Patents

Literature

1344 results about "Cyclic process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyclic process: When a system returns to its original state after completing a series of changes, then it is known that a cycle is completed. This process is known as cyclic process. In a cyclic process the initial and the final state is same.

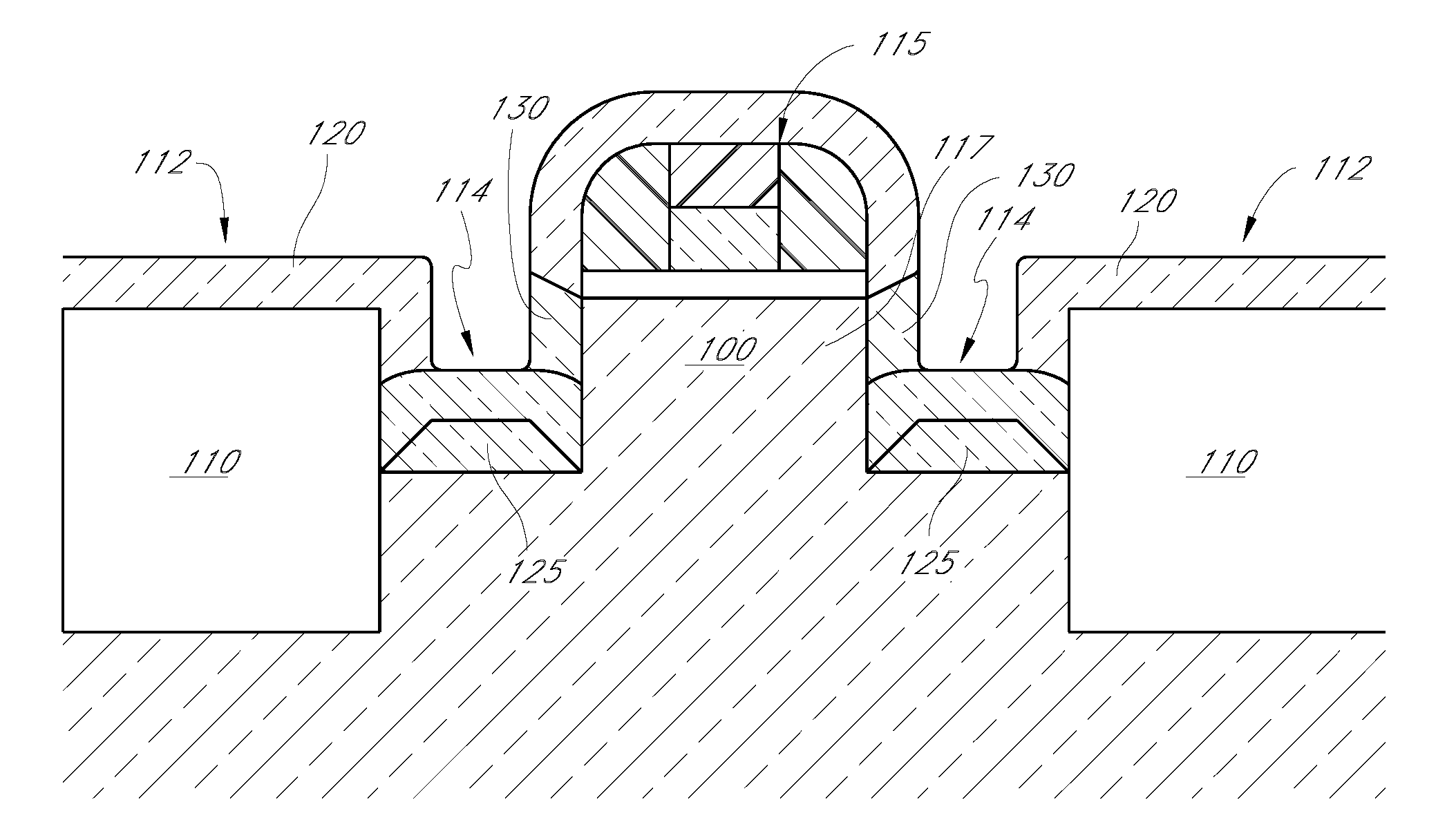

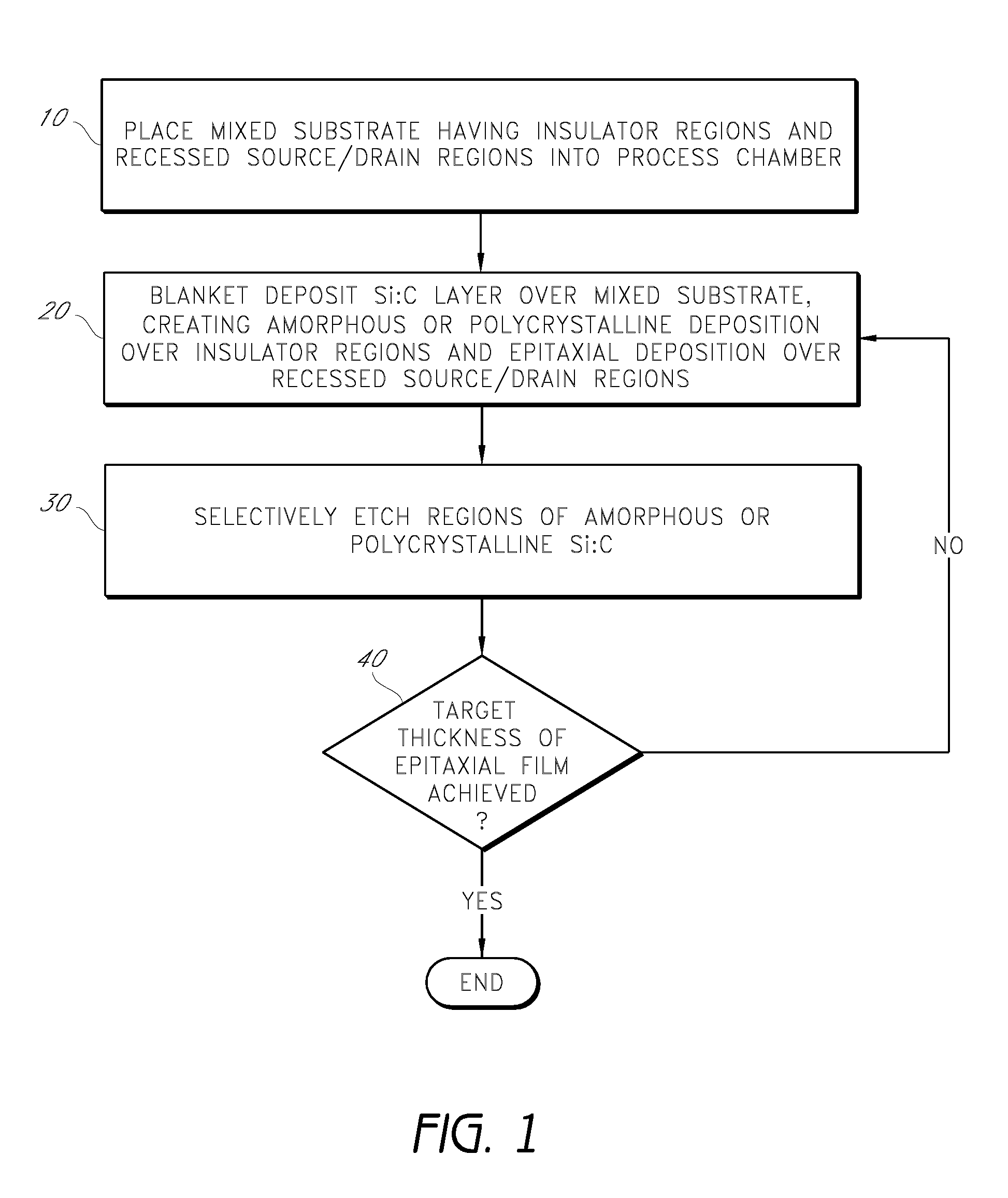

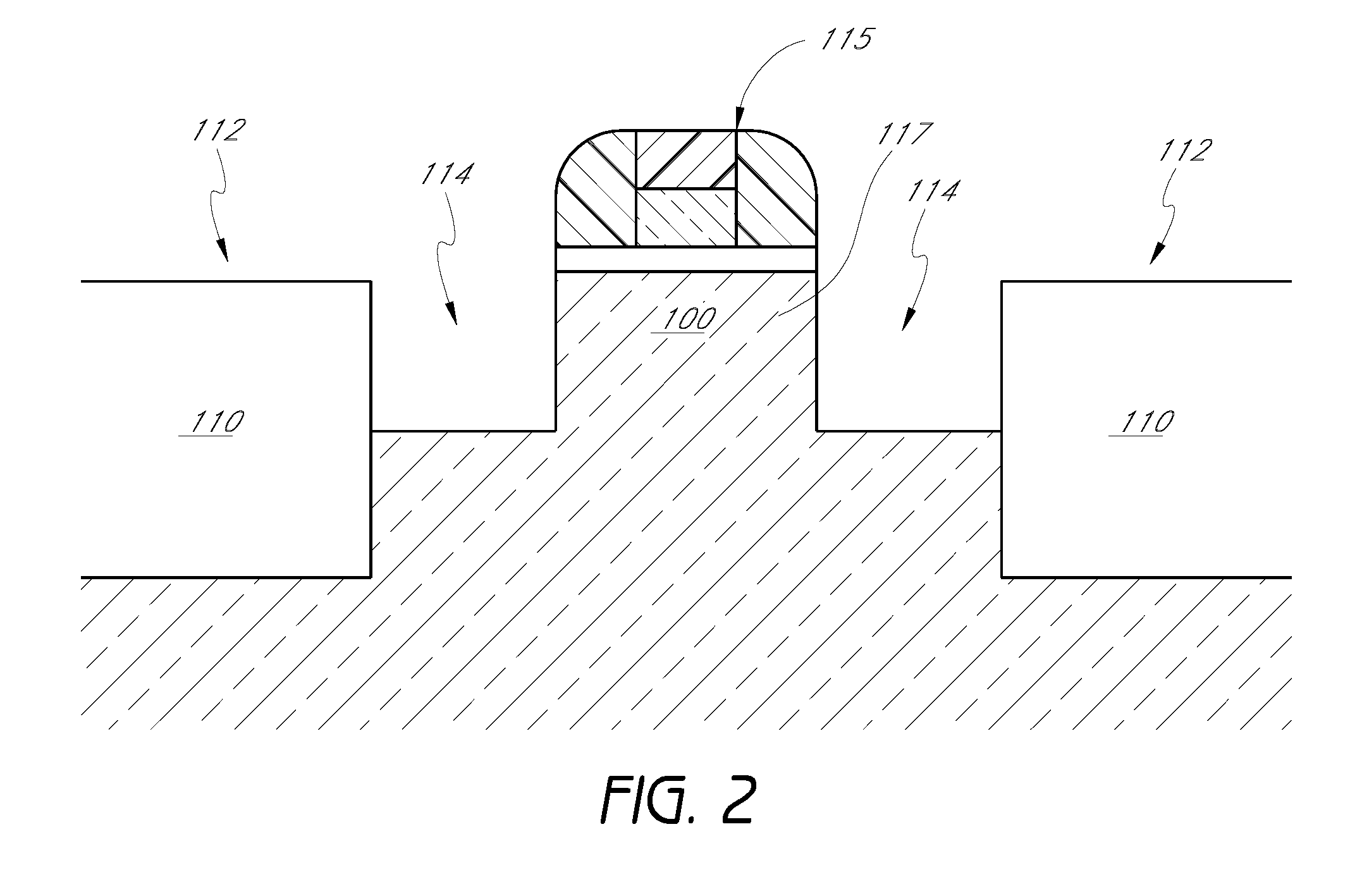

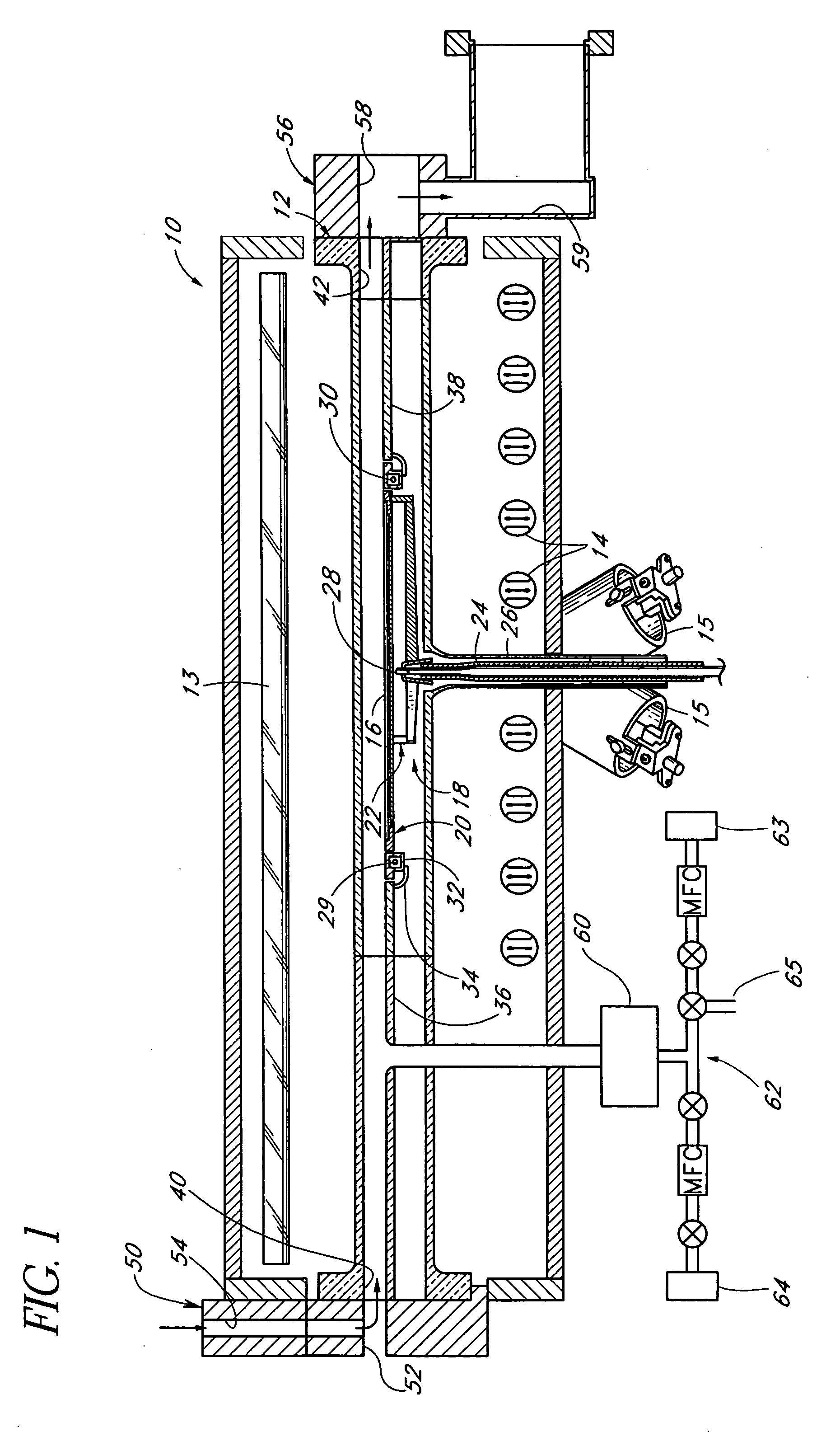

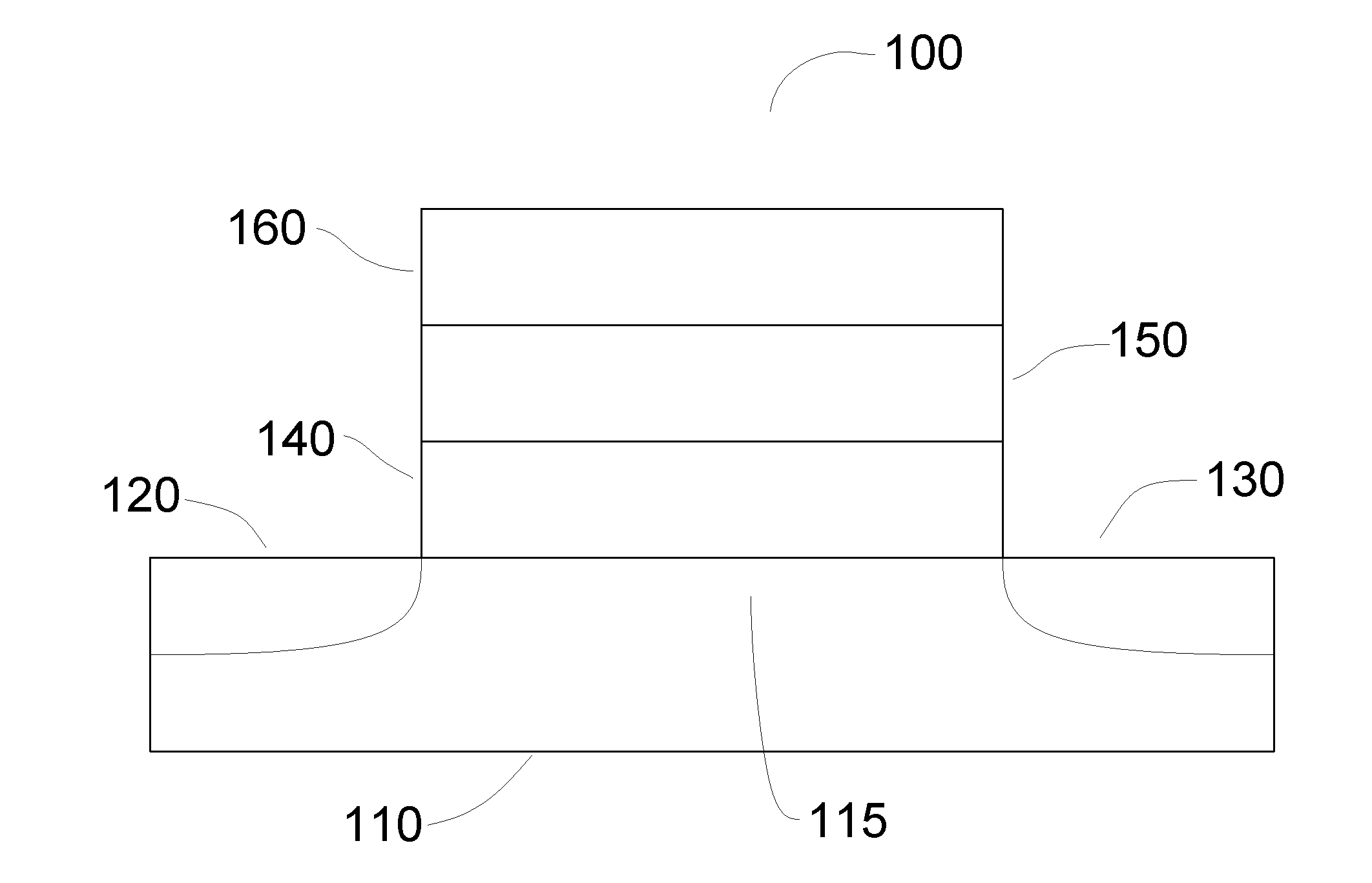

Selective epitaxial formation of semiconductor films

ActiveUS8278176B2Semiconductor/solid-state device manufacturingSemiconductor devicesCyclic processMetallurgy

Epitaxial layers are selectively formed in semiconductor windows by a cyclical process of repeated blanket deposition and selective etching. The blanket deposition phases leave non-epitaxial material over insulating regions, such as field oxide, and the selective etch phases preferentially remove non-epitaxial material while deposited epitaxial material builds up cycle-by-cycle. Quality of the epitaxial material improves relative to selective processes where no deposition occurs on insulators. Use of a germanium catalyst during the etch phases of the process aid etch rates and facilitate economical maintenance of isothermal and / or isobaric conditions throughout the cycles. Throughput and quality are improved by use of trisilane, formation of amorphous material over the insulating regions and minimizing the thickness ratio of amorphous:epitaxial material in each deposition phase.

Owner:ASM IP HLDG BV

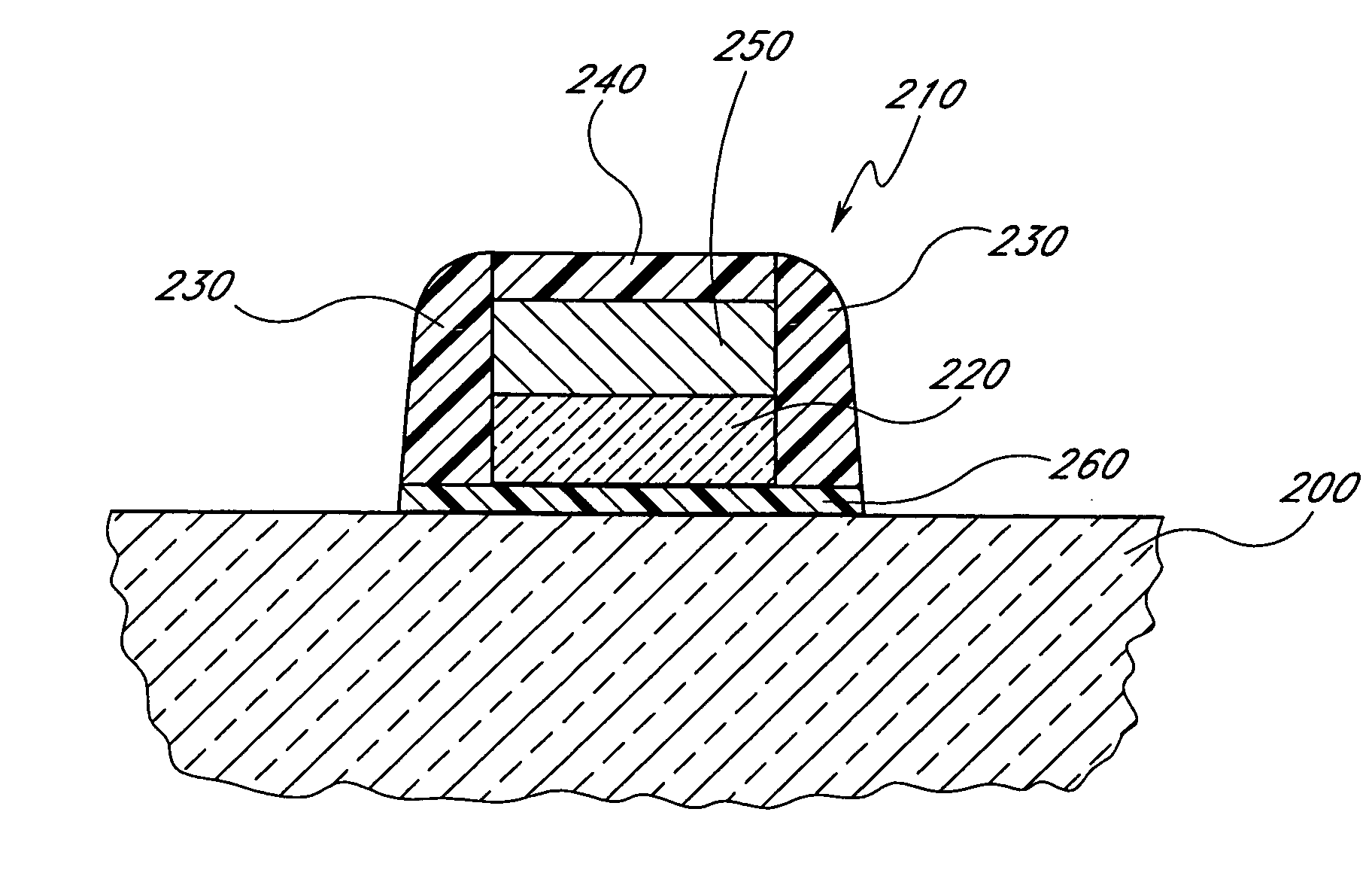

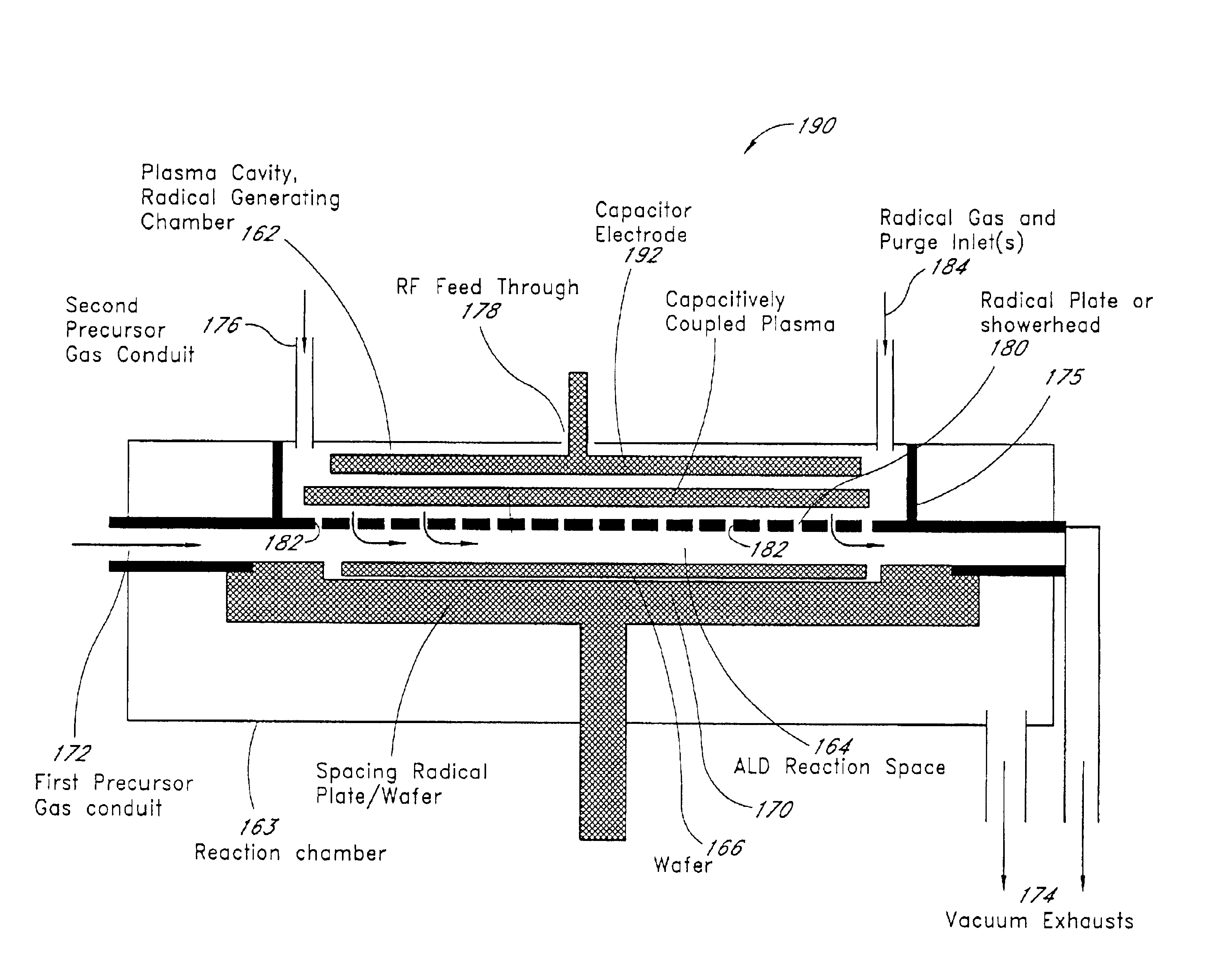

Incorporation of nitrogen into high k dielectric film

InactiveUS20050212119A1Semiconductor/solid-state device detailsSolid-state devicesDielectricCyclic process

A high k dielectric film and methods for forming the same are disclosed. The high k material includes two peaks of impurity concentration, particularly nitrogen, such as at a lower interface and upper interface, making the layer particularly suitable for transistor gate dielectric applications. The methods of formation include low temperature processes, particularly CVD using a remote plasma generator and atomic layer deposition using selective incorporation of nitrogen in the cyclic process. Advantageously, nitrogen levels are tailored during the deposition process and temperatures are low enough to avoid interdiffusion and allow maintenance of the desired impurity profile.

Owner:ASM IP HLDG BV

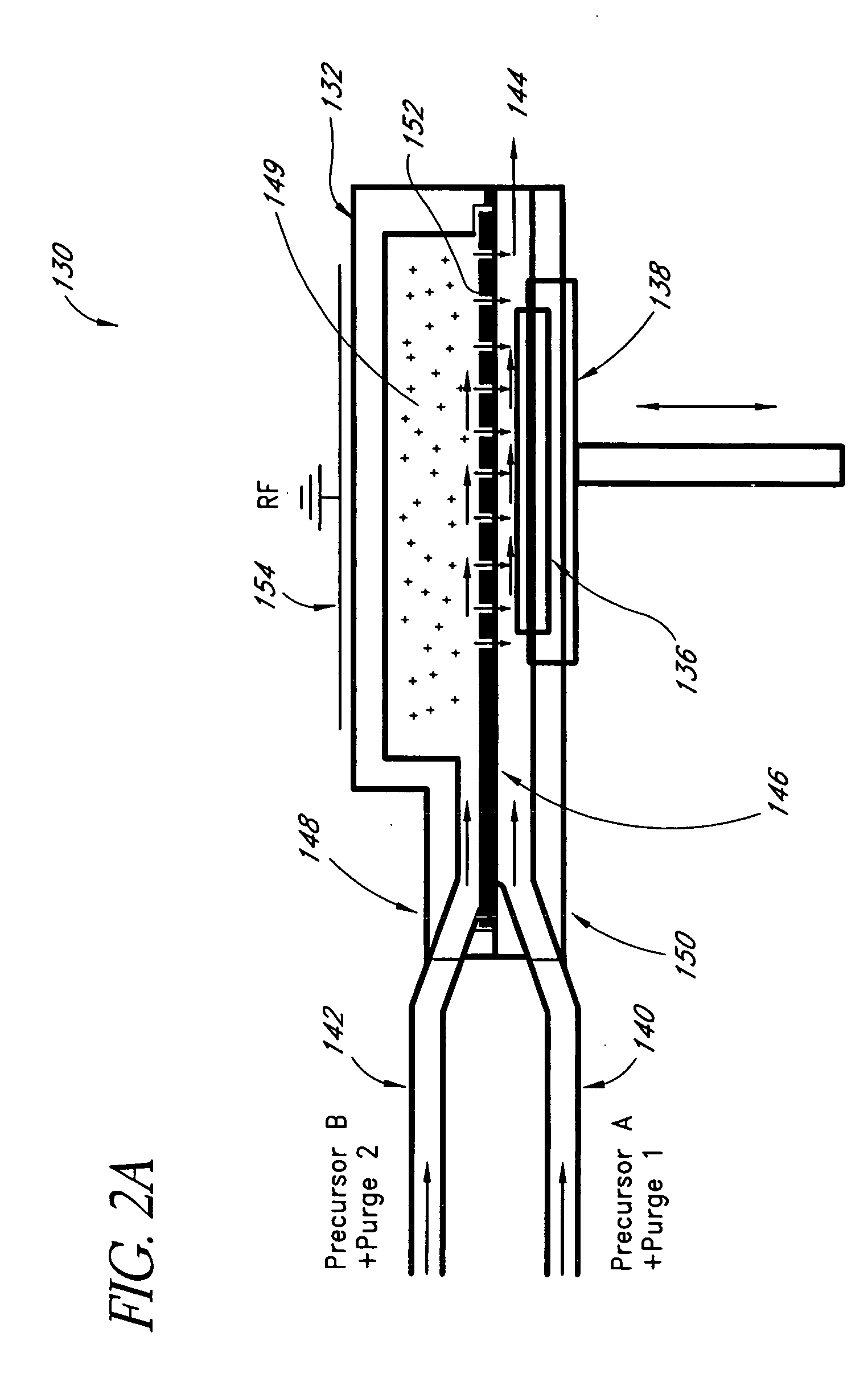

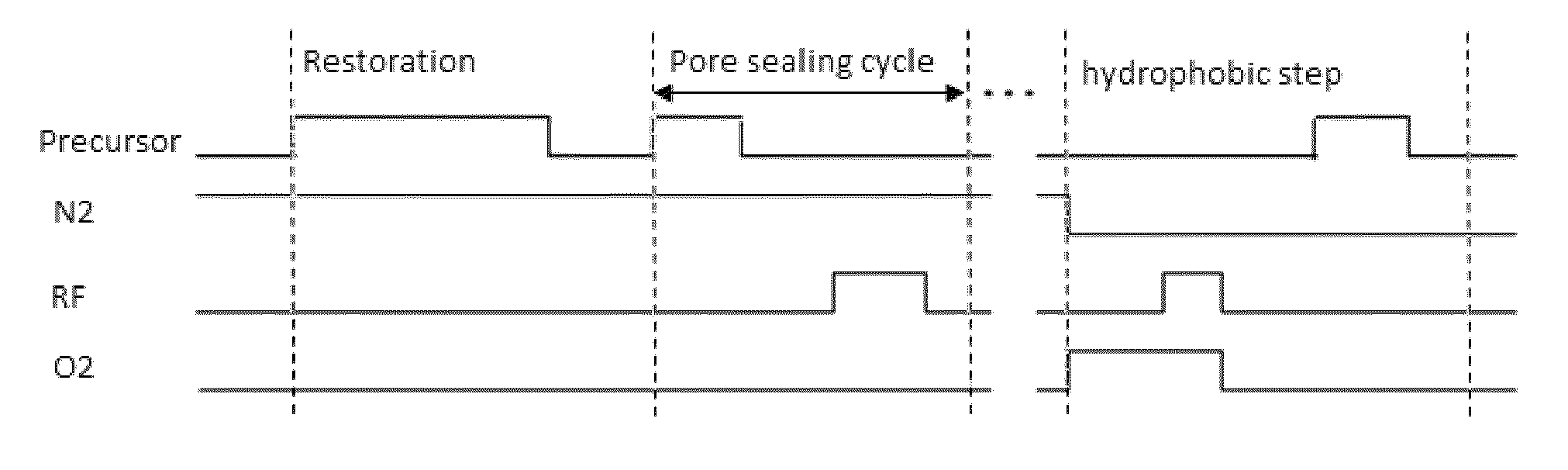

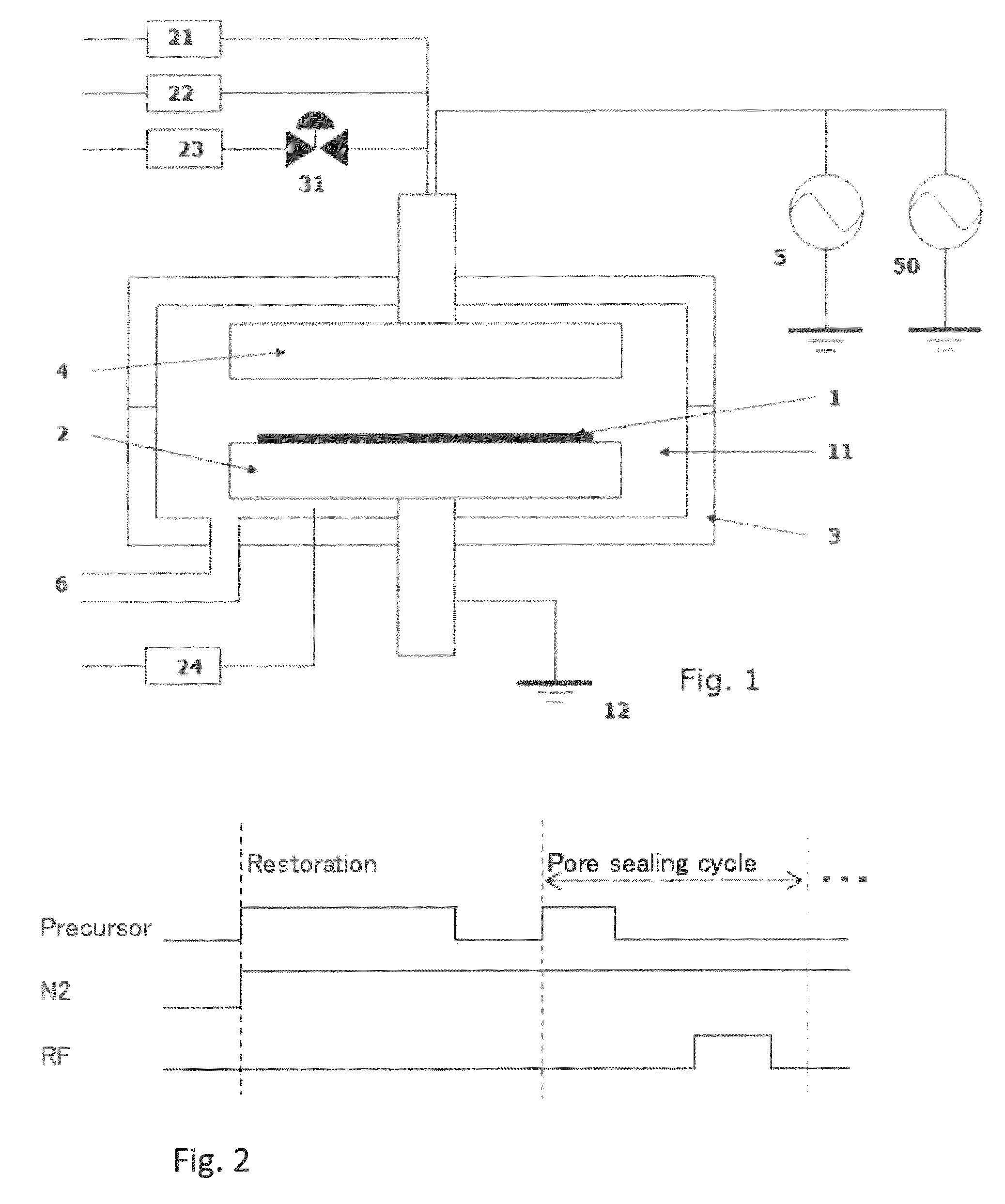

Method for repairing damage of dielectric film by cyclic processes

ActiveUS8785215B2Enhanced barrier functionPlasma-enhanced atomic layerSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCyclic processSilicon

