Patents

Literature

1633results about "Optical based geological detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

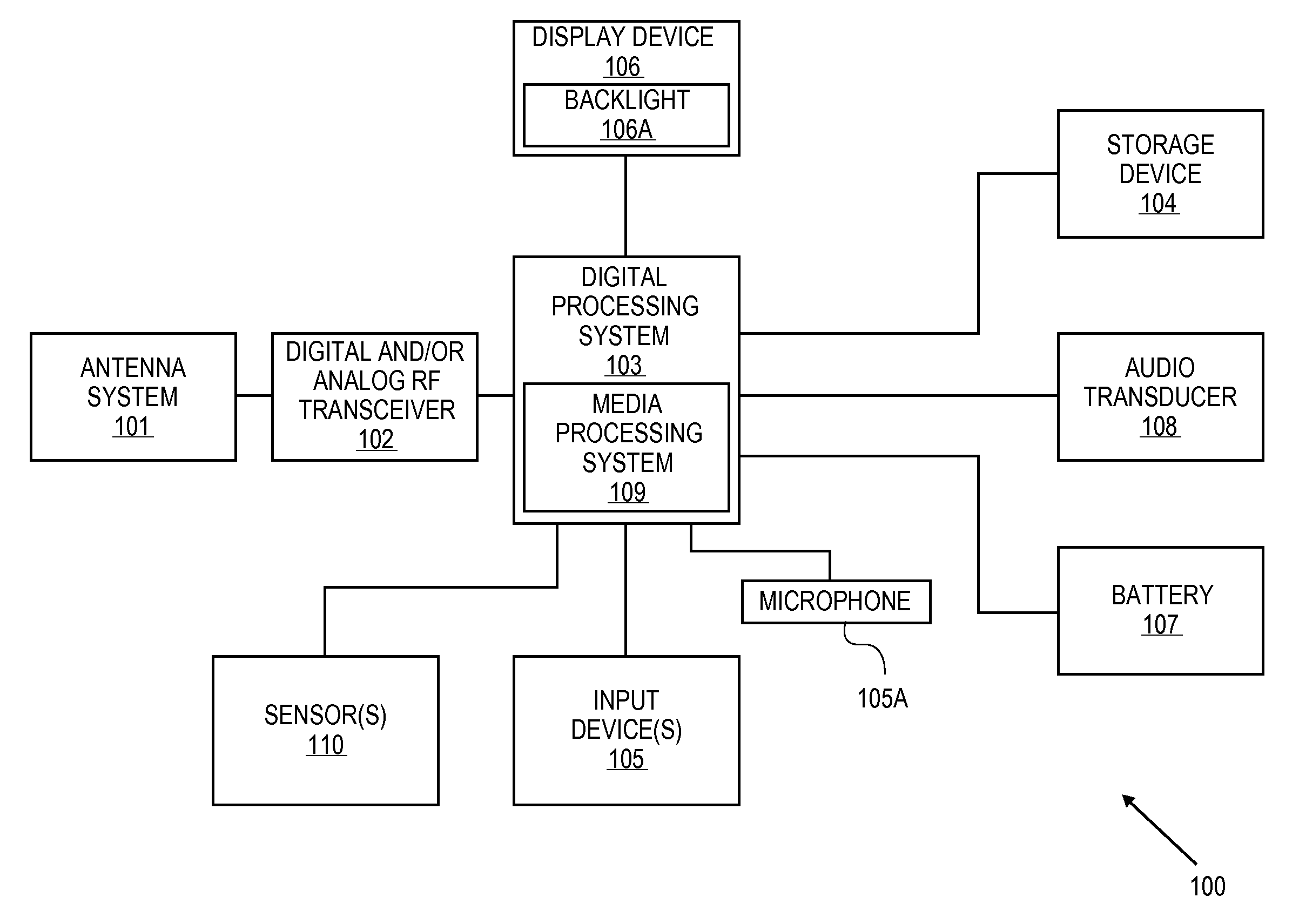

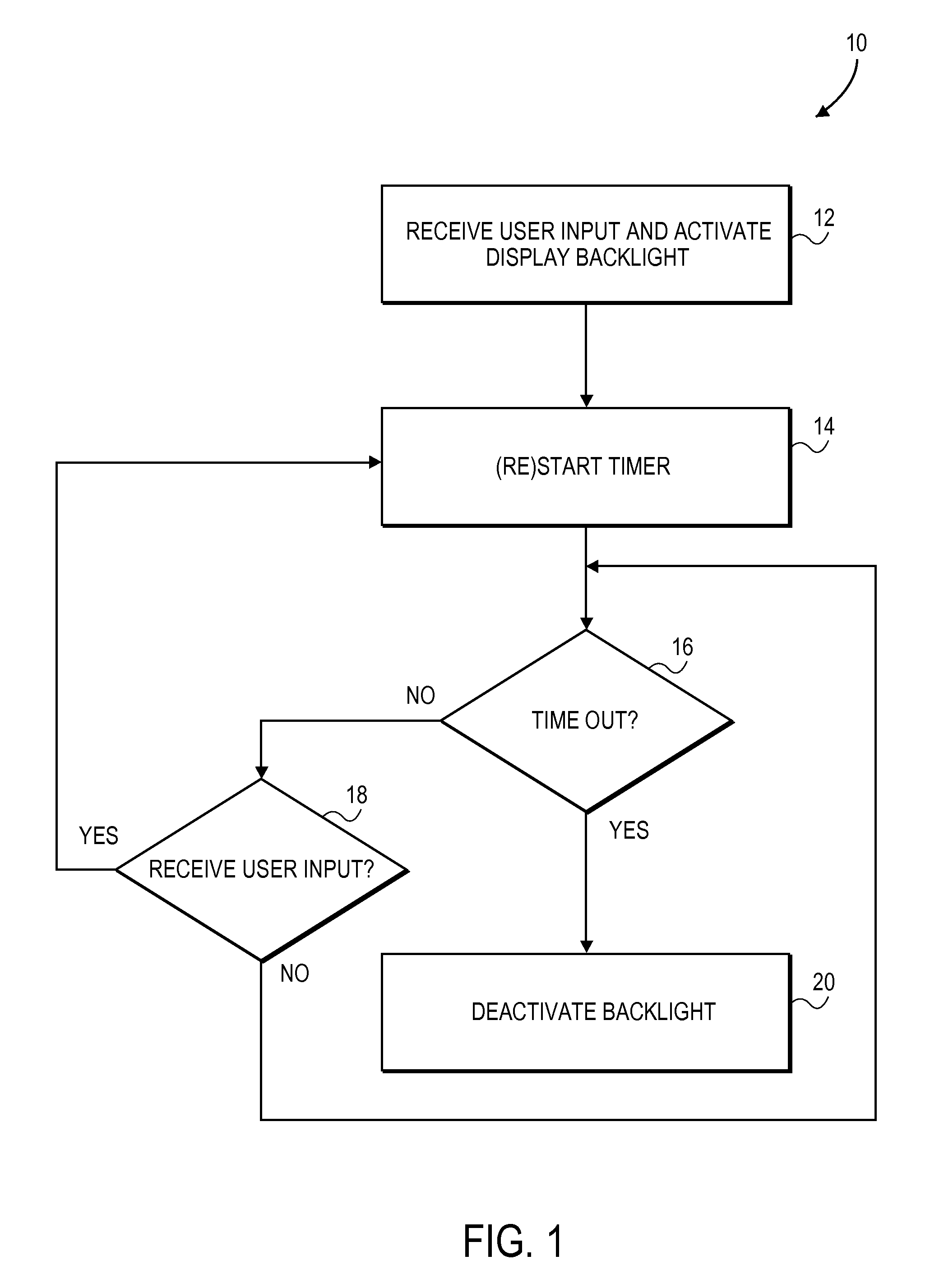

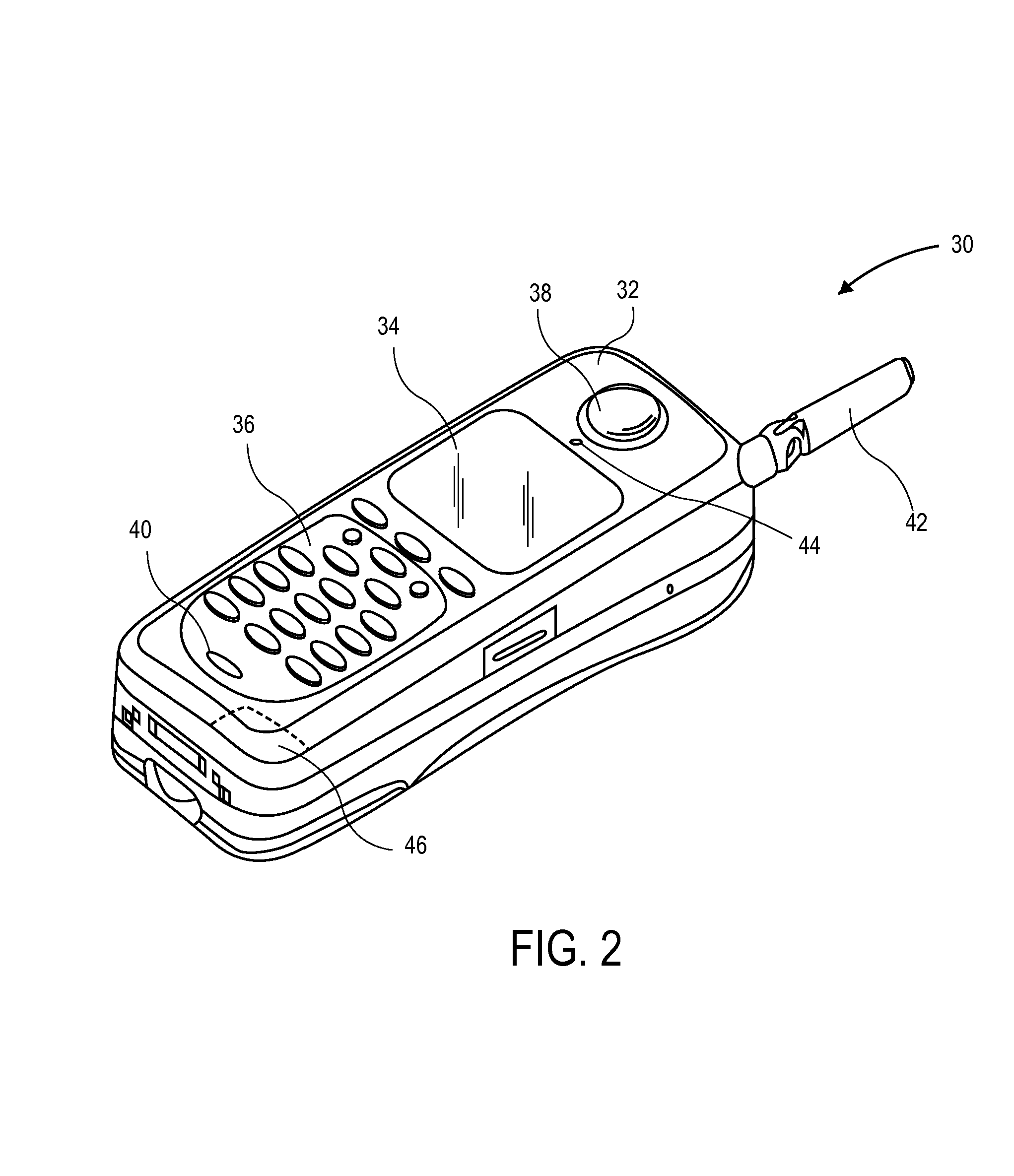

Automated response to and sensing of user activity in portable devices

ActiveUS7633076B2Input/output for user-computer interactionGain controlComputer scienceEquipment state

Owner:APPLE INC

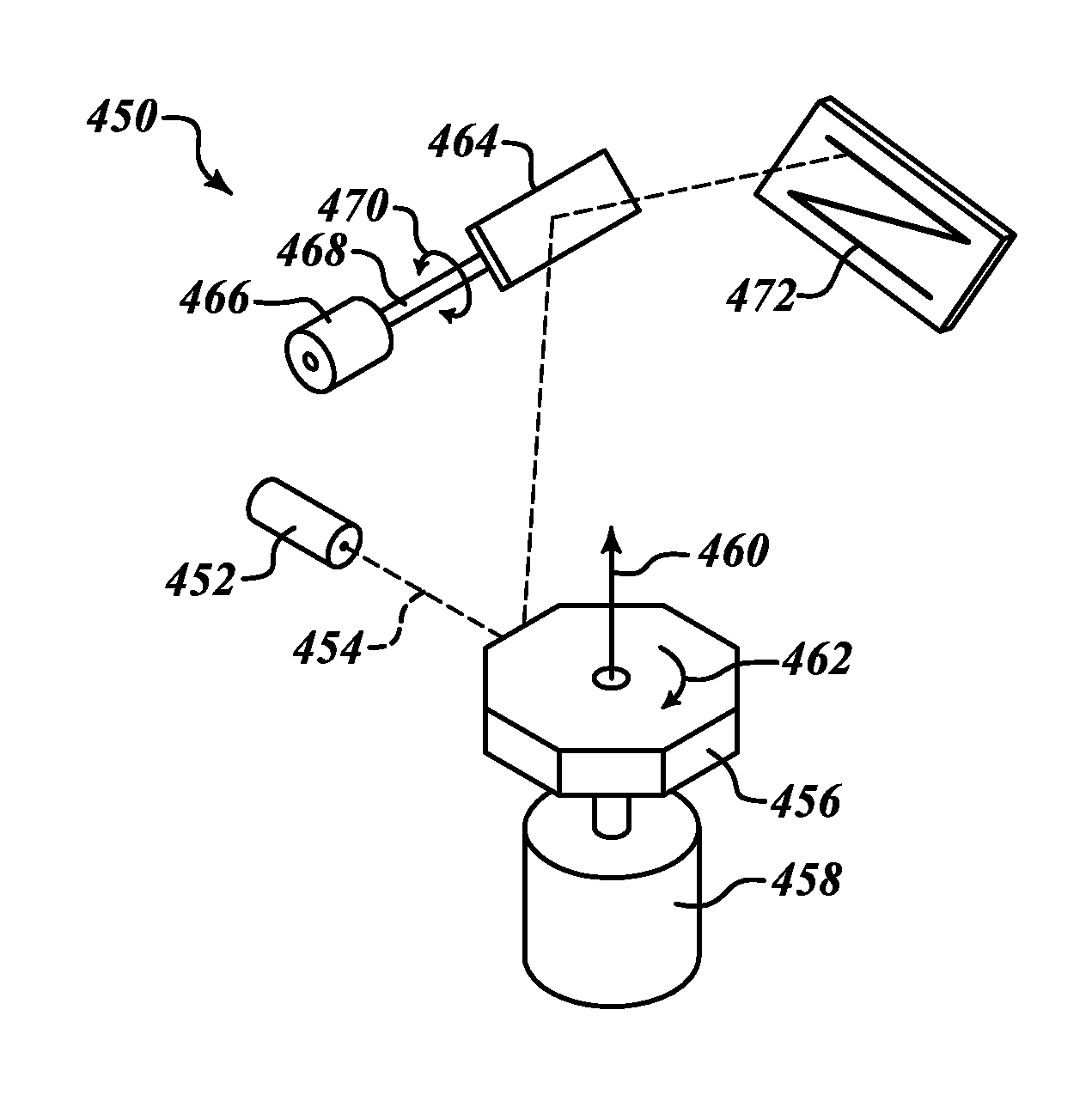

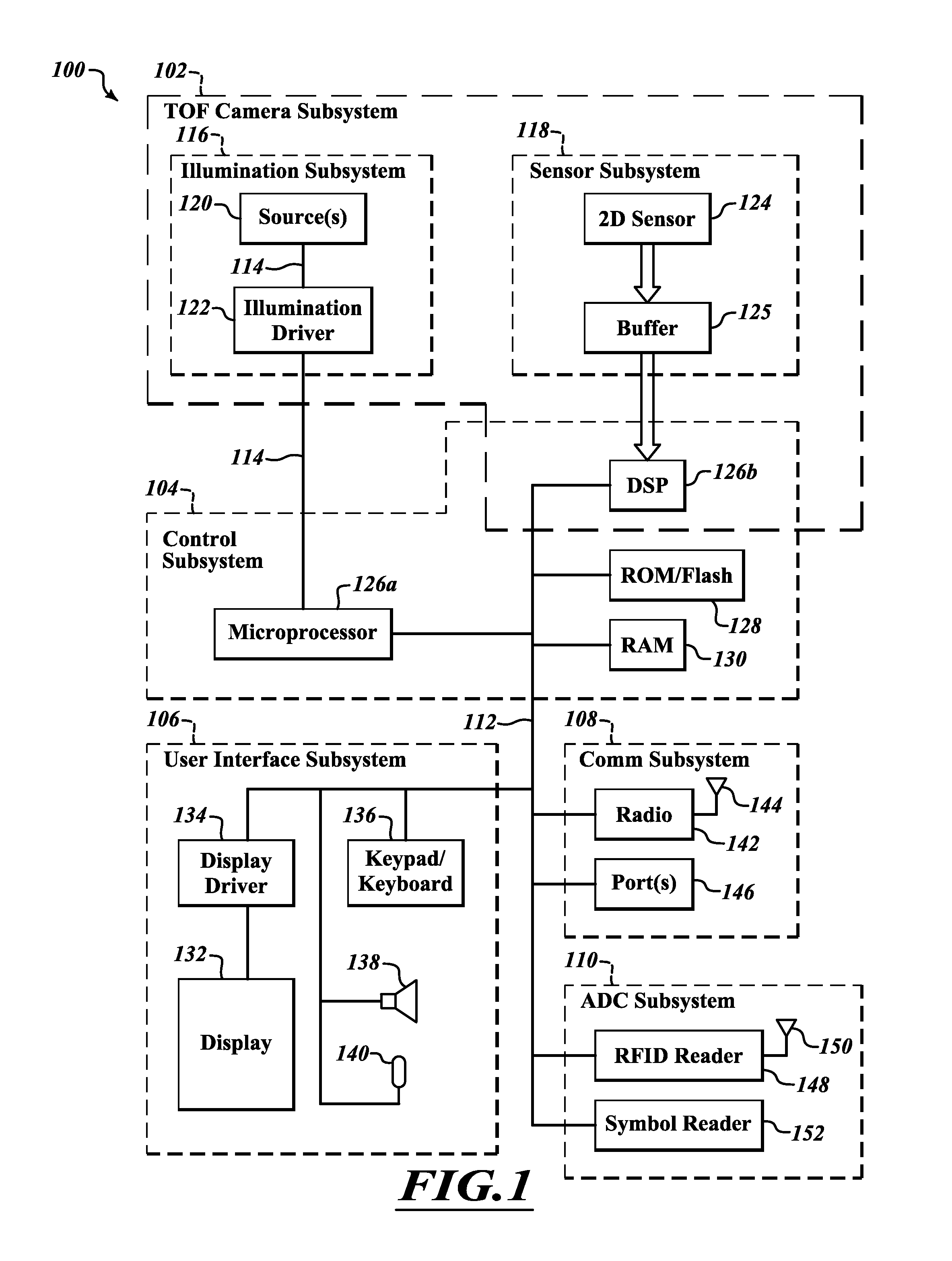

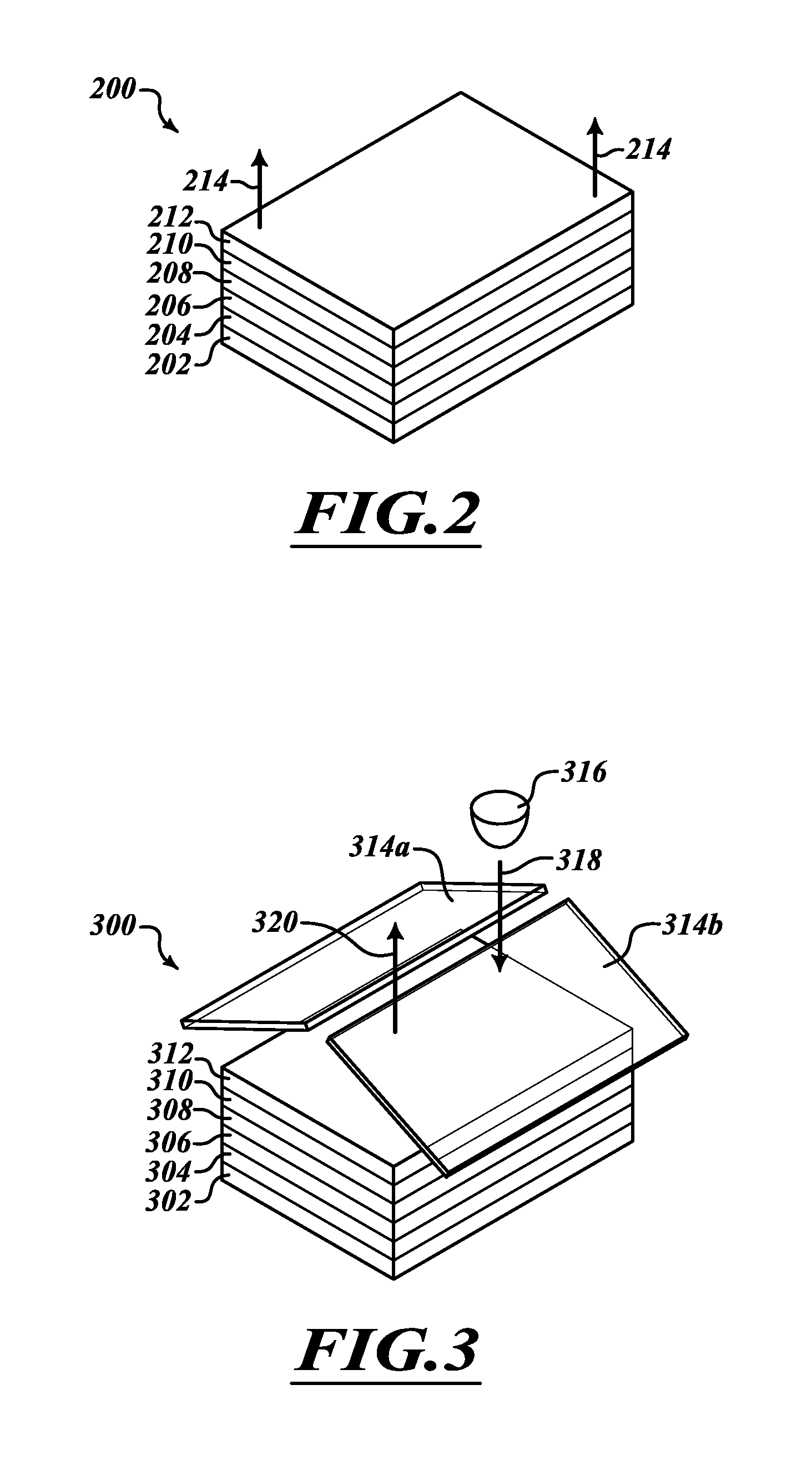

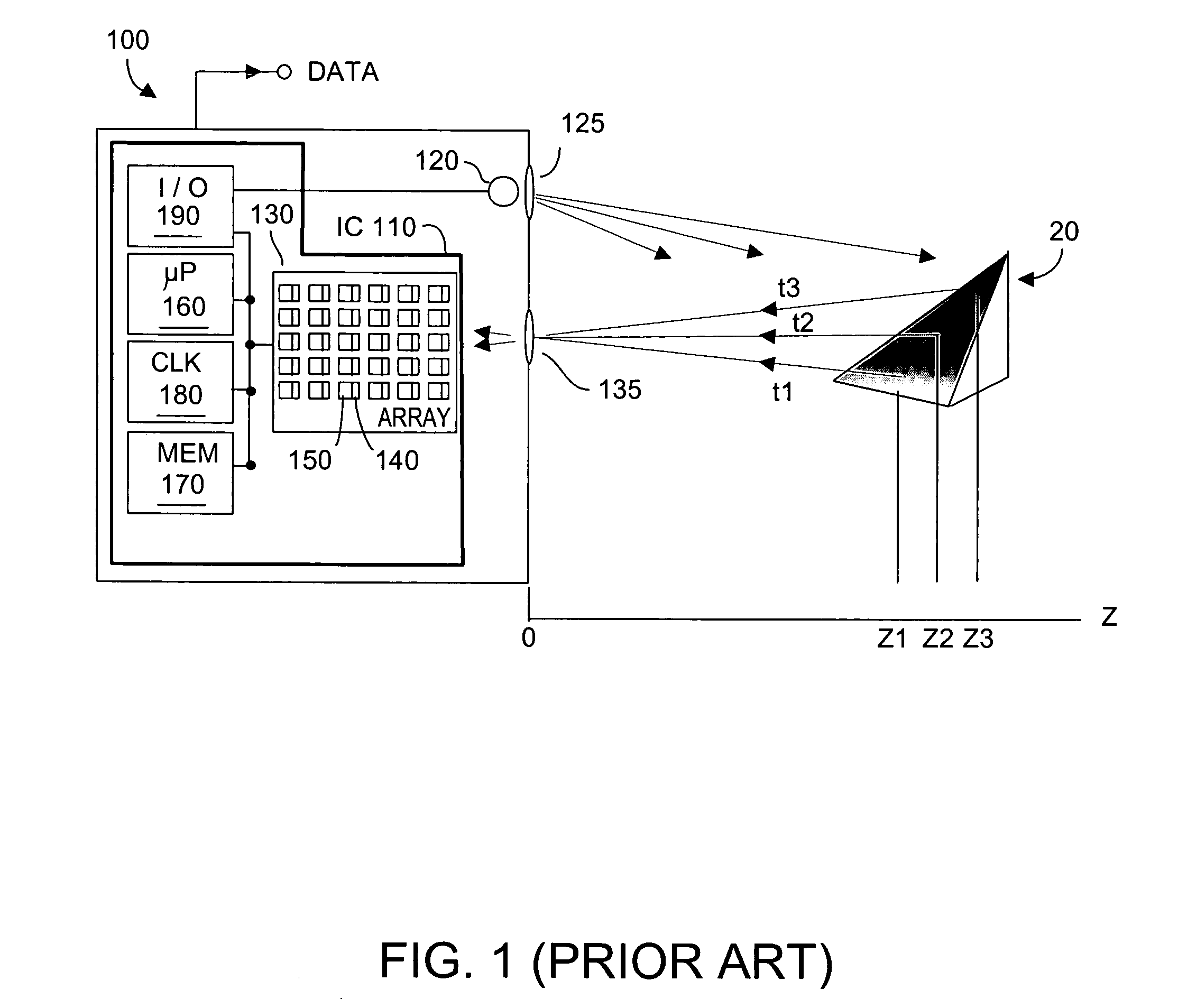

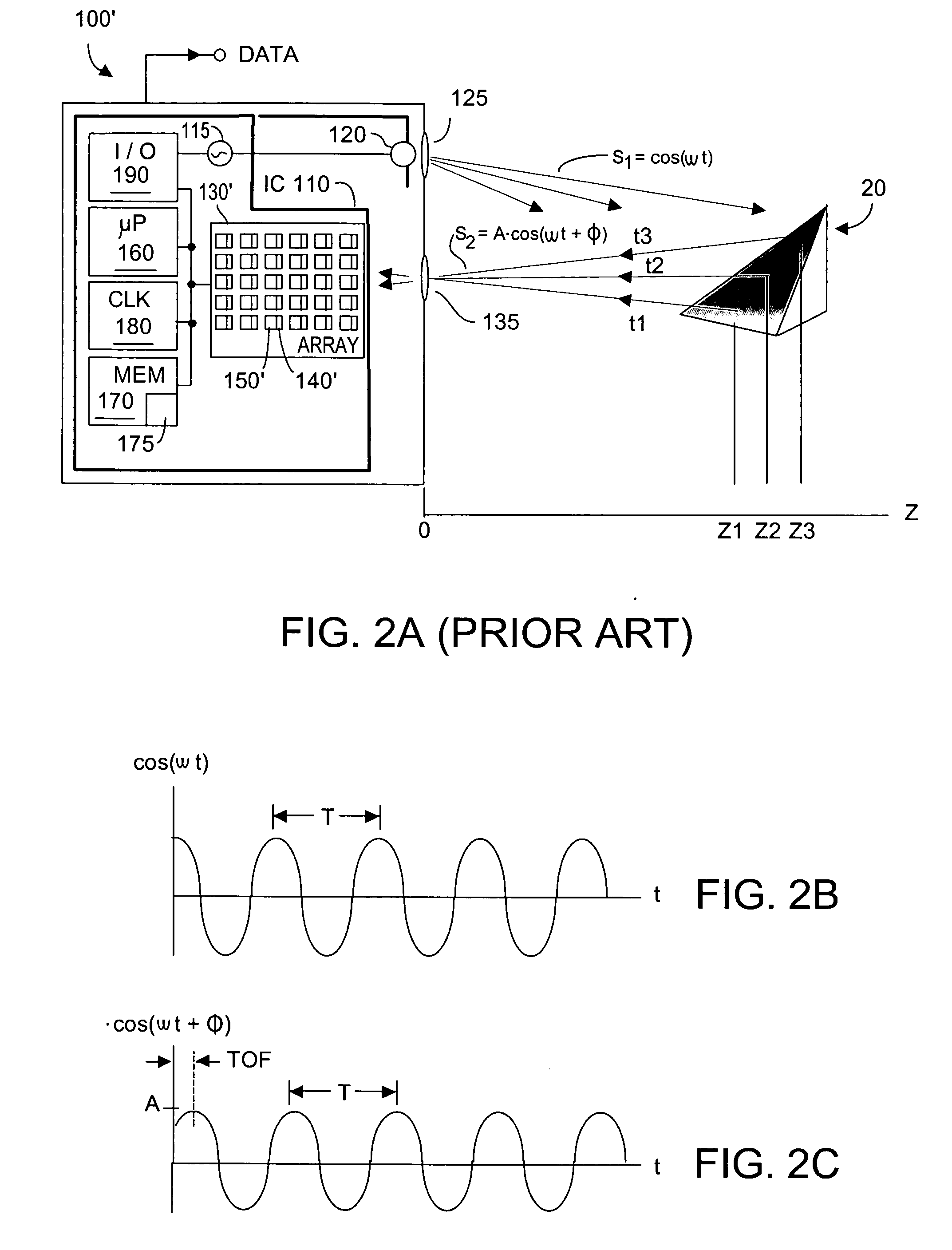

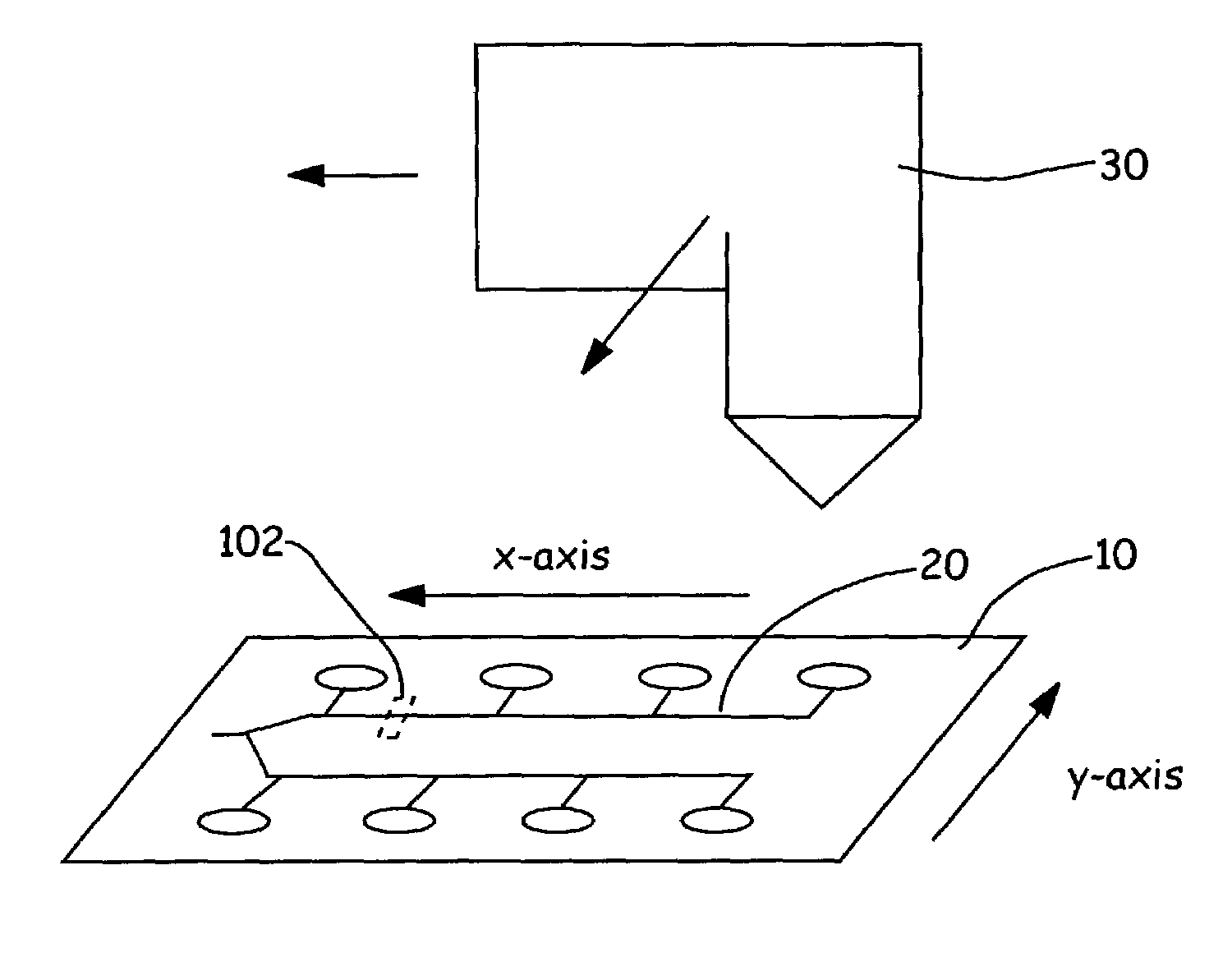

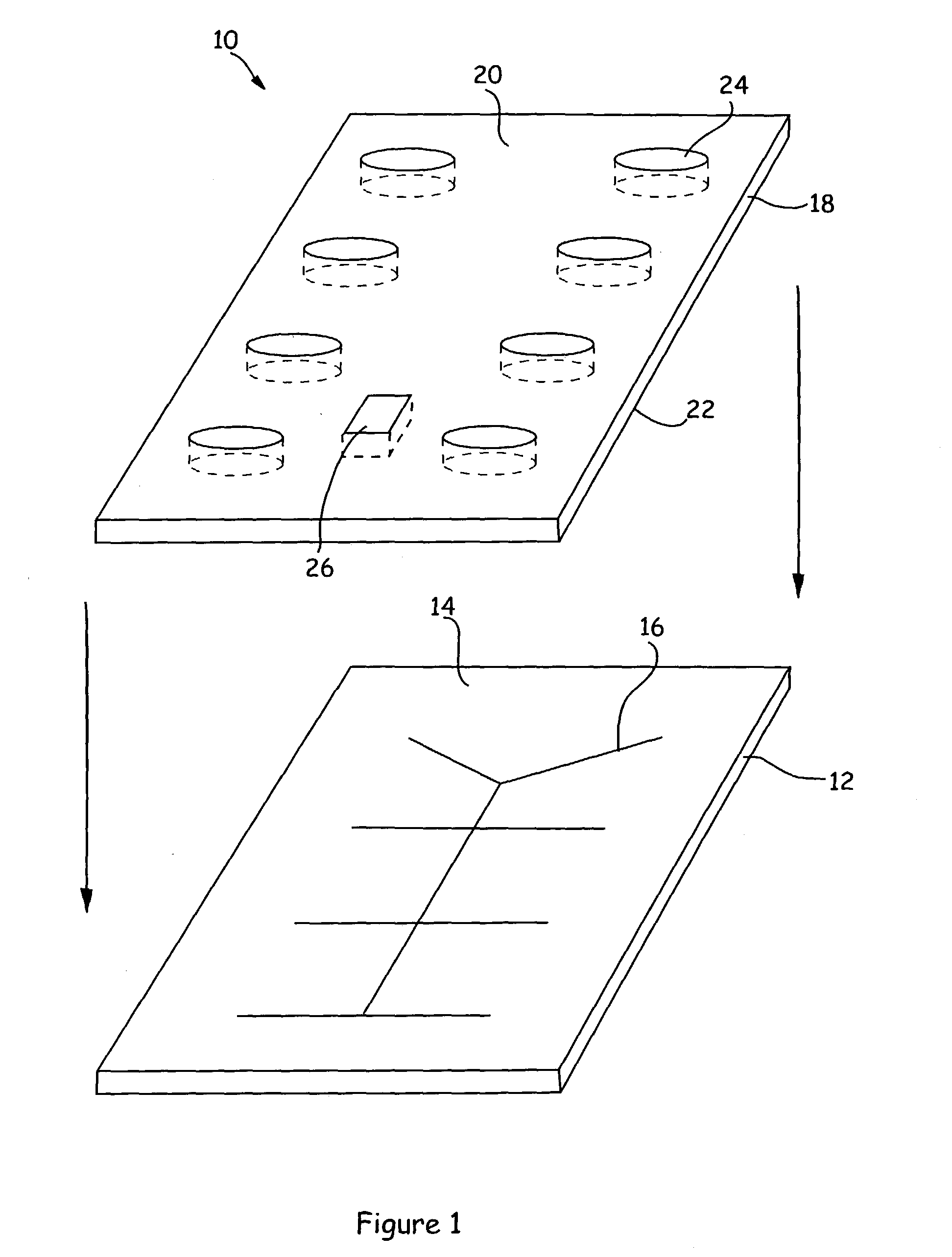

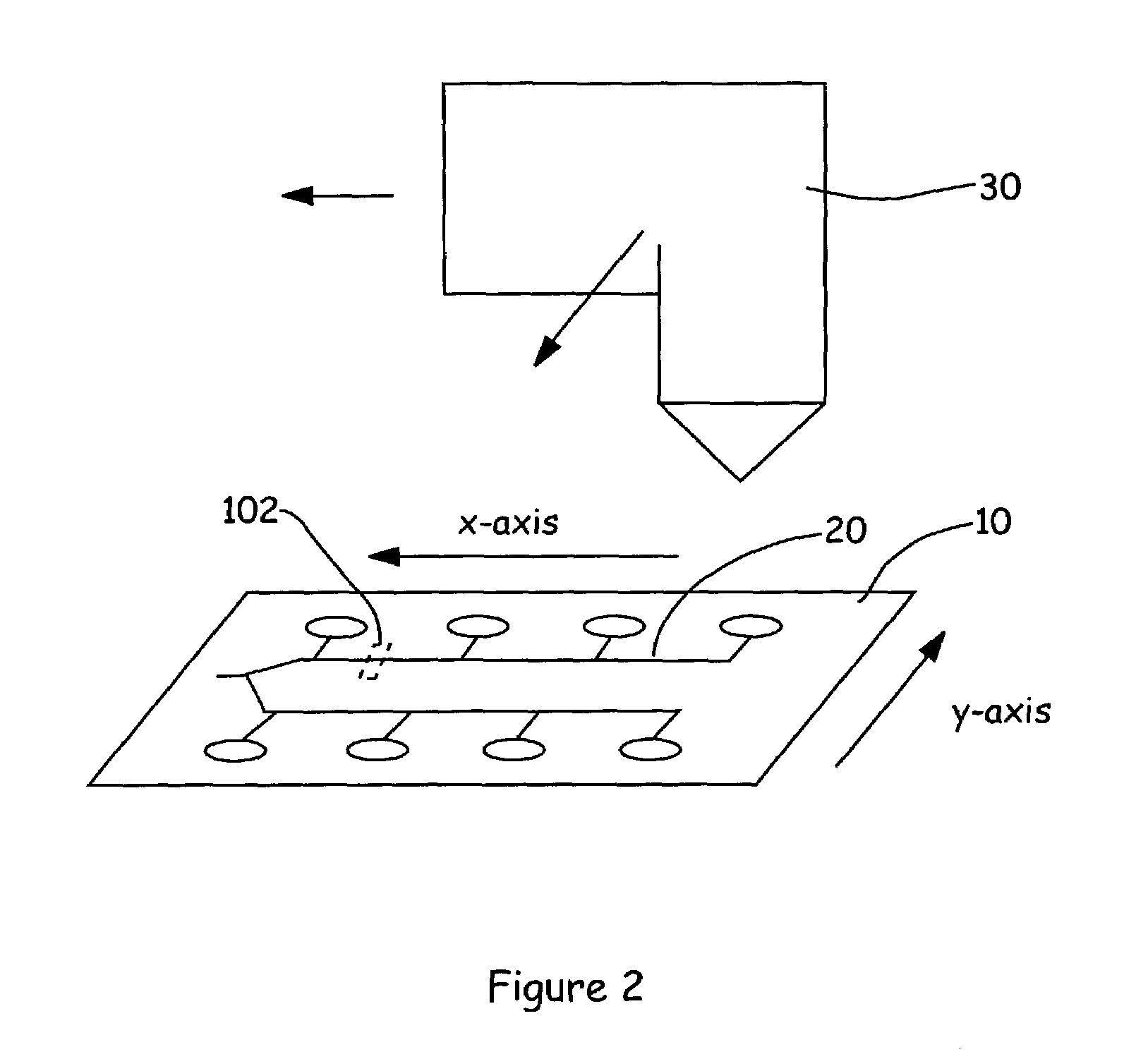

Volume dimensioning system and method employing time-of-flight camera

ActiveUS8854633B2Cost effectiveLess spaceInvestigating moving sheetsUsing optical meansPattern recognitionTime-of-flight camera

Volume dimensioning employs techniques to reduce multipath reflection or return of illumination, and hence distortion. Volume dimensioning for any given target object includes a sequence of one or more illuminations and respective detections of returned illumination. A sequence typically includes illumination with at least one initial spatial illumination pattern and with one or more refined spatial illumination patterns. Refined spatial illumination patterns are generated based on previous illumination in order to reduce distortion. The number of refined spatial illumination patterns in a sequence may be fixed, or may vary based on results of prior illumination(s) in the sequence. Refined spatial illumination patterns may avoid illuminating background areas that contribute to distortion. Sometimes, illumination with the initial spatial illumination pattern may produce sufficiently acceptable results, and refined spatial illumination patterns in the sequence omitted.

