Patents

Literature

16457results about "Indirect heat exchangers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic device

ActiveUS9313915B2Improve cooling efficiencyPump componentsDigital data processing detailsHeat conductingElectron device

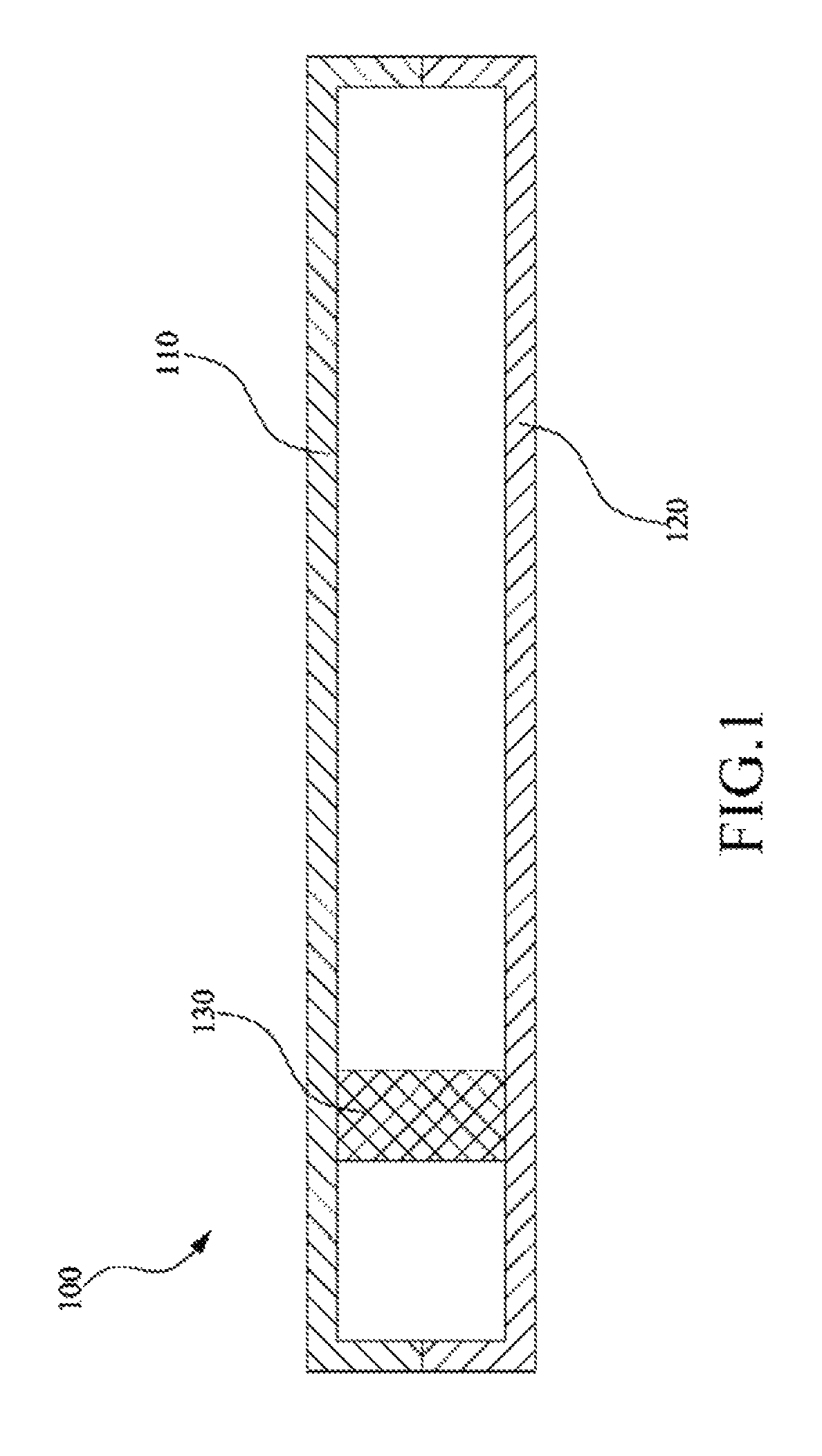

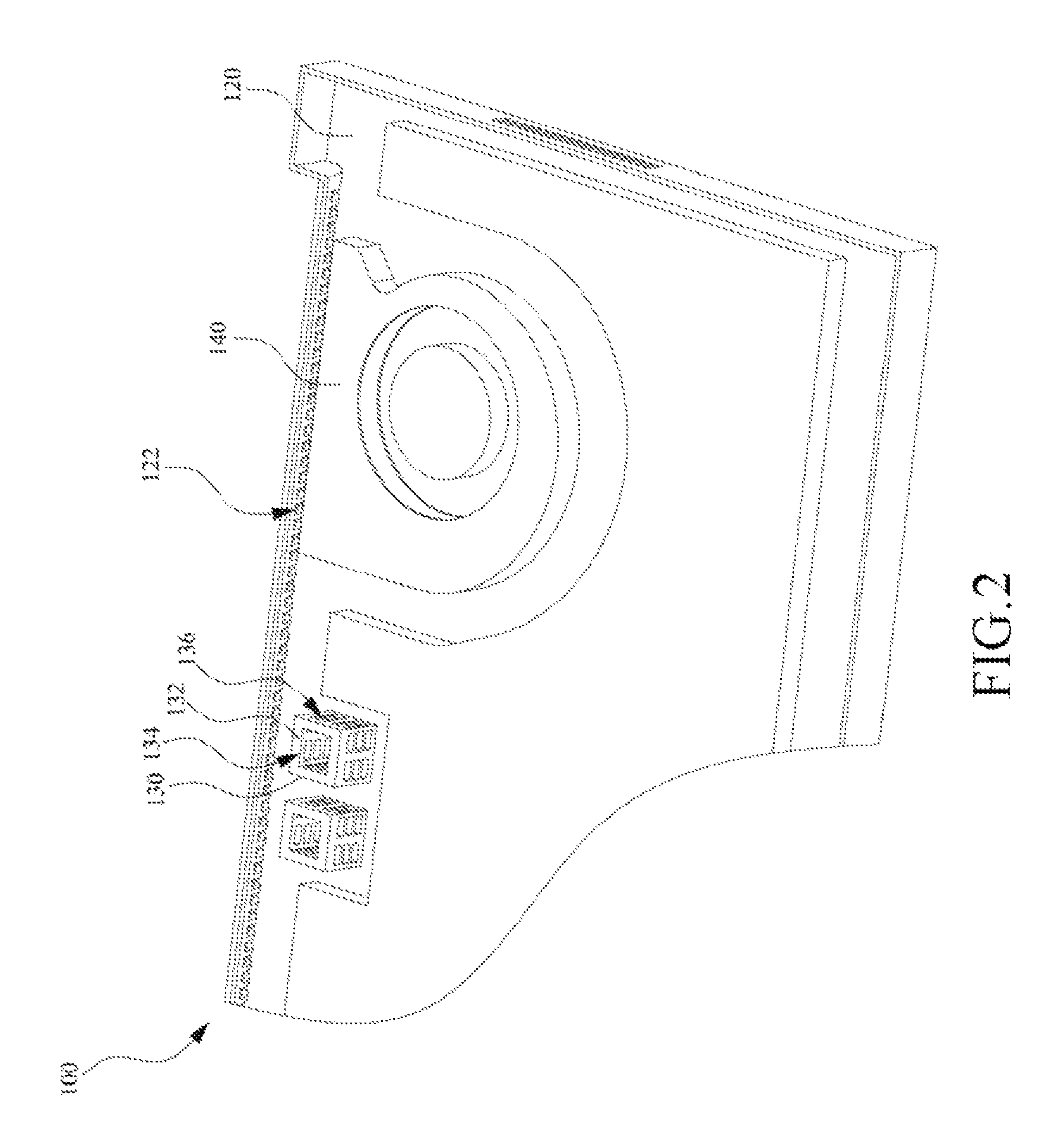

An electronic device includes an upper cover, a lower cover combined with the upper cover, and a heat conducting pillar. An accommodating space is formed by the upper cover and the lower cover. The heat conducting pillar is disposed in the accommodating space and physically connected with the upper cover and the lower cover to balance the temperature of the upper cover and the lower cover.

Owner:ASUSTEK COMPUTER INC

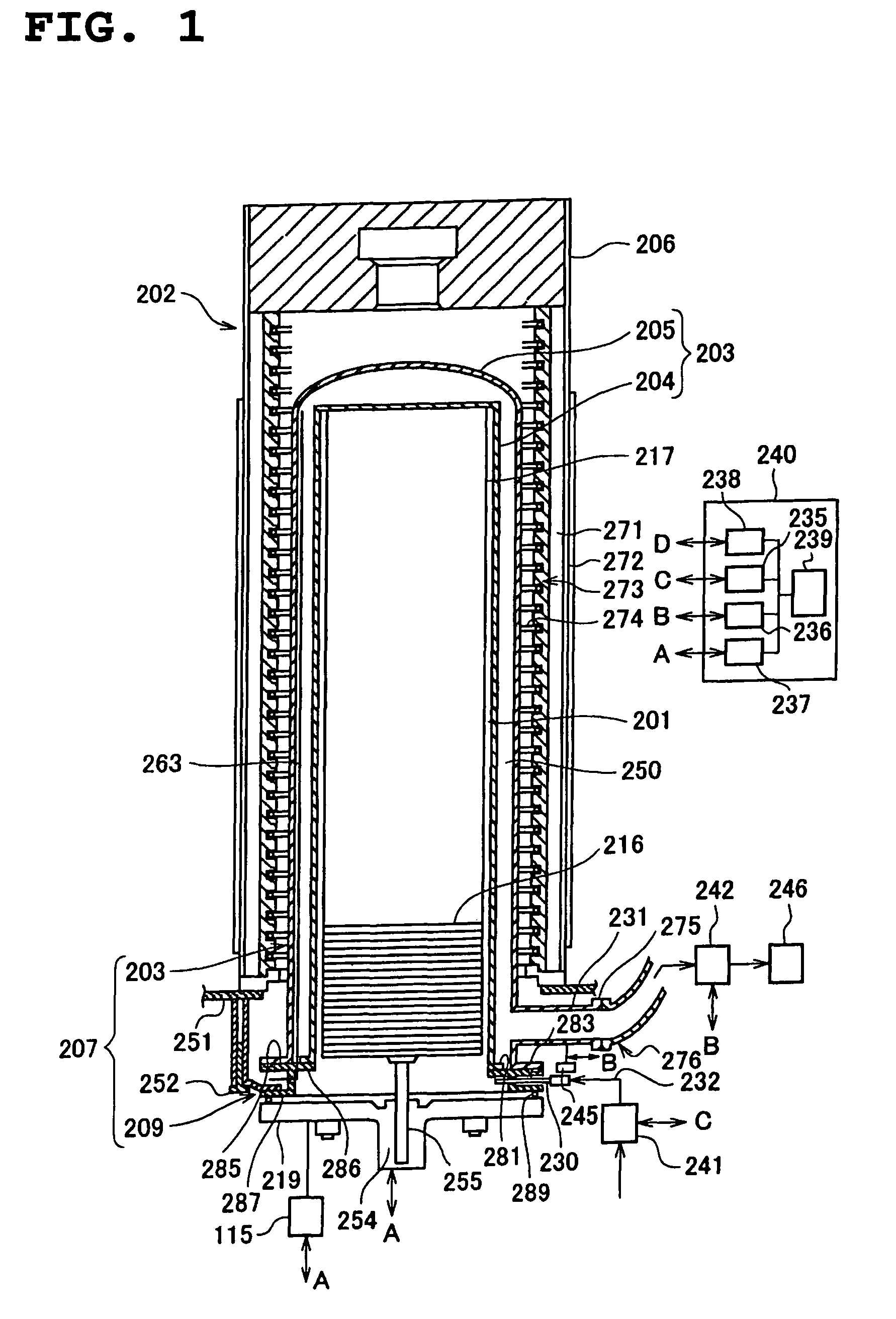

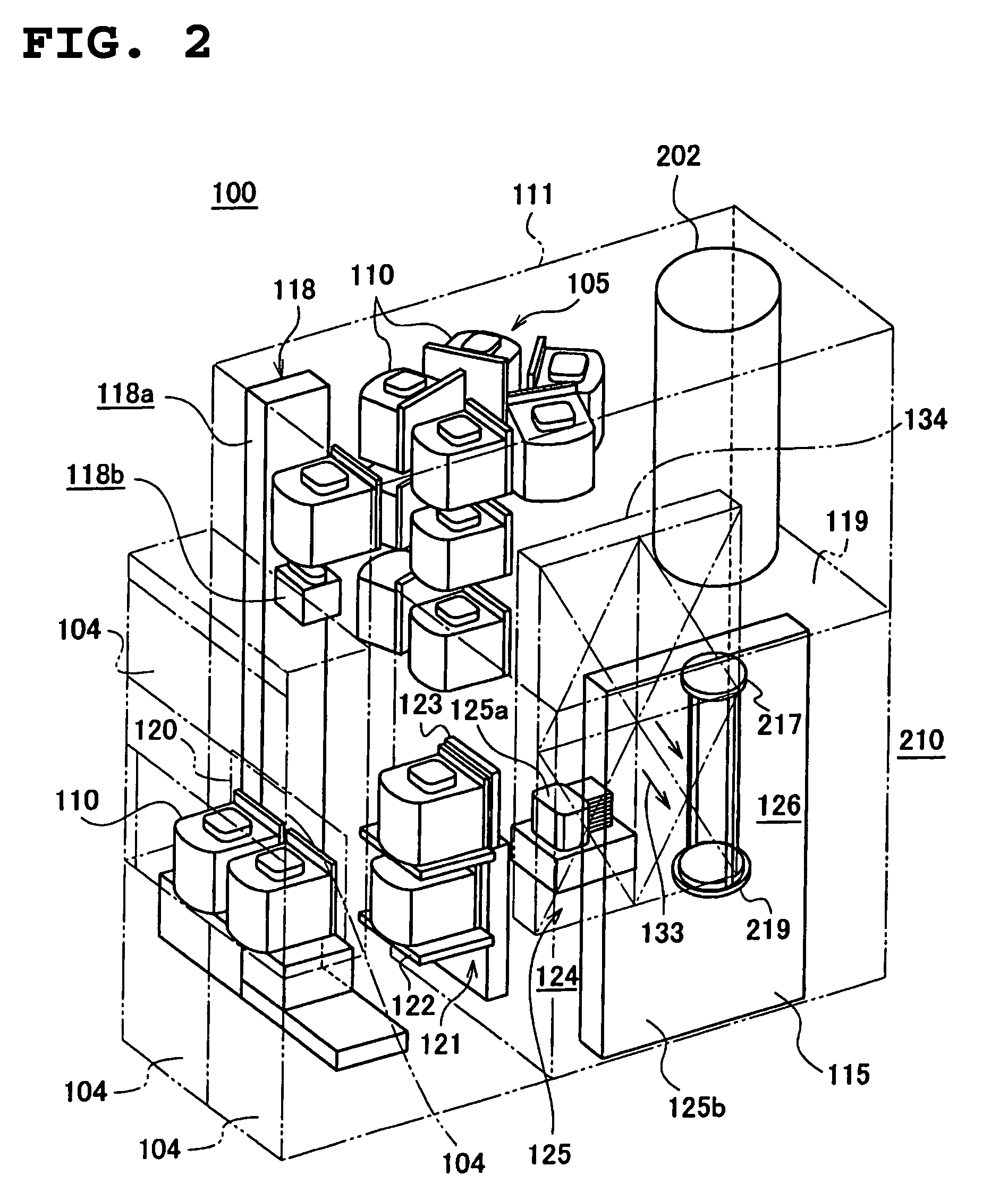

Substrate processing apparatus and attaching/detaching method of reaction vessel

ActiveUS8172947B2Linings repairSemiconductor/solid-state device manufacturingEngineeringMental detachment

Owner:KOKUSA ELECTRIC CO LTD

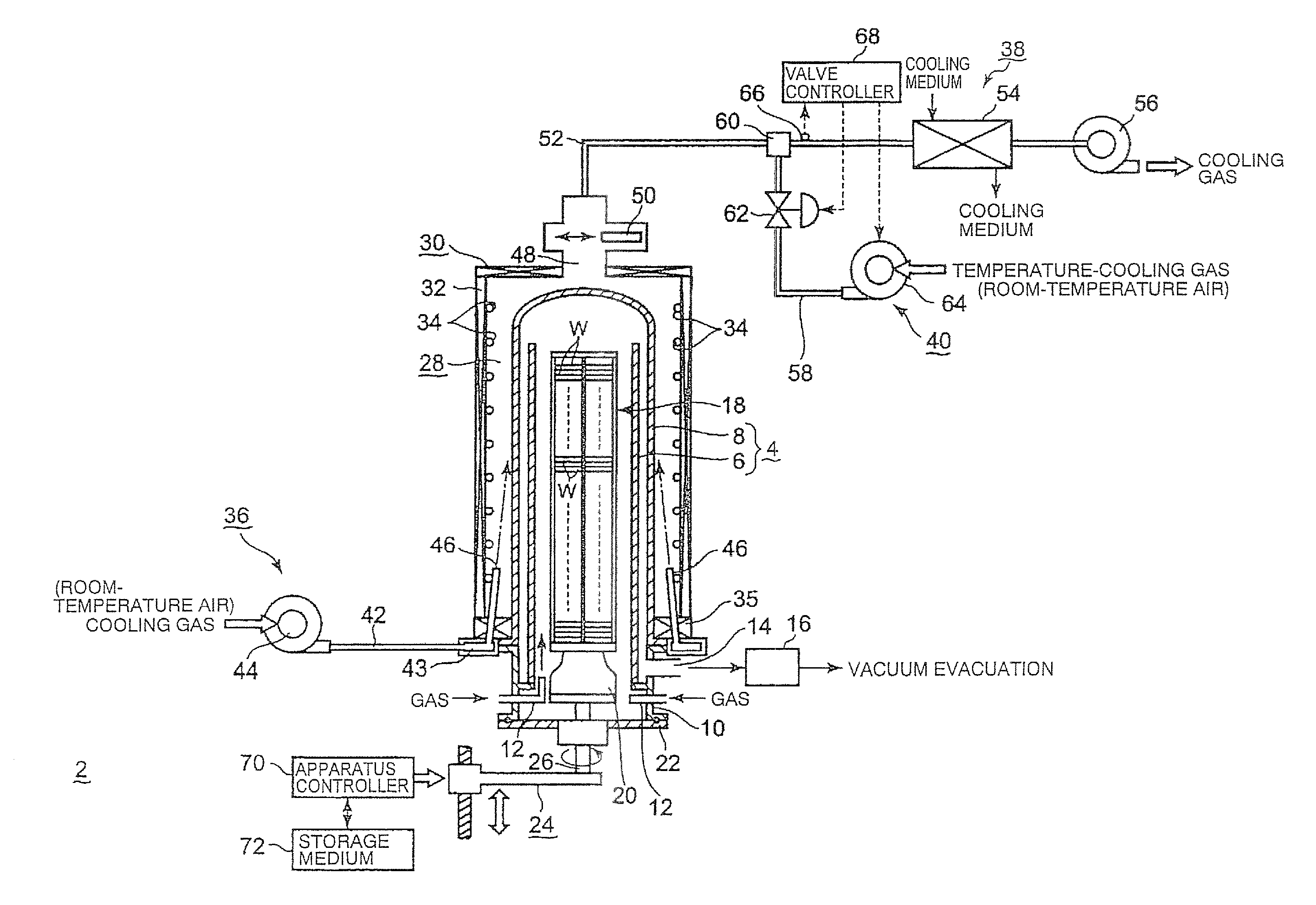

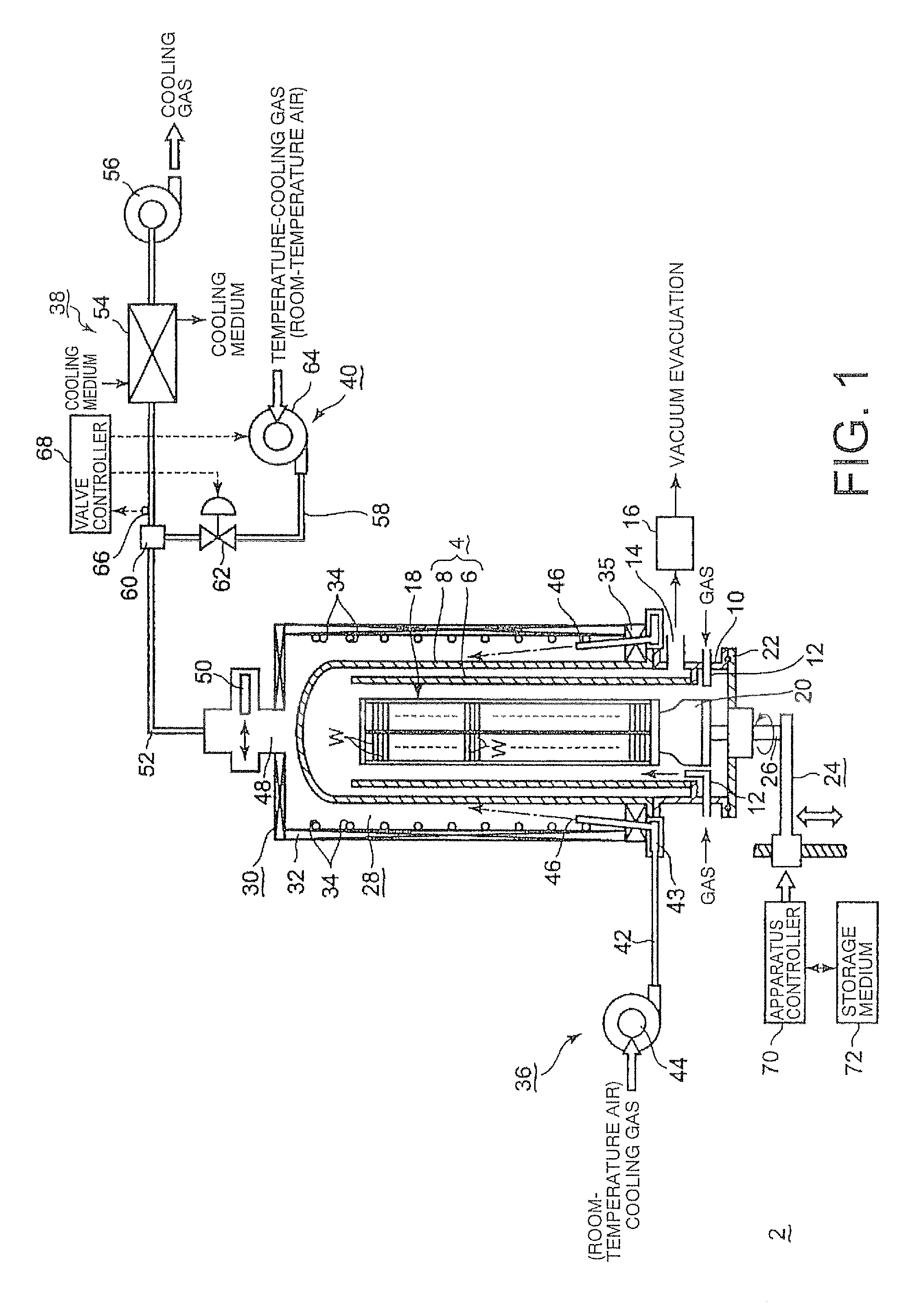

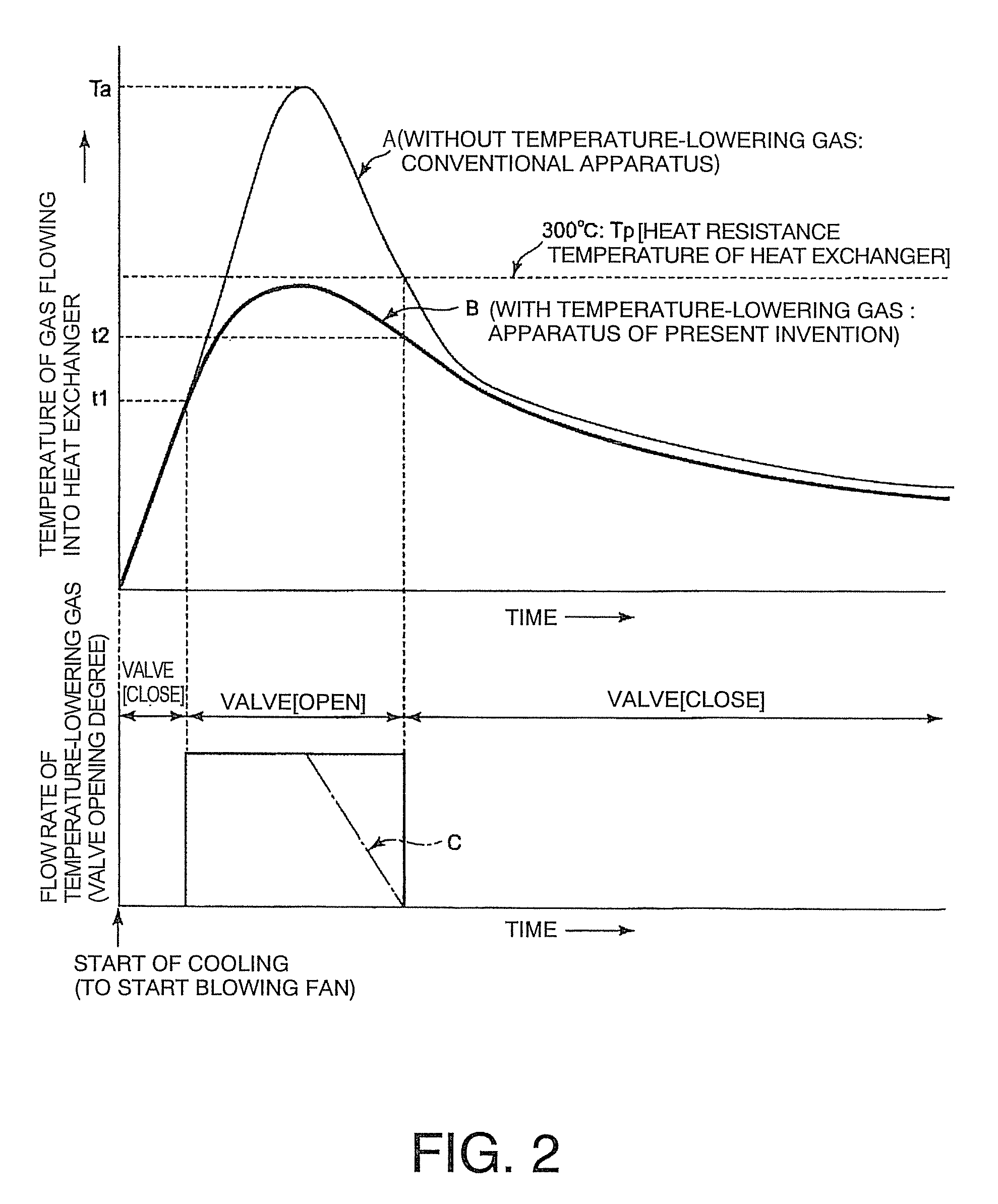

Thermal processing apparatus and cooling method

InactiveUS9099505B2Efficient solutionLow heat resistanceAfter-treatment apparatusSemiconductor/solid-state device manufacturingProcess engineeringHeating furnace

A thermal processing apparatus including: a cylindrical processing vessel; a support unit to be loaded into and unloaded from the vessel; and a heating furnace surrounding an outer periphery of the vessel, with a cooling space therebetween. The furnace is connected to a cooling-gas introduction unit, including a gas introduction passage to which a blowing fan is connected, for introducing a cooling gas into the cooling space during a temperature lowering operation after a thermal process. The furnace is connected to a cooling-gas discharge unit, including a heat exchanger, a suction fan, and a gas discharge passage, for discharging the cooling gas of a raised temperature from the cooling space. Connected to the gas discharge passage at a position upstream of the heat exchanger is a temperature-lowering gas introduction unit for introducing a temperature-lowering gas to the cooling gas of a raised temperature so as to lower its temperature.

Owner:TOKYO ELECTRON LTD

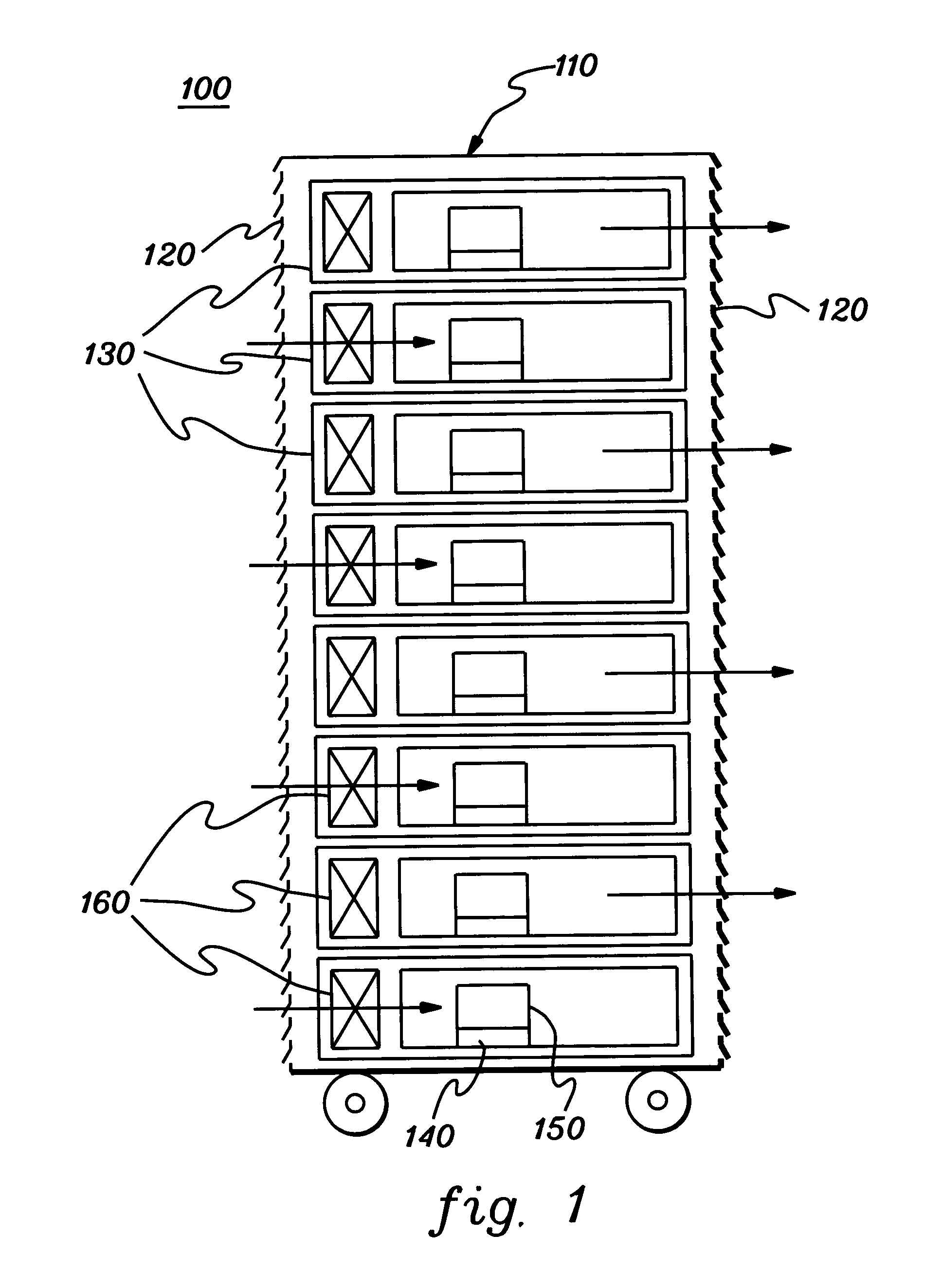

Exhaust air removal system

InactiveUS20050170770A1Mixing with airMeet the requirementsIndirect heat exchangersCooling/ventilation/heating modificationsExhaust fumesBack door

An exhaust air removal system and method for use with a rack or enclosure containing equipment is provided. The system and method are configured for removal of exhaust air vented from equipment during operation to thereby remove heat from the equipment. In one aspect, the system includes a fan unit preferably configured to serve as a back door of an equipment rack or enclosure and configured to provide access to an interior of the rack or enclosure. The fan unit provides multiple fans coupled to internal exhaust ducts that are arranged to draw and to remove exhaust air vented from rack-mounted equipment. The fan unit is further configured to vent exhaust air to an area external to a rack or enclosure, such as an external exhaust duct or plenum. Removal of hot and warm exhaust air vented from rack-mounted equipment enables the equipment to operate effectively, drawing sufficient amounts of cooling air to meet its cooling requirements. The fan unit is constructed for portability and for easy attachment to and removal from a rack or enclosure, providing flexibility in handling equipment exhaust needs.

Owner:SCHNEIDER ELECTRIC IT CORP

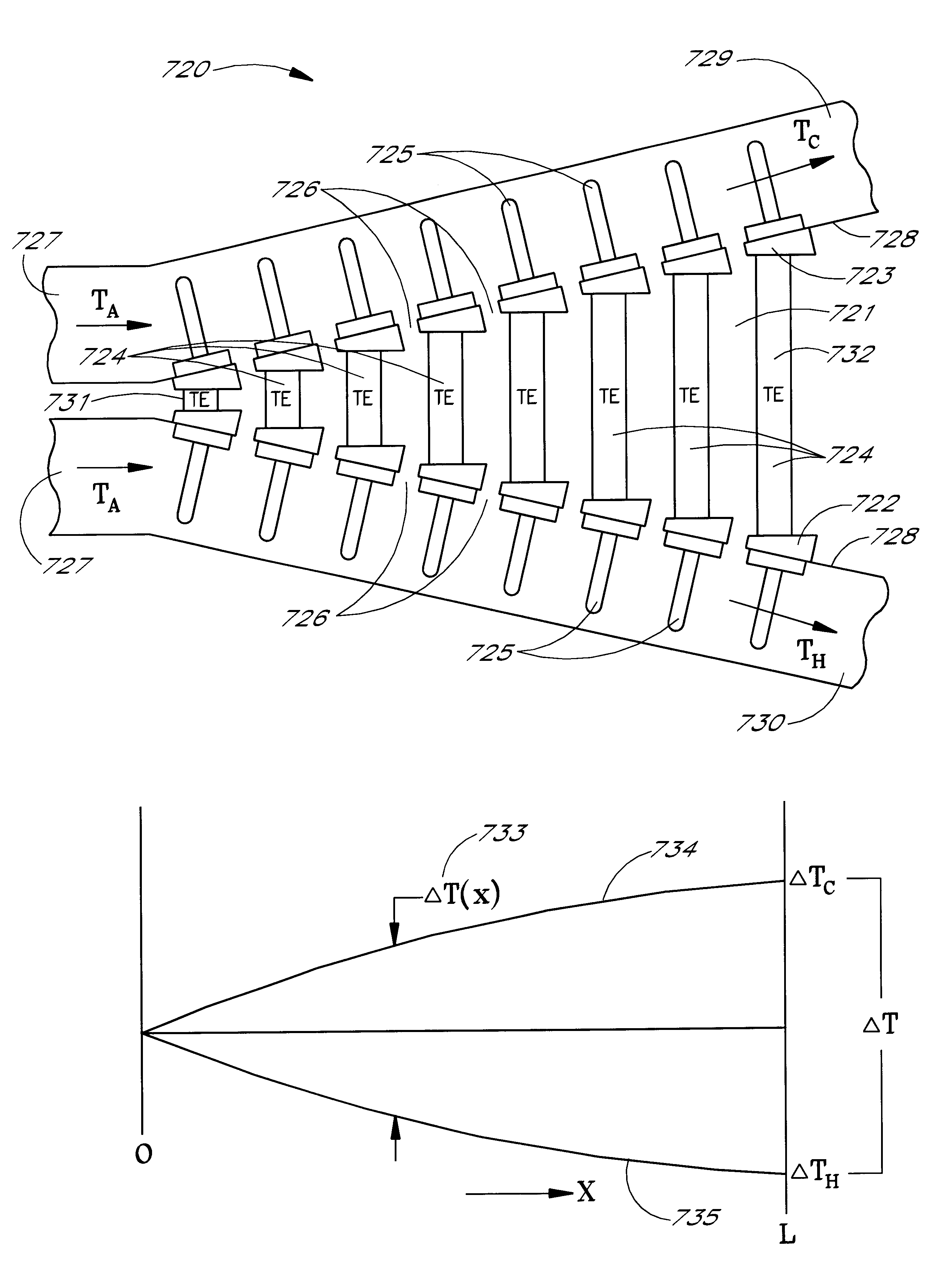

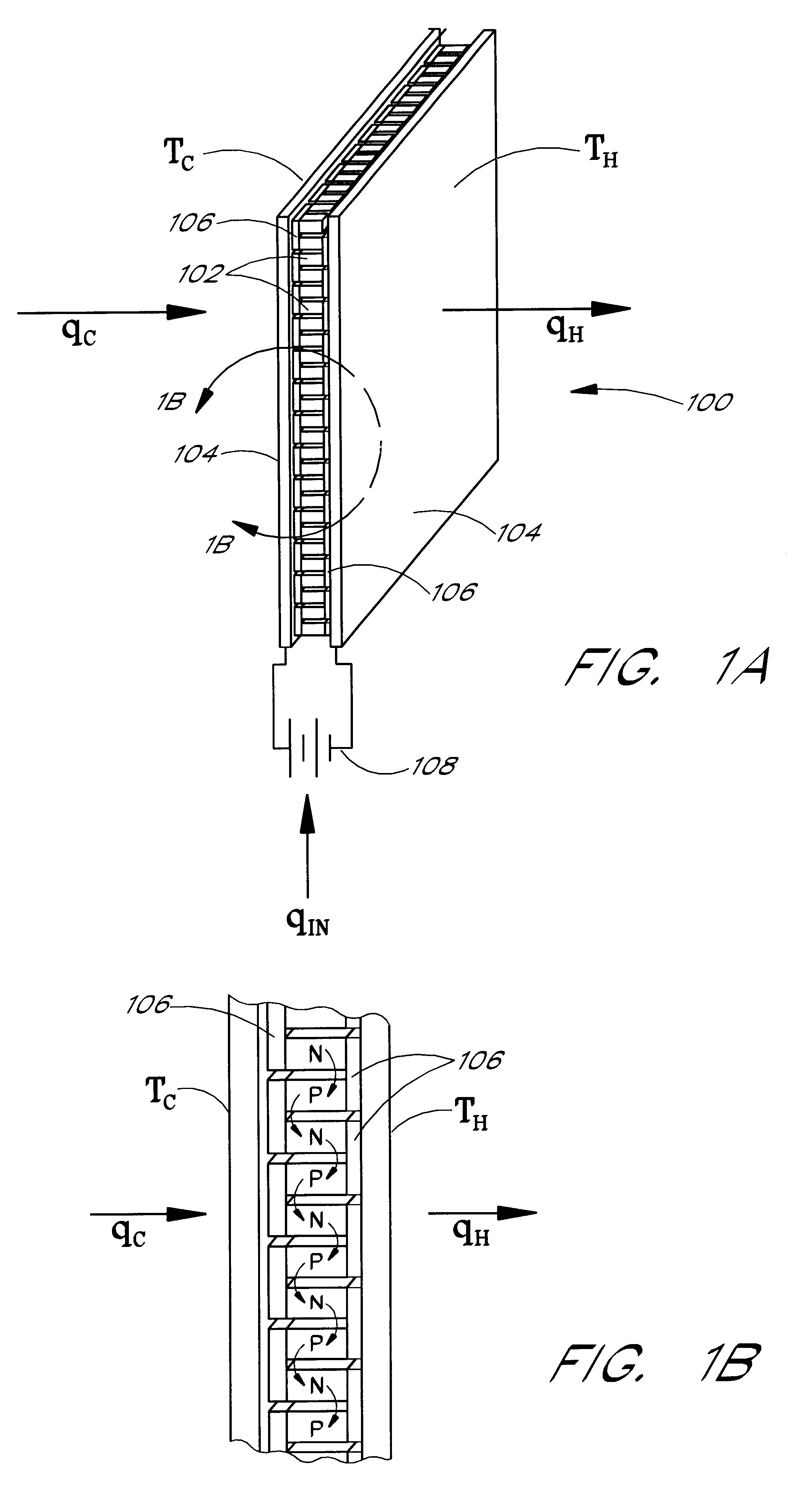

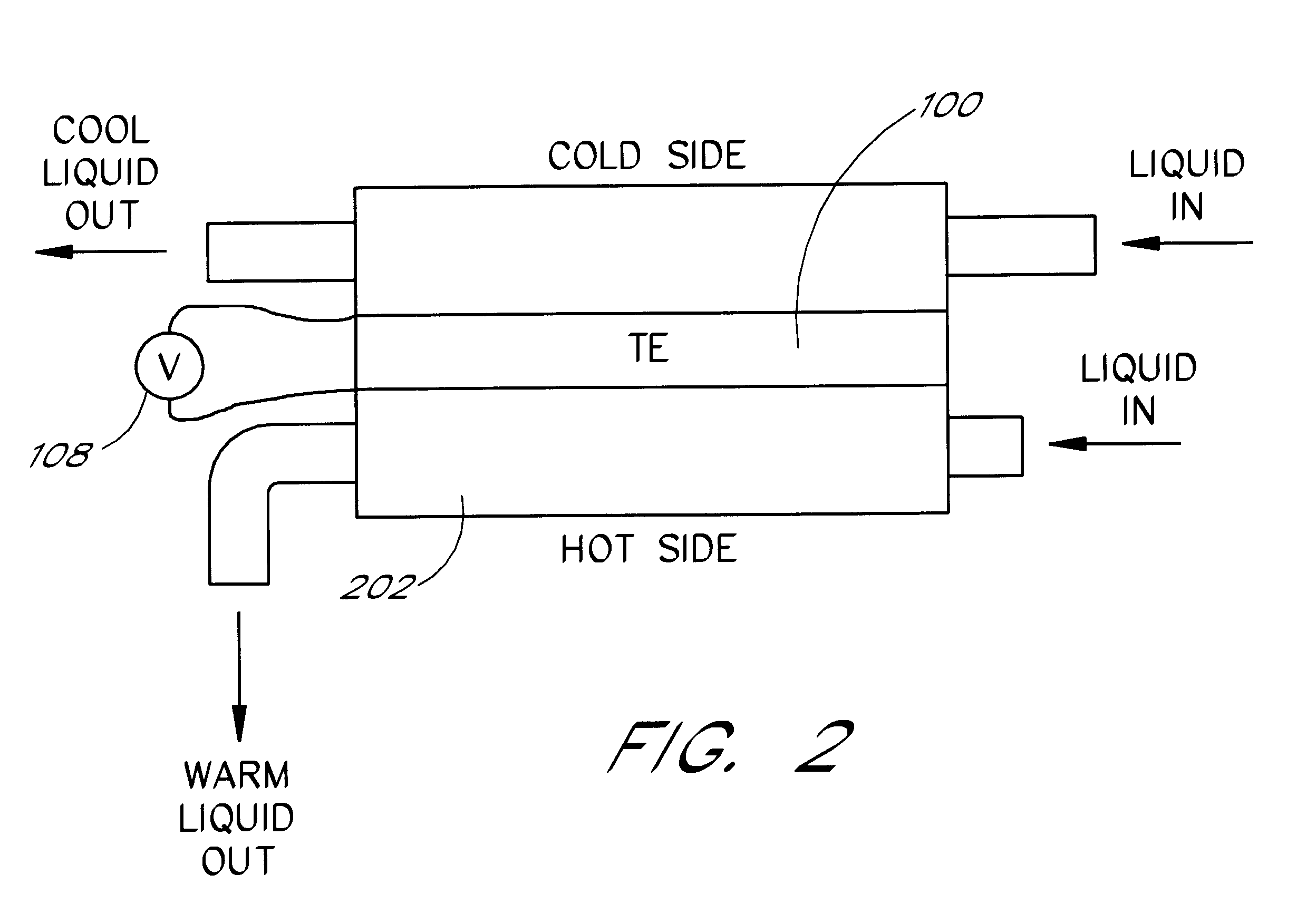

Efficiency thermoelectrics utilizing thermal isolation

InactiveUS6539725B2Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal isolationElectrical resistance and conductance

An improved efficiency thermoelectric system and method of making such a thermoelectric system are disclosed. Significant thermal isolation between thermoelectric elements in at least one direction across a thermoelectric system provides increased efficiency over conventional thermoelectric arrays. Significant thermal isolation is also provided for at least one heat exchanger coupled to the thermoelectric elements. In one embodiment, the properties, such as resistance or current flow, of the thermoelectric elements may also be varied in at least one direction across a thermoelectric array. In addition, the mechanical configuration of the thermoelectric elements may be varied, in one embodiment, according to dynamic adjustment criteria.

