Patents

Literature

2137 results about "Turbofan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

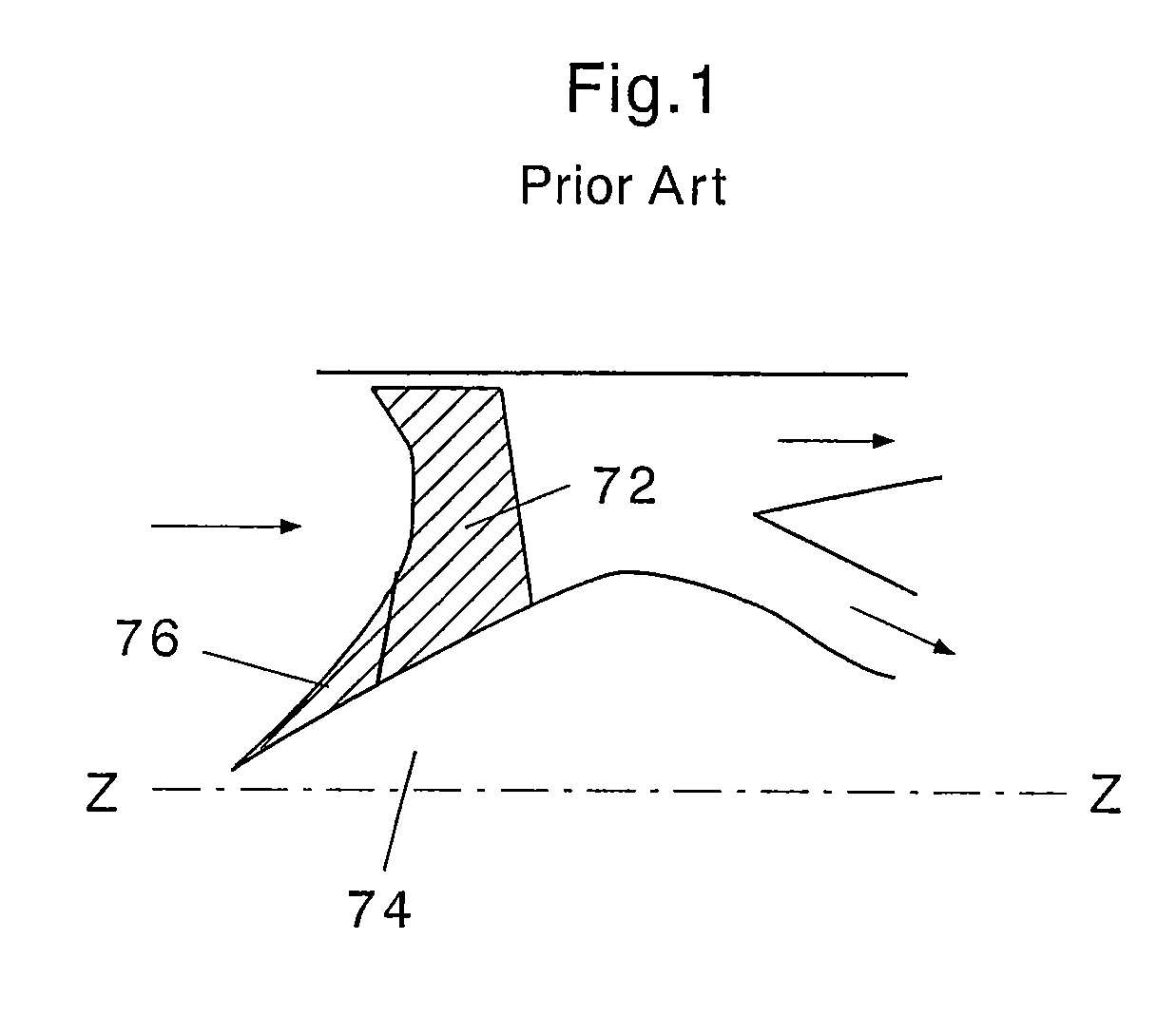

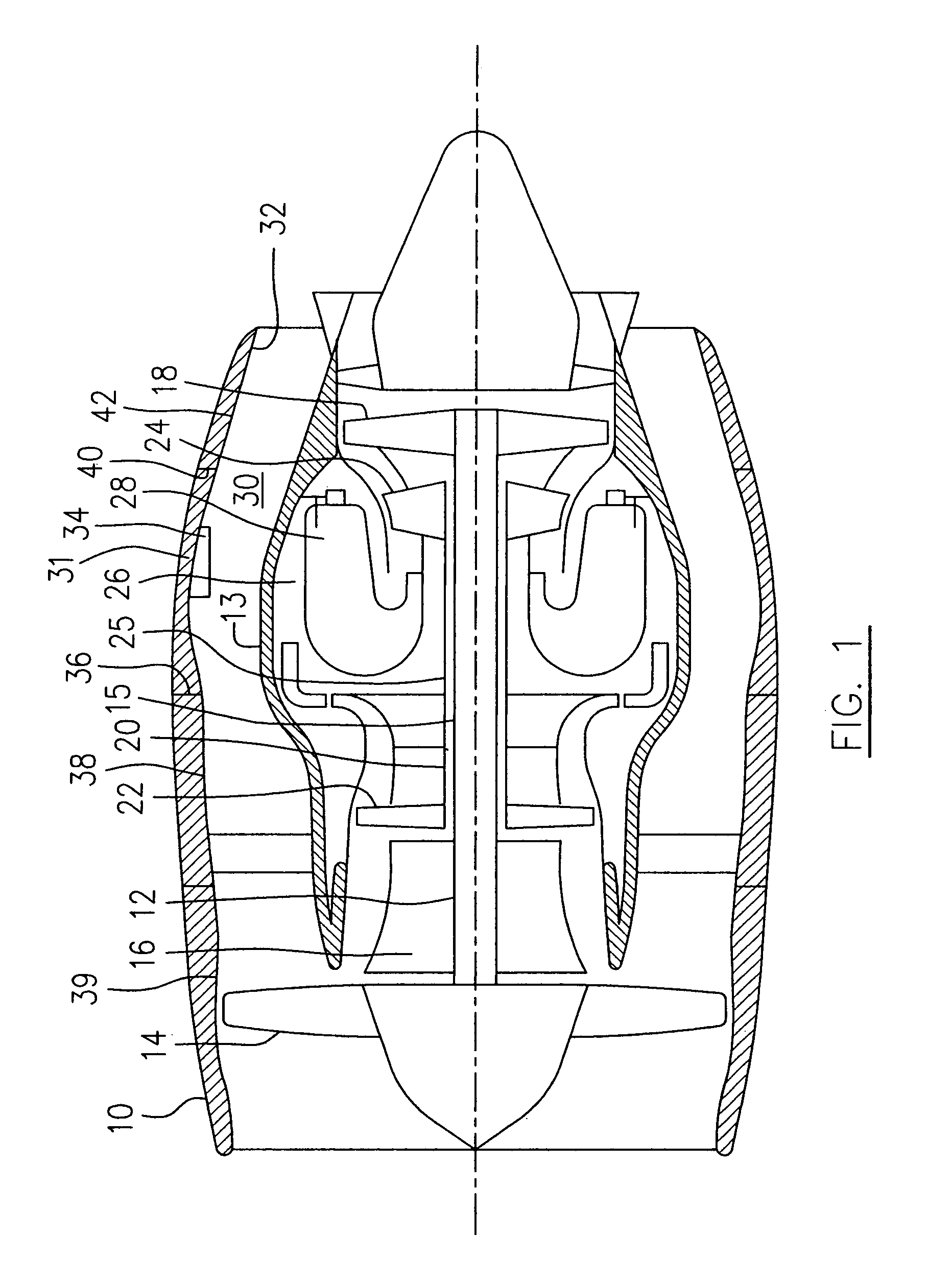

The turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a portmanteau of "turbine" and "fan": the turbo portion refers to a gas turbine engine which achieves mechanical energy from combustion, and the fan, a ducted fan that uses the mechanical energy from the gas turbine to accelerate air rearwards. Thus, whereas all the air taken in by a turbojet passes through the turbine (through the combustion chamber), in a turbofan some of that air bypasses the turbine. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

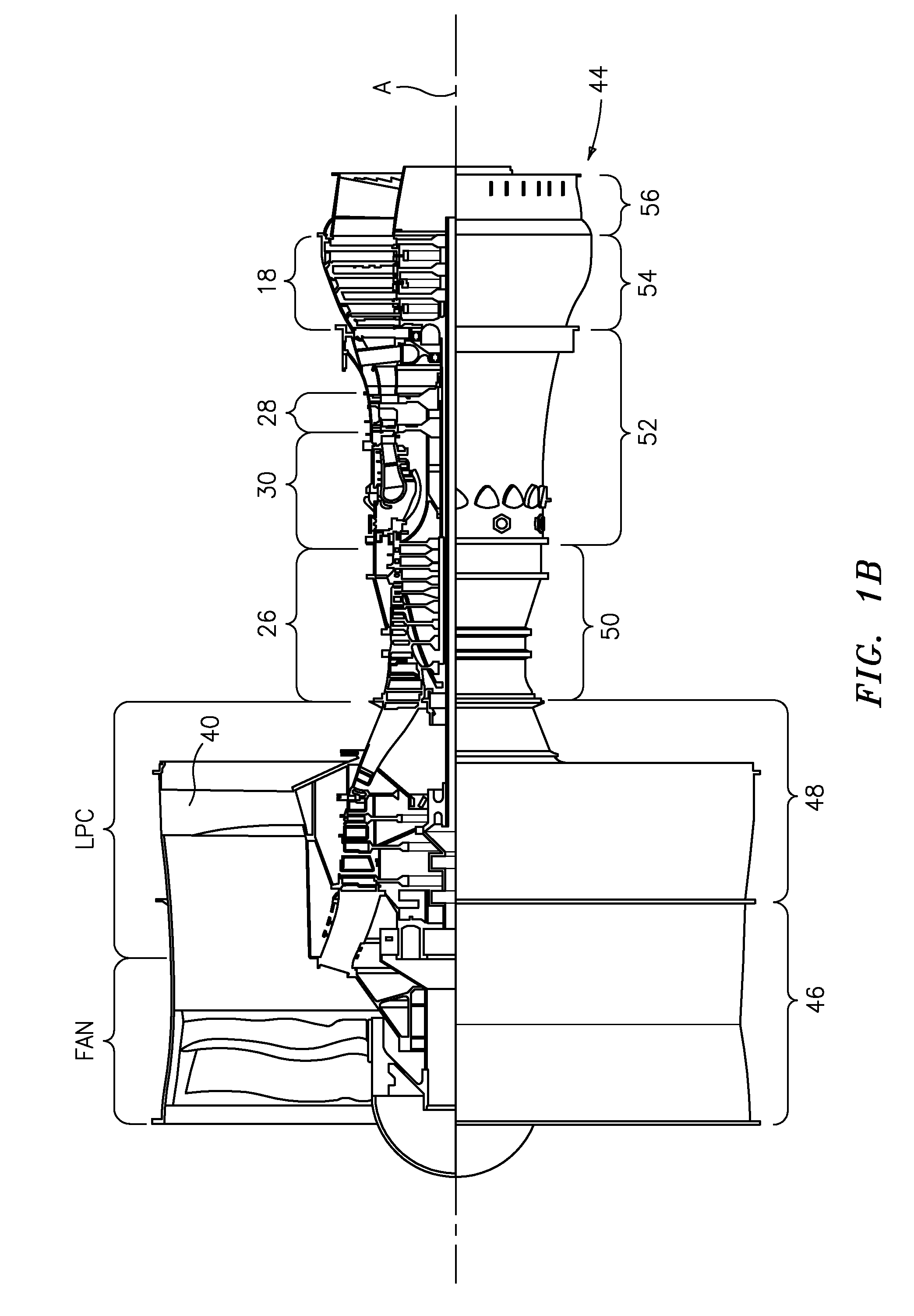

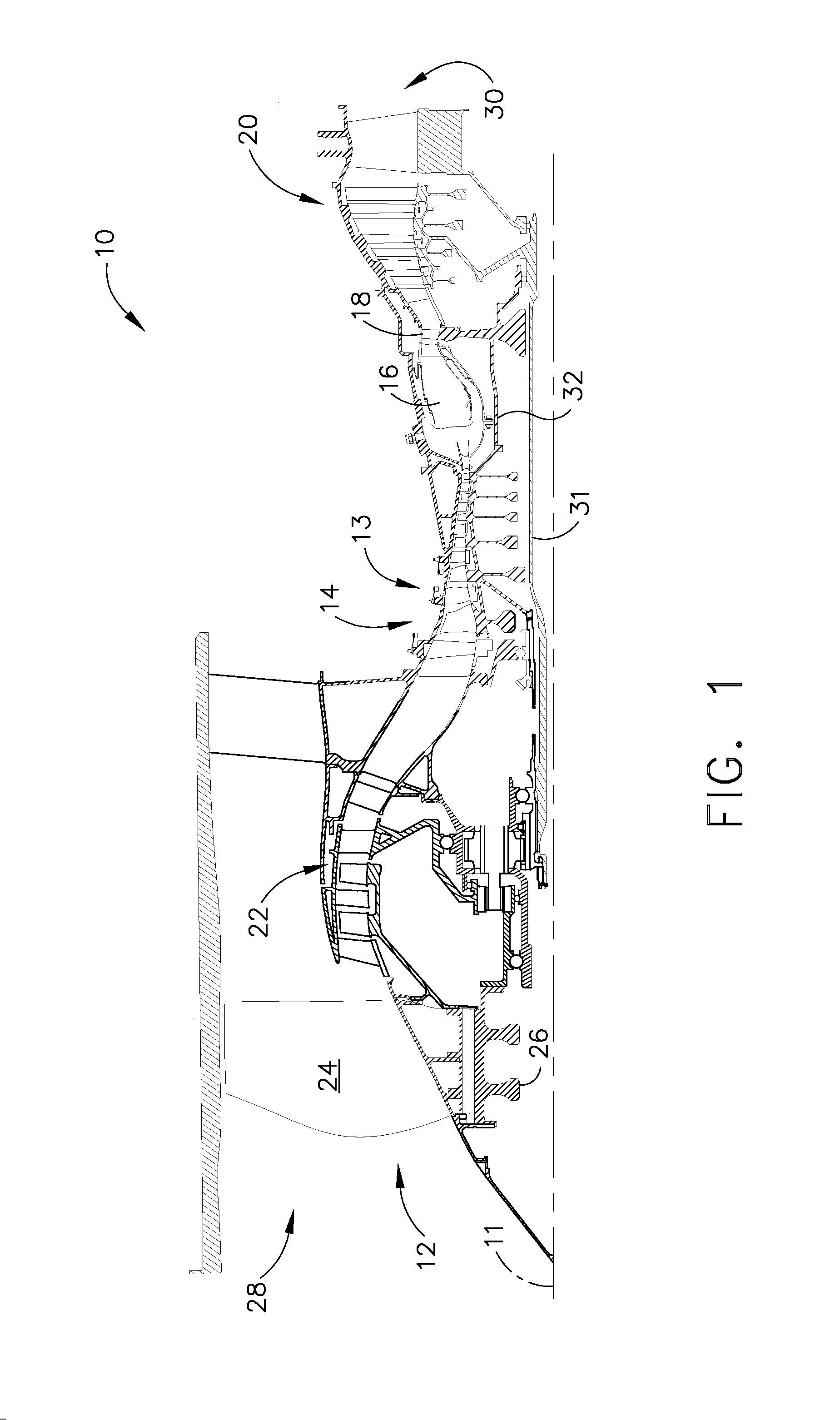

Geartrain coupling for a turbofan engine

Molybdenum disulfide (MoS2) is used as a journal coating for a gearing system. A particular application is the planetary gear system of a geared turbofan engine. Particularly advantageous coatings are deposited via physical vapor deposition (PVD) techniques.

Owner:RAYTHEON TECH CORP

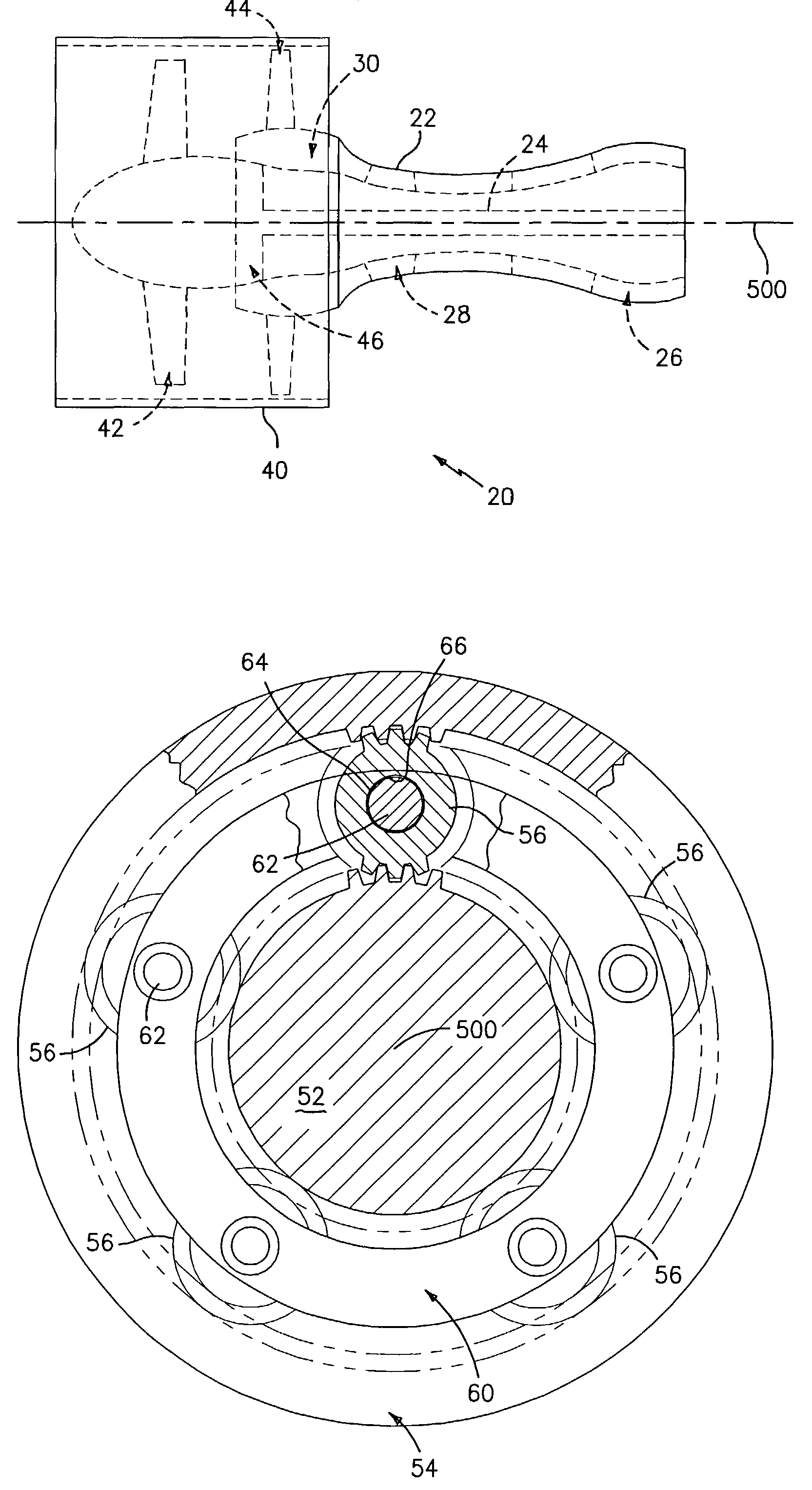

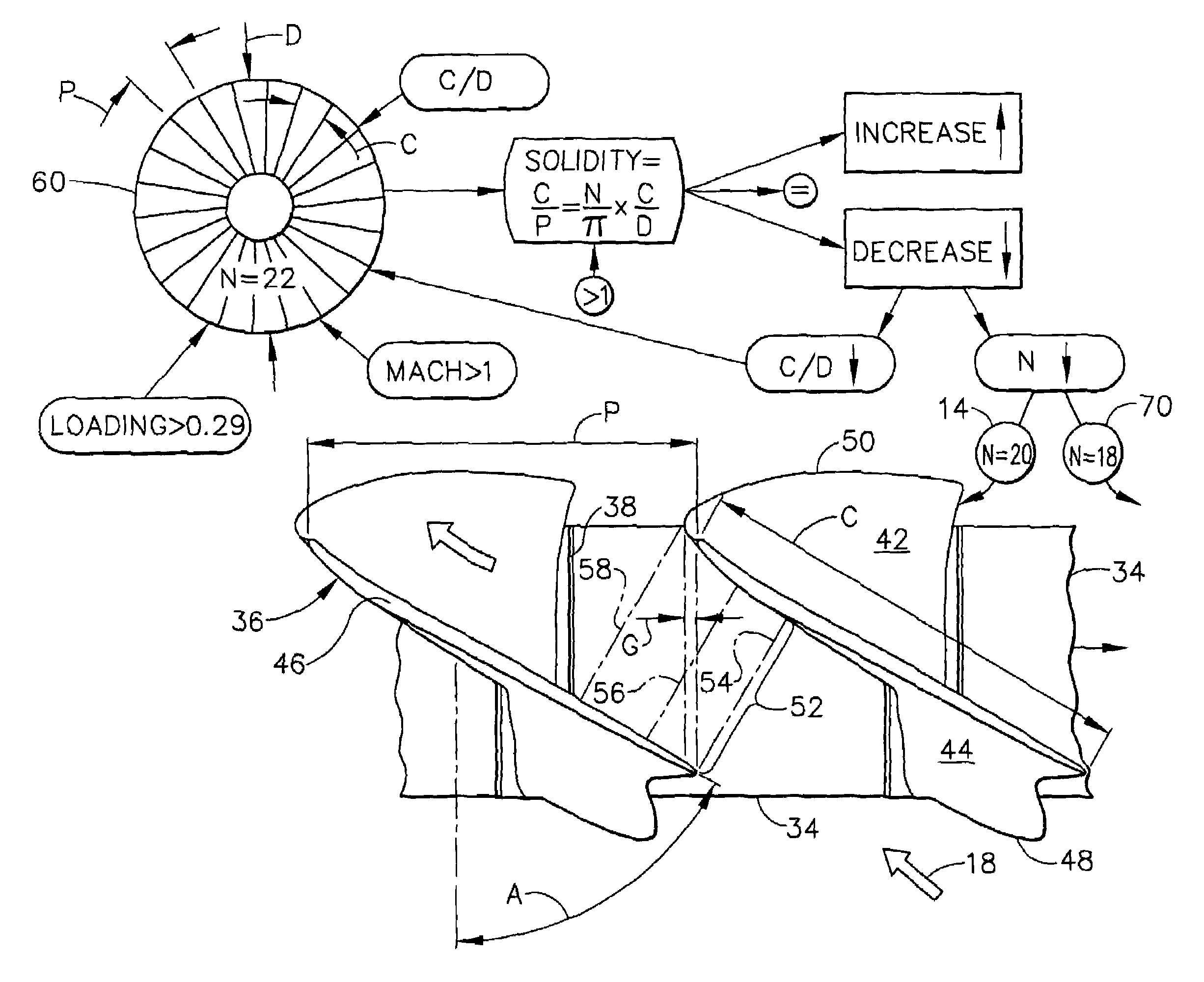

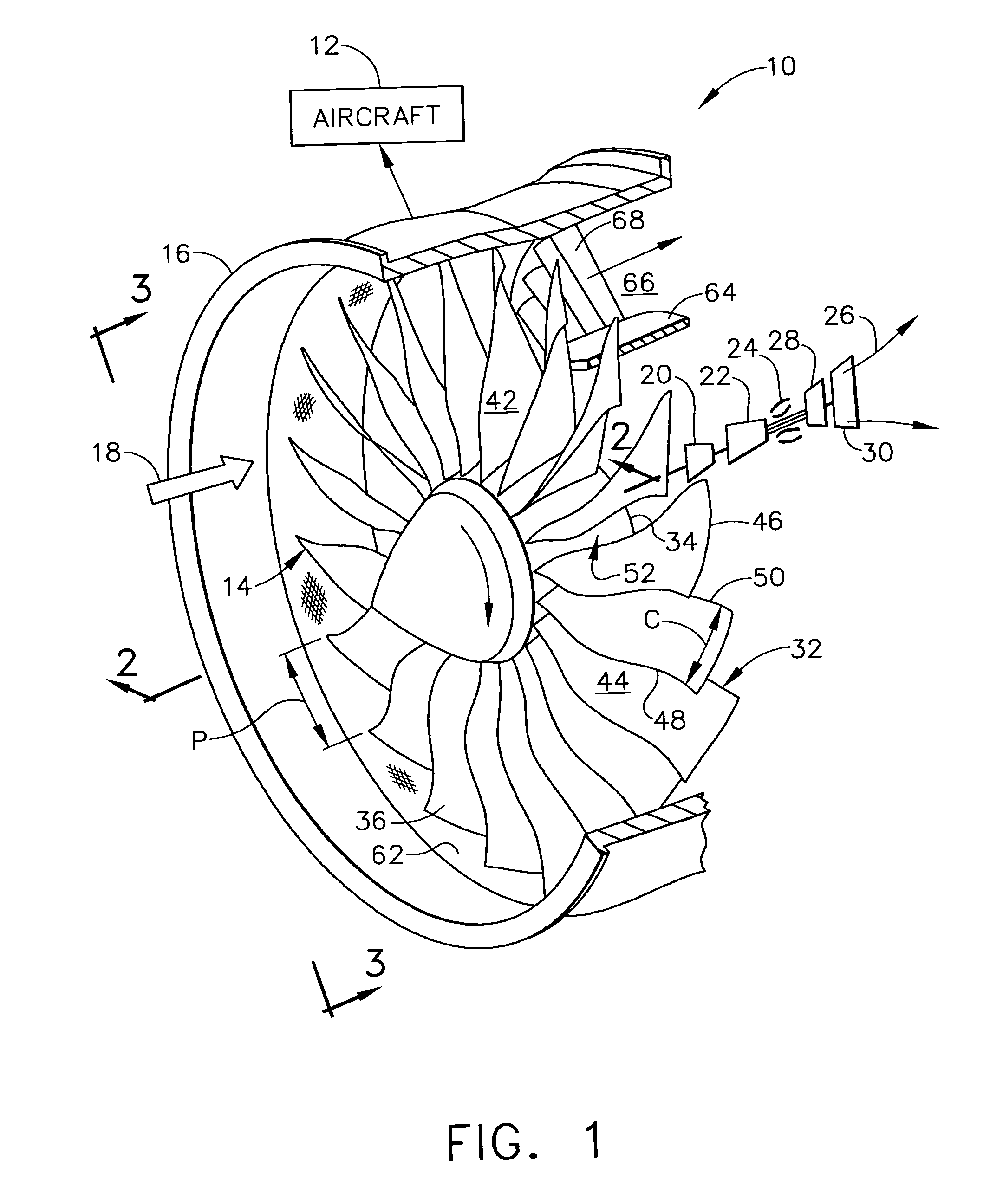

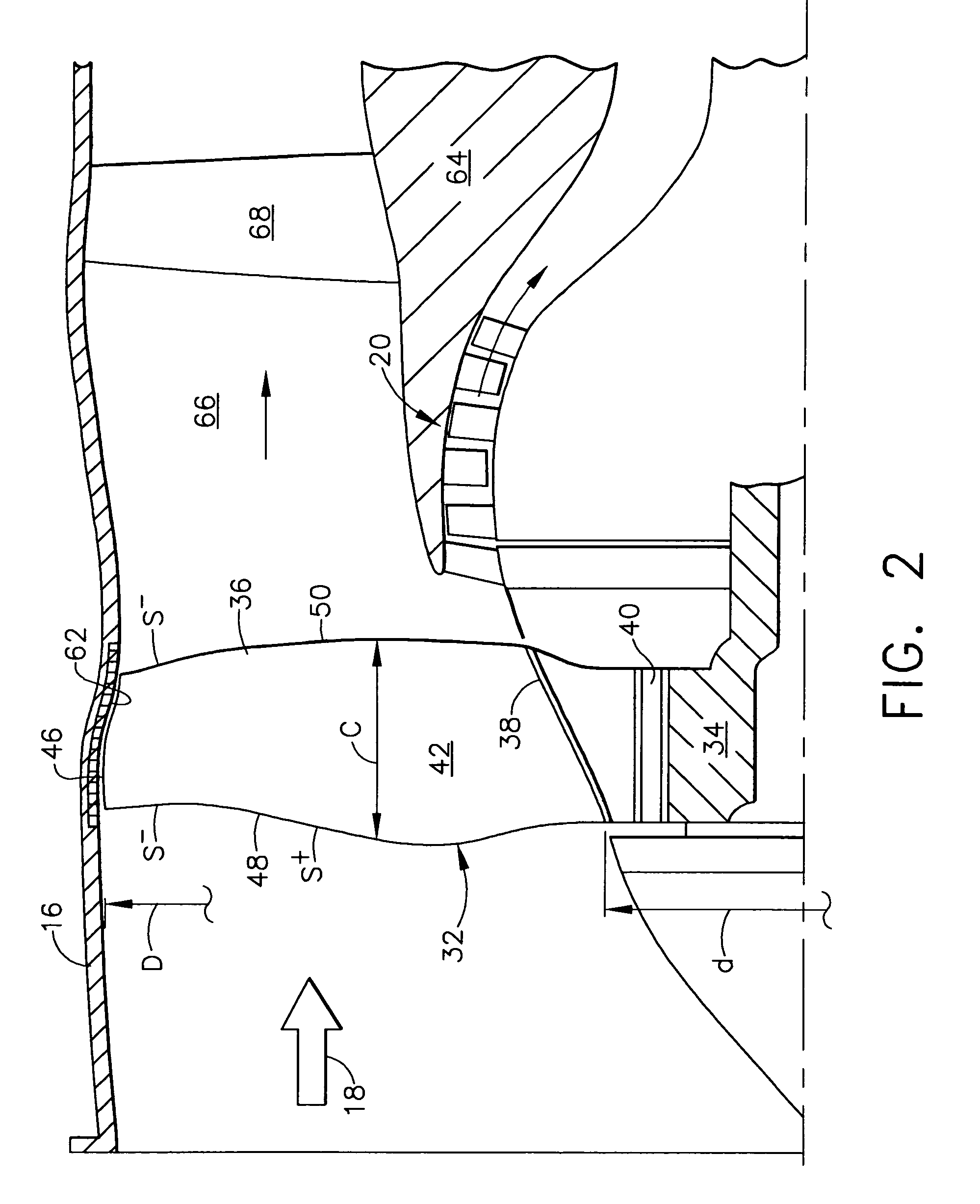

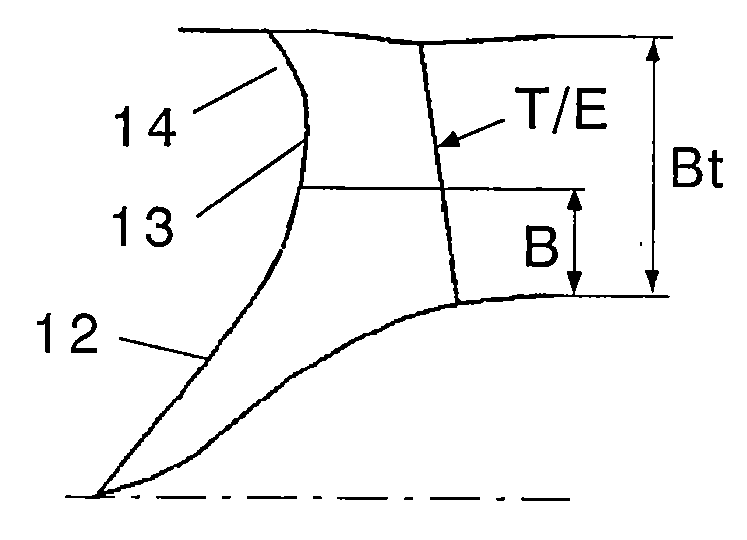

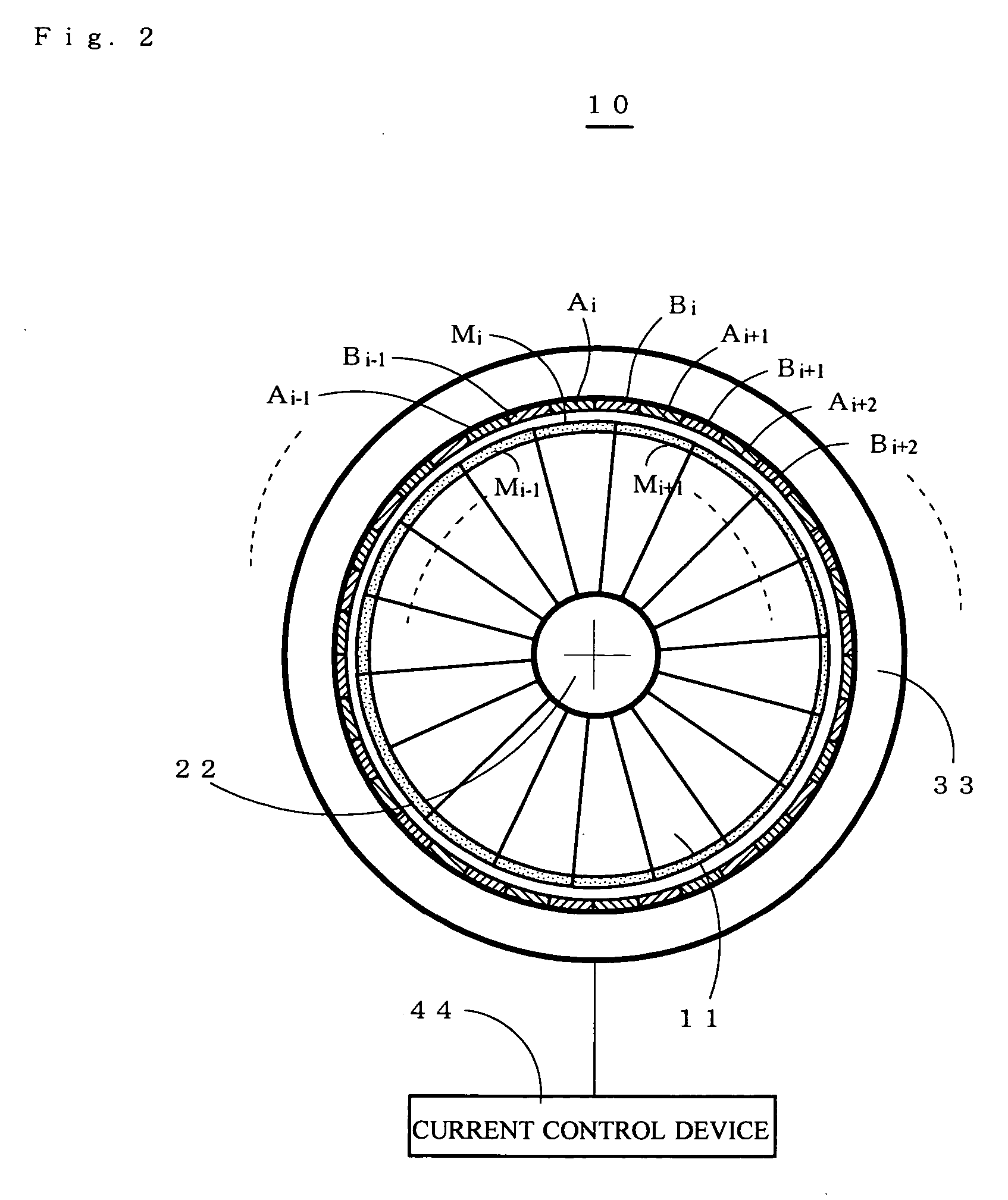

Low solidity turbofan

A turbofan includes a row of fan blades extending from a supporting disk inside an annular casing. Each blade includes an airfoil having opposite pressure and suction sides extending radially in span between a root and tip and axially in chord between leading and trailing edges. Adjacent airfoils define corresponding flow passages therebetween for pressurizing air. Each airfoil includes stagger increasing between the root and tip, and the flow passage has a mouth between the airfoil leading edge and the suction side of an adjacent airfoil and converges to a throat aft from the mouth. The row includes no more than twenty fan blades having low tip solidity for increasing the width of the passage throat.

