Patents

Literature

677results about How to "Facilitate heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

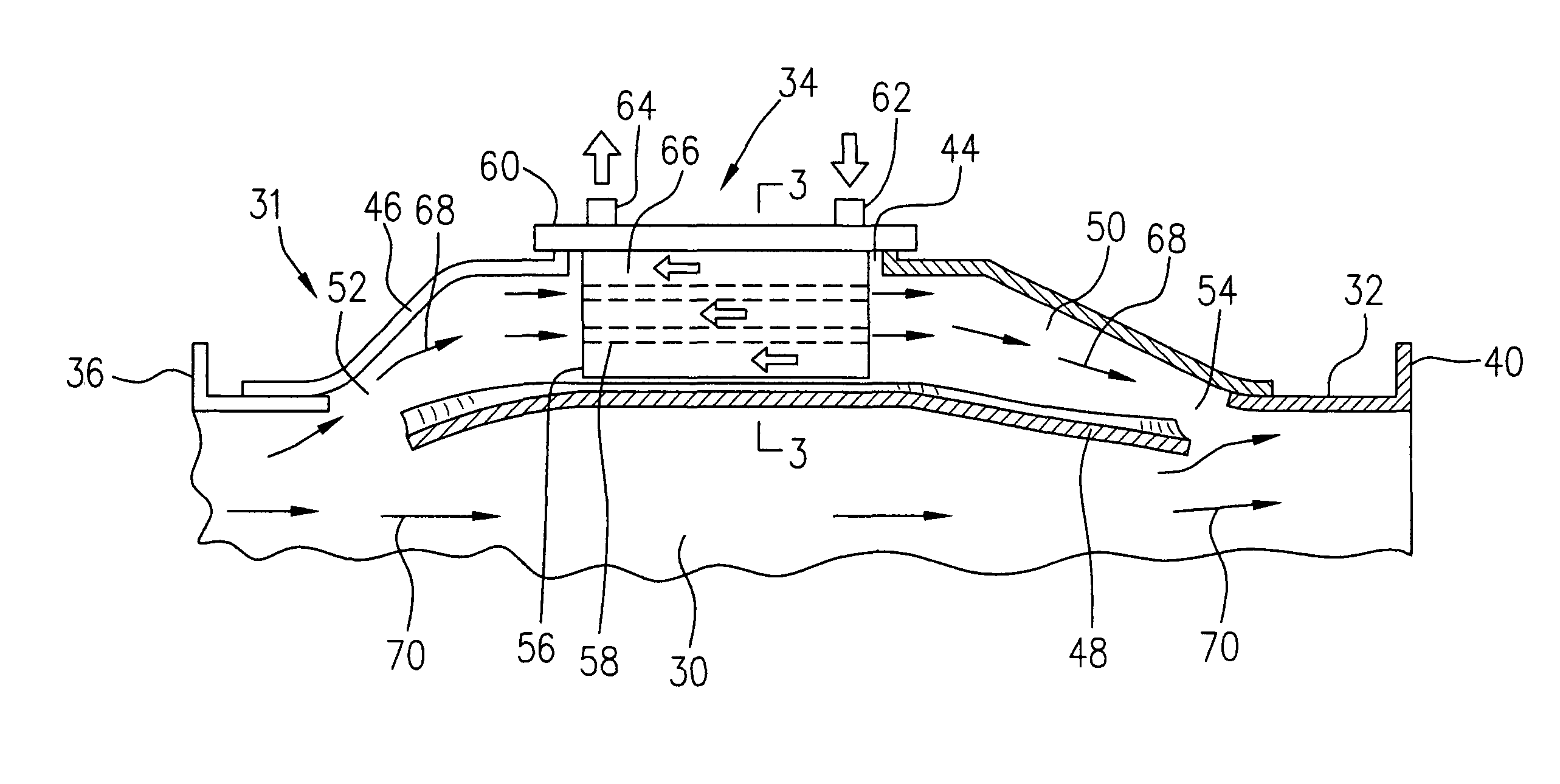

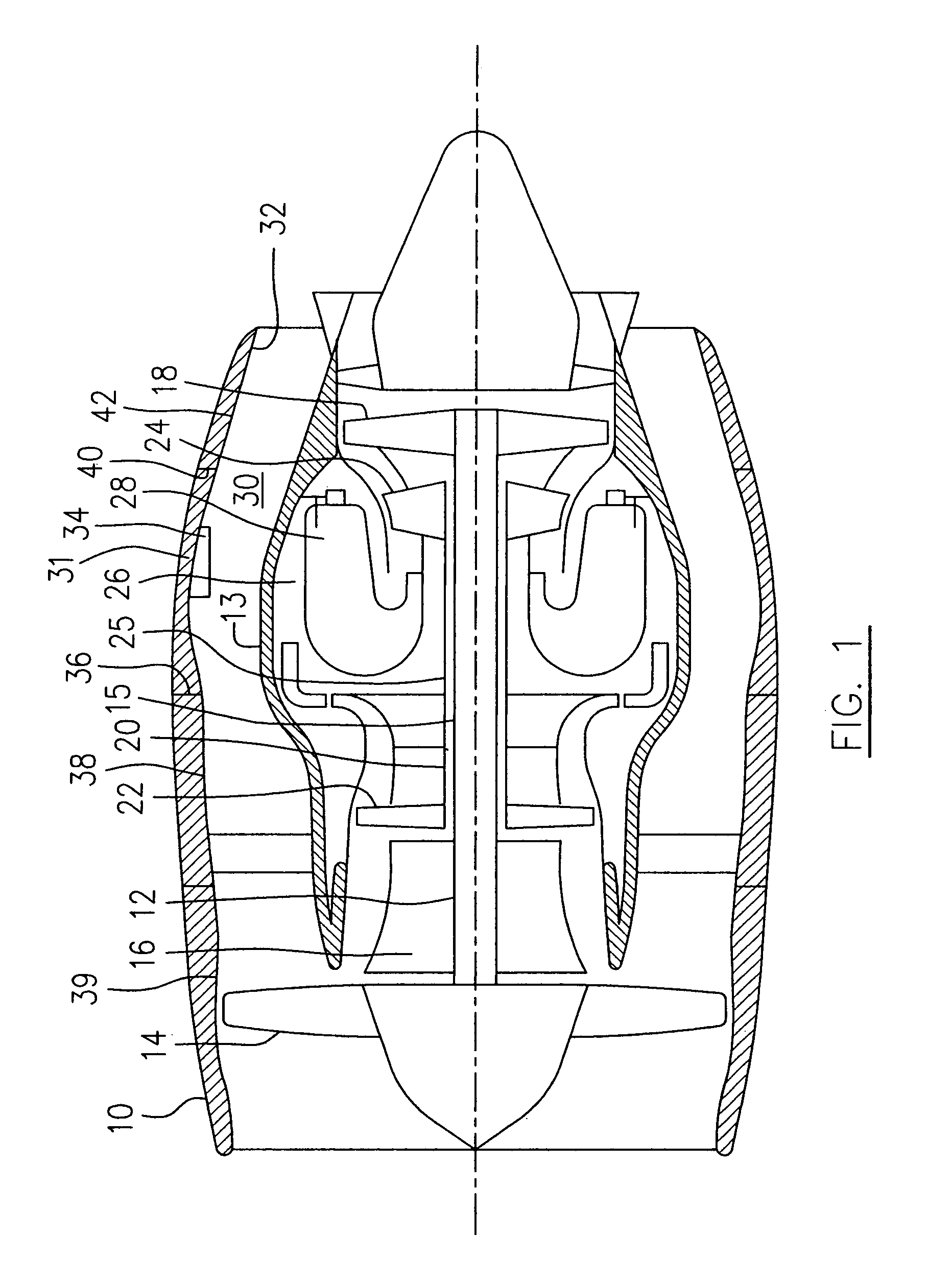

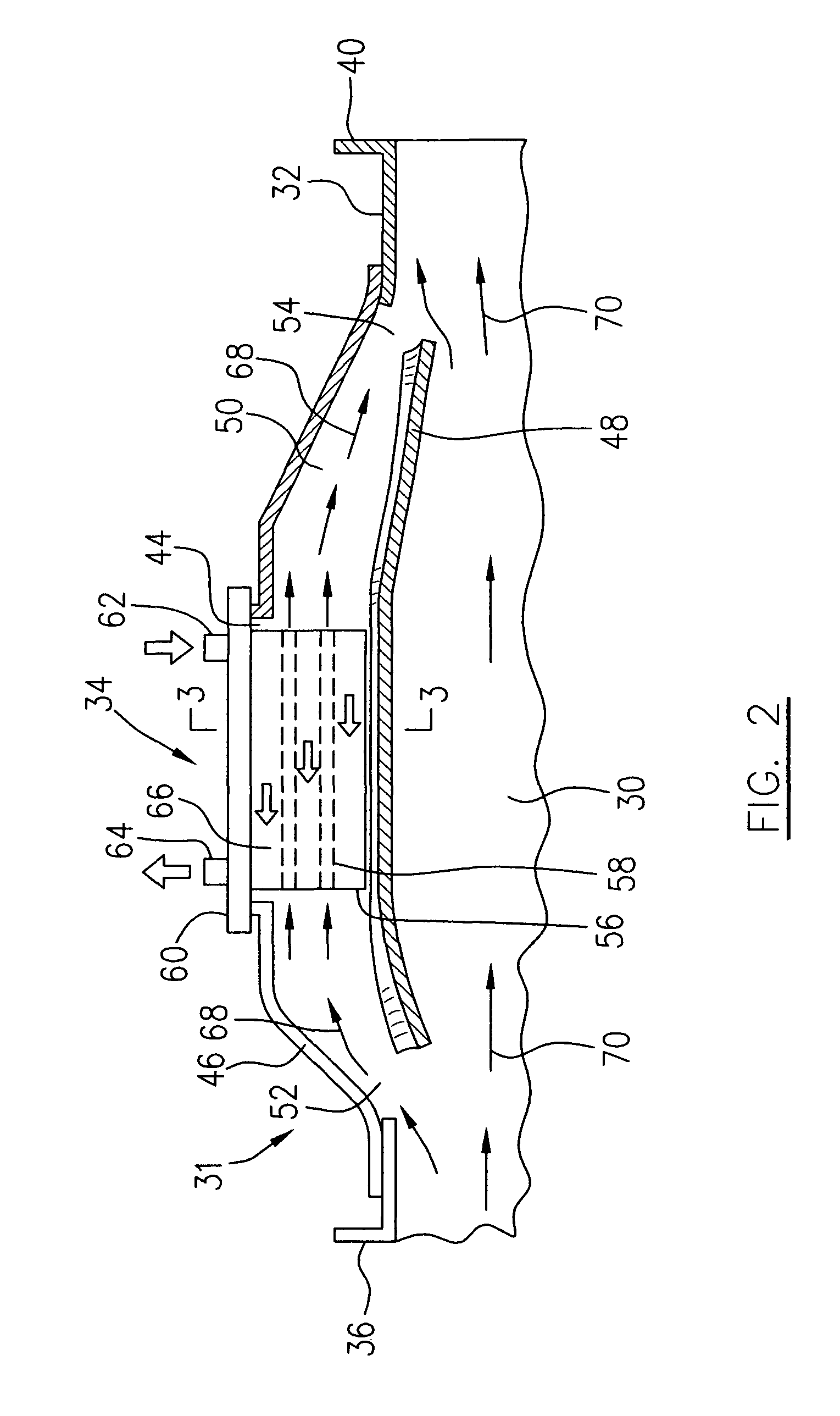

Turbofan bypass duct air cooled fluid cooler installation

ActiveUS7861512B2Facilitate heat exchangeTurbine/propulsion engine coolingEngine fuctionsCooling fluidTurbofan

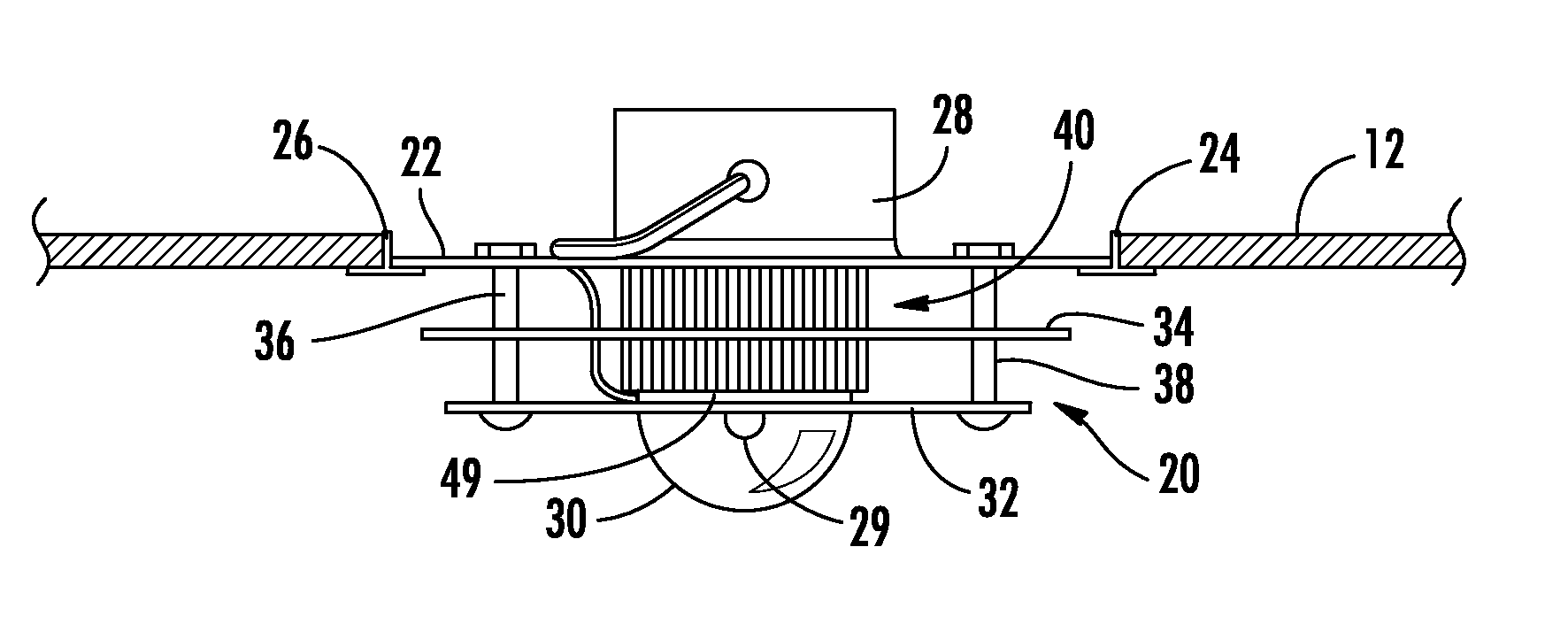

A cooling apparatus for cooling a fluid in a bypass gas turbine engine comprises a heat exchanger disposed within a bypass duct and accommodated by a sub-passage defined by a flow divider affixed to an annular wall of the bypass duct. The sub-passage defines an open upstream end and an open downstream end to direct a portion of the bypass air flow to pass therethrough.