Owner:GENTHERM INC +1

Nanotube/metal substrate composites and methods for producing such composites

InactiveUS20050238810A1Simplified and advantageous mannerReduce productionMaterial nanotechnologyIndirect heat exchangersHydrogen fuel cellChemical vapor deposition

Carbon nanotubes are grown directly on metal substrates using chemical vapor deposition. Metal substrates are comprised of catalysts which facilitate or promote the growth of carbon nanotubes. The nanotube coated metal substrates have applications including, but not limited to, heat transfer and thermal control, hydrogen storage, fuel cell catalytic reformers, electronics and semiconductors, implantable medical devices or prostheses, and tribological wear and protective coatings.

Owner:MAINSTREAM ENG

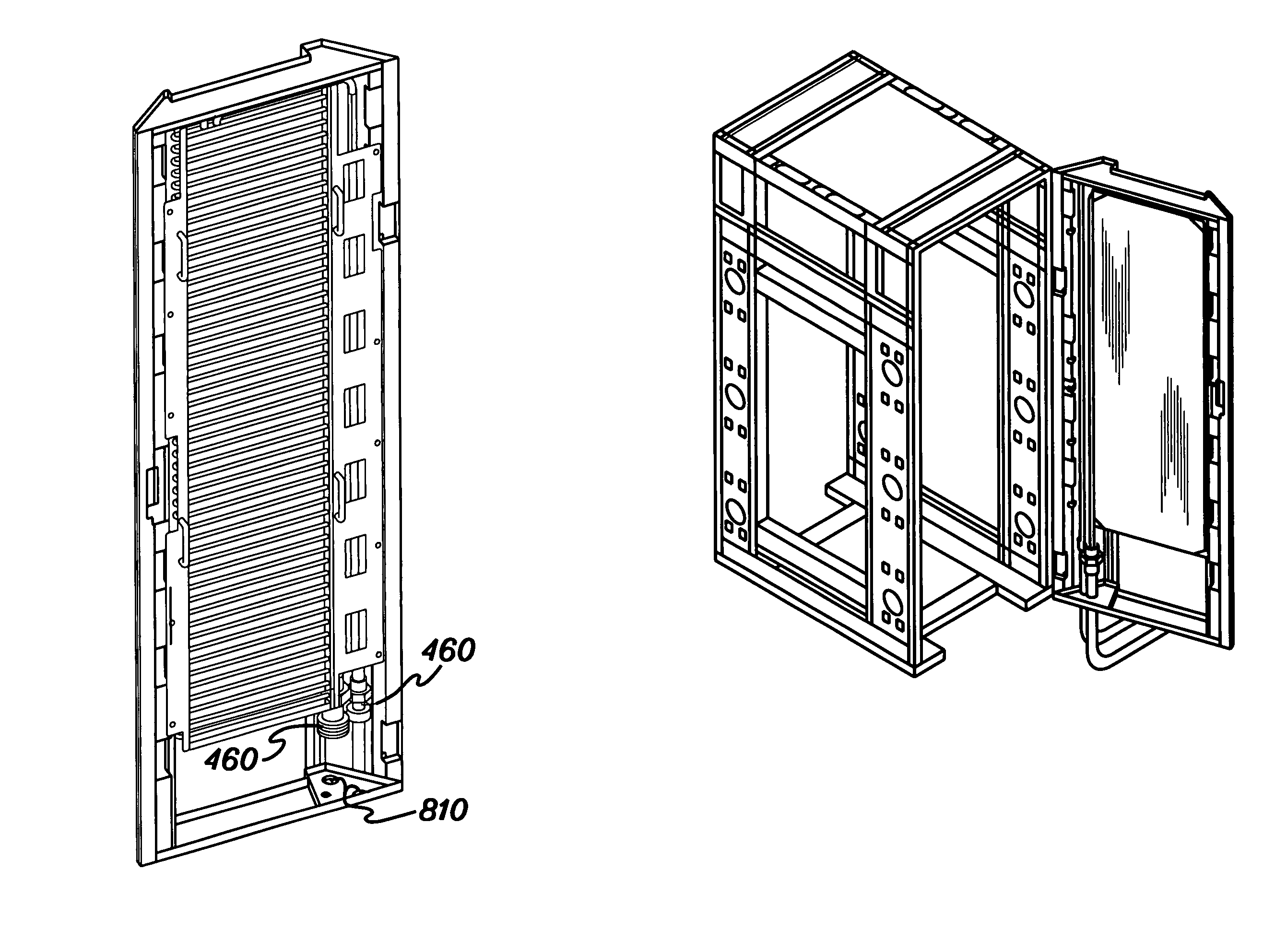

Apparatus and method for facilitating cooling of an electronics rack employing a heat exchange assembly mounted to an outlet door cover of the electronics rack

Apparatus and method are provided for facilitating cooling of an electronics rack employing a heat exchange assembly mounted to an outlet door cover hingedly affixed to an air outlet side of the rack. The heat exchange assembly includes a support frame, an air-to-liquid heat exchanger, and first and second perforated planar surfaces covering first and second main sides, respectively, of the air-to-liquid heat exchanger. The heat exchanger is supported by the support frame and includes inlet and outlet plenums disposed adjacent to the edge of the outlet door cover hingedly mounted to the rack. Each plenum is in fluid communication with a respective connect coupling, and the heat exchanger further includes multiple horizontally-oriented heat exchange tube sections each having serpentine cooling channel with an inlet and an outlet coupled to the inlet plenum and outlet plenum, respectively. Fins extend from the heat exchange tube sections.

Owner:VETTE TECH

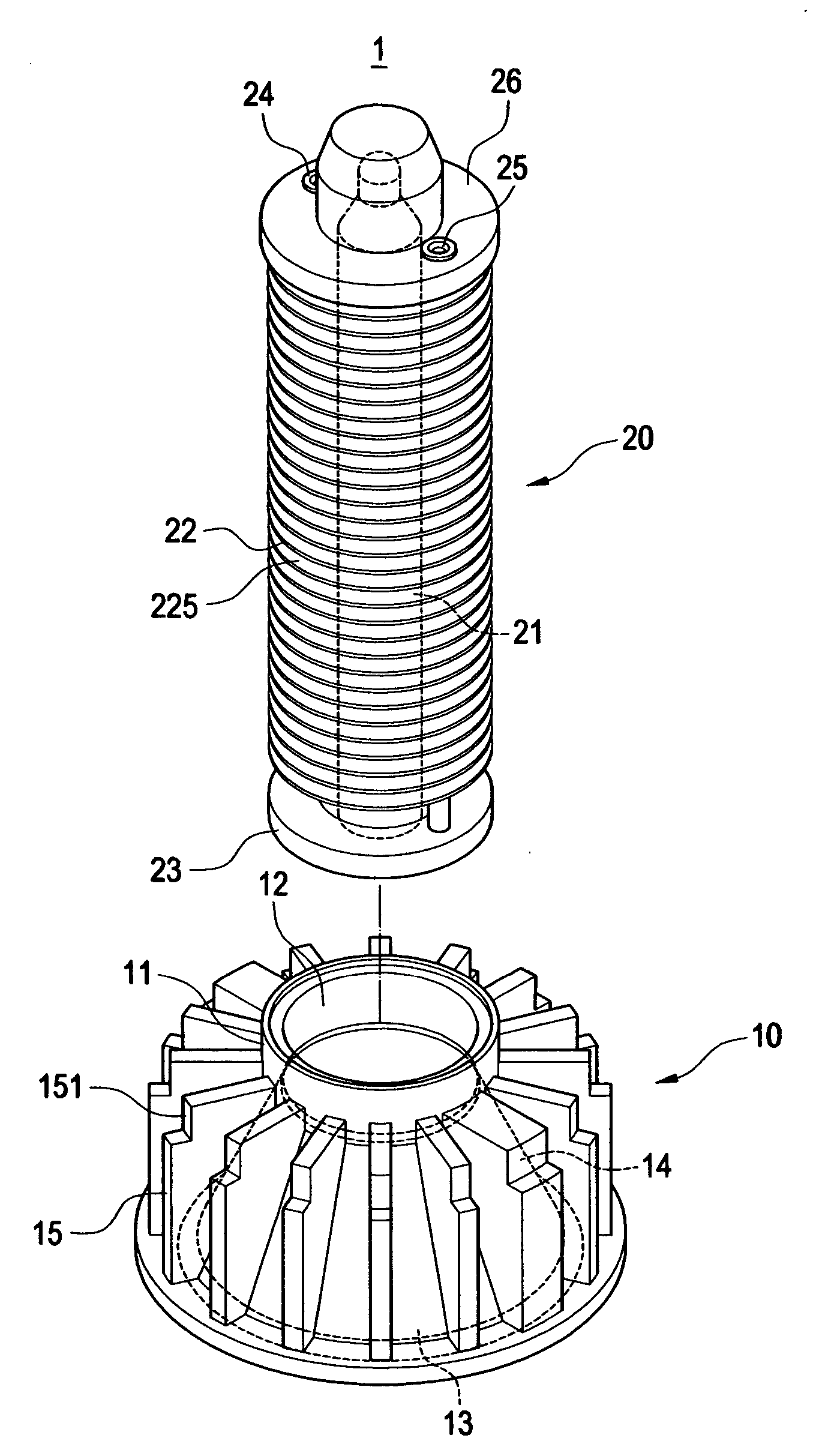

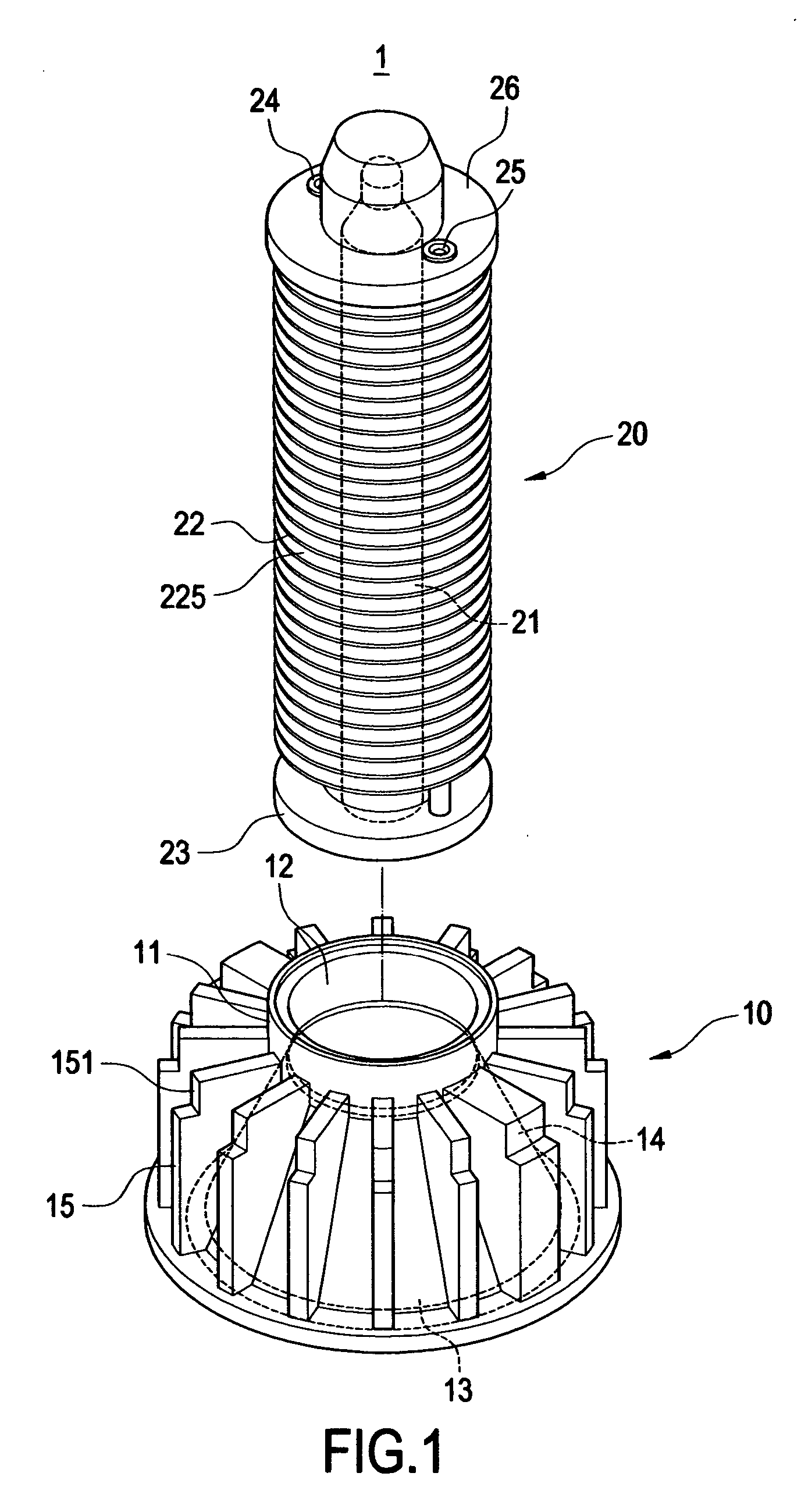

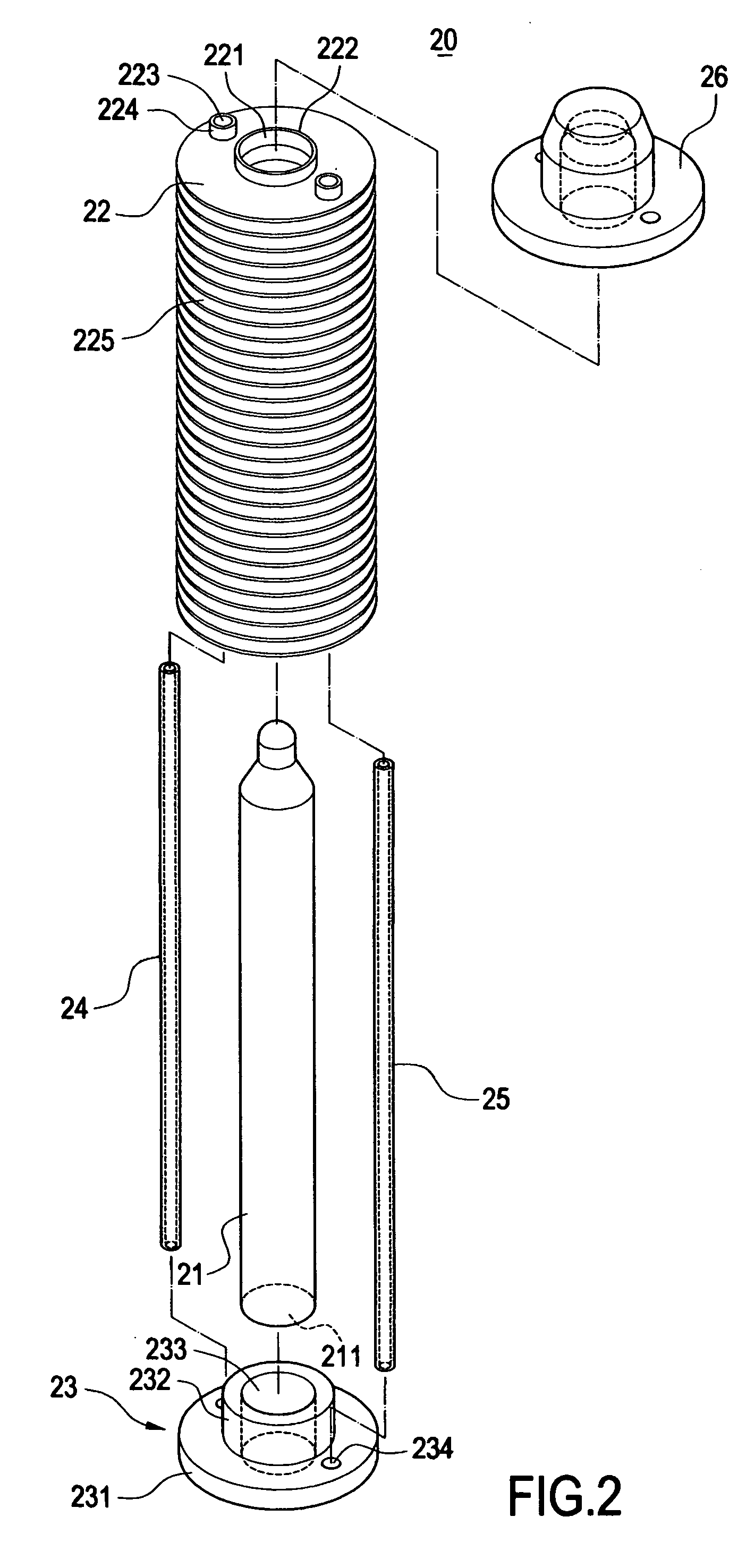

LED lamp and heat-dissipating structure thereof

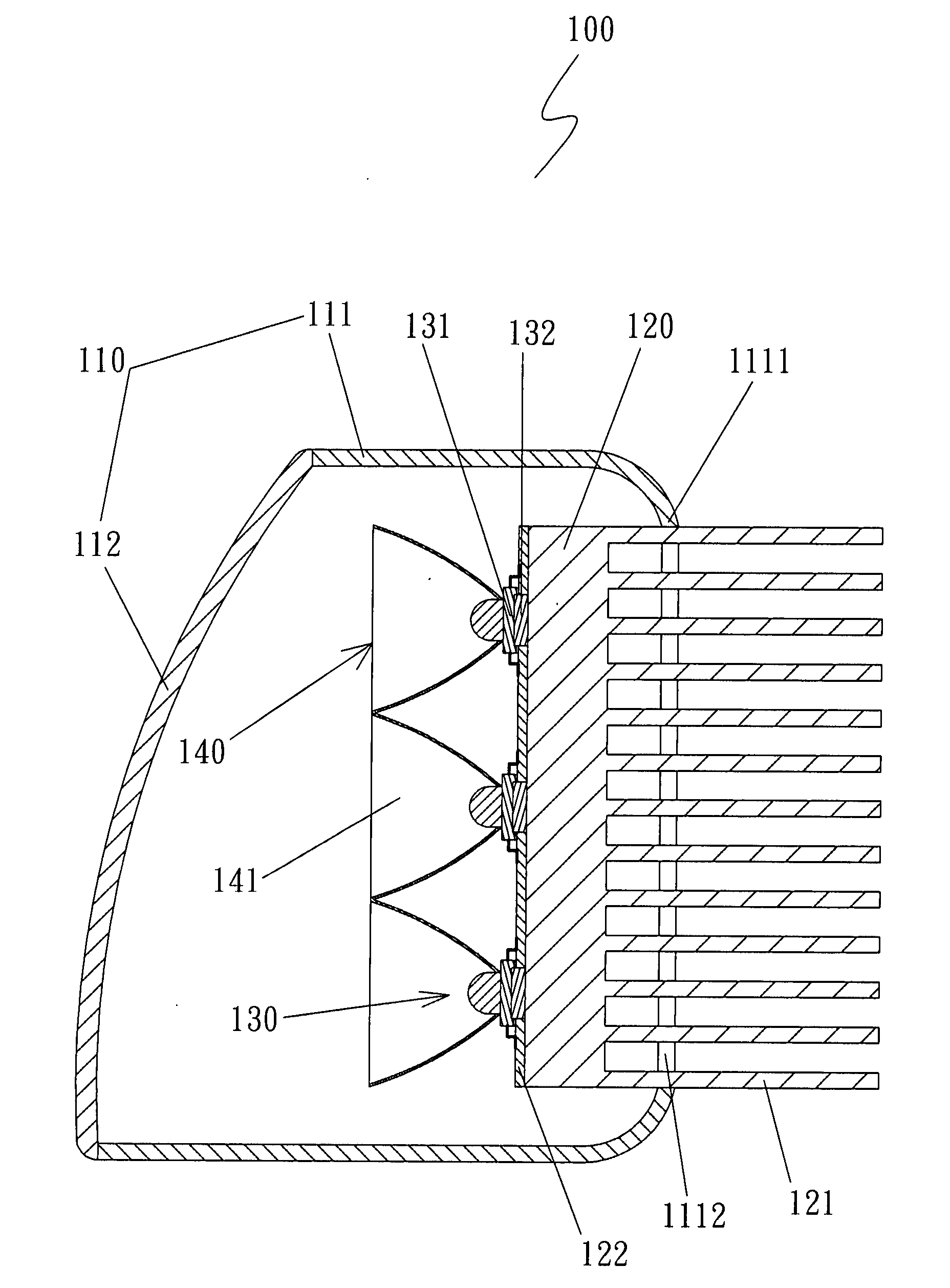

InactiveUS20070253202A1Prolong lifeThe production process is simplePoint-like light sourceLighting heating/cooling arrangementsWorking temperatureEngineering

The present invention is directed to a LED lamp and the heat-dissipating structure thereof. The heat-dissipating structure is used to dissipate the heat generated by the LED and comprises a first heat-dissipating body and a second heat-dissipating body. The first heat-dissipating body has a casing with an opening formed thereon. The second heat-dissipating body is connected on the first heat-dissipating body and comprises at least one heat pipe and a plurality of heat-dissipating fins connected to the heat pipe. With this arrangement, the LED continuously operates under a suitable working temperature and the life of the LED can thus be prolonged.

Owner:CHAUN CHOUNG TECH

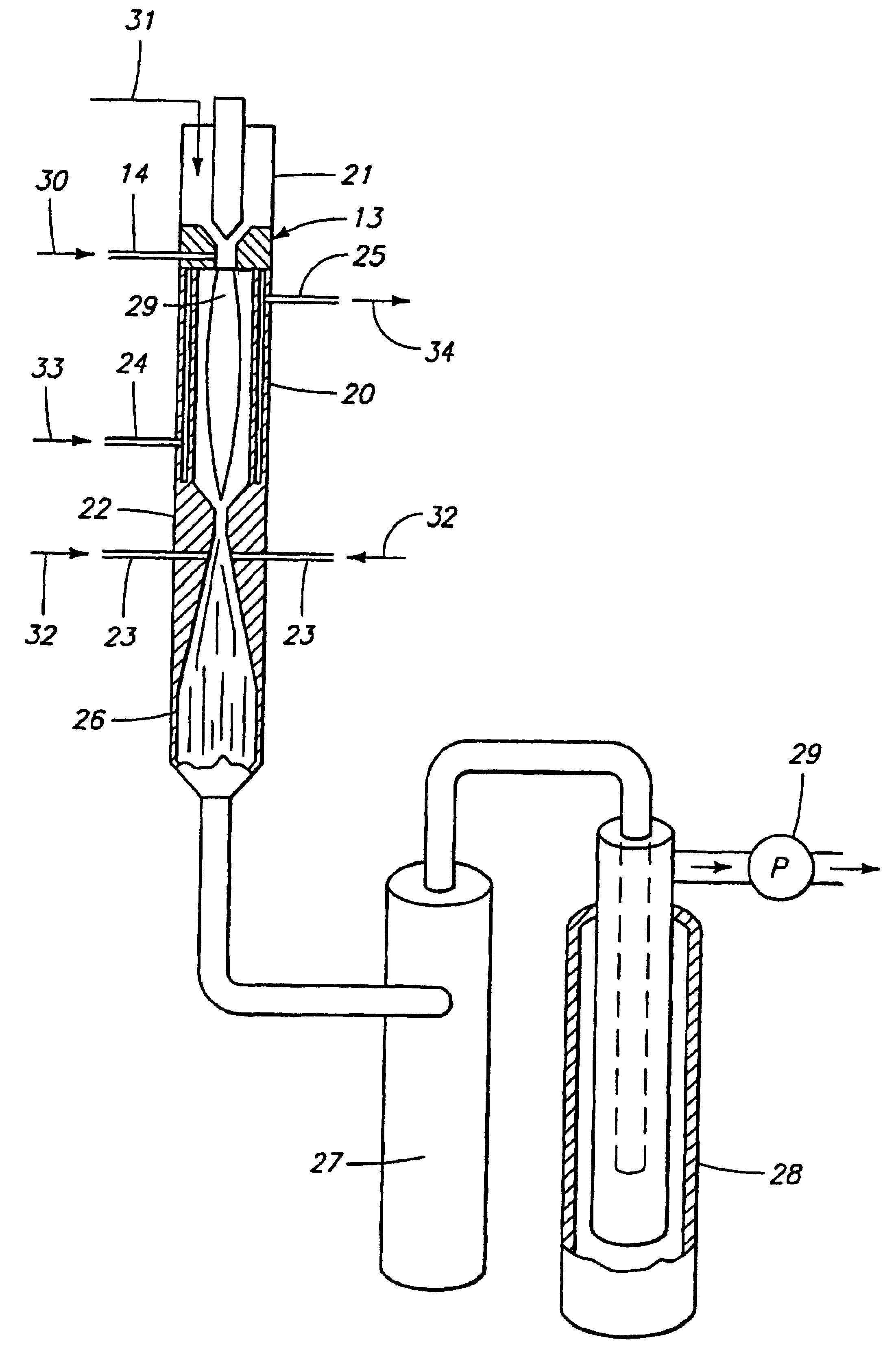

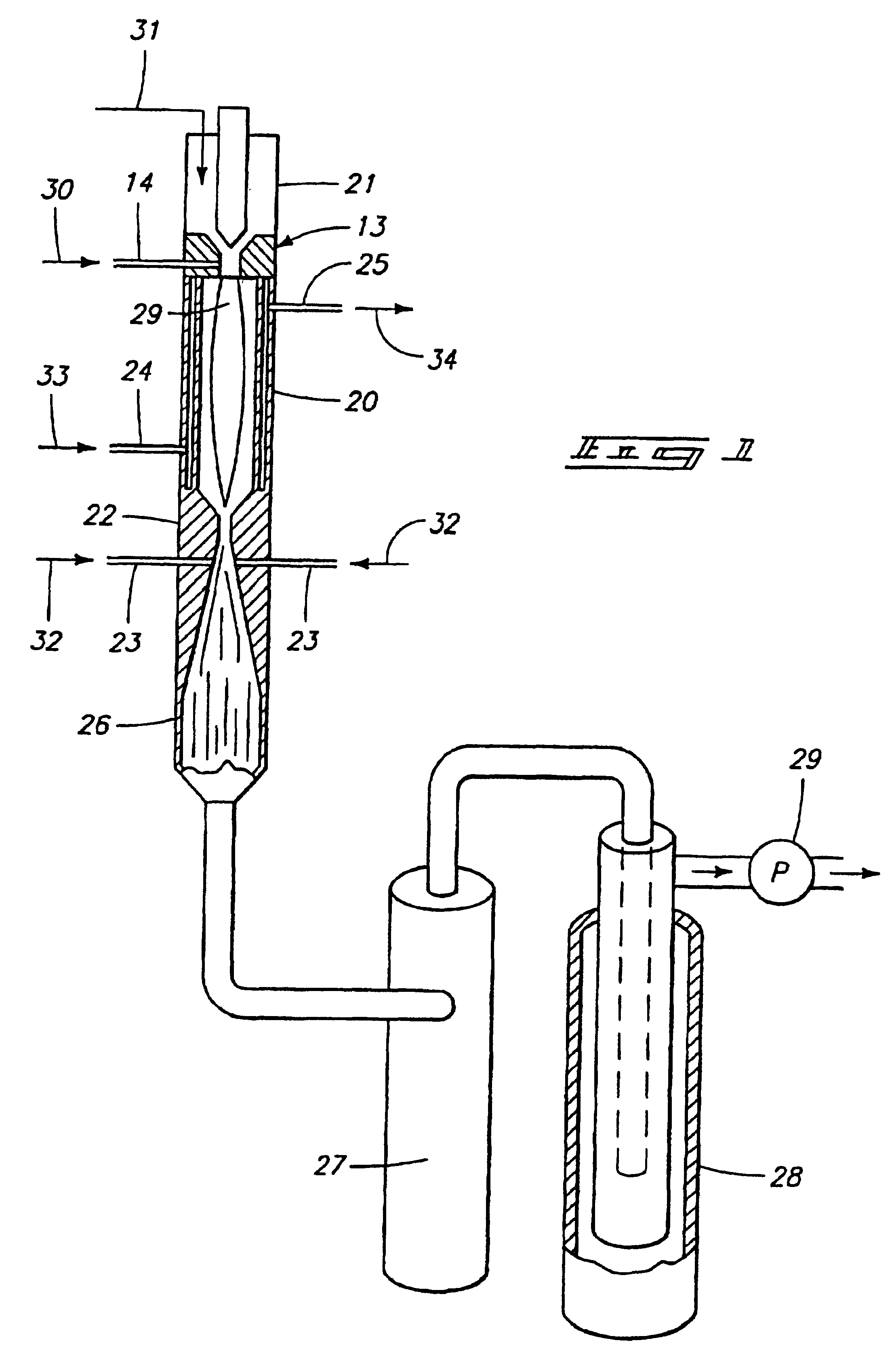

Fast quench reactor and method

InactiveUSRE37853E1Minimizing back reactionRapid coolingMaterial nanotechnologyIndirect heat exchangersThermodynamicsProcess engineering

A fast quench reaction includes a reactor chamber having a high temperature heating means such as a plasma torch at its inlet and a restrictive convergent-divergent nozzle at its outlet end. Reactants are injected into the reactor chamber. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle. This "freezes" the desired end product(s) in the heated equilibrium reaction stage.

Owner:BATTELLE ENERGY ALLIANCE LLC

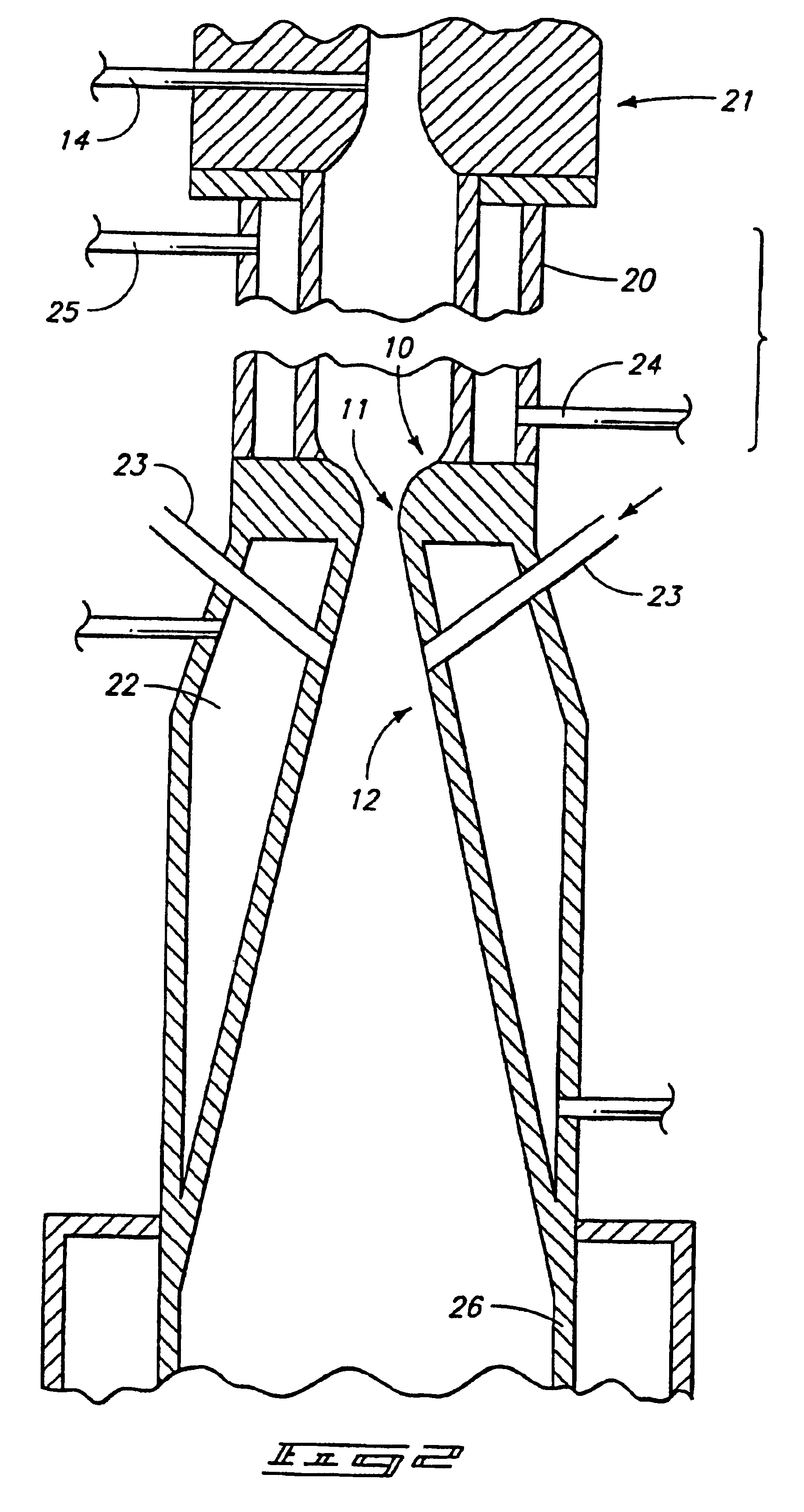

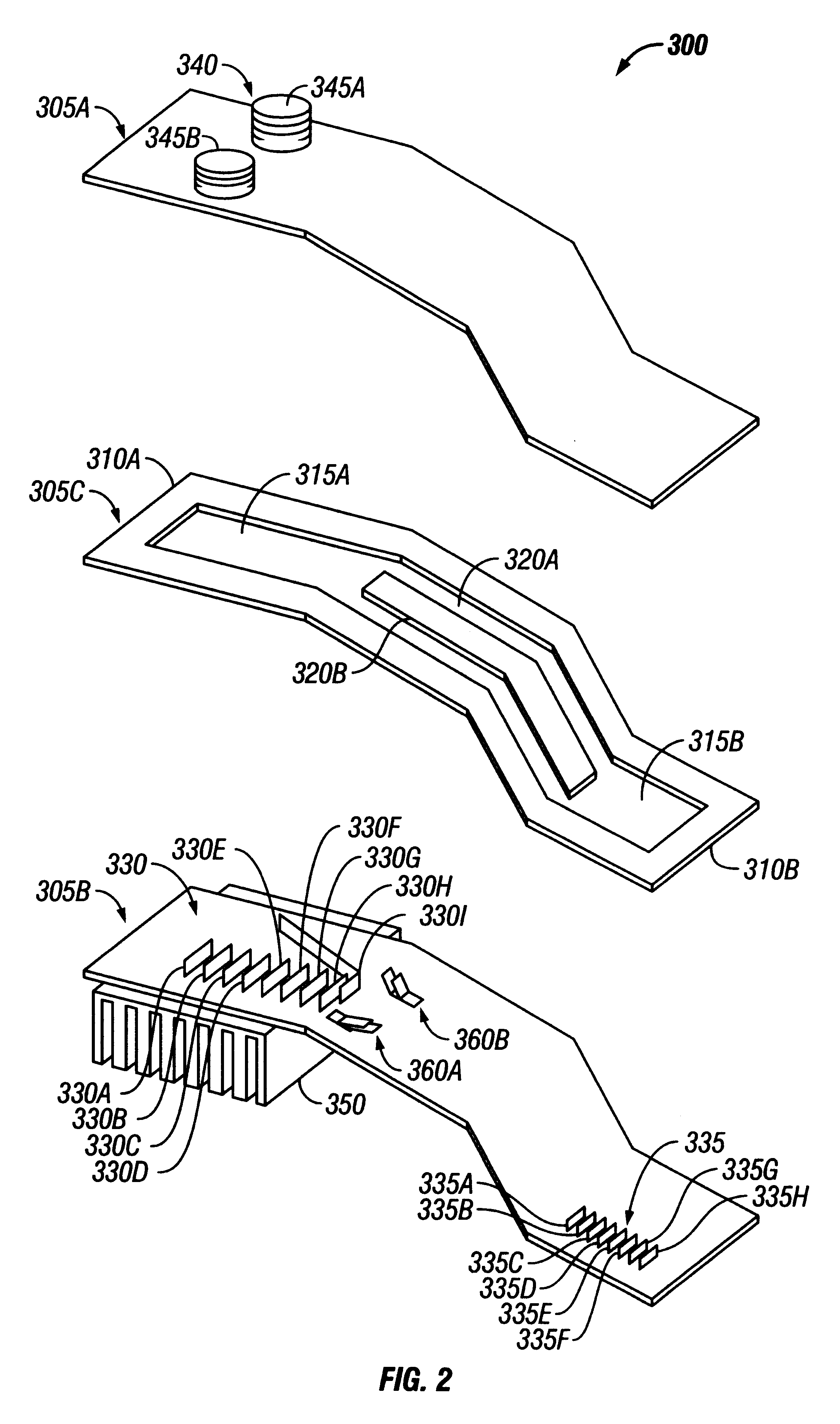

Integrated cooling system

InactiveUS6529377B1Cost effectiveQuality improvementOrganic active ingredientsDigital data processing detailsClosed loopEngineering

