Patents

Literature

808 results about "Surface type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

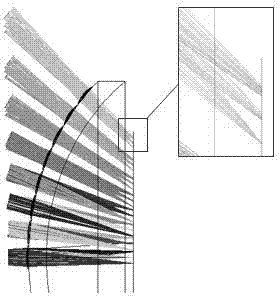

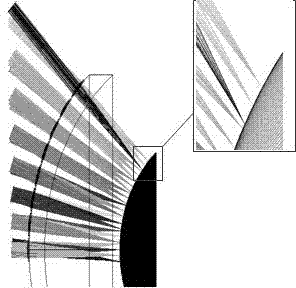

Surface types include: surfaces of rotation, developable surfaces, spherical surfaces, geodesic domes, tapering surfaces, and freeform surfaces. Discussions to follow include surface parameters, regularly spaced panels, and planar divisions.

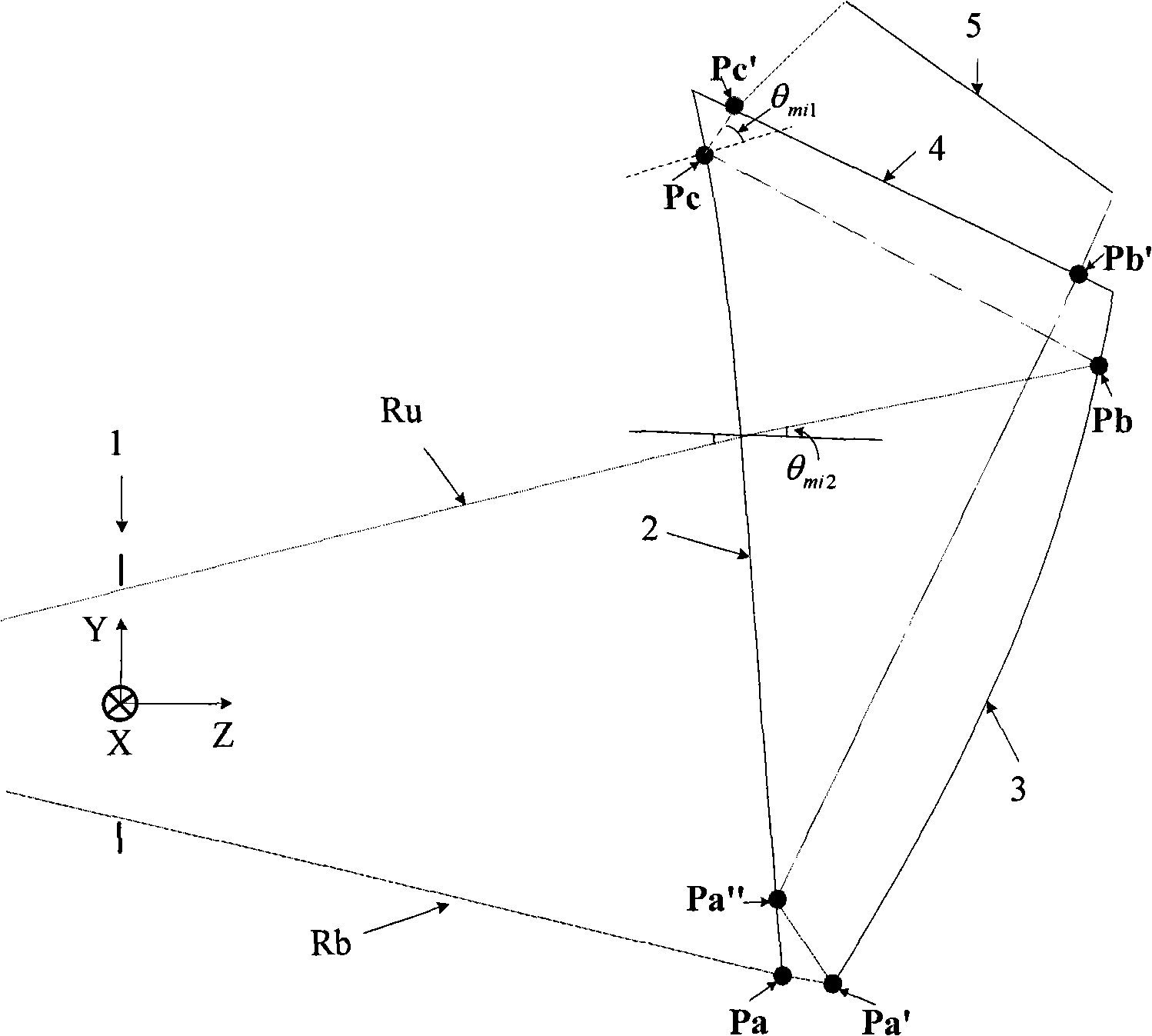

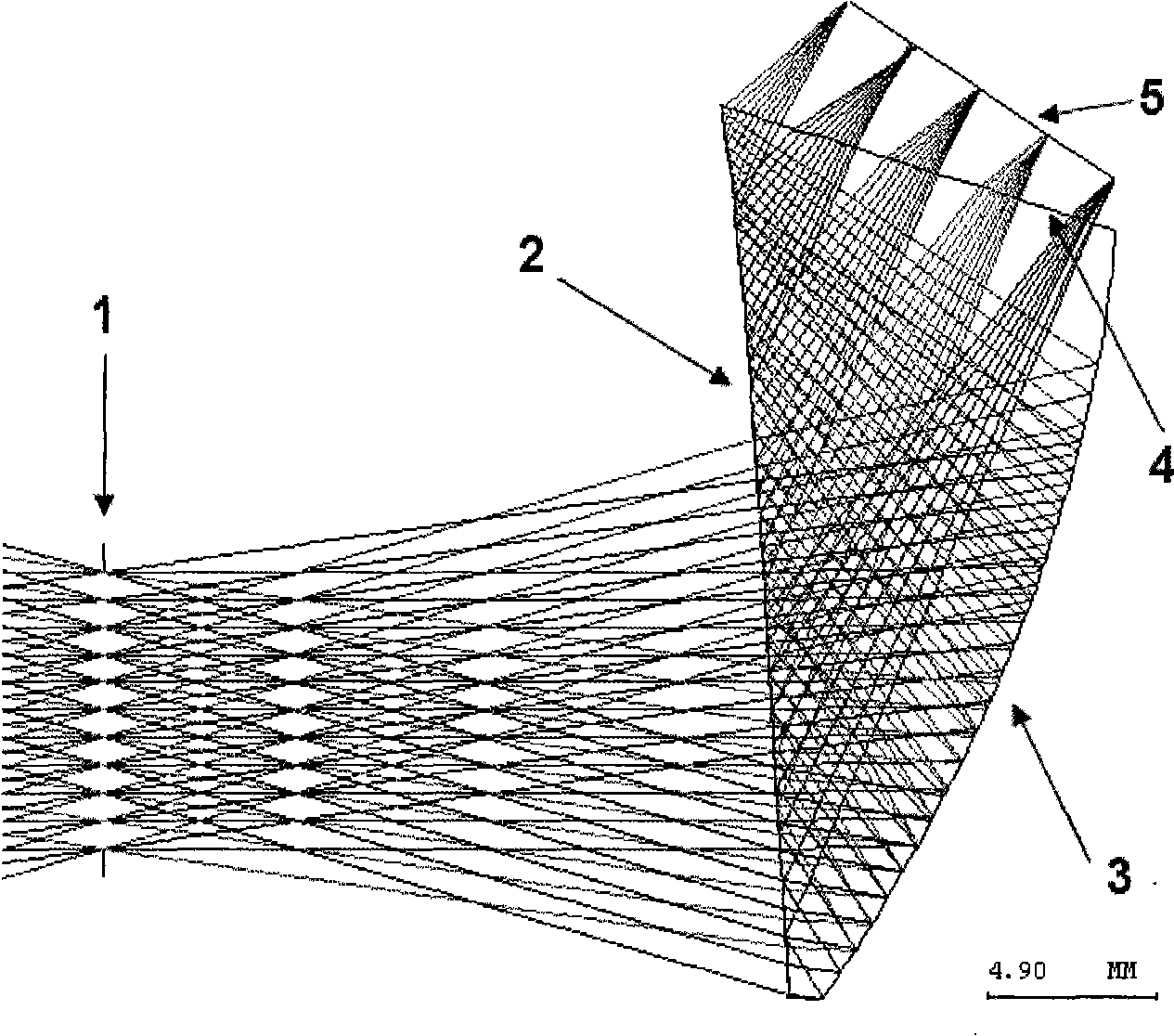

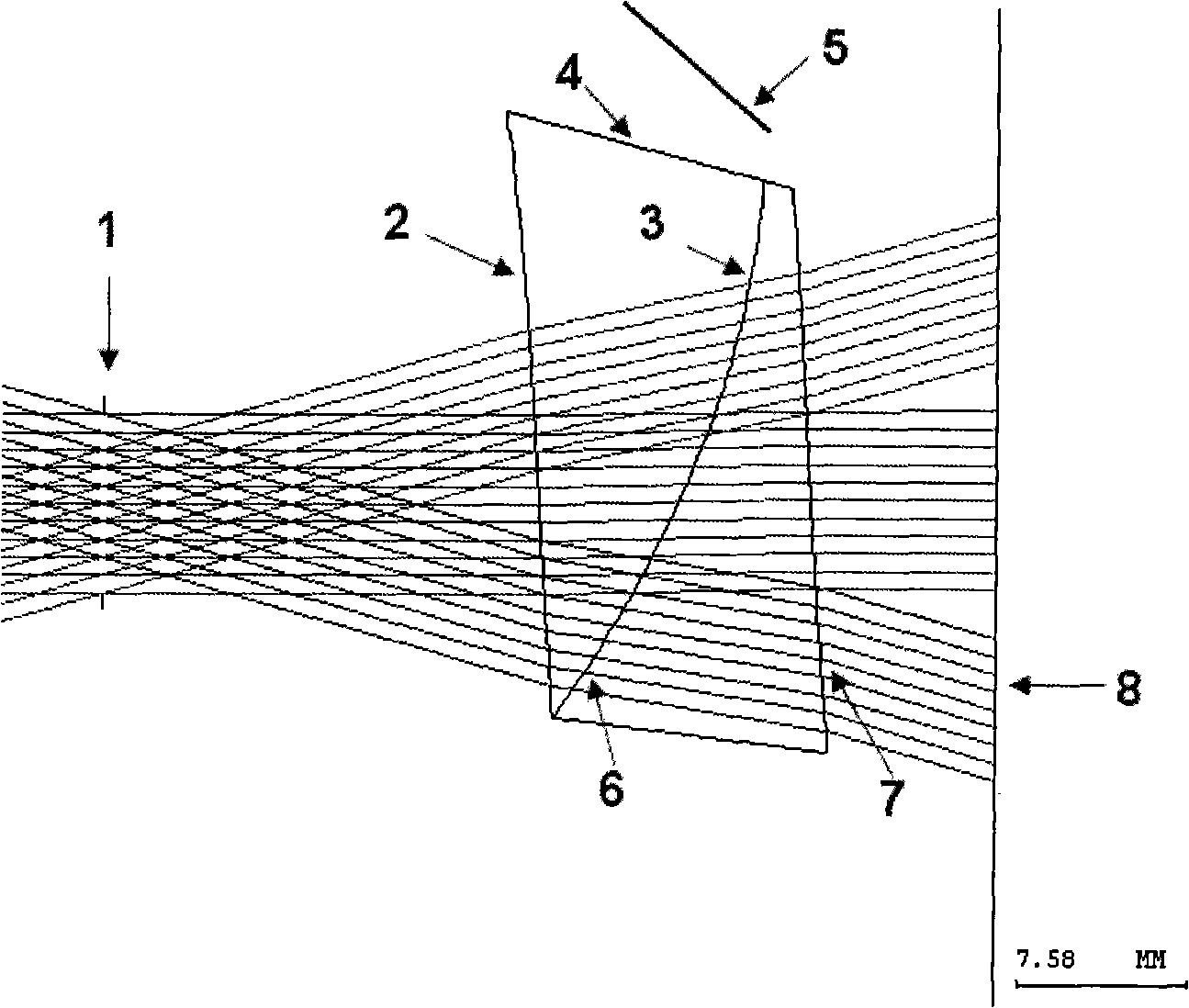

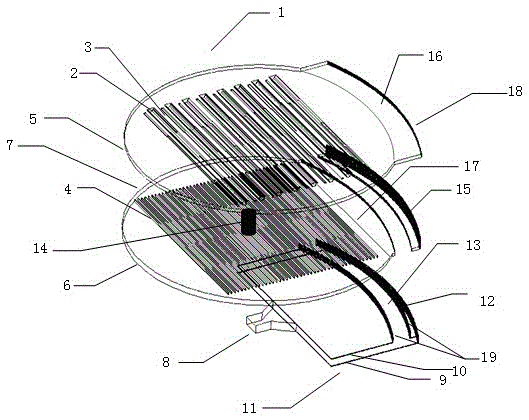

Optical system of light and small-sized big angular field free curved surface prism helmet display

The invention relates to a small and light wide-field free-form surface prism HMD optical system, which belongs to the field of optical system and device design and is applied to the virtual reality and augmented reality field. The invention comprises a free-form surface prism with three optical surfaces, and a micro-image display; the free-form surface prism is made of plastic glass materials with the refractive index greater than 1; the three free-form optical surfaces are concave surfaces, which meet one of the three surface-type equations, and the location relationship of each surface meets three condition equations; the incident angle formed between the widest-field upper edge rays emitted by an LCD and the second free-form surface meets the total reflection conditions; and an image source element is an LCD of 0.61 or 0.59 inches. The small and light wide-field free-form surface prism HMD optical system is light and compact and has the advantages of good aberration correction and high light energy utilization rate; the optical system enables the observer to see clear images in a wide field of view, and the displayed images do not have apparent brightness attenuation and can not easily cause visual fatigue to the observer.

Owner:BEIJING NEDPLUSAR DISPLAY TECH CO LTD

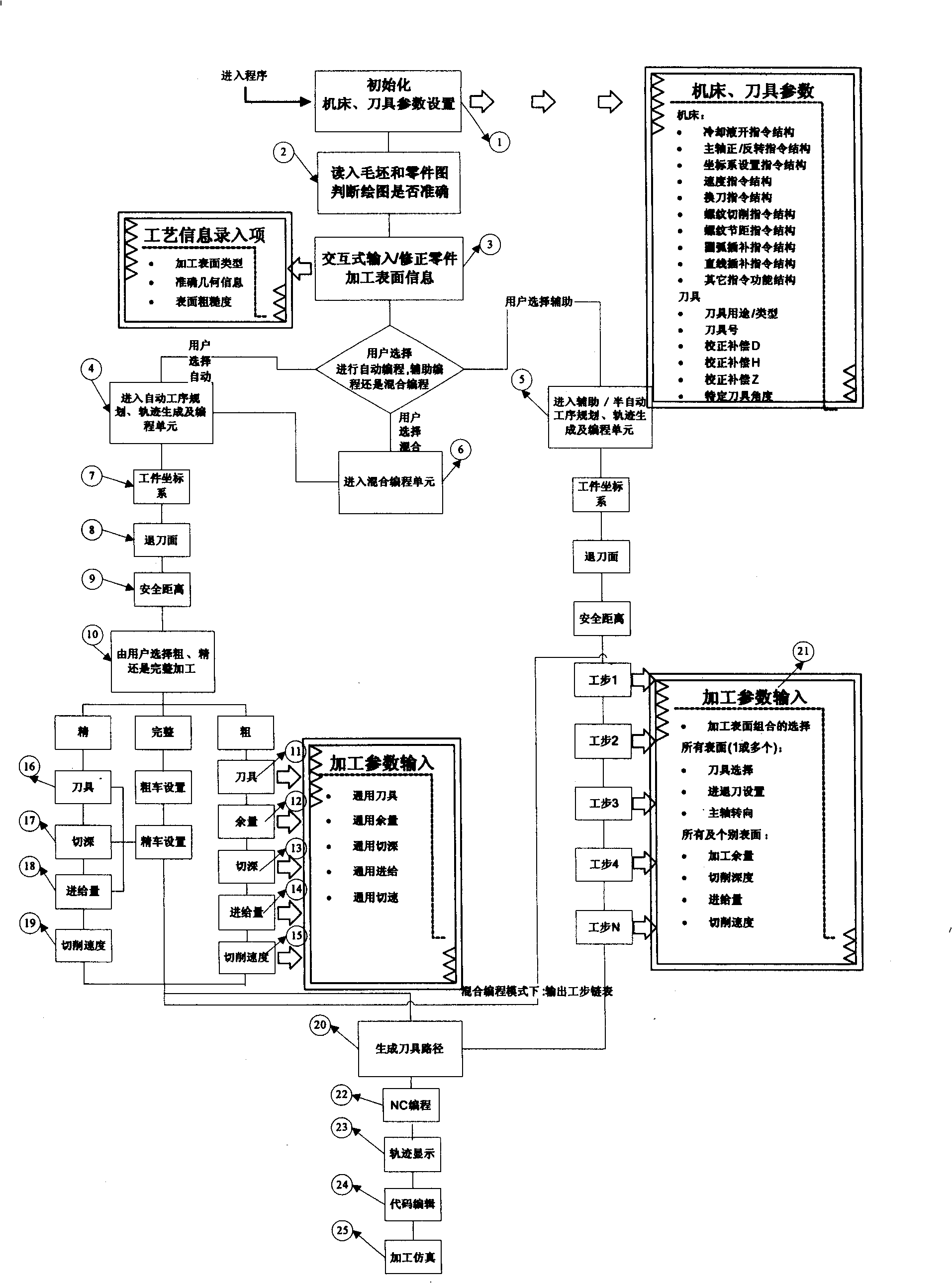

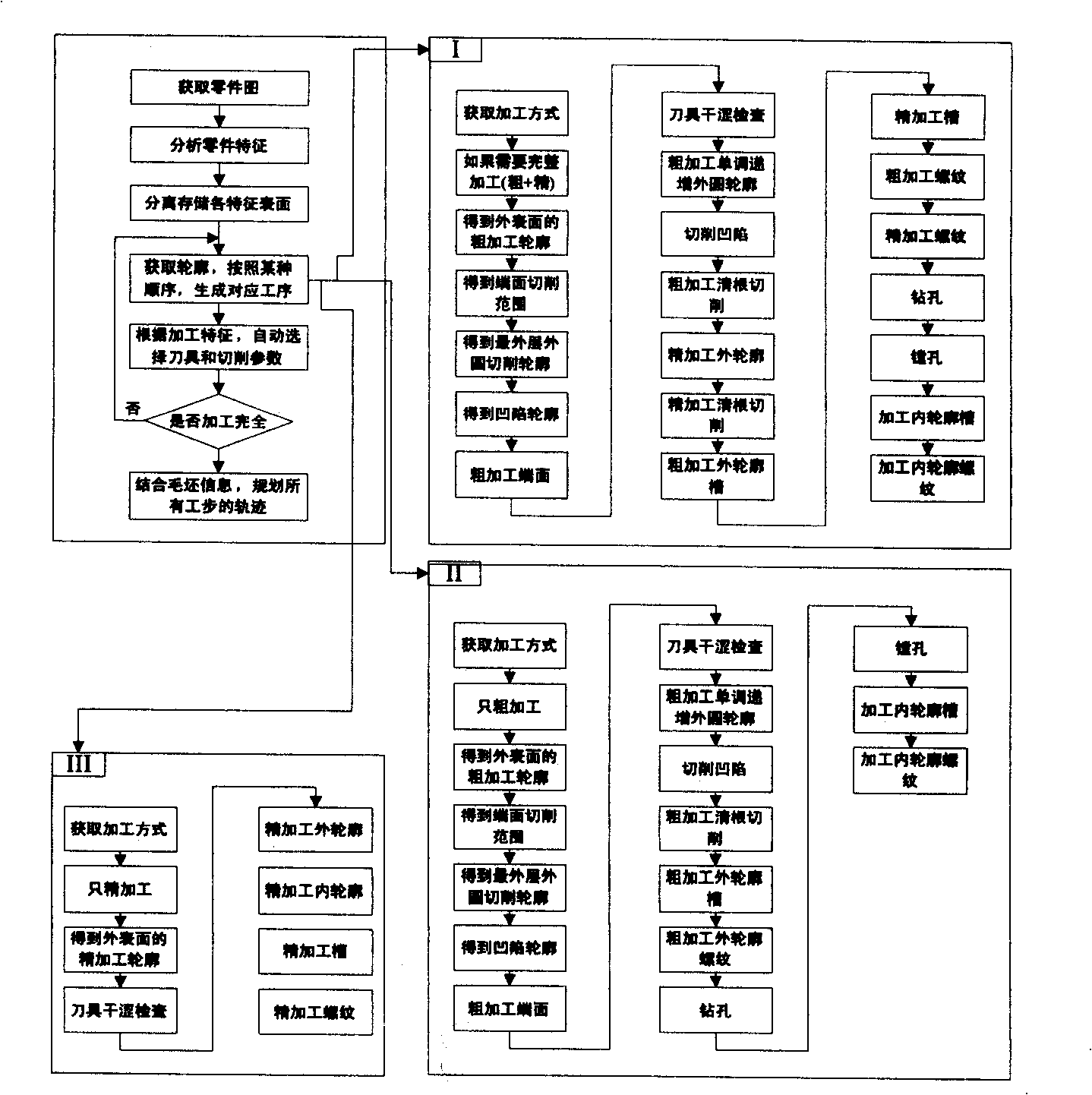

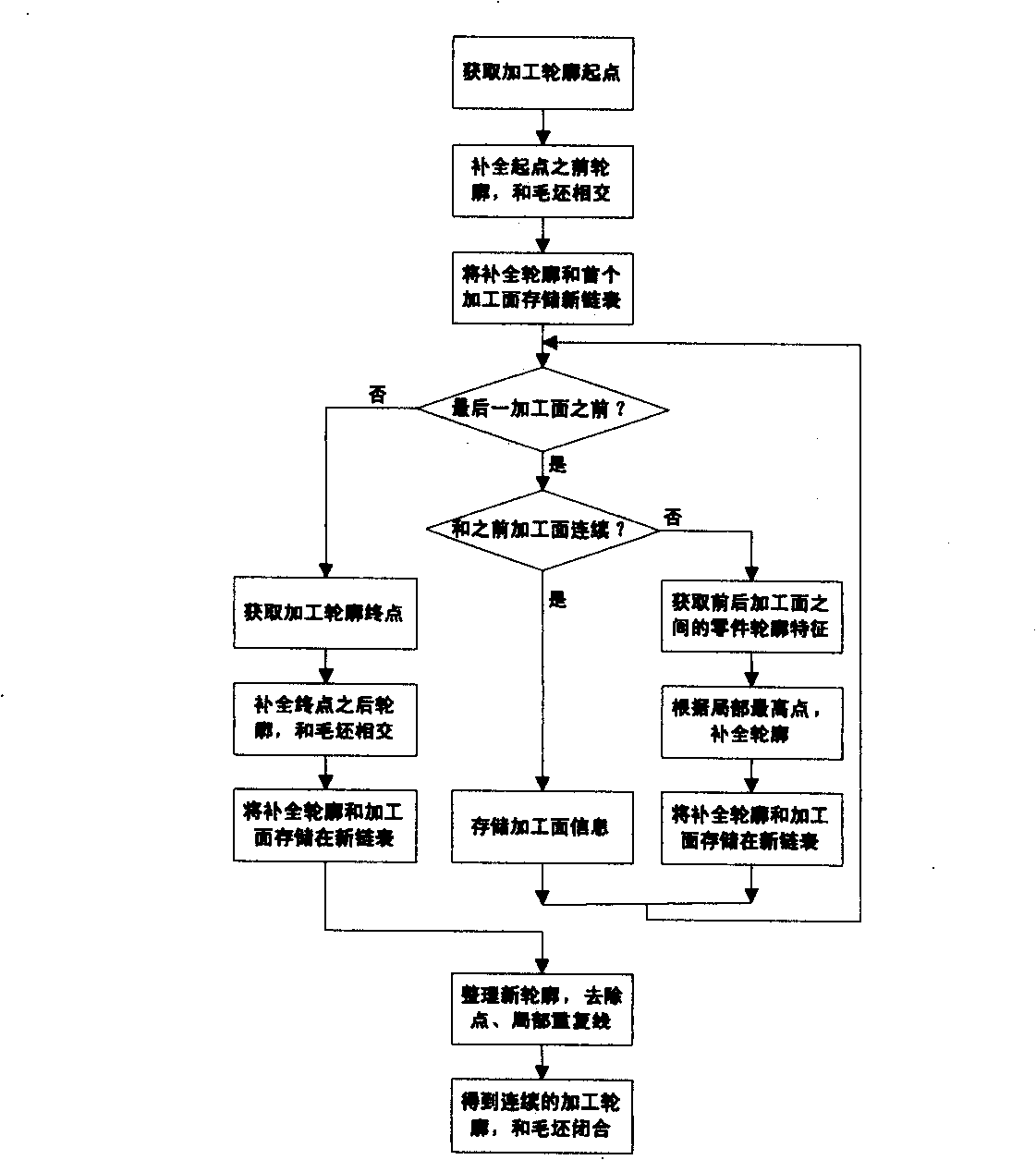

Imaging interactive numerical control turning automatic programming method and system

The invention provides an automatic graphical interaction-typed numerical control (NC) turning programming method and system used for improving programming efficiency and NC code quality, prompting quick product process realization (RPPR) and integrated product process development (IPPD). The technical proposal of the invention is that the automatic graphical interaction-typed numerical control turning programming method is characterized in that the method comprises the steps of: reading in blank and part drawing, removing redundant information, and judging whether the graphics are exact; leading the graphics to have real-time interaction function and be capable of correcting the information of the part processing surface, including processing surface type, exact geometrical information and surface roughness; determining whether to execute the corresponding system function modules by carrying out automatic programming or auxiliary programming or mixed programming according to the selection of the user. The automatic graphical interaction-typed numerical control turning control system is characterized in that the automatic graphical interaction-typed NC turning control system comprises a CAD data reading-in module which is respectively connected with an automatic programming module, an auxiliary programming module and a mixed programming module which are respectively connected with an automatic track layout module which is connected with an NC code generation module.

