Patents

Literature

233 results about "Paper recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The recycling of paper is the process by which waste paper is turned into new paper products. It has a number of important benefits: It saves waste paper from occupying landfill and producing methane as it breaks down. Because paper fibre contains carbon (originally absorbed by the tree from which is was produced), recycling keeps the carbon locked up for longer and out of the atmosphere. Around two thirds of all paper products in the US are now recovered and recycled, although it does not all become new paper. After repeated processing the fibres become too short for the production of new paper - this is why virgin fibre (from sustainably farmed trees) will be added to the pulp recipe.

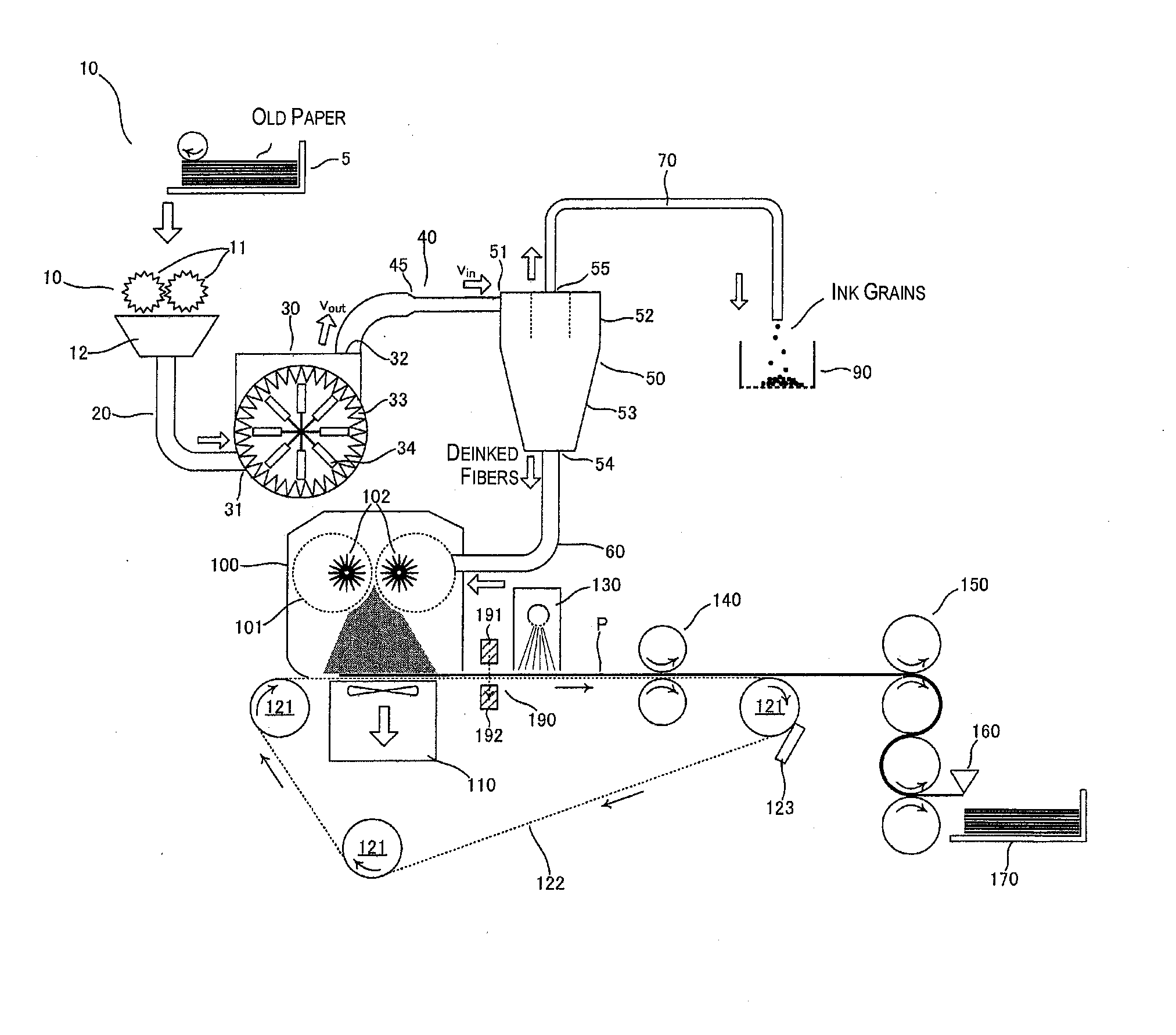

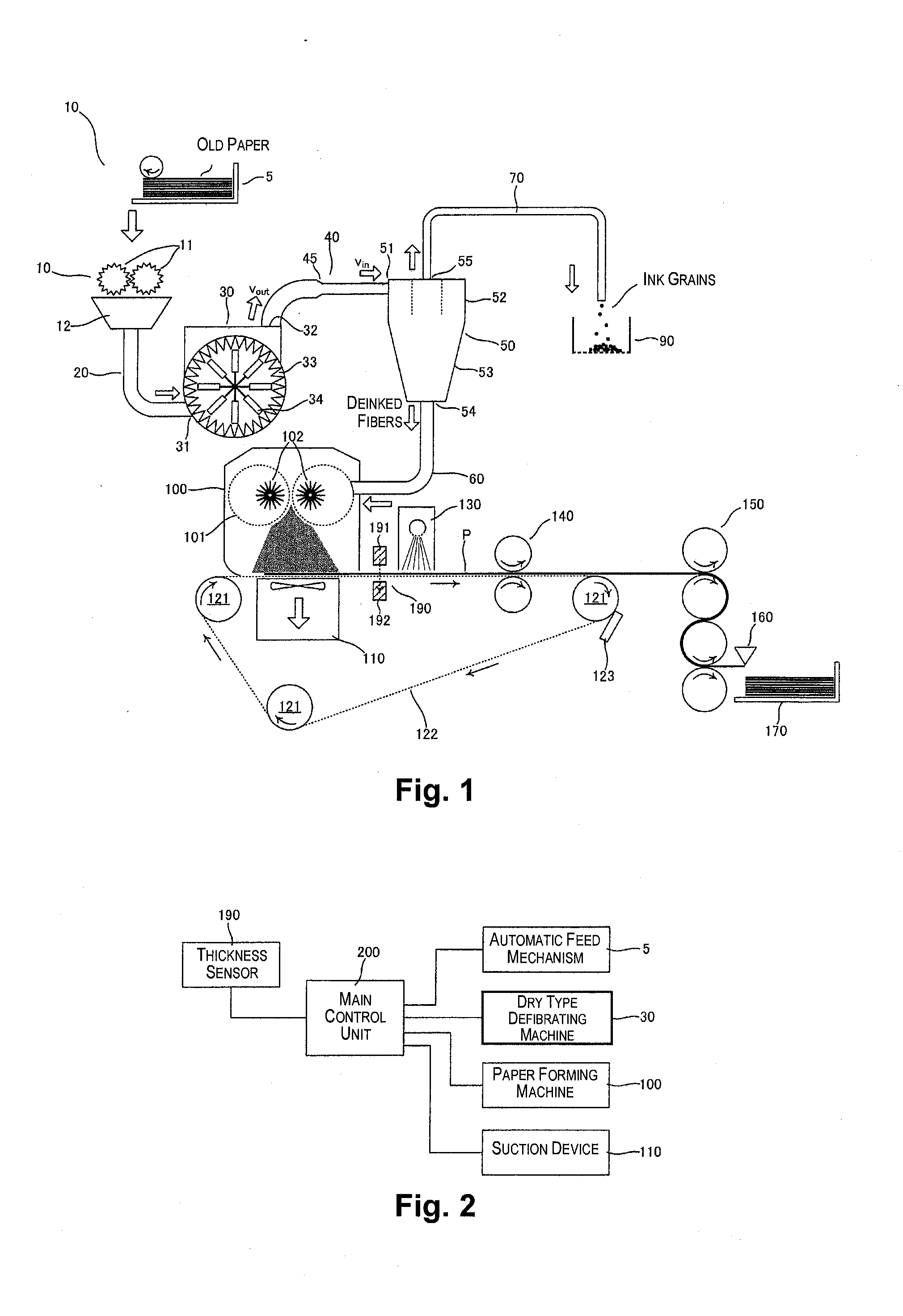

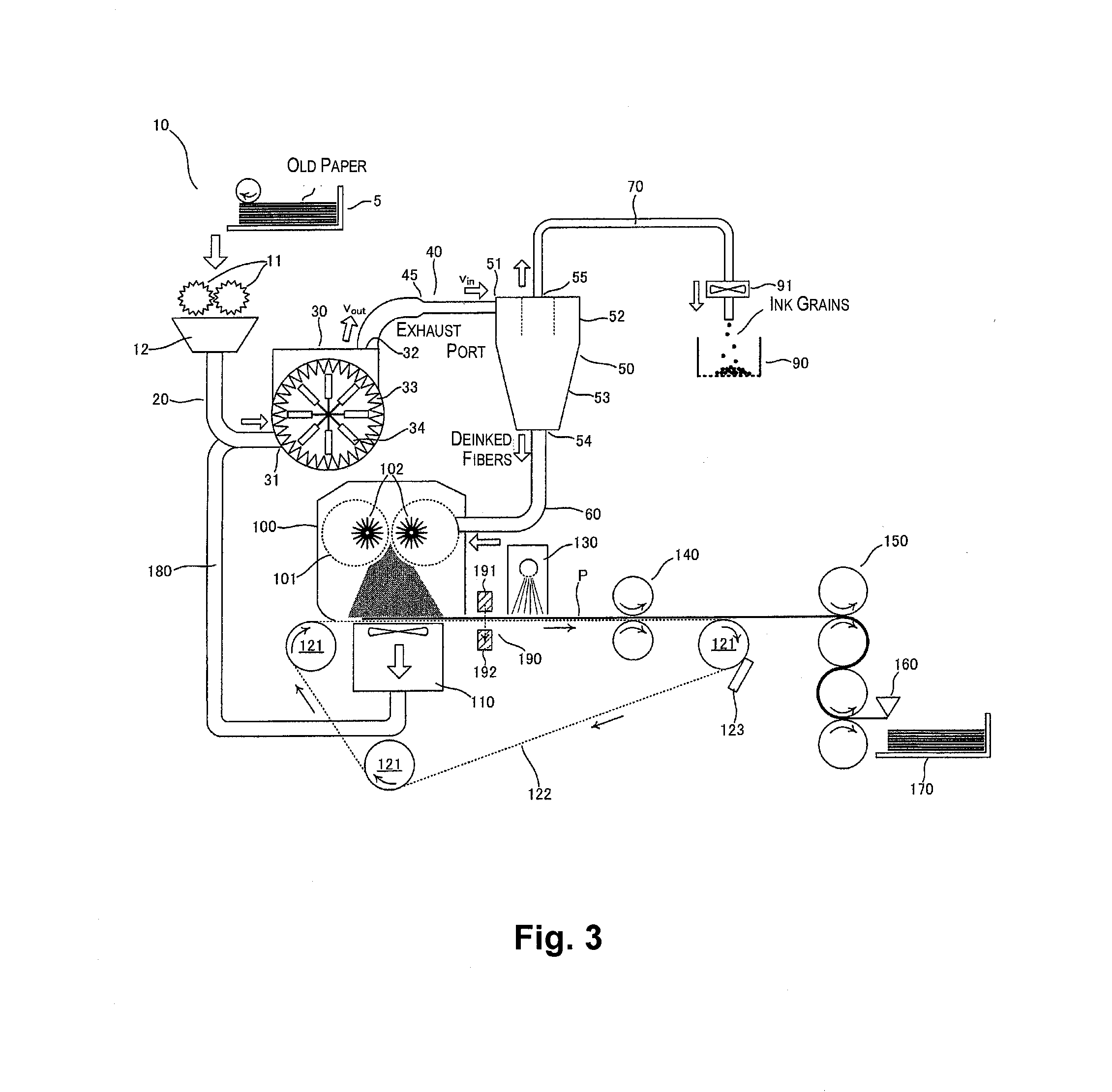

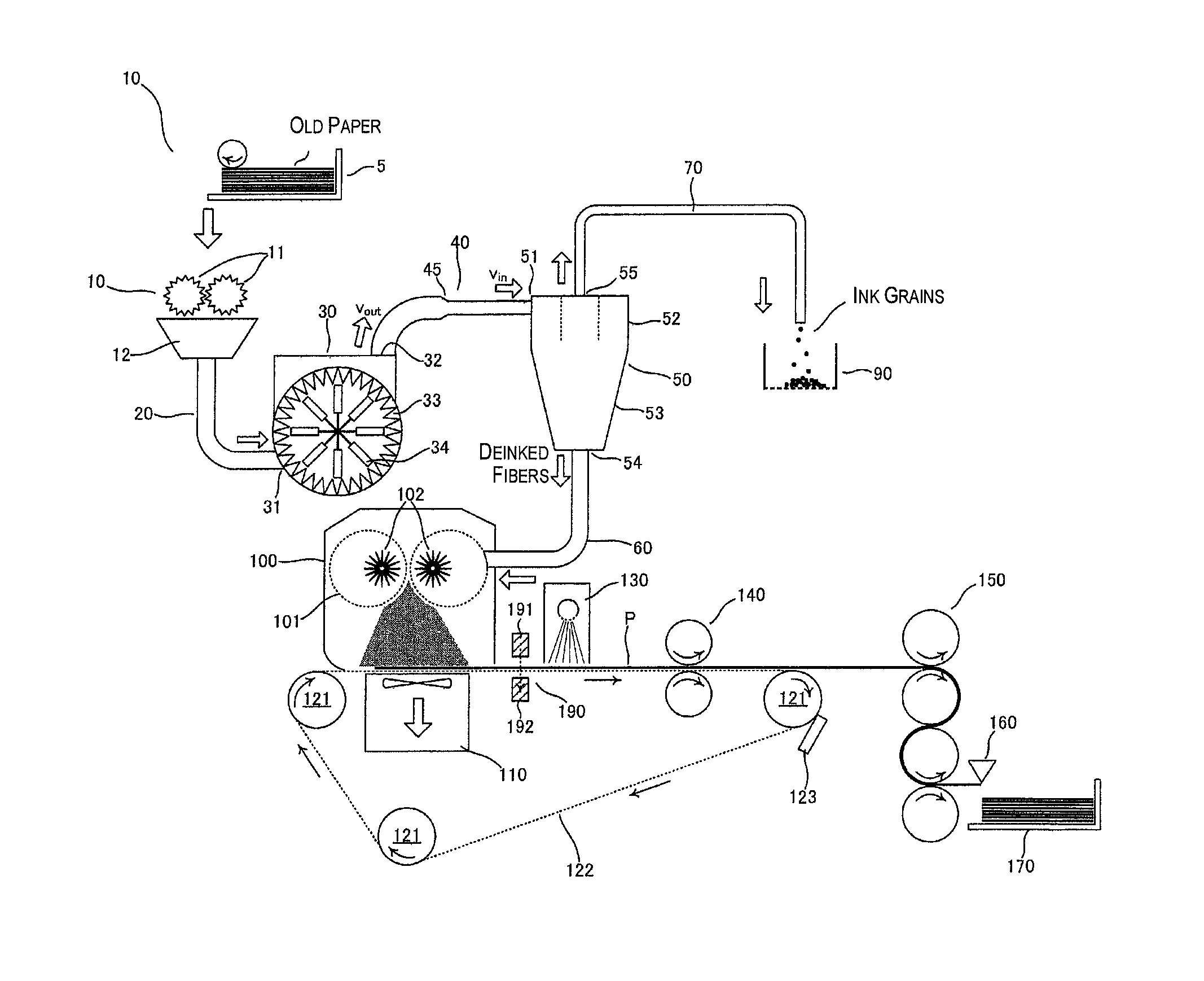

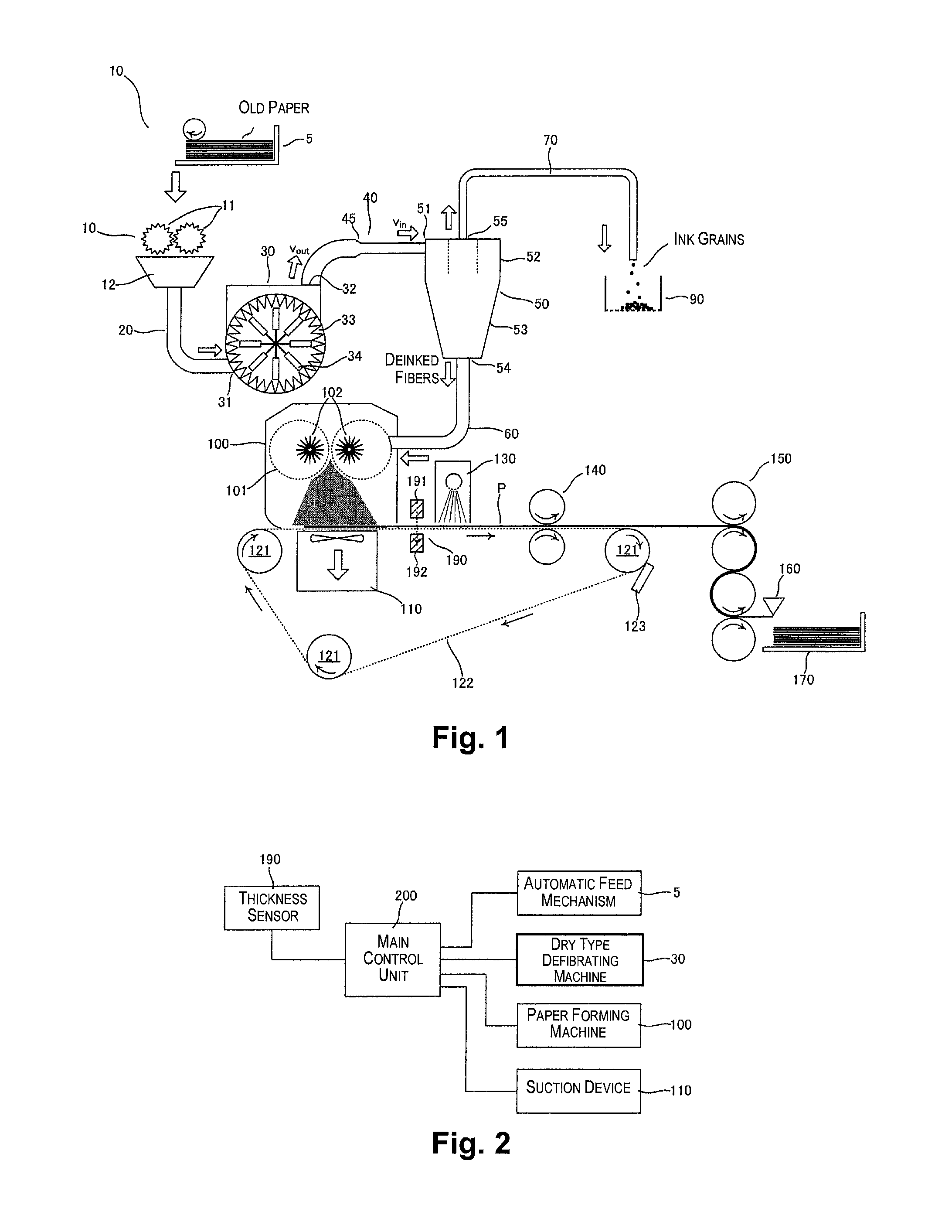

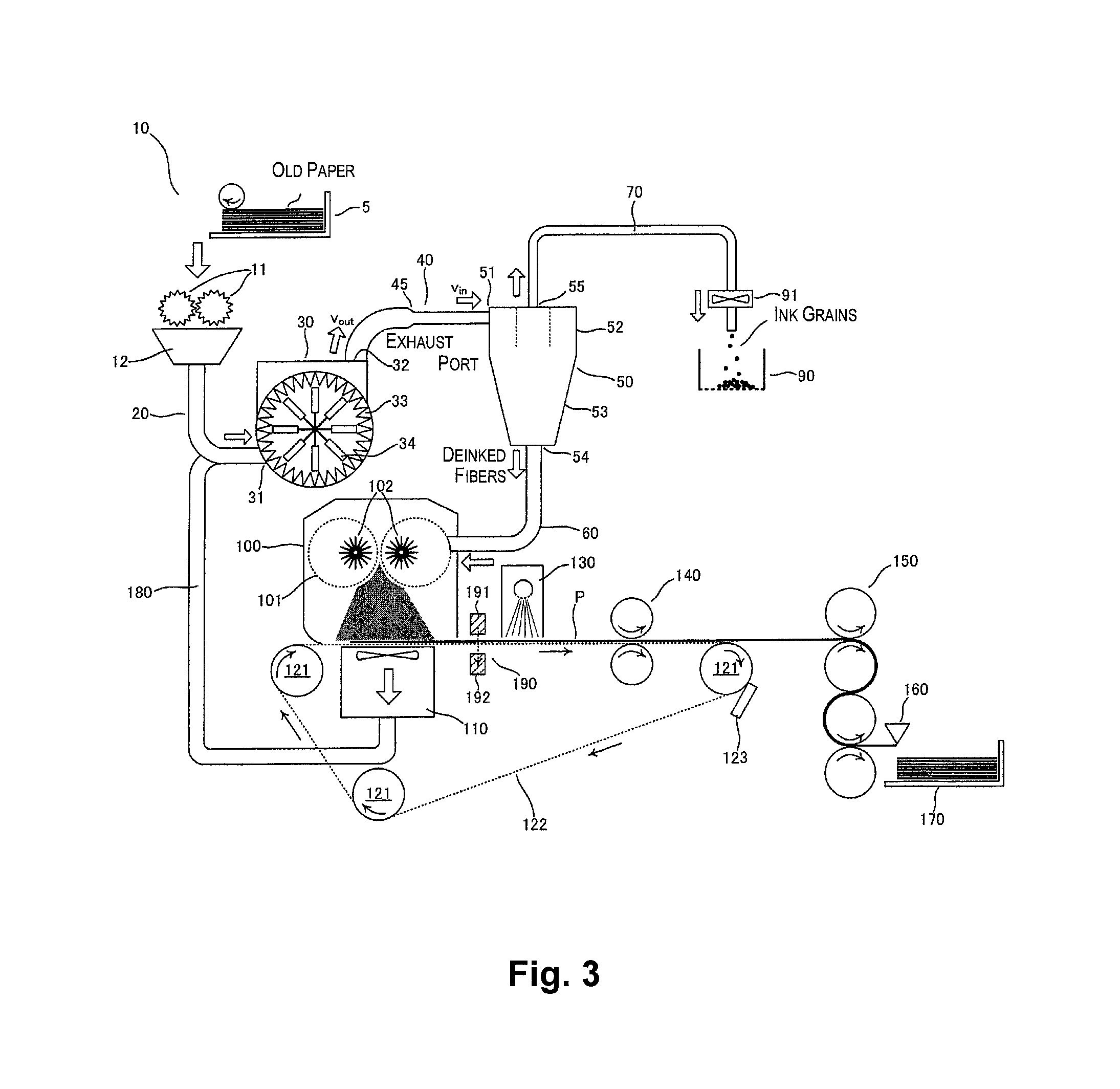

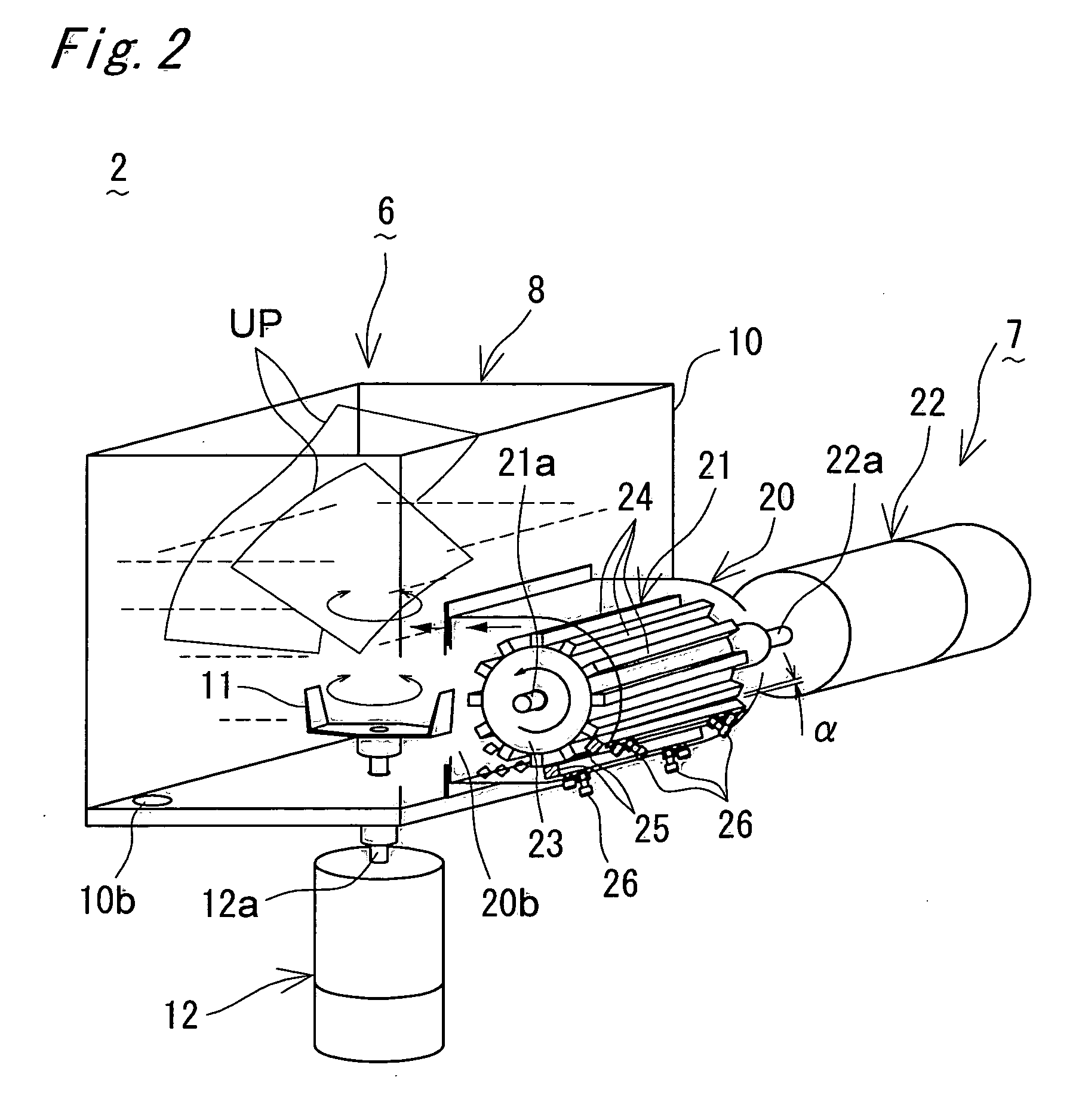

Paper recycling system and paper recycling method

InactiveUS20140027075A1Improve the level ofHigh whitenessPaper recyclingFlat articlesPaper recyclingPulp and paper industry

To provide a paper recycling device capable of recycling paper of increased whiteness level that can be widely used for applications other than paper for newspapers, the paper recycling device of the present invention has a dry type defibrator for crushing and defibrating paper, a first transport pipe for transporting defibrated material that was defibrated by the dry type defibrator, a cyclone for air classifying and deinking the defibrated material transported by the first transport pipe, a second transport pipe for transporting the defibrated material that was deinked by the cyclone, and a paper forming machine for forming paper with the defibrated material transported by the second transport pipe.