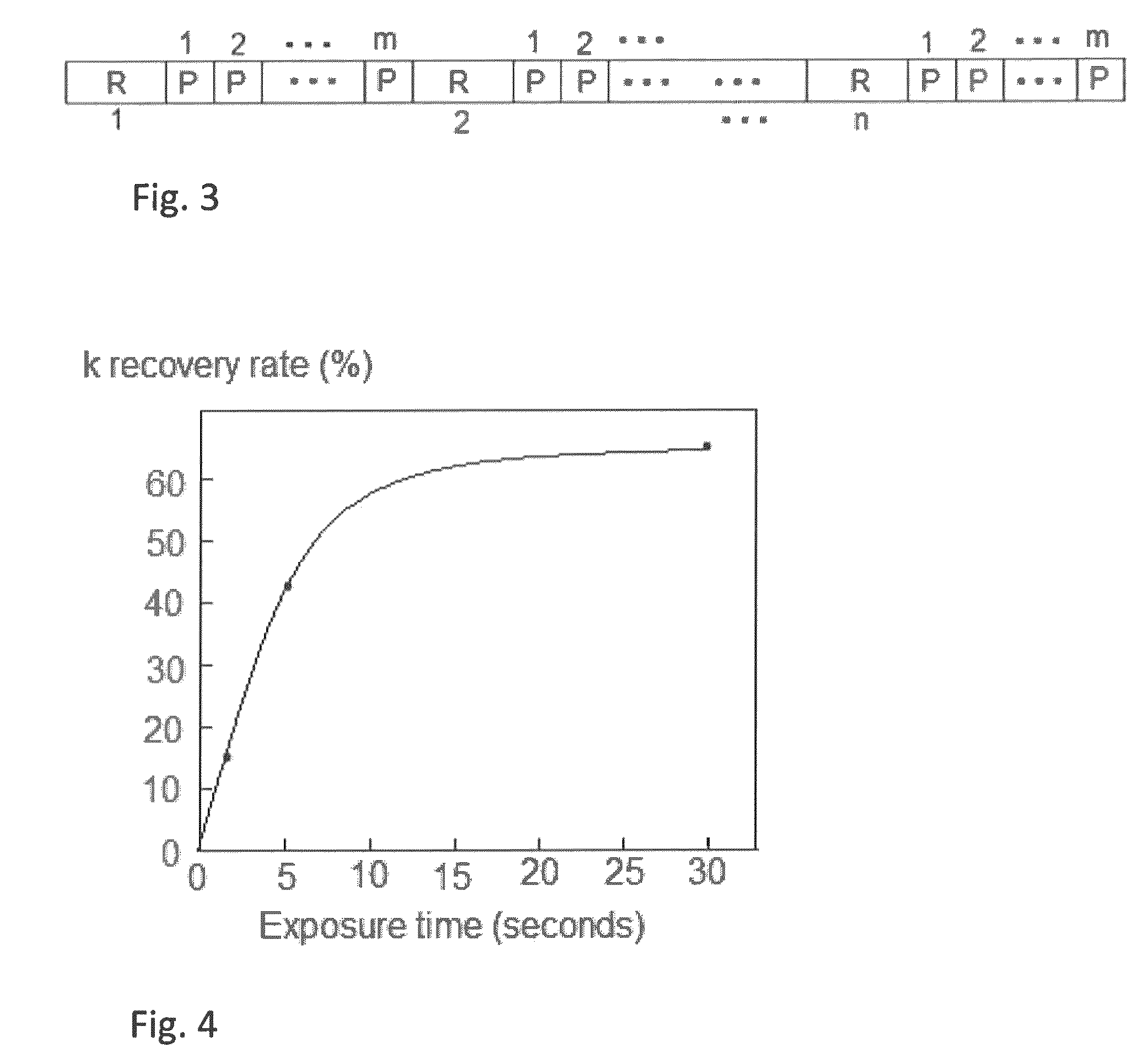

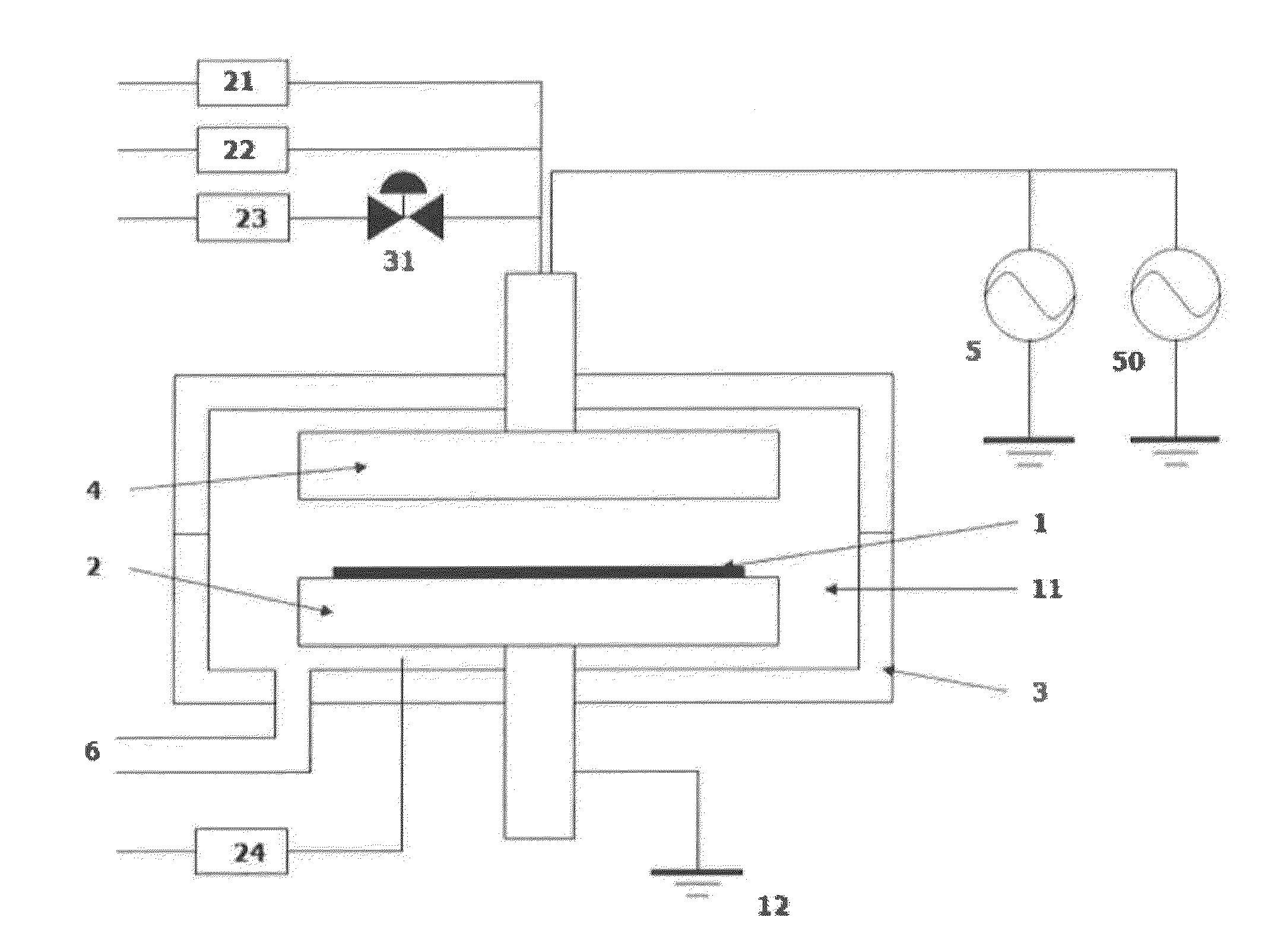

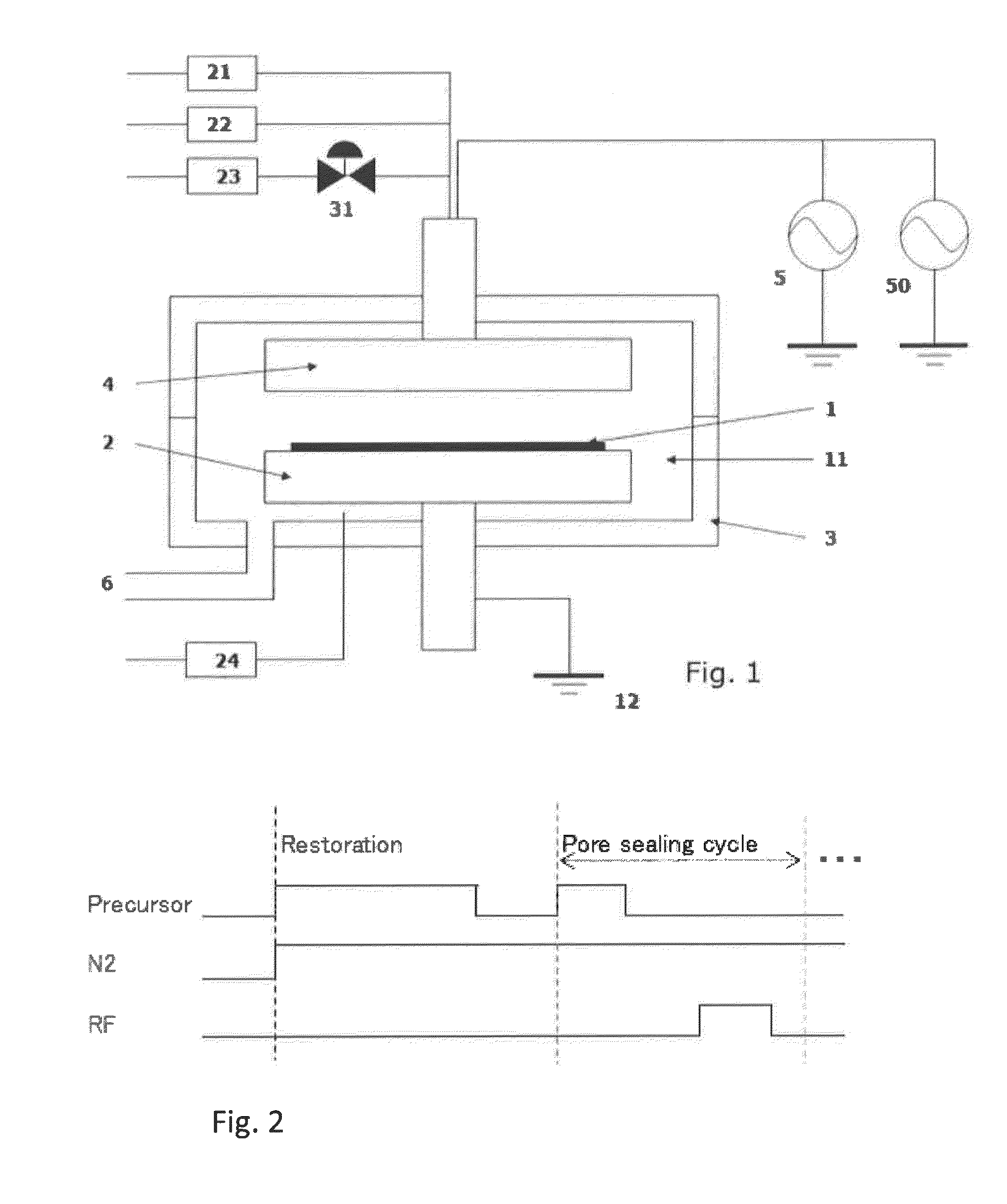

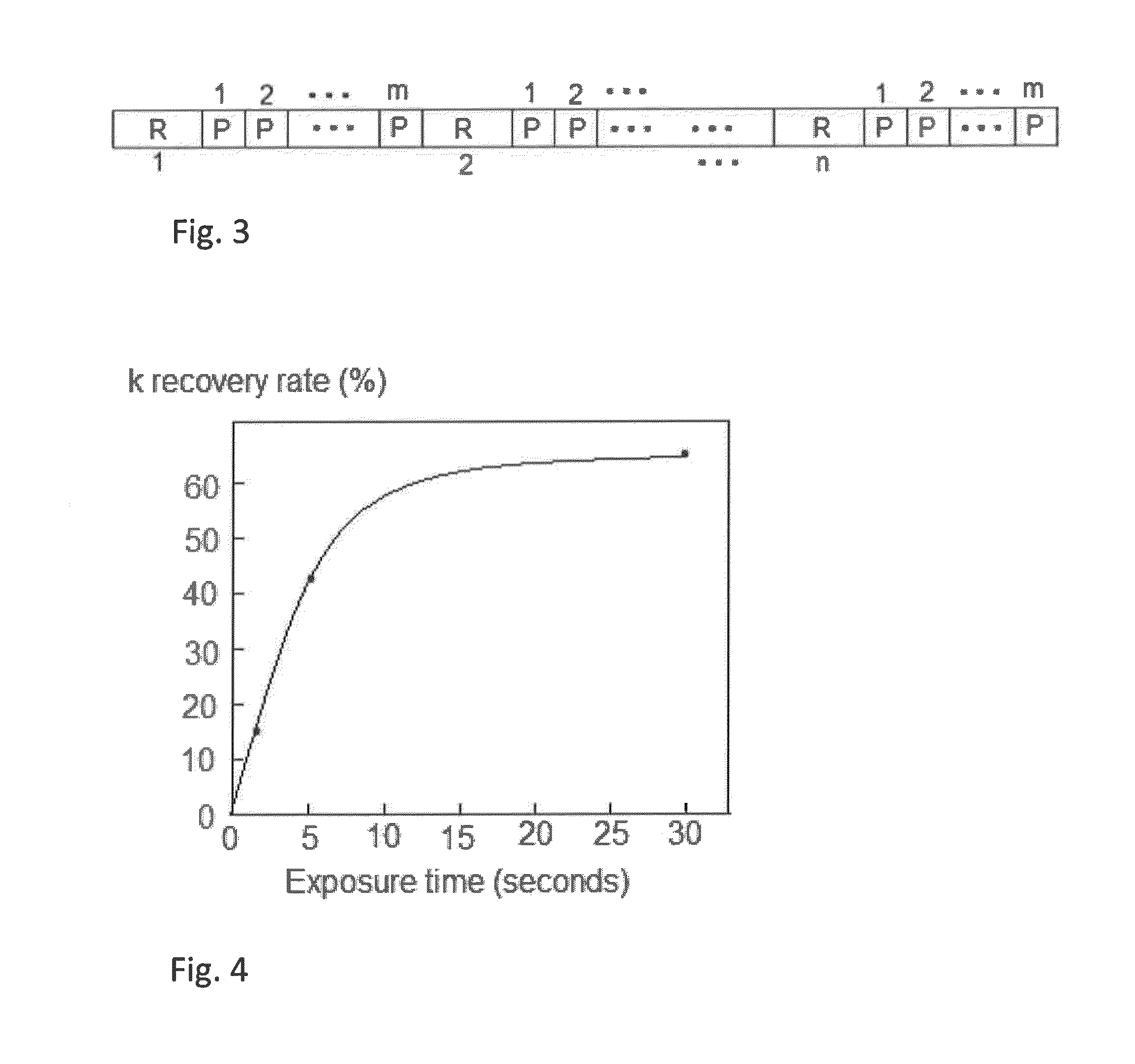

A method for repairing process-related damage of a dielectric film includes: (i) adsorbing a first gas containing silicon on a surface of the damaged dielectric film without depositing a film in the absence of reactive species, (ii) adsorbing a second gas containing silicon on a surface of the dielectric film, followed by applying reactive species to the surface of the dielectric film, to form a monolayer film thereon, and (iii) repeating step (ii). The duration of exposing the surface to the first gas in step (i) is longer than the duration of exposing the surface to the second gas in step (ii).

Owner:ASM IP HLDG BV

Method for repairing damage of dielectric film by cyclic processes

ActiveUS20130337583A1Enhanced barrier functionInhibited DiffusionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCyclic processMaterials science

A method for repairing process-related damage of a dielectric film includes: (i) adsorbing a first gas containing silicon on a surface of the damaged dielectric film without depositing a film in the absence of reactive species, (ii) adsorbing a second gas containing silicon on a surface of the dielectric film, followed by applying reactive species to the surface of the dielectric film, to form a monolayer film thereon, and (iii) repeating step (ii). The duration of exposing the surface to the first gas in step (i) is longer than the duration of exposing the surface to the second gas in step (ii).

Owner:ASM IP HLDG BV

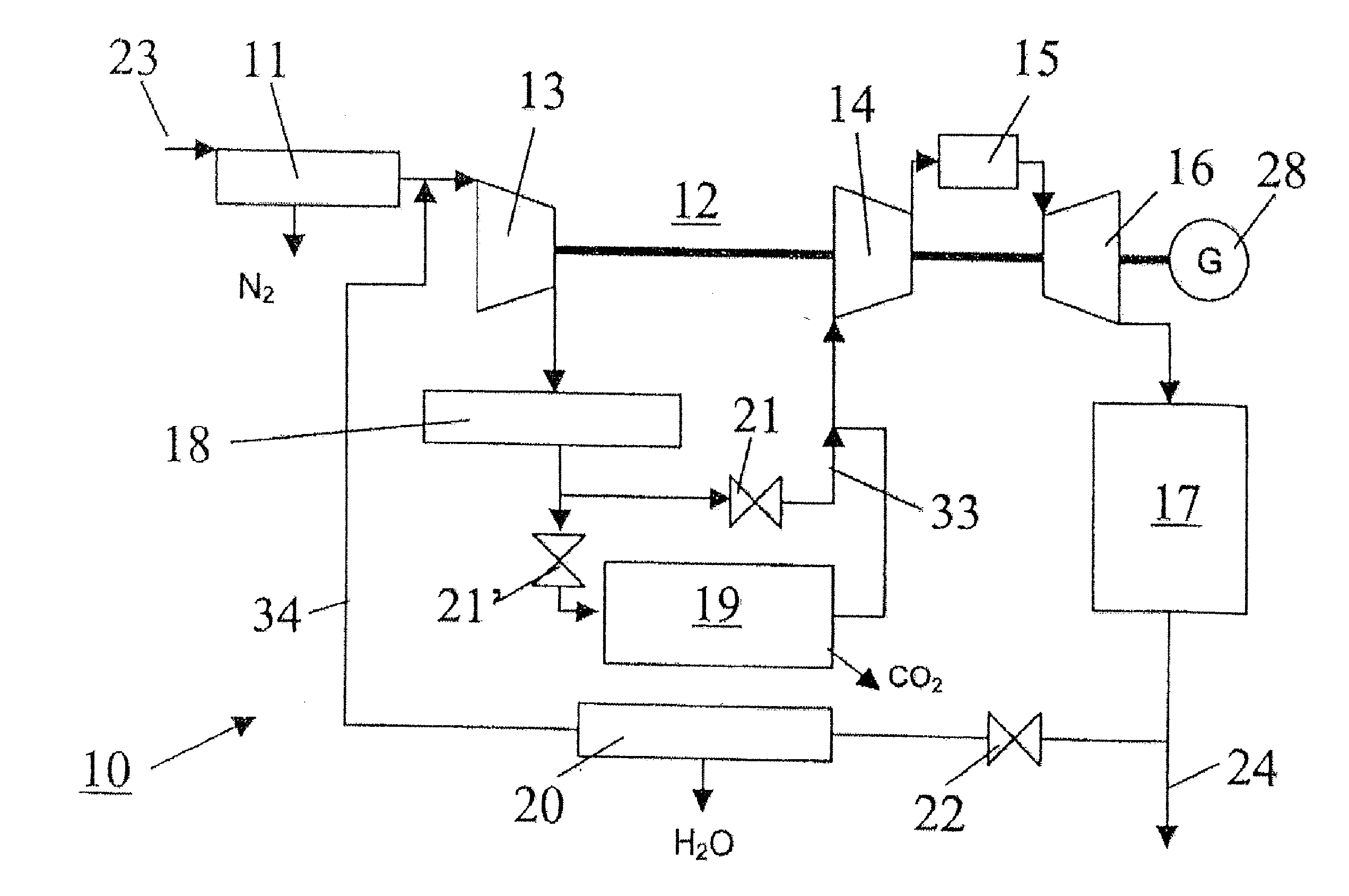

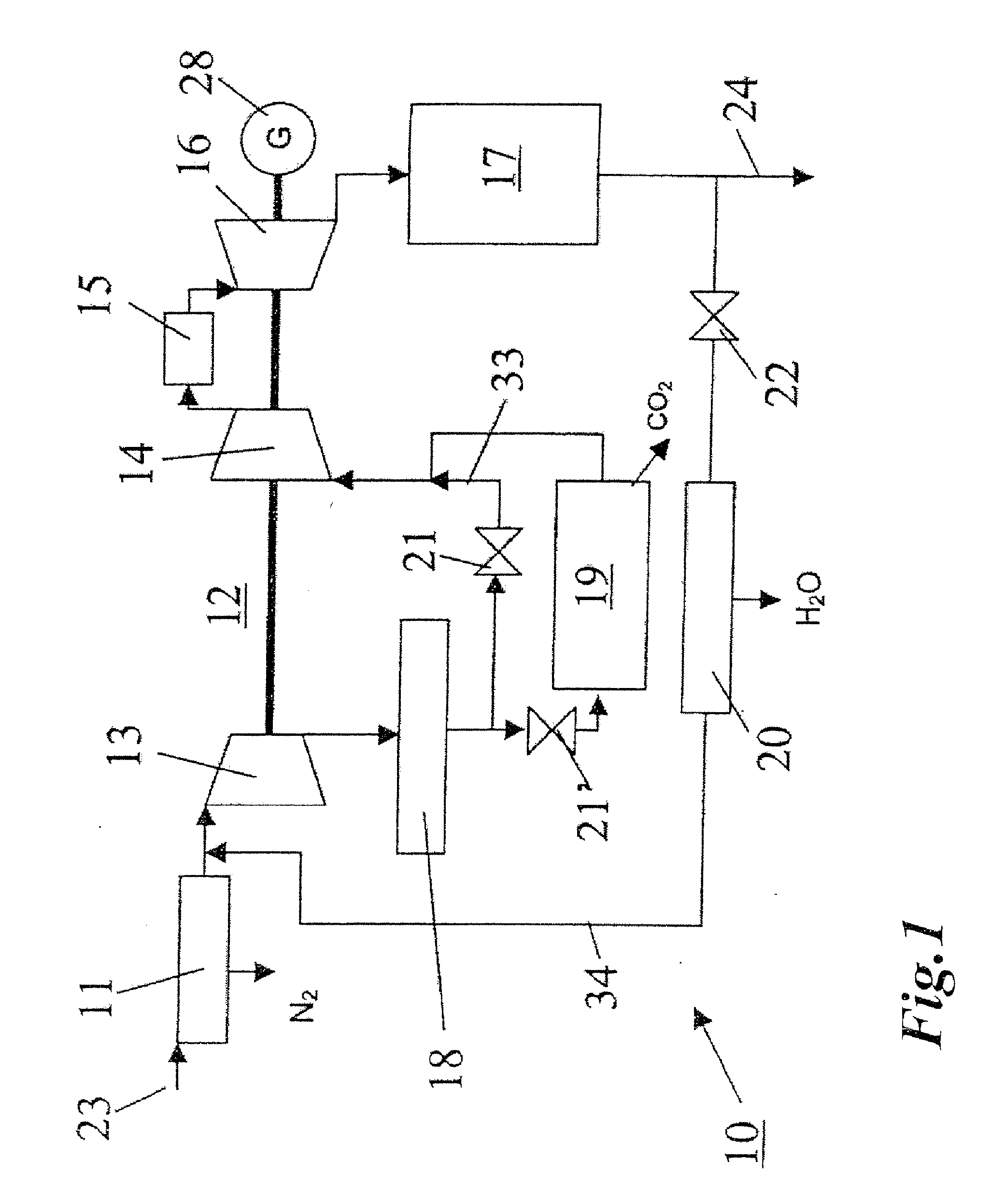

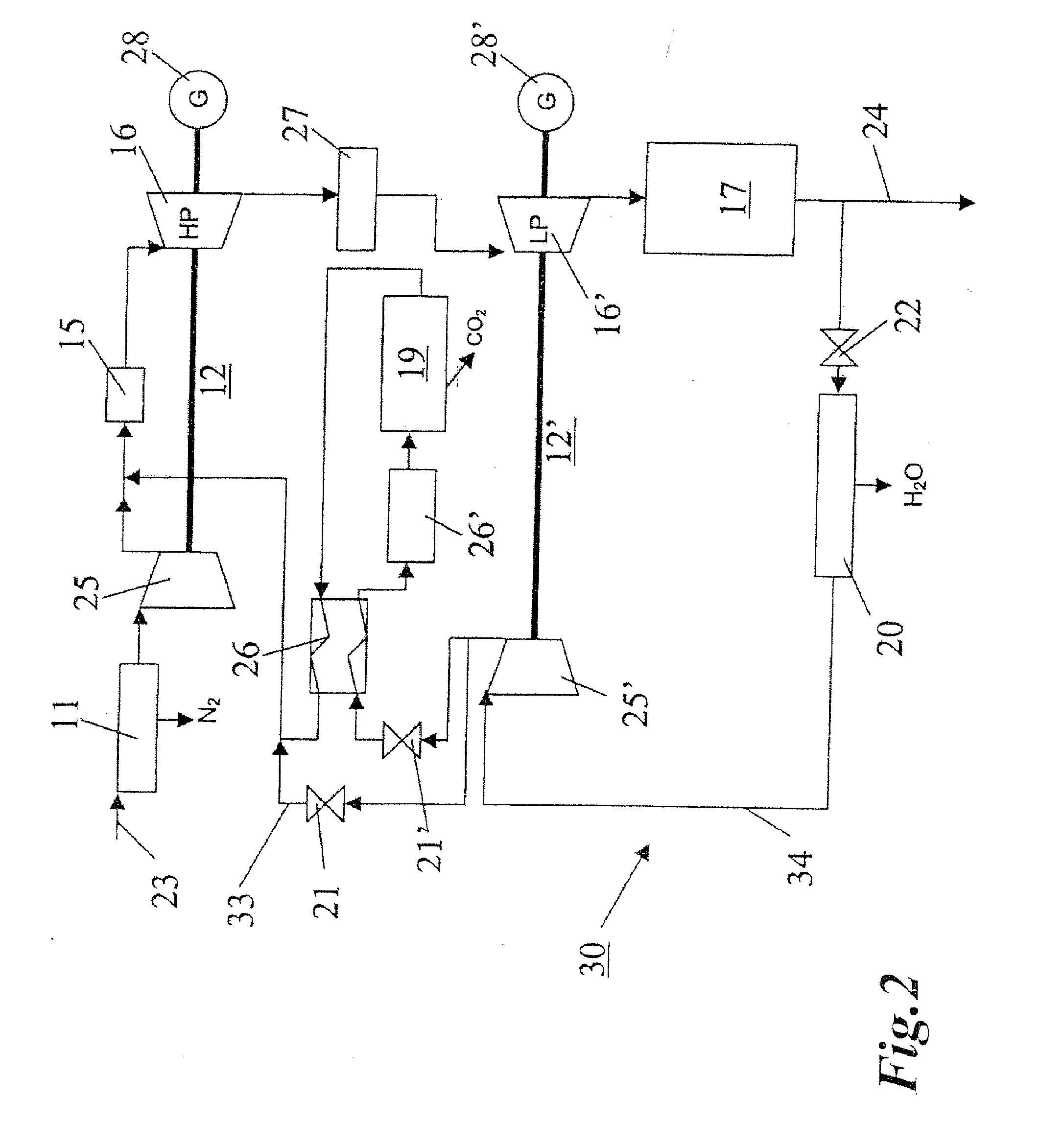

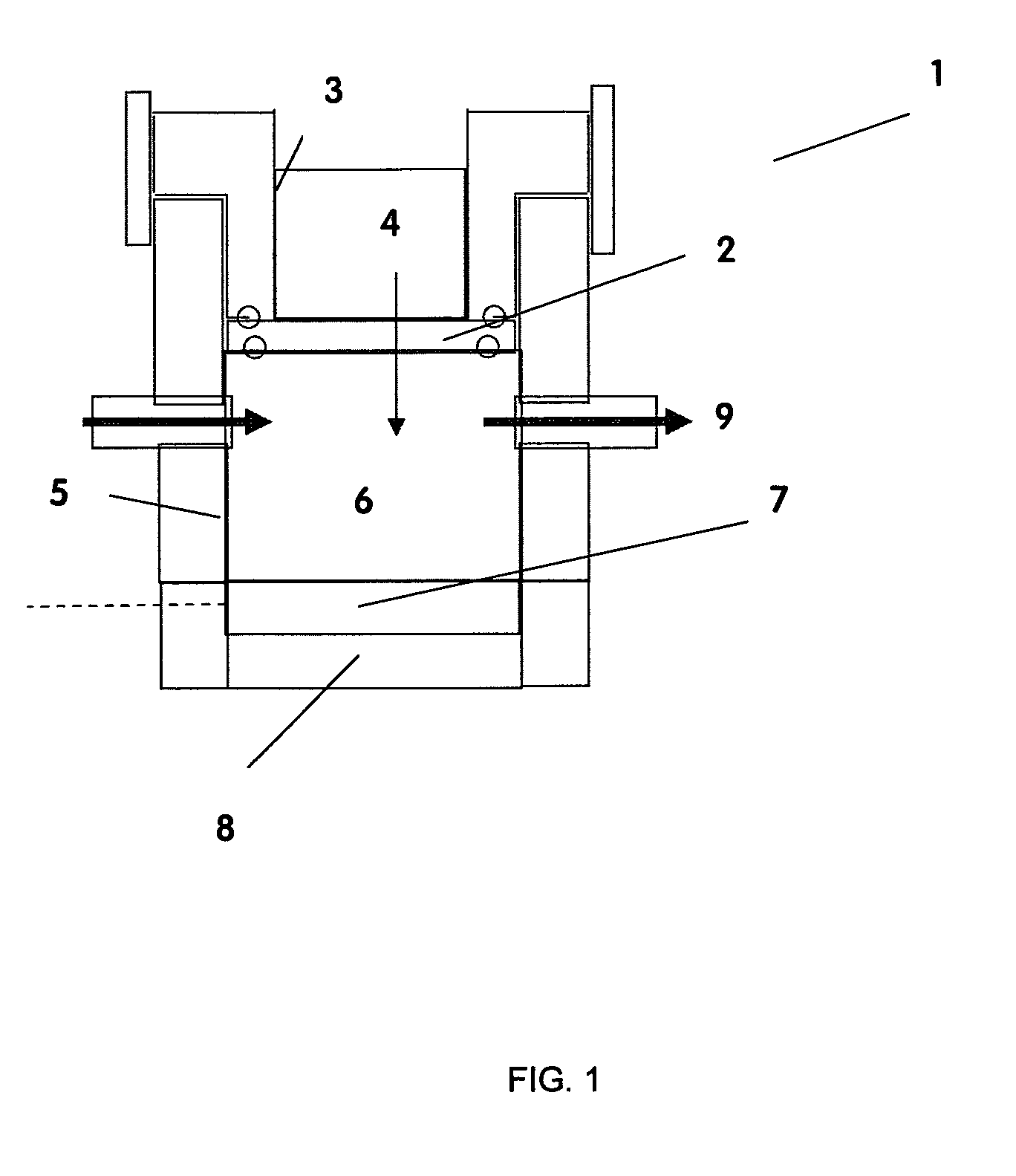

Method for Generating Energy in an Energy Generating Installation Having a Gas Turbine, and Energy Generating Installation Useful for Carrying Out the Method

InactiveUS20080010967A1Efficient removalImprove efficiencyDispersed particle separationGas turbine plantsCyclic processCombustion chamber

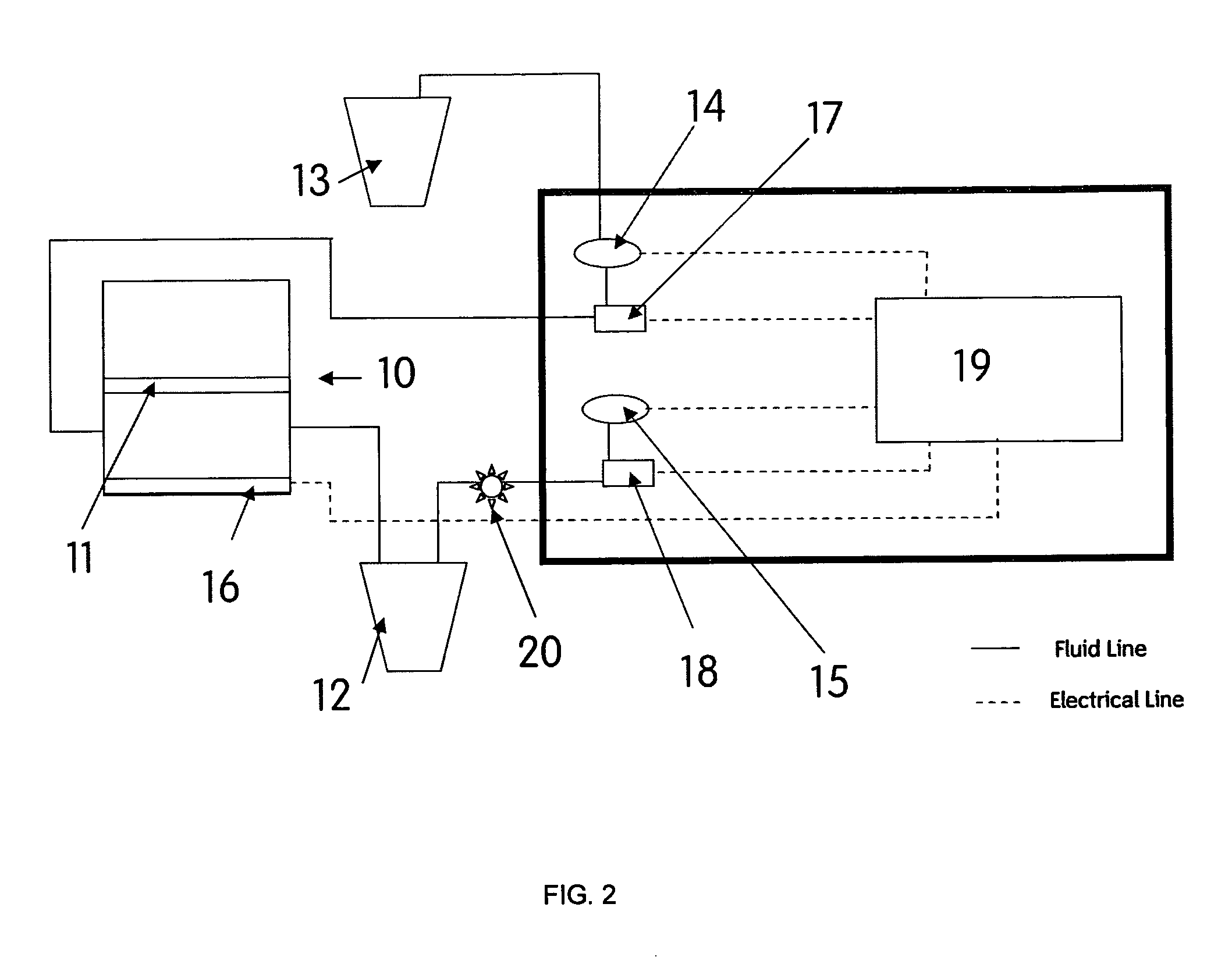

In a method for generating energy in an energy generating installation (10) having a gas turbine (12), in a first step, an oxygen-containing gas is compressed in a compressor (13, 14) of the gas turbine (12), in a second step the compressed gas is supplied, with the addition of fuel, for combustion in a combustion chamber (15), in a third step the hot flue gas from the combustion chamber (15) is expanded in a turbine (16) of the gas turbine (12) so as to perform work, and, in a fourth step, a branched-off part stream of the expanded flue gas is recirculated into a part of the gas turbine (12) lying upstream of the combustion chamber (15) and is compressed. A reduction in the CO2 emission, along with minimal losses of efficiency, is achieved in that carbon dioxide (CO2) is separated from the circulating gas in a CO2 separator (19), and in that measures are taken to compensate for the efficiency losses in the gas turbine cyclic process which are associated with the CO2 separation.