Owner:GENERAL ELECTRIC CO

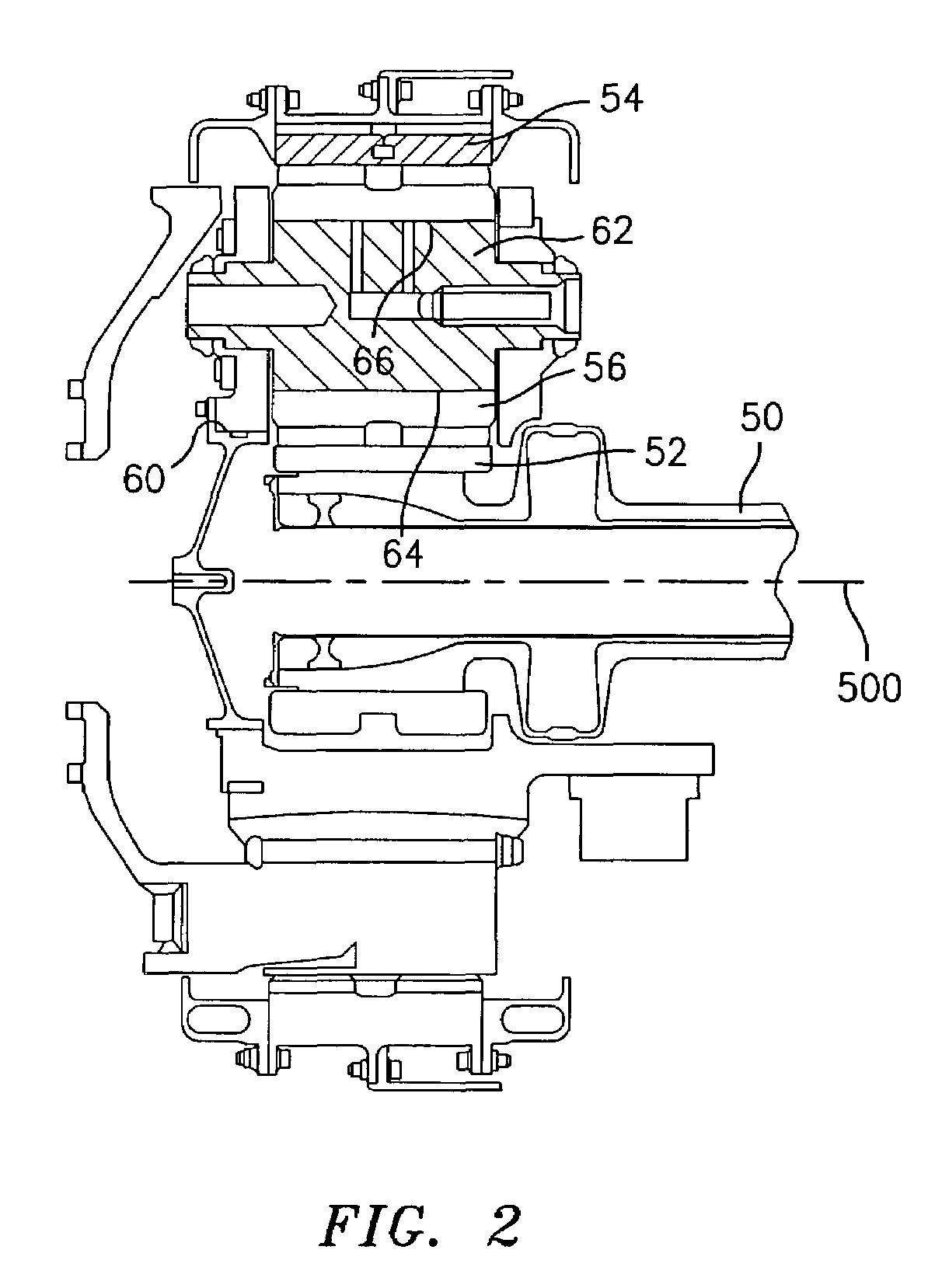

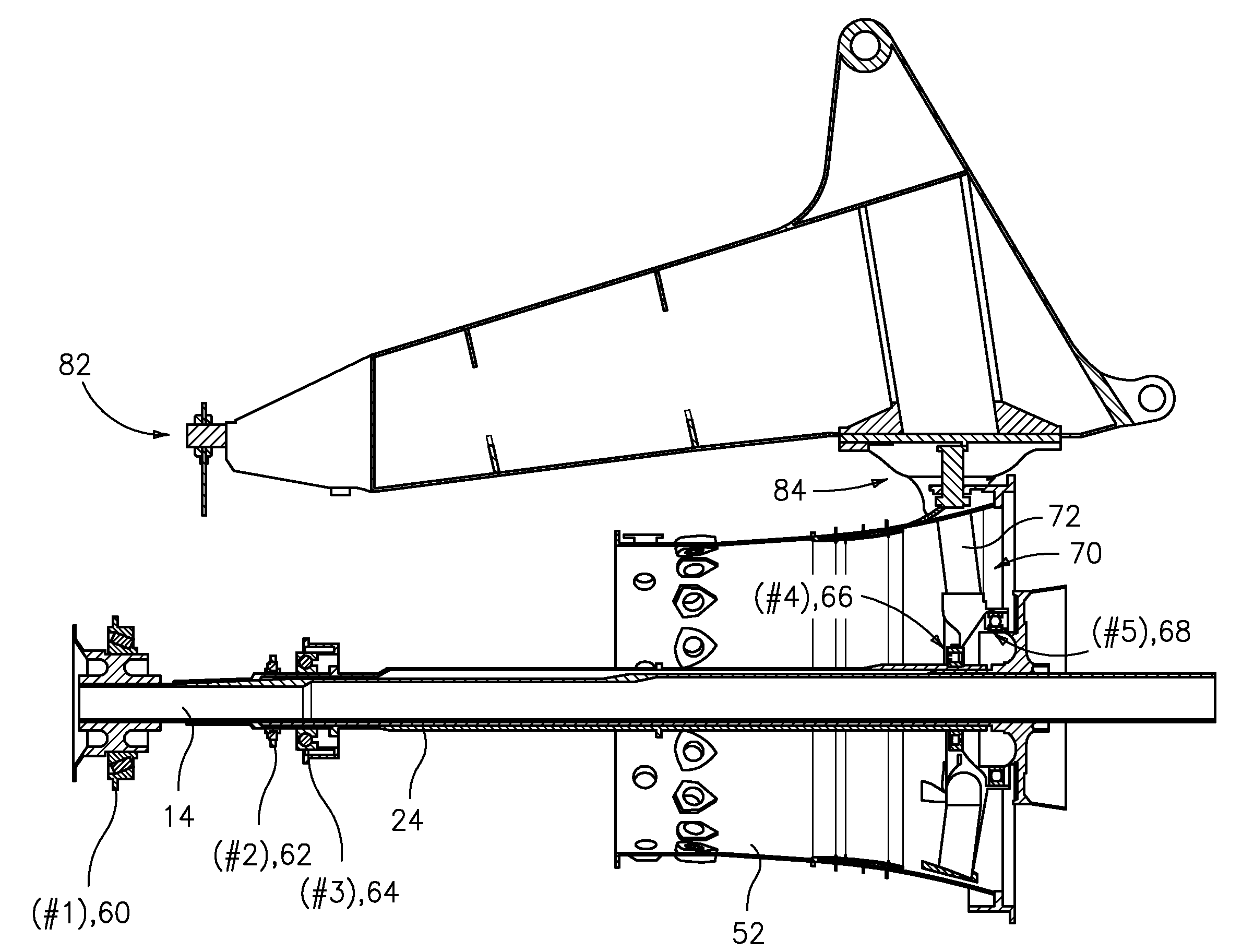

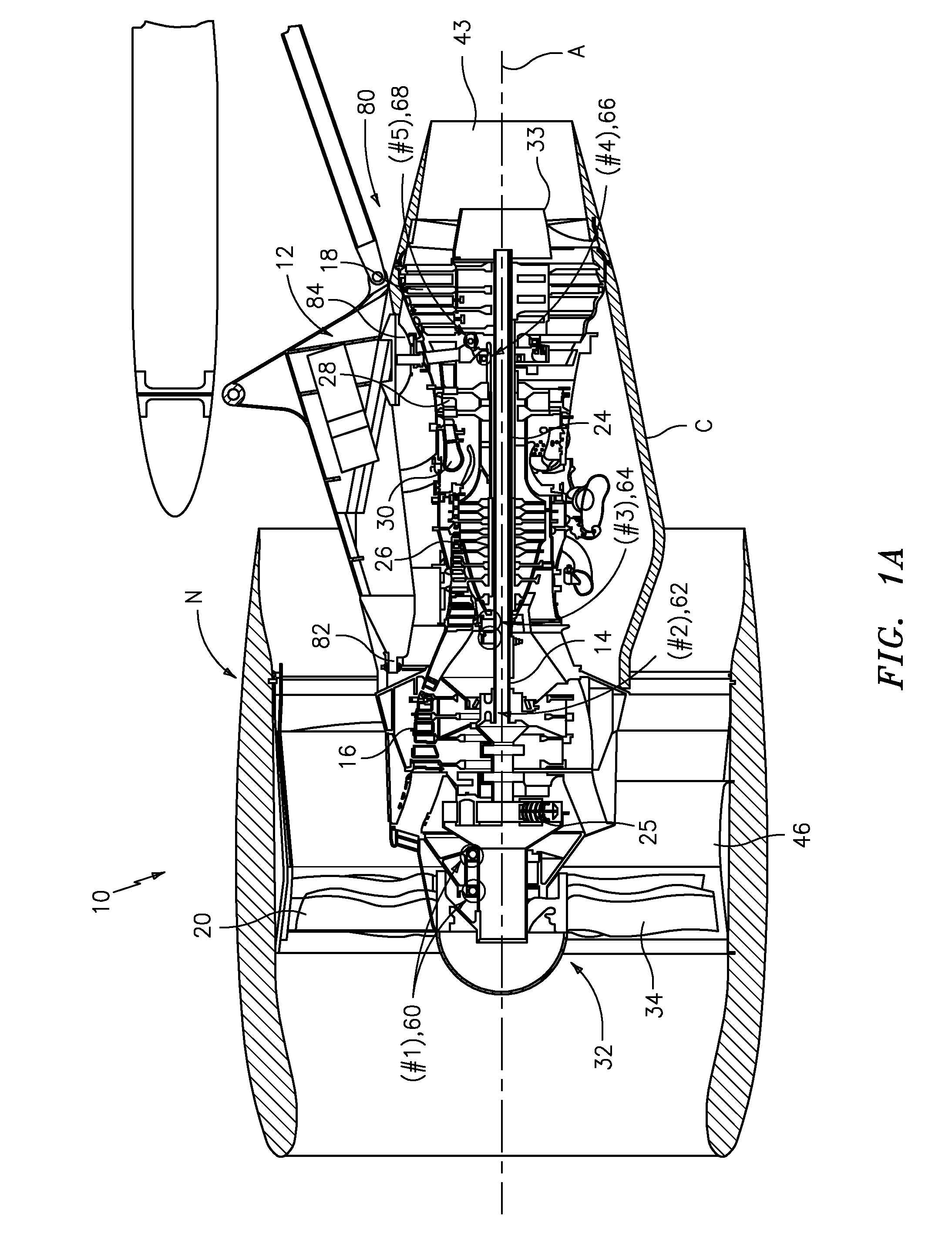

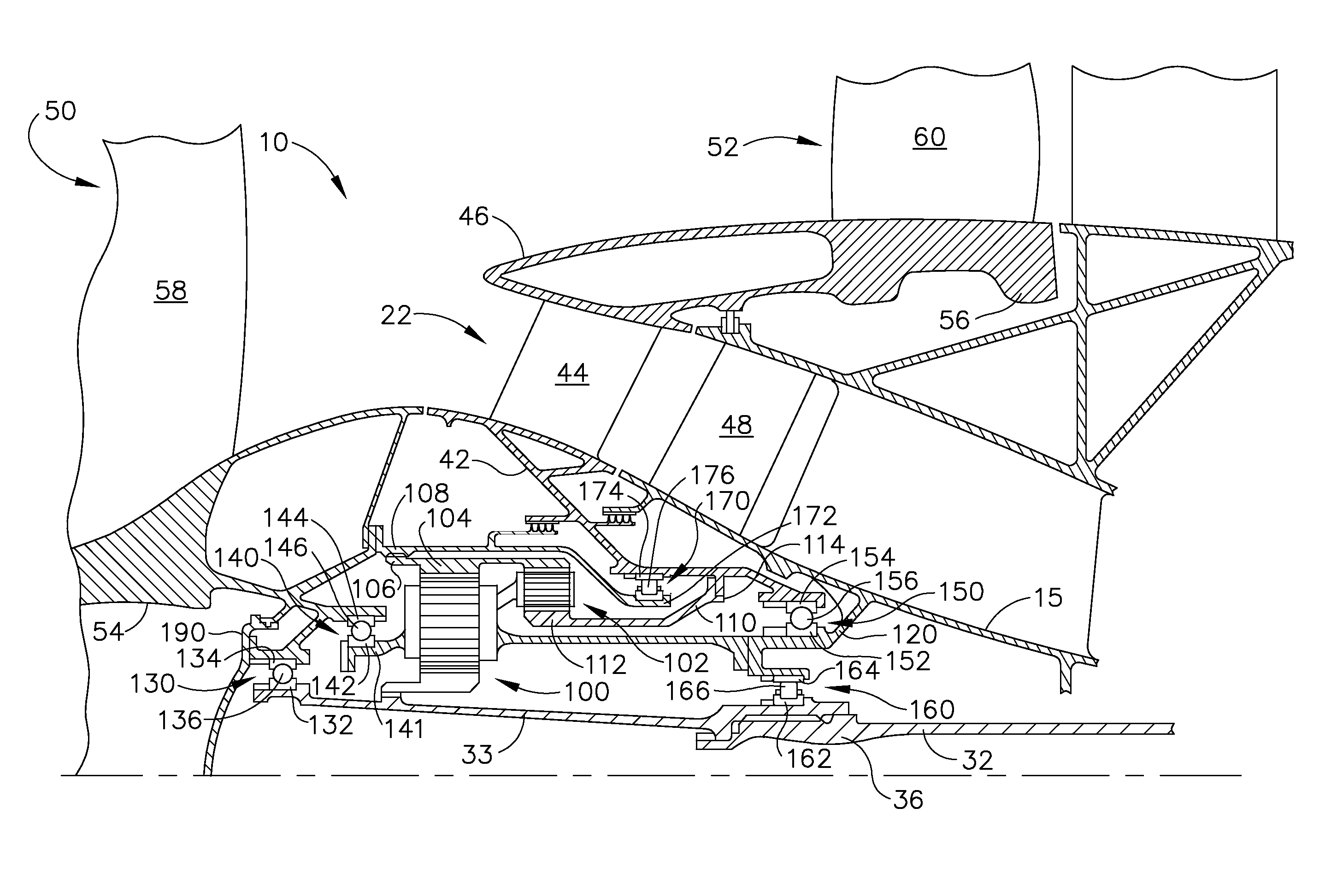

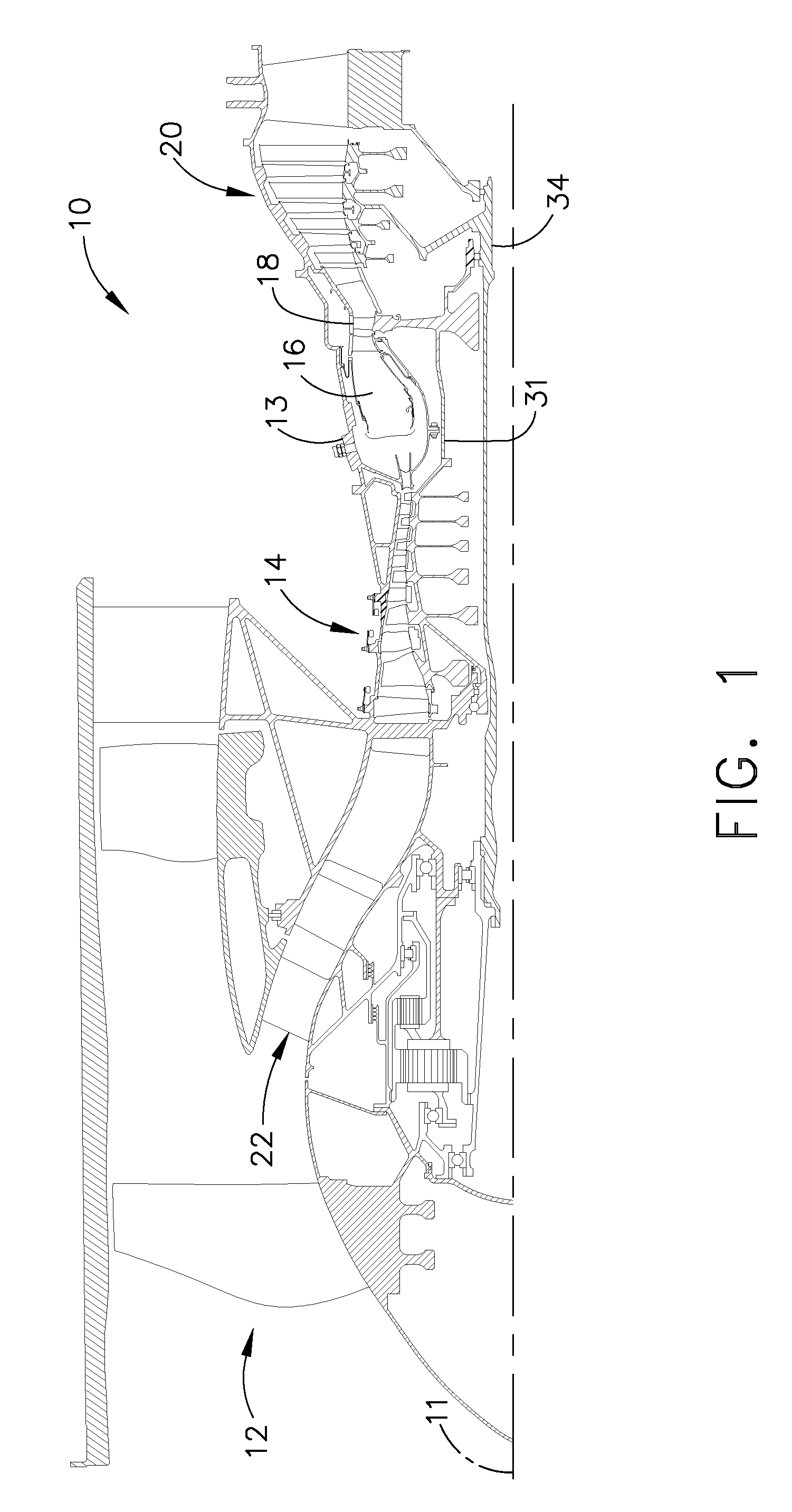

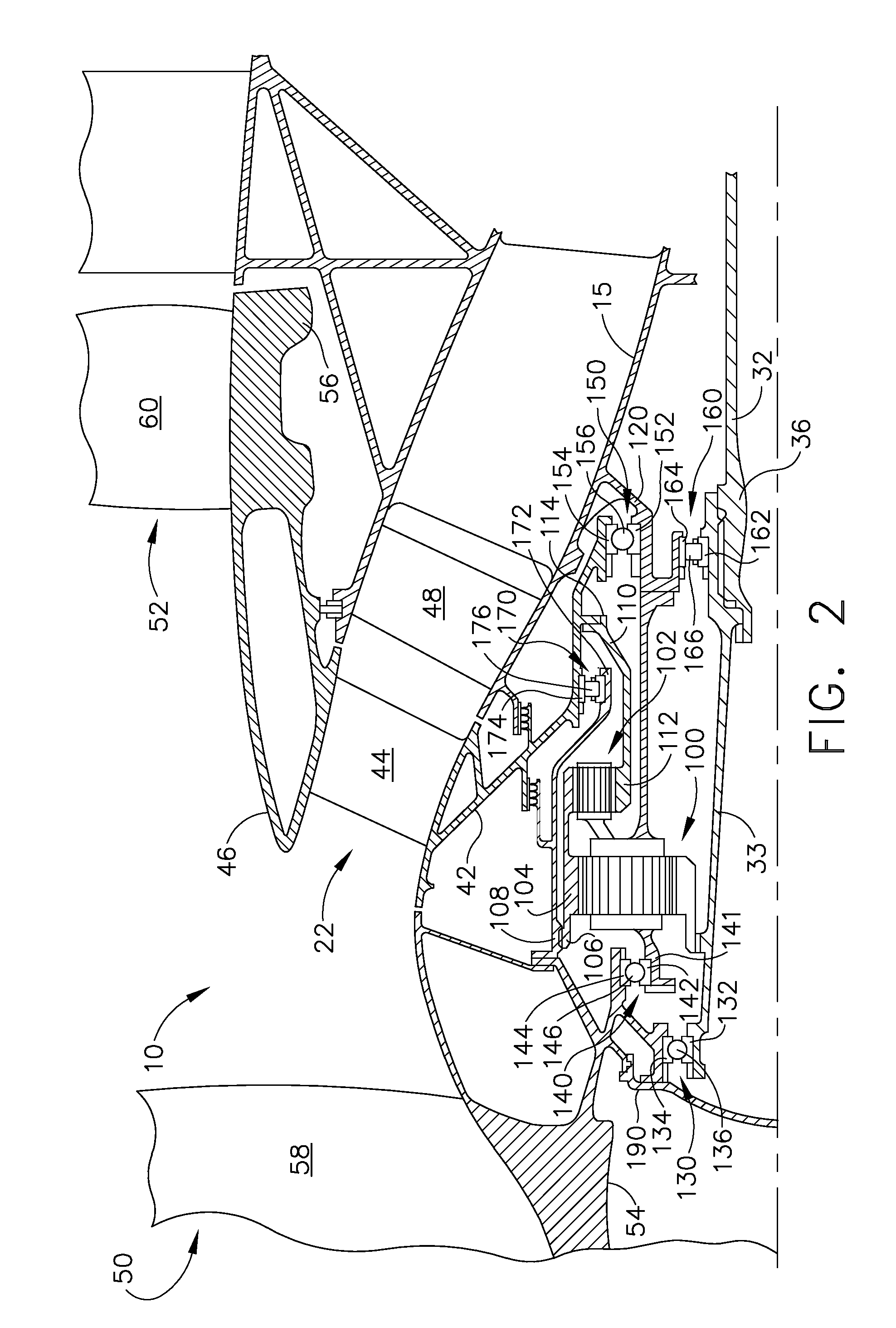

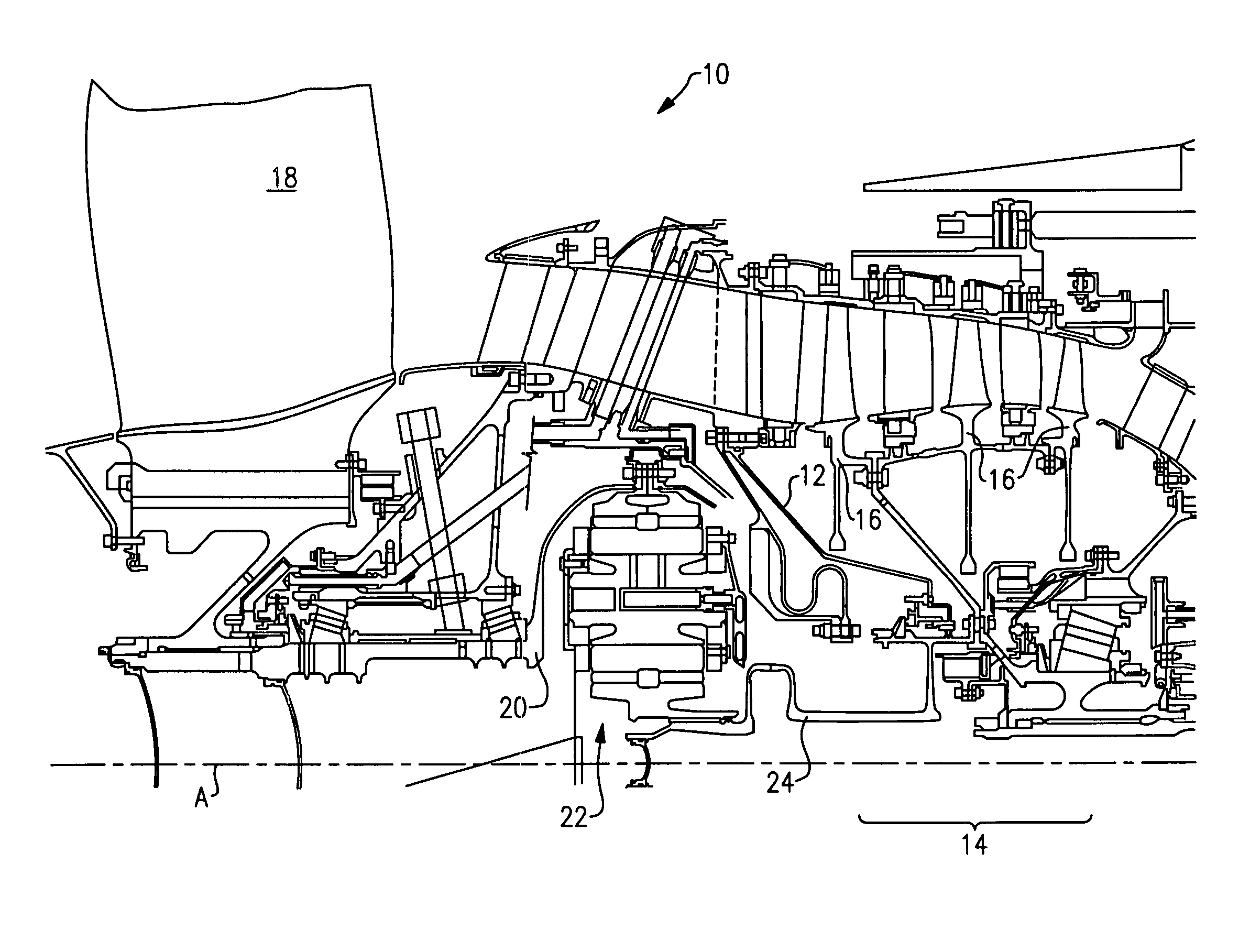

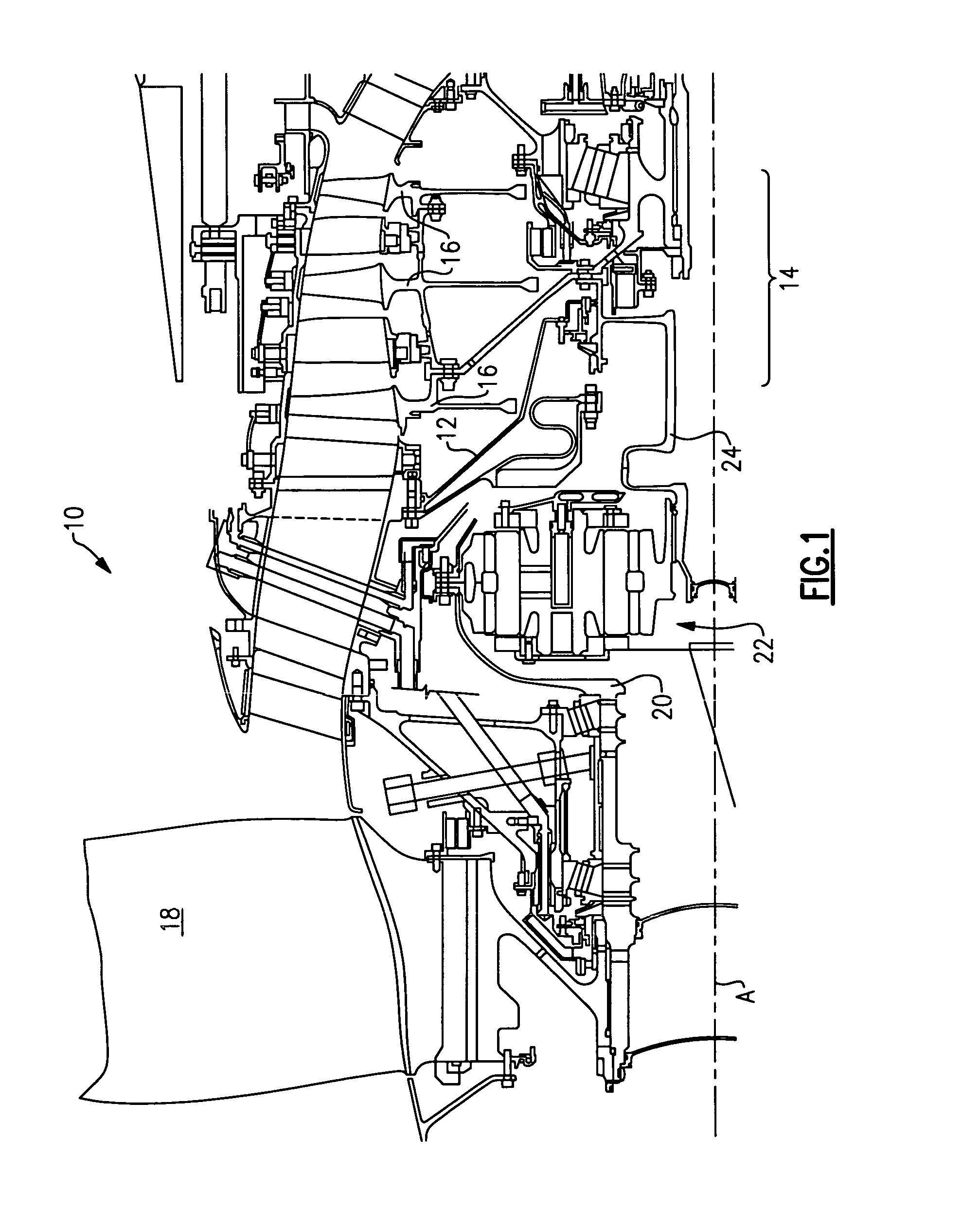

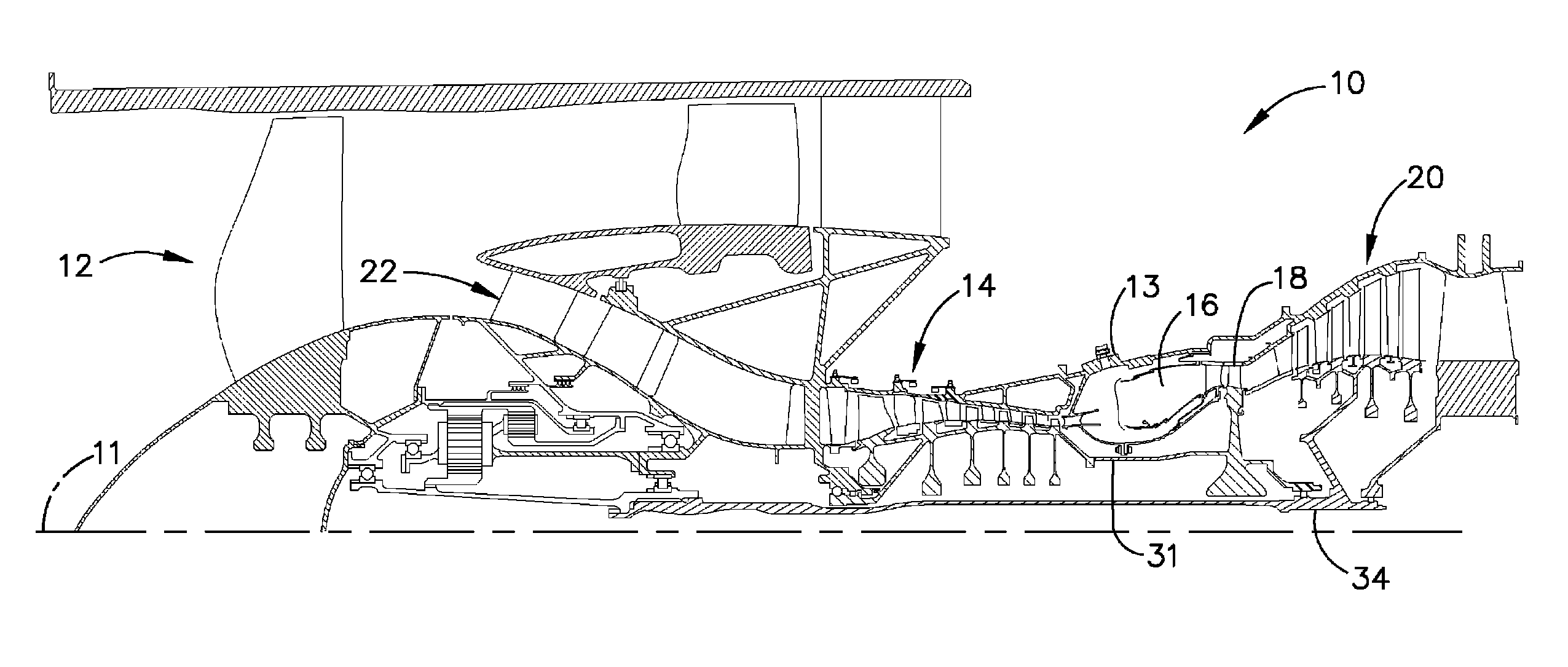

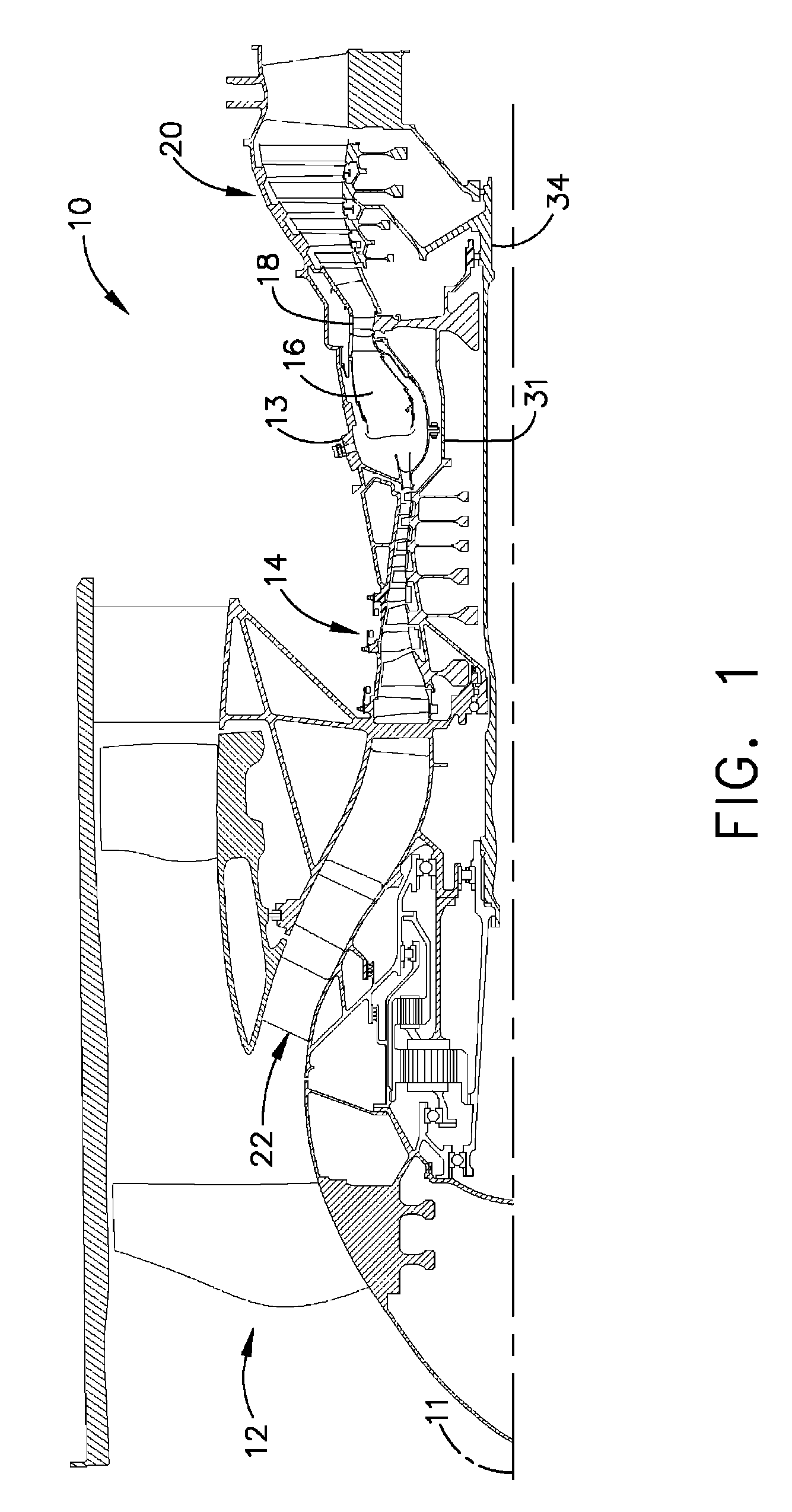

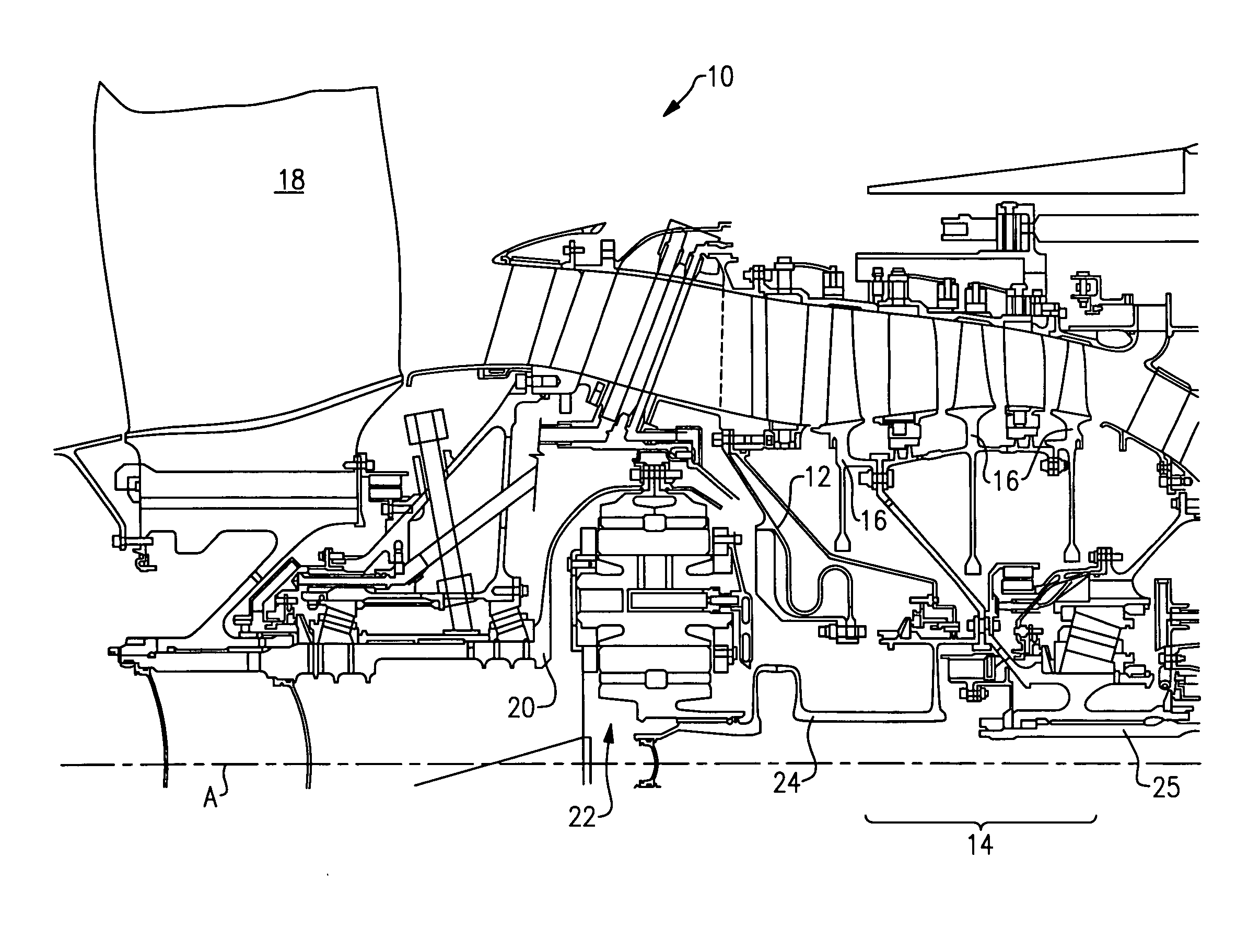

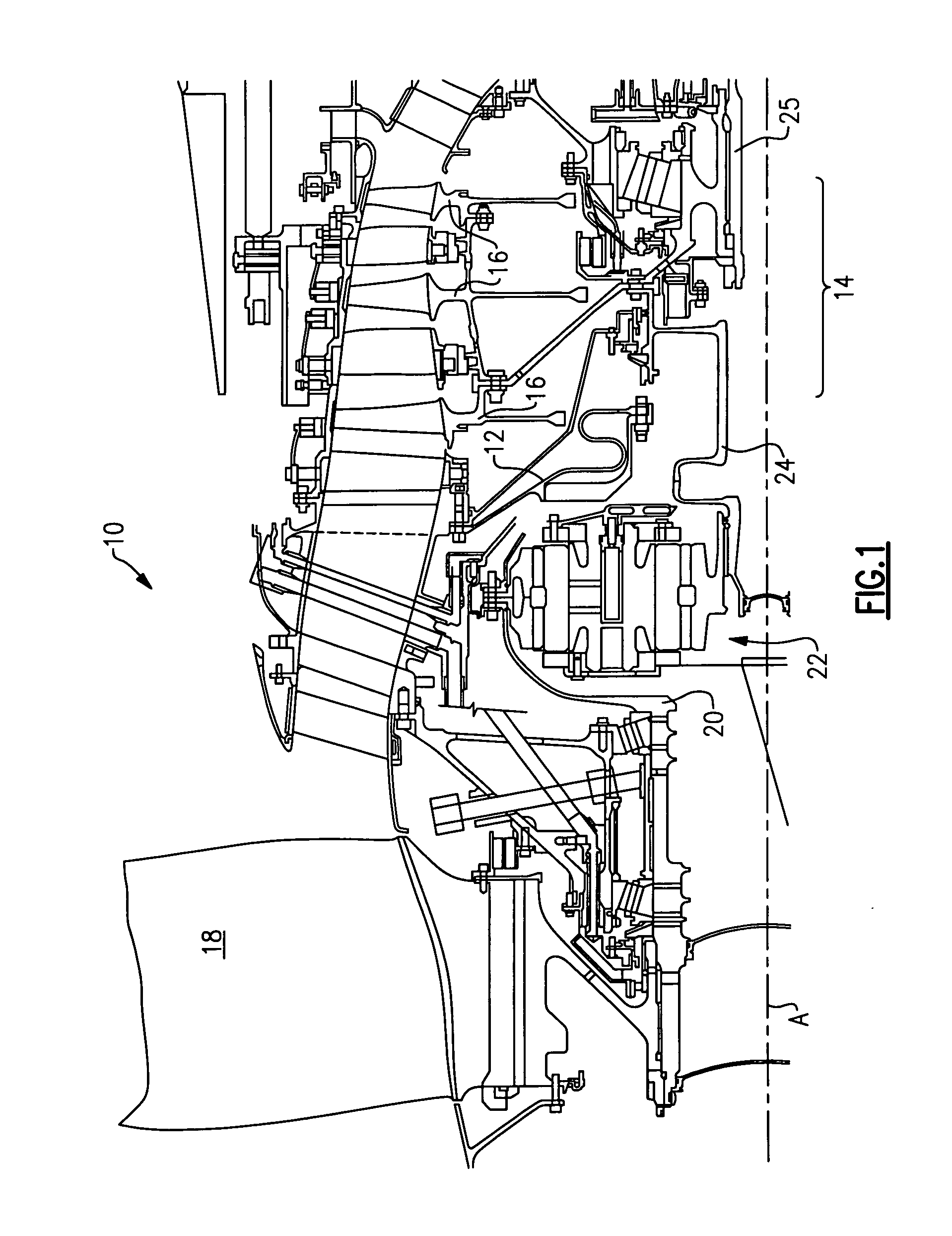

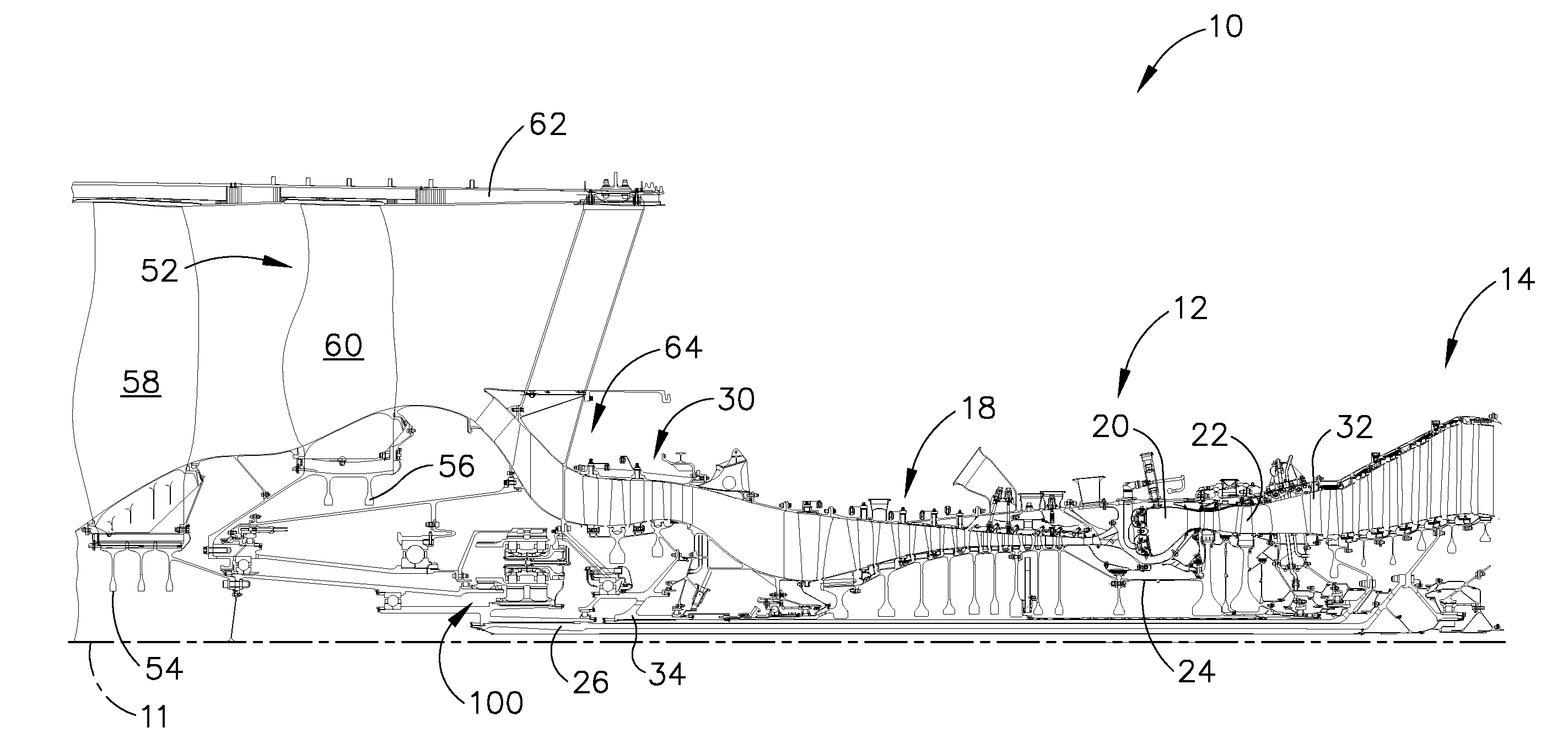

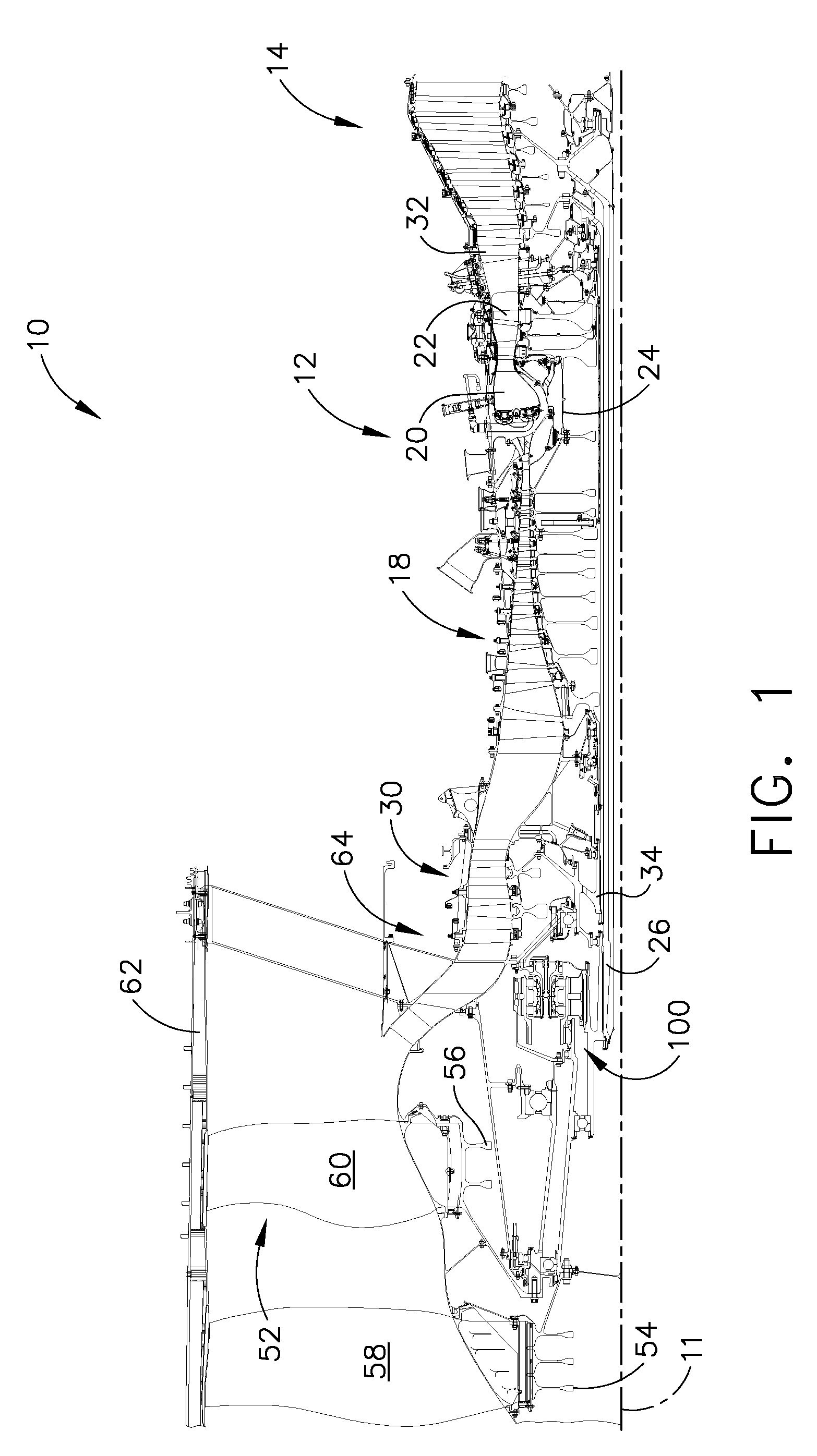

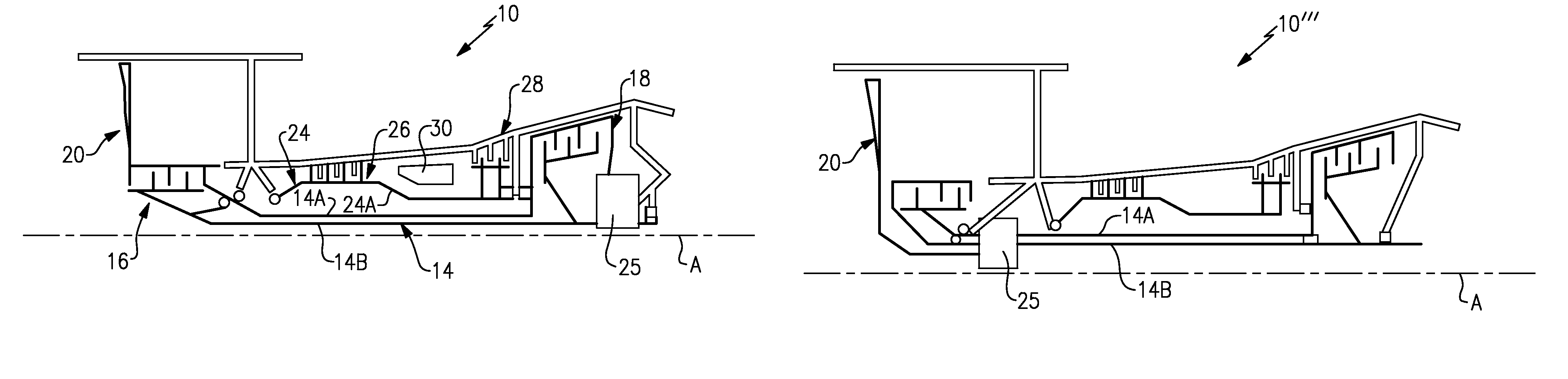

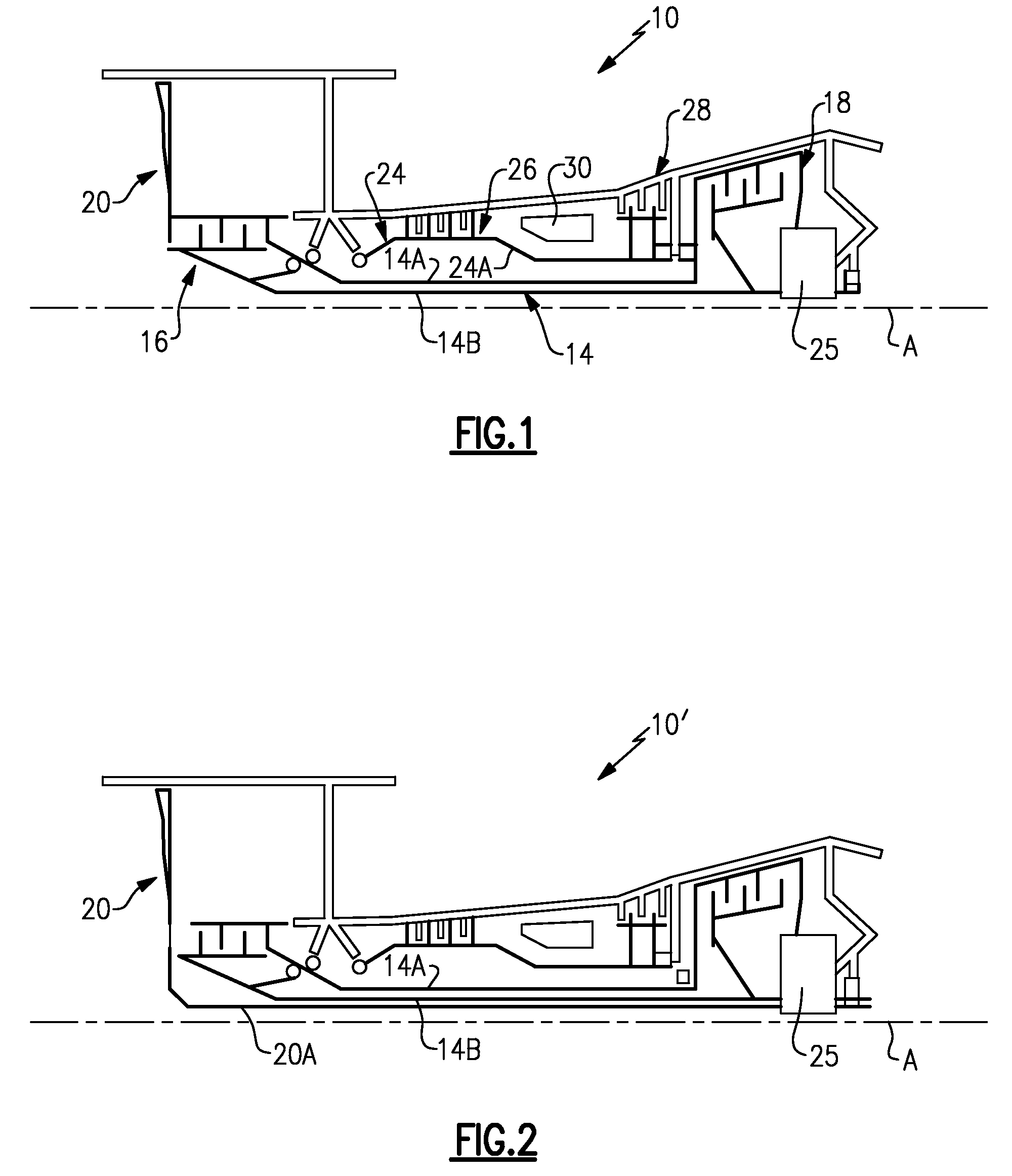

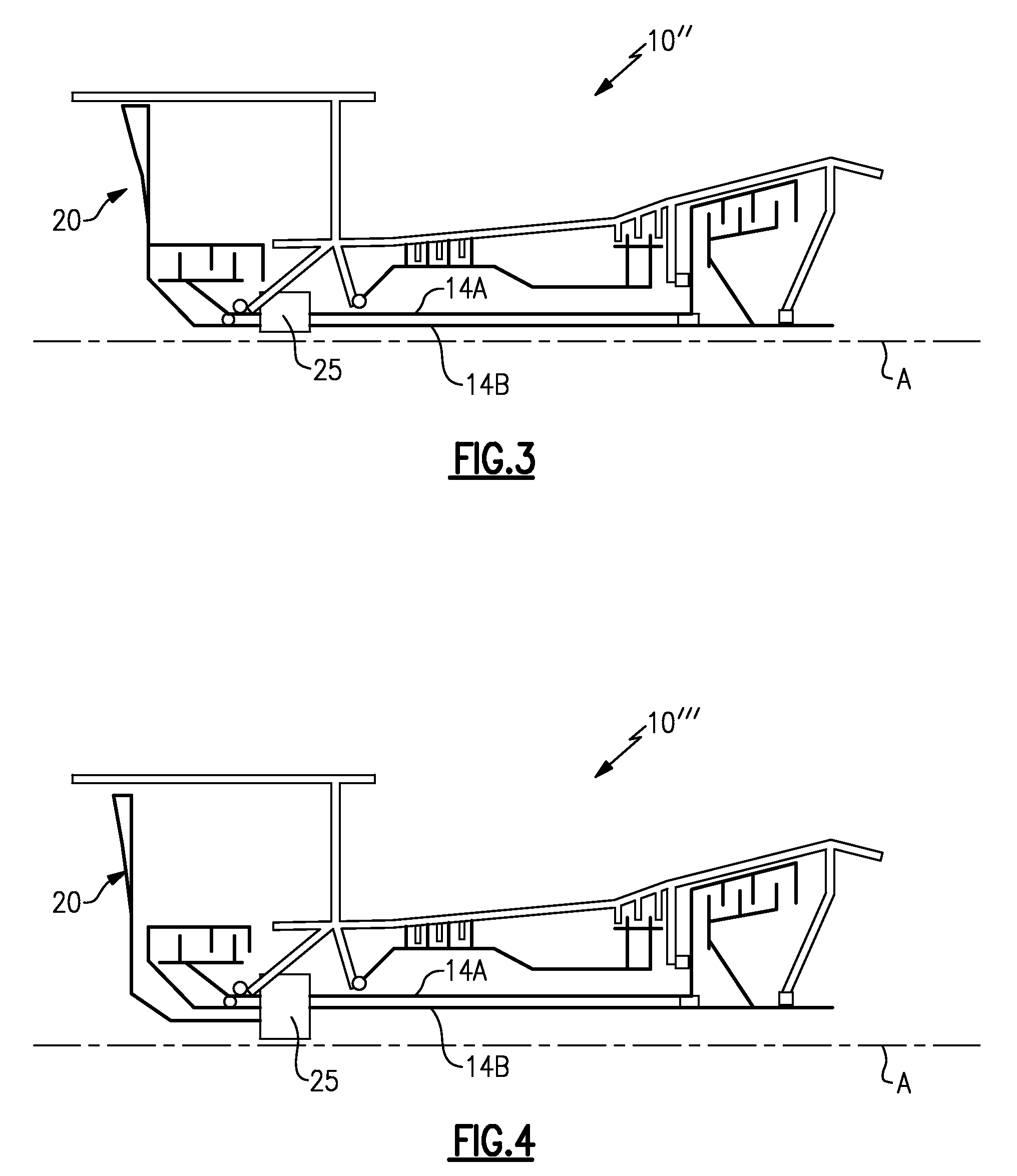

Engine mounting configuration for a turbofan gas turbine engine

ActiveUS20090056343A1Minimizes backbone bendingMinimizes engine case distortionPower plant constructionJet type power plantsNacelleEngine mount

An engine mounting configuration reacts engine thrust at an aft mount. The engine mounting configuration reduces backbone bending of the engine, intermediate case distortion and frees-up space within the core nacelle.