Owner:SEIKO EPSON CORP

Paper recycling system and paper recycling method

Owner:SEIKO EPSON CORP

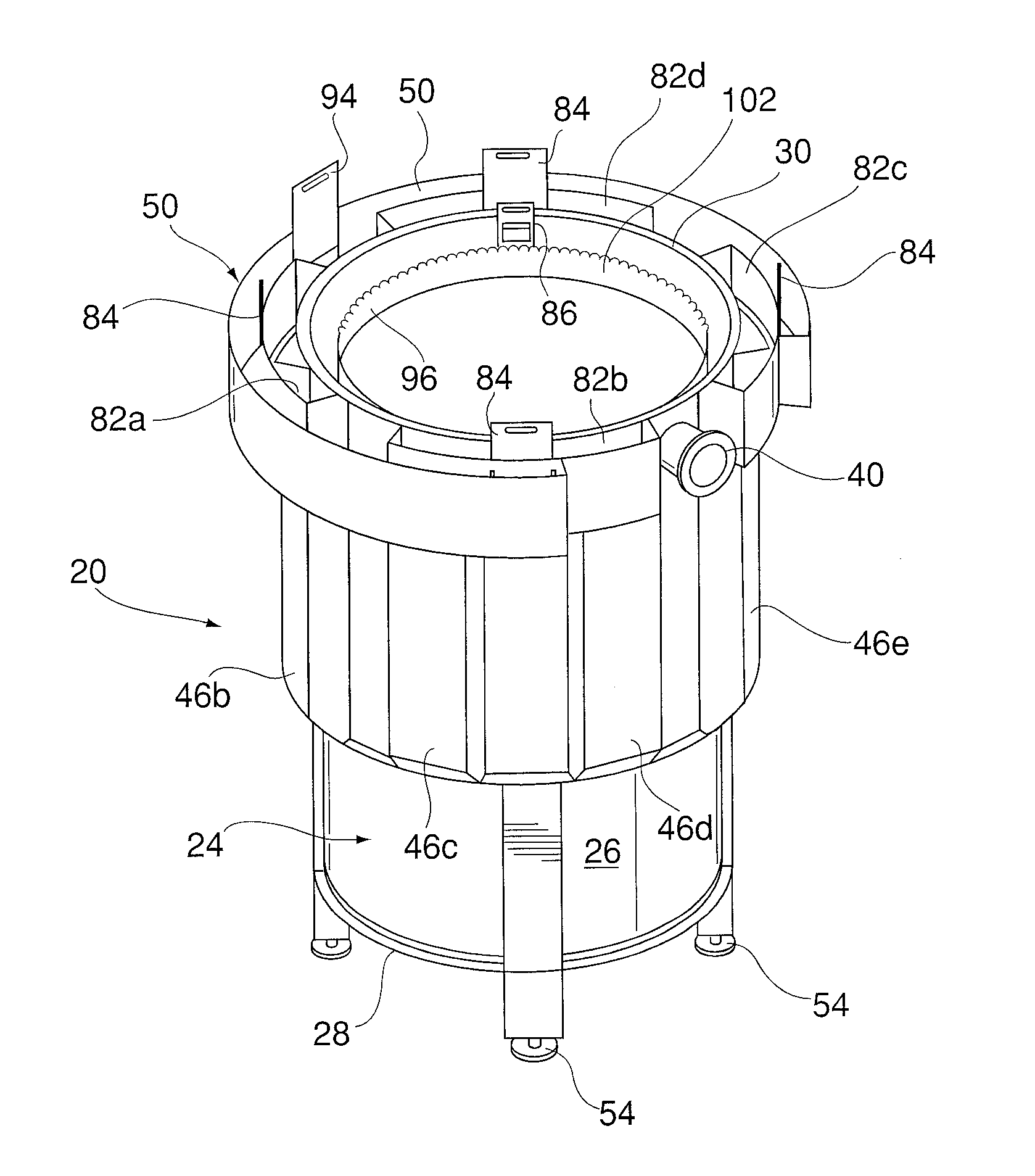

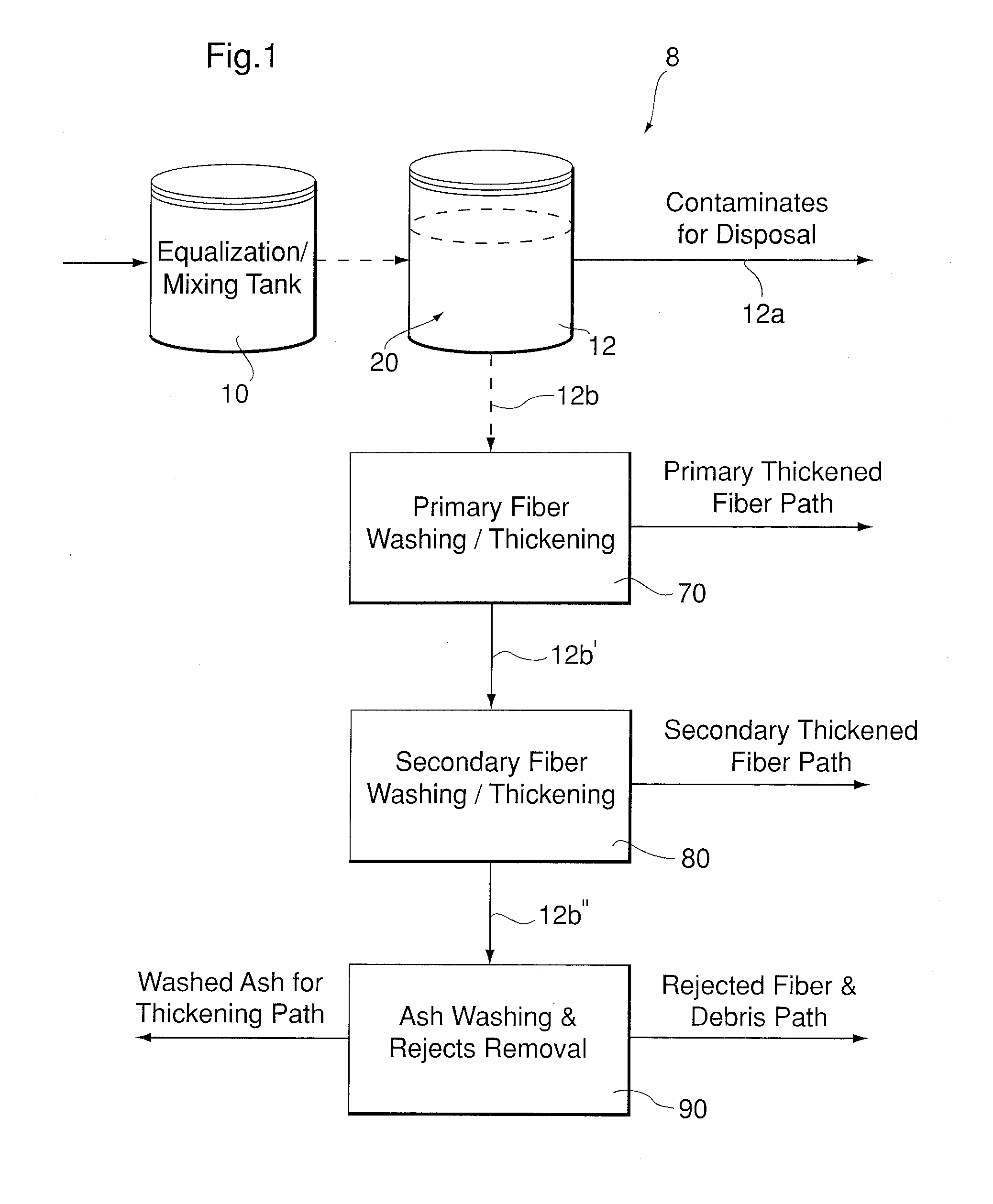

Apparatus for separating waste from cellulose fibres in paper recycling processes

InactiveUS20100133197A1Economically manufacturedEconomically usedLoose filtering material filtersFibrous raw materialsCyclic processWax

A contaminate separation apparatus for use in separating contaminant materials from cellulose and / or paper fibres in a paper recycling process includes a reservoir for receiving a waste paper slurry therein. The reservoir is provided with an inlet opening for the input of the slurry, one or more fibre discharge outlets or passages, and at least one waste outlet positioned vertically above the fibre discharge outlet opening. An agitator provided in a lower portion of the reservoir generates differential flow currents within the reservoir, to selectively divert plastics, waxes, adhesives and / or other sticky waste materials outwardly towards the waste outlet, while providing a flow of suspended paper and / or cellulose fibres to one or more of the fibre discharge outlets.

Owner:LANGNER HERBERT GUNTHER JOACHIM

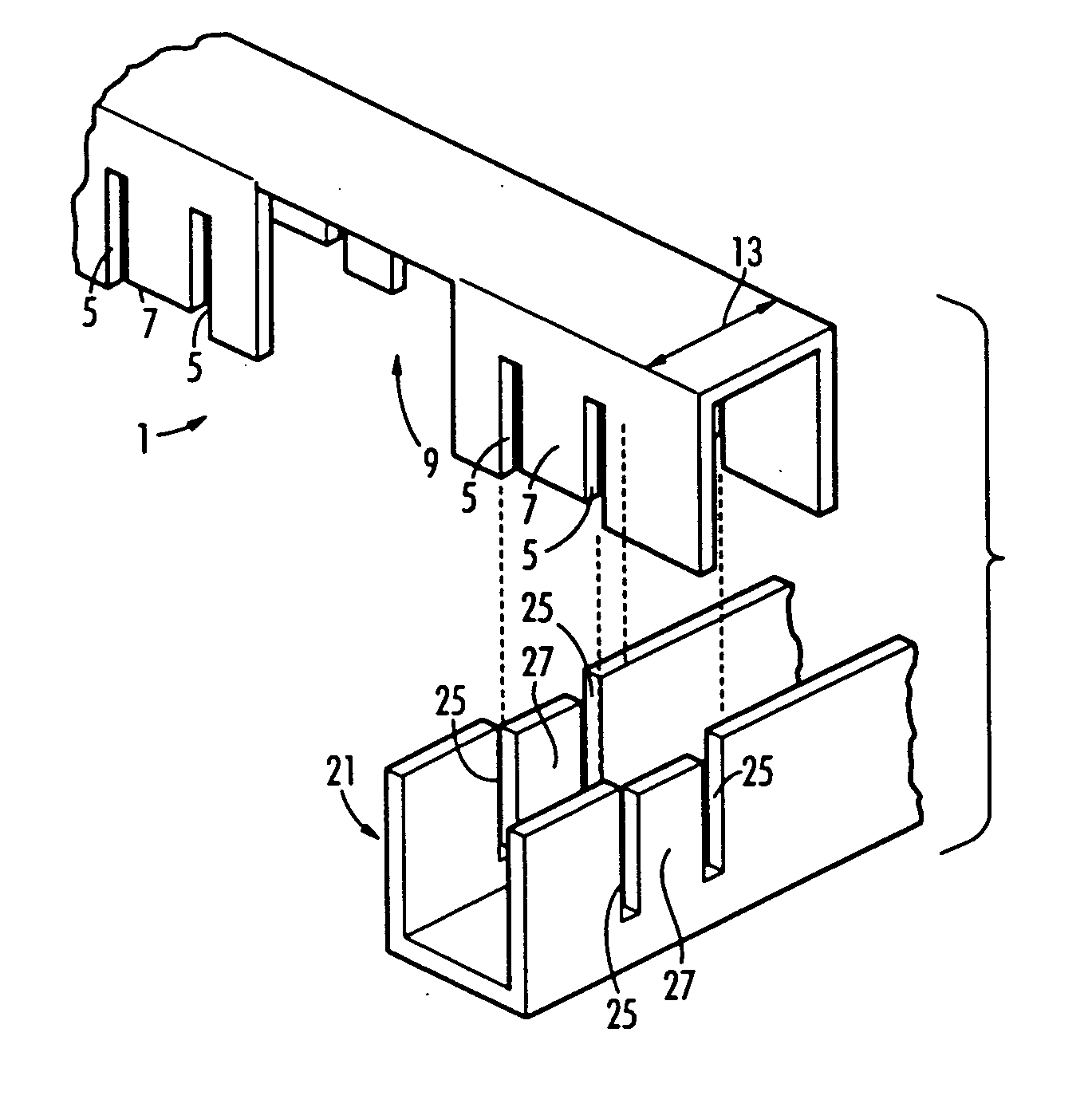

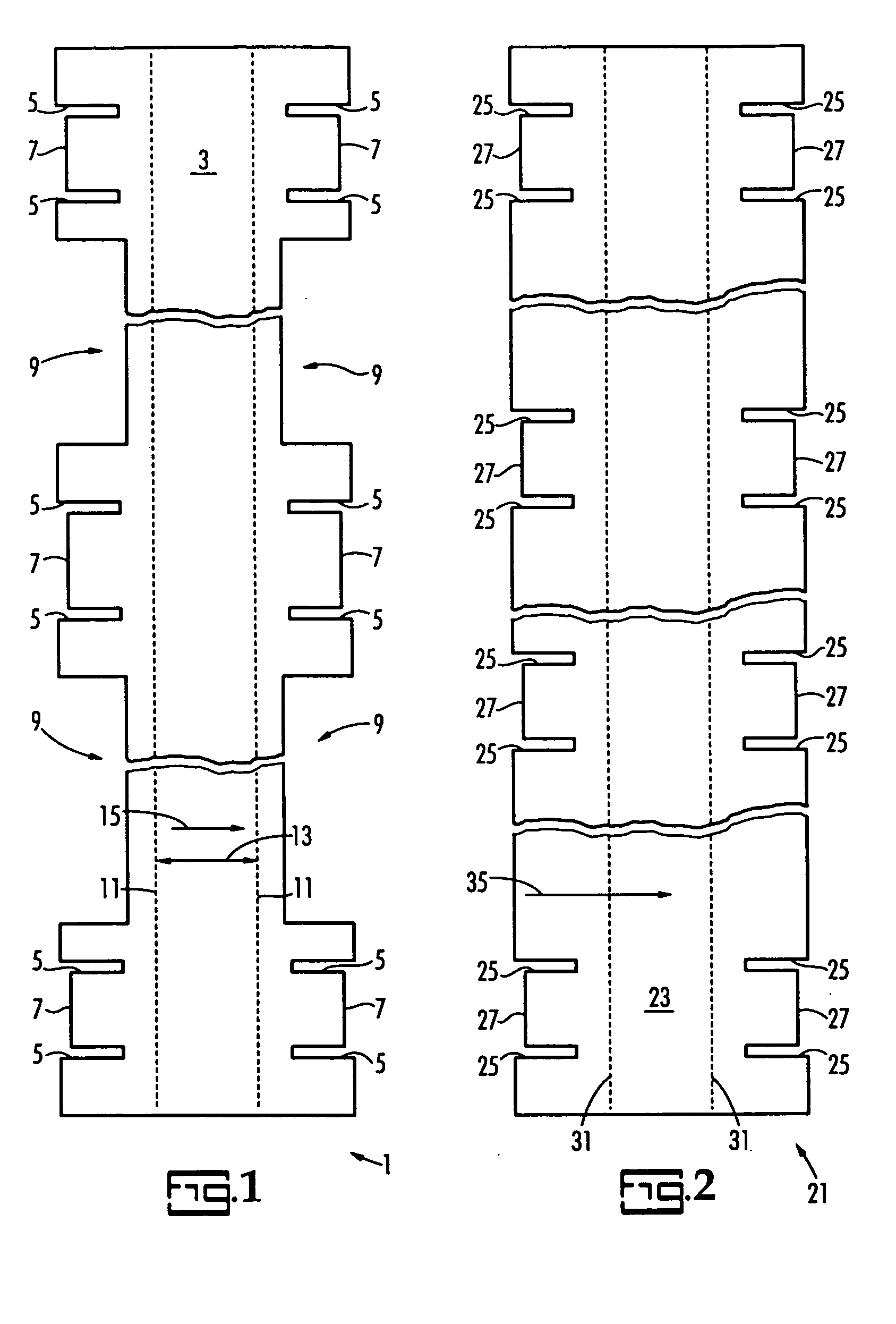

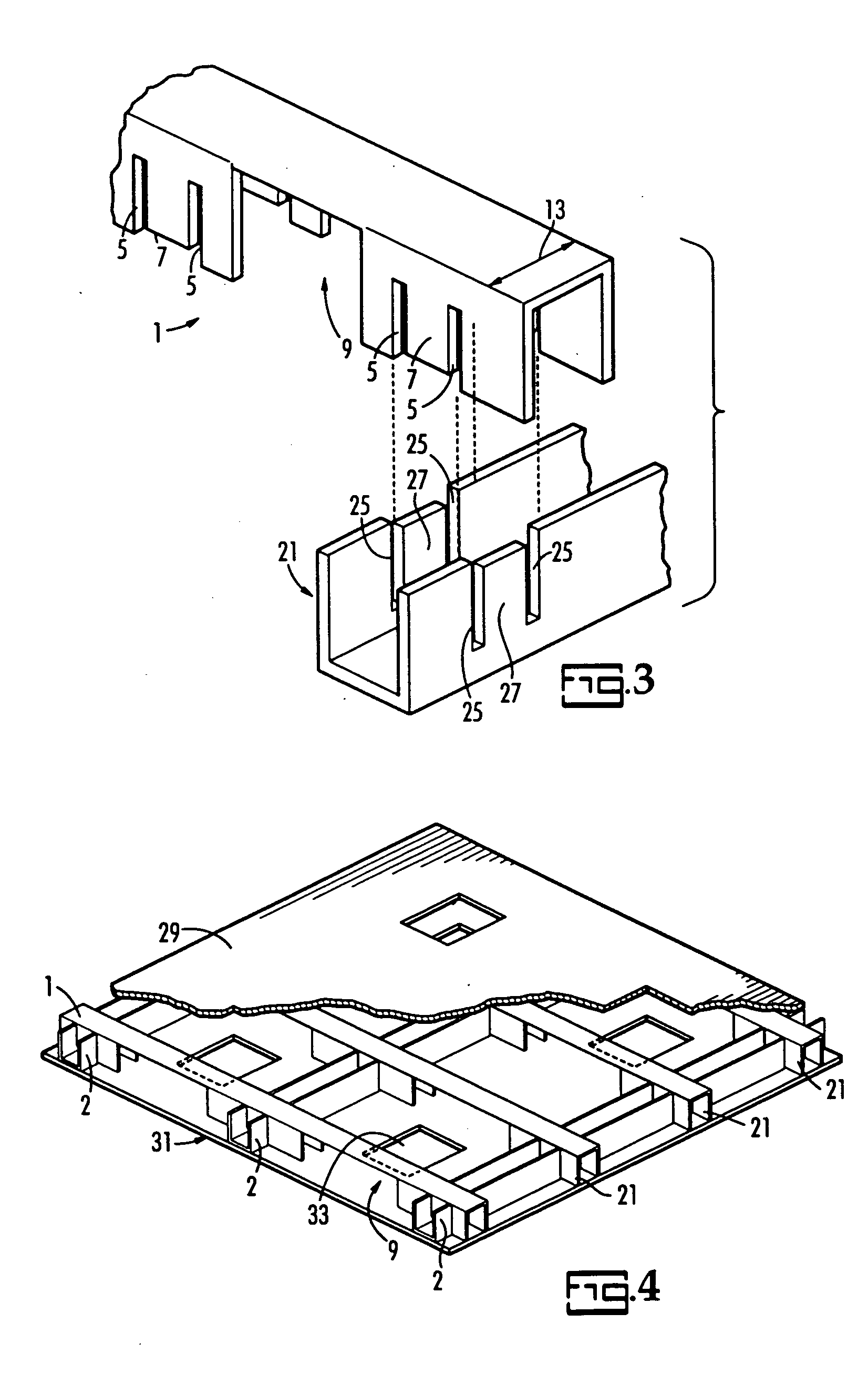

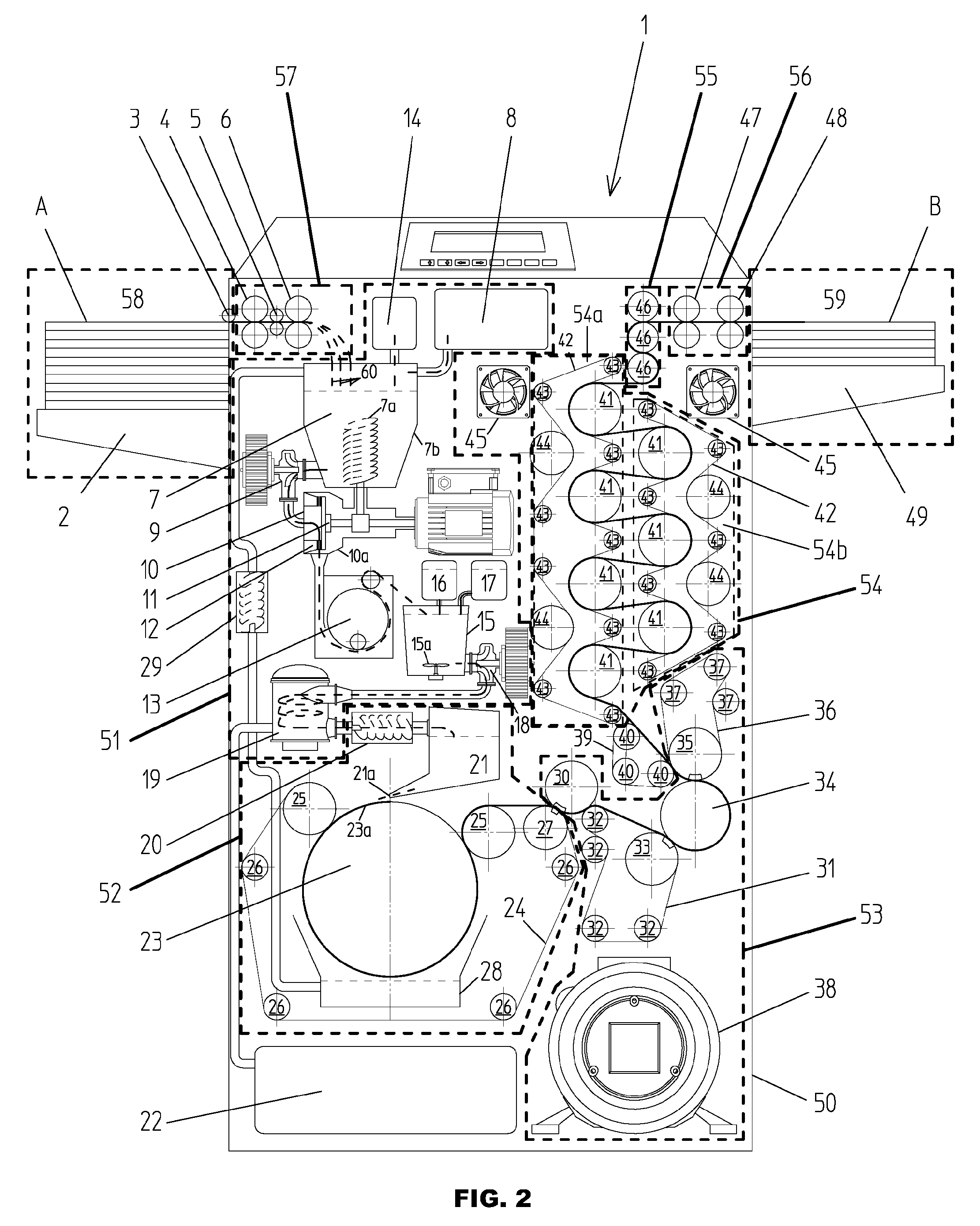

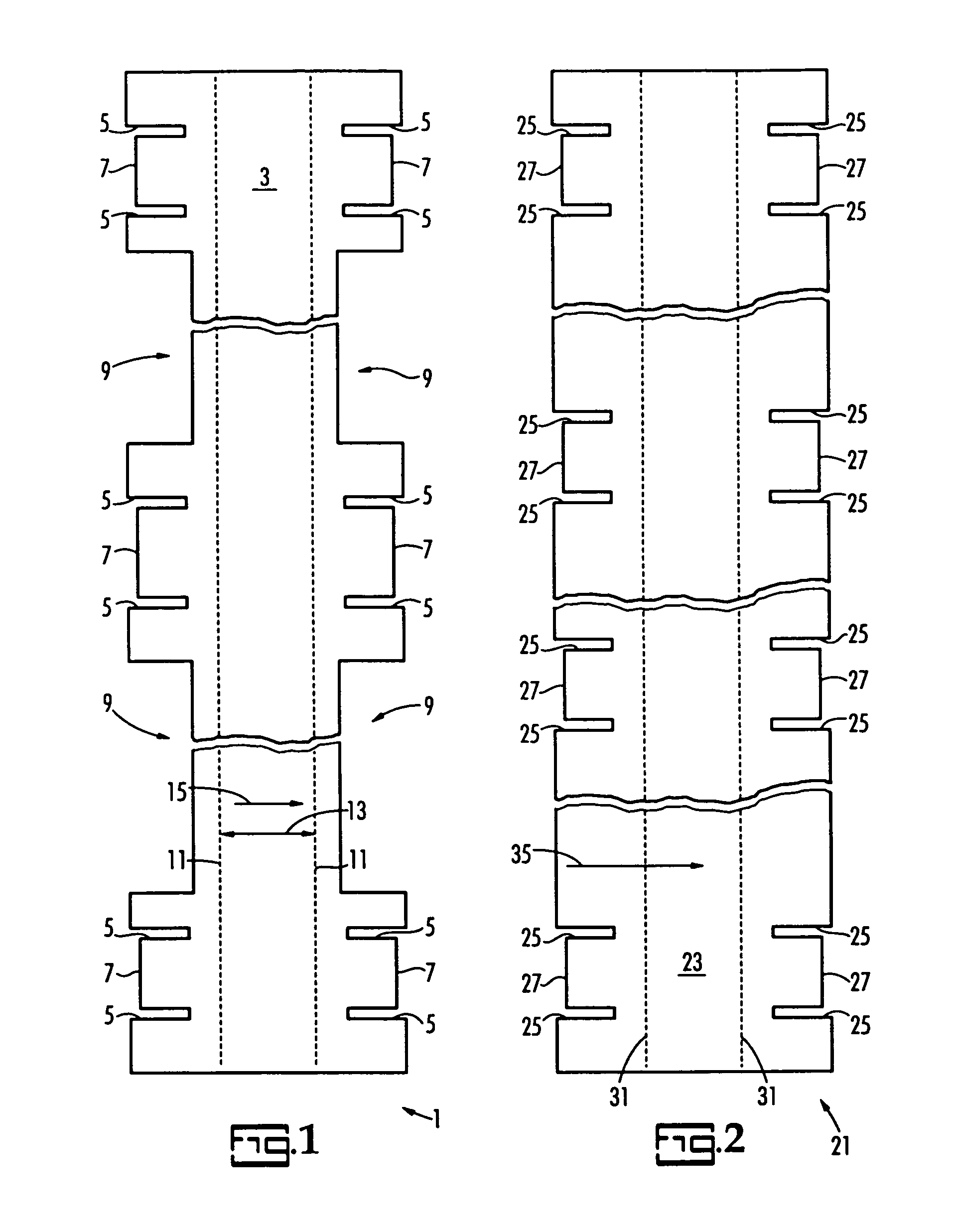

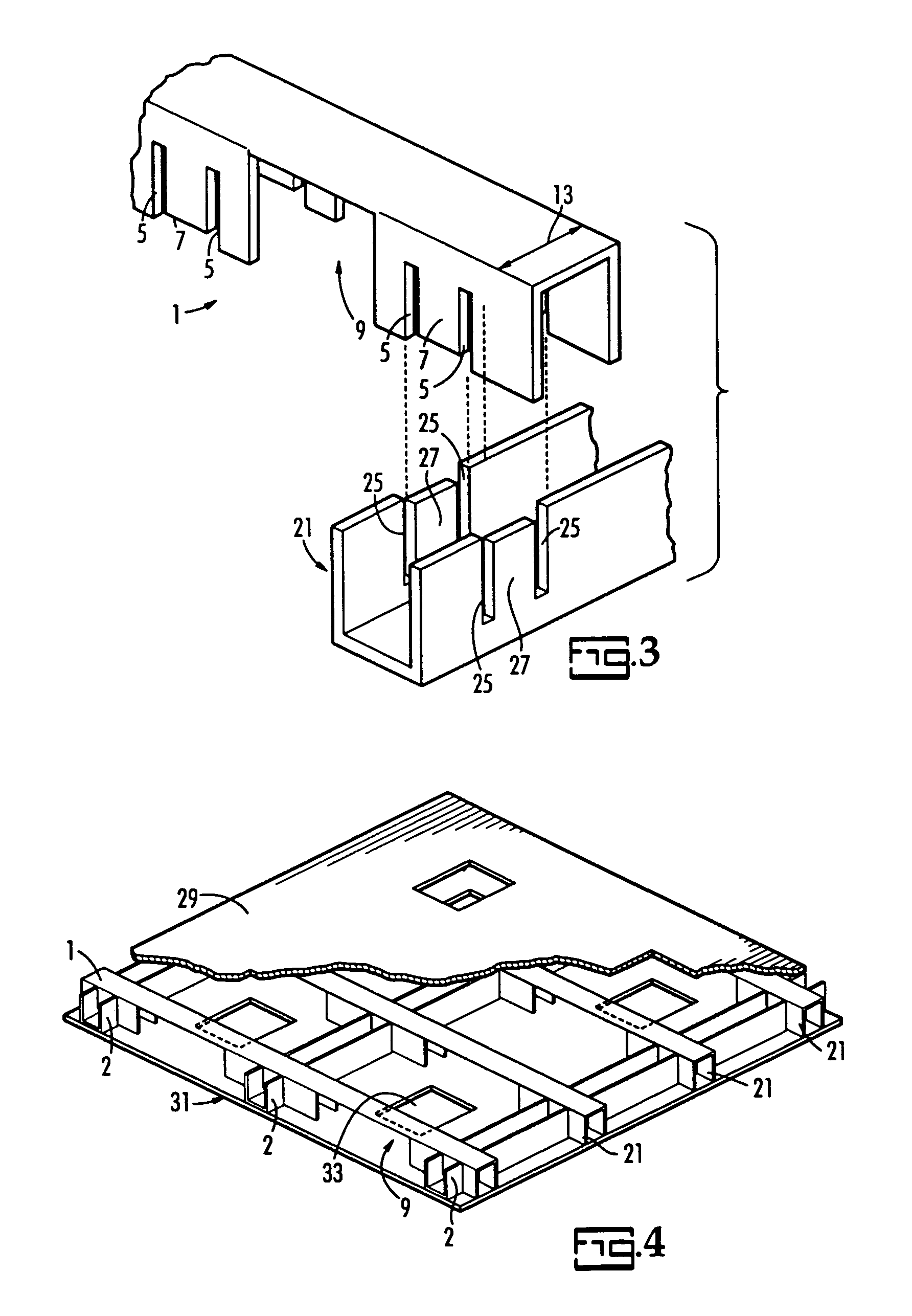

Corrugated pallet

InactiveUS20050247240A1Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces form an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