Owner:ALSTOM TECH LTD

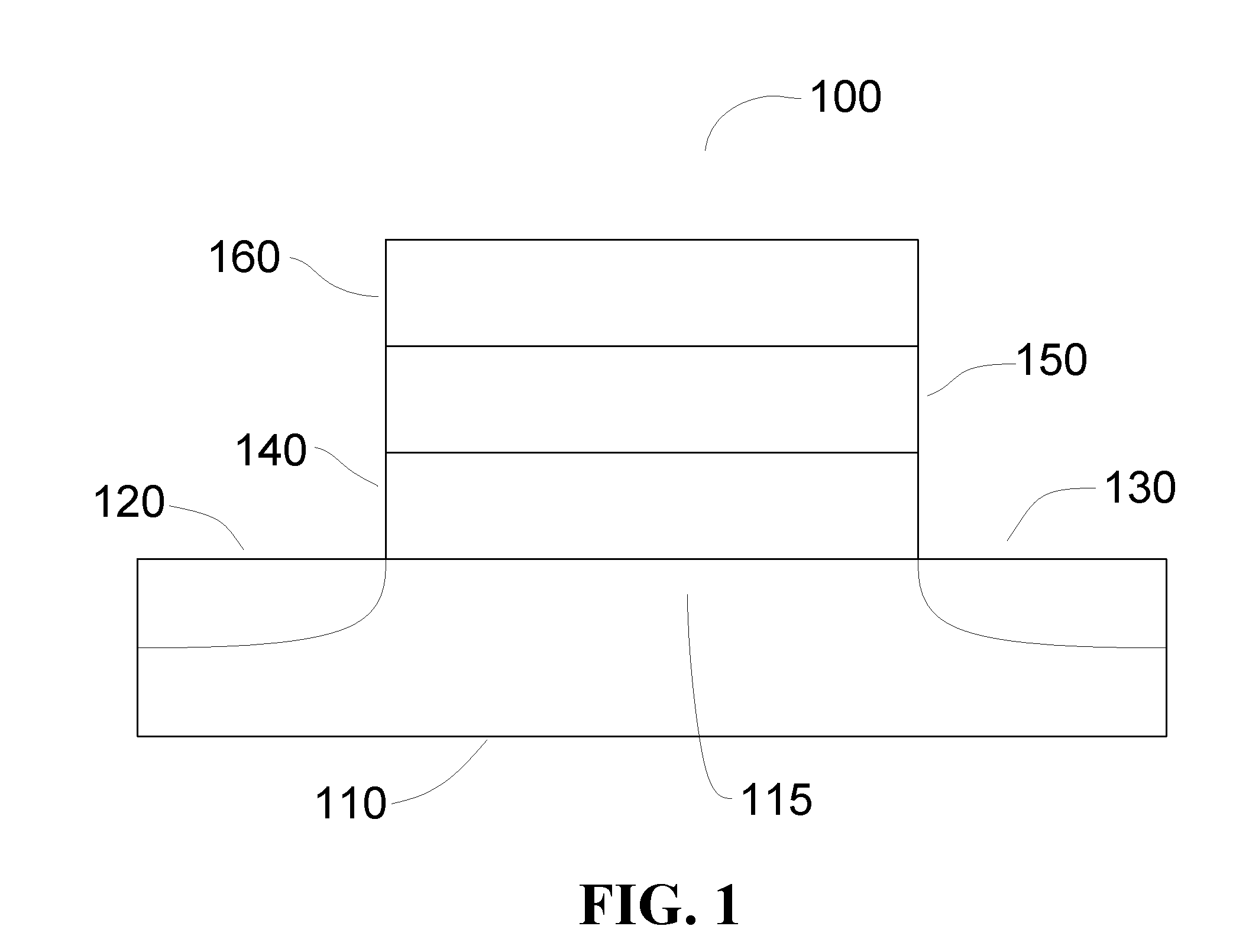

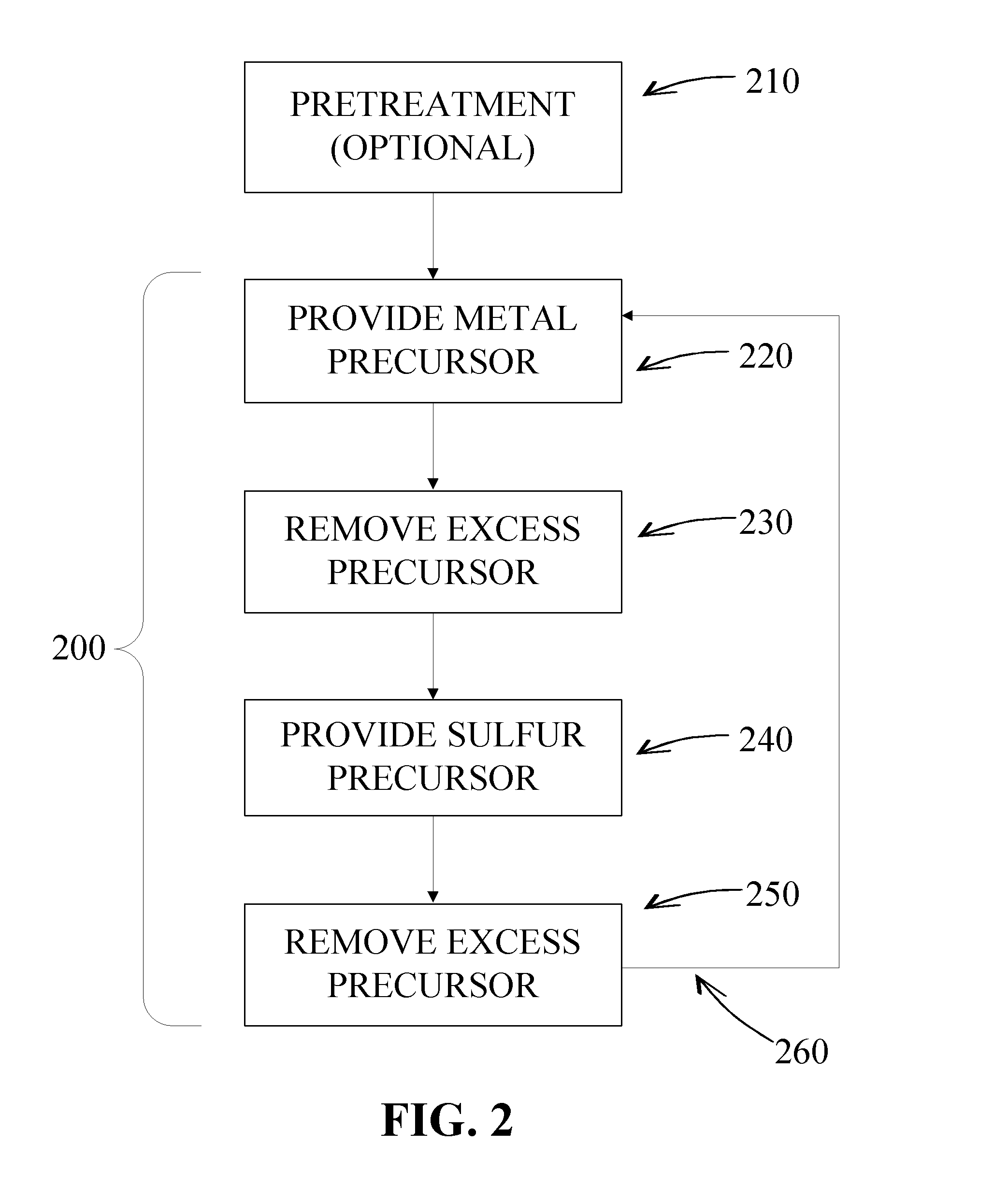

Sulfur-containing thin films

ActiveUS20150170907A1Semiconductor/solid-state device manufacturingSemiconductor devicesVapor phaseSulfur containing

In some aspects, methods of forming a metal sulfide thin film are provided. According to some methods, a metal sulfide thin film is deposited on a substrate in a reaction space in a cyclical process where at least one cycle includes alternately and sequentially contacting the substrate with a first vapor-phase metal reactant and a second vapor-phase sulfur reactant. In some aspects, methods of forming a three-dimensional architecture on a substrate surface are provided. In some embodiments, the method includes forming a metal sulfide thin film on the substrate surface and forming a capping layer over the metal sulfide thin film. The substrate surface may comprise a high-mobility channel.

Owner:ASM IP HLDG BV

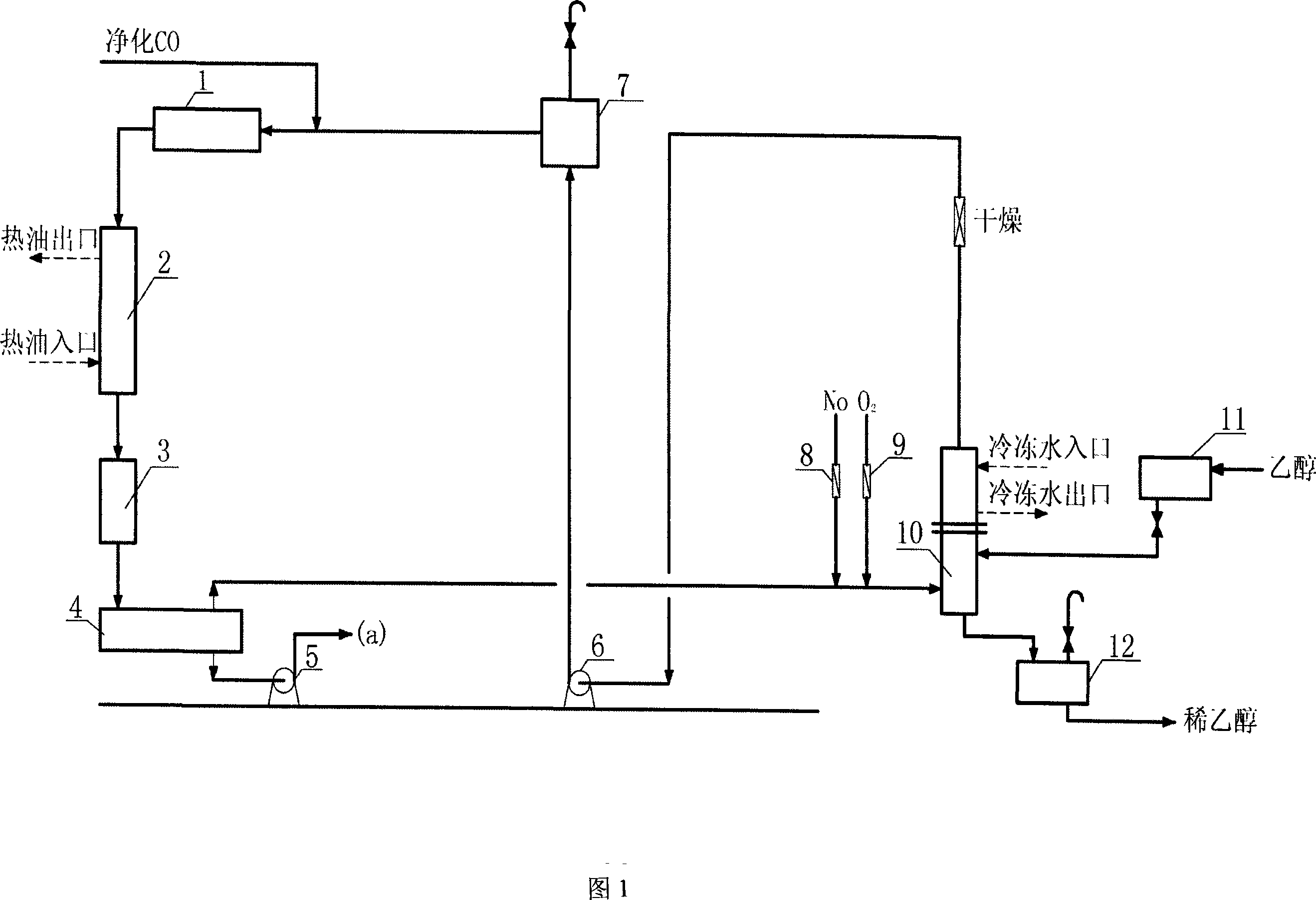

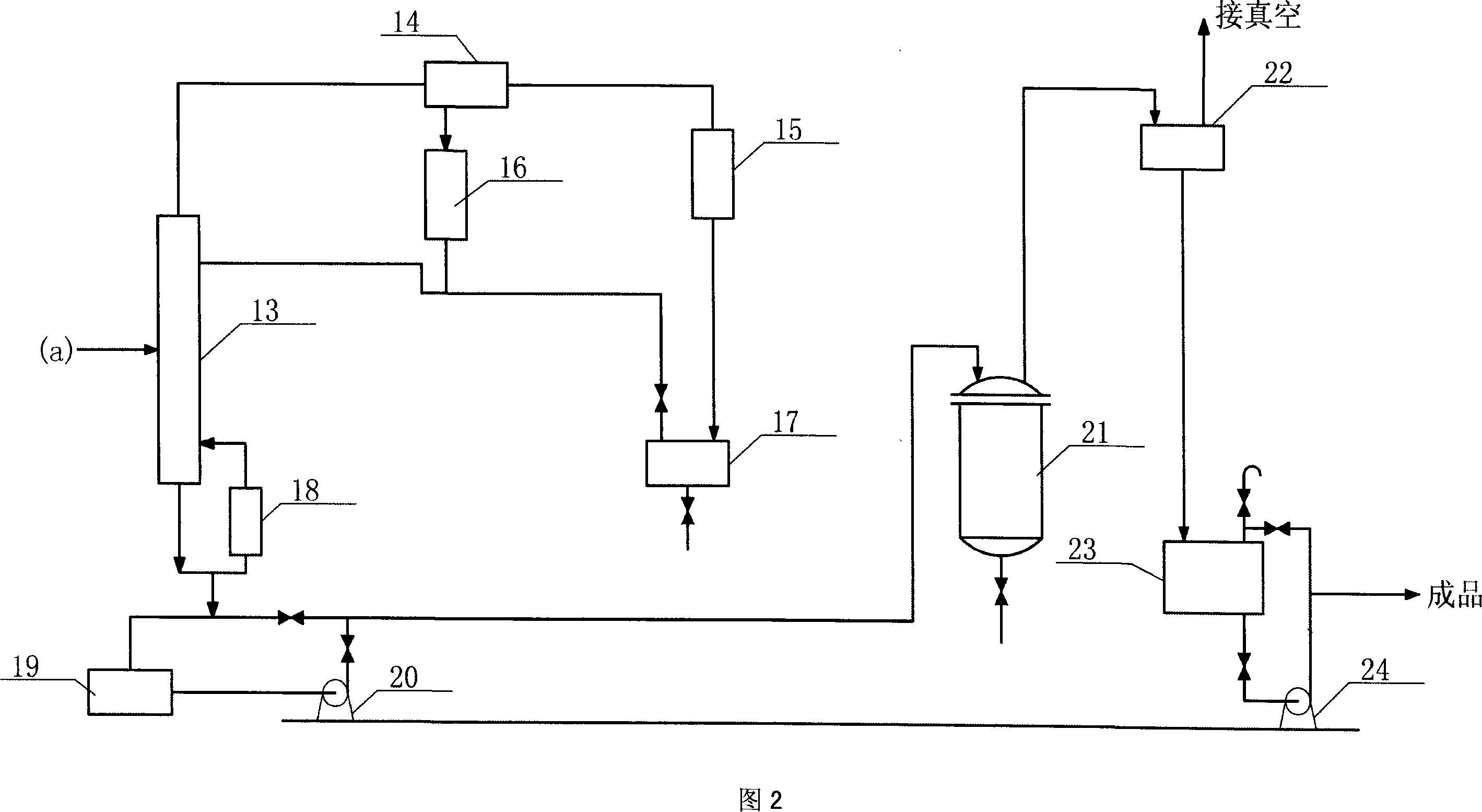

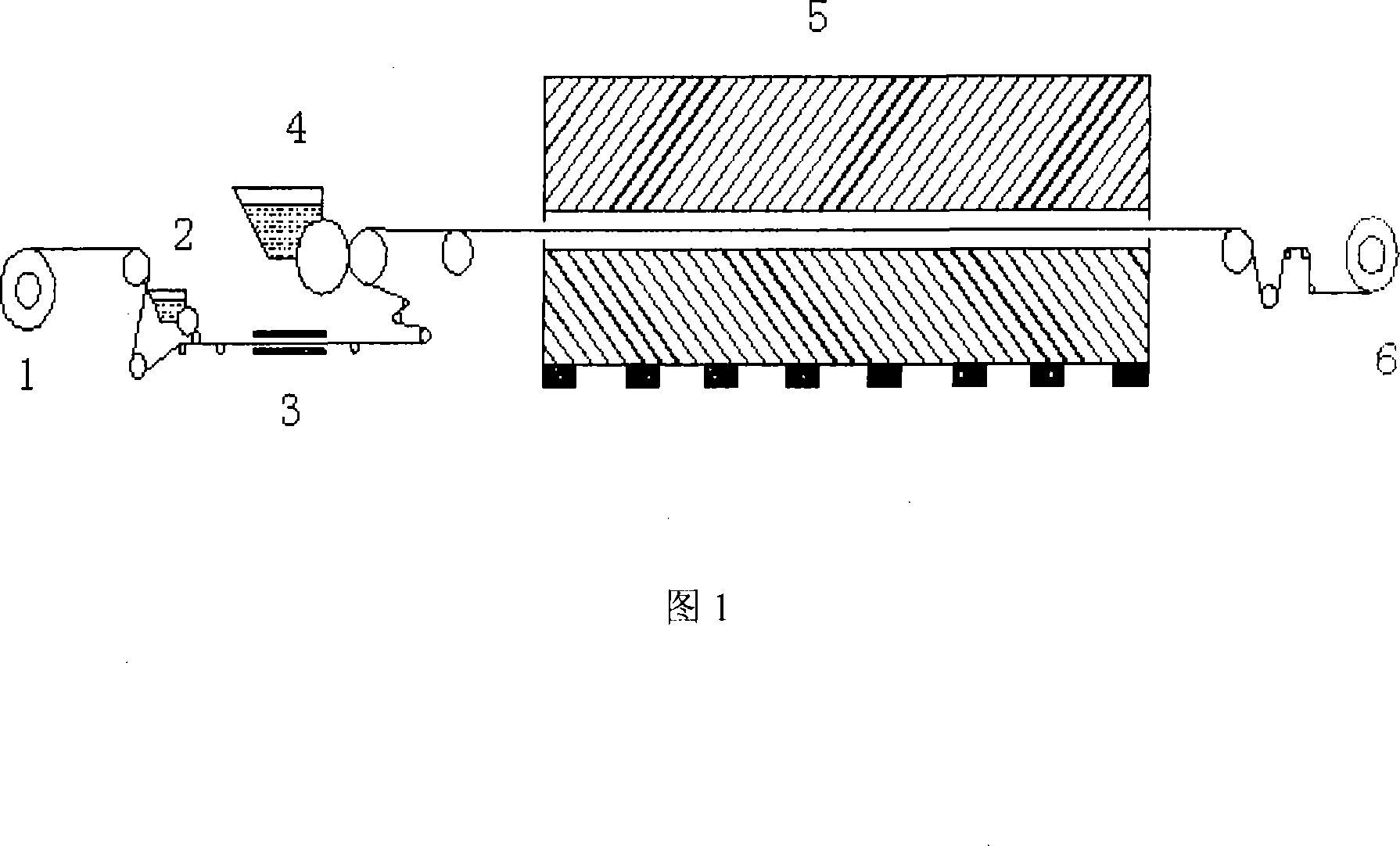

Method for preparing diethyl oxalate by coupling CO

ActiveCN101143821ANo pollution in the processImprove efficiencyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsCyclic processContinuous use

The invention discloses a method for preparing diethyl oxalate by CO coupling reaction. By applying a gas phase method, CO is coordinated with ethyl nitrite and is catalyzed by bimetallic supported catalyzer to couplingly generate crude diethyl oxalate, the reaction is a self-sealing circulation process, the CO gas mixed with the ethyl nitrite coming from a regeneration reactor is preheated and then enters into a coupling reactor, after the reaction, the gas is separated by condensation, so that the colorless and transparent condensed diethyl oxalate liquid is produced, and the uncondensed gas containing NO enters into the regeneration reactor to react with ethanol and oxygen in order to generate ethyl nitrite which is again circulated back to the coupling reactor for continuous use. The invention is carried out on the basis of previous laboratory research and under the background of industrial production and fulfils the continuous run examination of the bench scale test and pilot magnification under the condition of industrial operation, the temperature of the coupling reaction is low, and the concentration of products is increased. The method has the advantages of more energy saving, no pollution and high benefit. The total conversion rate of the CO generated by reaction is one hundred percent, and the selectivity of diethyl oxalate is over ninety six percent.

Owner:TIANJIN UNIV

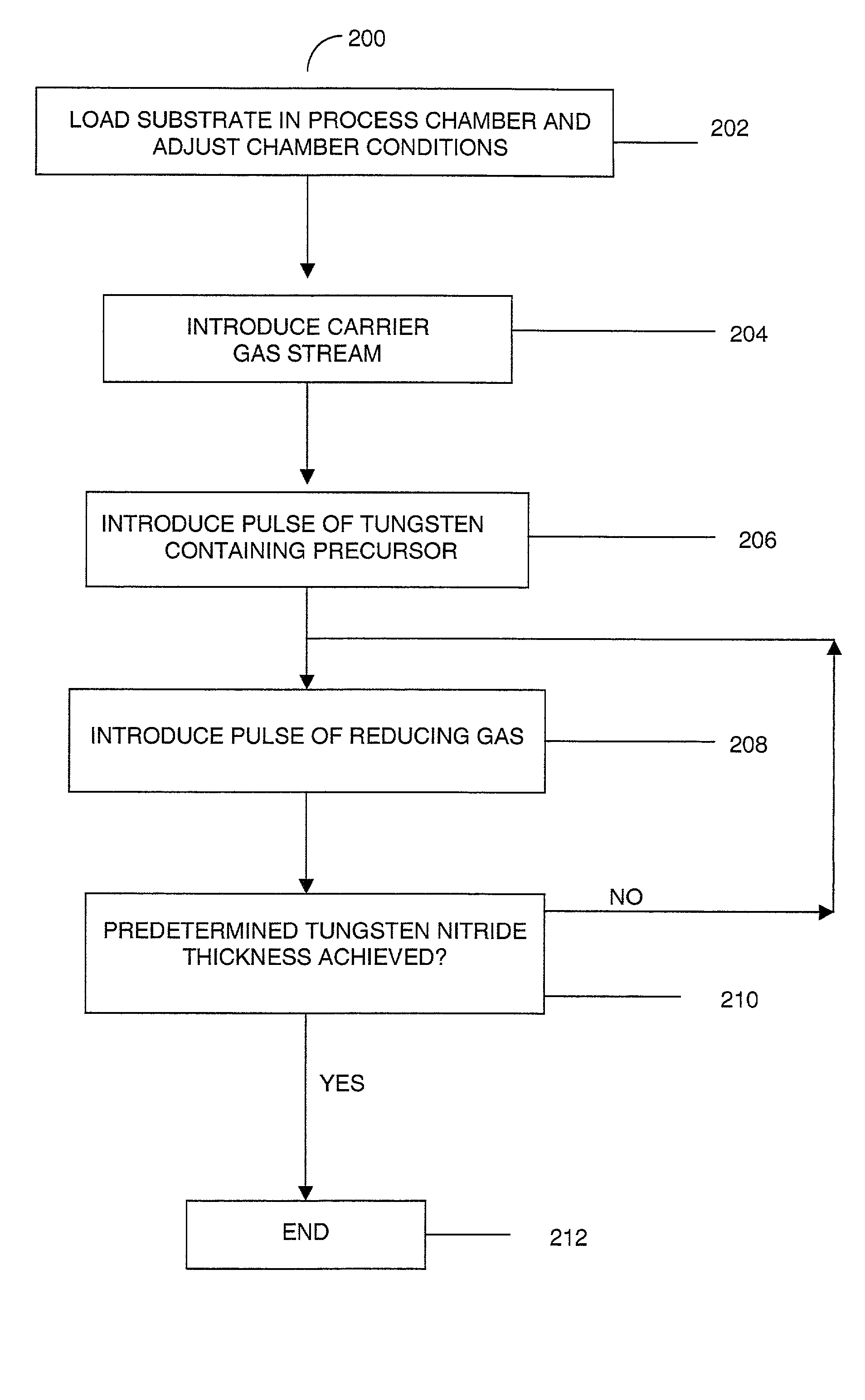

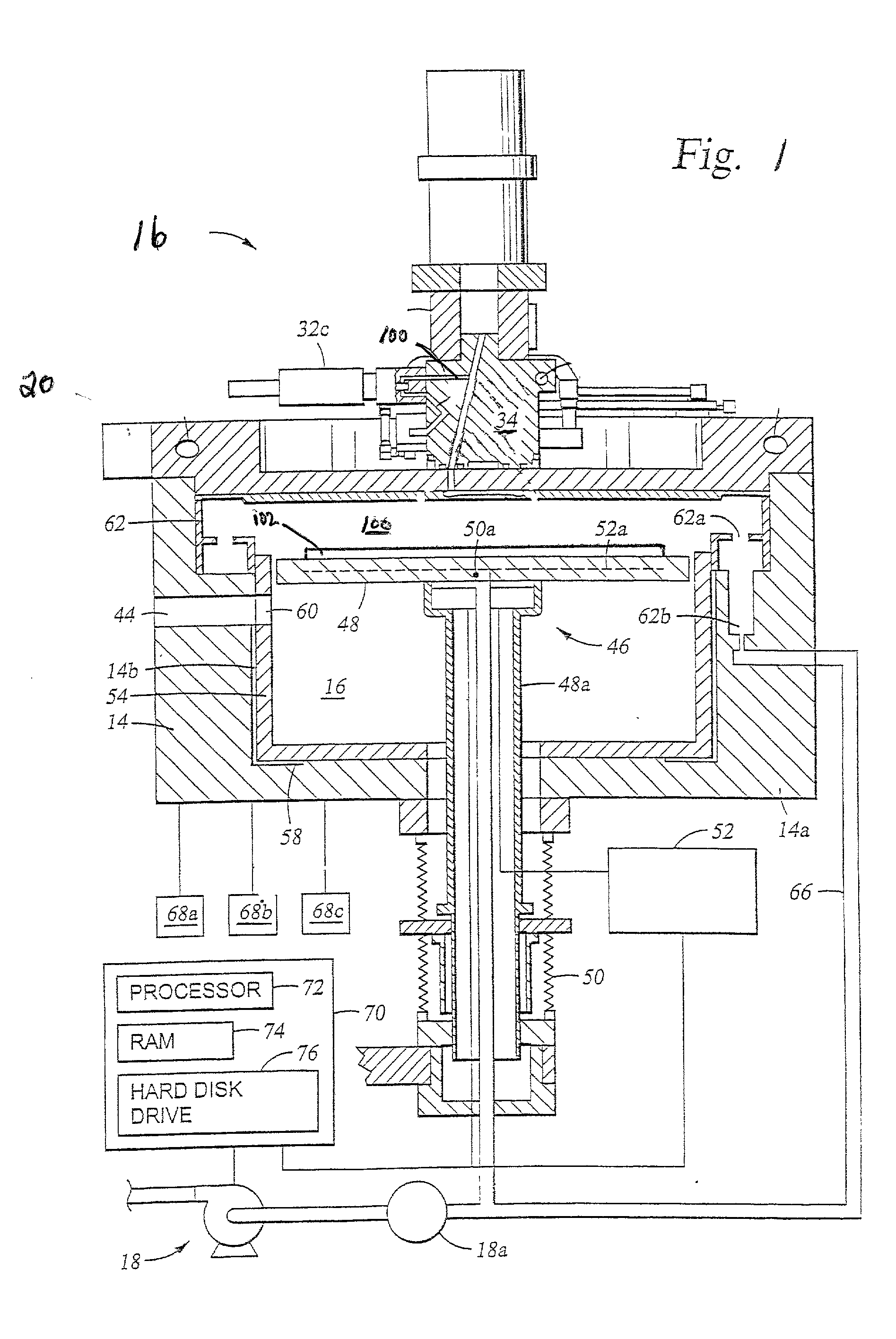

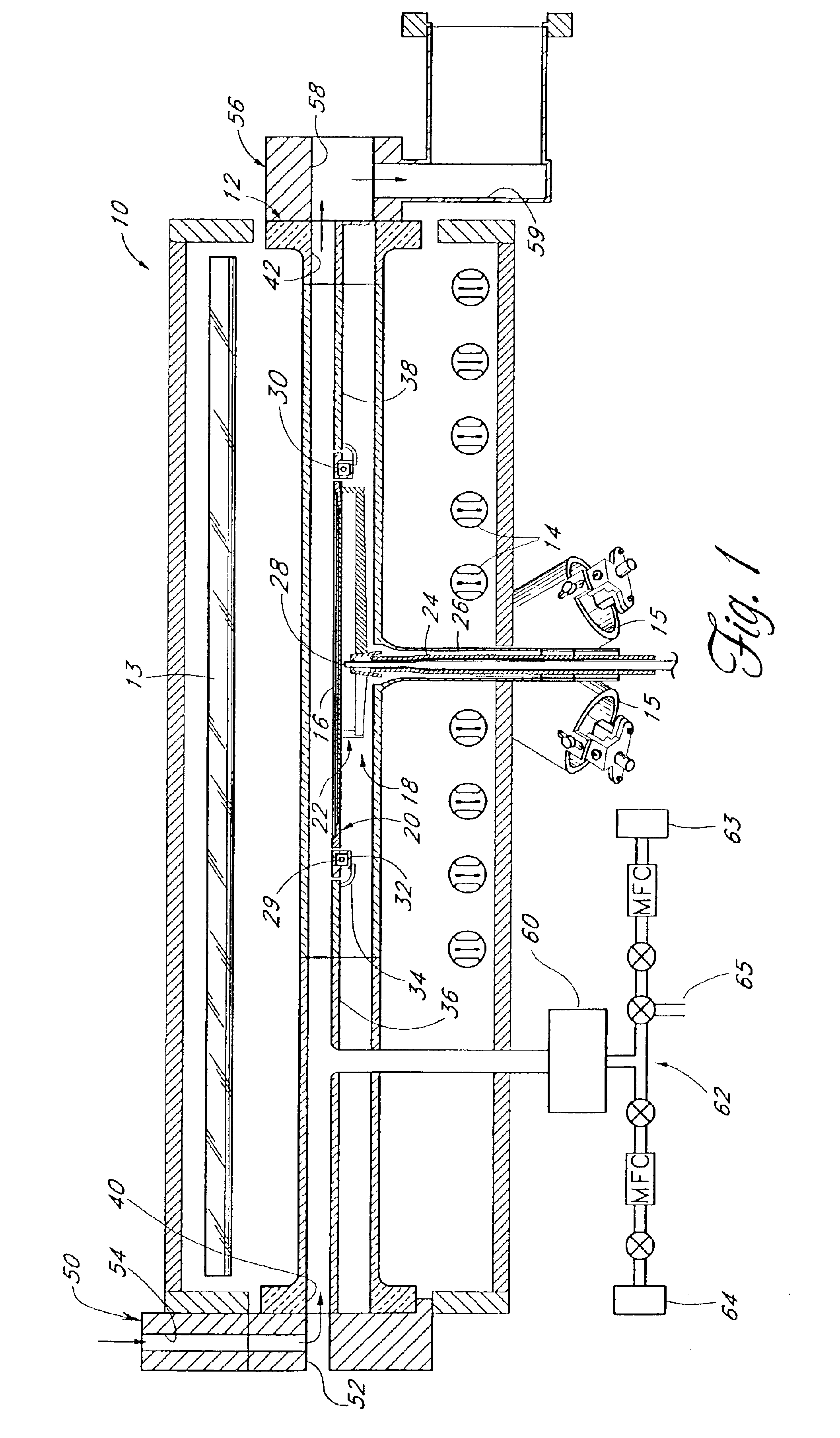

Cyclical deposition of tungsten nitride for metal oxide gate electrode

InactiveUS20030161952A1Solid-state devicesSemiconductor/solid-state device manufacturingCyclic processTungsten nitride

A method for depositing a tungsten nitride layer is provided. The method includes a cyclical process of alternately adsorbing a tungsten-containing compound and a nitrogen-containing compound on a substrate. The barrier layer has a reduced resistivity, lower concentration of fluorine, and can be deposited at any desired thickness, such as less than 100 angstroms, to minimize the amount of barrier layer material.