Owner:RAYTHEON TECH CORP

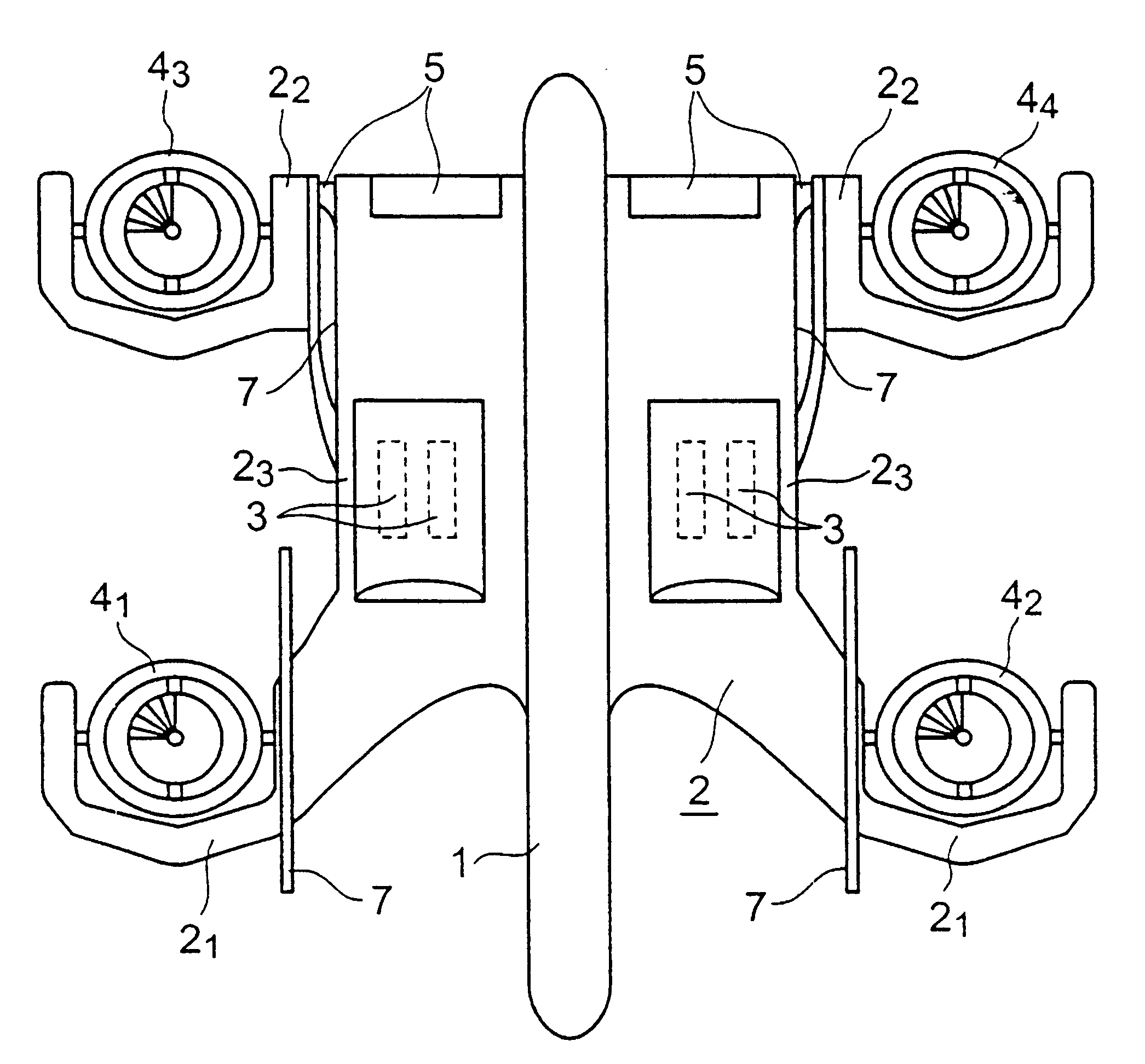

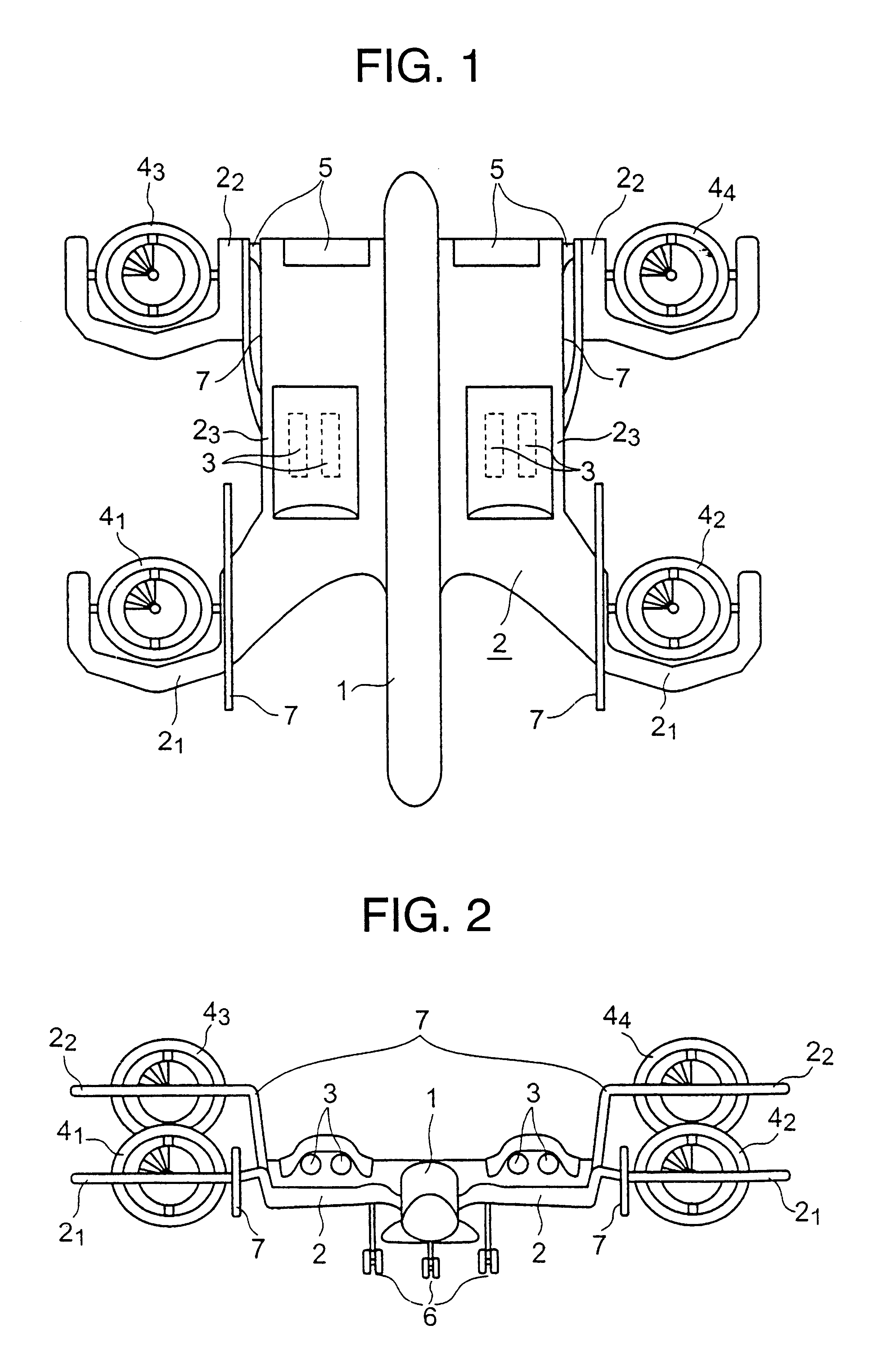

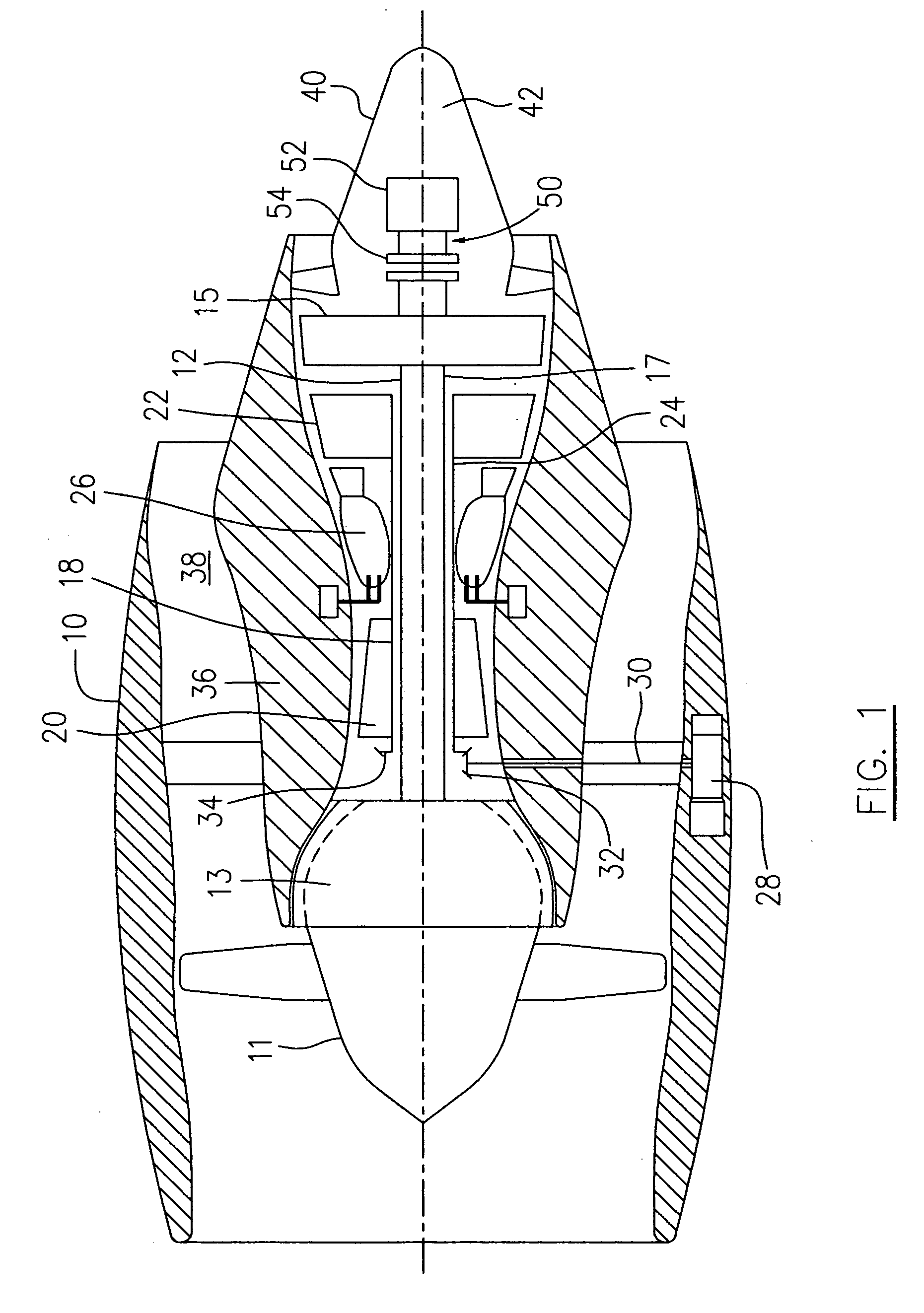

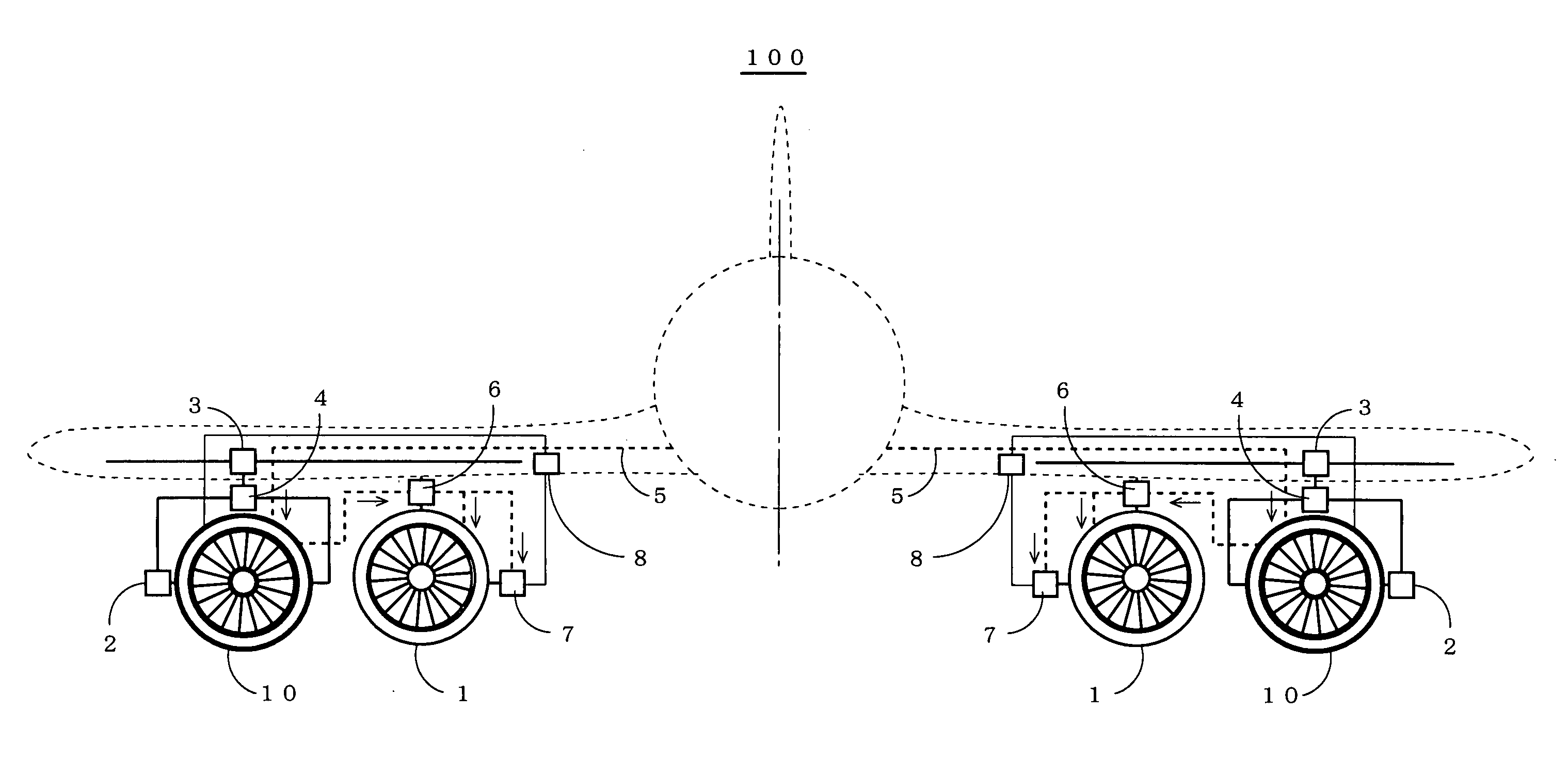

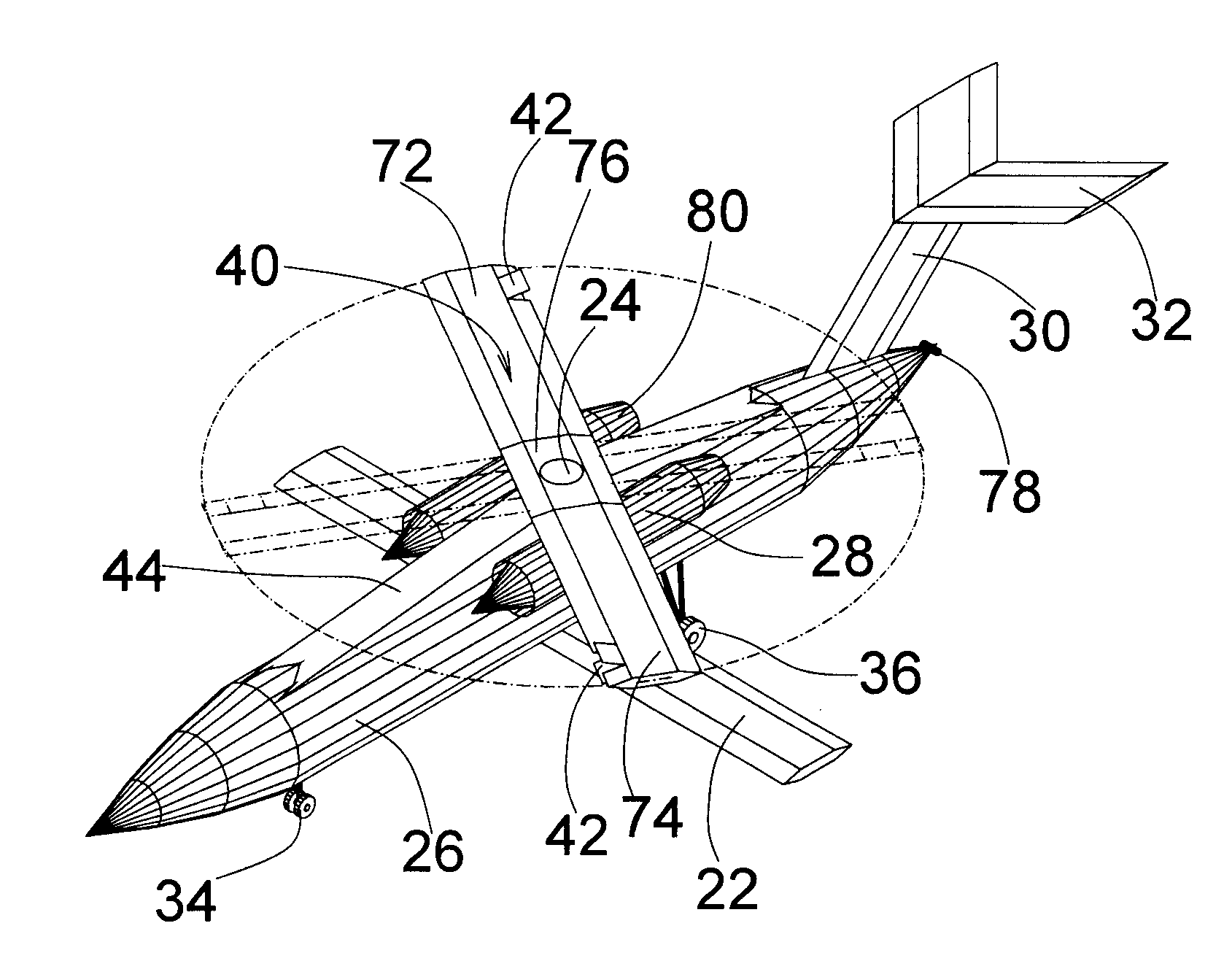

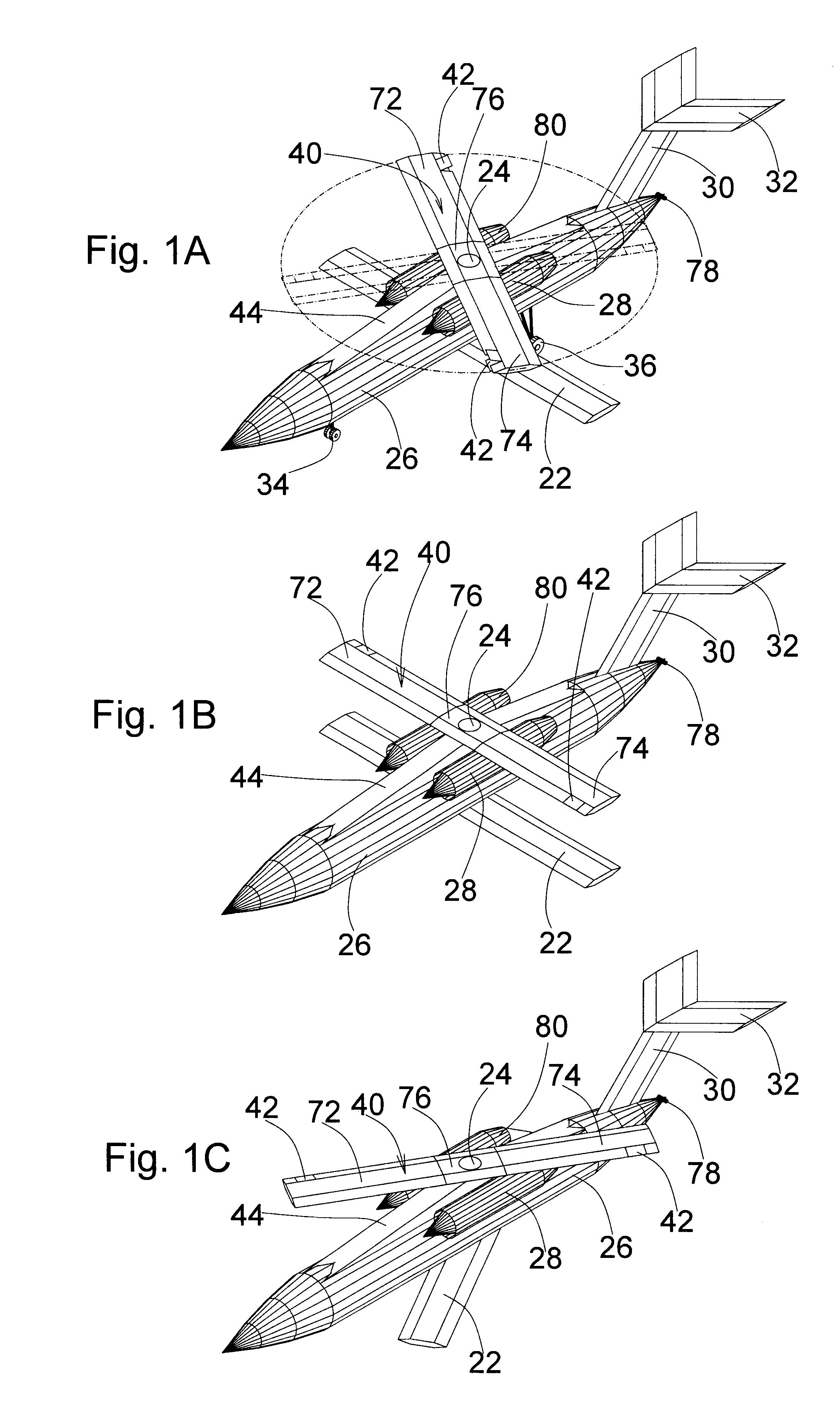

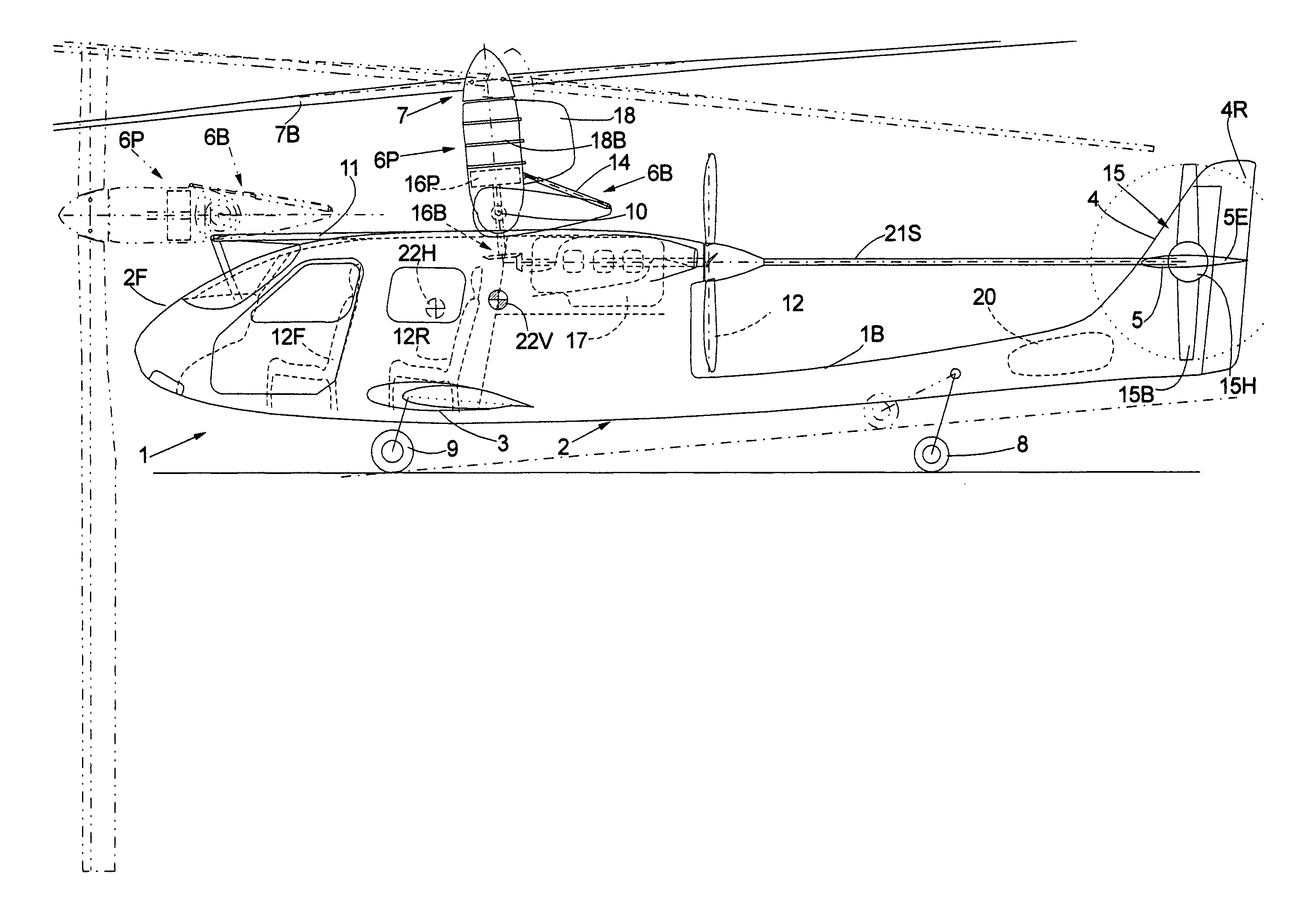

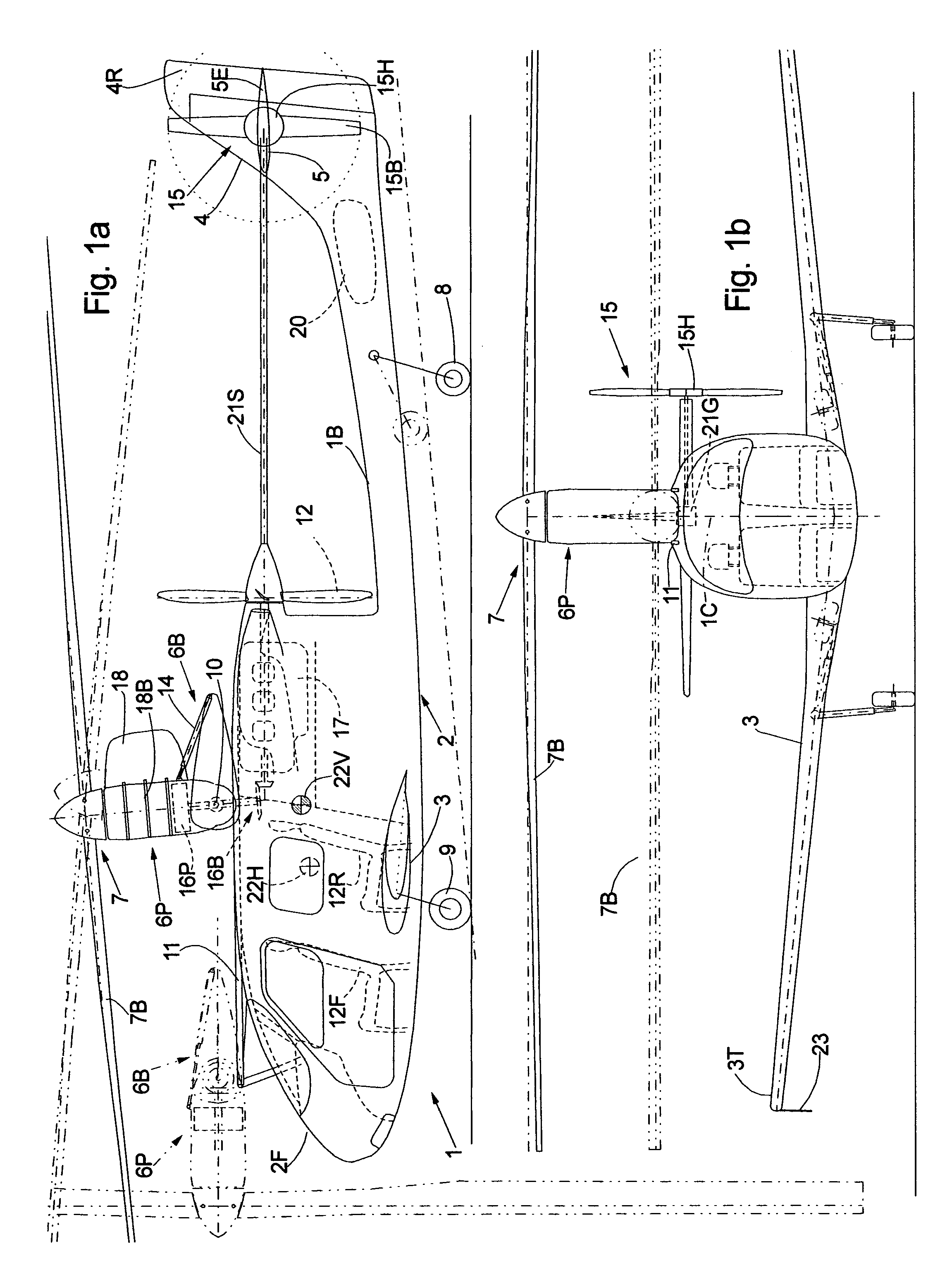

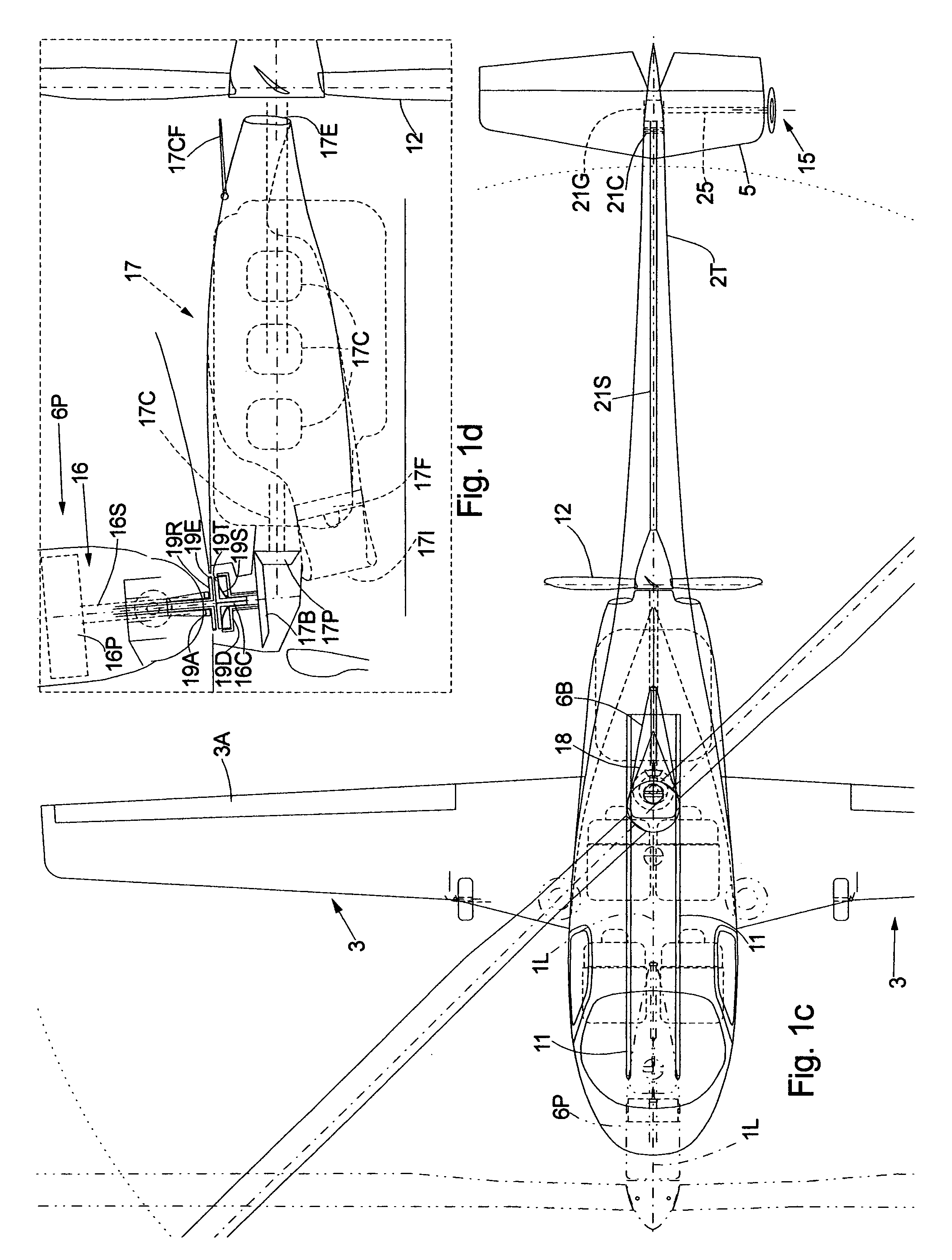

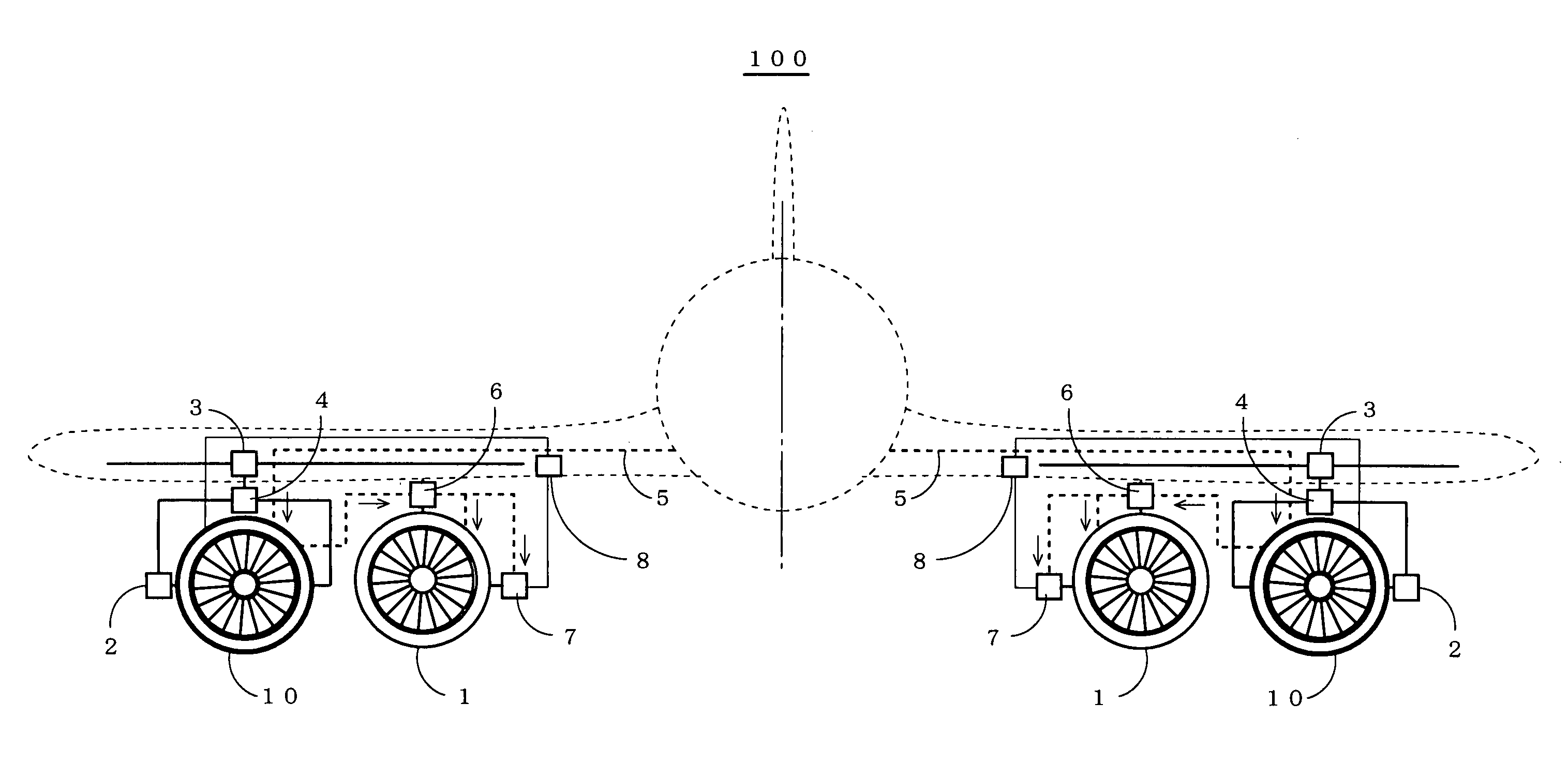

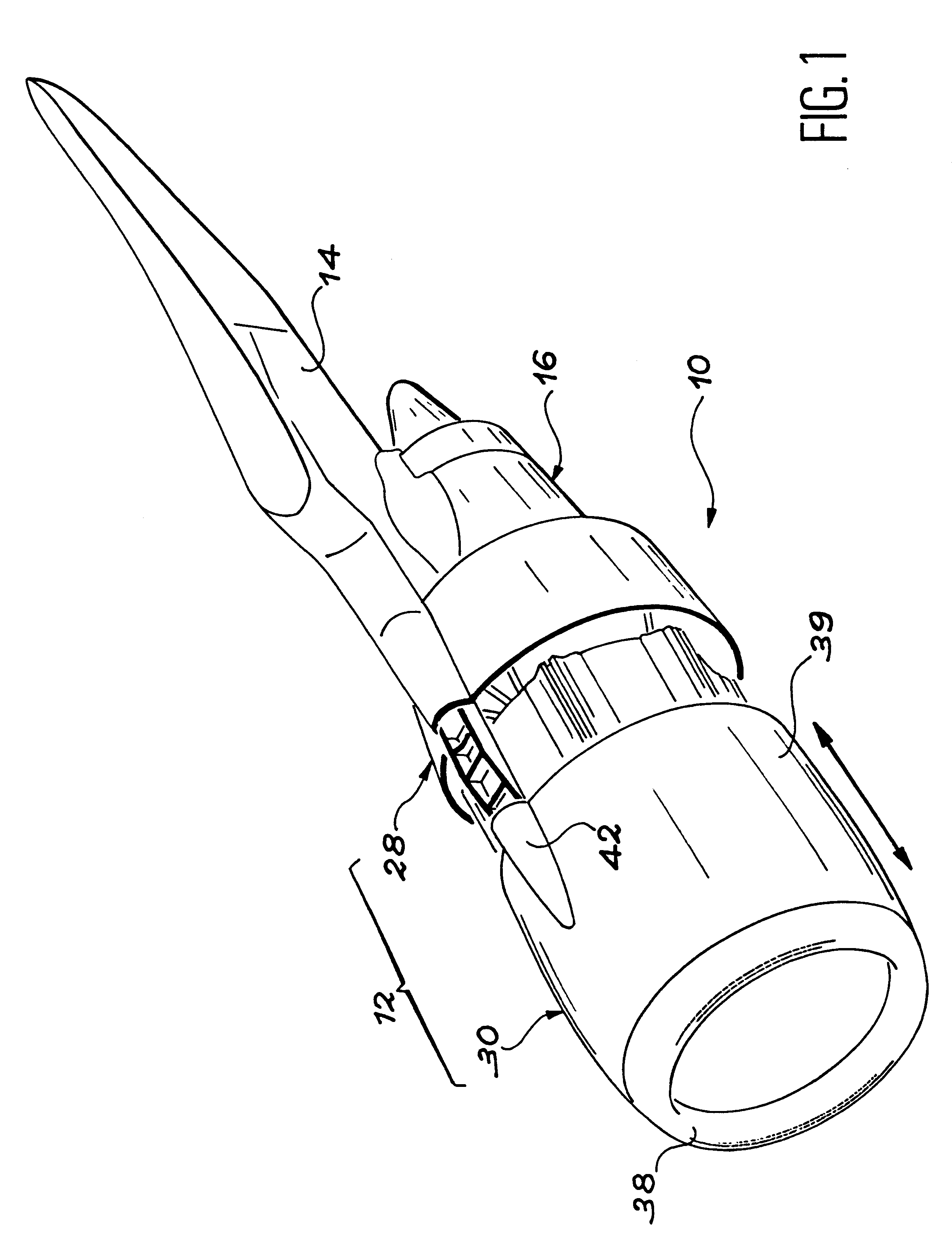

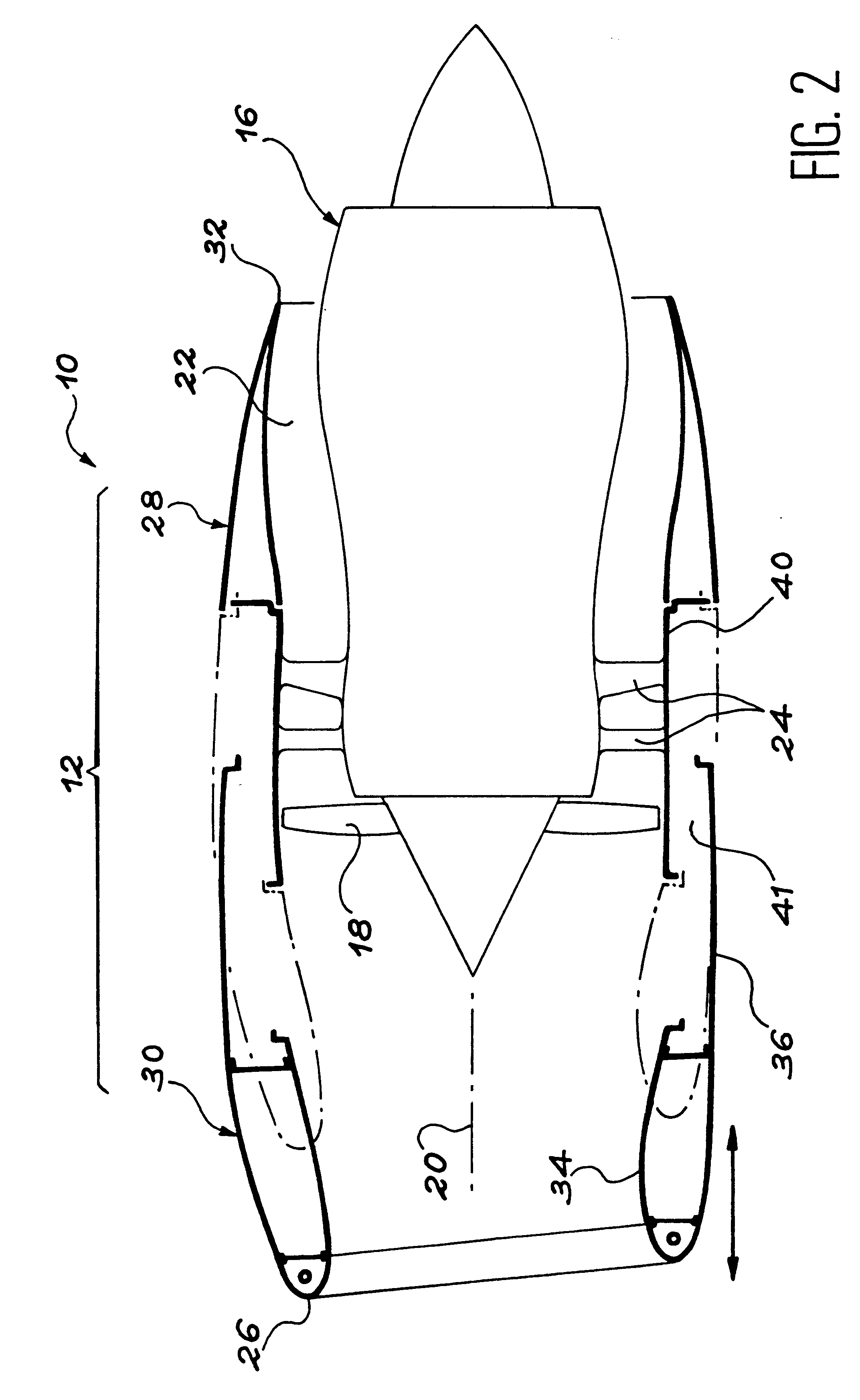

Vertical takeoff and landing aircraft

InactiveUS6892980B2Superior and stable maneuverabilityEasy to operateAircraft navigation controlPropellersJet aeroplaneTurbofan

A vertical takeoff and landing (VTOL) aircraft is superior in maneuverability, safety, and mobility. The aircraft has turbofan engines with separate core engines having fan engines used commonly for cruising and lifting up. The thrust from the fan engines can be directed to all directions by supporting the fan engines of the turbofan engines with separate core engines with biaxial support so that the fan engines are rotatable in the direction of pitching and rolling. The fan engines