Patents

Literature

27401results about "Blade accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

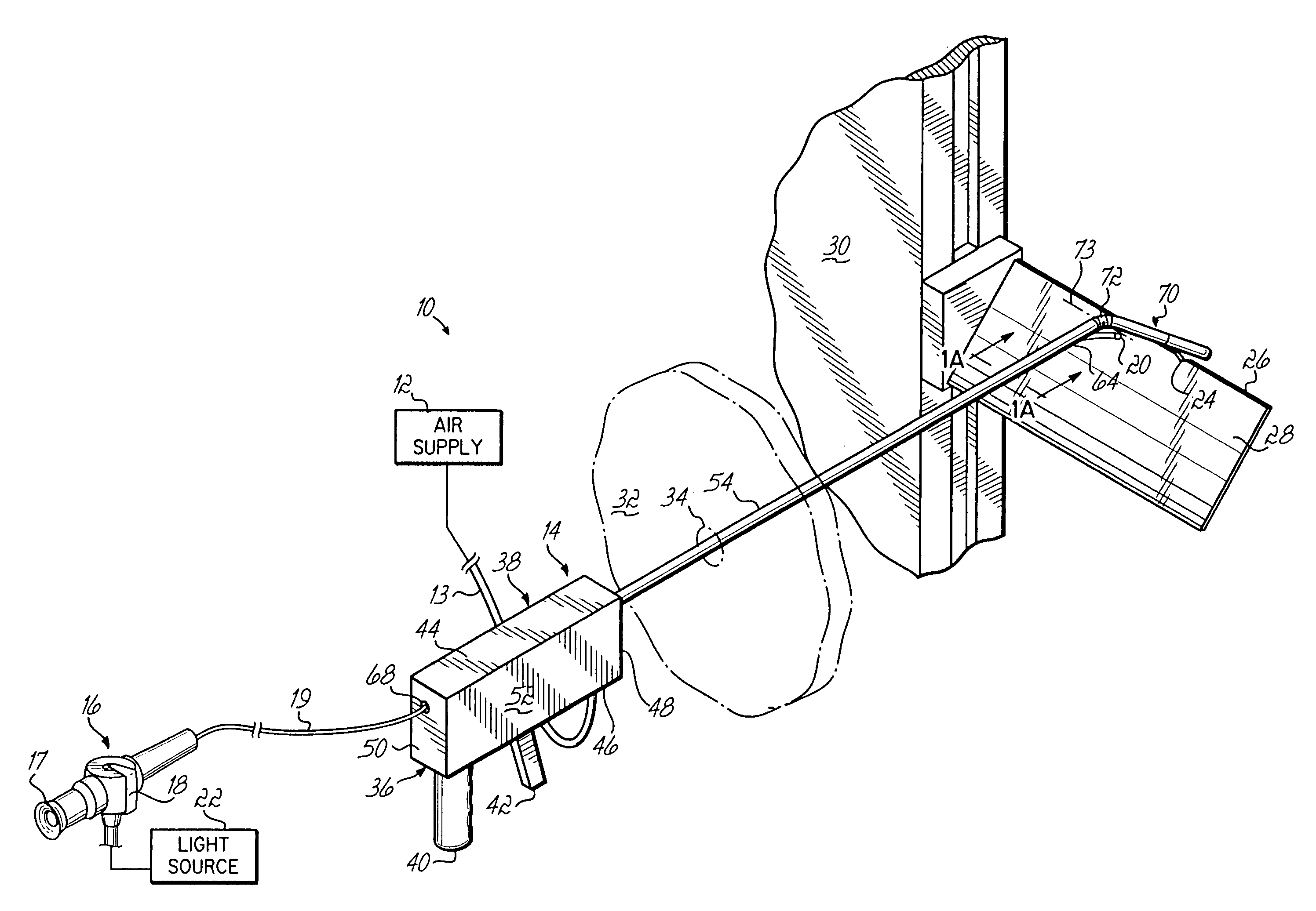

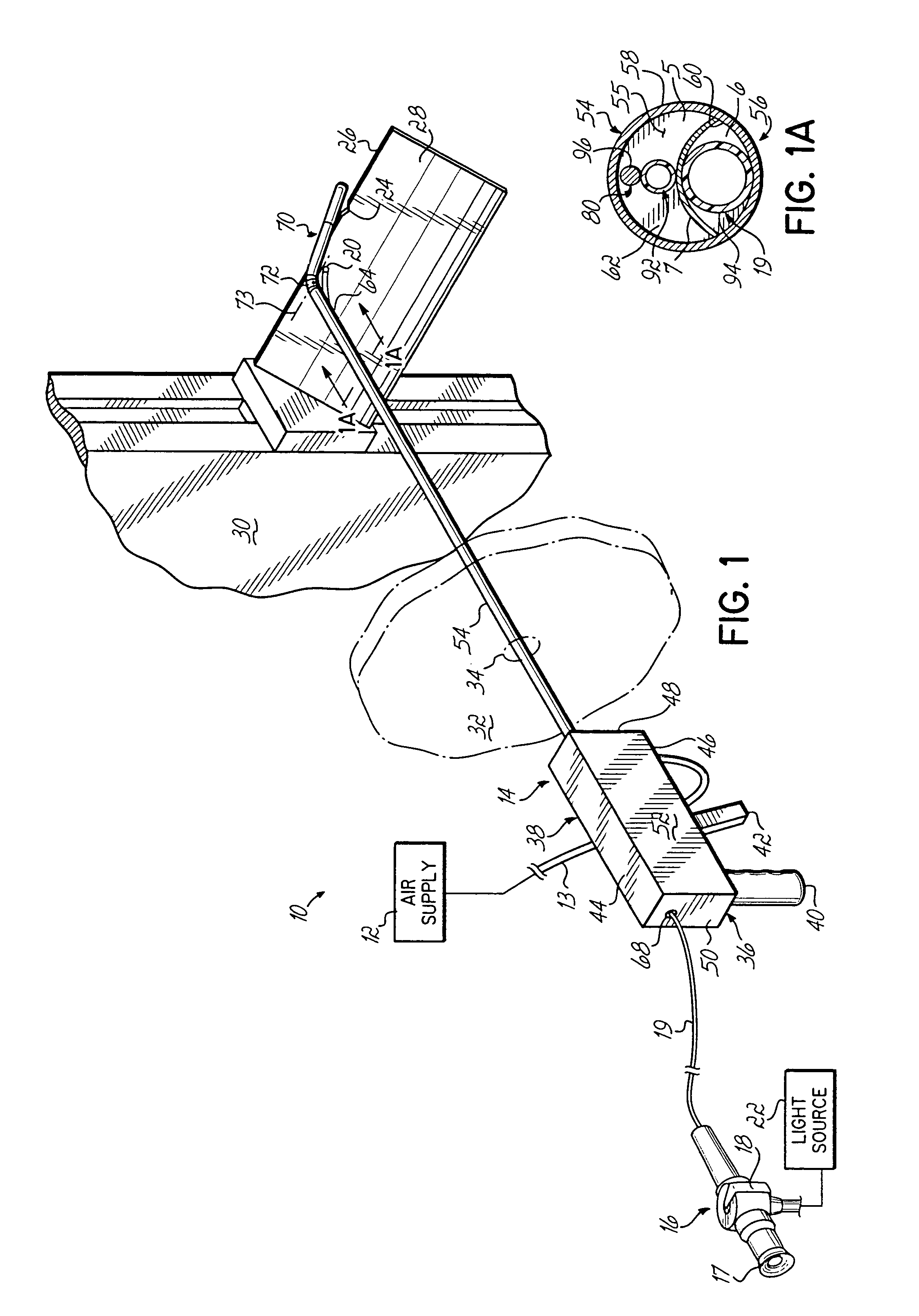

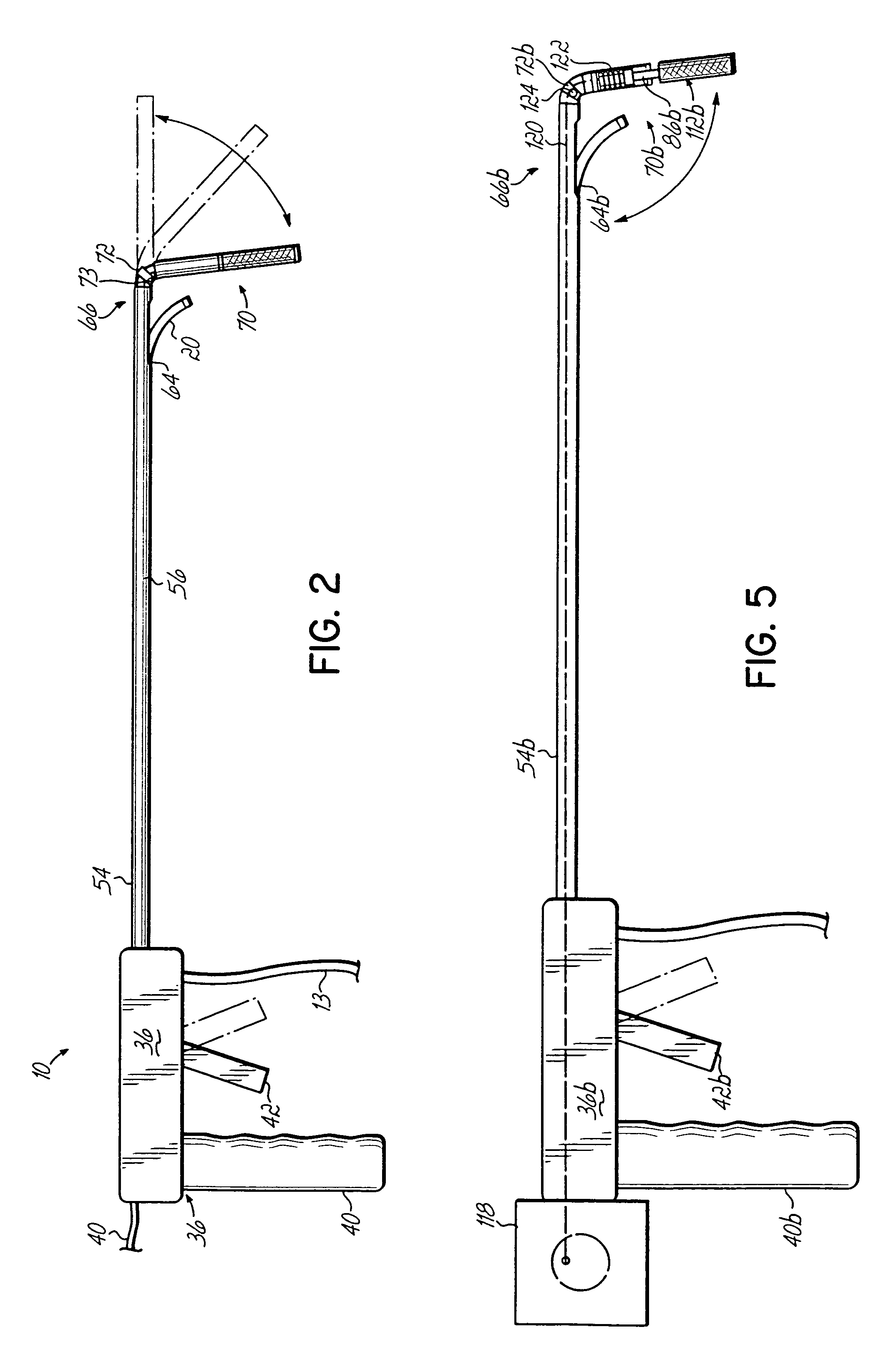

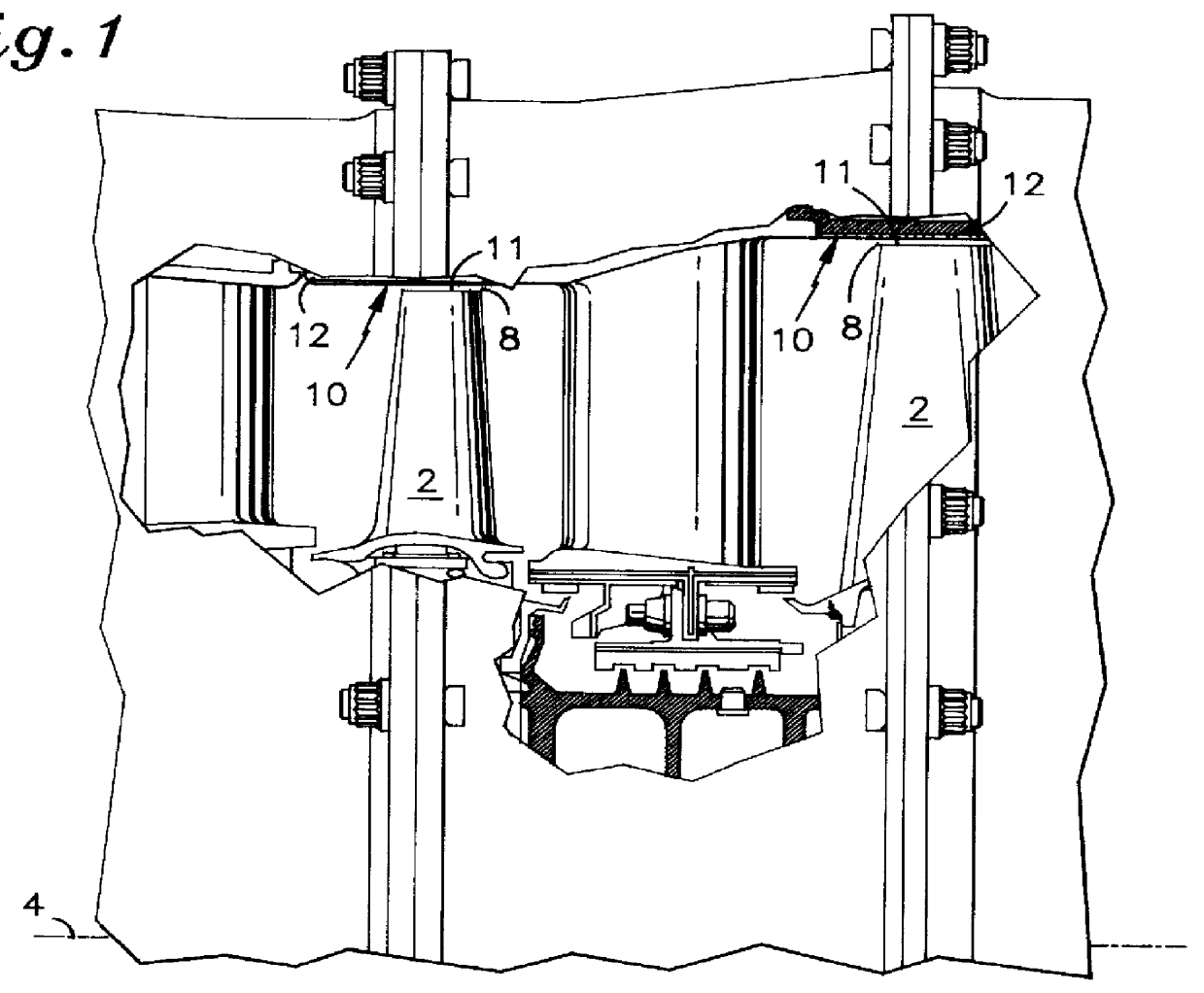

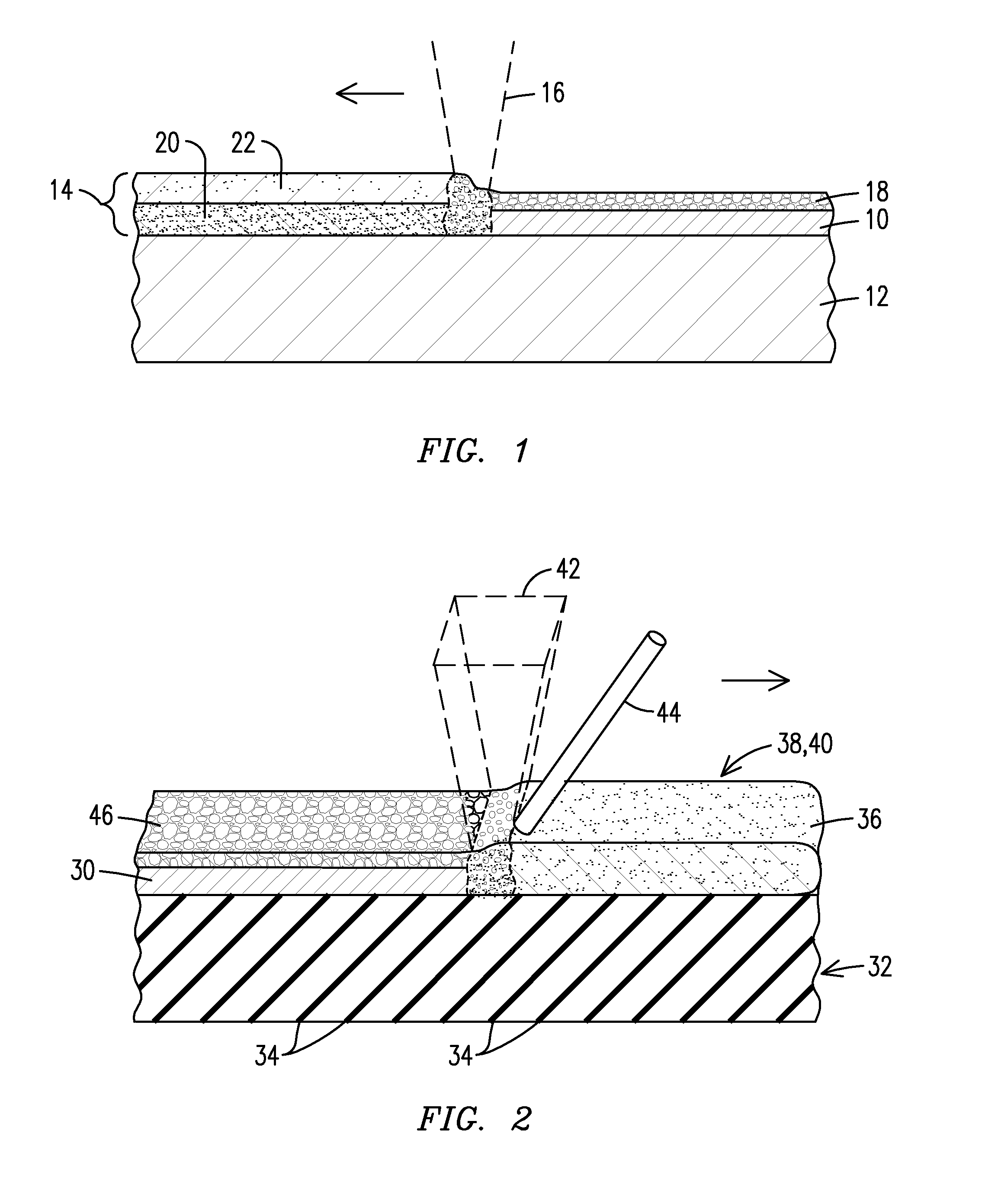

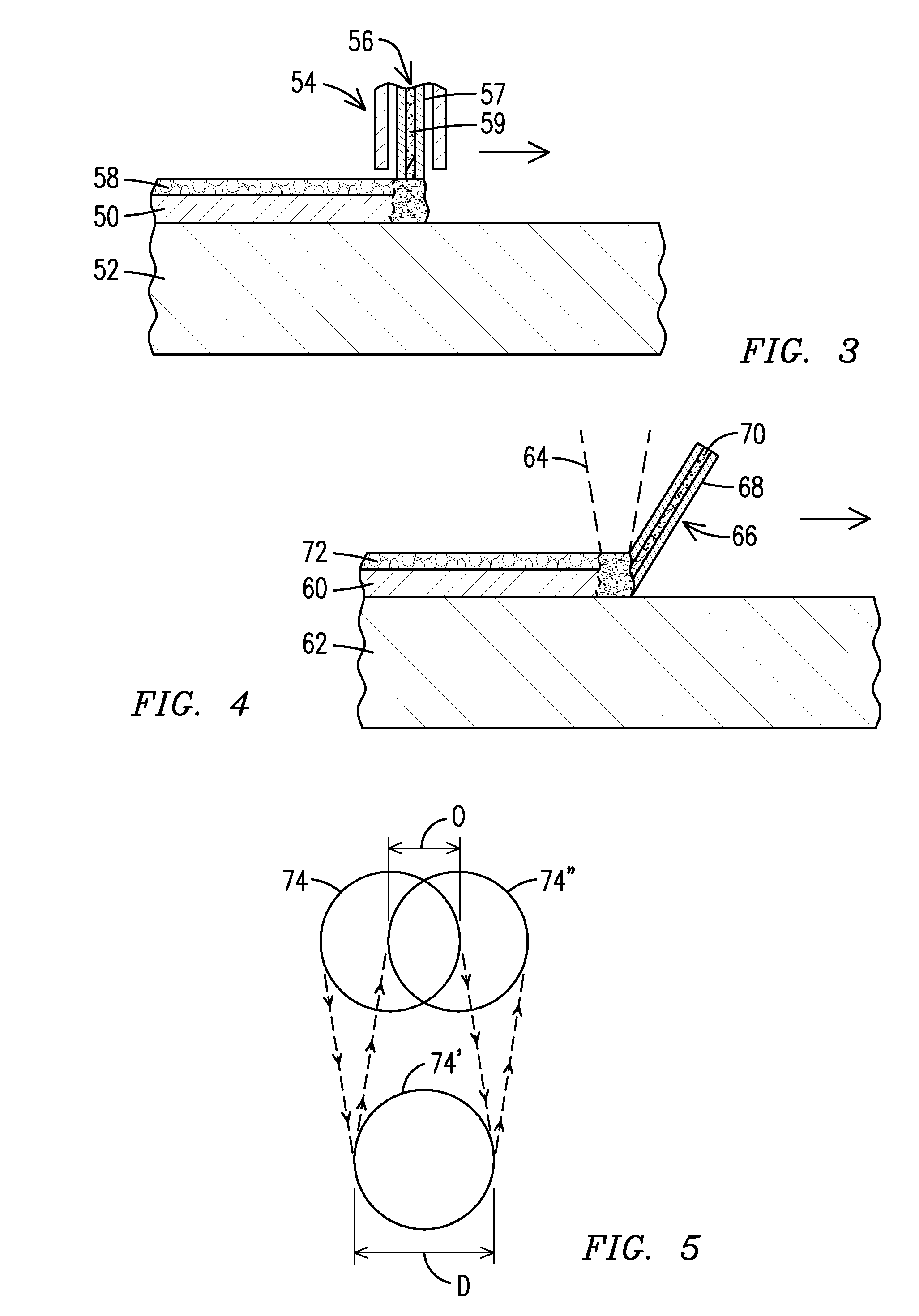

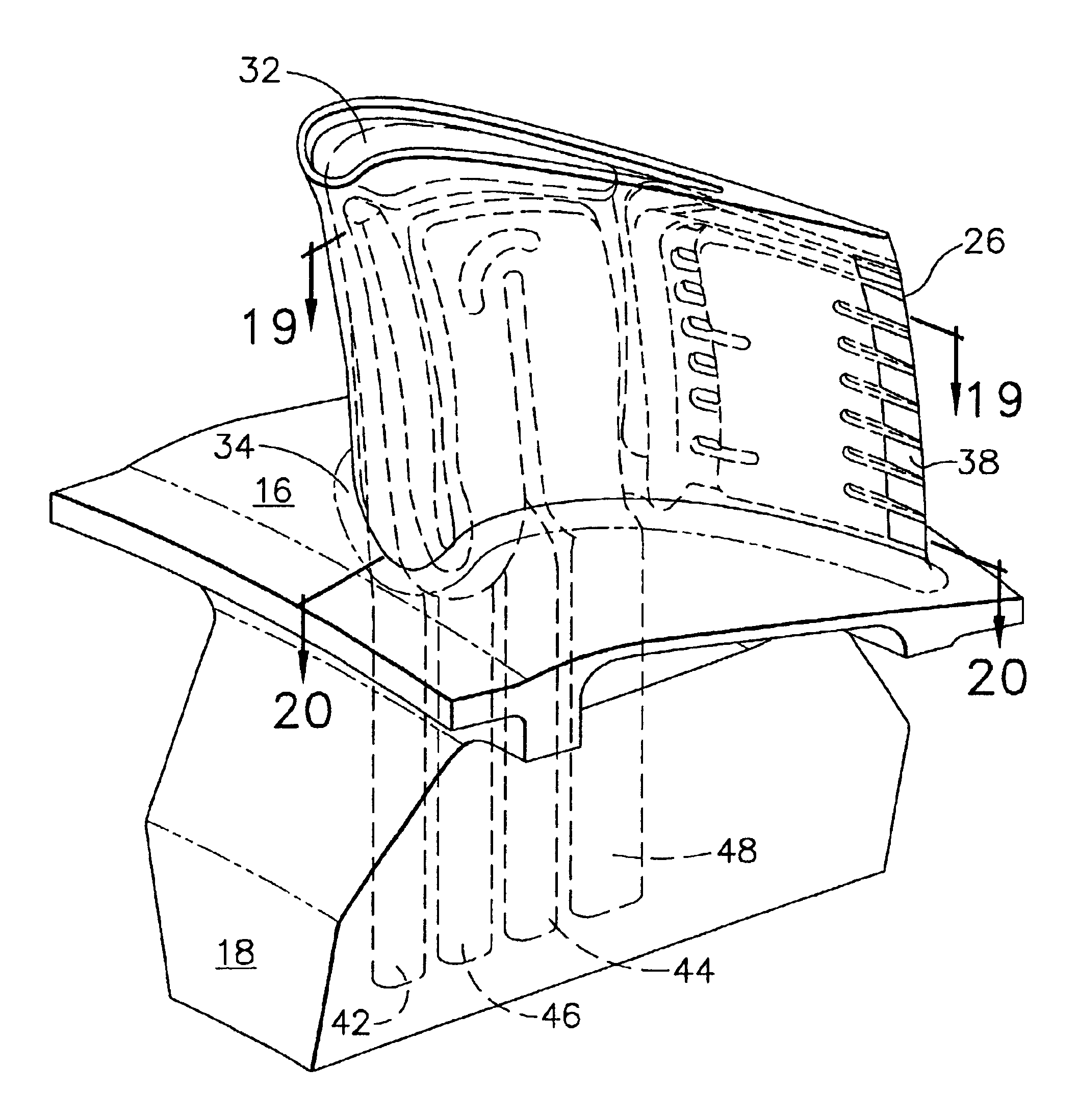

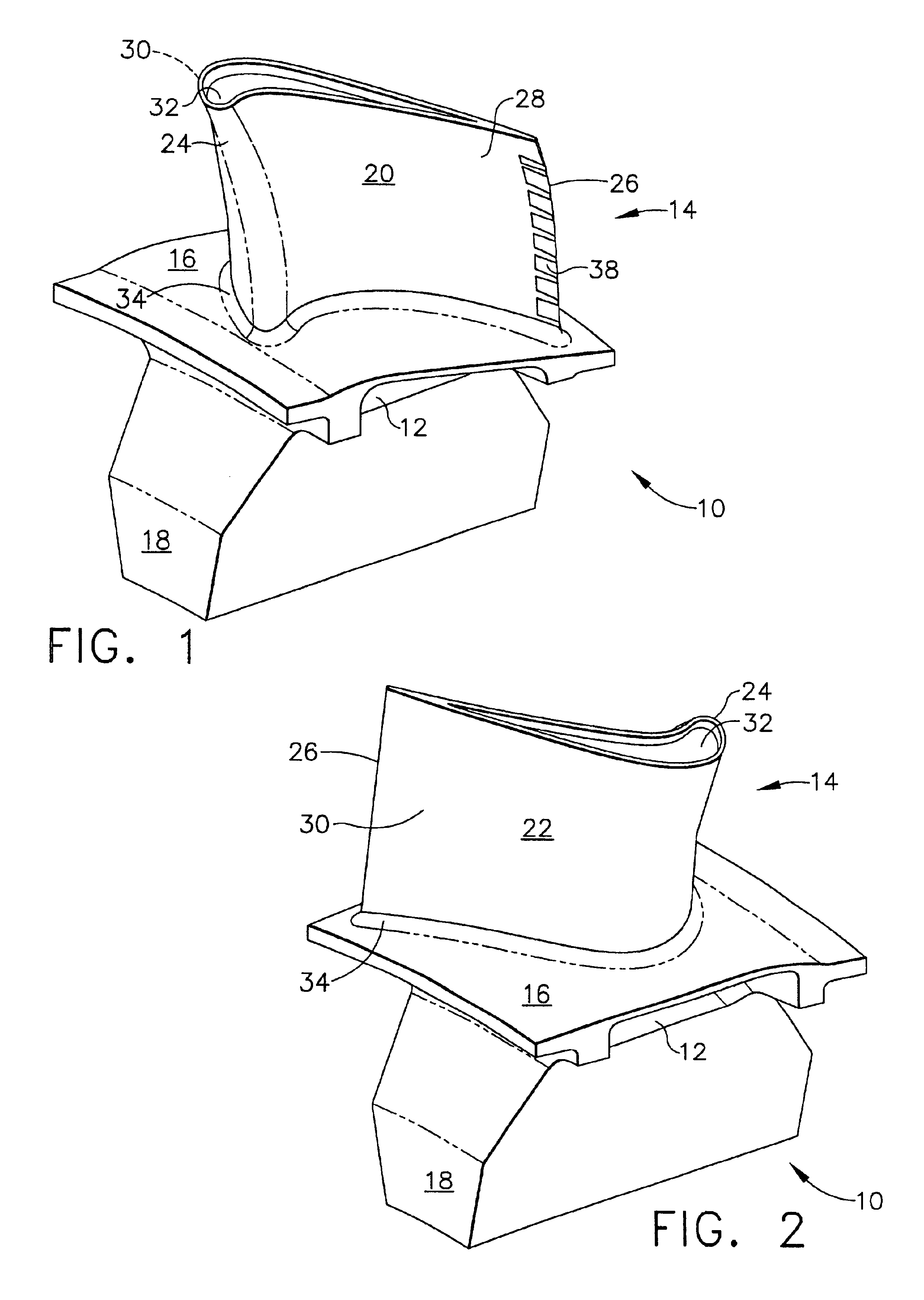

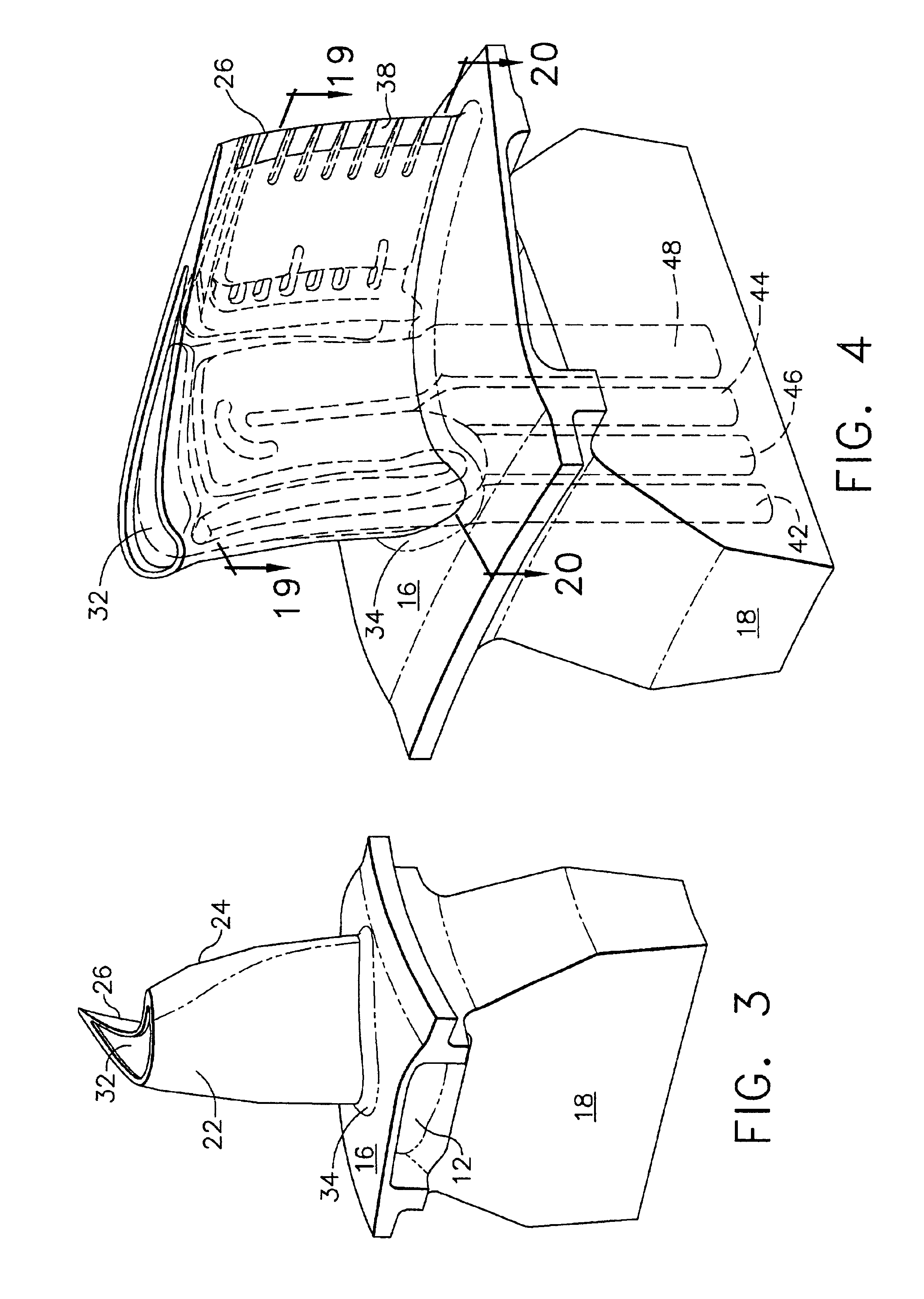

Grinding apparatus for blending defects on turbine blades and associated method of use

InactiveUS6899593B1Revolution surface grinding machinesBlade accessoriesReciprocating motionTurbine blade

A grinding apparatus for use with an endoscope for viewing and blending defects on a turbine engine blade is provided. In one preferred embodiment air pulses from an air supply cause a grinding head on the end of a grinding tool to reciprocate at a predetermined speed. The position of the grinding head is fixed via the operator via a trigger on the grinding tool which articulates an outer portion of a support tube of the grinding tool. In another preferred embodiment, fluid is used to reciprocate the grinding head.