Owner:TSINGHUA UNIV

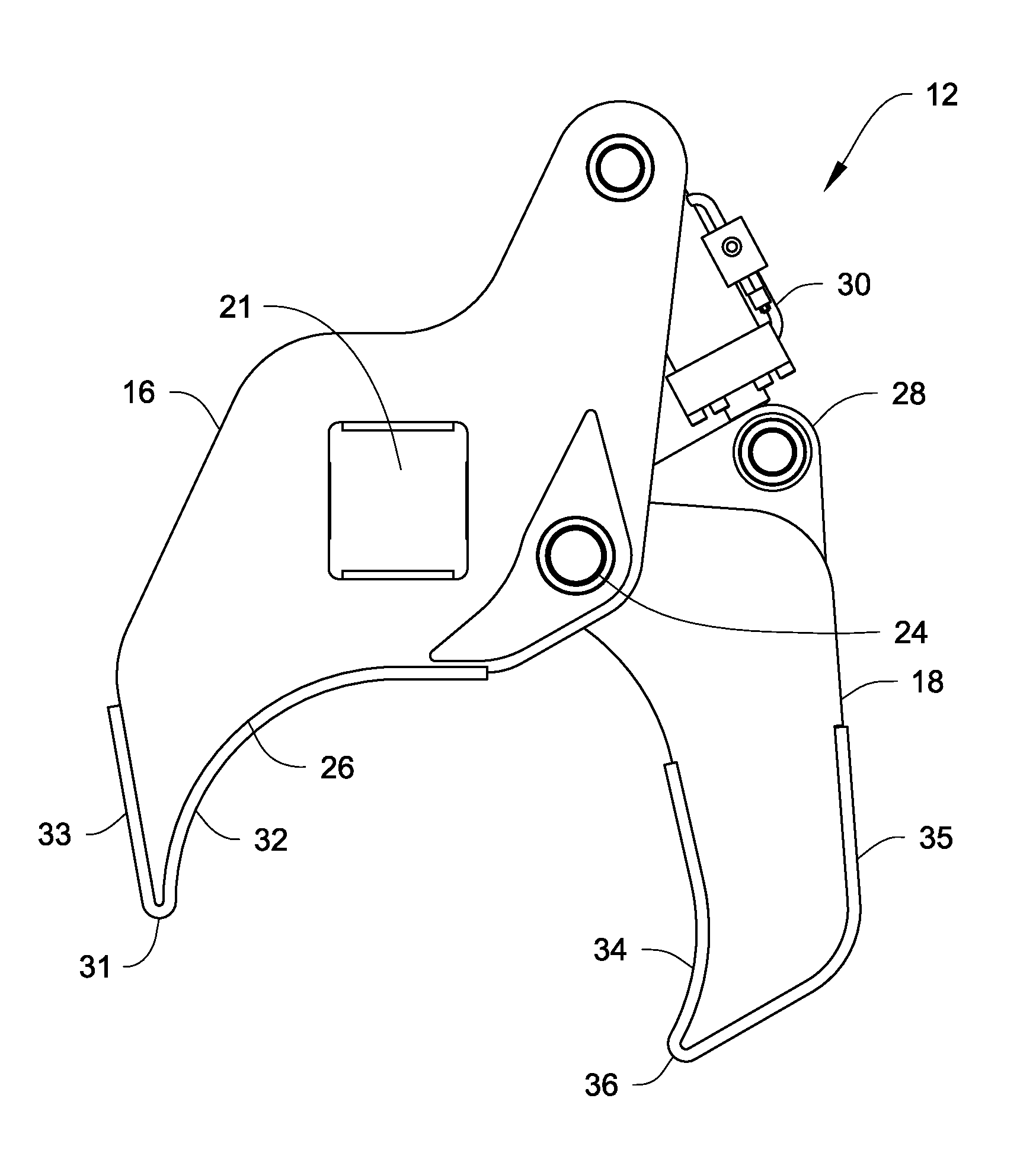

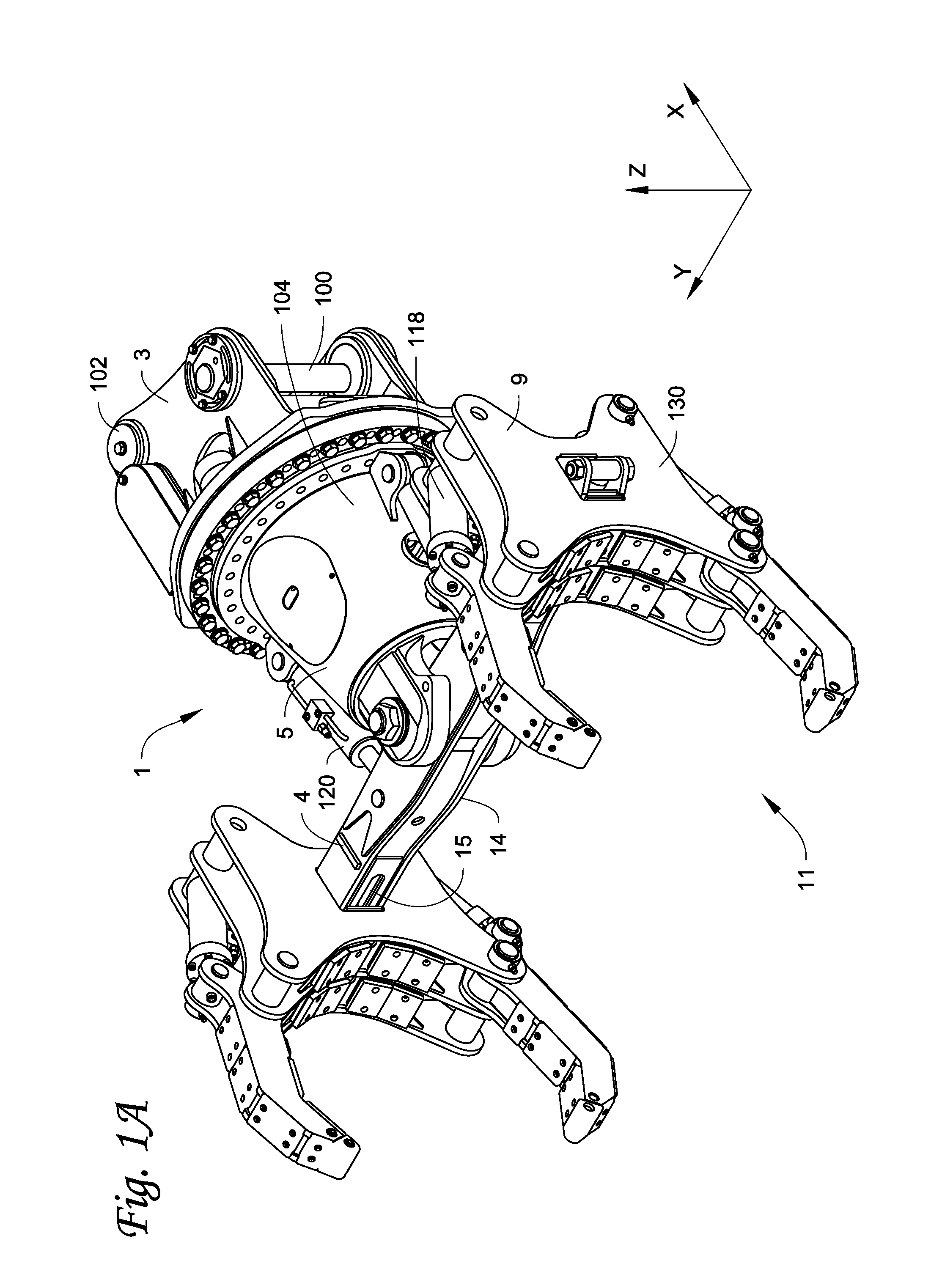

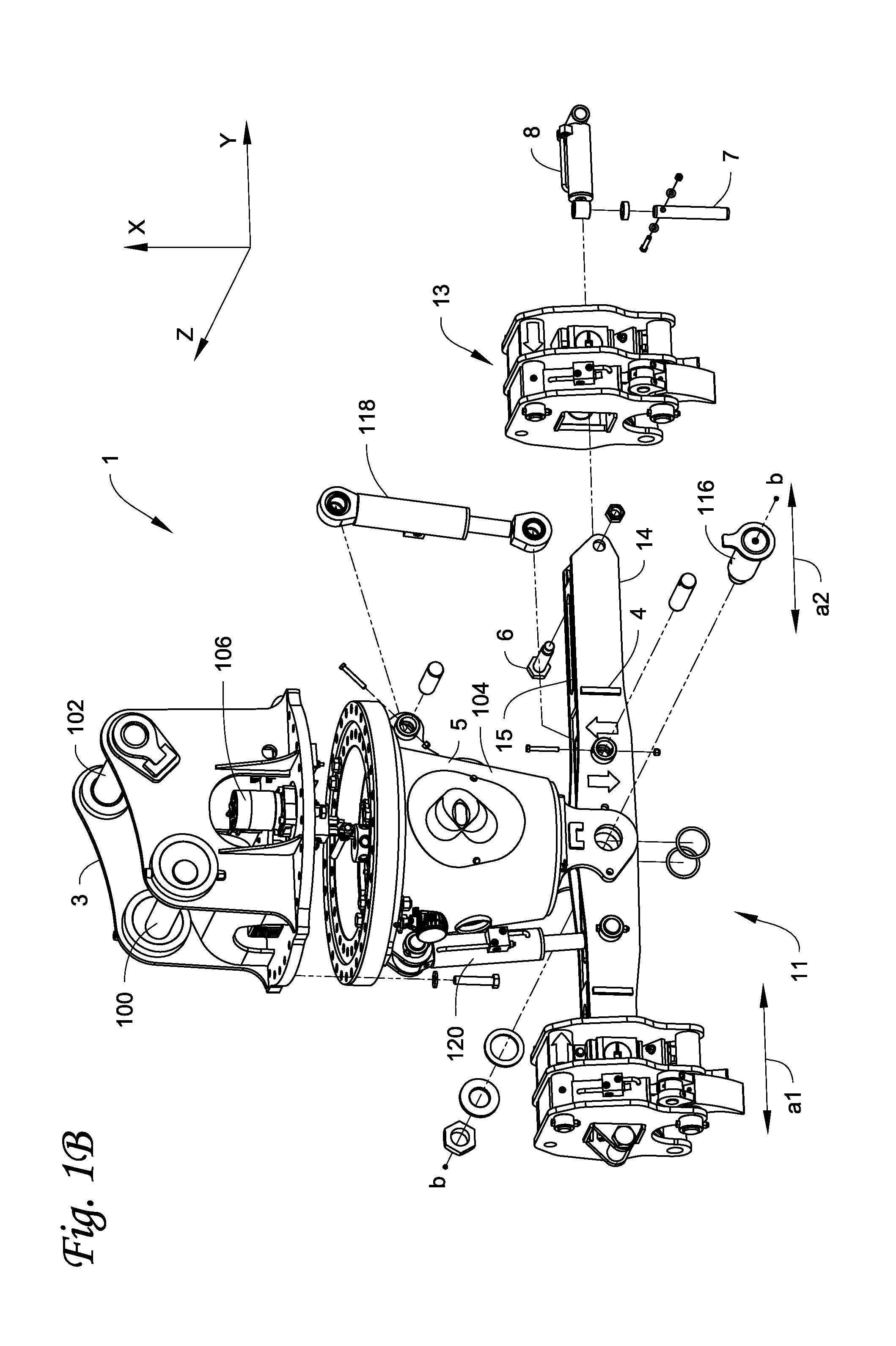

Gripping assembly and gripping members for a grapple attachment

ActiveUS20100308609A1Easy loading and unloadingReduce manpowerDrilling rodsGripping headsPositive controlEngineering

A gripping assembly with gripping members, as part of a grapple attachment, used to grasp and manipulate elongated objects, for example pipe, is described. Due to the gripping action of the gripping members and tilt control capabilities of the grapple attachment, total positive control of the pipe is maintained, even if the gripping assembly picks up pipe off center. The grapple attachment is able to be used on all pipe surface types, including pipe surfaces that are dirty, snow or ice covered. The gripping members are configured to prevent damage to the pipe and to adjacent pipes, and will not crush the pipe.

Owner:LAVALLEY IND

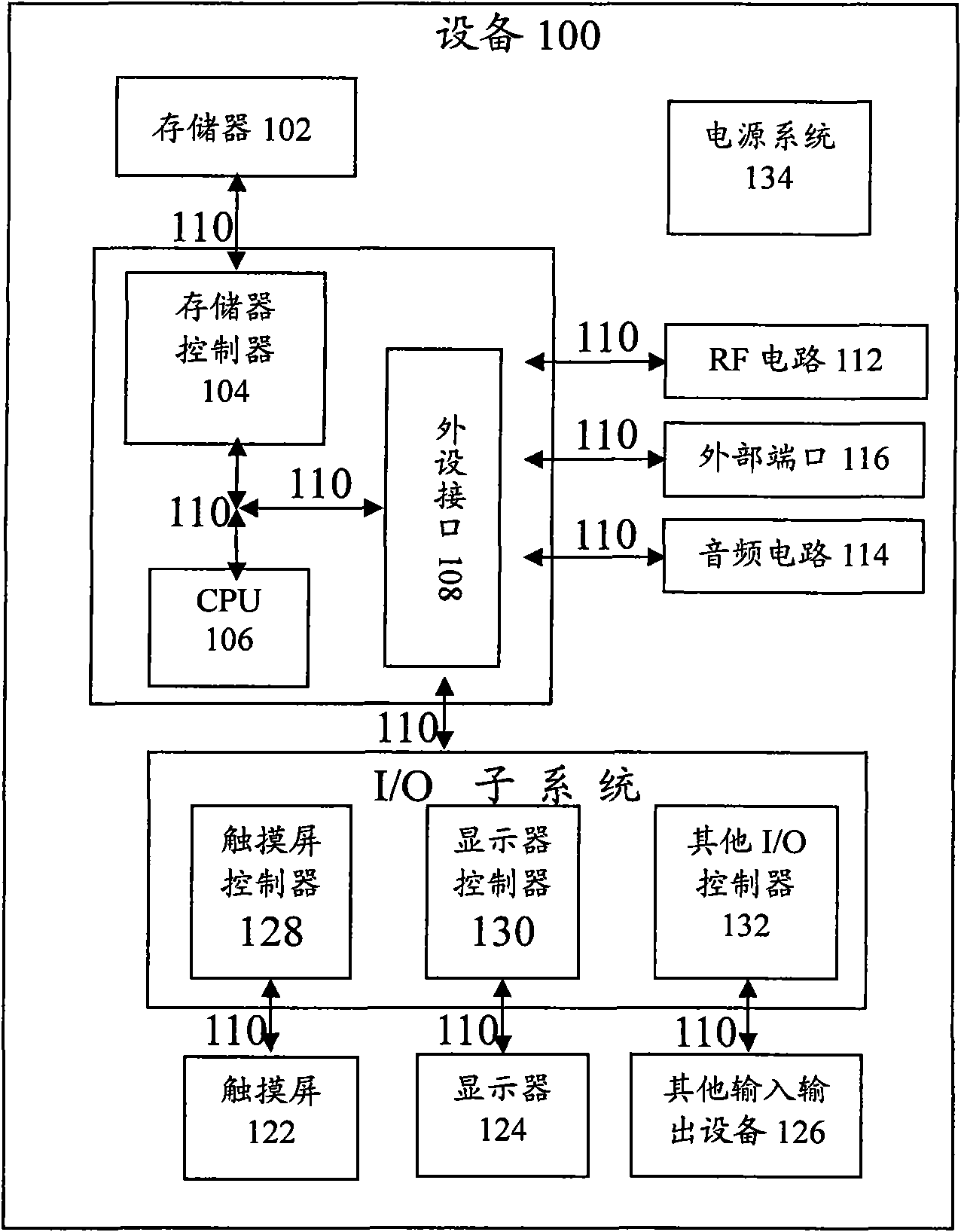

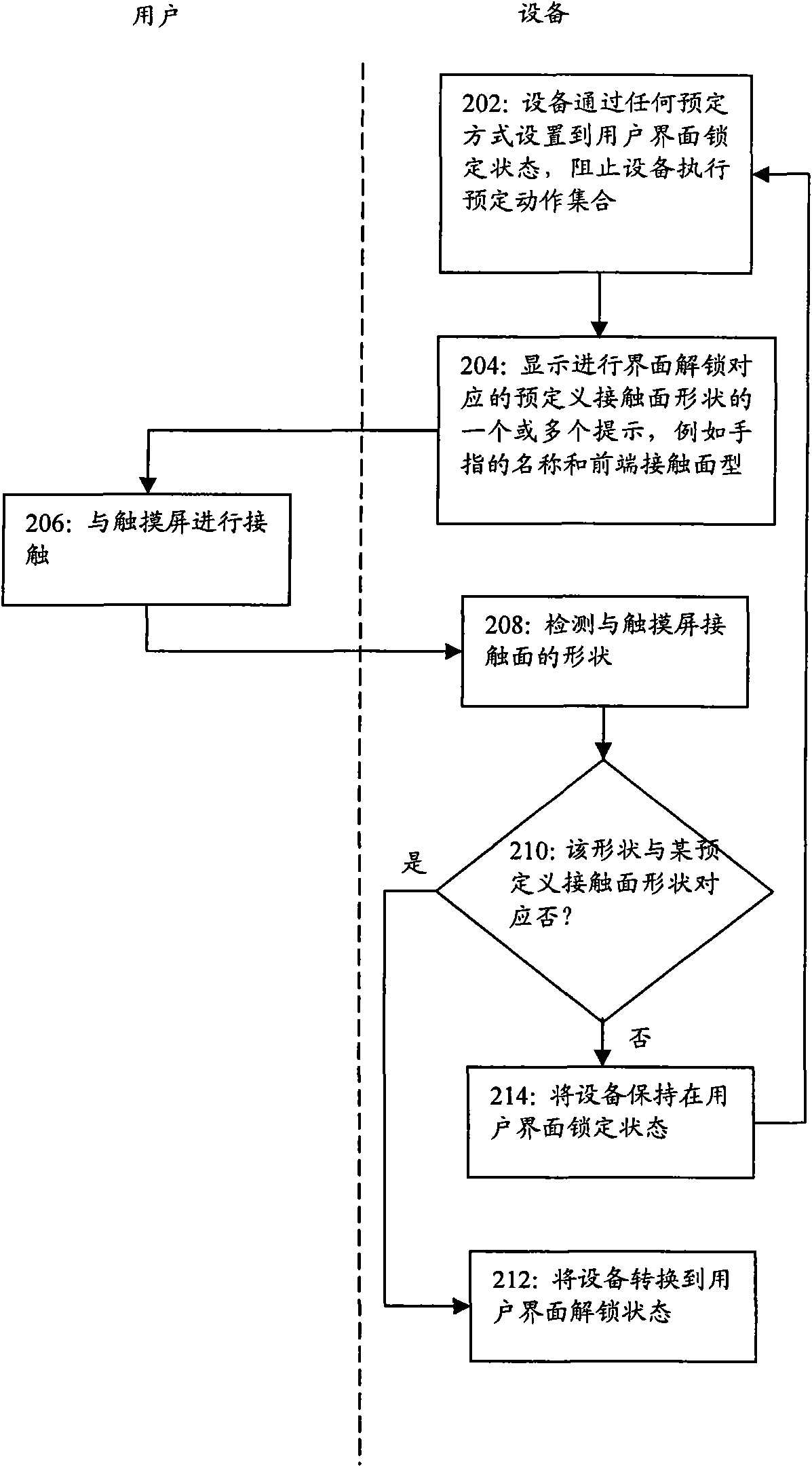

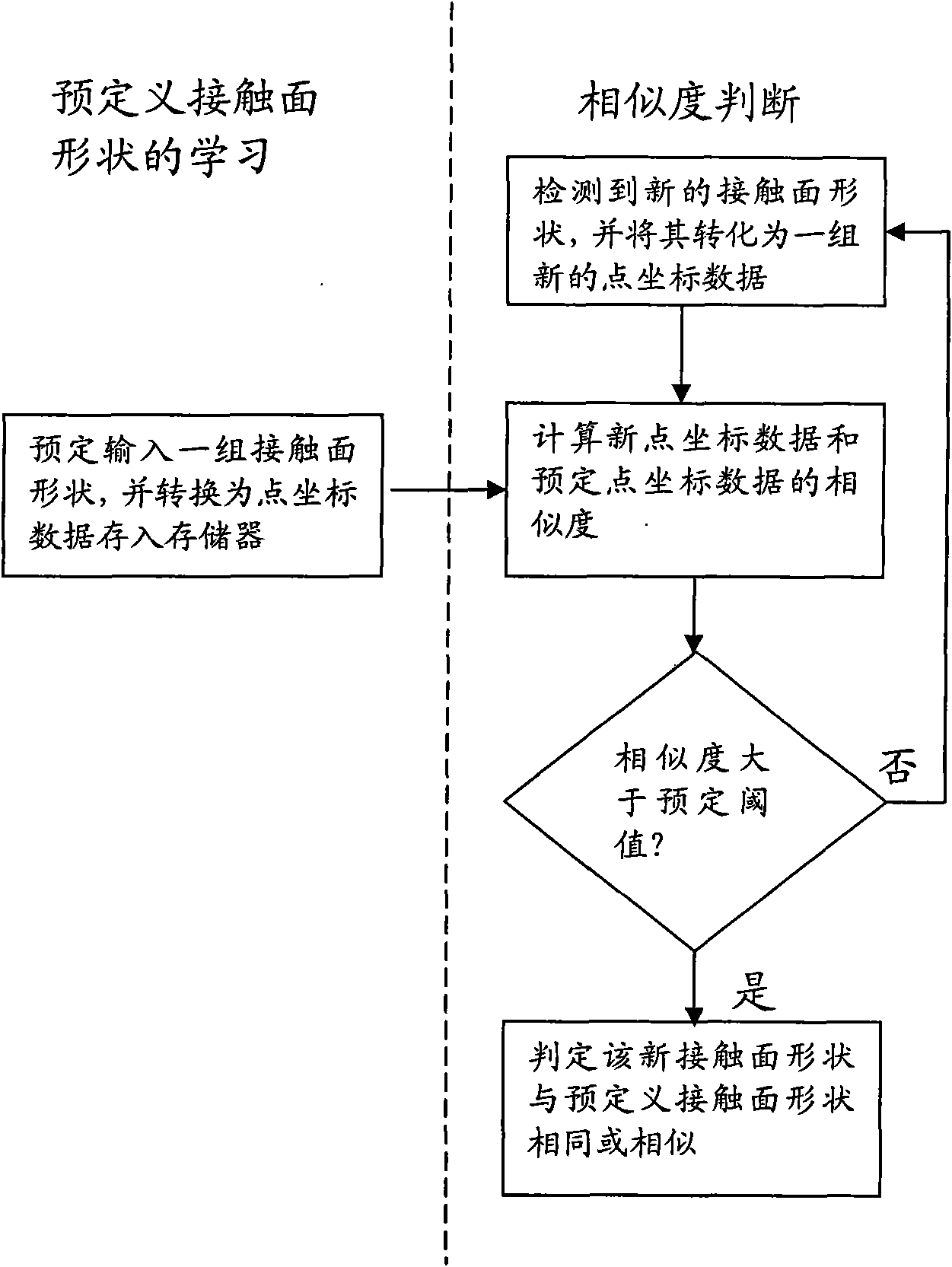

Method and device for identifying unlocking by contact surface type

InactiveCN101661373AFunction as password protectionEasy to operateDigital data authenticationInput/output processes for data processingState of artSurface type

The invention discloses a method and a device for identifying unlocking by contact surface type, which solves the technical defects of large occupied interface of operation, inconvenient operation and poor privacy when the active state of equipment is converted by an operation touch screen in the prior art. In the invention, the predefined contact surface shape corresponds to a user interface state of equipment; when the equipment detects that the contact surface shape generated on the touch screen by users is identical to or similar with the predefined contact surface shape, the equipment state is converted to the user interface state corresponding to the predefined contact surface shape. The invention can be applied to interface unlocking, application unlocking and the like, occupies small user interface, and has easy operation and good privacy.

Owner:ZTE CORP

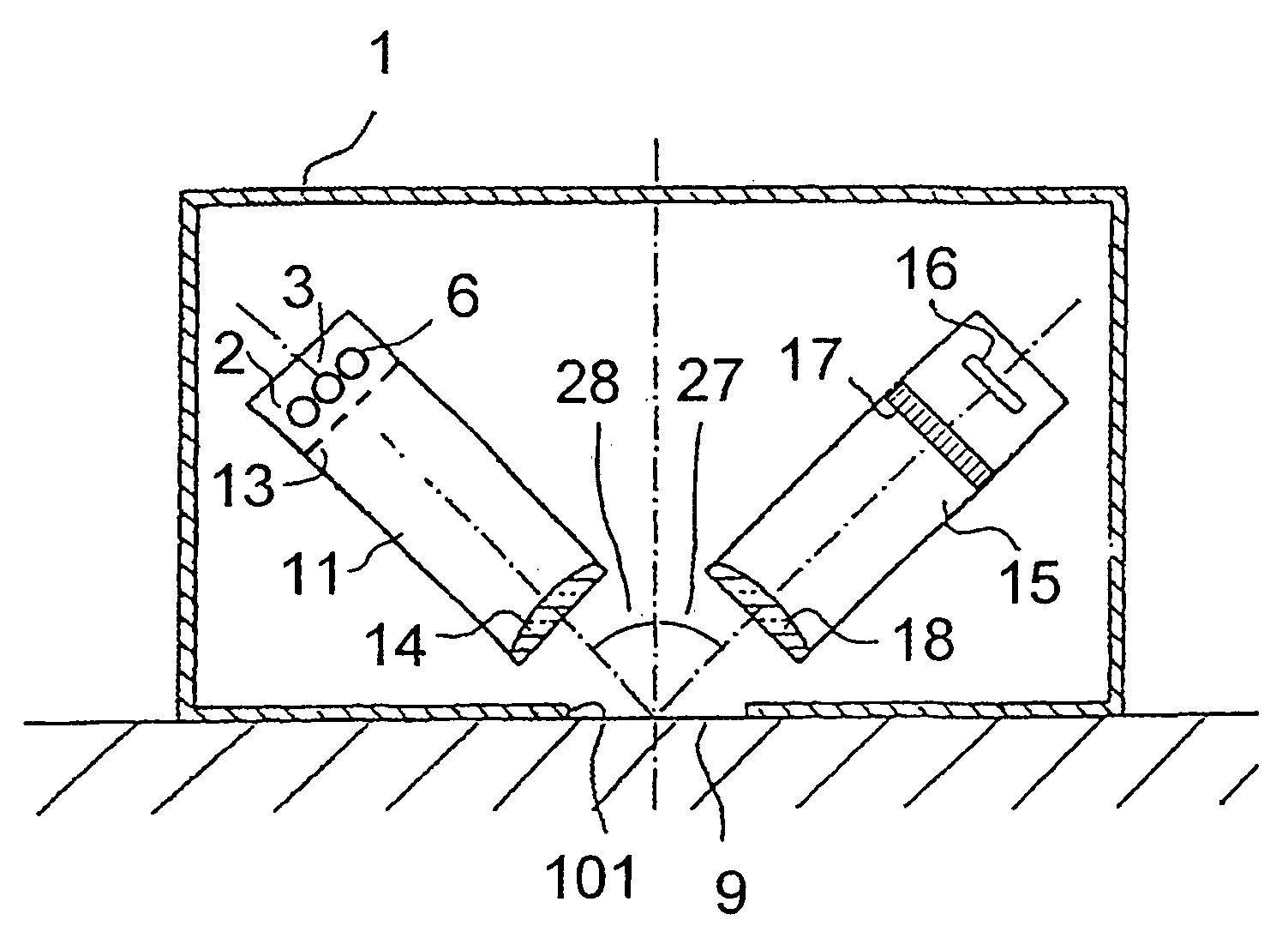

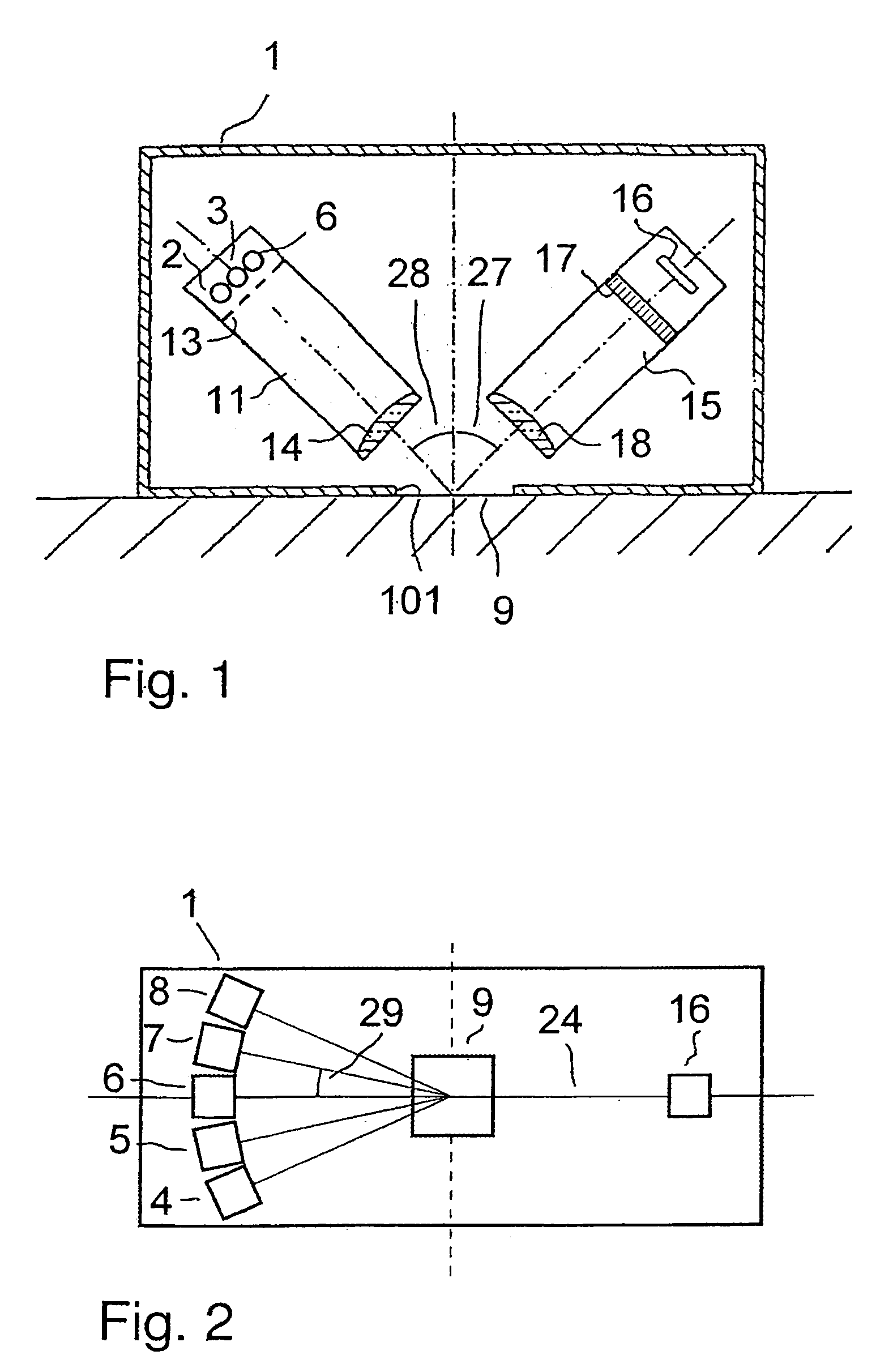

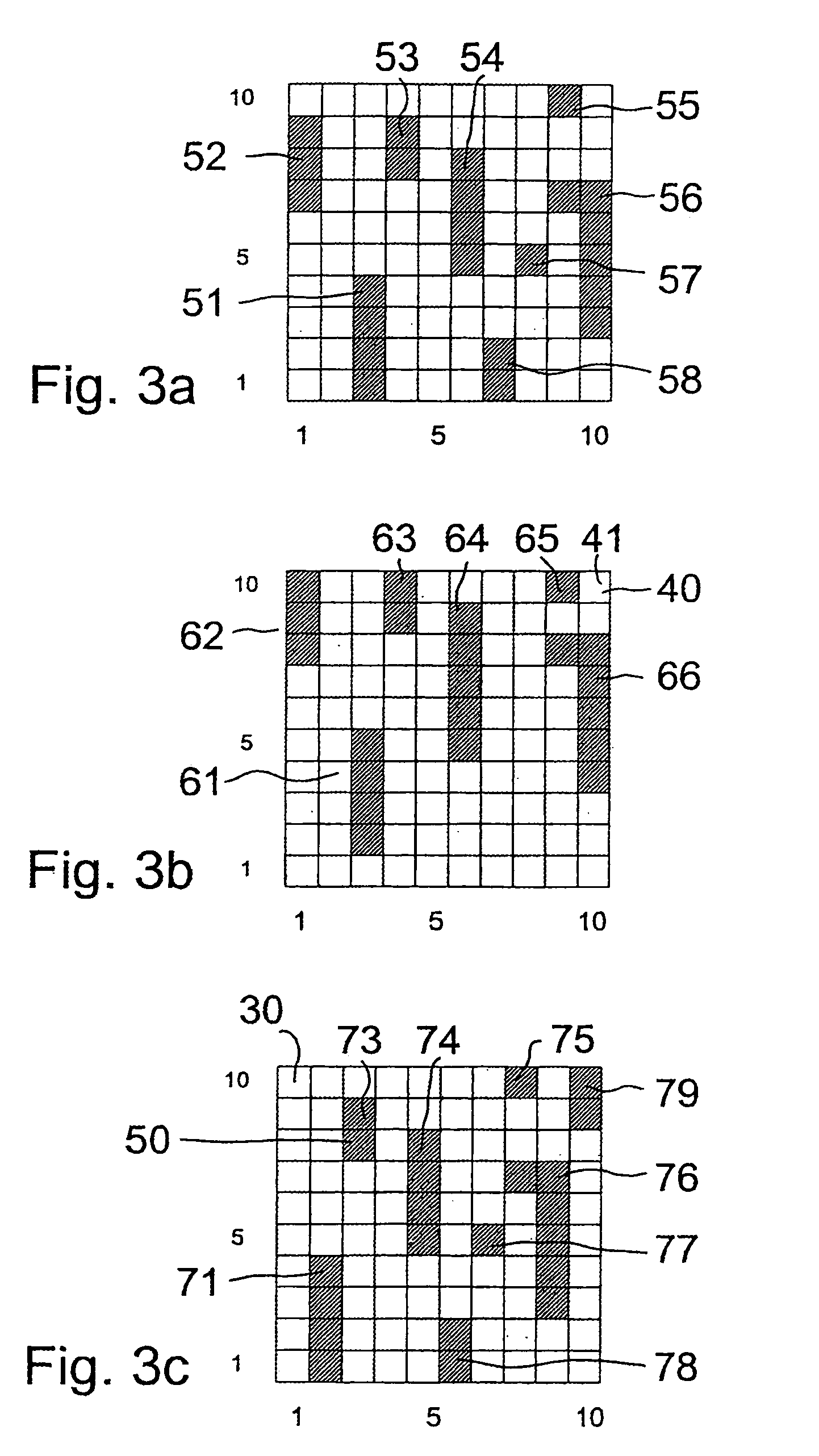

Device and process for the determination of the properties of reflective bodies

InactiveUS6975404B2Scattering properties measurementsOptically investigating flaws/contaminationSurface typeLight sensitive

A device for determining the properties of reflective bodies has at least one illuminator that emits light onto a measurement surface, at least one detector for recording the light reflected from the measurement surface, the at least one detector includes a plurality of light-sensitive sensors. Substantially each sensor issues a measurement value characteristic of the light received by each respective sensor. Also included is at least one memory, having at least one first predefined threshold, at least one controller for the measurement sequence which includes at least one processor, whereby a measurement sequence is controllable such that a measurement value of a sensor is allocated to a first surface type when same exceeds the first threshold, wherein at least two sensors are respectively associated with different locations to be measured on the measurement surface, and wherein the controller is configured to issue at least one surface characteristic statistical parameter.