are mounted on both sides of each of front and rear sings. With this construction, the VTOL aircraft can cruise and hover by tilting the fan engines about the two axes while using the fan engines commonly for cruising and hovering.

Owner:MITSUBISHI HEAVY IND LTD

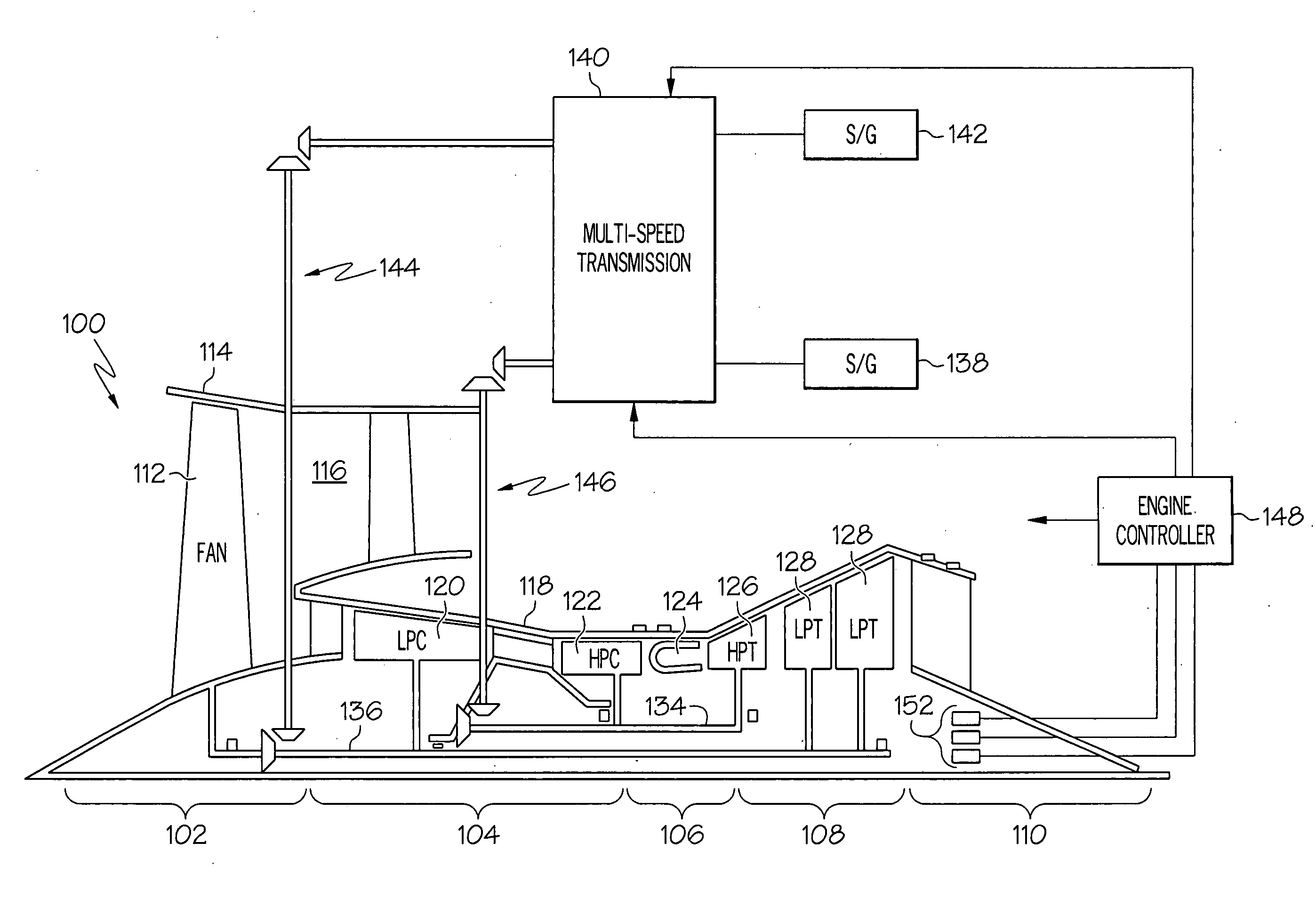

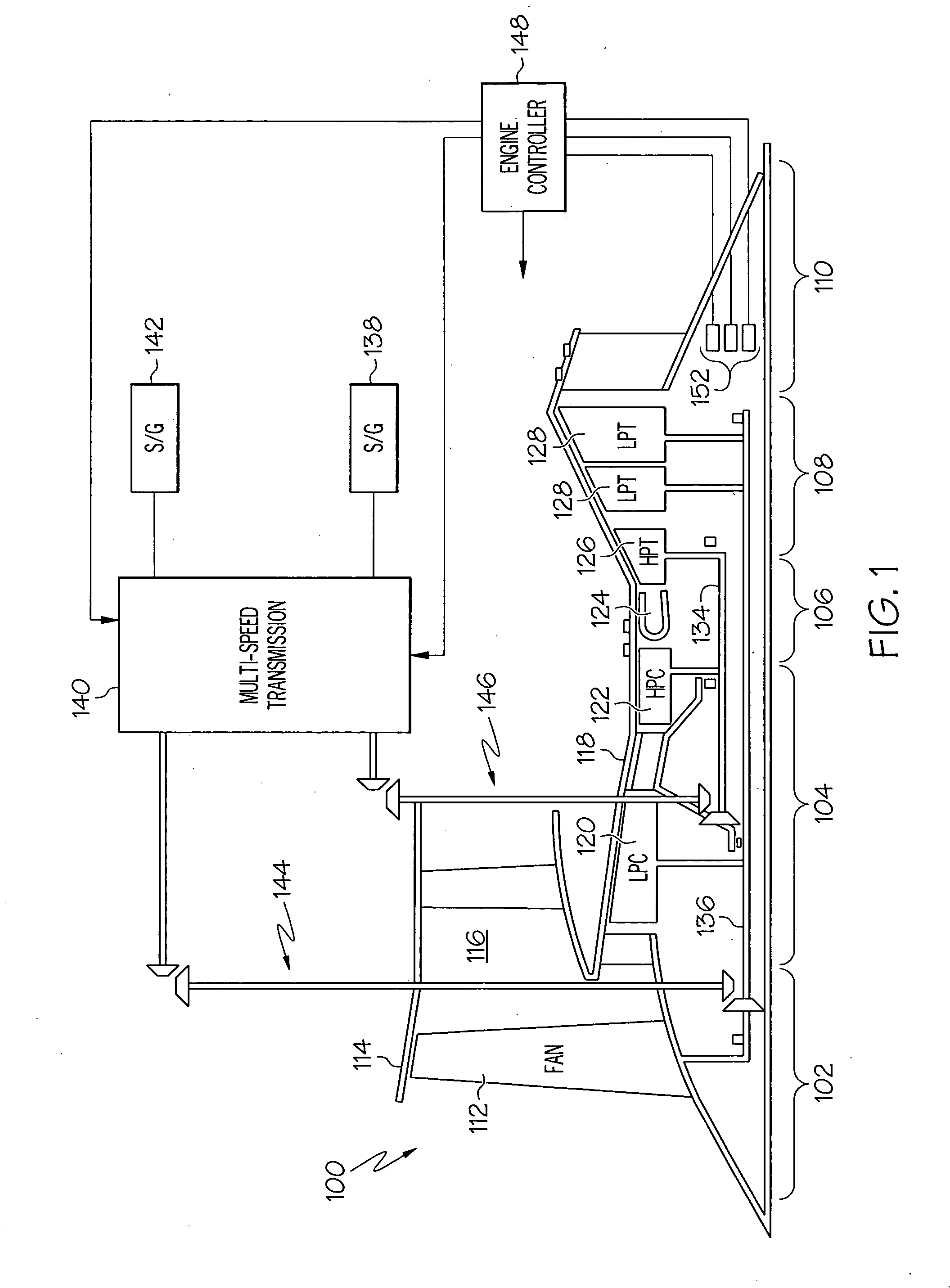

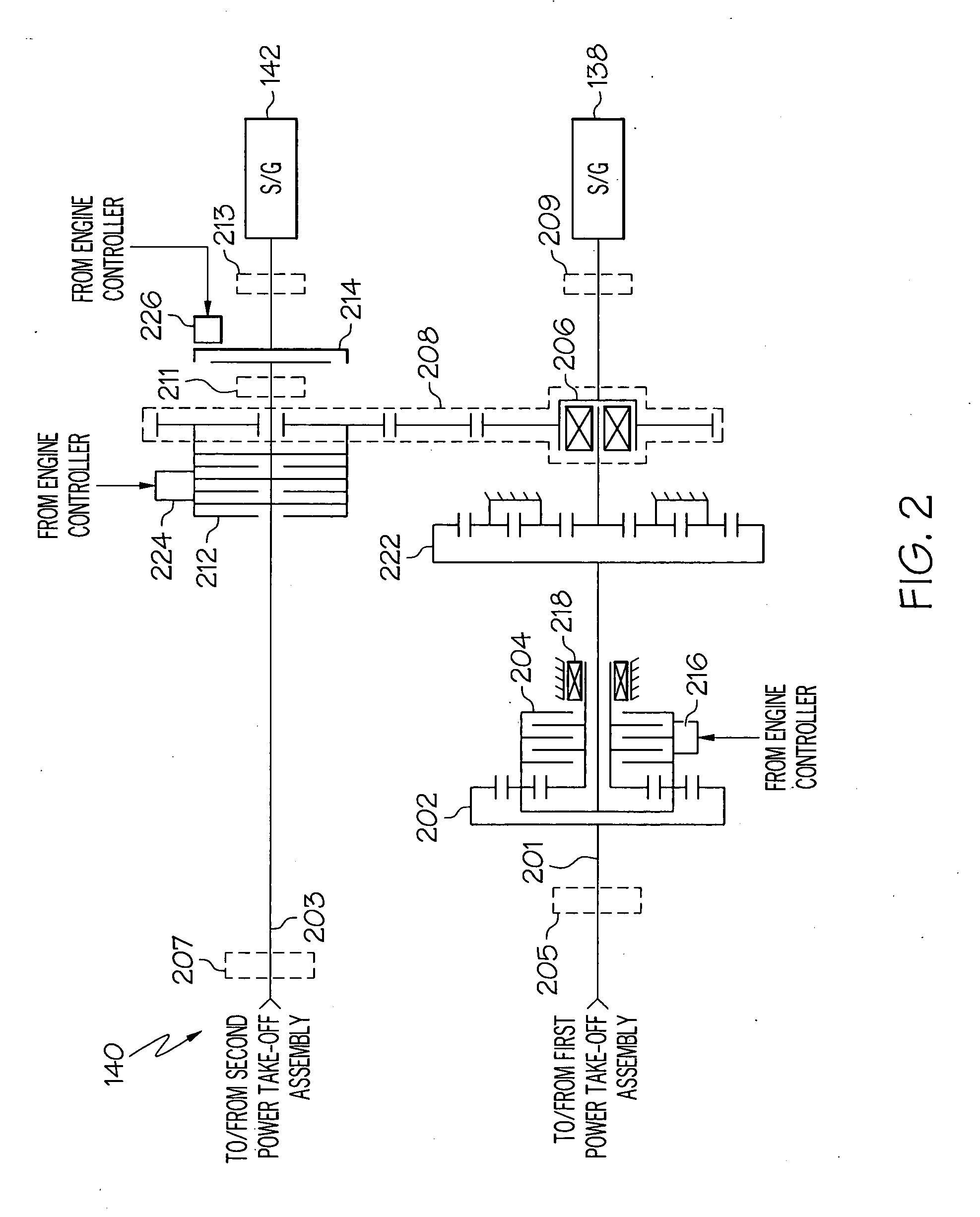

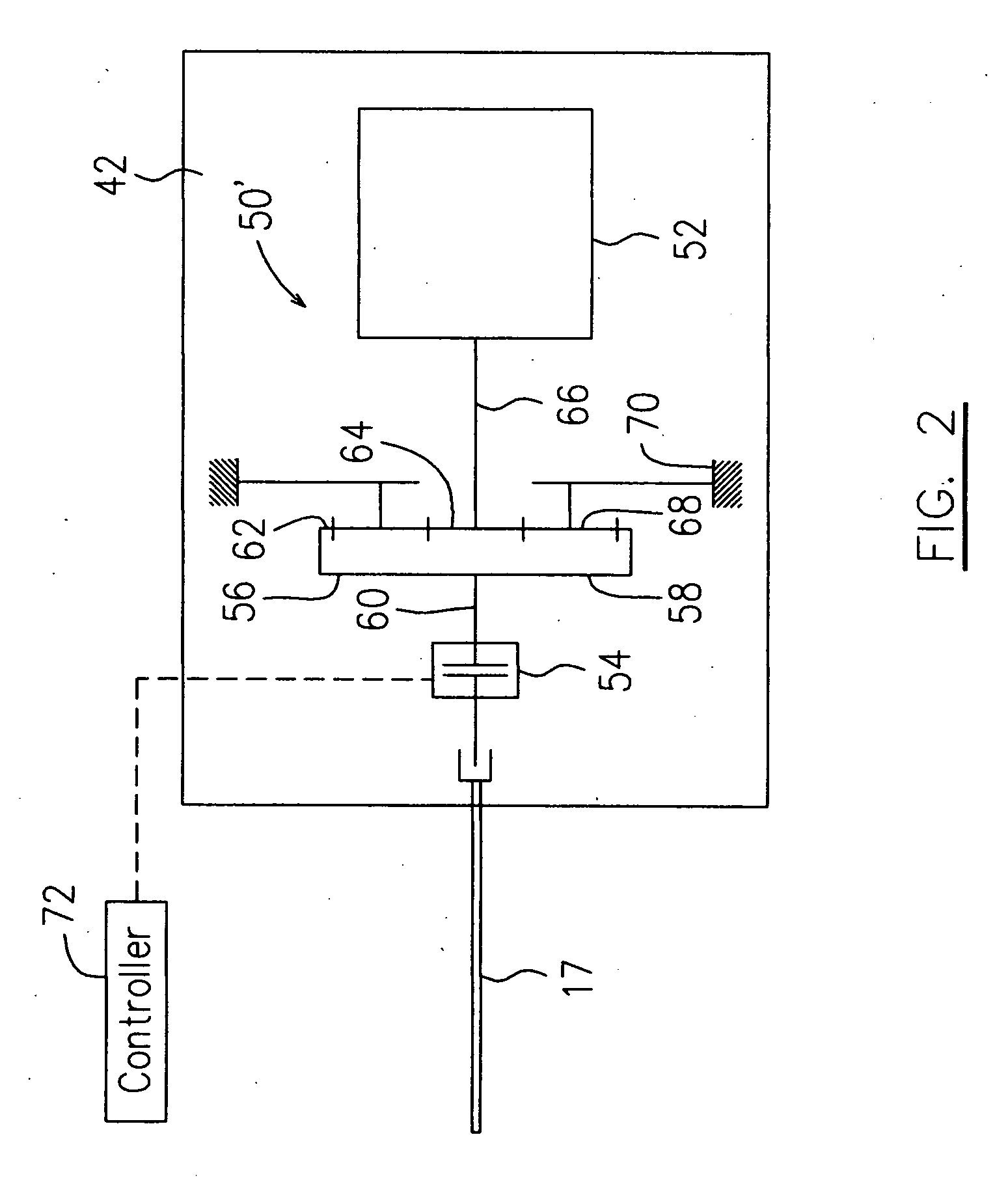

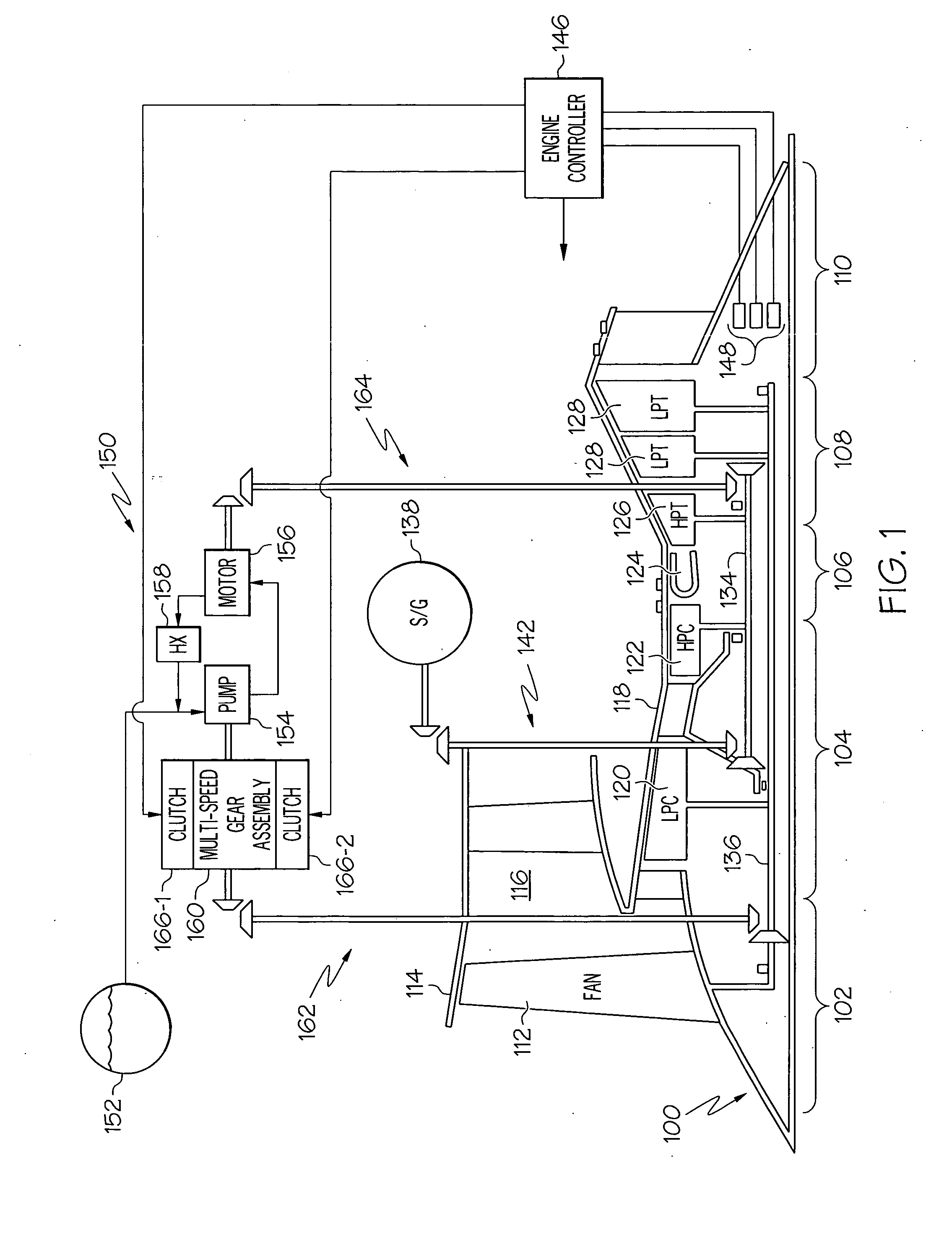

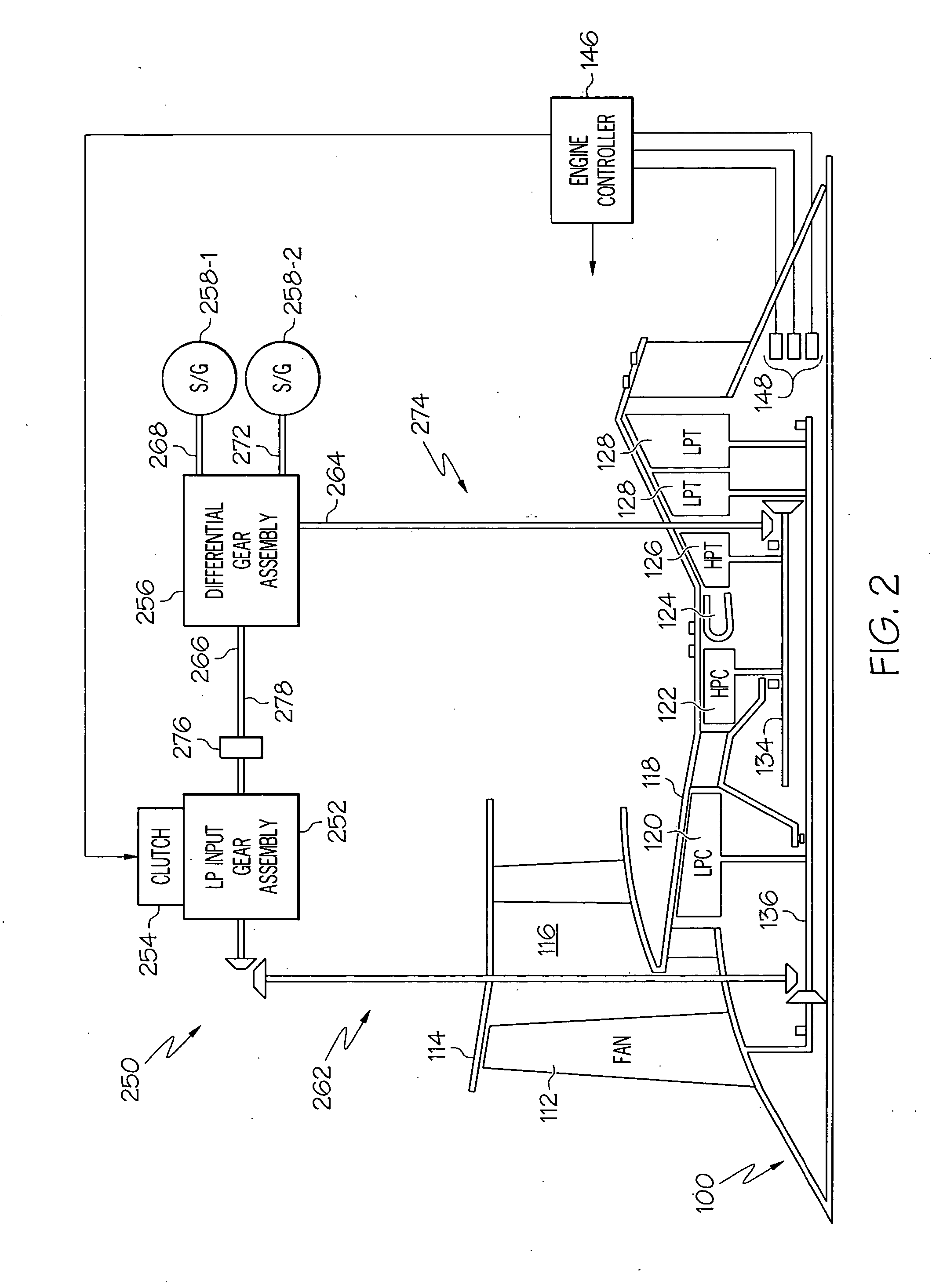

More electric aircraft starter-generator multi-speed transmission system

InactiveUS20070151258A1Reduces operating speed rangeReduce speed rangeToothed gearingsGas turbine plantsStarter generatorElectric aircraft

A turbofan gas turbine propulsion engine includes a multi-speed transmission between the high pressure and low pressure turbines and associated high pressure and low pressure starter-generators. The multi-speed transmission reduces the operating speed range from the low pressure turbine to its associated starter-generator, and is configurable to allow the starter-generator associated with the low pressure turbine to supply starting torque to the engine.