Owner:APPLIED MATERIALS INC

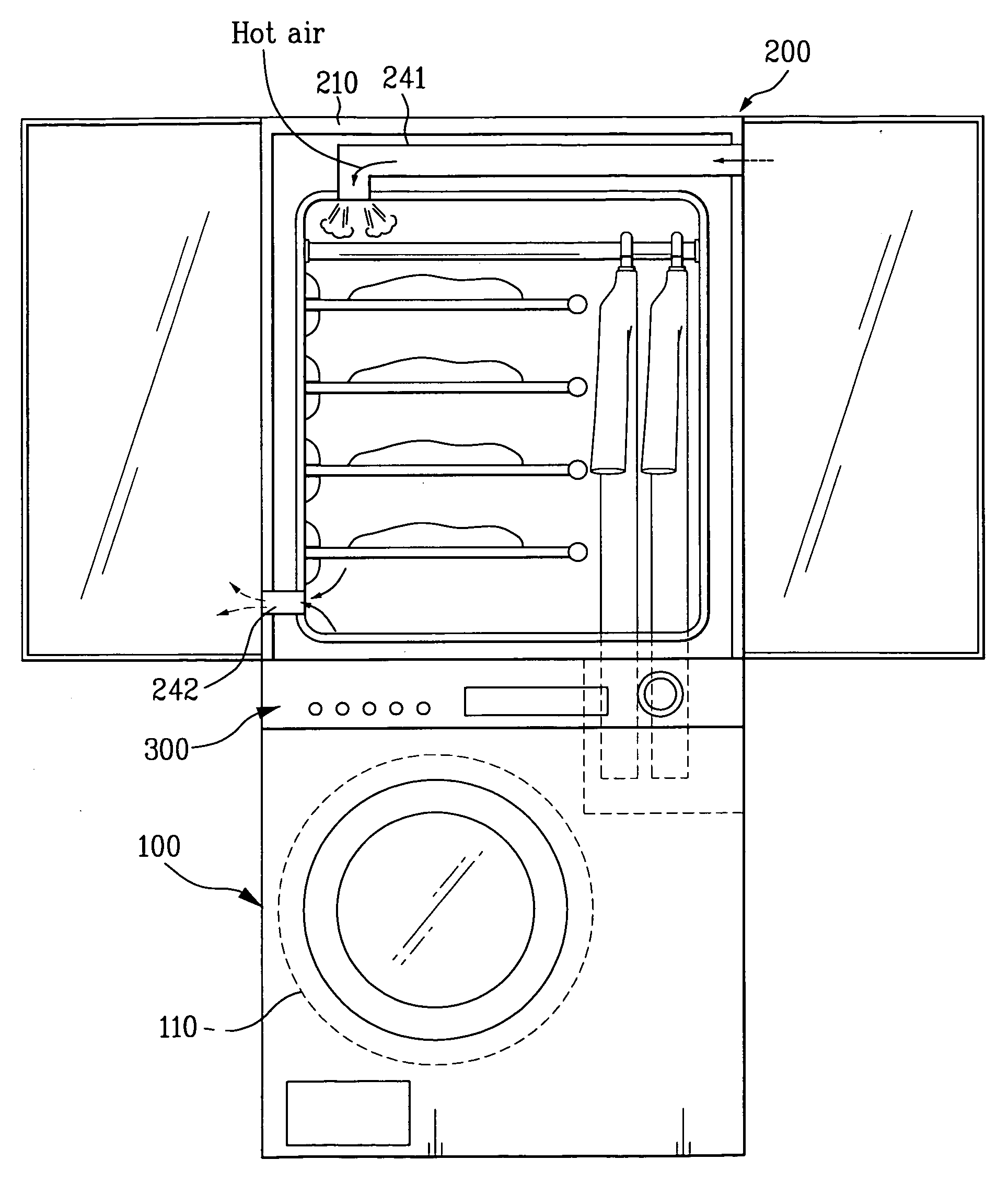

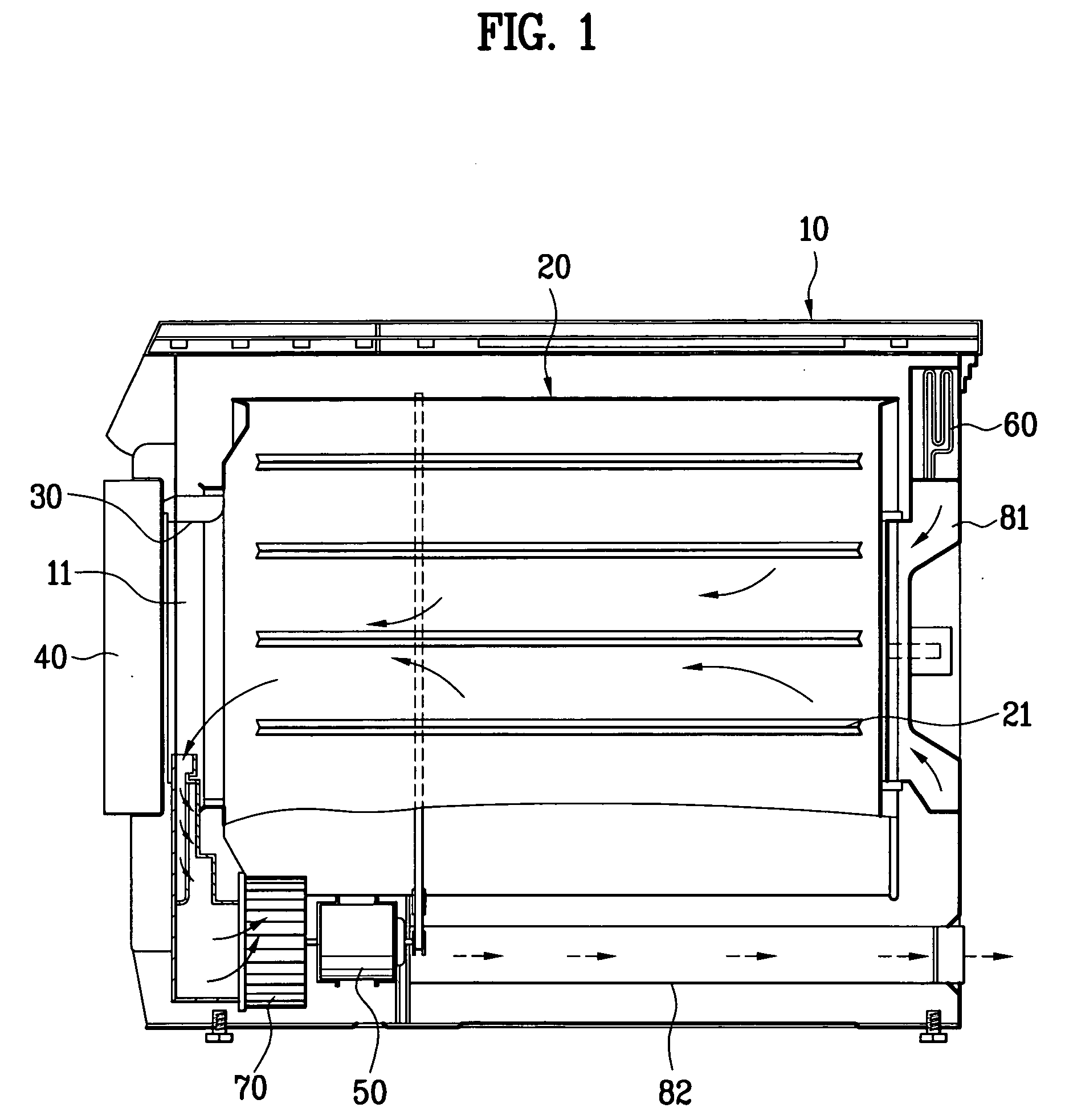

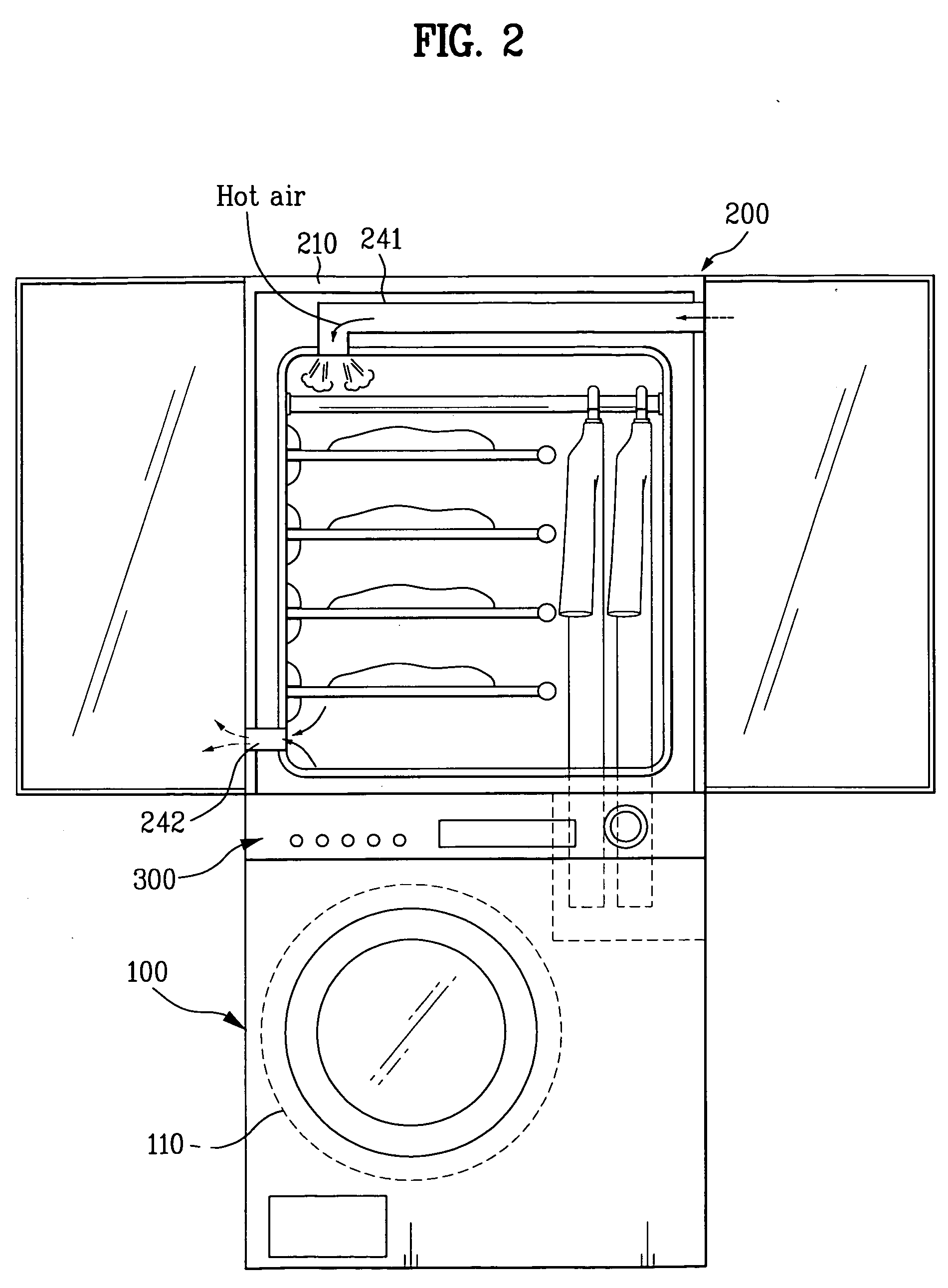

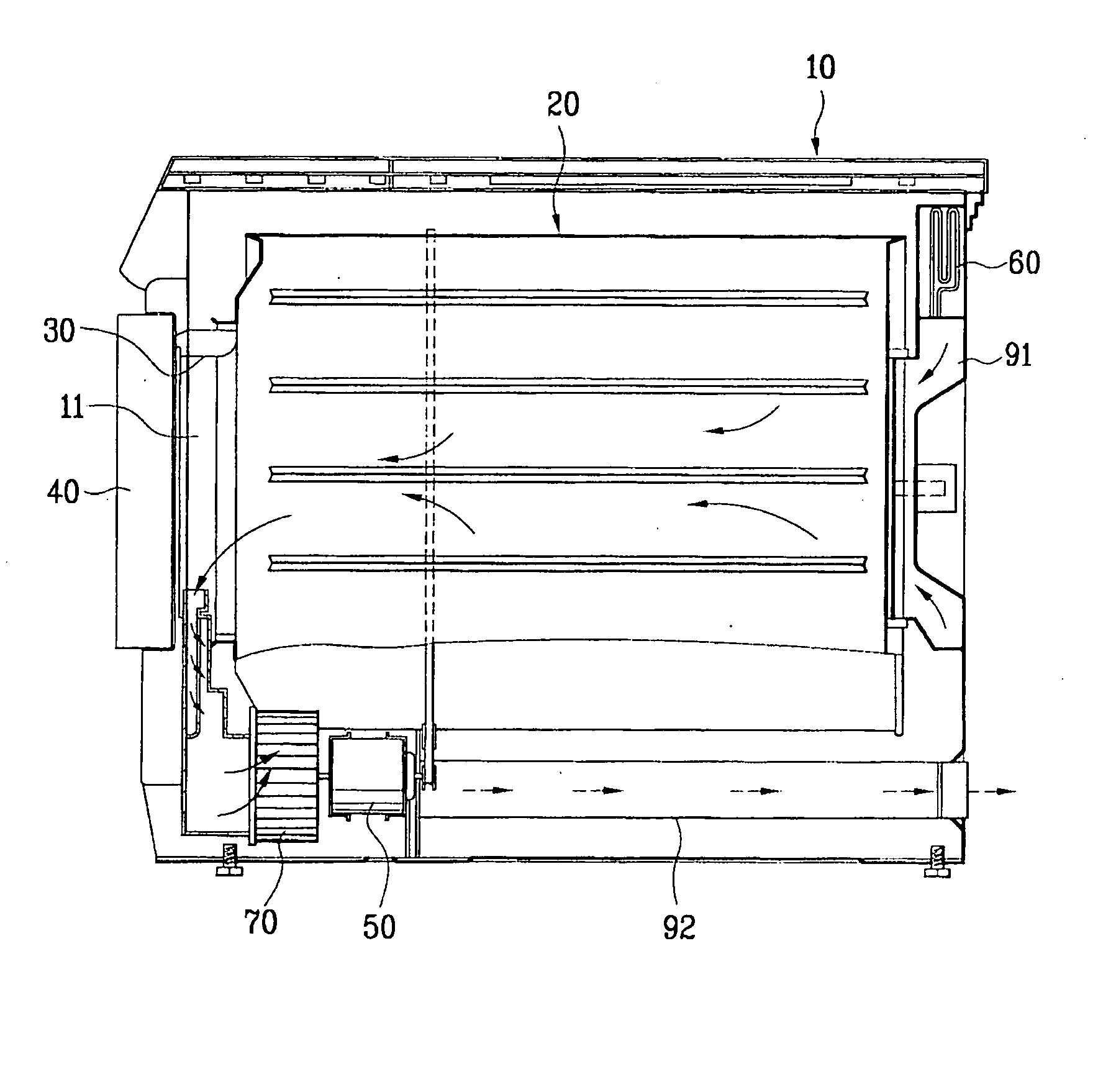

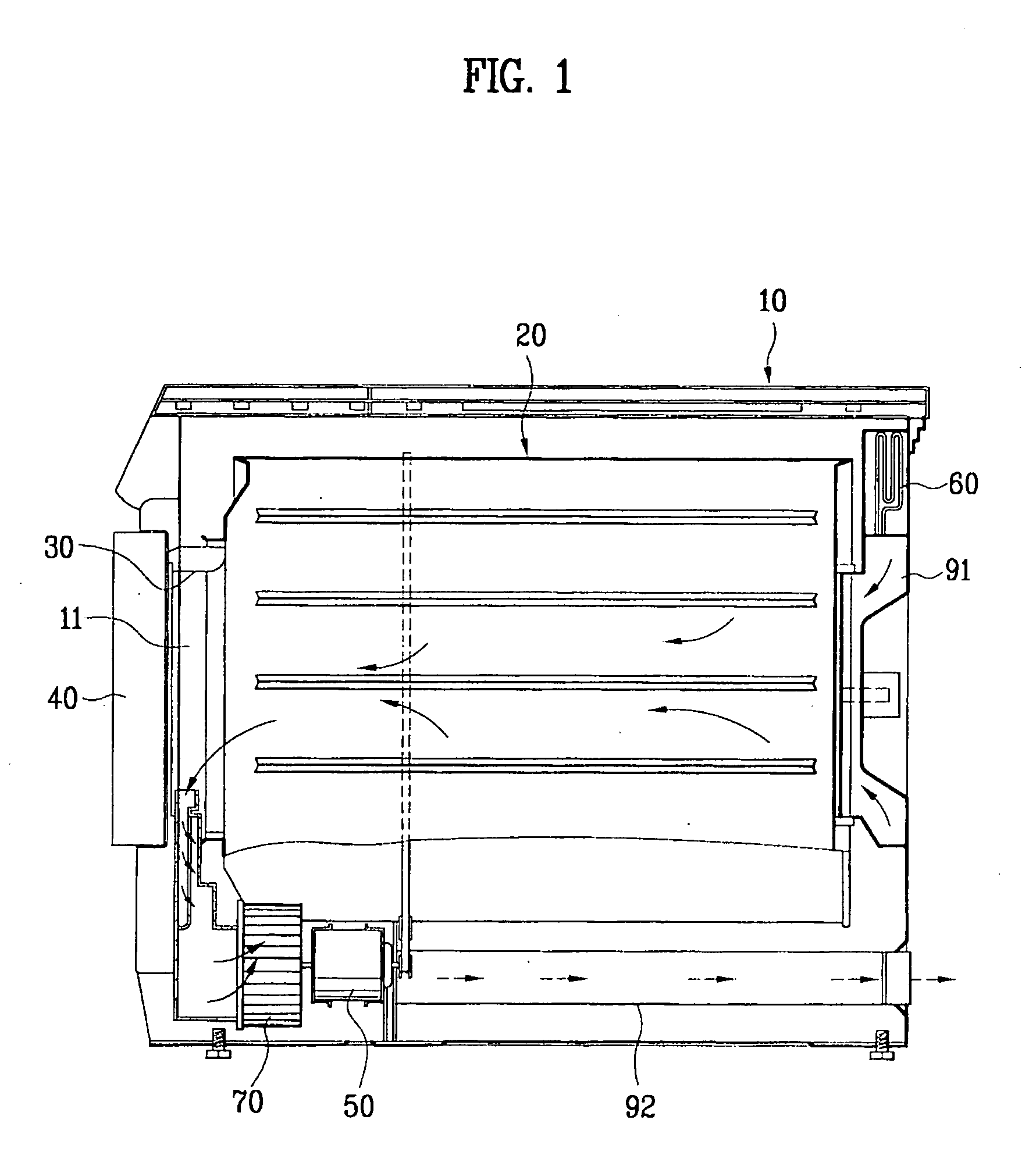

Operation method for combination dryer

InactiveUS20060112585A1Eliminate the problemDrying gas arrangementsOther washing machinesCyclic processRefresh cycle

An operation method for a combination dryer is disclosed. The present invention relates to a combination dryer, and more particularly, to an operation method for a combination dryer which enables air in a drying drum and a cabinet for drying the laundry to circulate continuously and enables condensed water generated in the circulation process to perform a refreshing cycle by using the water.

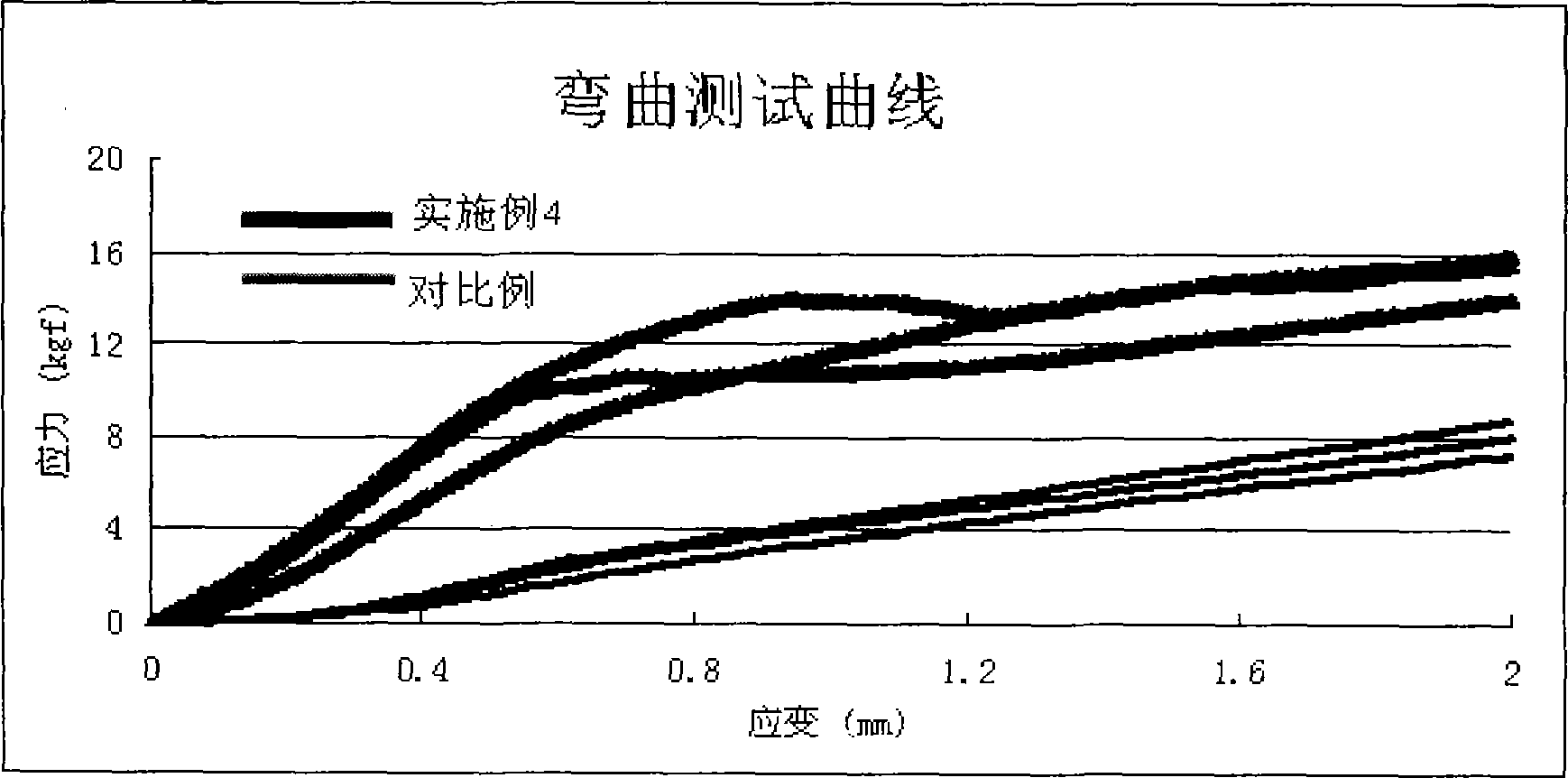

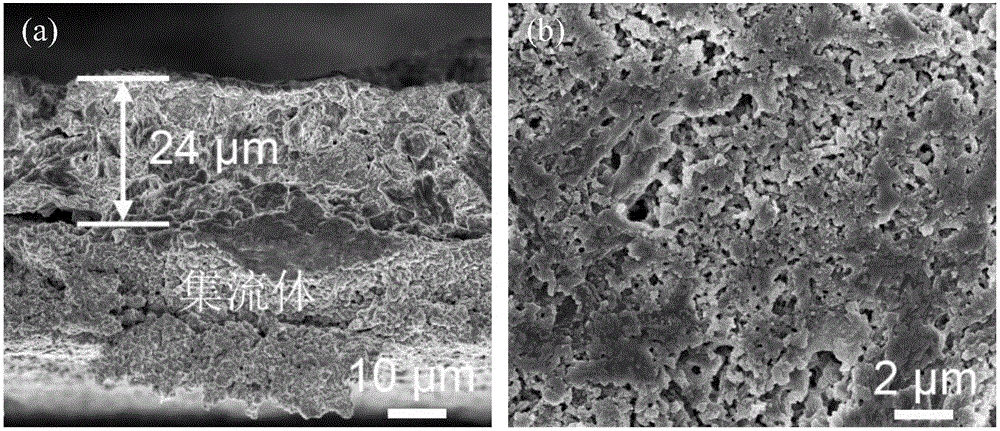

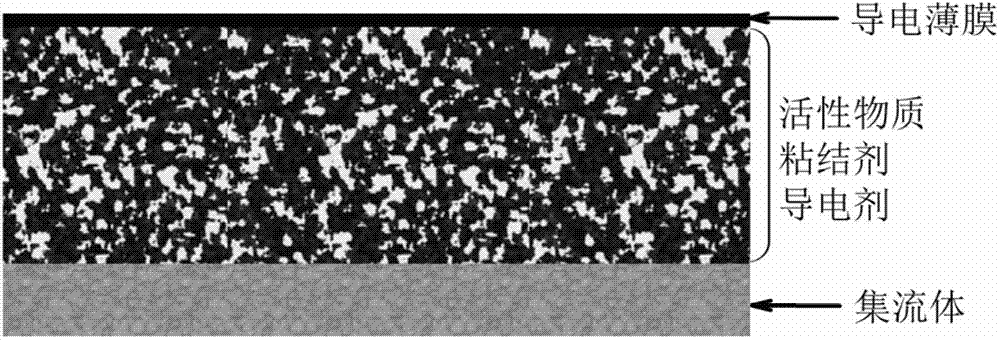

Anode or cathode pole piece of lithium ion battery and coating method thereof

InactiveCN101174685ALower surface energyLow densityElectrode manufacturing processesActive material electrodesCyclic processPole piece

The present invention relates to a lithium-ion battery anode or cathode pole piece and a spreading method of the anode pole piece or the cathode pole piece, wherein, the anode pole piece and the cathode pole piece consists of a foil, a conducting adhesive thin layer and an electrode active material layer in turn; the thickness of the conducting adhesive thin layer is five to ten microns. The electrode pole piece is made in the procedures that a layer of conducting adhesive thin layer in the thickness of five to ten microns are pre-coated on the surface of the foil before the sizing agent is spread, so that a conducting adhesive thin layer having good adhesive force, good conductivity and compact structure is formed on the surface of the foil. Then the electrode active material sizing agent is spread on the conducting adhesive thin layer, and is dried under an appropriate temperature to produce a required pole piece. The present invention can reduce the surface of the foil, and can improve the wetting quality of the sizing agent, thereby improving the adhesion performance of the anode material and the collecting body (aluminum foil) so as to reduce the powder-dropping of the battery during the cycling process, and to prolong the cycling service life of the battery; moreover, the present invention can reduce the content of the adhesive agent in the sizing agent, and improve the utilization rate of the active substance, and the method of the present invention does not produce negative influence on the performance of the battery.

Owner:CENT SOUTH UNIV

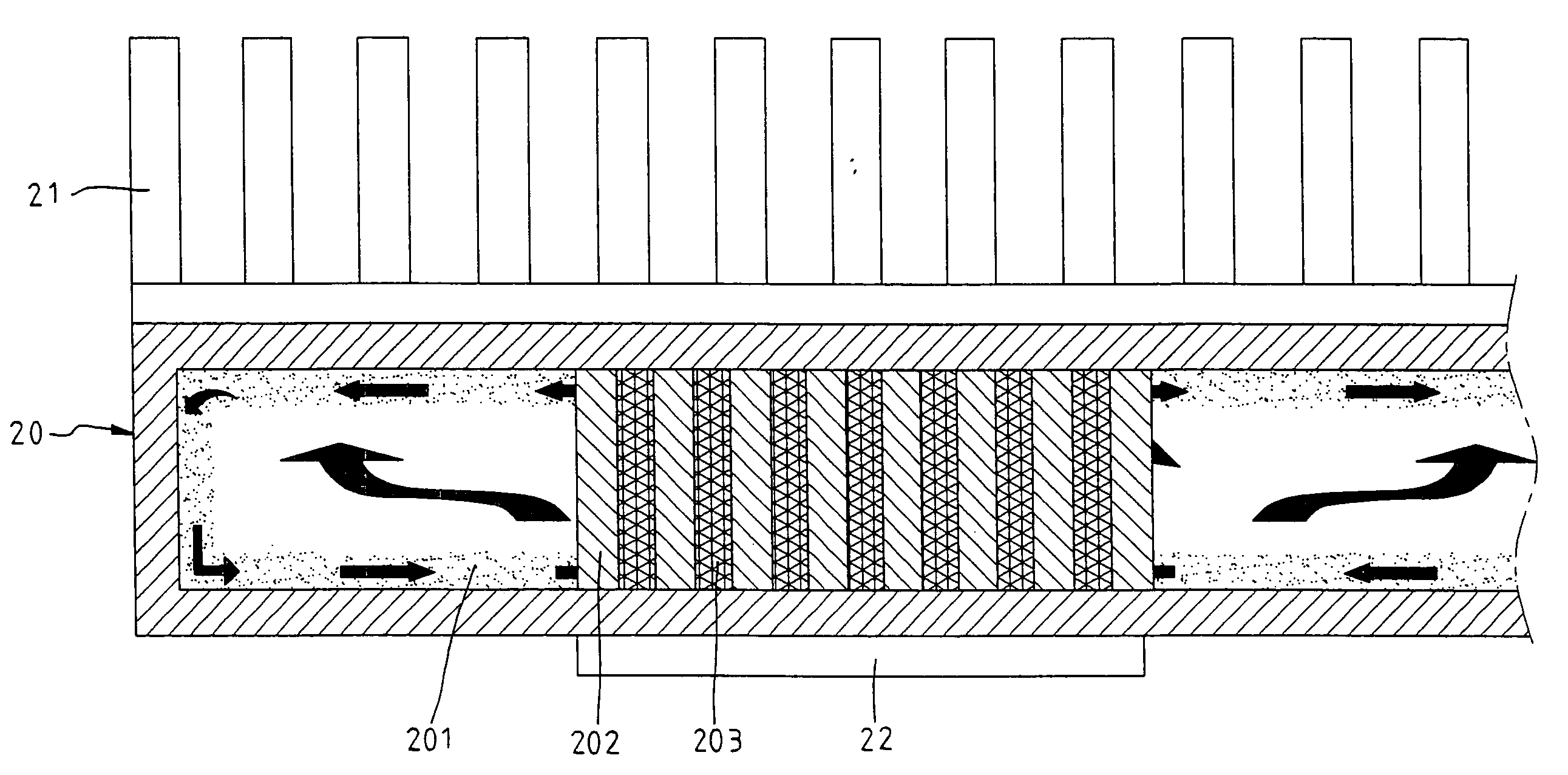

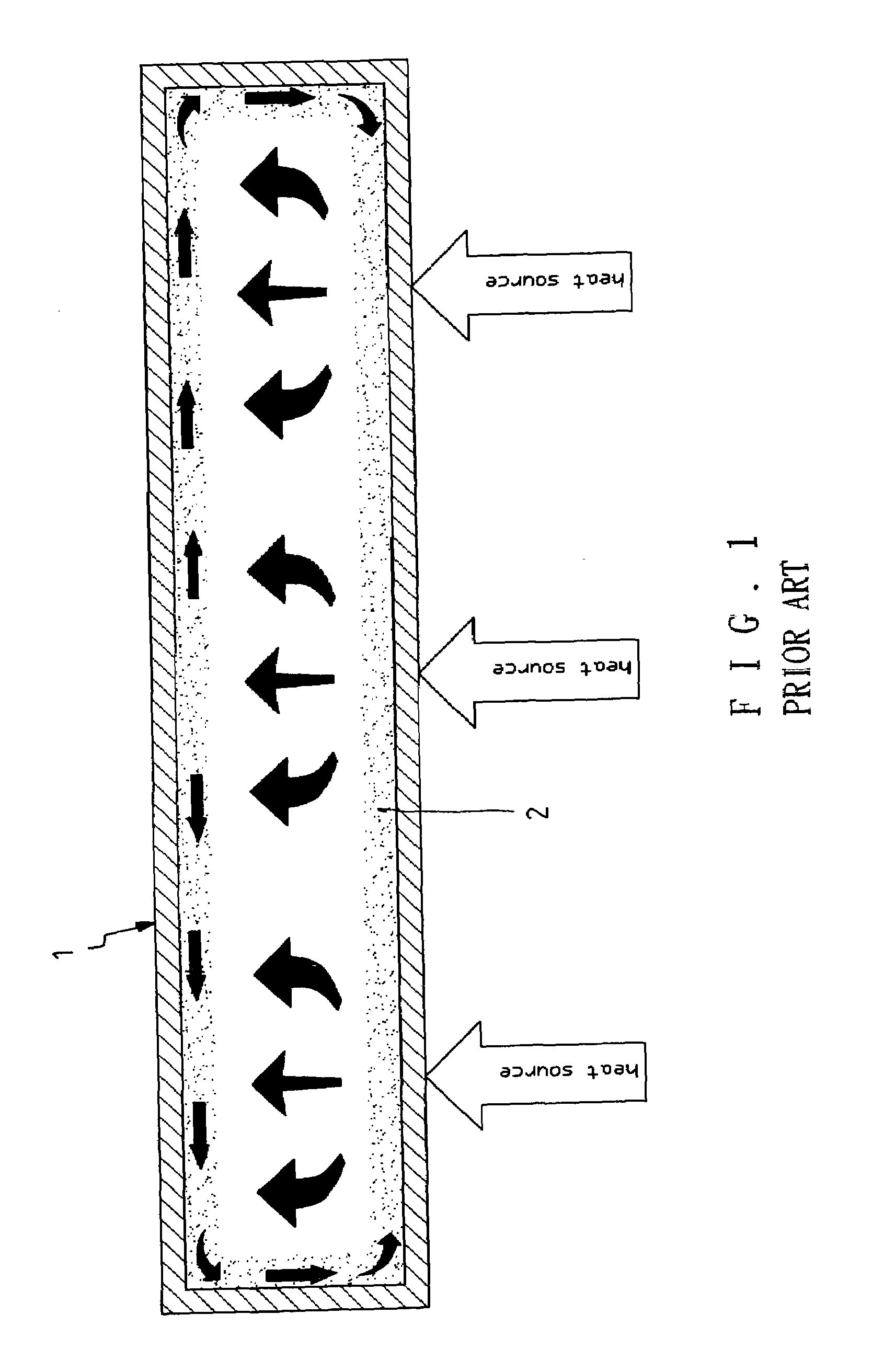

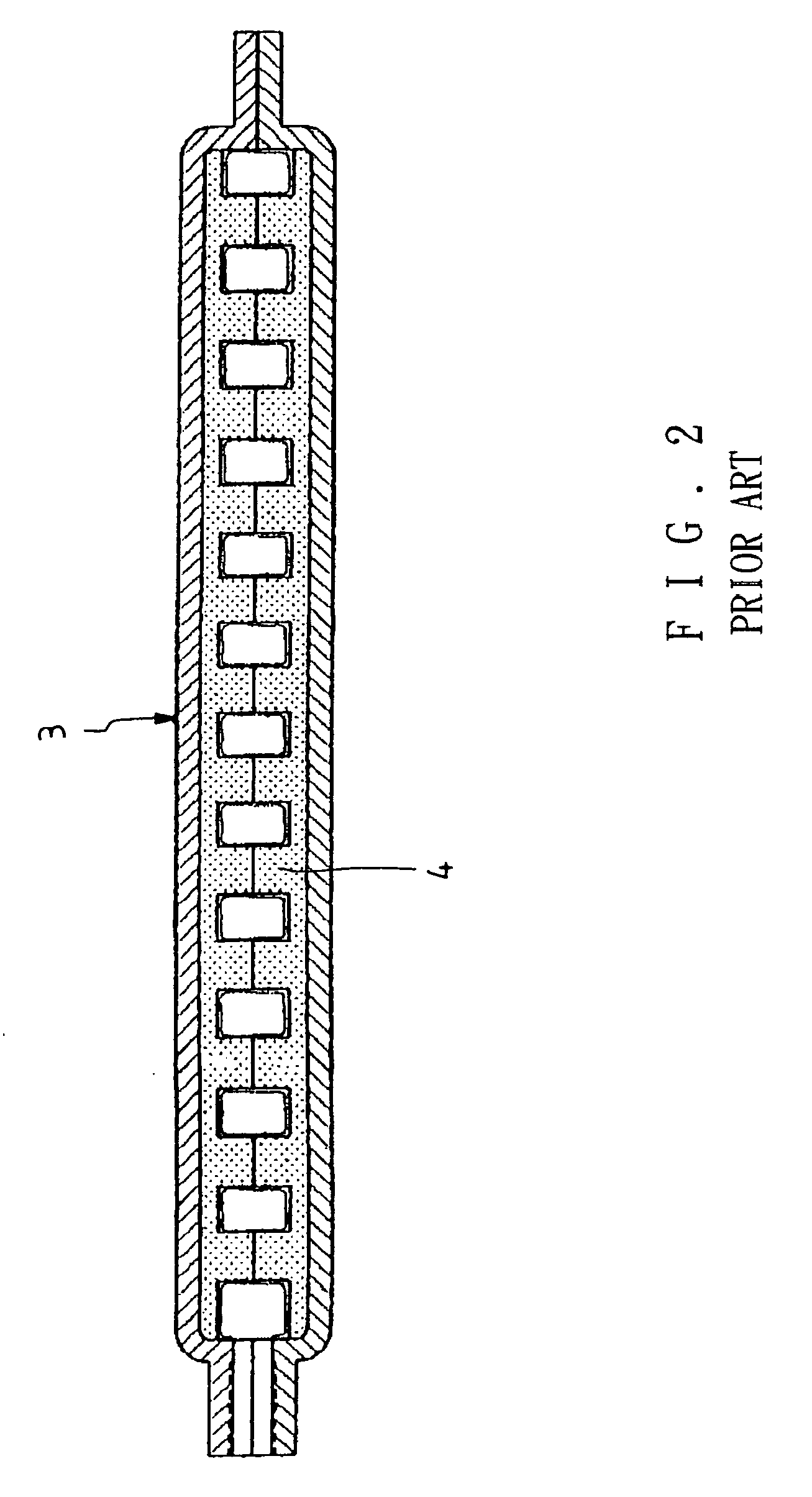

Flat heat pipe provided with means to enhance heat transfer thereof

ActiveUS6901994B1Improve cooling effectUniform temperature distributionSemiconductor/solid-state device detailsSolid-state devicesCyclic processWorking fluid

A flat heat pipe has a vacuum chamber, an evaporator connected to a heating element, and a condenser connected to a cooling device. The vacuum chamber is provided in an interior with a wick structure and a working fluid by which an evaporation-condensation cyclic process is effected. The vacuum chamber is further provided in the interior with a plurality of heat conduction pillars, which are confined to the area of the evaporator and are connected with an upper wall and a lower wall of the interior of the chamber. The heat conduction pillars serve to enhance the heat conduction to the condenser from the evaporator.

Owner:IND TECH RES INST

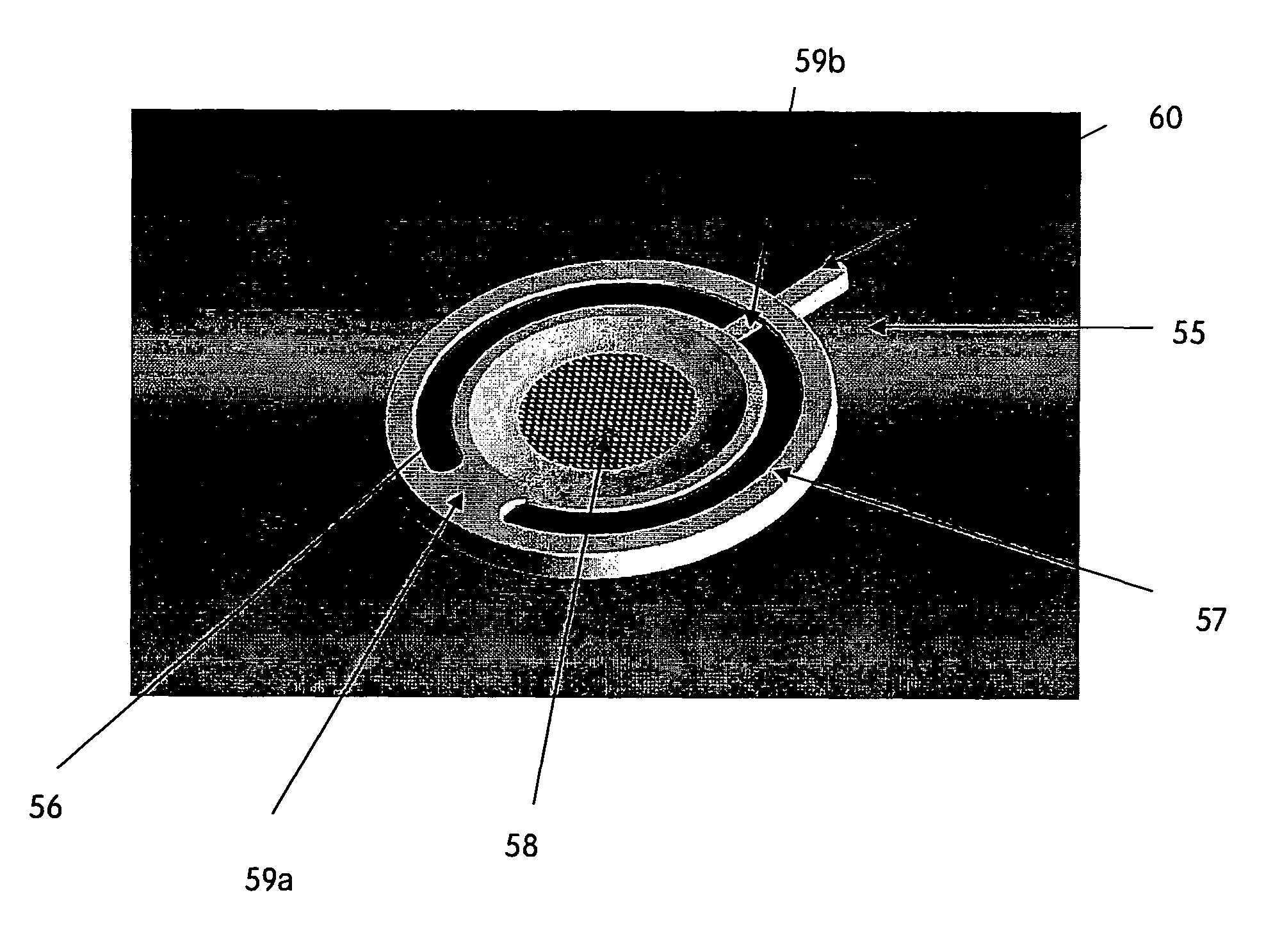

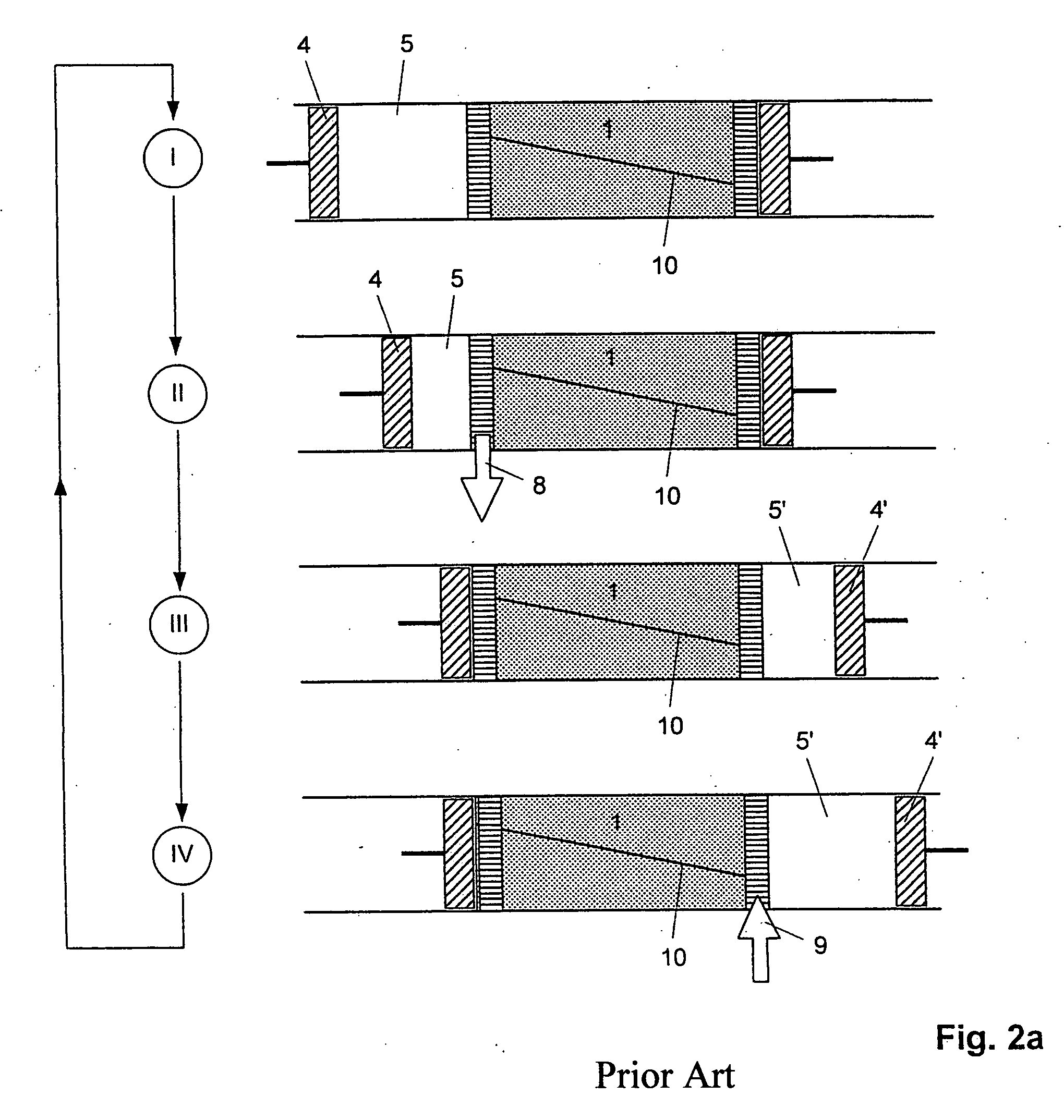

Apparatus and method for filter cleaning by ultrasound, backwashing and filter movement during the filtration of biological samples

InactiveUS8273253B2Minimises fouling and clogging of filterImprove overall efficiency and accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsCyclic processVacuum pressure

The present application is directed to the separation of—a solid fraction from a fluid sample particularly a therapeutic cellular fraction from a biological sample such as a bone marrow sample by a porous filter (2) which separates a filtration unit (1) into an upper pre-filtration chamber (3) into which a fluid sample (4) requiring cell separation is introduced and a lower post-filtration chamber (5) into which a fluid (6) capable of transmitting an acoustic standing wave is introduced. An acoustic element (8) is coupled to a substrate (7) which is located within and at the bottom of the lower chamber (5) and which resonates in response to the acoustic generating element (8) and generates a standing wave through the two fluid phases and the filter to agitate the sample (4). Simultaneously, a cyclic process of vacuum draw (9). causes movement of the sample (4) downwards through the filter (2). Vacuum pressure, fluid flow rate and frequency of vibration are controlled from a remote unit housing appropriate pumps and valves.

