Patents

Literature

11976results about "Drying machines with non-progressive movements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

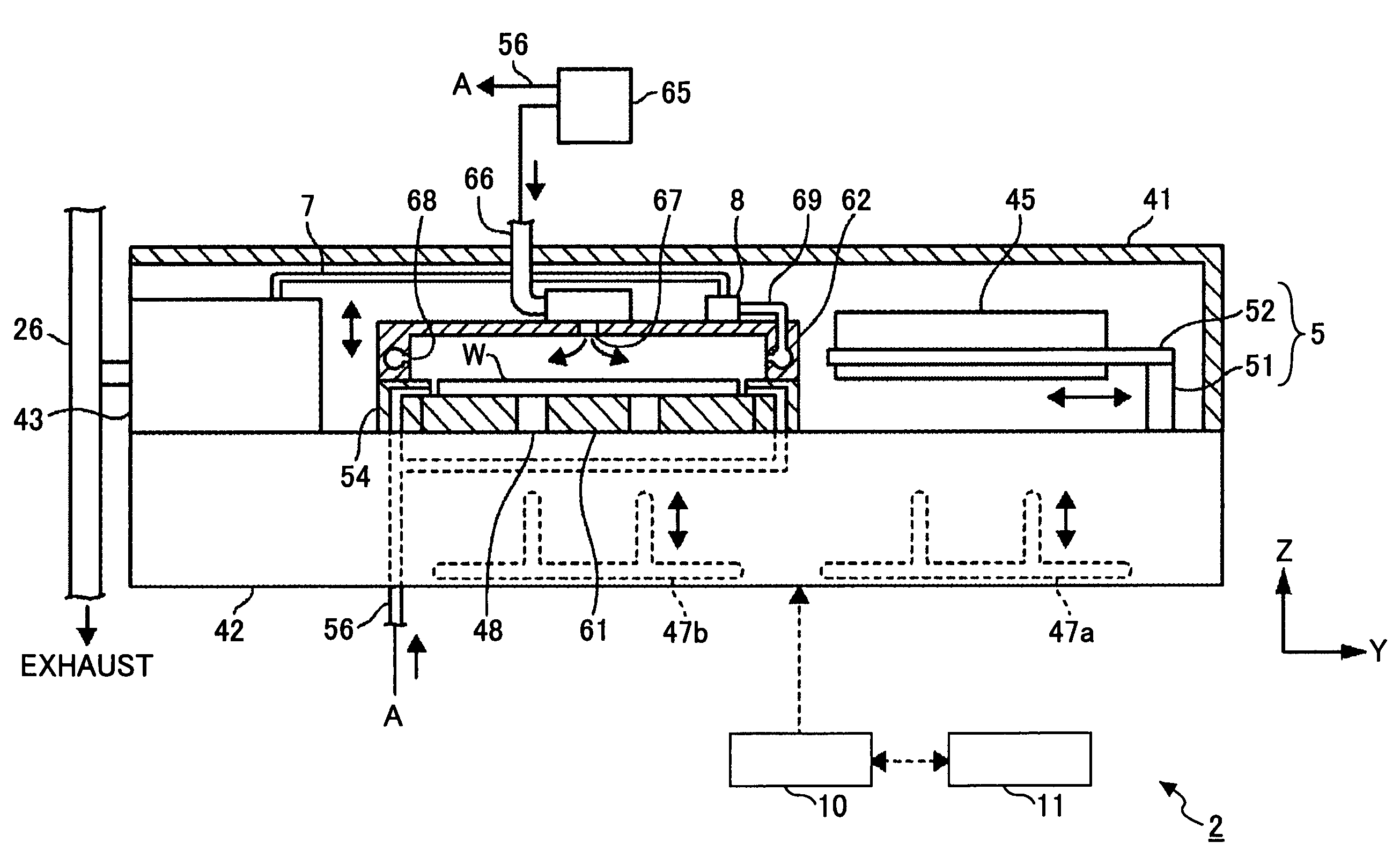

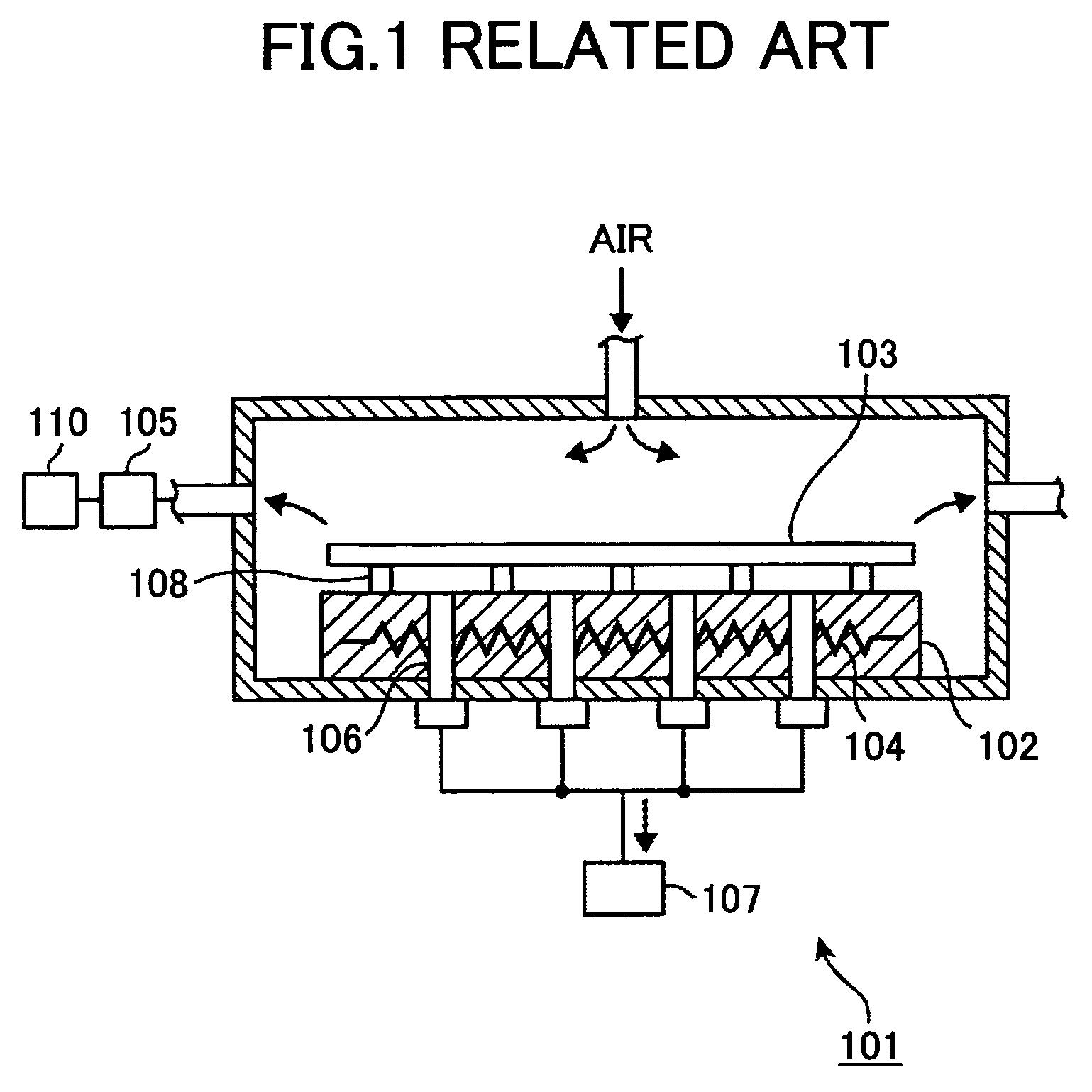

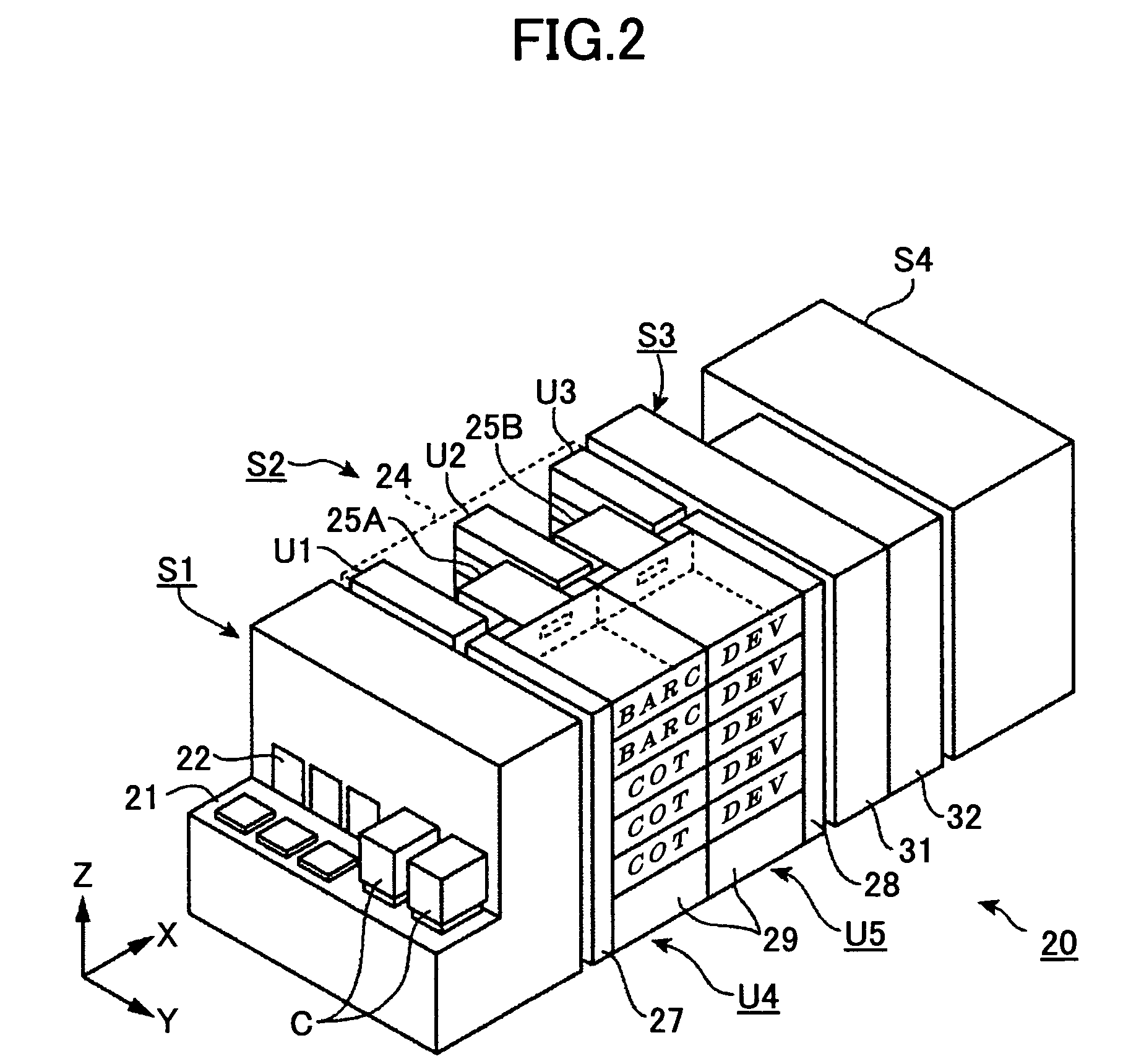

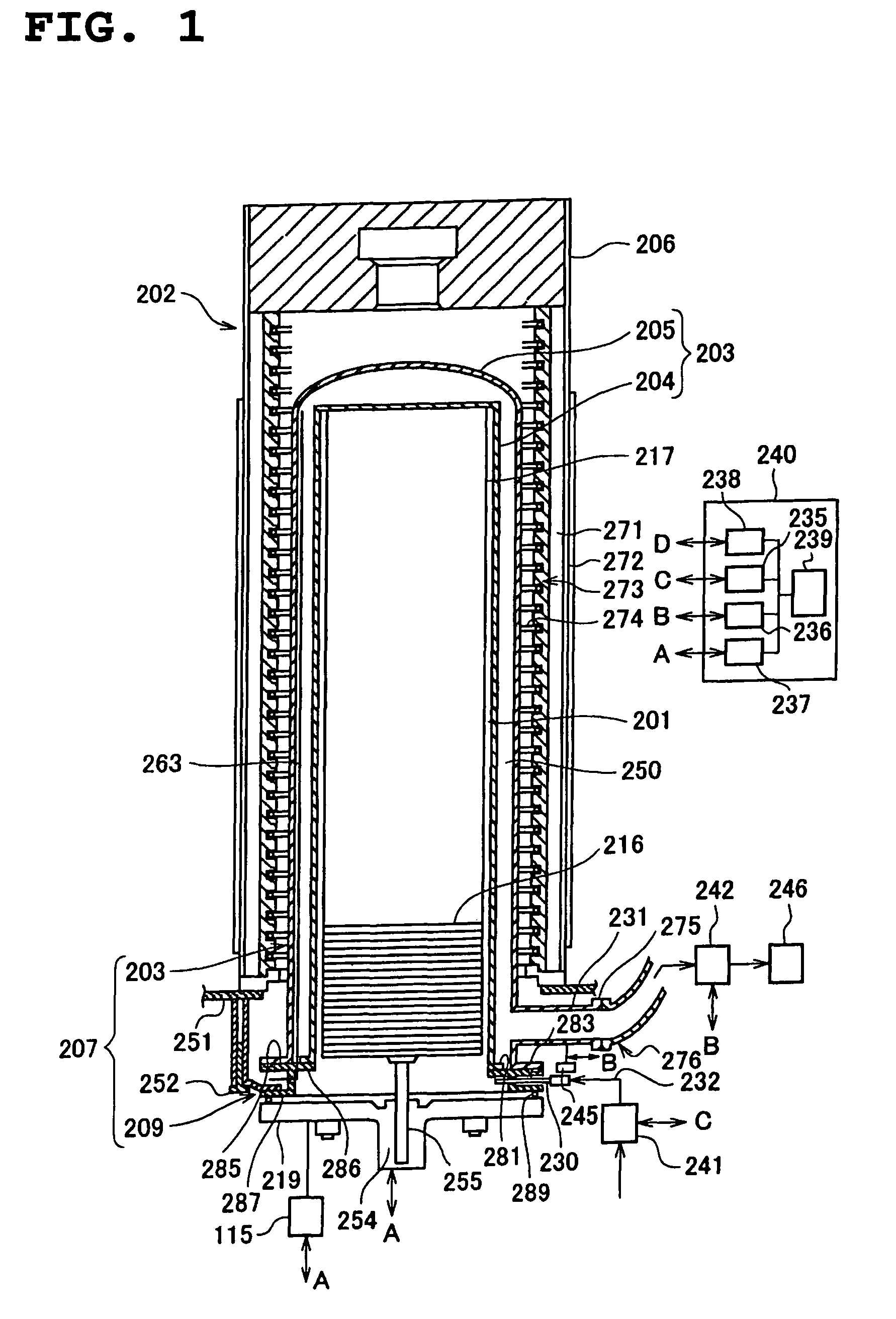

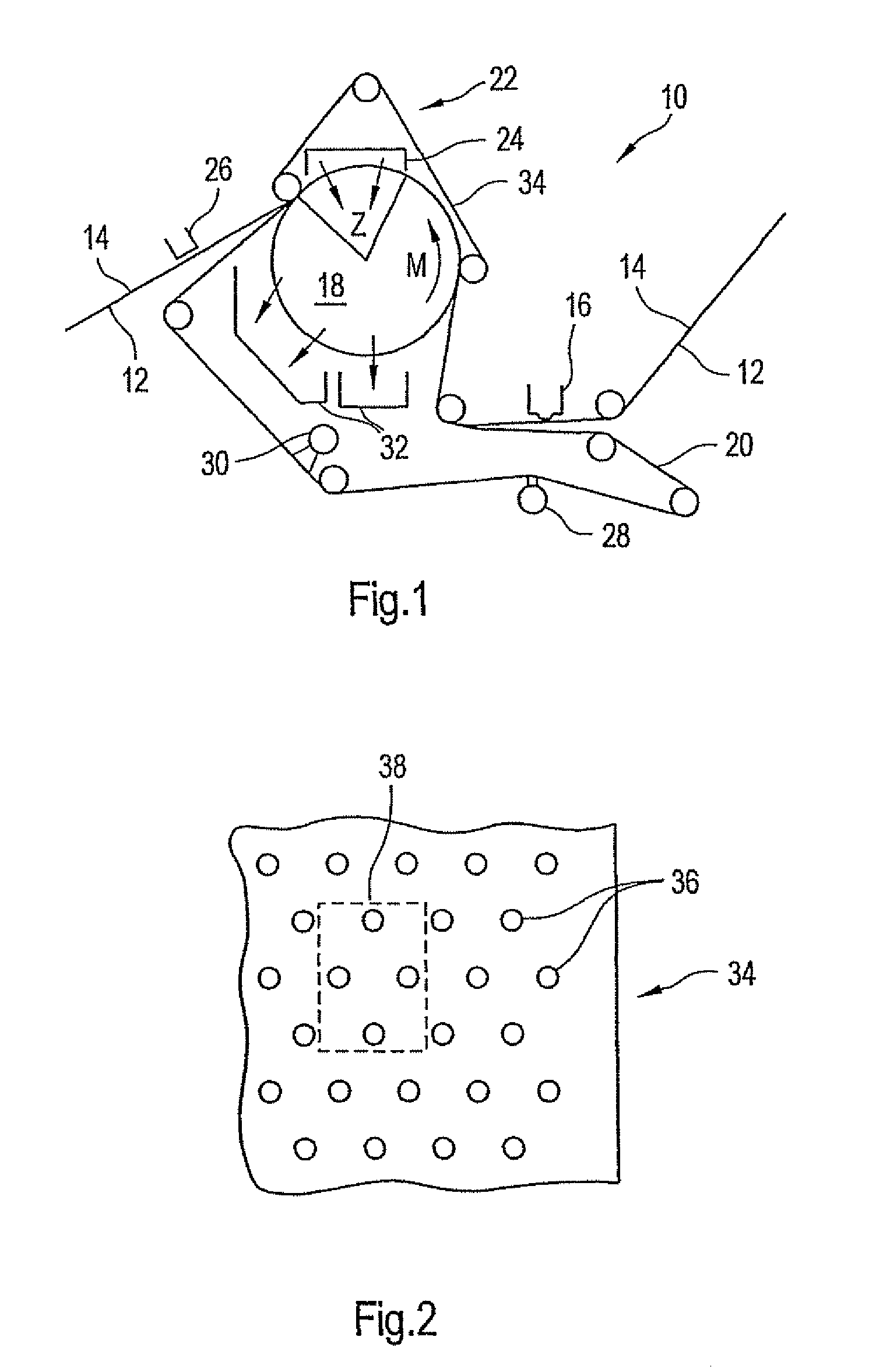

Heating apparatus, heating method, and computer readable storage medium

ActiveUS7992318B2Improve temperature uniformityDryer sectionDrying gas arrangementsProcess engineeringGas supply

A disclosed heating apparatus for heating a substrate on which a film is coated includes a process chamber having a gas supply opening for supplying a first gas to the process chamber and a gas evacuation opening for evacuating the first gas from the process chamber; a heating plate that is arranged in the process chamber and includes a heating element for heating the substrate; plural protrusions arranged on the heating plate so as to support the substrate; plural suction holes formed in the heating plate so as to attract by suction the substrate toward the heating plate; and a gas inlet adapted to supply a second gas to a gap between the heating plate and the substrate supported by the plural protrusions.

Owner:TOKYO ELECTRON LTD

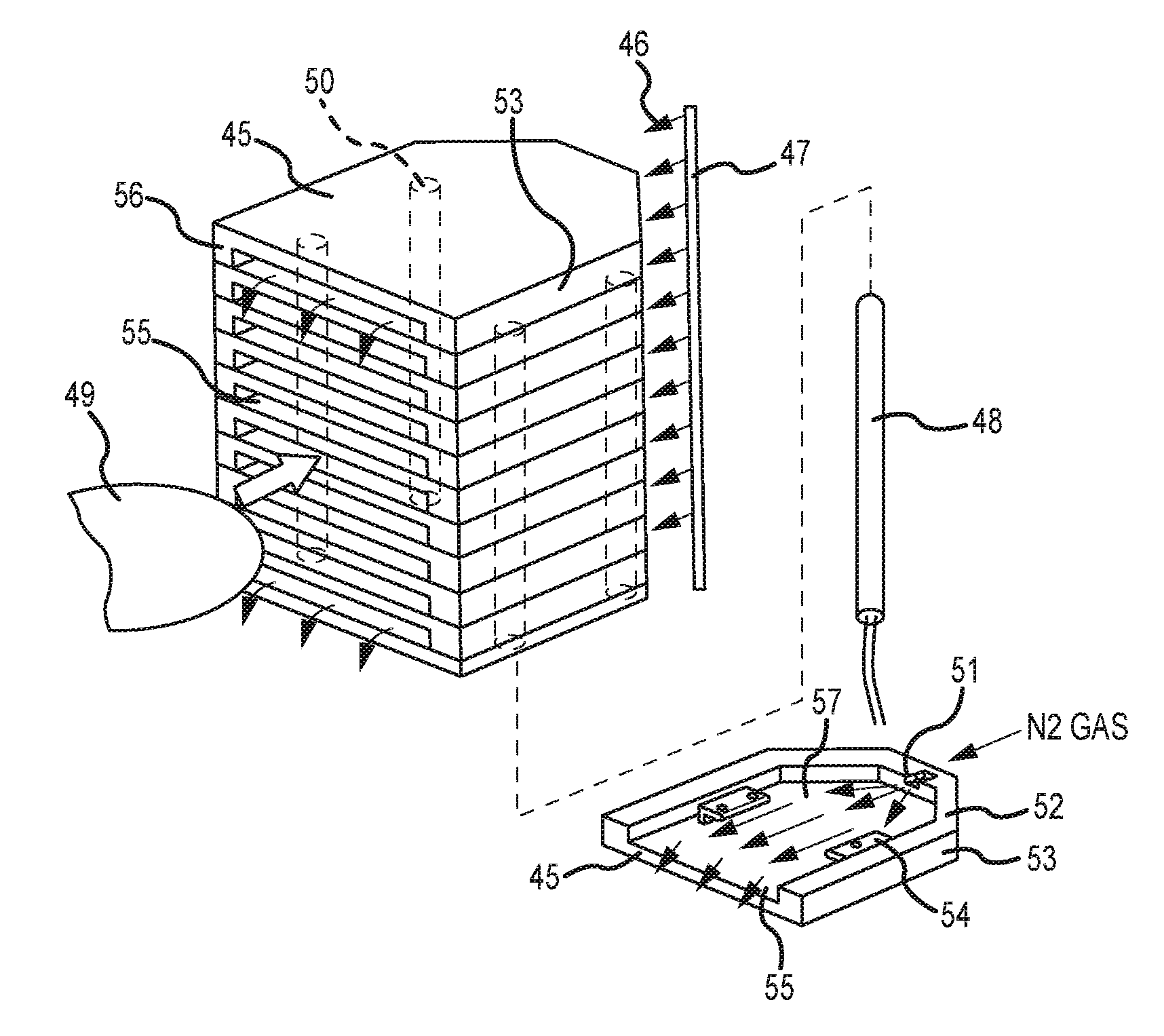

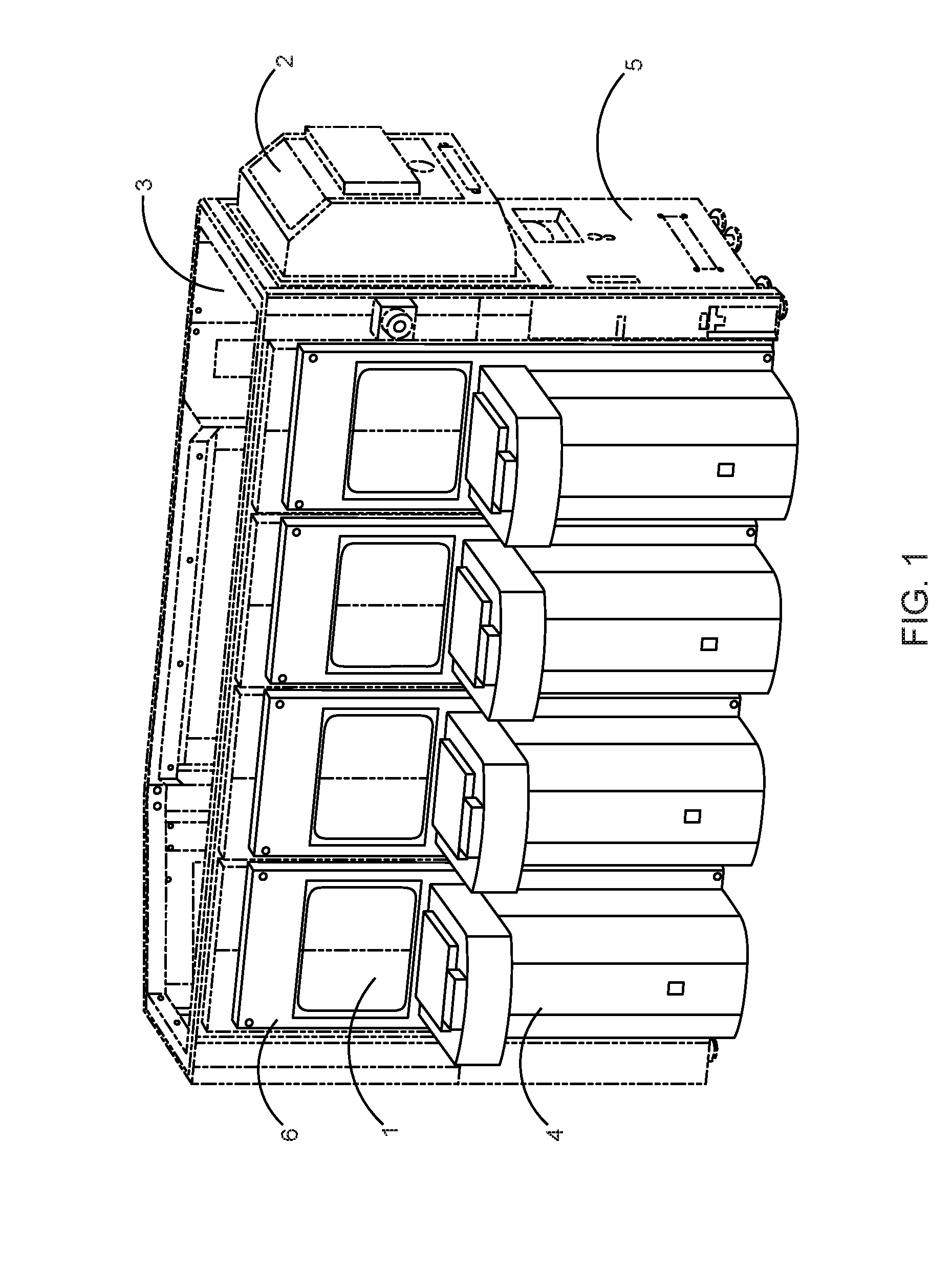

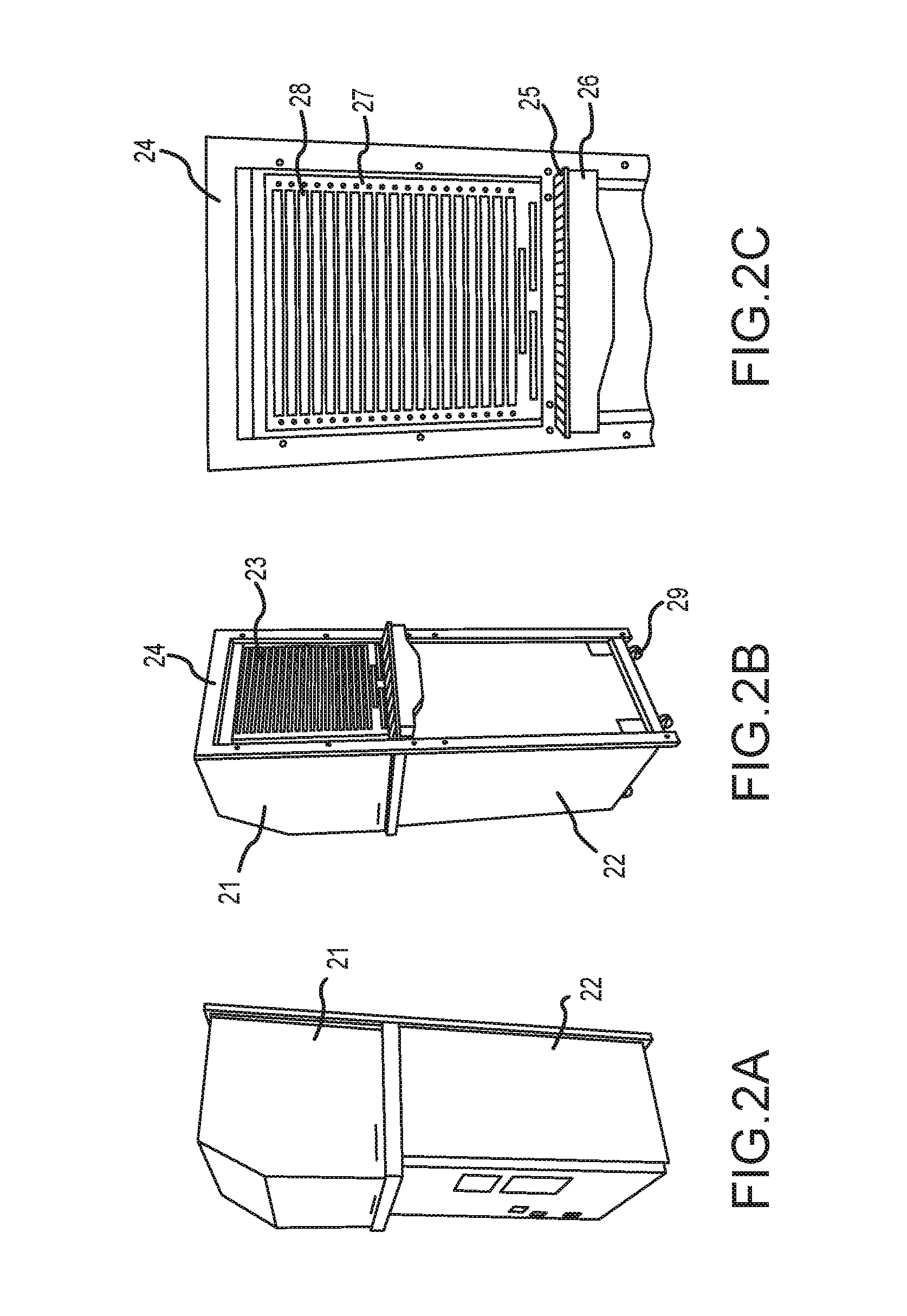

Apparatus and method for pre-baking substrate upstream of process chamber

ActiveUS9349620B2Efficient heatingGuaranteed uptimeSemiconductor/solid-state device manufacturingFurnace typesCooking & bakingInjection port

A pre-baking apparatus for heating a substrate upstream of a process tool is adapted to be connected to an EFEM (equipment front end module) and includes: a chamber which has a front face with multiple slots arranged in a height direction of the chamber, and which is divided into multiple compartments extending from the multiple slots, respectively, toward a rear end of the chamber for loading and unloading substrates; and a connecting frame for connecting the chamber to the process tool. The multiple compartments are separated from each other by a divider plate and provided with heaters for heating the multiple compartments, and each compartment has a gas injection port for blowing a hot inert gas over the substrate placed therein toward the slot.

Owner:ASM IP HLDG BV

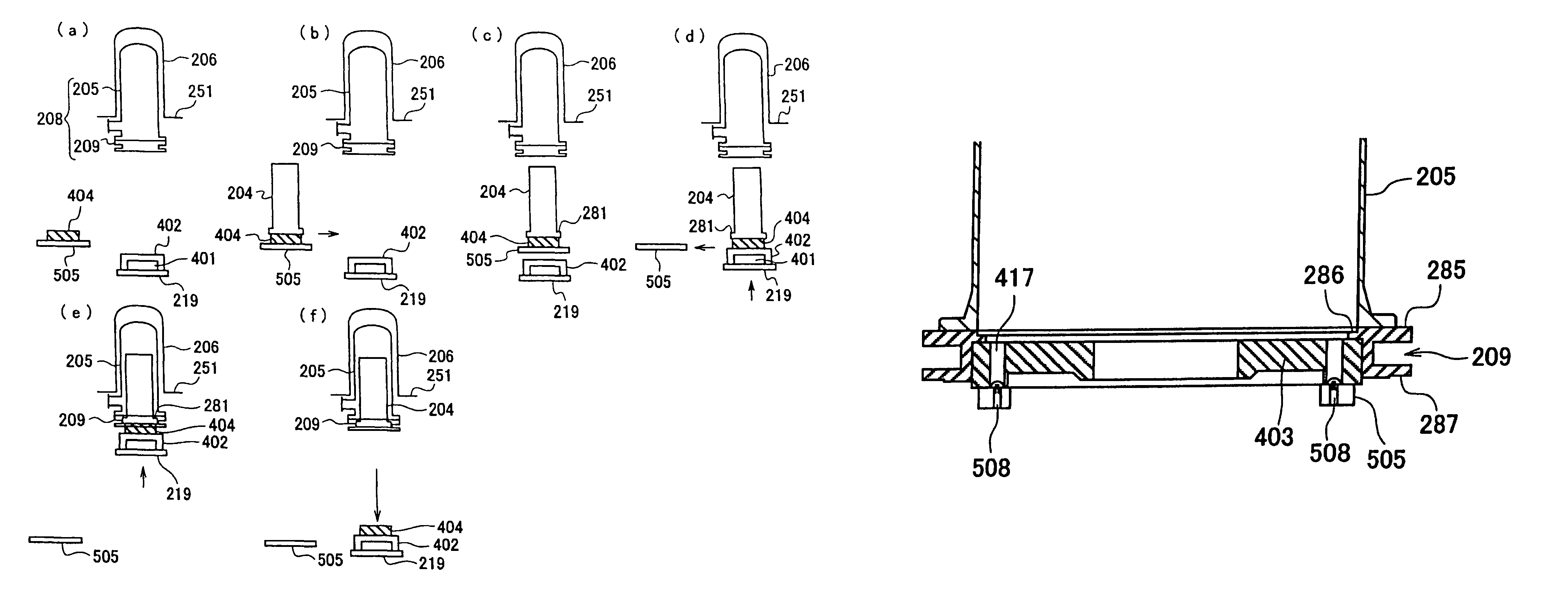

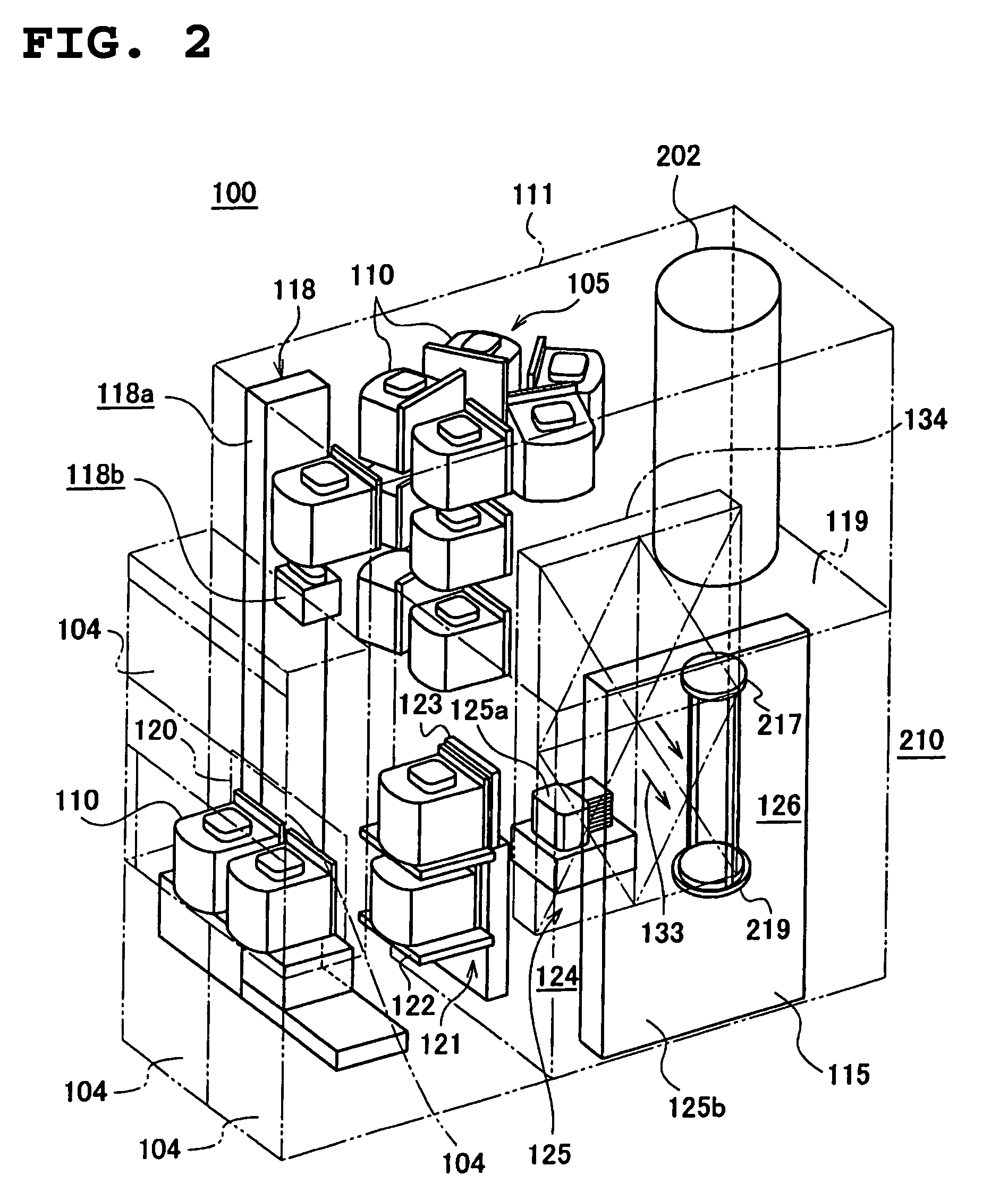

Substrate processing apparatus and attaching/detaching method of reaction vessel

ActiveUS8172947B2Linings repairSemiconductor/solid-state device manufacturingEngineeringMental detachment

