Patents

Literature

12743results about "Stationary tubular conduit assemblies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

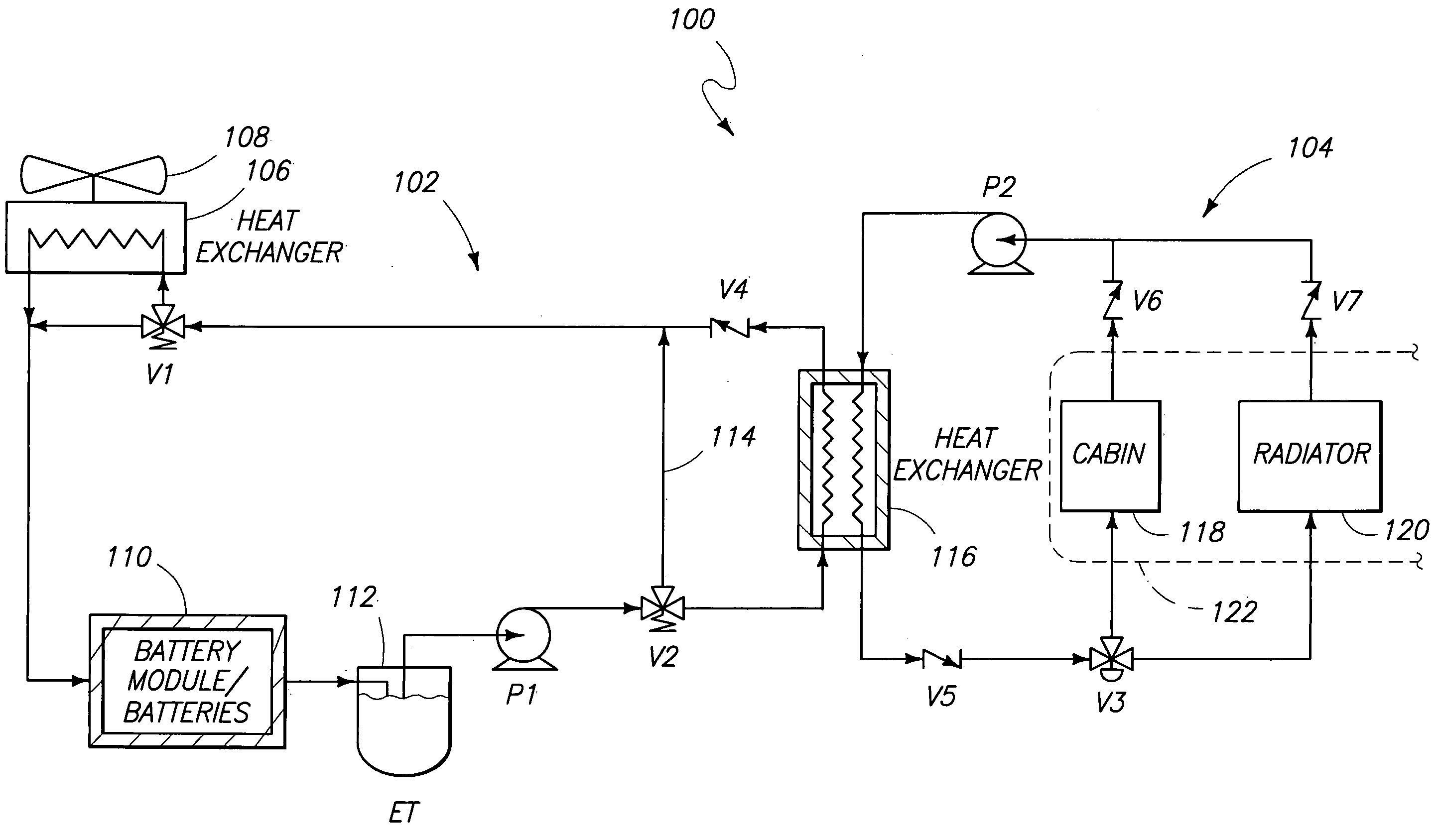

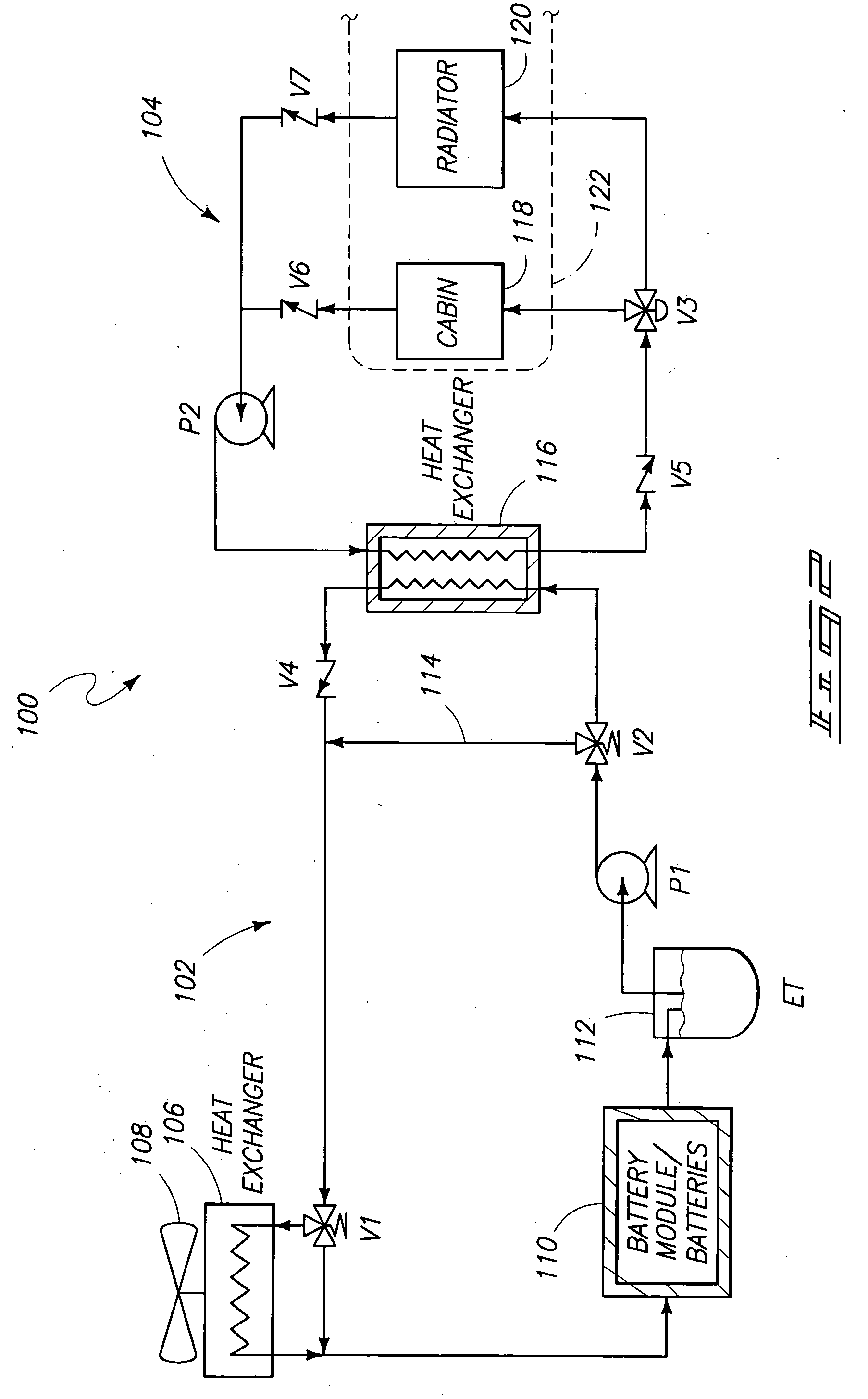

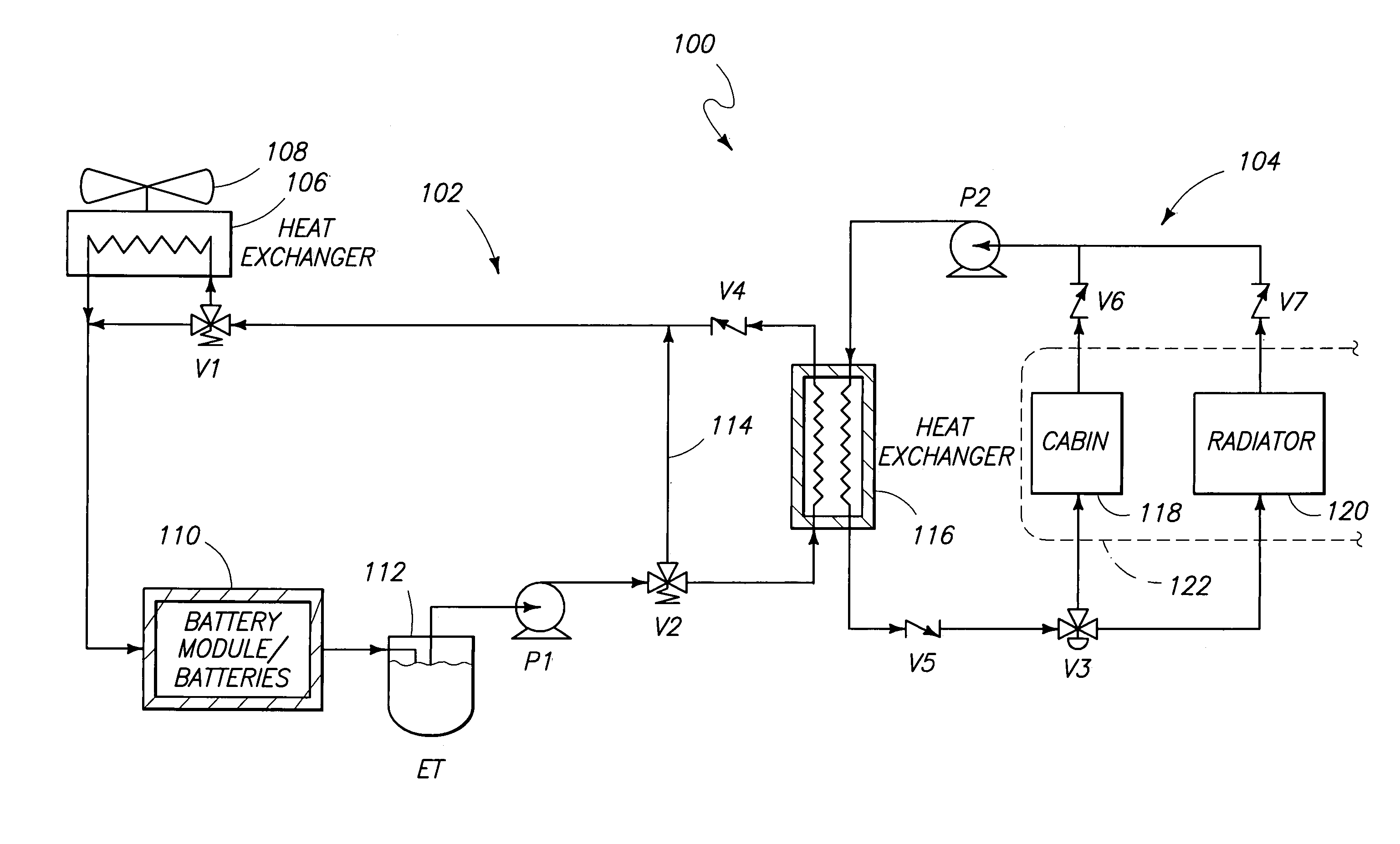

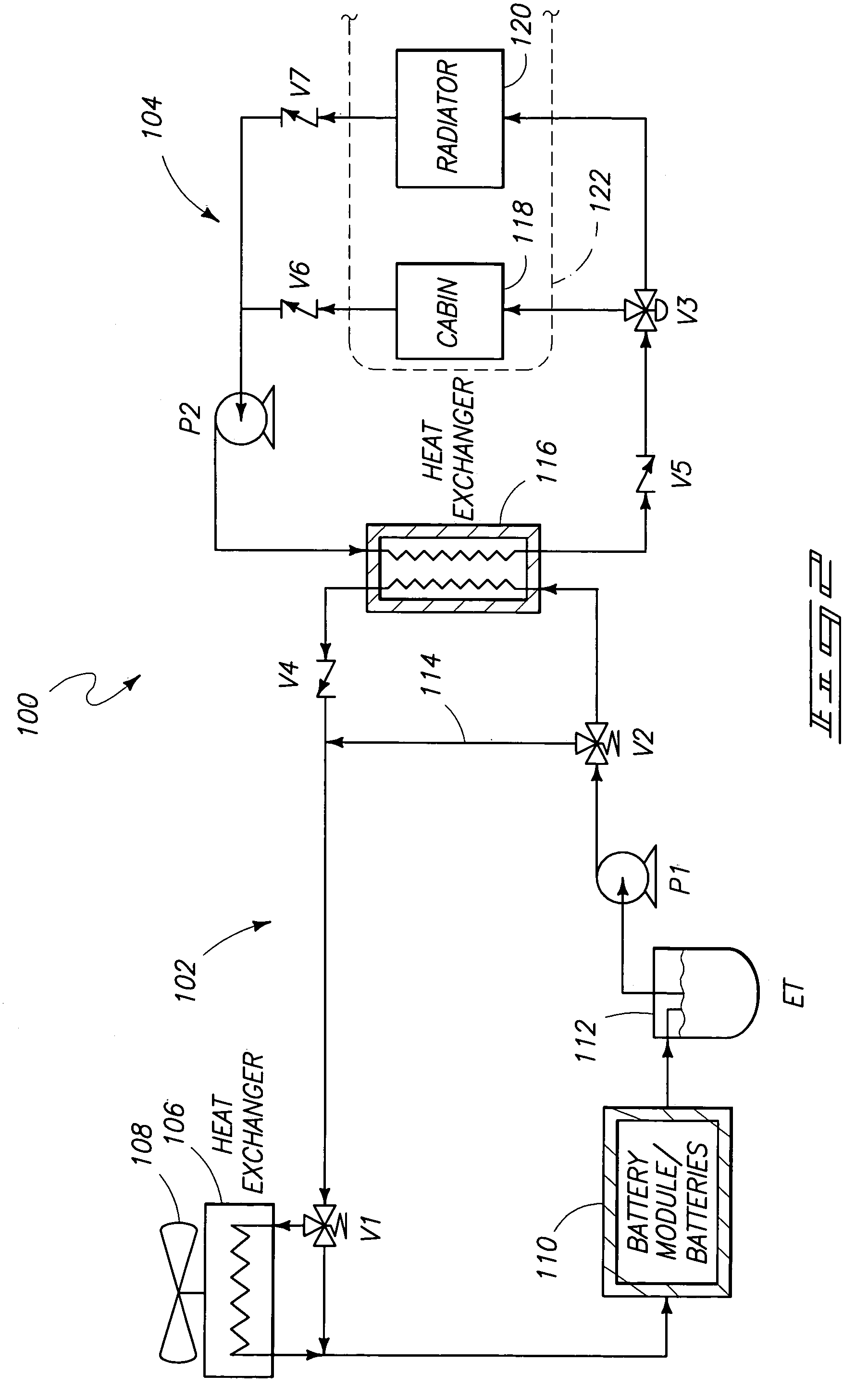

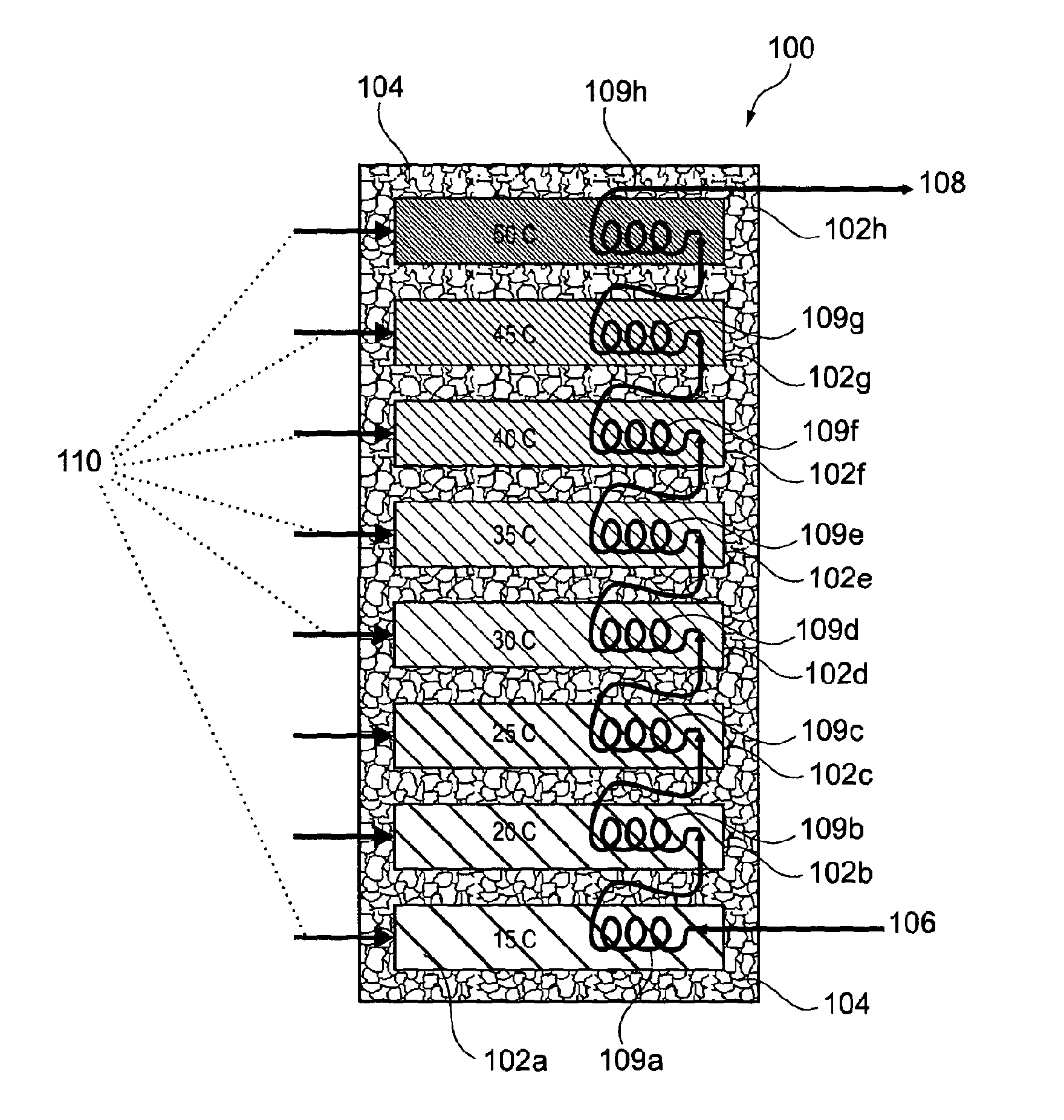

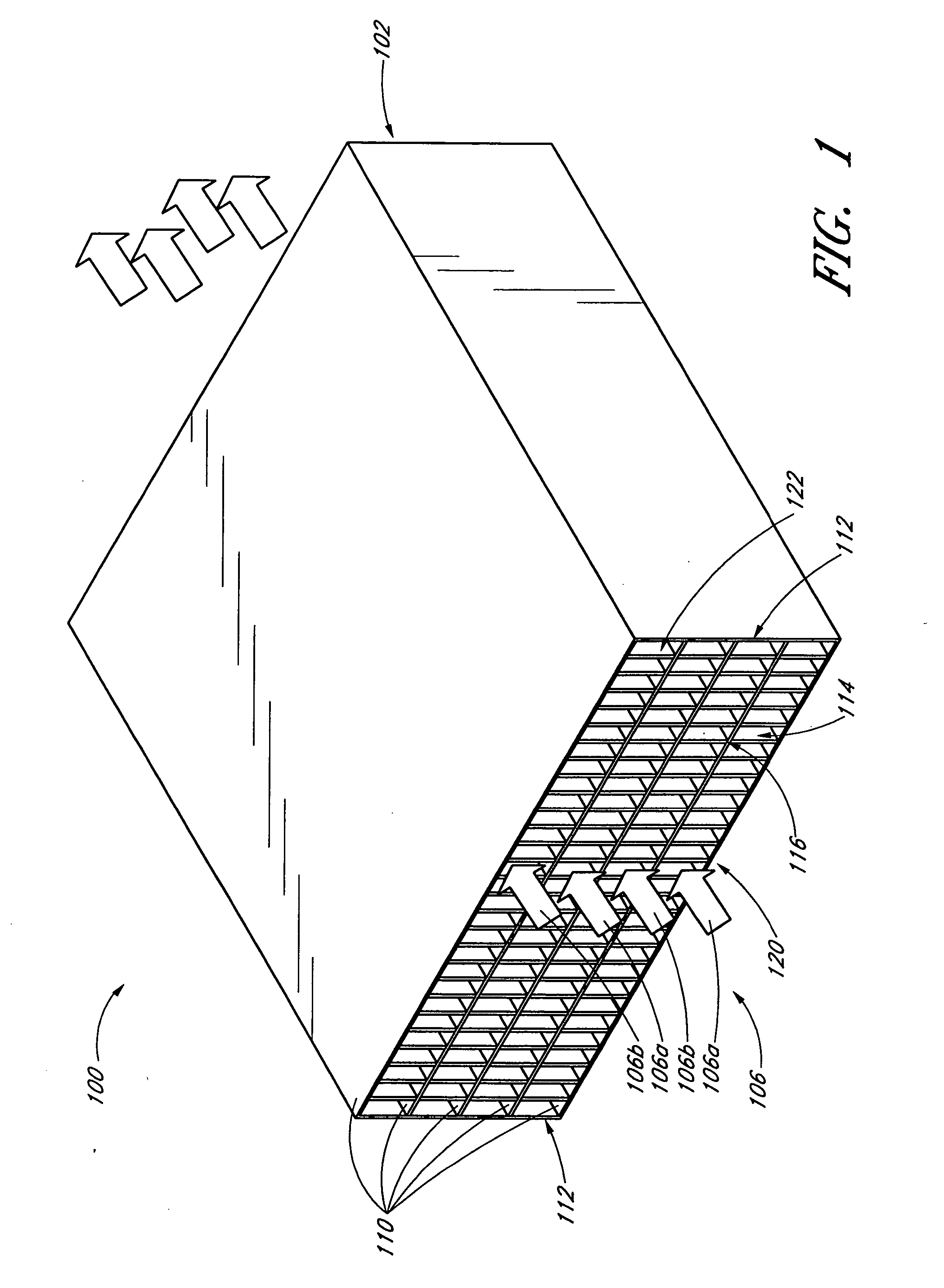

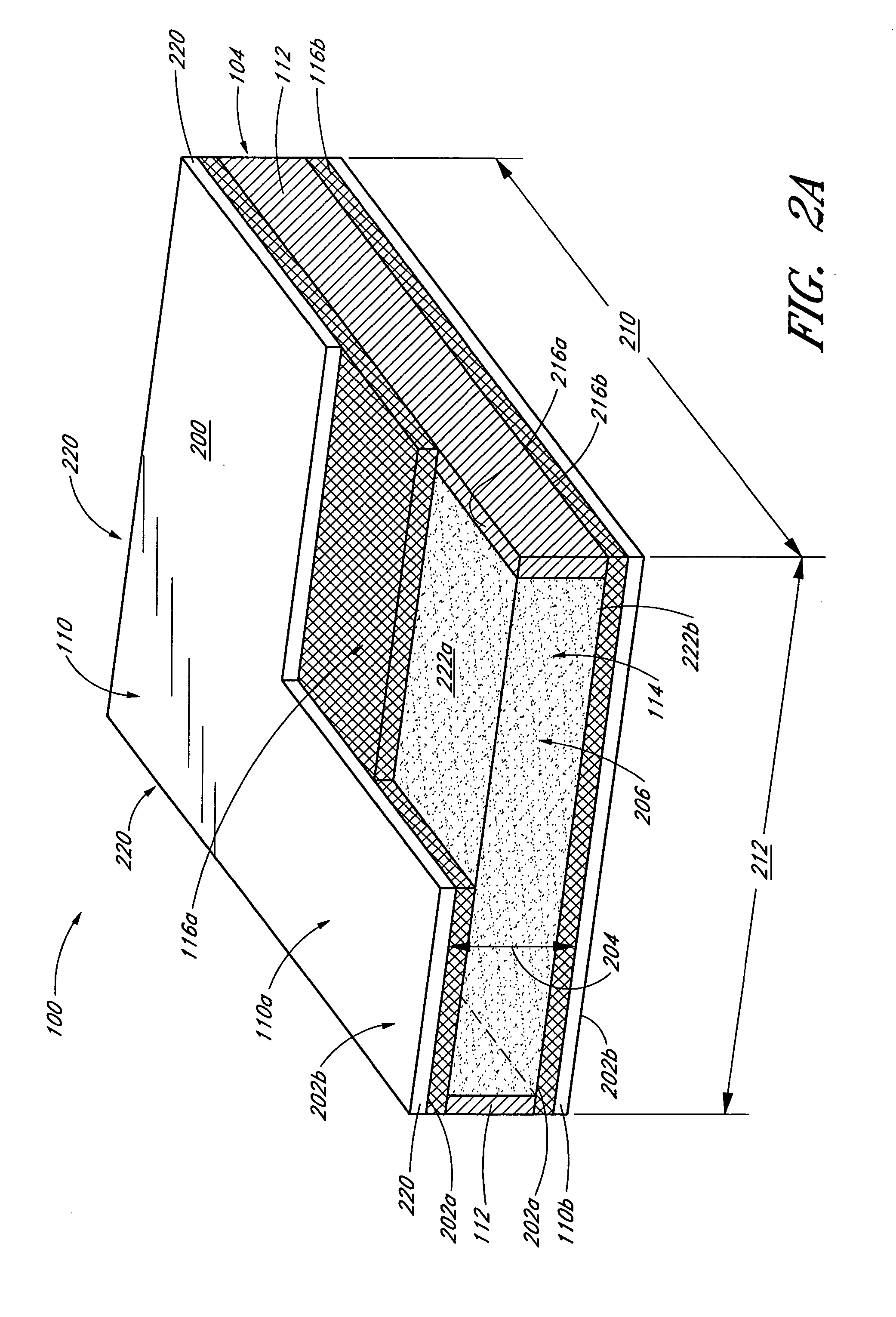

Thermal management systems and methods

InactiveUS20050167169A1Increase heatCell temperature controlMachines/enginesThermal energyThermal energy storage

A thermal management system for a vehicle includes a heat exchanger having a thermal energy storage material provided therein, a first coolant loop thermally coupled to an electrochemical storage device located within the first coolant loop and to the heat exchanger, and a second coolant loop thermally coupled to the heat exchanger. The first and second coolant loops are configured to carry distinct thermal energy transfer media. The thermal management system also includes an interface configured to facilitate transfer of heat generated by an internal combustion engine to the heat exchanger via the second coolant loop in order to selectively deliver the heat to the electrochemical storage device. Thermal management methods are also provided.

Owner:BATTELLE ENERGY ALLIANCE LLC

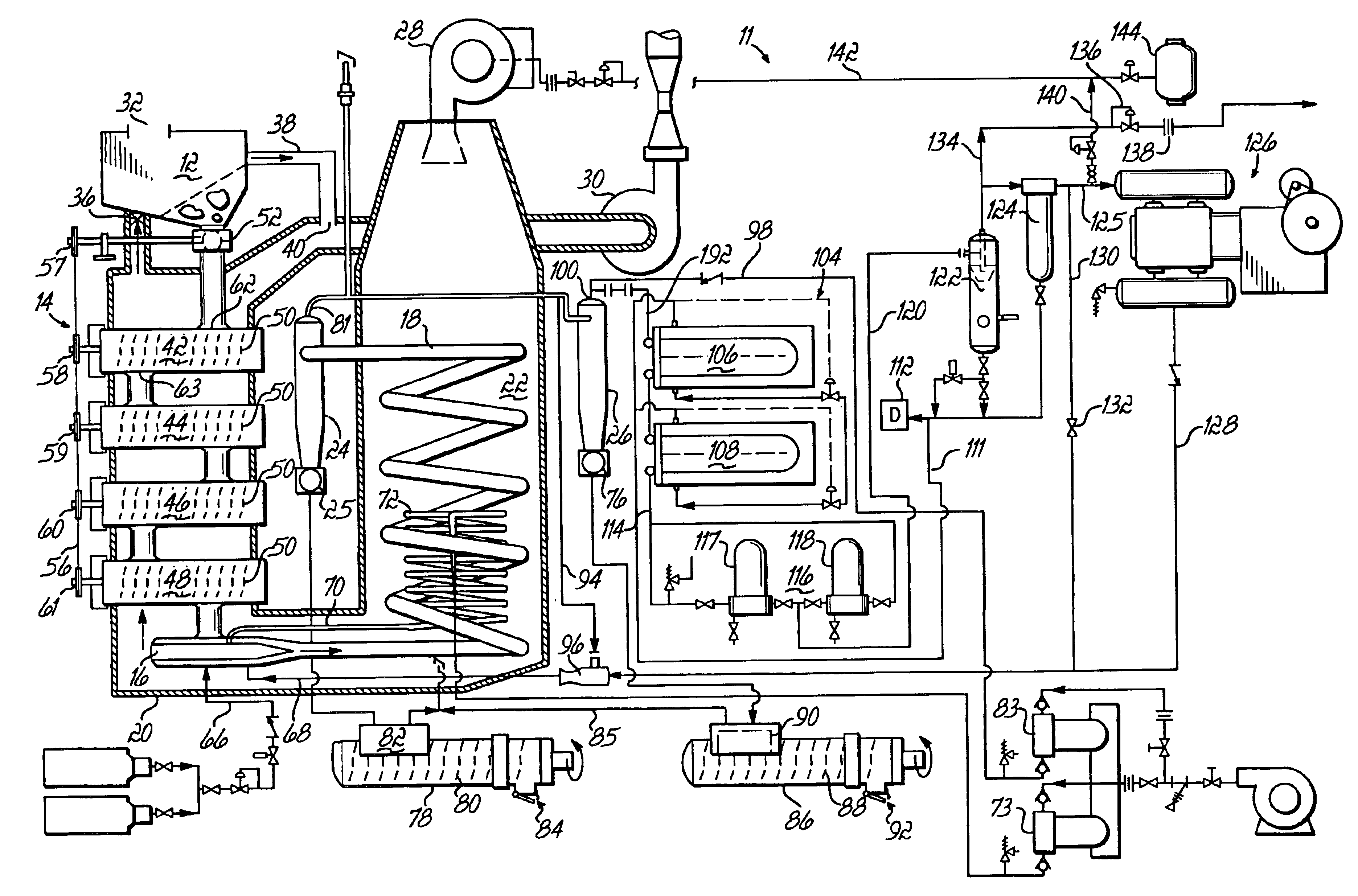

Method and apparatus for producing synthesis gas from carbonaceous materials

A method of producing syn gas from biomass or other carbonaceous material utilizes a controlled devolatilization reaction in which the temperature of the feed material is maintained at less than 450° F. until most available oxygen is consumed. This minimizes pyrolysis of the feed material. The method and apparatus utilizes the formed synthesis gas to provide the energy for the necessary gasification. This provides for a high purity syn gas and avoids production of slag.

Owner:JBK EXTRACTIONS

Marine engine fuel cooling system

InactiveUS20060124113A1Internal combustion piston enginesThermal treatment of fuelNuclear engineeringFuel tank

A fuel cooling system for a marine inboard engine, including a fuel tank, a fuel supply conduit, and a heat exchanger. The fuel supply conduit includes first and second ends, and extends between the fuel tank and a fuel injection system for the engine. The heat exchanger is disposed intermediate the first and second ends of the fuel supply conduit, and includes a fuel passage in fluid communication with the fuel supply conduit, and a coolant passage in fluid communication with a coolant side of a closed-loop auxiliary cooling system.

Owner:ROBERTS FOREST G SR

Thermal management systems and methods

InactiveUS7147071B2Increase heatCell temperature controlMachines/enginesThermal energyThermal energy storage

A thermal management system for a vehicle includes a heat exchanger having a thermal energy storage material provided therein, a first coolant loop thermally coupled to an electrochemical storage device located within the first coolant loop and to the heat exchanger, and a second coolant loop thermally coupled to the heat exchanger. The first and second coolant loops are configured to carry distinct thermal energy transfer media. The thermal management system also includes an interface configured to facilitate transfer of heat generated by an internal combustion engine to the heat exchanger via the second coolant loop in order to selectively deliver the heat to the electrochemical storage device. Thermal management methods are also provided.

Owner:BATTELLE ENERGY ALLIANCE LLC

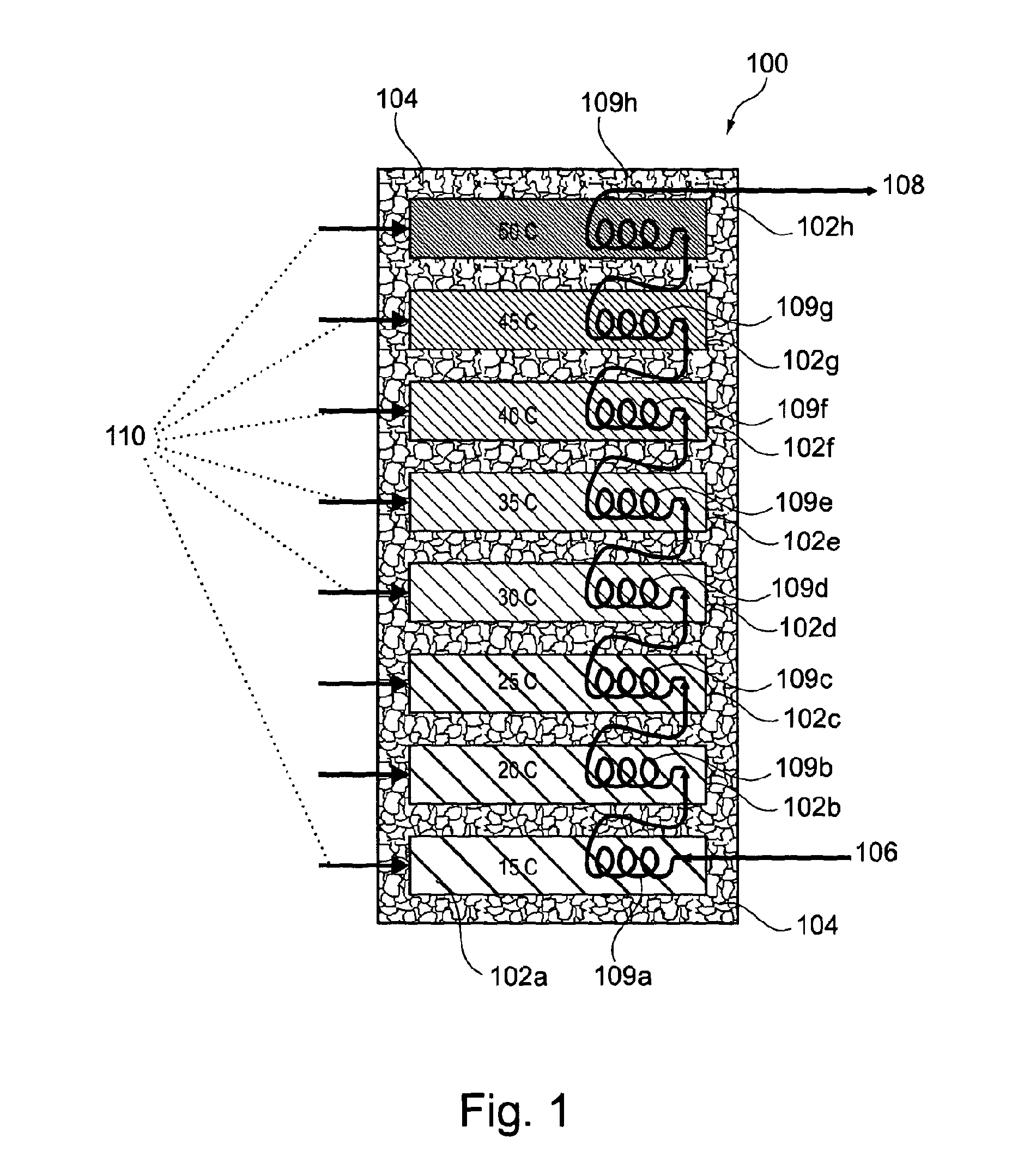

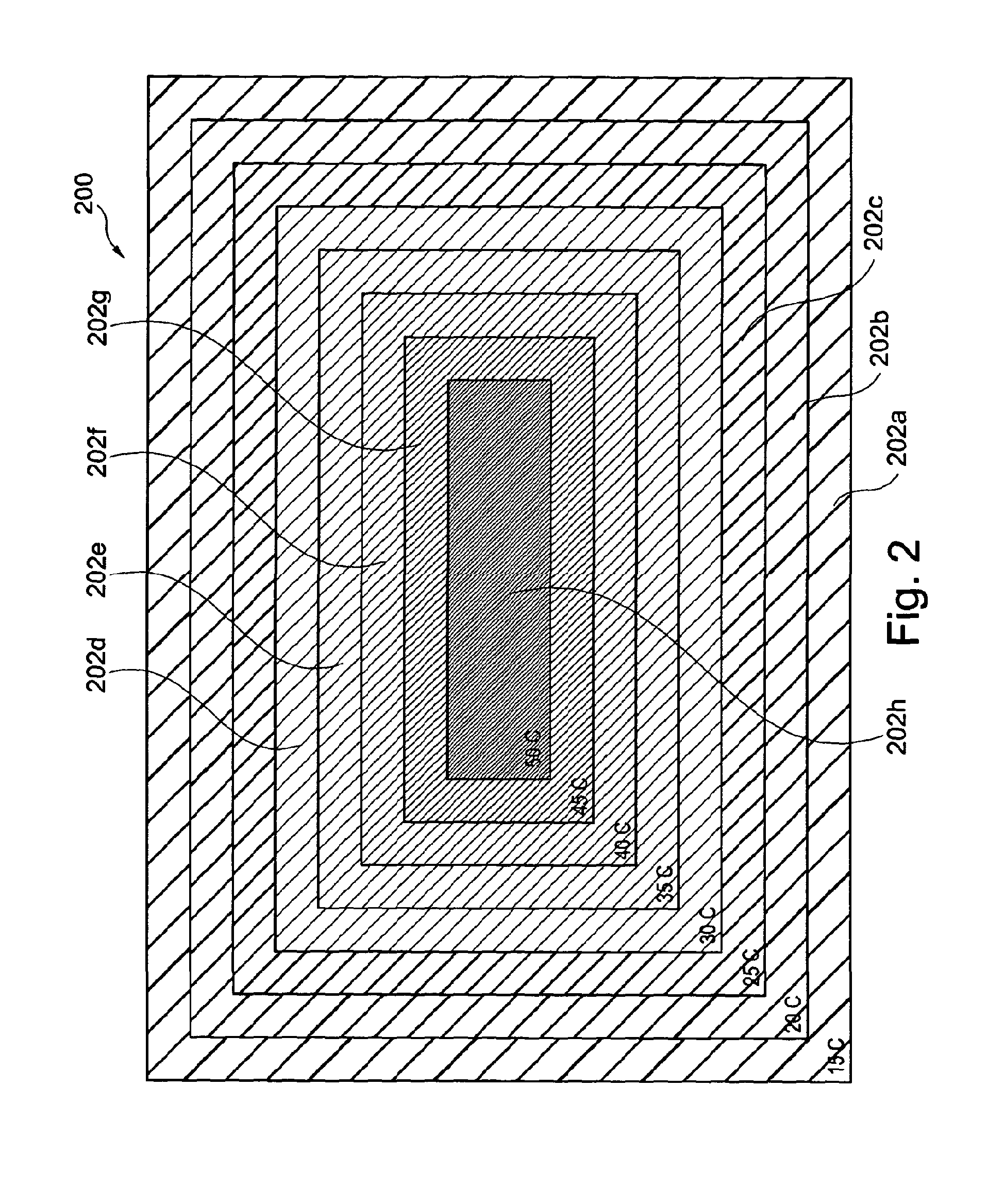

Energy storage systems

InactiveUS20120227926A1Low costReduce usageSolar heating energySolar heat devicesThermal energyThermal energy storage

There is herein described energy storage systems. More particularly, there is herein described thermal energy storage systems and use of energy storable material such as phase change material in the provision of heating and / or cooling systems in, for example, domestic dwellings.