Owner:MOELLER DIETER +2

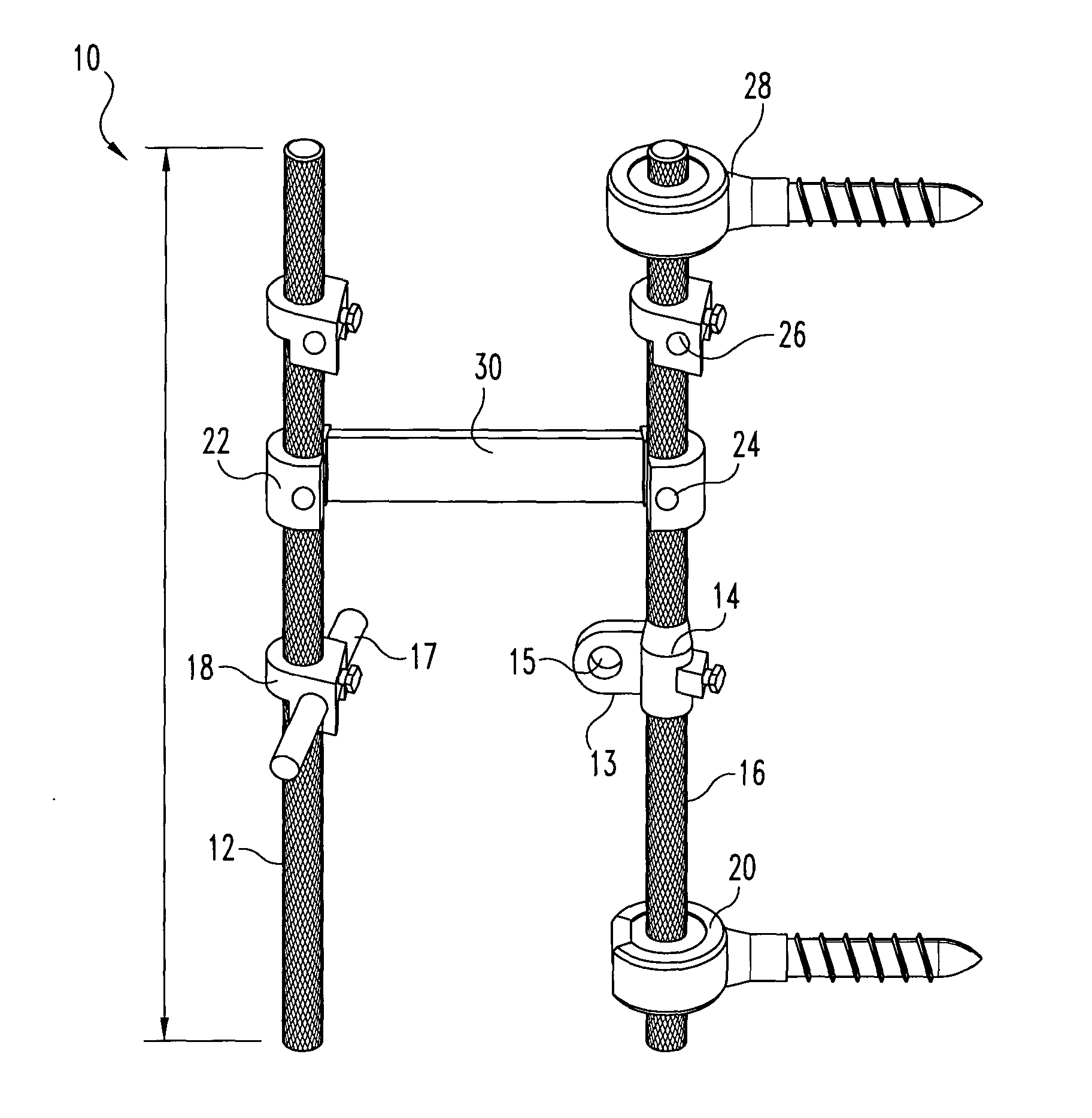

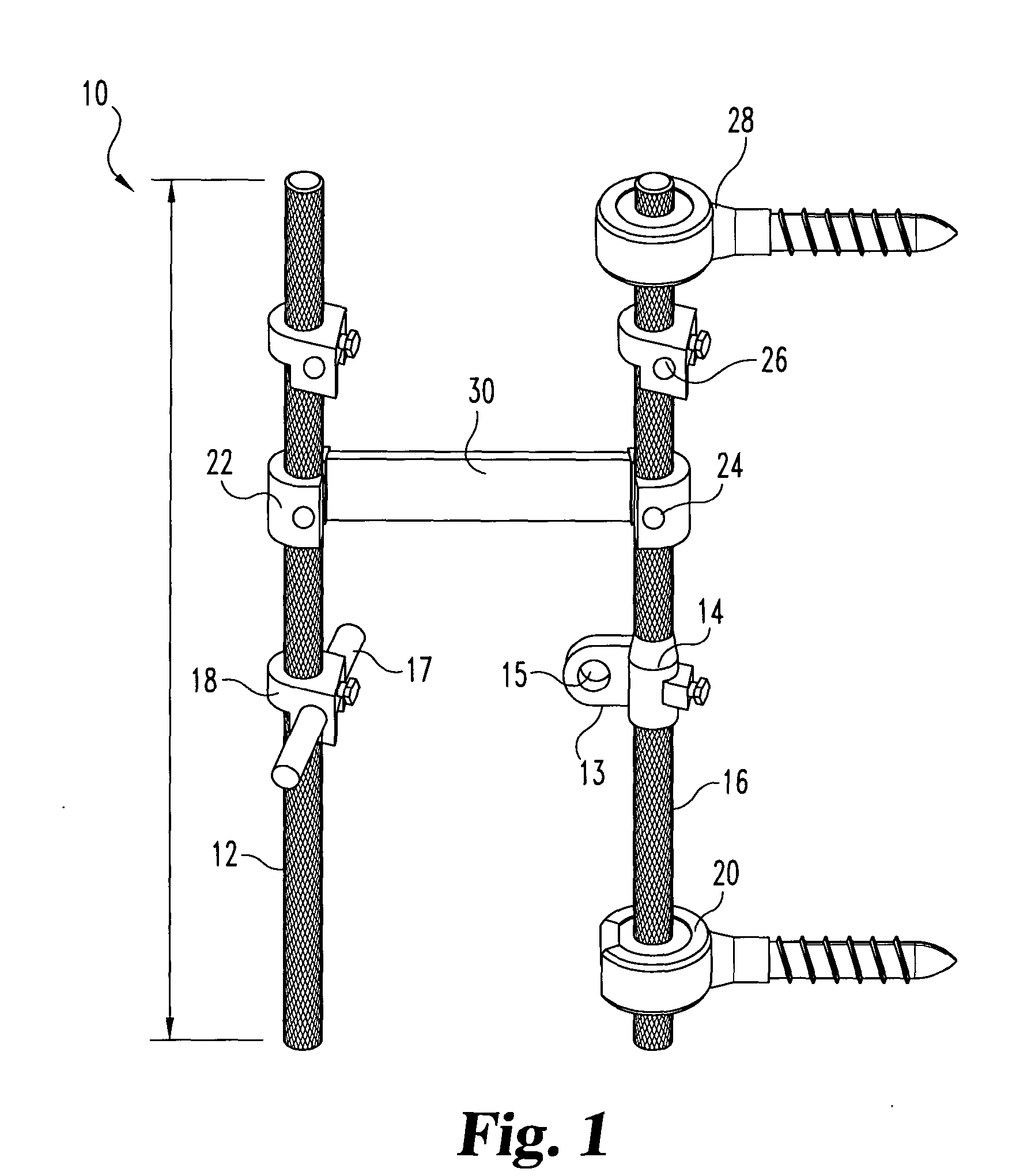

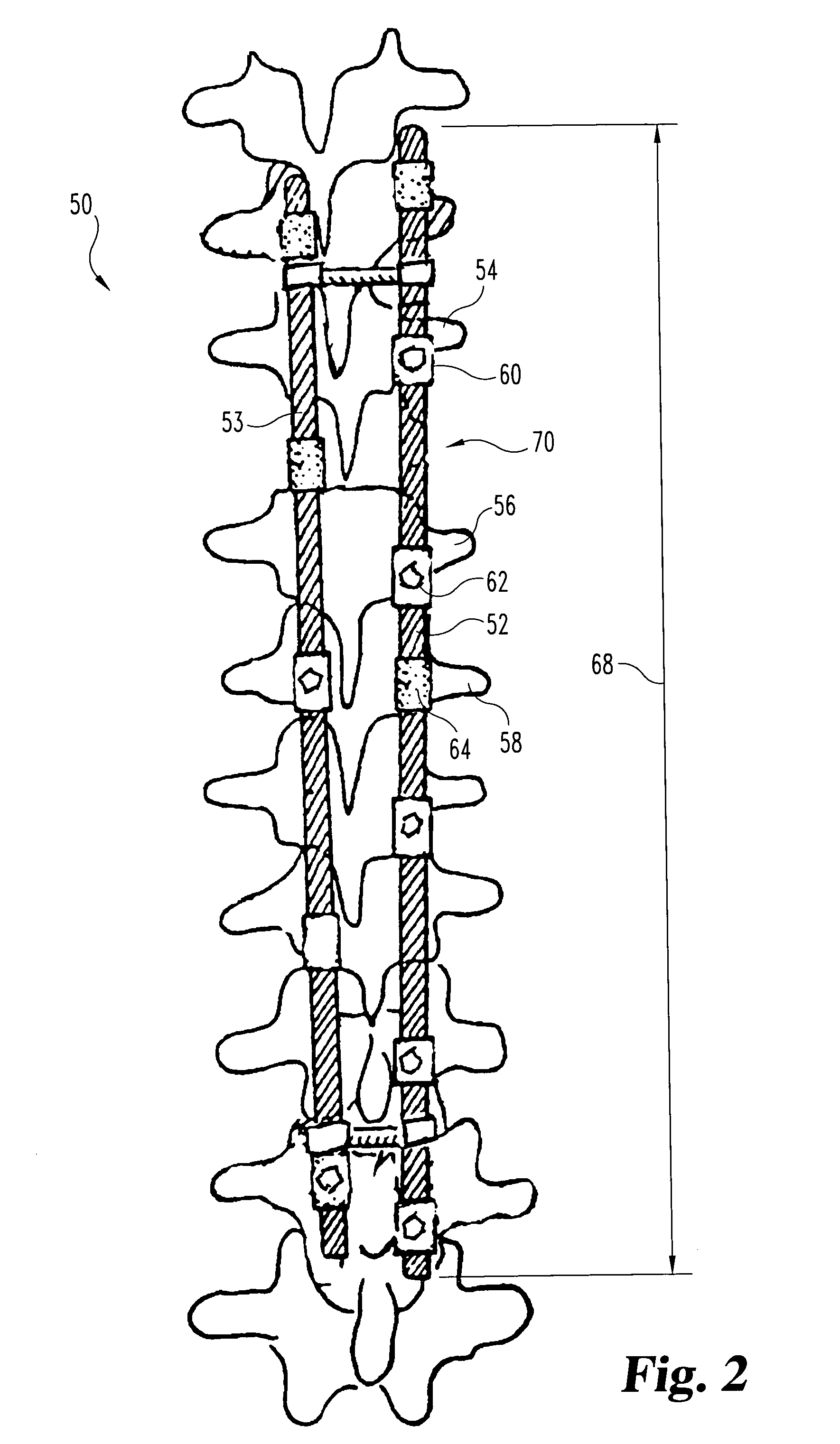

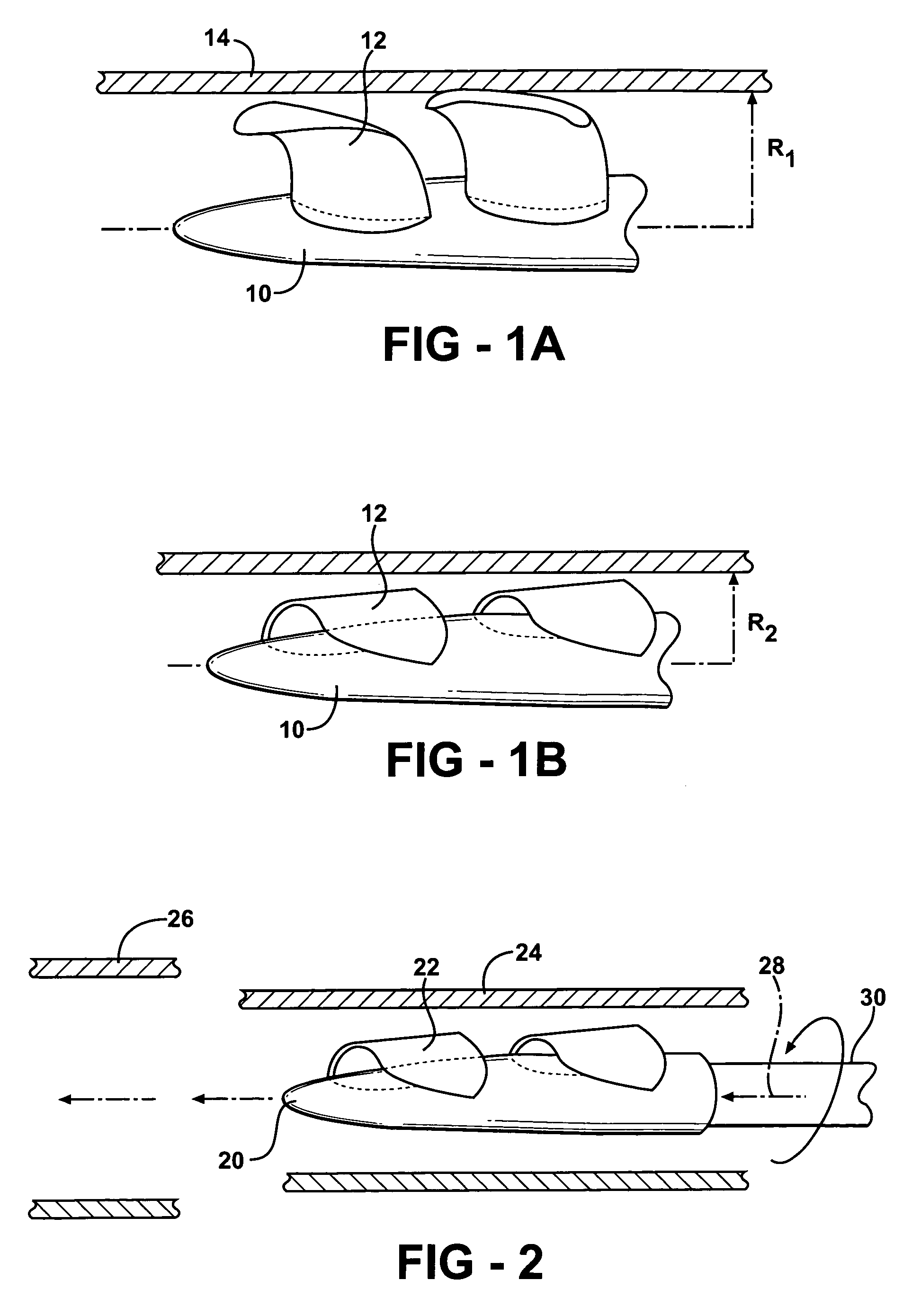

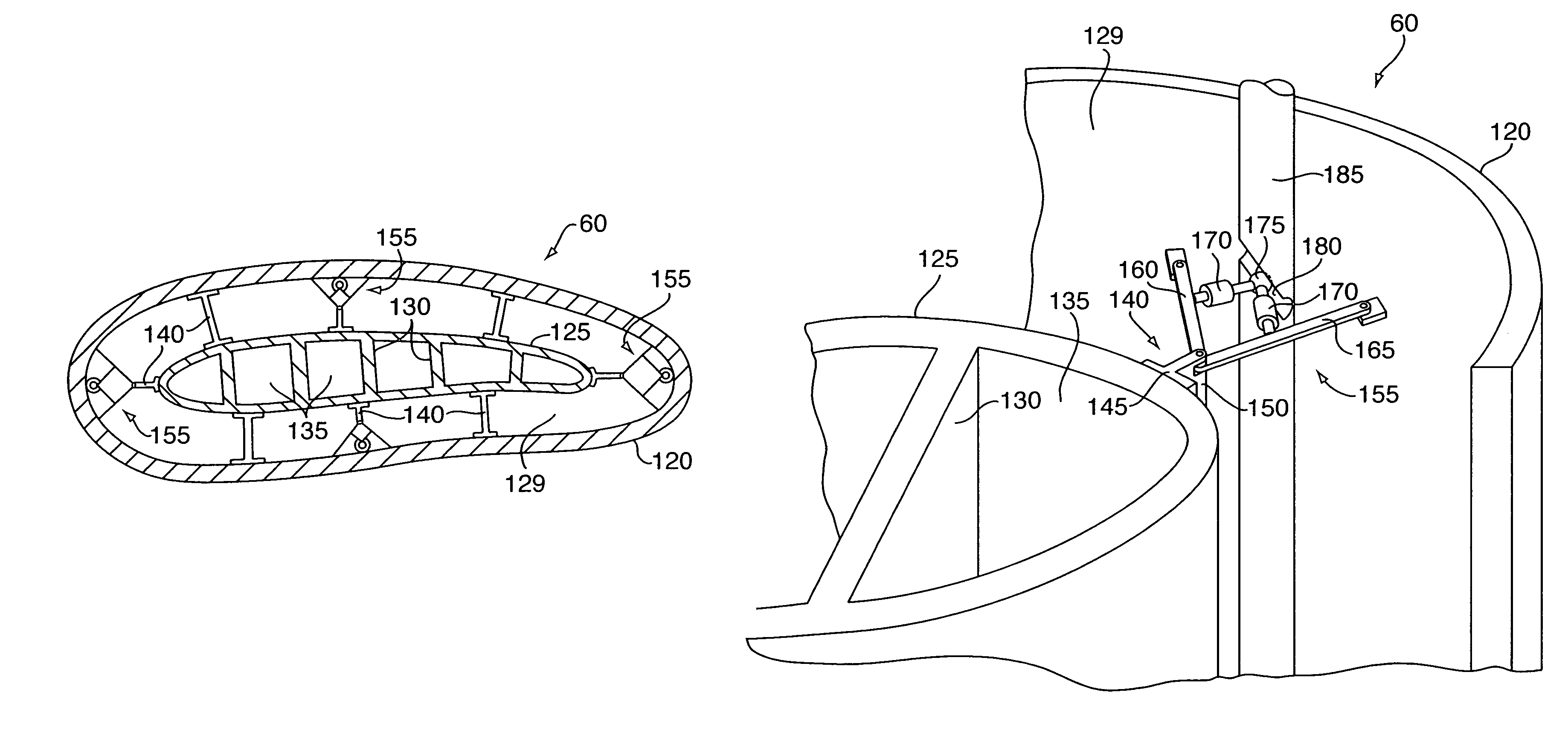

Implants formed of shape memory polymeric material for spinal fixation

ActiveUS20050033295A1Absorb energySuture equipmentsInternal osteosythesisJoint arthrodesisImplanted device

This invention relates to a orthopedic implant that comprises a shape memory polymeric material. The orthopedic implant can be fabricated or molded in a desired configuration selected to provide support or tension to bony structures. Examples of implantable devices include spinal rods, bone plates, and bone fixation cords. The orthopedic implant can be deformed to a second configuration different from the first configuration either prior to implantation or after implantation. When desired, the shape memory polymeric material can be induced to revert to it original molded configuration. This can compress the attached bony structure and / or promote arthrodesis.

Owner:WARSAW ORTHOPEDIC INC

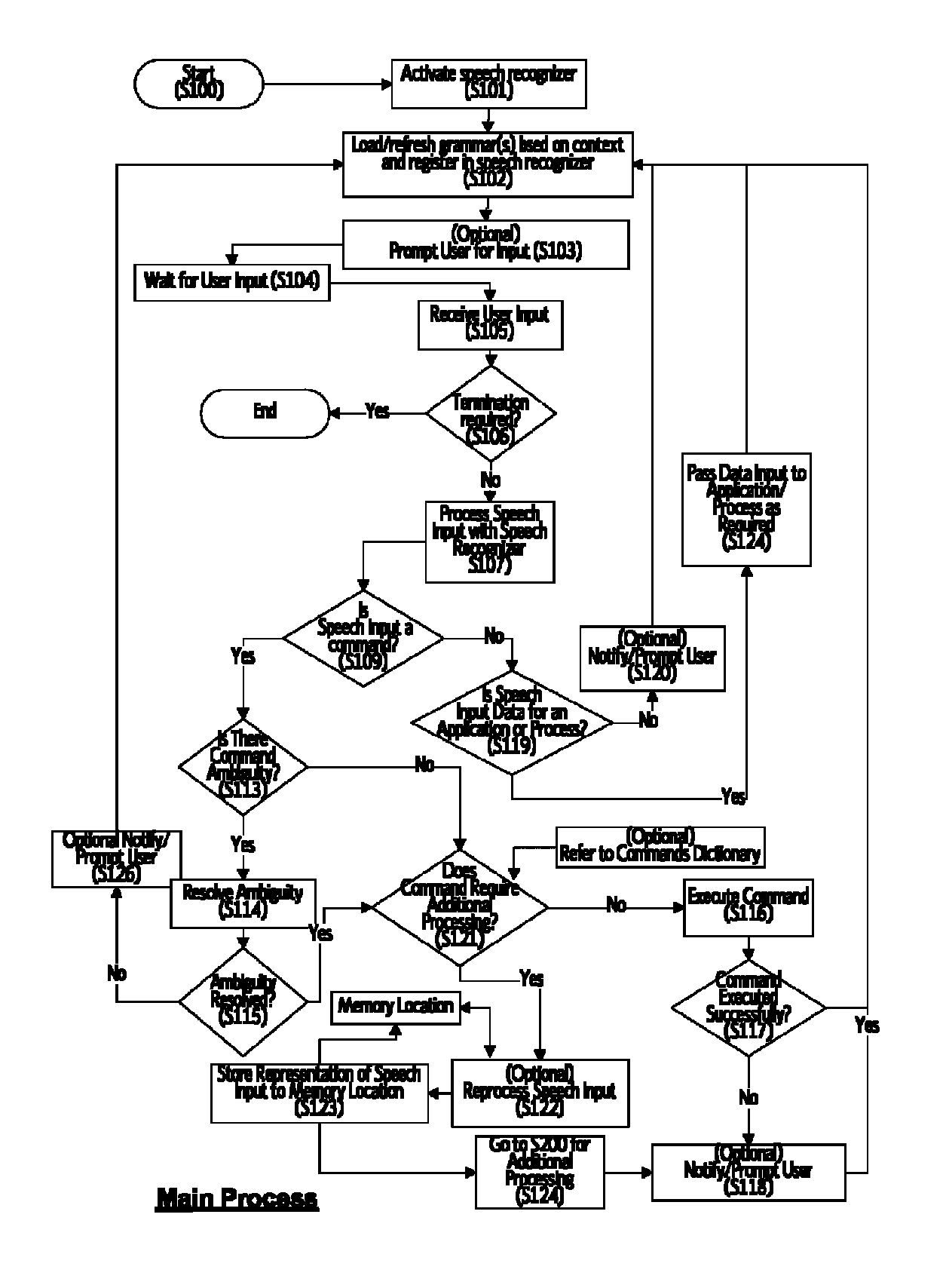

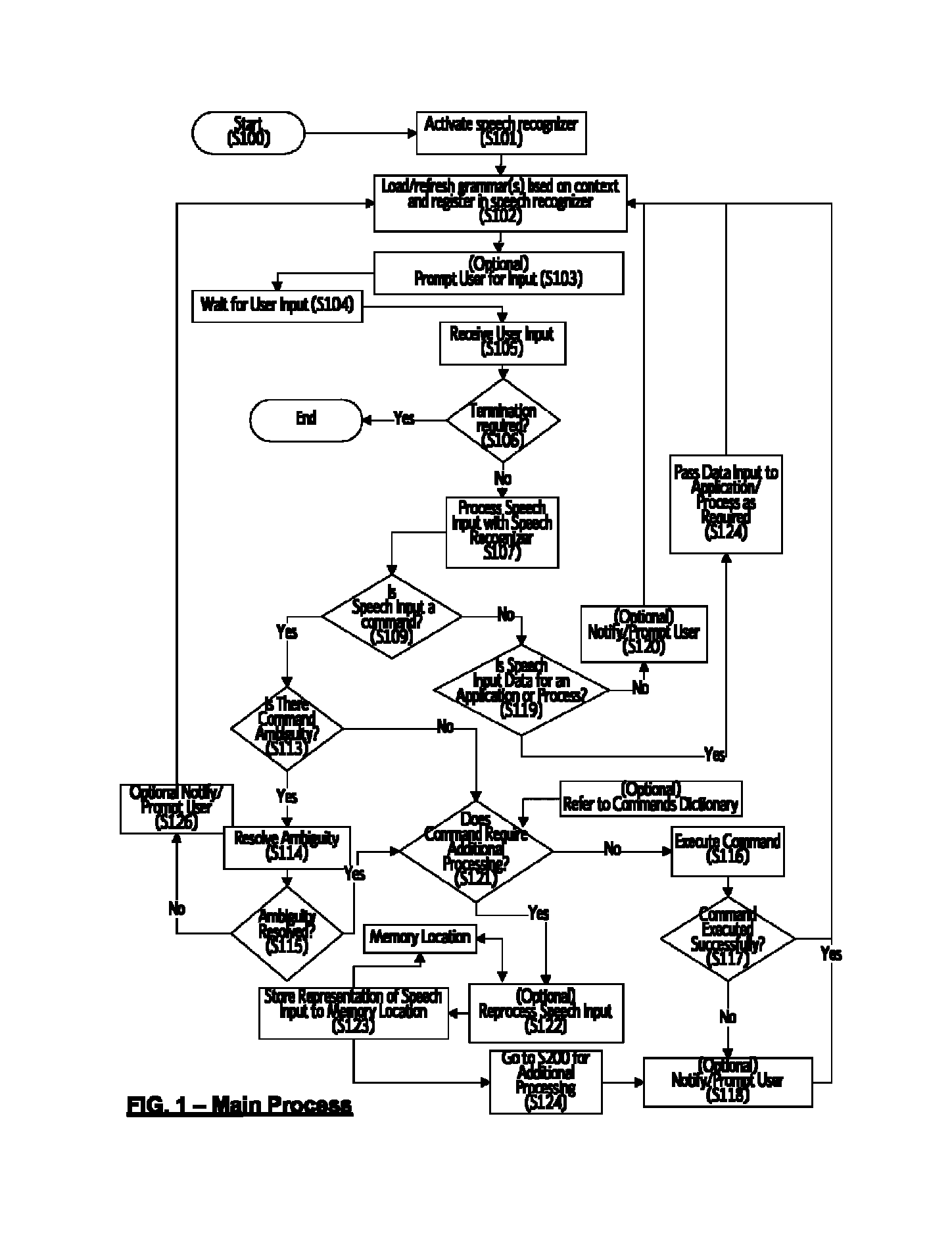

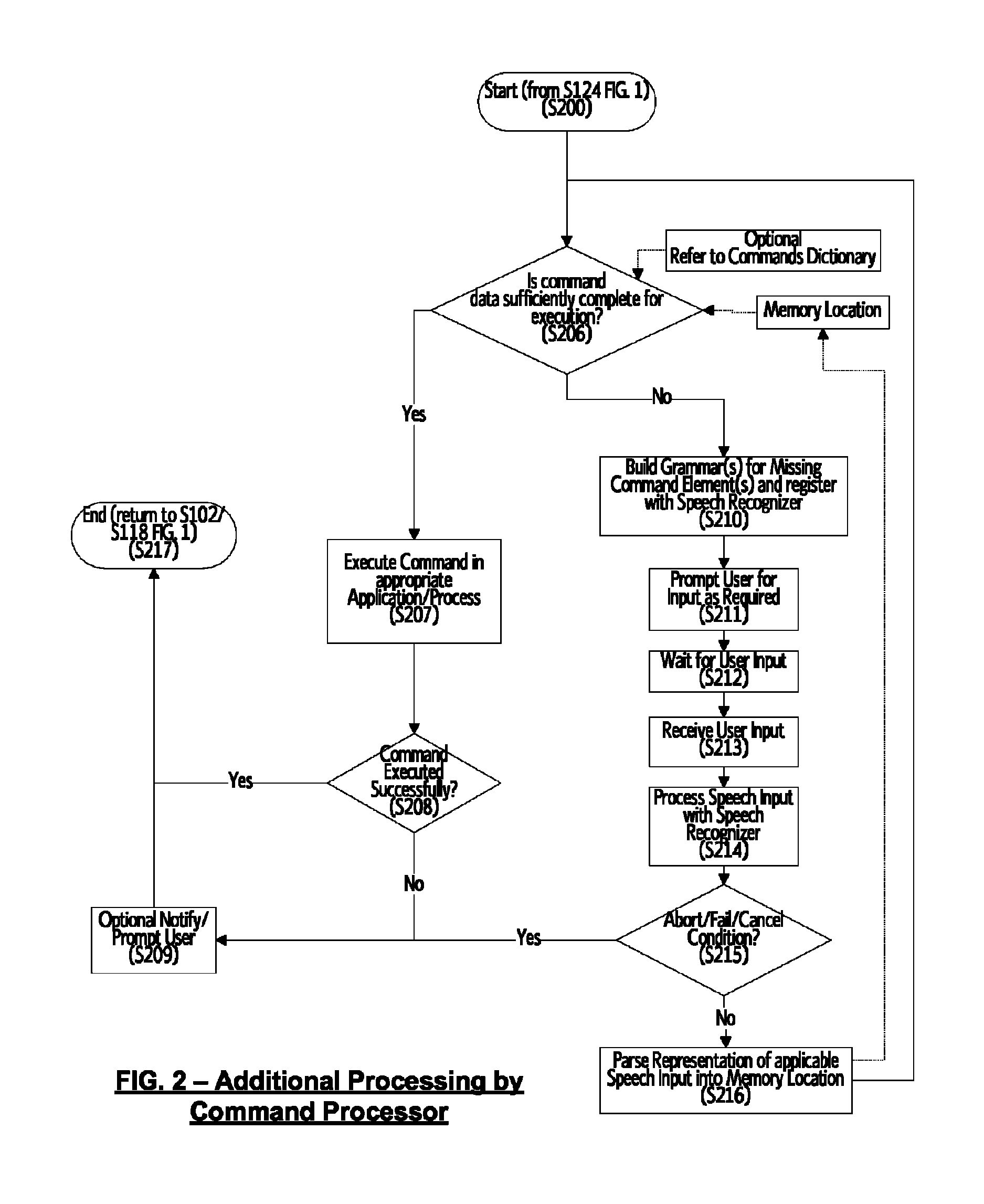

Method for processing the output of a speech recognizer

ActiveUS8219407B1Improve integrityReduce ambiguityEngine fuctionsBlade accessoriesUser inputSpeech identification

A system and method for processing speech input comprising a speech recognizer and a logical command processor which facilitates additional processing of speech input beyond the speech recognizer level. A speech recognizer receives input from a user, and when a command is identified in the speech input, if the command meets conditions that require additional processing, a representation of the speech input s stored for subsequent processing. A logical command processor performs additional processing of command input by analyzing the command and its elements, determining which elements are required for successful processing the command and which elements are present and lacking. The user is prompted to supply missing information, and subsequent user input is added to the command structure until the command input is aborted or the command structure reaches sufficient completeness to enable execution of the command. Thereby, speech input of complex commands in natural language in a system running a plurality of applications and processes is made possible.