Owner:KOKUSA ELECTRIC CO LTD

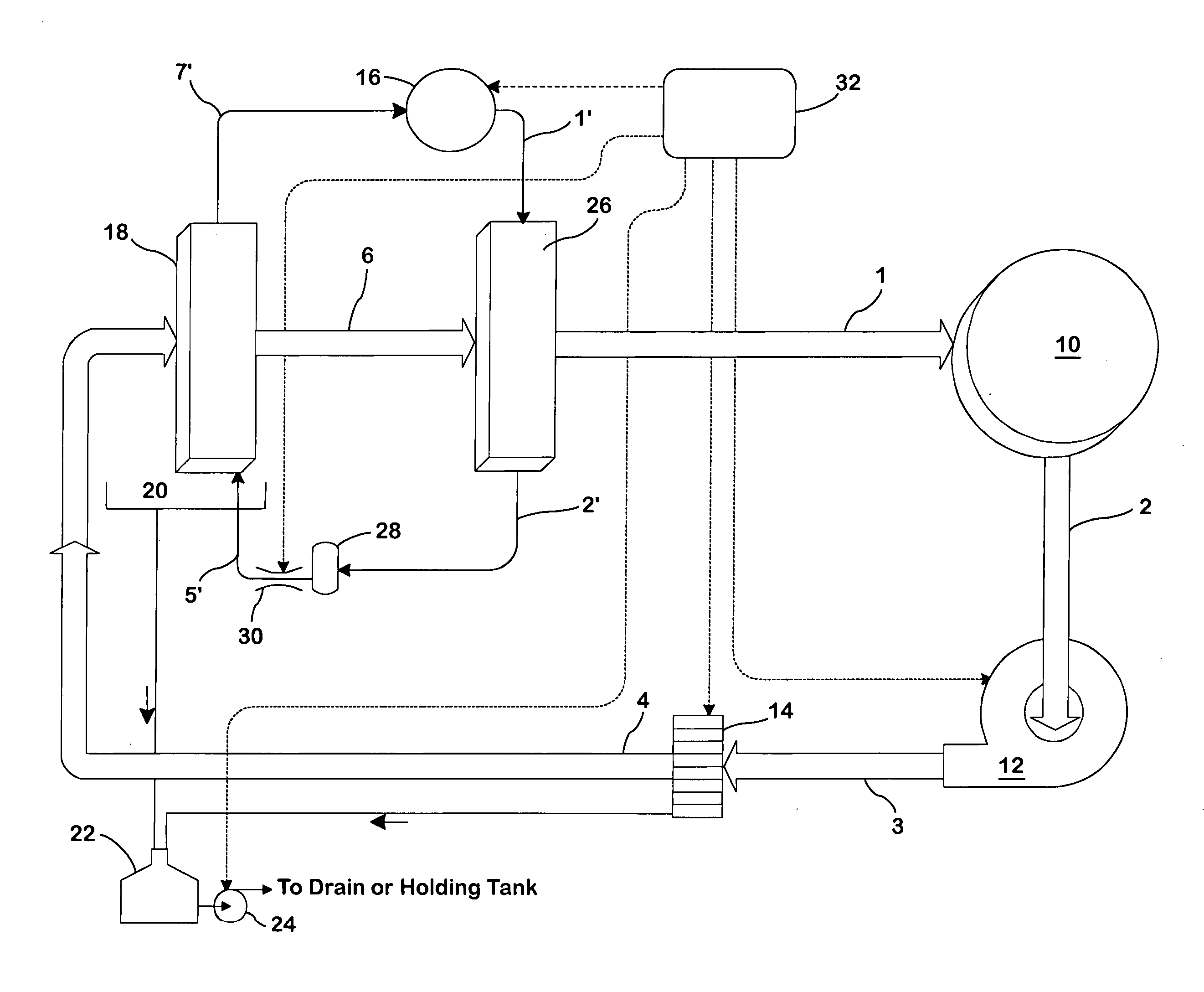

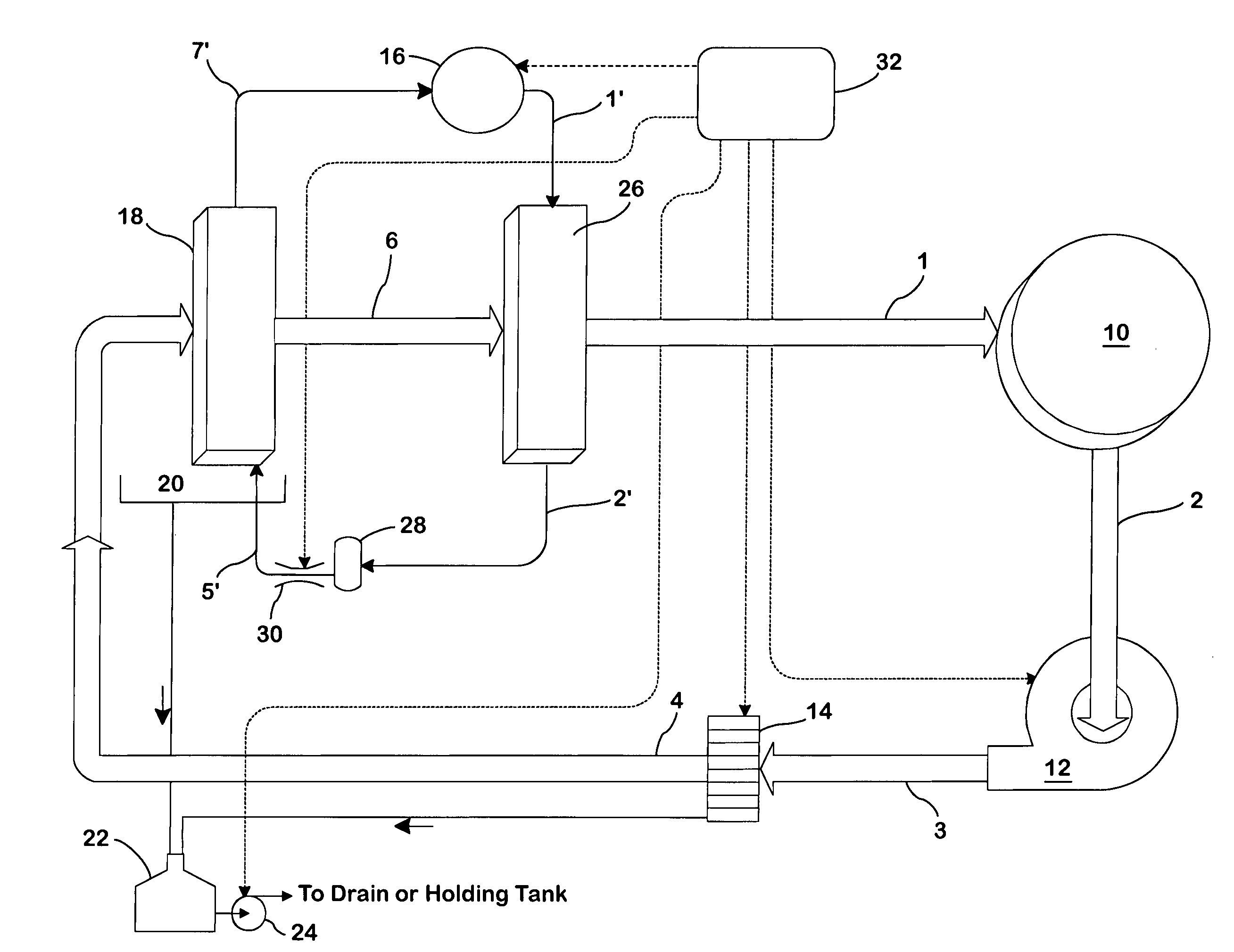

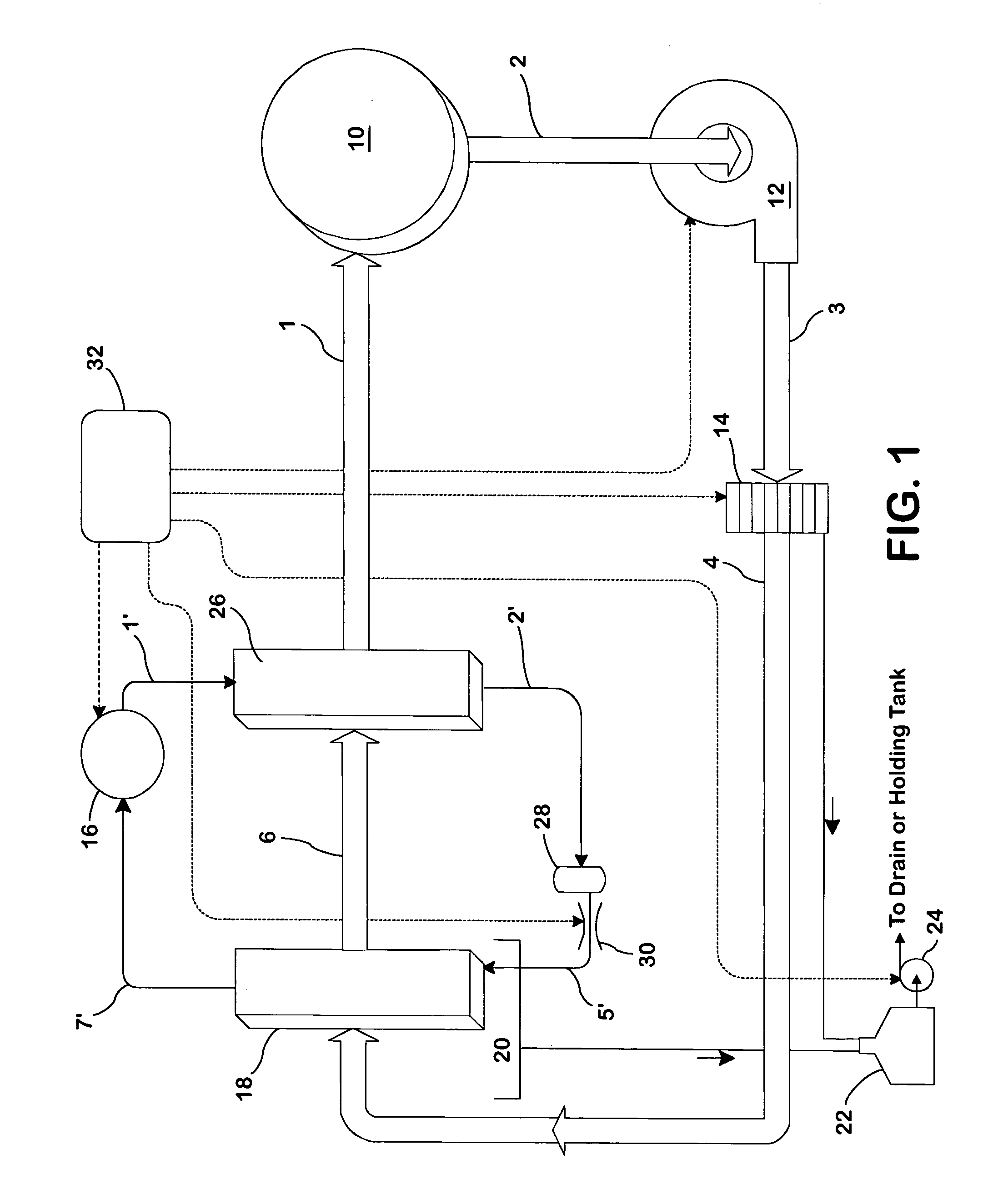

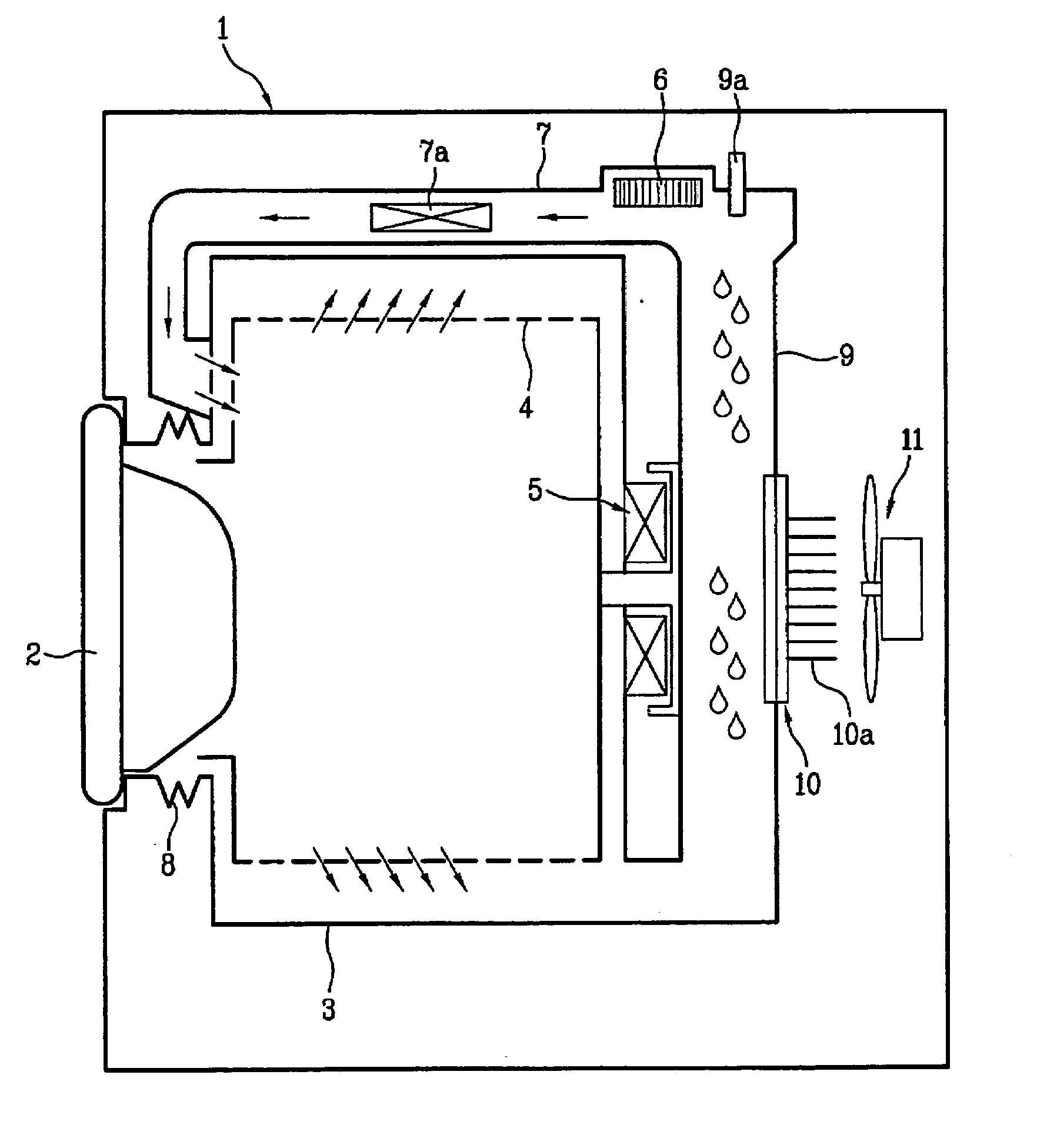

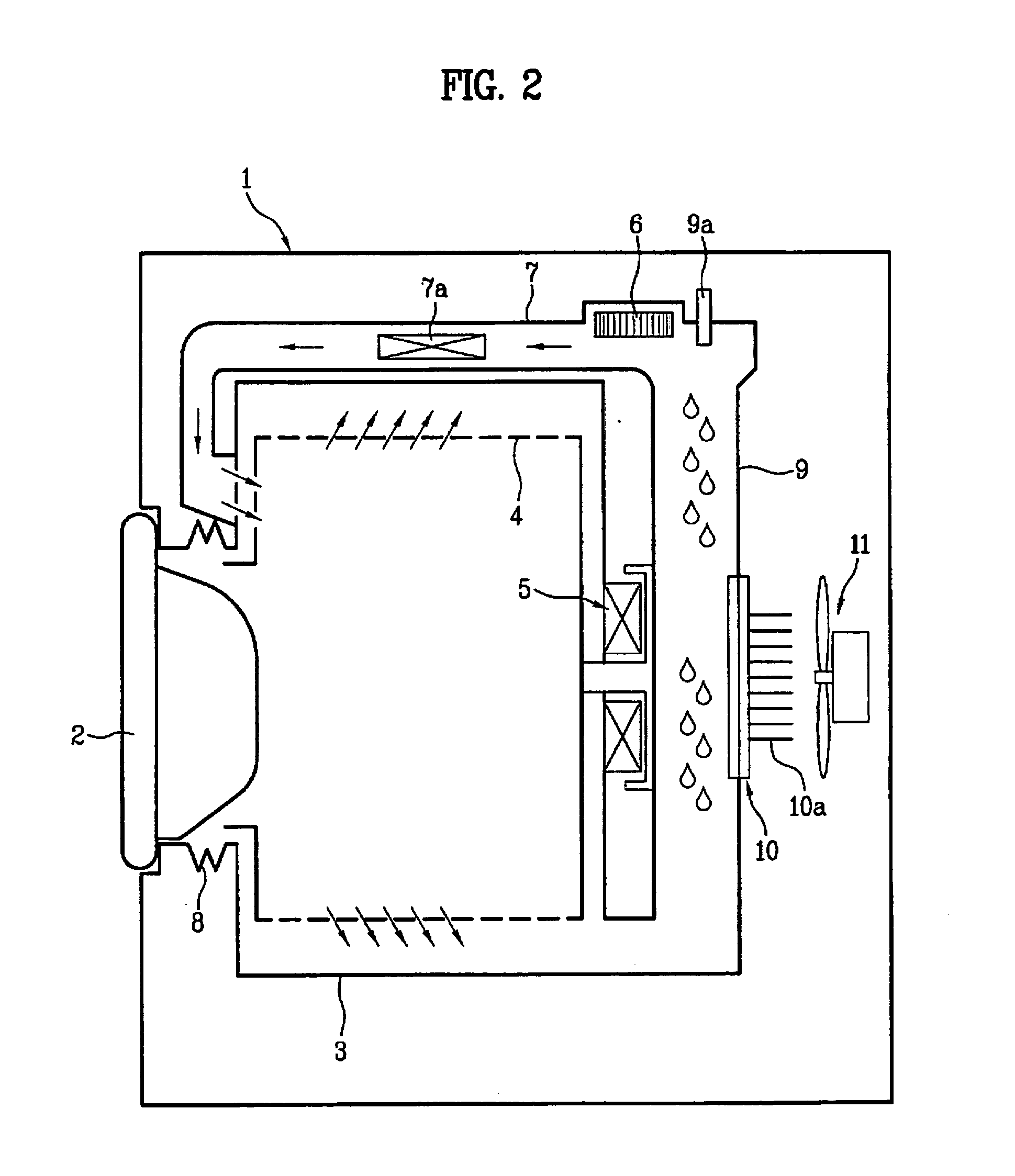

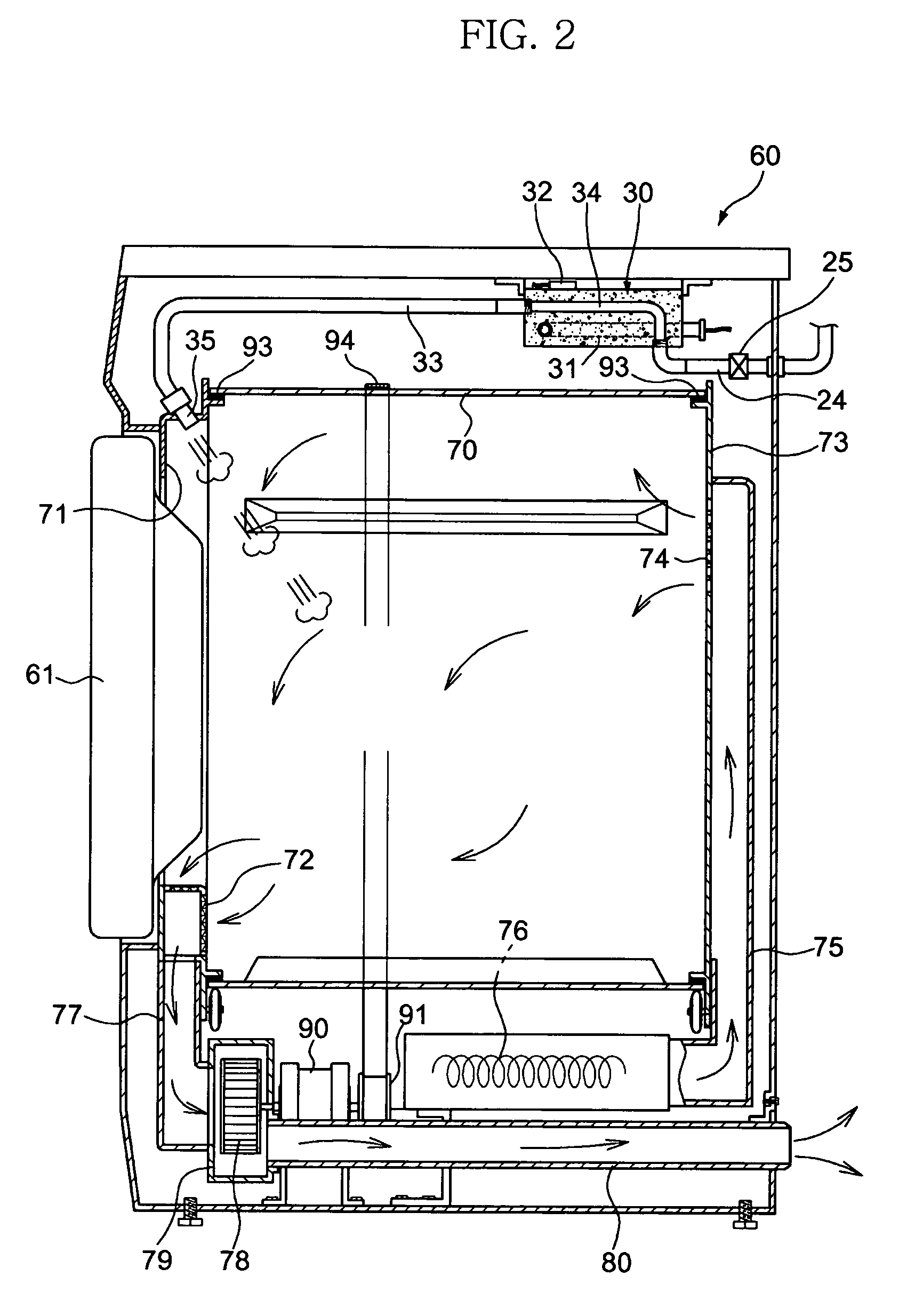

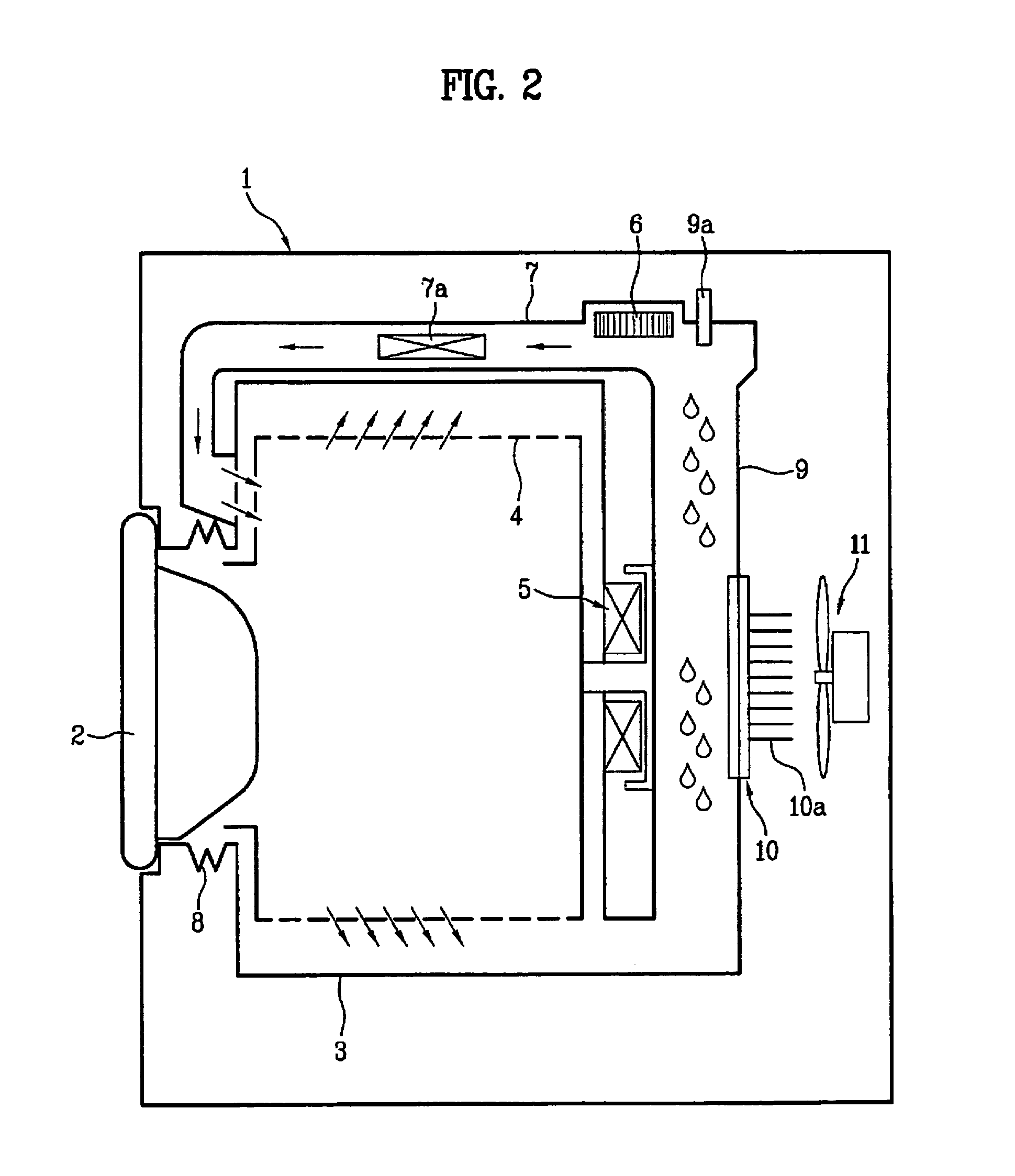

Heat pump clothes dryer

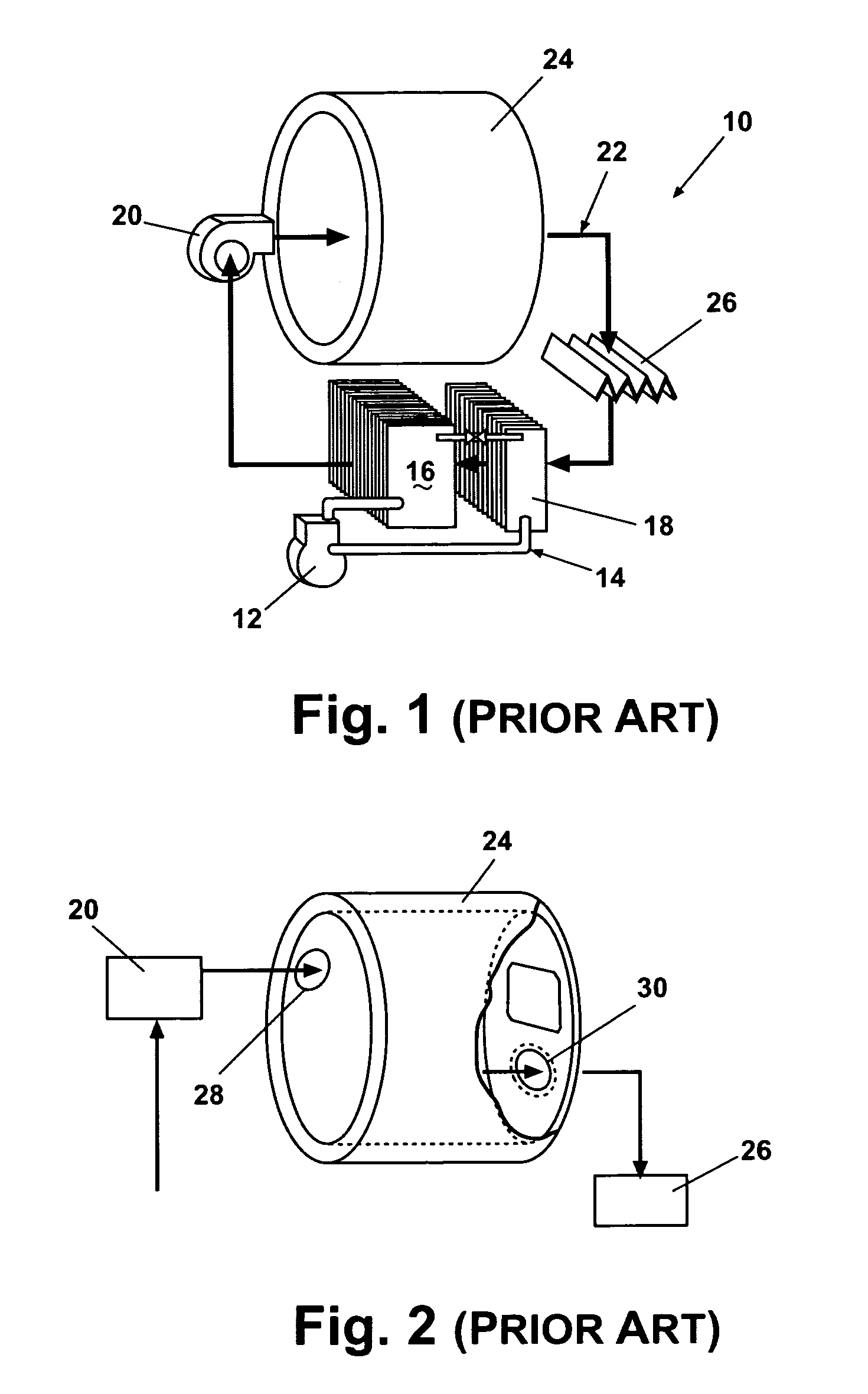

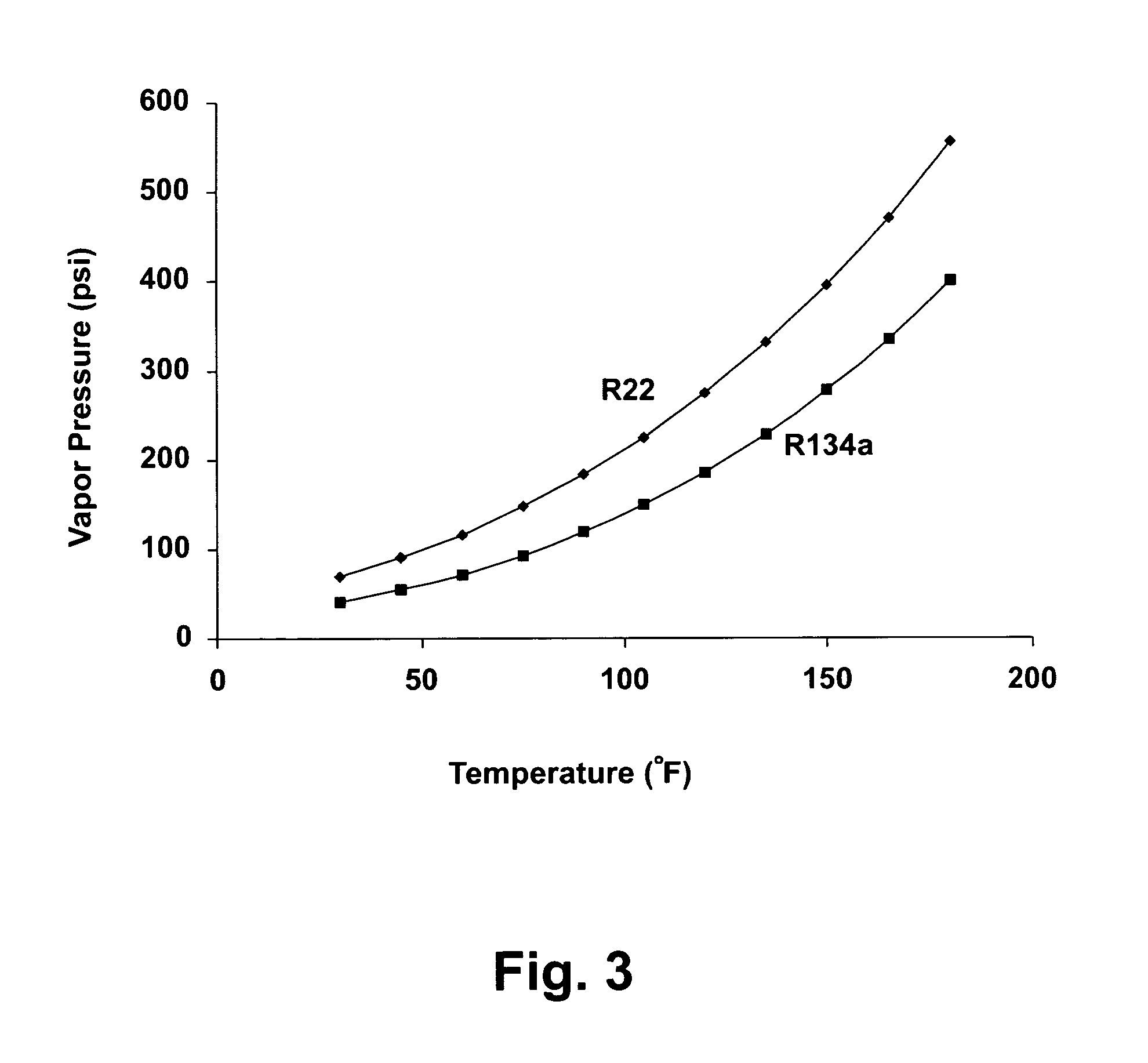

InactiveUS20050066538A1Improve performanceImprove efficiencyDrying gas arrangementsDrying chambers/containersEngineeringRefrigerant

A drying apparatus for drying articles such as clothing is provided. The drying apparatus includes a chamber for containing articles to be dried and a system for supplying heated dry air at a first temperature to the chamber. The air supplying system comprises an air flow pathway having an evaporator for removing moisture from air exiting the chamber and for decreasing the temperature of the air to below dew point temperature. The air supply system further has a condenser for increasing the temperature of the air exiting the evaporator to the first temperature. The drying apparatus further has a heat pump system having a refrigerant loop which includes a compressor, the condenser, a TEV valve, and the evaporator.

Owner:FLI HLDG COMPANY

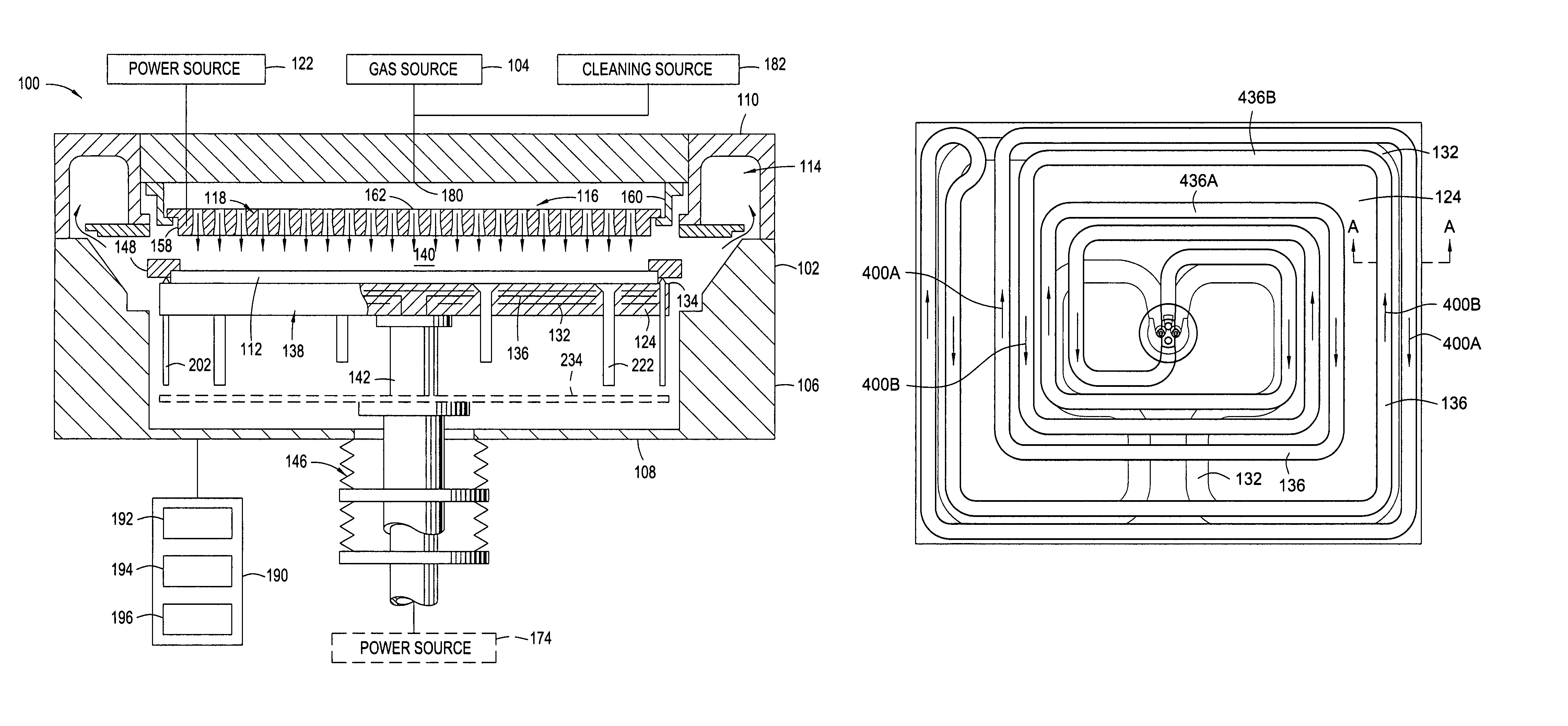

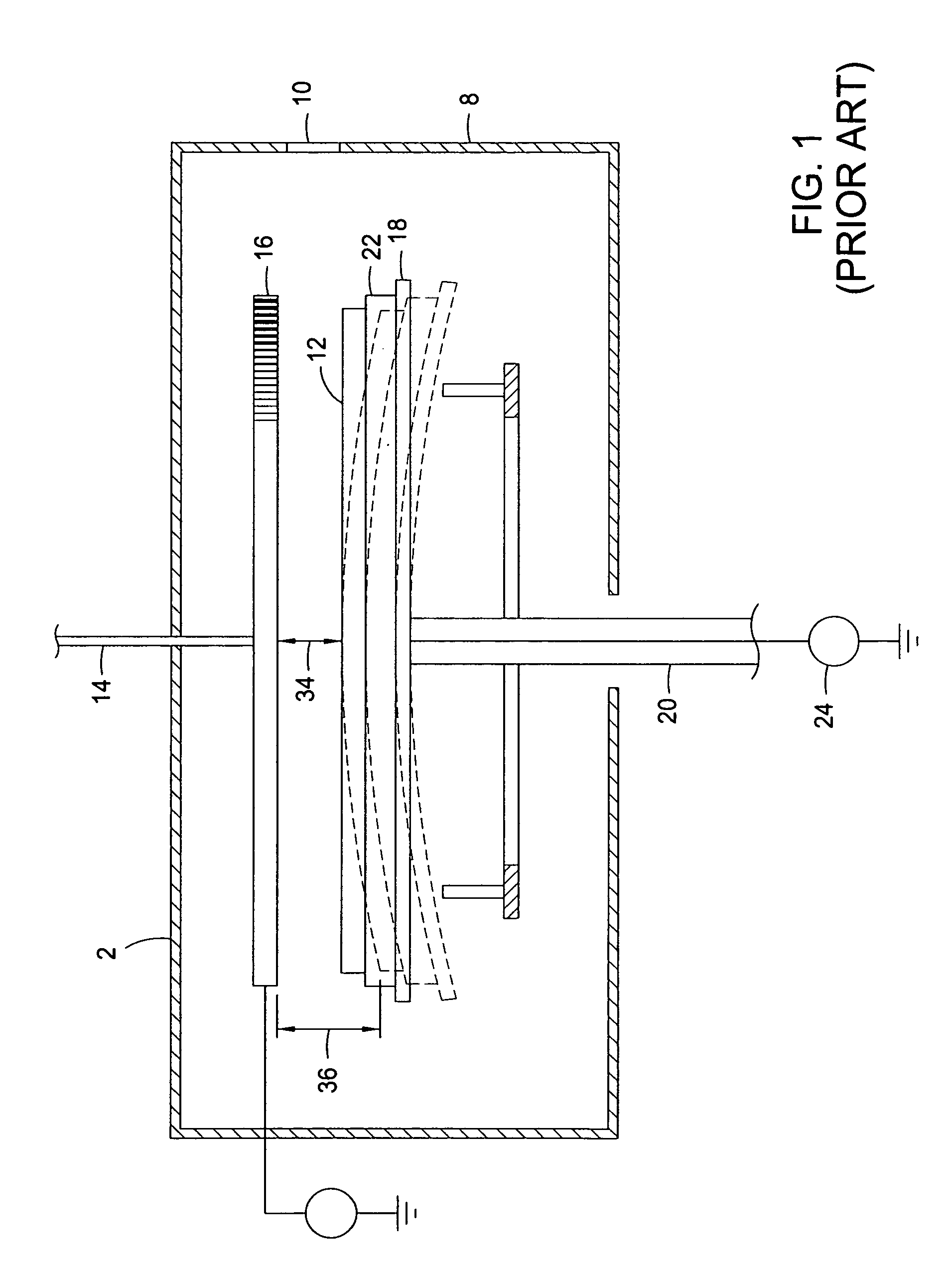

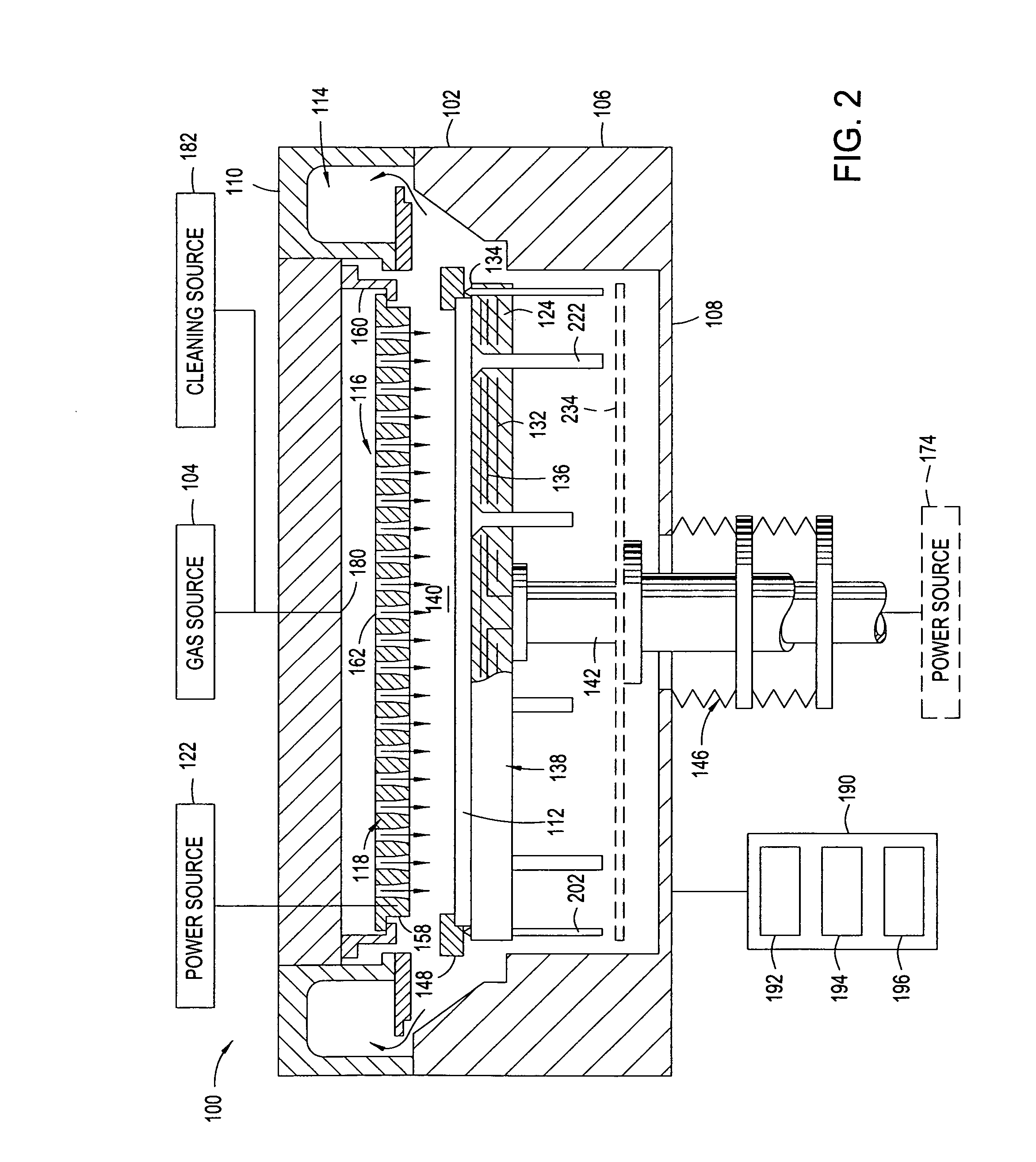

Active cooling substrate support

ActiveUS8709162B2Electric discharge tubesSemiconductor/solid-state device manufacturingActive coolingEngineering

A substrate support assembly and method for controlling the temperature of a substrate within a process chamber with a temperature uniformity of + / −5° C. are provided. A substrate support assembly includes a thermally conductive body comprising an aluminum material, a substrate support surface on the surface of the thermally conductive body and adapted to support the large area glass substrate thereon, one or more heating elements embedded within the thermally conductive body, and one or more cooling channels embedded within the thermally conductive body and positioned around the one or more heating elements. A process chamber comprising the substrate support assembly of the invention is also provided.