Owner:SUNAMP

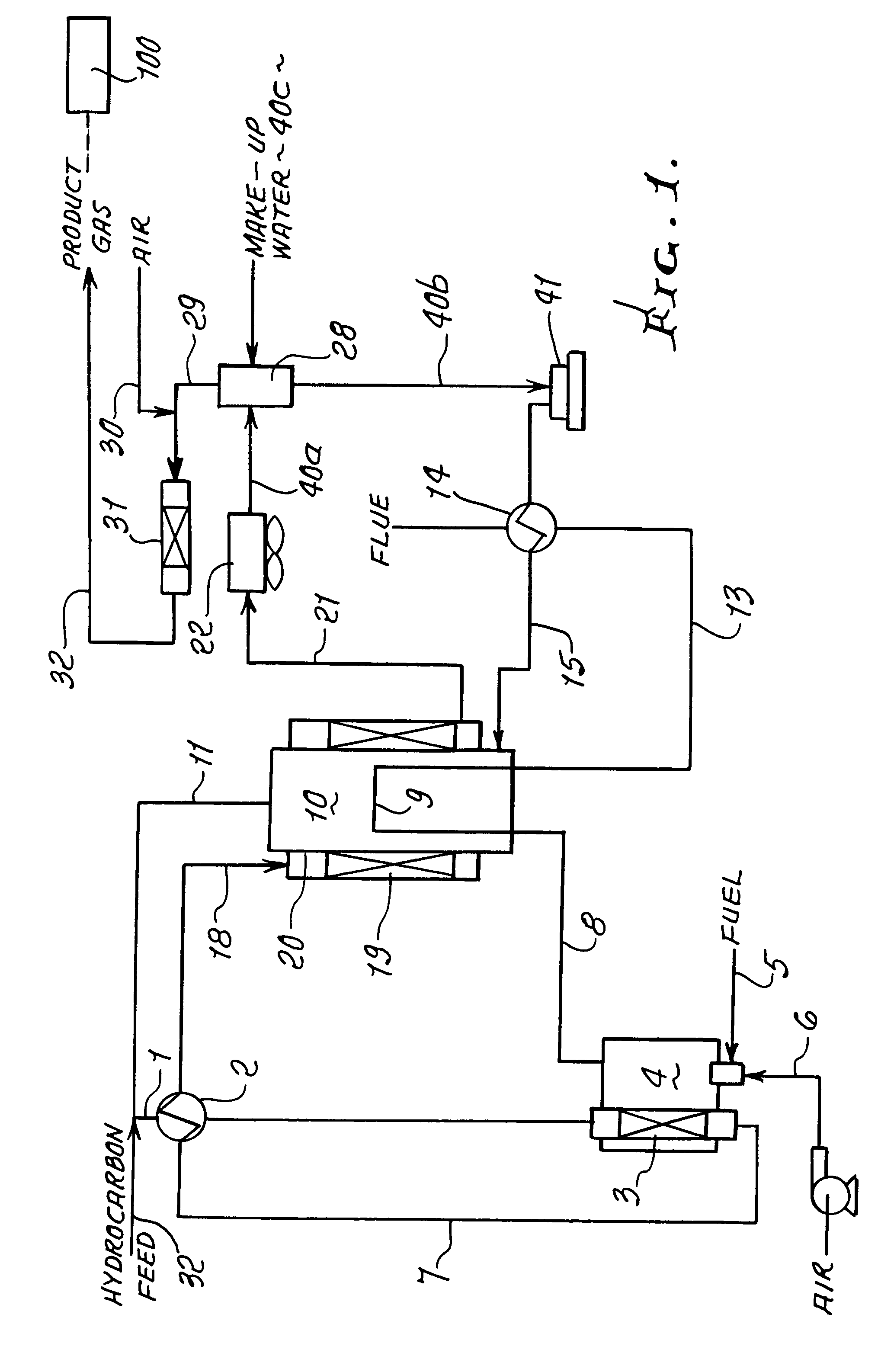

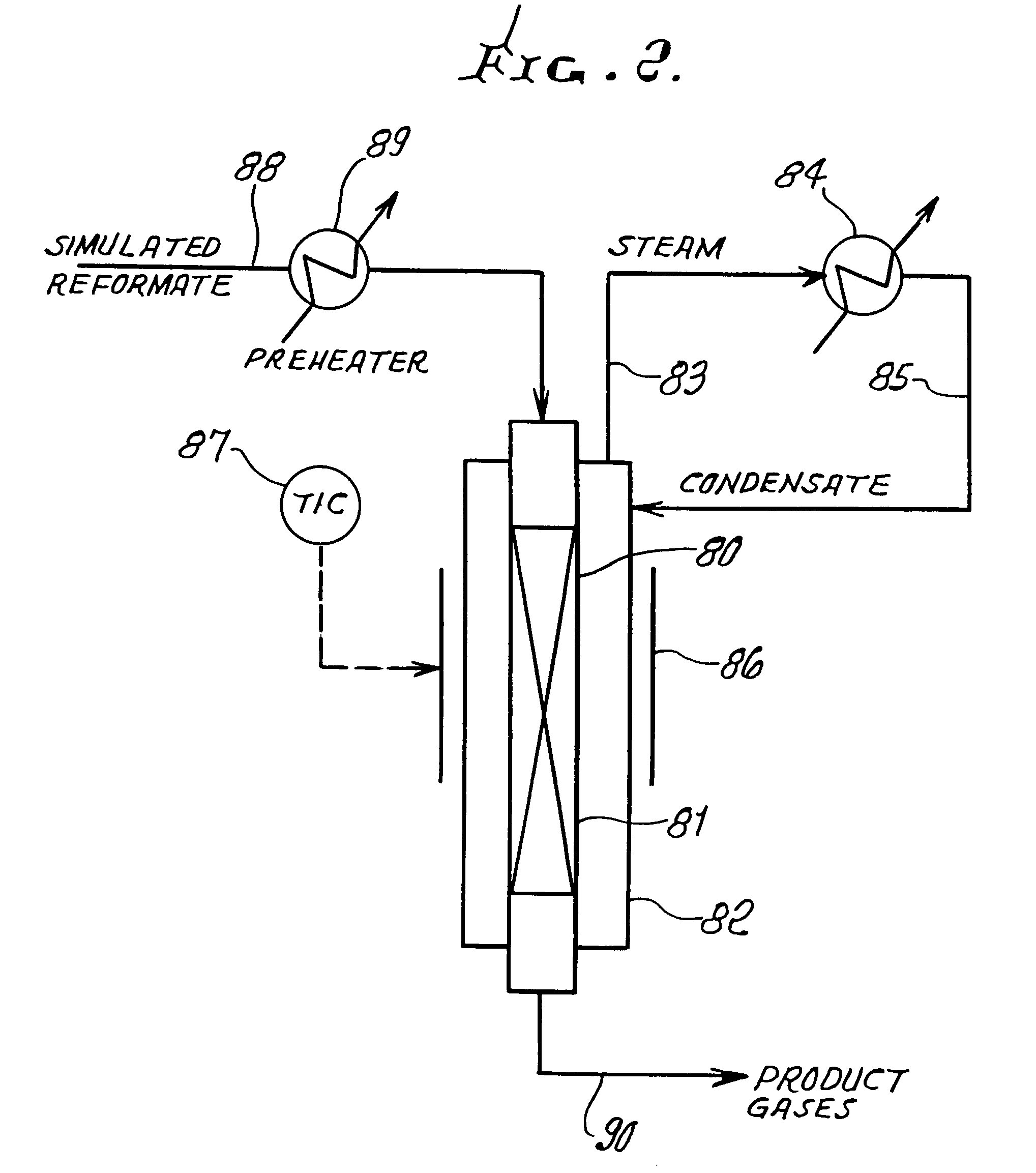

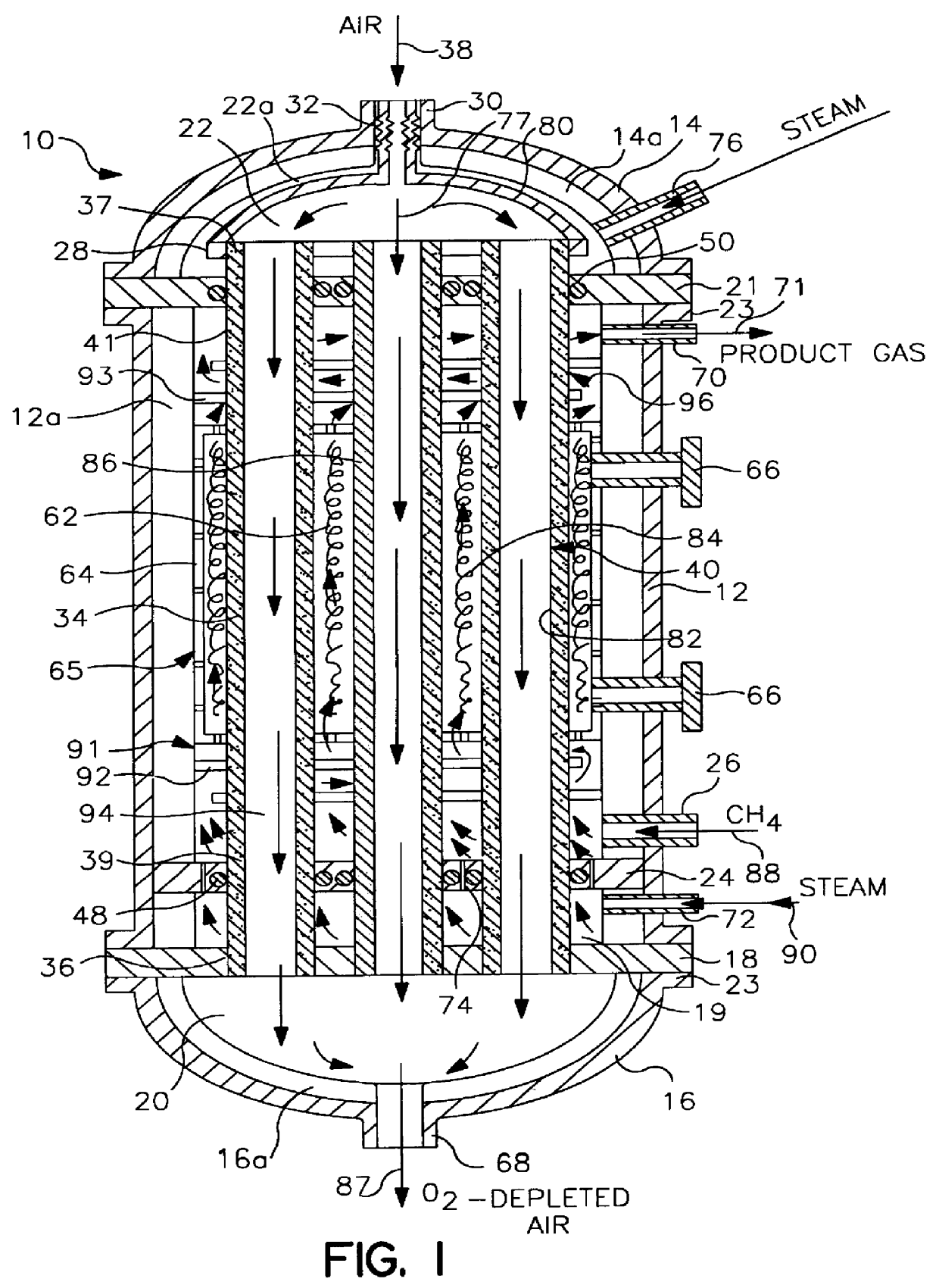

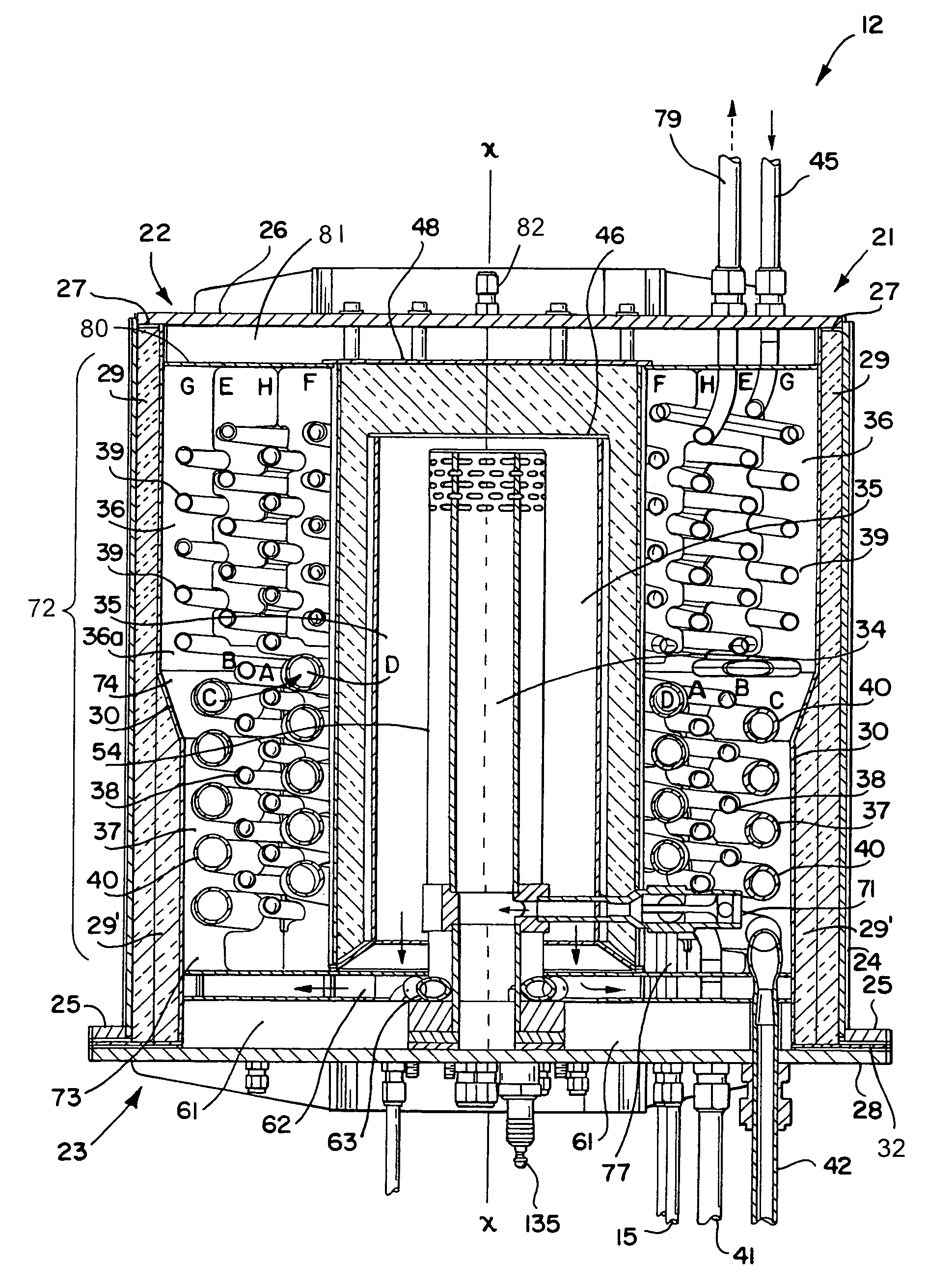

Thermally-integrated low temperature water-gas shift reactor apparatus and process

InactiveUS7074373B1Reduced toleranceExtended temperature rangeHydrogenPhysical/chemical process catalystsWater-gas shift reactionProduct gas

A thermally-integrated lower temperature water-gas shift reactor apparatus for converting carbon monoxide in the presence steam comprises a catalyst bed that is disposed within an outer region surrounding a waste heat recovery steam generator operating at a selected pressure corresponding to the optimum temperature for conducting the catalytic water-gas shift reaction and a process for useful recovery of the exothermic heat of reaction to generate steam that is used in a process for the conversion of hydrocarbon feedstock into useful gases such as hydrogen.