Owner:BYK GARDNER

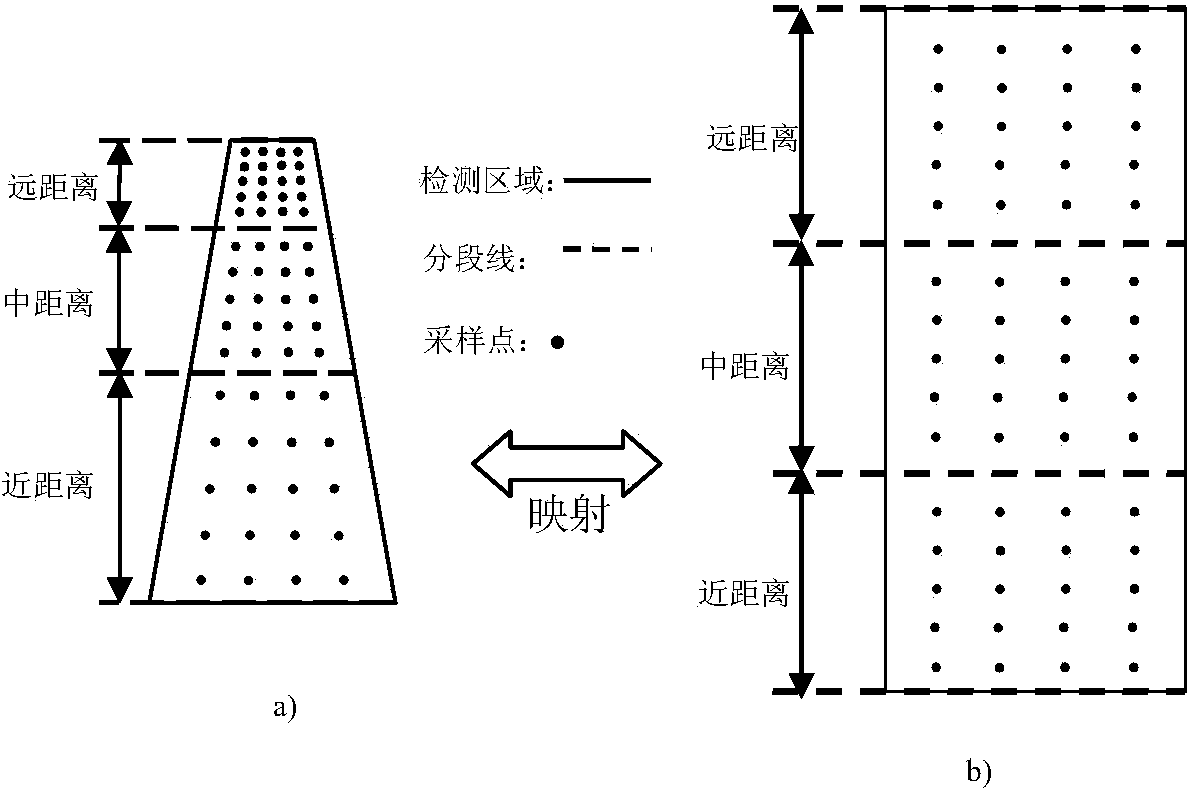

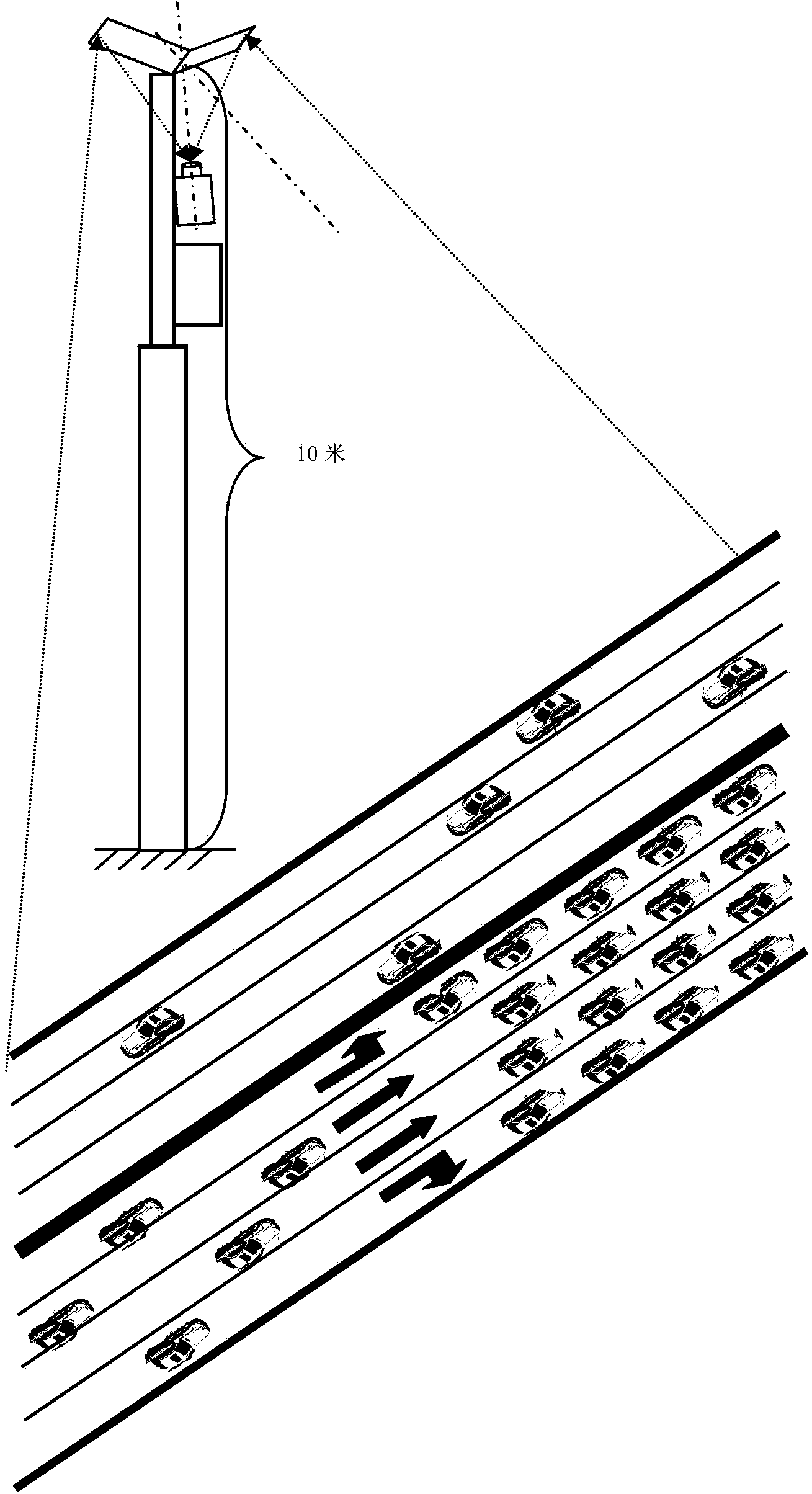

Light-weight holographic road traffic state visual inspection device

ActiveCN103985250AAccurate and efficient background update methodNo errorsDetection of traffic movementMeasurement pointSimulation

The invention discloses a light-weight holographic road traffic state visual inspection device comprising visual sensors installed at measuring points in each road on a road network, and a microprocessor for analyzing and evaluating the road traffic state according to video image data of the visual sensors. According to the invention, a point replacing surface type video image detection method is adopted to reduce spatial redundancy; an accurate background update strategy based on sampling points is adopted to realize a light-weight, accurate and efficient background update method; and at the same time, the detection of road traffic jam and the detection of various of traffic basic parameters can be completed.

Owner:ZHEJIANG UNIV OF TECH

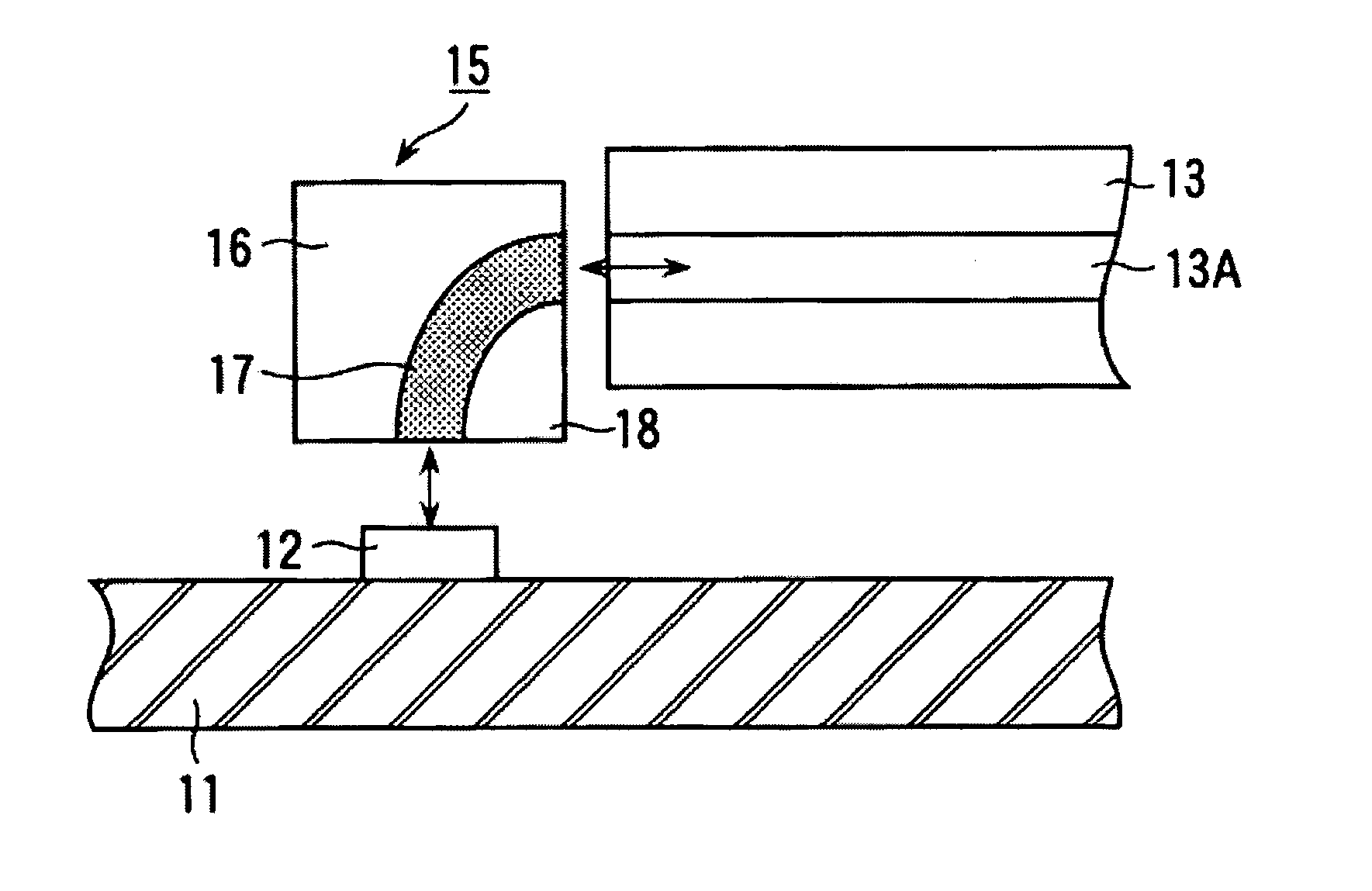

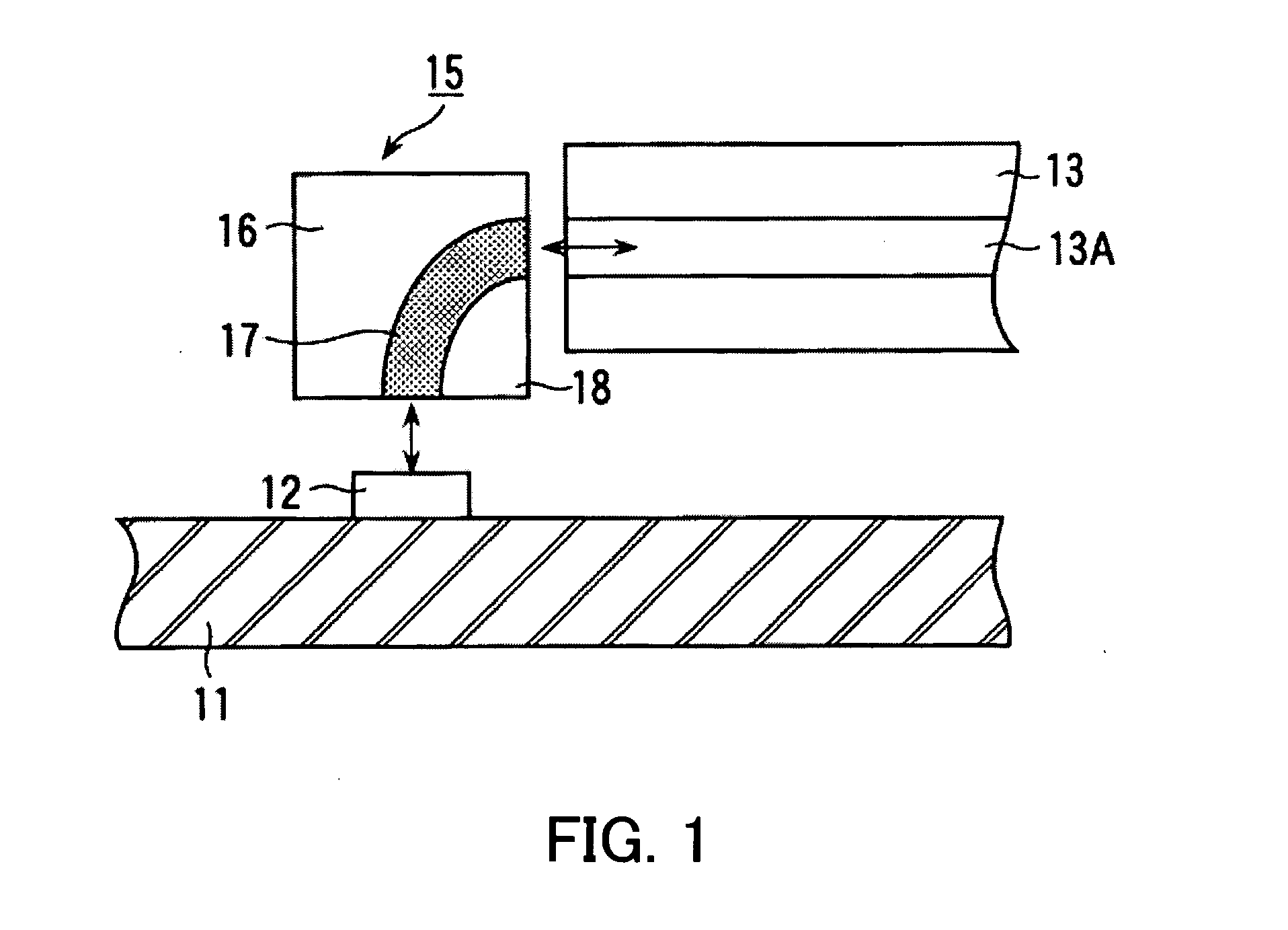

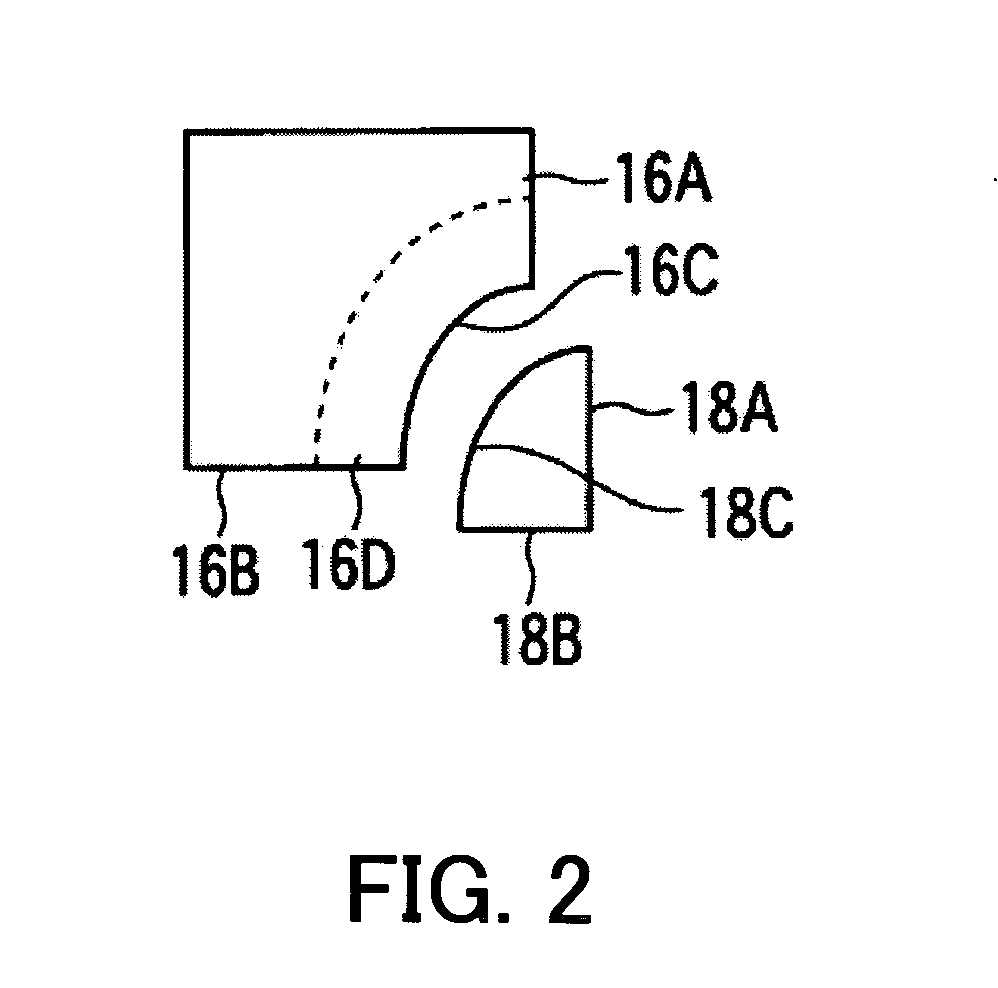

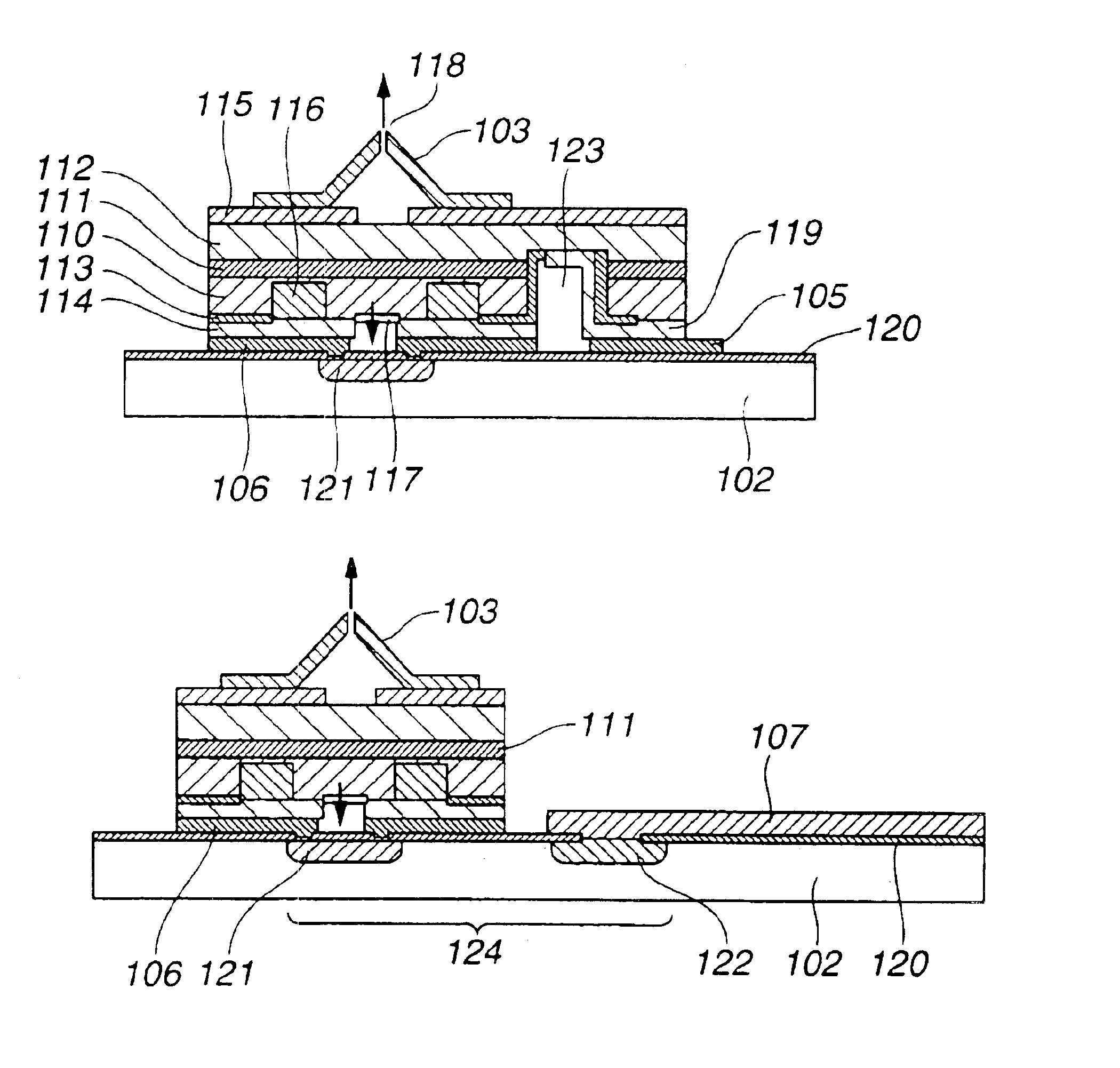

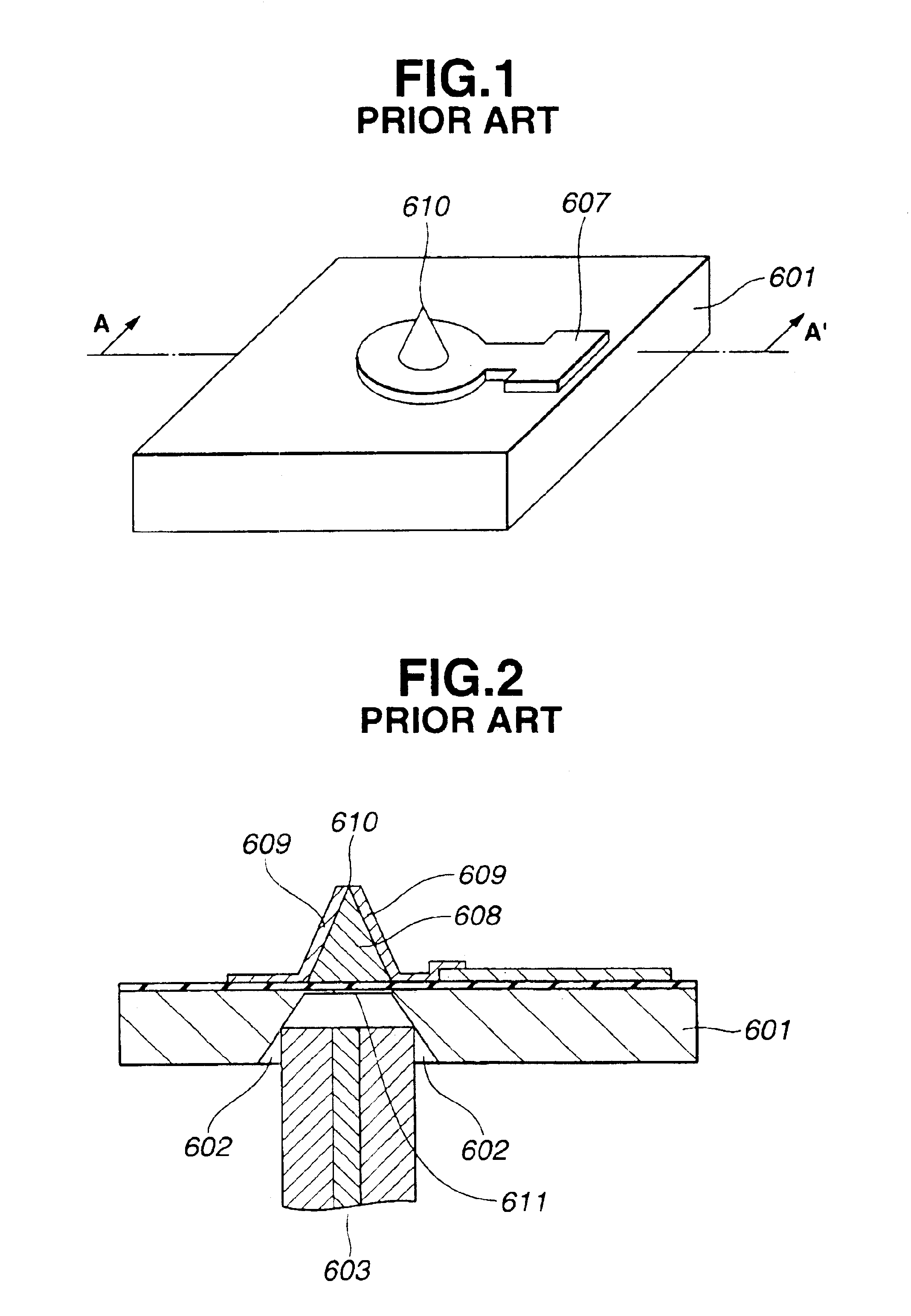

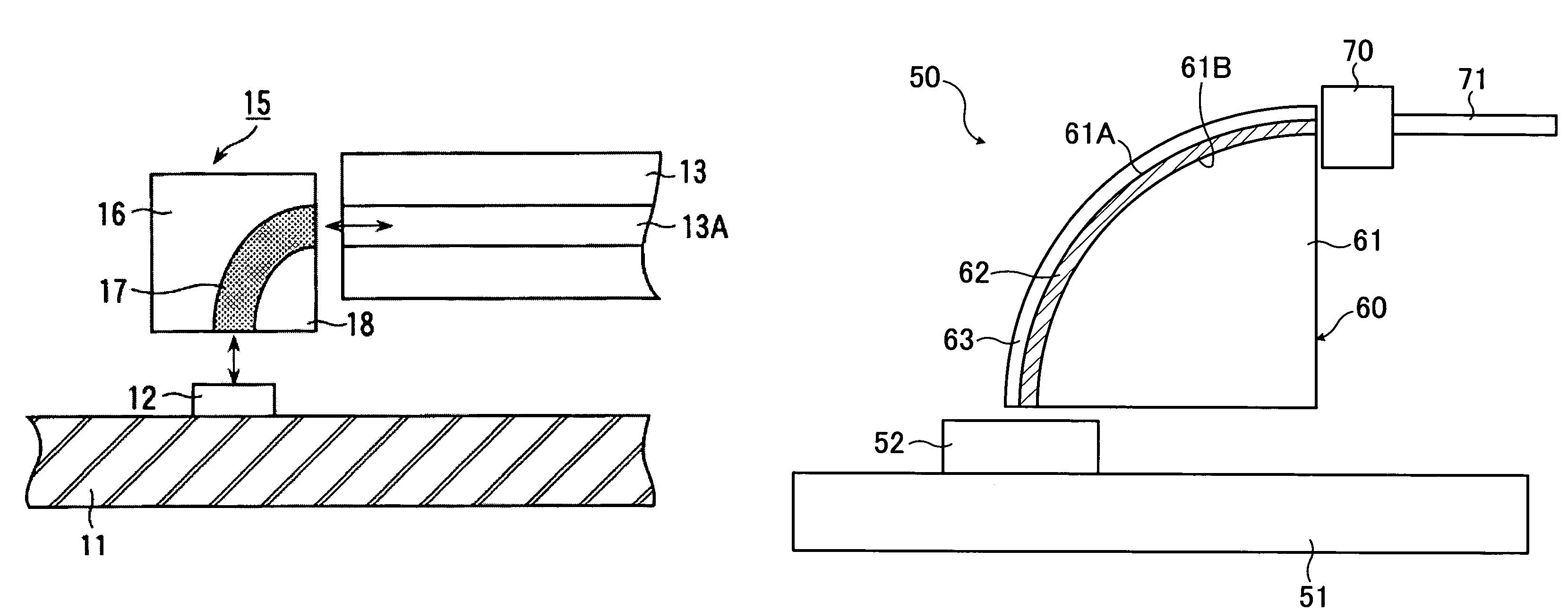

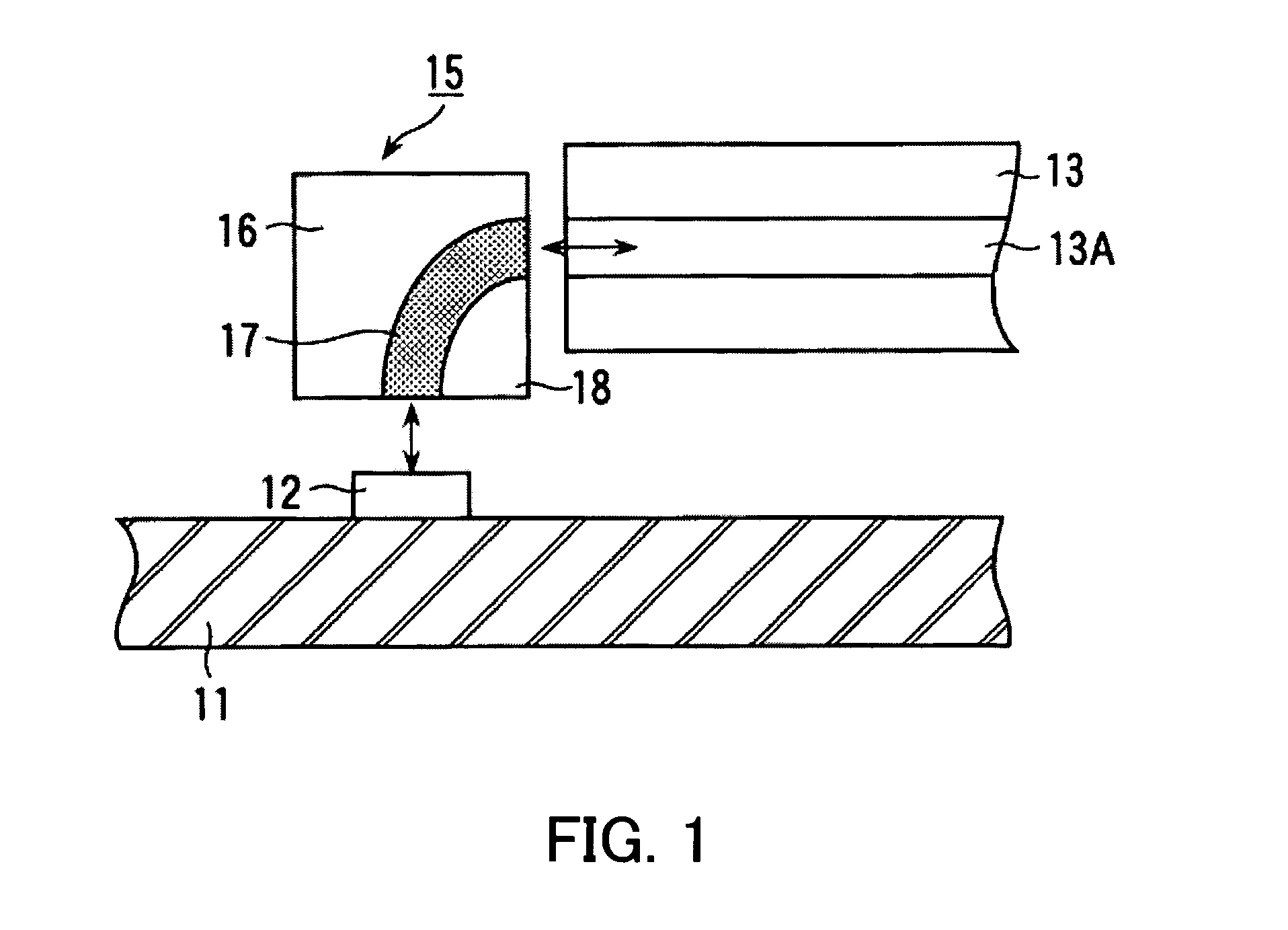

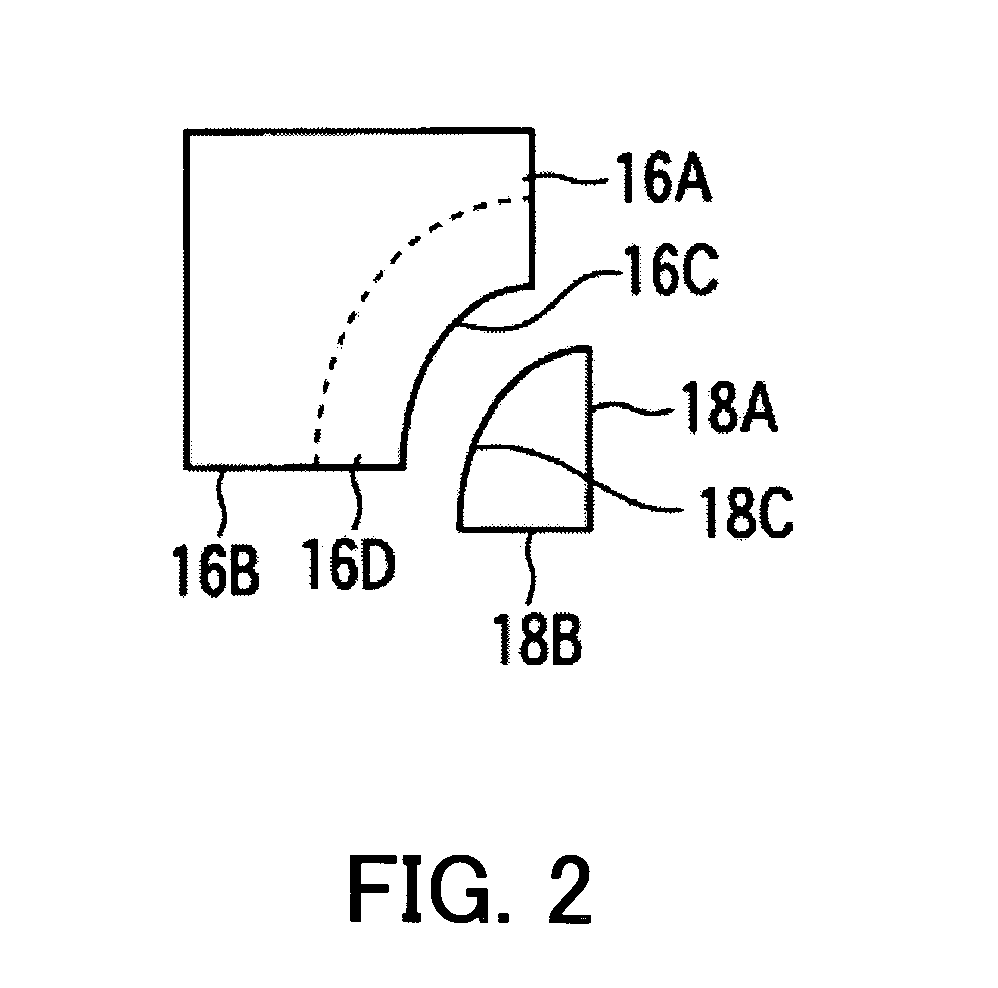

Optical waveguide structure and optical module

InactiveUS20050058399A1Coupling light guidesOptical waveguide light guideOptical ModuleRefractive index

An optical waveguide structure capable of optically coupling a surface type optical device, such as a surface emitting laser diode or a photodiode, and a transmission medium, such as an optical fiber, located so that their light output surface and light input surface will form an angle of about 90° with each other simply and easily. The optical waveguide structure comprises a first clad section having a curved surface for gradually turning the direction in which light travels almost squarely and a groove formed in the curved surface along the direction in which light travels, a core section which is made from a transparent material with a refractive index higher than the refractive index of the first clad section and with which the groove is filled in, and a second clad section which covers an exposed surface of the core section and the curved surface of the first clad section and which is integrated with the first clad section.