Owner:INTERMEC IP CORP

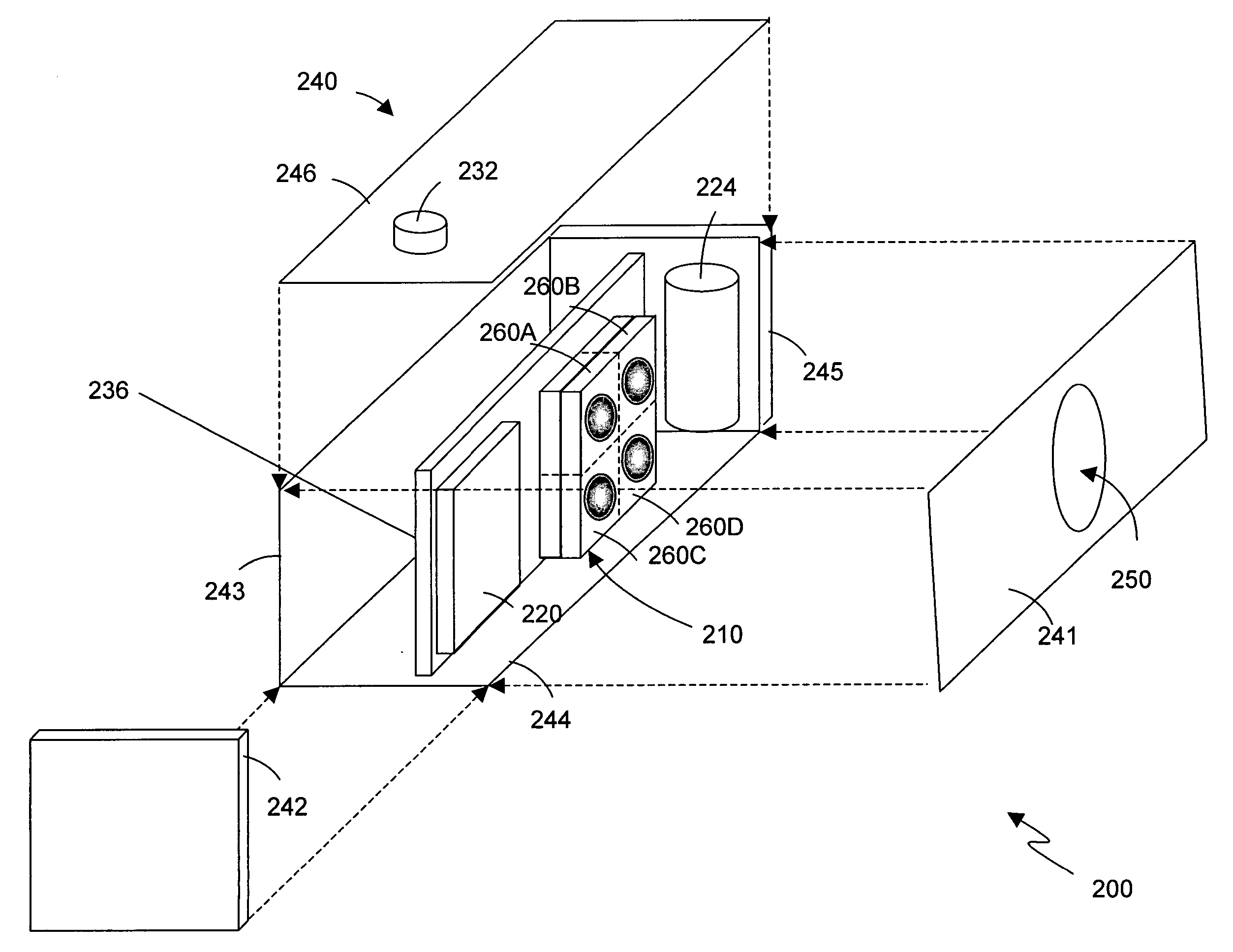

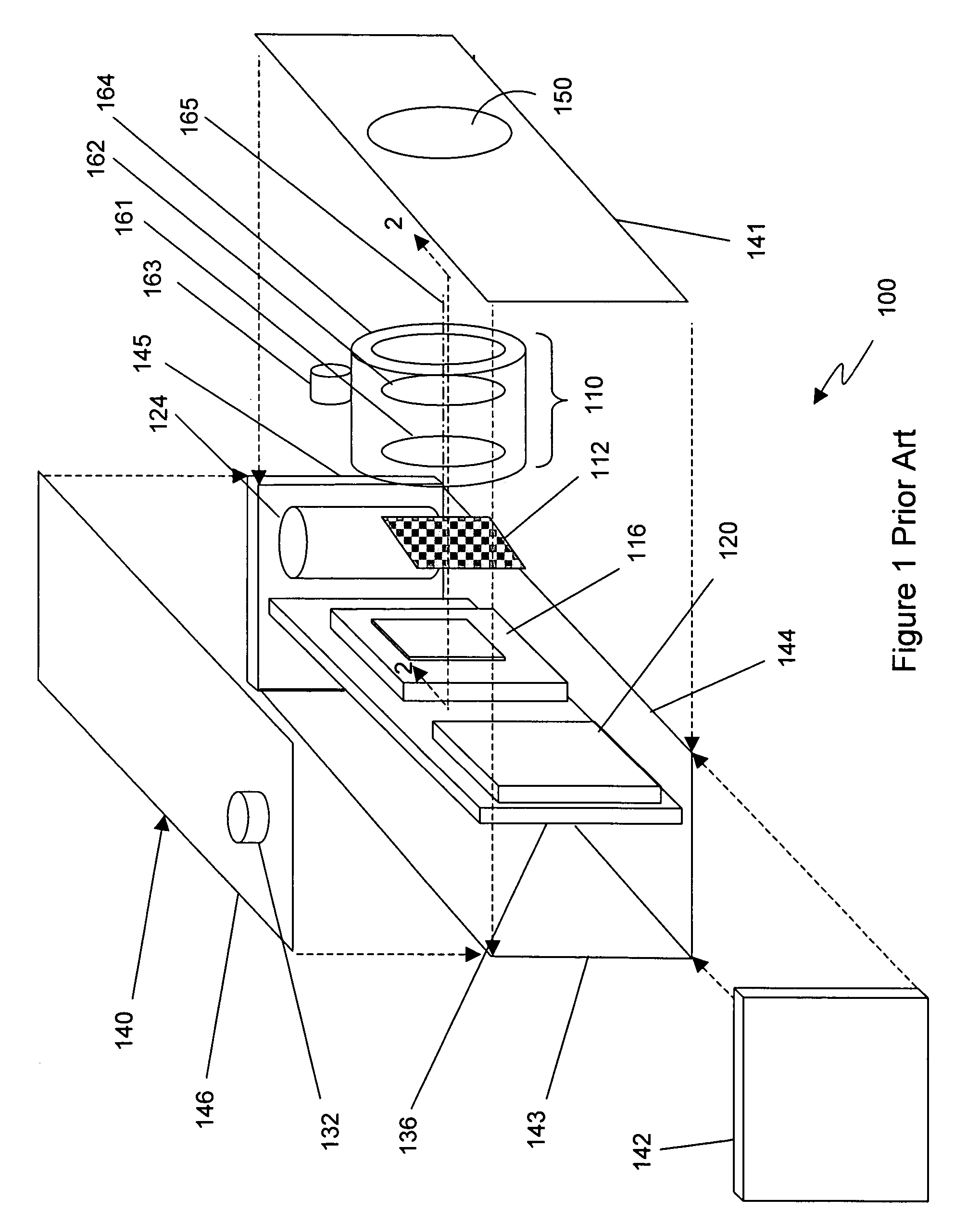

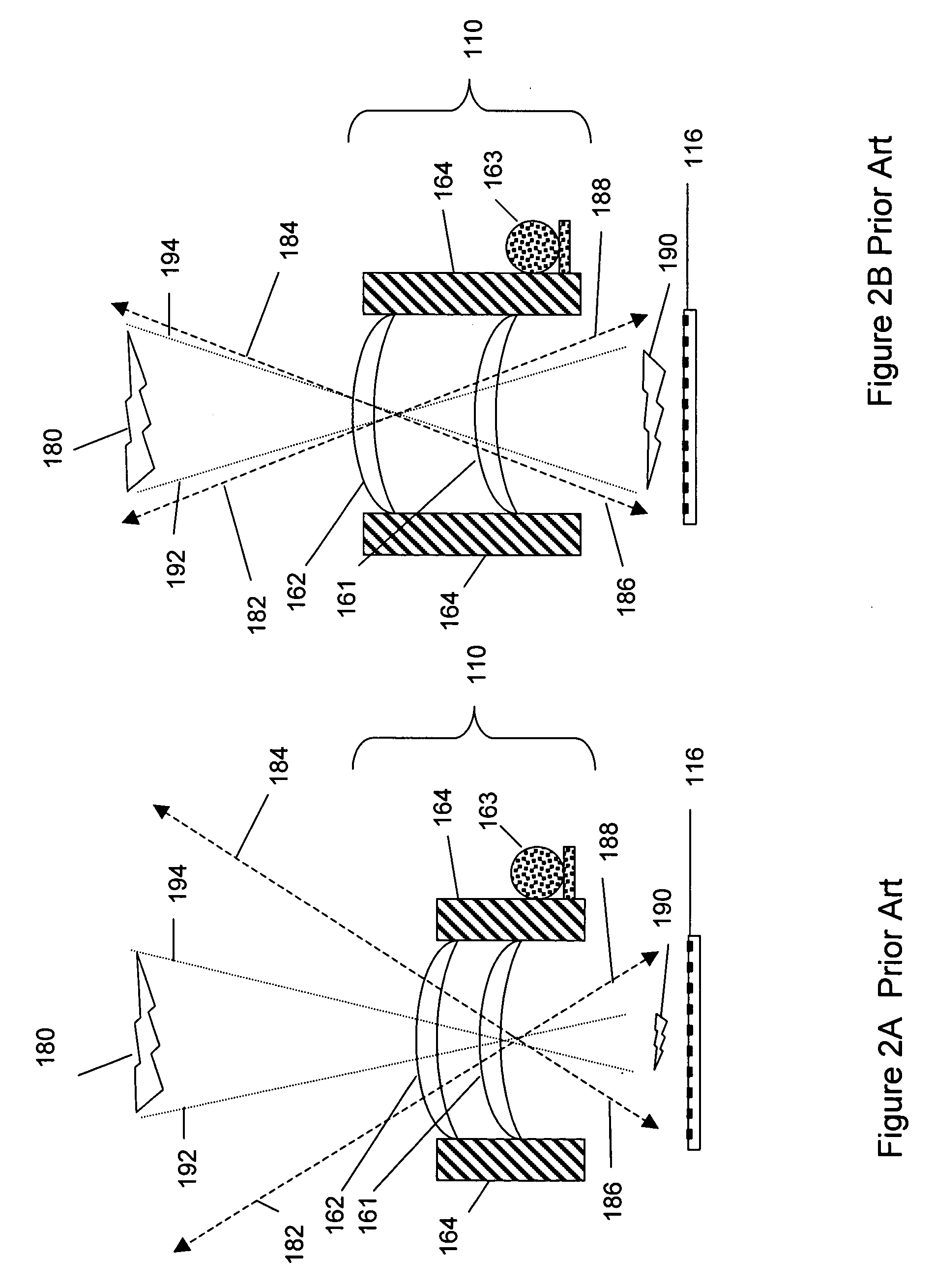

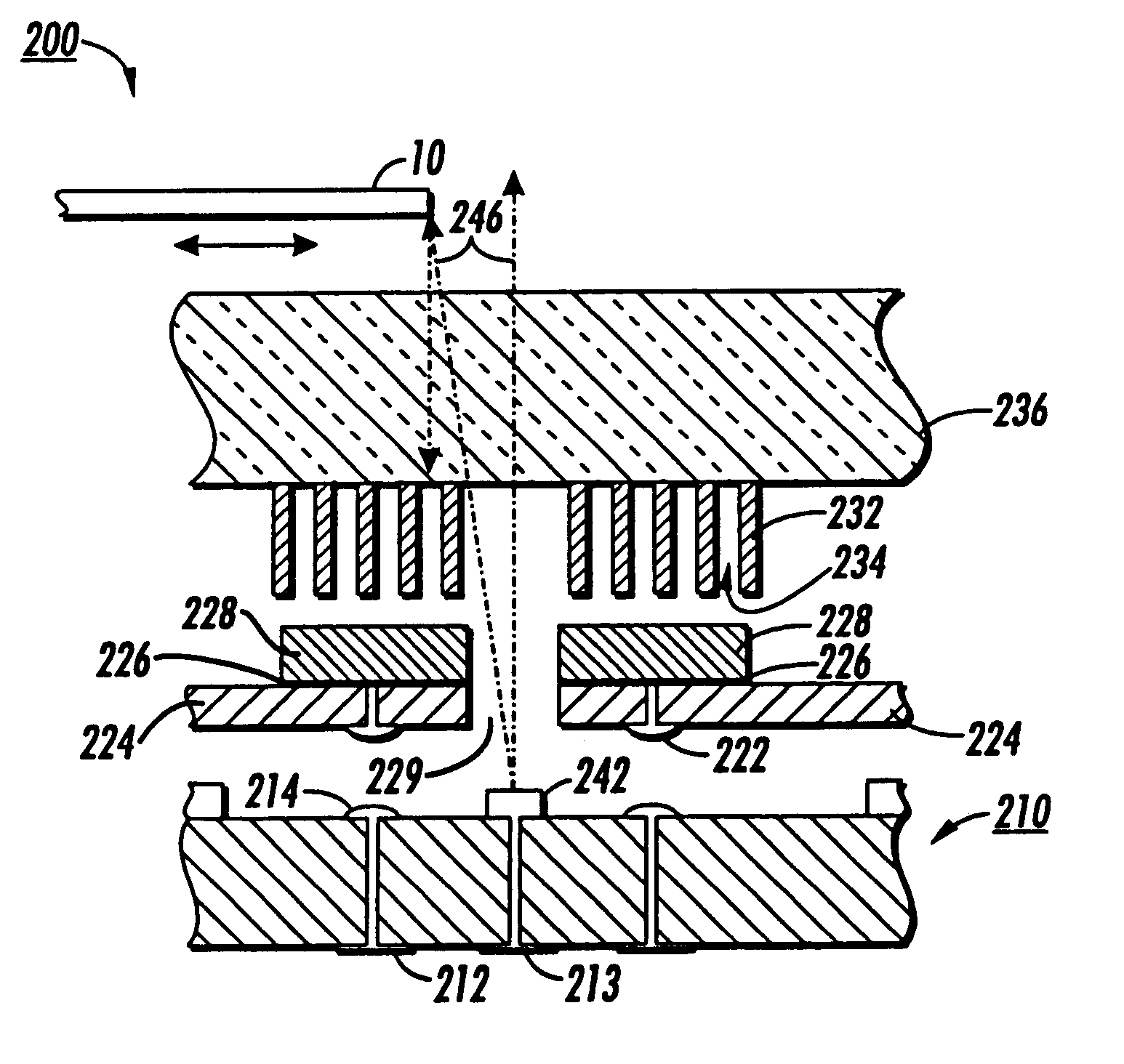

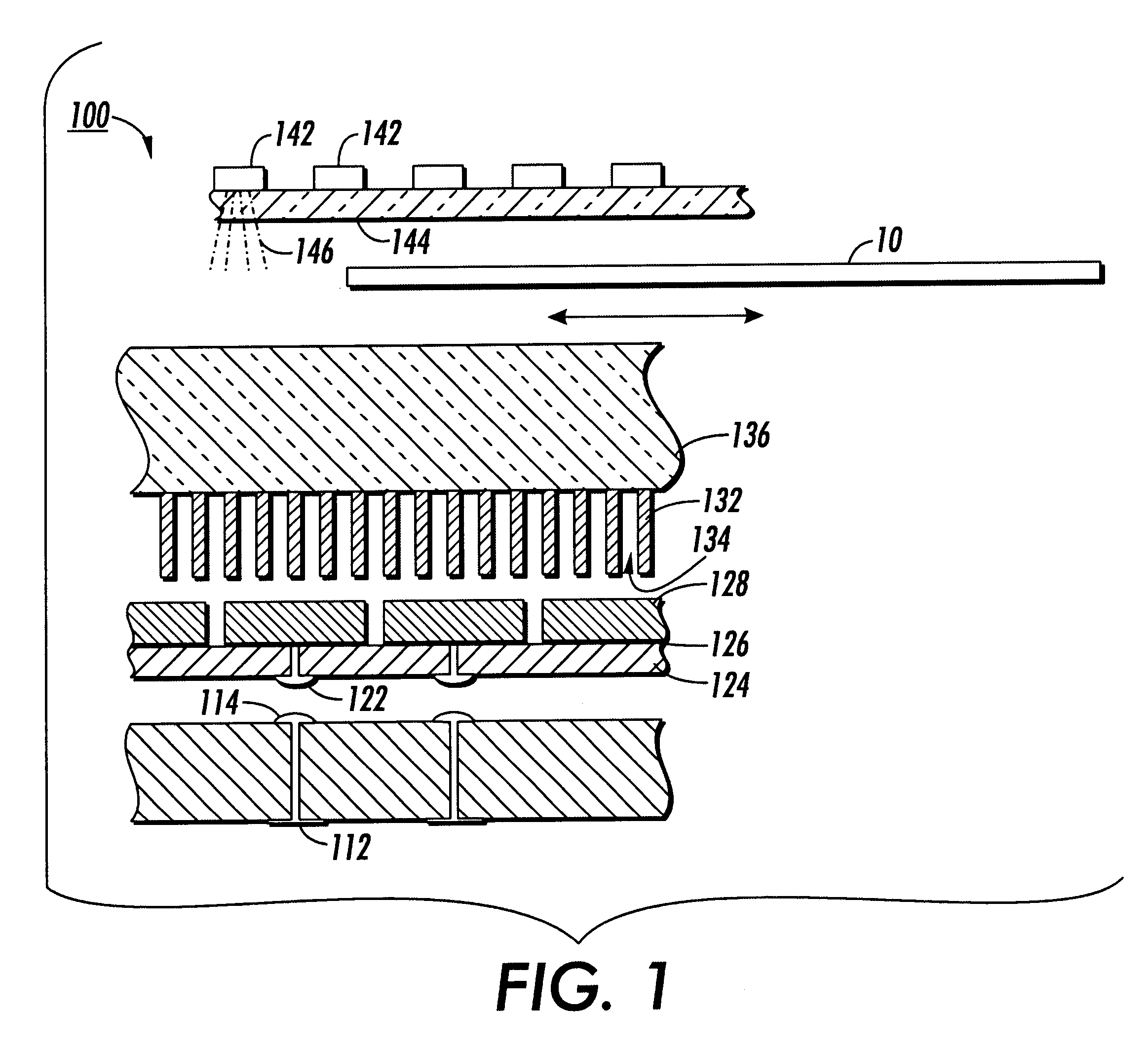

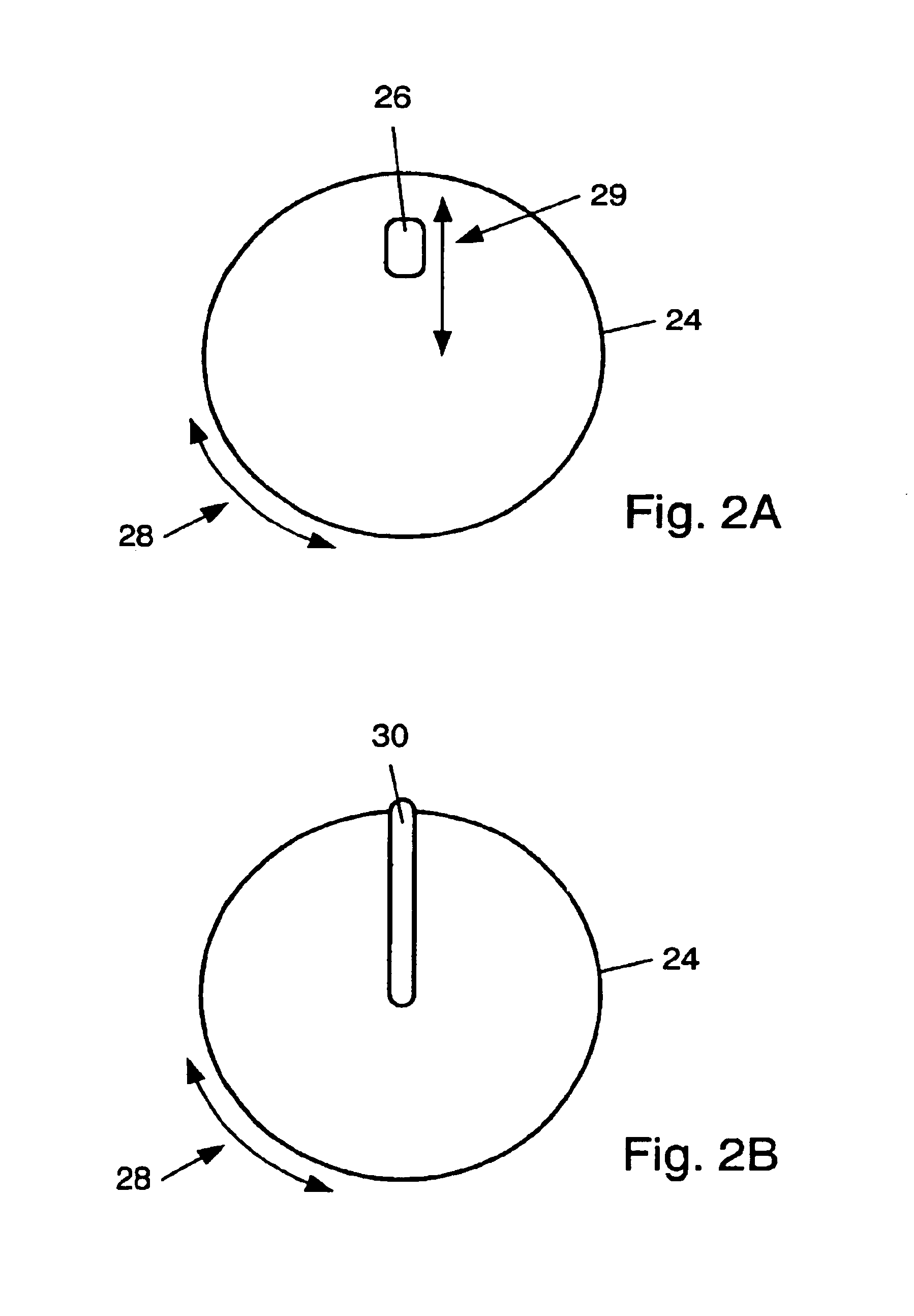

Method and apparatus for use in camera and systems employing same

ActiveUS20070002159A1High resolutionTelevision system detailsSolid-state devicesControl signalImage resolution

There are many inventions described herein. Some aspects are directed to methods and / or apparatus to provide relative movement between optics, or portion(s) thereof, and sensors, or portion(s) thereof, in a digital camera. The relative movement may be in any of various directions. In some aspects, relative movement between an optics portion, or portion(s) thereof, and a sensor portion, or portion(s) thereof, are used in providing any of various features and / or in the various applications disclosed herein, including, for example, but not limited to, increasing resolution, optical and electronic zoom, image stabilization, channel alignment, channel-channel alignment, image alignment, lens alignment, masking, image discrimination, range finding, 3D imaging, auto focus, mechanical shutter, mechanical iris, multi and hyperspectral imaging, and / or combinations thereof. In some aspects, movement is provided by actuators, for example, but not limited to MEMS actuators, and by applying appropriate control signal thereto.

Owner:INTELLECTUAL VENTURES II

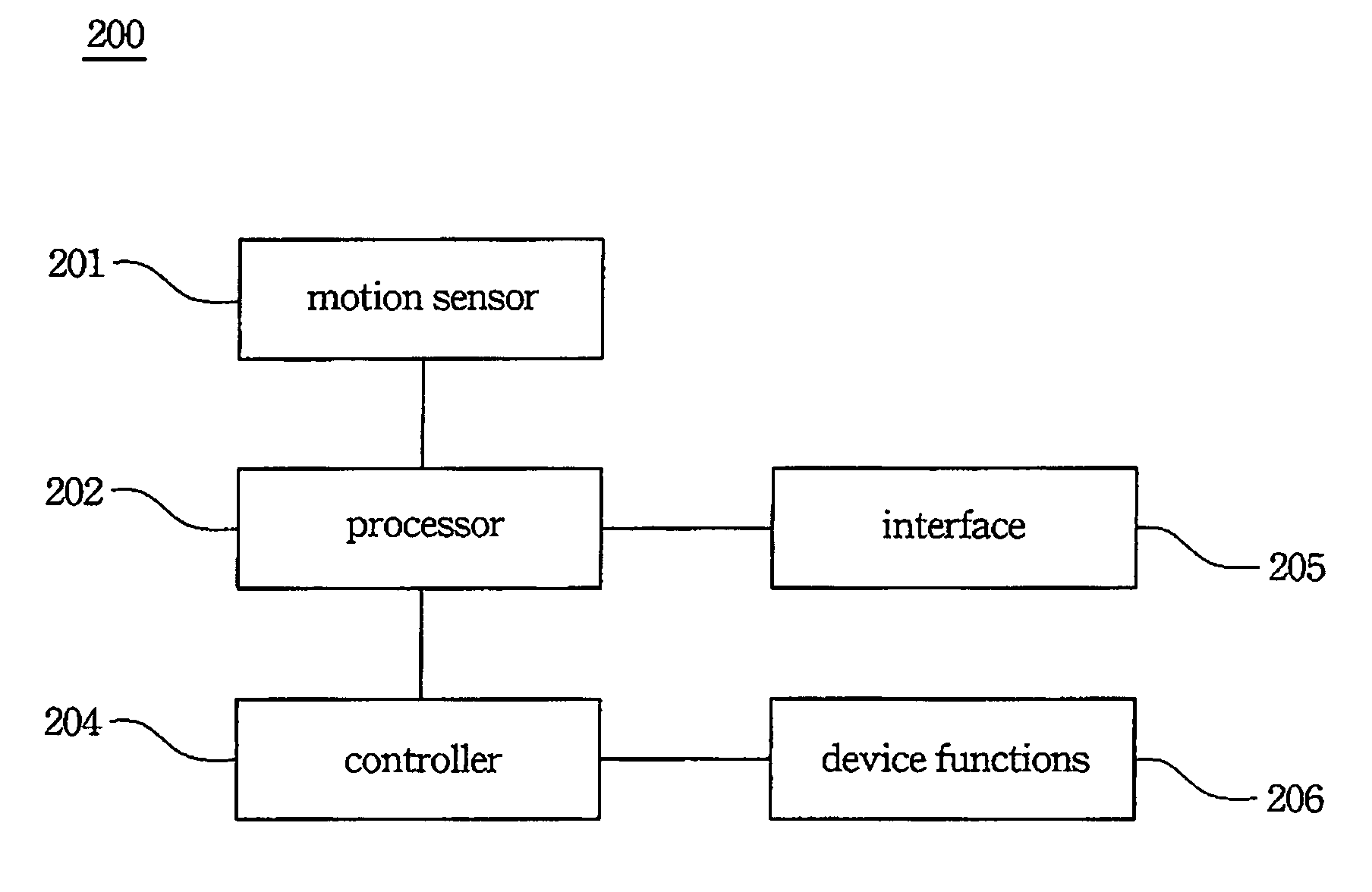

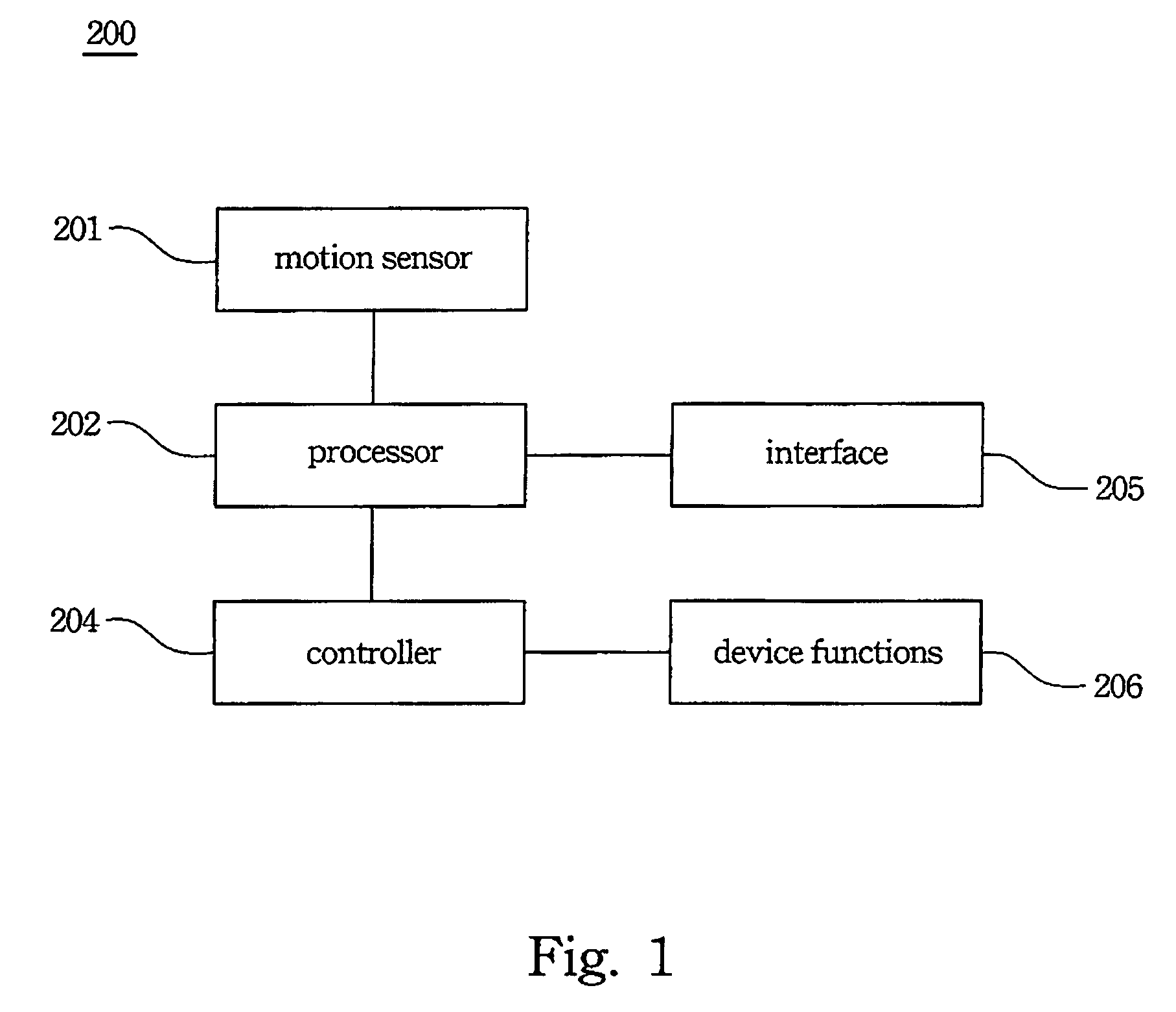

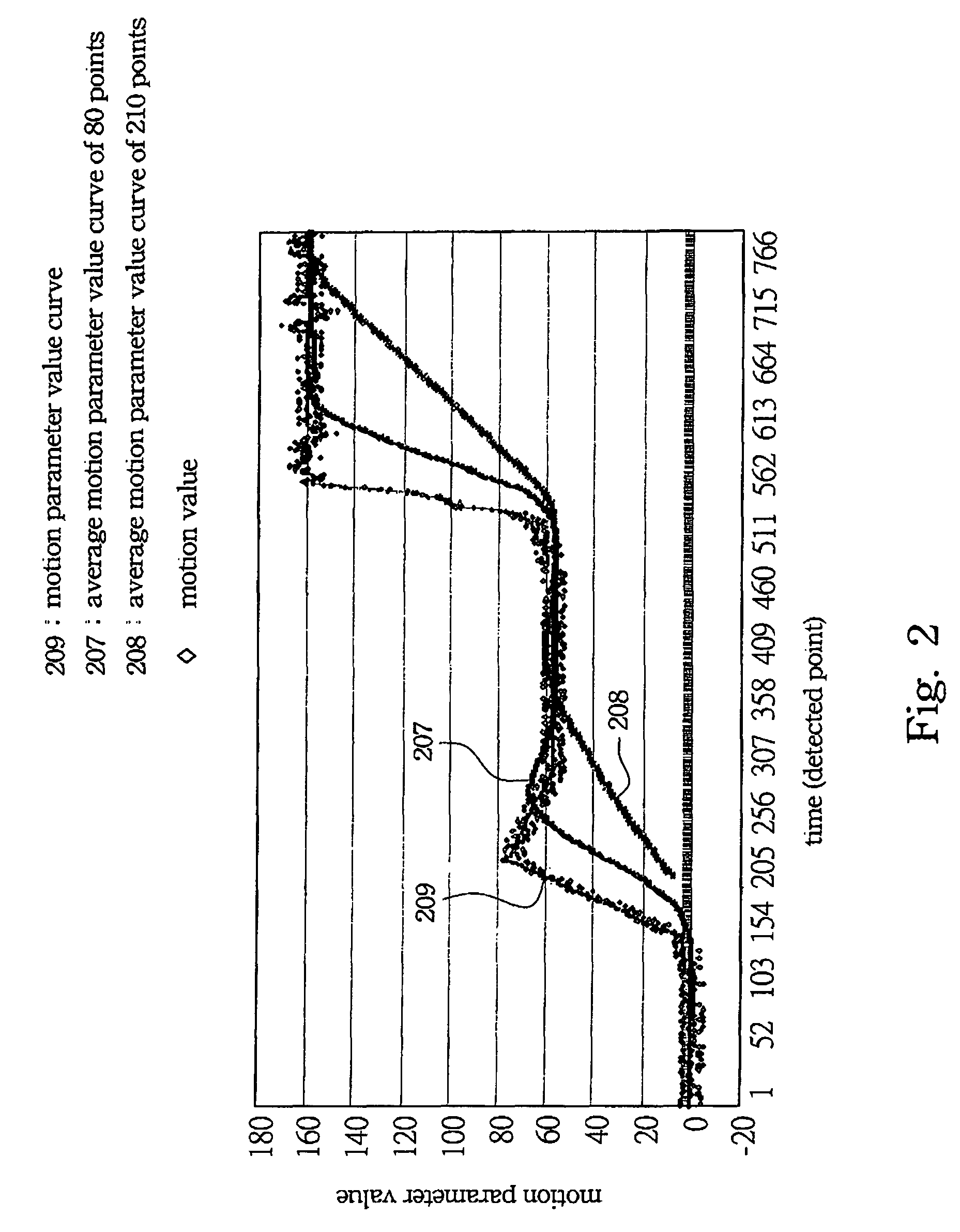

Motion determination apparatus and method thereof

ActiveUS7763842B2Avoid triggerComputer controlInvestigating moving sheetsMotion parameterComputer science

The motion determination apparatus includes a motion sensor for sensing motion of an electronic device and sending out a motion parameter. A processor receives the motion parameter to determine whether or not his motion is a meaningful motion. A device controller activates a device function according to the determination.

Owner:HTC CORP

Two dimensional object position sensor

InactiveUS6476376B1Inexpensive to fabricateReduce the amount requiredInvestigating moving sheetsCounting objects on conveyorsSensor arrayLight energy

Apparatus and method for sensing the position, size, shape and location orientation of one or more objects in two dimensions. The position sensor uses arrays of light sensors mounted on a substrate. When an object passes in proximity to the light sensors light energy from a plurality of light sources is either reflected from the object to the light sensors, or is emitted directly to the light sensors. The light energy is then converted to individual signals and transmitted through circuit traces in a printed circuit board to a local controller. The information may then be processed to determine the size, position, shape and location orientation of an object.

Owner:XEROX CORP

Multi-plane optical apparatus

InactiveUS20060221448A1Guaranteed normal transmissionEfficient disseminationInvestigating moving sheetsCathode-ray tube indicatorsLength waveLight spectrum

Owner:MIRAGE INNOVATIONS

Method and system to segment depth images and to detect shapes in three-dimensionally acquired data

ActiveUS20060239558A1Rapidly correctly characterizeQuick identificationImage enhancementImage analysisSystems analysisHistogram

A method and system analyzes data acquired by image systems to more rapidly identify objects of interest in the data. In one embodiment, z-depth data are segmented such that neighboring image pixels having similar z-depths are given a common label. Blobs, or groups of pixels with a same label, may be defined to correspond to different objects. Blobs preferably are modeled as primitives to more rapidly identify objects in the acquired image. In some embodiments, a modified connected component analysis is carried out where image pixels are pre-grouped into regions of different depth values preferably using a depth value histogram. The histogram is divided into regions and image cluster centers are determined. A depth group value image containing blobs is obtained, with each pixel being assigned to one of the depth groups.