Owner:HARVEST ENERGY TECH

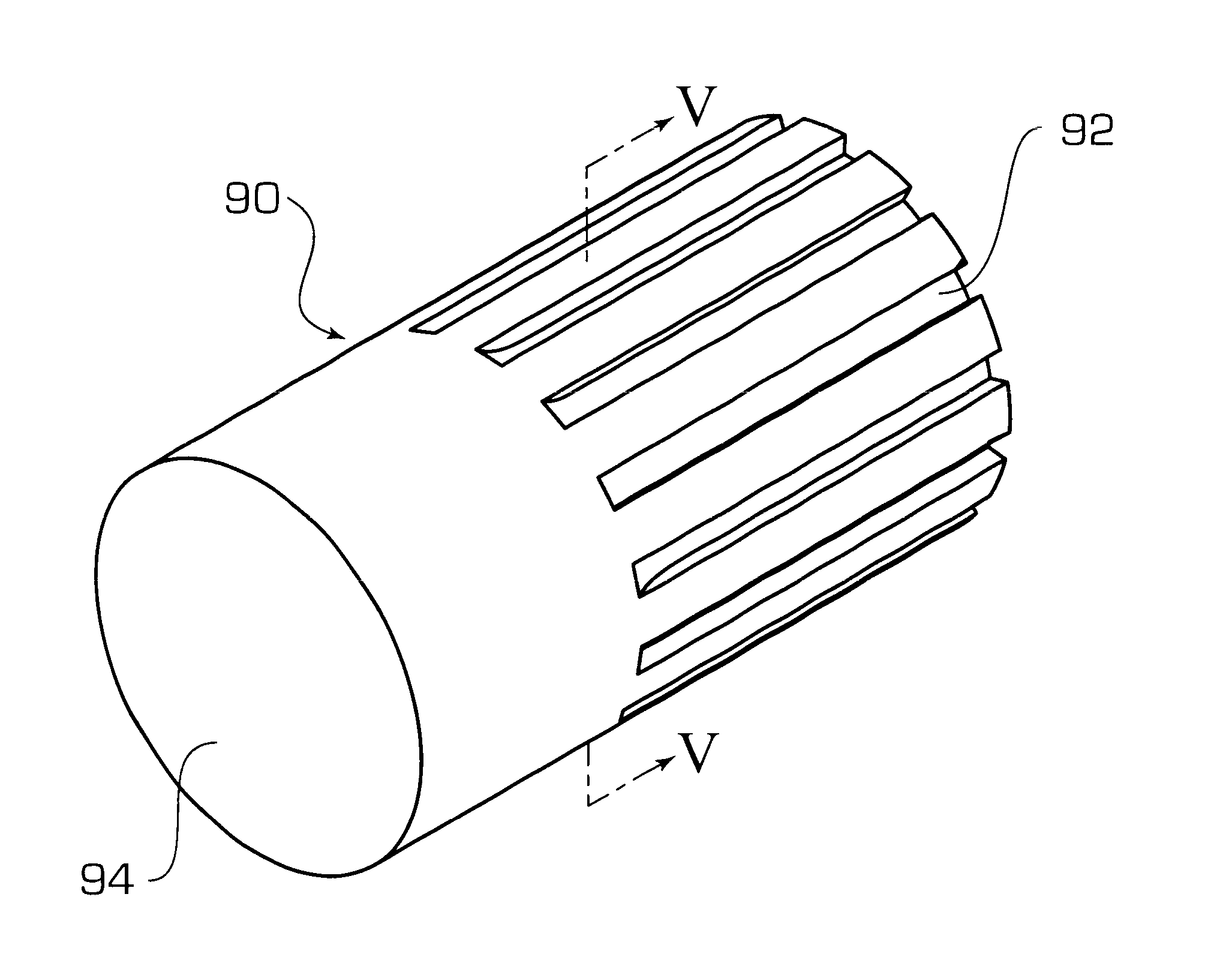

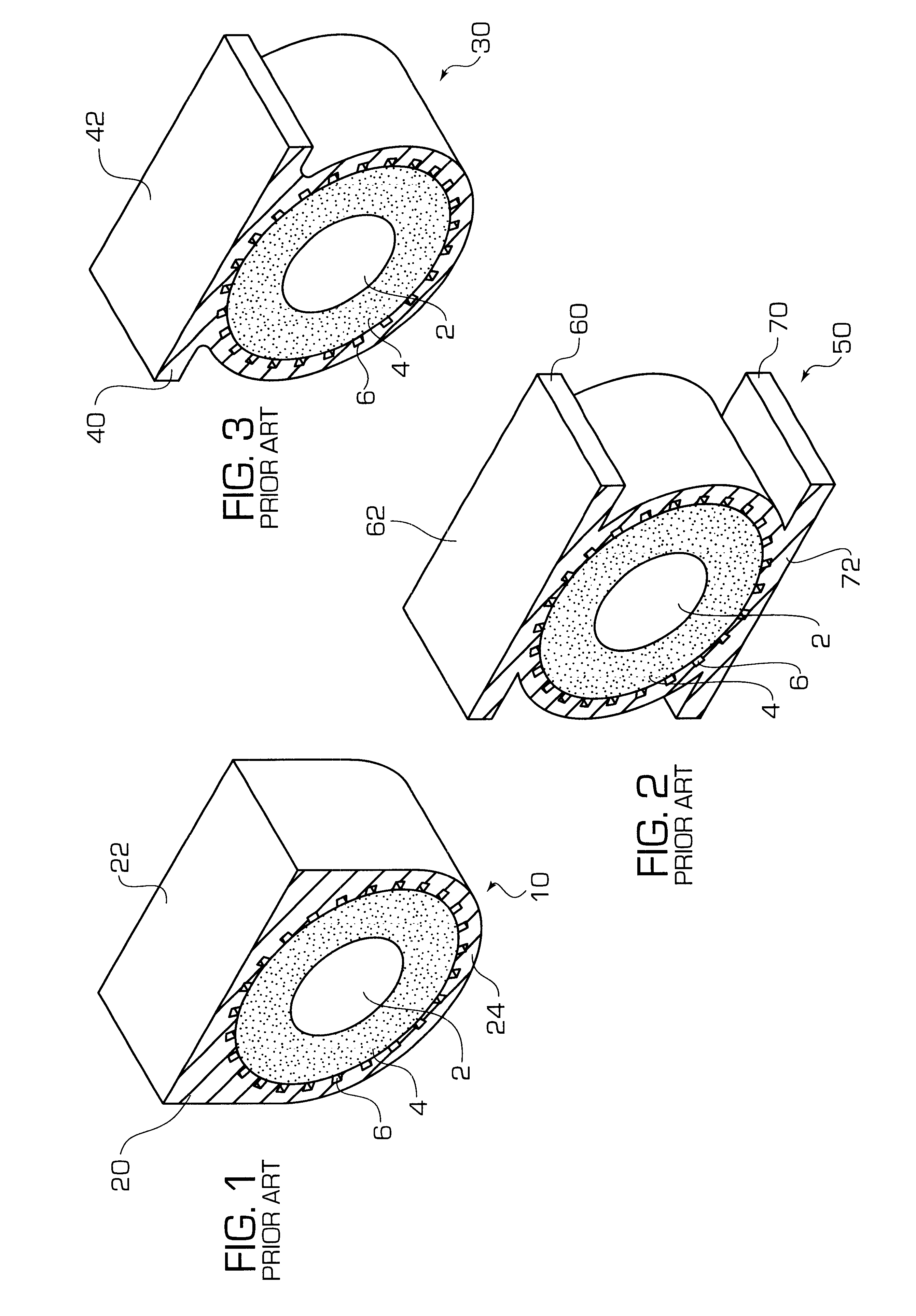

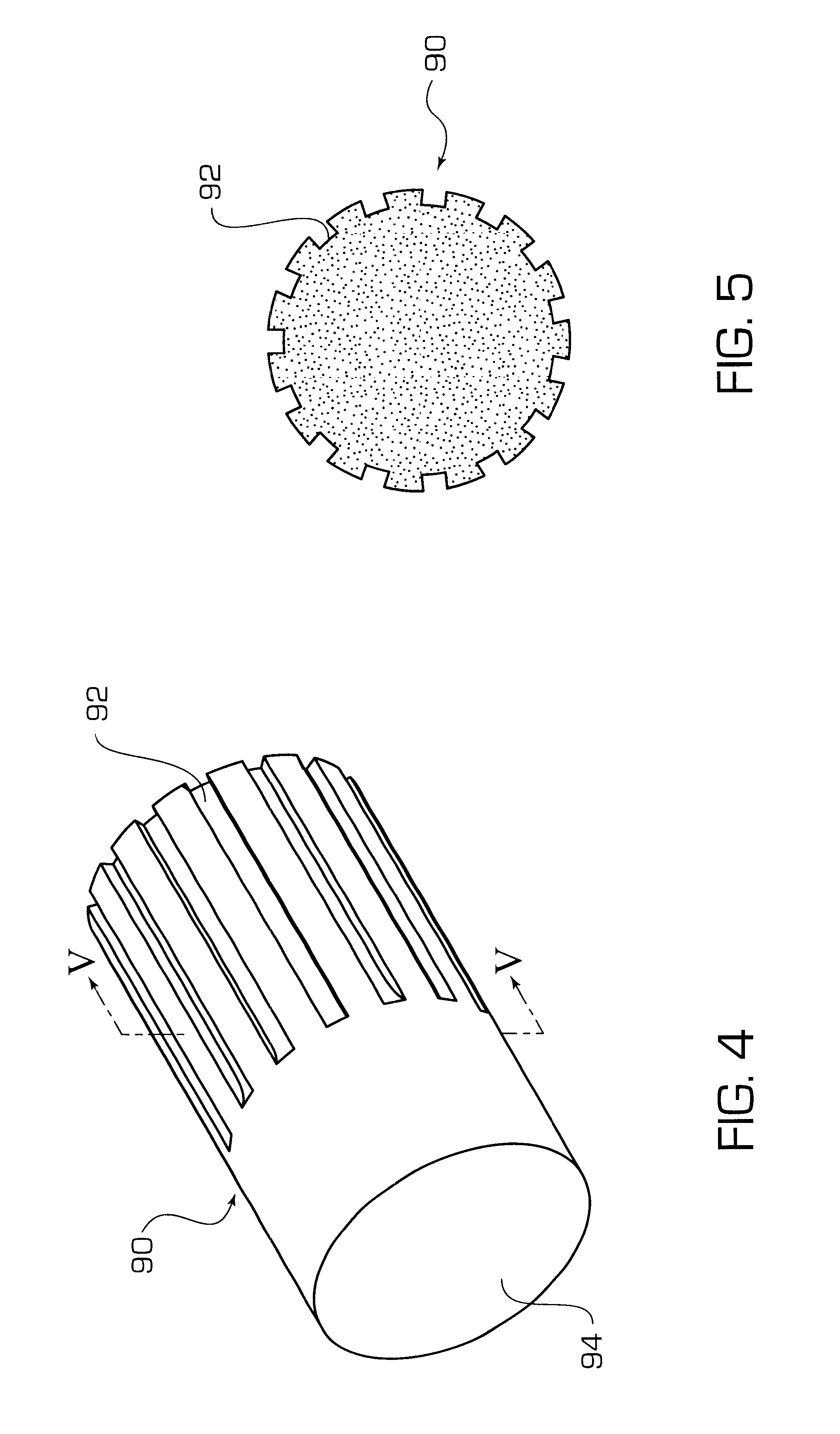

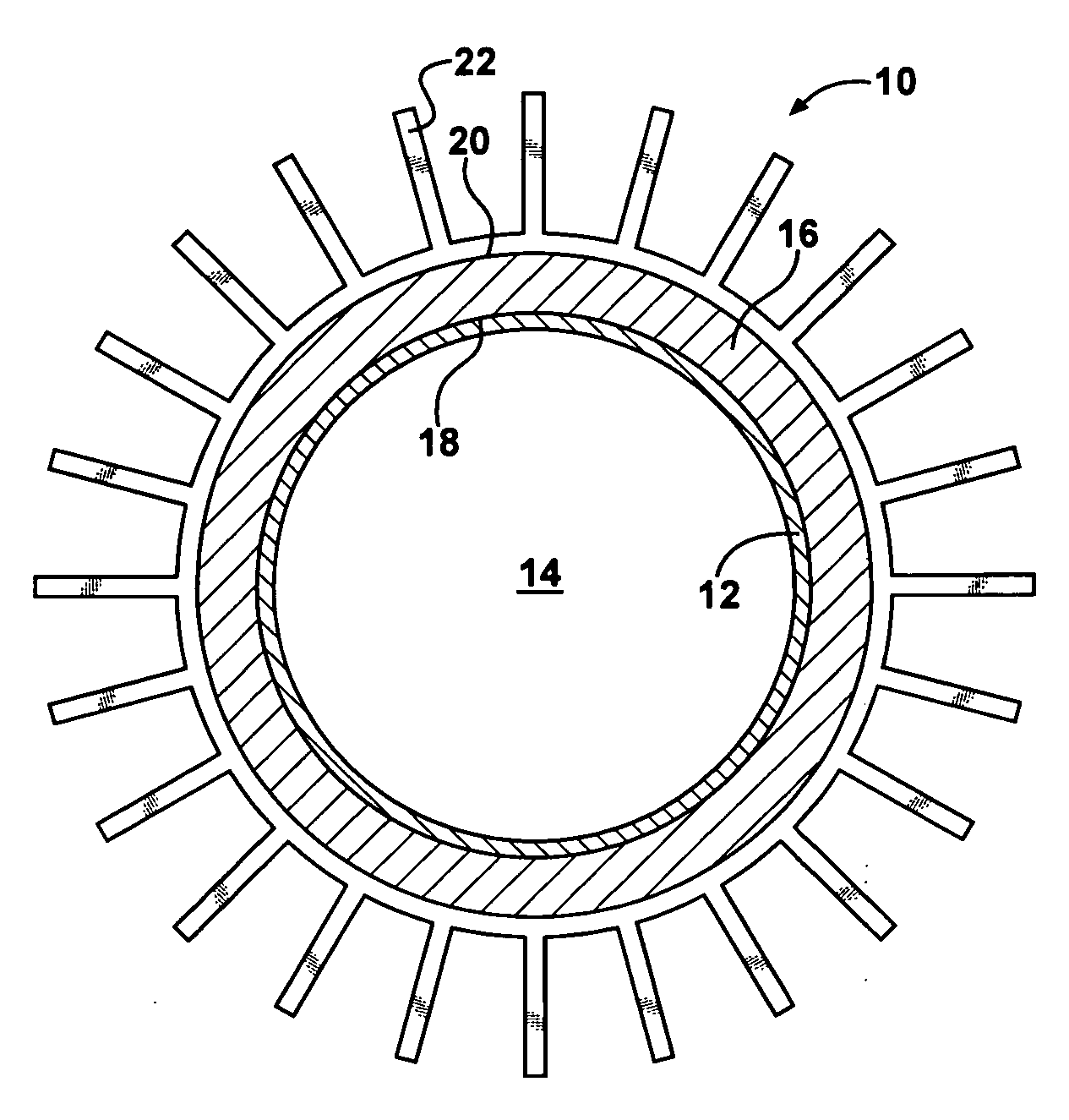

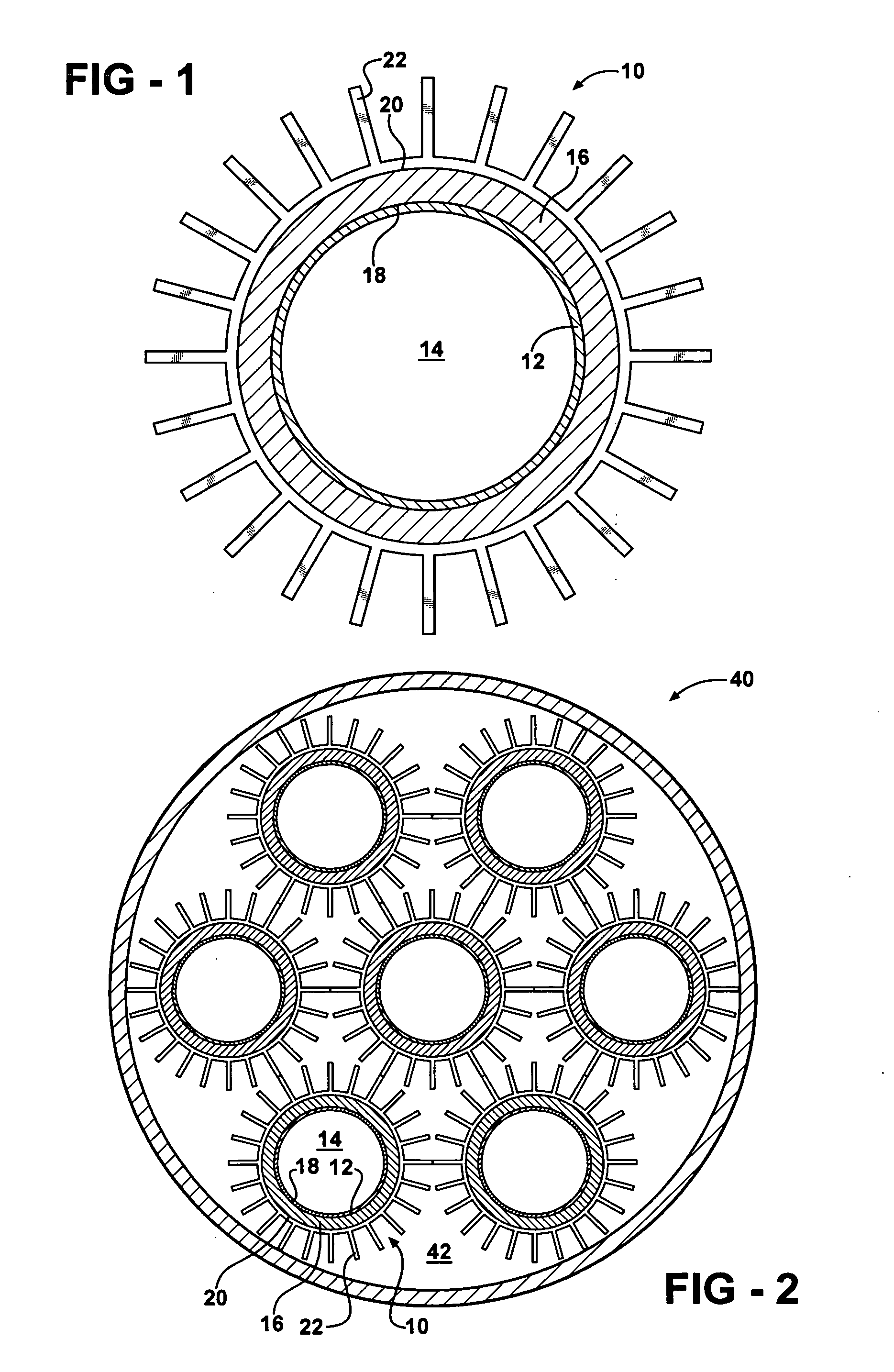

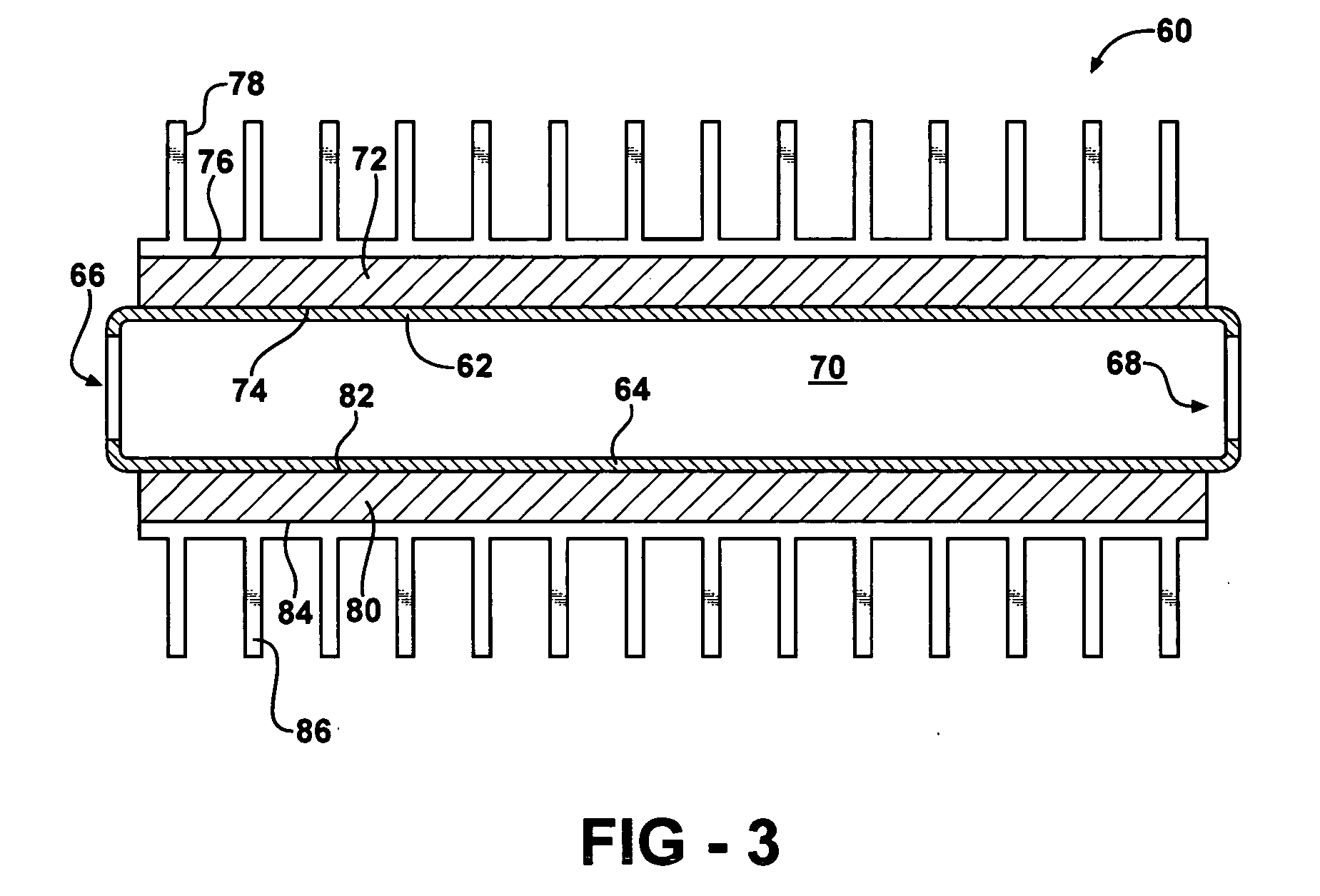

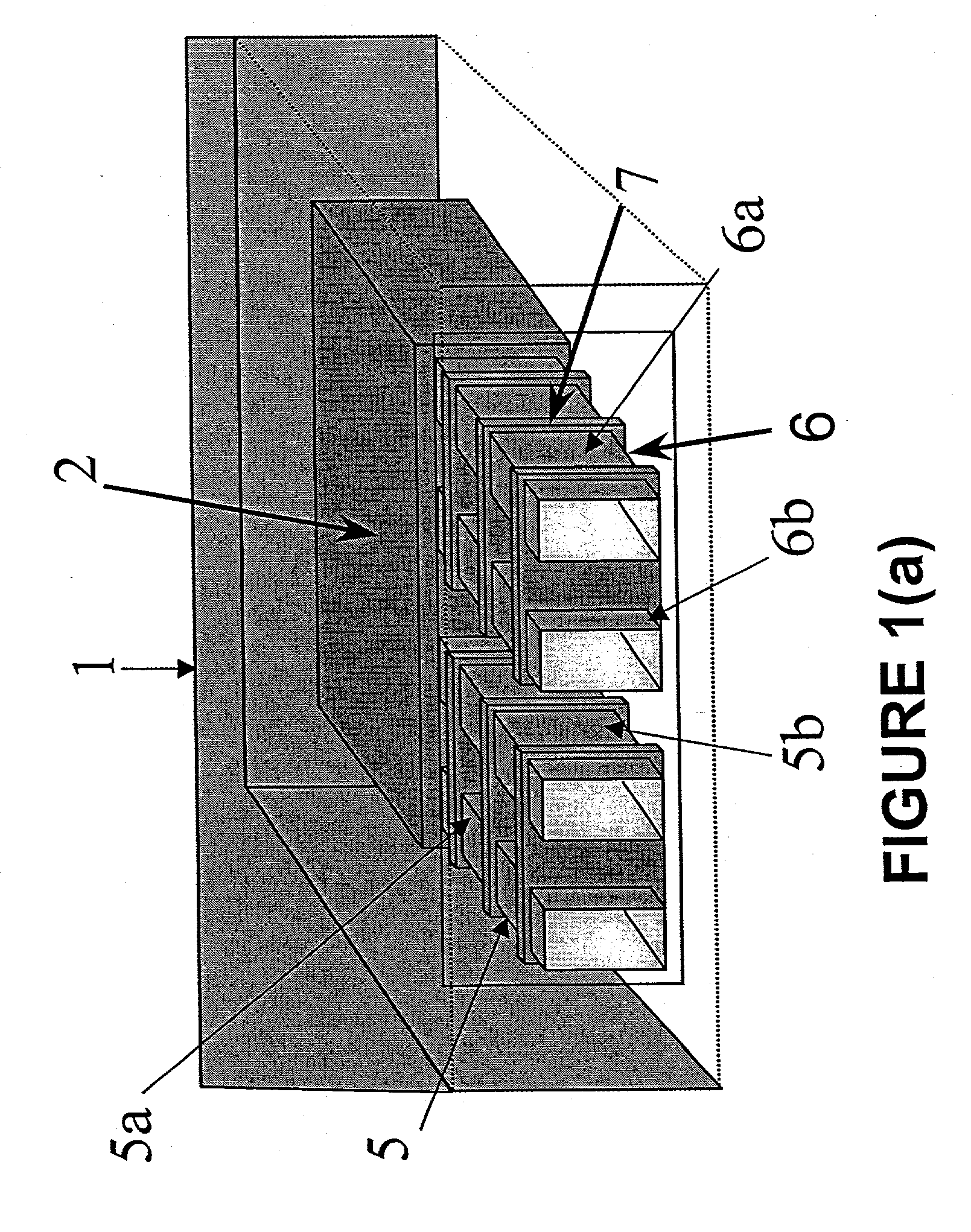

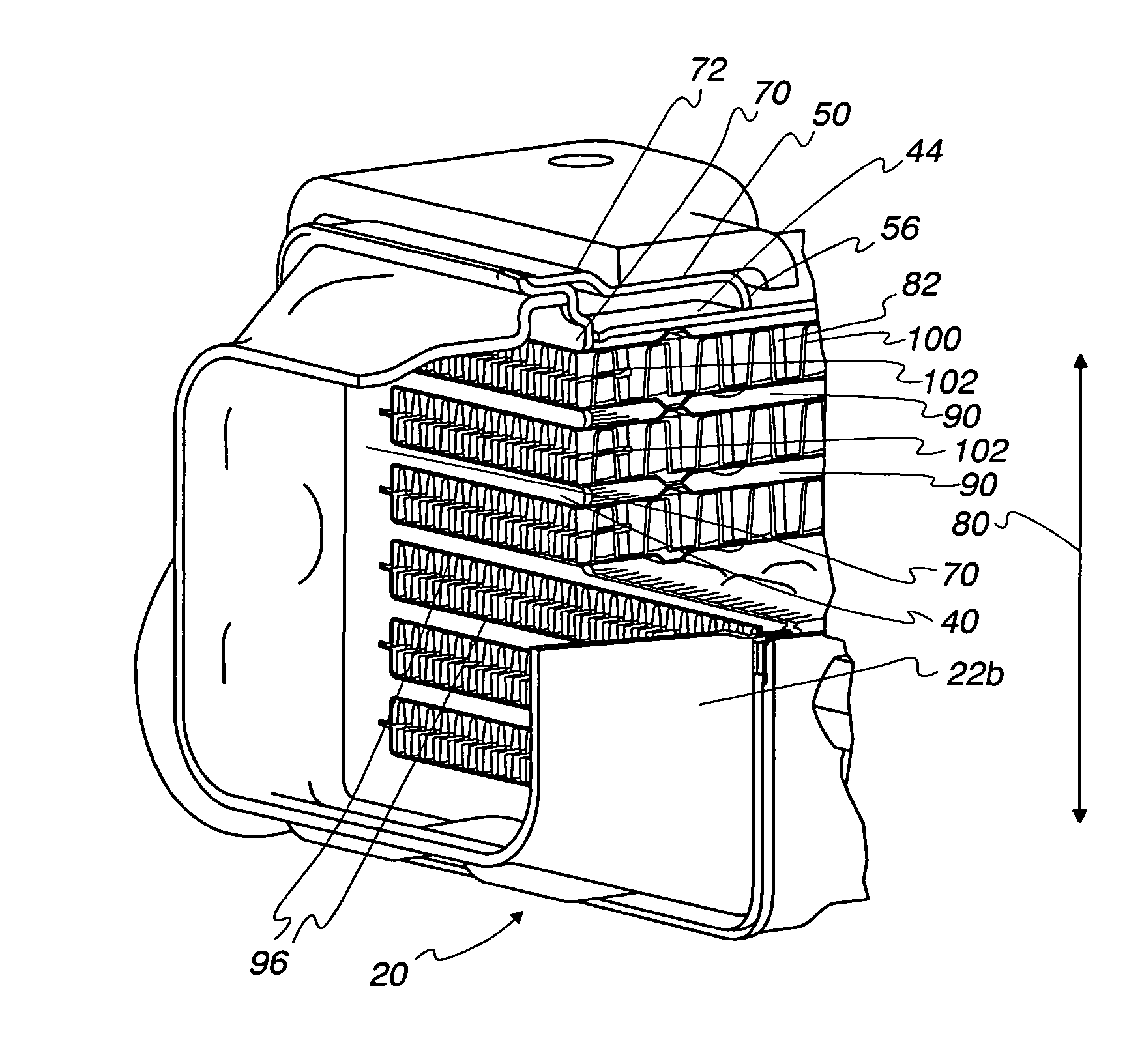

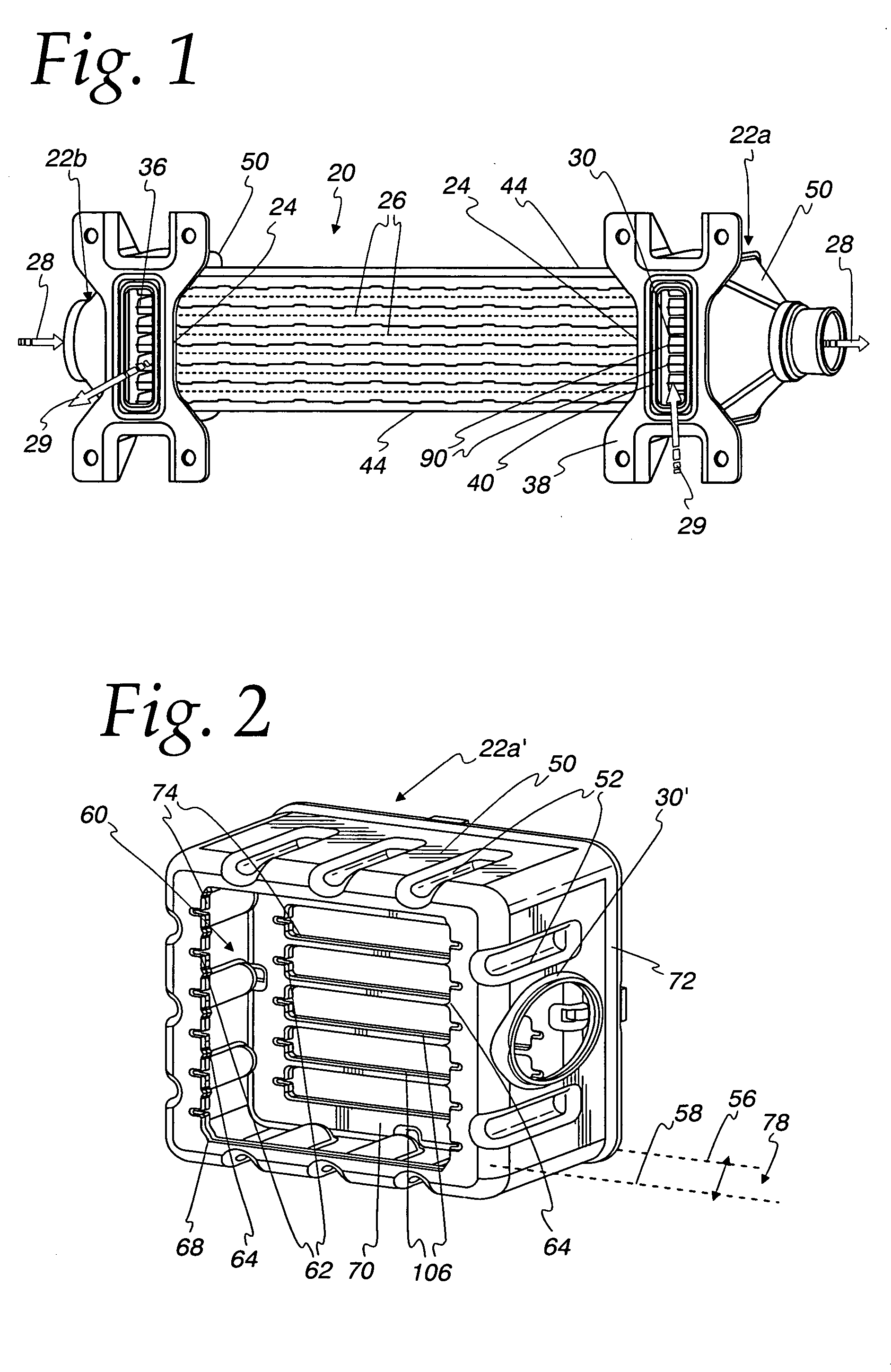

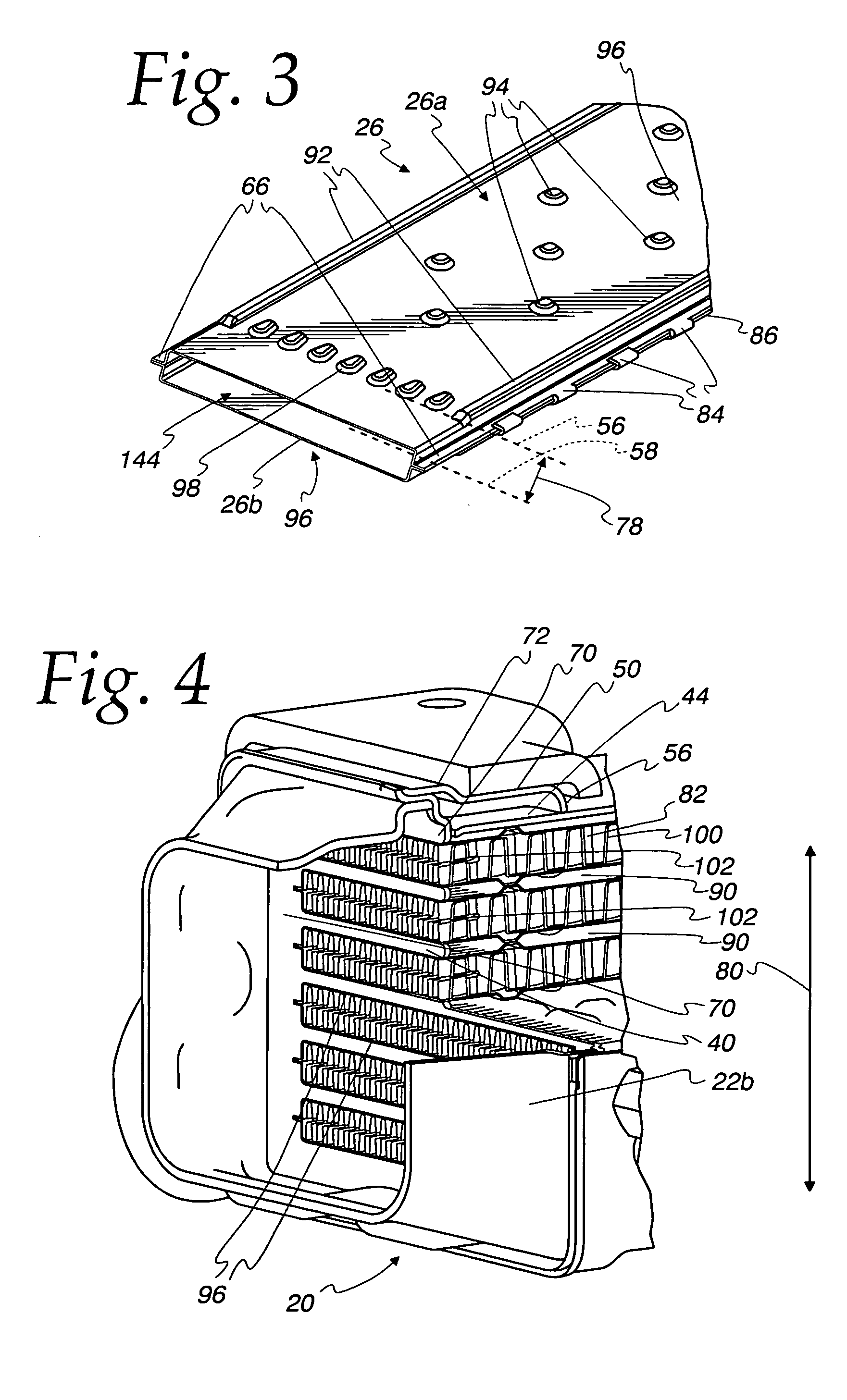

Loop heat pipe incorporating an evaporator having a wick that is liquid superheat tolerant and is resistant to back-conduction

InactiveUS6382309B1Semiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A capillary wick for use in capillary evaporators has properties that prevent nucleation inside the body of the wick, resulting in suppression of back-conduction of heat from vapor channels to the liquid reservoir. Use of a central liquid flow channel in the wick is eliminated, and pore size in the wick is chosen to maximize available pressure for fluid pumping, while preventing nucleation in the wick body. The wick is embodied with different geometries, including cylindrical and flat. A flat capillary evaporator has substantially planar heat input surfaces for convenient mating to planar heat sources. The flat capillary evaporator is capable of being used with working fluids having high vapor pressures (i.e., greater that 10 psia). To contain the pressure of the vaporized working fluid, the opposed planar plates of the evaporator are brazed or sintered to opposing sides of a metal wick. Additionally, a terrestrial loop heat pipe and a loop heat pipe having overall flat geometry are disclosed.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

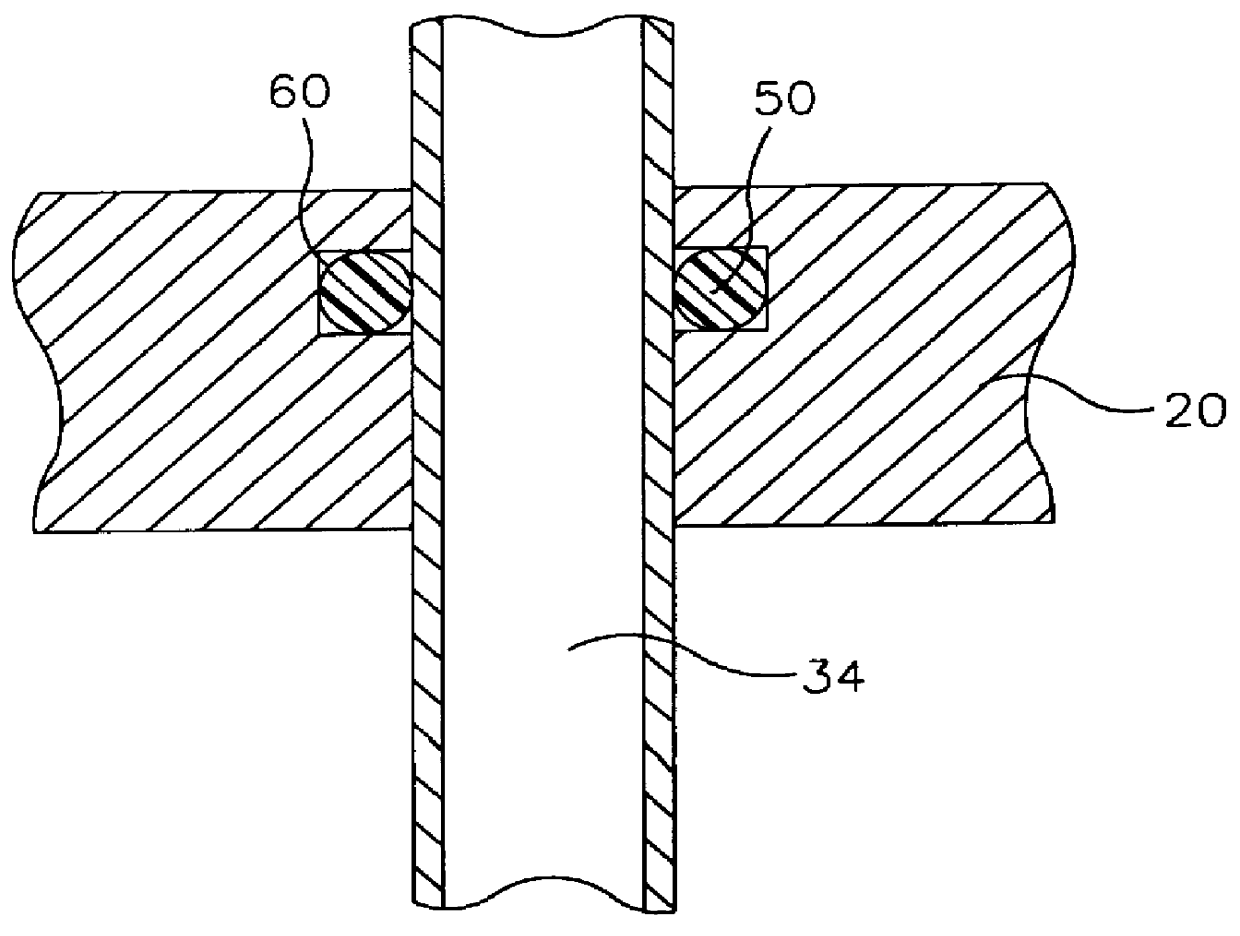

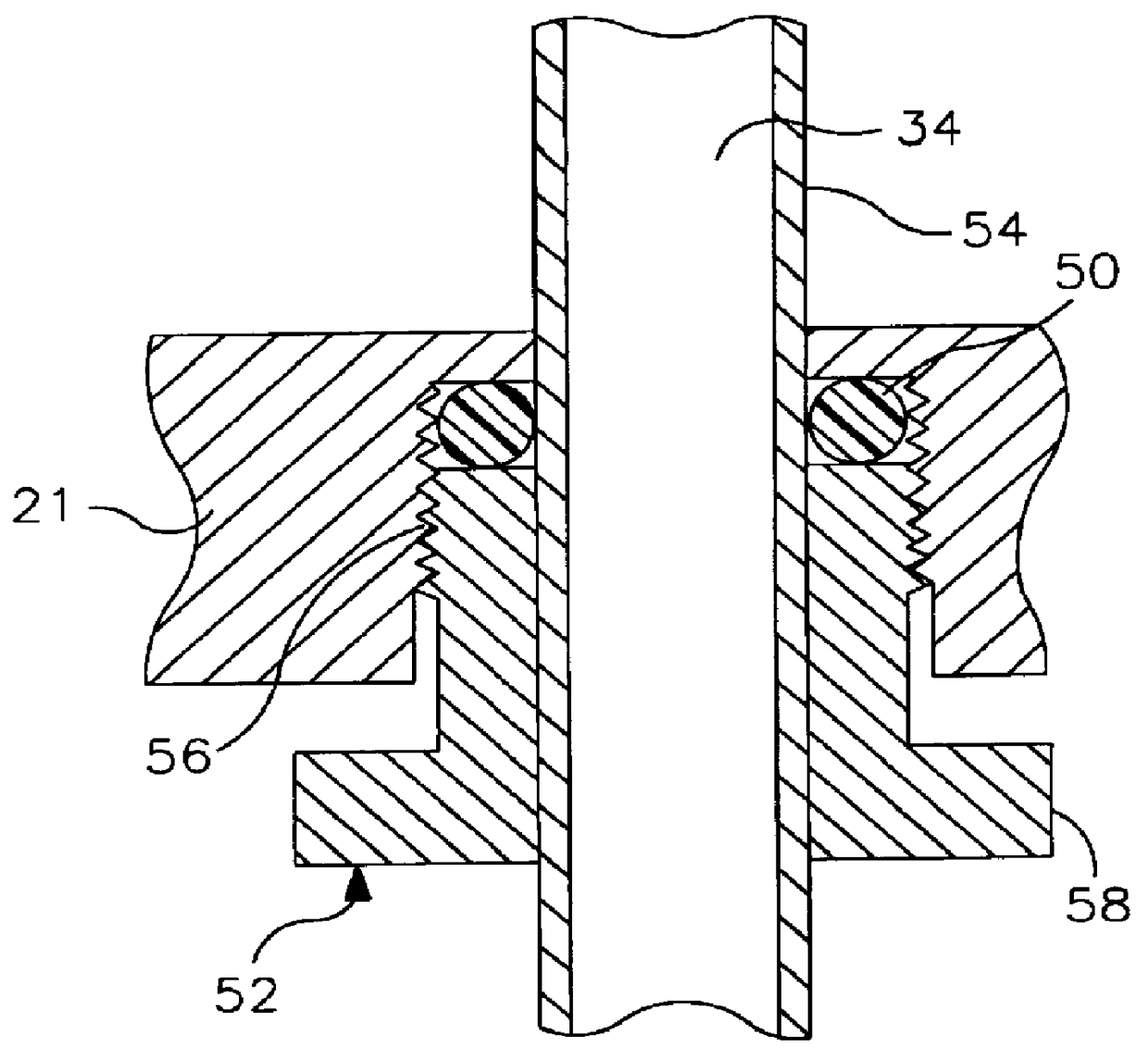

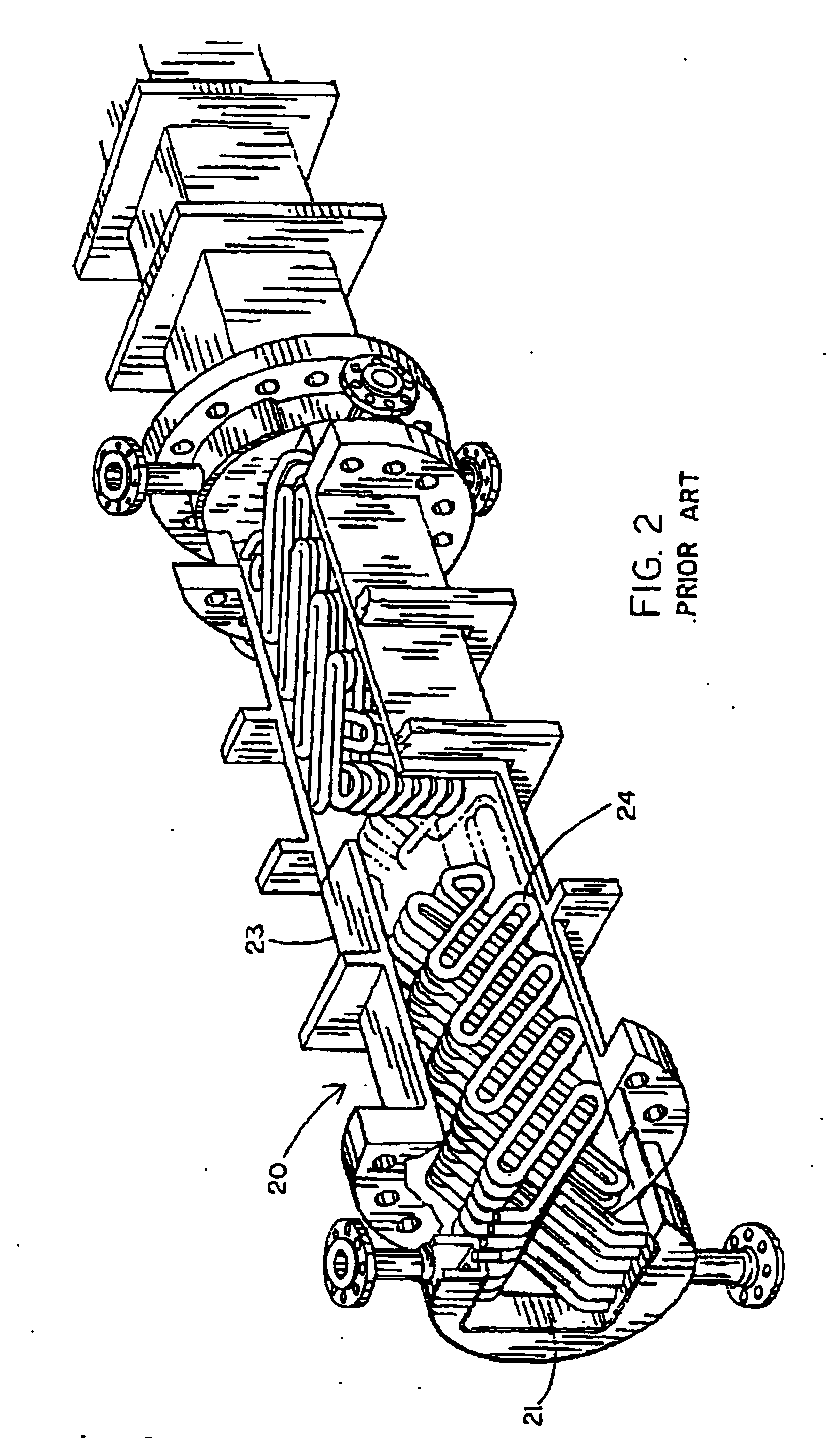

Tube and shell reactor with oxygen selective ion transport ceramic reaction tubes

InactiveUS6139810AIncrease oxygen fluxDecreasing anode side partial oxygen pressureIsotope separationHydrogen/synthetic gas productionPtru catalystElectrical conductor

A reactor comprising: a hollow shell defining a hermetic enclosure; a plurality of tube sheets disposed within said hermetic enclosure, a first one of said plurality of tube sheets defining a first chamber; at least one reaction tube each having a first end and an opposing second end, said first end being fixedly attached and substantially hermetically sealed to one end of said plurality of tube sheets and opening into said first chamber, the second end being axially unrestrained; each of said reaction tubes is comprised of an oxygen selective ion transport membrane with an anode side wherein said oxygen selective ion transport membrane is formed from a mixed conductor metal oxide that is effective for the transport of elemental oxygen at elevated temperatures and at least a portion of said first and second heat transfer sections are formed of metal; each of said reaction tubes includes first and second heat transfer sections and a reaction section, said reaction section disposed between said first and second heat transfer sections; a reforming catalyst disposed about said anode side of said oxygen selective ion transport membrane; a first process gas inlet; a second process gas inlet; and, a plurality of outlets.

Owner:STANDARD OIL CO +1

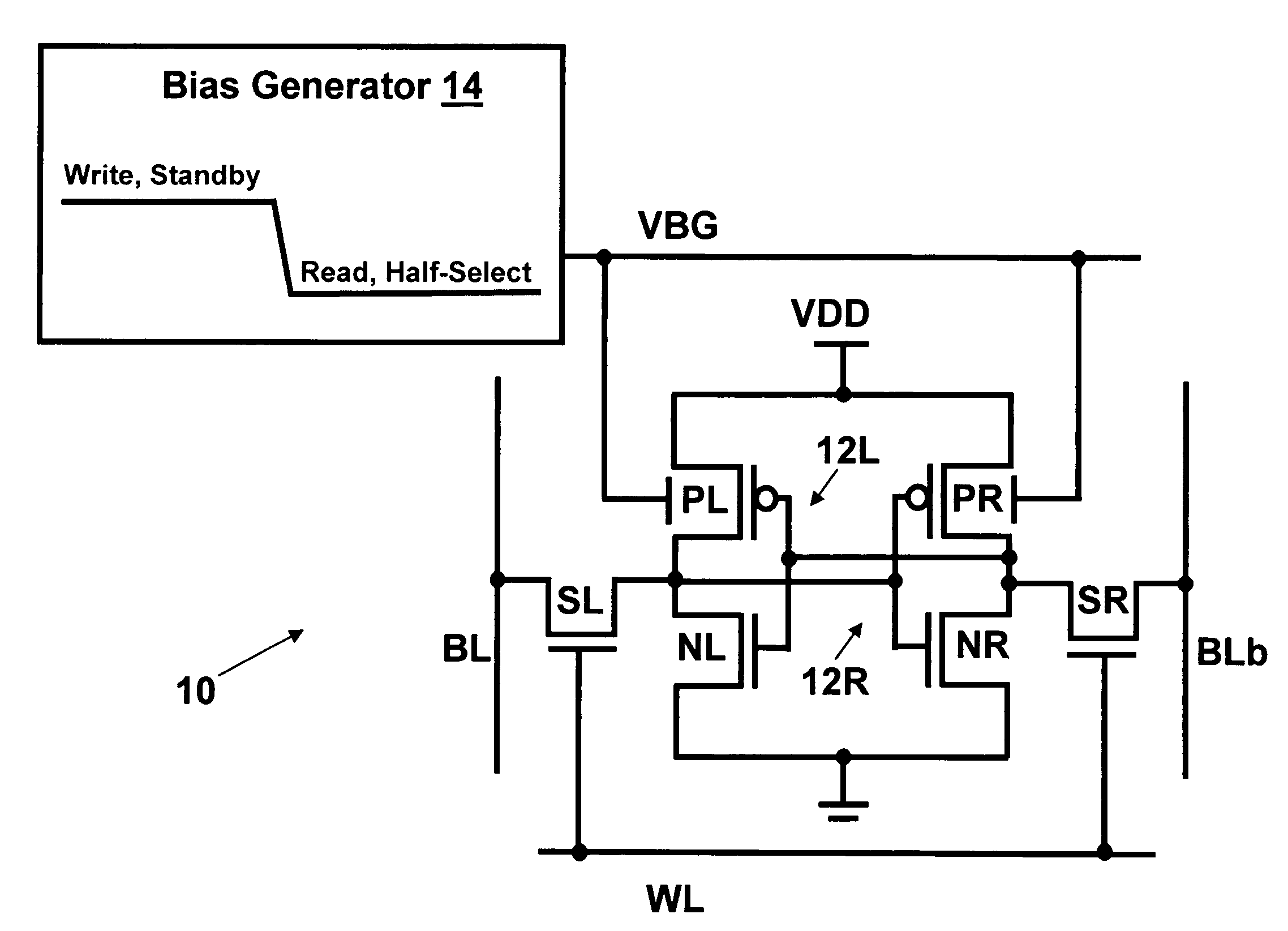

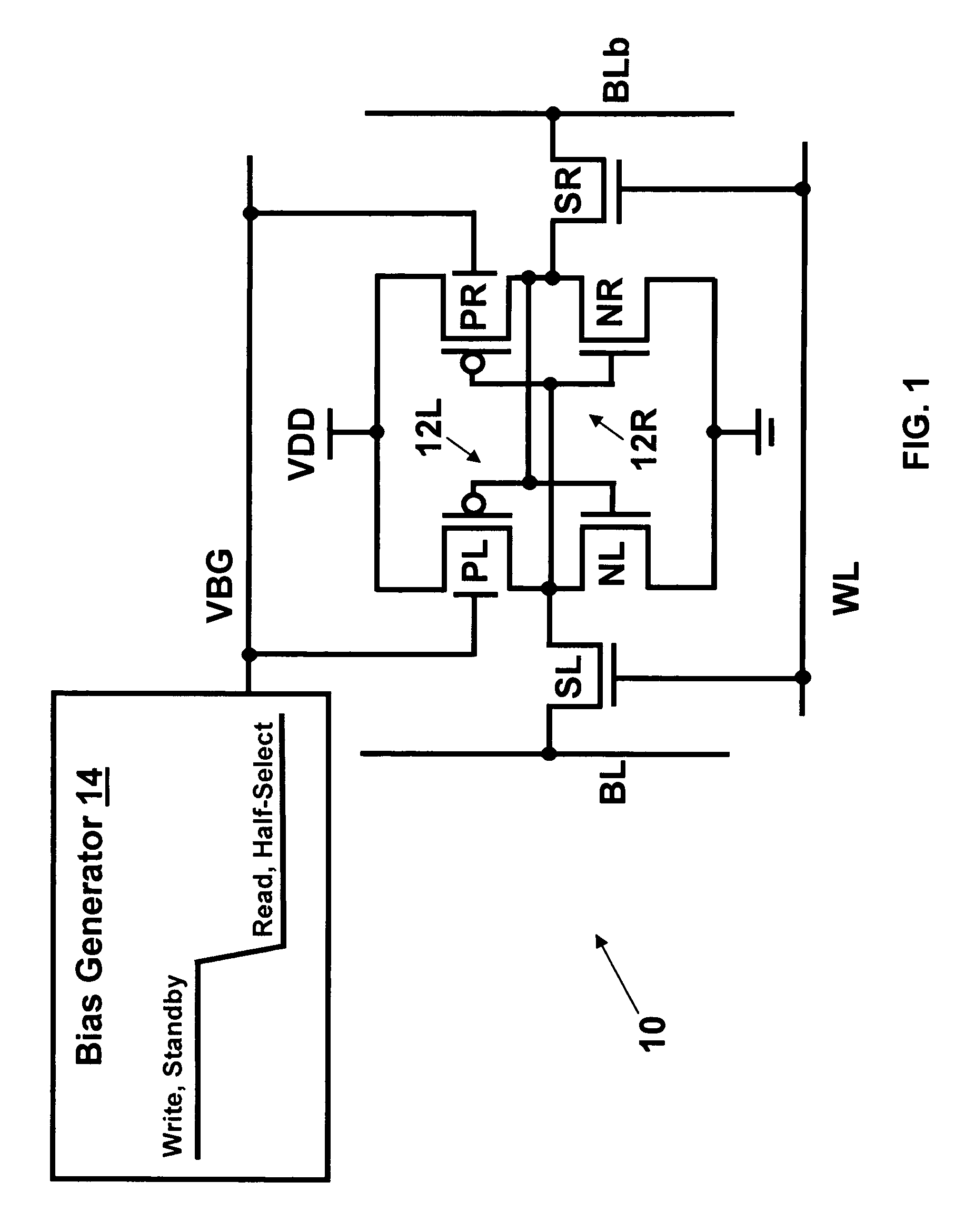

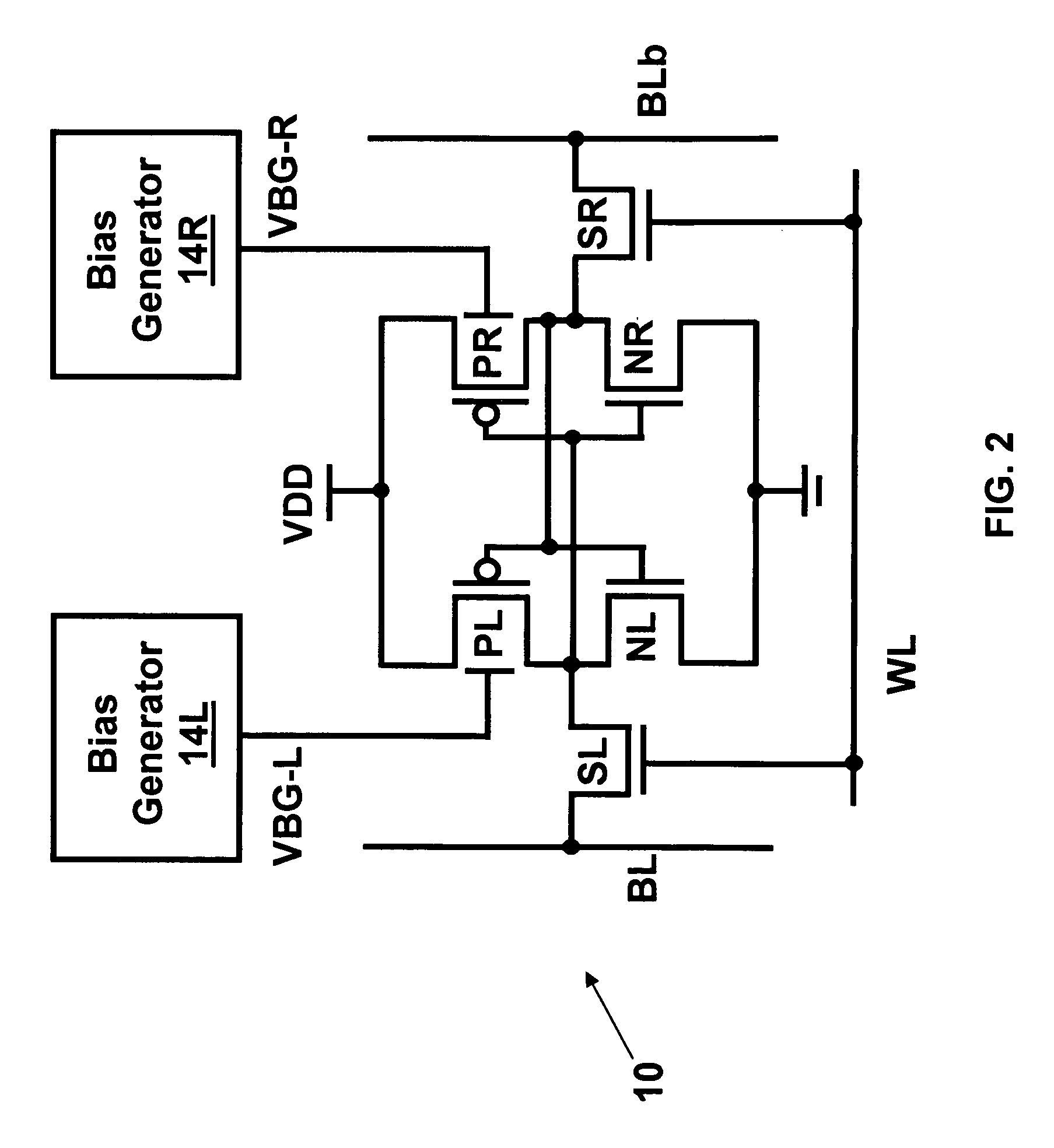

Dynamic control of back gate bias in a FinFET SRAM cell

The present invention provides dynamic control of back gate bias on pull-up pFETs in a FinFET SRAM cell. A method according to the present invention includes providing a bias voltage to a back gate of at least one transistor in the SRAM cell, and dynamically controlling the bias voltage based on an operational mode (e.g., Read, Half-Select, Write, Standby) of the SRAM cell.