Owner:FUJITSU LTD

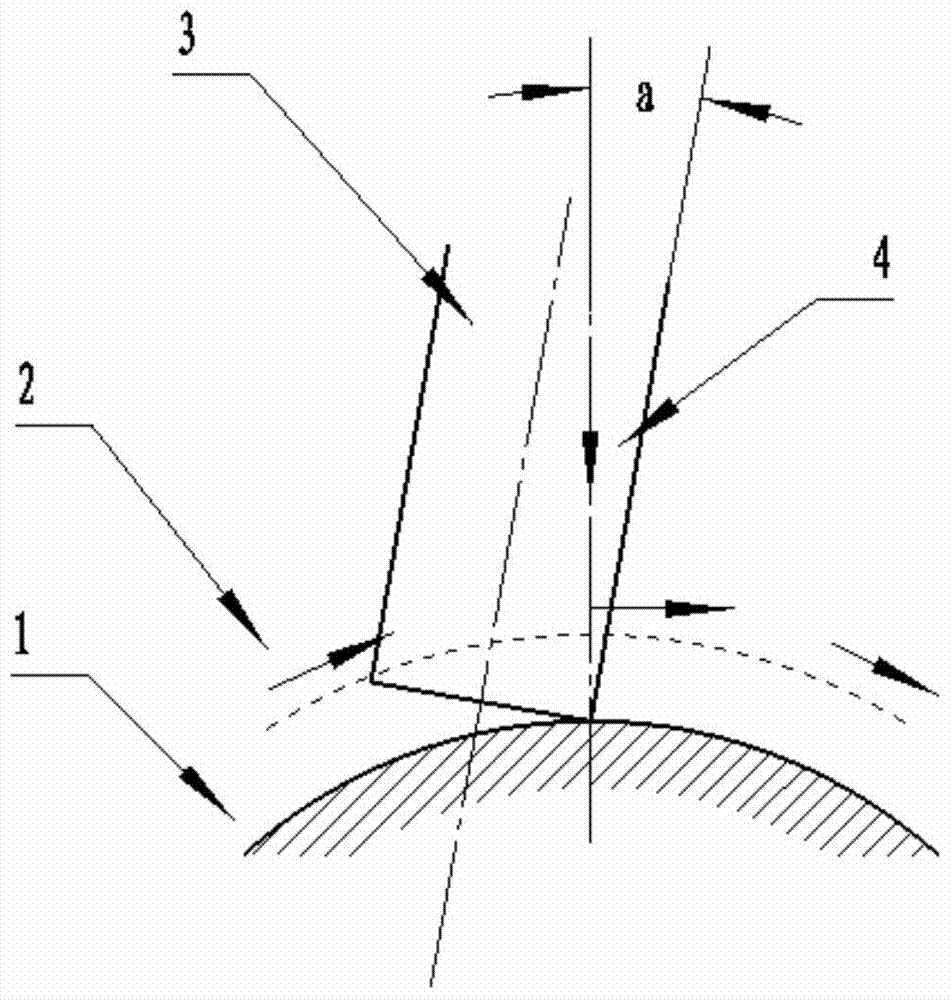

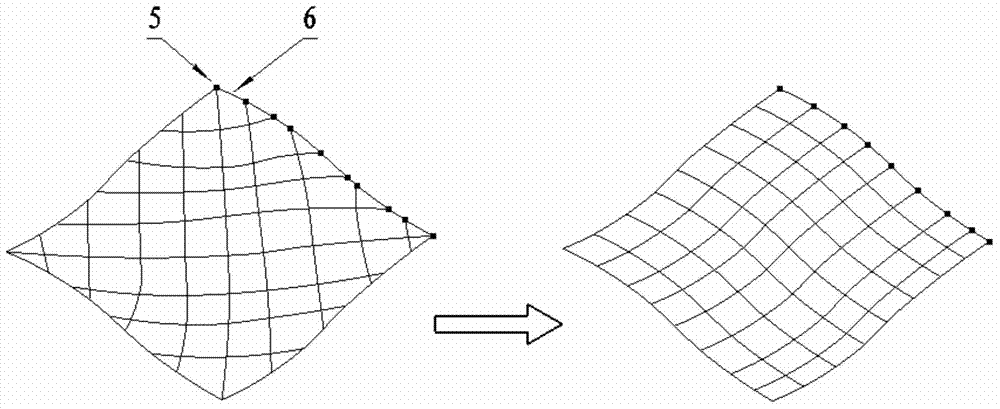

Multi-axis curved surface type numerically-controlled method for machining complicated curved surface part

ActiveCN103537743AImprove cutting efficiencySmall residualAutomatic control devicesFeeding apparatusNumerical controlMilling cutter

The invention discloses a multi-axis curved surface type numerically-controlled method for machining a complicated curved surface part. According to the method disclosed by the invention, the axis of a cutter can be arranged according to the directions of longitude and latitude normal lines for forming a curved surface, an inclined angle is adjusted to generate a cutter path, and the machining efficiency and the part surface smoothness can be improved. The numerically-controlled method can be realized by the following technical scheme: a part is fixed in a rotary center of a five-shaft machine tool; a curved surface is reconstructed according to the curvature change, the normal line direction of the curved surface and a machining path; a space change of an axis vector of the cutter is controlled by adjusting the front inclined angle and the side inclined angle of a cutter shaft of a flat-bottom end mill so that the cutter always keeps that a cutter tip participates in curved surface cutting in the five-axis continuous cutting process; a curved surface projection machining manner is adopted in the programming process so that the mill can carry out multi-axis linked milling machining according to the curvature change of the curved surface; the axis of the cutter is similar with a relatively small front inclined angle alpha overlapped to the normal line direction of the cutter path and a side inclined angle is set as 0; the axis of the cutter is kept vertical to the direction of the machining path to implement a five-axis linked machining numerical control procedure.

Owner:四川泛华航空仪表电器有限公司

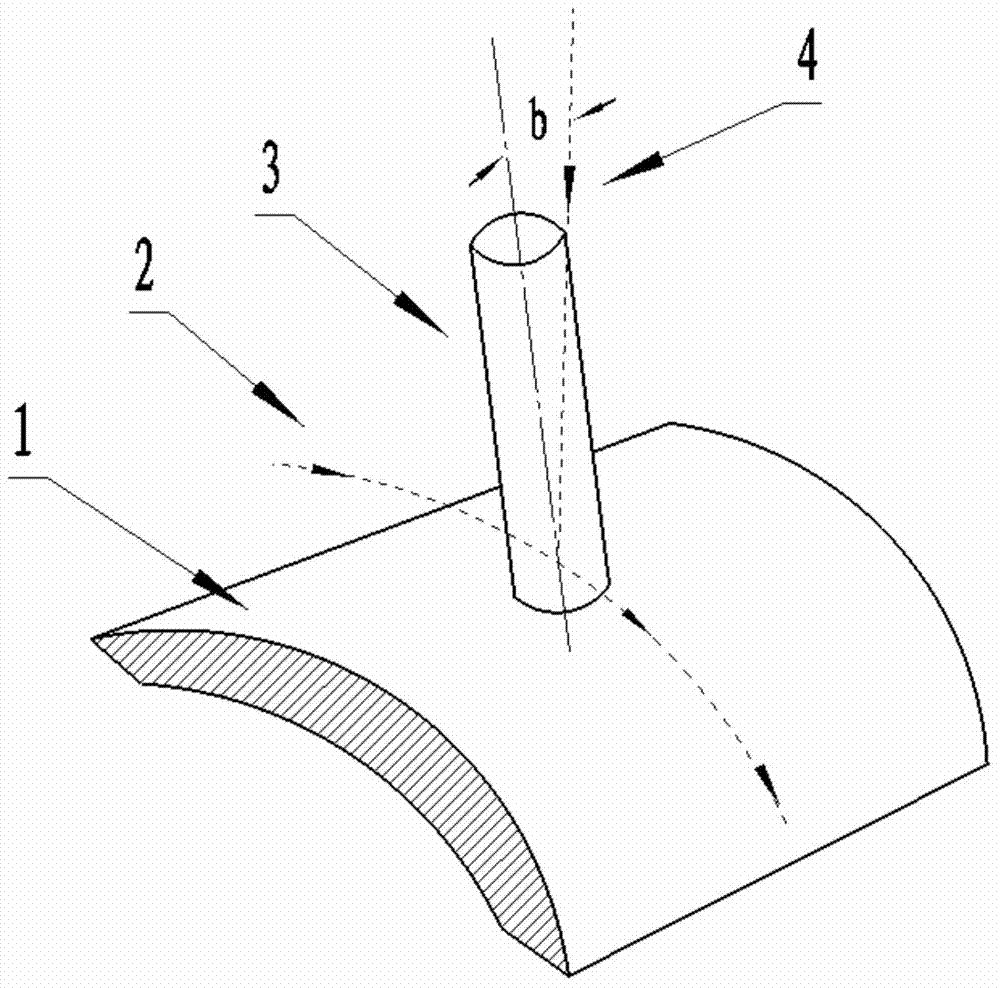

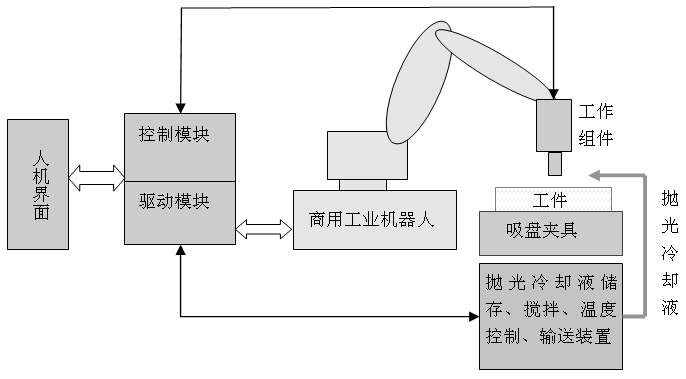

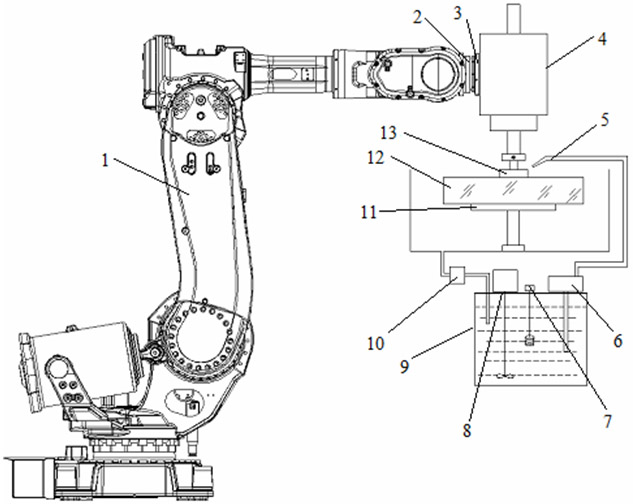

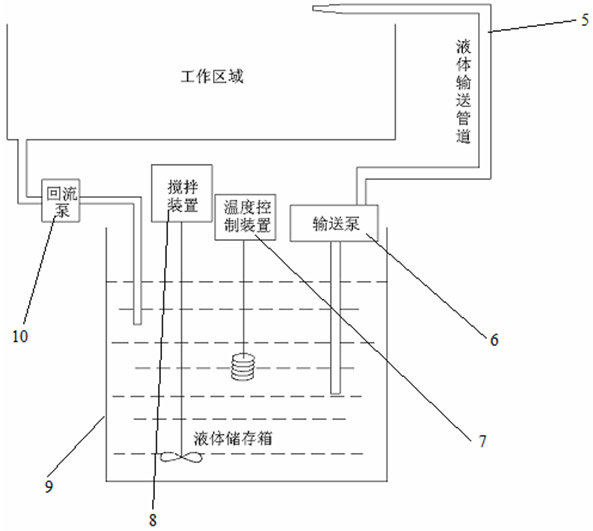

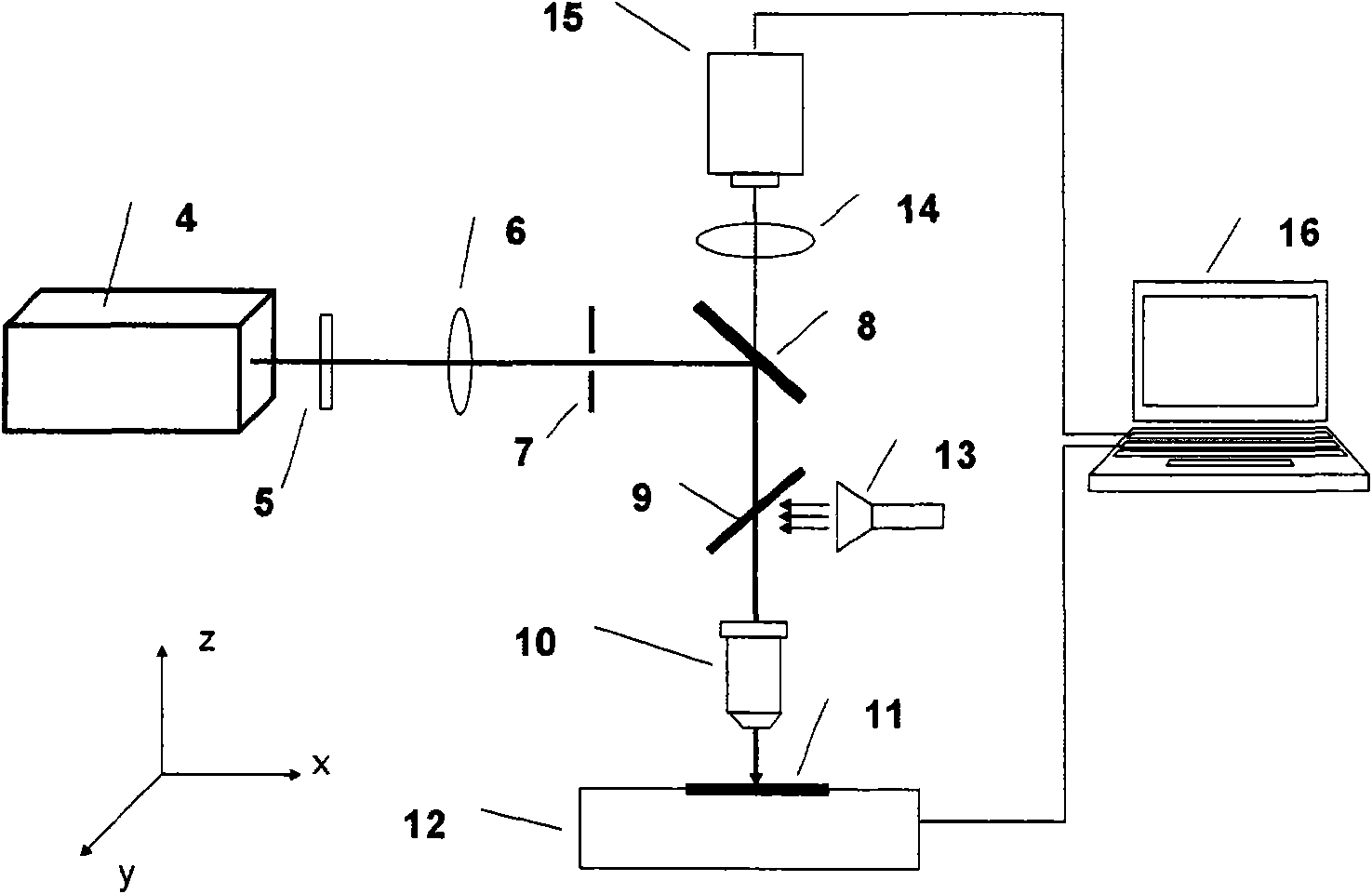

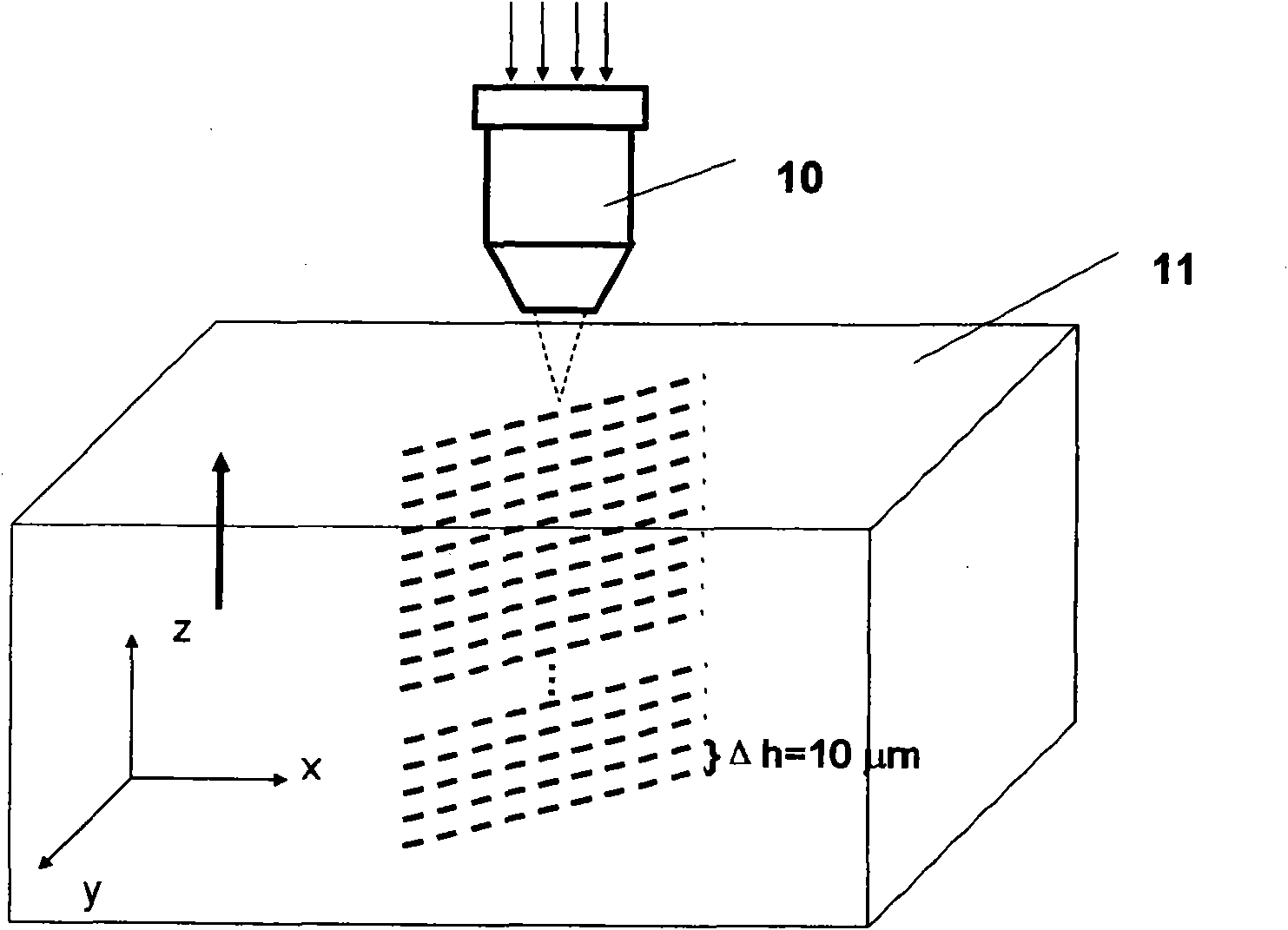

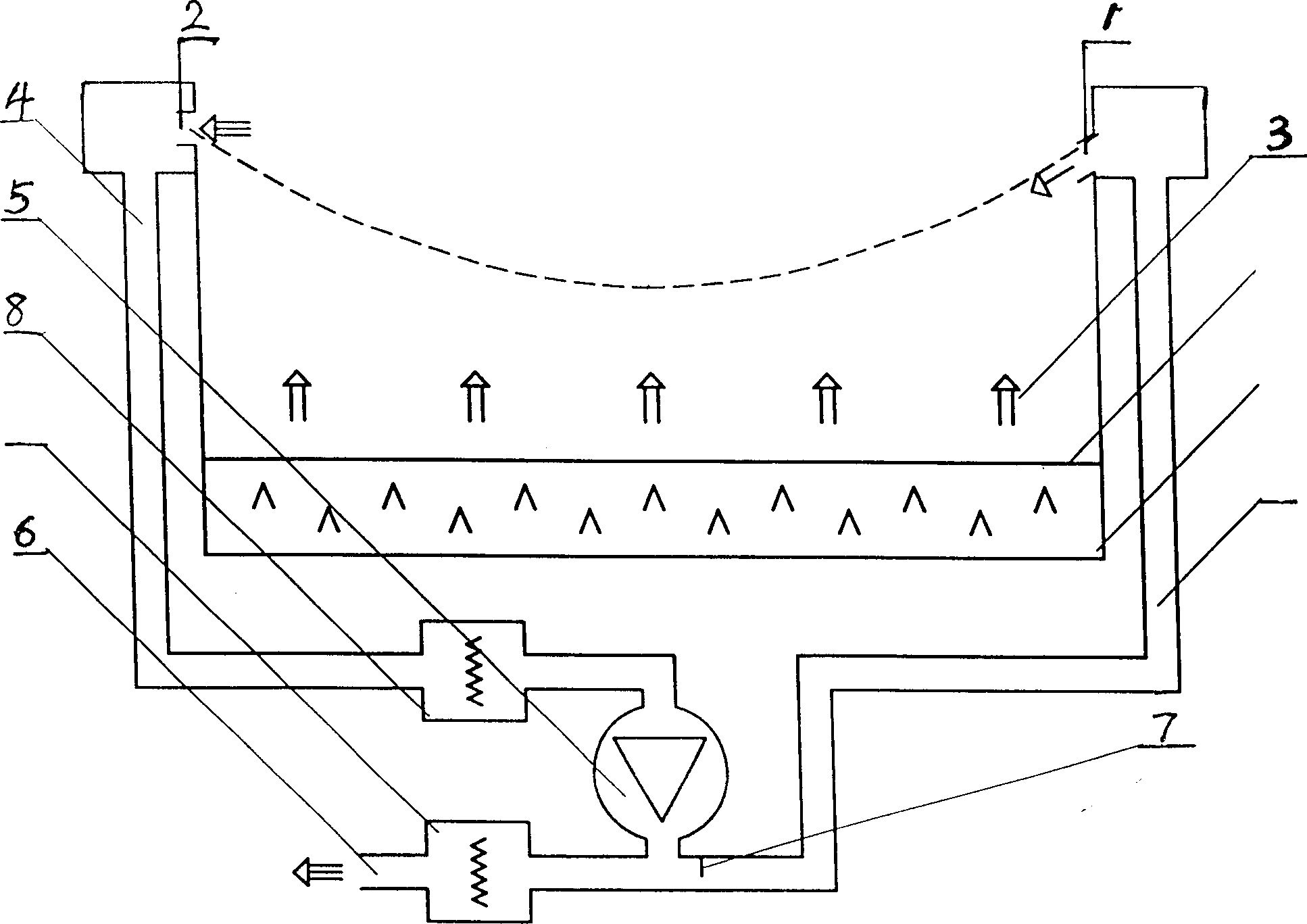

Milling, grinding and polishing device based on intelligent numerically-controlled platform

InactiveCN101983838AAchieve deterministic grindingRealize the processing effectOptical surface grinding machinesGrinding feed controlSurface typeSpatial movement

The invention relates to a milling, grinding and polishing device based on an intelligent numerically-controlled platform, belonging to the technical field of modern optical processing. The device comprises an industrial robot, a control module, a driving module, a human-computer interaction interface, a working component, a polishing and cooling liquid cyclic control system and a sucker clamp, wherein the control module and the driving module control and drive the spatial movement and spatial positioning of the industrial robot, thereby controlling the working state of the working component, namely a grinding / polishing module; the control module also controls the human-computer interaction interface and simultaneously controls a stirring device, a temperature control device and a conveying device of the polishing and cooling liquid cyclic control system; and the sucker clamp is used for clamping a workpiece to be processed. The device of the invention has low manufacturing cost, large processing caliber and wide processed surface types, and two functions of grinding and polishing can be realized by replacing grinding heads.