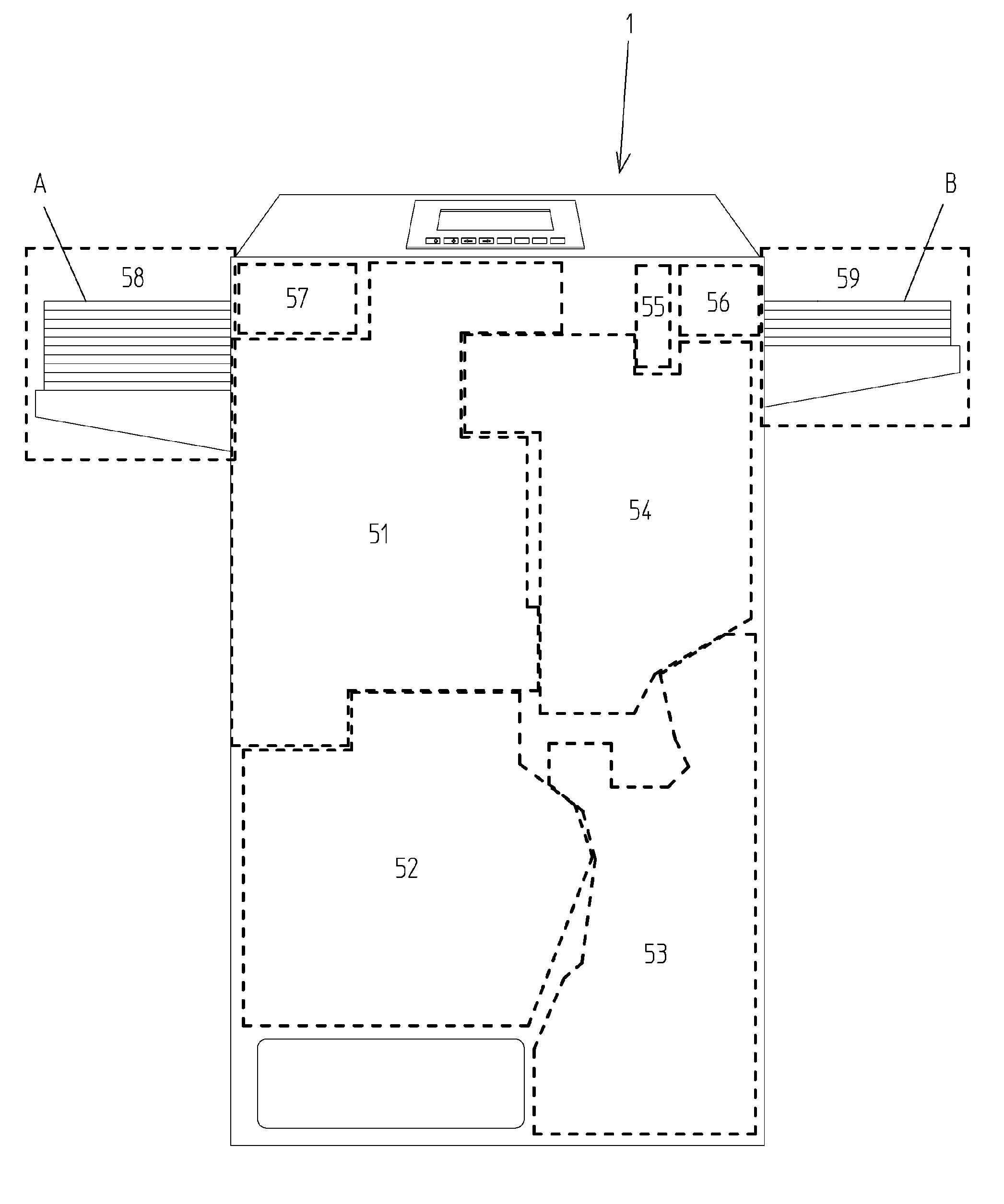

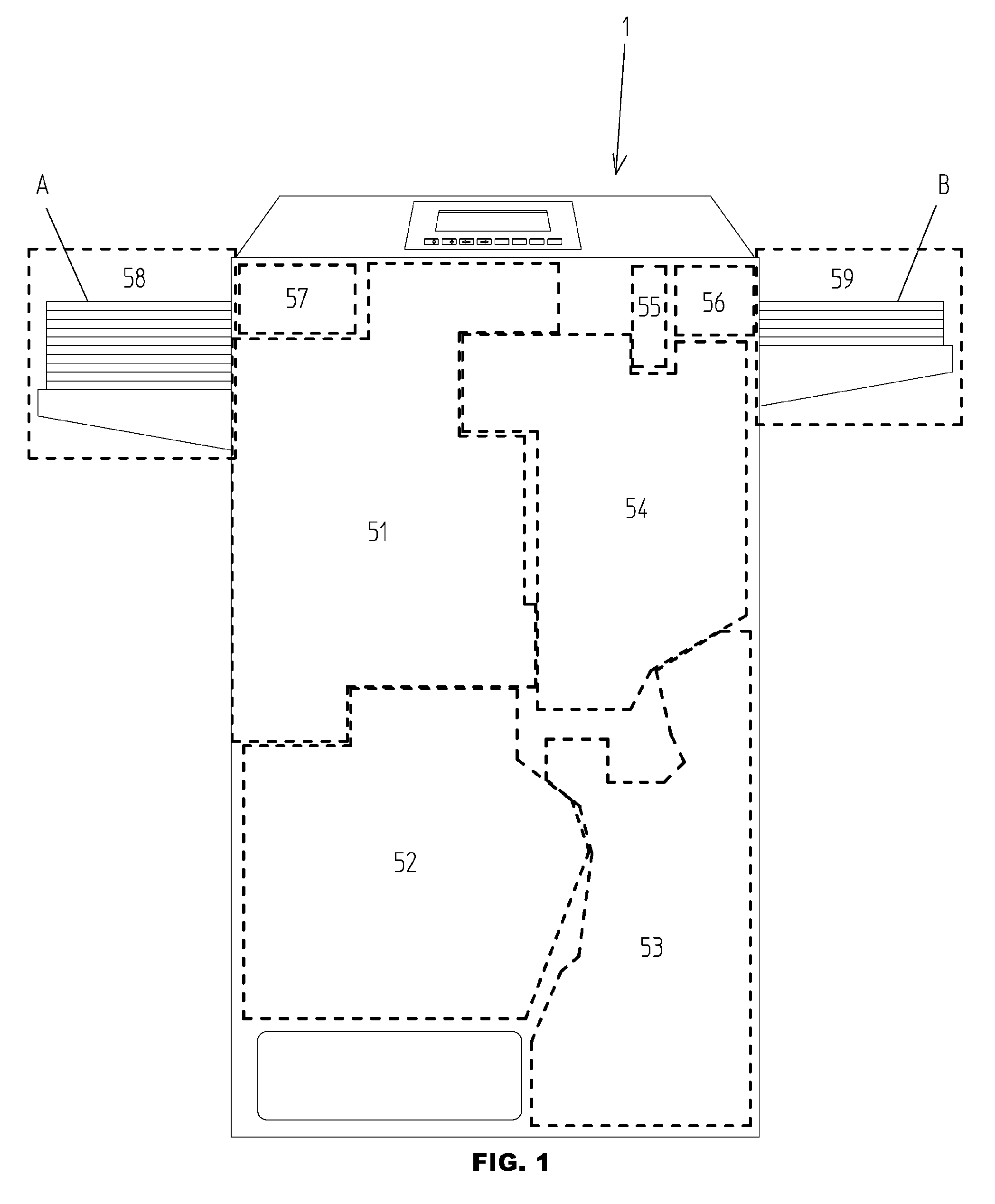

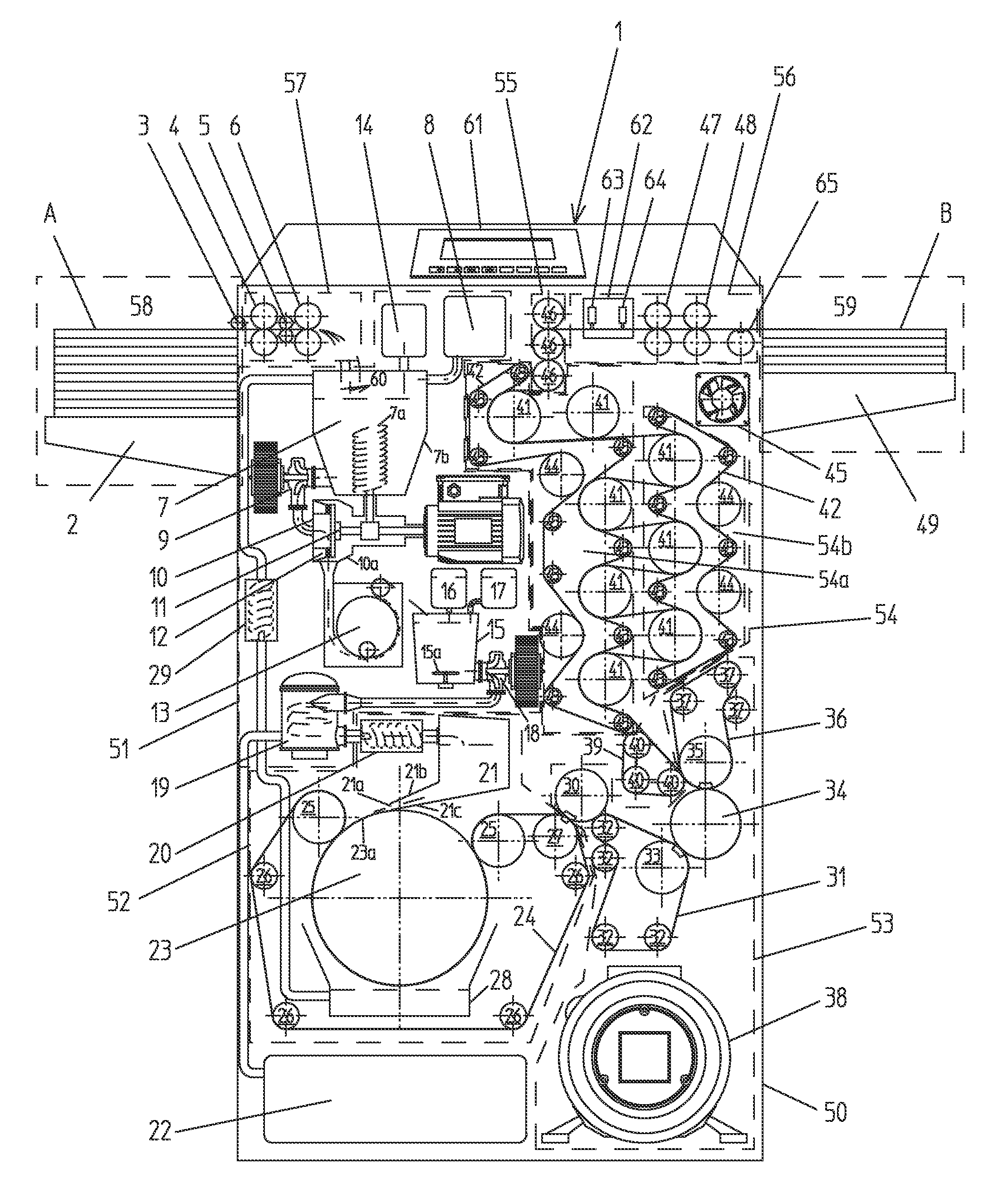

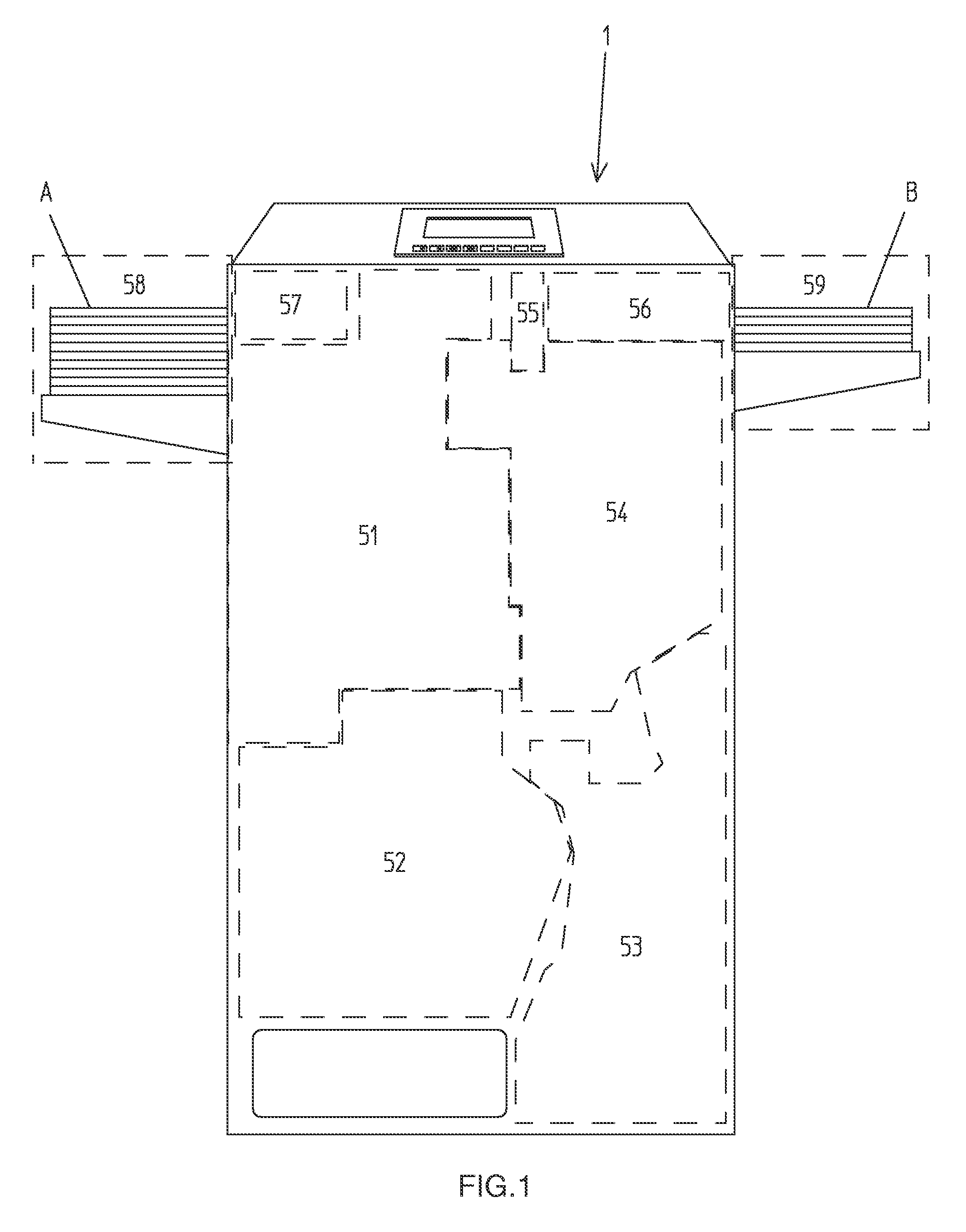

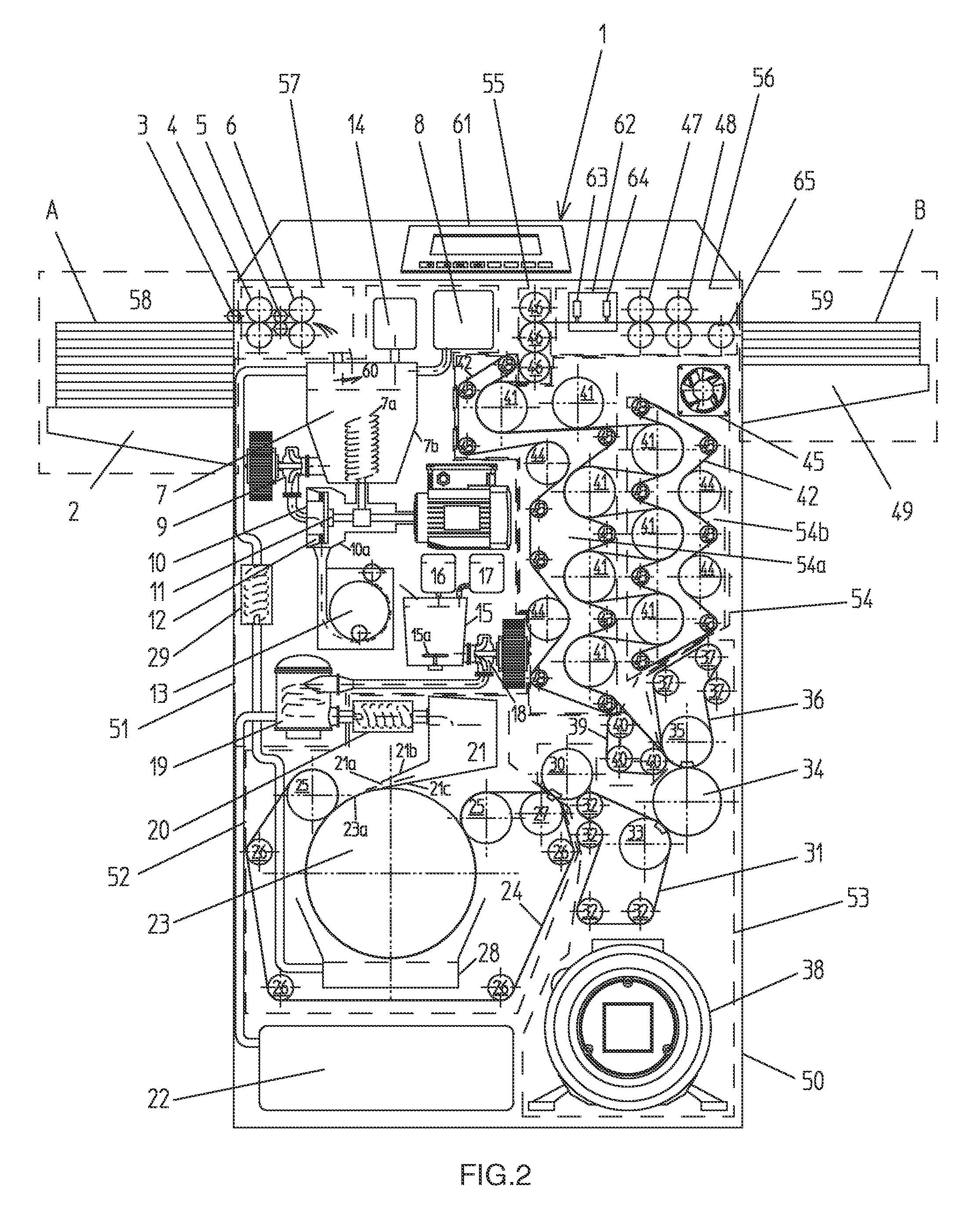

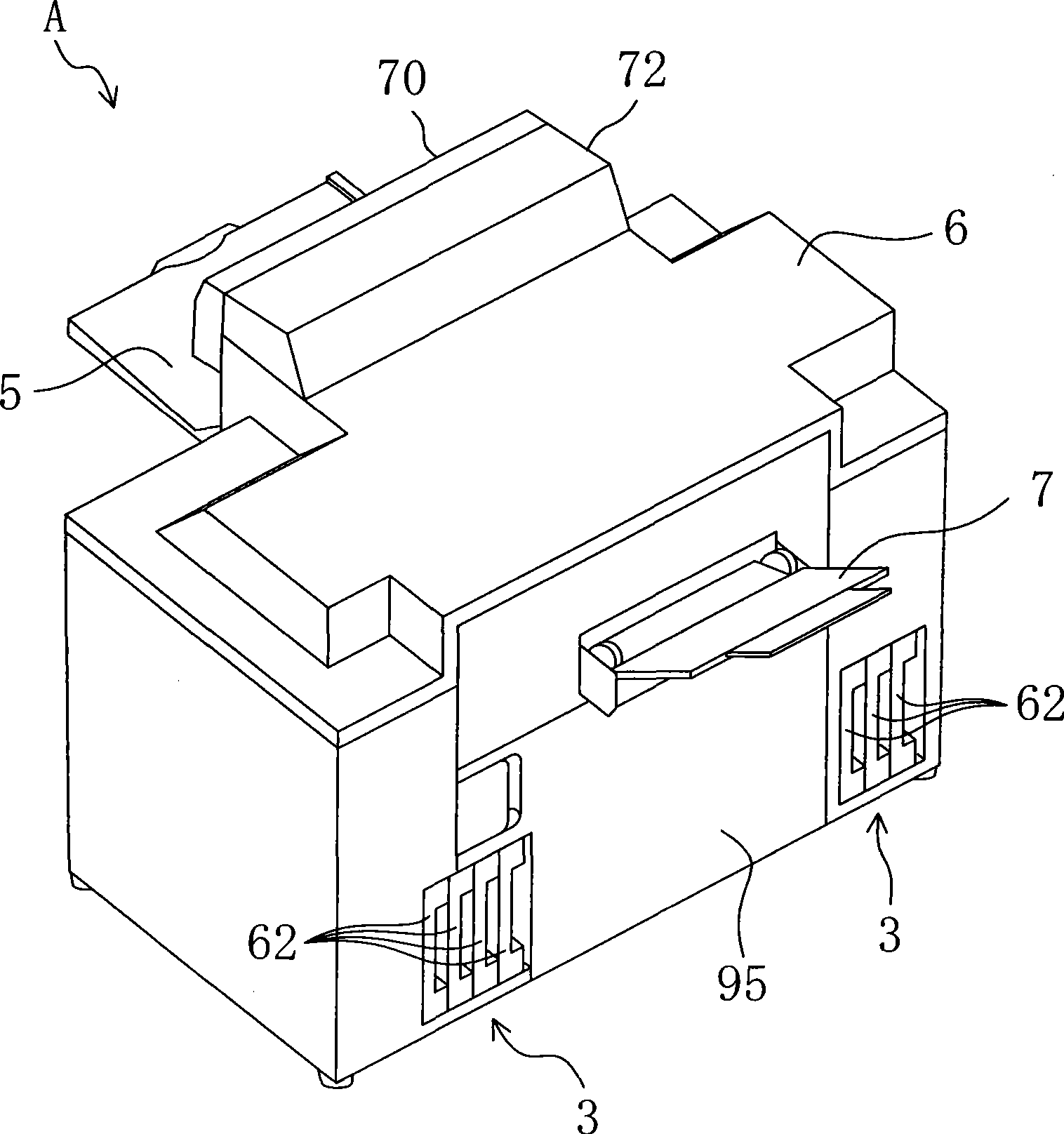

Office equipment for paper recycling

InactiveUS20070006987A1Surface strength and smoothnessDigestersPaper recyclingPaper recyclingPulp and paper industry

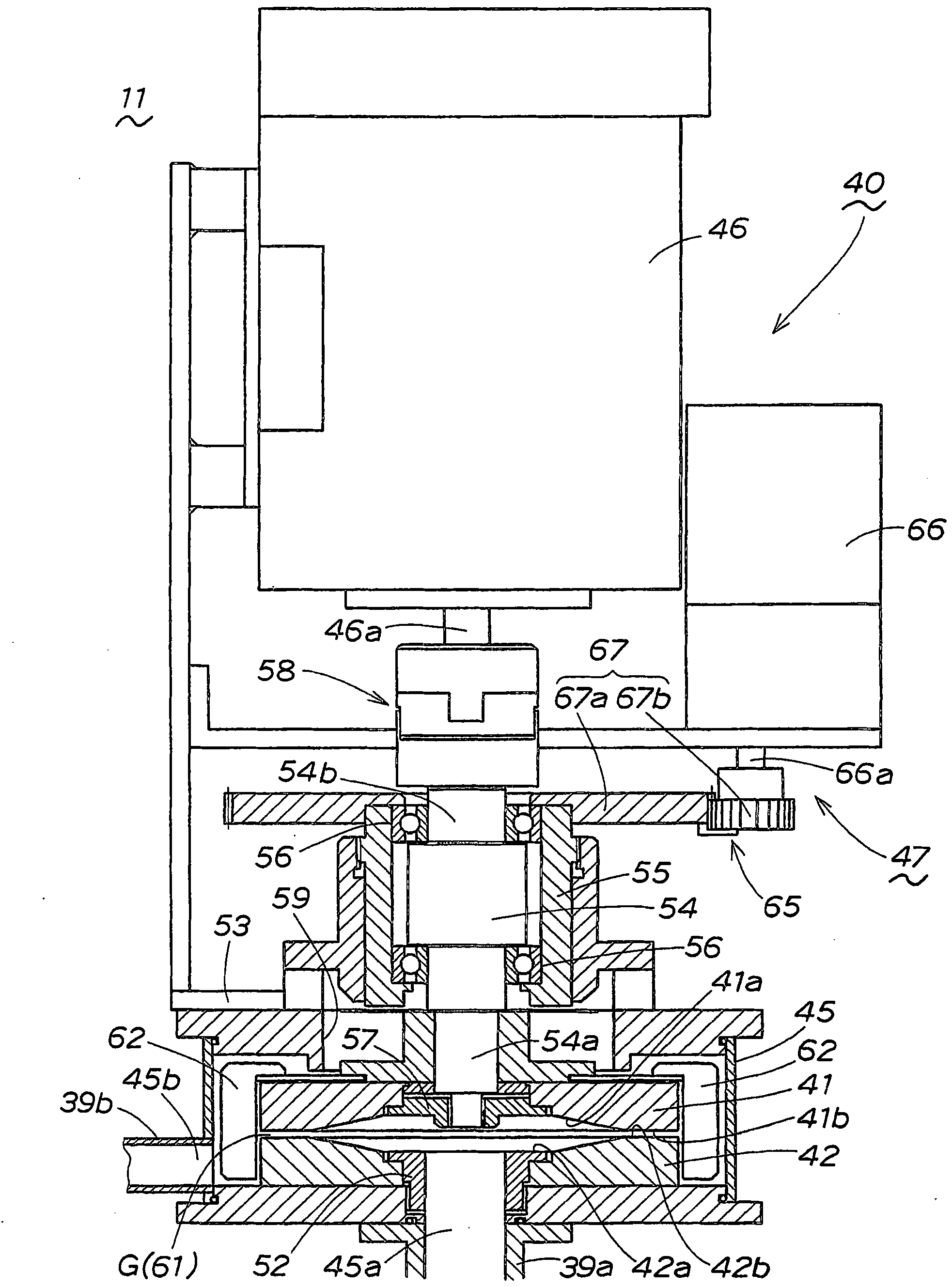

An office paper recycling apparatus makes new office paper from used paper directly in an office building. The apparatus (1) comprises a used paper-feeding portion (58); a paper-shredding portion (57); a pulping portion (51); a paper-forming portion (52); a paper-press portion (53); a paper-drying portion (54); a paper-sizing portion (55); a paper-finishing portion (56) and a final paper-collecting portion (59), where the new sheets are collected and stacked, ready to be used in office equipment.

Owner:BRAMBILLA STEFANO

Corrugated pallet

InactiveUS7000549B2Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces from an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

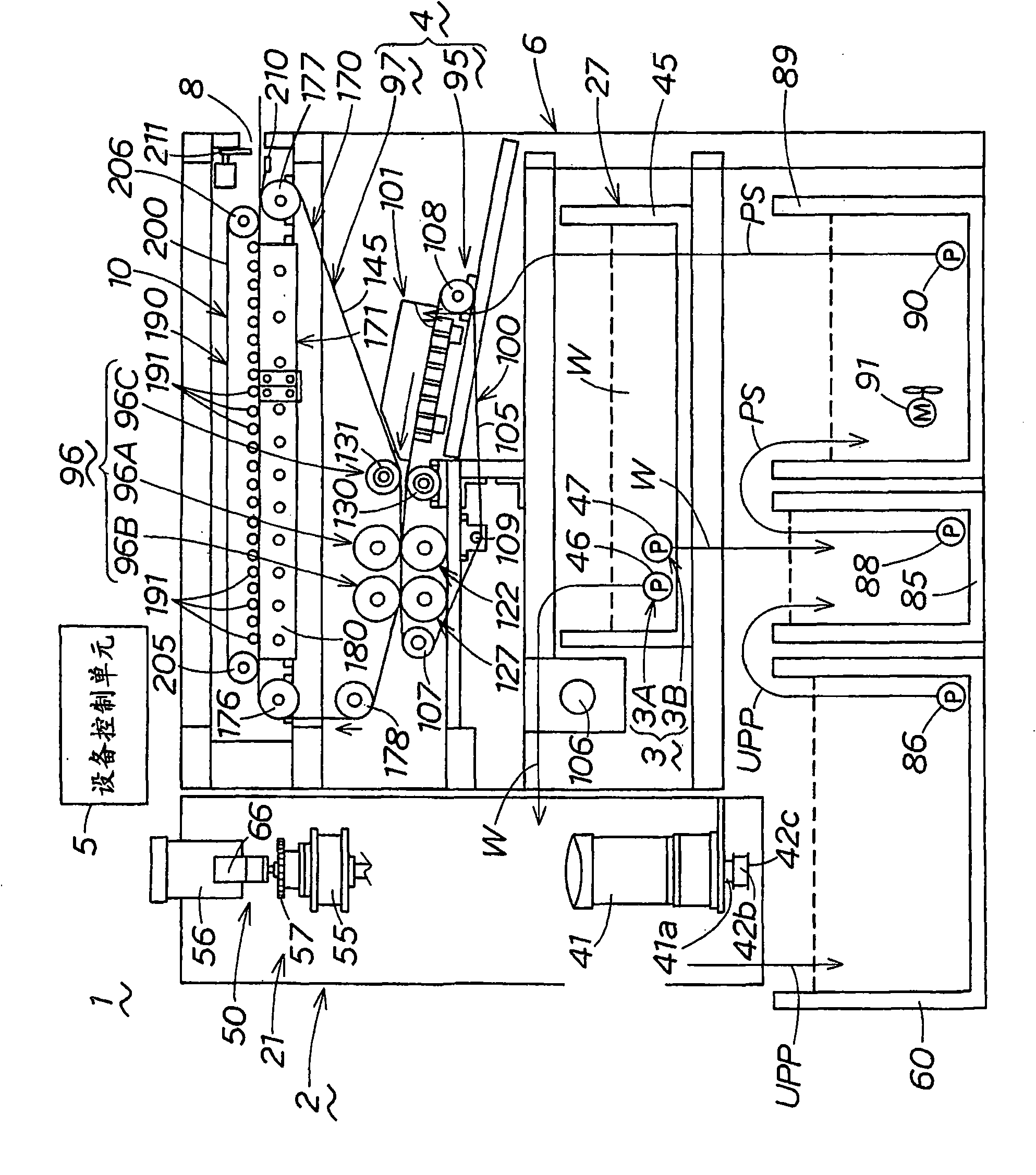

Office equipment for paper recycling

An office paper recycling apparatus within a unitary body makes new office paper for use in office equipment from used office machine paper. The apparatus comprises a paper-shredding portion; a pulping portion; a paper-forming portion; a paper-press portion; a paper-drying portion; a paper-finishing portion having a means to trim the paper, a means to adjust the paper forming process by monitoring the stiffness properties and fiber orientation and a means to remove dust debris; and, a paper-collecting portion, where the new sheets are collected and stacked, ready to be used in office equipment.