Owner:GREAT NORTHERN RES

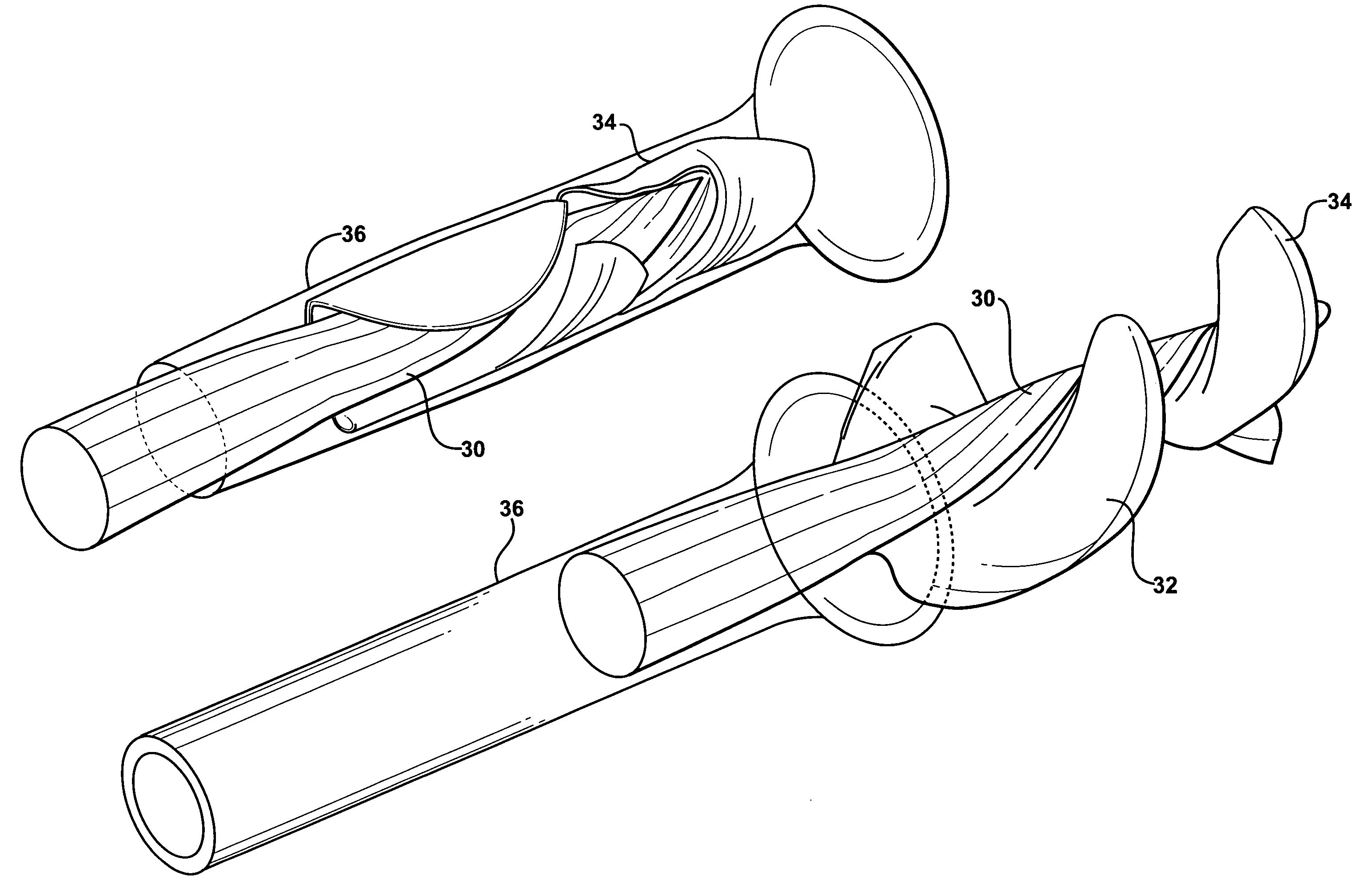

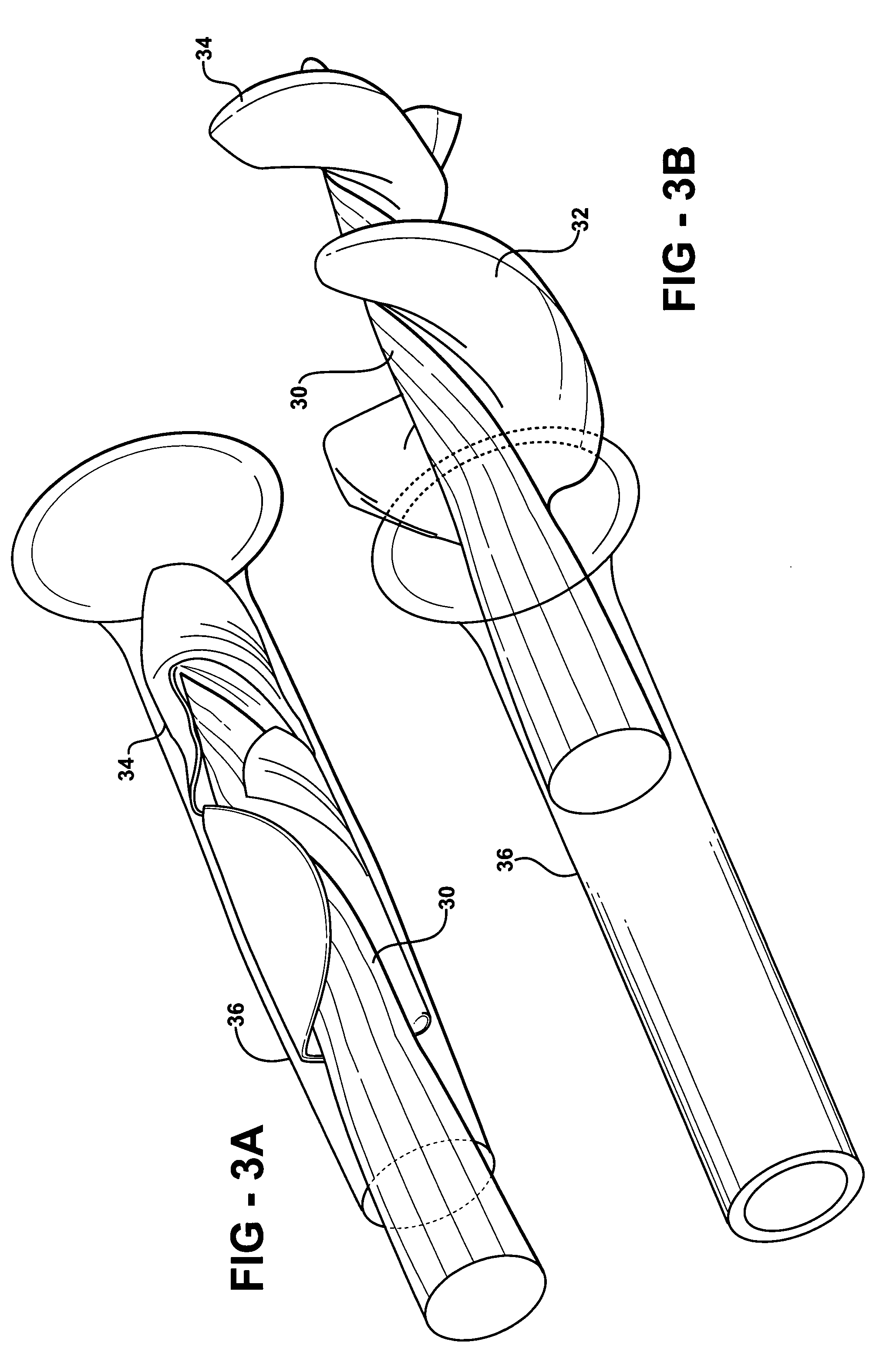

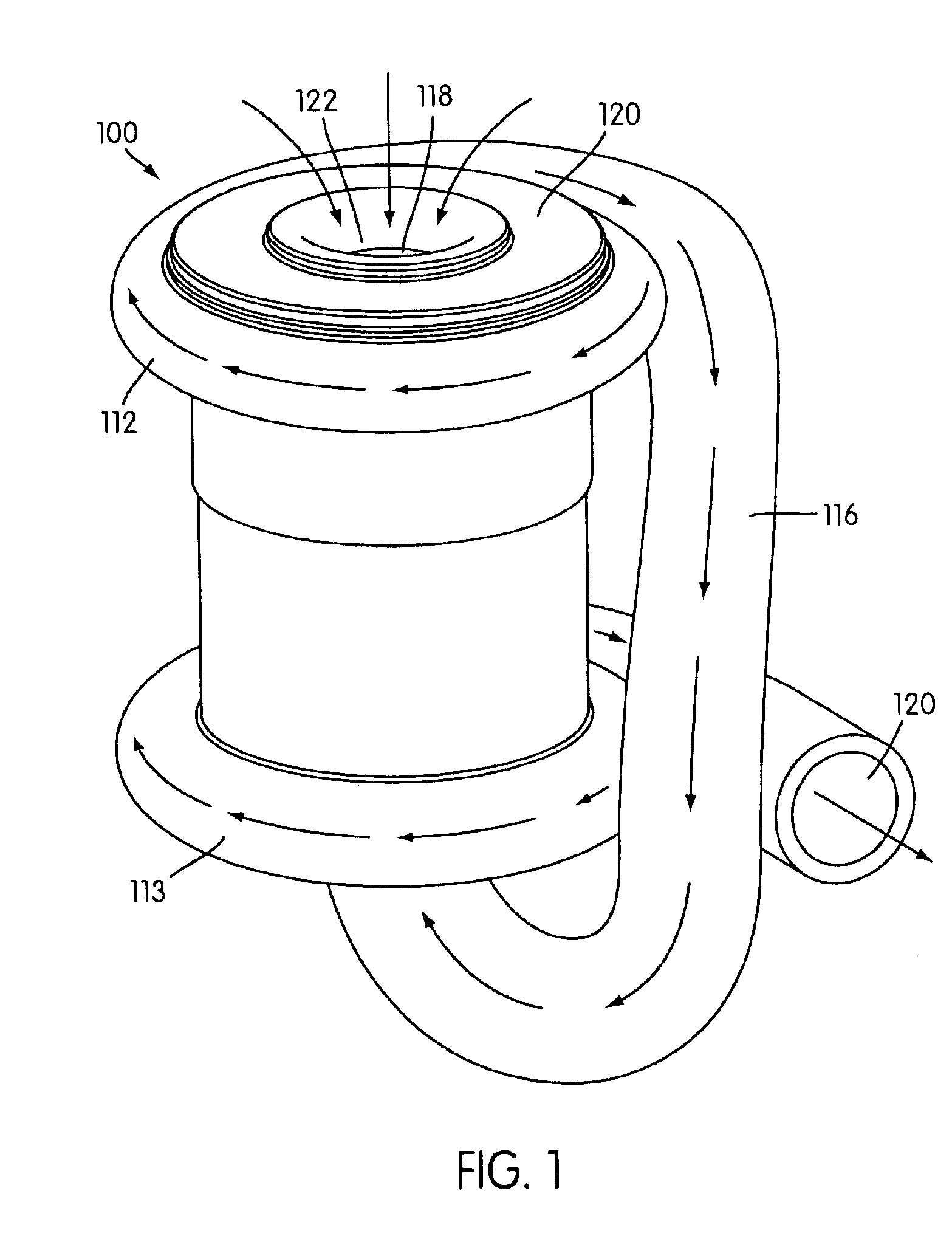

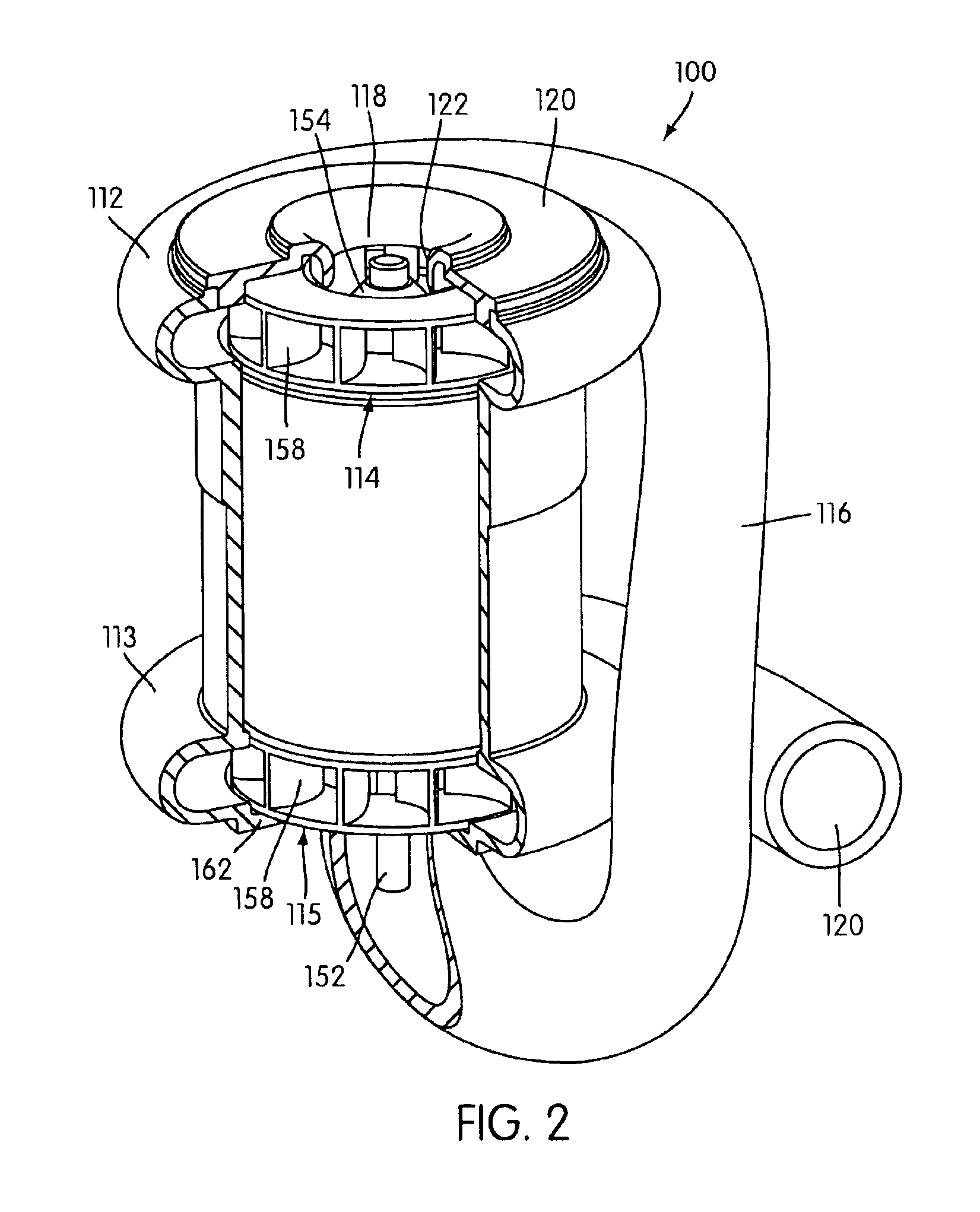

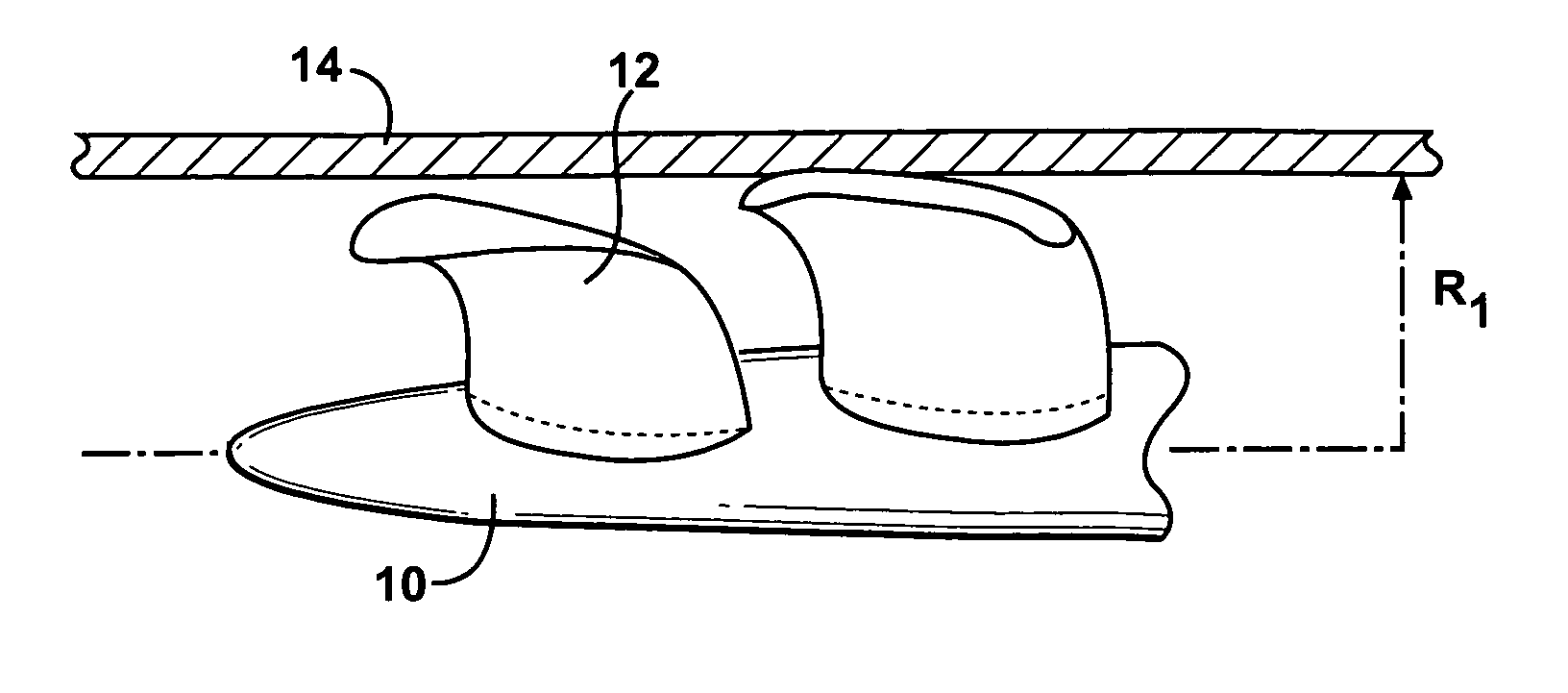

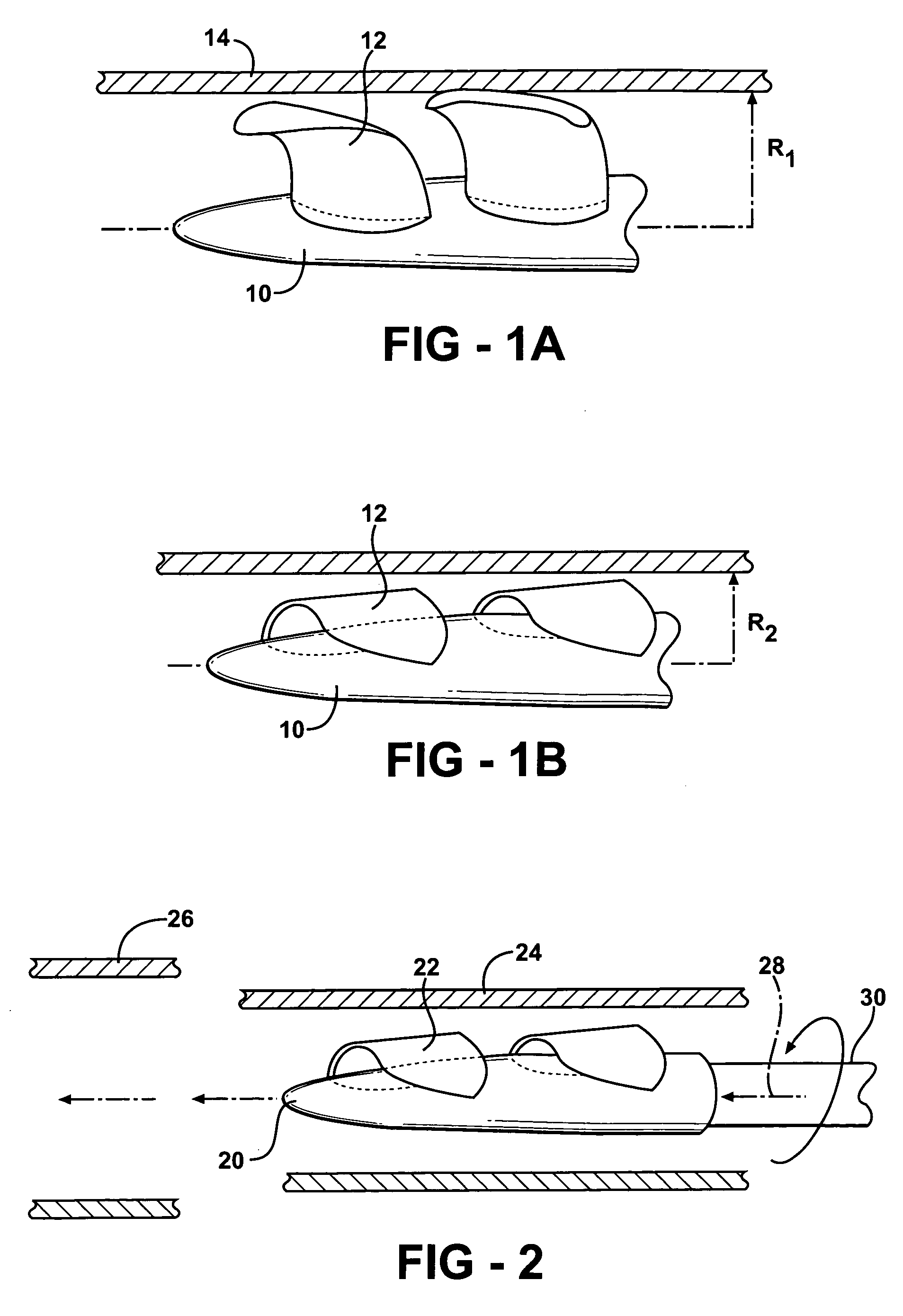

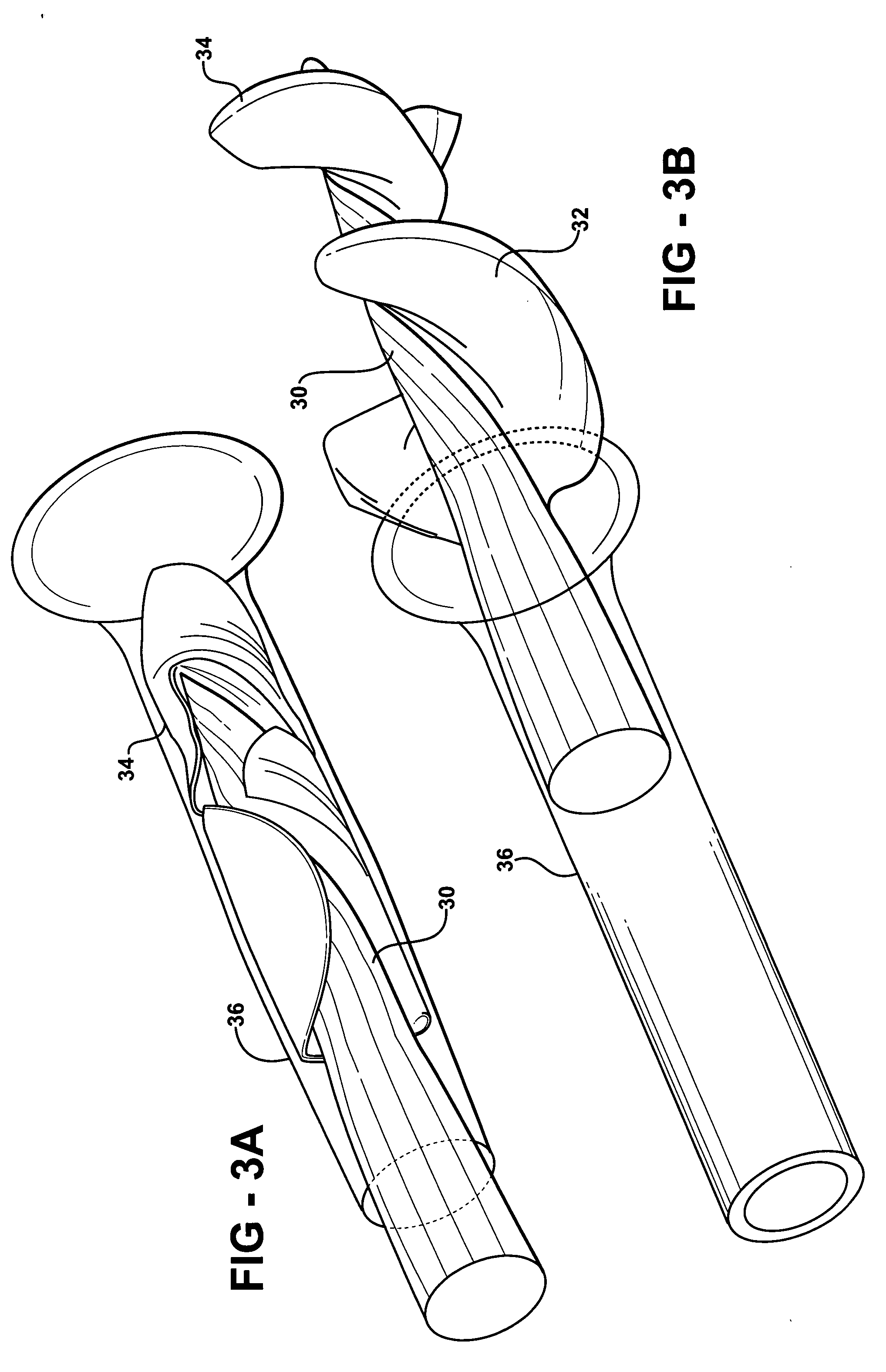

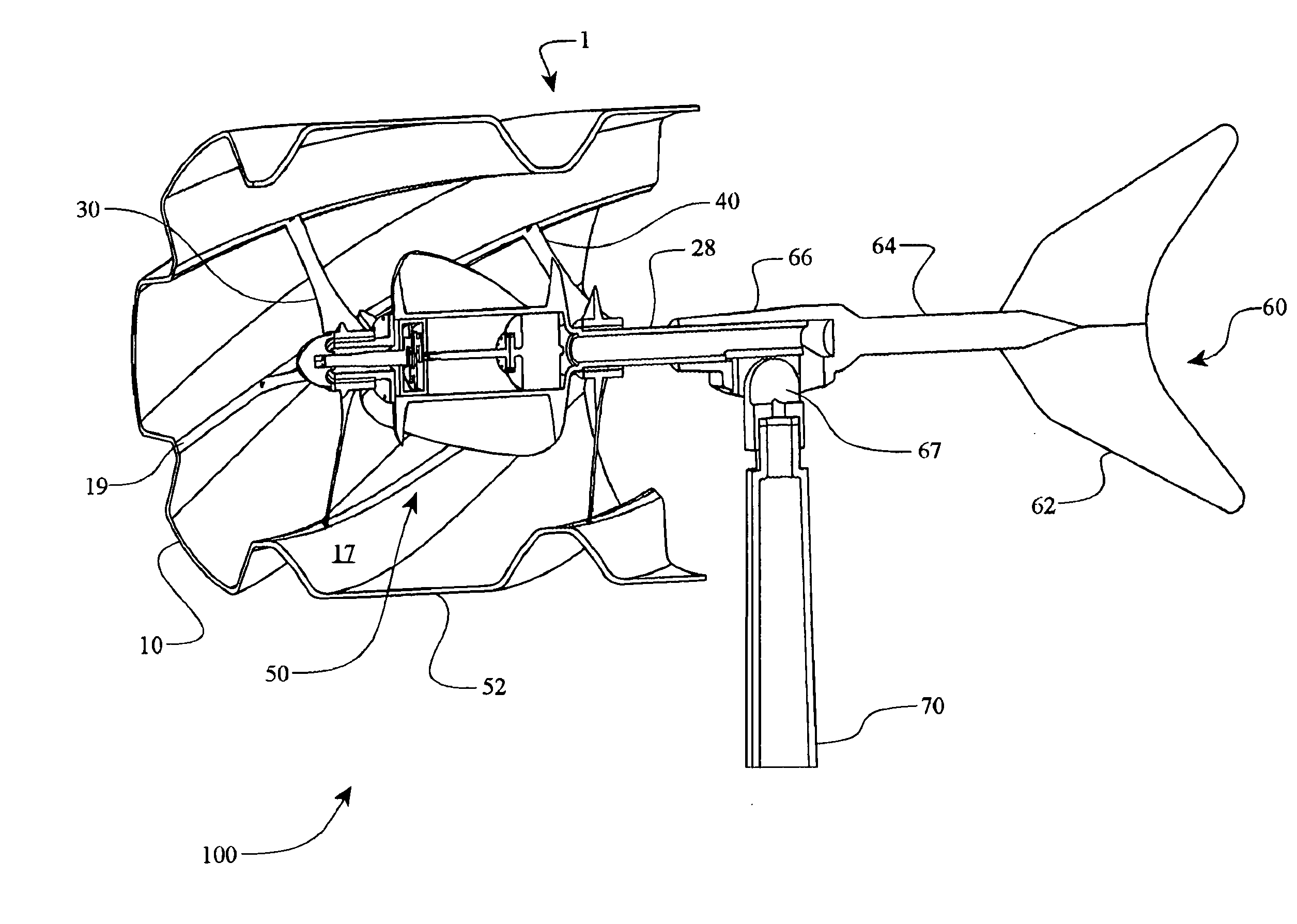

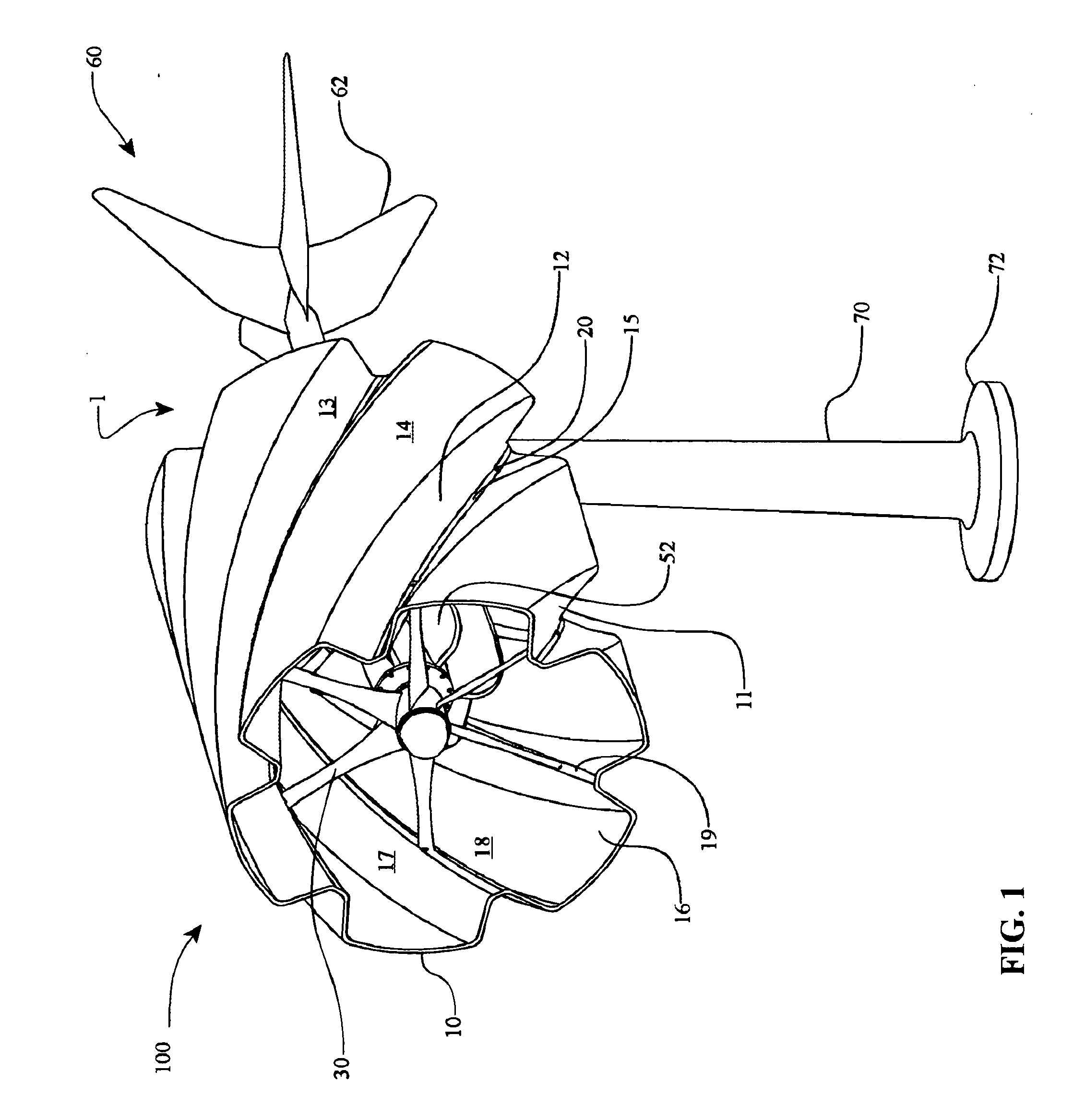

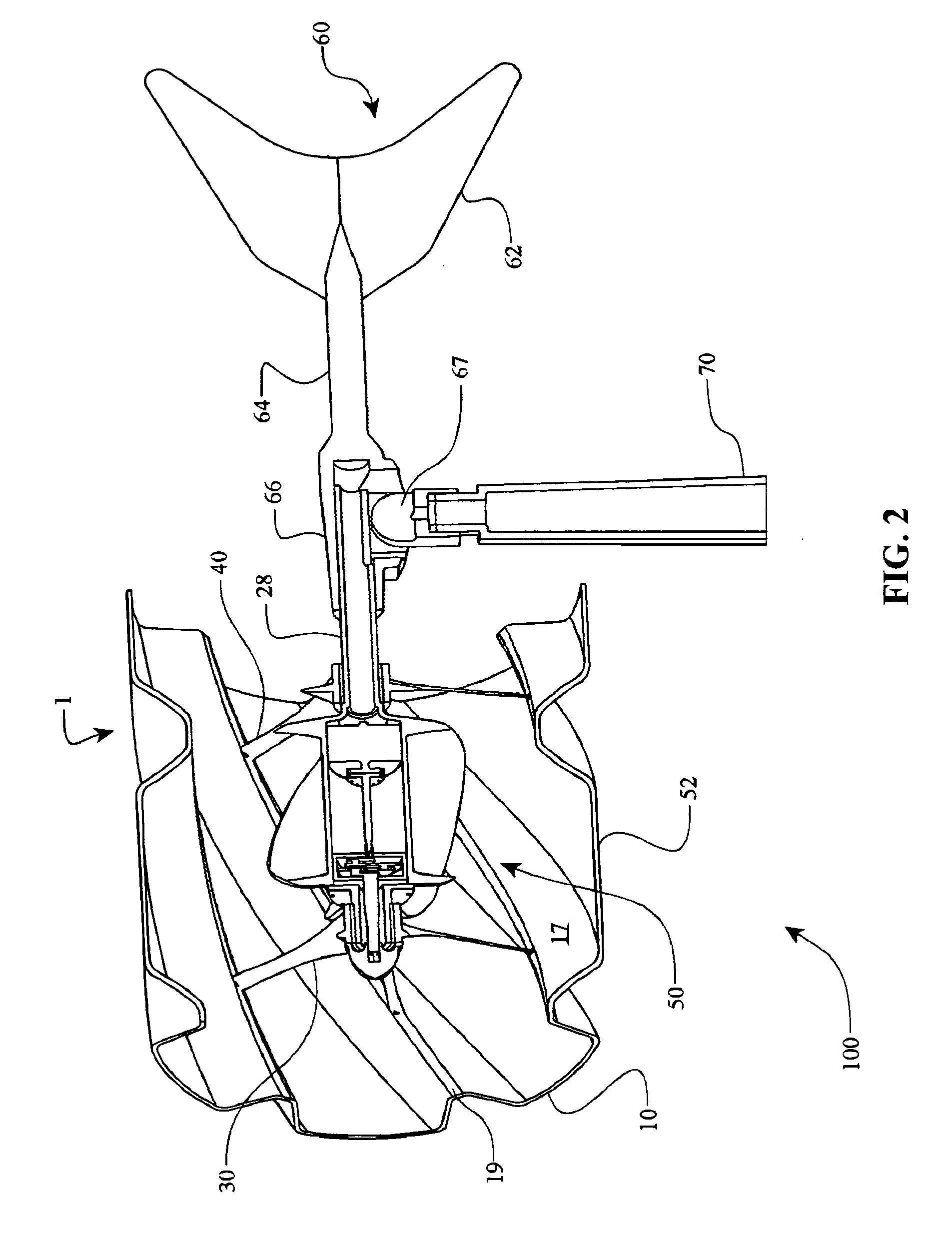

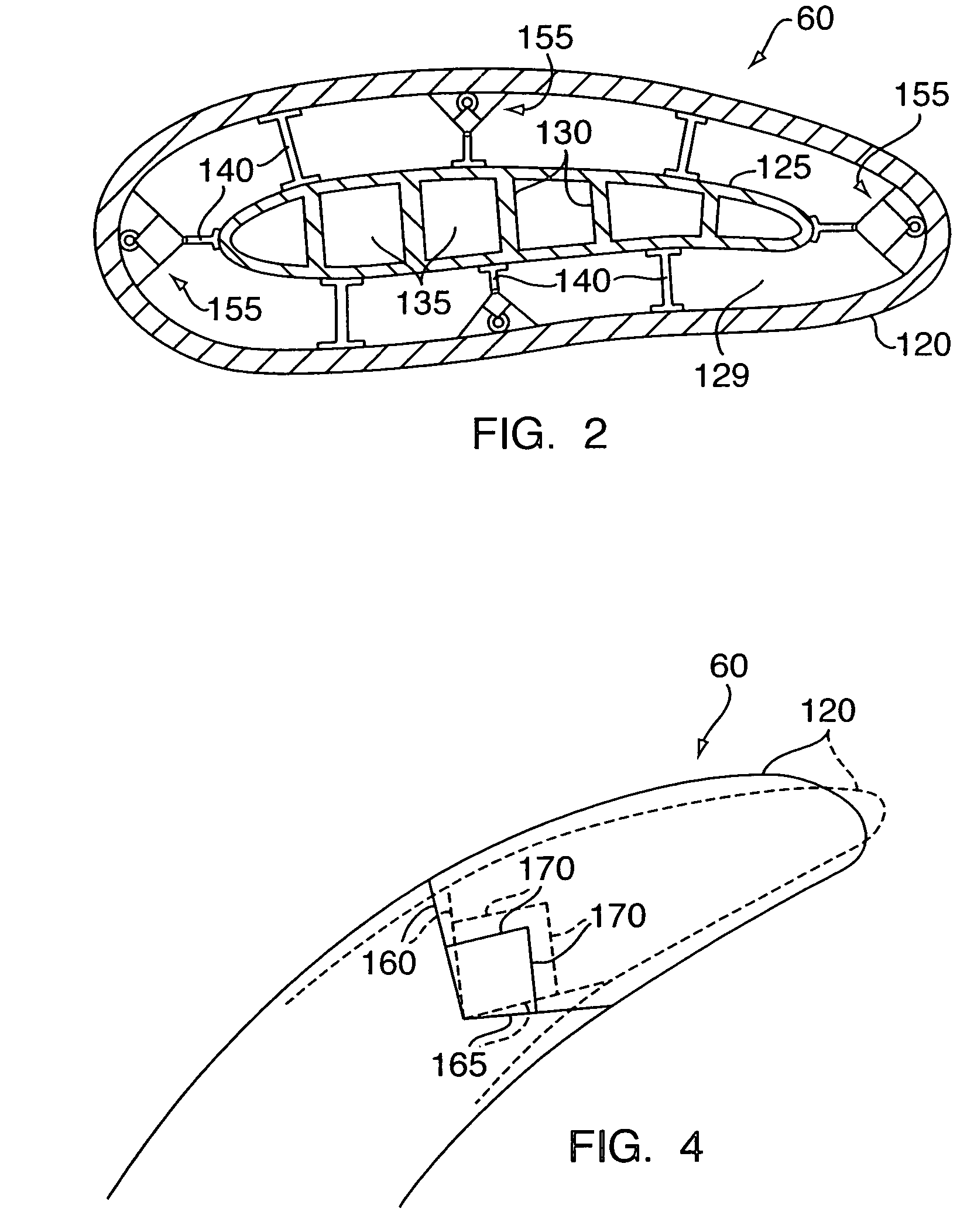

Expandable impeller pump

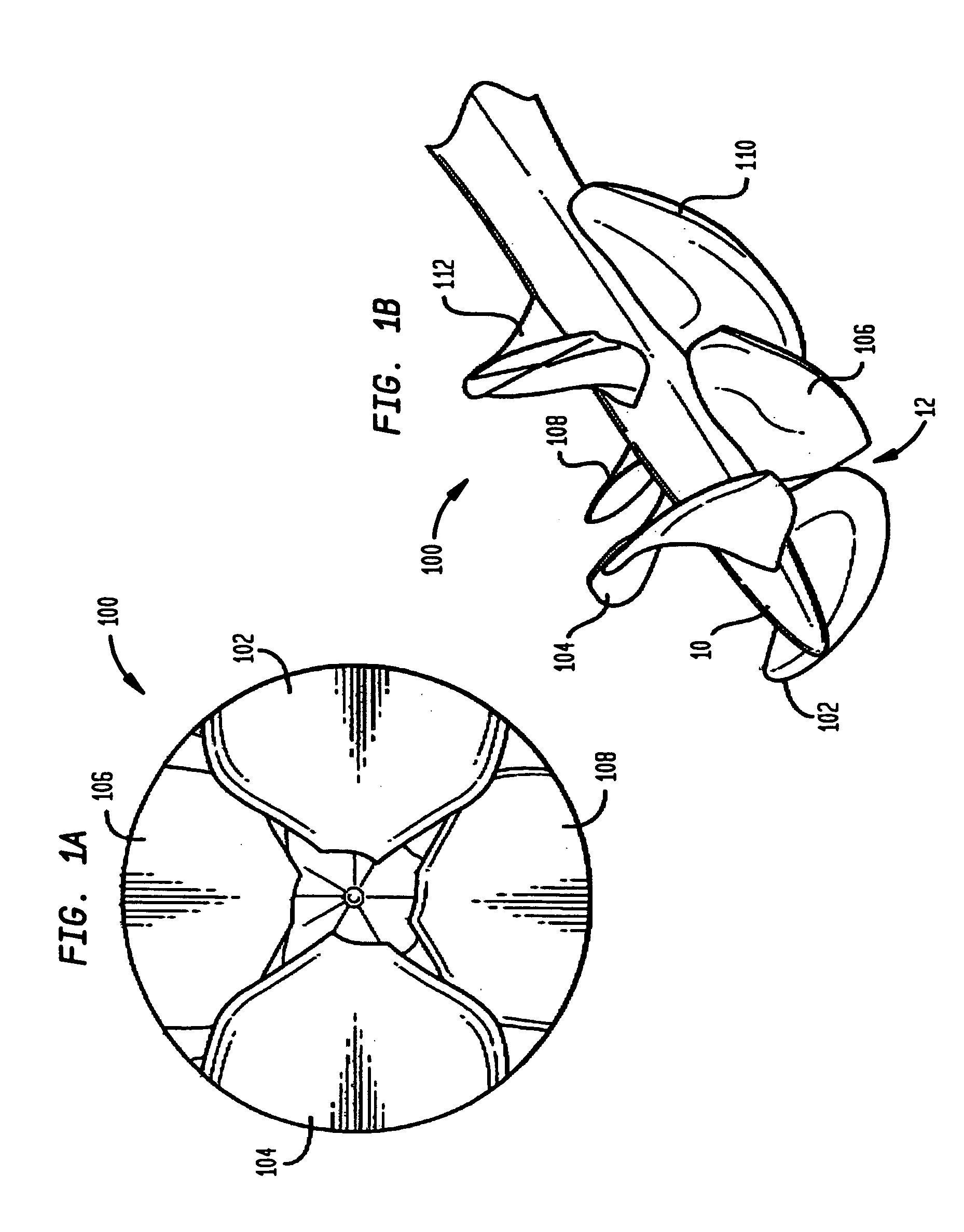

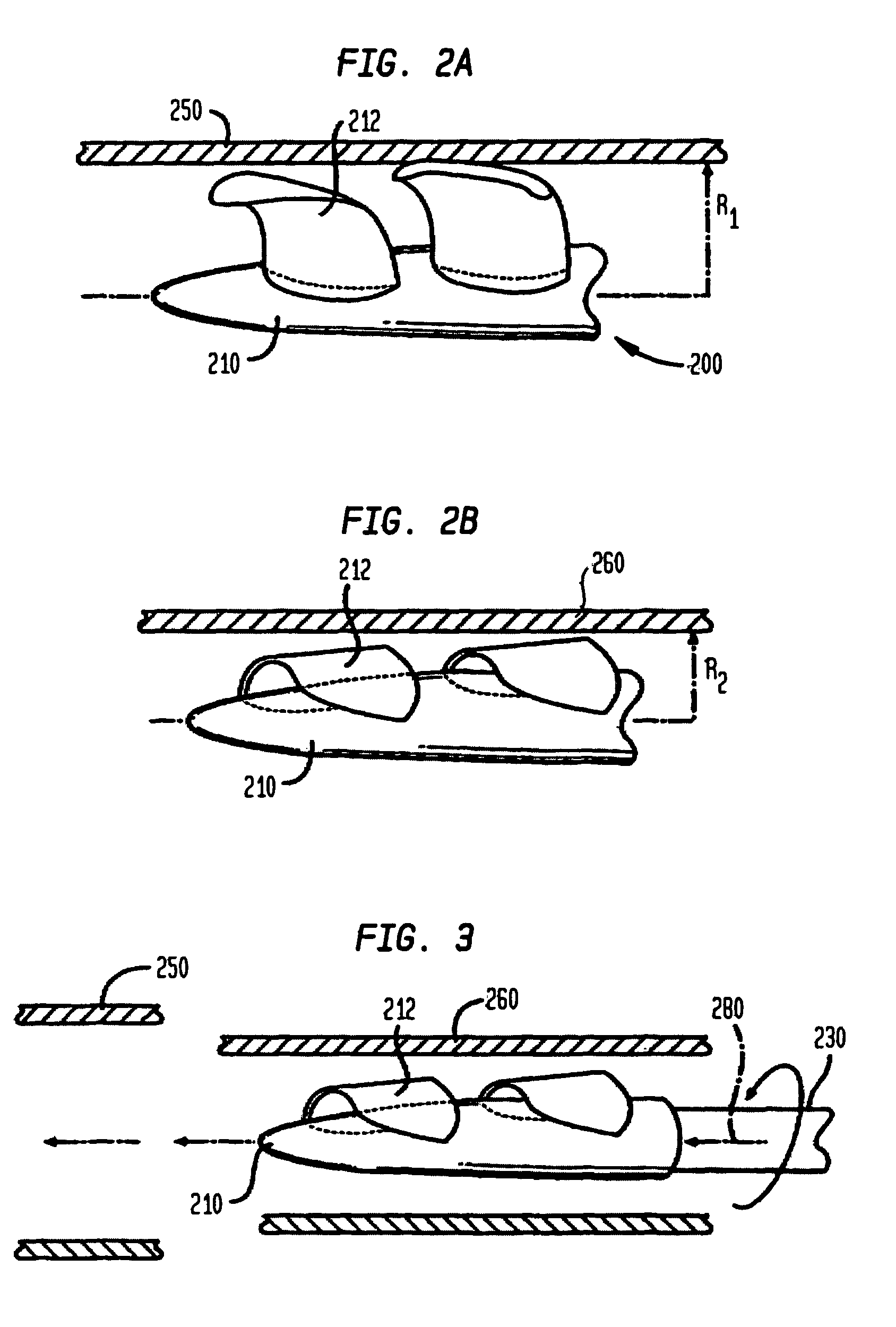

ActiveUS7393181B2Easy to compressReduced form requirementsPropellersEngine manufactureImpellerEngineering

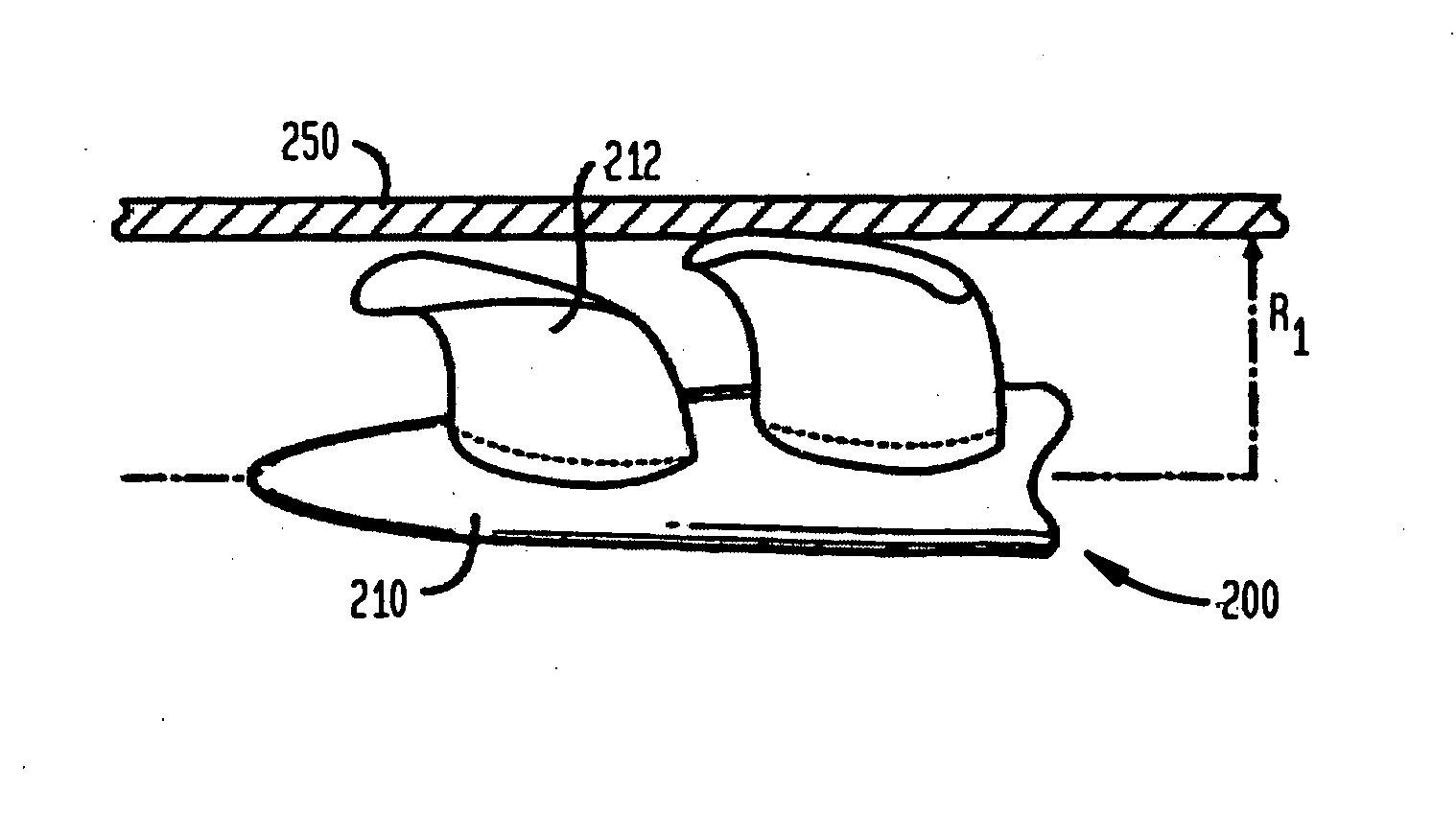

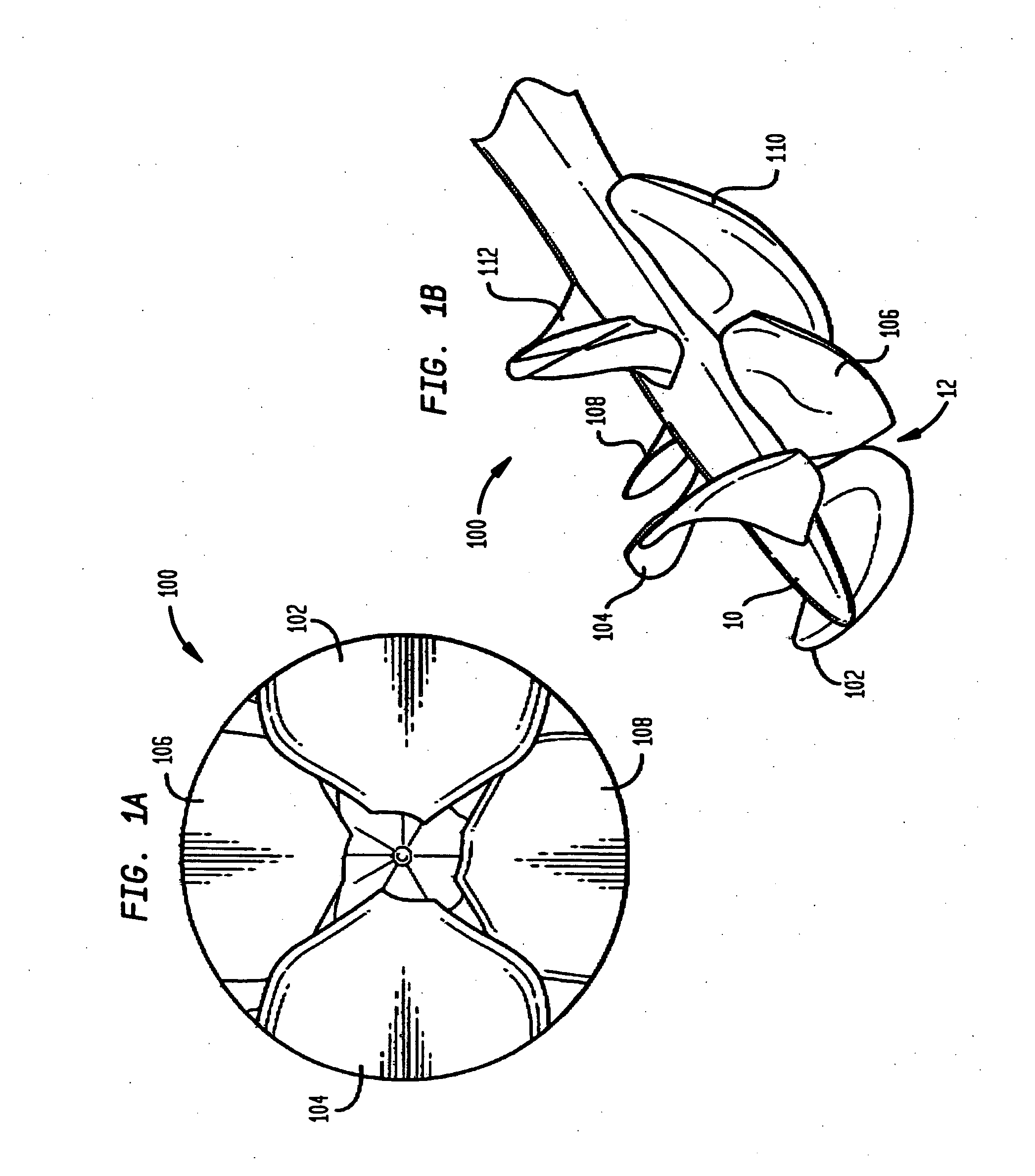

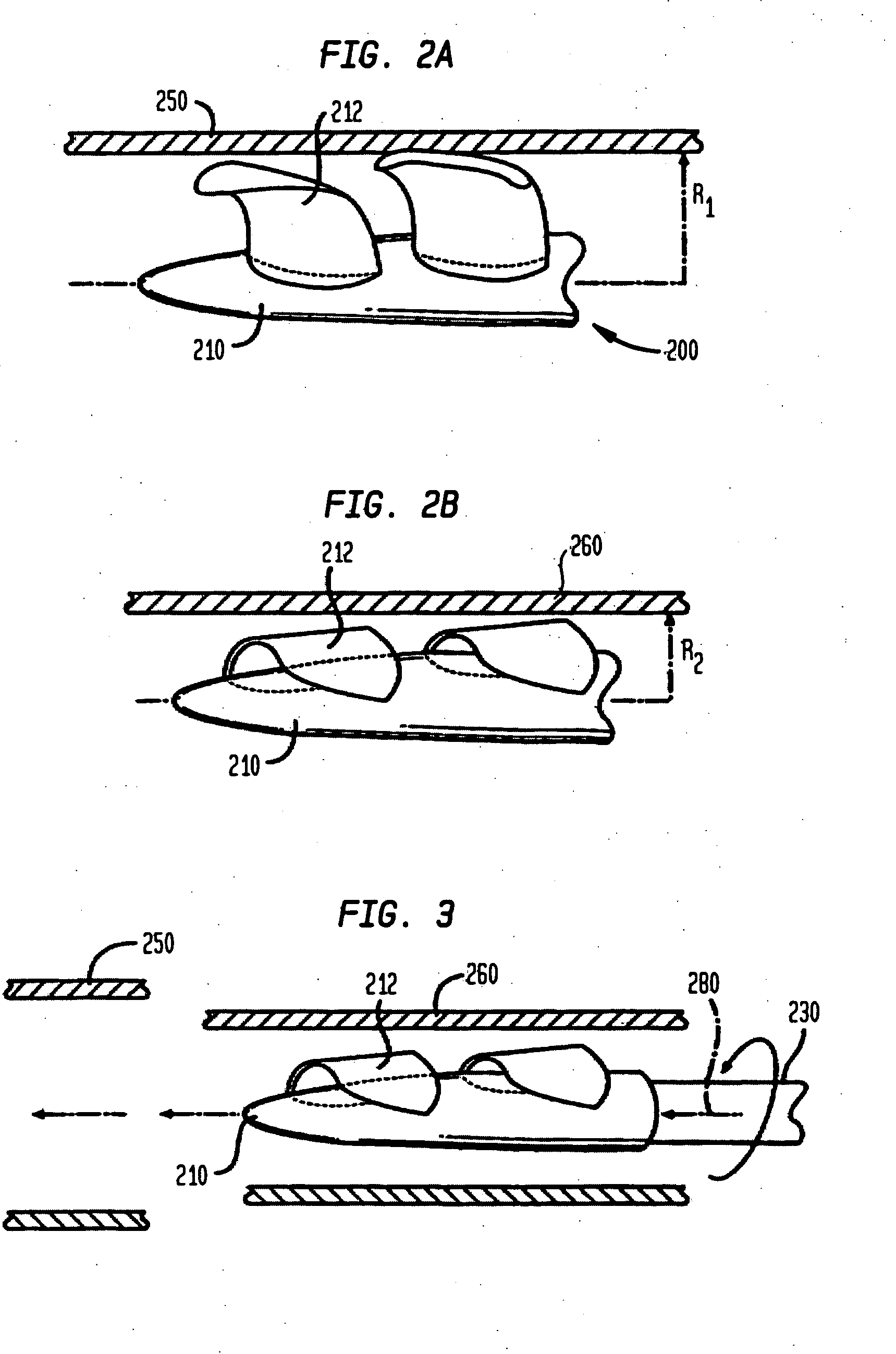

An impeller according to an example of the present invention comprises a hub, and at least one blade supported by the hub. The impeller has a deployed configuration in which the blade extends away from the hub, and a stored configuration in which the impeller is radially compressed, for example by folding the blade towards the hub. The impeller may comprise a plurality of blades, arranged in blade rows, to facilitate radial compression of the blades. The outer edge of a blade may have a winglet, and the base of the blade may have an associated indentation to facilitate folding of the blade.