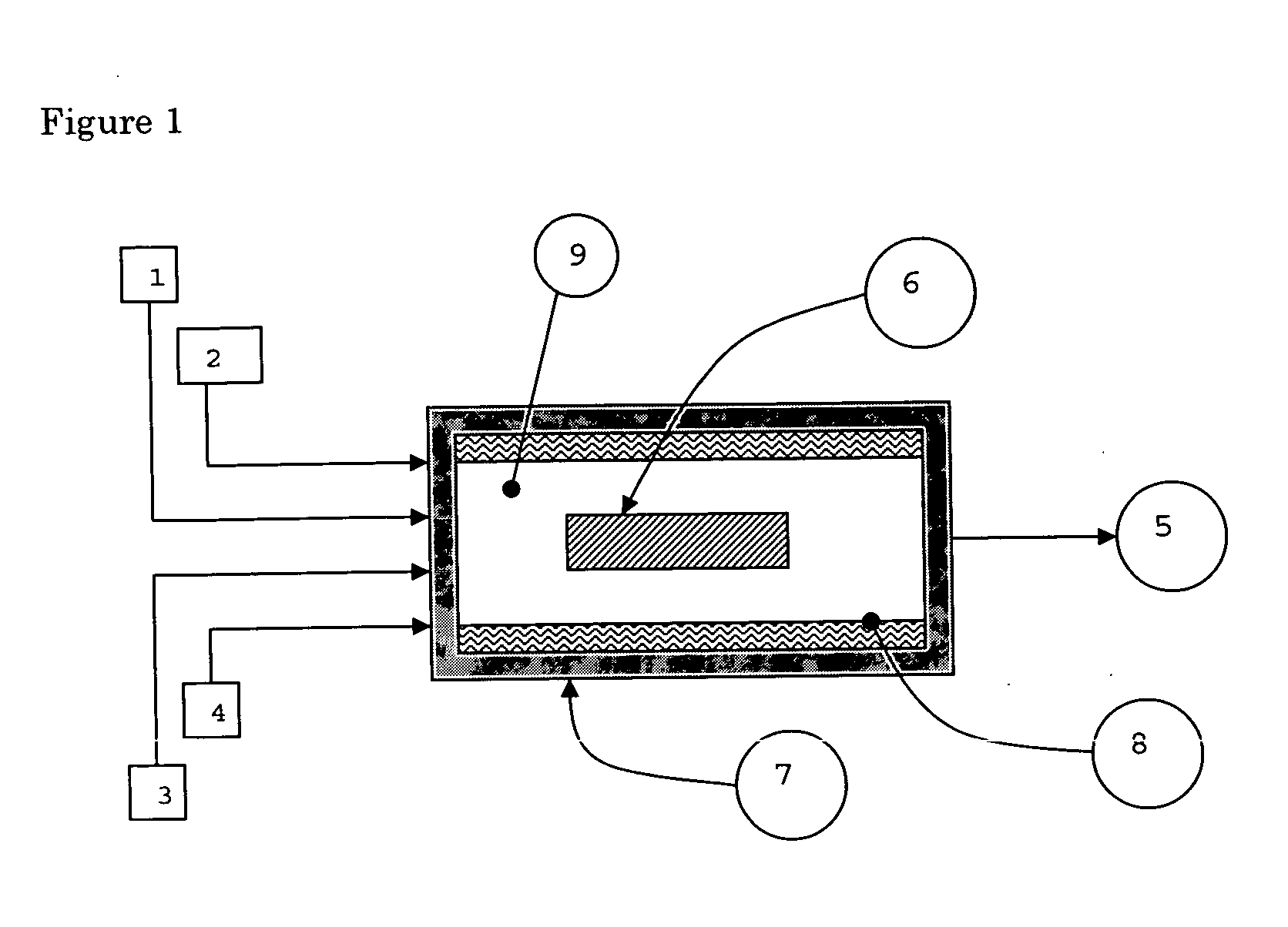

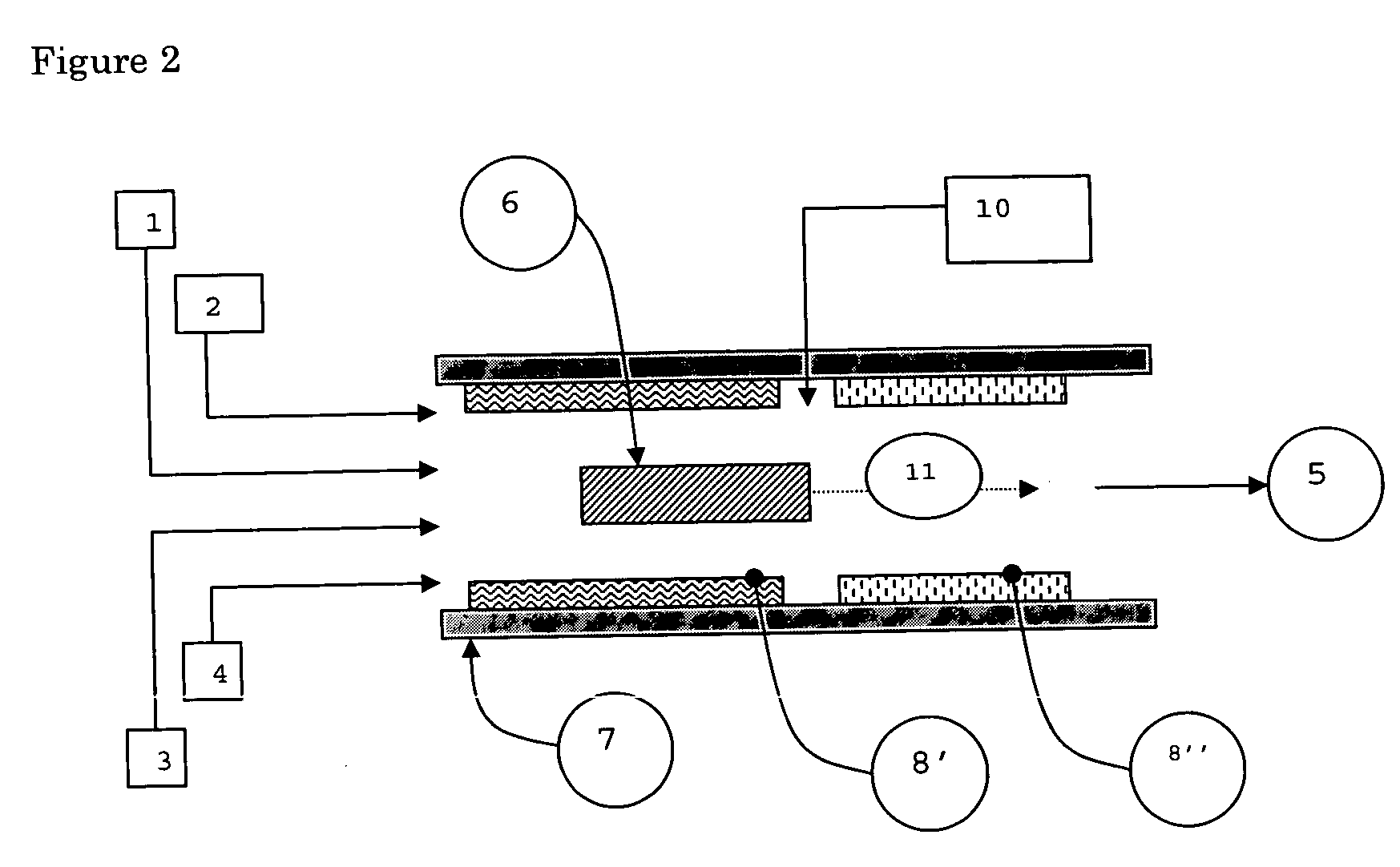

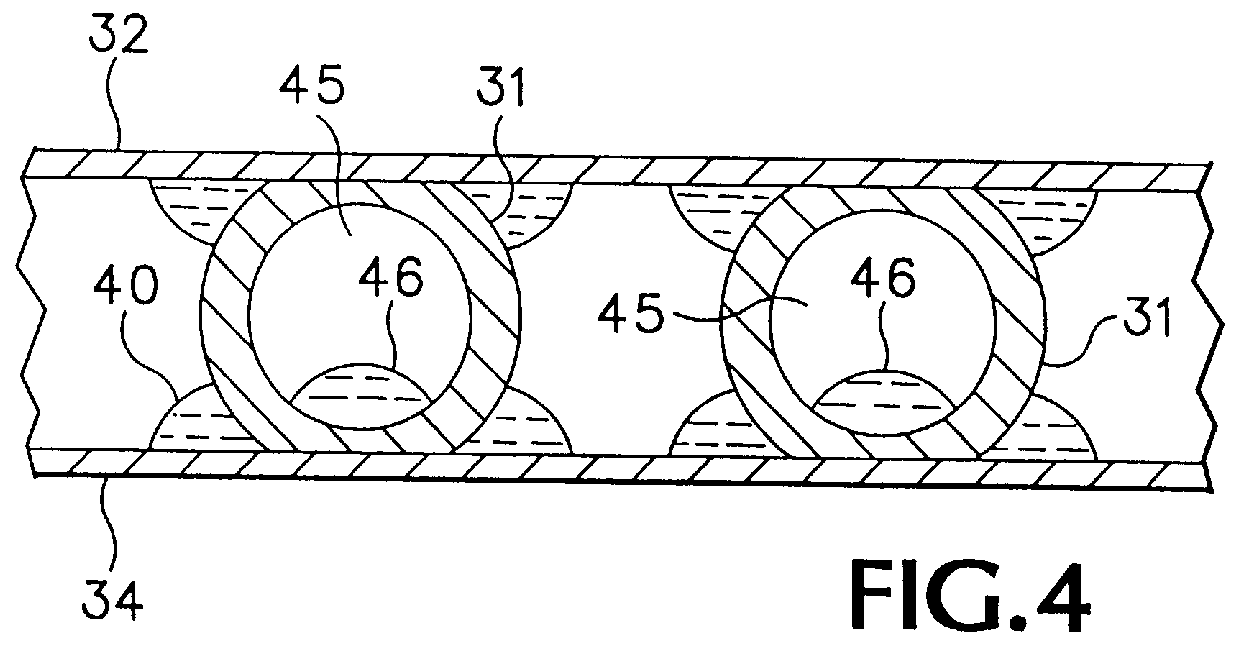

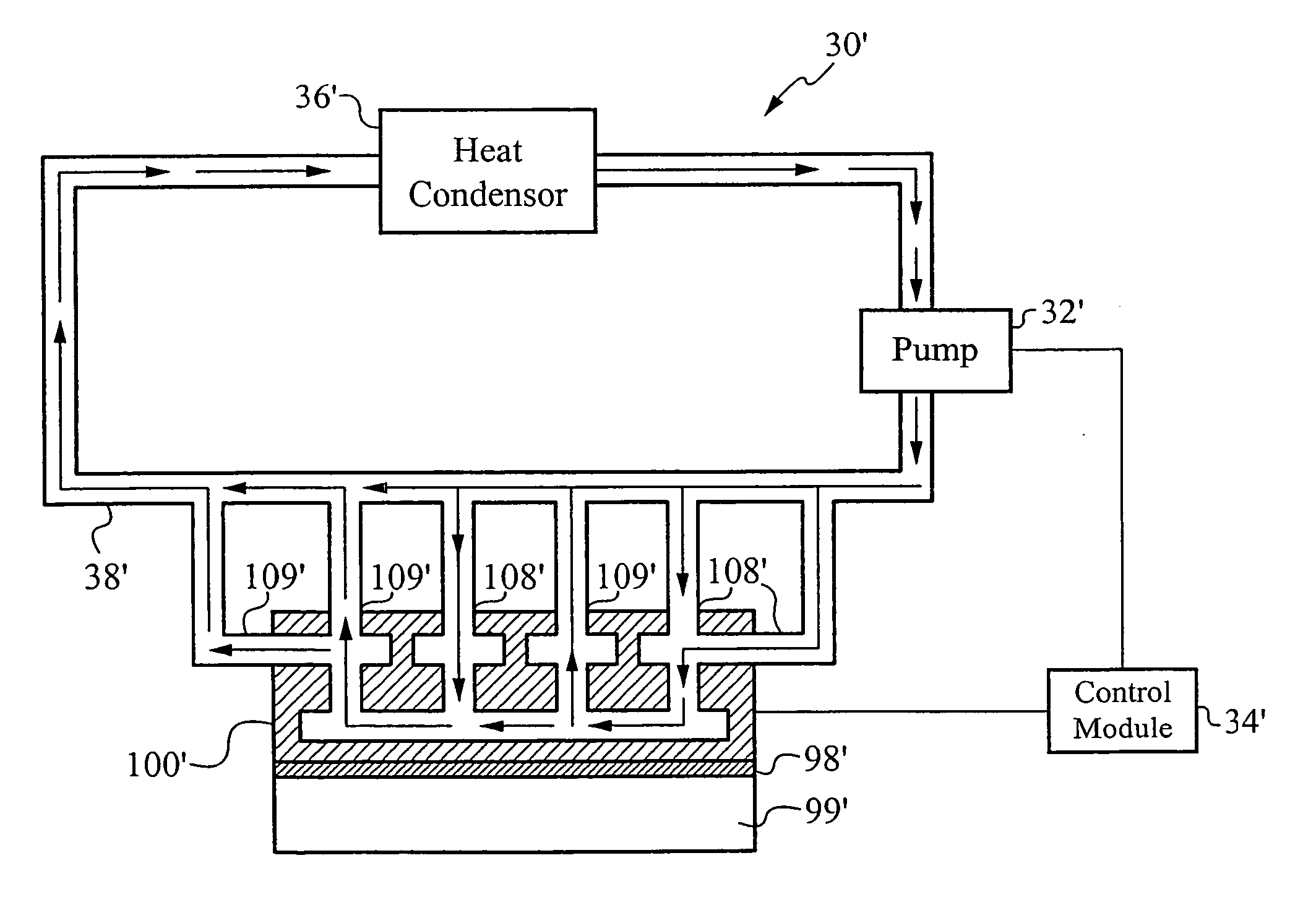

Systems and methods are described for integrated cooling system. A method includes: circulating a liquid inside a flexible multi-layer tape; and transporting heat between a heat source that is coupled to the flexible multi-layer tape and a heat sink that is coupled to the flexible multi-layer tape. A method includes installing a flexible multi-layer tape in an electrical system, wherein the flexible multi-layer tape includes a top layer; an intermediate, layer coupled to the top layer; and a bottom layer coupled to the intermediate layer, the intermediate layer defining a closed loop circuit for a circulating fluid. An apparatus includes a flexible multi-layer tape, including: a top layer; an intermediate layer coupled to the top layer; and a bottom layer coupled to the intermediate layer, wherein the intermediate layer defines a closed loop circuit for a circulating fluid.

Owner:STOVOKOR TECH

Electroosmotic microchannel cooling system

InactiveUS6942018B2High heat fluxIncrease powerFixed microstructural devicesSemiconductor/solid-state device detailsElectricityClosed loop

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Thermal dissipation assembly and fabrication method for electronics drawer of a multiple-drawer electronics rack

Owner:LENOVO GLOBAL TECH INT LTD

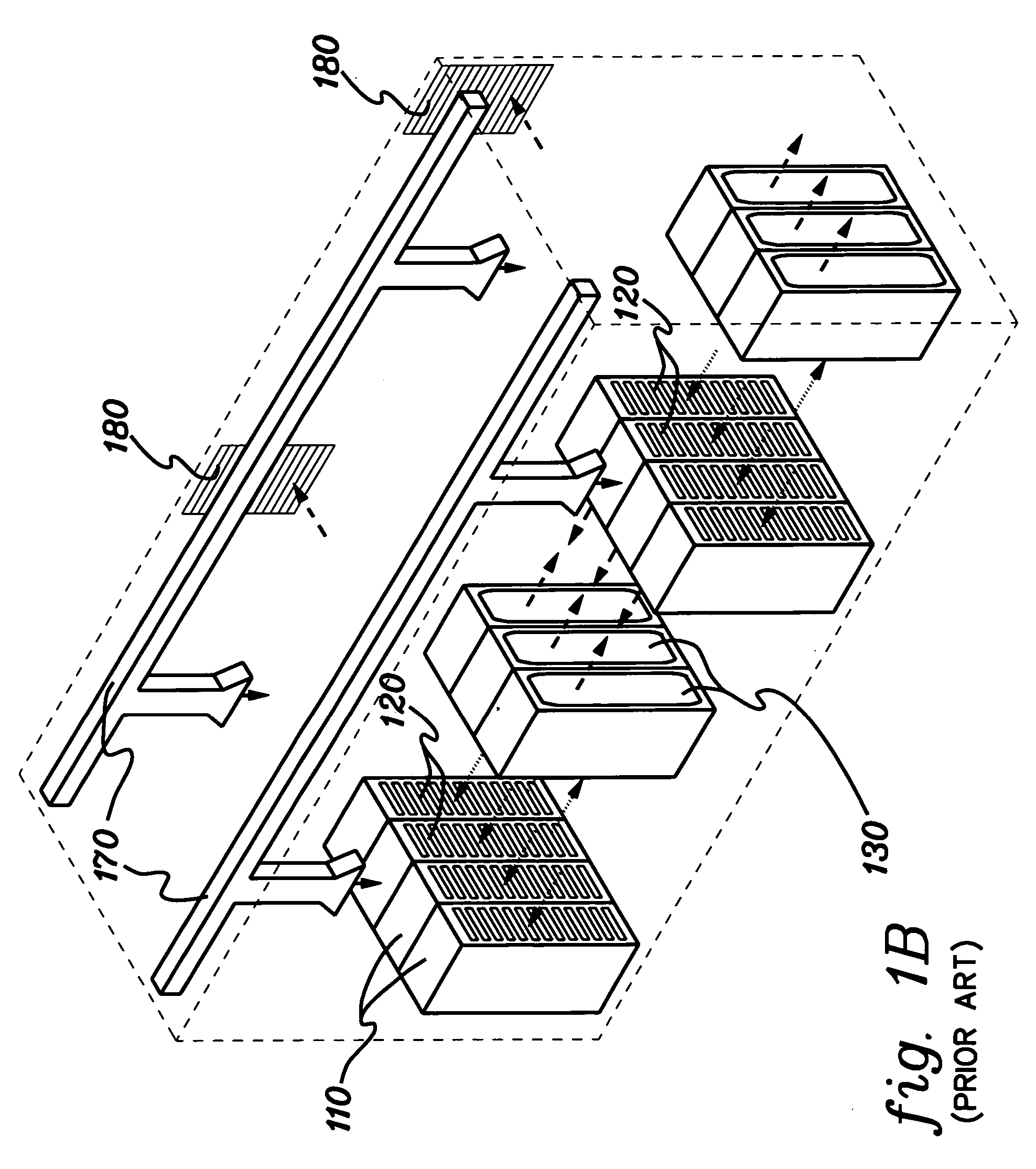

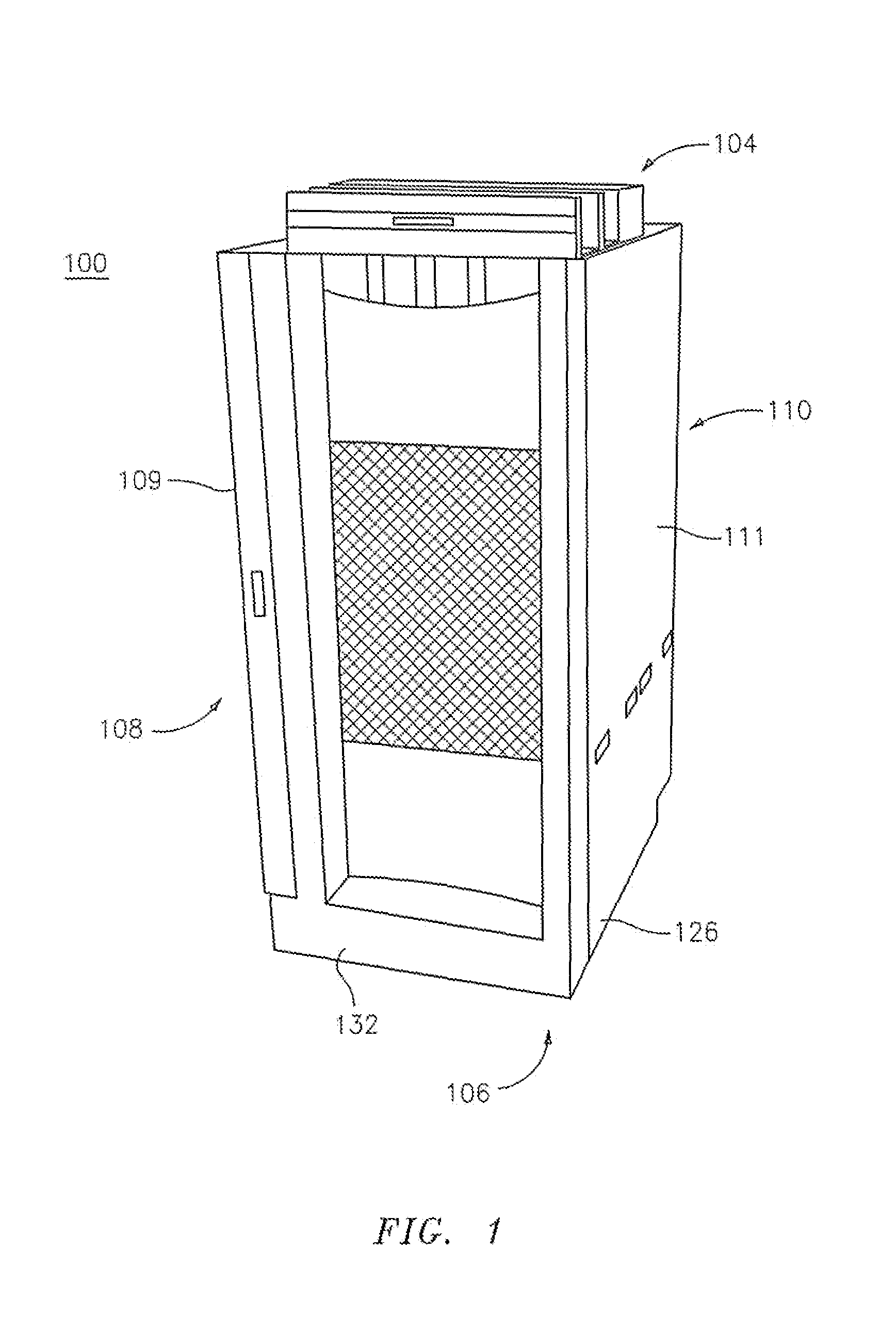

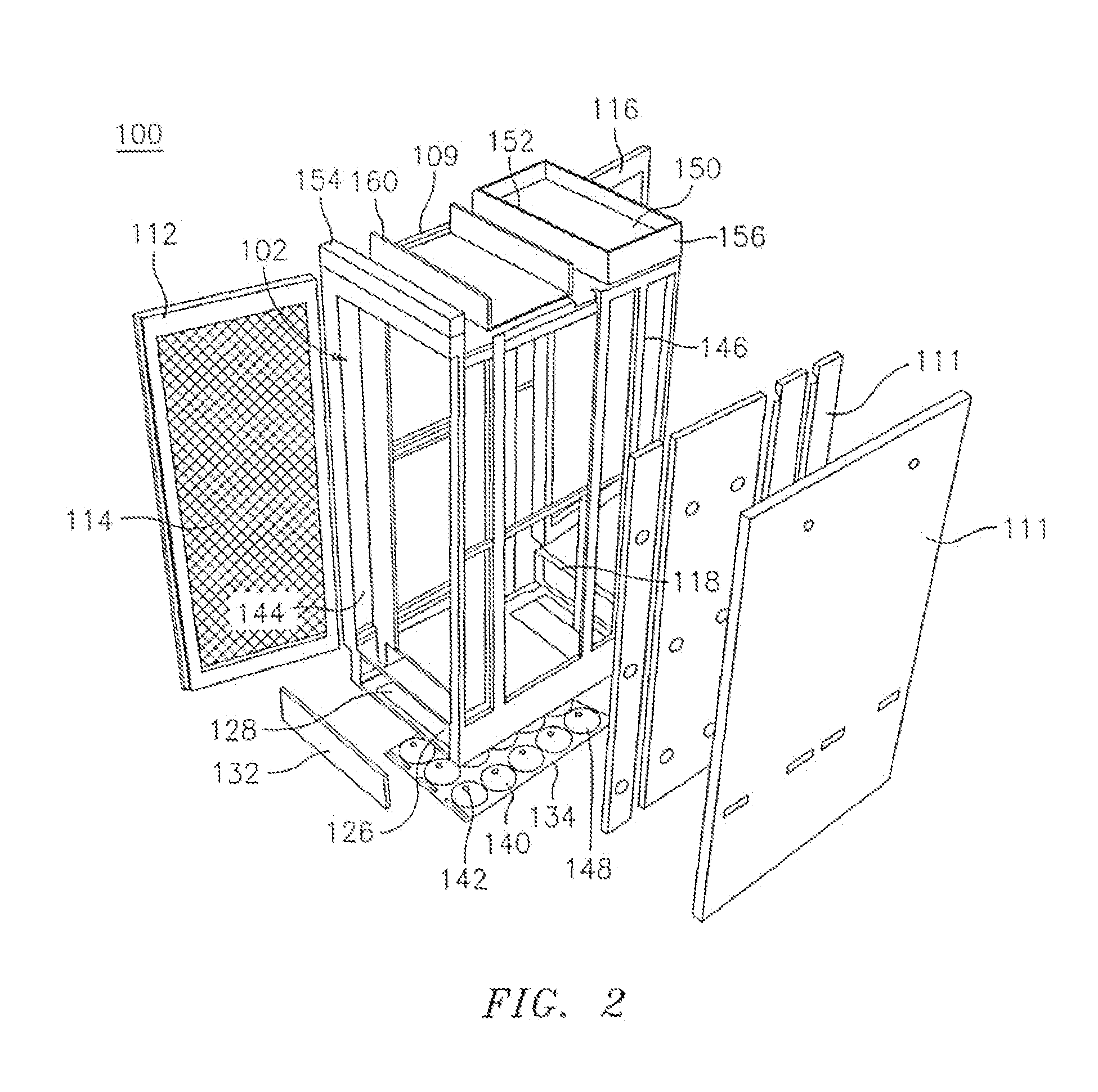

Exhaust air removal system

InactiveUS7500911B2Avoid heat buildupIndirect heat exchangersCooling/ventilation/heating modificationsExhaust fumesBack door

An exhaust air removal system and method for use with a rack or enclosure containing equipment is provided. The system and method are configured for removal of exhaust air vented from equipment during operation to thereby remove heat from the equipment. In one aspect, the system includes a fan unit preferably configured to serve as a back door of an equipment rack or enclosure and configured to provide access to an interior of the rack or enclosure. The fan unit provides multiple fans coupled to internal exhaust ducts that are arranged to draw and to remove exhaust air vented from rack-mounted equipment. The fan unit is further configured to vent exhaust air to an area external to a rack or enclosure, such as an external exhaust duct or plenum. Removal of hot and warm exhaust air vented from rack-mounted equipment enables the equipment to operate effectively, drawing sufficient amounts of cooling air to meet its cooling requirements. The fan unit is constructed for portability and for easy attachment to and removal from a rack or enclosure, providing flexibility in handling equipment exhaust needs.

Owner:SCHNEIDER ELECTRIC IT CORP

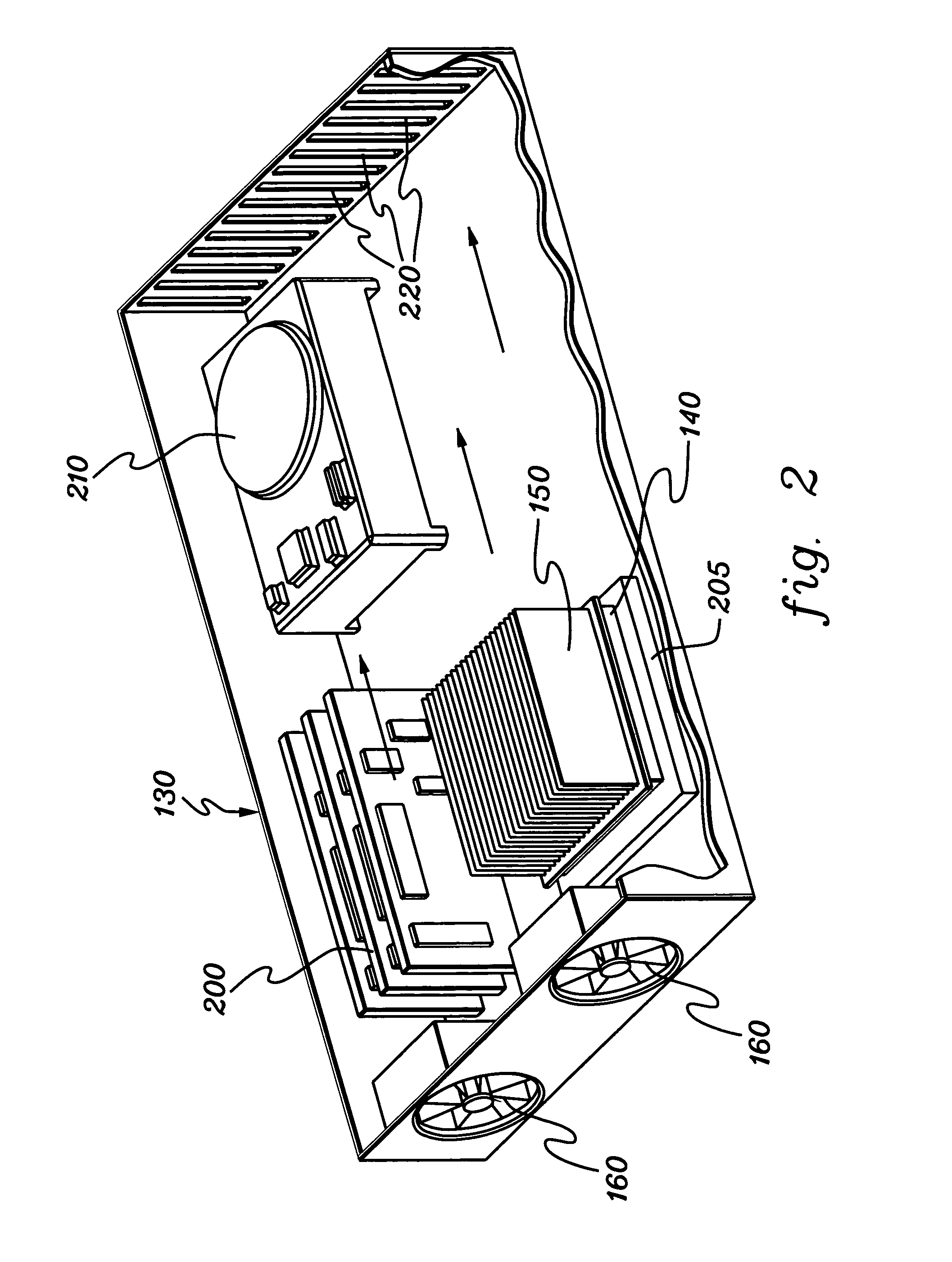

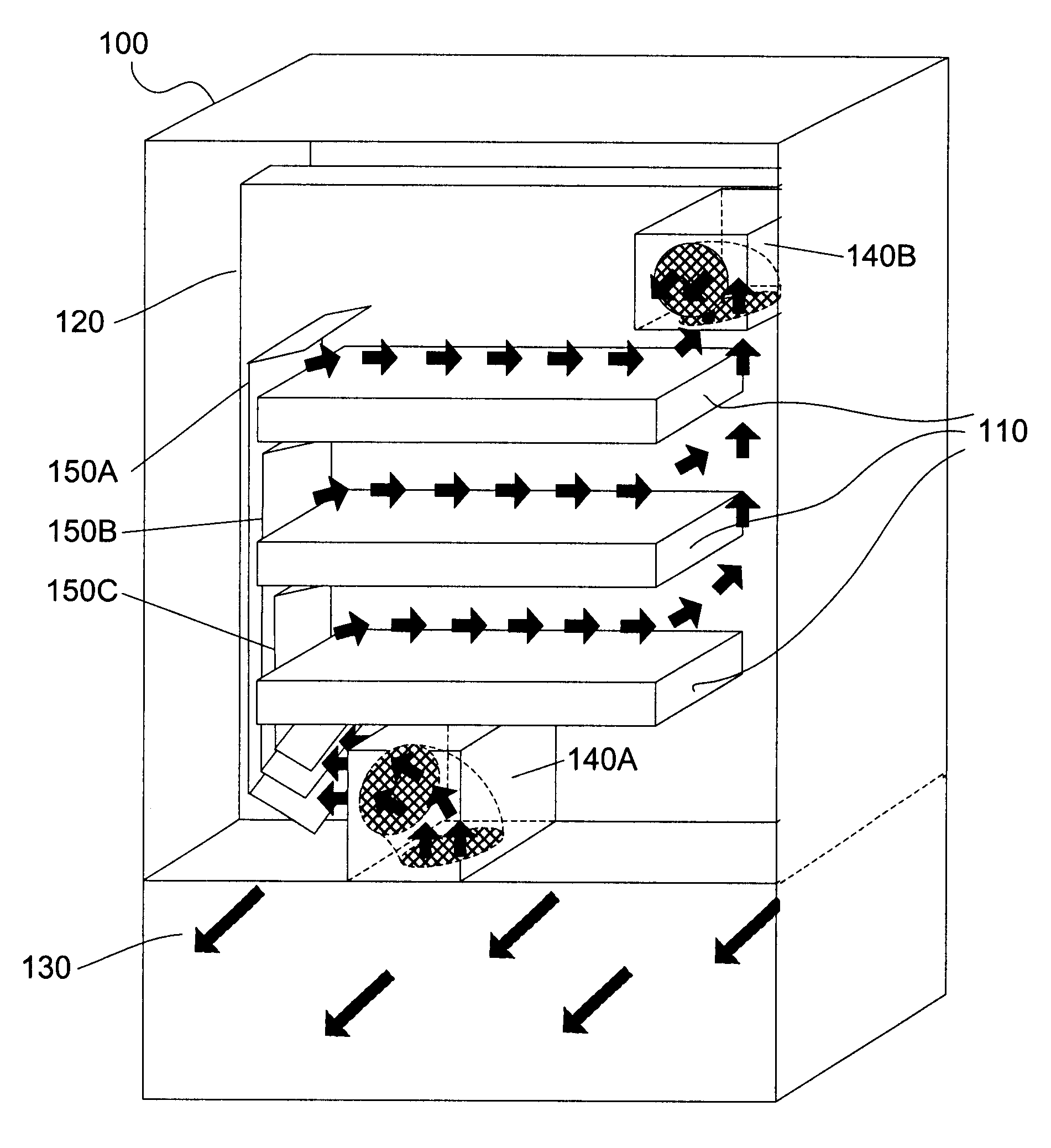

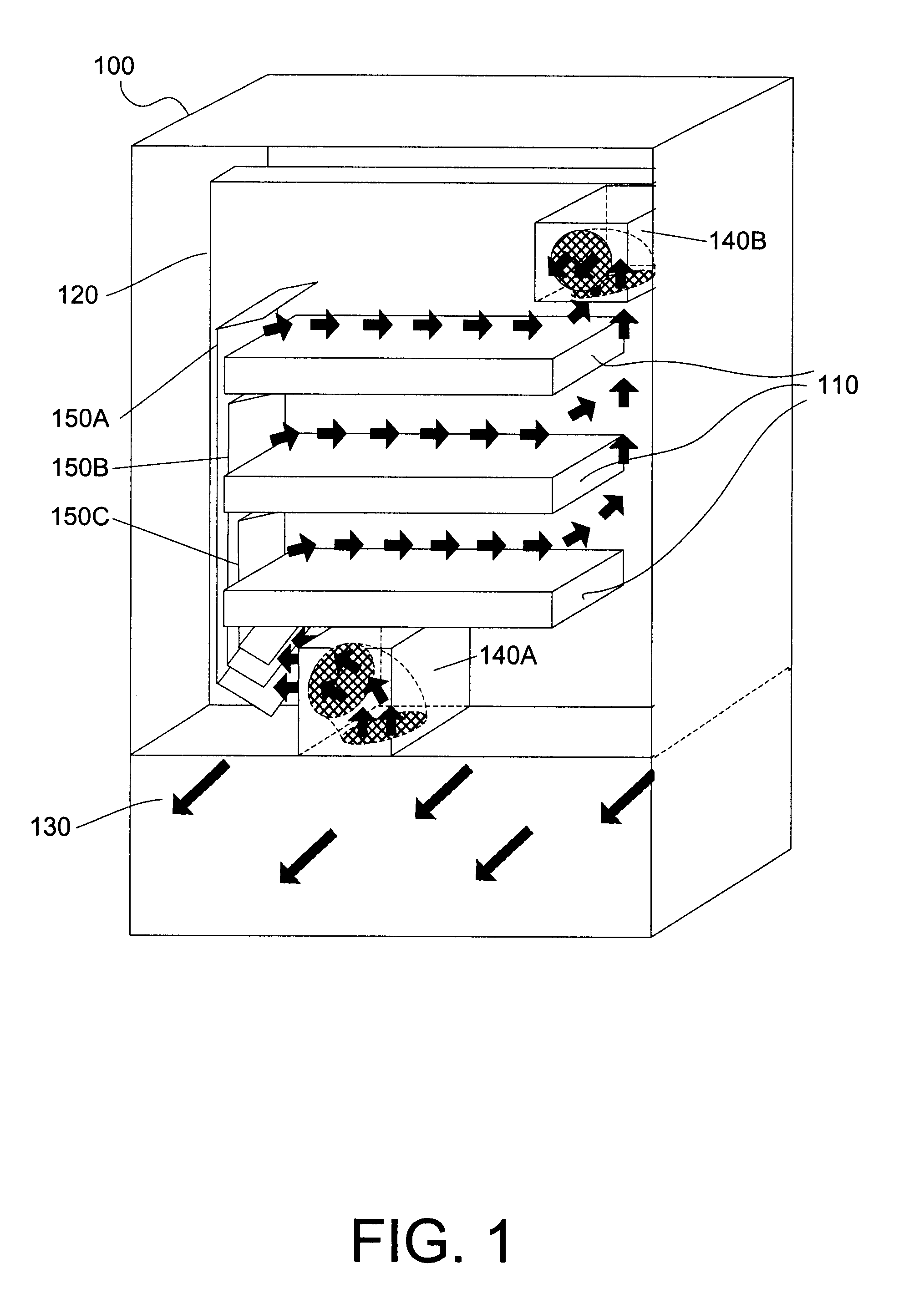

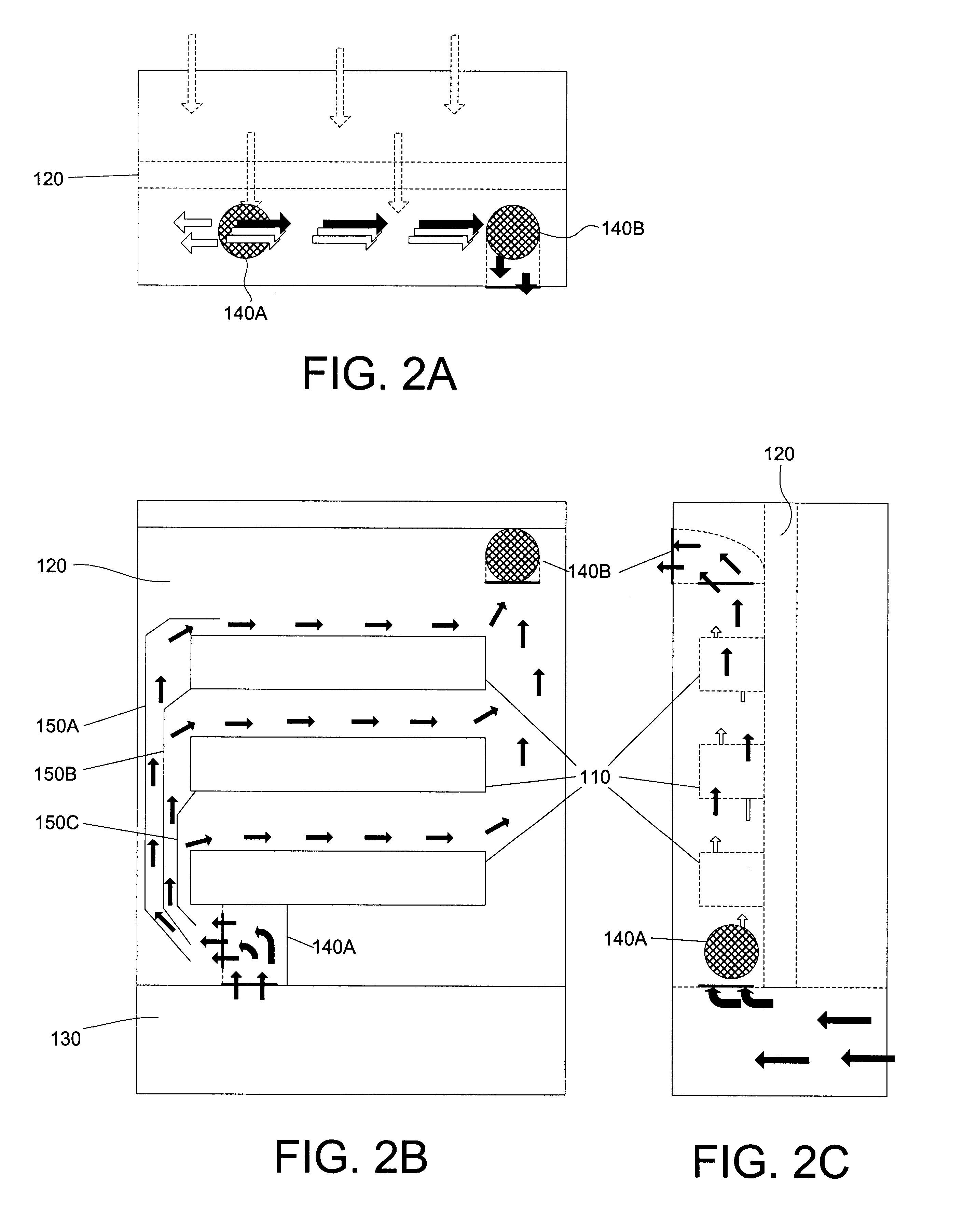

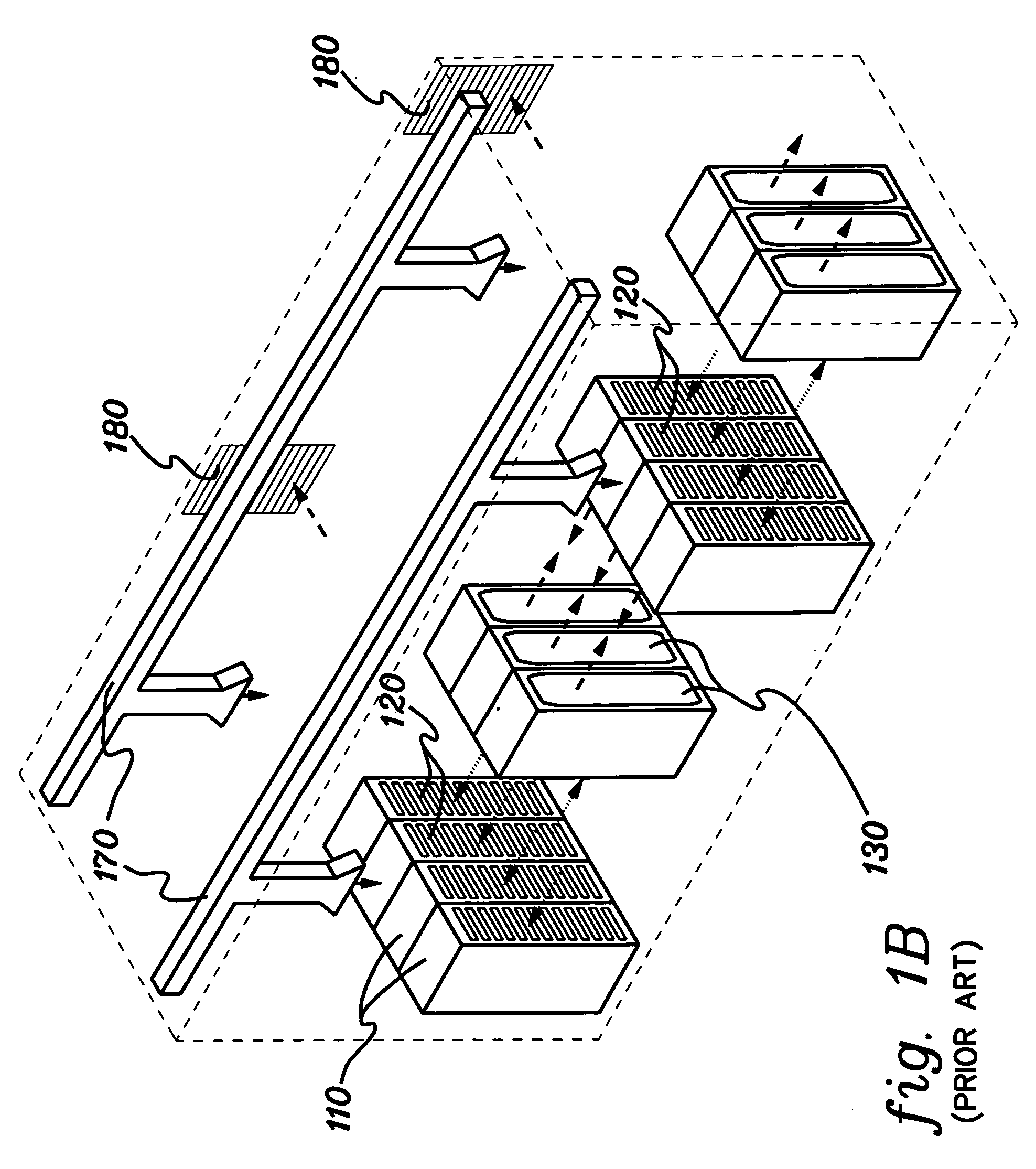

Apparatus and method for directing airflow in three dimensions to cool system components

The invention provides forced-air cooling to components mounted on circuit boards oriented in a side-to-side direction in a system. Airflow may enter and exit the system through the front and back (or vice-versa), rather than the sides of the system. In one embodiment, airflow entering the front of the system is re-directed in an upward direction, then split to form airflow branches traversing in a side-to-side direction. The airflow branches traverse across the surfaces of circuit boards, then are directed in an upward direction and out the back (or front) of the system. The airflow branches preferably move substantially the same volume of air per unit of time.