Owner:BRAMBILLA STEFANO

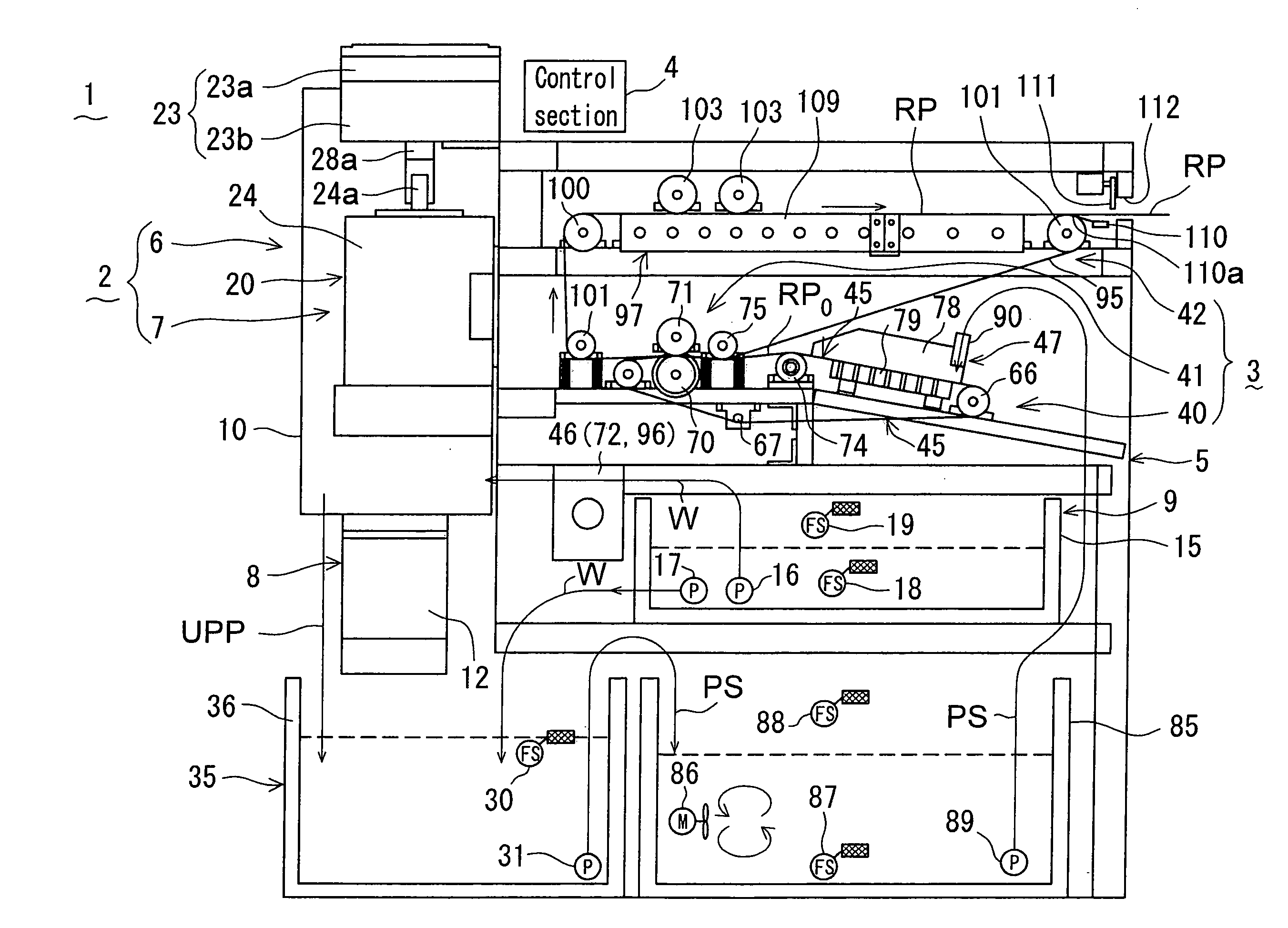

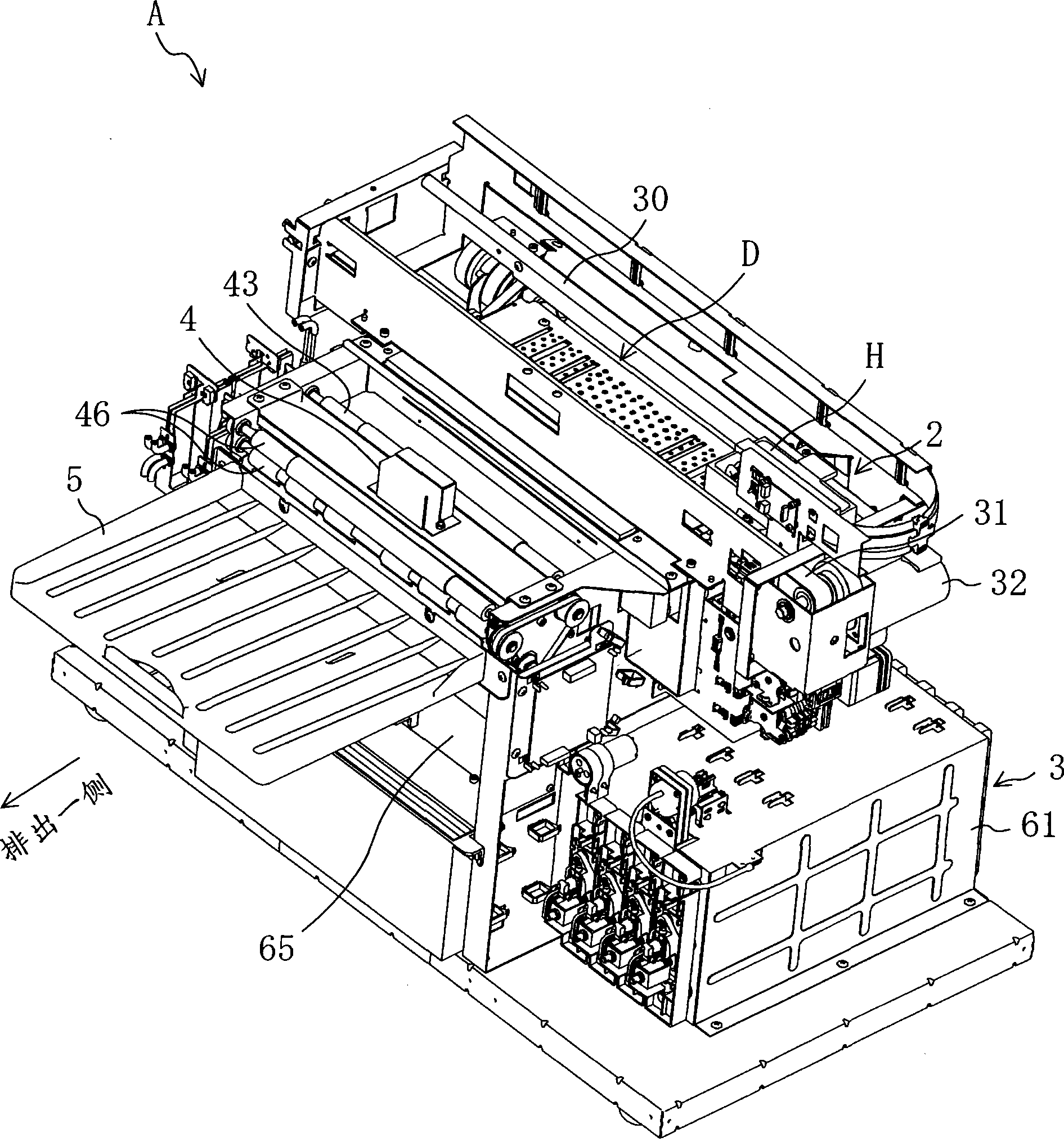

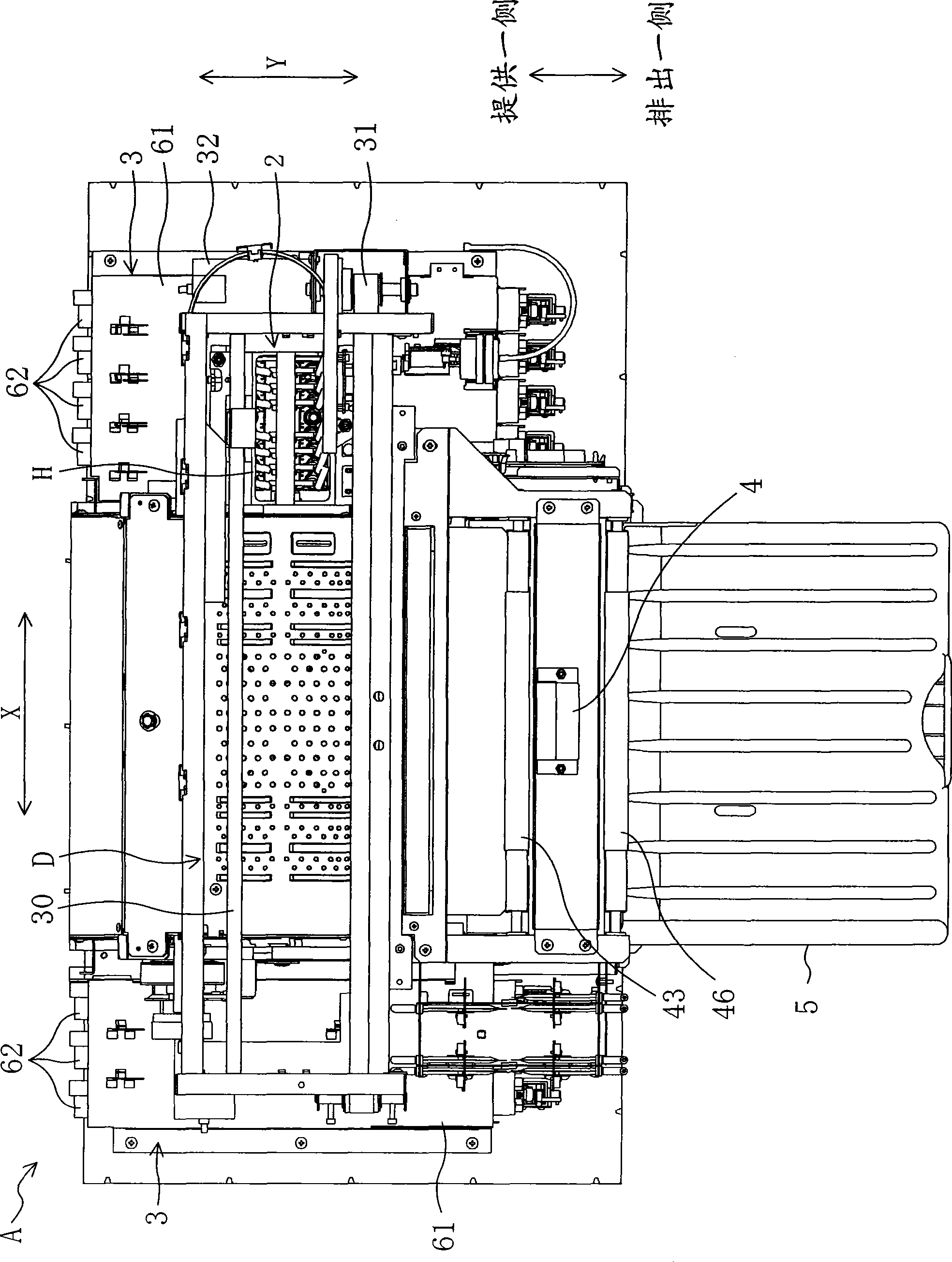

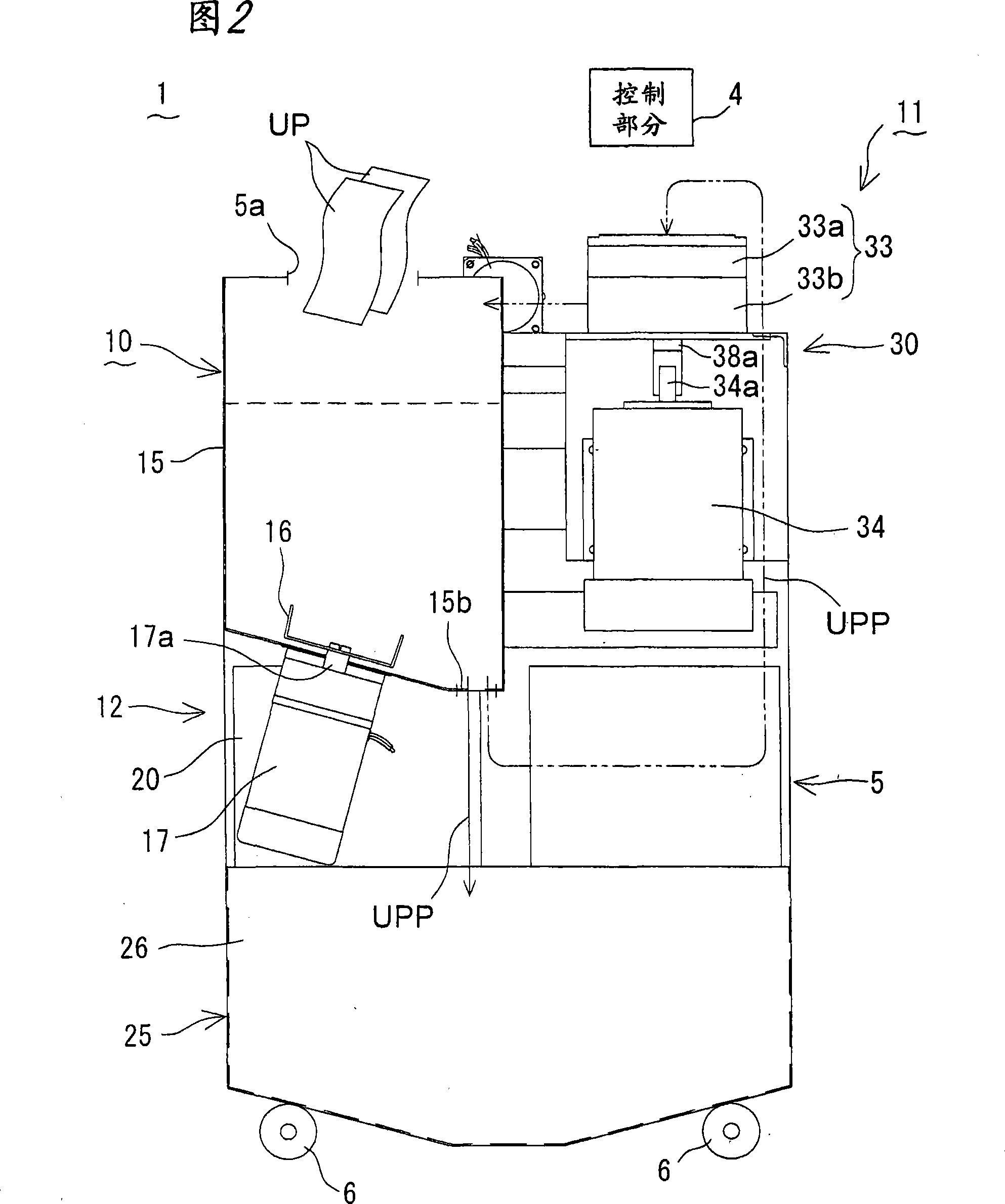

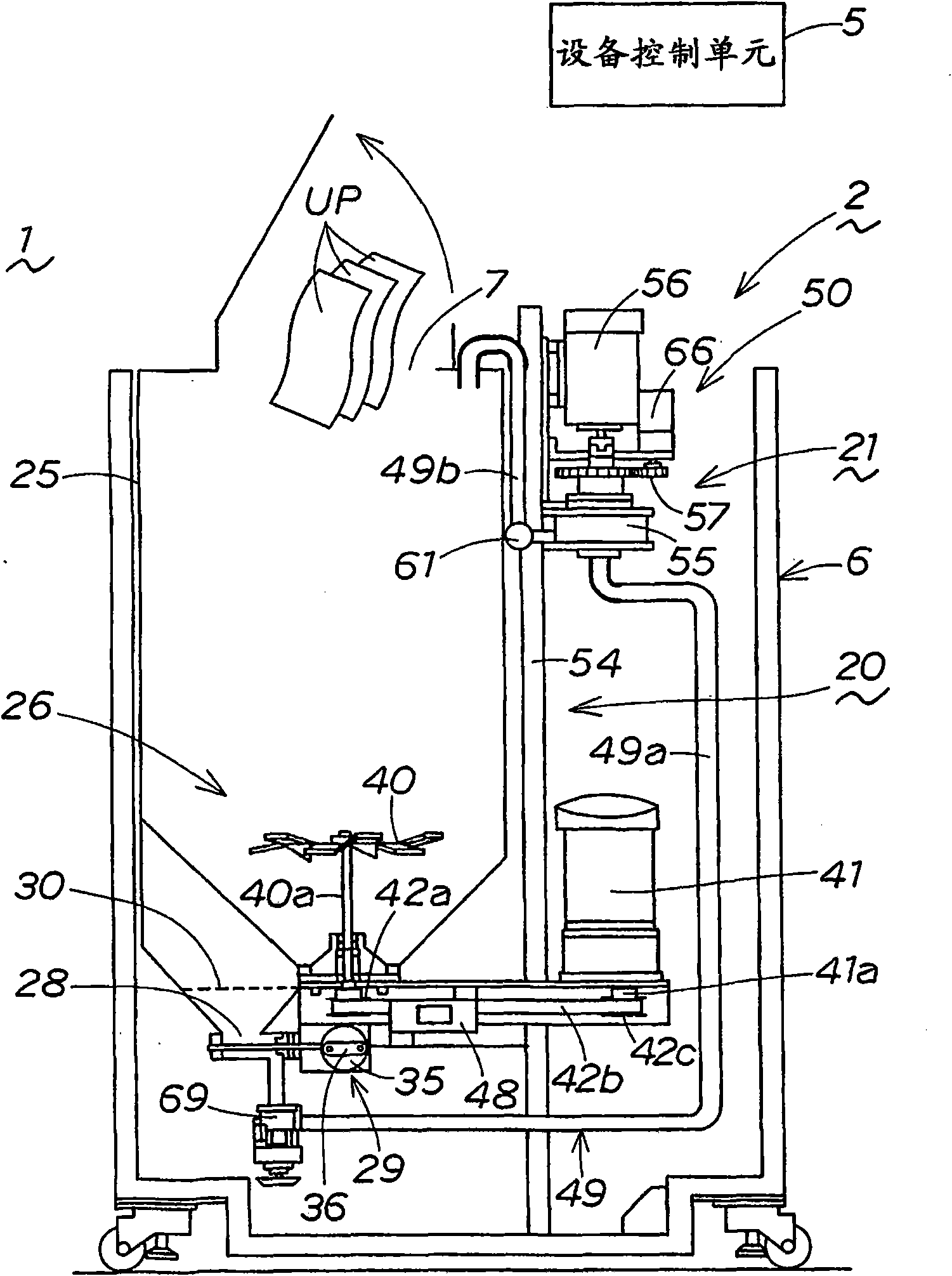

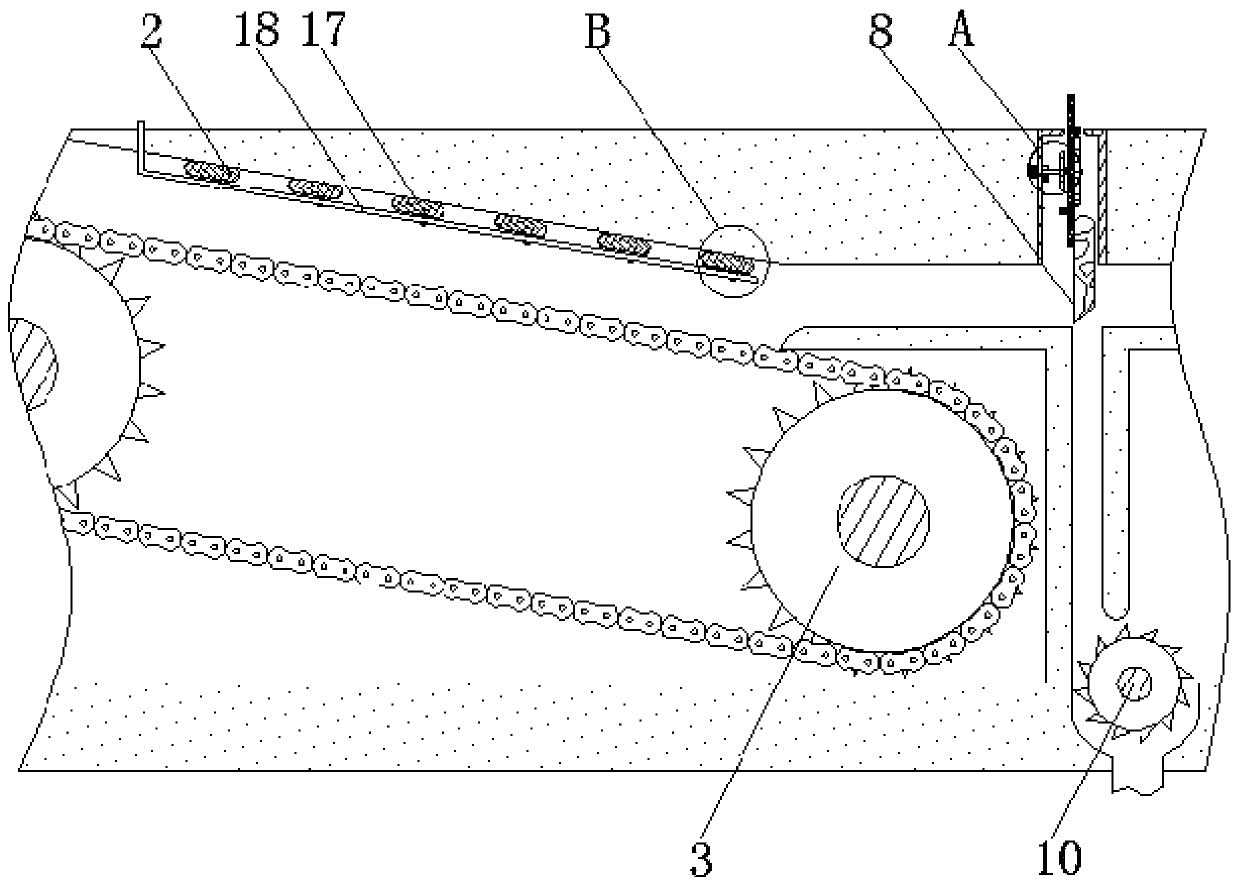

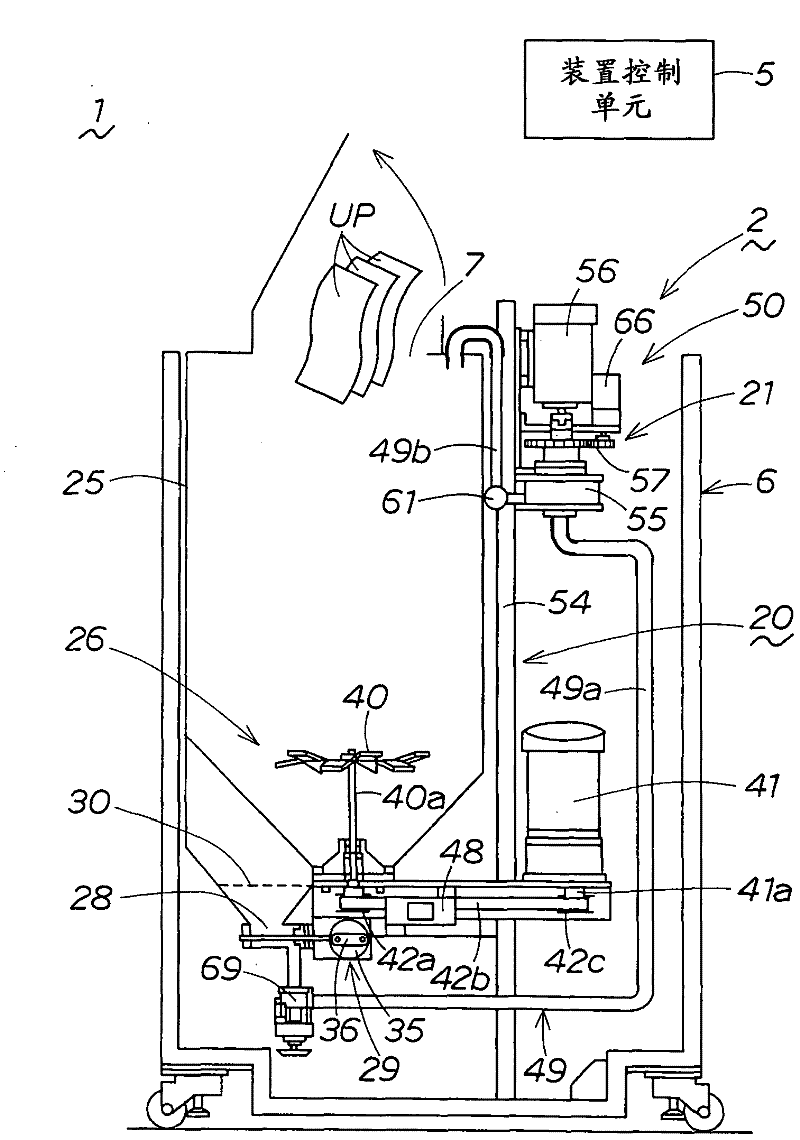

Used paper recycling apparatus and its constitutent devices

InactiveUS20070267163A1Prevent leakage of confidential informationPrevent leakage of private informationWaste product additionPulp de-wateringPaper recyclingPulp and paper industry

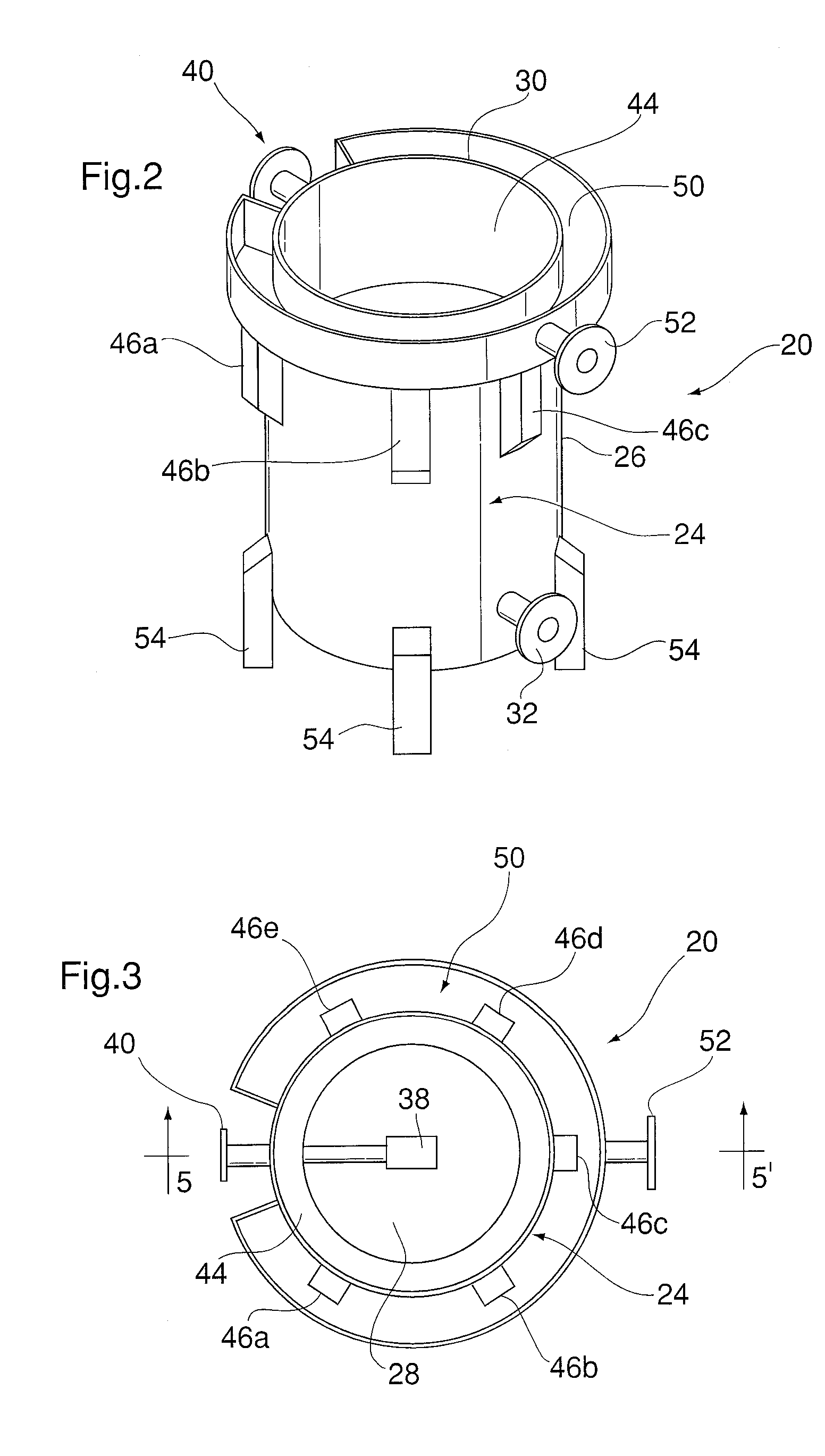

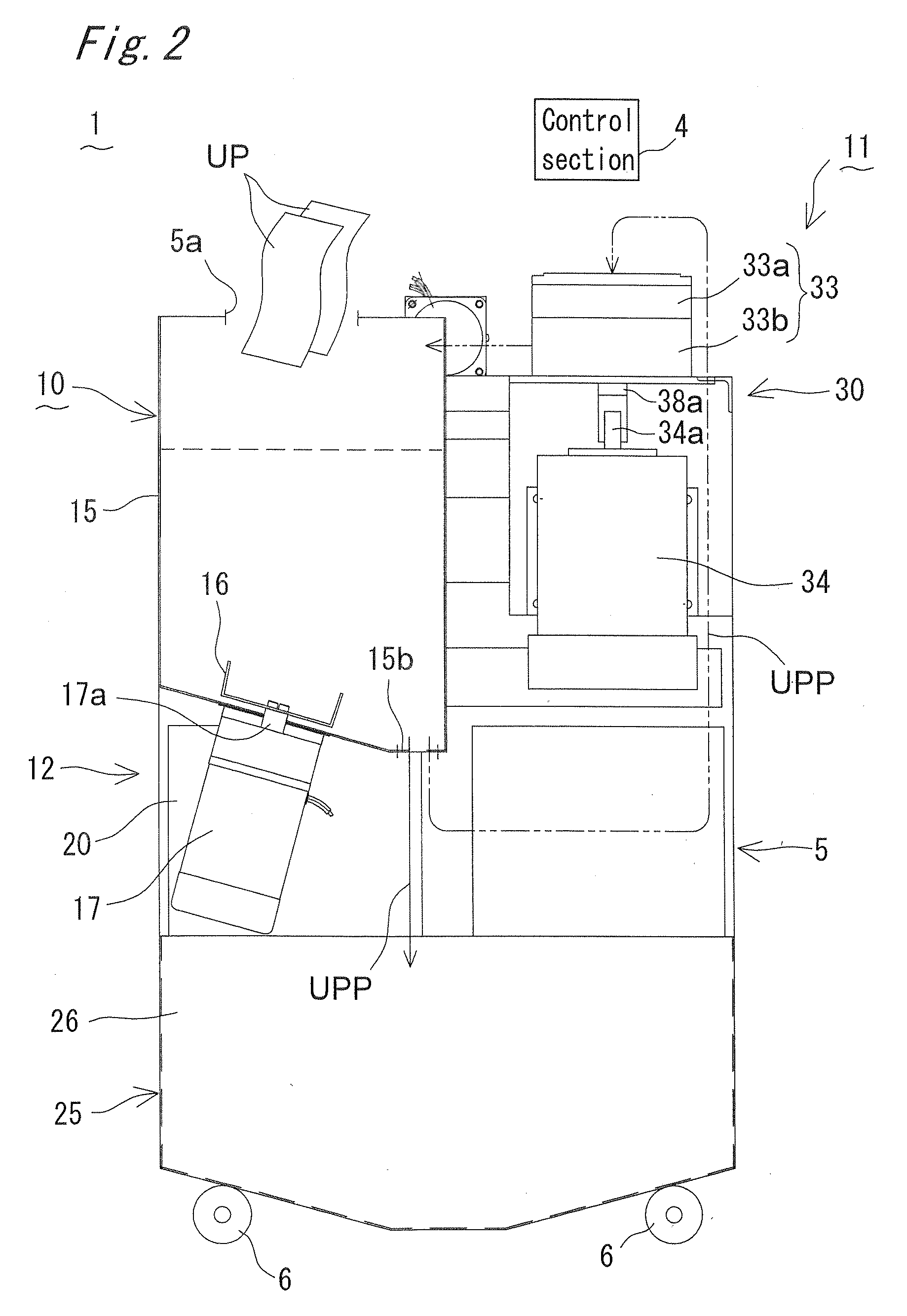

A used paper recycling apparatus being installed in a room of a small shop or the like, friendly to the environment, low in running cost, and capable of maintaining a high confidentiality. The apparatus includes, in an apparatus case of furniture size, a pulp making section for manufacturing used paper pulp by macerating and mashing used paper, a paper making section for manufacturing recycled paper by making the used paper pulp manufactured in the pulp making section, and a control section for driving and controlling the pulp making section and paper making section, in which the pulp making section comprises a macerating unit for macerating the used paper by agitating and tearing, and a mashing unit for mashing the used paper macerated in the macerating unit, and the mashing machine of the mashing unit has mashing members rotating relatively being disposed oppositely across a slight mashing clearance, and the opposing faces of these mashing members cooperate to form a mashing action surface, and the used paper passing the mashing clearance is pressurized and mashed by the mashing action surface, and the inks forming characters and patterns on the used paper are pulverized.

