Patents

Literature

867 results about "Loop heat pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

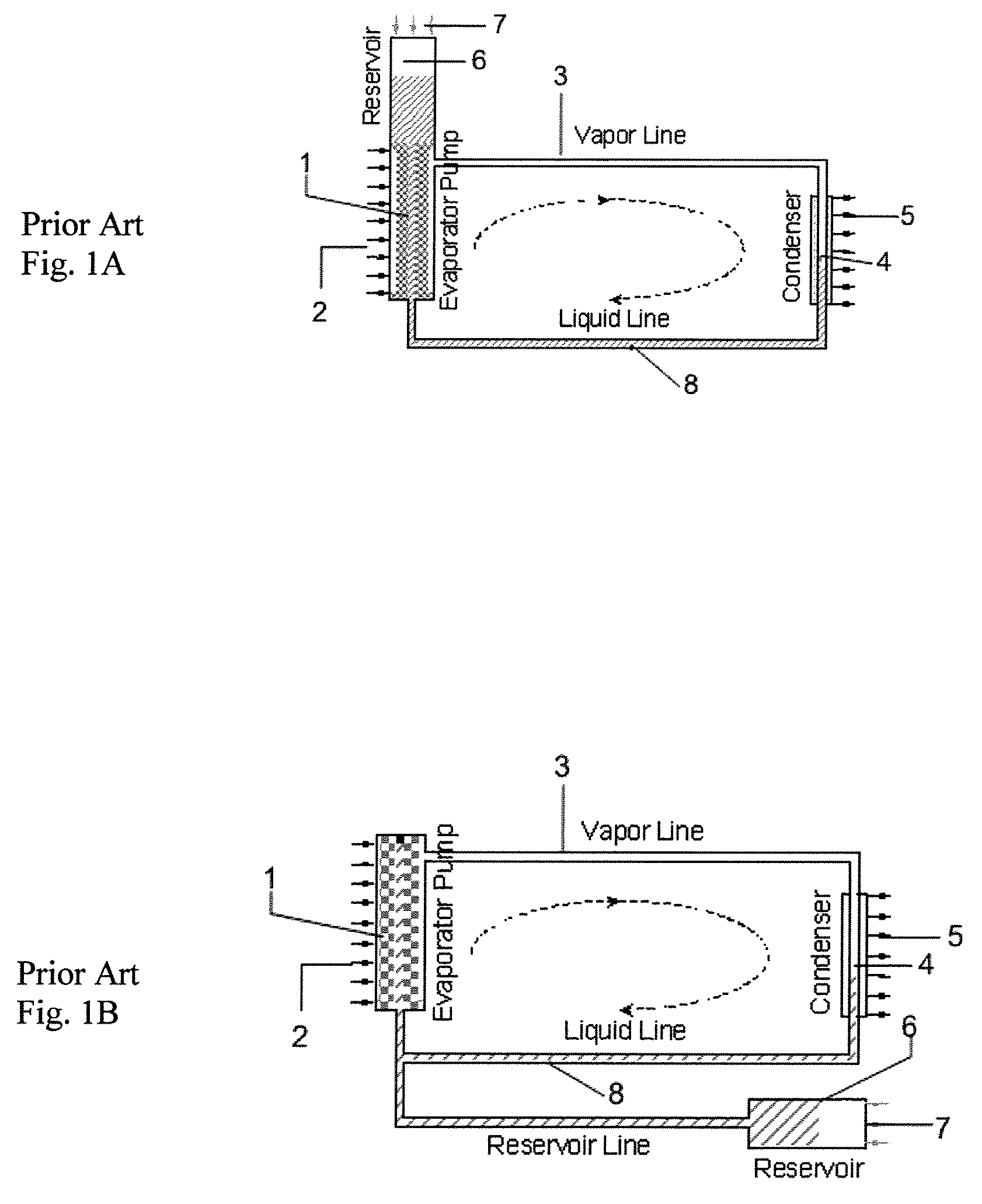

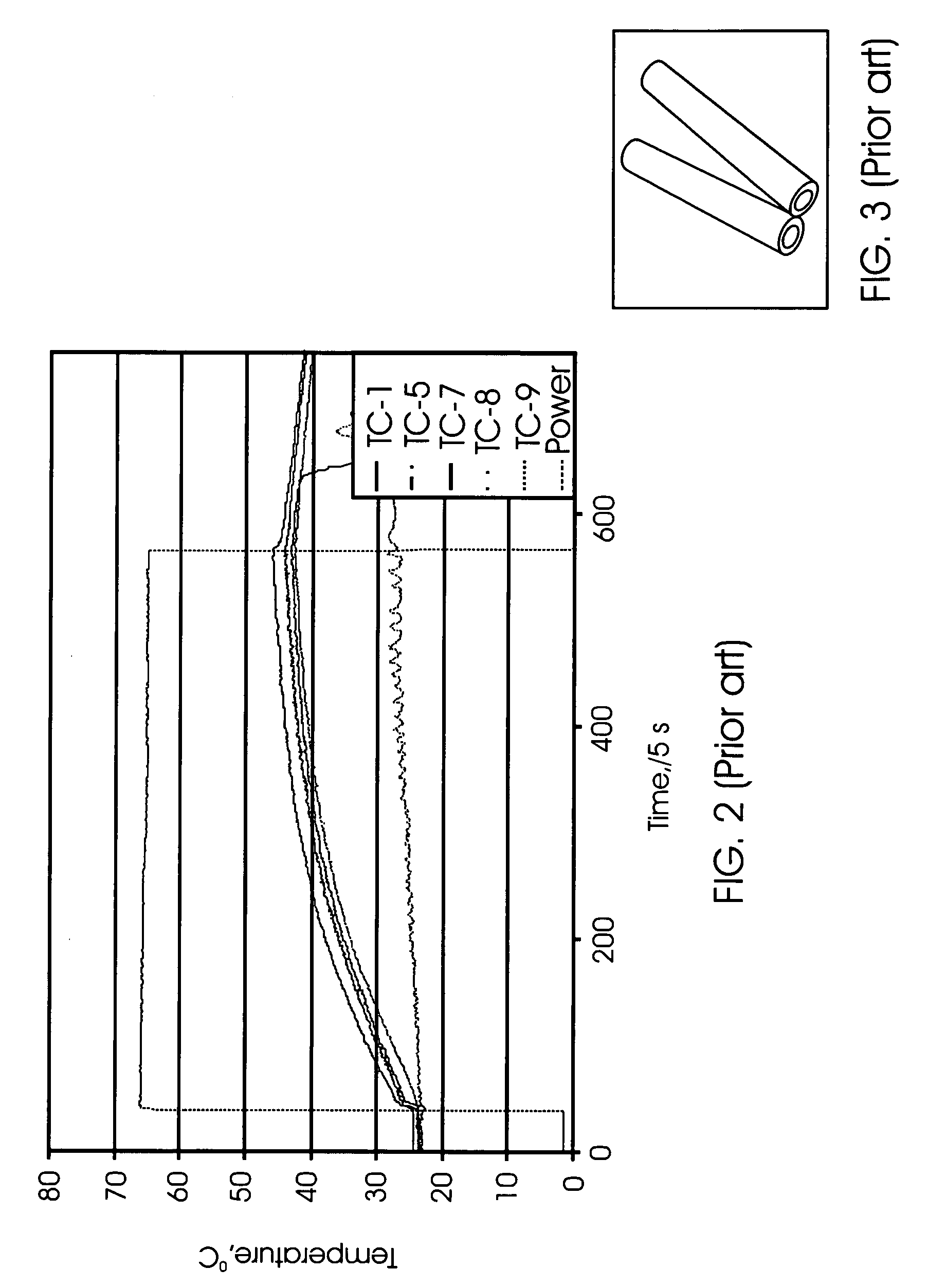

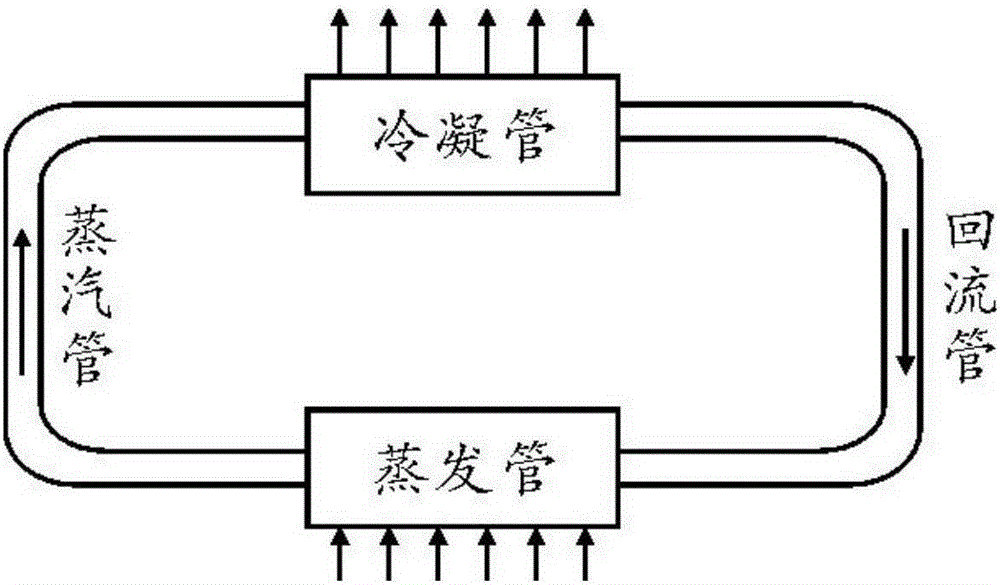

A loop heat pipe (LHP) is a two-phase heat transfer device that uses capillary action to remove heat from a source and passively move it to a condenser or radiator. LHPs are similar to heat pipes but have the advantage of being able to provide reliable operation over long distance and the ability to operate against gravity. They can transport a large heat load over a long distance with a small temperature difference. Different designs of LHPs ranging from powerful, large size LHPs to miniature LHPs (micro loop heat pipe) have been developed and successfully employed in a wide sphere of applications both ground and space-based applications.

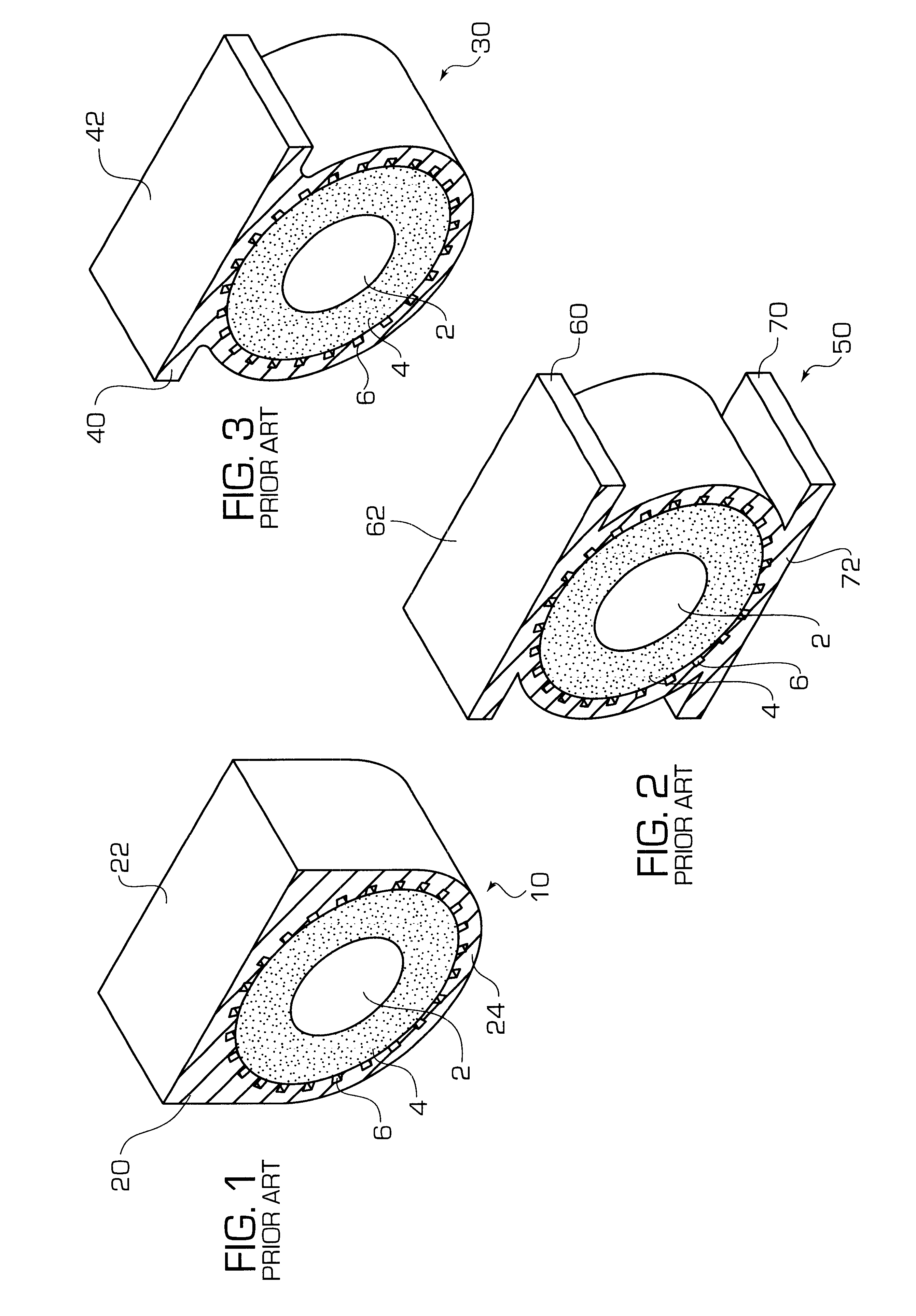

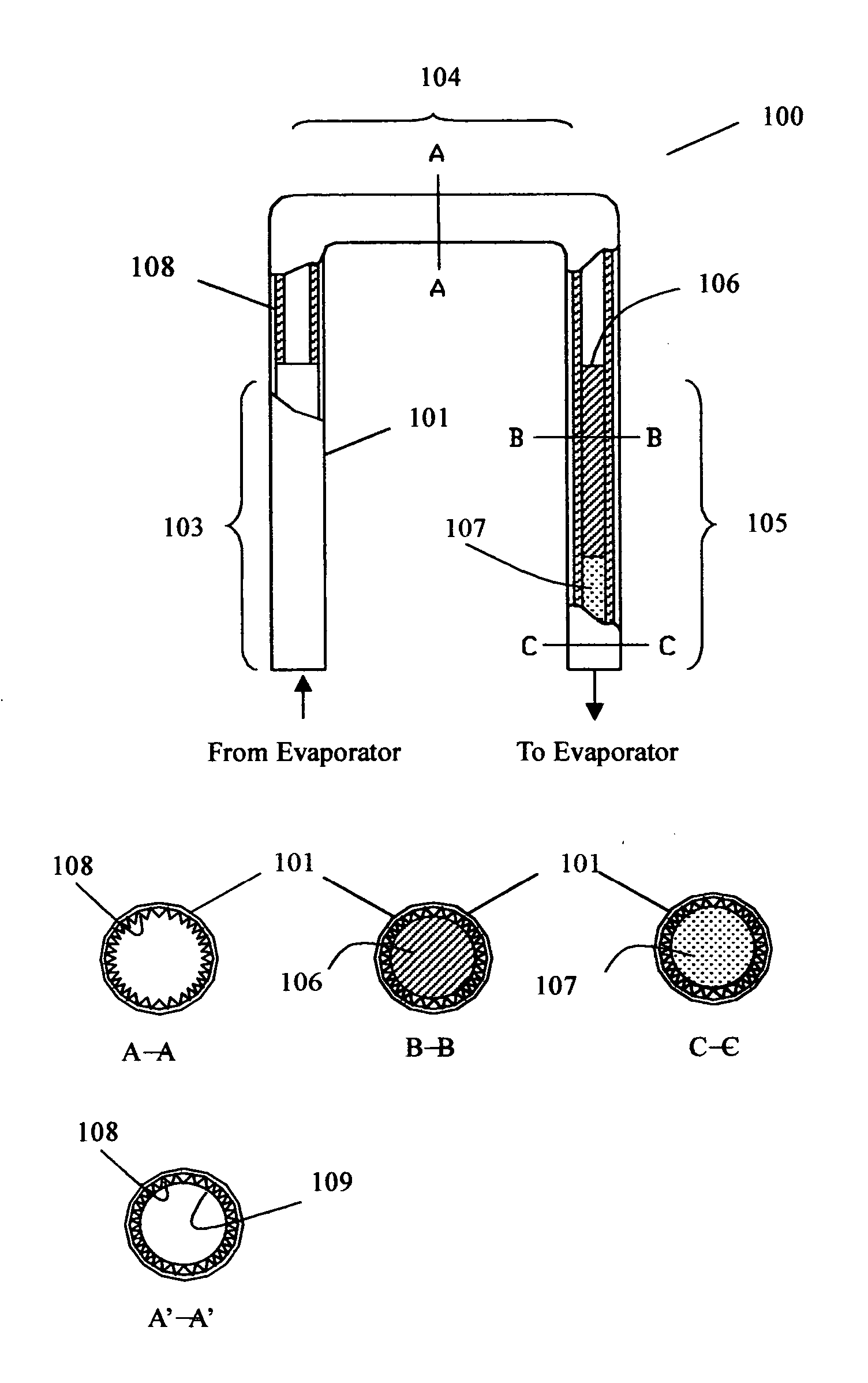

Loop heat pipe incorporating an evaporator having a wick that is liquid superheat tolerant and is resistant to back-conduction

InactiveUS6382309B1Semiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

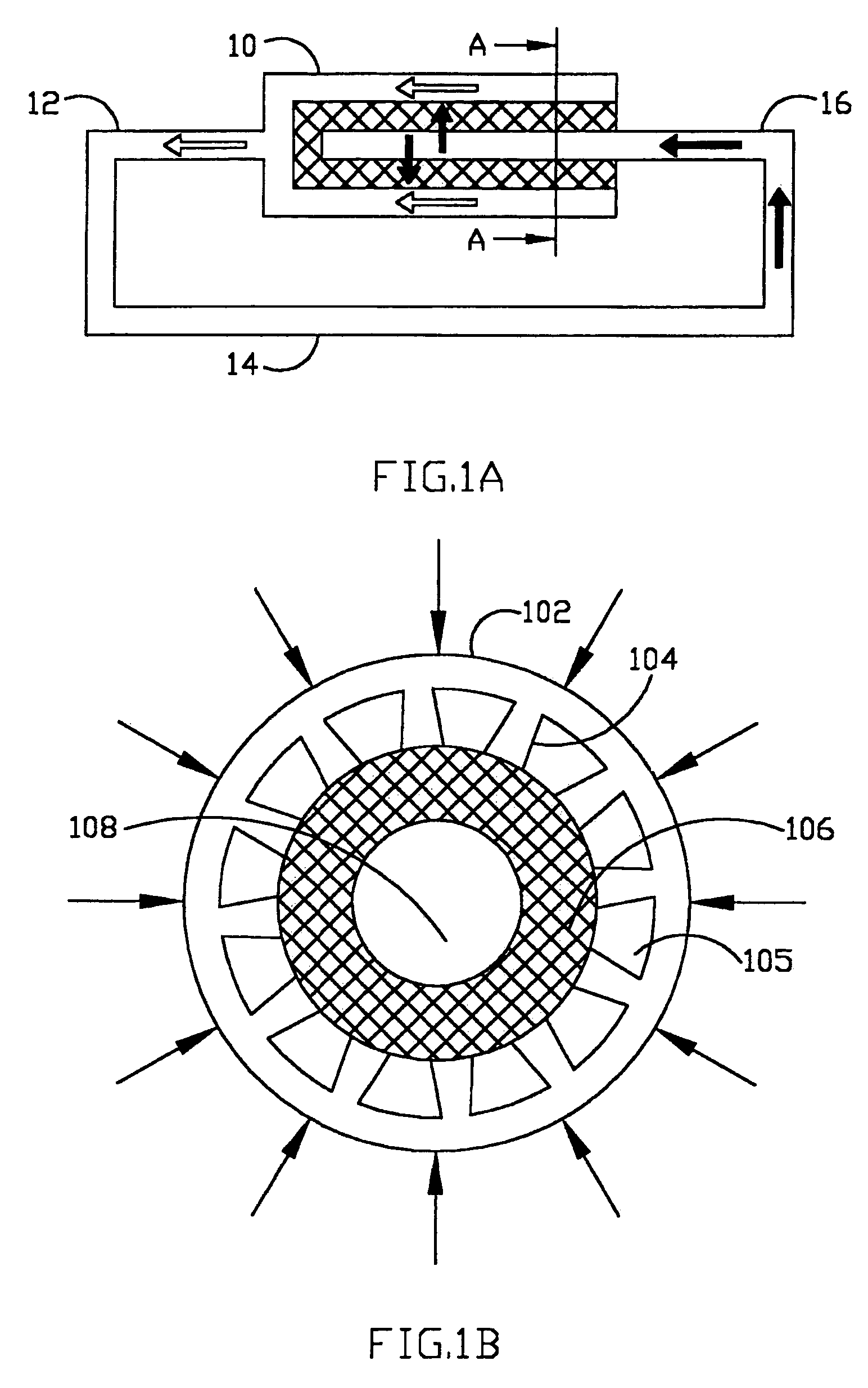

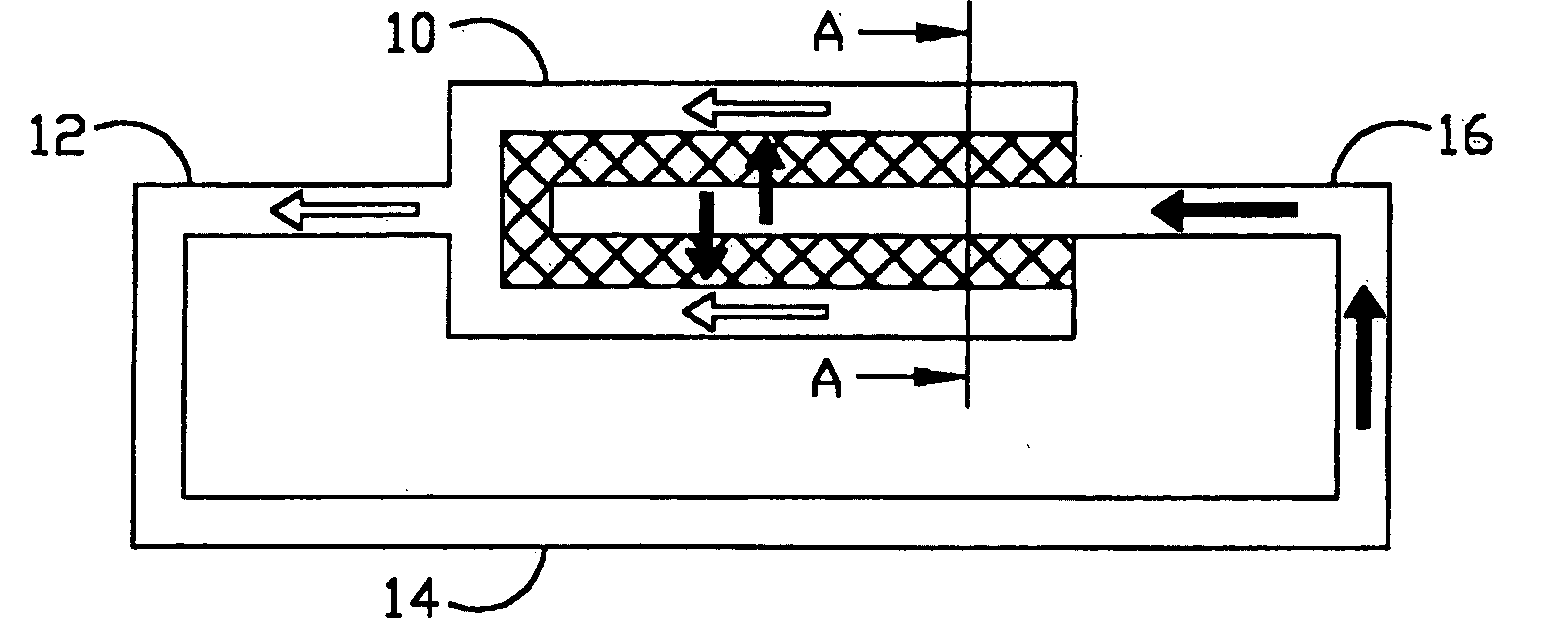

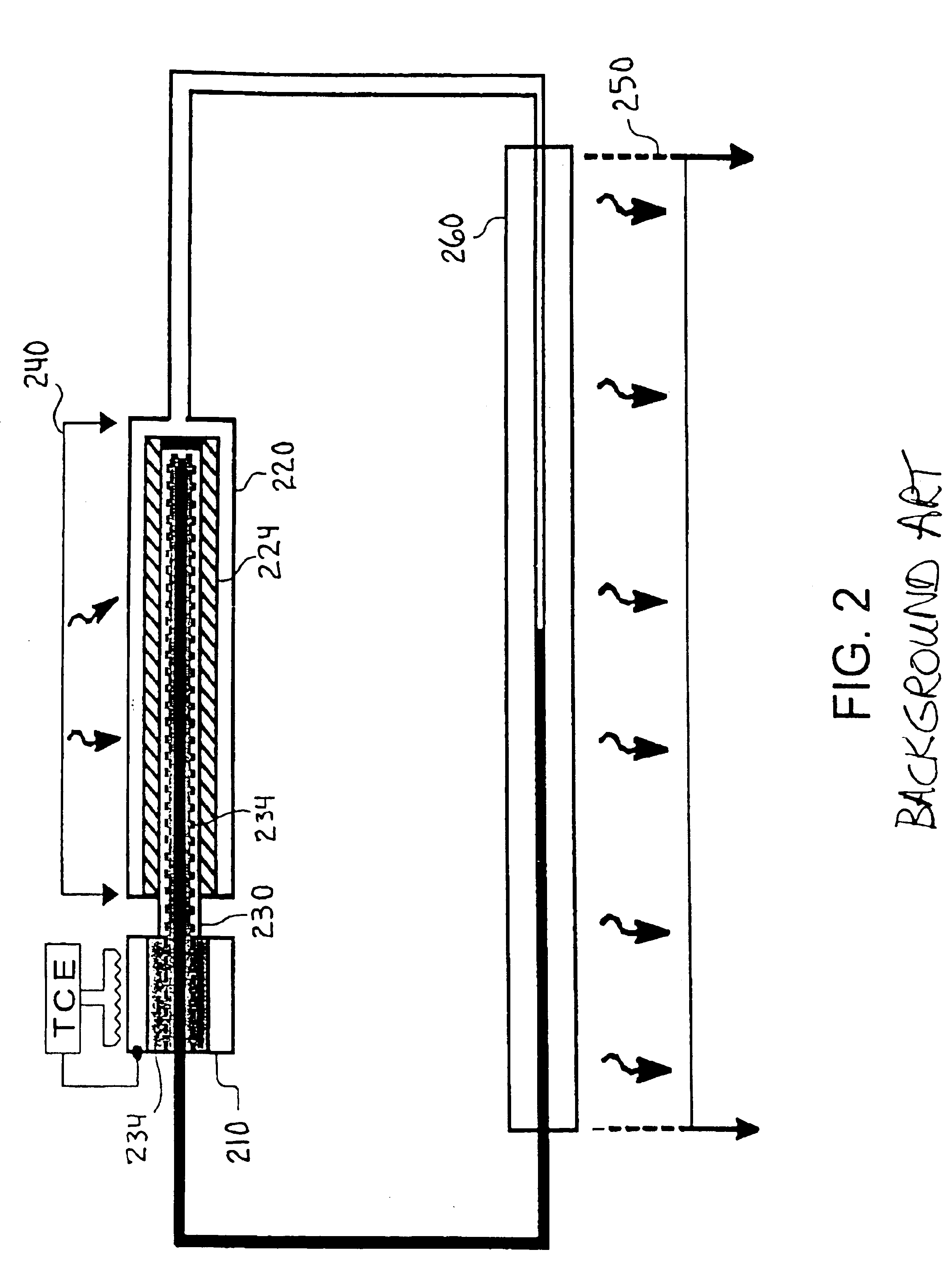

A capillary wick for use in capillary evaporators has properties that prevent nucleation inside the body of the wick, resulting in suppression of back-conduction of heat from vapor channels to the liquid reservoir. Use of a central liquid flow channel in the wick is eliminated, and pore size in the wick is chosen to maximize available pressure for fluid pumping, while preventing nucleation in the wick body. The wick is embodied with different geometries, including cylindrical and flat. A flat capillary evaporator has substantially planar heat input surfaces for convenient mating to planar heat sources. The flat capillary evaporator is capable of being used with working fluids having high vapor pressures (i.e., greater that 10 psia). To contain the pressure of the vaporized working fluid, the opposed planar plates of the evaporator are brazed or sintered to opposing sides of a metal wick. Additionally, a terrestrial loop heat pipe and a loop heat pipe having overall flat geometry are disclosed.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

Illumination apparatus of light emitting diodes and method of heat dissipation thereof

InactiveUS7210832B2Extended service lifeDissipate heat generatedDomestic stoves or rangesPoint-like light sourceEngineeringLoop heat pipe