Owner:APPLIED MATERIALS INC

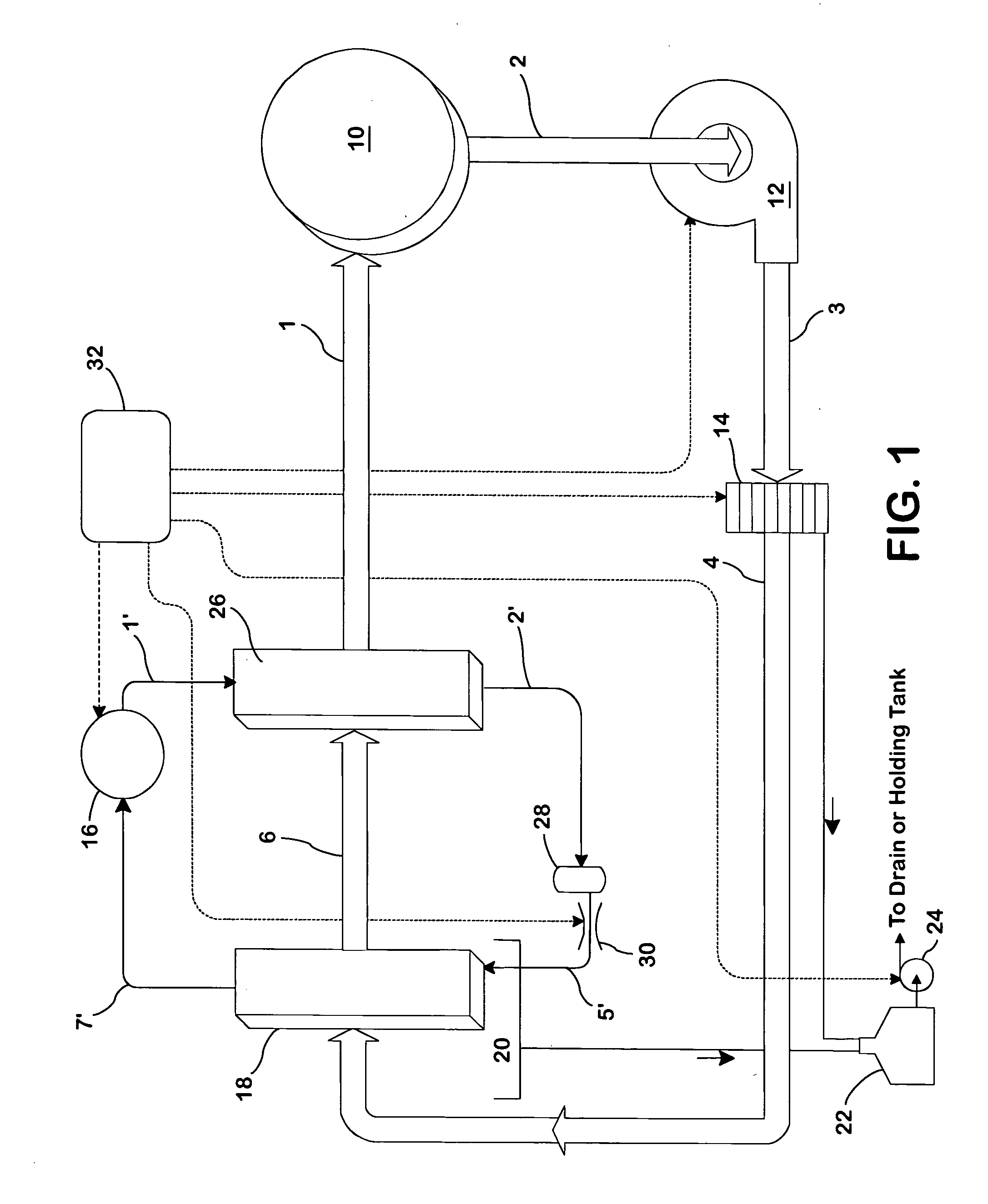

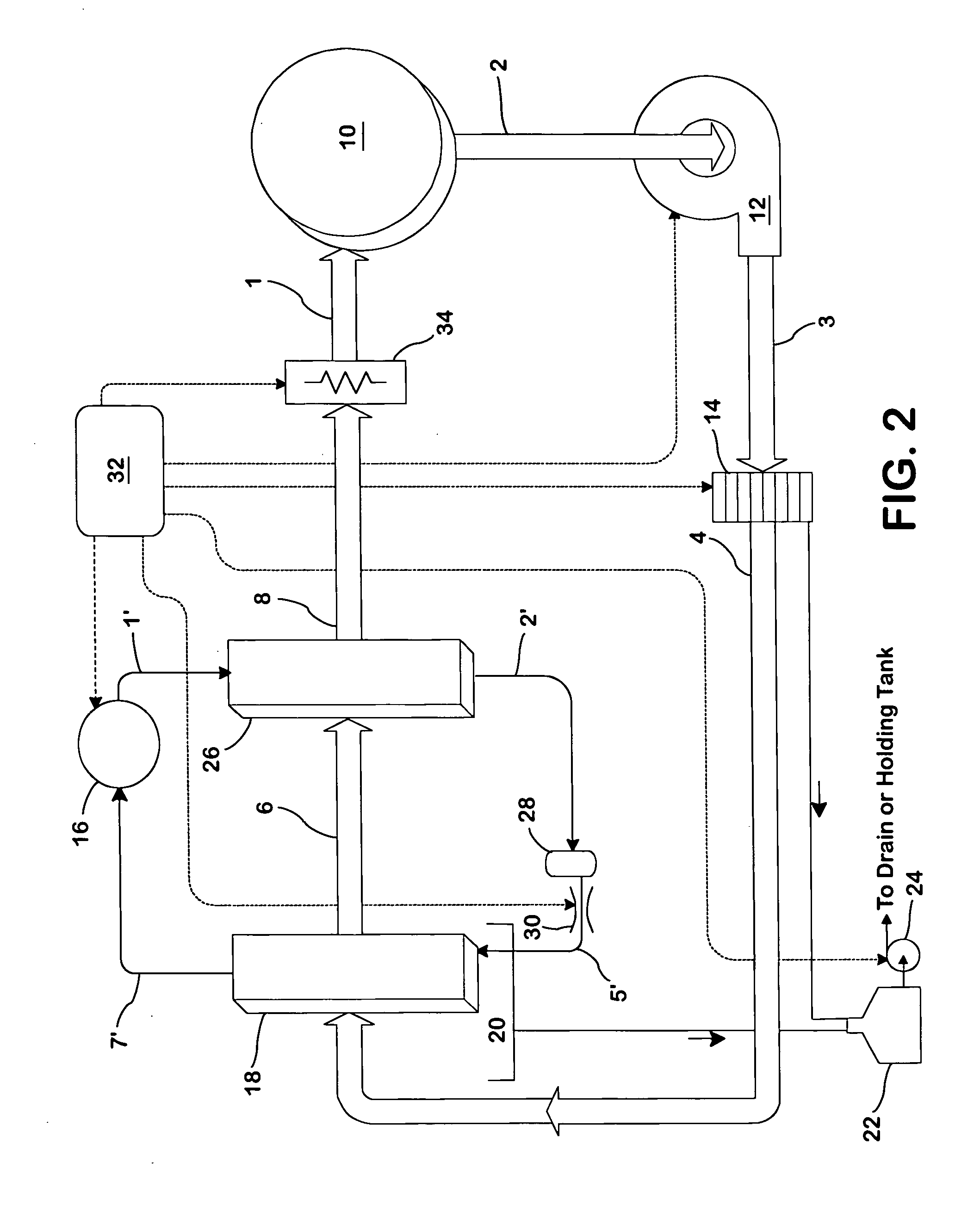

Heat pump clothes dryer

InactiveUS7055262B2Improved performance and efficiencyDrying solid materials without heatDrying gas arrangementsEngineeringRefrigerant

A drying apparatus for drying articles such as clothing is provided. The drying apparatus includes a chamber for containing articles to be dried and a system for supplying heated dry air at a first temperature to the chamber. The air supplying system comprises an air flow pathway having an evaporator for removing moisture from air exiting the chamber and for decreasing the temperature of the air to below dew point temperature. The air supply system further has a condenser for increasing the temperature of the air exiting the evaporator to the first temperature. The drying apparatus further has a heat pump system having a refrigerant loop which includes a compressor, the condenser, a TEV valve, and the evaporator.

Owner:FLI HLDG COMPANY

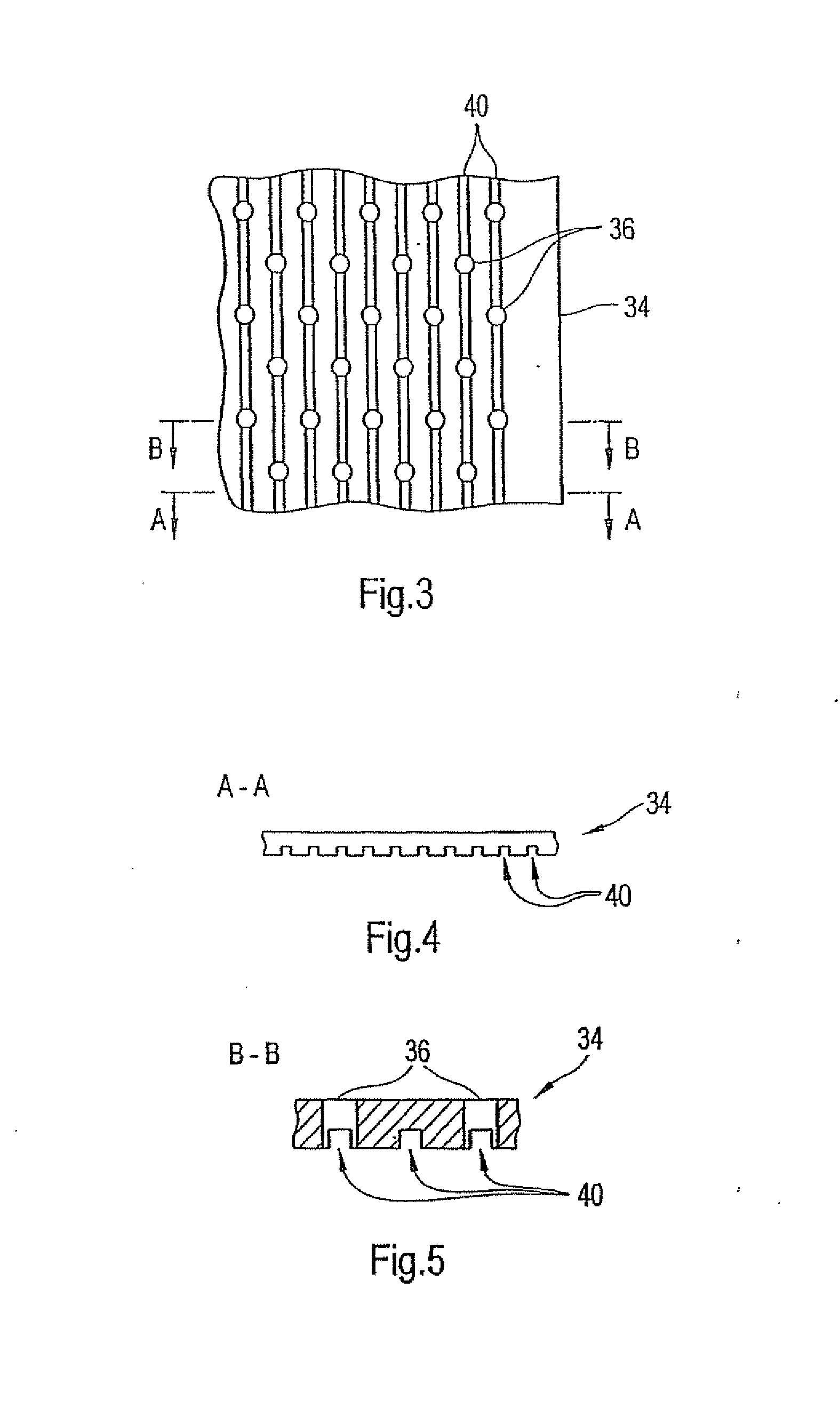

Operation method for combination dryer

InactiveUS20060112585A1Eliminate the problemDrying gas arrangementsOther washing machinesCyclic processRefresh cycle

An operation method for a combination dryer is disclosed. The present invention relates to a combination dryer, and more particularly, to an operation method for a combination dryer which enables air in a drying drum and a cabinet for drying the laundry to circulate continuously and enables condensed water generated in the circulation process to perform a refreshing cycle by using the water.

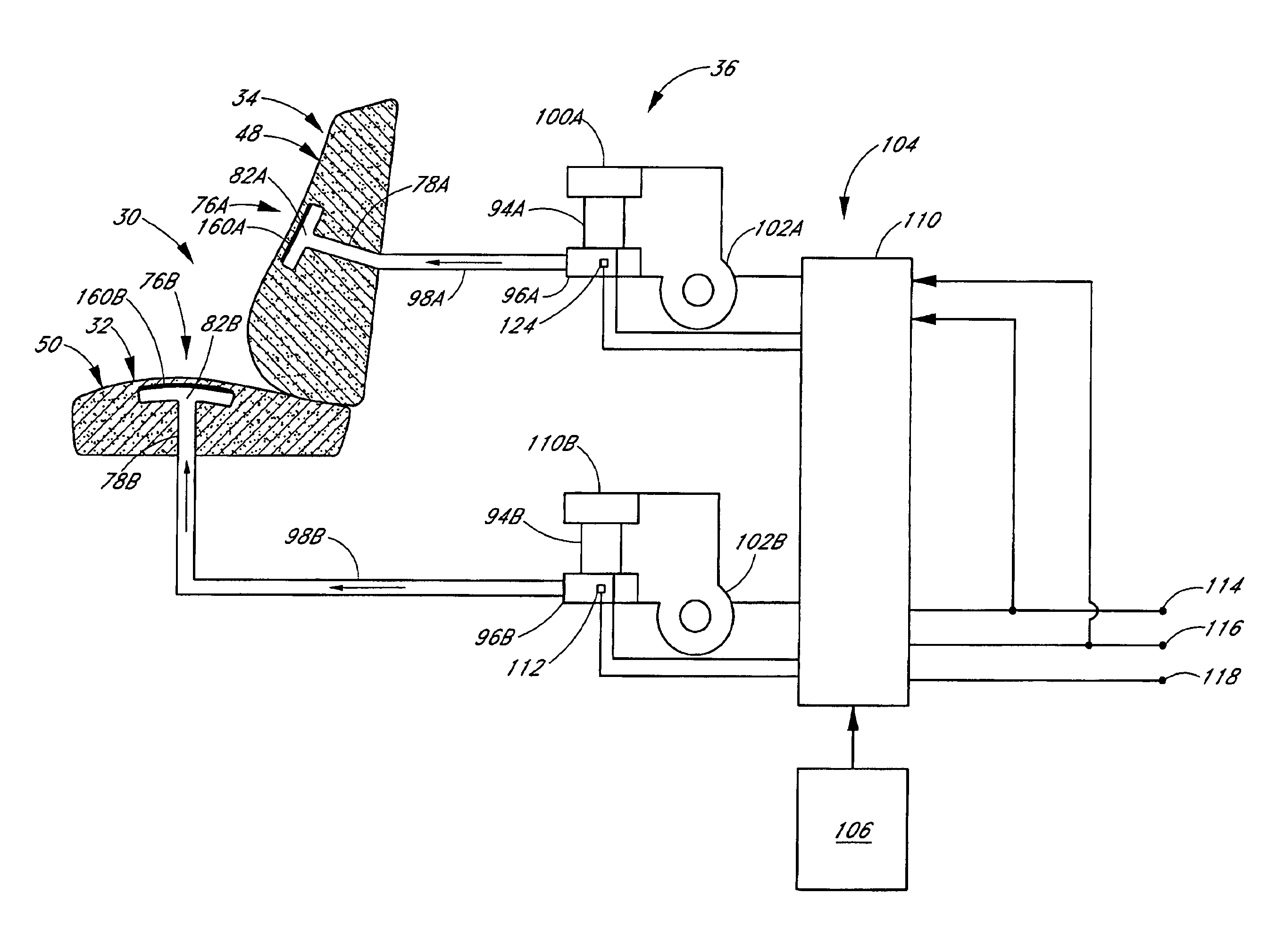

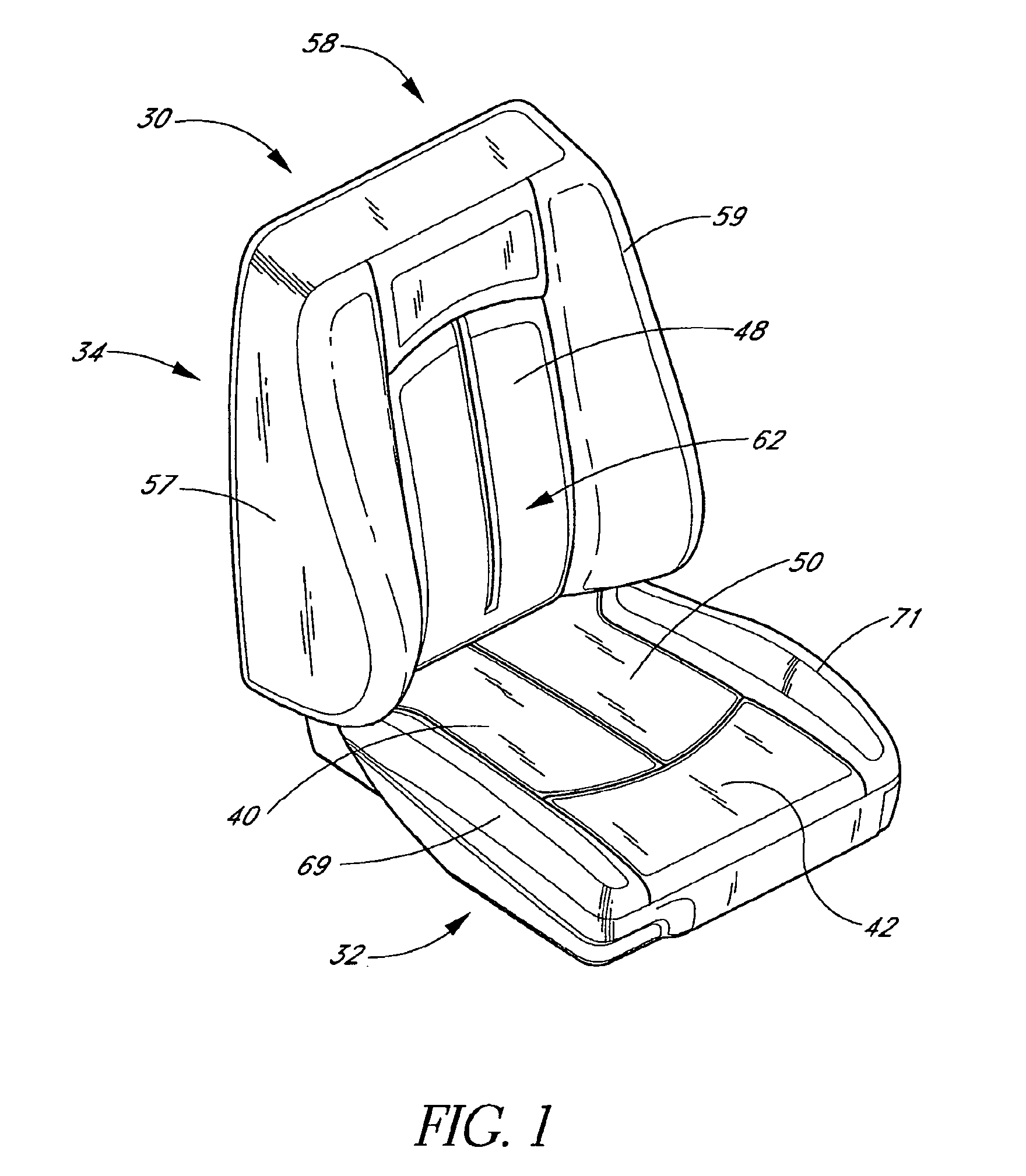

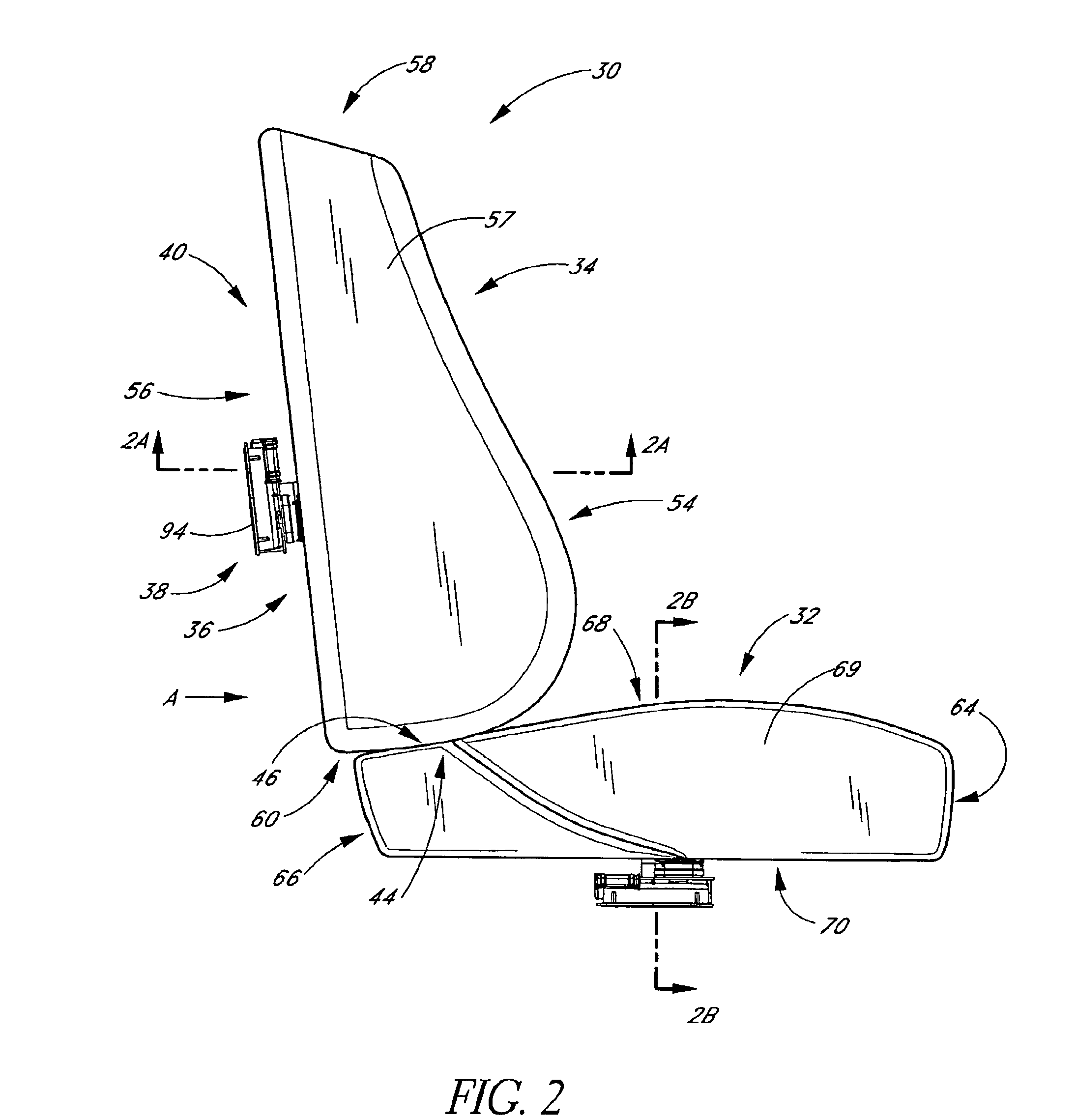

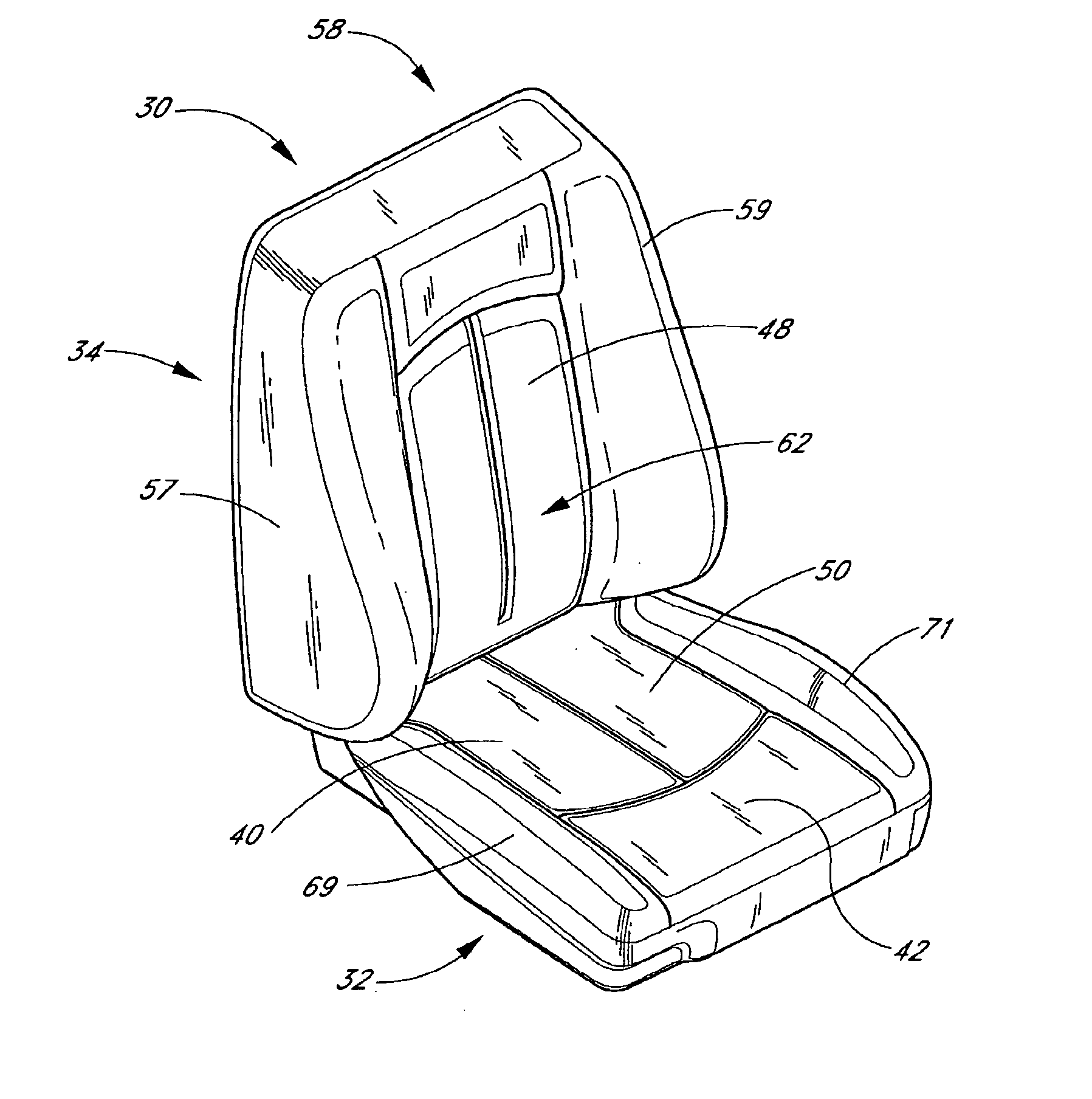

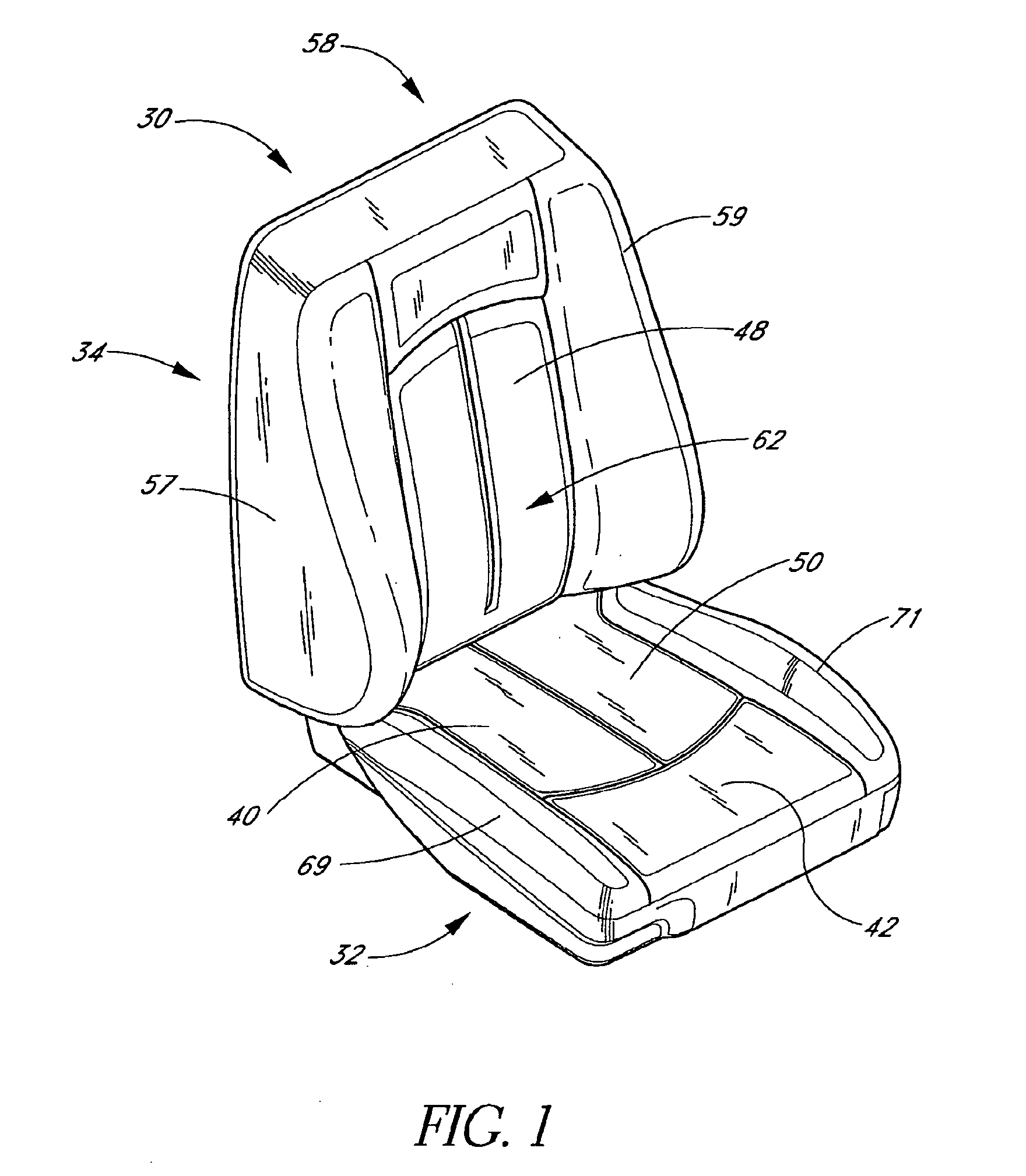

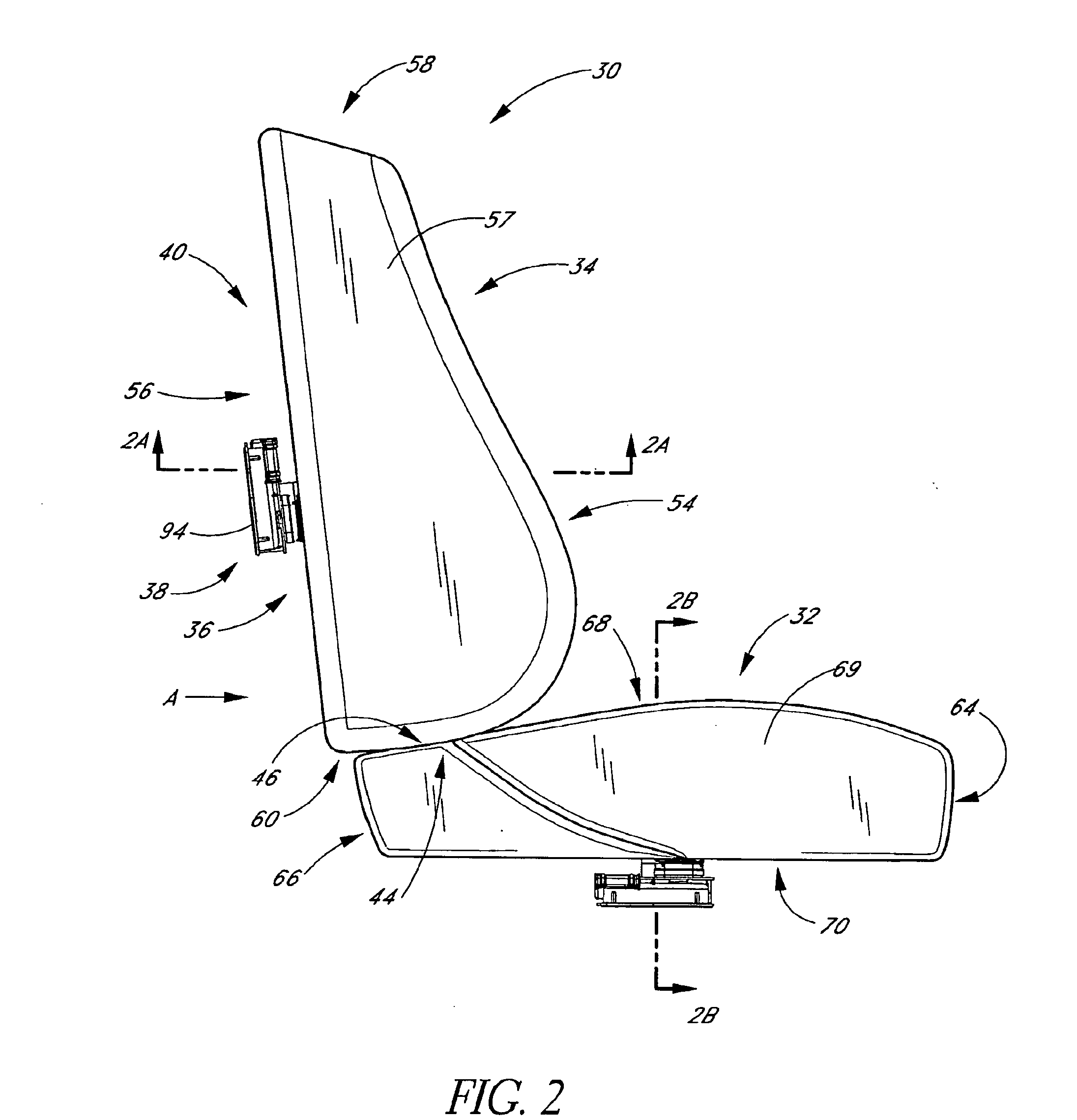

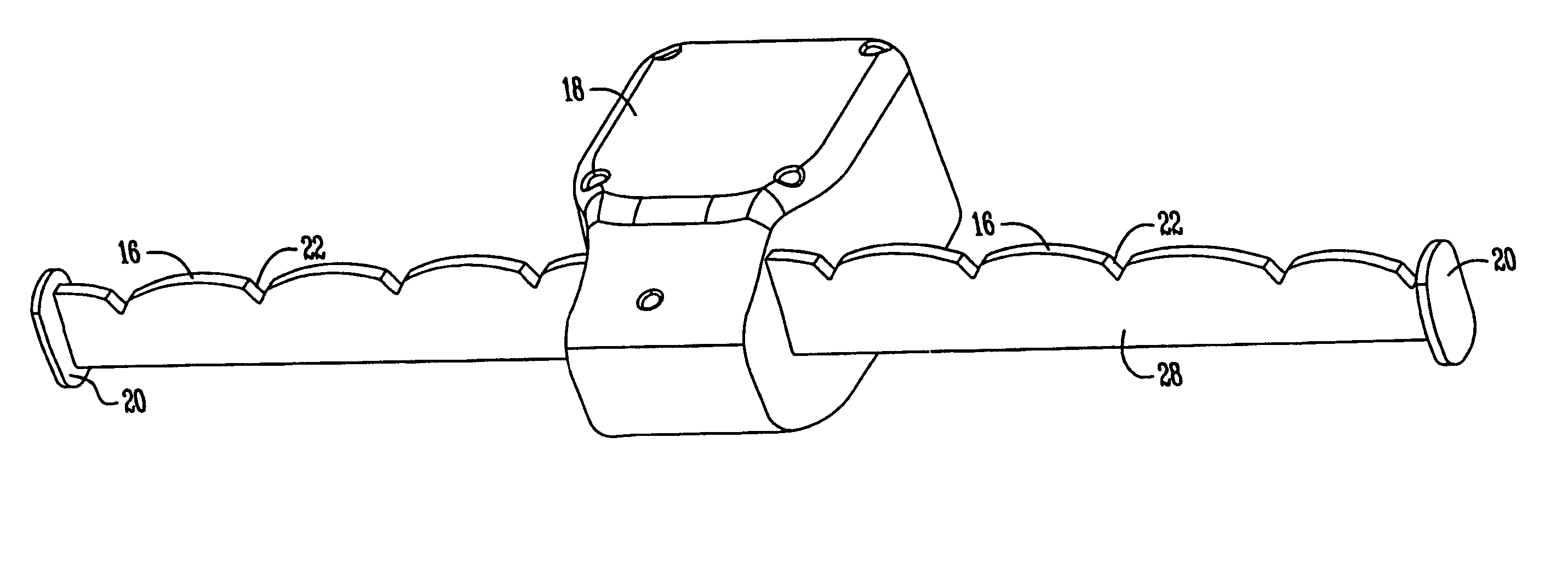

Seat climate control system

A method for thermally conditioning a space adjacent a seat assembly includes activating a heating element positioned within the seat assembly beneath a seat covering. A fluid module that includes a fluid supply device and a thermoelectric element is activated to direct heated air from the fluid module to a space adjacent the seat assembly through a distribution system formed at least partially in the seat cushion. After a period of time, the heating element is deactivated.

