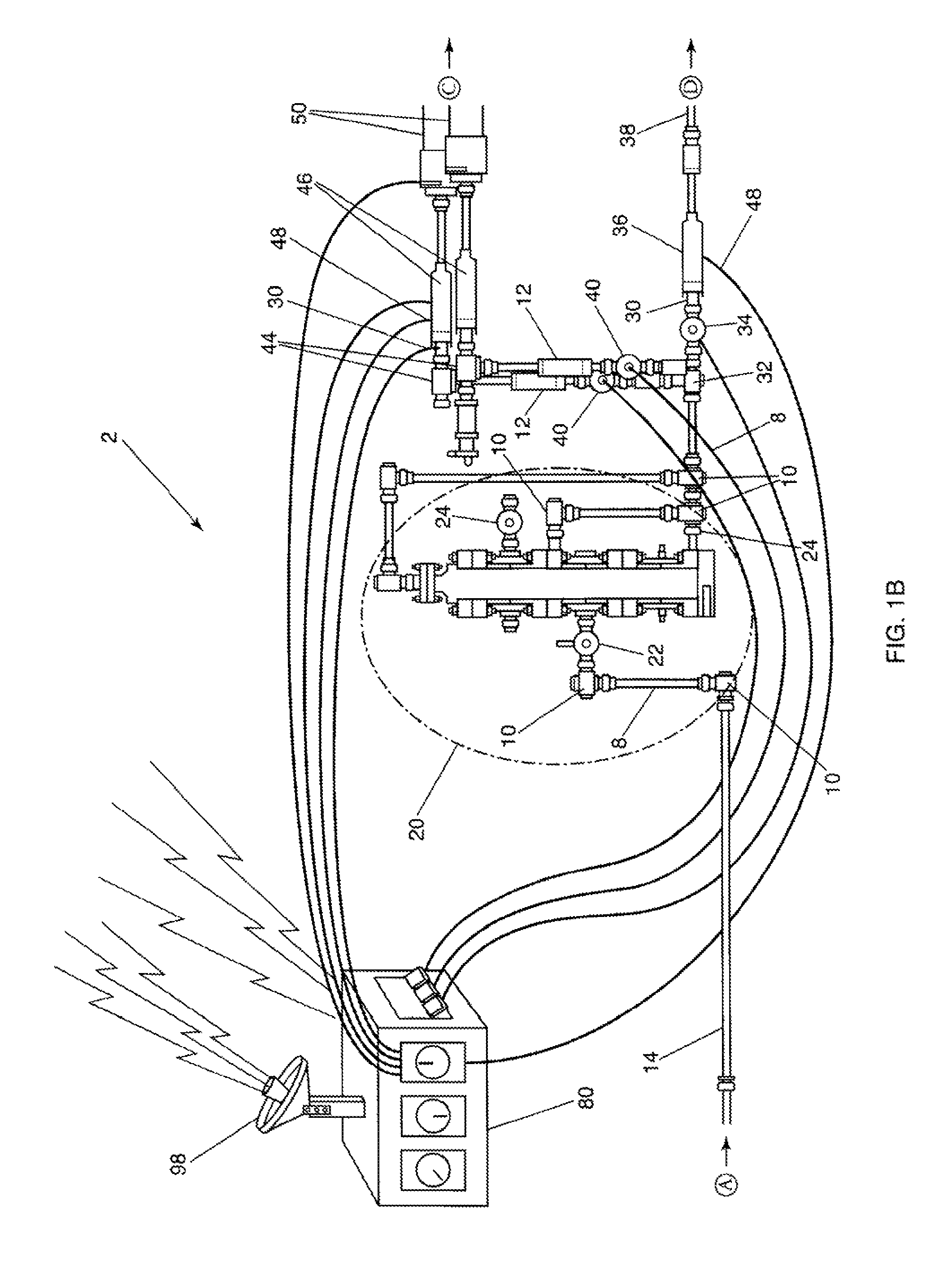

Automated closed loop flowback and separation system

InactiveUS20100206560A1Realize automatic adjustmentSurveyDrilling rodsAutomatic controlHuman–machine interface

An automated closed loop flowback and separation system that allows automated control and remote operation of a flowback operation from a safe distance without any fluid or gas release to the atmosphere. Four-phase separation tanks allow the transport gas, well bore cuttings, produced oil, and produced water to be automatically separated and transported through process piping for reuse or sale, eliminating the need for auxiliary equipment. Flow measurement instruments, pressure transmitters, and level transmitters work in conjunction with an automated blast choke to send data to a programmable logic controller for use in calculating the erosion status of the choke restriction and adjusting the choke to compensate. The programmable logic controller works with a touch-screen or similar human-machine interface to allow remote monitoring and control or automated control of the system. The automated blast choke can vary the choke restriction opening based on the pressure differential and flow rate conditions.