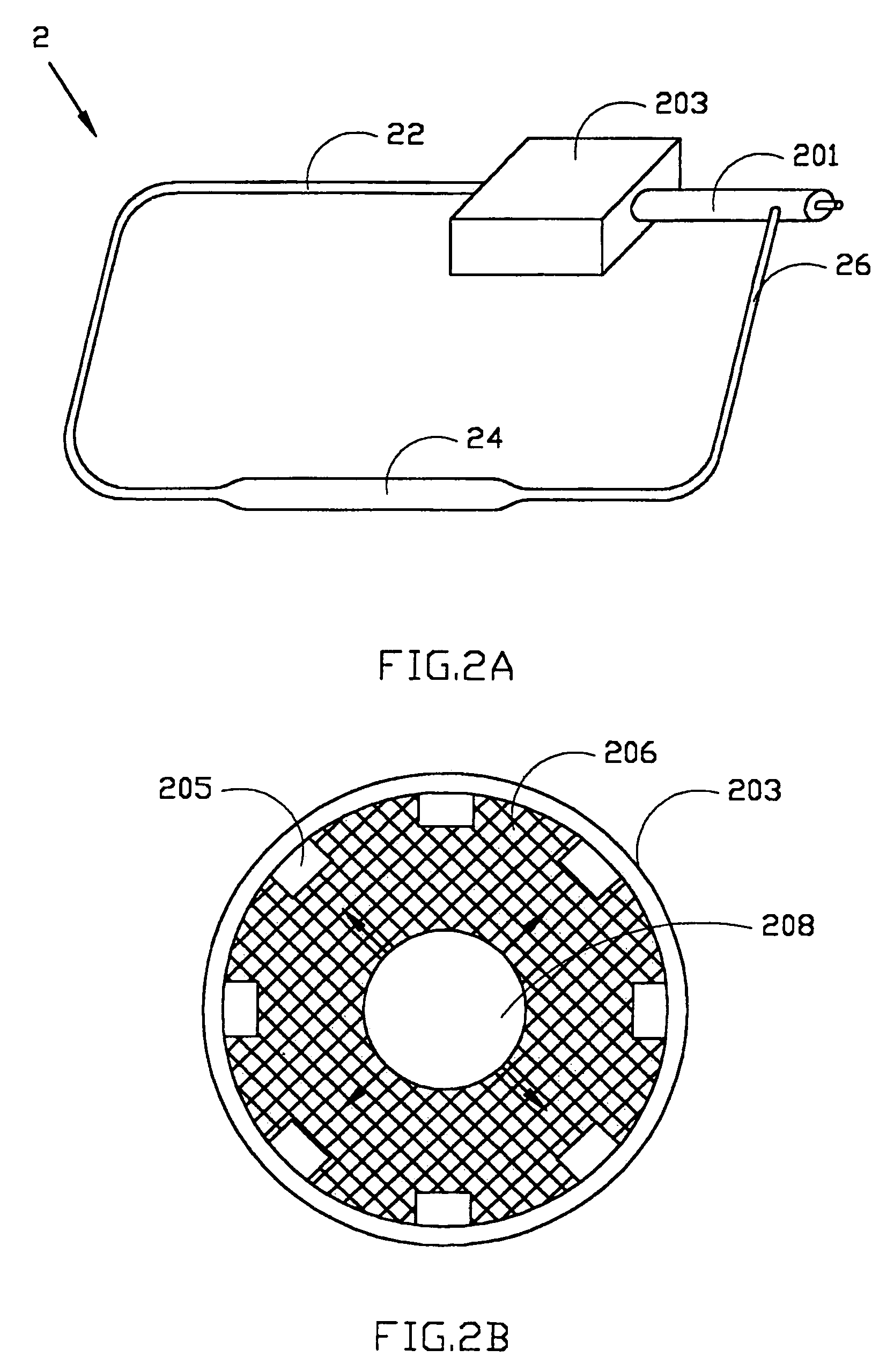

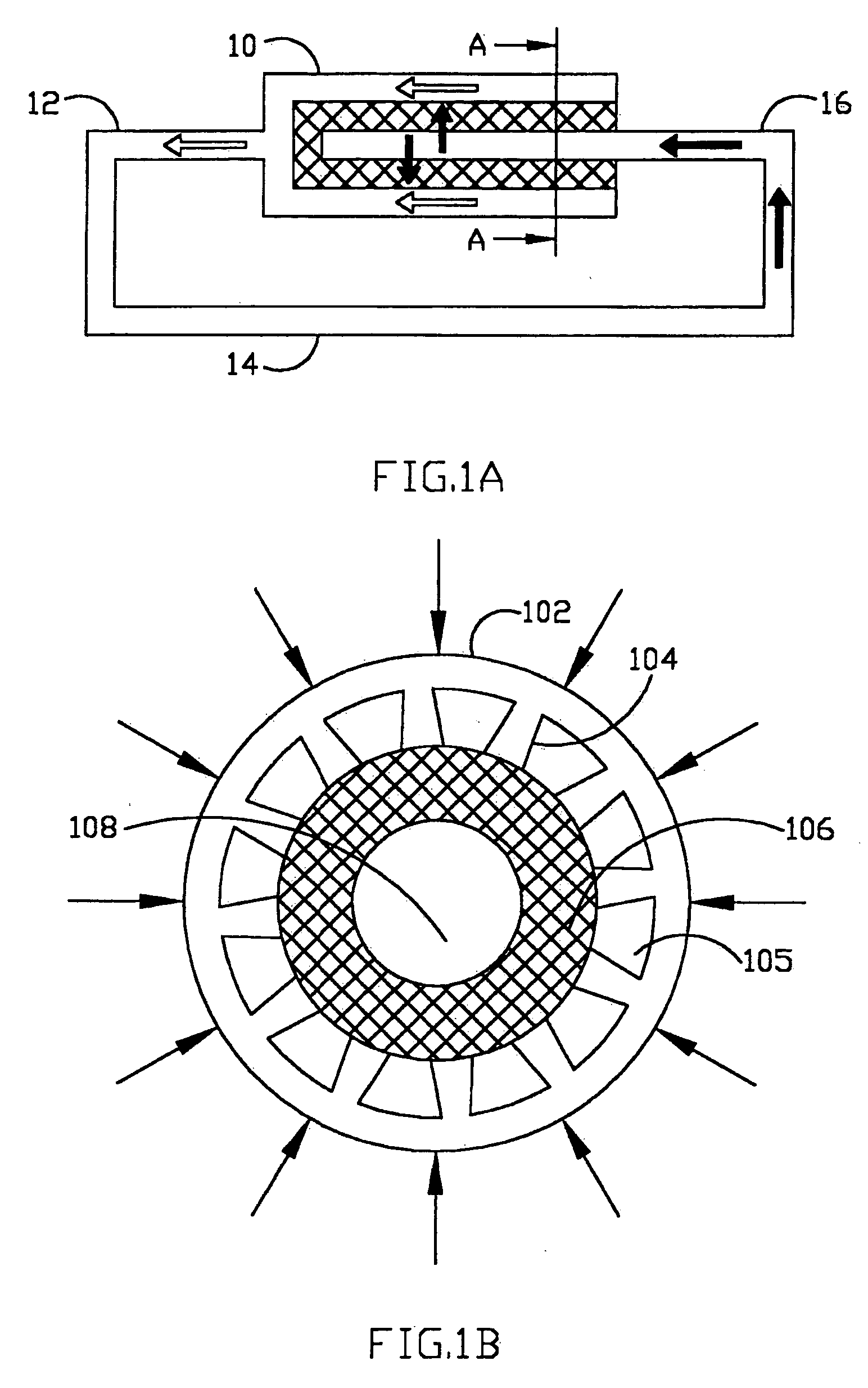

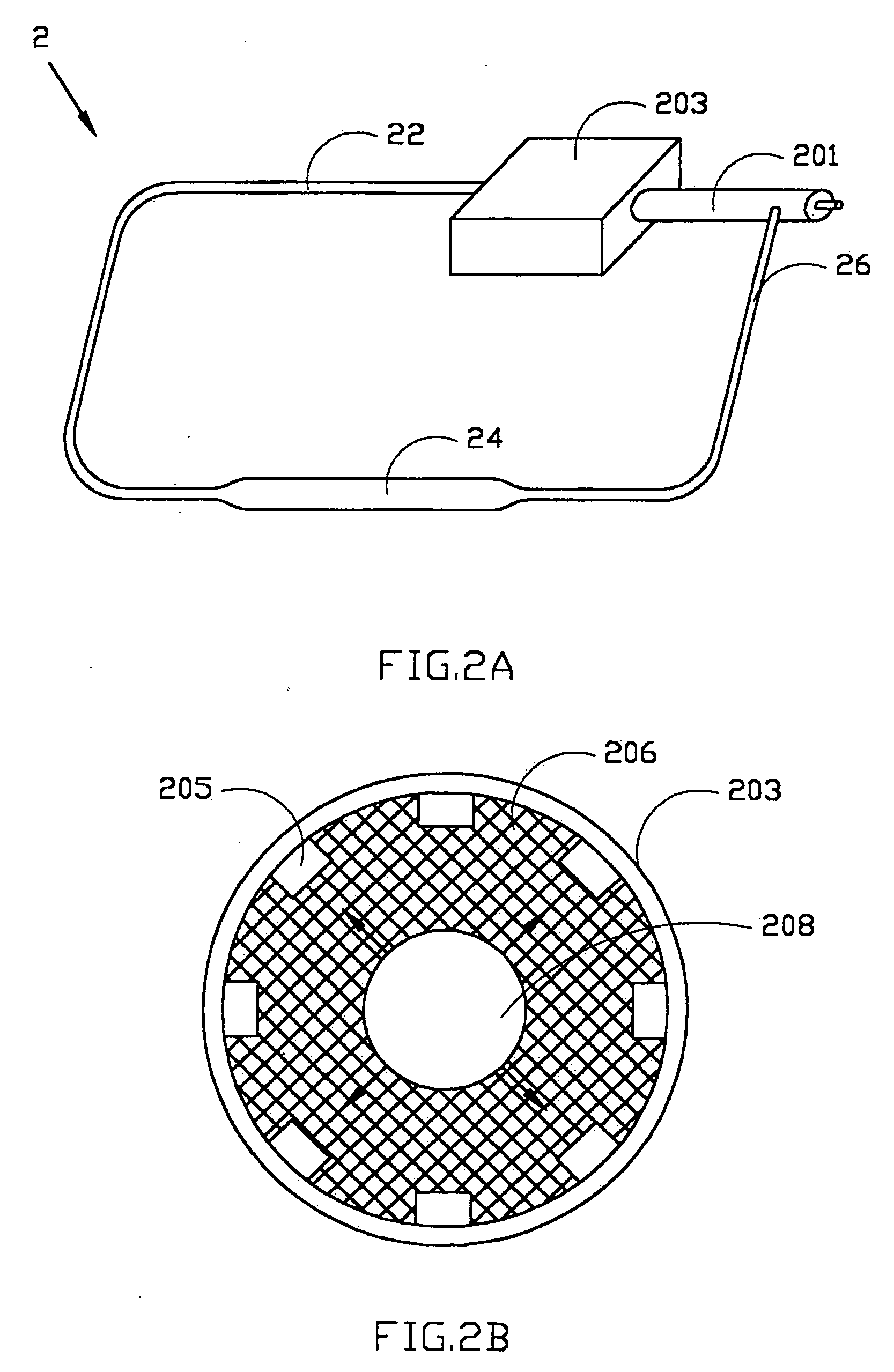

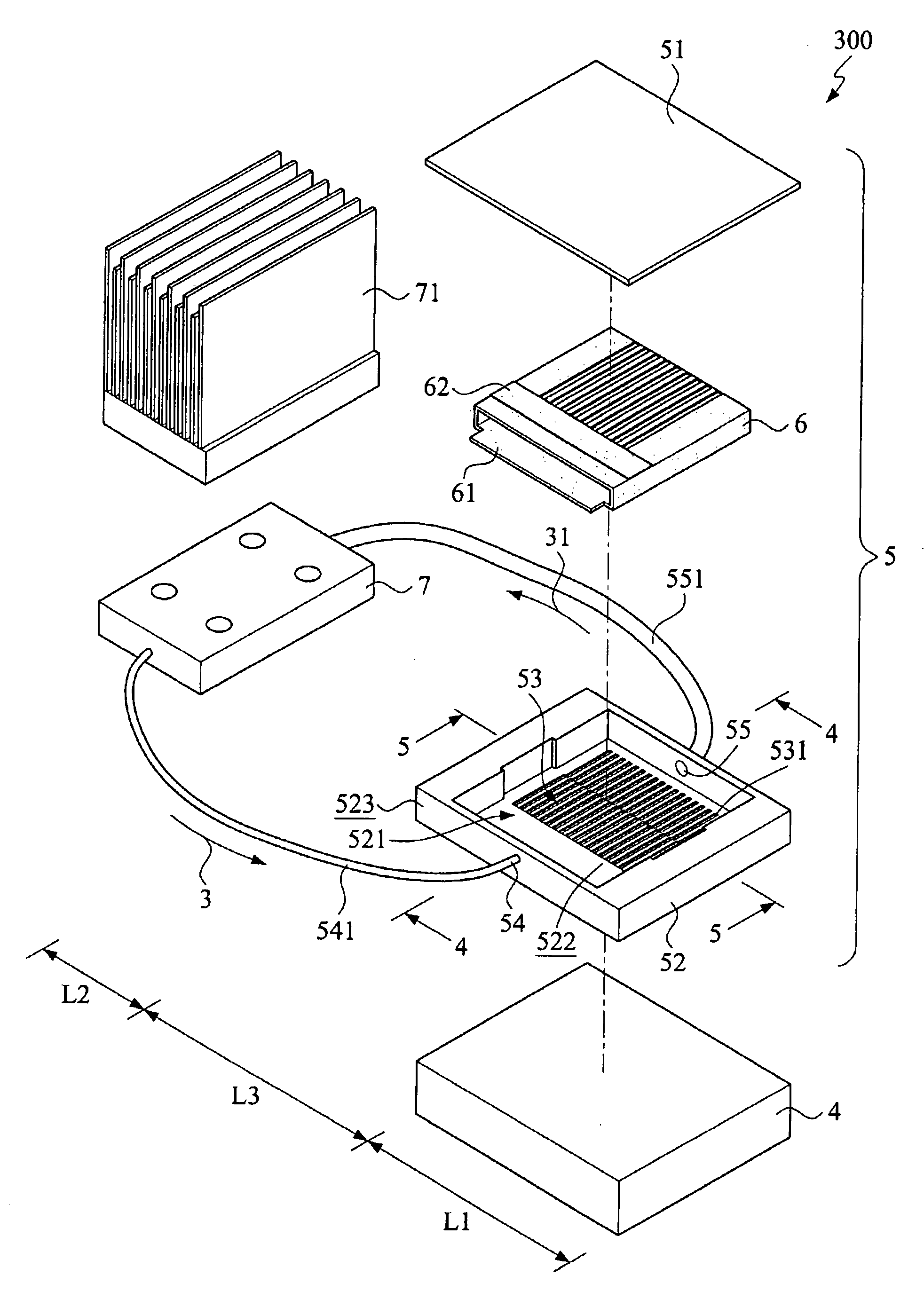

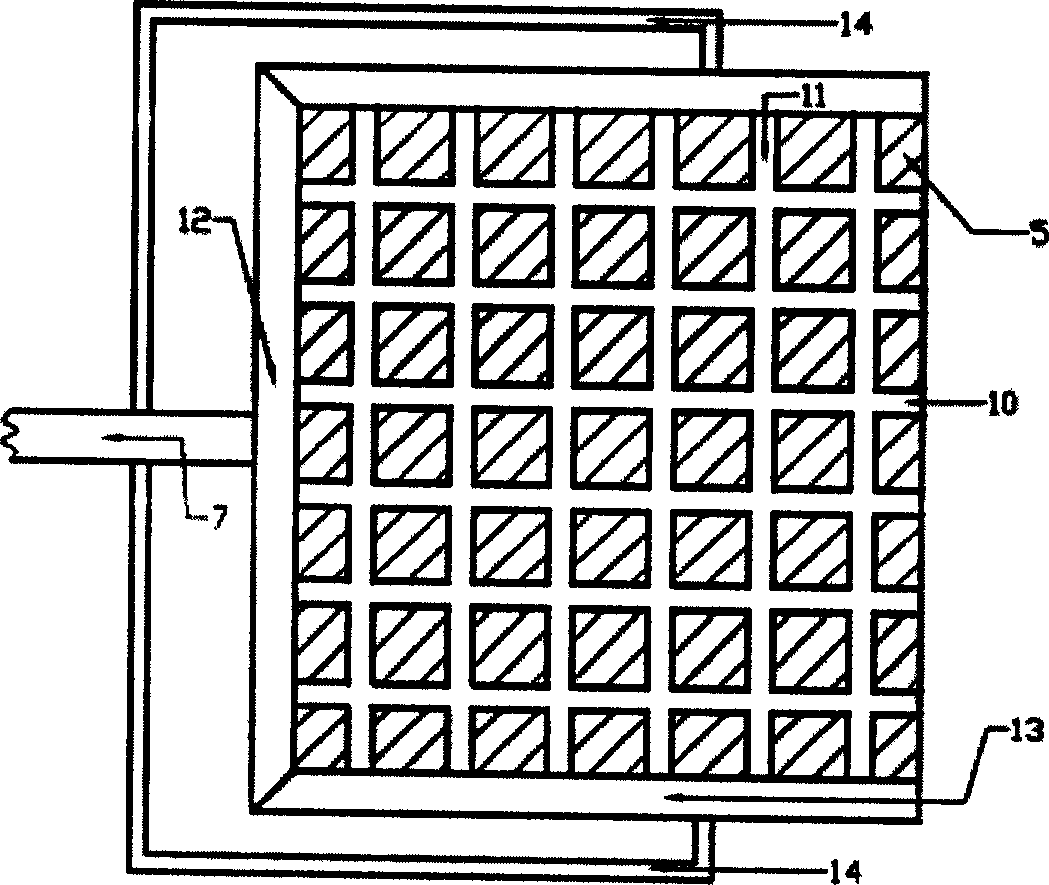

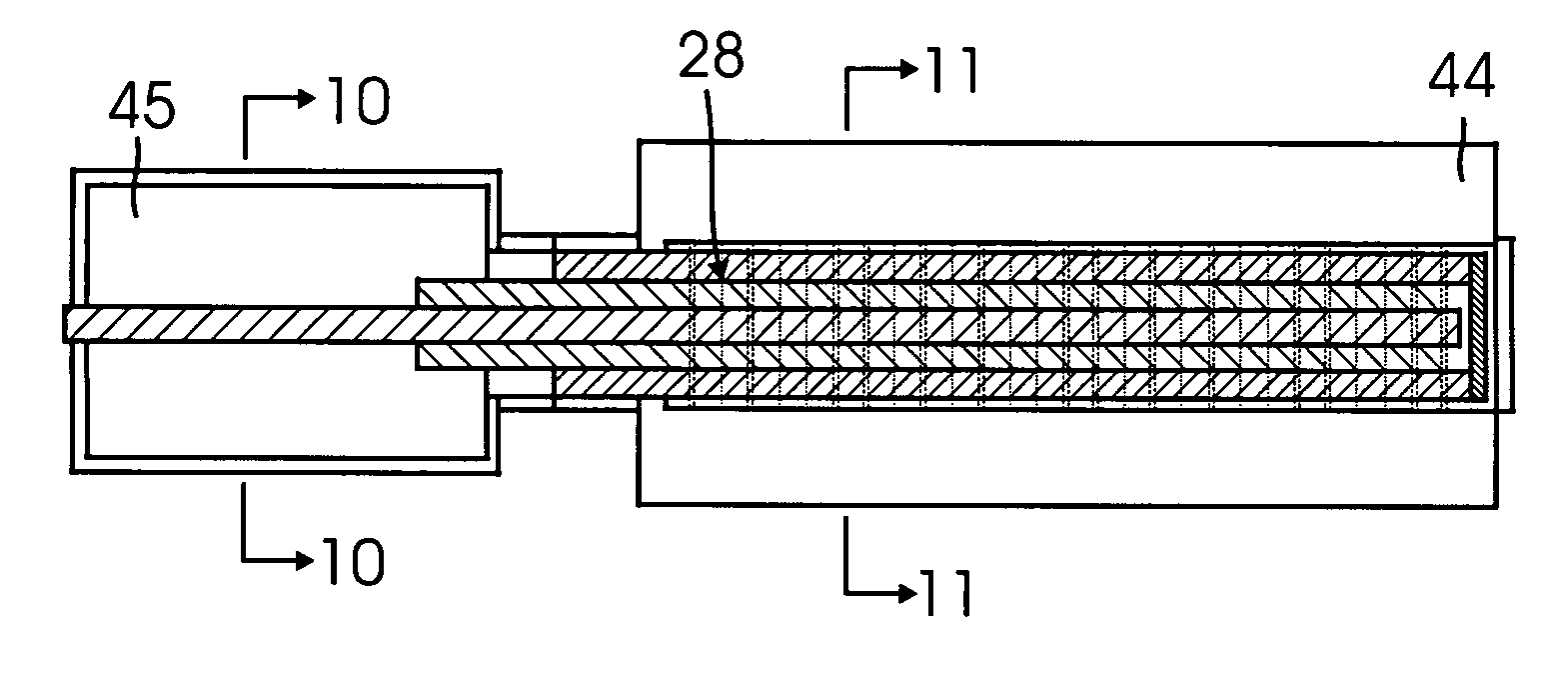

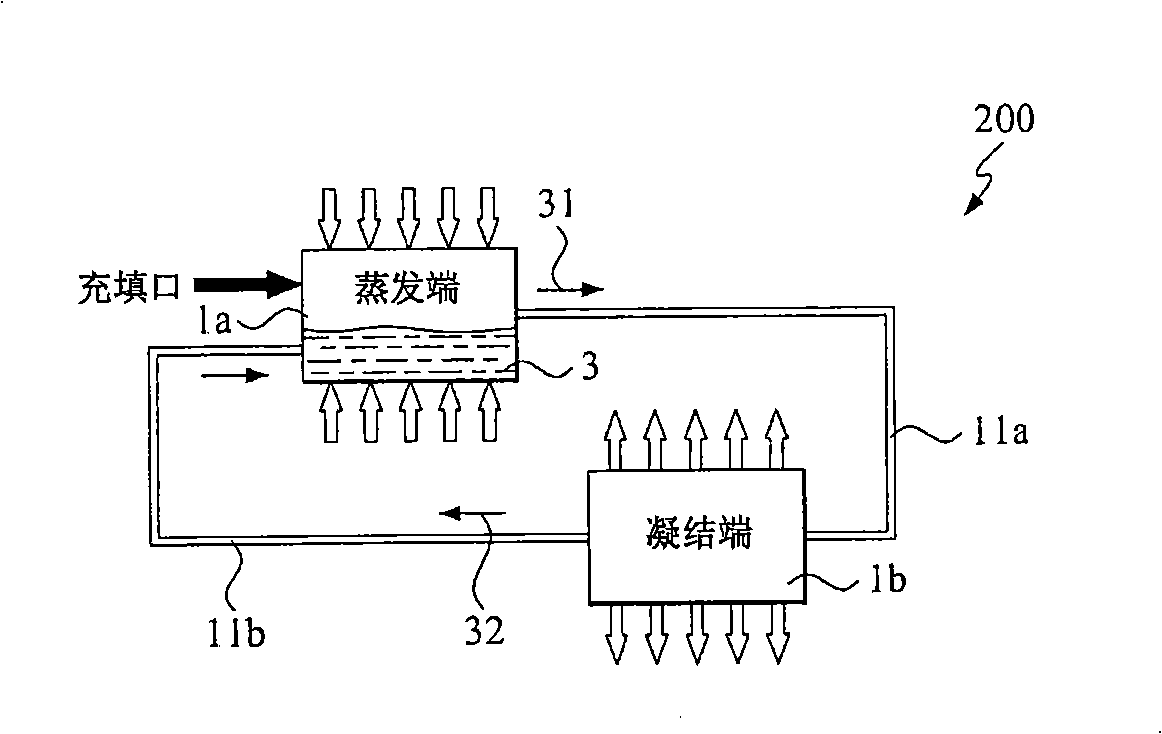

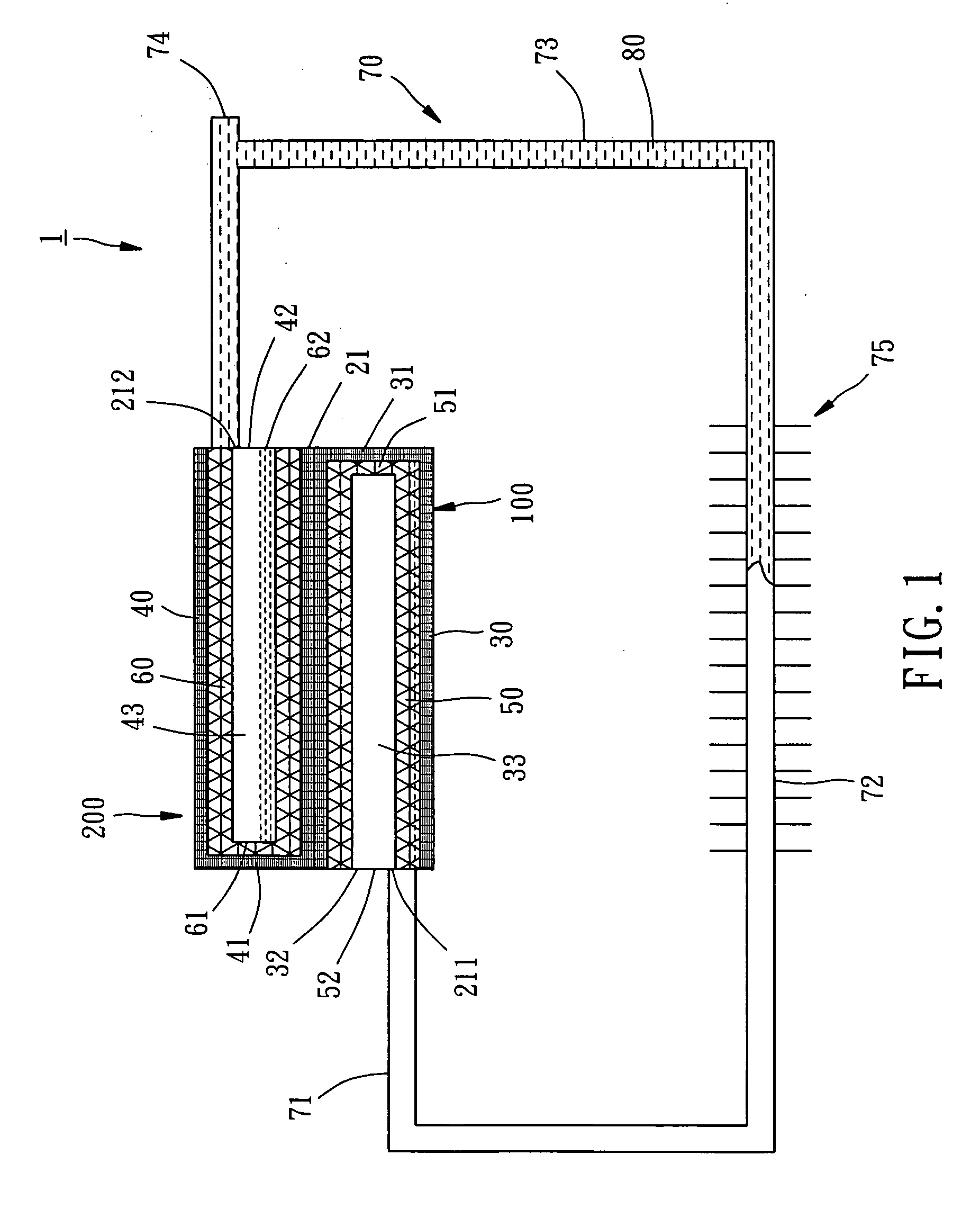

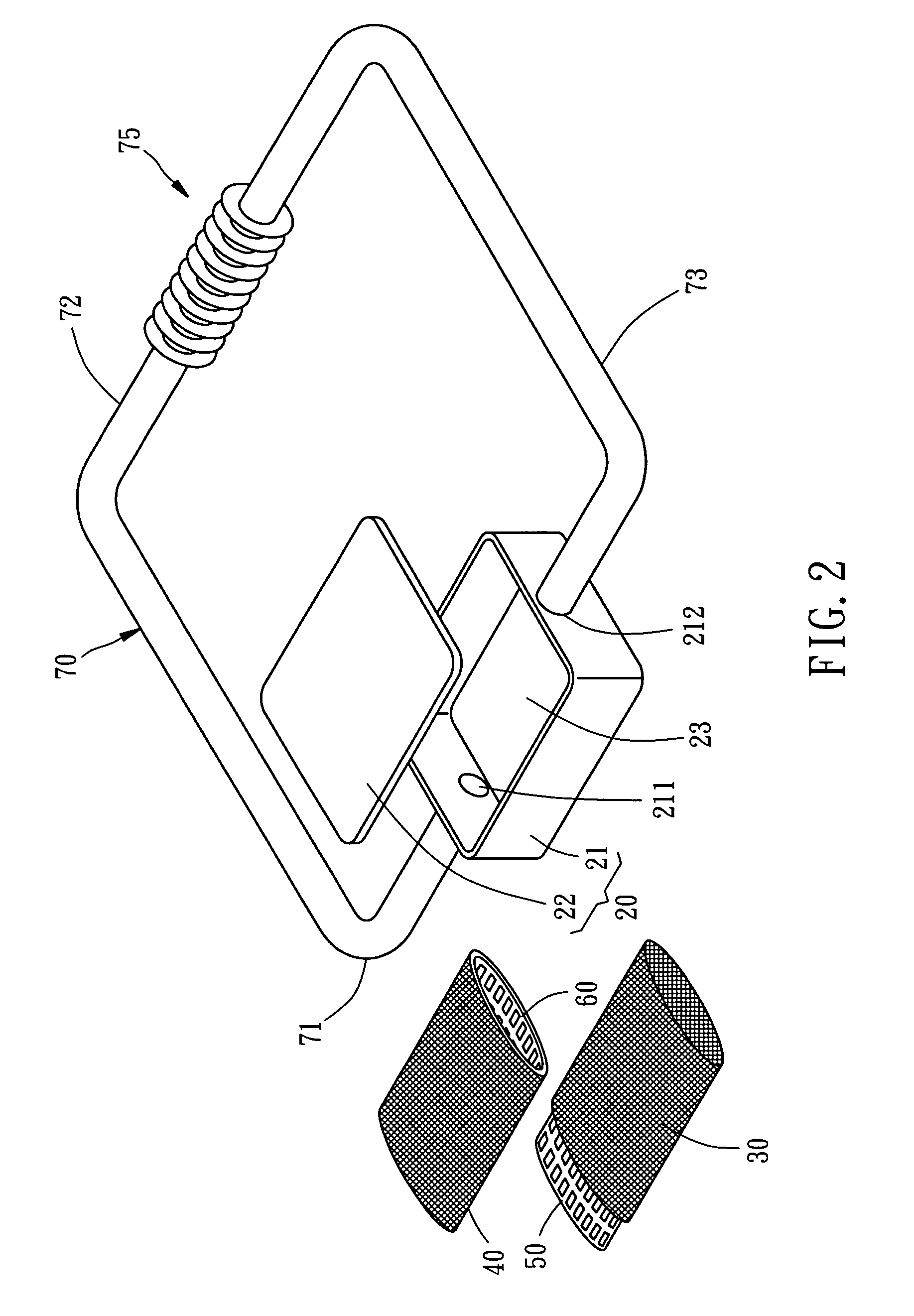

An illumination apparatus of light emitting diodes and method of heat dissipation thereof are provided. The present illumination apparatus is associated with a loop heat pipe (LHP) device. The LHP device includes a condenser communicating with an evaporator. The illumination apparatus includes a base having a plurality of light emitting diodes disposed thereon and a cover with a light exit enclosing the base. The evaporator is associated with the base and the condenser is associated with the cover. The heat generated from the light emitting diodes is conducted to the cover, and thereby dissipated away.

Owner:ADVANCED THERMAL DEVICES

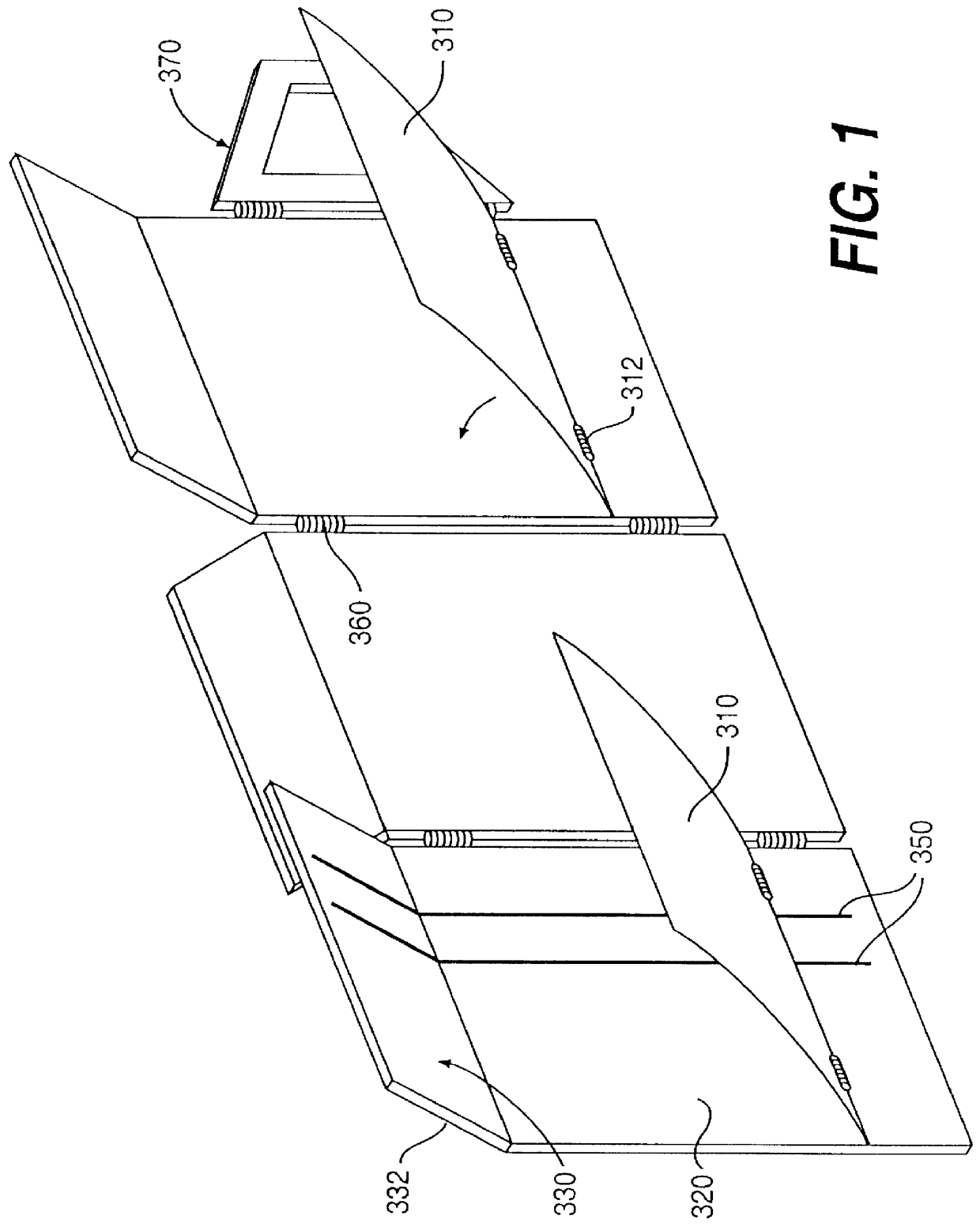

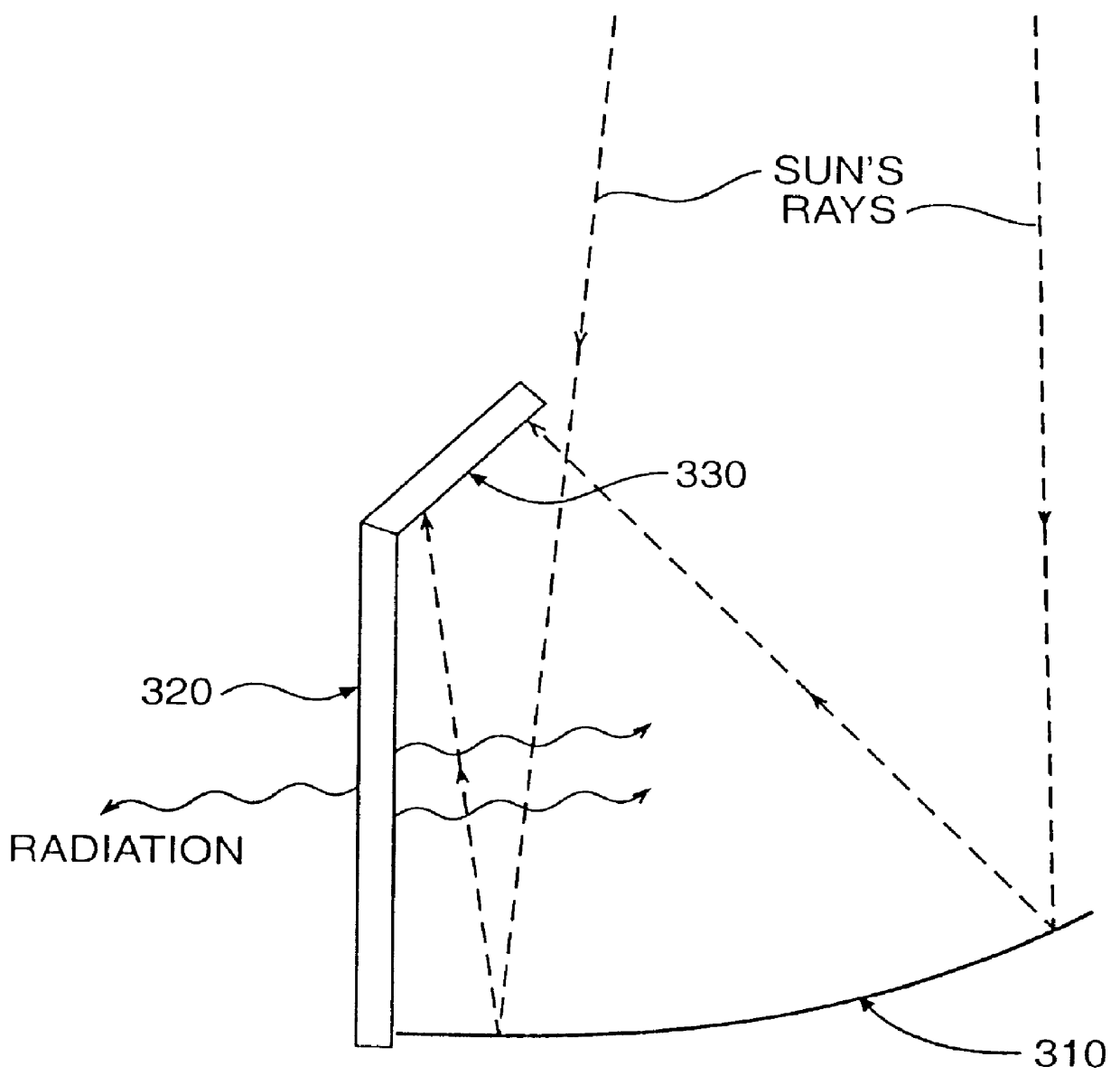

Method and apparatus for improved solar concentration arrays

InactiveUS6118067AIncrease concentrationSimple designSolar heating energyCosmonautic vehiclesCells panelEngineering

A lightweight photovoltaic concentrator is disclosed. The concentrator comprises at least two sections each comprising a cell panel, a radiator panel and a reflector panel. In one embodiment, the concentrator system of the present invention comprises at least two hinged sections each comprising a solar cell panel, a flat radiator panel, and a curved reflective concentrator panel. The solar cell panel comprises at least one photovoltaic cell for generating electrical power in response to radiation. The solar cell panel is aligned with the radiator panel at an angle less than 180 degrees but not less than 90 degrees facing the reflective concentrator panel. In another embodiment, the cell panels on adjoining sections are angled in opposite directions with respect to the radiator panels and wherein the reflective concentrator panels are located on opposite sides of the radiator panels. A heat pipe or loop heat pipe is located in the radiator panel to dissipate heat from the solar cells.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

Illumination apparatus of light emitting diodes and method of heat dissipation thereof

InactiveUS20050092469A1Extended service lifeDissipate heat generatedDomestic stoves or rangesPoint-like light sourceEngineeringLoop heat pipe

An illumination apparatus of light emitting diodes and method of heat dissipation thereof are provided. The present illumination apparatus is associated with a loop heat pipe (LHP) device. The LHP device includes a condenser communicating with an evaporator. The illumination apparatus includes a base having a plurality of light emitting diodes disposed thereon and a cover with a light exit enclosing the base. The evaporator is associated with the base and the condenser is associated with the cover. The heat generated from the light emitting diodes is conducted to the cover, and thereby dissipated away.

Owner:ADVANCED THERMAL DEVICES

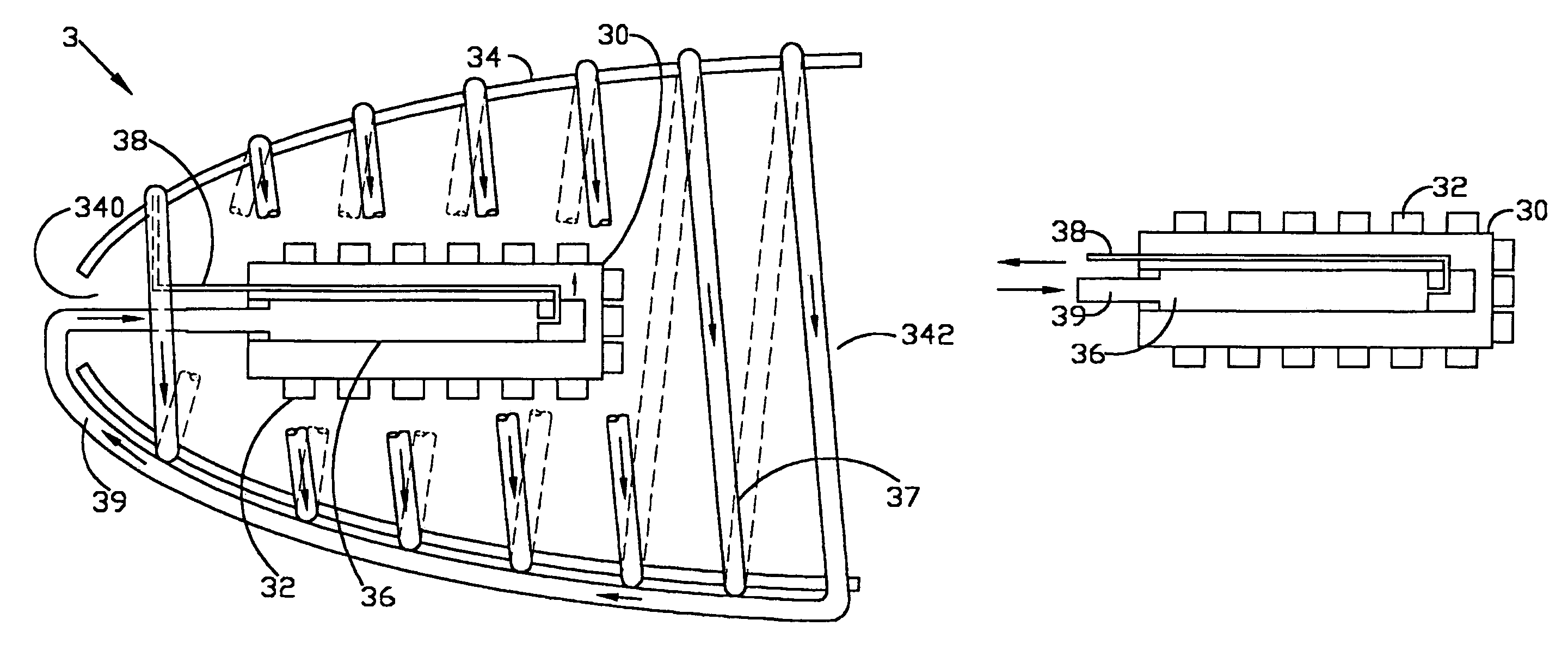

Phase control in the capillary evaporators

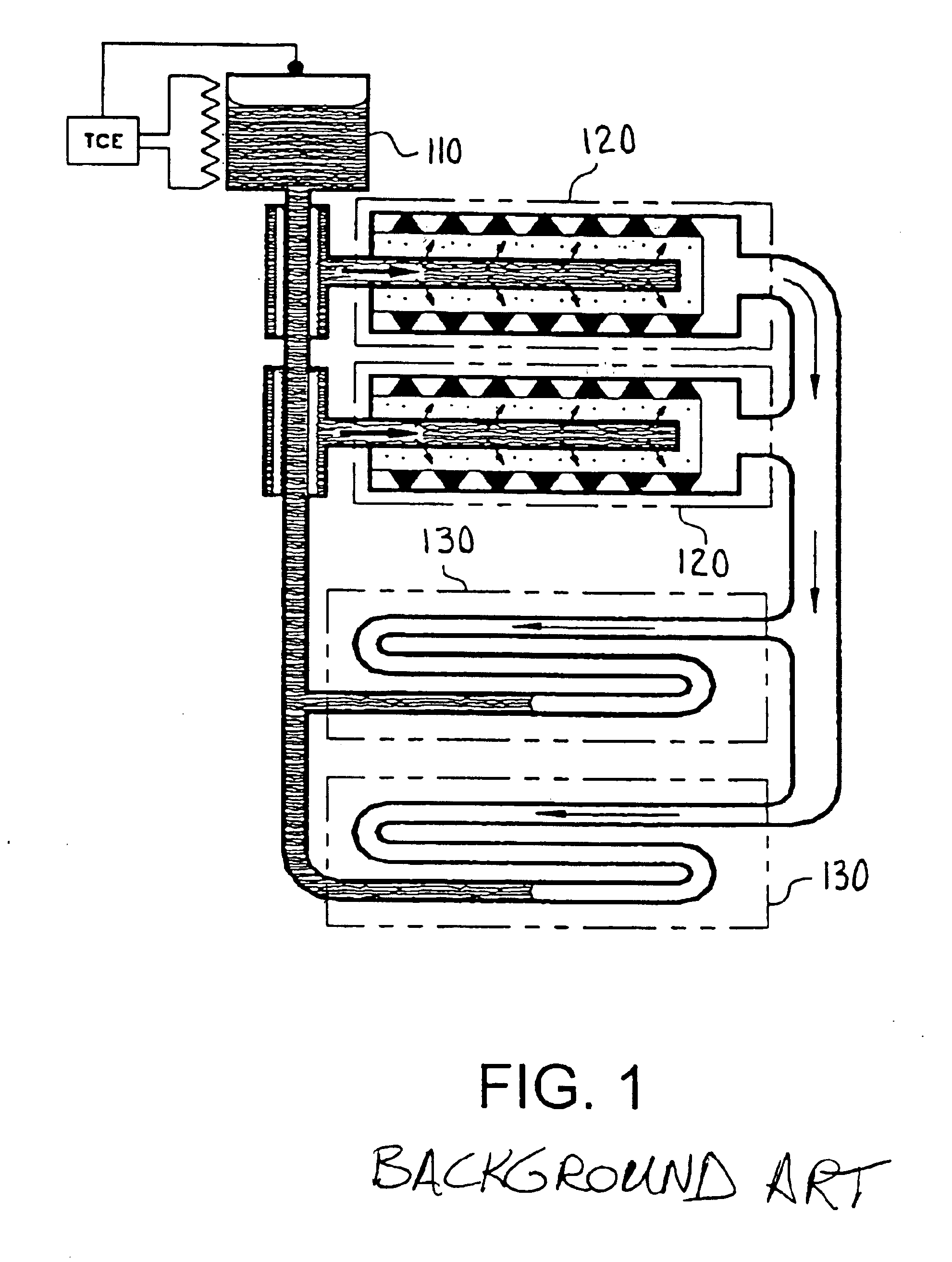

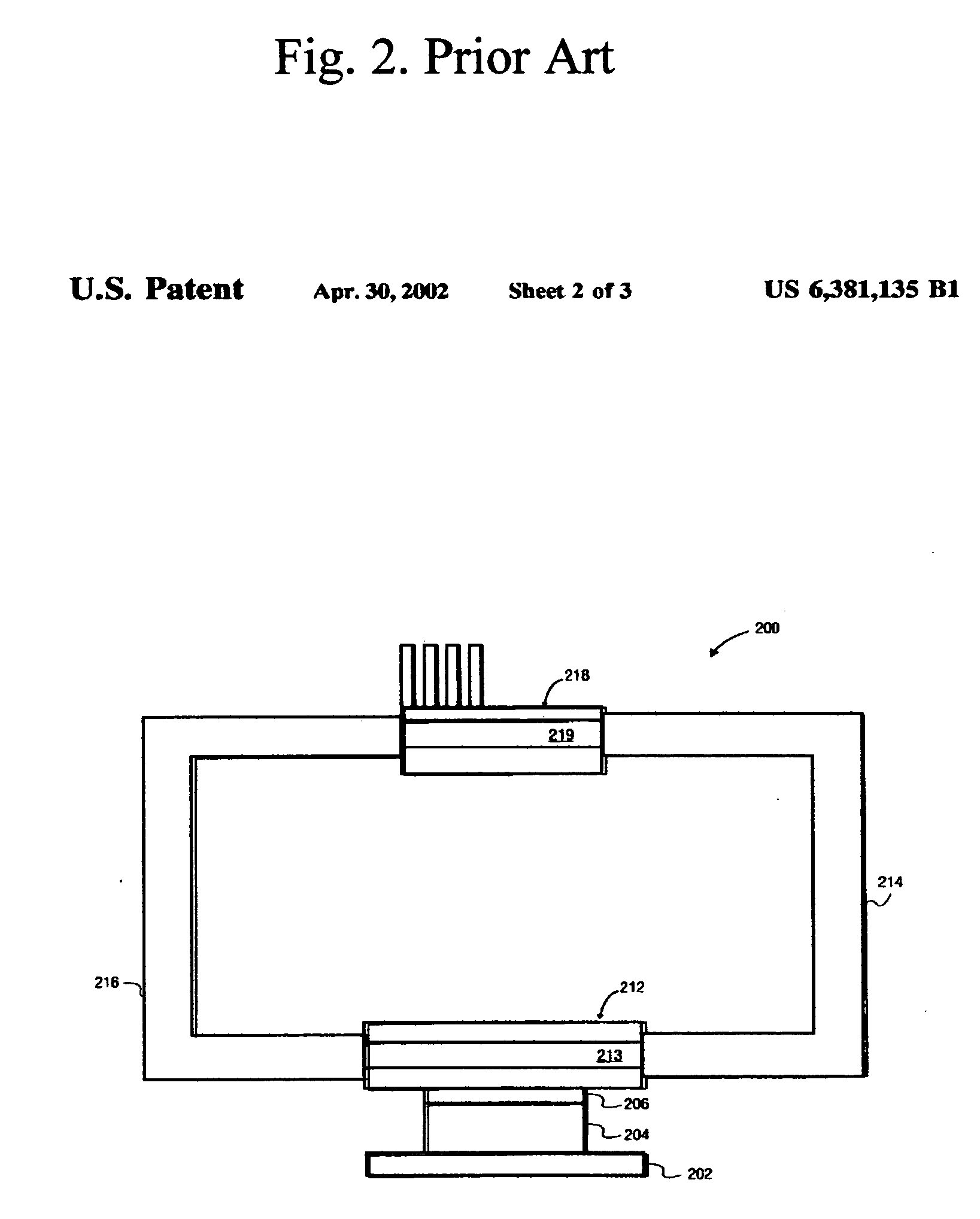

InactiveUS6889754B2Guaranteed uptimeIndirect heat exchangersRefrigeration machinesTransport systemEngineering