Owner:PENN STATE RES FOUND +2

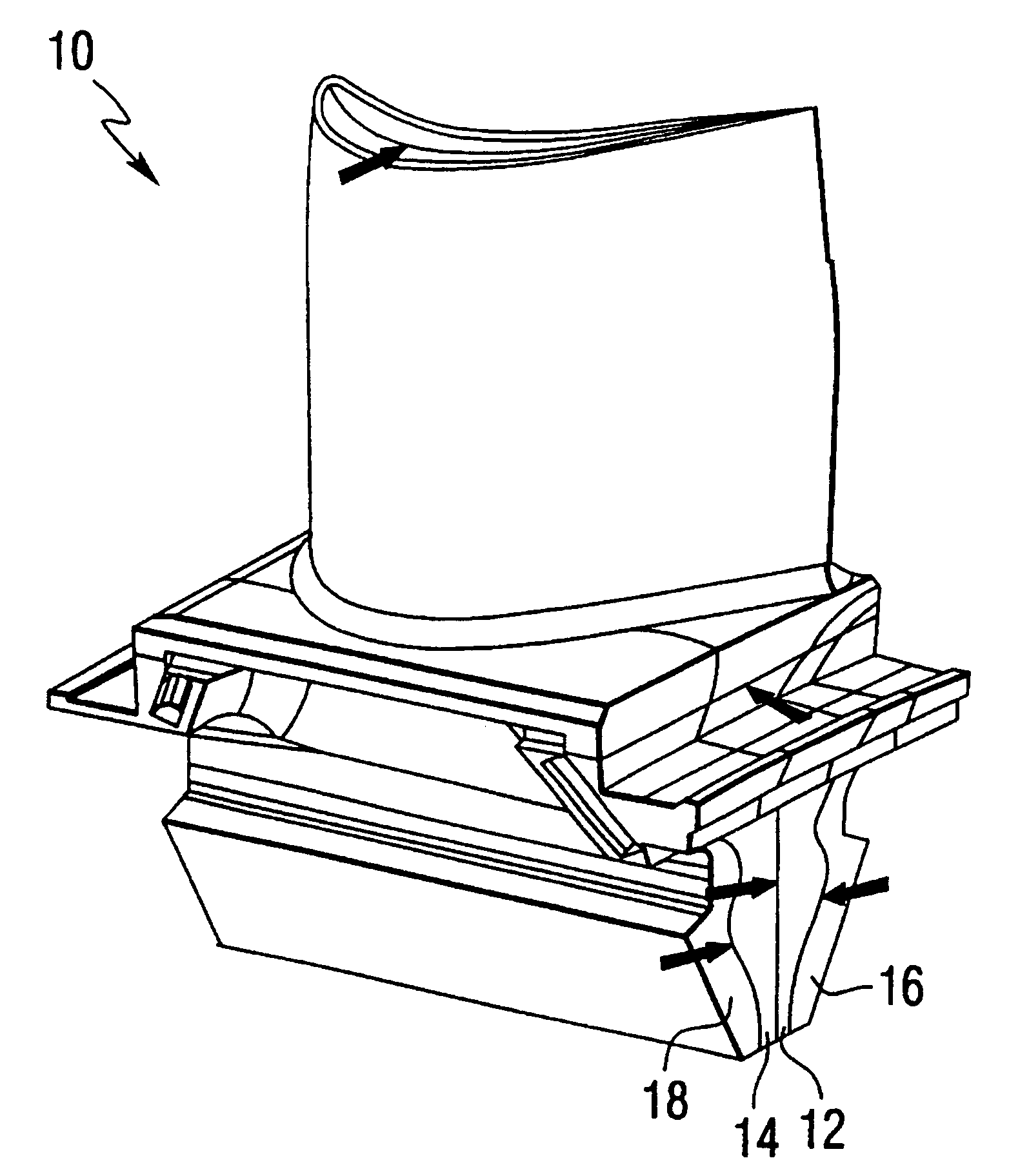

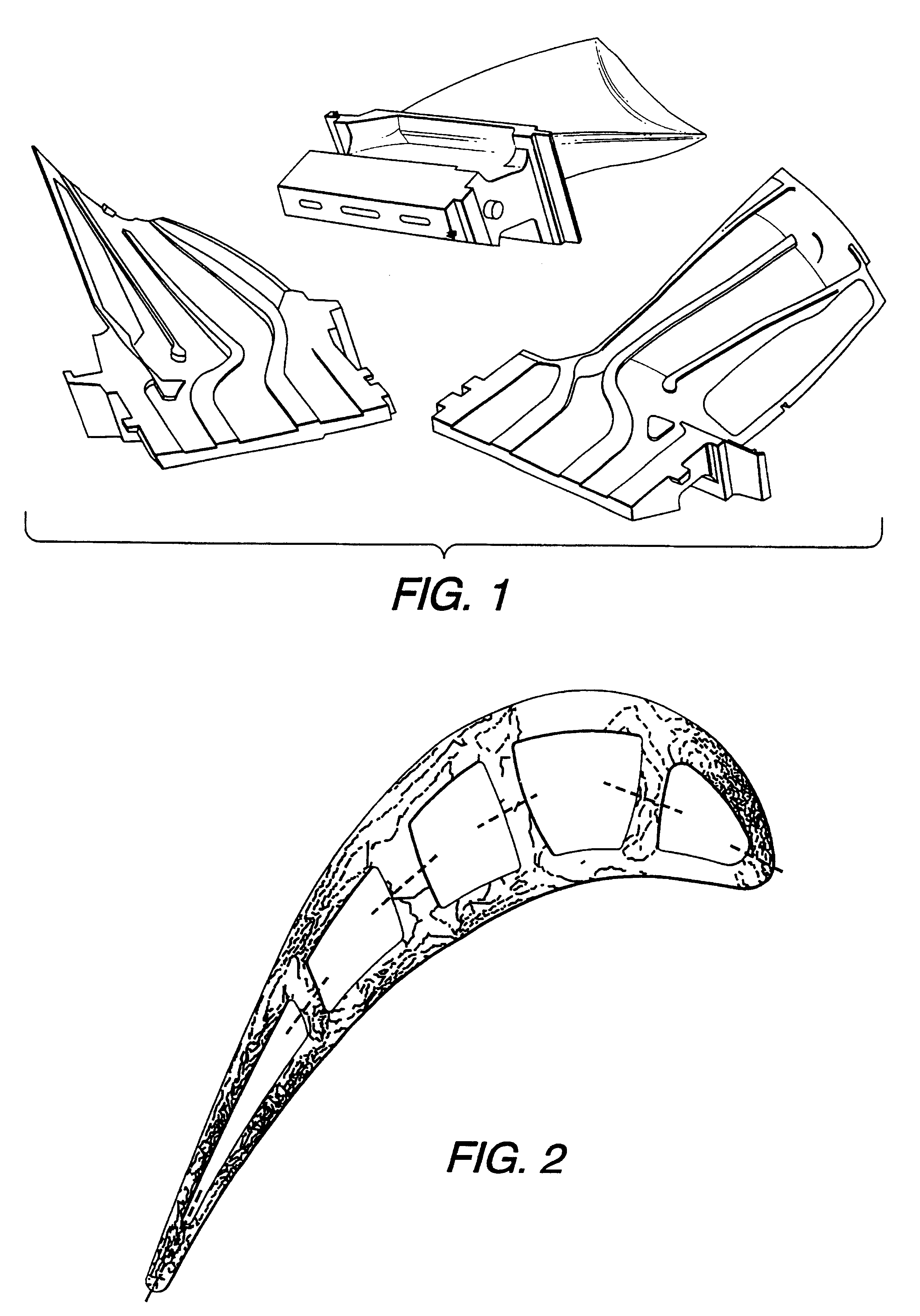

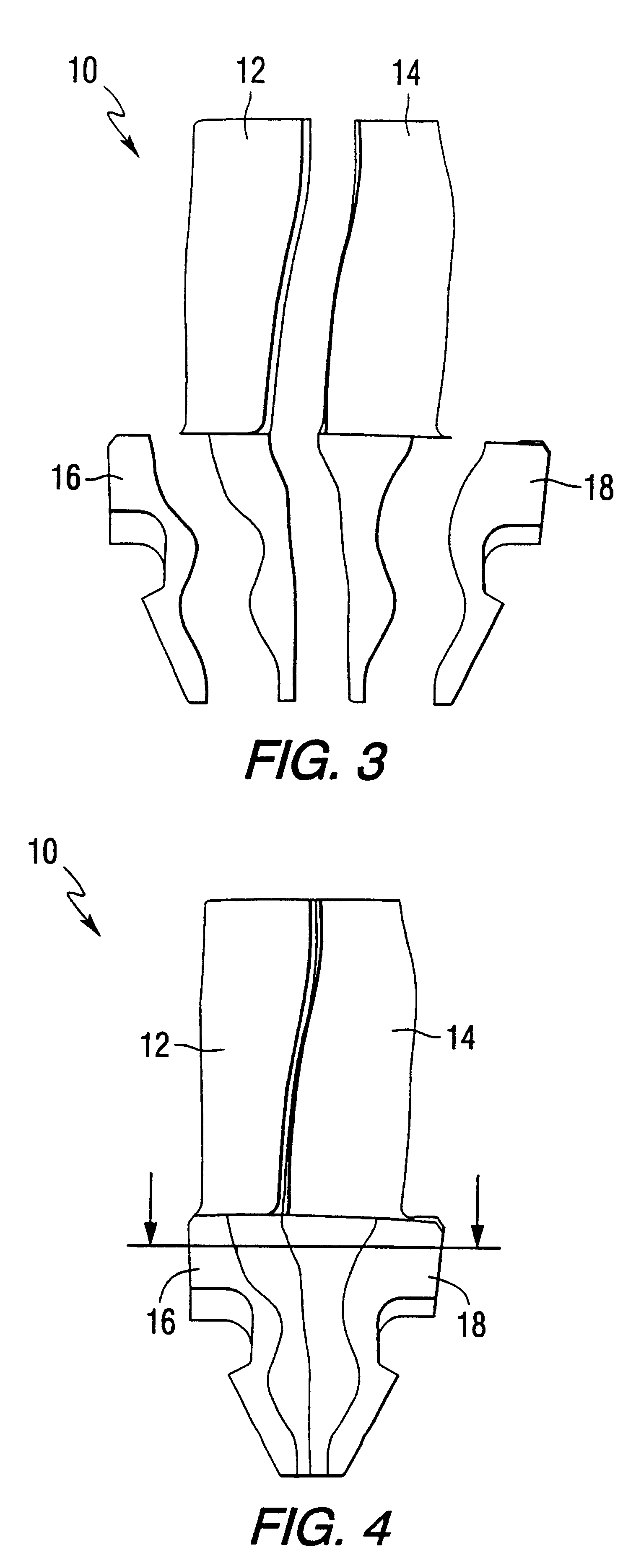

Heart assist device with expandable impeller pump

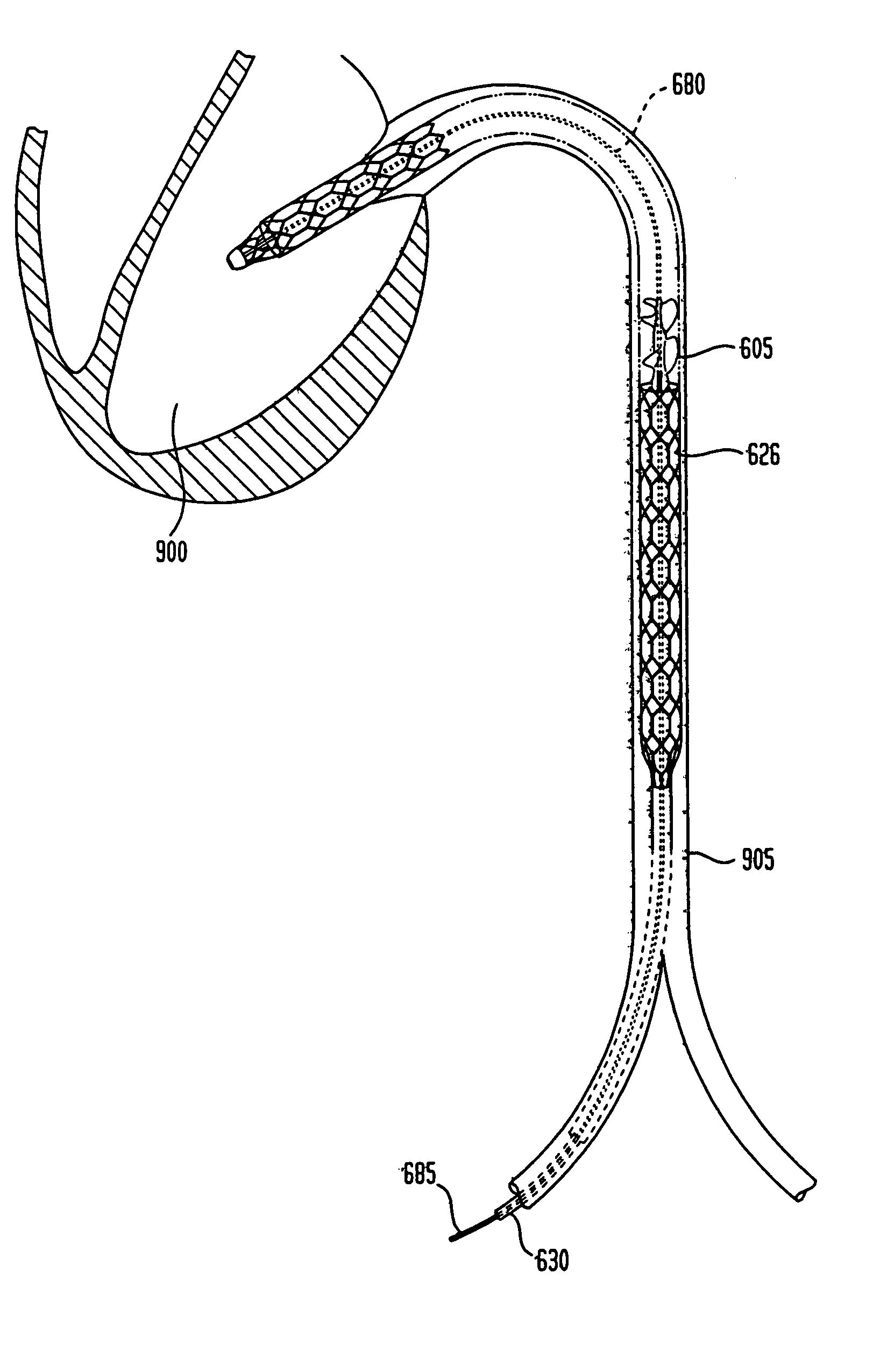

An impeller includes a hub and at least one blade supported by the hub. The impeller has a stored configuration in which the blade is compressed so that its distal end moves towards the hub, and a deployed configuration in which the blade extends away from the hub. The impeller may be part of a pump for pumping fluids, such as pumping blood within a patient. A blood pump may include a cannula having a proximal portion with a fixed diameter, and a distal portion with an expandable diameter. The impeller may reside in the expandable portion of the cannula. The cannula may have a compressed diameter which allows it to be inserted percutaneously into a patient. Once at a desired location, the expandable portion of the cannula may be expanded and the impeller expanded to the deployed configuration. A flexible drive shaft may extend through the cannula for rotationally driving the impeller within the patient's body.

Owner:PENN STATE RES FOUND +2

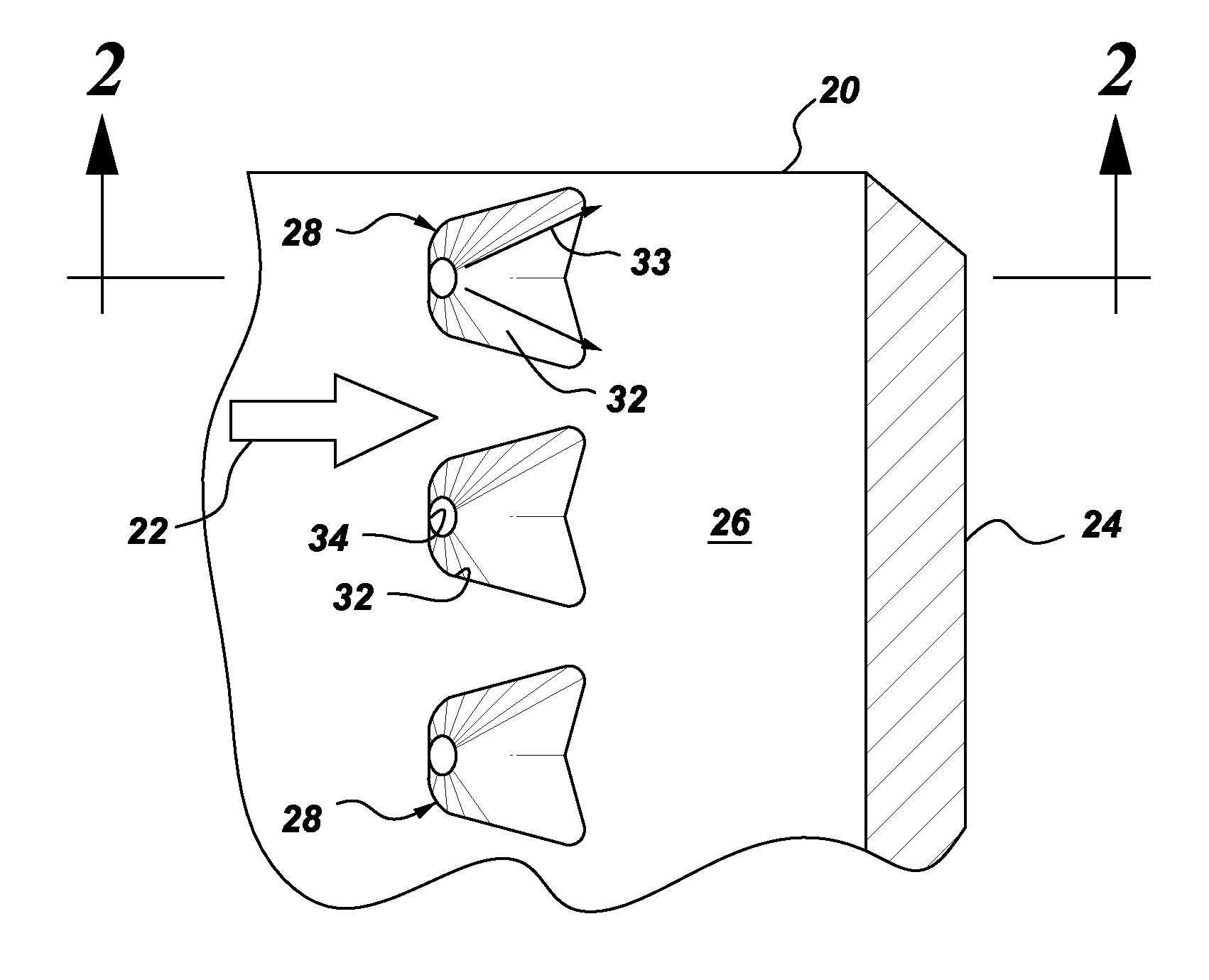

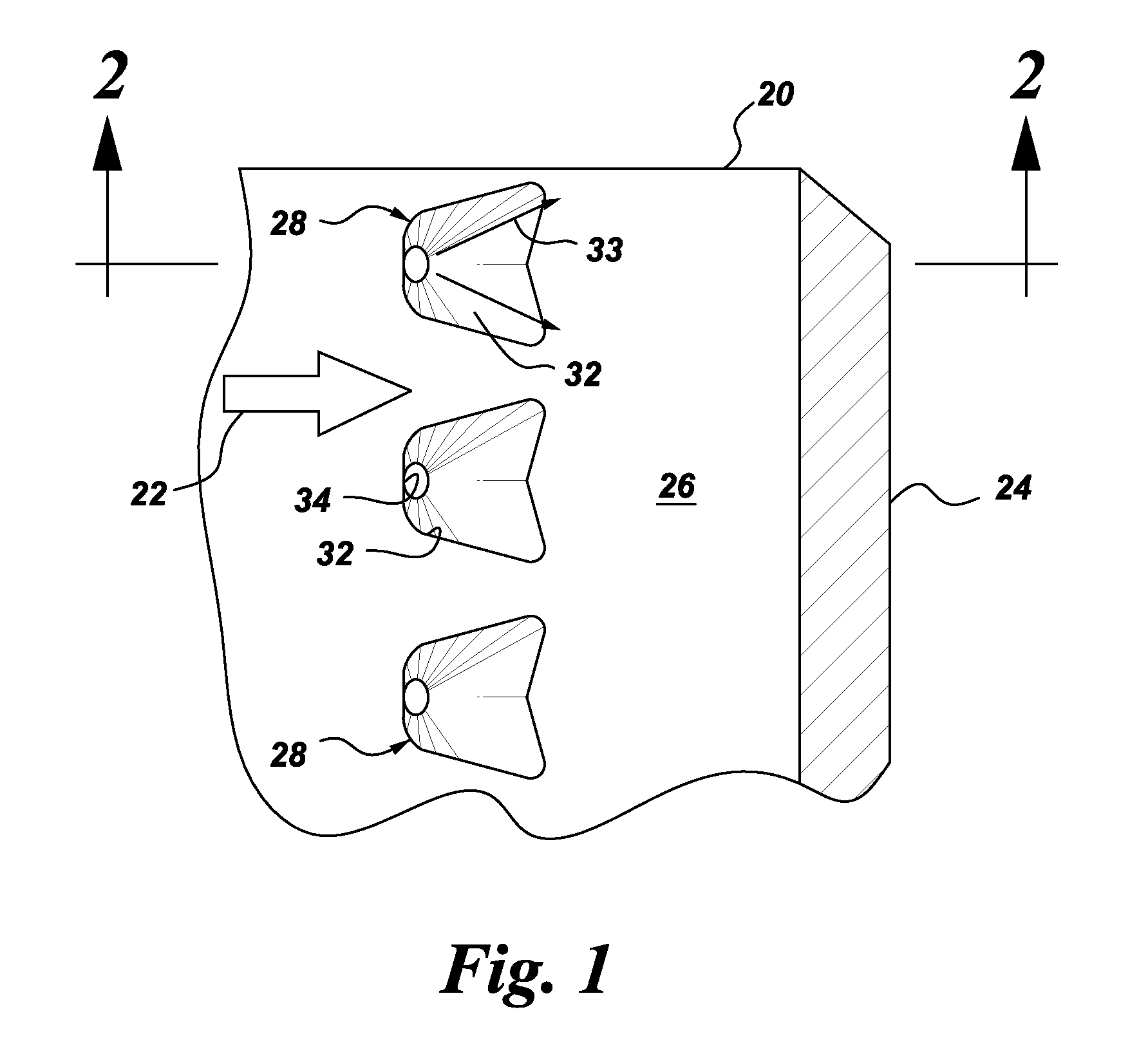

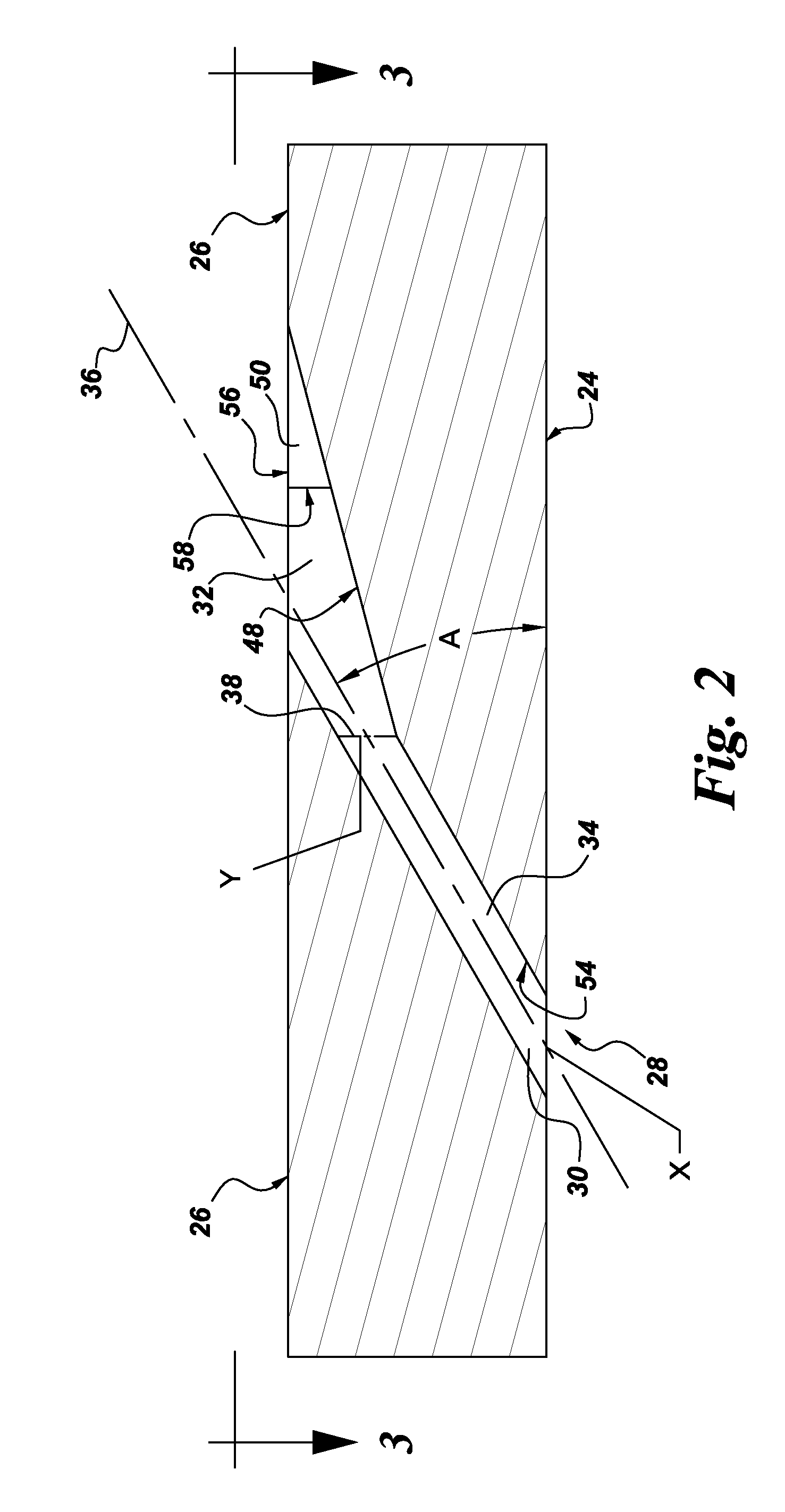

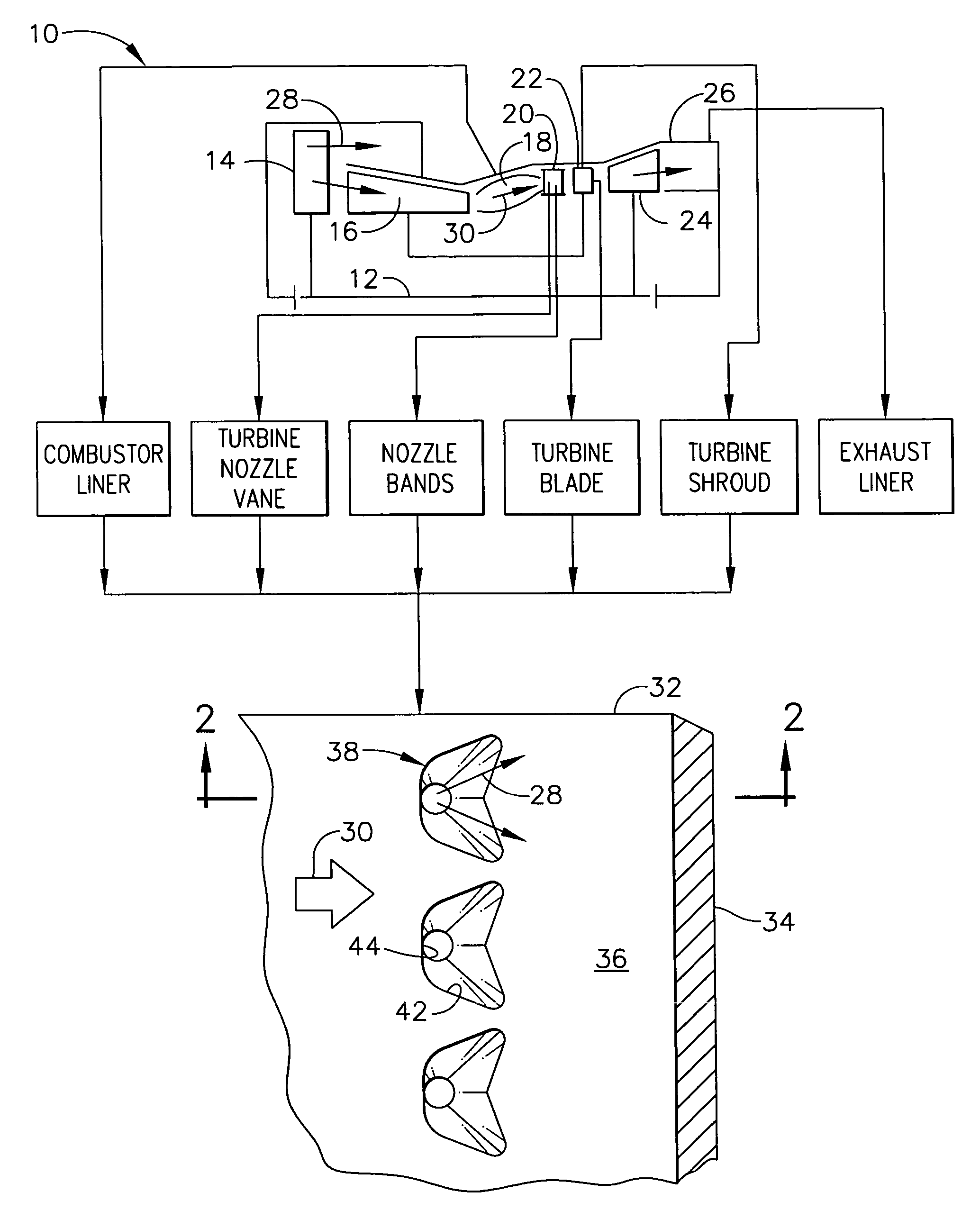

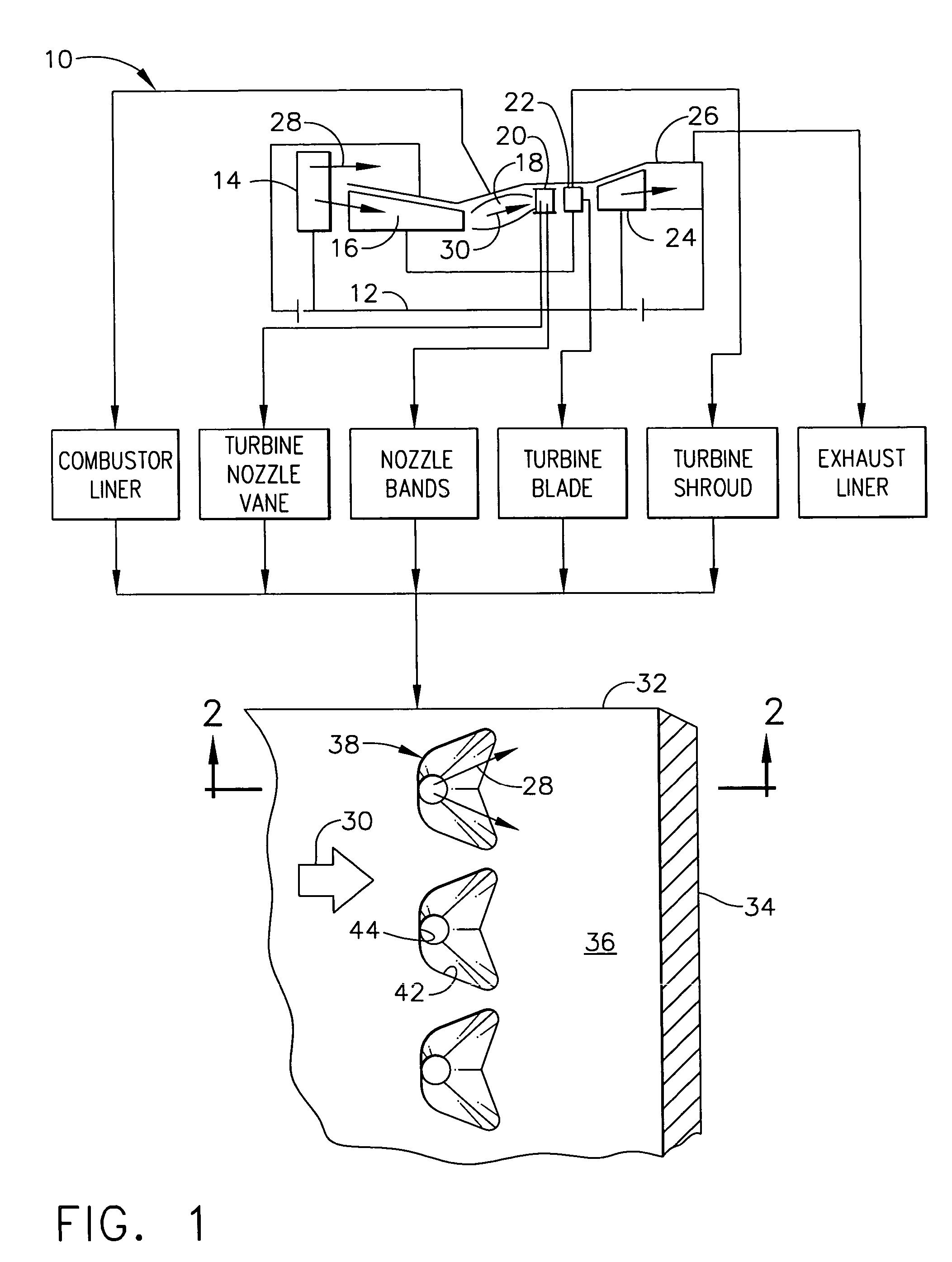

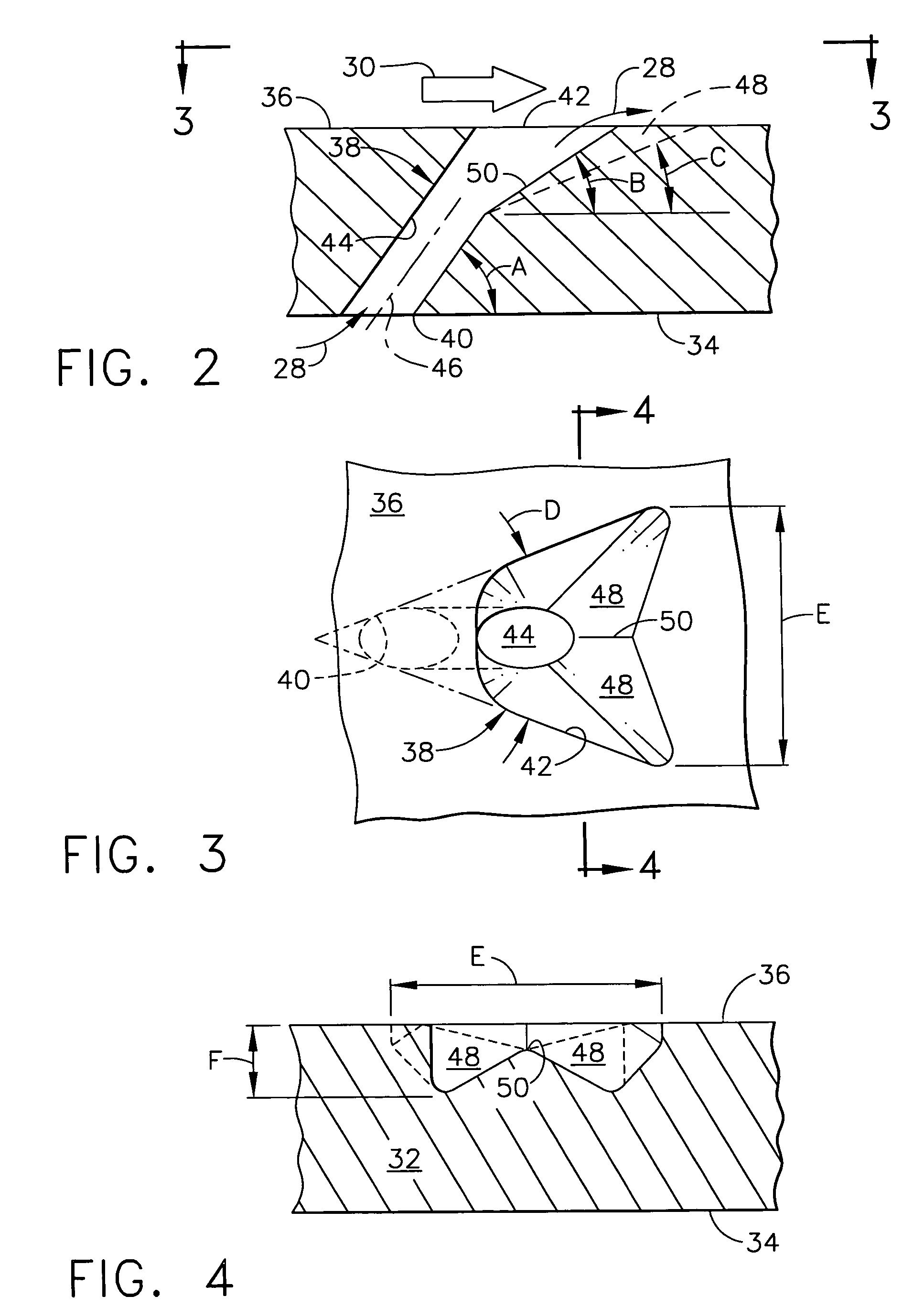

Articles which include chevron film cooling holes, and related processes

An article is described, including an inner surface which can be exposed to a first fluid; an inlet; and an outer surface spaced from the inner surface, which can be exposed to a hotter second fluid. The article further includes at least one row or other pattern of passage holes. Each passage hole includes an inlet bore extending through the substrate from the inlet at the inner surface to a passage hole-exit proximate to the outer surface, with the inlet bore terminating in a chevron outlet adjacent the hole-exit. The chevron outlet includes a pair of wing troughs having a common surface region between them. The common surface region includes a valley which is adjacent the hole-exit; and a plateau adjacent the valley. The article can be an airfoil. Related methods for preparing the passage holes are also described.