Owner:CANADIAN FRACMASTER

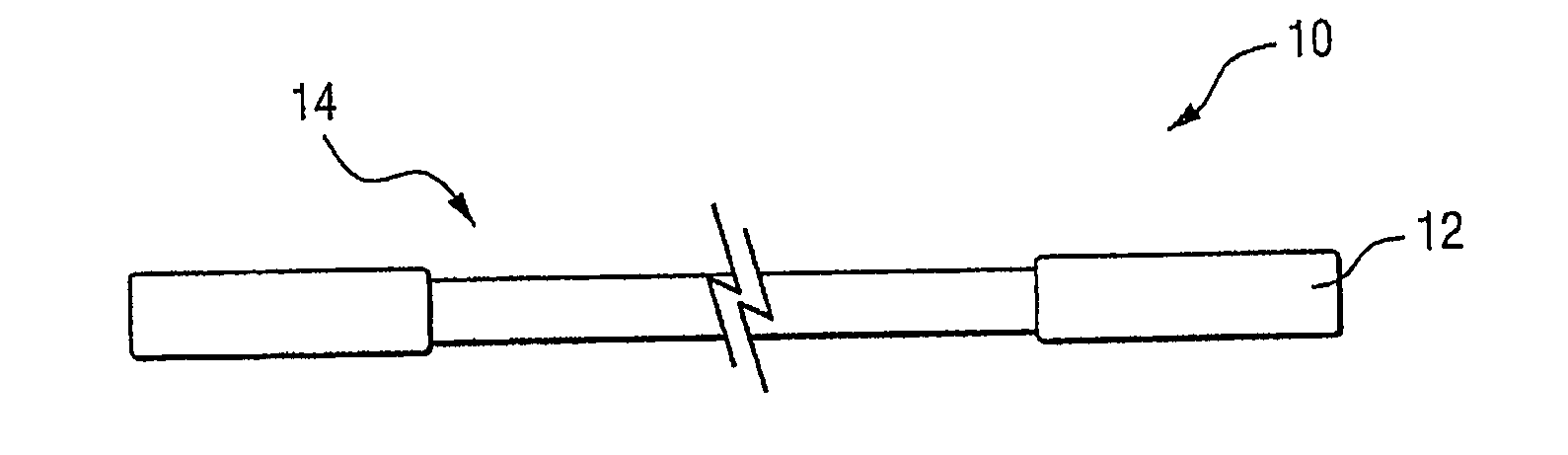

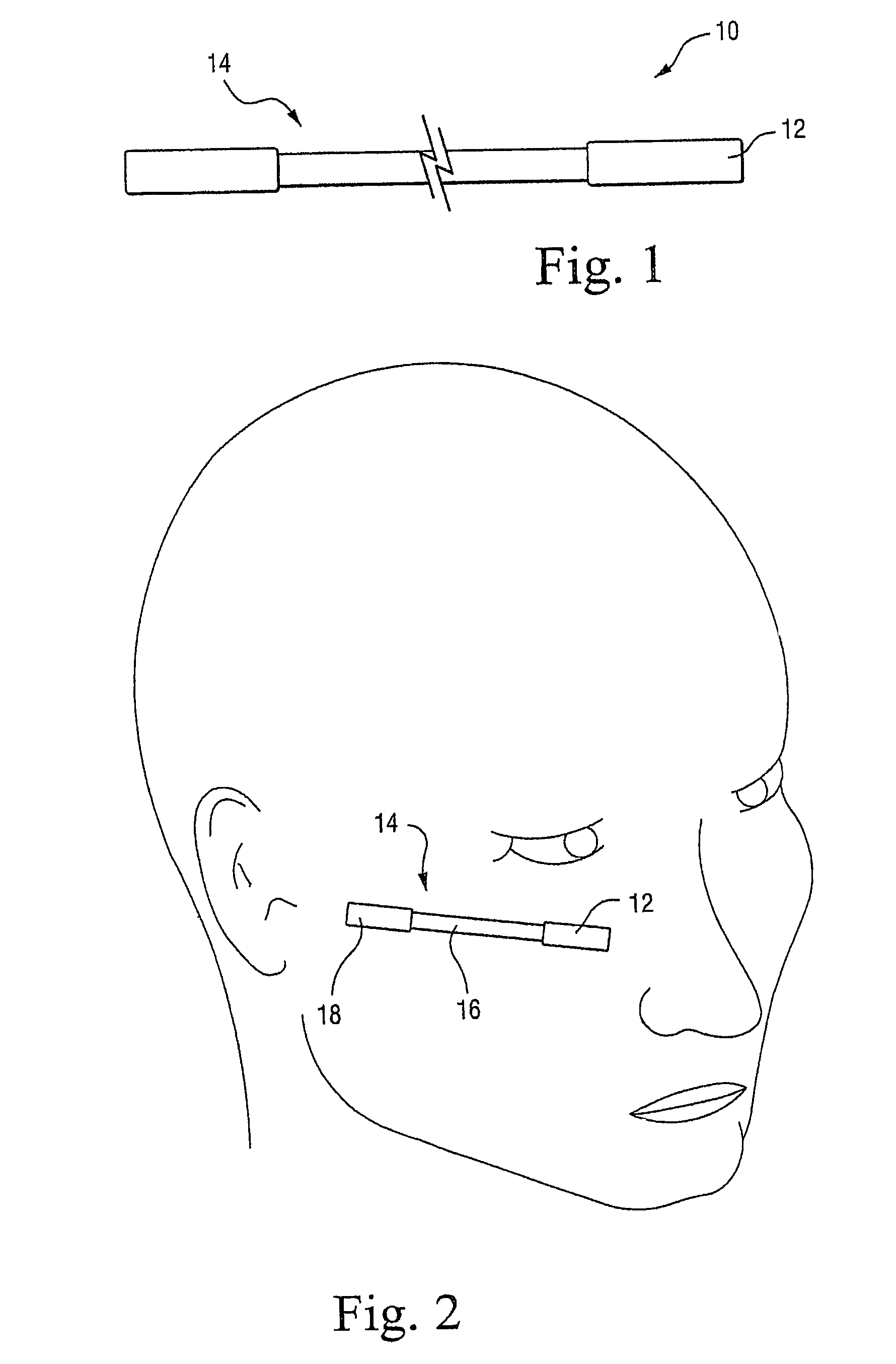

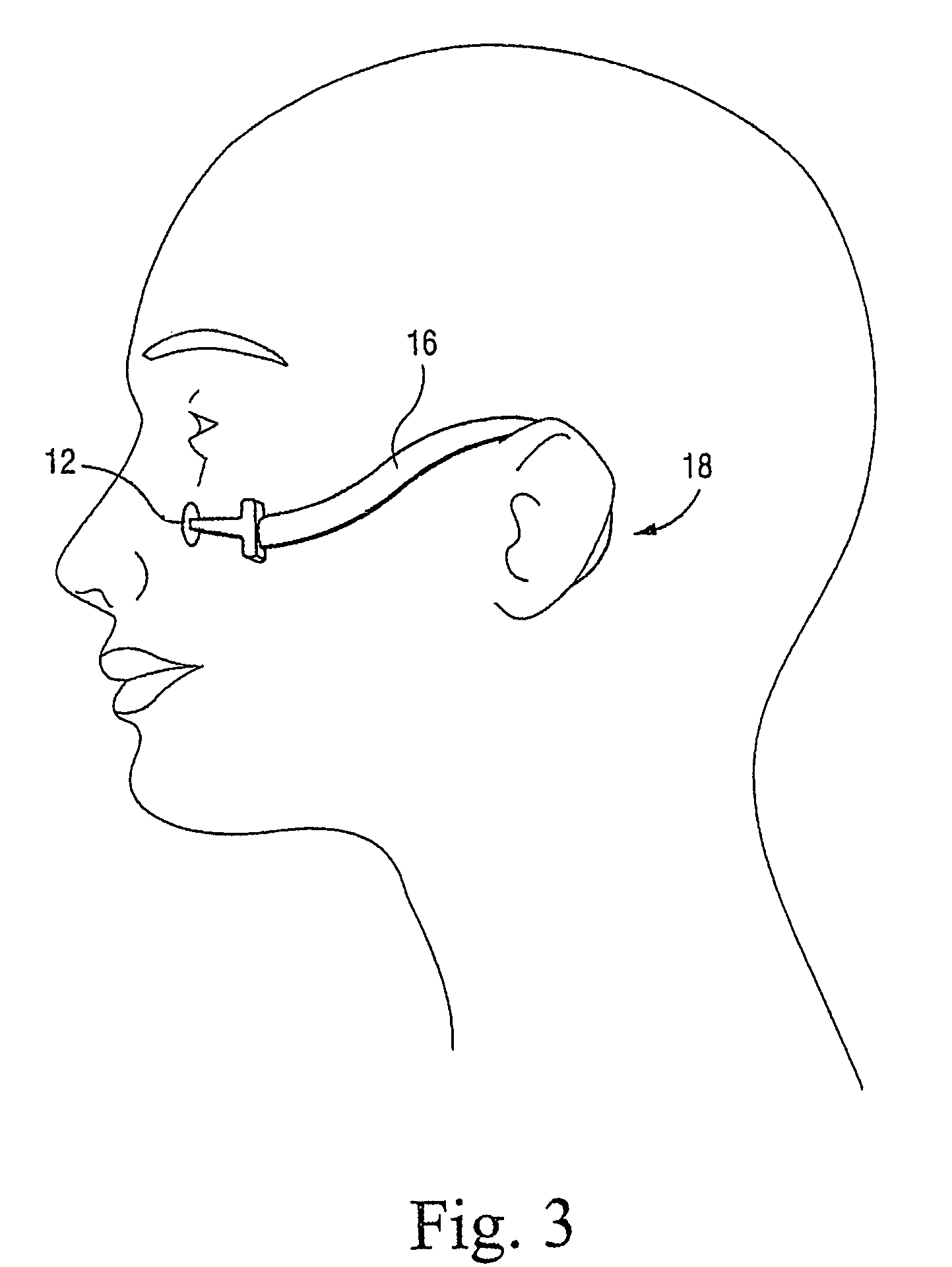

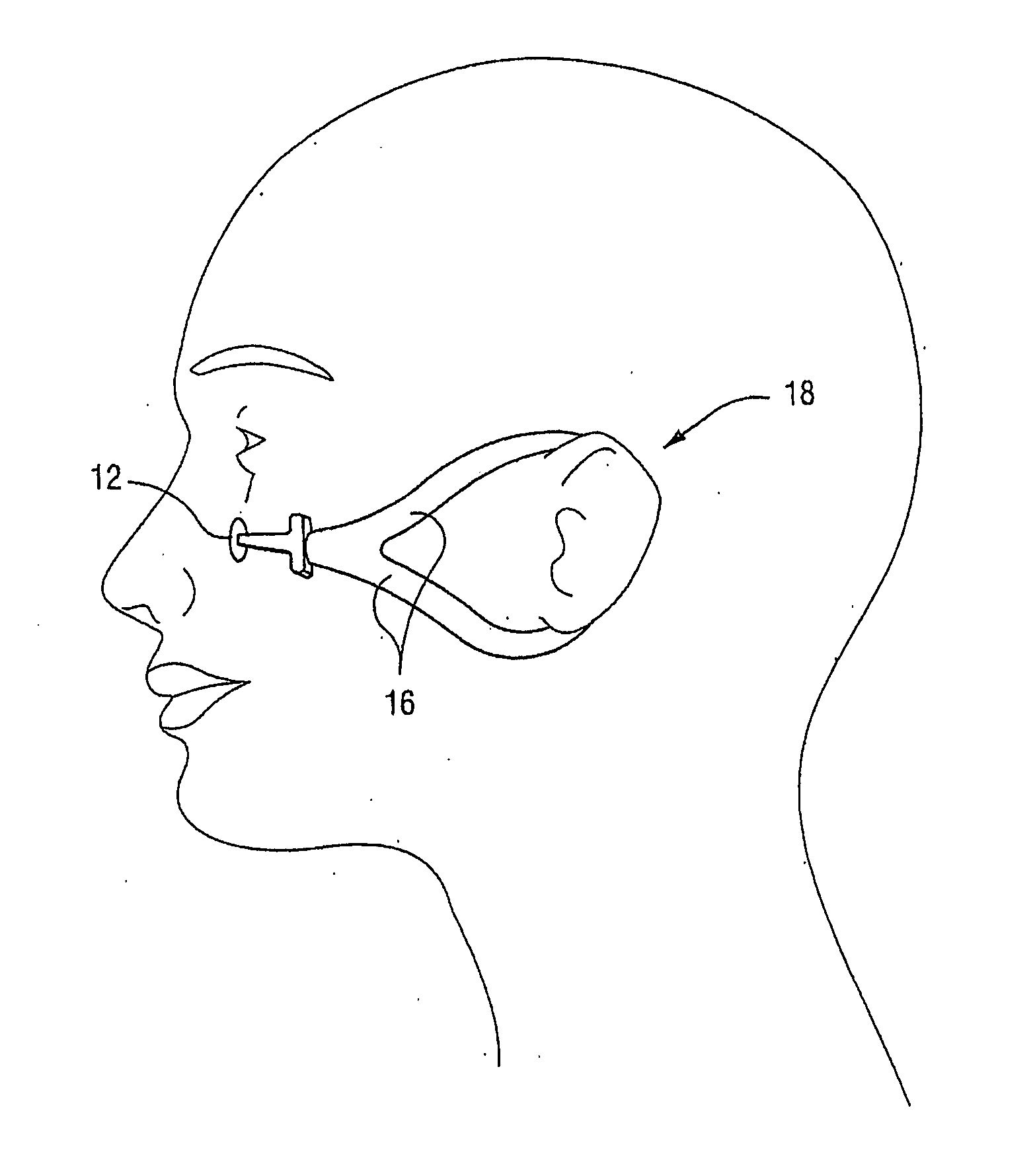

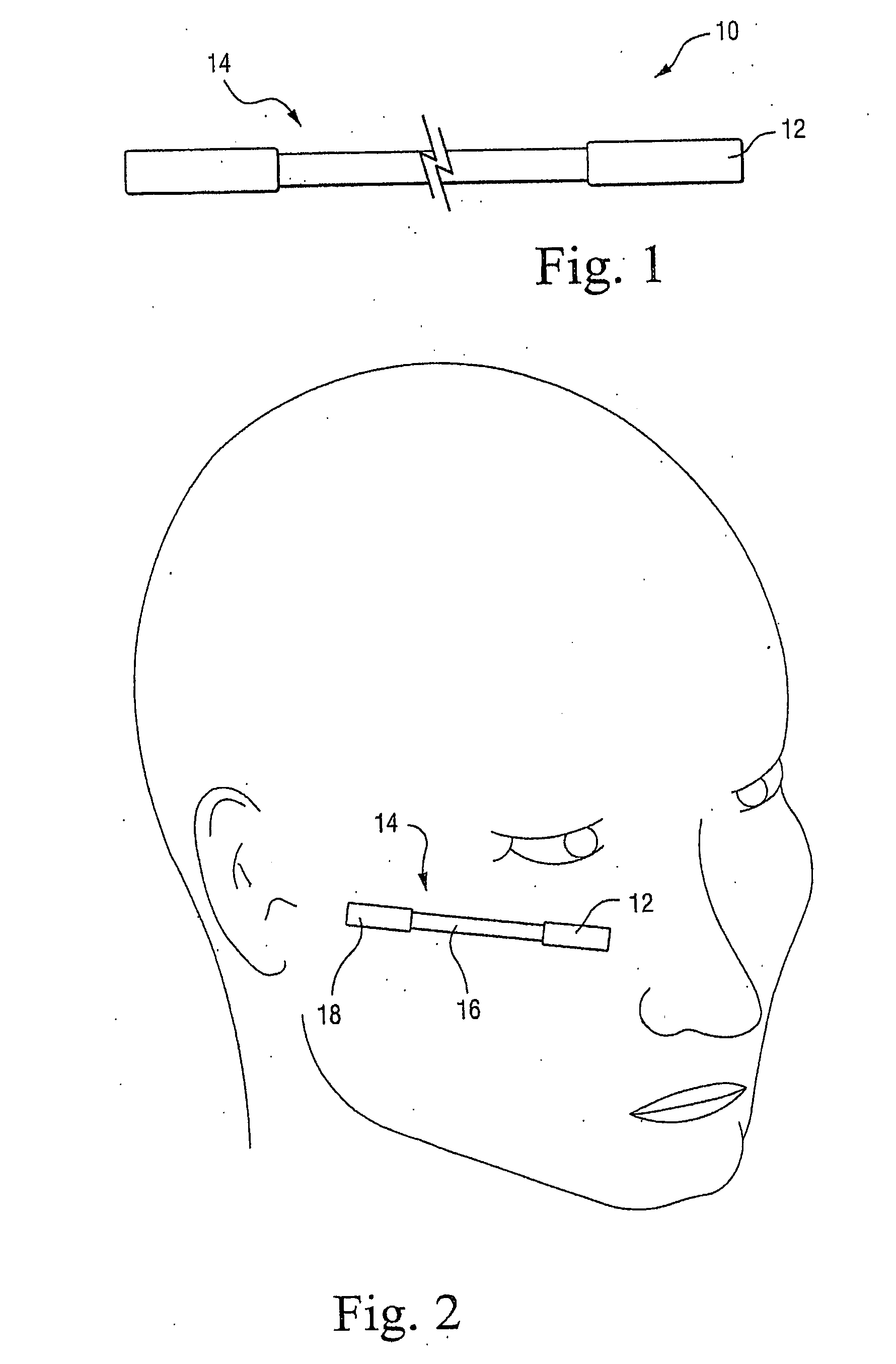

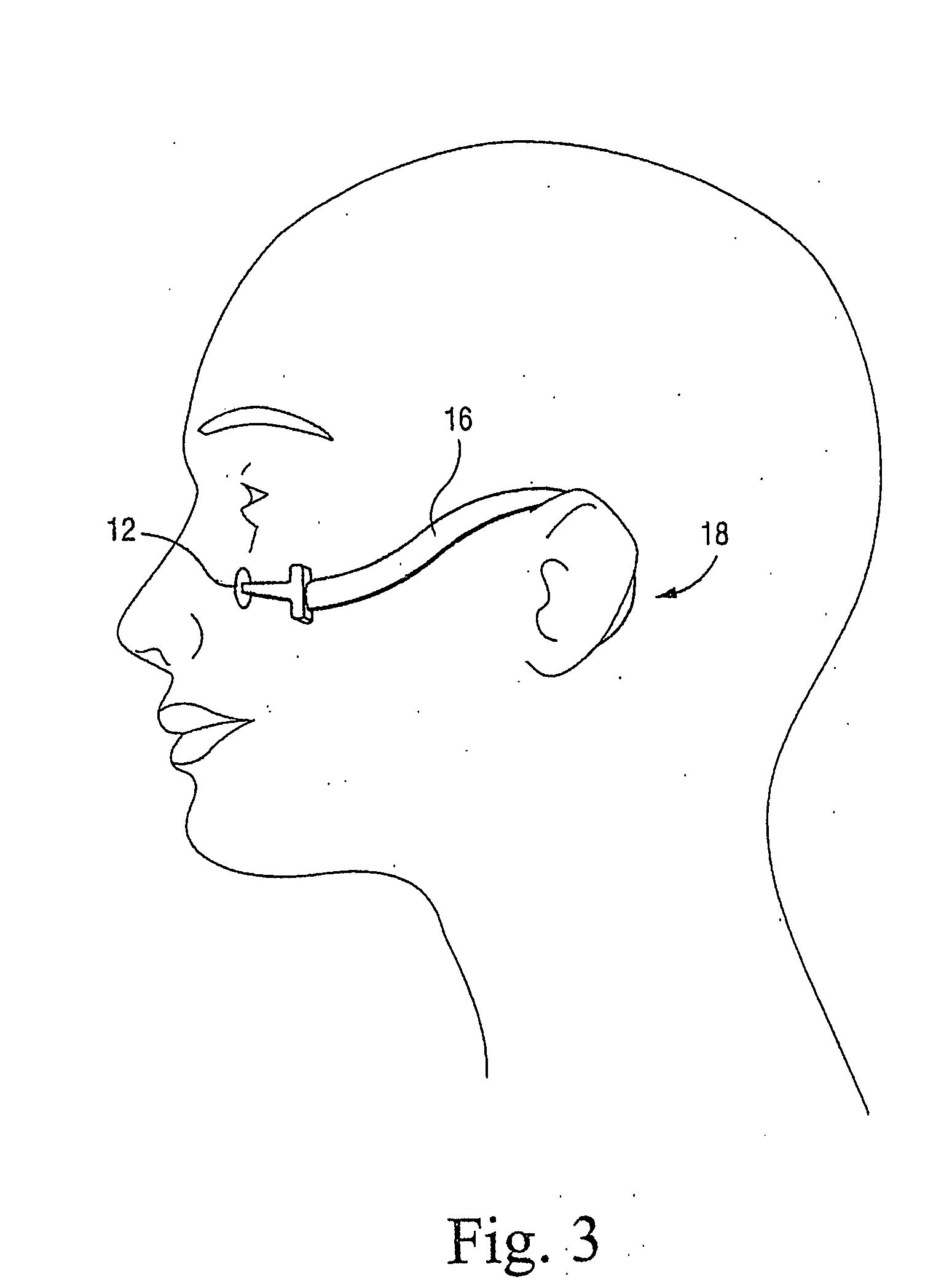

Nasal dilator

InactiveUS8051850B2Reduce flow resistanceLower impedanceRespiratory masksBreathing masksNasal passageNasal passages

A nasal dilator includes a contact pad attachable to a user's facial region below the user's eye and outboard from the user's nose. A tugging device is coupled with the contact pad and urges the contact pad in a direction away from the user's nose. With this structure, effective dilation of the nasal passages can be achieved in a comfortable manner. The dilator may also be incorporated into a CPAP mask and / or form part of an automated control system.