Owner:SMITH & NEPHEW INC

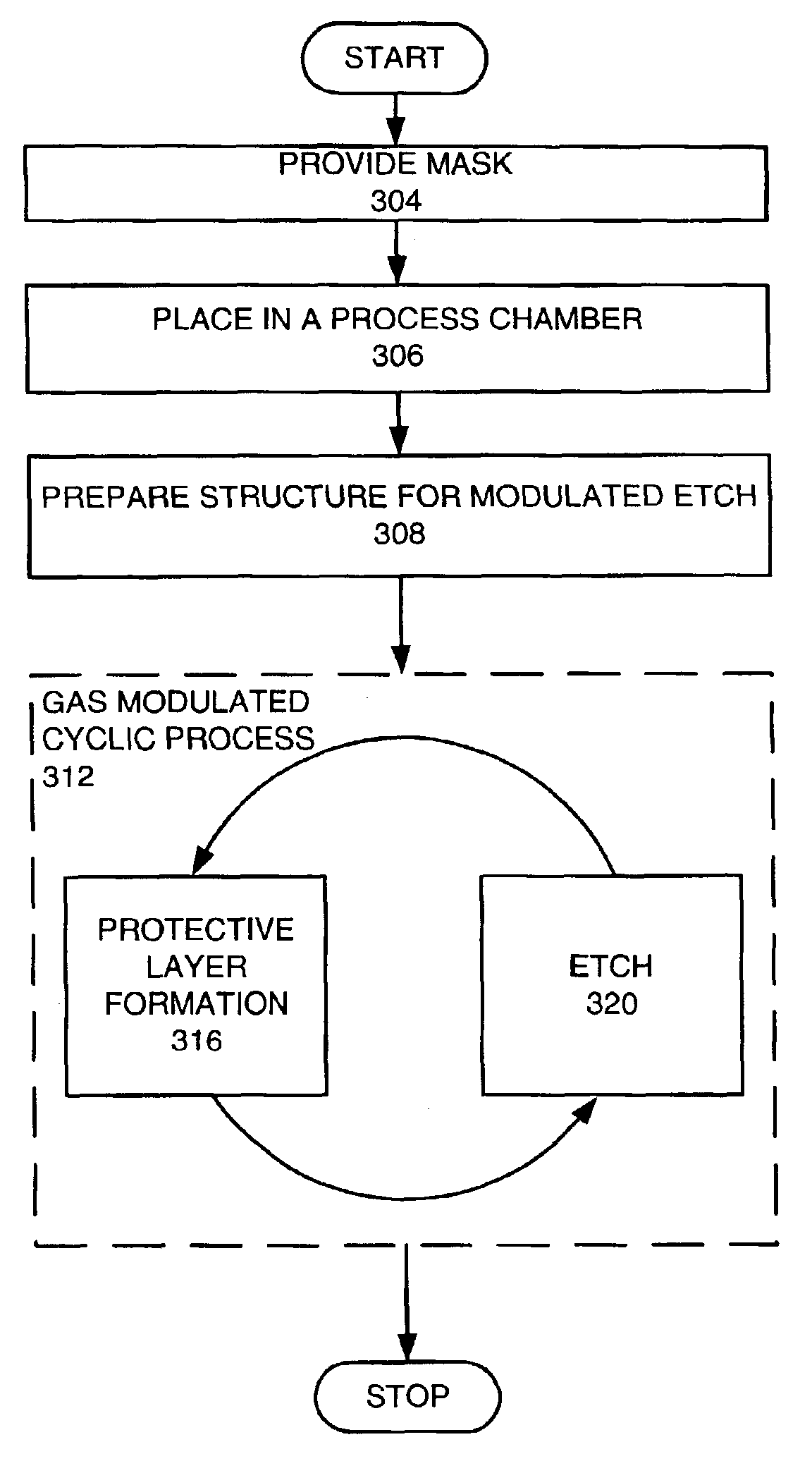

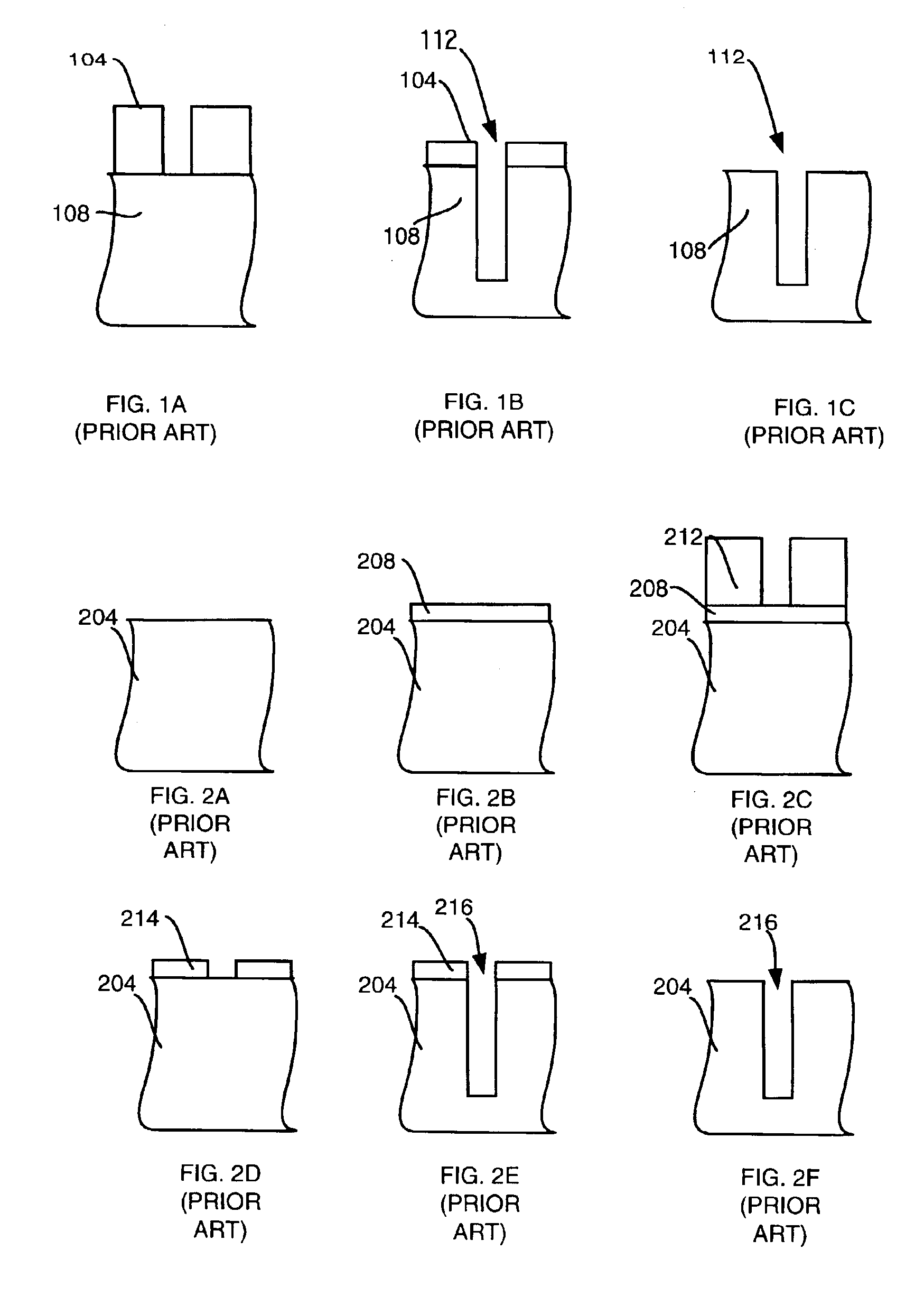

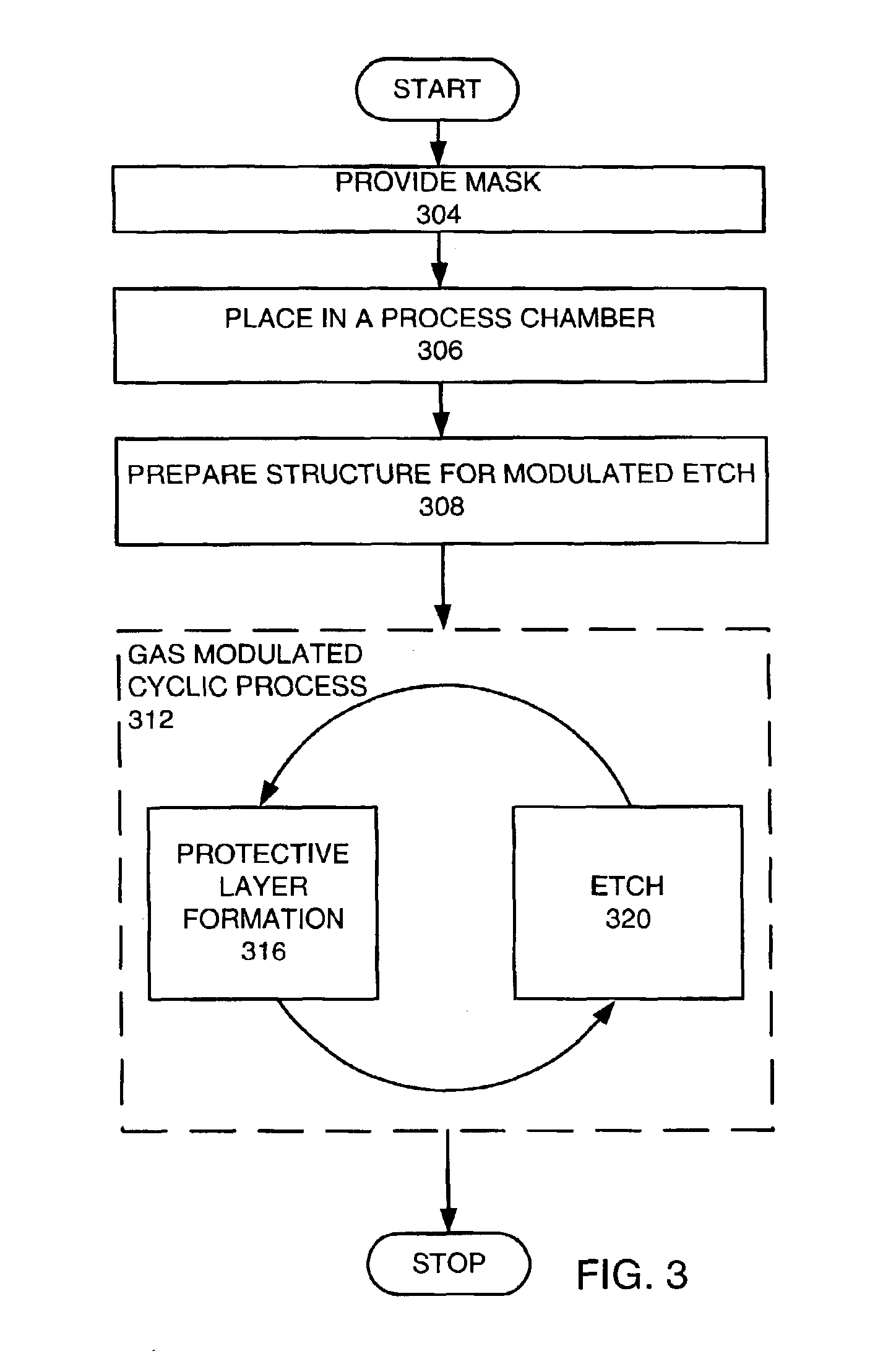

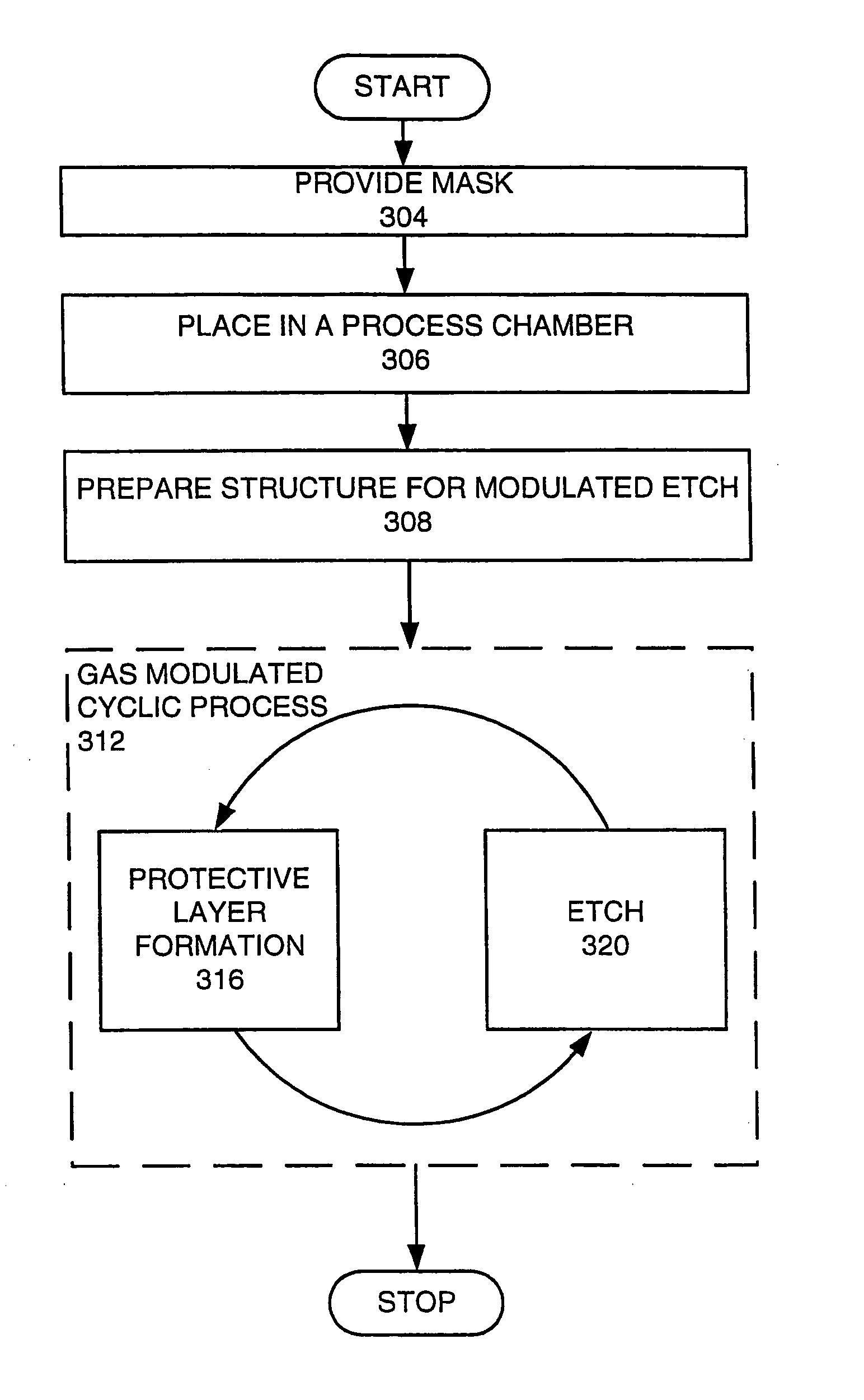

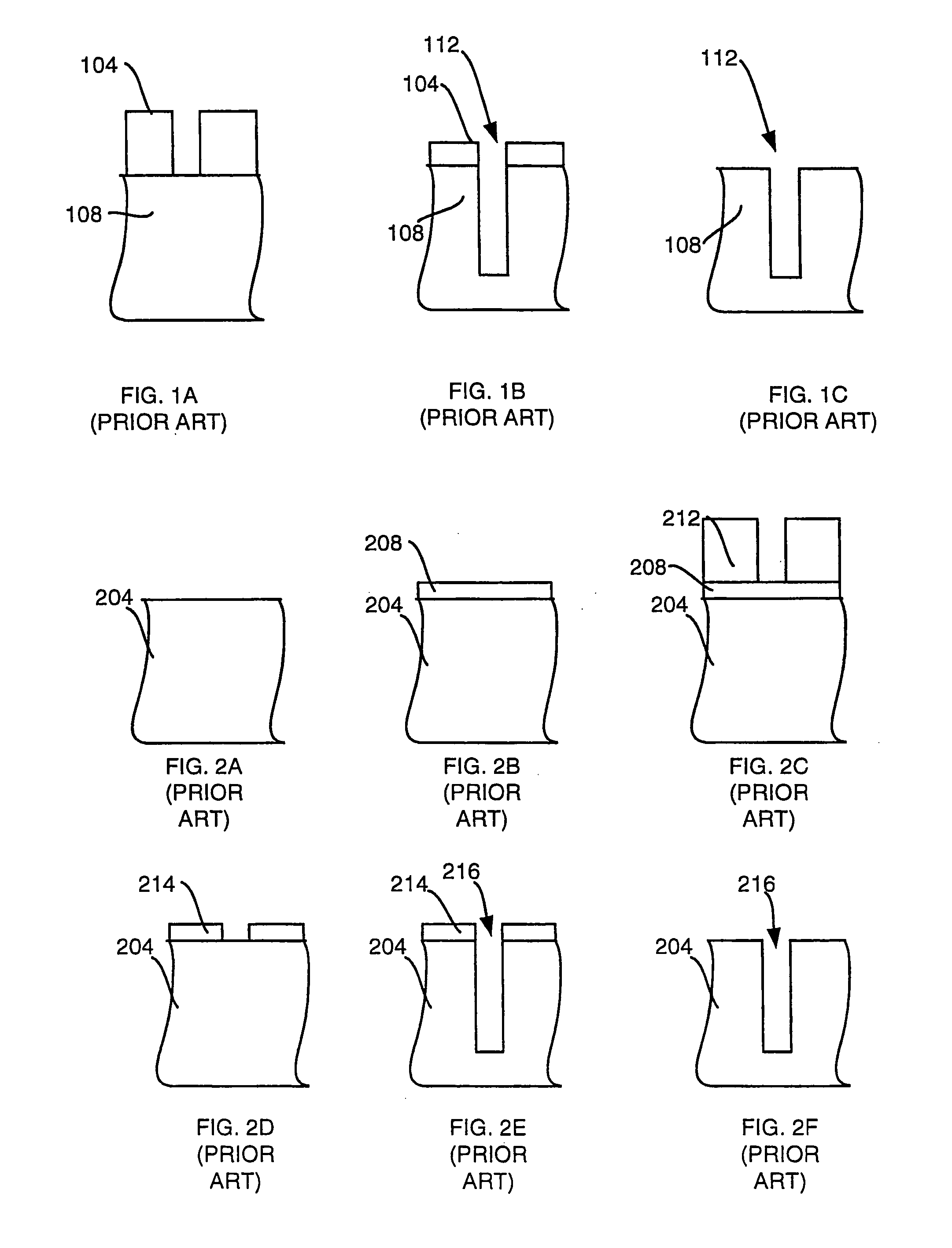

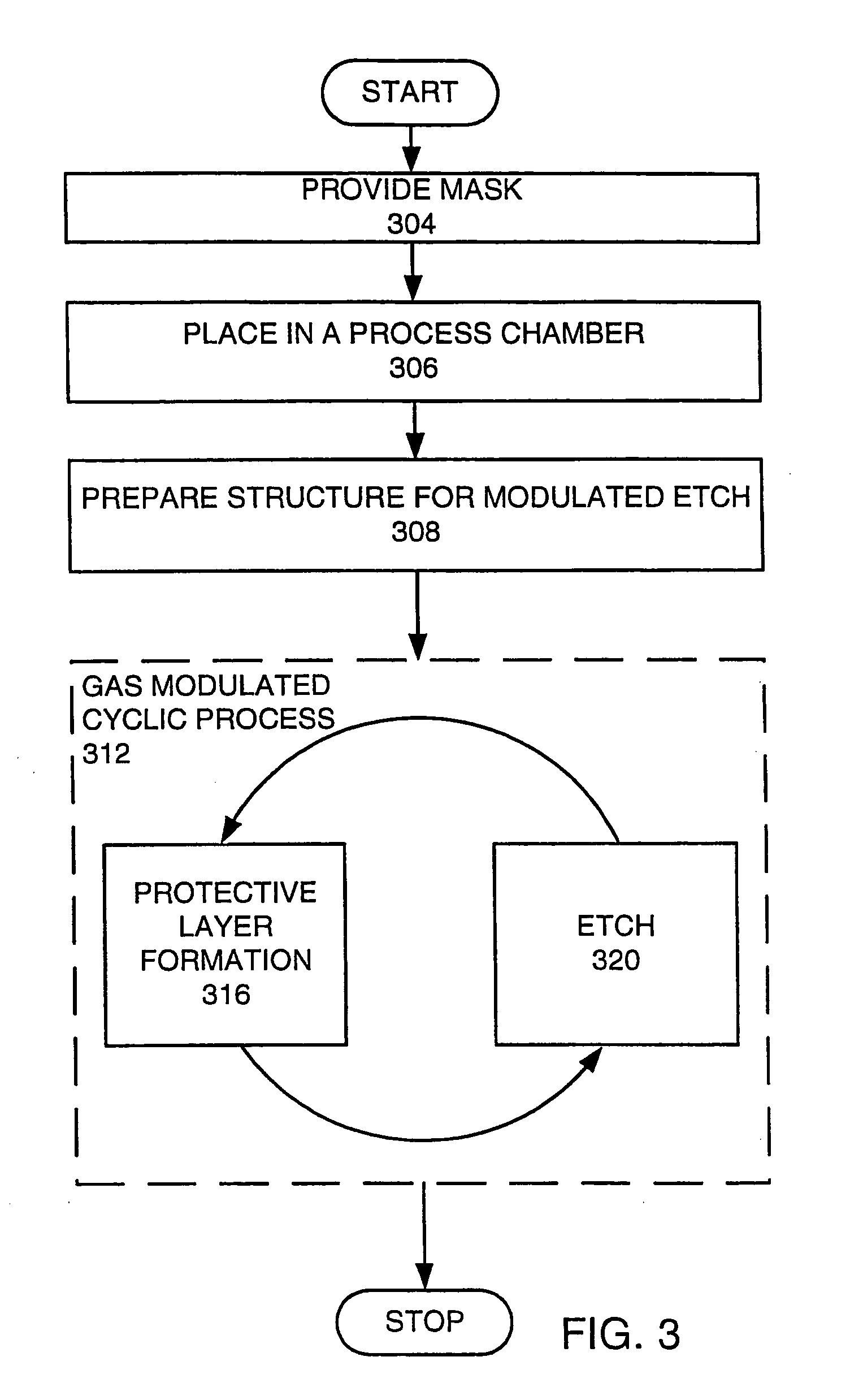

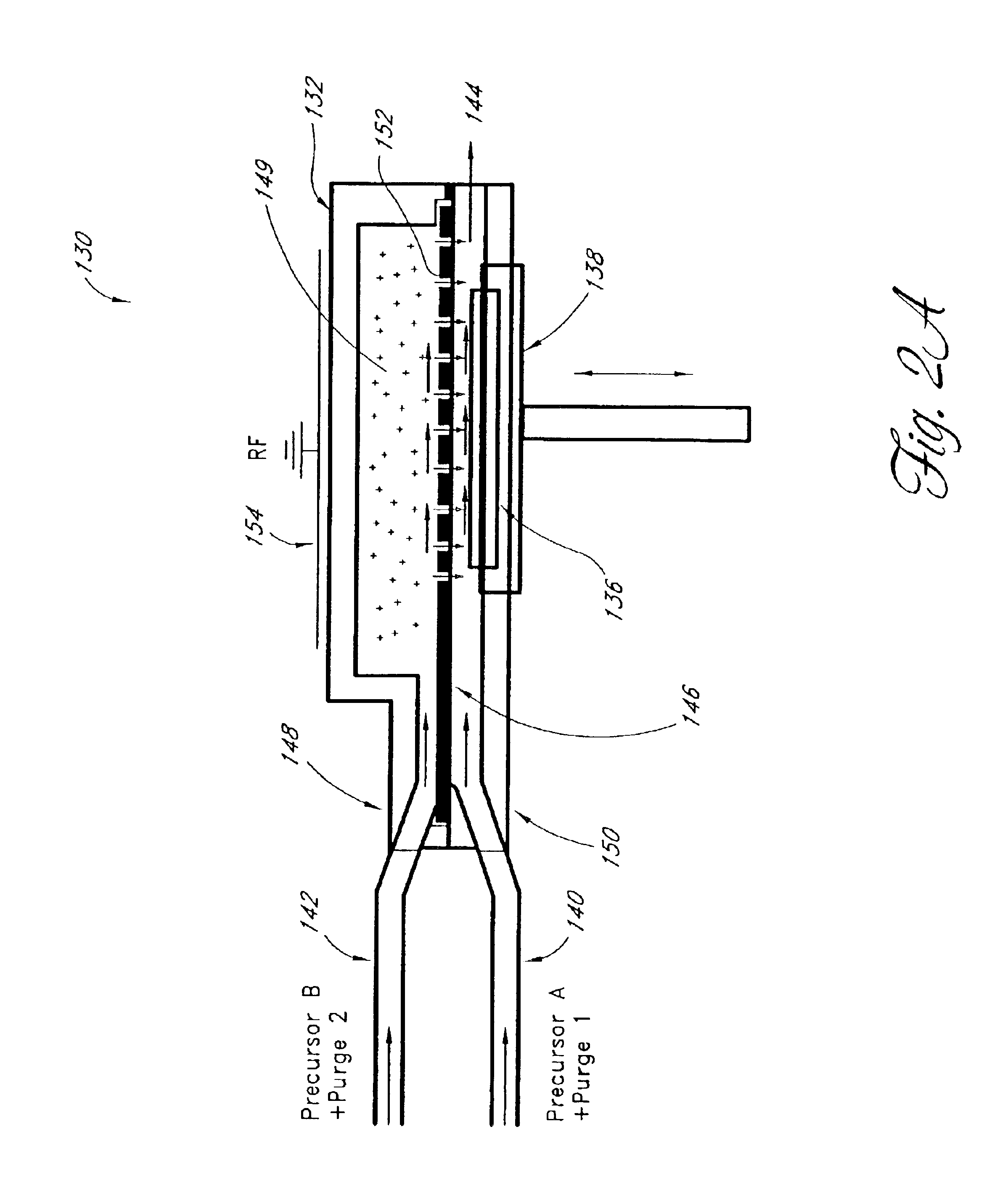

Method for plasma etching using periodic modulation of gas chemistry

InactiveUS6916746B1Decorative surface effectsSemiconductor/solid-state device manufacturingCyclic processGas chemistry

A method for etching a layer over a substrate is provided. A gas-modulated cyclic process is performed for more than three cycles. Each cycle comprises performing a protective layer forming phase using first gas chemistry with a deposition gas chemistry, which is performed in about 0.0055 to 7 seconds for each cycle and performing an etching phase for the feature through the etch mask using a second gas chemistry using a reactive etching gas chemistry, which is performed in about 0.005 to 14 seconds for each cycle. The protective layer forming phase comprises providing the deposition gas and forming a plasma from the deposition gas. Each etching phase comprises providing a reactive etching gas and forming a plasma from the reactive etching gas.

Owner:LAM RES CORP

Method for plasma etching using periodic modulation of gas chemistry

A method for etching a layer over a substrate is provided. A gas-modulated cyclic process is performed for more than three cycles. Each cycle comprises performing a protective layer forming phase using first gas chemistry with a deposition gas chemistry, which is performed in about 0.0055 to 7 seconds for each cycle and performing an etching phase for the feature through the etch mask using a second gas chemistry using a reactive etching gas chemistry, which is performed in about 0.005 to 14 seconds for each cycle. The protective layer forming phase comprises providing the deposition gas and forming a plasma from the deposition gas. Each etching phase comprises providing a reactive etching gas and forming a plasma from the reactive etching gas.

Owner:LAM RES CORP

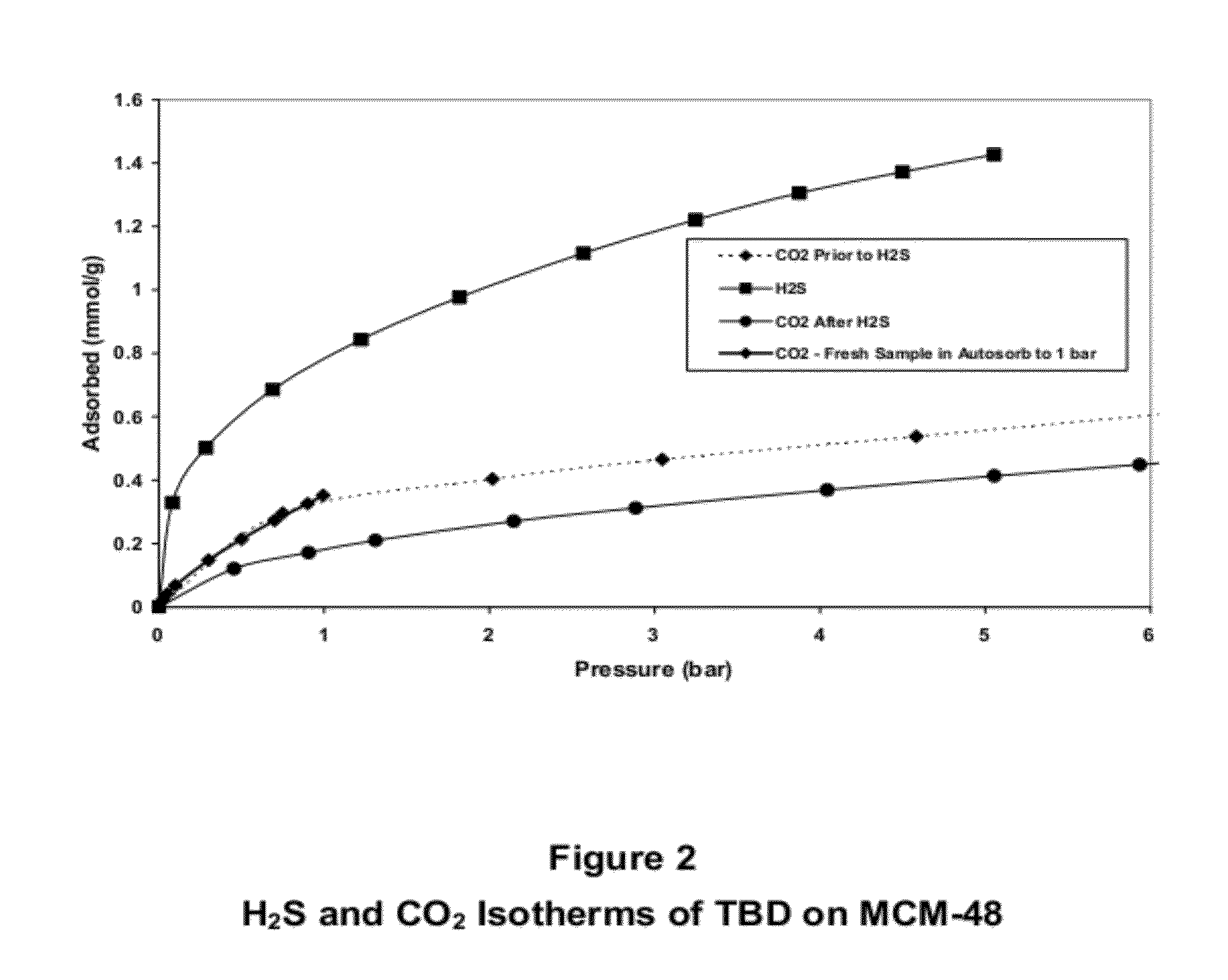

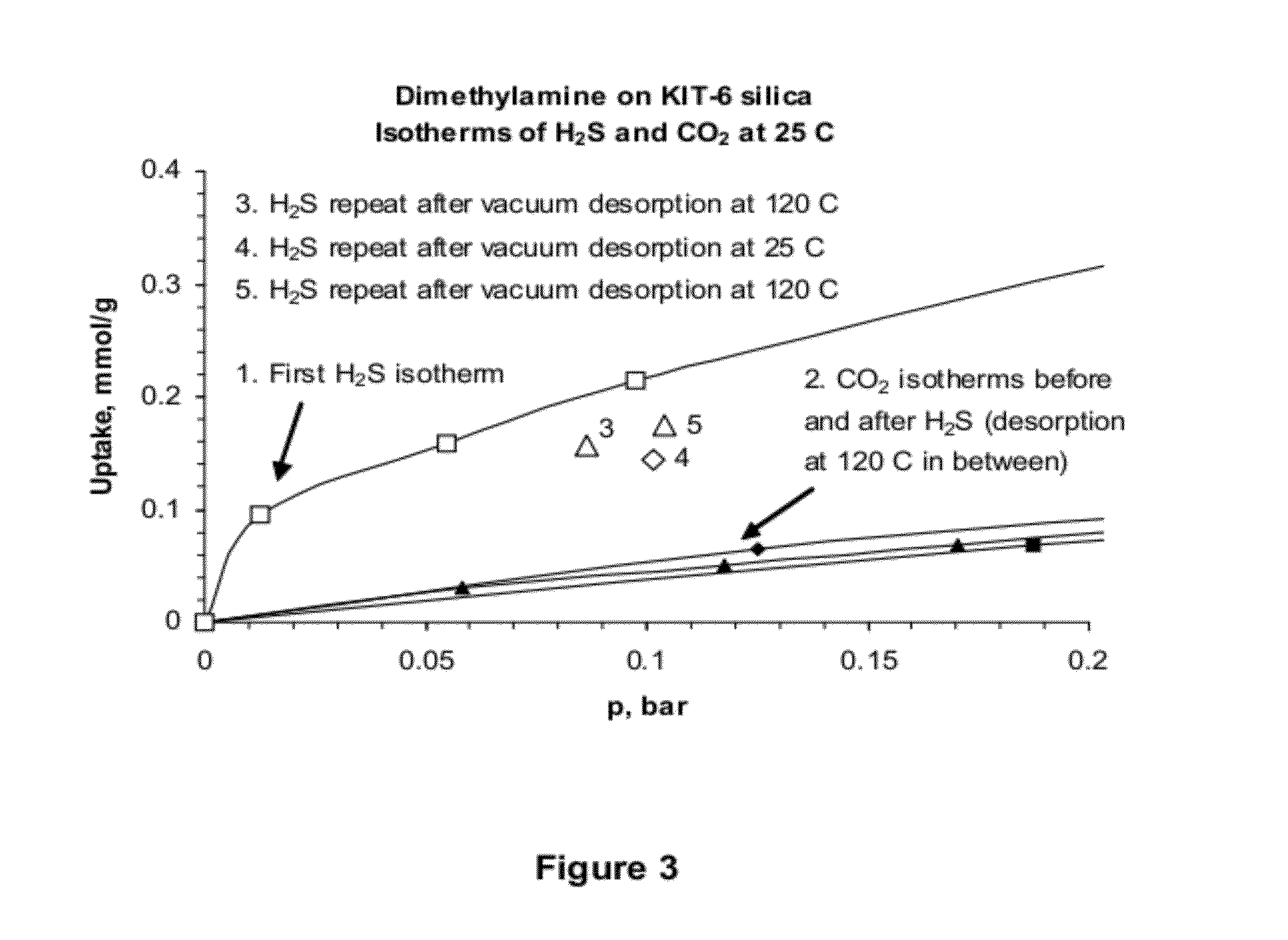

Selective Sulfur Removal Process

Owner:EXXON RES & ENG CO

Incorporation of nitrogen into high k dielectric film

InactiveUS6960537B2Semiconductor/solid-state device detailsSolid-state devicesDielectricCyclic process

A high k dielectric film and methods for forming the same are disclosed. The high k material includes two peaks of impurity concentration, particularly nitrogen, such as at a lower interface and upper interface, making the layer particularly suitable for transistor gate dielectric applications. The methods of formation include low temperature processes, particularly CVD using a remote plasma generator and atomic layer deposition using selective incorporation of nitrogen in the cyclic process. Advantageously, nitrogen levels are tailored during the deposition process and temperatures are low enough to avoid interdiffusion and allow maintenance of the desired impurity profile.

