Imaging interactive numerical control turning automatic programming method and system

An automatic programming and interactive technology, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as unintuitive, high error rate, and inability to modify the results of command code operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

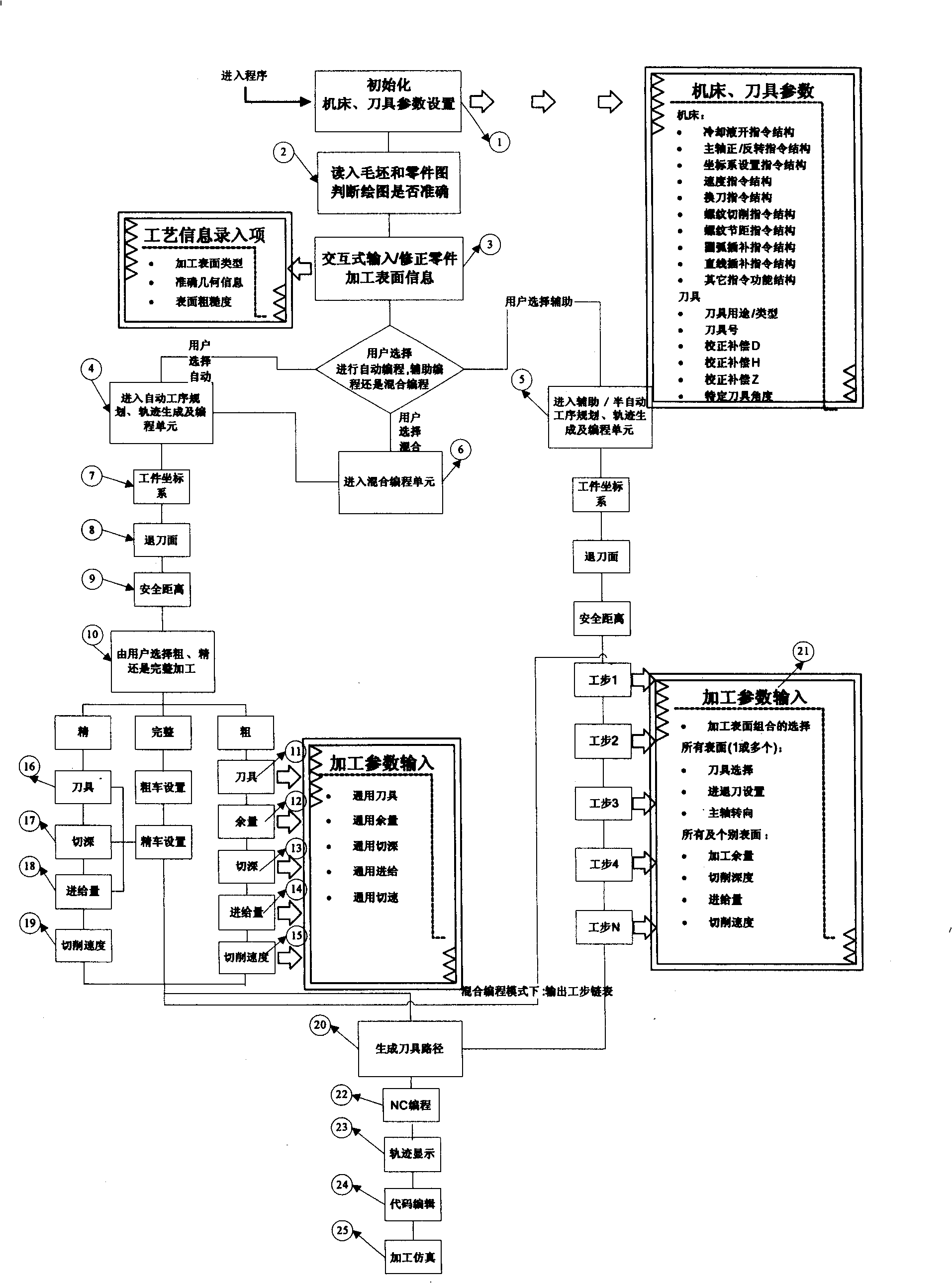

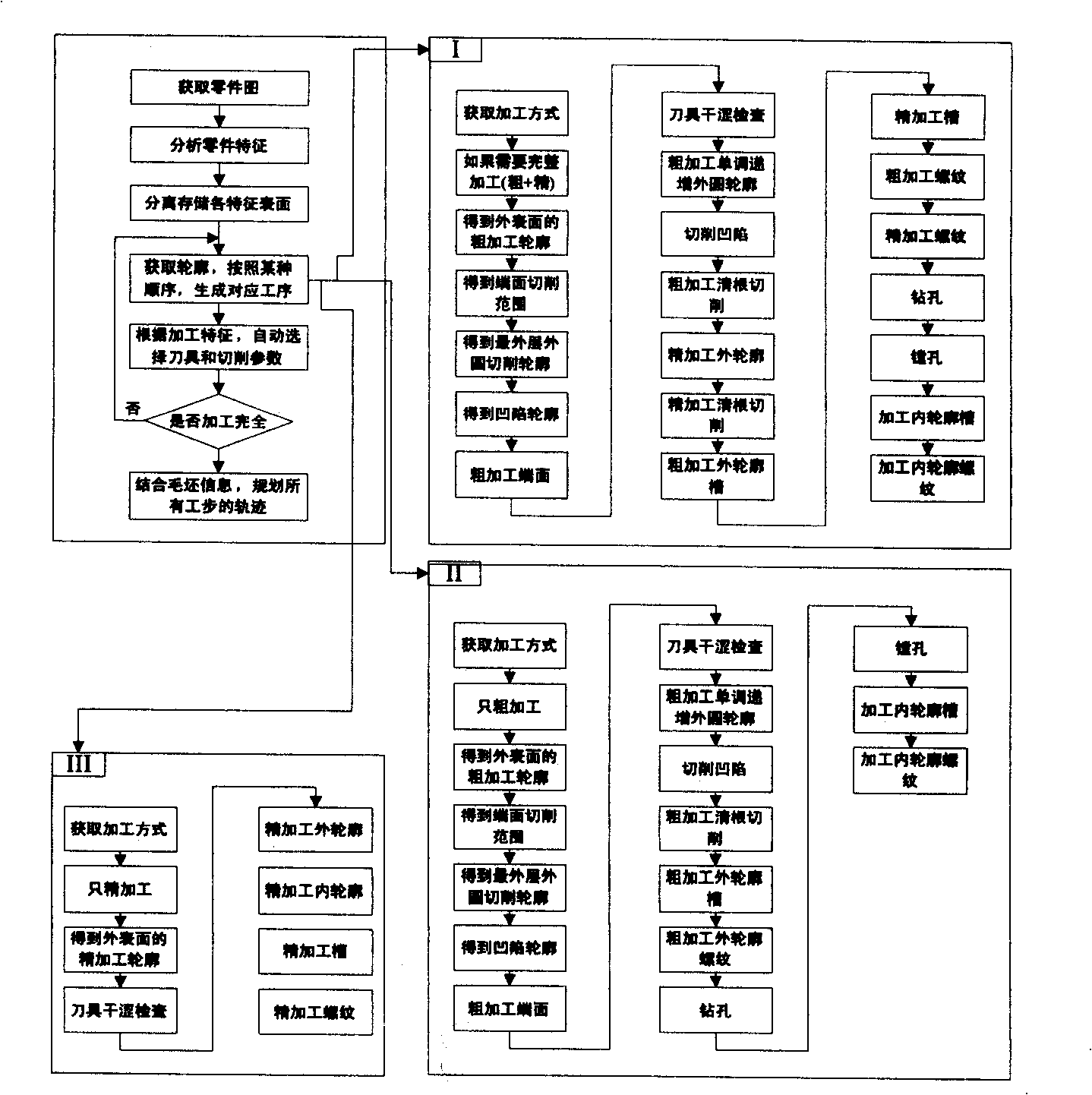

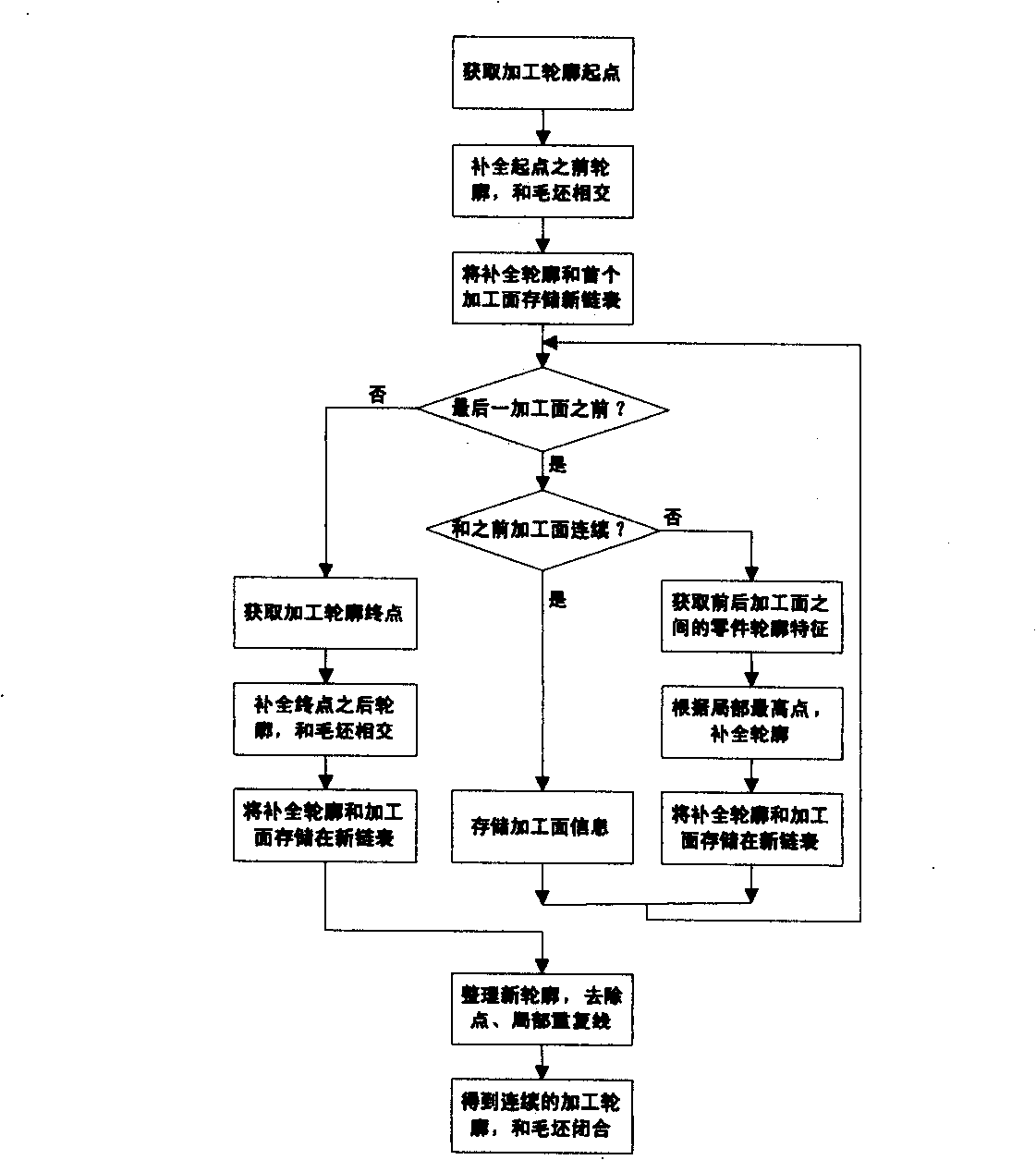

[0040] The specific embodiment part is divided into two parts, and the first part shows the system structural diagram and workflow, automatic process planning, track generation and programming method, auxiliary / semi-automatic process planning, track generation and programming method and automatic-assistant phase of the present invention design The specific algorithm used by the system when the combined hybrid programming method is implemented. The second part is the specific interface introduction of the present invention.

[0041] first part:

[0042] figure 1 The overall flow chart of the graphic interactive numerical control turning automatic control method of the present invention is shown. Such as figure 1As indicated, first enter the system, initialize the machine tool and tool parameters in step 1, read in the blank and part drawings in step 2, and pass (1) CAD data storage specifications; (2) geometric symmetry and closure of CAD graphics Judging and removing all k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com