Owner:PRATT & WHITNEY CANADA CORP

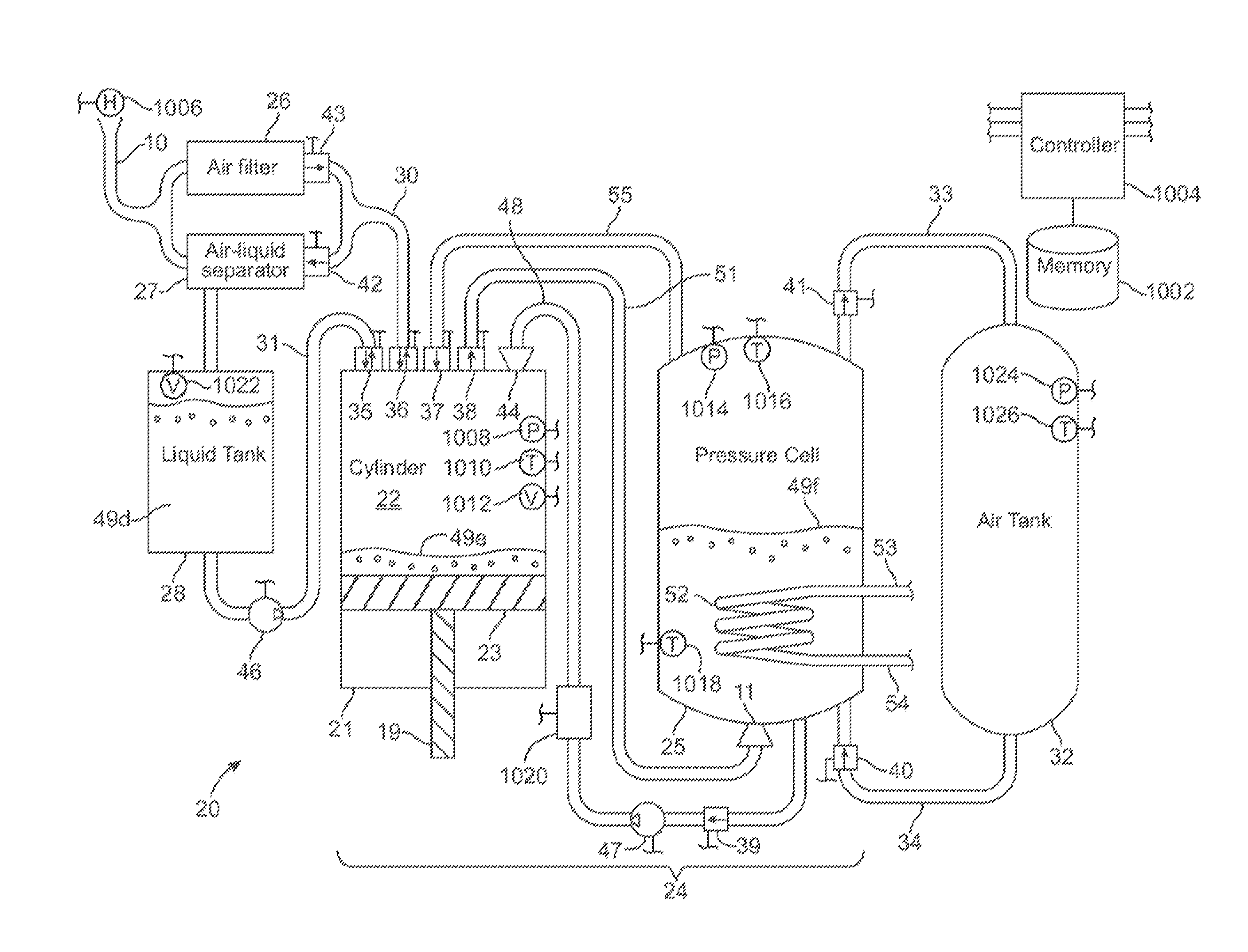

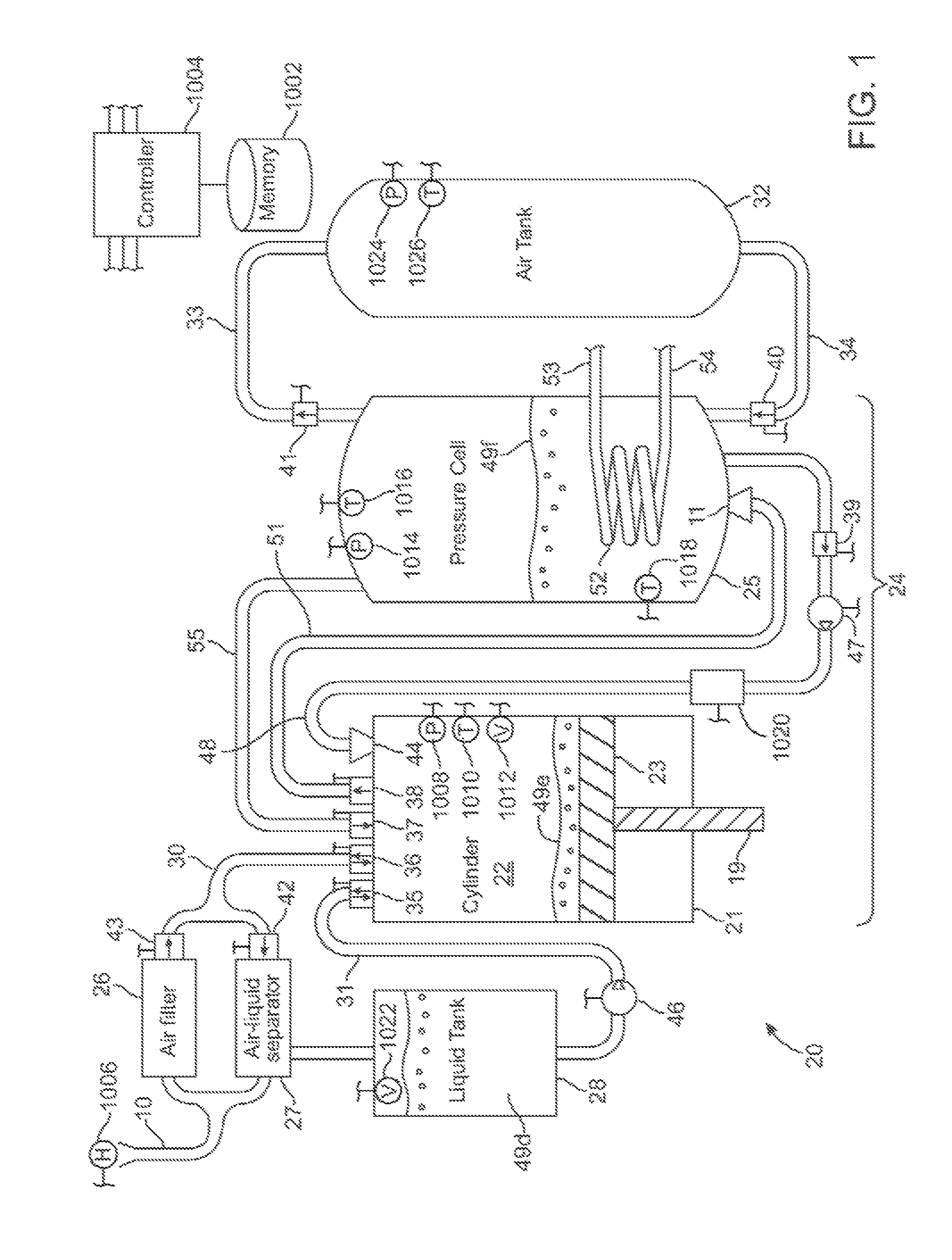

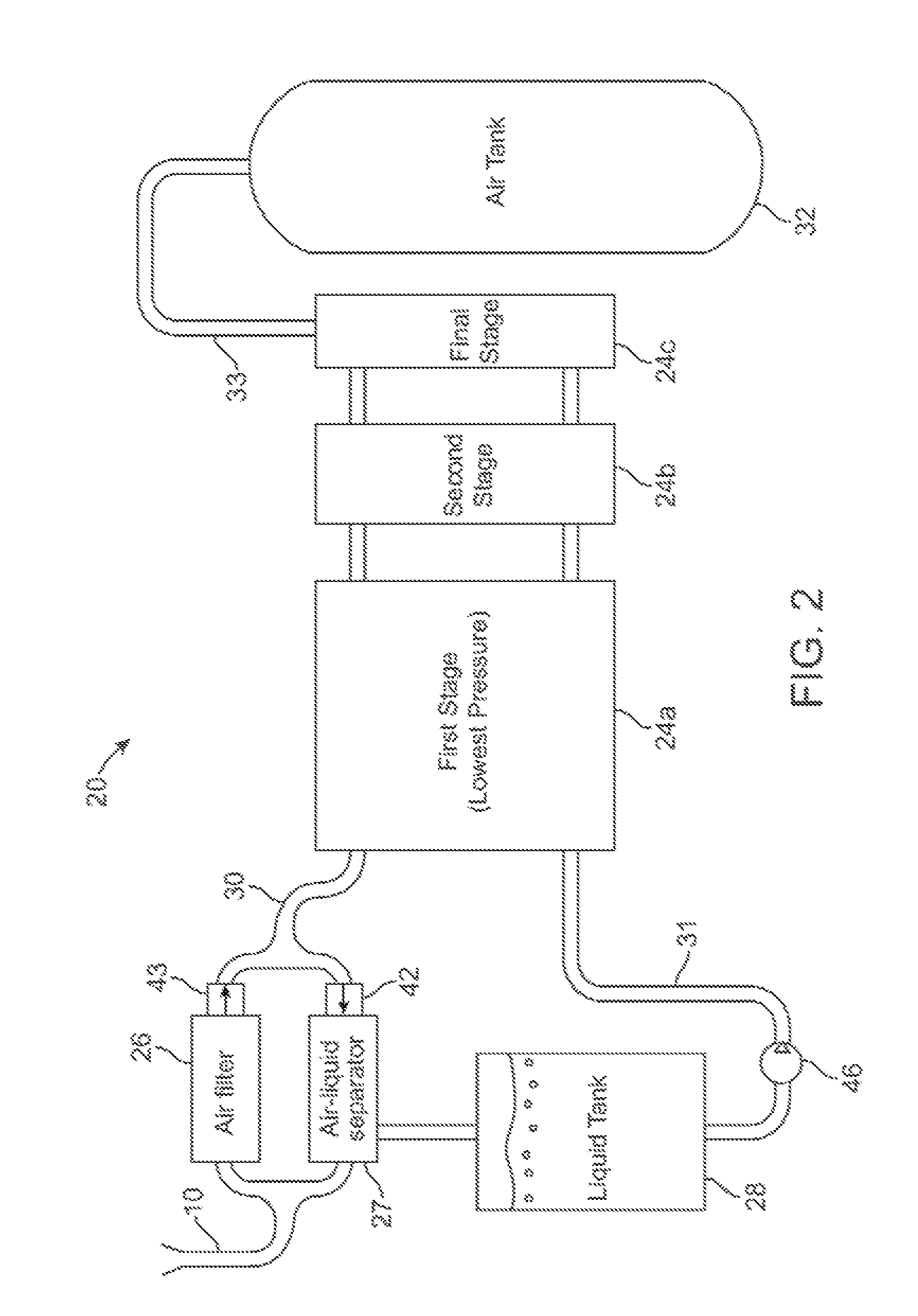

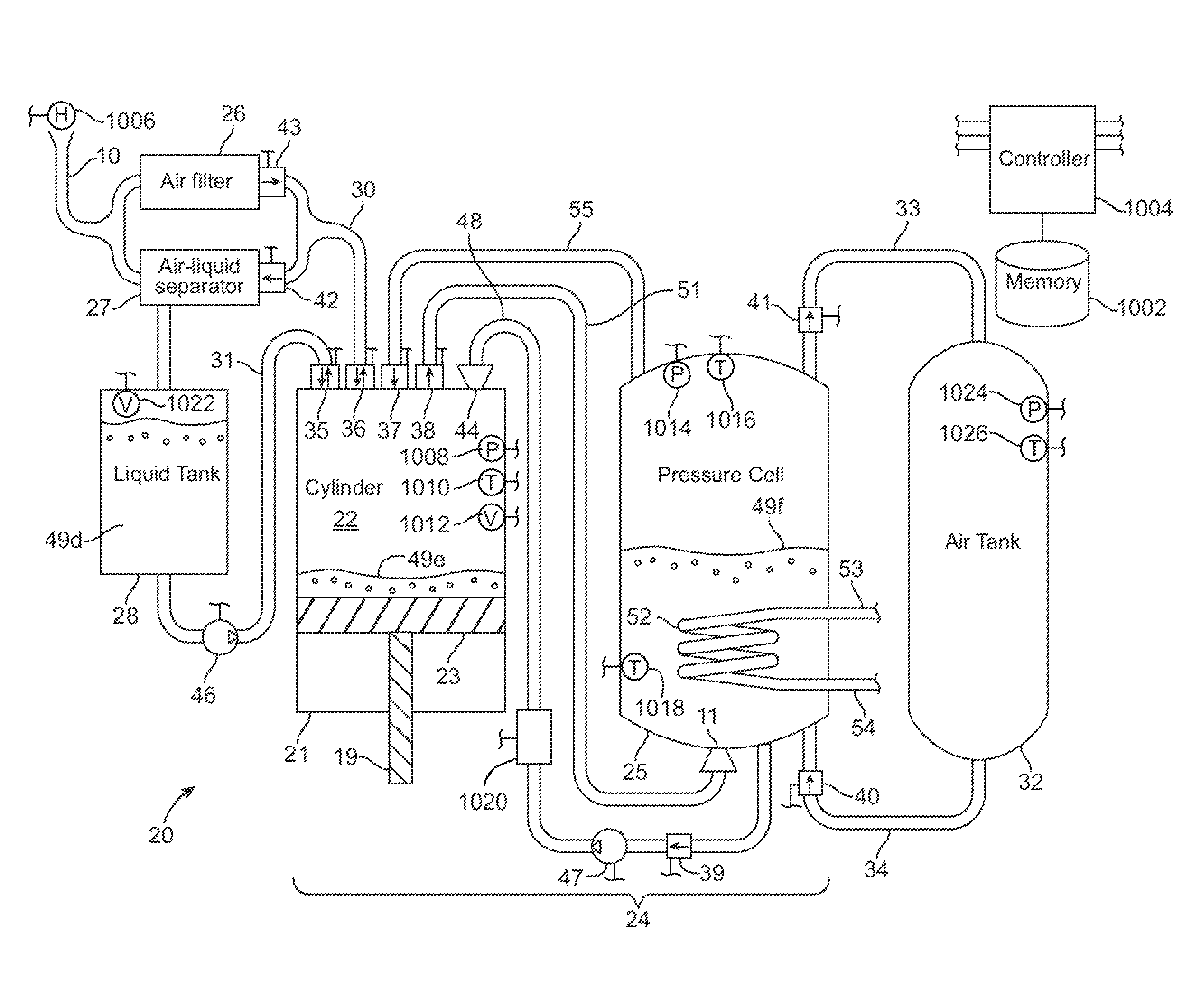

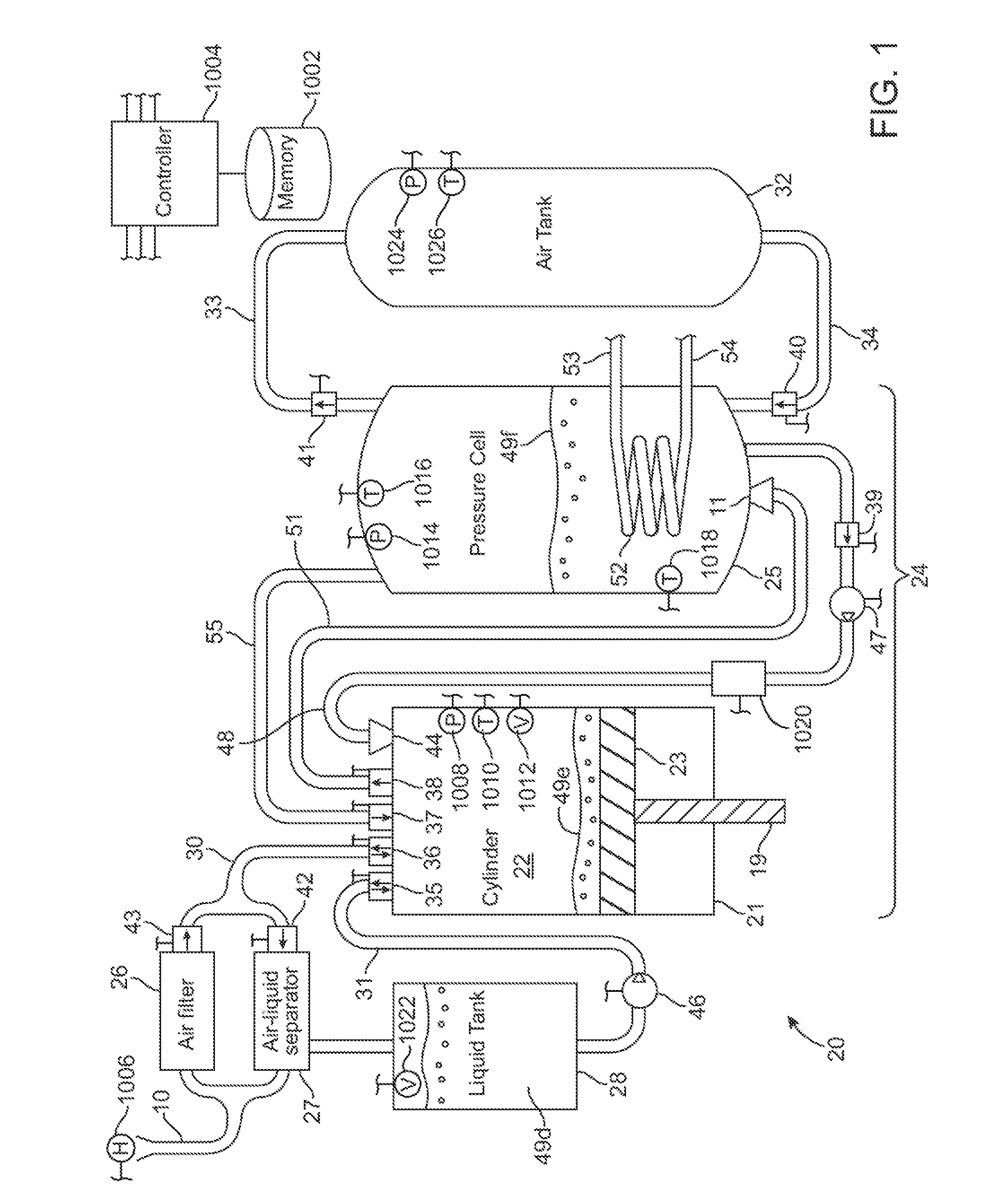

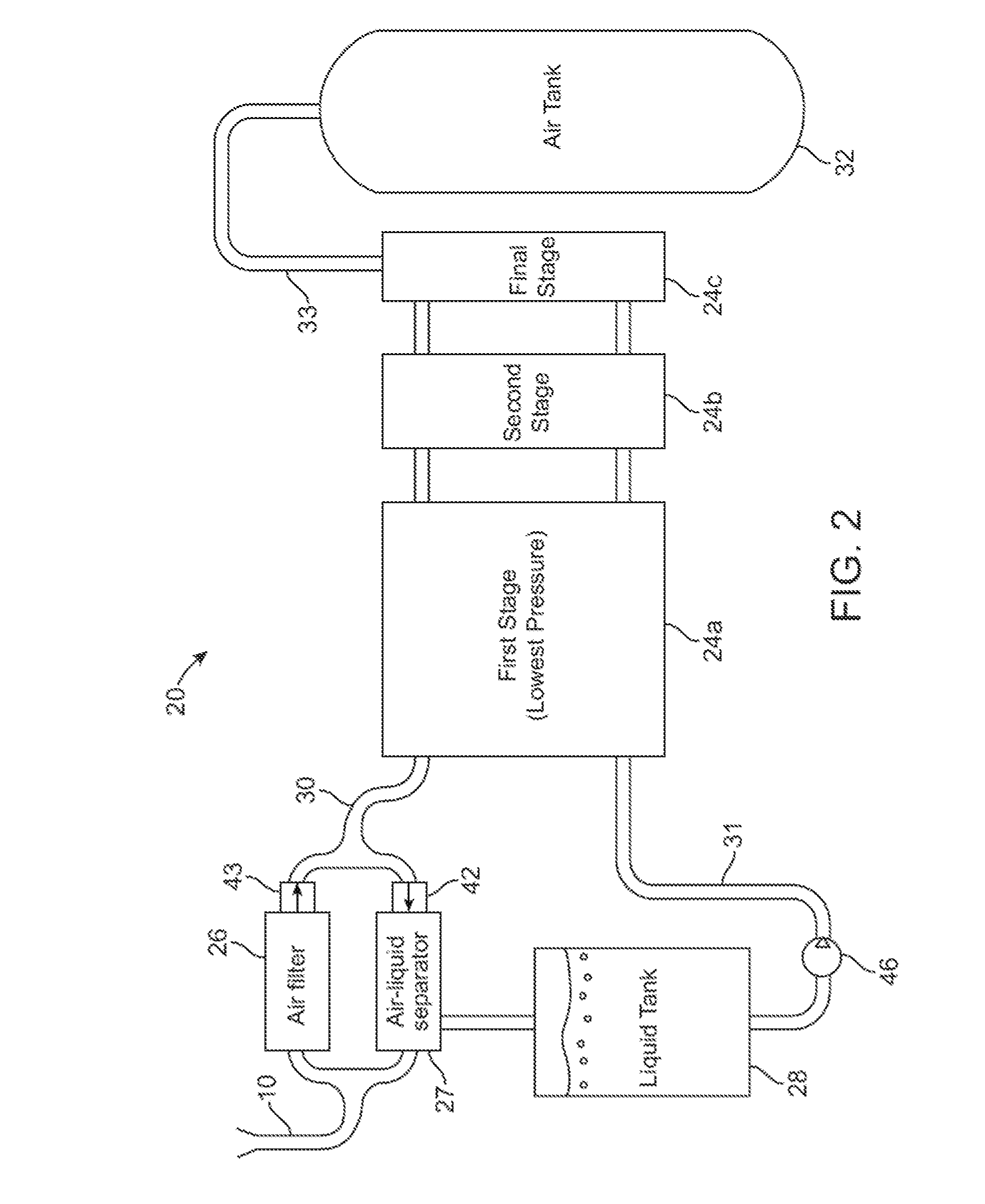

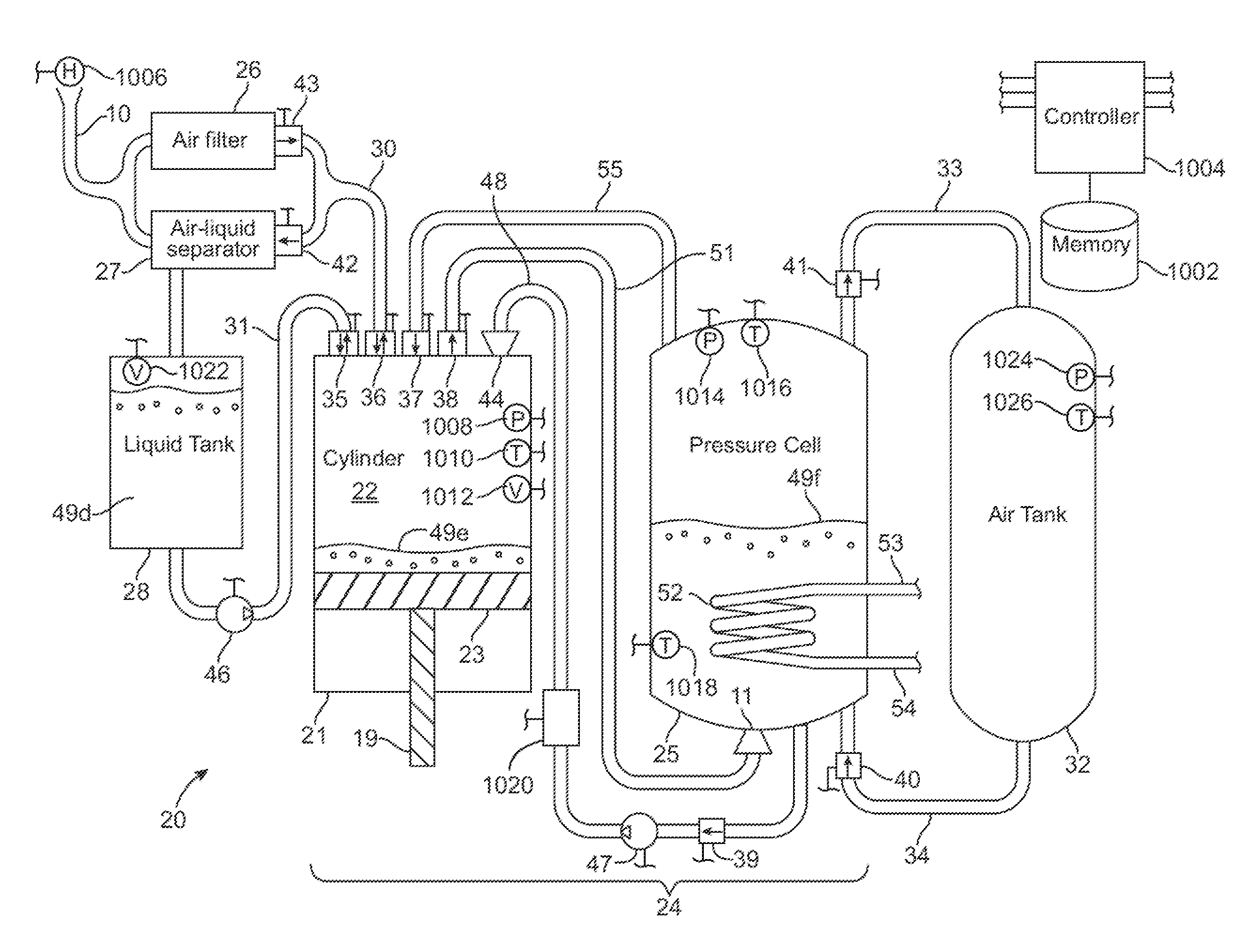

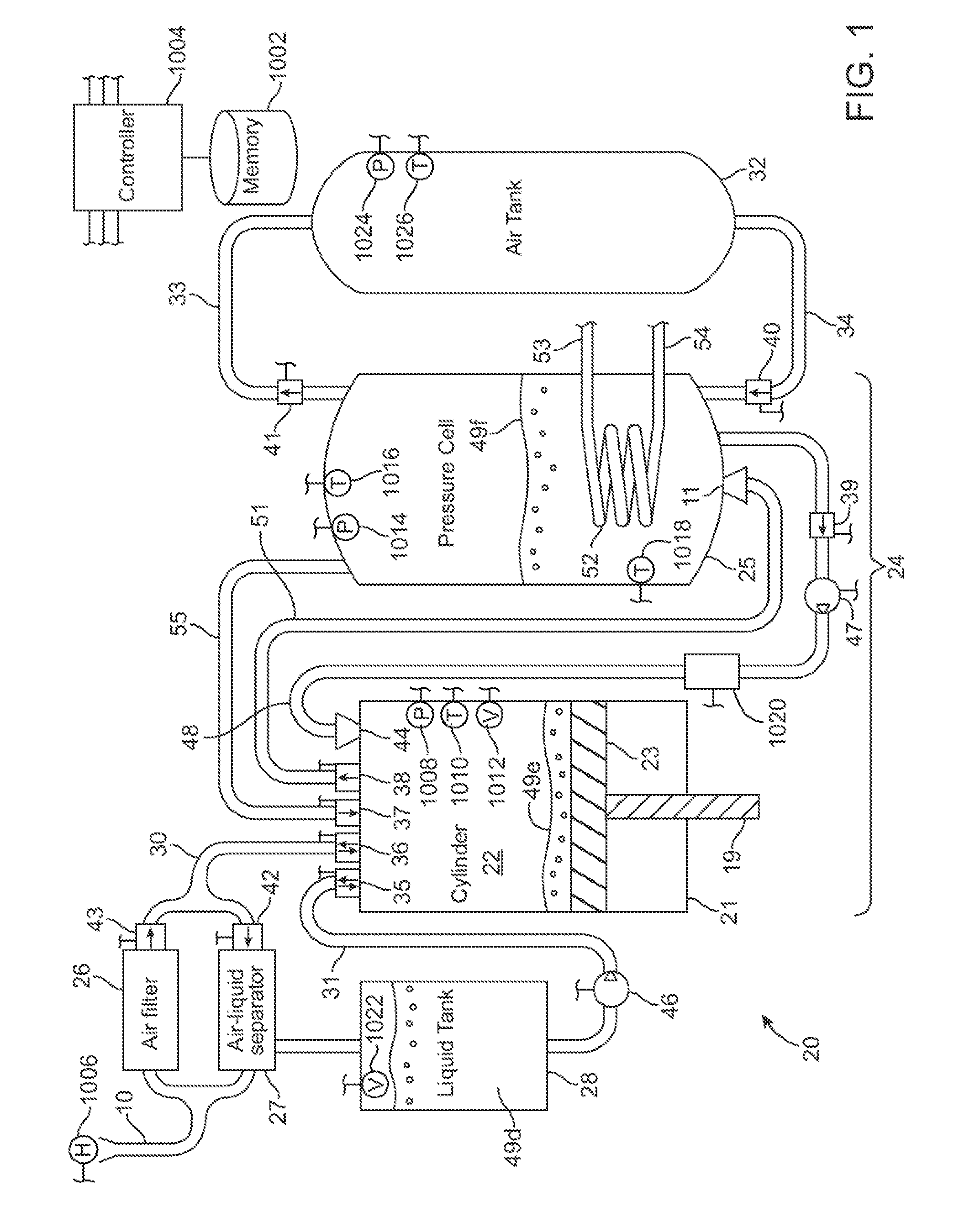

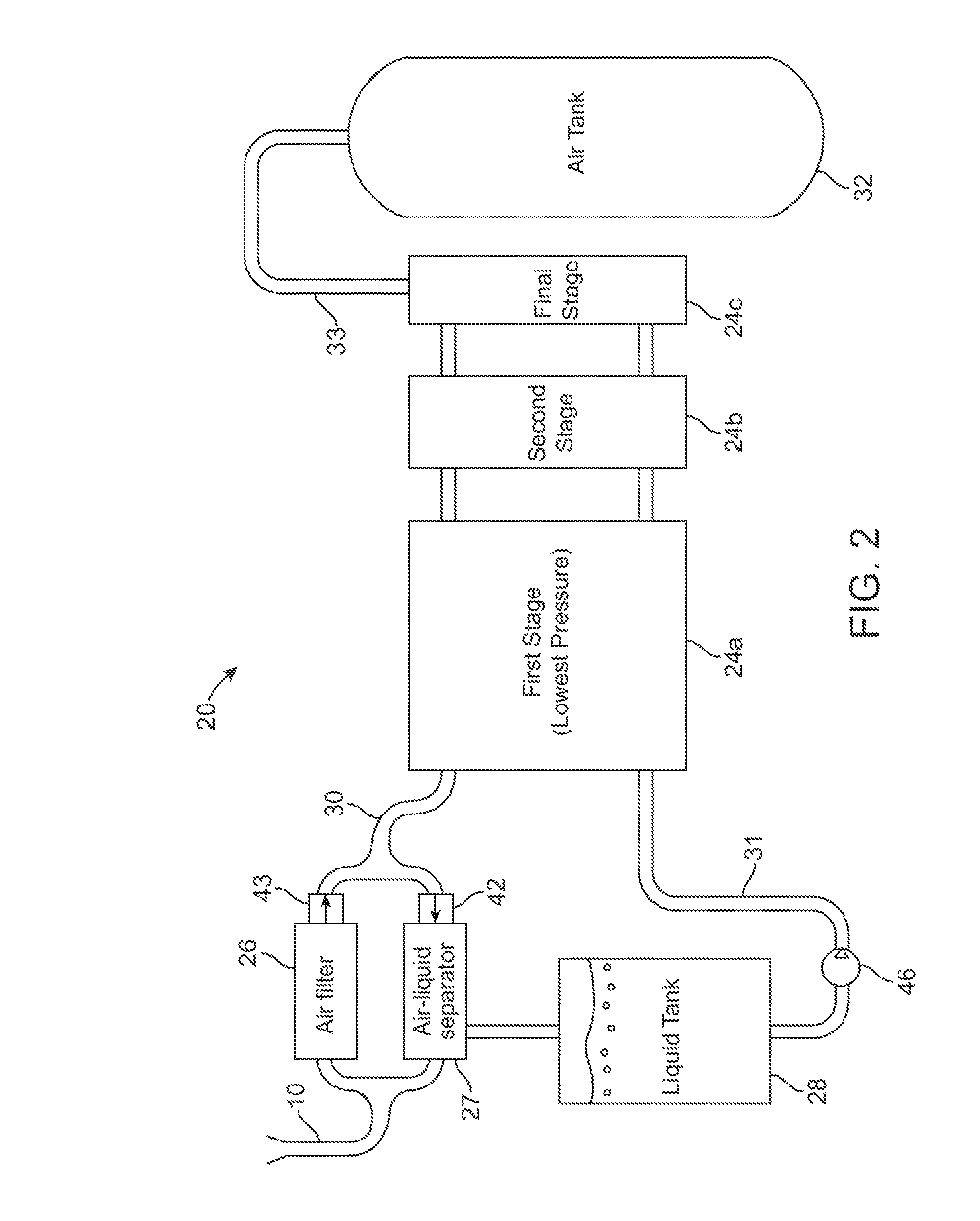

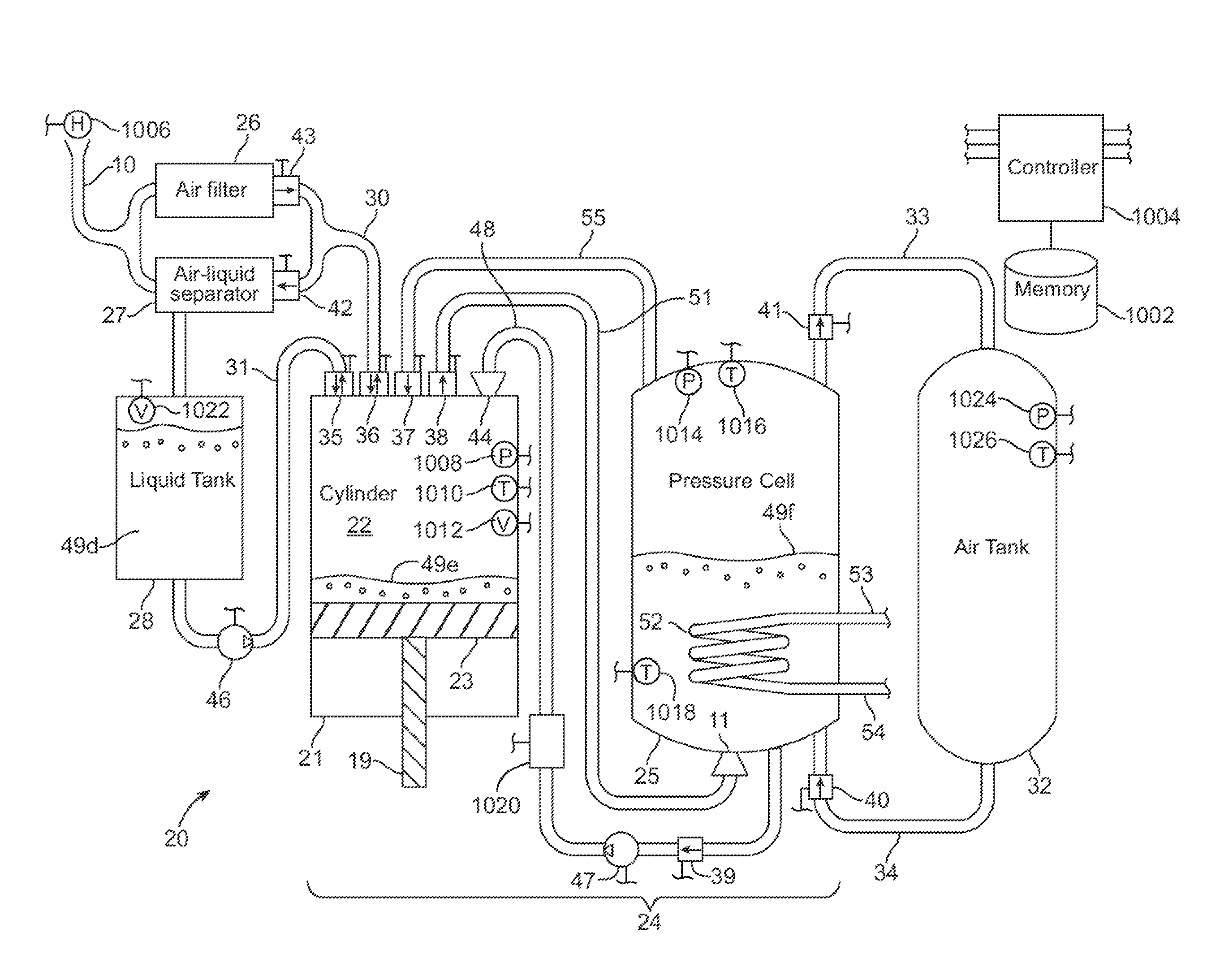

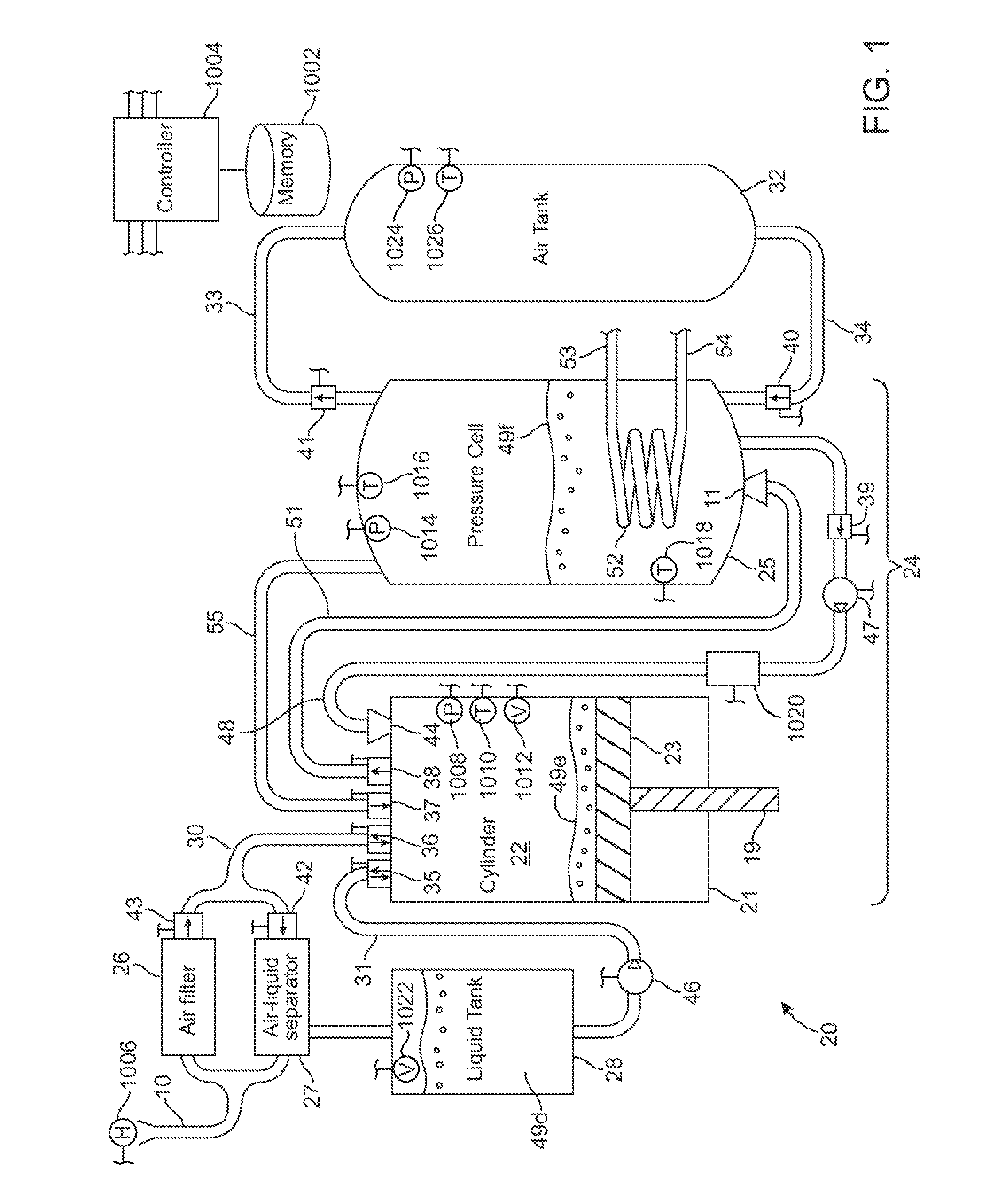

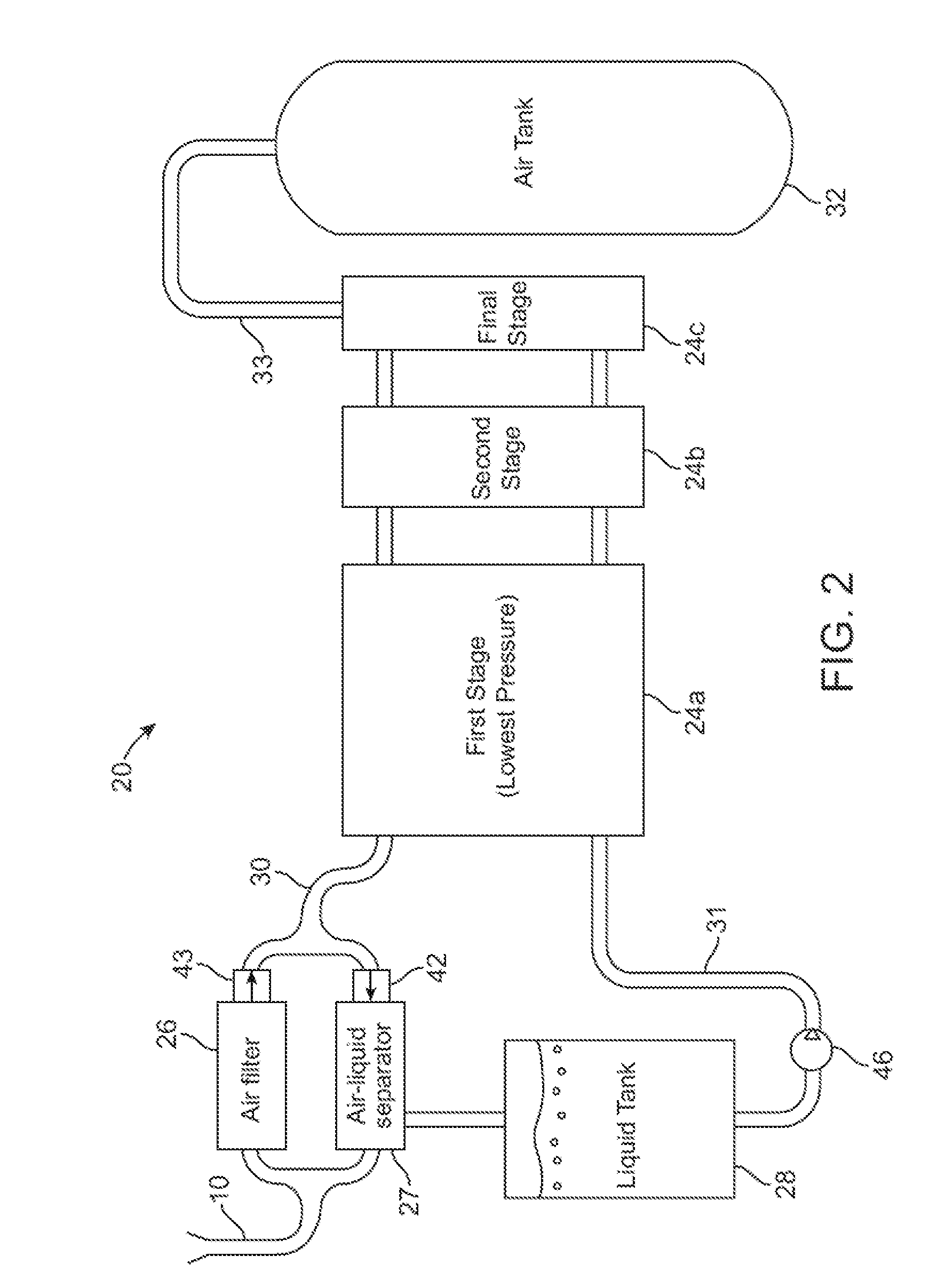

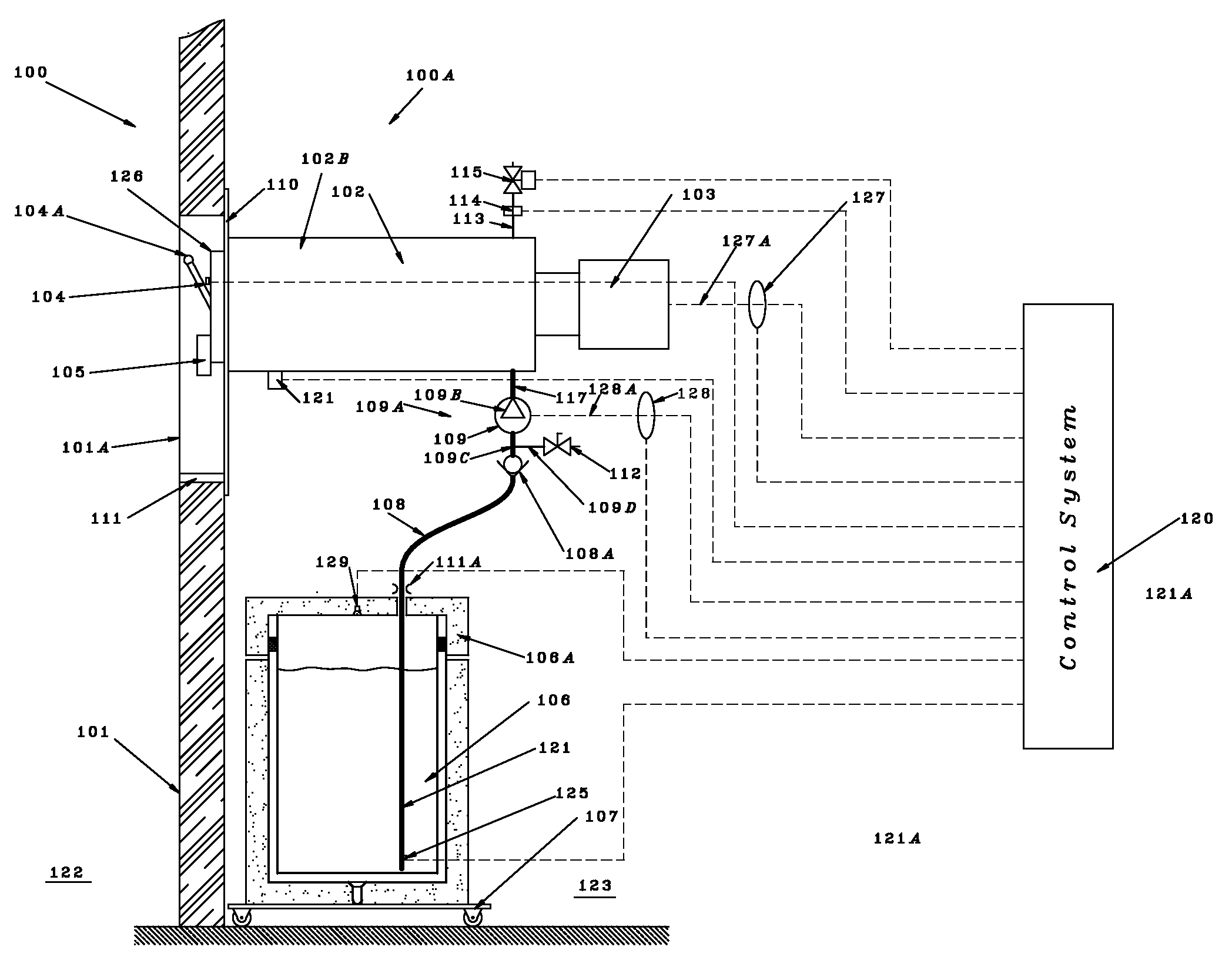

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326066A1High efficiencyFacilitate heat exchangeElectrical storage systemServomotor componentsAir compressorControl system

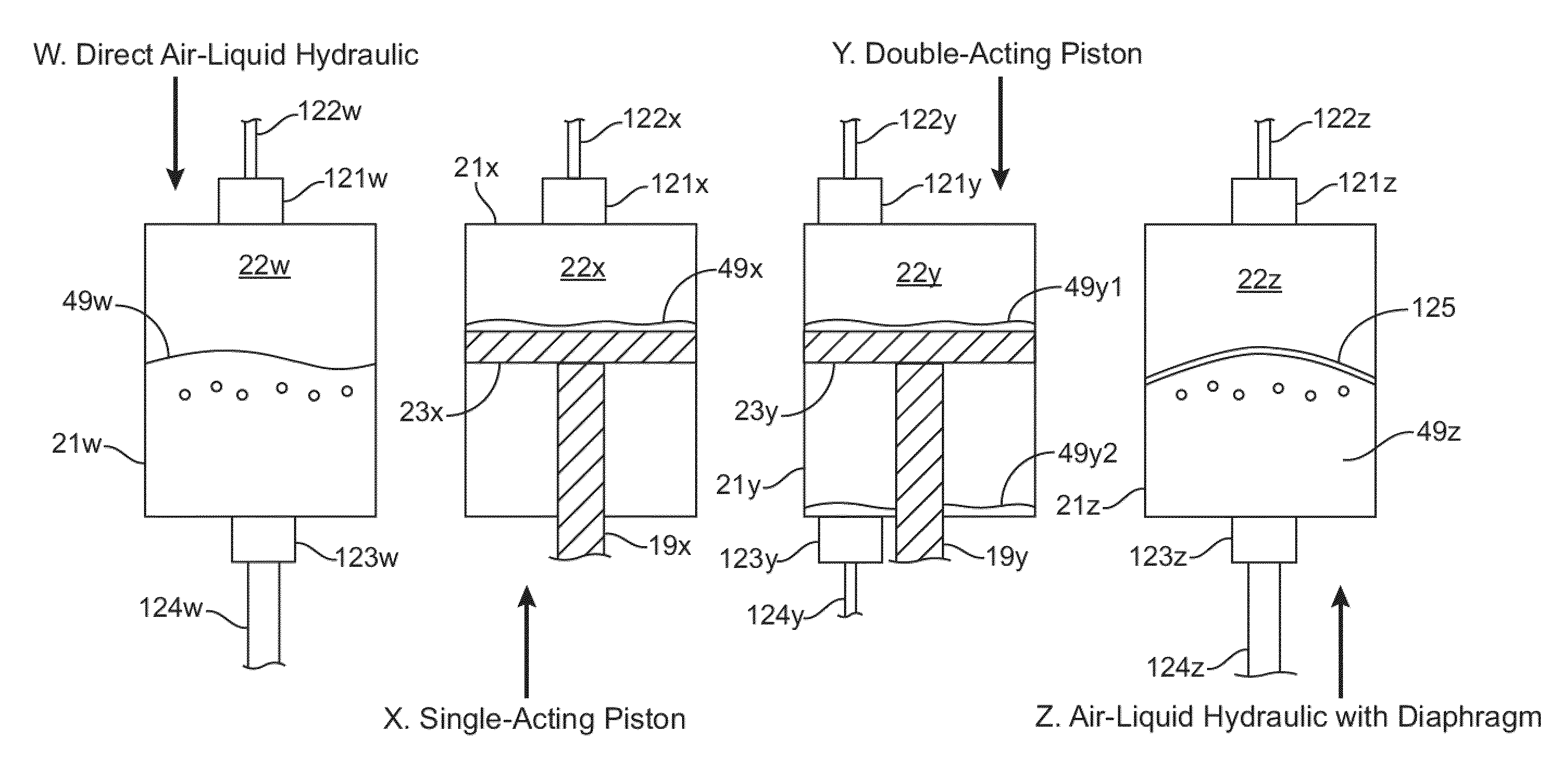

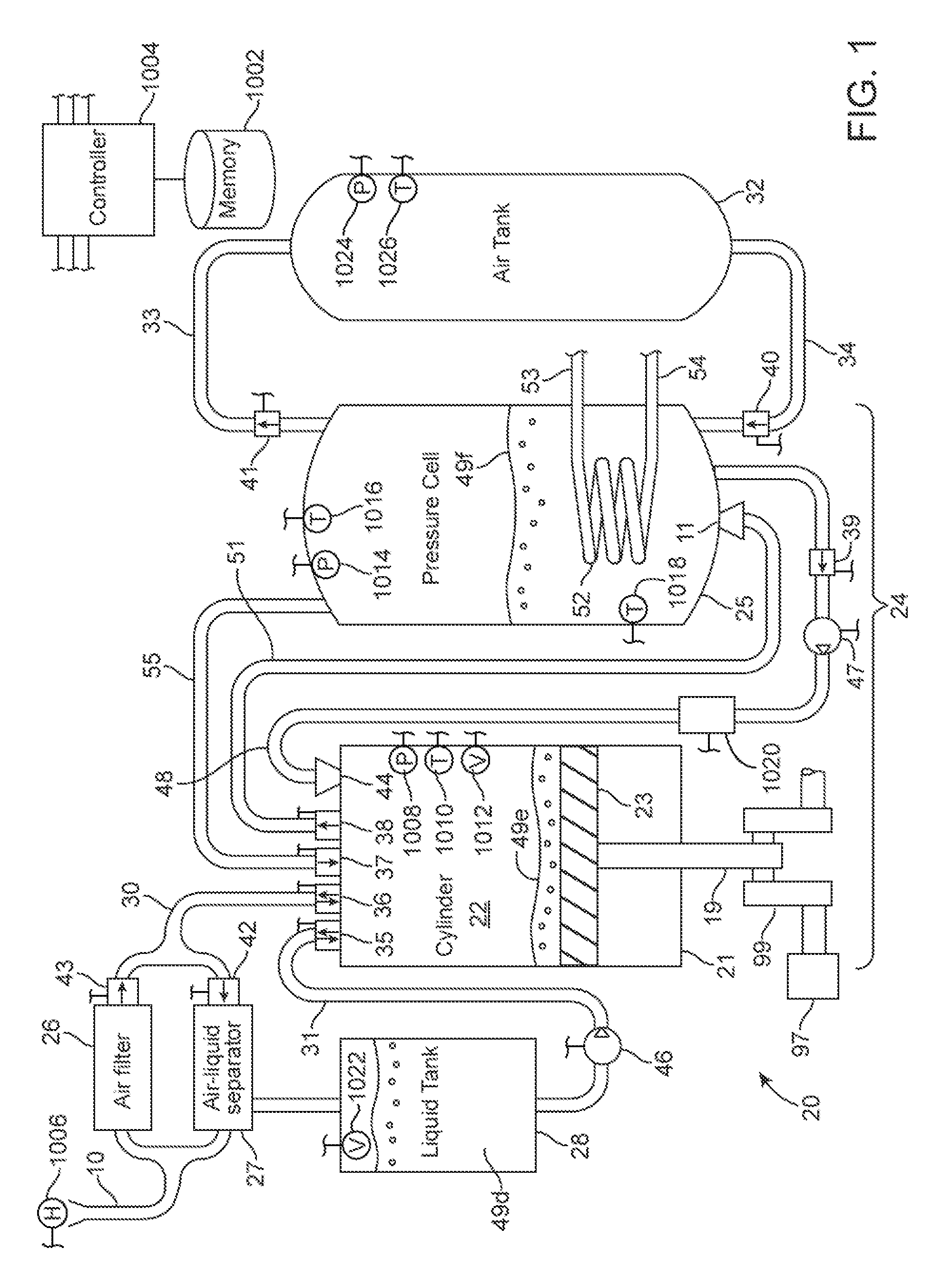

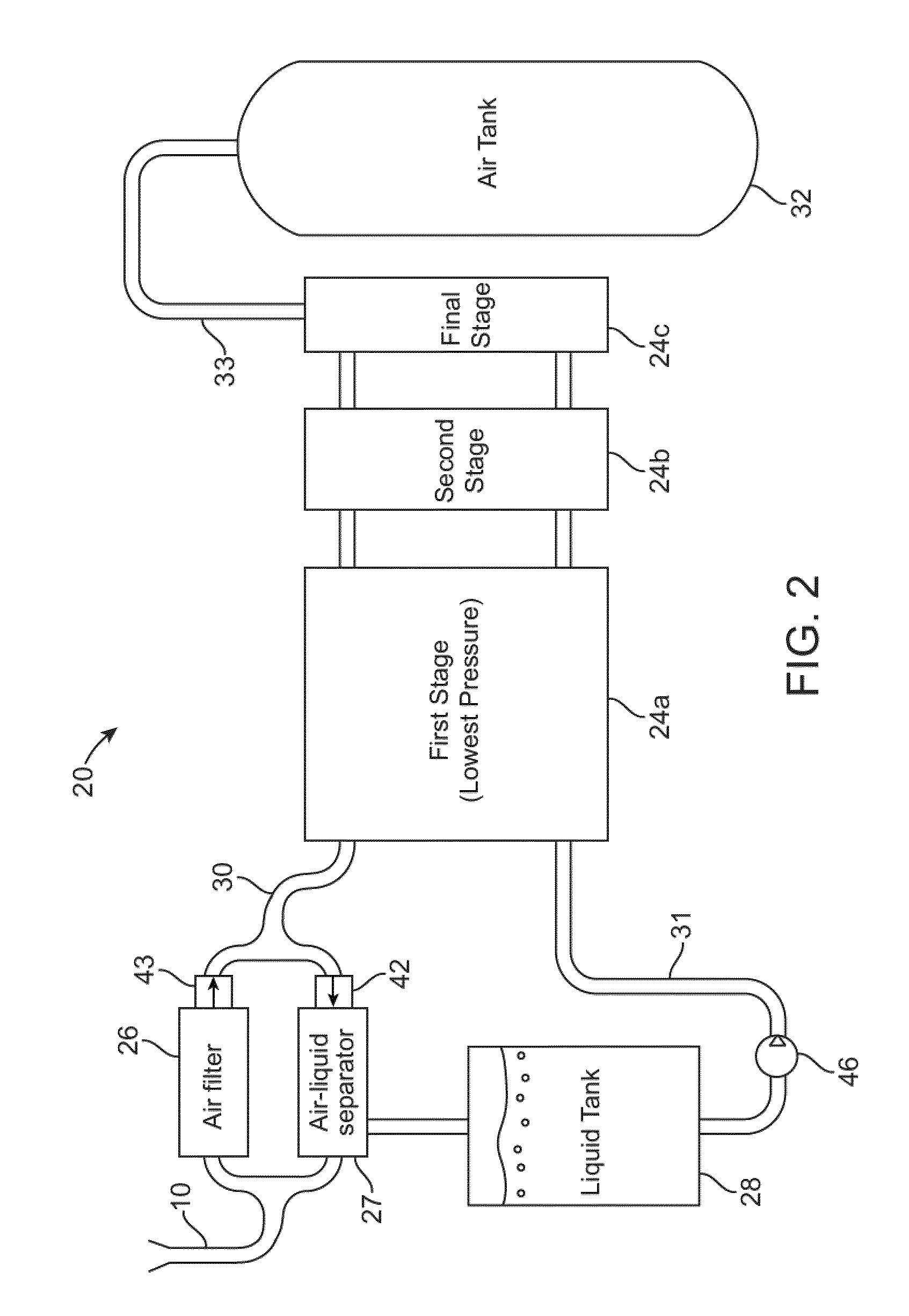

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

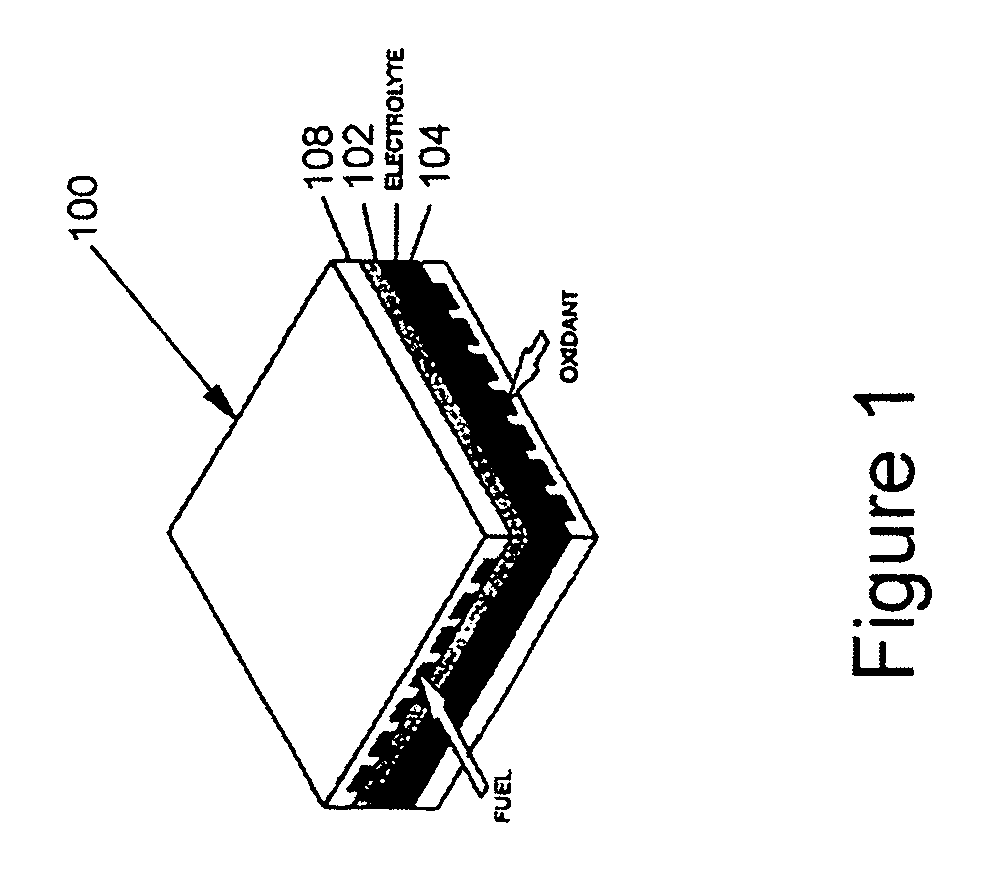

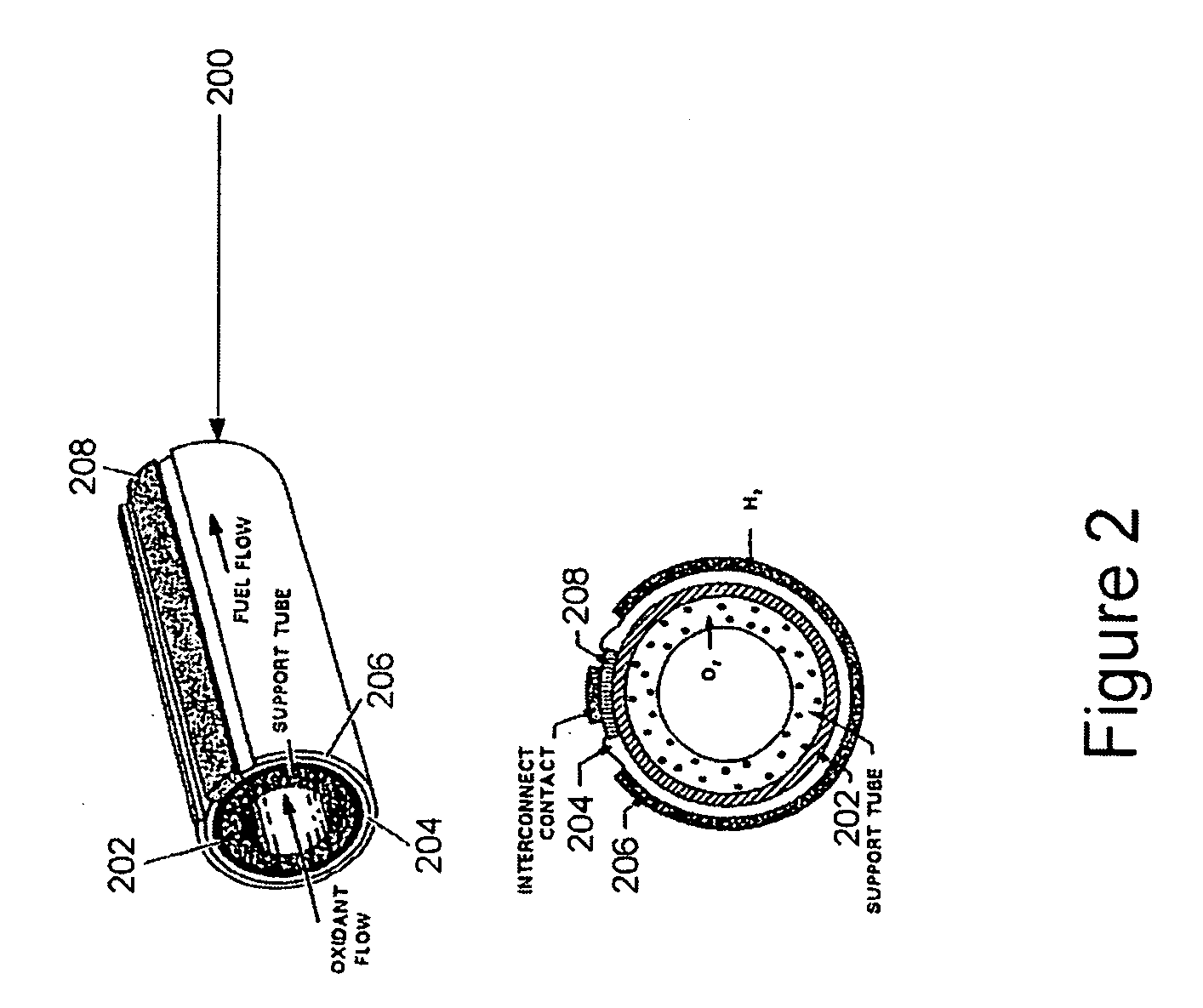

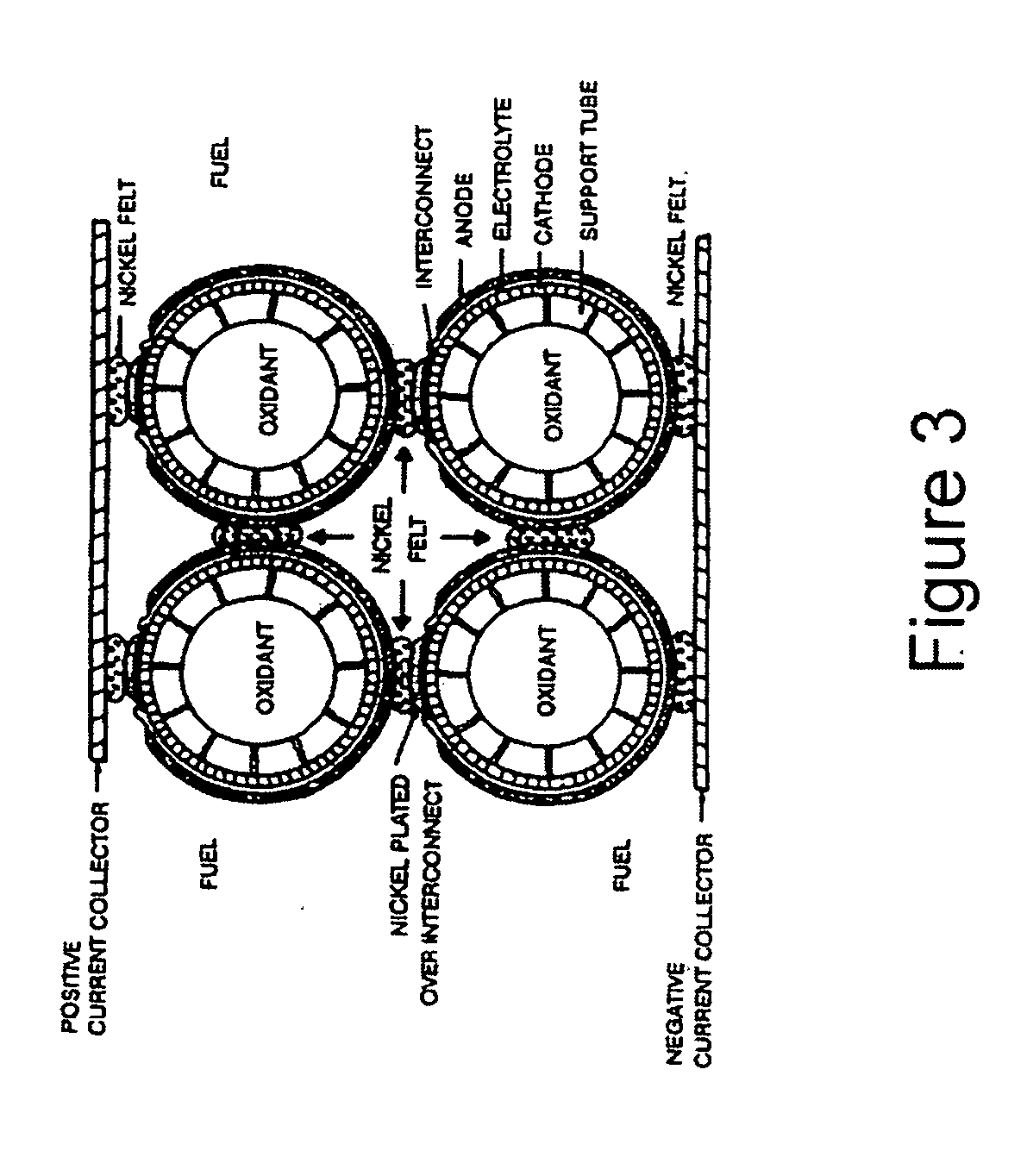

Tubular solid oxide fuel cells

InactiveUS20050037252A1Strong electrical contactImprove power densityFuel cells groupingCell electrodesFuel cellsThermal expansion

An anode-supported tubular fuel cell stack includes interconnect structures that are oxidation resistant at high temperature, flexible to accommodate thermal expansion stress and to provide strong electrical contact, have low electrical resistance, and are inexpensive and light weight. The interconnect structures may be formed out of metal sheet, which provide improved heat homogeneity throughout the fuel cell stack because of the high thermal conductivity of the metal. The interconnect structures are further shaped to provide resilience or spring-like features to allow movement between the tubular cells. Thus good electrical contact, thermal stress release, and shock absorption are simultaneously achieved.