Owner:JUMIPER NETWORKS INC

Apparatus and method for facilitating cooling of an electronics rack employing a heat exchange assembly mounted to an outlet door cover of the electronics rack

Apparatus and method are provided for facilitating cooling of an electronics rack employing a heat exchange assembly mounted to an outlet door cover hingedly affixed to an air outlet side of the rack. The heat exchange assembly includes a support frame, an air-to-liquid heat exchanger, and first and second perforated planar surfaces covering first and second main sides, respectively, of the air-to-liquid heat exchanger. The heat exchanger is supported by the support frame and includes inlet and outlet plenums disposed adjacent to the edge of the outlet door cover hingedly mounted to the rack. Each plenum is in fluid communication with a respective connect coupling, and the heat exchanger further includes multiple horizontally-oriented heat exchange tube sections each having serpentine cooling channel with an inlet and an outlet coupled to the inlet plenum and outlet plenum, respectively. Fins extend from the heat exchange tube sections.

Owner:VETTE TECH

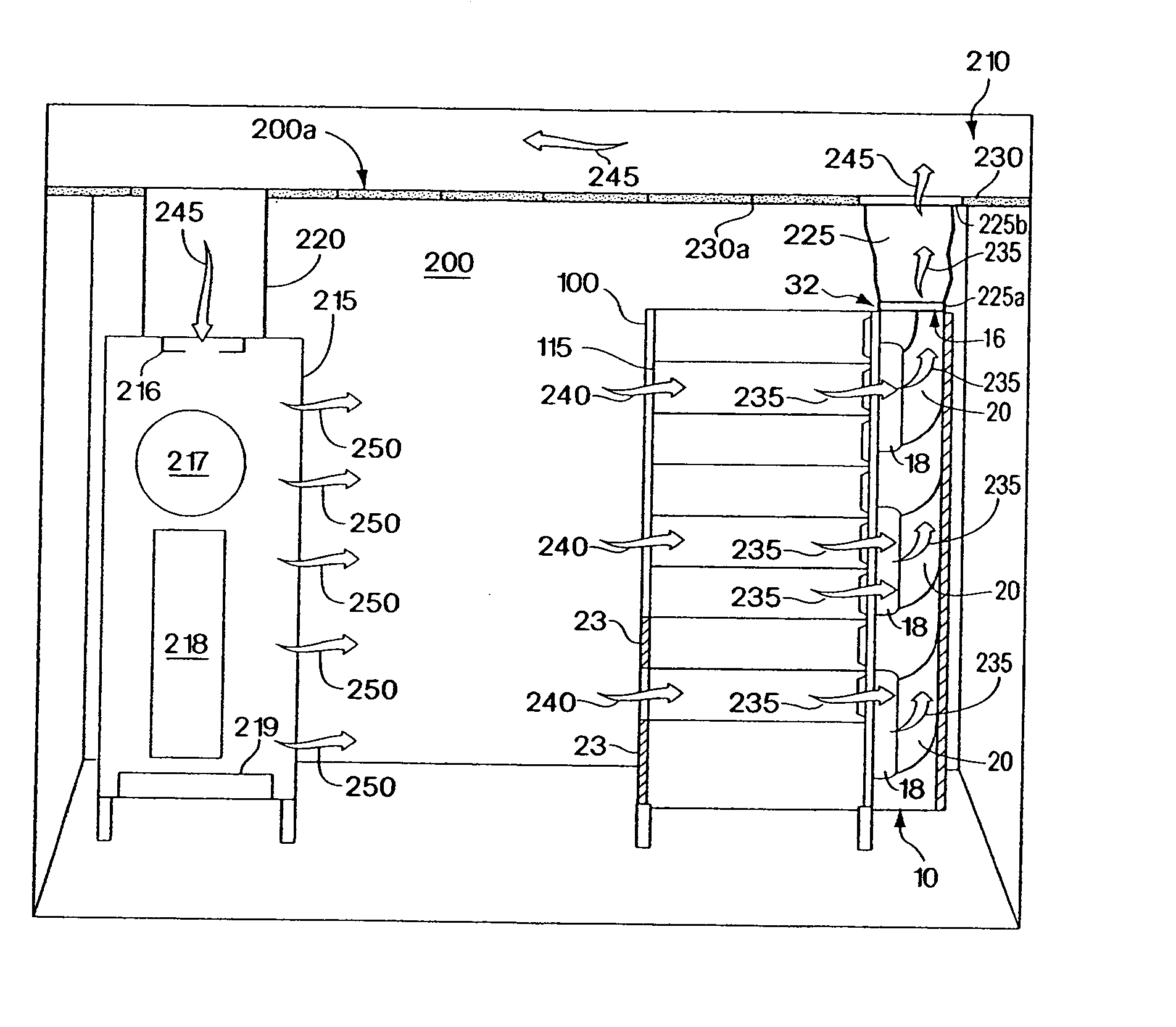

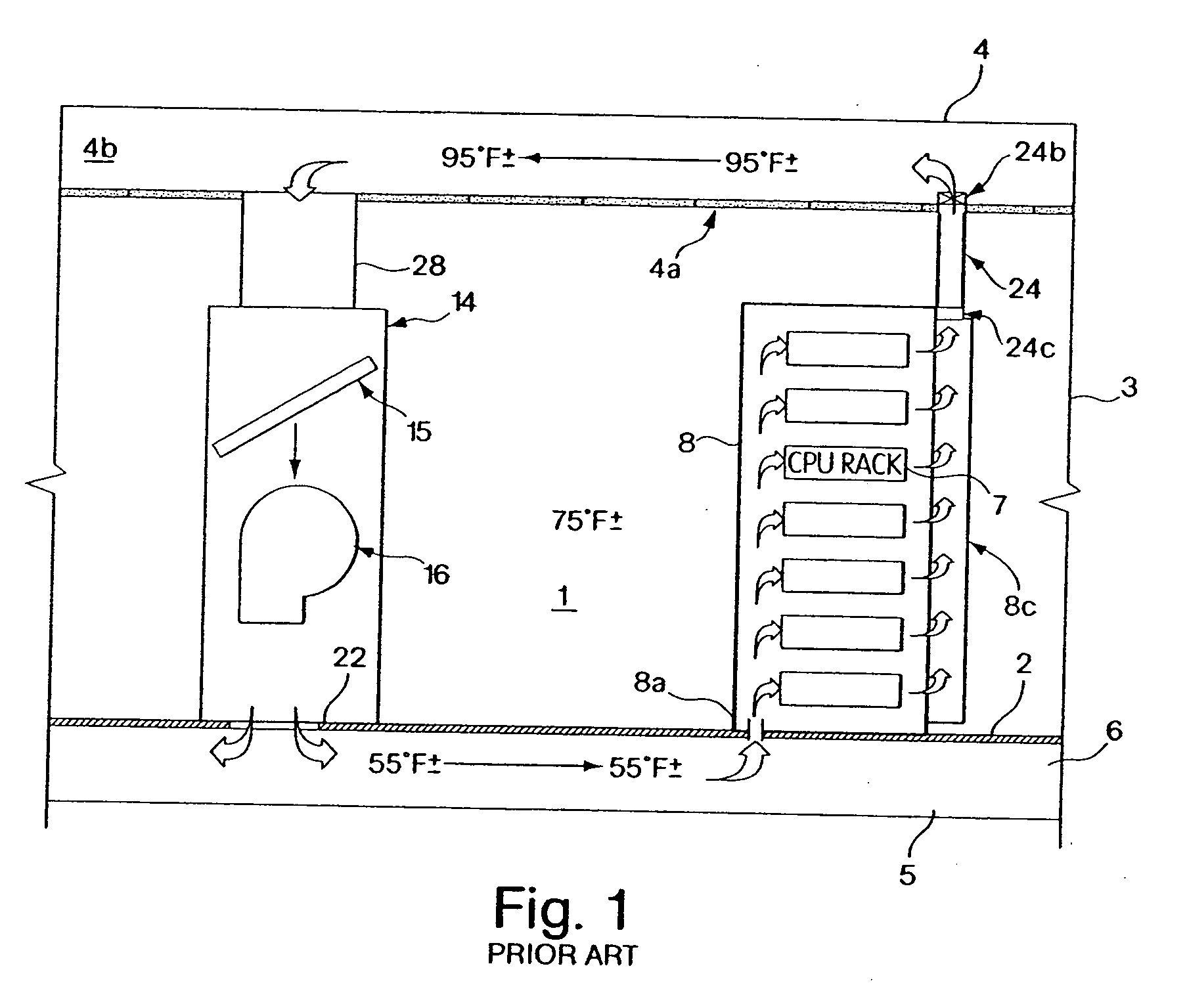

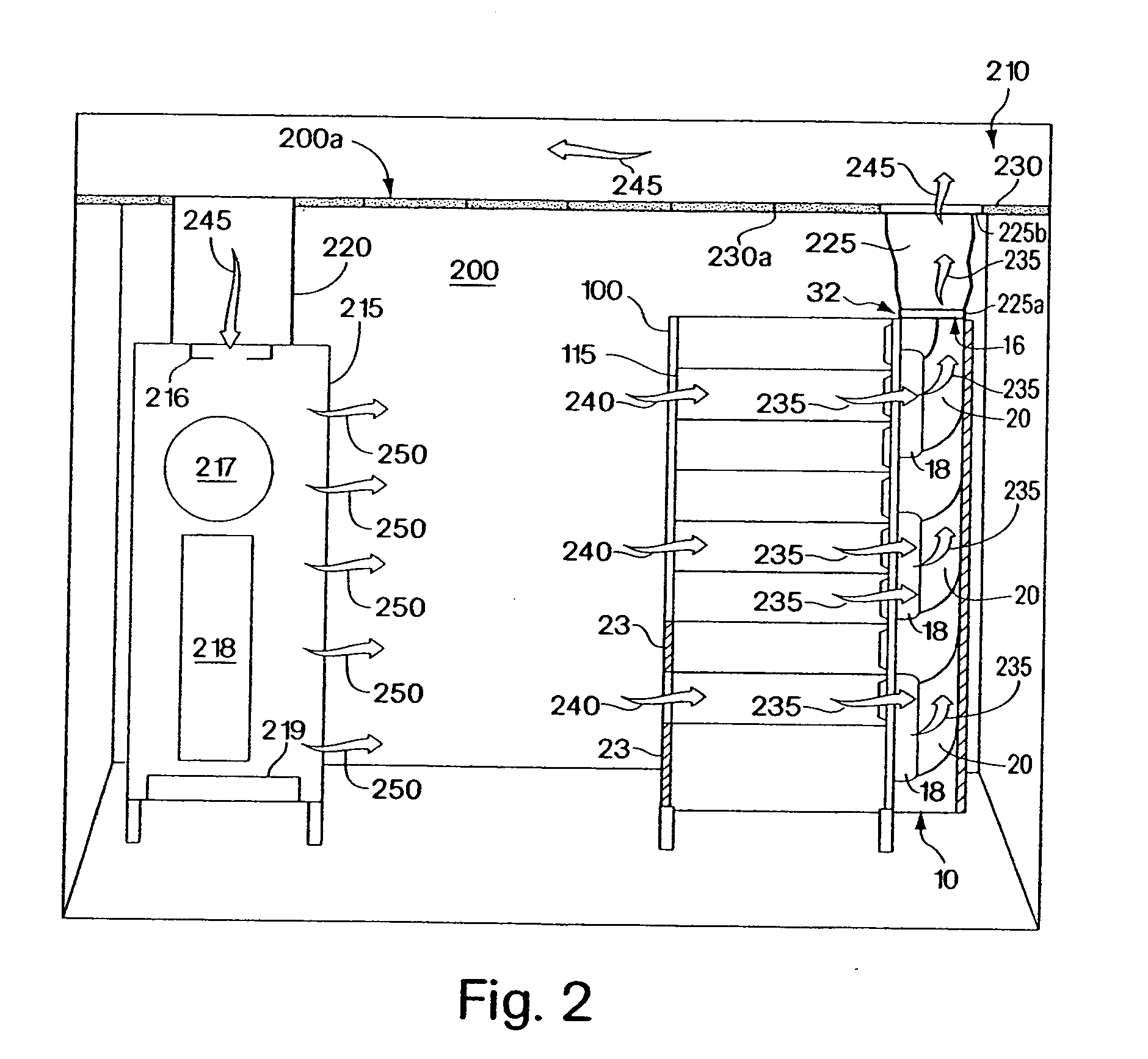

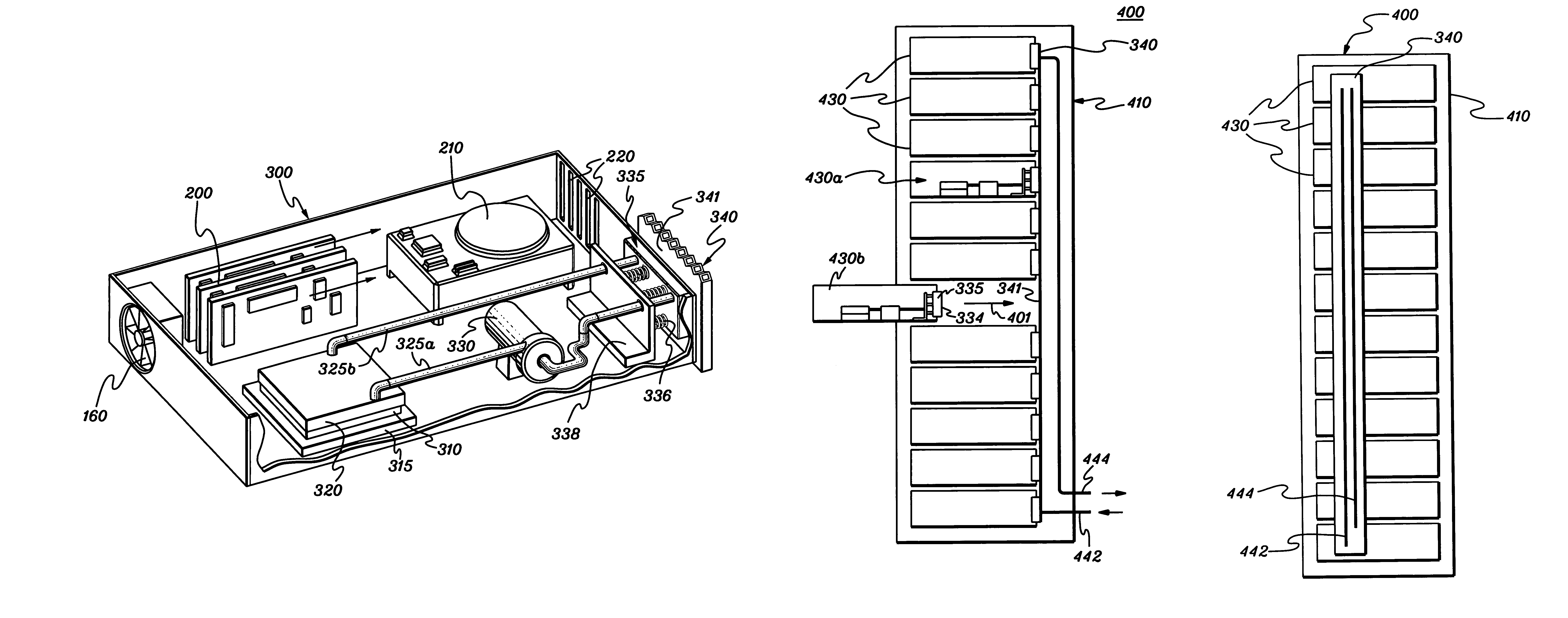

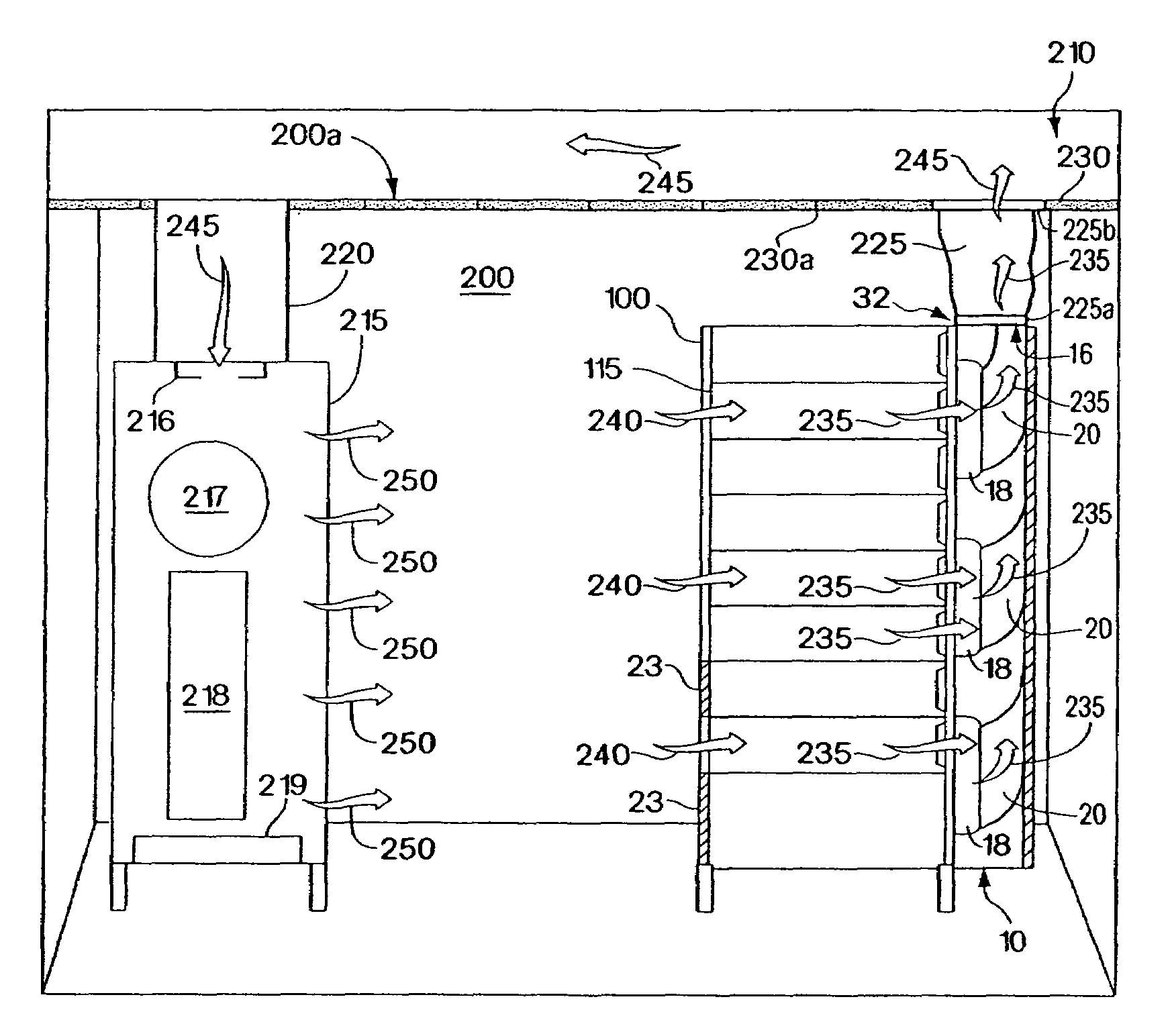

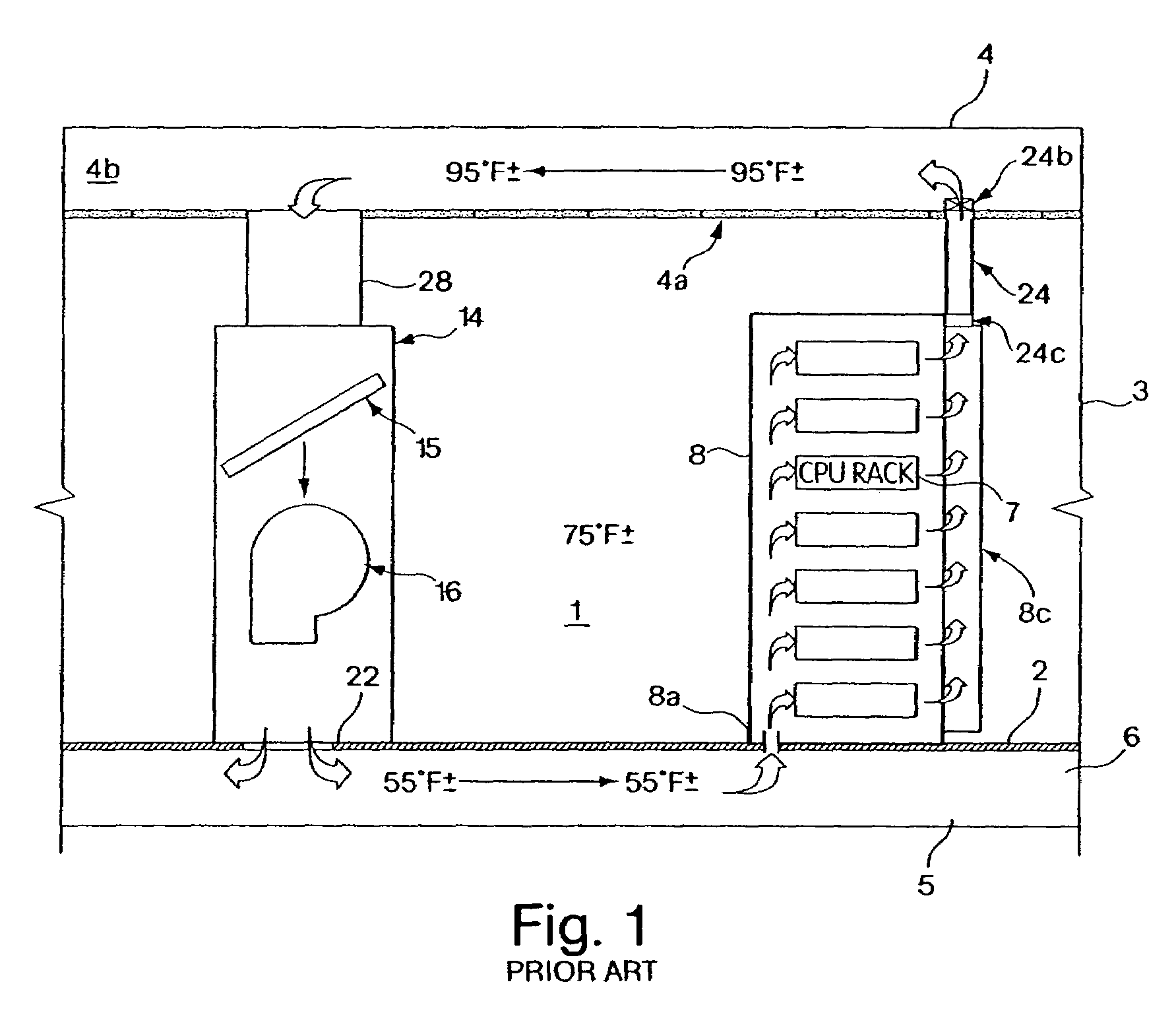

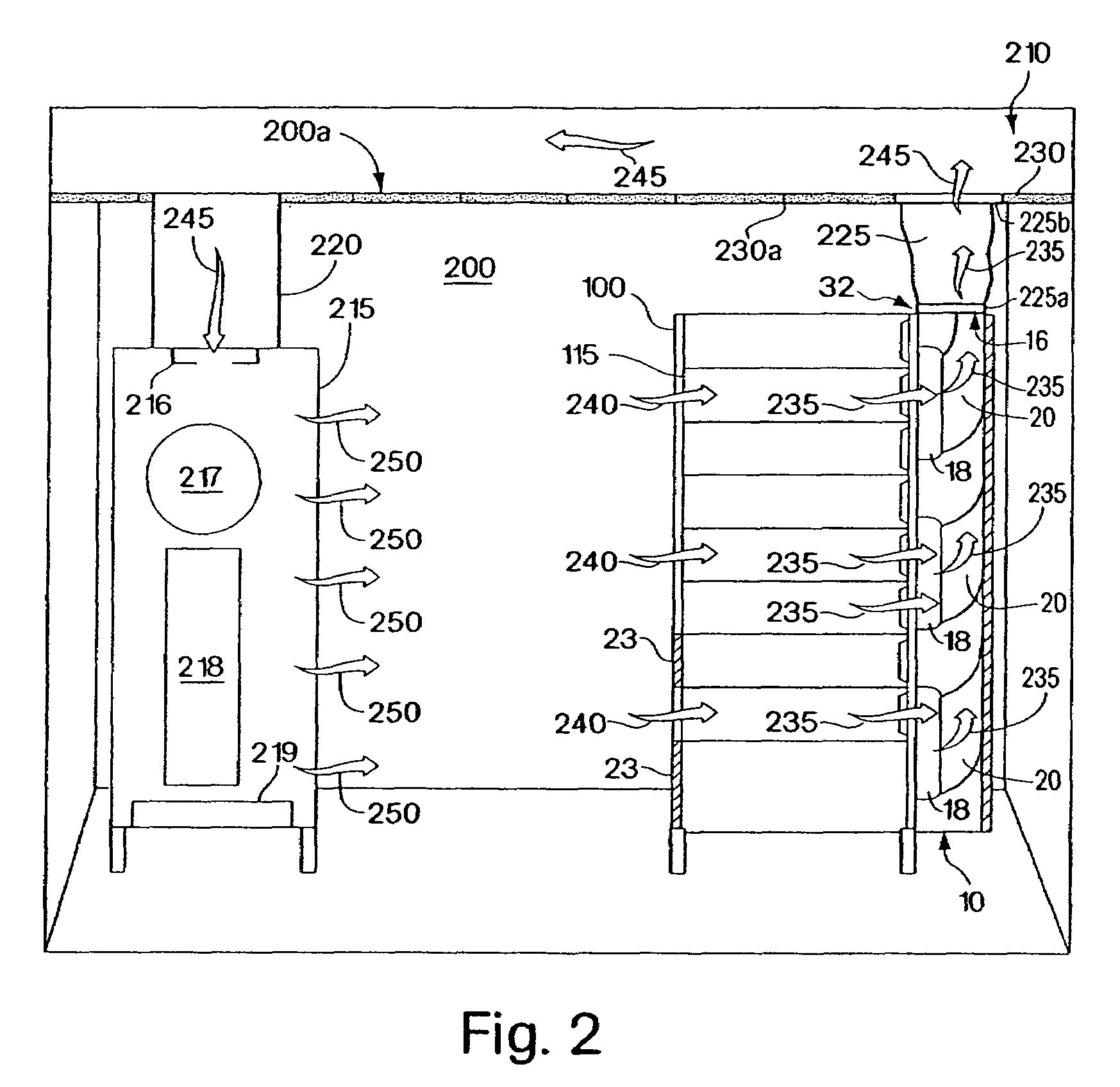

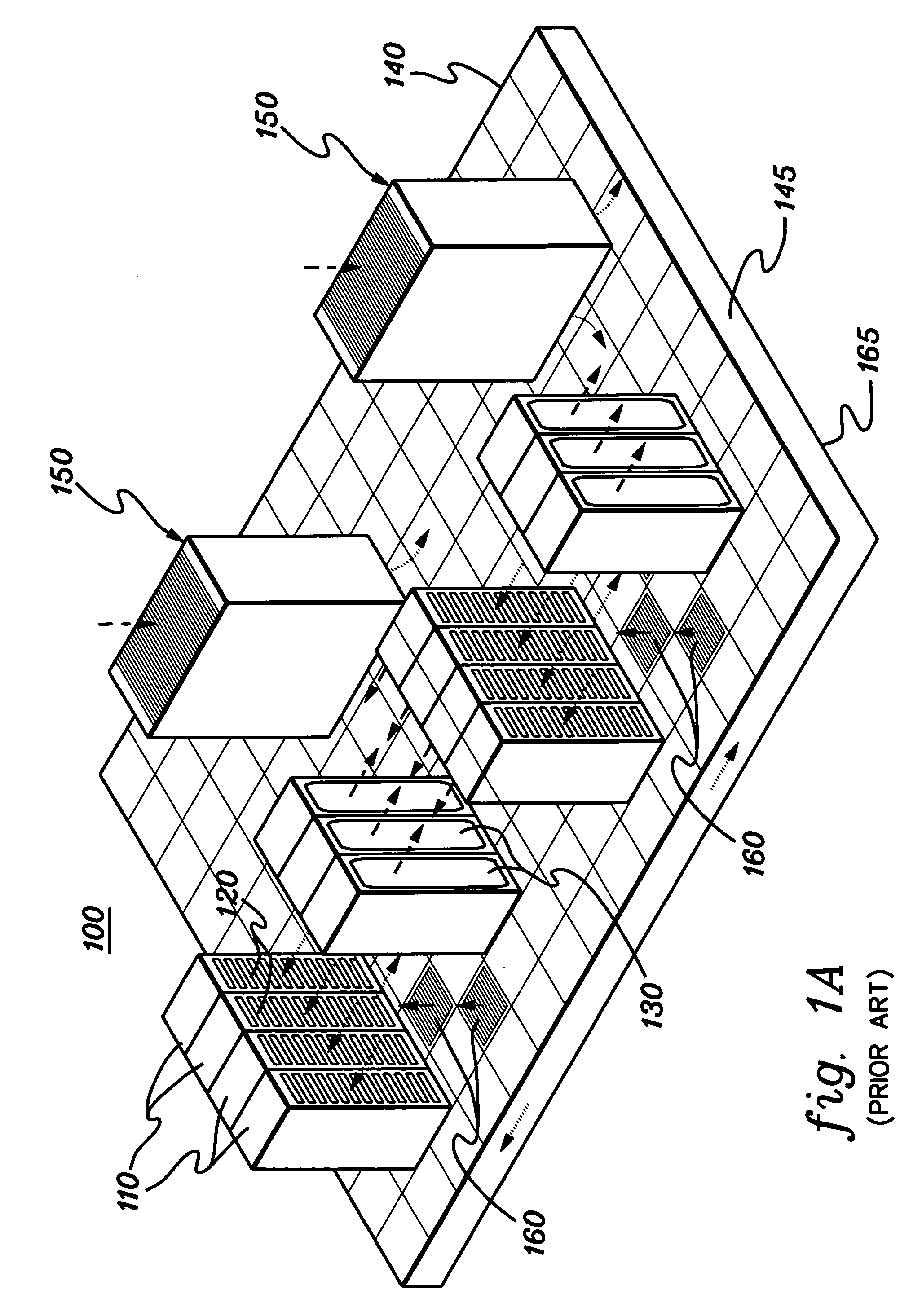

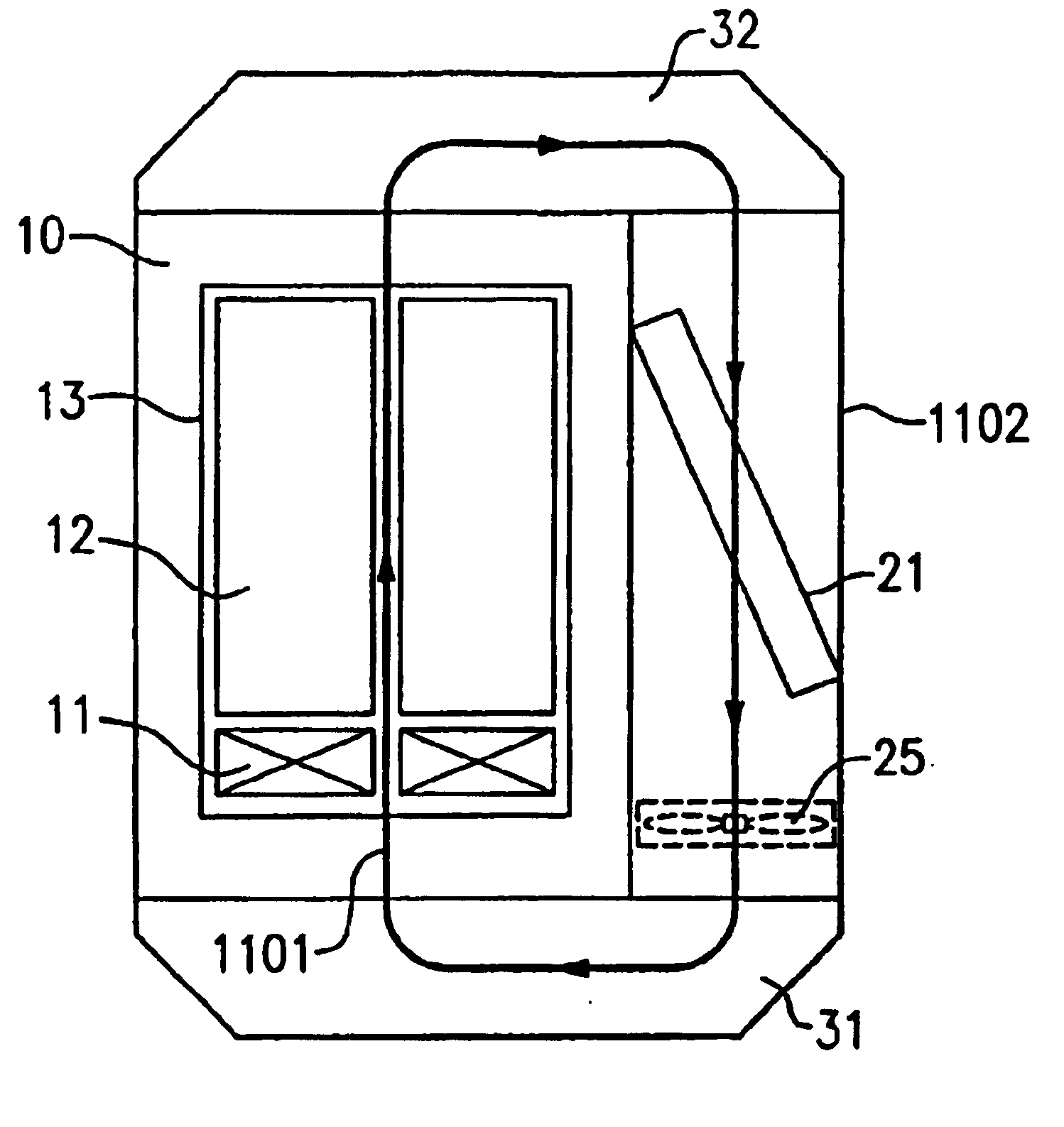

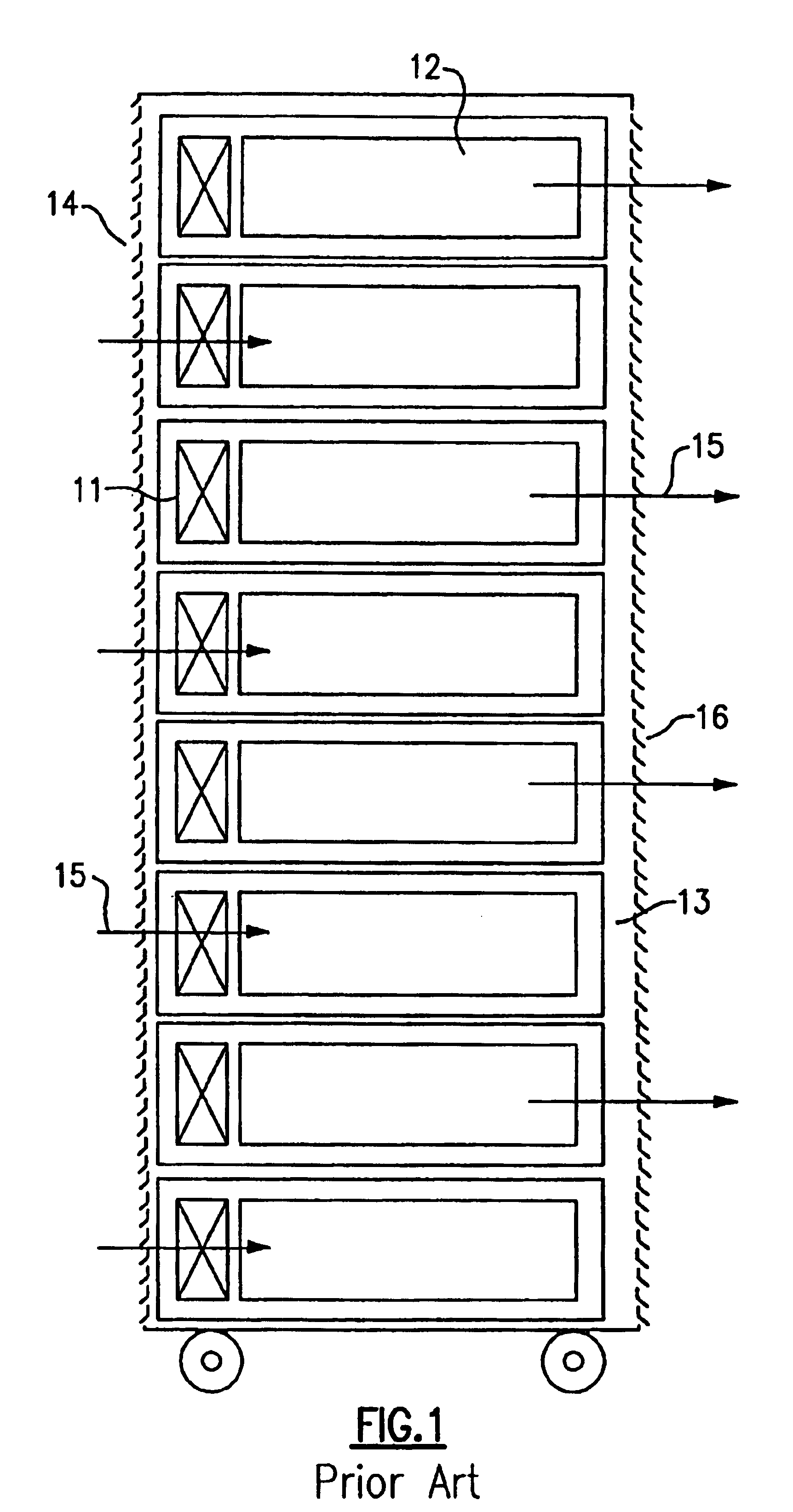

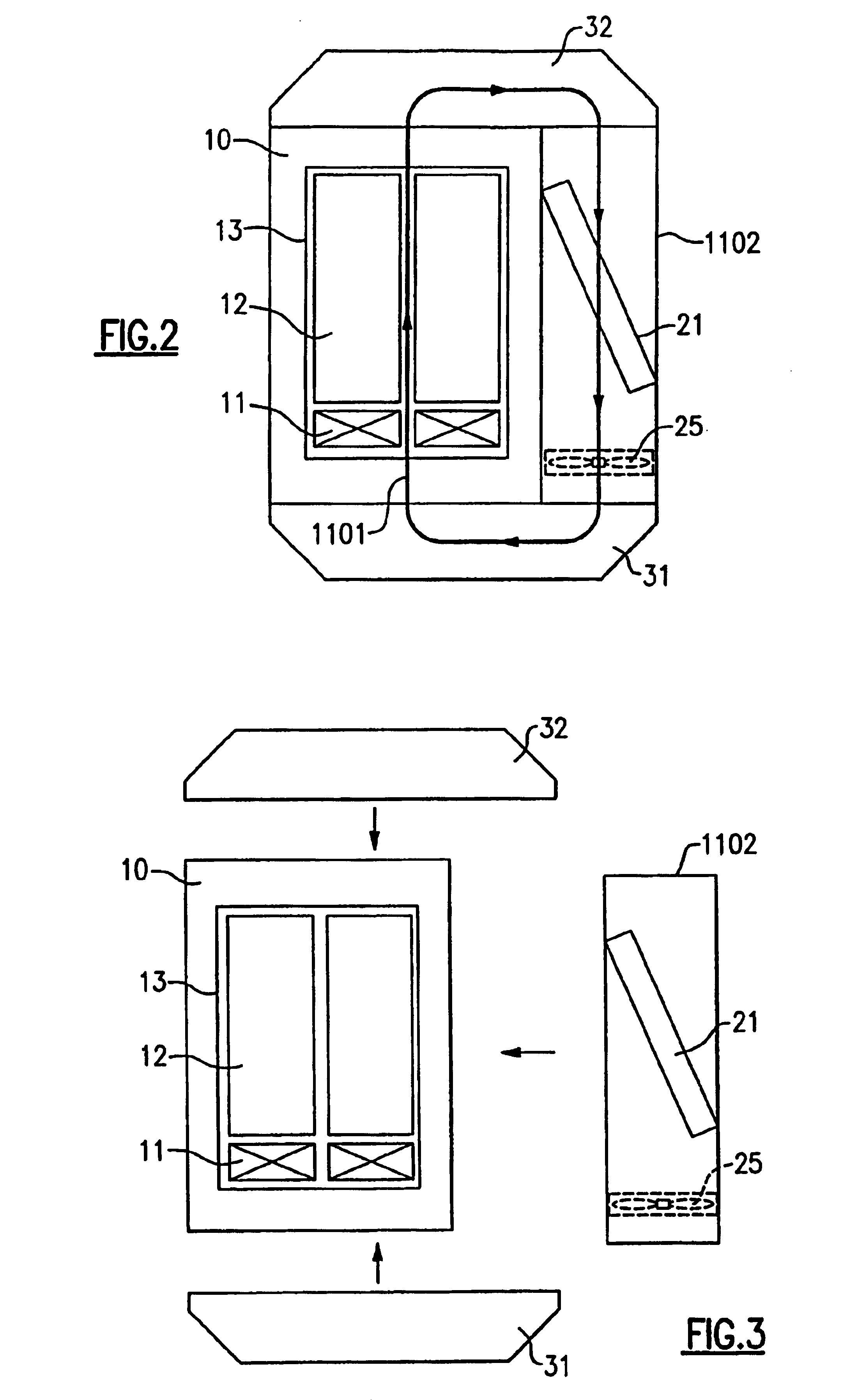

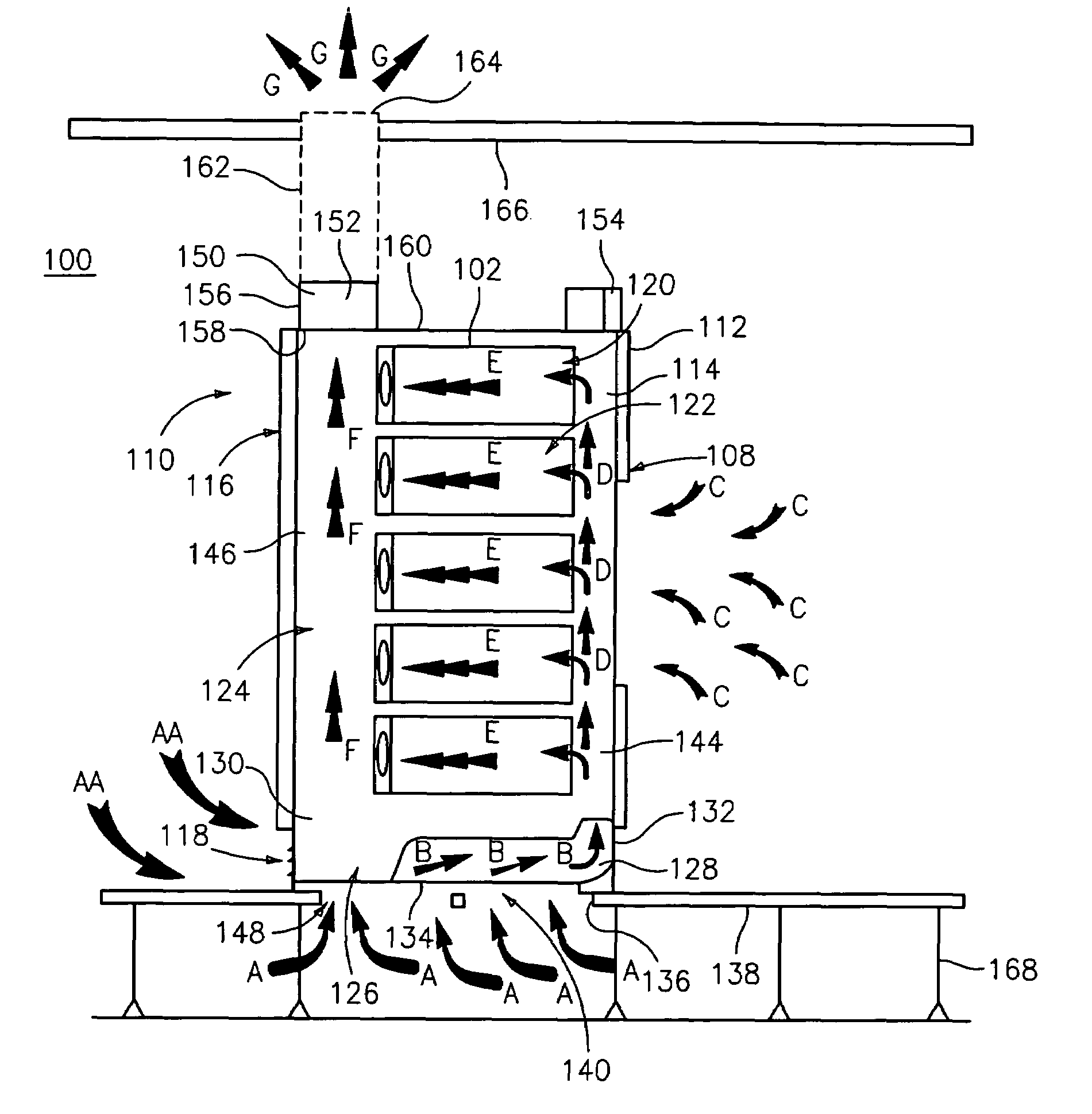

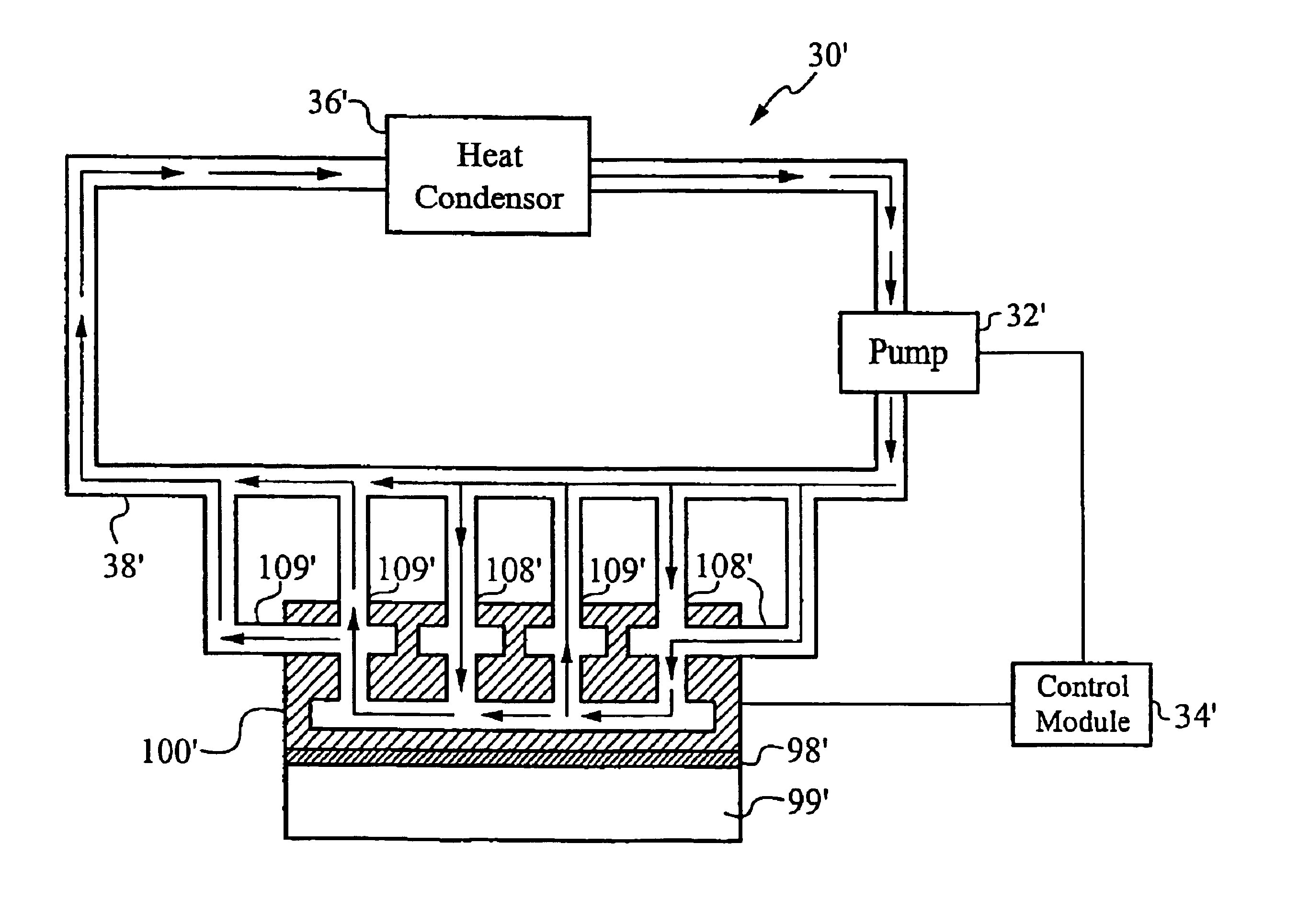

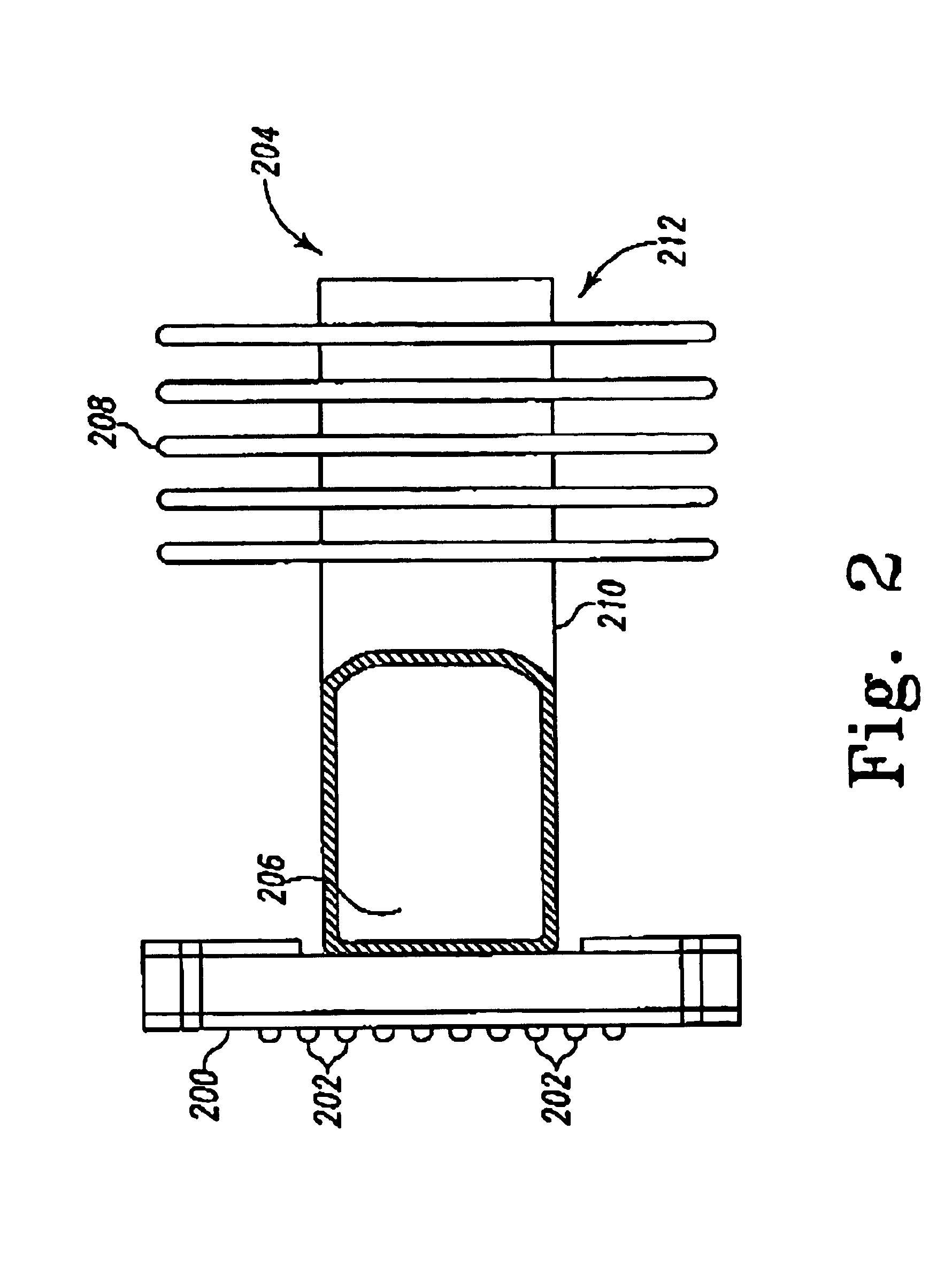

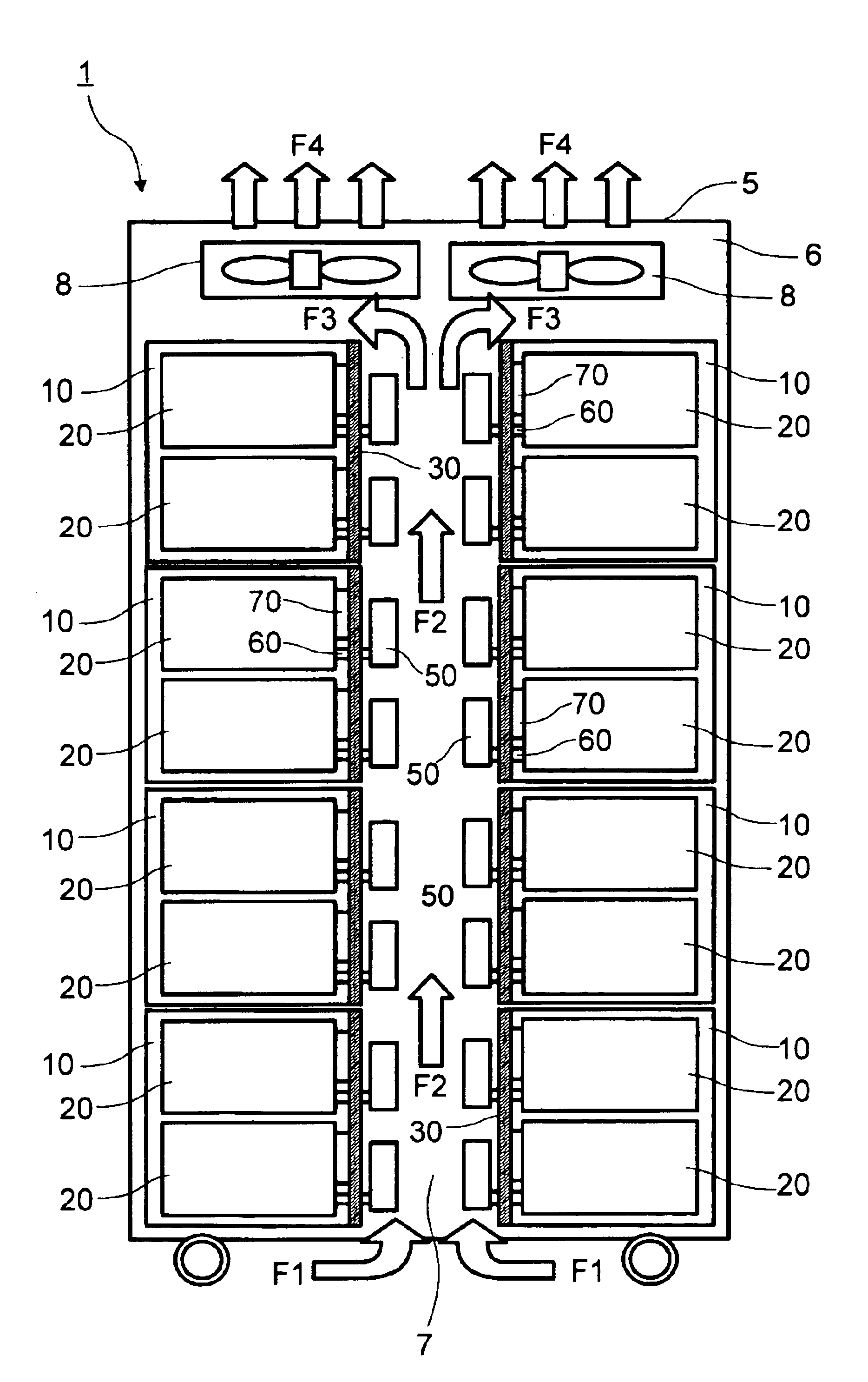

Method for combined air and liquid cooling of stacked electronics components

InactiveUS6924981B2Improve featuresReduce sensitivityDigital data processing detailsIndirect heat exchangersCombined methodElectronic component

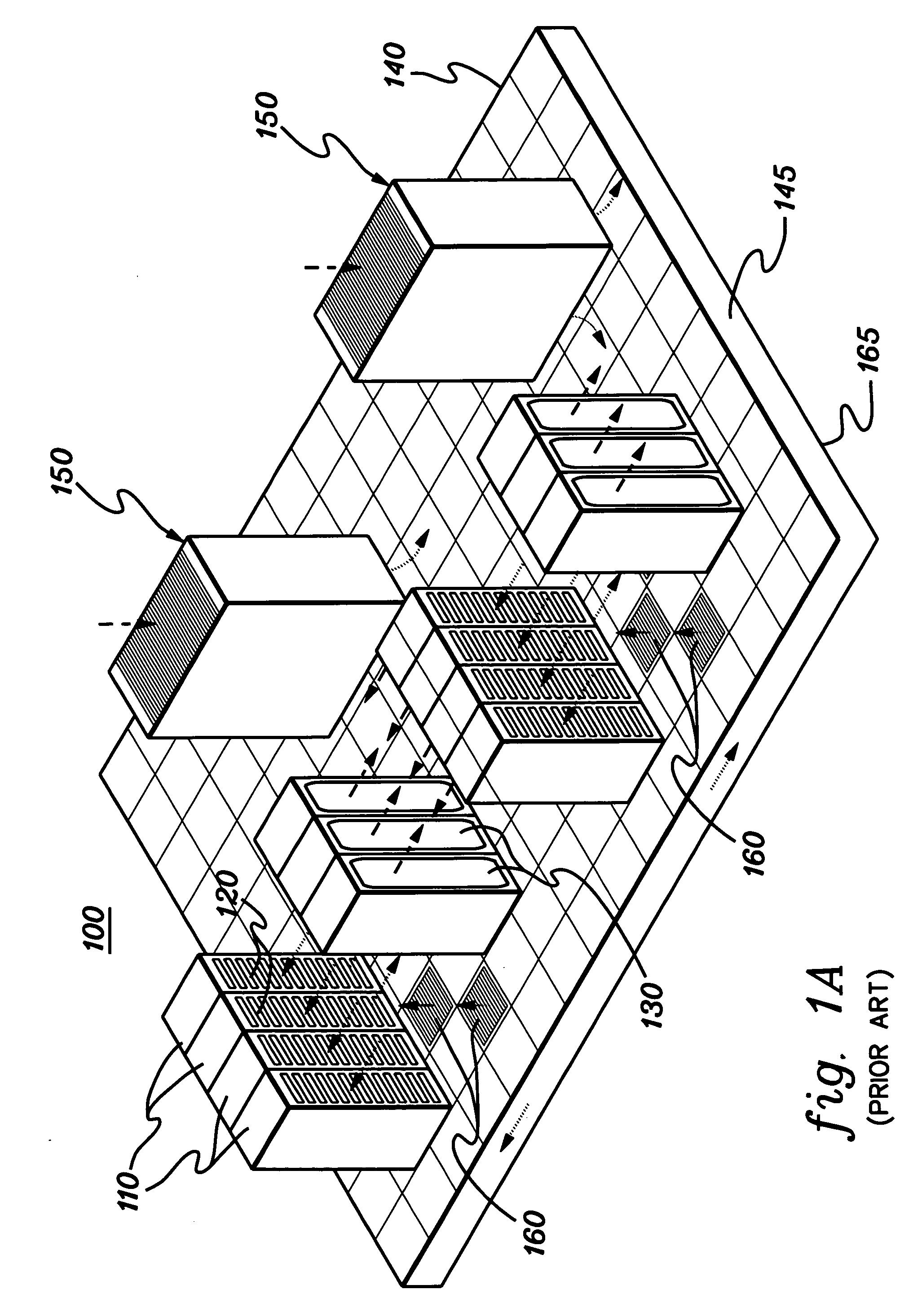