Owner:FUDAN UNIV +1

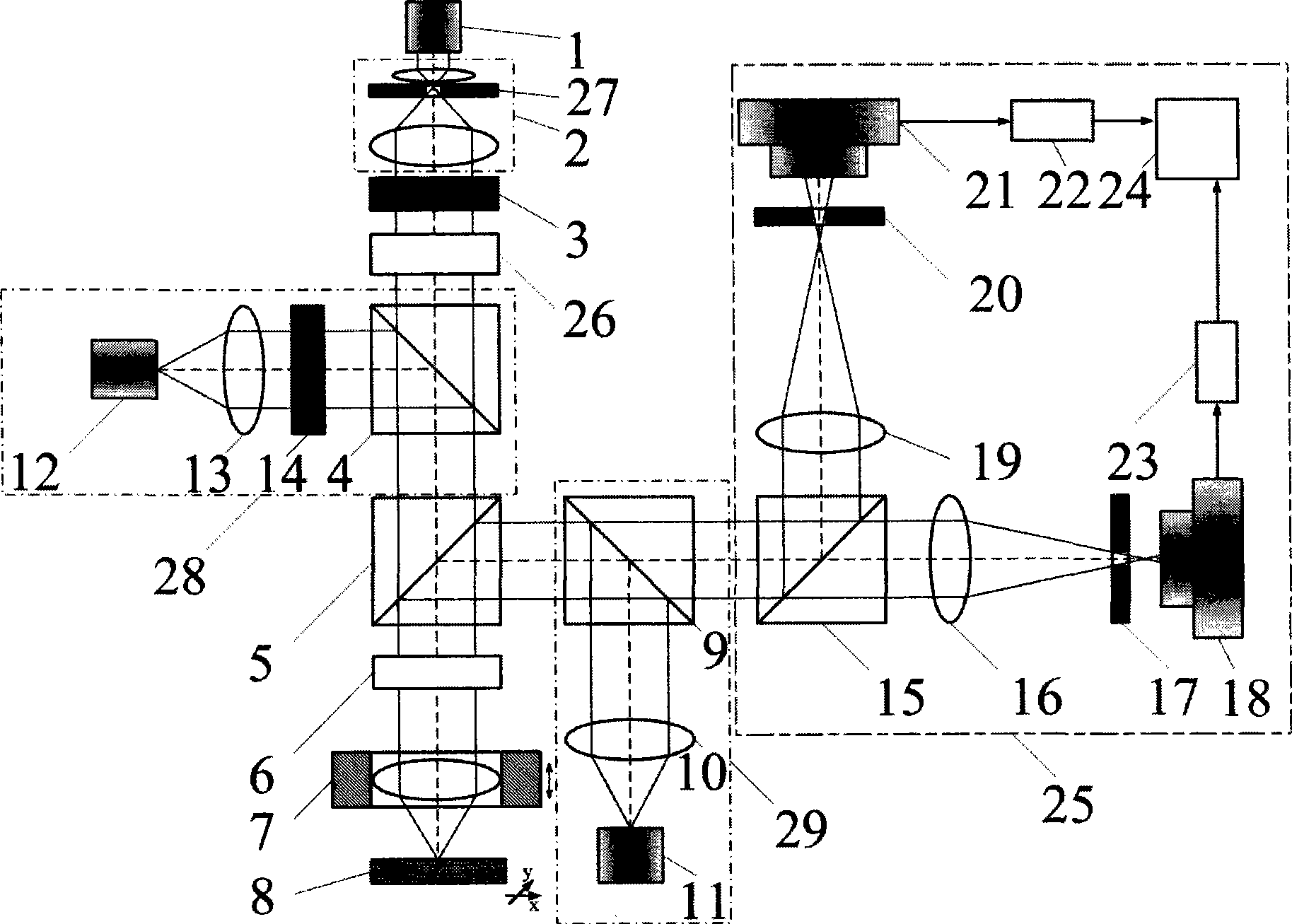

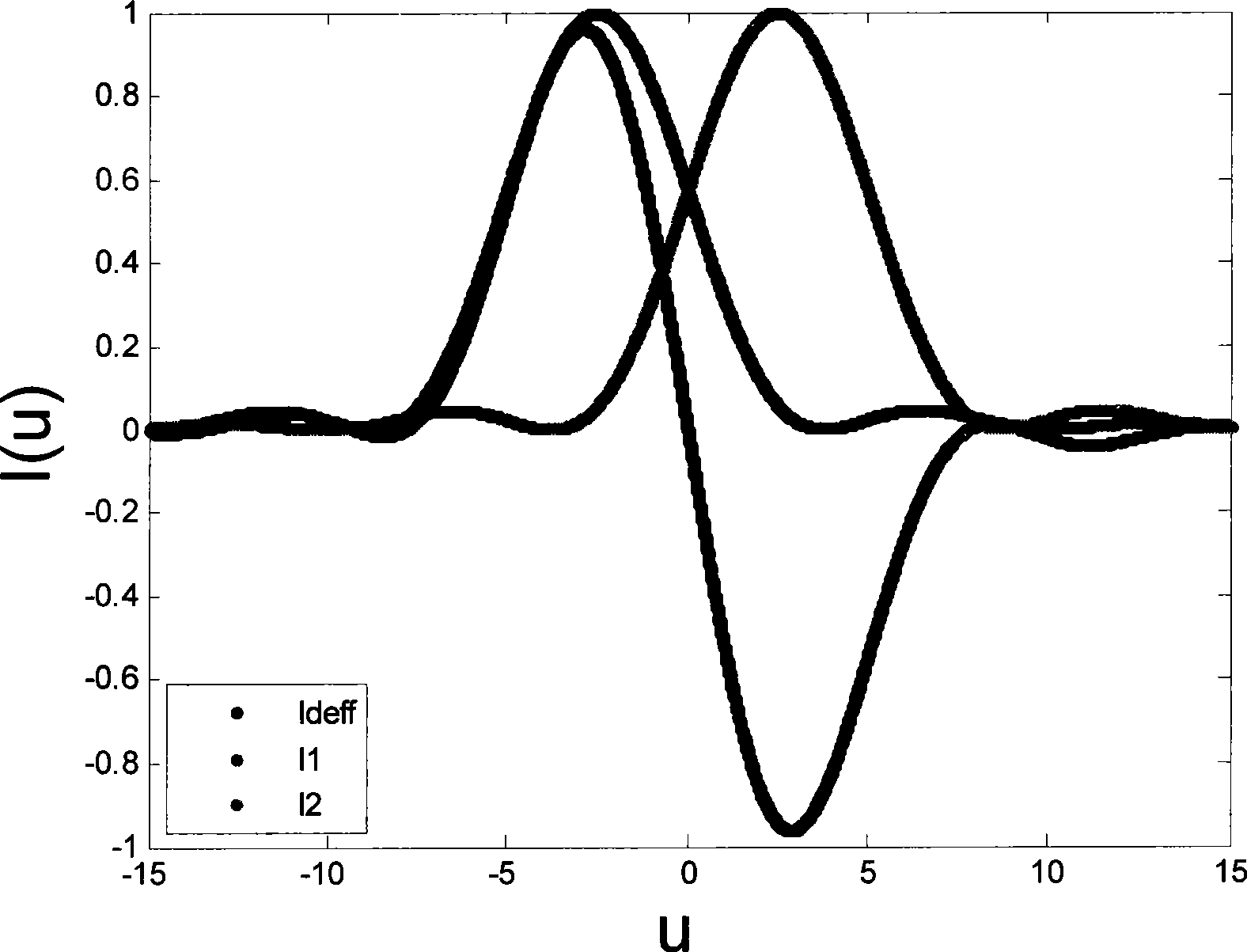

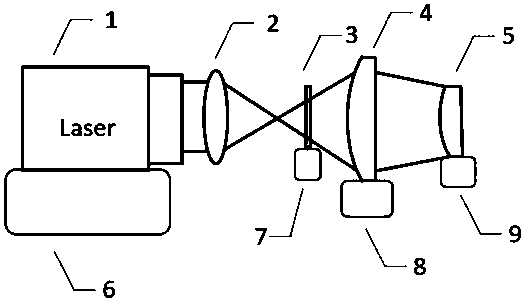

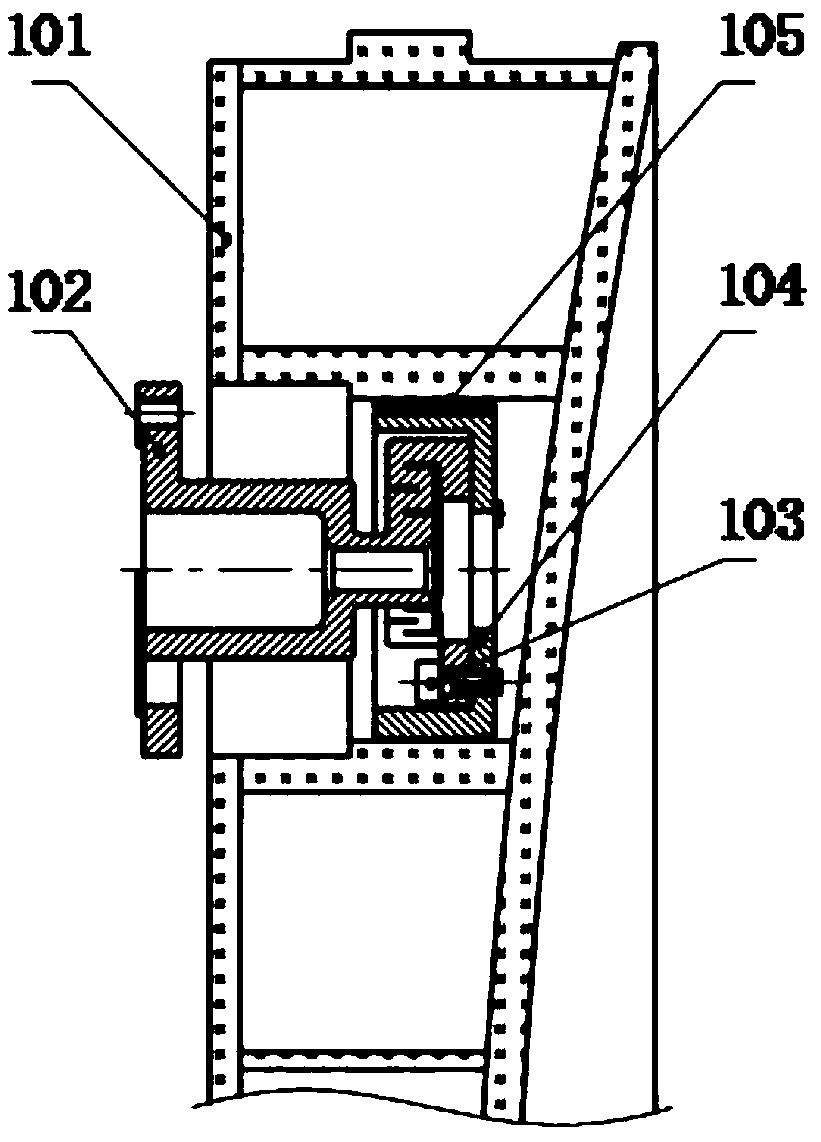

Ultra-discrimination differential confocal microscope with macro-micro view field observation

The invention belongs to the technical field of optical microscopic imaging and optical precision measurement and relates to a super-resolution differential con-focal microscope with both macro field coverage observation and micro field coverage observation. The invention mainly comprises a laser (1), a beam expander (2), a spectroscope (4), a polarization spectroscope (5), a range extension tracking and measuring system (6), a measuring objective lens (7), two optical collectors (16) and (19), pinholes (17) and (20), detectors (18) and (21), an LED light emitting diode (12) which is arranged in a direction opposite to the reflection direction of the spectroscope and a CCD detector (11) which is arranged in a direction opposite to the reflection direction of a spectroscope (9). The LED light emitting diode and the CCD detector are used for realizing macro-field coverage observation of a con-focal microscope through imaging the surface type of the detected samples, and the axial resolution power of the con-focal microscope can be raised through deploying the optical path of the differential con-focal microscope.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

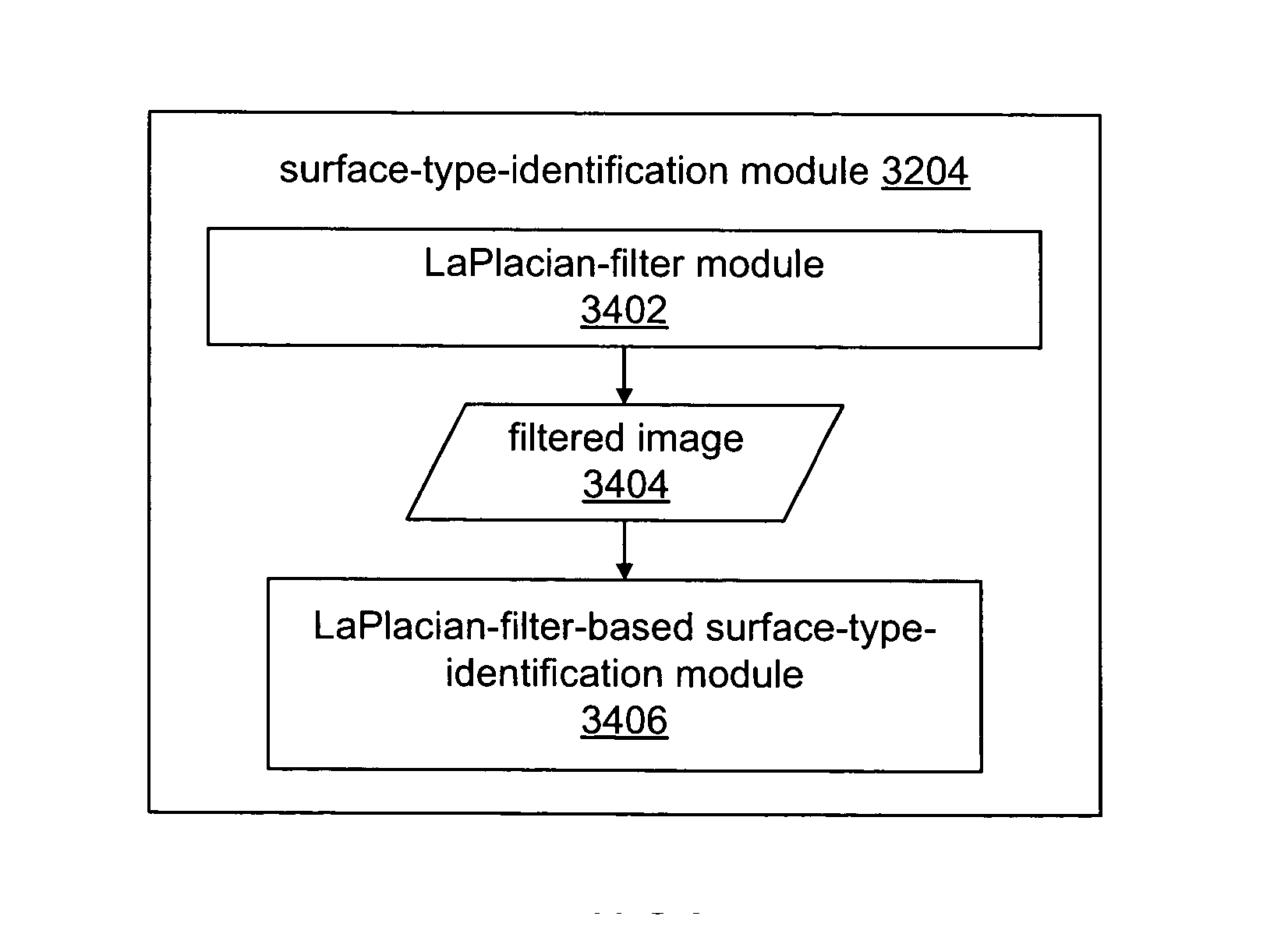

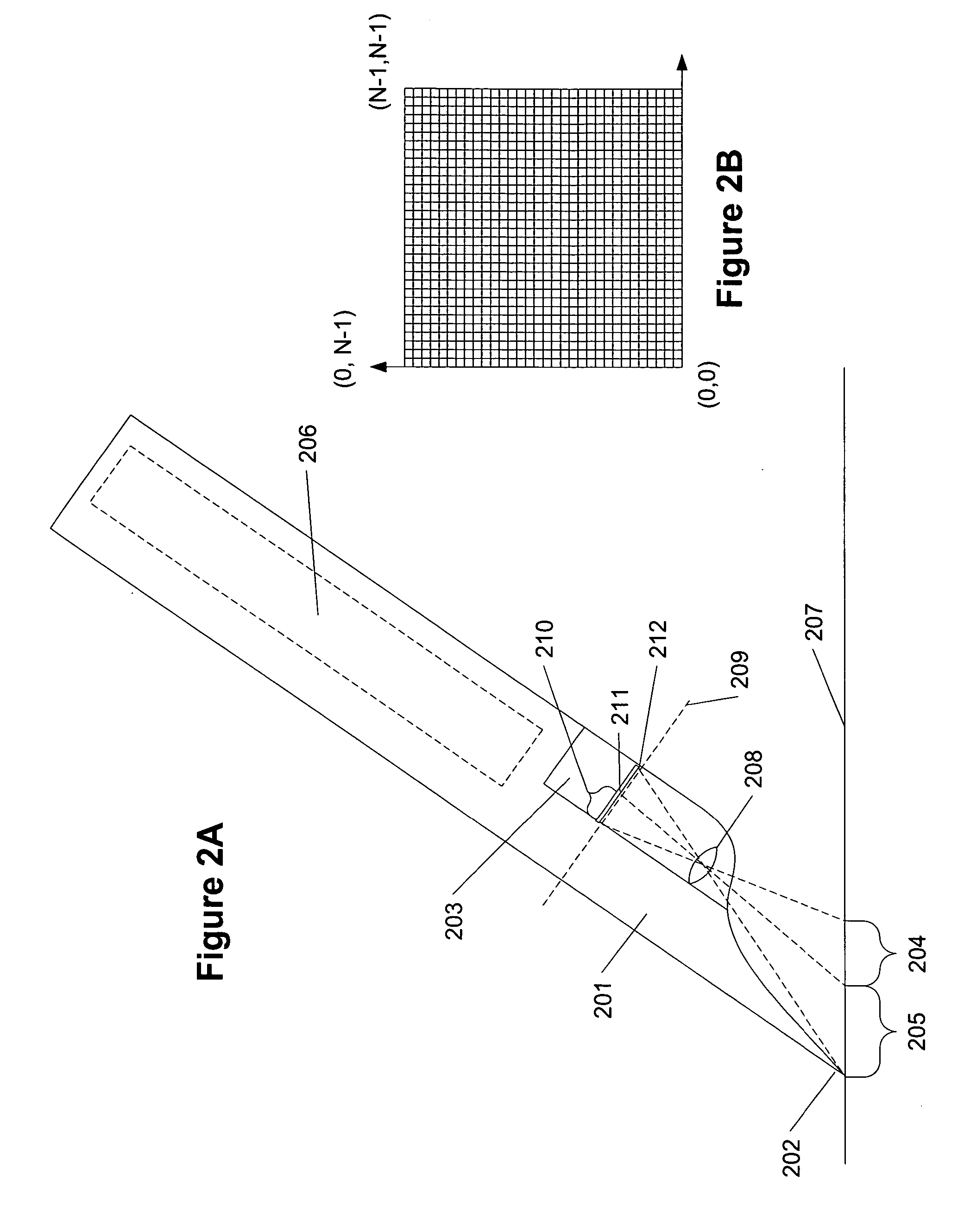

Embedded interaction code enabled surface type identification

InactiveUS20070041654A1Well formedCharacter and pattern recognitionInput/output processes for data processingComputer graphics (images)Surface type

At least one image captured from a printed document and at least one image captured from a display surface other than a printed document are processed. A surface-type-identification module accepts as input both types of images and identifies, for a particular image, the type of surface from which the image was captured. A display-surface-preprocessing module preprocesses the at least one embedded-interaction-code image captured from a display surface other than a printed document. A printed-document-preprocessing module preprocesses the at least one embedded-interaction-code images captured from a printed document. An embedded-interaction-code-processing module outputs location information for at least one of the at least one image captured from a printed document and the at least one image captured from a display surface other than a printed document.

Owner:MICROSOFT TECH LICENSING LLC

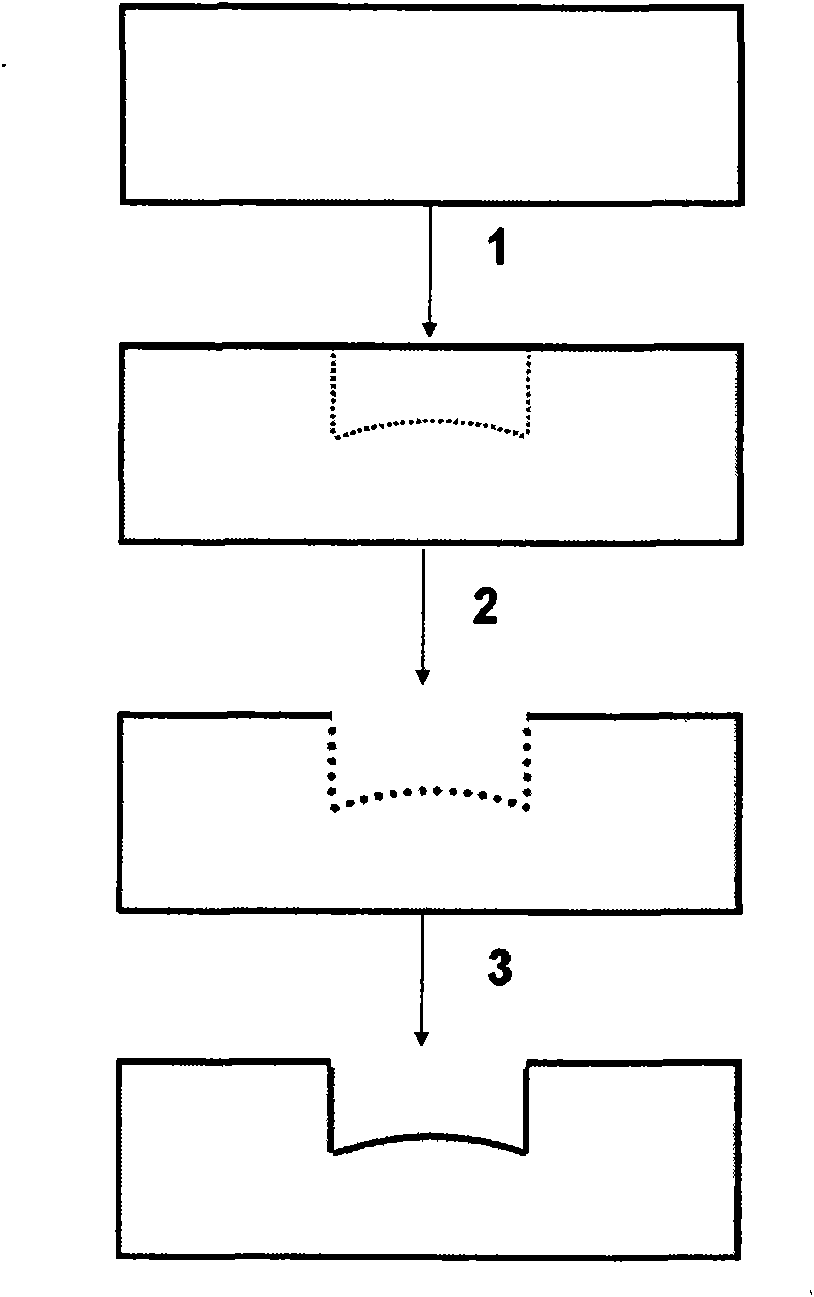

Method for preparing micro optical element on quartz glass substrate by applying femto-second laser

InactiveCN101571603AReduce thermal effectsAchieve high precision machiningPhotomechanical apparatusCleaning using liquidsChemical reactionEtching

The invention relates to a method for preparing a micro optical element on a quartz glass substrate by applying femto-second laser, which is characterized by comprising three steps of femto-second laser irradiation, chemical etching and hydrogen-oxygen flame polishing. The method can achieve processing of any surface types including a plane, a standard spherical surface, a non-spherical surface and the like; and the step of the hydrogen-oxygen flame polishing only has a generated product of water, thus the method is environment-friendly, has quick polishing, avoids physical contacts and chemical reactions at the same time, and solves the difficulty which cannot be solved by a common polishing wheel because the high temperature of the flame can repair lattice damages caused by micro-machining.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

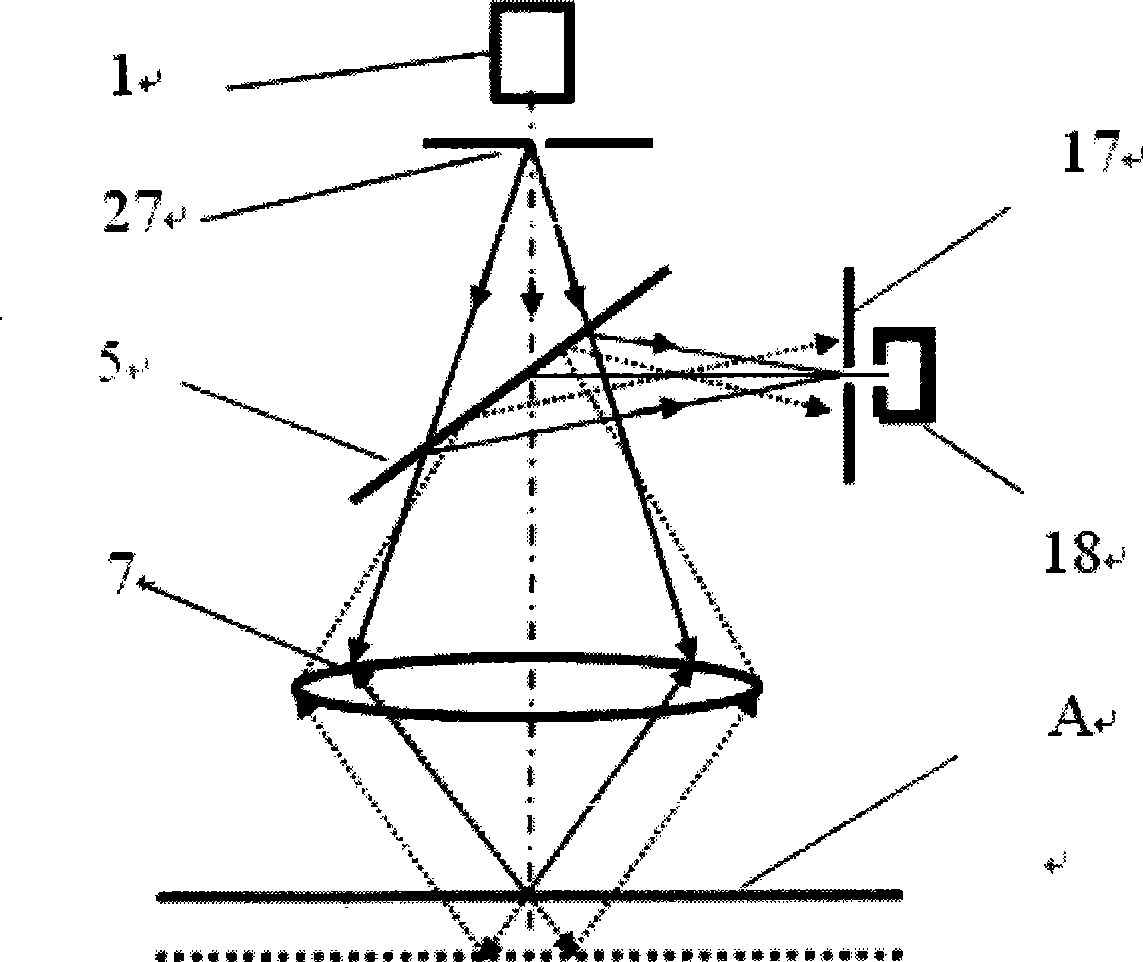

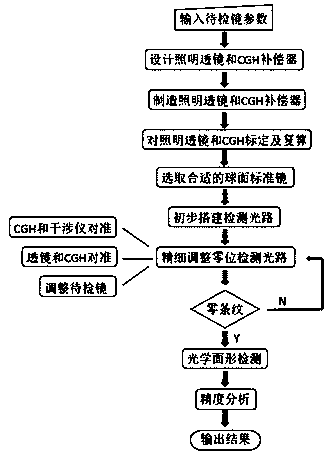

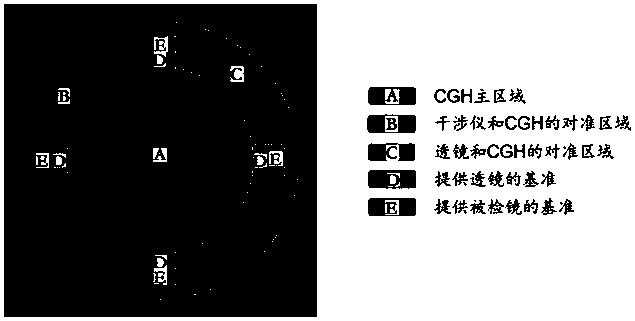

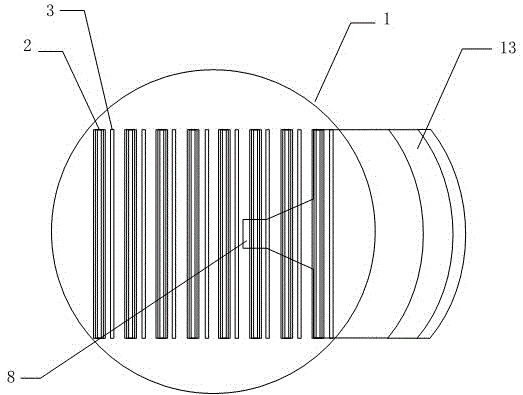

Convex aspheric surface reflector surface shape detection device and method

ActiveCN107796329ASmall caliberRealize high-precision detectionUsing optical meansCompensation effectPhase difference

The present invention discloses a convex aspheric surface reflector surface shape detection device and method which can detect a convex aspheric surface reflector of a large caliber (the caliber is more than 200 mm) by using a CGH compensator of a small size on the condition of guaranteeing the detection precision. The device of the present invention converges the light beams via a lens, so that the caliber of the adopted CGH compensator is very small, and the CGH compensator can realize the high-precision detection of the surface shape of the convex aspheric surface reflector of the large caliber within a high-precision processing size range. The method of the present invention is characterized by combining the phase difference compensation effect of the CGH compensator to the wavefrontsand the convergence effect of the lens to the light beams and using the CGH compensator of the small size to detect the convex aspheric surface reflector of the large caliber, solves the problems thata conventional CGH compensation detection method only can detect the surface shape of the convex aspheric surface reflector of the small caliber, and can detect the convex aspheric surface reflectorsof various curved surface types by being compared with the conventional convex aspheric surface reflector surface shape detection method.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Broad-band high-gain scannable panel antenna of parabolic reflection surface feeding

InactiveCN105655720AWith broadband characteristicsSame radiationRadiating elements structural formsAntennas earthing switches associationParallel plateBeam scanning

The invention relates to a broad-band high-gain scannable panel antenna of parabolic reflection surface feeding. A radiation unit is a step-type variable inclination continuous transverse stub groove (VICTS). A feeding network comprises a series connection feeding structure and a parabolic reflection surface feeding network. An electromagnetic wave is reflected into a plane wave through the parabolic reflection surface type feeding network, is coupled to an upper-layer series connection feeding network and finally is radiated to a free space through the VICTS. Through relative rotation between upper and lower layers of a parallel plate waveguide, wave beam scanning is realized. The antenna of the invention covers a satellite communication ku wave band, an antenna work frequency is 10.2GHz-14.8GHz and an impedance bandwidth reaches 36.8%. At a 13GHz frequency point, a 25.7dBi gain is possessed. A antenna scanning angle scope is from 0 DEG to 56 DEG. Compared to a traditional communication in moving system antenna, by using the antenna of the invention, the feeding is simple; wave beam scanning is easy to realize; a dynamic response is fast and is in a panel shape; and a large engineering application prospect is possessed.