Owner:EVOGY

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326068A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

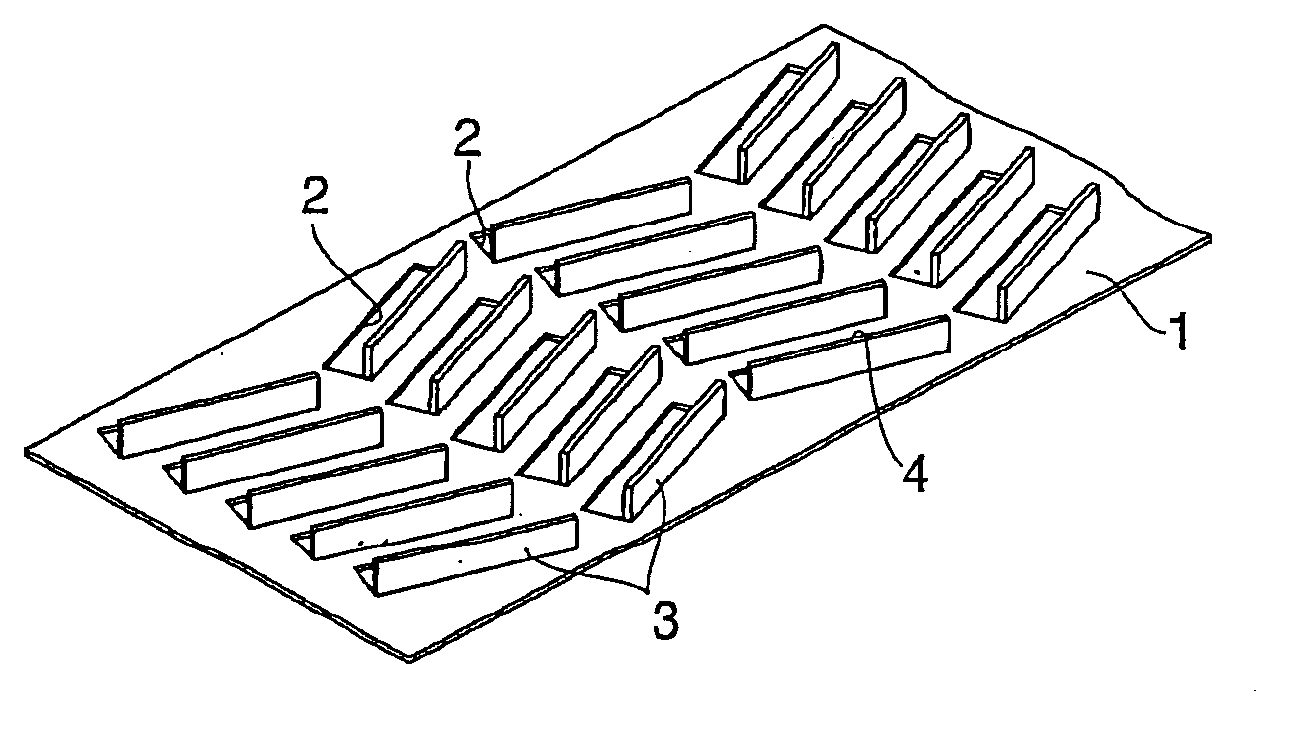

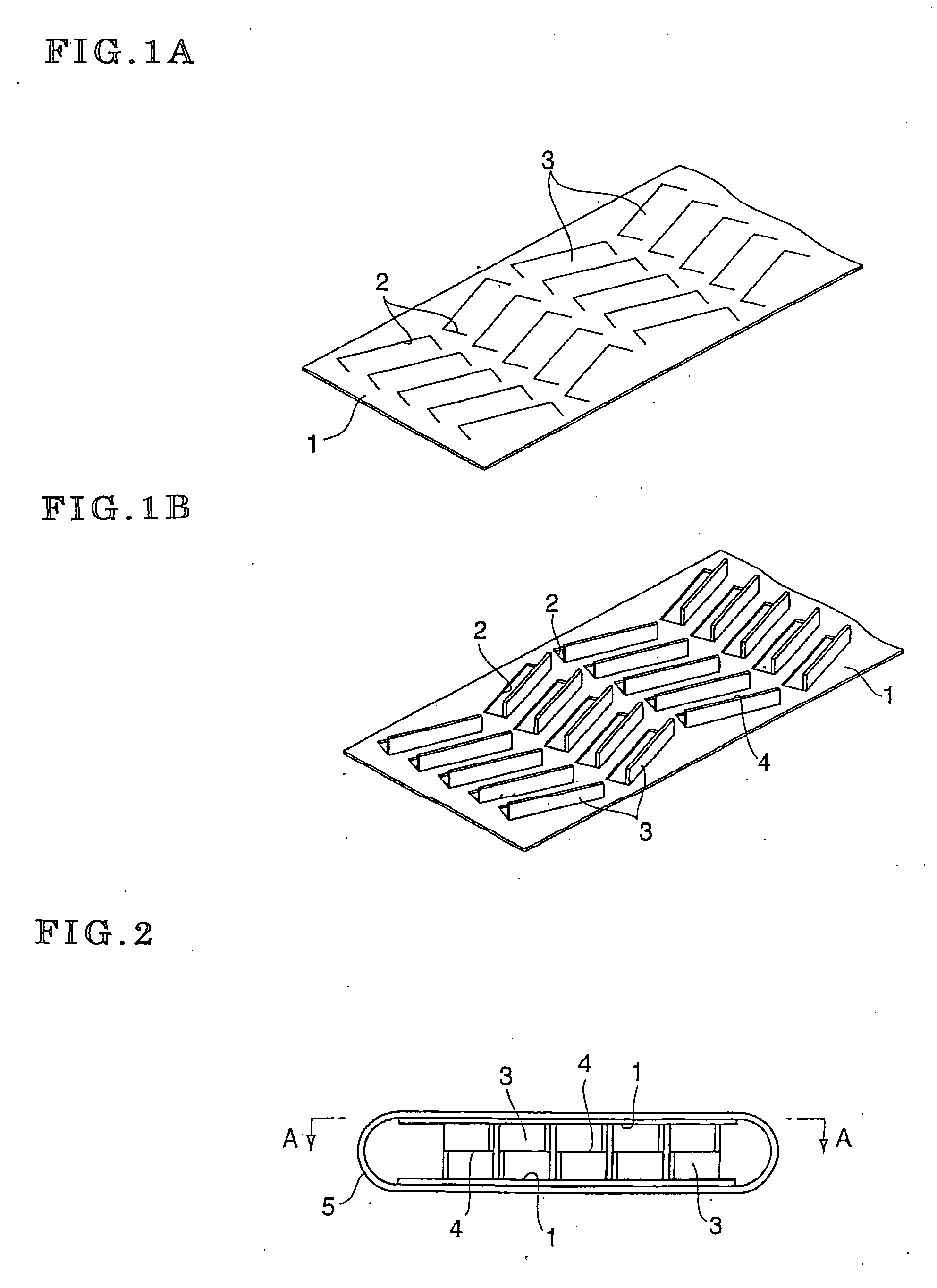

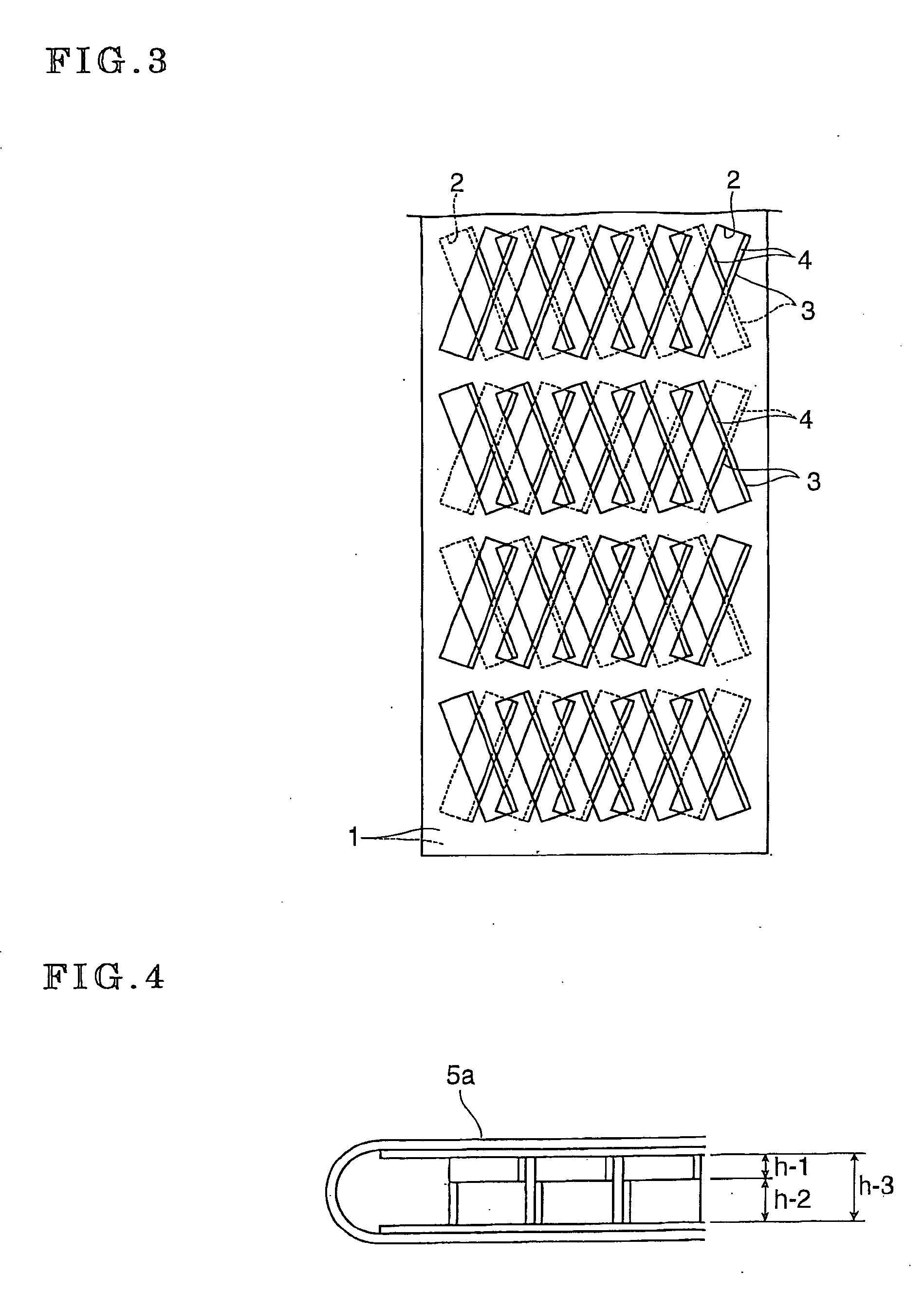

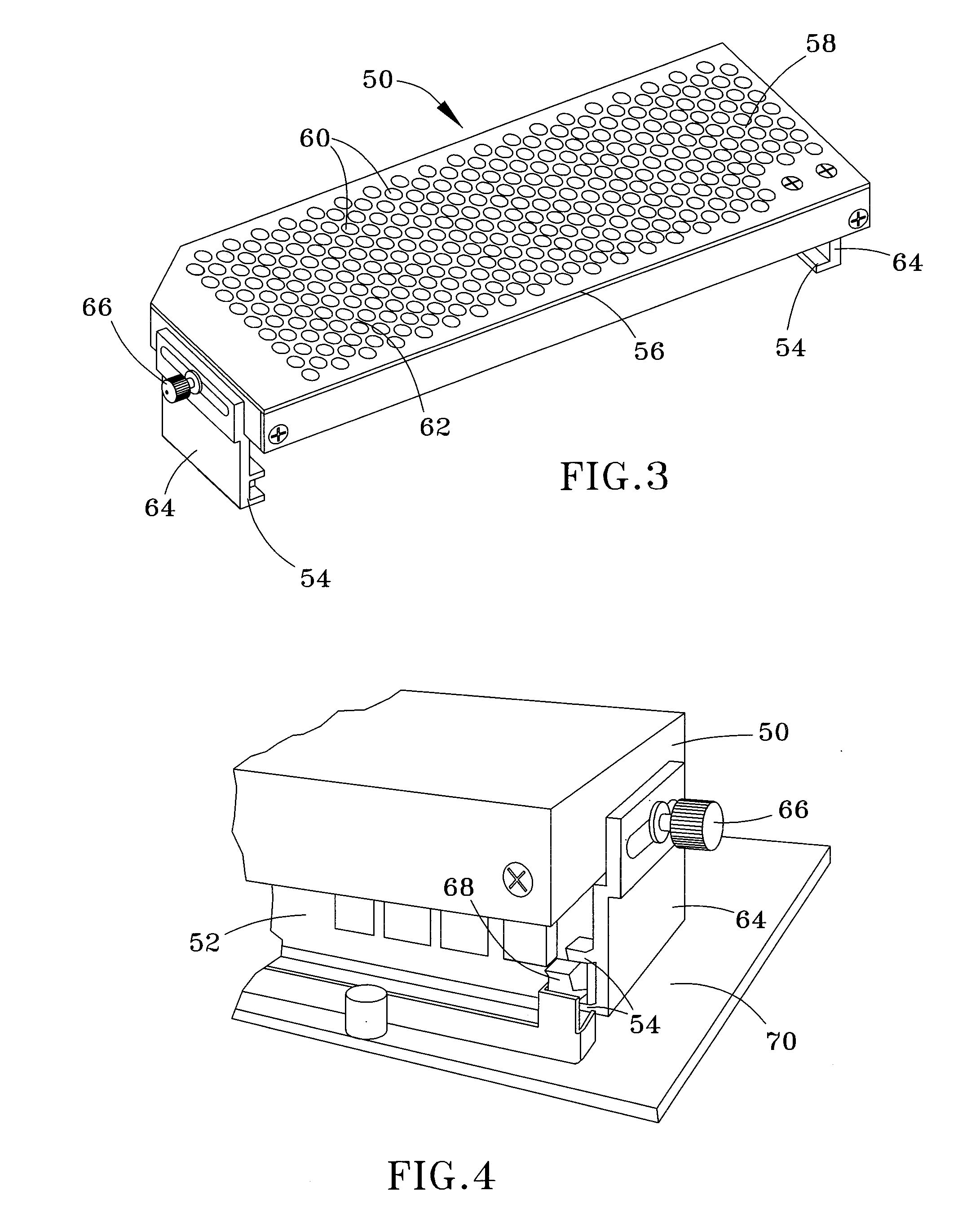

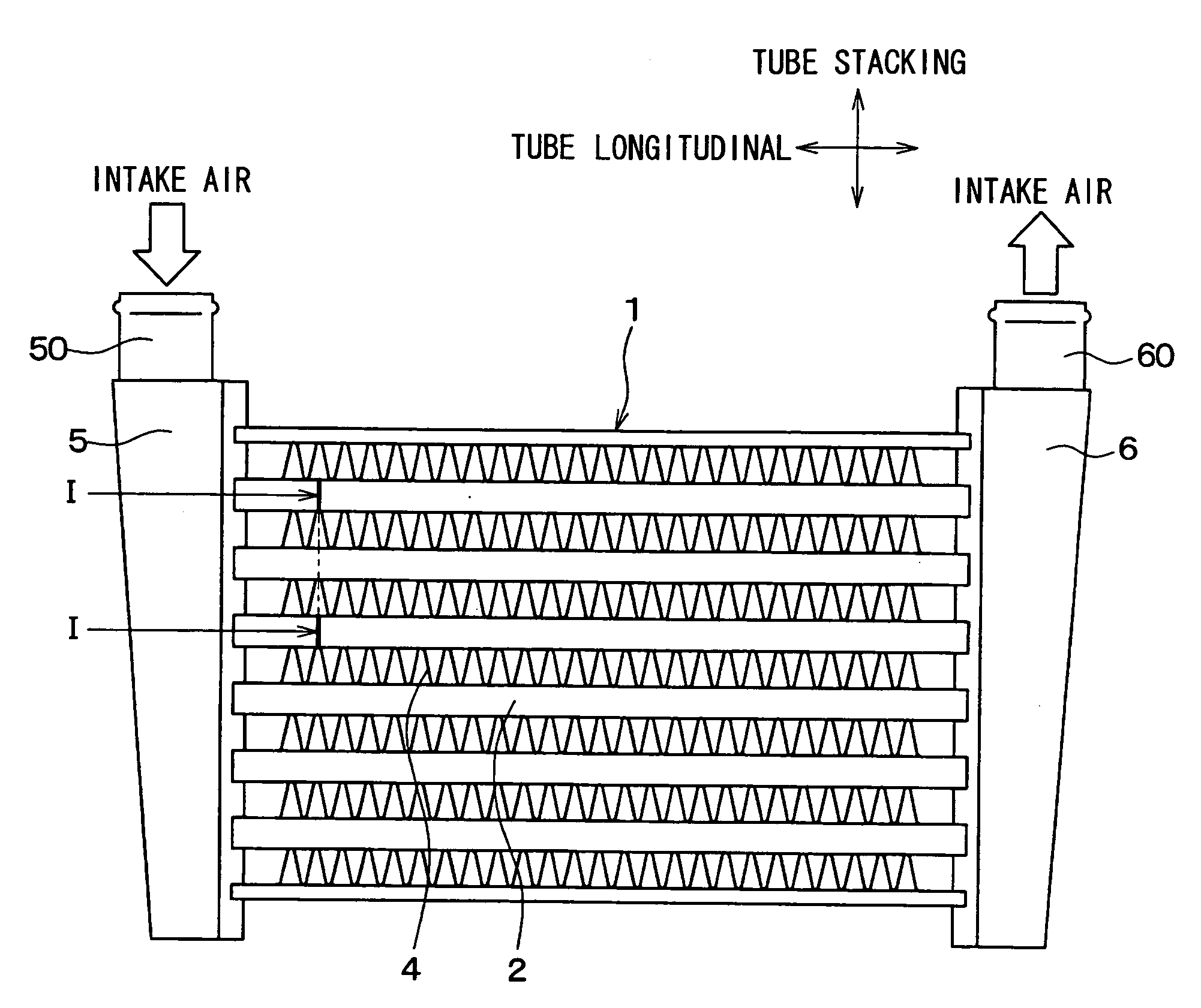

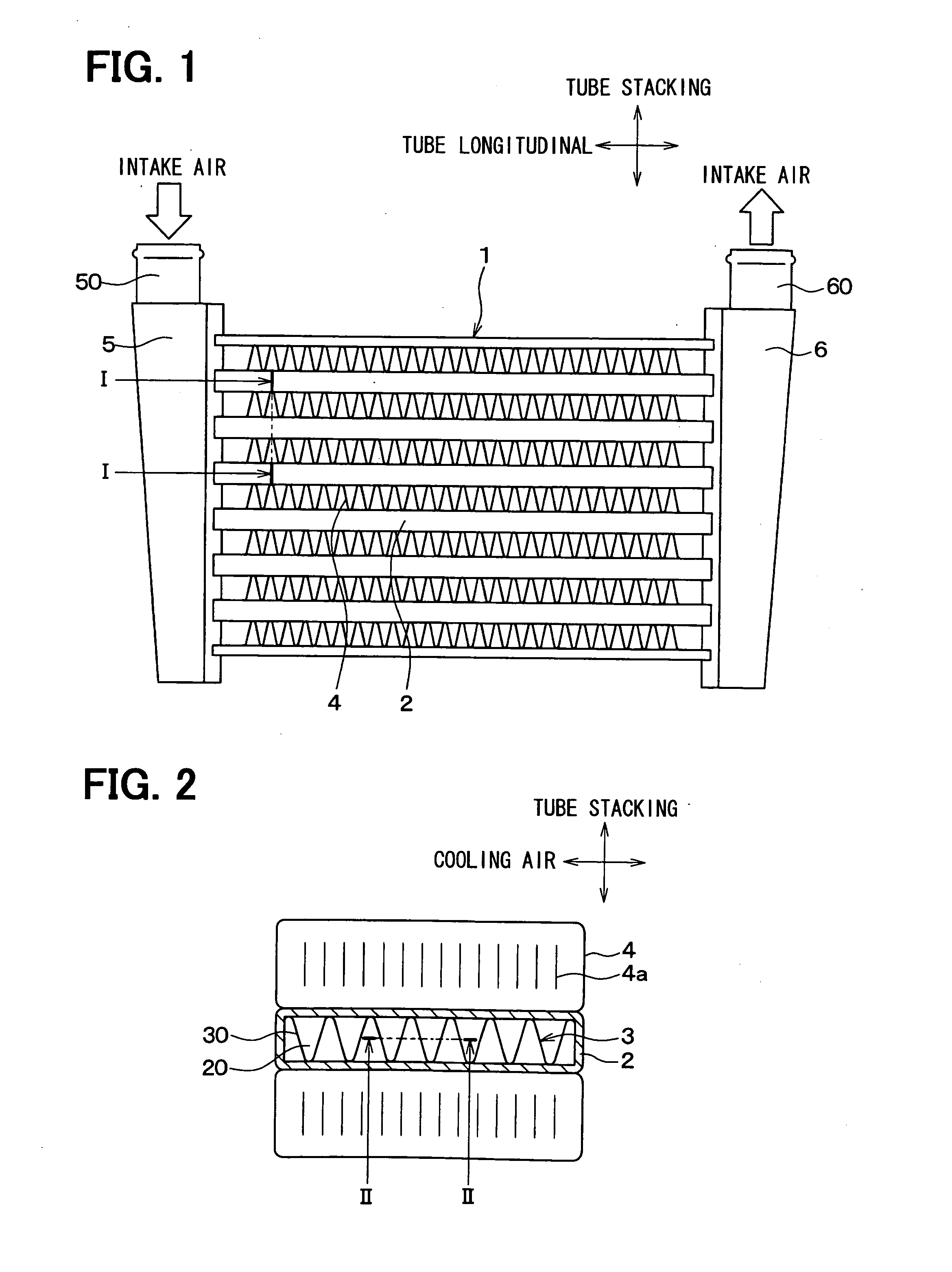

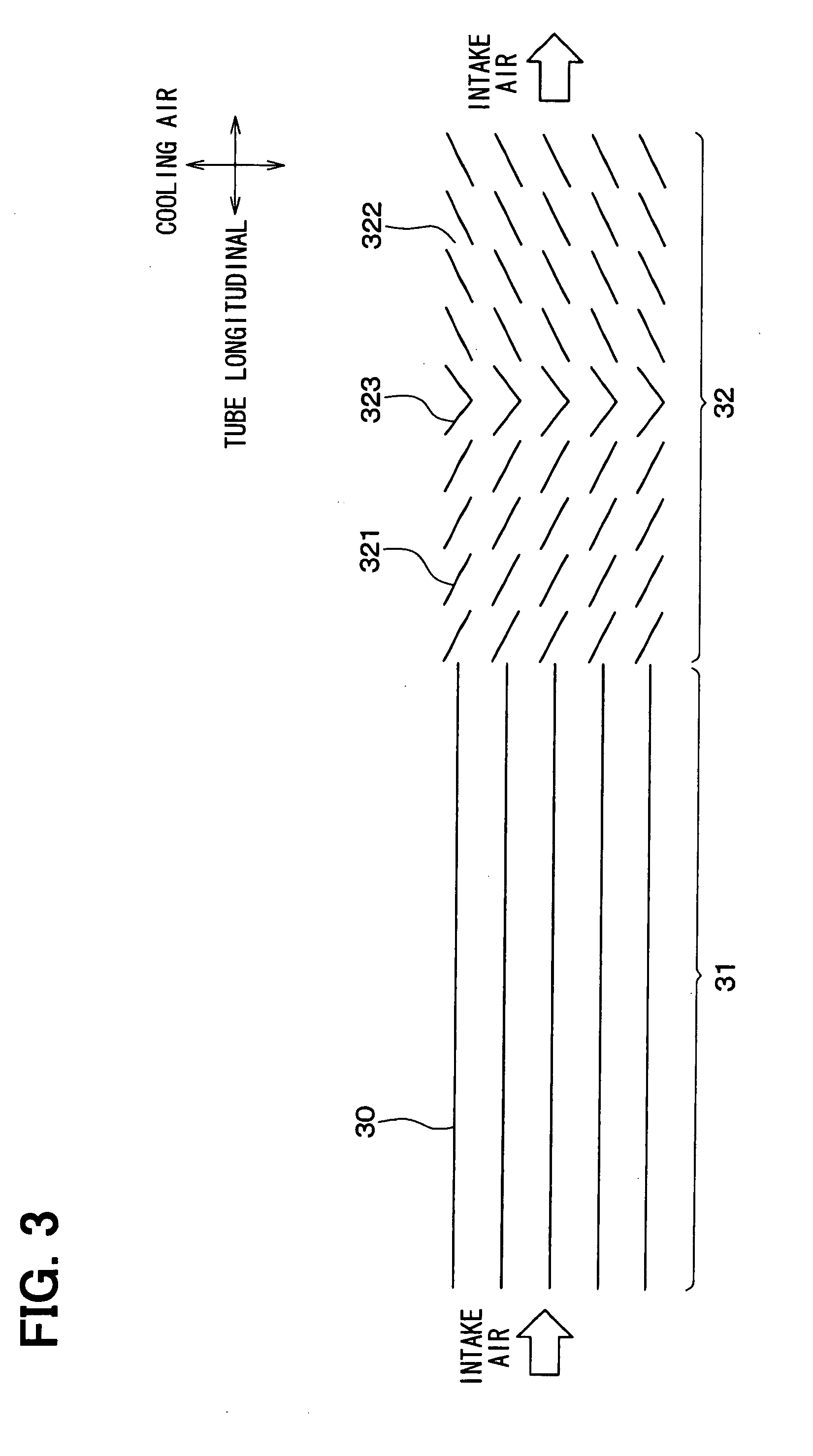

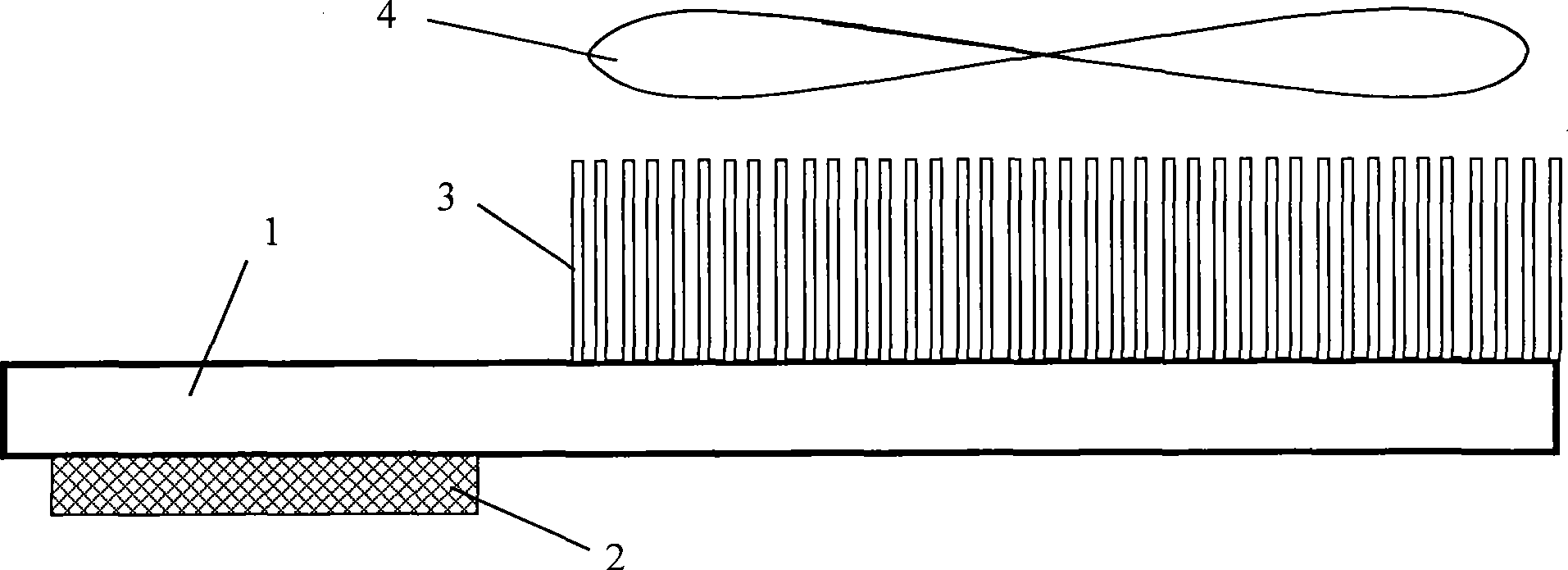

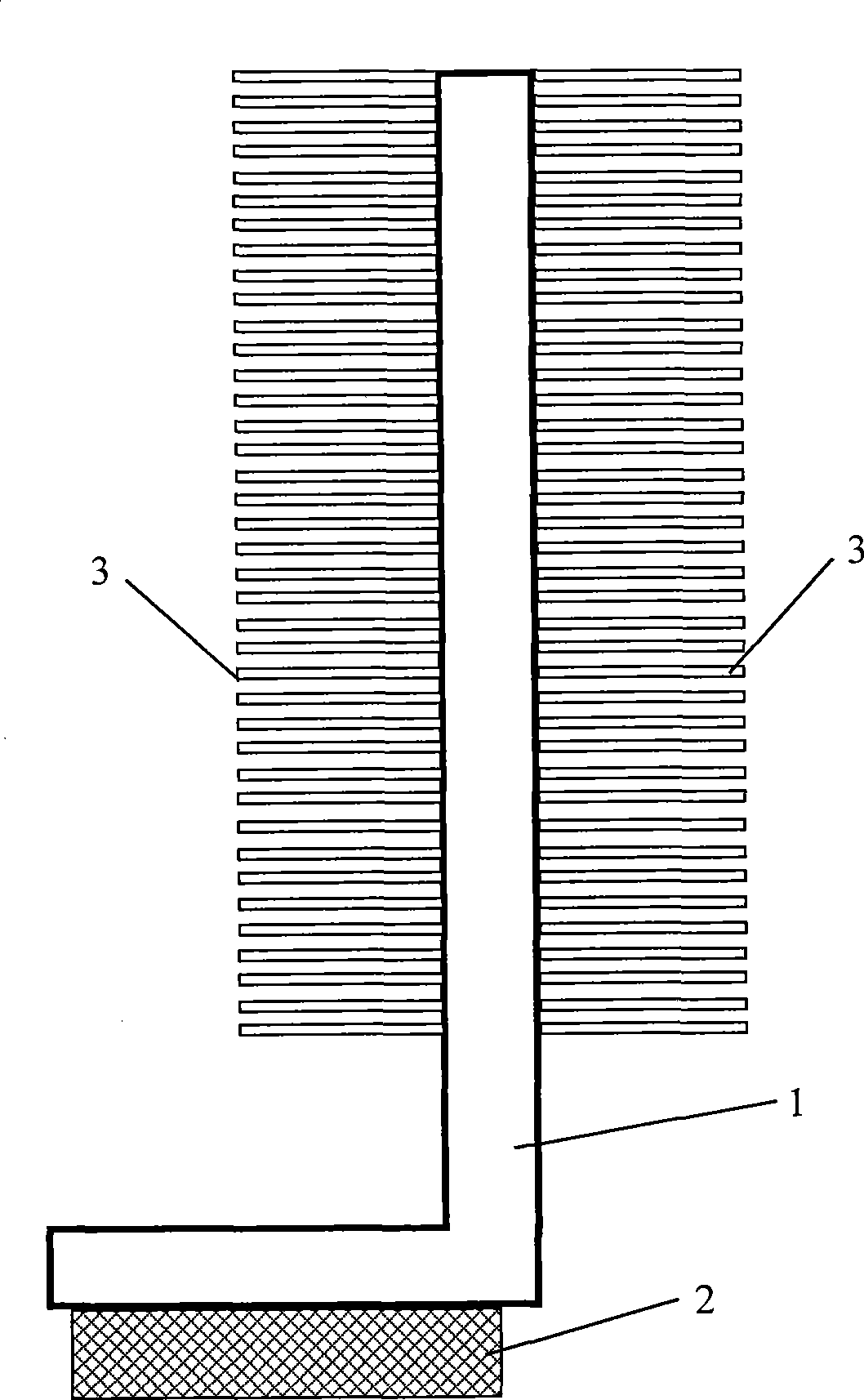

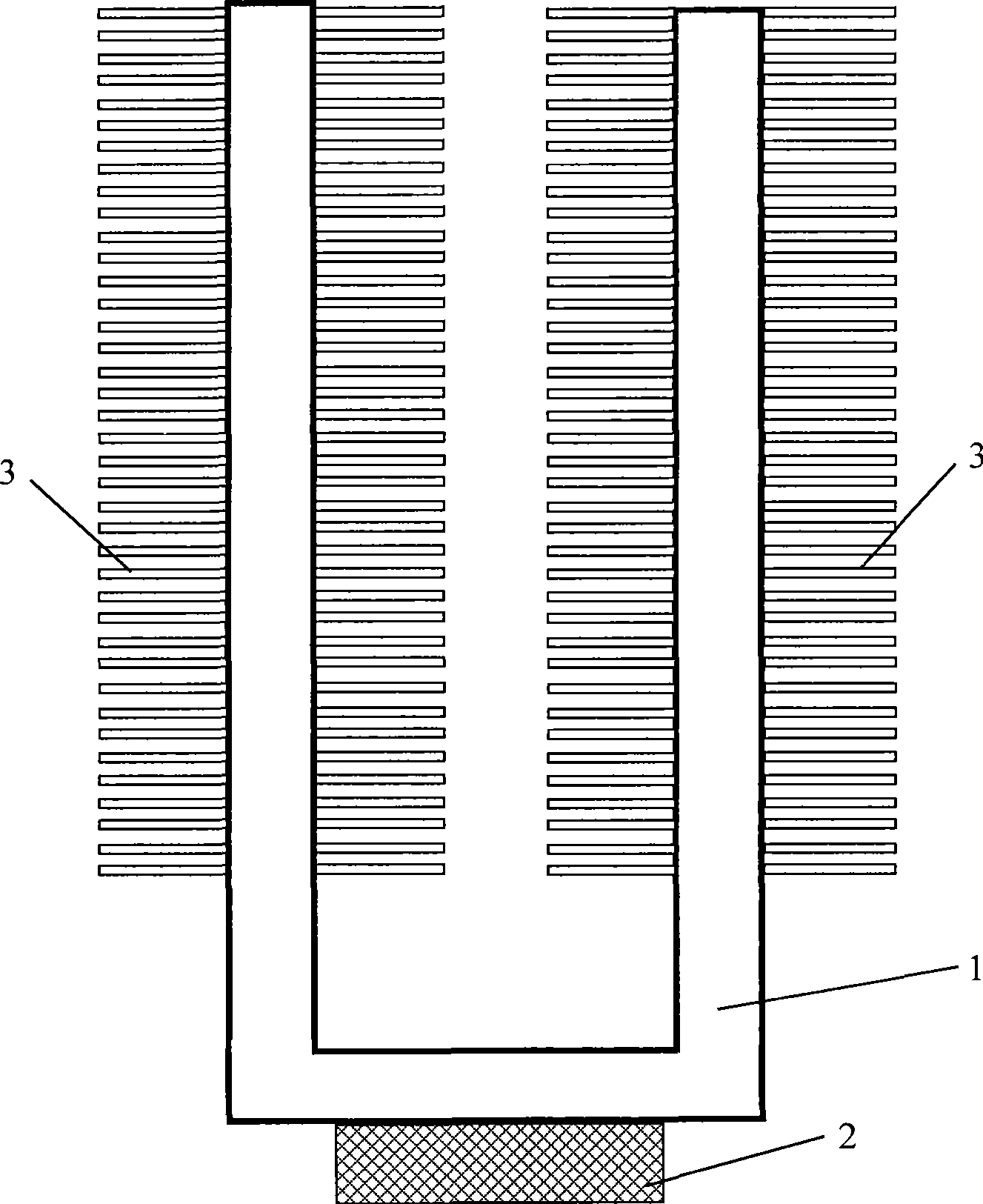

Fluid agitating fin, method of fabricating the same and heat exchanger tube and heat exchanger or heat exchanging type gas cooling apparatus inwardly mounted with the fin

InactiveUS20060016582A1Improve cooling efficiencyEfficiently agitatedInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringCooling fluid

A fluid agitating plate fin is mounted to a heat exchanger tube to agitate a cooling fluid and to create a turbulent flow. Edges of the plate fins are opposed to each other and the opposed butted blade edges cross each other.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100329891A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsBattery energy storageAir compressor

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100329909A1High efficiencyFacilitate heat exchangeElectrical storage systemServomotor componentsAir compressorControl system