Owner:GENTHERM INC

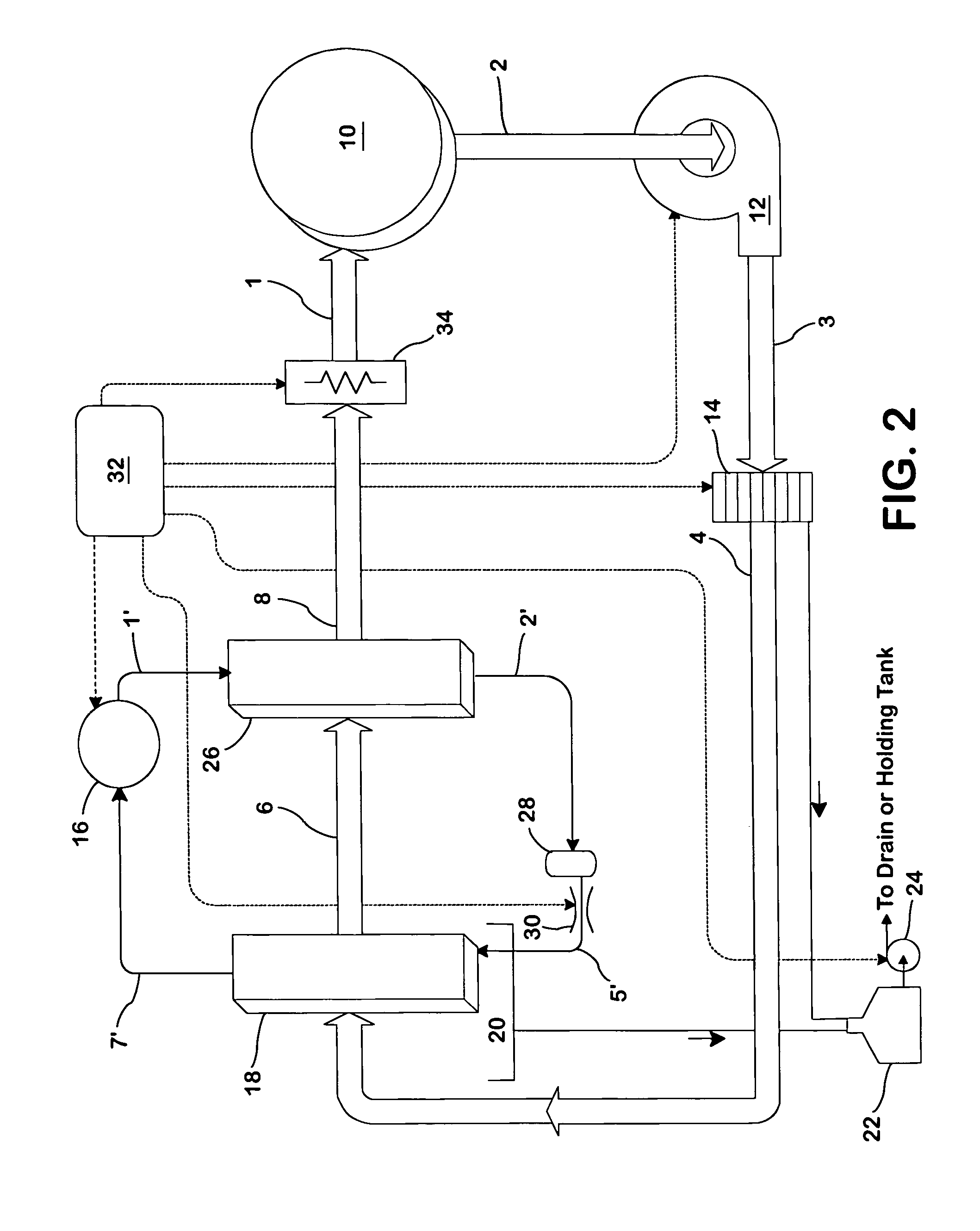

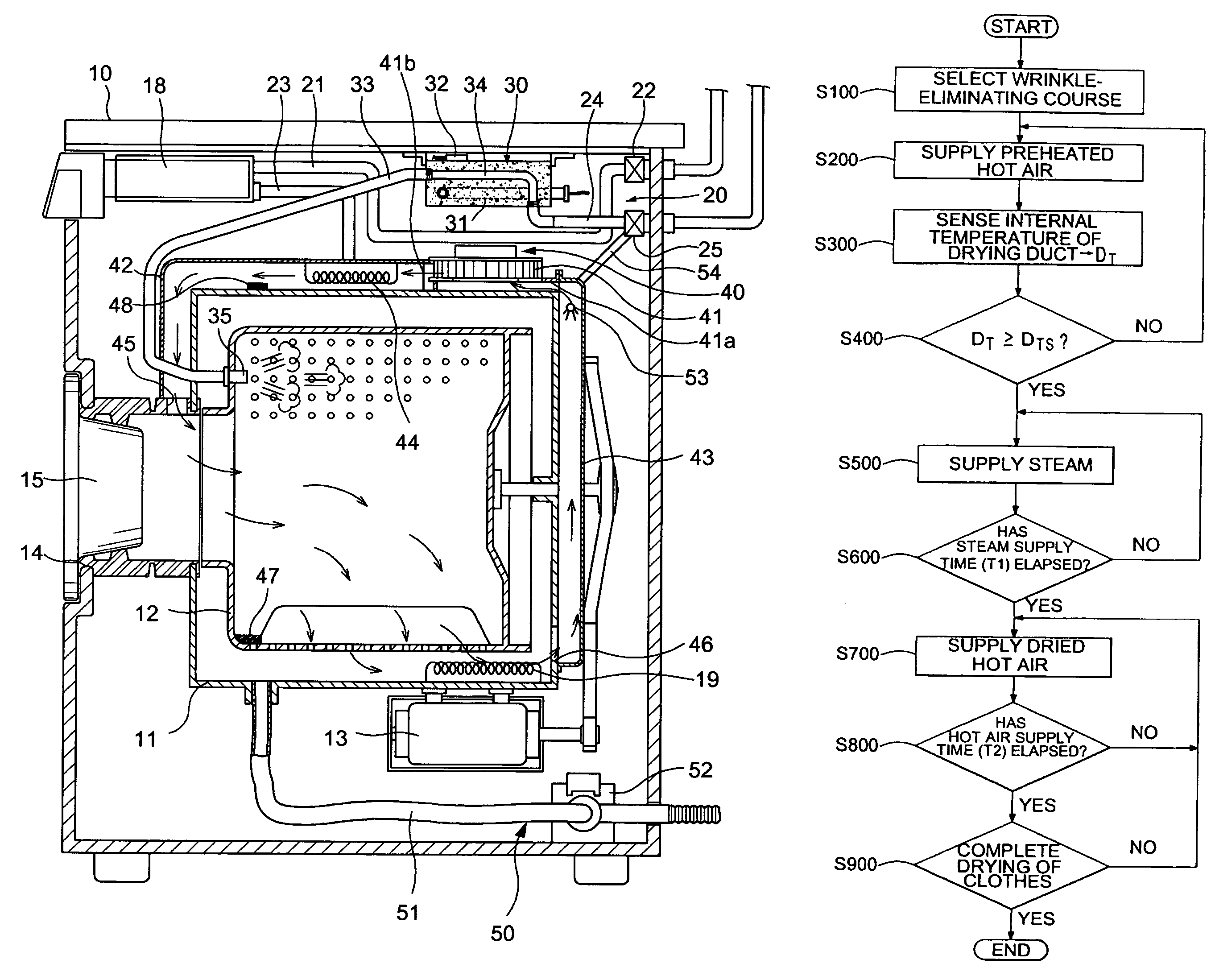

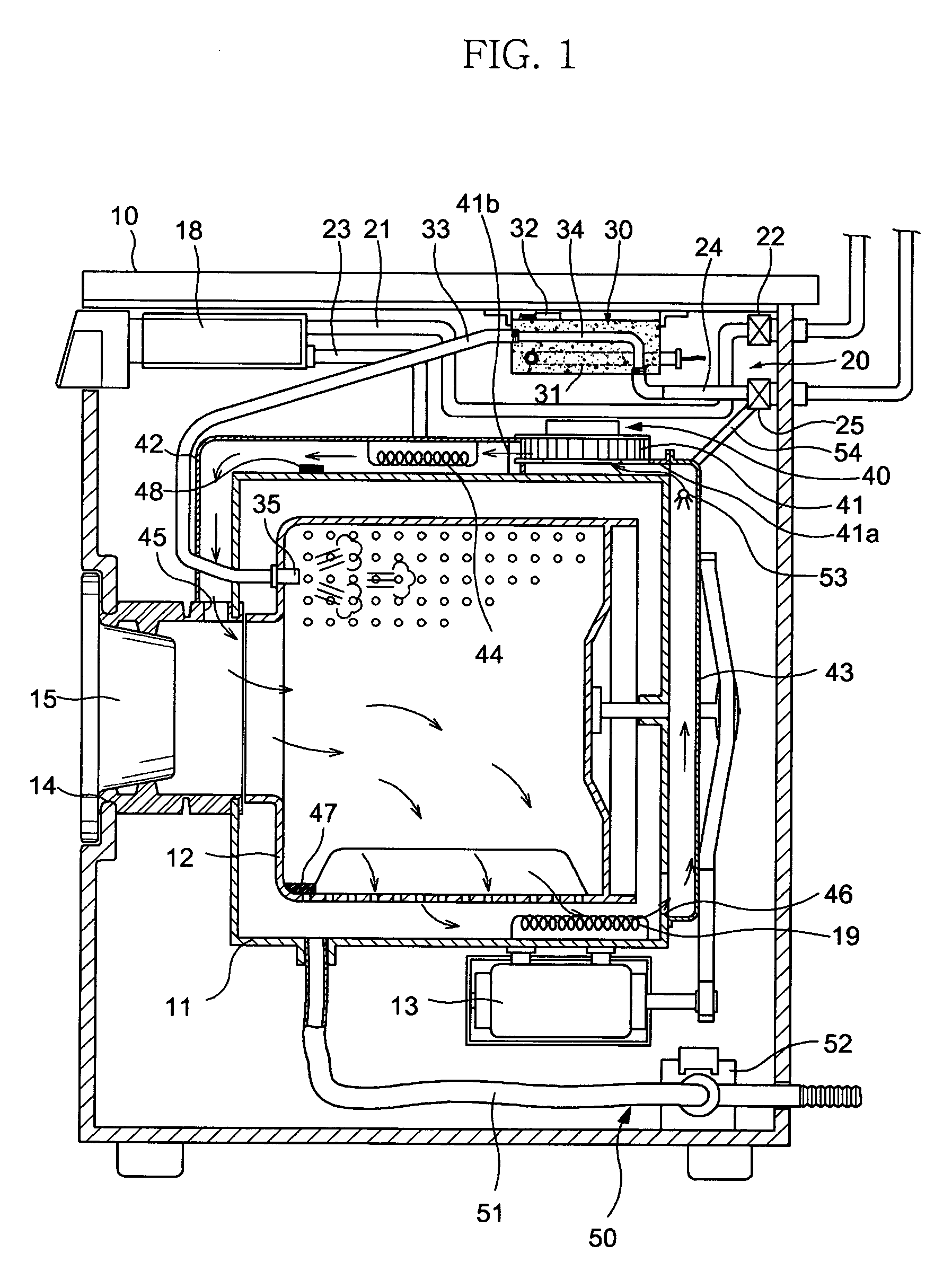

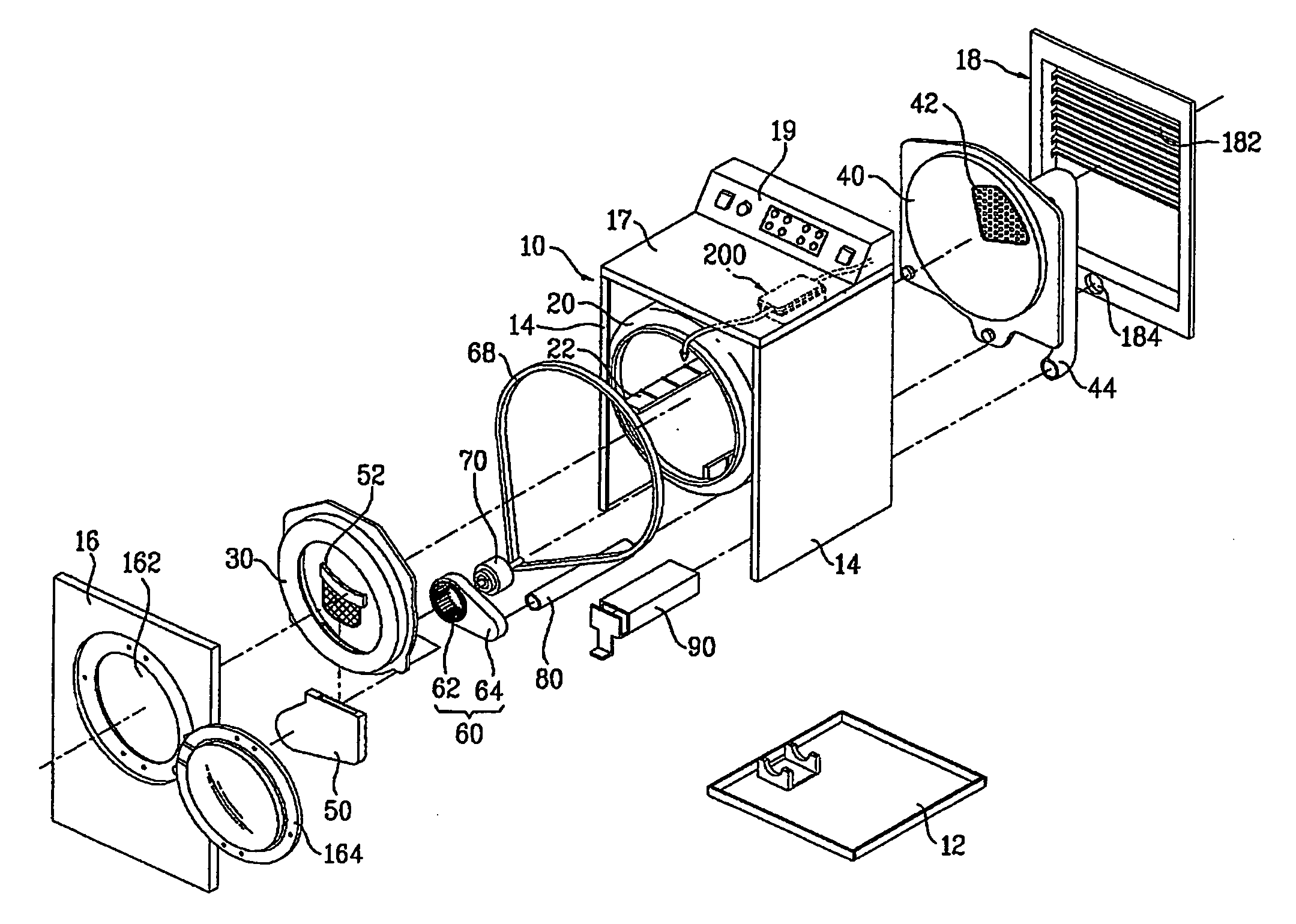

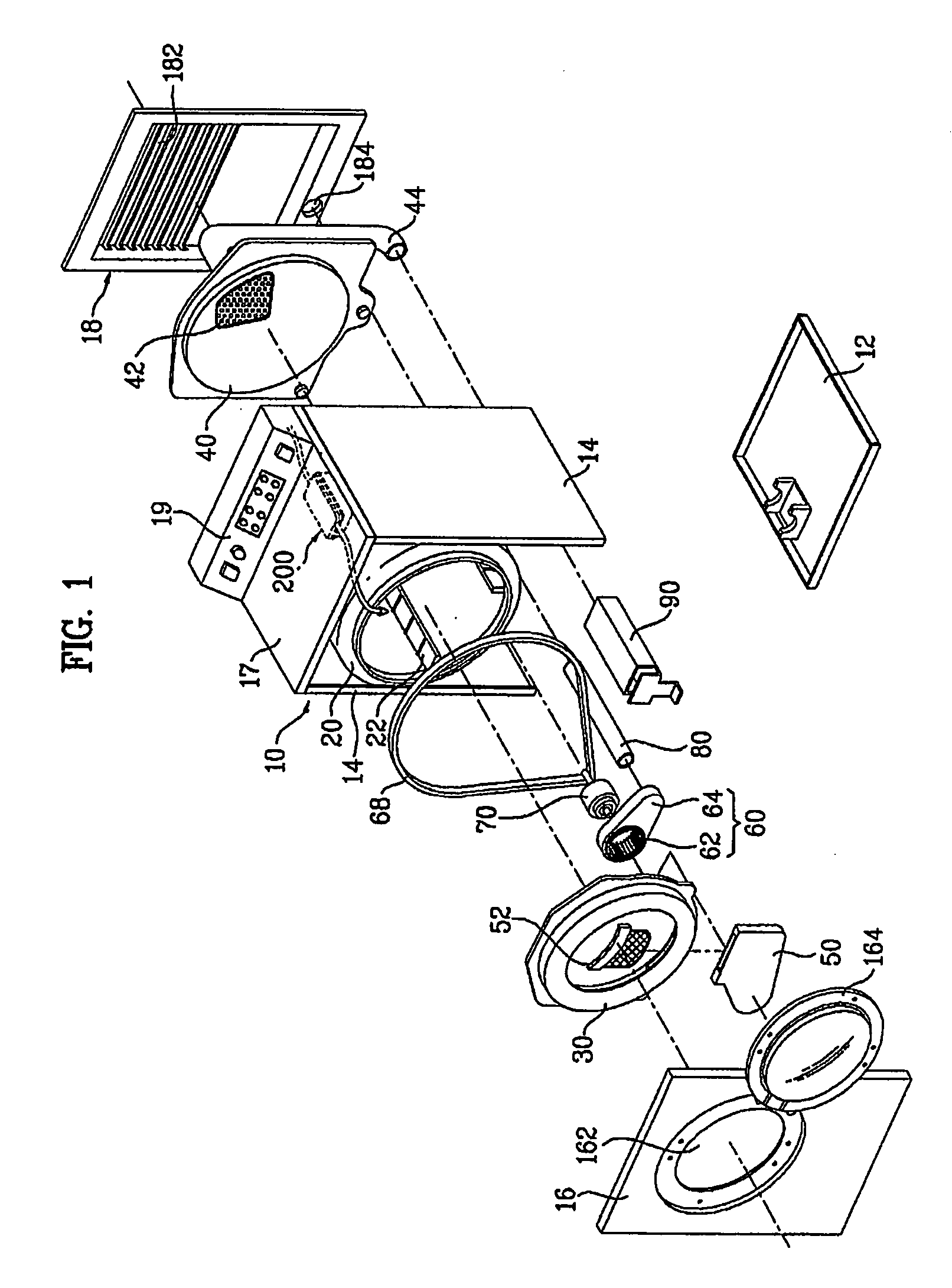

Apparatus and method for eliminating wrinkles in clothes

ActiveUS7325330B2Eliminate wrinklesEffectively eliminating the wrinkles in the clothesDrying solid materials without heatHollow article cleaningWrinkle skinEngineering

Apparatus and method for eliminating wrinkles in clothes in a washing or drying machine using steam to eliminate the wrinkles in clothes, in a state in which the clothes are worn by a user or stored, as well as in a state in which washing of the clothes is terminated. The method includes determining whether or not a wrinkle-eliminating course is selected; supplying hot air to the clothes to eliminate dust from the clothes when it is determined that the wrinkle-eliminating course is selected; and supplying steam to the clothes, from which the dust was eliminated, to eliminate the wrinkles in the clothes.

Owner:SAMSUNG ELECTRONICS CO LTD

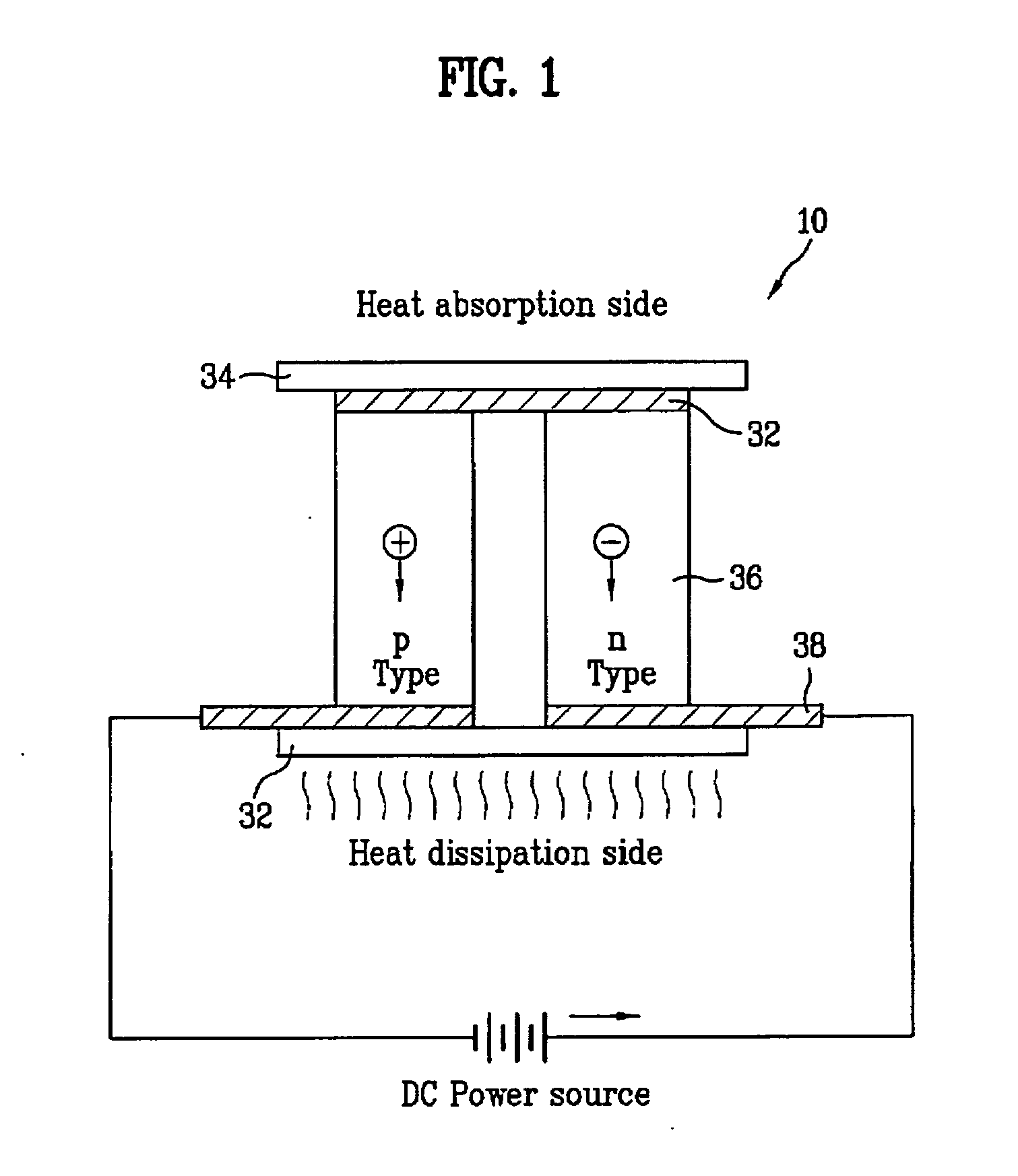

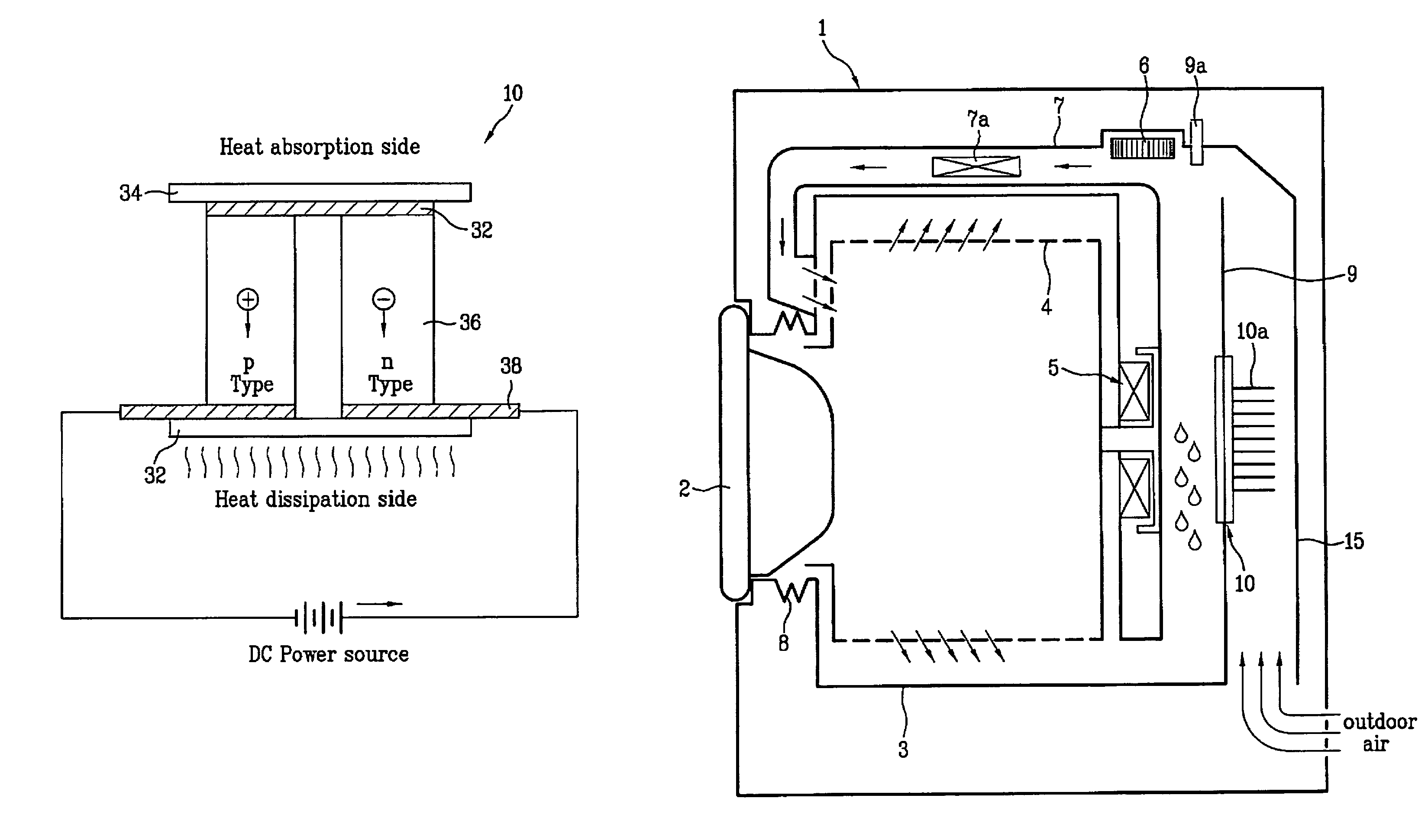

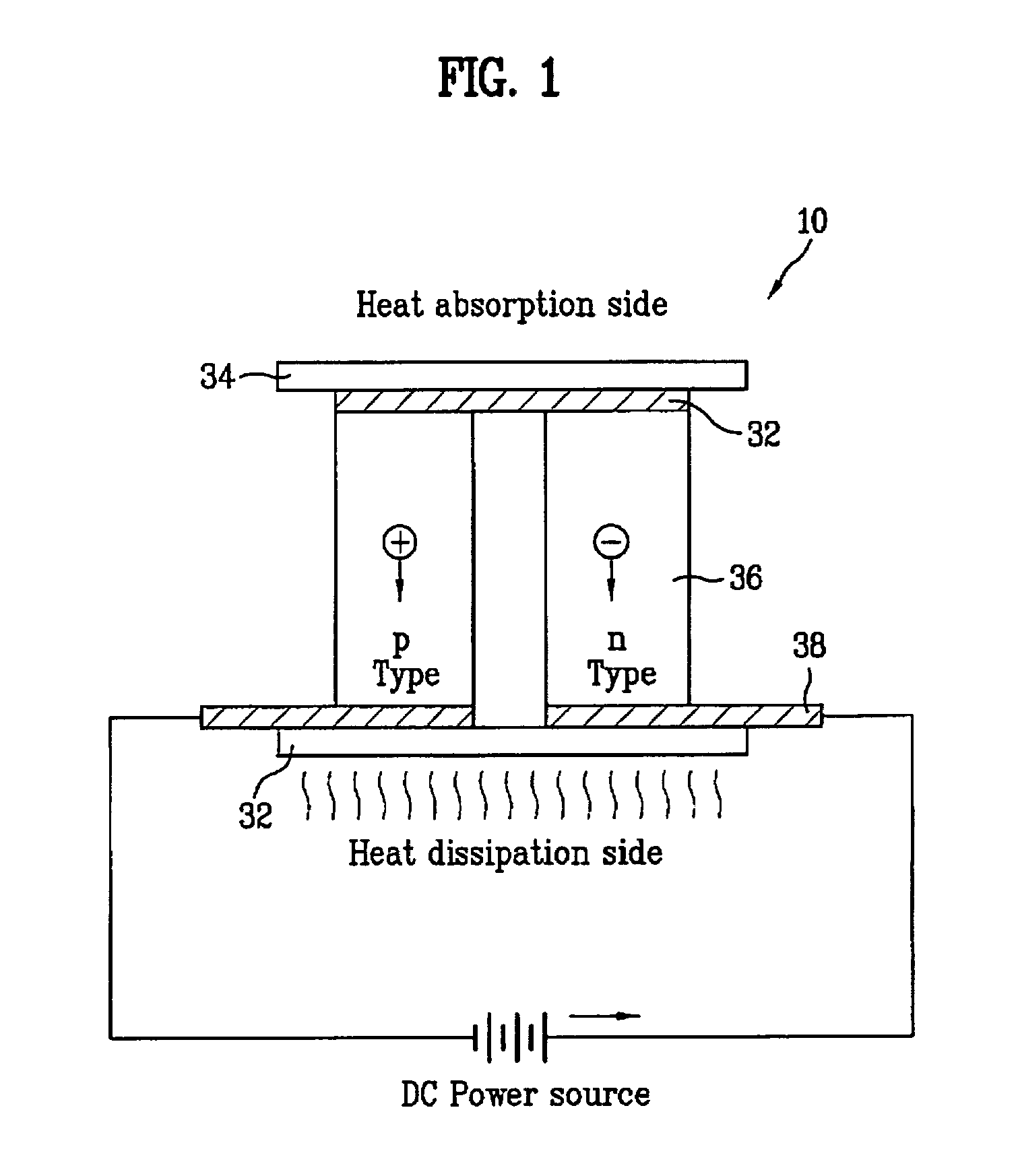

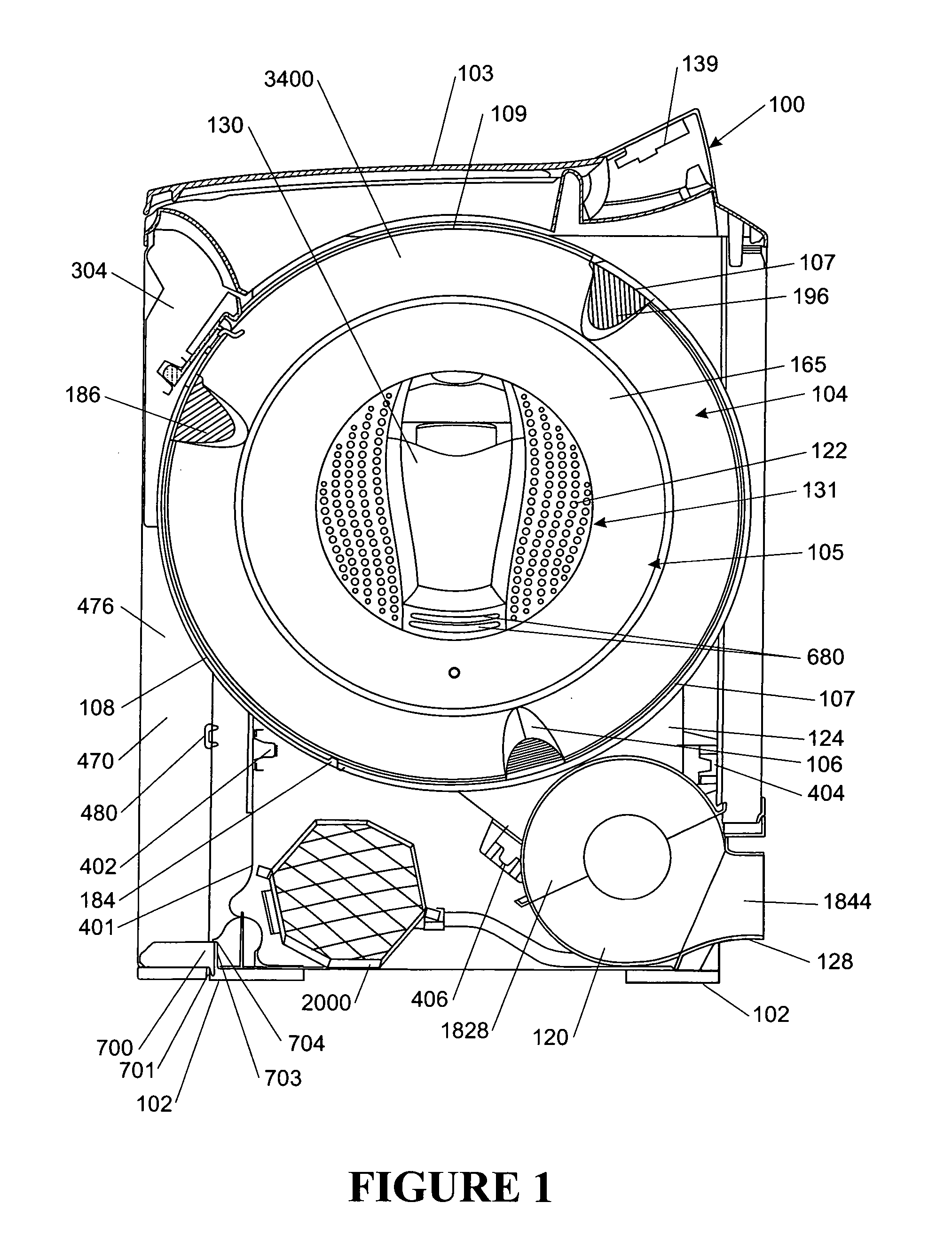

Drum washing machine and clothes dryer using thermoelectric module

InactiveUS20070101602A1Improve drying efficiencyImprove energy efficiencyAgriculture tools and machinesDrying gas arrangementsProcess engineeringElectrical current

A drum washing machine and a clothes dryer equipped with a thermoelectric module are disclosed. The thermoelectric module includes a heat absorption side and a heat dissipation side which absorbs and dissipates heat at a junction between two dissimilar metals depending on direction of current flow through the junction. The heat absorption side is disposed at a hot air flowing passage. Accordingly, the drying apparatus can increase energy efficiency with minor structural modification and becomes environmentally friendly unlike a conventional drying apparatus using a heat pump.

Owner:LG ELECTRONICS INC

Apparatus and method for eliminating wrinkles in clothes

ActiveUS20060117596A1Eliminate wrinklesEffectively eliminating the wrinkles in the clothesDrying solid materials without heatHollow article cleaningWrinkle skinEngineering

Apparatus and method for eliminating wrinkles in clothes in a washing or drying machine using steam to eliminate the wrinkles in clothes, in a state in which the clothes are worn by a user or stored, as well as in a state in which washing of the clothes is terminated. The method includes determining whether or not a wrinkle-eliminating course is selected; supplying hot air to the clothes to eliminate dust from the clothes when it is determined that the wrinkle-eliminating course is selected; and supplying steam to the clothes, from which the dust was eliminated, to eliminate the wrinkles in the clothes.