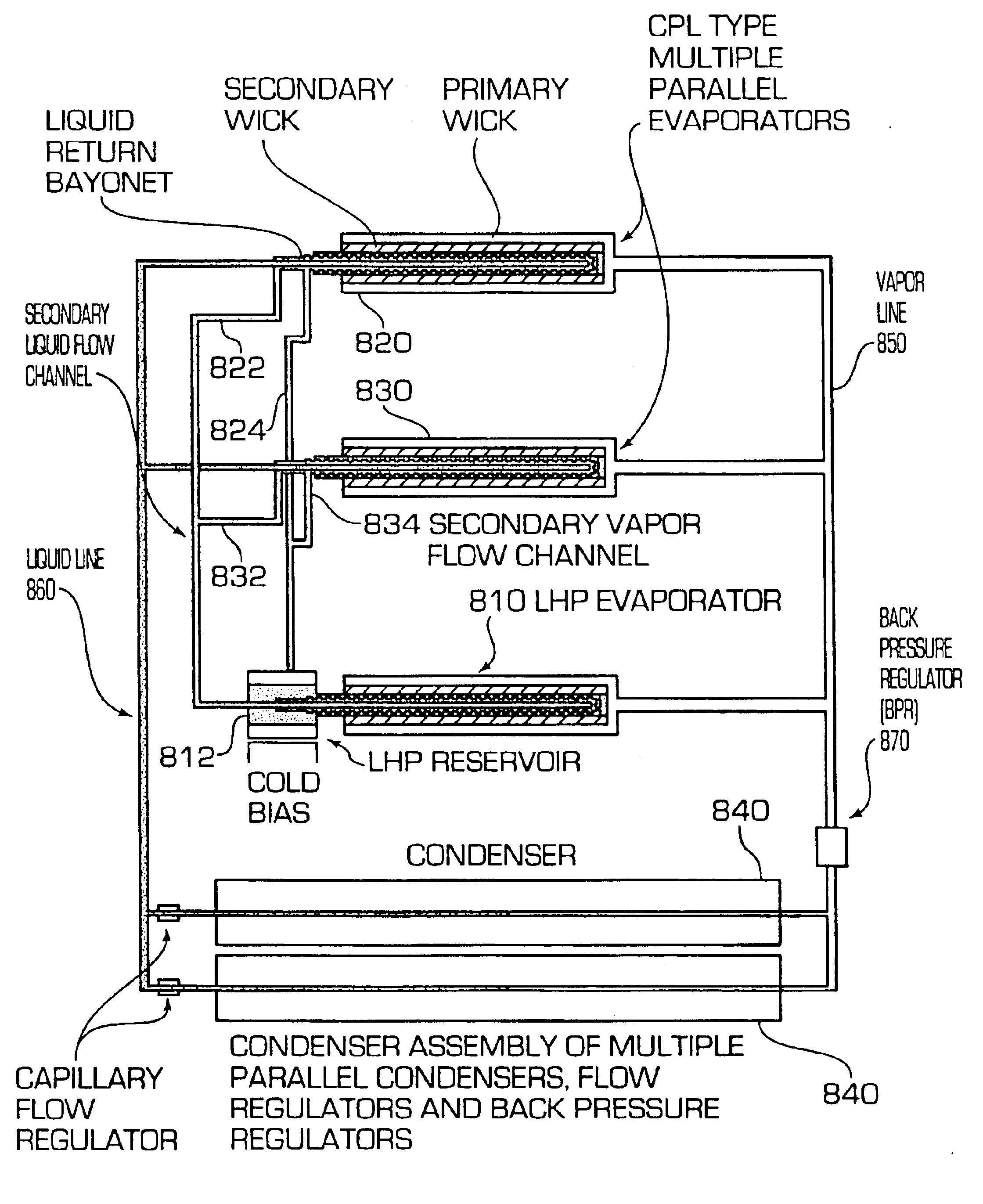

A capillary pump two phase heat transport system that combines the most favorable characteristics of a capillary pump loop (CPL) with the robustness and reliability of a loop heat pipe (LHP). Like a CPL, the hybrid loop has plural parallel evaporators, plural parallel condensers, and a back pressure flow regulator. Unlike CPLs, however, the hybrid system incorporates elements that form a secondary loop, which is essentially a LHP that is co-joined with a CPL to form an inseparable whole. Although secondary to the basic thermal management of the system thermal bus, the LHP secondary loop portion of the system provides for important operational functions that maintain healthy, robust and reliable operation. The LHP secondary loop portion provides a function of fluid management during start-up, steady state operation, and heat sink / heat source temperature and power cycling.

Owner:NORTHROP GRUMMAN SYST CORP

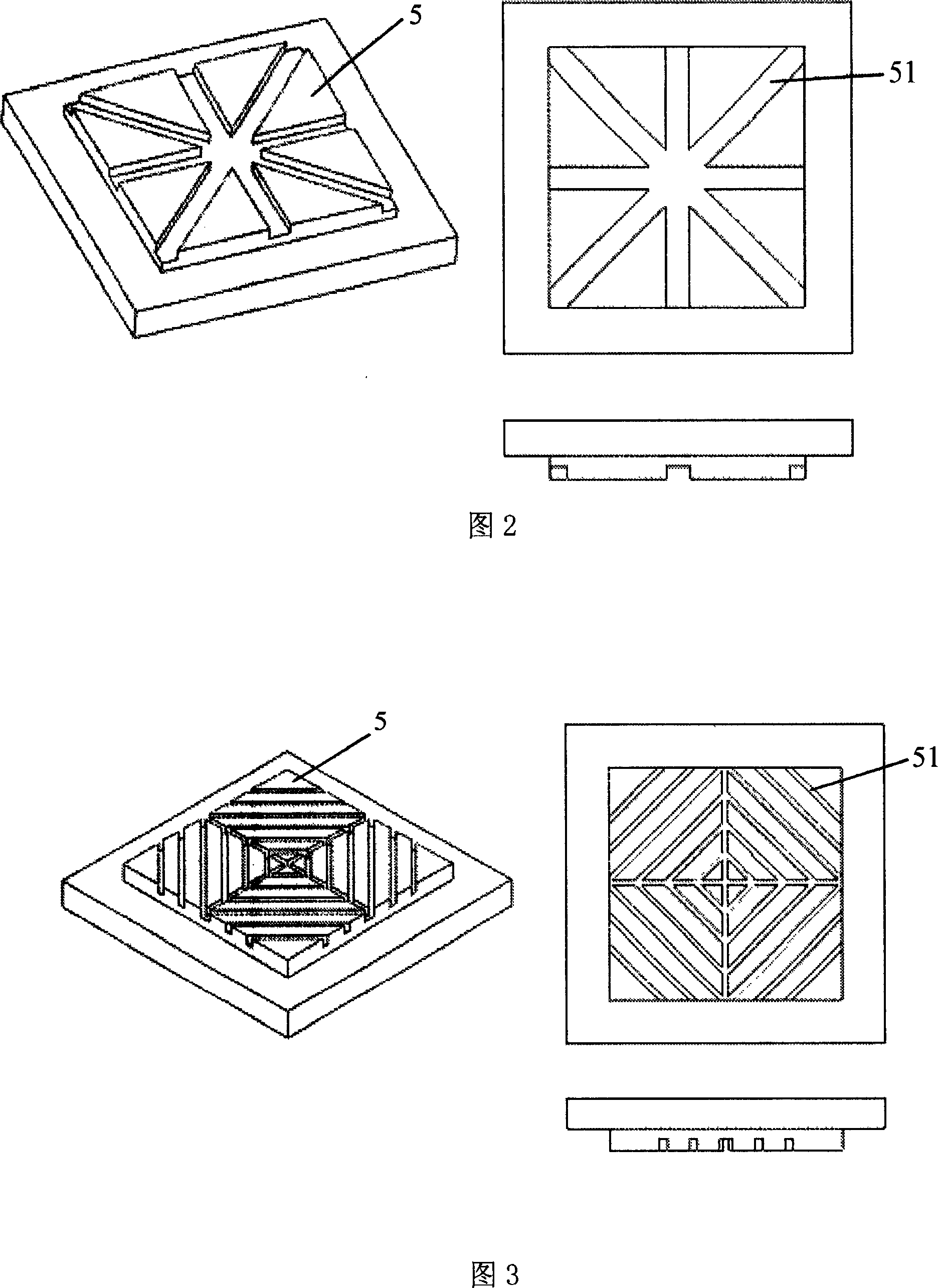

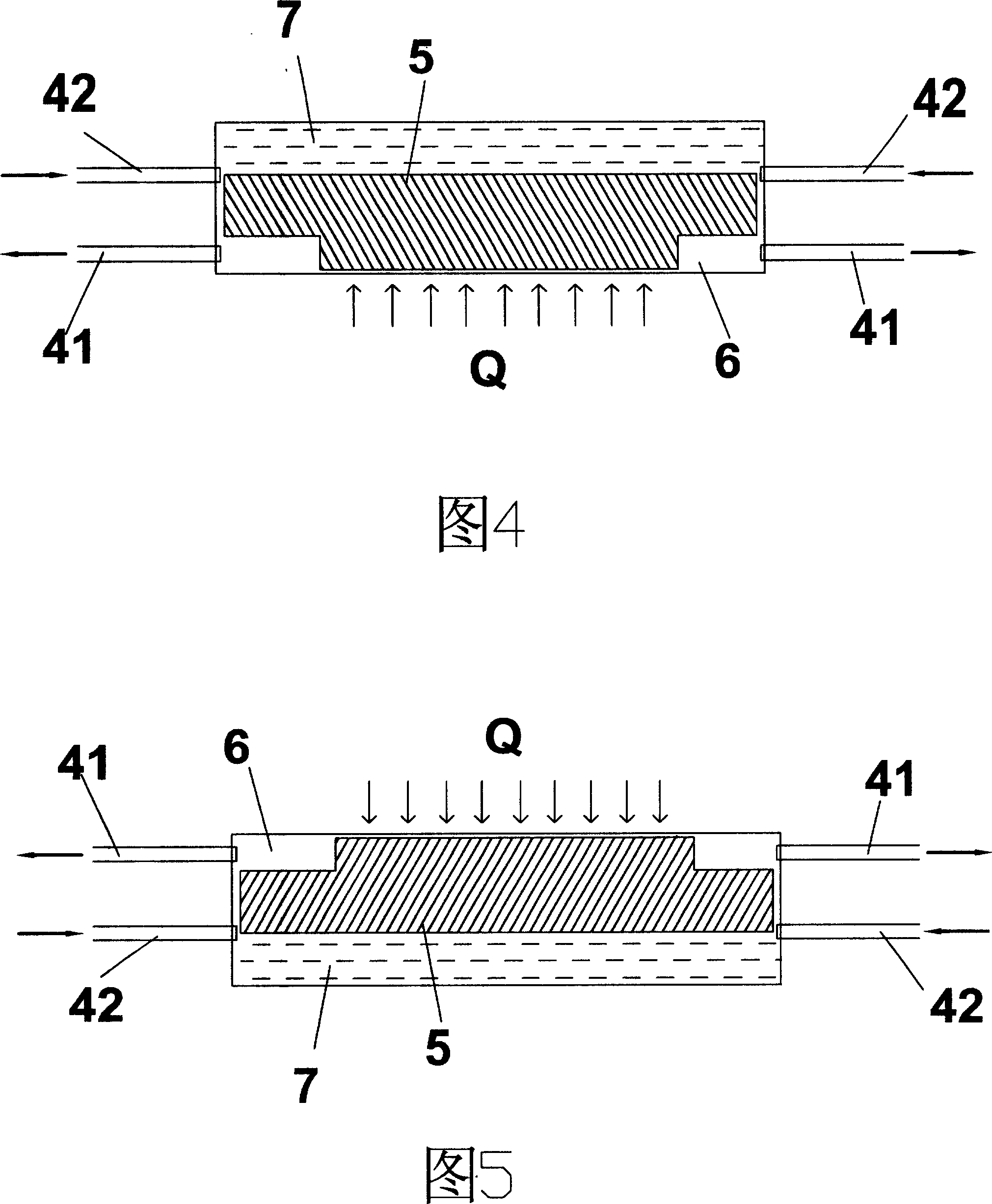

Loop heat pipe with flat evaportor

InactiveUS20080164010A1Mitigate such drawbackImproves entertainment limitSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEvaporation

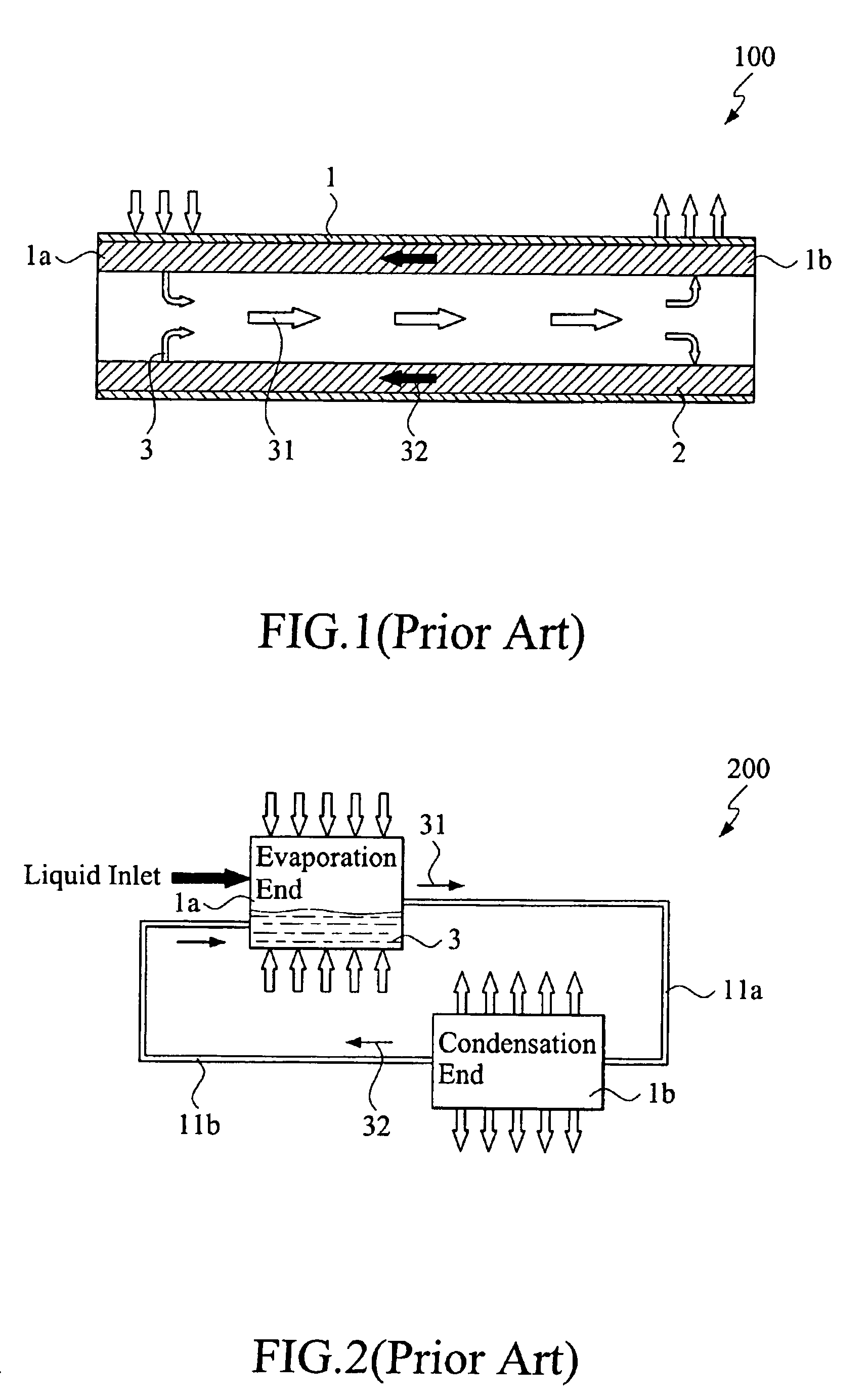

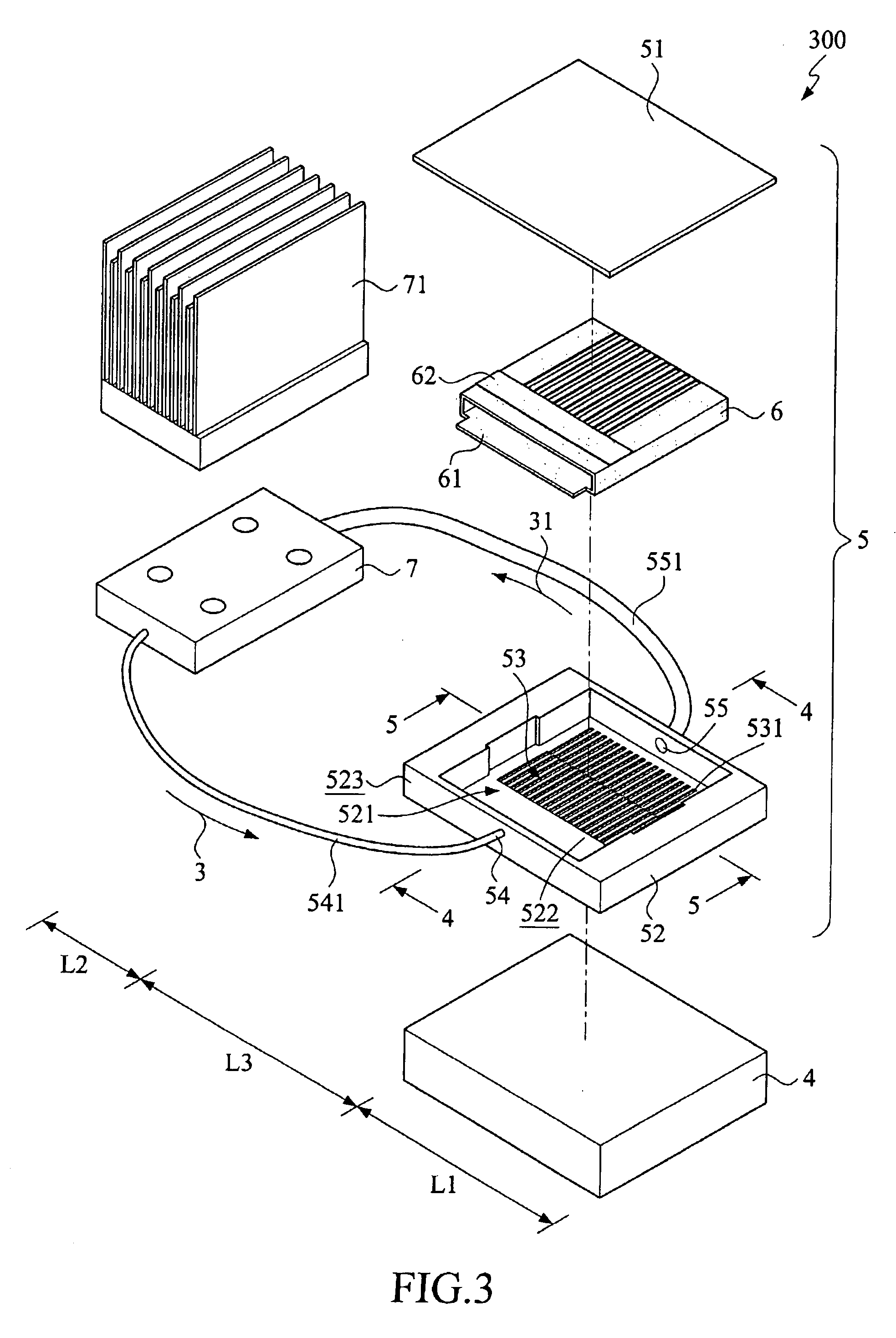

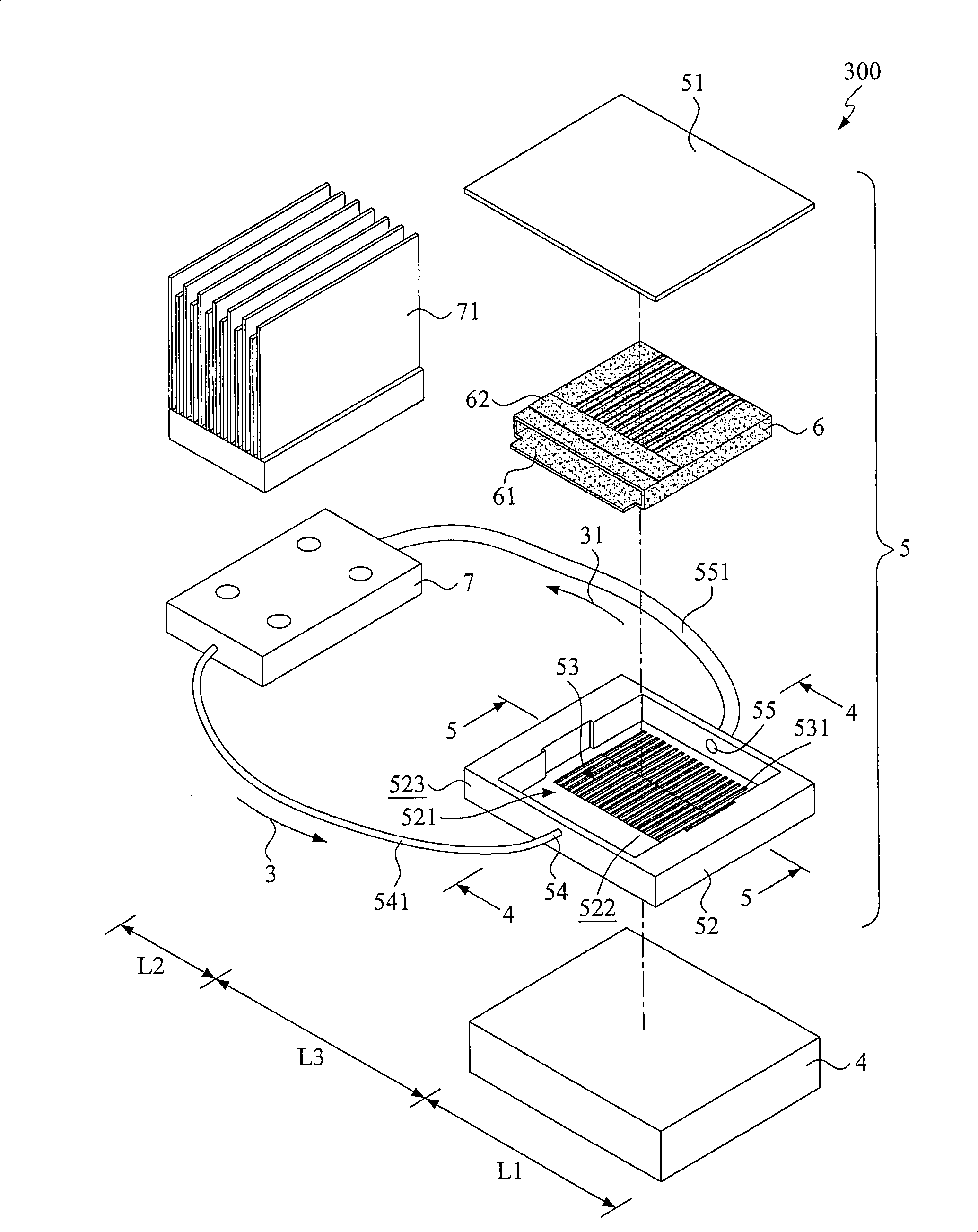

A loop heat pipe with flat evaporator includes an evaporation section, a condensation section, and a transportation section connected between the evaporation section and the condensation section. The evaporation section includes a heat source, an enclosed containment structure, and a capillary structure. The enclosed containment structure is positionable on the heat source and forms an enclosed containment space which receives a working fluid and has a bottom in which a channel structure is formed and further forms a liquid inlet and a gas outlet in a circumferential wall thereof the container to respectively connect a liquid passage and a gas passage so that when the working fluid is heated by the heat source to become vapor, the vapor moves through the gas outlet and the gas passage to a condensing device provided in the condensation section where the vapor is cooled and converted back to the liquid form of the working fluid that is then guided through the liquid passage back to the enclosed containment space for next cycle.

Owner:TAMKANG UNIVERSITY

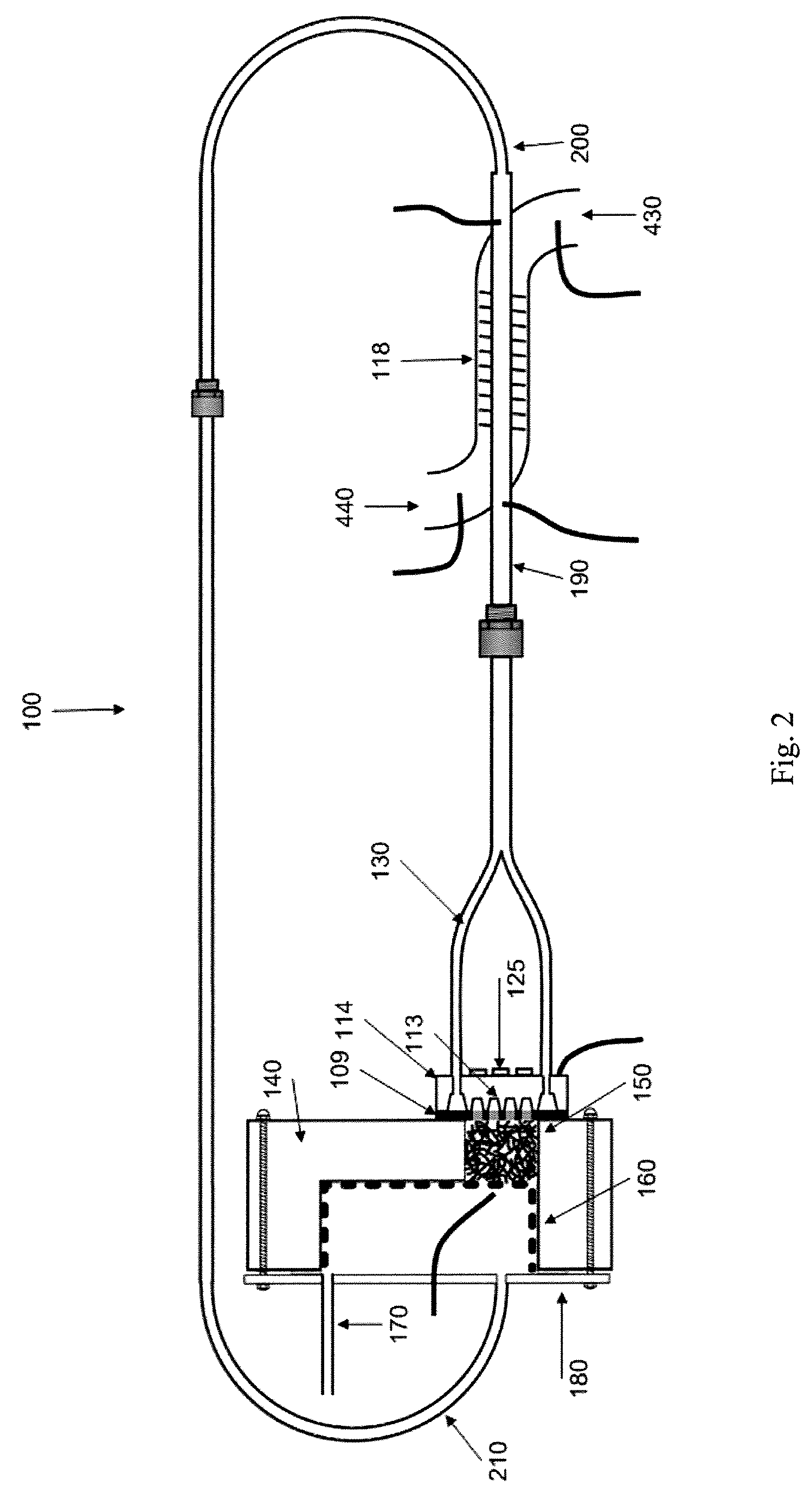

Loop heat pipe with flexible artery mesh

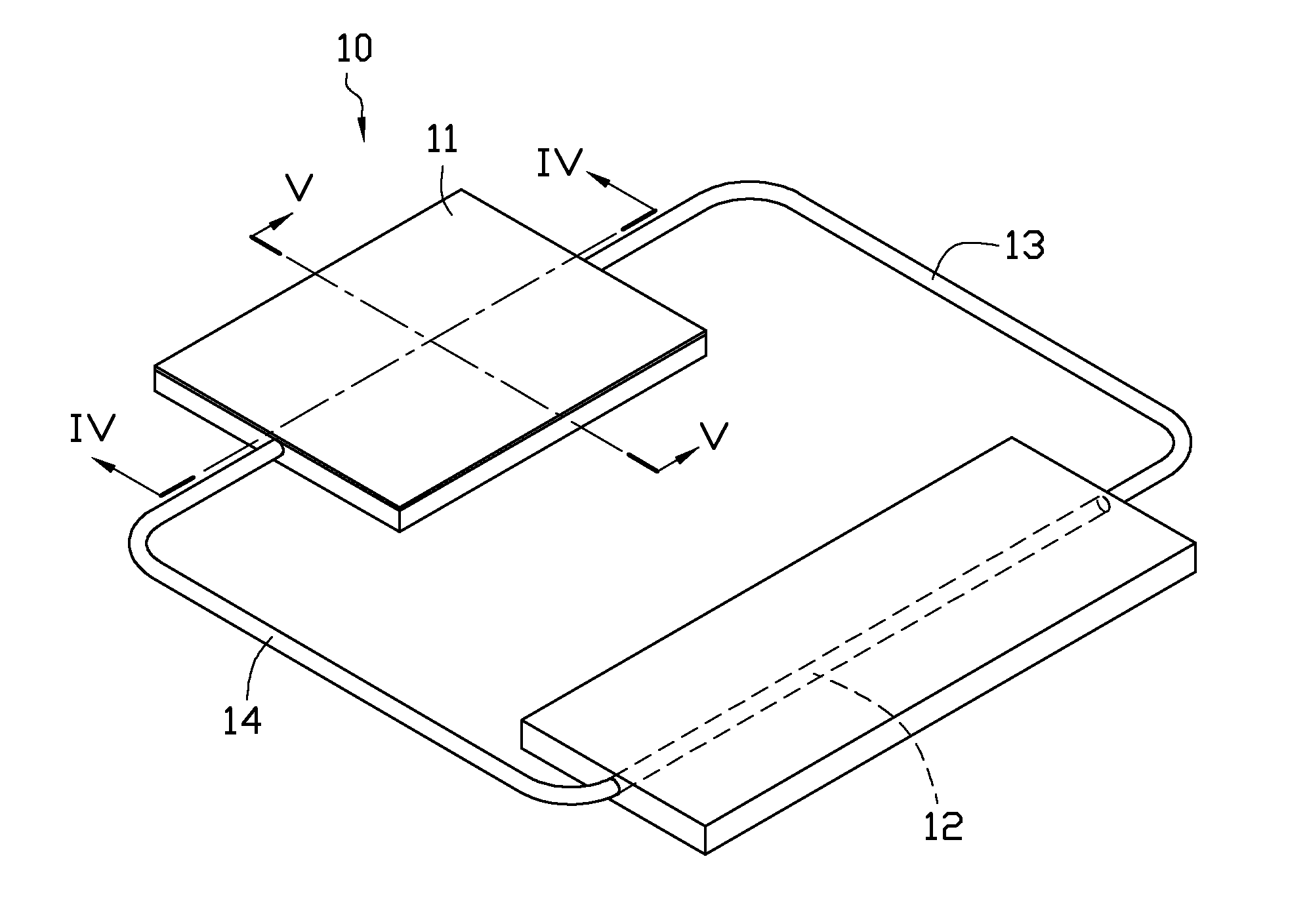

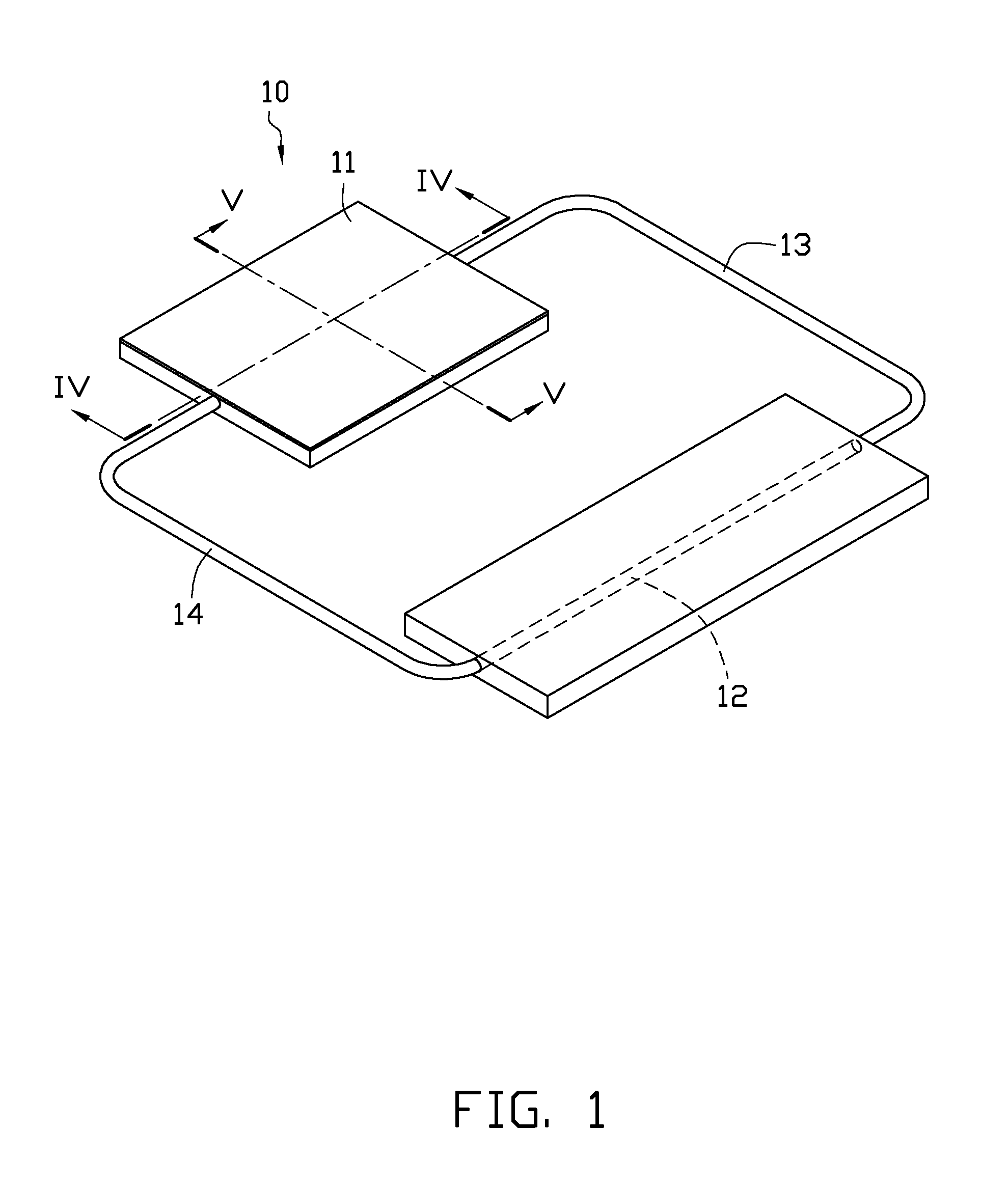

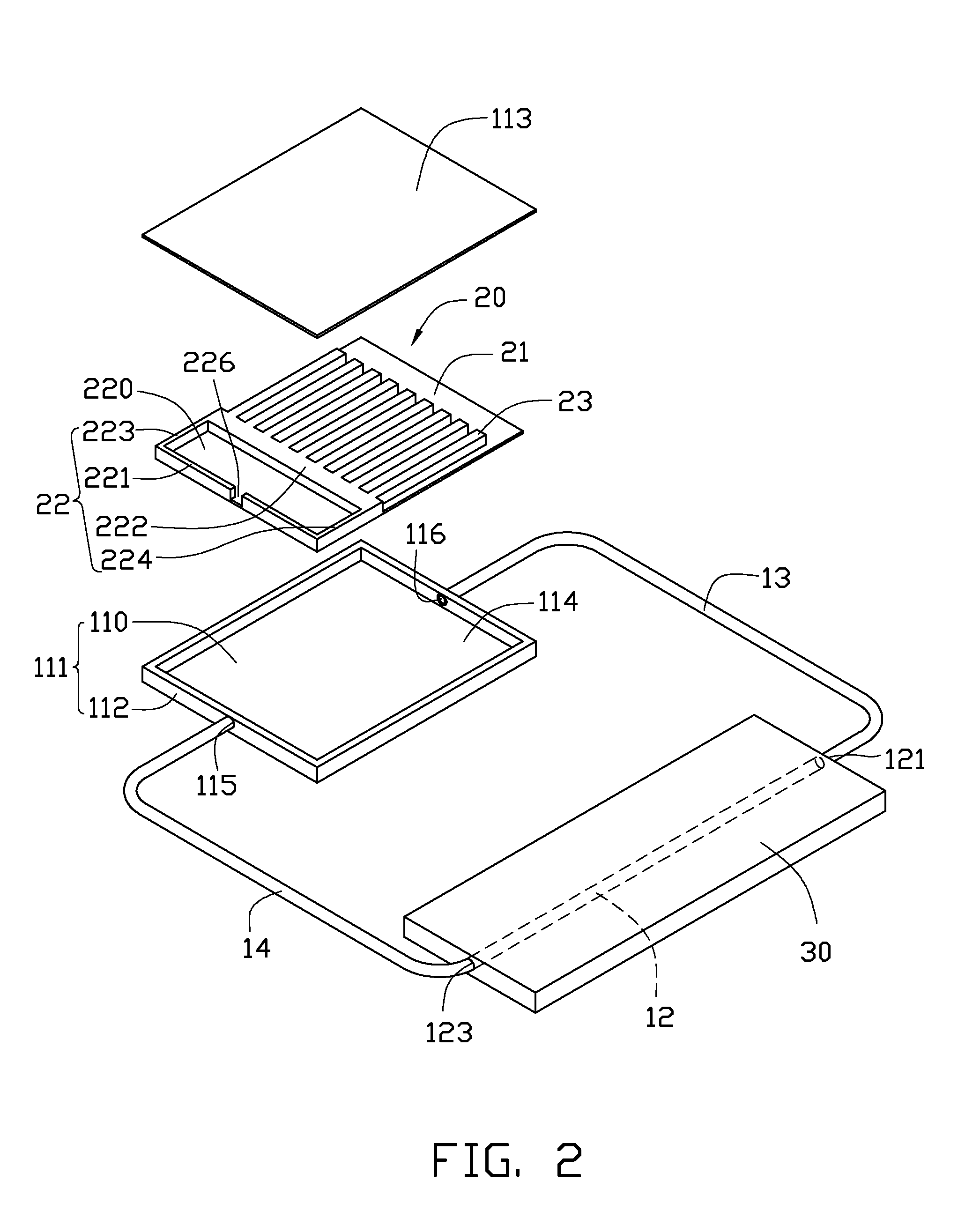

InactiveUS20080078530A1Semiconductor/solid-state device detailsSolid-state devicesLiquid lineClosed loop