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

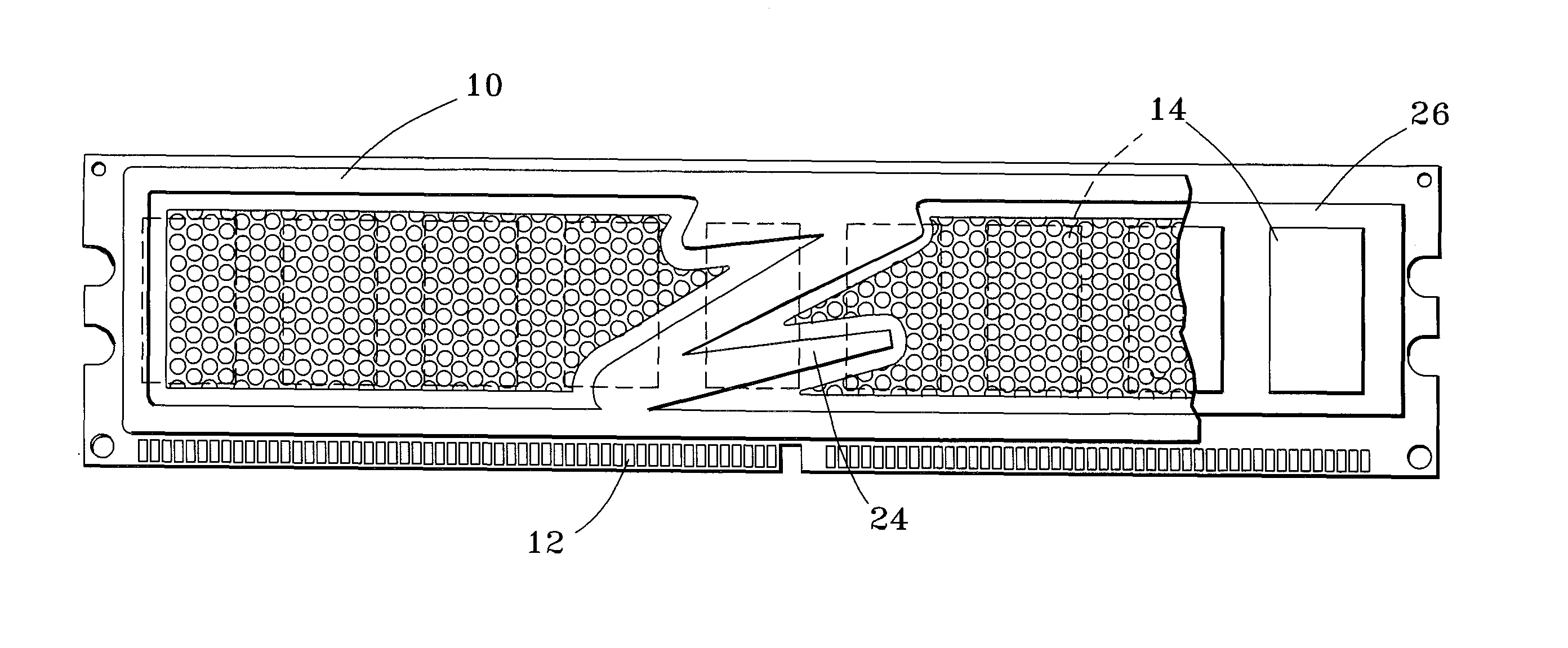

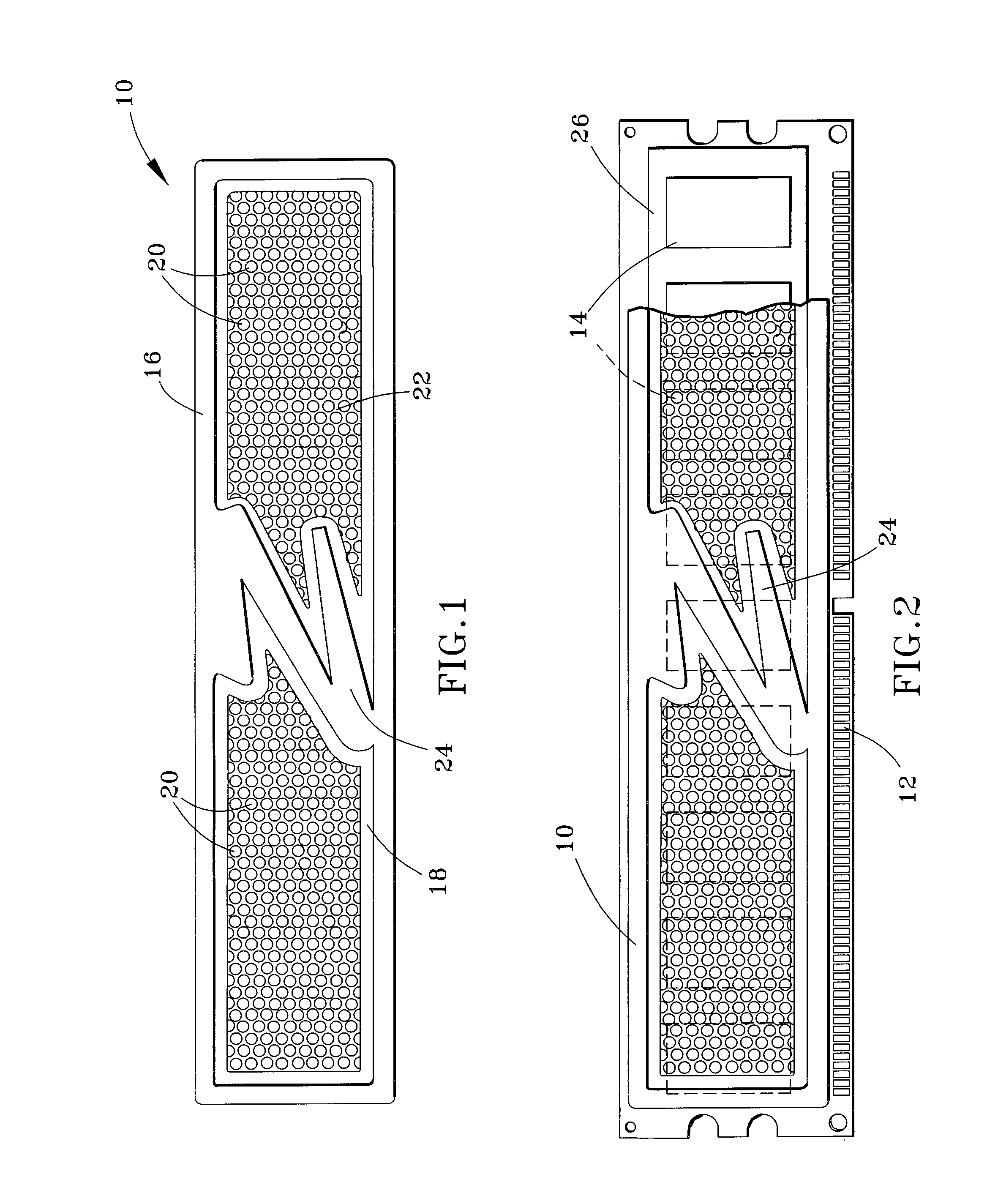

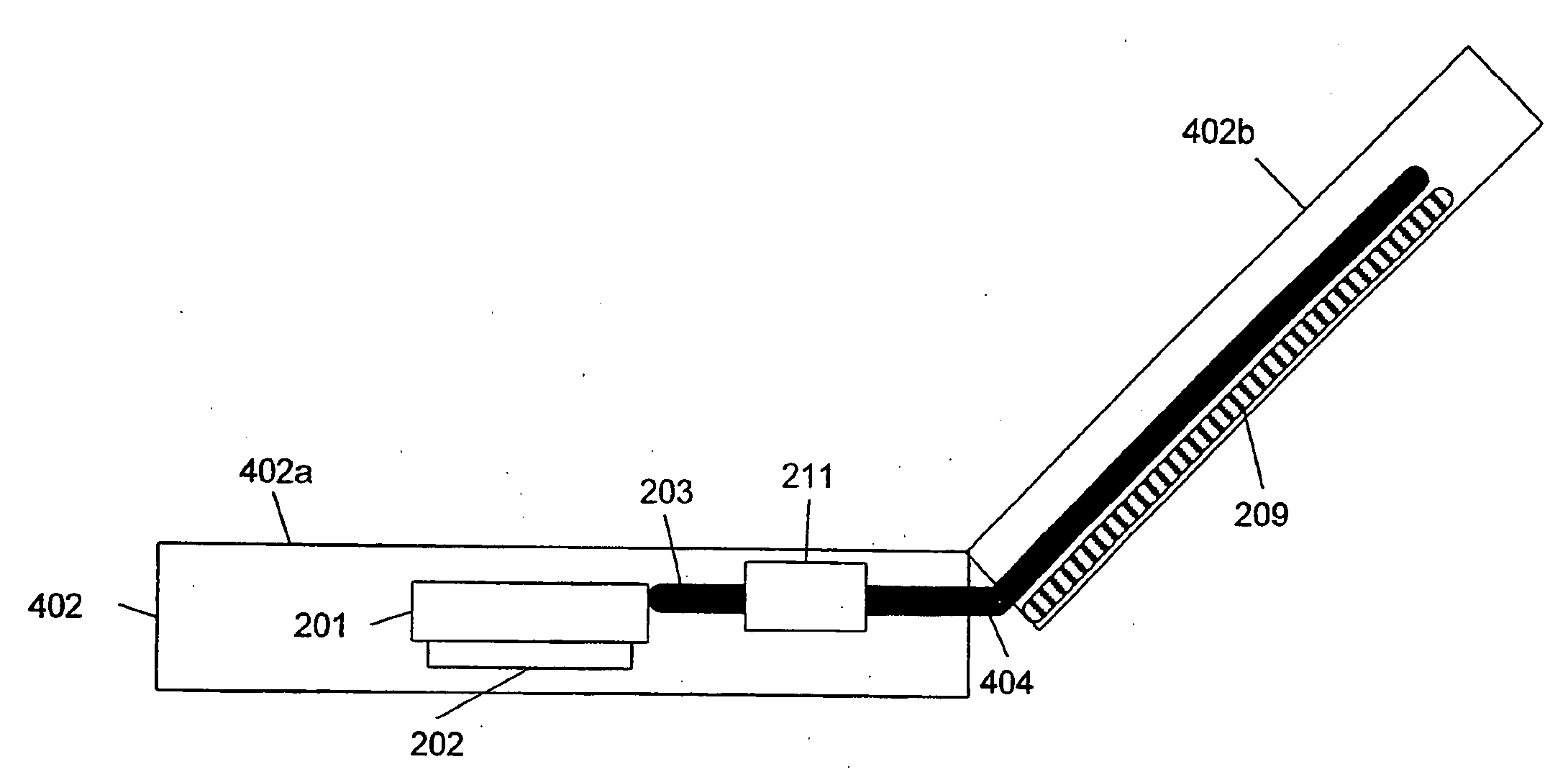

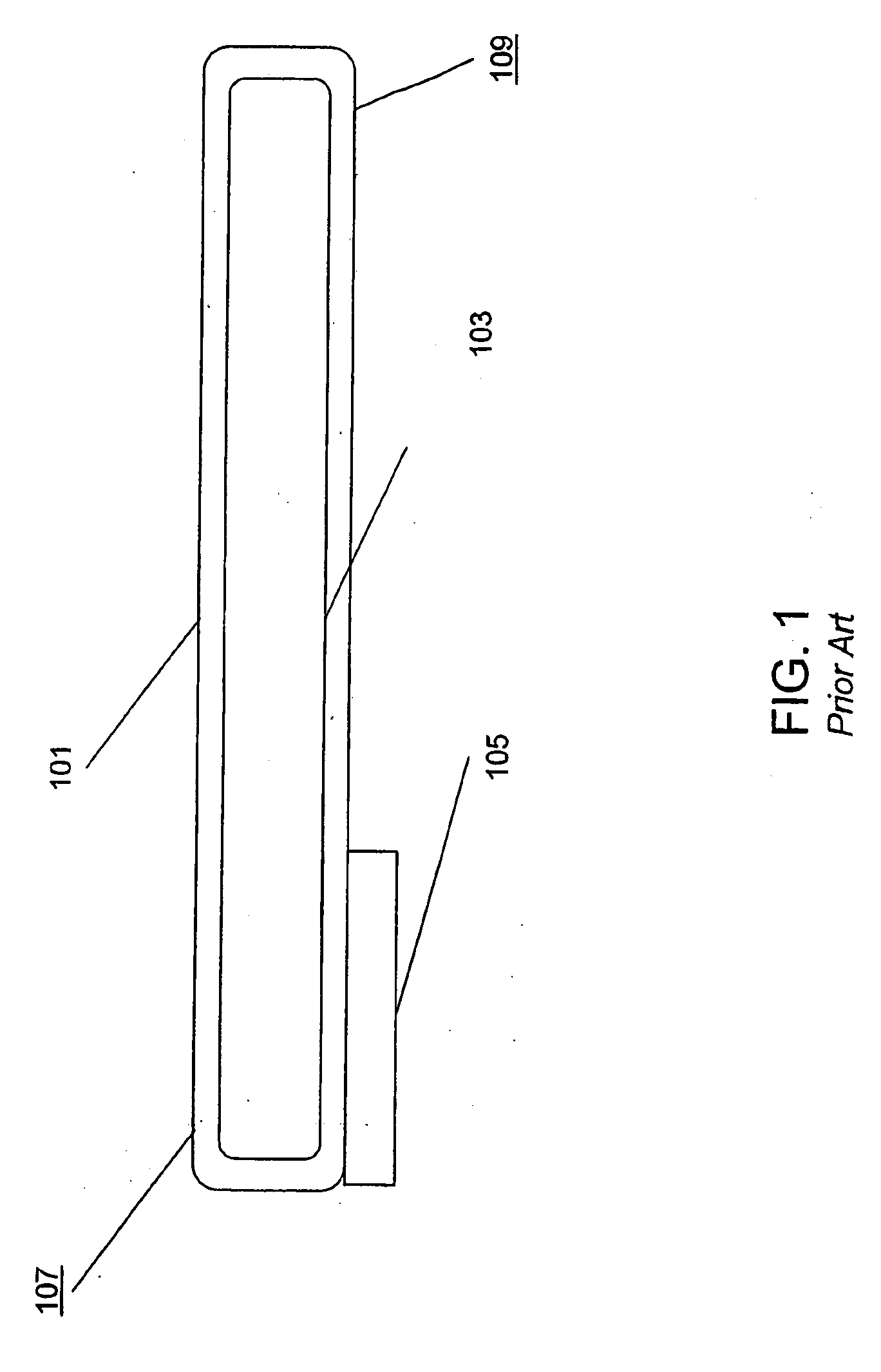

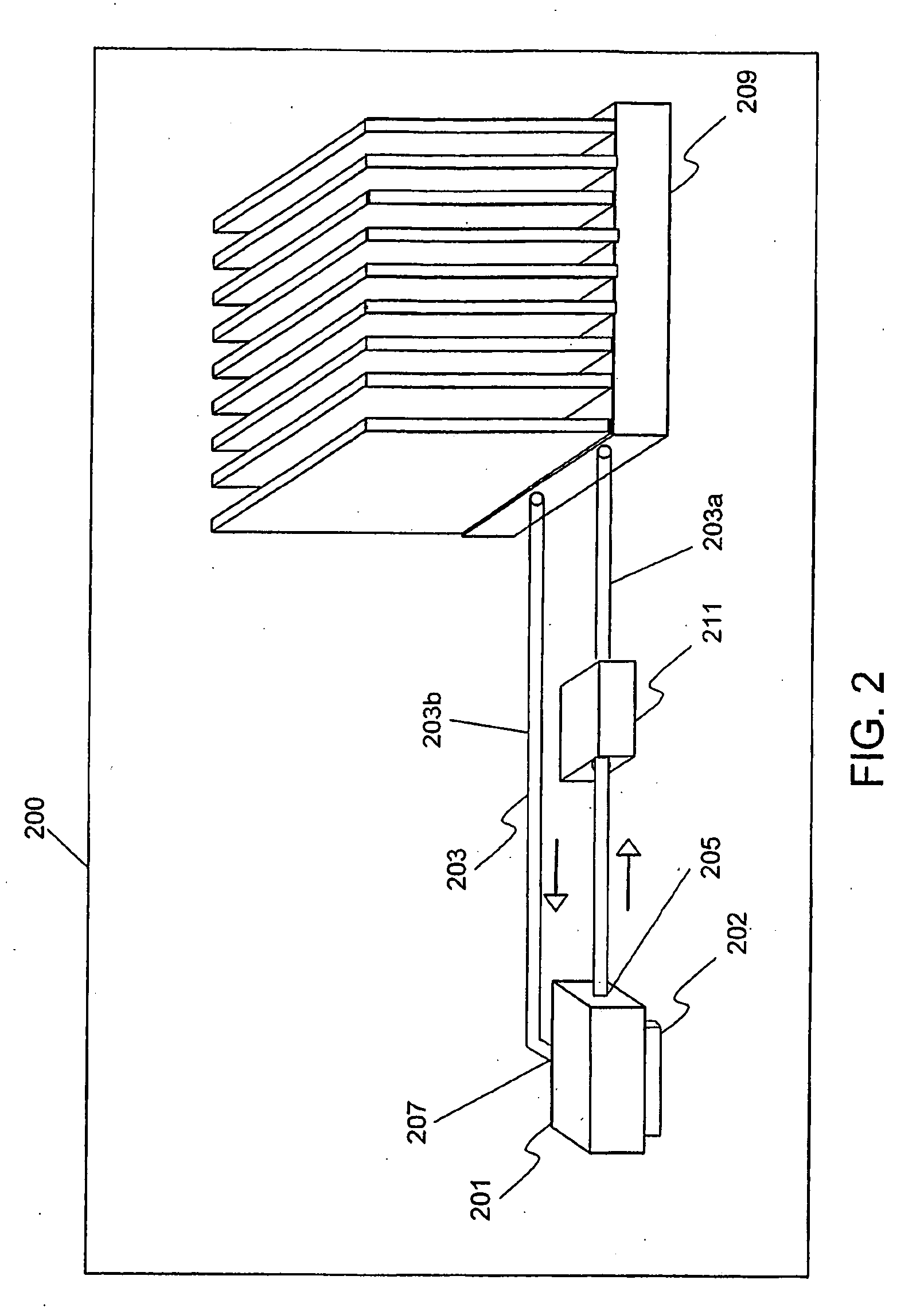

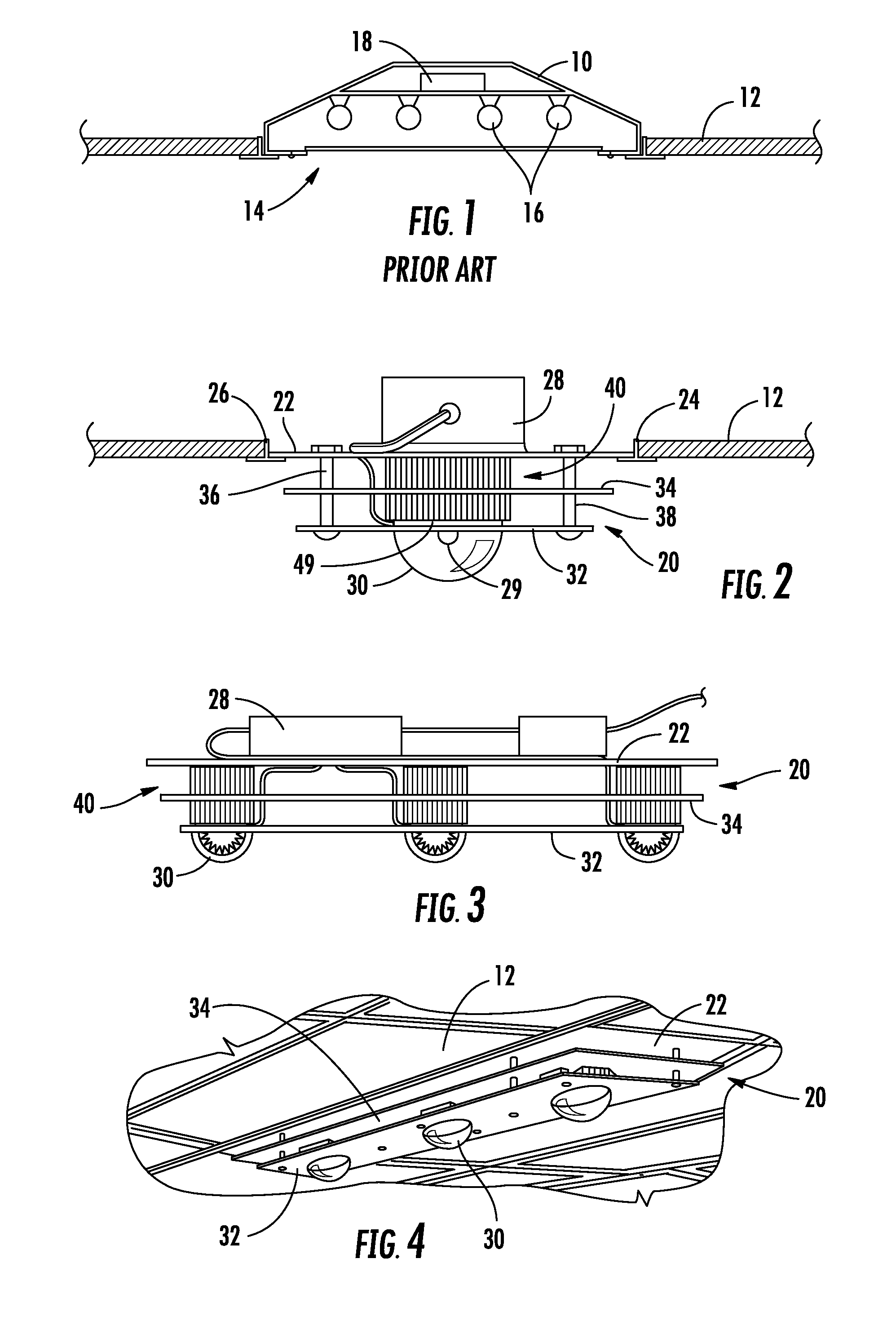

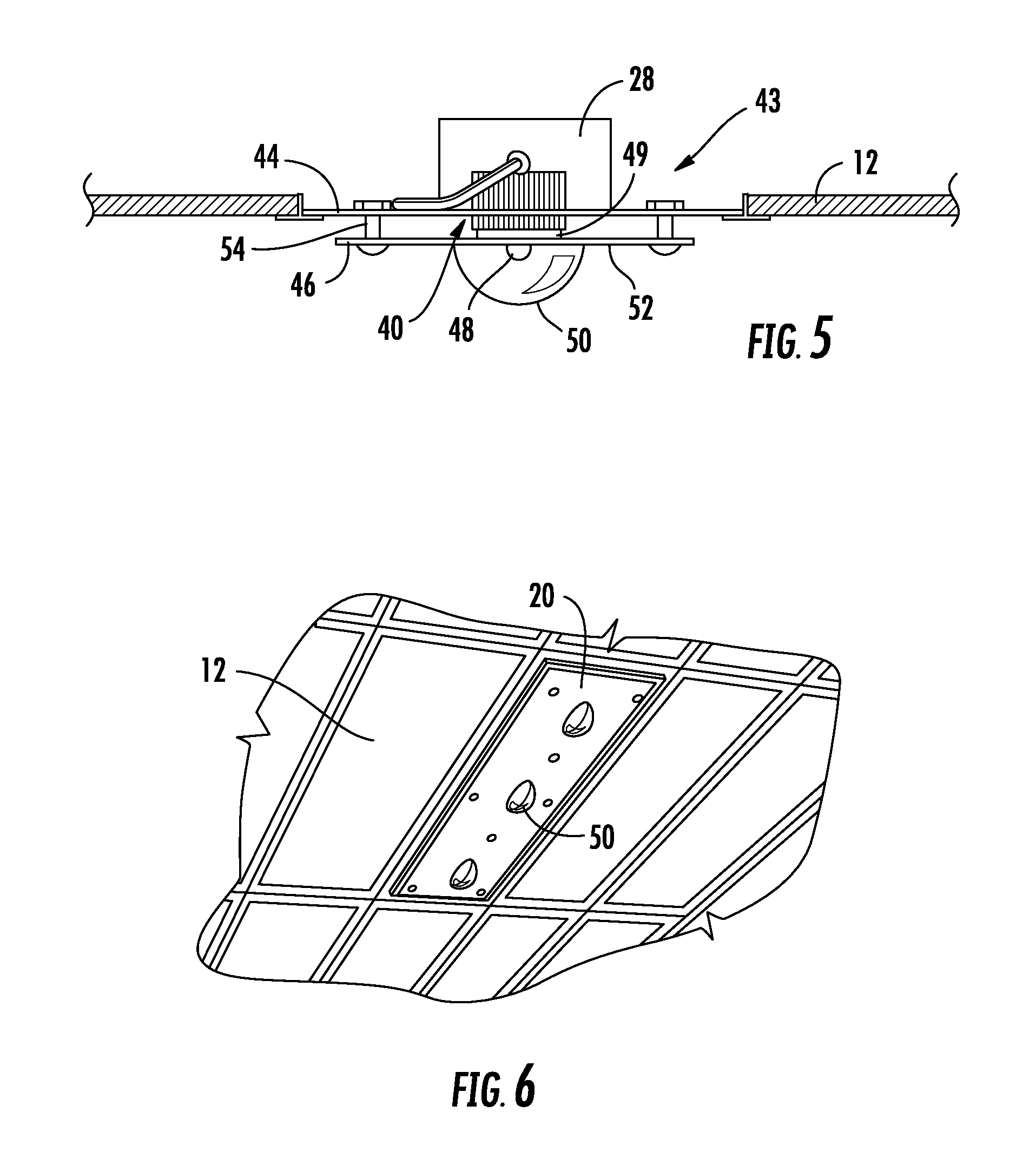

Method and apparatus for thermal management of computer memory modules

ActiveUS7738252B2Facilitate heat exchangeSpeed up the flowDigital data processing detailsSemiconductor/solid-state device detailsInterior spaceComputer module

Owner:KIOXIA CORP

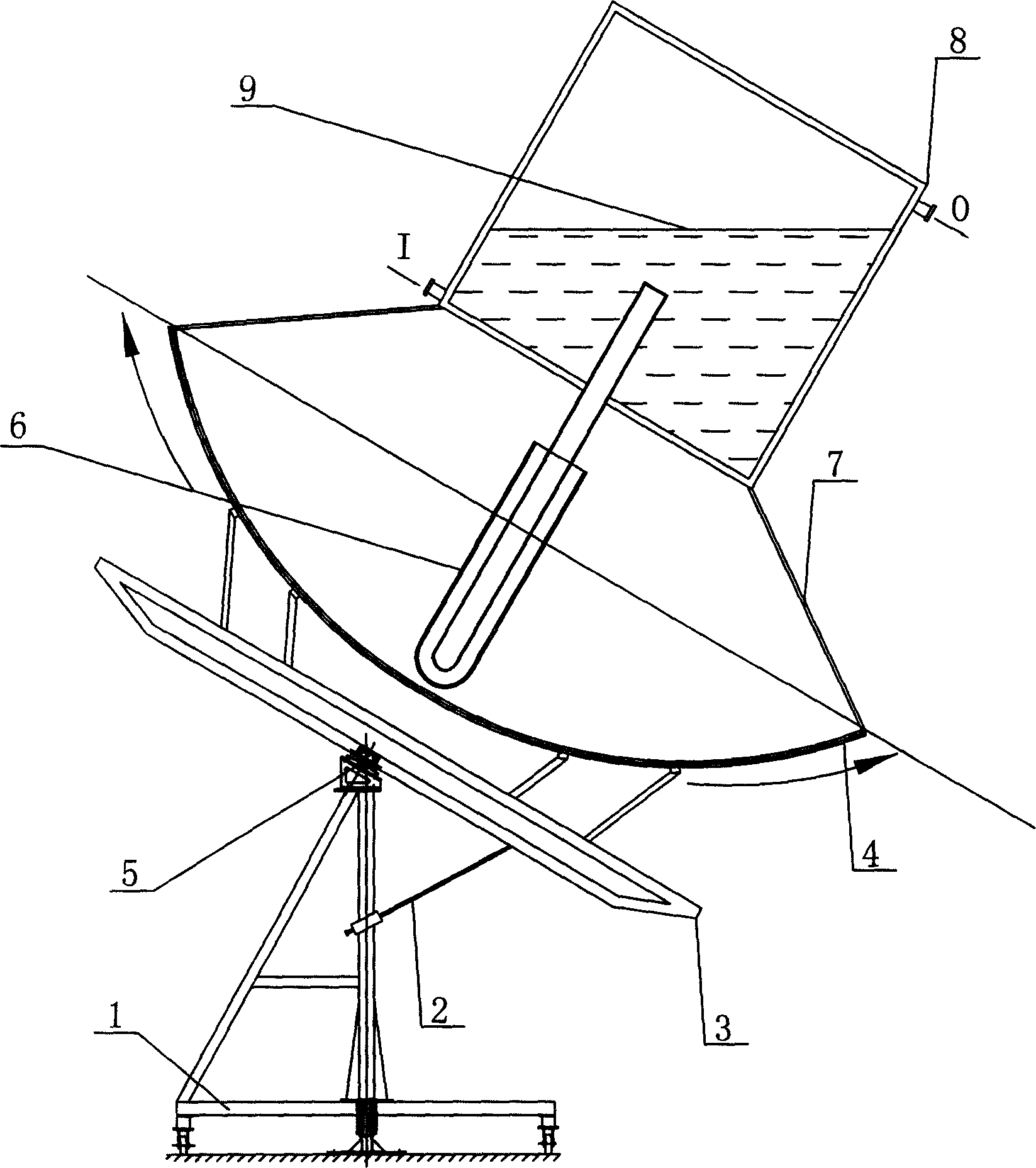

Heat pipe type spherical disc type solar energy light and heat collector

InactiveCN1908549ALow costPromote absorptionSolar heating energySolar heat devicesHeating effectEngineering

The present invention relates to a heat pipe type spherical disc type solar energy light and heat collector, belonging to the solar energy heat collection establishment technical field, which includesa spherical reflecting mirror disposed on the solar energy optical tracker system and a steam drum supported above the reflecting mirror. The steam drum is made up of an inlet and an outlet and stored up with working medium. A heat pipe type vacuum heat collecting pipe is arranged on the focusing part of the spherical reflecting mirror. The heating zone of the heat pipe type vacuum heat collecting pipe is positioned on the condensing wimble of the spherical reflecting mirror. The cooling zone of the heat pipe type vacuum heat collecting pipe is inserted into the working medium of the stream drug. The invention has simple technology, low cost, scientific design and easy to generalization and application. It has been found that the invention has fast tempera the rise, excellent heating effect, high efficiency, suitable for large scale industrialization production, secure and reliable performance.

Owner:HOHAI UNIV

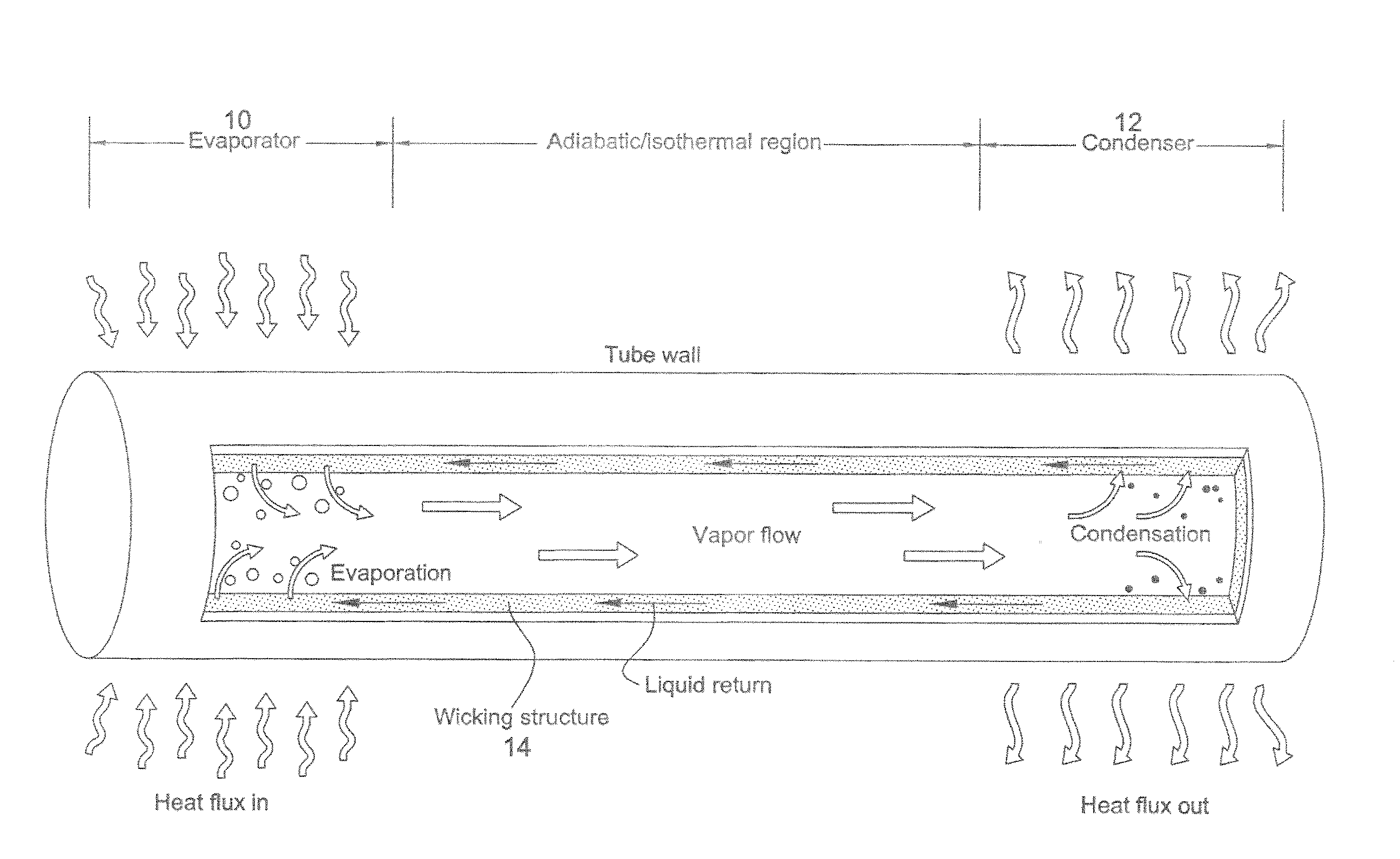

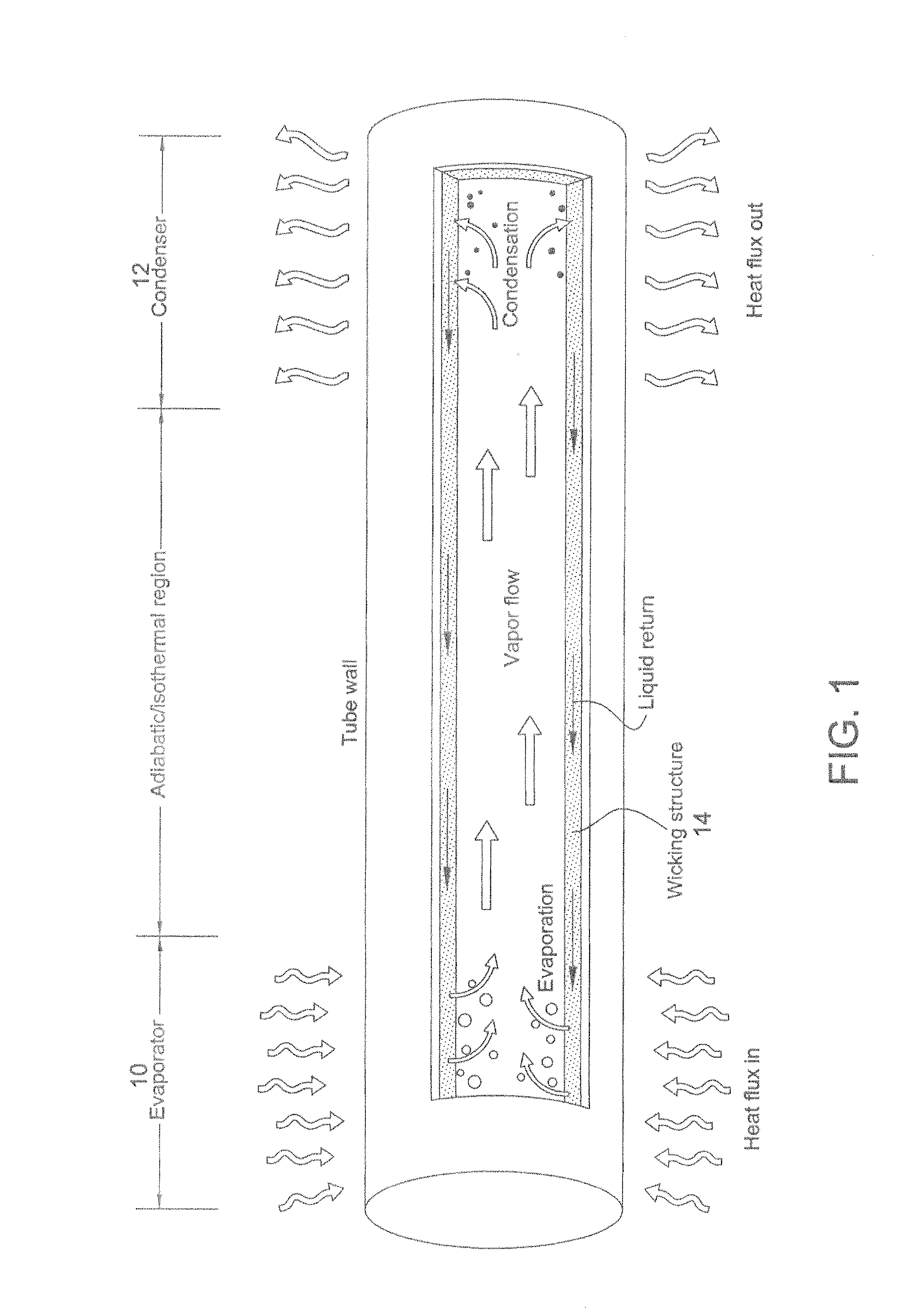

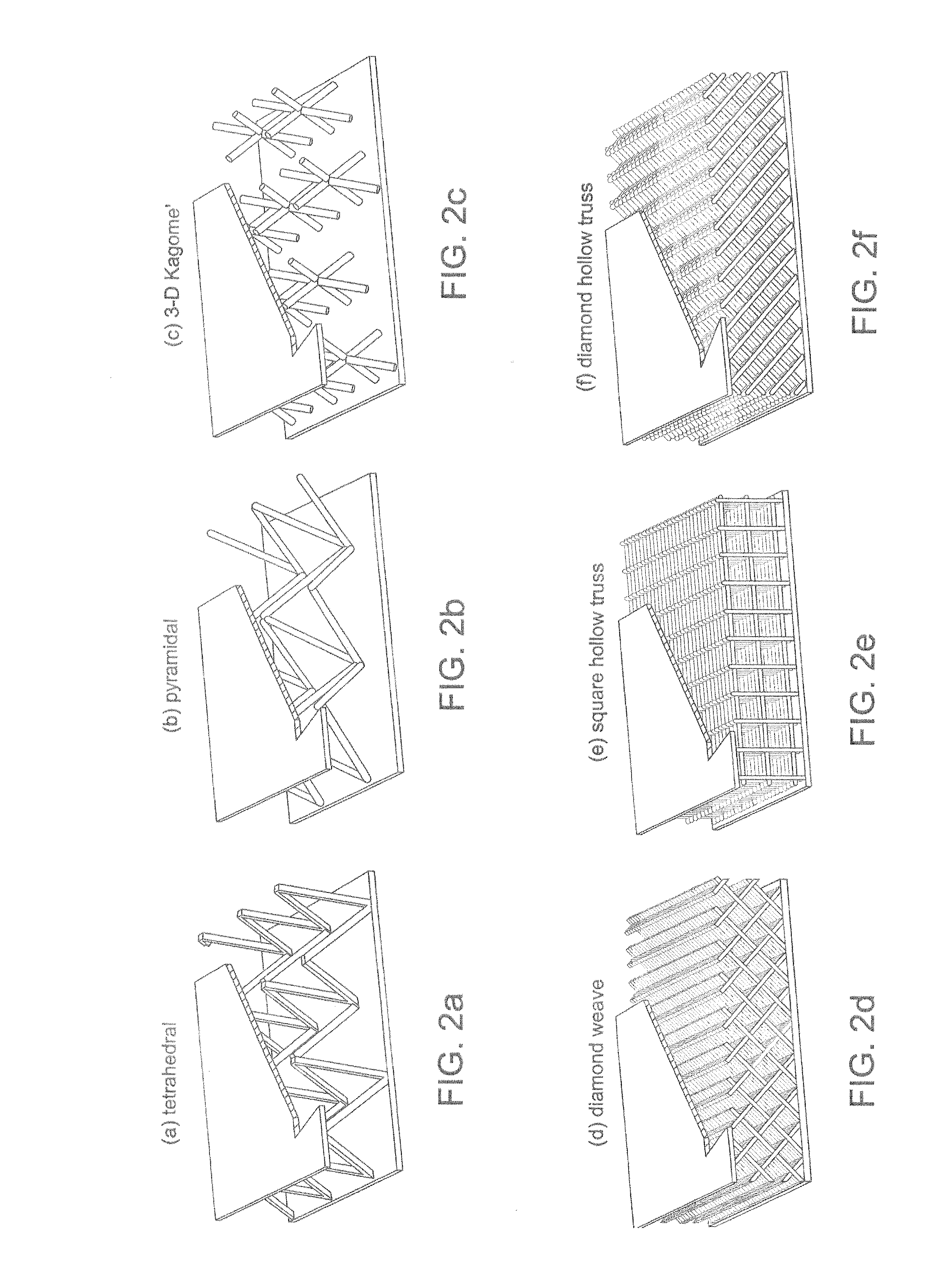

Heat-Managing Composite Structures

ActiveUS20100236759A1Improve spraying effectHigh dynamic strengthCorrosion preventionBuilding componentsHigh stressRocket

Light-weight, heat-managing structures feature open-cell lattice, honeycomb, and / or corrugated (prismatic) arrangements in their substructures, combined with heat pipe / heat plate arrangements for managing heat to which the structures are subjected. The structures are well suited to aerospace applications and may be employed in the leading edge of wings or other airfoil-shaped components; gas turbine engine components; rocket nozzles; and other high-heat, high-stress environments.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