Owner:RESMED LTD

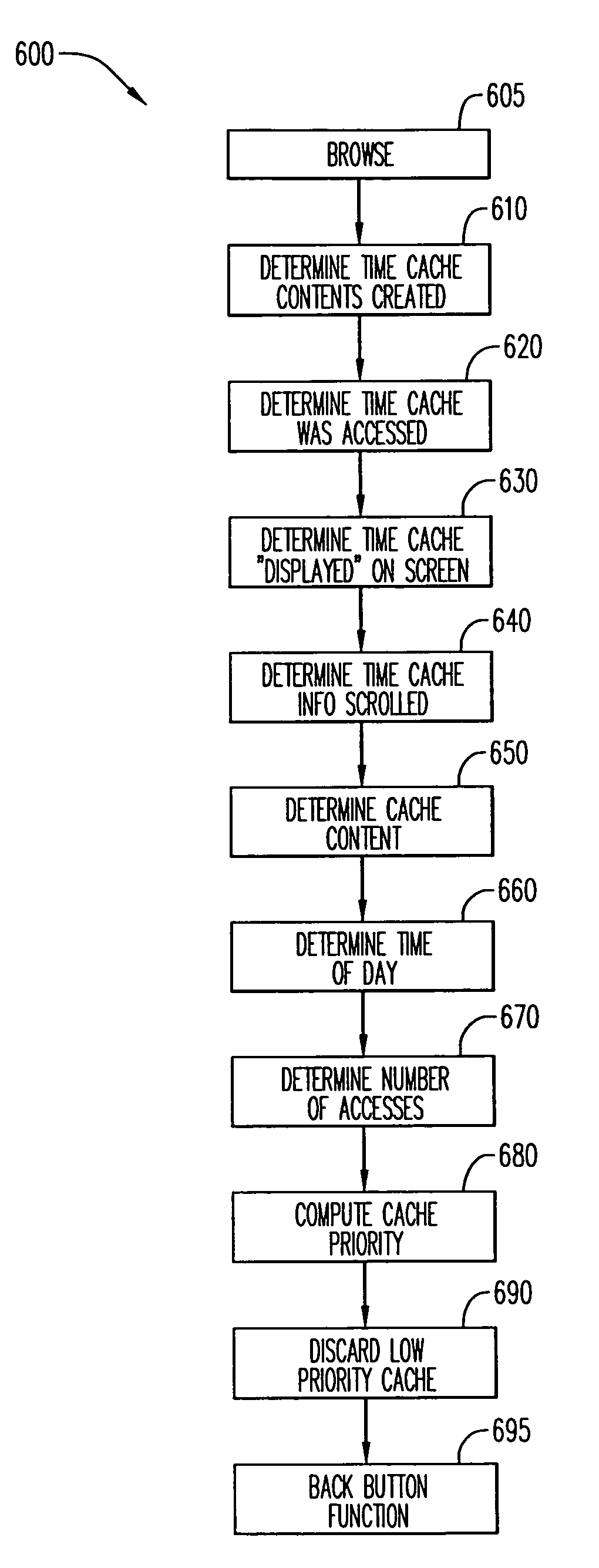

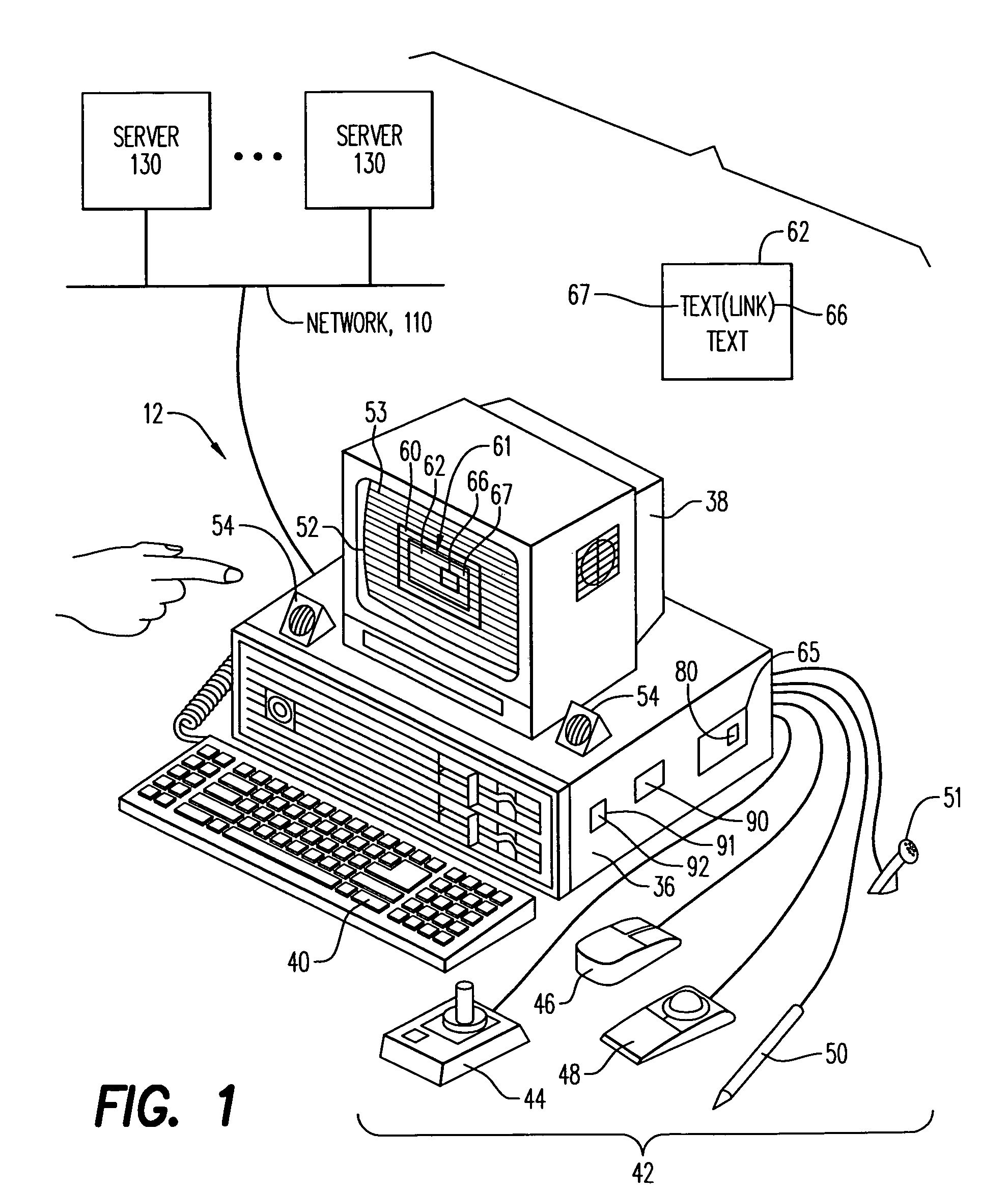

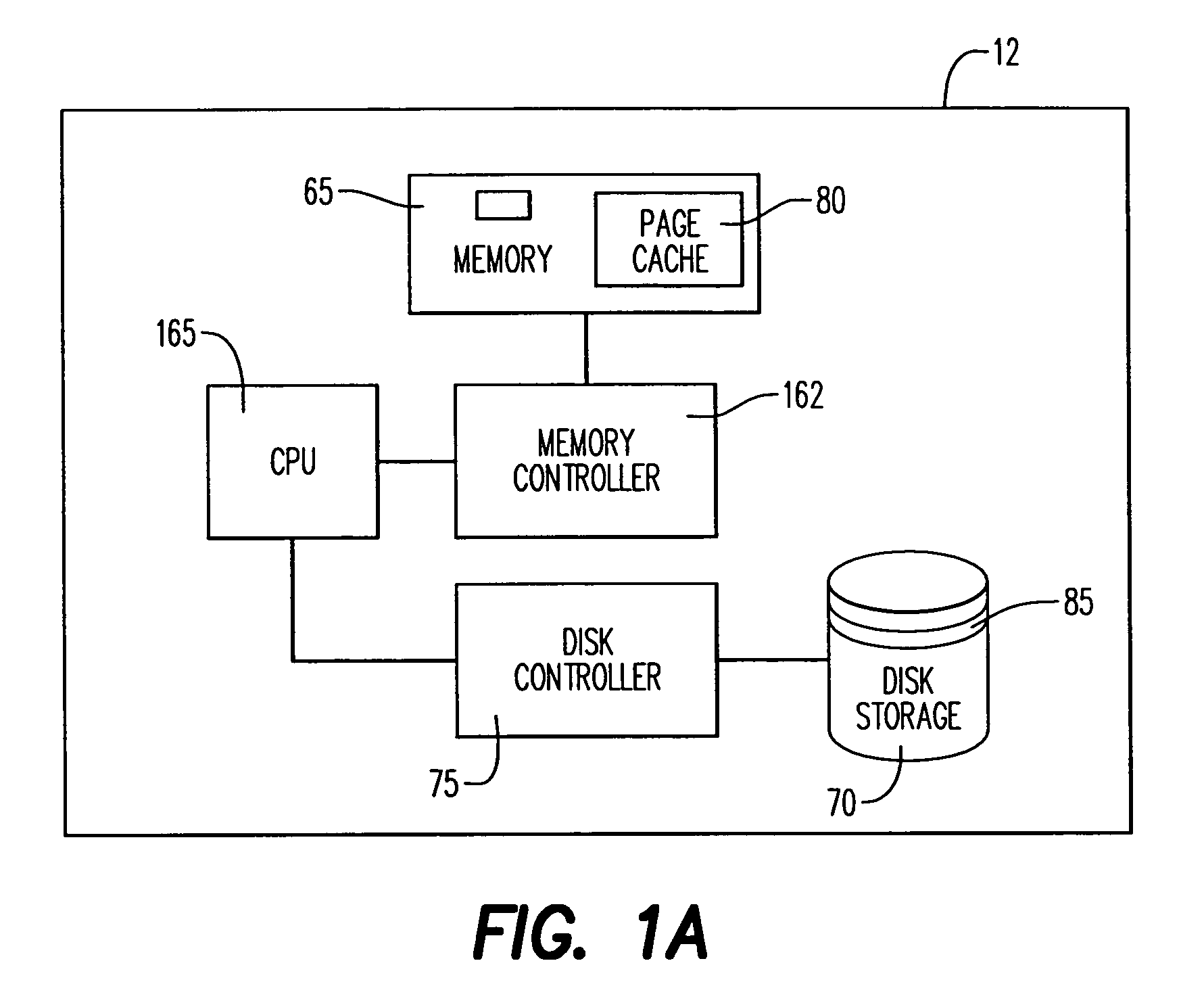

System and method for automatic control of window viewing

InactiveUS7257777B1Easy accessExecution for user interfacesInput/output processes for data processingGraphical user interfaceWeb browser

A system and method for automatic ways of prioritizing the presentation of windows on a graphical user interface (GUI) and for prioritizing and accessing information stored in cache that is used by a web browser. The viewing (tiling) priority of windows, the size of windows, and the position of windows on a GUI are automatically determined from the following criteria: the time the window was first opened, the time the window was last opened, the length of time the window was visible on the screen, the percentage visibility of the window, the amount of scrolling the window has undergone, the content of the window, the time of day, the number of window accesses, and / or some mathematical function of these criteria. Additionally, these same criteria are applied to cached information associated with web pages so that more “relevant” cached web pages are automatically stored in cache for longer periods of time before being discarded in a finite sized cache. The cached information is more quickly accessible by hitting a “back-like” button that shows more relevant (i.e. higher priority) information before less relevant information.