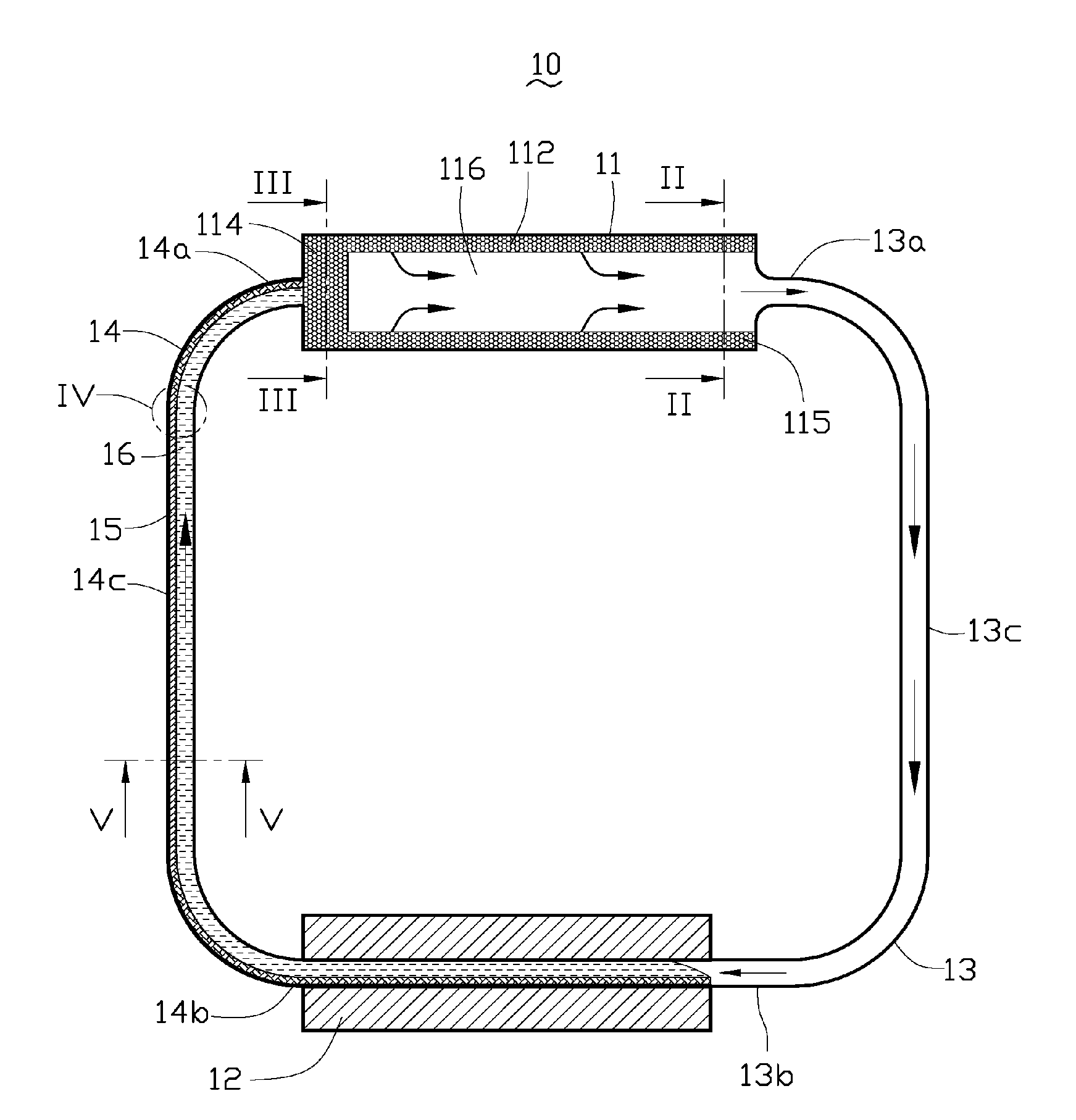

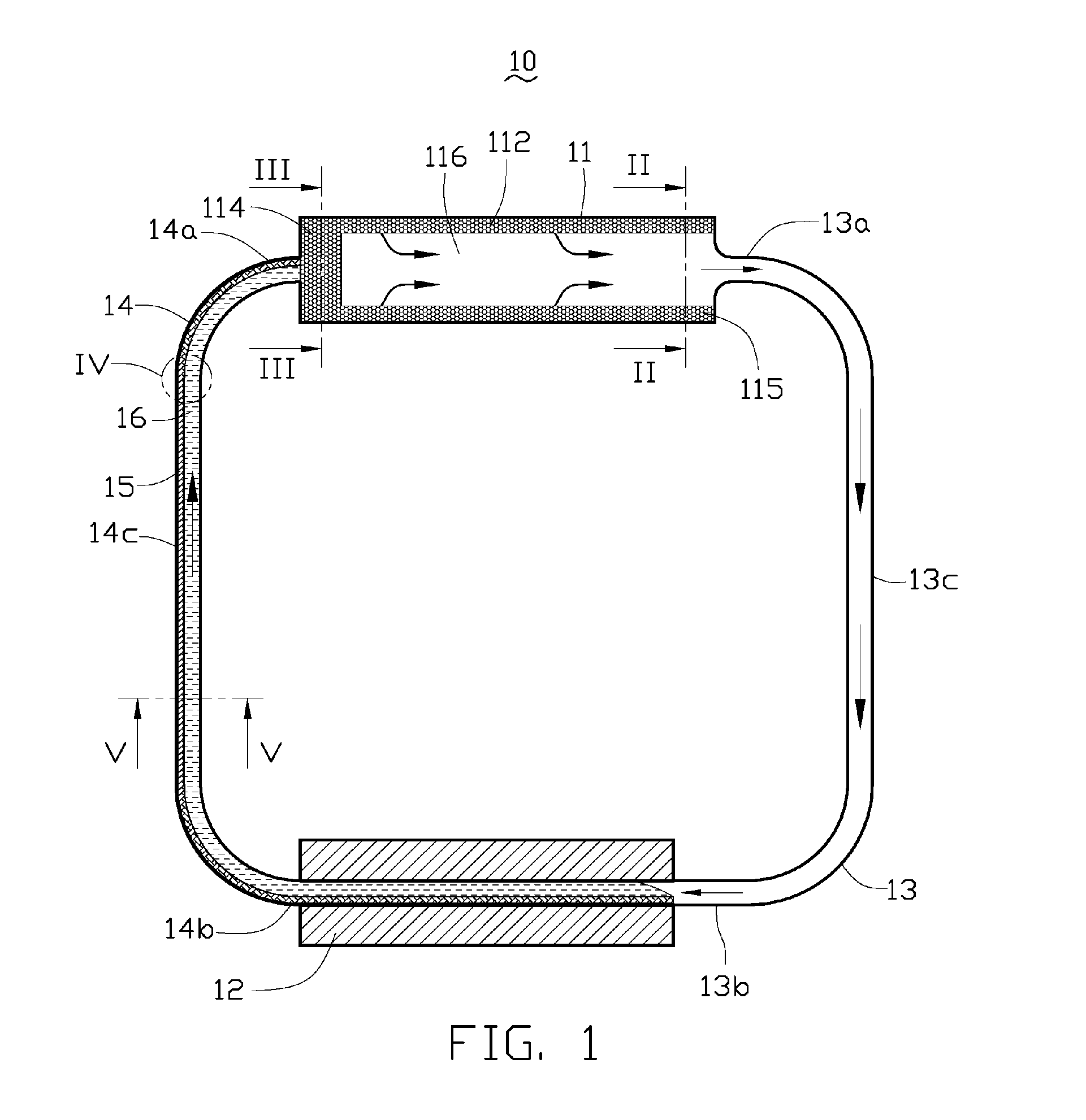

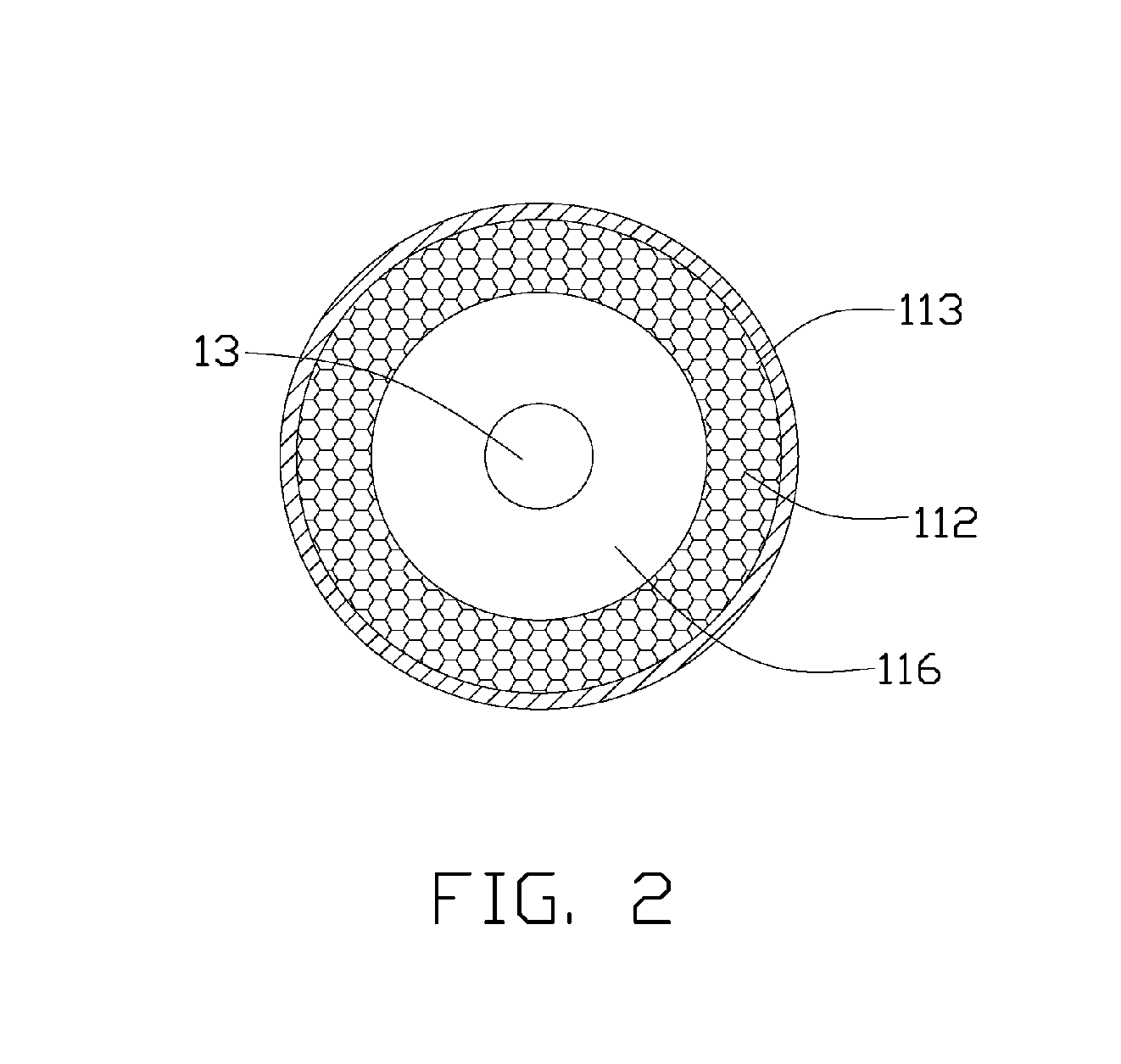

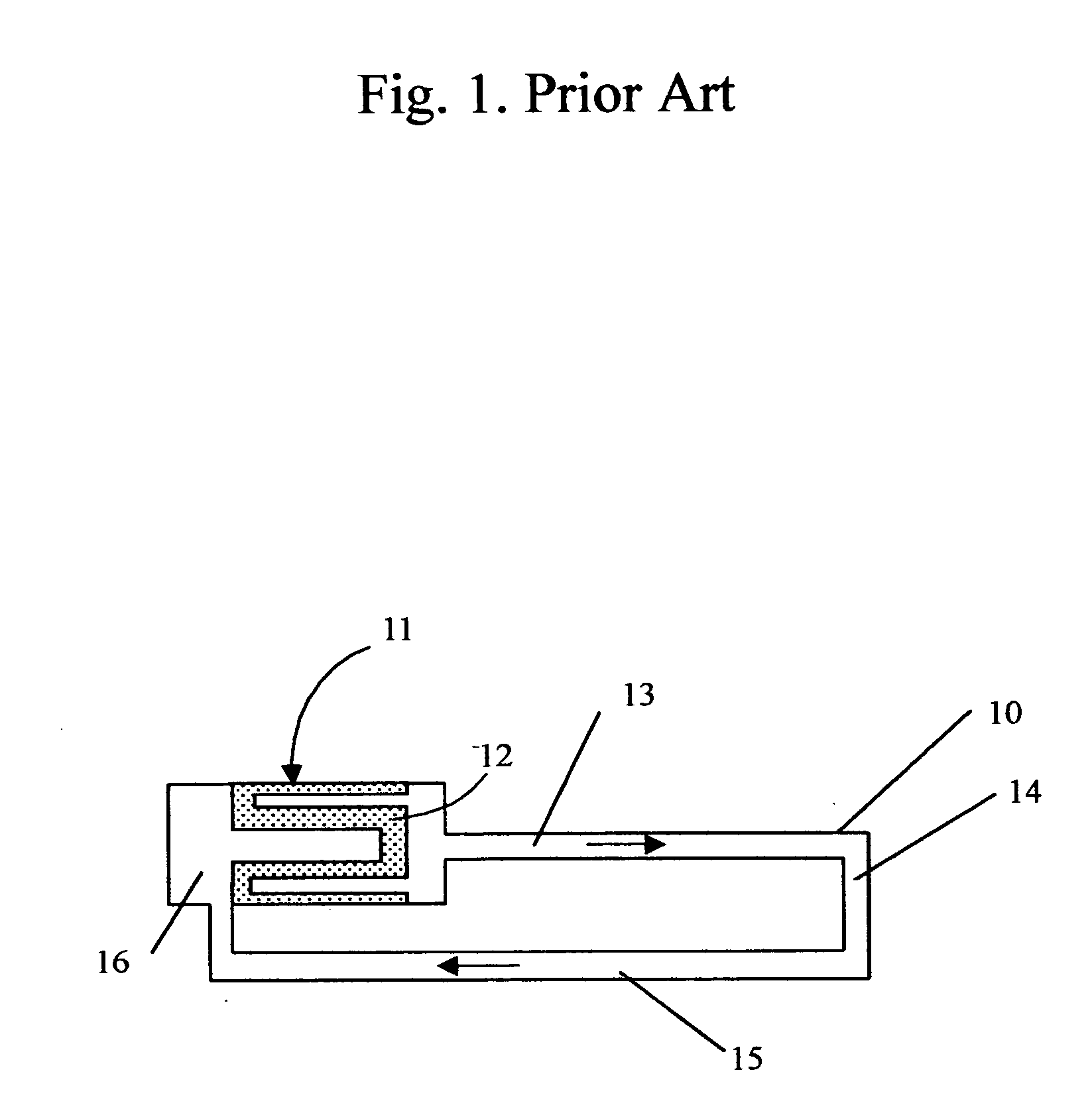

A loop heat pipe (10) includes an evaporator (11) thermally connected with a heat generating electronic component and including a wick structure (112) disposed therein, a condenser (12) thermally connected with a heat dissipating component, a vapor line (13) and a liquid line (14) connecting the evaporator with the condenser to form a closed loop, a predetermined quantity of bi-phase working medium contained in the closed loop, and an artery mesh (15) located within the liquid line.