Owner:MICROSOFT TECH LICENSING LLC

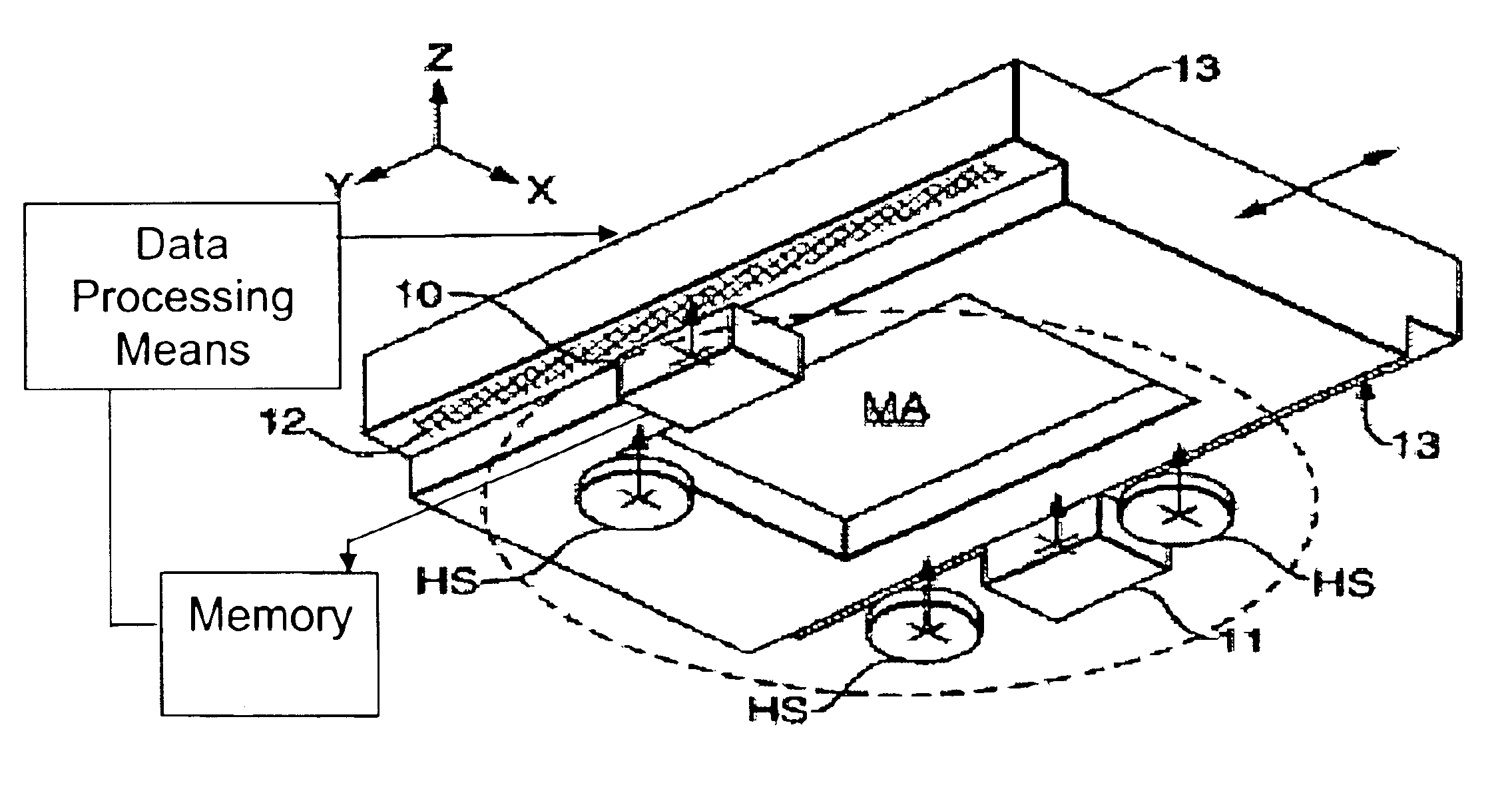

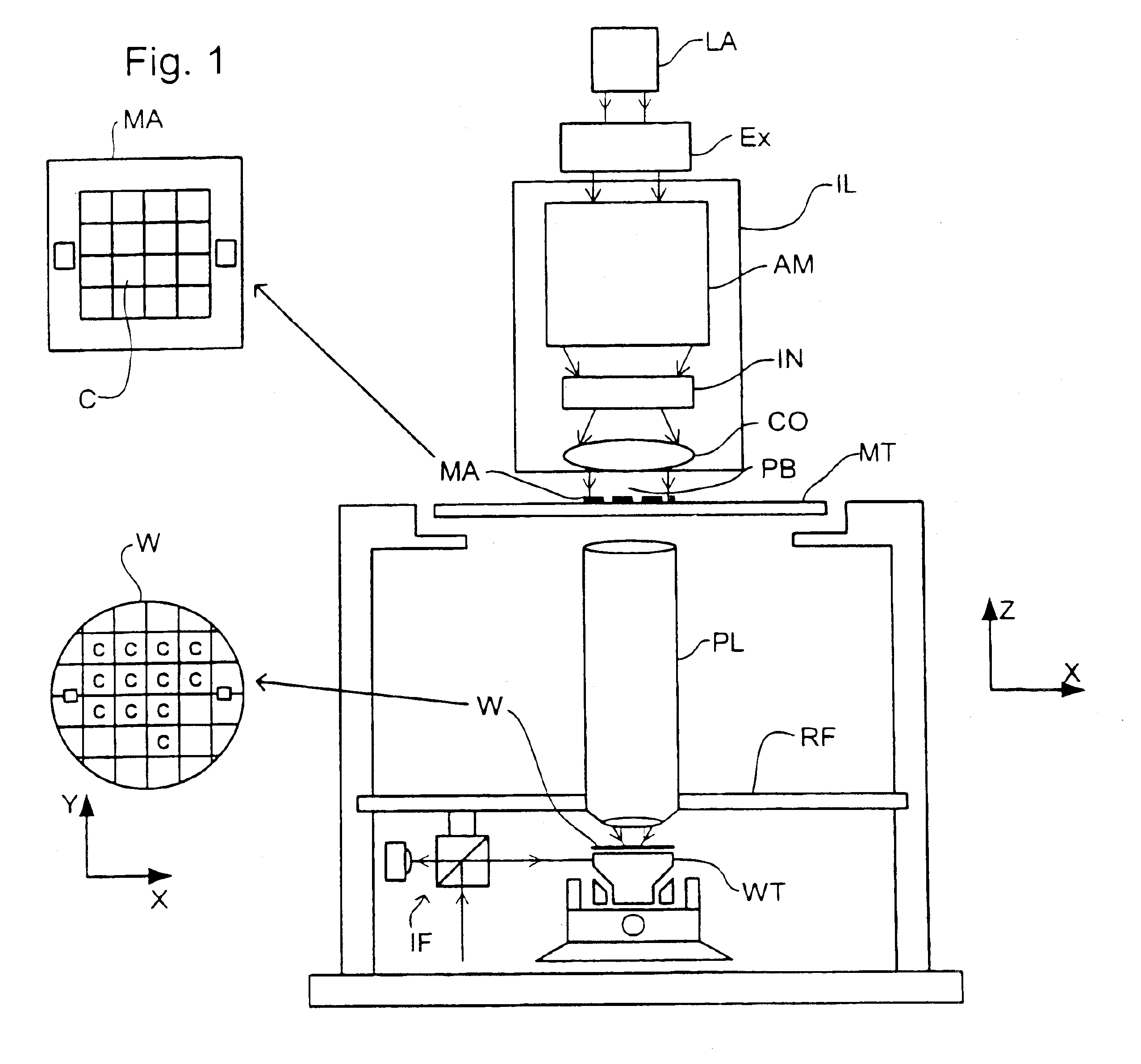

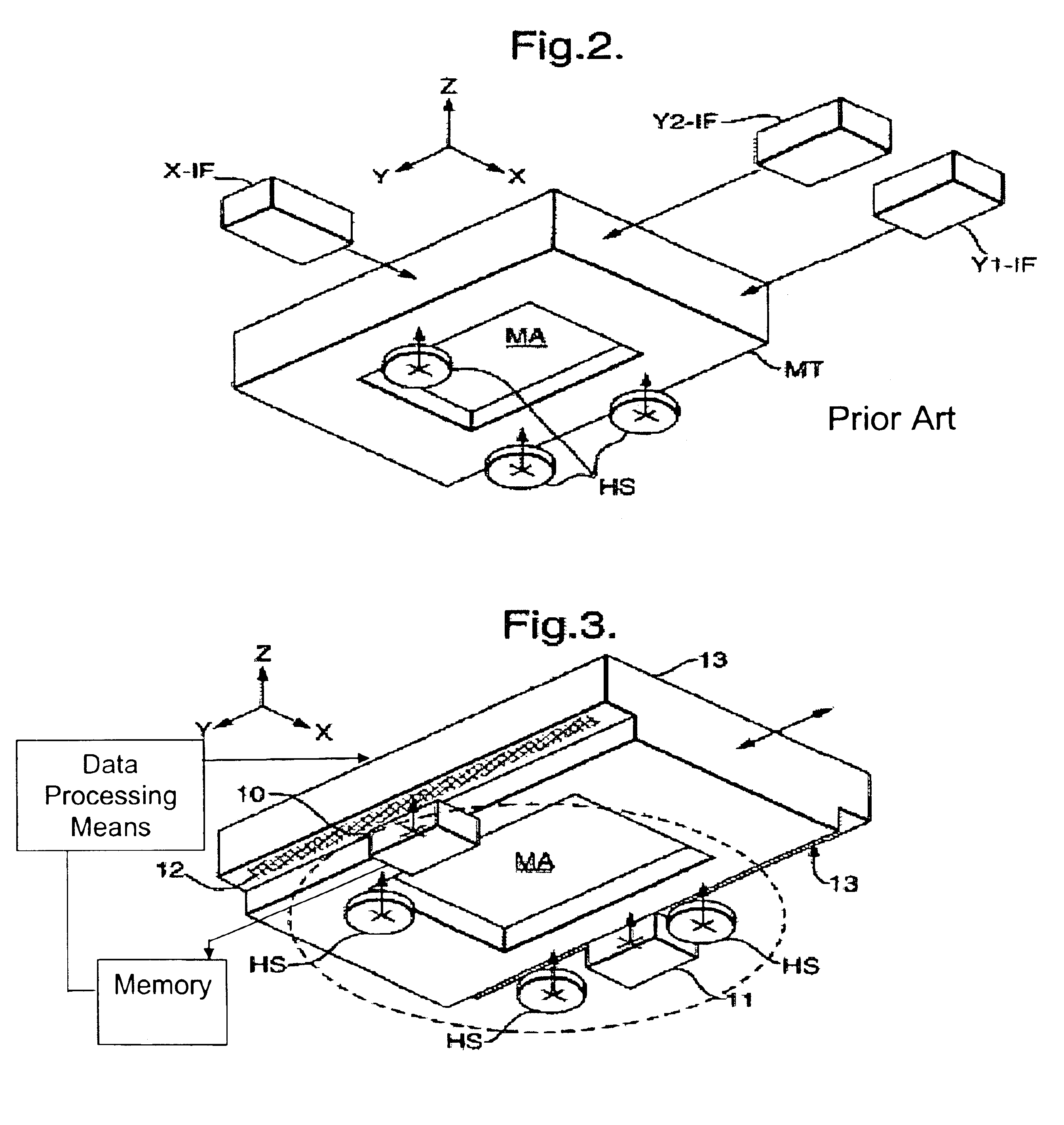

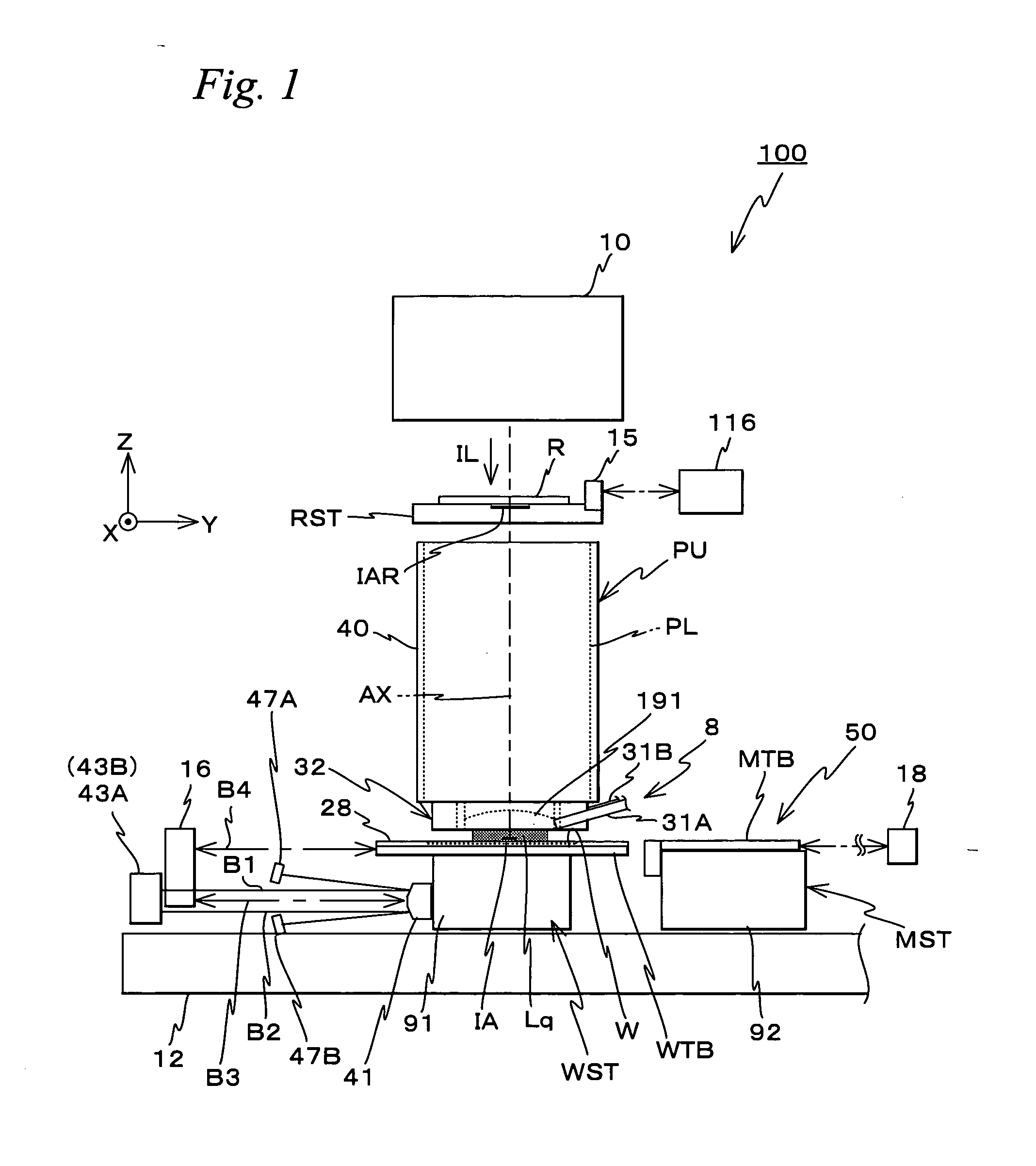

Lithographic apparatus, device manufacturing method, and device manufactured thereby

InactiveUS6819425B2Improve stabilityReduce impactInvestigating moving sheetsSemiconductor/solid-state device manufacturingCapacitanceGrating

The X, Y and Rx positions of a mask stage are measured using two optical encoder-reading heads measuring displacements of respective grid gratings mounted on the mask stage. The grid gratings are preferably provided on cut-away portions of the mask table so as to be co-planar with the pattern on the mask itself. Measurements of the table position in the other degrees of freedom can be measured with capacitative or optical height sensors.

Owner:ASML NETHERLANDS BV

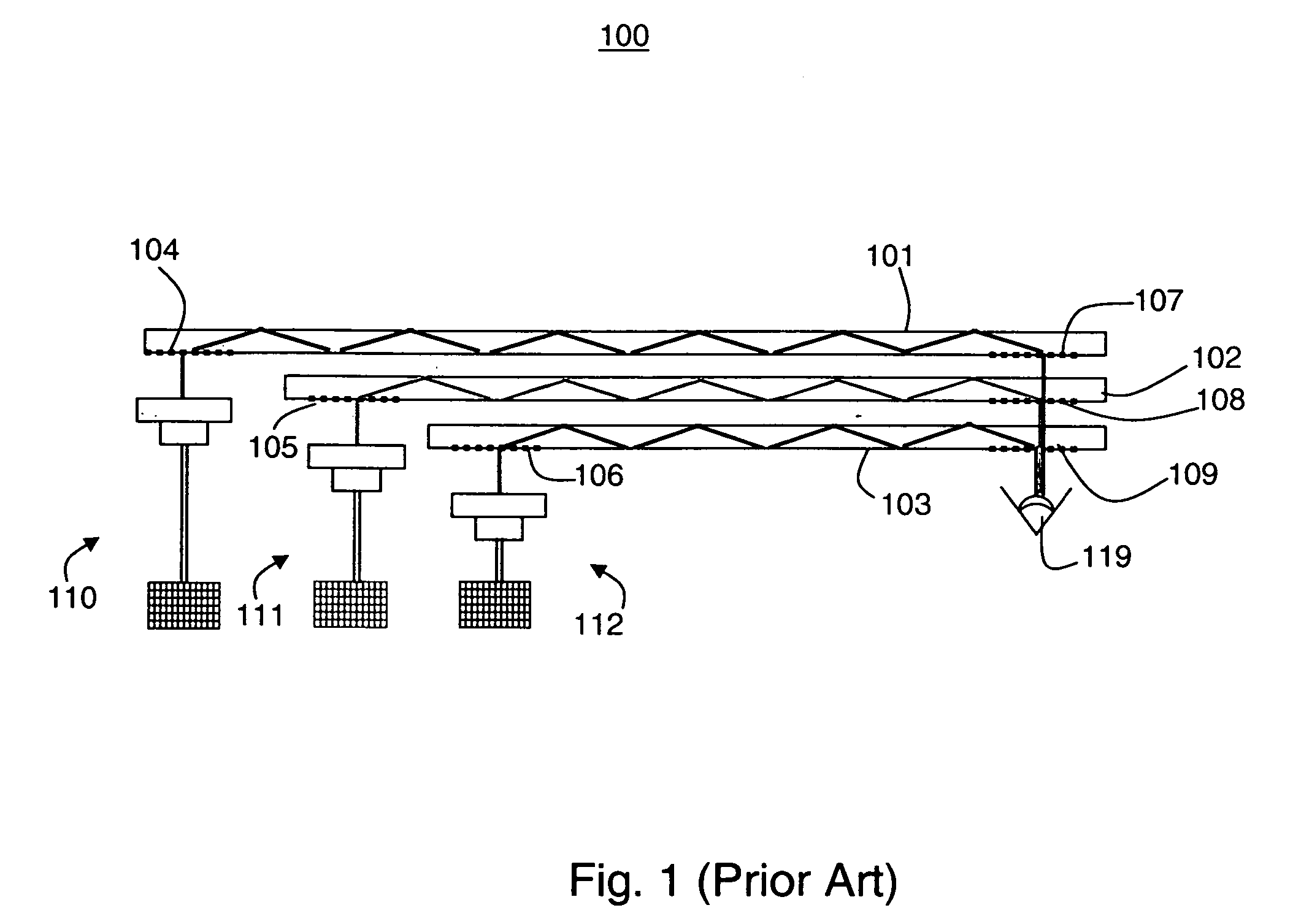

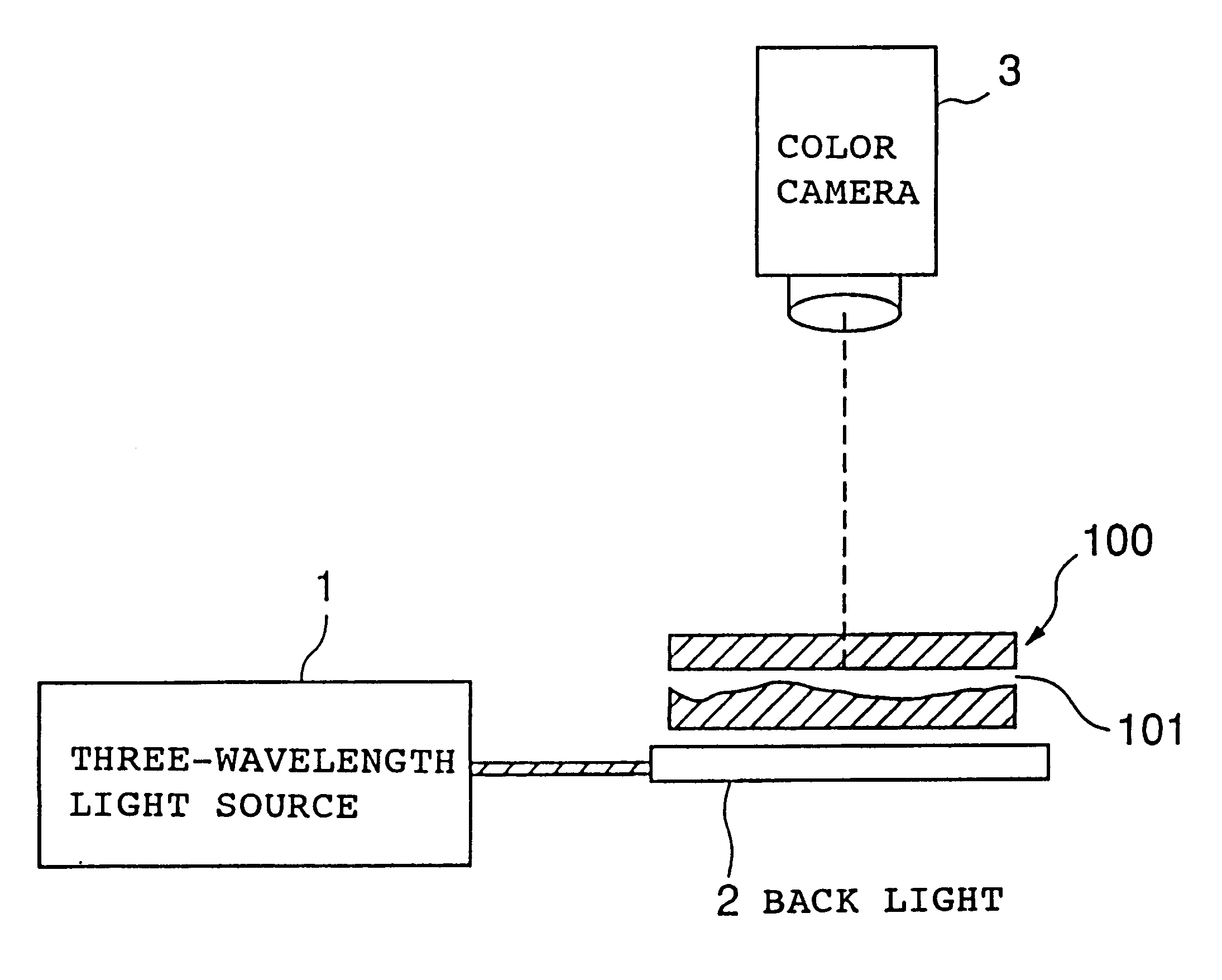

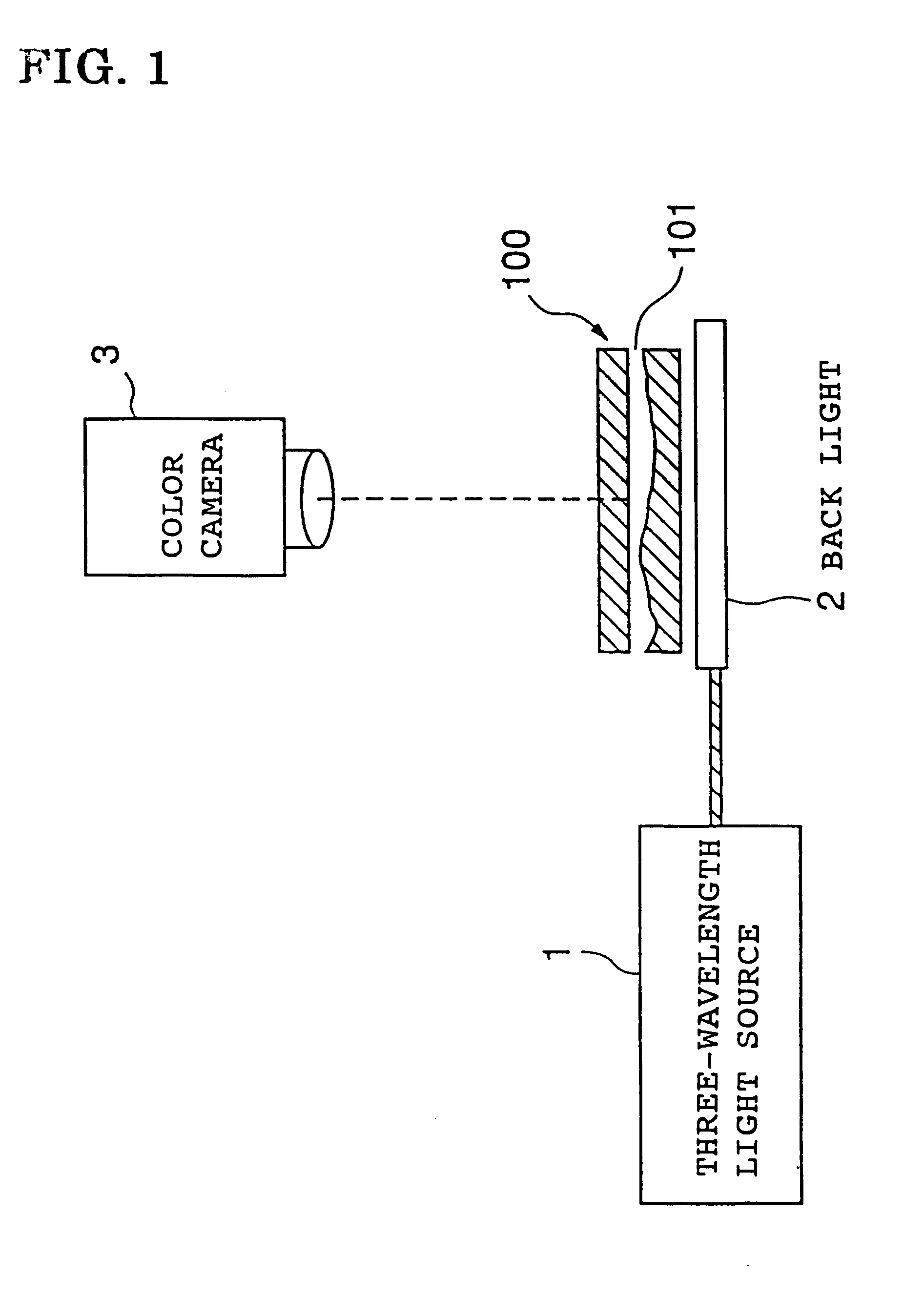

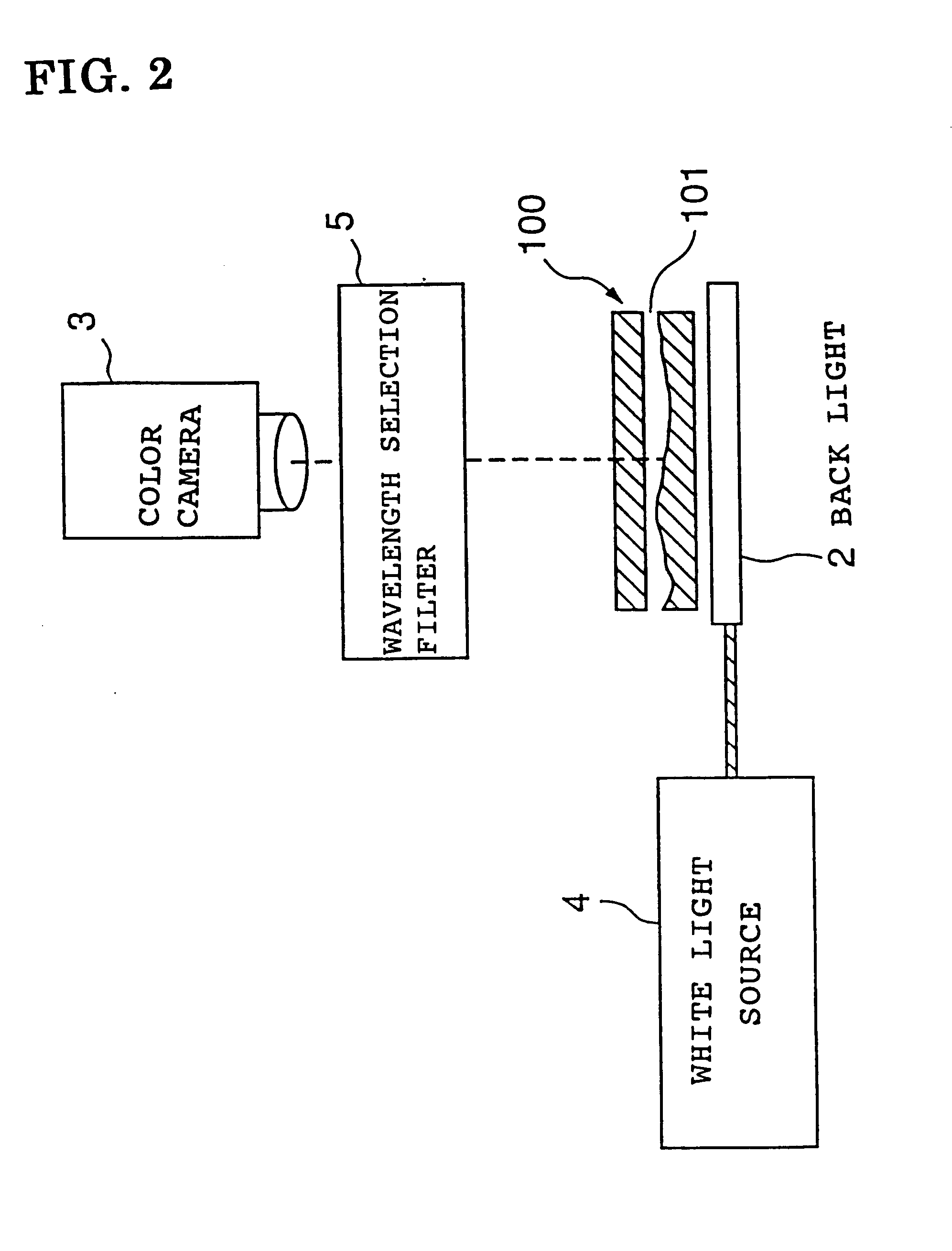

Method and apparatus for measuring gap, method and apparatus for measuring shape and method for manufacturing liquid crystal device

Owner:138 EAST LCD ADVANCEMENTS LTD

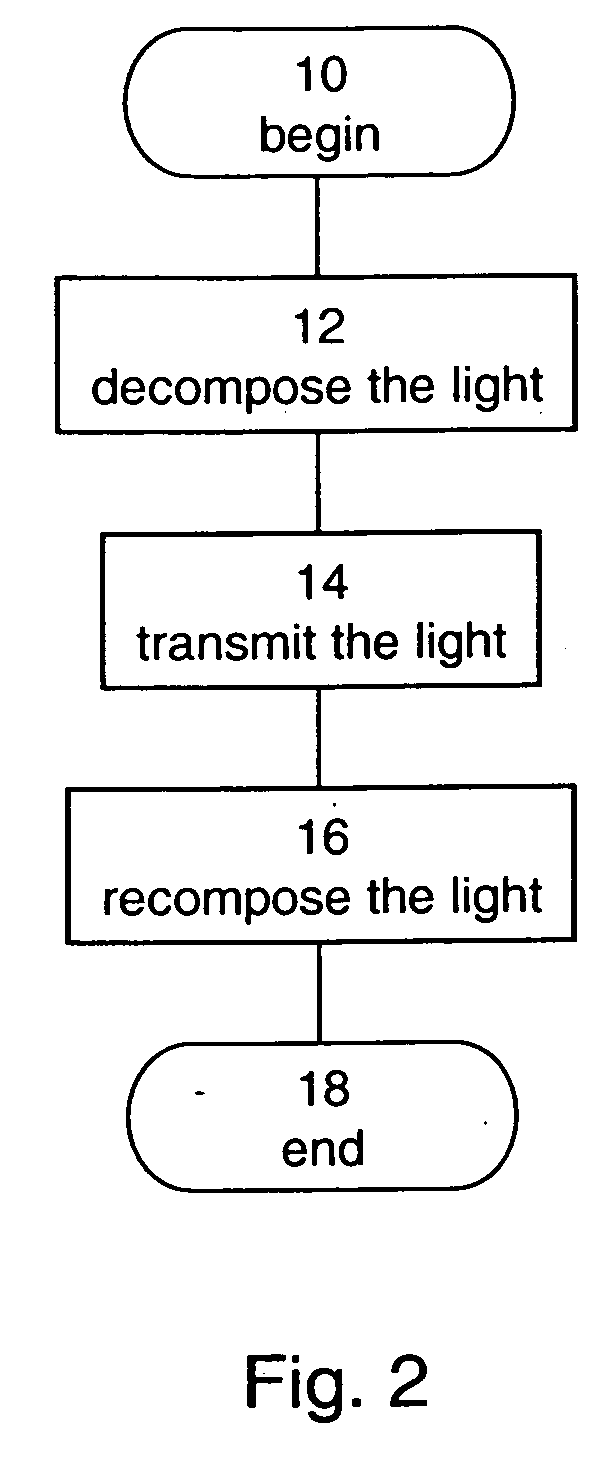

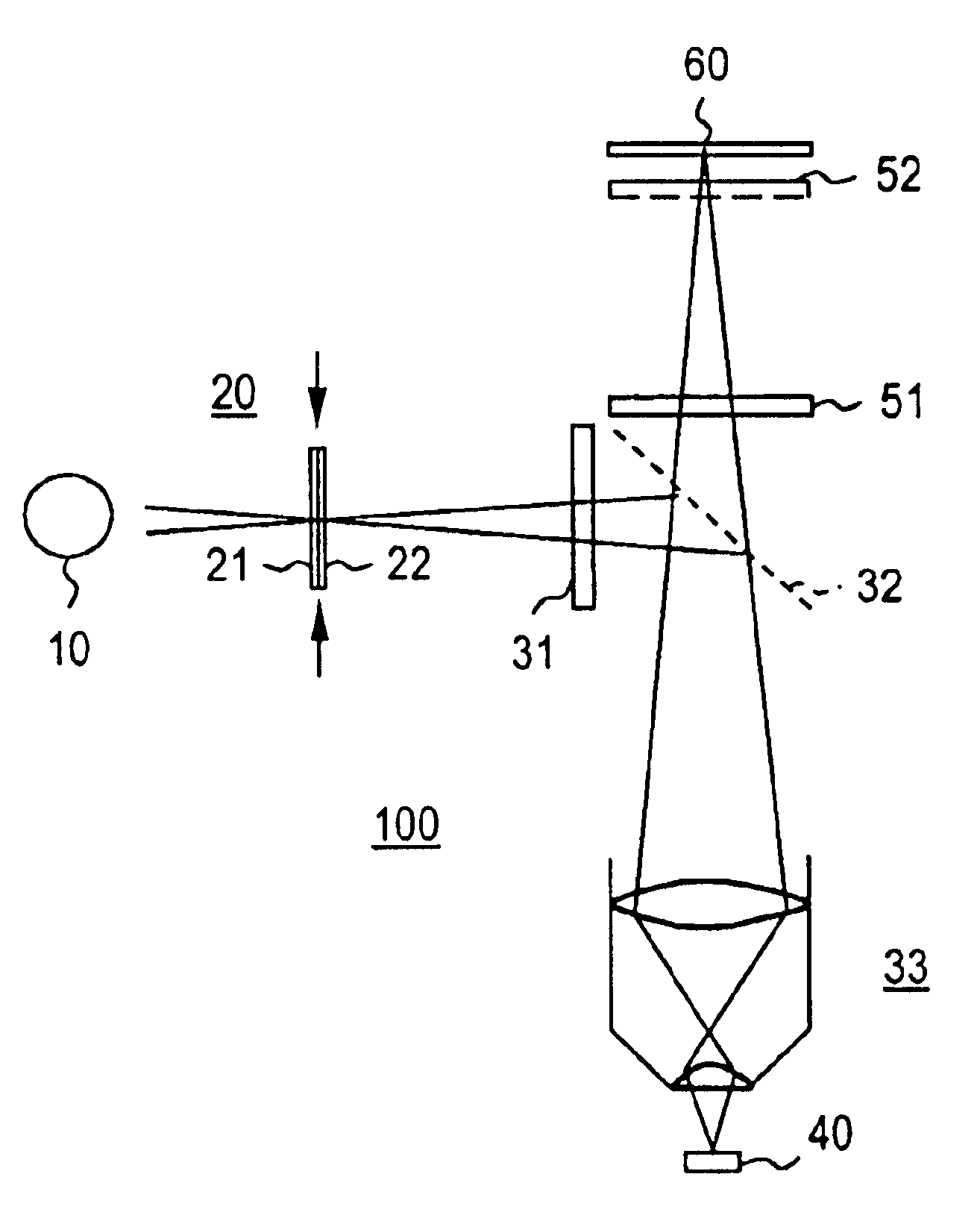

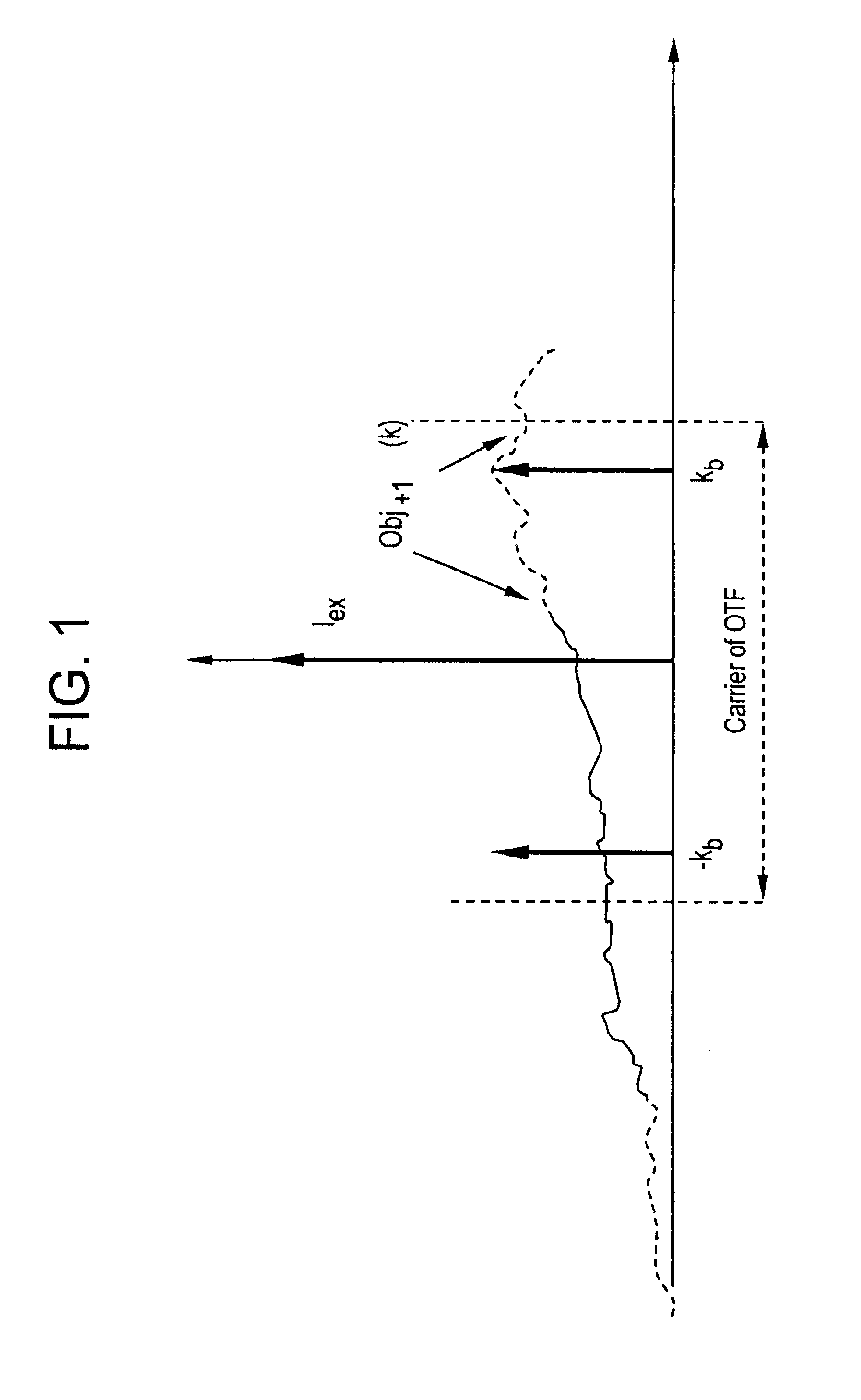

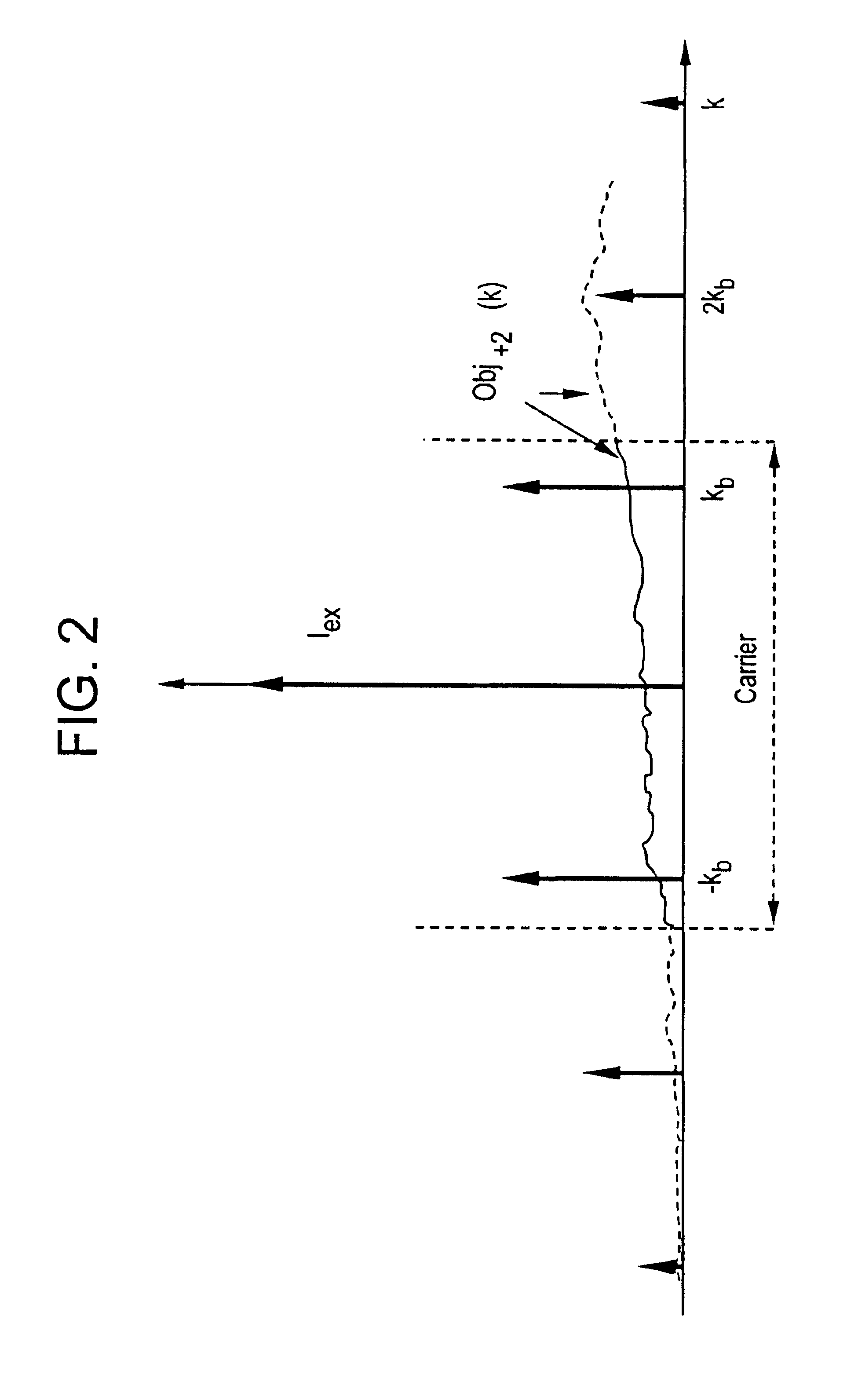

Method and device for representing an object

InactiveUS6909105B1Increased frequency rangeEasy to getImage analysisInvestigating moving sheetsPattern recognitionObject structure

A process for obtaining an object image of at least one object (40) is described, wherein at least two partial images of the object (40) are taken under differing object conditions which are formed on the object with spatial patterns, wherein a non-linear dependence of the light detectable from the object point on the object conditions given at the object point exists and the partial images contain different contributions of various space frequency components of the object structure, and the desired object image is determined from the partial images by reconstruction of the space frequency components. Optical systems for implementing this type of process are also described.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