An enclosure apparatus provides for combined air and liquid cooling of rack mounted stacked electronic components. A heat exchanger is mounted on the side of the stacked electronics and air flows side to side within the enclosure, impelled by air-moving devices mounted behind the electronics. Auxiliary air-moving devices may be mounted within the enclosure to increase the air flow. In an alternative embodiment, air-to-liquid heat exchangers are provided across the front and back of the enclosure, and a closed air flow loop is created by a converging supply plenum, electronics drawers through which air is directed by air-moving devices, diverging return plenum, and a connecting duct in the bottom. In a variant of this embodiment, connecting ducts are in both top and bottom, and supply and return ducts are doubly convergent and doubly divergent, respectively. Auxiliary blowers may be added to increase total system air flow. The enclosure also may be provided with automatically opening vent panels to allow room air to circulate and cool in the event of an over-temperature condition. The design of the enclosure permits it to be constructed apart from the rack-mounted apparatus and subsequently attached to the rack, if desired, at the facility at which the rack had been previously operating.

Owner:IBM CORP

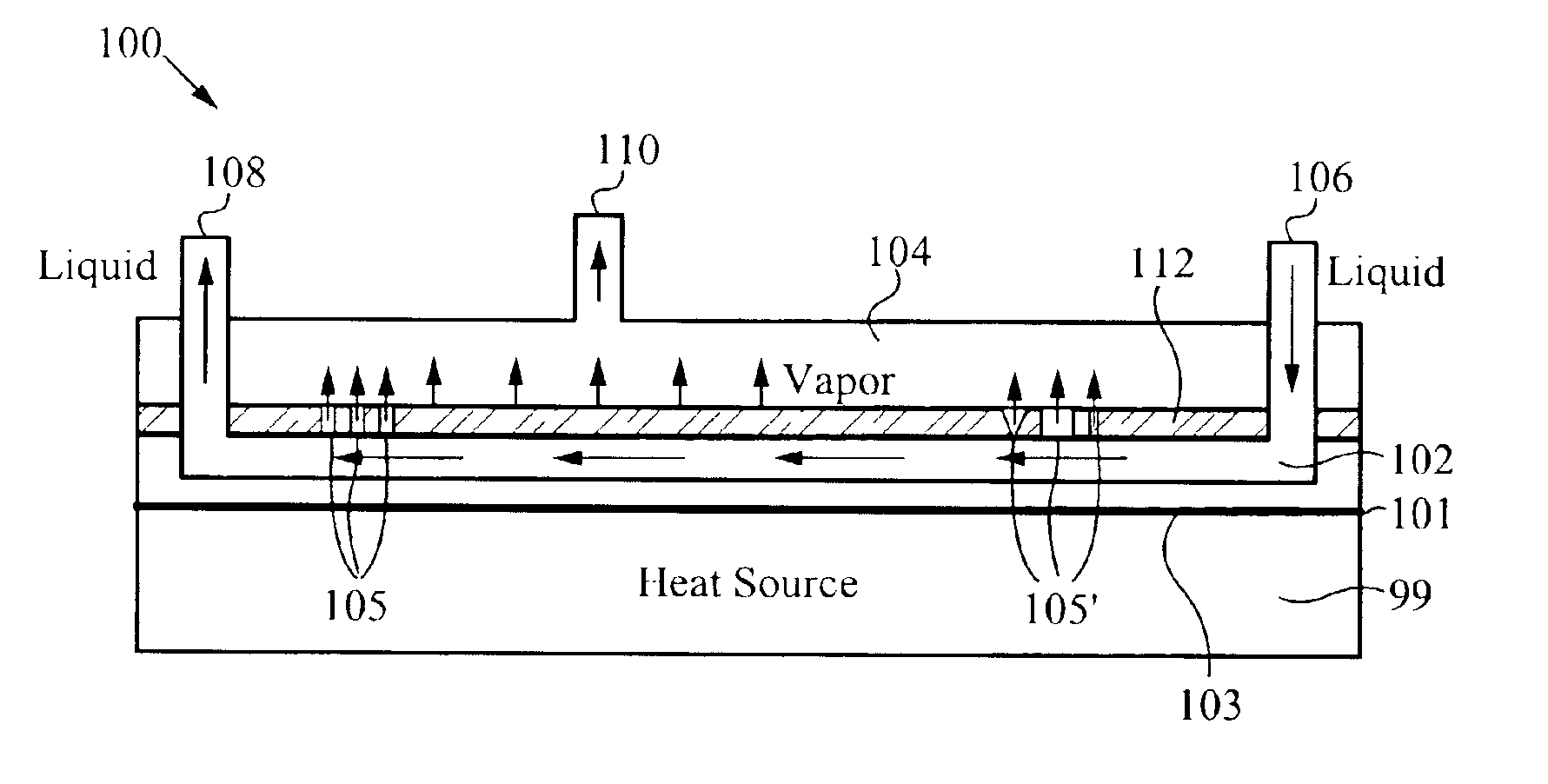

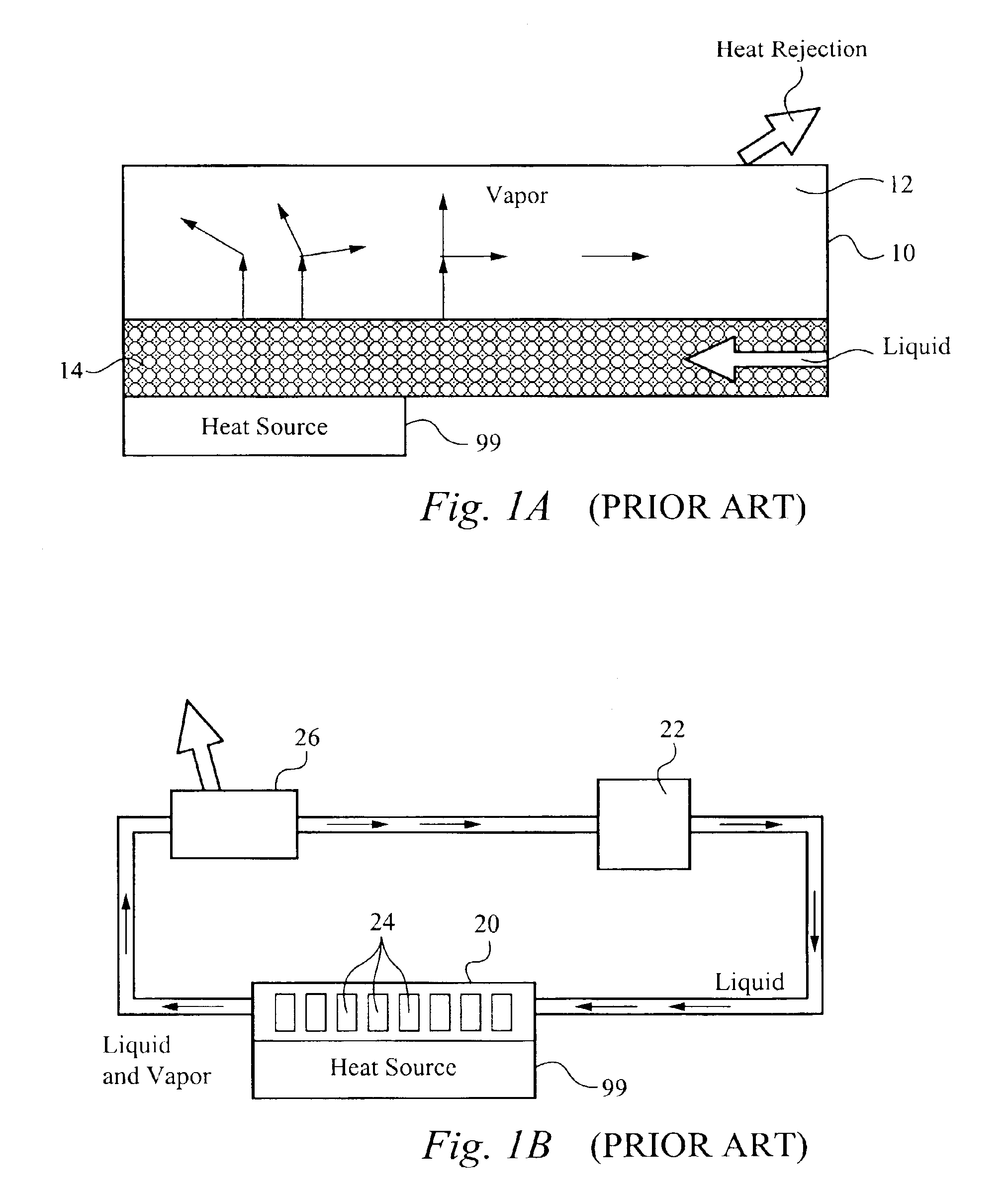

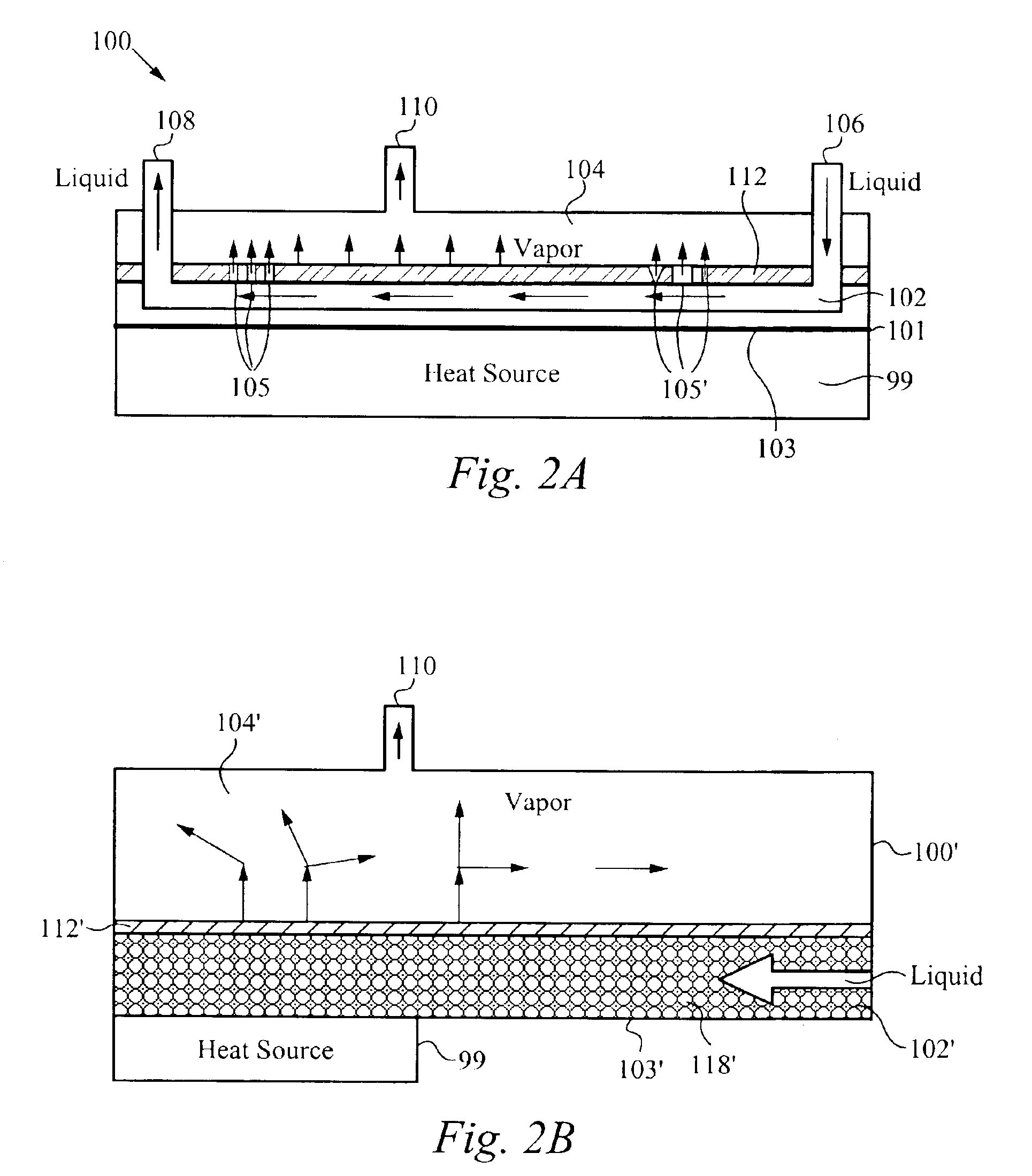

Vapor escape microchannel heat exchanger

InactiveUS6994151B2Semiconductor/solid-state device detailsSolid-state devicesHeat pipeHydrophobic surfaces

A vapor escape membrane for use in a heat exchanging device, including a heat pipe or heat sink that runs liquid into a cooling region positioned adjacent to the heat producing device, the vapor escape membrane comprising: a porous surface for removing vapor produced from the liquid in the cooling region, the membrane configured to confine the liquid only within the cooling region. The vapor escape membrane transfers vapor to a vapor region within the heat exchanging device, wherein the membrane is configured to prevent liquid in the cooling region from entering the vapor region. The membrane is configured to include a hydrophobic surface between the membrane and the cooling region, wherein the liquid in the cooling region does not flow through the porous surface. The vapor escape membrane includes a plurality of apertures for allowing vapor to transfer therethrough, each of the apertures having a predetermined dimension.