Owner:ASM IP HLDG BV

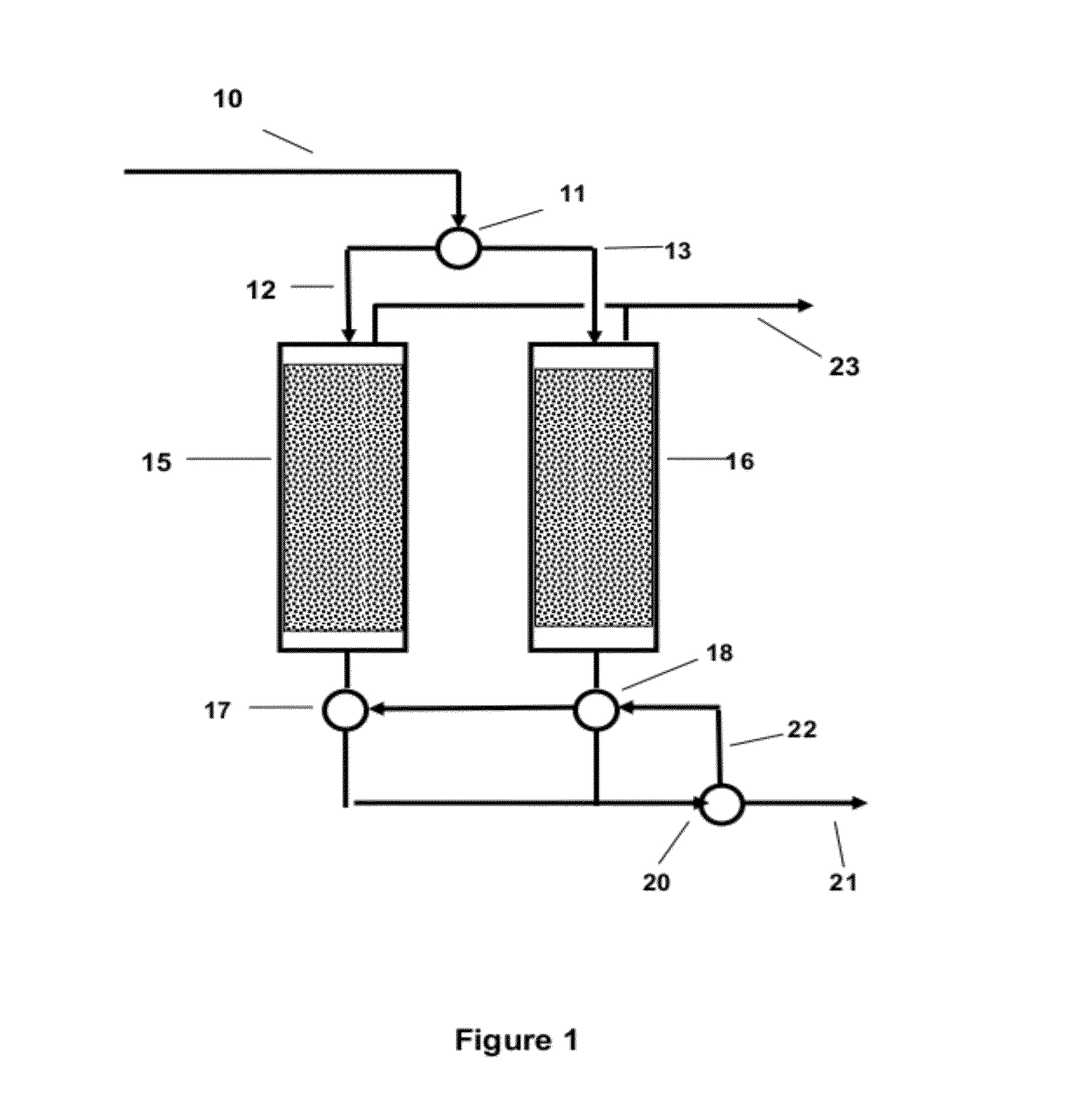

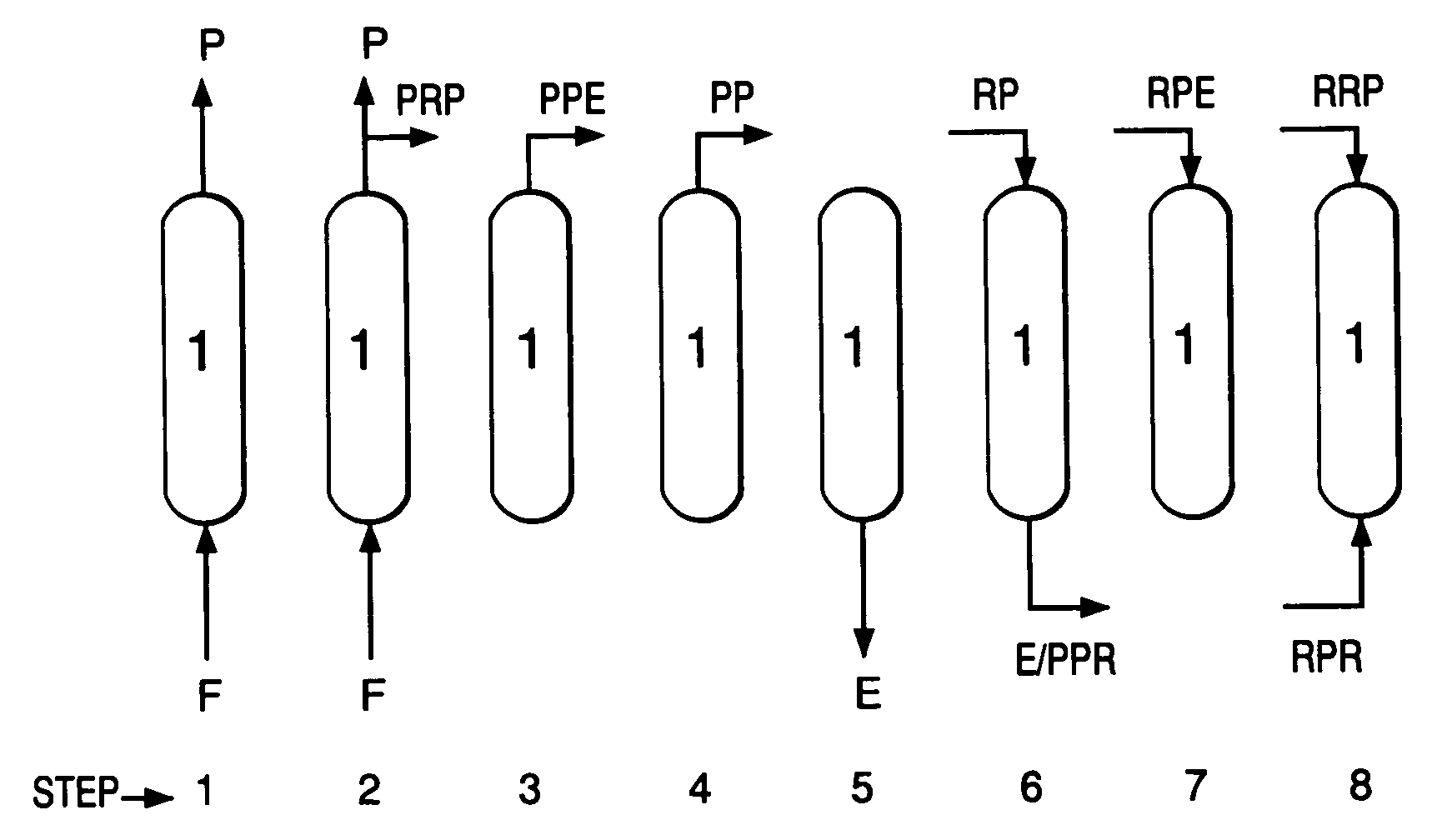

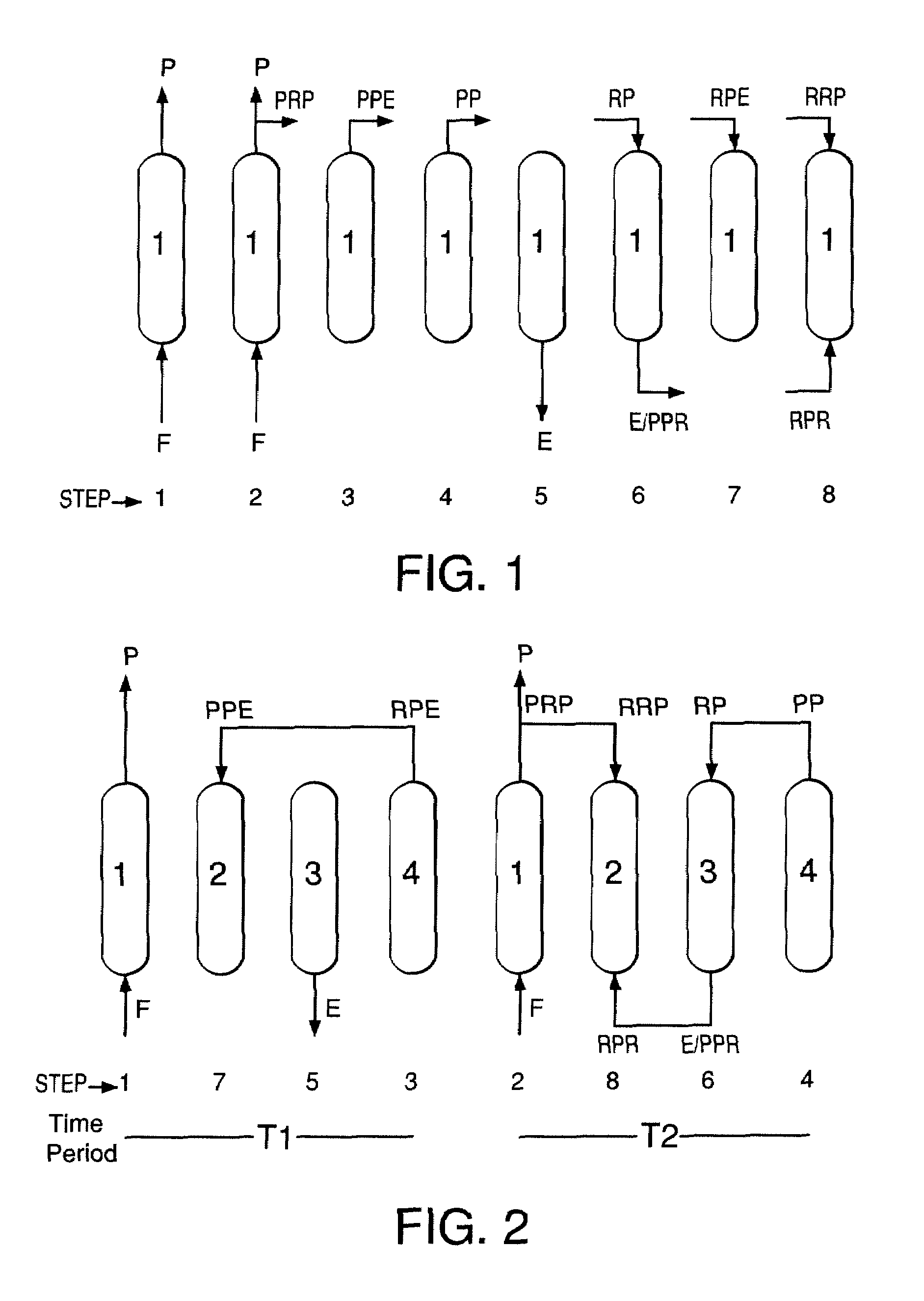

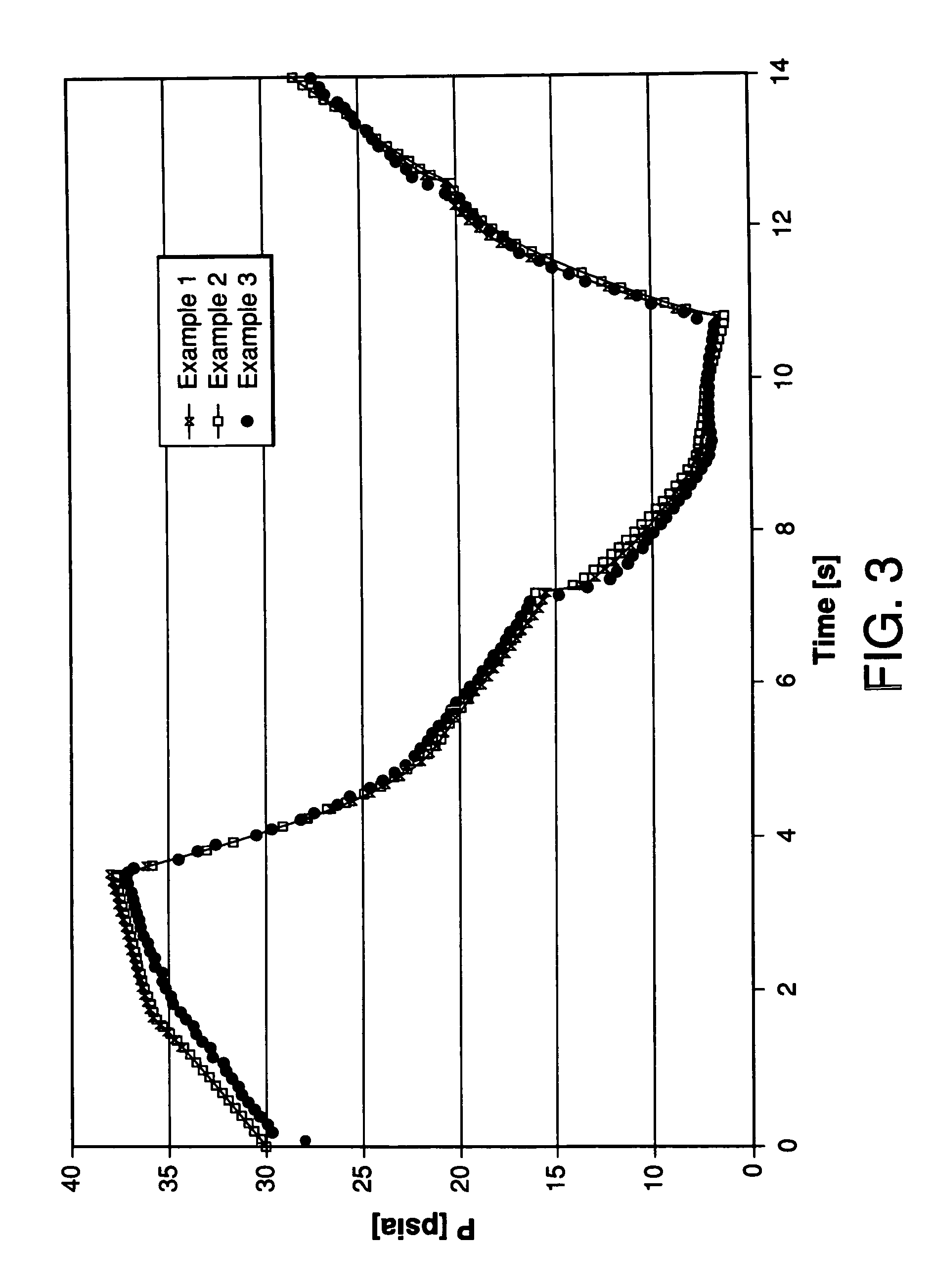

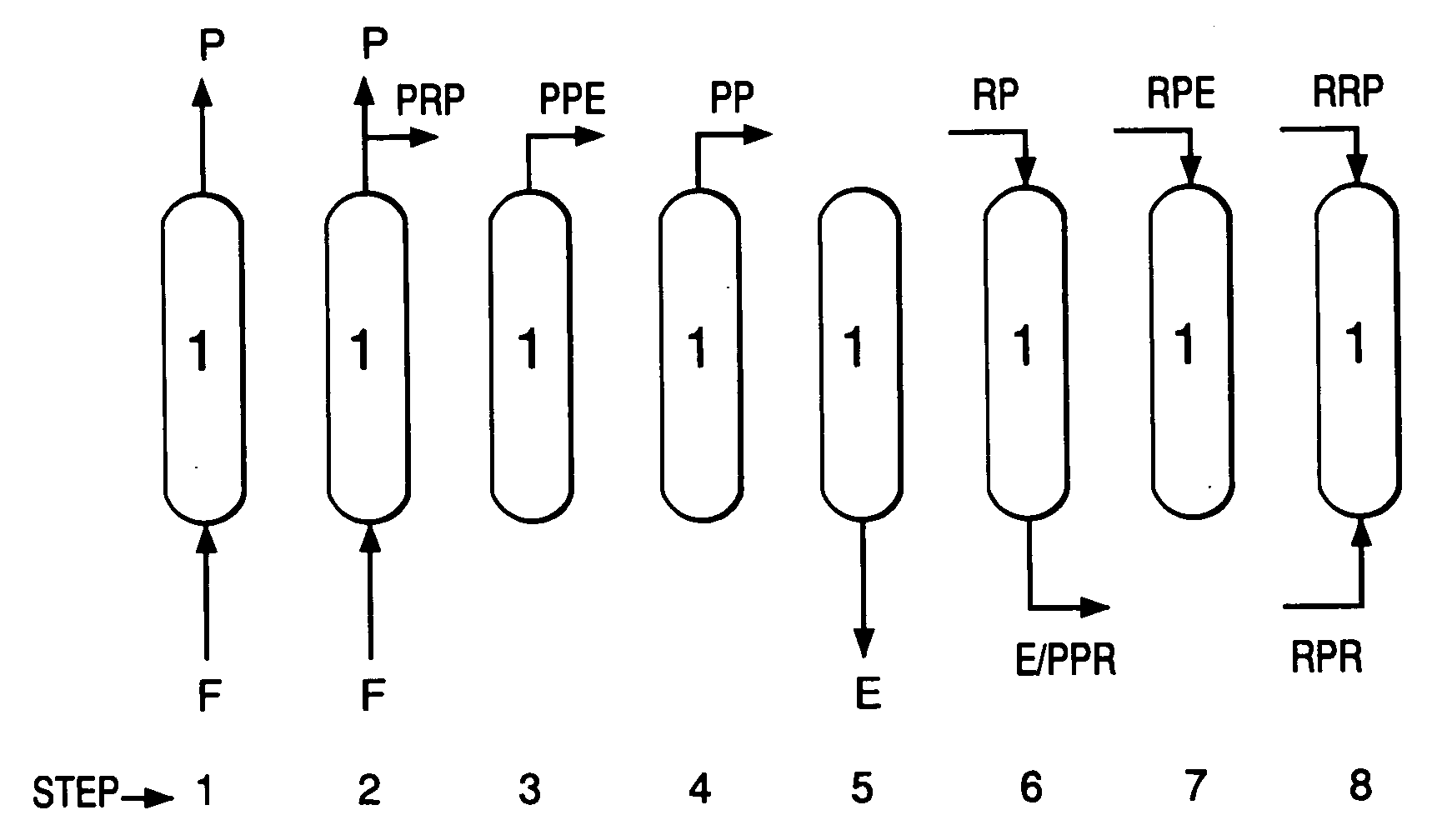

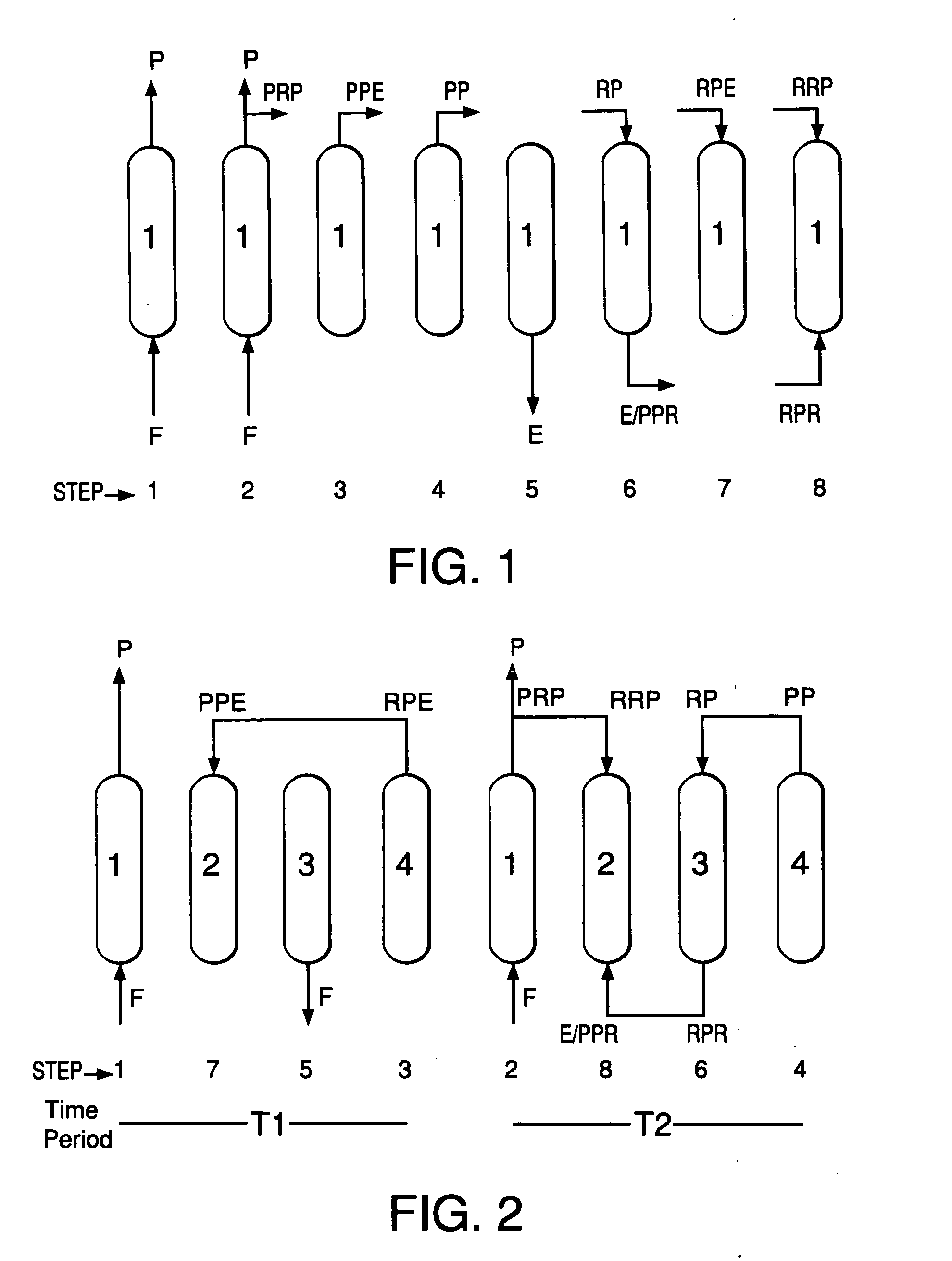

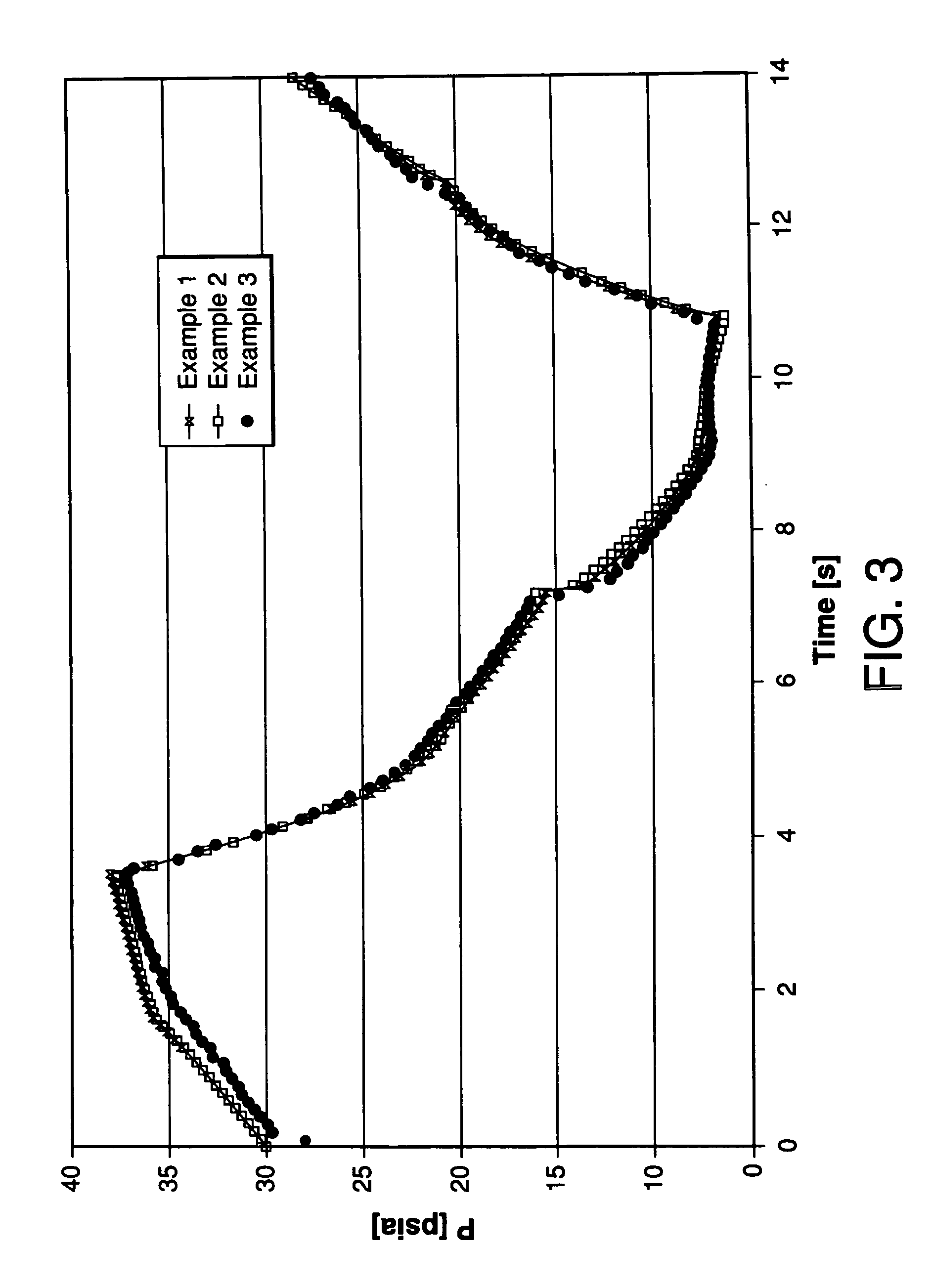

Pressure swing adsorption process with improved recovery of high-purity product

Process step in a pressure swing adsorption process using multiple parallel adsorbent beds operating in cyclic process steps to recover a less strongly adsorbable component from a feed gas mixture containing at least one less strongly adsorbable component and at least one more strongly adsorbable component, wherein each adsorbent bed has a feed end and a product end, wherein each bed is subjected to at least a feed / product step, one or more depressurization steps, a purge step in which a purge gas enriched in the less strongly adsorbable component is introduced into the product end of the bed and a purge effluent gas is withdrawn from the feed end of the bed, and one or more repressurization steps. The process step comprises introducing at least a portion of the purge effluent gas from a first bed into the feed end of a second adsorbent bed at any time other than during the feed / product step in the second adsorbent bed.

Owner:AIR PROD & CHEM INC

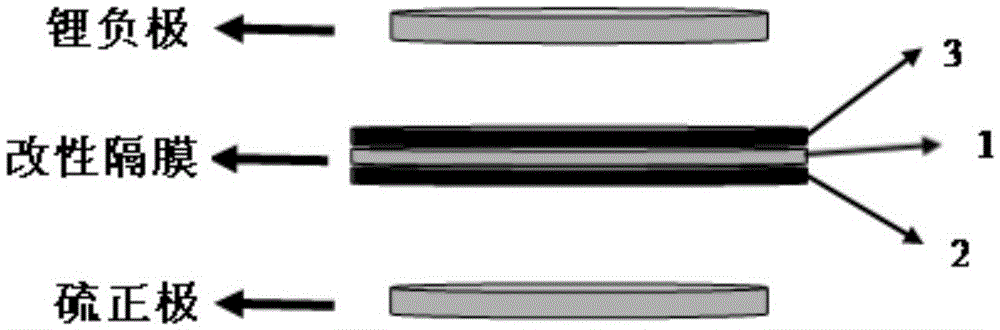

Polymer lithium ion battery and diaphragm thereof

ActiveCN102610773AImprove thermal stabilityImprove mechanical propertiesSecondary cellsCell component detailsCyclic processSwelling capacity

The invention belongs to the technical field of polymer lithium ion batteries, in particular to a diaphragm for the polymer lithium ion battery. The diaphragm comprises a multihole base material, wherein an inorganic substance coating layer and an organic substance coating layer are coated on at least one surface of the multihole base material; and the organic substance coating layer is in island-type and / or linear distribution and coated on the surface of the multihole base material and / or the inorganic substance coating layer. Compared with the prior art, due to the inorganic substance coating layer, the diaphragm can keep relatively high heat stability and mechanical performance, so that the lithium ion battery has high safety performance; the organic substance coating layer has high imbibition swelling capacity, and an interface has high stability, so that the manufactured lithium ion battery has perfect mechanical performance; due to the distribution characteristic of the organic substance coating layer, spaces are provided for charging and discharging processes of a pole piece and a circulation process; and the problem of deformation of the polymer lithium ion battery is well solved. Furthermore, the invention also discloses a polymer lithium ion batter with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

Pressure swing adsorption process with improved recovery of high-purity product

Process step in a pressure swing adsorption process using multiple parallel adsorbent beds operating in cyclic process steps to recover a less strongly adsorbable component from a feed gas mixture containing at least one less strongly adsorbable component and at least one more strongly adsorbable component, wherein each adsorbent bed has a feed end and a product end, wherein each bed is subjected to at least a feed / product step, one or more depressurization steps, a purge step in which a purge gas enriched in the less strongly adsorbable component is introduced into the product end of the bed and a purge effluent gas is withdrawn from the feed end of the bed, and one or more repressurization steps. The process step comprises introducing at least a portion of the purge effluent gas from a first bed into the feed end of a second adsorbent bed at any time other than during the feed / product step in the second adsorbent bed.

Owner:AIR PROD & CHEM INC

Method for making polyolefins

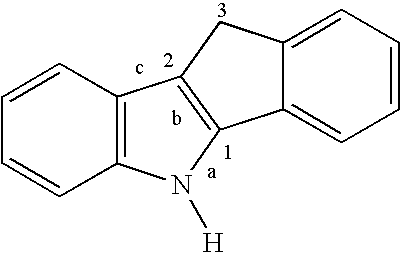

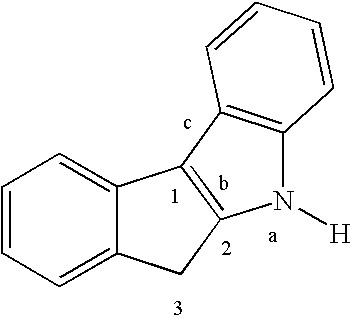

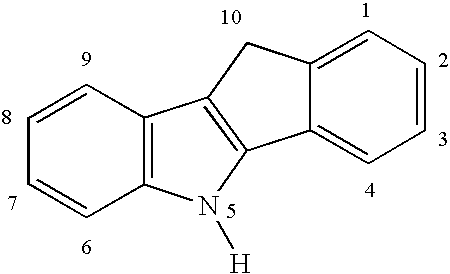

A method for making ethylene polymers and copolymers is disclosed. The method uses a catalyst system comprising a low level of an aluminum-containing activator, a bridged indenoindolyl transition metal complex, and a treated silica support. The method enables economical preparation of ethylene copolymers having very low density. The silica-supported, bridged complexes incorporate comonomers efficiently and are valuable for a commercial slurry loop process. Use of a bridged indeno[2,1-b]indolyl complex provides exceptionally efficient comonomer incorporation, and gives polymers with a substantial and controlled level of long-chain branching. The method facilitates the production of a wide variety of polyolefins, from HDPE to plastomers.

Owner:EQUSR CHEM LP

Modified diaphragm and preparation method and application therefor

InactiveCN105679983AImprove ionic conductivityLarge specific surface areaCell seperators/membranes/diaphragms/spacersLi-accumulatorsCyclic processPorous carbon

The invention discloses a modified diaphragm. The modified diaphragm comprises a diaphragm substrate, and an electronic conductive coating layer and an inorganic hard coating layer positioned on the two surfaces of the diaphragm substrate respectively, wherein the electronic conductive coating layer is a mixed coating layer with graphene and a porous carbon material; and the inorganic hard coating layer is a nitrogen-carbon material coating layer, a nitrogen-silicon material coating layer, a carbon-boron material coating layer or a silicon-carbon material coating layer. The preparation method comprises the steps of uniformly coating the two surfaces of the diaphragm substrate with the electronic conductive coating layer and the inorganic hard coating layer respectively, and drying the two surfaces respectively obtain the modified diaphragm. The modified diaphragm has high diffusion and absorption capacity for an organic electrolyte, high ionic conductivity, and an obvious adsorption and blocking effect on poly-sulfur-lithium; in addition, the modified diaphragm can further restrain a shuttle effect, prevent battery short-circuit, effectively restrain the growth of negative electrode metal lithium dendrites in a cyclic process, prevent from punching the diaphragm, and protect the lithium negative electrode, so that the problem that the diaphragm is punched after dendrites formation is solved, and the safety performance of the battery is improved.

