Plate loop heat pipe (I)

A flat-plate, loop technology, used in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as rising prices, reduced heat transfer, and large temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

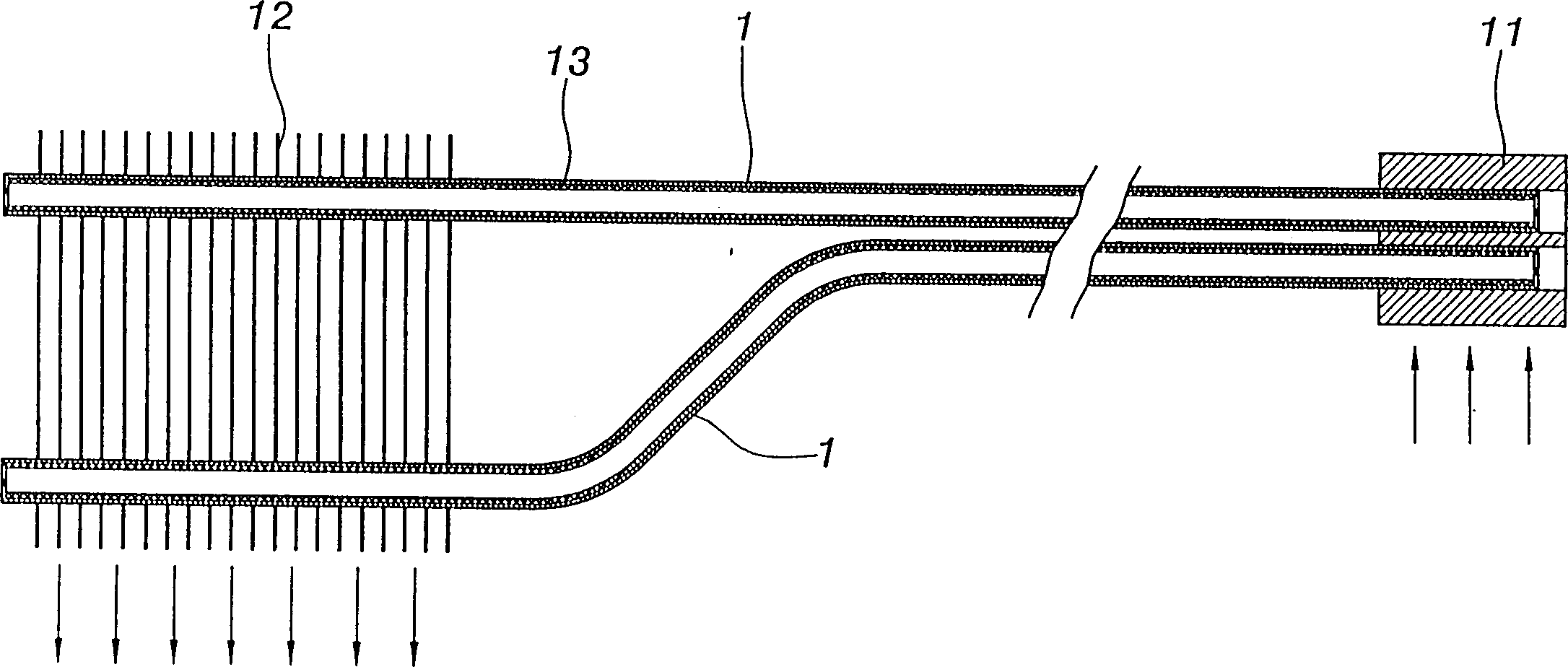

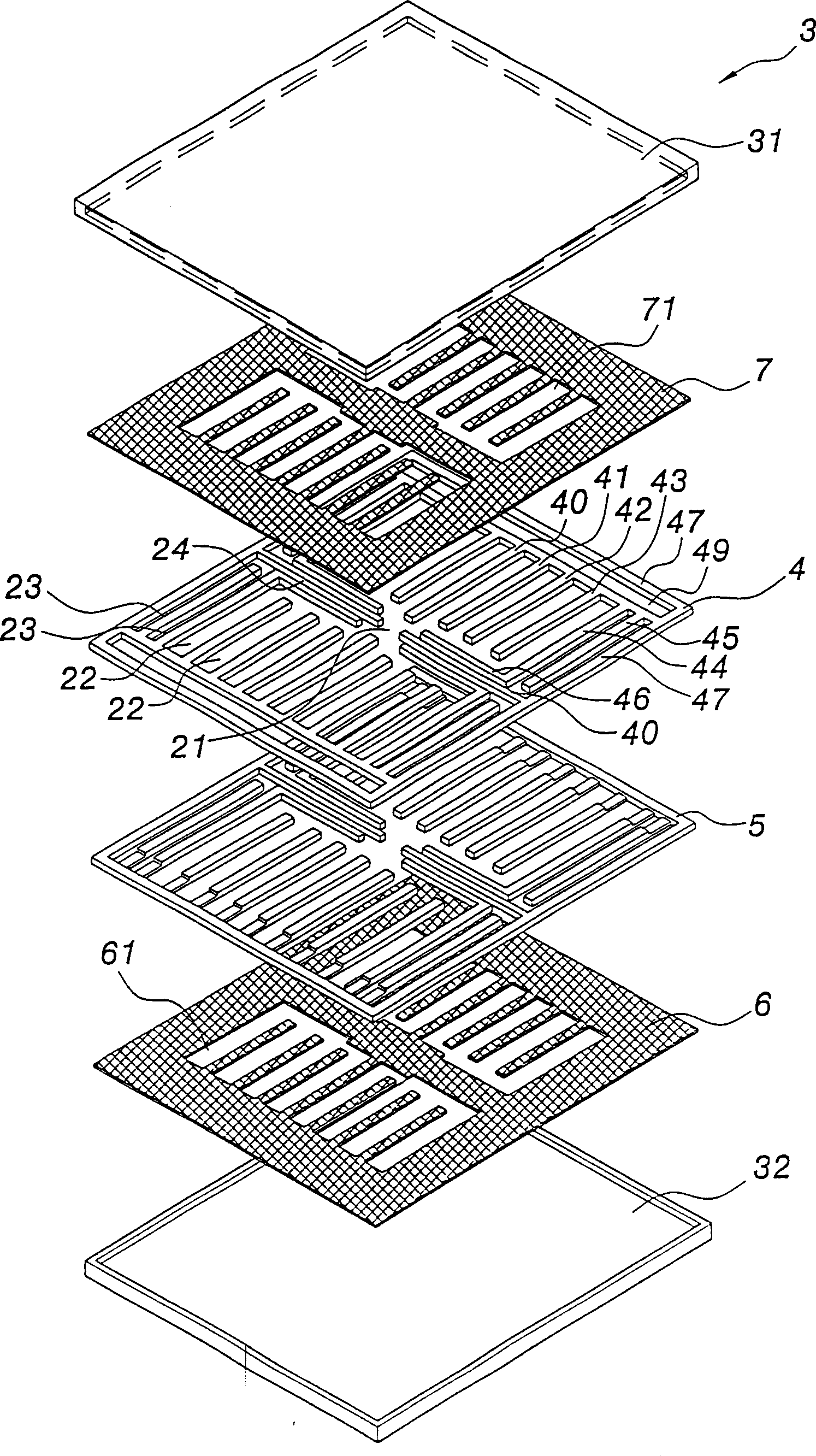

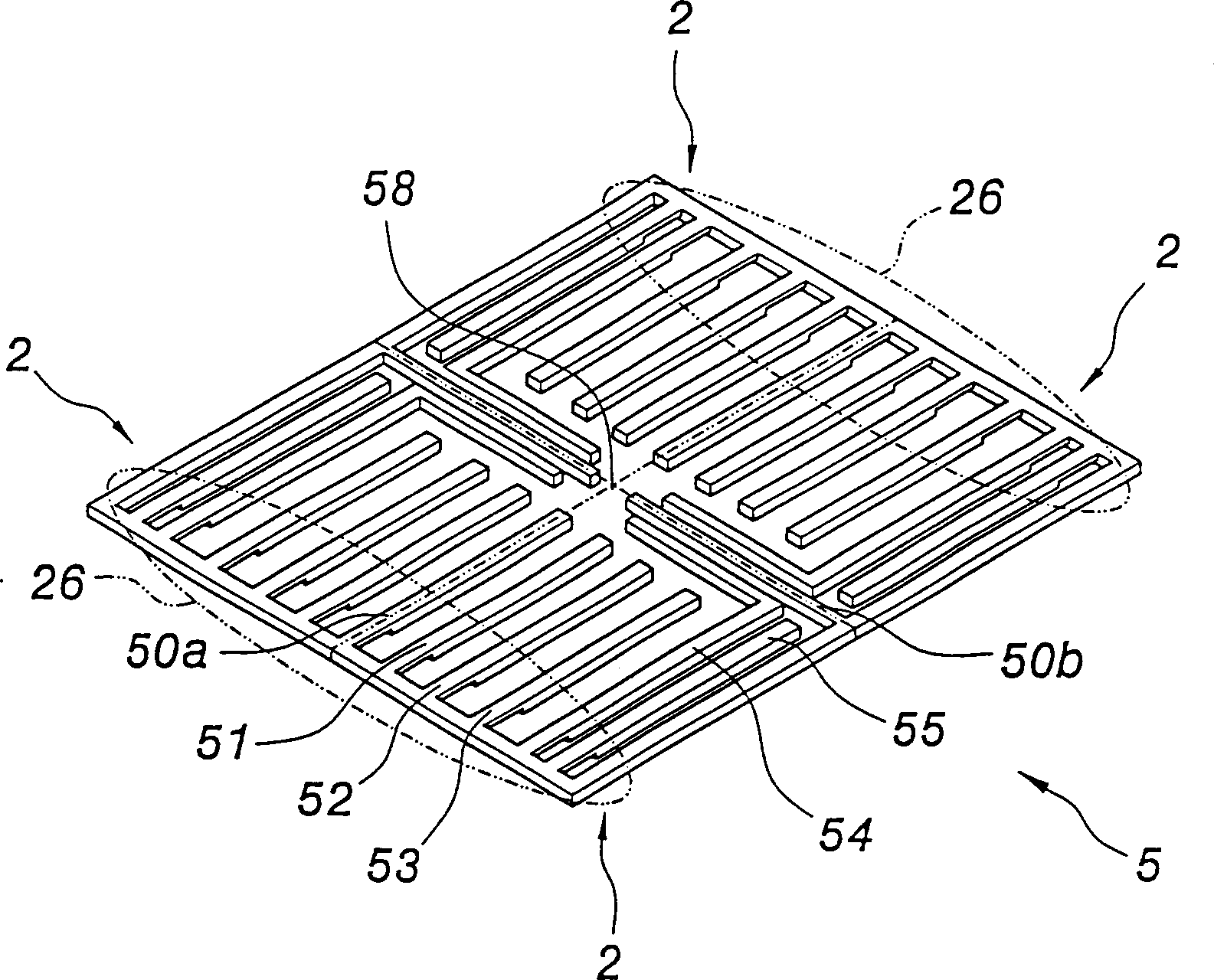

[0017] exist figure 2 , 3 , 4, 5, 6 and Figure 7 Among them, one embodiment of the present invention is a loop type heat pipe, which has a shell 3, which is a hollow closed body, and the shell 3 is filled with an appropriate amount of liquid. The filling amount of the liquid refers to the range from filling the capillary tissue that can appear and exist in the housing to filling up 80-90% of the volume of the passages in each circuit of the first annular circuit board in the circuit.

[0018] There is at least one hollow first annular circuit board 5 and at least one second annular circuit 4 which is hollow. The circuit board 4 is formed with at least one circuit 2 in the housing 3, and the circuit 2 is to form each channel with a hollow space, and the housing 3 is composed of a top case 31 and a bottom case 32, and the periphery of the top case 31 and the bottom case The peripheral edges of the bottom case 32 are joined together to form the casing 3 in an airtight manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com