Owner:VIEWDLE INC

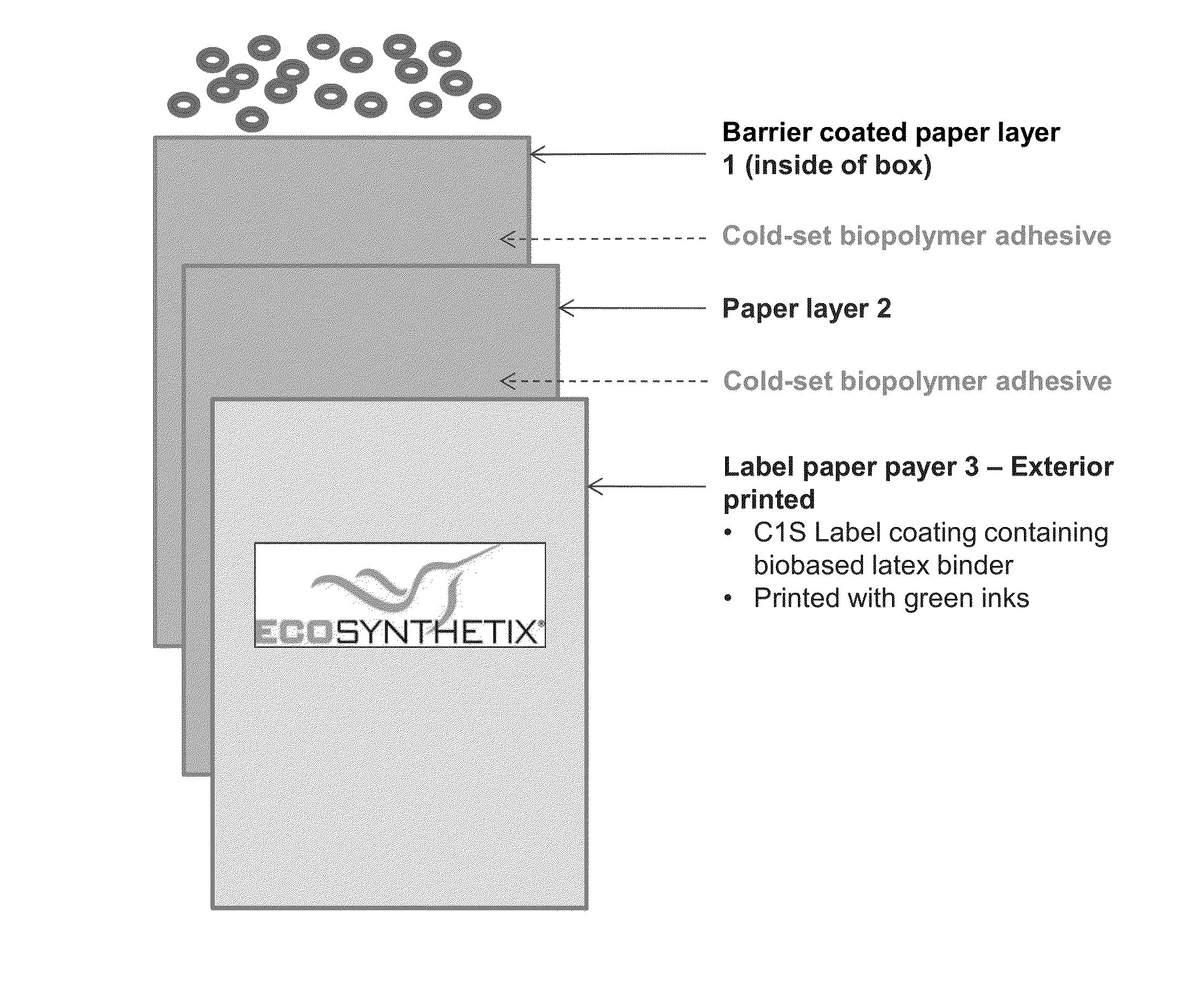

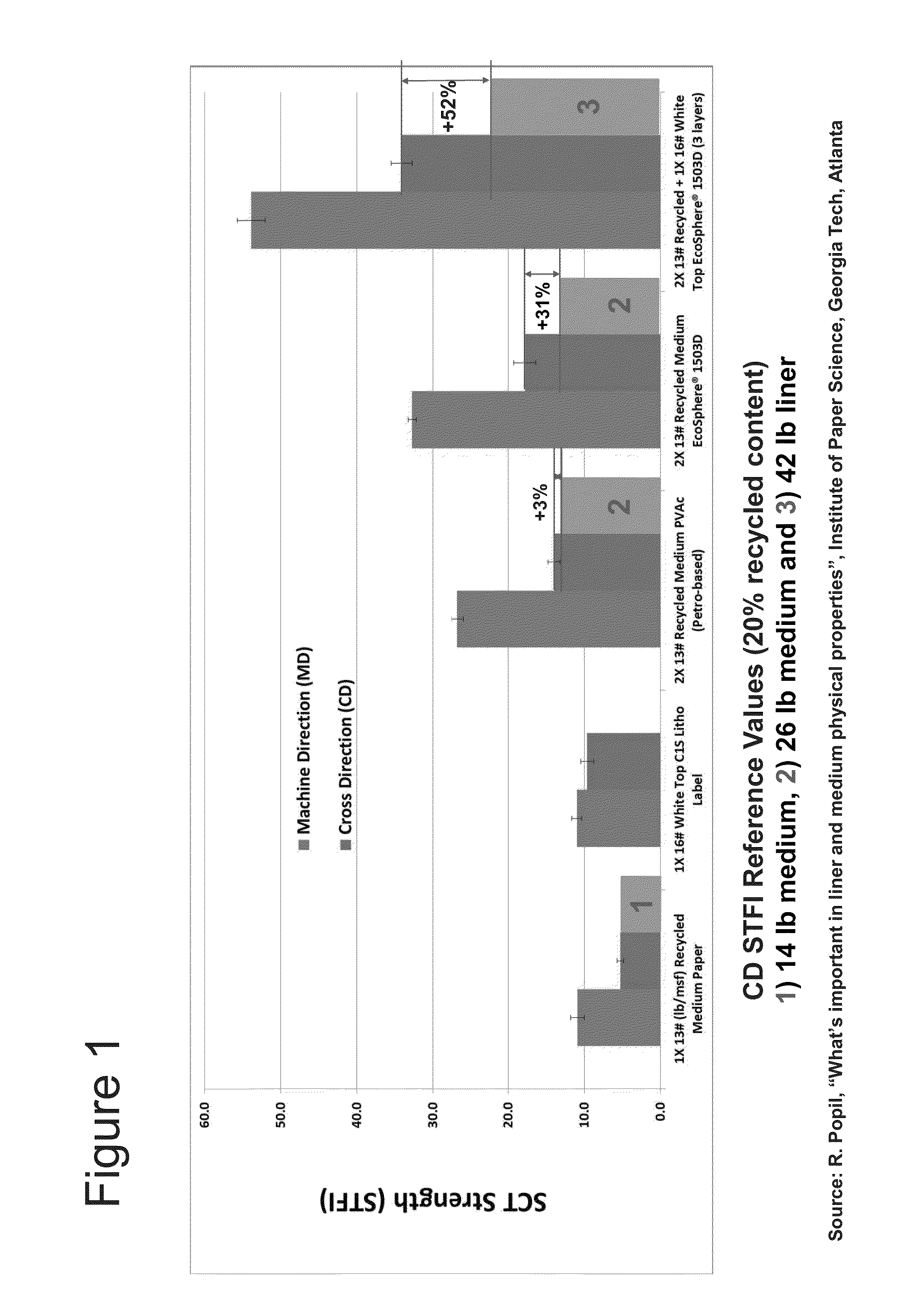

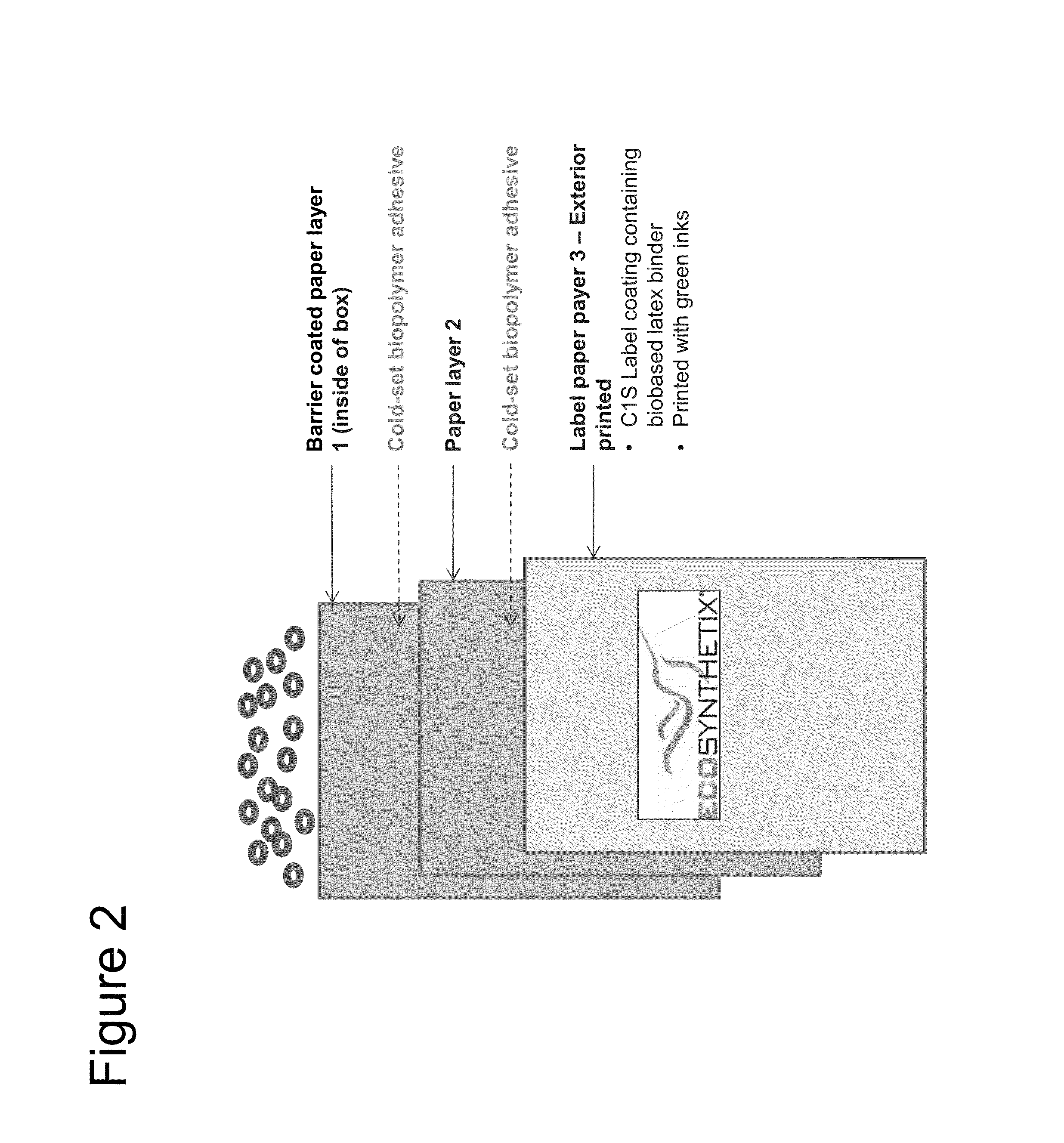

Cold-set biobased laminating adhesive for paper or paperboard products, and packaging materials

InactiveUS20160194527A1Non-macromolecular adhesive additivesStarch derivtive adhesivesFiberPaper recycling

This specification relates to cold-set biobased adhesive compositions, comprising aqueous formulations of biopolymers, optionally with alkaline additives, optionally fortified with high-aspect-ratio inorganic and organic fillers, fibers and nanofibers, optionally with barrier-inducing additives. The adhesive may be used, for example, as a cold-set, preferably biobased, laminating adhesive. In particular, the laminating adhesive may be used to create liner and / or medium paperboard products for light-weight paperboard and corrugated boxboard materials that, in some examples, have enhanced strength and / or barrier properties as compared with similar weight paperboard products. These laminated paperboard and corrugated boxboard materials are used, for example, as light weight packaging materials that are compatible with paper recycling and composting operations. In the context of this abstract, the term “lamination” or “laminating” relates to the adhesion of two flat (rather than pre-corrugated) paper surfaces, i.e. the gluing together of two continuous sheets of paper or liner or medium paperboard.

Owner:ECOSYNTHETIX INC

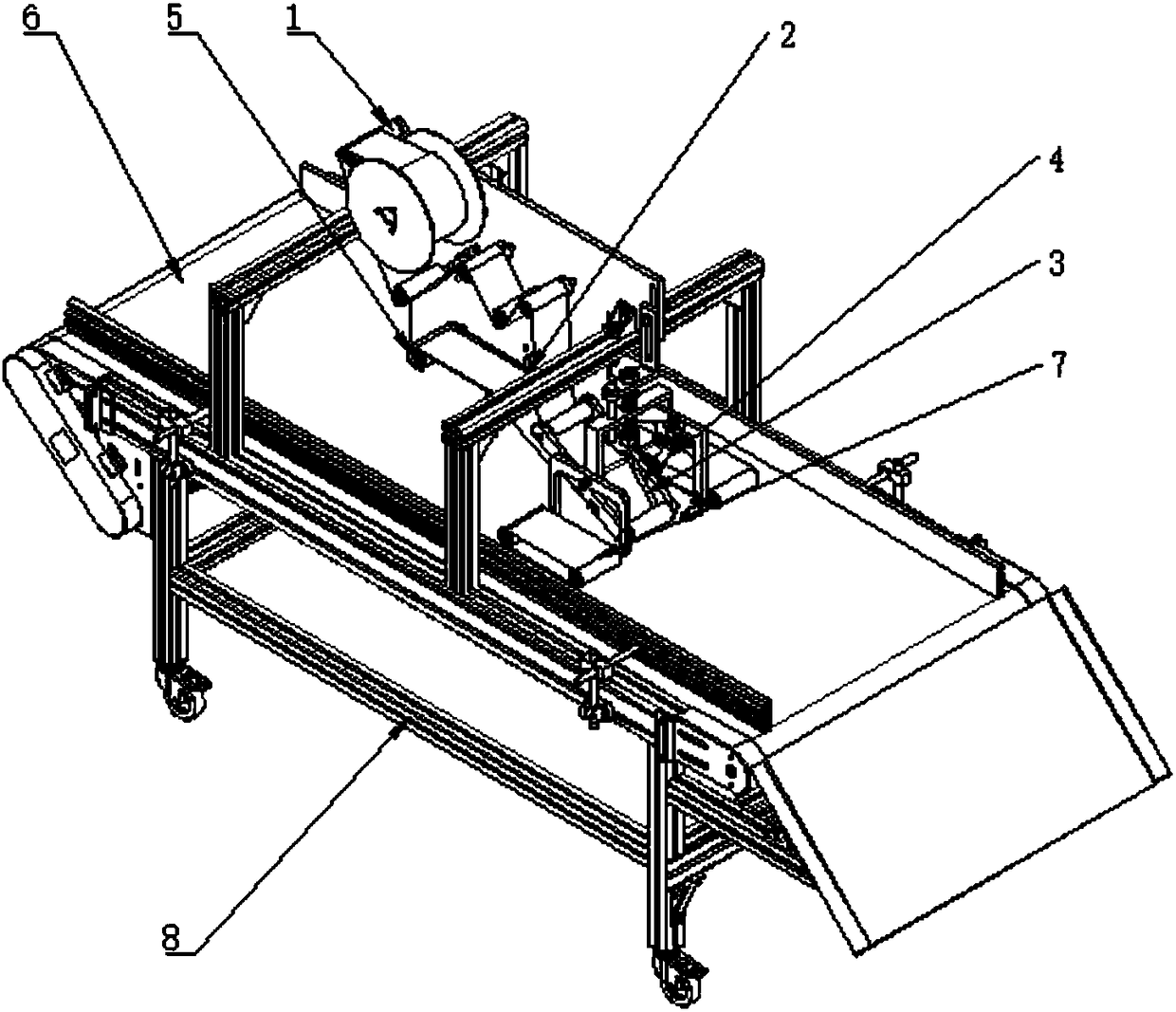

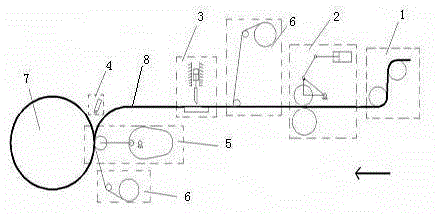

Souvenir bag labeling machine

ActiveCN108190164AAdapt to market demandEasy to installLabelling machinesWebs handlingPaper recyclingEngineering

The invention relates to a souvenir bag labeling machine. A souvenir bag conveying device is mounted on a rack and provided with a photoelectric sensor. A braking mechanism is mounted on the souvenirbag conveying device, and a drawing mechanism is mounted blow the front portion of the braking mechanism. A label peeling mechanism and a pneumatic label covering mechanism are mounted below the frontportion of the drawing mechanism, and a label flattening roller is mounted at the front end of the pneumatic label covering mechanism. A souvenir bag compressing device is mounted between the label peeling mechanism and the souvenir bag conveying device, and a wax paper recycling mechanism is mounted below the drawing mechanism. Wax paper separated from a label is recycled and wound around a label rolling device of the wax paper recycling mechanism through a drawing shaft and a pressing roll of the drawing mechanism. According to the souvenir bag labeling machine, the labeling work of souvenir bags can be automatically completed, and a synchronous contact pasting method of a brush-pasting method is adopted for achieving the aim of reliable and efficient labeling; and the whole mechanism is high in movement speed, simple in structure and convenient to operate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