Owner:GENERAL ELECTRIC CO

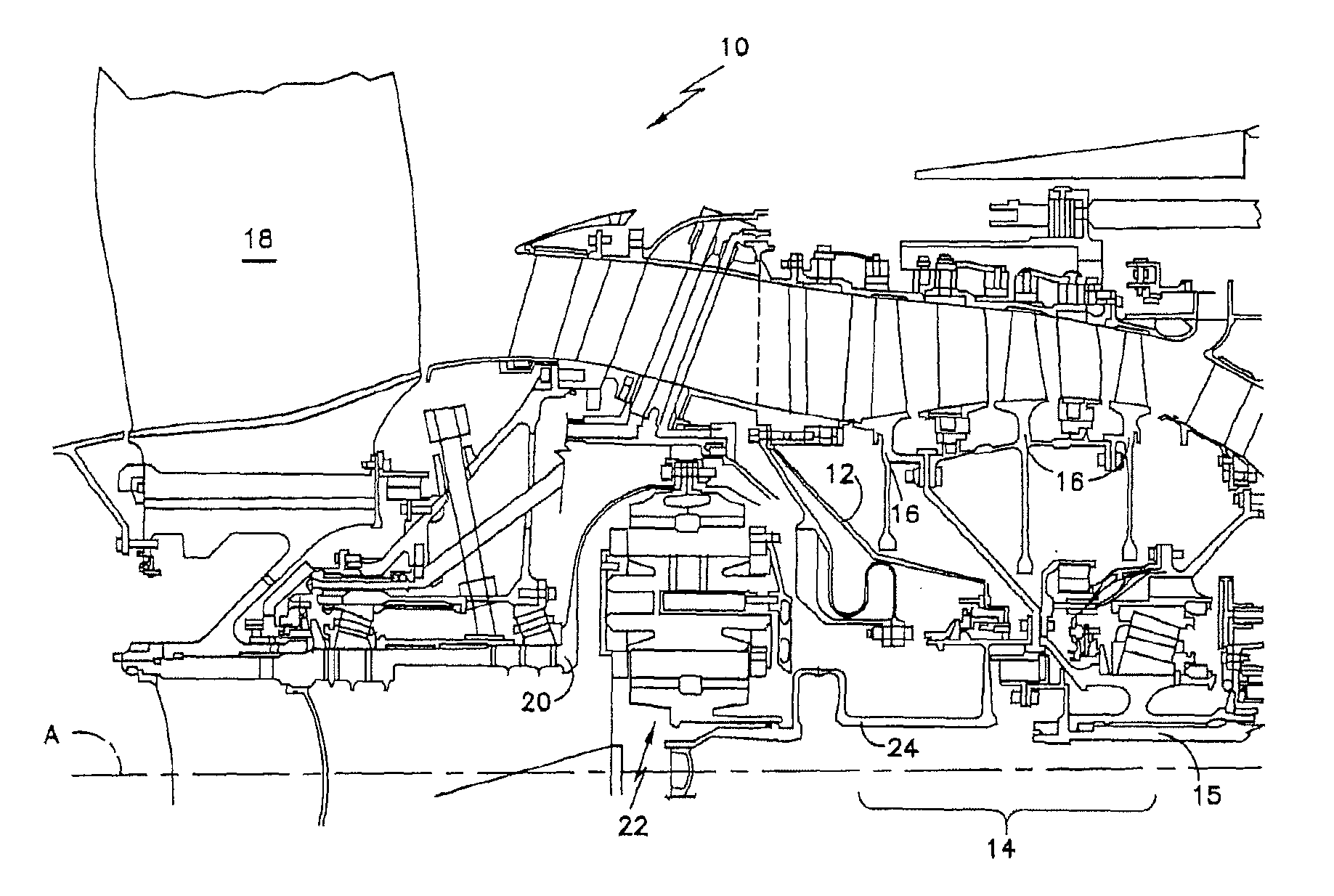

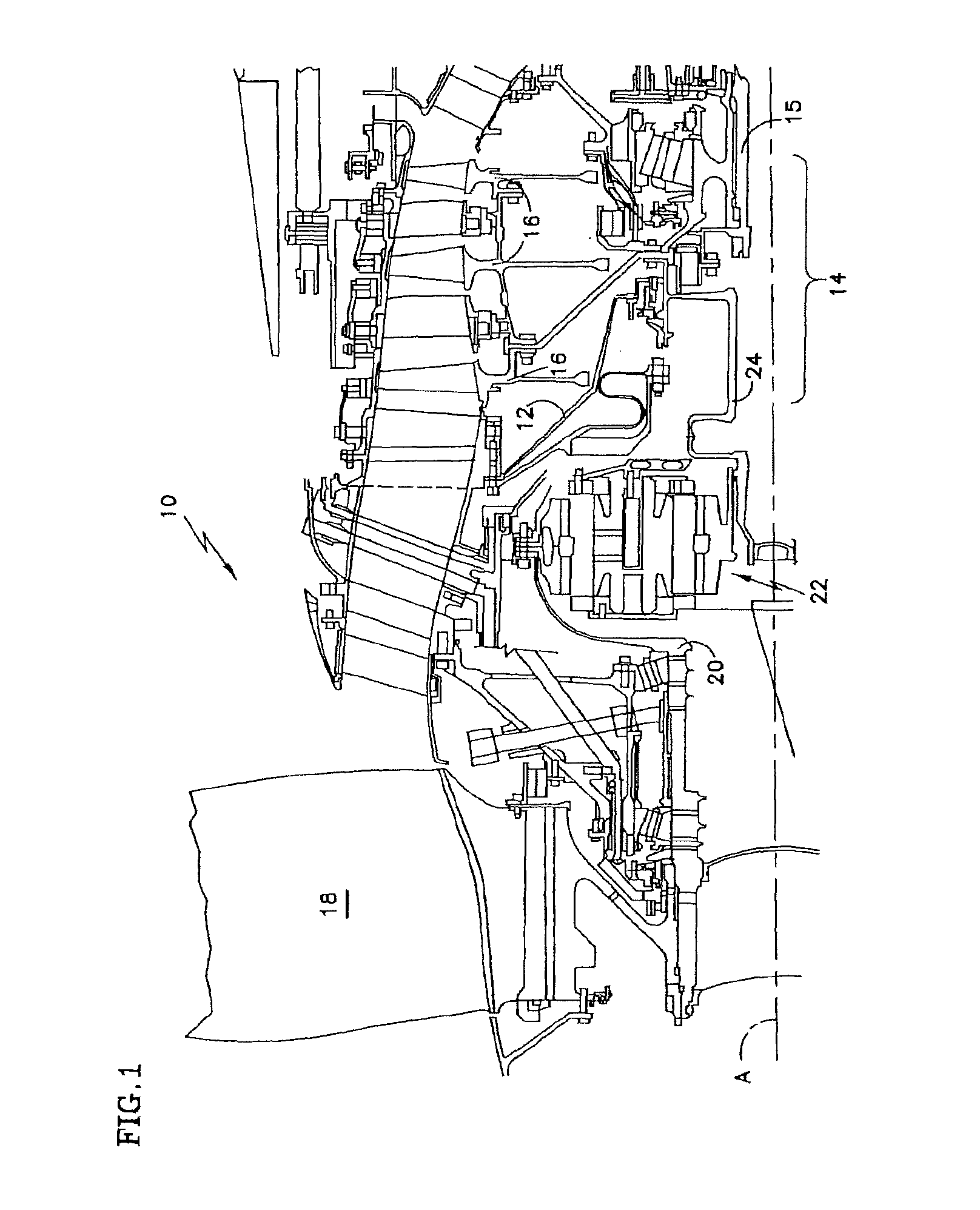

Flexible shaft for gas turbine engine

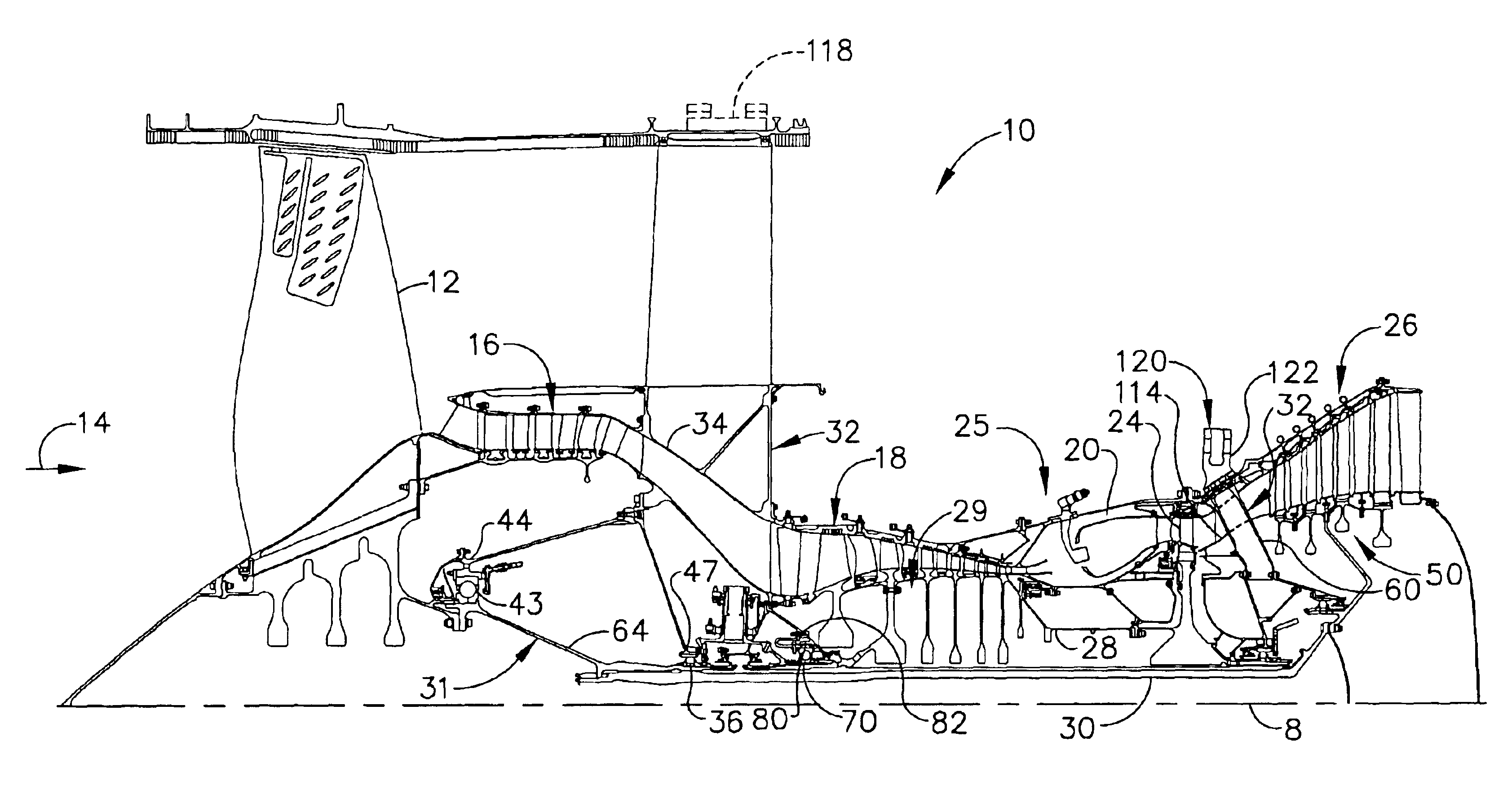

A shaft for a gas turbine engine is provided that includes a first shaft section, a second shaft section, a first flexible linkage, and a second flexible linkage. The first shaft section extends between a forward axial end and an aft axial end along a first axial centerline. The second shaft section extends between a forward axial end and an aft axial end along a second axial centerline. The first flexible linkage includes a bridge section connected between a first diaphragm and a second diaphragm. The first diaphragm is connected to the aft axial end of the first shaft section. The second diaphragm is connected to the forward axial end of the second shaft section. The second flexible linkage includes a diaphragm and a hub. The second flexible linkage diaphragm cantilevers radially outwardly from an inner radial end to an outer radial end, and is connected to the aft axial end of the second shaft section. The hub is connected to the outer radial end of the second flexible linkage diaphragm, and includes an engine shaft coupling connected to the hub.

Owner:RTX CORP

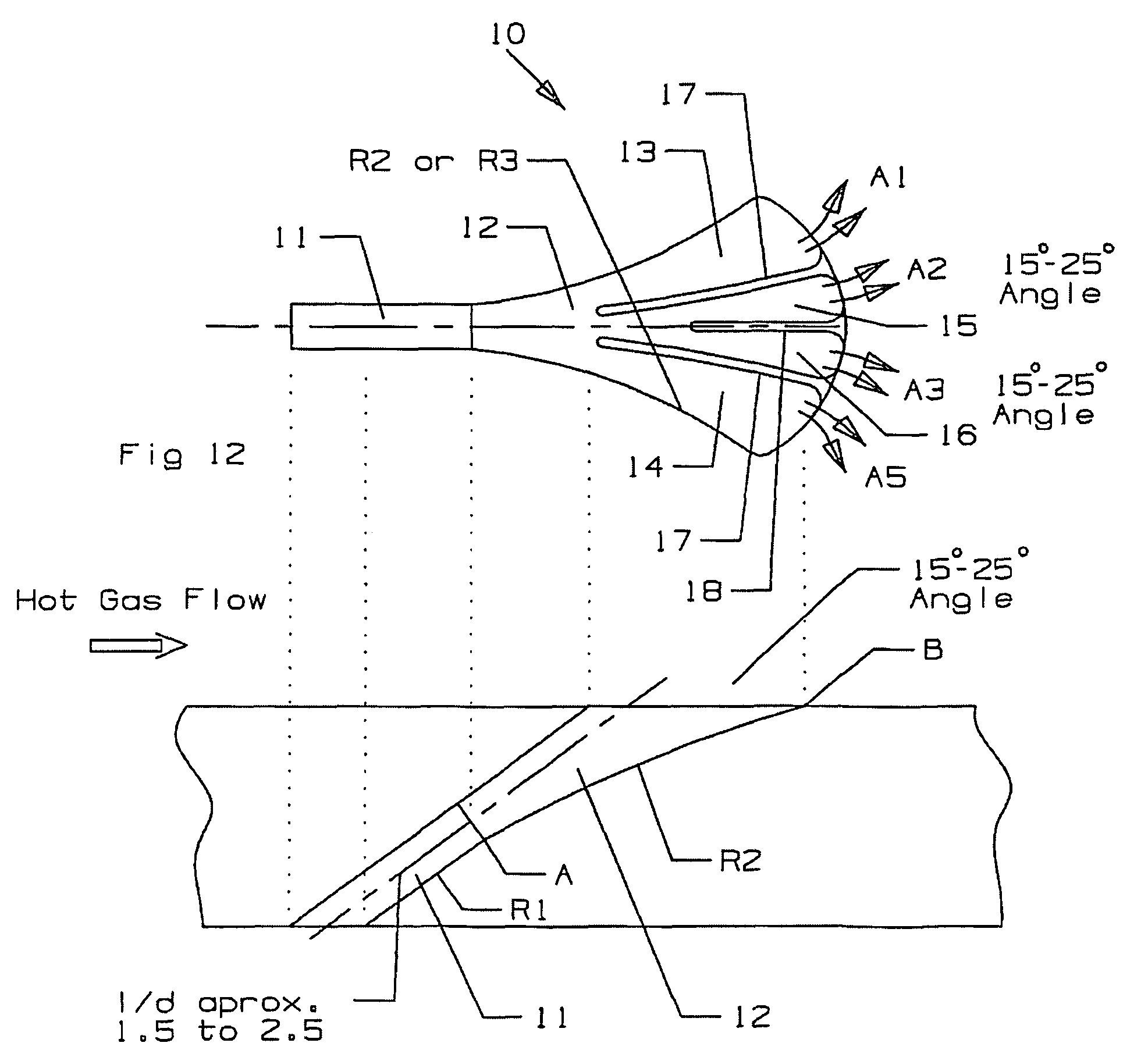

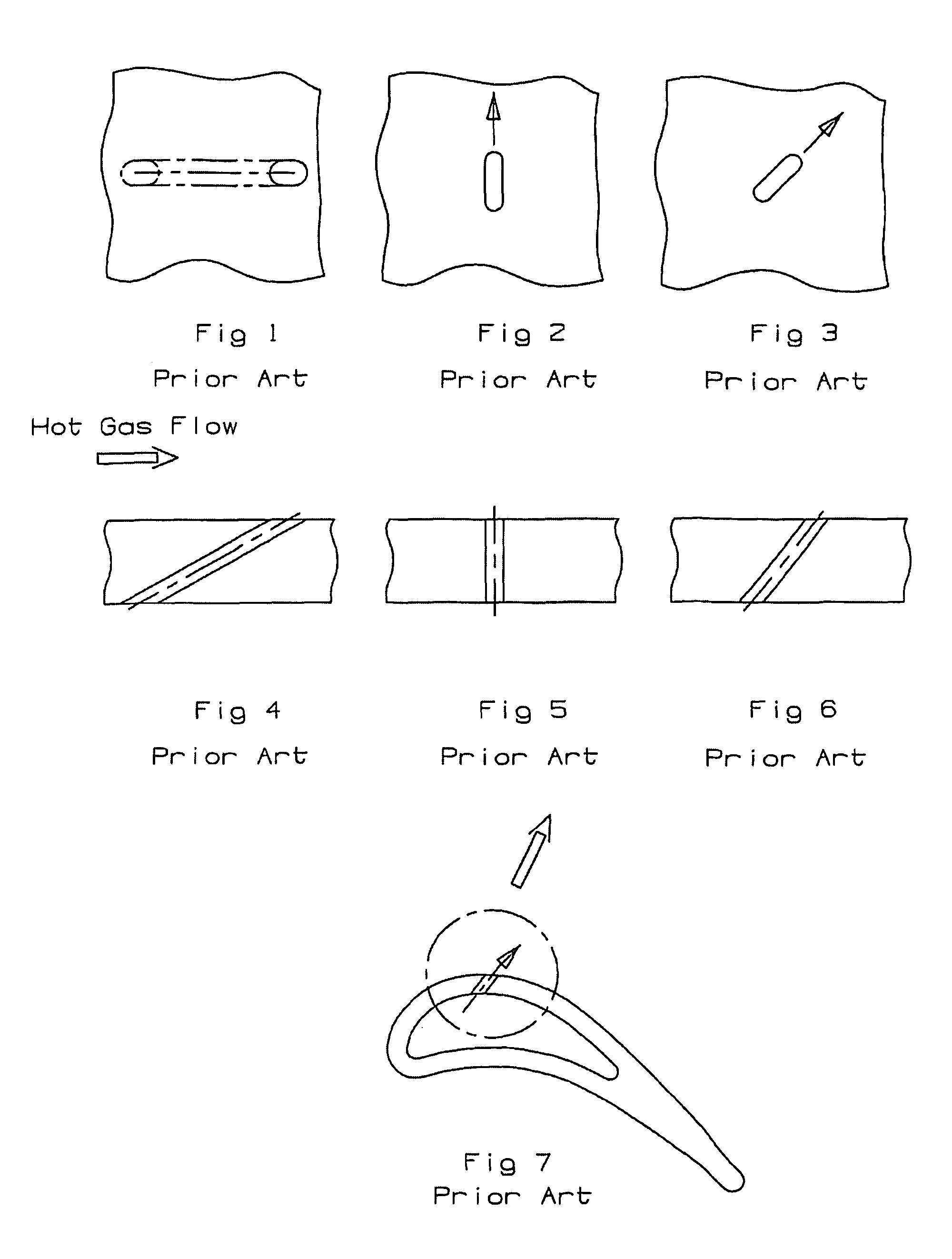

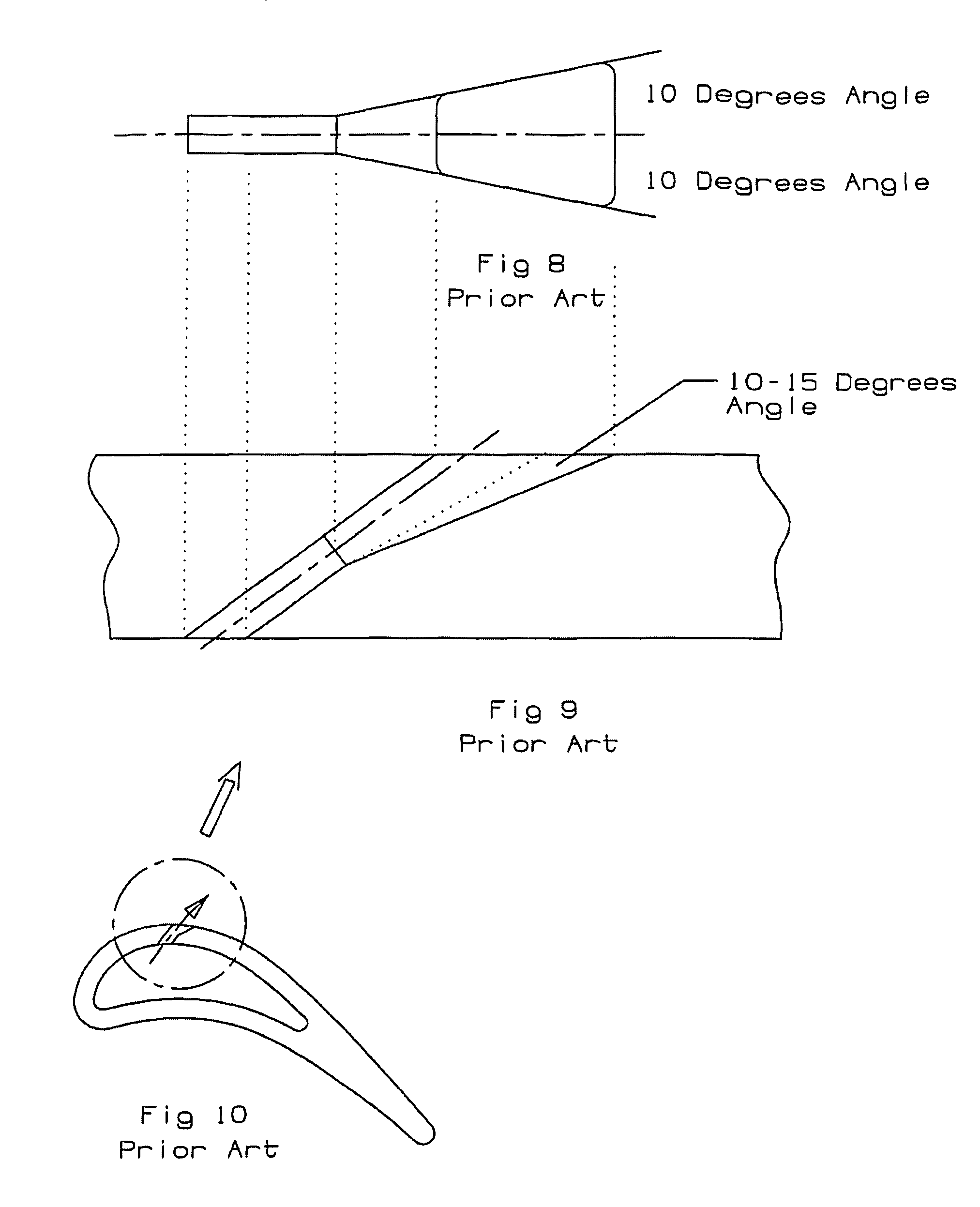

Film cooling hole for turbine airfoil

InactiveUS7997868B1Less turbulenceMinimize shear mixingEngine manufactureEngine fuctionsStructural engineeringTurbine

A turbine airfoil with a film cooling hole having a bell mouth shaped opening that has expansion in both the side walls and the downstream wall of from 15 to 25 degrees. The film cooling hole includes an expansion section formed with two long ribs and one short rib to form three inlets of equal cross sectional areas so that the flows into the three passages are the same. The short rib forms two middle passages to combine with two outer passages to form four exit passages for the film hole. The two side walls are curved outward in the stream-wise oriented film hole and have an expansion of from 0 to 5 degrees in the compound angled film hole.

Owner:SIEMENS ENERGY INC

Chevron film cooled wall

A wall in a gas turbine engine includes inner and outer surfaces having a row of compound chevron film cooling holes extending therethrough. The chevron holes diverge both longitudinally and laterally between an inlet at the wall inner surface and a chevron outlet at the wall outer surface.

Owner:GENERAL ELECTRIC CO

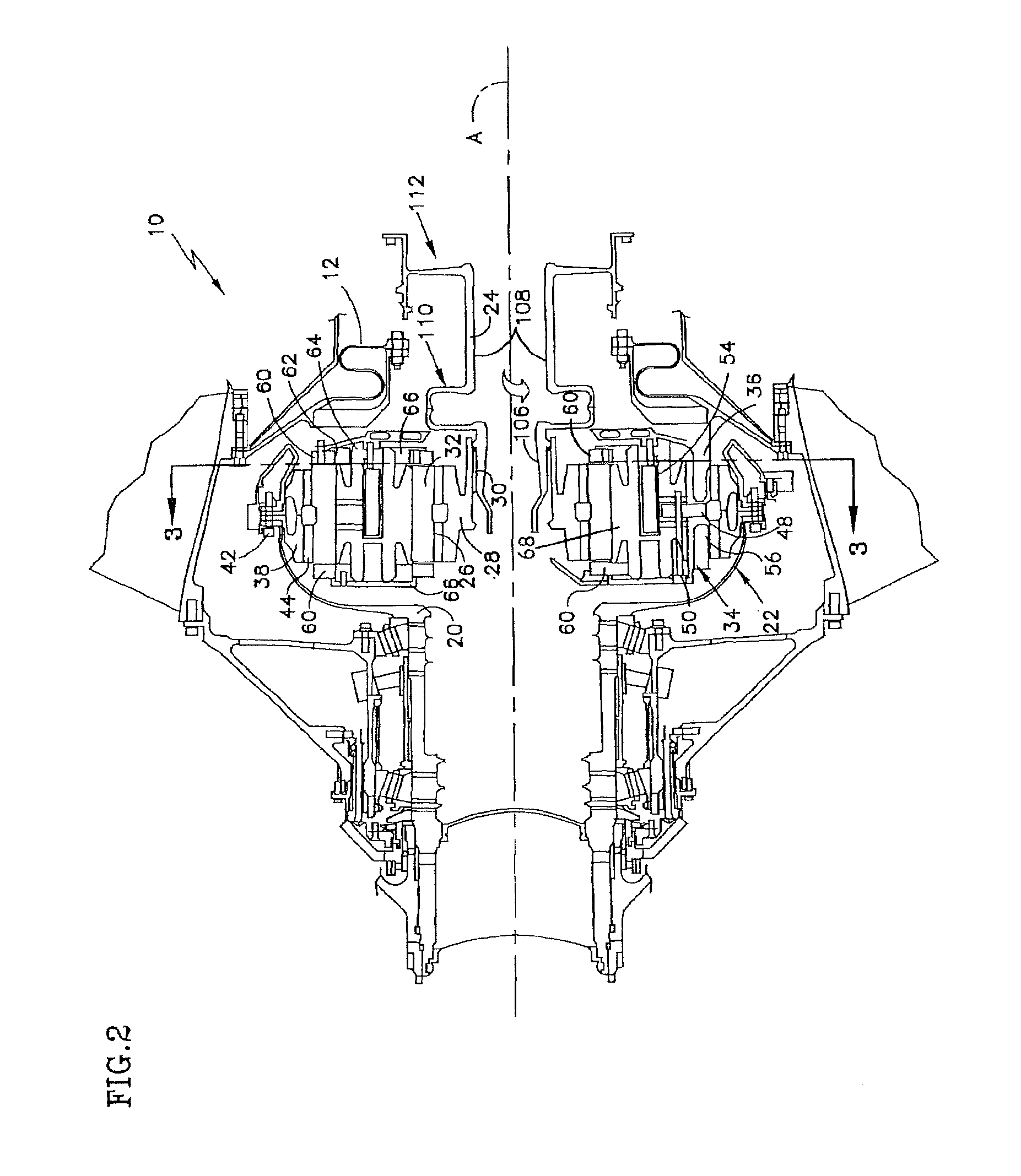

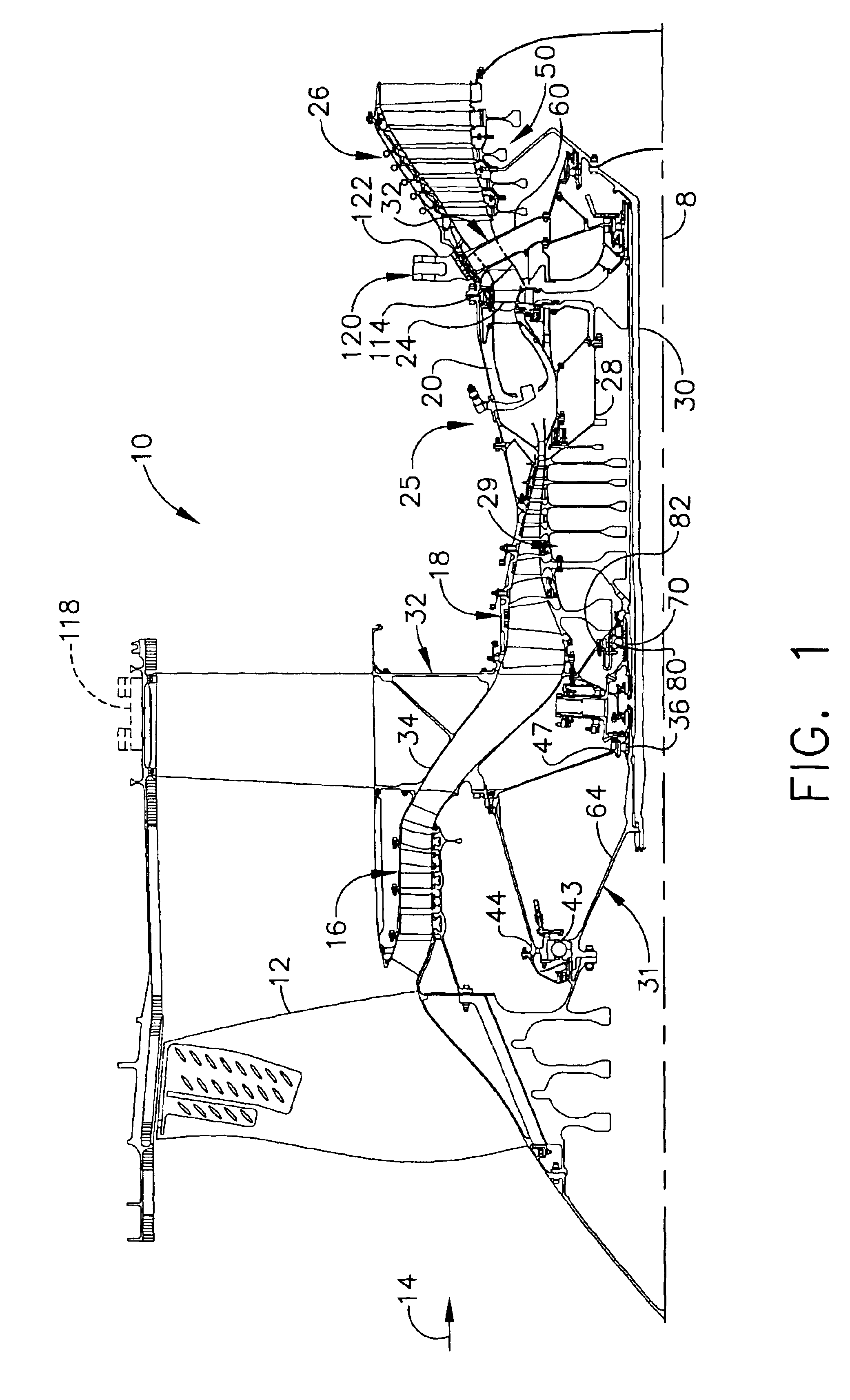

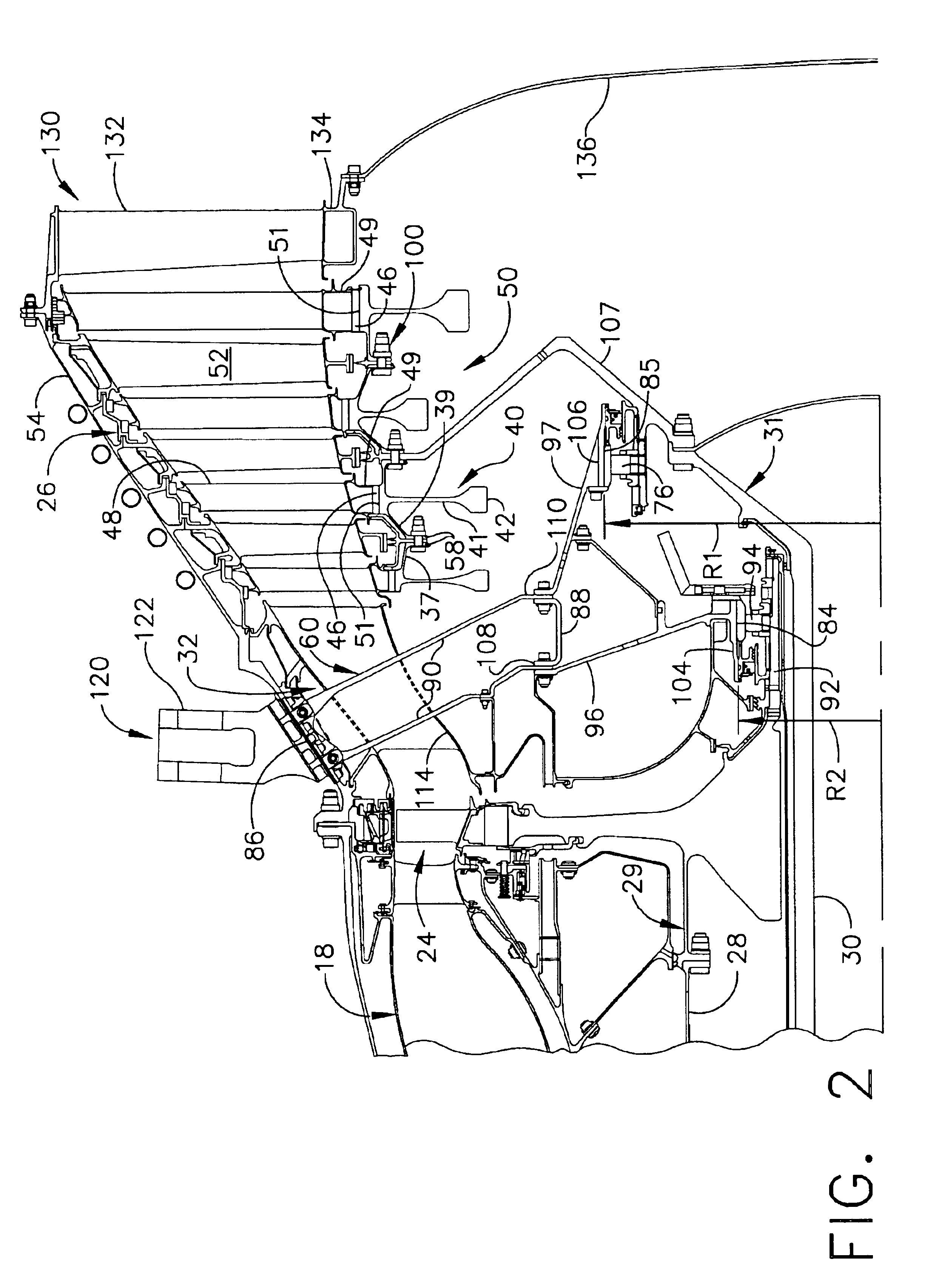

Aircraft engine with inter-turbine engine frame

An aircraft engine turbine frame includes a first structural ring, a second structural ring disposed co-axially with and radially spaced inwardly of the first structural ring about a centerline axis. A plurality of circumferentially spaced apart struts extend between the first and second structural rings. Forward and aft sump members having forward and aft central bores are fixedly joined to forward and aft portions of the turbine frame respectively. A frame connecting means for connecting the engine to an aircraft is disposed on the first structural ring. The frame connecting means may include a U-shaped clevis. The frame may be an inter-turbine frame axially located between first and second turbines of first and second rotors of a gas turbine engine assembly. An axial center of gravity of the second turbine passes though or very near a second turbine frame bearing supported by the aft sump member.

Owner:GENERAL ELECTRIC CO

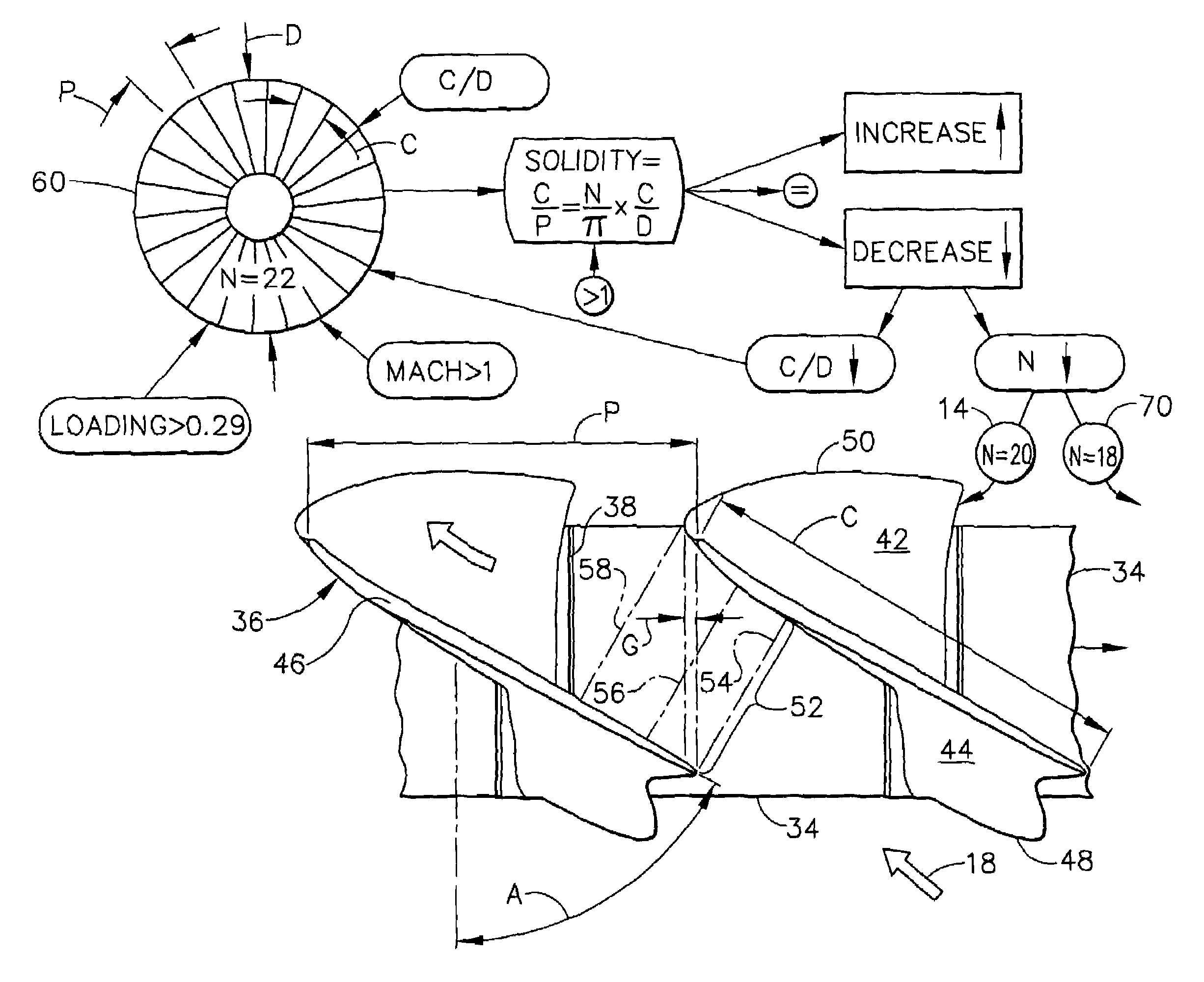

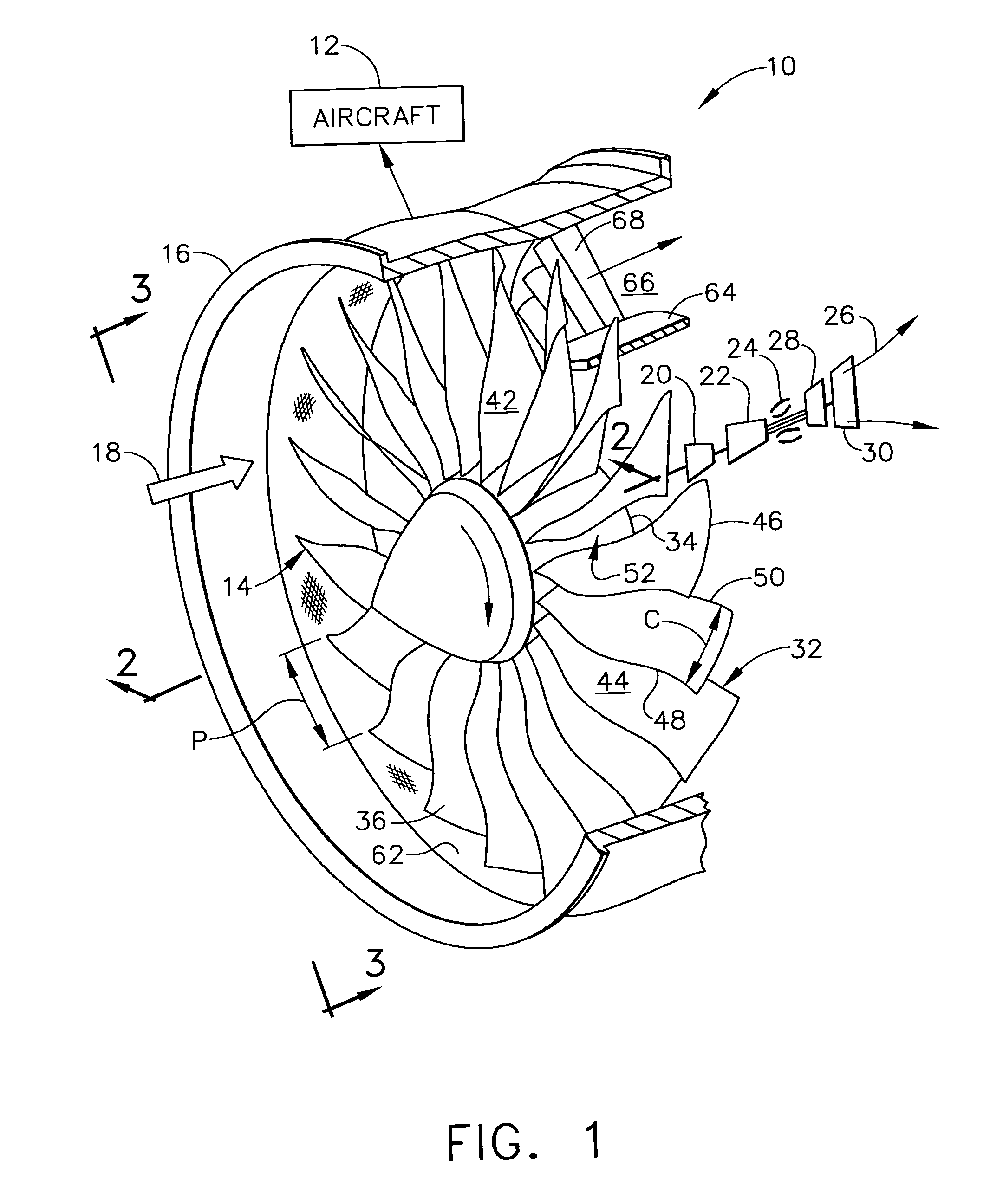

Low solidity turbofan

A turbofan includes a row of fan blades extending from a supporting disk inside an annular casing. Each blade includes an airfoil having opposite pressure and suction sides extending radially in span between a root and tip and axially in chord between leading and trailing edges. Adjacent airfoils define corresponding flow passages therebetween for pressurizing air. Each airfoil includes stagger increasing between the root and tip, and the flow passage has a mouth between the airfoil leading edge and the suction side of an adjacent airfoil and converges to a throat aft from the mouth. The row includes no more than twenty fan blades having low tip solidity for increasing the width of the passage throat.