Owner:SAMSUNG ELECTRONICS CO LTD

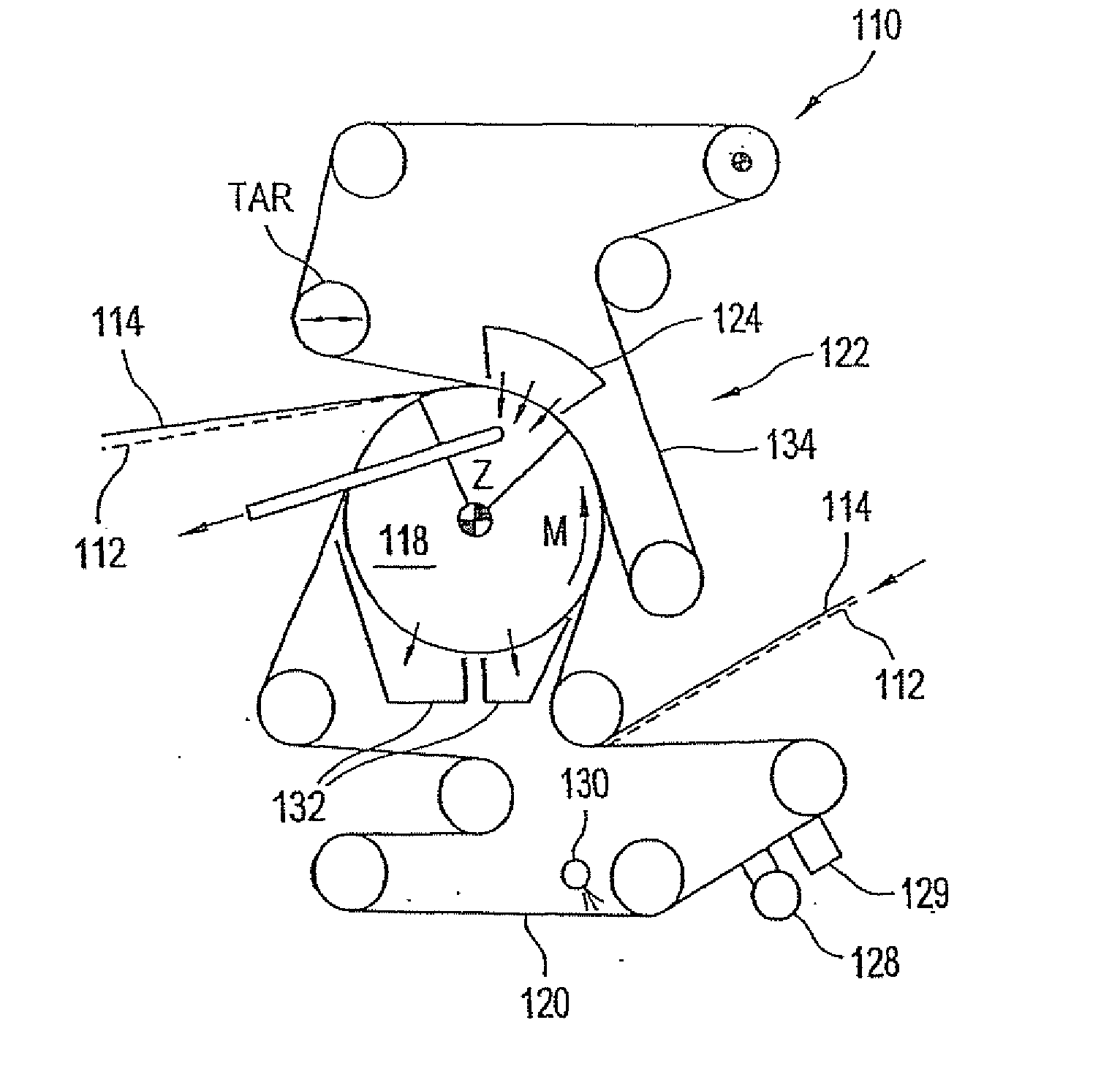

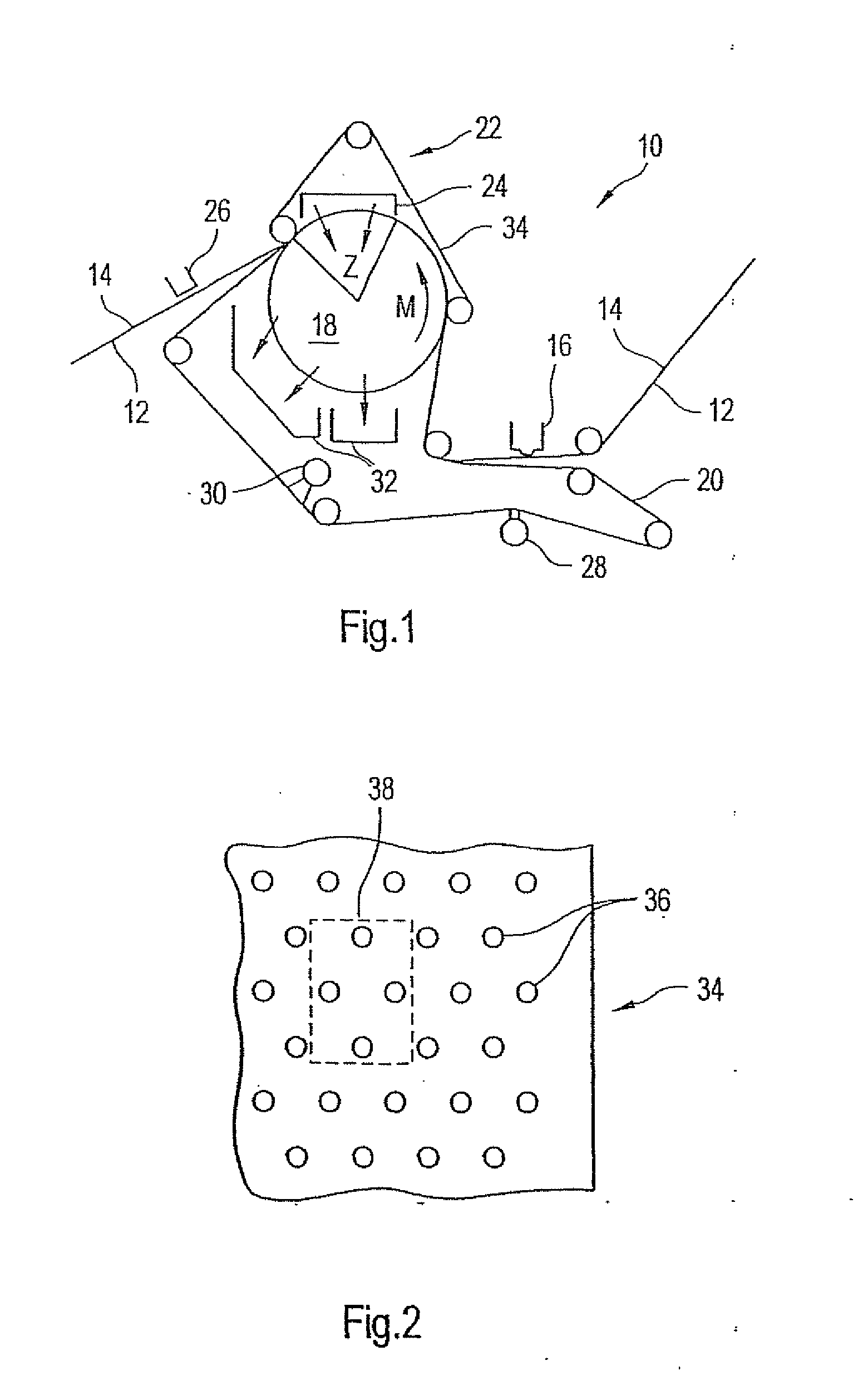

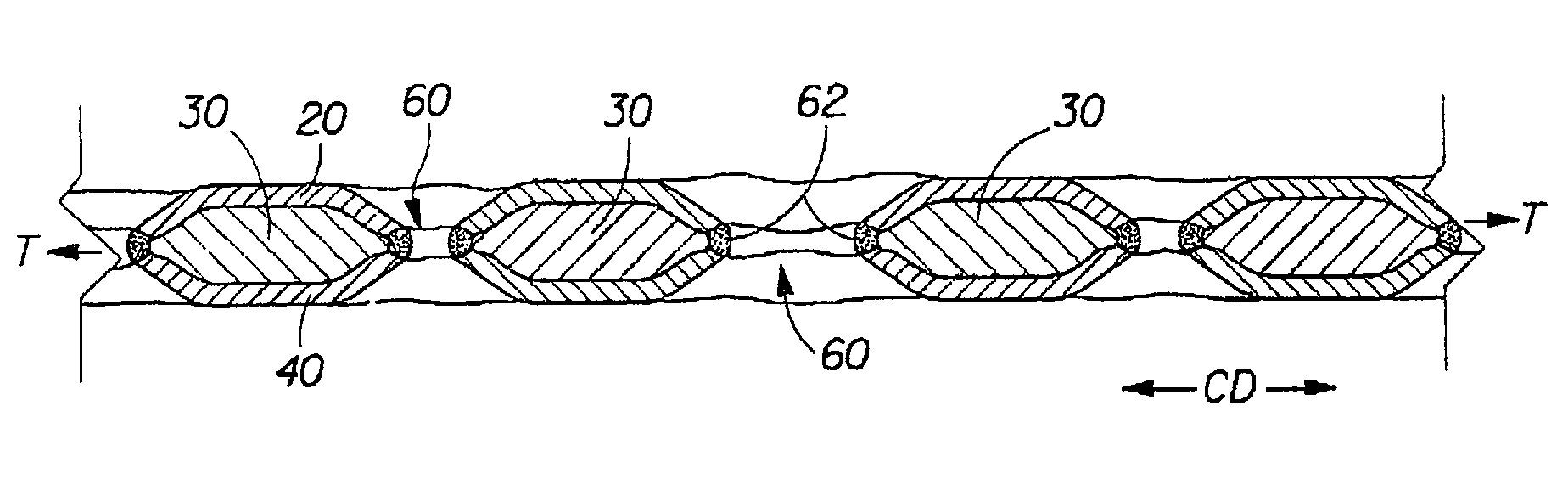

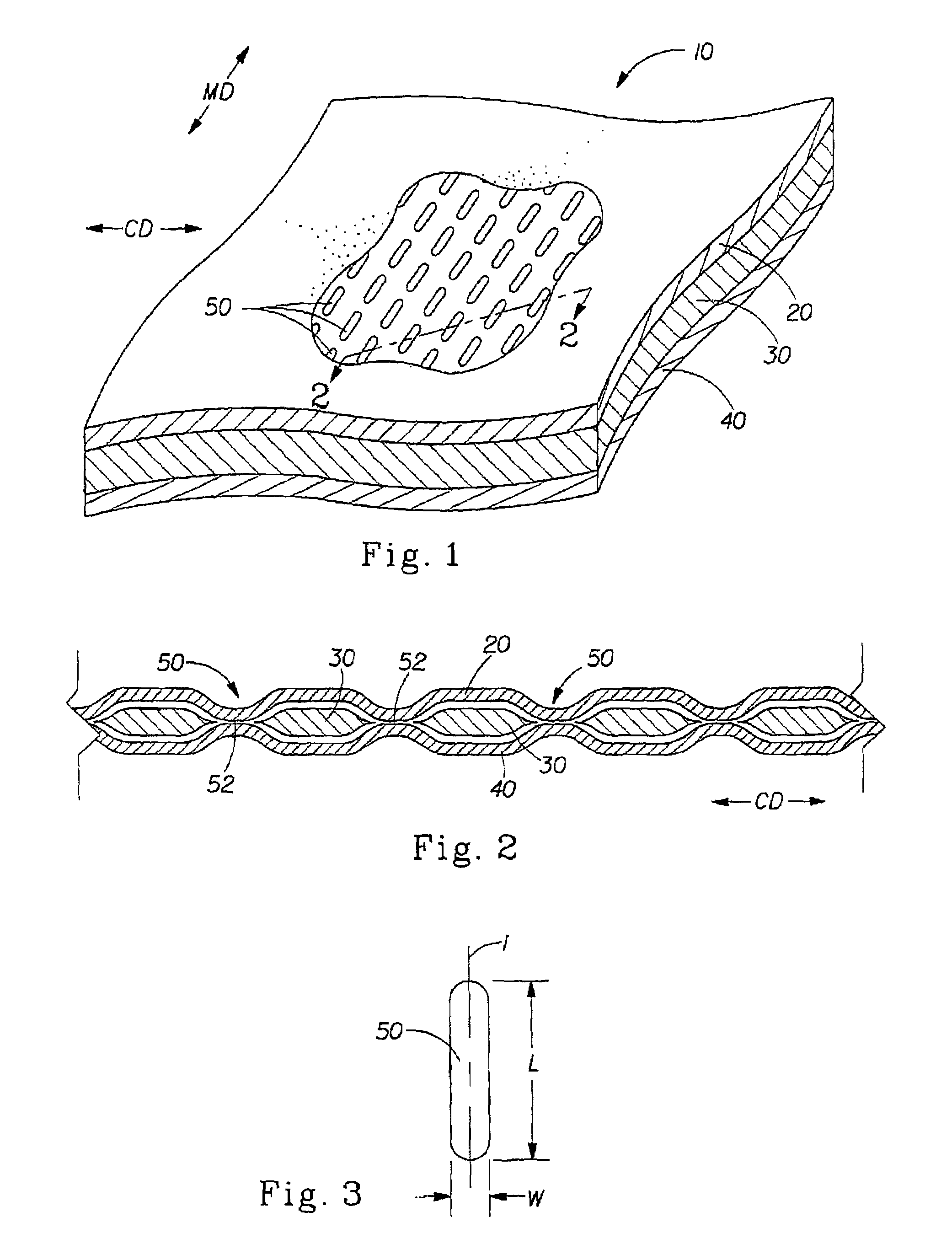

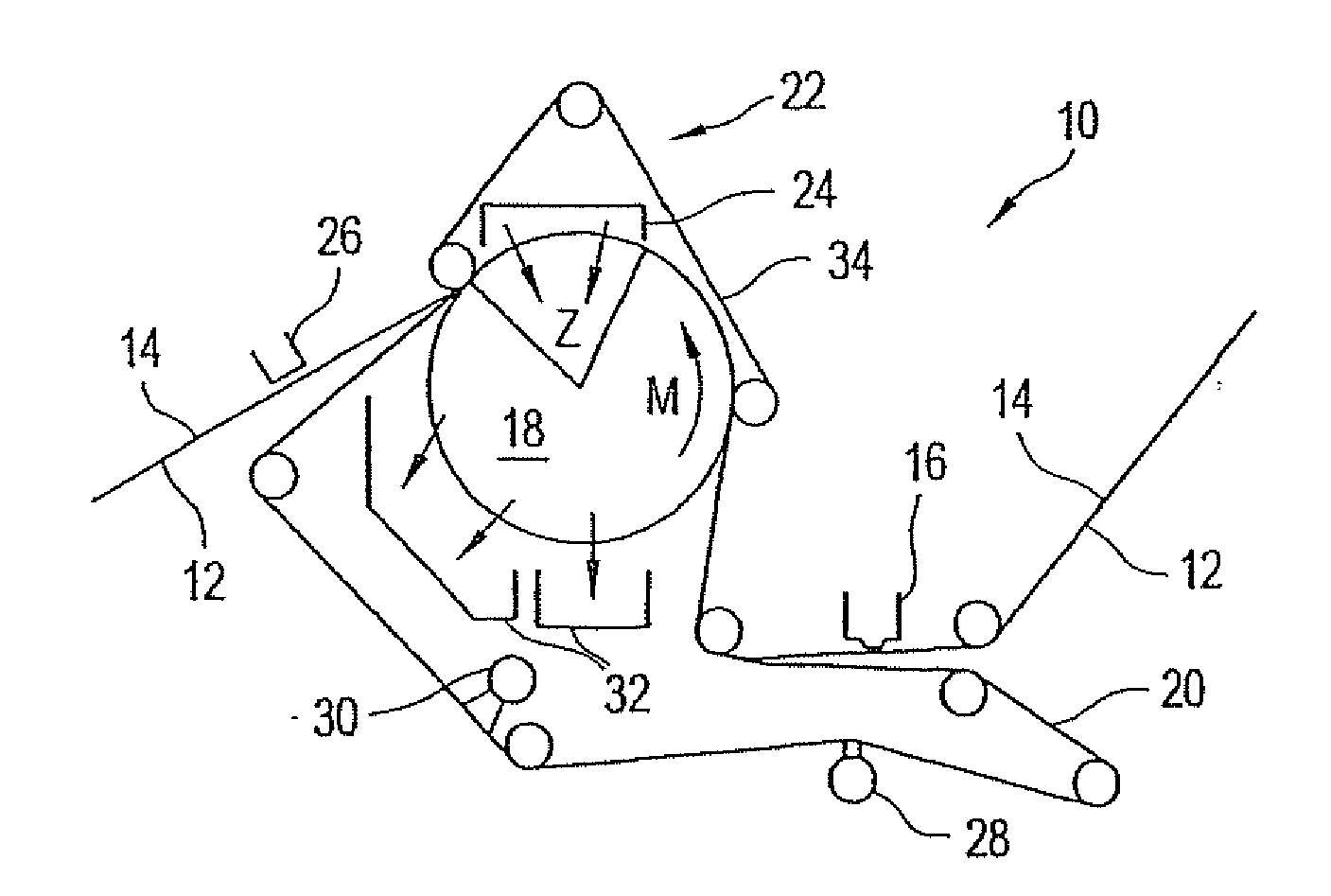

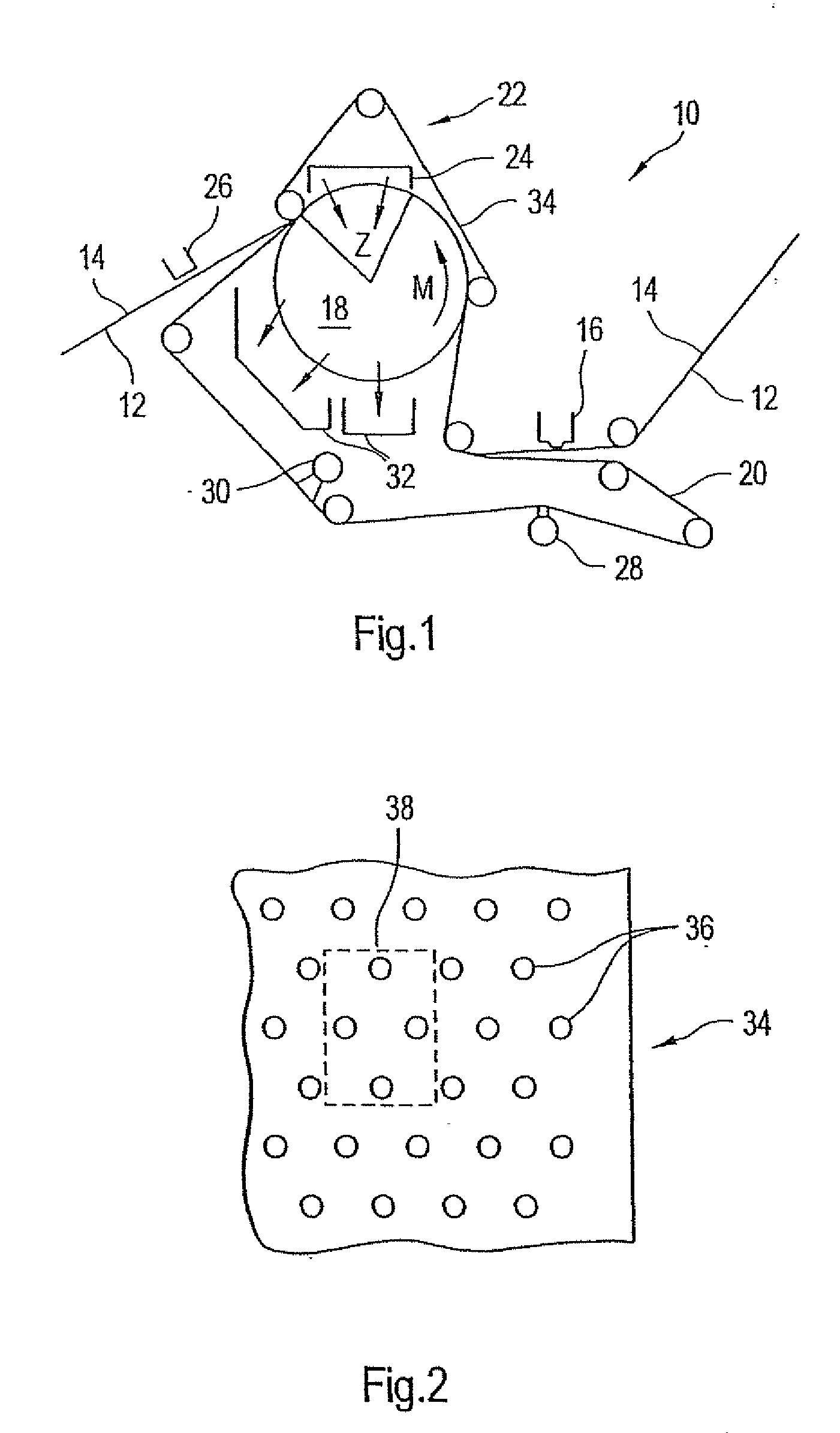

Forming fabric and/or tissue molding belt and/or molding belt for use on an atmos system

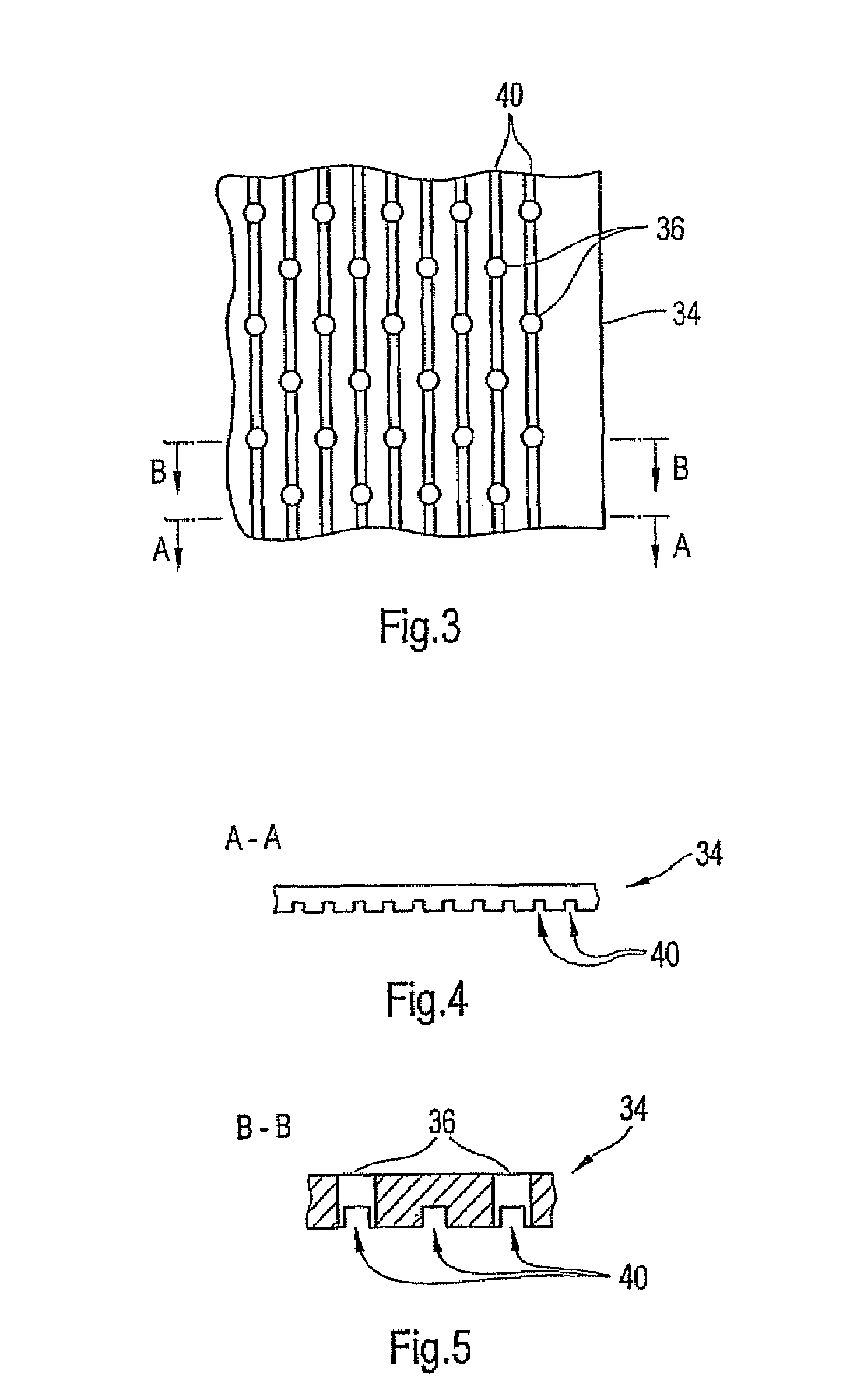

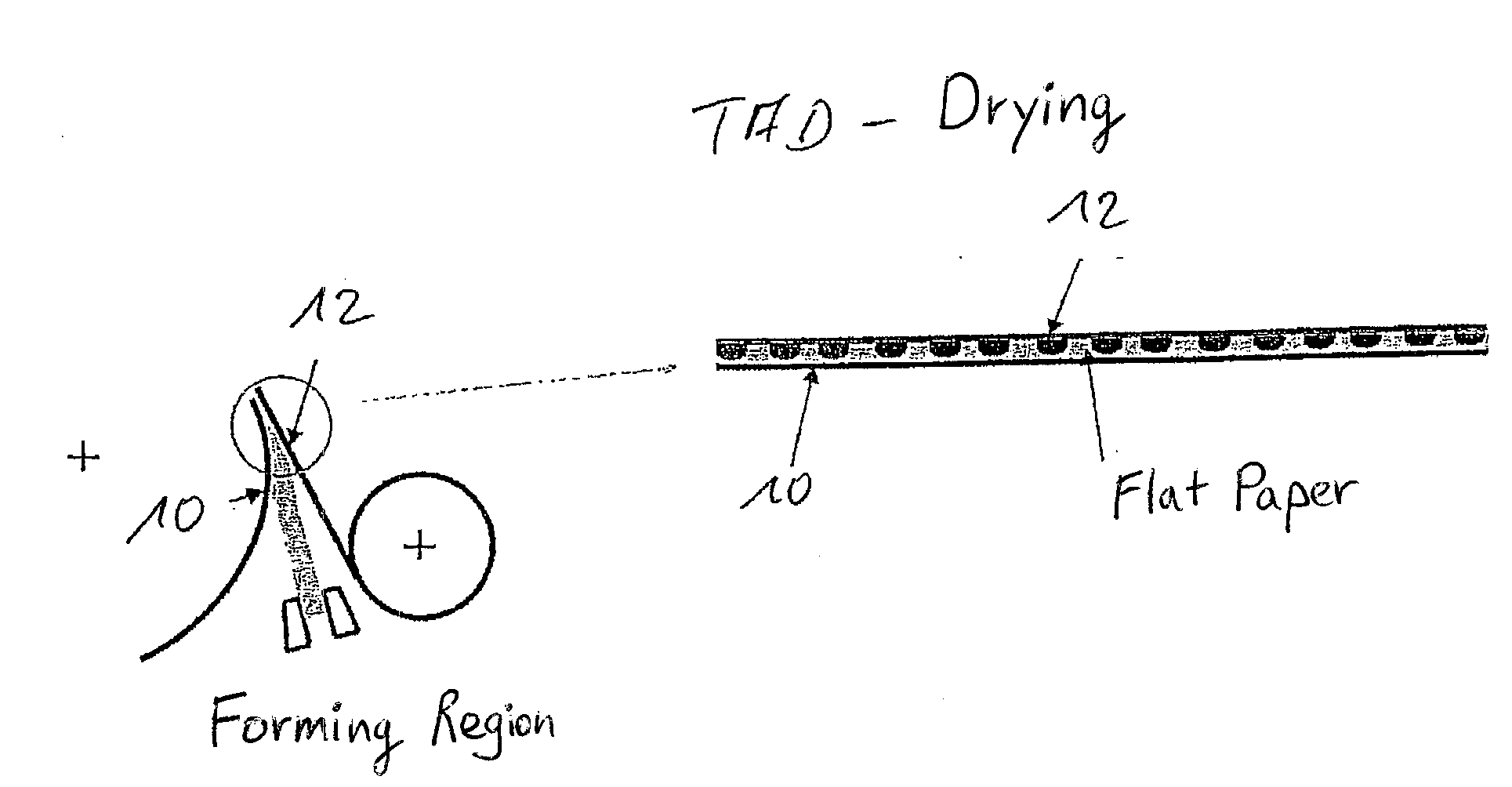

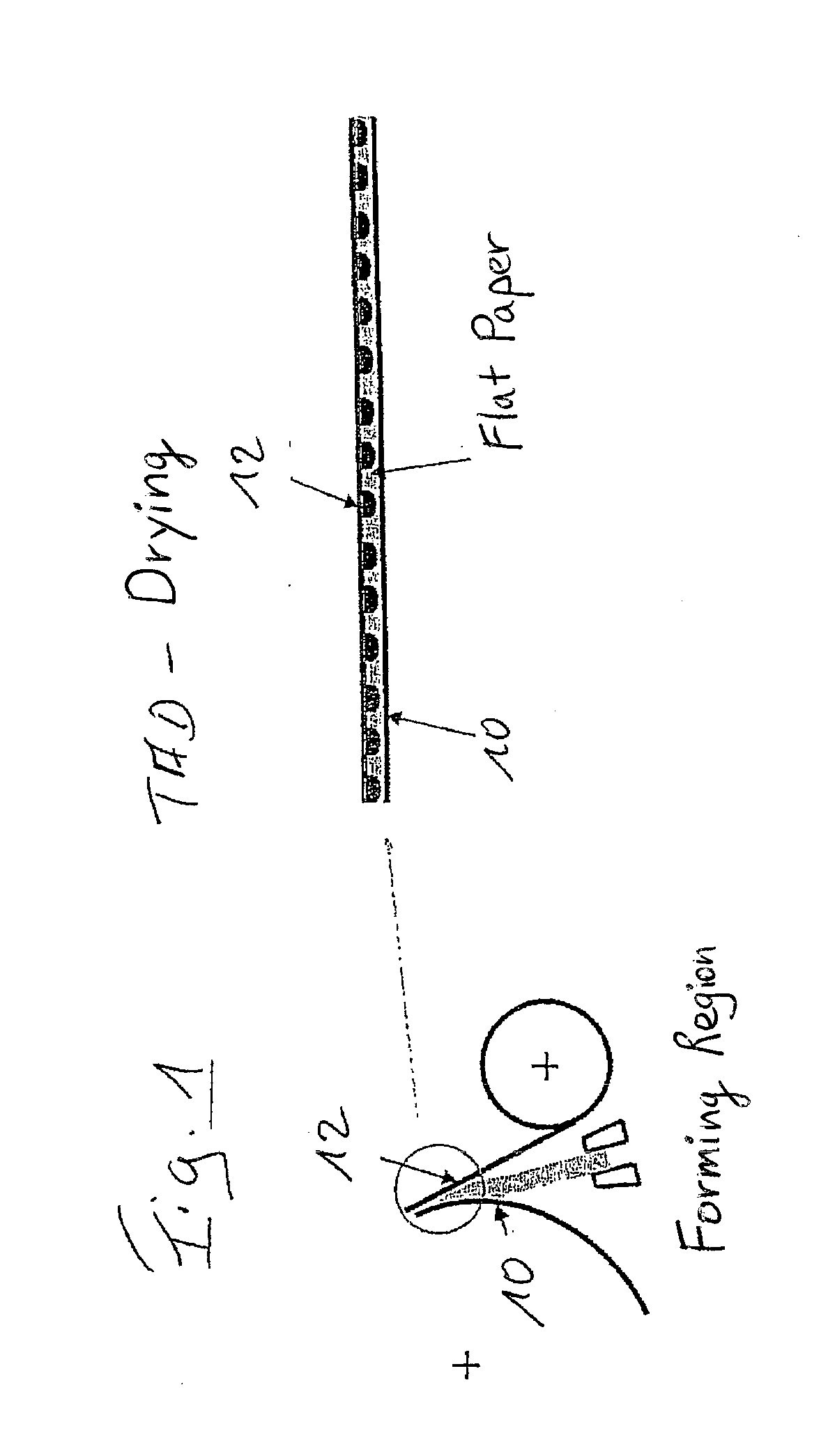

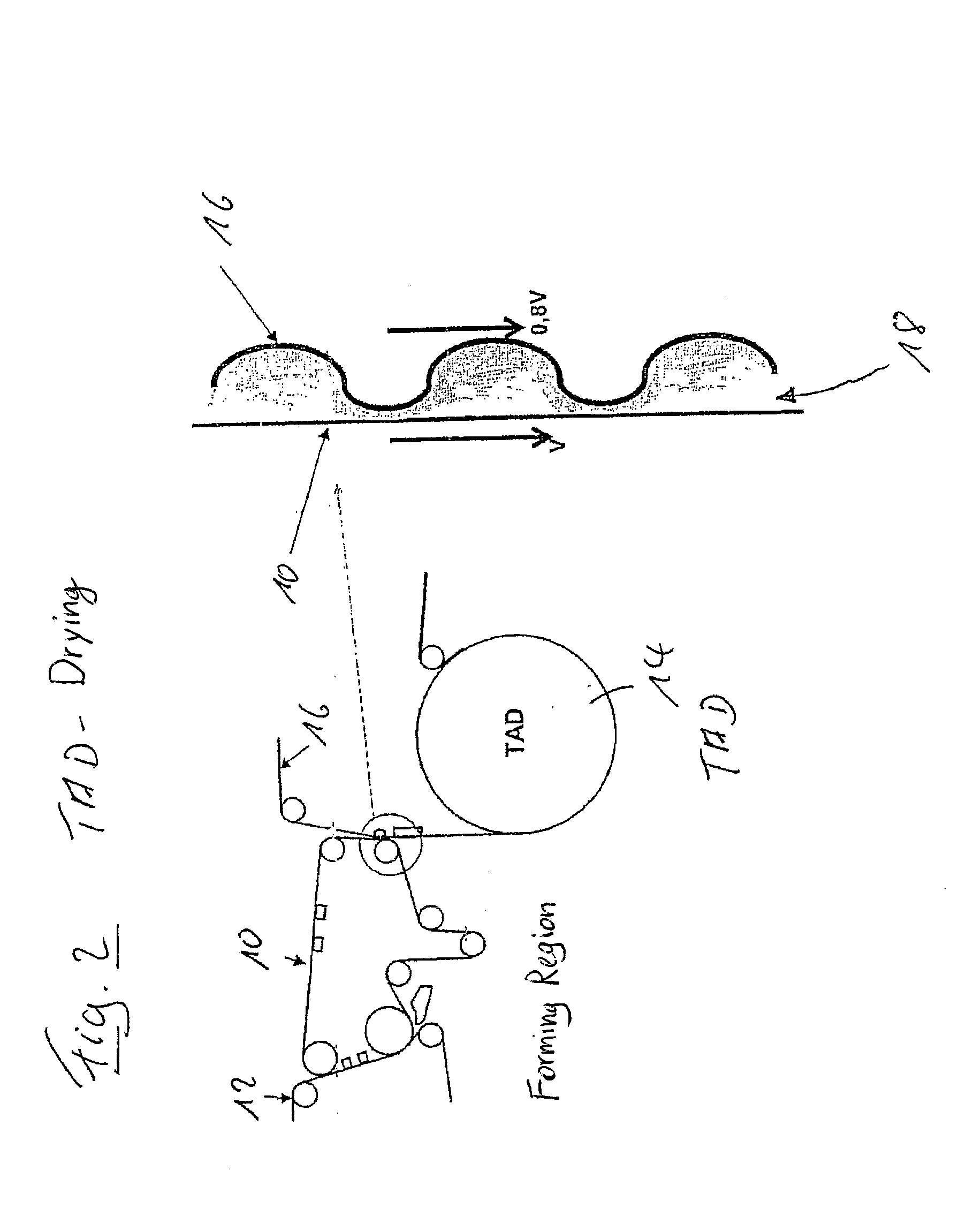

ActiveUS20070251659A1Increase the opening areaLong dwell timePaper/cardboardMachine wet endPaper machine

A forming fabric for an ATMOS system or a TAD machine. The forming fabric includes a permeability value of between approximately 100 cfm and approximately 1200 cfm, a paper surface contact area of between approximately 0.5% and approximately 90% when not under pressure and tension, and an open area of between approximately 1.0% and approximately 90%. A belt press for a paper machine can utilize the forming fabric. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

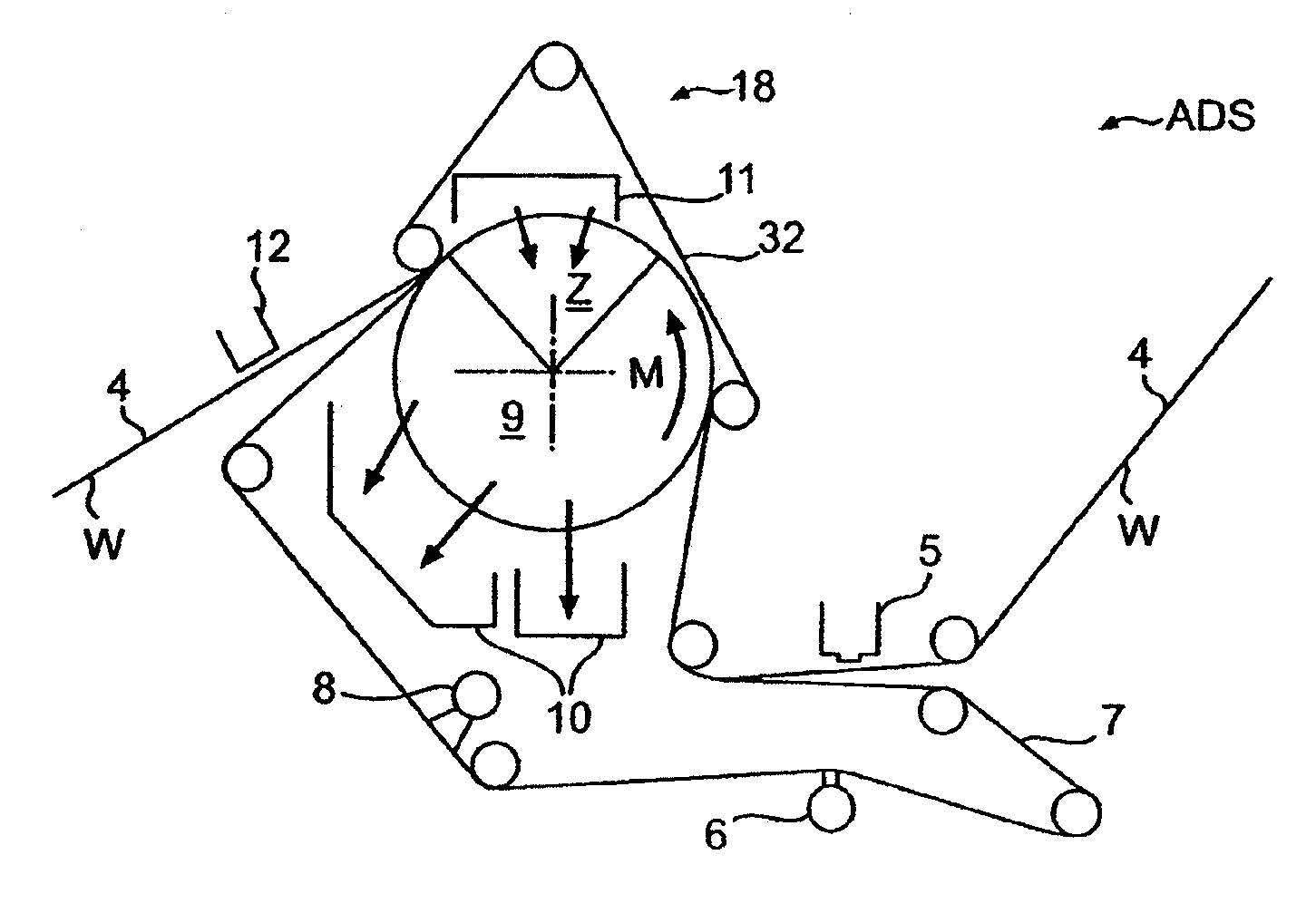

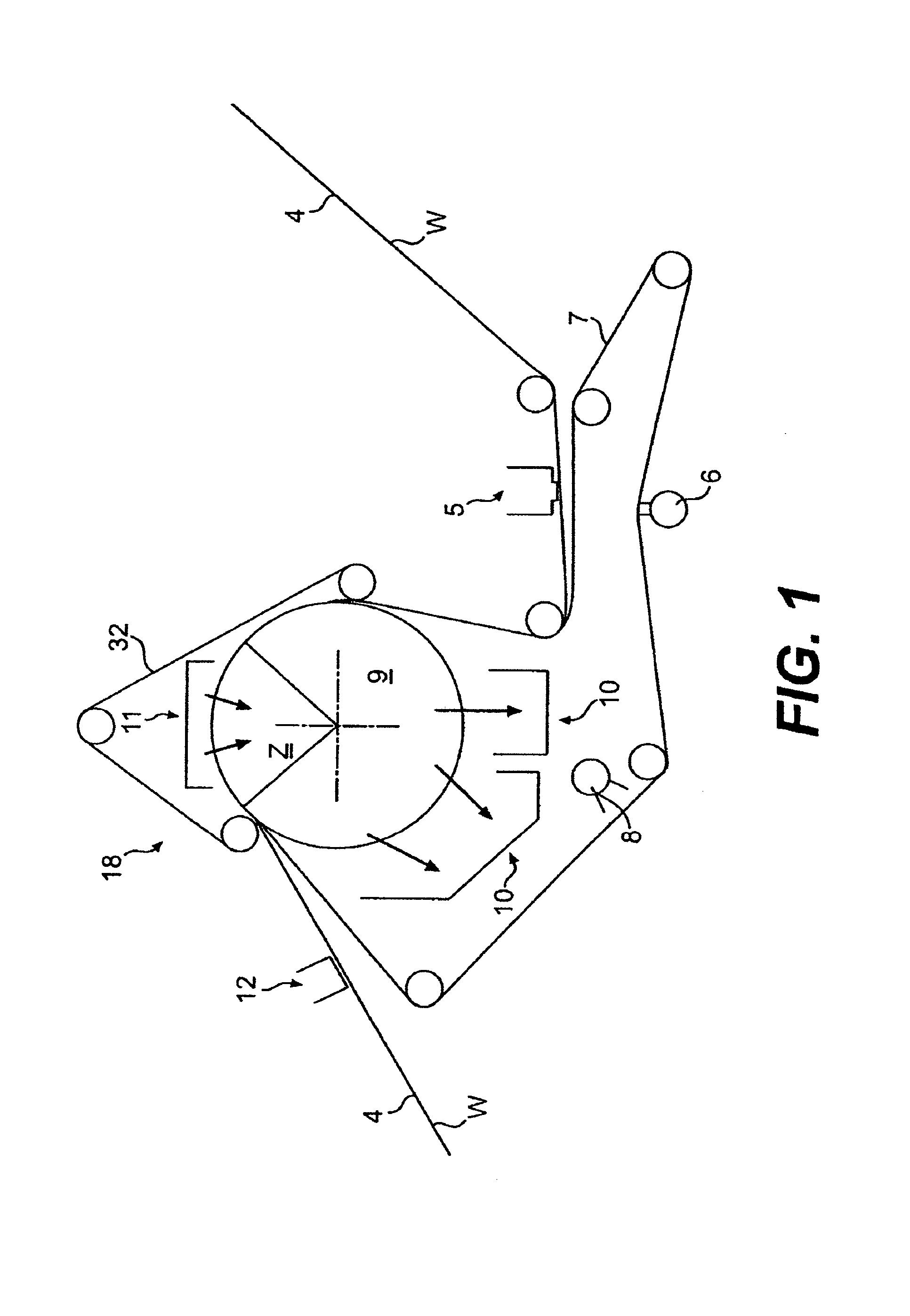

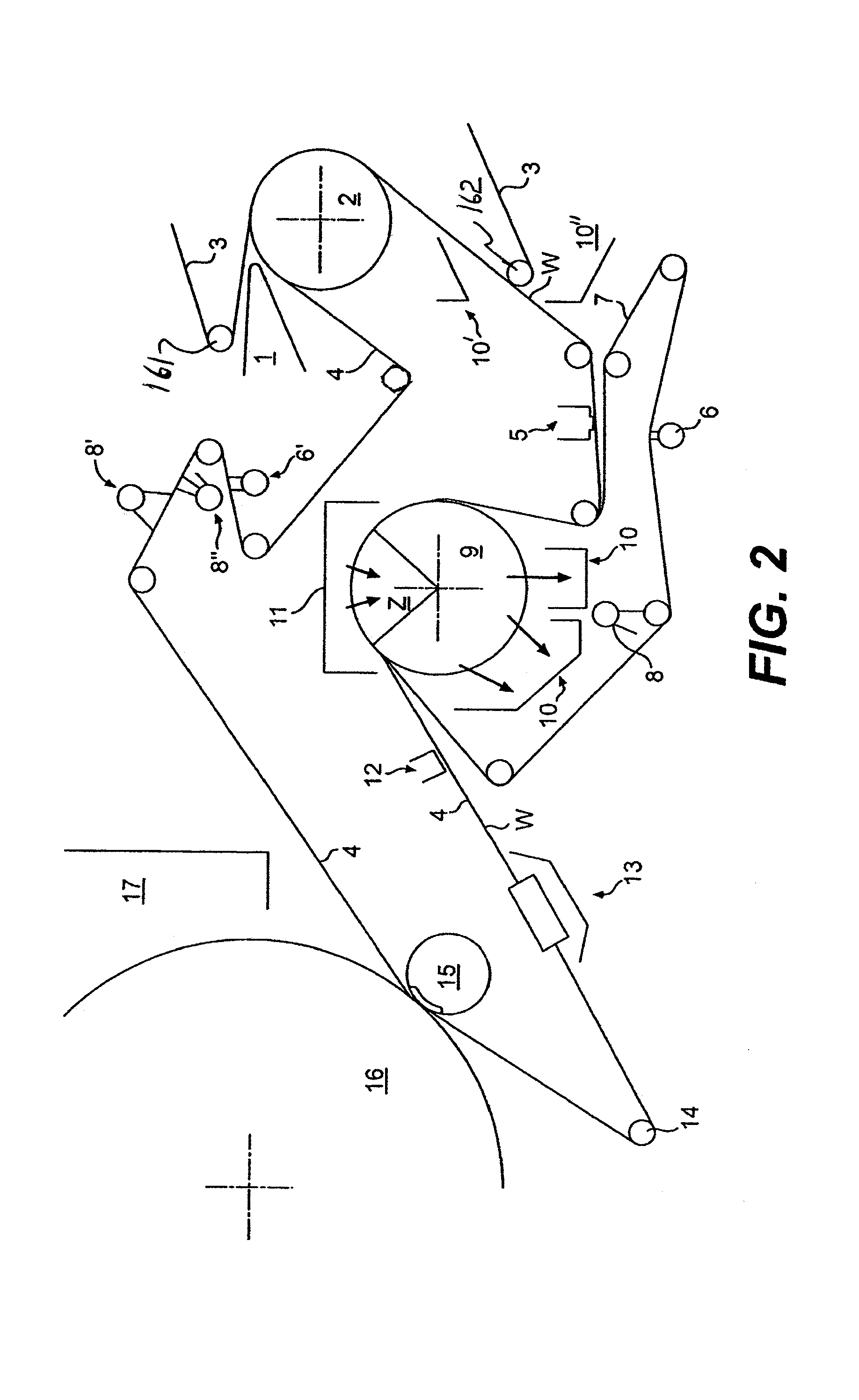

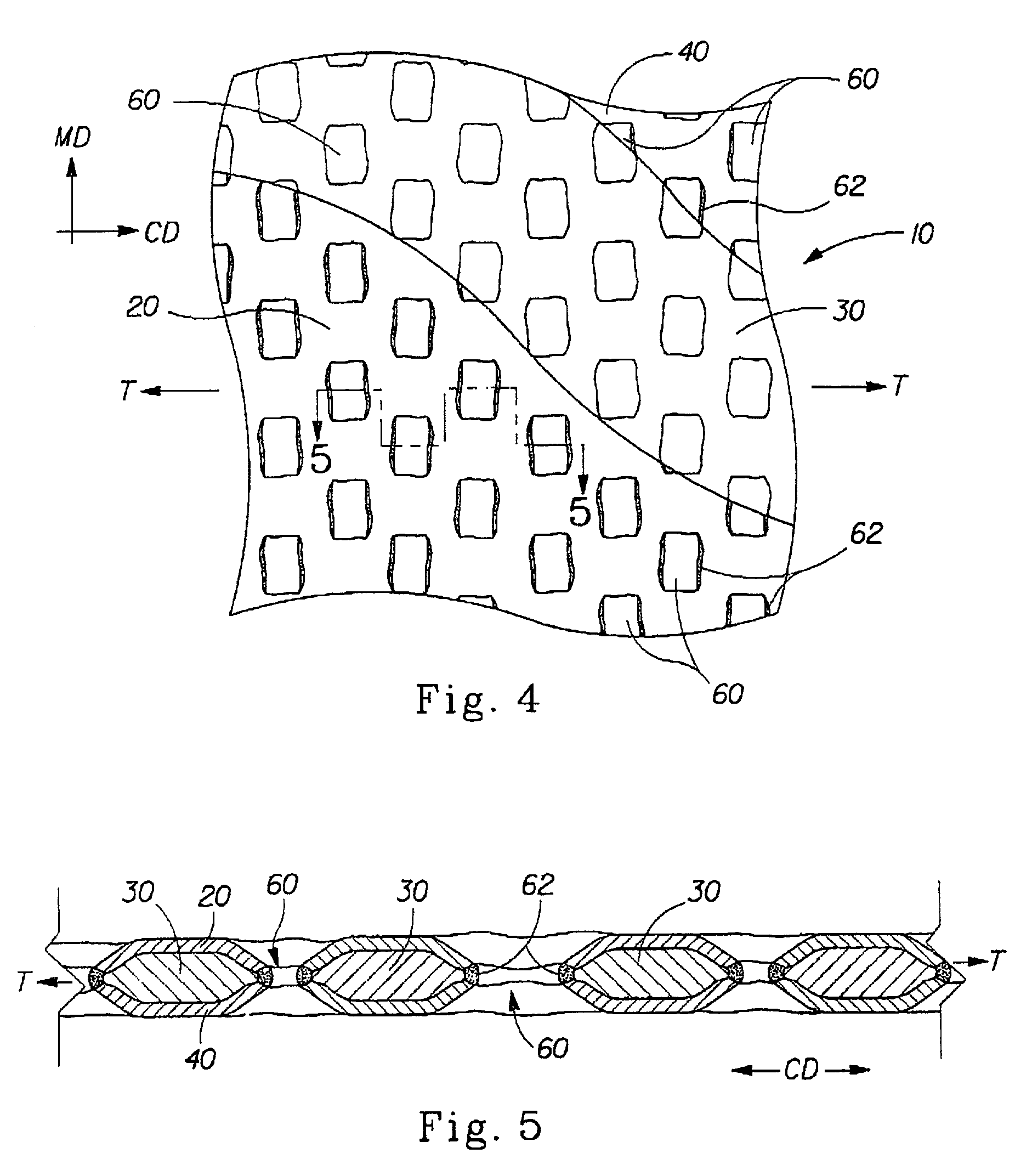

Advanced dewatering system

ActiveUS7510631B2Large tensionIncrease the opening areaDrying solid materials with heatDryer sectionFacial tissueHygiene

System for drying a tissue or hygiene web. The system includes a permeable structured fabric carrying the web over a drying apparatus. A permeable dewatering fabric contacts the web and is guided over the drying apparatus. A mechanism is utilized for applying pressure to the permeable structured fabric, the web, and the permeable dewatering fabric at the drying apparatus. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

Seat climate control system

A method for thermally conditioning a space adjacent a seat assembly includes activating a heating element positioned within the seat assembly beneath a seat covering. A fluid module that includes a fluid supply device and a thermoelectric element is activated to direct heated air from the fluid module to a space adjacent the seat assembly through a distribution system formed at least partially in the seat cushion. After a period of time, the heating element is deactivated.