Owner:GLOBALFOUNDRIES INC

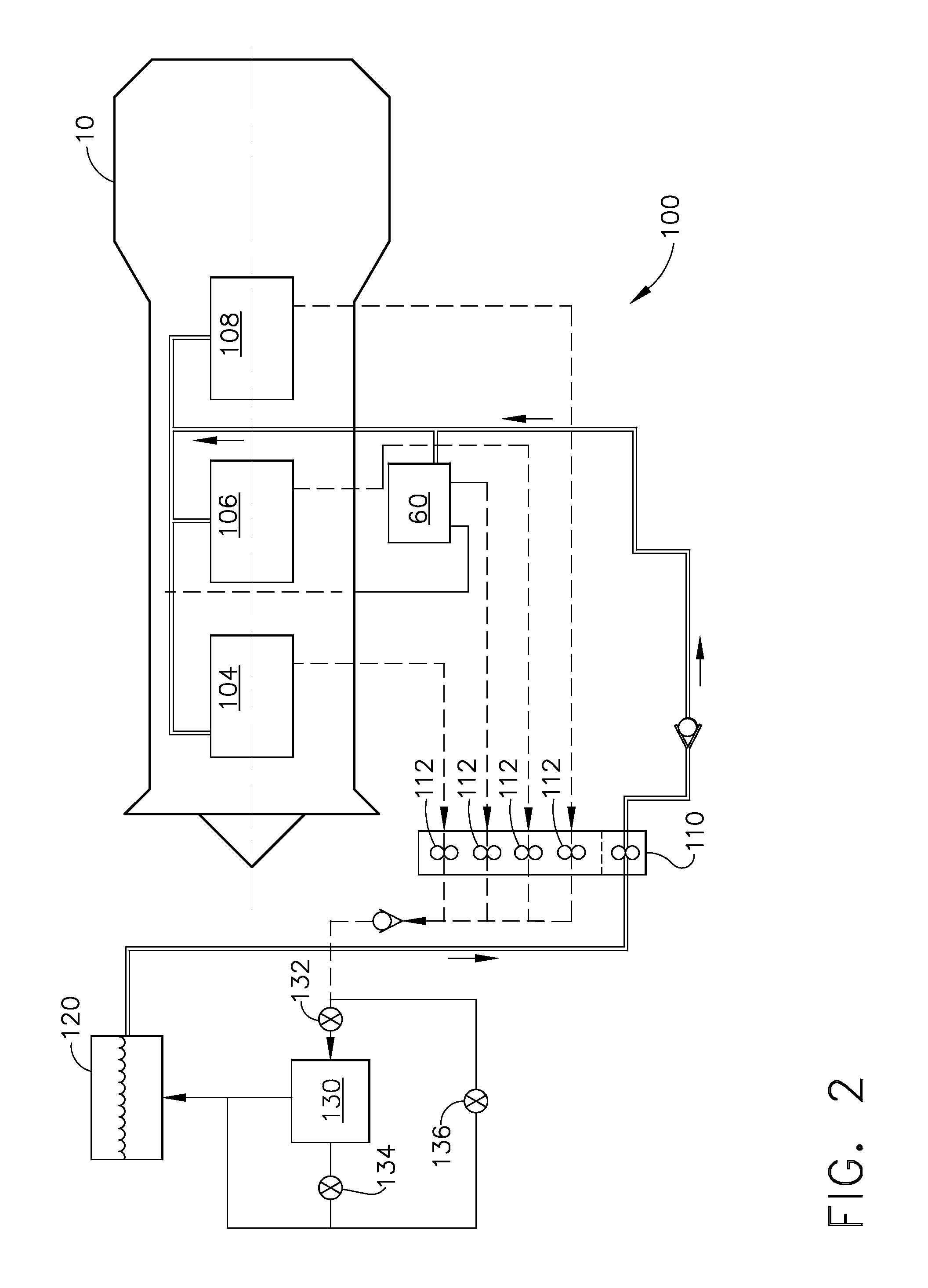

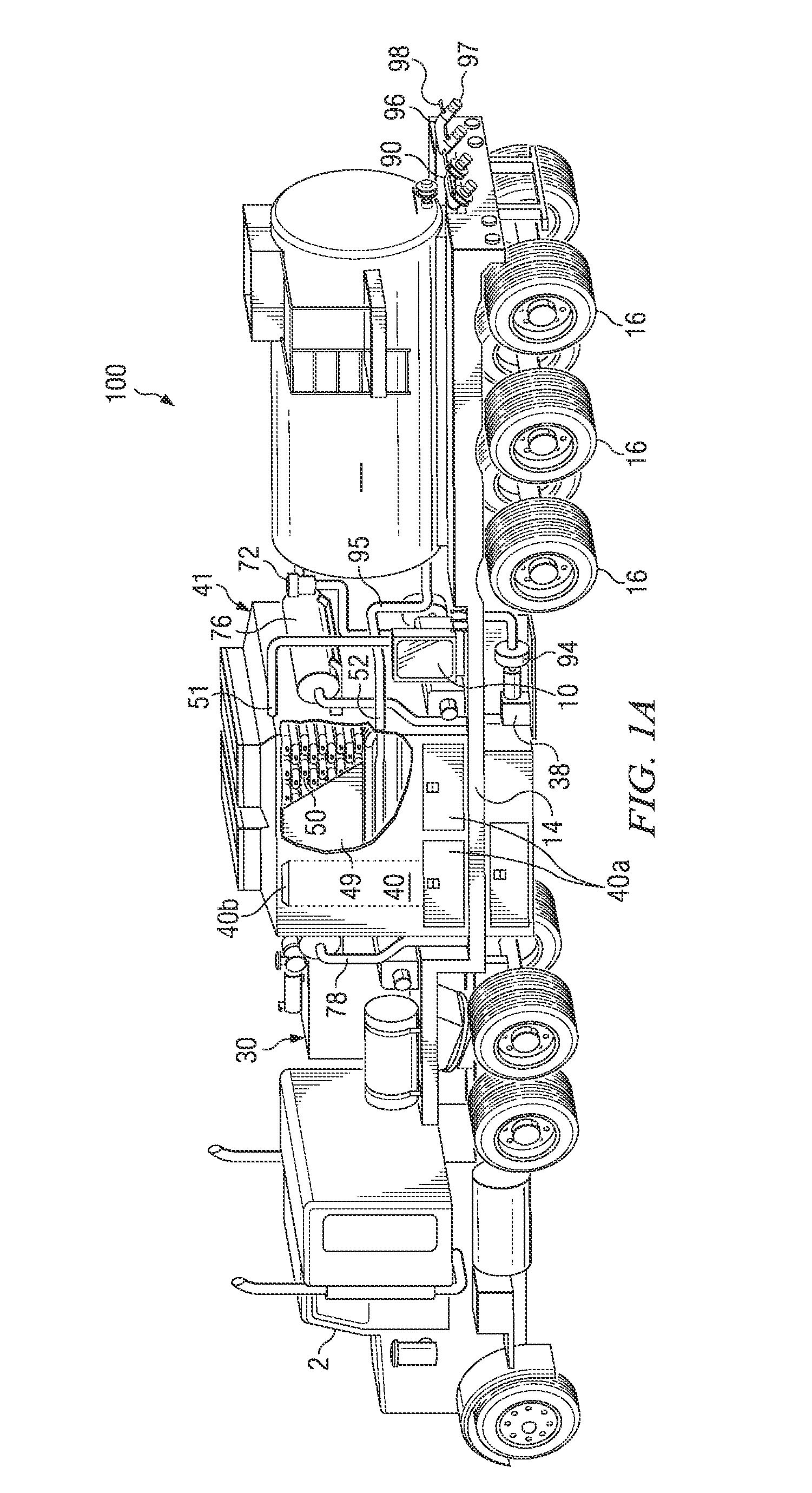

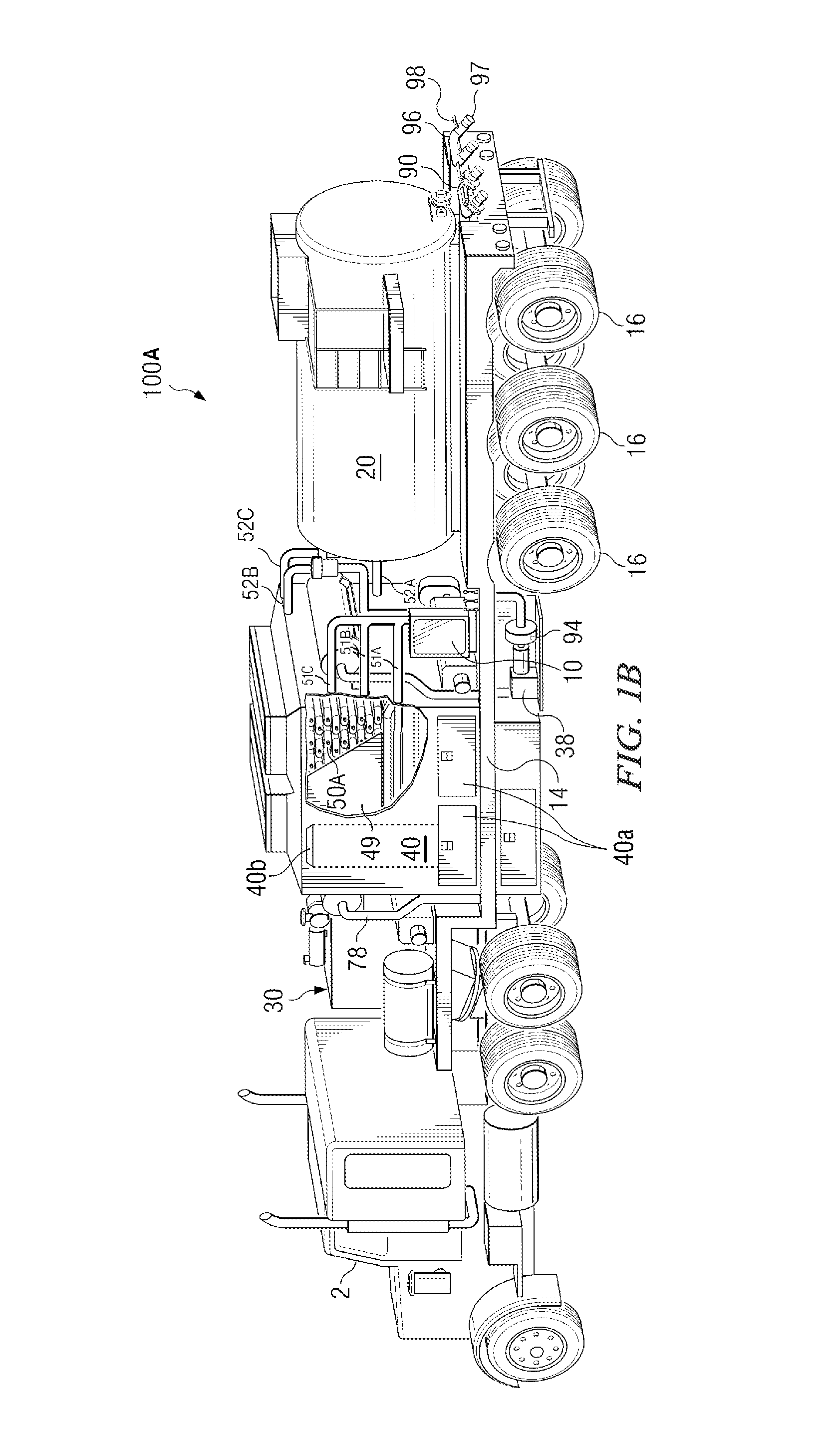

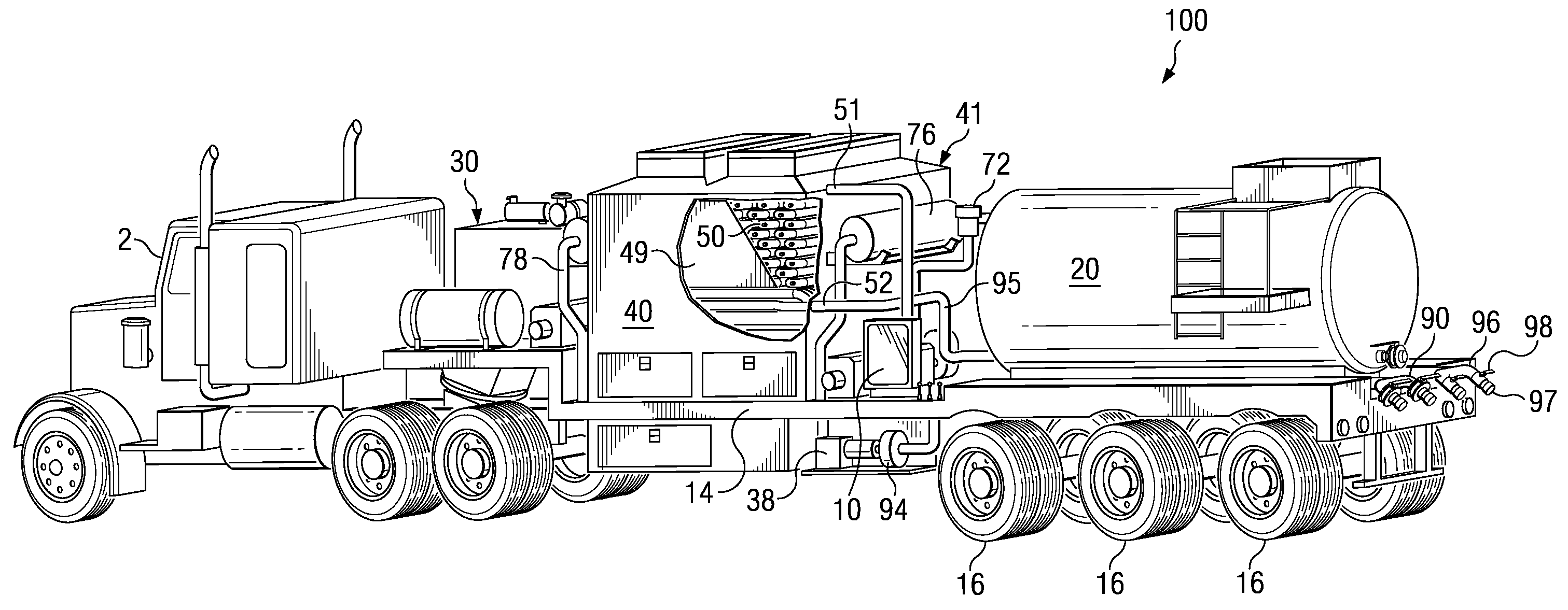

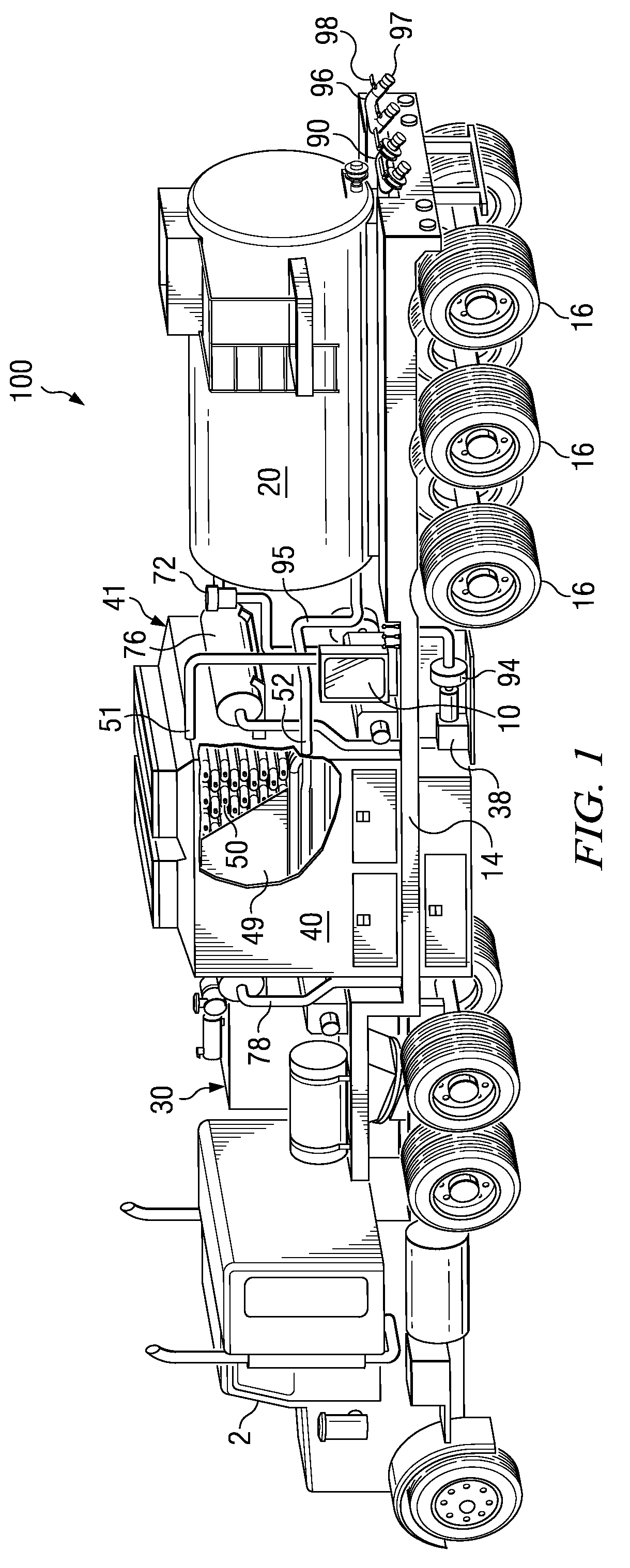

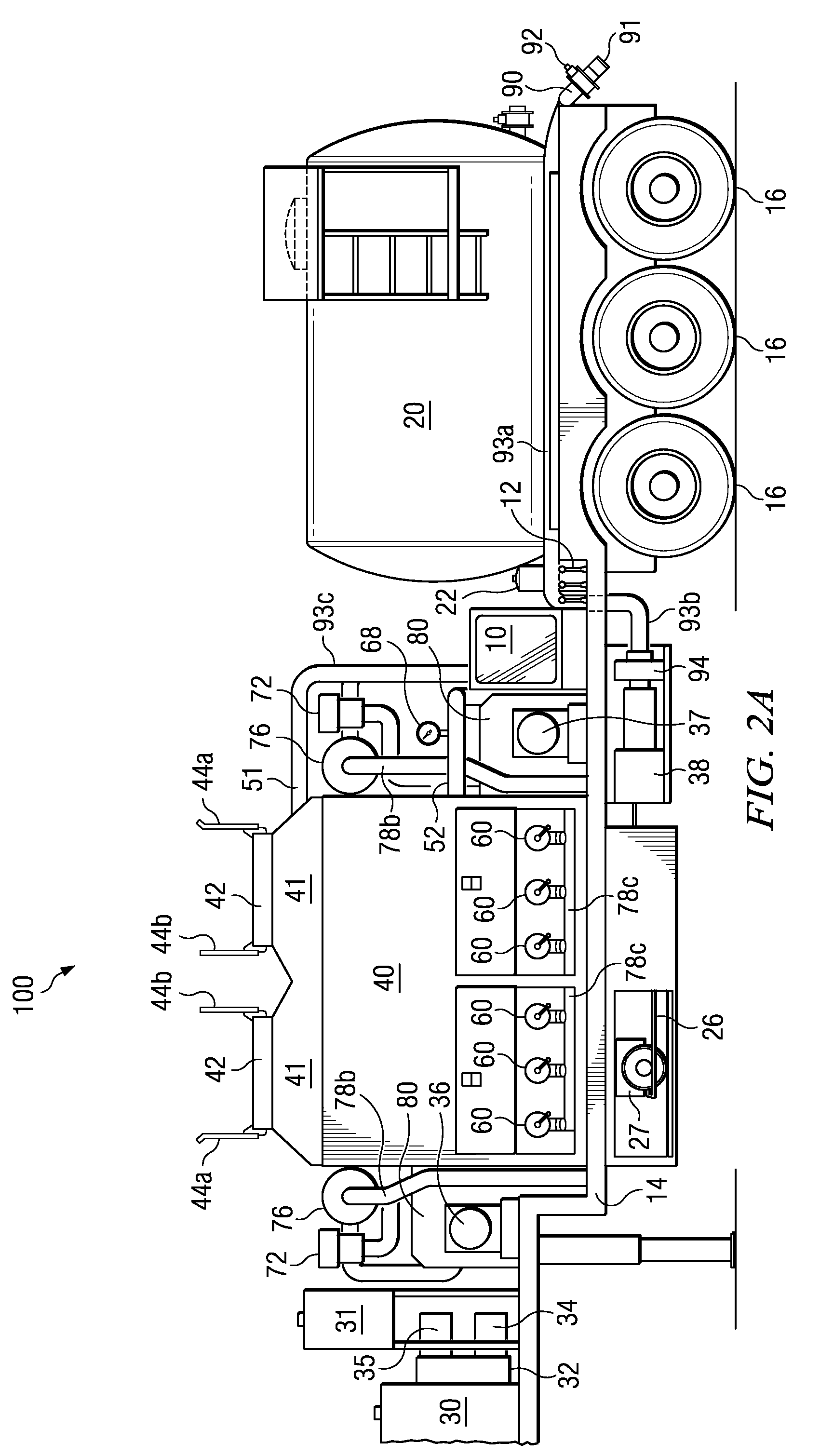

Hydraulic fracturing system and method

ActiveUS9840897B2Multiple-effect/fractional condensationSteam/vapor condensersDistilled waterHydraulic fracturing

Disclosed herein is a fracturing unit for hydraulic fracturing having an engine and a fracturing pump connected to the engine through a variable speed torque converter. Also disclosed is a hydraulic fracturing system using multiple fracturing units which are sized similar to ISO containers. A hydraulic fracturing system may also force flow back water, produced water, or fresh water through a heat exchanger so that heat from the fracturing engines can be transferred to these liquids in order to vaporize them. A force cooled fractioning unit then can accept the vapor / steam in order to condense the various components and produce distilled water for re-use in the fracturing process or for release into the environment.

Owner:LARSON KEVIN

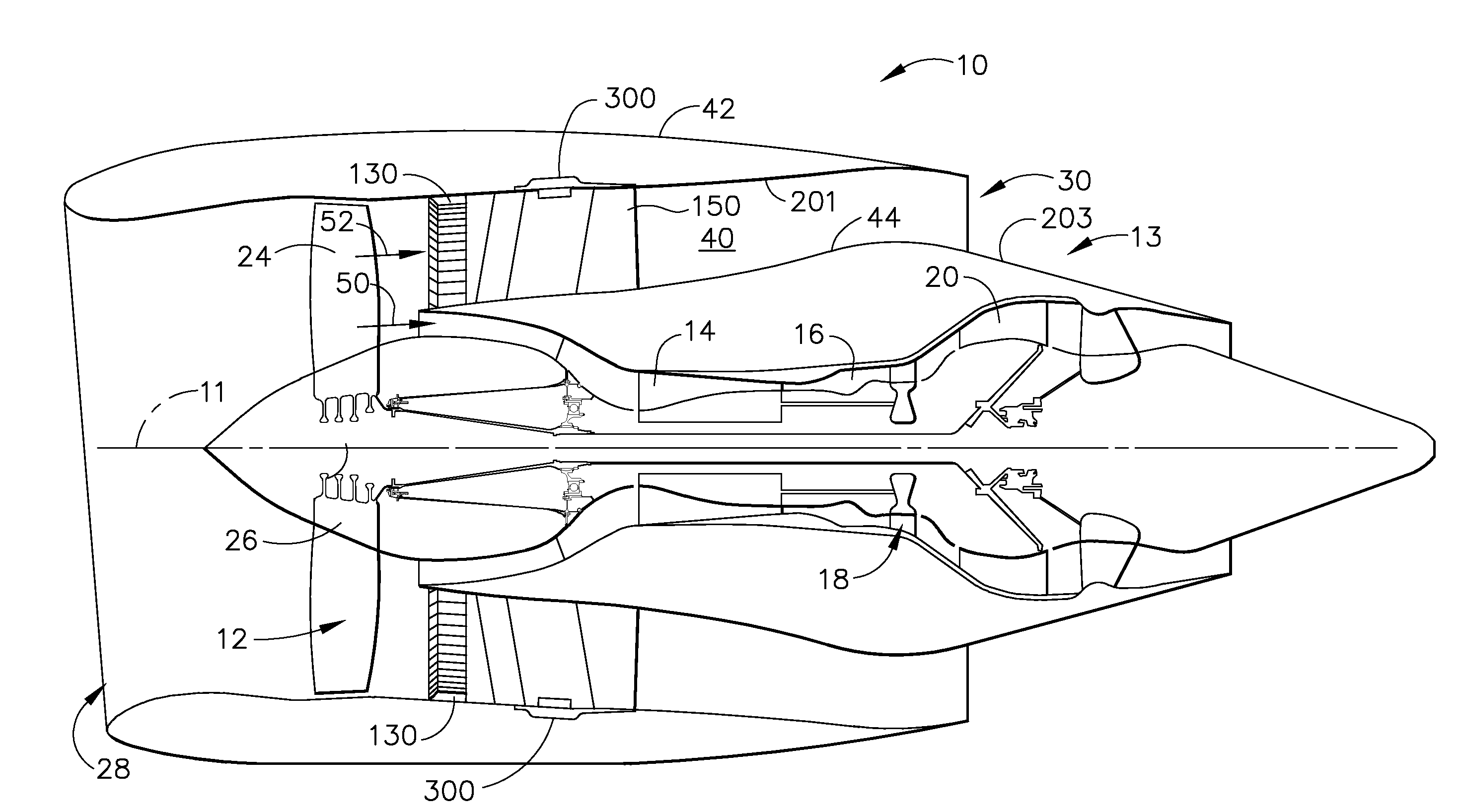

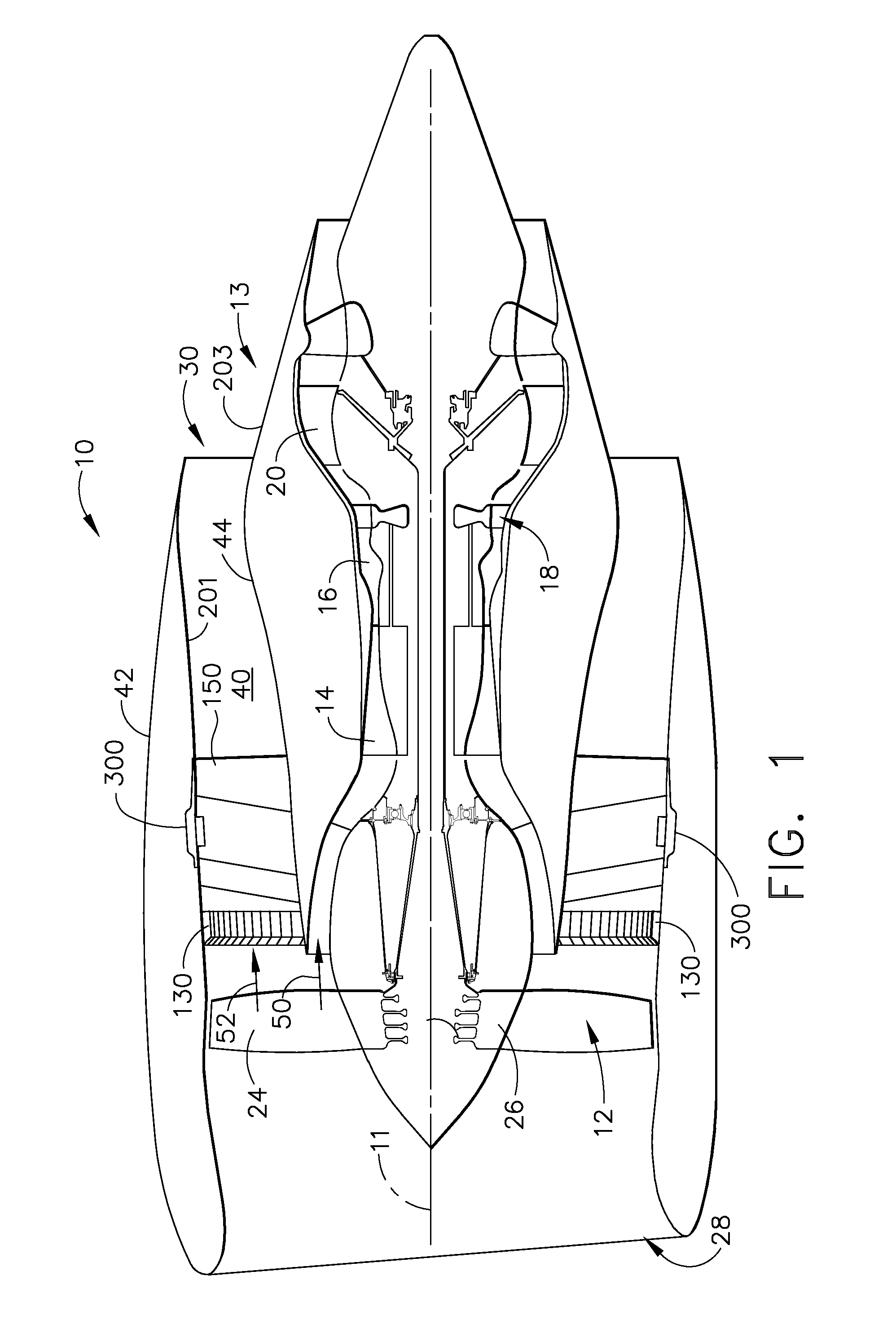

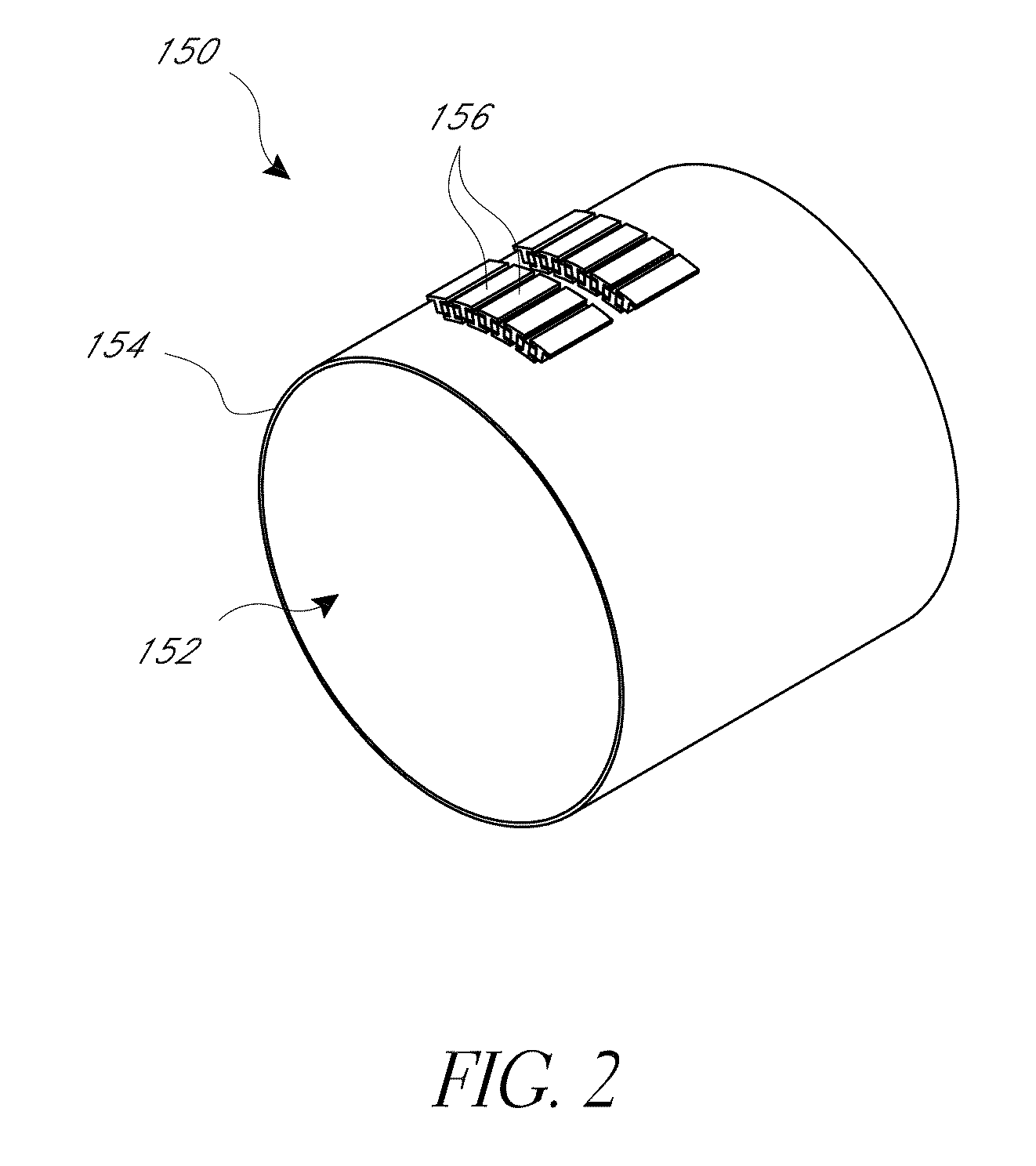

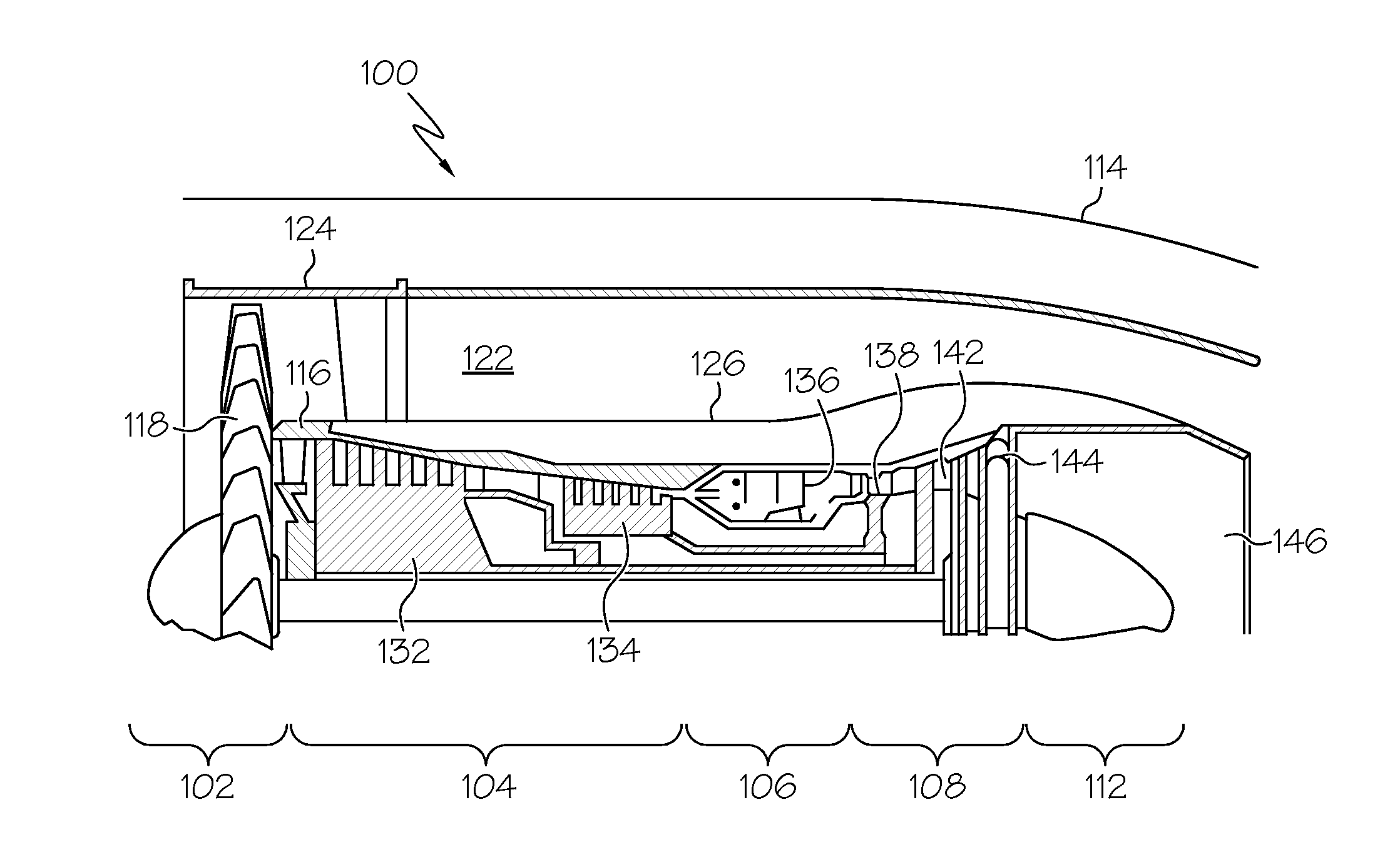

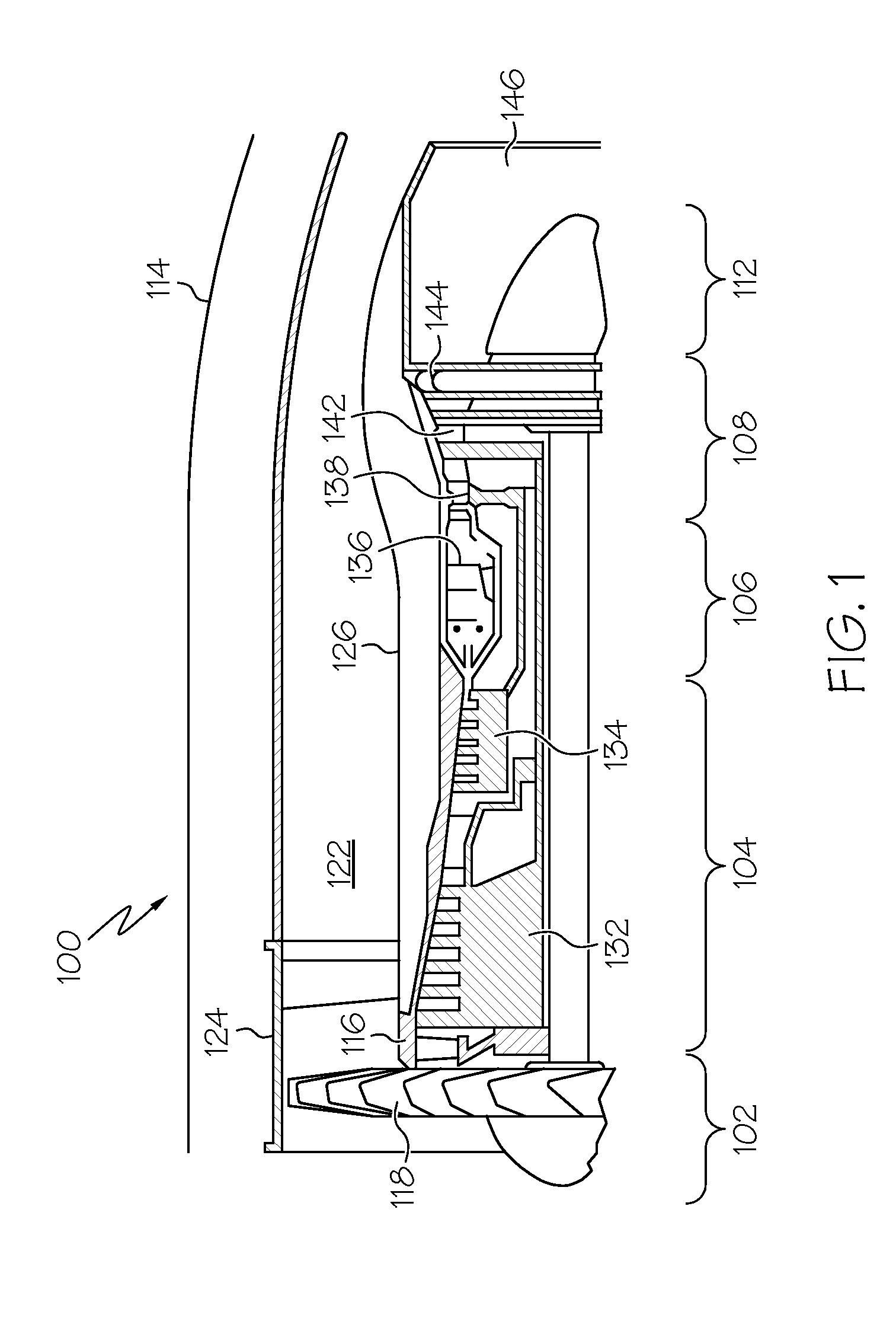

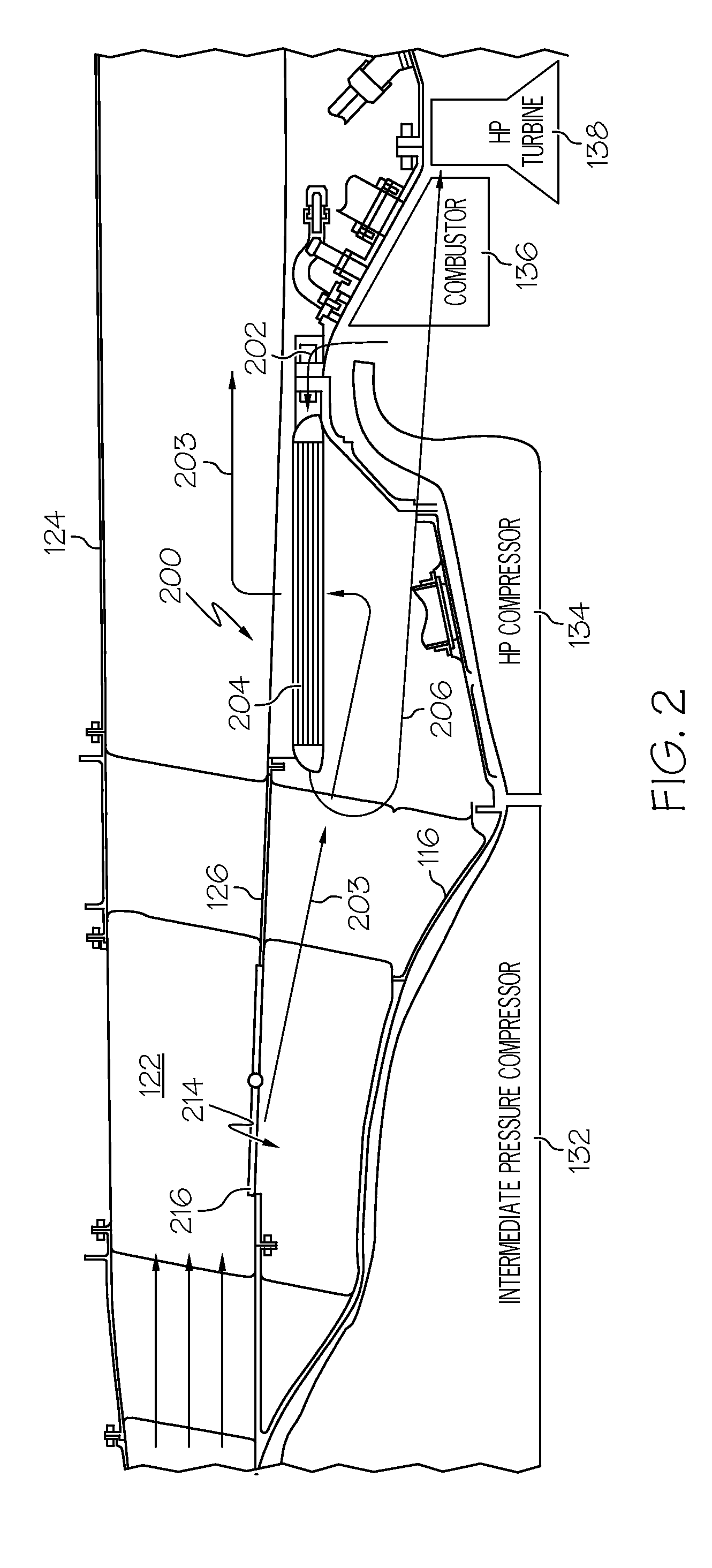

Method and apparatus for operating gas turbine engine heat exchangers

ActiveUS20080095611A1Turbine/propulsion engine coolingEfficient propulsion technologiesEngineeringTurbine

A method for assembling a turbine engine includes assembling a heat exchanger assembly that includes at least a radially inner plate, a radially outer plate, and a heat exchanger coupled between the radially inner and outer plates, forming the heat exchanger assembly such that the heat exchanger assembly has a substantially arcuate shape, and coupling the heat exchanger to a fan casing such that the heat exchanger is positioned upstream or downstream from the fan assembly.

Owner:UNISON INDUSTRIES +1

Heat exchanger tube having integrated thermoelectric devices

InactiveUS20080028769A1Maximize heating efficiencyMaximize efficiencyThermoelectric device with peltier/seeback effectVehicle heating/cooling devicesEngineeringThermoelectric effect

A heat exchanger for a vehicle is shown, wherein the heat exchanger includes a plurality of tubes having integrated thermoelectric devices disposed thereon to facilitate heat transfer between the tubes and an atmosphere surrounding the tubes.