Owner:SHANGHAI UNIV

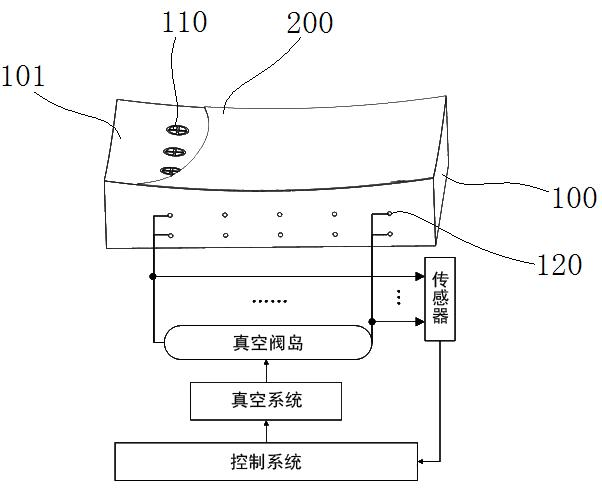

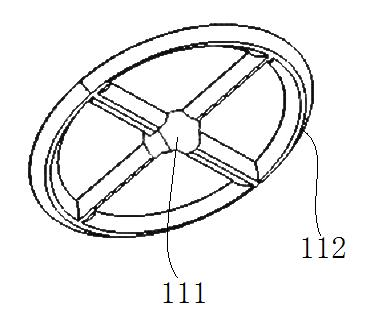

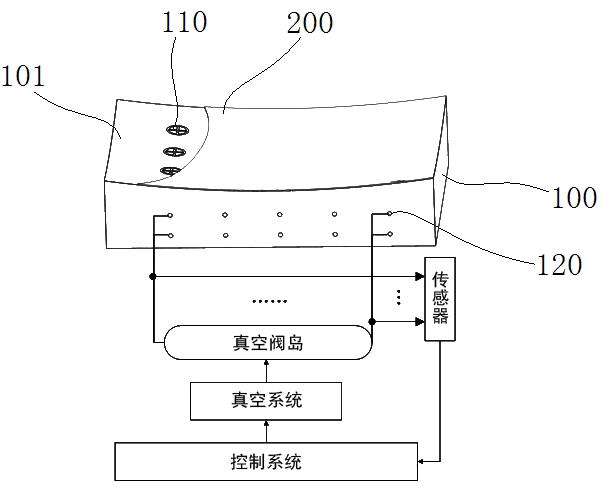

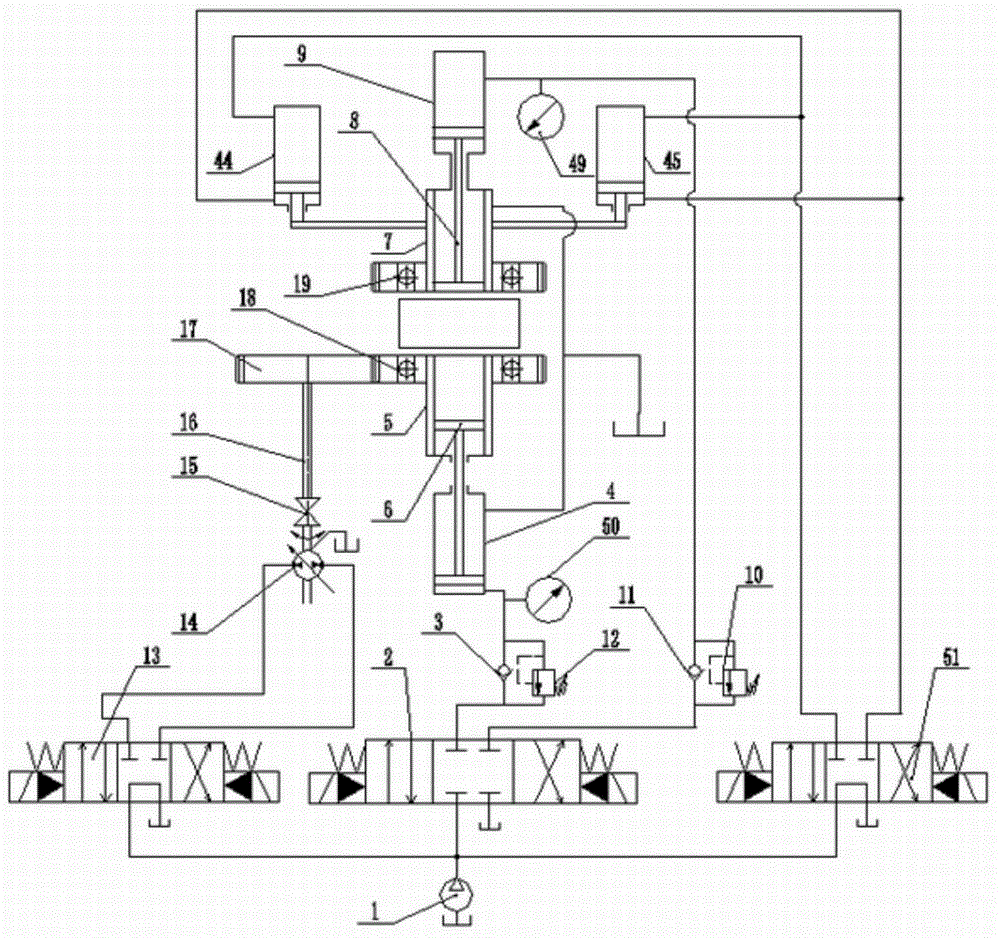

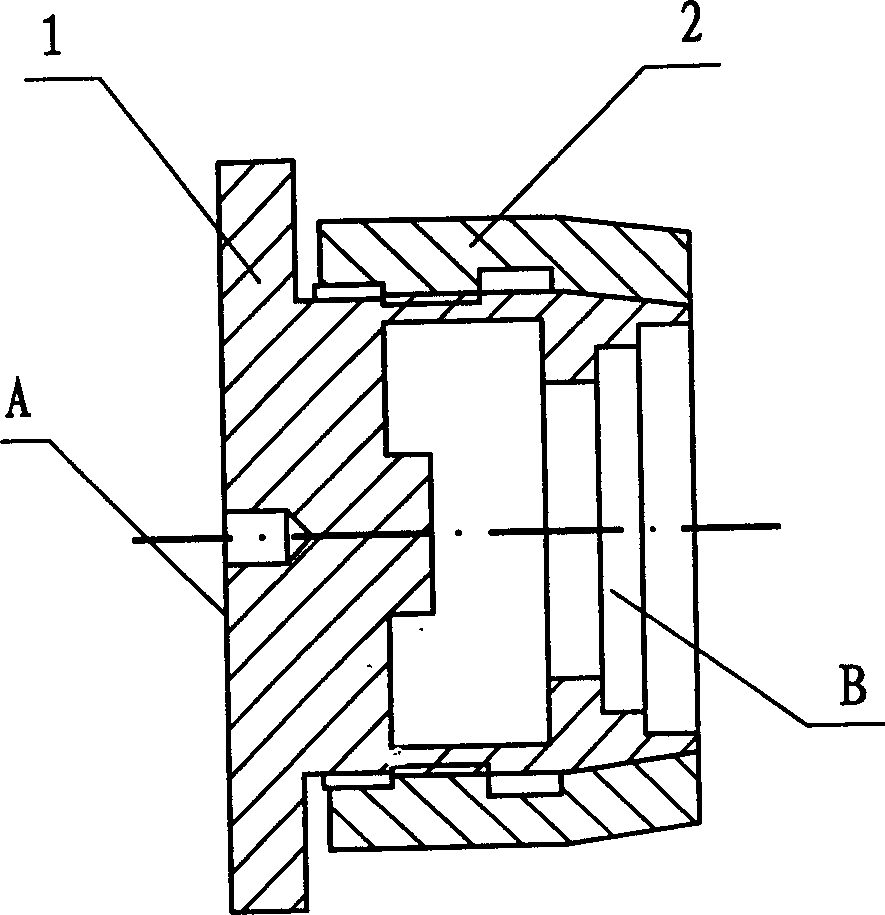

Multipoint profiling rigid clamp and method for processing thin-wall workpiece by using same

InactiveCN102179708ASolve rigid problemsSolve Vibration ProblemsPositioning apparatusMetal-working holdersControl systemSurface type

The invention discloses a multipoint profiling rigid clamp, comprising a clamp body. The clamp body is provided with a positioning surface for positioning a processed workpiece; the positioning surface is provided with a vacuum sucker; the clamp body is internally provided with a vacuum hole channel; one end of the vacuum hole channel is connected with the vacuum sucker, and the other end of the vacuum hole channel is connected with a vacuum valve island arranged at the outer part of the clamp body; the vacuum valve island is connected with a vacuum system connected with a control system; andthe vacuum hole channel is also connected with the control system by a vacuum sensor. A method for processing a thin-wall workpiece by using the multipoint profiling rigid clamp comprises the steps of: modeling, analyzing, determining and optimizing key positioning points, arranging the vacuum sucker, processing the positioning surface of the clamping body and finally carrying out processing on the thin-wall workpiece. The multipoint profiling rigid clamp is used for a high-speed milling finish processing stage of the complex profile of the thin-wall workpiece, the positioning surface of the clamp is consistent to the surface type of the processed workpiece, the uniform distribution of a clamping force is guaranteed and the clamping and the deformation of the thin-wall workpiece are avoided.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

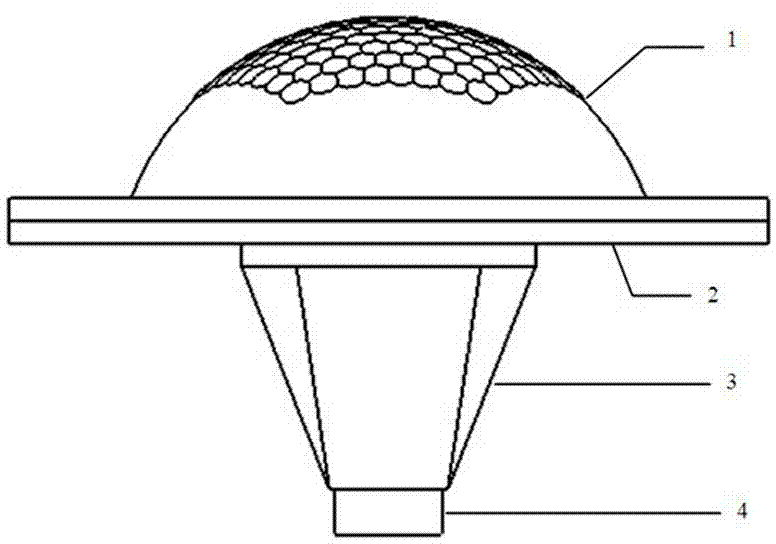

Large field-of-view bionic compound eye visual system adopting dome light cone

InactiveCN102819053ASolve the problem of severe imaging defocusCompact structureCoupling light guidesMountingsCouplingSurface type

The invention discloses a large field-of-view bionic compound eye visual system adopting a dome light cone. The system comprises a curved surface compound eye lens, an aperture diaphragm, the light cone and an image detector, which are connected with one another in sequence; the curved surface compound eye lens comprises sub eyes and a substrate, the sub eyes are hermetically bonded in the hexagonal array mode, the surface type of the sub eyes are non-spherical, the substrate is a curved surface substrate, the aperture diaphragm is a stepped type aperture diaphragm, and the light cone is a dome light cone. According to the invention, the dome light cone coupling strategy is used as the light path conduction mode, on one hand, a curved image formed by the compound eye lens is converted into a planar image, so as to be received by a plane detector, on the other hand, the large field of view image formed by the compound eye lens is compressed into a smaller image according to an equal ratio, so that the large field of view image can be completely imaged in a small-sized detector in a lossless mode, the coupling is realized, and the technical requirements on the size of detectors are accordingly reduced.

Owner:MDTP OPTICS

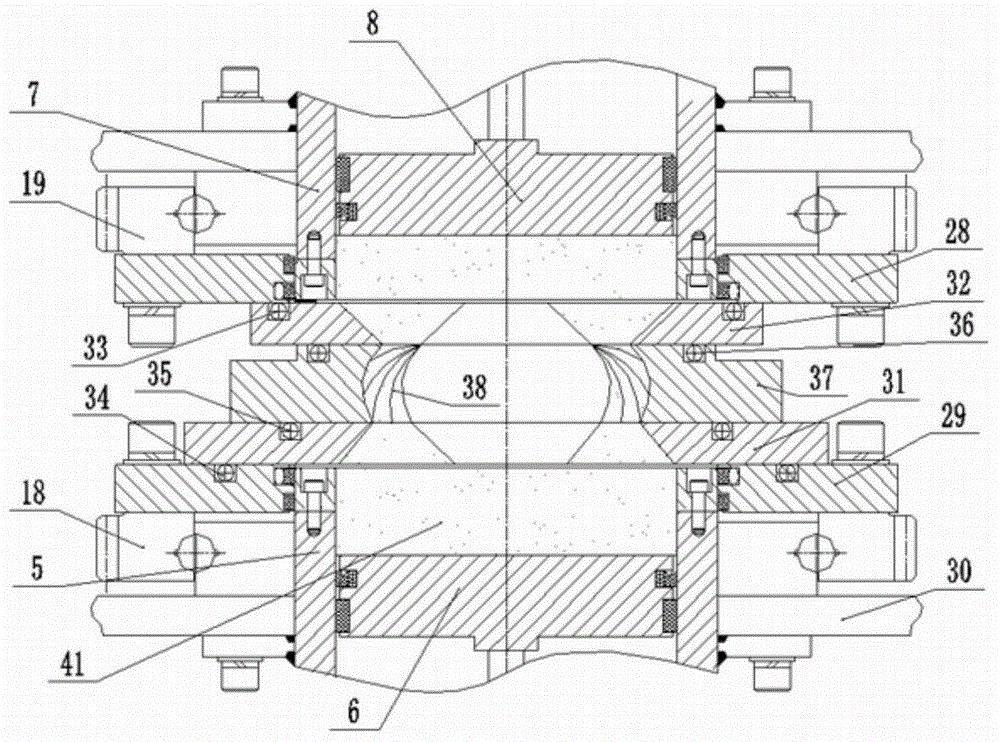

Efficient constant-pressure-difference intermittent rotation extrusion abrasive flow polishing method

ActiveCN104526531ASolve the problem of high-efficiency uniform polishing of the surfaceHigh surface aerodynamic performanceEdge grinding machinesPolishing machinesHydraulic motorImpeller

The invention relates to an efficient constant-pressure-difference intermittent rotation extrusion abrasive flow polishing method and belongs to the technical field of automatic polishing of large-size complex-curved-surface type part intermittent rotation extrusion abrasive flows which are high in surface quality uniformity requirement. The method comprises that a gear is driven by a hydraulic motor to be meshed with a negative-clearance rotation disc bearing to perform rotation grinding polishing, seal rings are arranged at all connected faces to achieve high-pressure abrasive static seal, easily abrasive seal rings are arranged at the rotation friction positions special high-pressure abrasive seal rings and high-pressure abrasive seals are arranged at the piston abrasive extrusion positions to achieve high-pressure abrasive dynamic seal, and finally, high-pressure abrasive intermittent rotation grinding and polishing are achieved. The 'over-polishing' and 'rounding' phenomena of traditional abrasive flow extrusion are prevented, efficient precise uniform polishing of complex curved surfaces of impellers, blades and the like high in pneumatic performance and surface uniformity is achieved, and the surface roughness Ra of various complex parts can be reduced below 0.8.

Owner:珂尔默(东莞)制造技术有限公司

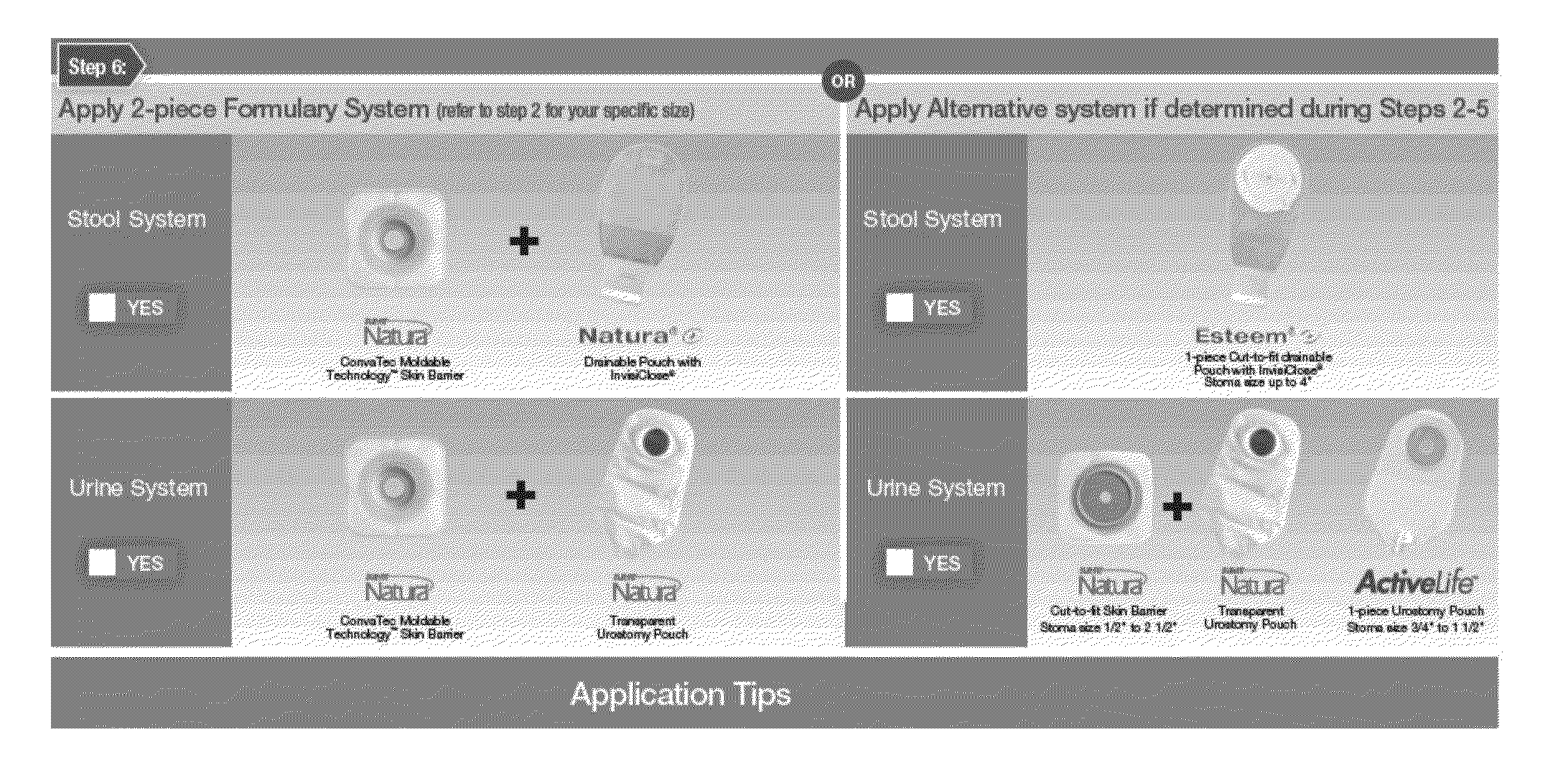

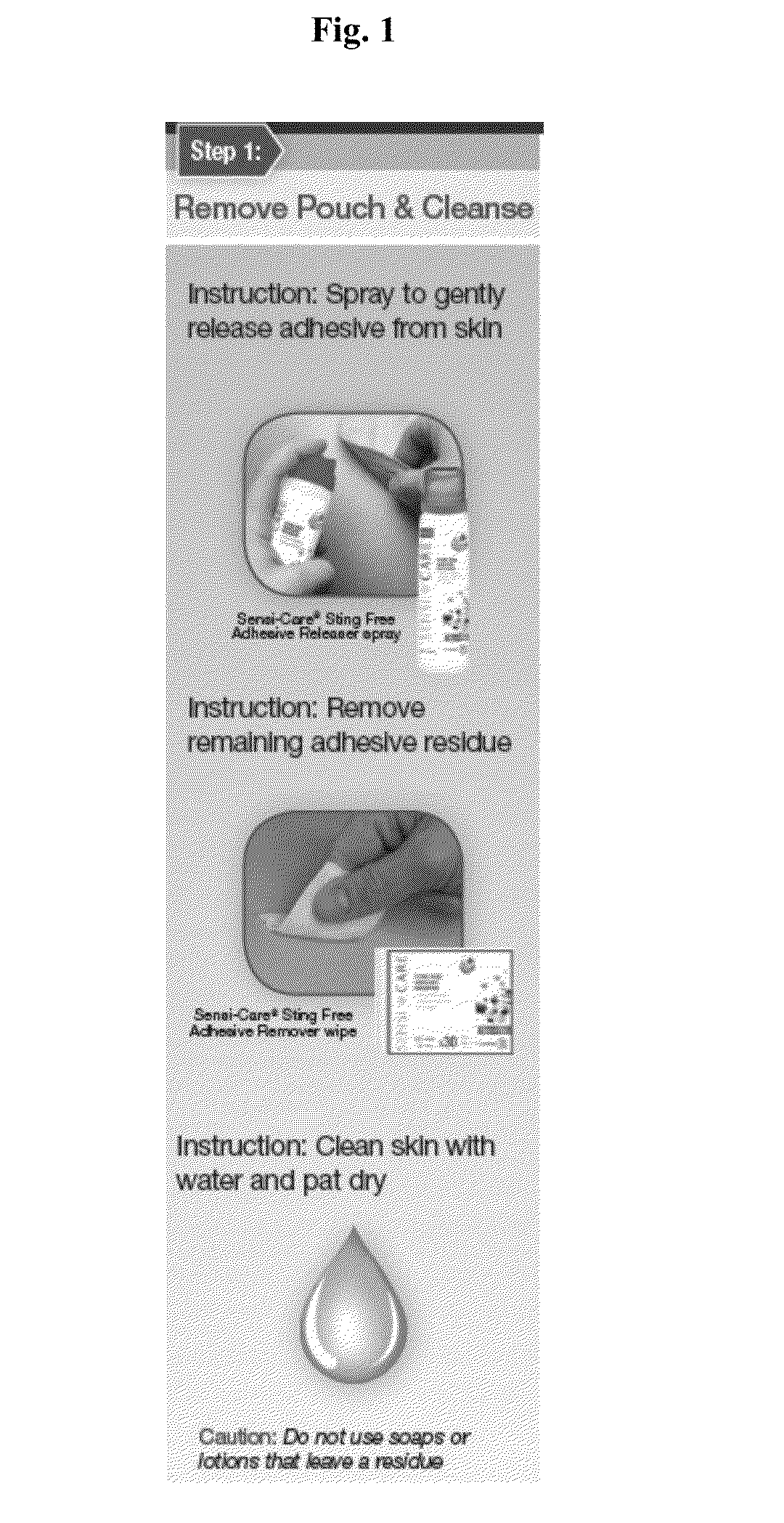

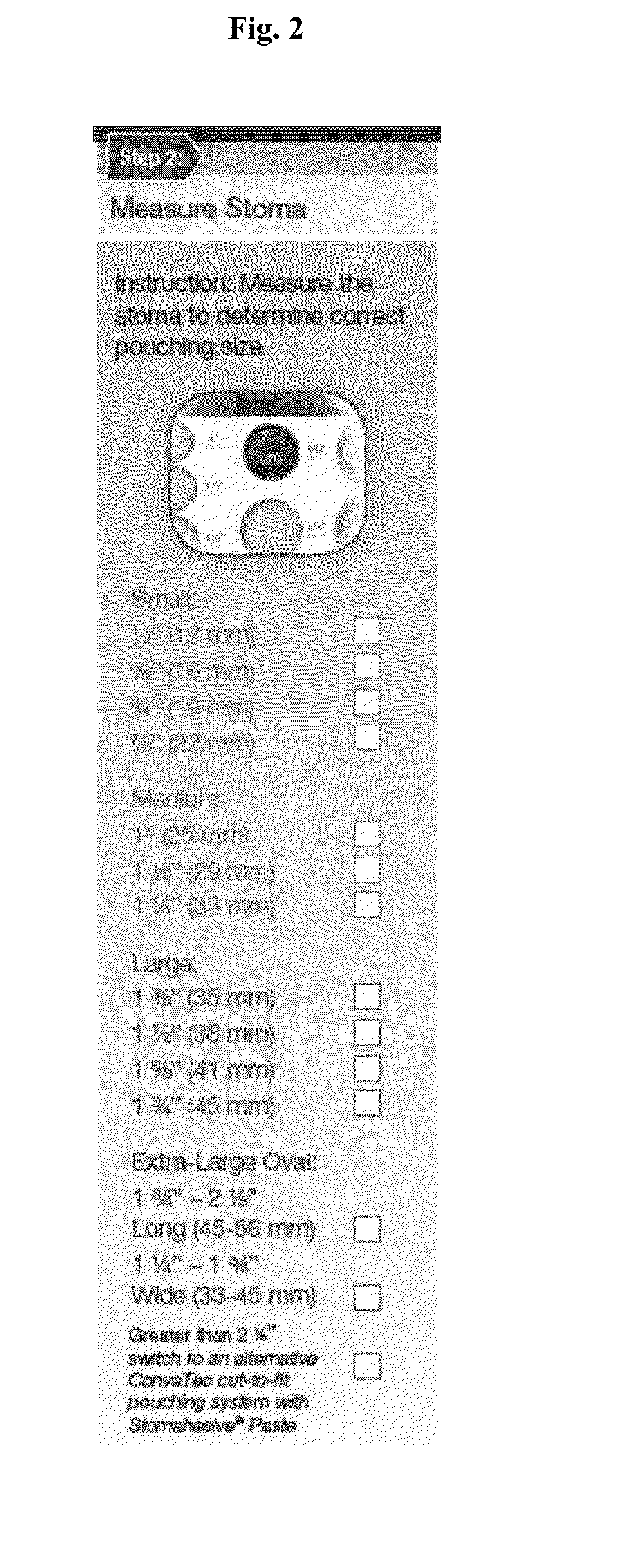

Methods and systems for ostomy care

ActiveUS20140236111A1Mechanical/radiation/invasive therapiesNon-surgical orthopedic devicesComputer moduleSurface type

Disclosed are computer-based systems and media for providing an interactive ostomy treatment guide, and methods of using the same, the guide comprising: a software module configured to receive ostomy assessment information, the assessment information comprising one or more of: condition of skin adjacent an ostomy, topographical location of any peristomal lesion, stoma type, pouching surface type, stoma devices present, and stoma complications; a software module configured to apply a treatment algorithm to the ostomy assessment information to generate an output; and a software module configured to display one or more ostomy management options based on the output.

Owner:CONVATEC TECH INC

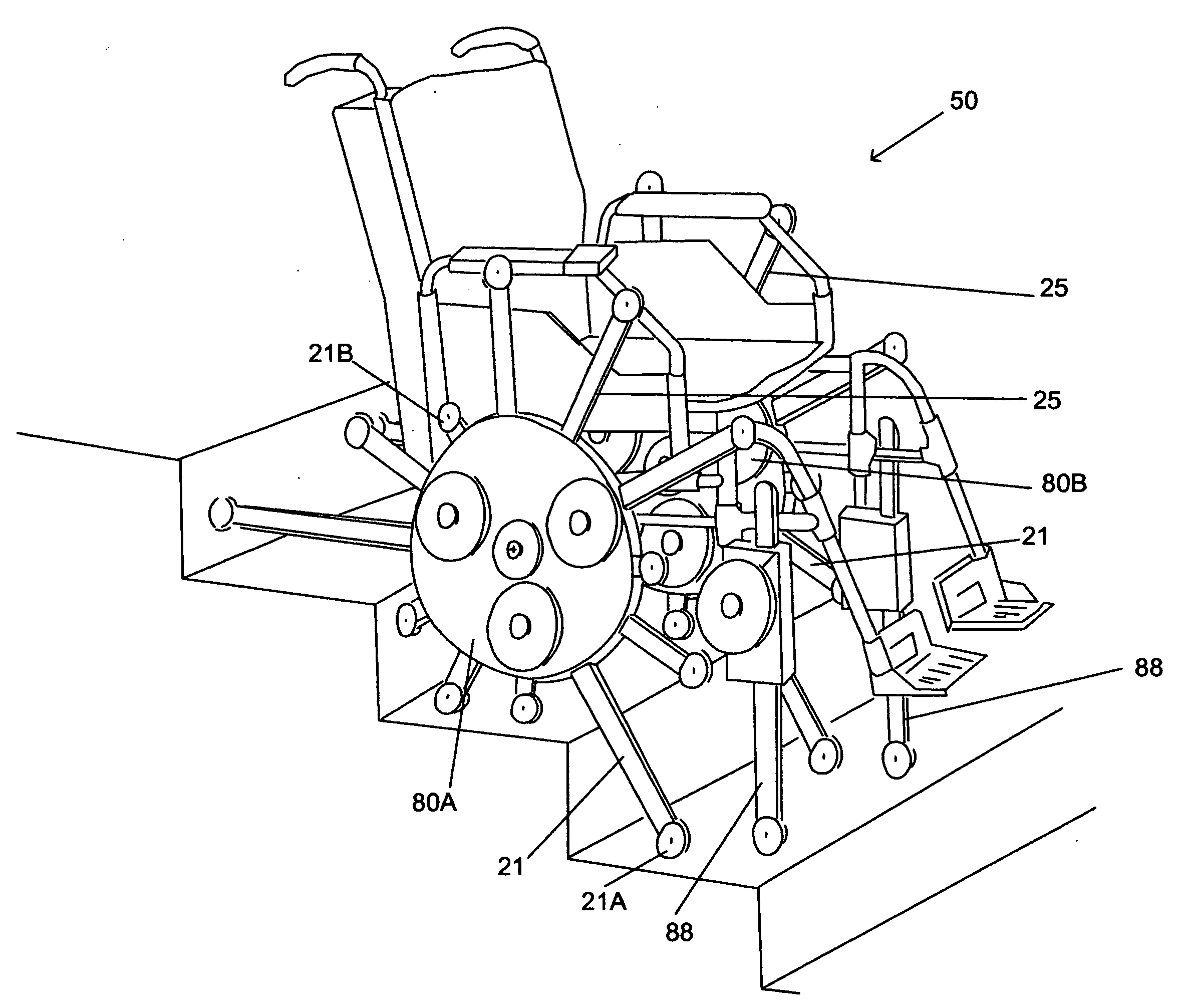

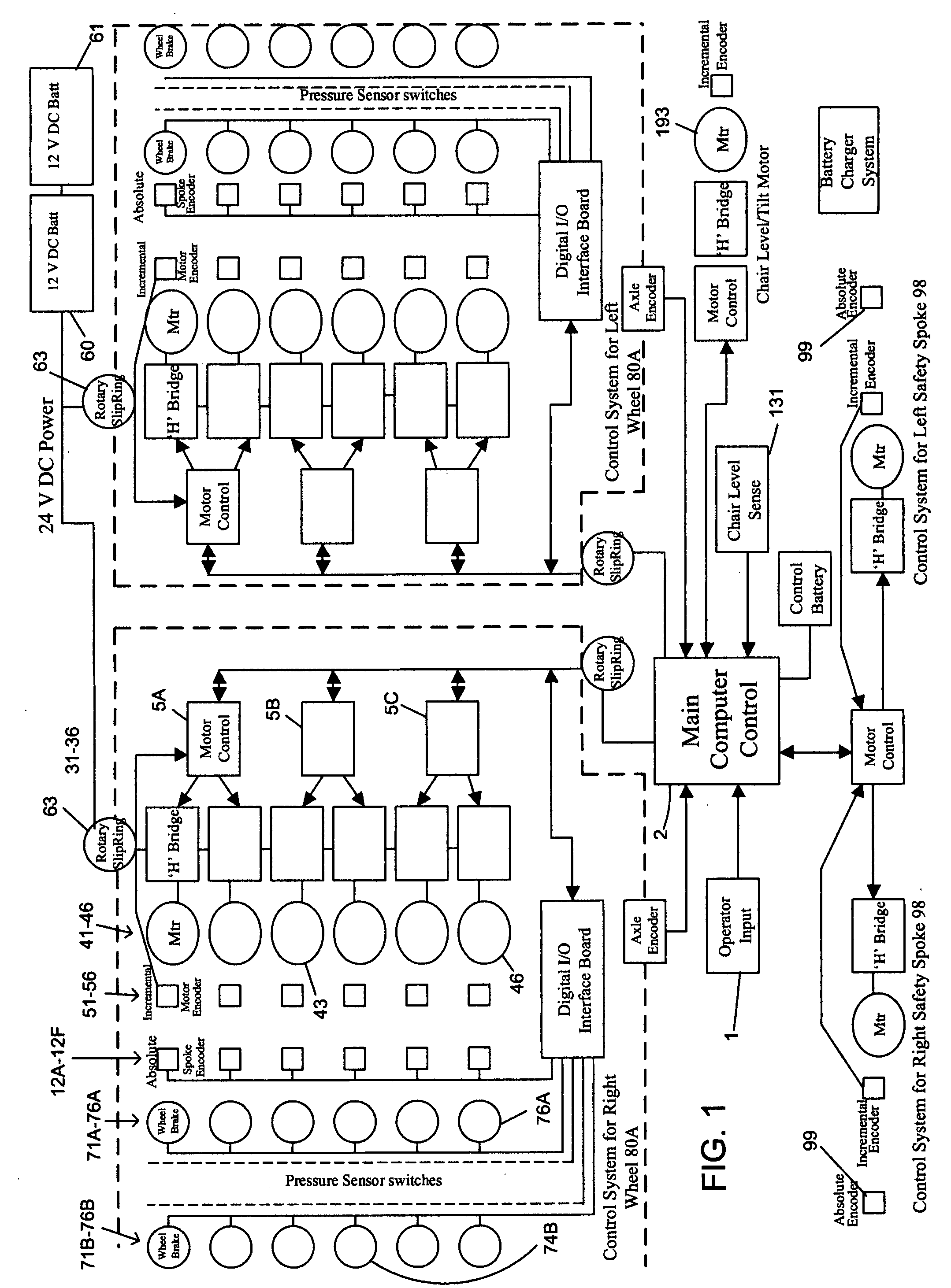

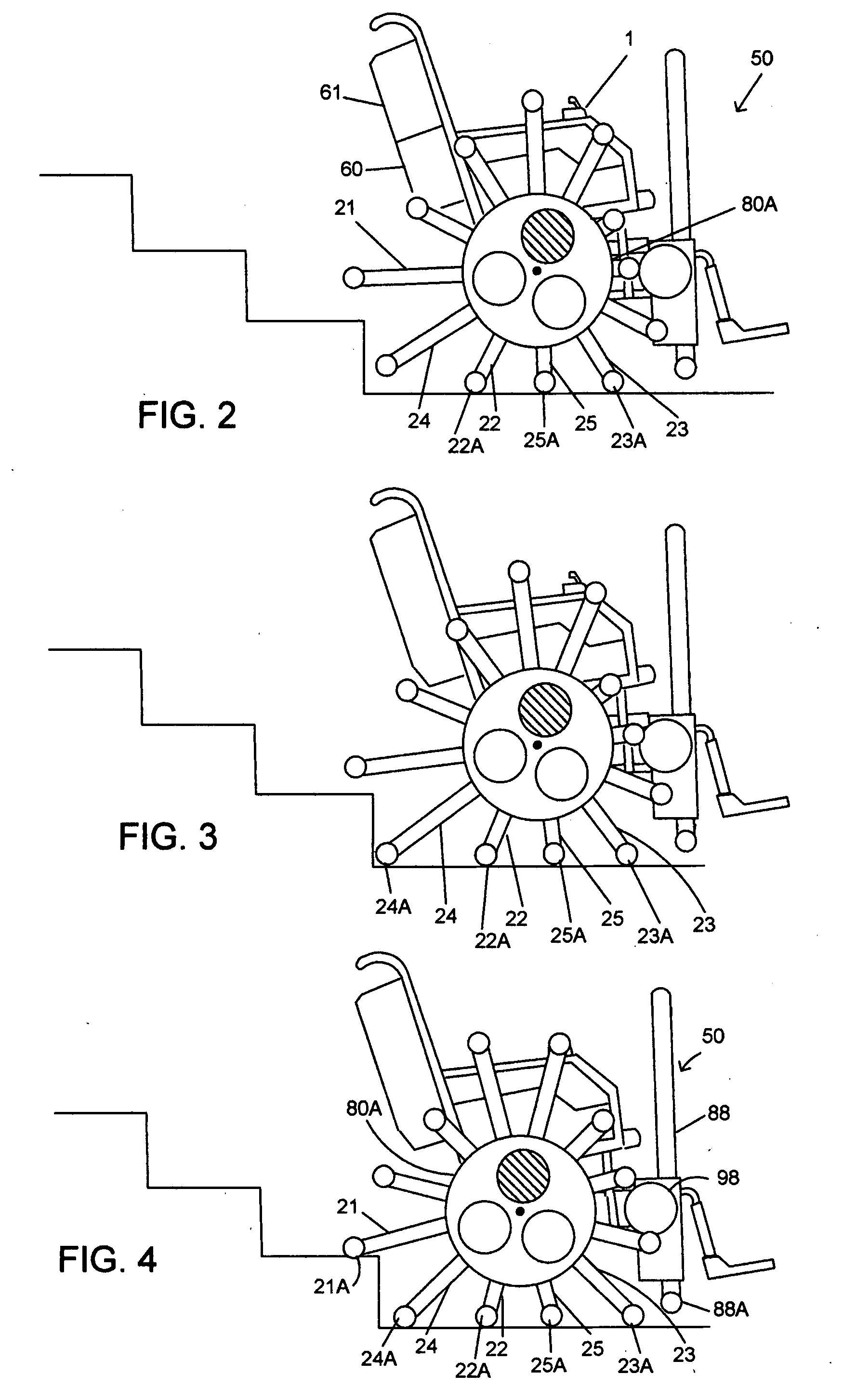

Automated wheelchair

ActiveUS20080251300A1Carriage/perambulator accessoriesWheelchairs/patient conveyanceTerrainControl signal

An automated wheelchair for moving over a contact surface. The automated wheelchair includes an operator chair for seating the wheelchair operator, a control computer, an operator input device for transmitting operator inputs to the control computer, and two wheelchair wheels for propelling the wheelchair. Each wheelchair wheel includes extendable and retractable spokes. The extension and retraction of each spoke is controlled by a motor. At the ends of each spoke are contact sensor devices. The control computer is programmed to receive inputs transmitted from the contact sensor devices to generate a terrain profile. The control computer generates and sends control signals to each spoke motor in response to the operator inputs and in response to the terrain profile generated by the contact sensor devices. In a preferred embodiment the contact sensor devices are pressure sensor devices. Also in a preferred embodiment, rotatable pneumatic wheels are attached to both ends of each spoke. Preferably, a brake is applied to at least one pneumatic wheel per wheelchair wheel while the wheelchair is moving over the contact surface. Preferably, the automated wheelchair is capable of moving over a variety of contact surface types, including: a set of stairs with uniform rise to run ratio, a set of stairs with non-uniform rise to run ratio, a set of straight stairs, a set of curved stairs, over a curb or over rough terrain.