Owner:VERTIV CORP

Cabinet for electronic equipment

InactiveUS7643291B2High densityEasy and efficient assemblyMechanical apparatusDigital data processing detailsElectrical and Electronics engineeringElectronic equipment

Owner:ORTRONICS INC

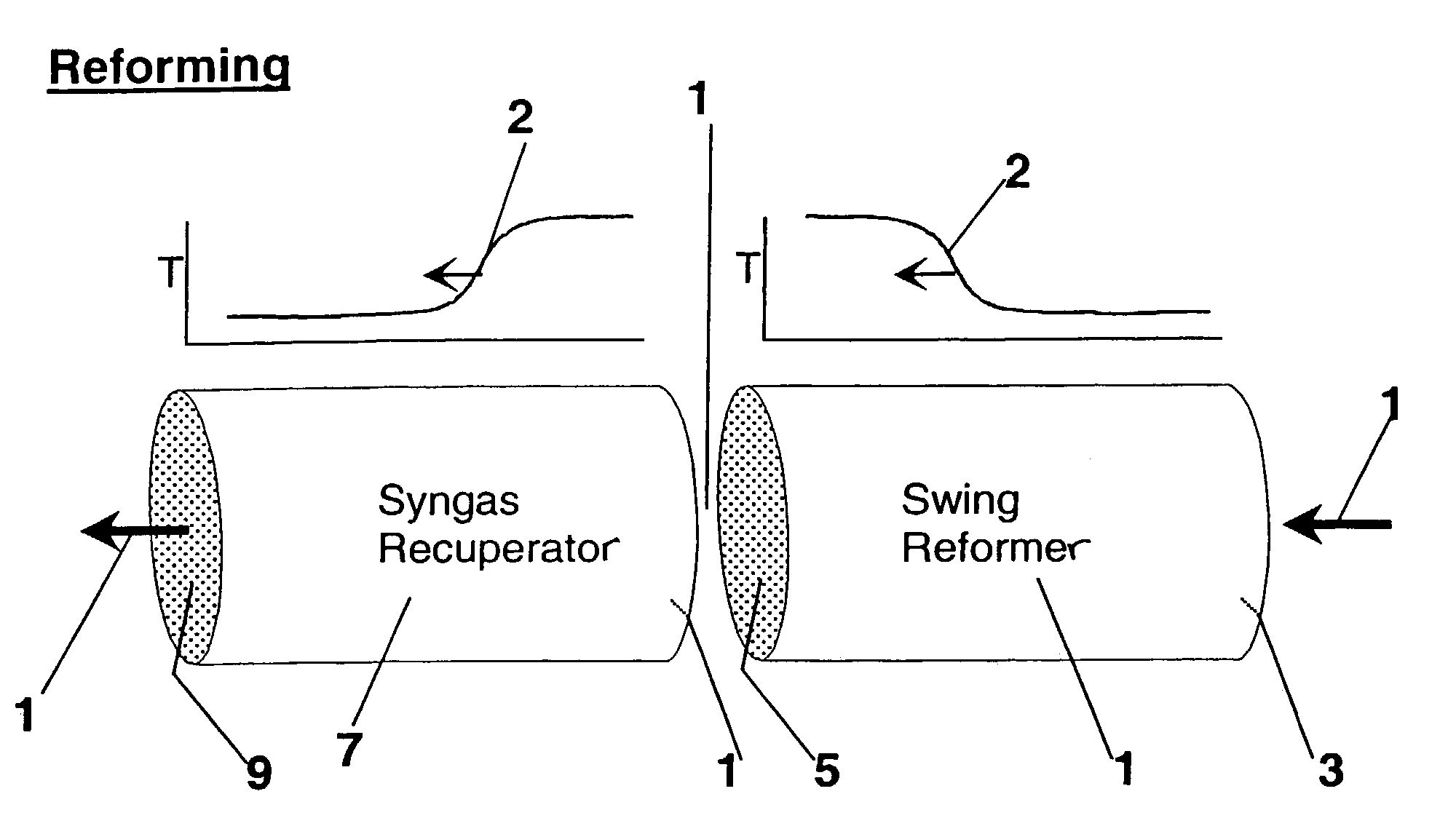

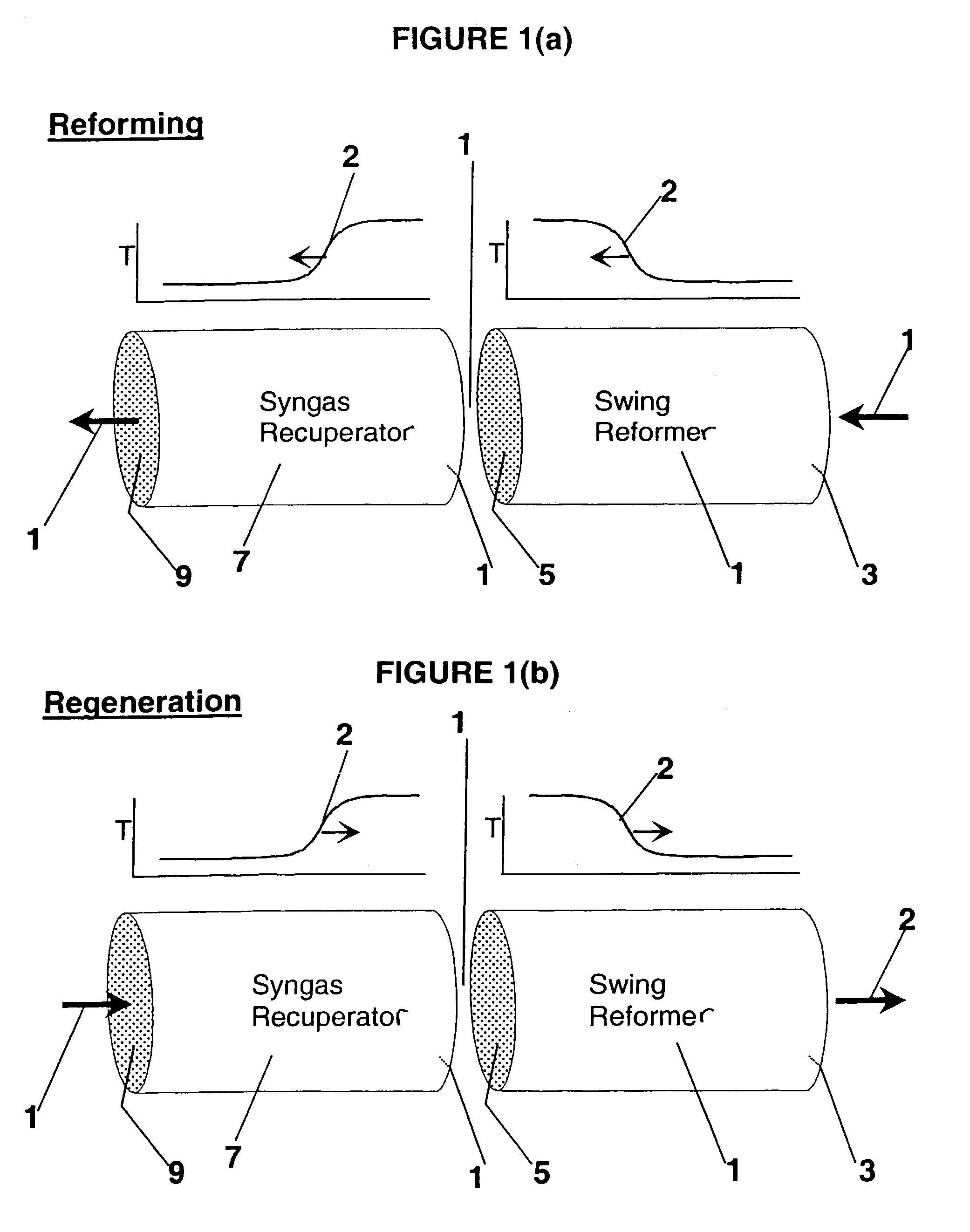

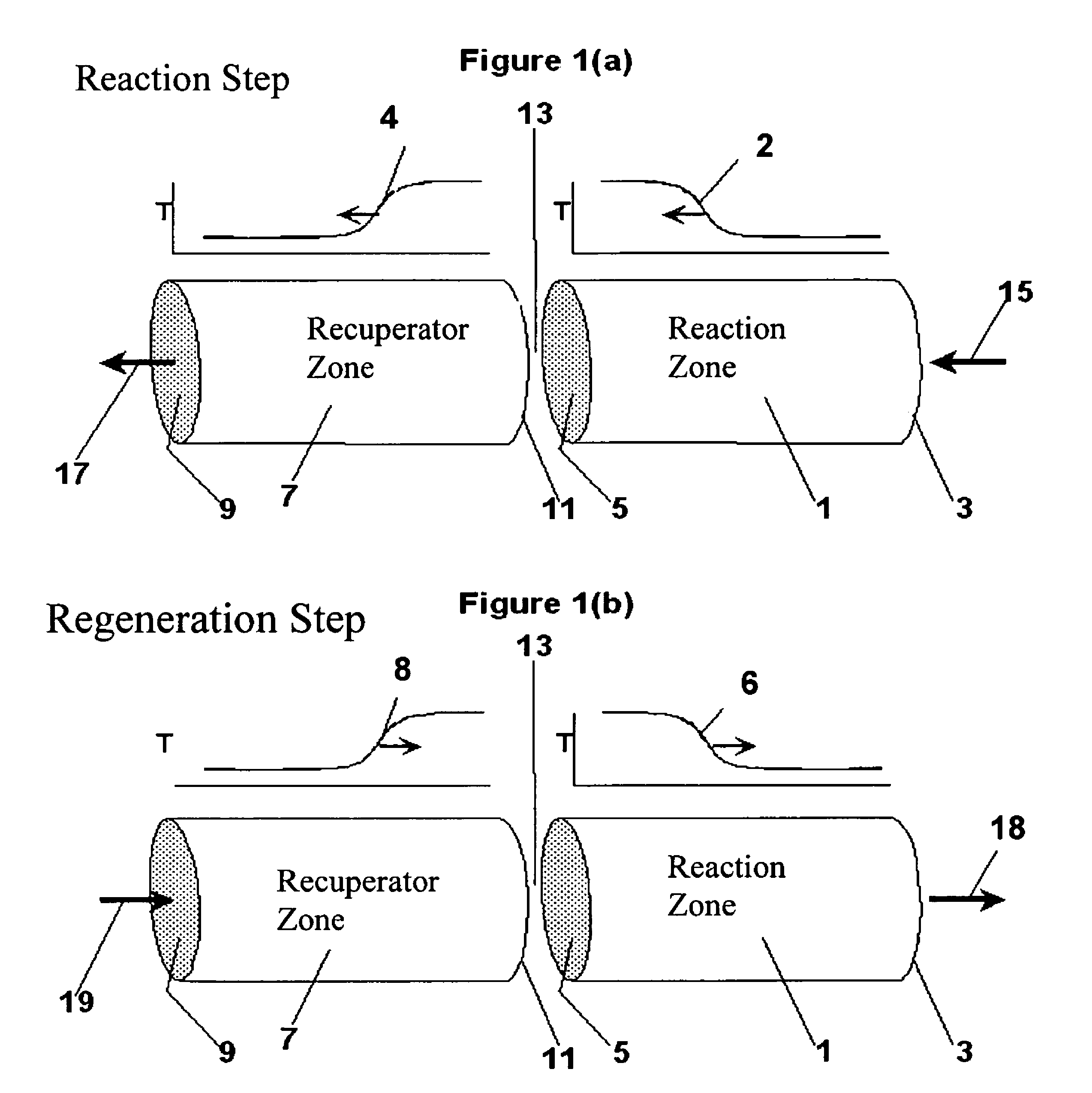

Pressure swing reforming

Synthesis gas is produced though a cyclic method where the first step of the cycle includes reforming a hydrocarbon feed over a catalyst to synthesis gas in a first zone of a bed and the second step reheats this first zone. A hydrocarbon feed is introduced to a bed along with CO2 and optionally steam where it is reformed into synthesis gas. The synthesis gas is collected at a second zone of the bed and an oxygen-containing gas is then introduced to this second zone of the bed and combusted with a fuel, thereby reheating the first zone to sufficient reforming temperatures. Additionally, a non-combusting gas can also be introduced to the second zone to move heat from the second zone to the first zone.

Owner:EXXON RES & ENG CO

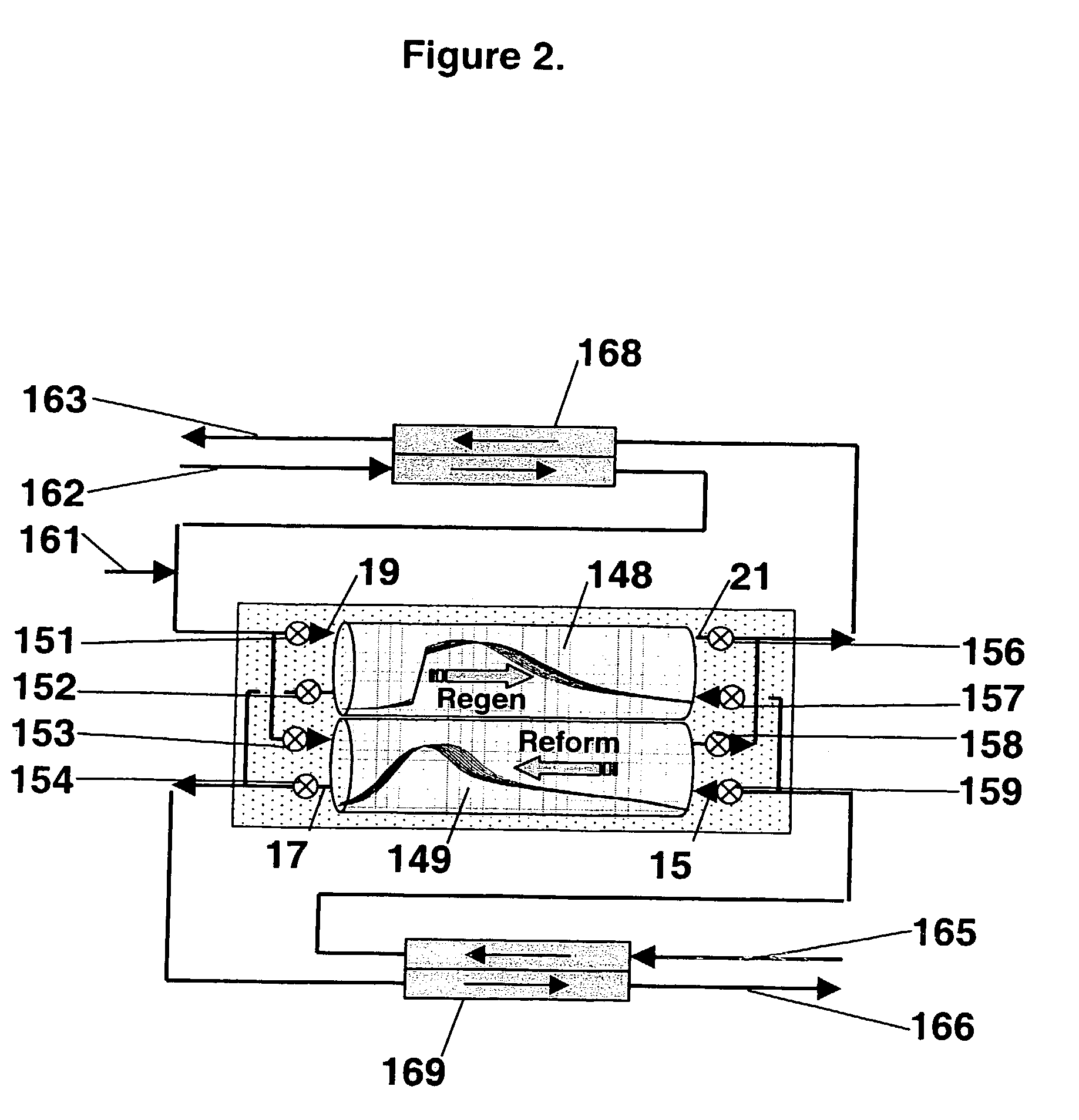

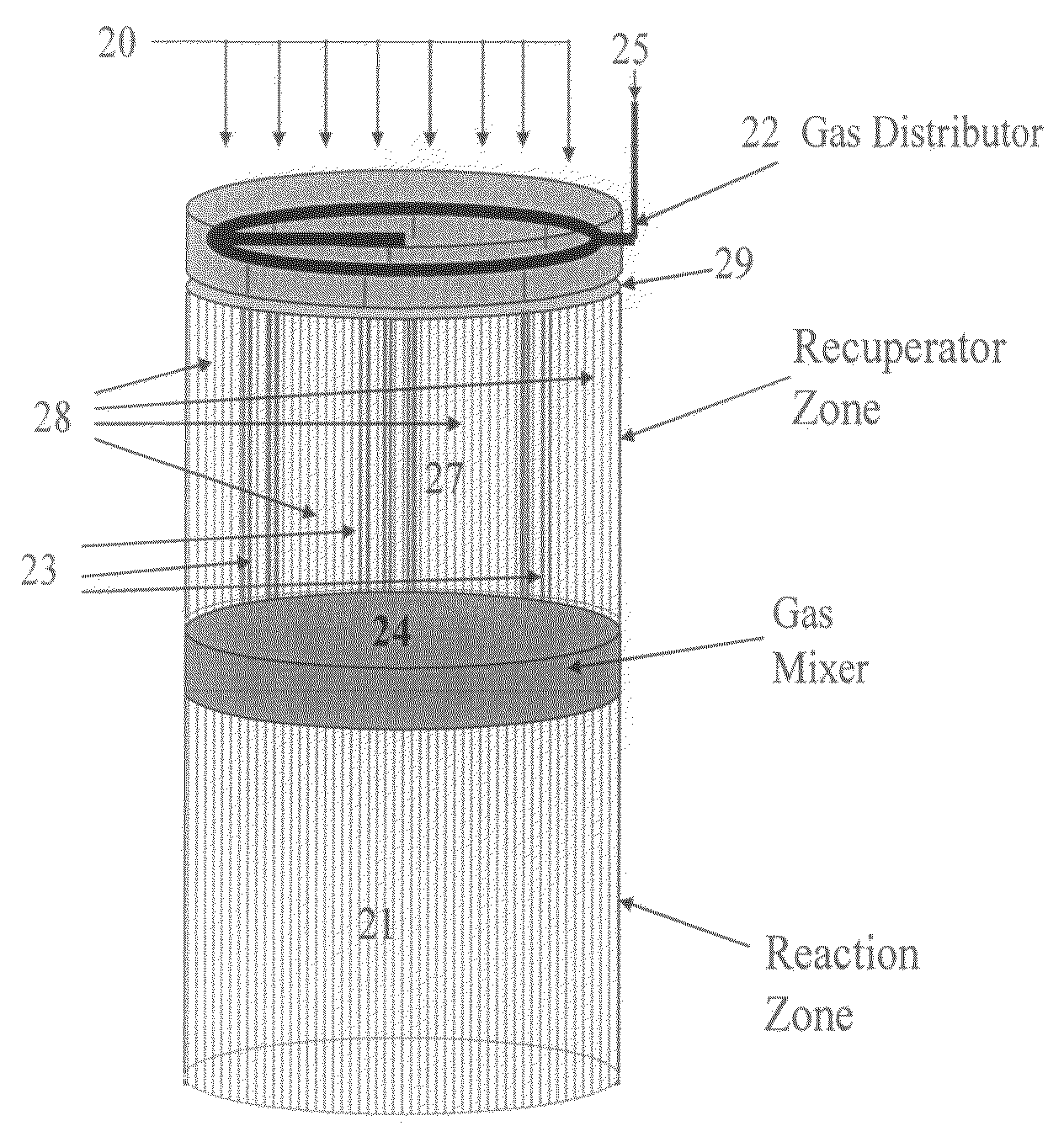

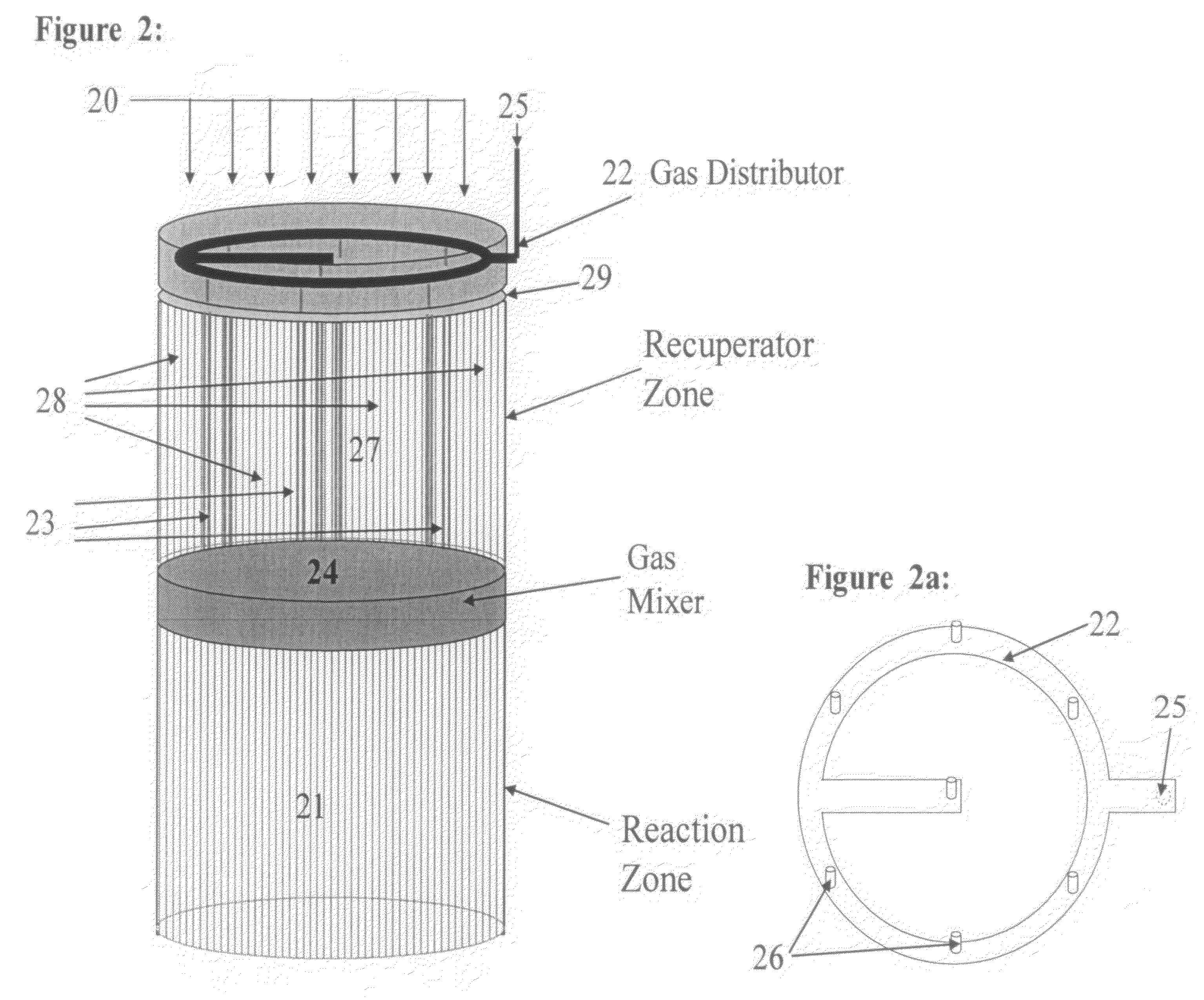

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

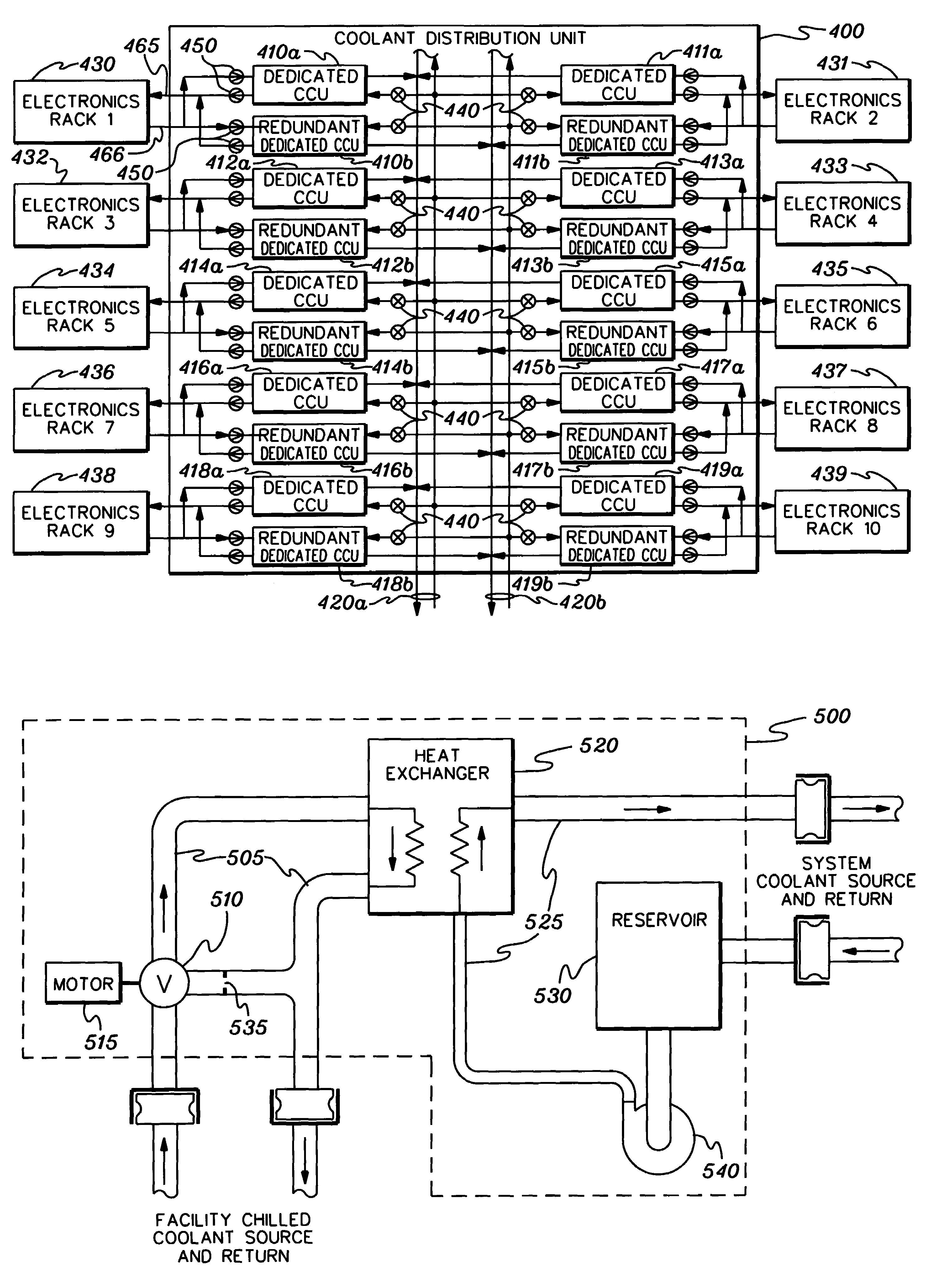

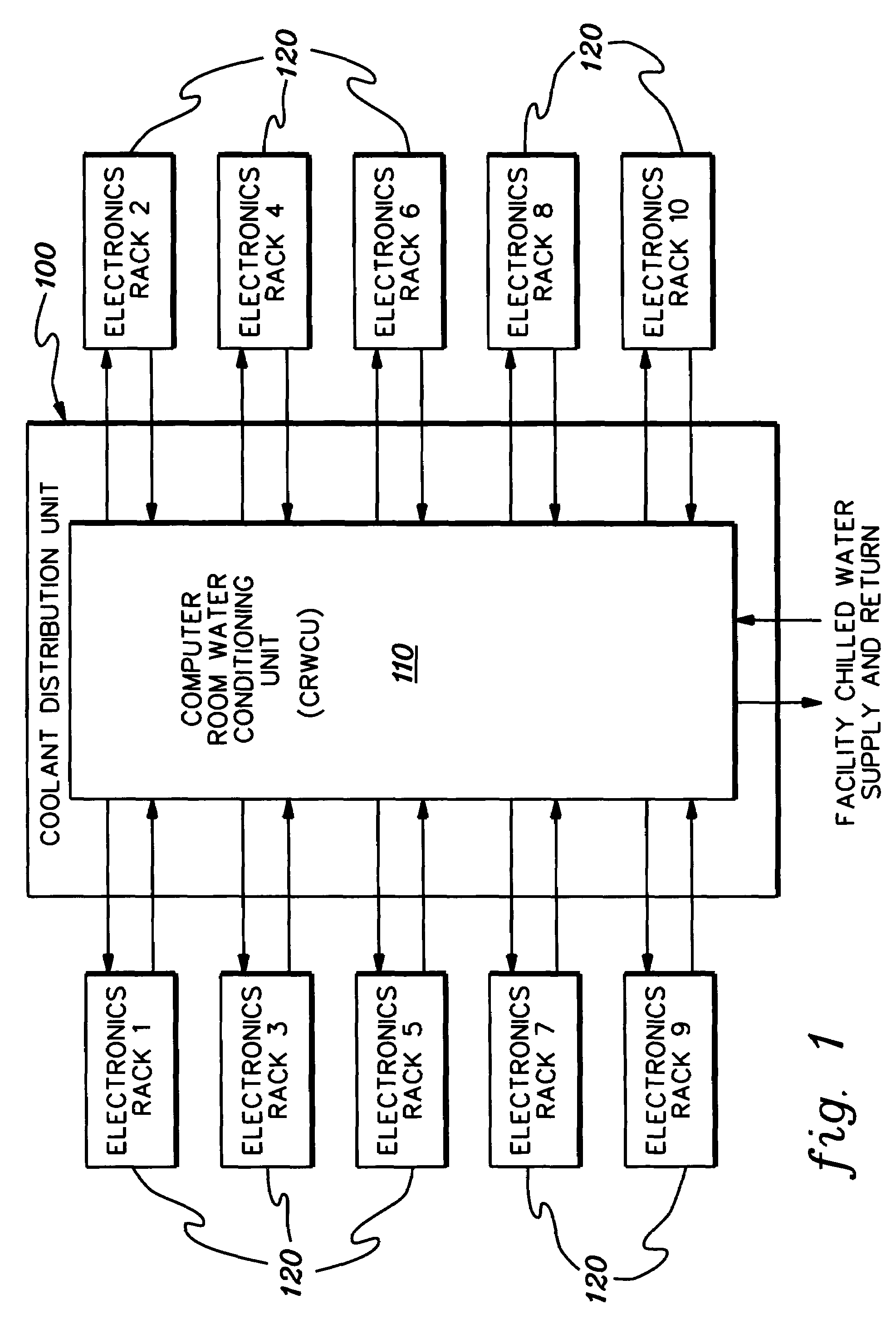

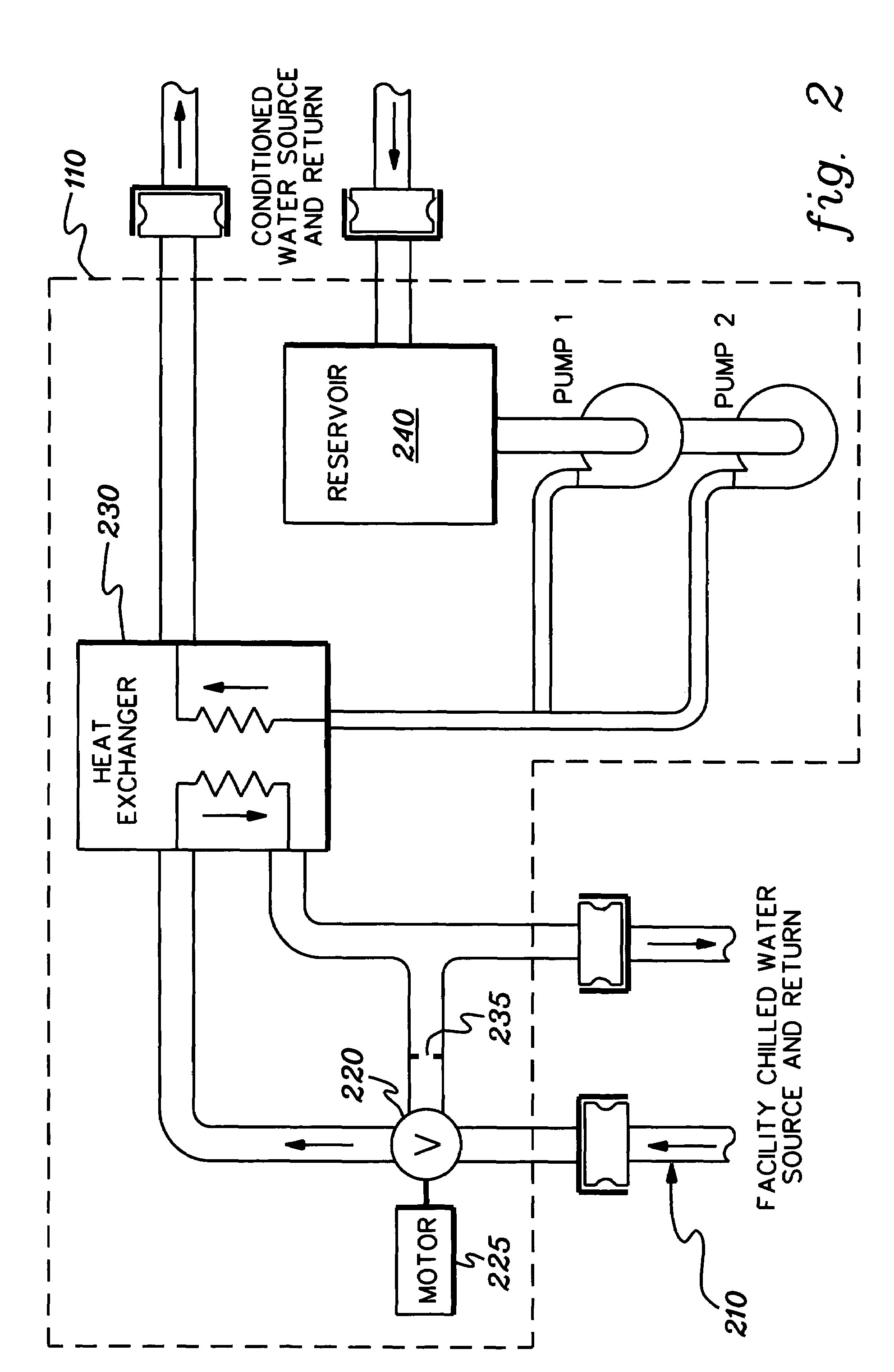

Cooling system and method employing multiple dedicated coolant conditioning units for cooling multiple electronics subsystems

InactiveUS7106590B2Superconductors/hyperconductorsDomestic cooling apparatusCoolant flowNuclear engineering

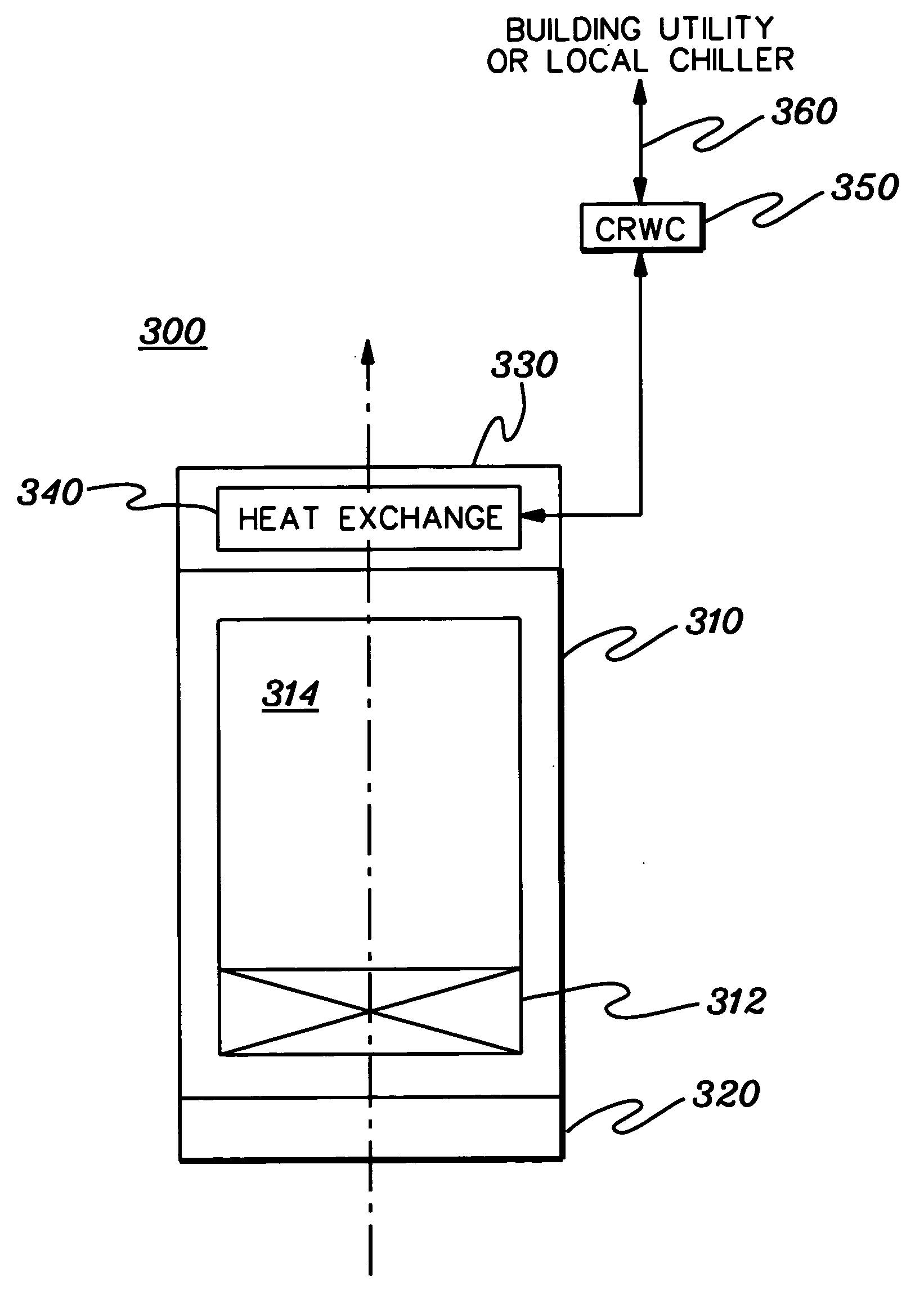

A cooling system is provided employing multiple coolant conditioning units (CCUs). Each CCU, which is coupled to a different, associated electronics rack of multiple electronics racks to be cooled, includes a heat exchanger, a first cooling loop with a control valve, and a second cooling loop. The first cooling loop receives chilled facility coolant from a source and passes at least a portion thereof via the control valve through the heat exchanger. The second cooling loop provides cooled system coolant to the associated electronics rack, and expels heat in the heat exchanger from the electronics rack to the chilled facility coolant in the first cooling loop. The control valve allows regulation of the facility coolant flow through the heat exchanger, thereby allowing independent control of temperature of the system coolant in the second cooling loop. Various CCU and associated component redundancies of the cooling system are also provided.