Owner:HONEYWELL INT INC

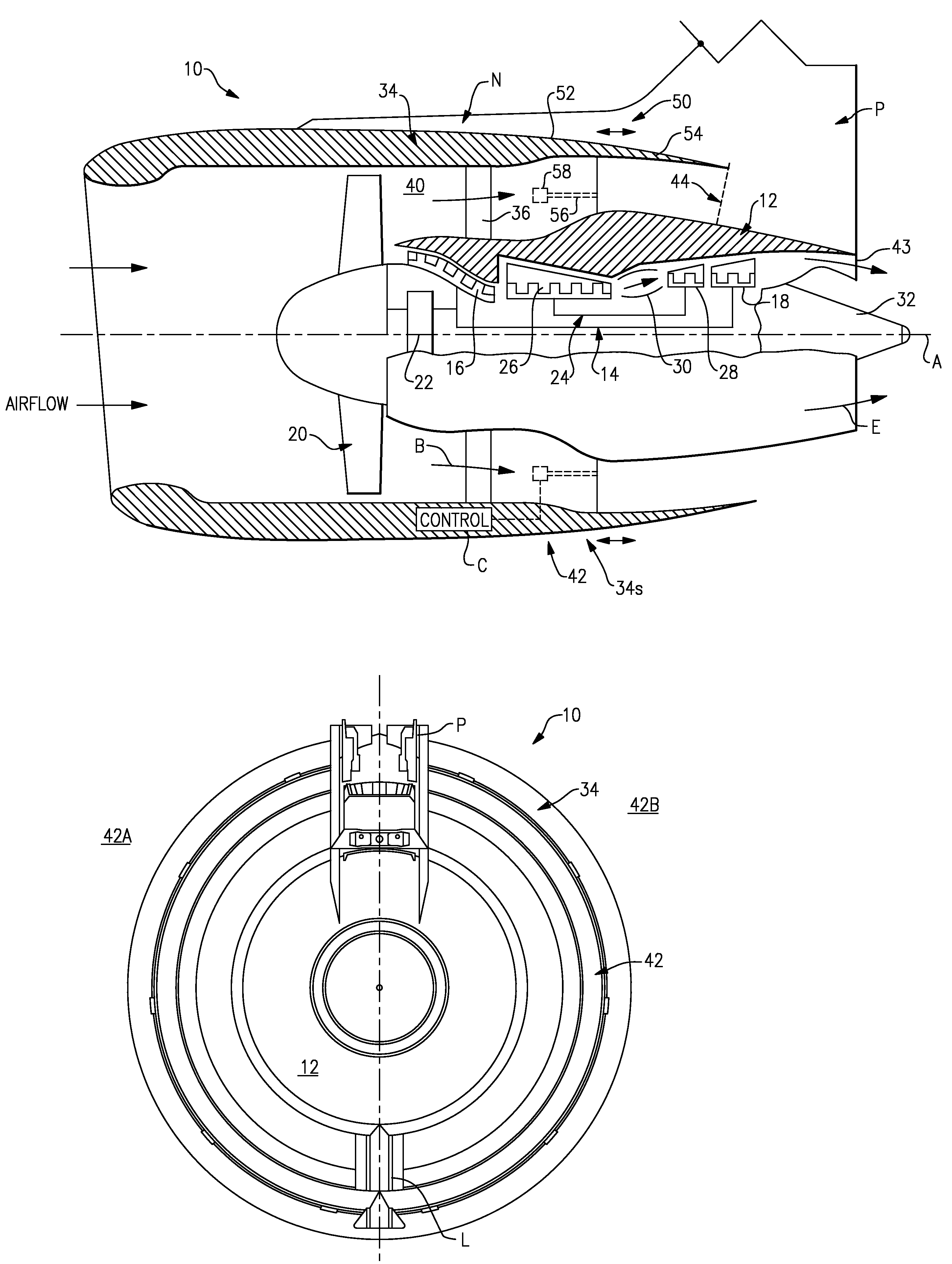

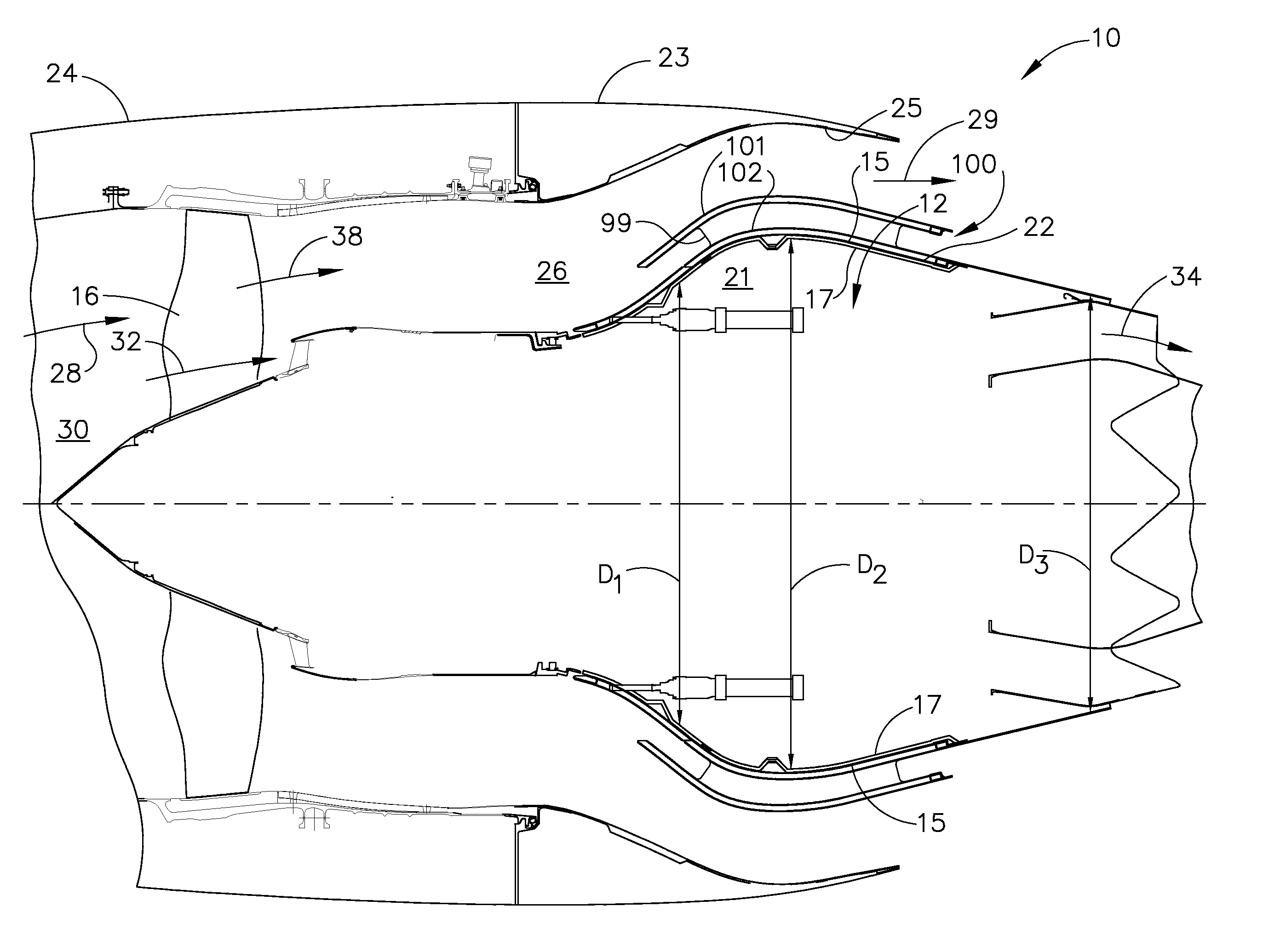

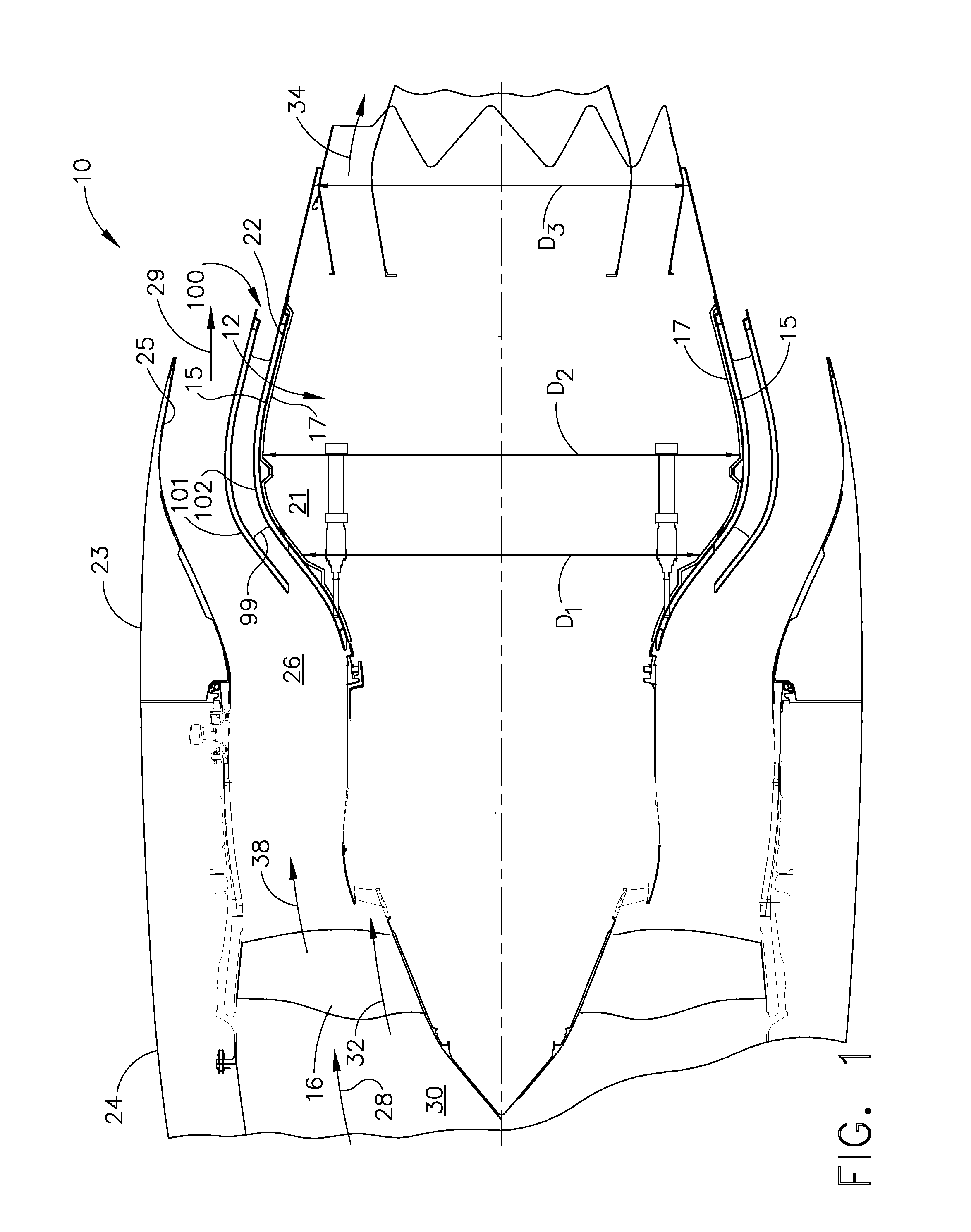

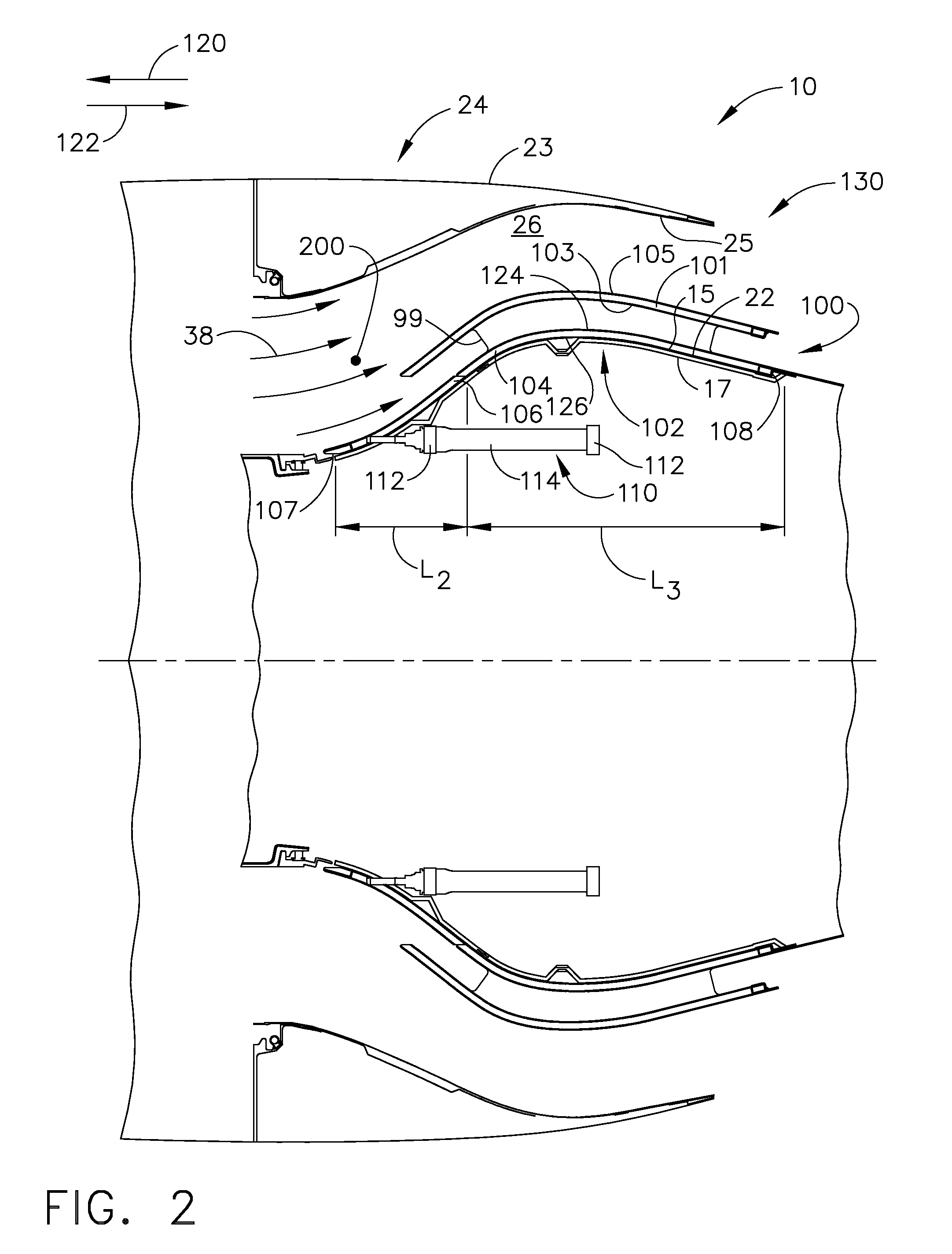

Gas turbine engine with axial movable fan variable area nozzle

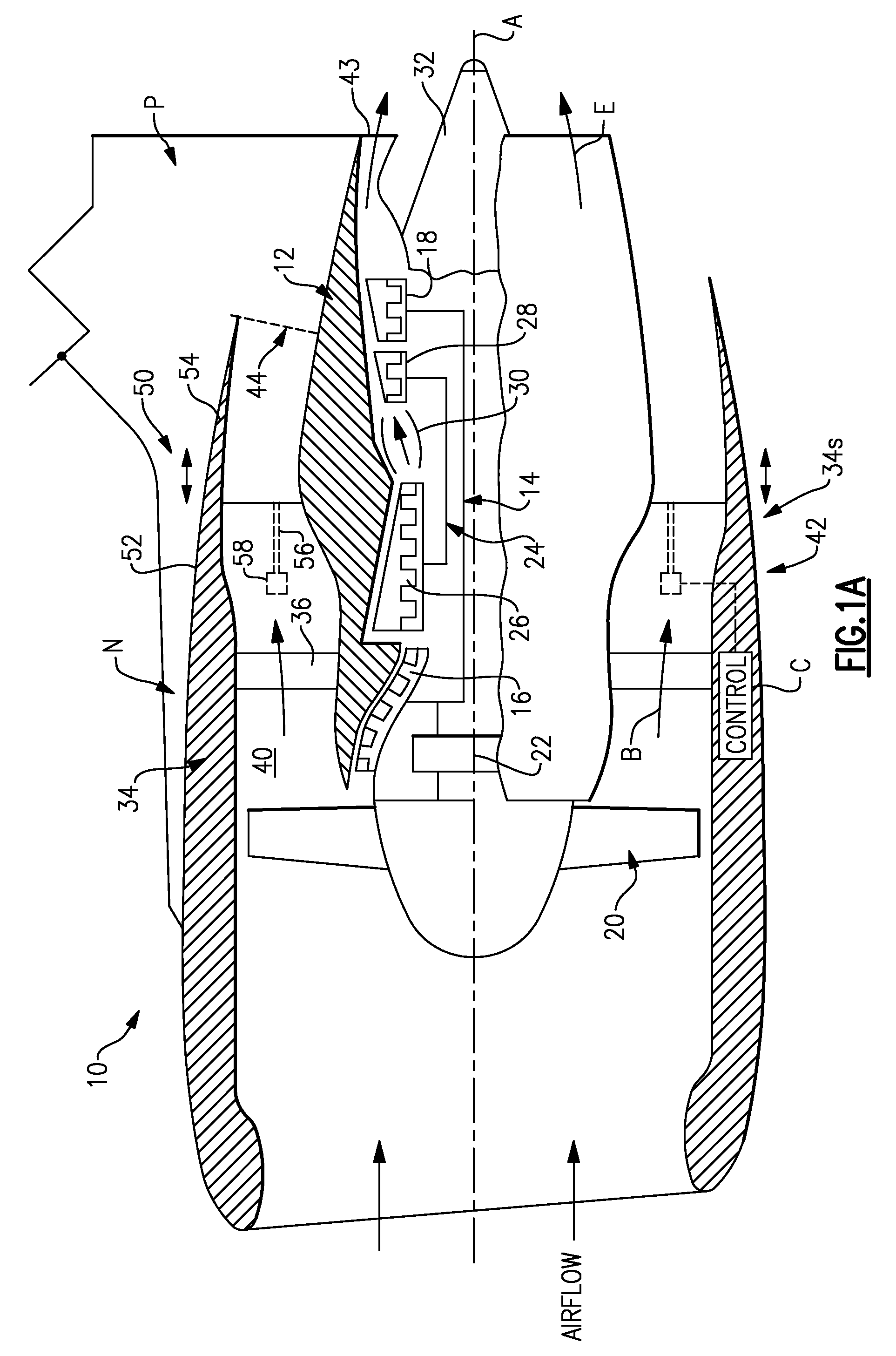

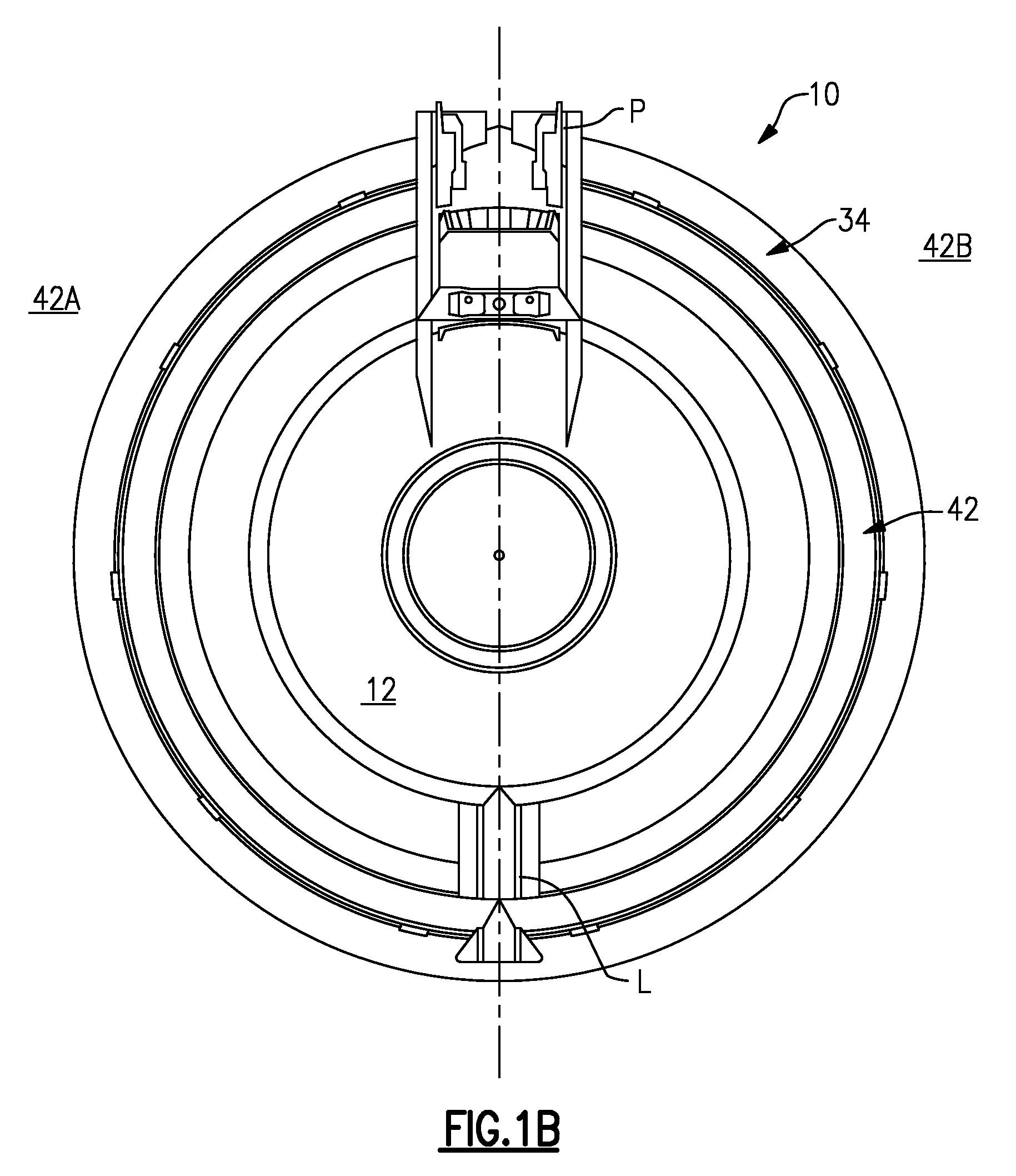

ActiveUS20090053058A1Efficiency sometimes variesEnhanced ground operationPower plant exhaust arrangementsPump componentsNacelleTurbofan

A turbofan engine includes a fan variable area nozzle includes having a first fan nacelle section and a second fan nacelle section movably mounted relative the first fan nacelle section. The second fan nacelle section axially slides aftward relative to the fixed first fan nacelle section to change the effective area of the fan nozzle exit area.

Owner:RTX CORP

Cascade reverser without blocker doors

A translating cowl composed of two sub-structures forms the thrust reverser for a turbofan engine. The two sub-structures form the rear part of a nacelle, are translatable, and have operative and inoperative modes of operation. The operative mode is used for direct or reverse thrust operation of the engine and the inoperative mode is used for access to the engine.

Owner:AERONAUTICAL CONCEPT OF EXHAUST

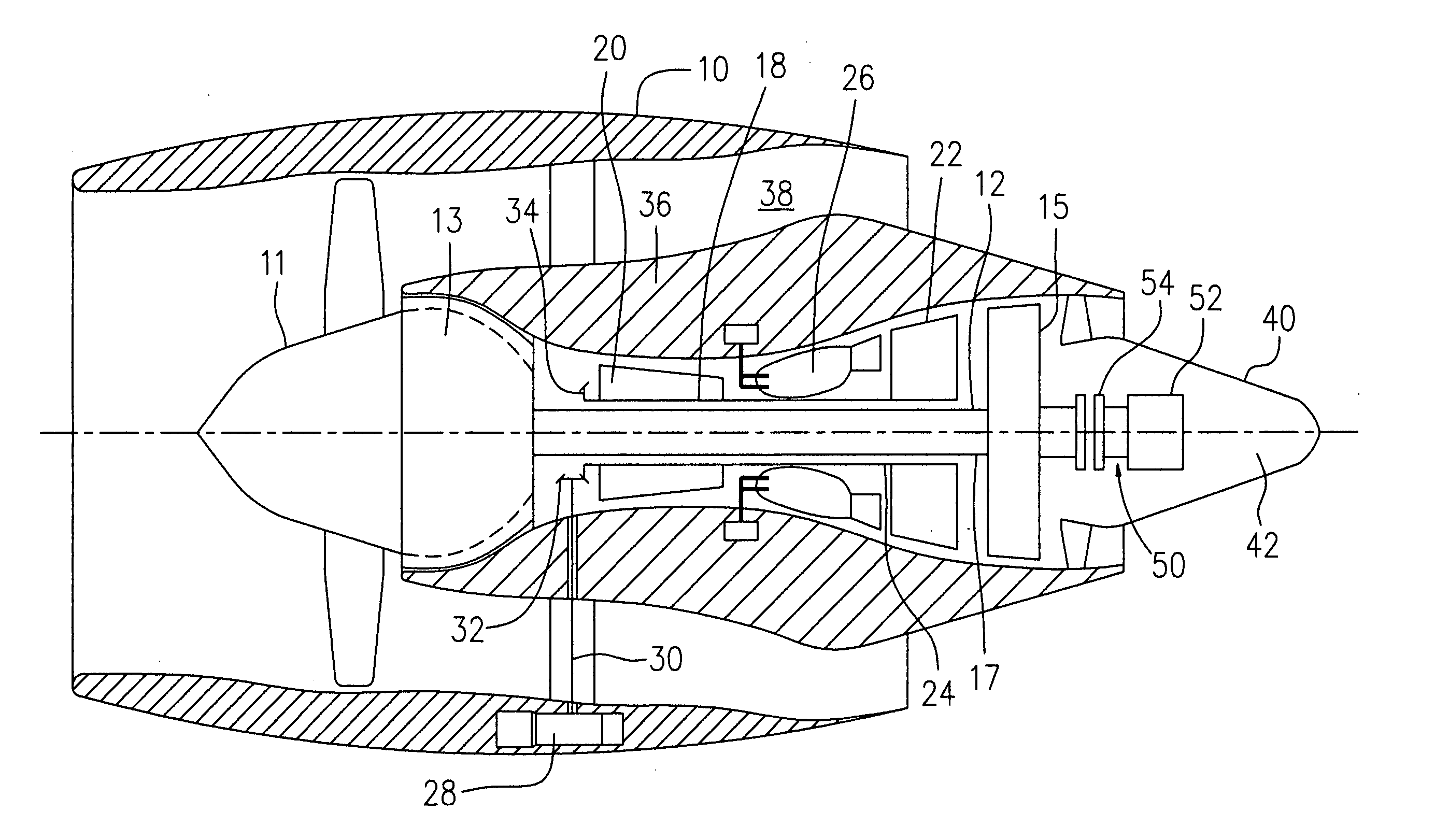

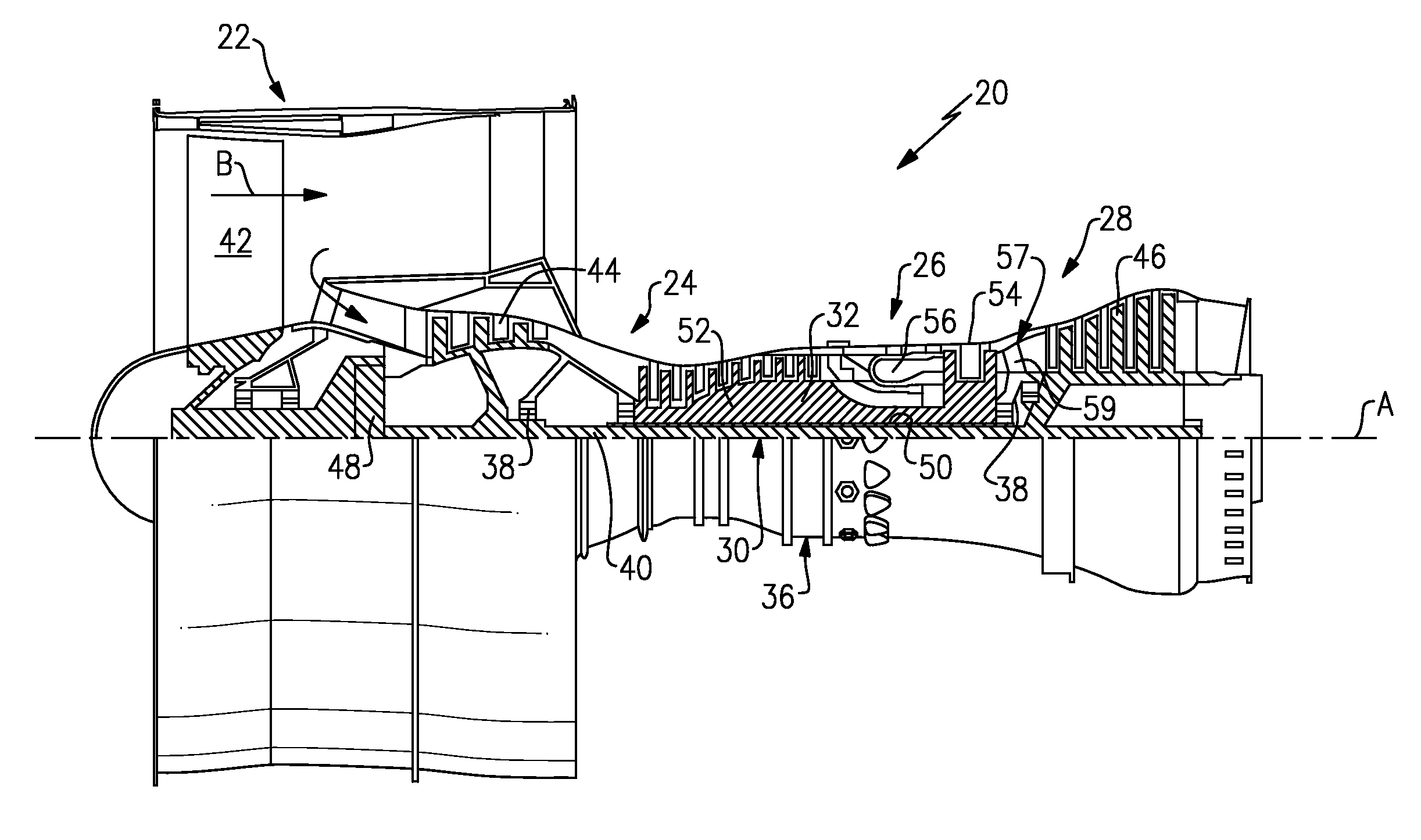

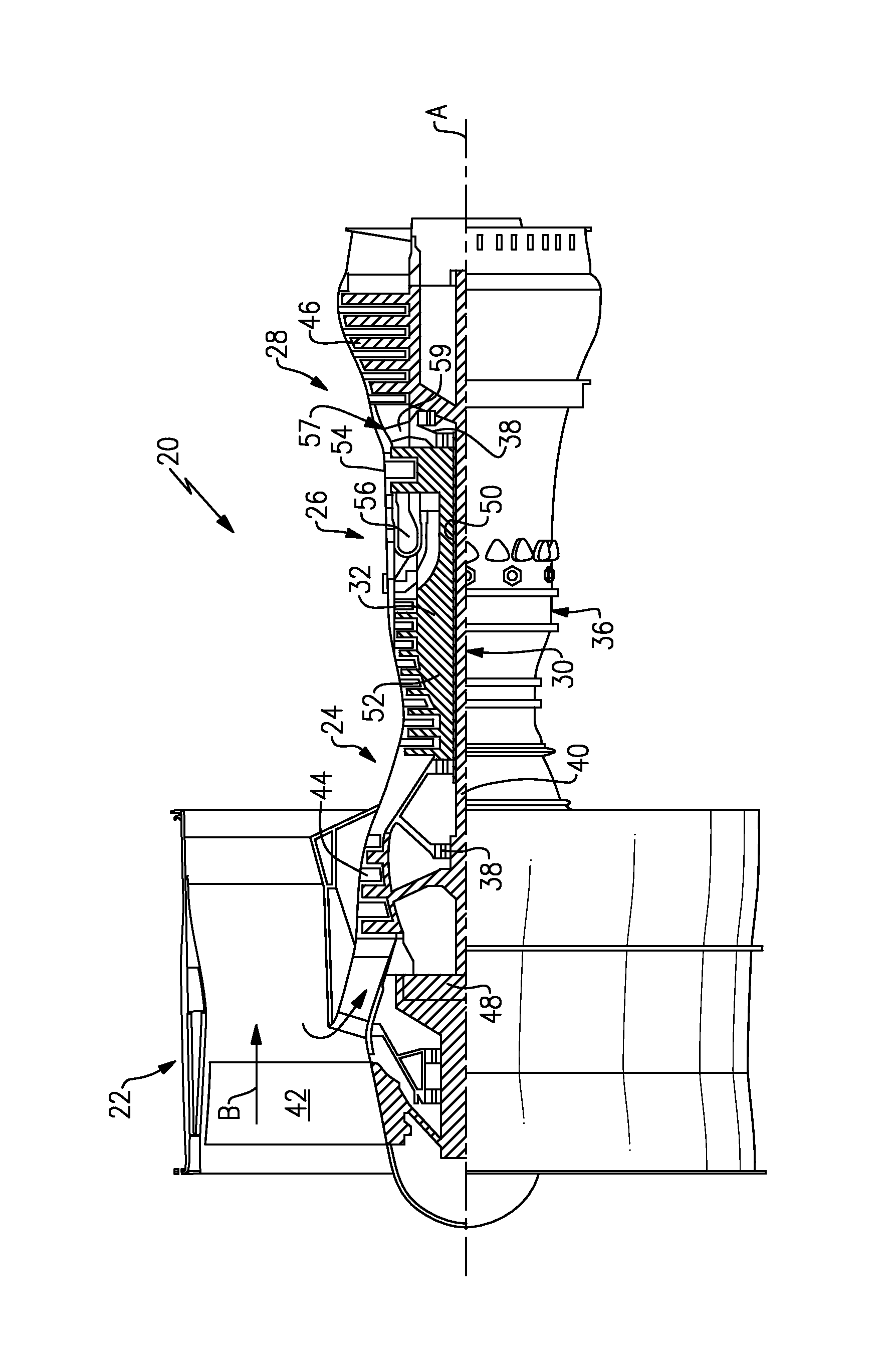

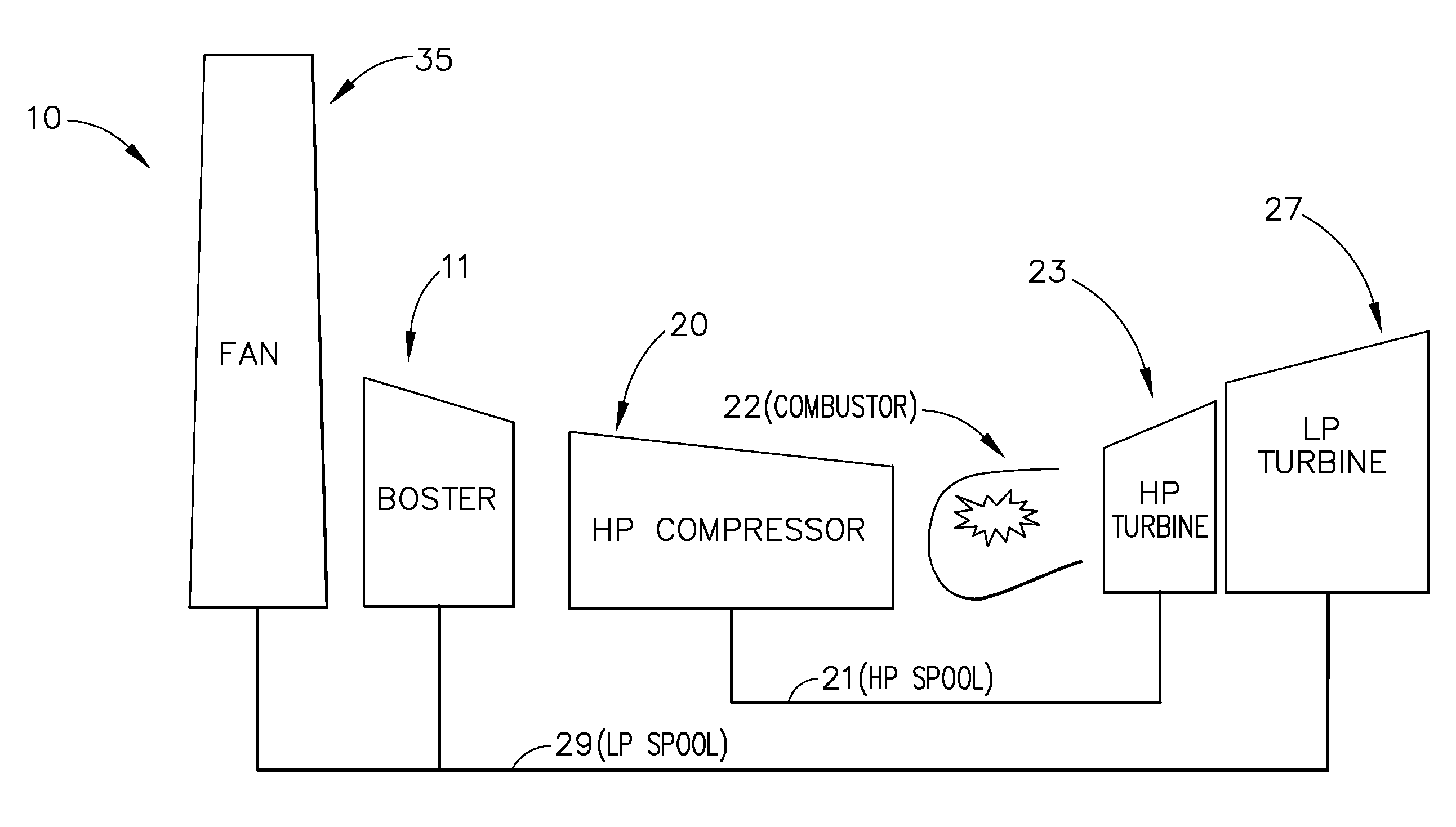

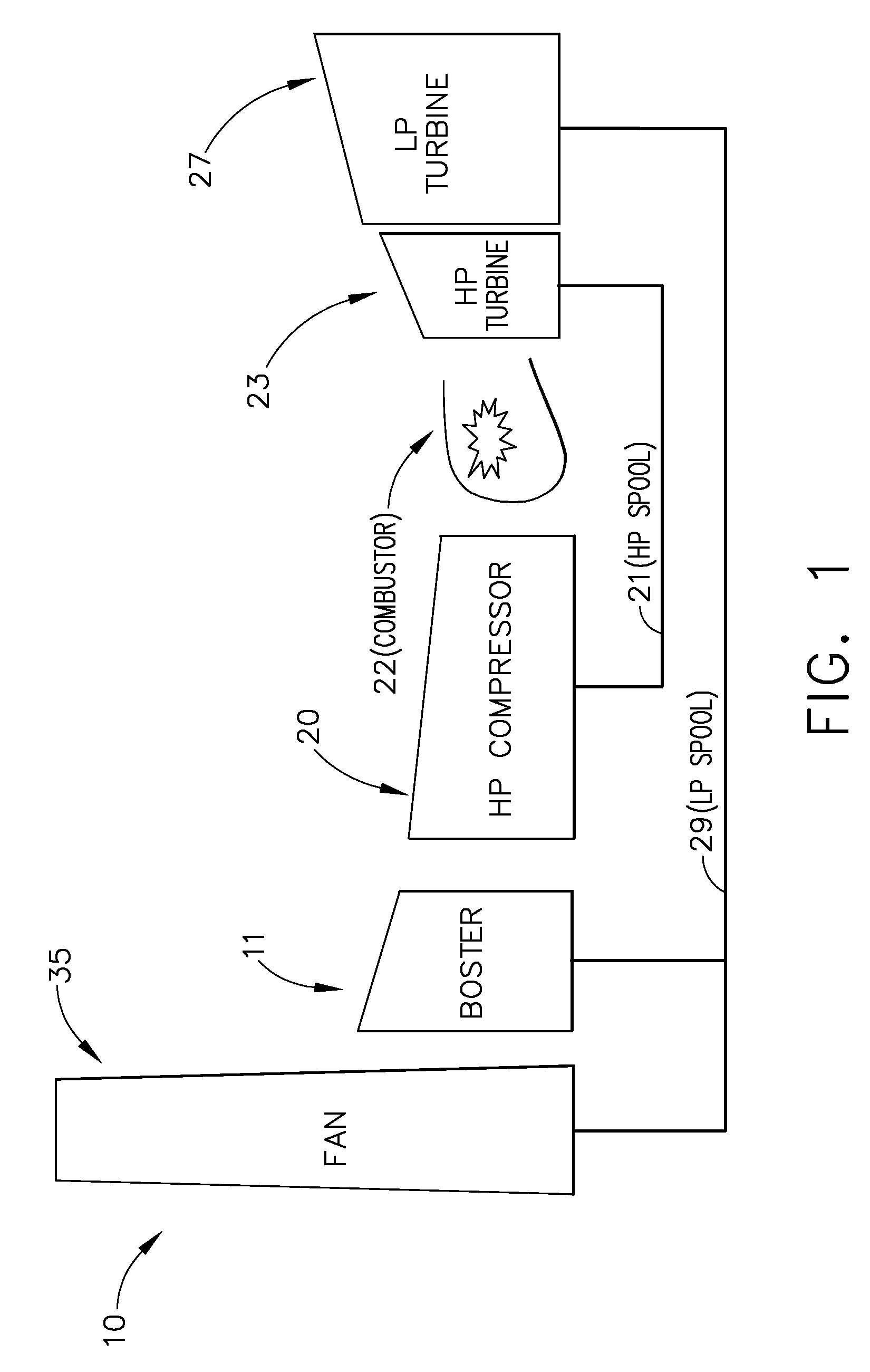

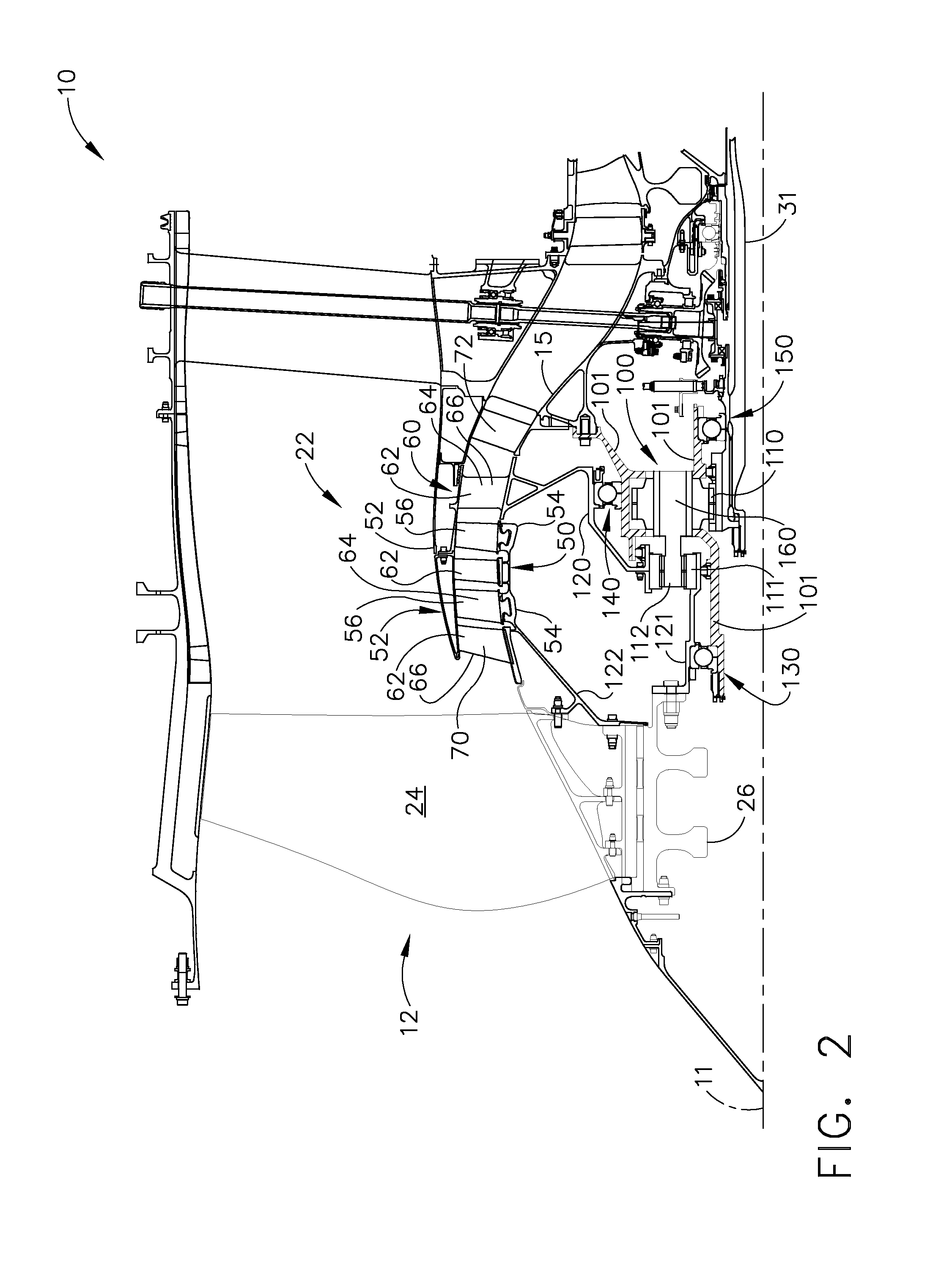

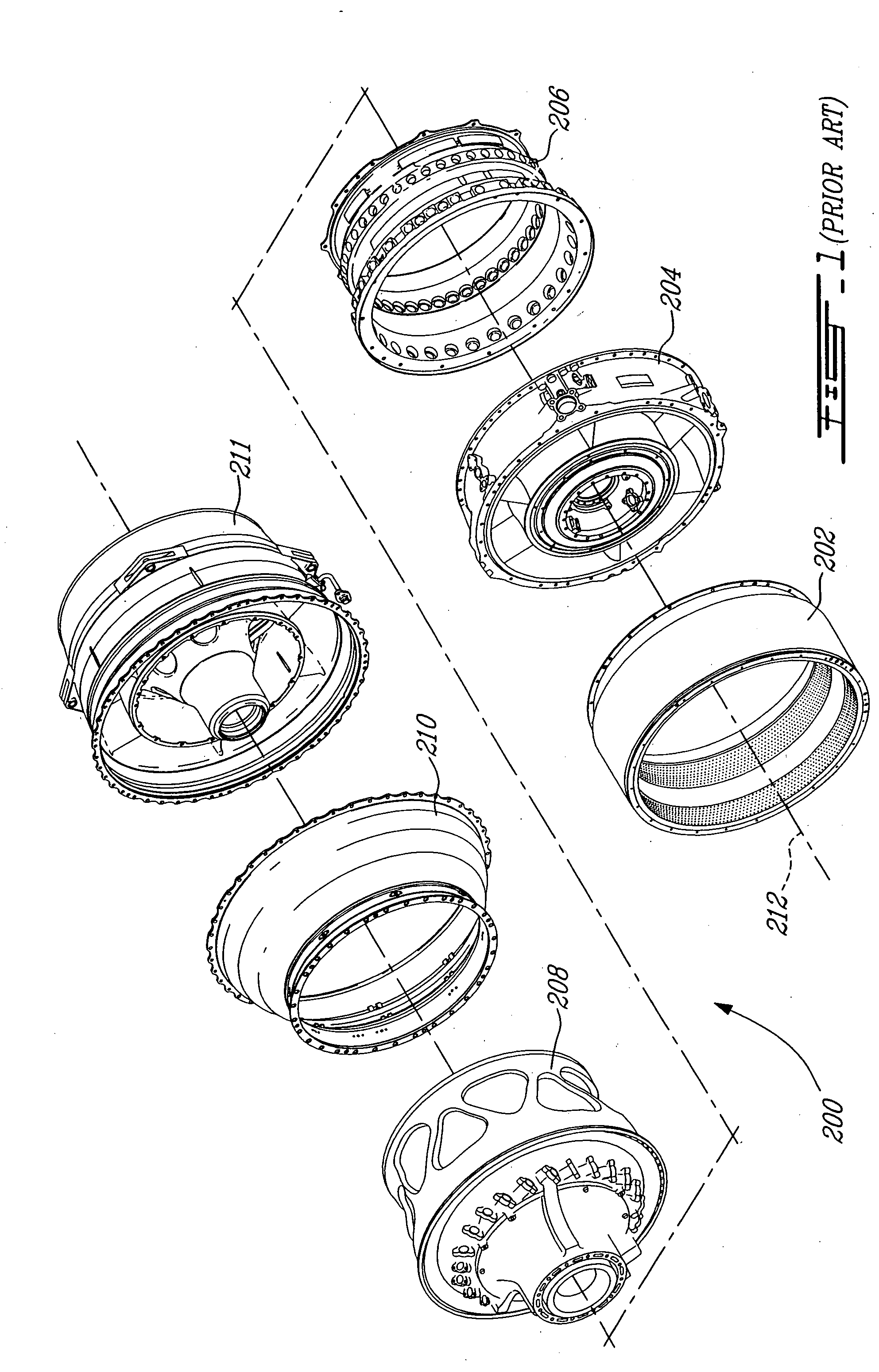

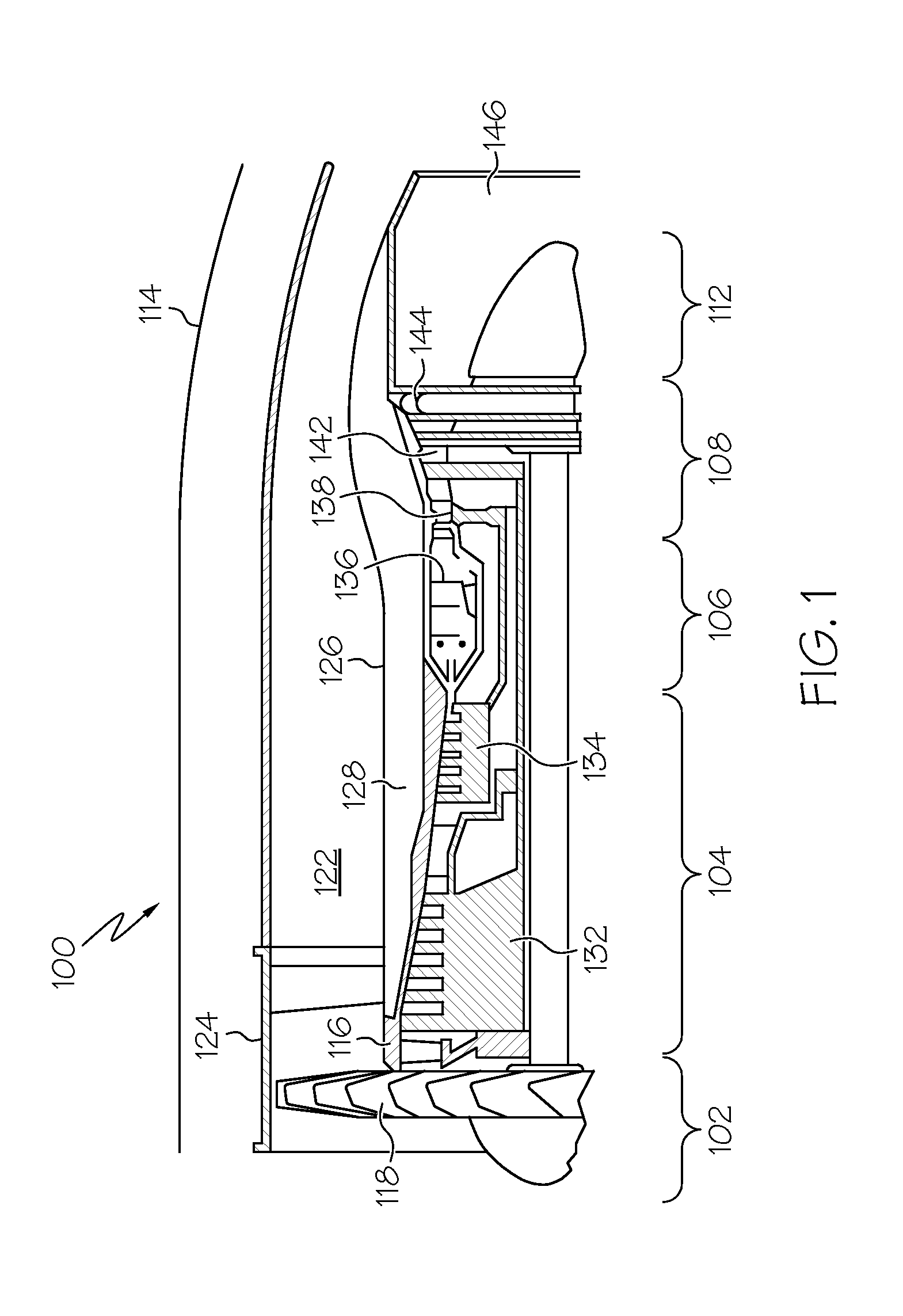

Turbofan engine assembly and method of assembling same

InactiveUS20080120839A1Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustorHigh pressure

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a first fan assembly disposed upstream from the core gas turbine engine, a first gearbox coupled to the first fan assembly, and a second gearbox coupled to a booster compressor such that the booster compressor rotates in a rotational direction that is opposite to the rotational direction of the first fan assembly. A method of assembling the above turbofan engine assembly is also described herein.