Owner:FRIE THOMAS T

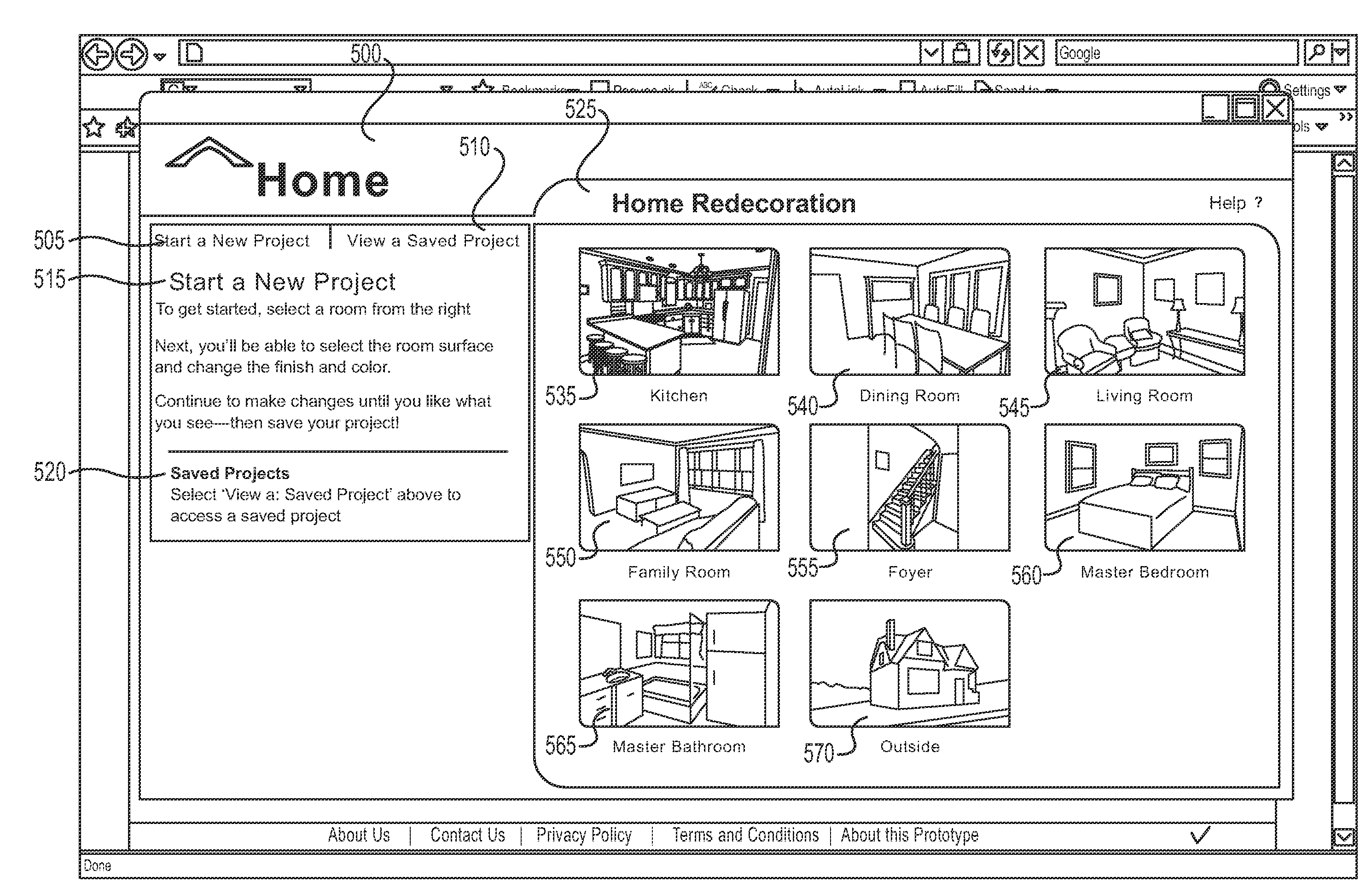

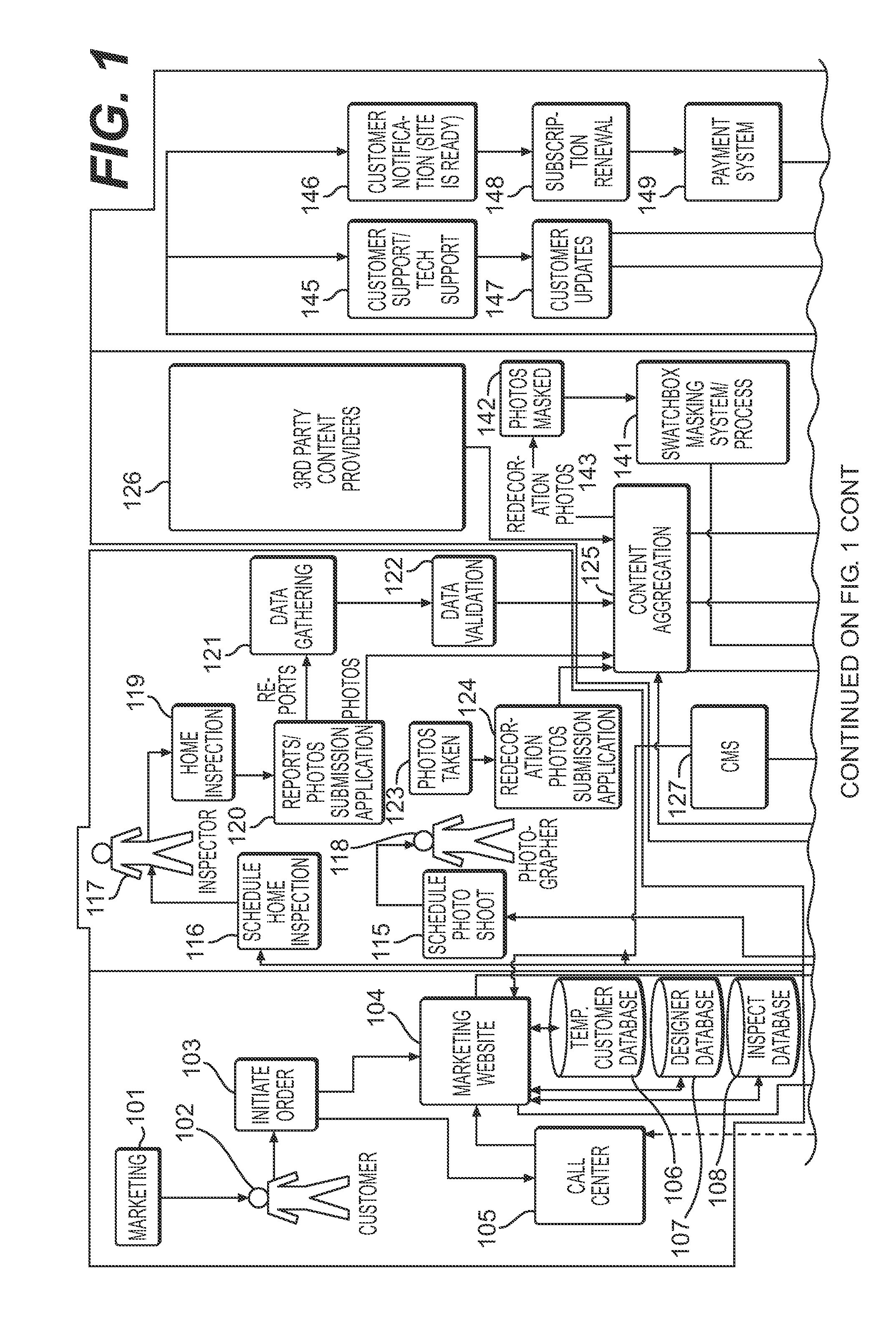

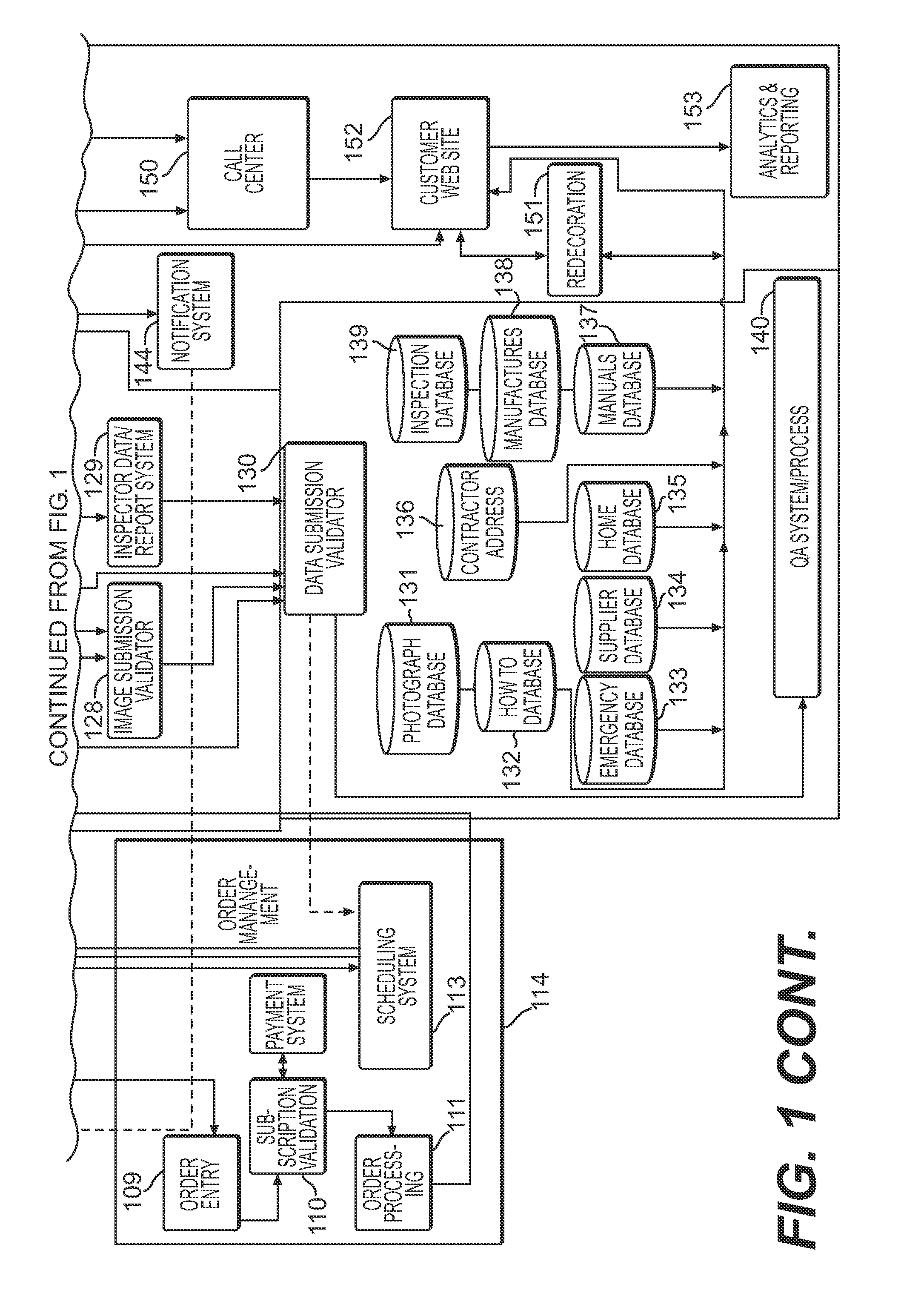

Home management, maintenance, repair, remodeling and redecoration system and method

Embodiments of the invention provide a home management system and method with a 360-degree virtual surface rendering application. Embodiments of the invention generate a listing of home improvement projects from the inspection report to be viewed through a user interface. Homeowners may manage, prioritize, rank, and educate themselves on each listed home improvement project. Embodiments of the invention may contain a 360-degree virtual surface rendering application allowing a homeowner to select different surface types for a room, and then view them on a re-rendered image of the room before purchasing the new surfaces.

Owner:UNITED STATES GYPSUM CO

Surface-type optical apparatus

InactiveUS6852968B1Little coupling lossQuick scanMaterial analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsPhotodetectorSurface type

A surface optical apparatus that includes a surface optical device with p-side and n-side electrodes, such as a surface emitting laser, a first substrate for supporting the surface optical device directly or through an elastic supporter formed of one or plural layers, and a first electrode wiring of at least a wire formed on the first substrate and electrically connected to one of the electrodes. A current is injected into or a voltage is applied across the surface optical device through the first electrode wiring and the p-side and n-side electrodes. A photodetector for detecting light from the surface optical device may also be arranged in the vicinity of the optical device.

Owner:CANON KK

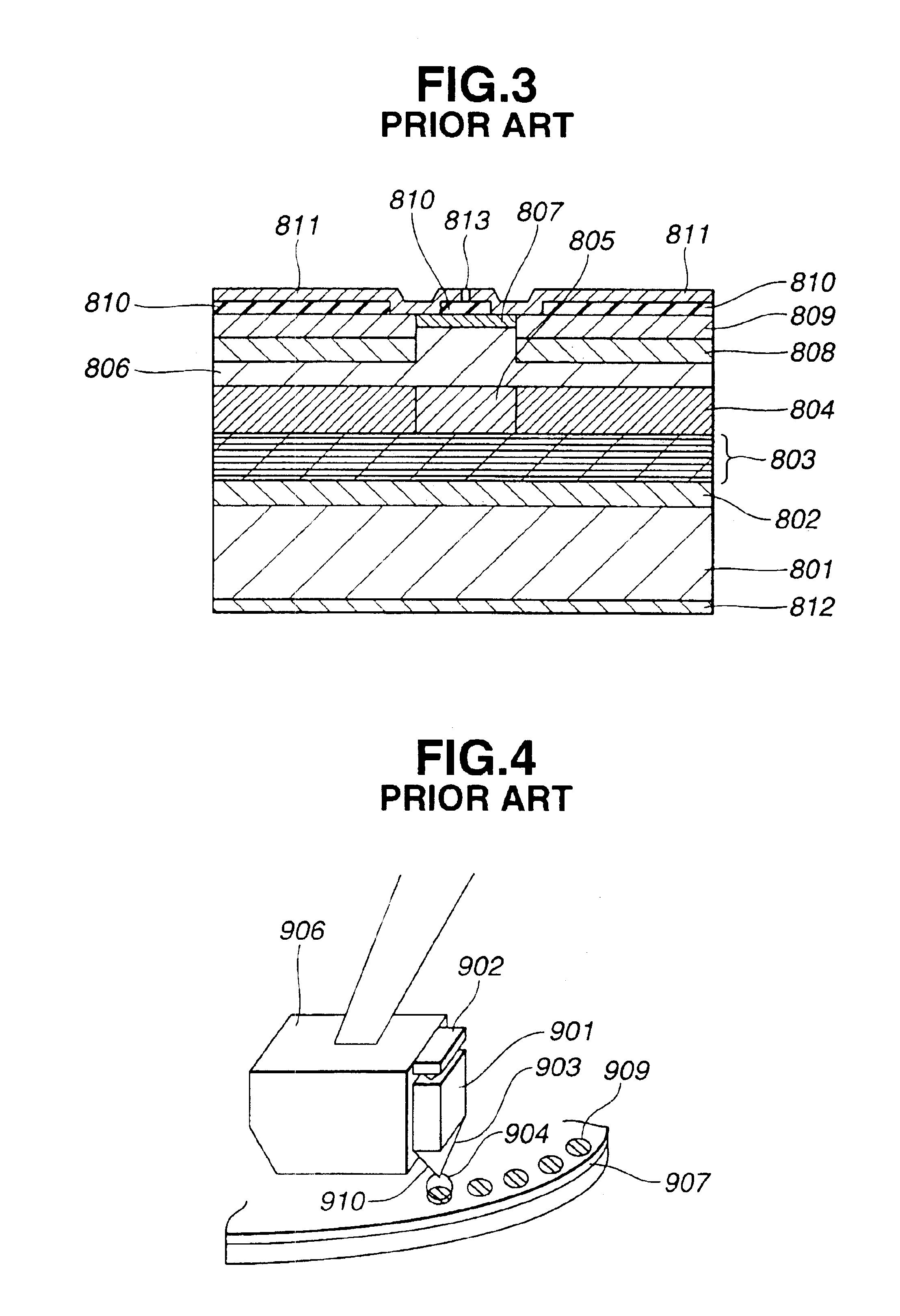

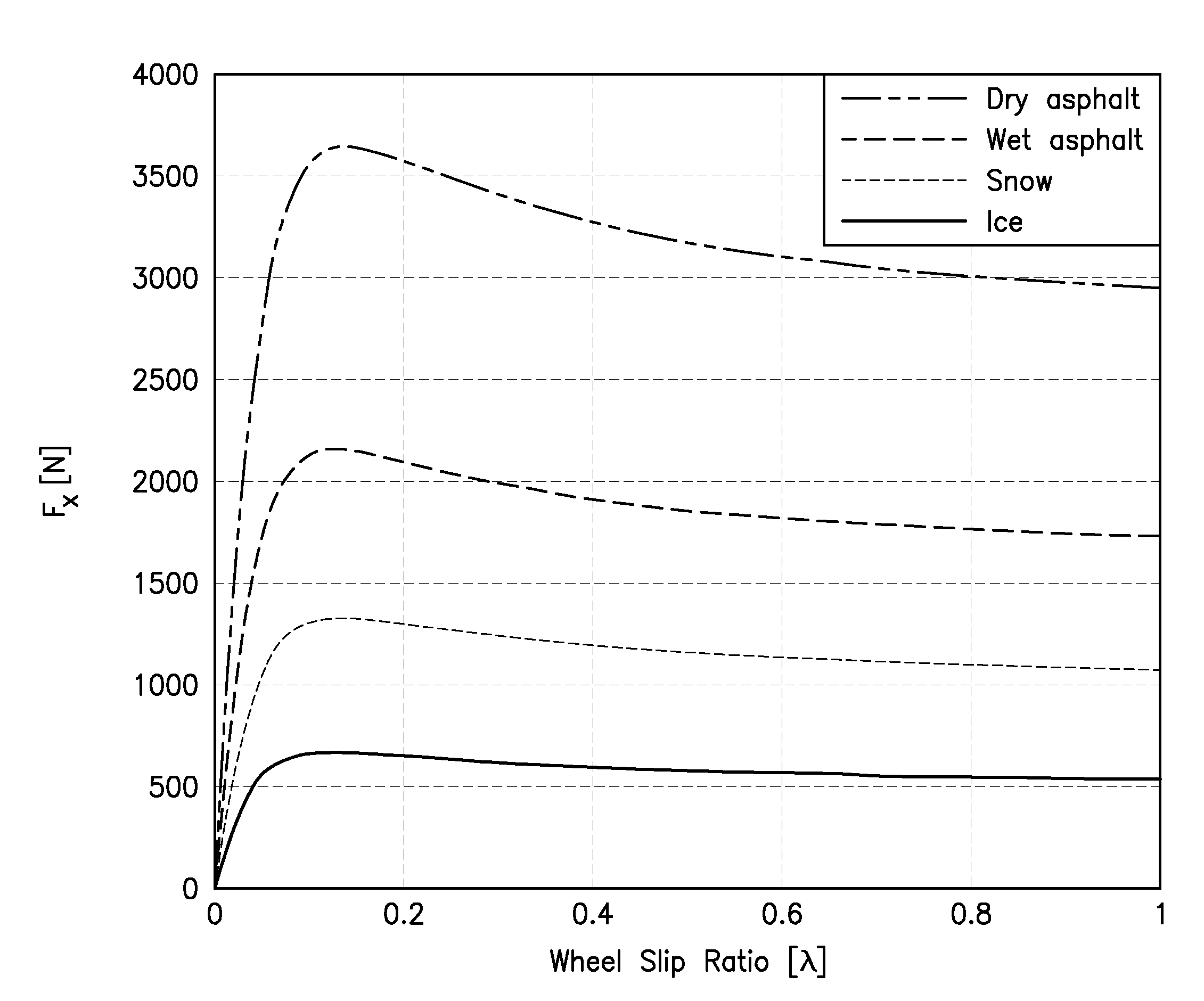

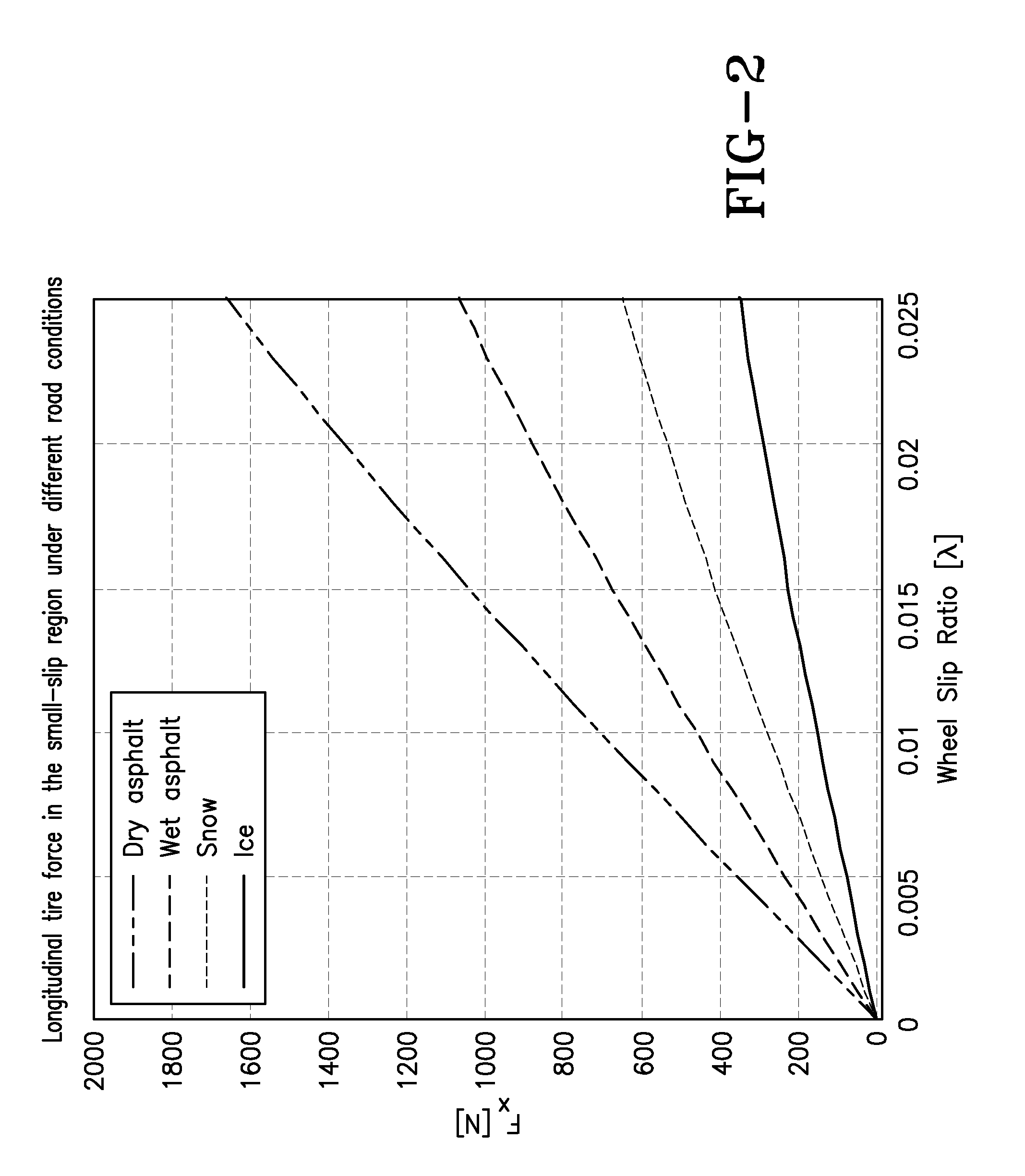

Road surface friction and surface type estimation system and method

ActiveUS20150284006A1Great tractionError minimizationBrake control systemsForce measurementRoad surfaceMoisture measurement

A tire-based system and method for estimating road surface friction includes a model-based longitudinal stiffness estimation generator using tire-based parameter inputs and vehicle-based parameter inputs; an actual longitudinal stiffness estimation generator using real-time vehicle-based parameter inputs; and a tire road friction estimation generator for deriving a tire road friction estimation from a comparative analysis between the actual longitudinal stiffness estimation and the model-based longitudinal stiffness estimation. A road surface classifier algorithm is employed to generate a road surface type analysis from the road friction estimation, an ambient air temperature measurement, and an ambient air moisture measurement.

Owner:THE GOODYEAR TIRE & RUBBER CO

Exhaust gas post treatment system

ActiveUS20080041040A1MinimizeCounter pressure is increasedInternal combustion piston enginesSilencing apparatusInternal combustion engineReducing agent

An exhaust gas post treatment system for nitrogen oxide and particle reduction of internal combustion engines operated with excess air, comprising a particle filter disposed in the exhaust gas stream of the internal combustion engine. The particle filter is a surface-type particle filter or a deep bed filter, and is charged on an outlet side with an SCR-active catalyst material for reducing nitrogen oxides. Ammonia or an ammonia-releasing reduction agent is supplied to the exhaust gas stream upstream of the particle filter.

Owner:MAN NUTZFAHRZEUGE AG

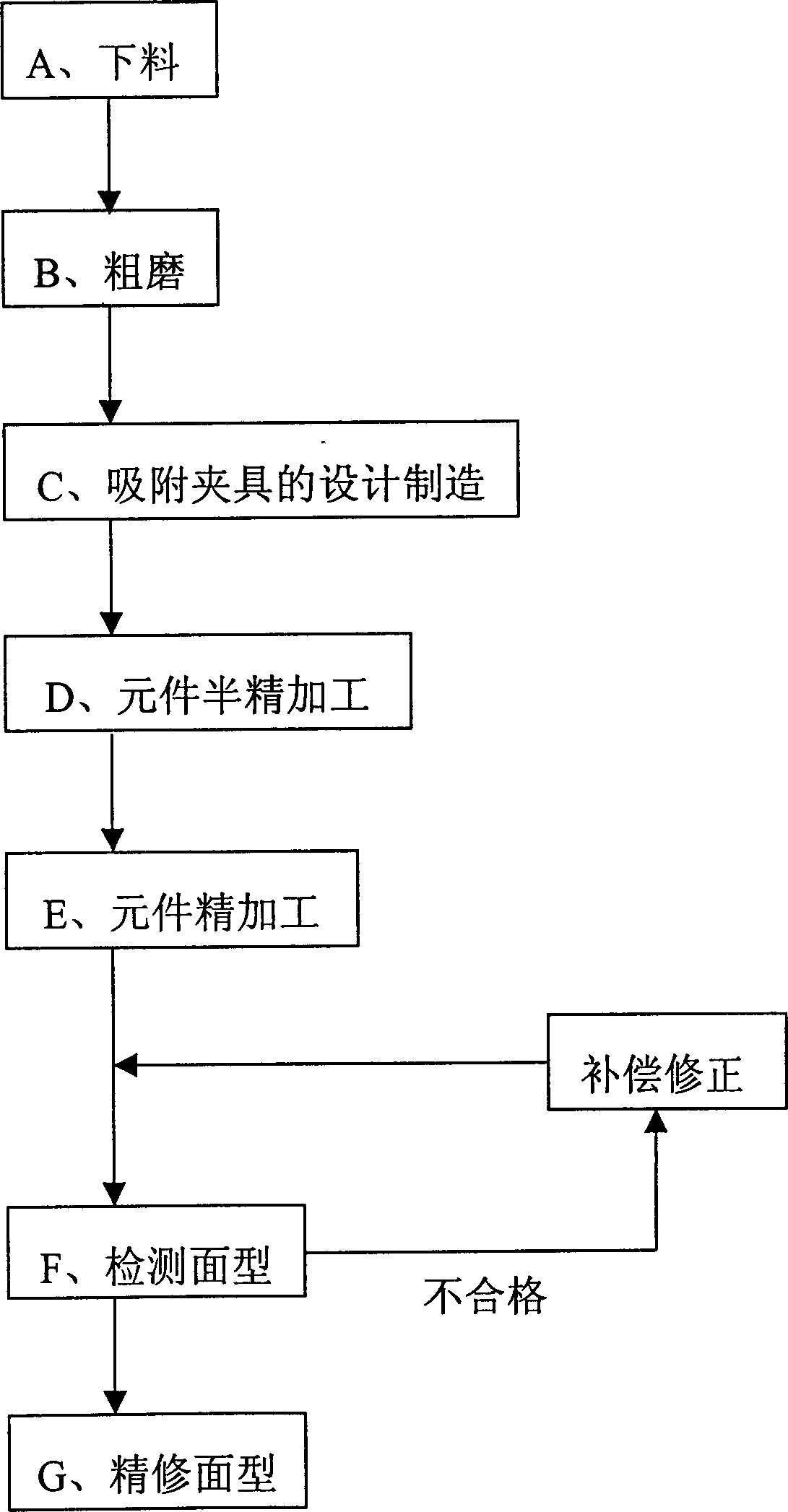

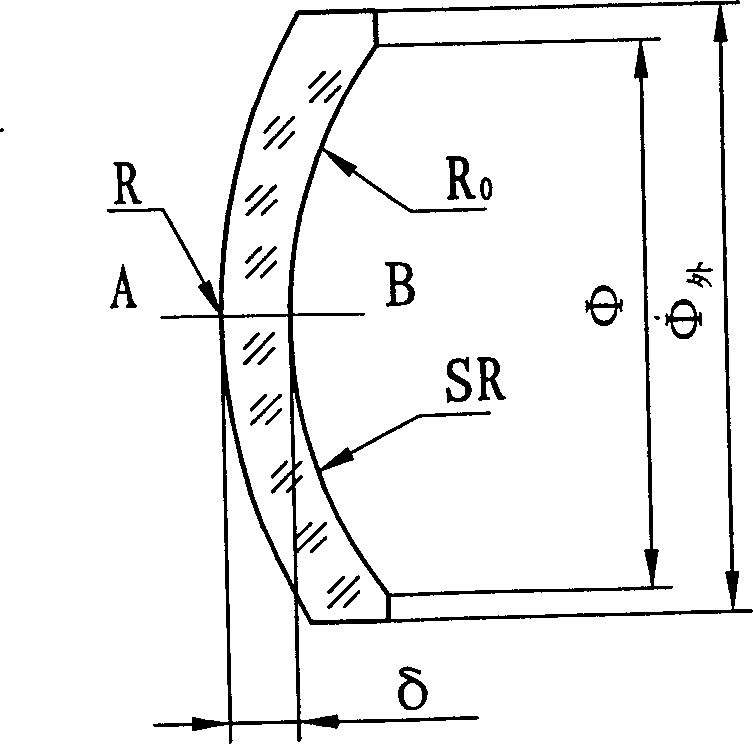

Processing method of germanium single crystal non spherical surface optical element

A technology for machining the non-spherical optical element with monocrystal of Ge features use of numerally controlled lathe and arc diamond cutter. Its technological steps include blanking, coarse grinding, designing and manufacturing attractive fixture, semi-fine machining, fine machining, testing surface type, and trimming. It has high productivity.