Owner:GOOGLE LLC

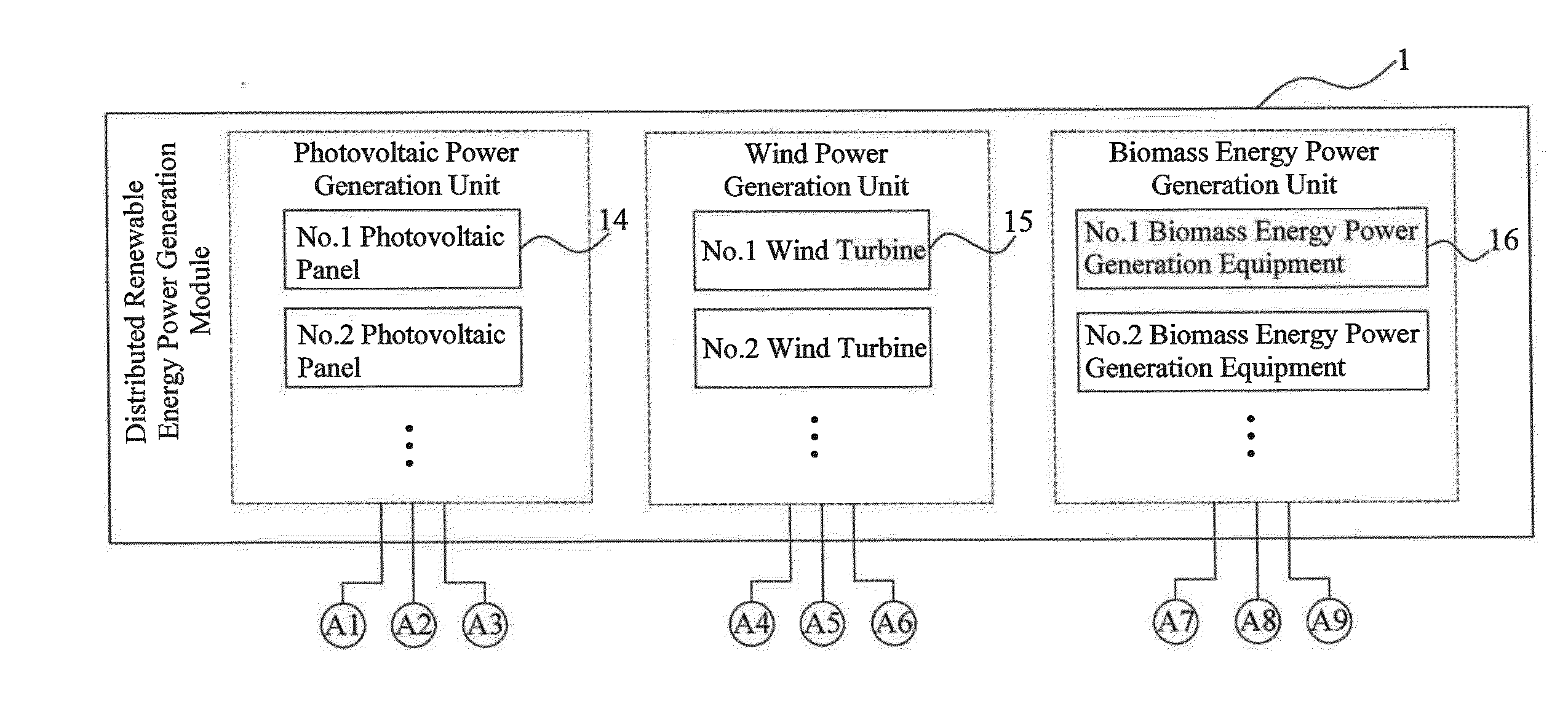

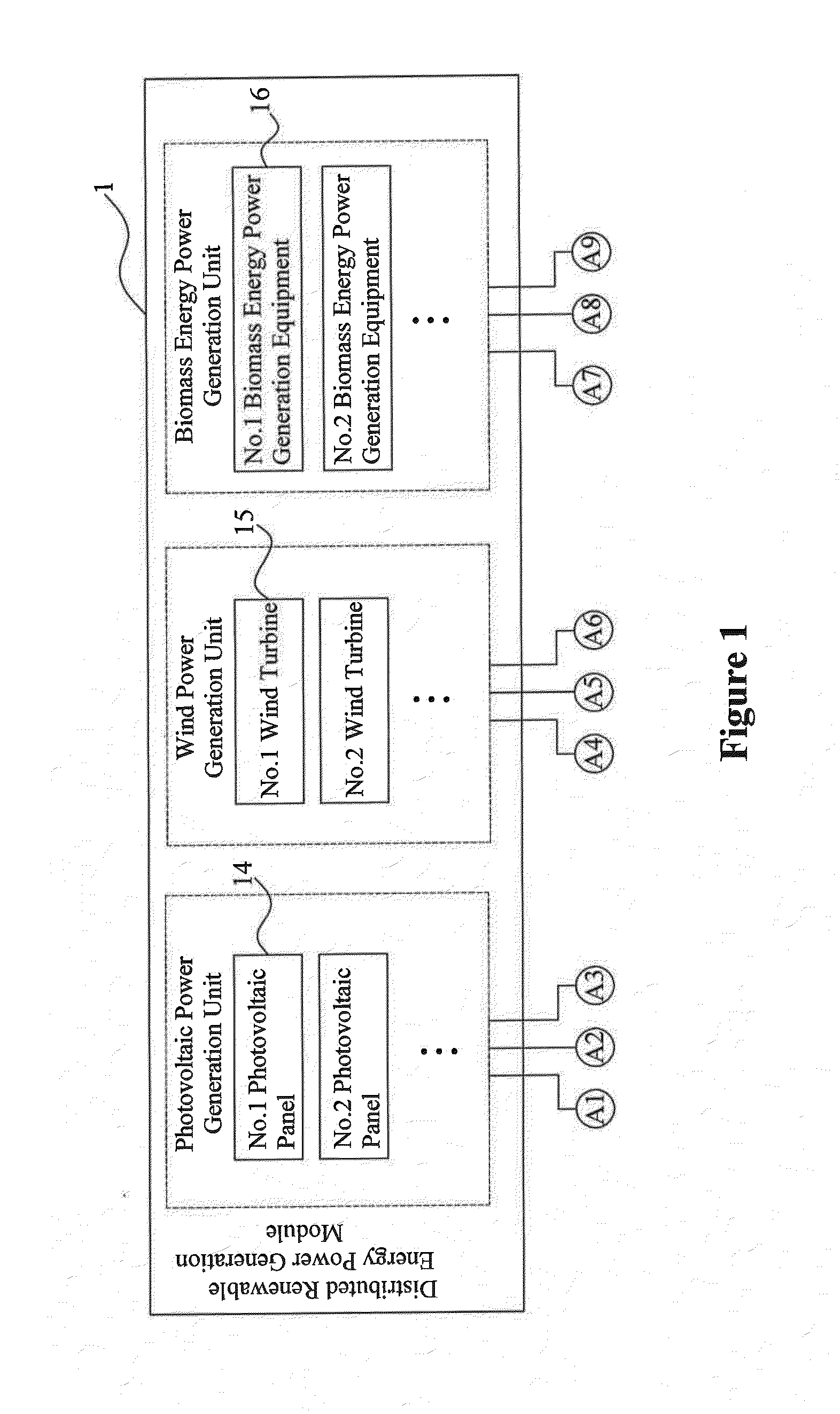

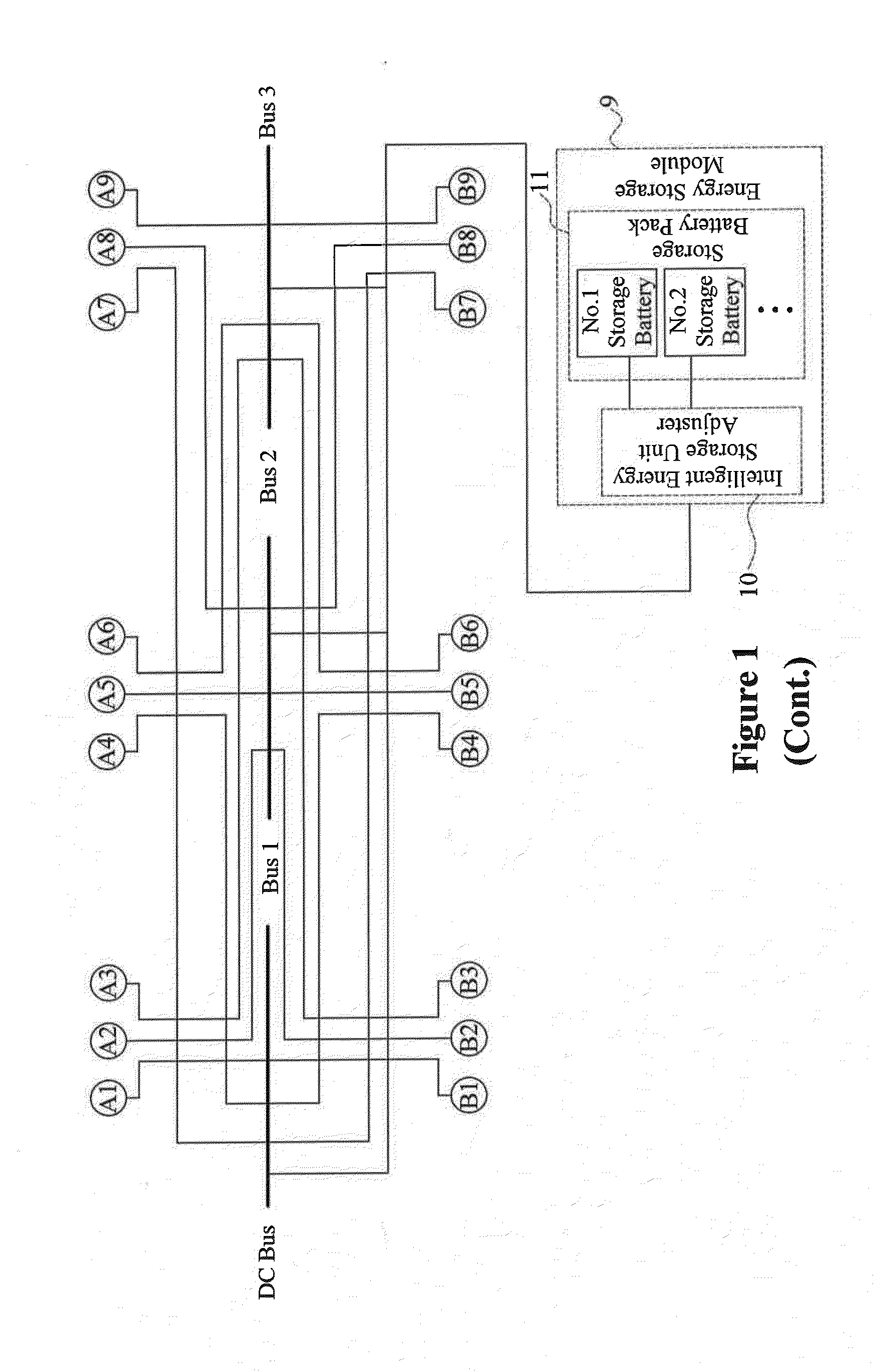

Energy resource-grid-load automatic control system of smart microgrid and control methods thereof

InactiveUS20140297051A1Guaranteed smooth progressEfficient solutionBatteries circuit arrangementsLevel controlSmart microgridAutomatic control

The present invention relates to an energy resource-grid-load automatic control system of smart microgrid and control methods thereof, which belong to the field of microgrid control and electrical technology. The energy resource-grid-load automatic control system comprises a distributed renewable energy power generation module, a distributed renewable energy inverter module, a conventional power generation module, a user load module, a bidirectional grid-connected control module, a distributed renewable energy intelligent optimizing power generation control module, an energy storage module, an intelligent energy storage unit adjuster and a storage battery pack. Compared with the conventional microgrid comprising a distributed renewable energy power generation system, the present invention guarantees the stability and the high energy utilization of the power generation system and effectively solves the problem of non-uniform frequency of use of storage batteries to unify the service life of the storage battery pack.

Owner:NORTHEASTERN UNIV

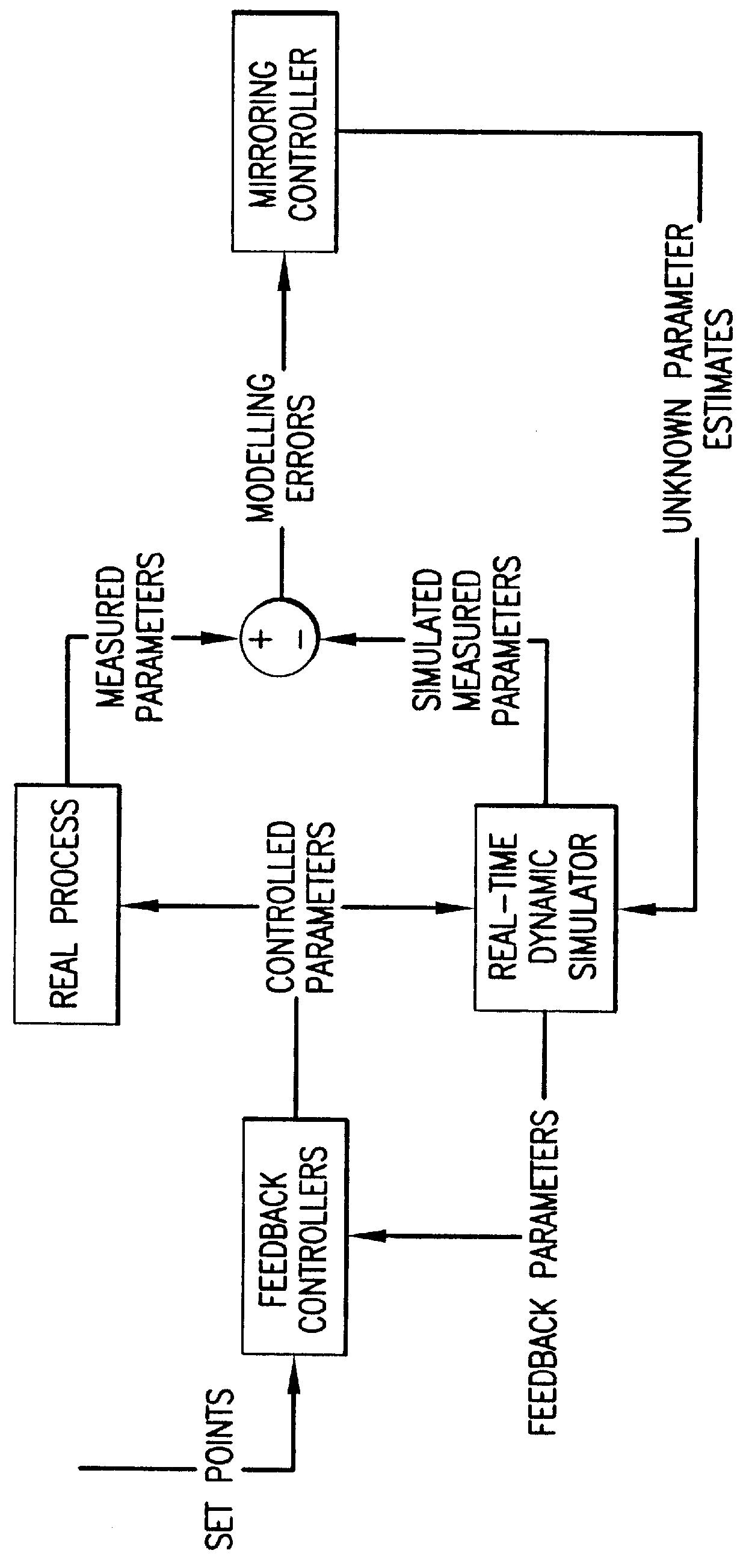

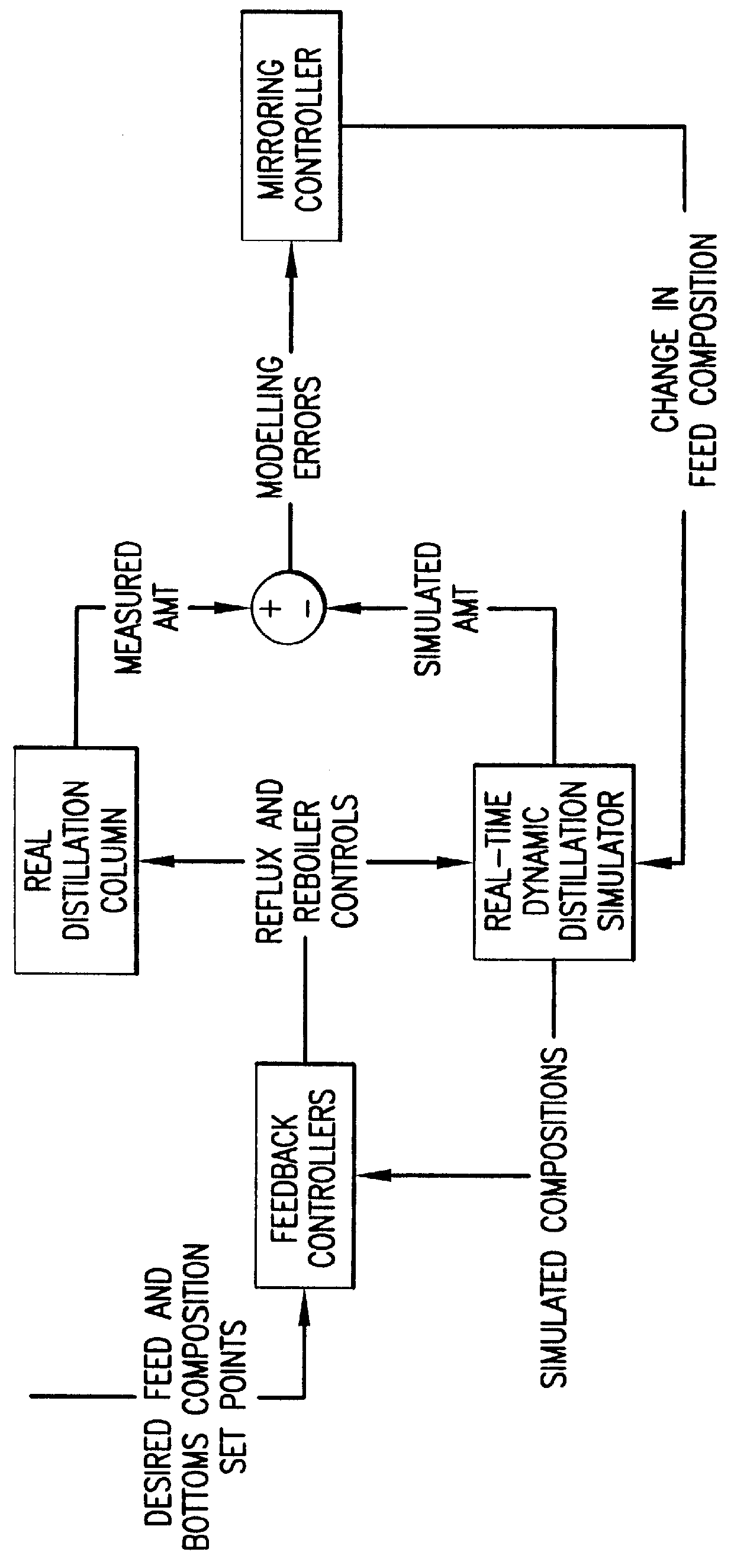

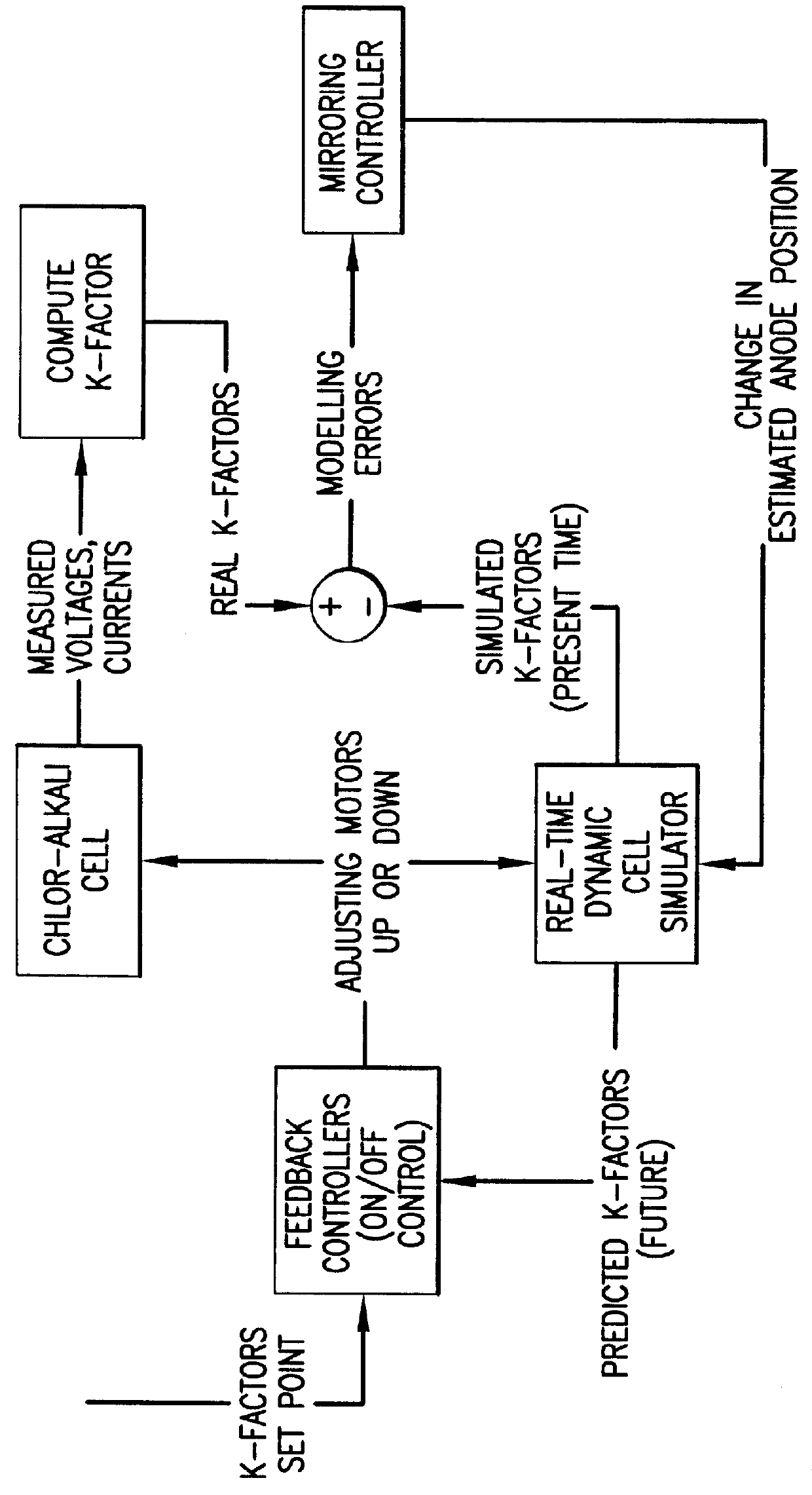

Automatic control system for unit operation

InactiveUS6088630AImprove stabilityAccurate predictionSampled-variable control systemsPhotography auxillary processesAutomatic controlAutomatic train control

Automatic control systems, and corresponding processes, for controlling either an anode adjuster in a chlor / alkali cell or at least one average middle temperature of a distillation column wherein the combination of feedback control from at least one real unit operation variable and an embedded real-time dynamic simulation of that variable are used.