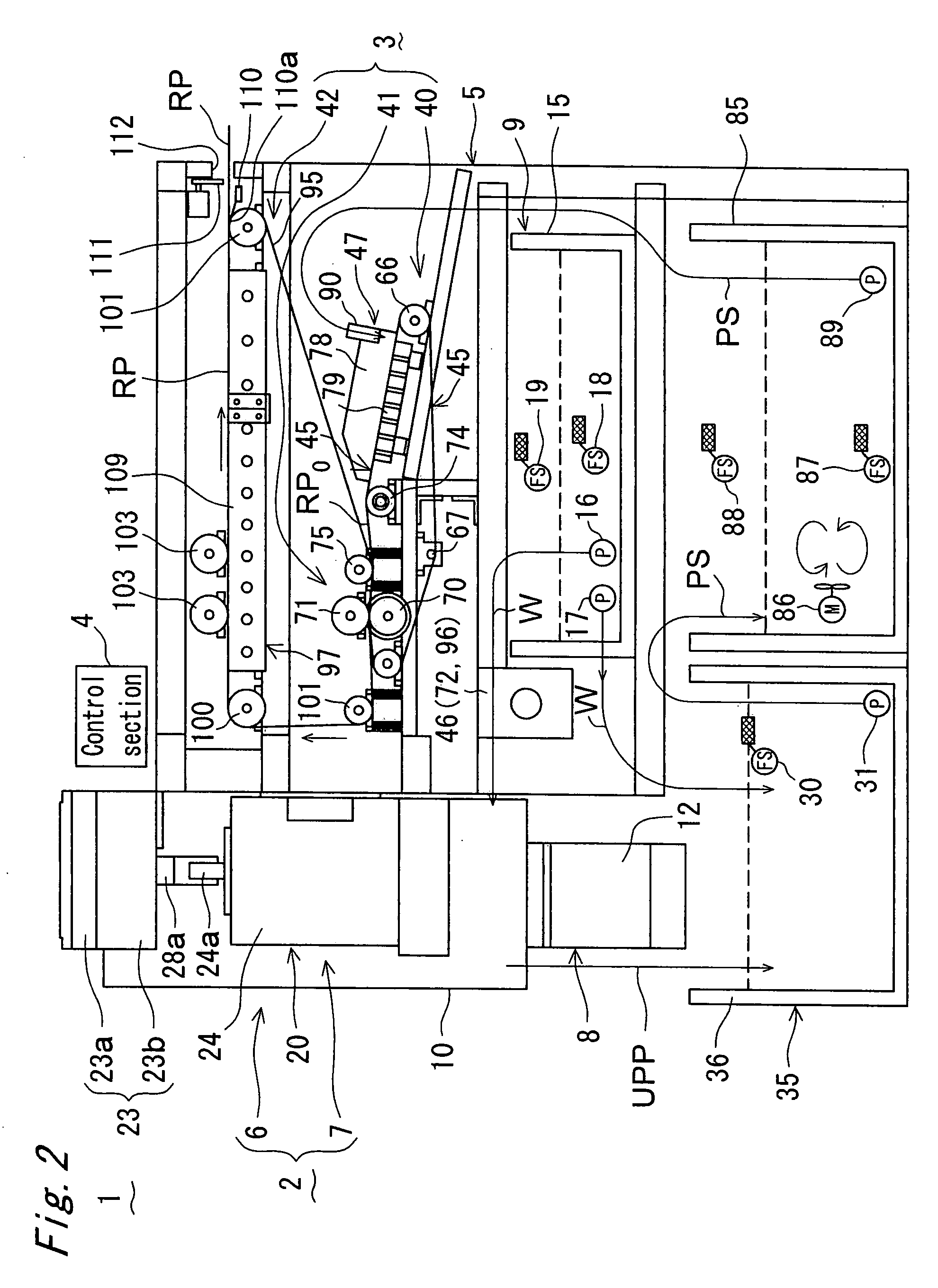

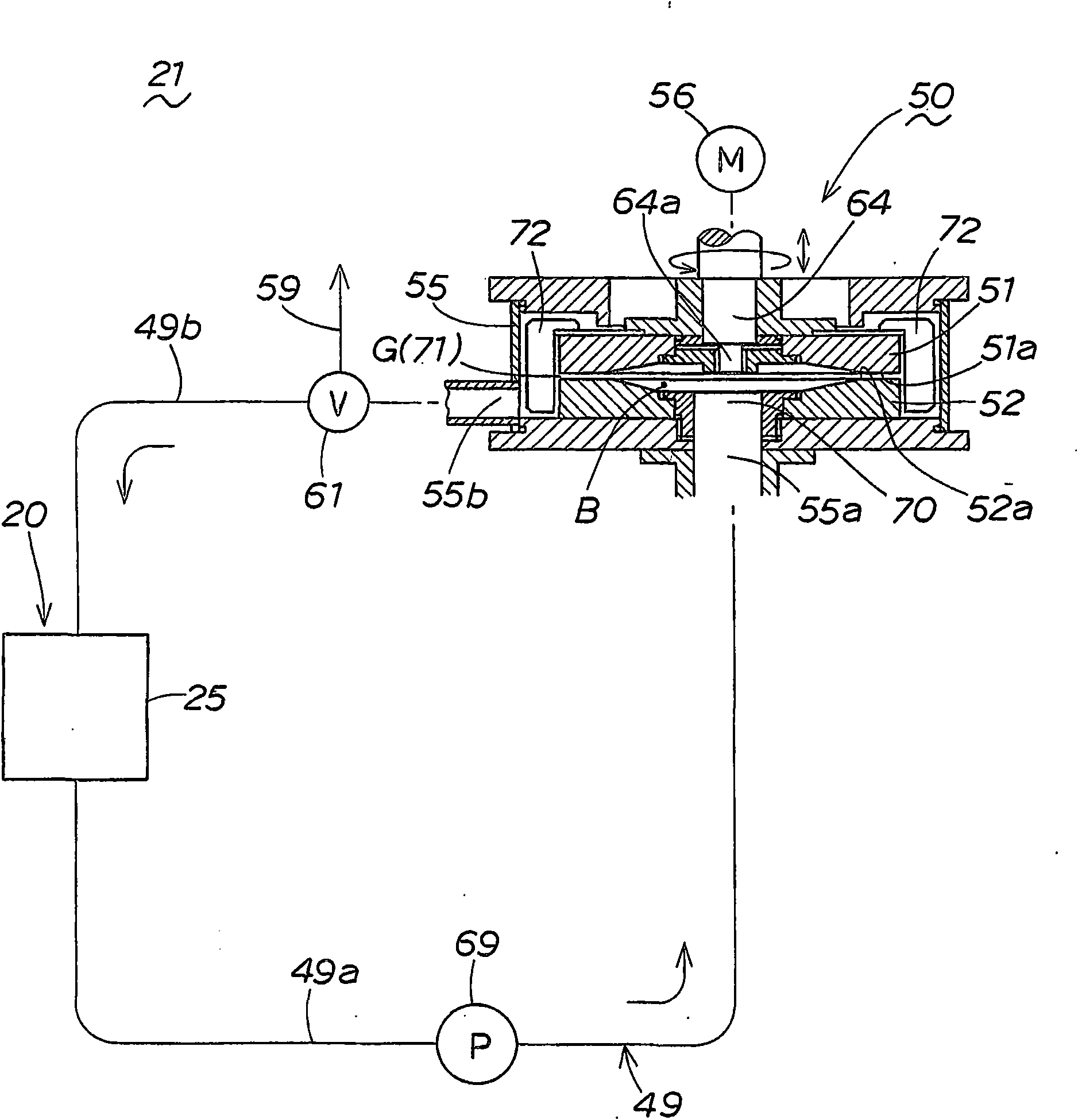

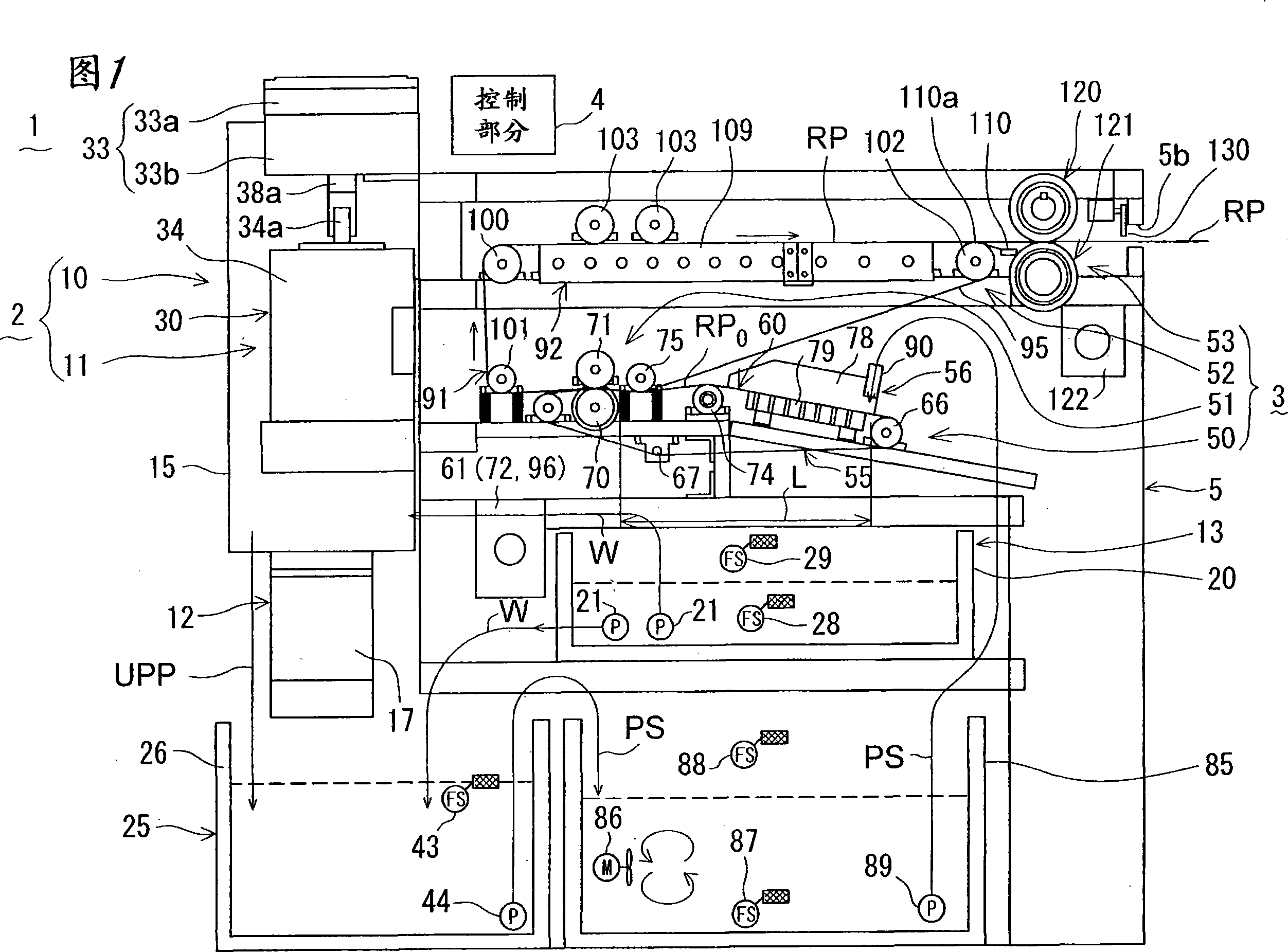

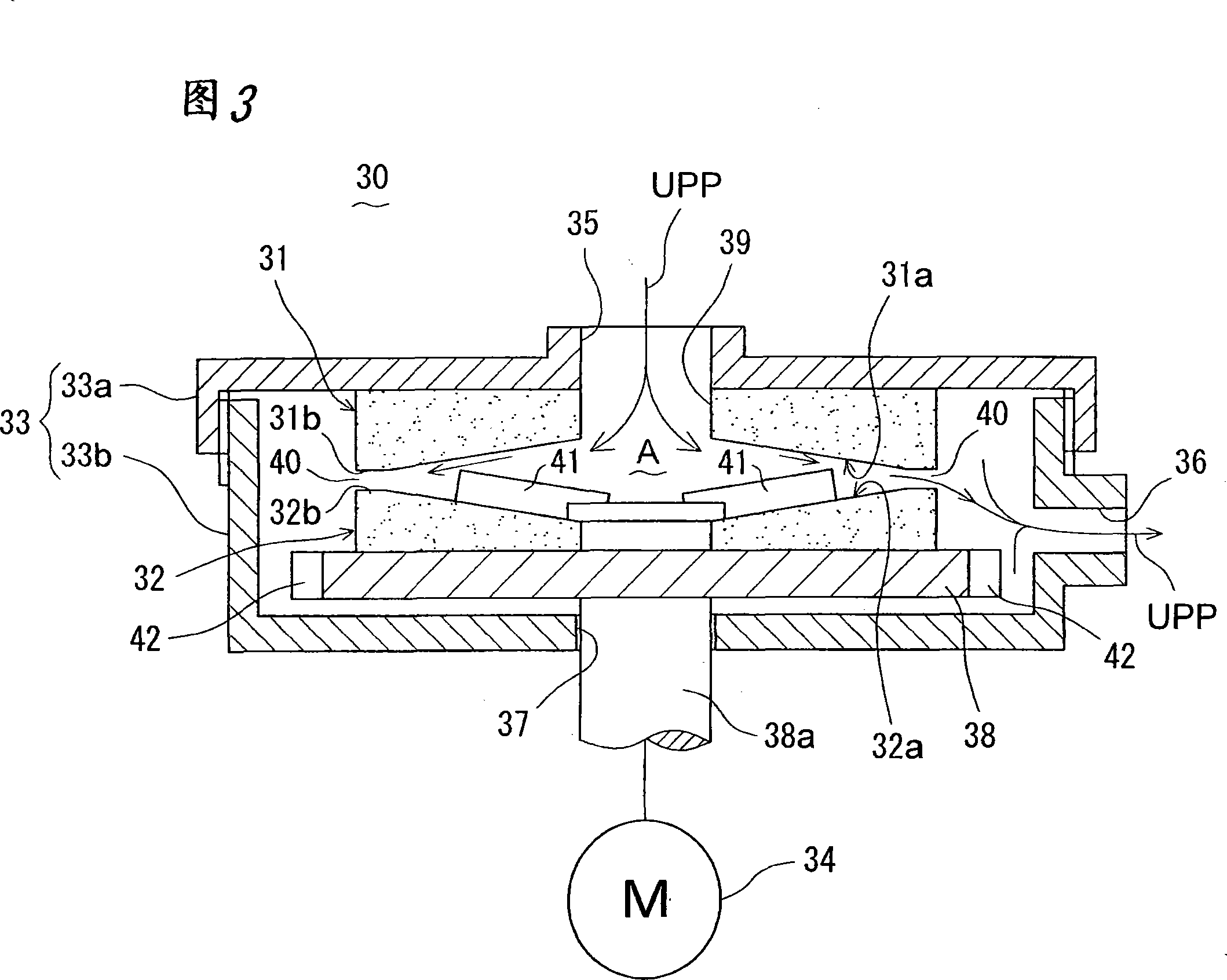

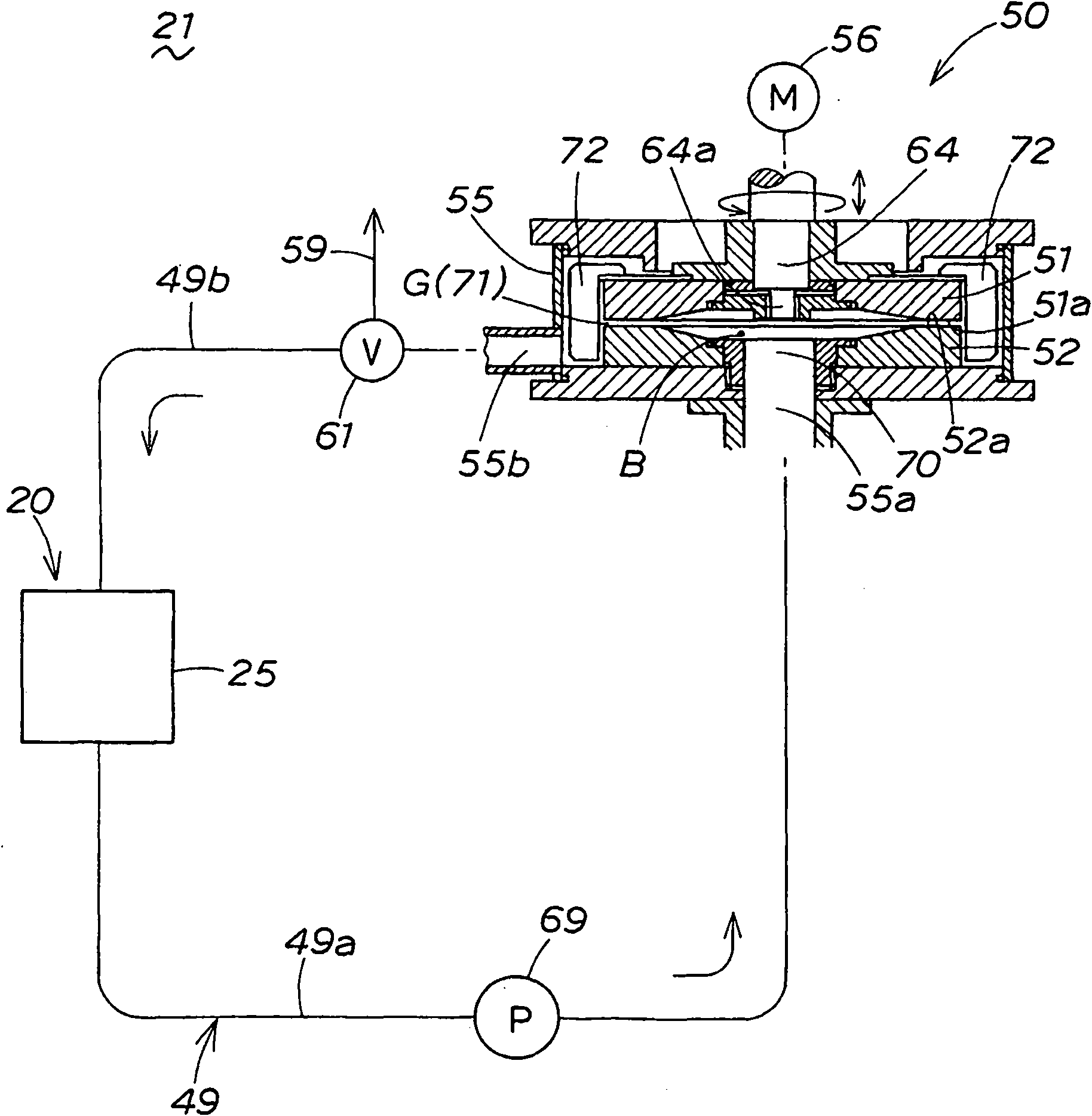

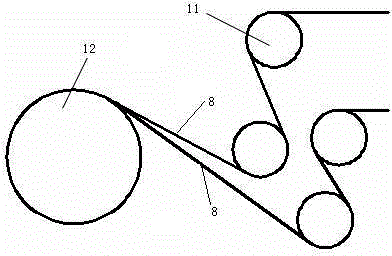

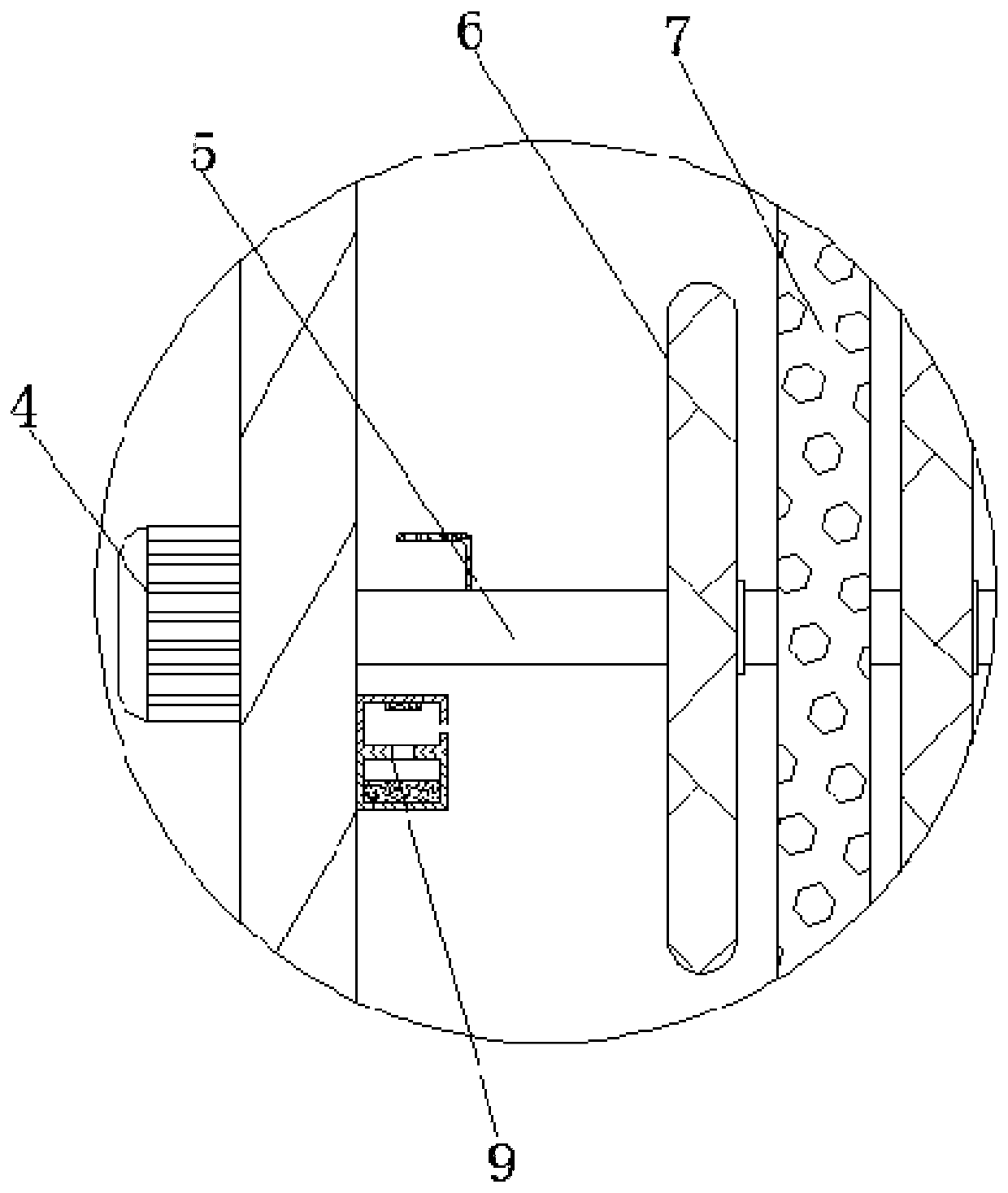

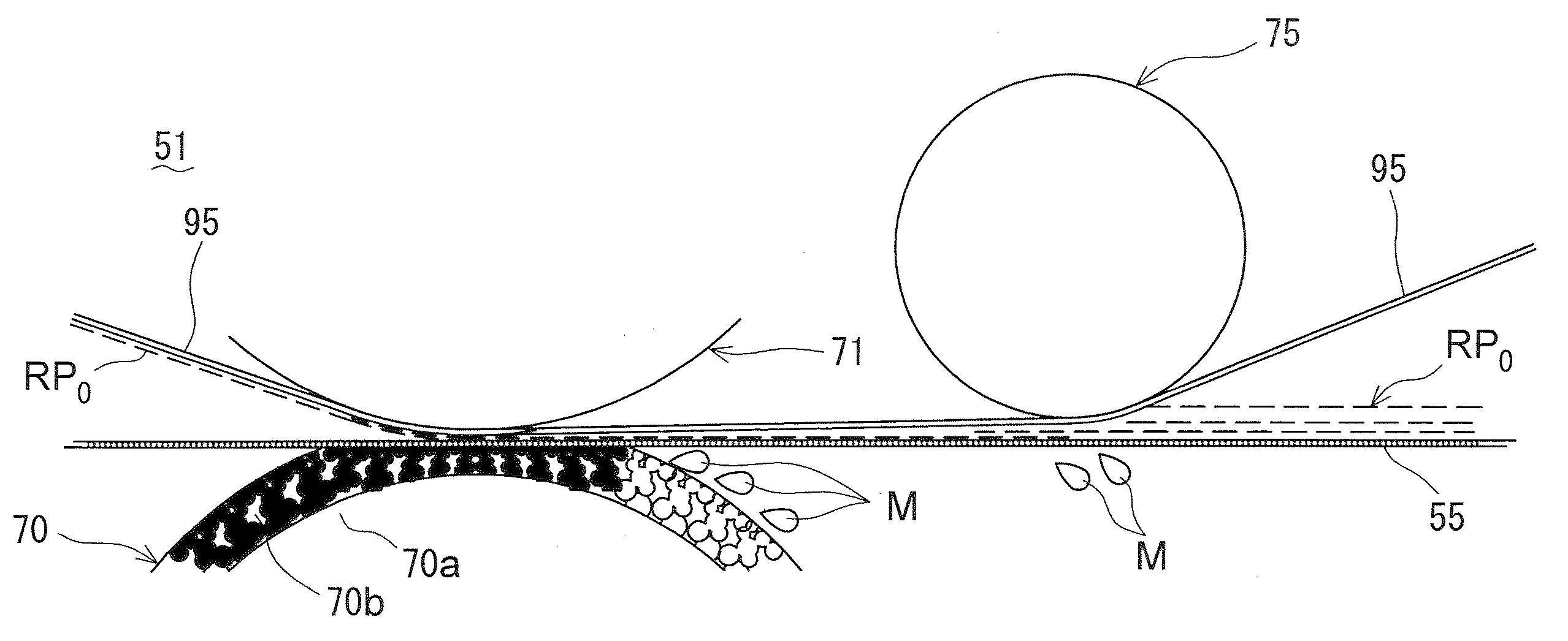

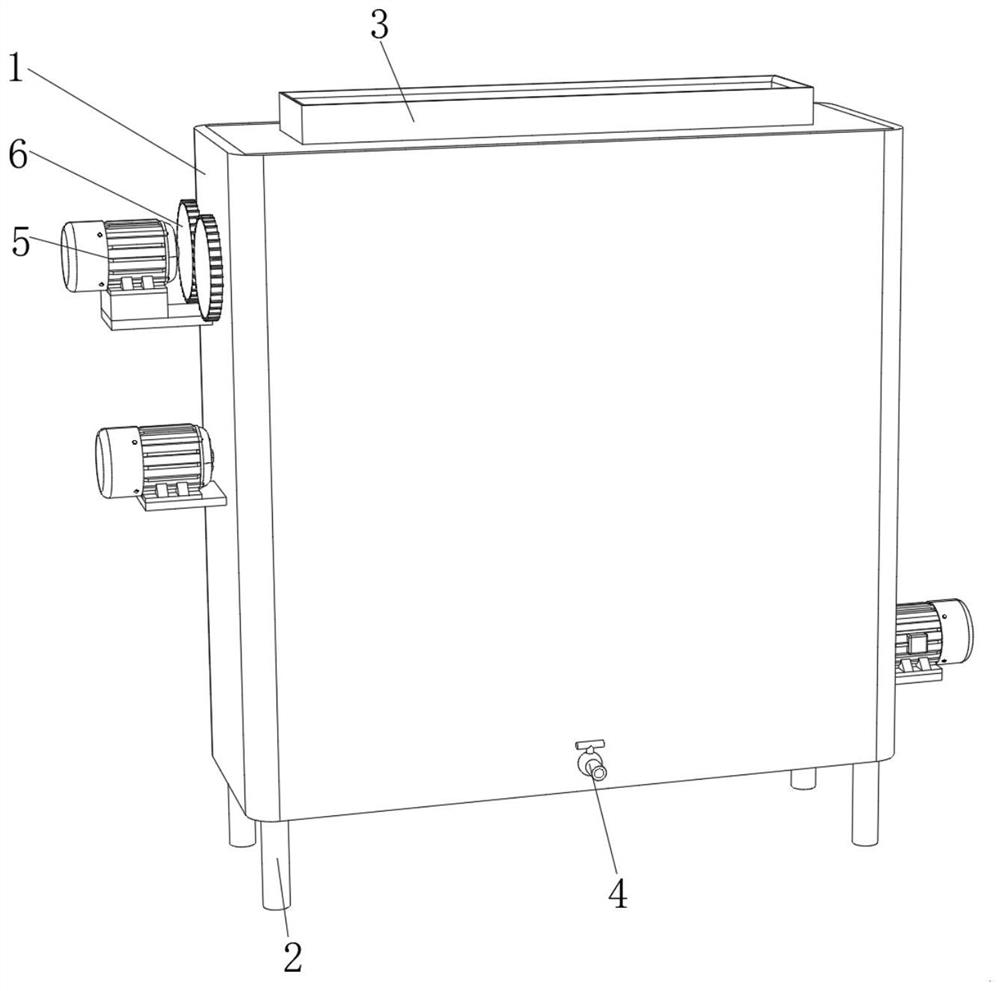

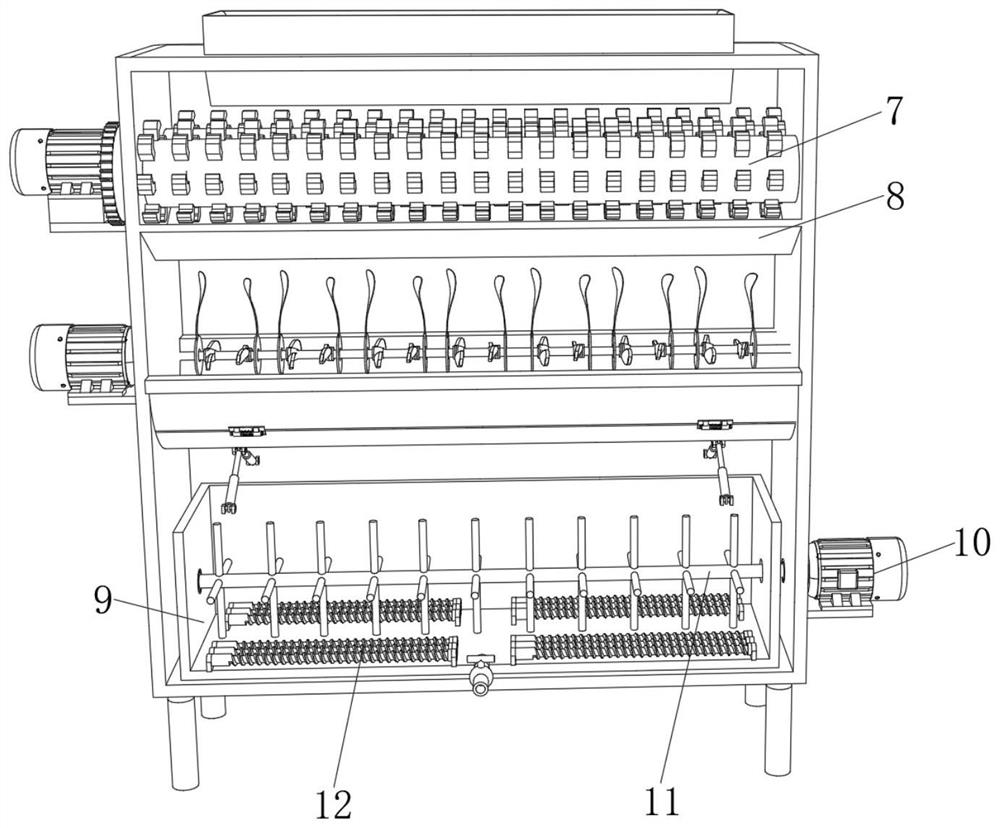

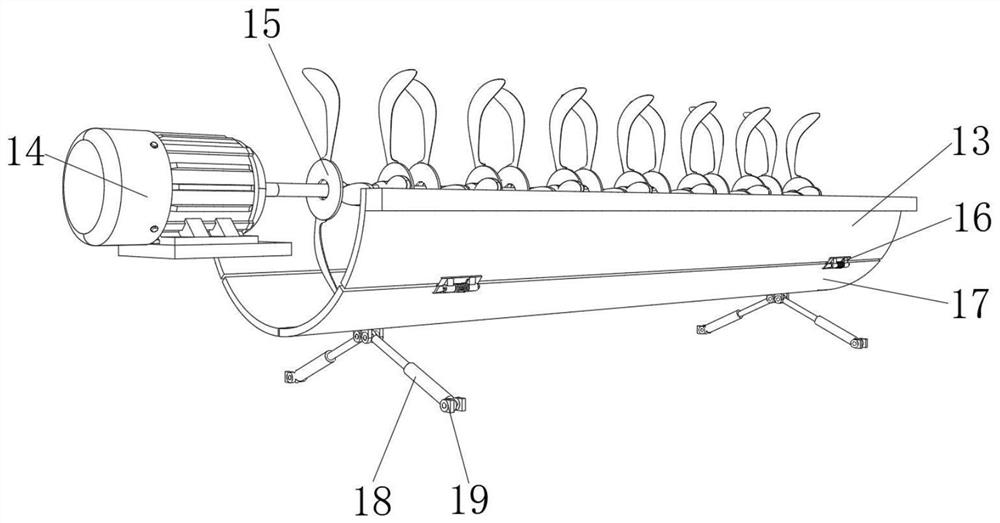

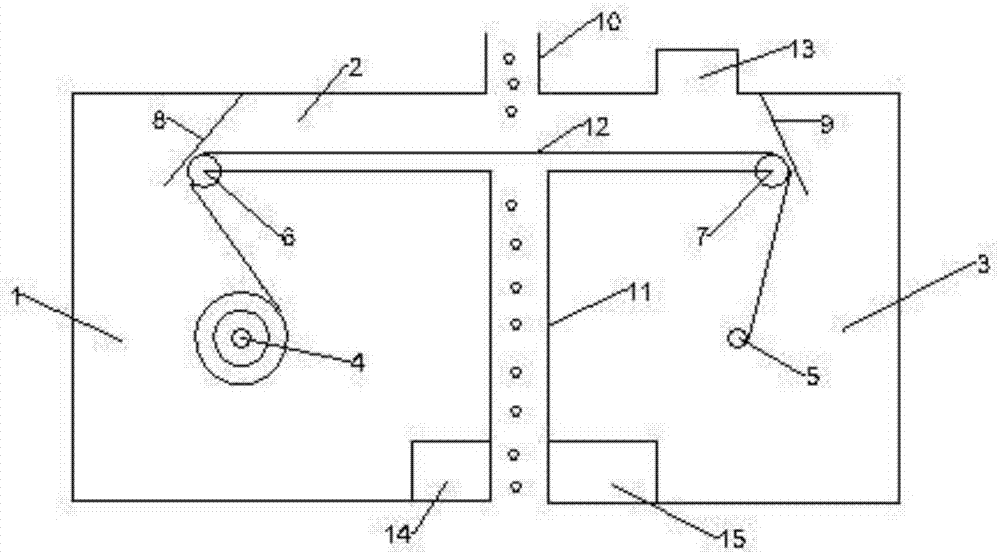

Dewatering device of used paper recycling apparatus and used paper recycling apparatus

InactiveCN101876152ASmooth and efficient papermaking processQuality improvementPulp de-wateringPaper recyclingPaper recyclingPulp and paper industry

In a narrow used paper processing space of a used paper recycling apparatus of furniture size, this is a dewatering device for executing smoothly and efficiently a dewatering process as a principal component of a paper making process for manufacturing used paper pulp. Being disposed in a linkage location between a mesh belt and a smooth surface belt, and configured to roll and squeeze the mesh belt and the smooth surface belt from the upper and lower sides in a compressed state, the apparatus includes a preliminary dewatering roll unit for squeezing and dewatering preliminarily the wet paper on the mesh belt, and a final dewatering roll unit for squeezing and dewatering the wet paper on the mesh belt preliminarily dewatered in the preliminary dewatering roll unit to obtain dry paper of specified water content. Therefore, in a very narrow used paper processing space of a used paper recycling apparatus of furniture size, the dewatering process in the paper making process for manufacturing used paper pulp can be executed smoothly and very efficiently.

Owner:SEED RUBBER CO LTD

Hot-melt adhesive capable of losing adhesion after contacting of water, and product thereof

ActiveCN106336834AEasy to recycleSolve the cumbersomeNon-macromolecular adhesive additivesFilm/foil adhesivesFiberFoaming agent

The invention relates to a hot-melt adhesive capable of losing adhesion after contacting of water, and a product thereof, and belongs to the technical field of new materials. The hot-melt adhesive contains, by mass, 100 parts of a conventional hot-melt adhesive (softening point of 60-150 DEG C), 10-80 parts of a macromolecule water absorption material, 0-20 parts of a filler, and 0-10 parts of a foaming agent. According to the present invention, the hot-melt adhesive has the following special performance that the hot-melt adhesive can be adhered after sequential heating and cooling and can lose the adhesion after contacting of the water, such that the hot-melt adhesive can be used for easy-fiber-separation bookbinding during paper recovery, can be used for producing hot-melt adhesive labels capable of being peeled with water, can replace the current complicated manual paste painting and calligraphy mounting and the painting and calligraphy mounting incapable of being remounted by the ordinary hot-melt adhesive film, and can further be used for special composite materials requiring adhesion and convenient peeling.

Owner:刘景阳

Image forming apparatus

InactiveCN101544135AAvoid contactWon't hurtOther printing apparatusMetal working apparatusPaper recyclingImage formation

The invention discloses an image forming apparatus. Printing paper (P1, P2) is cut by moving the lower one (52) of a pair of upper and lower cutting blades with the upper one (51) fixed. A protective member (53) for preventing the printed surface of the printing paper (P1, P2) being conveyed from coming into contact with the cutting edge of the upper cutting blade (51) is disposed upstream of the upper cutting blade (51) in the direction of paper conveyance. Therefore, being able to cut off the back-end blank portion of the last image of the images formed on papers and return to the cutting paper recycling box reliably, and being able to prevent the printing side from contacting with the upper side blades and damaging the printing side in paper transportion process.

Owner:NK WORKS CO LTD

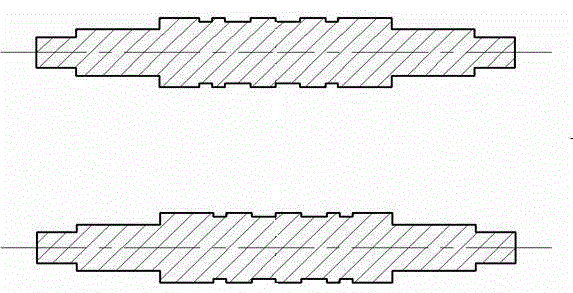

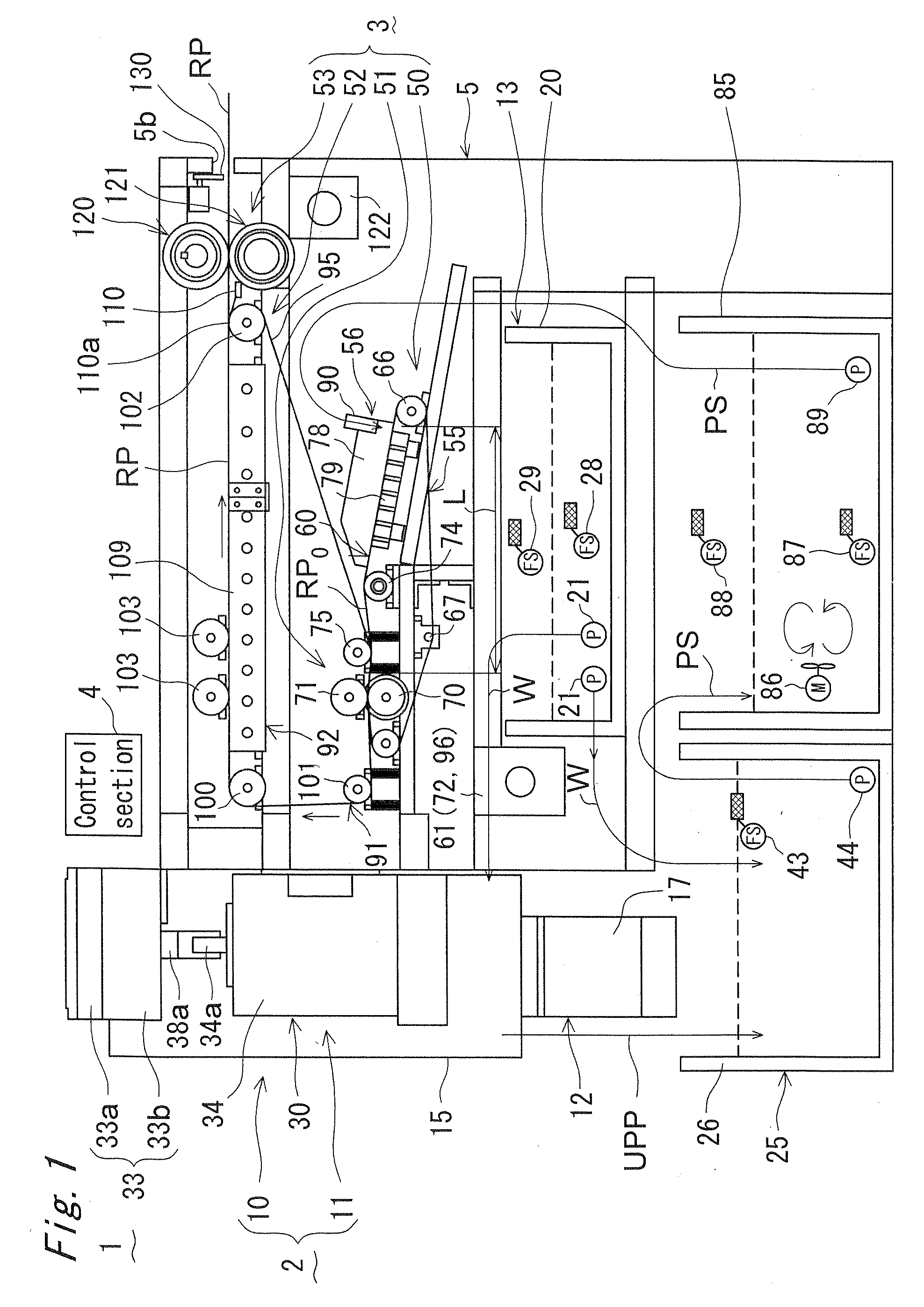

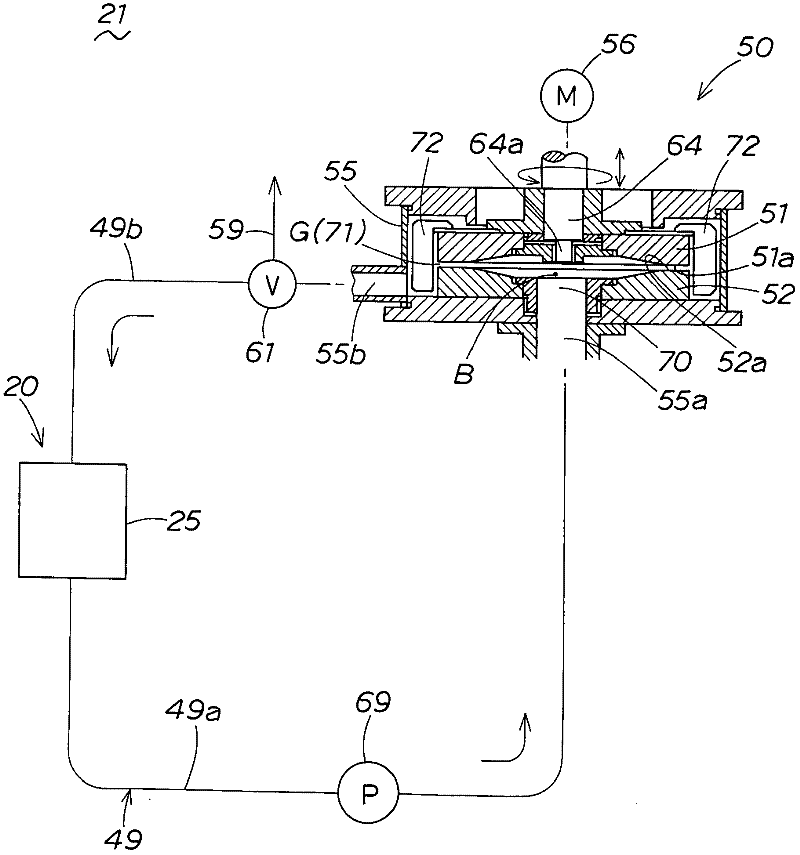

Paper machine for used paper recycling apparatus

InactiveCN101230551APrevent leakageLow running costDryer sectionPaper recyclingPaper recyclingSlurry

To present a paper machine for a used paper recycling apparatus small enough to be installed in a room of small shop or the like, friendly to the environment, low in running cost, and high in confidentiality. The paper machine includes a paper making process unit for manufacturing wet paper from slurry pulp suspension sent from the pulp making section in preceding process, a drying process unit for drying and regenerating the wet paper manufactured in the paper making process unit, and a calender roll unit for calendering the dry paper dried in the drying process unit, in which the calender roll unit is disposed adjacently to the downstream side position of the drying process unit, and calenders the dry paper discharged from the drying process unit by rolling and pressing from both face and back sides.