Owner:GENERAL ELECTRIC CO

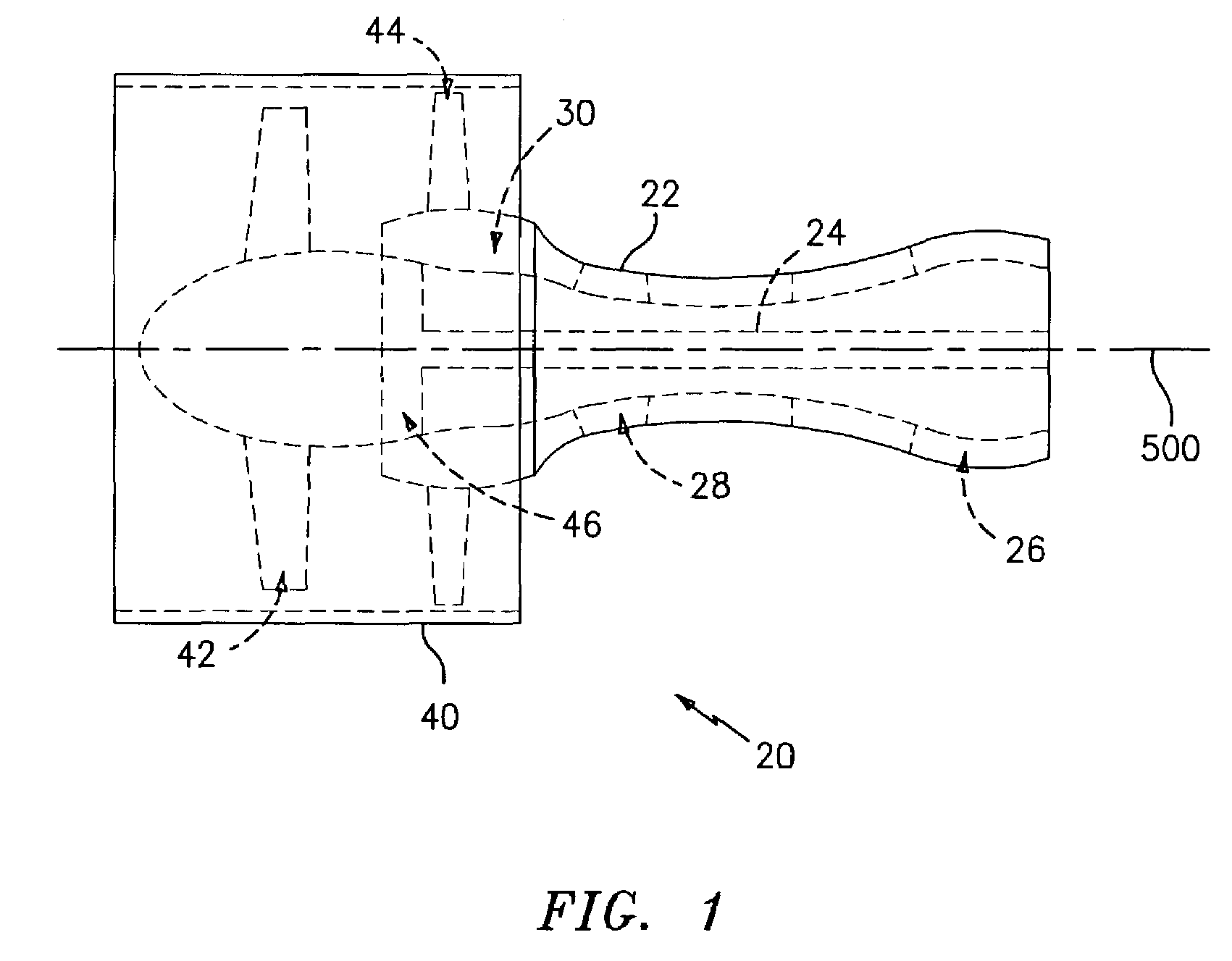

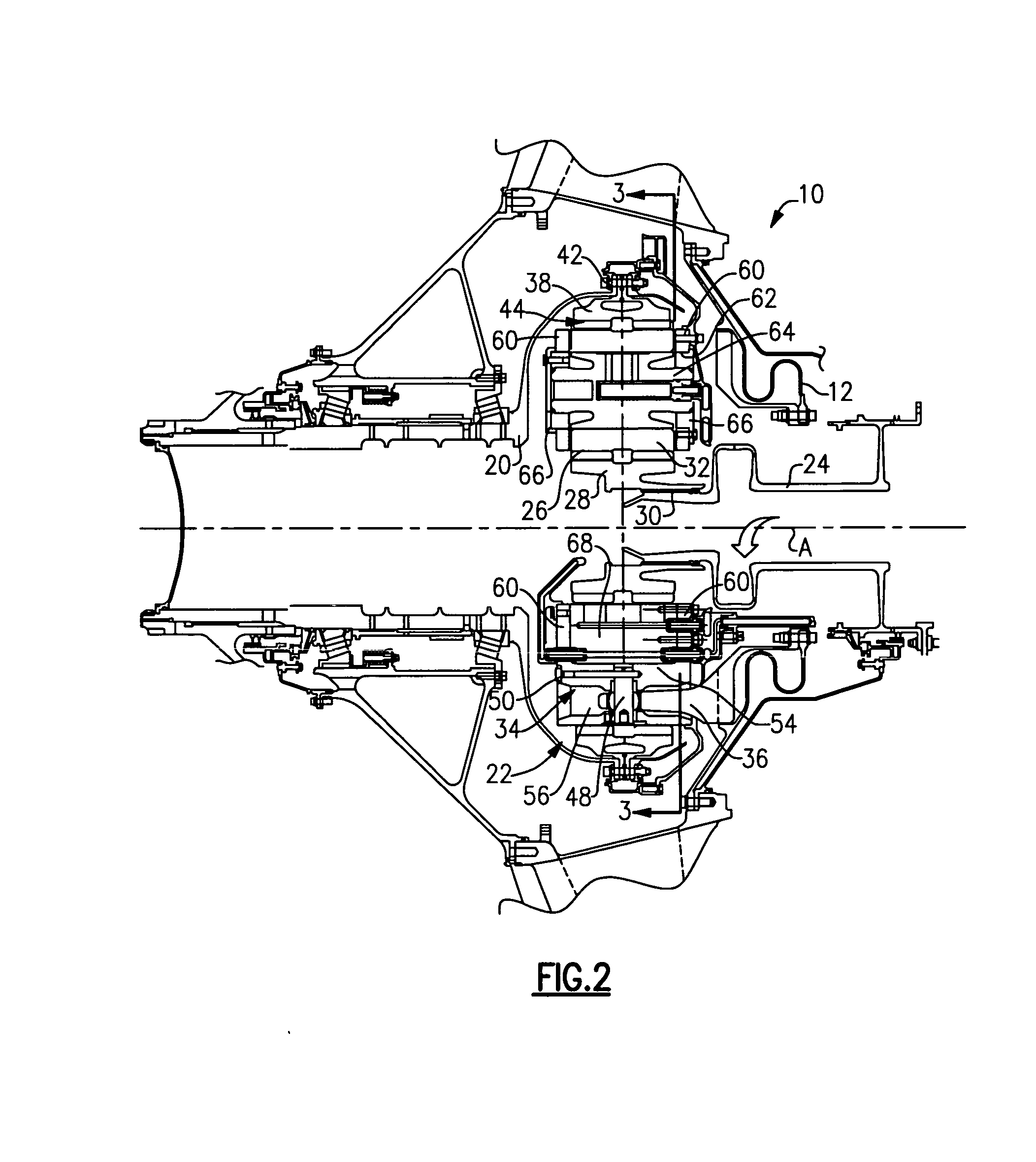

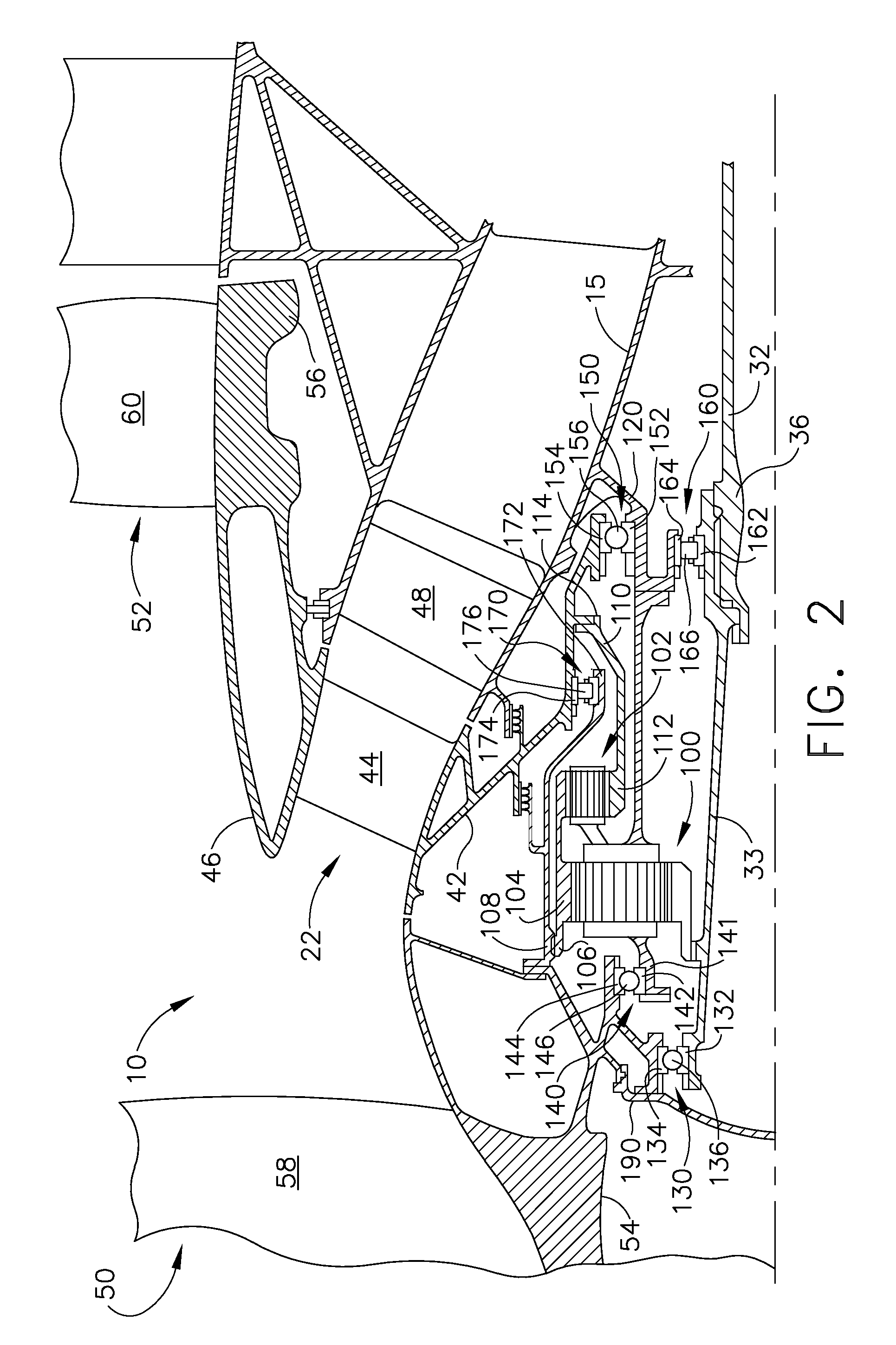

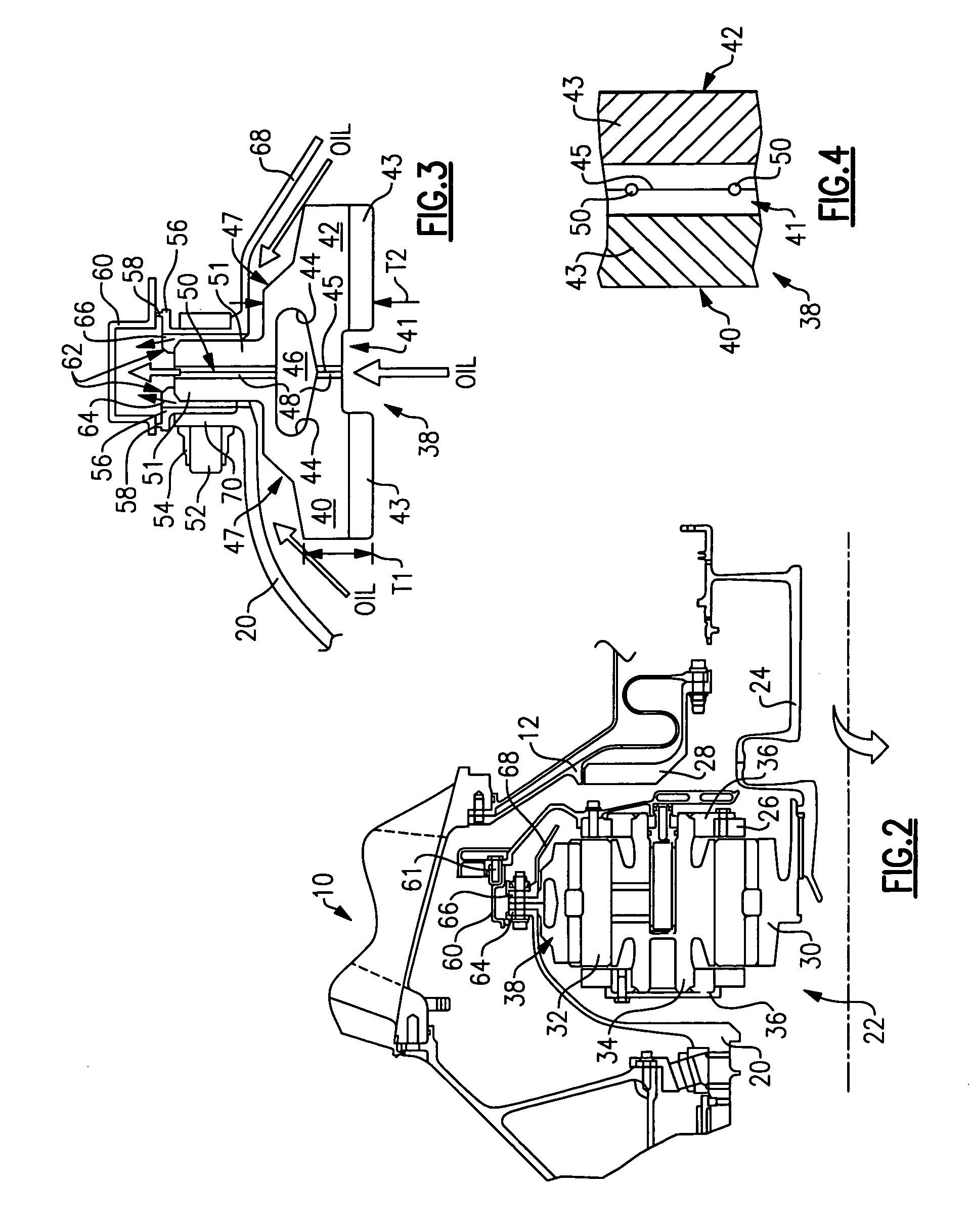

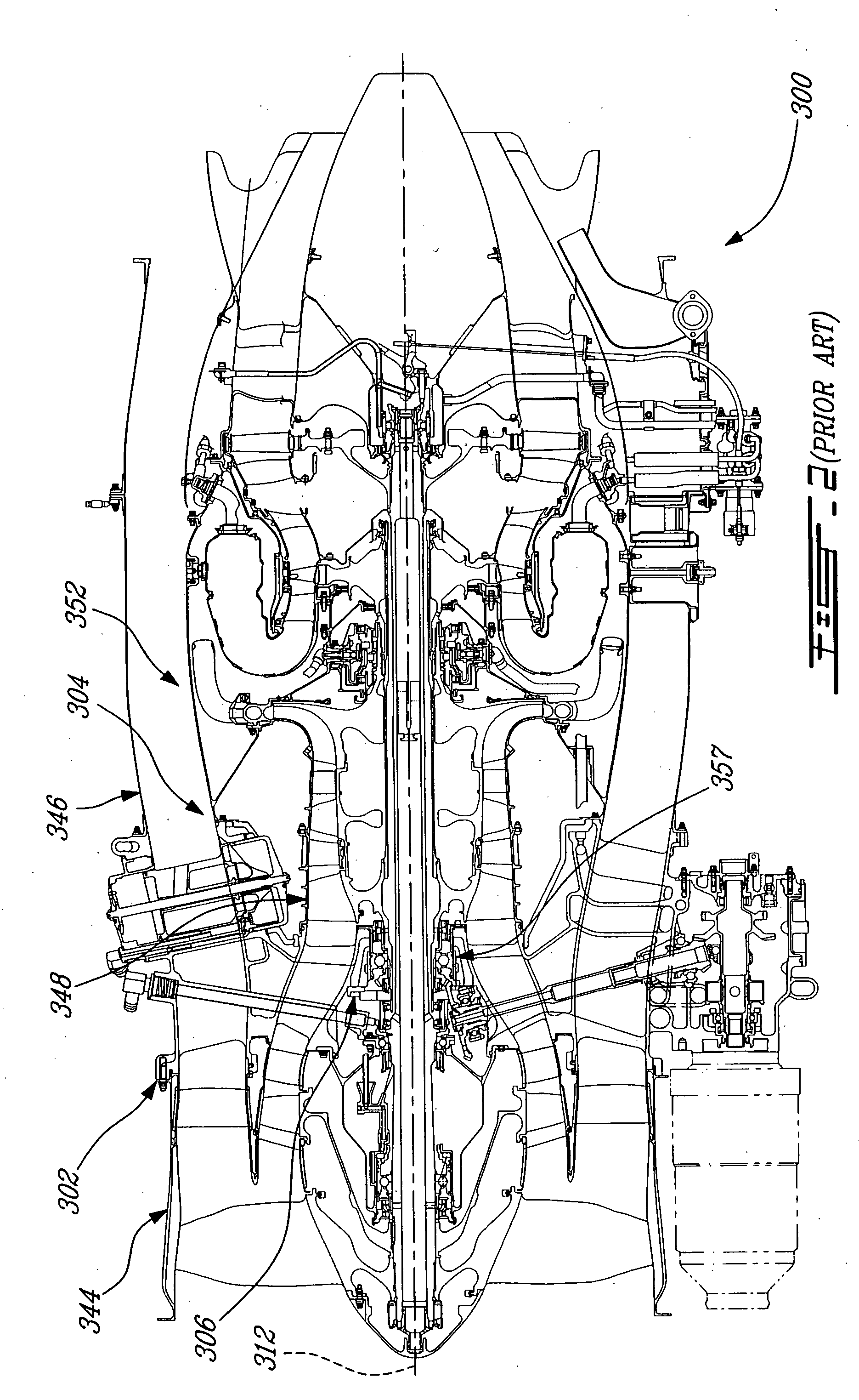

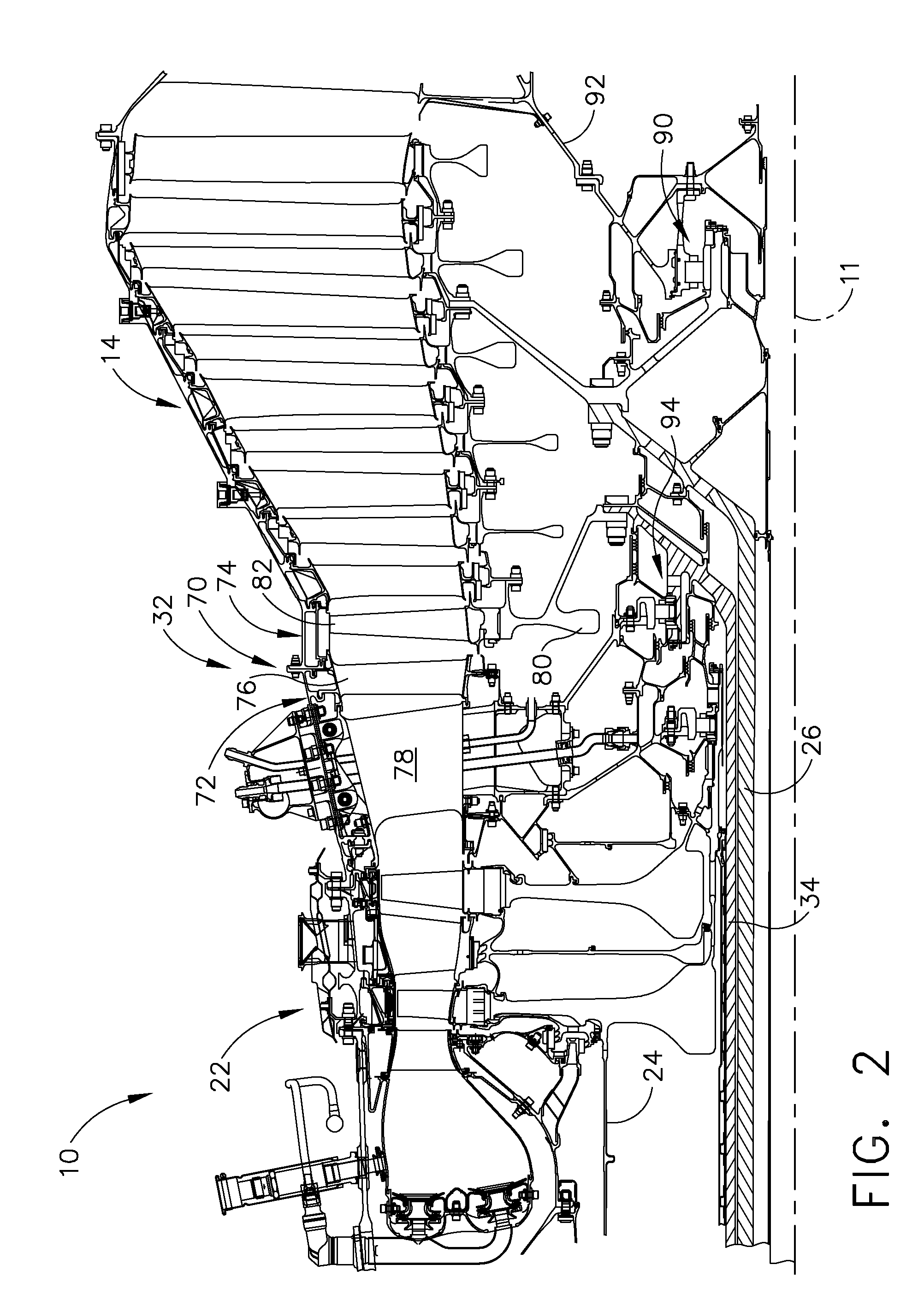

Oil baffle for gas turbine fan drive gear system

A gas turbine engine includes an epicyclic gear train that drives a turbo fan. The epicyclic gear train employs a one-piece carrier in which the spaced side walls are interconnected with circumferentially spaced apart mounts to form a unitary structure. Baffles are secured to the carrier near the mounts and provide lubrication passages that spray oil onto the sun gear and / or intermediate gears arranged between the baffles. The baffles can be constructed from a different material than the carrier since the baffles are not structural components in the gear train.

Owner:RAYTHEON TECH CORP

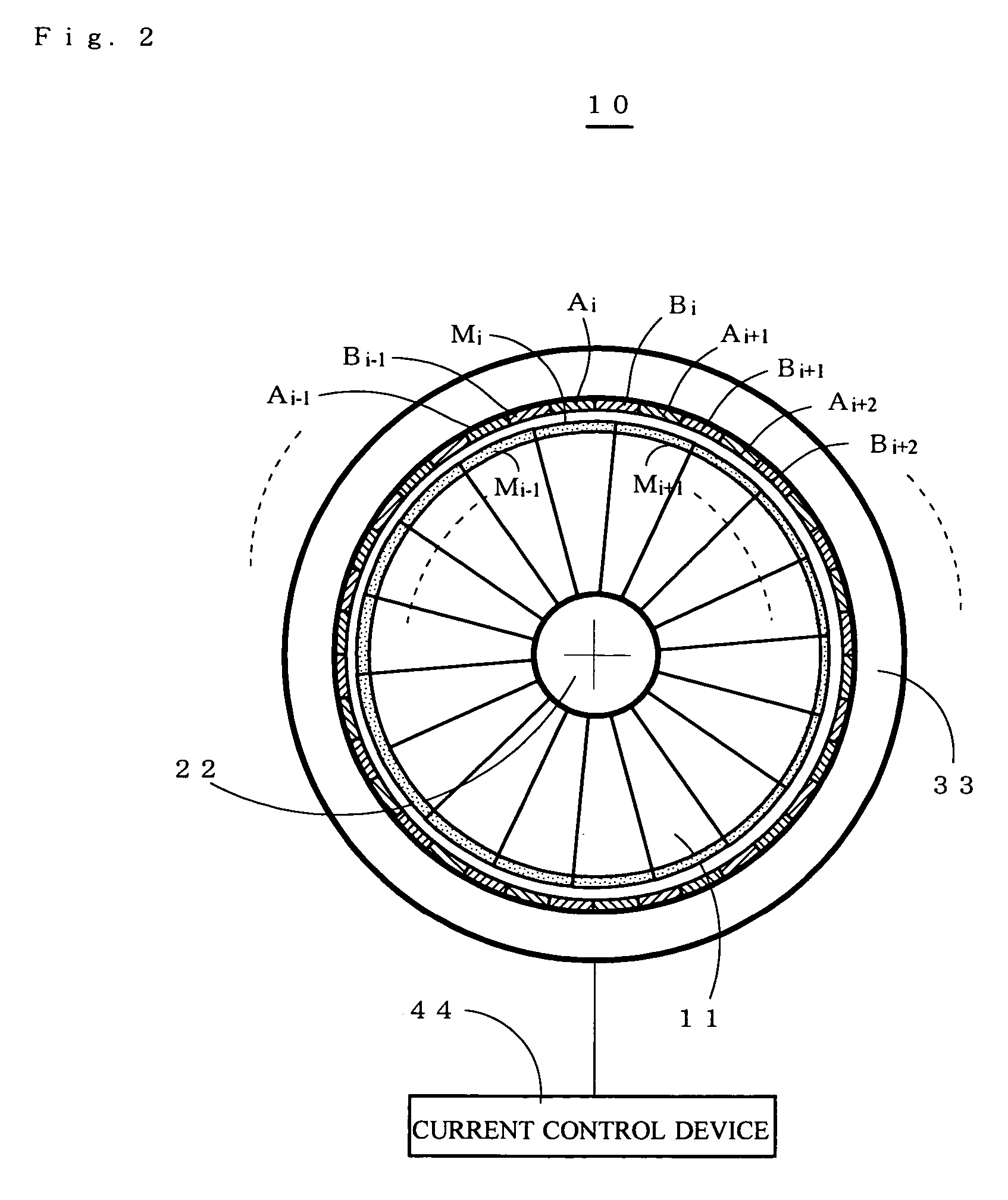

Turbofan engine

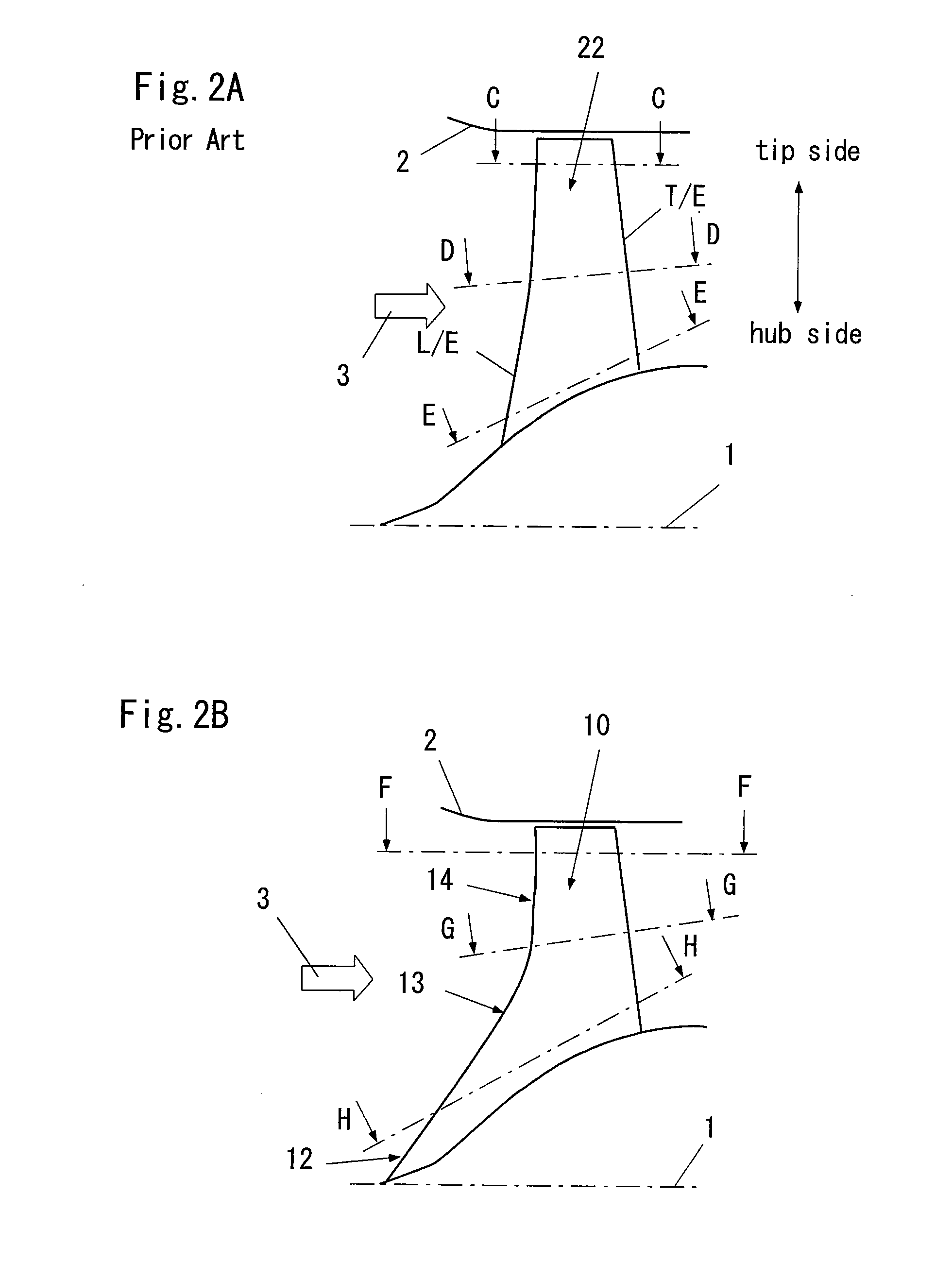

ActiveUS20090304518A1Increase flow rateSame flow rateEngine manufacturePump componentsLeading edgeEngineering

A hub-side leading edge part of a fan first-stage rotating blade 10 for taking an air thereinto more extends in a forward direction of an engine than a tip-side leading edge part and a mid-span leading edge part. The hub side of the fan first-stage rotating blade 10 is integrally connected as one with the tip side and the mid span while having a longer chord length than those of the tip side and the mid span. A radius at a root of the hub-side leading edge part is set in a boss ratio of 0 to 0.4.

Owner:IHI CORP

Turbofan engine assembly and method of assembling same

InactiveUS7882693B2Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustorHigh pressure

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a first fan assembly disposed upstream from the core gas turbine engine, a first gearbox coupled to the first fan assembly, and a second gearbox coupled to a booster compressor such that the booster compressor rotates in a rotational direction that is opposite to the rotational direction of the first fan assembly. A method of assembling the above turbofan engine assembly is also described herein.

Owner:GENERAL ELECTRIC CO

Low noise turbine for geared turbofan engine

A gas turbine engine is utilized in combination with a gear reduction to reduce the speed of a fan relative to a low pressure turbine speed. The gas turbine engine is designed such that a blade count in the low pressure turbine multiplied by the speed of the low pressure turbine will result in operational noise that is above a sensitive range for human hearing. A method and turbine module are also disclosed.