Owner:GENERAL ELECTRIC CO

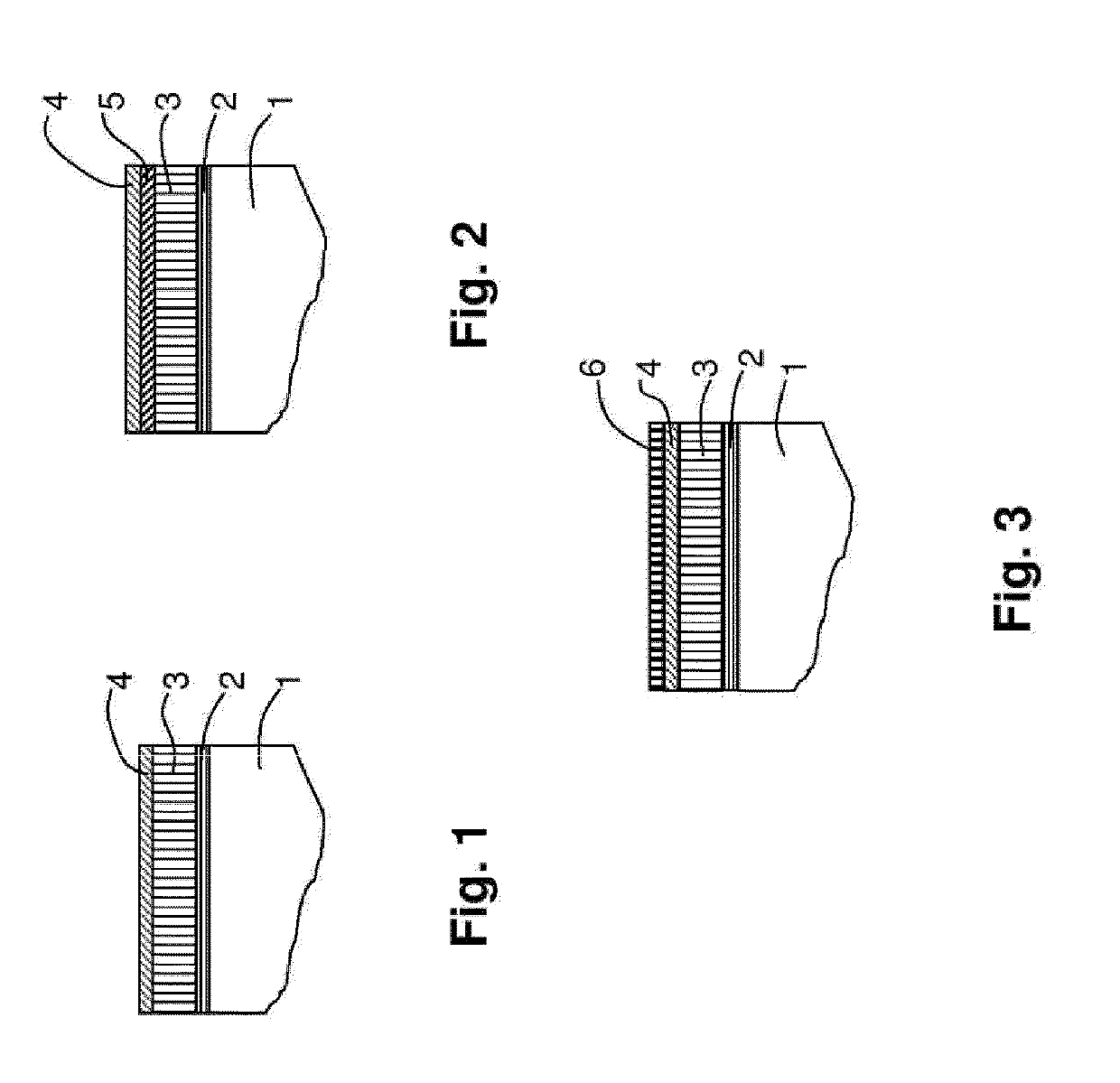

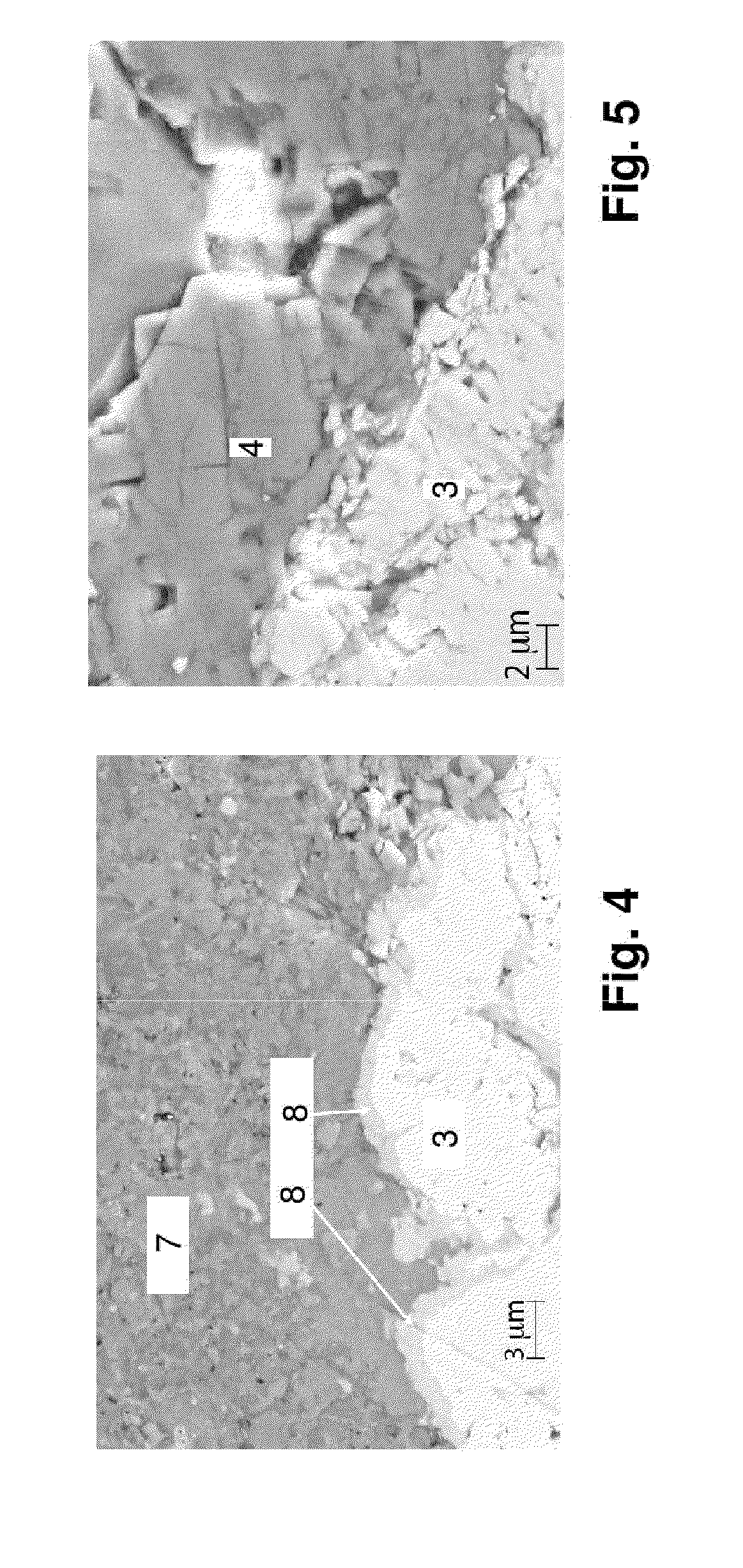

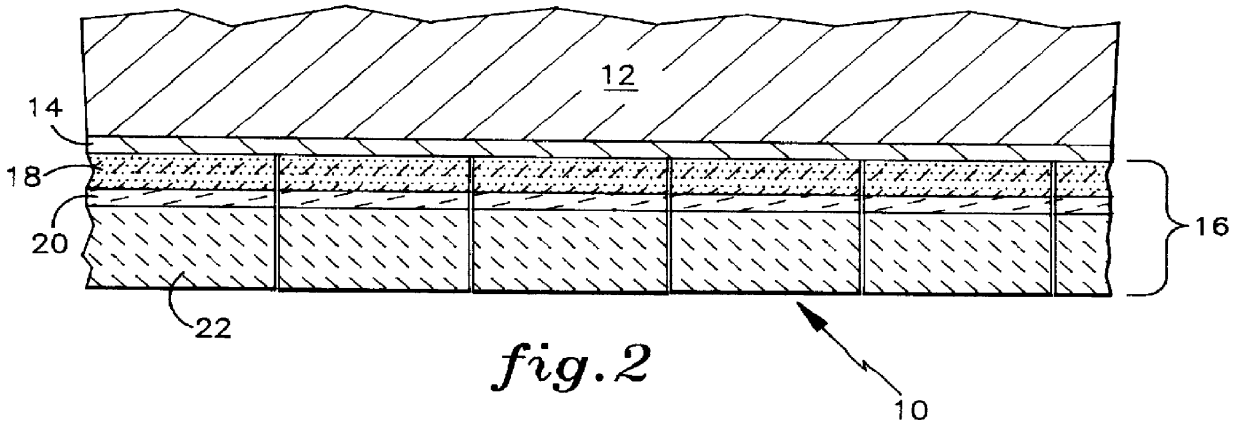

Multilayer thermal barrier coating

InactiveUS20090324989A1Improved thermal barrier coatingAttackLiquid surface applicatorsMolten spray coatingThermal barrier coatingZirconium oxide

Components (1) have a thermal barrier coating (2-6) on the surface thereof, wherein the thermal barrier coating includes at least one layer (3) having chemically stabilized zirconia, and wherein at least indirectly adjacent to the layer (3) with chemically stabilized zirconia and on its surface facing side, there is provided a protective layer (4) and / or a infiltration zone (5) which does not react with environmental contaminant compositions that contain oxides of calcium and which does not react with the material of the layer (3) having chemically stabilized zirconia. Methods for making such components as well as to uses of specific systems for coating thermal barrier coatings, can prevent CMAS.

Owner:ANSALDO ENERGIA IP UK LTD +1

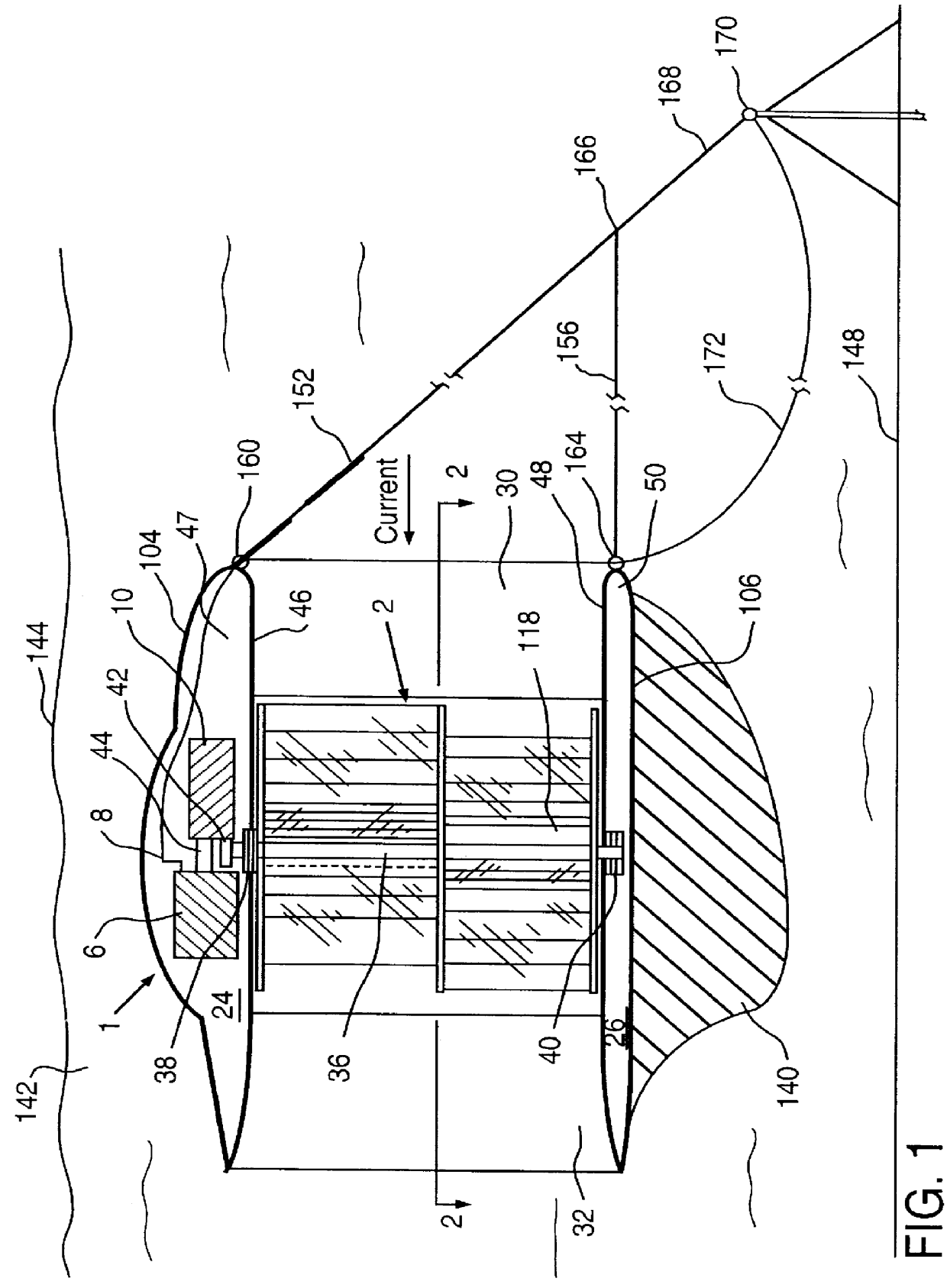

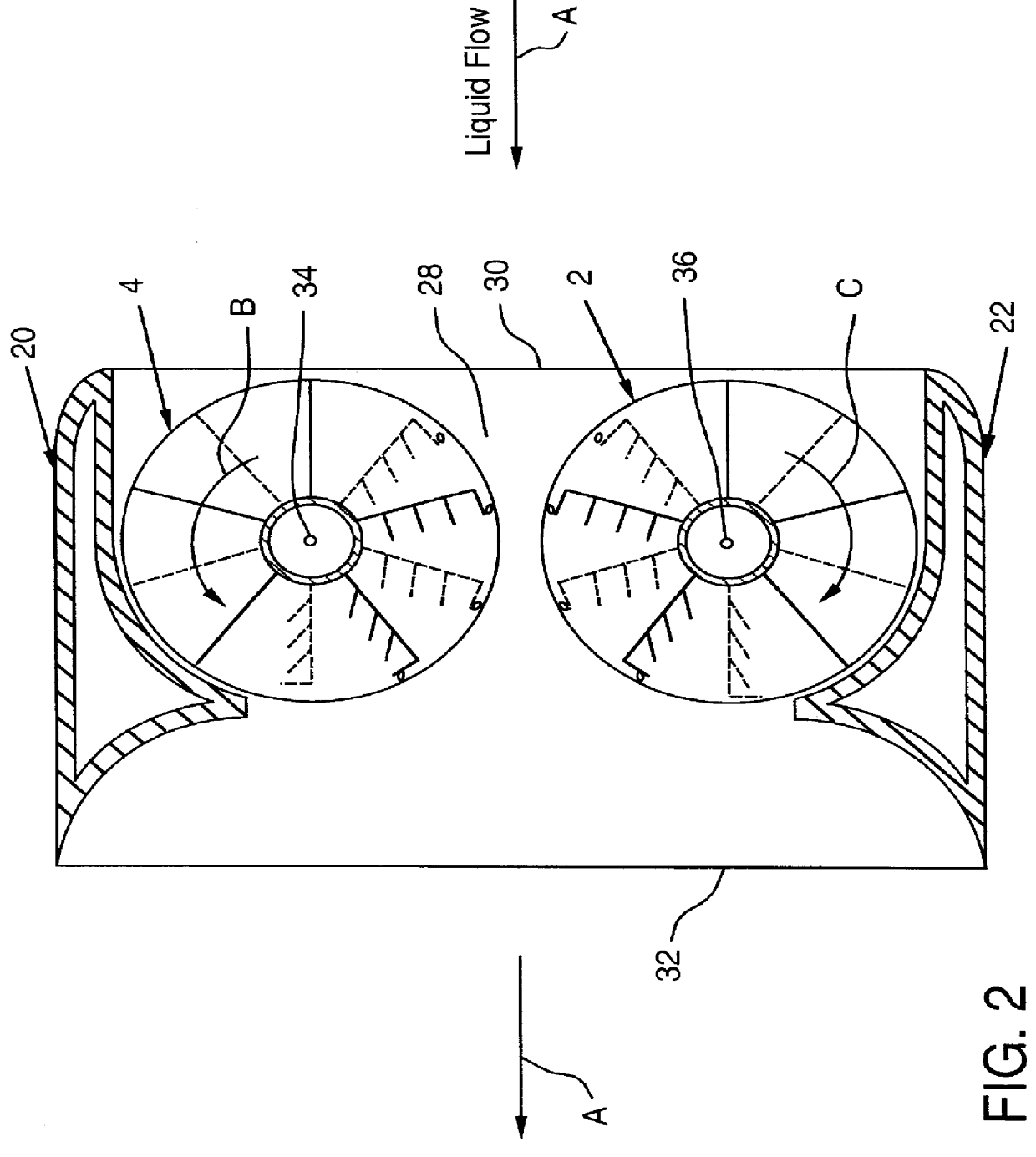

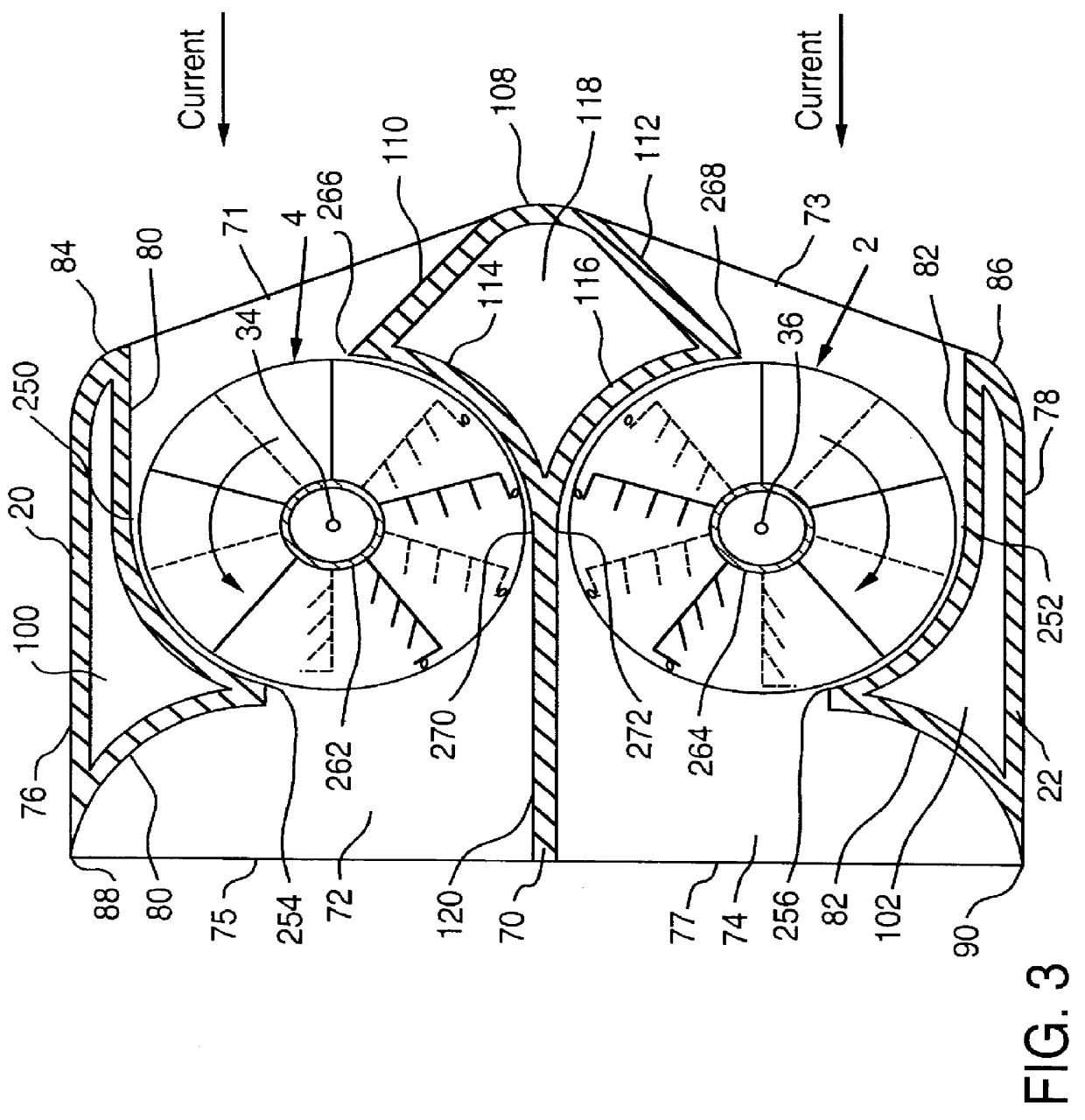

Submersible appartus for generating electricity and associated method

InactiveUS6109863AReduce the impactReduce impactCircumferential flow pumpsWind motor controlElectricityMarine engineering

A fully submersible apparatus for generating electricity from liquid flow as in an ocean or river current. A buoyant structure is fully submersible and has at least one pair of counter-rotating side-by-side motors with a plurality of angularly spaced radial vanes each having a plurality of rotatable subvanes such that current impinging upon the motor will impinge on a closed or solid vane to effect rotation of the motor and its shaft during a first phase of the rotational cycle and will impinge on open vanes for free passage therethrough on the return or second phase of rotation of the motor. Motors may also be provided with vanes in overlying and underlying relationship. An associated method is provided.

Owner:MILLIKEN LARRY D

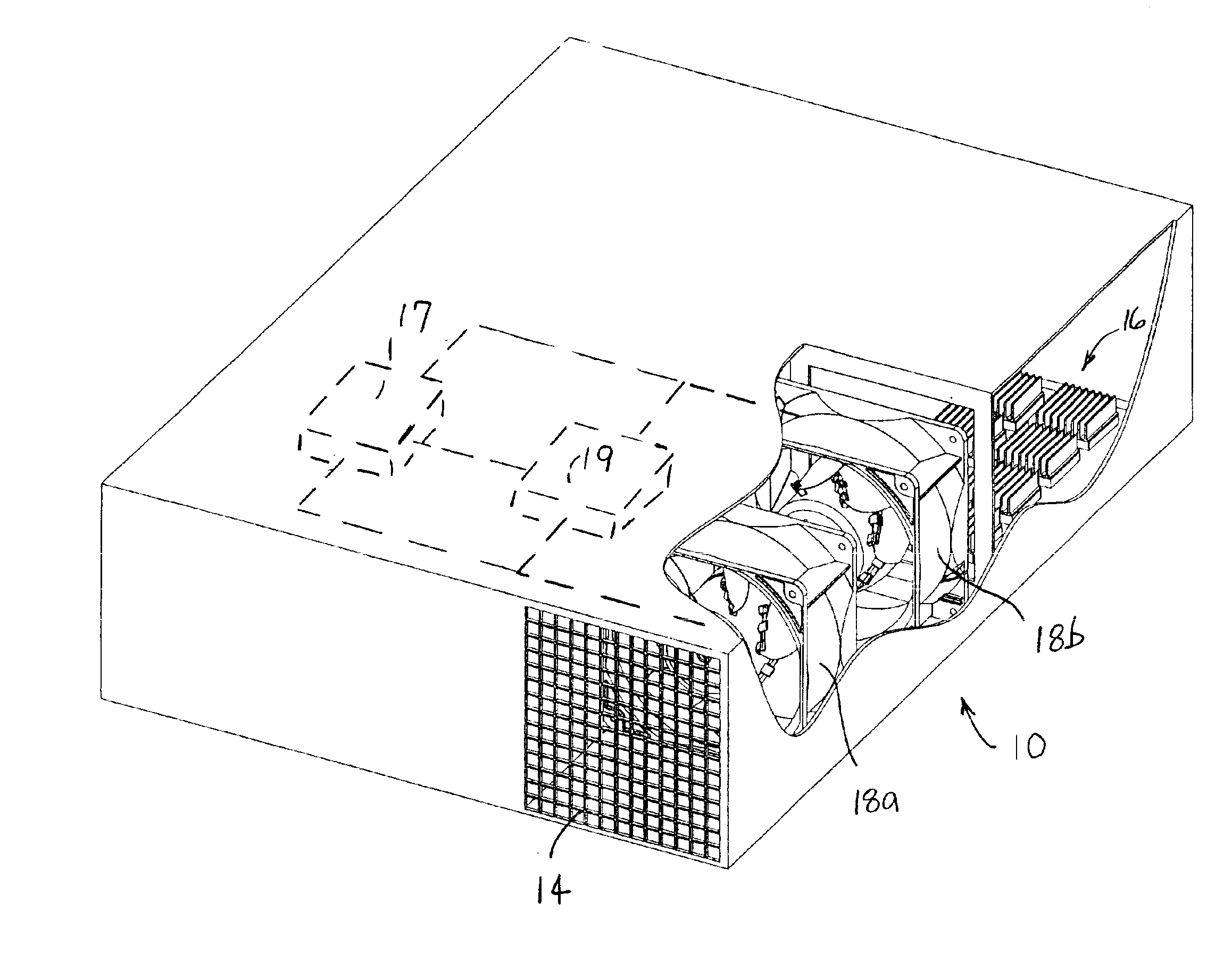

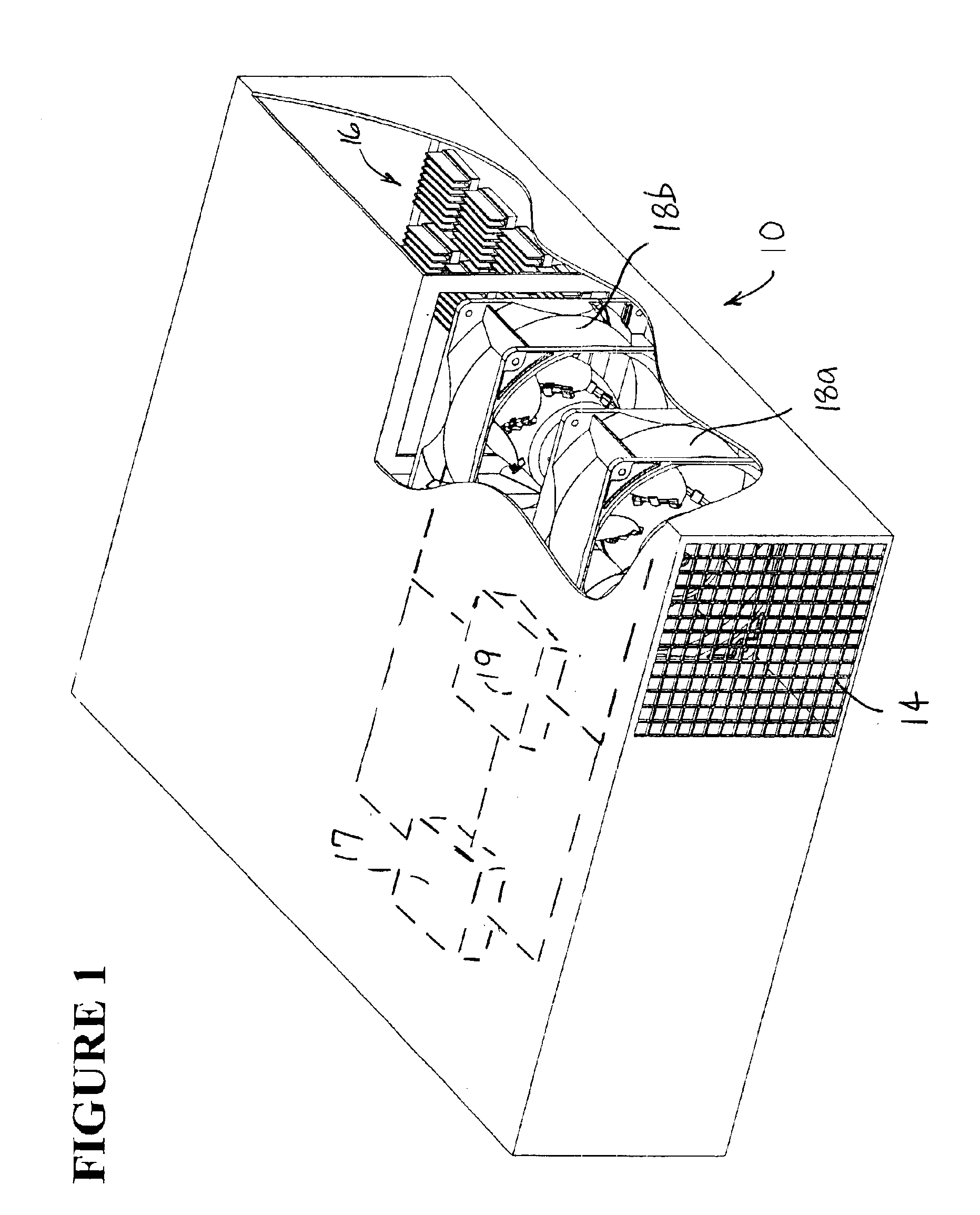

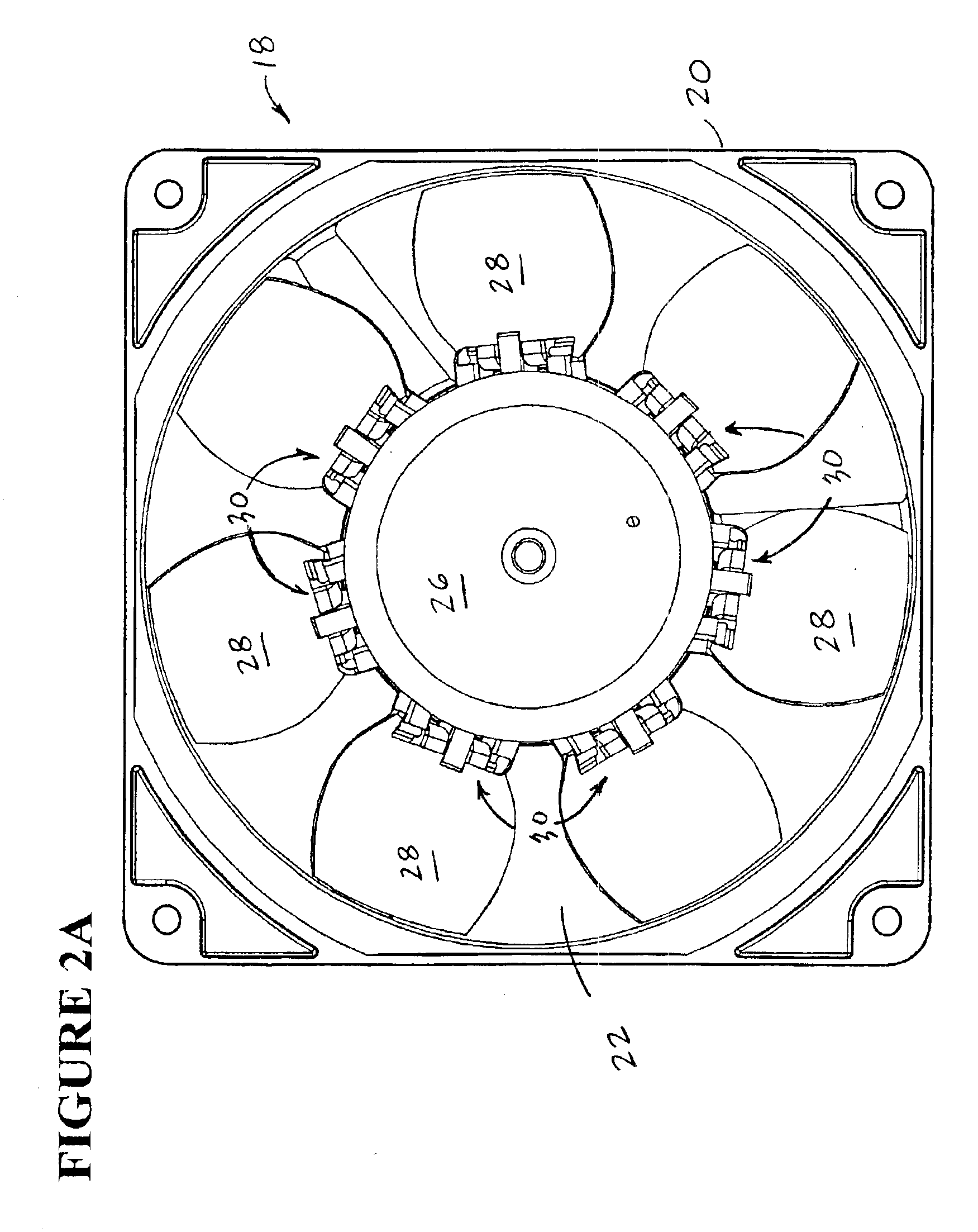

Fan with collapsible blades, redundant fan system, and related method

InactiveUS6860713B2Reduces fan inefficiencyPrevent undesirable blockagePropellersPump componentsFan bladeAirflow

A redundant fan system for a computer includes two fans installed in series with at least one of the fans having collapsible blades. A fan system of this type reduces the fan inefficiency caused when one fan in a series mounted pair is not operating, either because it is free-wheeling or in a locked rotor condition. When non-operational, the fan blades of the collapsible fan fold inward due to airflow generated by the operational fan over the collapsible blades. The ability of the blades to fold reduces the inefficiency of the operational fan, having less of an effect on fan life. Also, because the flow of air is less restricted, proper airflow can be maintained, thus preventing overheating of the computer.

Owner:NIDEC AMERICA CORP

Heart assist device with expandable impeller pump

An impeller includes a hub and at least one blade supported by the hub. The impeller has a stored configuration in which the blade is compressed so that its distal end moves towards the hub, and a deployed configuration in which the blade extends away from the hub. The impeller may be part of a pump for pumping fluids, such as pumping blood within a patient. A blood pump may include a cannula having a proximal portion with a fixed diameter, and a distal portion with an expandable diameter. The impeller may reside in the expandable portion of the cannula. The cannula may have a compressed diameter which allows it to be inserted percutaneously into a patient. Once at a desired location, the expandable portion of the cannula may be expanded and the impeller expanded to the deployed configuration. A flexible drive shaft may extend through the cannula for rotationally driving the impeller within the patient's body.

Owner:PENN STATE RES FOUND +2

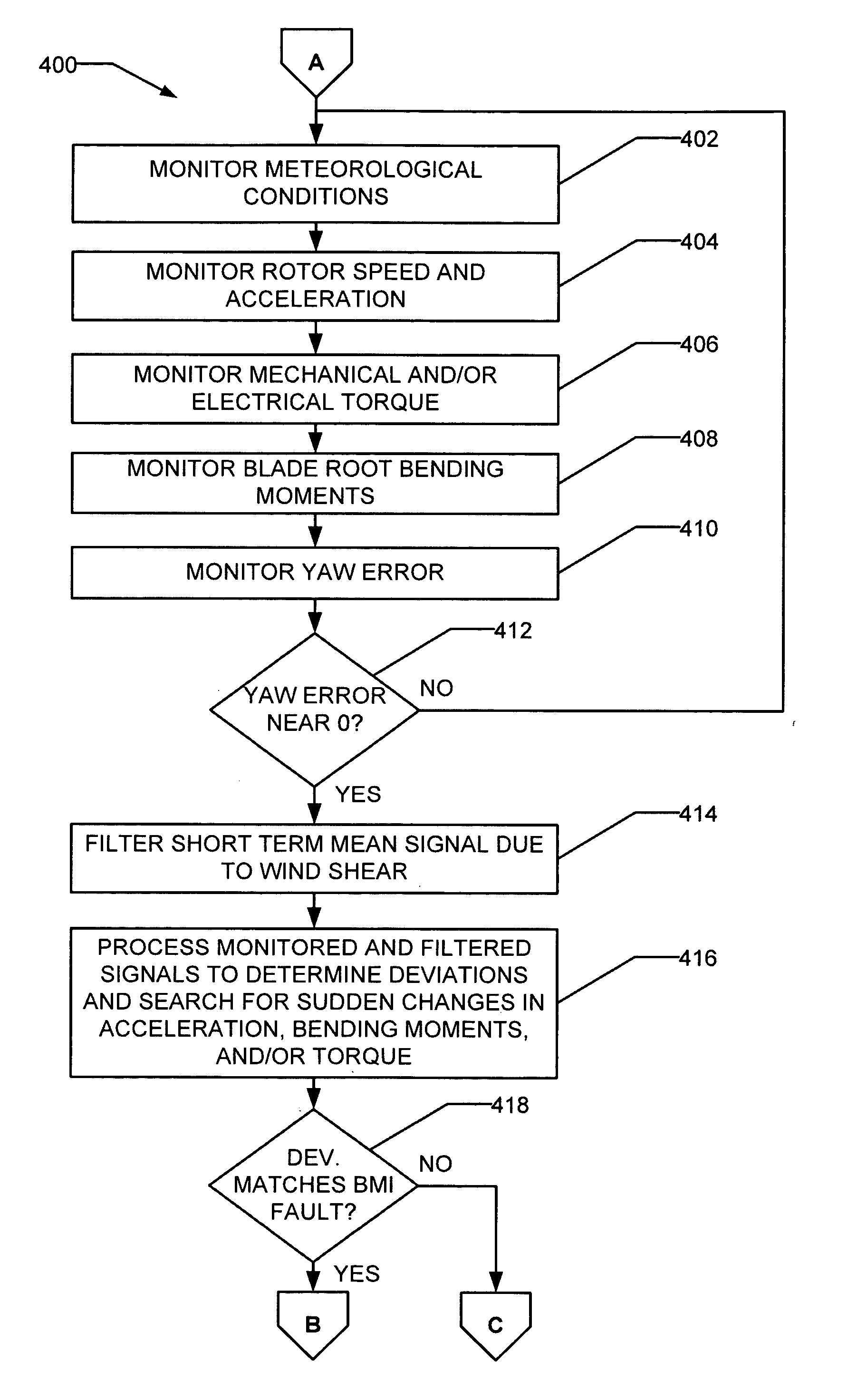

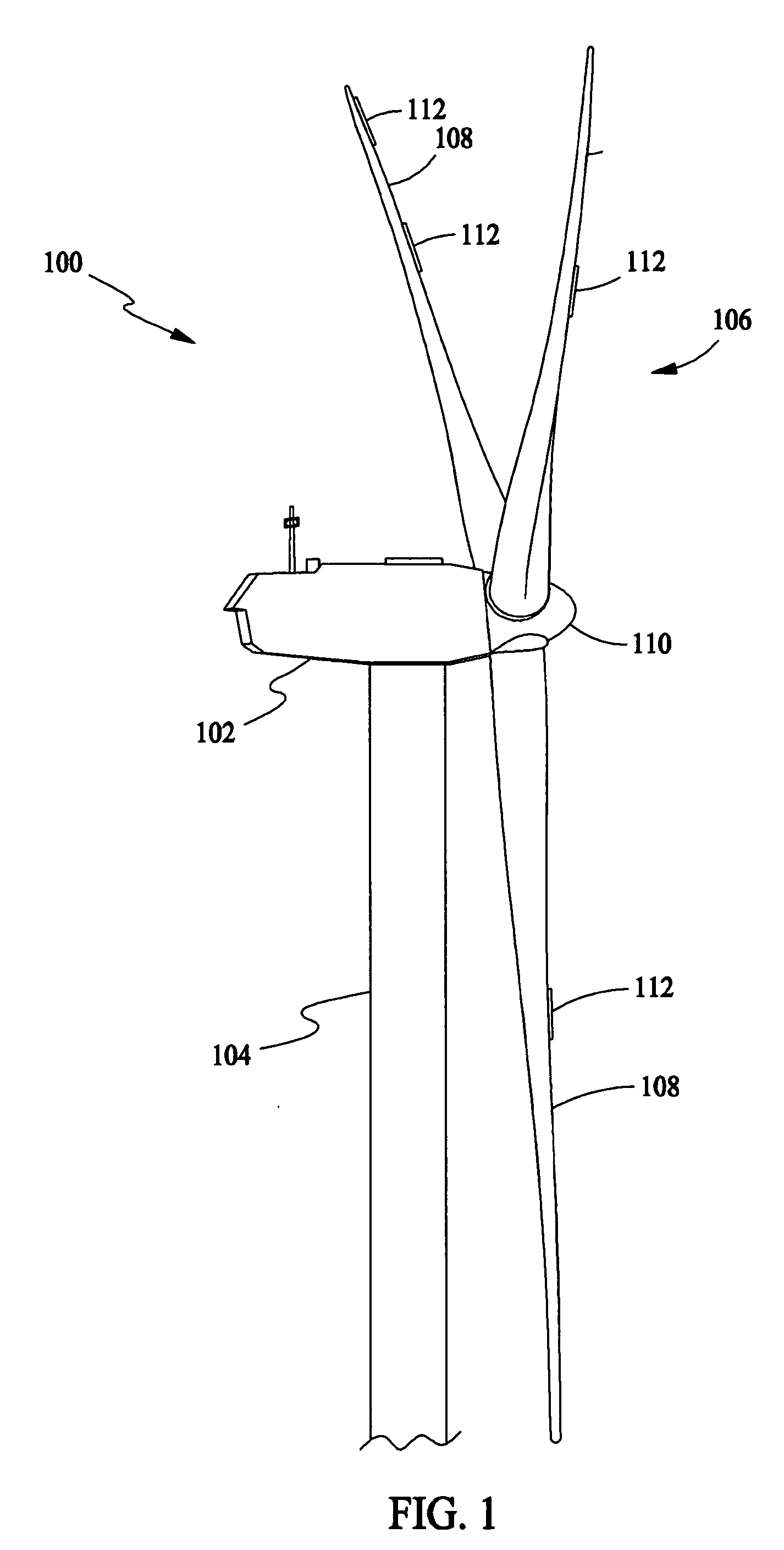

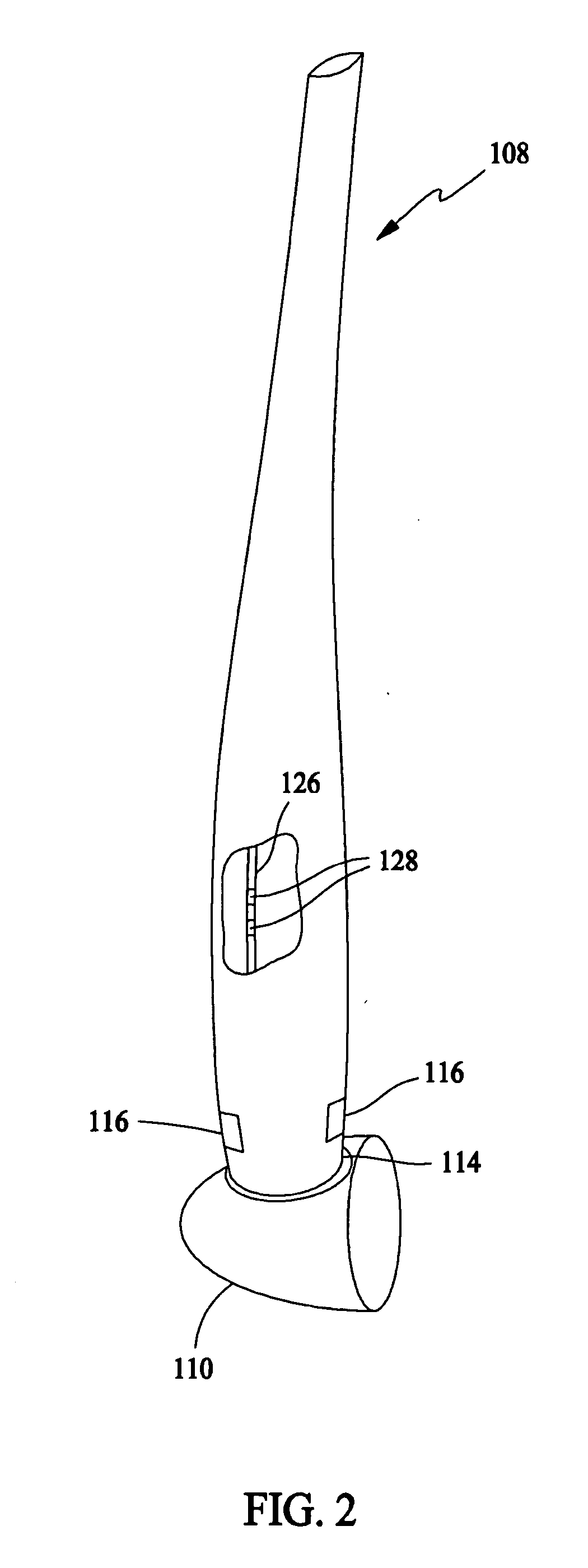

Methods and apparatus for rotor blade ice detection

ActiveUS20050276696A1Reduced lifting capabilityDiminished aerodynamic rotor blade performancePropellersWind motor controlIcing conditionsEngineering

A method for detecting ice on a wind turbine having a rotor and one or more rotor blades each having blade roots includes monitoring meteorological conditions relating to icing conditions and monitoring one or more physical characteristics of the wind turbine in operation that vary in accordance with at least one of the mass of the one or more rotor blades or a mass imbalance between the rotor blades. The method also includes using the one or more monitored physical characteristics to determine whether a blade mass anomaly exists, determining whether the monitored meteorological conditions are consistent with blade icing; and signaling an icing-related blade mass anomaly when a blade mass anomaly is determined to exist and the monitored meteorological conditions are determined to be consistent with icing.