Owner:SEED RUBBER CO LTD

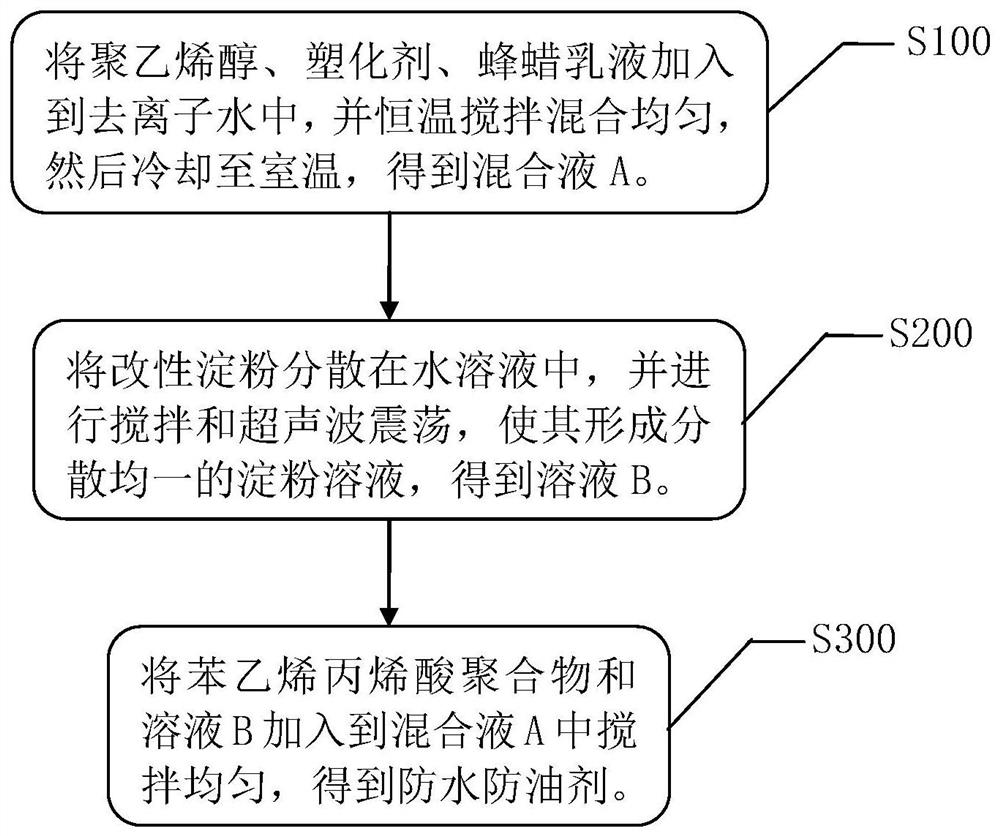

Waterproof and oilproof agent as well as preparation method and application thereof

InactiveCN111749042AGood film formingImproved water and oil repellencyNon-macromolecular organic additionPaper coatingPolymer sciencePolyvinyl alcohol

The invention relates to a waterproof and oilproof agent as well as a preparation method and application thereof. The waterproof and oilproof agent is prepared from the following components in percentage by weight: 30%-50% of styrene acrylic polymer, 5%-10% of beeswax emulsion, 2.5%-4.5% of polyvinyl alcohol, 2%-5.5% of modified starch, 0.5%-2% of plasticizer and 28%-60% of deionized water. The waterproof and oilproof agent is good in film-forming property; beeswax emulsion in a formed coating and the styrene-acrylic acid polymer are combined to form a hydrophobic and oleophobic surface layer;meanwhile, the hydrophobic and oleophobic surface layer is compounded with the modified starch, so that the waterproof and oilproof effects of the waterproof and oilproof coating on food-grade raw paper are obviously improved; the waterproof and oilproof properties of the waterproof and oilproof agent are extremely good; the waterproof and oilproof agent can completely replace traditional waxing,silicon coating and laminating processes; and the paper can directly enter a papermaking pulping system to be recycled when being recycled, the pollution of the laminated paper to the environment isreduced; and therefore, the waterproof and oilproof agent is an environment-friendly material.

Owner:ZHONGSHAN TIAN JIA PAPER PROD

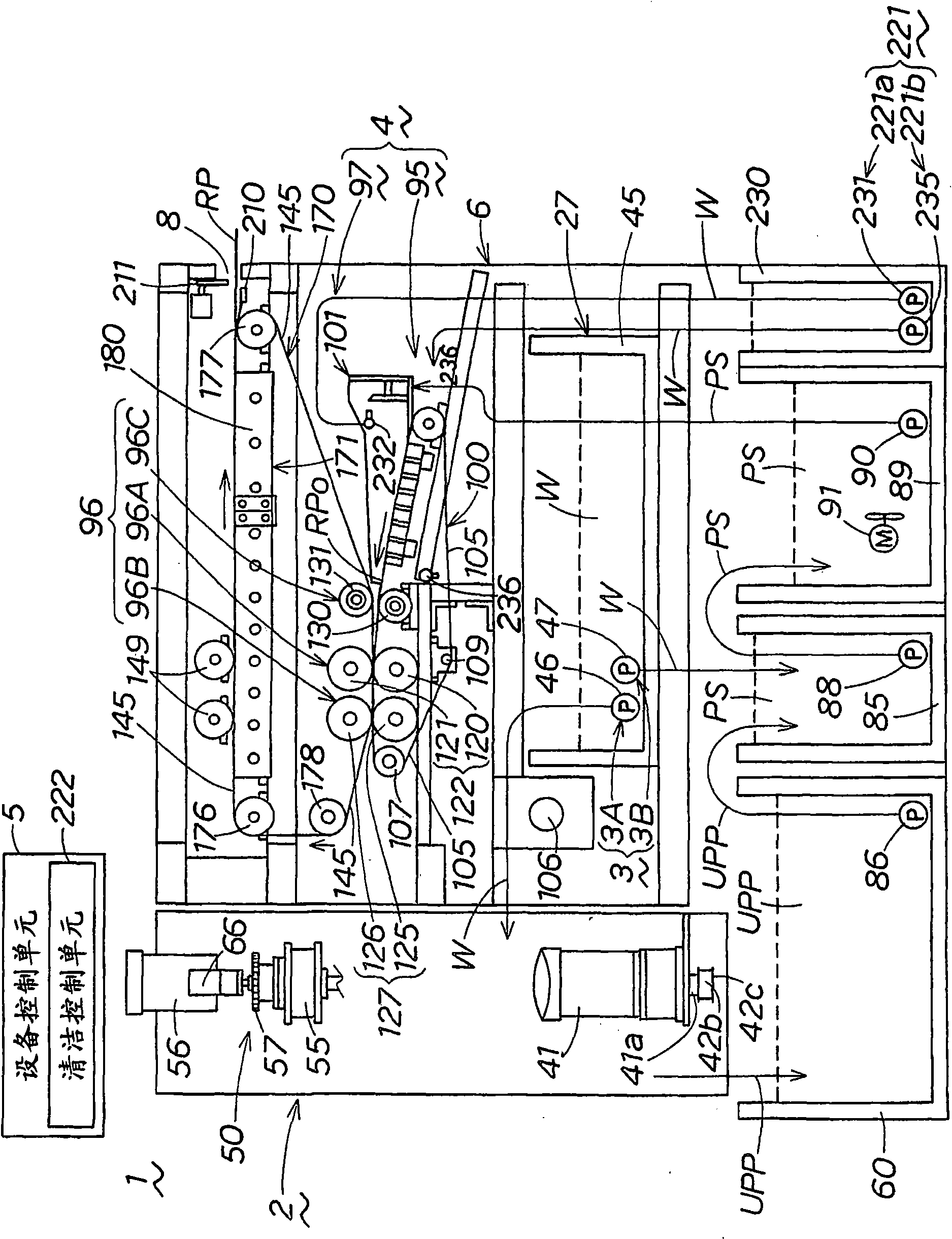

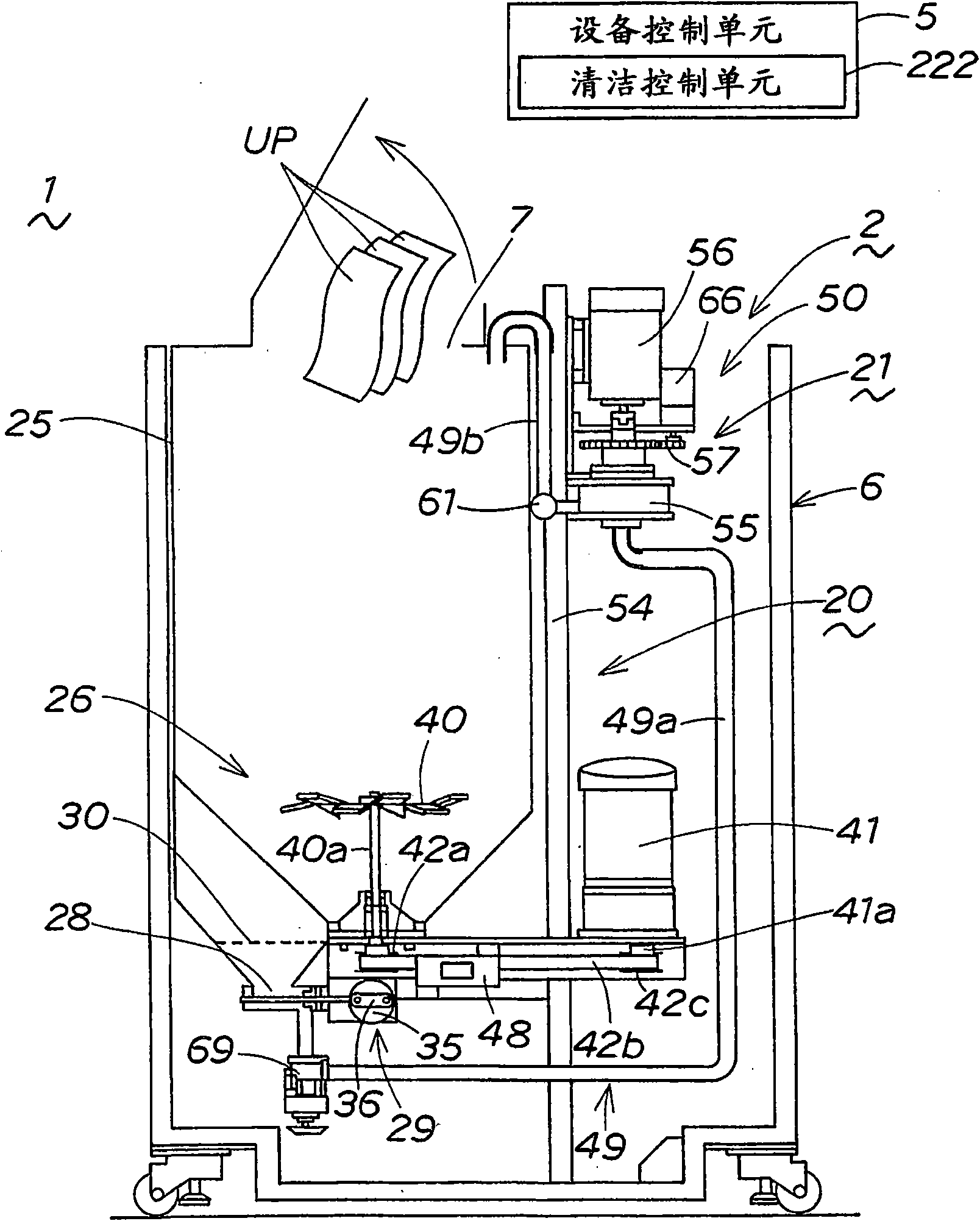

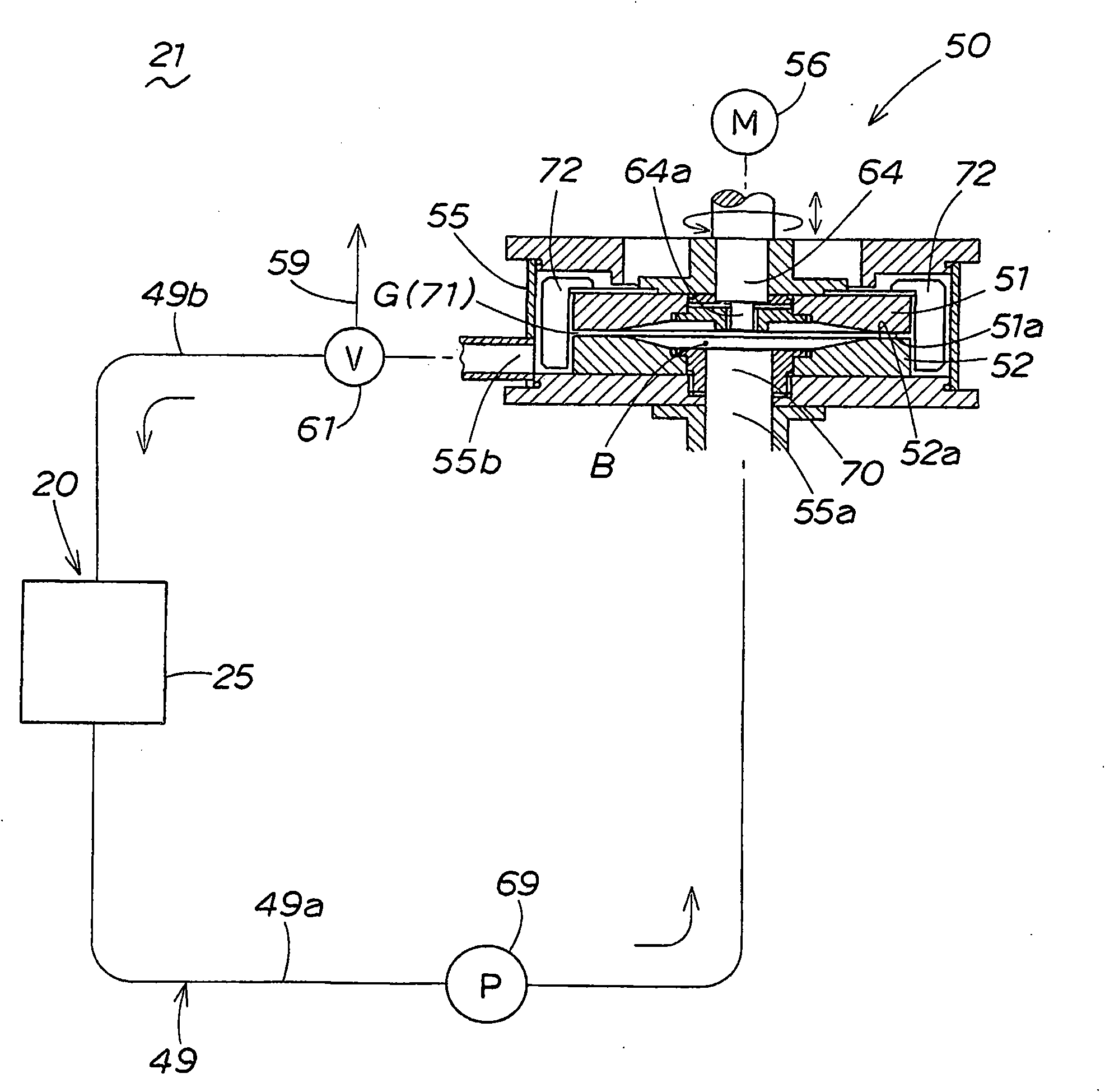

Cleaning method of used paper recycling apparatus, cleaning system, and used paper recycling apparatus

InactiveCN101992191AStable recirculation operationEasy to cleanPaper recyclingCleaning using liquidsPaper recyclingPulp and paper industry

The present invention presents a cleaning technology in a used paper recycling apparatus capable of assuring a stable used paper recycling operation all the time, by removing and cleaning securely the used paper pulp remaining in the parts of the apparatus components of a used paper recycling apparatus of furniture size. The cleaning method of the cleaning system includes a white water cleaning process of circulating white water dewatered and collected in the paper making unit for manufacturing regenerated paper from used paper pulp in a pulp making unit and a pulp concentration adjusting unit of apparatus components for composing the used paper recycling apparatus by a white water cleaning unit, and cleaning the pulp making unit and the pulp concentration adjusting unit, and clean water cleaning processes of cleaning the paper making unit by clean water by a clean water cleaning unit. As a result, the used paper pulp remaining in the parts of the apparatus components can be securely cleaned and removed, and a stable used paper recycling operation can be assured all the time.

Owner:SEED RUBBER CO LTD

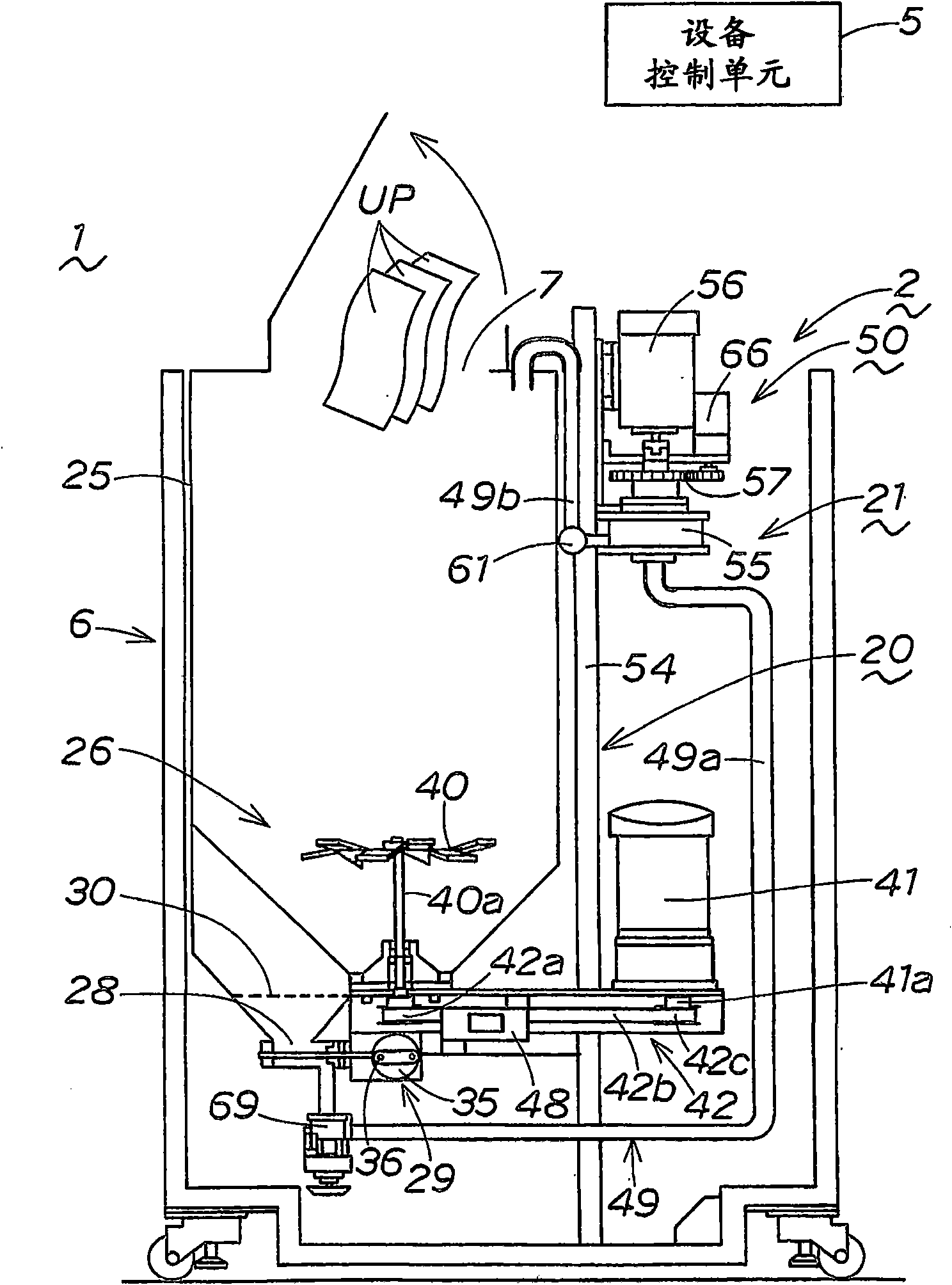

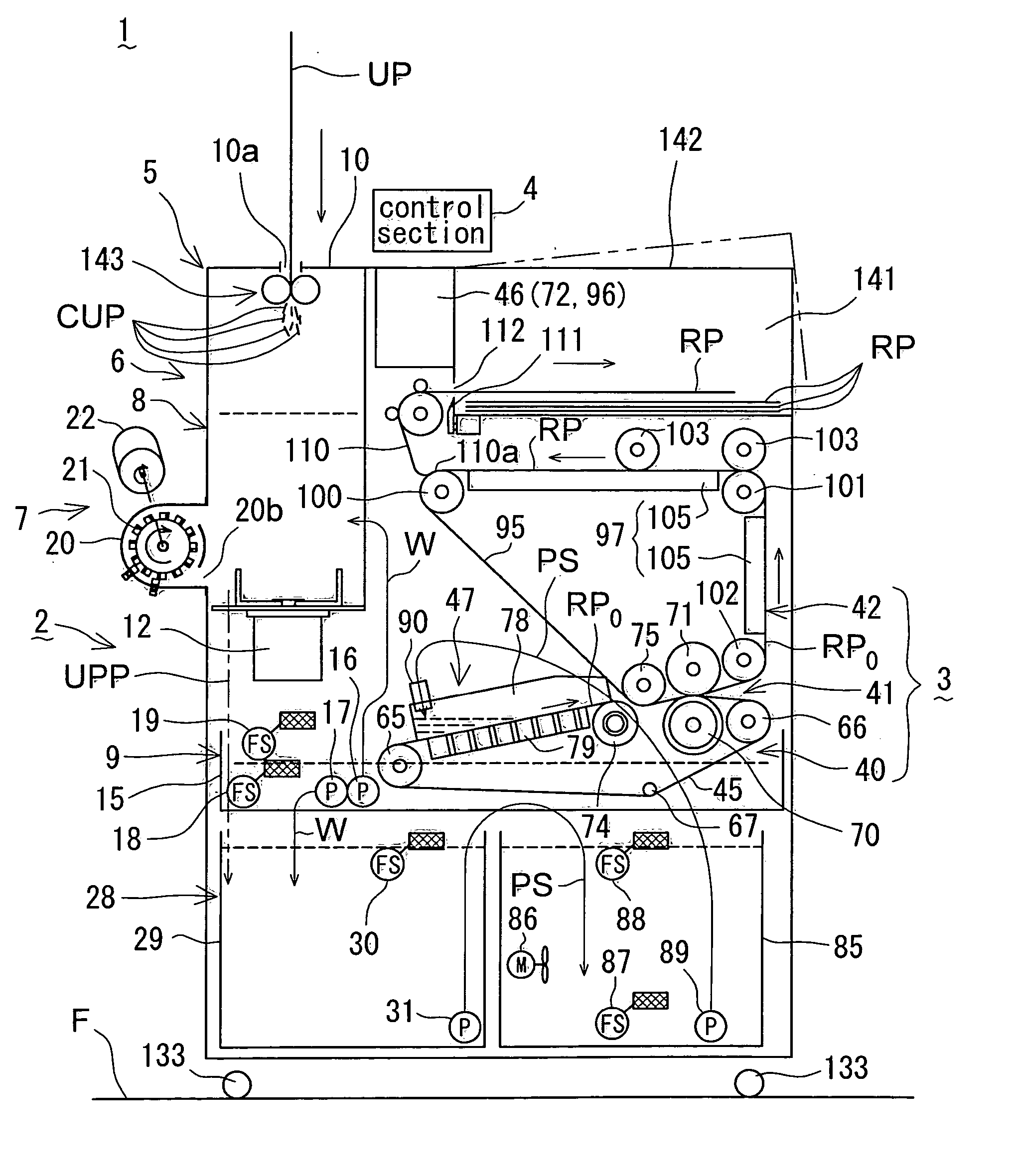

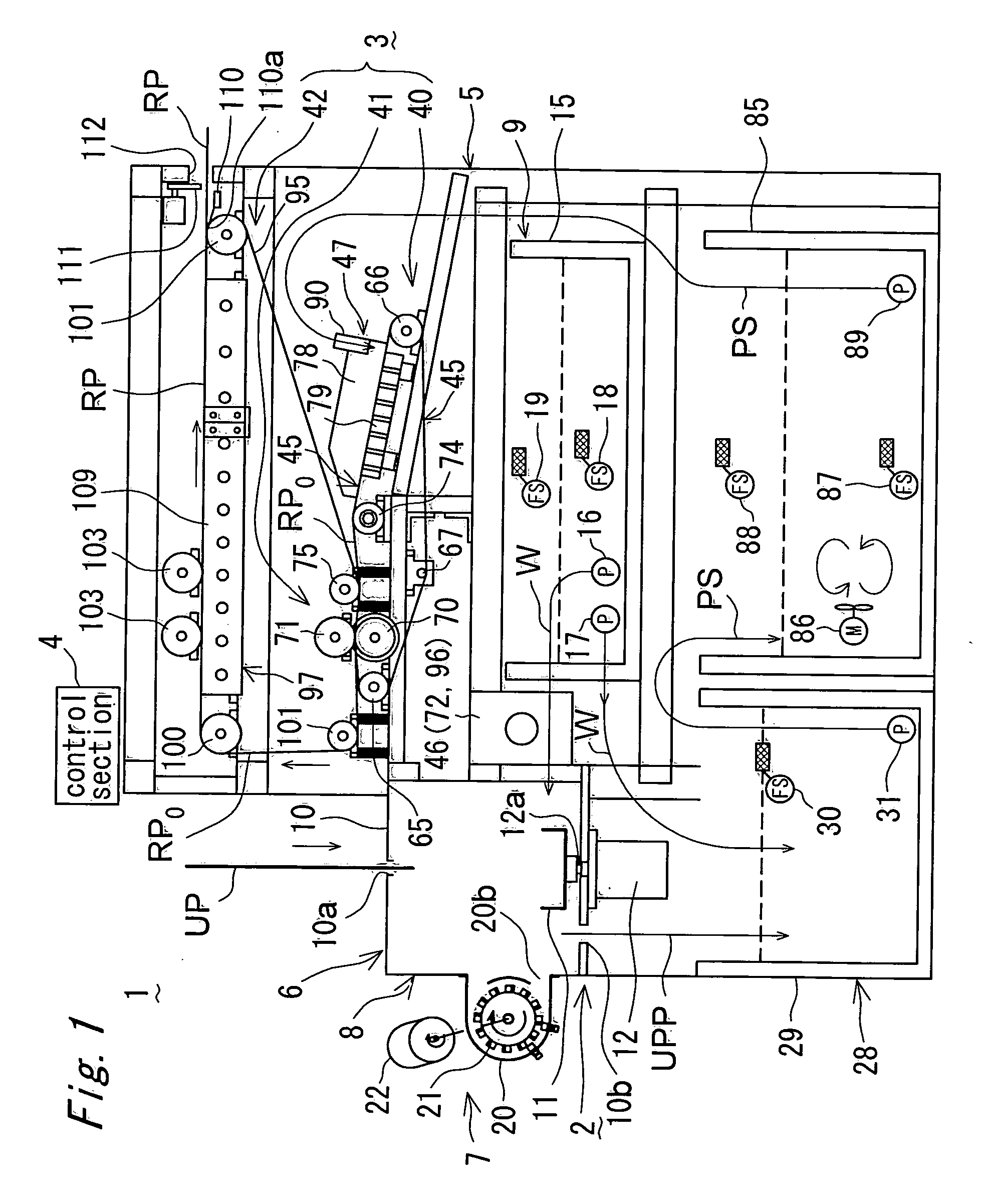

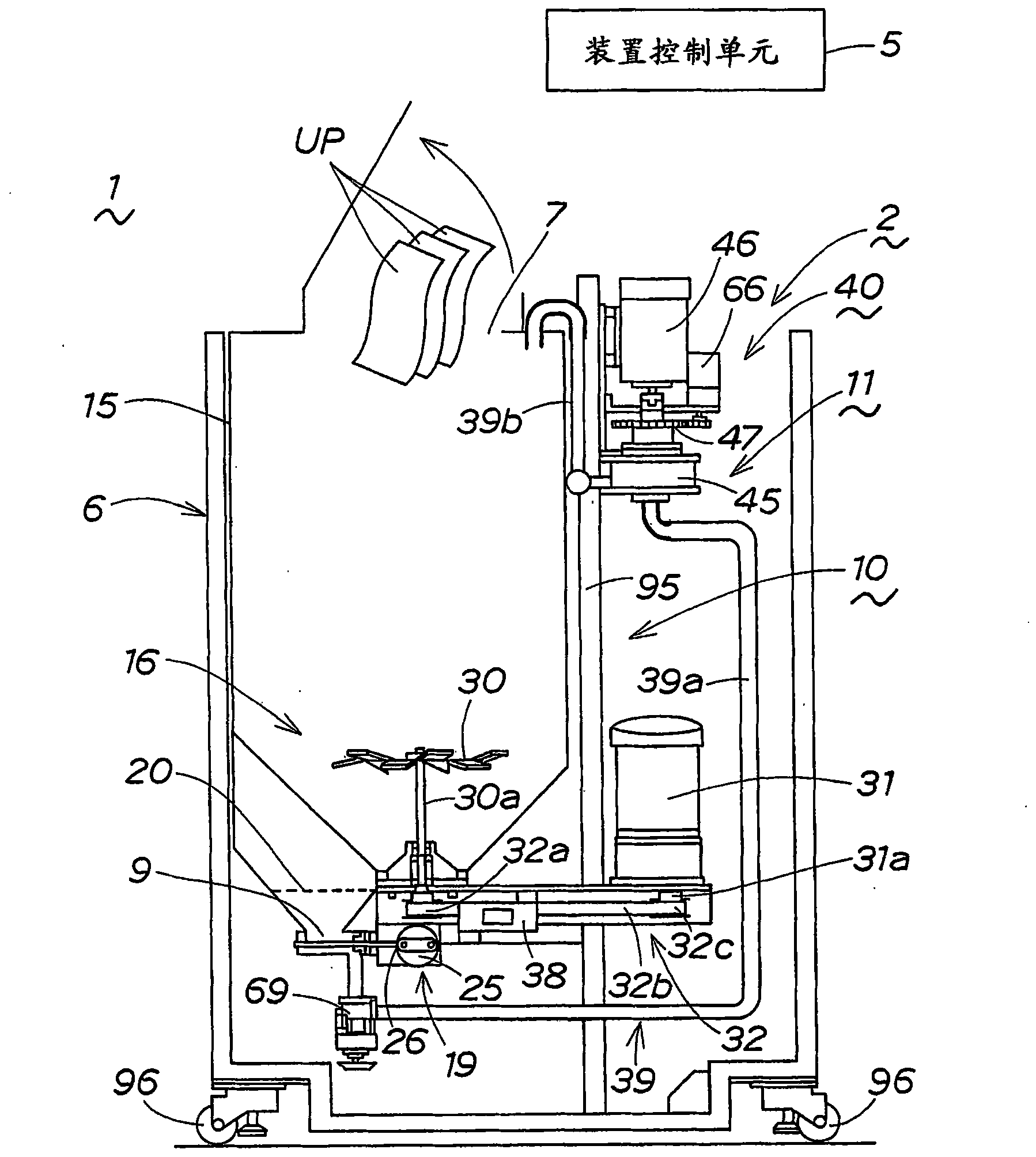

Used paper recycling apparatus and its constituent devices

InactiveUS20070062663A1Prevent leakage of confidential informationLeak of personal informationWaste product additionPaper/cardboard wound articlesPaper recyclingPulp and paper industry

A used paper recycling apparatus capable to be installed in small office or general household, friendly to environment and low in running cost, and assuring high confidentiality. A used paper recycling apparatus comprising a pulp making section for crushing and beating used paper and making into pulp, a paper making section for recycling paper by making used paper pulp from the pulp making section, and a control section for driving and controlling by interlocking the pulp making section and paper making section, which are incorporated in a furniture size apparatus case, in which the pulp making section includes a crushing unit for stirring and grinding the used paper, and a beating unit for beating the crushed used paper from the crushing unit, and the crushing unit and beating unit are circulating the used paper pulp.