Owner:GENTHERM INC

Drum washing machine and clothes dryer using peltier thermoelectric module

InactiveUS7526879B2Drying efficiencyDrying energyAgriculture tools and machinesDrying gas arrangementsPower flowEngineering

A drum washing machine and a clothes dryer equipped with a thermoelectric module are disclosed. The thermoelectric module includes a heat absorption side and a heat dissipation side which absorbs and dissipates heat at a junction between two dissimilar metals depending on direction of current flow through the junction. The heat absorption side is disposed at a hot air flowing passage. Accordingly, the drying apparatus can increase energy efficiency with minor structural modification and becomes environmentally friendly unlike a conventional drying apparatus using a heat pump.

Owner:LG ELECTRONICS INC

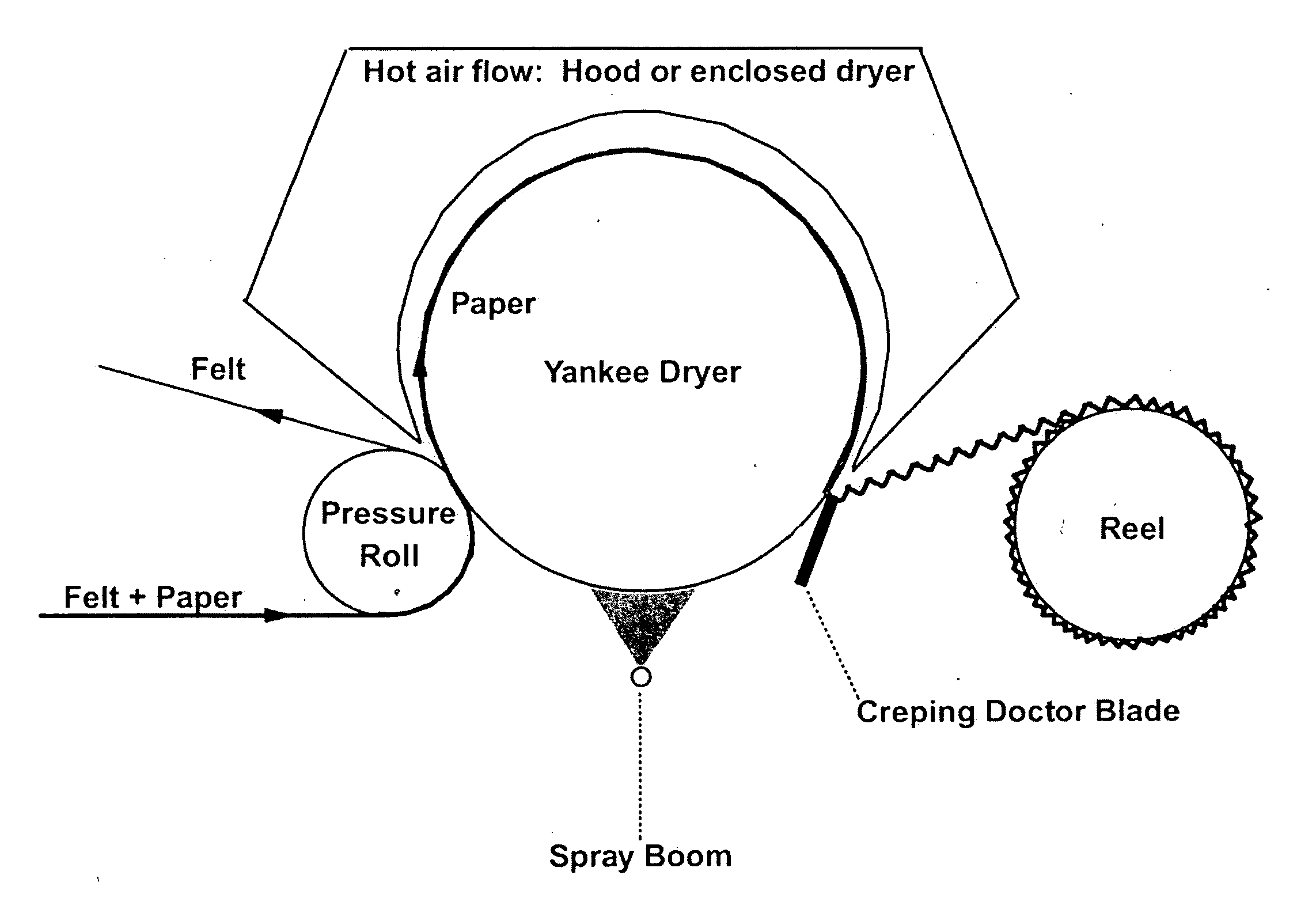

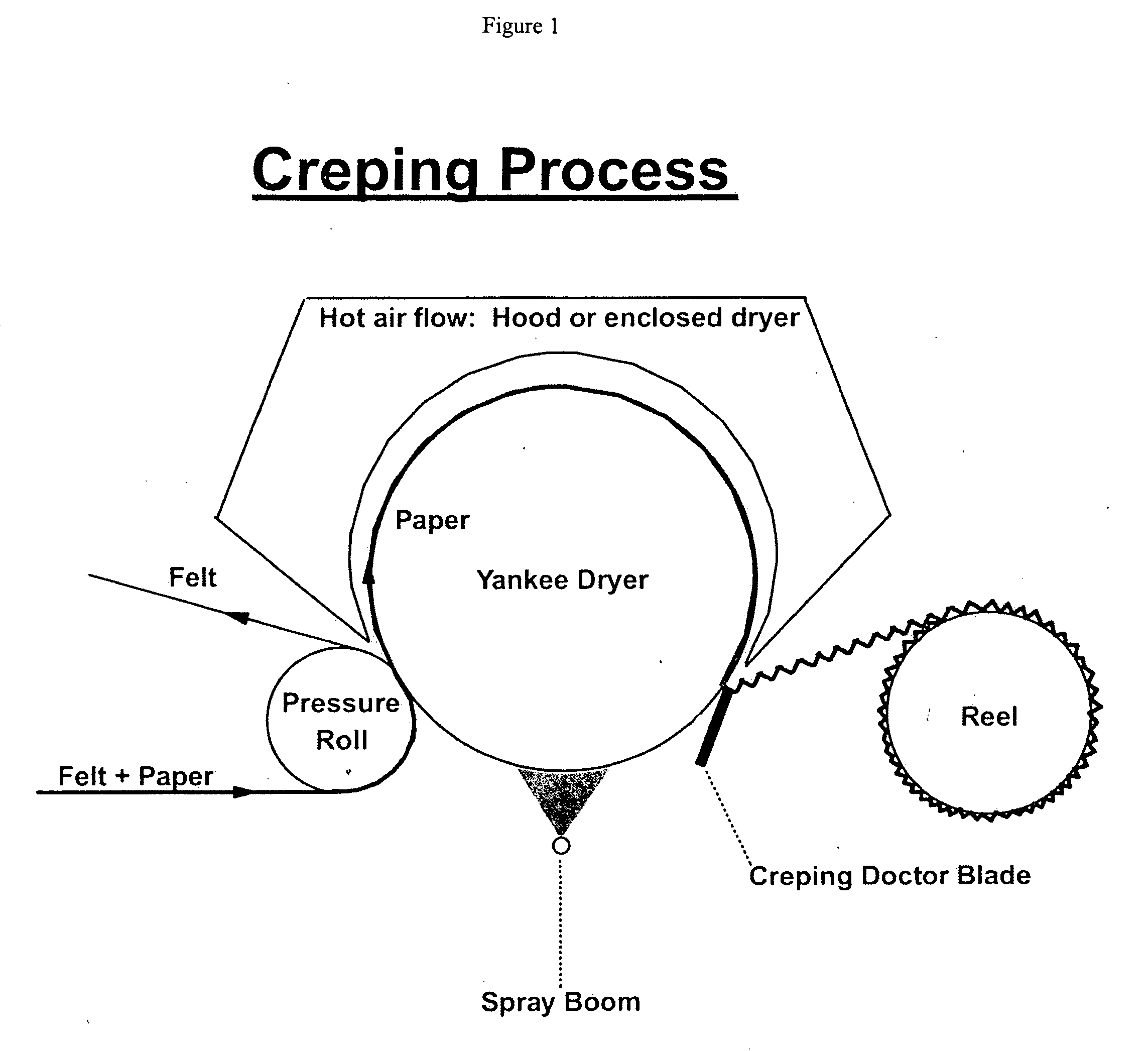

Modified creping adhesive composition and method of use thereof

ActiveUS20050245669A1Soften and plasticizeSoften and/or plasticize the creping adhesiveNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industry

A modified creping adhesive composition, comprising an adhesive component and at least one terpene modifier, and its use in the production of creped paper products by a process which includes the steps of adhering a paper web to the surface of a drying cylinder and separating the paper web from the drying cylinder with a creping blade.

Owner:GPCP IP HLDG LLC

Fold-resistant cleaning sheet

InactiveUS7423003B2Reduce and inhibit liquid transferResisting foldingDry-cleaning apparatus for textilesDetergent compounding agentsEngineeringPleat

The present invention relates to cleaning sheets that resist folding, especially refolding upon themselves even after an initial fold has been formed in the sheet.

Owner:THE PROCTER & GAMBLE COMPANY

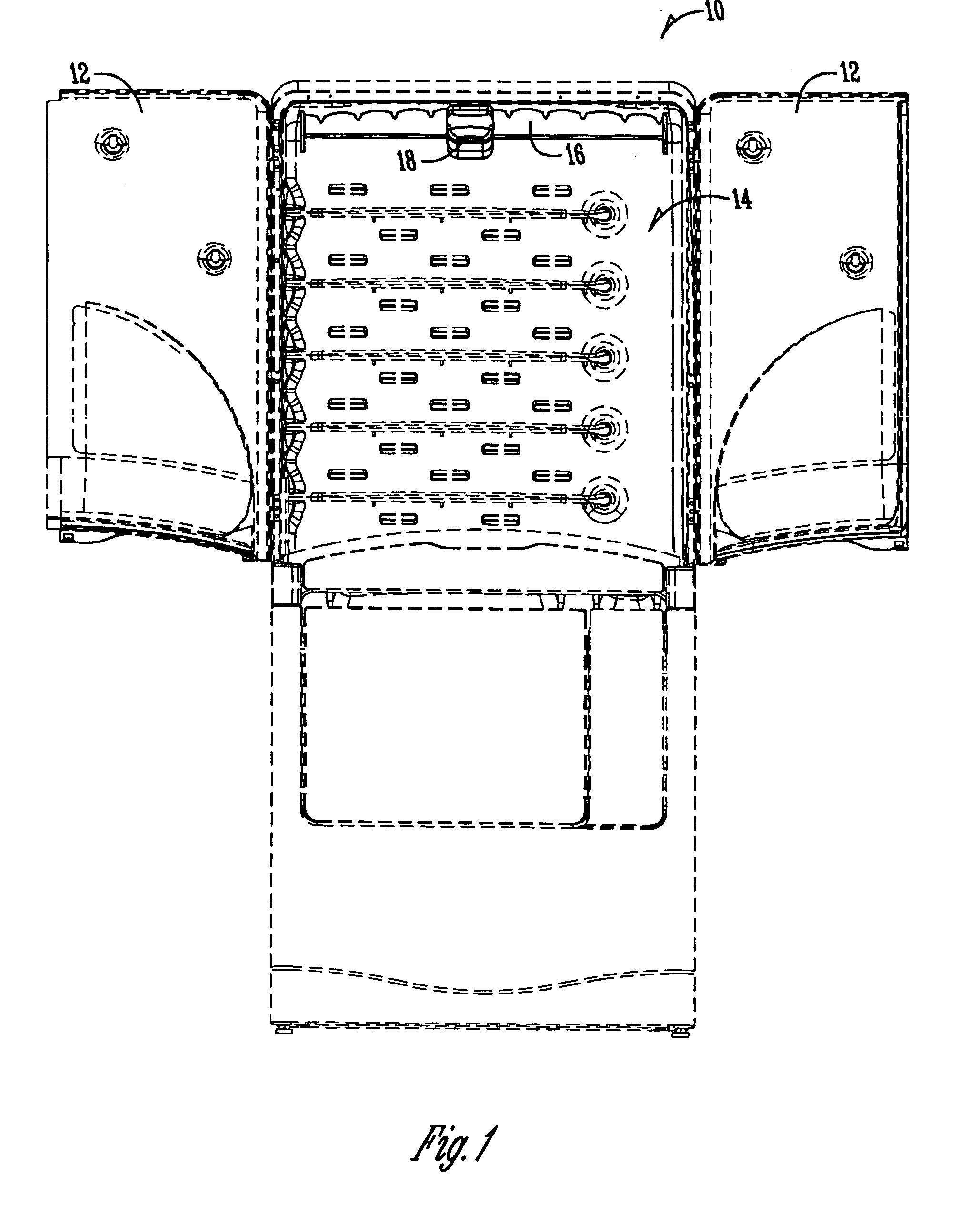

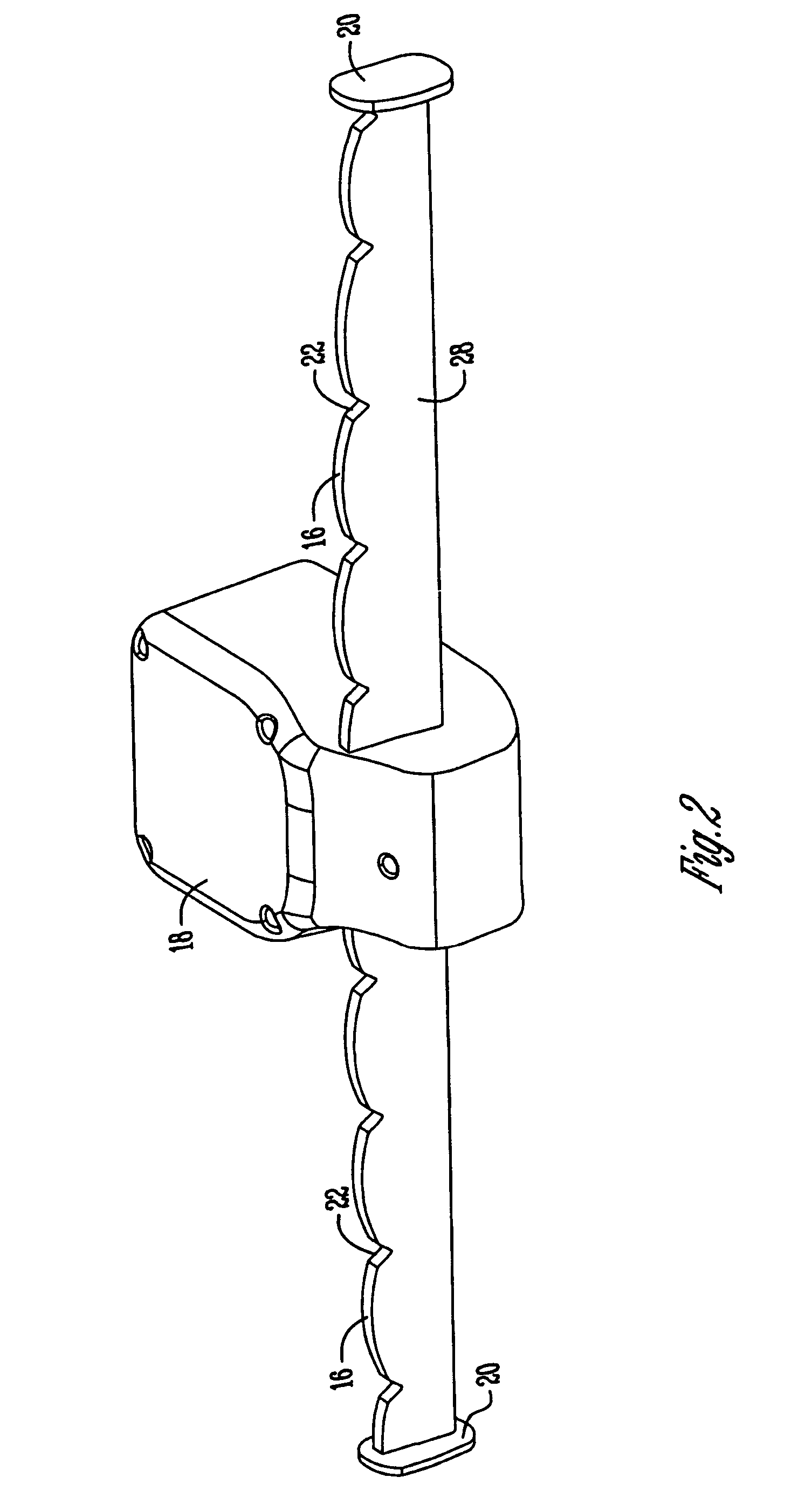

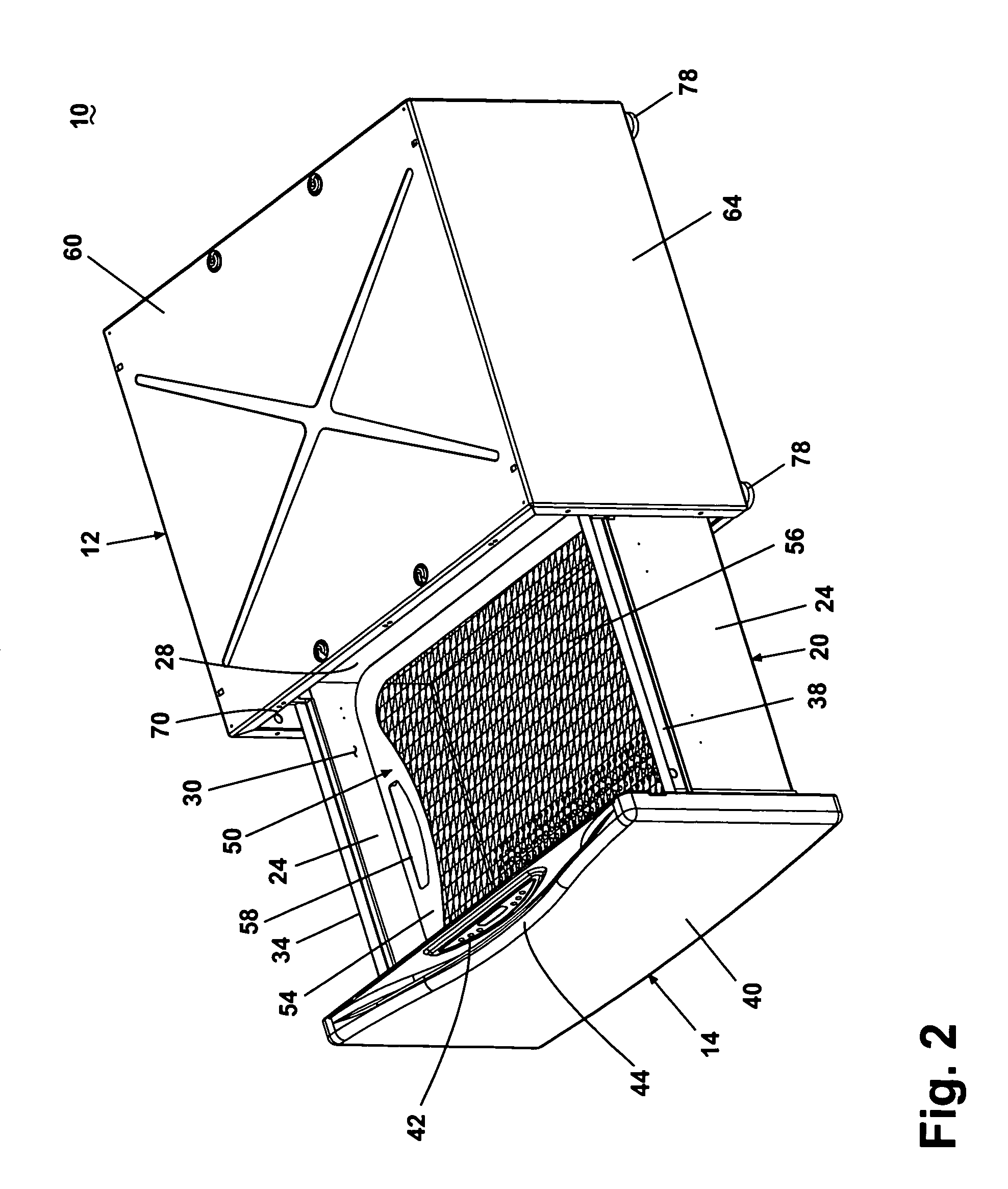

Hanger rod for drying cabinet

InactiveUS20050035076A1Prevent rotationImprove drying efficiencyAgriculture tools and machinesDrying chambers/containersMechanical engineeringClothes hanger

A hanger rod is provided for a clothes drying cabinet. The rod includes a plurality of notches, each adapted to receive a hanger. Each notch is V-shaped, with opposite side walls which converge downwardly to a substantially pointed apex. The rod has front and rear walls defining a thickness ranging between 30%-75% of the hanger hook diameter. The notches provide four contact points on the hanger hook to prevent rotation of the hanger hook on the rod during the drying process.

Owner:MAYTAG

Dewatering tissue press fabric for an atmos system and press section of a paper machine using the dewatering fabric

A dewatering fabric for an ATMOS system or a TAD machine that includes a caliper of between approximately 0.1 mm and approximately 15 mm, a permeability value of between approximately 1 cfm and approximately 500 cfm, an overall density of between approximately 0.2 g / cm3 and approximately 1.10 g / cm3, and a weight of between approximately 100 g / m2 and approximately 3000 g / m2. A belt press for a paper machine can utilize the dewatering fabric. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in anyway.

Owner:VOITH PATENT GMBH

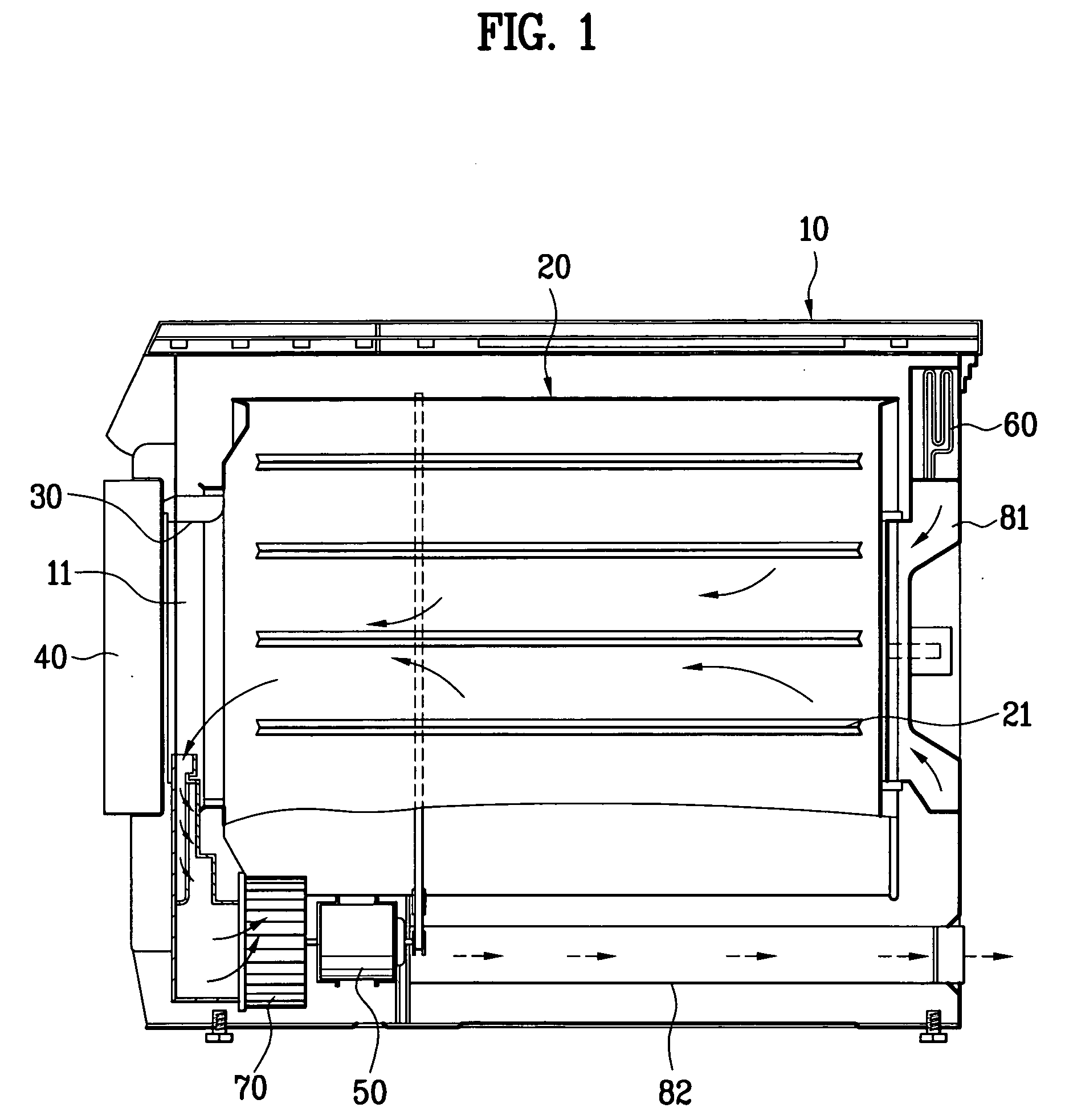

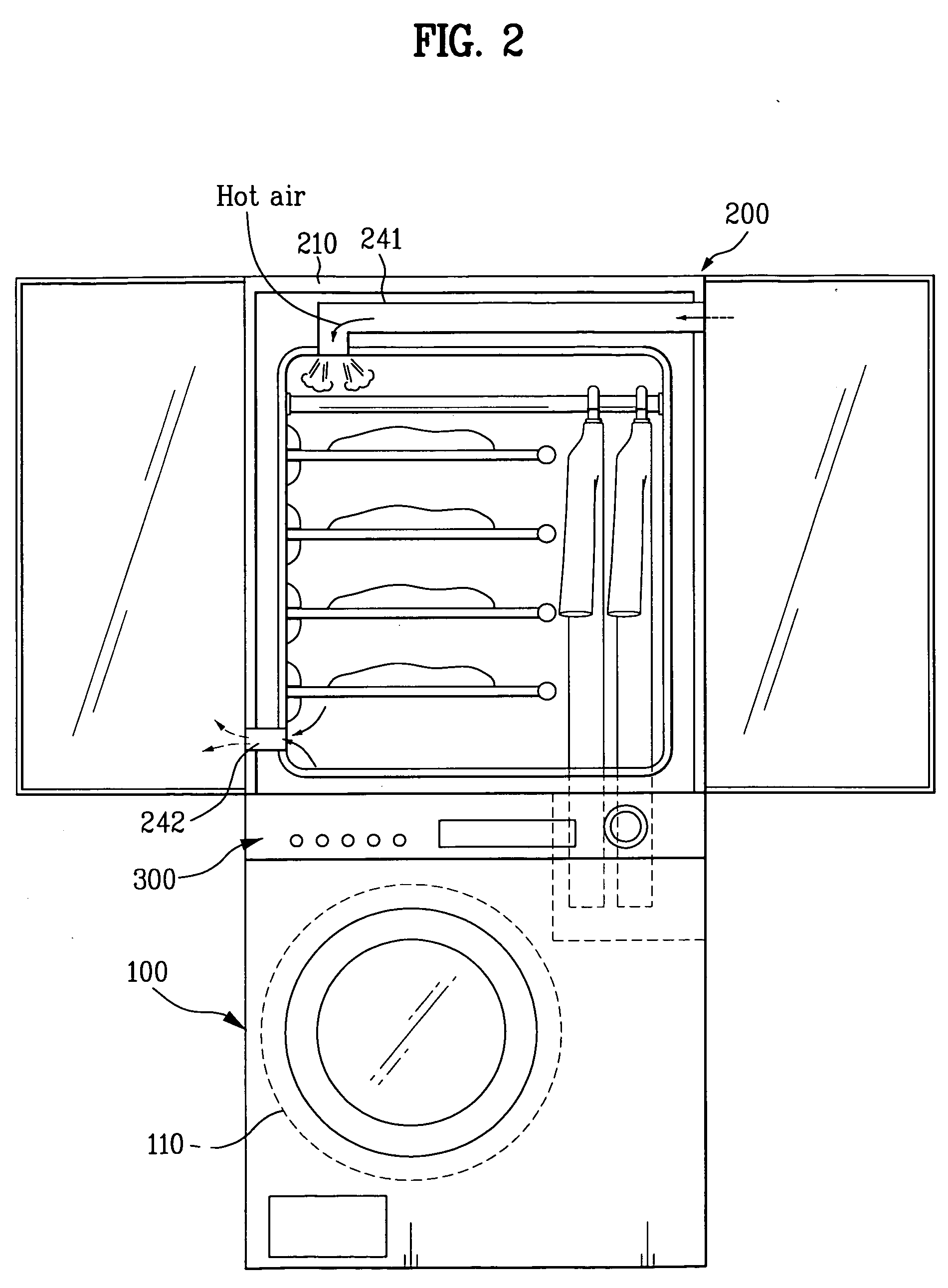

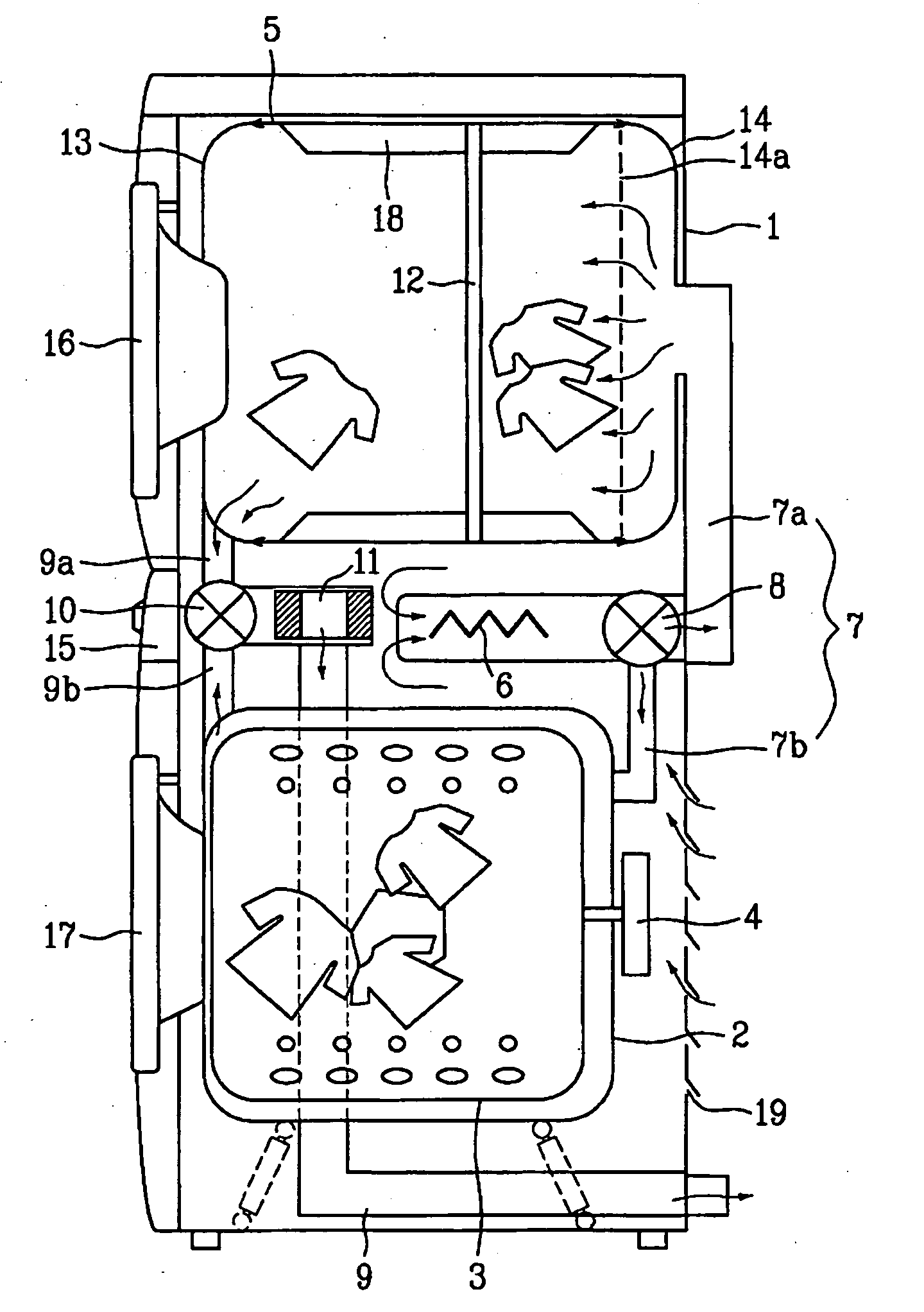

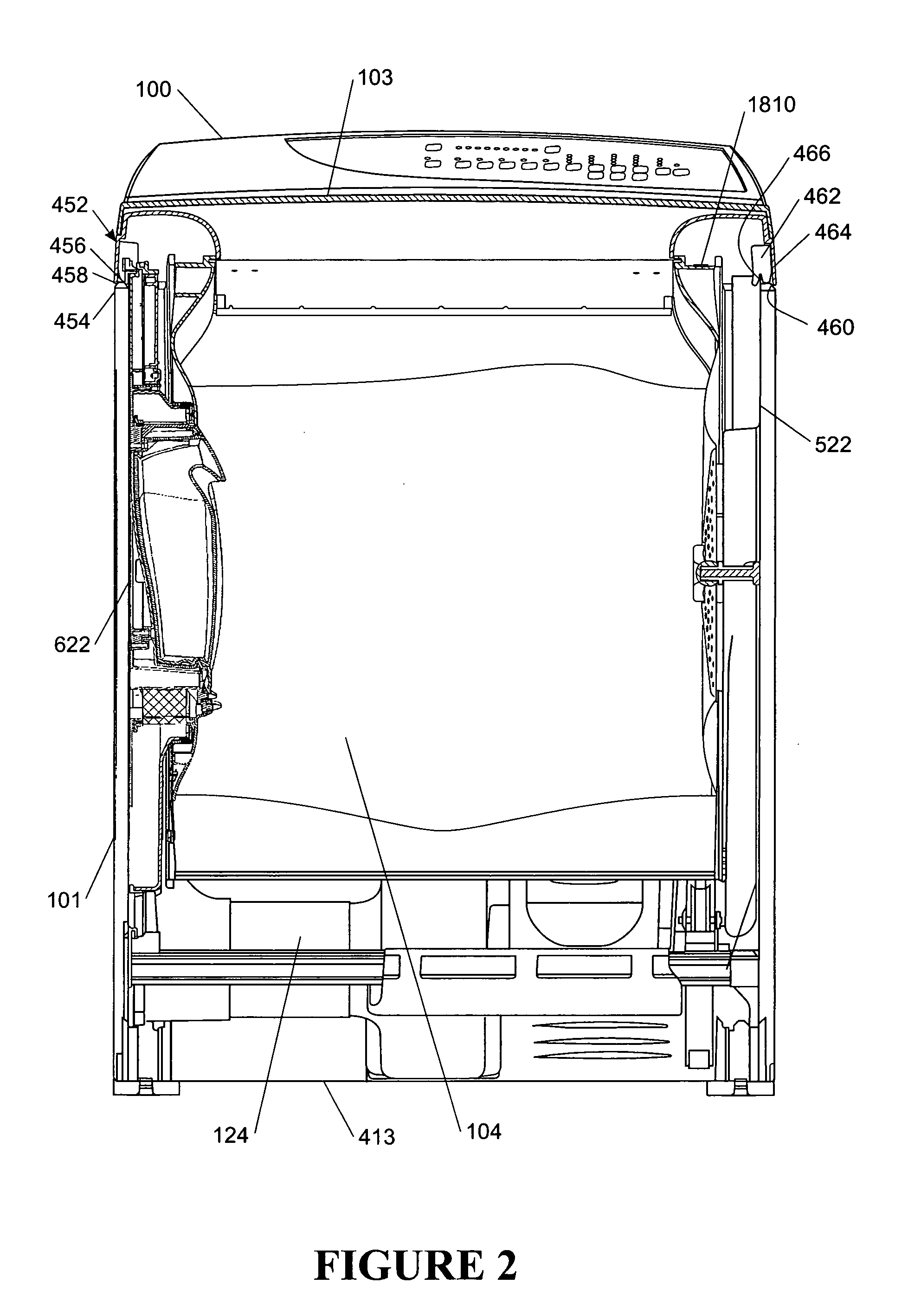

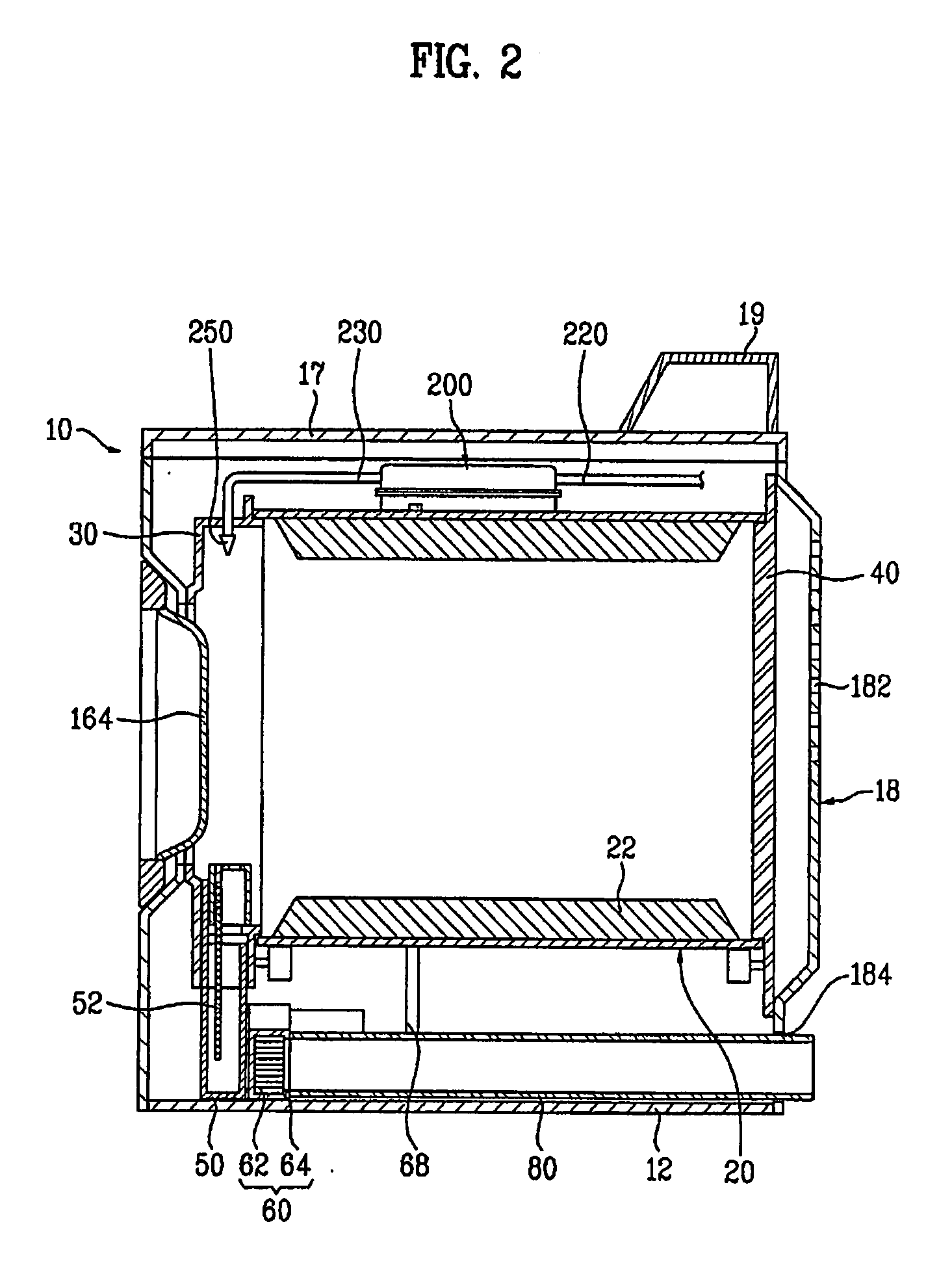

Single body washing machine and dryer device and a method for controlling the same

InactiveUS20070119072A1Other washing machinesDrying machines with non-progressive movementsEngineeringMechanical engineering

The present invention relates to a single body washing machine and dryer device, and more particularly, to a washing machine component and dryer component which are fabricated as a single body to enable the combination washing machine component and the dryer component to perform drying functions using a single heater that is shared between the two components. The single body washing machine and dryer device includes a cabinet for forming an inside space, a tub on one side of the inside space of the cabinet, a washing and drying combination drum rotatably mounted in the tub, a drying drum rotatably mounted on the other side of the inside space of the cabinet, and a heater for supplying hot air to the drying drum or the washing and drying combination drum selectively, or at the same time.