Owner:云南北方光学电子集团有限公司

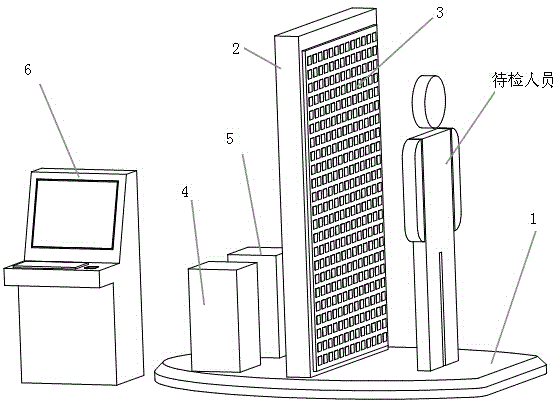

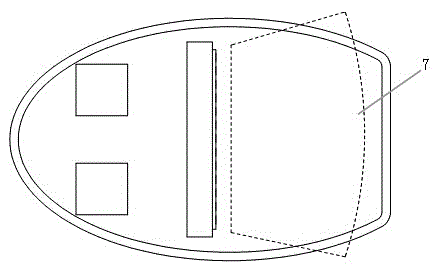

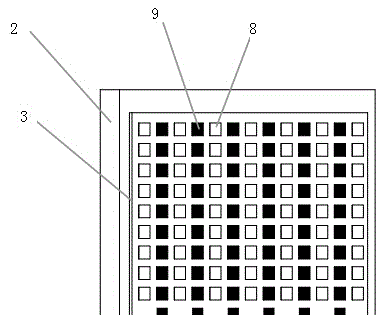

Surface-type millimeter wave scanning three-dimensional holographic imaging safety check system

InactiveCN104991283AShorten the timeNot easy to cause wear and tearOptical based geological detectionHolographic imagingSurface type

The invention relates to a surface-type millimeter wave scanning three-dimensional holographic imaging safety check system which comprises a millimeter wave signal emission driving module, a millimeter wave signal acquisition module, a millimeter wave signal processing module, a millimeter wave emission antenna and a millimeter wave reception antenna. The millimeter wave emission antenna and the millimeter wave reception antenna form a surface-type millimeter wave antenna array, wherein the surface-type millimeter wave antenna array is used for scanning a region to be detected; the millimeter wave emission antenna is connected with the millimeter wave signal emission driving module; the millimeter wave reception antenna is connected with the millimeter wave signal acquisition module; and the millimeter wave signal processing module is connected with the millimeter wave signal acquisition module. According to the surface-type millimeter wave scanning three-dimensional holographic imaging safety check system, through the surface-type millimeter wave antenna array, single scanning time is greatly reduced; and meanwhile, since equipment does need to be subjected to mechanical rotation, equipment wearing is not easy to cause, service time of the equipment is substantially prolonged and equipment fault is reduced.

Owner:深圳市太赫兹科技有限公司

Methods and compositions for improved fragrancing of a surface

InactiveUS7208465B2Facilitated releaseLower levelCosmetic preparationsToilet preparationsPresent methodSurface type

The invention provides a method for improving release, on a surface, of a fragrance from an entrapment structure of at least one fragrance oil and at least one entrapment material. The method destabilizes the entrapment structure by providing at least one trigger molecule which preferentially associates with the entrapment material; and / or at least one release agent which at least partially disrupts the entrapment structure.The invention also provides a composition for improving release of a fragrance from a surface. The composition comprises at least one fragrance oil; at least one entrapment material, the at least one fragrance oil and the at least one entrapment material being capable, in use, of forming an entrapment structure on the surface. The composition also comprises at least one destabilizing material, which permits formation of the entrapment structure on the surface but which destabilizing material can, in use, destabilize the entrapment structure by providing at least one trigger molecule which preferentially associates with the entrapment material; and / or at least one release agent which partially disrupts the entrapment structure; and at least one compatible solvent which doesn't interfere with the formation of the entrapment structure on the surface.The present methods and compositions can improve fragrance perception, by overcoming the differences in fragrance perception that result from different surface, for example, skin, hydration levels and / or different surface types.

Owner:PROCTER & GAMBLE CO

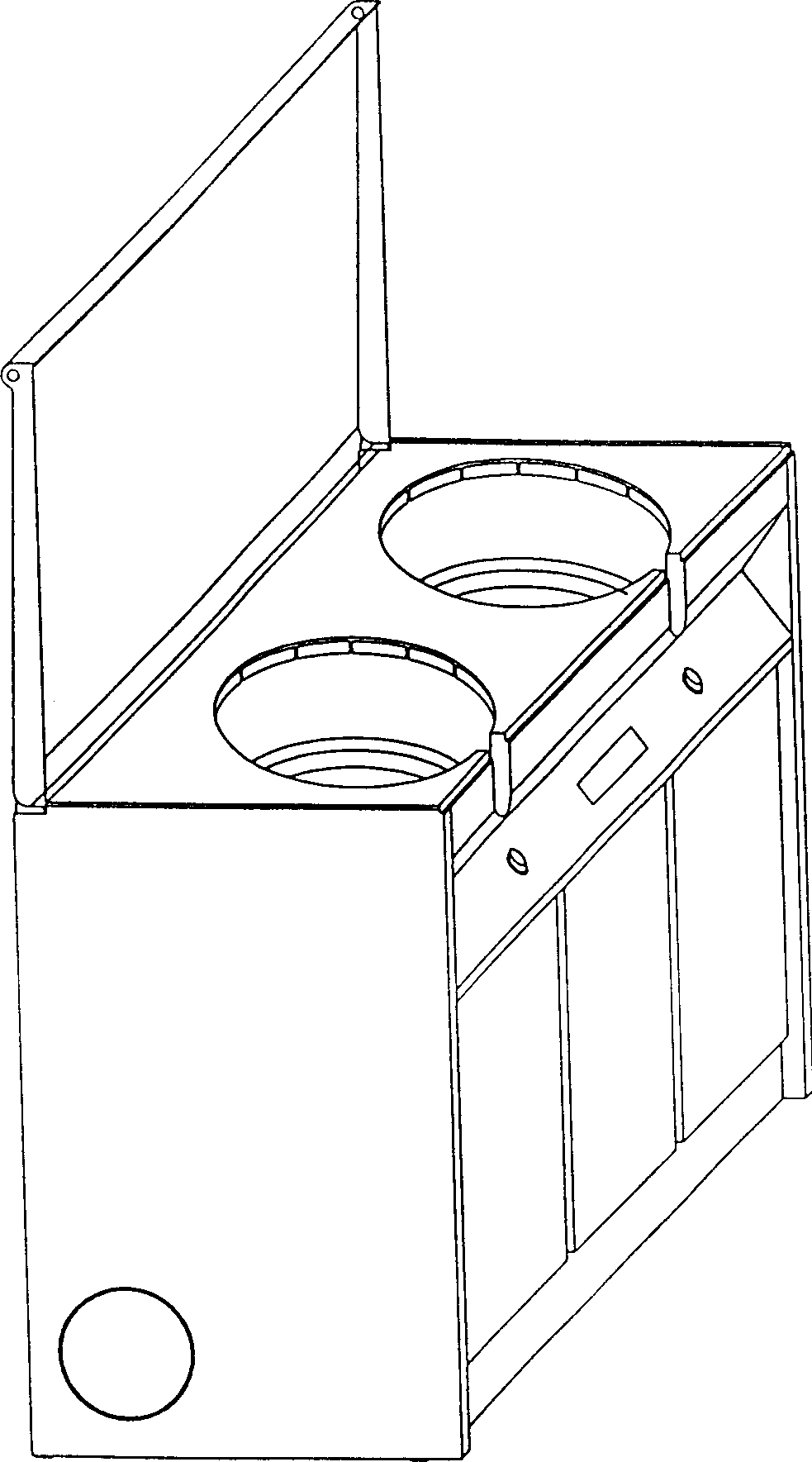

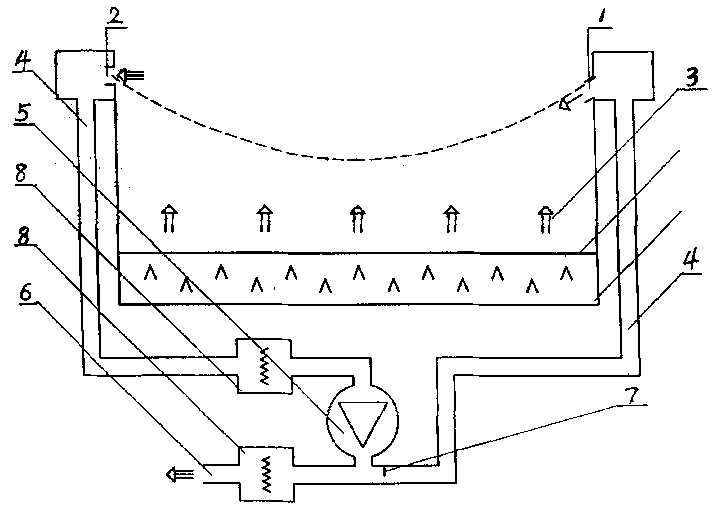

Fluid envelope surface type apparatus for shielding, separating and exhausting powdered smoke dust

InactiveCN1381696ARealize side suction forced exhaustReduce pollutionCombination devicesDomestic stoves or rangesLow noisePositive pressure

An equipment for shielding separating and exhausting smoke dust is composed of supporting frame, negative-pressure wind ring generator including a major arc-shaped wind inlet, and positive-pressure wind generator including a minor and arc-shaped wine inlet. The wind guide pipe, blower and exhaust pipe are connected with the said wind inlet. Its advantags are high effect, low noise, and compact structure.

Owner:ZHEJIANG MEIDA IND CO LTD

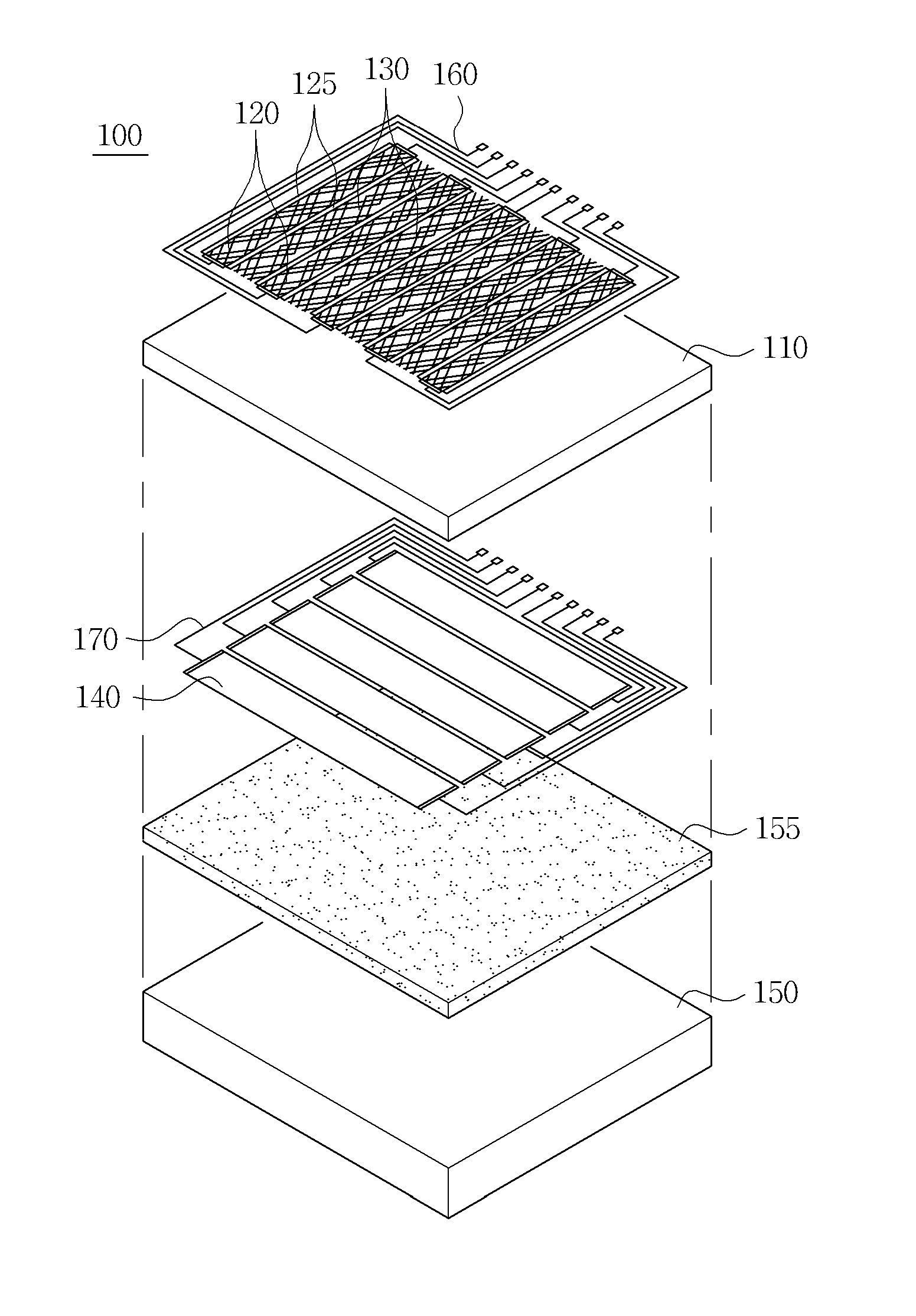

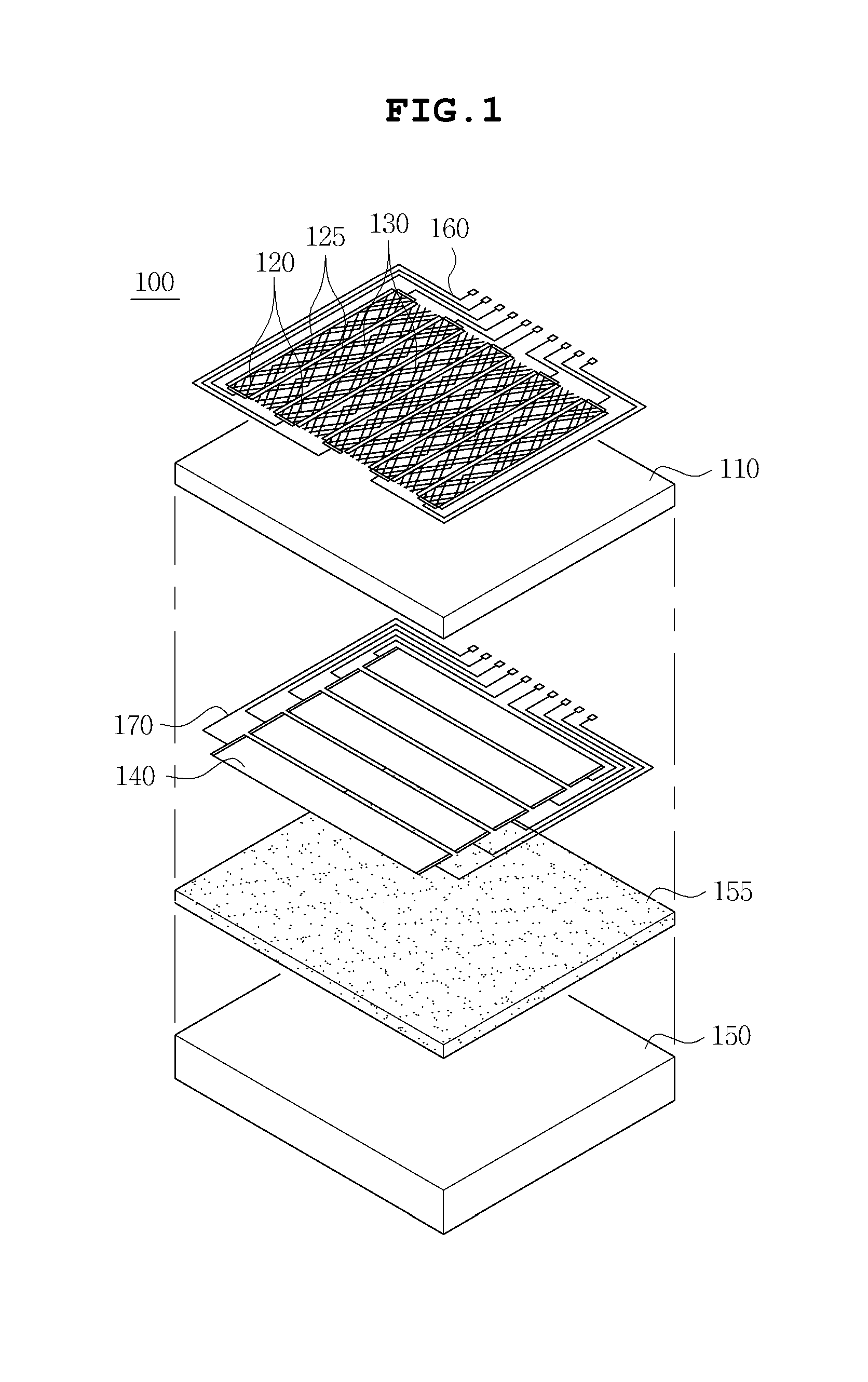

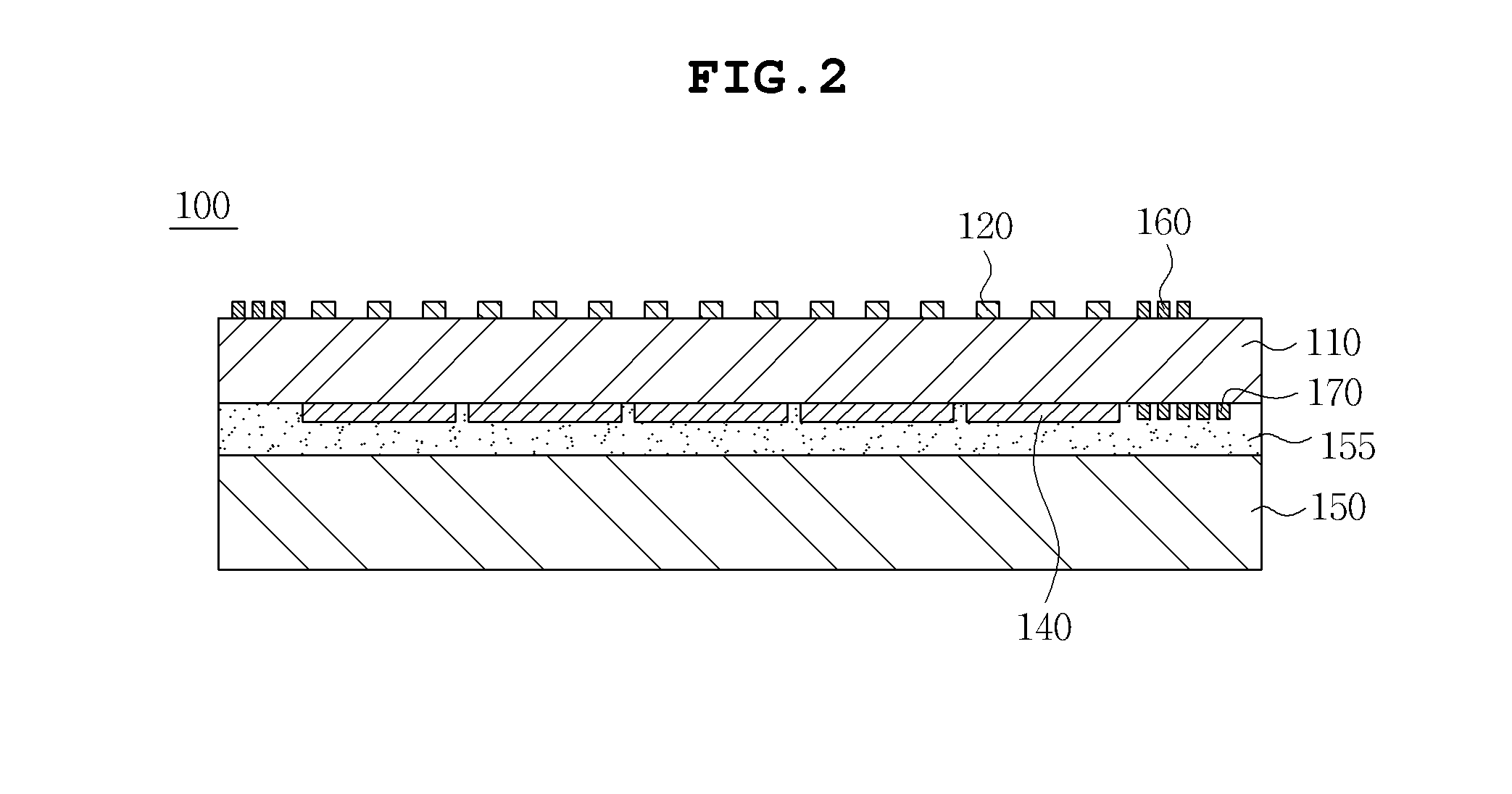

Touch panel

InactiveUS20130169548A1Reduce channel resistanceBlock noise generatedInput/output processes for data processingVisibilityDisplay device

Disclosed herein is a touch panel, including a transparent substrate; first electrode patterns formed in a mesh pattern on one surface of the transparent substrate; second electrode patterns formed in a surface type on the other surface of the transparent substrate; and an image display device provided in a direction of the other surface of the transparent substrate, thereby effectively blocking noise generated in the image display device, lowering a sheet resistance, and improving visibility.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Optical waveguide structure and optical module

Owner:FUJITSU LTD

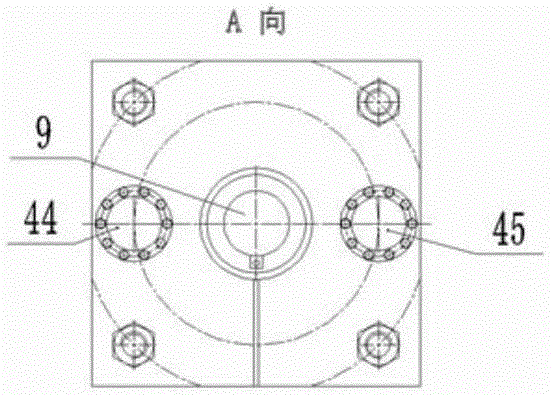

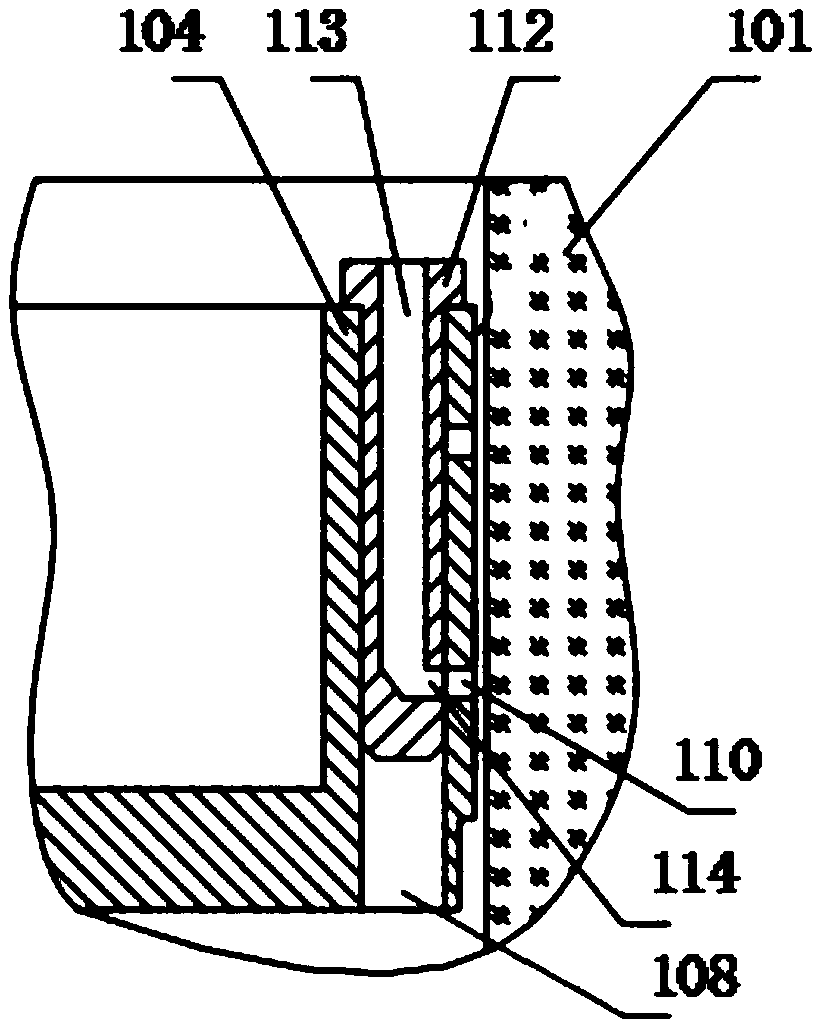

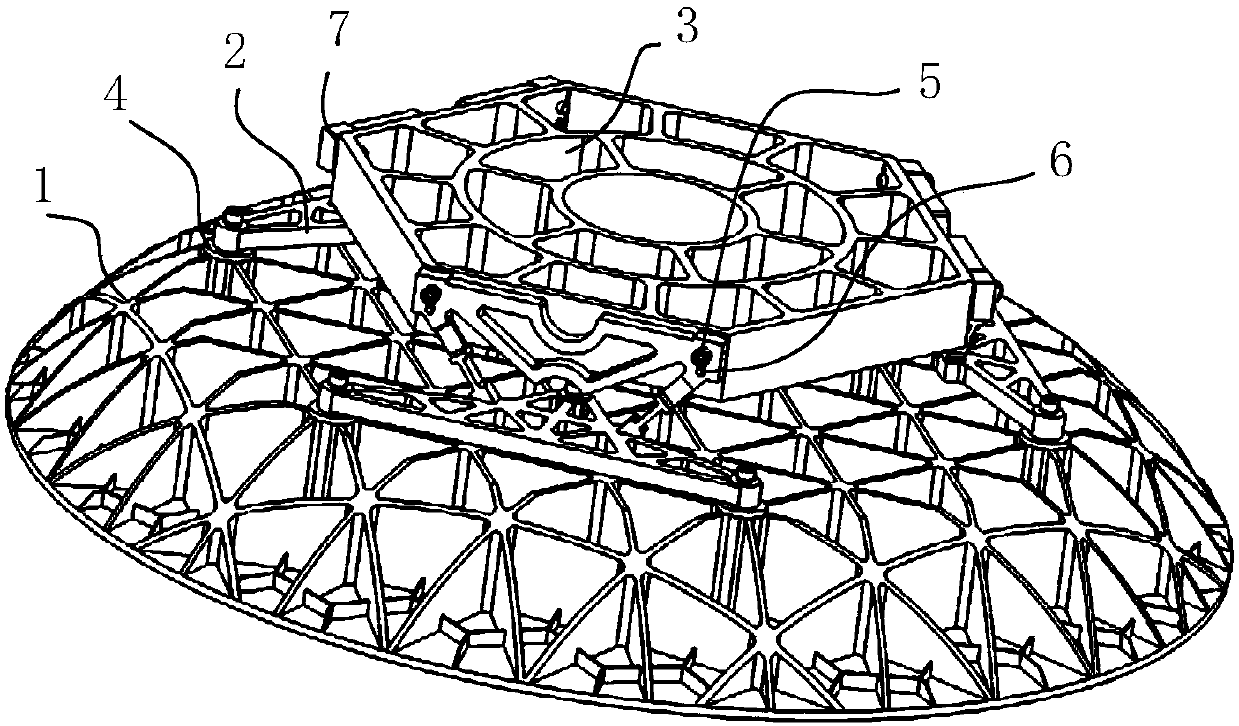

Large-caliber optical reflector with back flexible supporting structure

PendingCN109633859AImproved Gravity DeformationImplementation constraintsMountingsOptical reflectionEngineering

The invention relates to a large-caliber optical reflector with a back flexible supporting structure. The problems that too much supporting links exist, the assembling process is complex, the size andthe quality of the supporting back plate are too large in the existing large-caliber reflector back multi-point supporting technology, and the requirement for surface type precision is high under theworking conditions of gravity release and environment temperature change is difficult to be ensured at the same time are effectively solved. The reflector comprises a reflector mirror body, flexiblesupports and a supporting back plate, the number of the flexible supports is three, and the flexible supports are uniformly distributed between the reflector mirror body and the supporting back platein the circumferential direction; each flexible support comprises an isosceles triangular bottom frame and a trapezoid vertical frame which are perpendicular to each other; the three vertexes of the isosceles triangular bottom frame are connected with the back of the reflector mirror body; the top edge of the trapezoid vertical frame is connected with the isosceles triangle bottom frame, the bottom edge of the trapezoid vertical frame is connected with the side surface of the supporting back plate; and the bottom edge of the trapezoid vertical frame adopts a flexible hinge structure, and the two waist parts of the trapezoid vertical frame are correspondingly of a flexible reed structure.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com