Owner:HON HAI PRECISION IND CO LTD

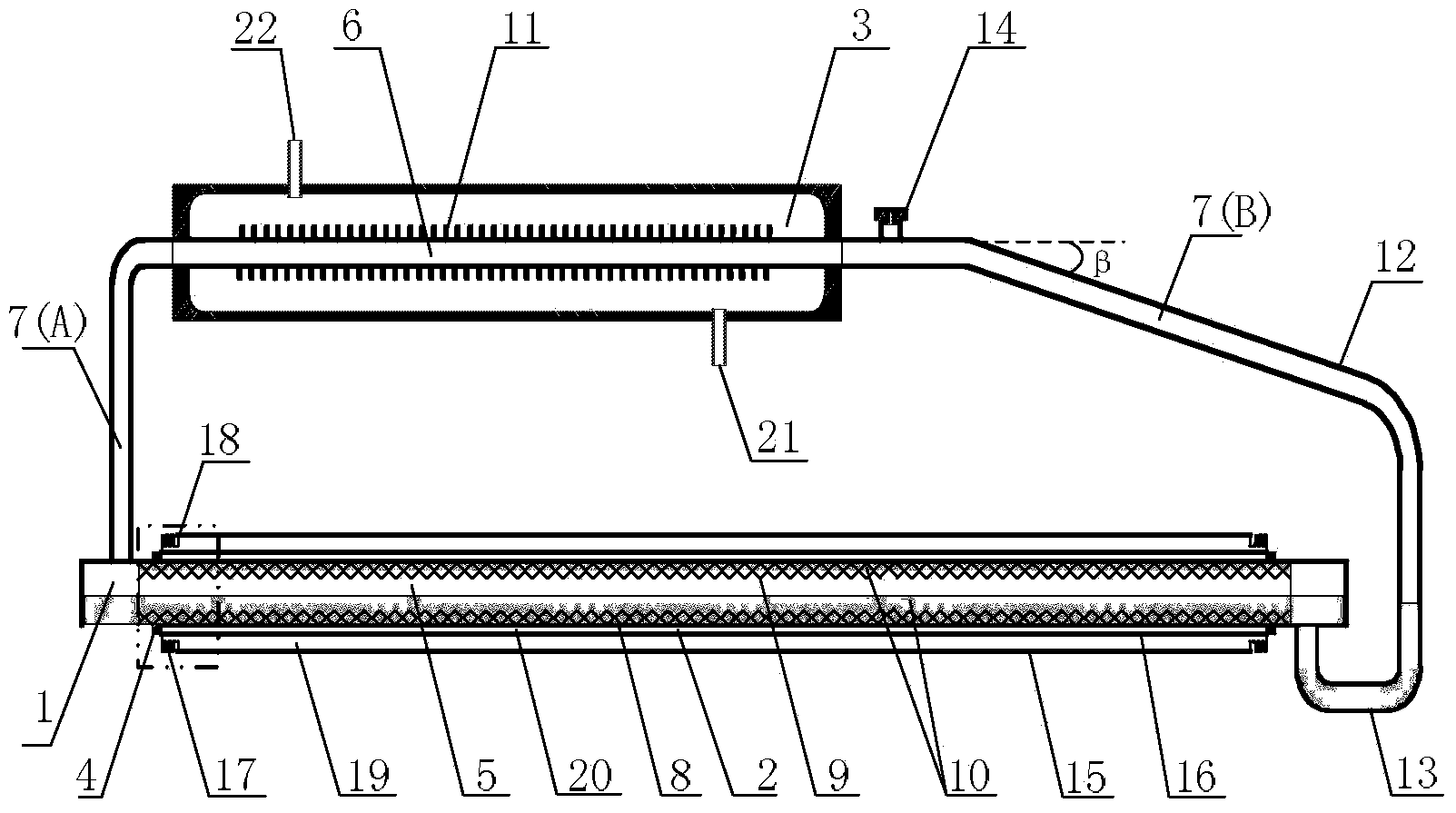

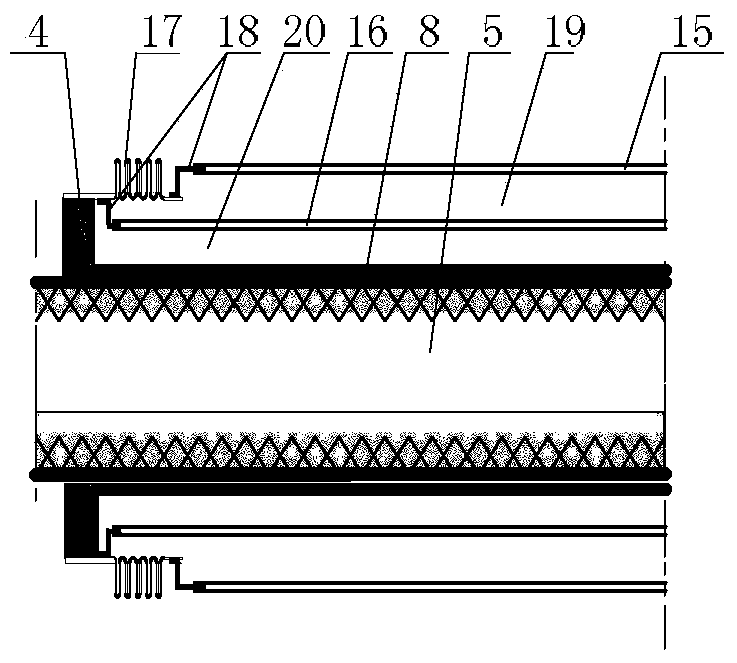

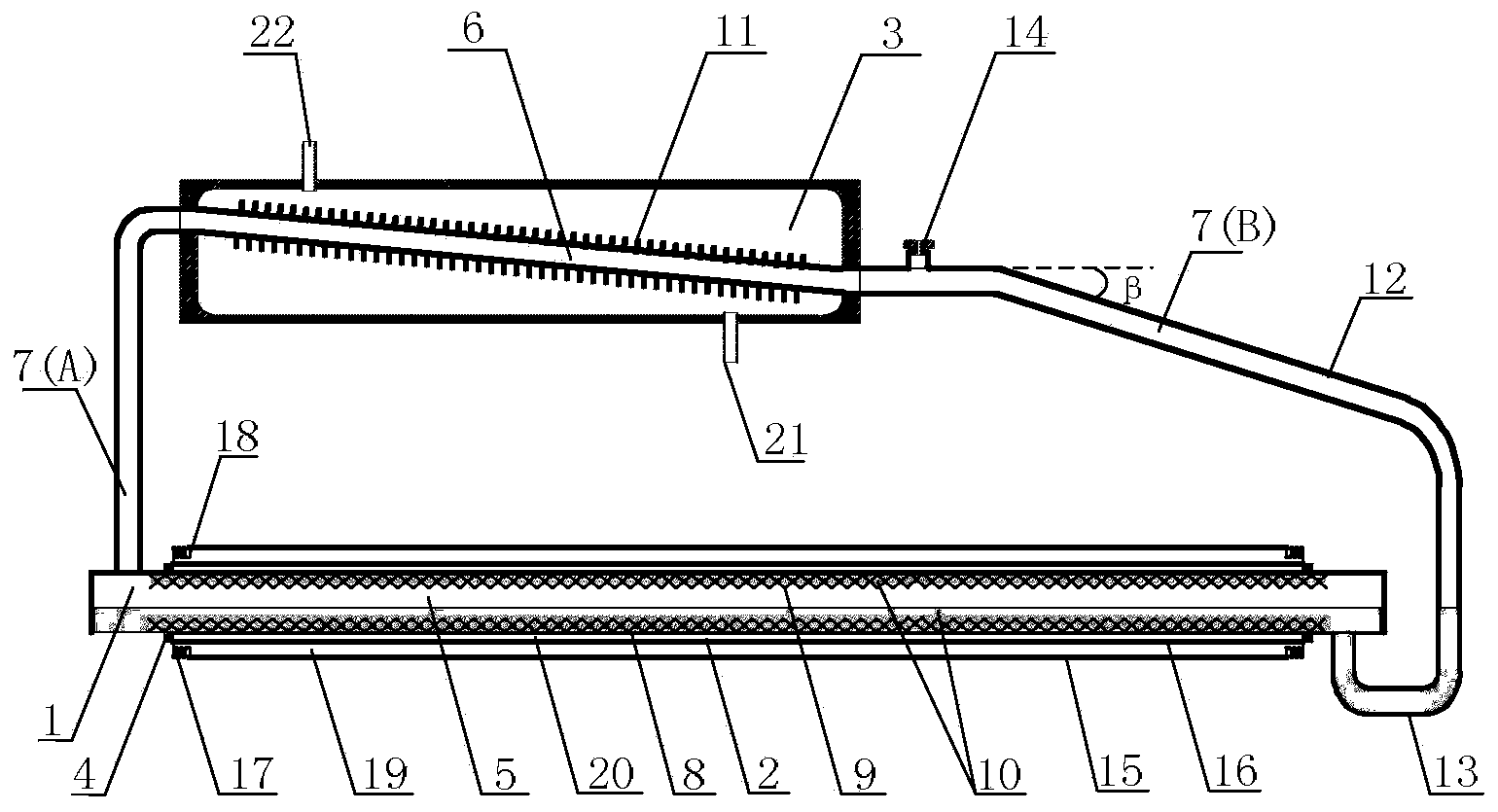

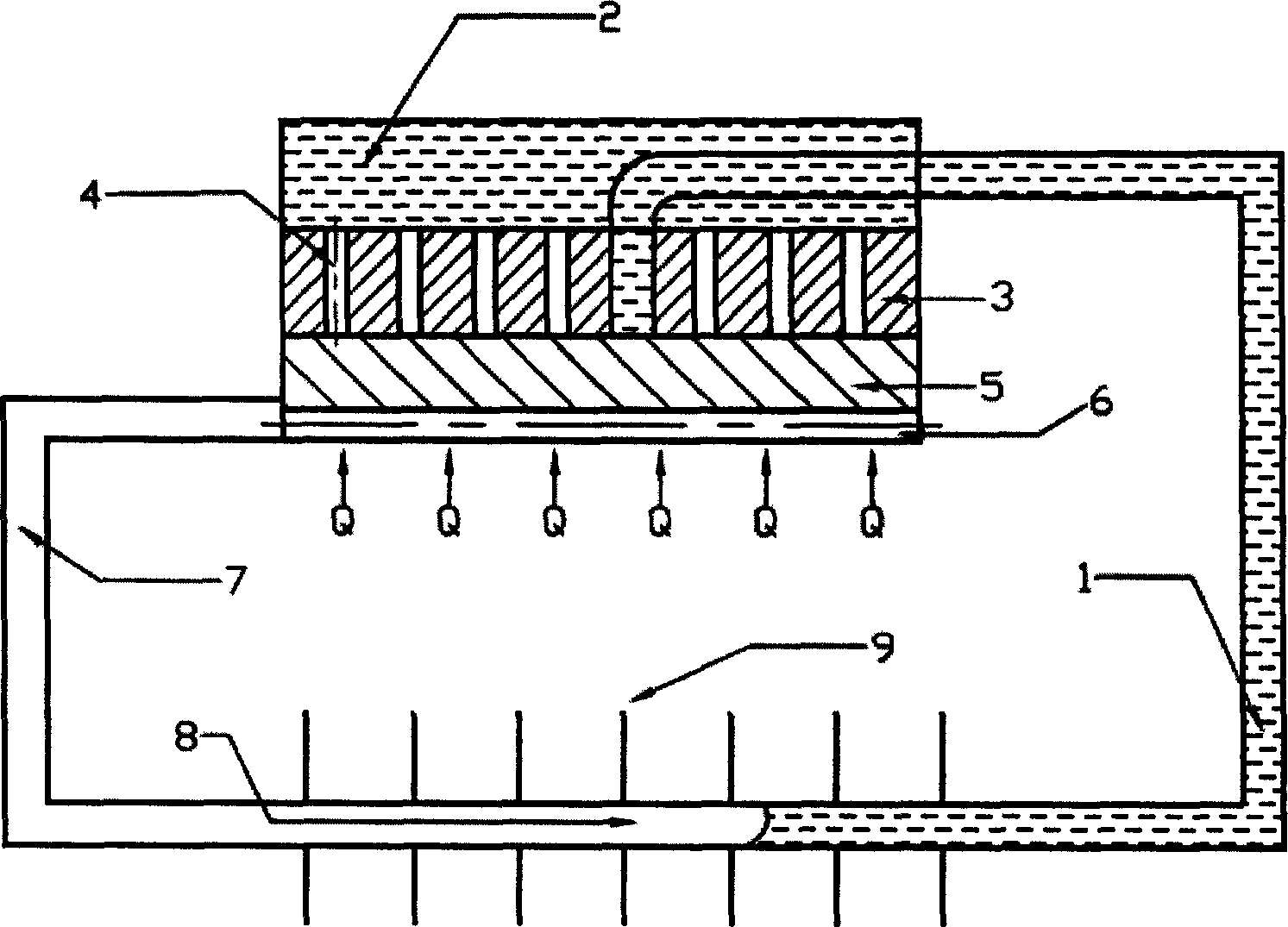

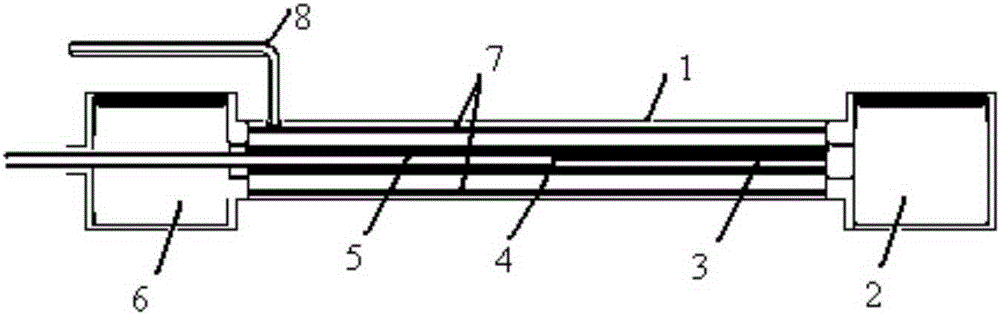

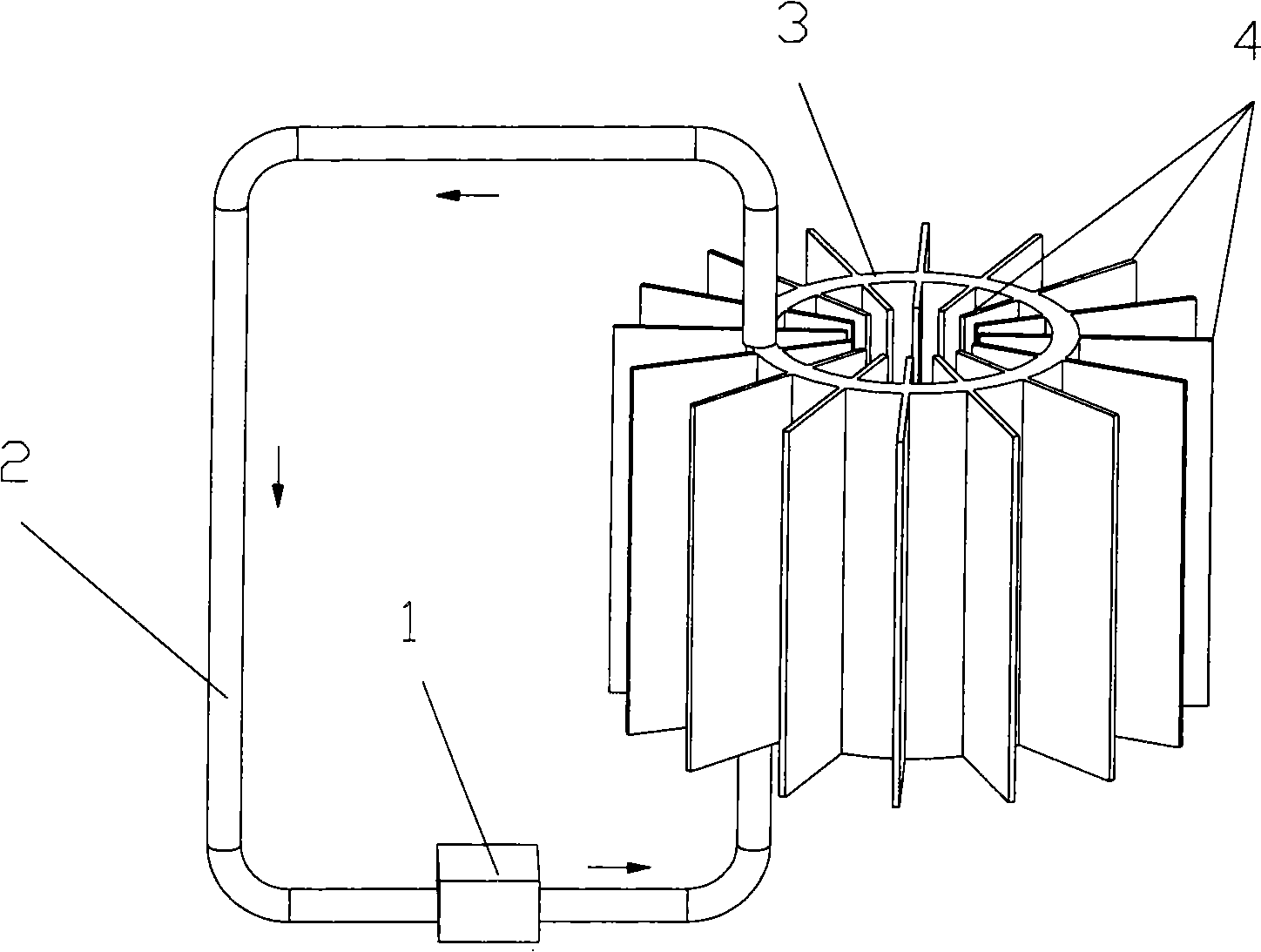

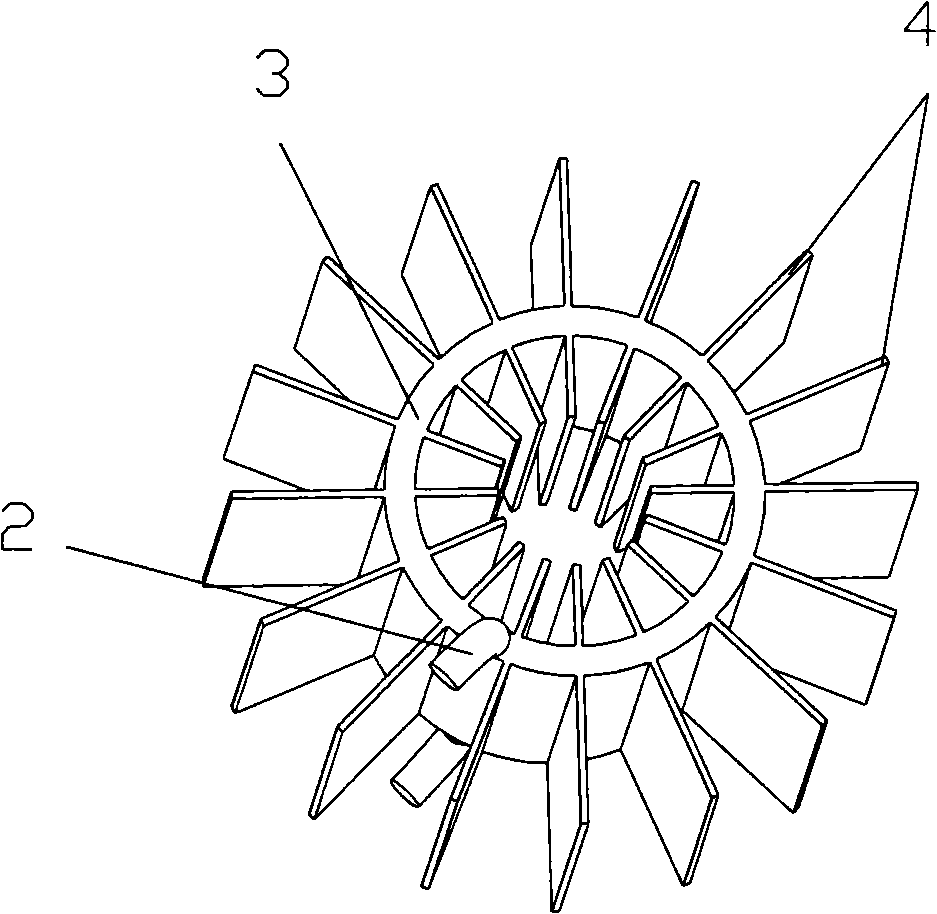

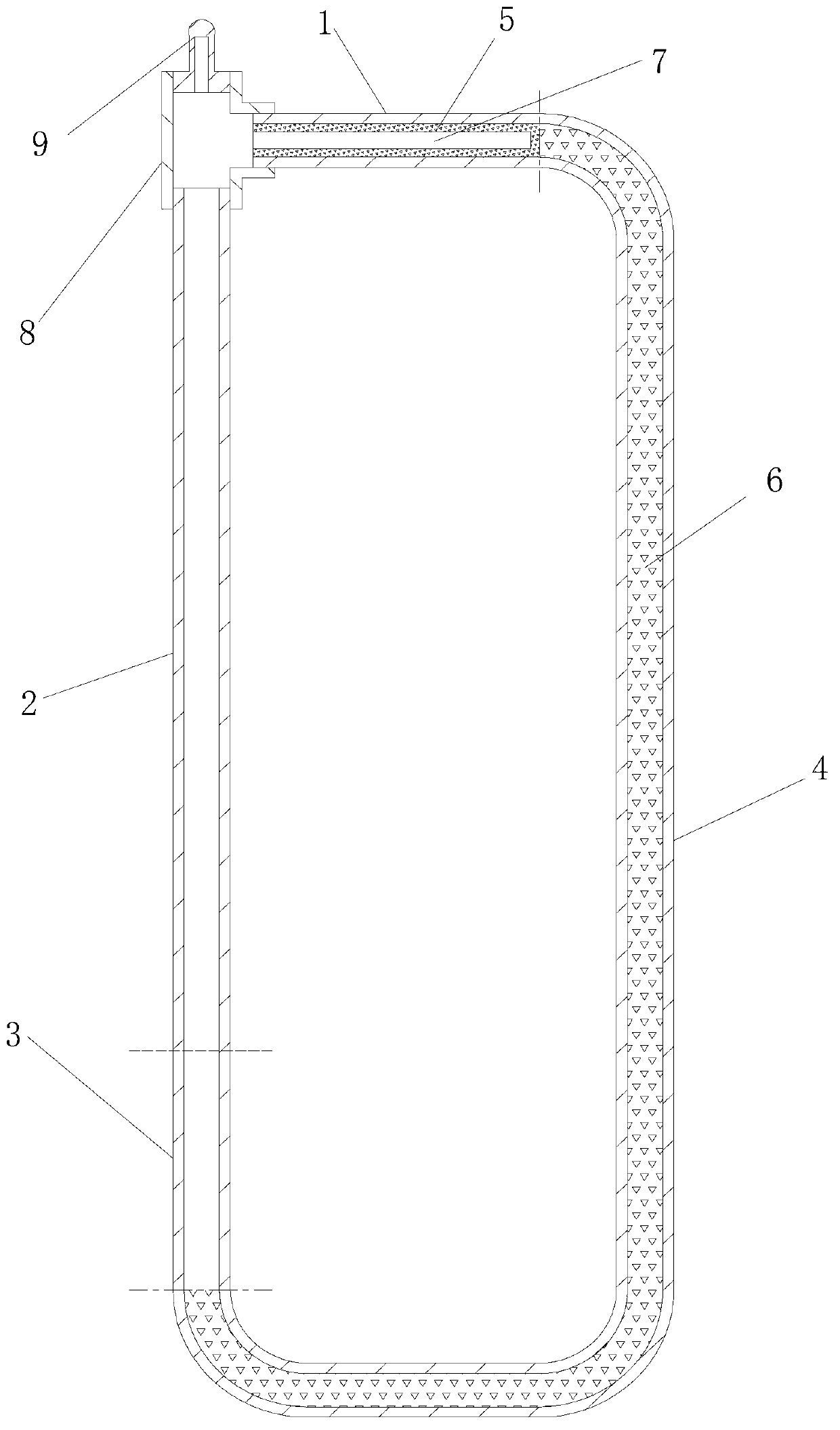

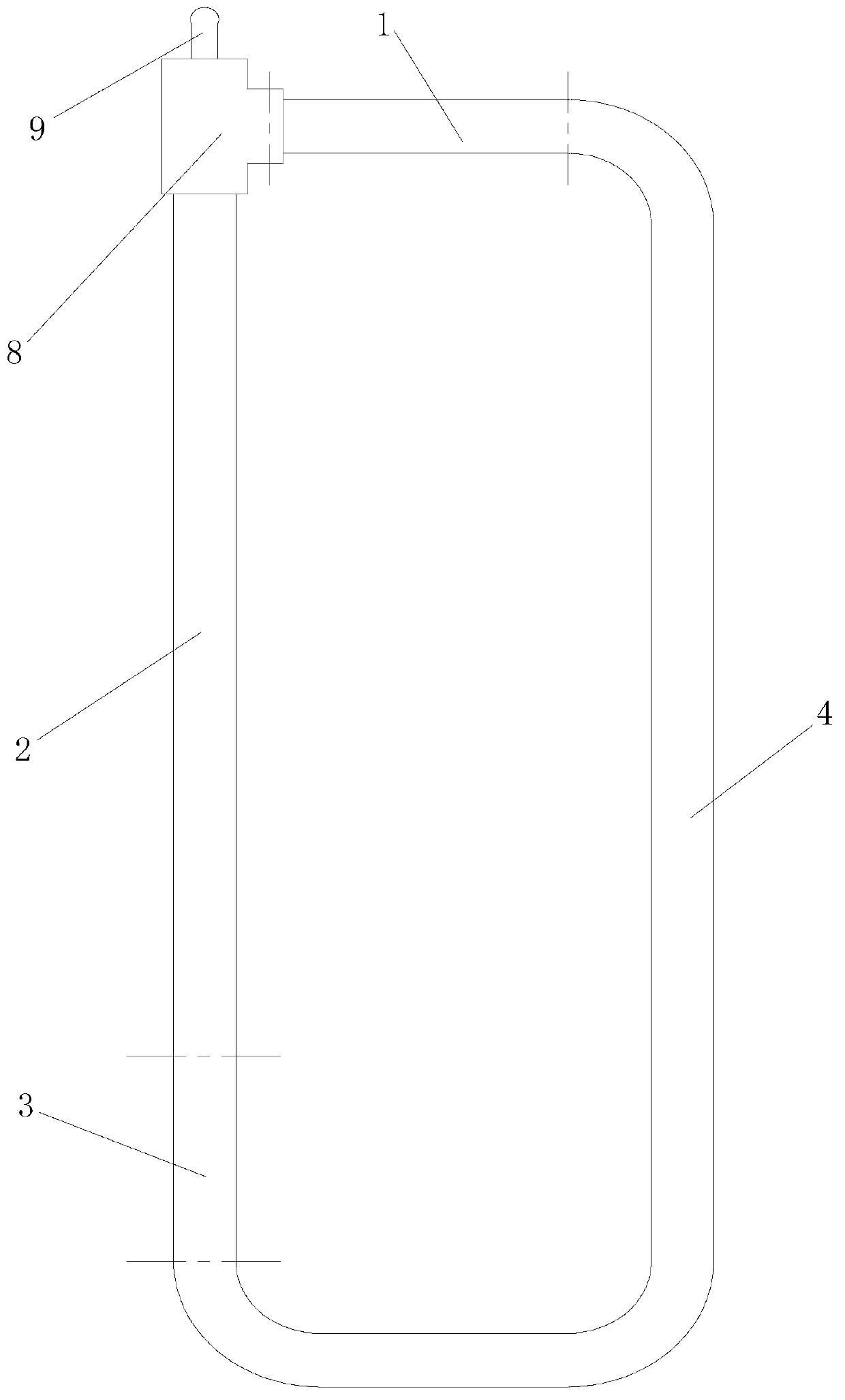

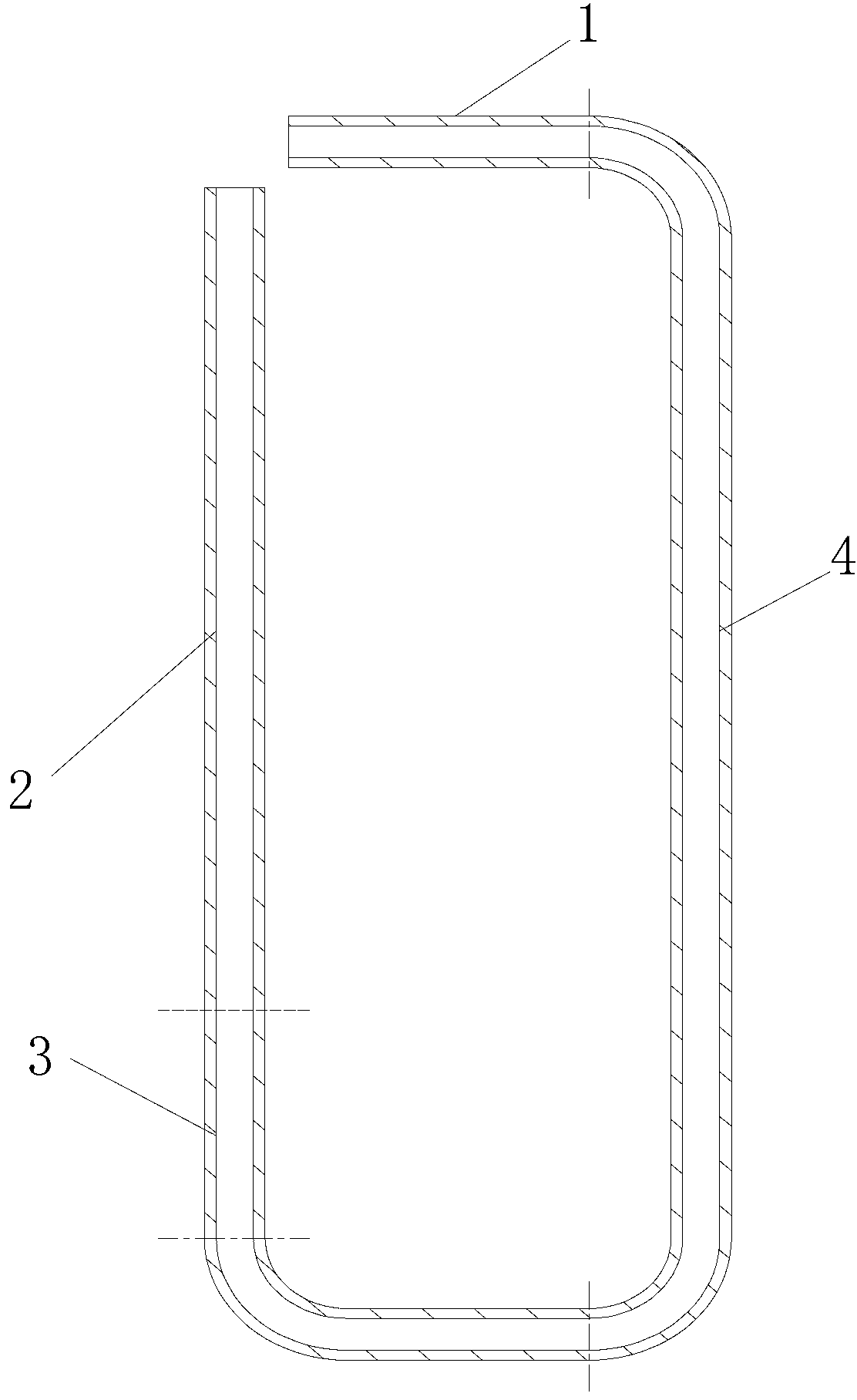

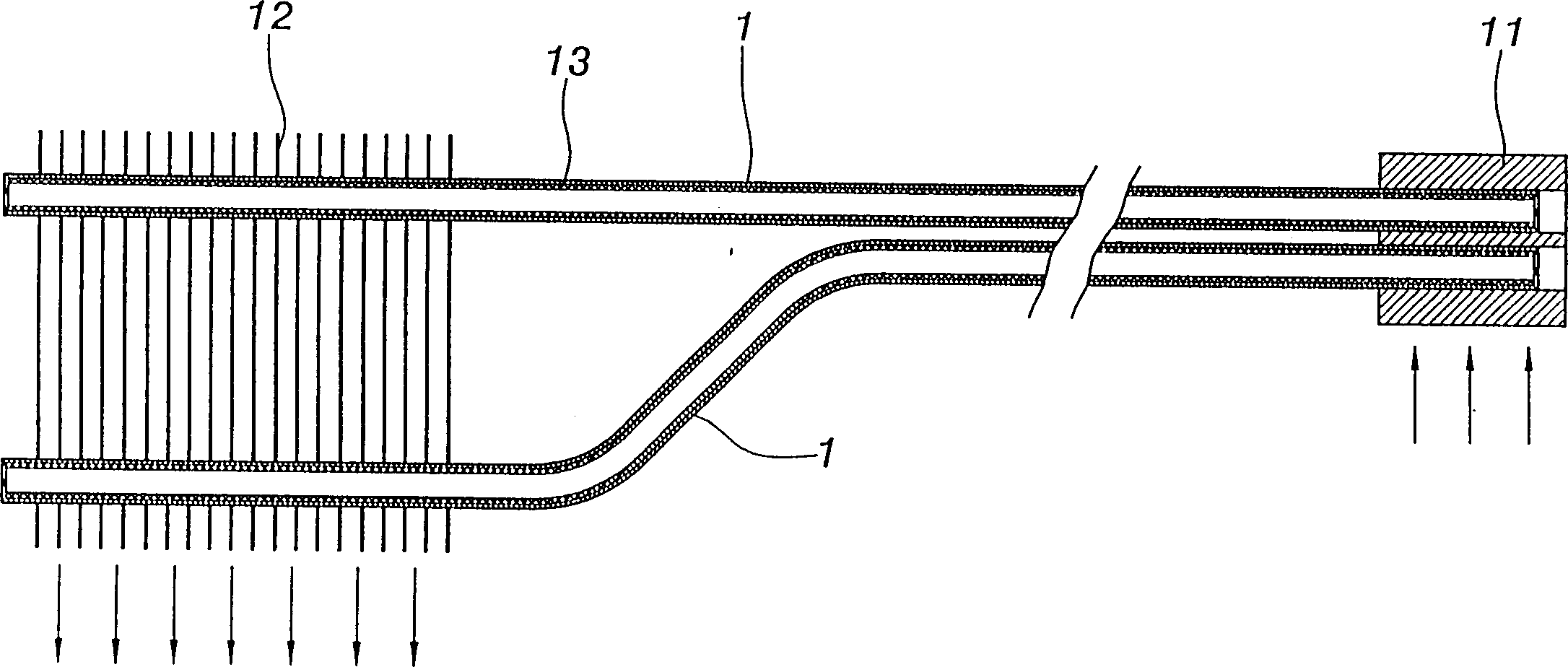

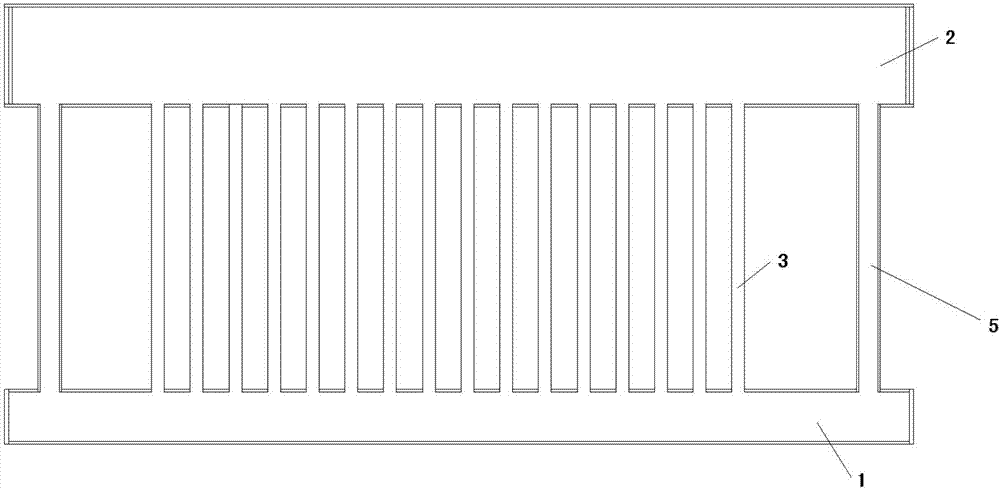

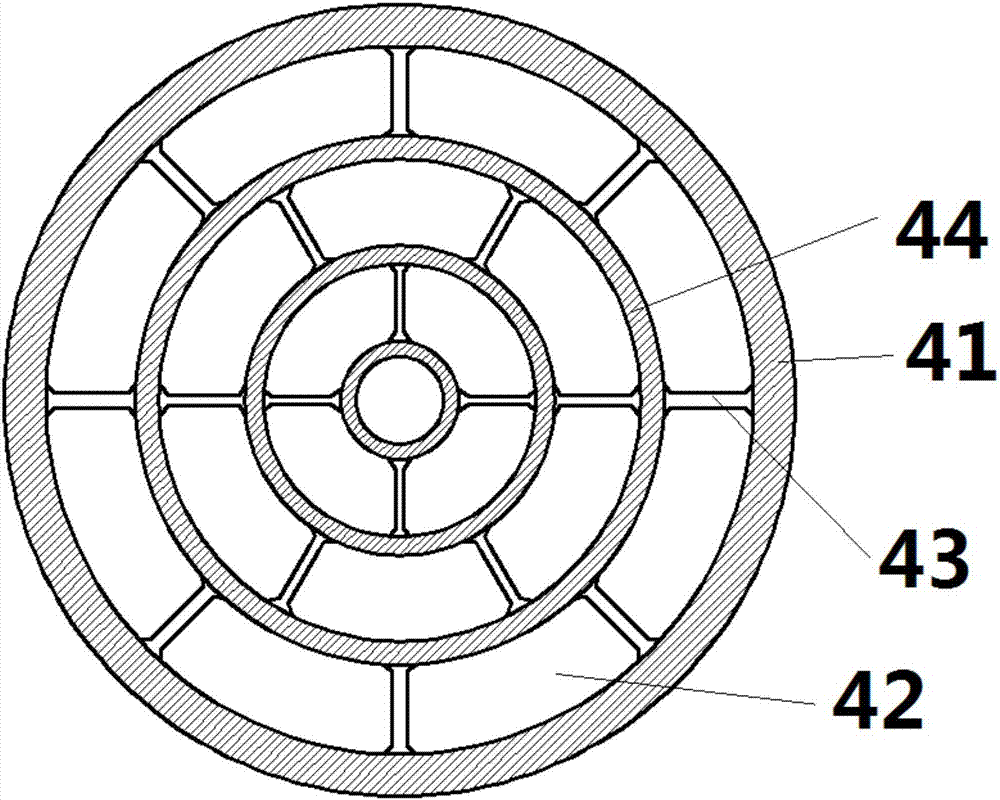

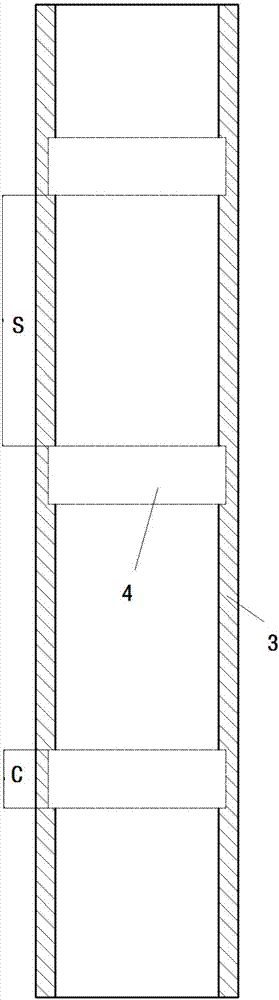

Solar medium-high-temperature loop heat pipe steam generator

ActiveCN104279770ALow costImprove reliabilitySolar heating energySteam generation heating methodsMicro-loop heat pipeEvaporation

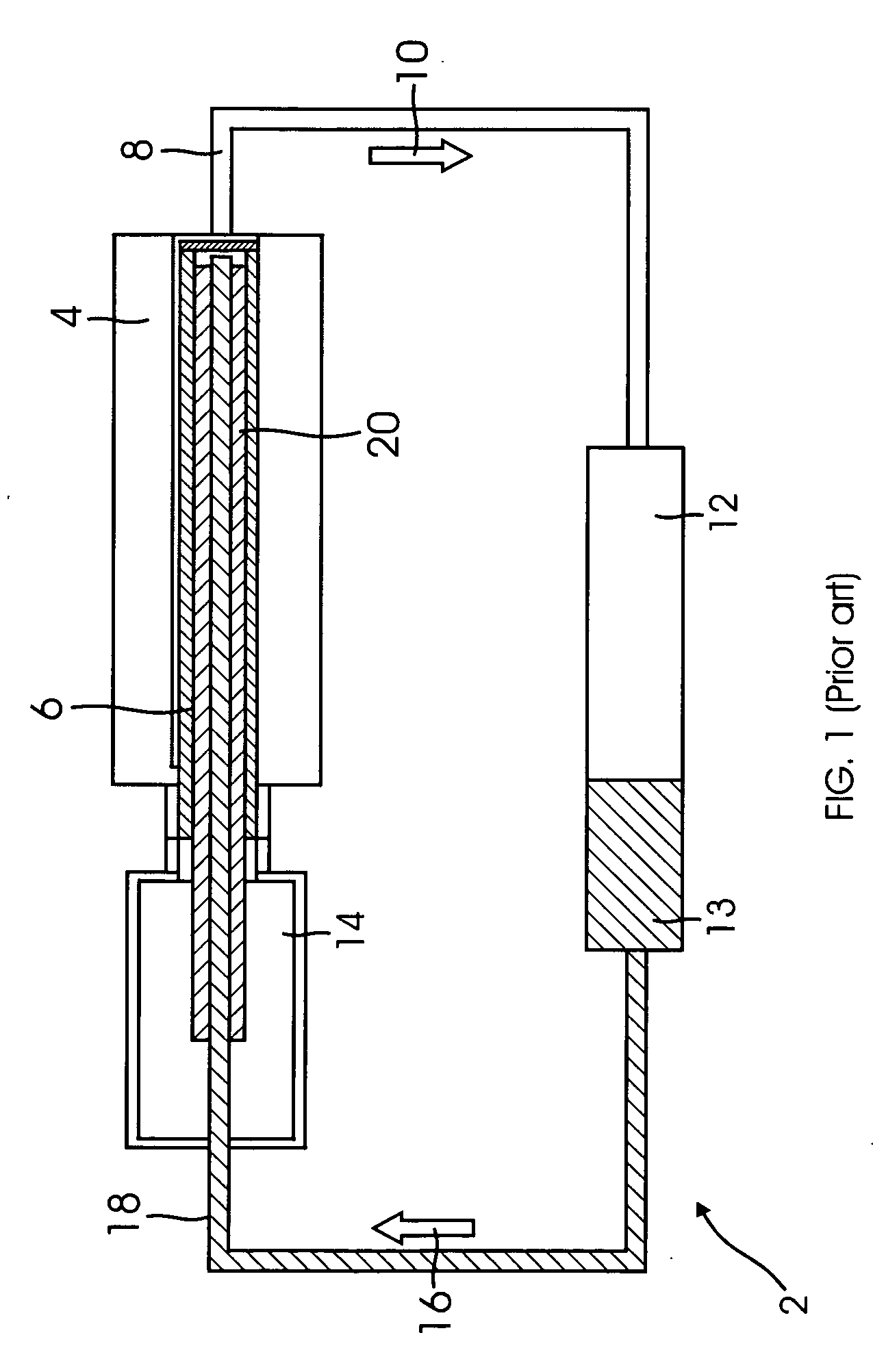

The invention relates to a solar medium-high-temperature loop heat pipe steam generator which is composed of a loop heat pipe (1), a straight-through all-glass vacuum pipe (2), a steam pocket (3) and a sealing ring (4). The loop heat pipe (1) is a closed loop formed by an evaporation section (5), a condensation section (6), a first heat insulation section (7(A)) and a second heat insulation section (7(B)), the first heat insulation section (7(A)) is a steam ascending pipe, the second heat insulation section (7(B)) is formed by a condensing liquid descending pipe (12) and a U-shaped liquid storage pipe (13), the straight-through all-glass vacuum pipe (2) and the evaporation section (5) are placed coaxially to form an annular non-vacuum space (20), two ends of the annular non-vacuum space (20) are sealed by adopting sealing rings (4), and the steam pocket (3) is in sealed connection with the condensation section (6) of the loop heat pipe (1). The solar medium-high-temperature loop heat pipe steam generator is suitable for groove-type solar DSG technology, high-efficiency phase change of the heat pipe is utilized for heat transfer to heat water in the steam generator so as to directly generate high-temperature steam, system cost is lowered, and system running reliability is improved.

Owner:NANJING UNIV OF TECH

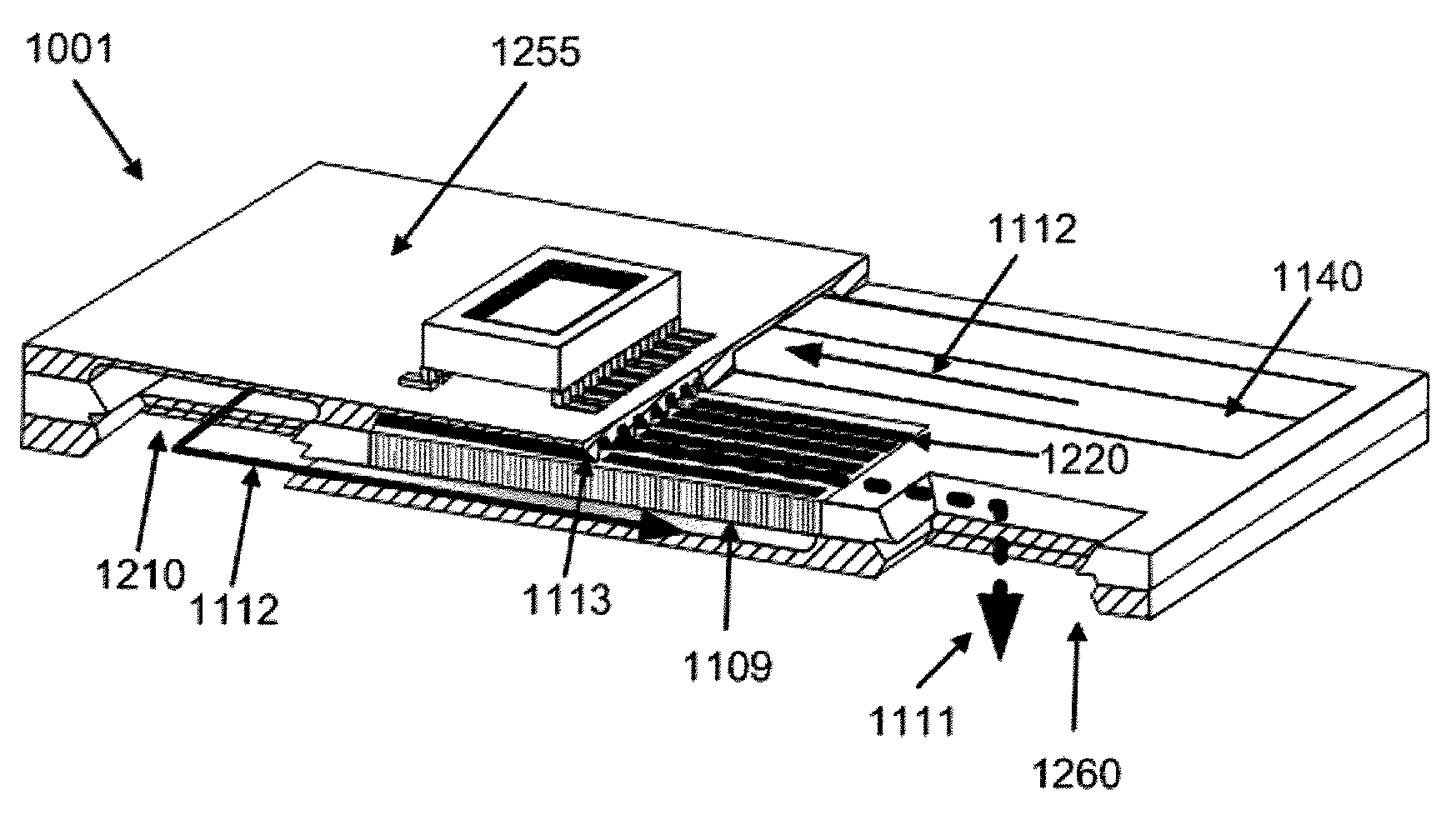

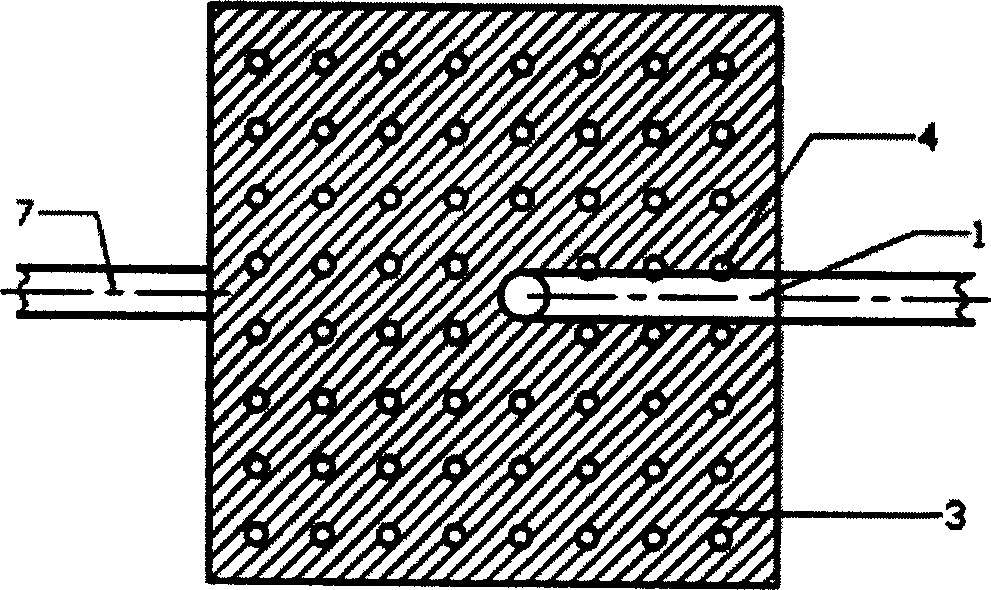

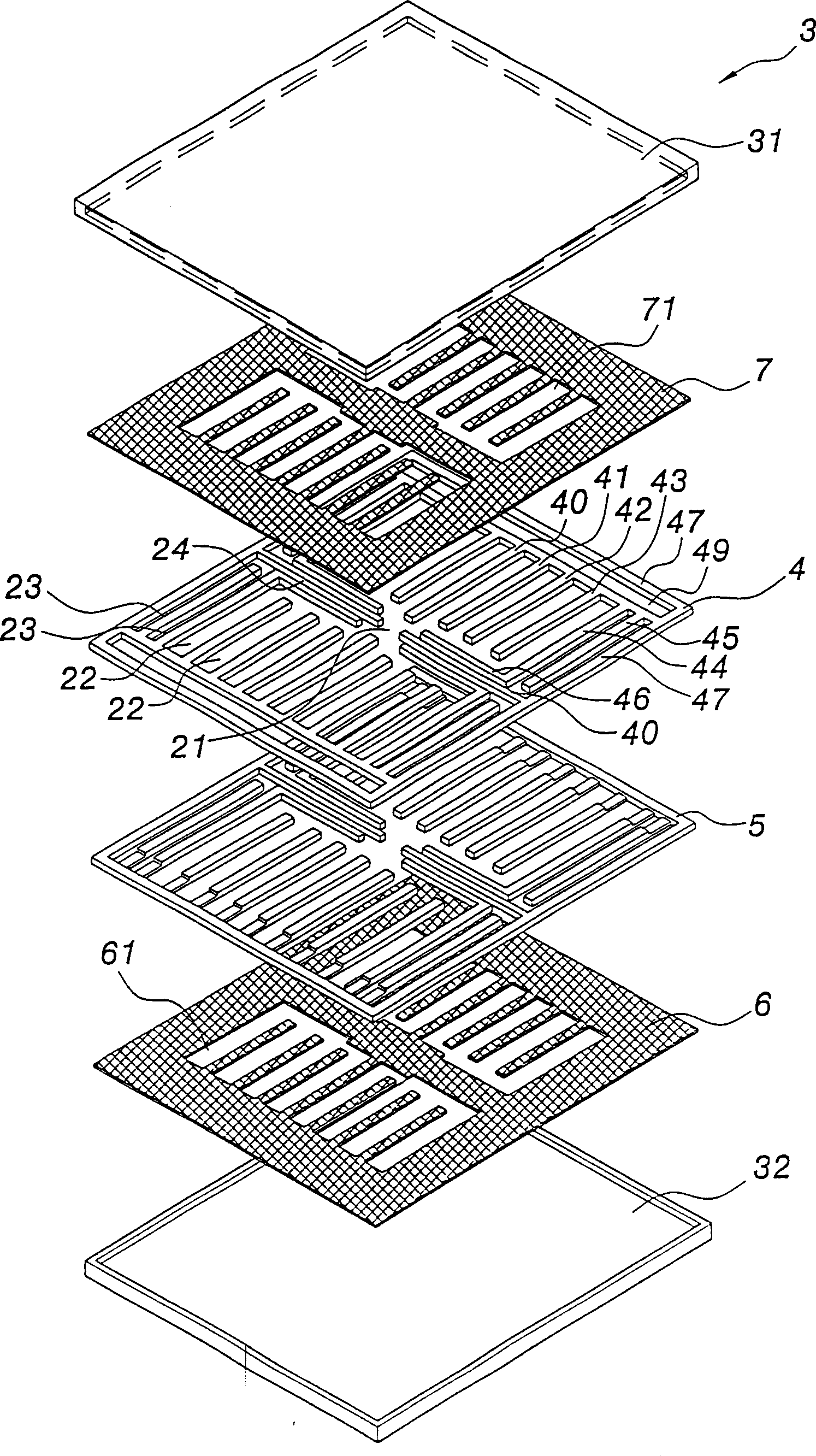

Silicon MEMS based two-phase heat transfer device

InactiveUS20070095507A1Semiconductor/solid-state device detailsSolid-state devicesMicron scaleVolumetric Mass Density

The present invention is a MEMS-based two-phase LHP (loop heat pipe) and CPL (capillary pumped loop) using semiconductor grade silicon and microlithographic / anisotrophic etching techniques to achieve a planar configuration. The principal working material is silicon (and compatible borosilicate glass where necessary), particularly compatible with the cooling needs for electronic and computer chips and package cooling. The microloop heat pipes (μLHP™) utilize cutting edge microfabrication techniques. The device has no pump or moving parts, and is capable of moving heat at high power densities, using revolutionary coherent porous silicon (CPS) wicks. The CPS wicks minimize packaging thermal mismatch stress and improves strength-to-weight ratio. Also burst-through pressures can be controlled as the diameter of the coherent pores can be controlled on a sub-micron scale. The two phase planar operation provides extremely low specific thermal resistance (20-60W / cm2). The operation is dependent upon a unique micropatterened CPS wick which contains up to millions per square centimeter of stacked uniform micro-through-capillaries in semiconductor-grade silicon, which serve as the capillary “engine,” as opposed to the stochastic distribution of pores in the typical heat pipe wick. As with all heat pipes, cooling occurs by virtue of the extraction of heat by the latent heat of phase change of the operating fluid into vapor. In the cooling of a laptop computer processor the device could be attached to the processor during laptop assembly. Consistent with efforts to miniaturize electronics components, the current invention can be directly integrated with a unpackaged chip. For applications requiring larger cooling surface areas, the planar evaporators can be spread out in a matrix and integrally connected through properly sized manifold systems.