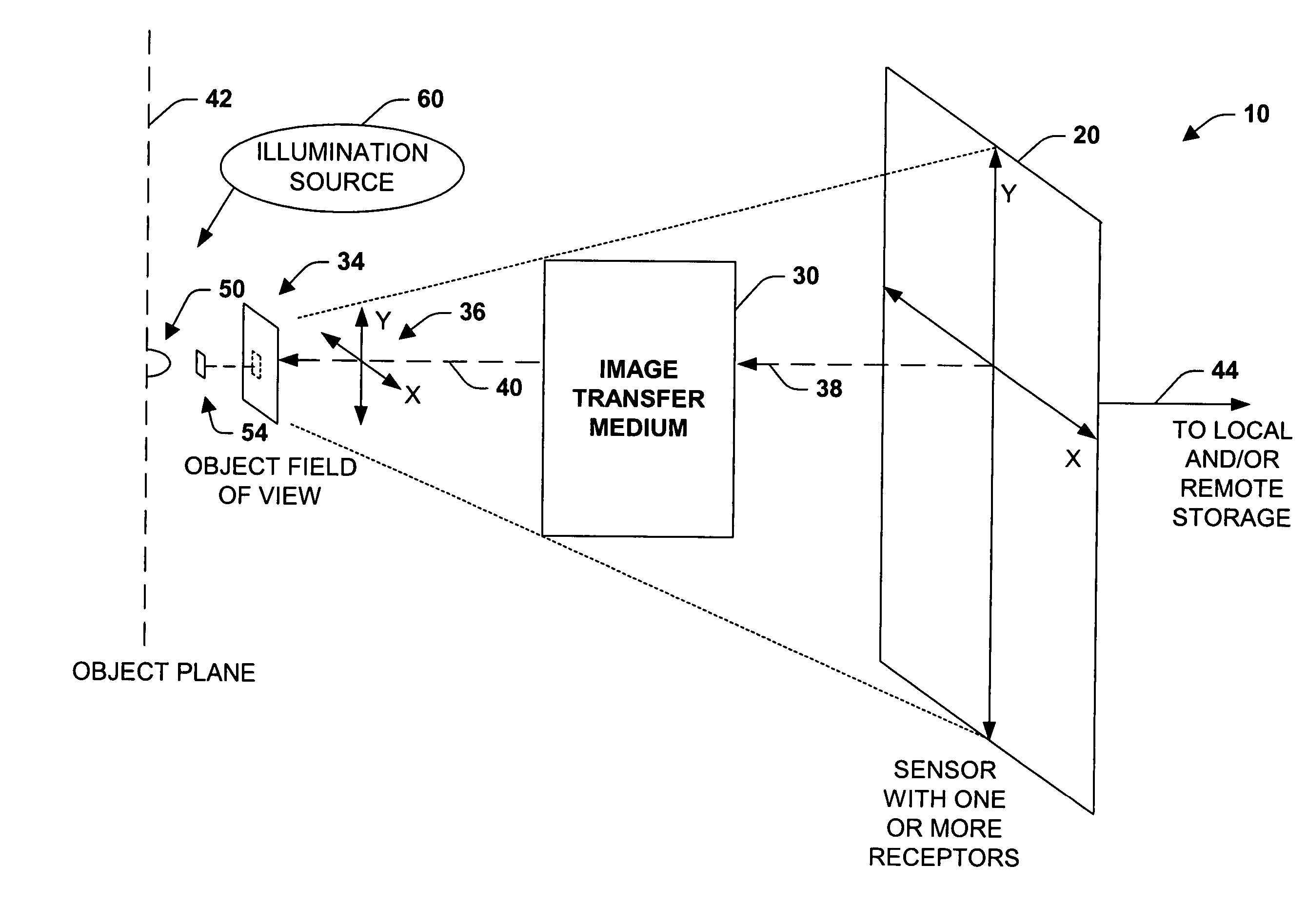

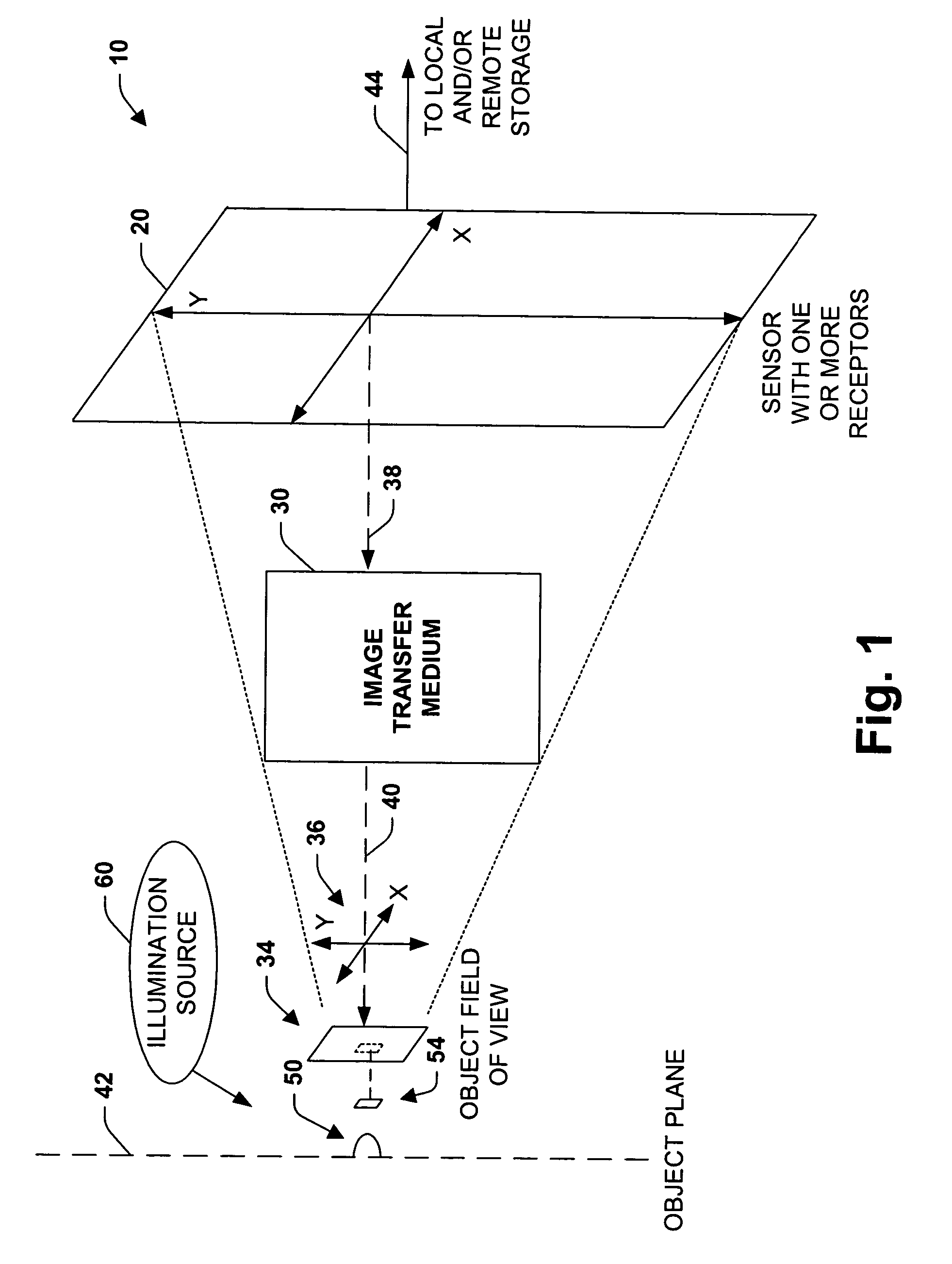

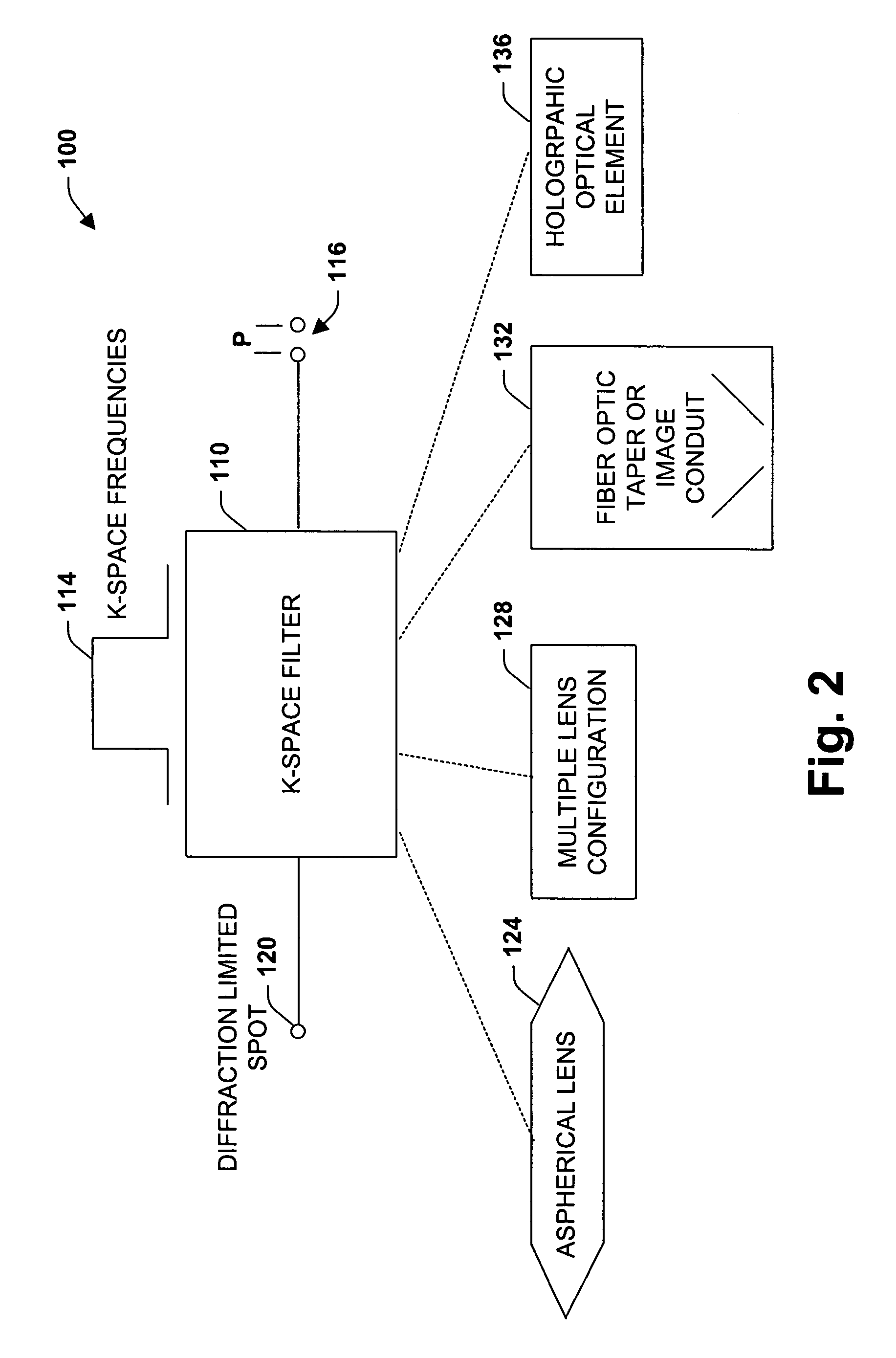

Imaging system and methodology

InactiveUS7151246B2Improve performanceEffectively scaledTelevision system detailsGeometric image transformationImage transferDisplay device

An imaging system, methodology, and various applications are provided to facilitate optical imaging performance. The system contains a sensor having one or more receptors and an image transfer medium to scale the sensor and receptors in accordance with resolvable characteristics of the medium, and as defined with certain ratios. A computer, memory, and / or display associated with the sensor provides storage and / or display of information relating to output from the receptors to produce and / or process an image, wherein a plurality of illumination sources can also be utilized in conjunction with the image transfer medium. The image transfer medium can be configured as a k-space filter that correlates projected receptor size to a diffraction-limited spot associated with the image transfer medium, wherein the projected receptor size can be unit-mapped within a certain ratio to the size of the diffraction-limited spot, both in the object plane.

Owner:HIMANSHU S AMIN +3

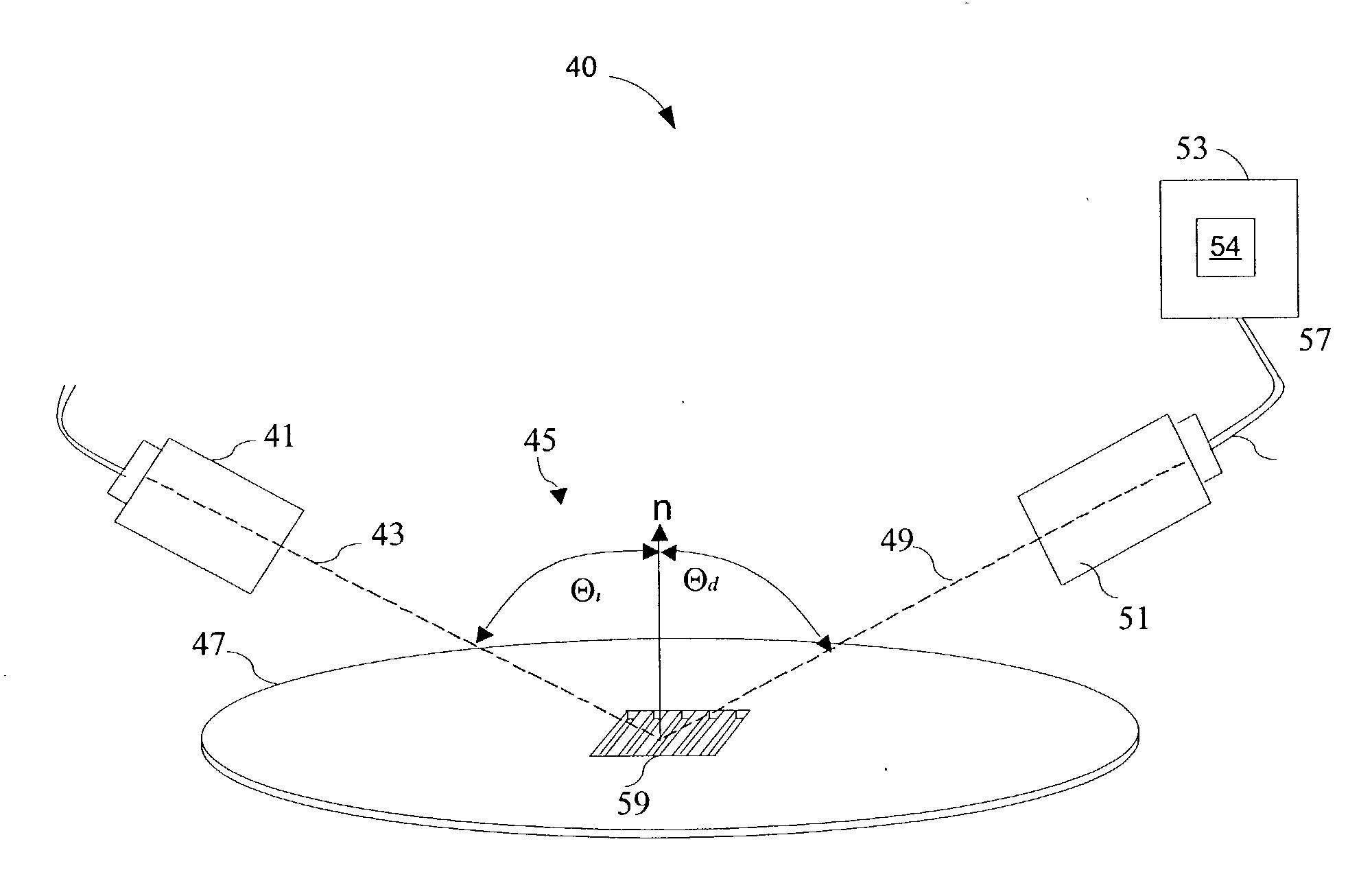

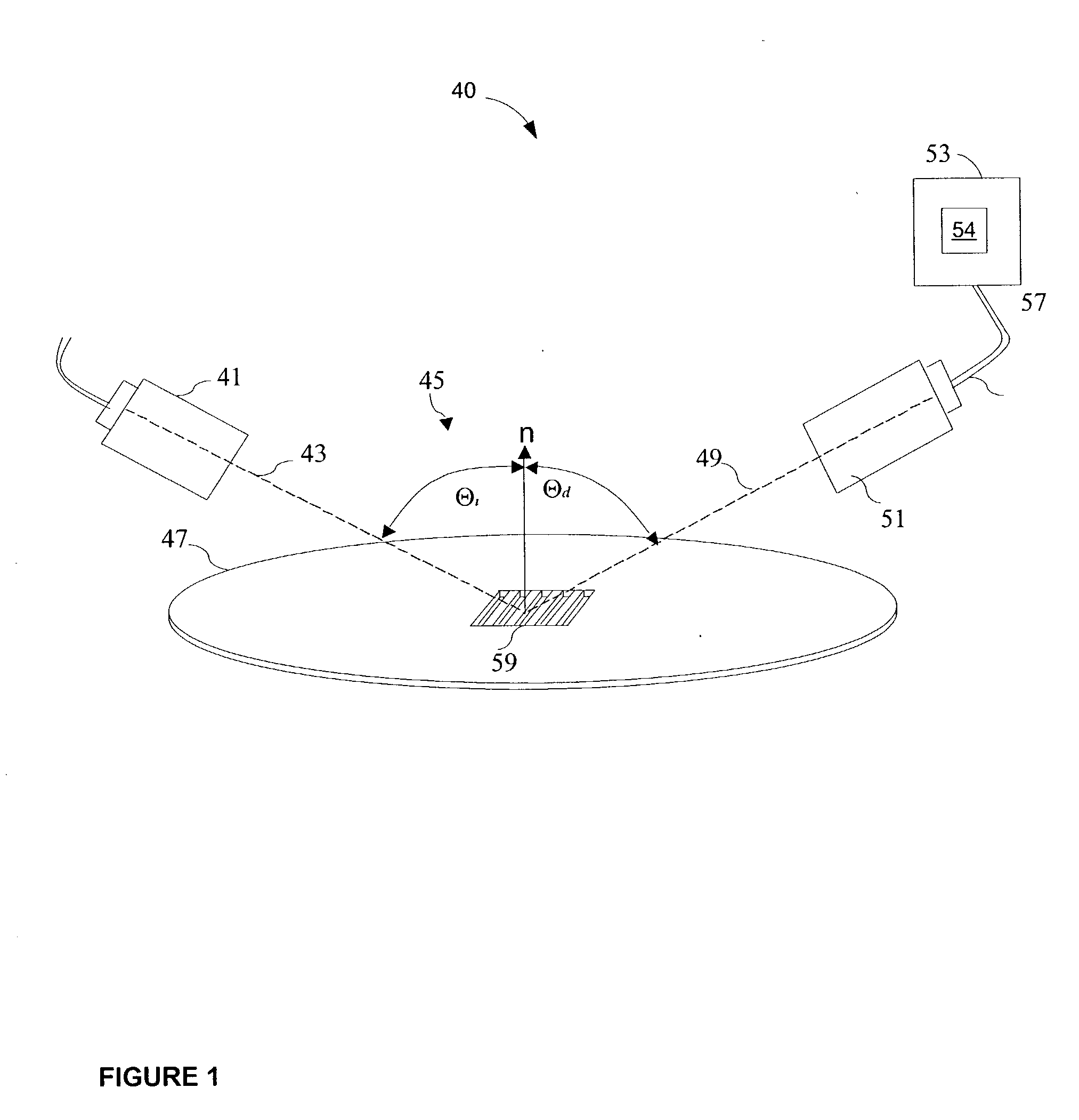

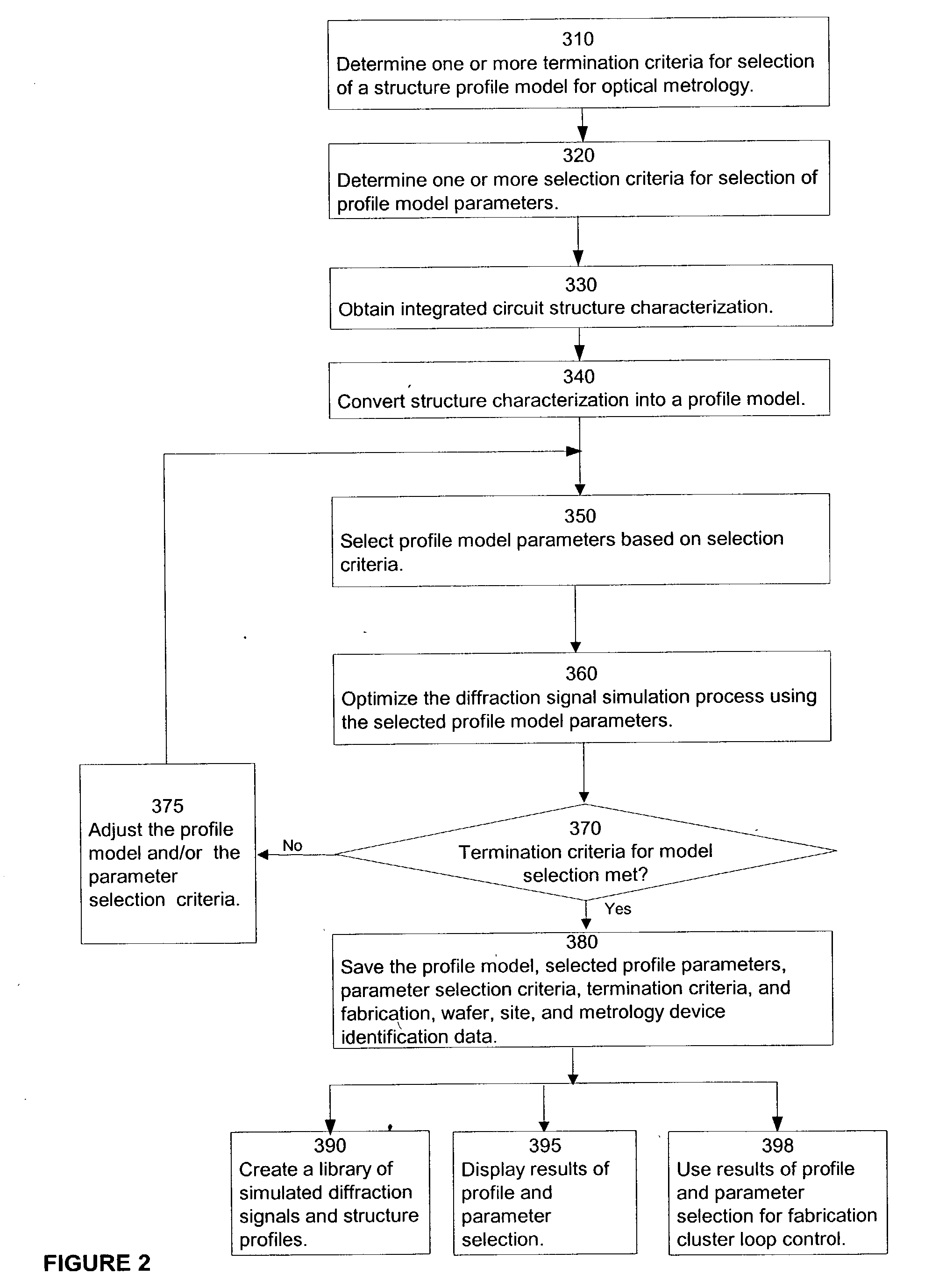

Model and parameter selection for optical metrology

ActiveUS20040017574A1Semiconductor/solid-state device testing/measurementPhase-affecting property measurementsEngineeringSelection criterion

A profile model for use in optical metrology of structures in a wafer is selected, the profile model having a set of geometric parameters associated with the dimensions of the structure. A set of optimization parameters is selected for the profile model using one or more input diffraction signals and one or more parameter selection criteria. The selected profile model and the set of optimization parameters are tested against one or more termination criteria. The process of selecting a profile model, selecting a set of optimization parameters, and testing the selected profile model and set of optimization parameters is performed until the one or more termination criteria are met.

Owner:TOKYO ELECTRON US HOLDINGS INC

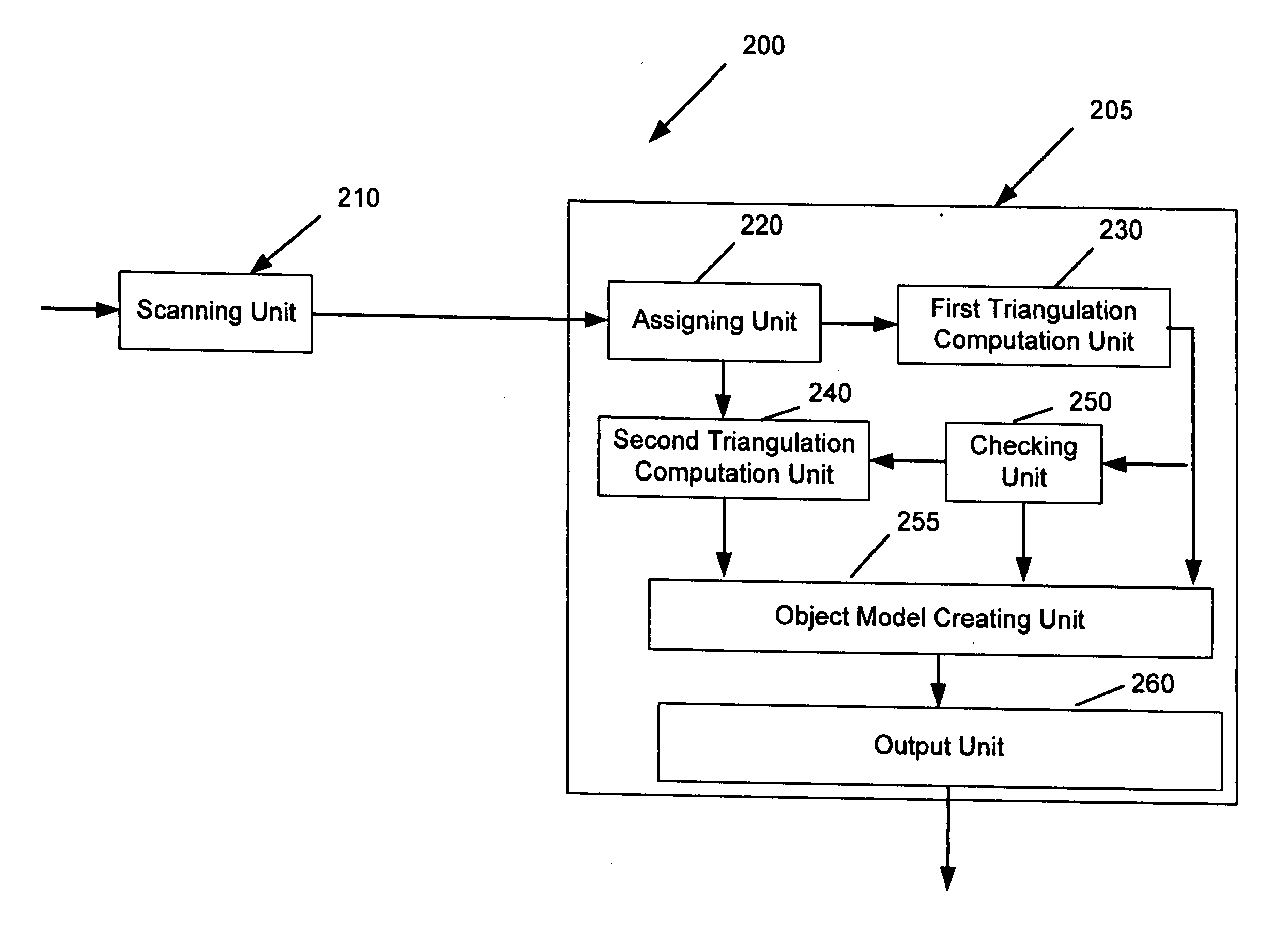

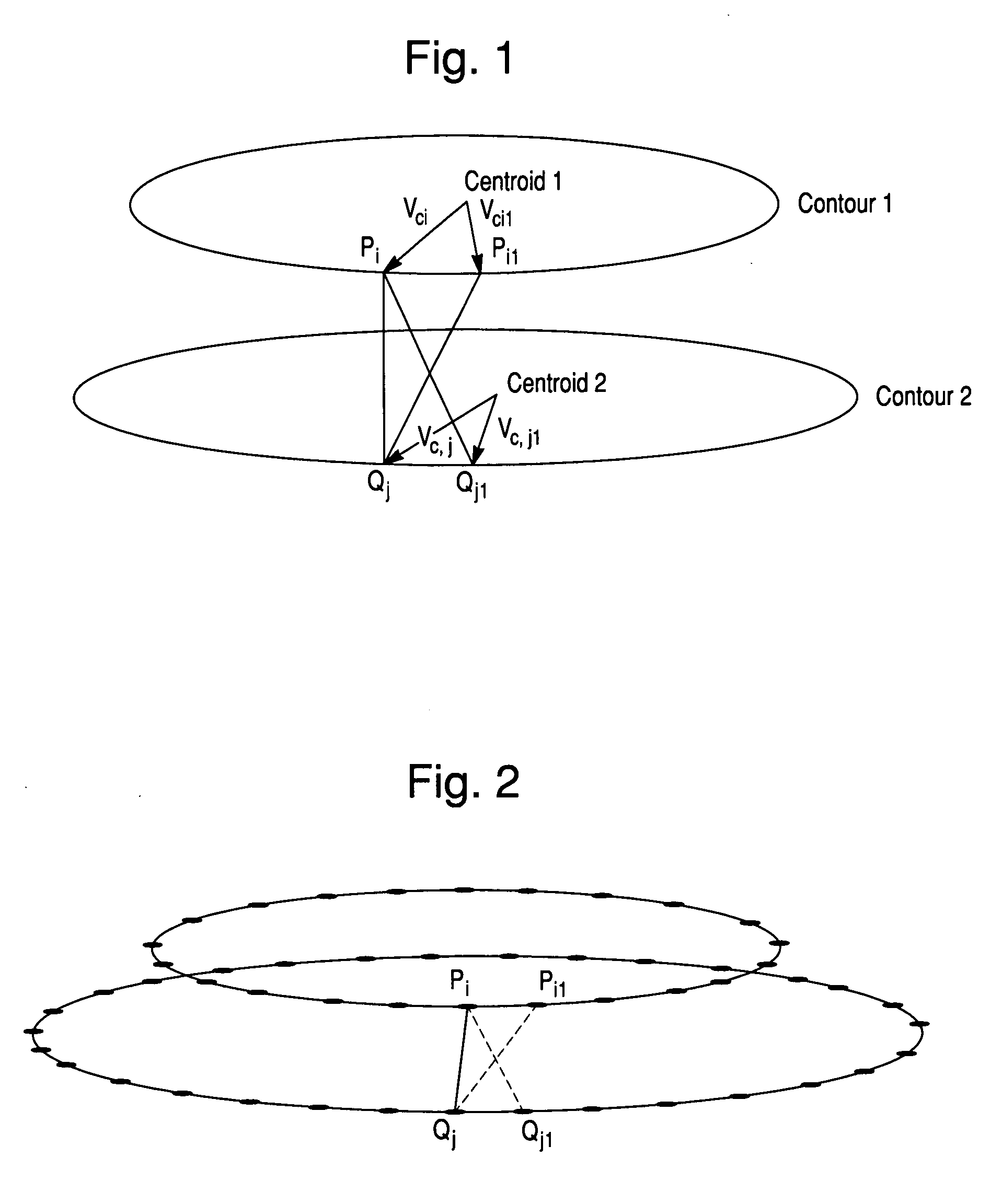

Contour triangulation system and method

ActiveUS20070253617A1Investigating moving sheetsCharacter and pattern recognitionTriangulationComputer vision

A method and apparatus for reconstructing a surface shape of an object having contour lines, includes assigning points to each contour line. A first triangulation scheme is performed with respect to respective points on two adjacently-positioned contour lines, to determine a first surface shape for a portion of the object corresponding to the two contour lines. The first surface shape is checked to determine if the first surface shape is in error. If the first surface shape is not in error, the first surface shape is outputted for the portion of the object as determined by the first triangulation scheme, as a reconstructed surface shape for that portion of the object. If the first surface shape is in error, a second triangulation scheme is performed with respect to the respective points on the two contour lines, to determine a second surface shape for that portion of the object, and the second surface shape is outputted for that portion of the object as determined by the second triangulation scheme, as a reconstructed surface shape.

Owner:MAKO SURGICAL CORP

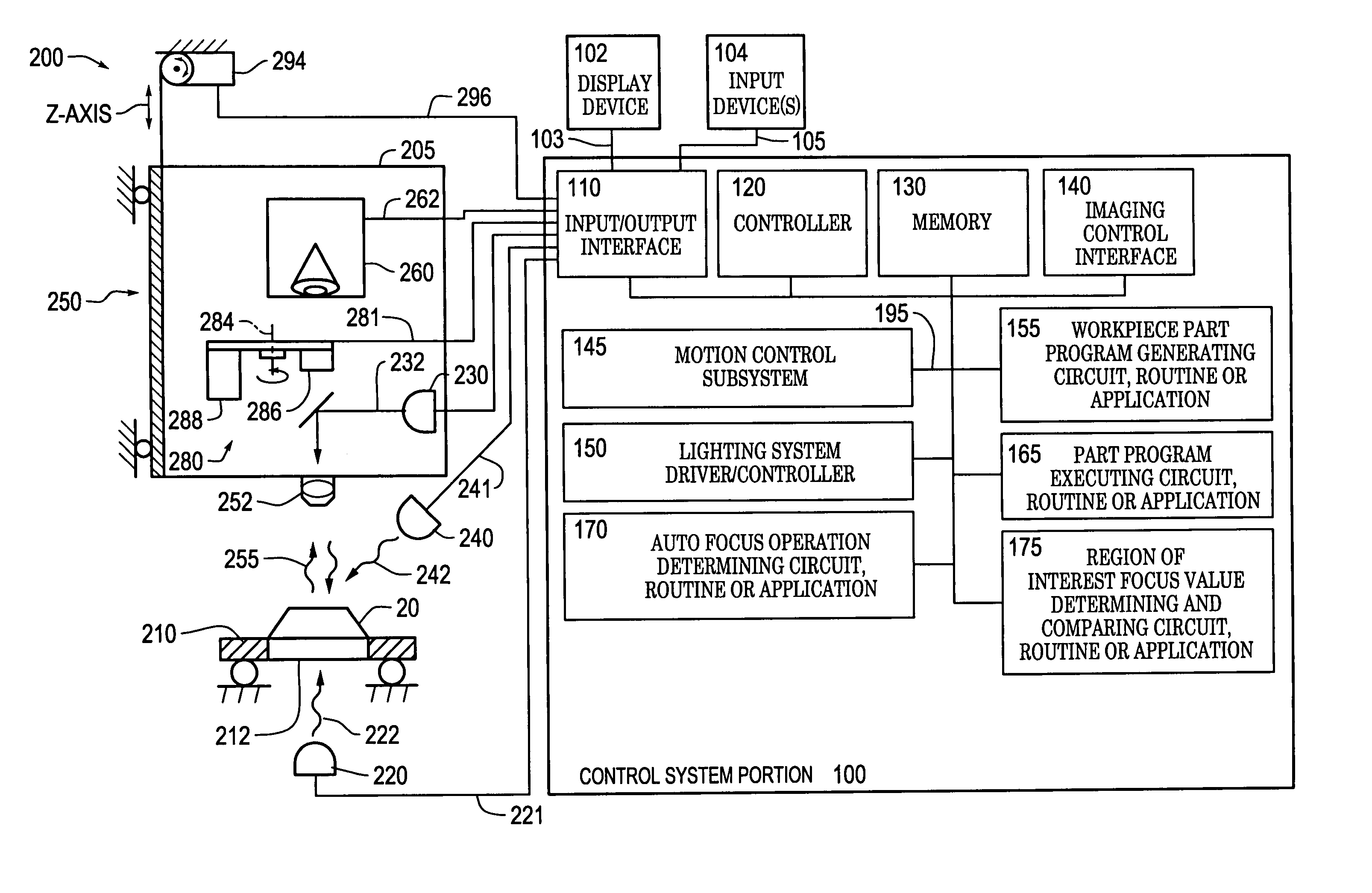

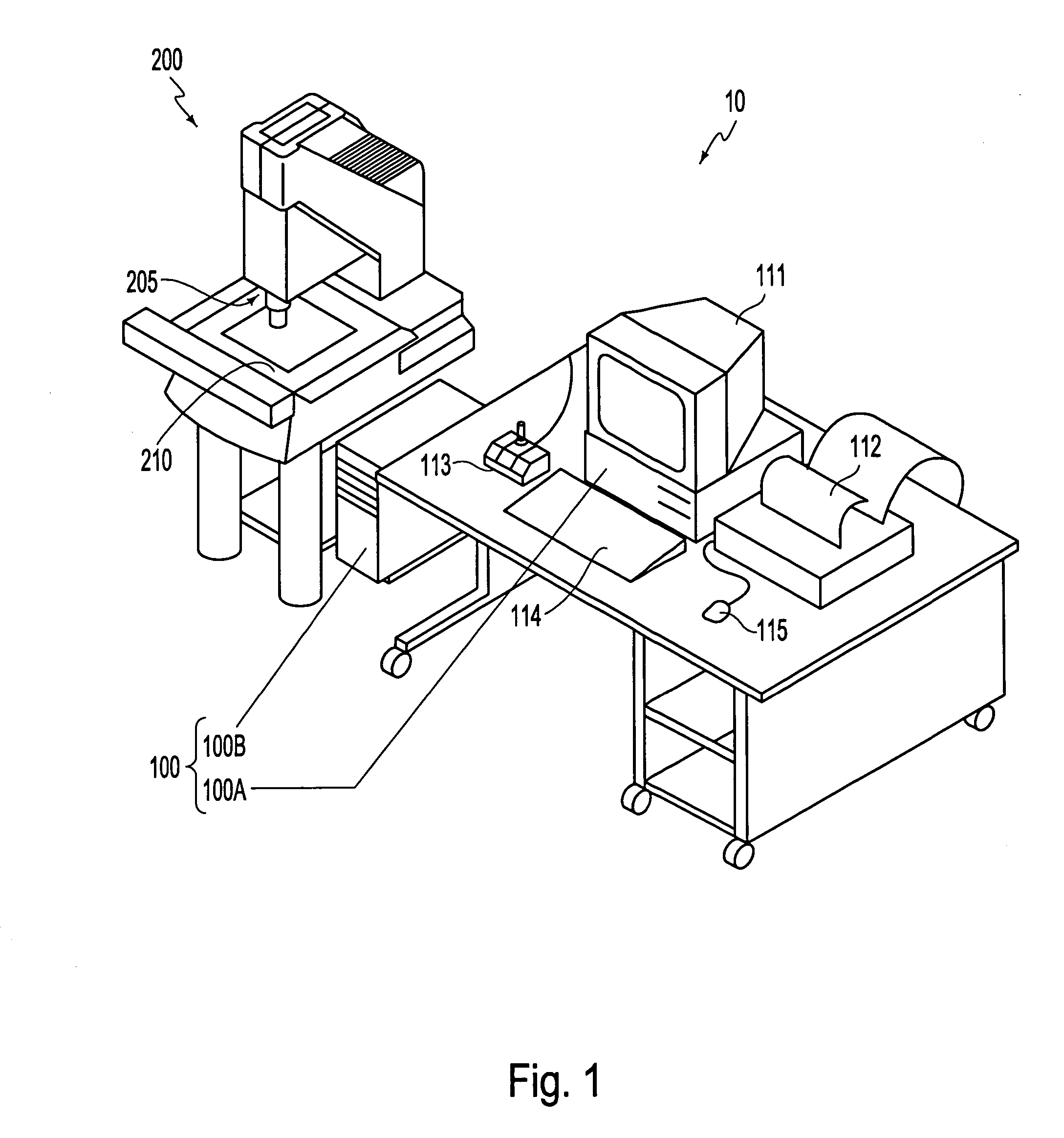

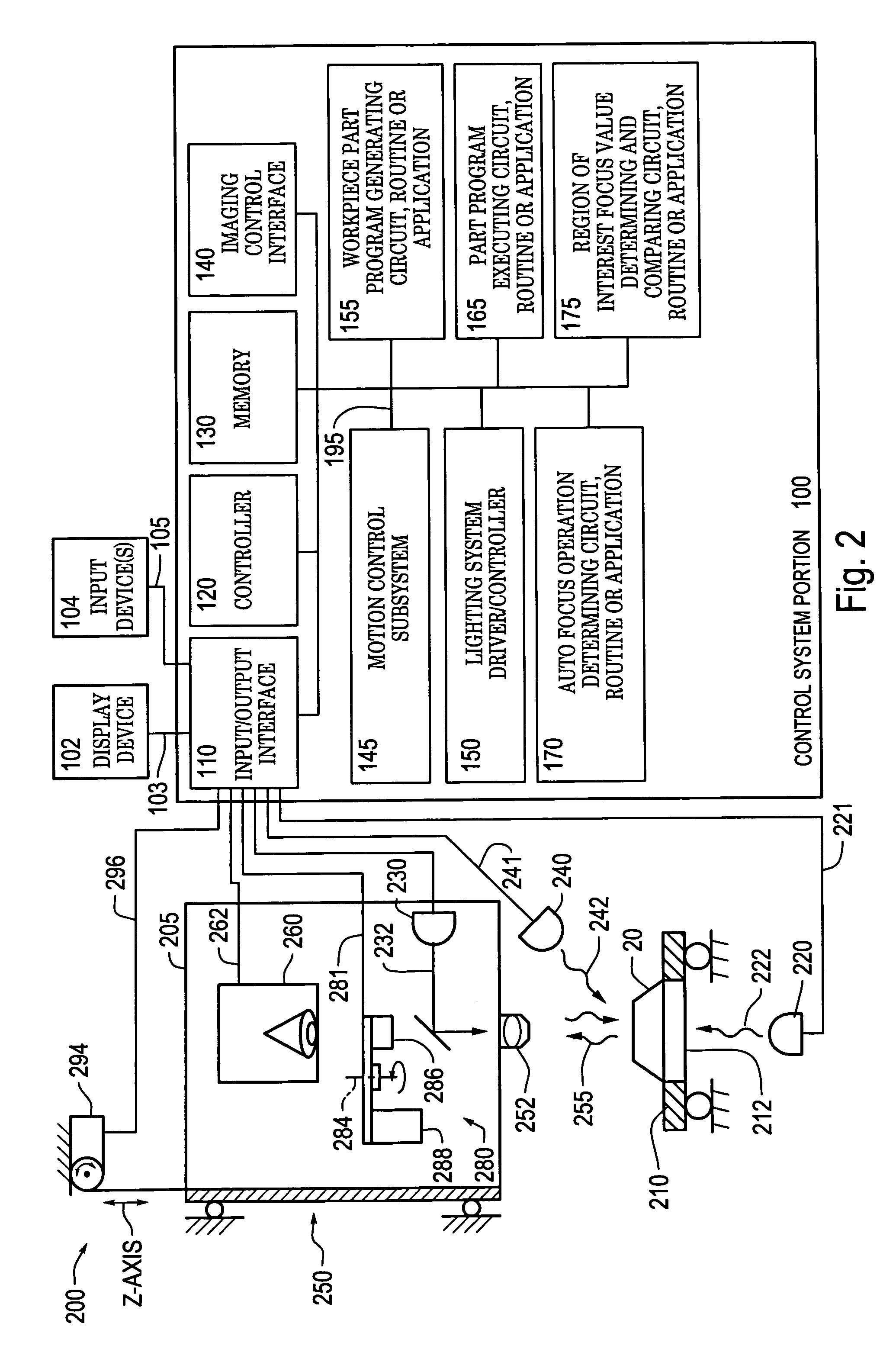

Systems and methods for rapidly automatically focusing a machine vision inspection system

ActiveUS7030351B2Increase speedAccurate autofocusTelevision system detailsSolid-state devicesMachine visionMetrology