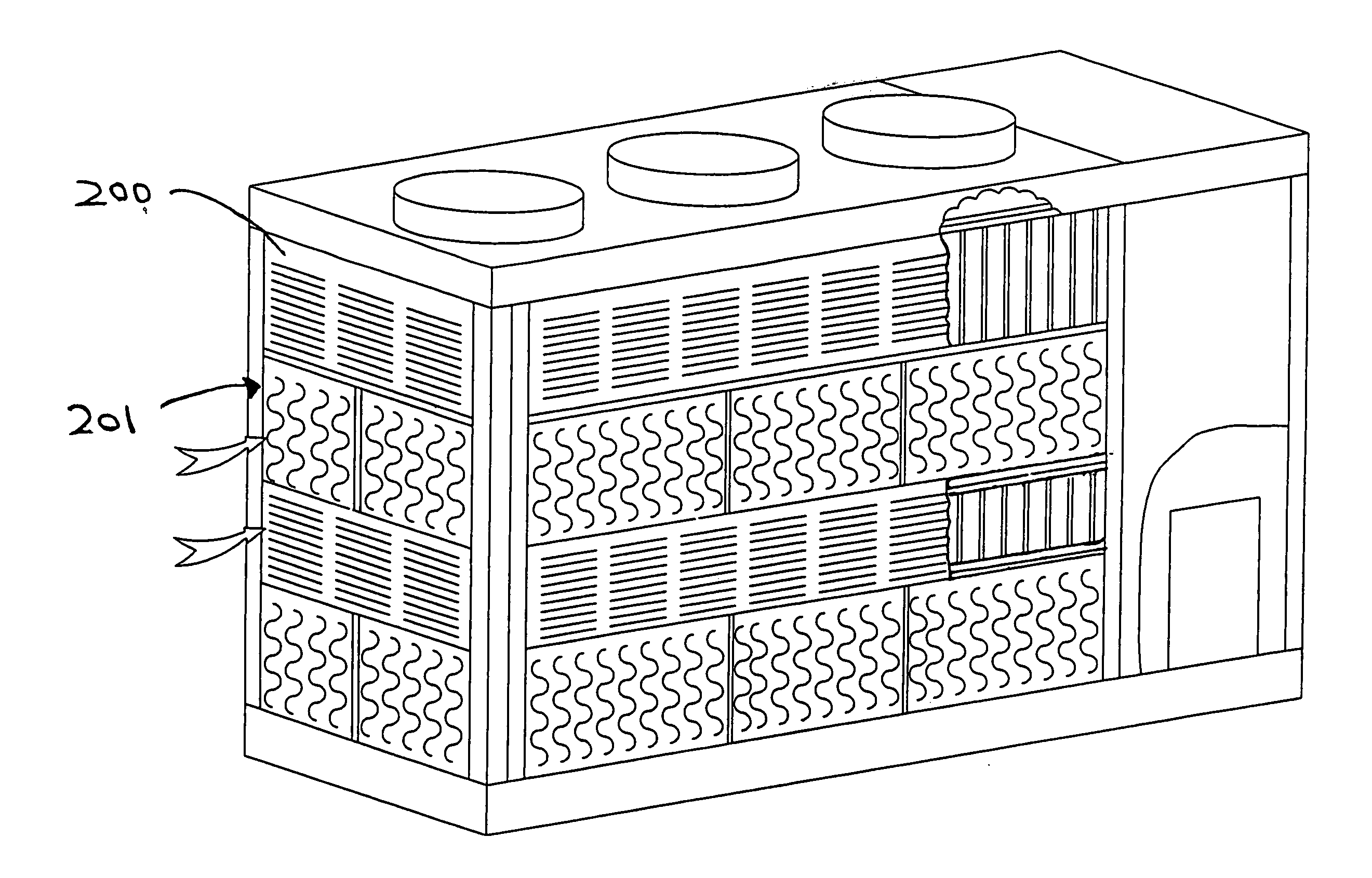

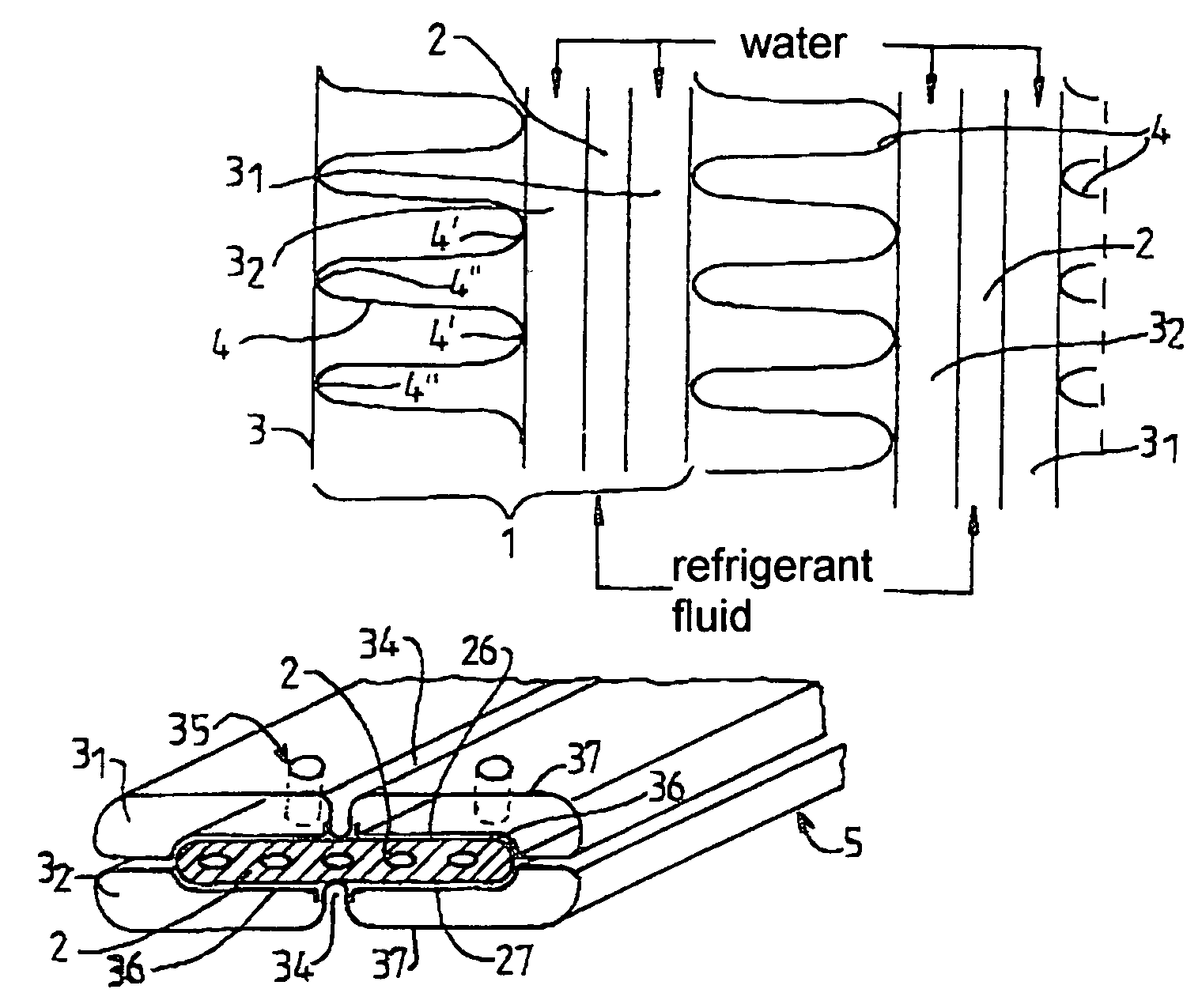

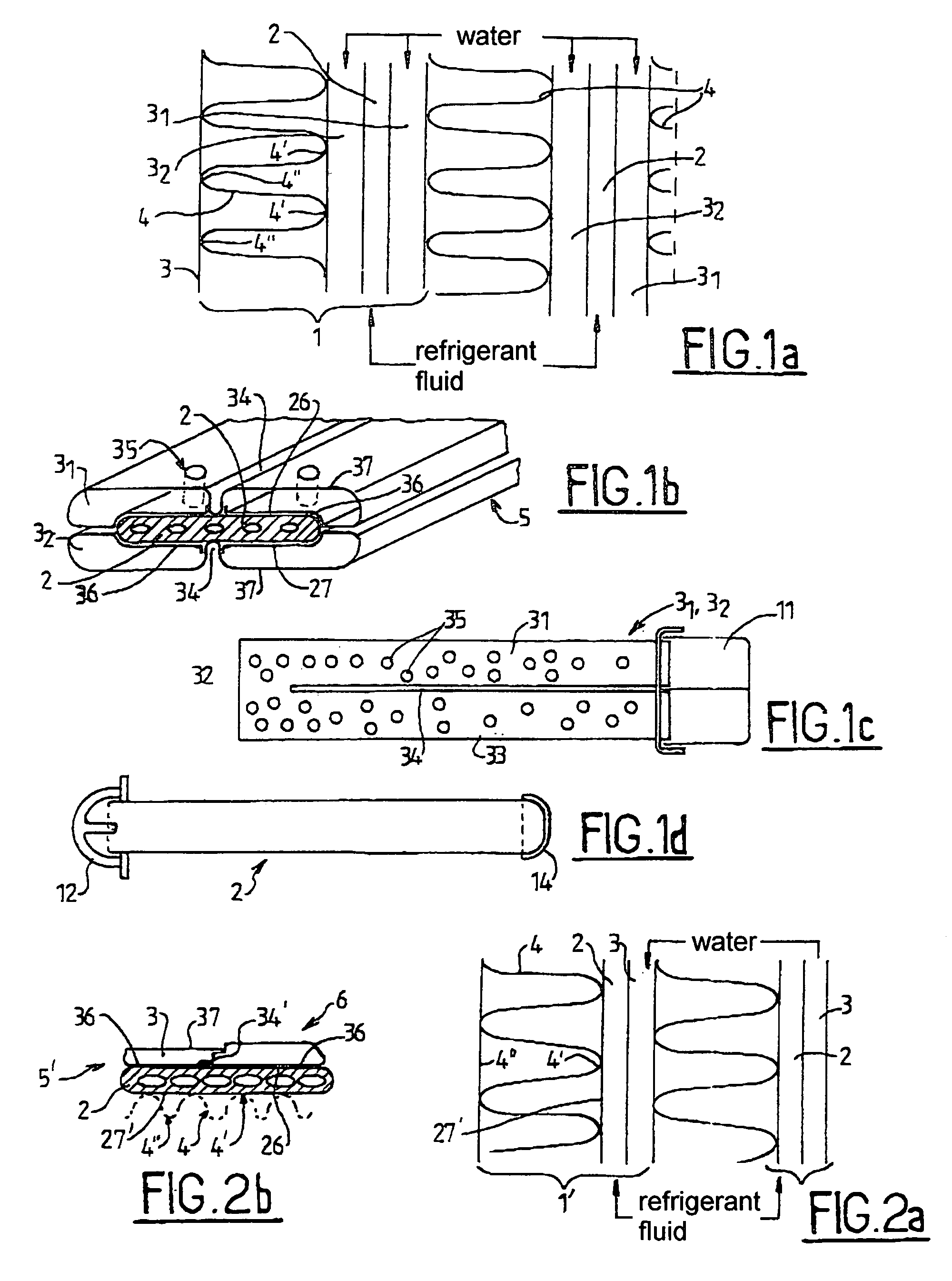

Air conditioning system with multiple-effect evaporative condenser

ActiveUS20130276476A1Improve efficiencyIncrease the areaEvaporators/condensersSteam/vapor condensersEngineeringAir conditioning

An air conditioning system includes a multiple effect evaporative condenser, at least one compressor, at least one heat exchanger, an expansion valve, and at least one multiple-effect evaporative condensers. The multiple effect evaporative condenser and the heat exchanger utilize a highly efficient heat exchanging pipe for performing heat exchange between water and refrigerant.

Owner:WONG LEE WA

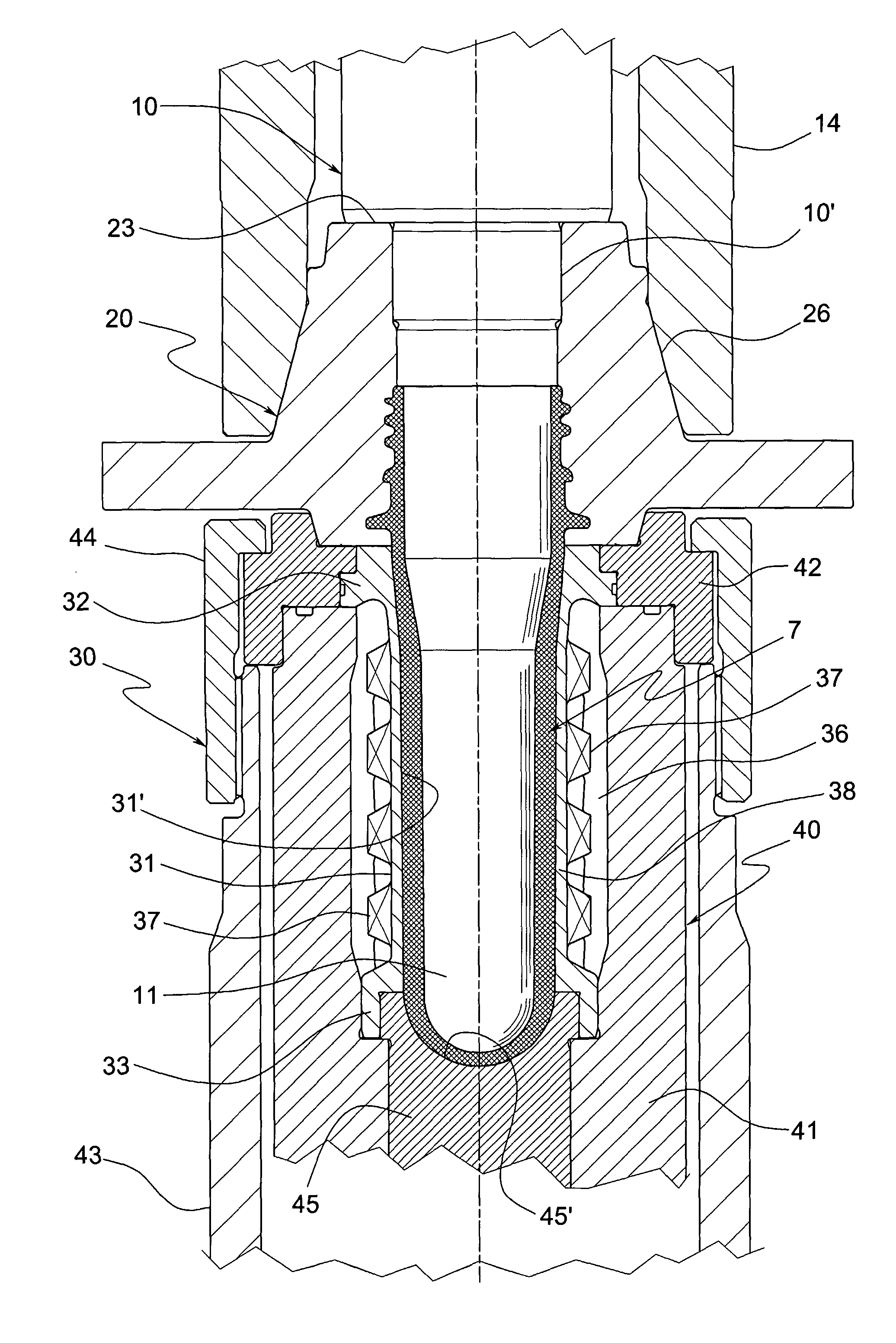

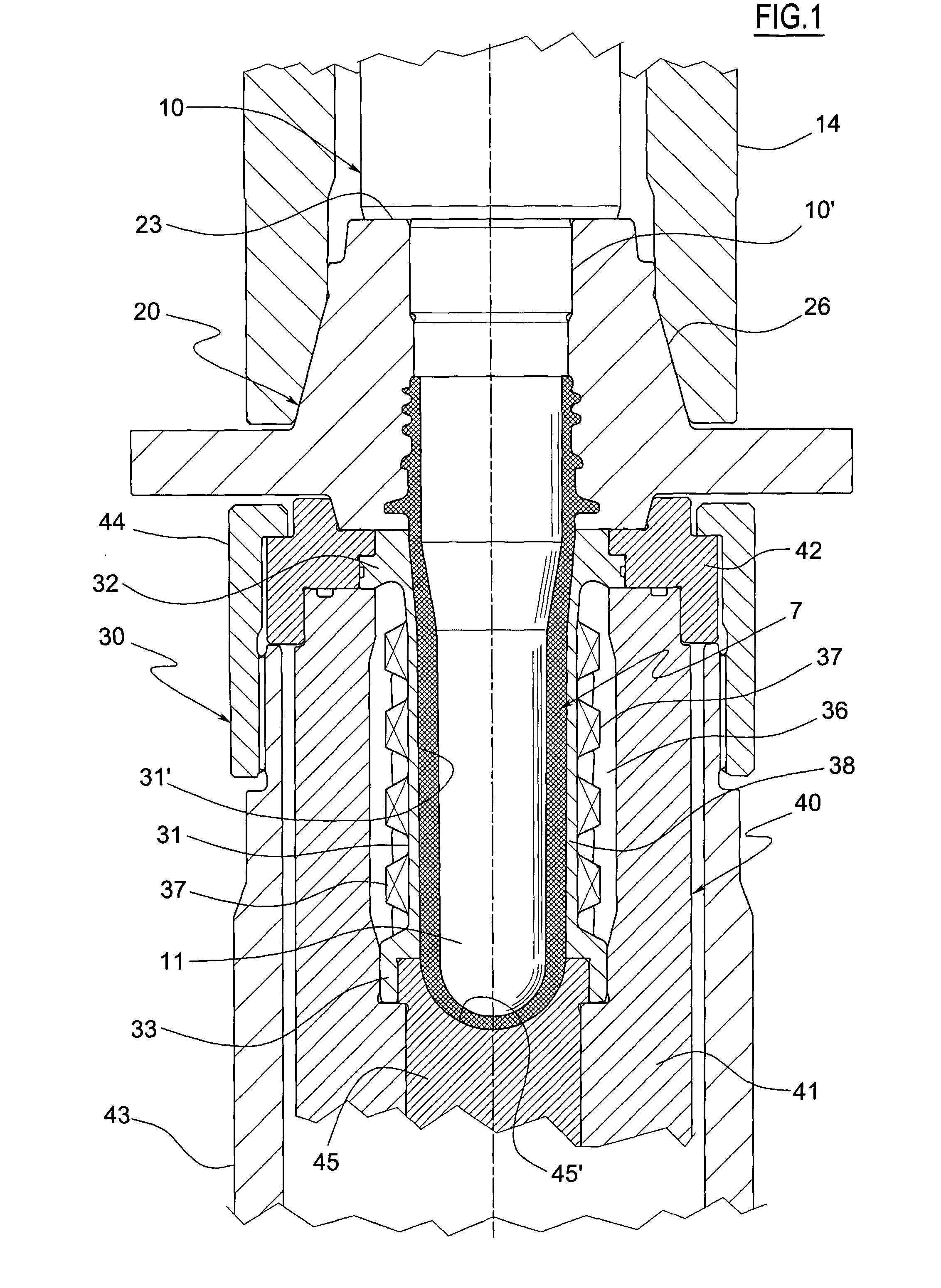

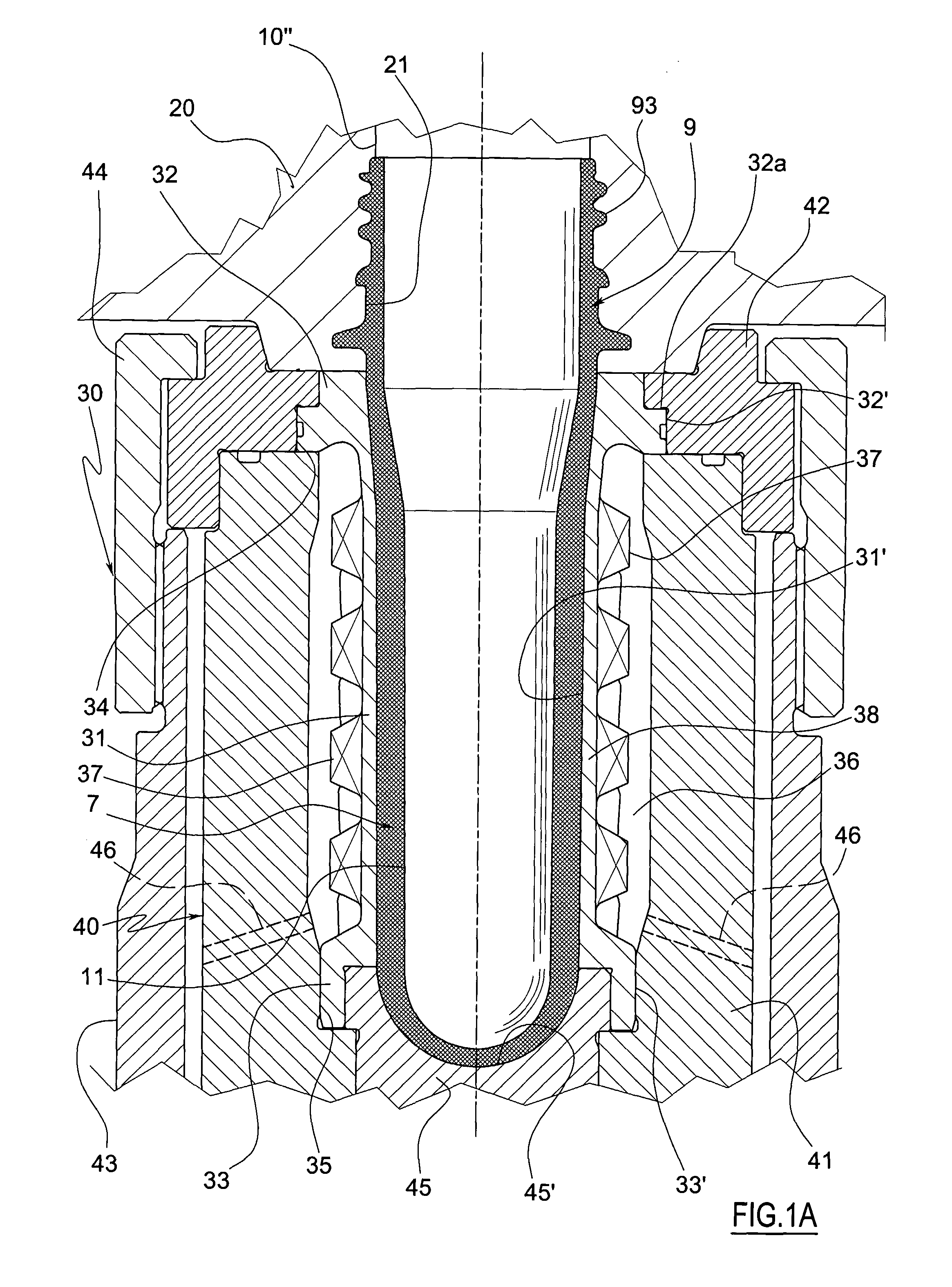

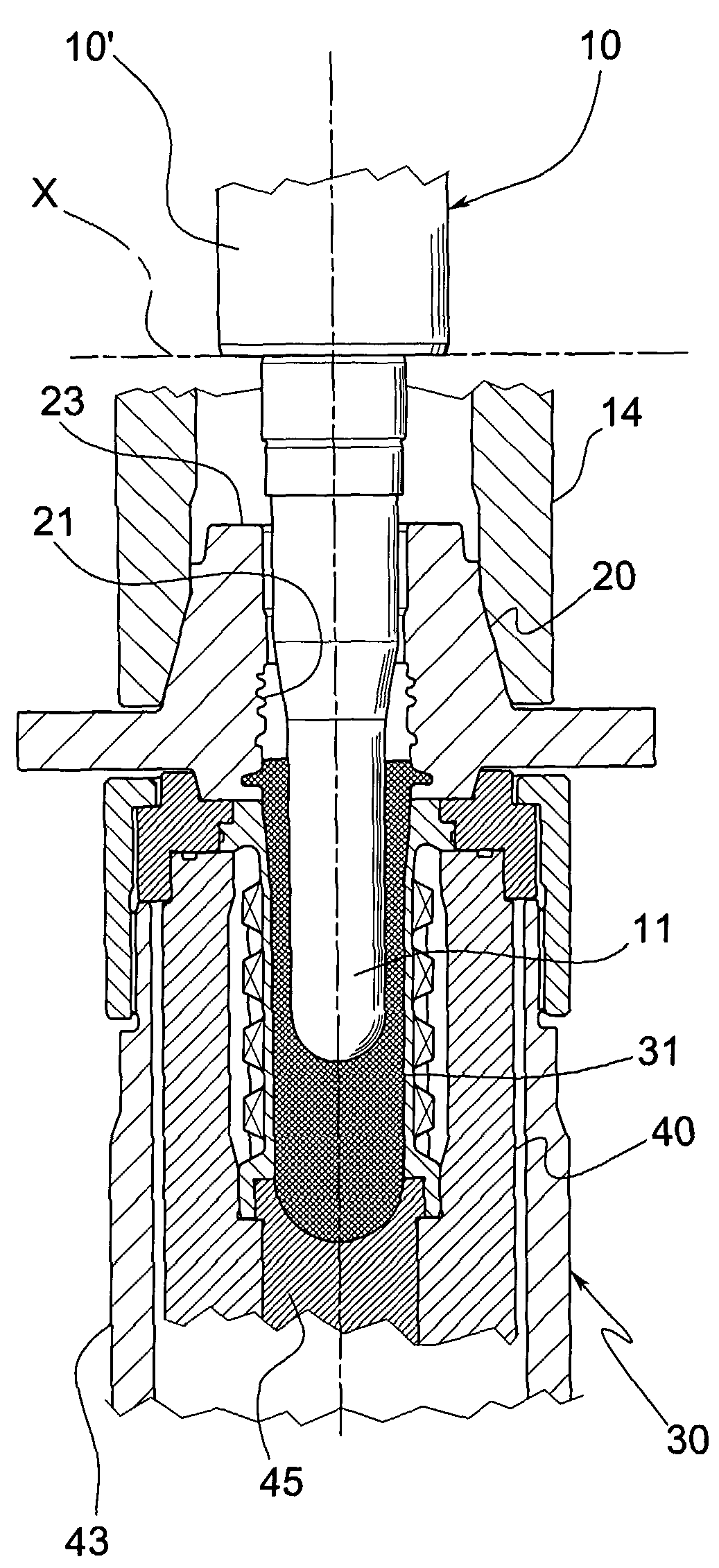

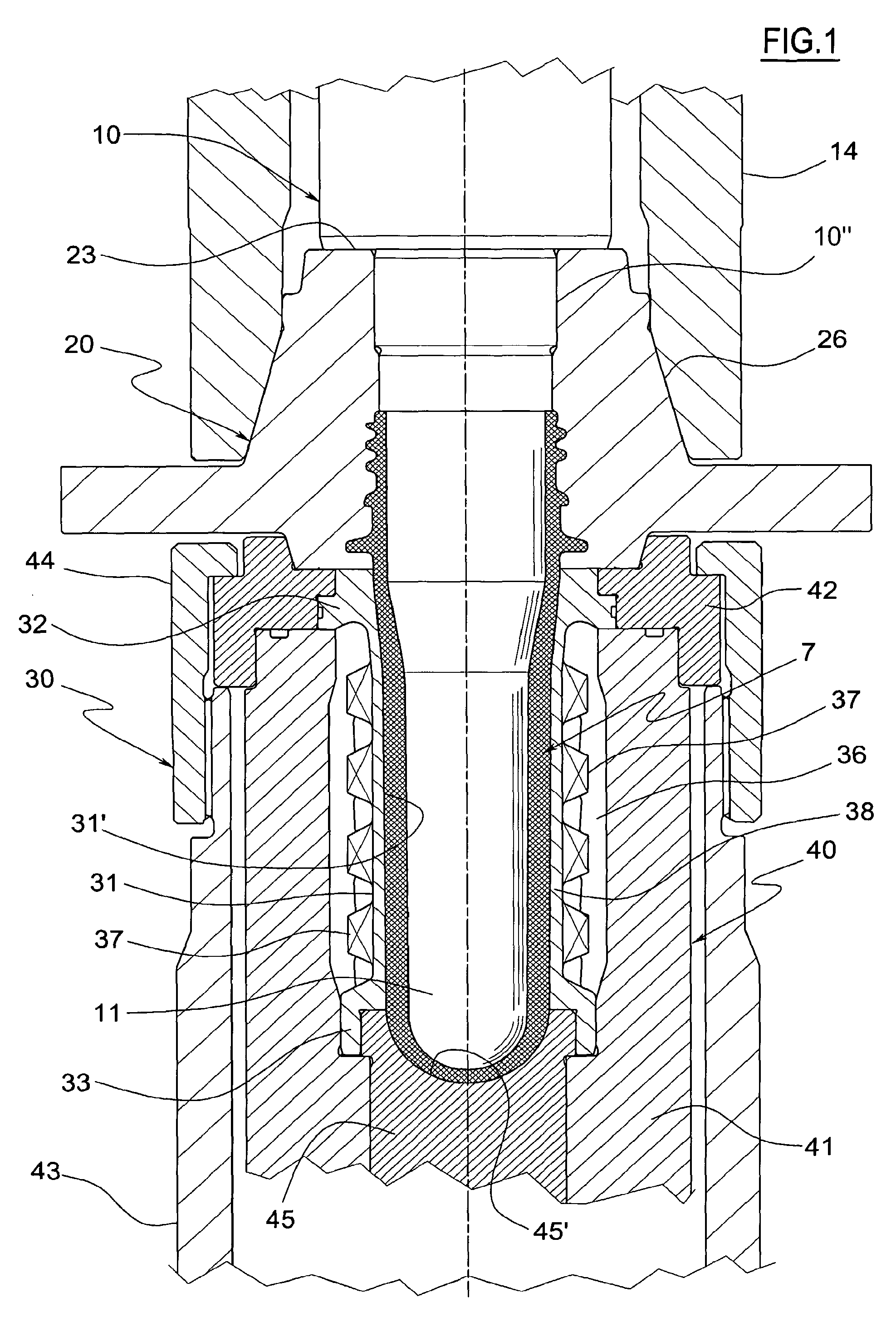

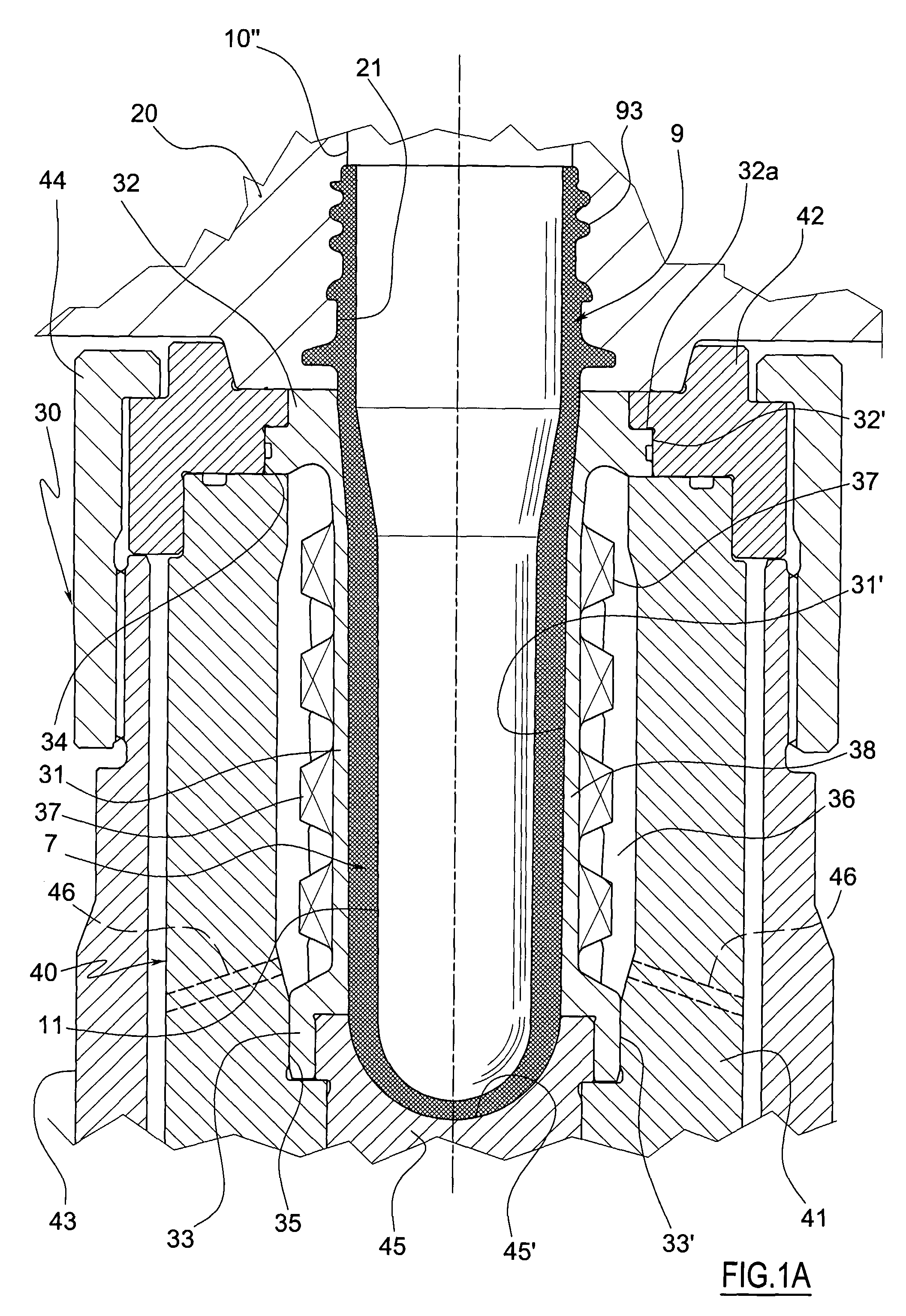

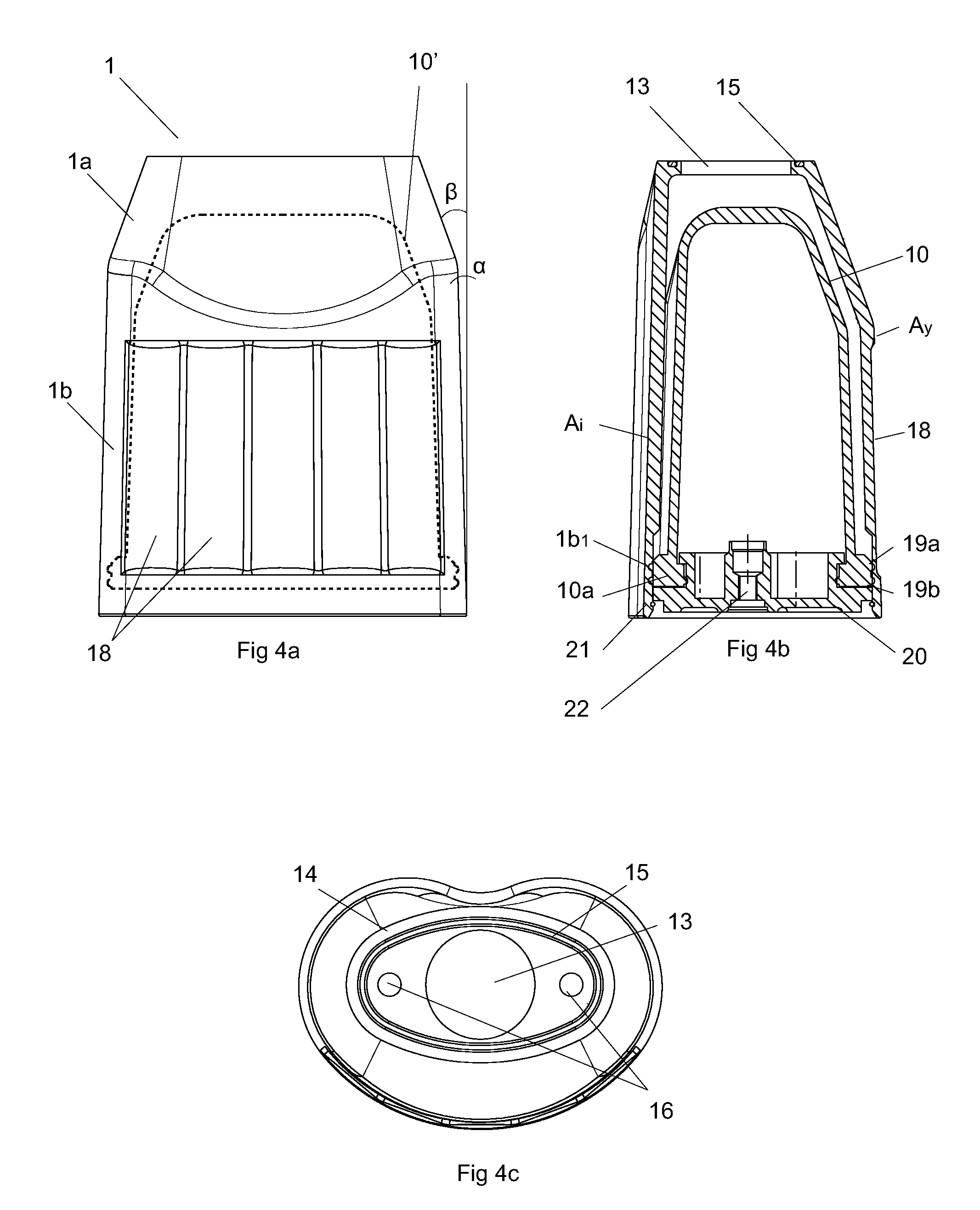

Method and Group for the Compression Molding of Preforms for Containers in Polymeric Material

InactiveUS20080026239A1Reduce tensionIncreasing the thicknessConfectioneryWood working apparatusCompression moldingPolymer science

The preform is formed by an upper neck which maintains unchanged its form in the final object and a hollow body, joined to the neck. The method foresees the insertion, within a matrix cavity, of a metered body of polymeric material whose mass is metered according to a reference value, and the subsequent pressure insertion of a punch within the matrix cavity until it closes the mold's molding chamber, the punch conferring the shape to the inner surface of the preform and the matrix having an inner surface which confers the shape to the outer surface of the preform. According to the invention, in the molding of the preform, the error of the mass of the metered body with respect to the reference value is distributed in the hollow body, which undergoes a subsequent hot deformation until it achieves the final shape. In the mold, the matrix comprises at least one deformable wall ( 31 ) whose inner surface defines at least part of the inner surface of the matrix part intended to give form to the hollow body of the preform, said deformable wall ( 31 ) having, at least in part, a relatively thin thickness which permits it to be elastically deformed under the pressure of the polymeric material in the final preform molding step, thereby varying the thickness of the hollow body.