Owner:UNIVERSITY OF CINCINNATI

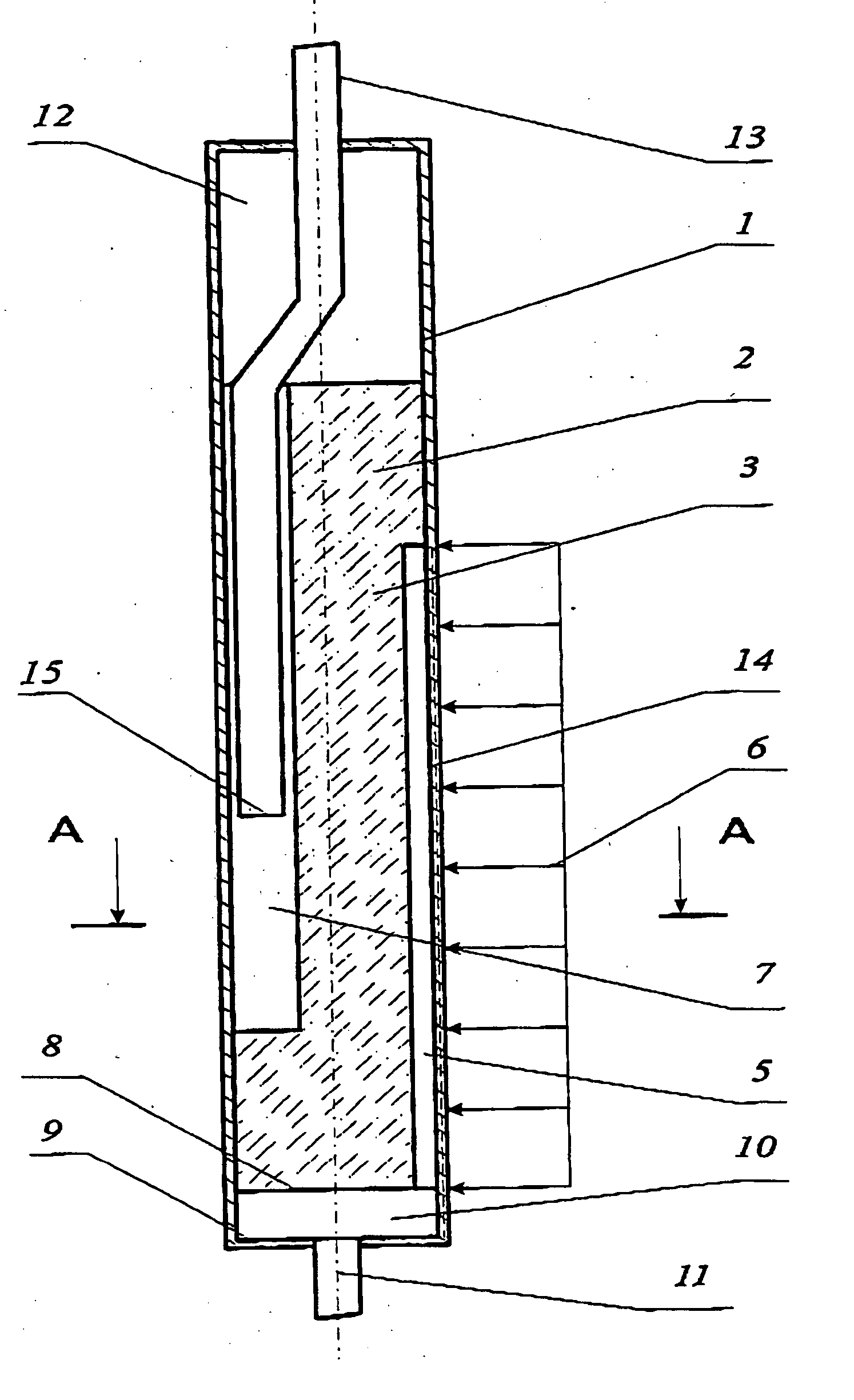

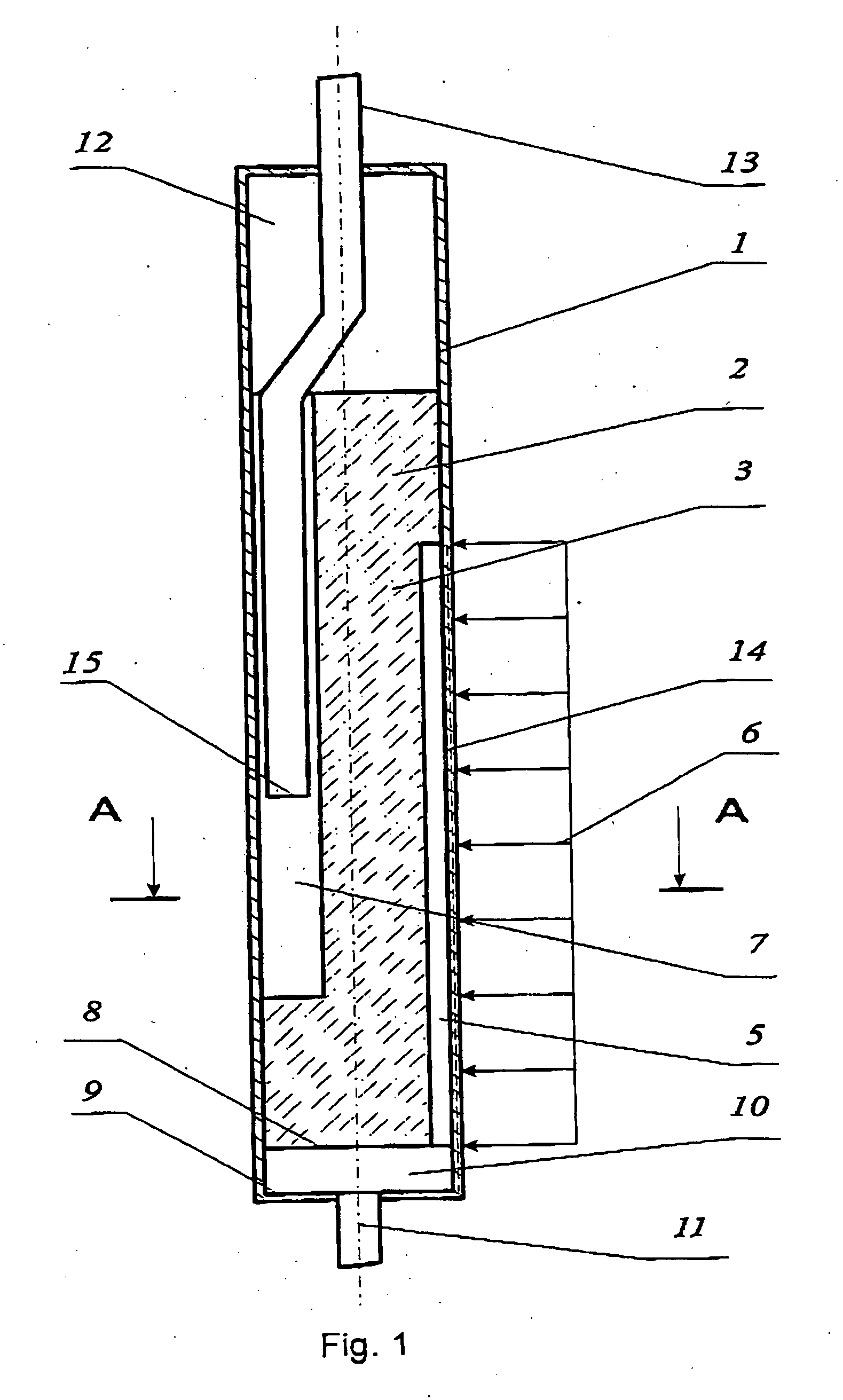

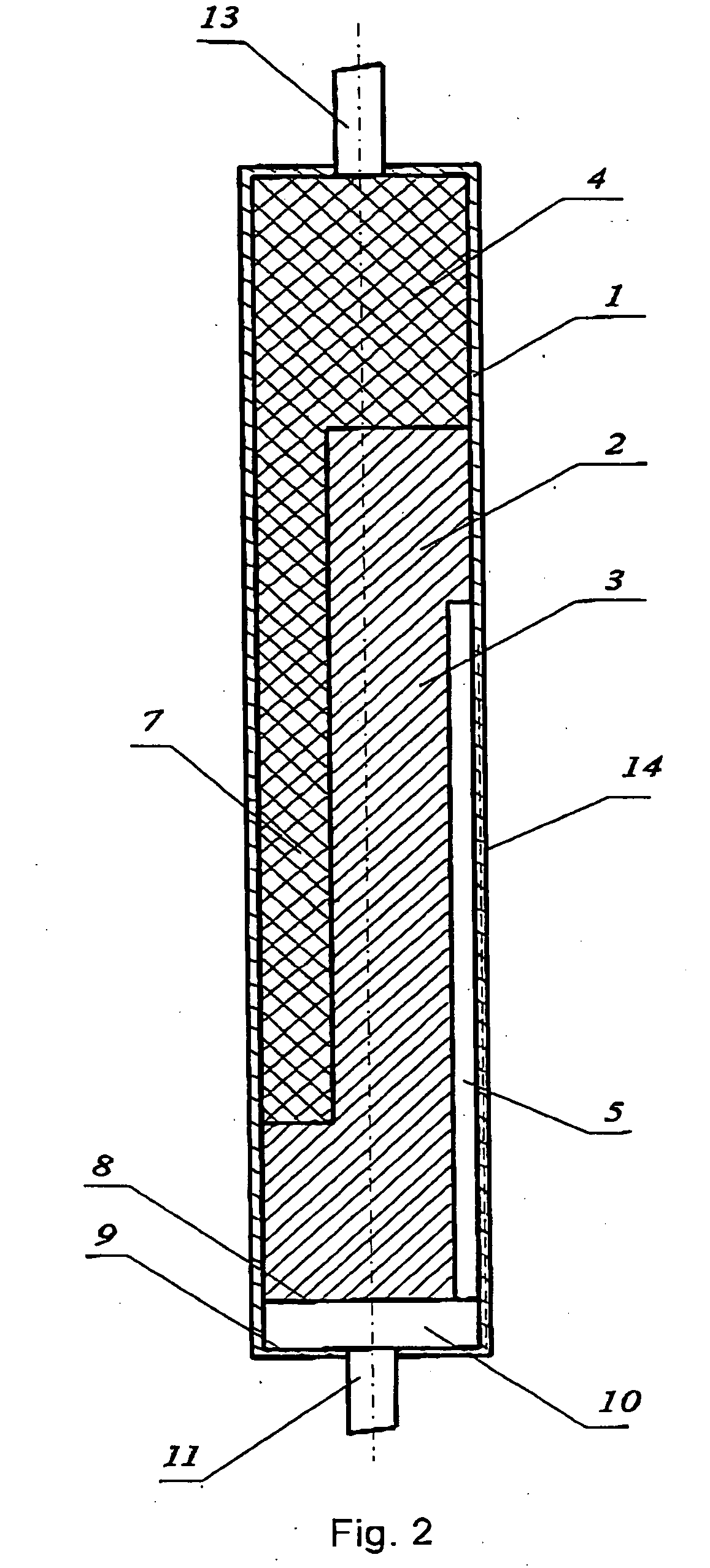

Evaporation chamber for a loop heat pipe

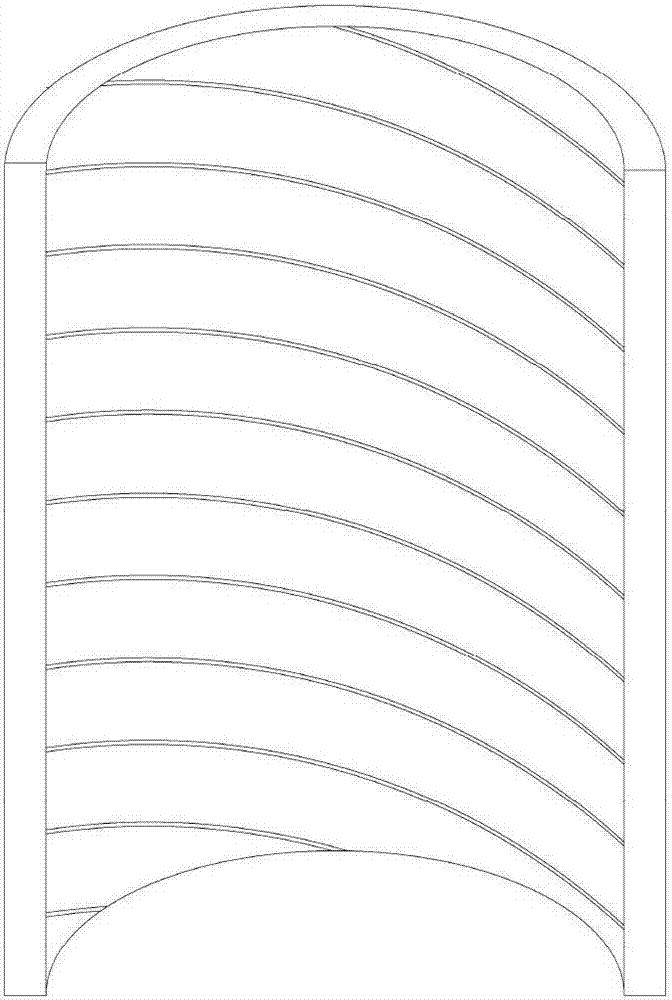

InactiveUS20040206480A1Decrease in parasitic heat leakageIncrease heat loadAir-treating devicesSemiconductor/solid-state device detailsMicro-loop heat pipeCapillary Tubing

The invention relates to heat engineering, in particular to heat pipes, and may be used for heat removal from miniature heat-tensioned objects, in particular elements of radioelectronic devices and computers requiring effective heat removal within minimum dimensions of a cooling system. The invention is aimed at increasing a heat load of the evaporating chamber at a given operating temperature and reducing its dimensions. For this purpose, in the evaporating chamber of a loop heat pipe comprising a body that includes side and end-face walls and a capillary porous packing accommodated in said body and having vapor-removal channels tied together by a vapor collector, and disposed on a portion of the packing perimeter at the heat-supply side, and having an asymmetrical longitudinal opening shifted in the direction opposite to the heat supply, the end-faces of the vapor-removal channels being blind at one side, the asymmetrical longitudinal opening is also being blind at the side opposite to the blind end-faces of the vapor-removal channels, and the vapor collector is formed by one of the end-face walls of the body and the packing end-face. Besides, on the inner side surface of the body, additional vapor-removal grooves are provided. Cross-section of the asymmetrical longitudinal opening may have the form of a rectangle elongated in the direction of the heat supply and limited at the opposite side by a body wall, or the form of a wedge, whose apex faces the heat supply and whose base is a body wall, or the form of a segment, whose chord is directed towards the heat supply and the arc is a body wall, or the form of a circle limited by a capillary porous packing and whose center is shifted in the direction opposite to the heat supply. Cross-section of the evaporating chamber may be made rectangular, the asymmetrical longitudinal opening, which has the form of a slot gap being shifted in the direction opposite to the heat supply. The capillary porous packing may consist of two interconnected parts. The outlet of the condensate line is positioned in the asymmetrical longitudinal opening of the capillary porous packing.

Owner:MICROWAY

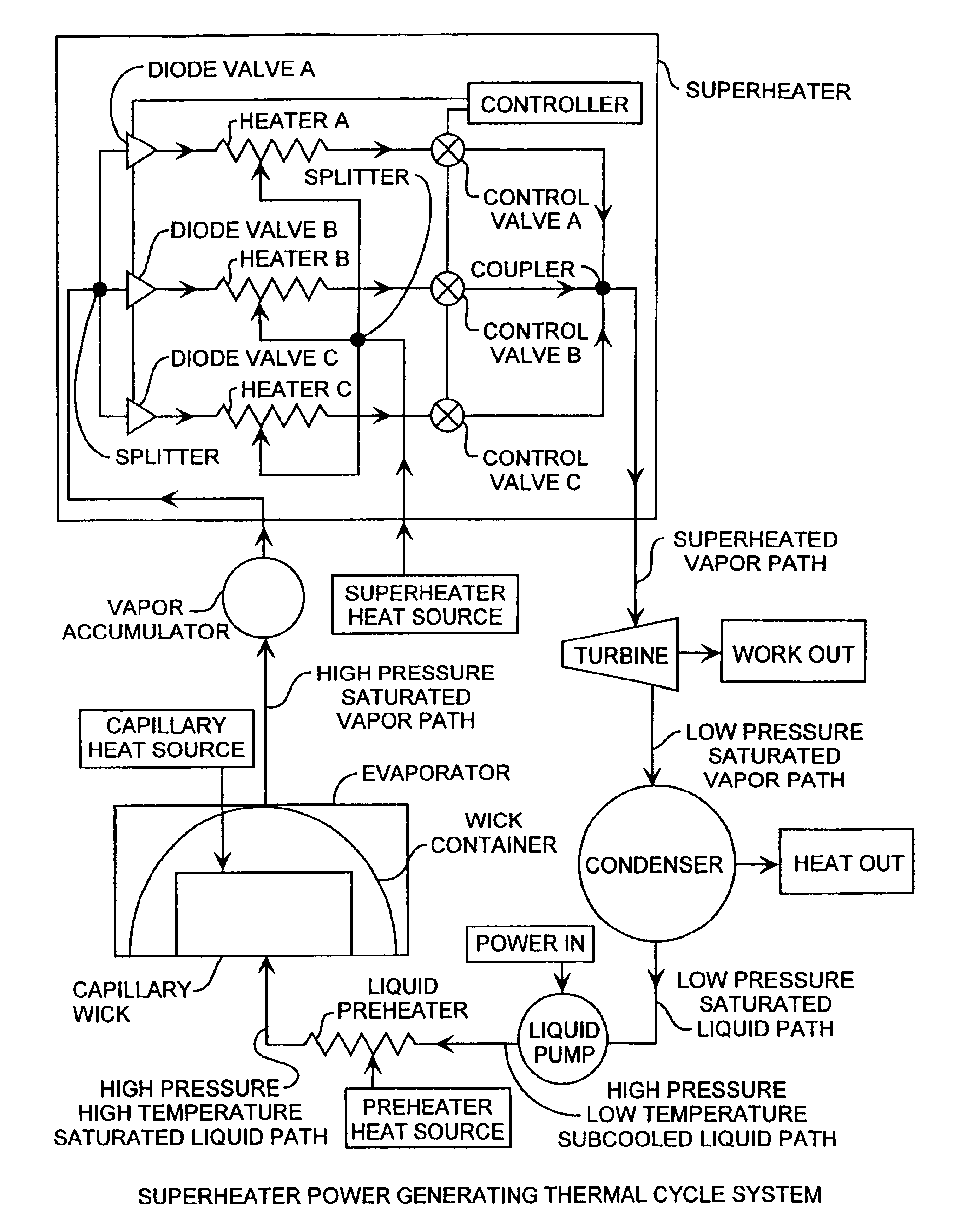

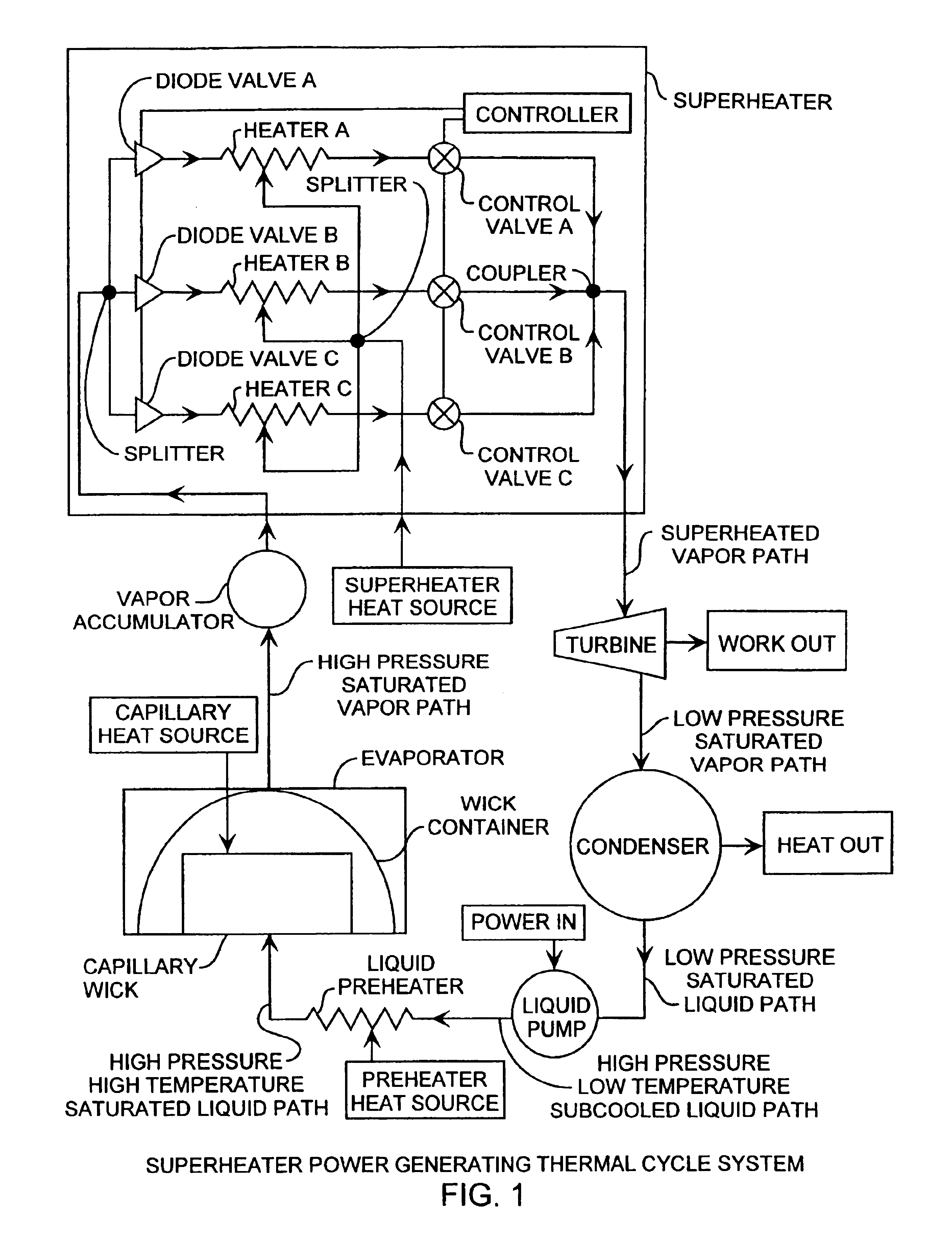

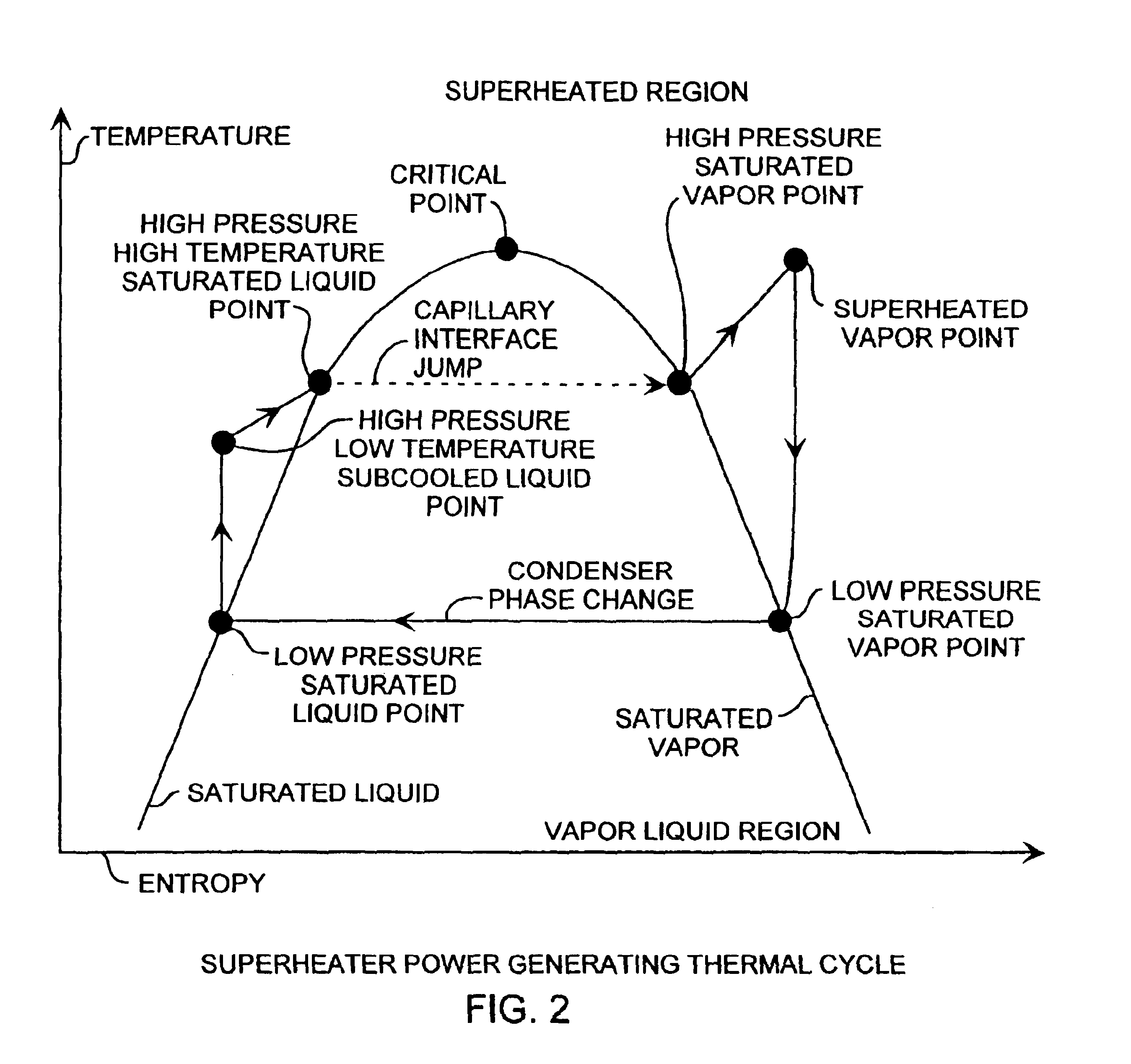

Superheater capillary two-phase thermodynamic power conversion cycle system

InactiveUS6918254B2Power generationImprove efficiencyIndirect heat exchangersSteam engine plantsThermal energyThermal energy storage

A two-phase thermodynamic power system includes a capillary device, vapor accumulator, superheater, an inline turbine, a condenser, a liquid pump and a liquid preheater for generating output power as a generator. The capillary device, such as a loop heat pipe or a capillary pumped loop, is coupled to a vapor accumulator, superheater, the inline turbine for generating output power for power generation, liquid pump and liquid preheater. The capillary device receives input heat that is used to change phase of liquid received from the liquid preheater, liquid pump and condenser into vapor for extra heating in the superheater used to then drive the turbine. The power system is well suited for space applications using a radioisotope, active nuclear or solar heat source. The system can use waste heat from various dynamic or static power systems as a heat source and waste heat from spacecraft components such as electronics as a heat source. These heat sources can be used separately or in any combination. The power system can be combined with thermal energy storage devices when operated with heat sources that are not steady state. Heat sources are useful for driving the capillary wick, superheater and liquid preheater for increased power efficiency and long lifetime operation. The power system is well suited for space receiving heat from a heat source to produce useful mechanical energy. A superheater in combination with a liquid pump and preheater are implemented for use with the evaporator for improved thermal efficiency while operating at maximum cycle temperatures well below other available power conversion cycles.

Owner:THE AEROSPACE CORPORATION

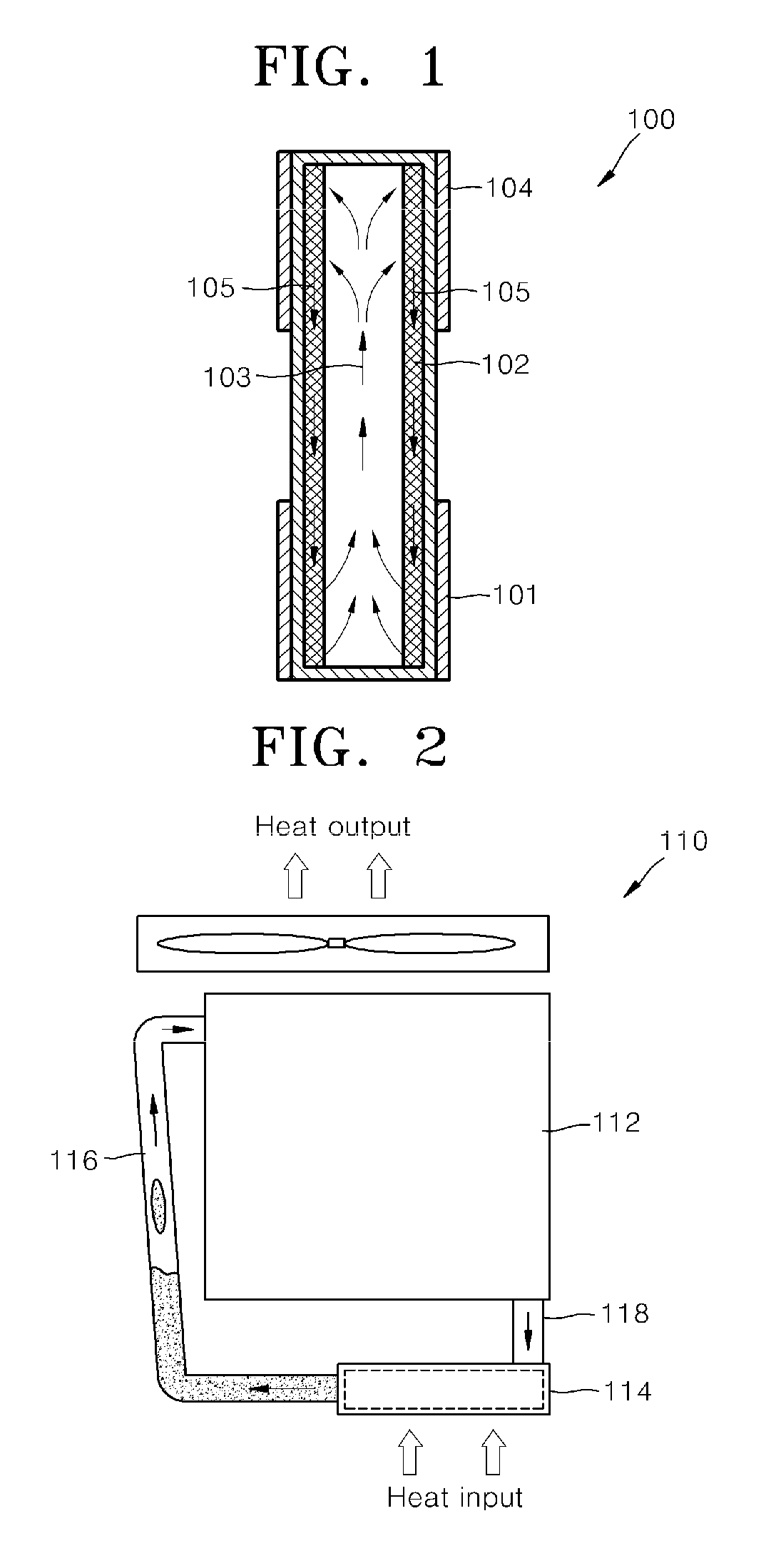

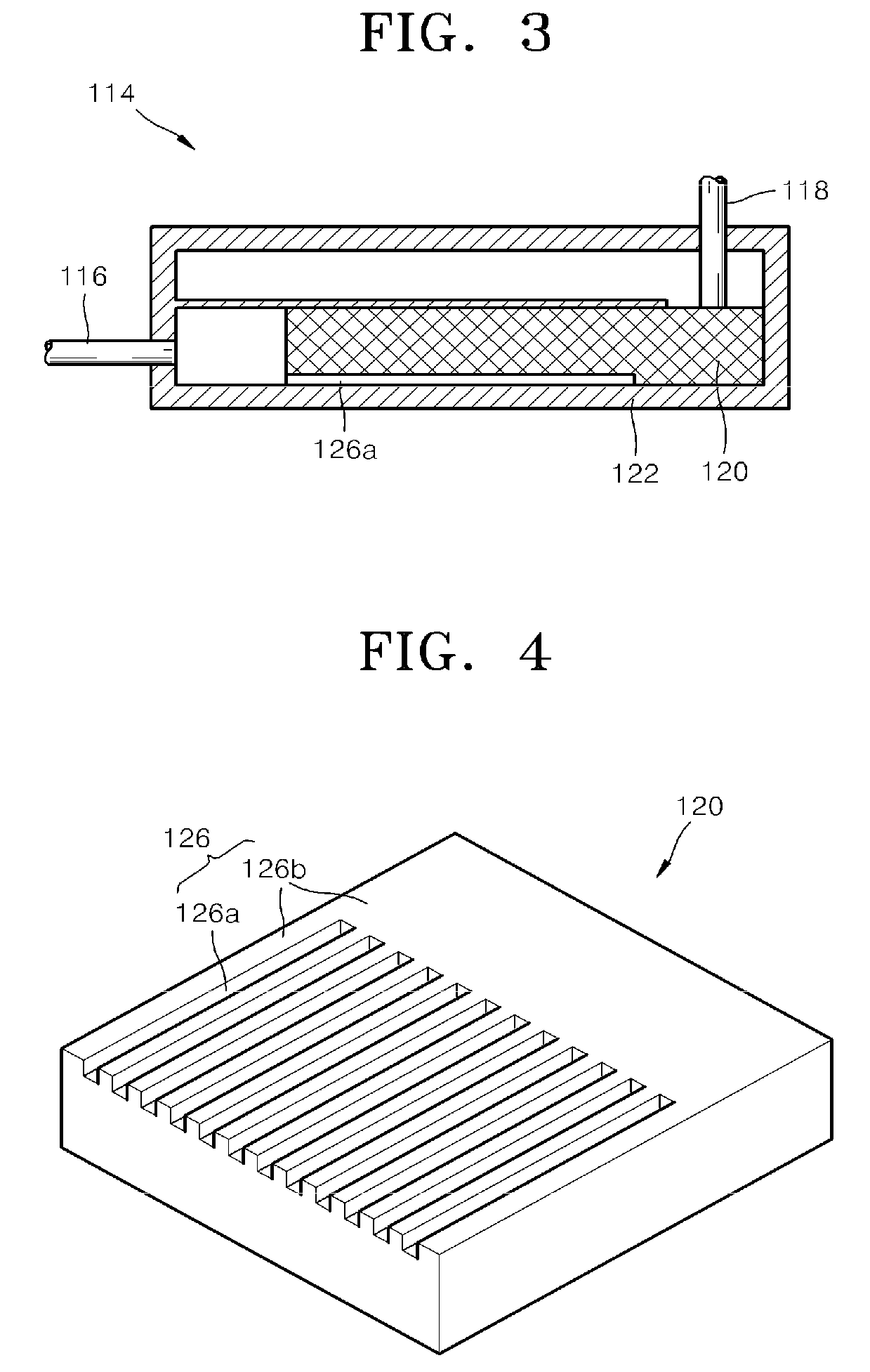

Evaporator For Loop Heat Pipe System

InactiveUS20090314472A1Increased contact conductanceIndirect heat exchangersEngineeringLoop heat pipe

Provided is an evaporator for a loop heat pipe system including a condenser, a vapor transport line, and a liquid transport line, and more particularly, to an evaporator having an increased contact area between a sintered wick and a heating plate.

Owner:ZALMAN TECH CO LTD +1

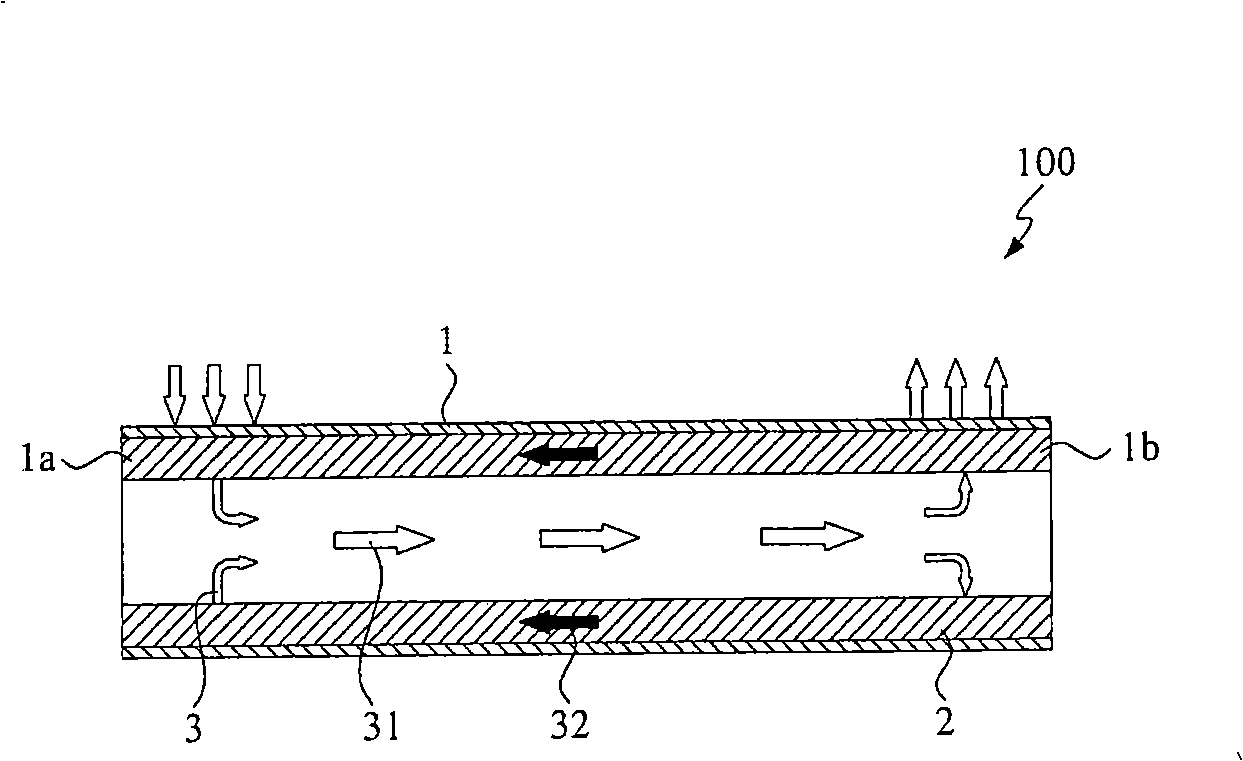

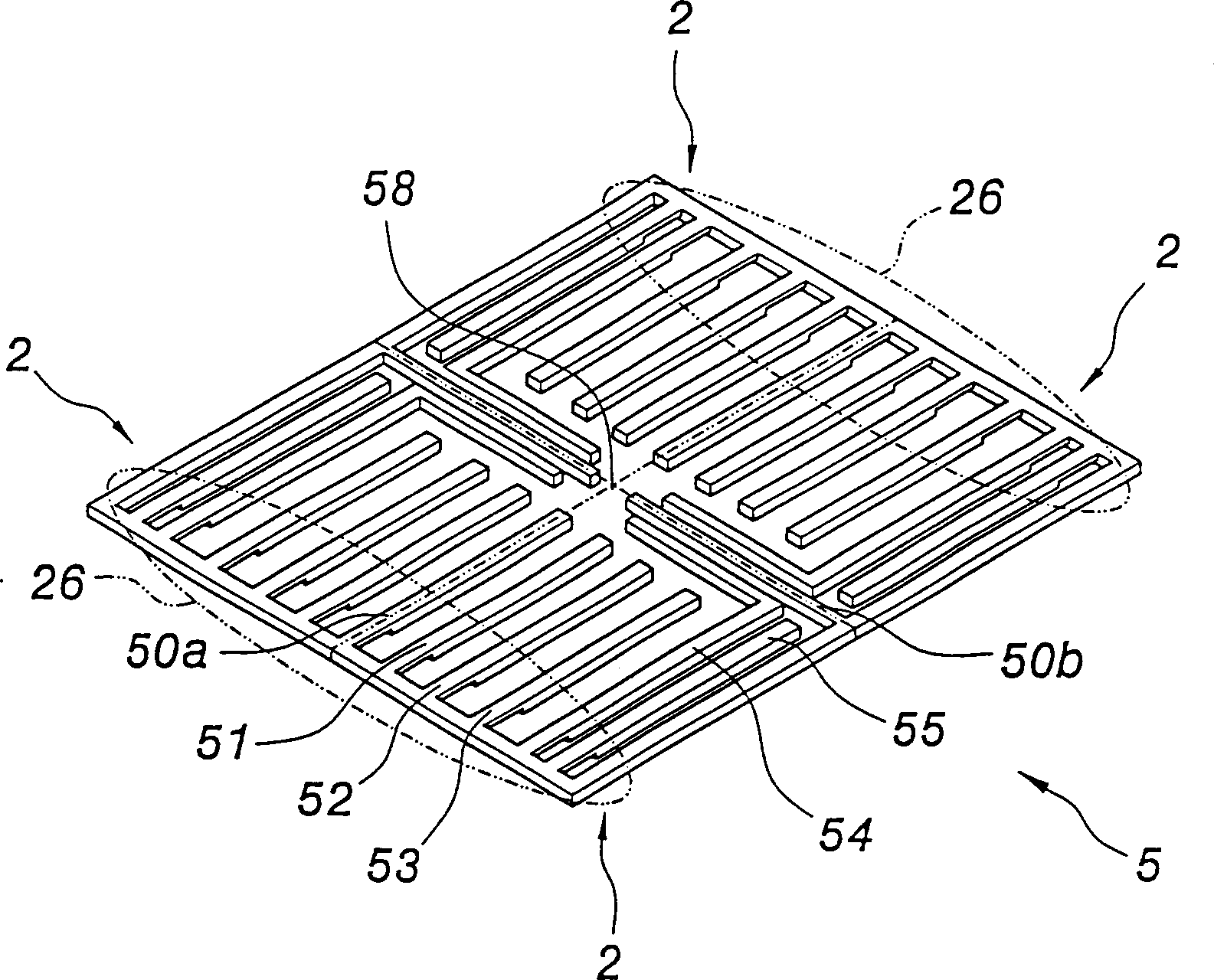

Transport line with grooved microchannels for two-phase heat dissipation on devices

InactiveUS20050077030A1Ensure efficient flowReduce forceSemiconductor/solid-state device detailsSolid-state devicesLiquid lineLoop heat pipe

Grooved microchannels are used to enhance the capillary action in the transport line of two-phase heat dissipation devices, such as loop heat pipes, capillary pump loops, or spray cooling devices, or others. Efficient heat dissipations achieved by enhancing the capillary pumping force for the liquid flow without significantly increasing the friction force. The effective cross-sectional area of the liquid line is made smaller than that of the condensation section, either by inserting a plug or shrinking the liquid line, to provide additional pumping force for the coolant recycling.