Owner:MITUTOYO CORP

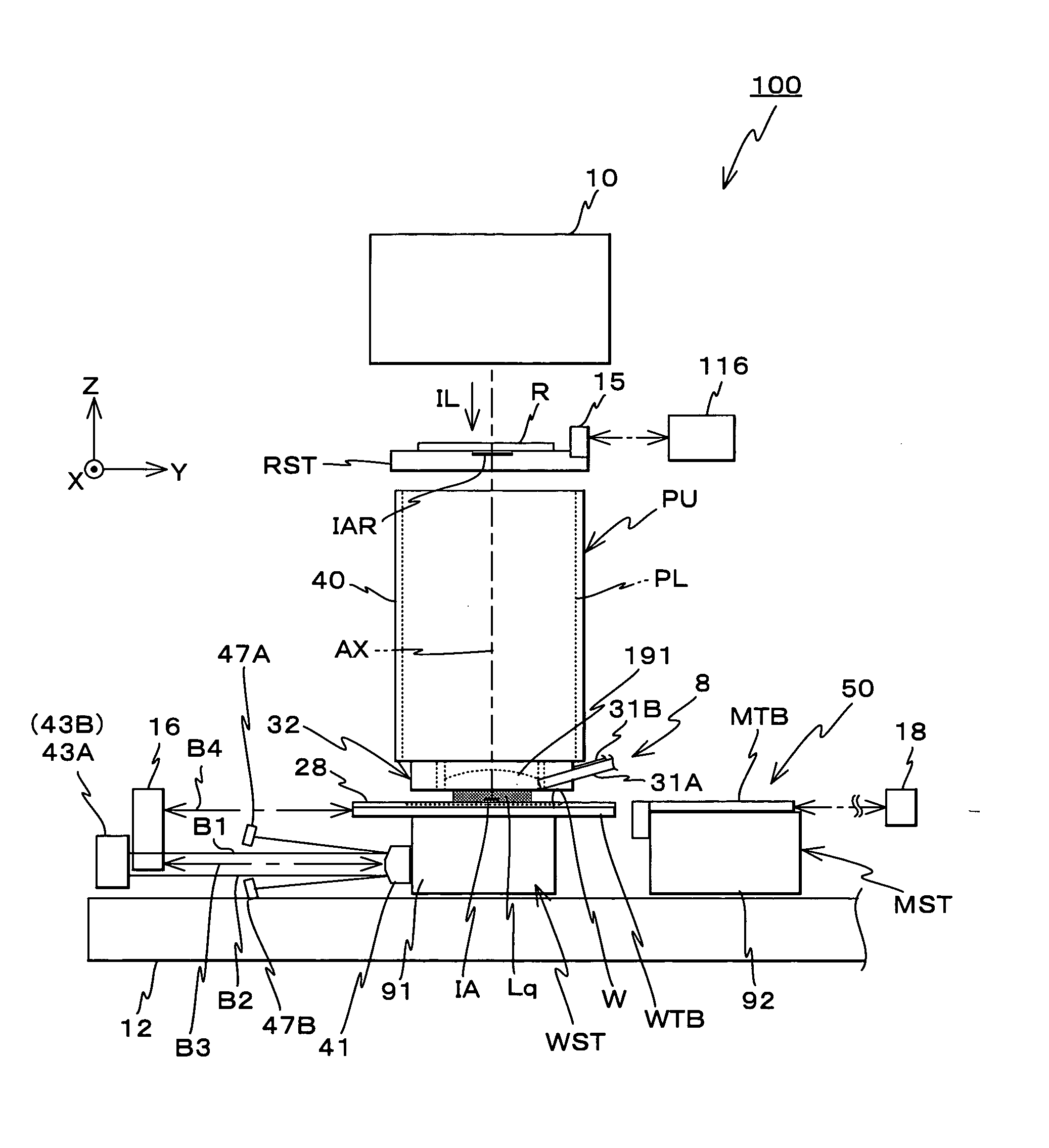

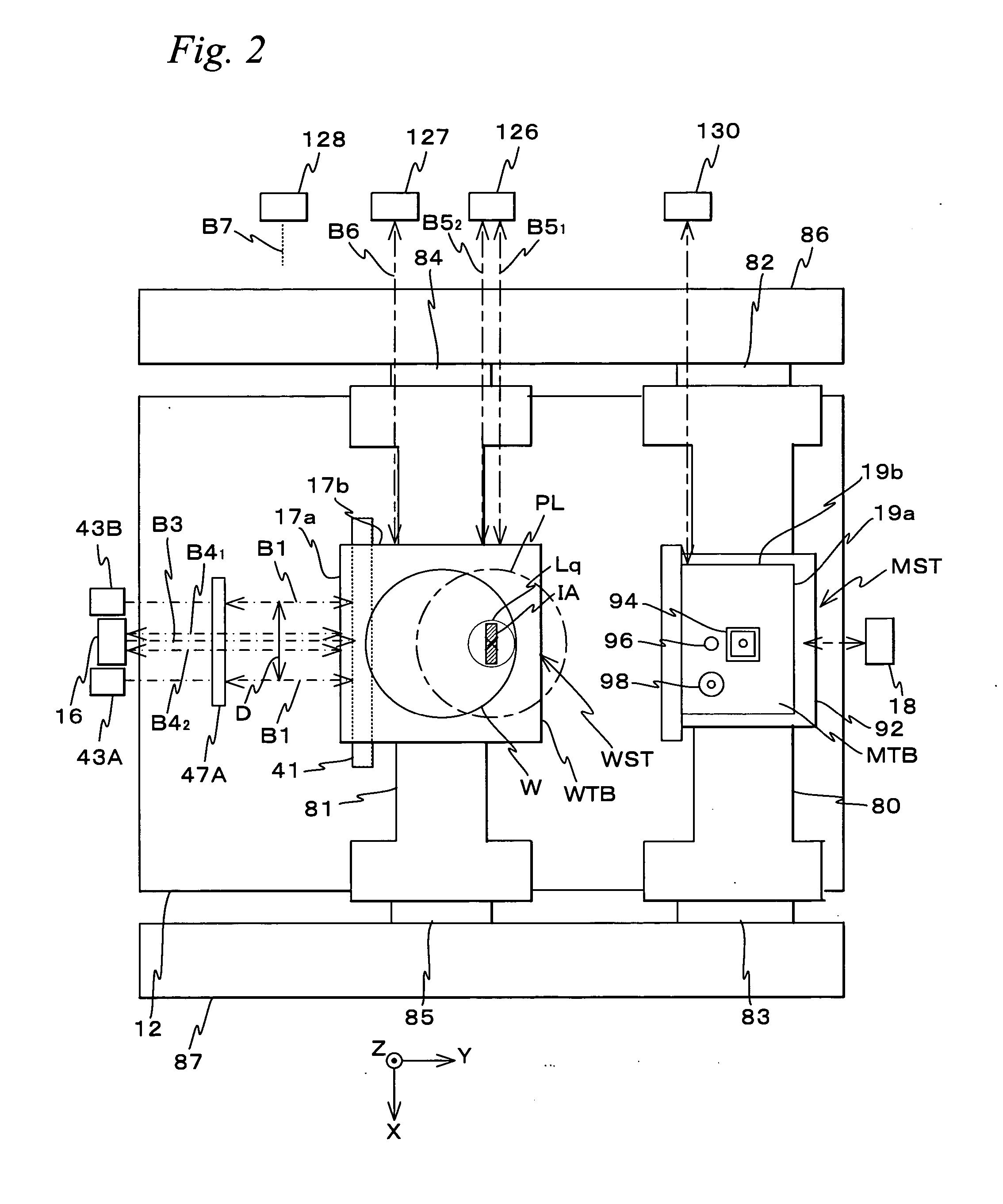

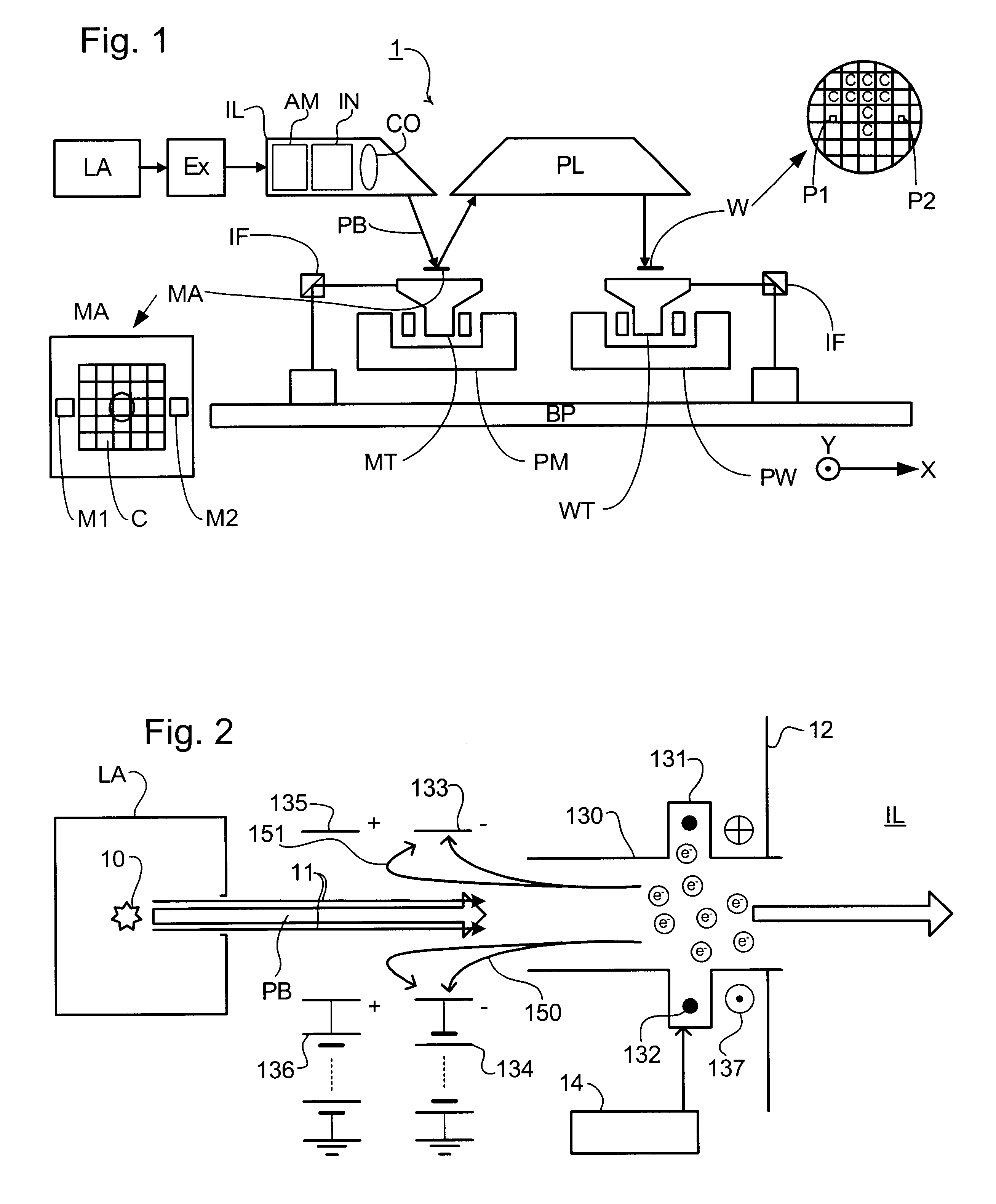

Movable body drive system and movable body drive method, pattern formation apparatus and method, exposure apparatus and method, device manufacturing method, and decision-making method

InactiveUS20080106722A1Improve accuracyDrive precisionBeam/ray focussing/reflecting arrangementsSemiconductor/solid-state device manufacturingRelative displacementEngineering

A drive unit drives a wafer table in a Y-axis direction based on a measurement value of an encoder that measures position information of the wafer table in the Y-axis direction and based on known correction information in accordance with position information of the wafer table in a non-measurement direction (e.g. Z, θz and θx directions) that is measured by an interferometer at the time of the measurement by the encoder. That is, the wafer table (a movable body) is driven in the Y-axis direction based on the measurement value of the encoder that has been corrected by correction information for correcting a measurement error of the encoder that is caused by a relative displacement of a head and a scale in the non-measurement direction. Accordingly, the movable body can be driven with high accuracy in a desired direction while measuring the position by the encoder, without being affected by the relative motion between the head and the scale in directions other than a direction to be measured (measurement direction).

Owner:NIKON CORP

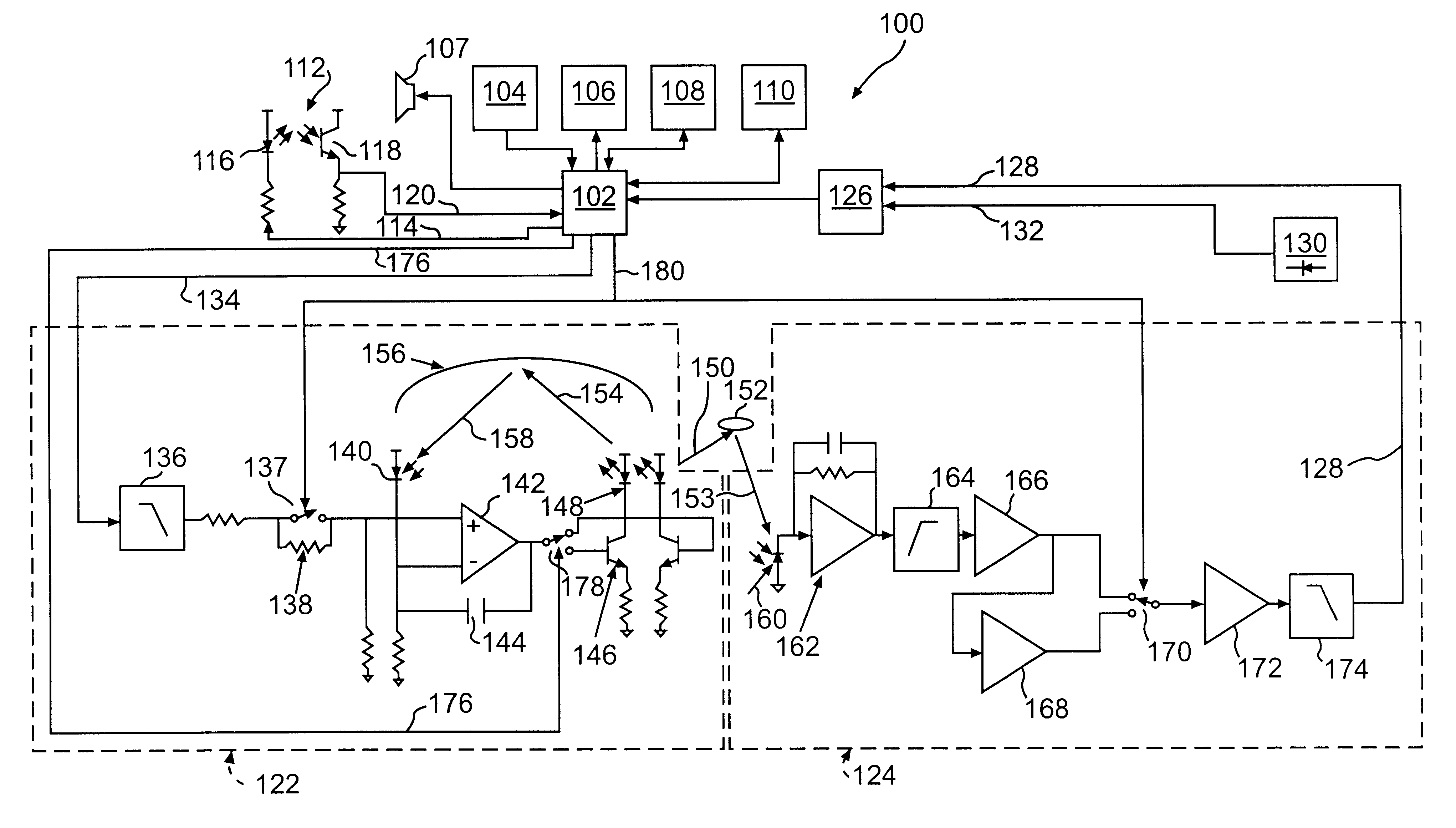

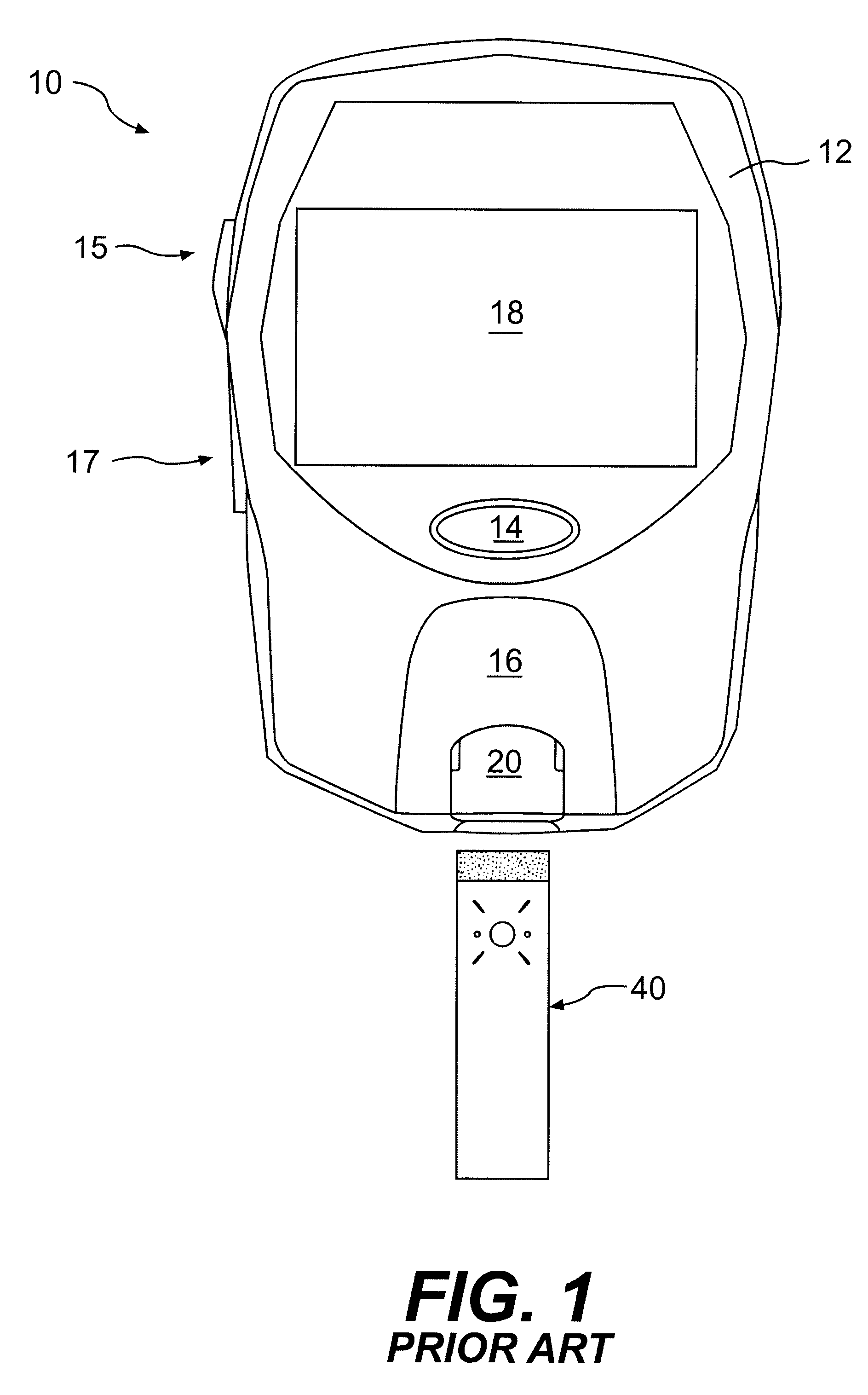

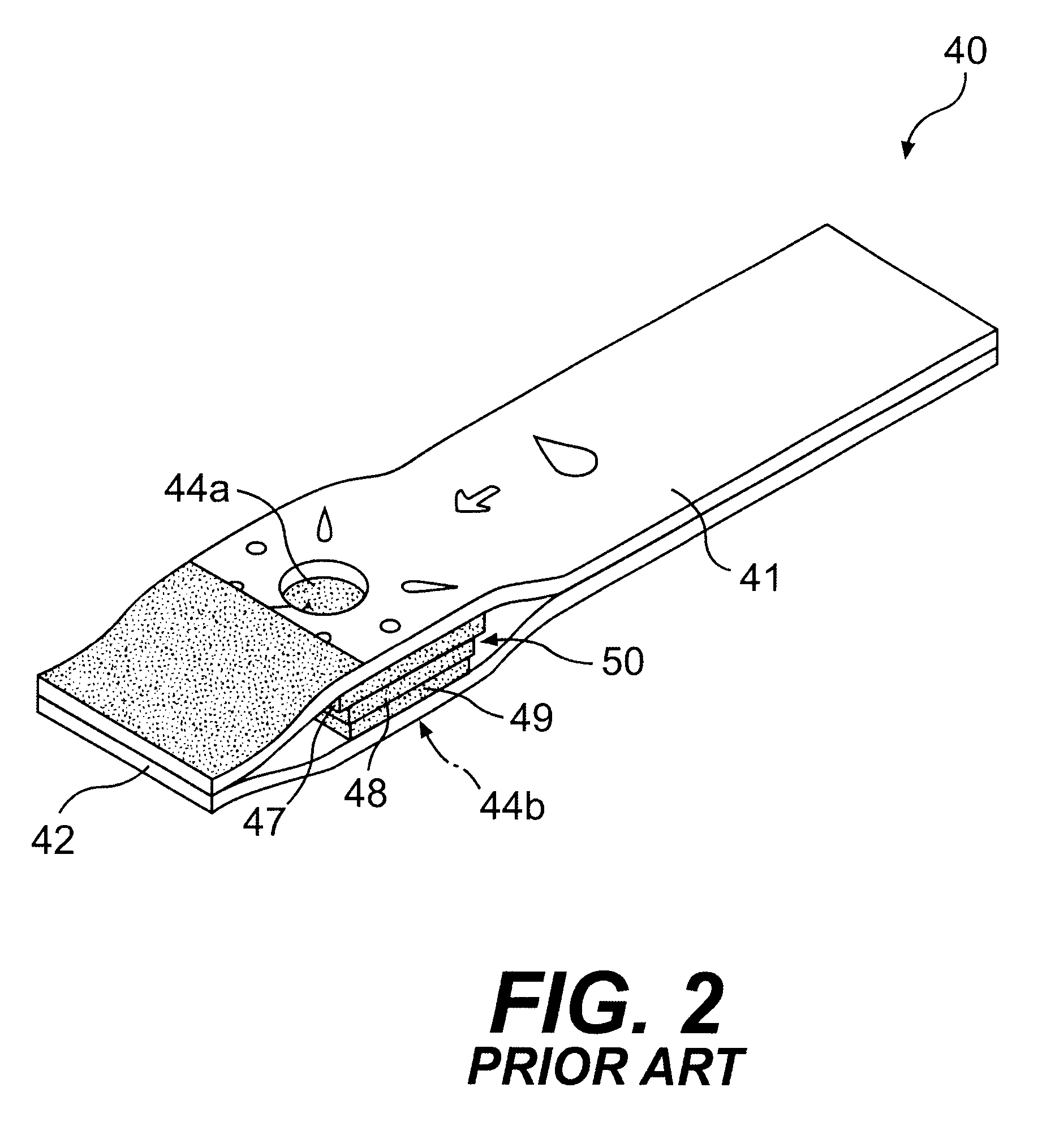

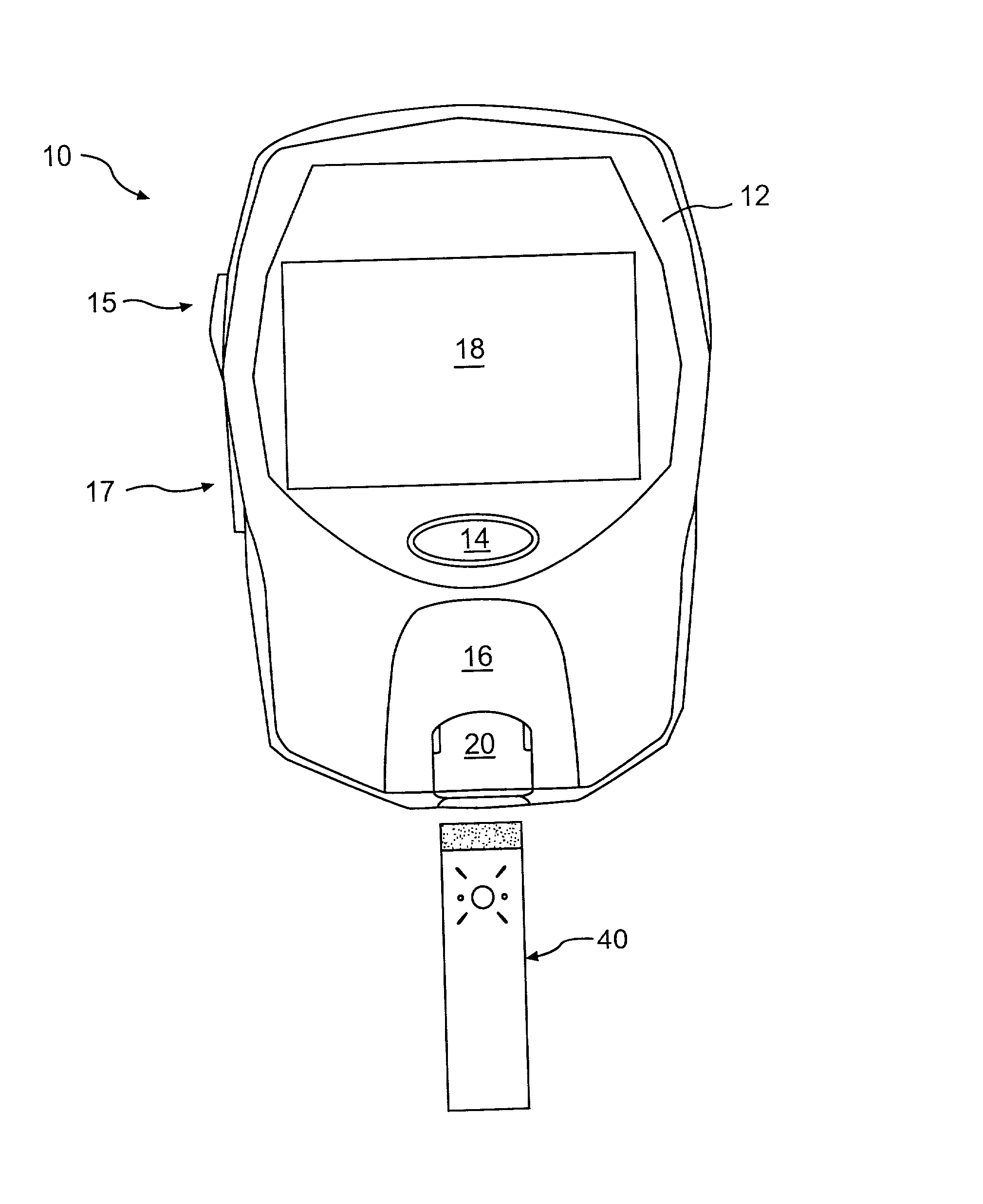

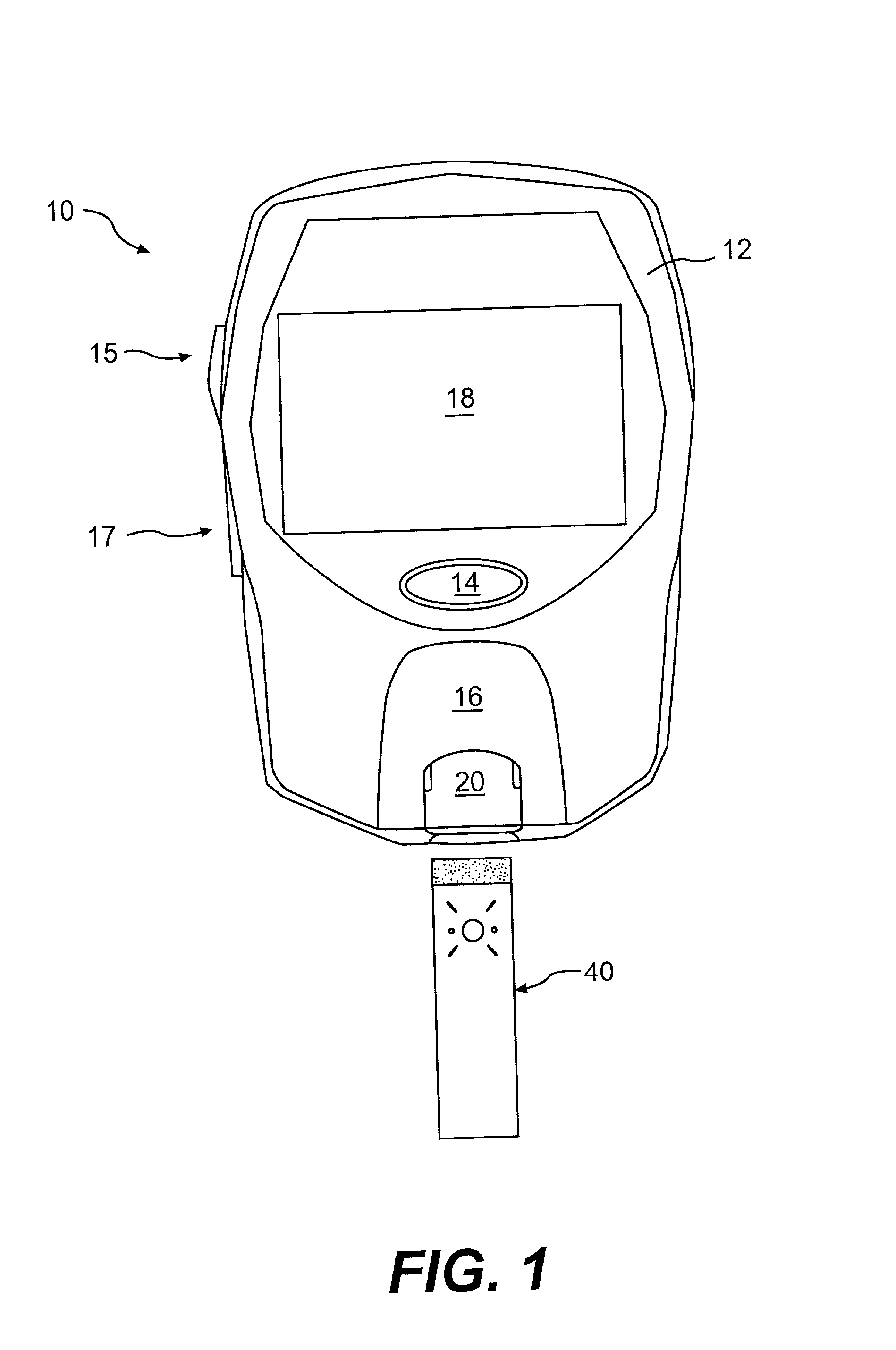

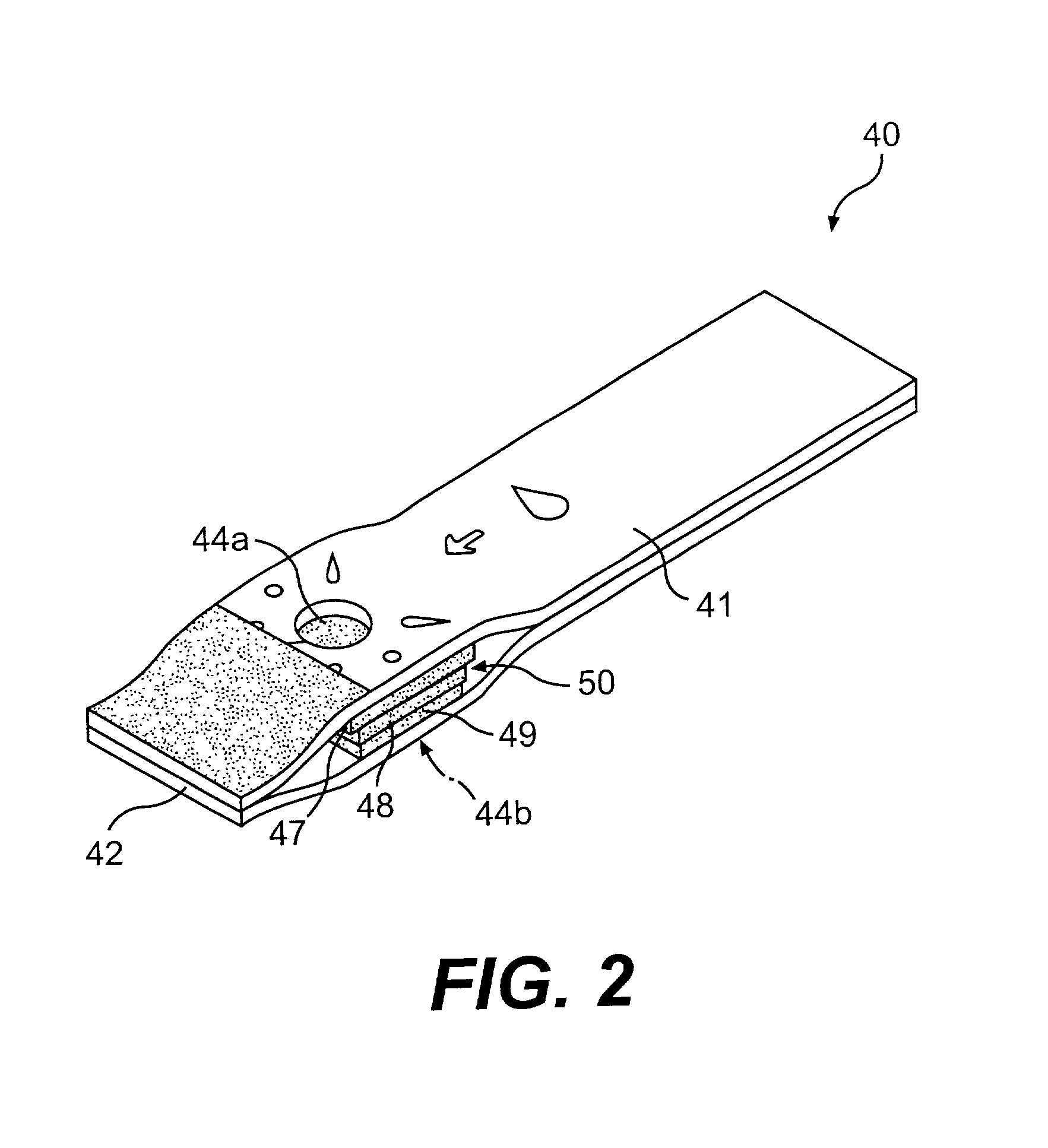

Method of strip insertion detection

InactiveUS6525330B2Material analysis by observing effect on chemical indicatorInvestigating moving sheetsEngineeringSelf adaptive

A method and apparatus for strip insertion detection in an analytical meter system. The invention allows for individual meter calibration, adaptive thresholding and ambient light correction. Increased performance is economically realized, while providing enhanced meter accuracy in varying light conditions.

Owner:TRIVIDIA HEALTH

Method of strip insertion detection

InactiveUS20020117639A1Material analysis by observing effect on chemical indicatorInvestigating moving sheetsEngineeringSelf adaptive

A method an apparatus for strip insertion detection in an analytical meter system. The invention allows for individual meter calibration, adaptive thresholding and ambient light correction. Increased performance is economically realized, while providing enhanced meter accuracy in varying light conditions.

Owner:TRIVIDIA HEALTH

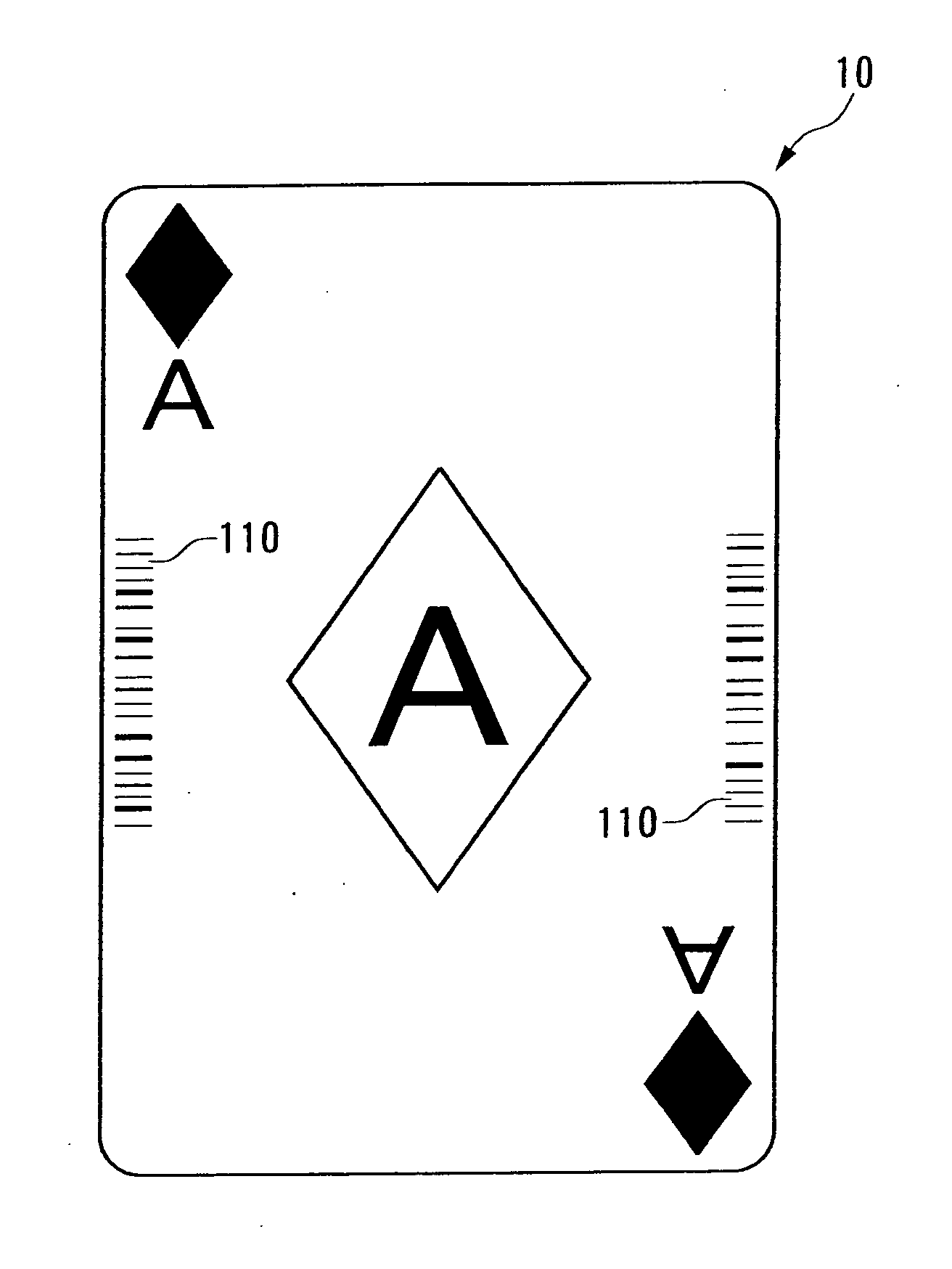

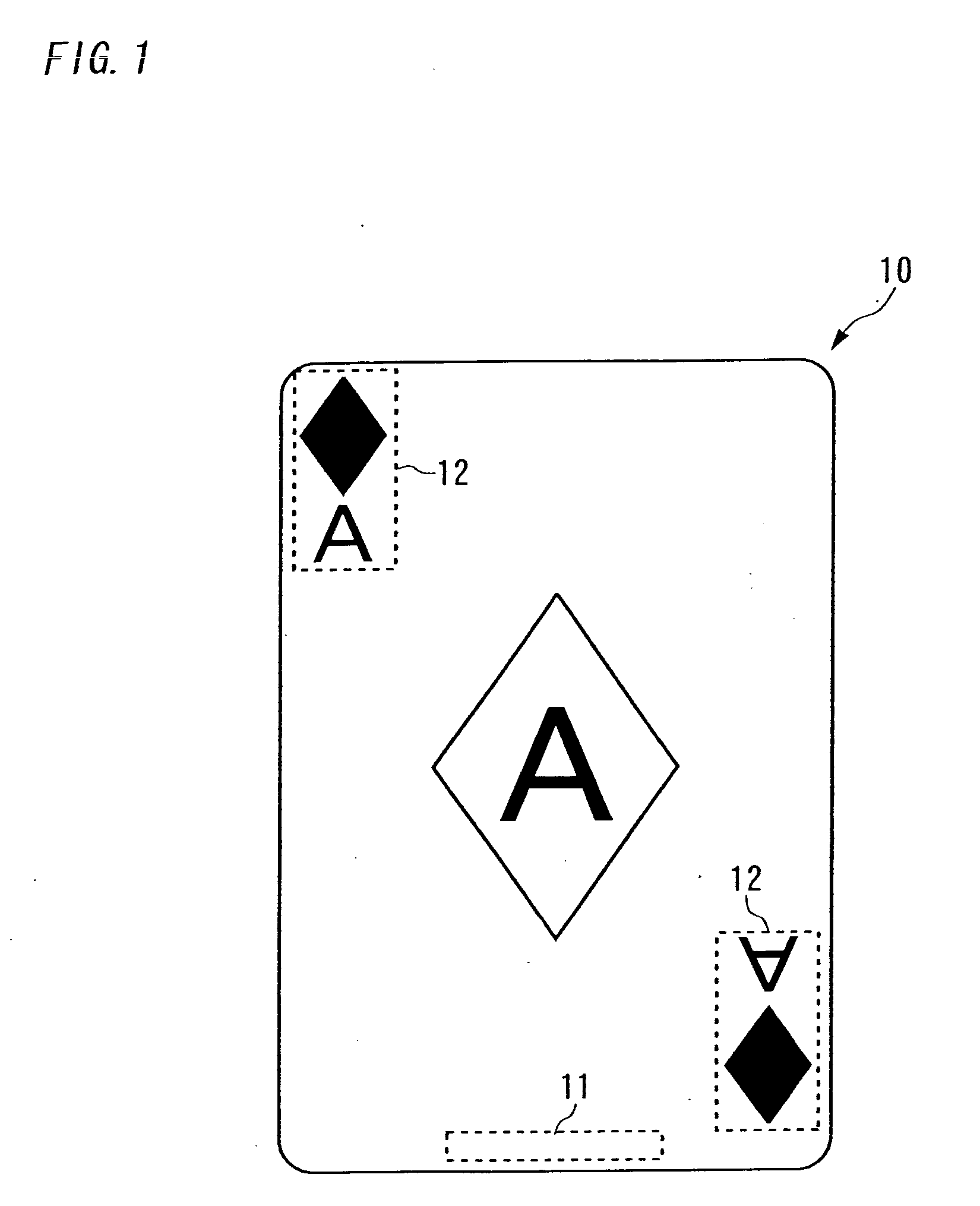

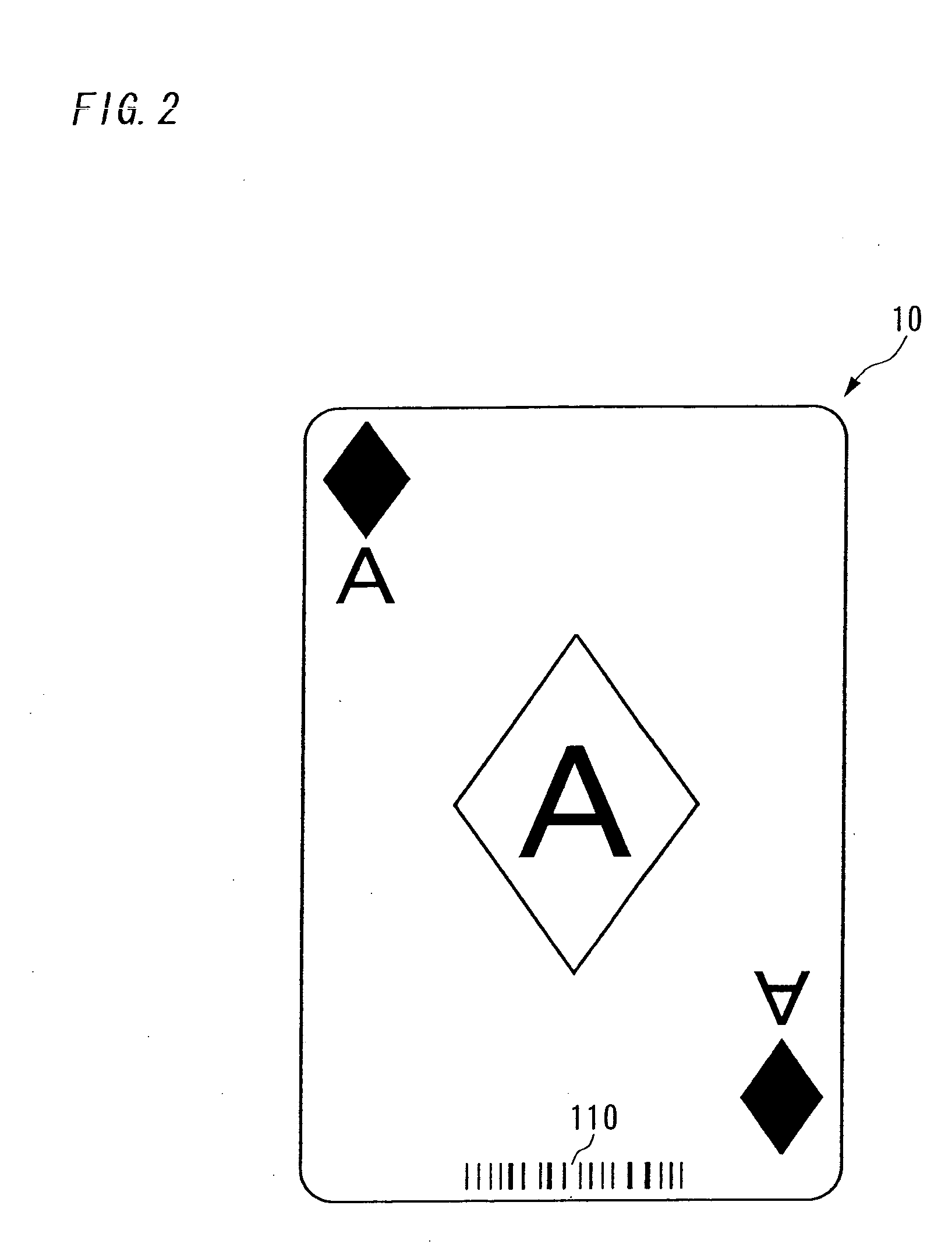

Device and method for inspecting playing card and playing card used therefor

InactiveUS20040026636A1Improve workabilityLow costInvestigating moving sheetsCard gamesComputer hardwarePlaying card

In the present invention, an identification code representing that a playing card constitutes a prescribed group is given to the playing card in order to discover an abnormal playing card mingled in with genuine playing cards for illicit purposes. The identification code is read from each of a plurality of playing cards constituting the prescribed group so as to determine whether the playing card is a genuine playing card or an abnormal playing card. The identification code may be provided on the playing card in a condition invisible to the human eye under normal usage conditions.