Owner:GENTHERM INC

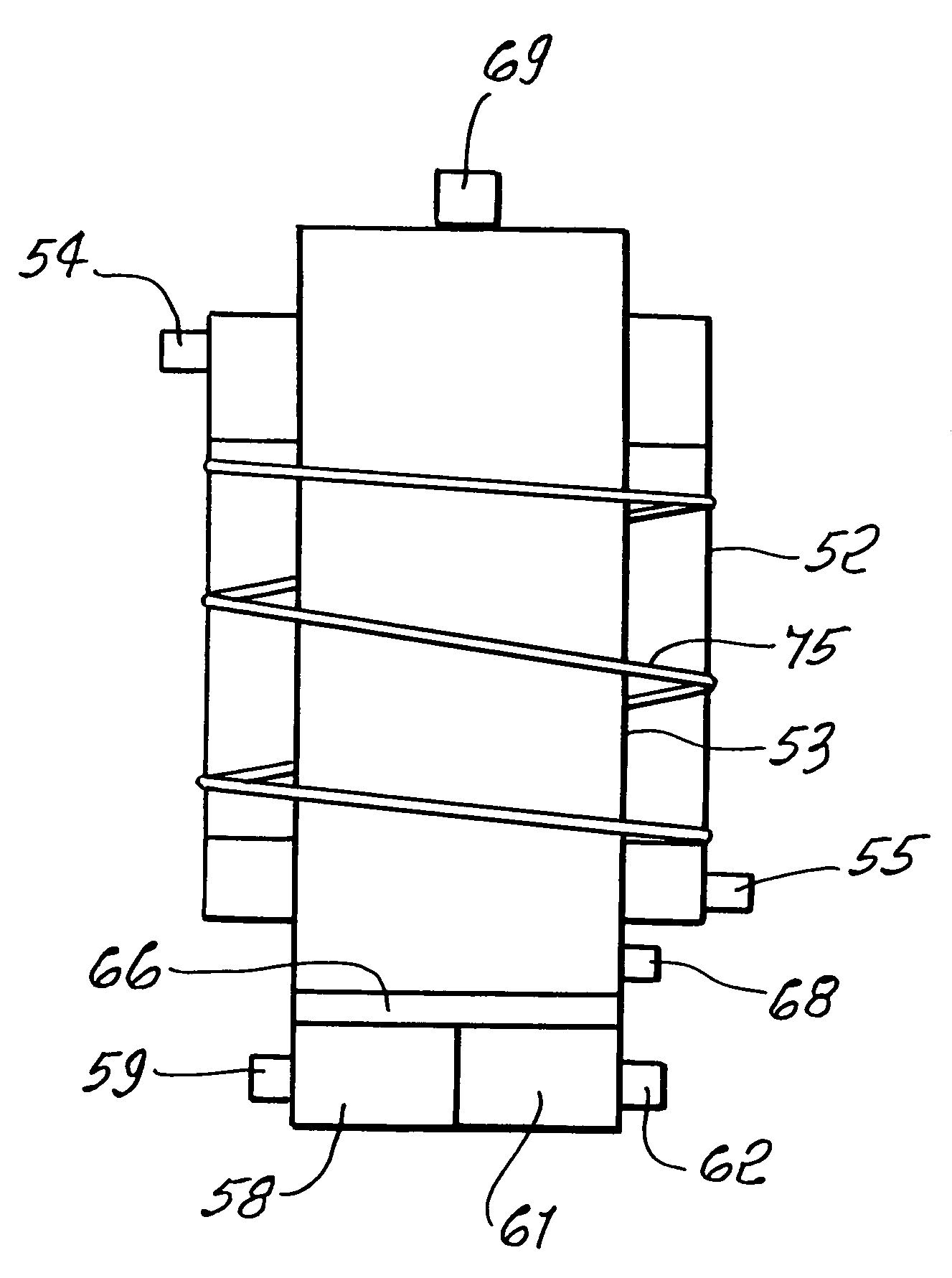

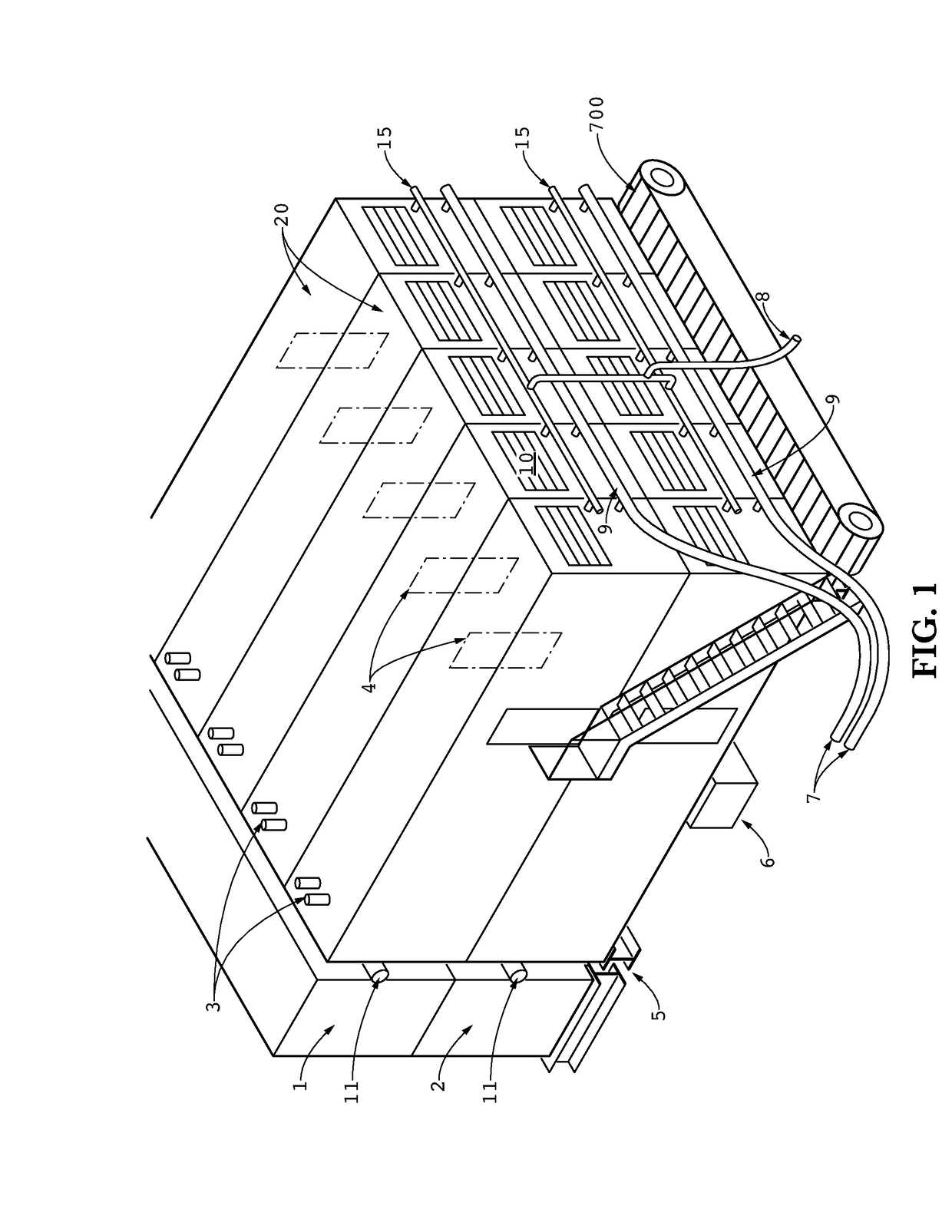

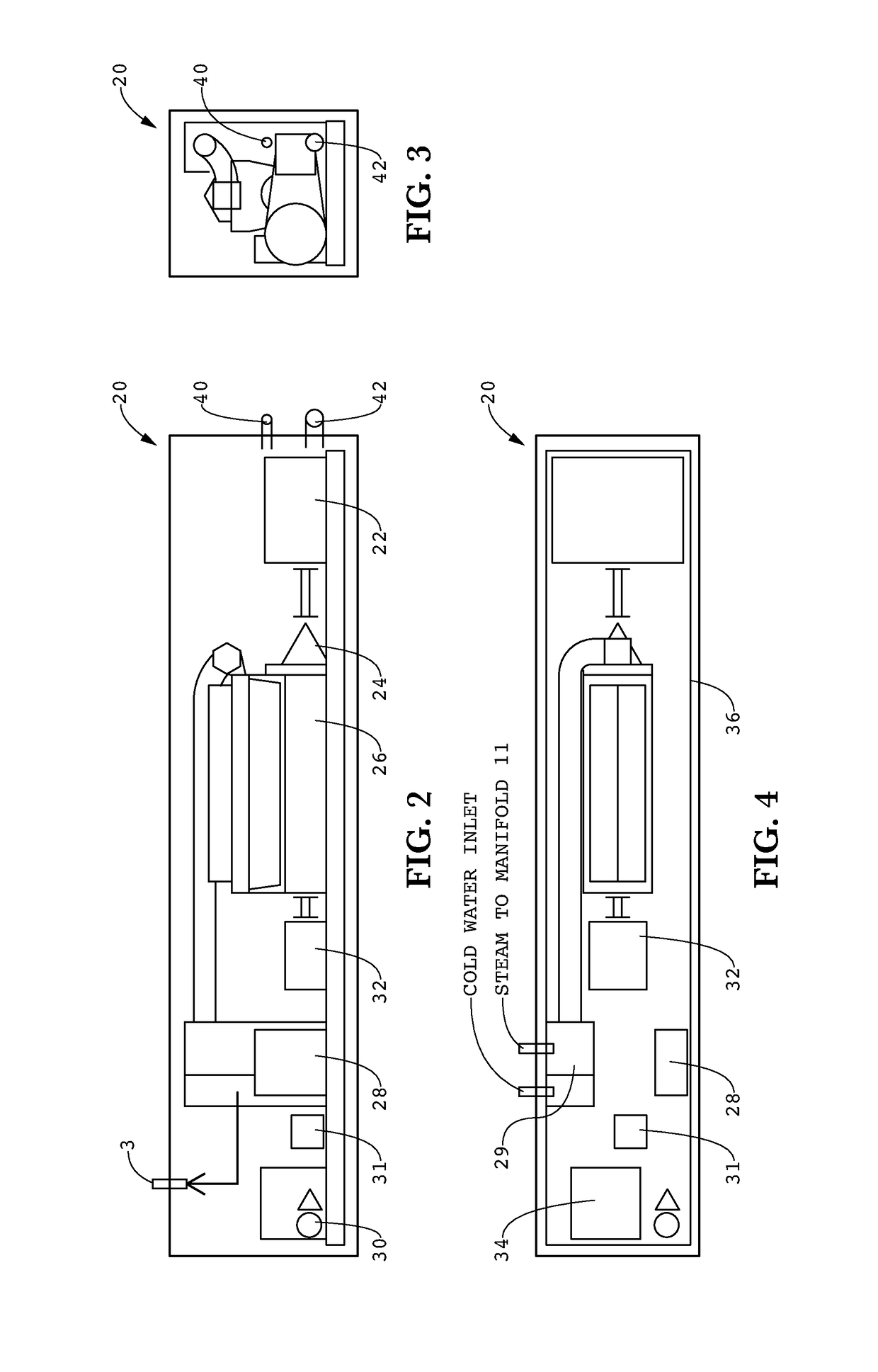

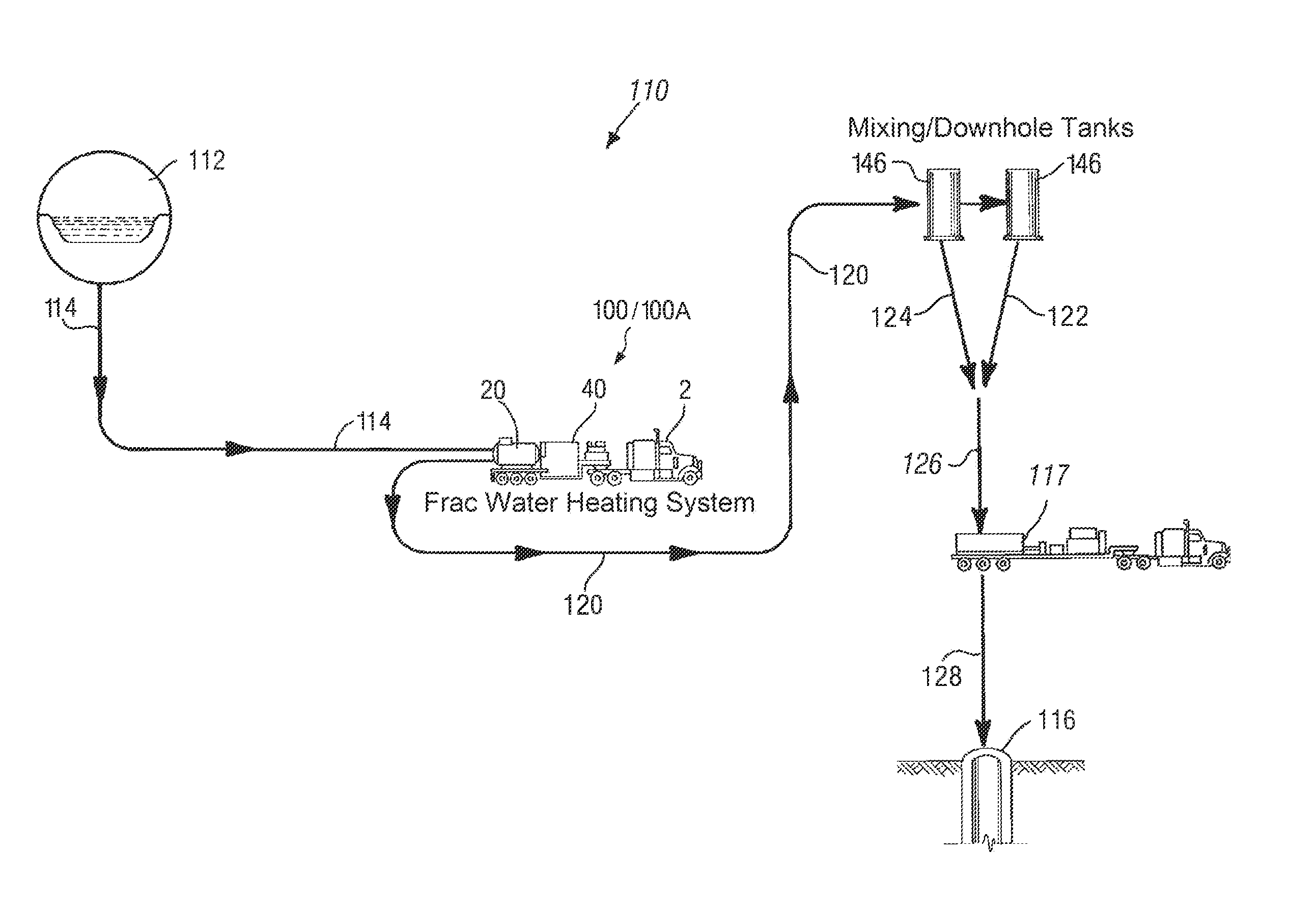

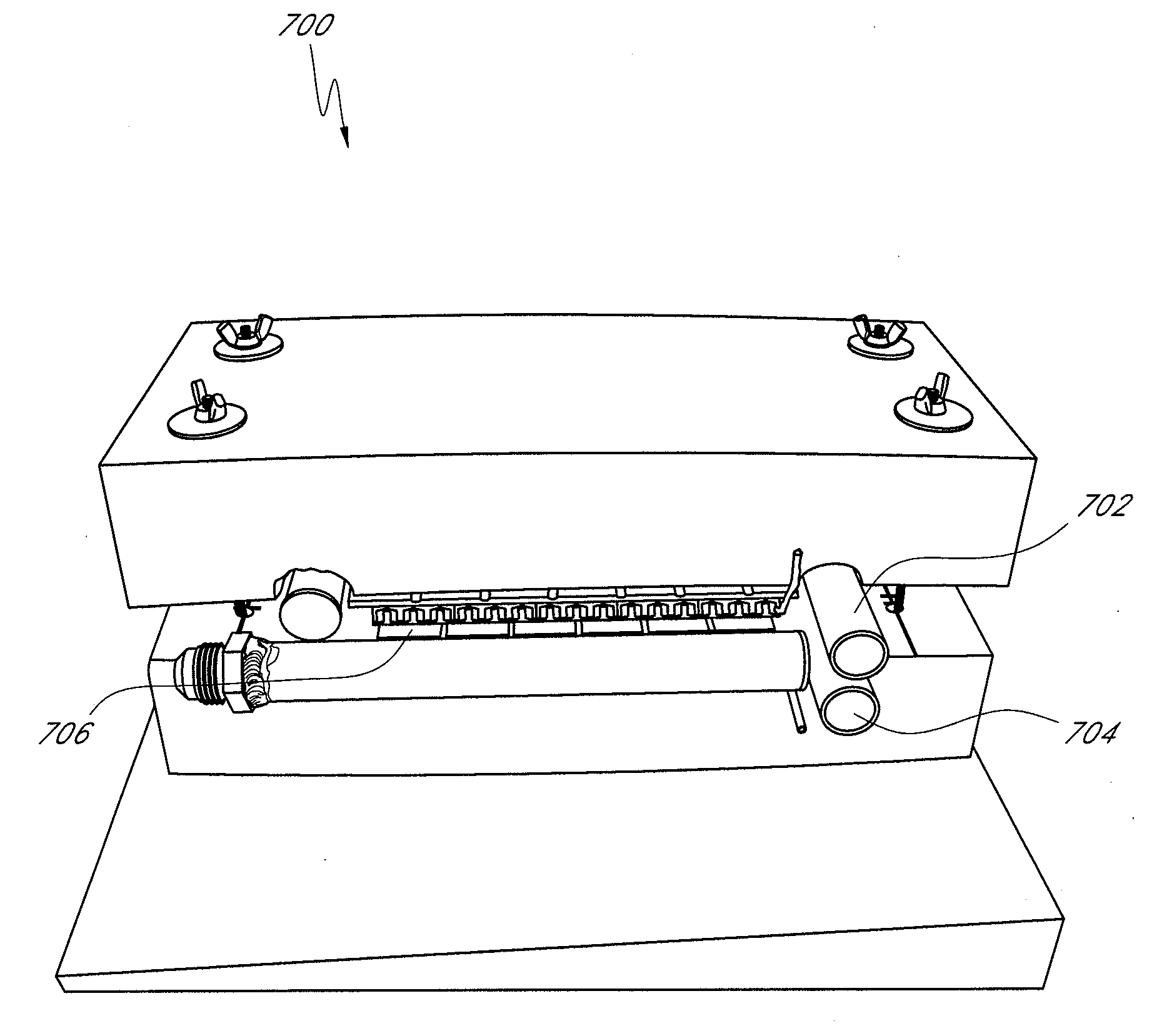

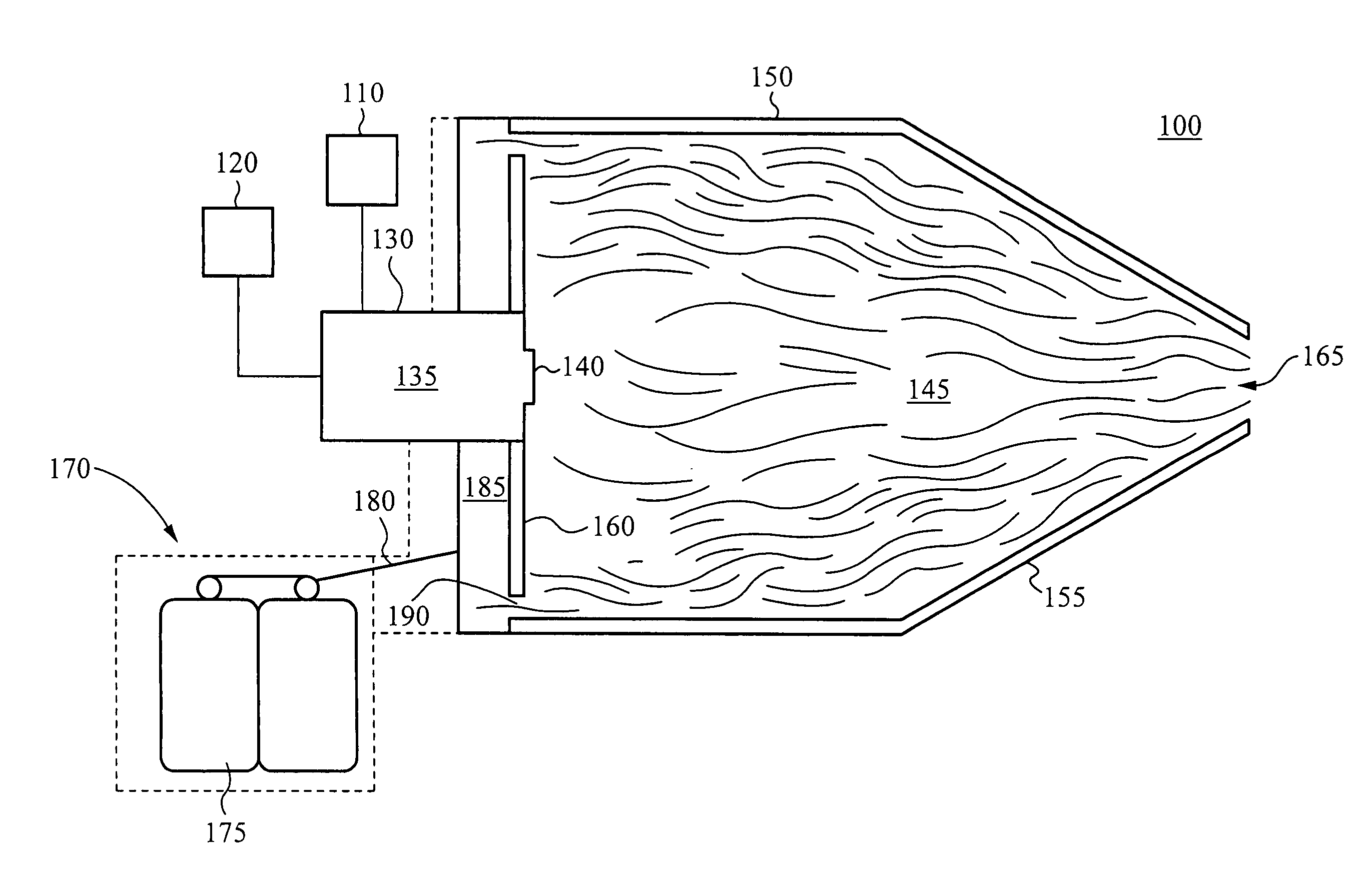

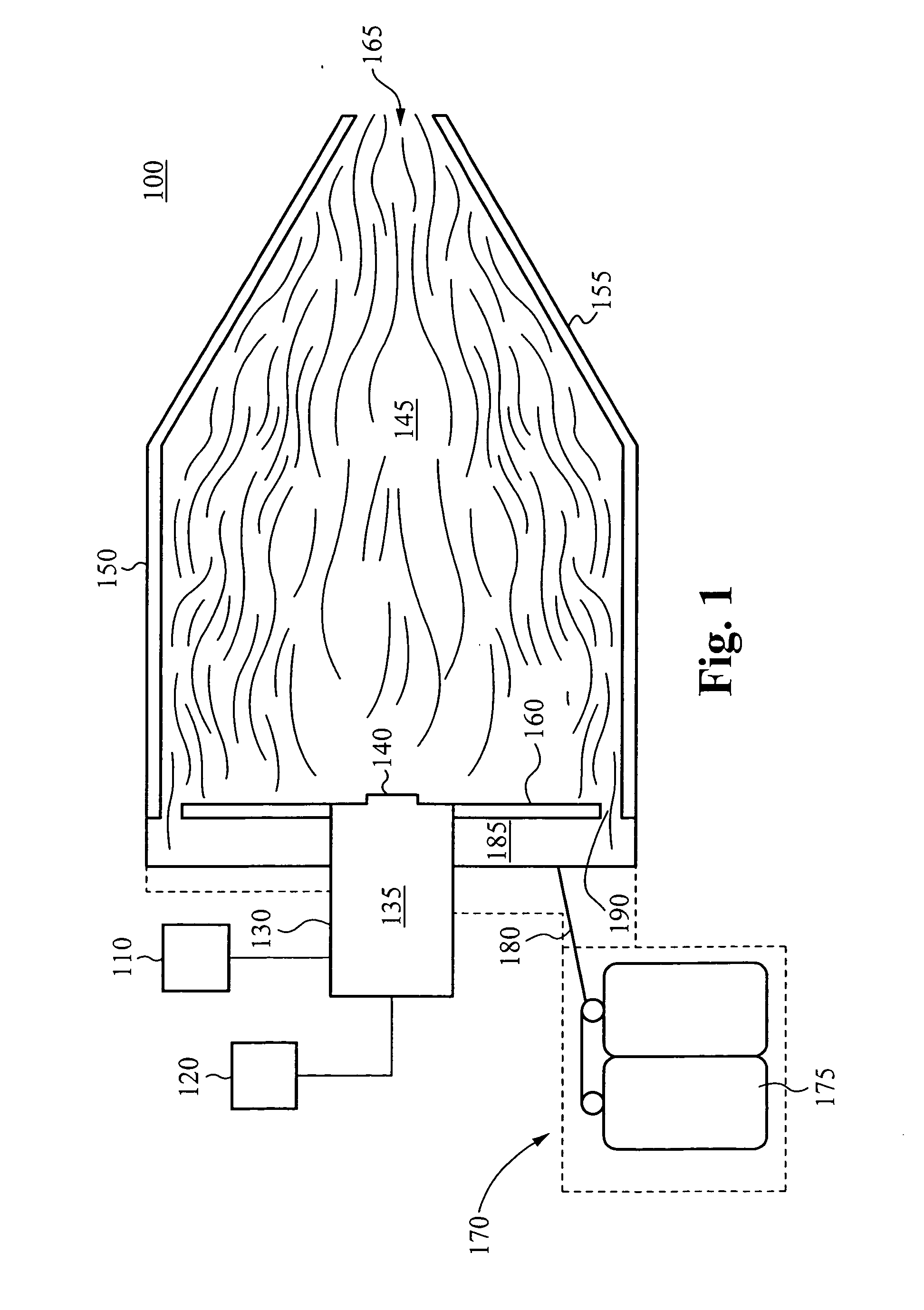

Frac water heating system and method for hydraulically fracturing a well

InactiveUS20140144641A1Safely and continuously heatingMaximize atomization and combustionInsulationFluid removalCombustion chamberFuel tank

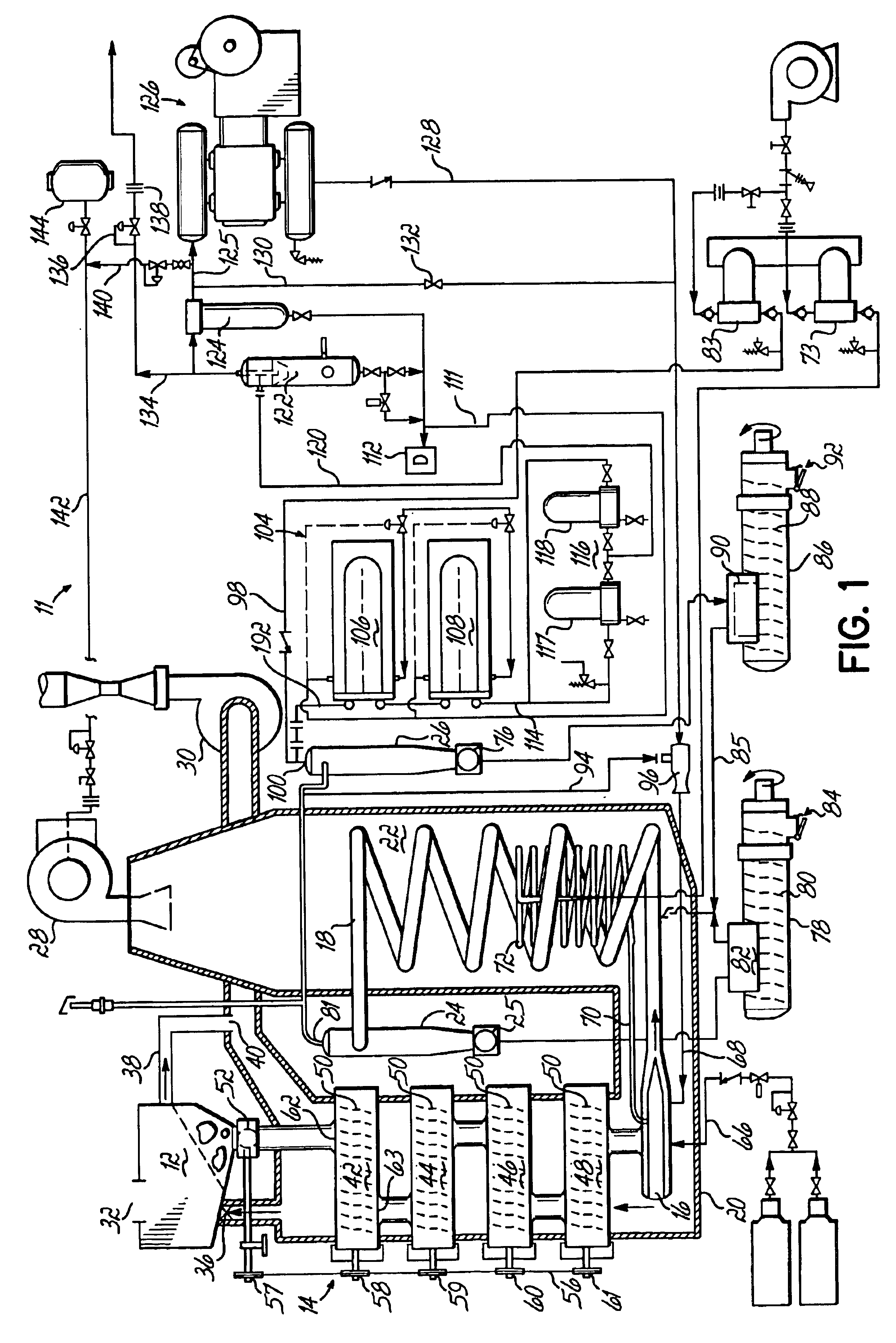

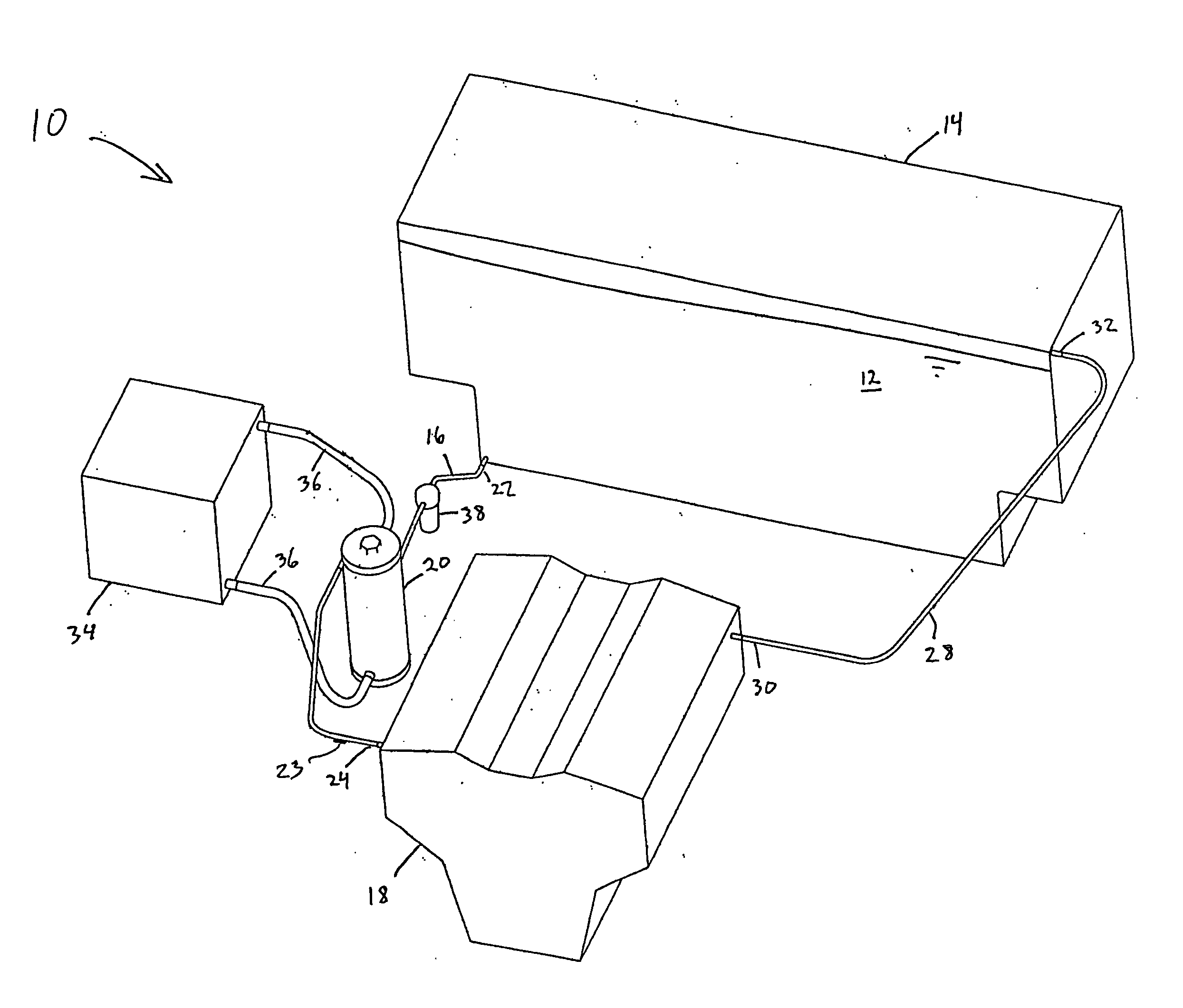

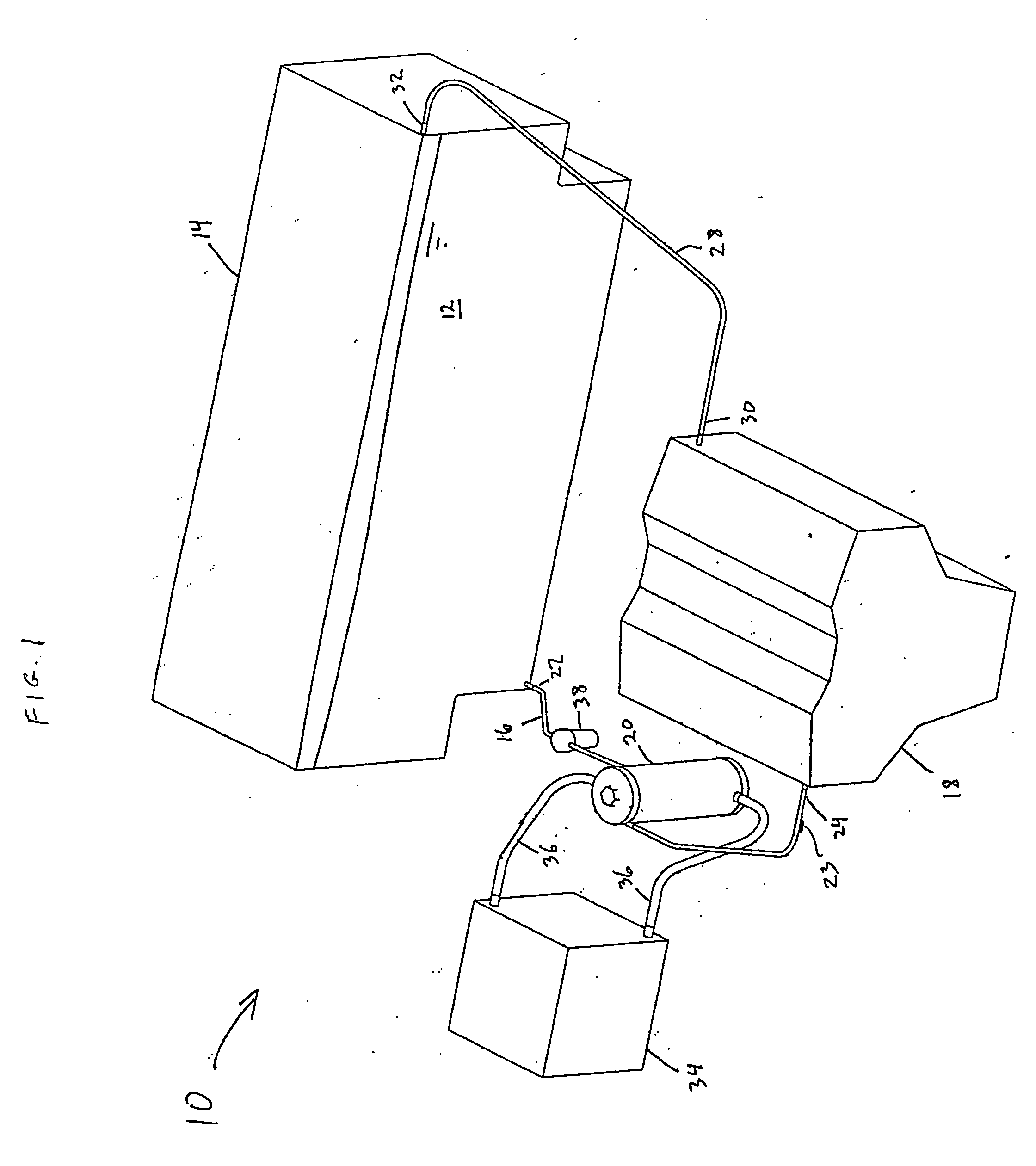

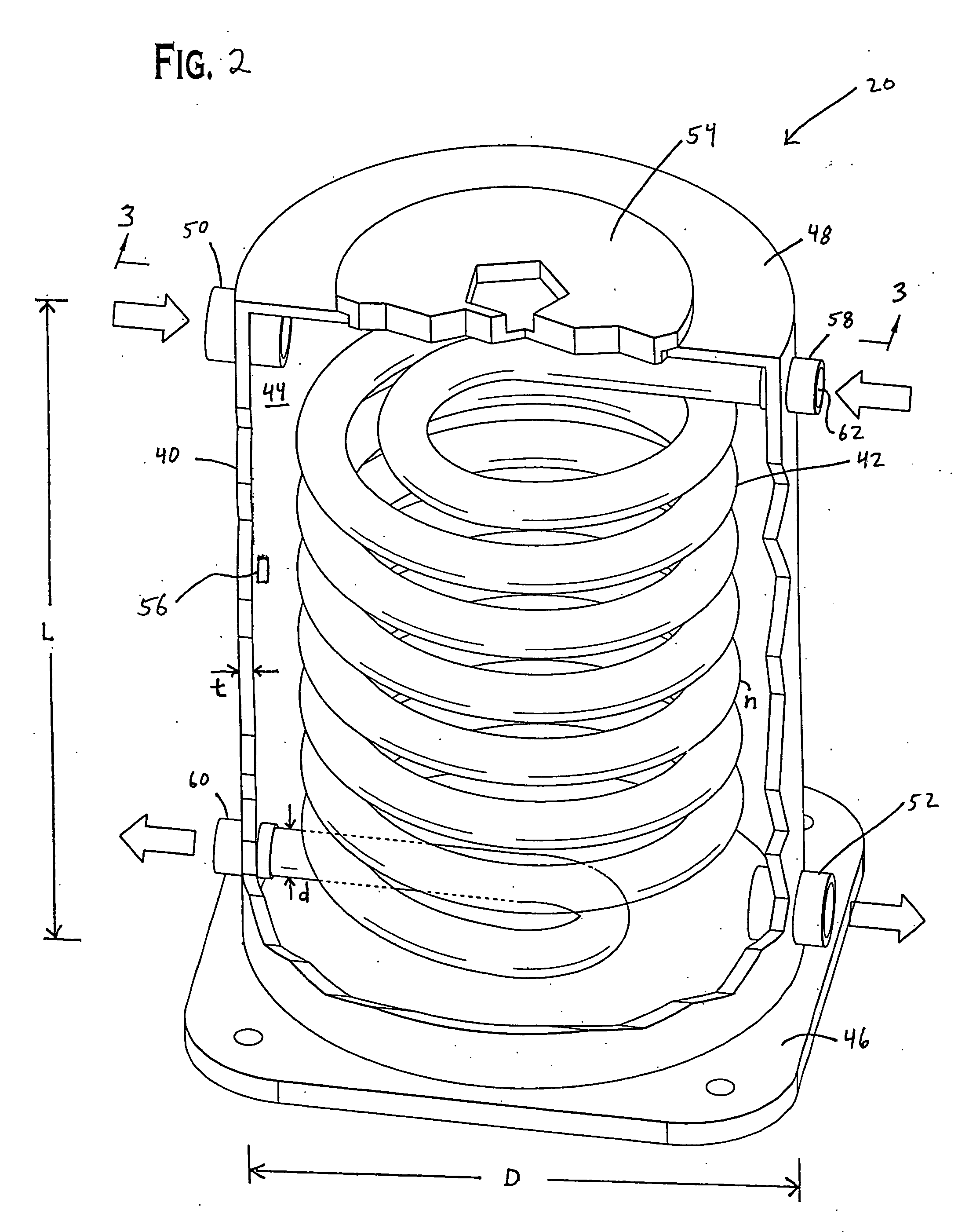

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an improved frac water heating system. The present invention is a self-contained unit which is easily transported to remote locations. In one embodiment, the present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. In another embodiment, the present invention includes multiple, single-pass heat exchanger units arranged in a vertically stacked configuration. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in all weather environments. In a preferred embodiment, the improved frac water heating system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

Oil-fired frac water heater

ActiveUS20100000508A1Maximize atomization and combustionMaximize combustionAir-treatment apparatus arrangementsAir heatersFuel tankEngineering

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an oil-fired heat exchange system. The present invention is a self-contained unit which is easily transported to remote locations. The present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in ail weather environments. In a preferred embodiment, the oil-fired heat exchanger system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

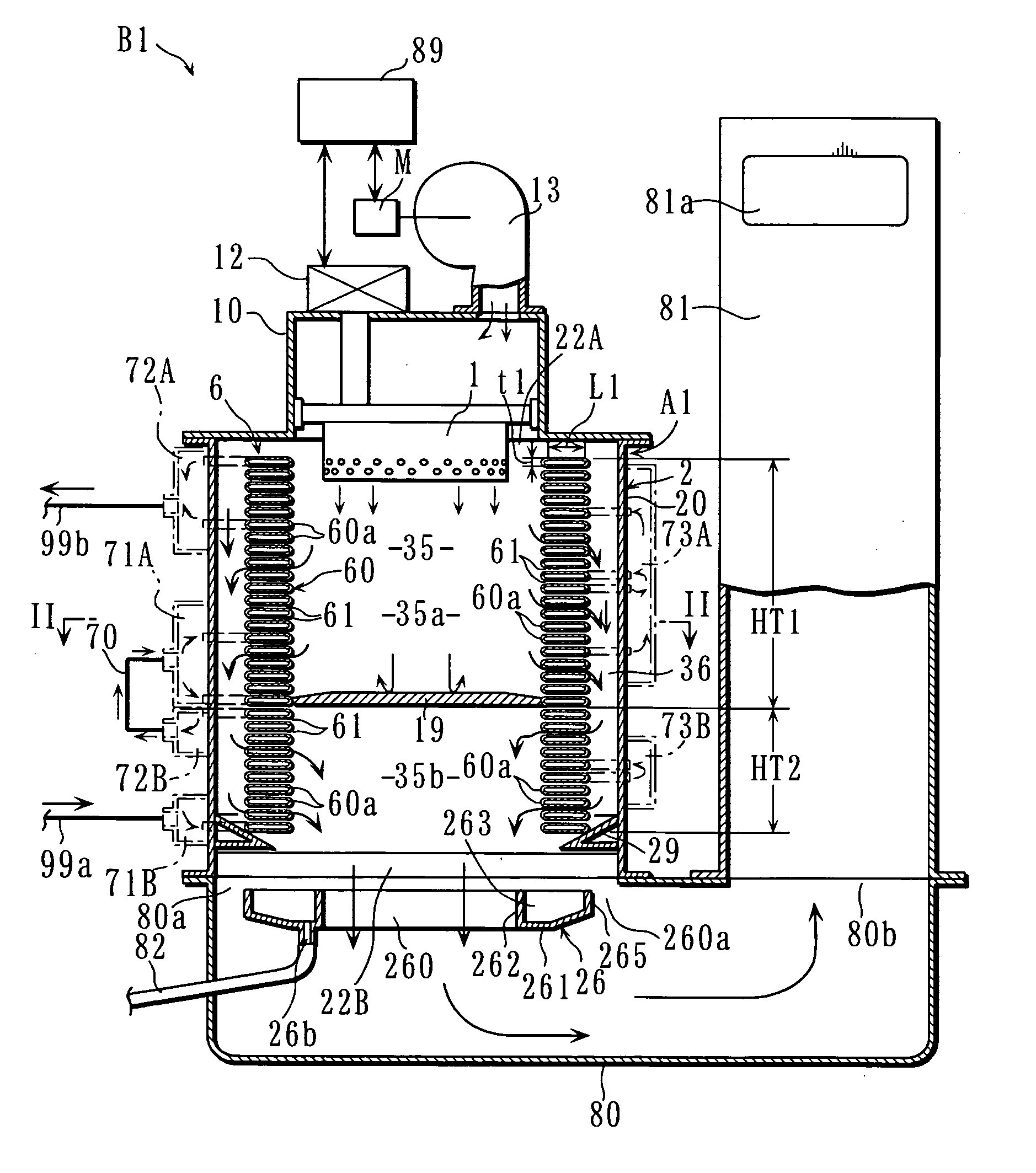

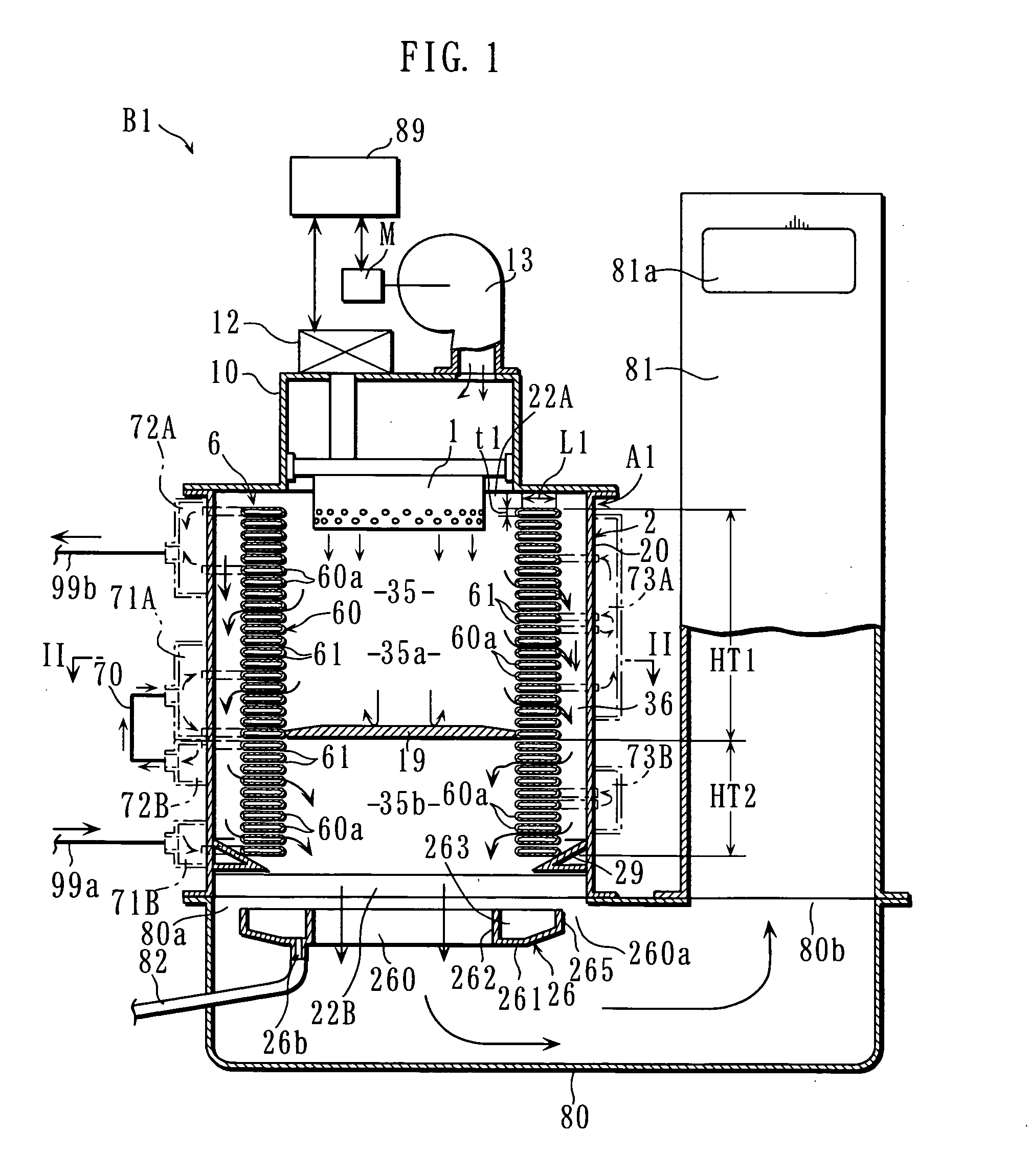

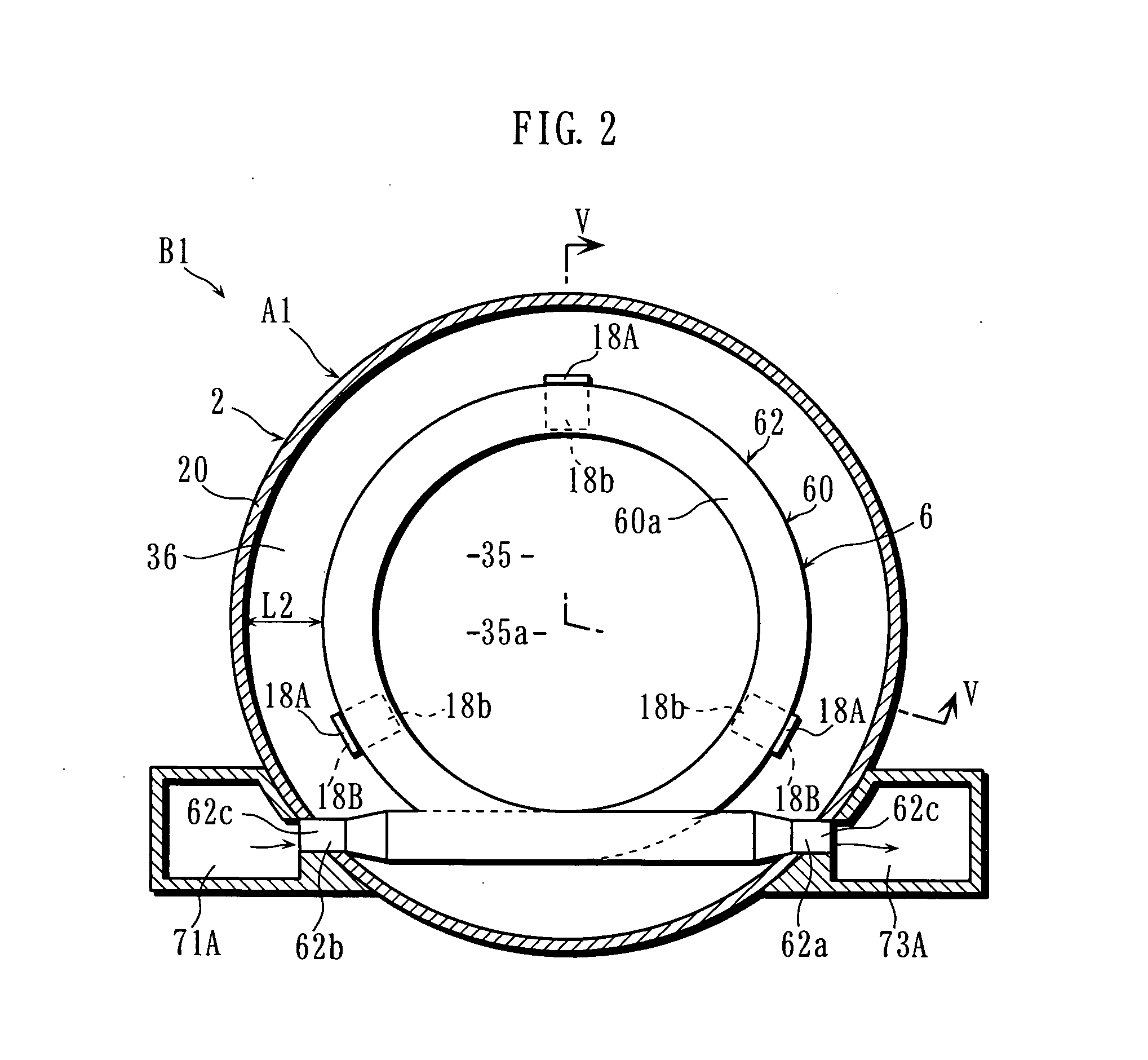

Heat Exchanger and Water Heater

A heat exchanger A1 includes a partition 19 partitioning the space 35 surrounded by a coiled tube 60 at an axially intermediate portion of a housing 2 into a first and a second regions 35a and 35b and partitioning the coiled tube 60 into a first and a second heat exchanging portions HT1 and HT2. The combustion gas supplied to the first region 35a flows to a combustion gas path 36 by passing through a clearance 61 of the first heat exchanging portion HT1 and then passes through a clearance 61 of the second heat exchanging portion HT2. With this structure, the amount of heat recovery is increased, and the heat exchange efficiency is enhanced while simplifying the overall structure of the heat exchanger A1 and reducing the size of the heat exchanger.