Owner:CENT SOUTH UNIV

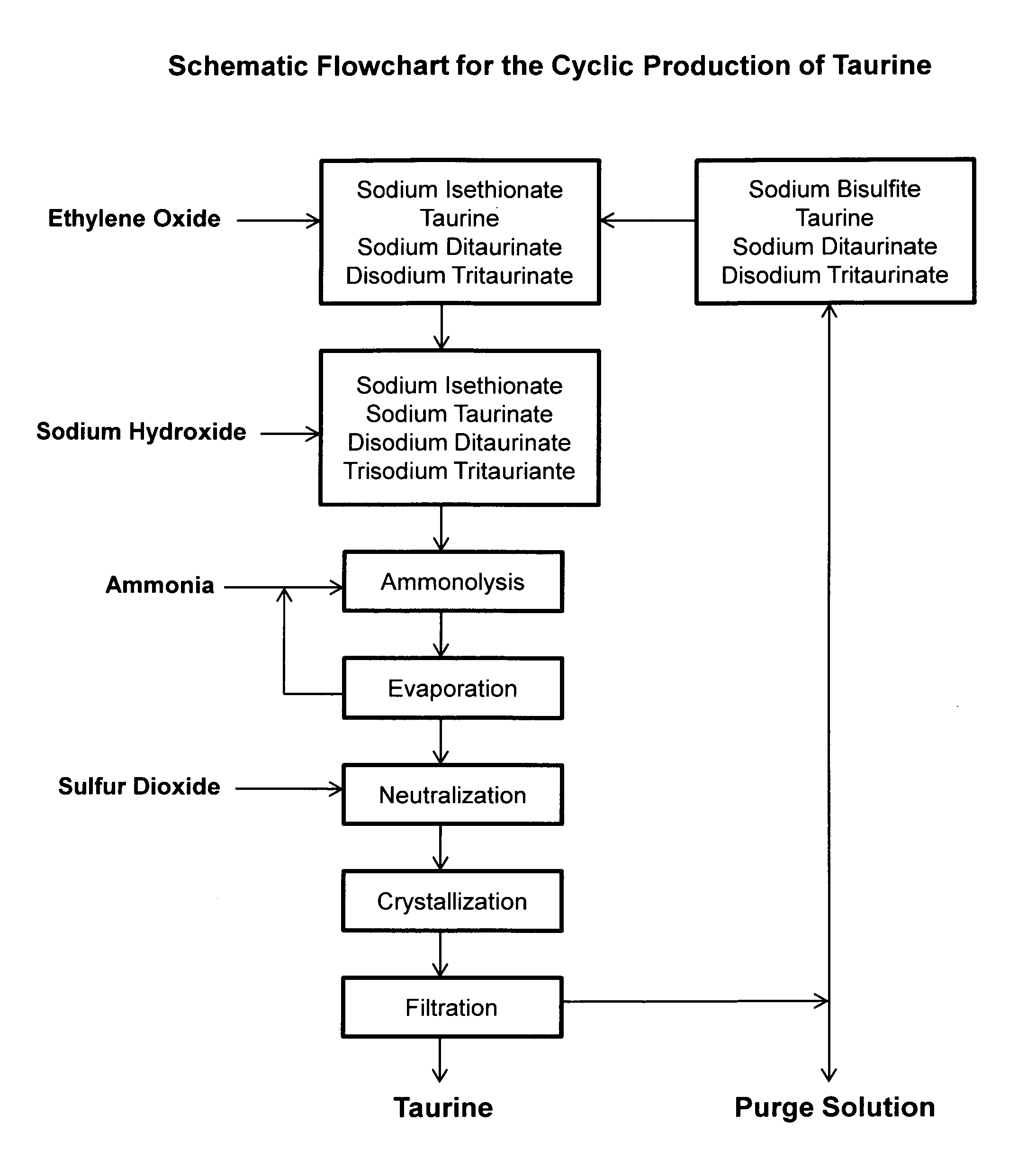

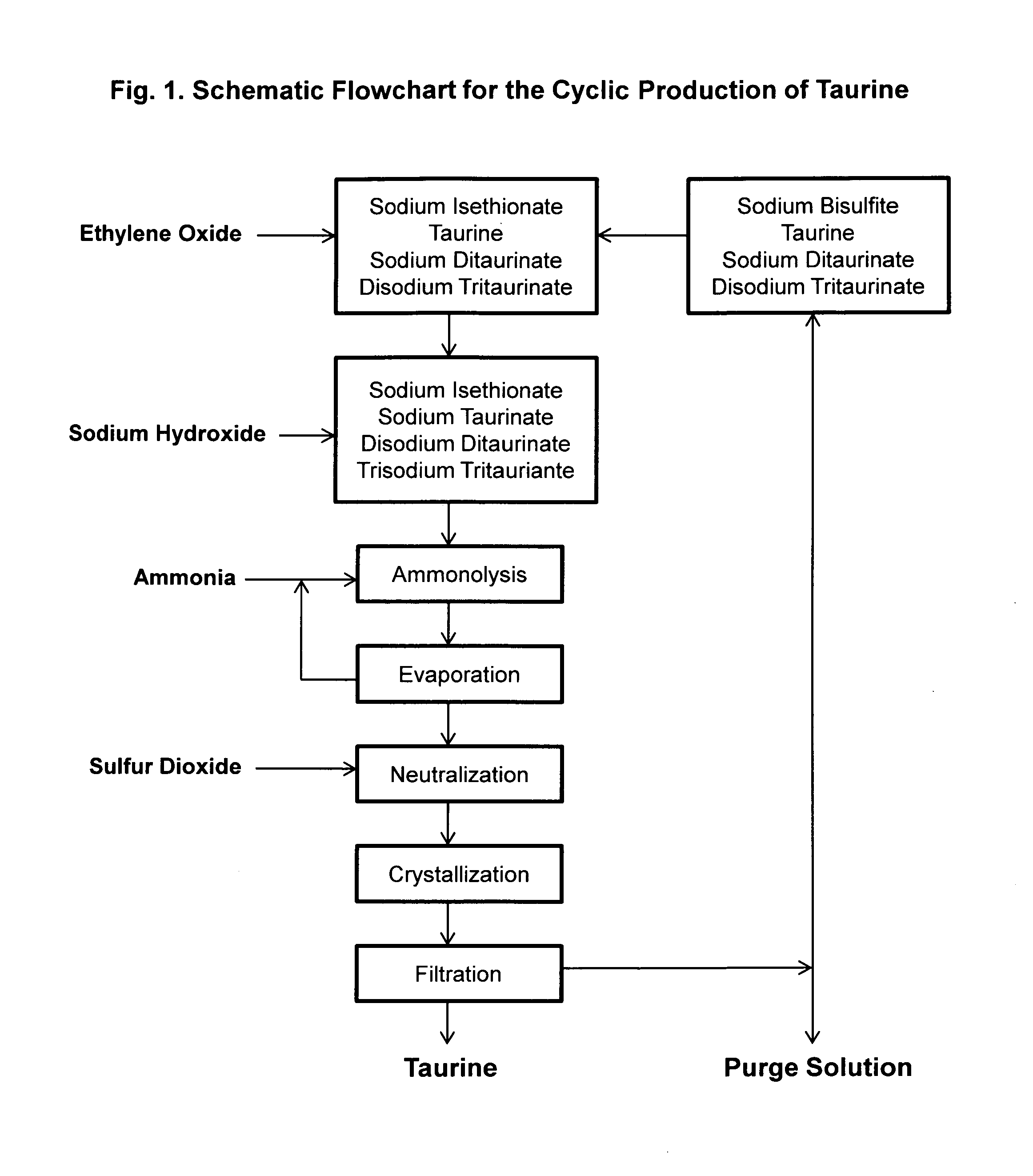

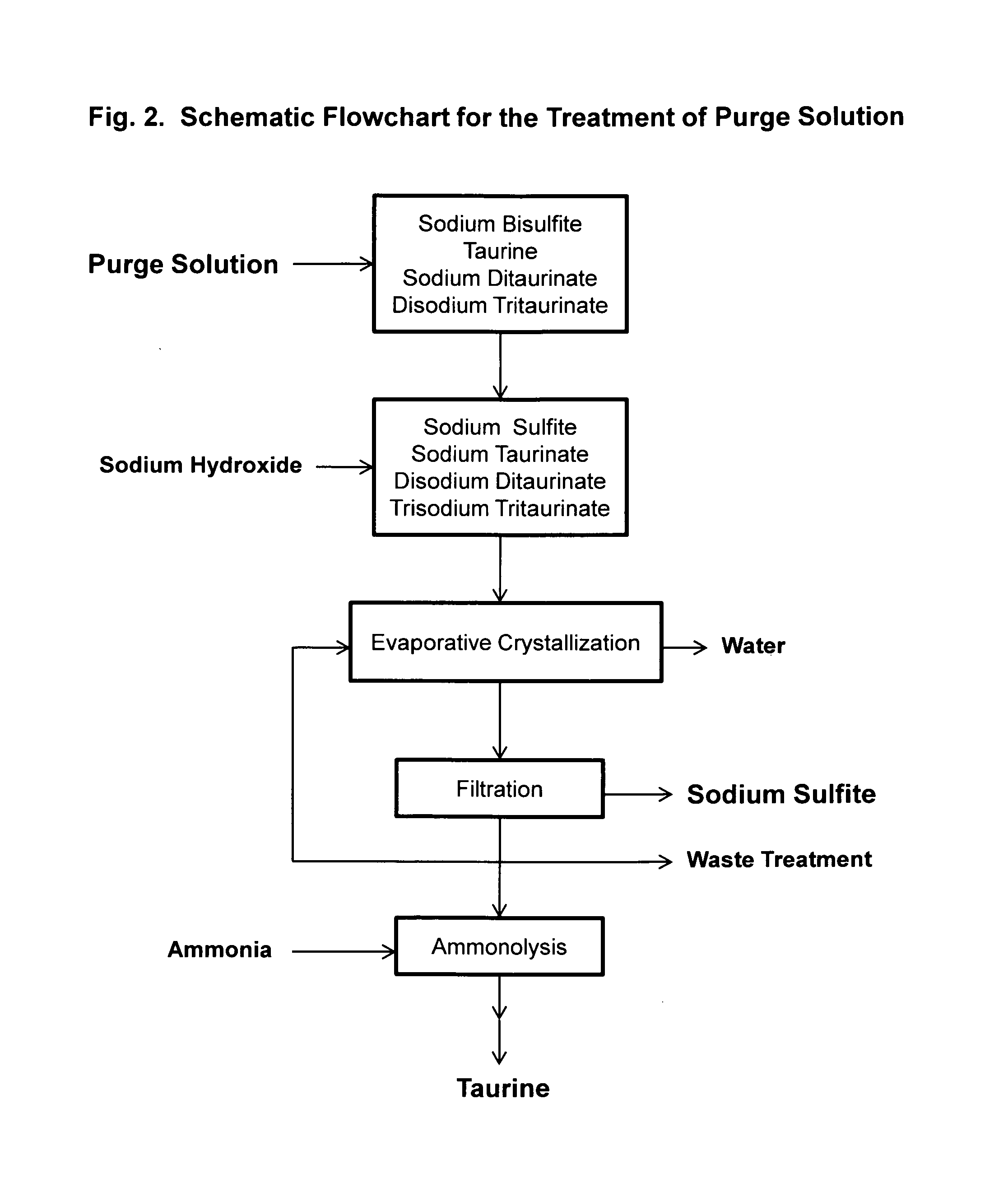

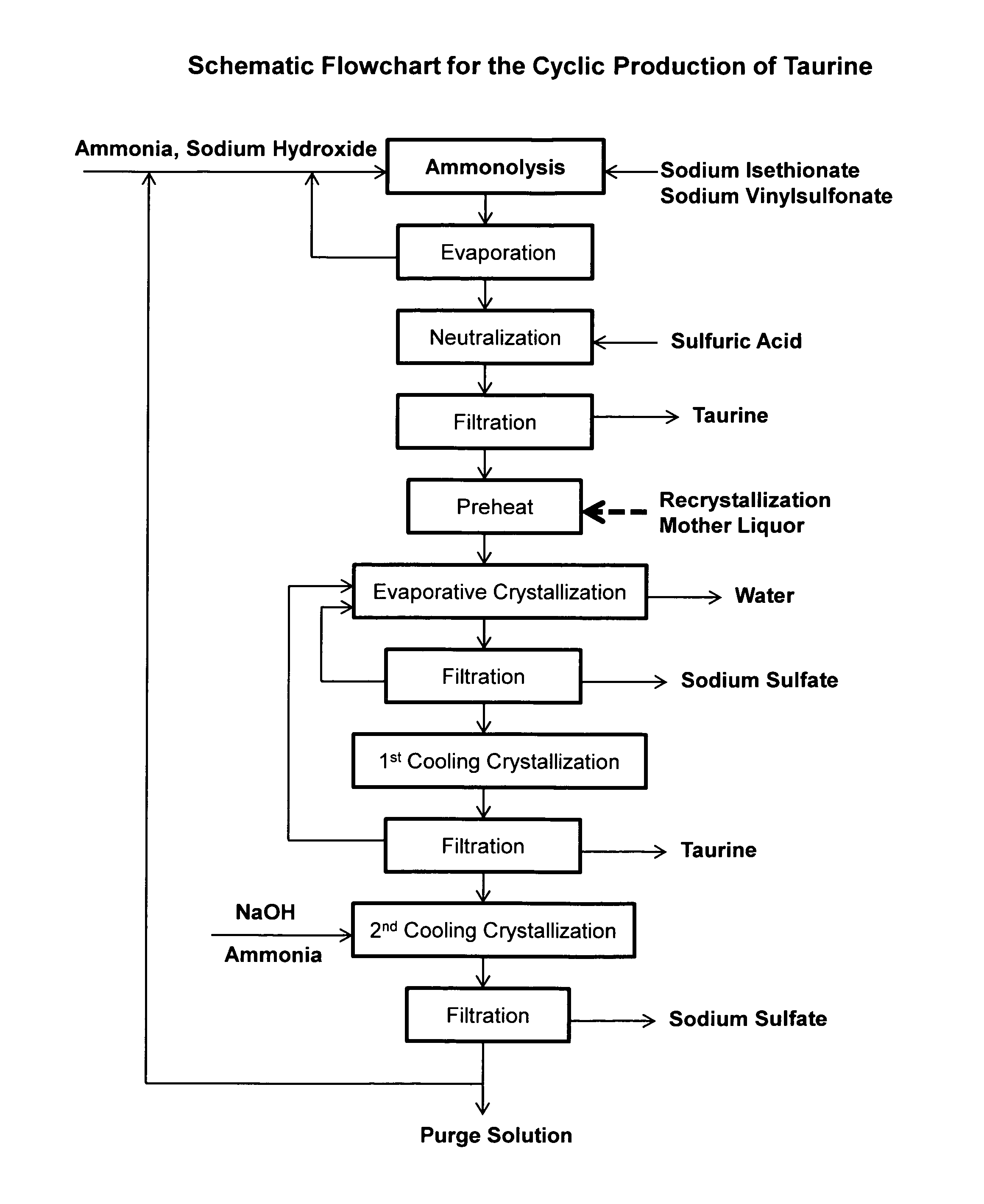

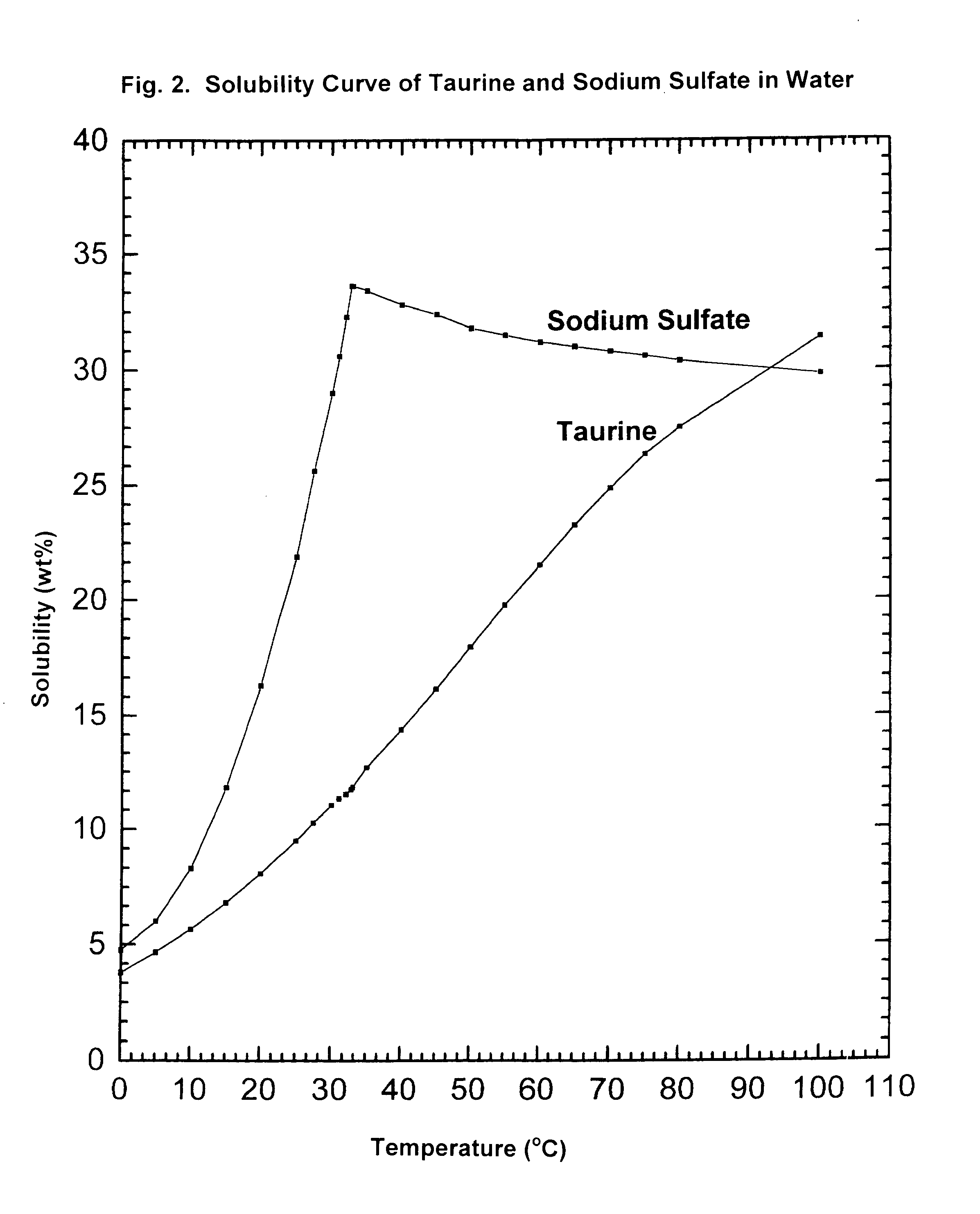

Cyclic process for the production of taurine from ethylene oxide

ActiveUS9061976B1Organic compound preparationSulfonic acids salts preparationCyclic processSodium dithionite

The present invention discloses a cyclic process for the production of taurine from ethylene oxide in a high yield of greater than 95% by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. The cyclic process is completed by using sulfur dioxide or sulfurous acid to neutralize sodium taurinates to recover taurine and to regenerate sodium bisulfite, which is then reacted with ethylene oxide.

Owner:VITAWORKS IP LLC

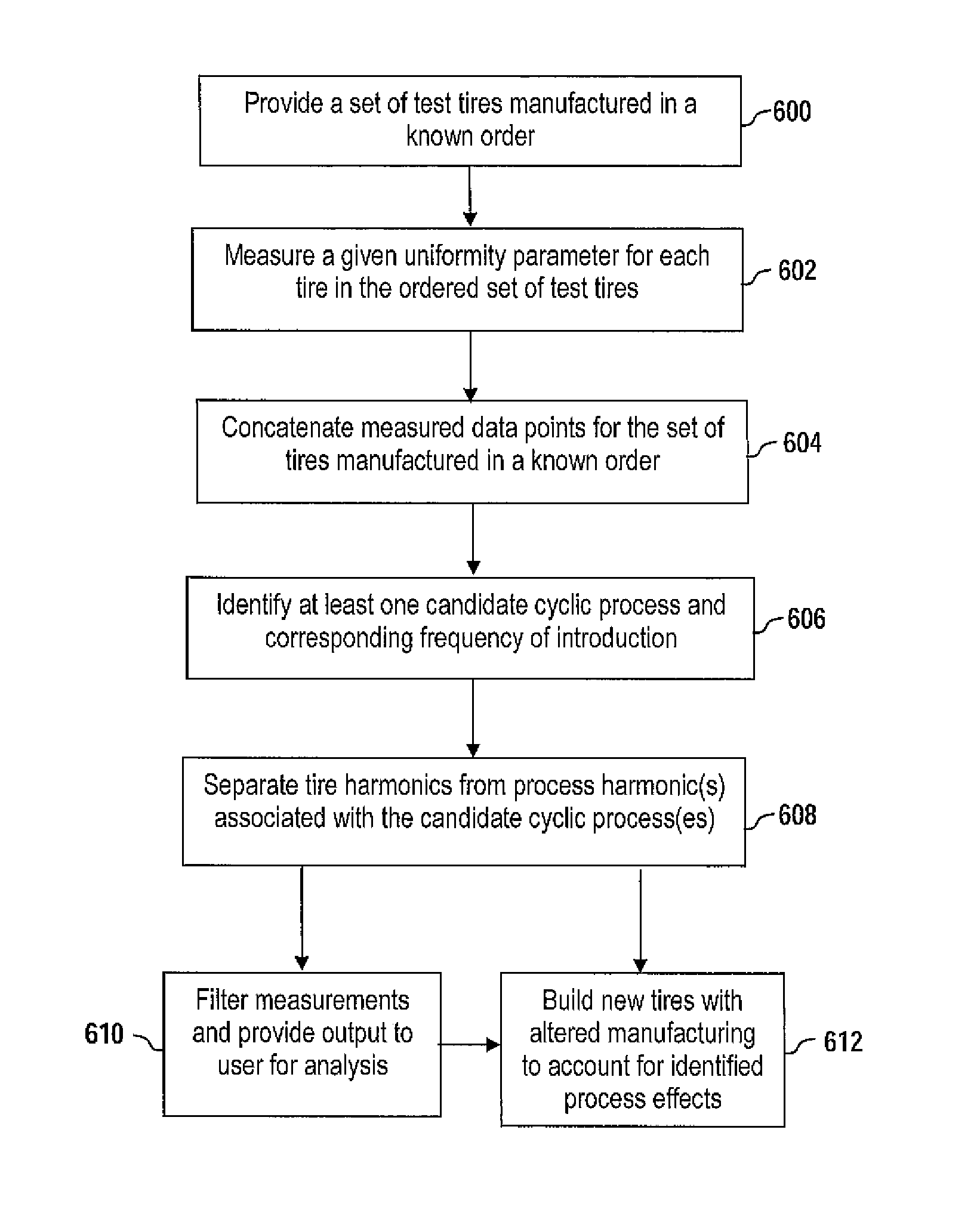

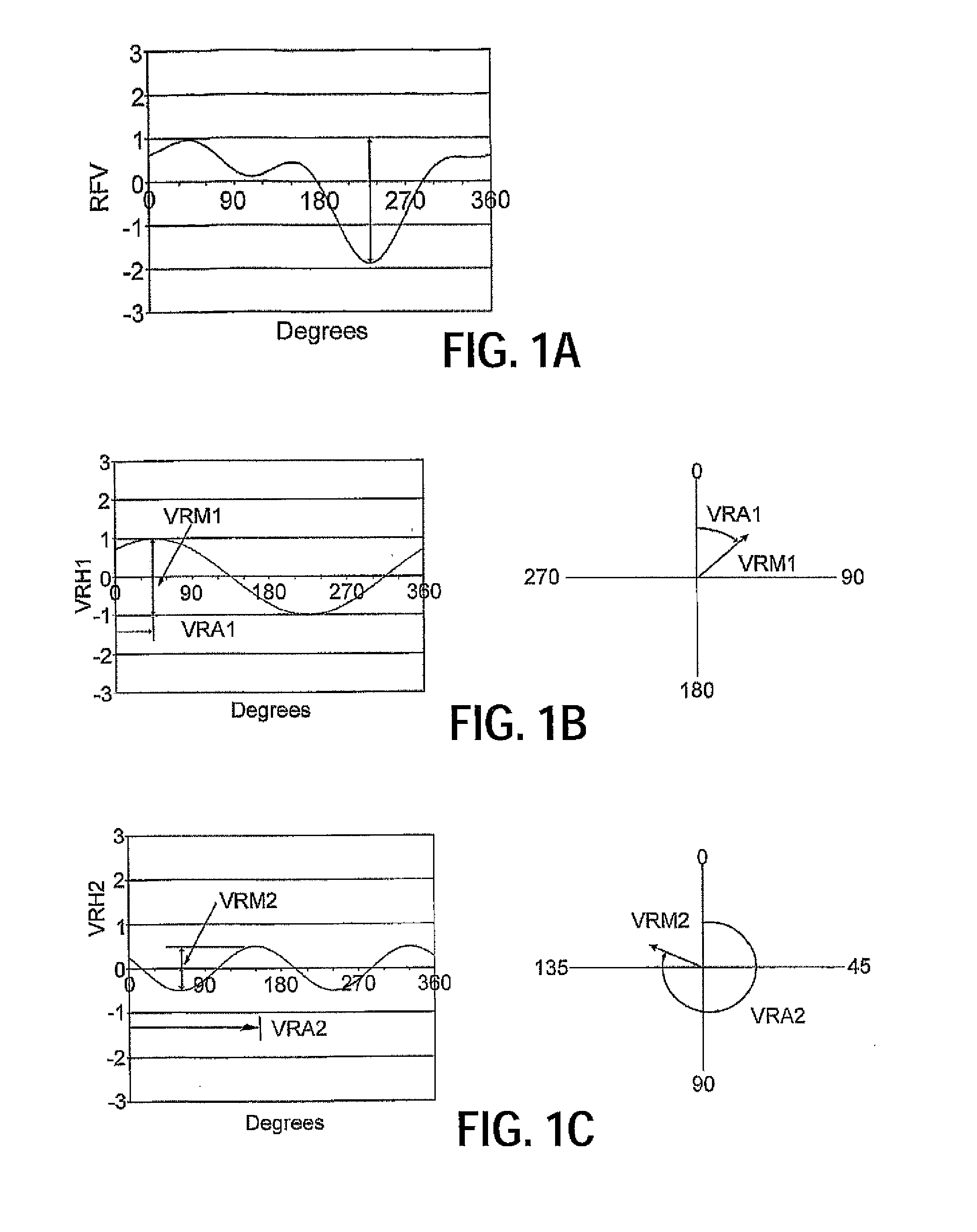

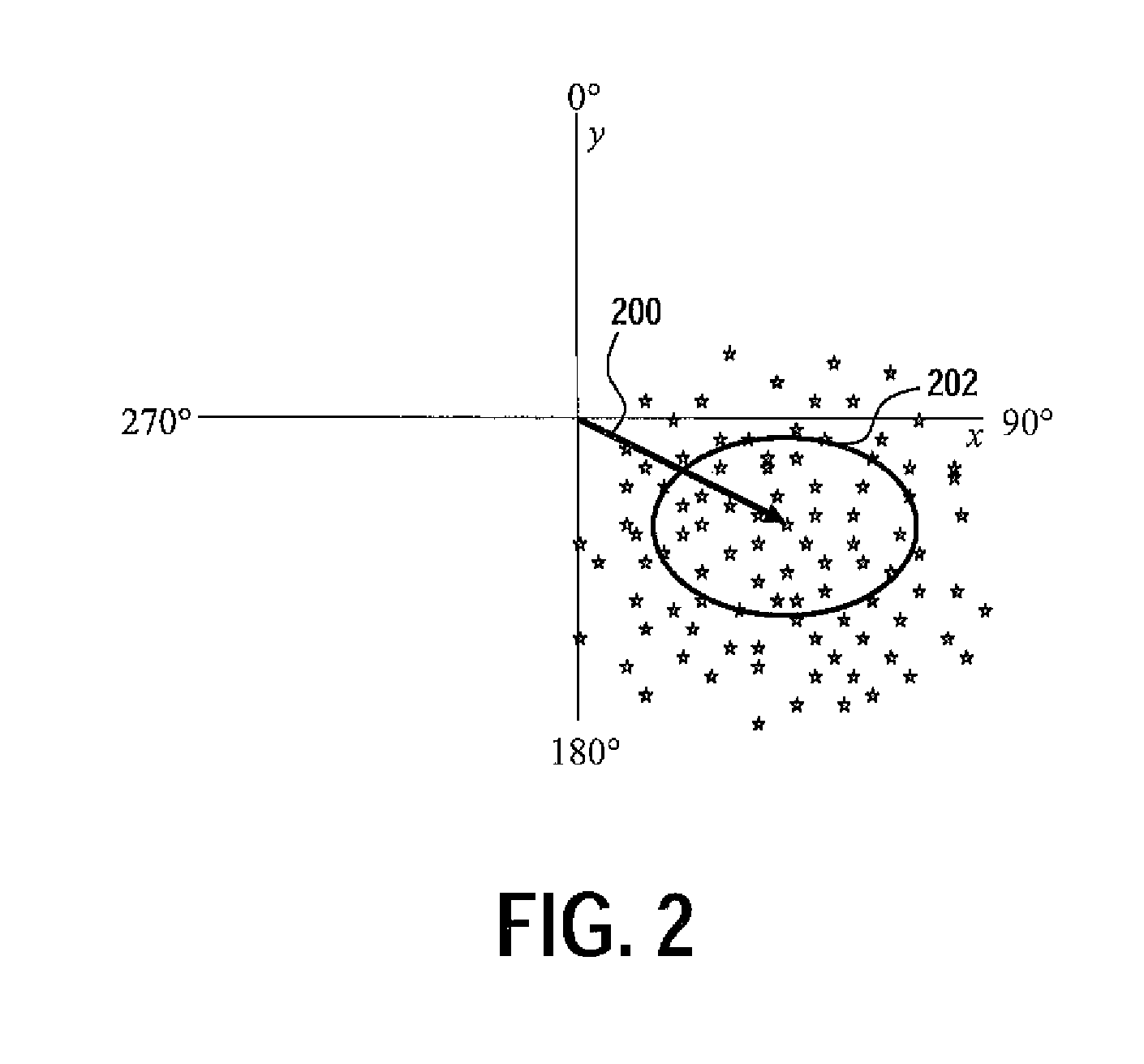

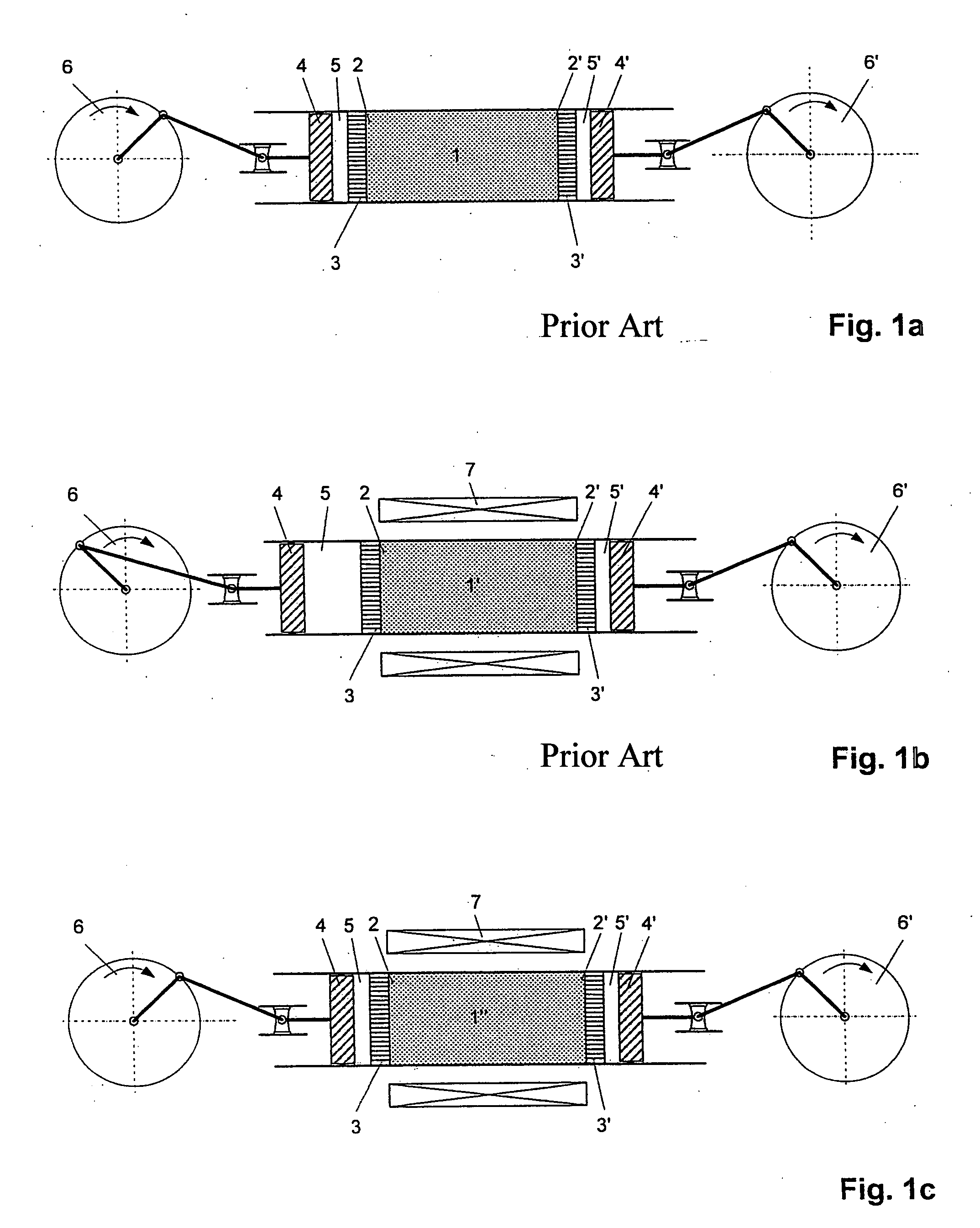

Improvement of tire uniformity through identification of process signatures

ActiveUS20120035757A1Improve uniformityOptimizing componentsTyresSpecial data processing applicationsTire uniformityCyclic process

A system and related method for improving tire uniformity includes providing a number (n) of test tires manufactured in a known order and identifying at least one candidate cyclic process effect with a corresponding frequency of introduction (f). A given uniformity parameter, such as radial or lateral run-out, balance, mass variation, radial lateral or tangential force variation, is measured for each tire in the test set, and measured data points are combined into a concatenated composite waveform. At least one process harmonic associated with each identified cyclic process effect is separated from the tire harmonics, for example, by Fourier transformation with identification of the process harmonics as positive integer multiples of the mth harmonic of the measured uniformity parameter where m=n / f. Once the process harmonics are extracted, filtered uniformity measurements can be provided or new tires can be built with the process effect minimized.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

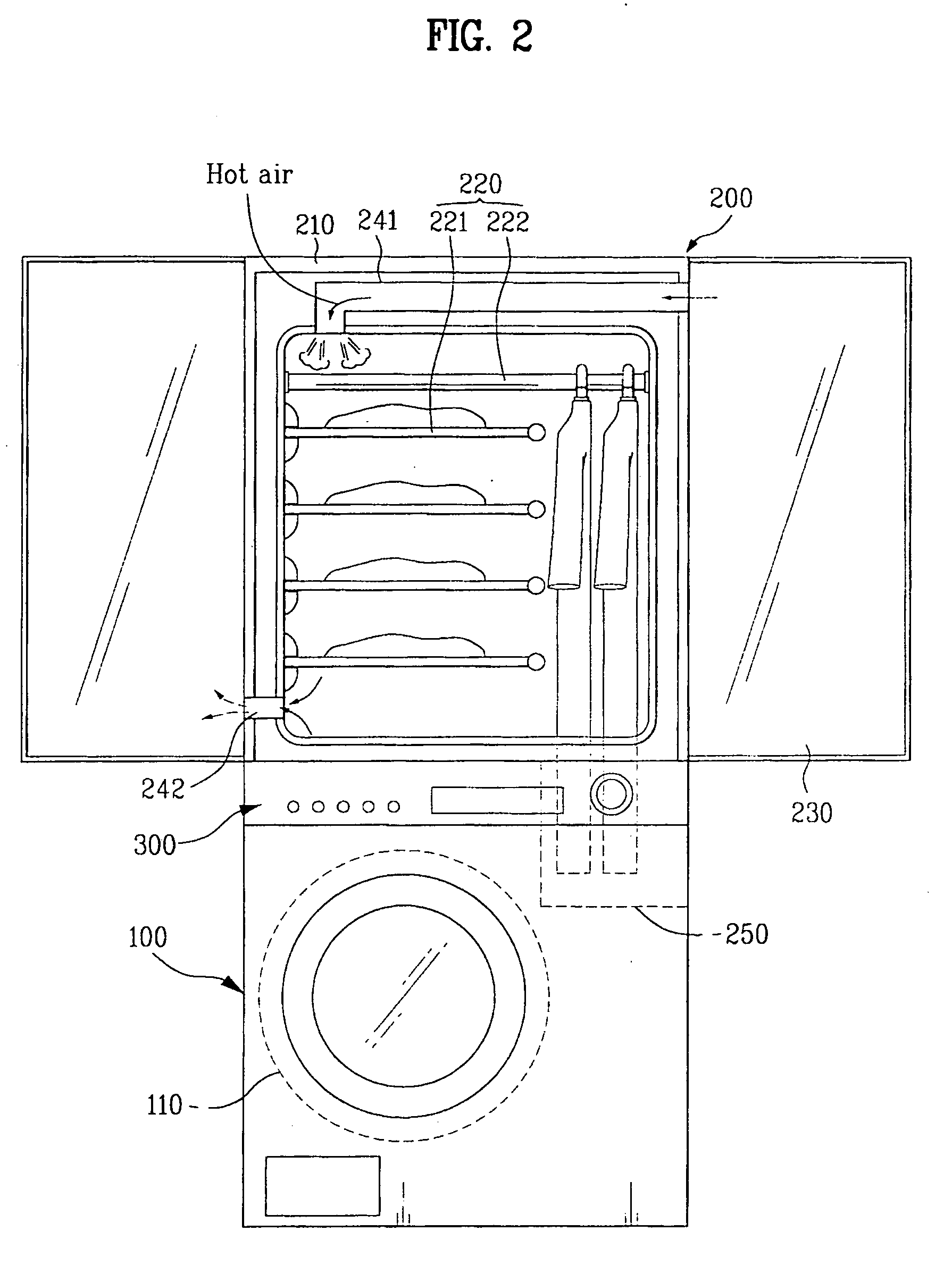

Combination dryer and method thereof

InactiveUS20060130354A1Avoid changeDrying using combination processesDrying gas arrangementsCyclic processRefresh cycle

An operation method for a combination driver is disclosed. The present invention relates to a combination dryer, and more particularly, to an operation method for a combination dryer which enables air in a drying drum and a cabinet for drying the laundry to circulate continuously and enables water generated in the circulation process to perform a refreshing cycle by using the water.