Owner:ANGEL CO LTD

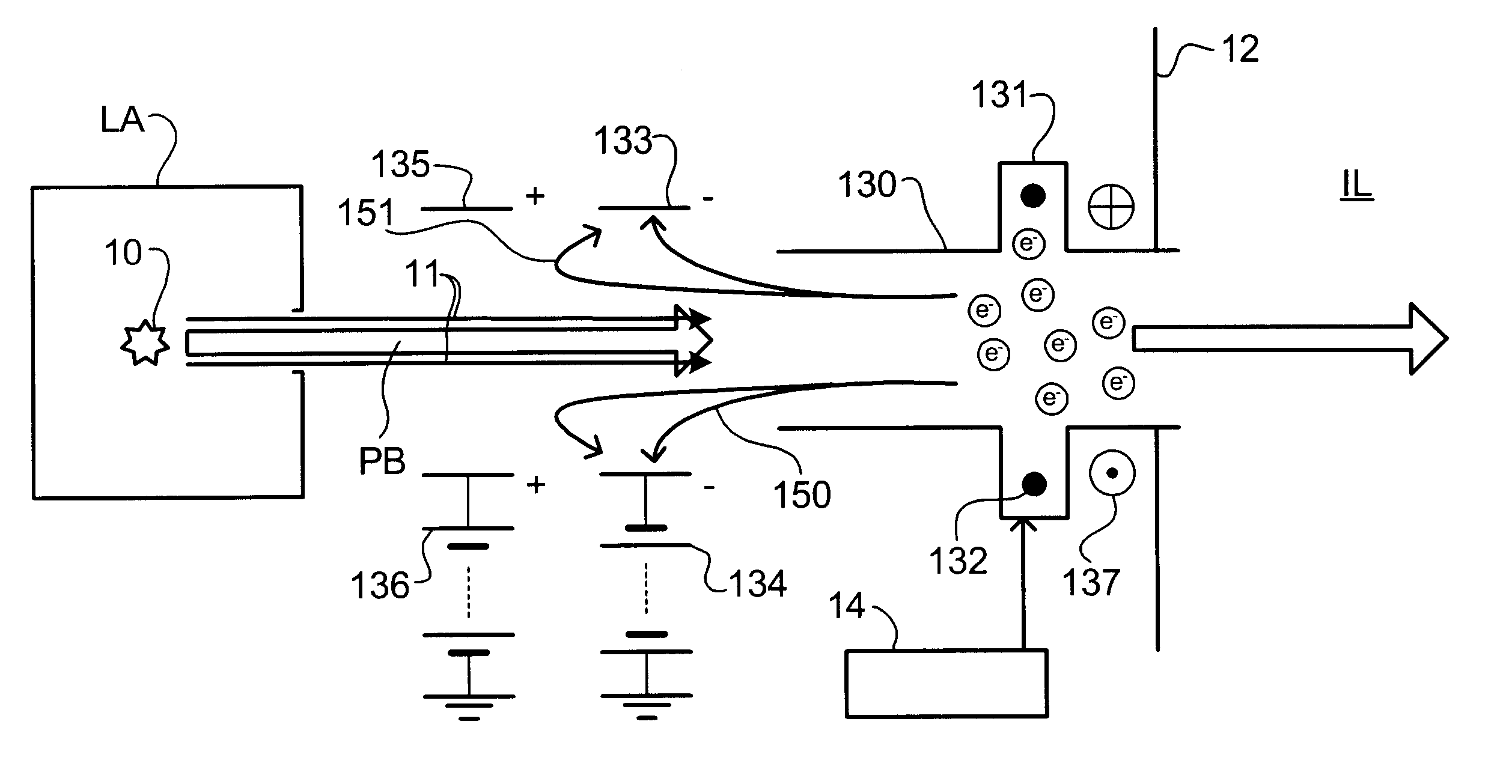

Lithographic projection apparatus, device manufacturing method, and device manufactured thereby

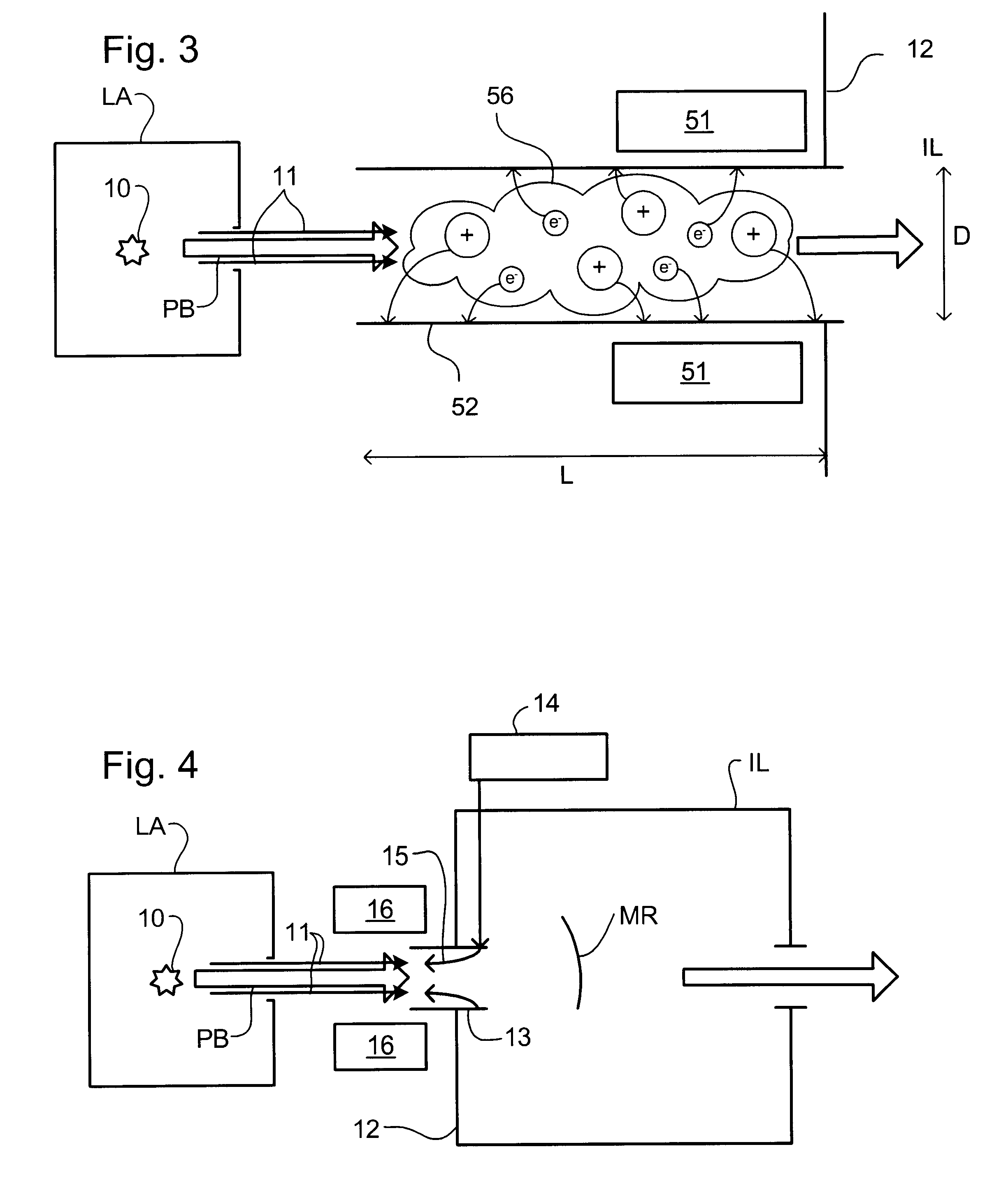

InactiveUS6614505B2Good removal effectImprove the ionization effectInvestigating moving sheetsSemiconductor/solid-state device manufacturingIonizationGas supply

Contaminant particles travelling with a projection beam in a lithographic projection apparatus are ionized. A purge gas may be attracted towards getter plates provided upstream of the purge gas supply. A magnetic field traps electrons generated by the ionizer to improve the ionization of the purge gas. The contaminant particles can be ionized by generating a plasma in a tube having a greater length than width.

Owner:ASML NETHERLANDS BV

Coordinate tracking system, apparatus and method of use

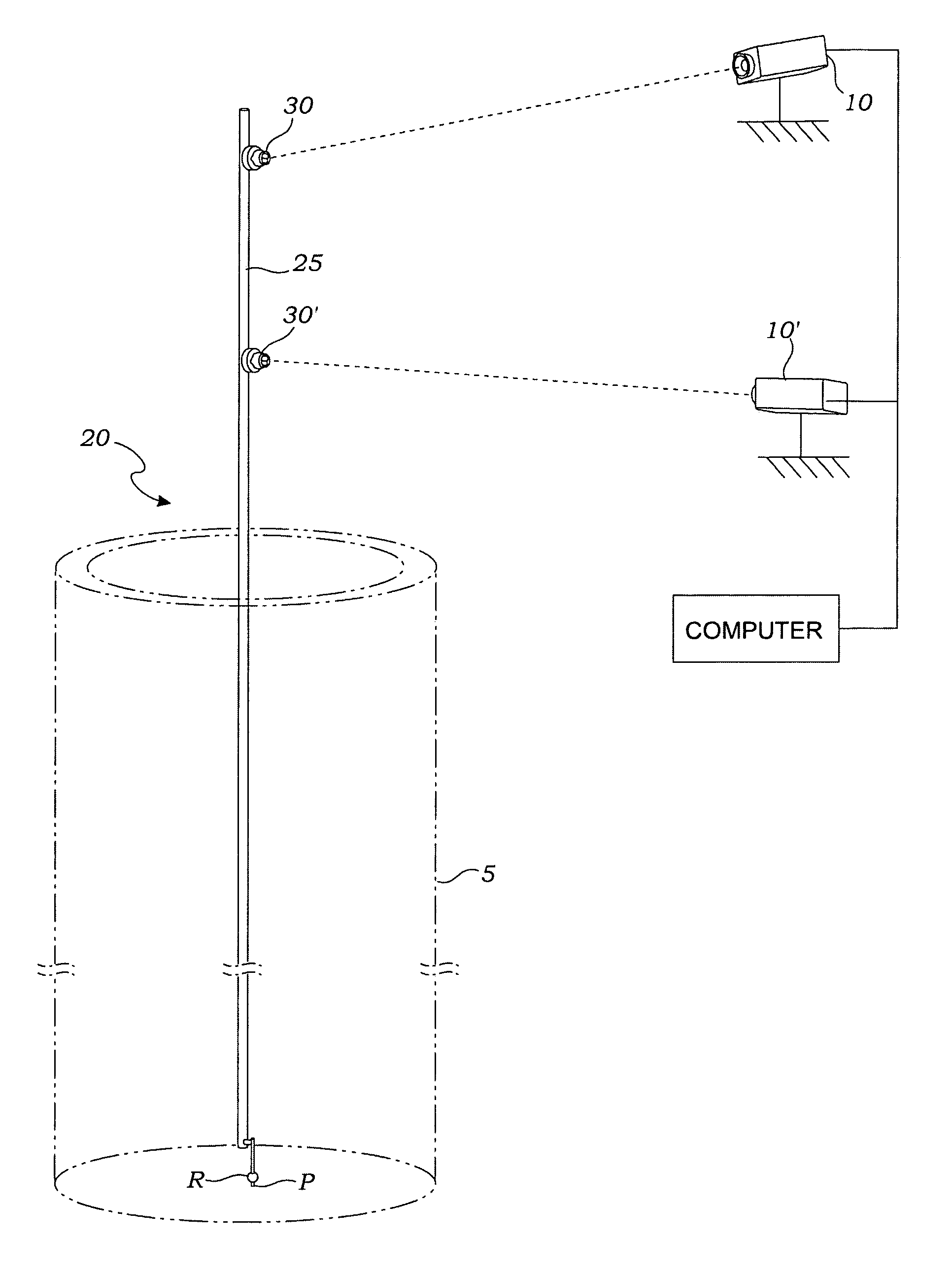

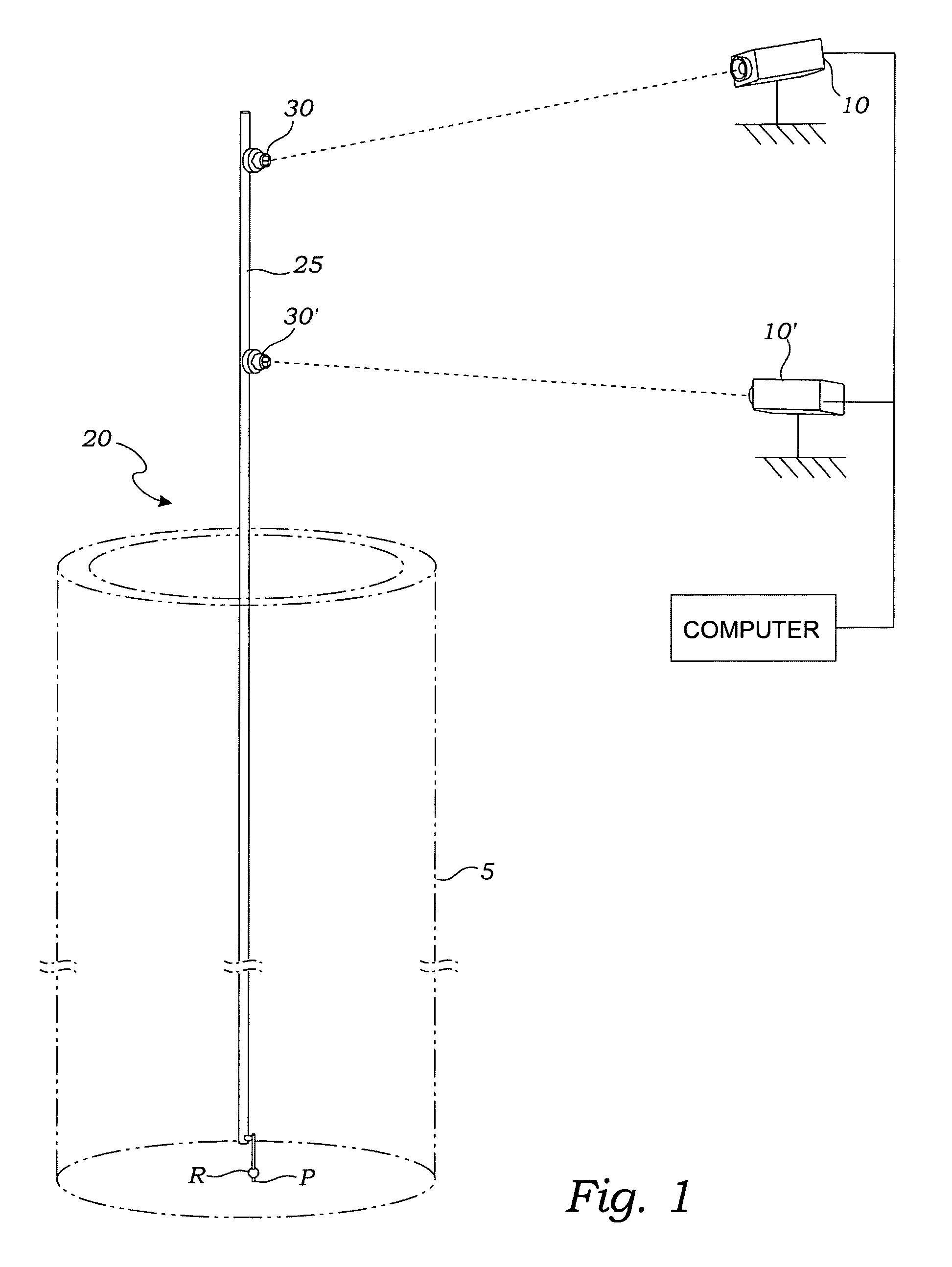

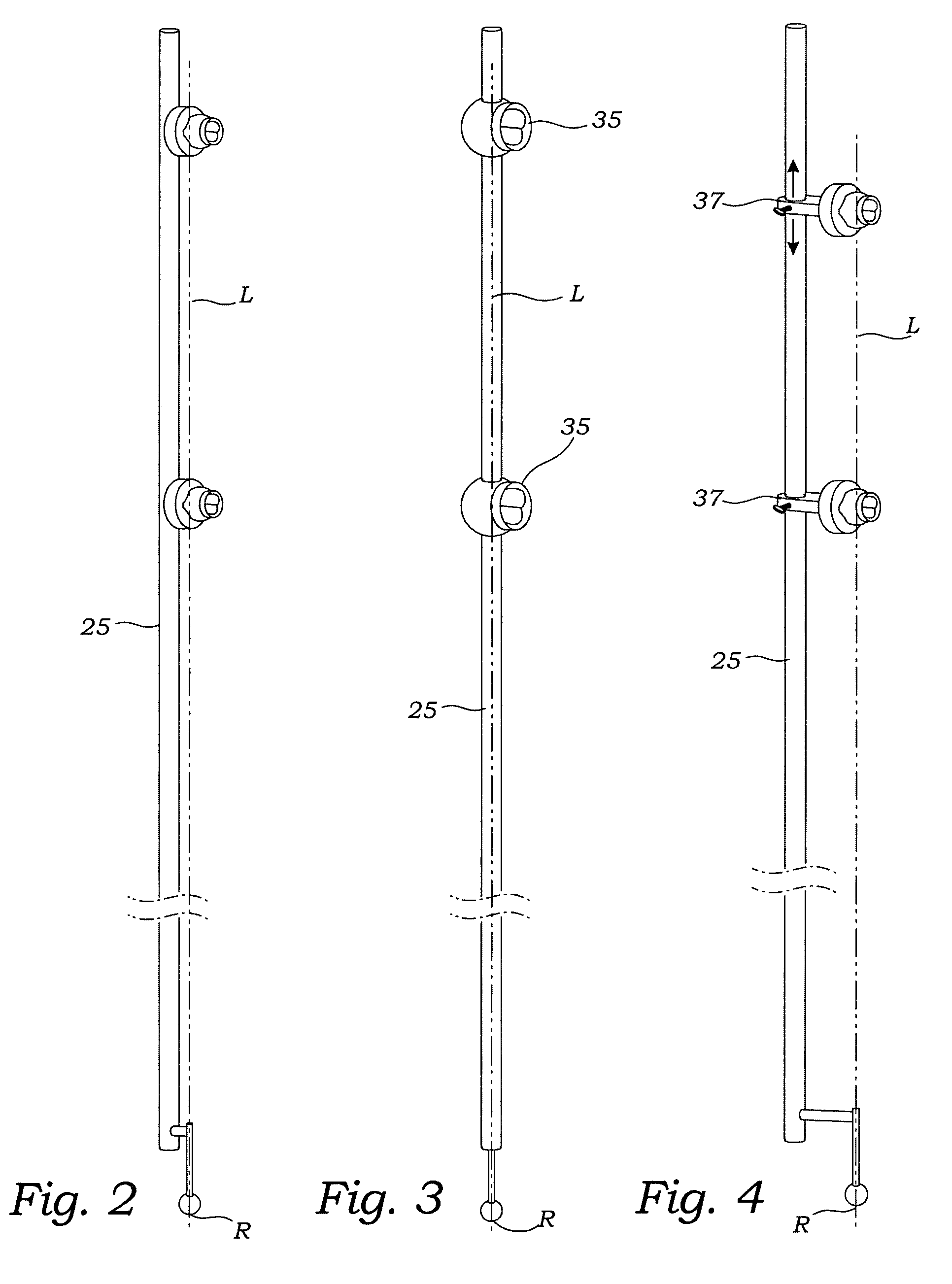

InactiveUS7285793B2Easy to moveScattering properties measurementsParticle suspension analysisLight beamEngineering

A system enables indirect determination of a position vector (VR) of a point position (P). The system uses two fixed trackers (10 and 10′) whose absolute positions are known. A movable measuring device (20) provides a rigid rod (25) supporting a pair of reflectors (30 and 30′) which are mounted at fixed positions. A reference point (R) is mounted at a further fixed position on the rod (25) and is on a straight line (L) through the reflectors (30 and 30′). Light beams from the trackers (10 and 10′) acquire the reflectors (30 and 30′) so that when the reference point (R) is positioned at the point position (P), the position vector (VR) of point position (P) is determinate by vector addition.

Owner:VERISURF SOFTWARE

Methods and systems for alignment of detection optics

InactiveUS7023007B2Convenient and rapid formatExcellent optical propertiesInvestigating moving fluids/granular solidsInvestigating moving sheetsIdentification deviceComputer science

The present invention provides methods and systems for aligning detection optics with a device by obtaining an optical profile of the system and comparing it with a preprogrammed layout of the various optical features of the device. The invention also provides methods of identifying devices by comparing the optical profile with a library of preprogrammed optical profiles of multiple devices.

Owner:CAPLIPER LIFE SCI INC

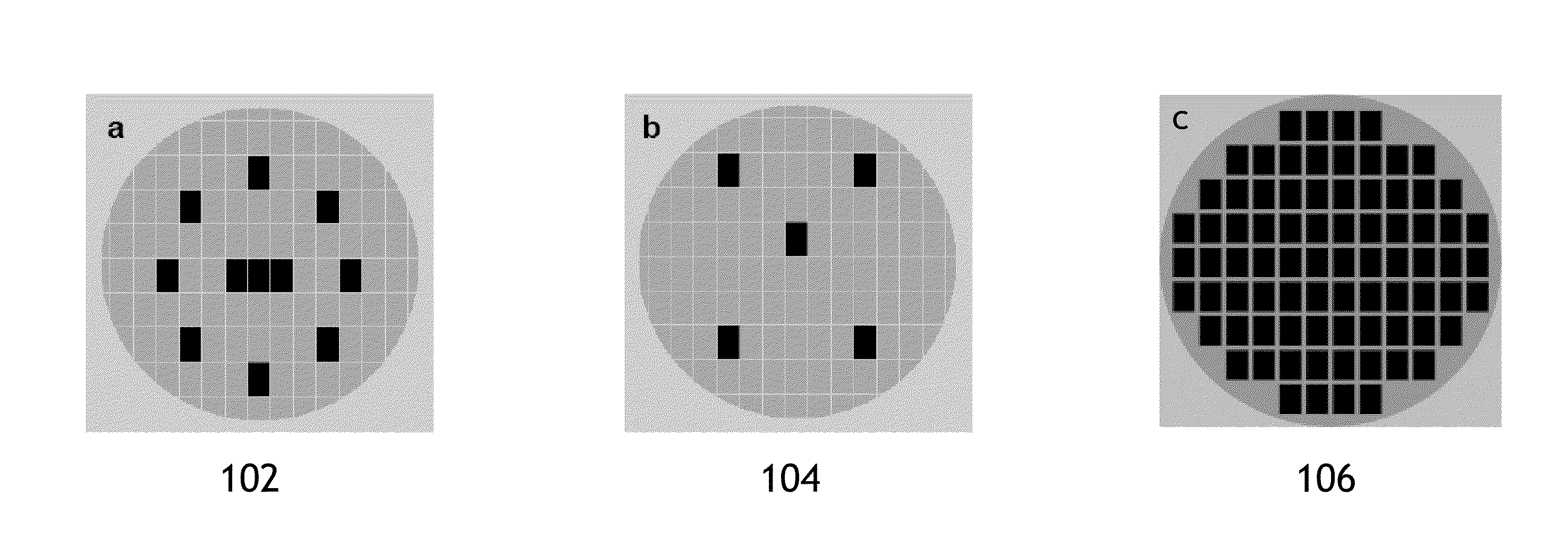

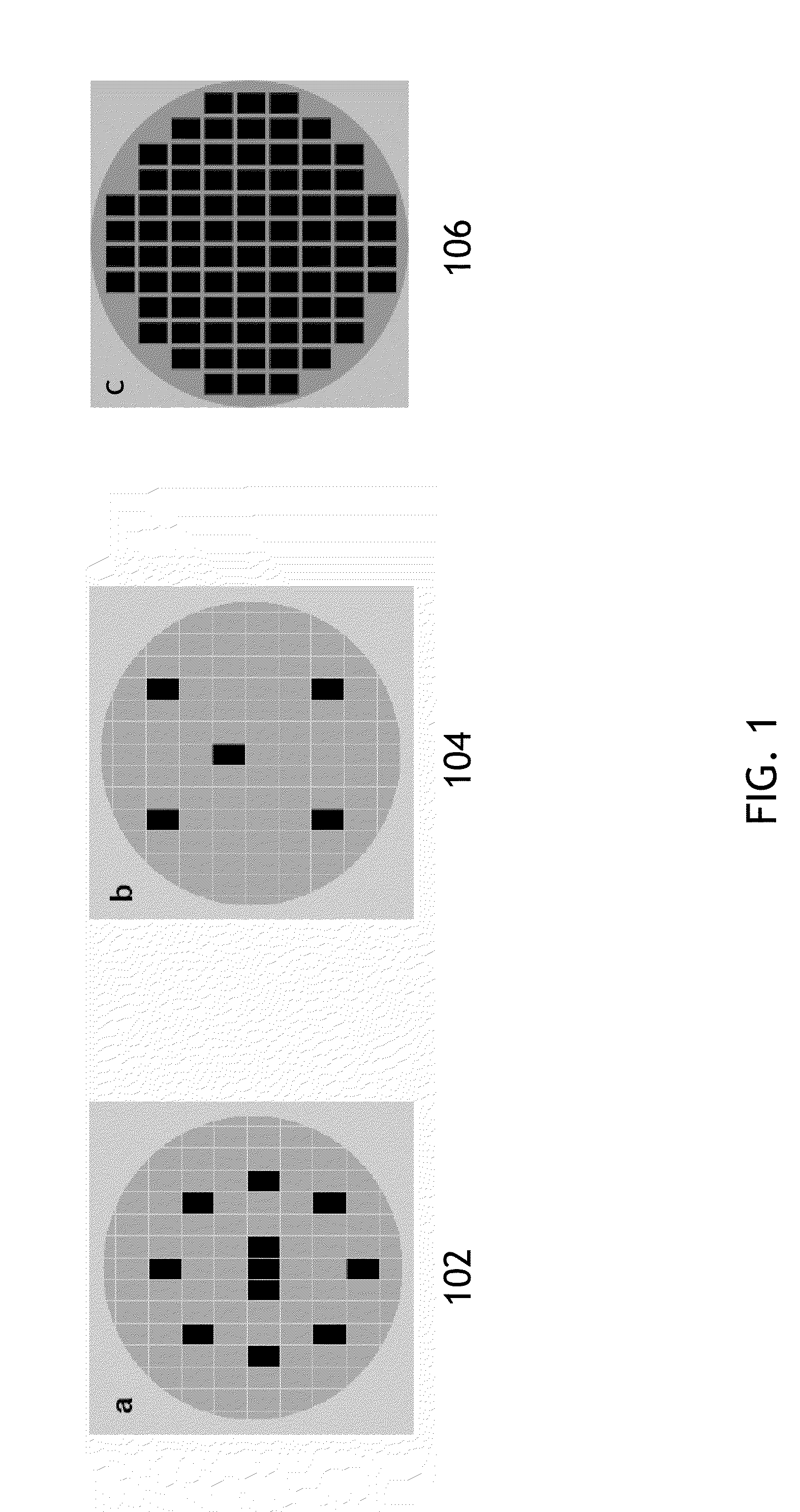

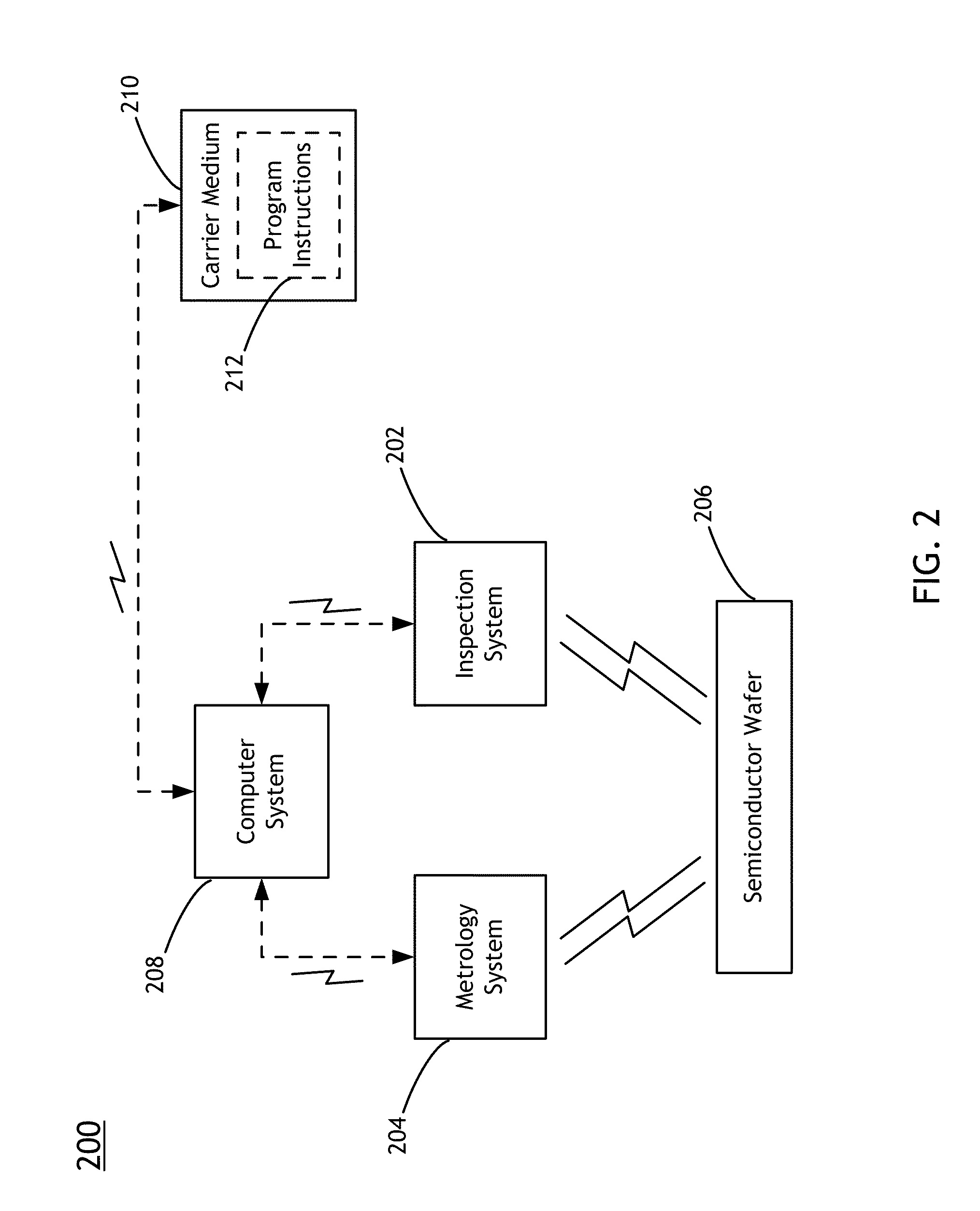

Inspection guided overlay metrology

ActiveUS20110170091A1Semiconductor/solid-state device testing/measurementSolid-state devicesMetrologySemiconductor

Inspection guided overlay metrology may include performing a pattern search in order to identify a predetermined pattern on a semiconductor wafer, generating a care area for all instances of the predetermined pattern on the semiconductor wafer, identifying defects within generated care areas by performing an inspection scan of each of the generated care areas, wherein the inspection scan includes a low-threshold or a high sensitivity inspection scan, identifying overlay sites of the predetermined pattern of the semiconductor wafer having a measured overlay error larger than a selected overlay specification utilizing a defect inspection technique, comparing location data of the identified defects of a generated care area to location data of the identified overlay sites within the generated care area in order to identify one or more locations wherein the defects are proximate to the identified overlay sites, and generating a metrology sampling plan based on the identified locations.

Owner:KLA TENCOR TECH CORP

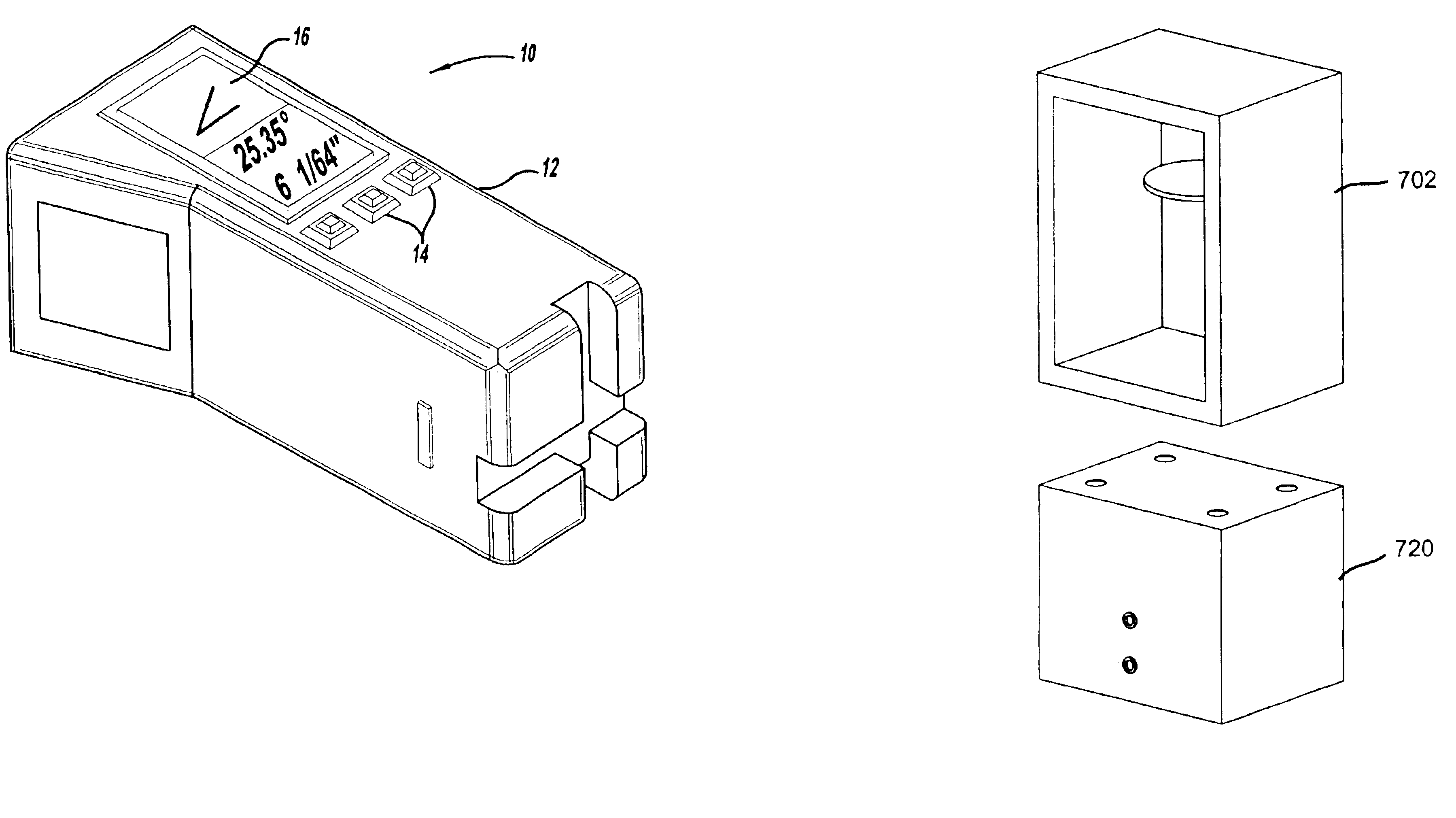

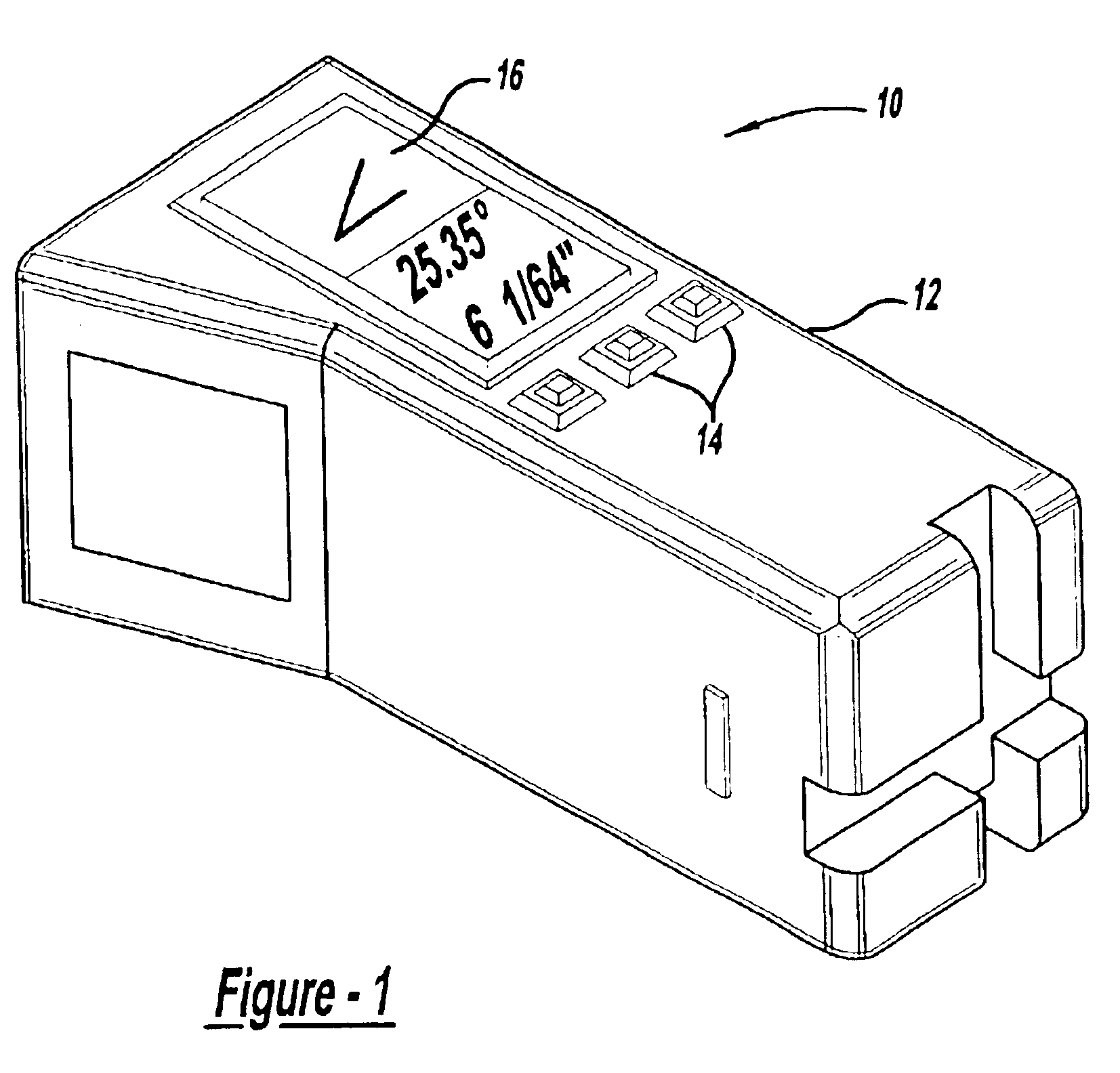

Modular non-contact measurement device for quickly and accurately obtaining dimensional measurement data

InactiveUS6858857B2Quickly and accurately performingRemove most human judgement of measurement resultsImage analysisMetal sawing accessoriesMeasurement deviceDimension measurement

A modular measurement device is provided for quickly and accurately performing non-contact measurements of various objects at different locations within a commercial or residential work area. The modular measurement device generally includes a laser base that is operable to project light onto a measured object; and a portable measurement module adapted to receive light reflected from a surface of the measured object and operable to determine dimensional measurement data for the measured object, where the portable measurement module is configured to releasably couple to the laser base. The operational components of the measurement device are partitioned between the portable measurement module and the laser base. In this way, a single portable measurement module having more expensive operational components may be used with different, less expensive laser bases, where each laser base may be adapted for a different application.