Owner:OLIN CORP

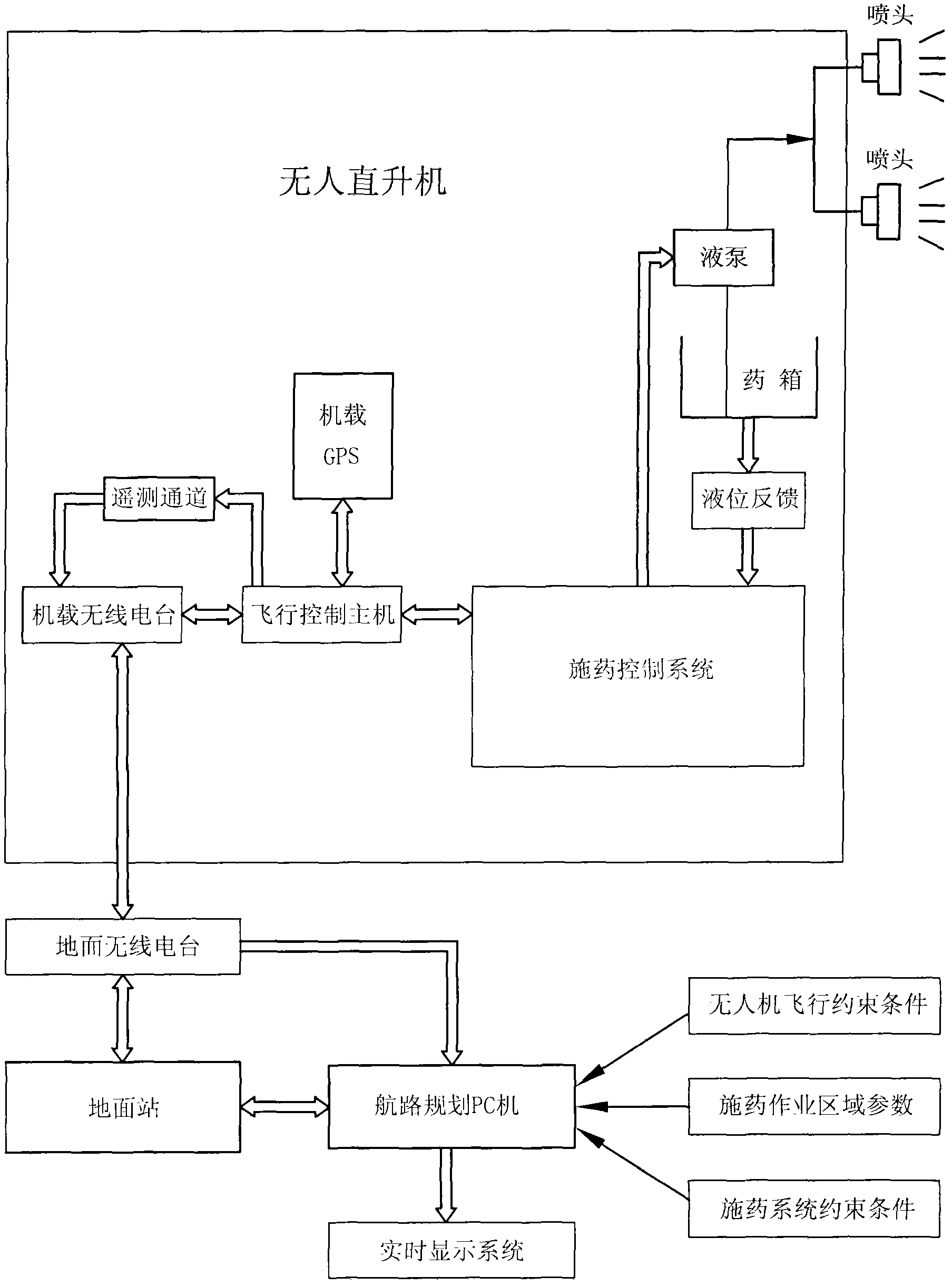

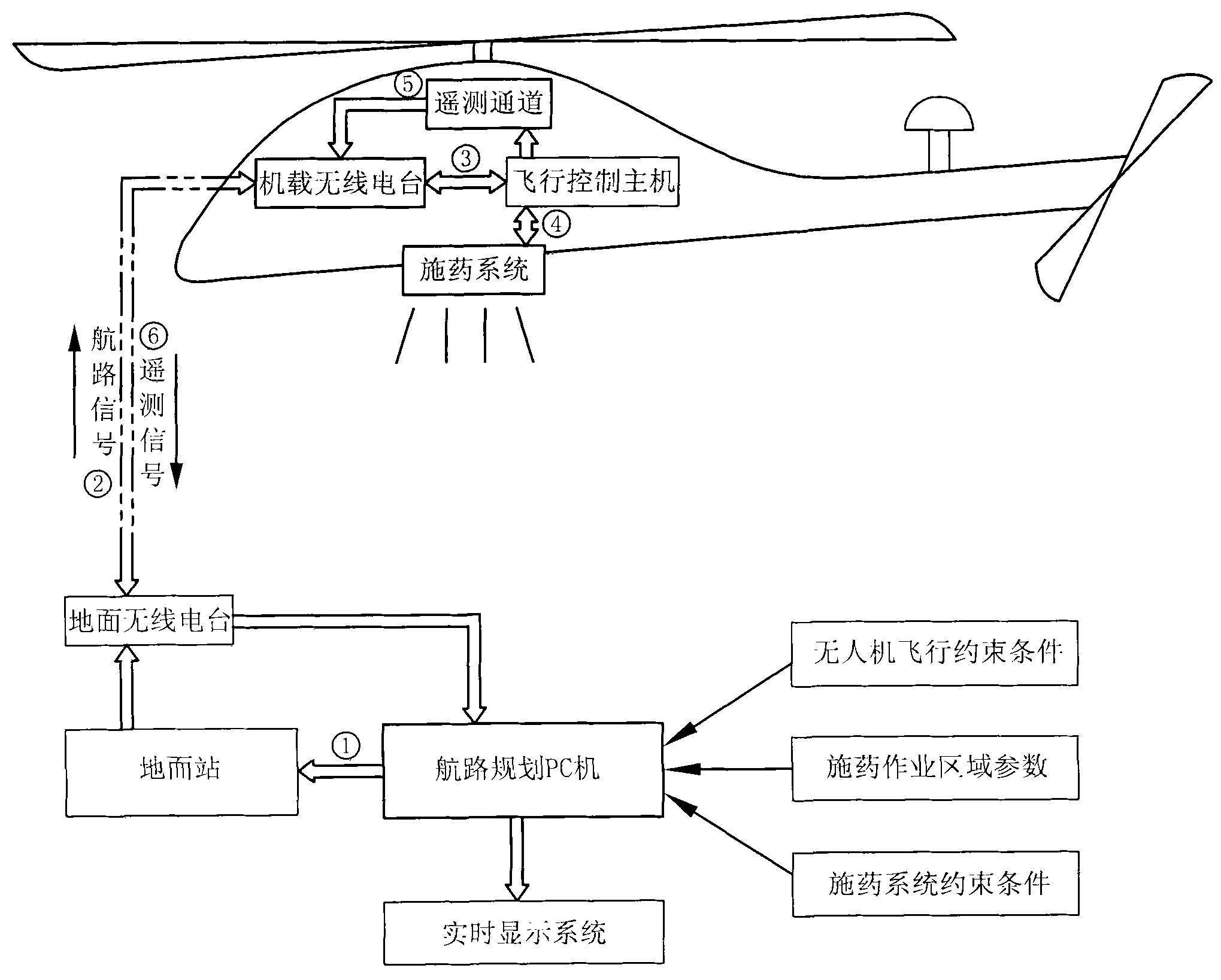

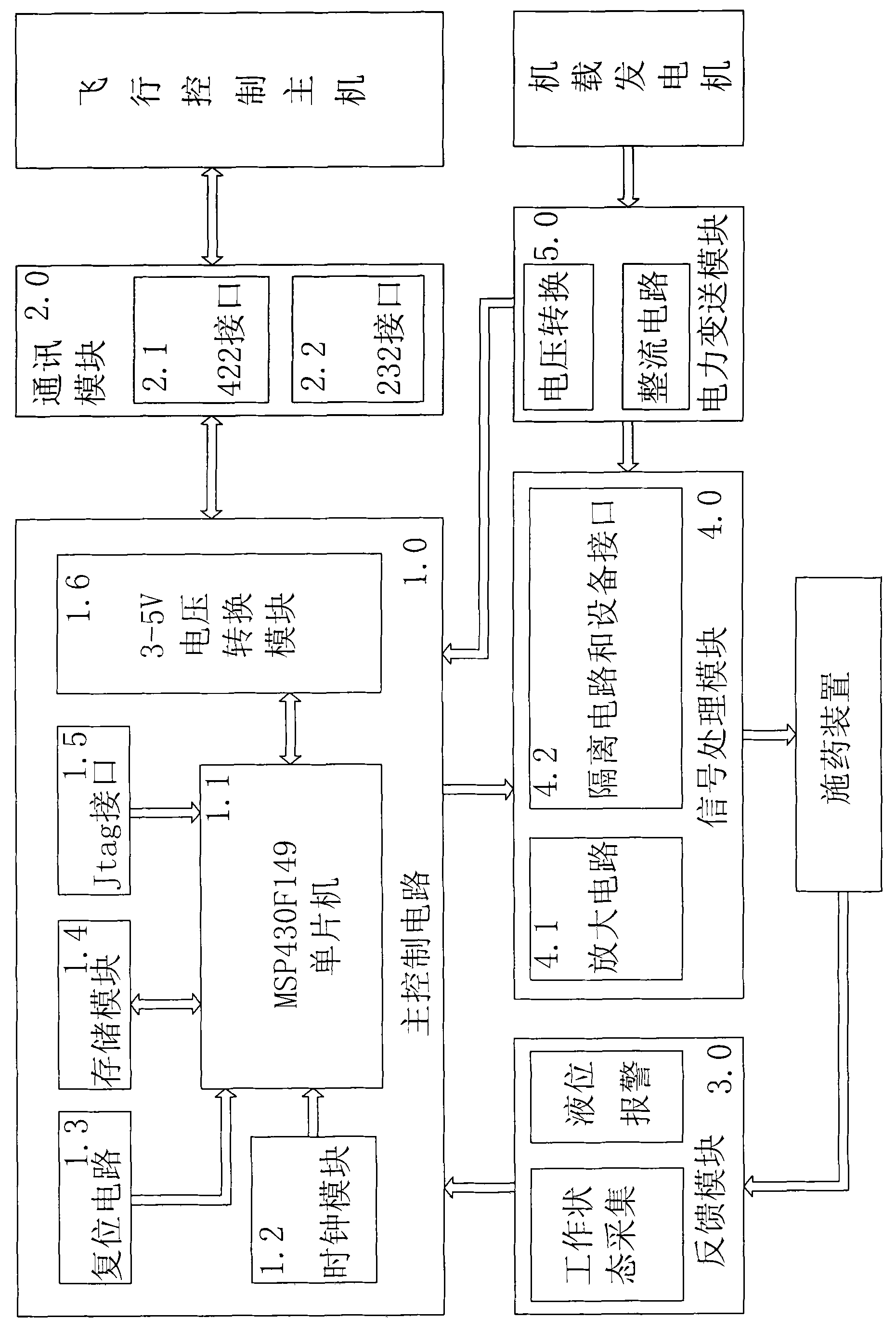

Unmanned helicopter pesticide applying operation automatic control system and method based on GPS (Global Positioning System) navigation

ActiveCN101963806AAvoid wastingReduce consumptionProgramme total factory controlAutomatic controlControl signal

The invention provides unmanned helicopter pesticide applying operation automatic control system and method based on GPS (Global Positioning System) navigation, belonging to the field of agricultural technology. The main communication end of a flight control host machine is communicated with a GPS, and the main control output end is connected with the controlled end of a rotor flight system to be used for sending a navigation control signal to the flight system according to a preset air line and real-time position information transmitted by the GPS; an unmanned helicopter is also provided with a pesticide applying device and a pesticide applying control system, wherein the pesticide applying device comprises a pesticide box, a liquid pump, a spray rod and a spray head; the pesticide applying control system comprises a main control circuit, a communication module, a feedback module, a signal processing module and a power transformation module; the main control circuit is used for feeding back the state information of the pesticide applying system to the flight control host machine by the communication module; and the signal processing module is used for amplifying a pesticide applying control signal transmitted by the main control circuit into an electric signal and controlling the liquid pump to carry out pesticide applying operation. The system and the method can control the unmanned helicopter to flight according to the preset air line by the GPS and perform a spray task according to a preset GPS air line.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