Owner:NORITZ CORP

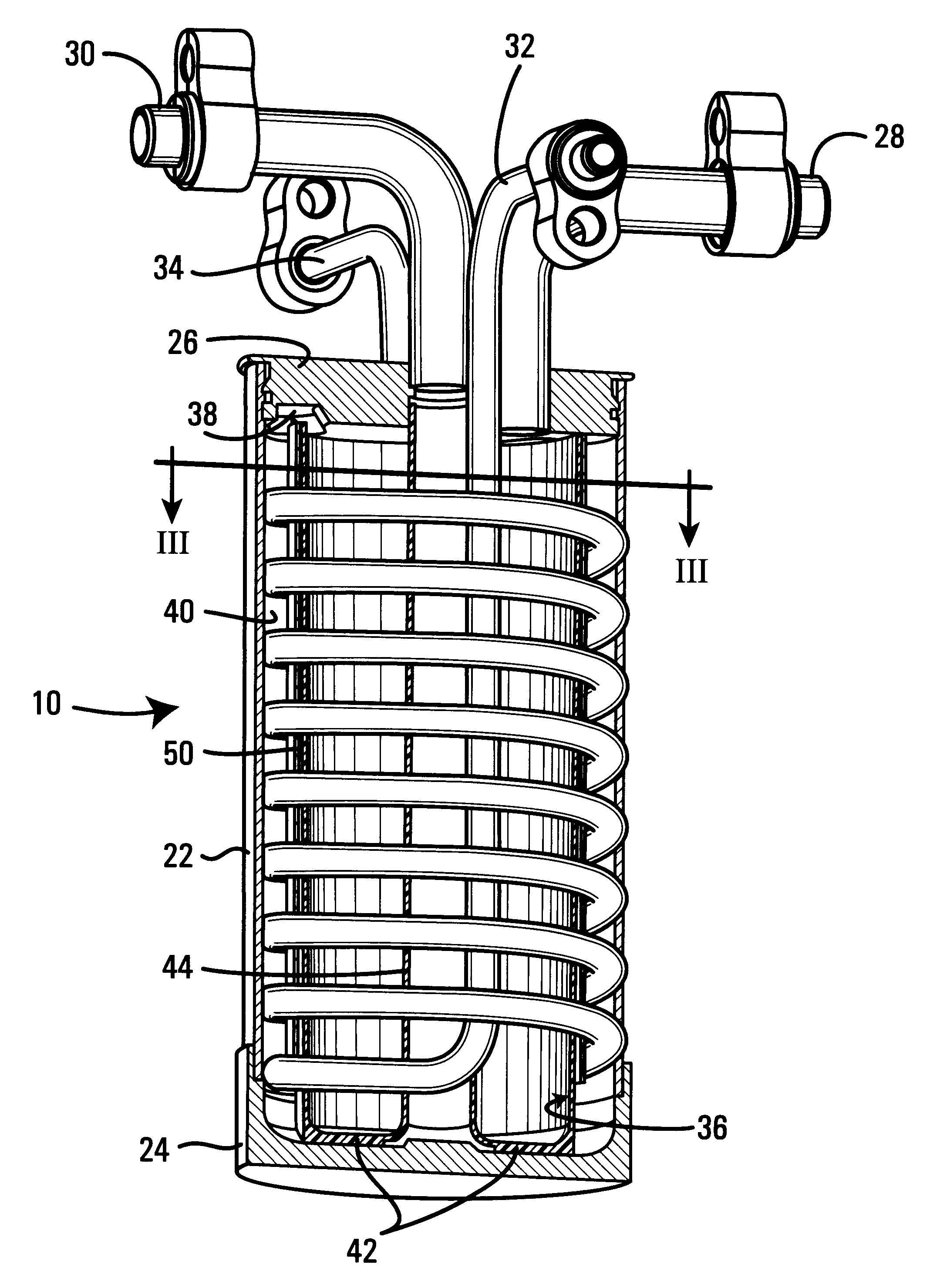

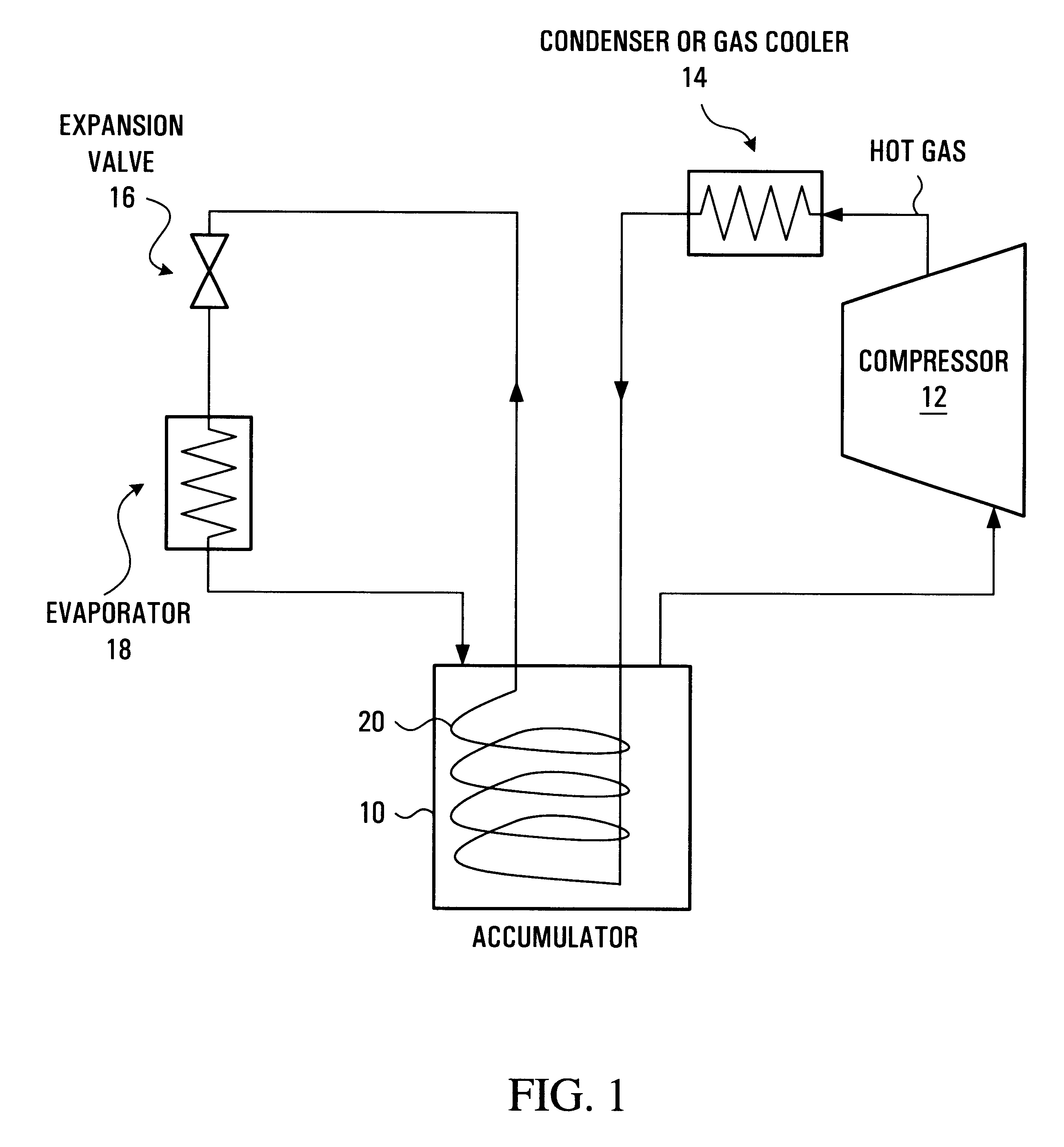

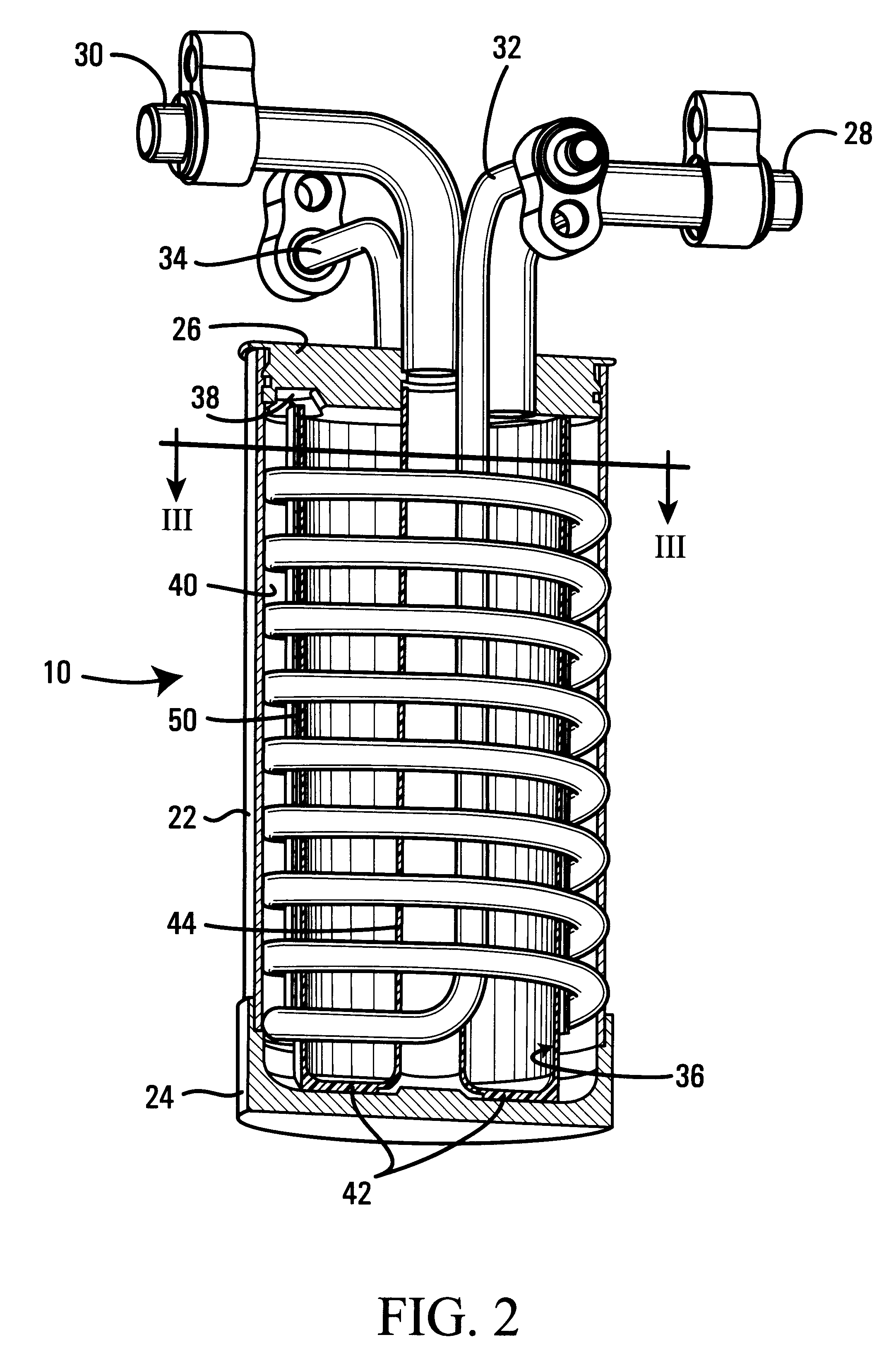

Internal heat exchanger accumulator

InactiveUS6463757B1Simple and cheap to manufactureIncrease surface areaAir-treating devicesEvaporators/condensersEvaporationEngineering

An accumulator for an air-conditioning (refrigeration or heat pump) system is designed to reduce flooding due to greater effective internal volume while at the same time incorporating an internal heat exchanger for better system performance, and providing better evaporation and controlled thermal properties. The accumulator embodies an outer housing that co-axially surrounds an inner liner. The inlet directs the refrigerant into the inner volume formed by the liner, wherein the liquid refrigerant and compressor oil are contained and insulated from the wall of the outer housing. A heat exchanger is arranged in the annular space between the outer housing and the inner liner and circulates a flow of condensate therethrough before delivering it to the expansion device. In this way the condensate is cooled for higher performance and at the same time refrigerant passing out of the accumulator is vaporized more completely.

Owner:HALLA CLIMATE CONTROL CANADA

Thermoelectric-based power generation systems and methods

InactiveUS20110067742A1Lower overall pressure dropInternal combustion piston enginesRecuperative heat exchangersExhaust valveEngineering

Some embodiments provide a waste heat recovery apparatus including an exhaust tube having a cylindrical outer shell configured to contain a flow of exhaust fluid; a first heat exchanger extending through a first region of the exhaust tube, the first heat exchanger in thermal communication with the cylindrical outer shell; a second region of the exhaust tube extending through the exhaust tube, the second region having a low exhaust fluid pressure drop; an exhaust valve operatively disposed within the second region and configured to allow exhaust fluid to flow through the second region only when a flow rate of the exhaust fluid becomes great enough to result in back pressure beyond an allowable limit; and a plurality of thermoelectric elements in thermal communication with an outer surface of the outer shell.

Owner:GENTHERM INC

Tubular heat exchange systems

A heat exchange system includes a first flow passage and a second flow passage. The heat exchange system is configured to transfer heat between a first fluid flowing through the first flow passage and a second fluid flowing through the second flow passage. The first flow passage includes an inlet header, a plurality of tubes, and an outlet header. The inlet header includes a plurality of header-tube transition portions configured to allow the first fluid to flow from the inlet header and into the tubes, the plurality of header-tube transition portions each including a smoothly curved inlet portion and a tapered tube connection portion.

Owner:HONEYWELL INT INC

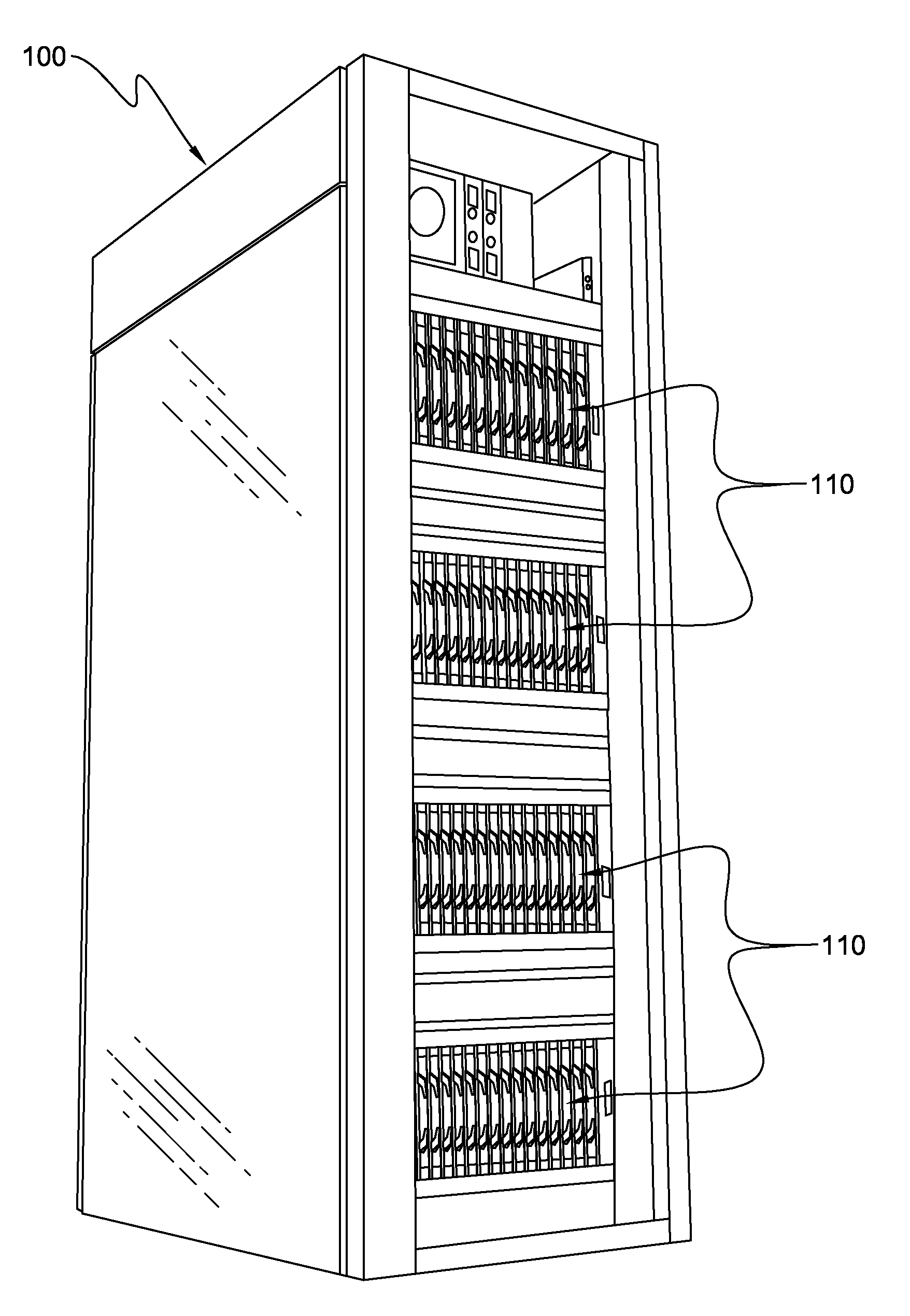

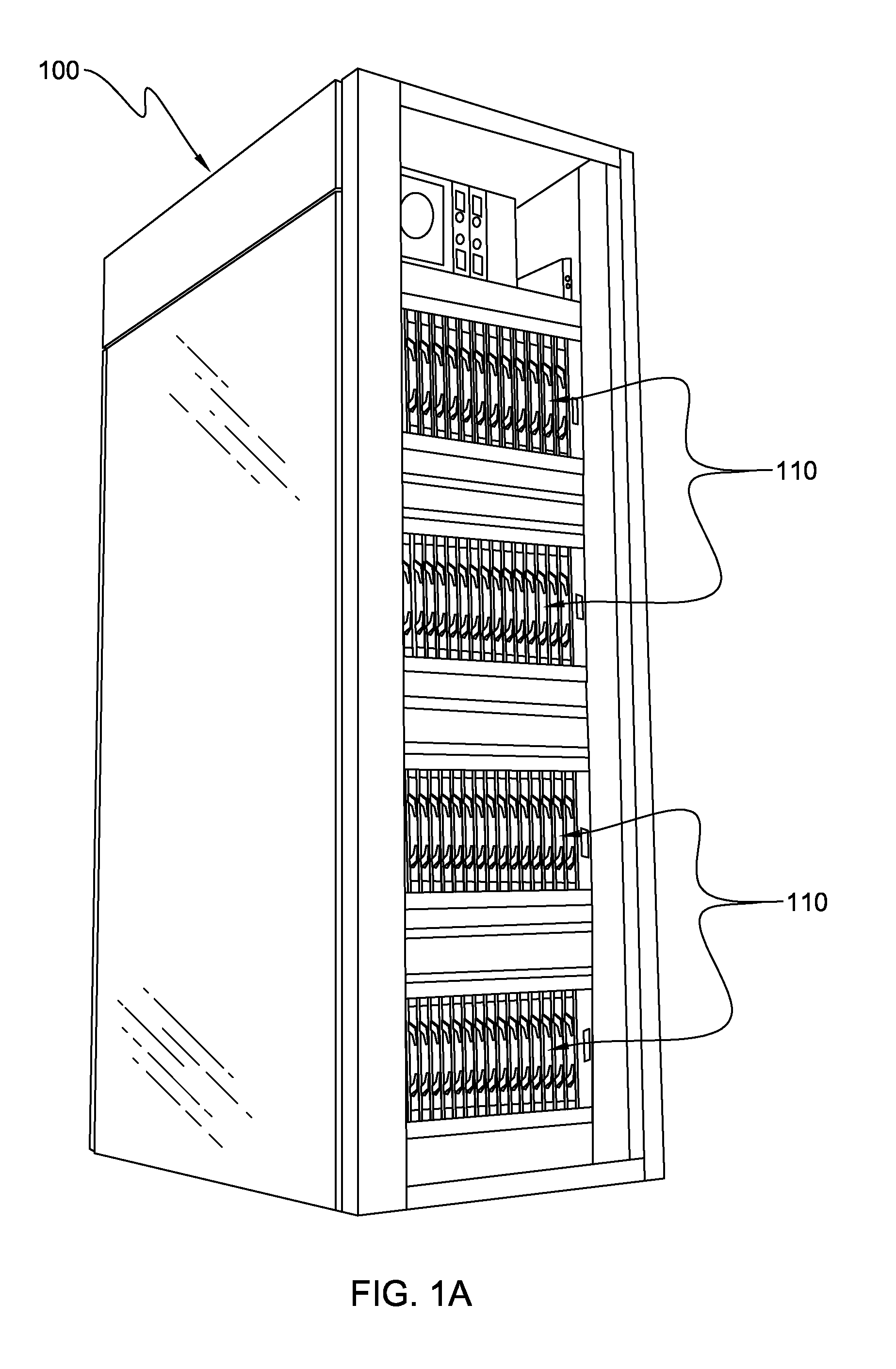

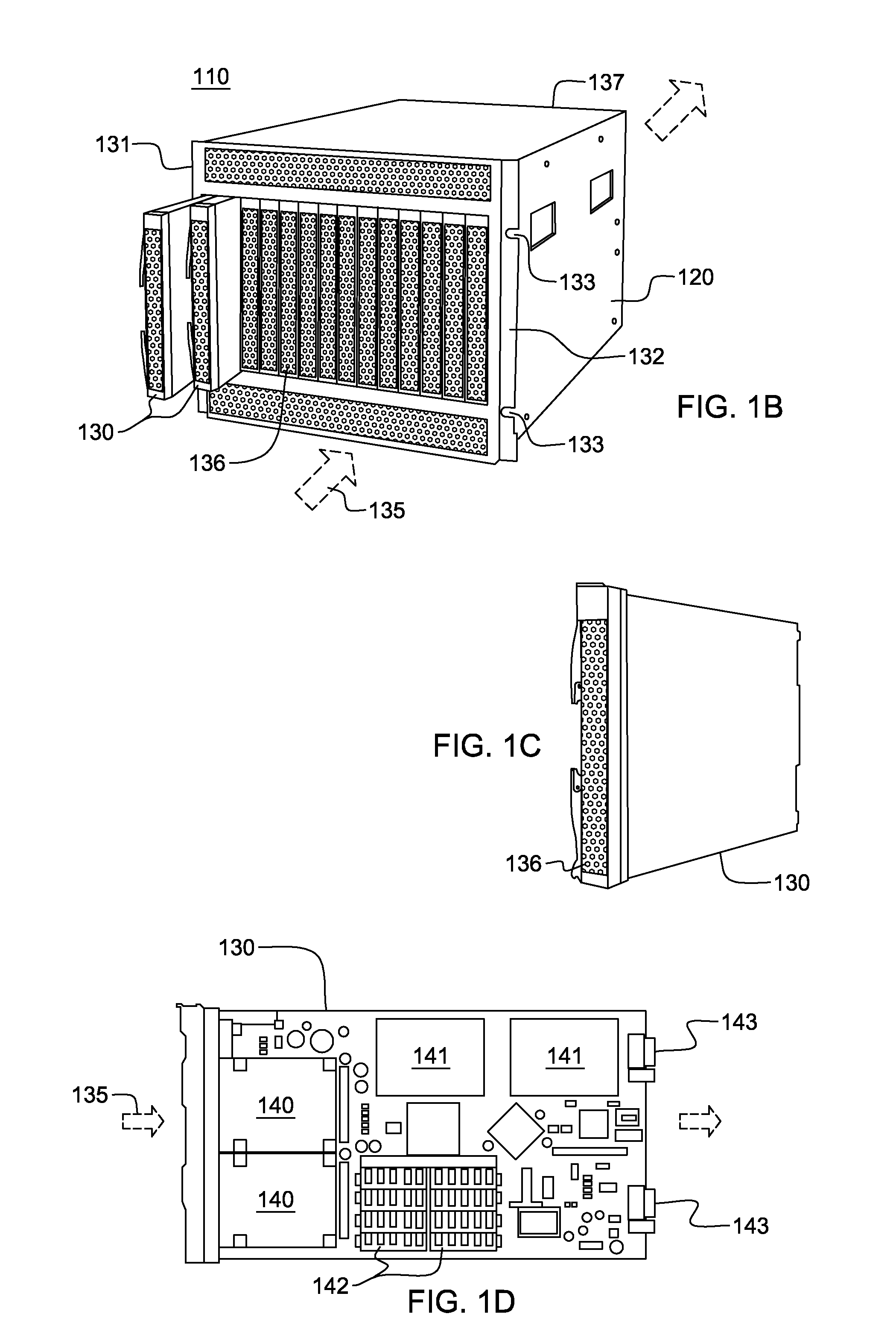

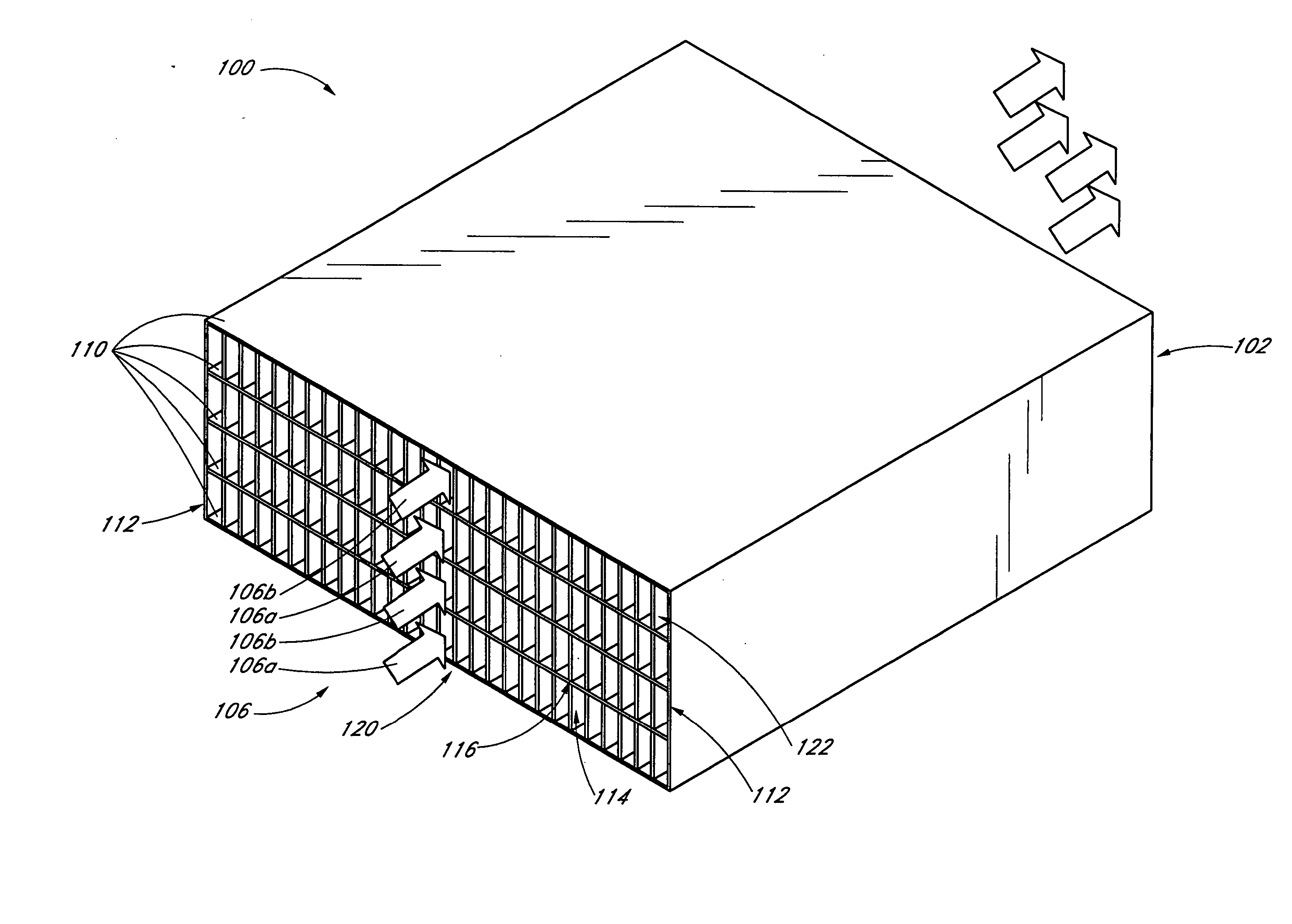

Liquid cooling apparatus and method for cooling blades of an electronic system chassis

InactiveUS20100101765A1Improve heat transfer performanceImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsElectronic systemsCoolant flow

Apparatus and method are provided for facilitating liquid cooling of a plurality of blades of an electronic system chassis. The apparatus includes a chassis-level manifold assembly with a first coolant path and a plurality of second coolant paths. The first coolant path is isolated from the plurality of second coolant paths by a heat exchanger. The heat exchanger facilitates transfer of heat from coolant within the second coolant paths to coolant within the first coolant path. Each second coolant path is isolated from the other second coolant paths, and coolant passing therethrough facilitates cooling of a respective blade. When operational, each second coolant path forms a portion of a respective closed loop coolant path extending between the manifold assembly and the electronic system chassis, and in one embodiment, each blade is an immersion-blade, with multiple components thereof immersion-cooled by coolant flowing through the respective second coolant path.

Owner:BRAINSCOPE SPV LLC +1

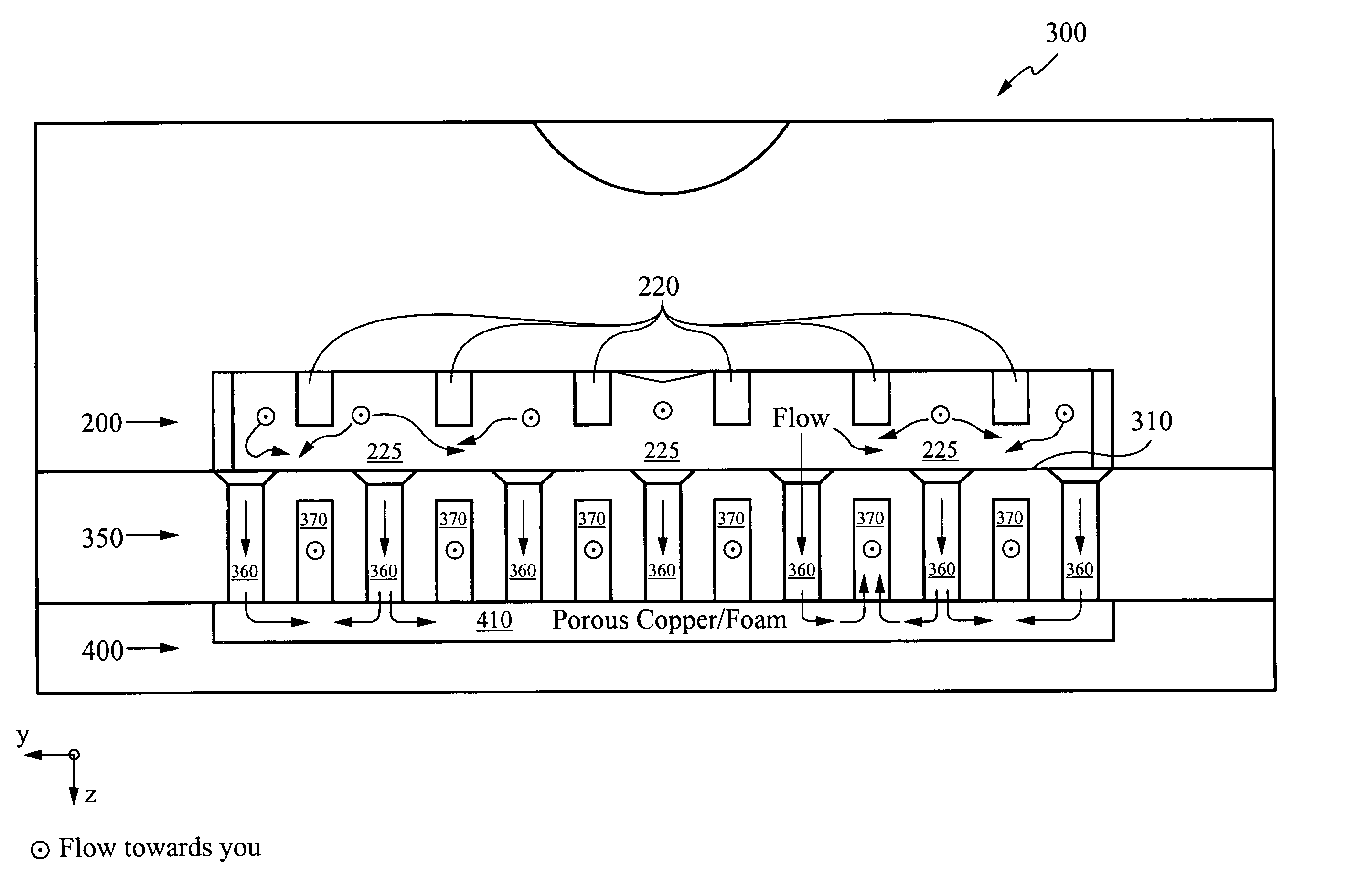

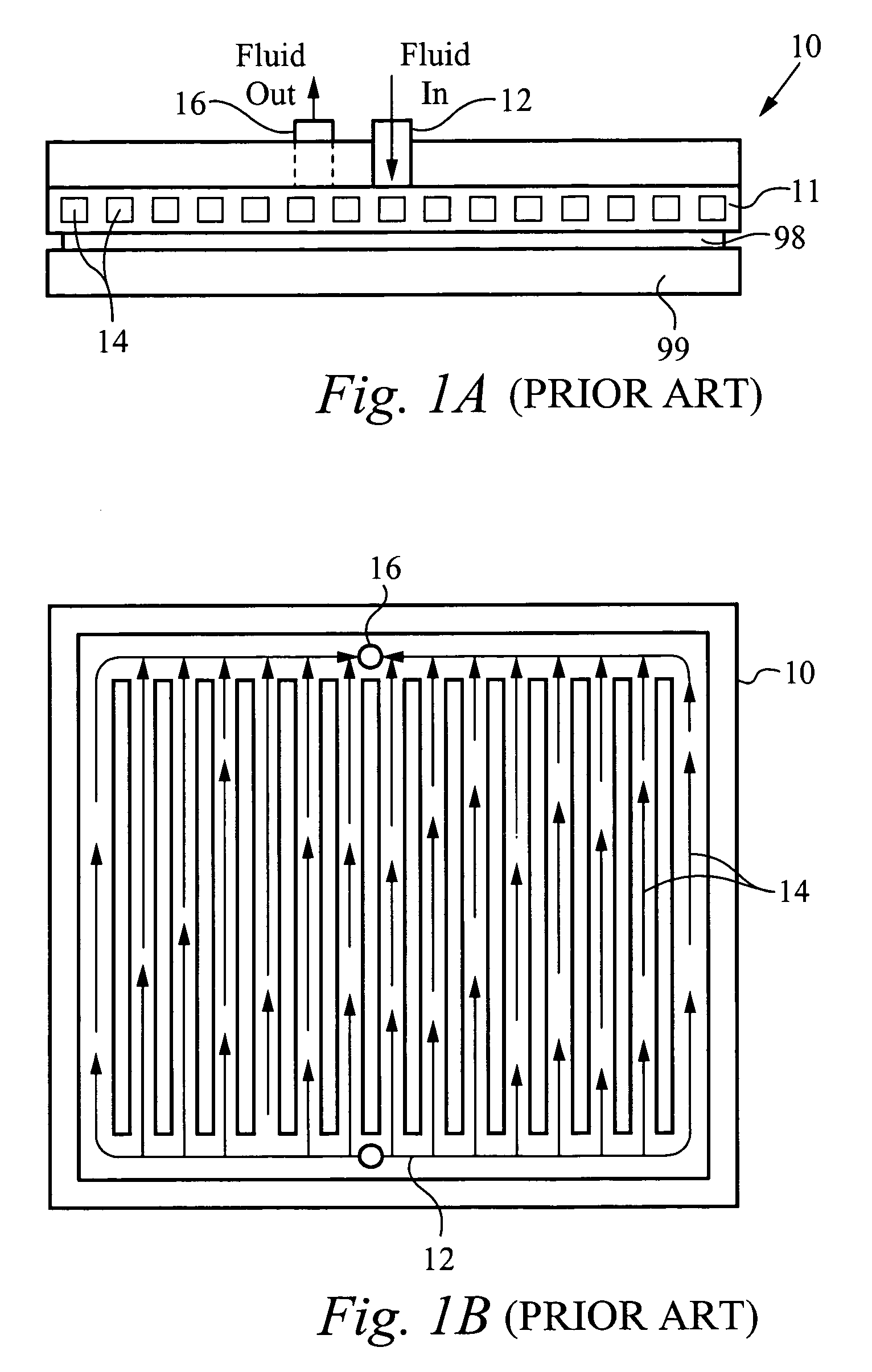

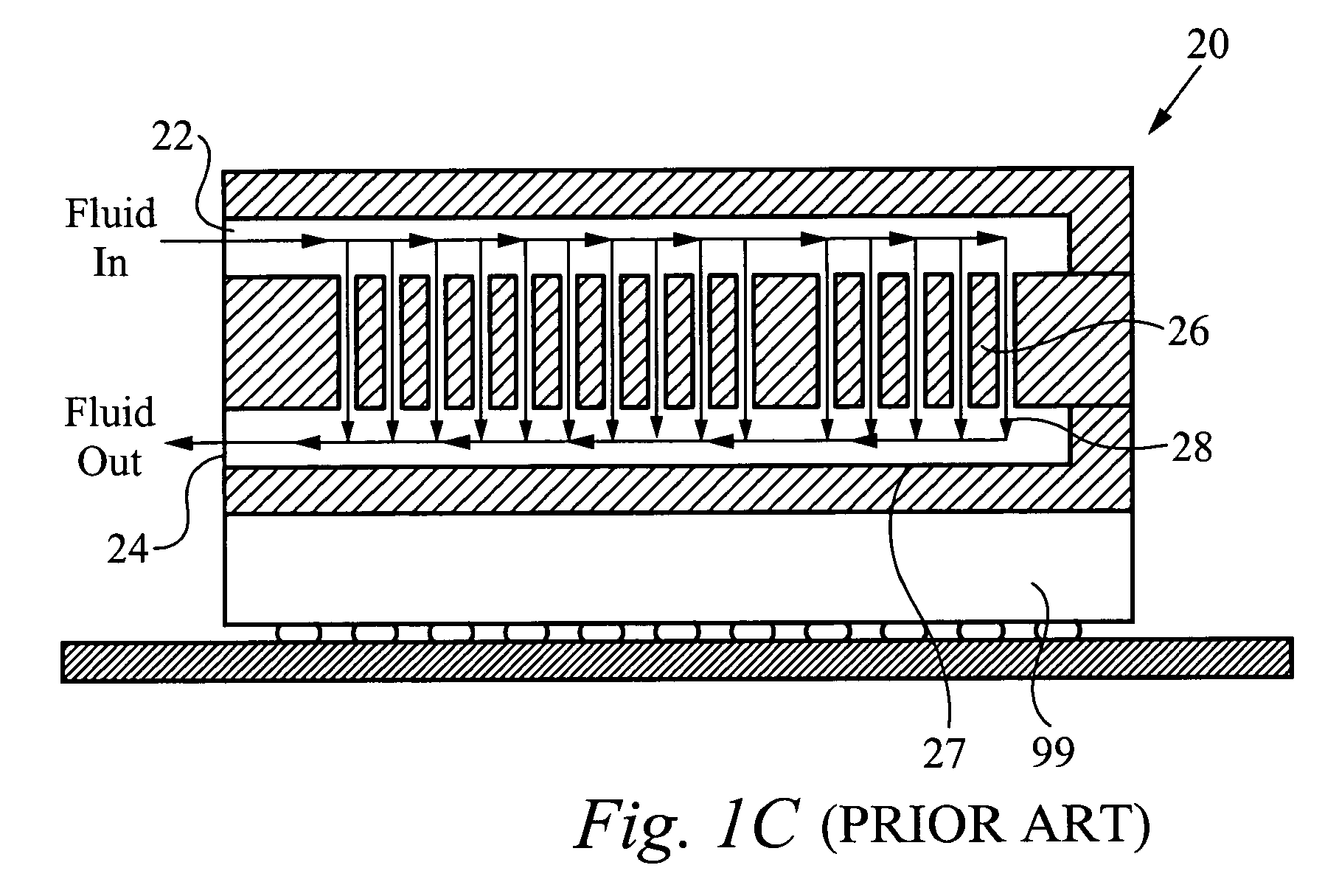

Apparatus and method of efficient fluid delivery for cooling a heat producing device