Owner:INT BUSINESS MASCH CORP

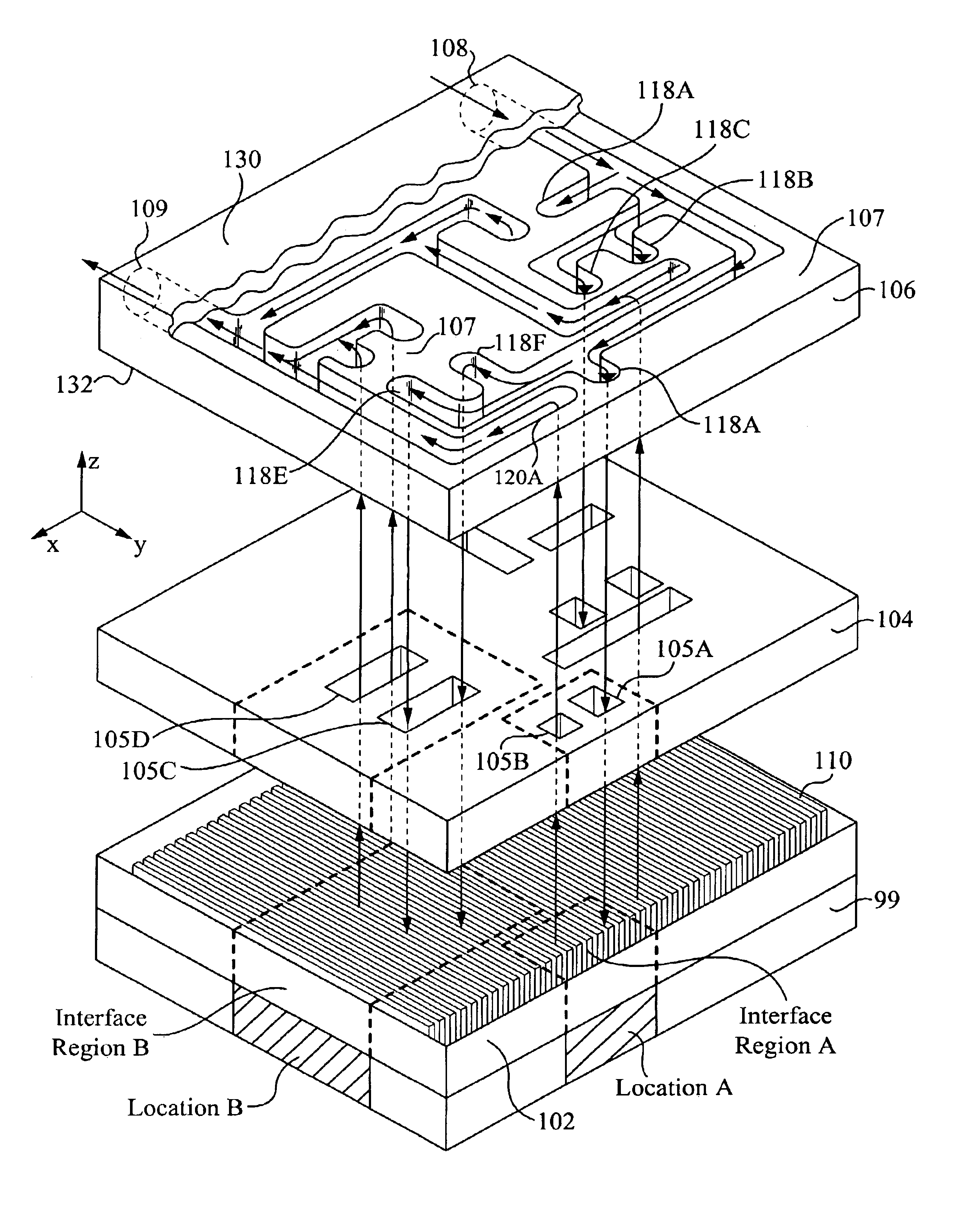

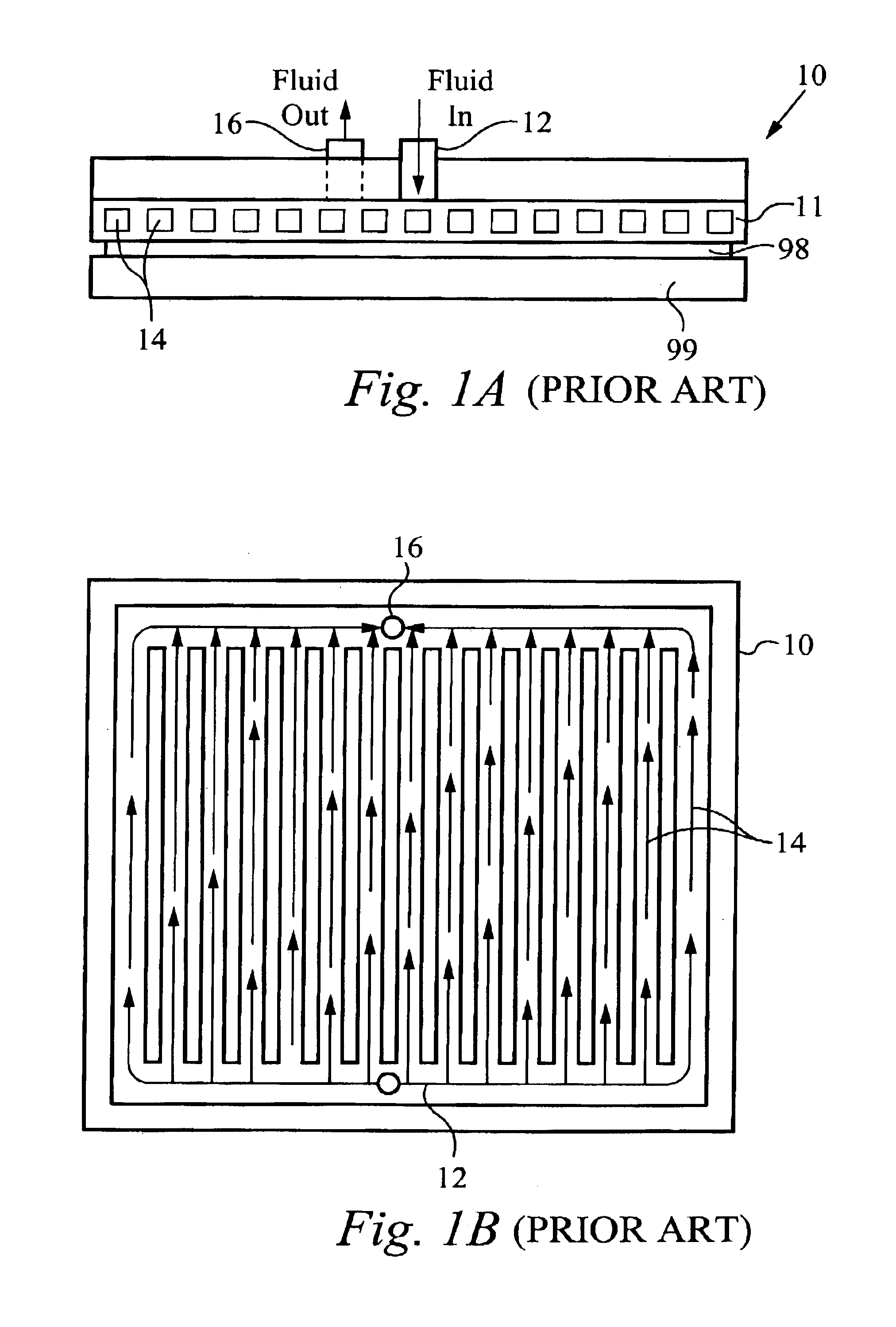

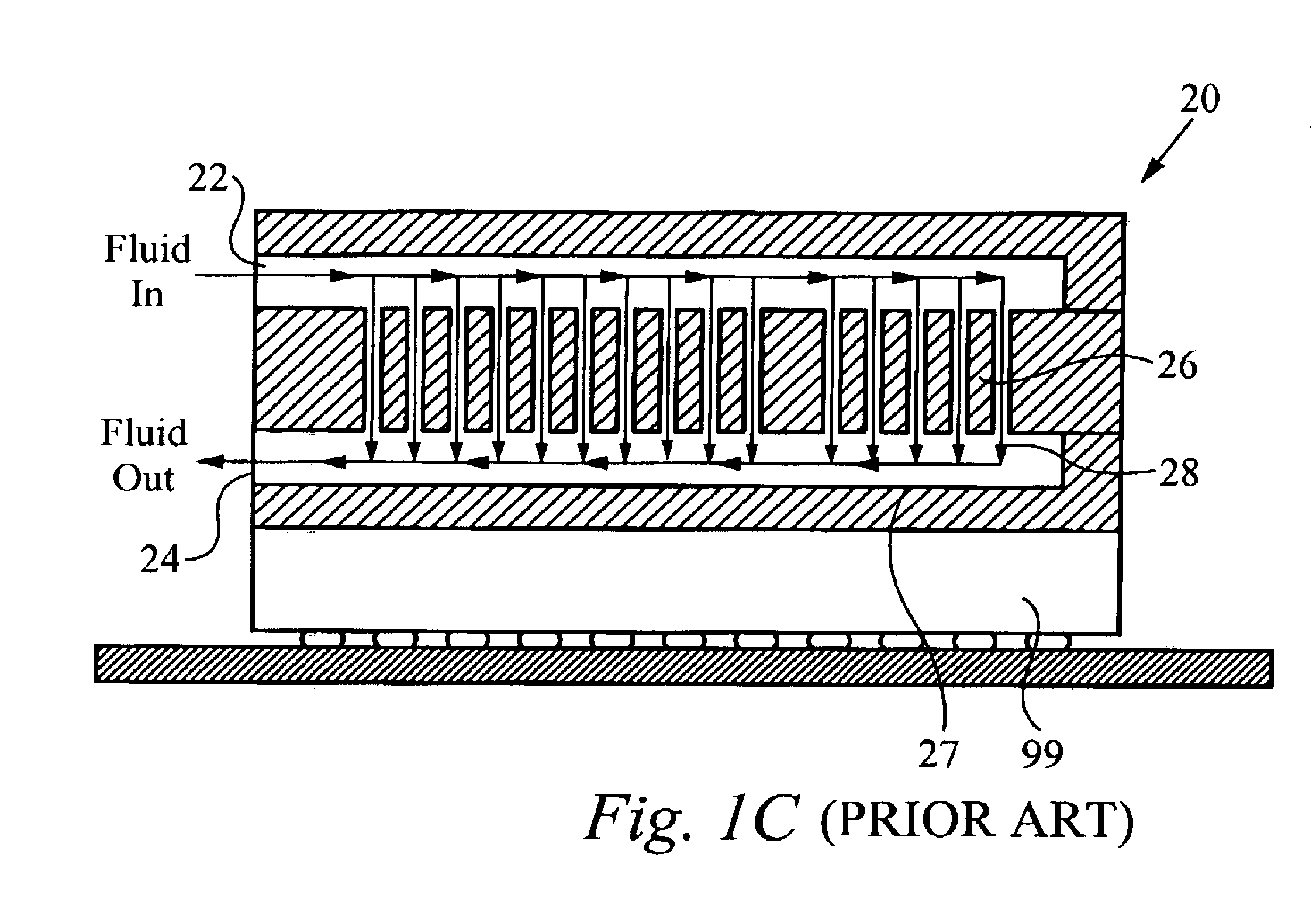

Method and apparatus for efficient vertical fluid delivery for cooling a heat producing device

InactiveUS7000684B2Minimized fluid path distanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesInterface layerPath distance

A heat exchanger and method of manufacturing thereof comprises an interface layer for cooling a heat source. The interface layer is coupled to the heat source and is configured to pass fluid therethrough. The heat exchanger further comprises a manifold layer that is coupled to the interface layer. The manifold layer includes at least one first port that is coupled to a first set of individualized holes which channel fluid through the first set. The manifold layer includes at least one second port coupled to a second set of individualized holes which channel fluid through the second set. The first set of holes and second set of holes are arranged to provide a minimized fluid path distance between the first and second ports to adequately cool the heat source. Preferably, each hole in the first set is positioned a closest optimal distance to an adjacent hole the second set.

Owner:VERTIV CORP

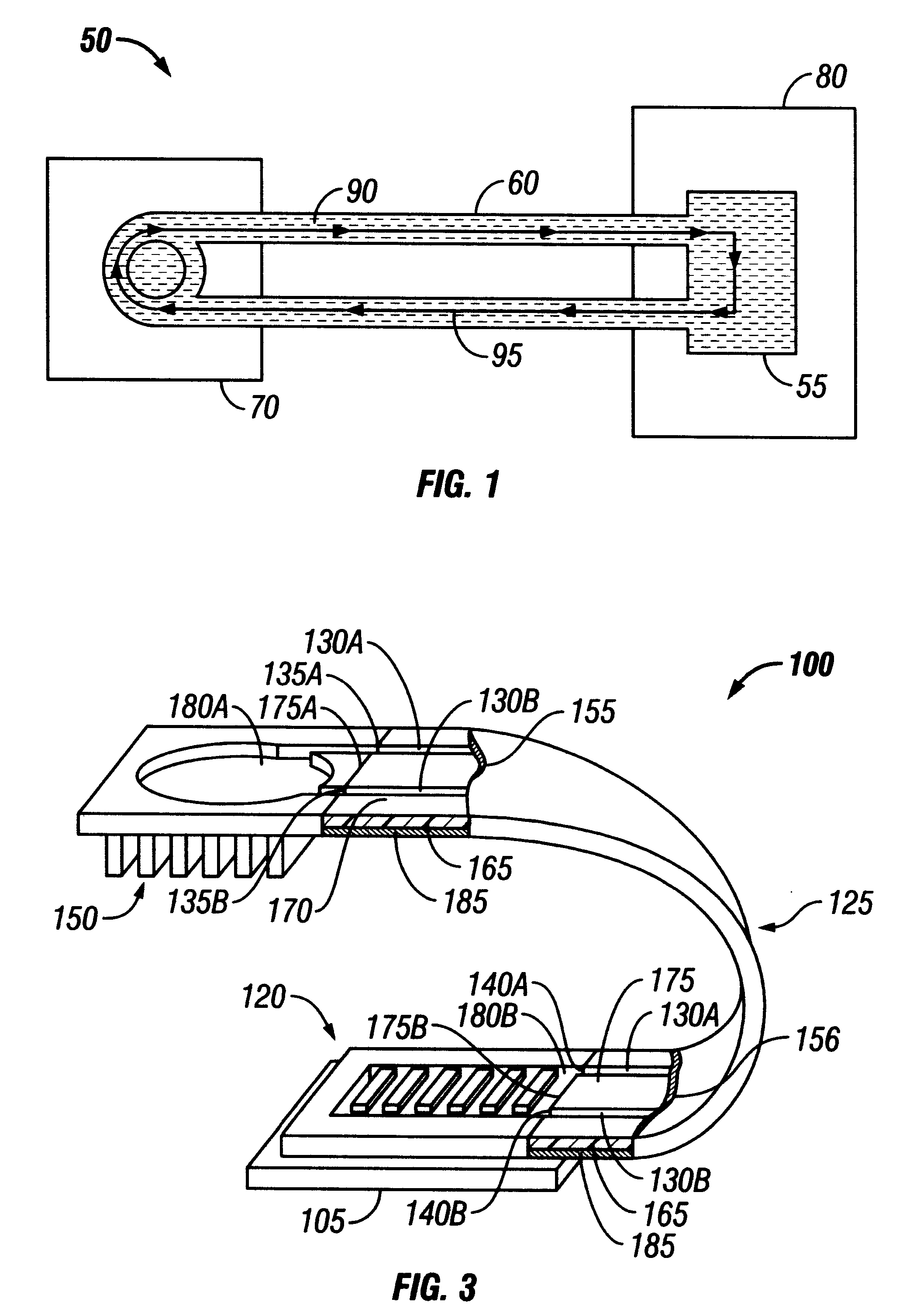

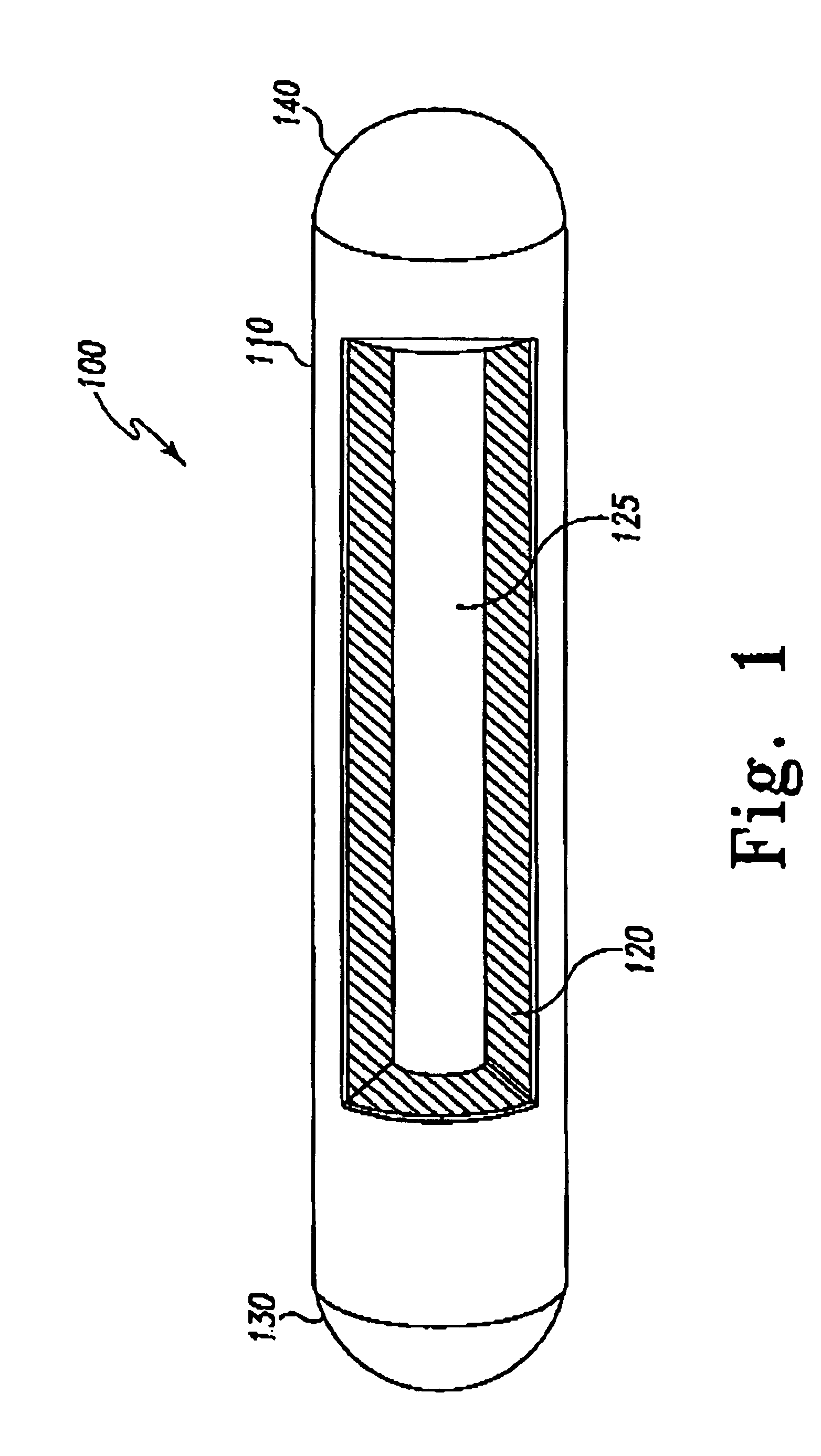

Flat plate heat pipe cooling system for electronic equipment enclosure

InactiveUS6148906ARemove heatDigital data processing detailsSemiconductor/solid-state device detailsEngineeringElectron

A cooling system for an electronic equipment enclosure employs a flat plate heat pipe to deliver heat from the interior of the enclosure through a connector to a removable external heat sink. The heat pipe includes a metallic bottom plate having a depression therein containing a set of rods evenly spaced from one another. A top plate covers the bottom plate with the rods compressed therebetween. Channels formed between adjacent rods are partially evacuated and injected with an evaporative fluid. The fluid and its vapor circulate in the channels to convey heat from a warm end of the heat pipe to a cool end. The heat sink is of similar construction.

Owner:SCIENTECH

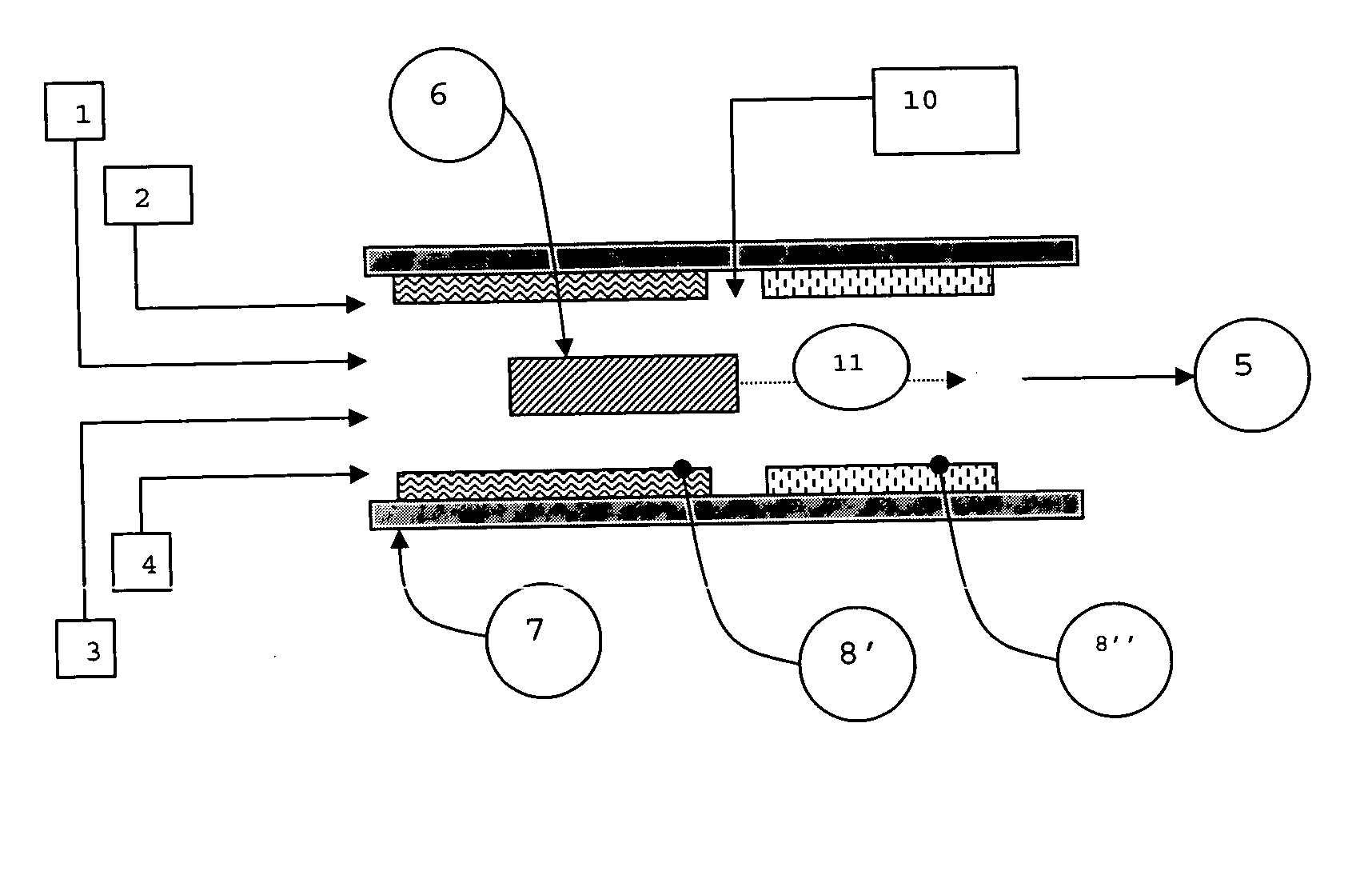

Cooling systems incorporating heat exchangers and thermoelectric layers

ActiveUS20070034356A1Thermoelectric device with peltier/seeback effectDigital data processing detailsEngineeringThermal contact

A method and system for cooling a heat source are presented. The system includes a fluid heat exchanger, a pump, a thermoelectric device having a cooling portion and a heating portion, and a heat rejector configured to be in thermal contact with at least a portion of the heating portion of the thermoelectric device. The pump is coupled with the fluid heat exchanger and configured to pass a fluid therethrough. The thermoelectric device is configured along with the heat exchanger in a cooling system to enhance the cooling efficiency of the system.

Owner:VERTIV CORP

Automotive lighting assembly cooling system

InactiveUS6910794B2Point-like light sourceLighting heating/cooling arrangementsMobile vehicleEffect light

An automotive lighting assembly cooling system includes a heat pipe with an evaporation area proximate to a heat generating component, such as a Light Emitting Diode (LED), and a condensing area located remote from the evaporation area. Evaporation of fluid within the heat pipe transfers heat away from the heat generating component. The efficiency of the cooling system in one embodiment is increased by including fins associated with the condensing area and placing the fins in an area where air flow external to a moving vehicle assists in cooling the fins.