Owner:WONG SHWIN CHUNG

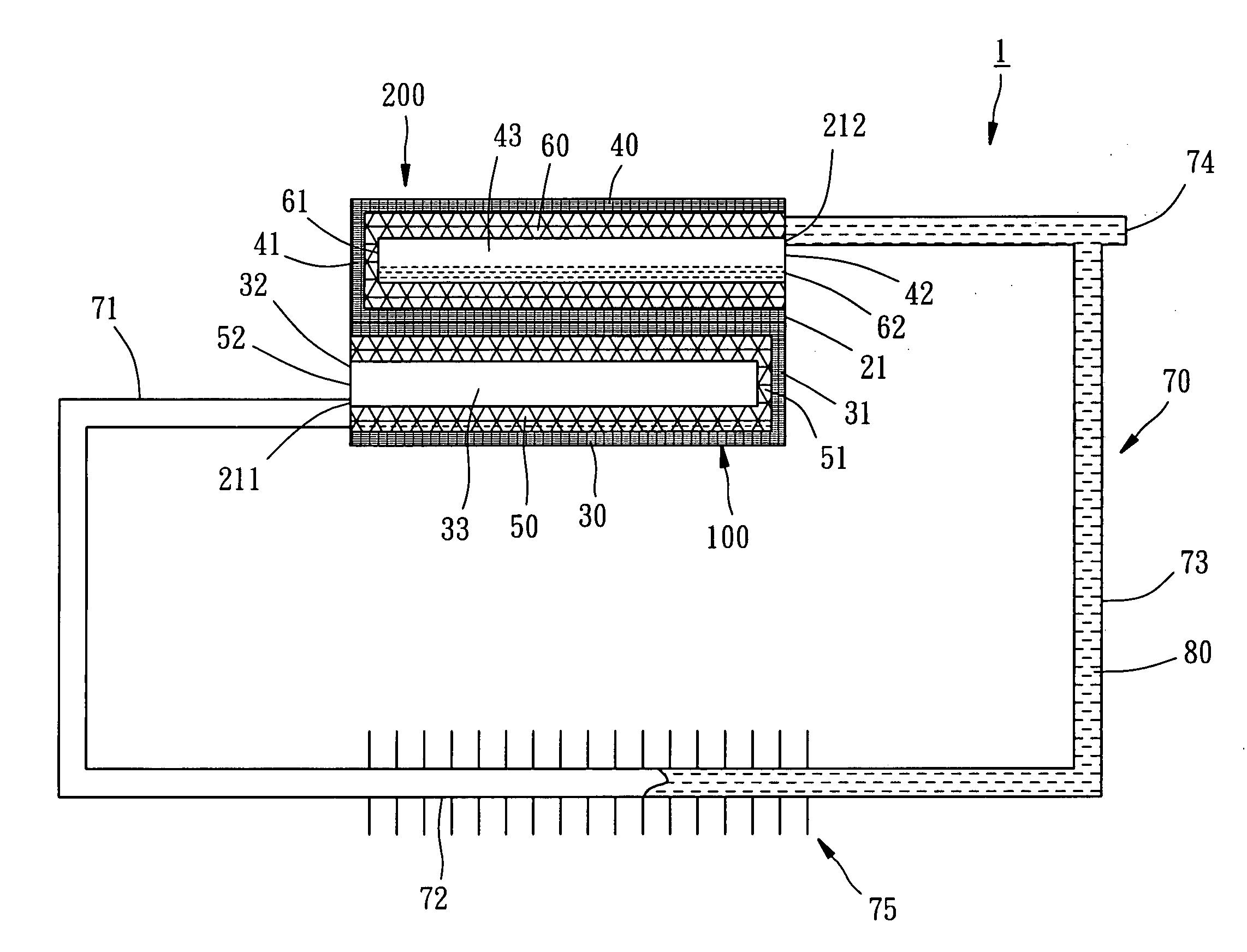

Highly effective flat-type loop heat-pipe apparatus

InactiveCN1703142ASimple structureSimple manufacturing processInstrumental cooling apparatusCooling/ventilation/heating modificationsEngineeringLoop heat pipe

This invention relates to one plate effective circuit heating tube device in conduction and electronic cooling field, which is characterized by the following: providing one plate circuit integration vapor and compensation structure; the first liquid absorptive chip acting as industry substances vapor, the second chips acts to enlarge the system capillary abstracting function with its holes structure easy to arrive the first absorptive chip and acts to reduce the system heat leakage; the first liquid absorptive chip comprises level groove and vertical groove.

Owner:SUN YAT SEN UNIV

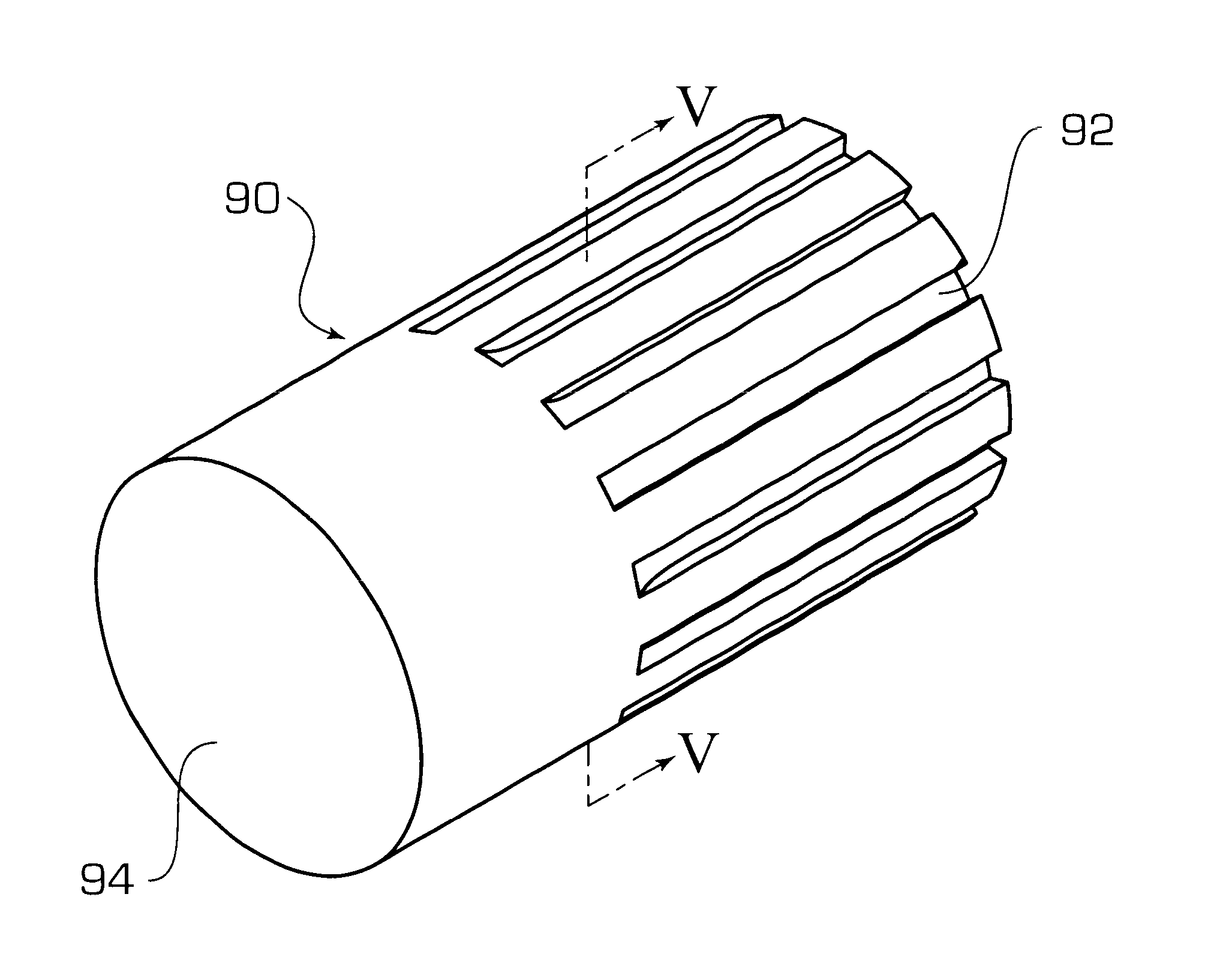

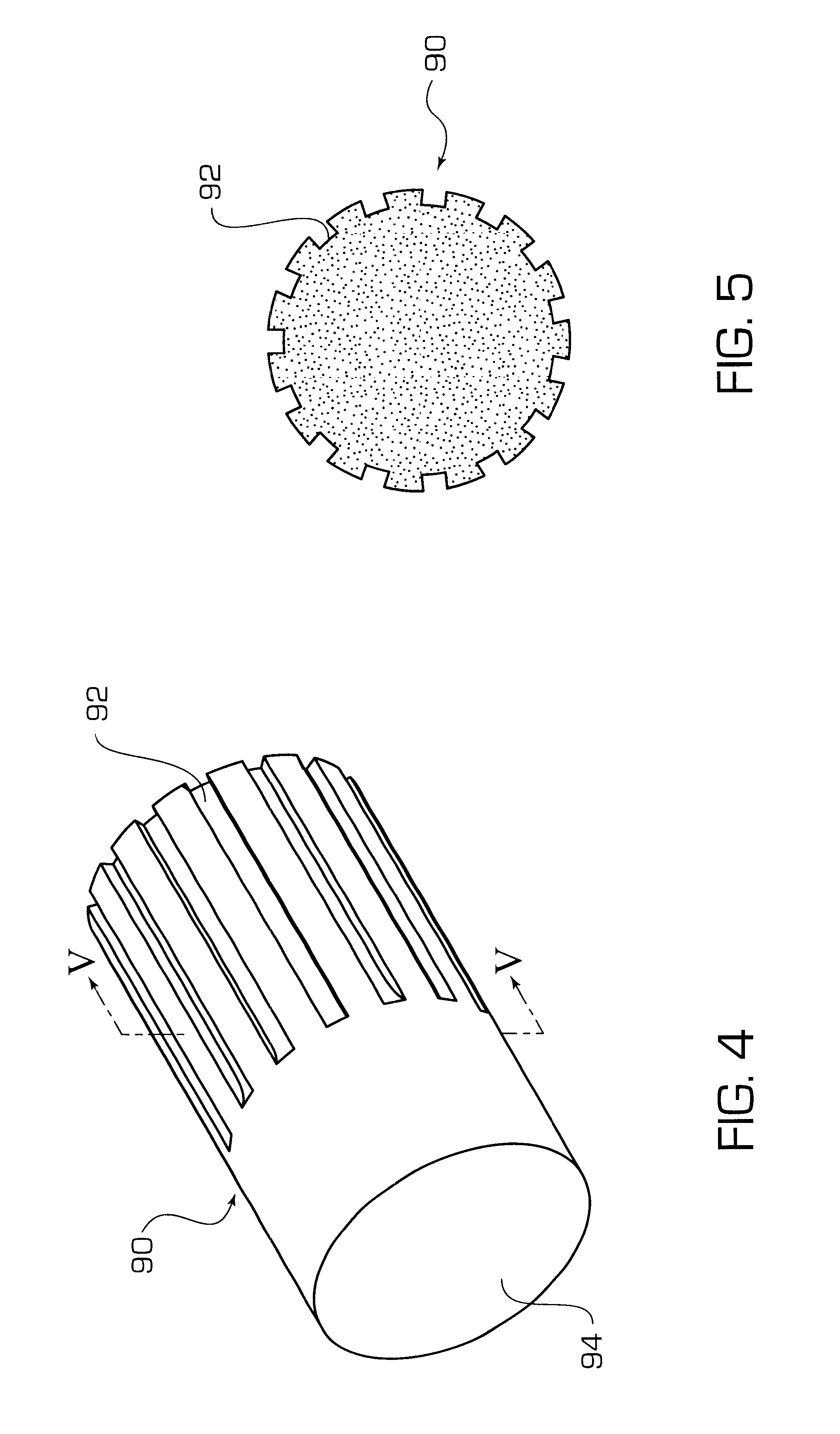

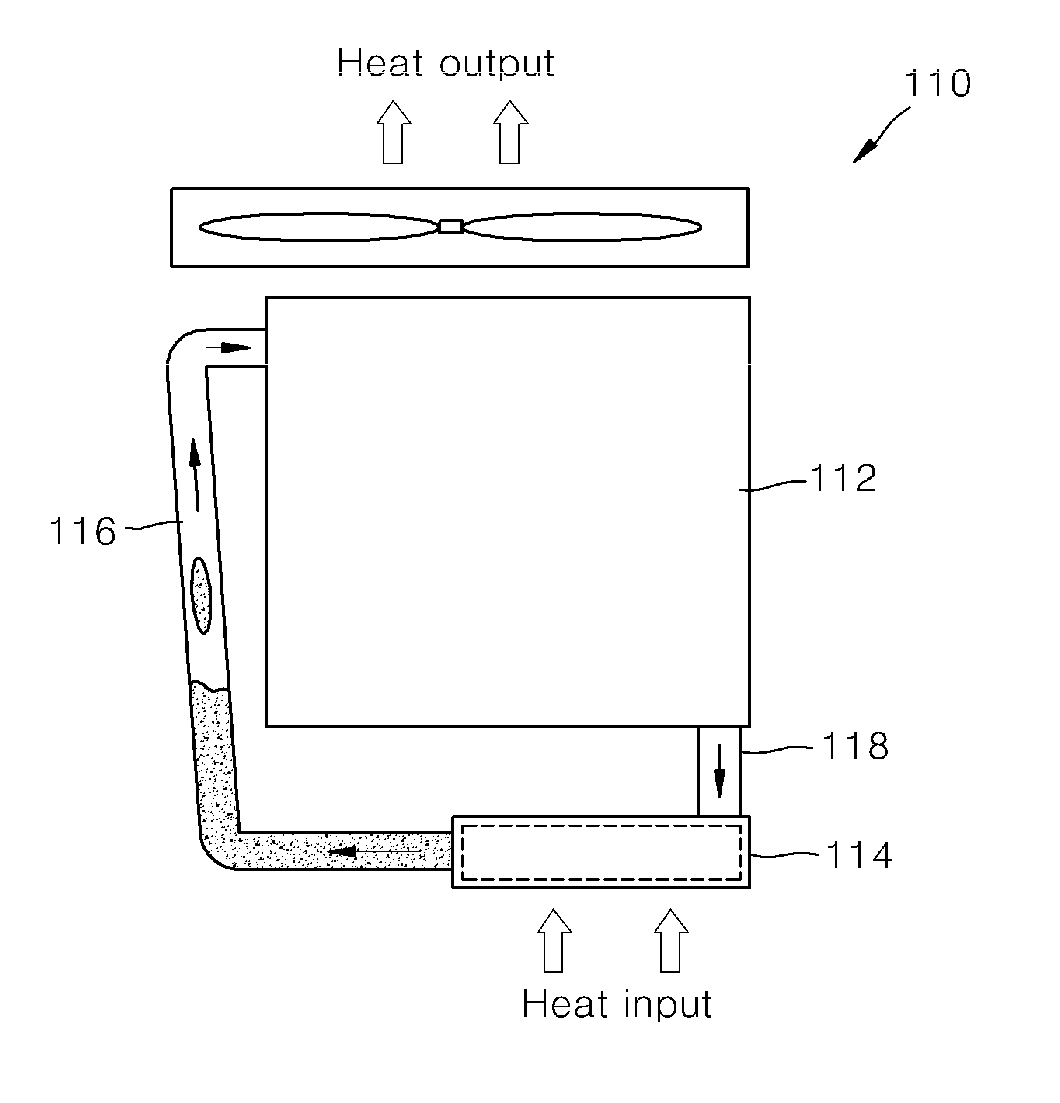

Multi-layer wick in loop heat pipe

In one aspect of the present invention, a multi-layer wick for a loop heat pipe is provided. The multi-layer wick includes a primary wick, the primary wick comprising: a first layer; and a second layer, wherein the first layer surrounds the second layer; and a secondary wick, wherein the second layer of the primary wick surrounds the secondary wick.In another aspect of the present invention, a method of fabricating a multi-layer wick is provided. The method includes machining the outer diameter of an inner layer larger than the inner diameter of an outer layer; heating the outer layer to enlarge the inner diameter; inserting the inner layer into the outer layer; and cooling the inner layer and the outer layer.

Owner:THE BOEING CO

Loop heat pipe

InactiveUS20120043060A1Improve heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesLiquid lineClosed loop

An exemplary loop heat pipe includes an evaporator, a condenser, a vapor line and a liquid line each connecting the evaporator with the condenser to form a closed loop. A working medium is contained in the closed loop. A wick structure is received in the evaporator, and includes a bottom wall contacting the bottom plate, a support wall extending up from the bottom wall and contacting the cover plate, and guide walls extending out laterally from the support wall. The support wall separates an interior of the evaporator into a liquid chamber adjacent to the liquid line and a vapor chamber adjacent to the vapor line. The guide walls are located in the vapor chamber. Guide channels are defined between the guide walls for guiding the working medium in a vapor state to flow from the vapor chamber through the vapor line to the condenser.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Flat-plate evaporators structure and loop type hot pipe possessing flat-plate evaporators structure

InactiveCN101307996ASolve the cooling problemReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesWorking fluidLateral margin

The invention discloses a flat evaporator structure and a loop heat pipe with the flat evaporator structure, the loop heat pipe has an evaporation section arranged on a heat source and a conduction section connected with a condensation section, the evaporation section includes an enclosed containment structure and a capillary structure, and has a bottom in which a channel structure is formed, and a liquid inlet and a gas outlet are arranged in a lateral margin of a container body to respectively connect a gas passage and a liquid passage, so that when a working fluid is heated by the heat source to become vapor, the vapor moves through the gas outlet and the gas passage to a condensing device in the condensation section where the vapor is cooled and converted back to the original form of the working fluid that is then guided through the liquid passage back to the enclosed containment structure for next cycle.

Owner:TAMKANG UNIVERSITY

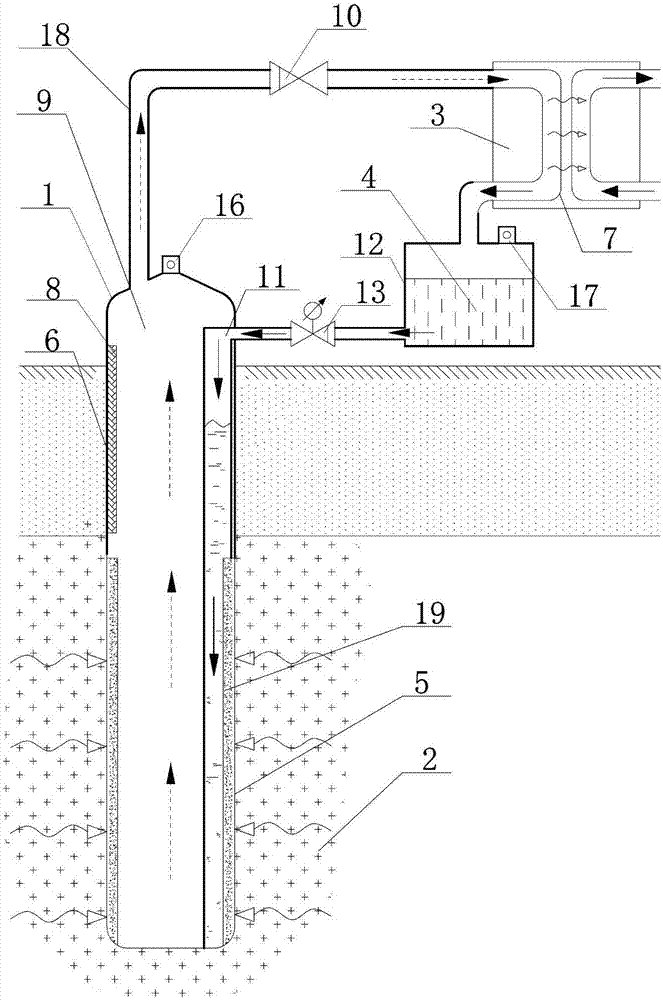

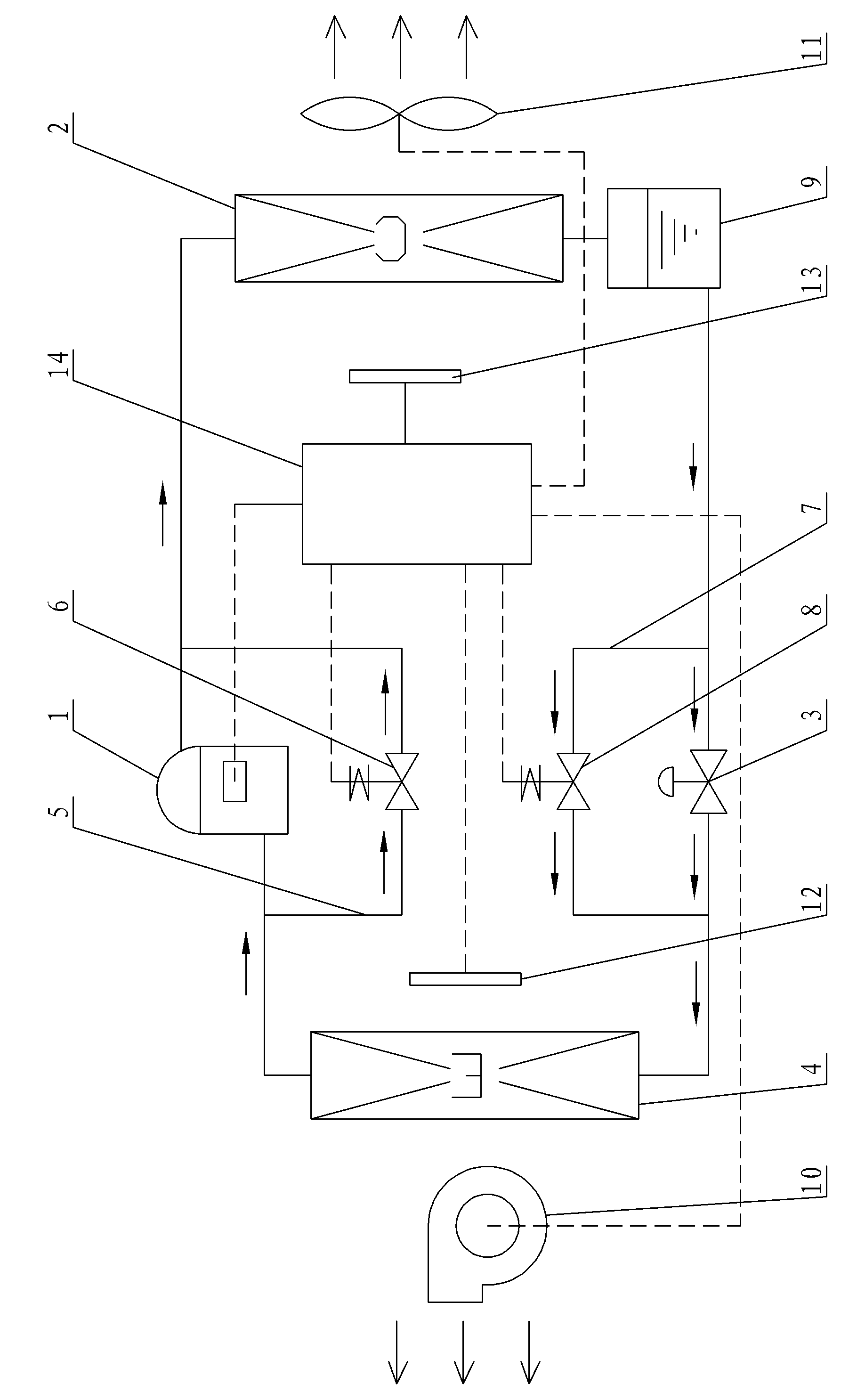

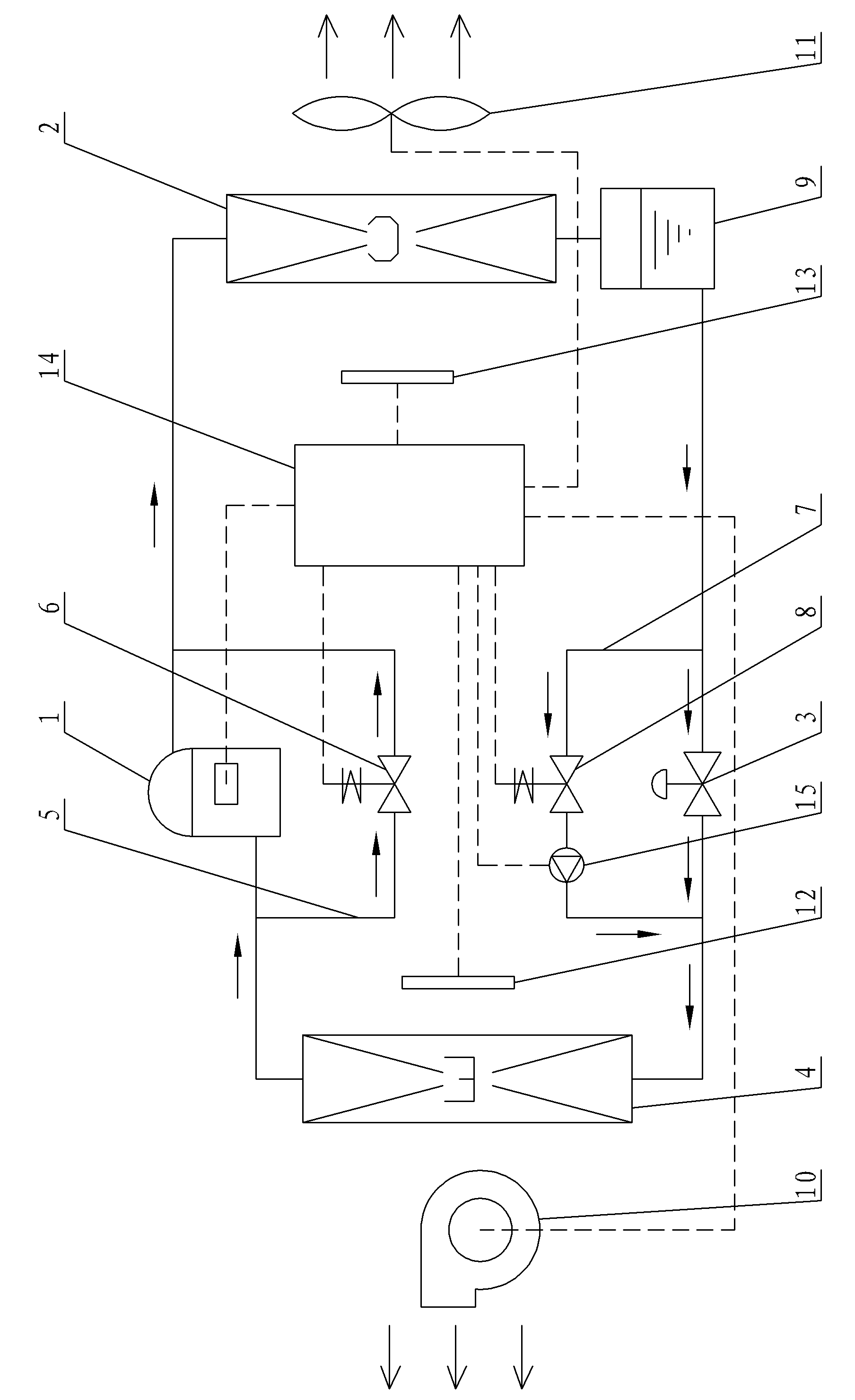

Loop heat pipe type terrestrial heat exploitation system with adjustable and controllable working medium circular flow

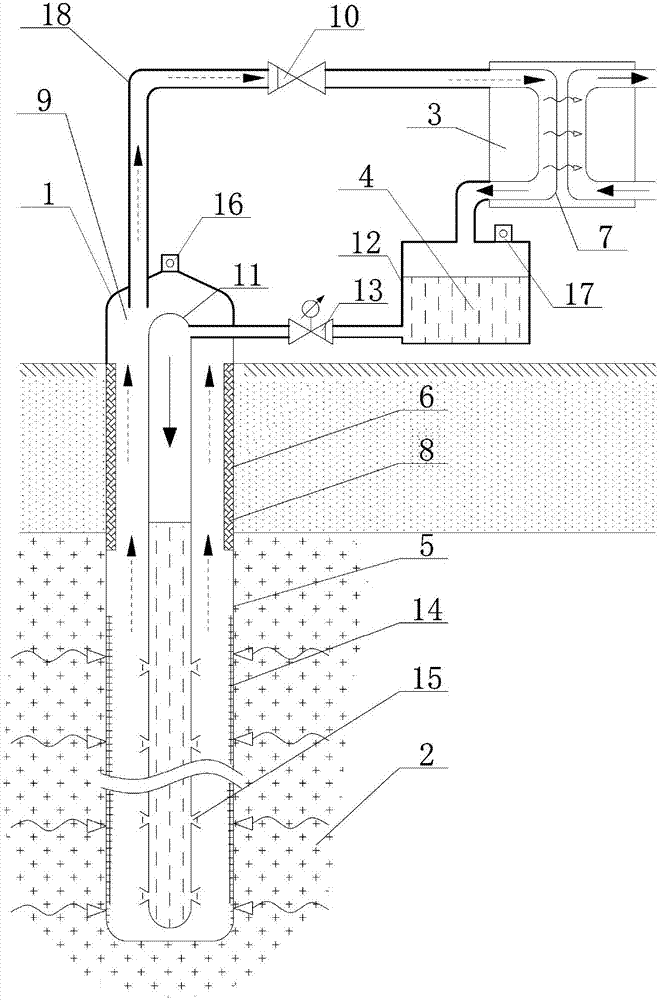

ActiveCN107144035AAchieve miningAvoid lostOther heat production devicesGeothermal energy generationEvaporationEngineering

The invention discloses a loop heat pipe type terrestrial heat exploitation system with adjustable and controllable working medium circular flow. The loop heat pipe type terrestrial heat exploitation system comprises a casing pipe type loop heat pipe, an earth surface heat exchanger and a liquid storage box. The earth surface heat exchanger and the liquid storage box are both located on the ground. The casing pipe type loop heat pipe comprises an evaporation section, a heat insulation section and a backflow section. The evaporation section is located in a high temperature heat reservoir. The earth surface heat exchanger is provided with a condensation section, and the condensation section and the outside carry out heat exchange. A one-way valve or a steam pump is arranged between the heat insulation section and the condensation section. A one-way throttle valve is arranged between the liquid storage box and the backflow section. The evaporation section, the heat insulation section, the condensation section, the liquid storage box and the backflow section are communicated in sequence end to end. Working medium fluid of the liquid storage box enters the evaporation section through the backflow section, and the liquid working medium fluid entering the evaporation section generates film boiling after absorbing heat. According to the loop heat pipe type terrestrial heat exploitation system, the working medium fluid of the liquid storage box passes through the backflow section, the liquid phase backflow mode and the boiling mode of the evaporation section are controlled, the effective filling factor of the terrestrial heat pipe can be adjusted in real time, and therefore terrestrial heat energy is stably and efficiently extracted.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

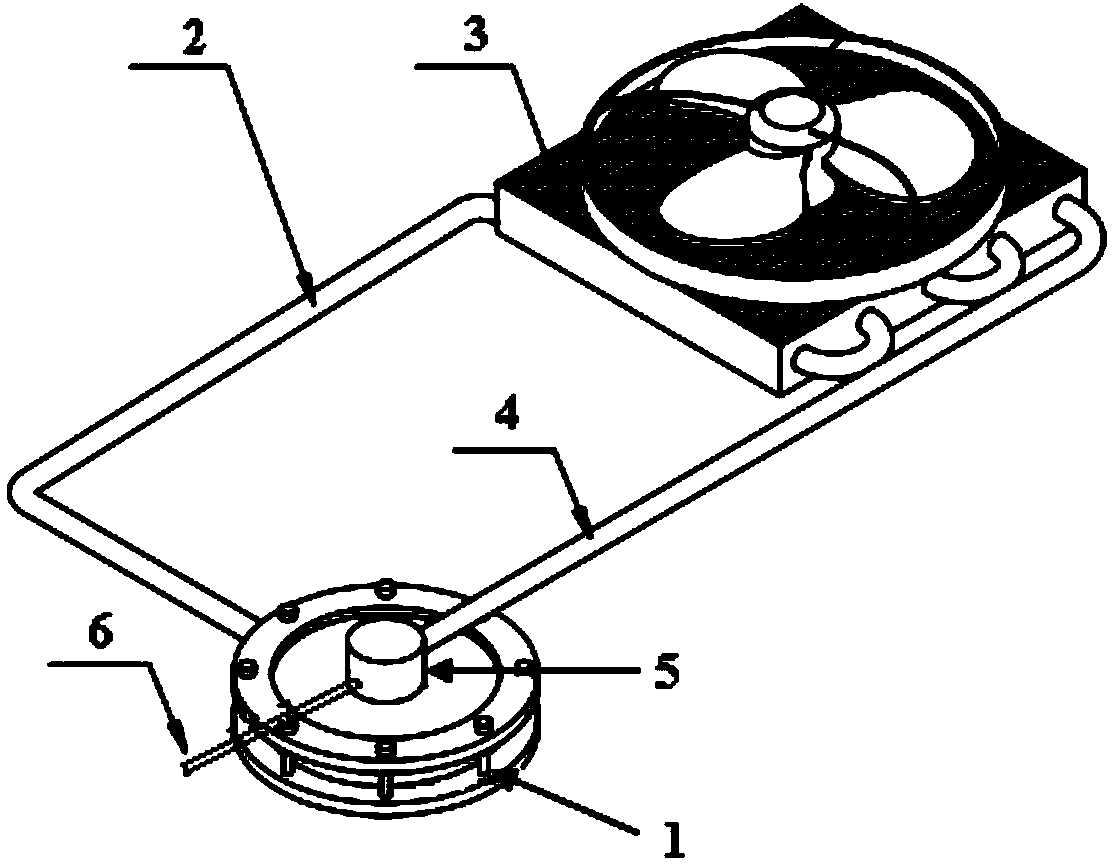

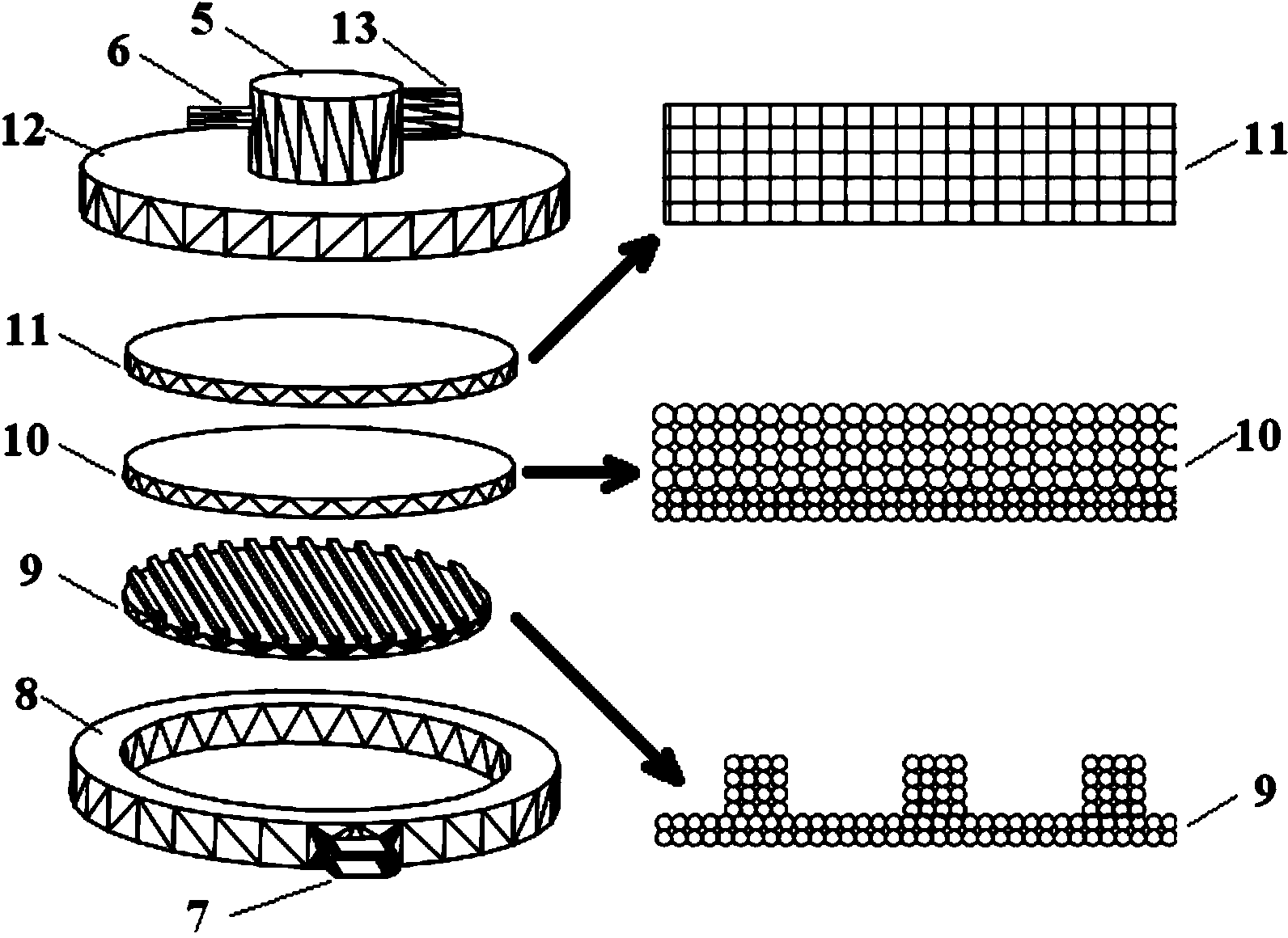

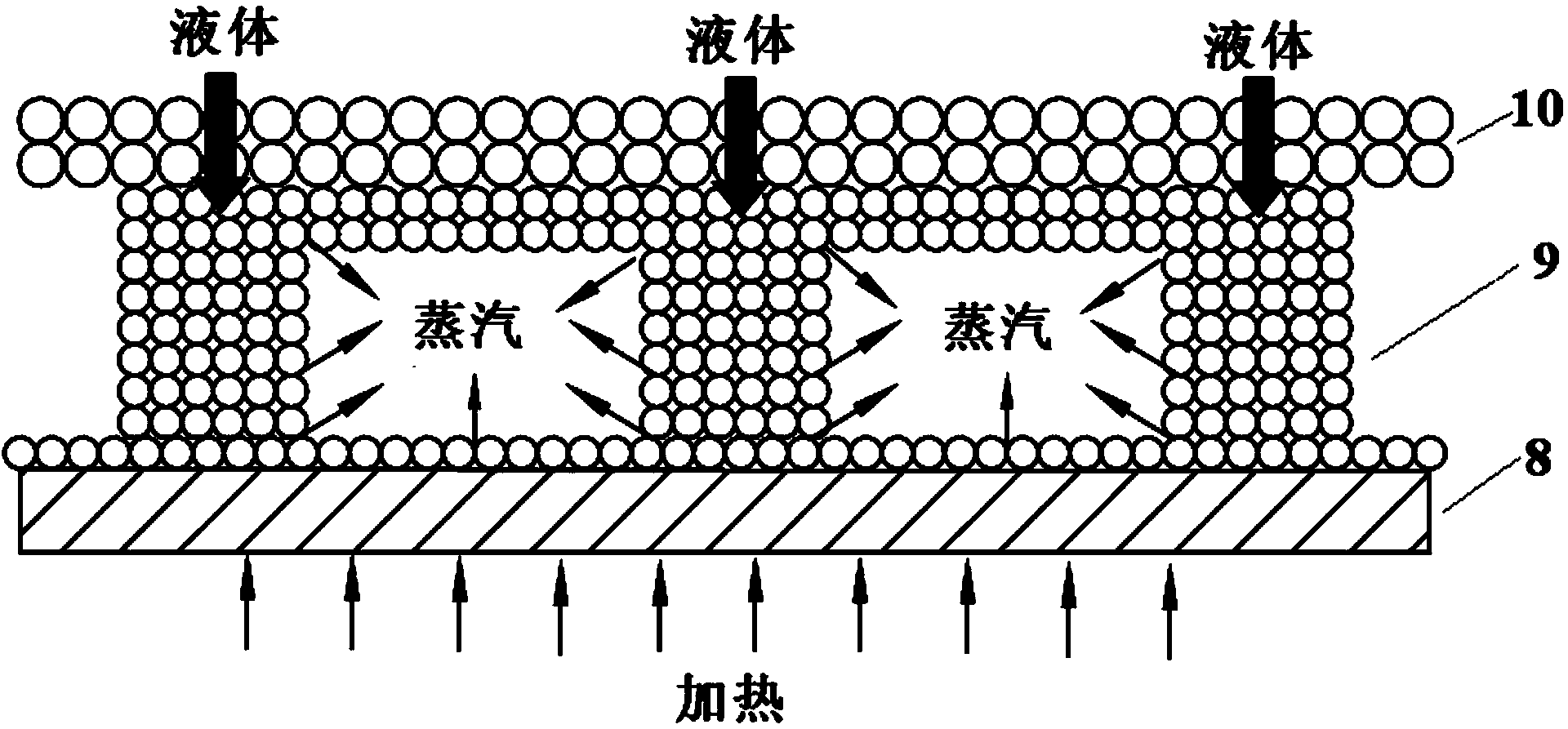

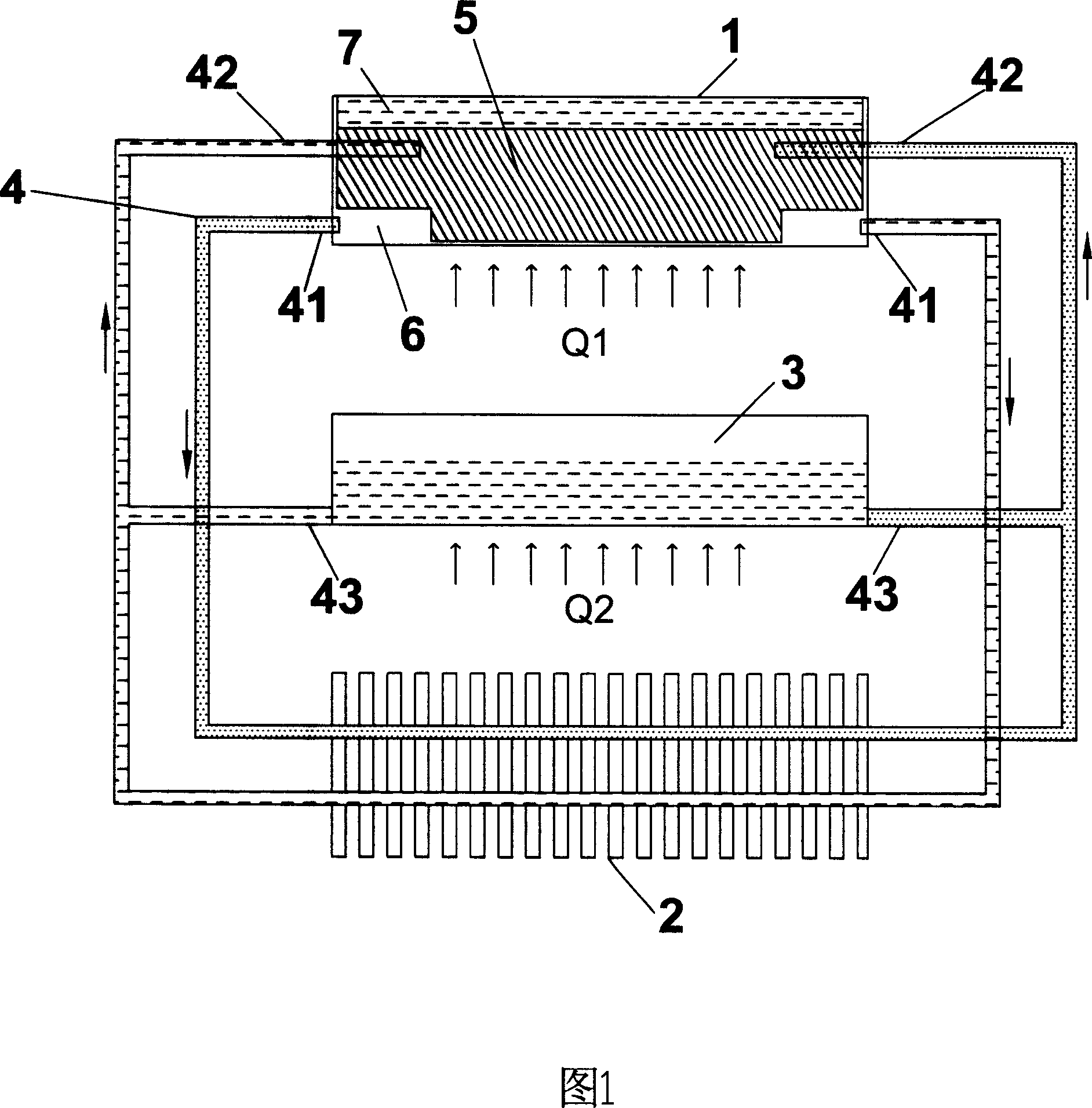

Multi-scale capillary core flat plate loop heat pipe type heat-dissipation device