Owner:MTU AERO ENGINES GMBH +1

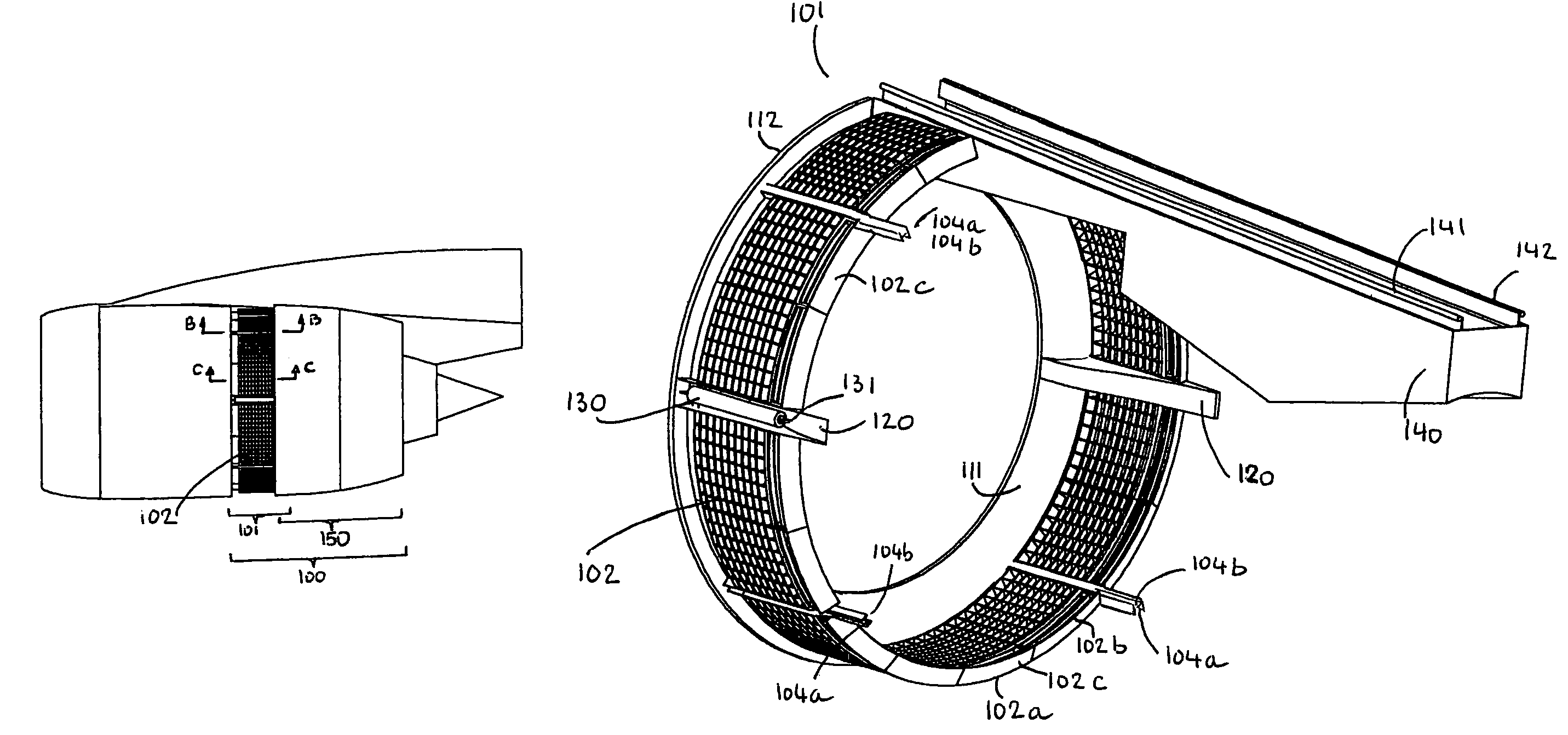

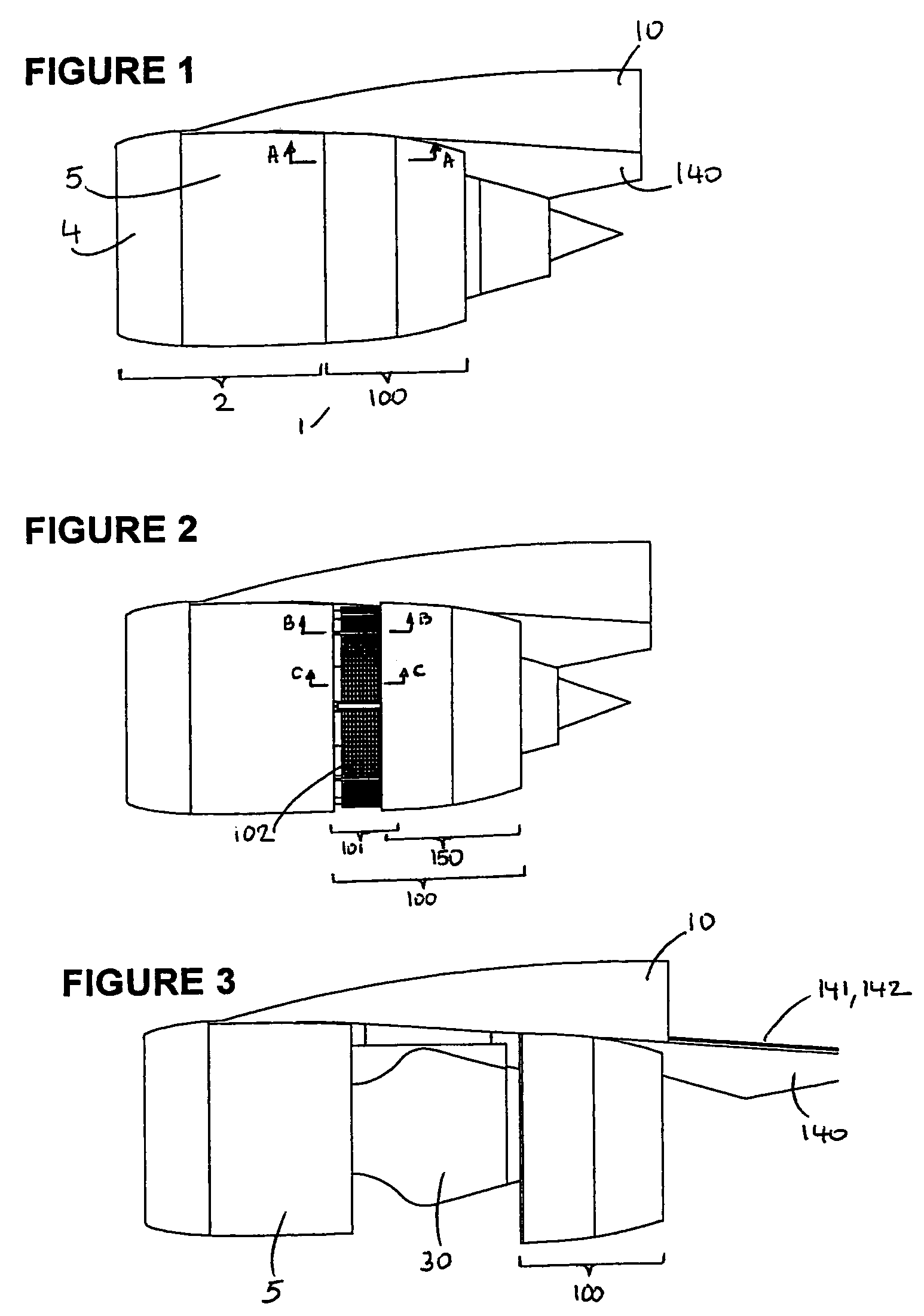

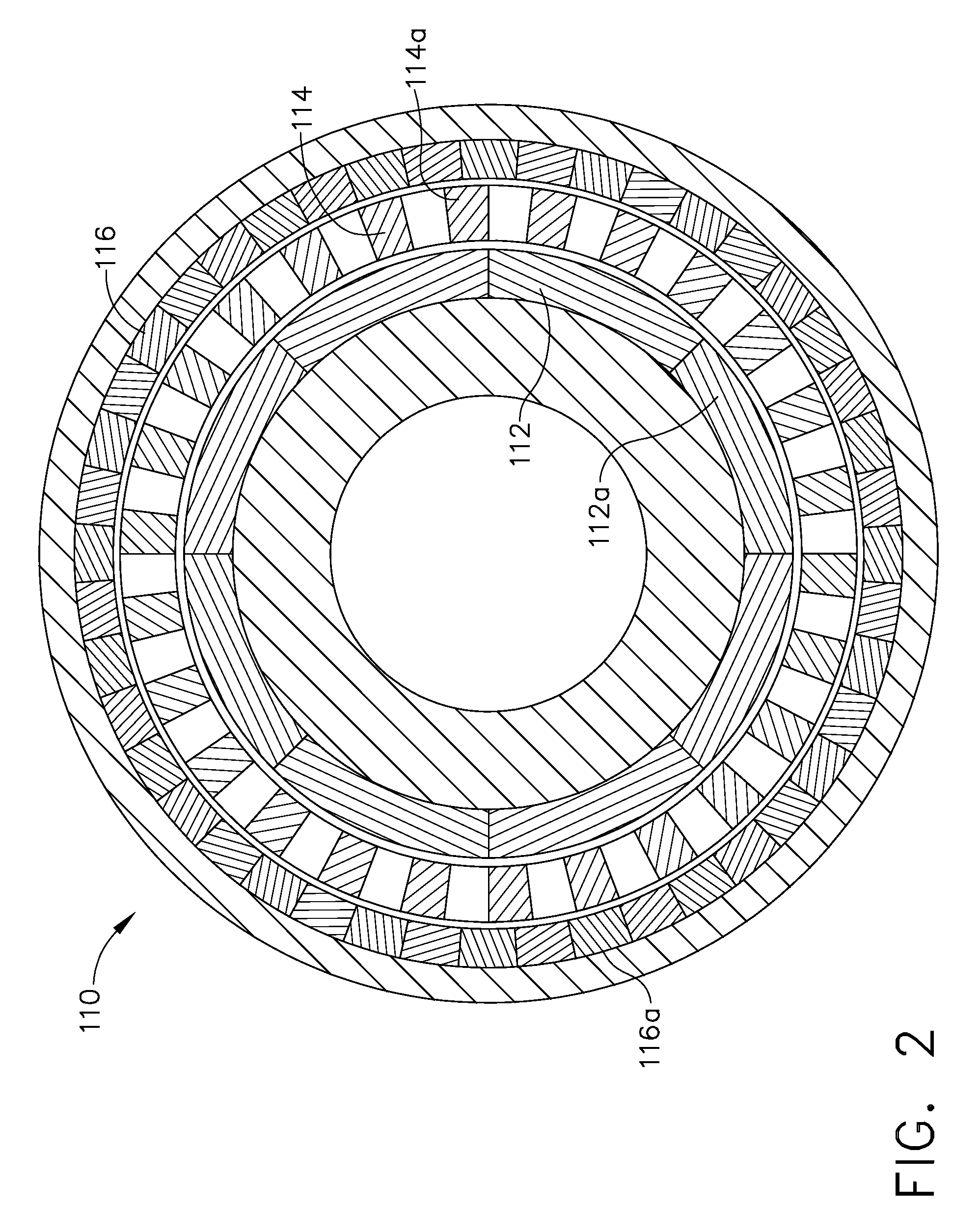

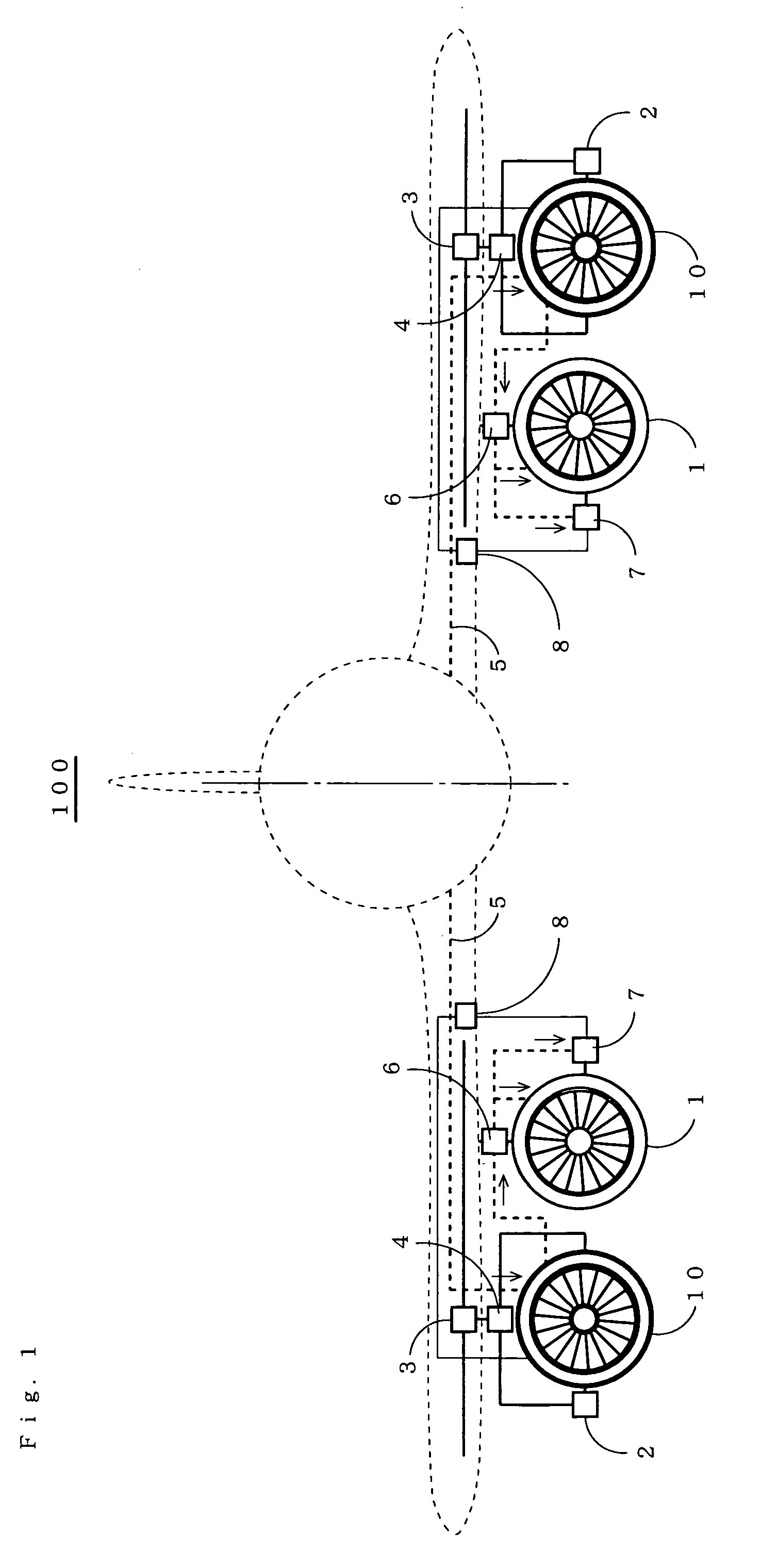

Variable Magnetic Coupling of Rotating Machinery

ActiveUS20080149445A1Reduce vibration transmissionMechanical actuated clutchesEngine fuctionsCouplingEngineering

A system for transferring torque between a pair of independently, concurrently rotating shafts of a turbofan engine includes a magnetic gearbox. The magnetic gearbox has a first ring structure, a second ring structure and an intermediate ring structure. Each ring structure has an annular aperture therethrough and a plurality of permanent magnets embedded therein. The intermediate ring structure is disposed between the first and the second ring structures. Each ring structure is coaxially concentric with, and independently rotatable with respect to the remaining ring structures. The first and second ring structures are each coupled to separate ones of the rotating engine shafts, and the intermediate ring is operable to transfer torque between the pair of shafts. Preferably, the intermediate ring structure is coupled to a rotating machine. The rotating machine has a controller, and is operable for adjusting a ratio of torque transferred between the pair of shafts.

Owner:GENERAL ELECTRIC CO

Ring gear mounting arrangement with oil scavenge scheme

ActiveUS20080044276A1Reliably rotationally balancedDesired stiffness and resistance to overturning momentsEngine fuctionsBlade accessoriesEngineeringGear train

A turbine engine includes an epicyclic gear train that has a two-piece ring gear. Each portion of the ring gear includes radially outwardly extending flanges that are axially constrained to a turbo fan shaft by bolts secured circumferentially along the flanges. Knife edge seals are secured to the flanges to contain oil expelled through the ring gear into a gutter. The ring gear and turbo fan shaft can be rotationally balanced together.

Owner:RAYTHEON TECH CORP

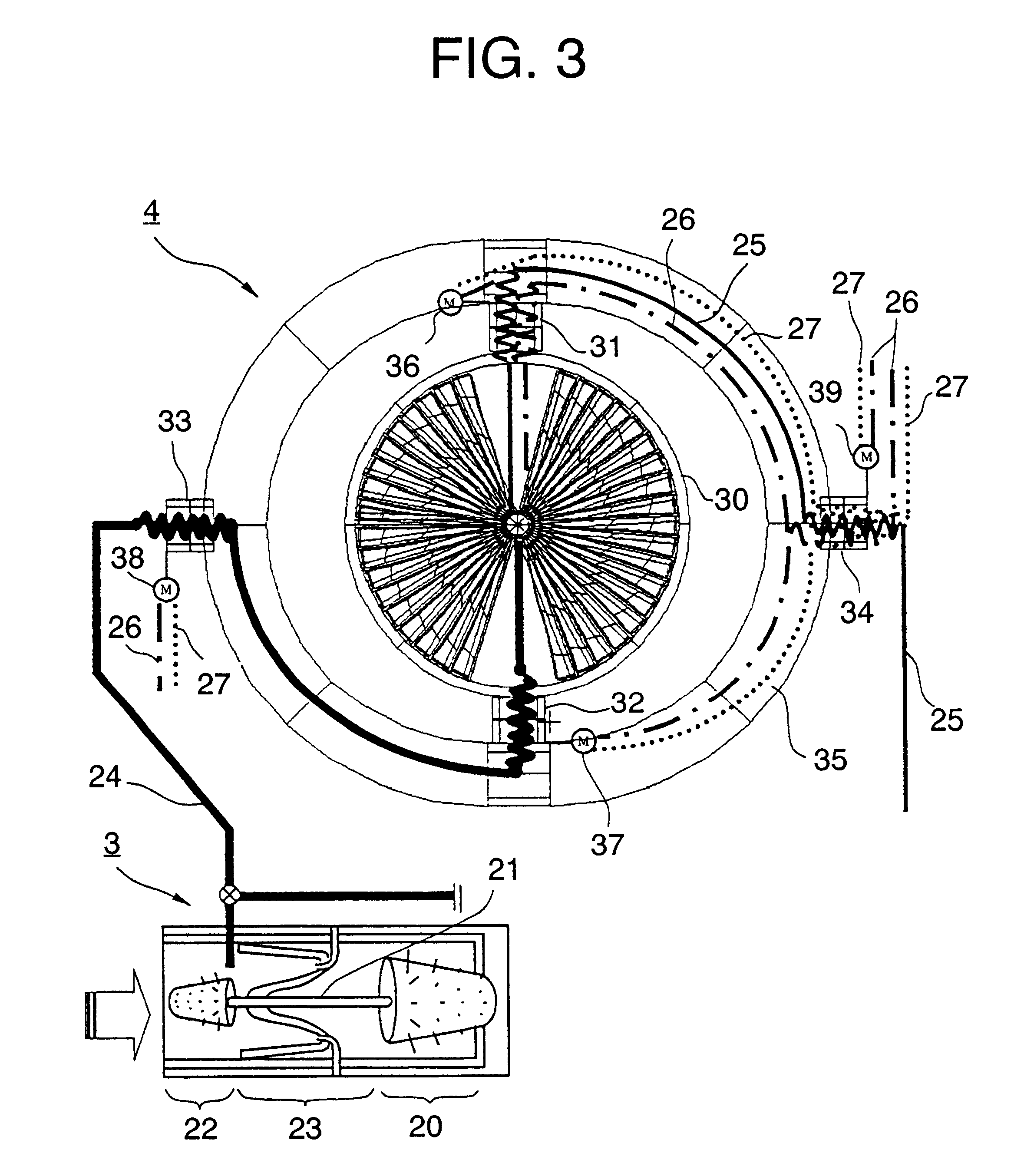

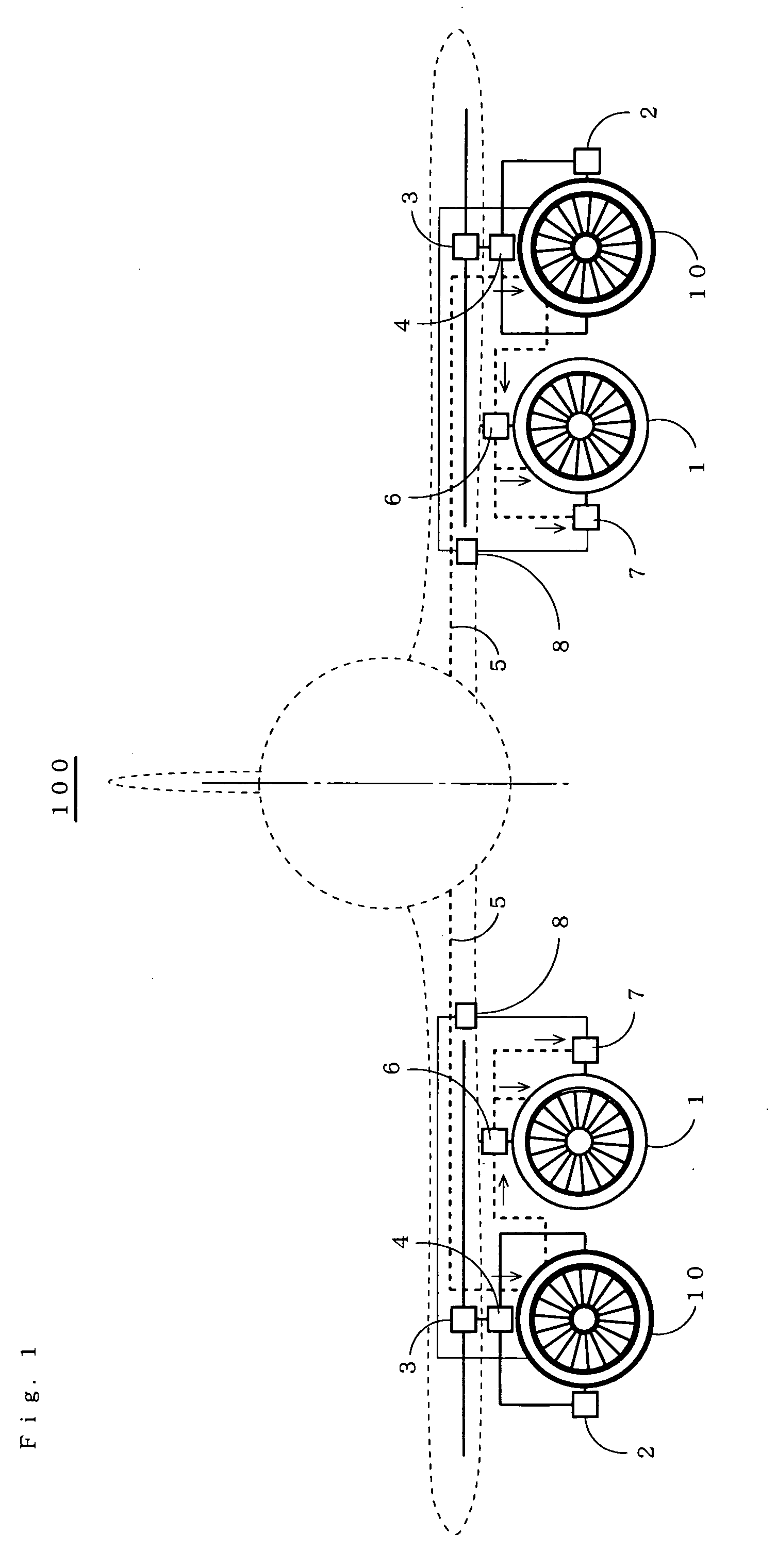

Aircraft propulsion system

InactiveUS20060254255A1Highly compatible with environmentSynchronous generatorsMagnetic circuitCombustion chamberLiquid hydrogen

To provide an aircraft propulsion system which can secure the optimum thrust and thrust vector for flight conditions, as well as the optimum sectional area for the engine, and which is highly compatible with the environment. An electrical generator is coupled to a turbofan engine, the electrical generator is driven by output power of the turbofan engine to output electric power, and an electromagnetic driving fan is driven by the electric power. On the other hand, after bringing each of coils in the electromagnetic driving fan to a superconductive state, liquid hydrogen is introduced to a heat exchanger, collects the energy of exhaust as heat, is then vaporized, and thereafter supplied to a combustor and to a fuel cell. Further, the electromagnetic driving fan is changed in its rotational phase by a rotating mechanism portion, is made movable in a width direction of a wing and a wing chord direction by a slide mechanism portion, and can be stored inside or outside the wing by a storage mechanism portion.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

Turbofan engine assembly and method of assembling same

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a low-pressure turbine coupled to said core gas turbine engine, a counter-rotating booster compressor comprising a first rotor section configured to rotate in a first direction and a second rotor section configured to rotate in an opposite second direction, and a gearbox comprising an input and an output, said gearbox output coupled to at least one of said first and second rotor sections, said gearbox input coupled to said low-pressure turbine. A method of assembling the turbofan engine assembly described herein is also provided.

Owner:GENERAL ELECTRIC CO

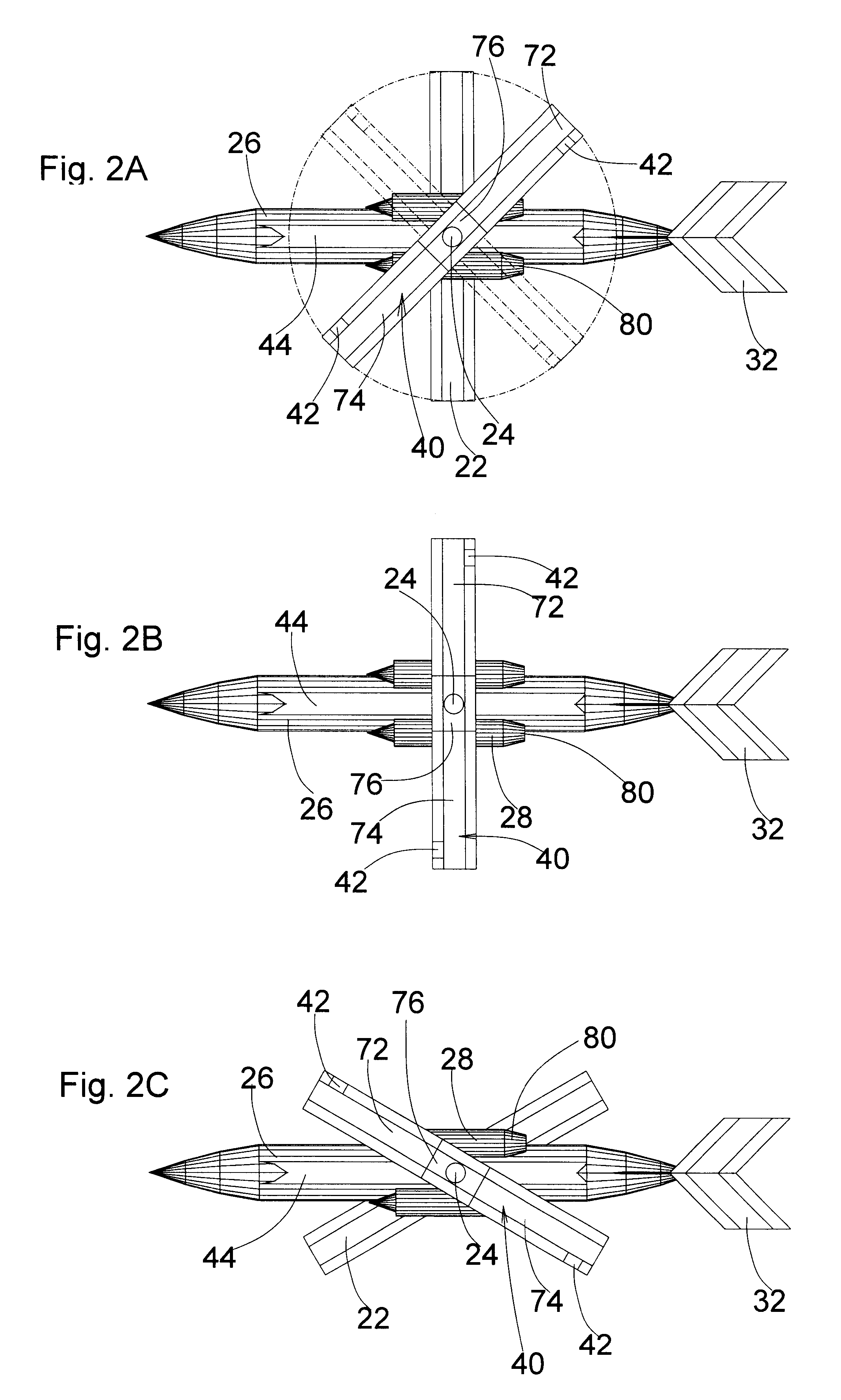

Air vehicle having rotor/scissors wing

InactiveUS6669137B1Easy to convertEfficiently and effectively flyJet type power plantsEfficient propulsion technologiesLow speedReverse order

An air vehicle, such as a manned or unmanned air vehicle, has a fuselage, a rotor / scissors wing, and a scissors wing. At helicopter mode, the rotor / scissors wing rotates to make the air vehicle fly like a helicopter to achieve vertical and / or short take-off and landing, hovering, and low speed flying. At airplane mode, the rotor / scissors wing and scissors wing form a scissors wings configuration to maximize the air vehicle's flying efficiency at a wide range of speed and flying conditions by adjusting the yaw angle of the rotor / scissors wing and scissors wing. During the conversion from helicopter mode to airplane mode, the scissors wing generates lift to offload the rotating rotor / scissors wing and eventually the offloaded rotor / scissors wing's rotating speed is slowed and stopped so that the rotor / scissors wing can be locked at a specific position and the conversion can be achieved. In a reverse order, the air vehicle can convert from airplane mode to helicopter mode. Either turbofan or turbojet engine, or turboshaft / turbofan convertible engine can be used to power the air vehicle.

Owner:CHEN ZHUO

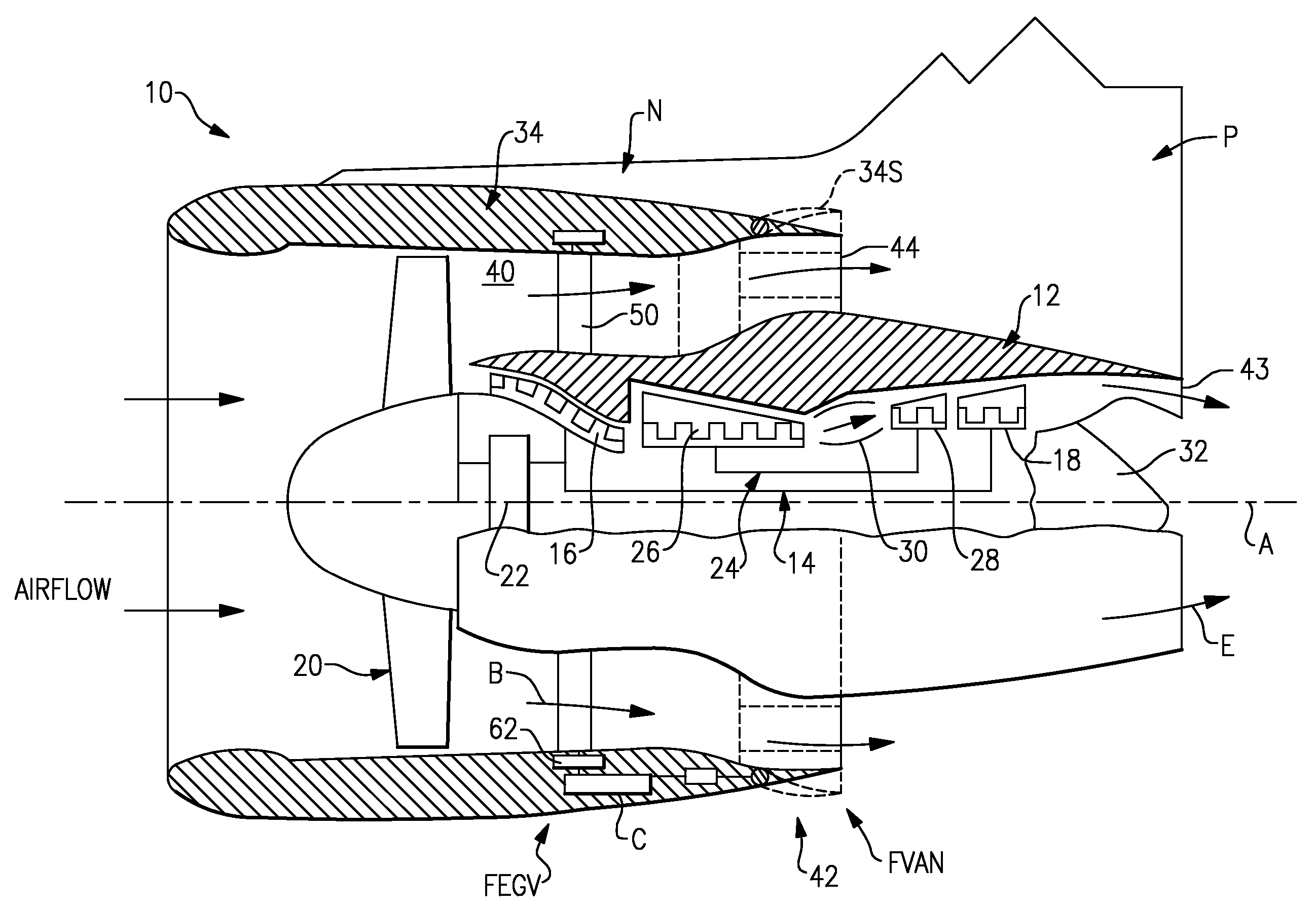

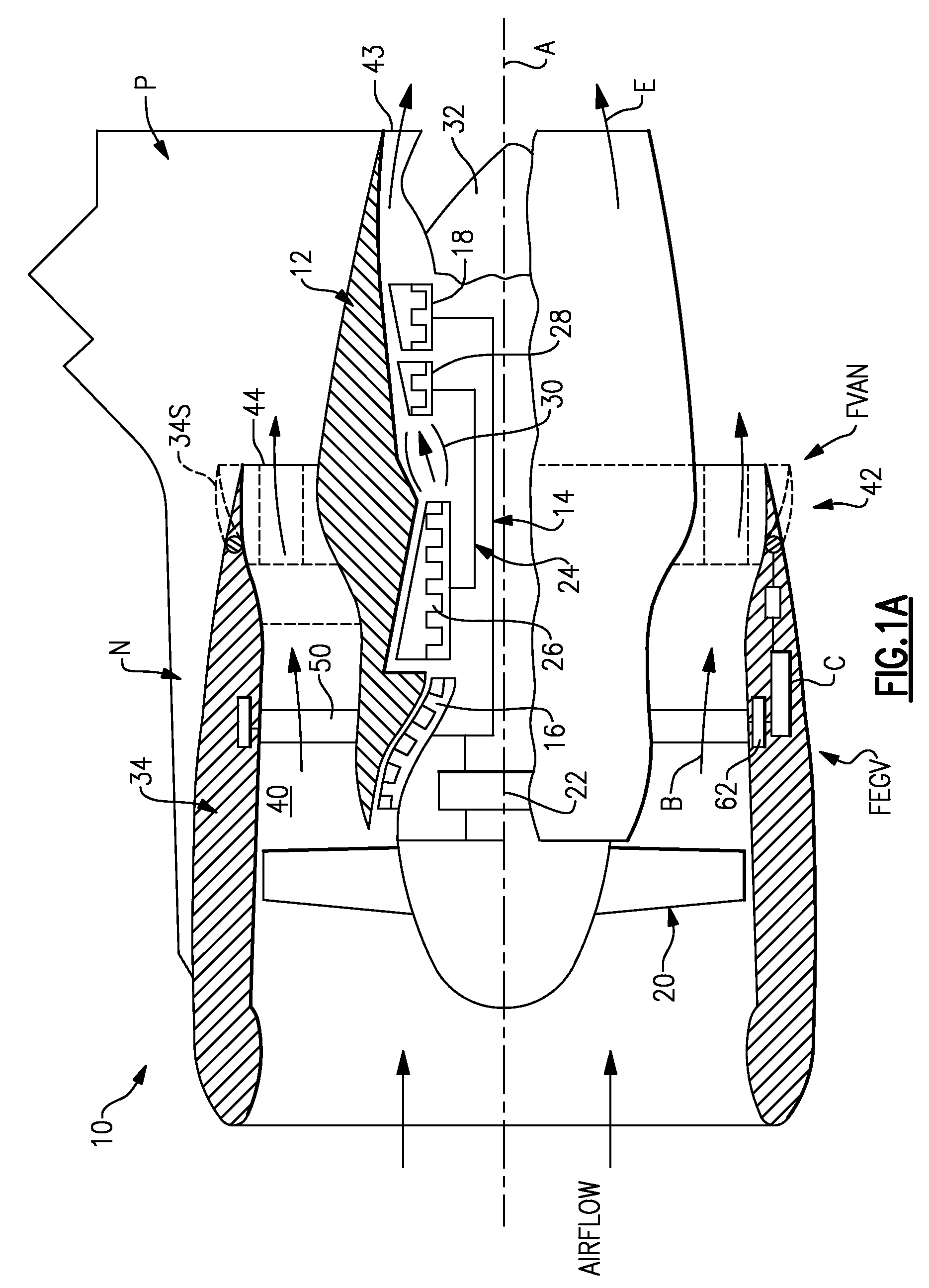

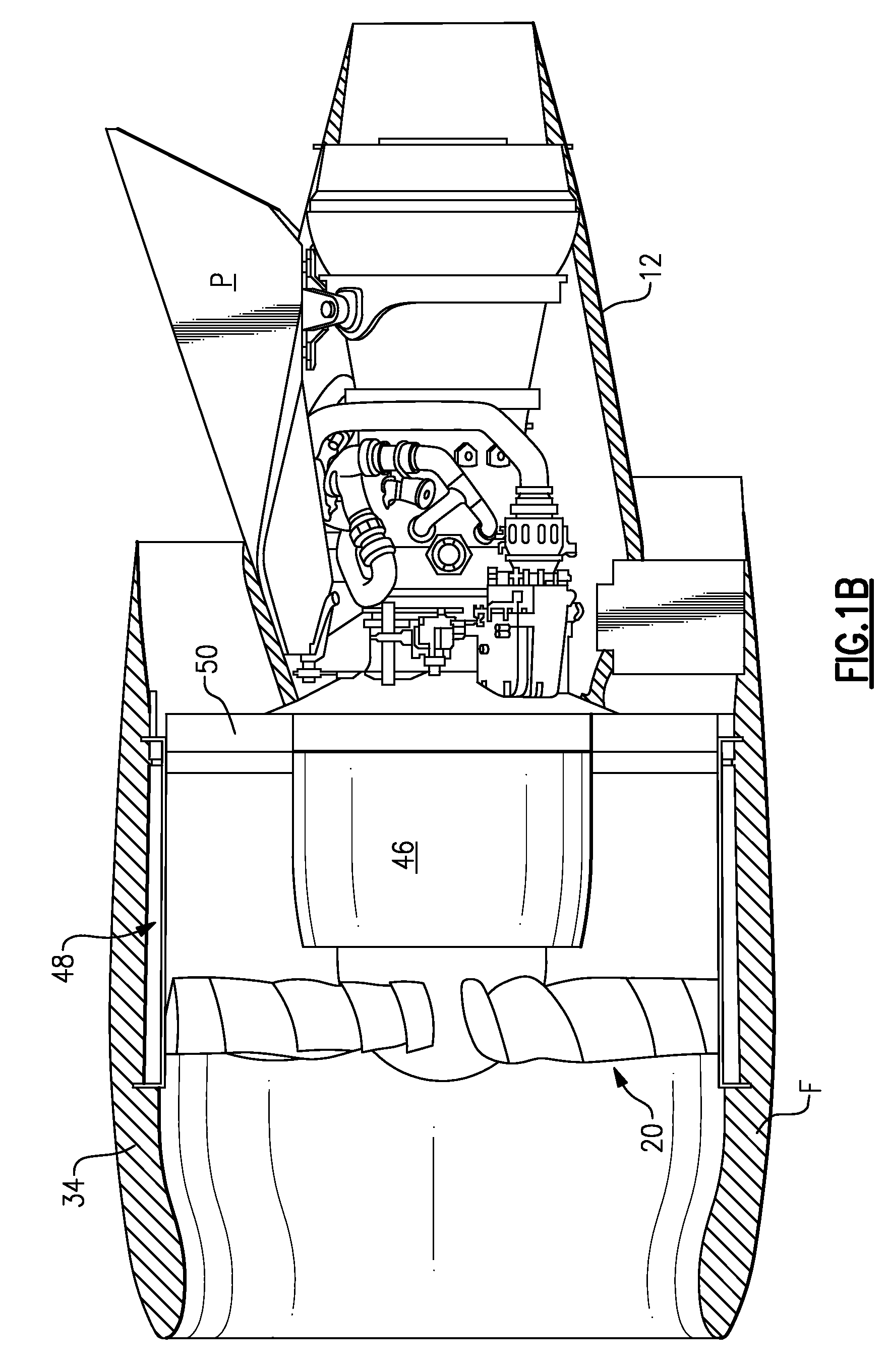

Gas turbine engine with variable geometry fan exit guide vane system

ActiveUS20090097967A1Reduce bypass flowMinimize thrust reverser requirementWind motor controlPump componentsTurbofanVariable geometry

A turbofan engine includes a variable geometry fan exit guide vane (FEGV) system having a multiple of circumferentially spaced radially extending fan exit guide vanes. Rotation of the fan exit guide vanes between a nominal position and a rotated position selectively changes a fan bypass flow path to permit efficient operation at various flight conditions.

Owner:RAYTHEON TECH CORP

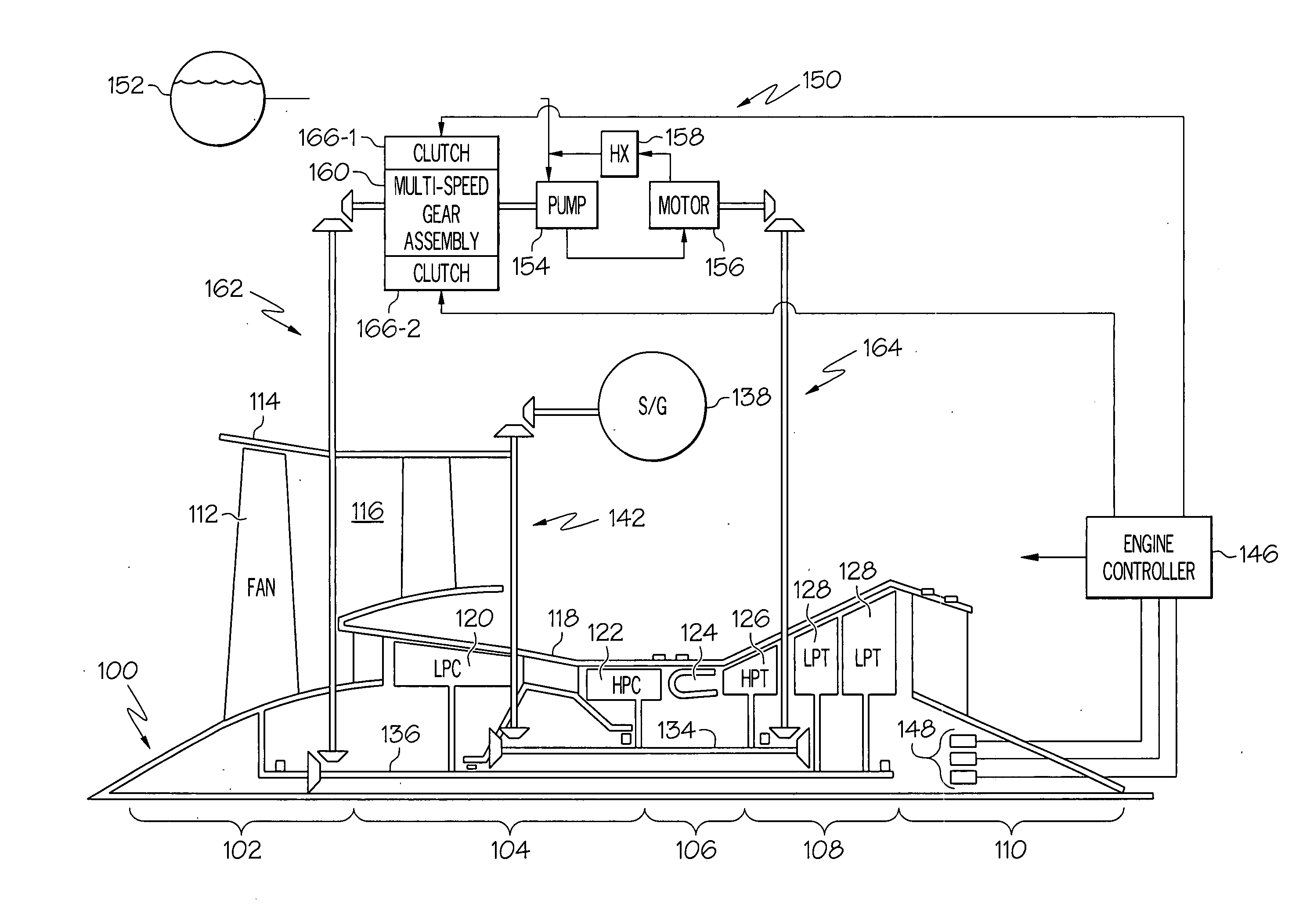

More electric aircraft power transfer systems and methods

InactiveUS20060272313A1Engine fuctionsTurbine/propulsion engine ignitionHydraulic motorElectric aircraft

A turbofan gas turbine propulsion engine includes a system to transfer power from the low pressure turbine to the high pressure turbine and / or extract additional load from the low pressure turbine during certain turbofan engine operational conditions. The systems include a hydrostatic power transfer system that includes a hydraulic pump and a hydraulic motor coupled to the low pressure and high pressure turbine, respectively. The systems additionally include a mechanical and electrical load shifting / loading sharing systems that use clutches and gear assemblies to share and / or shift load between the turbines.

Owner:HONEYWELL INT INC

Turbofan case and method of making

ActiveUS20050022501A1Reduce Tolerance BuildupSmall minimum blade tip clearanceBlade accessoriesEfficient propulsion technologiesEngineeringTurbofan

A casing for a gas turbine includes a fan case, an intermediate case and a gas generator case integrated with one another.

Owner:PRATT & WHITNEY CANADA CORP

High performance VTOL convertiplanes

InactiveUS6974105B2Improve performancePurchase costAircraft navigation controlVertical landing/take-off aircraftsJet aeroplaneGravity center

A single-tilt-rotor VTOL airplanes have a tiltable rotor attached to an elongated power pod containing the collective and cyclical pitch mechanism, and transmission. The power pod is pivotably attached to a base that is slidably mounted on a pair of slotted guide beams attached on top of the roof of the fuselage. The guide beams run longitudinally from the front of the aircraft to past the center of gravity (CG) of the aircraft in order to transport the power pod from the front section to the center section when converting from the horizontal cruising mode to the VTOL mode. In the horizontal cruising mode, the power pod perched horizontally on top of the fuselage front section with sufficient clearance for the rotor to rotate in front of the aircraft. Upon transitioning to the VTOL mode, a telescopic actuator is used to pivot the power pod vertically while a cable-winch system is used to move the entire power pod and base assembly rearwardly to stop at the center of gravity of the aircraft, and vice versa, thus allowing the power pod to travel significantly rearward and forward as required for proper balancing of vertical lift as the power pod pivots 90 degrees during transition from VTOL mode to the cruising mode. A single piston engine, or a single or pair of turbofan engines, mounted slightly to the rear of the CG, have drive shafts that can be clutched and mated onto respective receiving shaft from the transmission within the power pod in order to power the tiltable rotor. The engine is also attached to a propeller for horizontal propulsion, or if turbofan engines are used, jet thrust is generated for horizontal cruise. A small anti-torque rotor or ducted fan toward the tail of the aircraft is mechanically coupled to the engine via a drive shaft to provide the necessary side-way thrust to overcome the main rotor's torque. In the horizontal cruising mode, the tiltable rotor is allowed to windmill slowly at a minimum rotational speed necessary to maintain the integrity of the rotor blades. The same propulsion principle can be applied to VTOL airplanes having more than one tiltable rotor, thereby can potentially increase the speed, range and reliability of current twin-wing-mounted-tilt-rotor aircraft. A pair of high-aspect-ratio wings on both sides of the fuselage provide highly efficient lift during cruising flight with very little induced drag. Conventional horizontal and vertical tail planes are used for directional stability in the cruising mode.