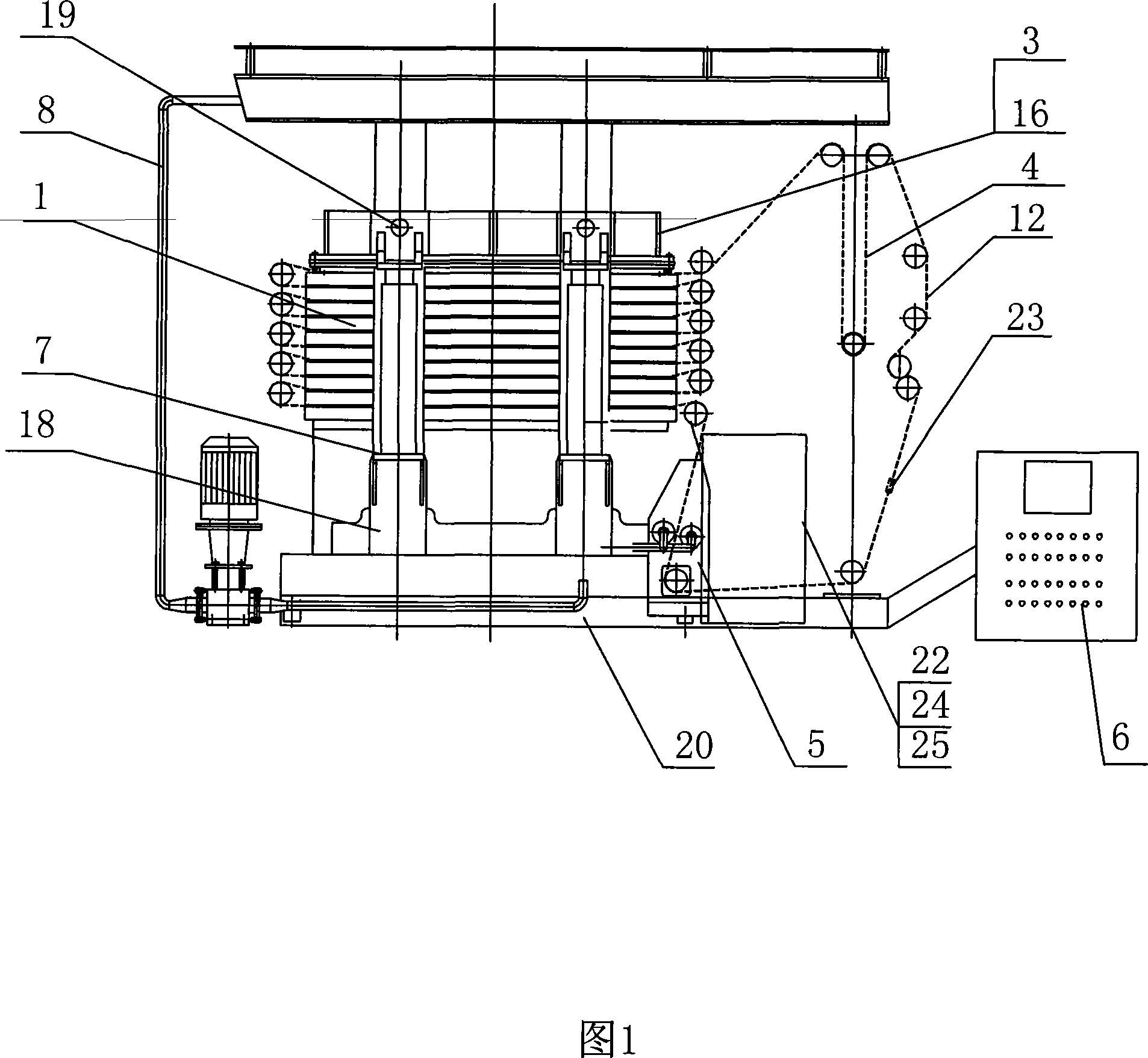

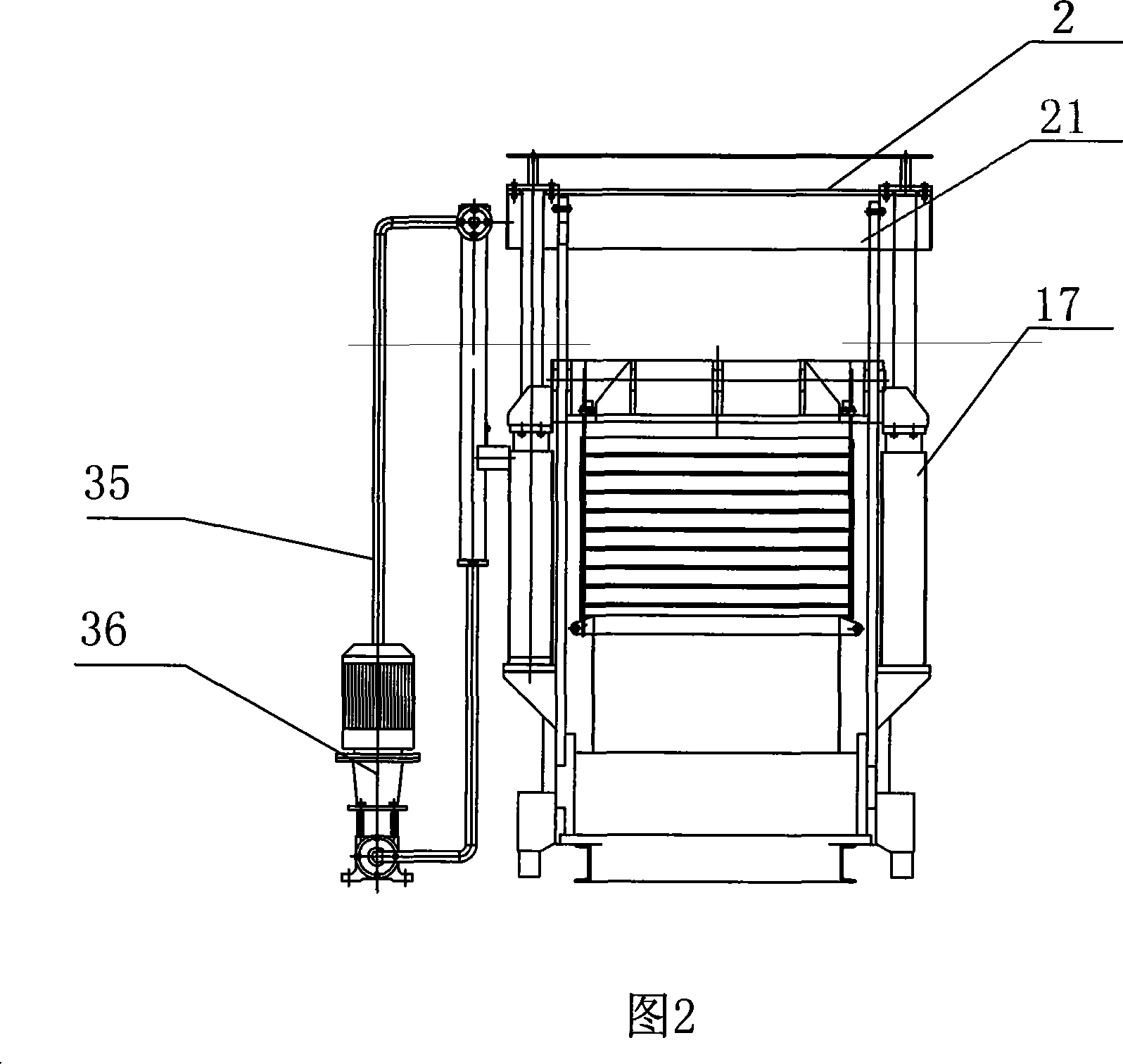

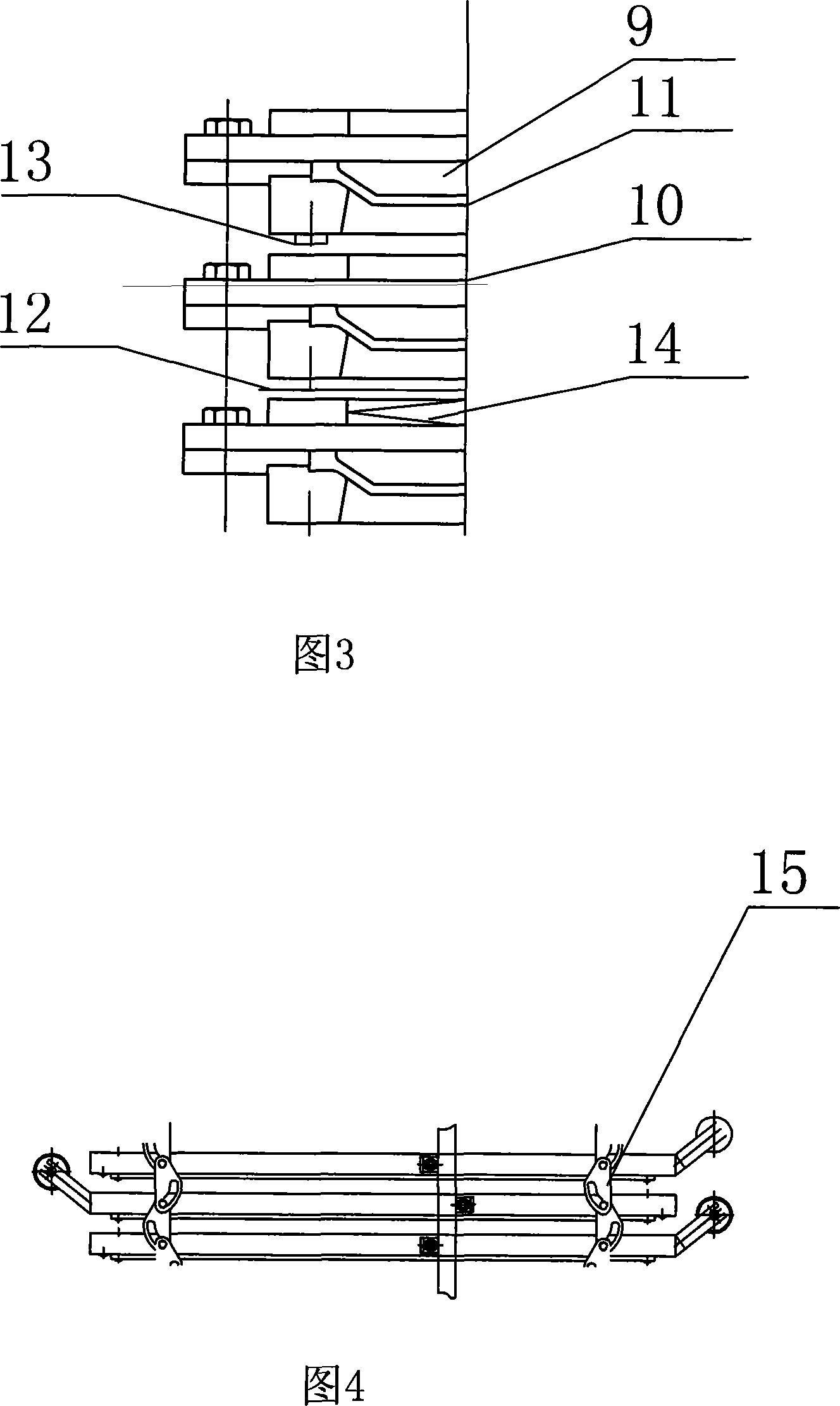

Vertical type full automatic plate-and-frame filter press, and filter technique

ActiveCN101091846AReduce moistureExtend working lifeFiltration separationAutomatic controlFiltration

The invention relates to a vertical full automation filter press. The existing filtration filter pressing installment as a result of the structure technology, ,the horizontal hand movement filtration frame which uses the plastic has low production efficiency and big environmental pollution; because the semiautomatic pressure filtration installment also uses the electrical controlled method, but the automated coordination performance of other organization is bad, its stability and the production efficiency are low, specially when the seal cavity bearing, the equipment presents vibration and spray phenomenon. The filter press includes the leveling board frame group, the main body support structure, the board frame group opening and holding apparatus, the filtering cloth automatic cycle running gear, the filtering cloth washing device, automatic control system, hydraulic system, craft circuitry and so on. It uses the vertical structure to realize the full automatic operation, thus has high filter efficiency, low energy consumption, high automaticity, high product quality, easy operation, the simple maintenance, and no pollution.

Owner:西安航天华威化工生物工程有限公司

Automated closed loop flowback and separation system

InactiveUS8424599B2Realize automatic adjustmentSurveyDrilling rodsHuman–machine interfaceAutomatic control

An automated closed loop flowback and separation system that allows automated control and remote operation of a flowback operation from a safe distance without any fluid or gas release to the atmosphere. Four-phase separation tanks allow the transport gas, well bore cuttings, produced oil, and produced water to be automatically separated and transported through process piping for reuse or sale, eliminating the need for auxiliary equipment. Flow measurement instruments, pressure transmitters, and level transmitters work in conjunction with an automated blast choke to send data to a programmable logic controller for use in calculating the erosion status of the choke restriction and adjusting the choke to compensate. The programmable logic controller works with a touch-screen or similar human-machine interface to allow remote monitoring and control or automated control of the system. The automated blast choke can vary the choke restriction opening based on the pressure differential and flow rate conditions.

