Surface-type millimeter wave scanning three-dimensional holographic imaging safety check system

A three-dimensional holographic and millimeter-wave technology, applied in the field of three-dimensional holographic imaging security inspection systems, can solve the problems of equipment wear and long time for a single scan, and achieve the effect of reducing equipment failures, prolonging equipment use time, and shortening scanning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

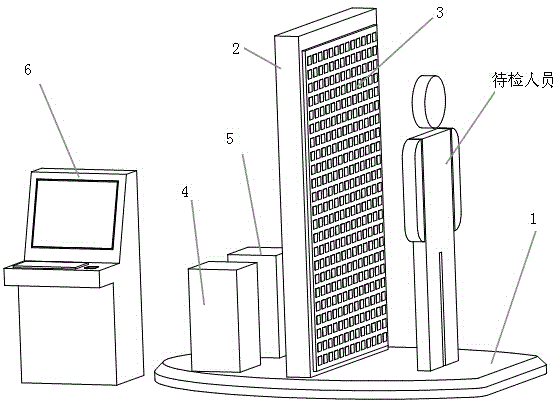

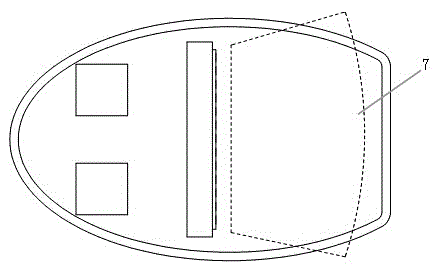

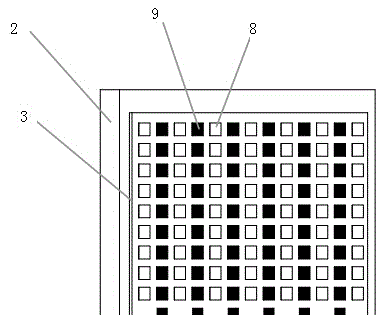

[0022] like figure 1 , figure 2 As shown, the specific embodiment of the present invention is to construct a three-dimensional holographic imaging security inspection system for surface millimeter wave scanning, including a millimeter wave signal transmission drive module 4, a millimeter wave signal acquisition module 5, a millimeter wave signal processing module 6, a millimeter A wave transmitting antenna 8 and a millimeter wave receiving antenna 9, the millimeter wave transmitting antenna 8 and the millimeter wave receiving antenna 9 form a planar millimeter wave antenna array 3, and the planar millimeter wave antenna array 3 scans the area 7 to be measured, The millimeter-wave transmitting antenna 8 is connected to the millimeter-wave signal transmitting drive module 4, the millimeter-wave receiving antenna 9 is connected to the millimeter-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com