Owner:SACMI COOP MECCANICI IMOLA S C R L

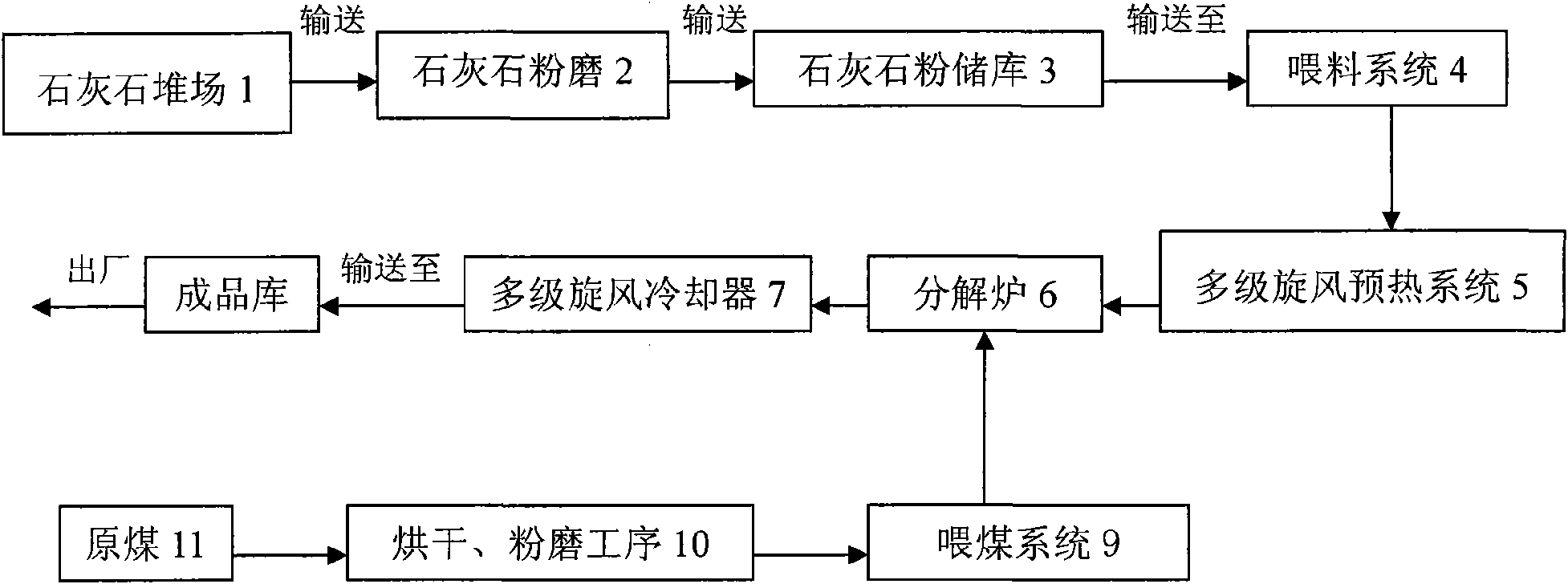

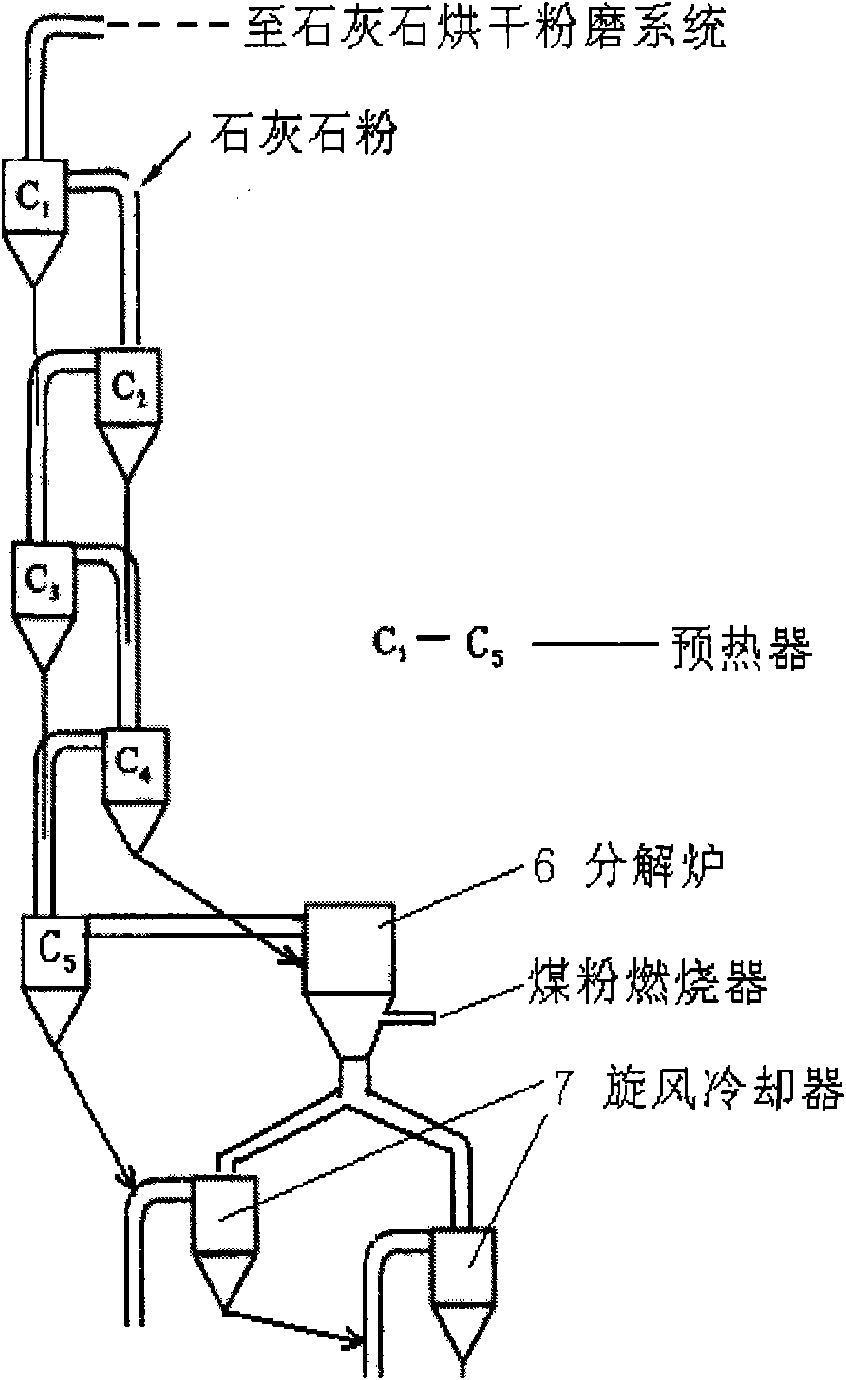

Calcination process of active lime

The invention discloses a calcination process of active lime. The calcination process adopts a preheating-suspension calcination device comprising a multi-stage cyclone preheating system, a decomposing furnace and a multi-stage cyclone cooler. The calcination process is characterized in that limestone powder which is broken and homogenized into blocks is ground into fine powder, the fine powder is placed in a storage tank for homogenization, then preheated by the multi-stage cyclone preheating system and sent to the decomposing furnace for calcination, thereby preparing the active lime, and the active lime is further cooled by the multi-stage cyclone cooler for obtaining the active lime; wherein the main control temperature of the decomposing furnace is 850-950 DEG C; and the calcination time is 3-5 seconds. The calcination process utilizes the preheating-suspension calcination reaction method for calcining the active lime, and fuel can use low-grade fuel-biluminous coal. Compared with the traditional process, the calcination time is short, the effective utilization rate of the lime product is high, the product quality is stable, the energy consumption is low, and a production region has no environmental pollution; meanwhile, the calcined active lime is the fine powder, the use is very convenient, and the range of applications is broader in comparison with the active lime calcined by the traditional process, thereby being conductive to promotion and implementation.

Owner:BEIJING LIULIHE CEMENT

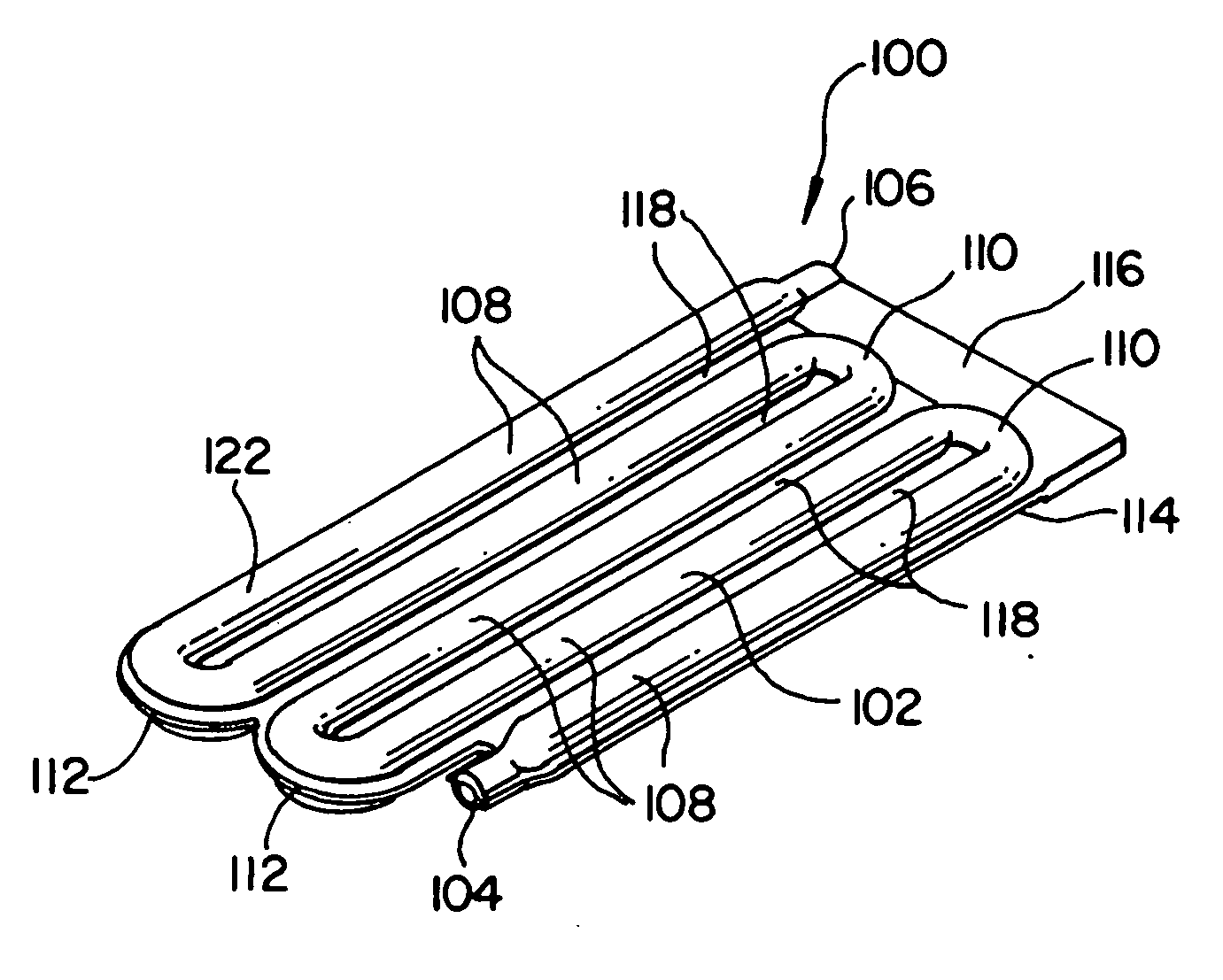

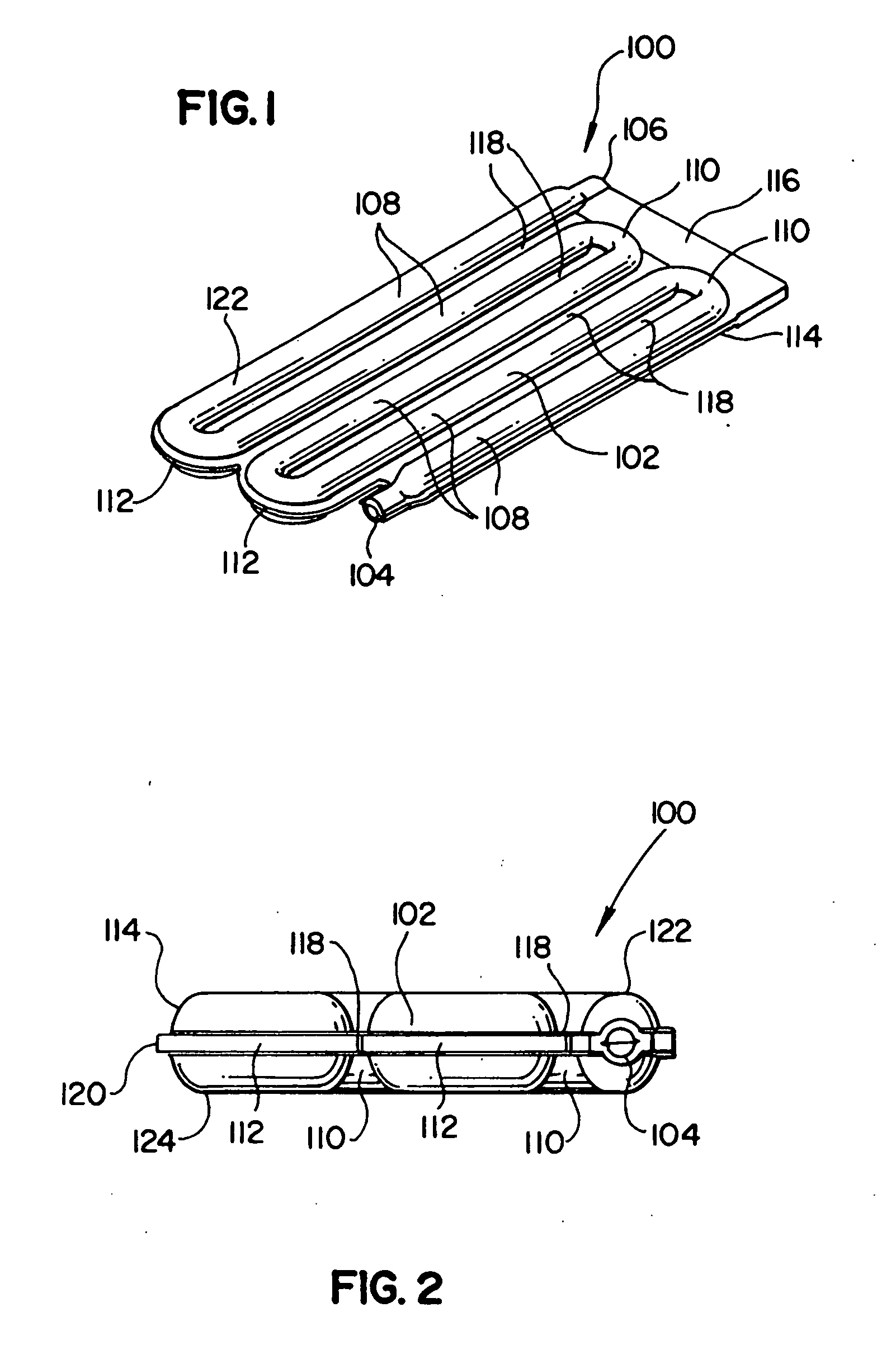

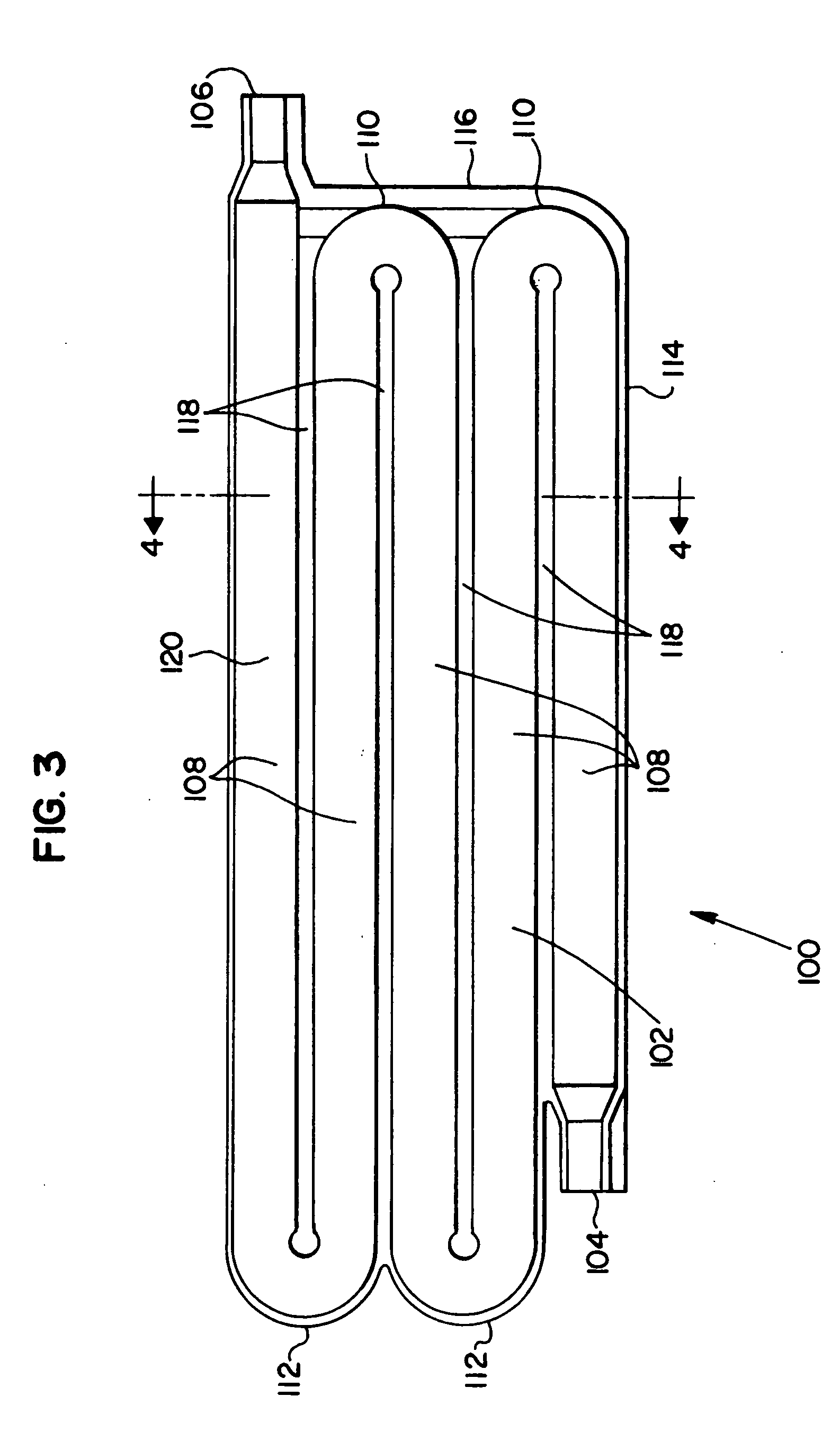

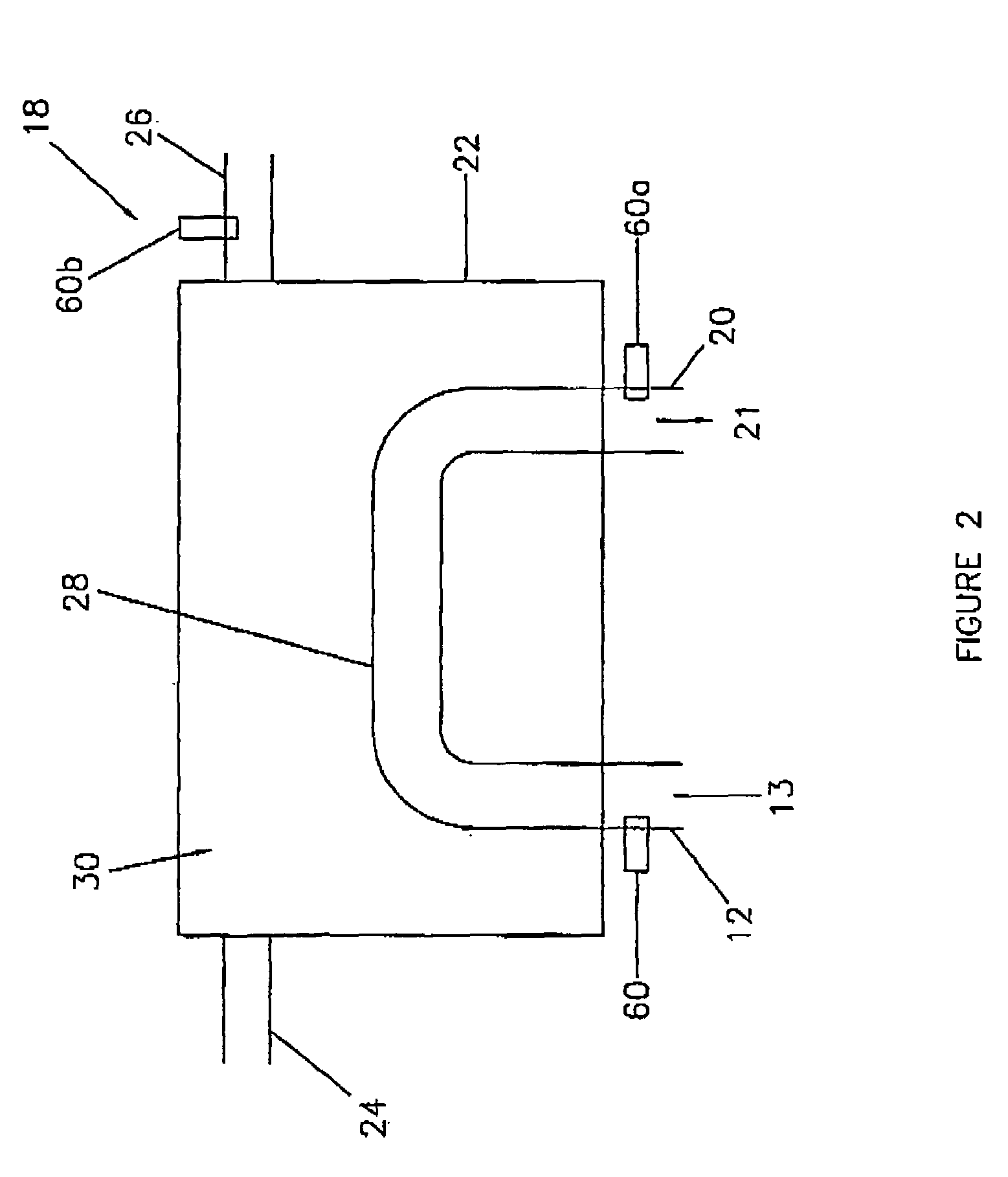

Heat exchanger and fluid reservoir

InactiveUS20060021745A1Low flow conditionEfficient heat exchangeStationary conduit assembliesDomestic articlesPlate heat exchangerDead volume

Improved fluid reservoir designs providing for little or no dead volume or un-swept volume while providing efficient heat exchange are disclosed. Representative fluid reservoirs can have a serpentine flow passage with a cross-section selected such that fluid flow sweeps the entire cross-sectional volume while reducing or eliminating dead volume. The cross-sectional shape of the flow passage can be selected to have a larger surface contact with the cooling environment relative to circular cross-sections. The fluid reservoirs can be molded from two sheets of polymer material that are joined to form the fluid reservoir. Alternatively, the fluid reservoir can be formed from flexible polymer materials that are bonded along seams to demarcate a flow channel. Fluid reservoirs can be located either upstream or downstream of a filtering system to provide chilled filtered liquid. Fluid reservoirs can be associated with an appliance, such as a refrigerator. Methods of fabricating the fluid reservoirs are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

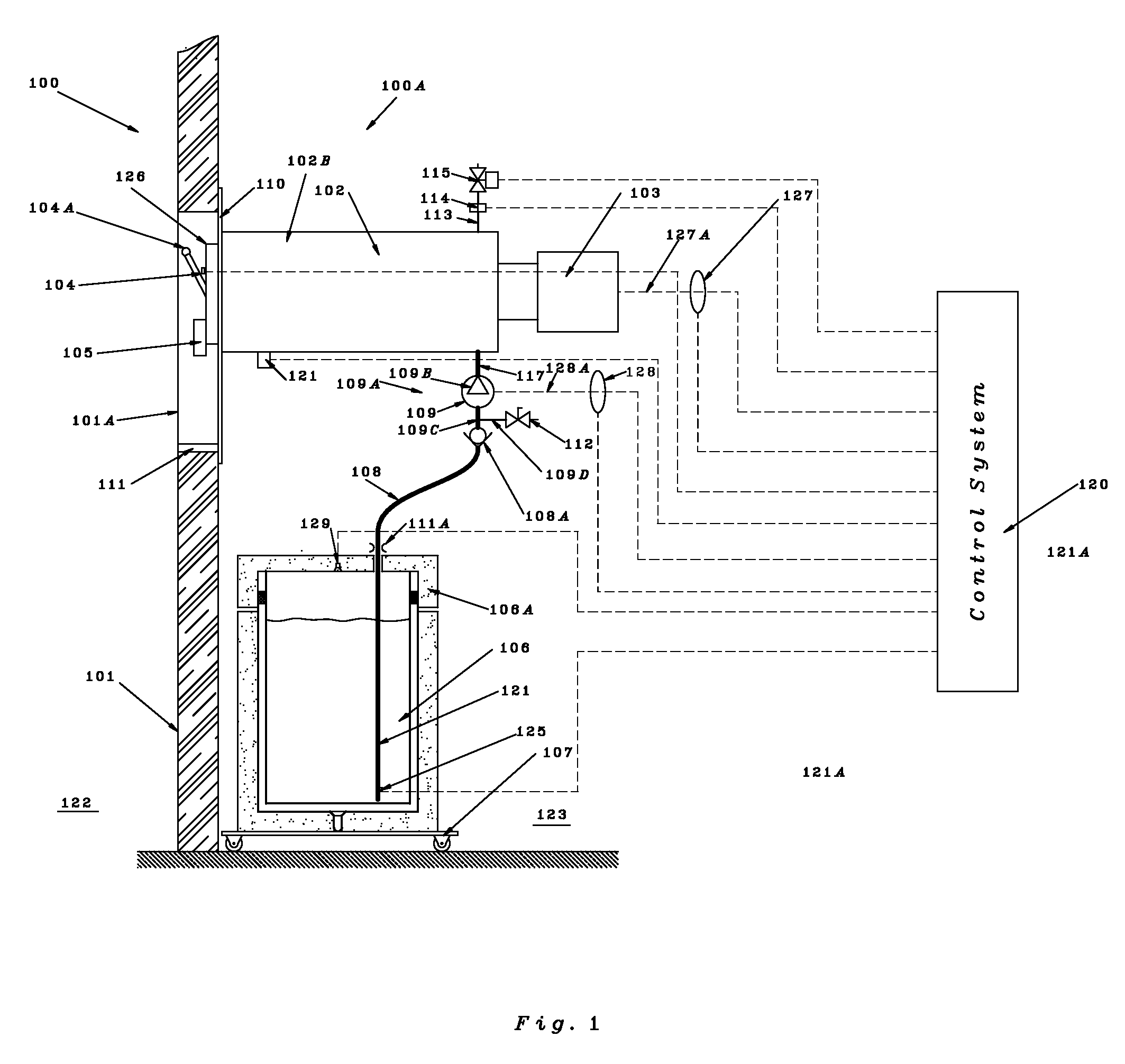

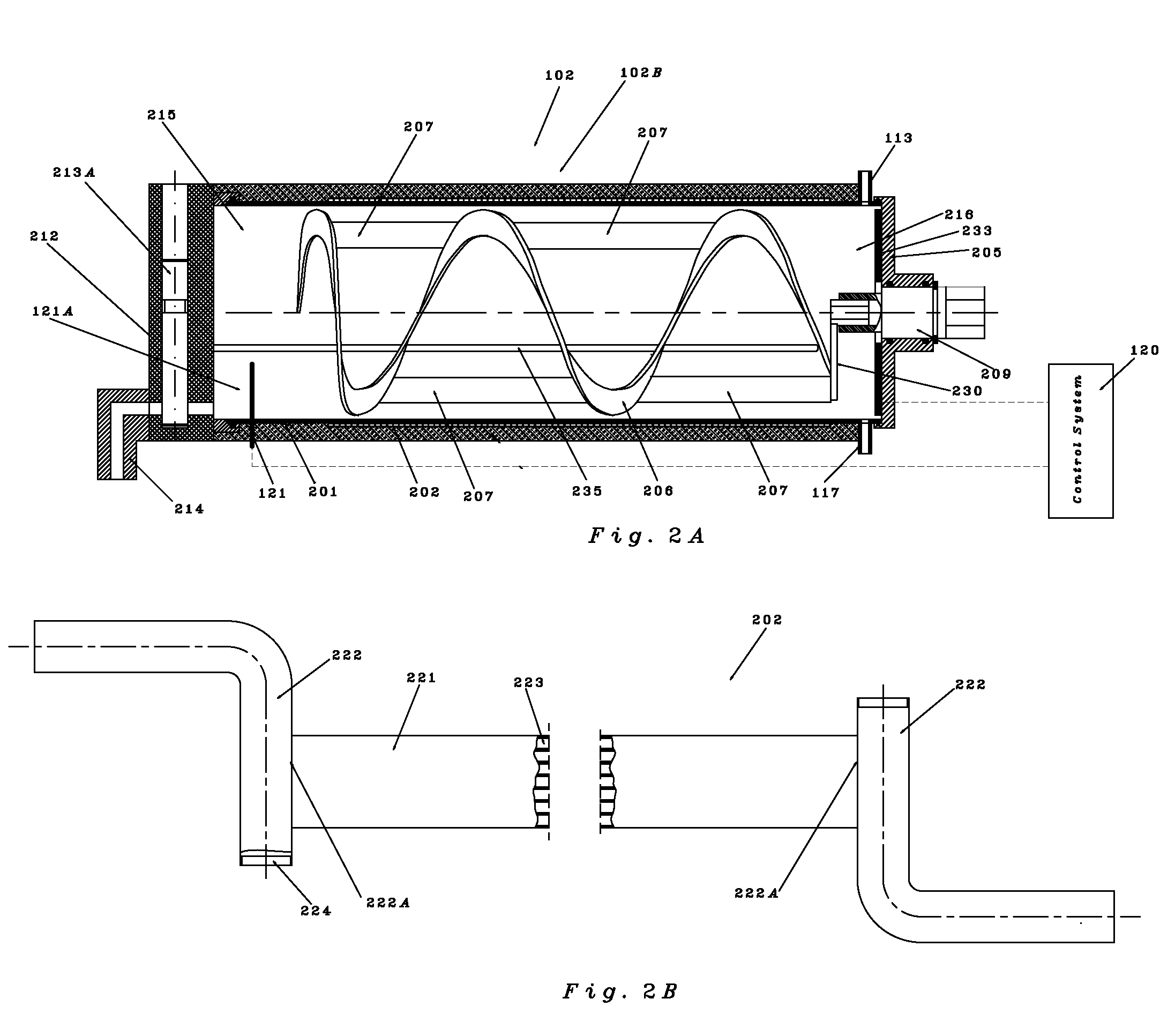

Multi-outlet soft frozen dessert apparatus for a self-service restaurant

A multi-outlet soft frozen dessert apparatus for a self-service restaurant with multiple freezers attached to the wall dividing the client area of the restaurant from the kitchen area is provided. The freezers of apparatus may include an evaporation tube comprised of an aluminum alloy micro-channel parallel flow extruded tape. The mix vats of the apparatus may include circulating water in a hydraulic system having added antifreeze to suppress a freezing temperature in the range of −2° C. to −5° C. to assure adequate approach temperature to cool a mix in the mix vat. The apparatus may include scrape blades mounted on a helical part of the beater-scraper that scrape a thin layer of ice crystals from an internal surface of the inner cylinder and fold the ice crystals inside the mix bulk.

Owner:REICH DANIEL +1

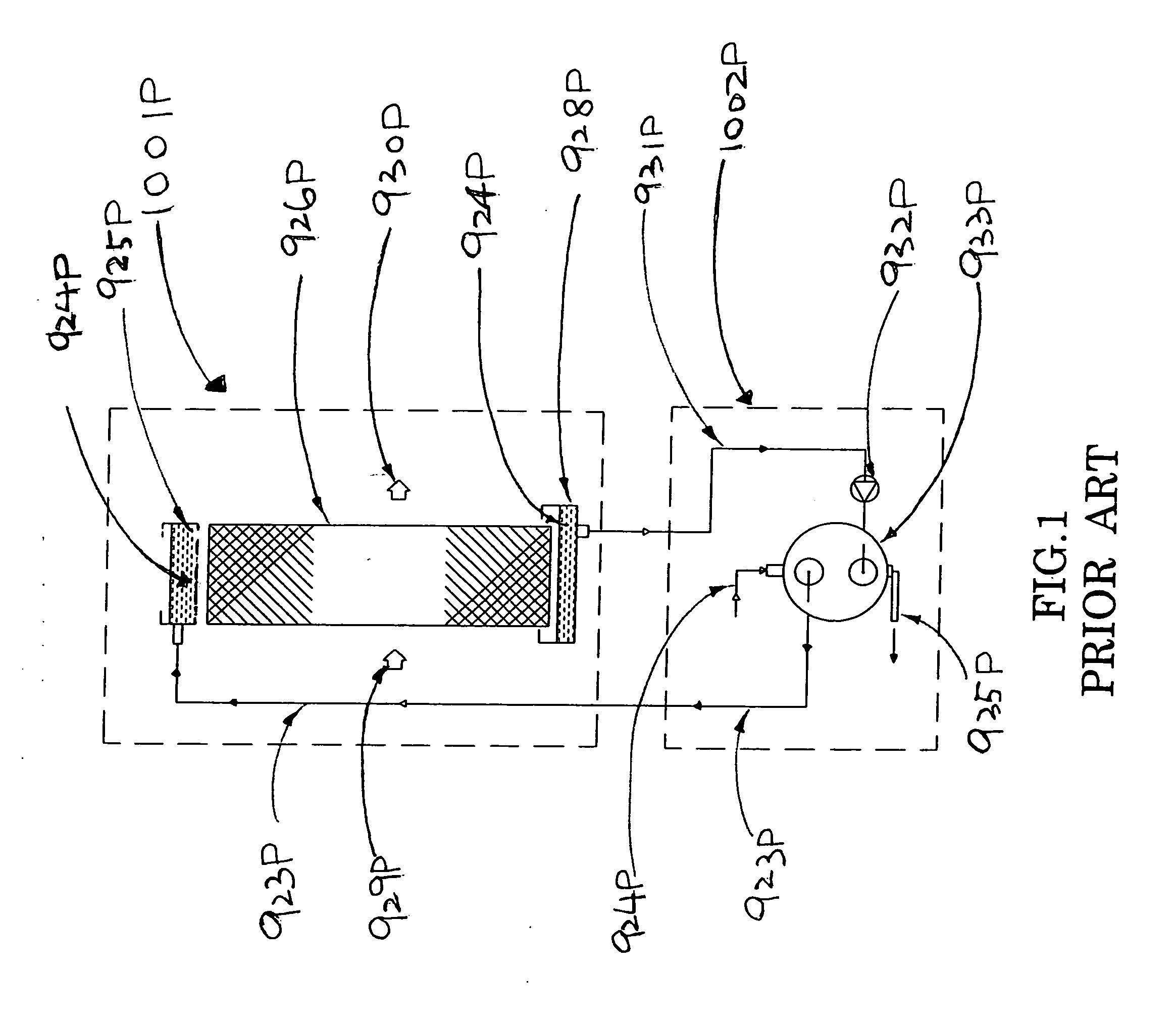

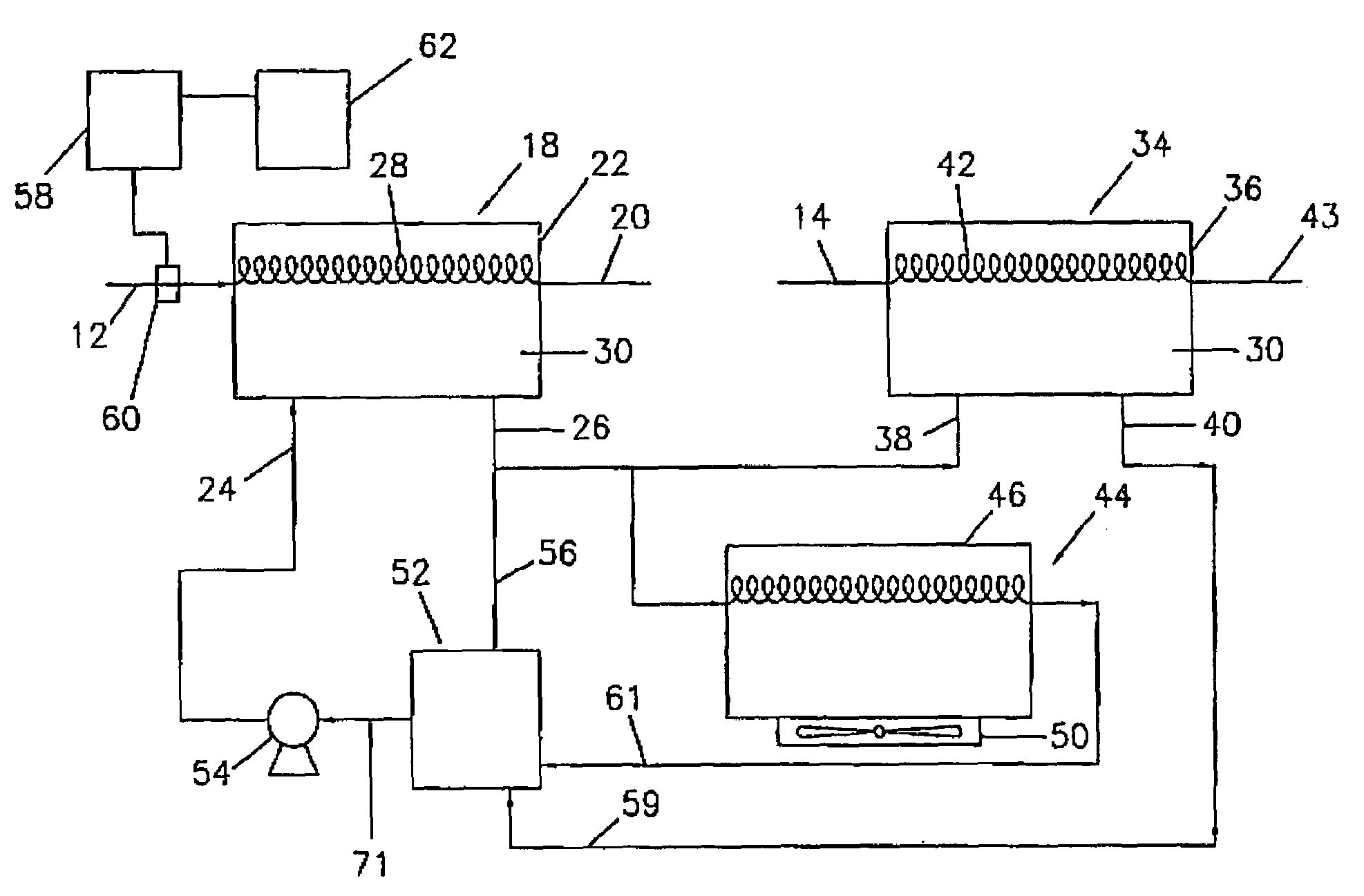

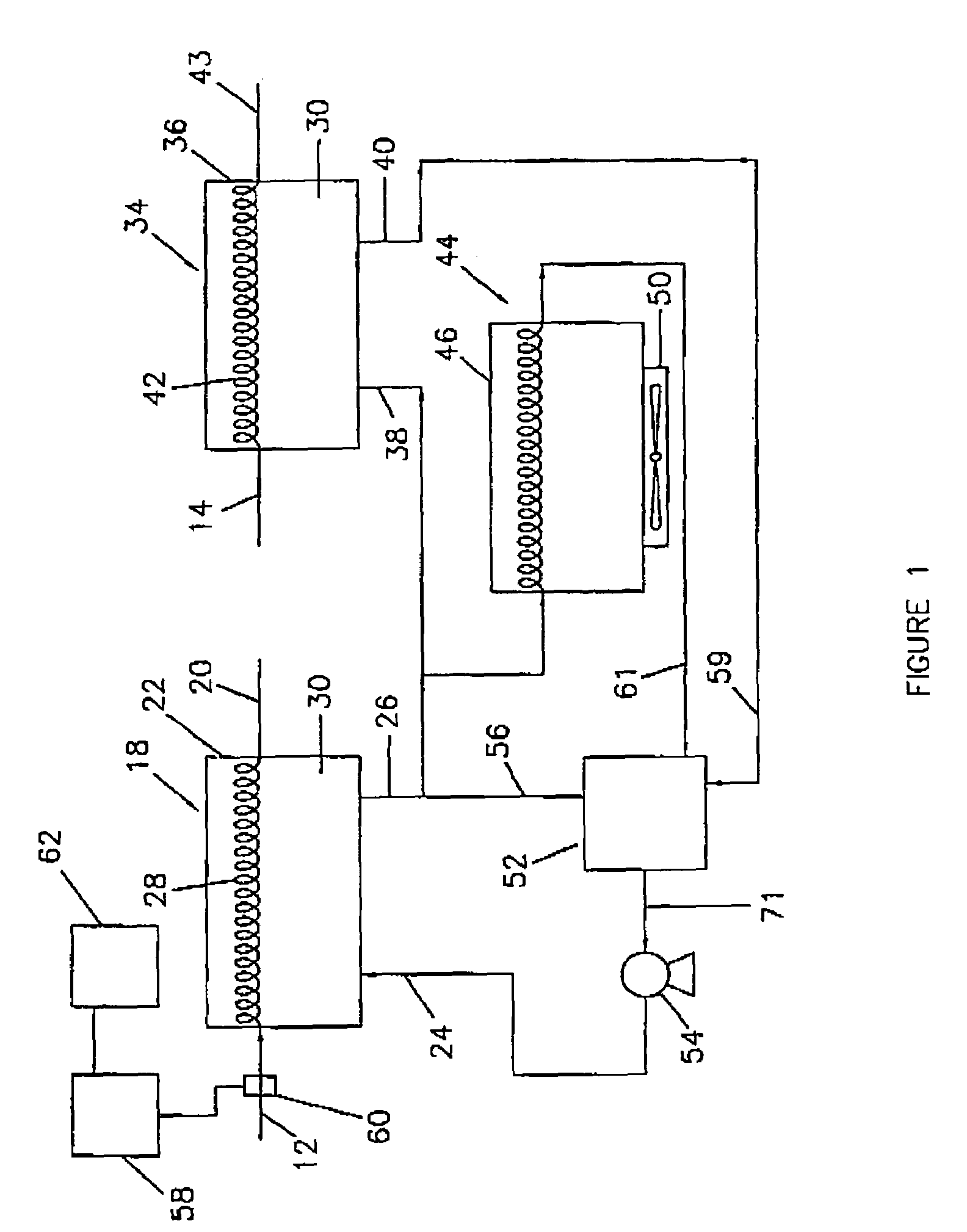

Heat exchange system

InactiveUS7124587B1Facilitate heat exchangeRecuperative heat exchangersSteam useEngineeringThermal expansion

The invention is a system for heating hydrocarbon flows with three heat exchangers, wherein the first heat exchanger transfers heat from compressed heated air to a pressurized heat exchange fluid; wherein the second heat exchanger transfers heat from the pressurized heat exchange fluid to a hydrocarbon flow and increases the hydrocarbon flow temperature between 50% and 900%; wherein the third heat exchanger receives the pressurized heat exchange fluid from the first heat exchanger and cools the fluid using at least one fan located in the third heat exchanger; and the system also has a vessel to accommodate thermal expansion of the pressurized heat exchange fluid and at least one pump for transporting fluid through the system.