Owner:LG ELECTRONICS INC

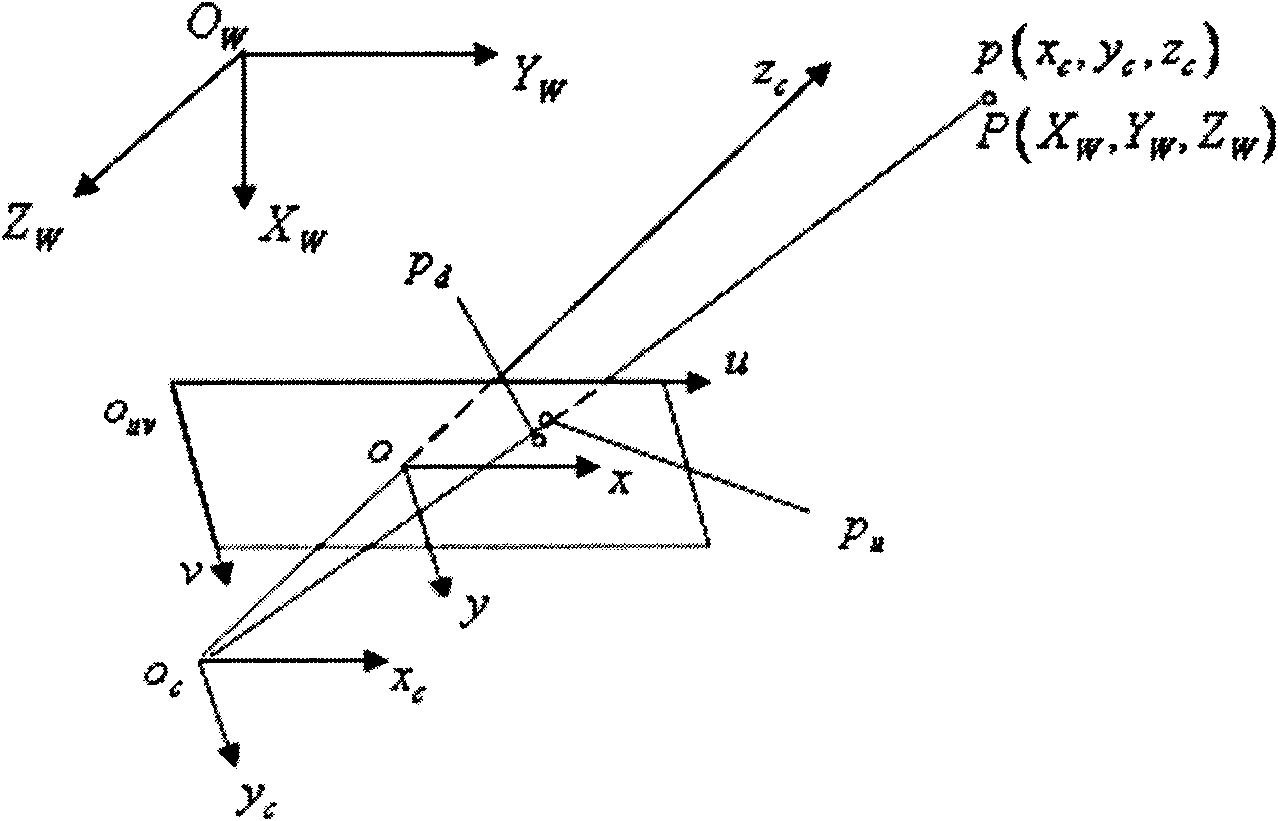

Vehicle intelligent method for automatically identifying road pit or obstruction

InactiveCN101549683AEnsure driving safetyReduce incidenceAutomatic initiationsCharacter and pattern recognitionInformation processingCyclic process

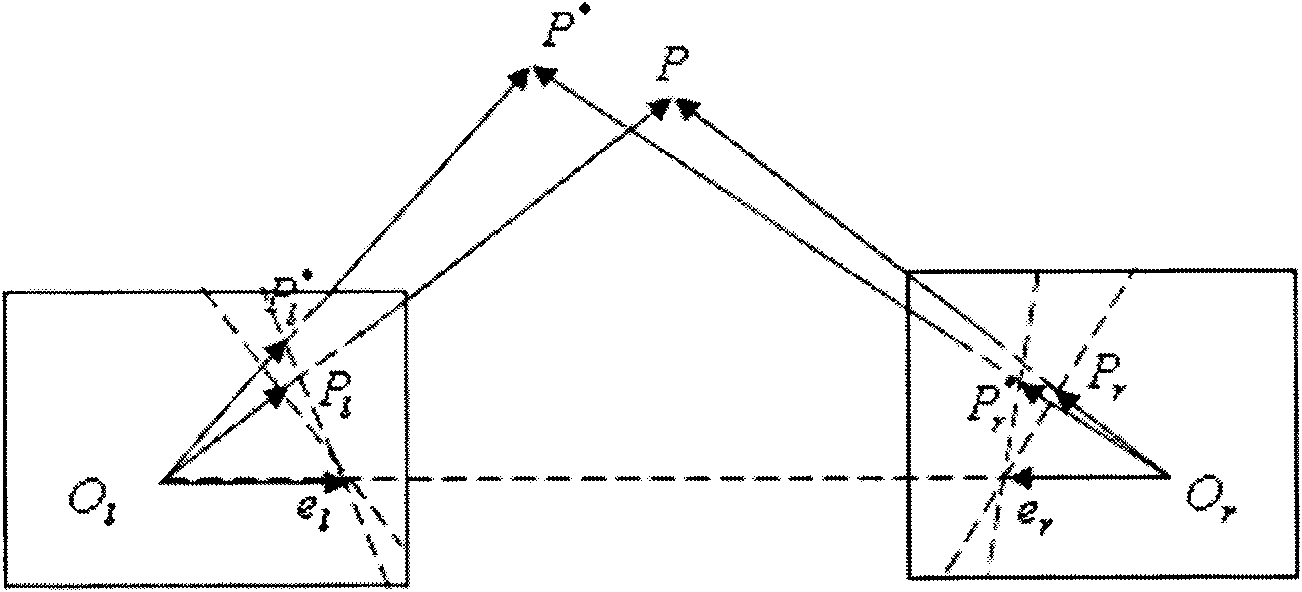

A vehicle intelligent method for automatically identifying road speed-limit sign in the technical field of information processing includes the following steps: step one, two pinhole cameras are respectively installed at the edge of the inner side of the vehicle front far-sight lamp; step two, the two pinhole cameras collect road surface scene images in real time, and the collected images are respectively transported to a signal processor; step three, the images are processed by eliminating image distortion; step four, aiming at corner points that already found out, the mutual matching of corner points is automatically realized in left and right views under the instruction of epipolar constraint; step five, the three-dimensional coordinate figure of object point is ensured; step six, pit or obstruction is identified; step seven, the vehicle driving is controlled; step eight, a cyclic process is carried out by repeating step two to step seven. The invention can further improve automatization and intelligentialization level on the aspect of guaranteeing the safety of vehicle driving without vehicle damages or traffic accidents due to pit or obstruction appearing on the road.

Owner:SHANGHAI JIAO TONG UNIV

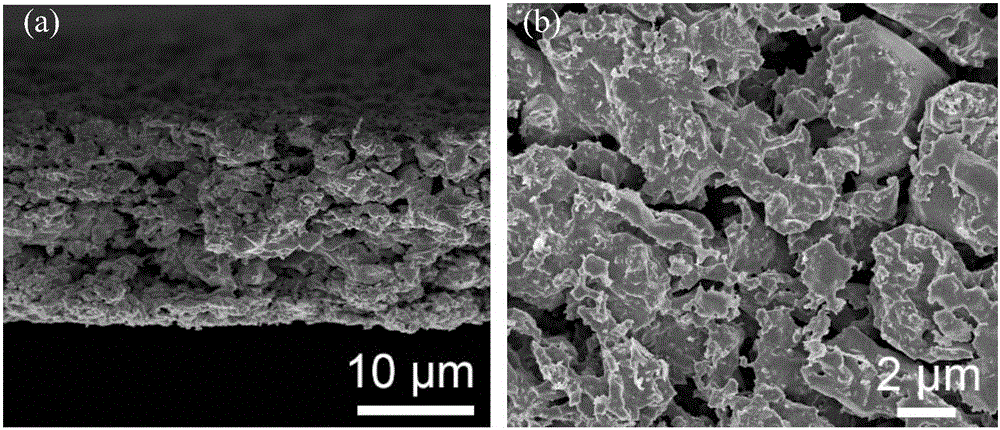

Metal lithium secondary battery and negative electrode and porous copper current collector thereof

InactiveCN105932295AGrowth inhibitionElectrode carriers/collectorsLi-accumulatorsCyclic processPorous channel

The invention belongs to the technical field of a lithium secondary battery, and particularly relates to a porous copper current collector, capable of retraining generation of lithium dendrites, of the metal lithium secondary battery. The porous copper current collector has a connected porous channel structure, and the pore diameter is 0.1-2[mu]m. Compared with the prior art, the three-dimensional porous structure can lower the effective current density of the electrode by enlarging the specific surface area of the electrode so as to restrain the generation of lithium dendrites and to stabilize the SEI film; in addition, the three-dimensional porous structure can accommodate the deposited lithium metal so as to slow down the volume change of the lithium metal negative electrode in the charging-discharging cyclic process; and therefore, when the three-dimensional porous copper current collector is applied to the negative electrode of the metal lithium secondary battery, the coulombic efficiency, the circulating stability and the safety of the battery can be effectively improved in the cyclic process.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

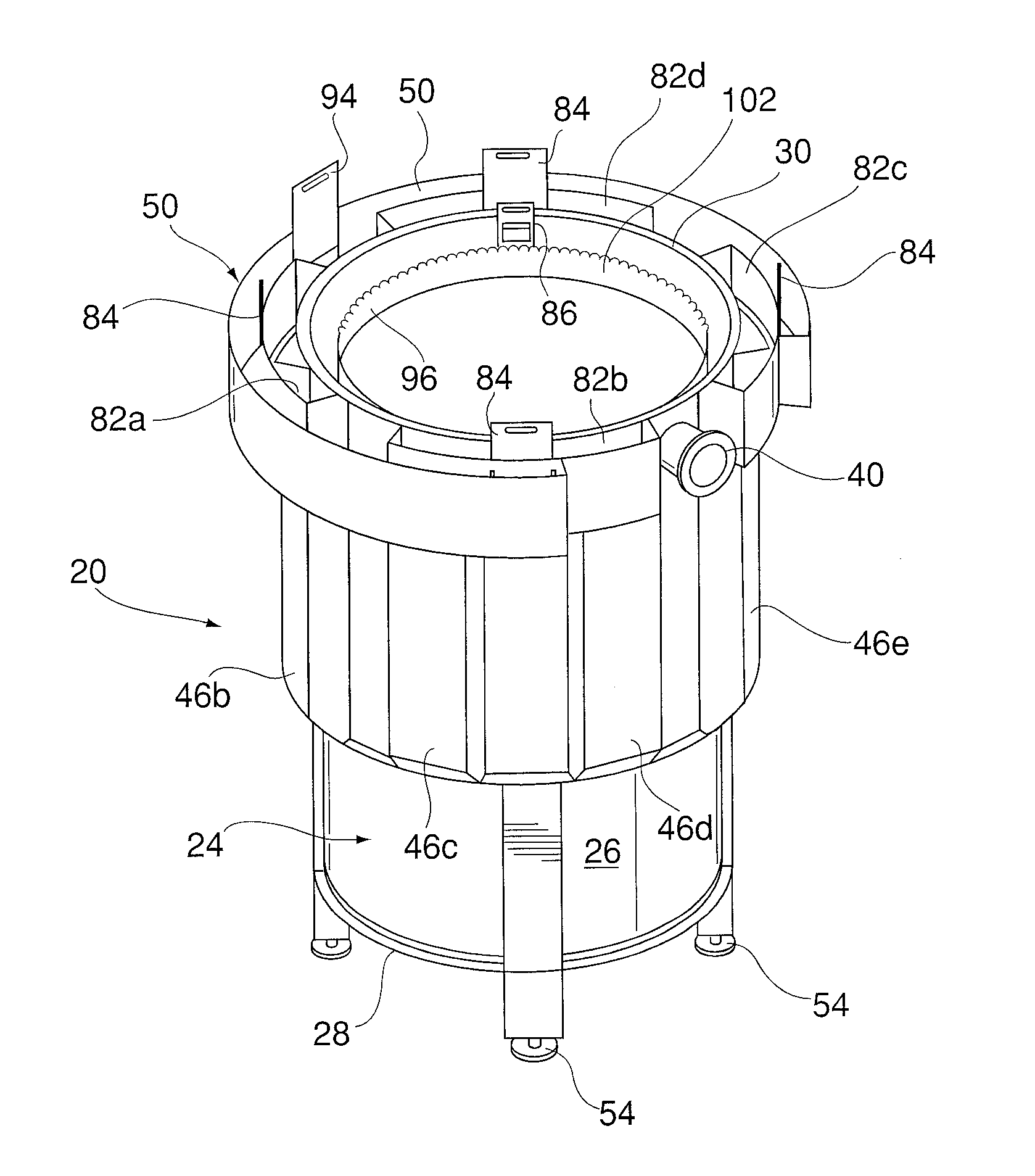

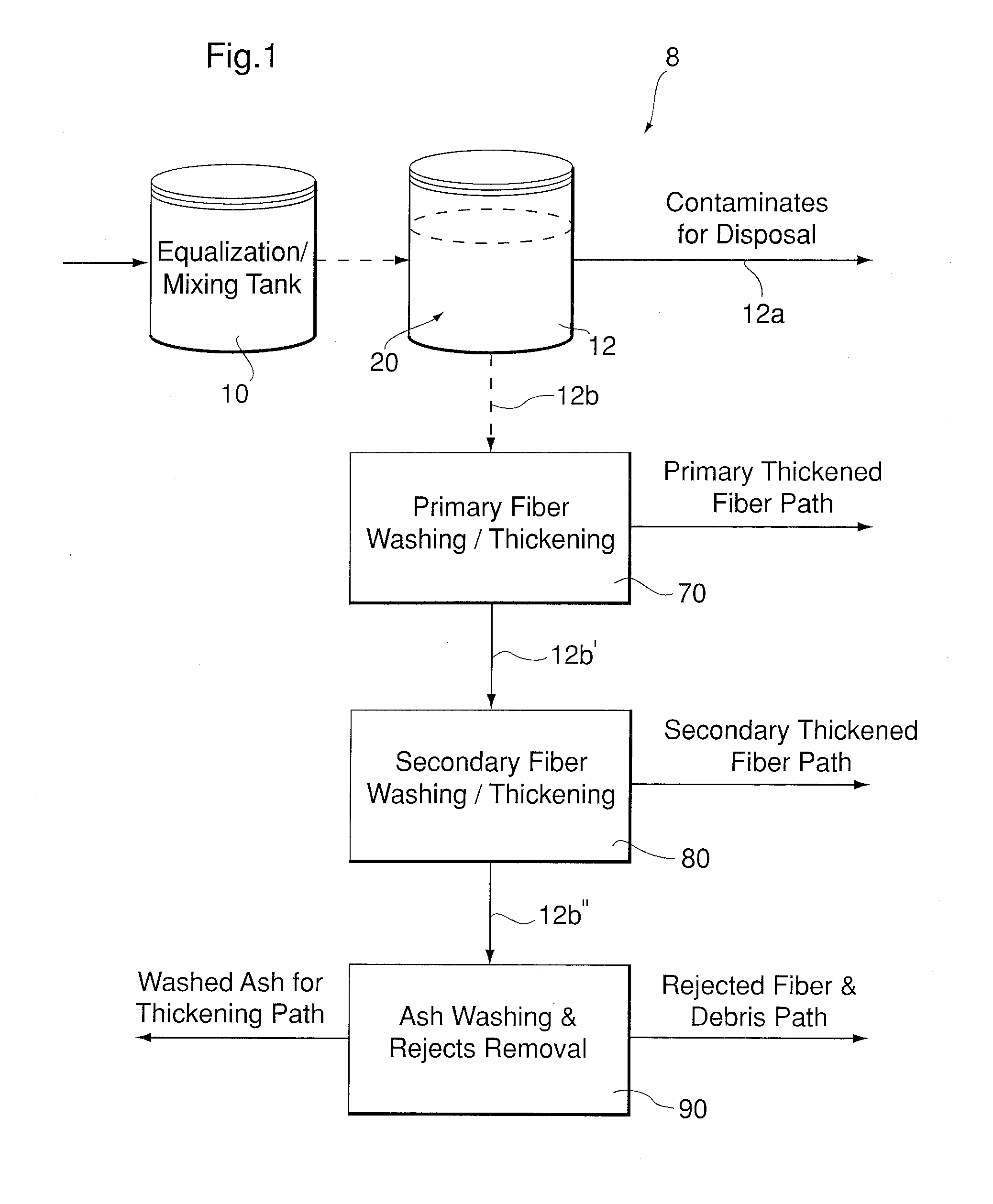

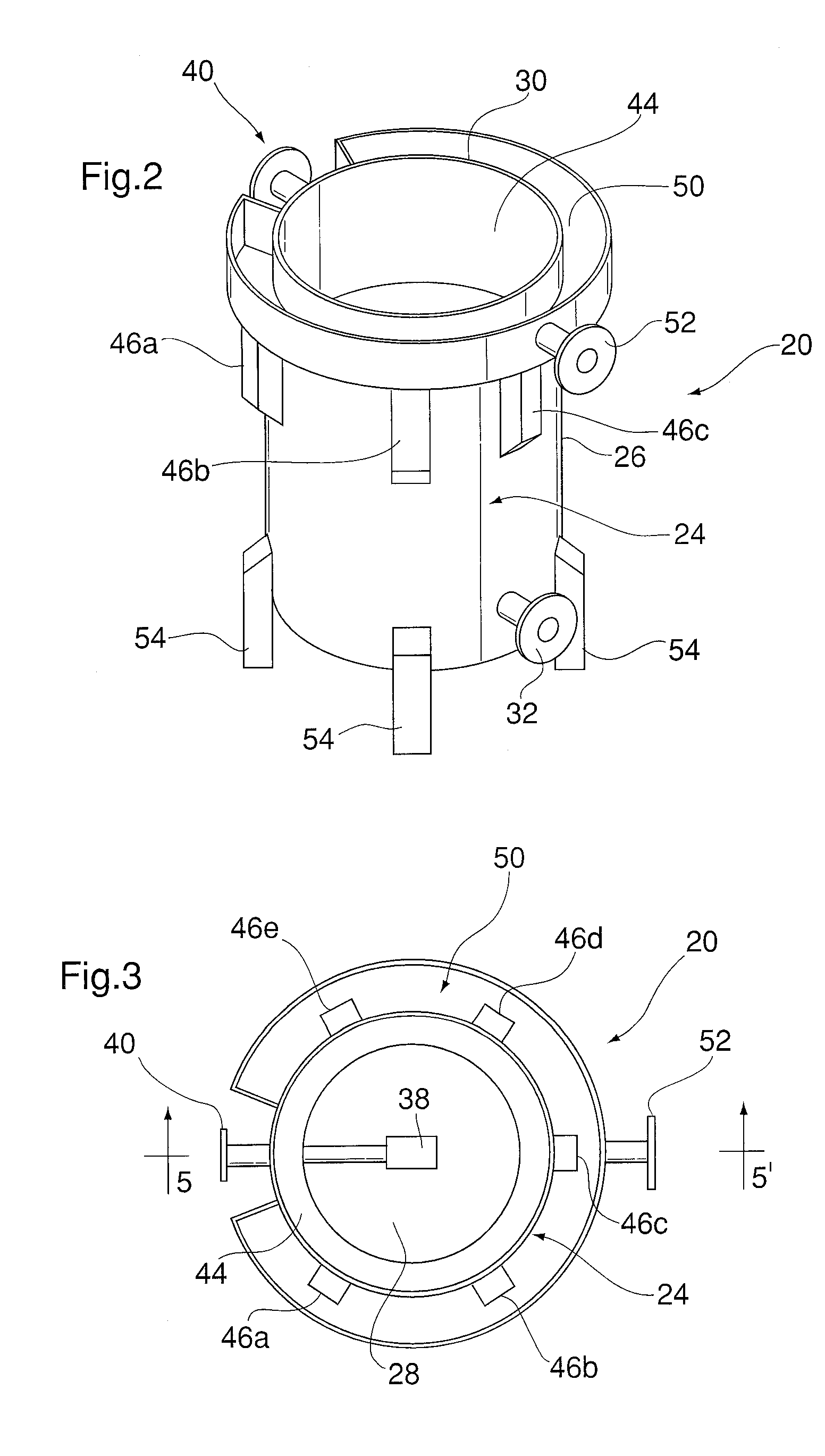

Apparatus for separating waste from cellulose fibres in paper recycling processes

InactiveUS20100133197A1Economically manufacturedEconomically usedLoose filtering material filtersFibrous raw materialsCyclic processWax

A contaminate separation apparatus for use in separating contaminant materials from cellulose and / or paper fibres in a paper recycling process includes a reservoir for receiving a waste paper slurry therein. The reservoir is provided with an inlet opening for the input of the slurry, one or more fibre discharge outlets or passages, and at least one waste outlet positioned vertically above the fibre discharge outlet opening. An agitator provided in a lower portion of the reservoir generates differential flow currents within the reservoir, to selectively divert plastics, waxes, adhesives and / or other sticky waste materials outwardly towards the waste outlet, while providing a flow of suspended paper and / or cellulose fibres to one or more of the fibre discharge outlets.

Owner:LANGNER HERBERT GUNTHER JOACHIM

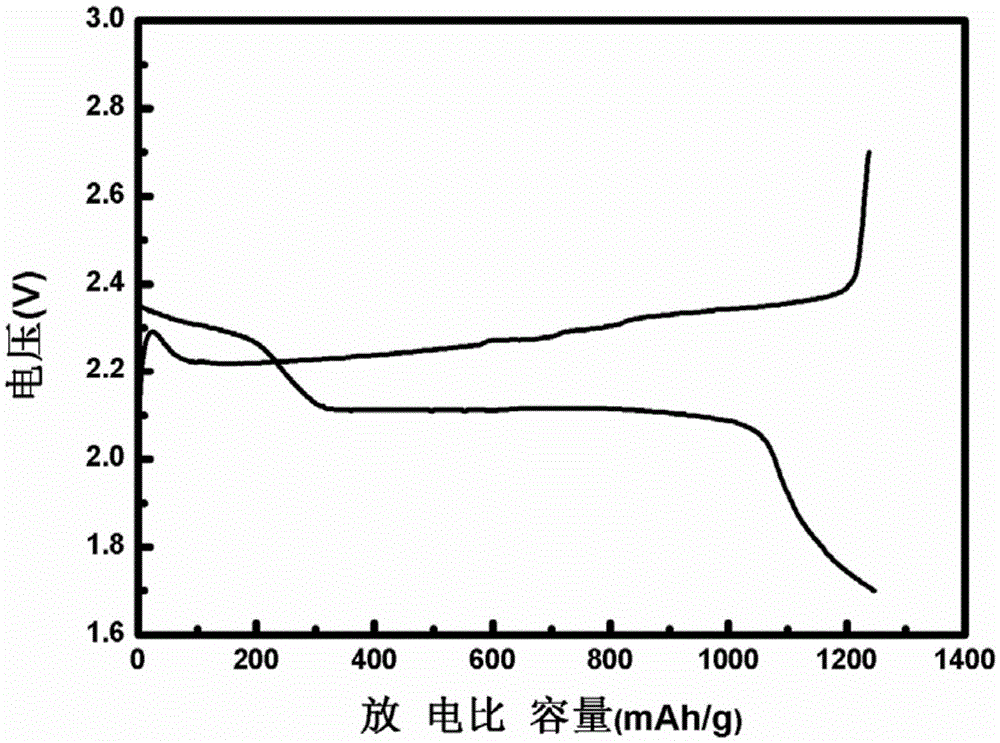

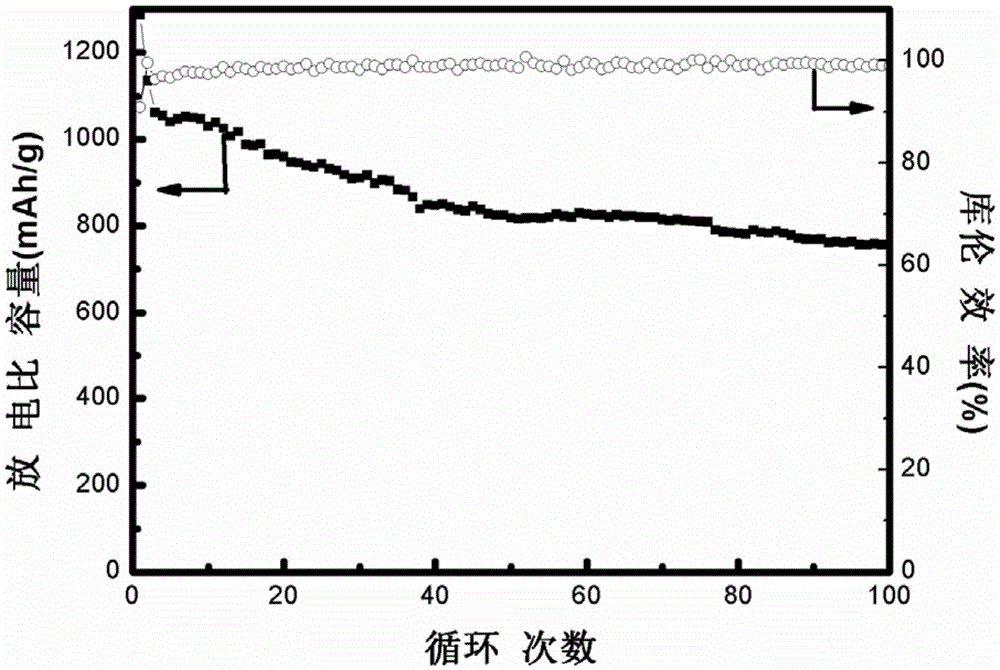

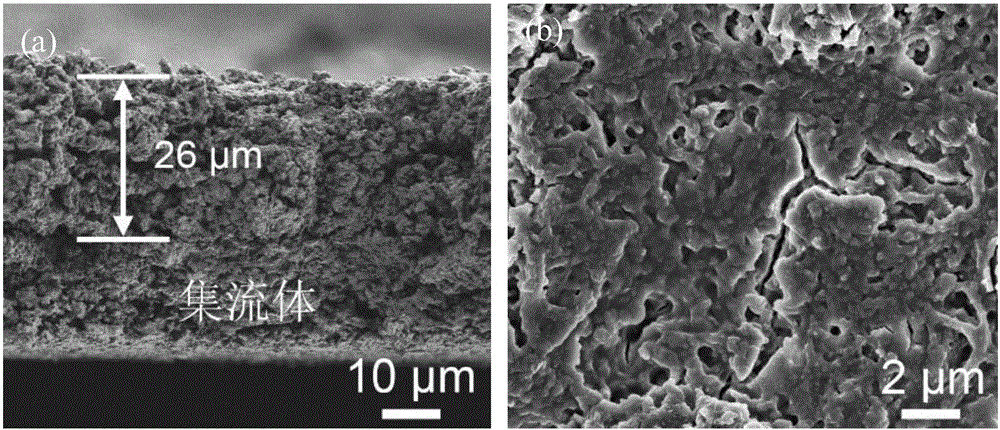

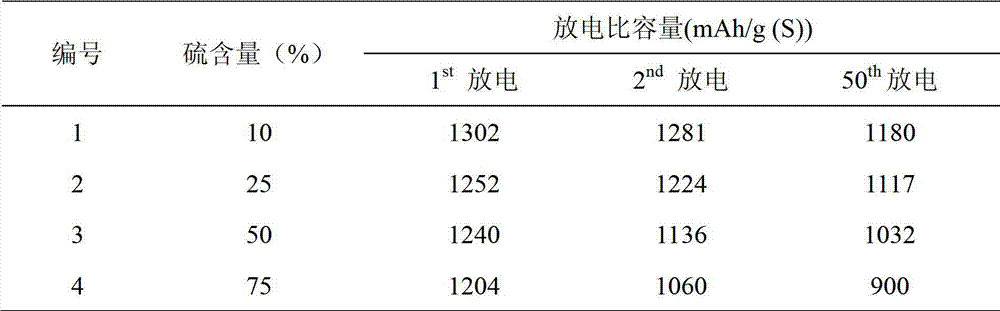

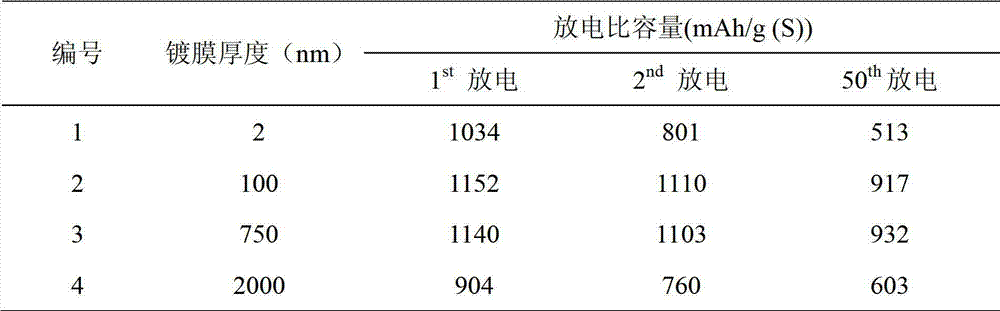

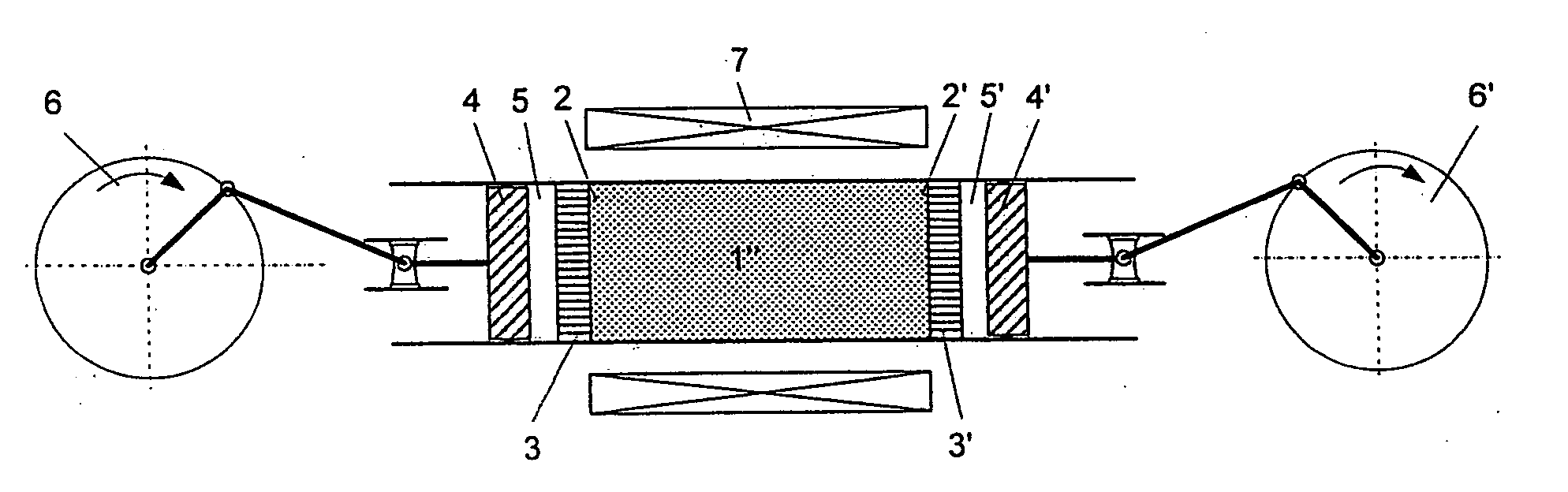

Composite anode of multi-layer structure for lithium-sulfur rechargeable battery and preparation method

InactiveCN103050667AImprove conductivityThickness is easy to controlElectrode manufacturing processesCyclic processSulfur

The invention provides a composite anode of a multi-layer structure for a lithium-sulfur rechargeable battery and a preparation method, which is characterized in that: an anode active substance, a conductive agent, and a binder are uniformly mixed, and then are coated on a current collector, and after coat is dried, a layer of conductive film is sprayed on the surface. The anode surface film is used for conducting and cutting off the sulfur in a cyclic process, thereby effectively raising a first capacity conservation rate of the battery and the cyclic stability.

Owner:CENT SOUTH UNIV

Hybrid heat pump / refrigerator with magnetic cooling stage

InactiveUS20070186560A1Improve efficiencyIncrease powerHeat recovery systemsCompression machines with cascade operationCyclic processWorking fluid

A device for transporting heat from a cold reservoir to a warm reservoir, in which at least two cyclic processes are employed for transporting heat thereby absorbing work, of which at least one is a regenerative cyclic process, and at least one is a magnetocaloric cyclic process, wherein the regenerative cyclic process has a working fluid and a heat storage medium, is characterized in that the heat storage medium of the regenerative cyclic process comprises a magnetocaloric material for the magnetocaloric cyclic process, wherein the magnetocaloric material is in a regenerator area with a cold end and a warm end, the working fluid of the regenerative cyclic process additionally serving as a heat transfer fluid for the magnetocaloric cyclic process. This produces a compact device with low apparative expense, wherein the power density and also the efficiency of the device are increased. The device may advantageously be used for cooling a superconducting magnet configuration.

Owner:BRUKER BIOSPIN

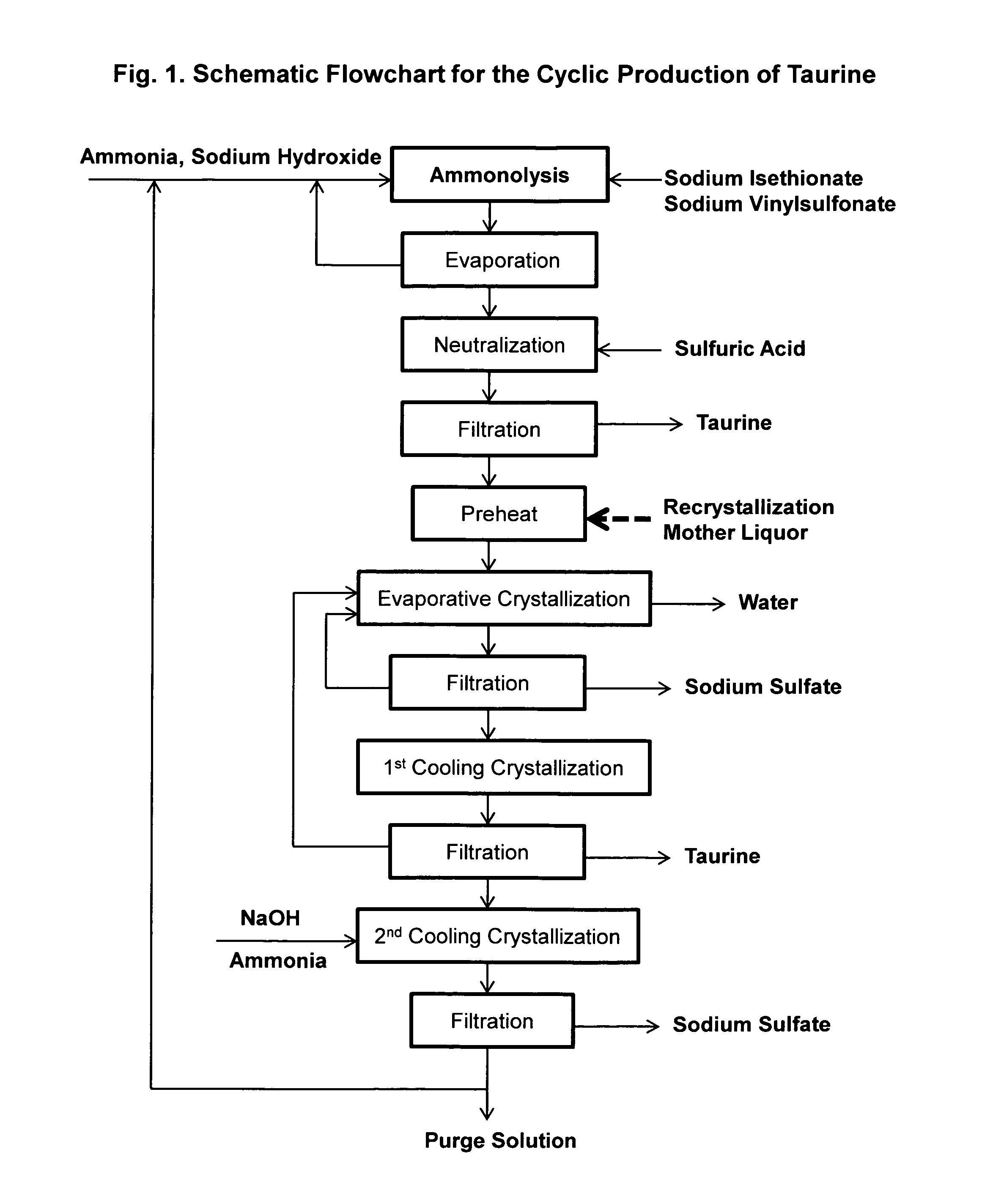

Cyclic process for the production of taurine from alkali isethionate

ActiveUS9428451B2Facilitate cooling crystallizationOrganic compound preparationSulfonic acids salts preparationCyclic processTaurine

A cyclic process is disclosed for the production of taurine from alkali isethionate in a high overall yield by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. Sodium sulfate and residual taurine in the crystallization mother liquor are efficiently separated by converting taurine into a highly soluble form of sodium taurinate or ammonium taurinate while selectively crystallizing sodium sulfate.

Owner:VITAWORKS IP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com