Owner:GENERAL ELECTRIC CO

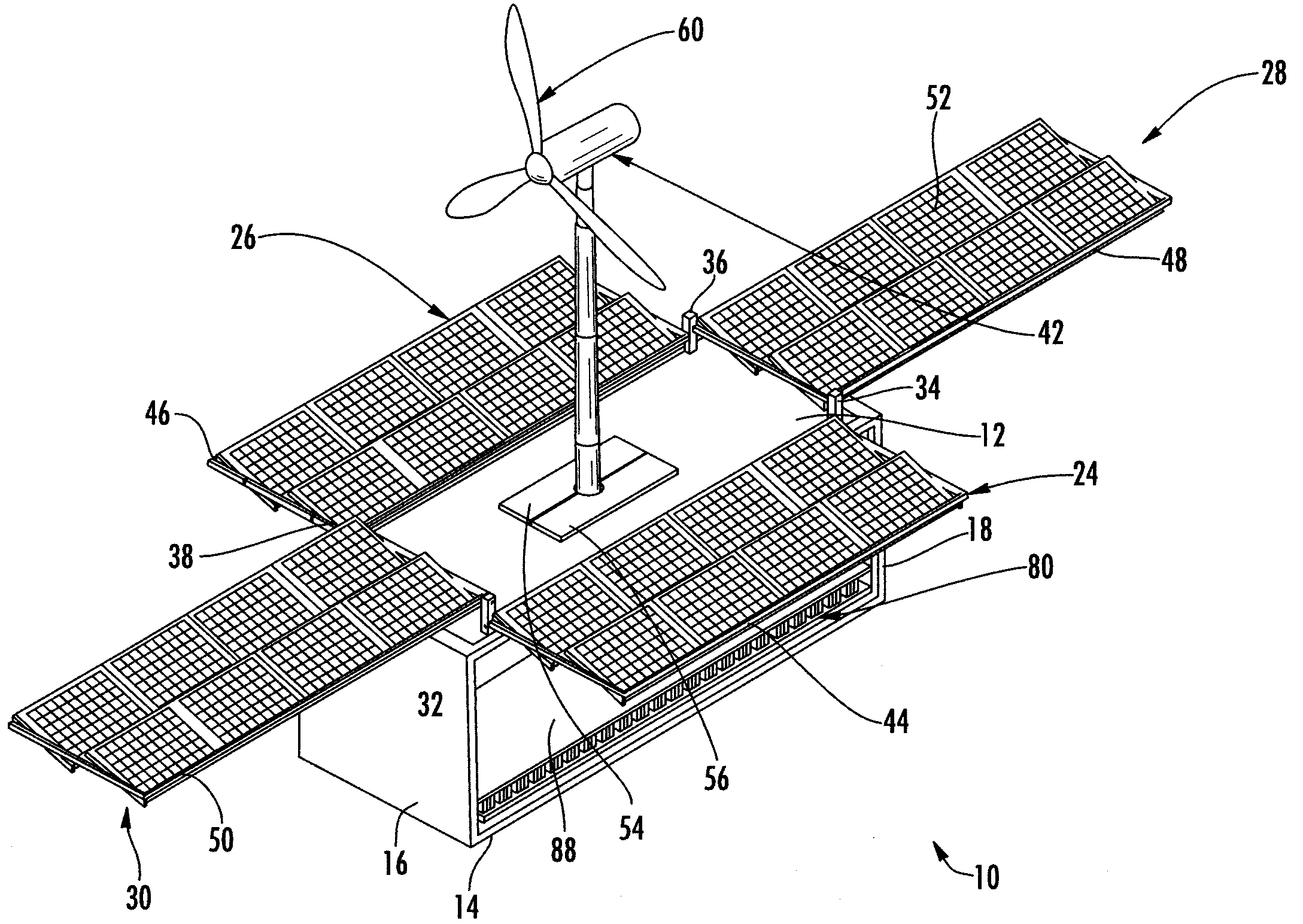

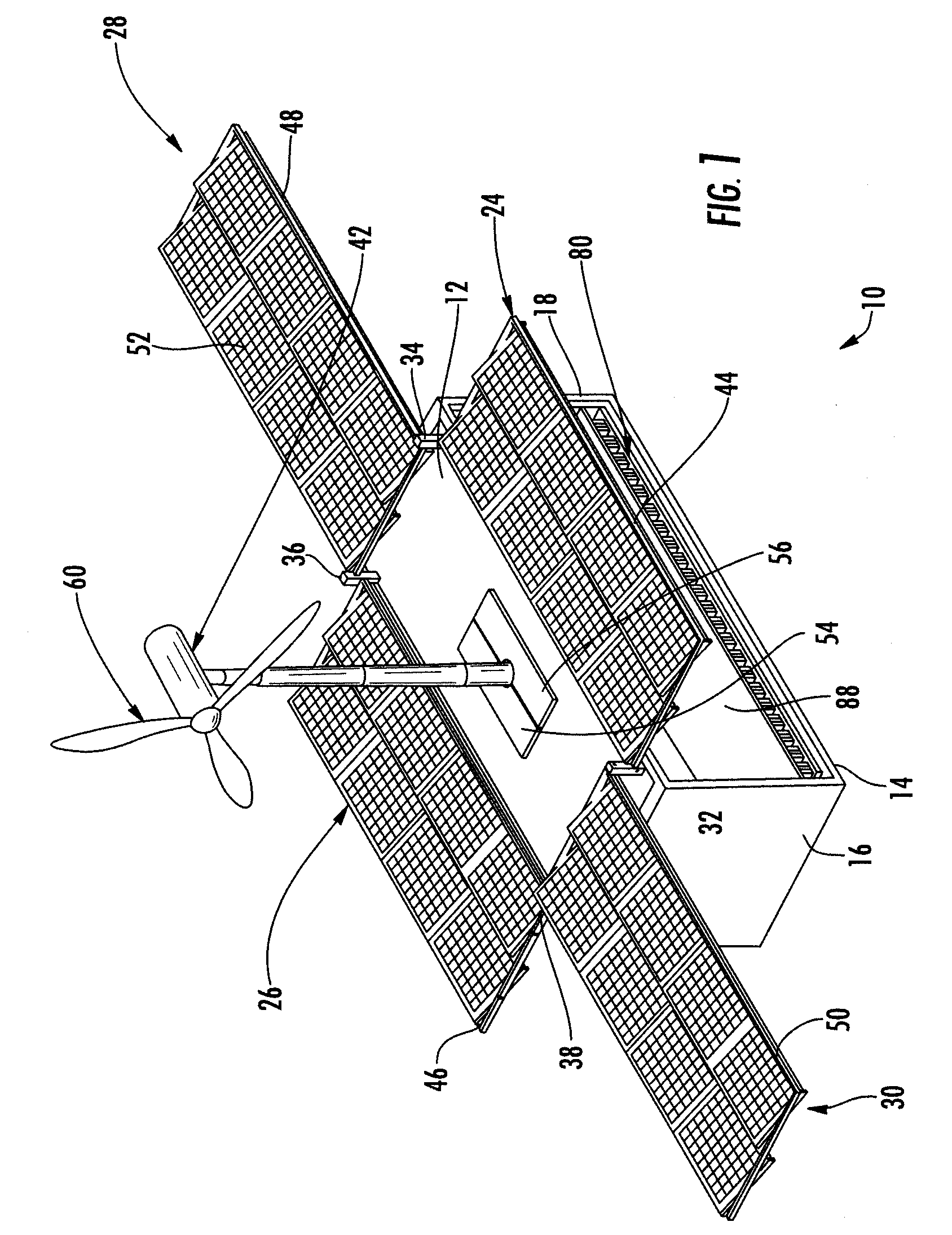

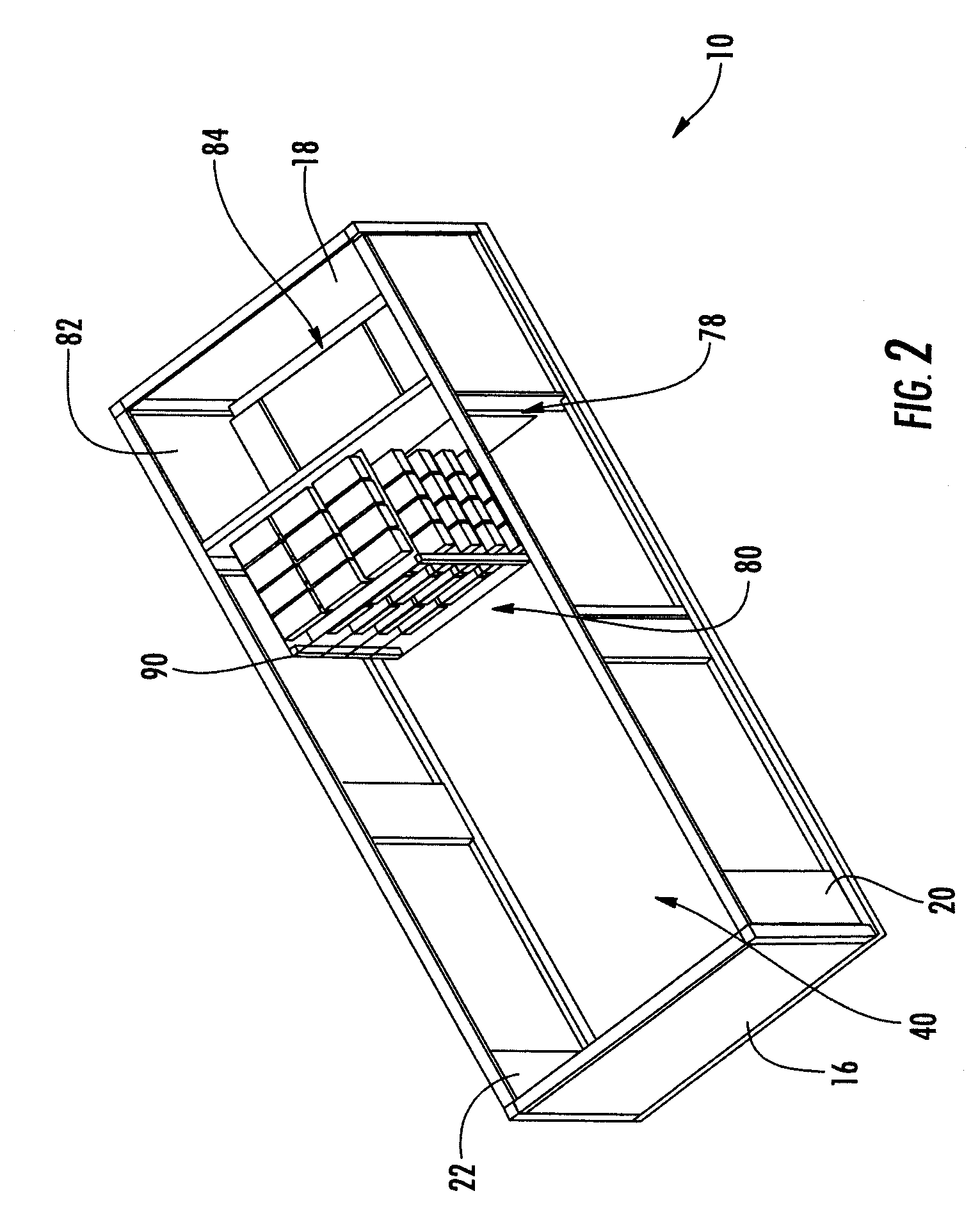

Portable, self-sustaining power station

InactiveUS20080196758A1Improve stabilityQuickly and easily deployed by a single personPhotovoltaic supportsPropellersElectricityPower station

A self-sustaining, portable, power station that may be moved by land, air, or sea to an area that has no utilities. The station is provided with at least one wind turbine and / or solar panel arrays in communication with at least one electrical distribution and storage means. The derived electricity is used to power various systems including, albeit not limited to, a communications system, a water filtration system, a water distribution system to allow the public to draw potable water and provide basic hygiene. The electricity derived may also be used to run outside systems, such as schools, hospitals, or the like.

Owner:ECOSPHERE TECH

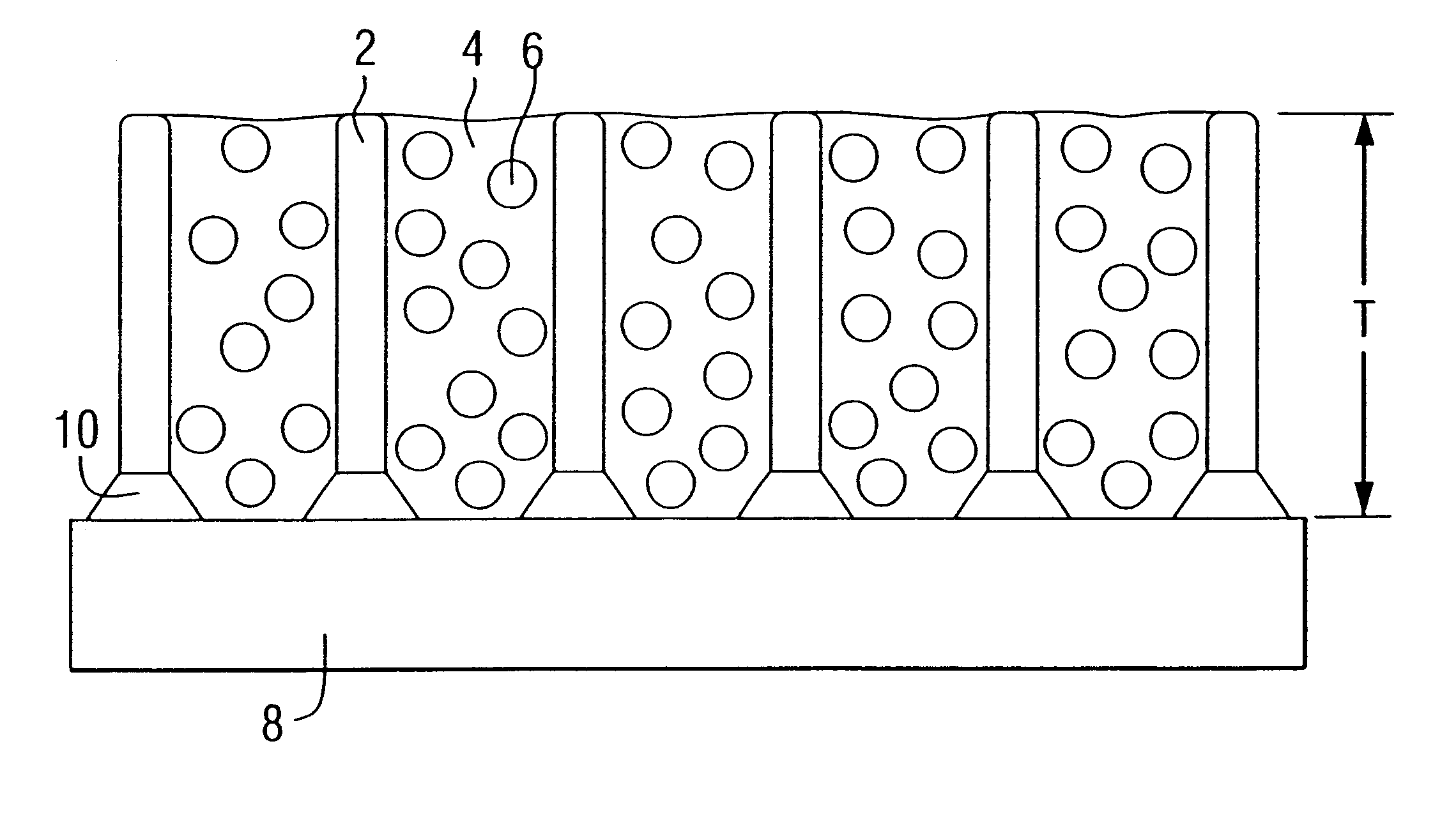

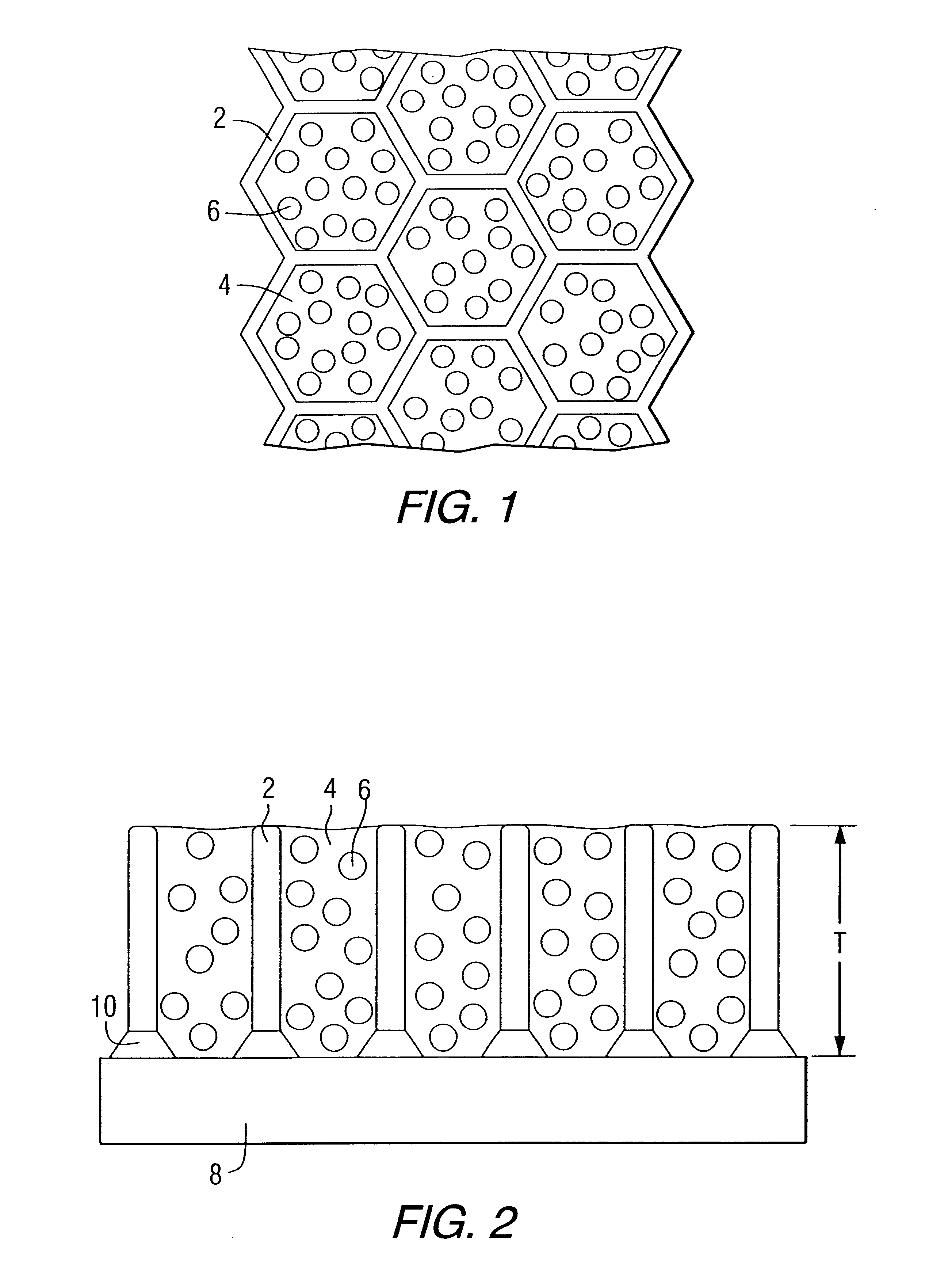

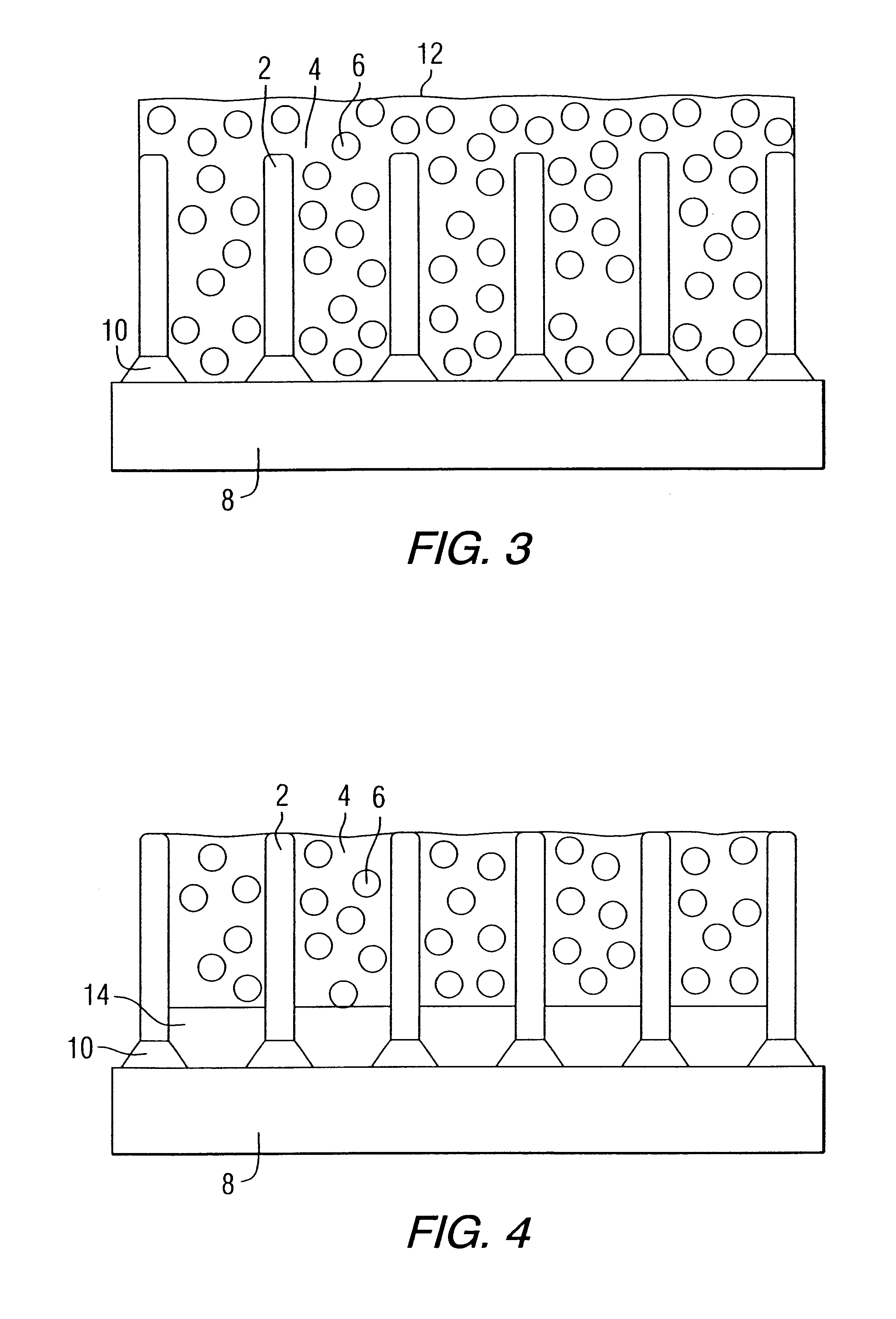

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

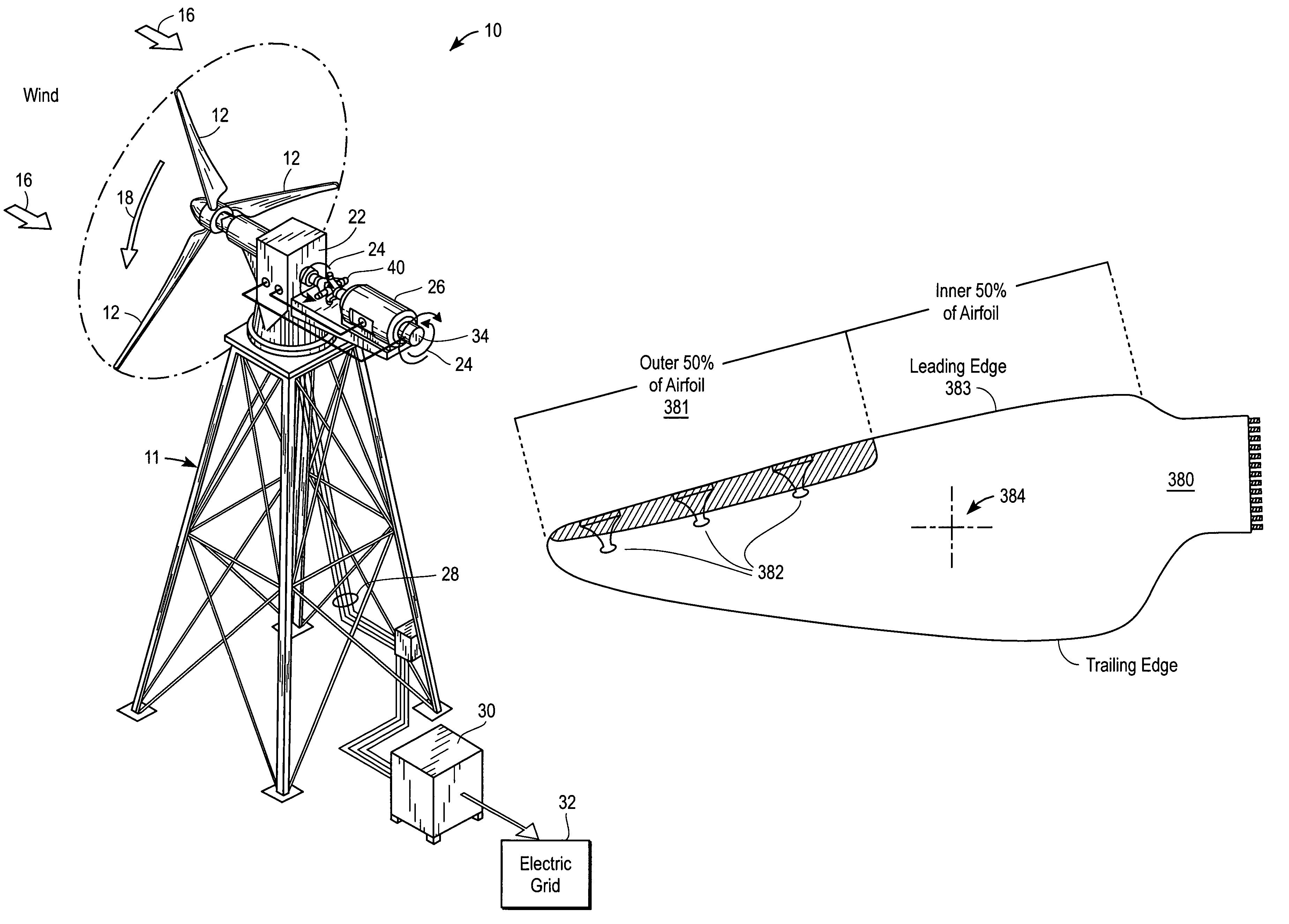

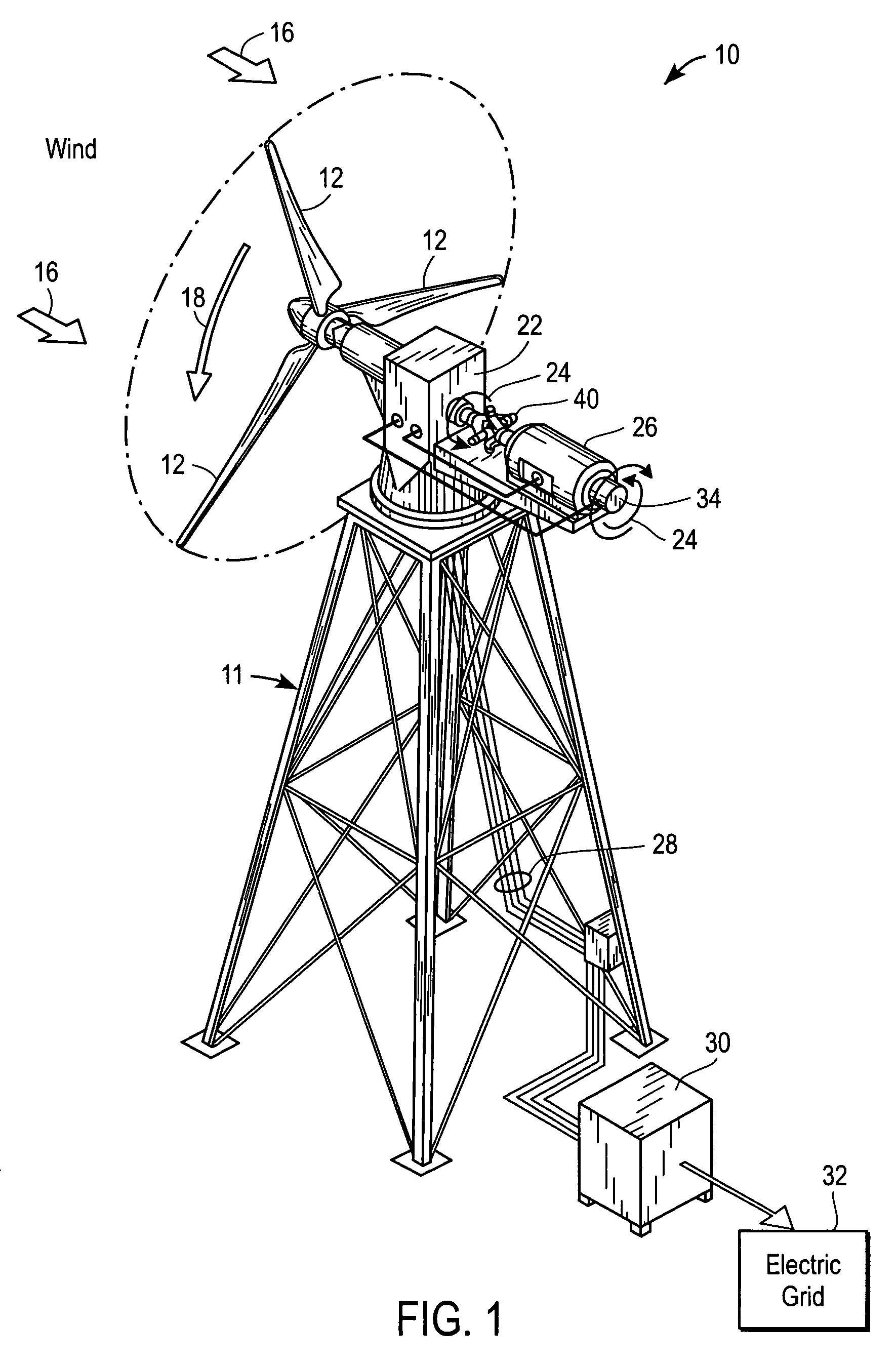

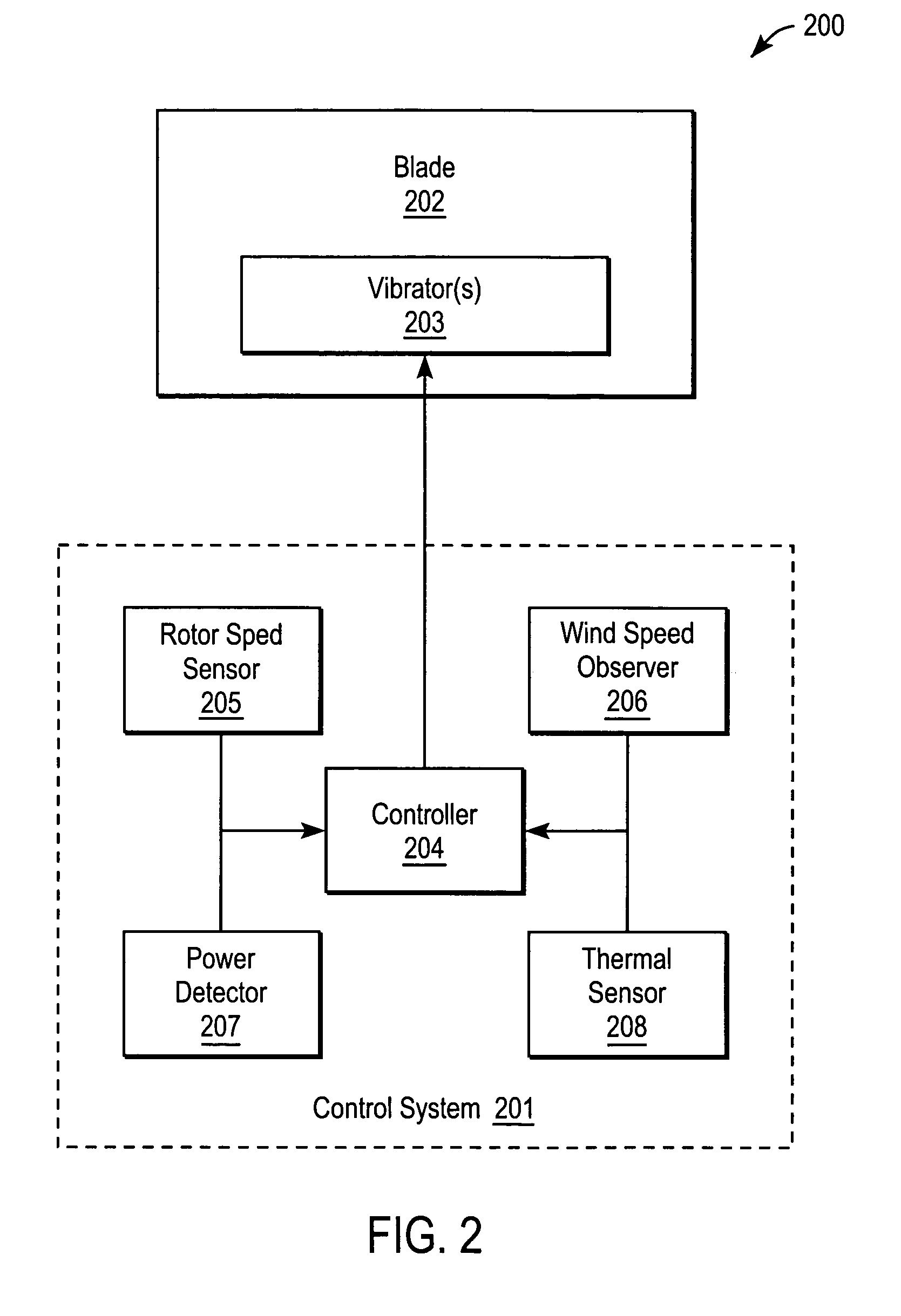

Deicing device for wind turbine blades

Methods and Apparatuses for deicing a wind turbine blade are described herein. In one embodiment, an exemplary process includes detecting an icy condition on a wind turbine blade and causing at least a portion of the wind turbine blade to vibrate, causing the ice built up on the wind turbine blade to break off.

Owner:GENERAL ELECTRIC CO

Double-ended blower and volutes therefor

InactiveUS6910483B2Faster pressure rise timeImprove reliabilityPropellersElement comparisonMotor speedImpeller

A double-ended variable speed blower for Continuous Positive Airway Pressure (CPAP) ventilation of patients includes two impellers in the gas flow path that cooperatively pressurize gas to desired pressure and flow characteristics. Thus, the double-ended blower can provide faster pressure response and desired flow characteristics over a narrower range of motor speeds, resulting in greater reliability and less acoustic noise.

Owner:RESMED LTD

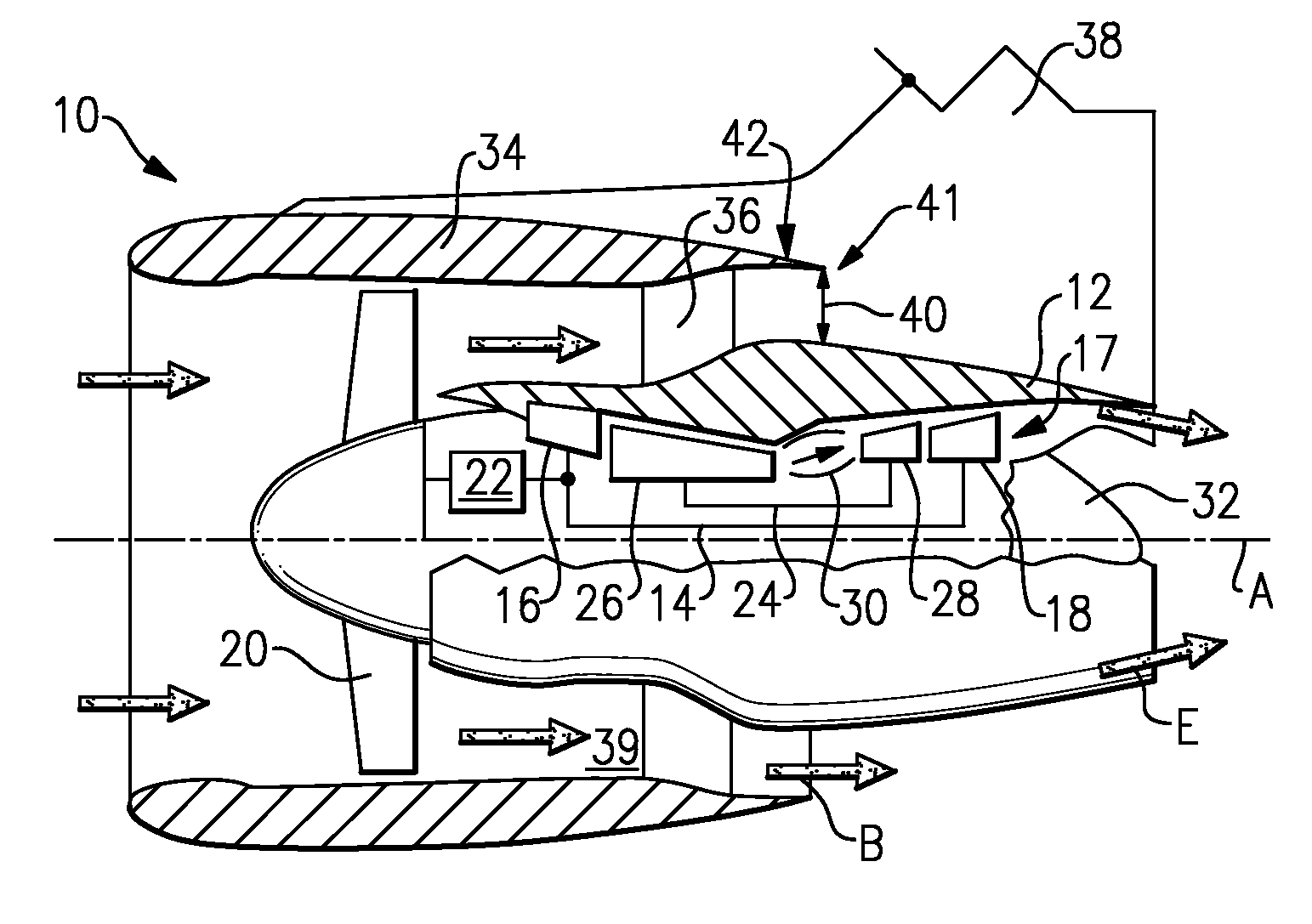

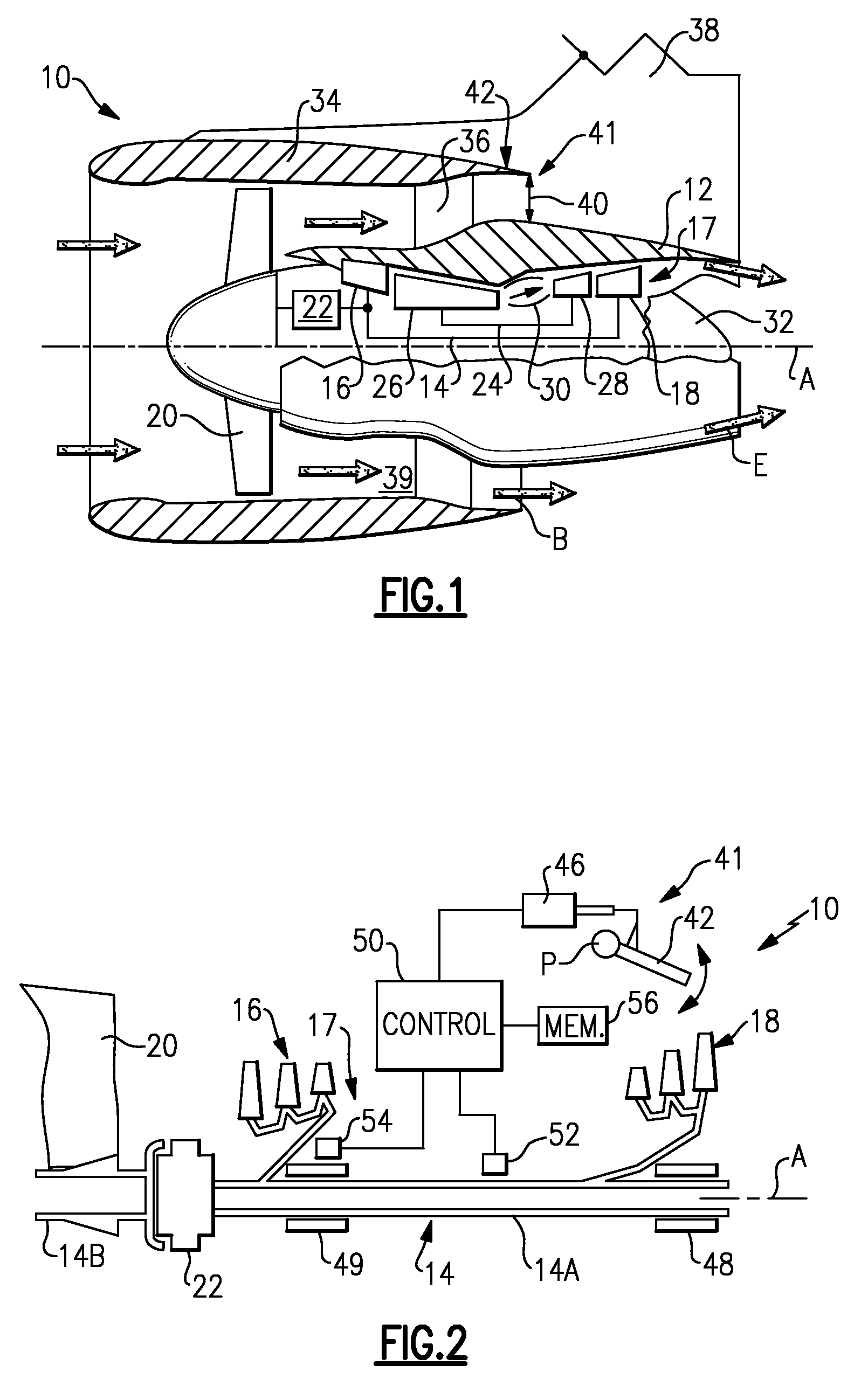

Managing spool bearing load using variable area flow nozzle

A turbine engine provides a spool supporting a turbine. The spool is arranged in a core nacelle and includes a thrust bearing. A fan is arranged upstream from the core nacelle and is coupled to the spool. A fan nacelle surrounds the fan and core nacelle and provides a bypass flow path that includes a fan nozzle exit area. A flow control device is adapted to effectively change the fan nozzle exit area. A controller is programmed to monitor the thrust bearing and command the flow control device in response to an undesired load on the thrust bearing. Effectively changing the fan nozzle exit area with the flow control device actively manages the bearing thrust load to desired levels.