Owner:LINNEY JOHNATHAN W

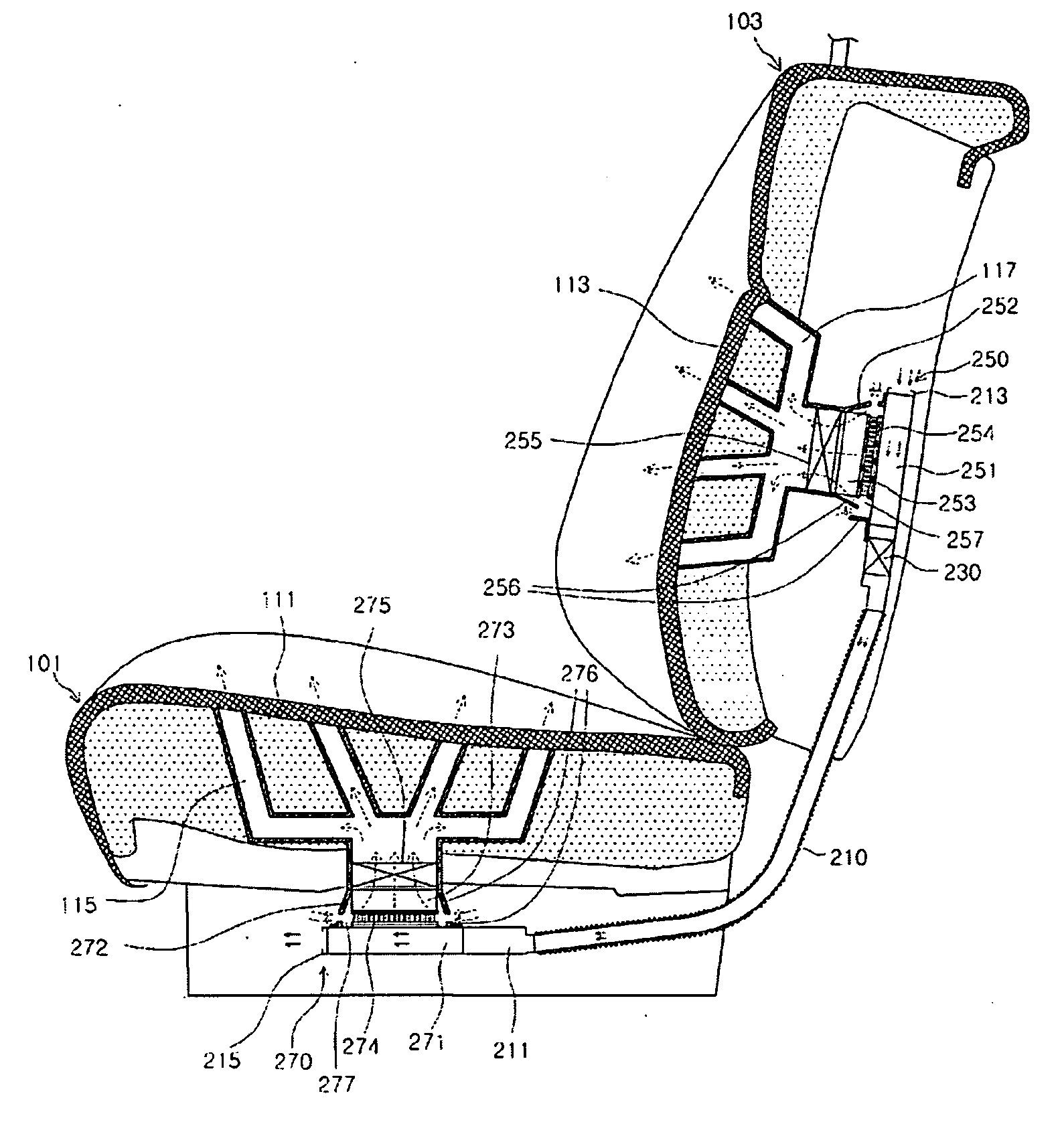

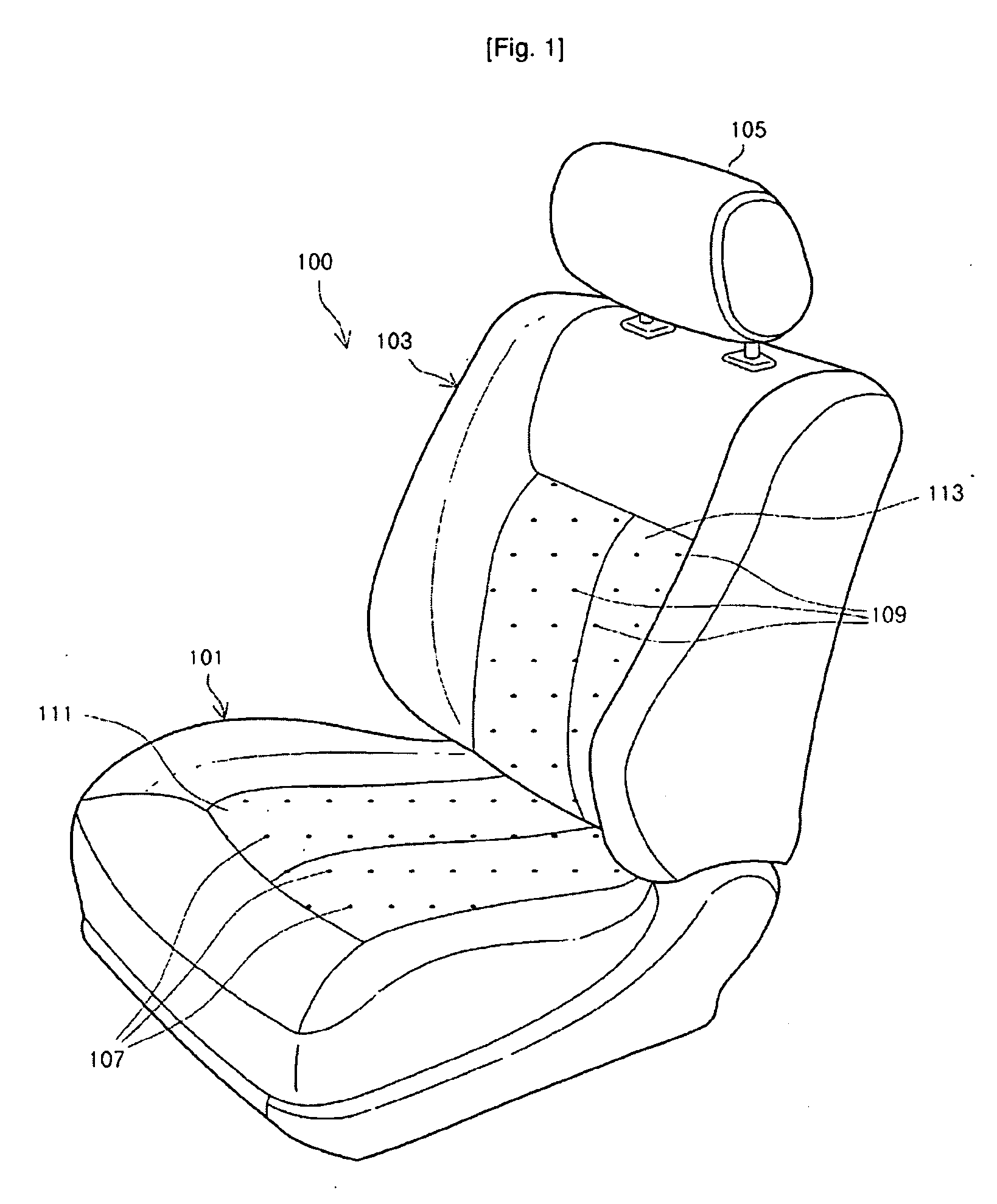

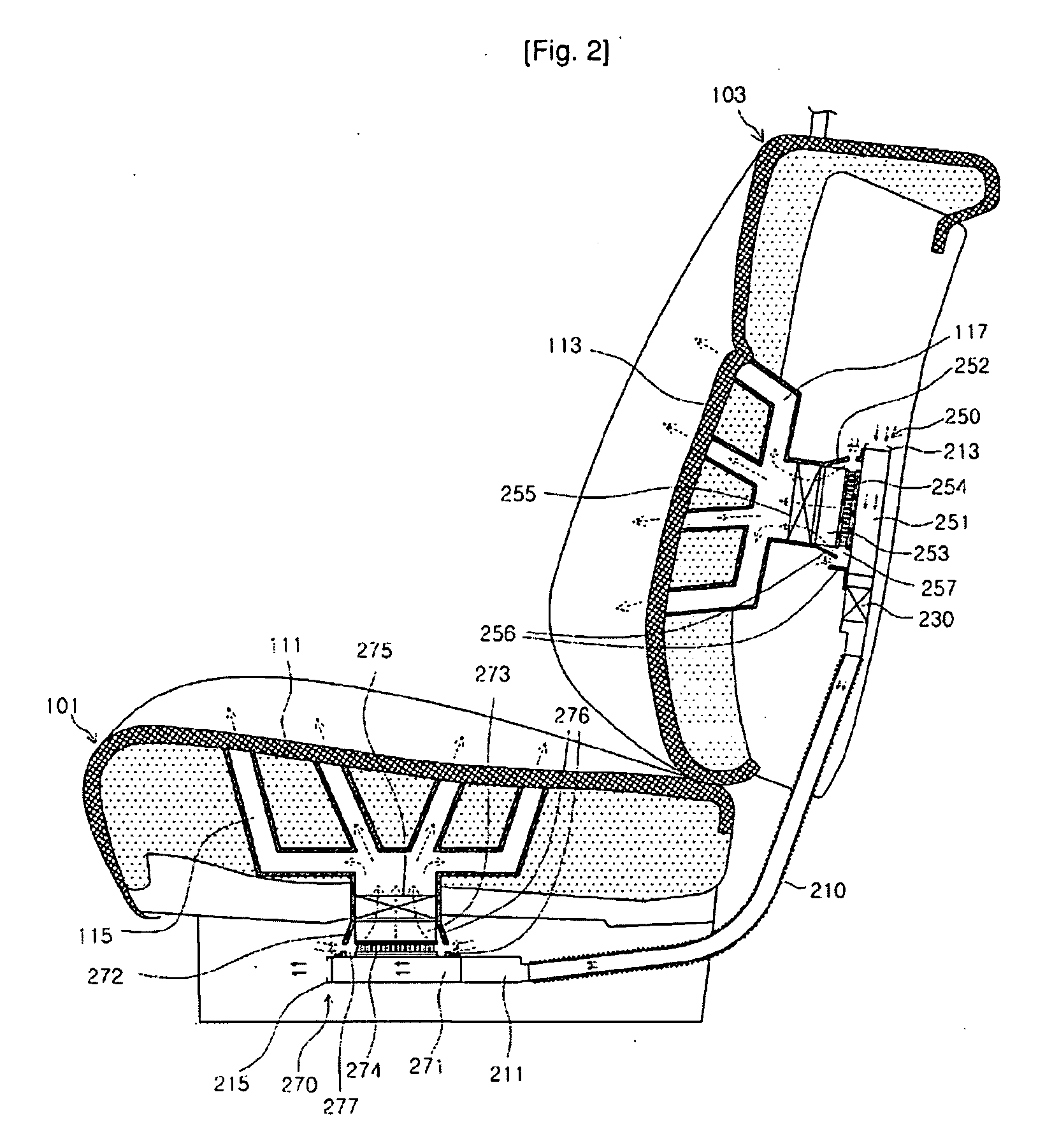

Temperature control system for seat of vehicles

InactiveUS20100300644A1Simple structureImprove heat transfer efficiencyAir-treating devicesSeat heating/ventillating devicesTemperature controlControl system

A temperature control system includes an air duct, an air-blowing device, a seat back temperature control unit, and a seat cushion temperature control unit. The air-blowing device urges air to flow through the air duct. The seat back temperature control unit and the seat cushion temperature control unit performs heat exchanges between air flowing in the air duct and air supplied to a seat back and air supplied to a seat cushion, respectively. The air duct forms a single air passage passing by the seat back temperature control unit and the seat cushion temperature control unit so that the air flowing in the air duct undergoes heat exchange with one of the seat back temperature control unit and the seat cushion temperature control unit and then undergoes heat exchange with the other.

Owner:CHUNG SANG HO

Cooling of High Power Density Devices Using Electrically Conducting Fluids

InactiveUS20080239672A1Reduce weightLow costDigital data processing detailsSemiconductor/solid-state device detailsLiquid metalEngineering

A system to extract heat from a high power density device and dissipate heat at a convenient distance. The system circulates liquid metal in a closed conduit using one or more electromagnetic pumps for carrying away the heat from high power density device and rejecting the heat at a heat sink located at a distance. The system may make use of a thermoelectric generator to power the electromagnetic pumps by utilizing the temperature difference between the inlet and outlet pipes of the heat sink. The system also provides networks of primary and secondary closed conduits having series and parallel arrangements of electromagnetic pumps for dissipating heat from multiple devices at a remotely located heat sink.

Owner:ZAGORIN OBRIEN GRAHAM

Heat exchanger

InactiveUS20090133860A1Improve heat exchange performanceImprove heat transfer effectStationary conduit assembliesStationary tubular conduit assembliesEngineeringPlate heat exchanger

In a heat exchanger, a tube is adapted to exchange heat between a first fluid flowing therein and a second fluid flowing through outside of the tube, and an inner fin is disposed in the tube to divide a flow passage in the tube into a plurality of flow paths. The inner fin includes a plurality of fin portions with different specifications, and the fin portions are arranged in series with respect to a flow direction of the first fluid. Furthermore, the fin portion with the smallest flowing resistance of the first fluid among the plurality of fin portions is arranged on an upstream side of the flow direction of the first fluid with respect to at least an another fin portion. Accordingly, heat exchange performance in the entire heat exchanger can be effectively improved.

Owner:DENSO CORP

Method and group for the compression molding of preforms for containers in polymeric material

InactiveUS7939009B2Quick stepsFacilitate heat exchangeConfectioneryWood working apparatusCompression moldingMaterials science

The preform is formed by an upper neck which maintains unchanged its form in the final object and a hollow body, joined to the neck. The method foresees the insertion, within a matrix cavity, of a metered body of polymeric material whose mass is metered according to a reference value, and the subsequent pressure insertion of a punch within the matrix cavity until it closes the mold's molding chamber, the punch conferring the shape to the inner surface of the preform and the matrix having an inner surface which confers the shape to the outer surface of the preform. According to the invention, in the molding of the preform, the error of the mass of the metered body with respect to the reference value is distributed in the hollow body, which undergoes a subsequent hot deformation until it achieves the final shape. In the mold, the matrix comprises at least one deformable wall (31) whose inner surface defines at least part of the inner surface of the matrix part intended to give form to the hollow body of the preform, said deformable wall (31) having, at least in part, a relatively thin thickness which permits it to be elastically deformed under the pressure of the polymeric material in the final preform molding step, thereby varying the thickness of the hollow body.

Owner:SACMI COOP MECCANICI IMOLA SOC COOP A R L

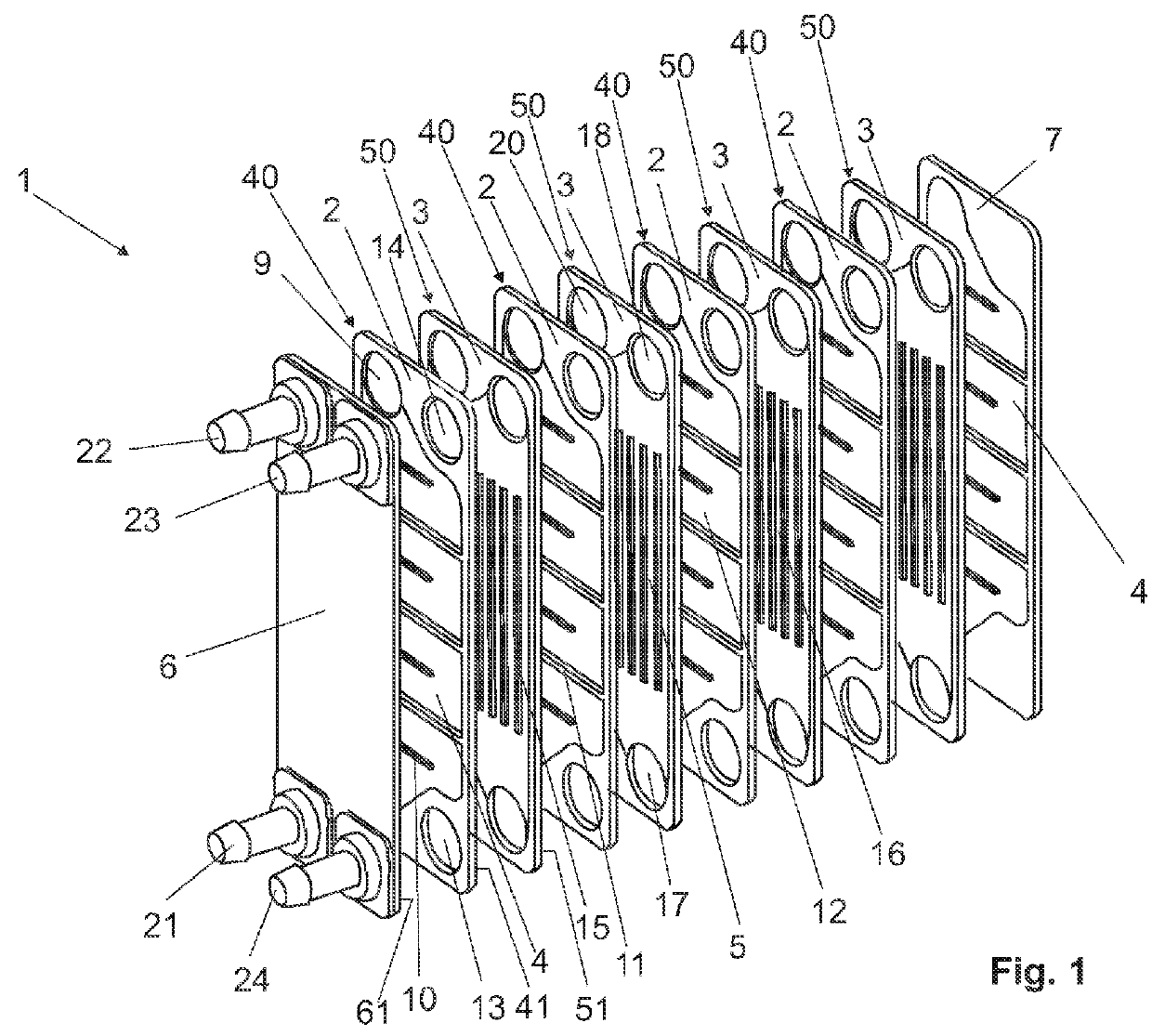

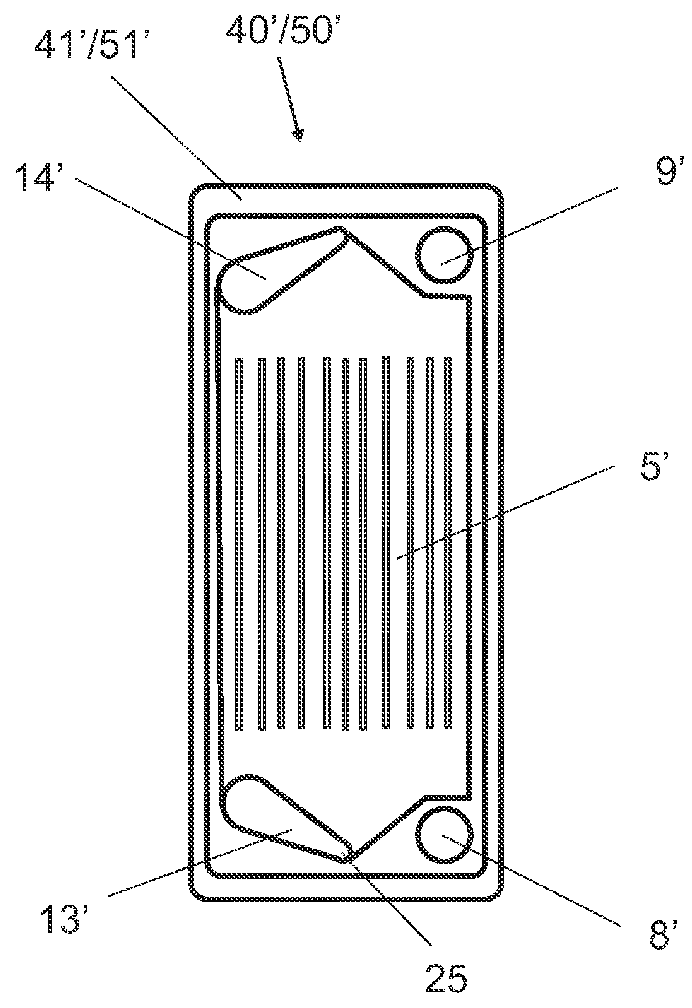

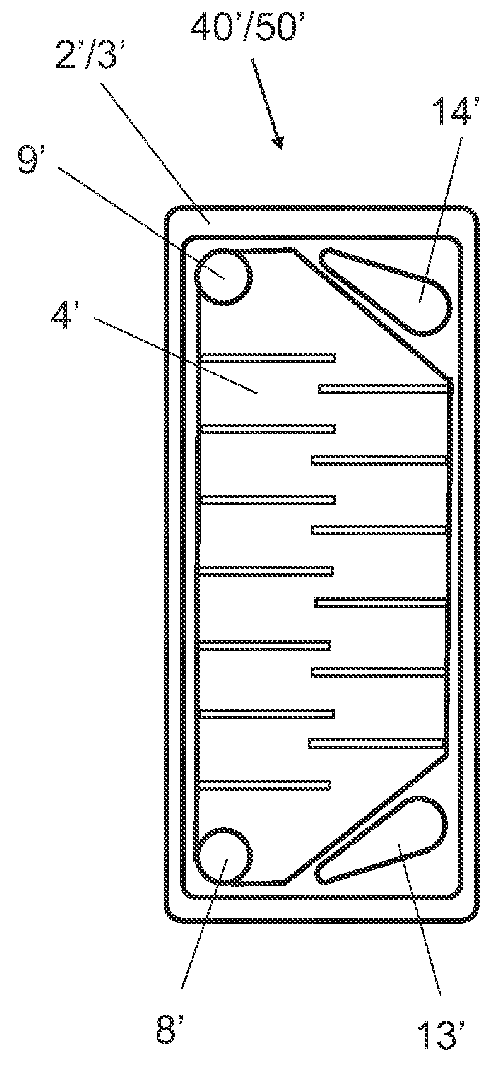

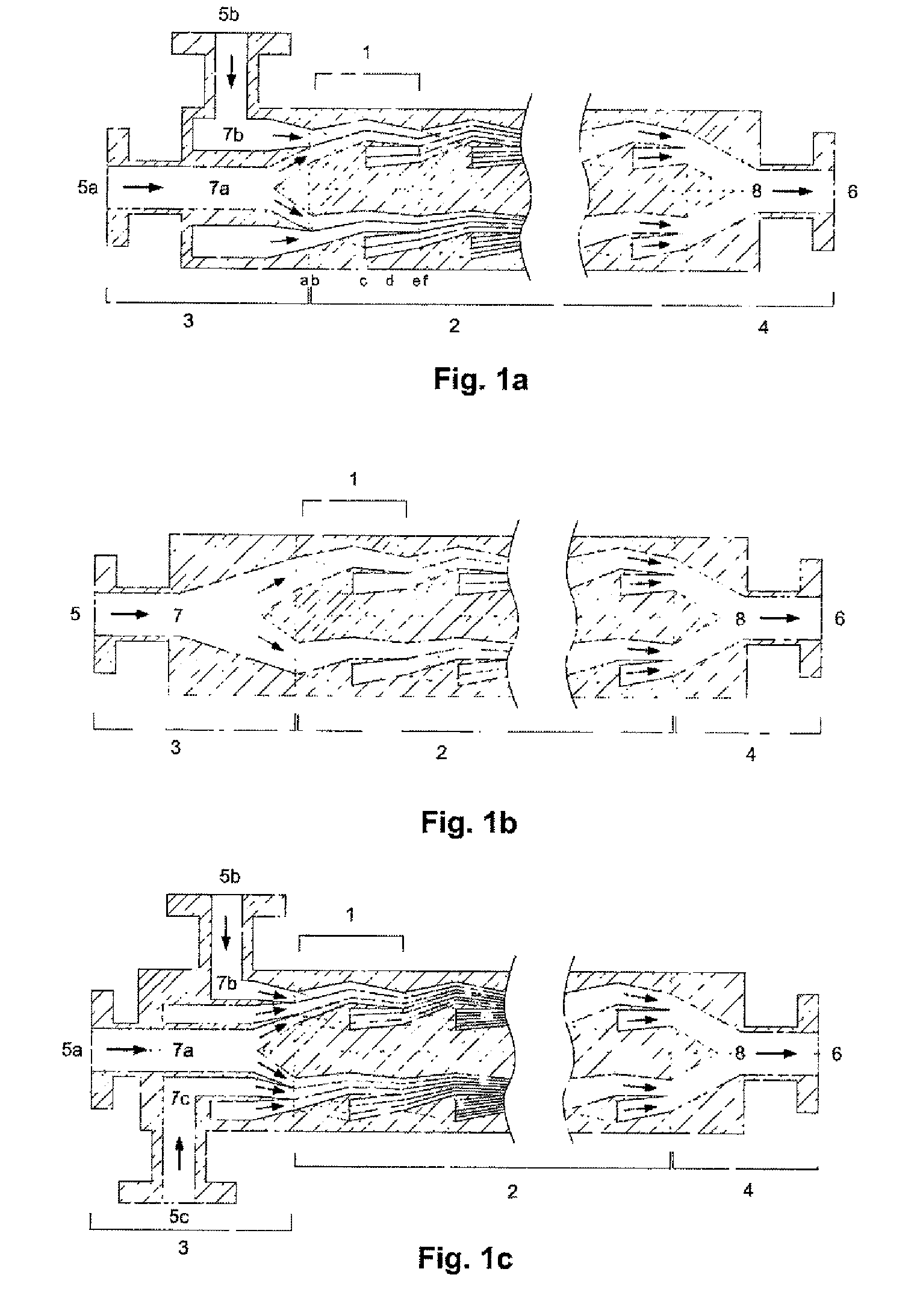

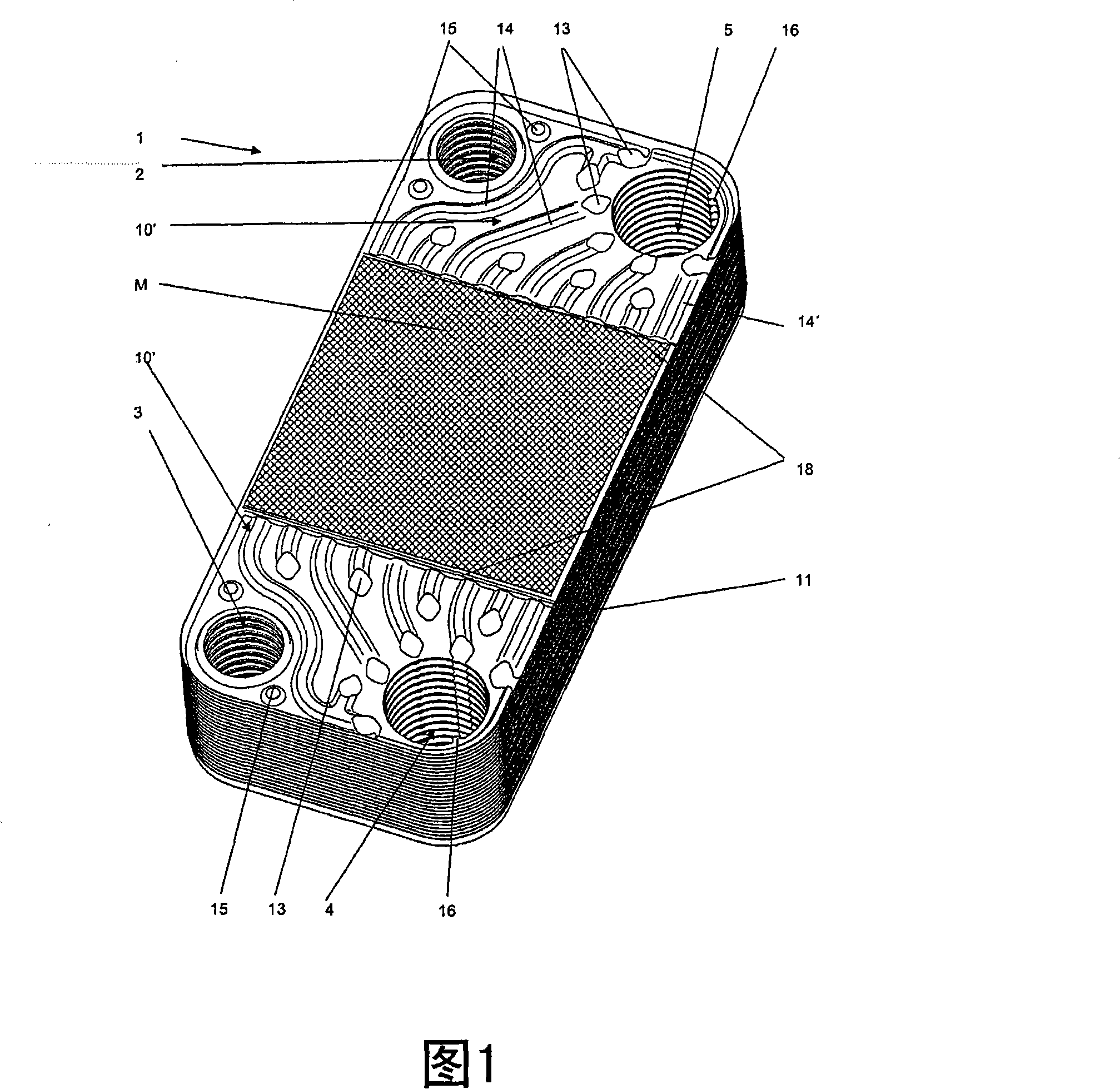

Plate heat exchanger

ActiveUS20120103579A1Easy to manufactureFacilitate heat exchangeIce removalMountingPlate heat exchangerEngineering

The invention relates to a plate heat exchanger comprising a plurality of plates having flow channels, wherein a first plate has a front side having at least one flow channel for a first fluid and a second plate has a front side having at least one flow channel for a second fluid, and wherein the plates have through openings via which the flow channels for the same fluid are respectively connected to one another, wherein a front plate, which is placed in front of the front side of the first plate, has ports for the first fluid and for the second fluid, wherein an end plate forms the end of the aligned plates, wherein the plates and ports are formed from plastic, and wherein the plates are bonded or welded tightly together.

Owner:SARTORIUS STEDIM BIOTECH GMBH

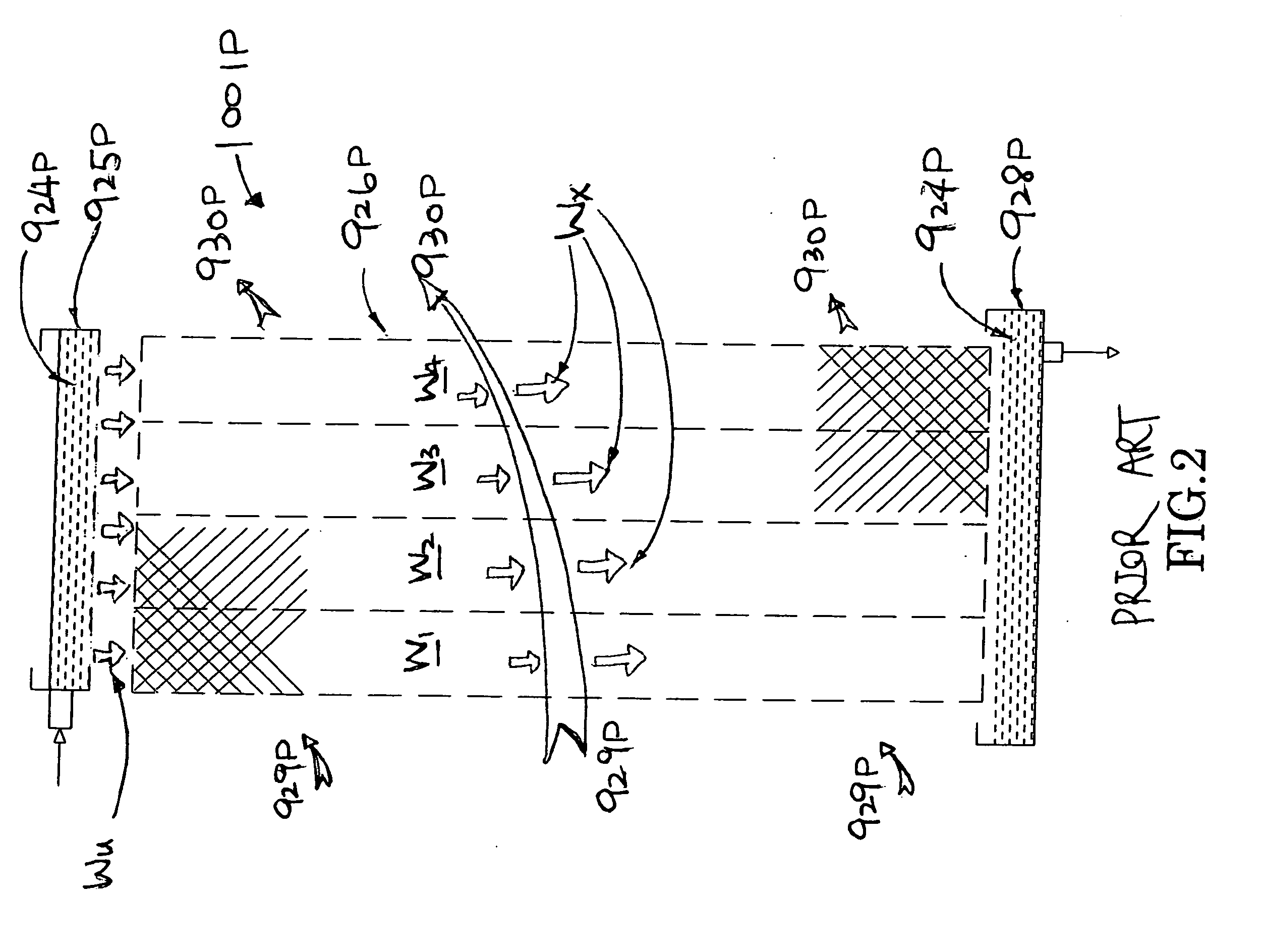

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS8037677B2Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

Multi-level thermal air cooled LED light fixture

InactiveUS8851699B2Improve cooling effectFine surfaceLighting support devicesPoint-like light sourceEffect lightEngineering

Owner:GEORGE ERIK MCMILLAN

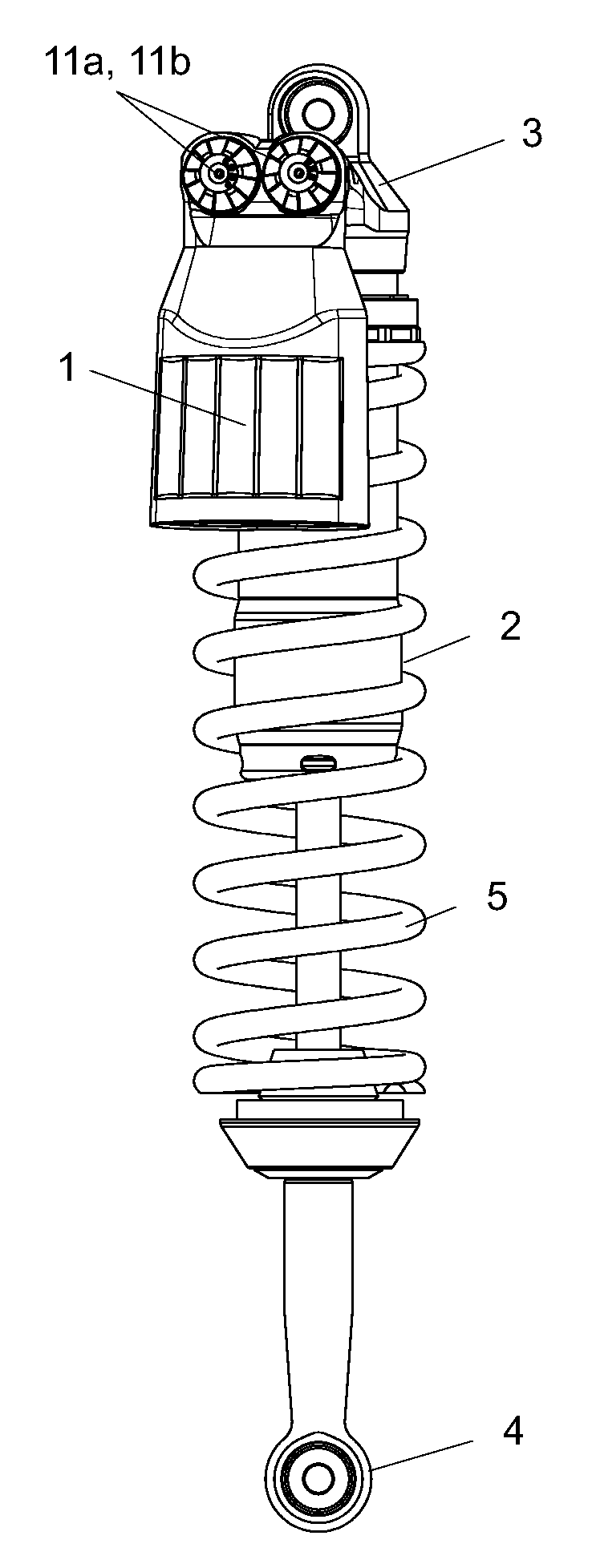

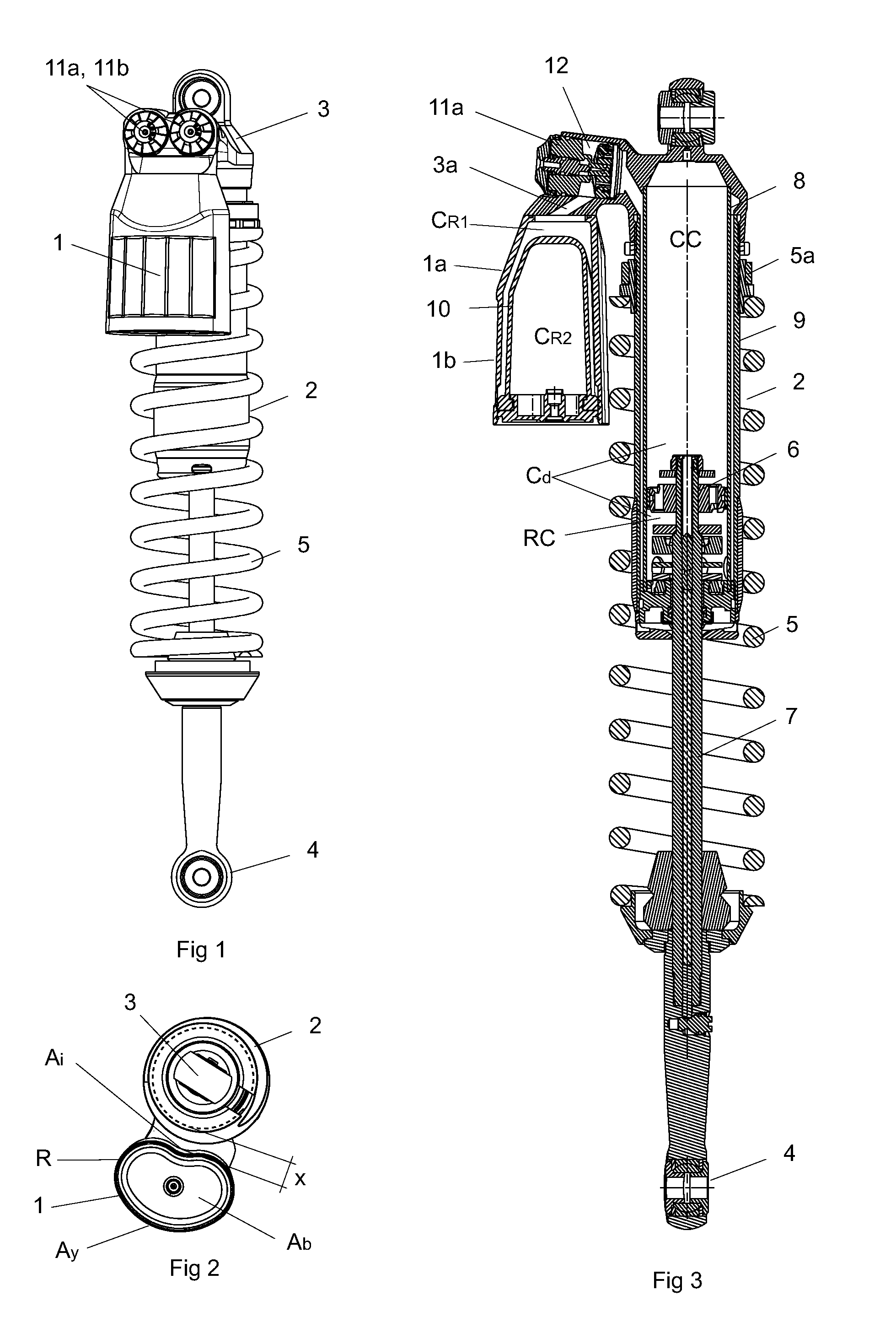

Pressure reservoir for shock absorber

InactiveUS20110017559A1Better and smoother workingFast decaySpringsResilient suspensionsEngineeringShock absorber

A reservoir comprises an upper reservoir part and a lower reservoir part divided by a member into a first reservoir chamber and second reservoir chamber. The reservoir mounts to a shock absorber having a generally cylindrical body. At least the lower reservoir part is delimited by two parallel-displaced flat base surfaces and has a reservoir wall as a contacting surface between these base surfaces. The reservoir has a vertical extent that is substantially parallel with the shock absorber body. One of or both of the base surfaces of the lower reservoir part are kidney-shaped and are connected by the reservoir wall so that the lower pat of the reservoir has a vertical extent that partially follows the cylindrical shape of the shock absorber body

Owner:OHLINS

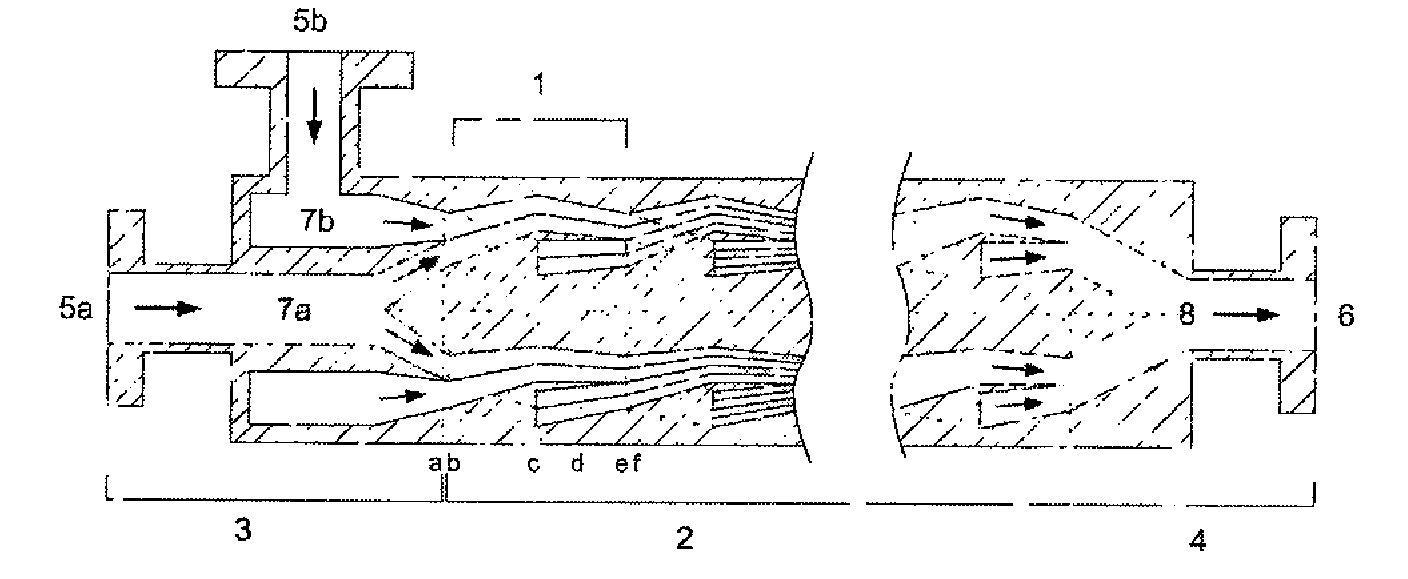

Coaxial compact static mixer and use thereof

ActiveUS8696193B2Reduce pressureReduce the temperatureFlow mixersTransportation and packagingEngineeringStatic mixer

Owner:EHRFELD MIKROTECHNIK BTS GMBH

Novel microelectronic device radiator

ActiveCN101510533AImprove heat transfer effectImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesMetalThermal conduction

The invention relates to a novel microelectronic device radiator which comprises a planar heat pipe being two or more through hole array flat plate structures arranged side by side and formed by extrusion or punching of metal materials and the equivalent diameters of through holes range from 0.2mm to 6mm. The through holes are filled with liquid working substance and two ends of the planar heat pipe are encapsulated in a sealing manner; an evaporation section of the planar heat pipe is in surface contact with a heating surface of a microelectronic device and a condensation section of the planar heat pipe eliminates heat through a heat elimination component. The novel microelectronic device radiator overcomes the defects of small contact area between the current round heat pipe and the heating surface of the microelectronic device, large equivalent resistance of heat conduction and complex manufacture technology, and has the advantages of high heat elimination efficiency and simple technology.