ActiveUS7188662B2Easy flow controlSemiconductor/solid-state device detailsSolid-state devicesInterface layerEngineering

Owner:VERTIV CORP

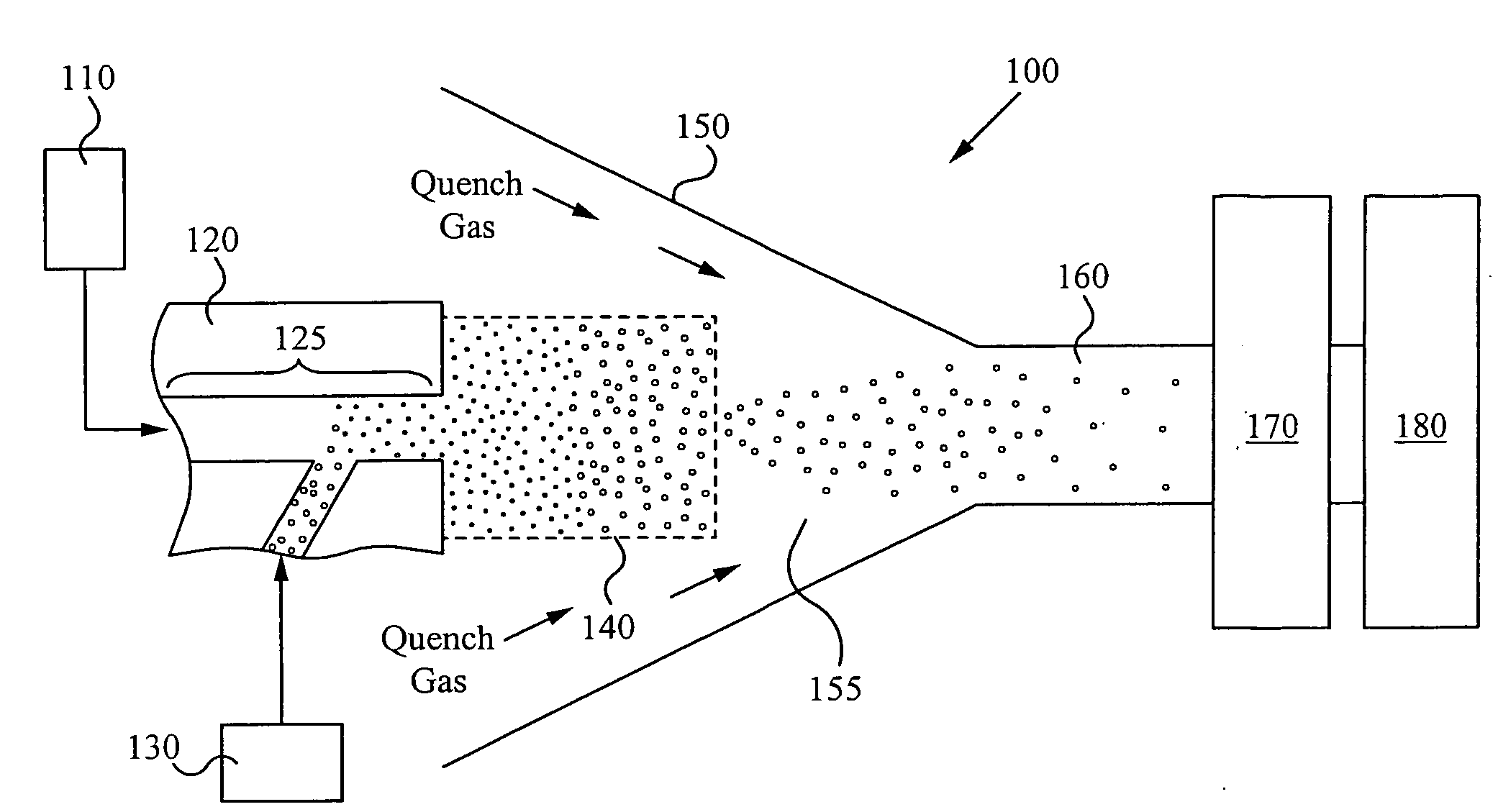

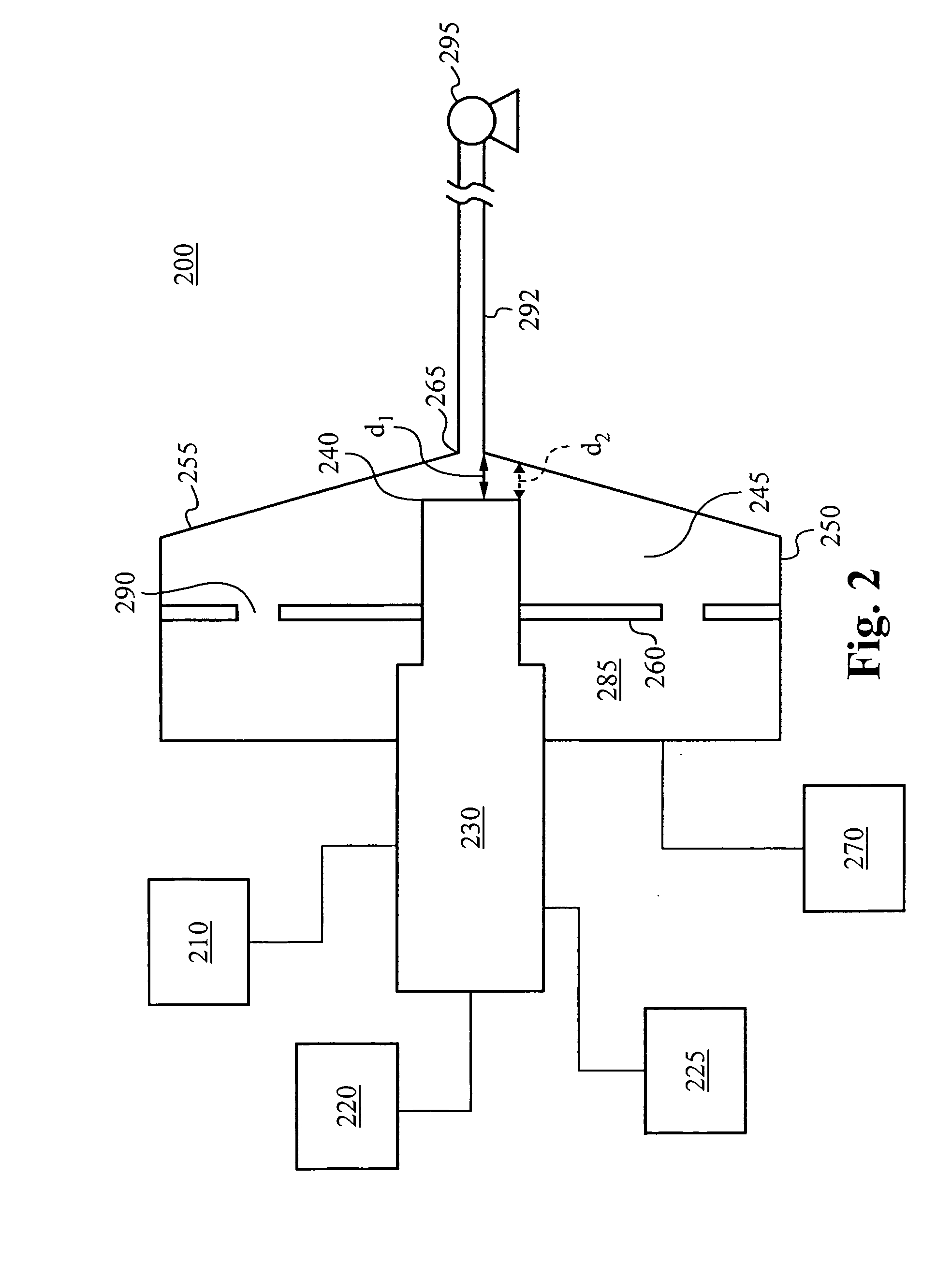

Method and apparatus for making uniform and ultrasmall nanoparticles

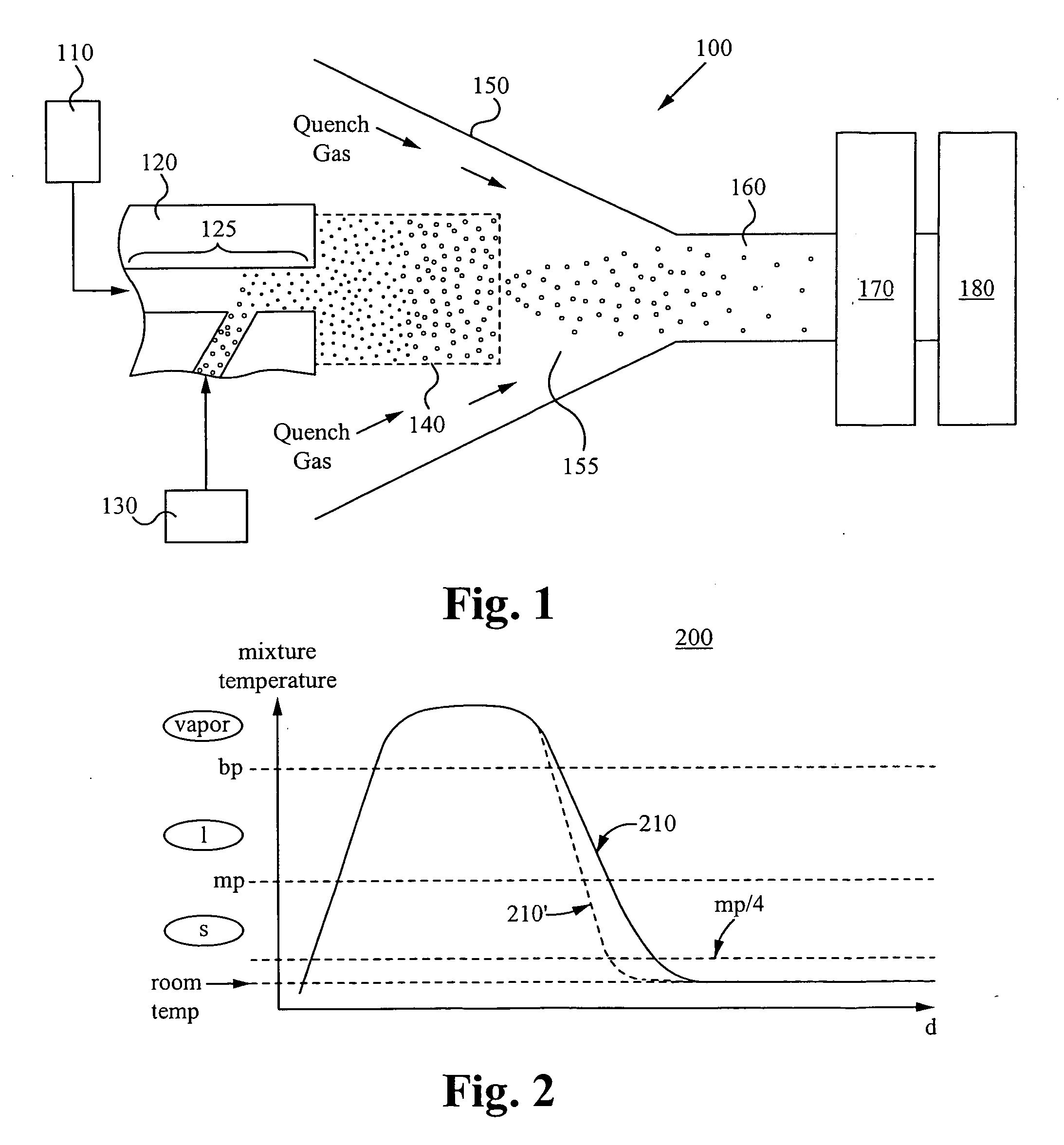

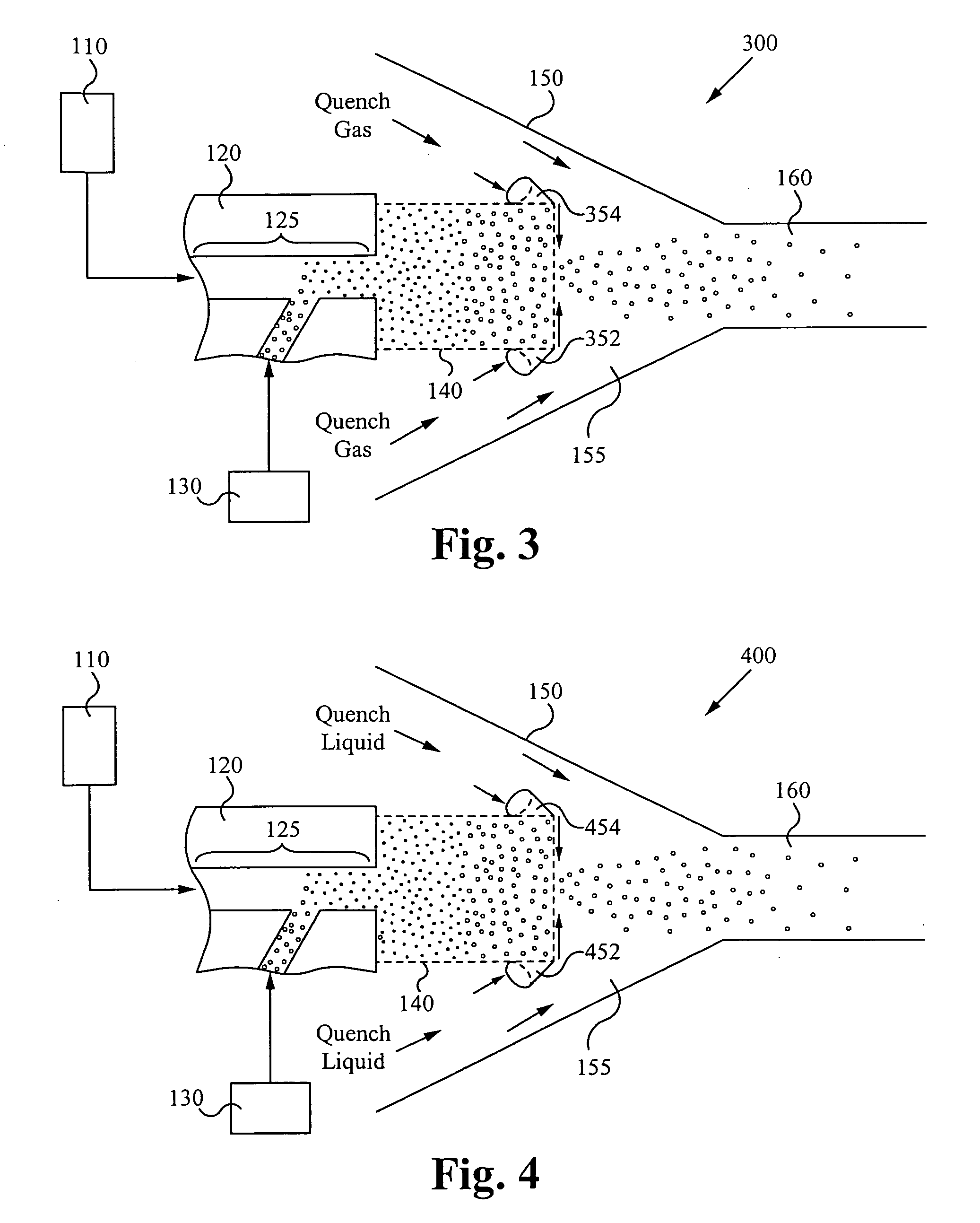

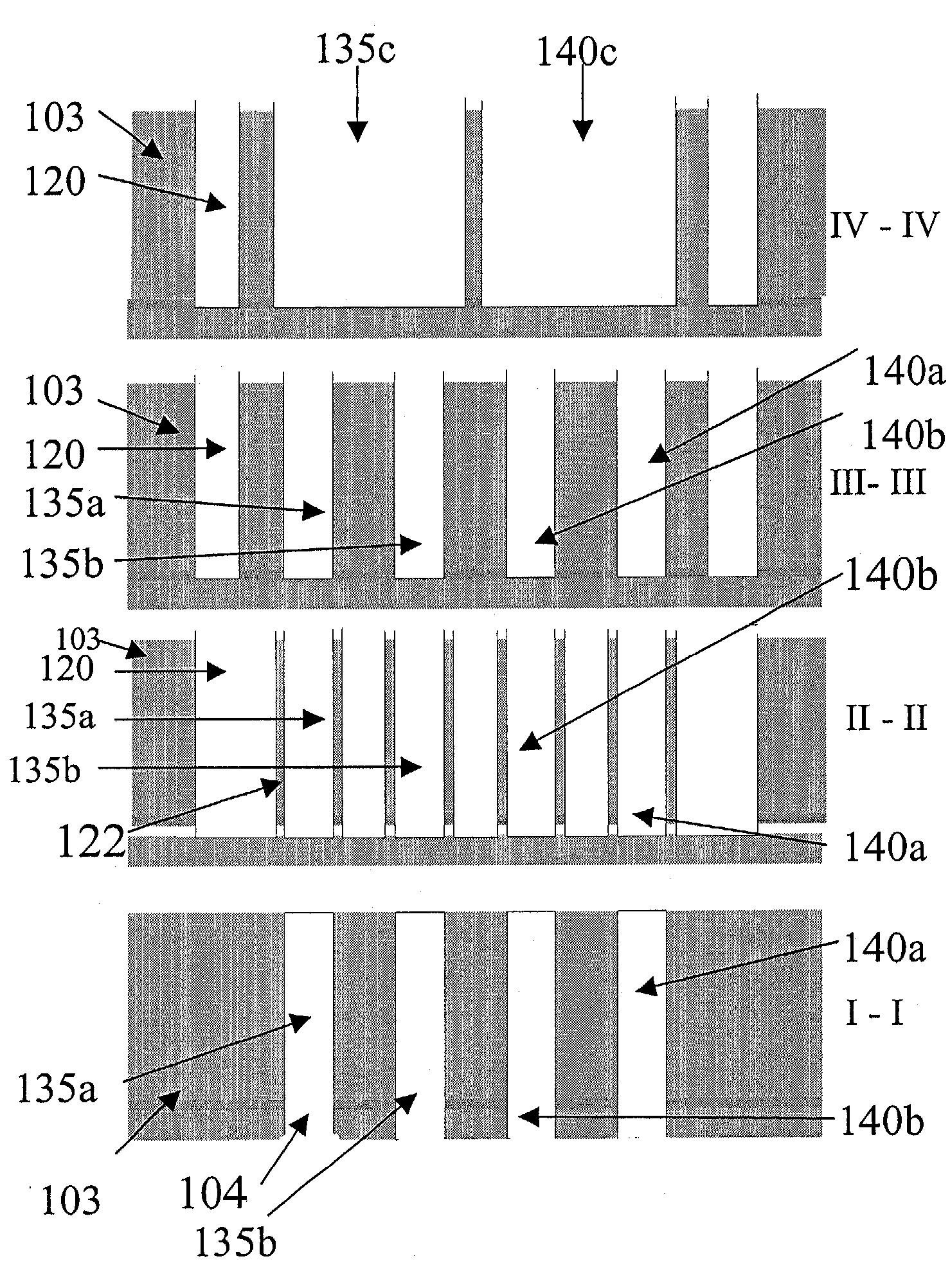

ActiveUS20080277270A1Catalyst activation/preparationDirect contact heat exchangersNanoparticleEngineering

A system comprising: a plasma production chamber configured to produce a plasma; a reaction chamber vaporize a precursor material with the plasma to form a reactive mixture; a quench chamber having a frusto-conical surface and a quench region formed within the quench chamber between an ejection port of the reaction chamber and a cooled mixture outlet, wherein the quench region configured to receive the reactive mixture from the ejection port, to cool the reactive mixture to form a cooled mixture, and to supply the cooled mixture to the cooled mixture outlet; and a conditioning fluid injection ring disposed at the ejection port and configured to flow a conditioning fluid directly into the reactive mixture as the reactive mixture flows through the ejection port, thereby disturbing the flow of the reactive mixture, creating turbulence within the quench region and cooling the reactive mixture to form a cooled mixture comprising condensed nanoparticles.

Owner:SDC MATERIALS +1

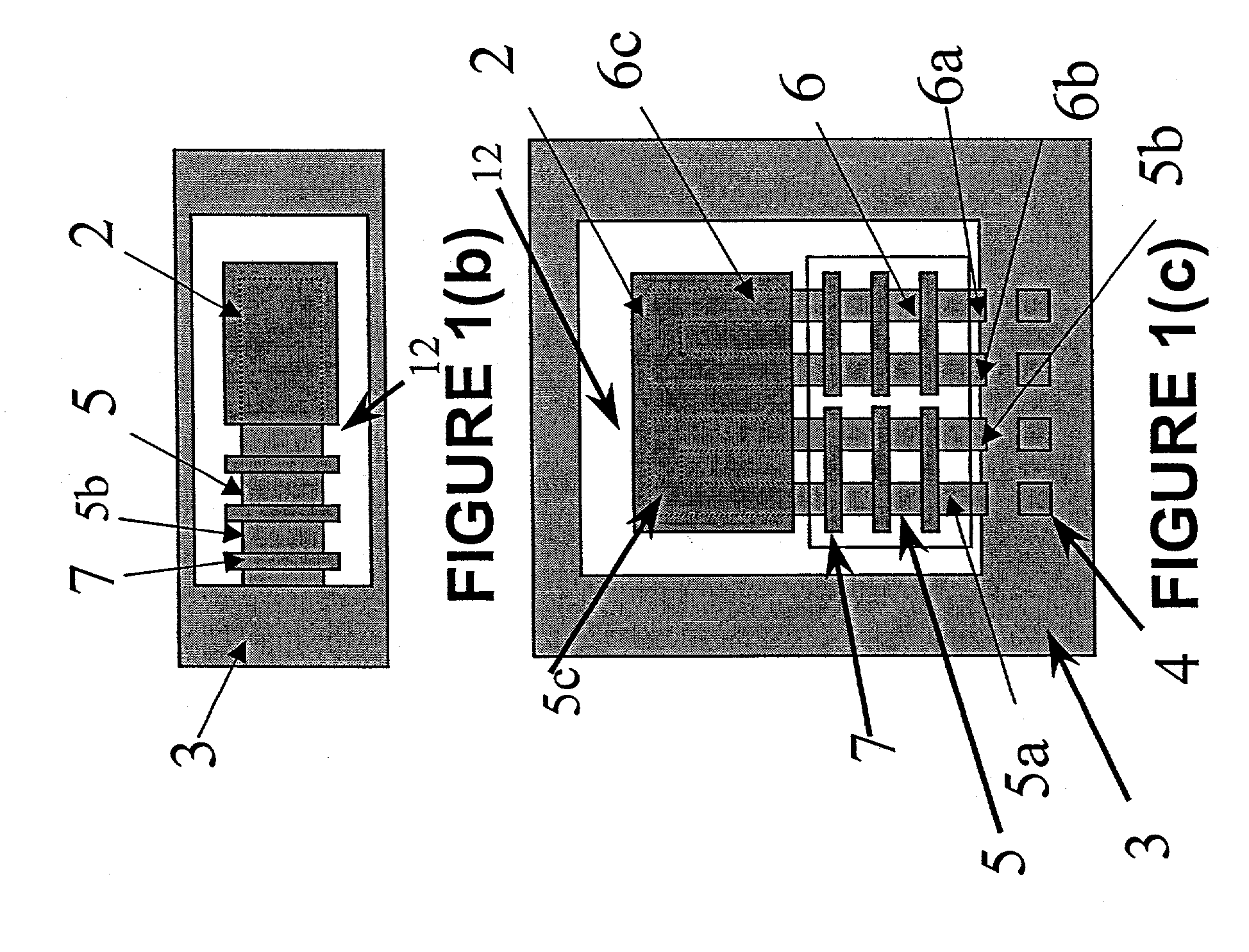

Thermally effcient micromachined device

InactiveUS20030027022A1Reduce system sizeImprove performanceFlow mixersFixed microstructural devicesFuel cellsCompound (substance)

A micromachined device for efficient thermal processing at least one fluid stream includes at least one fluid conducting tube having at least a region with wall thickness of less than 50 mum. The device optionally includes one or more thermally conductive structures in thermal communication with first and second thermally insulating portions of the fluid conducting tube. The device also may include a thermally conductive region, and at least a portion of the fluid conducting tube is disposed within the region. A plurality of structures may be provided projecting from a wall of the fluid conducting tube into an inner volume of the tube. The structures enhance thermal conduction between a fluid within the tube and a wall of the tube. A method for fabricating, from a substrate, a micromachined device for processing a fluid stream allows the selective removal of portions of the substrate to provide desired structures integrated within the device. As an example, the micromachined device may be adapted to efficiently react fluid reactants to produce fuel for a fuel cell associated with the device, resulting in a system capable of conversion of chemical to electrical energy.

Owner:MASSACHUSETTS INST OF TECH

Heat exchanger with flat tubes

ActiveUS20050161206A1Reinforcing meansInternal combustion piston enginesElectrical and Electronics engineeringHeat exchanger

A heat exchanger with a plurality of stacked flat tubes and a collecting tank having a wall extending around the entire periphery of, and connected to, the end of the stacked flat tubes. A first medium may be distributed through the collecting tank and flat tubes. Internal inserts are in the flat tubes, with the inserts being bonded between the broad sides of the tubes and, in the region of connection of the tubes to the collecting tank, being configured to compensate for length changes in the stacking direction caused by temperature changes, as by recesses in connectors such as wave flanks or by corrugated wave flanks. The flat tubes with inserts such as described may be separately provided for use in manufacture of heat exchangers.

Owner:MODINE MFG CO

Highly turbulent quench chamber

ActiveUS20080277267A1Temperature controlDirect contact heat exchangersStationary tubular conduit assembliesEngineeringQuenching

An apparatus for cooling a reactive mixture, comprising: a reactor configured to form the reactive mixture; a quench chamber comprising a frusto-conical body having a wide end, a narrow end, and a quench region formed between the wide and narrow end, wherein the quench chamber is configured to receive the reactive mixture from the plasma reactor through a reactive mixture inlet into the quench region, to receive a conditioning fluid through at least one fluid inlet, and to flow the conditioning fluid into the quench region, wherein the frusto-conical body is configured to produce a turbulent flow within the quench region with the flow of the conditioning fluid into the quench region, thereby promoting the quenching of the reactive mixture to form a cooled gas-particle mixture; and a suction generator configured to force the cooled gas-particle mixture out of the quench chamber.

Owner:UMICORE AG & CO KG +1

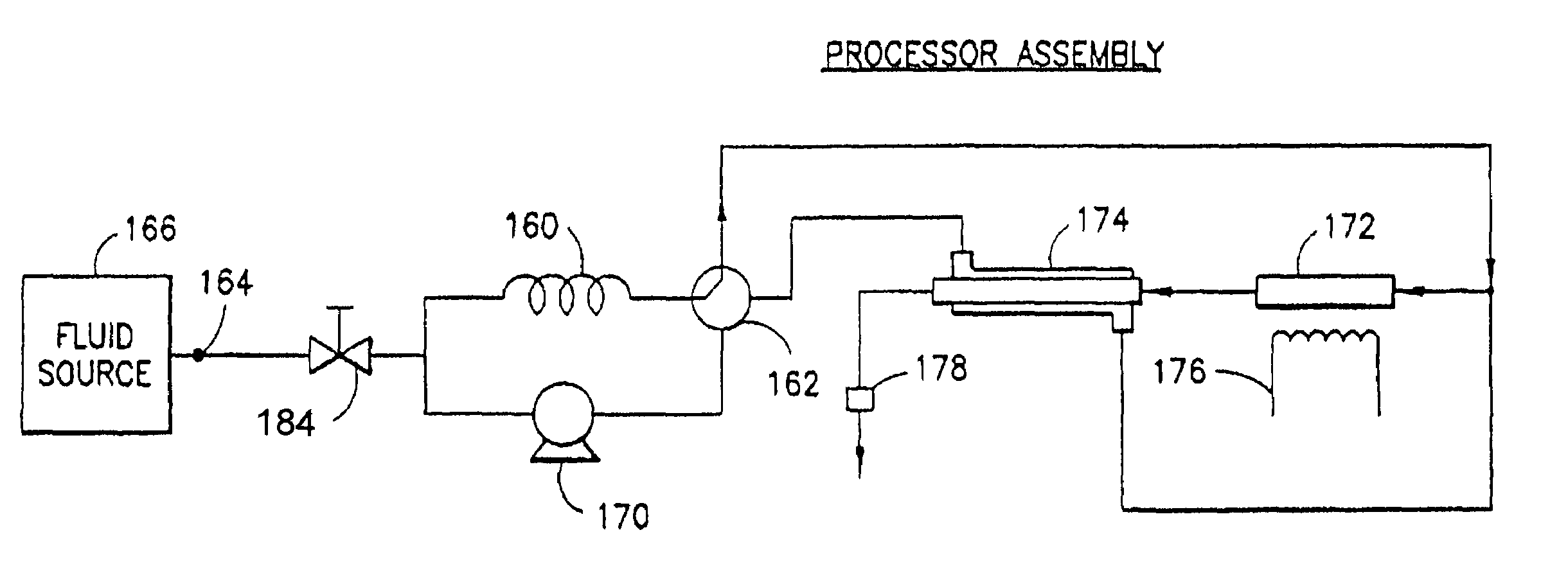

Apparatus and method for continuous depyrogenation and production of sterile water for injection

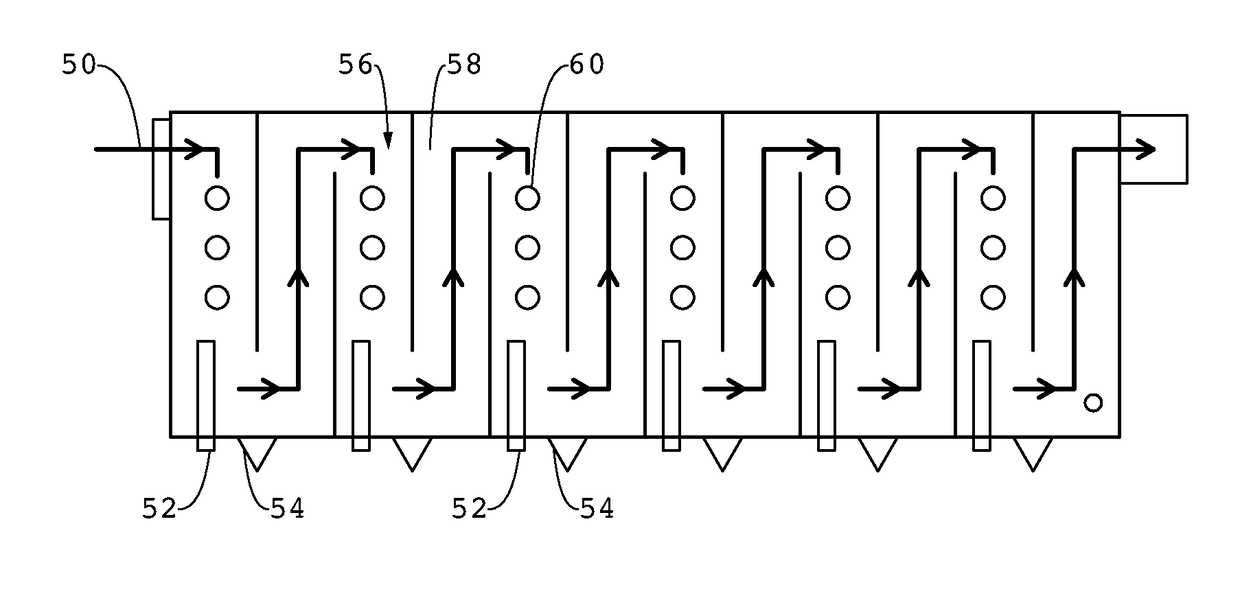

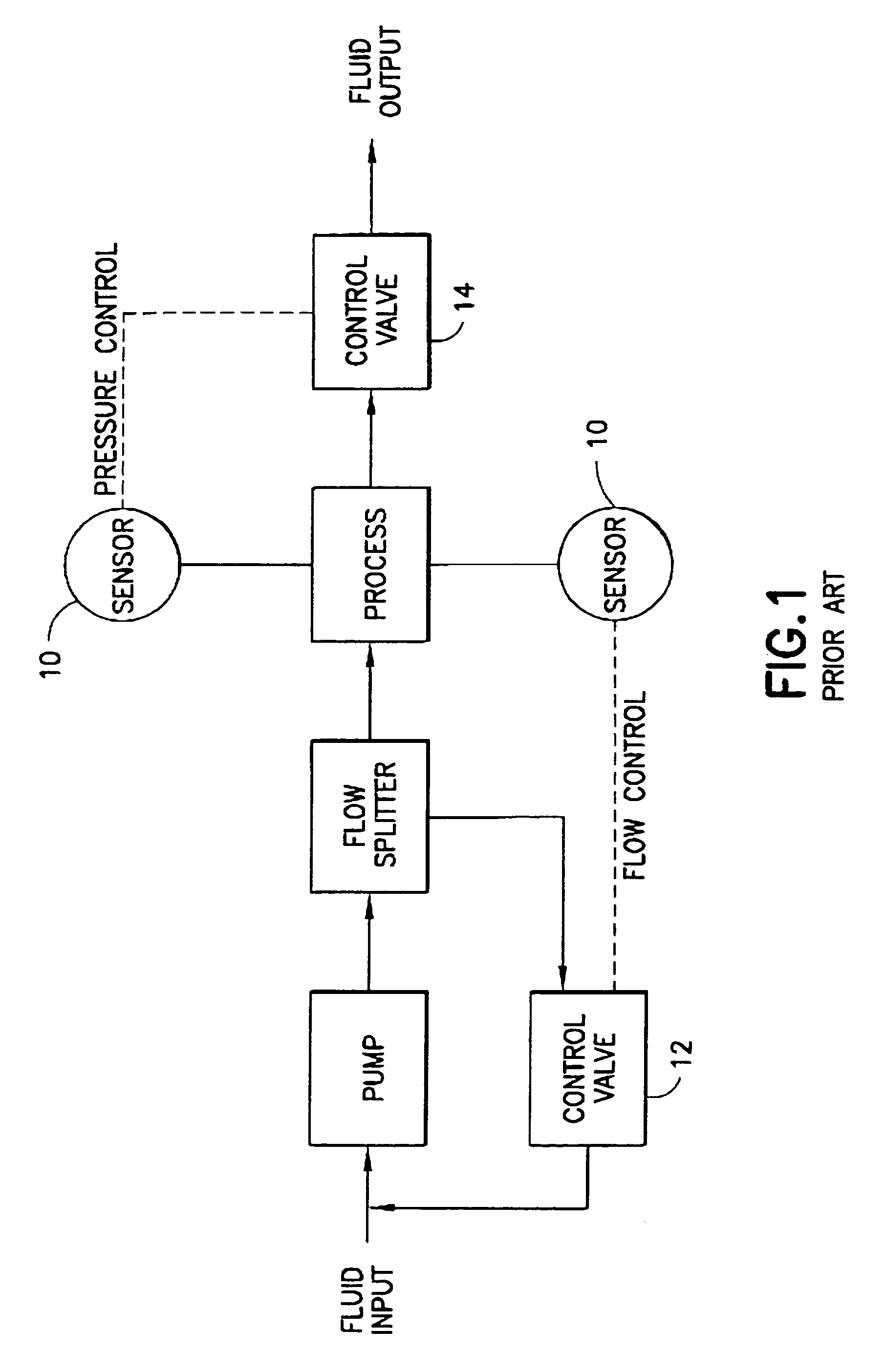

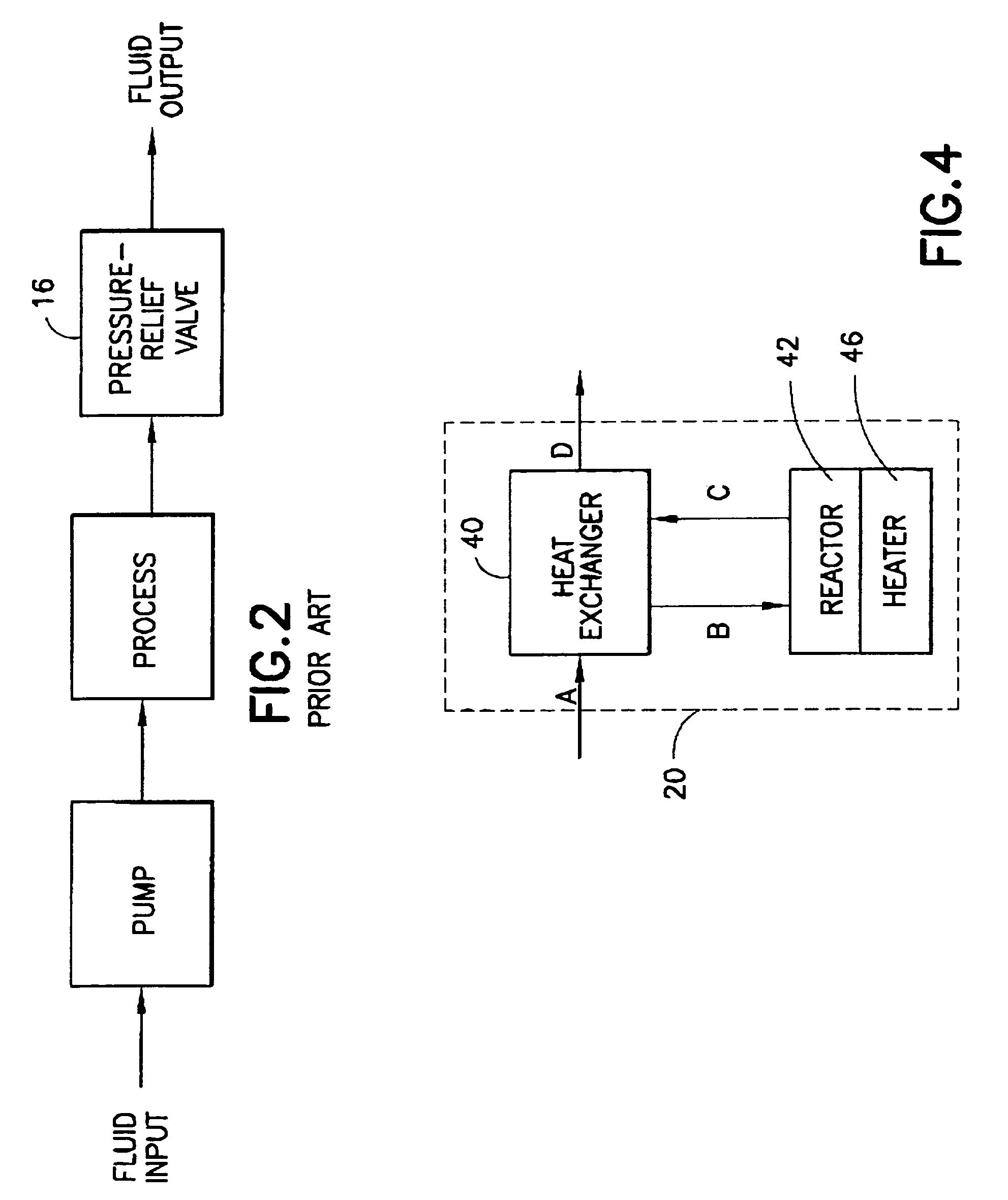

InactiveUS7122149B2Simple yet dependableReduce contact timeDialysis systemsTreatment involving filtrationDepyrogenationIon exchange

A fluid processor, suitable for the production of sterile water for injection, having a processor assembly and a process control system comprising a pump, a flow splitter, flow restrictors and a pressure relief valve. In a preferred embodiment, the processor assembly comprises a heat exchanger, a reactor and a heater arranged in a nested configuration. The preferred embodiment of the present invention also include a treatment assembly having a combination of filter, reverse osmosis and ion exchange devices and further incorporates an assembly and method allowing for the in situ sanitization of the fluid processor during cold start and shutdown to prevent bacteria growth during storage of the fluid processor. The fluid processor may include an electronic control system comprising a touch screen operator interface, a programmable logic controller and sensors for measuring temperature, pressure, flow rate, conductivity and endotoxin level.