Owner:RTX CORP

Expandable impeller pump

An impeller according to an example of the present invention comprises a hub, and at least one blade supported by the hub. The impeller has a deployed configuration in which the blade extends away from the hub, and a stored configuration in which the impeller is radially compressed, for example by folding the blade towards the hub. The impeller may comprise a plurality of blades, arranged in blade rows, to facilitate radial compression of the blades. The outer edge of a blade may have a winglet, and the base of the blade may have an associated indentation to facilitate folding of the blade.

Owner:PENN STATE RES FOUND +2

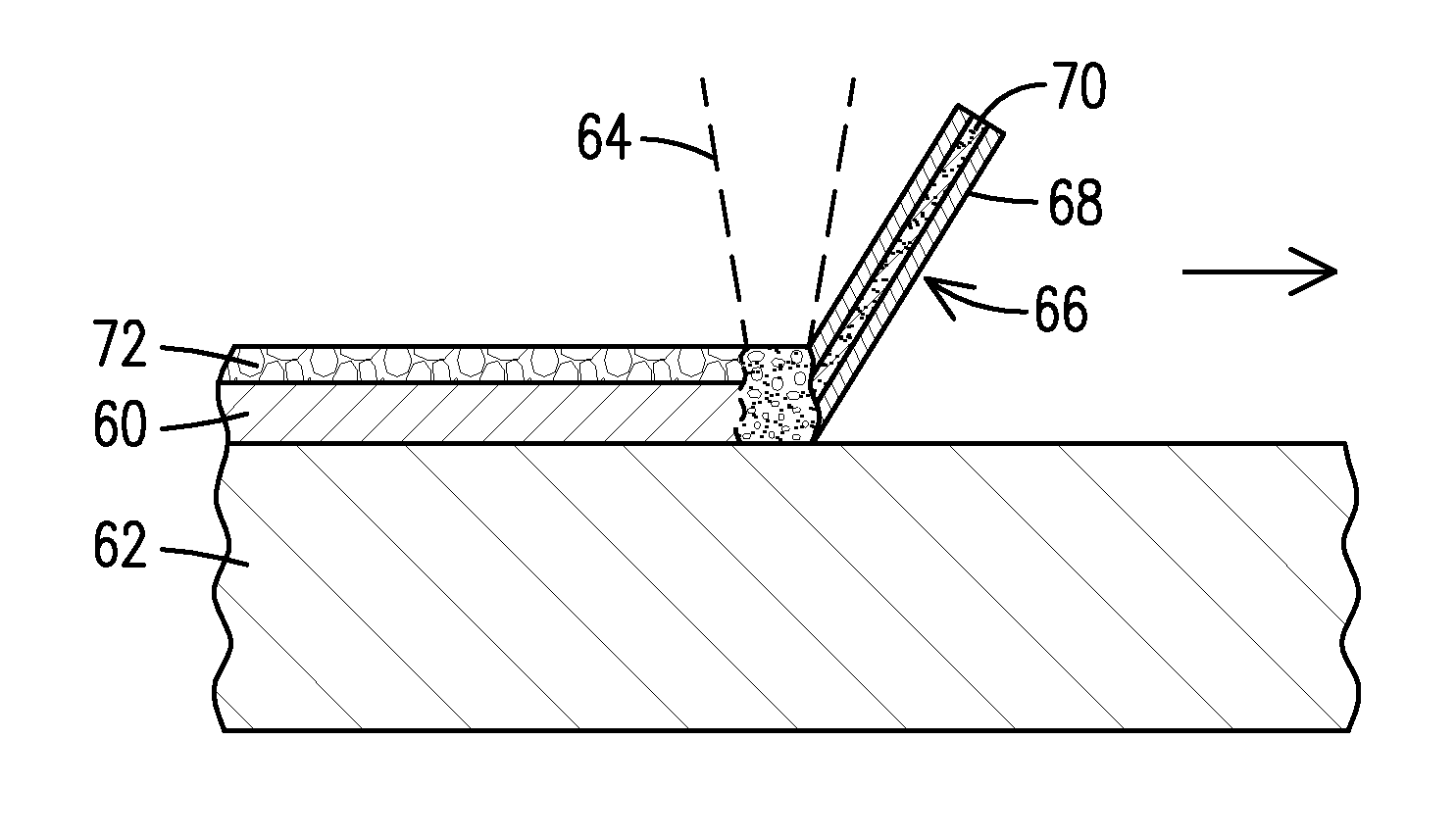

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

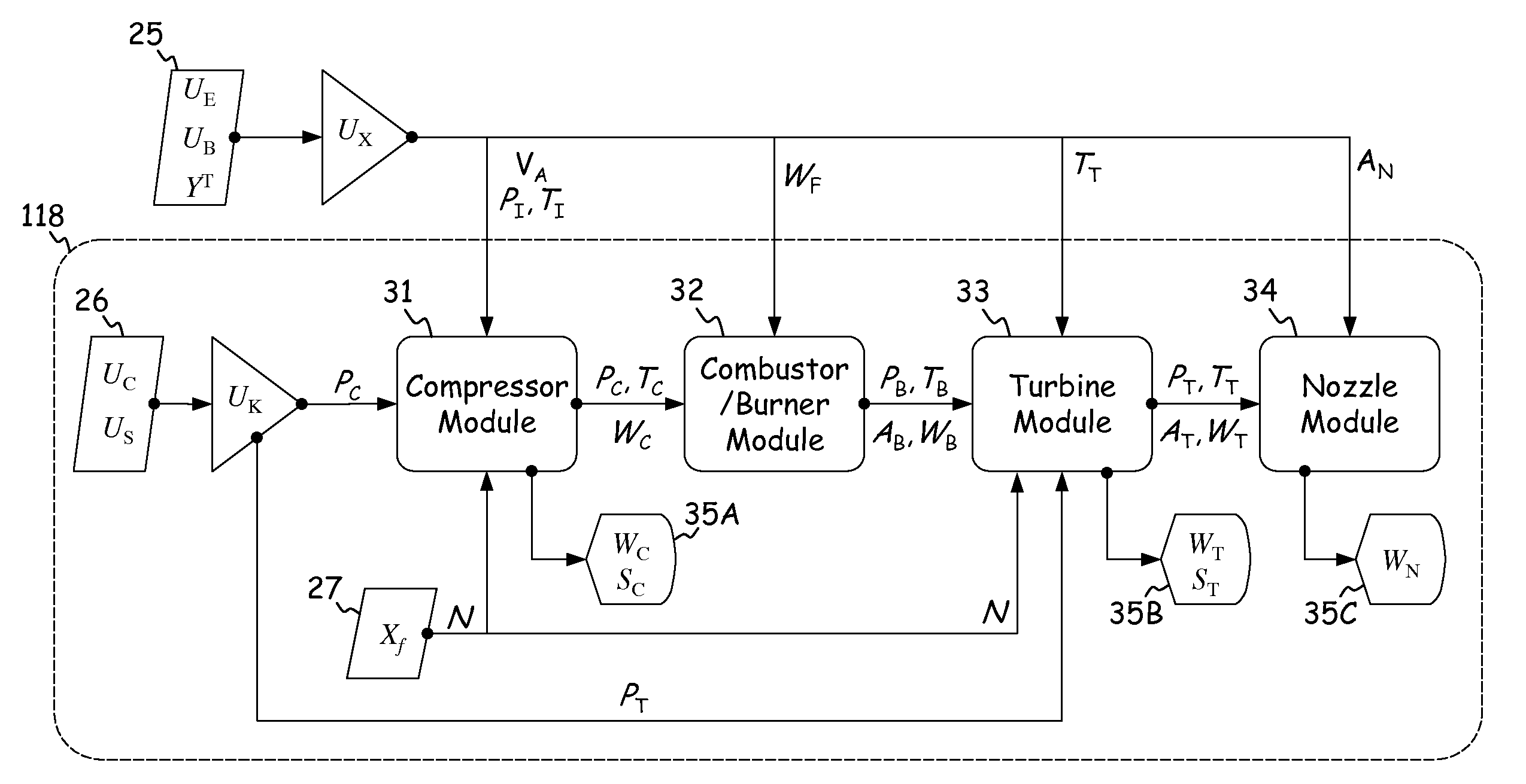

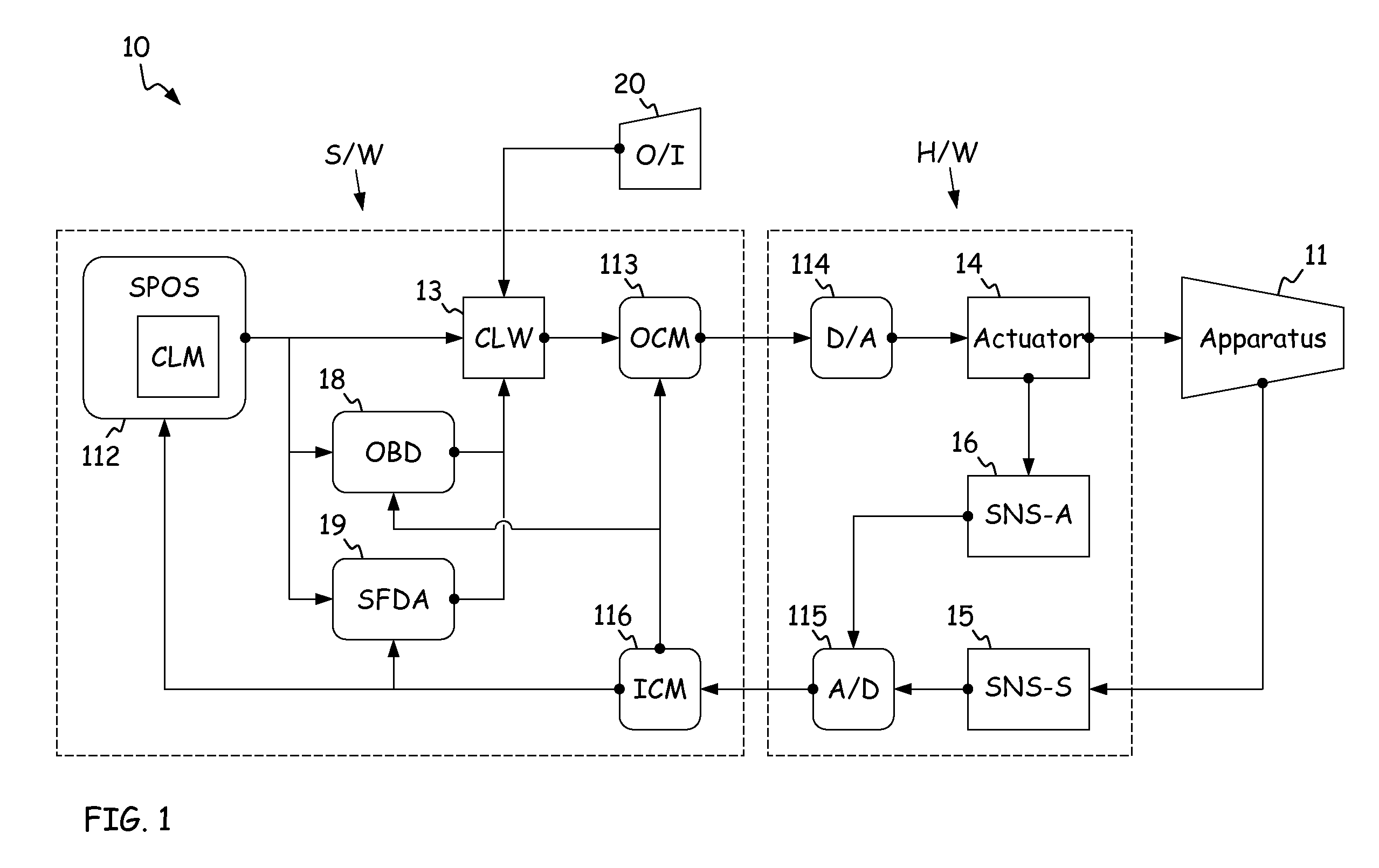

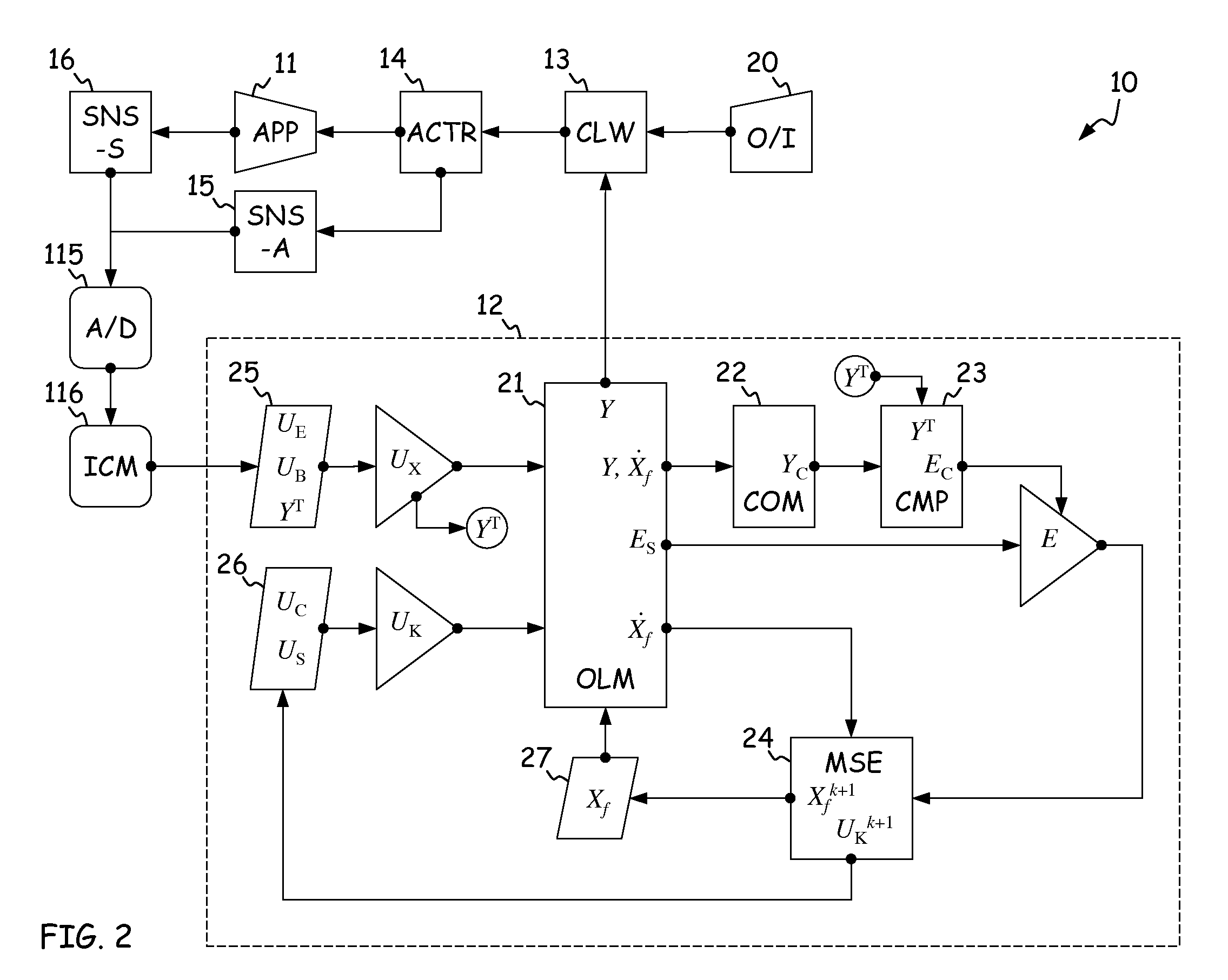

High fidelity integrated heat transfer and clearance in component-level dynamic turbine system control

ActiveUS20110054704A1Turbine/propulsion fuel supply systemsTemperatue controlControl flowEngineering

A system comprises a rotary apparatus, a control law and a processor. The rotary apparatus comprises a rotor and a housing forming a gas path therebetween, and the control law controls flow along the gas path. The processor comprises an output module, a plurality of temperature modules, a thermodynamic module, a comparator and an estimator. The output module generates an output signal as a function of a plurality of rotor and housing temperatures defined along the gas path, and the temperature modules determine time derivatives of the rotor and housing temperatures. The thermodynamic module models boundary conditions for the gas path, and the comparator determines errors in the boundary conditions. The estimator estimates the rotor and housing temperatures based on the time derivatives, such that the errors are minimized and the flow is controlled.

Owner:RTX CORP

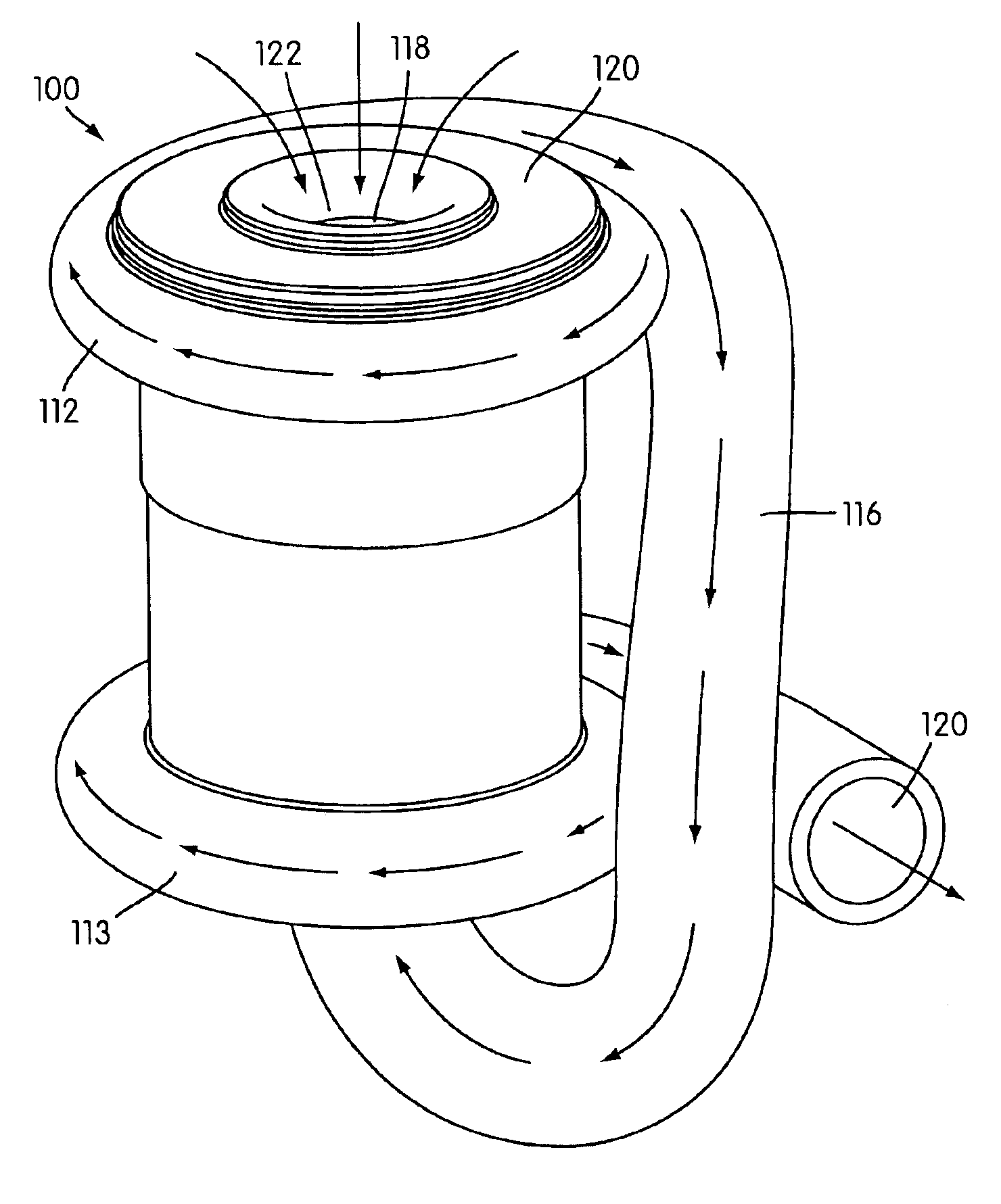

Fluid energy converter

Embodiments include apparatus and methods of fluid energy conversion. One embodiment relates to a tube for a fluid energy converter. The tube may include a generally cylindrical and hollow body having an interior surface, an exterior surface, and a longitudinal axis. Another embodiment includes a fluid energy converter having a longitudinal axis and a rotatable tube coaxial about the longitudinal axis. In some embodiments, the rotatable tube converts kinetic energy in a fluid into rotating mechanical energy, or converts rotating mechanical energy into kinetic energy in a fluid.

Owner:VIRYD TECH

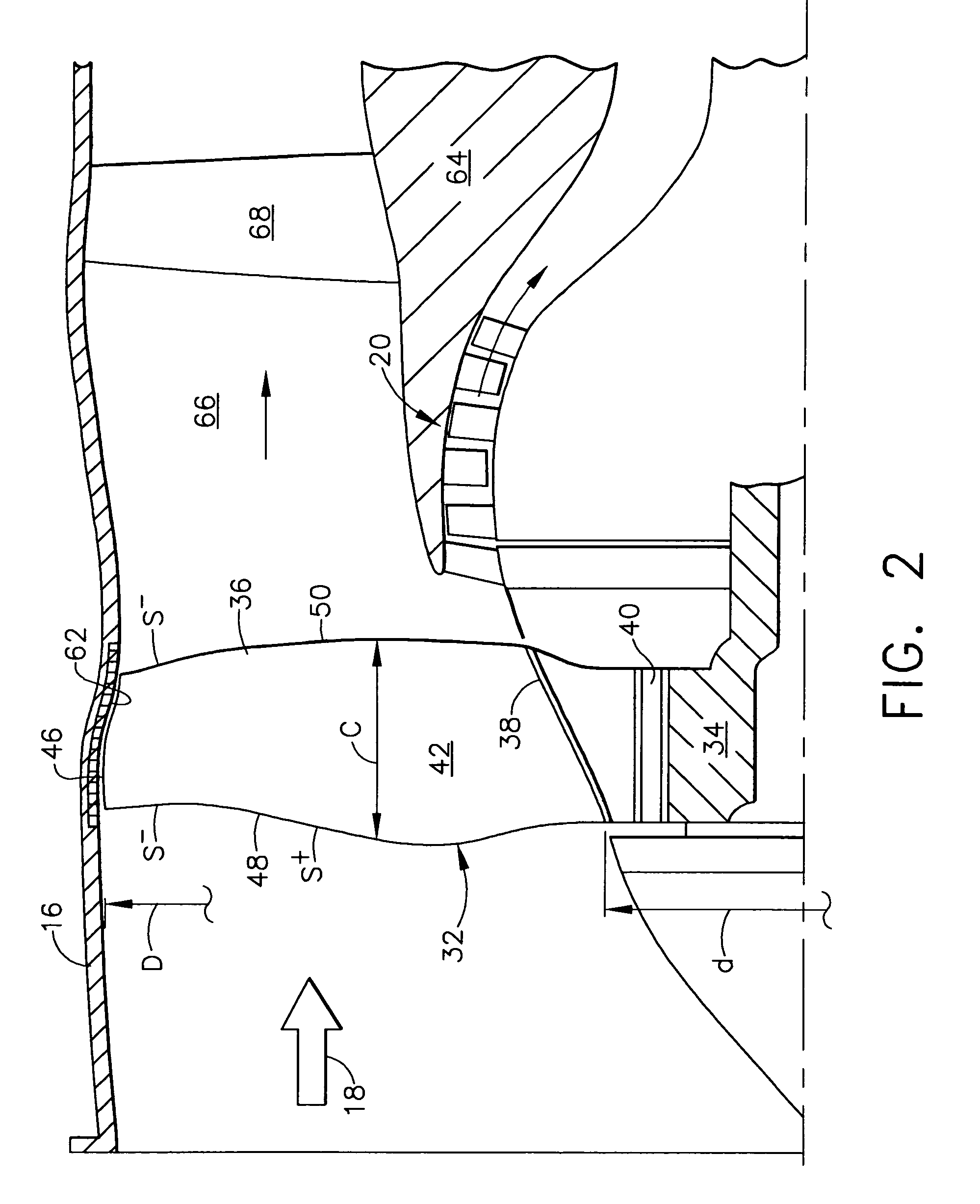

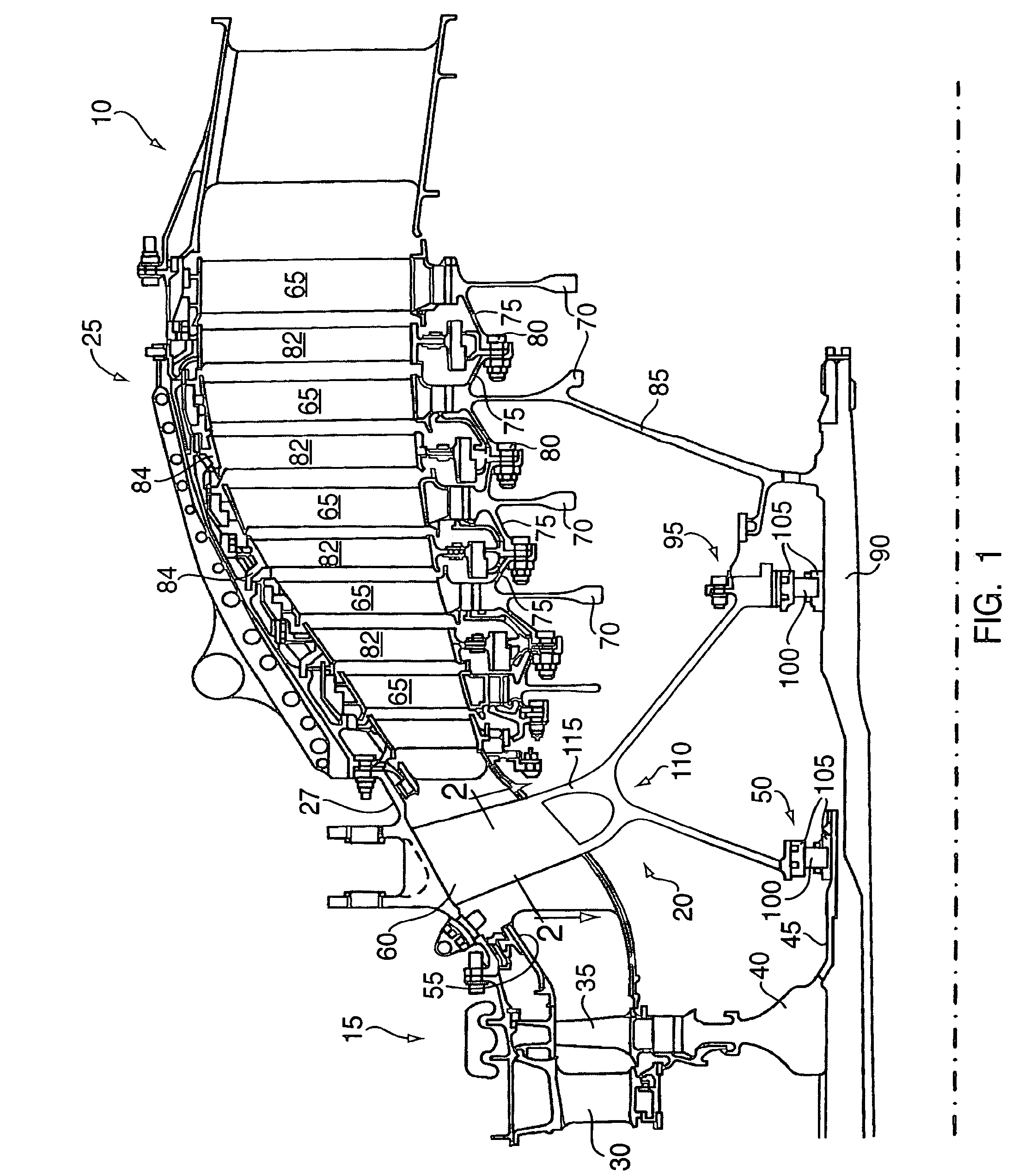

Variable geometry guide vane for a gas turbine engine

InactiveUS7632064B2Improve load balancingImprove performancePropellersGas turbine plantsTurbineInlet flow

A variable geometry inlet guide vane for a gas turbine aircraft engine includes an aerodynamic shell for turning inlet flow to a turbine or compressor and an internal spar spaced from the airfoil shell by an air gap. A number of actuation mechanisms grounded to the spar and connected to the inner surface of the aerodynamic shell adjust the shape of the shell in response to varying operating conditions of the engine, imbalanced aerodynamic loading of the shell or vibration or other transient loads on the shell.

Owner:RAYTHEON TECH CORP

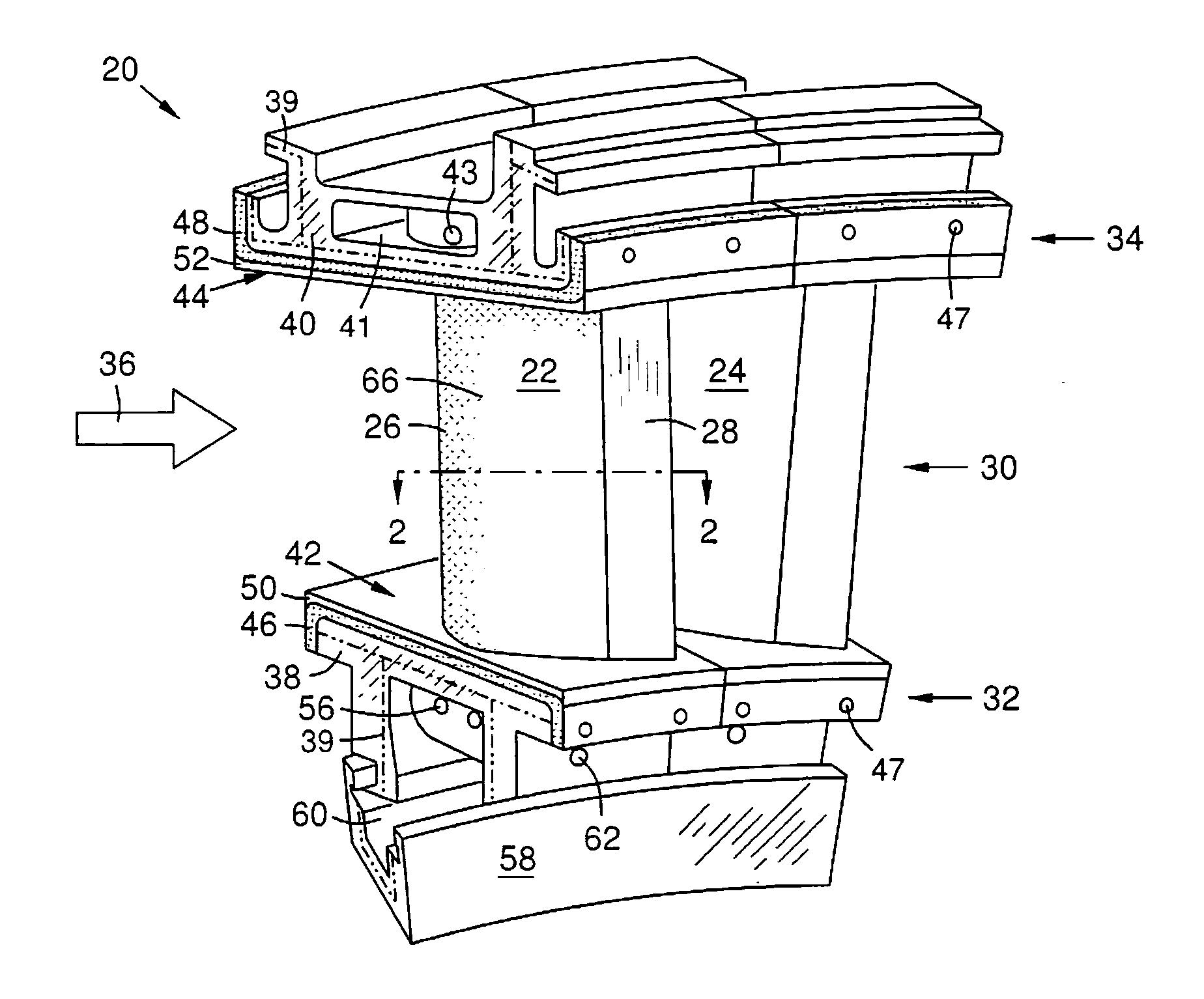

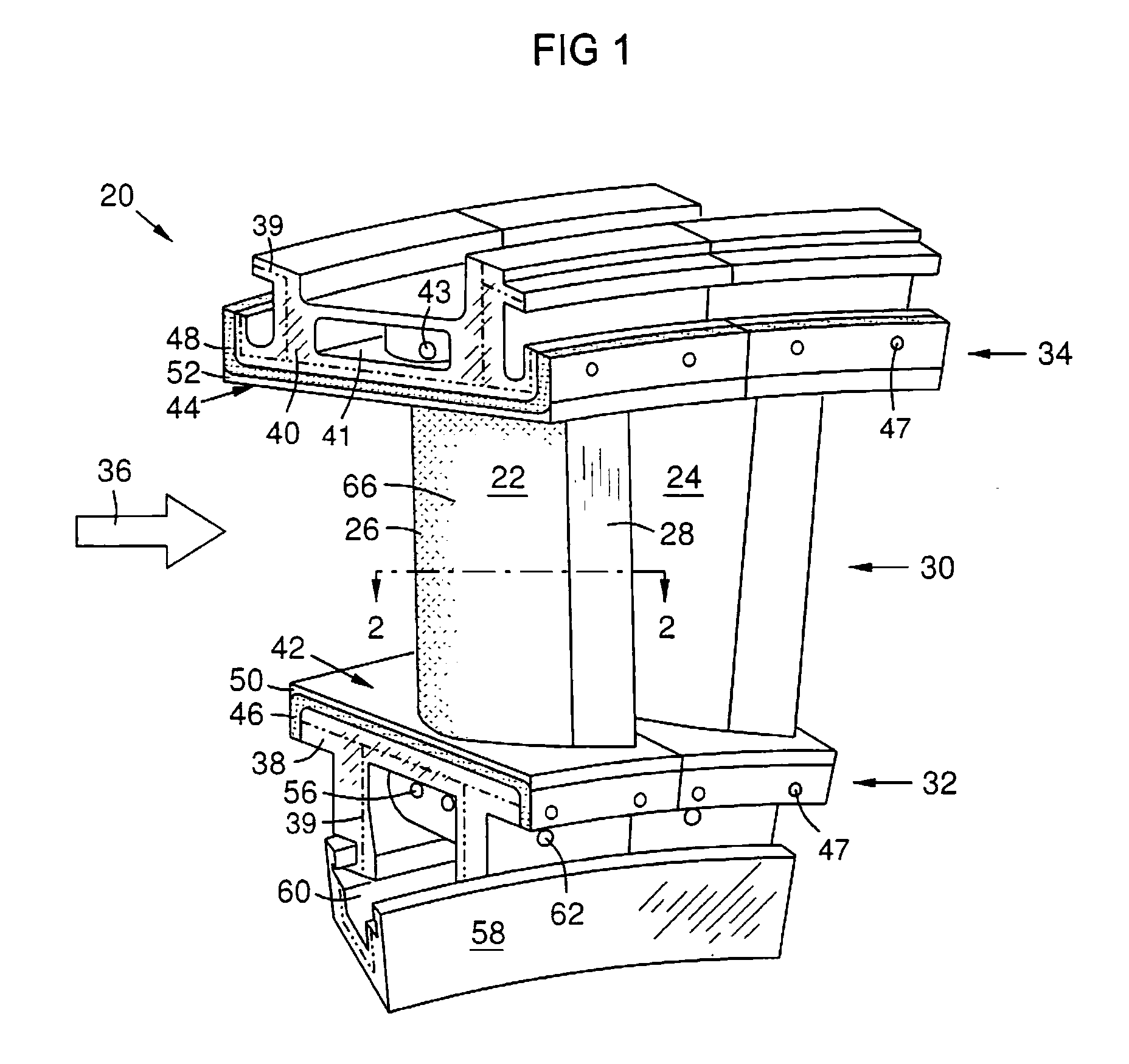

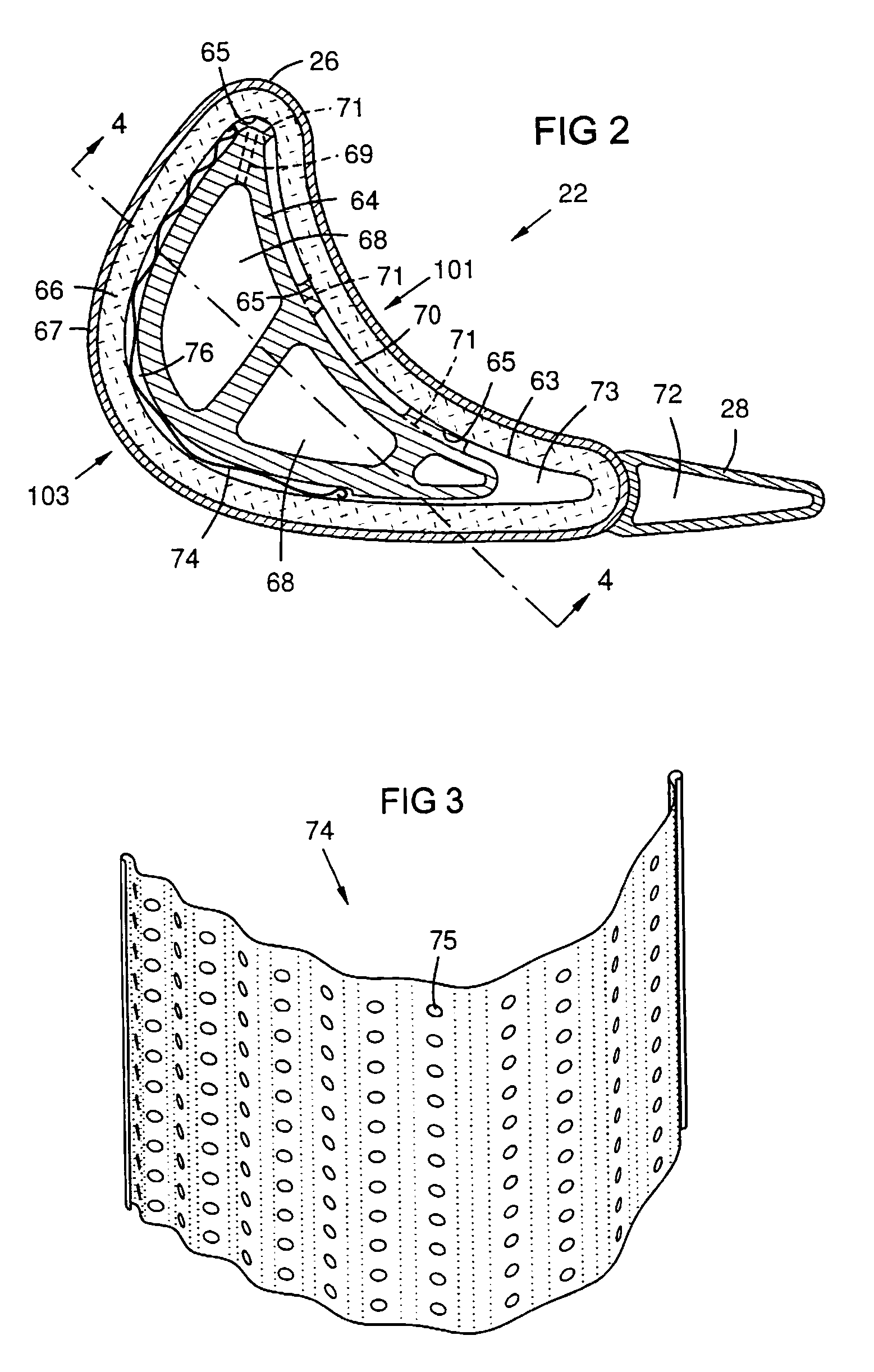

CMC Vane Assembly Apparatus and Method

A metal vane core or strut (64) is formed integrally with an outer backing plate (40). An inner backing plate (38) is formed separately. A spring (74) with holes (75) is installed in a peripheral spring chamber (76) on the strut. Inner and outer CMC shroud covers (46, 48) are formed, cured, then attached to facing surfaces of the inner and outer backing plates (38, 40). A CMC vane airfoil (22) is formed, cured, and slid over the strut (64). The spring (74) urges continuous contact between the strut (64) and airfoil (66), eliminating vibrations while allowing differential expansion. The inner end (88) of the strut is fastened to the inner backing plate (38). A cooling channel (68) in the strut is connected by holes (69) along the leading edge of the strut to peripheral cooling paths (70, 71) around the strut. Coolant flows through and around the strut, including through the spring holes.

Owner:SIEMENS ENERGY INC

Turbine blades made from multiple single crystal cast superalloy segments

InactiveUS6331217B1Improve bindingQuality improvementPropellersFrom frozen solutionsTurbine bladeSingle crystal

Large gas turbine blades made from separate cast segments of superalloys are disclosed. The turbine blade is designed such that bond lines between adjacent segments are placed in low stress regions of the blade. The cast superalloy segments of the blades are aligned and fitted together with specified tolerances. The turbine blade segments are then joined by transient liquid phase bonding, followed by a controlled heat treatment which produces the desired microstructure in the bond region. The method allows for the production of large, high quality turbine blades by joining small, high quality cast superalloy sections, in comparison with prior attempts to cast large turbine blades as single pieces which have produced very low yields and high individual component costs.

Owner:SIEMENS ENERGY INC

High effectiveness cooled turbine vane or blade

InactiveUS6974308B2Improve cooling efficiencyEasy to manufacturePump componentsEngine fuctionsSuction stressConventional casting

A robust multiple-walled, multi-pass, high cooling effectiveness cooled turbine vane or blade designed for ease of manufacturability, minimizes cooling flows on highly loaded turbine rotors. The vane or blade design allows the turbine inlet temperature to increase over current technology levels while simultaneously reducing turbine cooling to low levels. A multi-wall cooling system is described, which meets the inherent conflict to maximize the flow area of the cooling passages while retaining the required section thickness to meet the structural requirements. Independent cooling circuits for the vane or blade's pressure and suction surfaces allow the cooling of the airfoil surfaces to be tailored to specific heat load distributions (that is, the pressure surface circuit is an independent forward flowing serpentine while the suction surface is an independent rearward flowing serpentine). The cooling air for the independent circuits is supplied through separate passages at the base of the vane or blade. The cooling air follows intricate passages to feed the serpentine thin outer wall passages, which incorporate pin fins, turbulators, etc. These passages, while satisfying the aero / thermal / stress requirements, are of a manufacturing configuration that may be cast with single crystal materials using conventional casting techniques.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com