Owner:PERCEPTRON

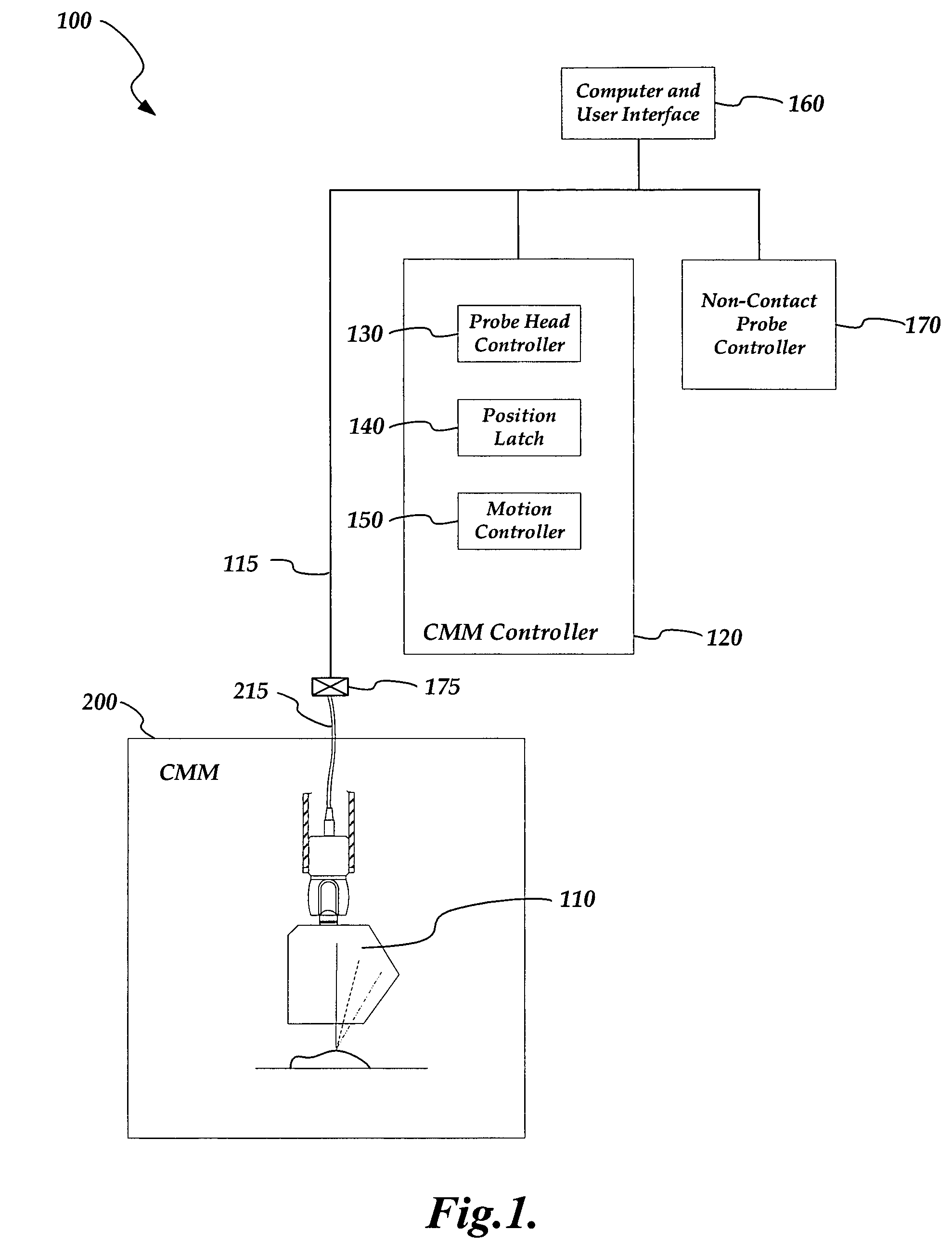

Non-contact probe control interface

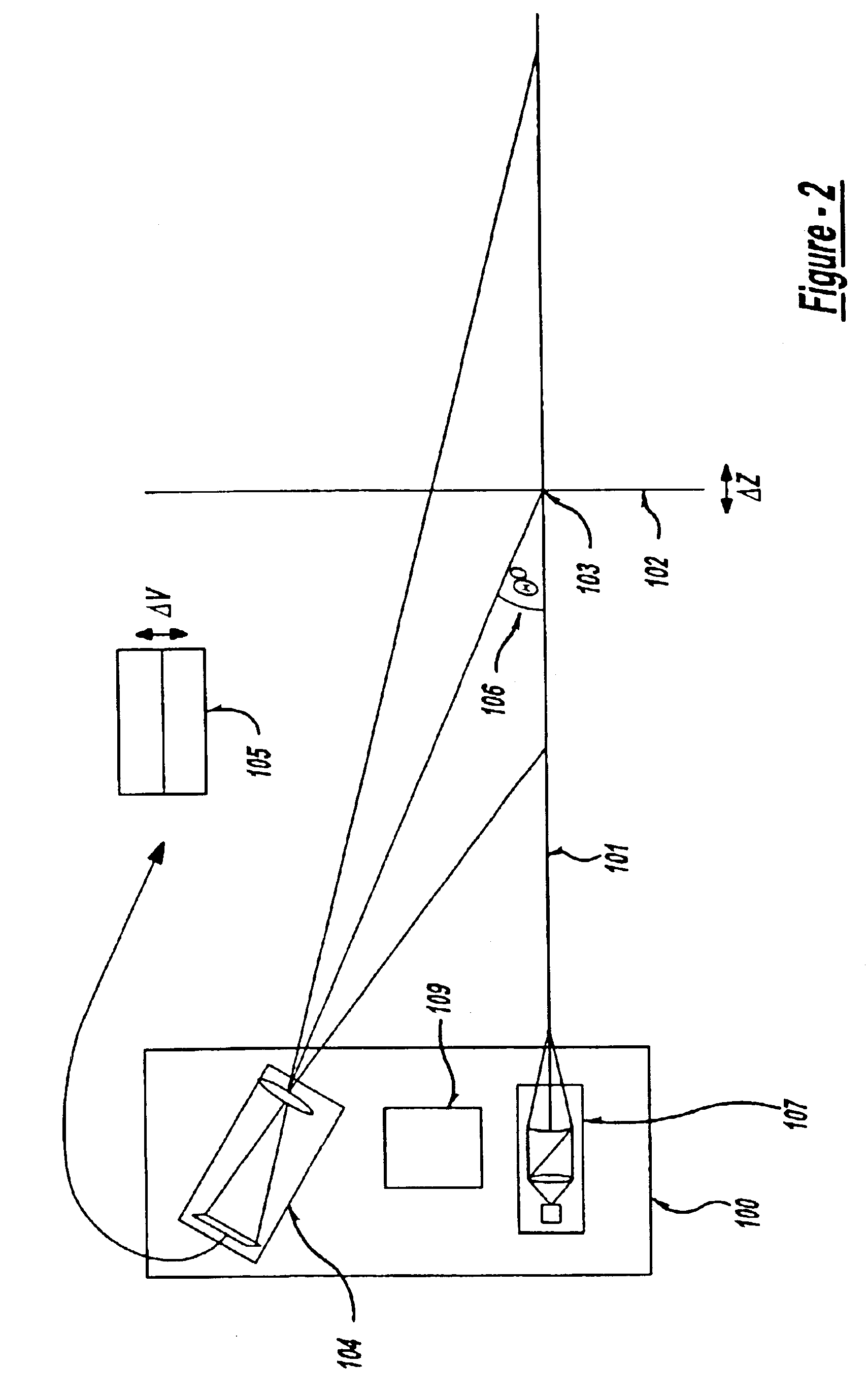

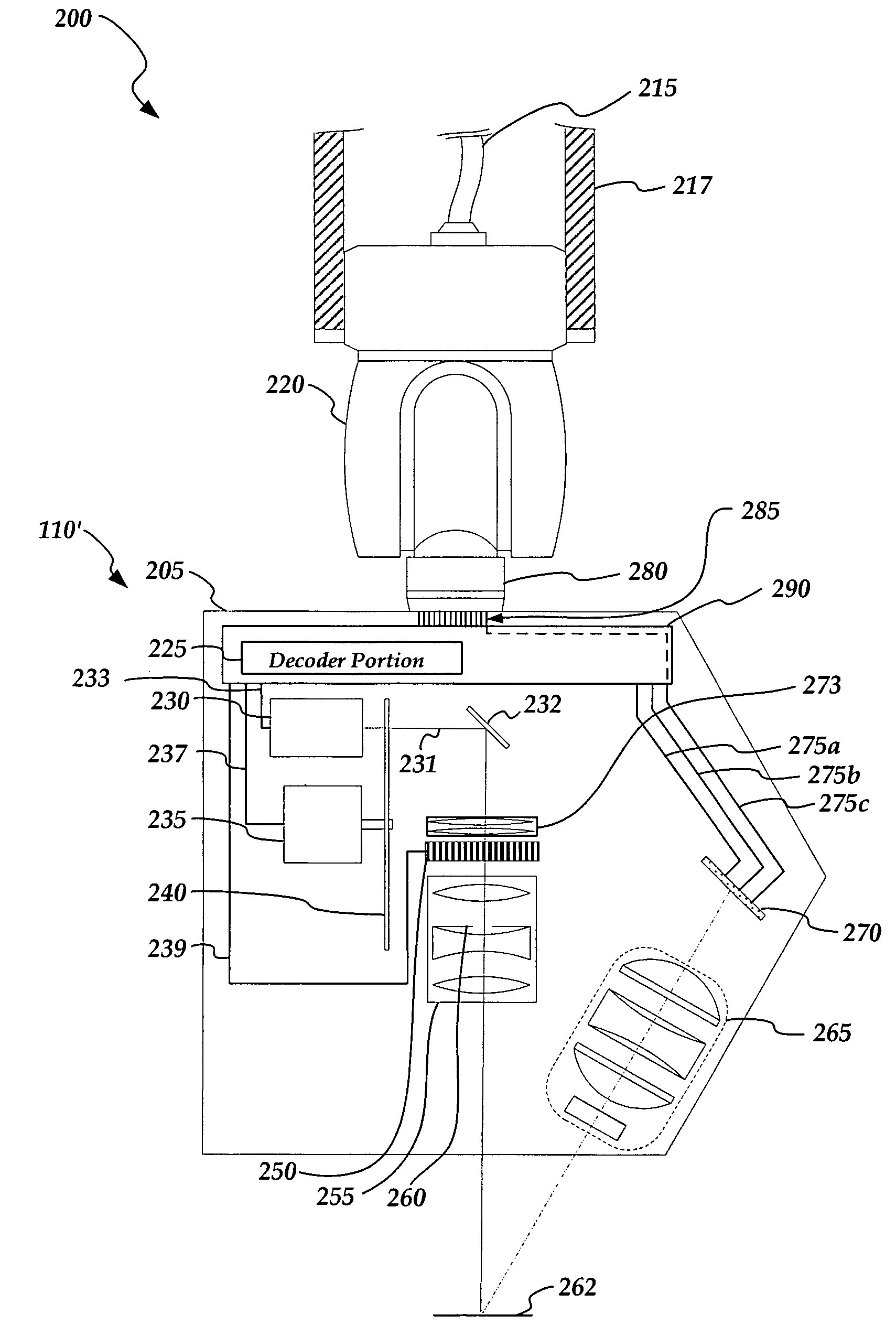

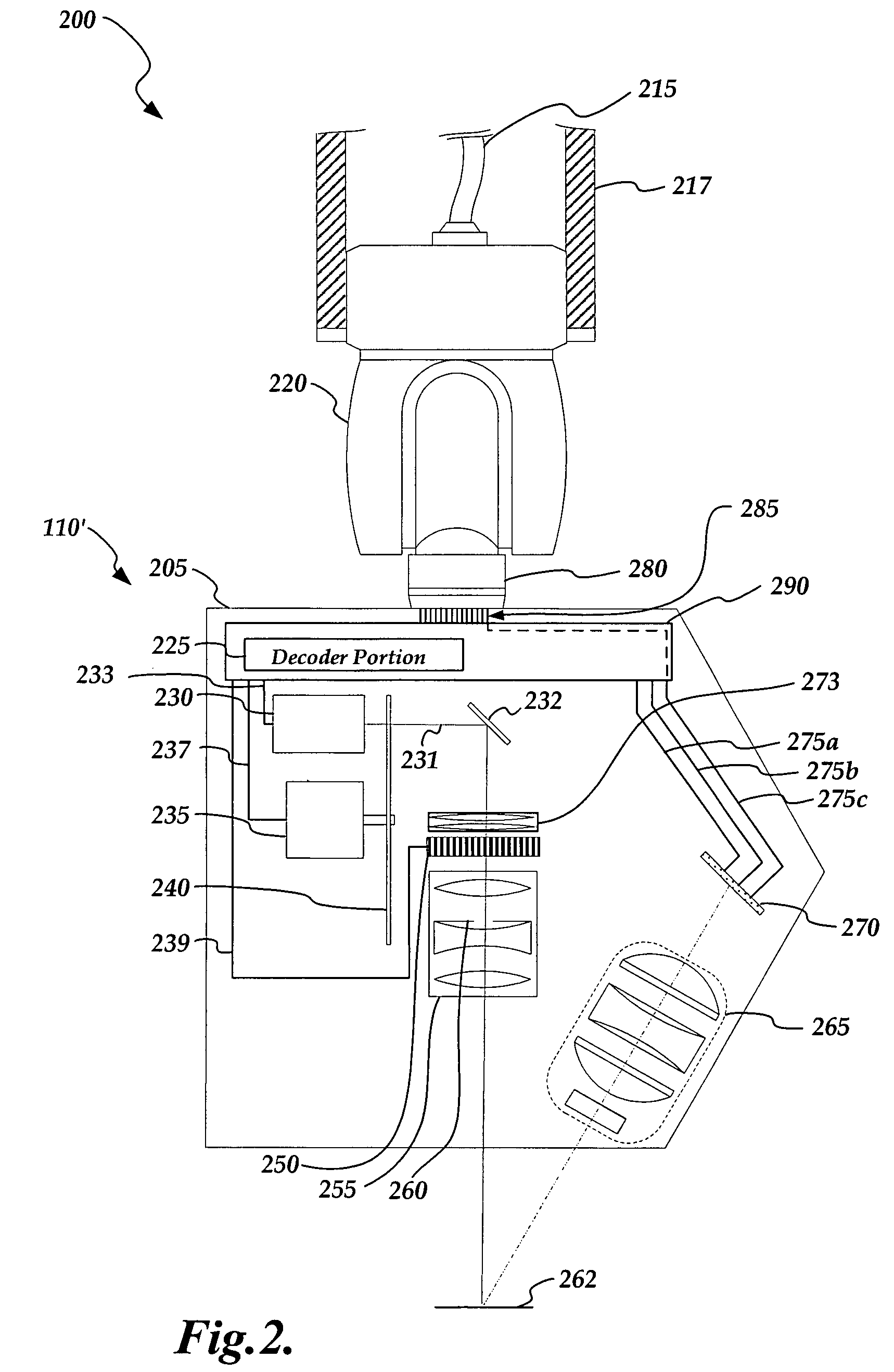

ActiveUS7652275B2Existing systems can be upgraded more easilyEasy to upgradeImage analysisOptical rangefindersSpatial light modulatorControl signal

A probe control interface is provided for a structured light non-contact coordinate measuring machine probe. Portions of a video control signal for controlling the grey level of selected rows of pixels of a spatial light modulator of the probe can be decoded into control signals for additional probe components or functions that have been added to increase the measuring capabilities or versatility of the non-contact probe. By providing the additional probe component control signals in this manner, a versatile structured light non-contact probe system can be made compatible with a standard probe head autojoint system (e.g. a Renishaw™ type system), thus allowing the probe to be automatically exchanged with other standard probes and allowing existing systems to use the non-contact probe more easily. Various aspects of the probe control interface allow for relatively simple, compact, lightweight and robust implementation.

Owner:MITUTOYO CORP

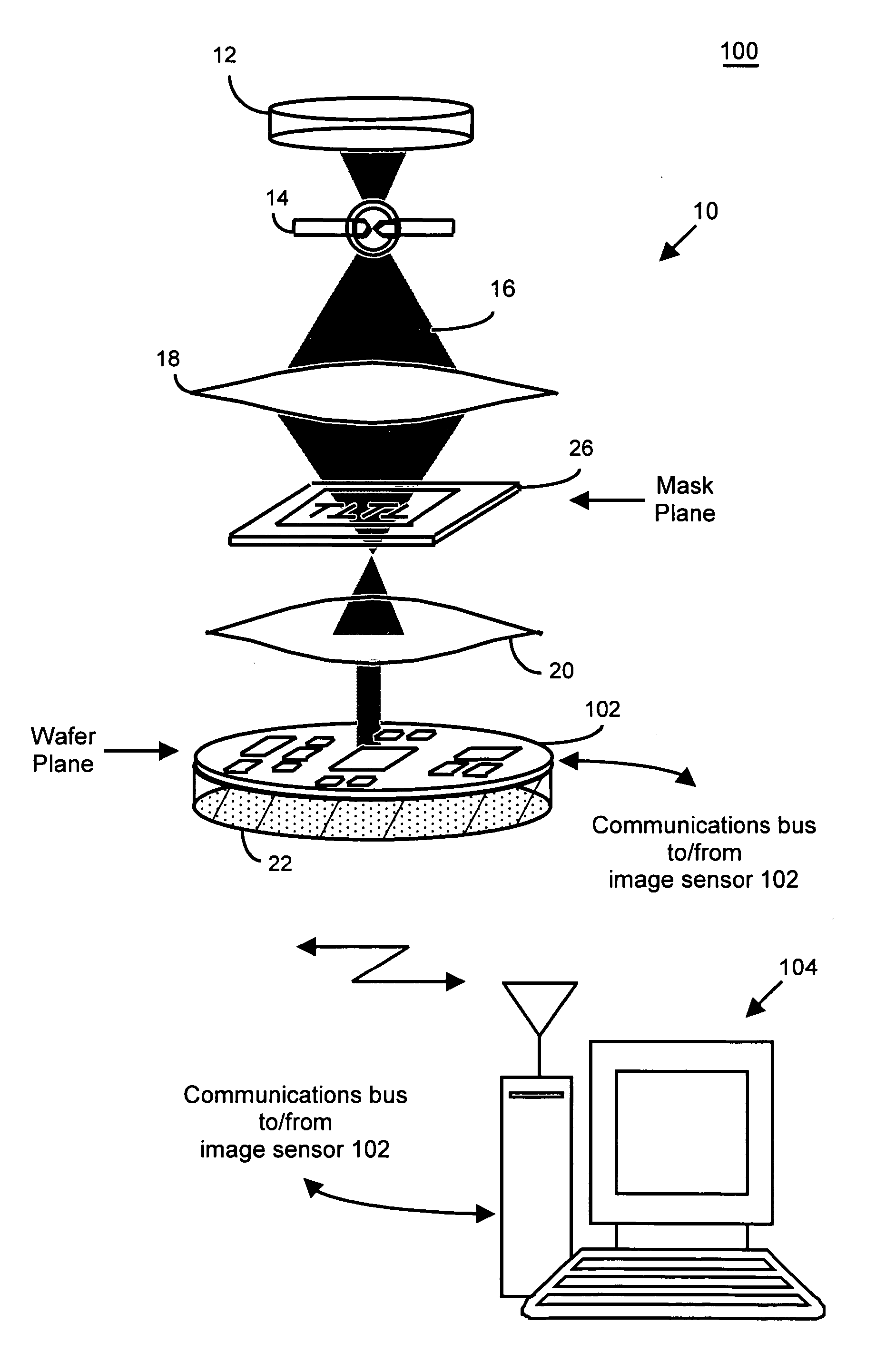

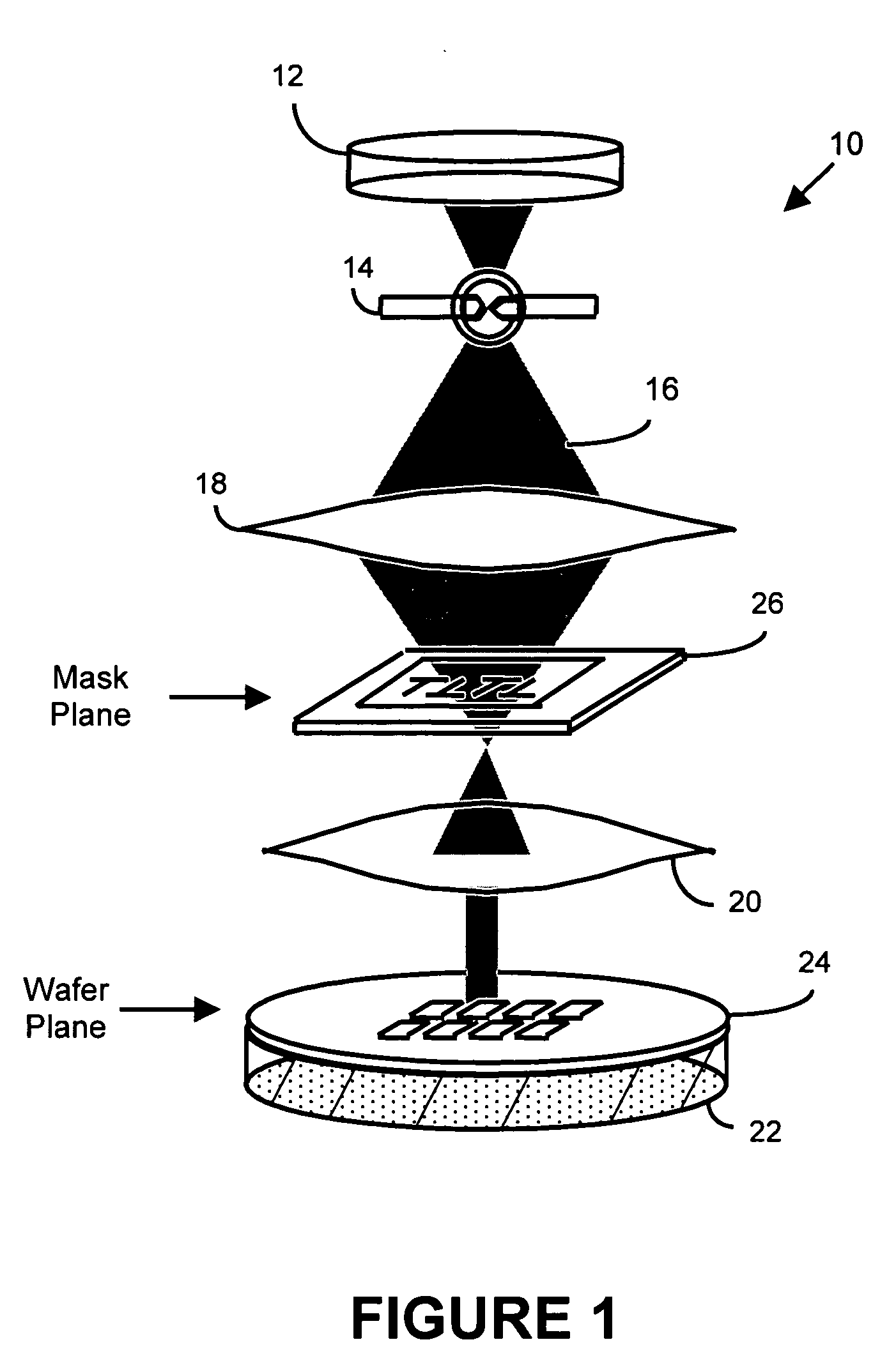

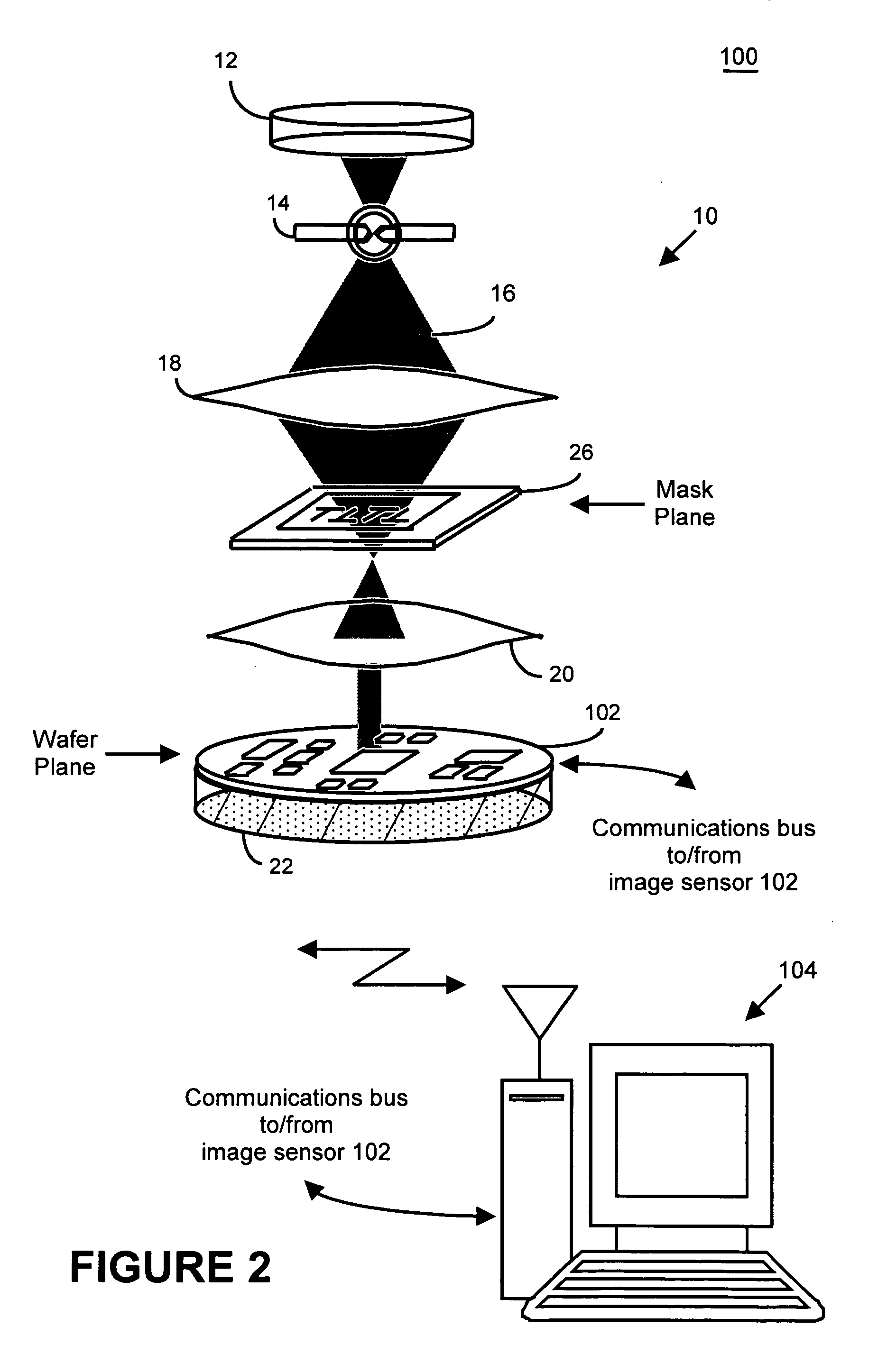

System and method for lithography process monitoring and control

InactiveUS20060000964A1Highly precise moveable platformSolid-state devicesPhotomechanical apparatusIntegrated circuit manufacturingLithography process

In one aspect, the present invention is a technique of, and a system and sensor for measuring, inspecting, characterizing and / or evaluating optical lithographic equipment, methods, and / or materials used therewith, for example, photomasks. In one embodiment, the system, sensor and technique measures, collects and / or detects an aerial image produced or generated by the interaction between the photomask and lithographic equipment. An image sensor unit may measure, collect, sense and / or detect the aerial image in situ—that is, the aerial image at the wafer plane produced, in part, by a product-type photomask (i.e., a wafer having integrated circuits formed during the integrated circuit fabrication process) and / or by associated lithographic equipment used, or to be used, to manufacture of integrated circuits. In this way, the aerial image used, generated or produced to measure, inspect, characterize and / or evaluate the photomask is the same aerial image used, generated or produced during wafer exposure in integrated circuit manufacturing. In another embodiment, the system, sensor and technique characterizes and / or evaluates the performance of the optical lithographic equipment, for example, the optical sub-system of such equipment. In this regard, in one embodiment, an image sensor unit measures, collects, senses and / or detects the aerial image produced or generated by the interaction between lithographic equipment and a photomask having a known, predetermined or fixed pattern (i.e., test mask). In this way, the system, sensor and technique collects, senses and / or detects the aerial image produced or generated by the test mask—lithographic equipment in order to inspect, evaluate and / or characterize the performance of the lithographic equipment.

Owner:ASML NETHERLANDS BV

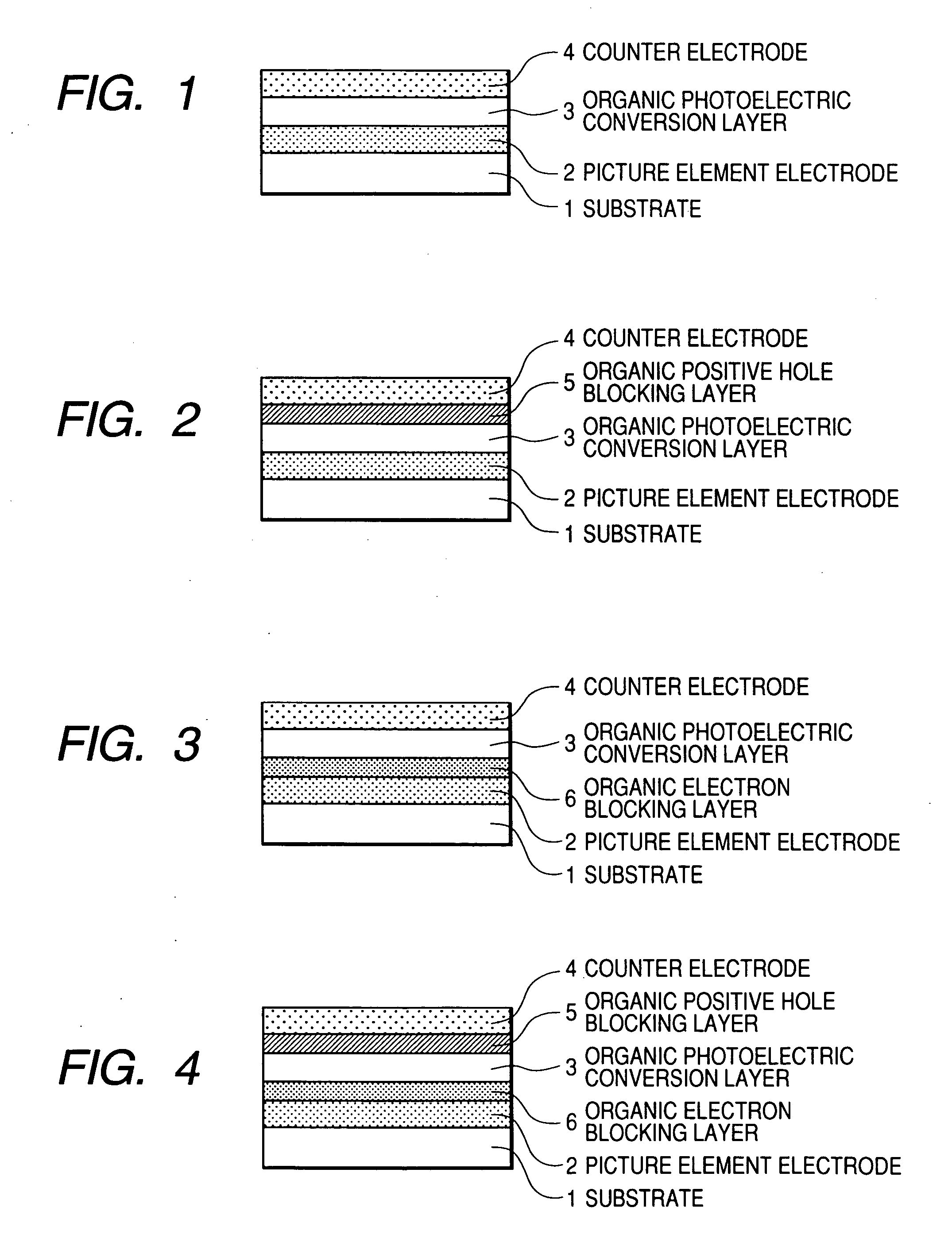

Organic photoelectric conversion element and image element

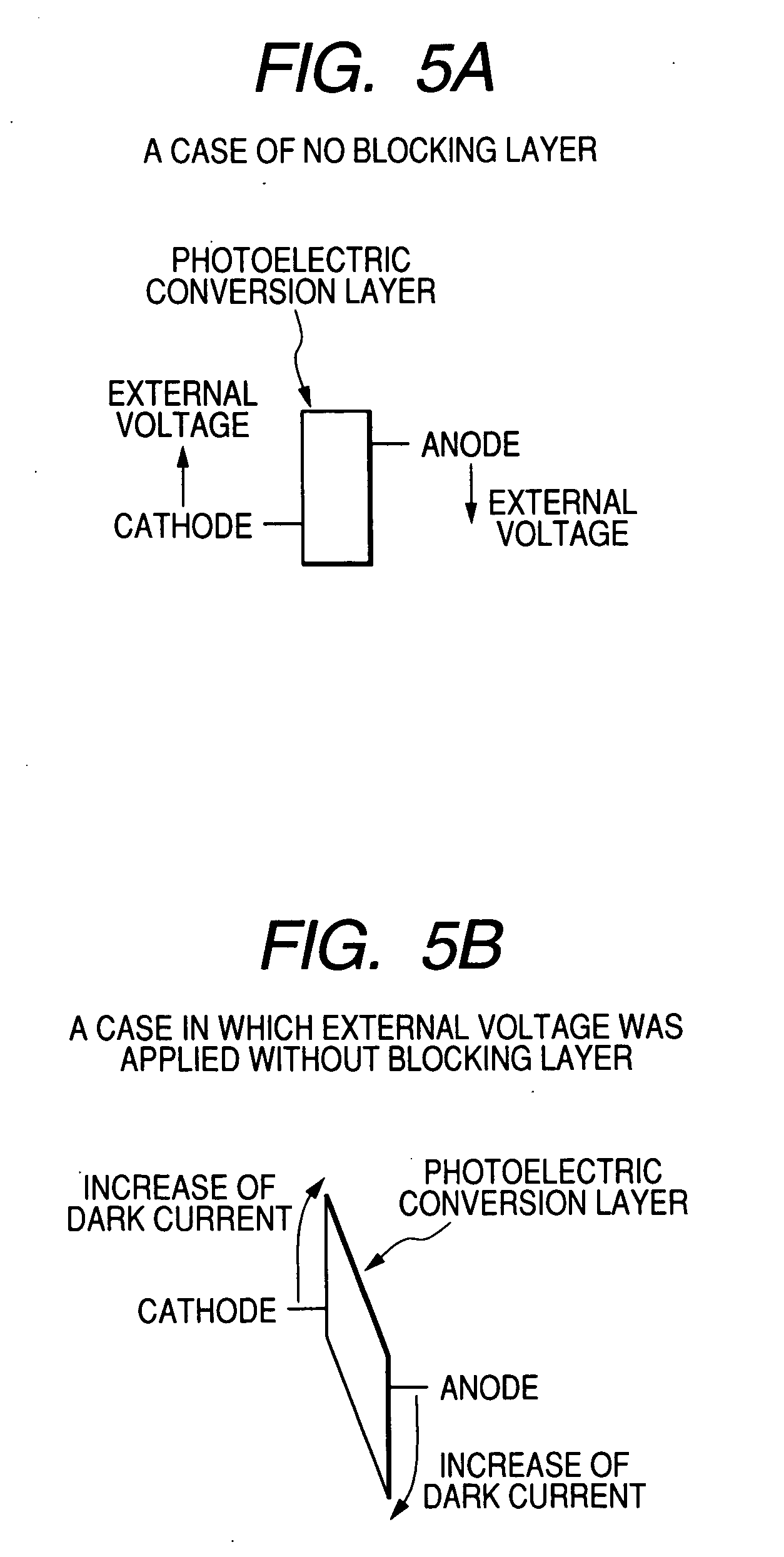

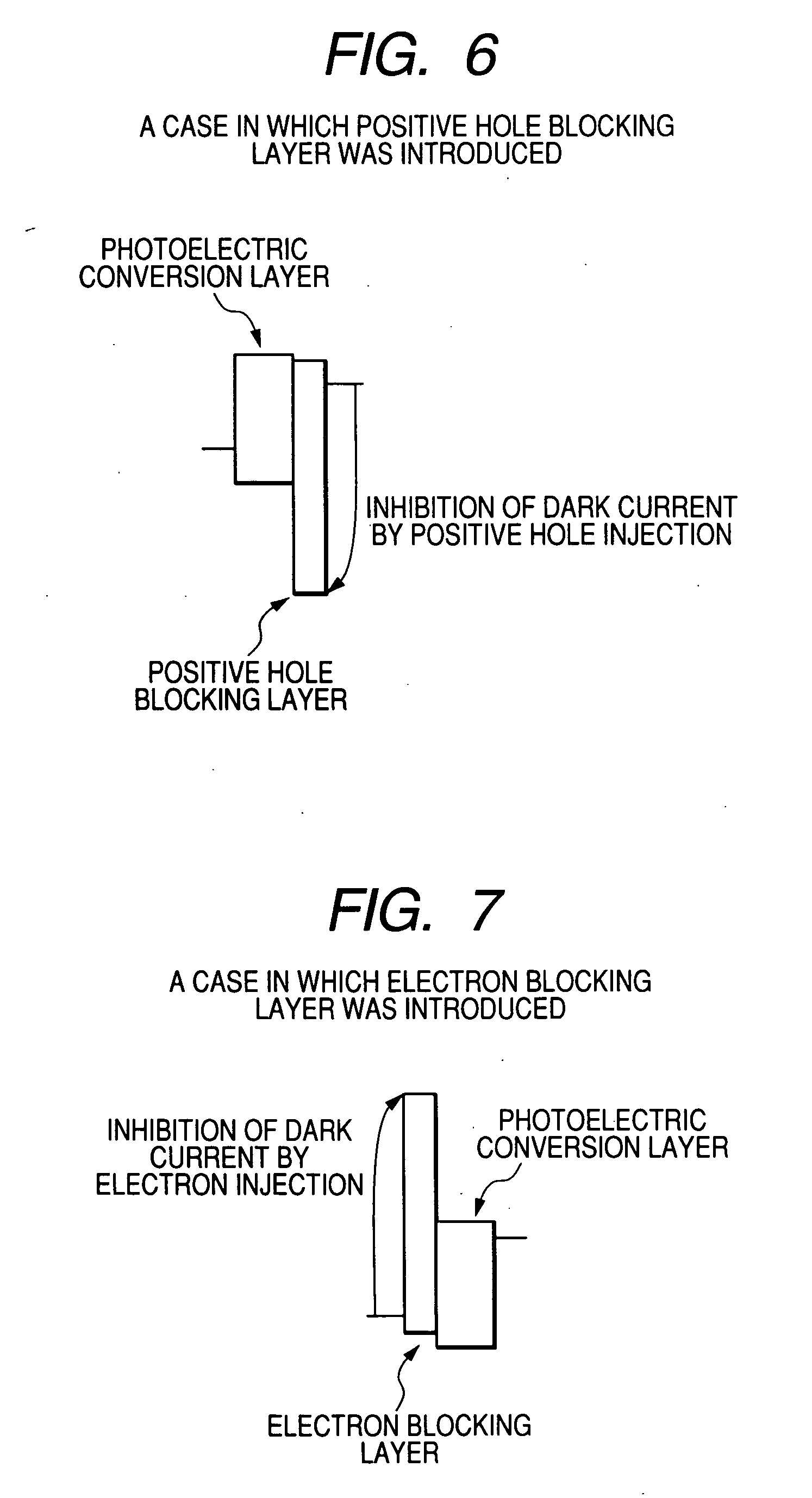

InactiveUS20070063156A1Photoelectric conversion efficiency is not reducedImprove photoelectric conversion efficiencySolid-state devicesInvestigating moving sheetsElectron holeWork function

An organic photoelectric conversion element comprises: a pair of electrodes; an organic photoelectric conversion layer arranged between the pair of electrodes; and an positive hole blocking layer arranged between one of the pair of electrodes and the organic photoelectric conversion layer, wherein an ionization potential of the positive hole blocking layer is larger than a work function of the adjoining electrode by 1.3 eV or more, and wherein an electron affinity of the positive hole blocking layer is equal to or larger than that of the adjoining organic photoelectric conversion layer. An electron blocking layer may be arranged between the other one of the pair of electrodes and the organic photoelectric conversion layer, wherein its electron affinity is smaller than a work function of the adjoining electrode by 1.3 eV or more, and its ionization potential is equal to or smaller than that of the adjoining organic photoelectric conversion layer.