Owner:LG ELECTRONICS INC

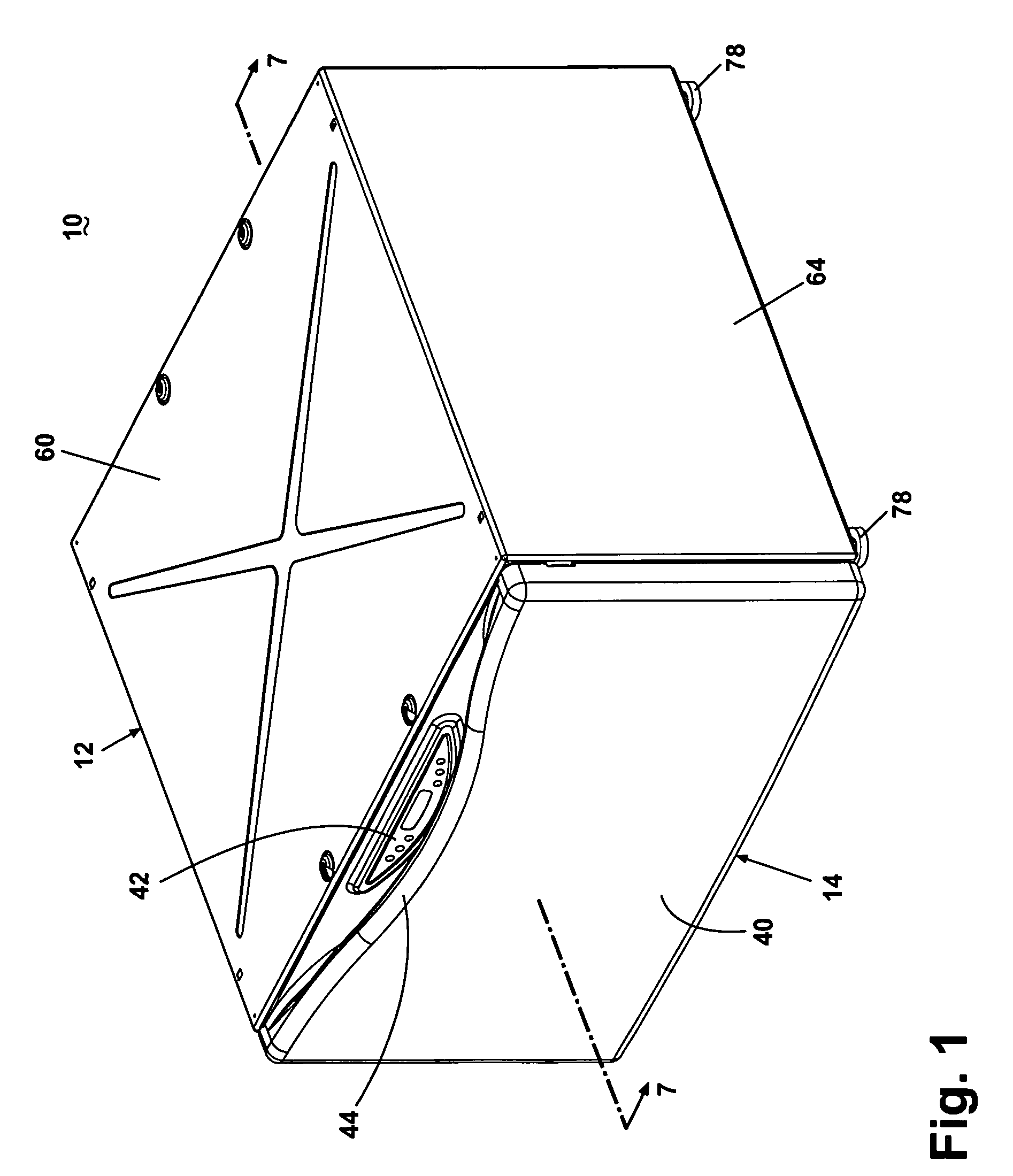

Laundry appliance

A drum hatch engaging mechanism is for inclusion in a laundry appliance having a cabinet and a drum rotatable within the cabinet. The mechanism includes a drum hatch engaging member connected with the cabinet with the connection providing for movement of the member between non-engagement and engagement positions. An actuator is provided to selectively move the drum hatch engaging member between the positions. A catch member is connected with a sliding hatch of the drum. The connection between the catch member and the sliding hatch provides for movement of the catch member between a position adjacent the skin of the drum and an outwardly displaced position. The drum hatch engaging member includes a ramped abutment to engage and lift the catch member to the outer position through movement of the catch member toward the abutment during an opening rotation of the drum. The hatch engaging member includes a closing abutment facing the ramped abutment. The closing abutment butts against the catch member during a closing rotation of the drum. There is a catch member support surface on the drum which tracks the circumference of the drum skin at a level to cooperate with the drum hatch engaging member. The support surface and the drum hatch engaging member cooperate to entrap the catch member in the outward position during opening and closing rotations of the drum.With a single actuator the mechanism can reliably open and close the drum without stopping the drum to engage and / or disengage from the drum hatch.

Owner:FISHER & PAYKEL APPLIANCES LTD

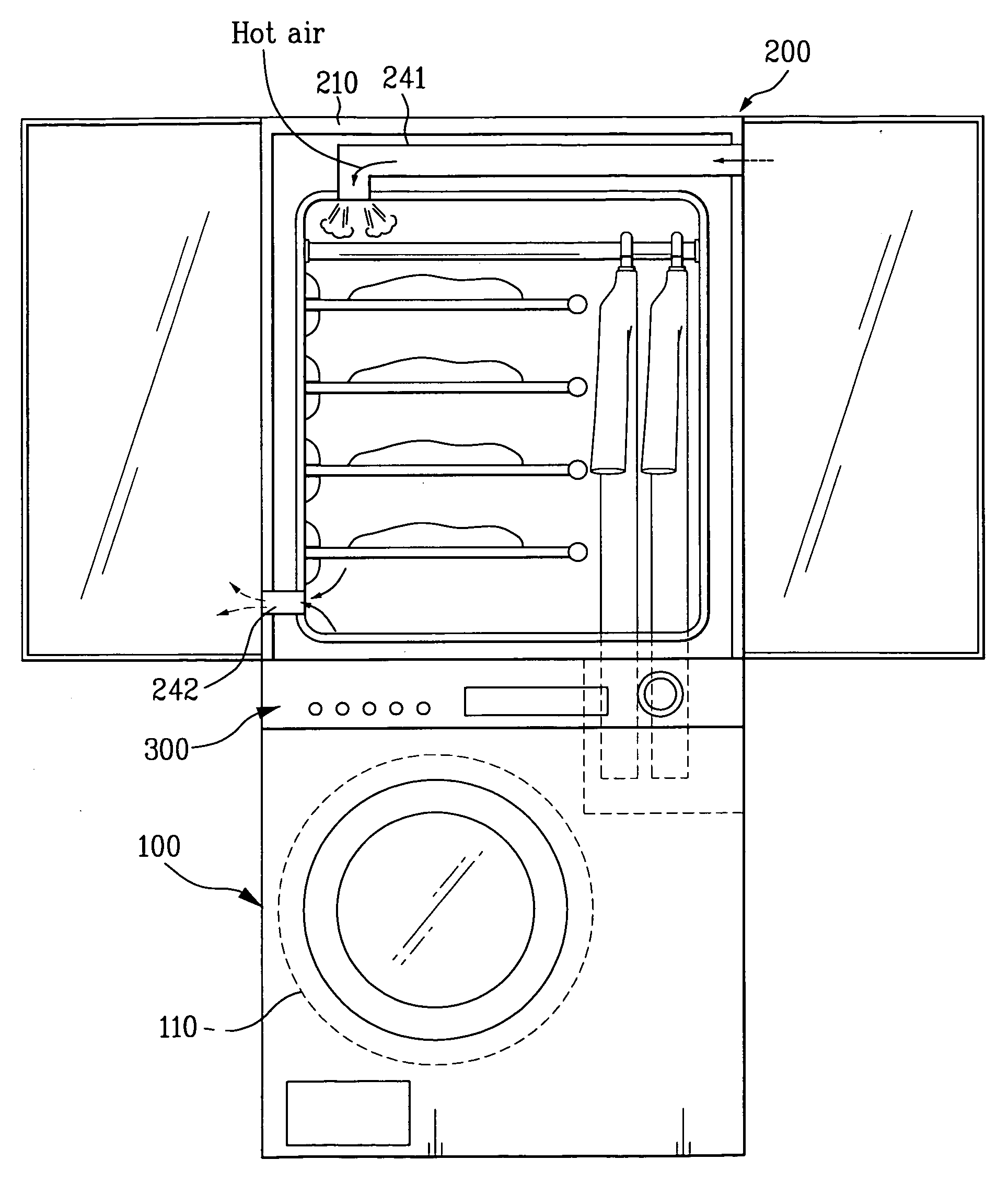

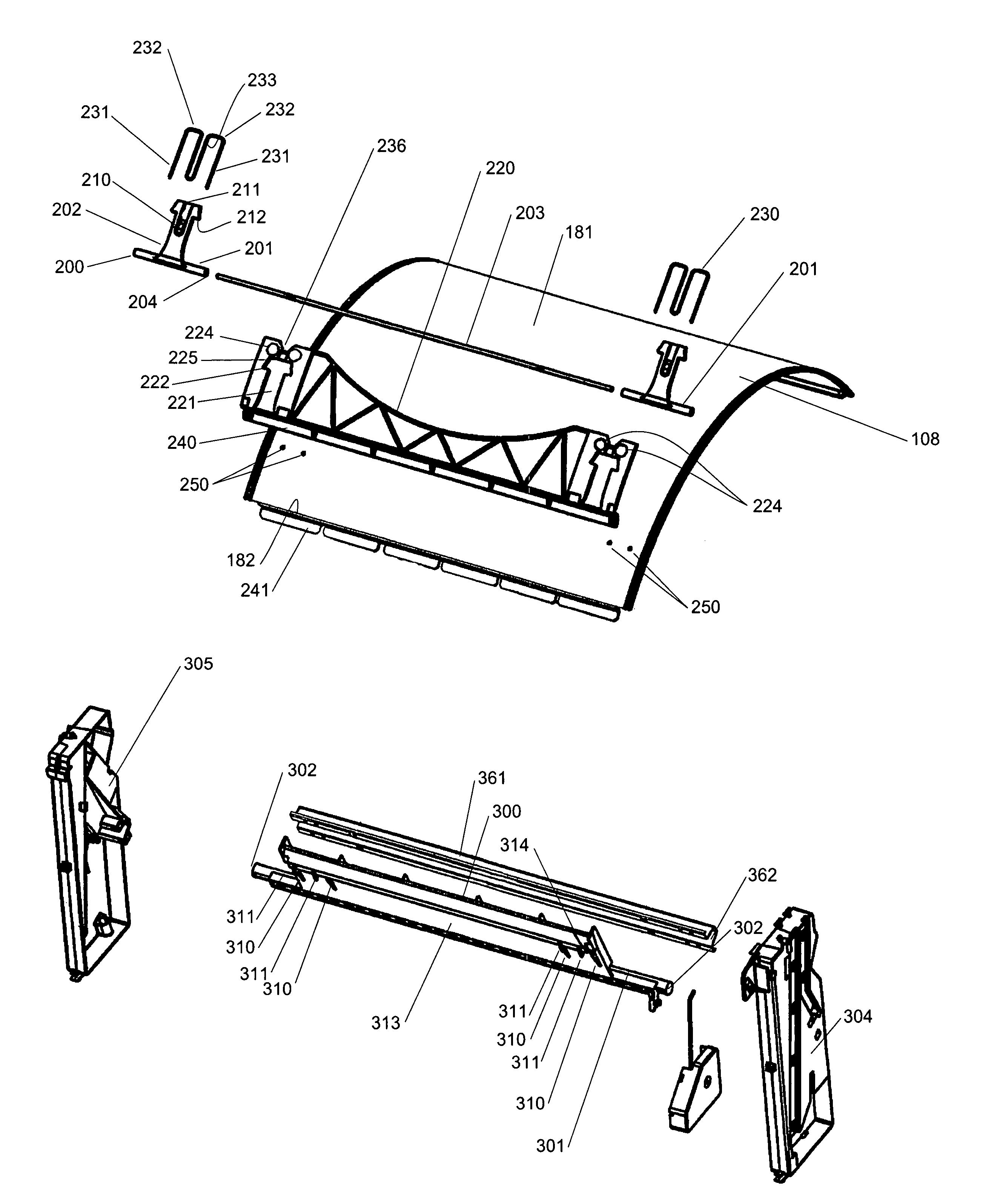

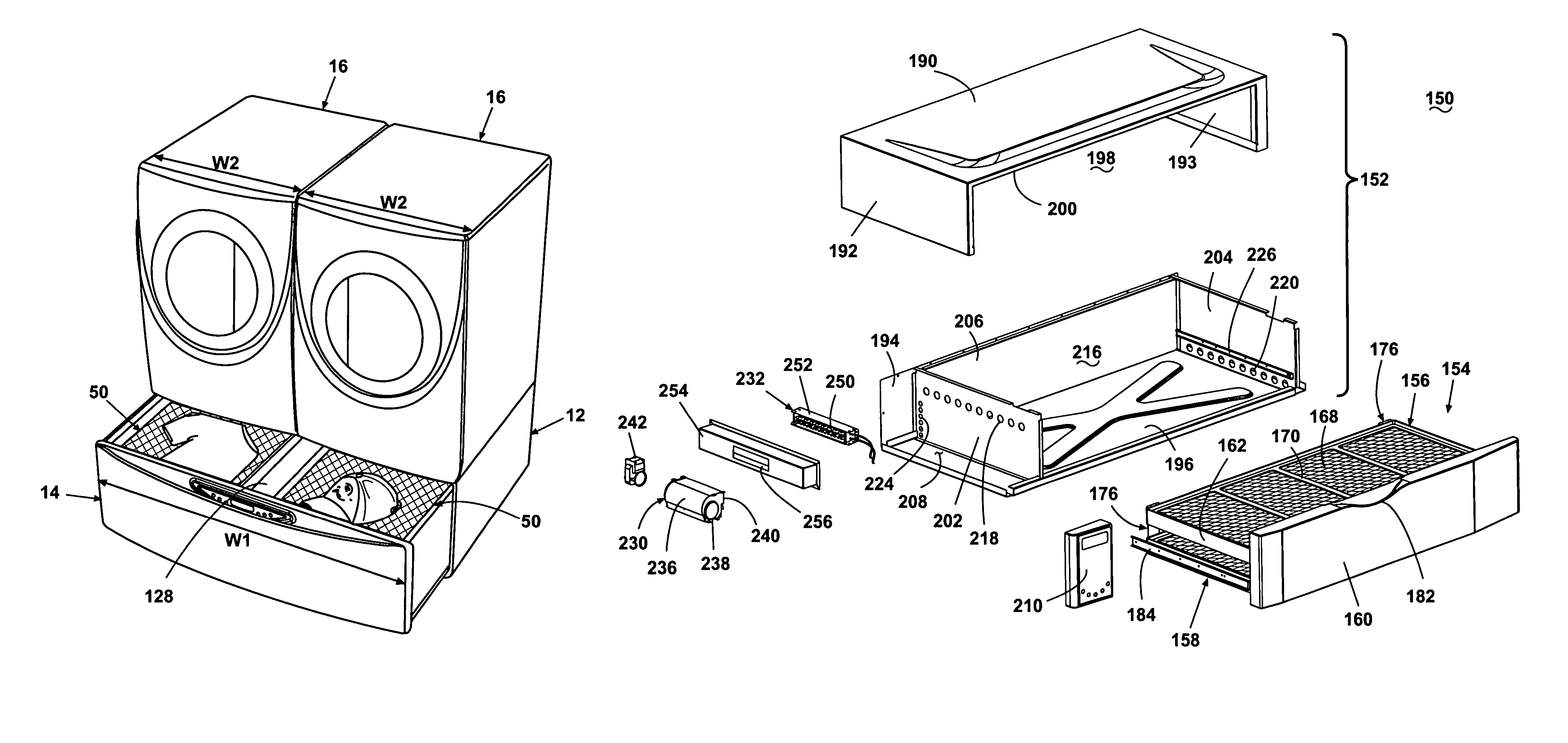

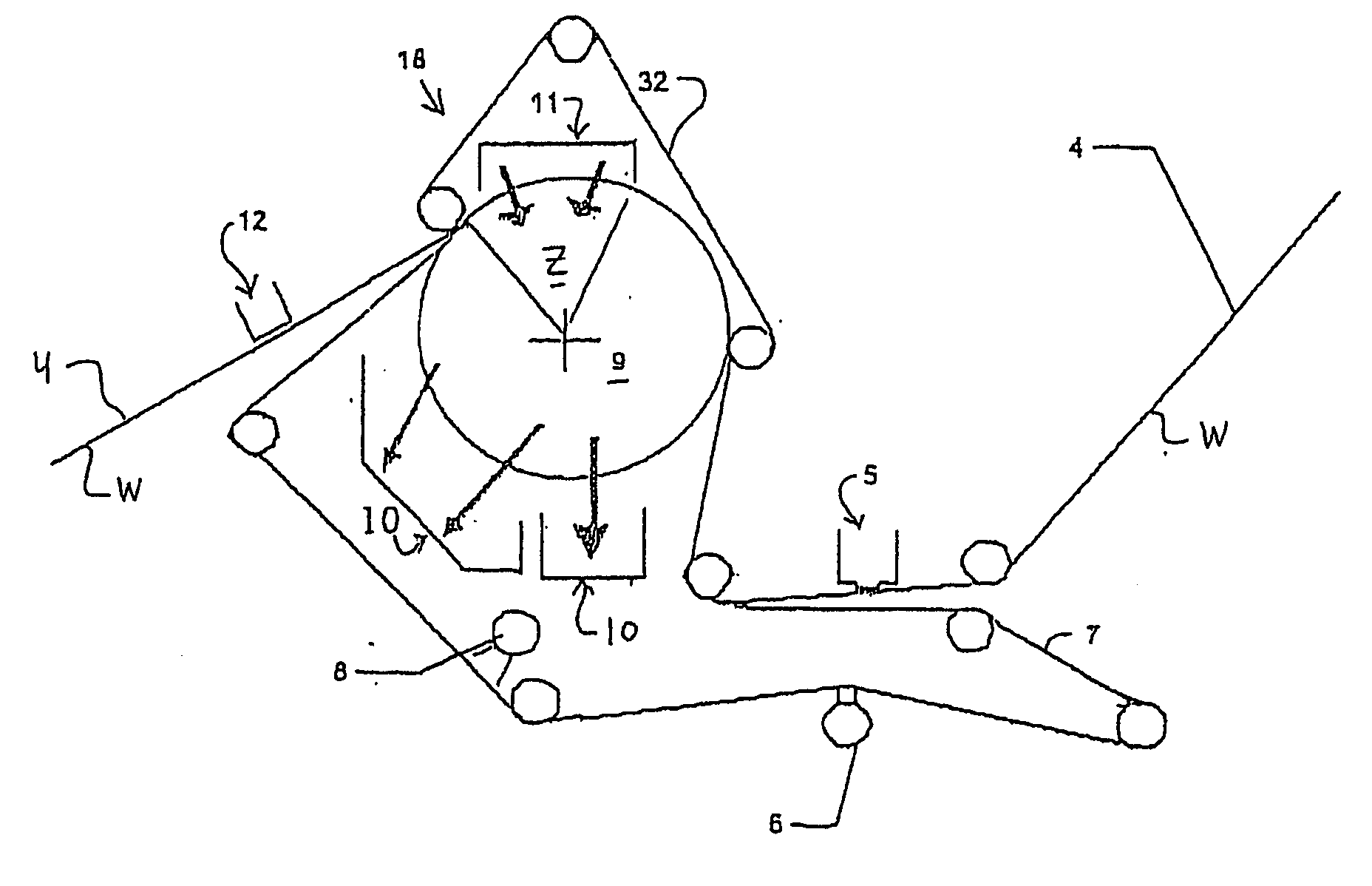

Non-tumble clothes dryer

A non-tumble dryer comprises a cabinet and a drawer configured to support an article to be dried and slidably mounted to the cabinet. An air supply system provides air to a drying chamber formed at least partially by one of the cabinet and the drawer for drying the article supported by the drawer. The non-tumble dryer can function as a pedestal whereby the top of the cabinet can be configured to support a laundry appliance in an elevated position. Alternatively, the cabinet can overlie one or more laundry appliances.

Owner:WHIRLPOOL CORP

Advanced dewatering system

ActiveUS20060085999A1Substantial airflowLarge tensionDrying solid materials with heatDryer sectionHygieneWaste management

System for drying a tissue or hygiene web. The system includes a permeable structured fabric carrying the web over a drying apparatus. A permeable dewatering fabric contacts the web and is guided over the drying apparatus. A mechanism is utilized for applying pressure to the permeable structured fabric, the web, and the permeable dewatering fabric at the drying apparatus. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

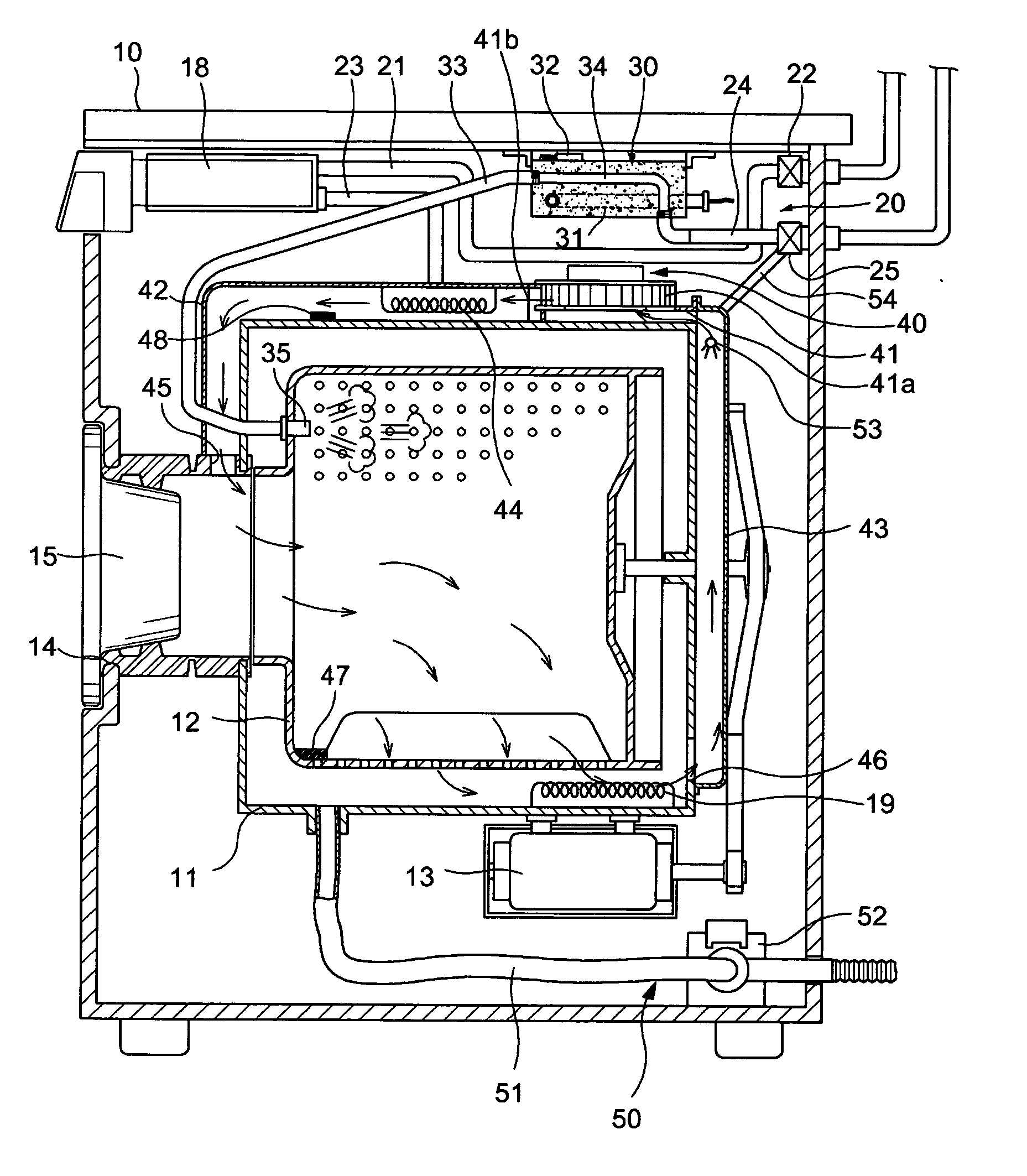

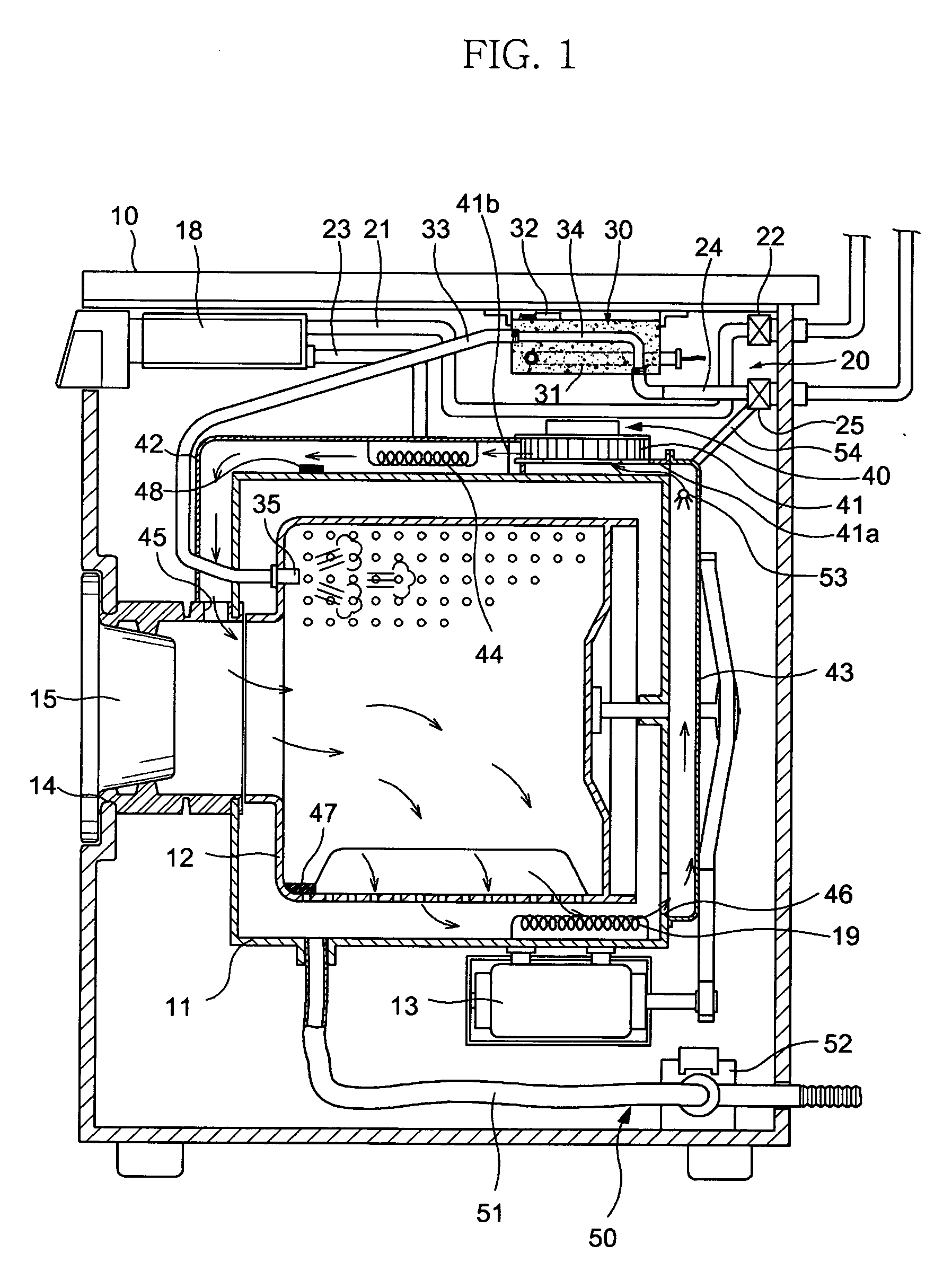

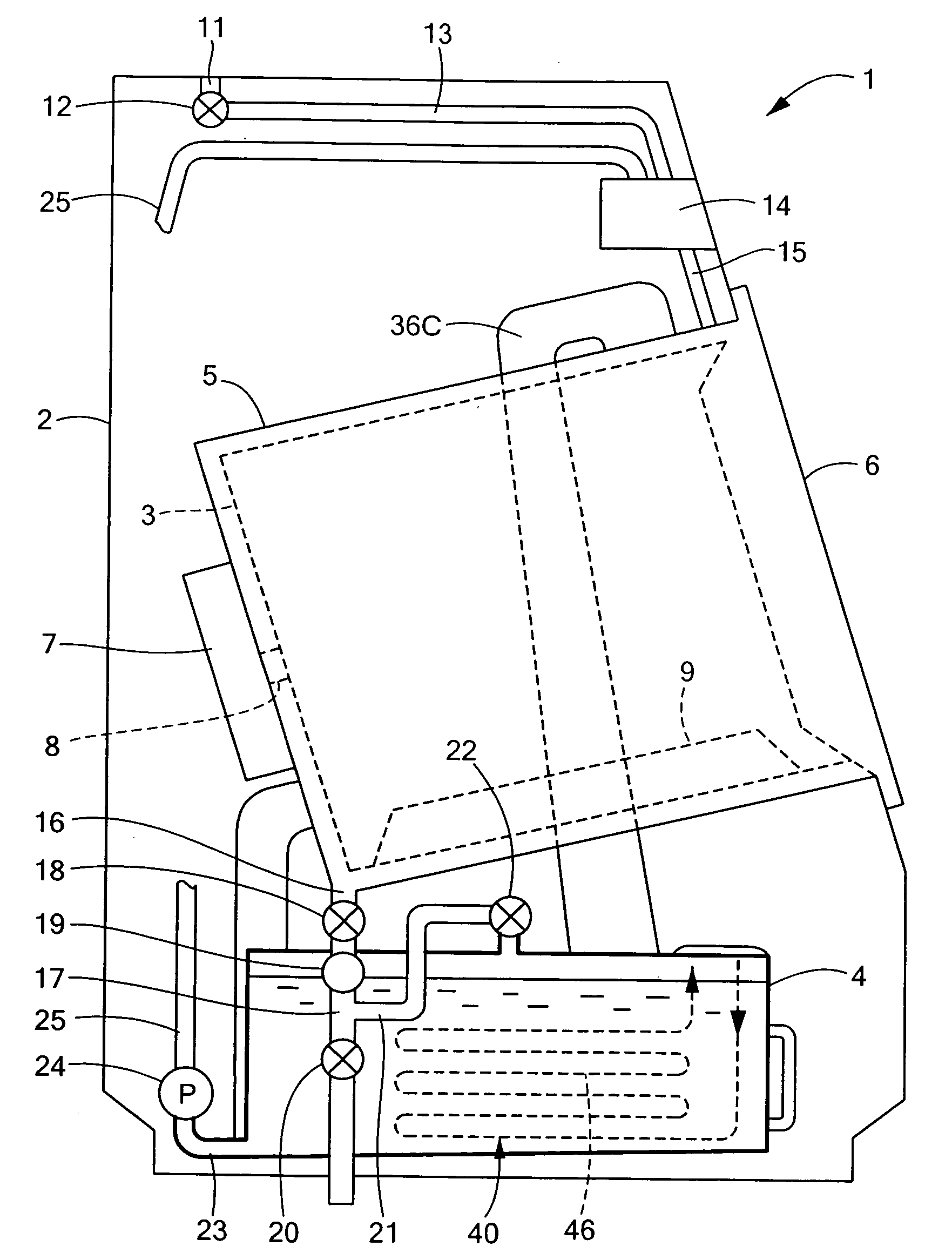

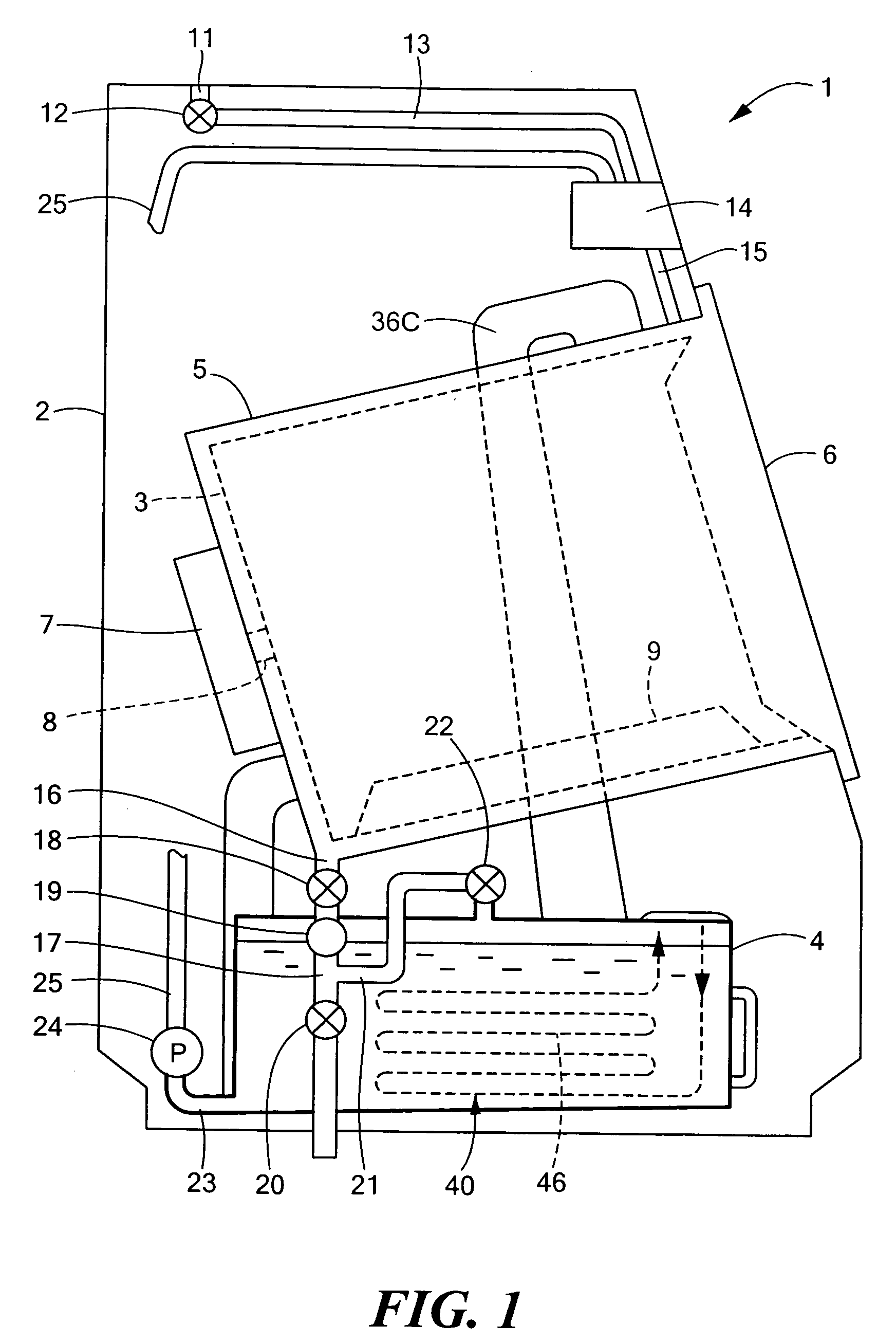

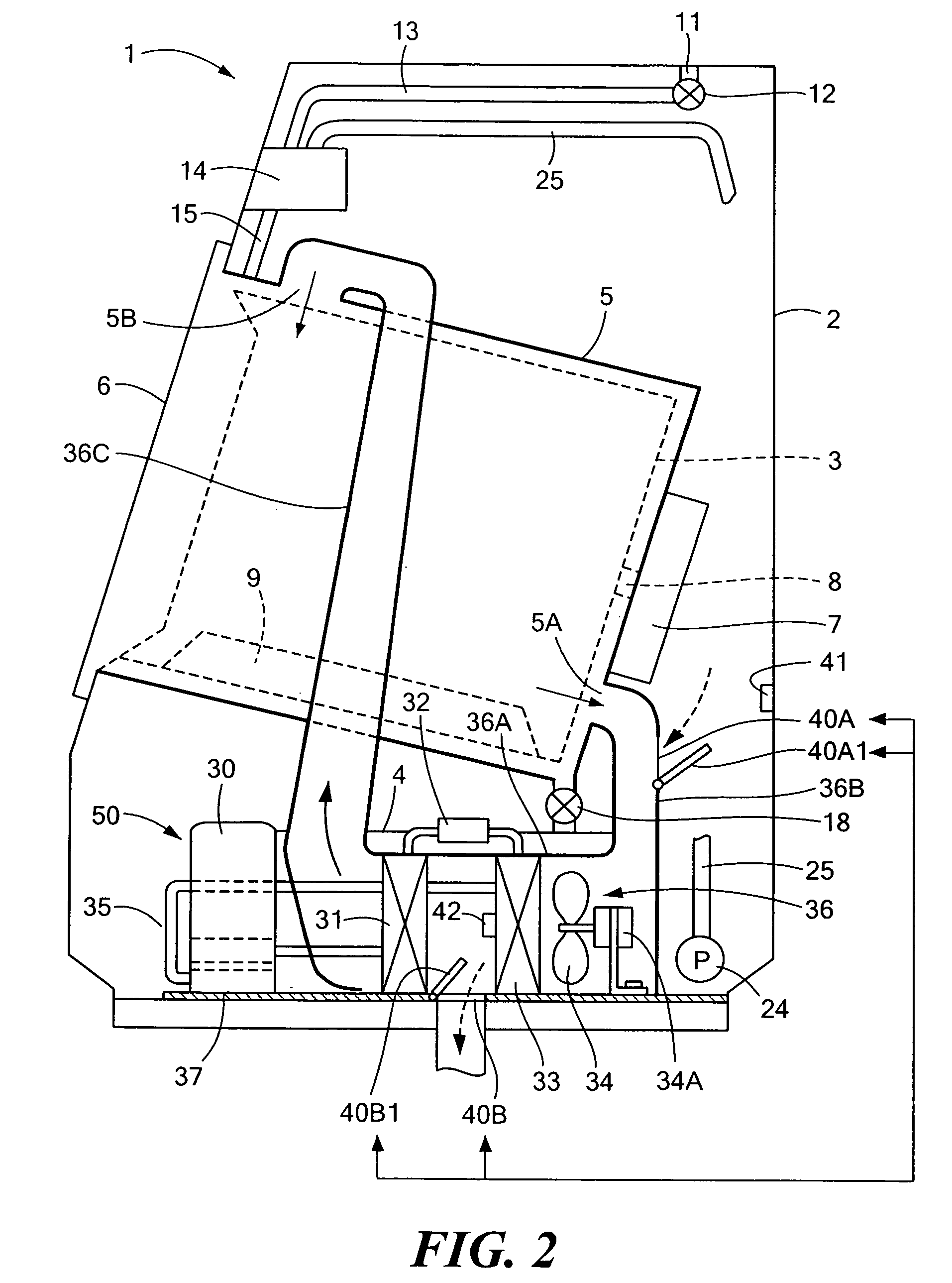

Drying unit and laundry washing/drying machine equipped with the drying unit

ActiveUS20080235977A1Increase the rate of heatingShorten the timeDrying gas arrangementsOther washing machinesAir cycleProcess engineering

In a laundry washing / drying machine involving drying by a heat pump cycle, in an initial stage of the drying operation the heat within an air circulation path is deficient and therefore it is impossible to effect quick heating of air on a drum inlet side up to a sufficiently high temperature. According to the present invention there is provided a drying unit capable of raising the drum inlet air temperature quickly up to a sufficiently high temperature in an initial stage of the drying operation and thereby shortening the drying time. The drying unit includes a heat pump cycle device for performing a cycle of radiating, with use of a radiator, the heat of a refrigerant compressed by a compressor, passing the refrigerant through a pressure reducing / expansion valve, evaporating the refrigerant in an evaporator and compressing the refrigerant again by the compressor, an air circulation path for allowing air to be circulated by a blower in such a manner that air heated by the radiator is introduced into a drying chamber to dry the laundry, exhaust air discharged from the drying chamber is passed through the evaporator, then is heated again by the radiator and the air thus dehumidified is circulated by the blower, and an external heat source applying device for applying the heat of an external heat source to the evaporator to quicken the rise in temperature of the air in an initial stage of the drying operation.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