Owner:PHAM ROGER N

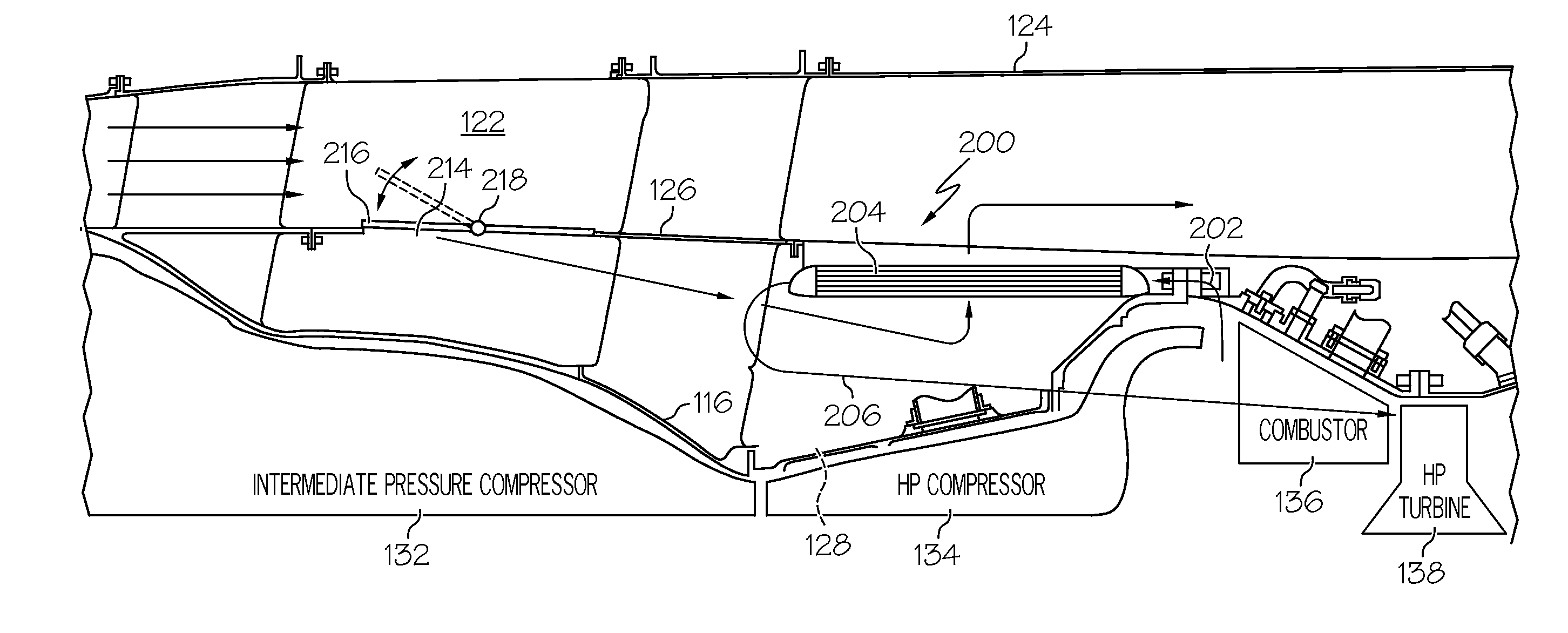

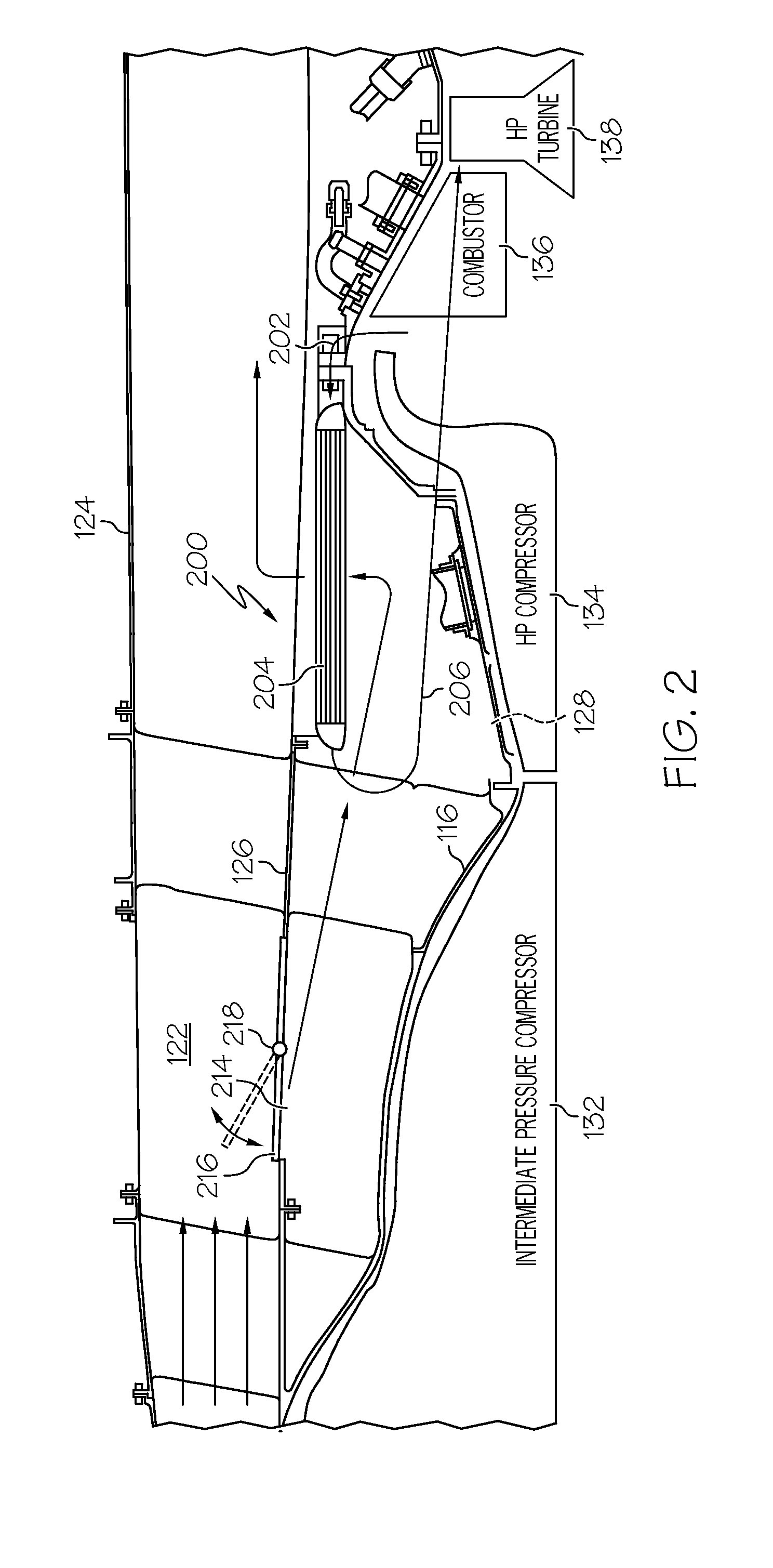

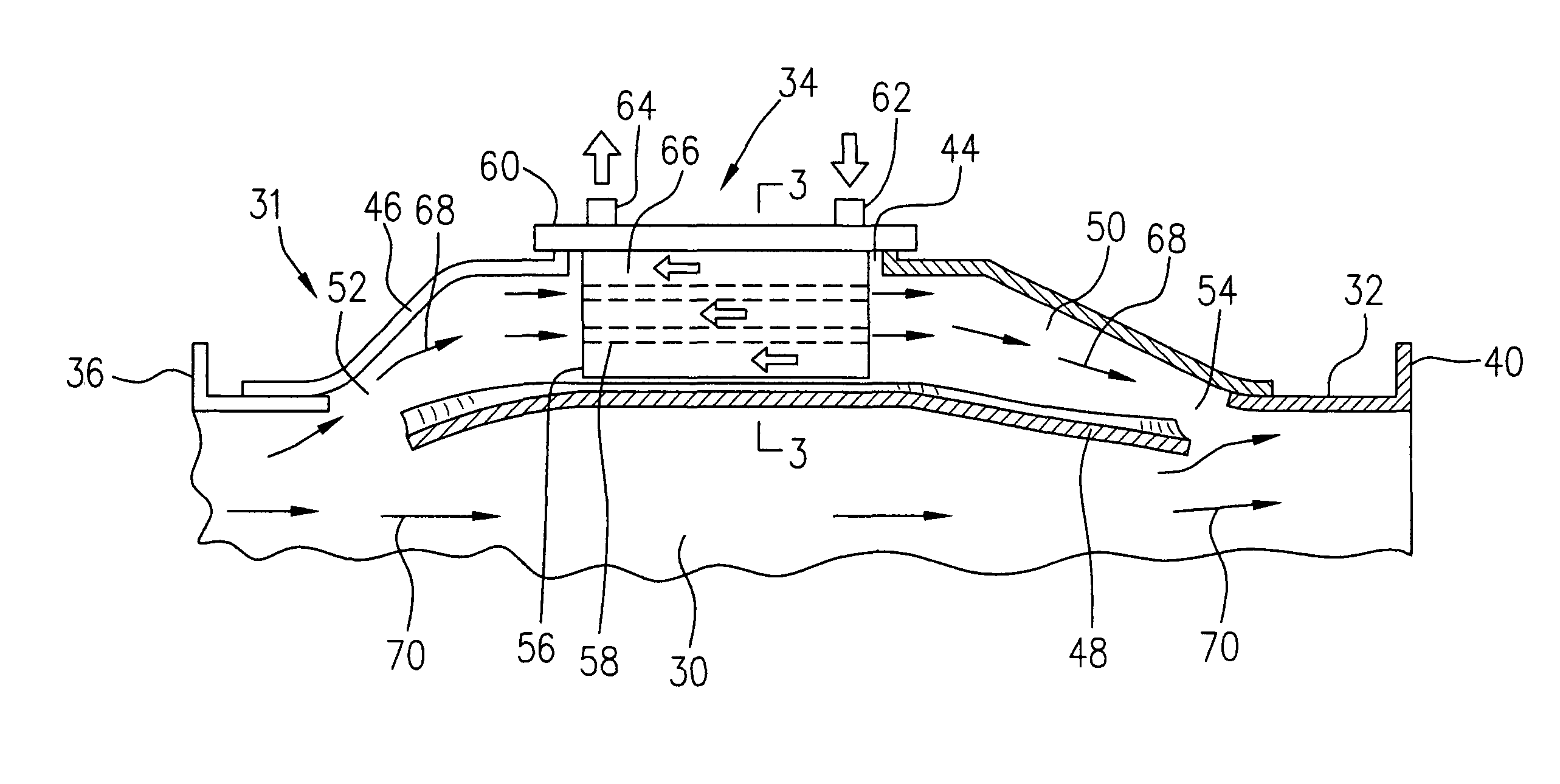

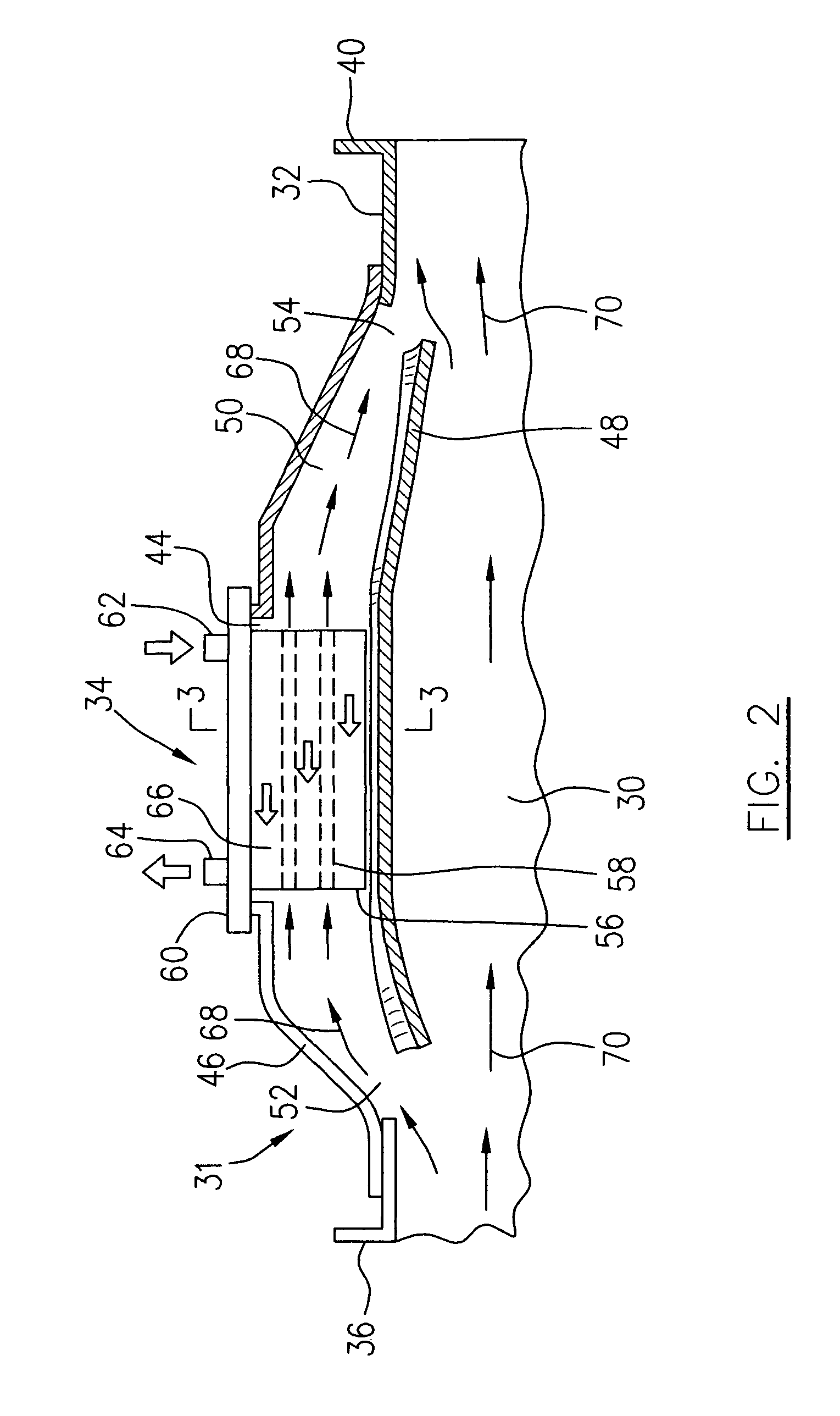

Gas turbine engine in-board cooled cooling air system

A system for supplying turbine cooling air flow includes a turbofan engine, a heat exchanger, and a door. The turbofan engine includes an engine case that has an inner volume within which at least a gas turbine engine is mounted, and a bypass flow passage that is defined by an outer fan duct and an inner fan duct and that is configured to direct fan air flow therethrough. The heat exchanger is disposed within the turbofan engine, is coupled to receive fluid and cooling air from the bypass flow passage, and is configured to transfer heat between fluid and the cooling air. The door is movably mounted in the turbofan engine and is movable between a closed position, in which the cooling air will not flow through the heat exchanger, and an open position, in which the cooling air may flow through the heat exchanger.

Owner:HONEYWELL INT INC

Aircraft propulsion system

InactiveUS7555893B2Highly compatible with environmentMagnetic circuitAircraft power plant componentsSpacecraft propulsionFuel cells

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

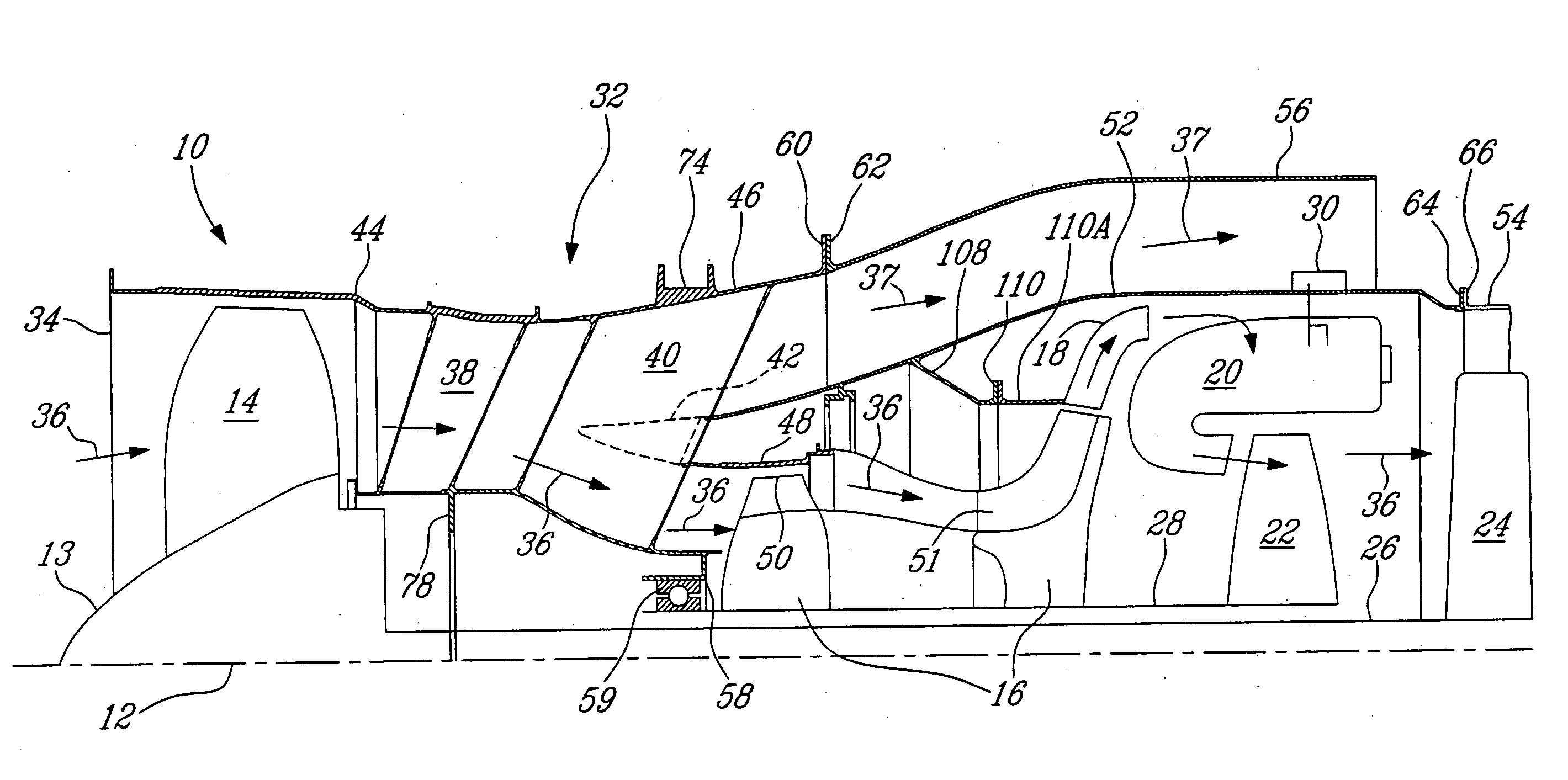

Gas turbine engine with variable pressure ratio fan system

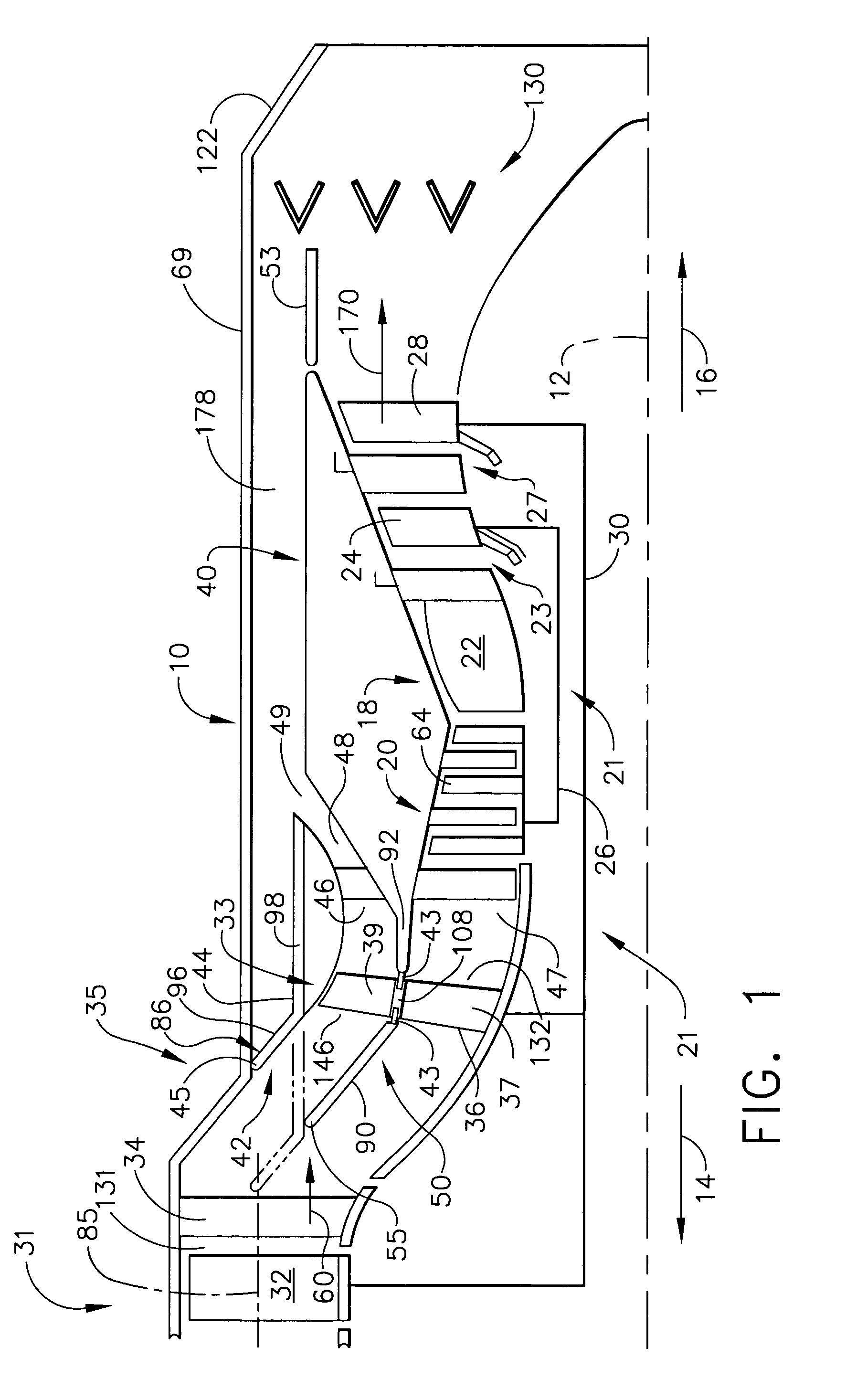

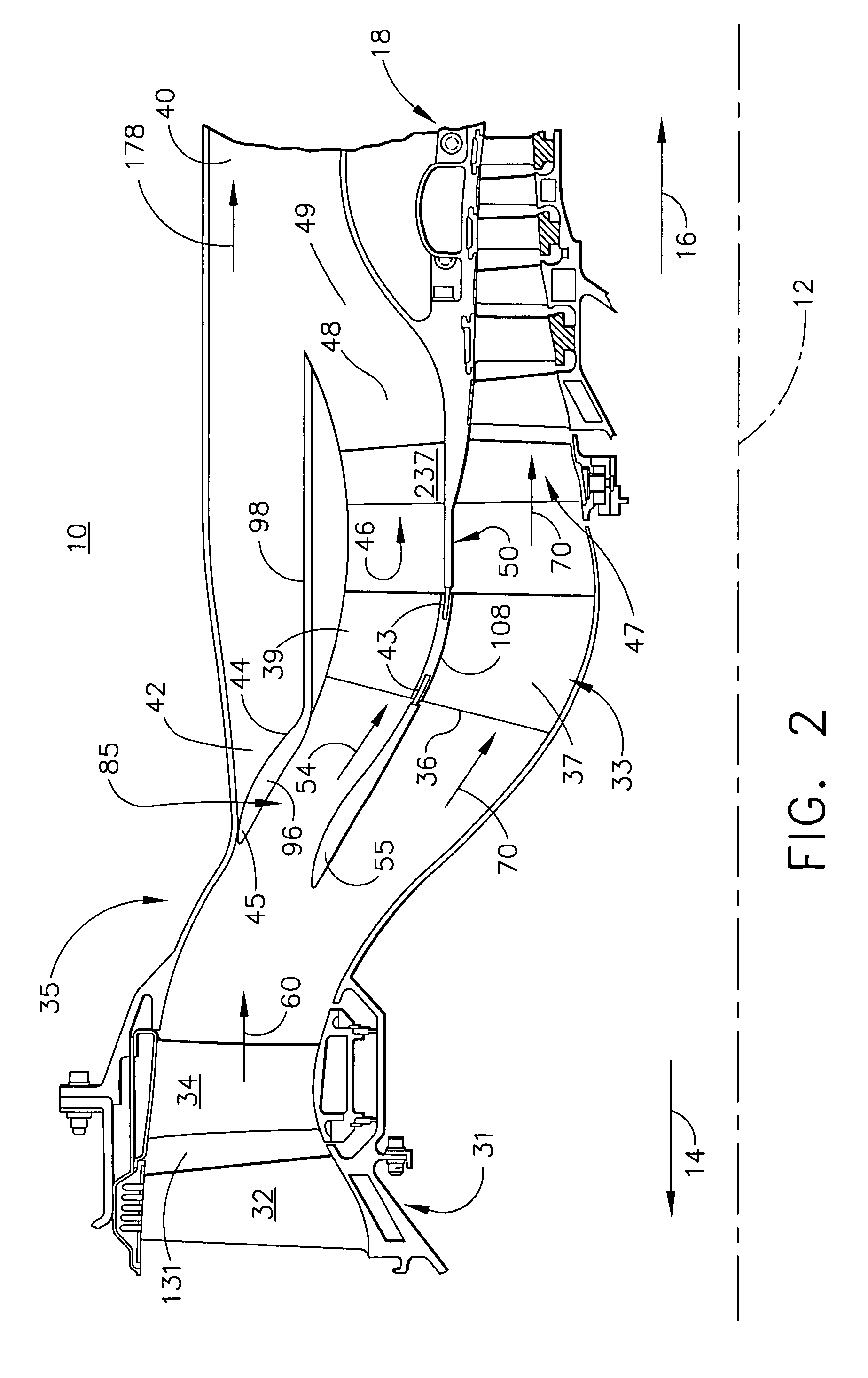

InactiveUS6901739B2High specific thrustReduce consumptionEngine componentsJet propulsion plantsFan bladeTurbofan

A multiple bypass turbofan engine includes axially spaced-apart first and second stage fans of the engine fan connected in driving engagement to a low pressure shaft. A fan bypass duct circumscribes the second stage fan. A first bypass inlet to the fan bypass duct is disposed axially between the first and second stage fans and a second bypass inlet is axially disposed between the second stage fan and an annular core engine inlet. A fan shroud divides the second stage fan blades into radially inner and outer fan hub and tip sections, respectively. The tip sections are radially disposed in a fan tip duct. An axially translatable deflector is positioned to close the fan tip duct when it opens the first bypass inlet and open the fan tip duct when it closes the first bypass inlet.

Owner:GENERAL ELECTRIC CO

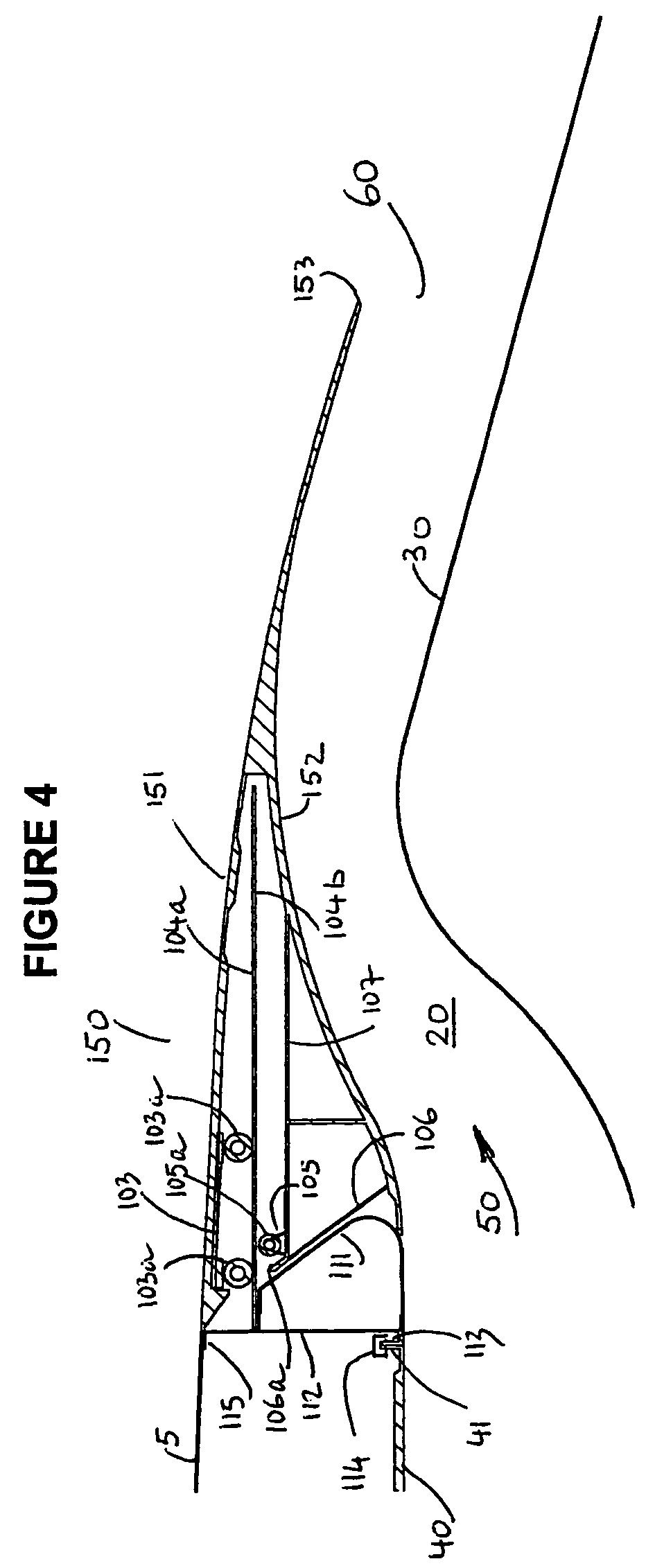

Turbofan engine assembly and method of assembling same

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a booster compressor coupled upstream from the core gas turbine engine, an intermediate-pressure turbine coupled to the booster compressor, the intermediate-pressure turbine disposed downstream from the core gas turbine engine, a counter-rotating fan assembly disposed upstream from the booster compressor, the counter-rotating fan assembly comprising a first fan configured to rotate in a first direction and a second fan configured to rotate in an opposite second direction, and a low-pressure turbine disposed downstream from the intermediate-pressure turbine, the low-pressure turbine configured to drive the counter-rotating fan assembly. A method of assembling the above turbofan engine assembly is also described herein.

Owner:GENERAL ELECTRIC CO

Geared counter-rotating gas turbofan engine

A gas turbine engine includes a gear system driven by a first and second counter rotating low pressure shaft and a fan driven by the gear system.

Owner:RTX CORP

Turbofan bypass duct air cooled fluid cooler installation

ActiveUS7861512B2Facilitate heat exchangeTurbine/propulsion engine coolingEngine fuctionsCooling fluidTurbofan

A cooling apparatus for cooling a fluid in a bypass gas turbine engine comprises a heat exchanger disposed within a bypass duct and accommodated by a sub-passage defined by a flow divider affixed to an annular wall of the bypass duct. The sub-passage defines an open upstream end and an open downstream end to direct a portion of the bypass air flow to pass therethrough.

Owner:PRATT & WHITNEY CANADA CORP

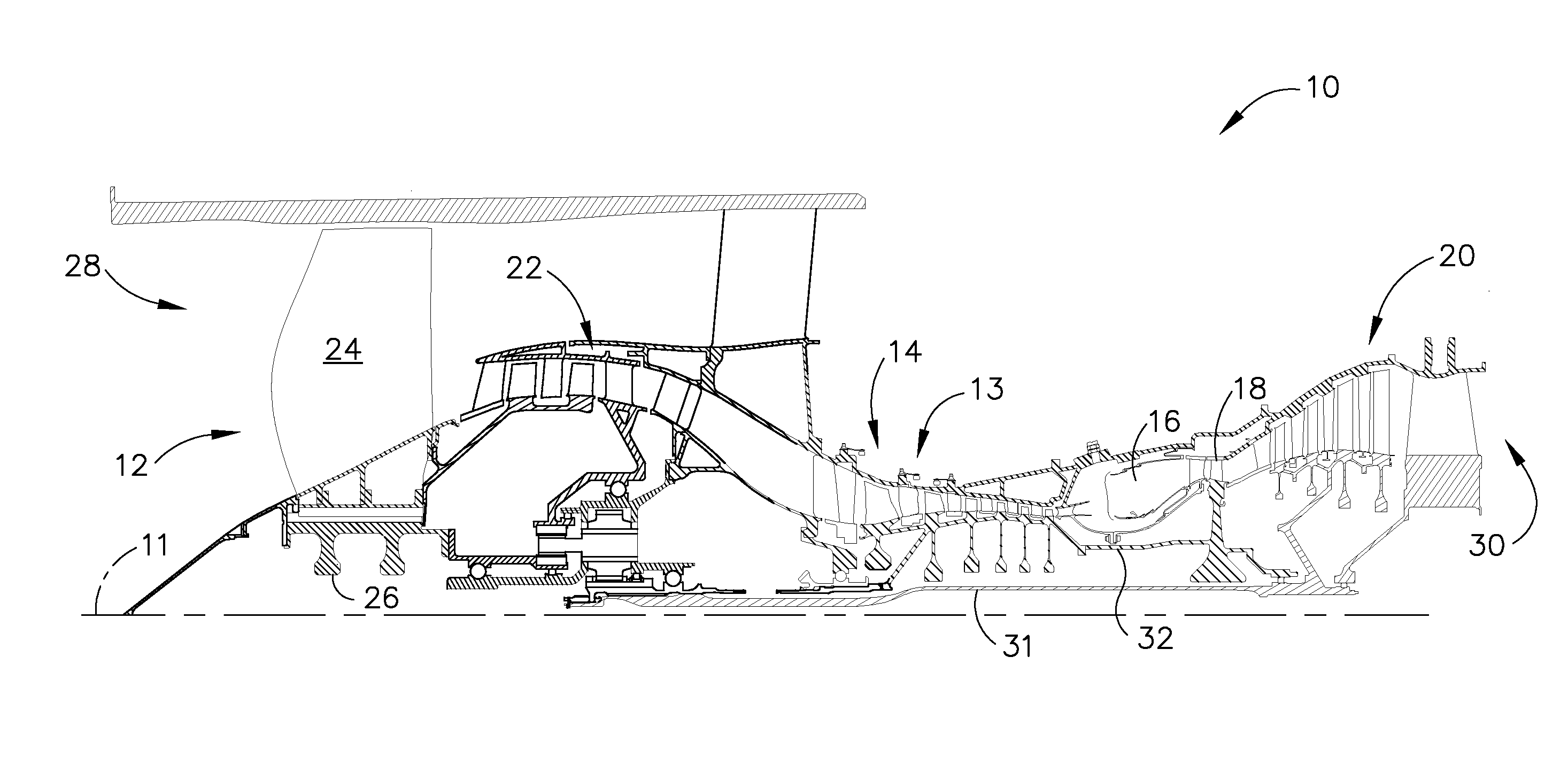

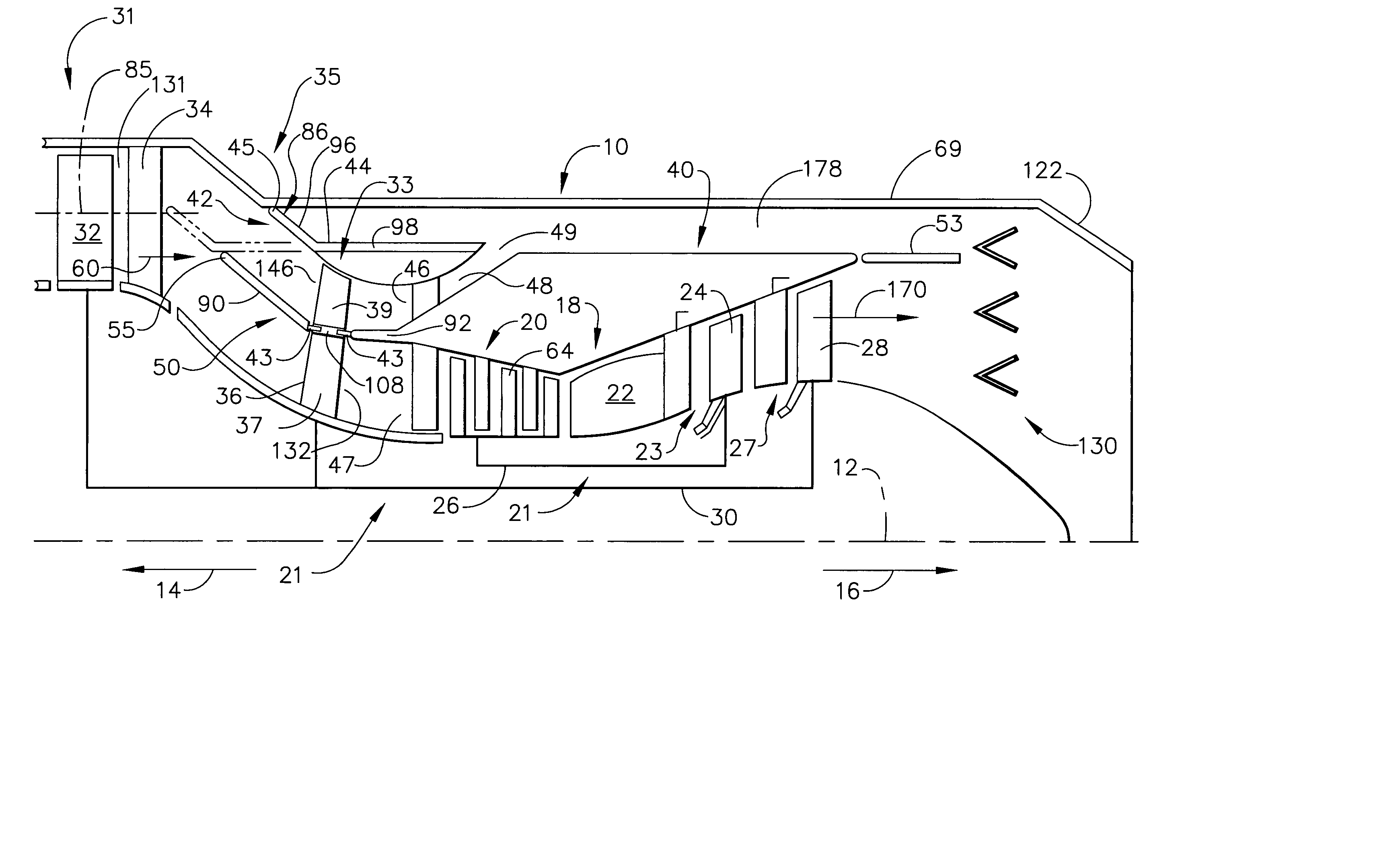

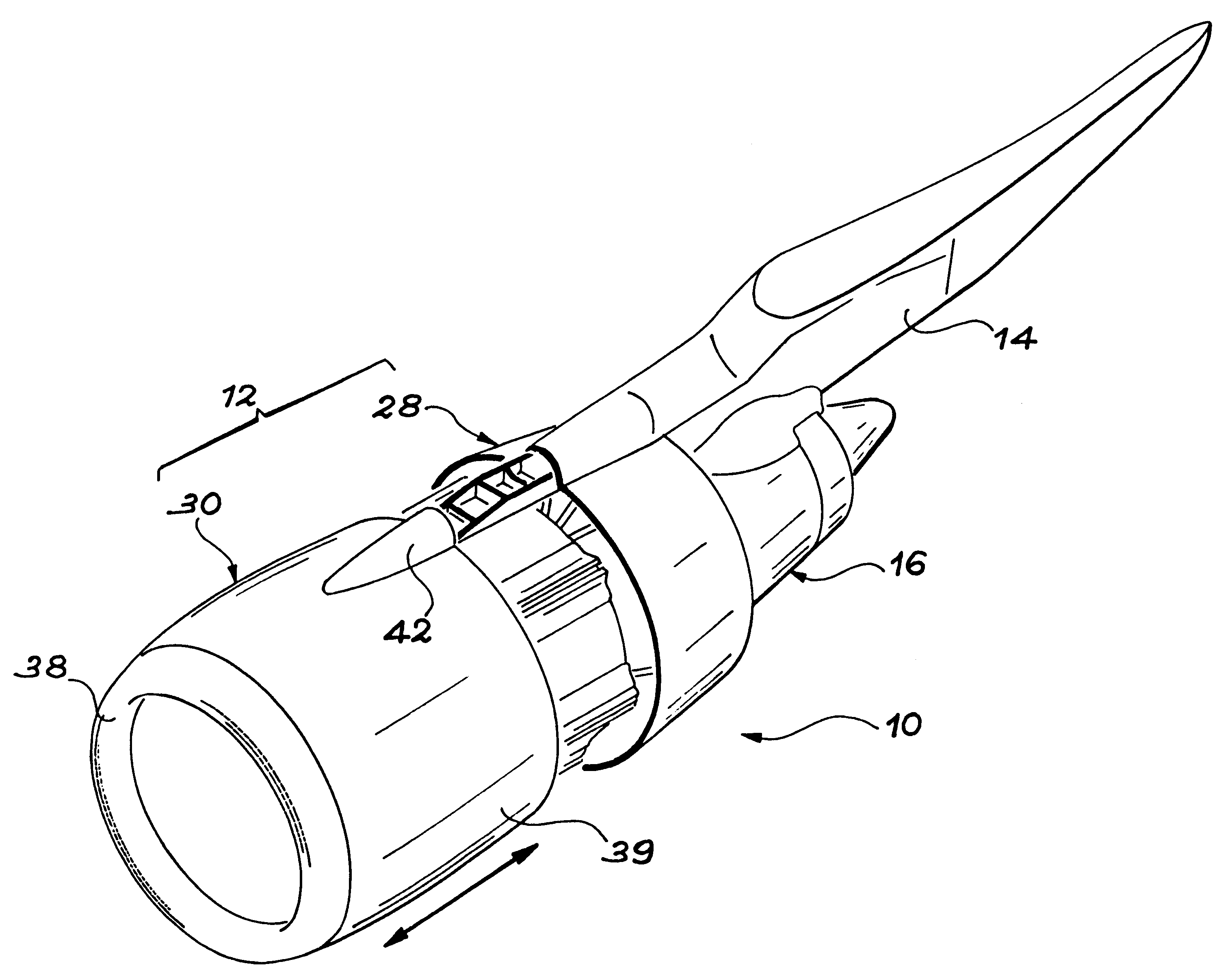

Turbojet pod with laminar flow

InactiveUS6179249B1Good aerodynamic shapeKeep shapeAircraft power plant componentsDe-icing equipmentsEngineeringTurbojet

The bay (12) of a turbofan engine (10) comprises a front structural element (30), whose external surface is continuous and extends over at least 50% of the geometrical chord of the bay. Said element (30) is installed on maintaining and guiding members (44), such as slides, which prevent a significant deformation in flight and allow a sliding to the front of the element (30) for maintenance purposes. A laminar air flow around the front half of the bay (12) is consequently ensured.

Owner:SOC NATIONALE INDUSTRIELLE AEROSPATIALE SA

Turbofan engine cowl assembly and method of operating the same

A turbofan engine assembly is provided. The turbofan engine assembly includes a core gas turbine engine, a core cowl which circumscribes the core gas turbine engine, a nacelle positioned radially outward from the core cowl, a fan nozzle duct defined between the core cowl and the nacelle, and an inner core cowl baffle assembly positioned within the fan nozzle duct. The inner core cowl baffle assembly includes a first core cowl baffle coupled to a portion of the core cowl within the fan nozzle duct, a second core cowl baffle coupled to a portion of the core cowl and positioned a distance radially inward from the first core cowl baffle, and an actuator assembly configured to vary the throat area of the fan nozzle duct by selectively repositioning the second core cowl baffle with respect to the first core cowl baffle. A method for operating the turbofan engine assembly is also provided.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com