Owner:CANADIAN FRACMASTER

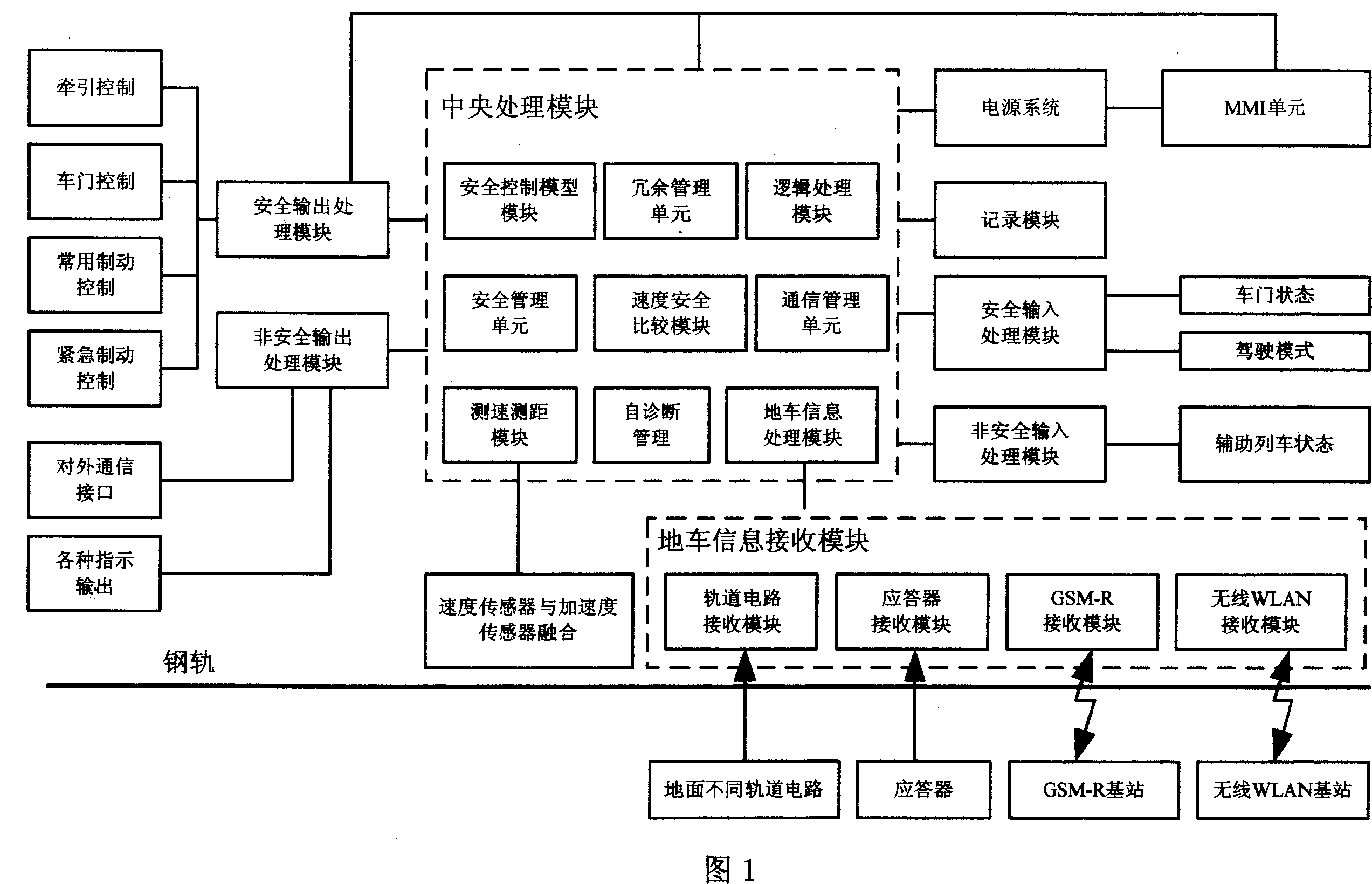

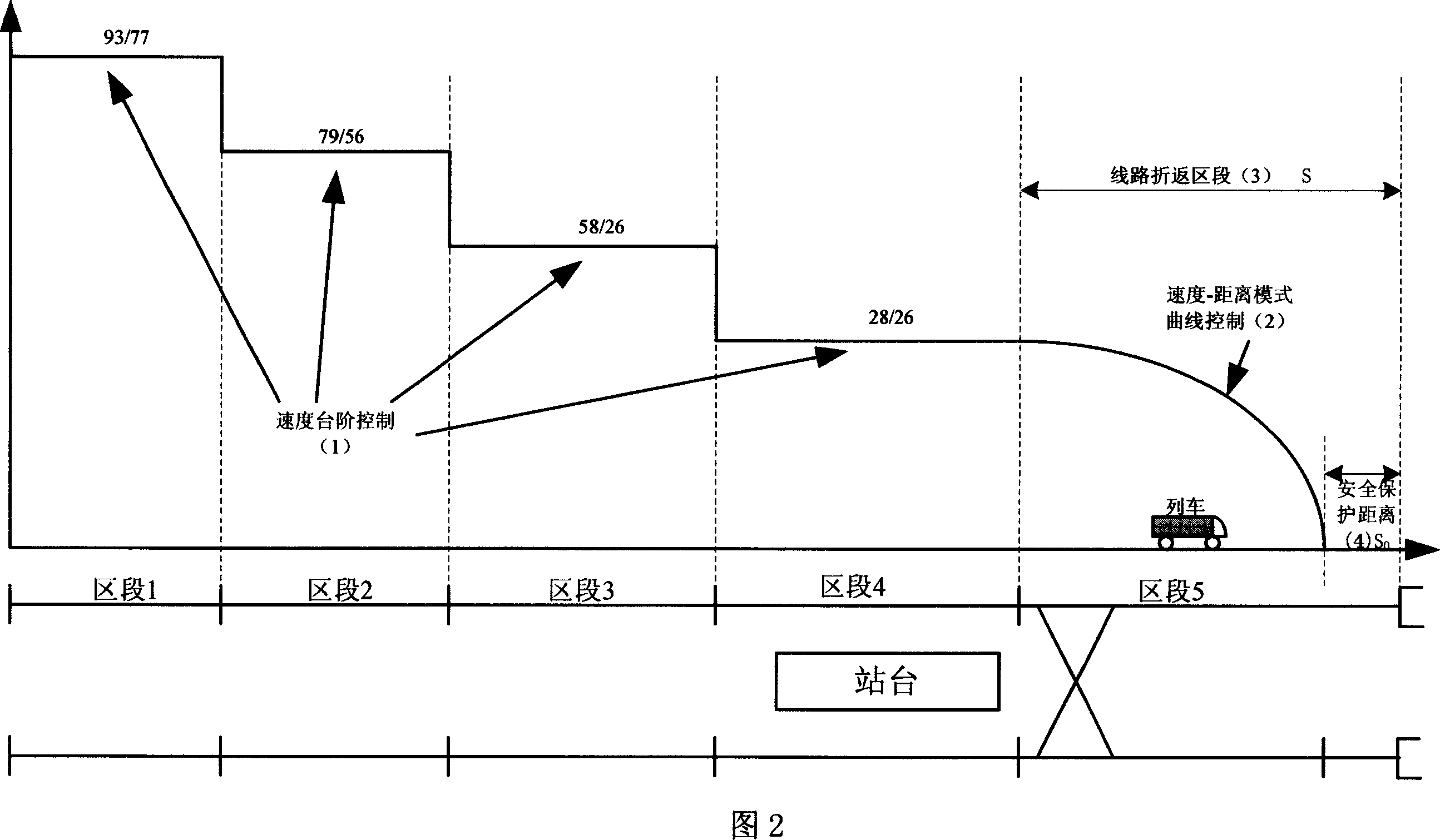

Universal automatic protection (ATP) vehicle-mounted system for train and its mode control method

InactiveCN101007537AReduce workloadIncrease flexibilityVehicle route interaction devicesDigital signal processingAutomatic control

A universal Automatic Train Protection ATP vehicle mounted system and mode control method. The invention mainly uses digital signal processing and safe redundant control technology, designs a safe Protection Automatic control system which can receive many varieties of ground vehicles information transmission modus, realize the combination of the train speed steps control and the first-order speed-distance model curve and realize the generalization of vehicle automatic protection system vehicle mounted equipments. And the ground vehicles information transmission modus consists of analog and digital track circuit, responder, GSM-R transmission, 2.4GHz wireless transmission, etc. the safe protect control is the safe braking model control using the combination of speed steps and first-order speed-distance model curve. The system mainly consists of power module, ground vehicles information transmission reception module, central processing module, recording module and man-machine interface MMI module, etc. The beneficial result is getting a solving program for users on the base of reducing construction costs and intercommunicating transport operation.

Owner:BEIJING JIAOTONG UNIV

Nasal Dilator

InactiveUS20090183734A1Reduce flow resistanceLower impedanceRespiratory masksBreathing masksNasal cavityNasal passage

A nasal dilator includes a contact pad attachable to a user's facial region below the user's eye and outboard from the user's nose. A tugging device is coupled with the contact pad and urges the contact pad in a direction away from the user's nose. With this structure, effective dilation of the nasal passages can be achieved in a comfortable manner. The dilator may also be incorporated into a CPAP mask and / or form part of an automated control system.

Owner:RESMED LTD

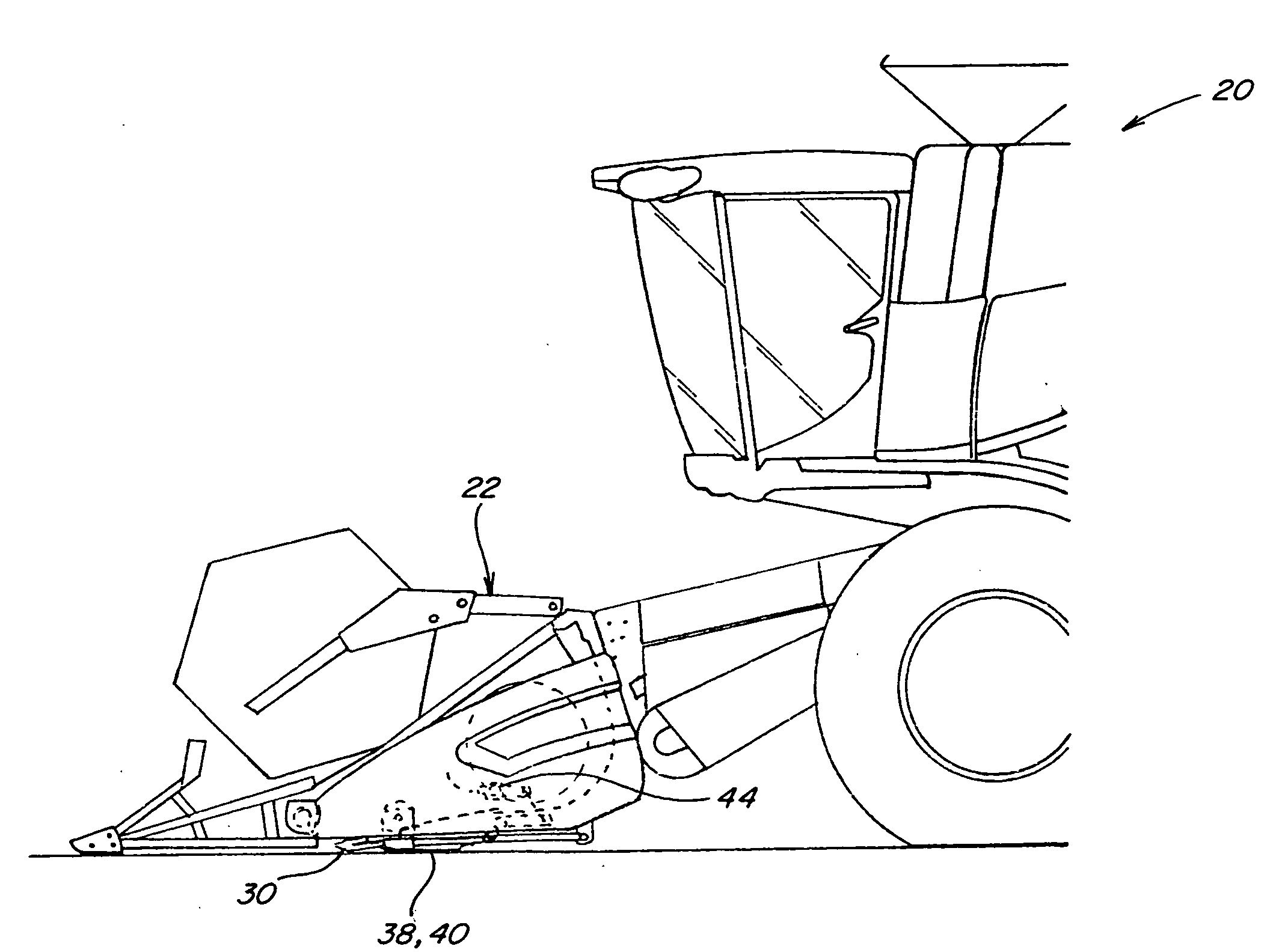

Automatic control system for a header of an agricultural harvesting machine and method of operation of the same

A control system for a header for an agricultural harvesting machine such as a combine, providing features including an automatic reel position control operable to provide at least one selectable predetermined cutter bar and reel position combination, and which can also automatically control height and / or fore and aft positions of the reel responsive to cutter bar movements, as required, for purposes such as for maintaining and / or optimizing the reel / cutter bar relationship for a particular crop and / or condition, and for avoiding interference between the tines or fingers of the reel and the sickle of the cutter bar, and possible damage to the tines and / or sickles, and slippage of the reel and / or sickle drive, that can result.