Owner:FUJIFILM CORP +1

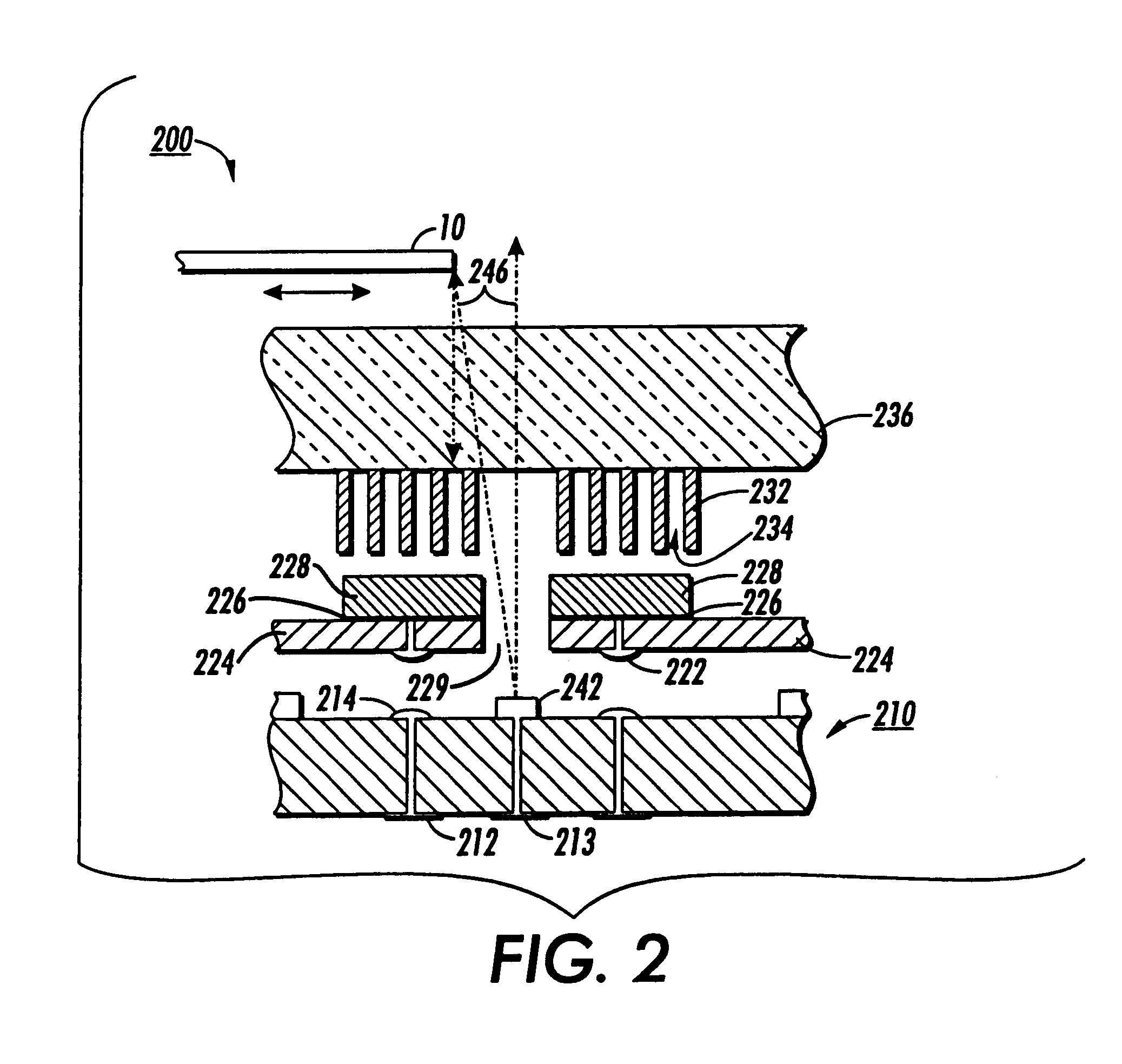

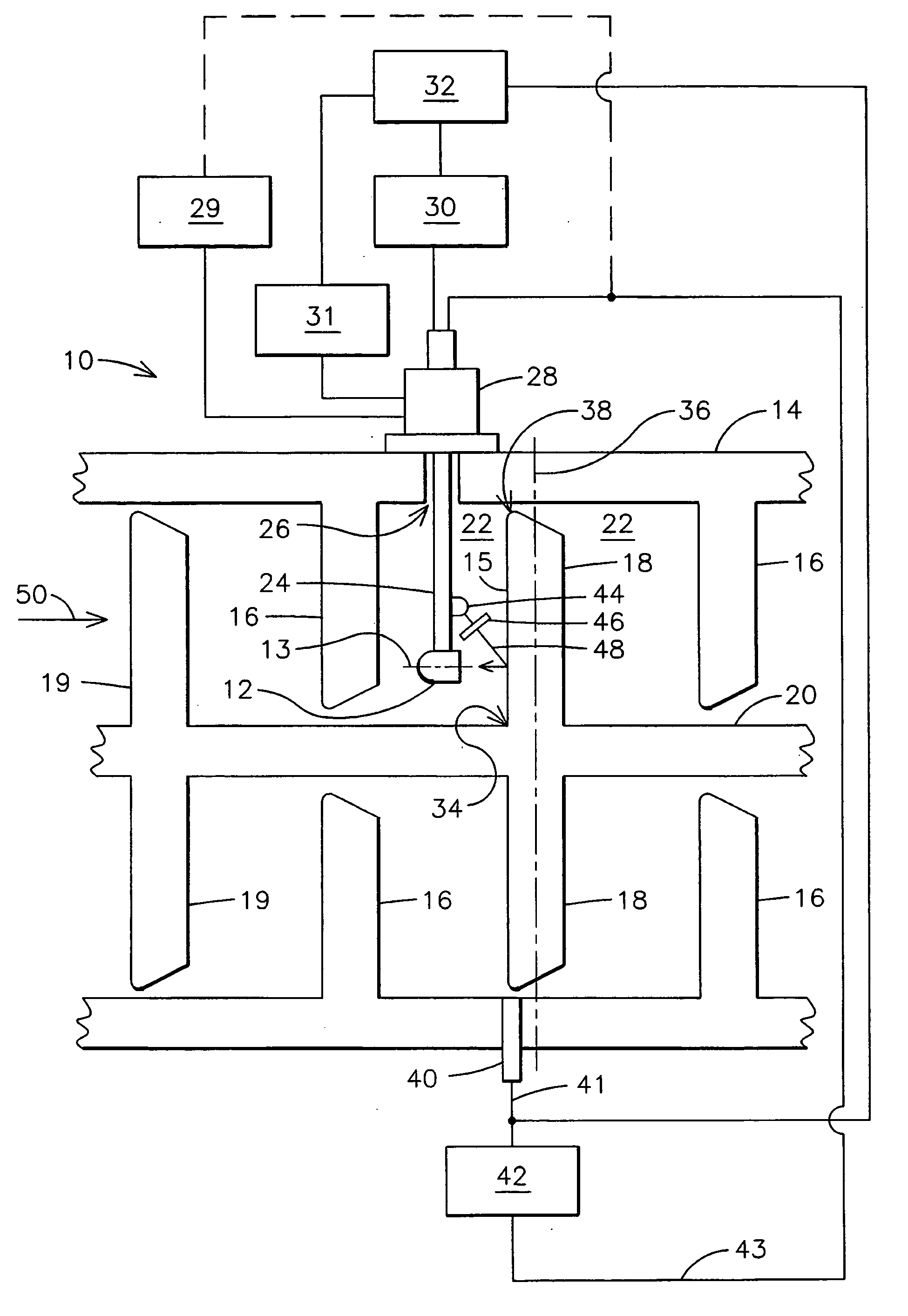

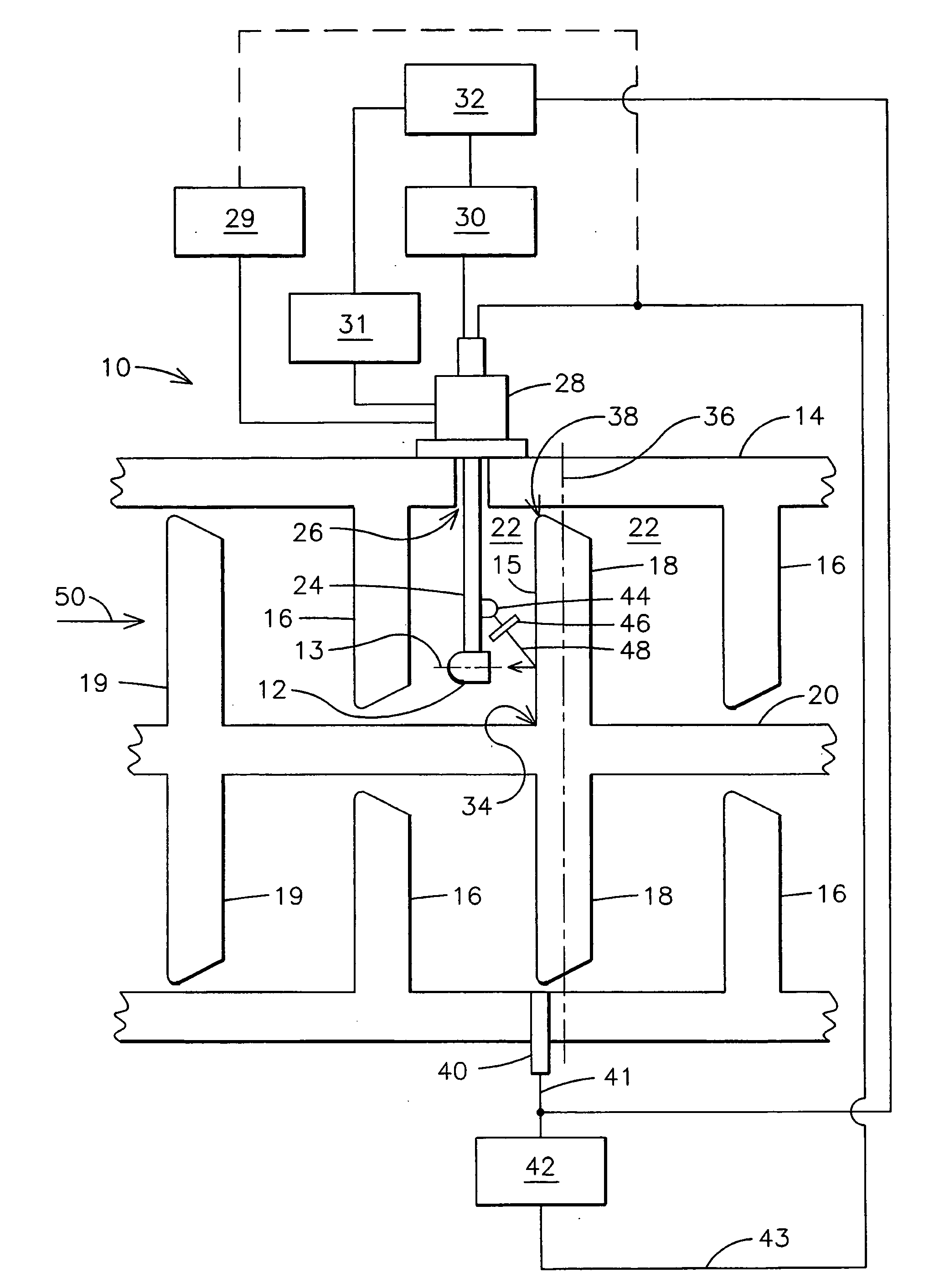

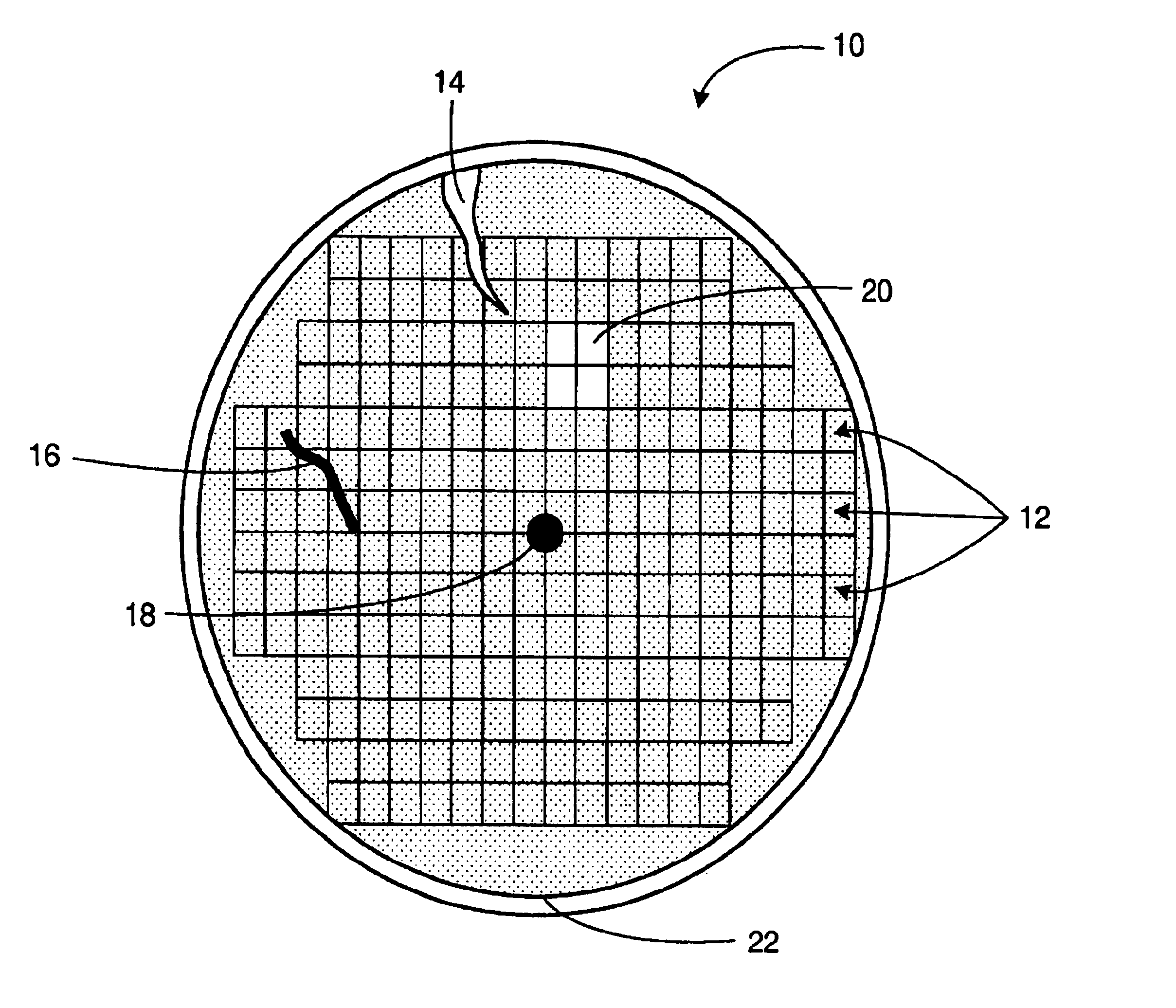

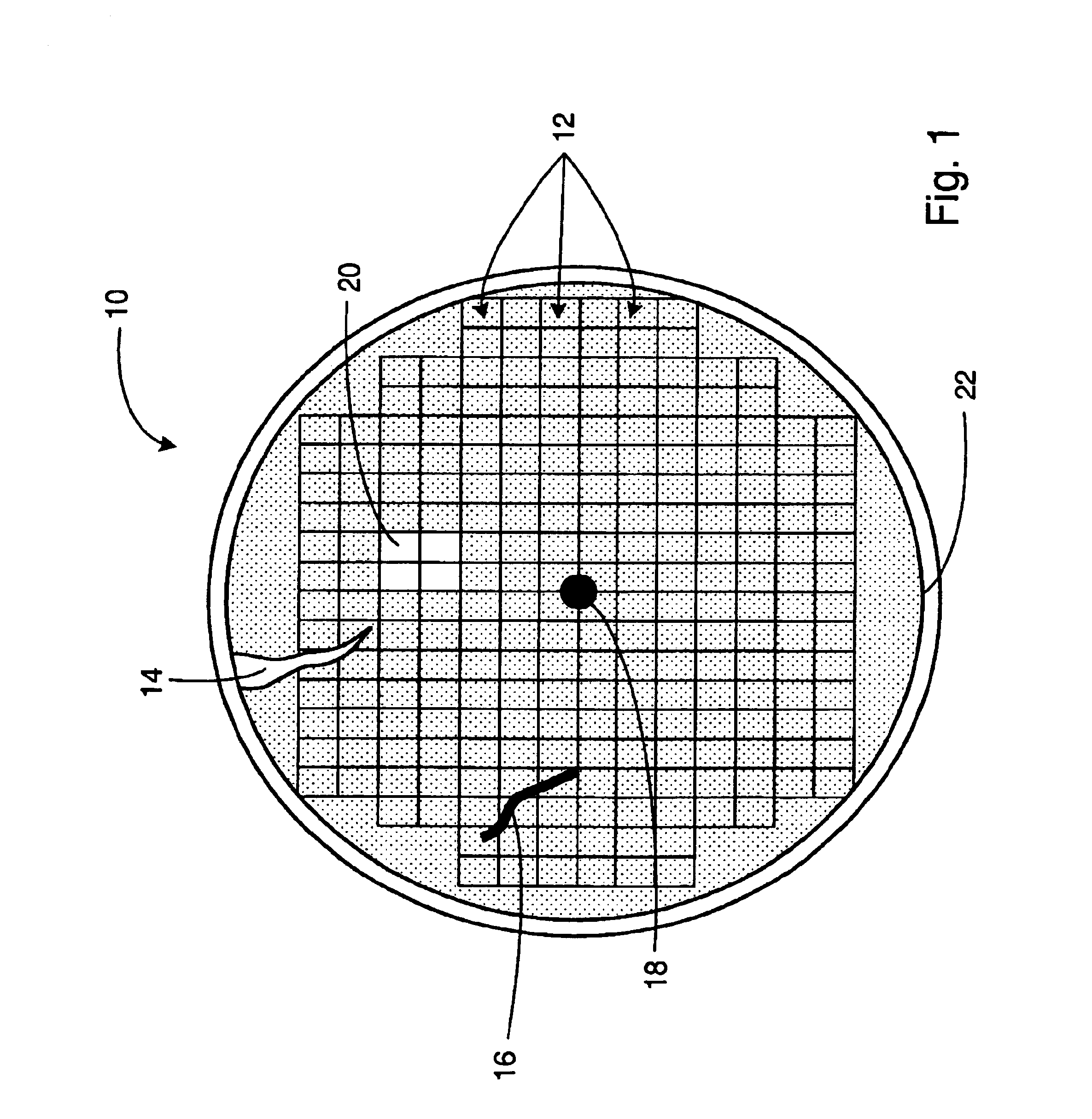

In situ combustion turbine engine airfoil inspection

A system (10) for imaging a combustion turbine engine airfoil includes a camera (12) and a positioner (24). The positioner may be controlled to dispose the camera within an inner turbine casing of the engine at a first position for acquiring a first image. The camera may then be moved to a second position for acquiring a second image. A storage device (30) stores the first and second images, and a processor (32) accesses the storage device to generate a composite image from the first and second images. For use when the airfoil is rotating, the system may also include a sensor (40) for generating a position signal (41) responsive to a detected angular position of an airfoil. The system may further include a trigger device (42), responsive to the position signal, for triggering the camera to acquire an image when the airfoil is proximate the camera.

Owner:SIEMENS ENERGY INC

Methods and systems for determining a critical dimension, a presence of defects, and a thin film characteristic of a specimen

InactiveUS6919957B2Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, critical dimension, a presence of defects, and a thin film characteristic. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA TENCOR TECH CORP

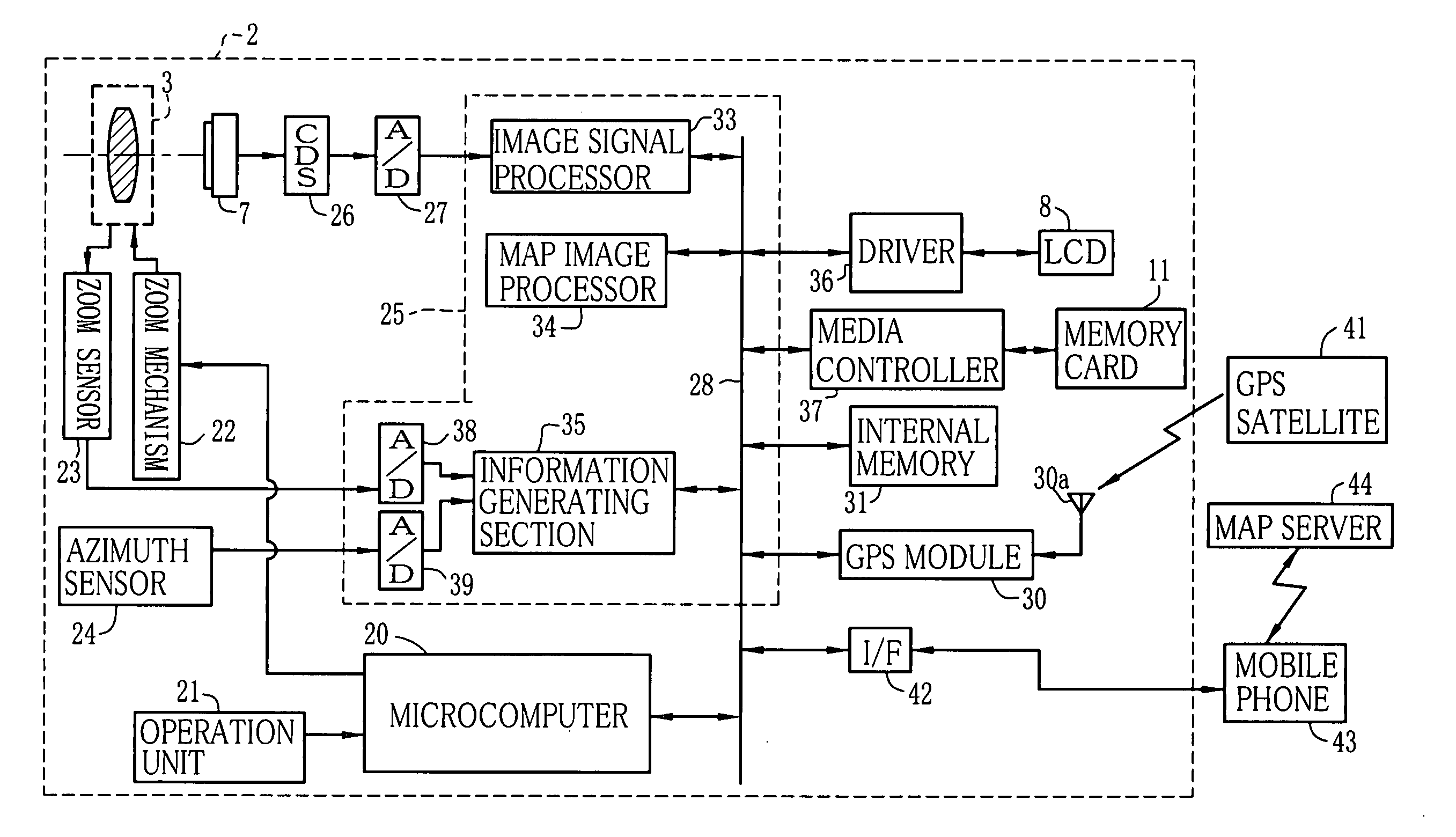

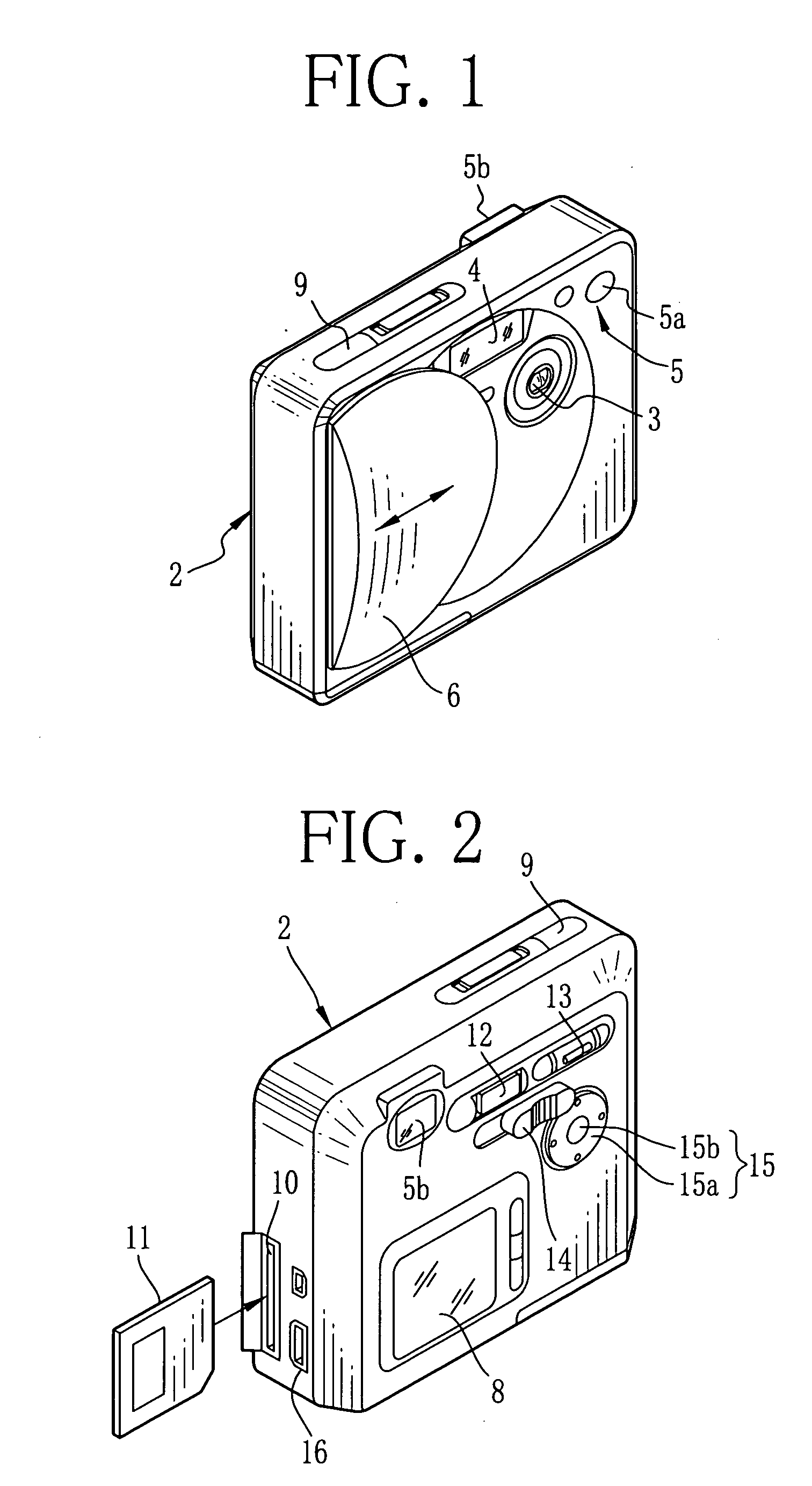

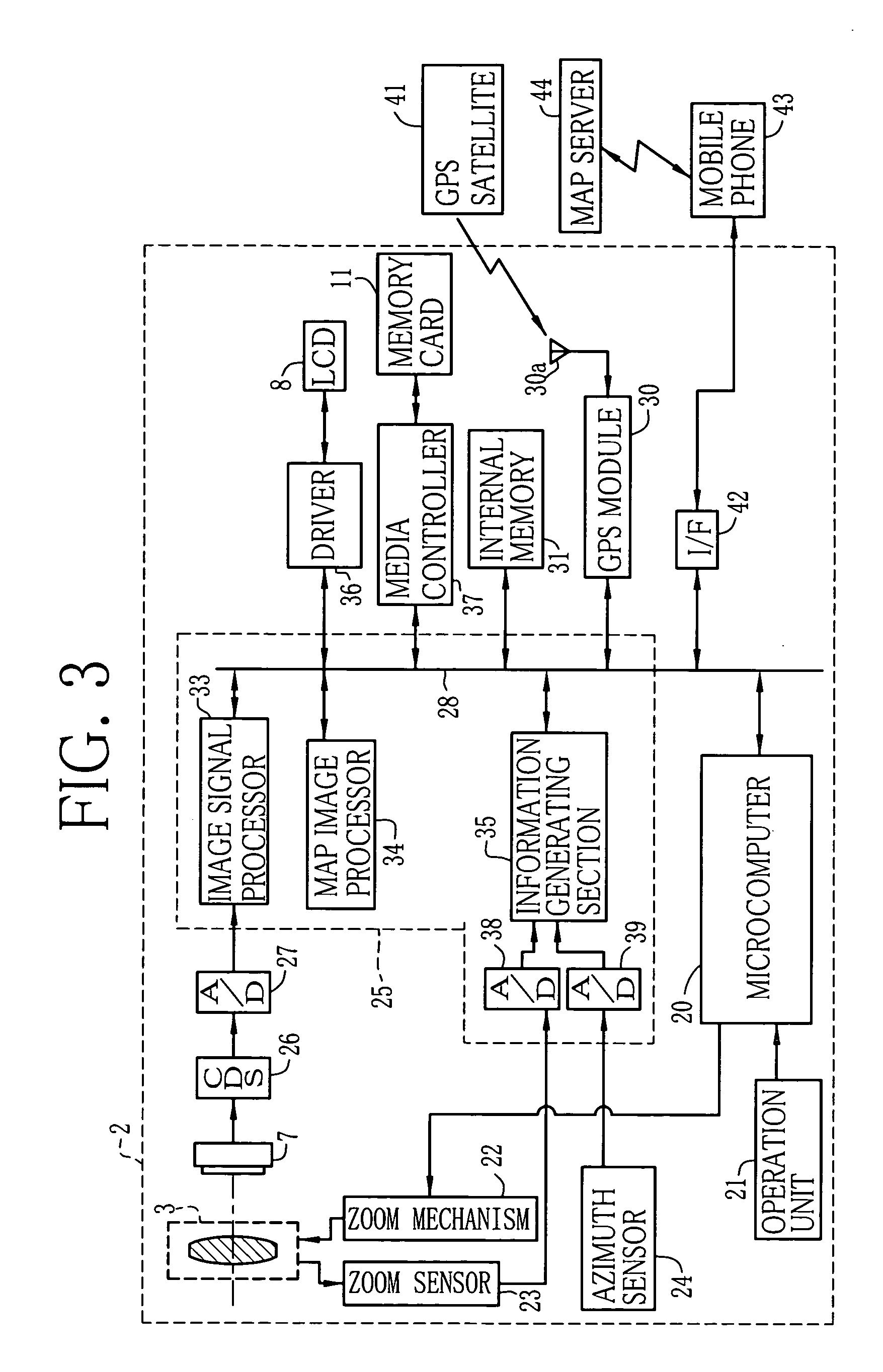

Map display system and digital camera

ActiveUS20060001757A1Easy to distinguishTelevision system detailsNavigational calculation instrumentsComputer graphics (images)Field of view

A digital camera receives position information from GPS satellites for detecting camera position when capturing an image. Additional information, which is composed of the camera position, camera azimuth and focal distance of the taking lens, is added to image data of the captured image as tag and recorded in an image file. When the captured image is reproduced, the map image generated according to the additional information is displayed below the captured image, covering an area from the image capture point toward the subject in the captured image. Field view lines and map symbols indicating the subjects are displayed in the map image. Further, the map image includes the extension line which passes the map symbol and is extended to the subject in the captured image for showing the correspondence between the map symbol and the subject.

Owner:FUJIFILM CORP

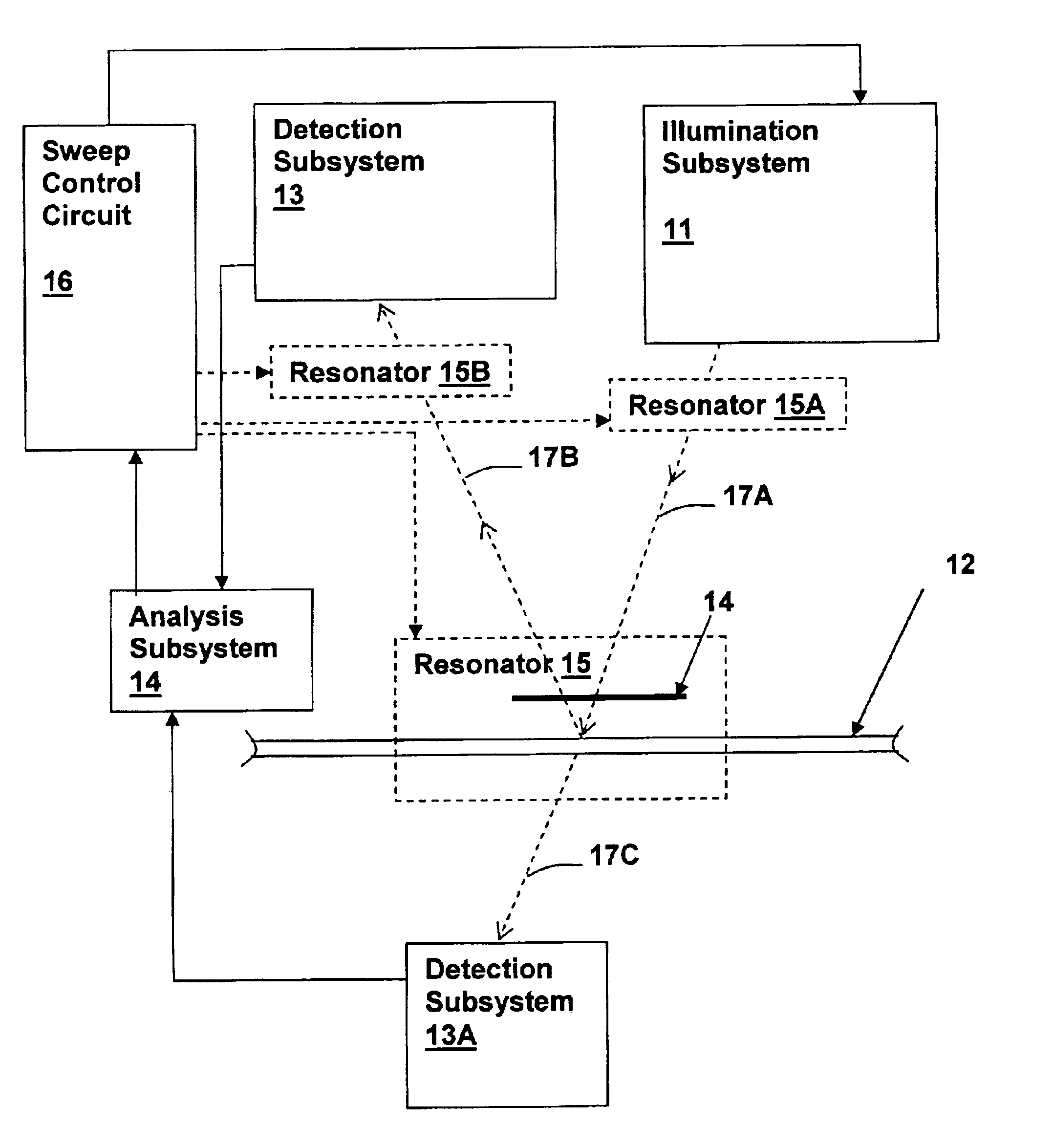

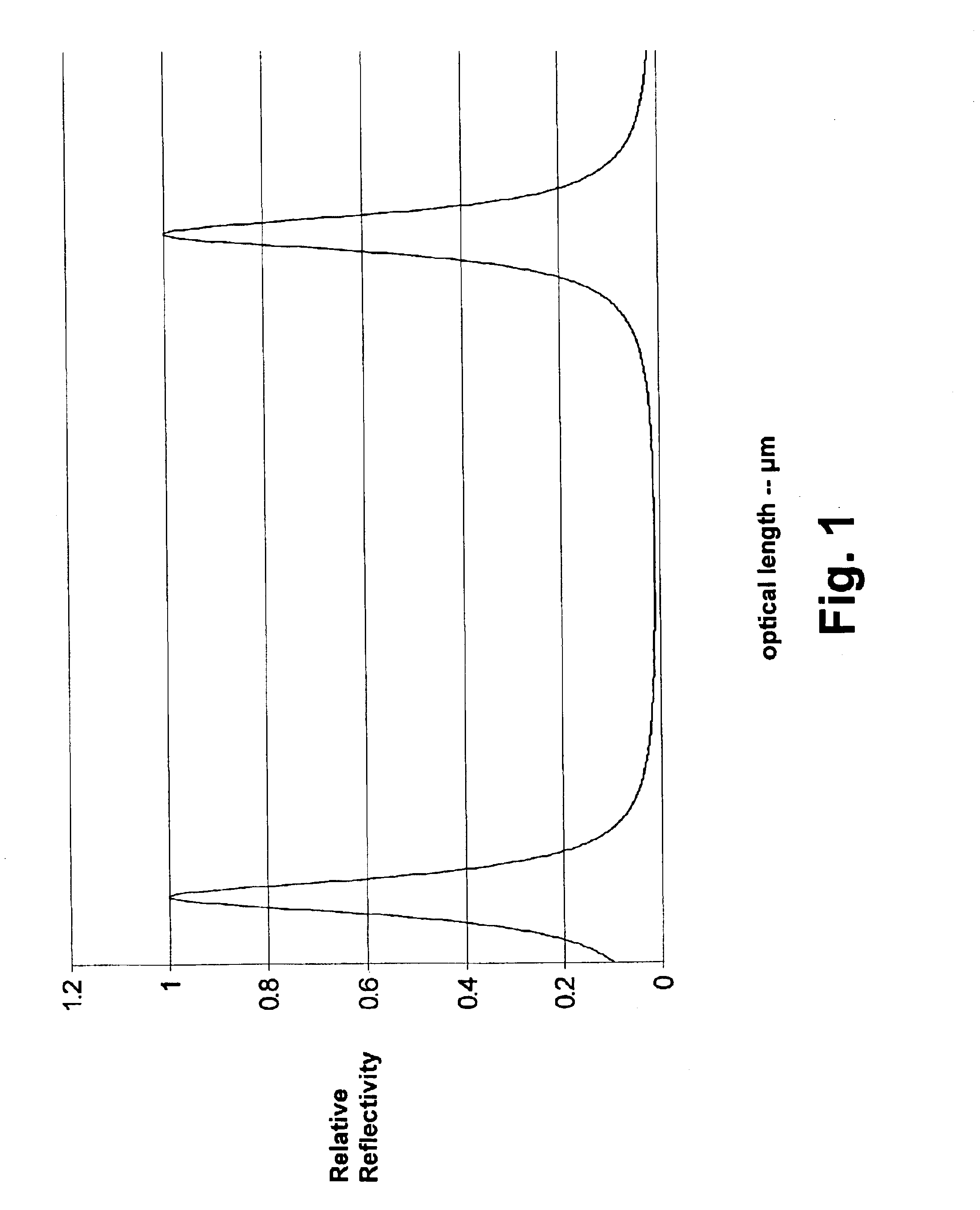

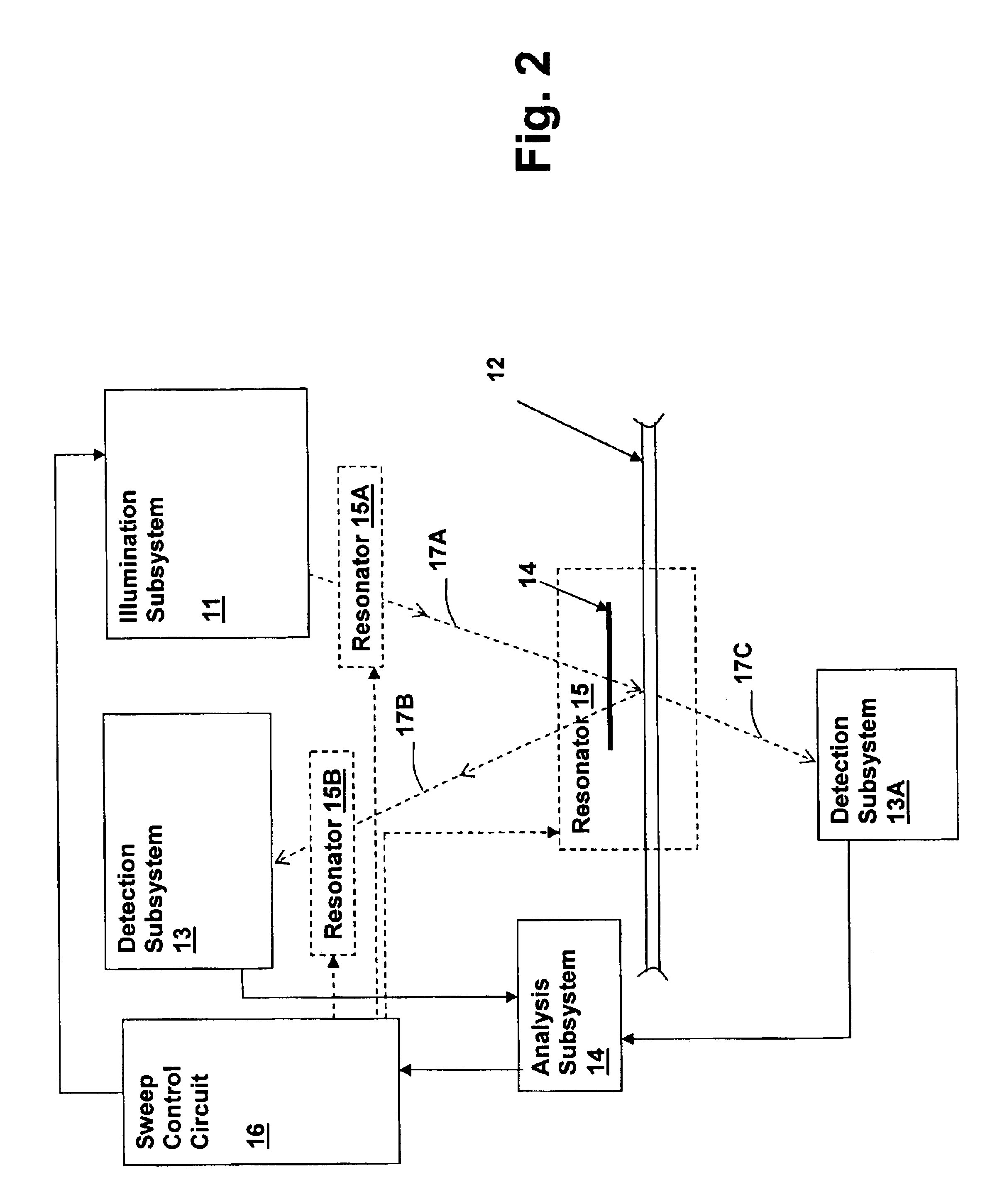

Method and system for performing swept-wavelength measurements within an optical system

A method and system for performing swept-wavelength measurements within an optical system provides improved operation in resonator-enhanced optical measurement and data storage and retrieval systems. The system includes an illumination subsystem having a swept-wavelength mode, a detection subsystem, an interferometer or an optical resonator interposed in an optical path between the illumination subsystem and the detection subsystem and a time domain analysis subsystem. Multiple resonance points of the optical resonator are detected by the time-domain subsystem when the illumination subsystem is in the swept-wavelength mode in order to determine resonator or interferometer characteristic changes. The resulting information can be used directly as a measurement output, or cavity length information may also be used to adjust the operating wavelength of a constant wavelength mode of the illumination subsystem.

Owner:XYRATEX CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com