Owner:APPLIED RES ASSOCS INC

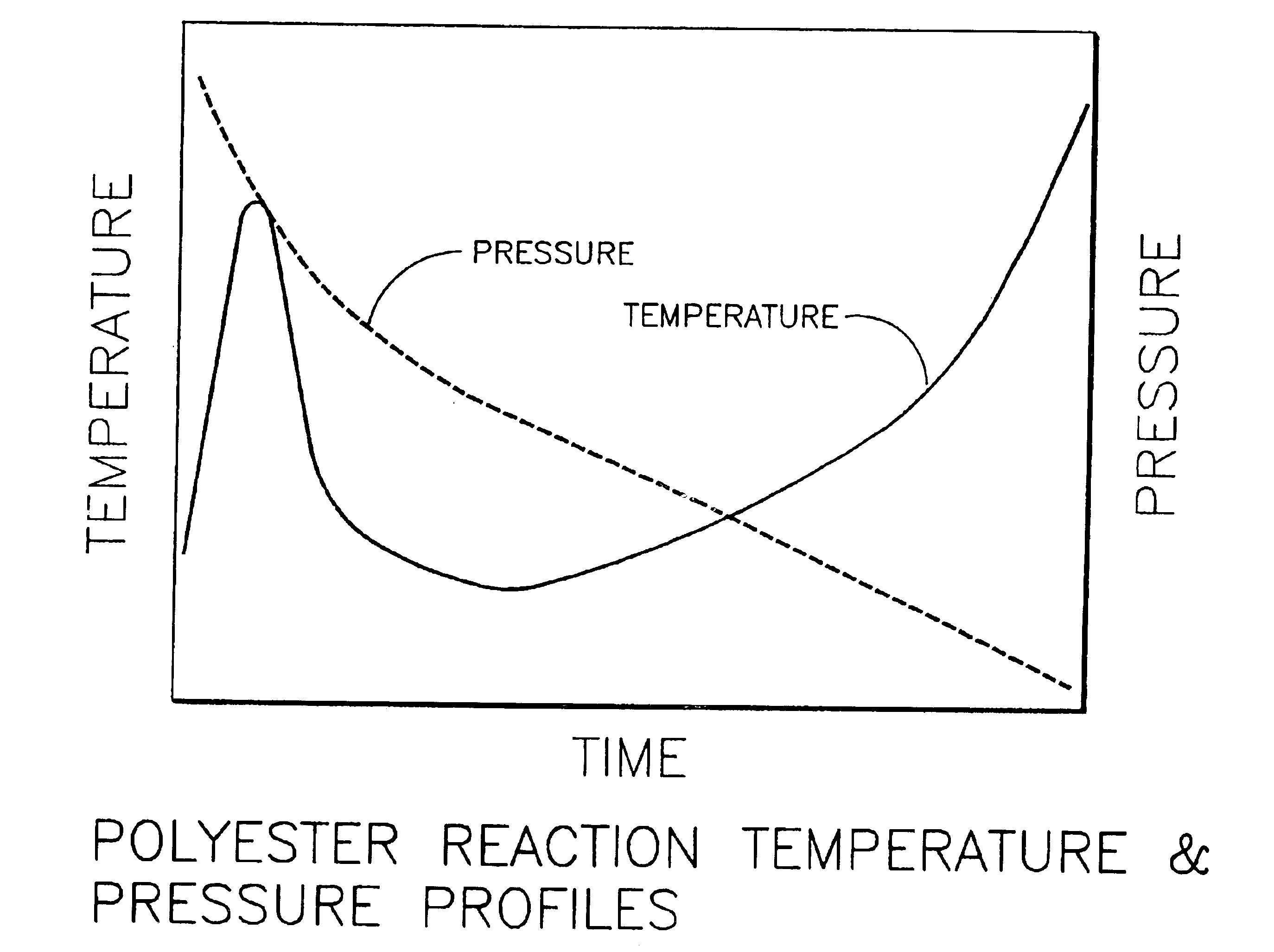

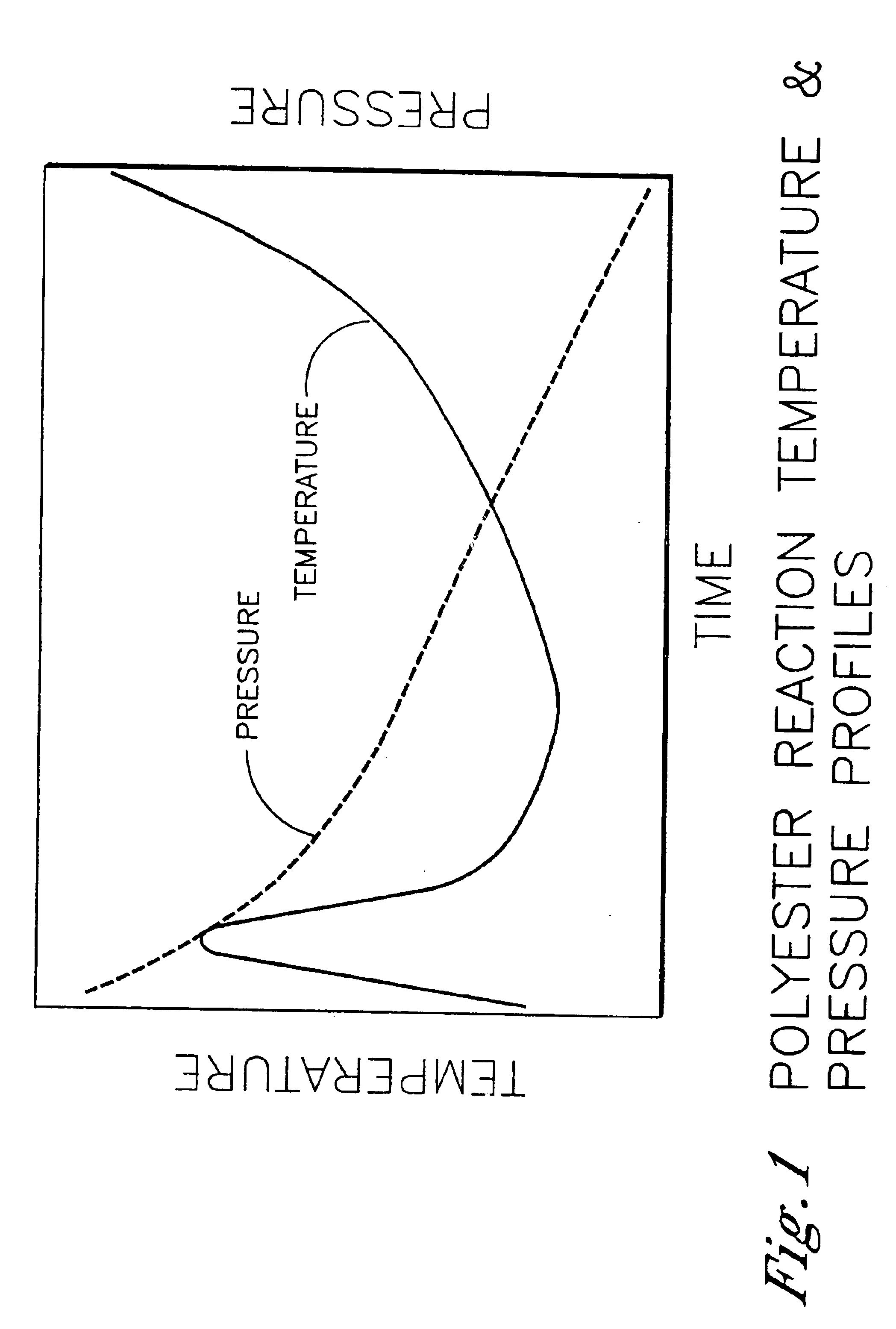

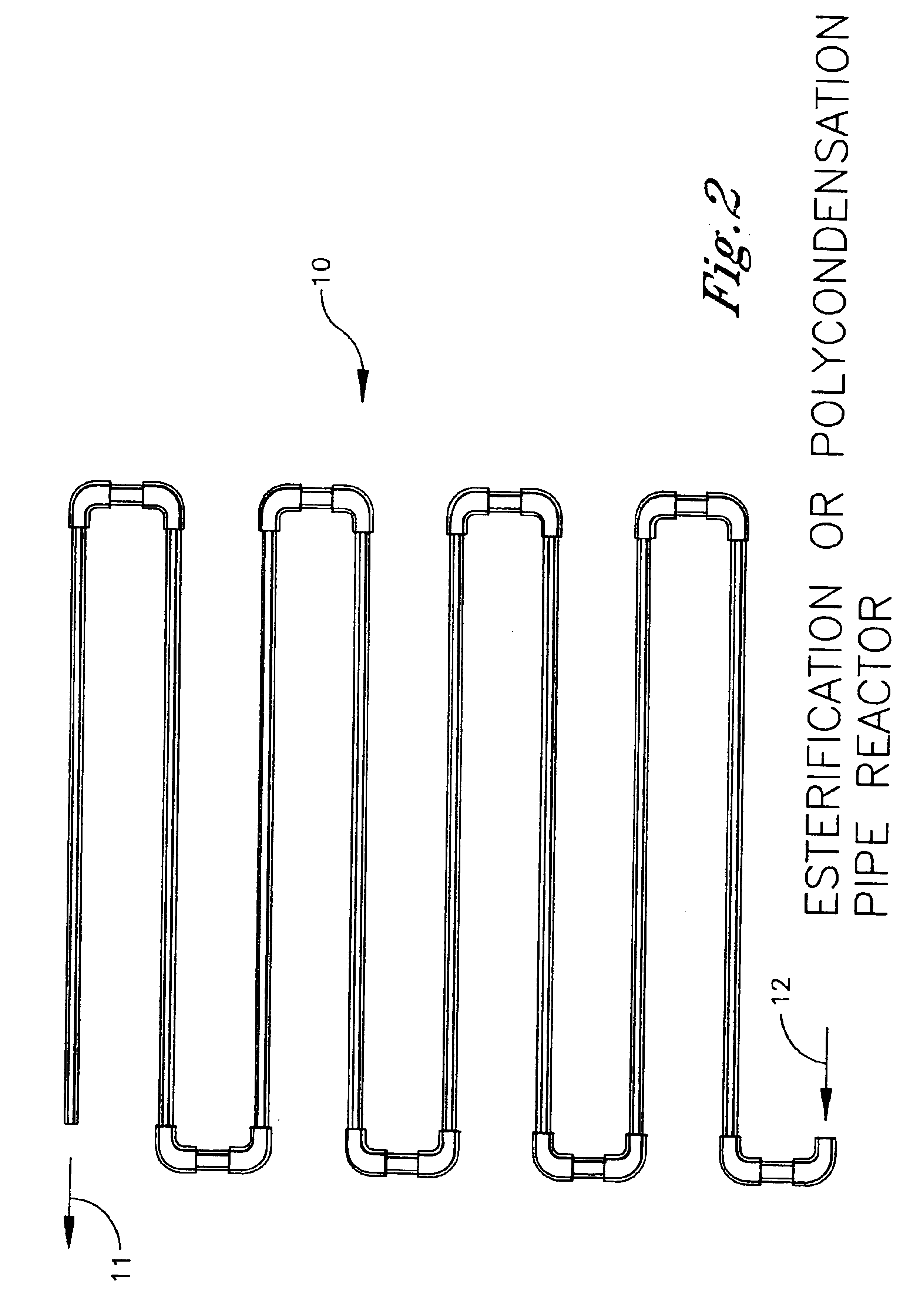

Polyester process using a pipe reactor

InactiveUS6906164B2Reduce pressureEliminate needLiquid degasificationFlow mixersPolyesterPolymer science

Owner:ALPEK POLYESTER SA DE CV

Device for cooling a vehicle battery

InactiveUS20110132580A1Effective and reliable coolingImprove pressure resistanceFuel cell heat exchangeThermal insulationElectricityElectrical battery

A device for cooling a vehicle battery is provided that includes a plurality of electrical storage elements, and a cooling element having ducts for a fluid to flow through, wherein the electrical storage elements are in thermal contact with the cooling elements and heat can be transmitted from the storage elements to the fluid, and wherein the cooling element which comprises the ducts is embodied as at least one extruded profile.

Owner:BEHR GMBH & CO KG

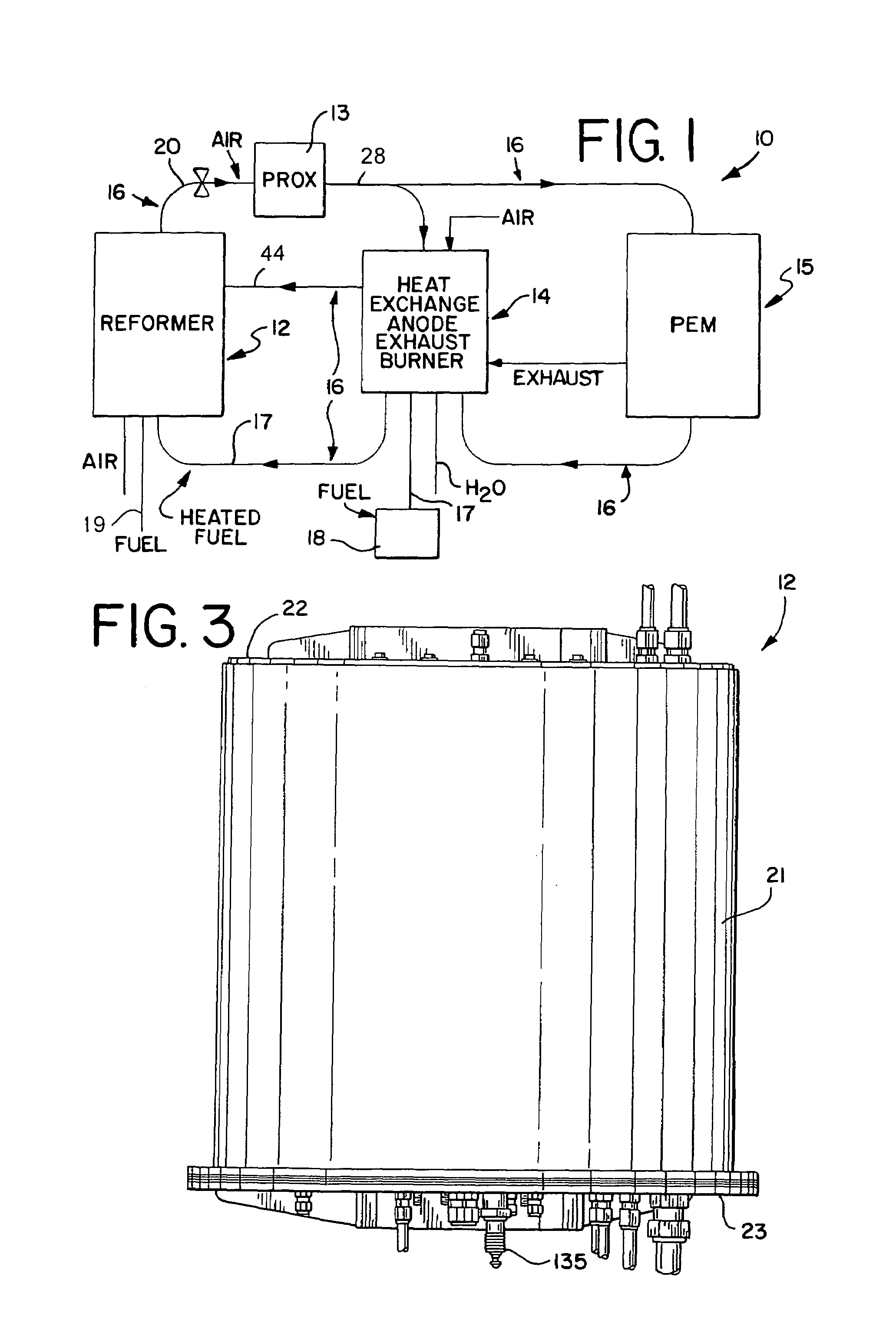

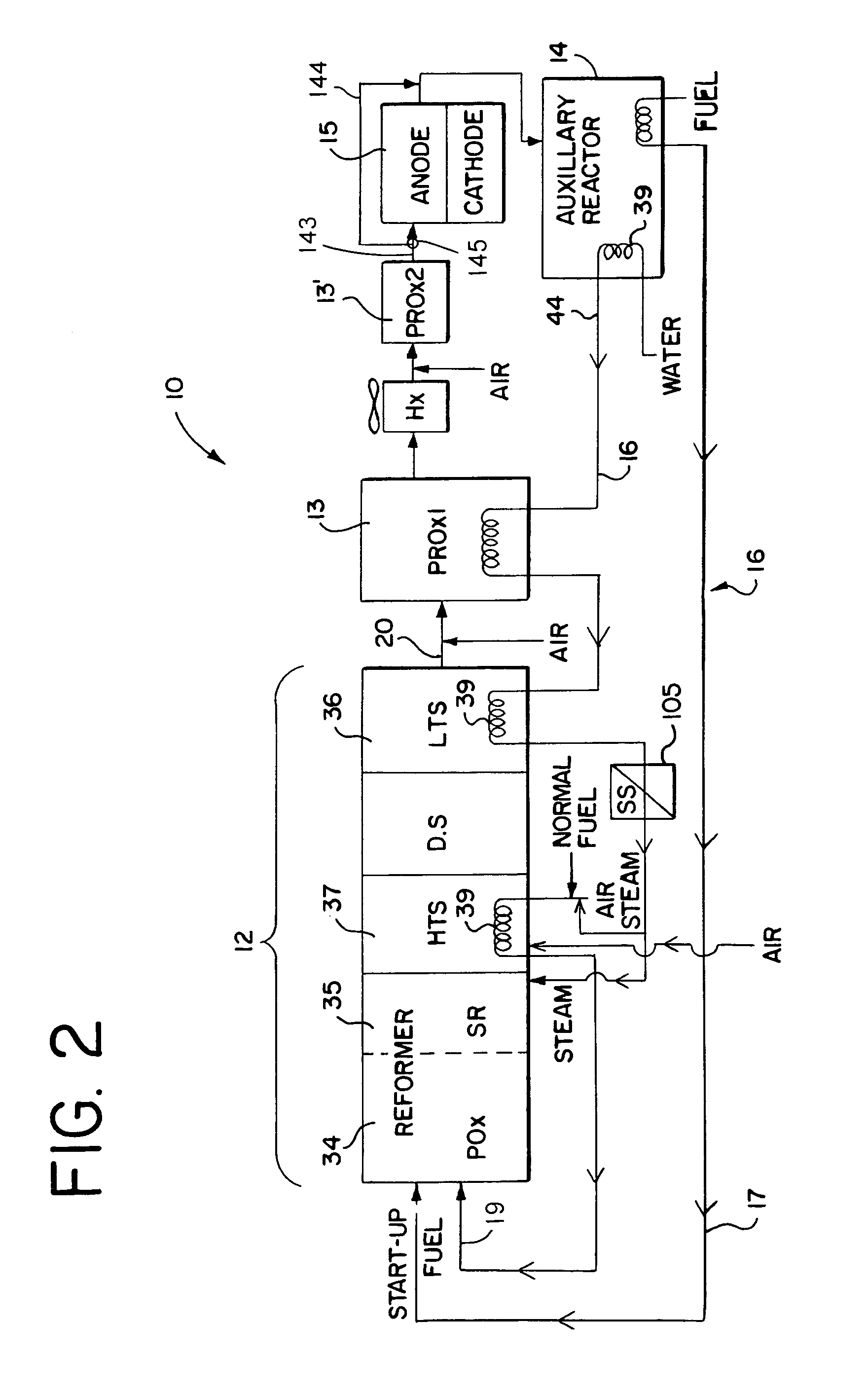

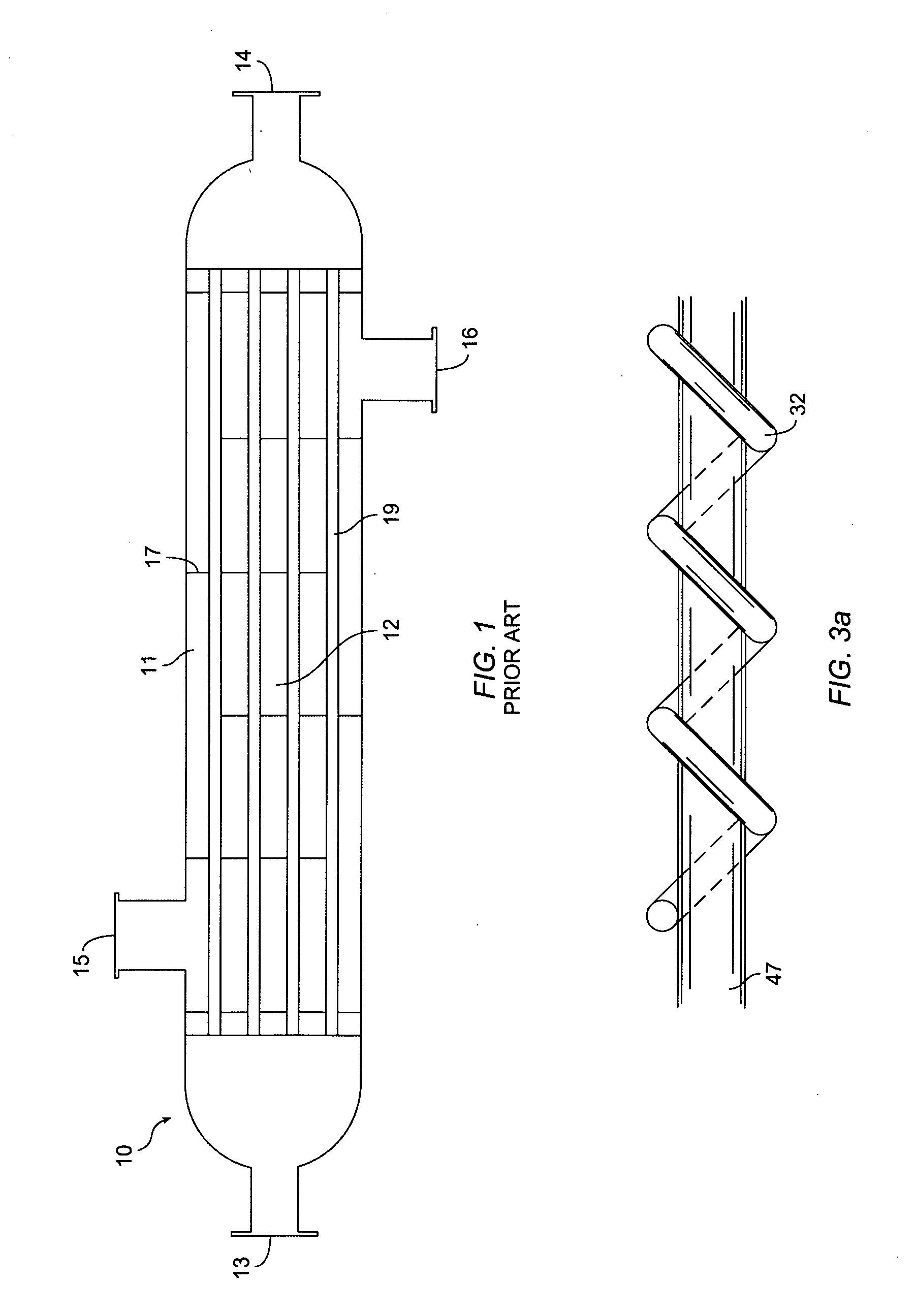

Integrated reformer and shift reactor

A hydrocarbon fuel reformer for producing diatomic hydrogen gas is disclosed. The reformer includes a first reaction vessel, a shift reactor vessel annularly disposed about the first reaction vessel, including a first shift reactor zone, and a first helical tube disposed within the first shift reactor zone having an inlet end communicating with a water supply source. The water supply source is preferably adapted to supply liquid-phase water to the first helical tube at flow conditions sufficient to ensure discharge of liquid-phase and steam-phase water from an outlet end of the first helical tube. The reformer may further include a first catalyst bed disposed in the first shift reactor zone, having a low-temperature shift catalyst in contact with the first helical tube. The catalyst bed includes a plurality of coil sections disposed in coaxial relation to other coil sections and to the central longitudinal axis of the reformer, each coil section extending between the first and second ends, and each coil section being in direct fluid communication with at least one other coil section.

Owner:NUVERA FUEL CELLS

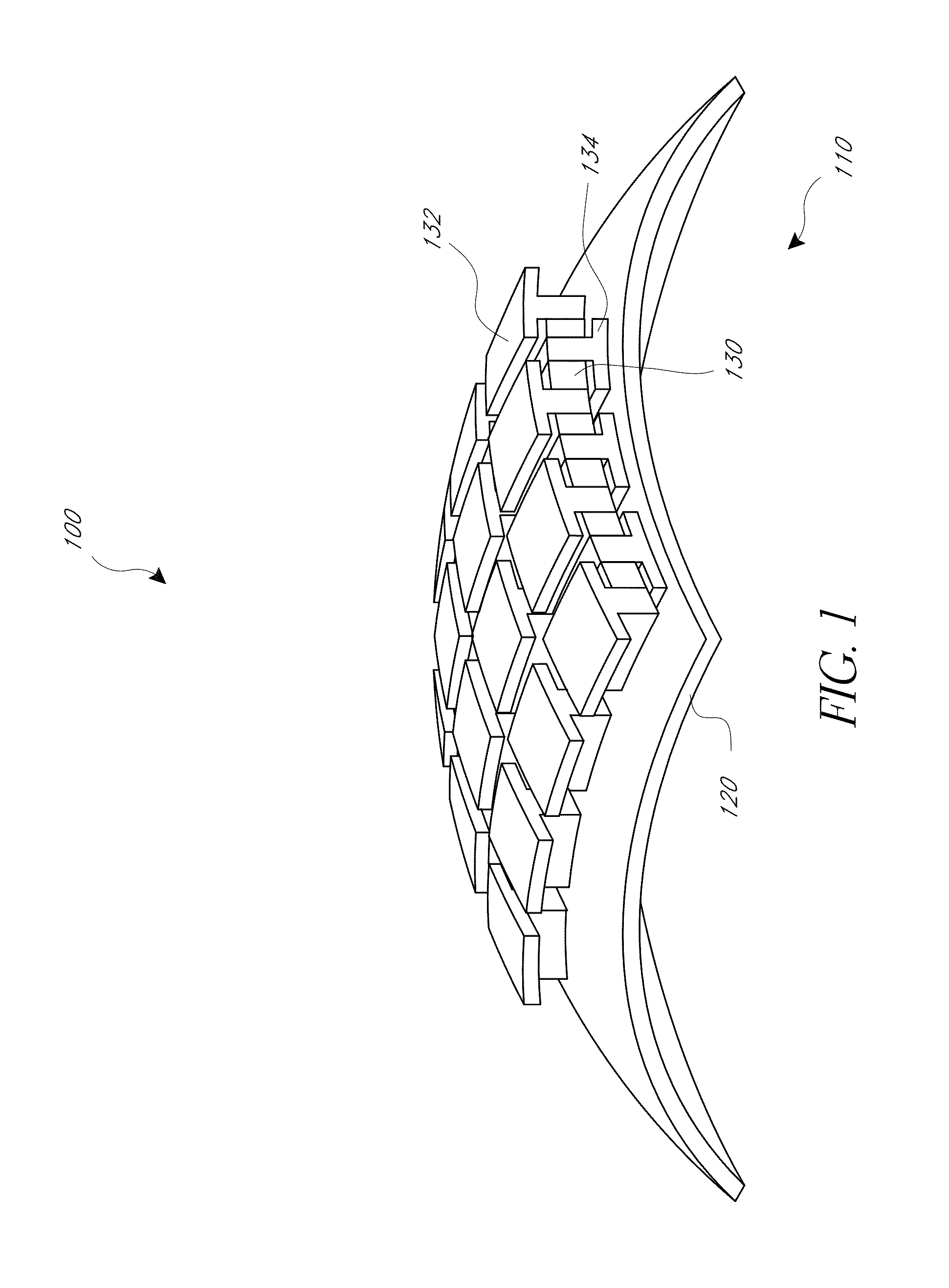

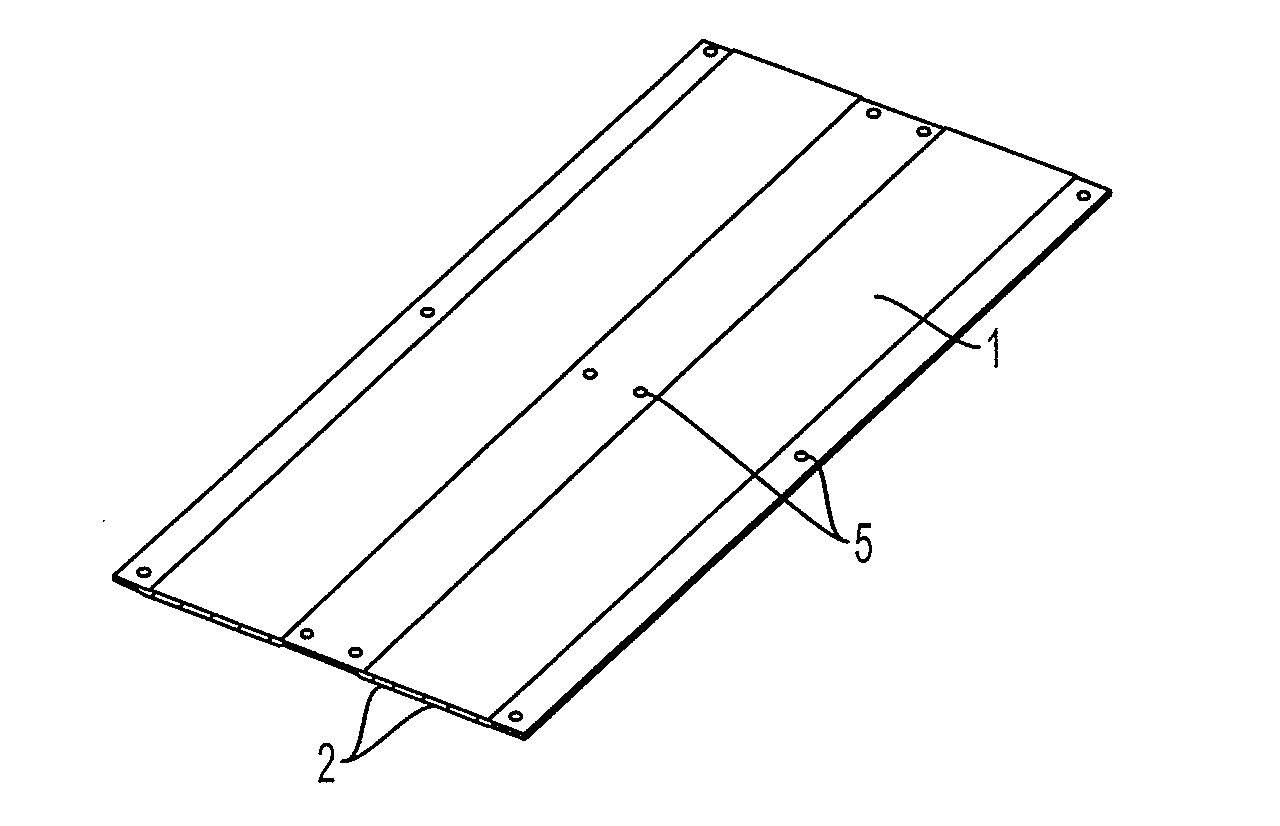

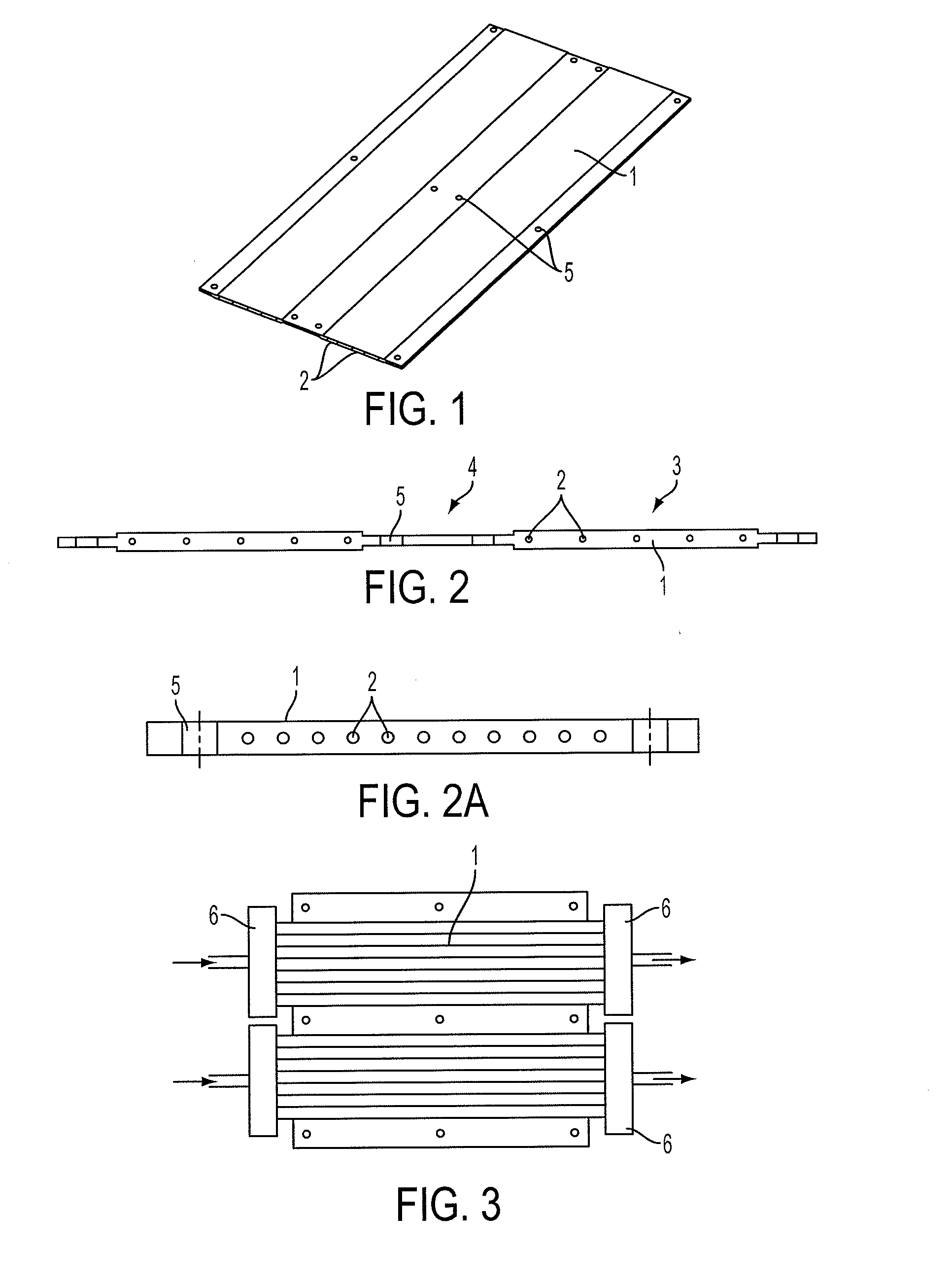

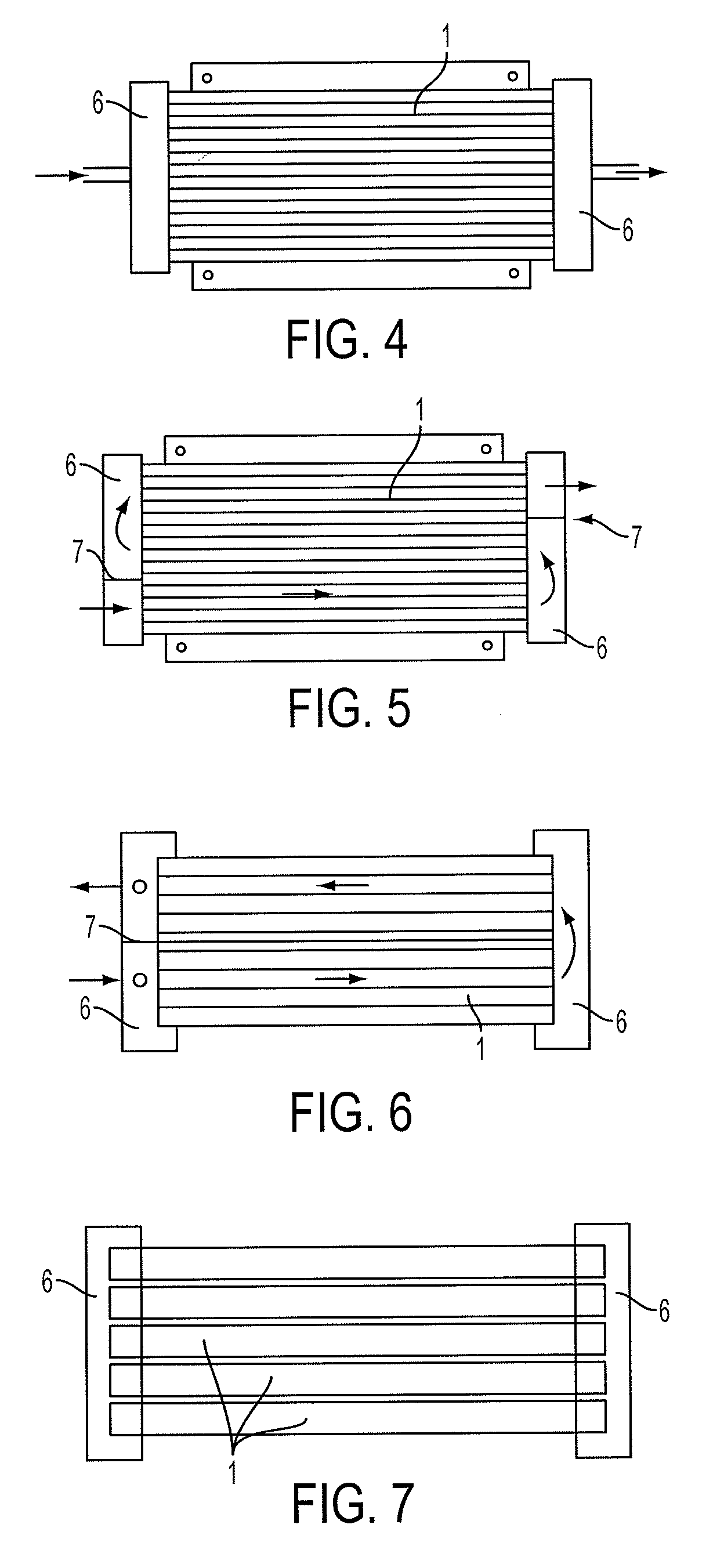

Hybrid heat exchangers

InactiveUS20070284095A1Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesCore component

A light weight hybrid heat exchanger core possessing low density and improved thermal conductivity is disclosed. The hybrid core is comprised of a plurality of parting sheets and interposed by a plurality of high thermal conductivity, light weight bridging elements and enclosure bars. These core members are comprised of dissimilar materials. The parting sheets and bridging elements are interconnected by a specially tailored joint which forms form a substantially strong, high thermal conductivity bond. In particular embodiments, carbon-based bridging elements are bonded to metallic parting sheets using a brazed joint. The parting sheets, in certain embodiments, may comprise titanium or Ni-based superalloys or carbon composites, while the carbon-based bridging elements may comprise fiber-reinforced composites. The carbon-based bridging elements reduce the core weight and increase the core thermal conductivity over conventional all-metal designs, while the brazed joint provides for improved leak resistance over all-composite designs.

Owner:ALLCOMP

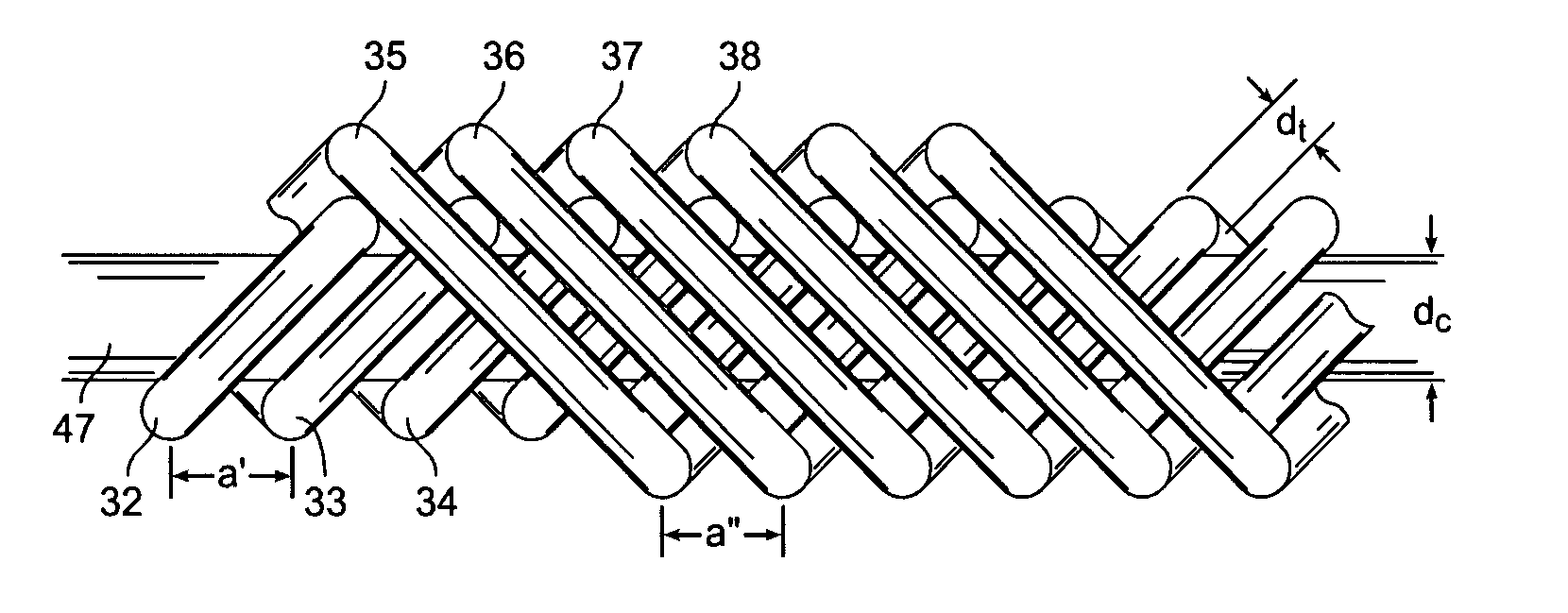

Static mixer-heat exchanger

InactiveUS20050077034A1Heat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerEngineering

A device for effecting heat transfer from a first fluid medium to a second fluid medium and for enhancing mixing and uniform distribution of the second fluid medium within the confines of a conduit. The device includes providing a core pipe for receiving the first fluid medium and a series of helically wound tubes in fluid communication with the core pipe along the longitudinal axis of the conduit. The second fluid passes within the conduit and is mixed by virtue of the static mixing effect of the helically wound tubes and engages in heat transfer as a result of the intimate contact between the second fluid, the core pipe and the helically wound tubes.

Owner:KOMAX SYST

Popular searches

Plural diverse prime-mover propulsion mounting Vehicular energy storage Propulsion cooling Liquid cooling Coolant flow control Electric propulsion mounting Gas pressure propulsion mounting Propulsion using engine-driven generators Battery/fuel cell control arrangement Granular/pulverulent flues gasification

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com