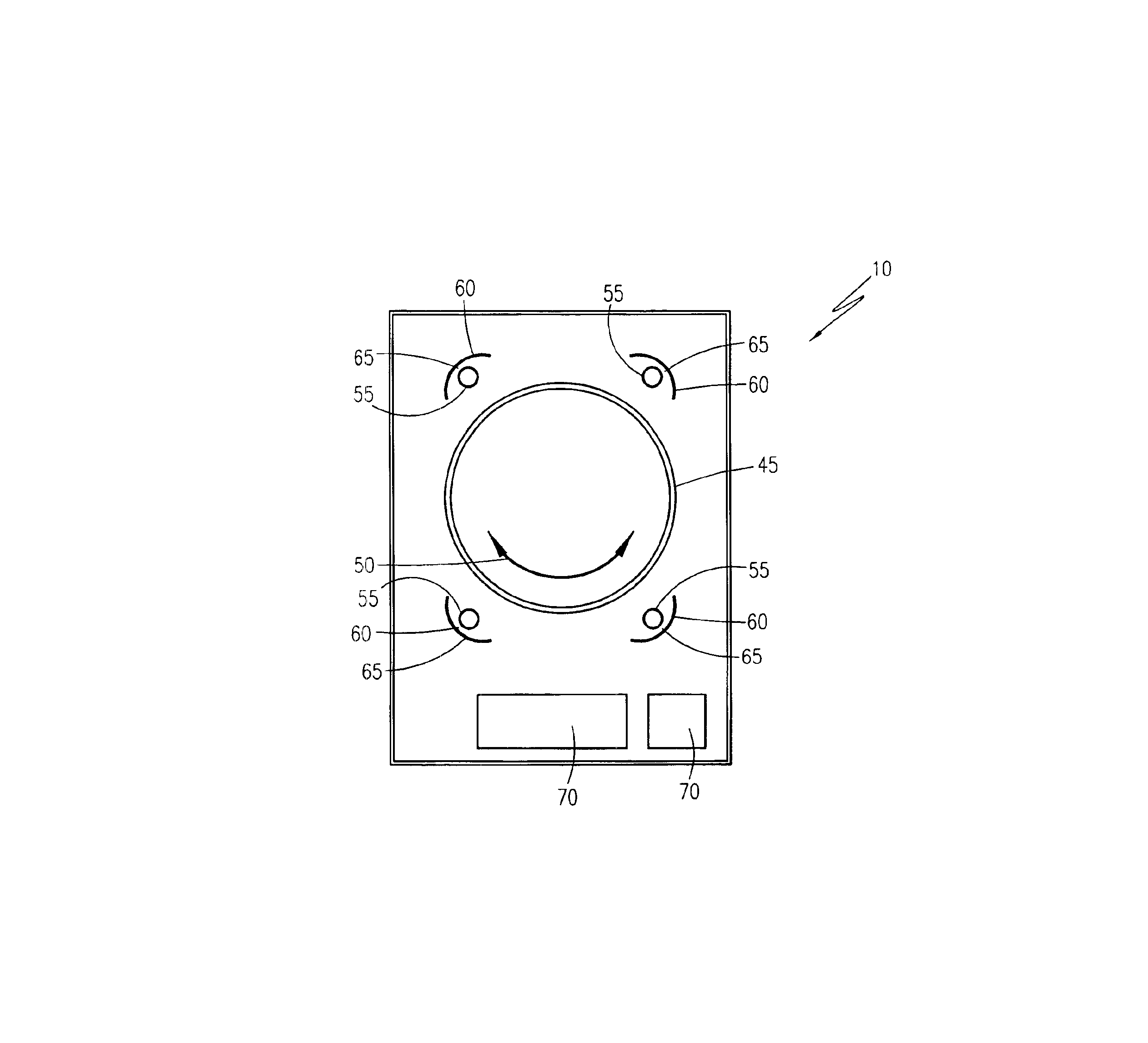

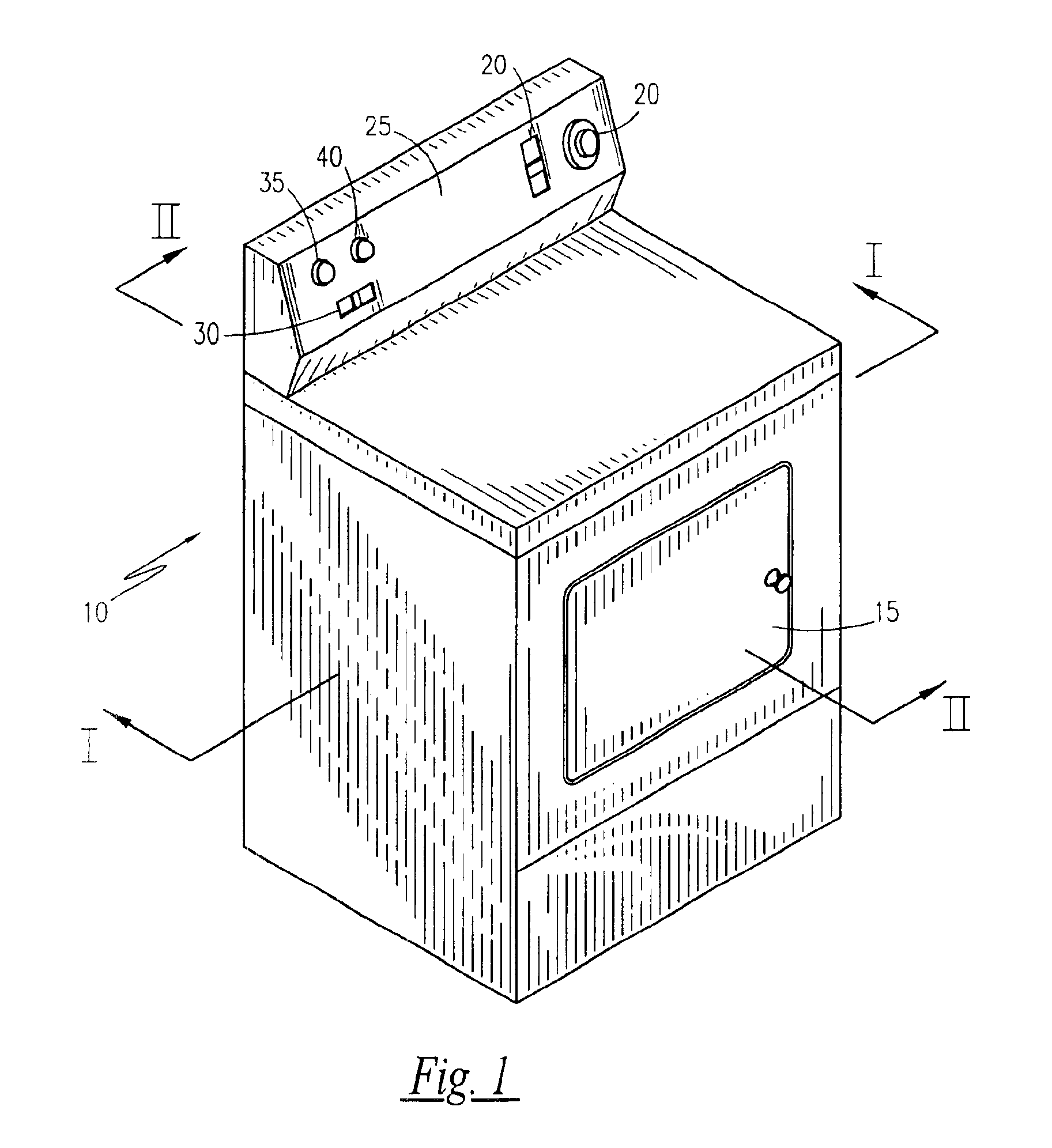

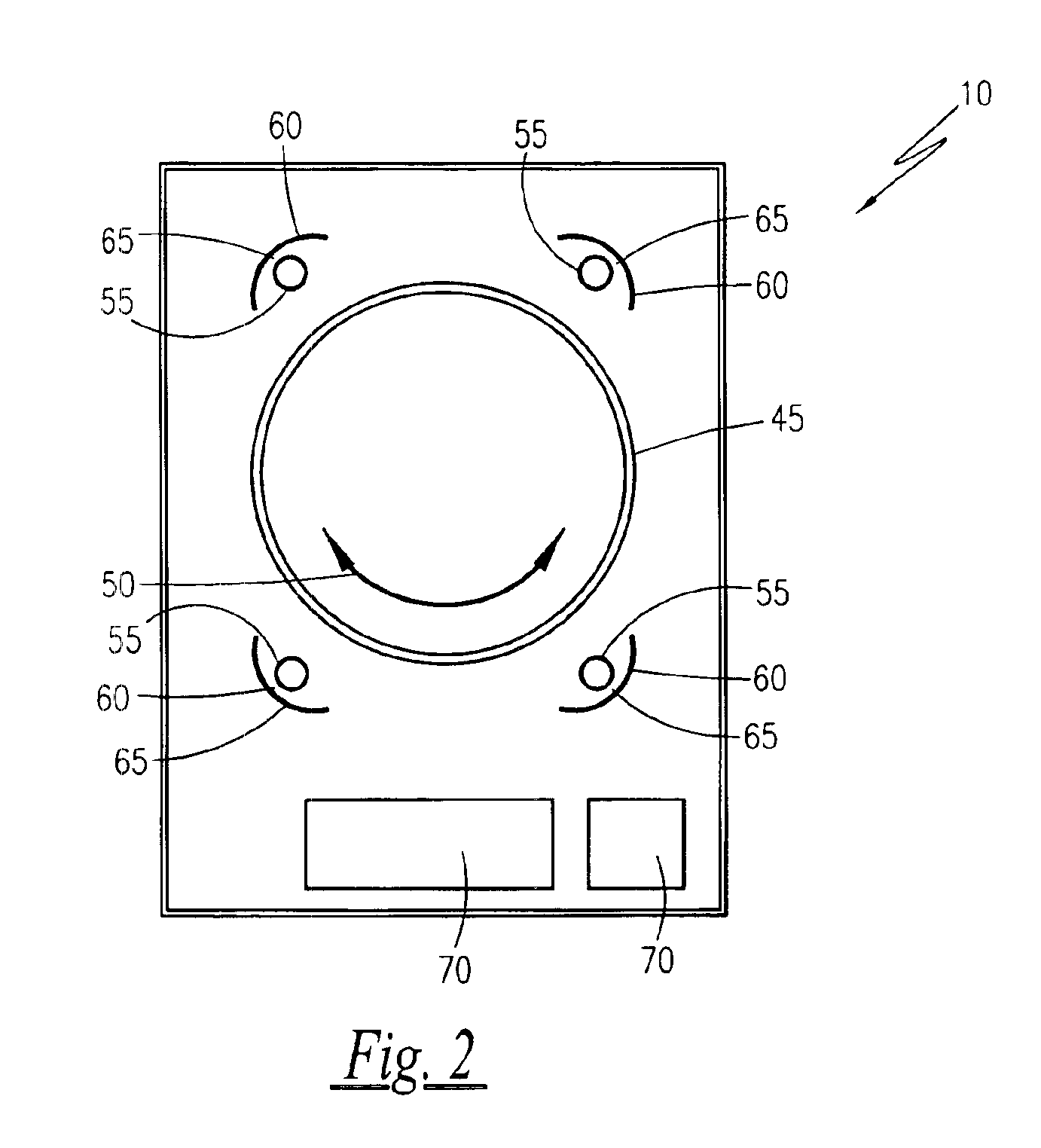

Clothes dryer with ultraviolet light

InactiveUS6877248B1Quick and easy and effectiveDrying solid materials with heatDrying machines with non-progressive movementsEngineeringBiological studies

A clothes dryer is provided which incorporates ultraviolet light sources to aid in the sterilization of the clothing as it is dried. A series of ultraviolet emitters, envisioned to be germicidal lamps, are located around the perimeter of the drying drum inside of the dryer. As the clothes dryer operates, these lamps are energized, and their light passed thru clear panels into the drying drum where they can aid in the killing of germs, bacteria and the like. Such a feature is envisioned as being particularly useful in hospitals, centers where biological studies are performed, or for those who are particularly susceptible to infectious diseases.

Owner:CROSS GREGORY N +1

High tension permeable belt for an ATMOS system and press section of paper machine using the permeable belt

ActiveUS7527709B2Large tensionIncrease the opening areaPaper/cardboardPress sectionFiberSupport surface

A permeable belt, a belt press including a roll having an exterior surface and the permeable belt, and a method of drying or pressing a web with the permeable belt. The permeable belt has a paper web facing side and is guided over a support surface. The permeable belt can have a tension of between approximately 20 kN / m and approximately 100 KN / m, a permeability value of between approximately 100 cfm and approximately 1200 cfm, a surface contact area of the paper web side that being between approximately 0.5% and approximately 90% when not under tension, and an open area of between approximately 1.0% and approximately 85%. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

Machine for producing a fibrous web

InactiveUS20080149292A1Reduce absorptionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaperboard

A machine for producing a fibrous web, in particular a paper web, paperboard web or tissue web, includes a former on which the fibrous web is formed on a structured belt and is dewatered between said structured belt and a forming belt, and a drying apparatus for the further dewatering of the fibrous web, through which the fibrous web is guided together with the structured belt and in which hot air flows through the permeable structured belt and the fibrous web. The forming fabric is formed by a printed forming fabric or a DSP fabric with zonally different permeability.

Owner:VOITH PATENT GMBH

Laundry dryer providing moisture application during tumbling and reduced airflow

ActiveUS20100024243A1Efficient removalStay hydratedDrying solid materials with heatDrying gas arrangementsEngineeringDrive motor

A laundry dryer includes a rotatable drum, an air delivery system selectively operable to provide air into the drum at a first flow rate and a second flow rate that is less than the first flow rate, and a moisture delivery system operable to provide moisture (e.g., water mist or steam) into the drum while air is being provided at the lower second flow rate, and during drum rotation (tumbling), to thus enhance dispersion of the moisture into the fabrics of the load, and the attendant dewrinkling / refresh benefits. The air delivery system can include a reversible blower that provides air at the first flow rate when operated in a first direction and provides air at the second flow rate when operated in an opposite second direction. The drum can be a reversibly rotatable drum that is rotatable in a first and an opposite second direction, and the dryer can include a drive motor that both rotates the drum and operates the blower. The moisture delivery system can include a nozzle to provide moisture directly into the drum.

Owner:ELECTROLUX HOME PROD CORP NV

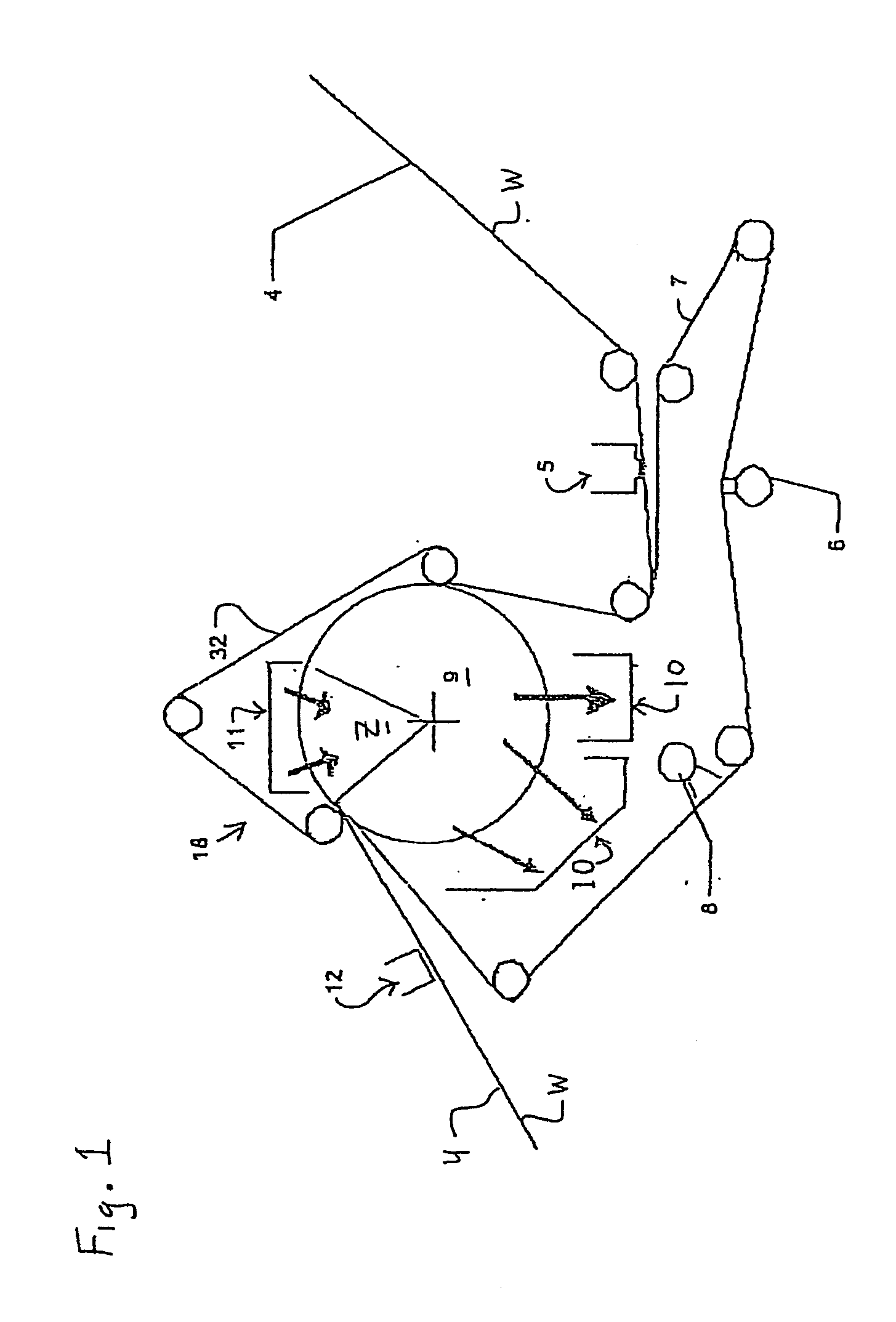

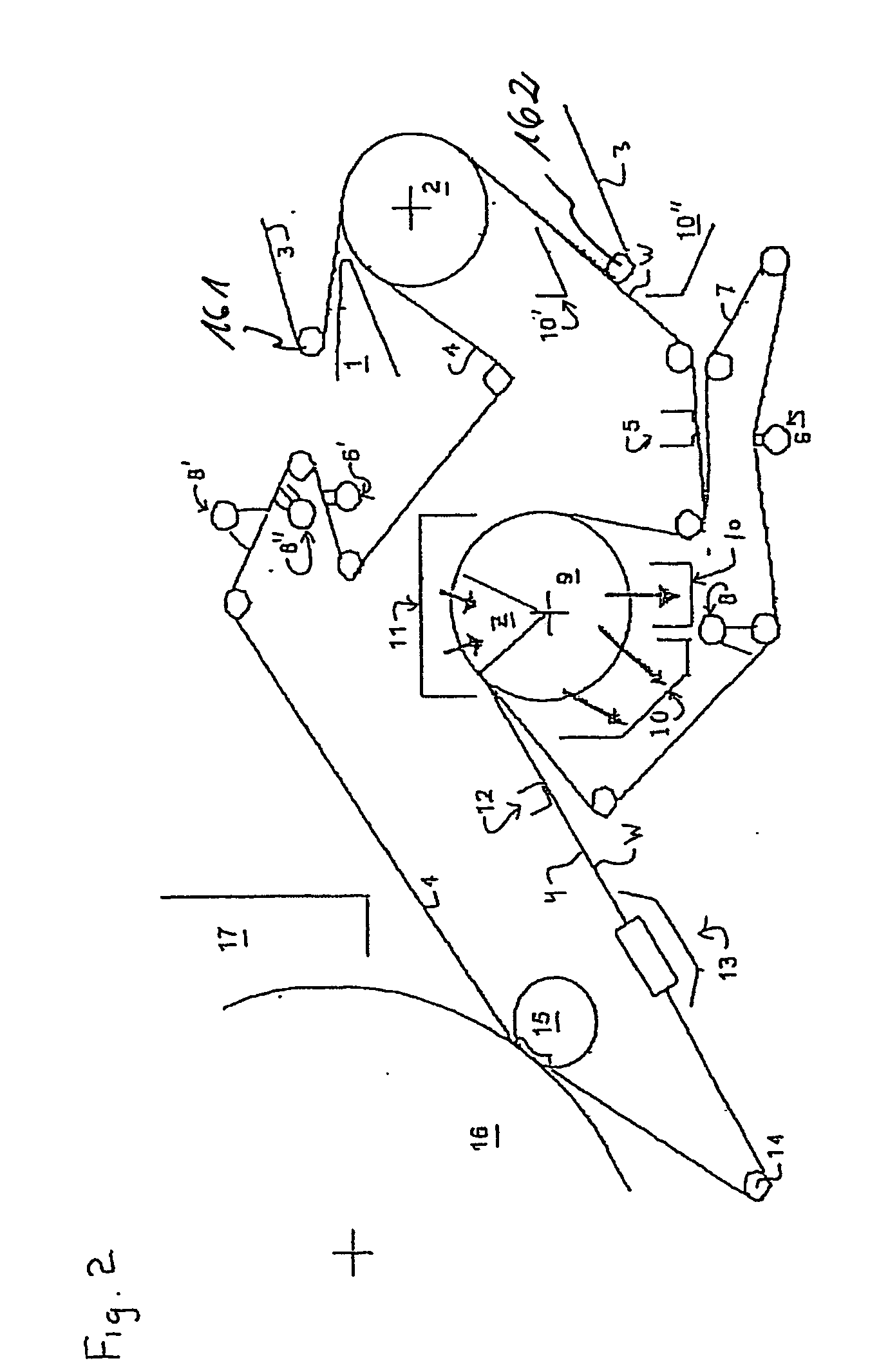

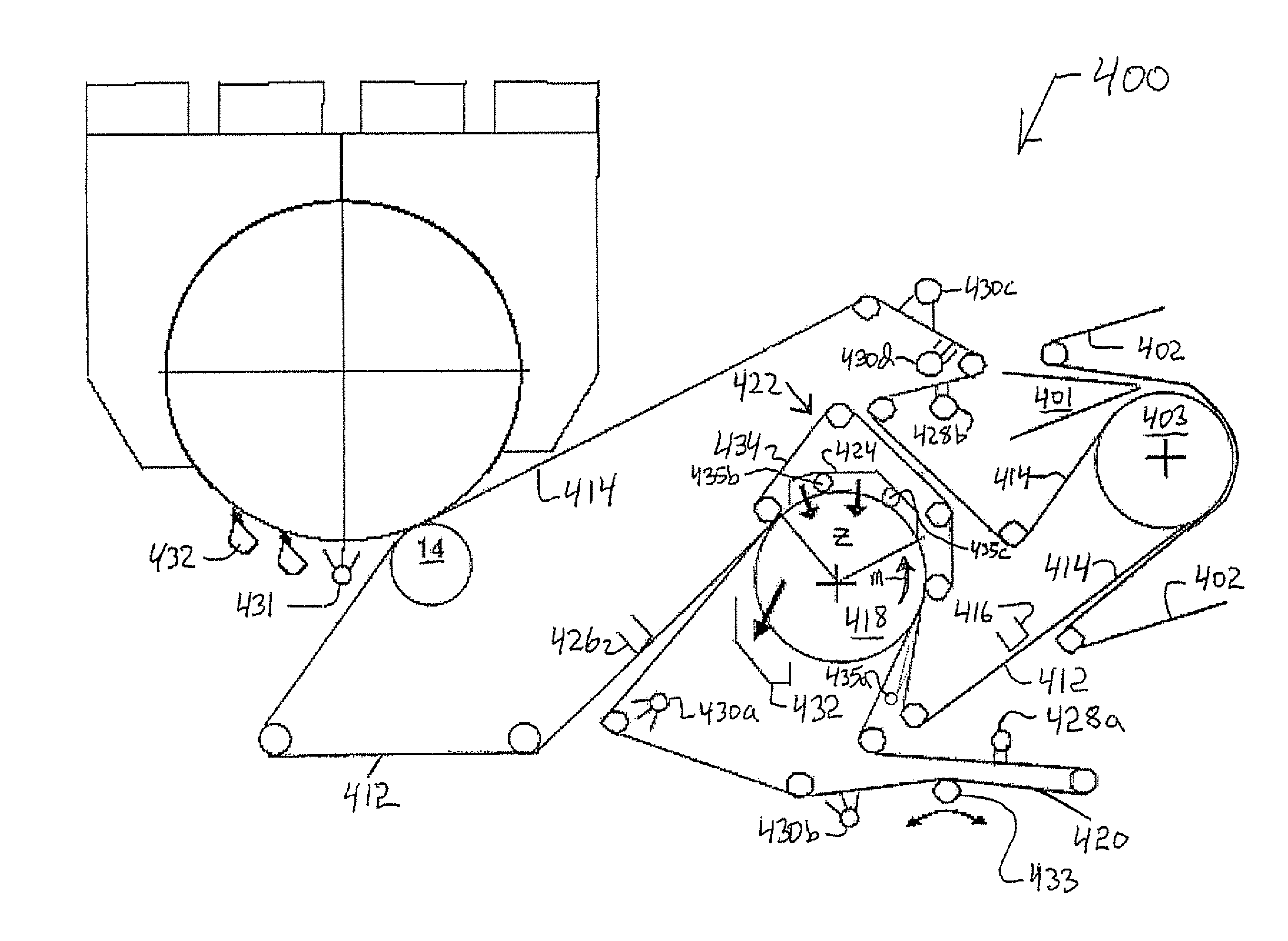

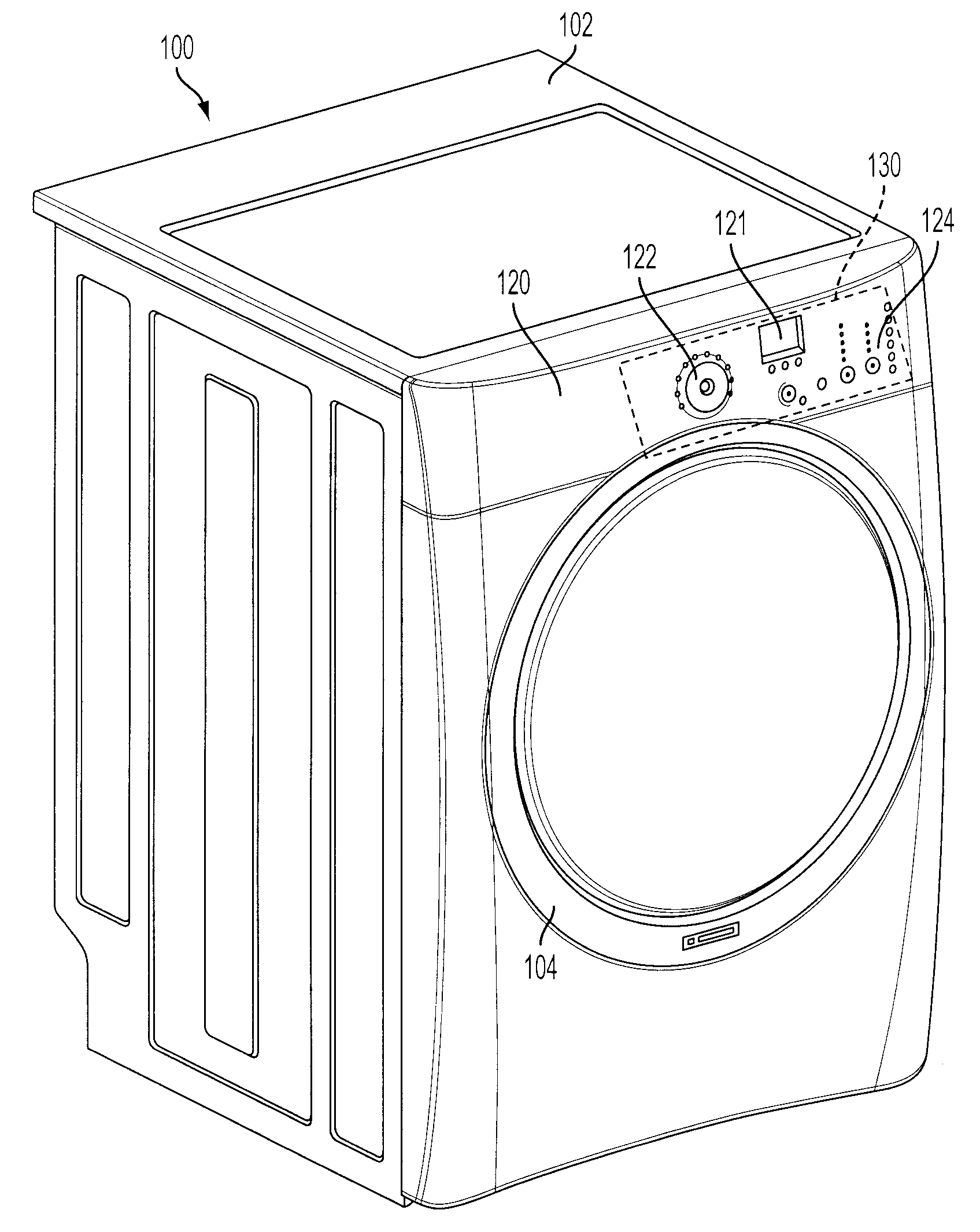

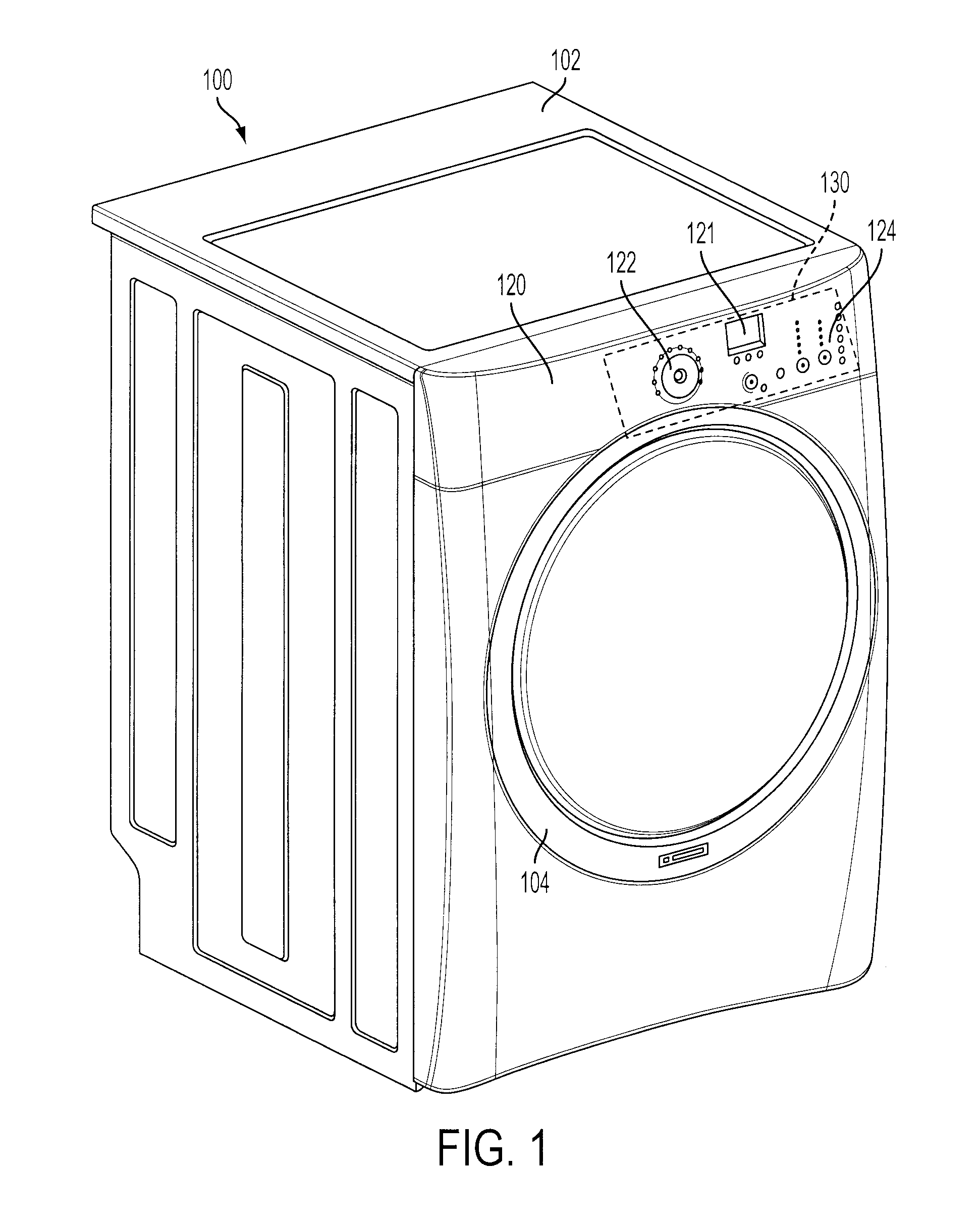

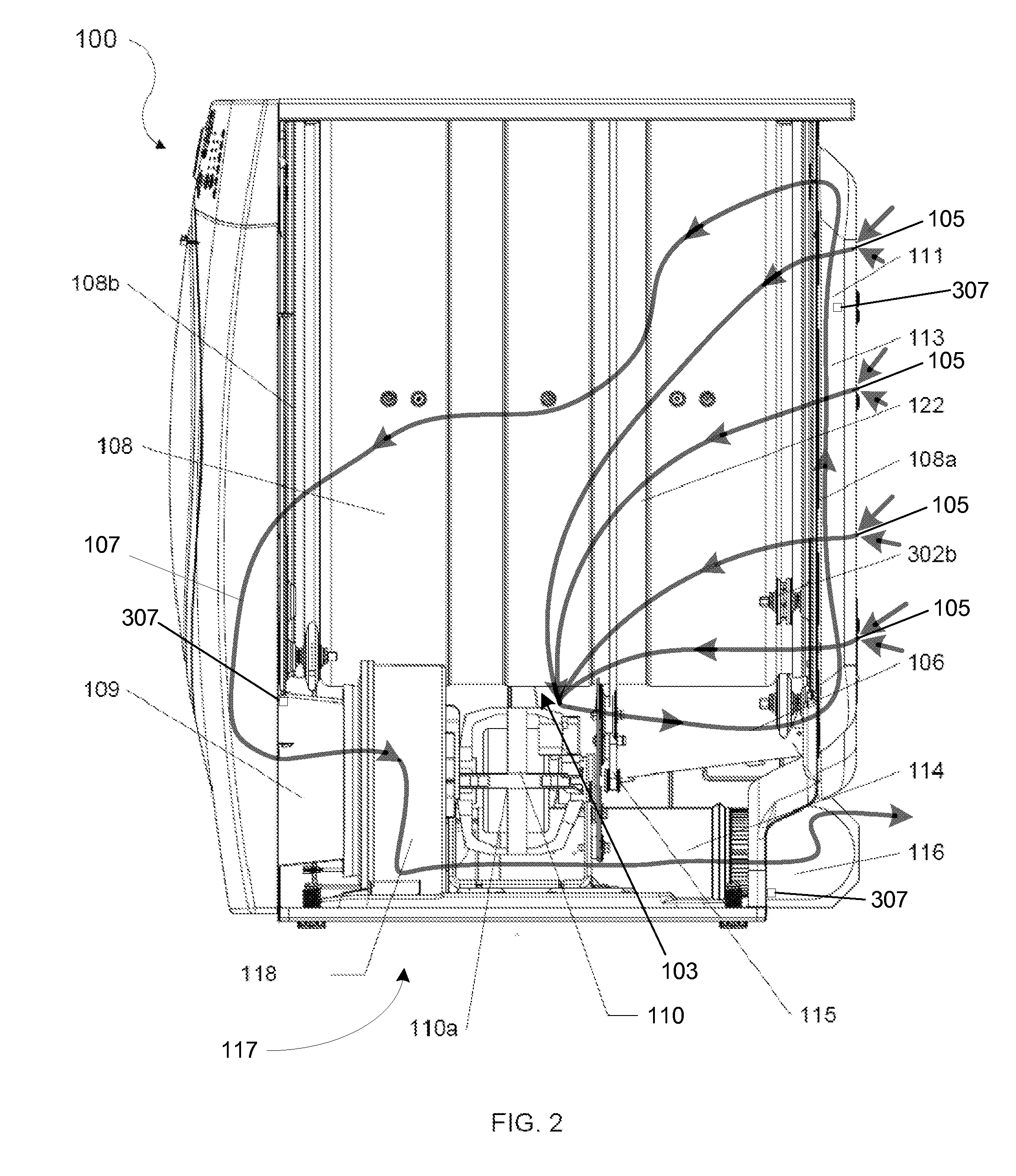

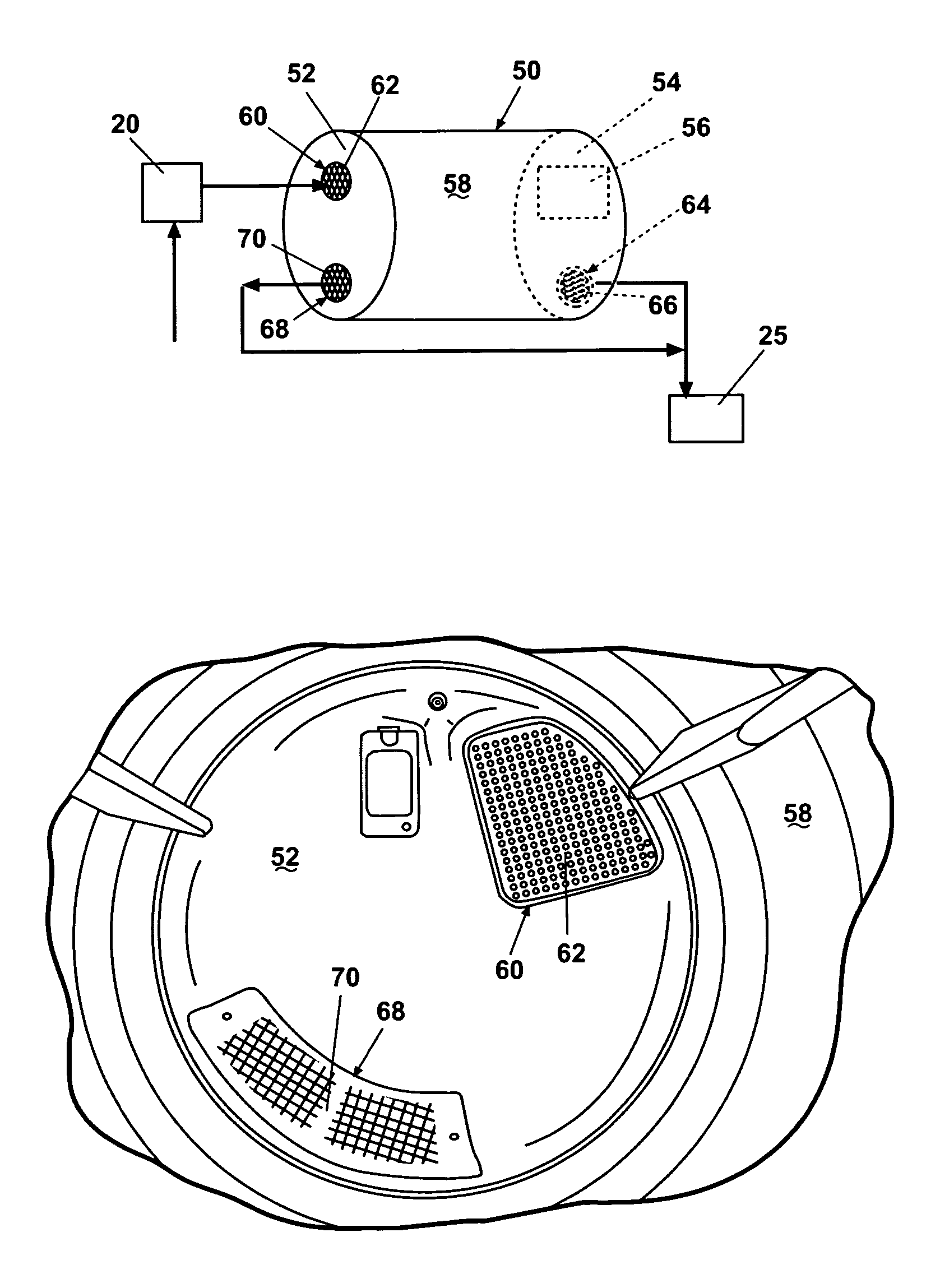

Multiple outlet air path for a clothes dryer

ActiveUS7020985B2Accelerated dryingLessDrying machines with non-progressive movementsTextiles and paperEngineeringDrying time

A clothes dryer has a heat source, preferably a heat pump, a rotating drum, and means to generate flow of air from the heat source to an inlet in the drum. At least two outlets are separated from each other in the drum to enable higher air flow rates without increase in pressure drop, resulting in reduced drying time.

Owner:WHIRLPOOL CORP

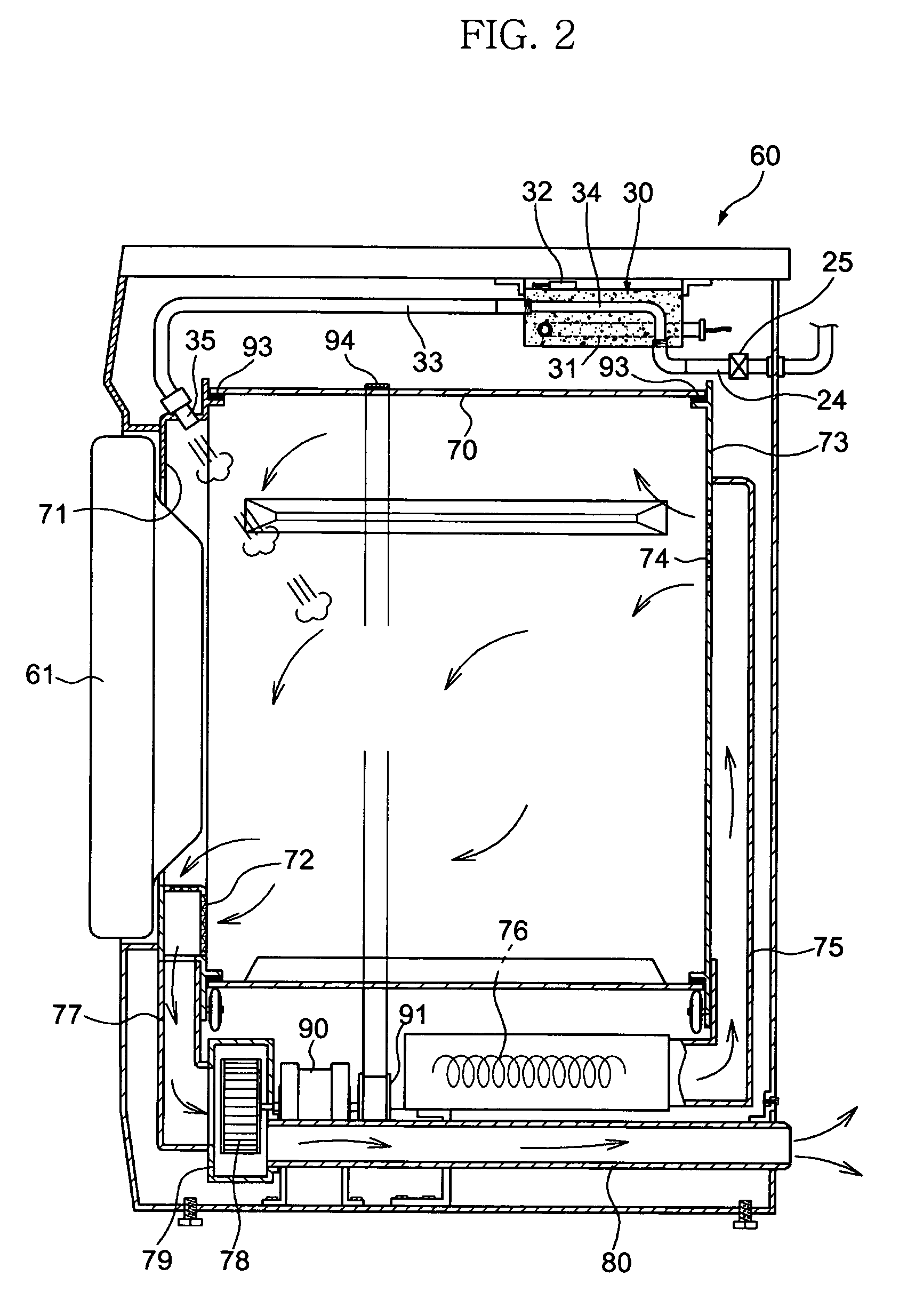

Drying machine and method for controlling the same

ActiveUS20080000098A1Prevent and eliminate creaseDrying gas arrangementsDrying machines with non-progressive movementsEngineeringMechanical engineering

A drying machine is disclosed. The drying machine includes a selectively rotatable drum receiving an object to be dried, a steam supply member having one side connected to a steam generator and the other side connected to the drum, and a swirler installed in the steam supply member at a predetermined position for swirling steam flowing through the steam supply member. A method for controlling the drying machine includes heating a drum, supplying steam generated in a steam generator into the drum, and supplying hot air into the drum. The drying machine having the above described configuration can efficiently eliminate creases of clothes.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com