InactiveCN103629963ASolve flow resistanceSolve the paradoxical relationship between capillary suctionSemiconductor/solid-state device detailsSolid-state devicesVapor liquidSuction force

The invention relates to a multi-scale capillary core flat plate loop heat pipe type heat-dissipation device, and belongs to the technical field of phase transition heat dissipation. The heat-dissipation device comprises an evaporating part, a condensing part, a compensating cavity, a gas phase pipeline and a liquid phase pipeline, wherein the gas phase pipeline is connected with the evaporating part and the condensing part, and the liquid phase pipeline is connected with the condensing part and the compensating cavity; a base plate of the evaporating part is in a flat plate shape, metal powder is sintered to form two layers of multi-scale capillary cores at the upper surface of the base plate, and a steam channel is constructed between the two layers of capillary cores; a layer of water absorption cotton tightly covers a second layer of capillary cores and is taken as a third layer of capillary cores, and the three layers of capillary cores form a multi-scale structure. By utilizing the multiple layers of multi-scale capillary cores and the constructed steam channel, the problem of the contradictoriness between the vapor-liquid flow resistance and the capillary suction force is solved, the starting temperature of a loop heat pipe is lowered, the high heating flux bearing capacity of the heat-dissipation device is improved, and the instability in heat transfer is reduced; the multi-scale capillary core flat plate loop heat pipe type heat-dissipation device has the advantages of high cooling capacity, large heat flux bearing capacity, low starting temperature, small temperature fluctuation, good antigravity performance and long transmission distance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

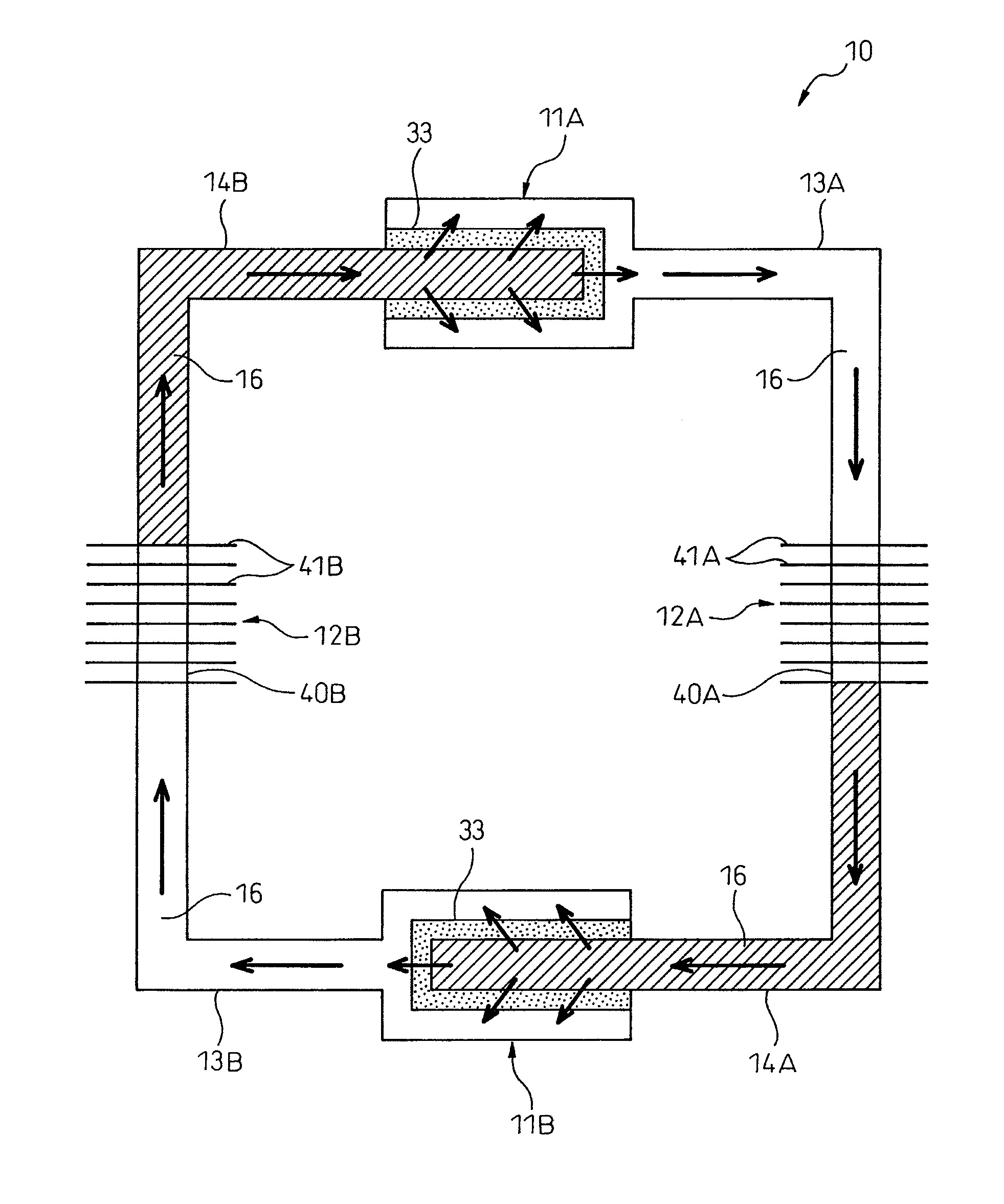

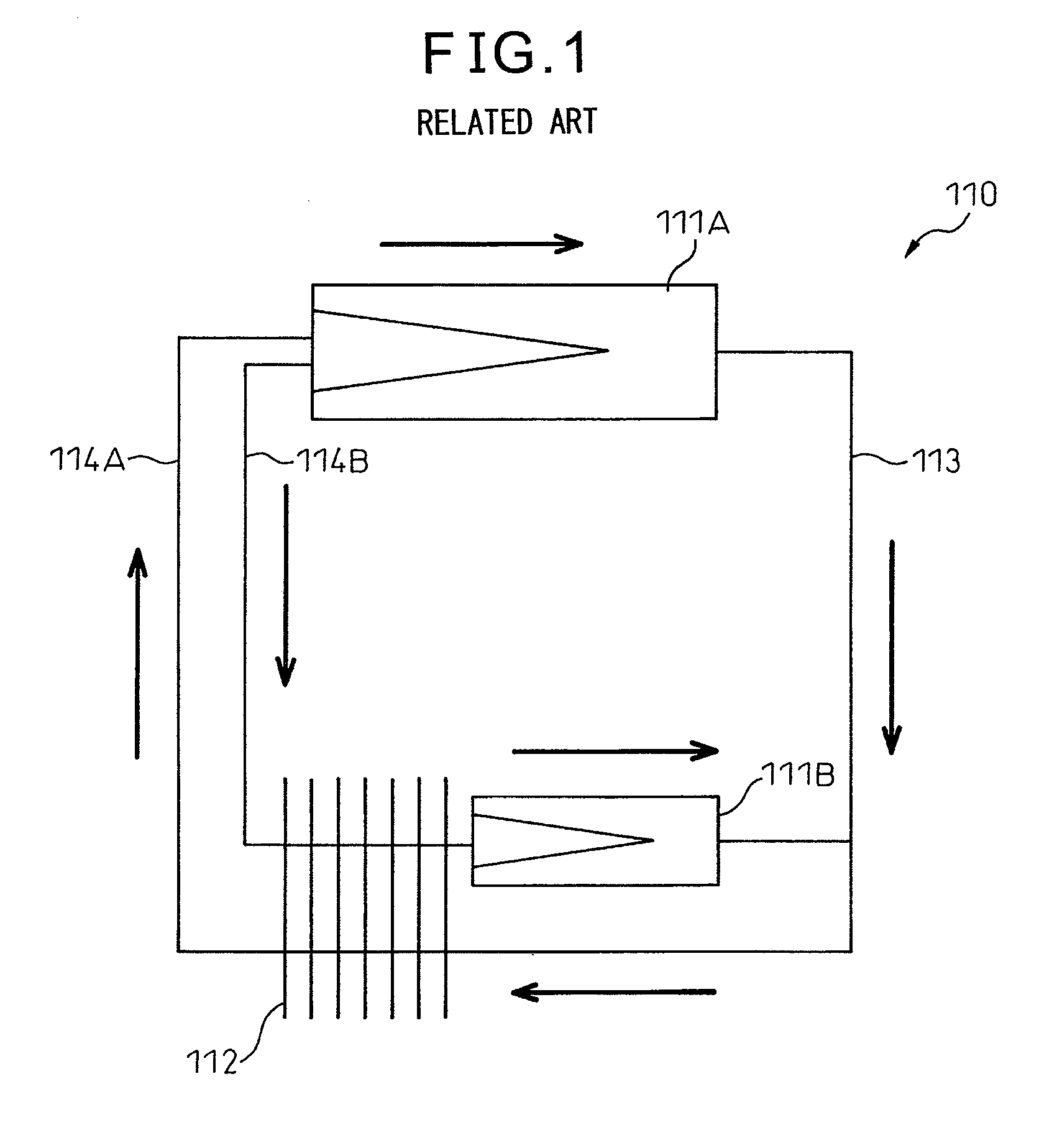

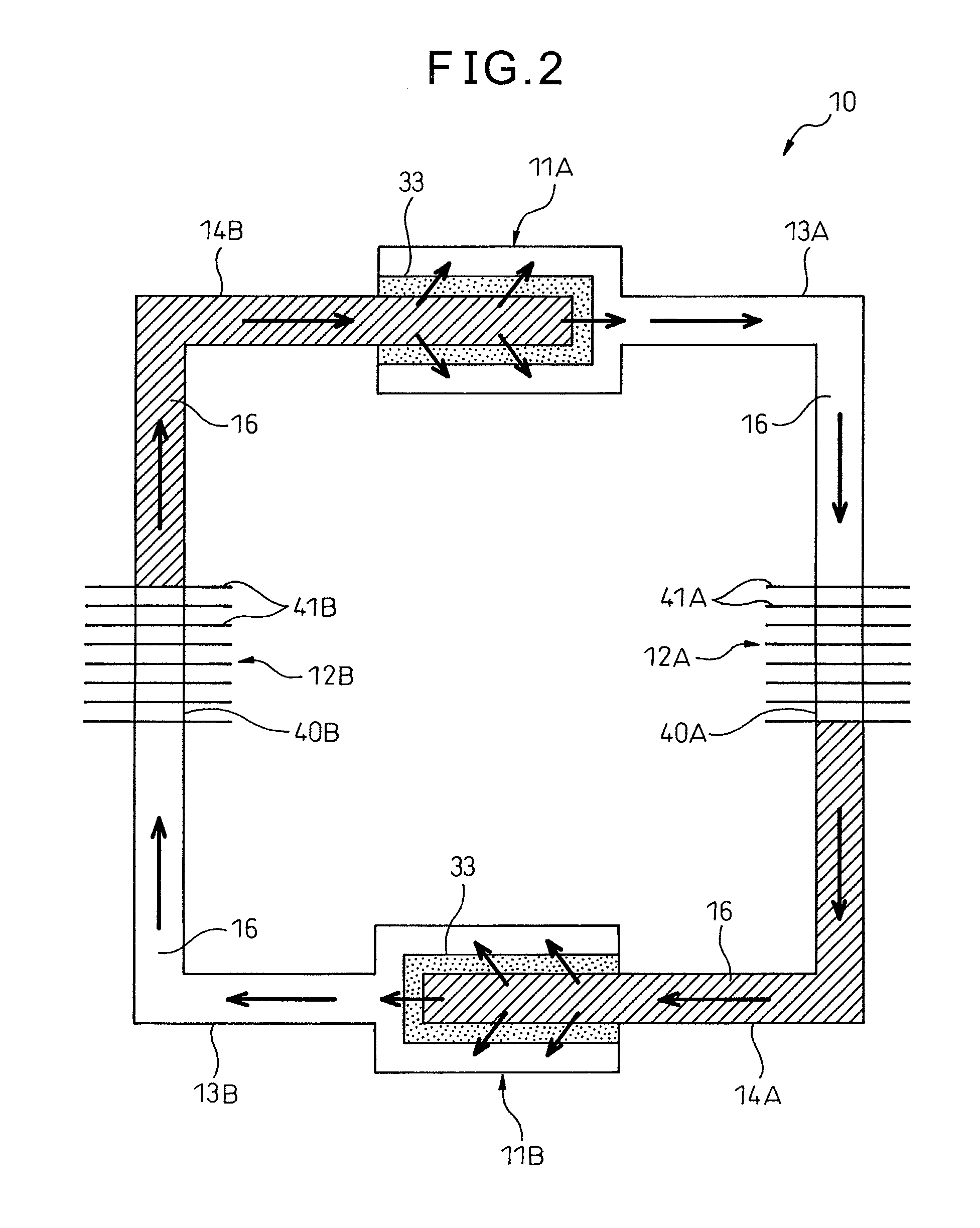

Loop heat pipe and startup method for the same

InactiveUS20120132402A1Semiconductor/solid-state device detailsSolid-state devicesLiquid lineWorking fluid

A loop heat pipe includes: a first evaporator and a second evaporator each of which vaporizes a liquid-phase working fluid and converts the liquid-phase working fluid to a vapor-phase working fluid; a first condenser and a second condenser each of which condenses the vapor-phase working fluid and converts the vapor-phase working fluid back to the liquid-phase working fluid; a first vapor line through which the working fluid converted to the vapor phase is transported to the first condenser; a first liquid line through which the working fluid converted to the liquid phase is transported to the second evaporator; a second vapor line through which the working fluid converted to the vapor phase is transported to the second condenser; and a second liquid line through which the working fluid converted to the liquid phase is transported to the first evaporator.

Owner:FUJITSU LTD

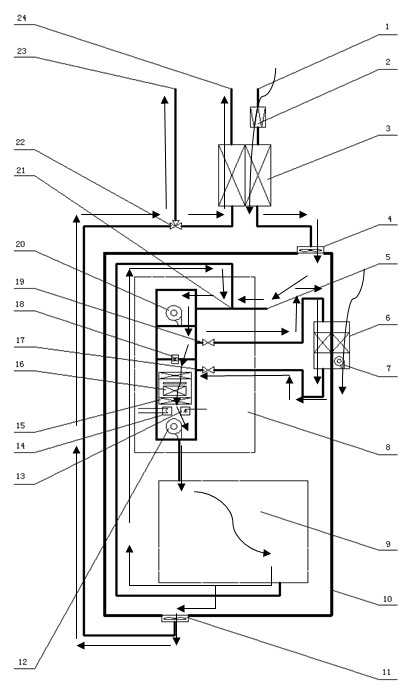

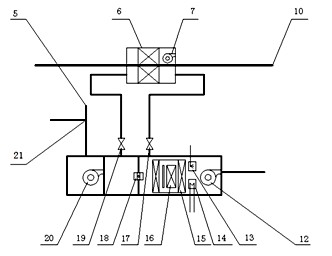

Energy saving device suitable for accurate control air conditioner in machine room

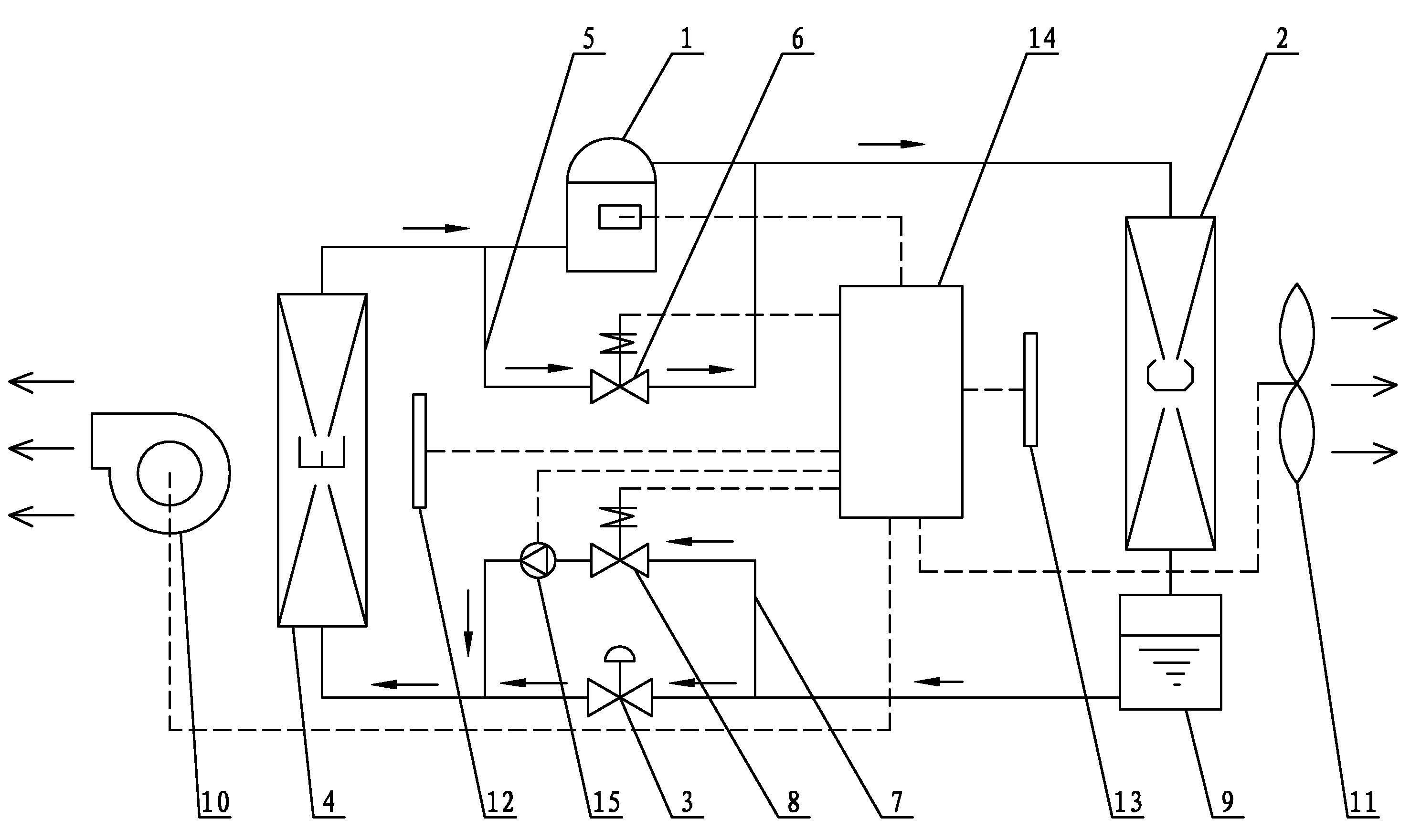

ActiveCN102425828AAvoid enteringReduce loadEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsAutomatic controlEngineering

The invention discloses an energy saving device suitable for an accurate control air conditioner in a machine room; the energy saving device comprises a refrigerating compression unit, a hot and humidity control device, a loop heat pipe device, separating air flue type heat pipe exchangers, an air valve, a fan, an air flue and an electronic control system. In transitional seasons and winter, the electronic control system automatically controls the opening and closing of the valve so that indoor air passes through a separating air flue inside the room and outdoor cold air passes through a separating air flue outside the room; and air inside the machine room is cooled by using the cold energy of outer air through the arrangement of a middle separating air flue type heat pipe exchanger. The separating air flue type heat pipe exchangers are used for recycling the part of cold energy of exhaust air in a summer working condition through the arrangement of an air supply / exhaust pipeline to precool new air. Loop heat pipe devices arranged before and after an evaporator can recycle the part of energy consumption of electric heating, thereby the energy is saved. According to the energy saving device, the energy saving scheme of the air conditioner in the machine room is further perfected and provides a very good reference value for energy saving of the air conditioner in the machine room.

Owner:合肥万豪环境科技有限责任公司

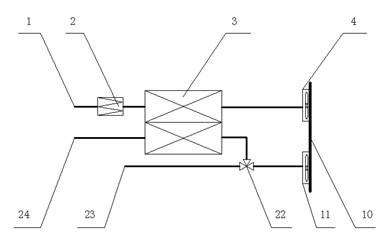

Natural cooling energy-saving air conditioner and control method thereof

InactiveCN101988723AAvoid problemsAvoid hidden dangersSpace heating and ventilation safety systemsLighting and heating apparatusStart stopSolenoid valve

The invention discloses a natural cooling energy-saving air conditioner and a control method thereof. The natural cooling energy-saving air conditioner comprises an indoor fan, an outdoor fan, and a compressor, a condenser, a throttler and an evaporator which are connected in turn to form an enclosed loop; an air bypass pipeline is connected between the inlet and the outlet of the compressor; the throttler is arranged between the condenser and the evaporator; a liquid bypass pipeline is connected between the inlet and the outlet of the throttler; the air bypass pipeline and the liquid bypass pipeline are respectively provided with a solenoid valve component which is connected in parallel with the compressor and the throttler; and a loop heat pipe LHP is formed between the evaporator and the condenser. The solenoid valve components are arranged, when the outdoor temperature is low, a natural cold source can be fully utilized to cool the indoor air through simple switching of the pipelines; therefore, the energy-saving effect is obvious, various problems and hidden troubles caused by low-temperature operation of a refrigeration system of the compressor and frequent start-stop of the compressor can be avoided, and the service life of the compressor can be effectively prolonged.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

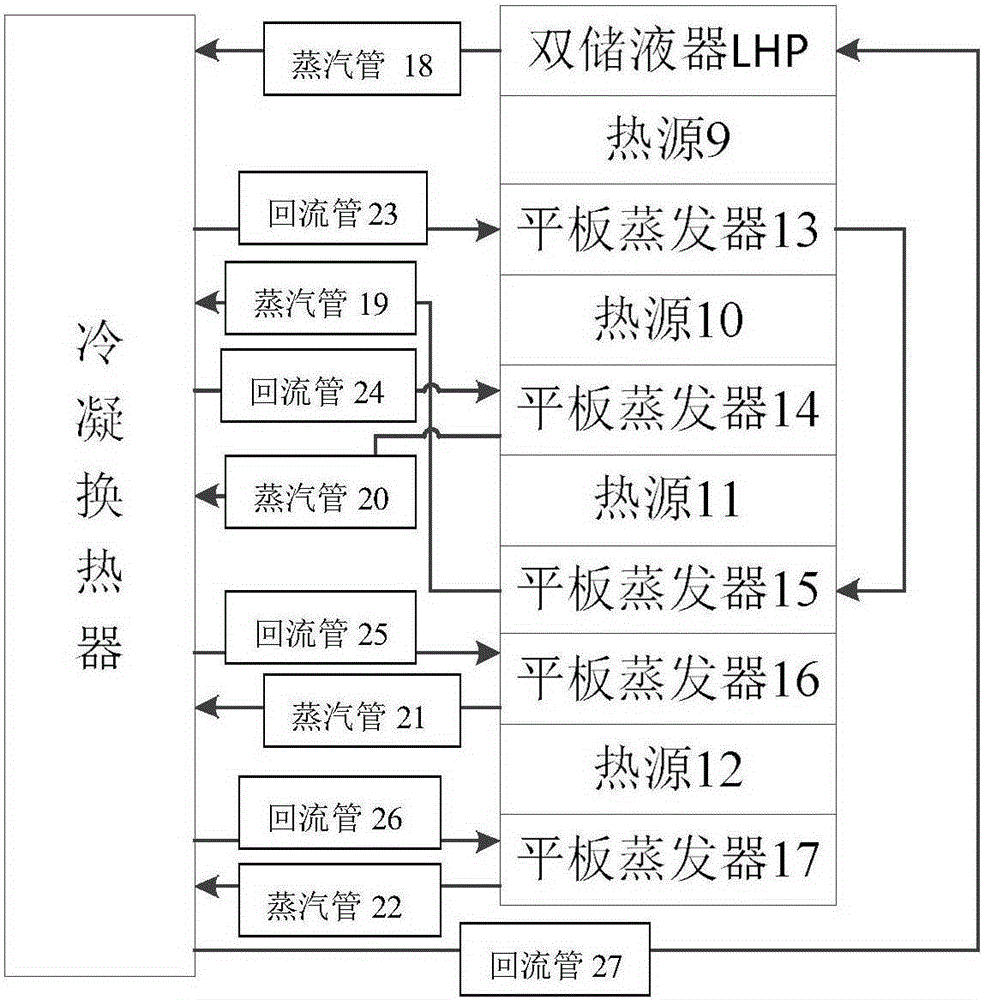

Multiple-pass self-regulating loop heat pipe device

InactiveCN101013011AGood temperature controlStrong self-regulation abilityIndirect heat exchangersTemperature controlHigh density

The invention discloses a multi-channel self-adjust circuit heat tube, comprising an evaporator, a condenser, a compensator, and at least two loop tubes. The evaporator is arranged with an internal liquid adsorption element which forms an evaporating chamber with the inner wall of evaporator. The steam inlet of loop tube is communicated with the evaporating chamber. The loop tube is through the condenser. The reflux outlet of loop tube is communicated with the evaporator. The reflux section of loop tube is communicated with the compensator filled with working liquid. The invention has high density of heat flow, accurate temperature control and self-adjusting ability.

Owner:SUN YAT SEN UNIV

Thermal control loop heat pipe of integrated structure

InactiveCN105277028AImprove temperature uniformityImprove anti-acceleration abilityIndirect heat exchangersMicro-loop heat pipeEvaporation

The invention provides a thermal control loop heat pipe of an integrated structure. The thermal control loop heat pipe comprises a structure thermal control hollow metal pipe body filled with phase change media. The structure thermal control hollow metal pipe body is a loop heat pipe (LHP) formed by connecting a condensation pipe and an evaporator in series, the two sides of the evaporator are connected with liquid accumulators where a steam pipe and a reflux pipe pass, and the liquid accumulators on the two sides are both filled with liquid working media. After heat emitted by a heat source is absorbed by an evaporation pipe, the phase of the liquid working media is changed, the liquid working media enter the condensation pipe through the steam pipe to release heat to be condensed and flows back to the evaporation pipe through the reflux pipe, and then a complete loop heat pipe cycle is completed. According to the thermal control loop heat pipe, integration is adopted, a semiconductor refrigeration manner is used, heat emitted out of the interior of the complex structure can be effectively led out accordingly, and the application range of a heat pipe thermal control system is greatly expanded.

Owner:10TH RES INST OF CETC

Flat loop Heat pipe

InactiveUS20100163212A1Improve cooling effectPrevent circulation of thermal dissipation from difficult activationReinforcing meansIndirect heat exchangersEvaporationEngineering

A flat loop heat pipe is formed of a first capillary core, a second capillary core, a first support member, and a second support member. The first capillary core and the first support member constitute an evaporation room. The second capillary core and the second support member constitute a compensation room. In light of this structure, it is not difficult to activate circulation of thermal dissipation under low-watt heat source and the first capillary core can avoid dry-out phenomenon.

Owner:CHIN CHI TE

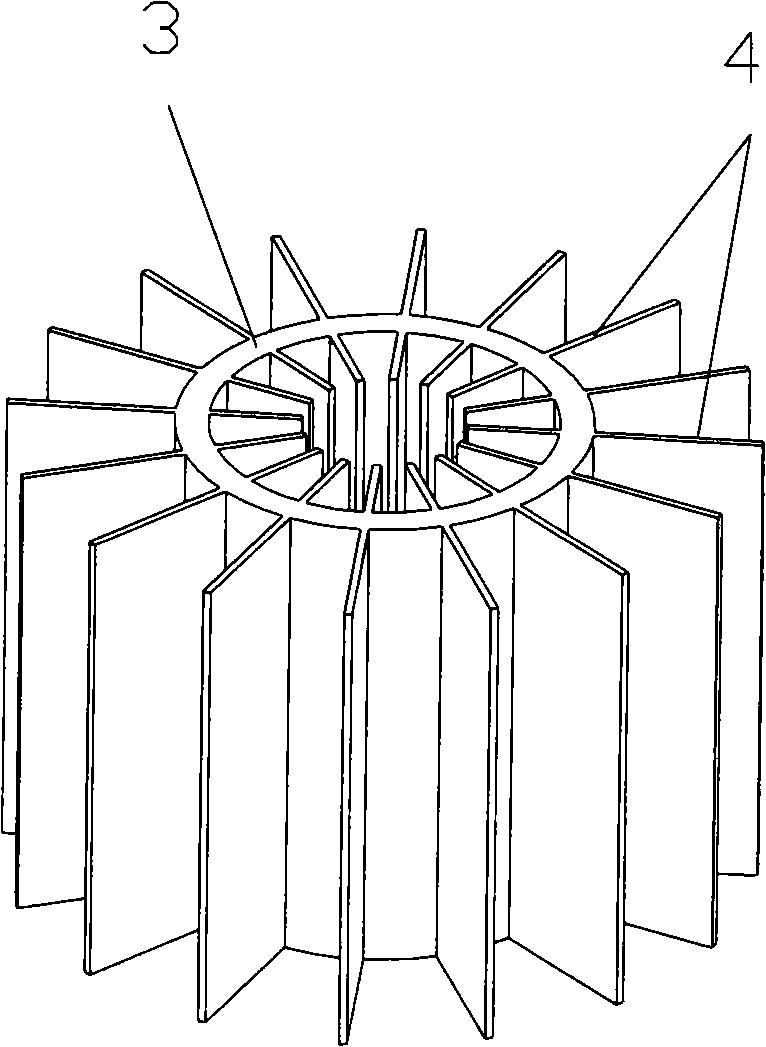

Loop circuit heat pipe condenser

InactiveCN101270961AIncrease the area where the working fluid condensesEnhanced natural convectionStationary conduit assembliesTubular elementsWorking fluidCooling effect

The invention discloses a loop heat pipe condenser, consisting of an evaporation chamber, a heat pipe and a sealed hollow condensation cavity, wherein the condensation cavity and the evaporation chamber are both provided with a working fluid inlet and a working fluid outlet; the working fluid outlet of the evaporation chamber is communicated with the working fluid inlet of the condensation cavity; the working fluid outlet of the condensation cavity is communicated with the working fluid inlet of the evaporation chamber through another pipe; the surface of the condensation cavity is provided with a plurality of fins. The heat pipes of the prior loop heat pipe devices directly extend through the fins; therefore, the condensation effect is not good; especially in case of heat dissipation through natural convection, the cooling effect is very poor. On the basis of the prior loop heat pipe devices, the invention is provided with a condensation cavity, and the evaporation chamber is connected with the condensation cavity through a pipeline; and then fins are arranged on the surface of the condensation cavity, thereby increasing the condensation area of the working fluid; at the same time, the loop structure of the condensation cavity effectively increases the effects of natural convection.

Owner:SUN YAT SEN UNIV

Loop heat pipe with wick passageways and heat transmission method and manufacturing method thereof

ActiveCN103344145AImprove heat transfer effectLower operating temperatureIndirect heat exchangersMicro-loop heat pipeHeat resistance

The invention discloses a loop heat pipe with wick passageways. The loop heat pipe with the wick passageways comprises an evaporation section, a heat insulation section, a condensation section and an infusion section, wherein the evaporation section, the heat insulation section, the condensation section and the infusion section are connected in sequence in an end-to-end mode to form a loop, the pipe body is filled with metal powder at the evaporation section and the infusion section and high sintering is carried out on the metal powder, a first wick passageway is formed by the pipe body at the evaporation section and the metal powder, and a second wick passageway is formed by the pipe body at the infusion section and the metal powder. According to the loop heat pipe with the wick passageways, liquid working media can still move fast under the condition of antigravity through capillary force in the first wick passageway and in the second wick passageway, and therefore heat transmission efficiency is improved, and operating temperature and heat resistance are reduced. The invention further provides a heat transmission method and a manufacturing method of the loop heat pipe with the wick passageways.

Owner:SOUTH CHINA UNIV OF TECH

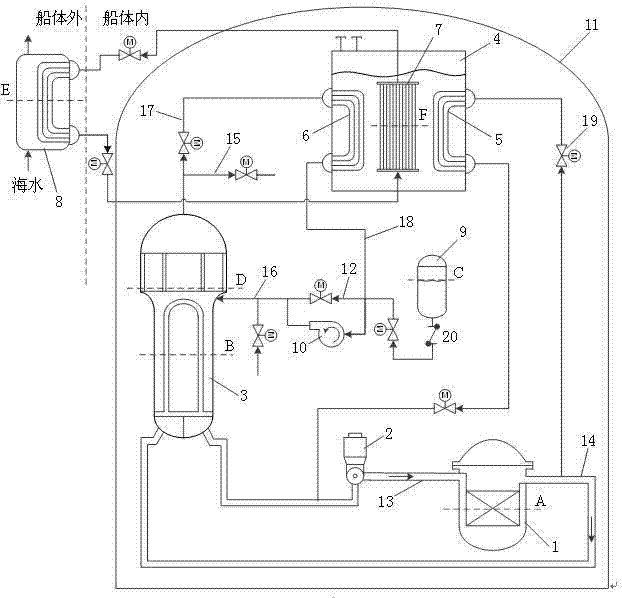

Passive residual heat removal system of marine nuclear power device

InactiveCN104733060AGuaranteed operational safetyIncrease safety redundancyNuclear energy generationCooling arrangementReactor pressure vesselNuclear power

The invention discloses a passive residual heat removal system of a marine nuclear power device. The passive residual heat removal system comprises a containment and a cooling heat exchanger. The containment is internally provided with a reactor pressure vessel, a loop cool pipe section, a loop heat pipe section, a steam generator, a refueling water tank, a 1# residual heat removal heat exchanger, a 2# residual heat removal heat exchanger and a cooling water pipe bundle; the refueling water tank is arranged at the top of the containment; the reactor pressure vessel and the steam generator are connected with the heat pipe section through the loop cool pipe section; the inlet and the outlet of the 1# residual heat removal heat exchanger are respectively connected with the loop heat pipe section and the loop cool pipe section; a main steam pipeline and a water supply pipeline which are connected with the inlet and the outlet of the 2# residual heat removal heat exchanger are arranged on the steam generator; upper and lower ends of the cooling water pipe bundle are respectively connected with the inlet and the outlet of the cooling heat exchanger. The passive residual heat removal system of the marine nuclear power device is independent from external power, is improved in capability of removing residual heat of reactor core through natural circulation, is improved in safety redundancy, power and operation stability, and guarantees operation safety of nuclear reactor.

Owner:SOUTHEAST UNIV

Plate loop heat pipe (I)

The plate loop heat pipe includes at least one annular loop plate inside a hollow casing to form at least one loop including successively connected evaporating area, steam channel, condensing area and fluid returning channel. Proper amount of fluid is filled inside the casing, the fluid returning channel is independent form the steam channel, the cover of the annular loop is provided with capillary structure, and the flow resistance of the steam channel is smaller than that of the fluid returning channel. The fluid is heated in the evaporating area, heat dissipated in the condensing area and made to flow stably in one direction, and thus the non-coagulating gas in the loop has less effect on the temperature homogeneity of the loop. The heat pipe has high heat homogeneity and large heat transferring amount.

Owner:李嘉豪

Loop heat pipe changing in height direction of annular separation device

InactiveCN107062960AReduce vibrationImprove heat transfer performanceSafety devices for heat exchange apparatusIndirect heat exchangersNoise levelEvaporation

The invention provides a heat pipe which comprises an evaporation header, a condensation header, ascending pipes and a backflow pipe. The ascending pipes and the evaporation header communicate with the condensation header. The evaporation header is located at the lower portion, and the condensation header is located at the upper portion. Fluid absorbs heat and is evaporated in the evaporation header and then enters the condensation header from the ascending pipes. The fluid exchanges heat in the condensation header and is then condensed, and the condensed fluid goes back to the evaporation header through the backflow pipe. Flow stabilizing devices are arranged in the ascending pipes, and the multiple flow stabilizing devices are arranged in the same ascending pipe. The length of the flow stabilizing devices is increased gradually in the height direction of the ascending pipes. By means of the heat pipe, due to the length changing of the flow stabilizing devices, when gas-liquid two phase flow in the ascending pipes, heat transfer is strengthened, meanwhile, vibration of the ascending pipes is weakened, and the noise level is lowered.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com