Owner:GUIDE

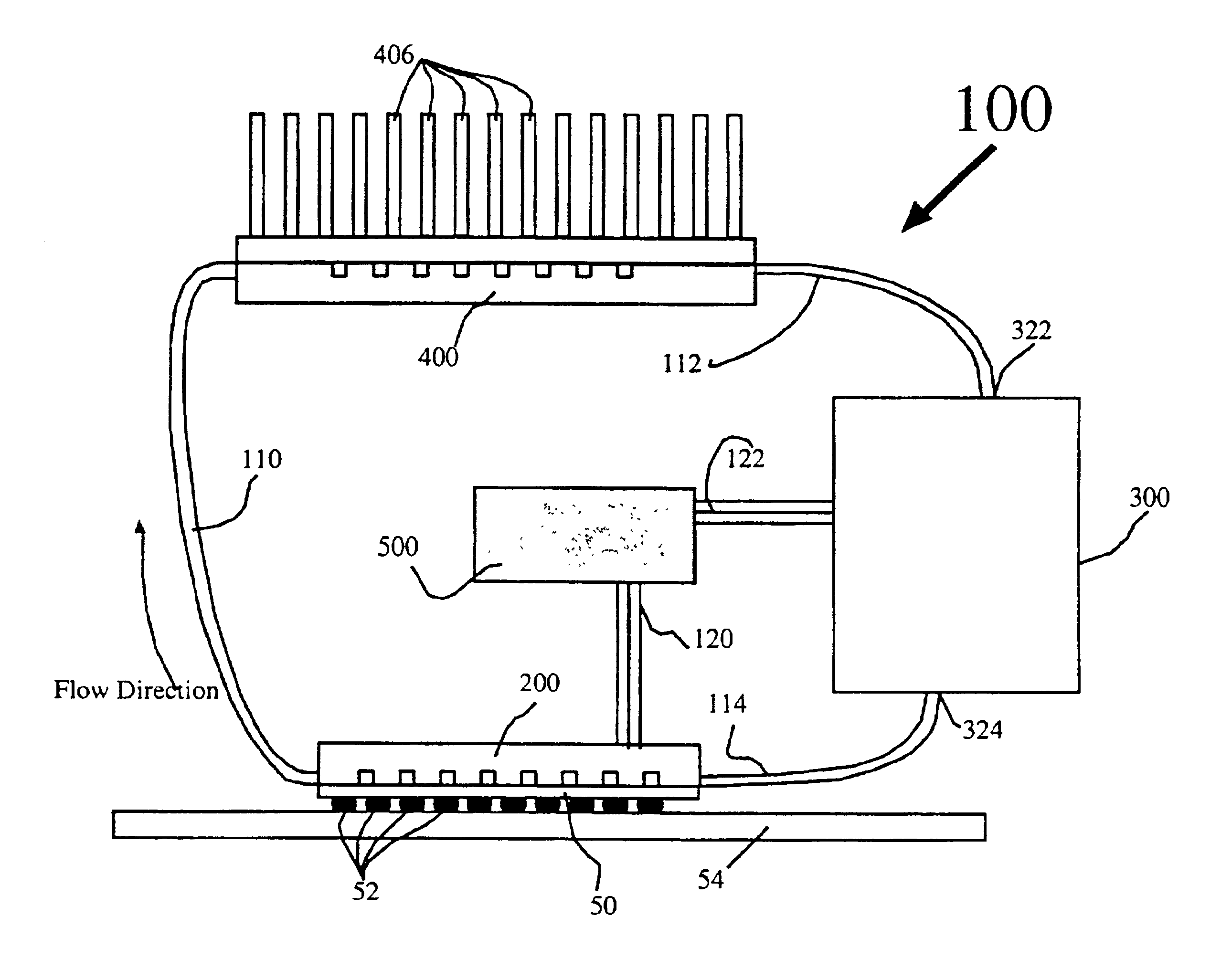

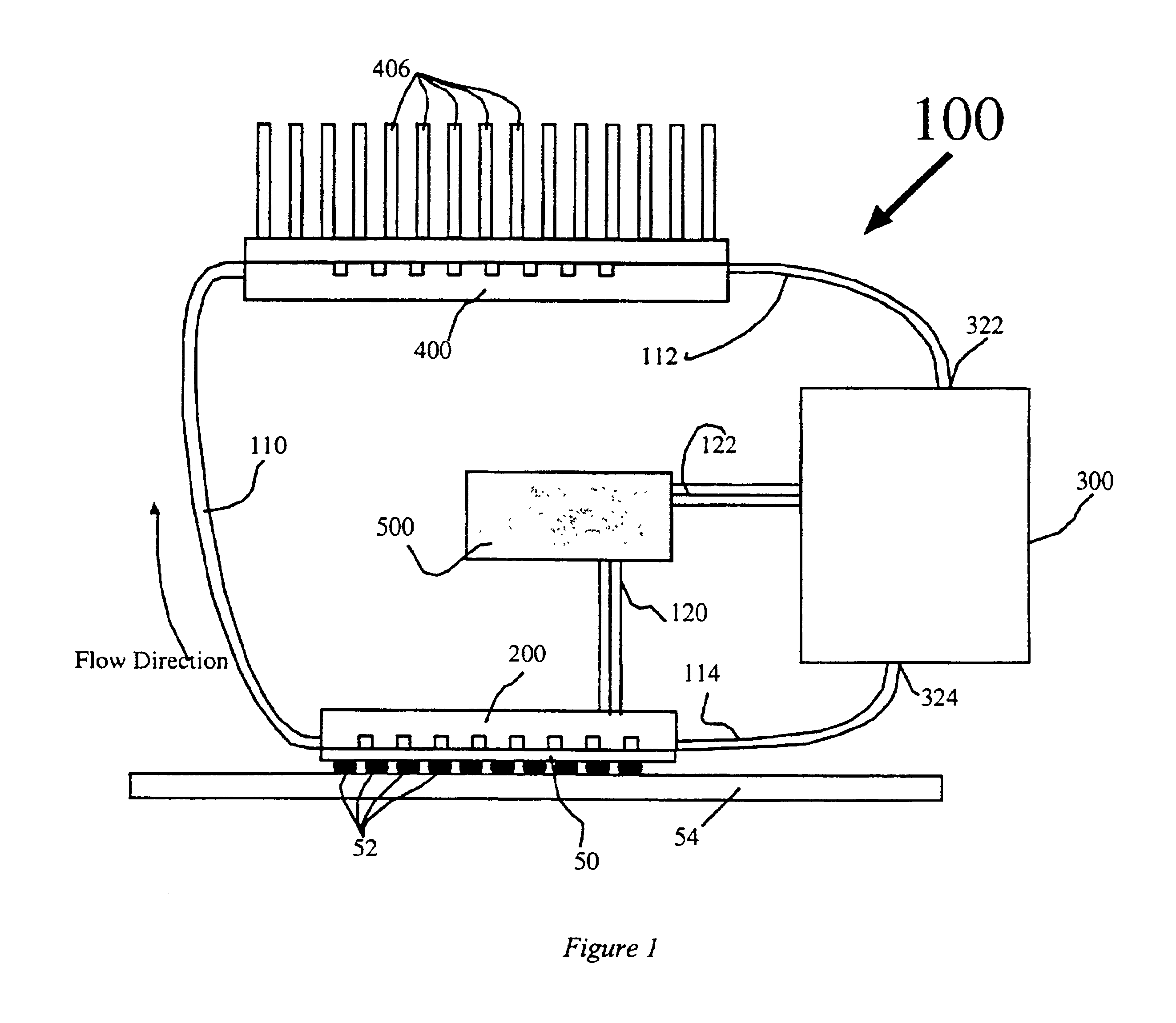

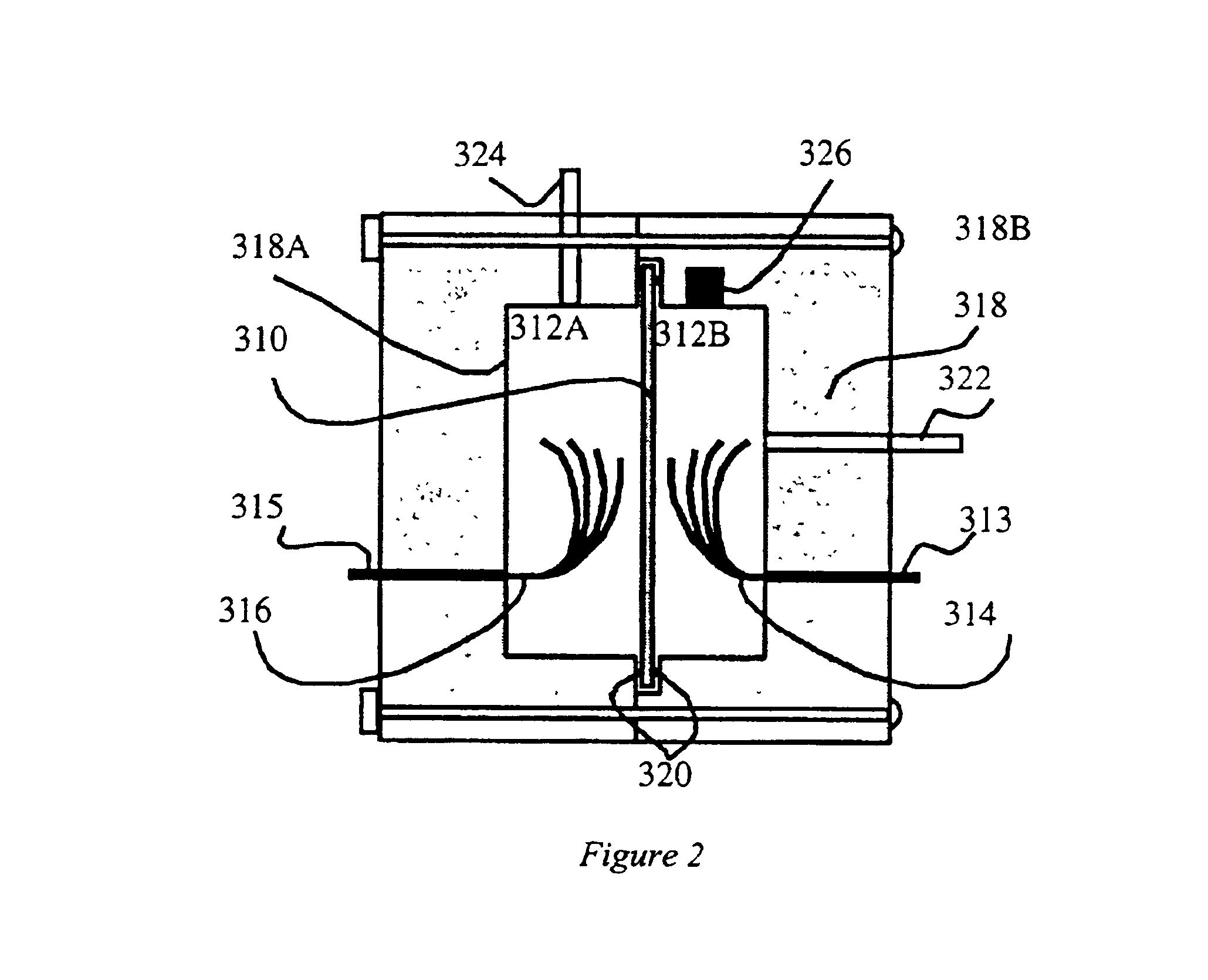

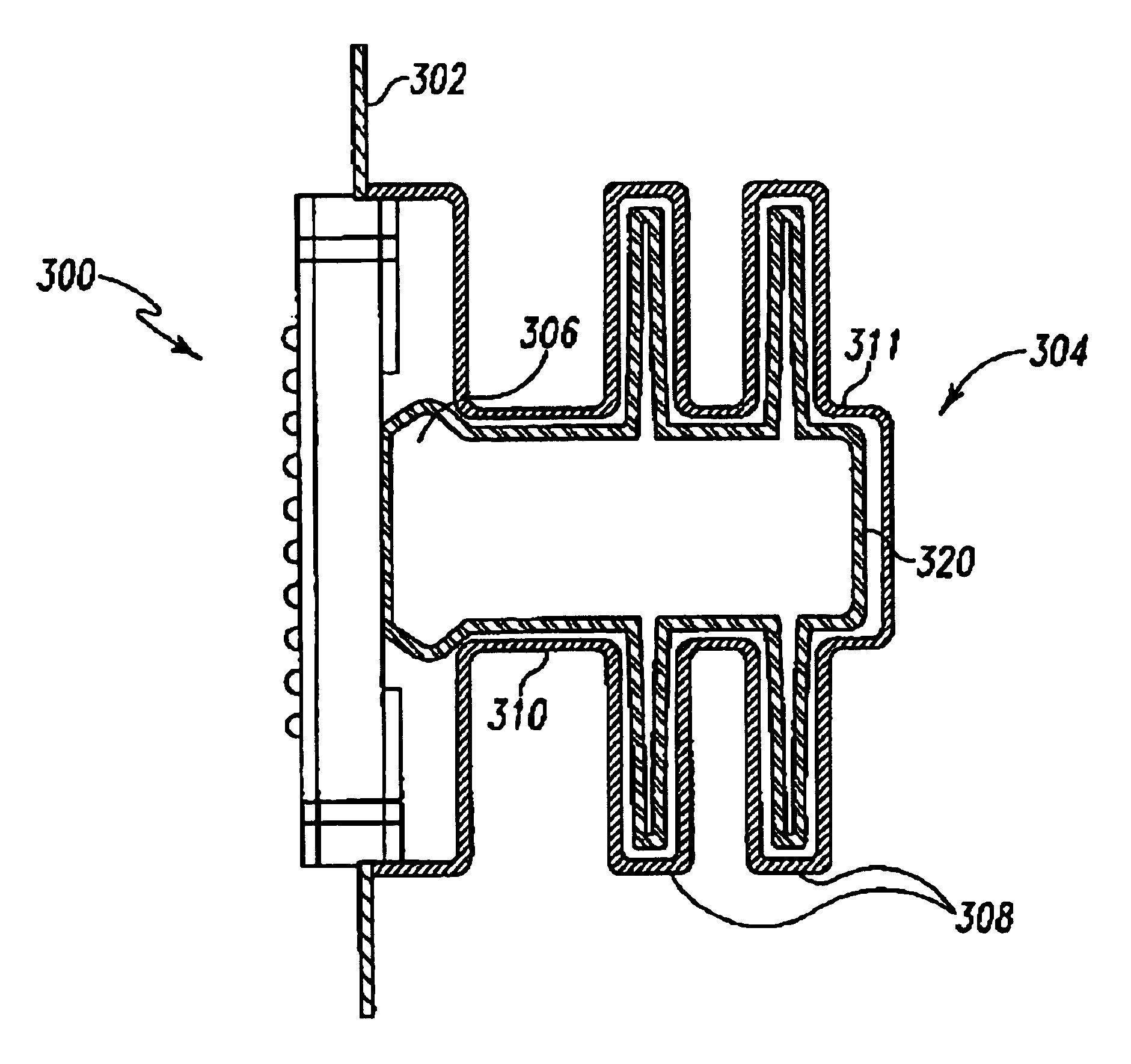

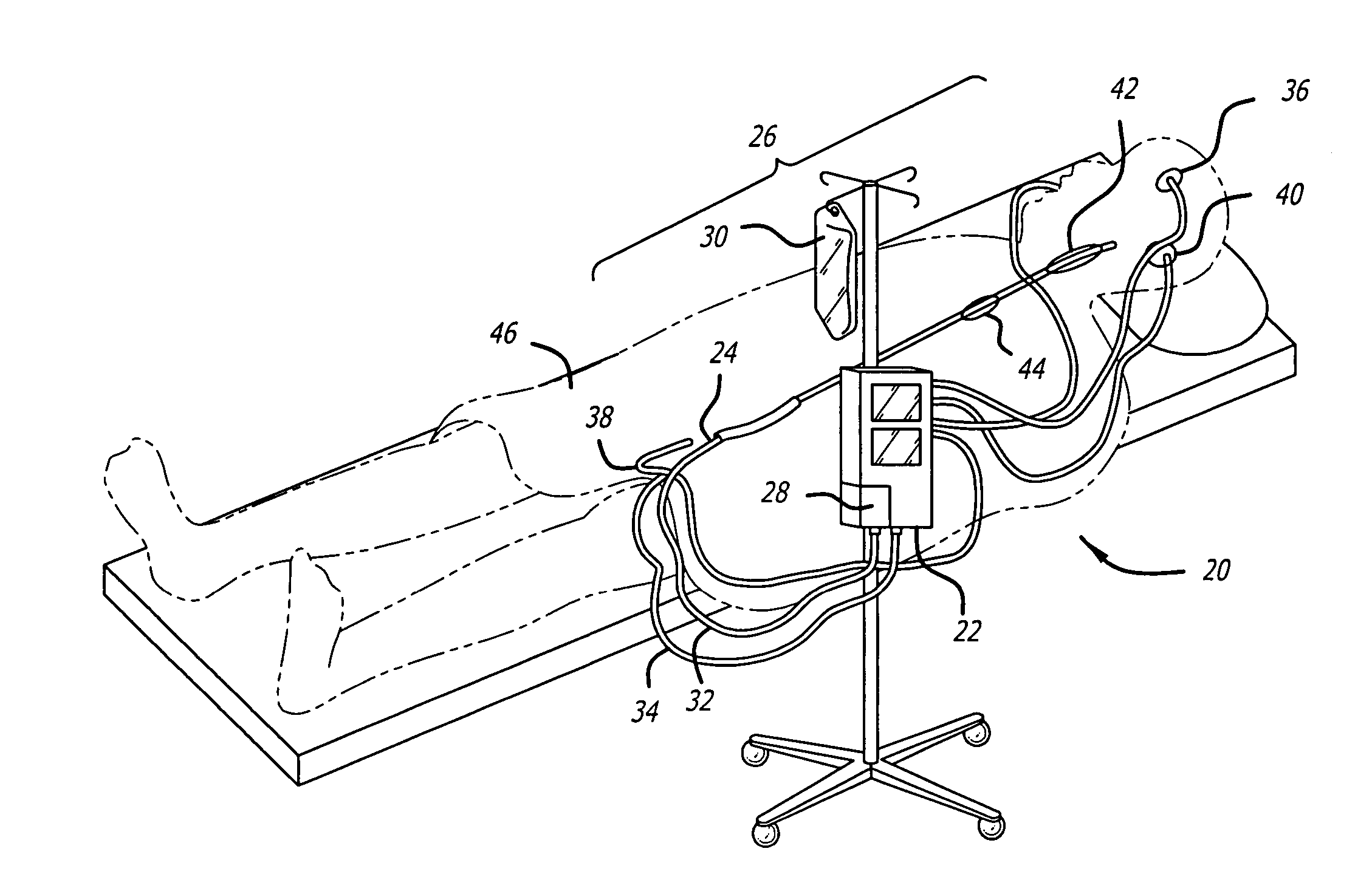

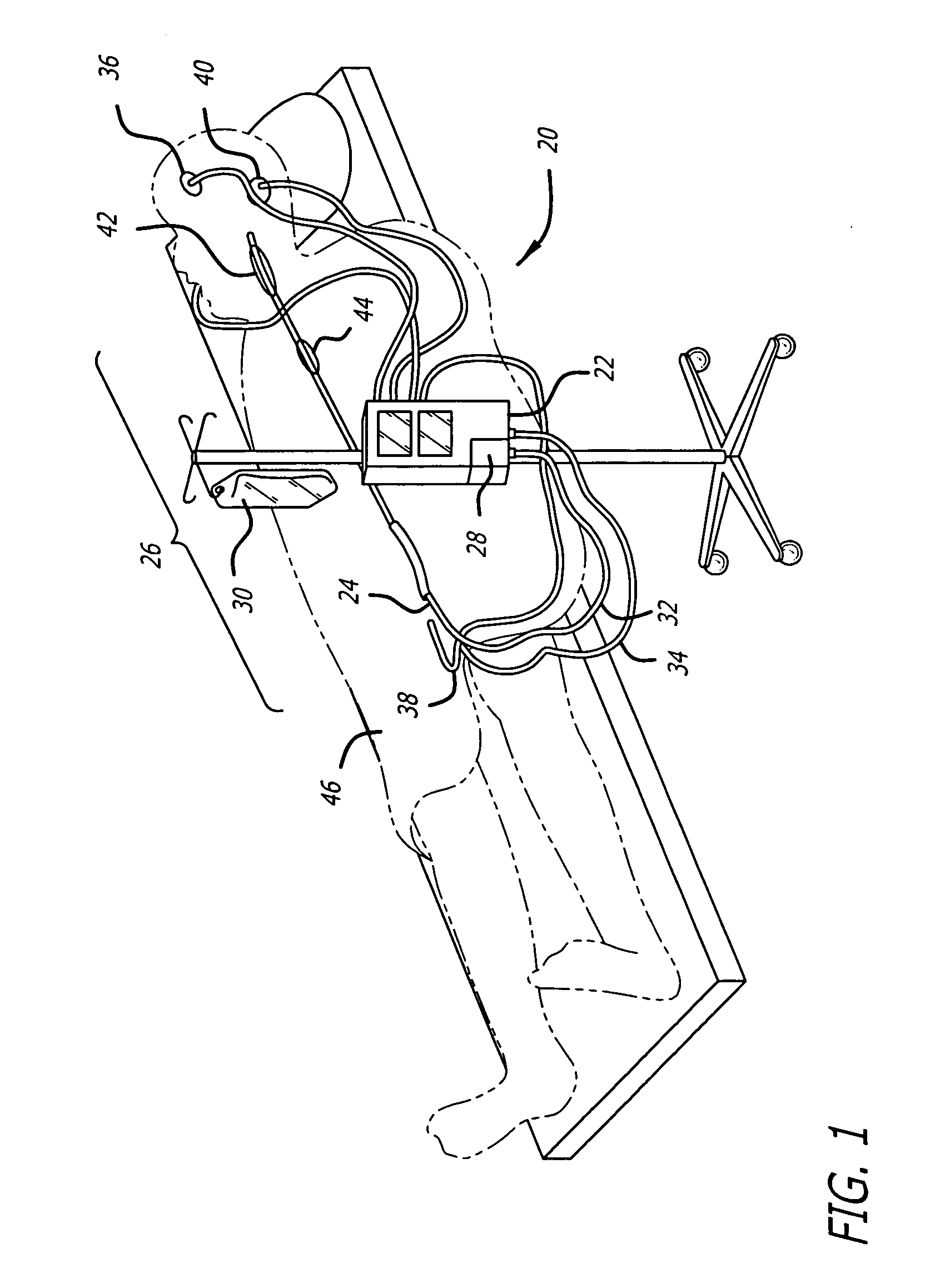

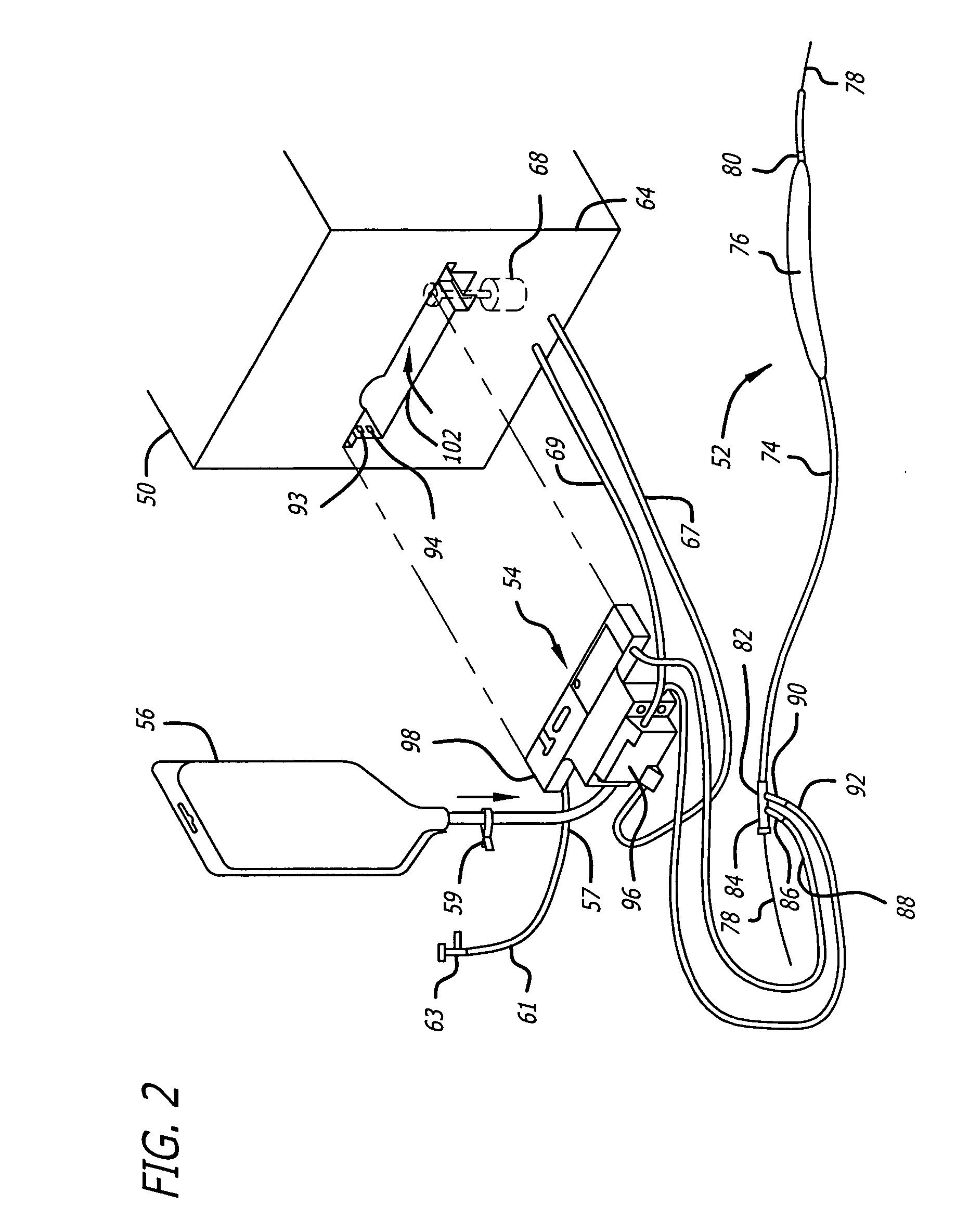

Apparatus and method for providing enhanced heat transfer from a body

ActiveUS20060293734A1Avoid possibilityIncrease volumeMedical devicesIndirect heat exchangersTemperature controlUser input

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette is attached to the circulatory conduits of the catheter, the heat exchange cassette being sized to engage a cavity within a control unit. The control unit includes a heater / cooler device for providing heated or cooled fluid to a heat exchanger in thermal communication with the fluid heat exchange medium circulating to the heat exchange catheter, a user input device, and a processor connected to receive input from various sensors around the body and the system. A temperature control scheme for ramping the body temperature up or down without overshoot is provided.

Owner:ZOLL CIRCULATION

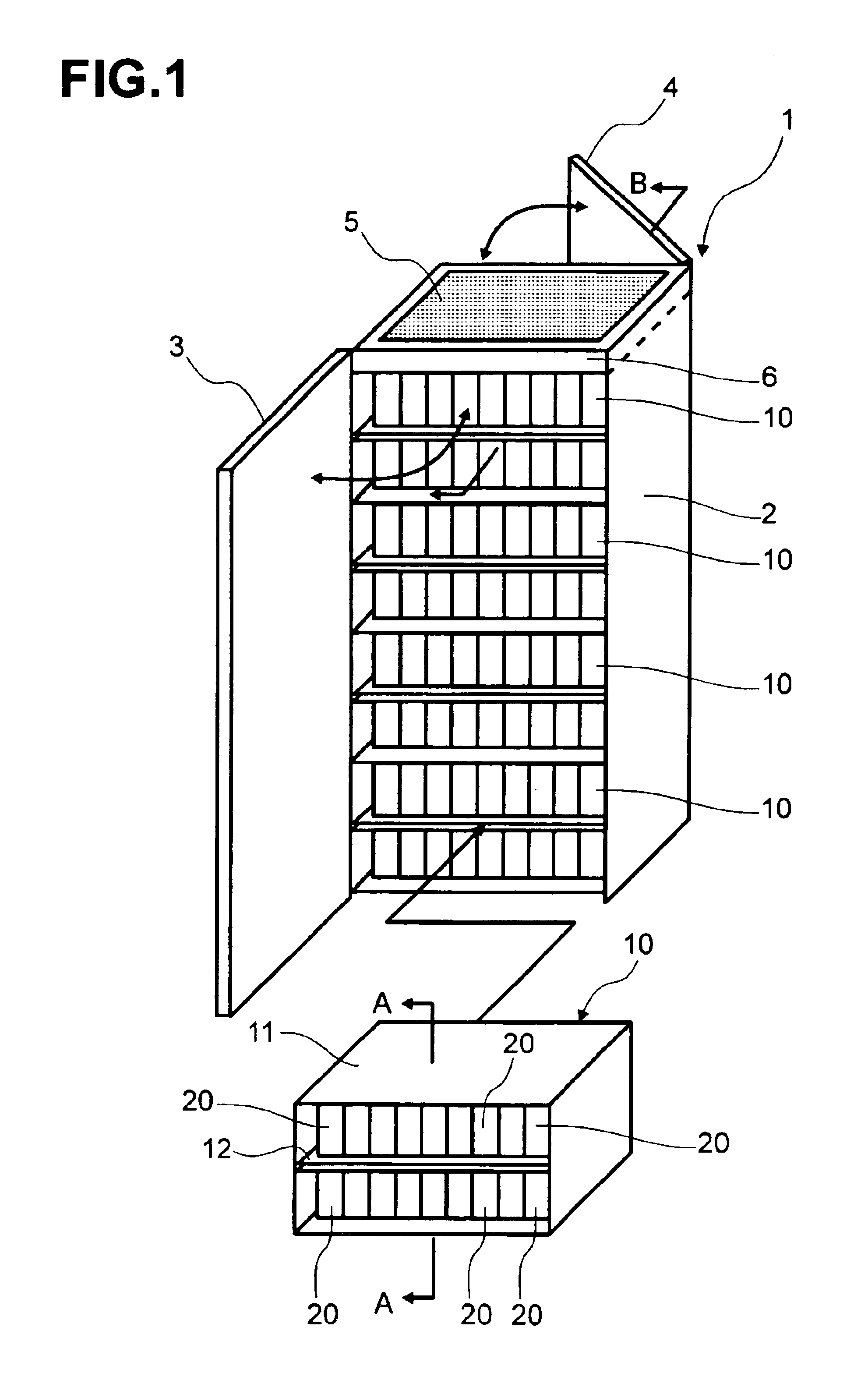

Cooling structure for disk storage device

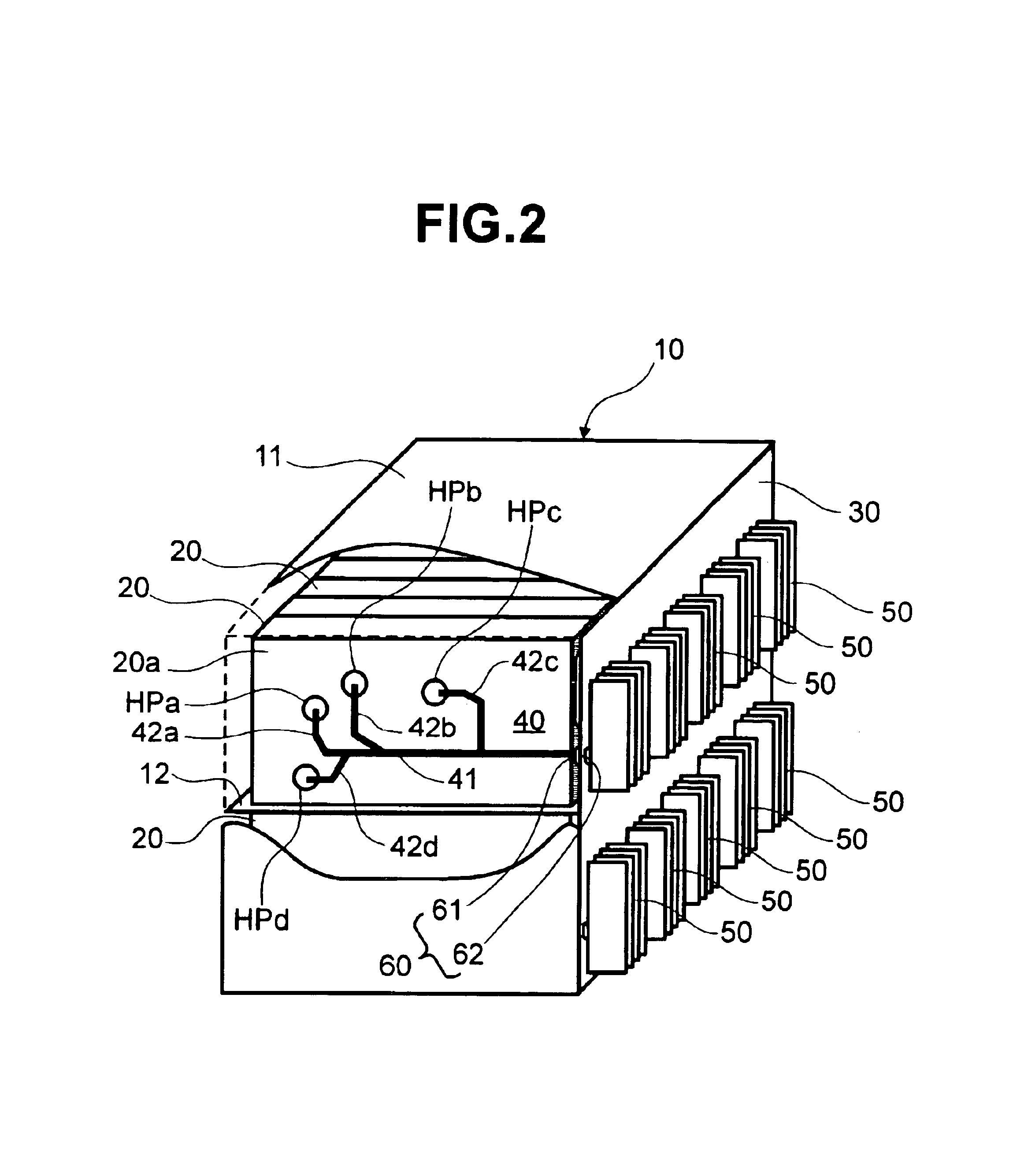

ActiveUS6927980B2Increase freedomImprove cooling effectReducing temperature influence on carrierDomestic cooling apparatusEngineeringSize reduction

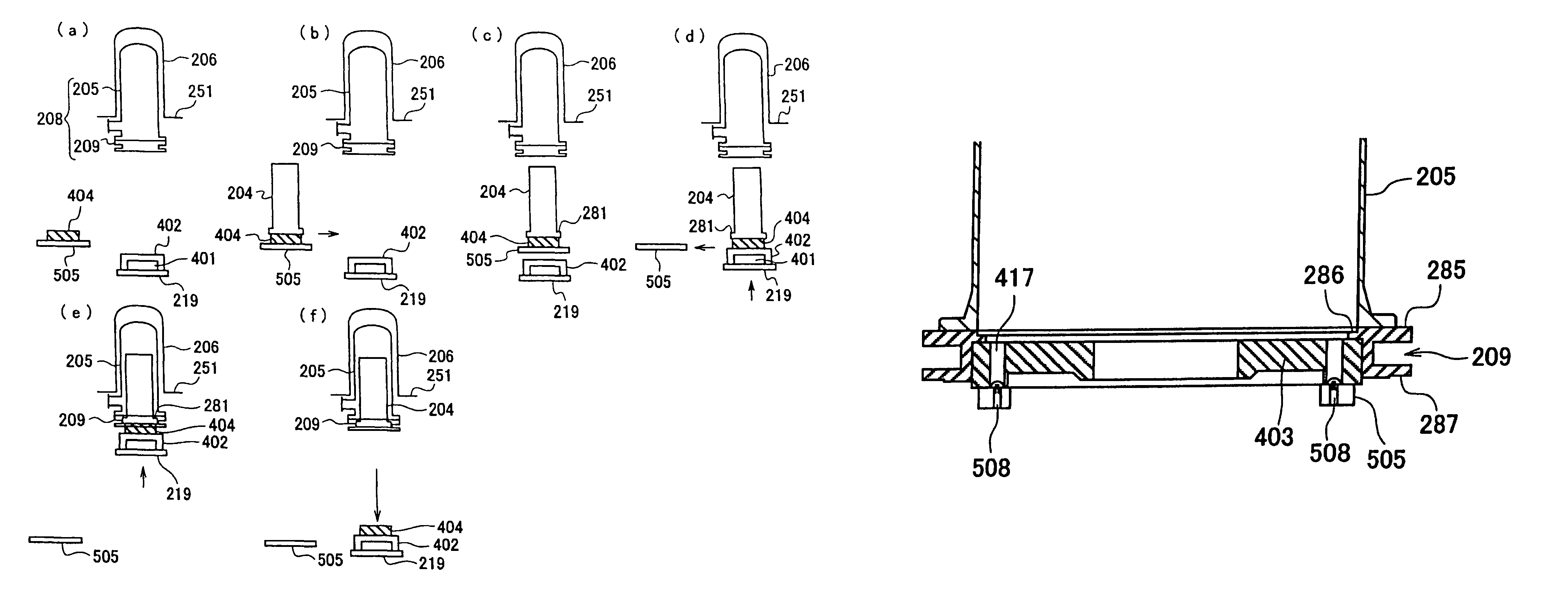

A disk drive box 10 accommodates a plurality of disk drives 20 within a case 11. A side face of each of the drives 20 is provided with a heat-absorbing part 40 including a heat pipe, corresponding to heat producing area HP. The heat taken away by the heat-absorbing part 40 is transmitted to a heat sink 50 of the rear of a backboard 30 via a heat connector 60. The heat sink 50 is cooled by cooling air flowing through an air duct 7. By cooling the drive 20 with the heat pipe, clearances between the drives 20 can be substantially eliminated, and it is made unnecessary to form an opening for air cooling in the backboard 30. Thus, size reduction is possible, and it is possible to increase the degree of freedom for a wiring pattern formed on the backboard 30.

Owner:GOOGLE LLC

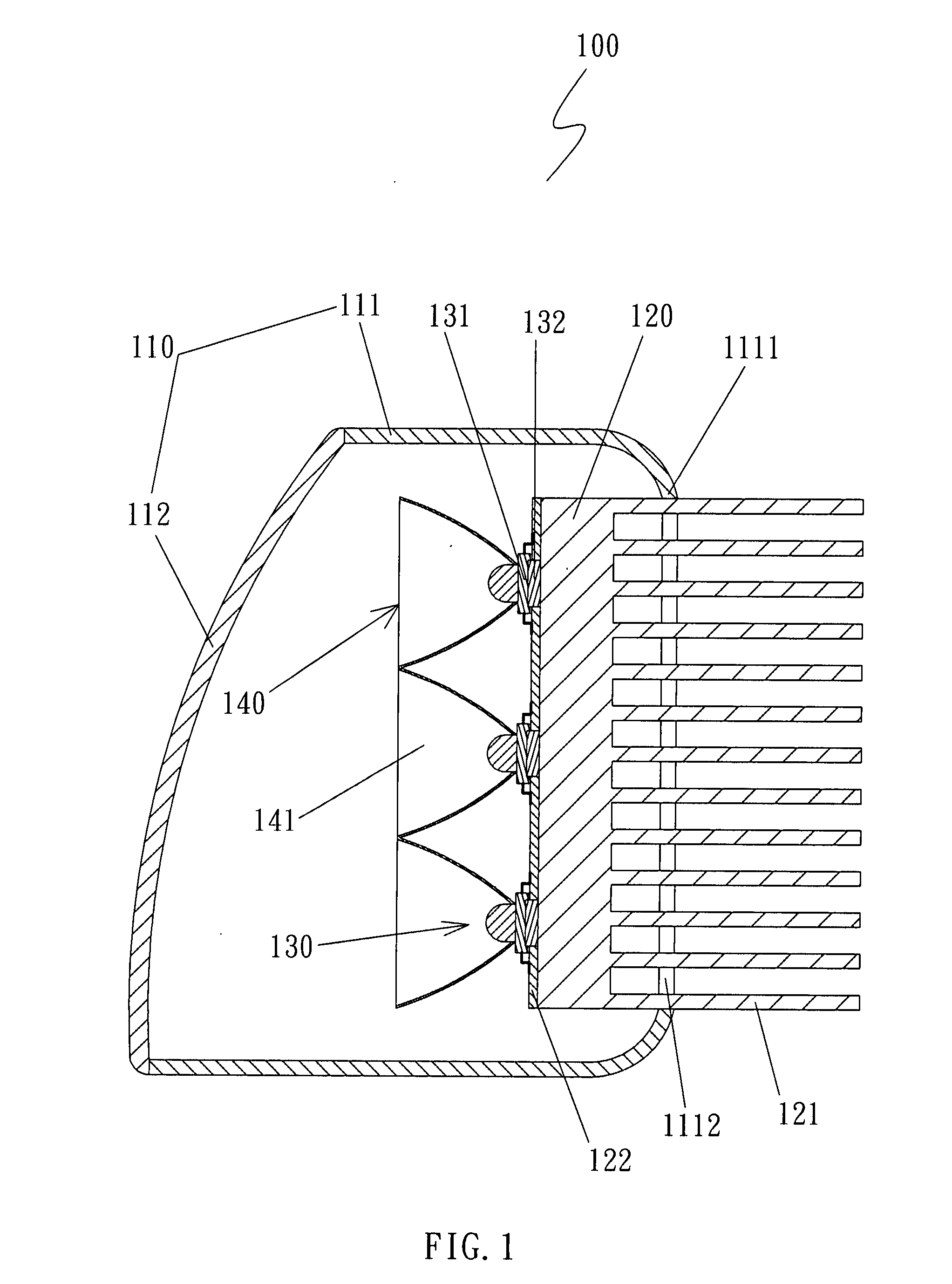

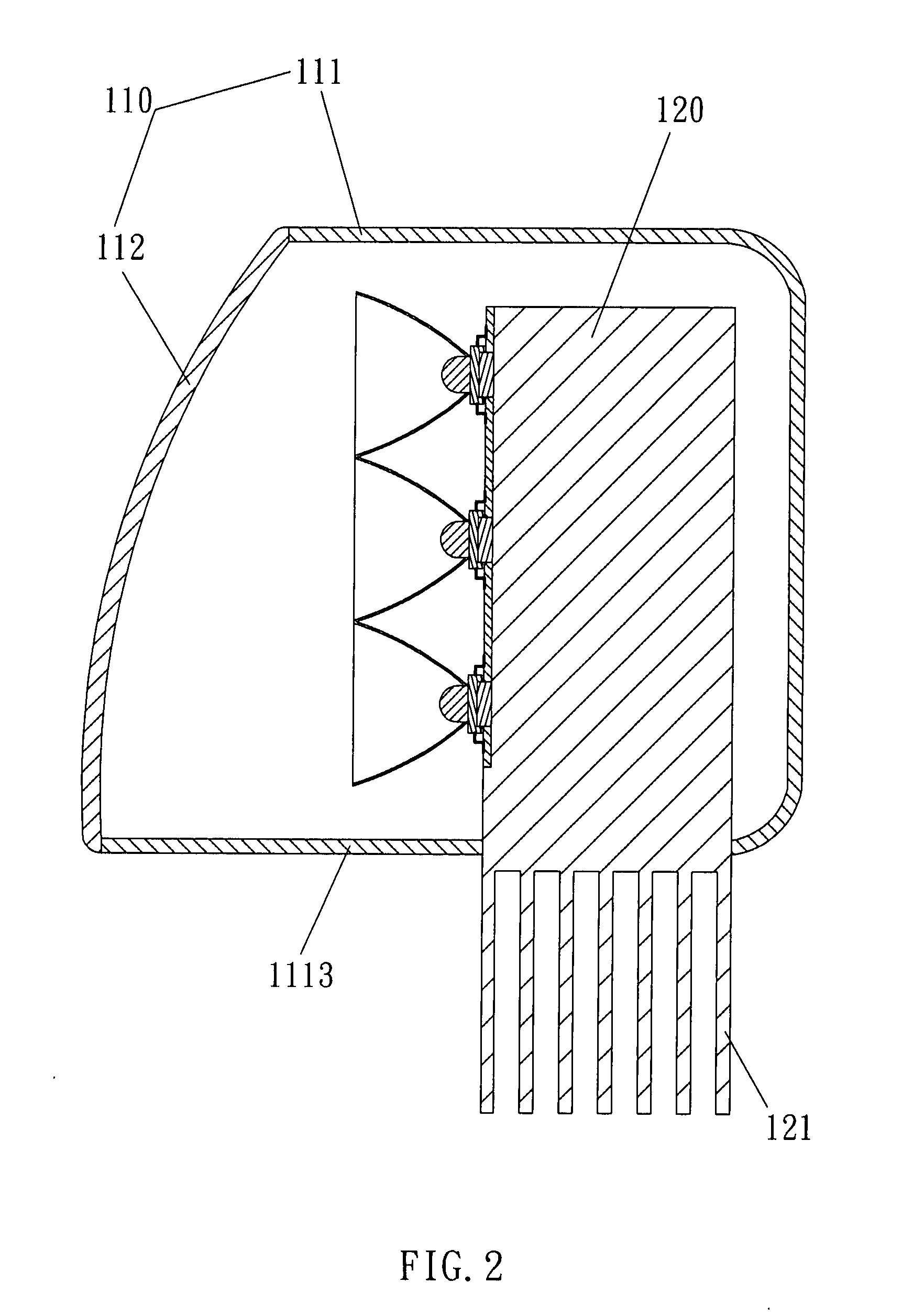

Heat dissipating apparatus for automotive LED lamp

InactiveUS20090059594A1Reduce the temperatureAvoid overall overheatingVehicle headlampsPoint-like light sourceCold airThermal energy

In a heat dissipating apparatus for an automotive LED lamp, the automotive LED lamp includes an automotive lamp set, a heat dissipating module, a plurality of LEDs, and a reflecting unit. The heat dissipating module is wrapped to form an insulation circuit for separating heat energy and electric power of the insulation circuit and heat dissipating module. The LED is electrically connected to the insulation circuit, and a main base of the LED installs a metal conducting plate for conducting the heat produced by the LED to the heat dissipating module. The reflecting unit is installed in the automotive lamp set, so that the heat dissipating module can use a cold air or a liquid coolant as the heat dissipating medium for dissipating heat, preventing a drop of light output caused by an overheat, and avoiding damages to the LED to extend the life expectancy of the automotive LED lamp.

Owner:YIH IND

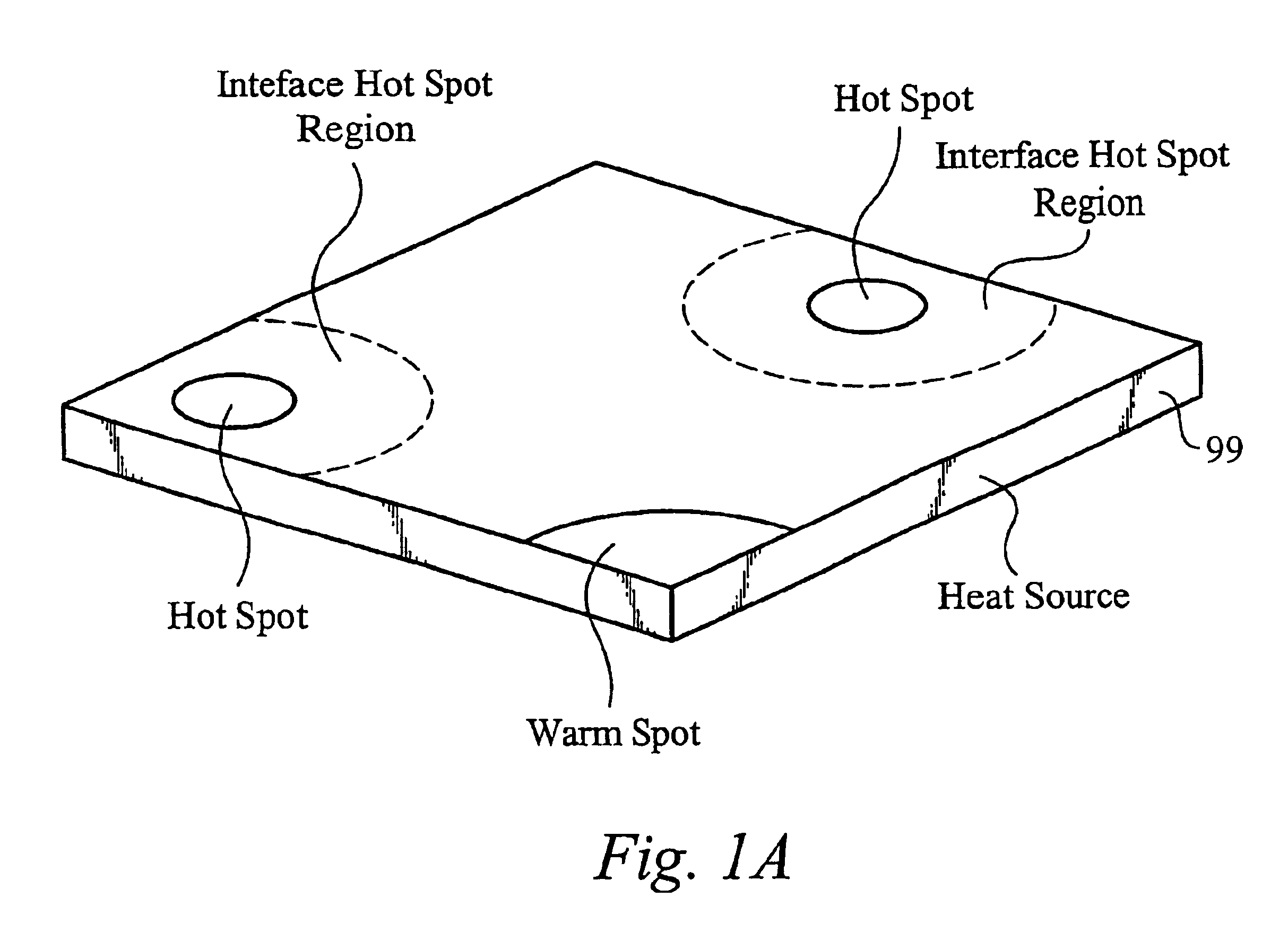

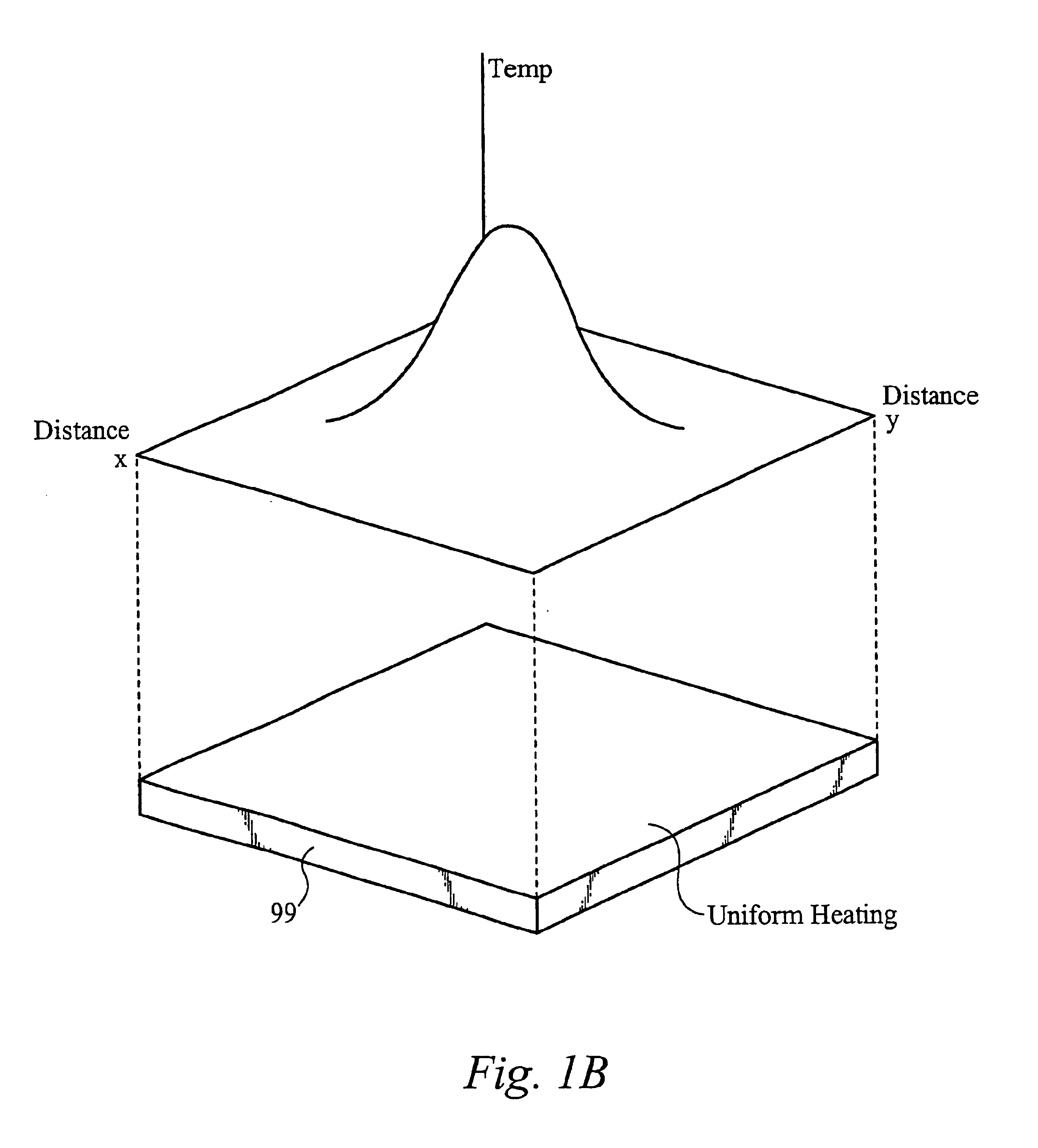

Method and apparatus for achieving temperature uniformity and hot spot cooling in a heat producing device

ActiveUS7104312B2Minimize temperature differenceTemperatue controlSemiconductor/solid-state device detailsTemperature differenceEngineering

A method of controlling temperature of a heat source in contact with a heat exchanging surface of a heat exchanger, wherein the heat exchanging surface is substantially aligned along a plane. The method comprises channeling a first temperature fluid to the heat exchanging surface, wherein the first temperature fluid undergoes thermal exchange with the heat source along the heat exchanging surface. The method comprises channeling a second temperature fluid from the heat exchange surface, wherein fluid is channeled to minimize temperature differences along the heat source. The temperature differences are minimized by optimizing and controlling the fluidic and thermal resistances in the heat exchanger. The resistances to the fluid are influenced by size, volume and surface area of heat transferring features, multiple pumps, fixed and variable valves and flow impedance elements in the fluid path, pressure and flow rate control of the fluid, and other factors.

Owner:VERTIV CORP

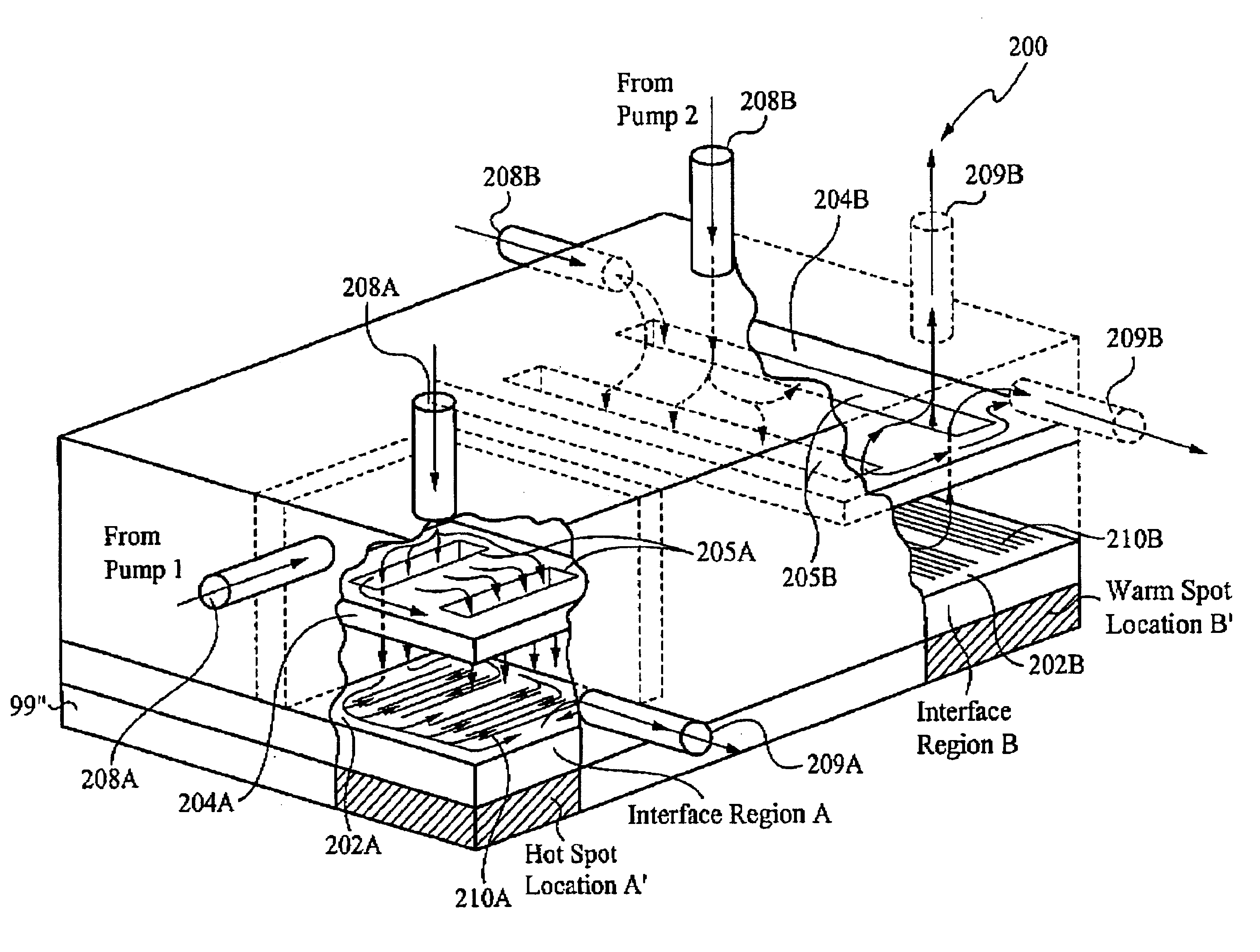

Method and apparatus for flexible fluid delivery for cooling desired hot spots in a heat producing device

InactiveUS6988534B2Temperatue controlSemiconductor/solid-state device detailsInter layerInterface layer

A heat exchanger apparatus and method of manufacturing comprising: an interface layer for cooling a heat source and configured to pass fluid therethrough, the interface layer having an appropriate thermal conductivity and a manifold layer for providing fluid to the interface layer, wherein the manifold layer is configured to achieve temperature uniformity in the heat source preferably by cooling interface hot spot regions. A plurality of fluid ports are configured to the heat exchanger such as an inlet port and outlet port, whereby the fluid ports are configured vertically and horizontally. The manifold layer circulates fluid to a predetermined interface hot spot region in the interface layer, wherein the interface hot spot region is associated with the hot spot. The heat exchanger preferably includes an intermediate layer positioned between the interface and manifold layers and optimally channels fluid to the interface hot spot region.

Owner:VERTIV CORP

Popular searches

Couplings bases/cases Pumps Printed circuits Semiconductor devices Electrical apparatus casings/cabinets/drawers Substation/switching arrangement cooling/ventilation Heat exchange apparatus Liquid fuel engine components Non-positive displacement fluid engines Drying machines with non-progressive movements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com