Owner:CNH IND AMERICA LLC

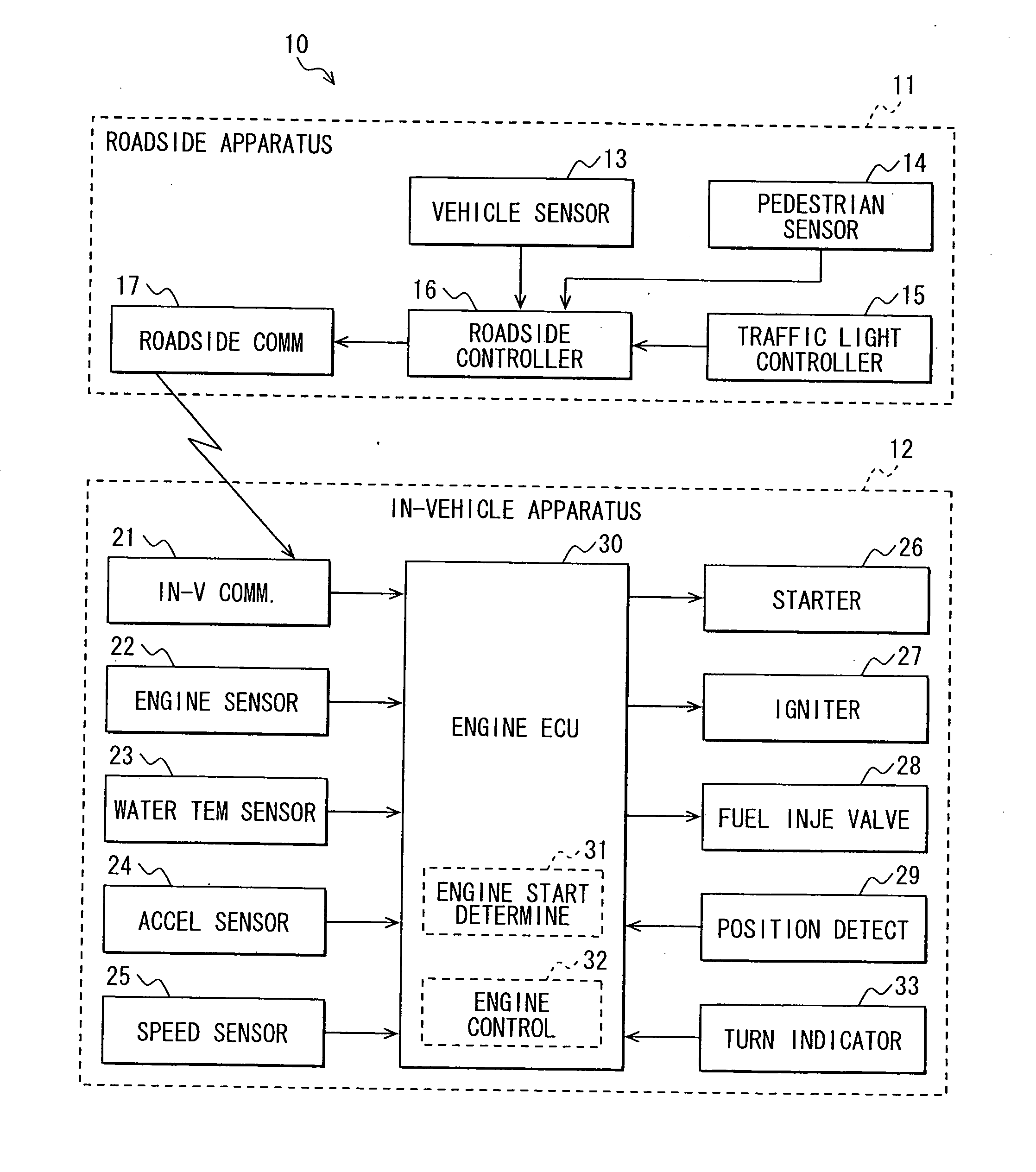

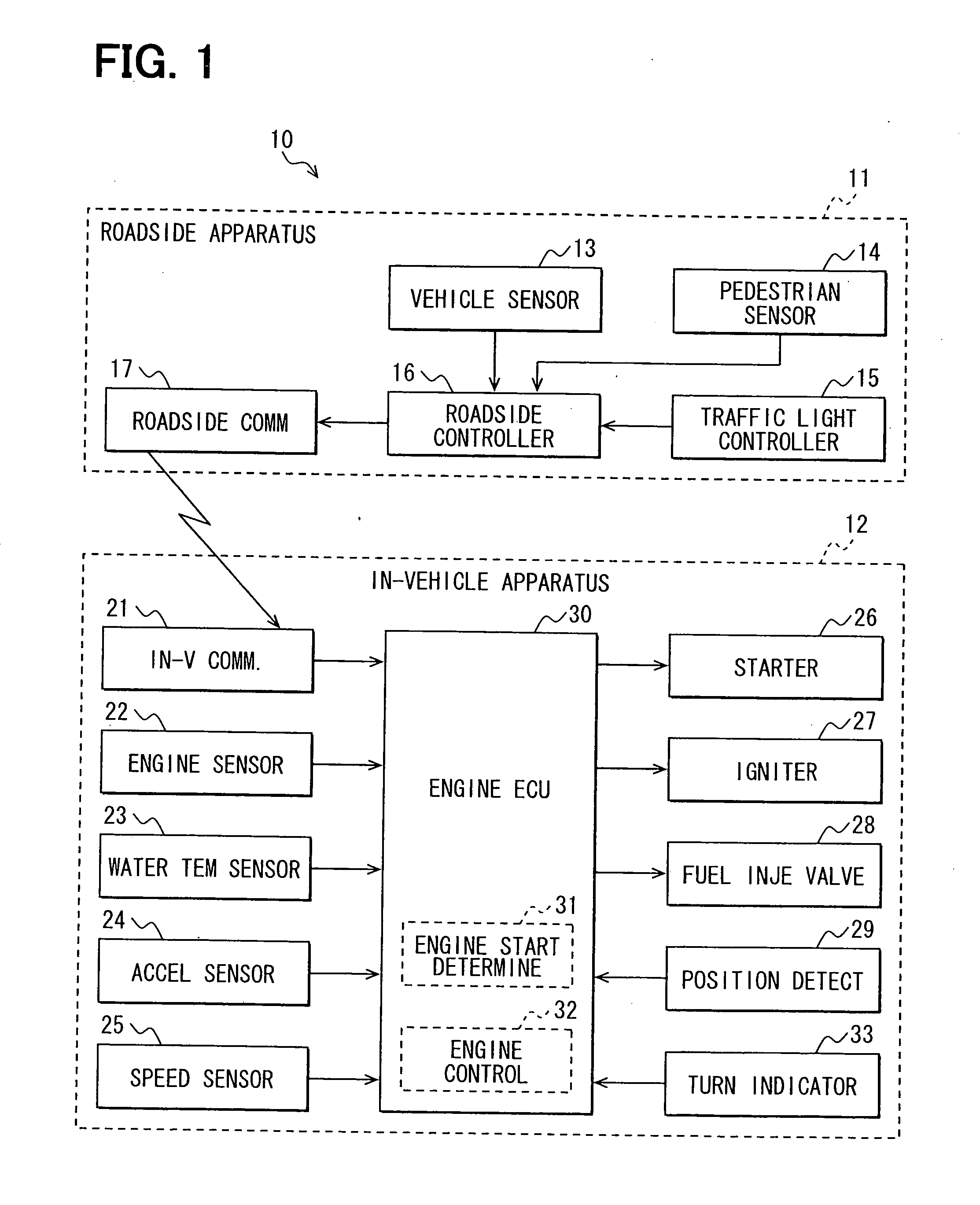

Engine automatic control system

ActiveUS20120029730A1Useless consumption of fuelImprove fuel efficiencyAnalogue computers for vehiclesInternal combustion piston enginesStart timeTraffic signal

A roadside communicator in a roadside around an intersection transmits, to vehicles around the intersection, traffic light information on traffic light at the intersection and mobile object information on vehicles and pedestrians around the intersection. An in-vehicle communicator mounted in a subject vehicle acquires the traffic light information and the mobile object information. An in-vehicle engine start determination section mounted in the subject vehicle determines a permission or prohibition of a start of an engine of the subject vehicle based on the traffic light information and mobile object information. The engine start determination section determines an engine start time in consideration of a display of the traffic light, and states of mobile objects that pass through the intersection. An in-vehicle engine control section in the subject vehicle starts the engine when the engine start determination section permits the start of the engine.

Owner:DENSO CORP

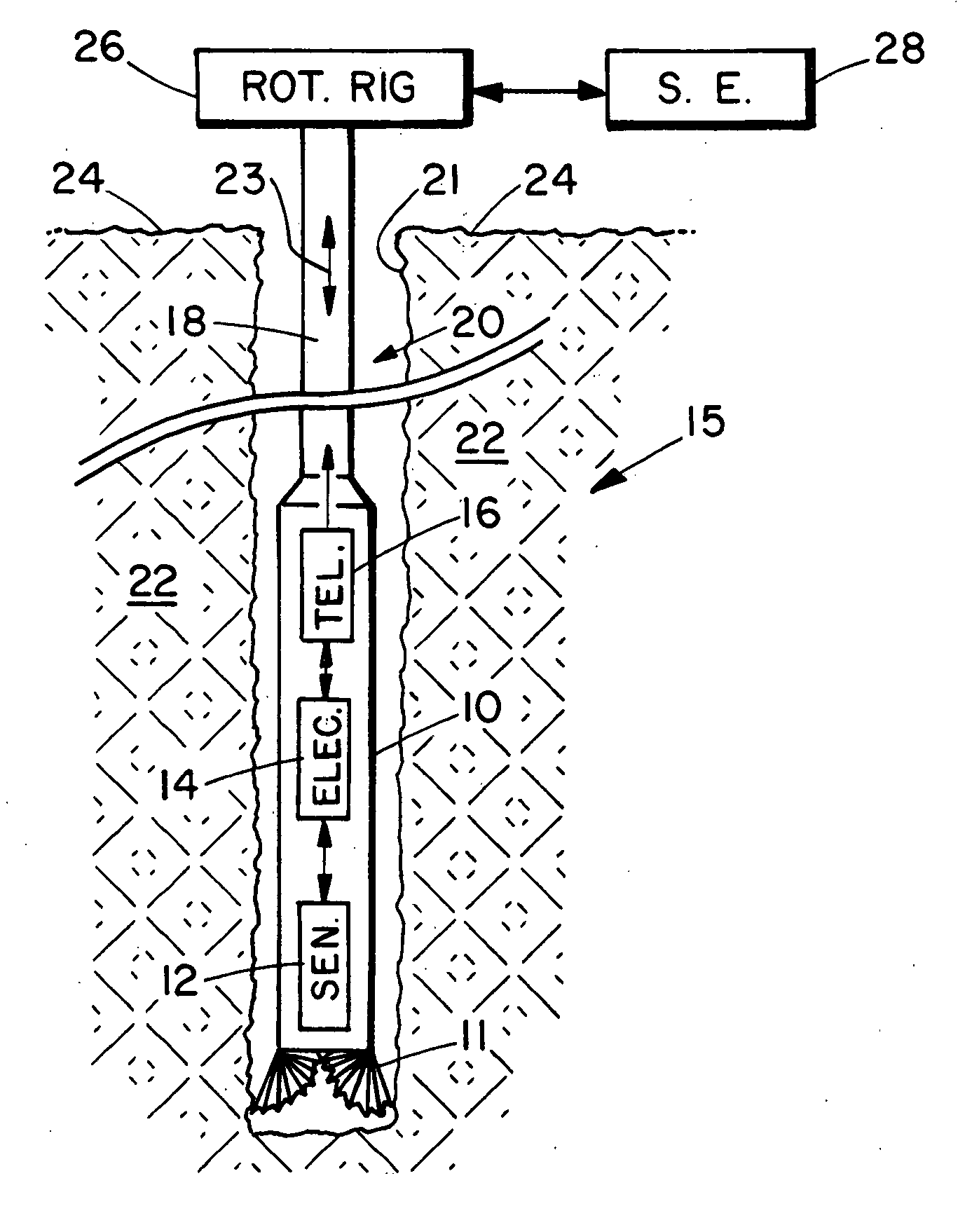

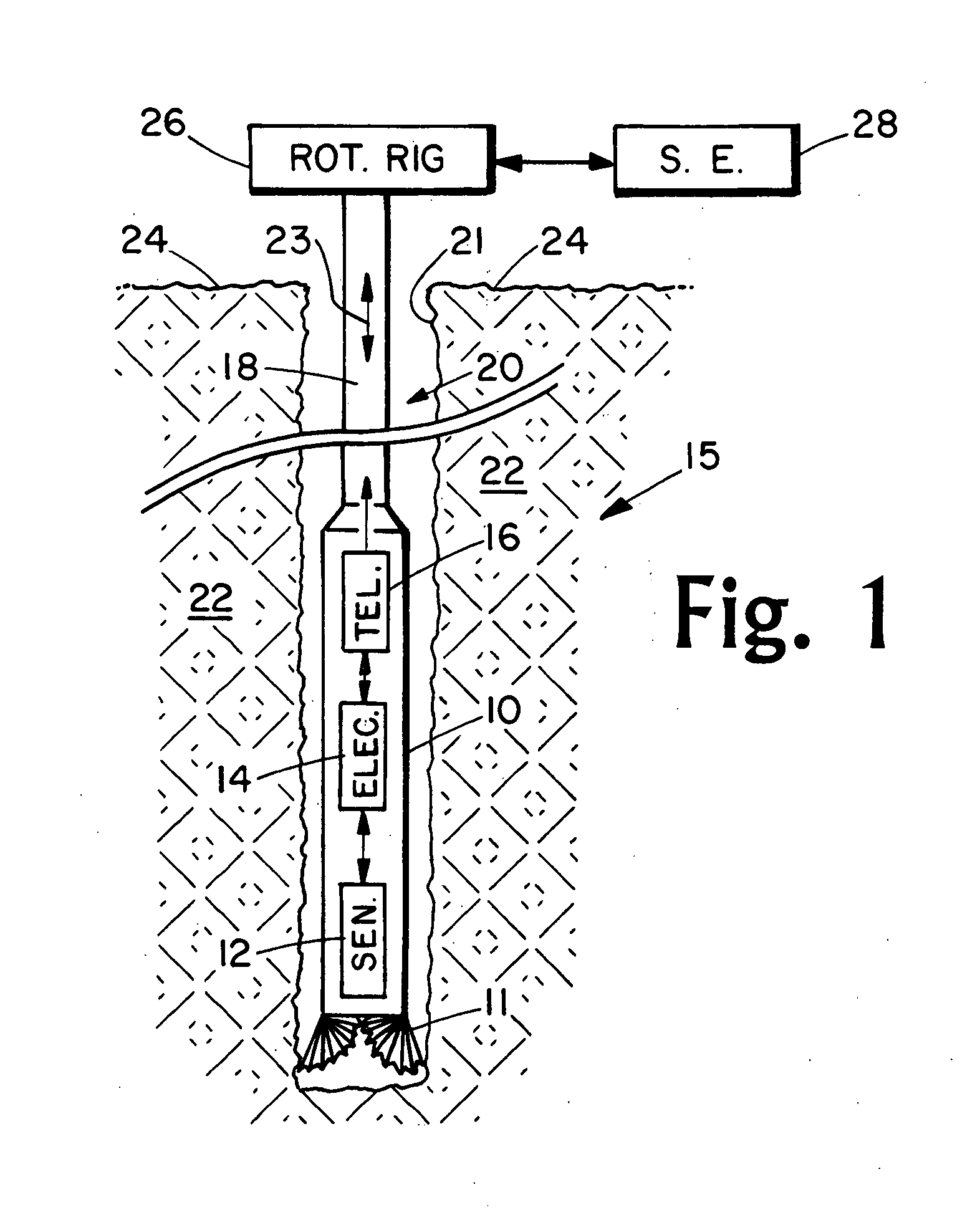

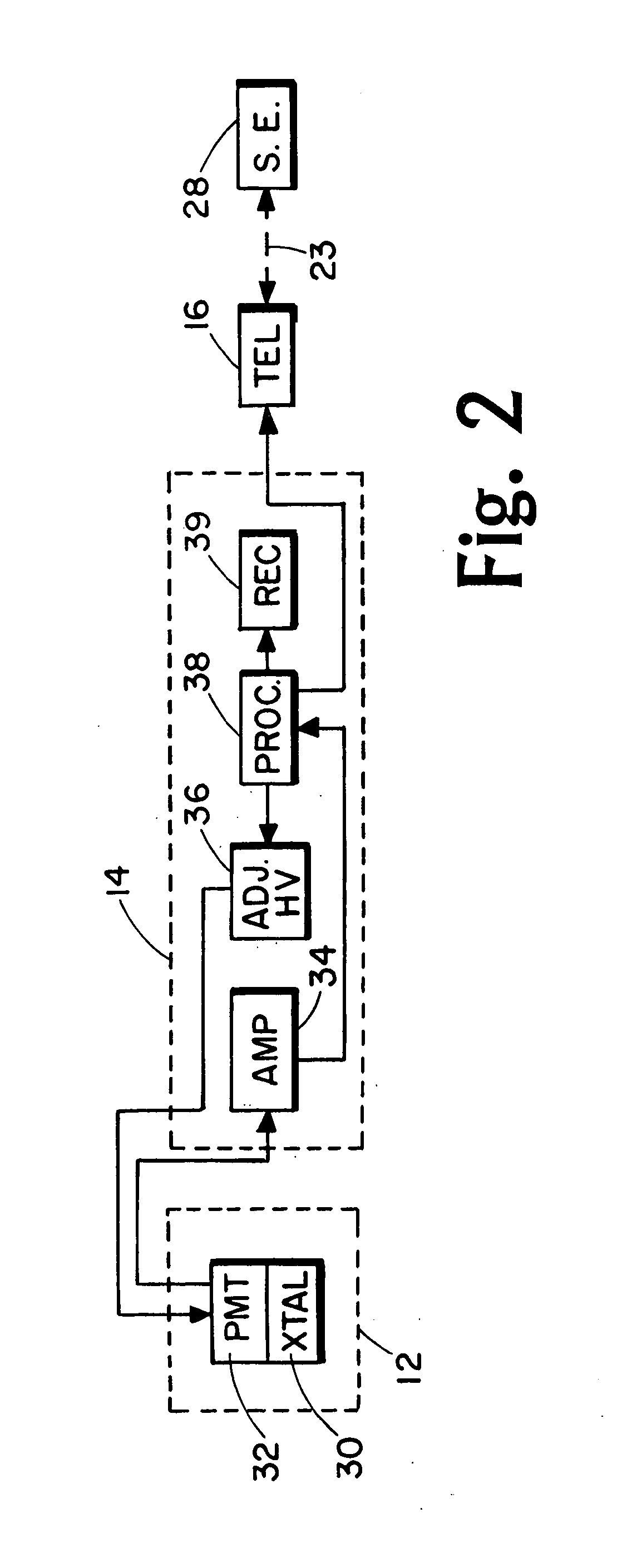

Gain stabilization apparatus and methods for spectraal gamma ray measurement systems

ActiveUS20060065824A1Minimize degradationMaximizing counting rateX-ray spectral distribution measurementConstructionsBiological activationAutomated control system

Owner:WEATHERFORD TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com