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

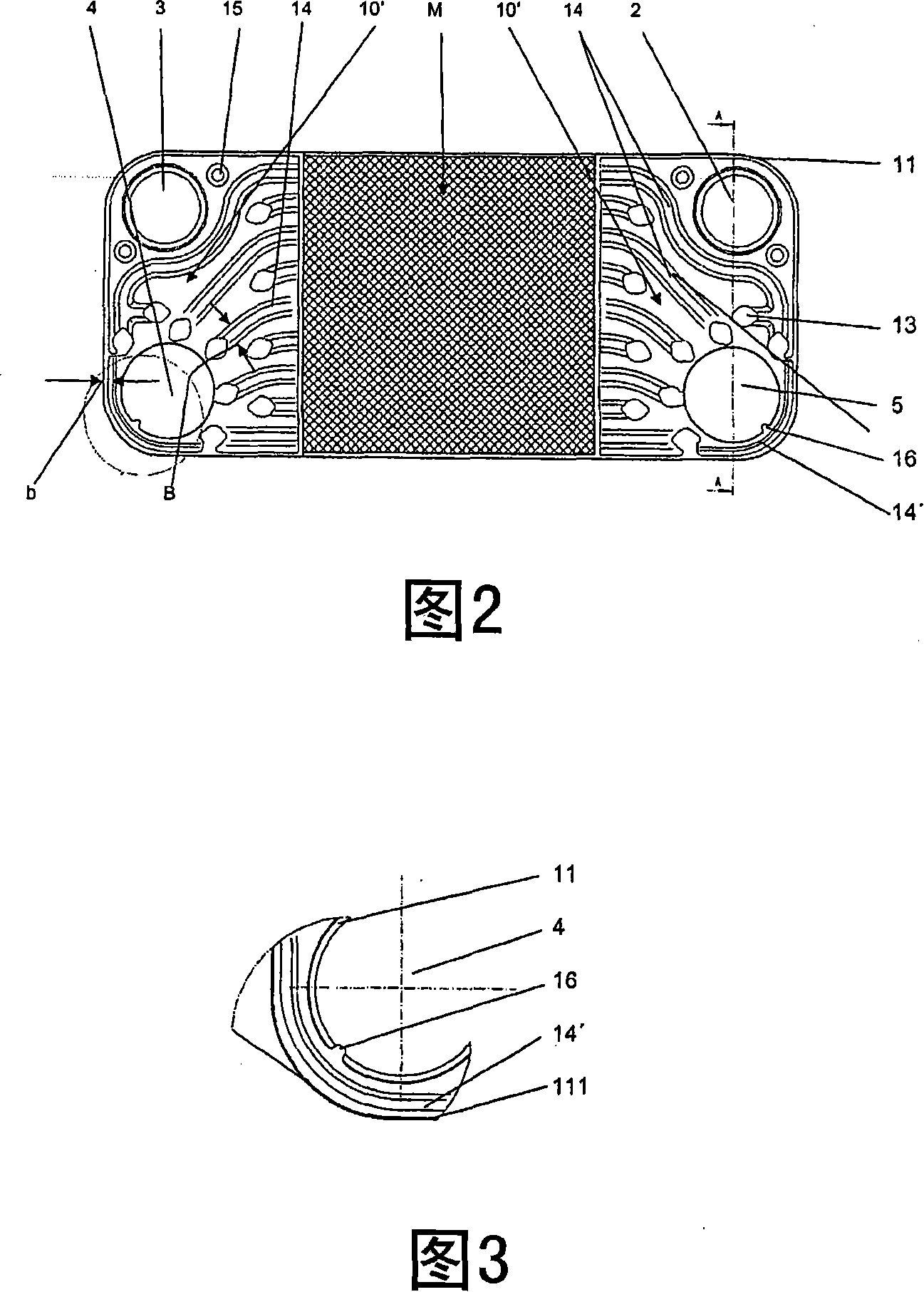

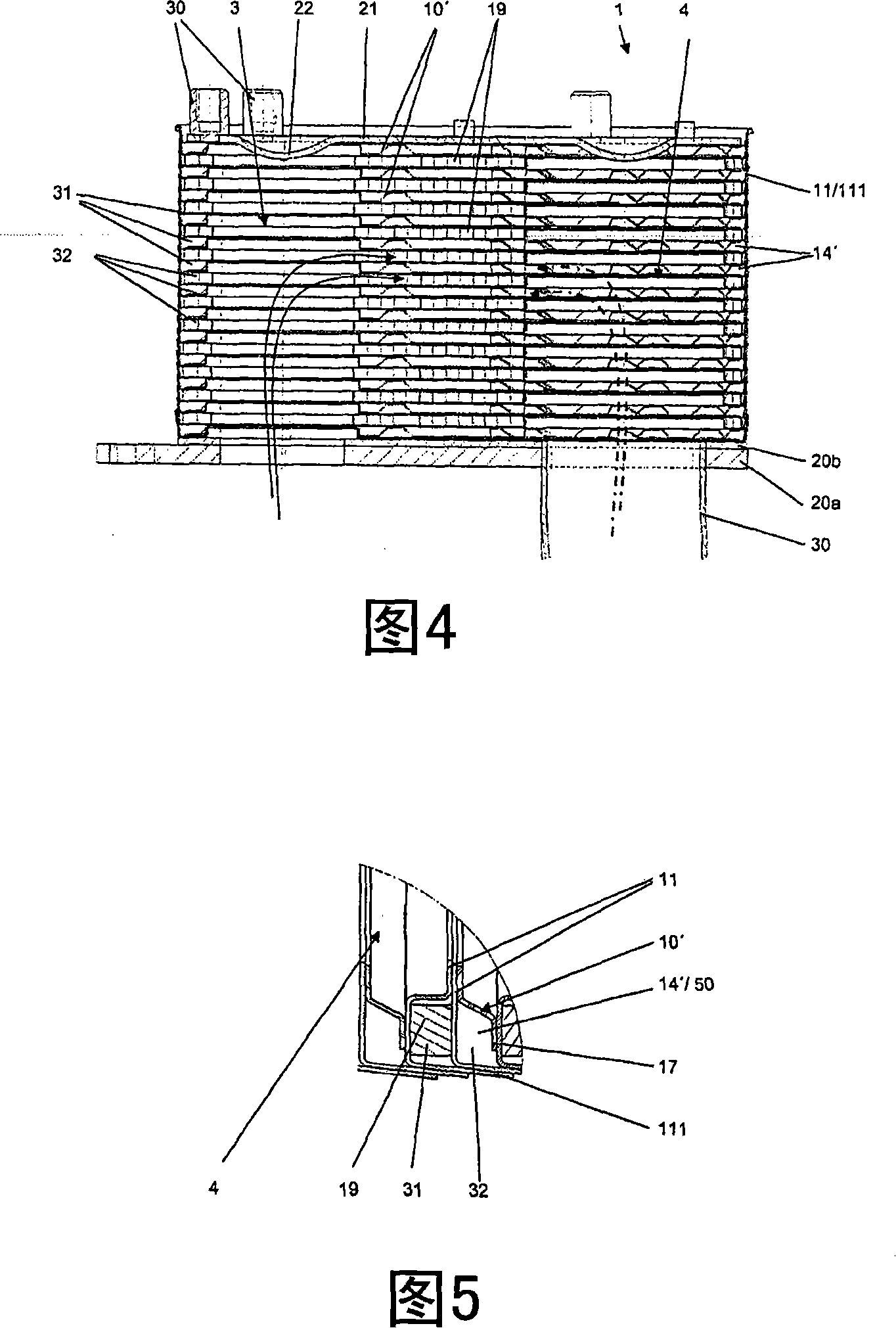

Plate heat exchanger

ActiveCN101162132AOptimization lossOptimize heat exchange efficiencyHeat exchanger casingsHeat transfer modificationPlate heat exchangerMetal sheet

The invention relates to a flat heat exchanger comprising a plurality of trough-shaped heat exchanger plates stacked on top of each other, the heat exchanger plates having edges abutting against each other. The plates may have flow conduits for the cooling fluid and for another fluid between the heat exchanger plates. The flow ducts are assembled with inserts in the form of turbulator plates. The heat exchanger has at least four inlet and outlet openings in the corners of the heat exchanger plates forming two vertical ducts for the cooling fluid and two for the other fluid in the stack. a vertical conduit. An insert in a flow conduit for a cooling fluid consists of one or more components. The flow duct for the cooling fluid is equipped with a plate-like insert with a width guiding the duct in the region near the opening. The insert is formed as a turbulence generator in the central area between the plate-like parts. The openings are arranged in the corners in such a way that only a narrow strip is left occupied by the guiding duct whose width is significantly smaller than that of the other guiding ducts.

Owner:MODINE MFG CO

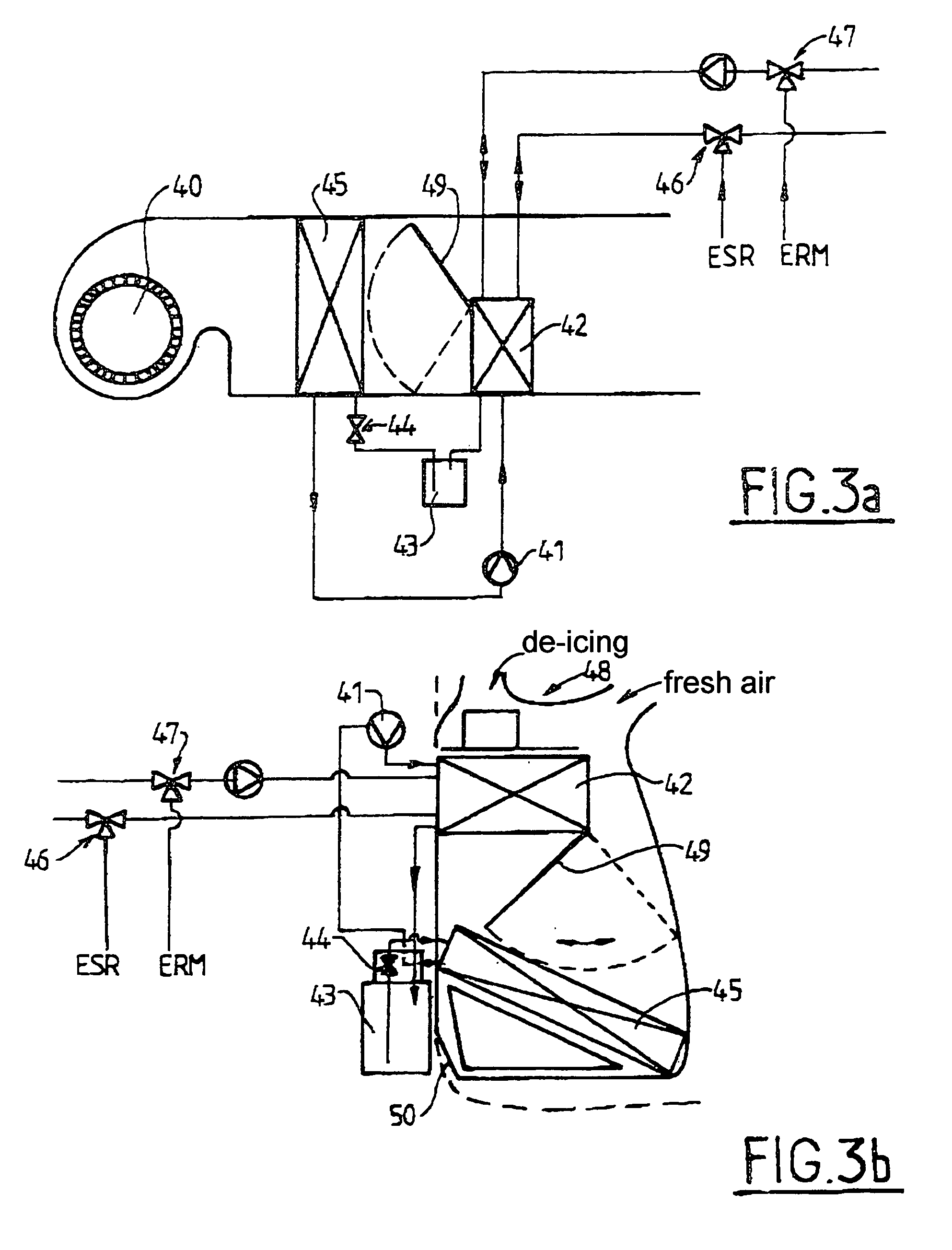

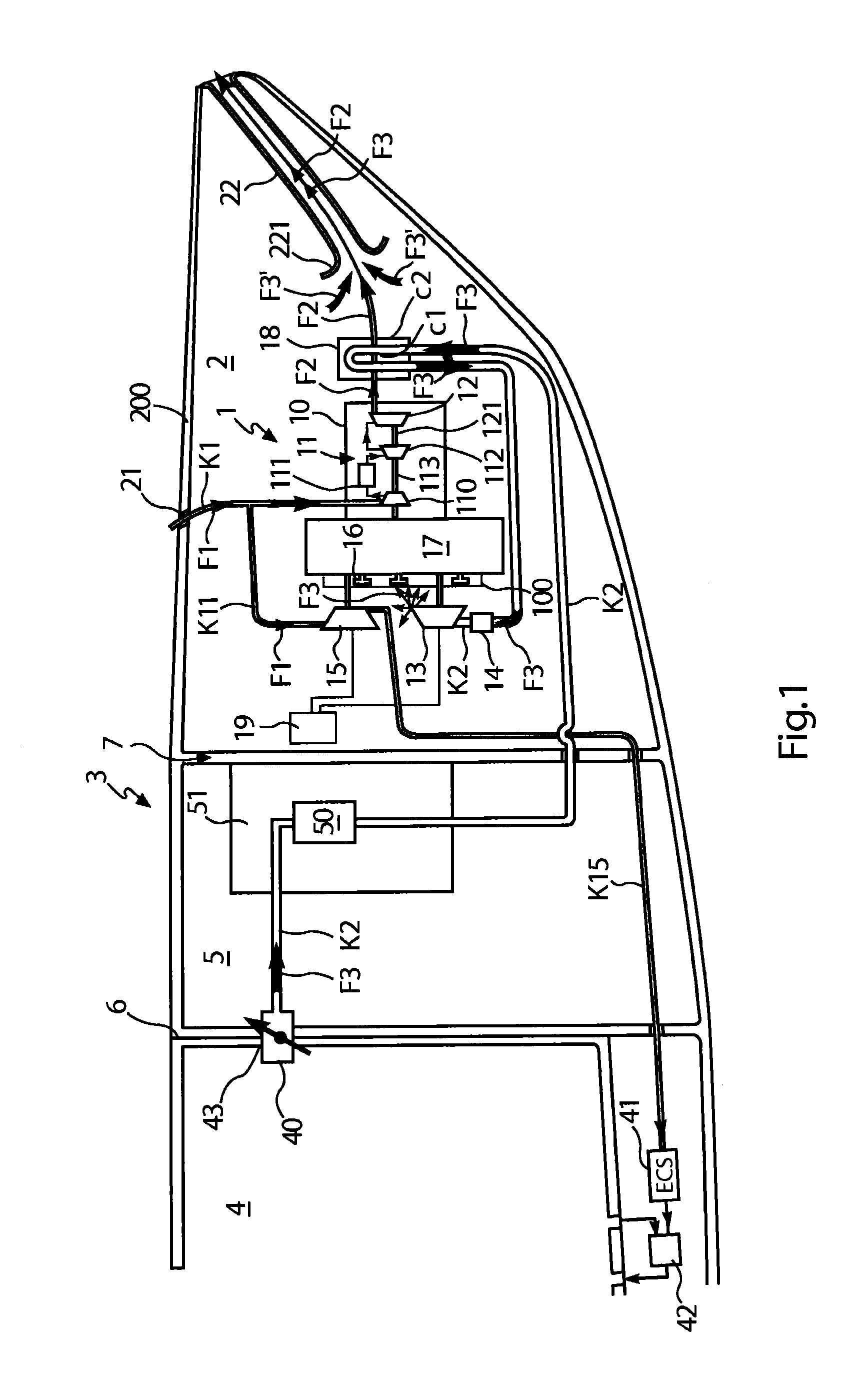

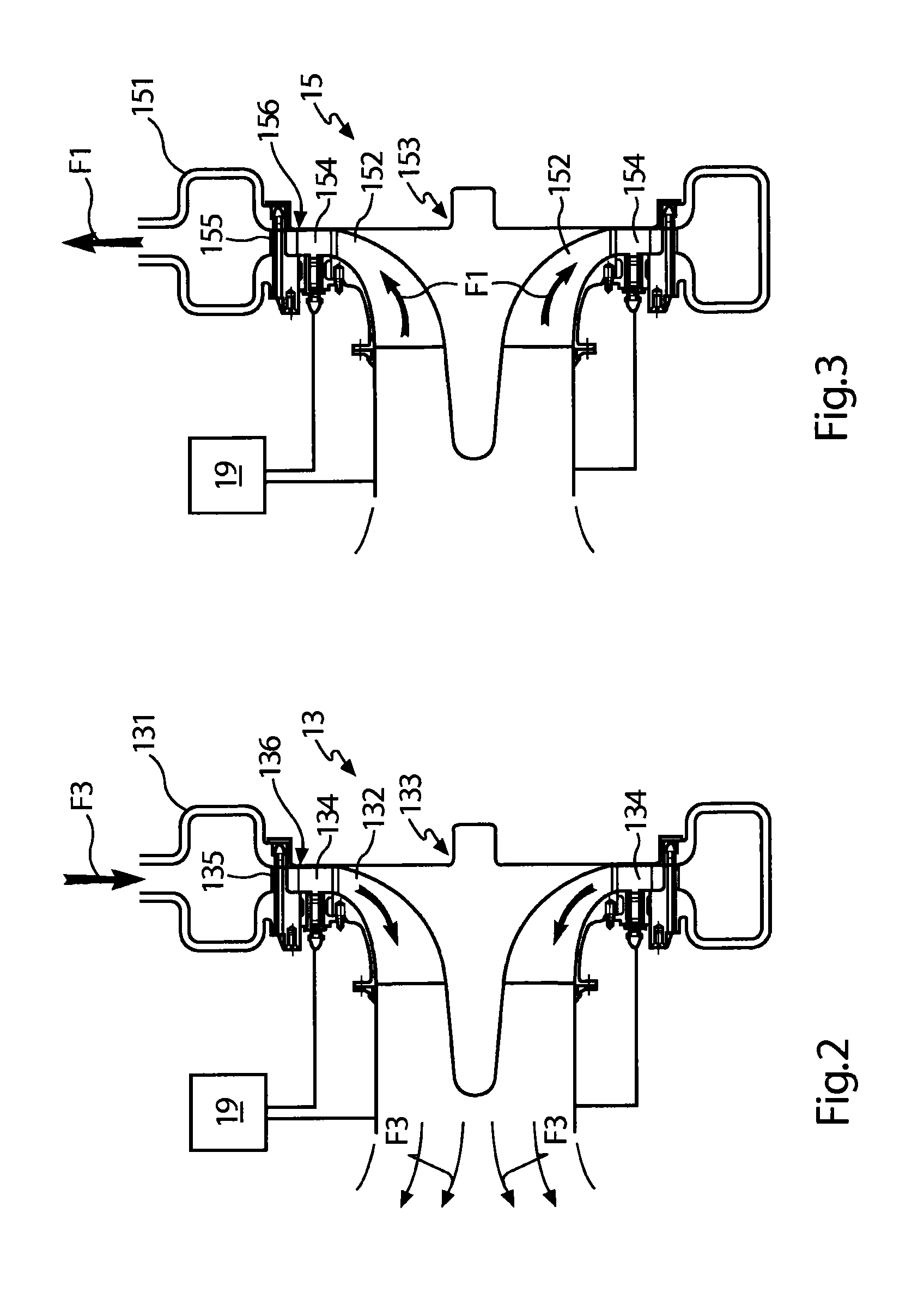

Heating/air conditioning installation for motor vehicle including main module forming fluid-carrying heat exchanger

InactiveUS6986385B1Enhance exchangeEnhanced efficiencyAir-treating devicesRailway heating/coolingChillerEvaporator

A heating / air-conditioning installation for a motor vehicle has a thermal loop which includes a refrigerating compressor, a gas cooler, a pressure-reducing valve, an evaporator, and a heating element. The gas cooler and the heating element are grouped together into a single exchanger including a main module forming a main fluid-carrying heat exchanger.

Owner:VALEO SYST THERMIQUES

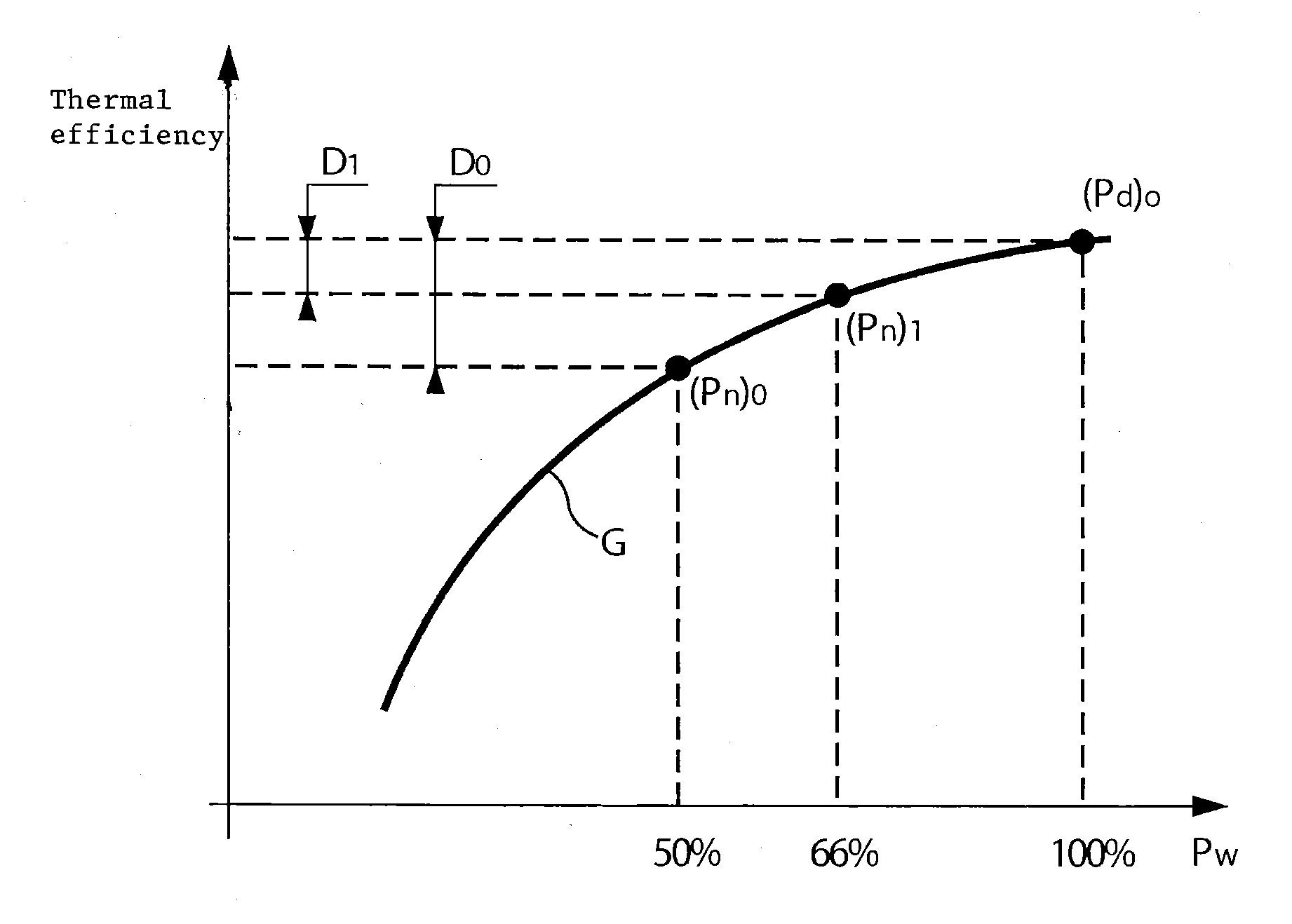

Method for optimizing the overall energy efficiency of an aircraft, and main power package for implementing same

InactiveUS20130151039A1Limiting specific consumptionEliminate the problemAircraft power plantsPower installationsNacelleElectric power

A method and system limiting specific consumption of an aircraft by matching sizing of a power supply to actual power needs of a cabin pressure control system. The method optimizes overall efficiency of energy supplied onboard an aircraft including, in an environment near the cabin, at least one main power-generating engine, sized to serve as a single pneumatic energy-generating source for the cabin and as an at most partial propulsive, hydraulic, and / or electric energy-generating source for the rest of the aircraft. The method minimizes power differential between a nominal point of the power sources when the sources are operating, and a sizing point of non-propulsive energy contributions of the sources when the main engine has failed, by equally dividing power contributions of the main engines and the main power generator under nominal operating conditions and in an event of failure of a main engine.

Owner:SAFRAN HELICOPTER ENGINES

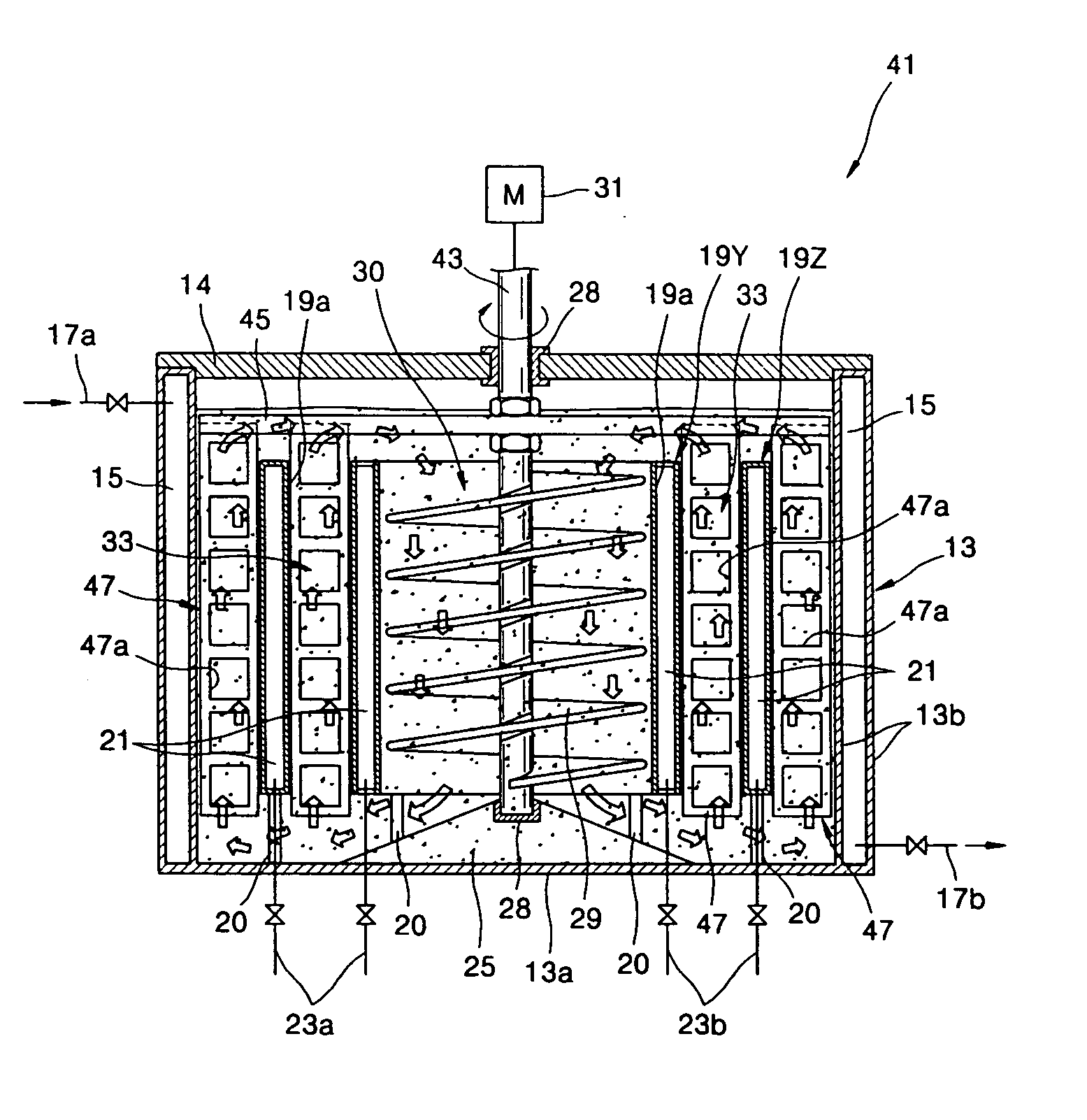

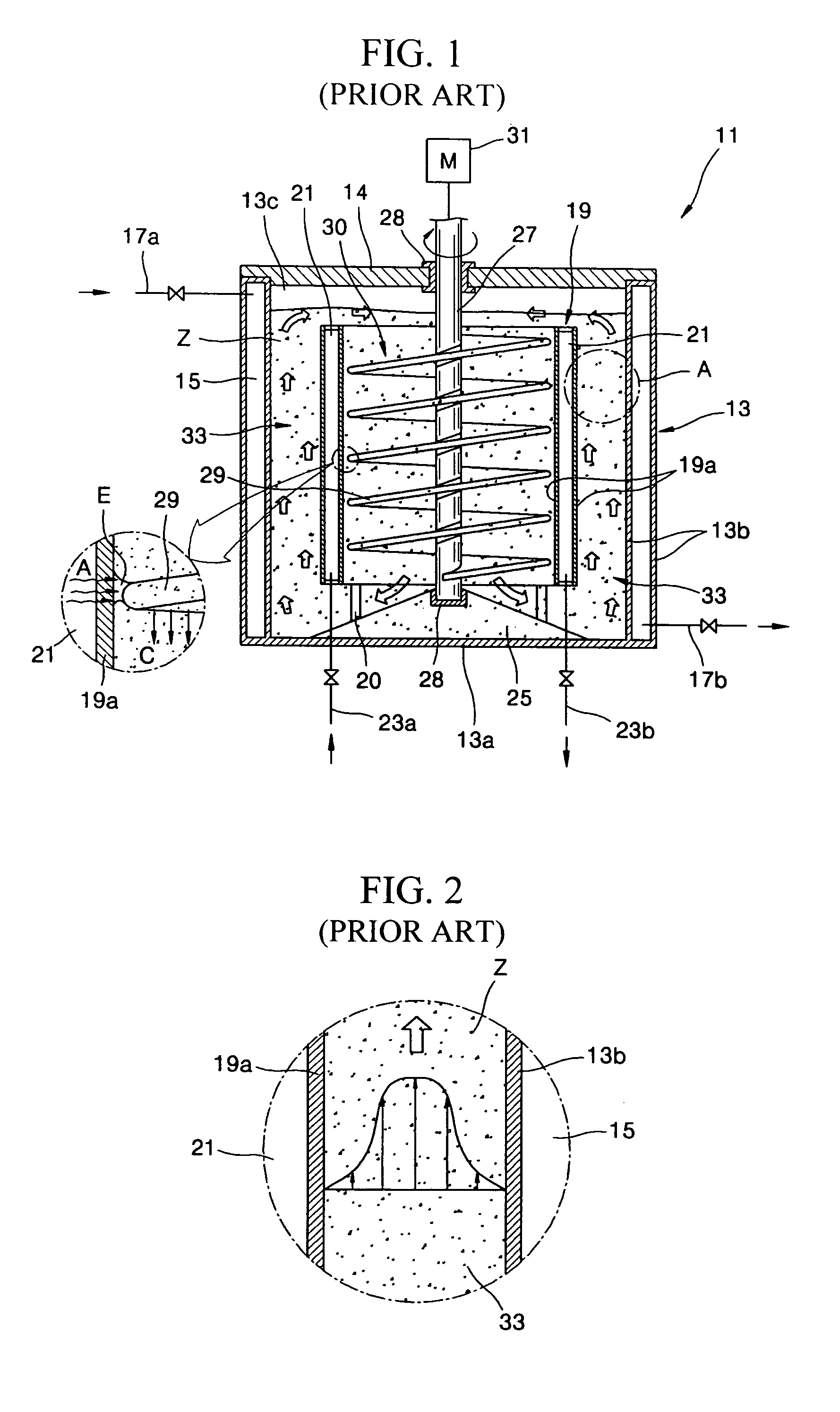

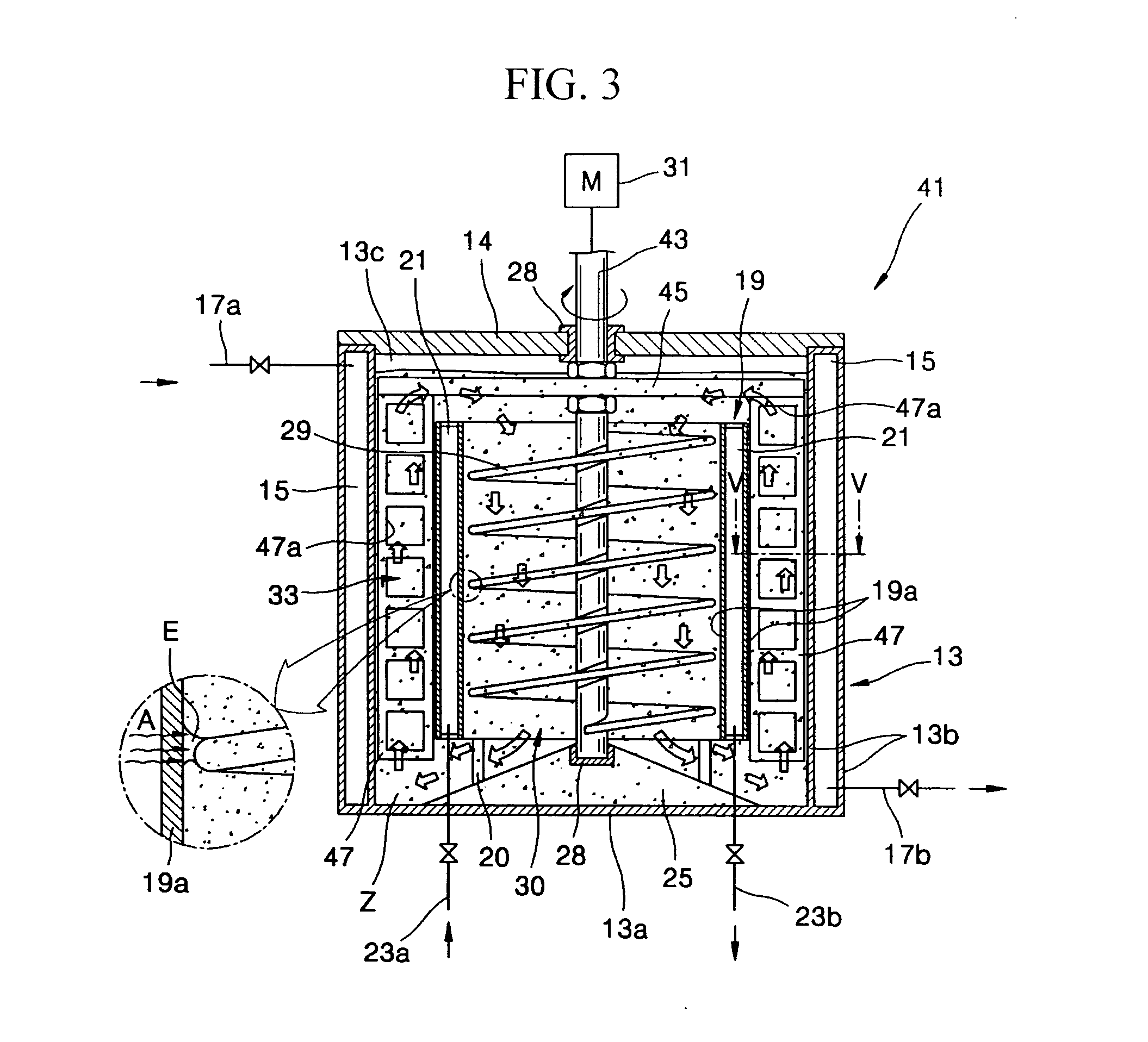

Apparatus for mixing viscous material

ActiveUS20070159919A1Promote heat exchangeConstant thickness and widthLiquid degasificationFlow mixersImpellerEngineering

An apparatus for mixing viscous material includes a chamber having a cylindrical sidewall and a bottom and receiving viscous material to be mixed; a cylindrical draft tube fixed at an inside center of the chamber to be spaced from the bottom and the sidewall and forming a space between the draft tube and the sidewall to allow passage of the viscous material, and including a heat medium passage therein; a carrying impeller installed in the draft tube and driven by a motor to transfer the viscous material above or below the draft tube and suck the viscous material in the space into the draft tube; and a sweeping impeller installed in the space and rotated in a circumferential direction by a motor to apply a pressure to the viscous material so that the viscous material in the space is not adhered to the draft tube and the sidewall.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com