Owner:VIEWDLE INC

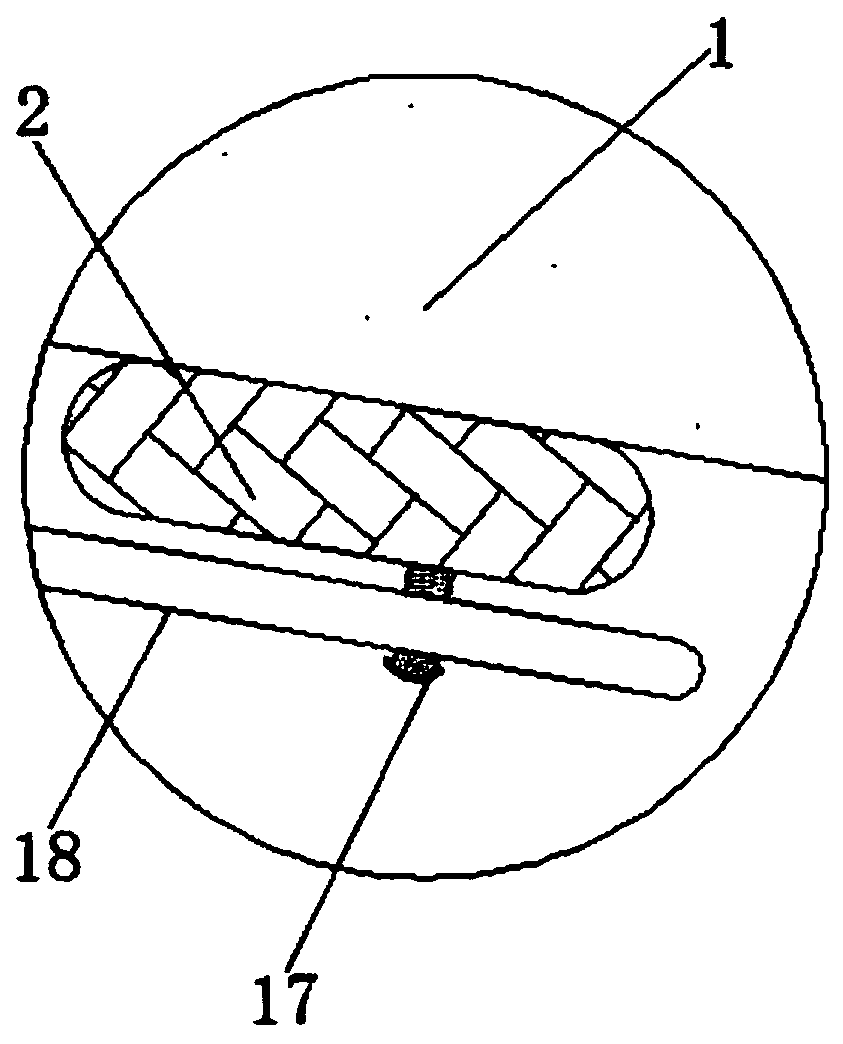

Regenerated paper smoothing device of used paper recycling apparatus, paper making device, and used paper recycling apparatus

InactiveCN101988275AWrinkle freeUniform pressureCalendersRaw material divisionWrinkle skinPaper recycling

The invention relates to a regenerated paper smoothing device of used paper recycling apparatus, a paper making device, and an used paper recycling apparatus. In a very narrow used paper processing space of a used paper recycling apparatus of furniture size, the present invention presents a recycled paper smoothing technology for manufacturing securely into a wrinkle-free and smooth recycled paper from wet paper made and formed in a paper making processing unit of a paper making unit. The recycled paper smoothing processing unit is formed as pressing means for pressing the entire wet paper conveyed on a smooth surface belt with a uniform pressure from the upper side in a heating and drying unit, and includes a covering belt conveyor having a covering belt running while covering the entire wet paper on the smooth surface belt in an enclosed state together with the smooth surface belt, and a plurality of pressing rollers disposed at specified intervals in the running direction of the covering belt for pressing this covering belt from the upper side, and therefore the wet paper made and formed in the paper making net conveyor is securely reproduced as a wrinkle-free and smooth recycled paper.

Owner:SEED RUBBER CO LTD

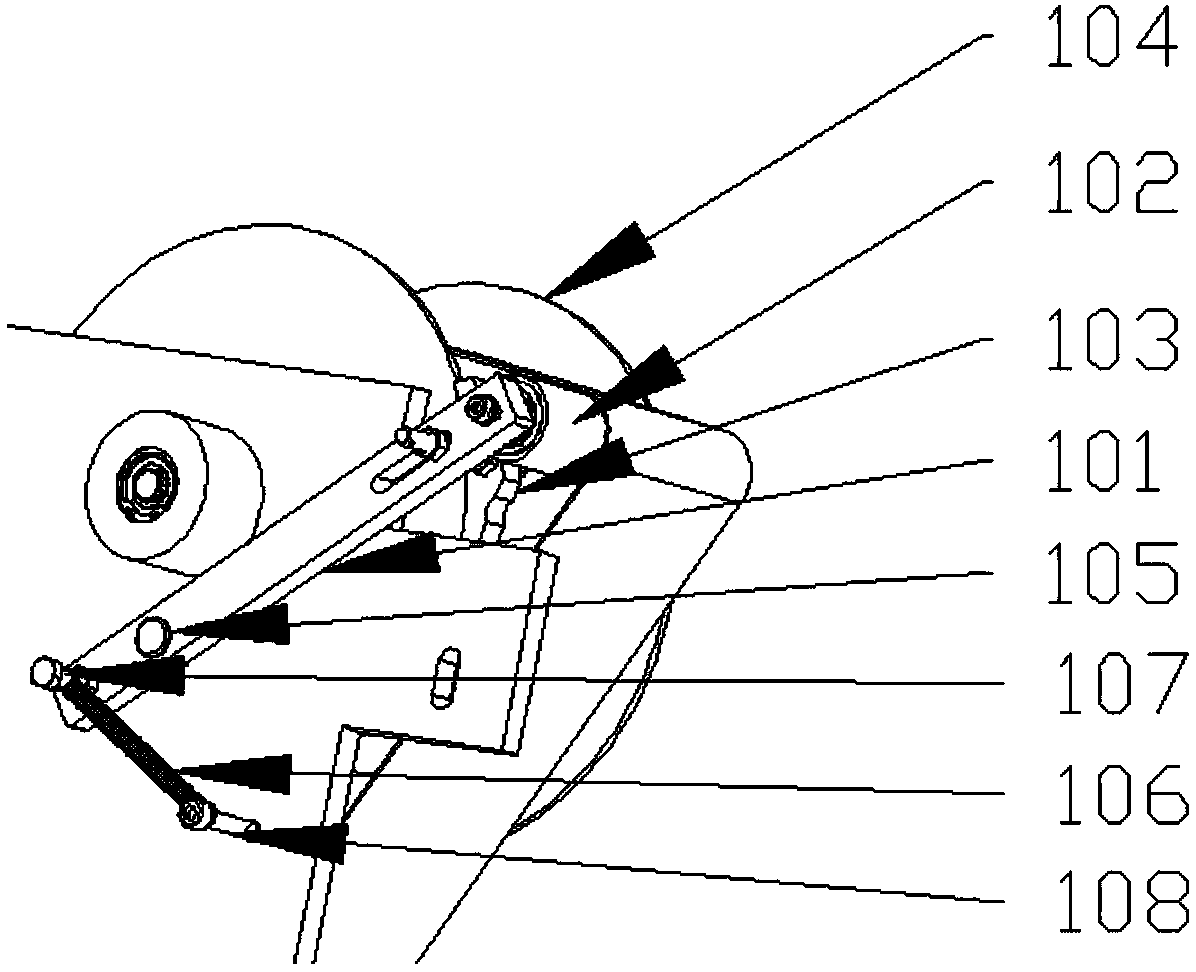

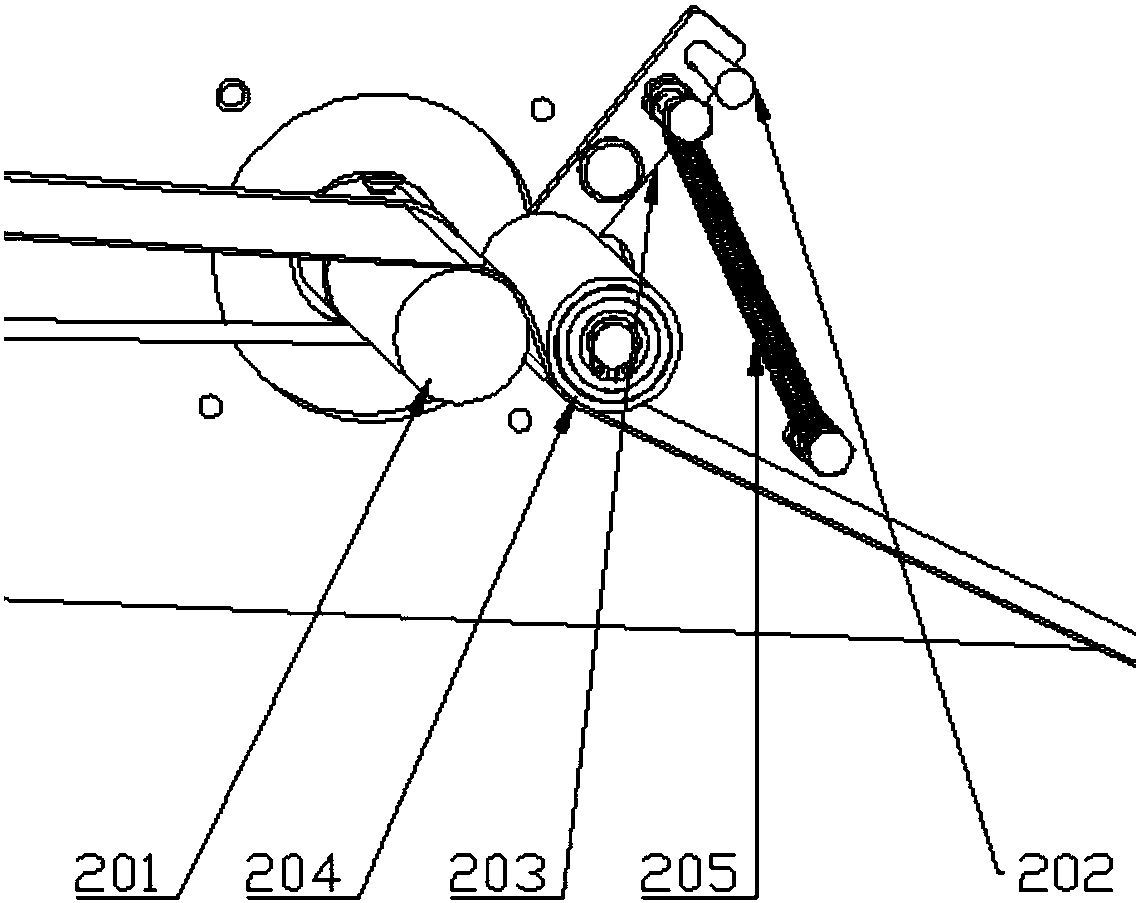

Handheld fiber wire laying device

The invention relates to a handheld fiber laying device. The device comprises a mechanical arm and a laying head, wherein the mechanical arm is fixed on the ground or on a trolley, and the laying head is fixed at the front end of the mechanical arm; the mechanical arm comprises a fixed column, a rotating column, a control box, a swinging arm, a main arm, a small arm, a suspension arm, a cylinder and a pneumatic balance system; and the laying head comprises a wire guiding module, a re-delivering module, a cutting module, a pressure head module, a lining paper recycling module and a heating module. The mechanical arm disclosed by the invention enables a worker to push the workpiece and complete the laying work by using a very weak force, and the mechanical arm can automatically maintain a state of equilibrium in any position and any condition; the laying head disclosed by the invention can laying a plurality of narrow fiber prepreg tapes at one time and can complete the functions of wire guiding, conveying, lining paper recycling, shearing, heating and laying, and the laying head is not only suitable for a mandrel with a simple structure of a cylinder, but also is suitable for a mandrel with a special structure of a cone or a latticed shape. The handheld fiber laying device has the advantages of simplicity in operation, less manpower, high efficiency, and good laying effect.

Owner:WUHAN UNIV OF TECH

Paperboard recycling and cutting device based on light sensation control principle

The invention relates to the technical field of environmental protection and discloses a paperboard recycling and cutting device based on a light sensation control principle. The device comprises a shell I and a shell II, wherein a transfer assembly is movably connected in the shell I, a motor is movably connected in the shell I, a rotating rod is movably connected outside the motor, a cam is fixedly connected outside the rotating rod, a movable plate is movably connected outside the rotating rod, a slicer is movably connected outside the movable plate, a light sensation assembly is movably connected in the shell I, and a cutting wheel is movably connected in the shell I. Under interaction of the shell I, the transfer assembly, the motor, the rotating rod, the cam, the movable plate, the slicer and the cutting wheel, a paperboard is cut transversely and longitudinally when being cut, so that it is more favorable to cut the paperboard fully, thereby providing a paperboard specificationmeeting the demand to recycling and processing of the paperboard, and therefore, the work efficiency of paper recycling is improved.

Owner:台州市亿源塑业有限公司

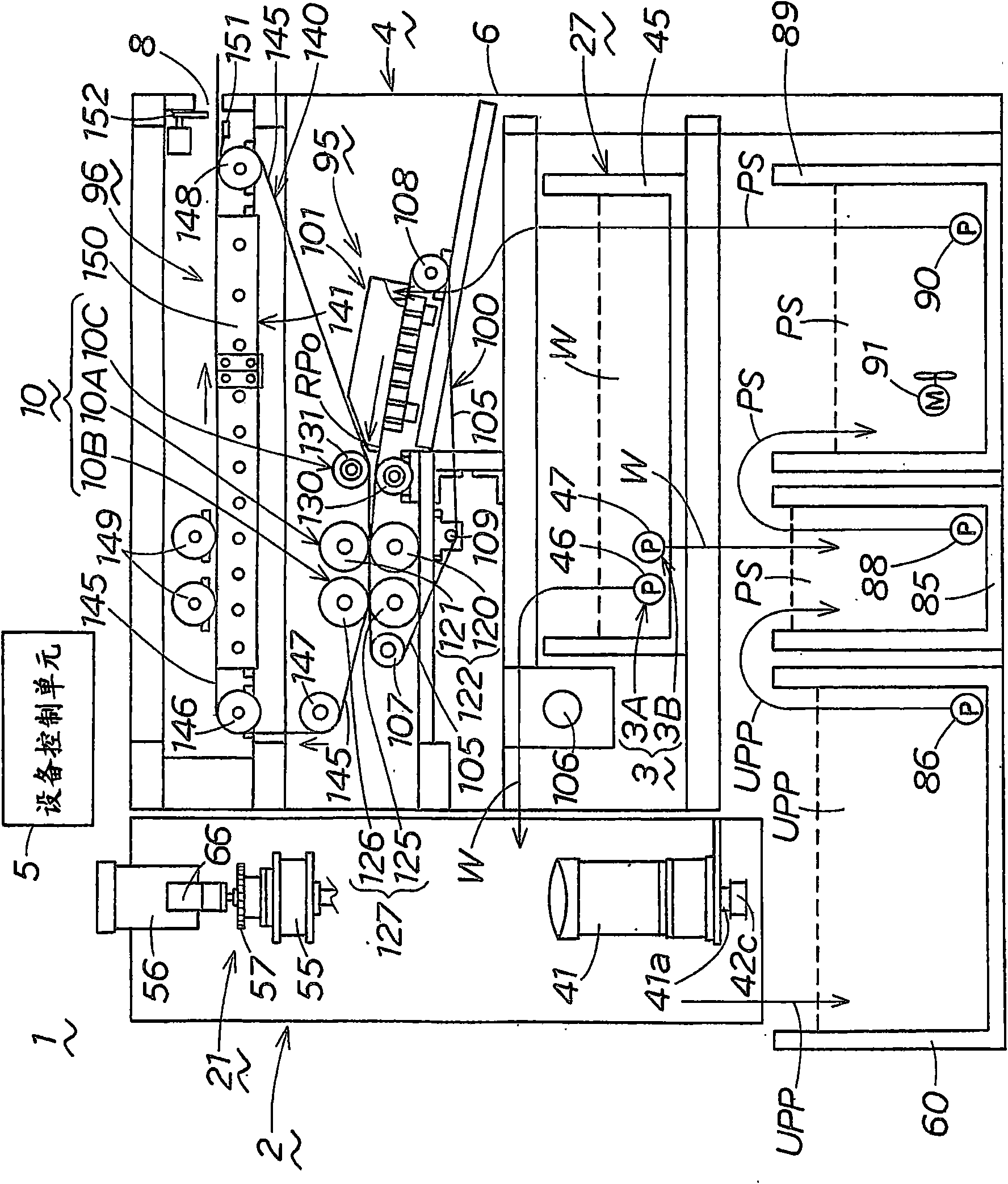

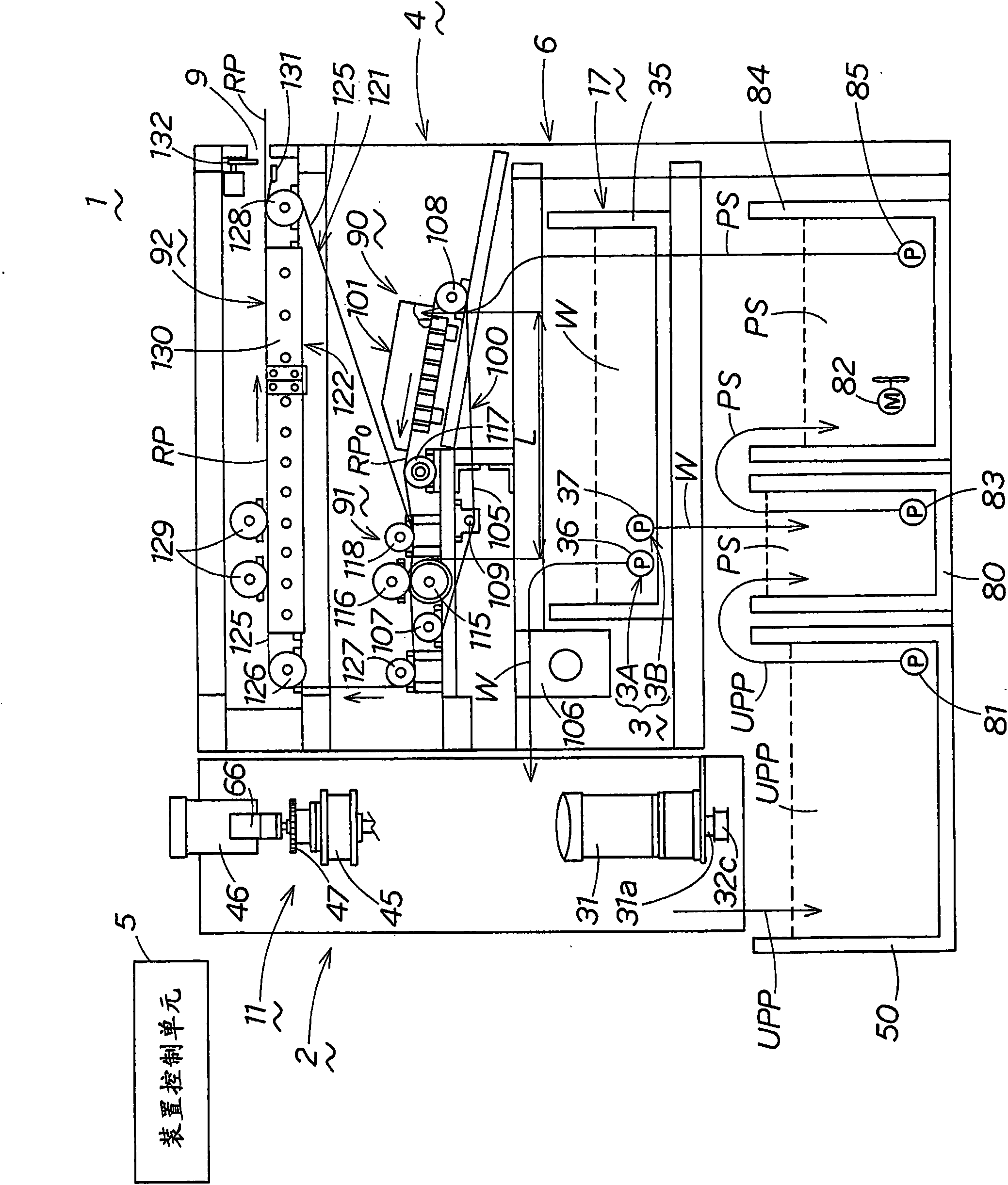

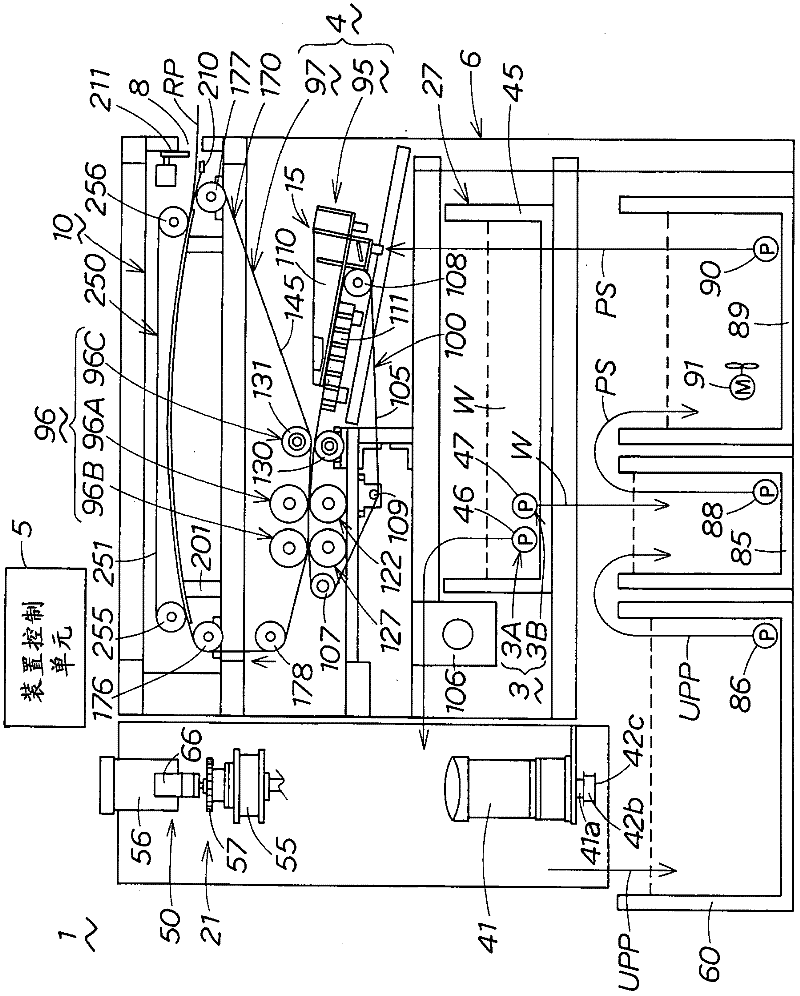

Paper machine for used paper recycling apparatus

InactiveUS20080179031A1Reduce disposalLimited resourceDryer sectionPaper recyclingPaper recyclingSlurry

To present a paper machine for a used paper recycling apparatus small enough to be installed in a room of small shop or the like, friendly to the environment, low in running cost, and high in confidentiality. The paper machine includes a paper making process unit for manufacturing wet paper from slurry pulp suspension sent from the pulp making section in preceding process, a drying process unit for drying and regenerating the wet paper manufactured in the paper making process unit, and a calender roll unit for calendering the dry paper dried in the drying process unit, in which the calender roll unit is disposed adjacently to the downstream side position of the drying process unit, and calenders the dry paper discharged from the drying process unit by rolling and pressing from both face and back sides.

Owner:VIEWDLE INC

Convenient-collect waste paper recycling device

InactiveCN112246399AEasy to collectEasy to crushTransportation and packagingMixer accessoriesPaper recyclingElectric machine

The invention relates to the technical field of paper recycling and discloses a convenient-collect waste paper recycling device which comprises a smashing box, supporting legs are fixedly connected tothe four corners of the lower surface of the smashing box, a feeding inlet is formed in the upper surface of the smashing box, and a discharging valve communicates with the bottom of the front face of the smashing box. The top of the left side face of the smashing box is fixedly connected with a driving motor, and the output end of the driving motor is fixedly connected with an opposite rotatinggear. According to the convenient-collect waste paper recycling device, a rotary motor drives a smashing cutter to rotate to be matched with a rotary arc plate to conduct two-stage deep smashing on waste paper, a better smashing effect on the waste paper is achieved, the waste paper can be better smashed, melting and recycling of the waste paper are more convenient, and better recycling of the waste paper is facilitated. The waste paper is prevented from being discarded everywhere to damage the surrounding environment, the waste paper recycling efficiency is further improved, and the use convenience is greatly improved.

Owner:新邵县金龙纸业有限责任公司

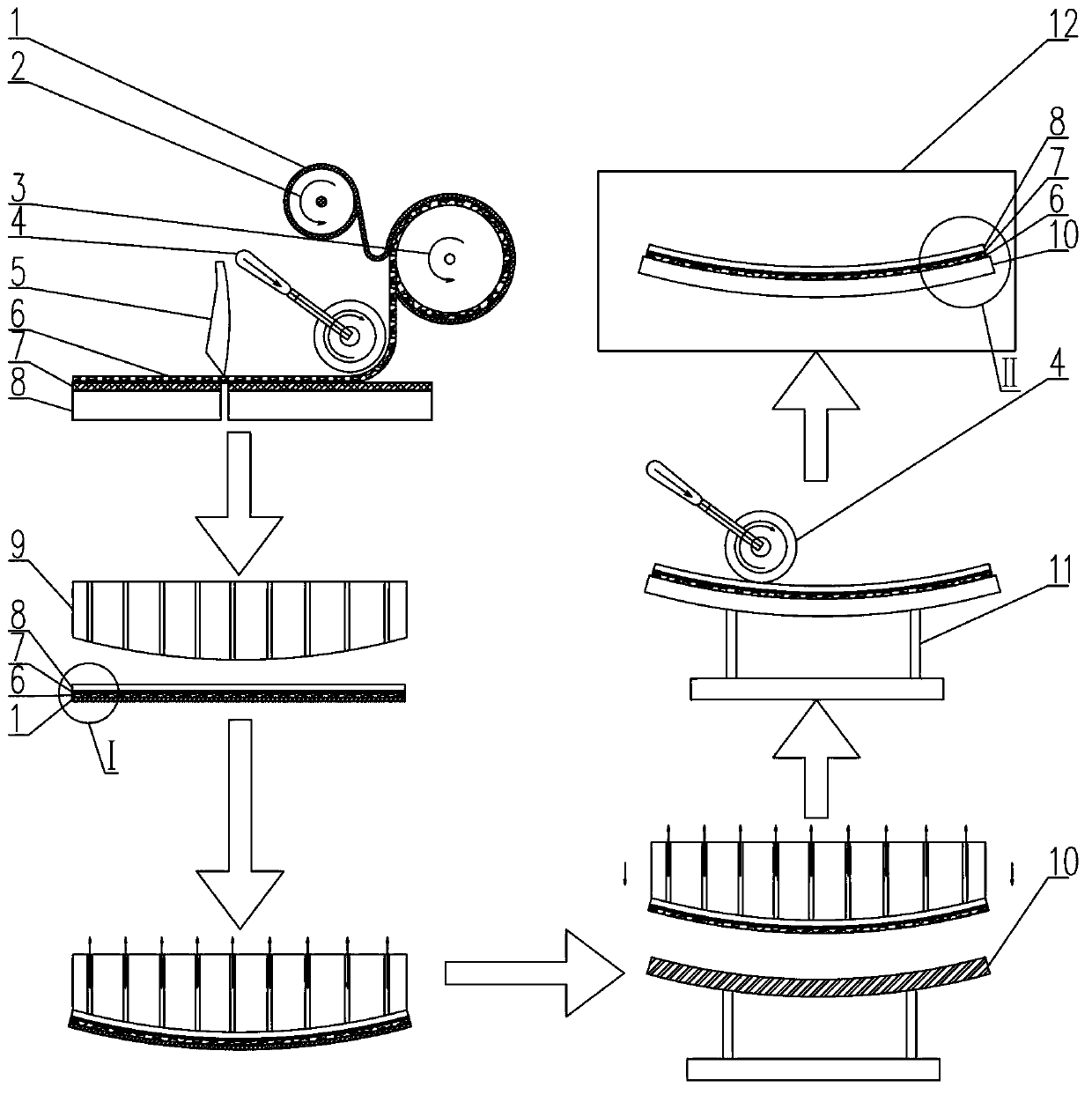

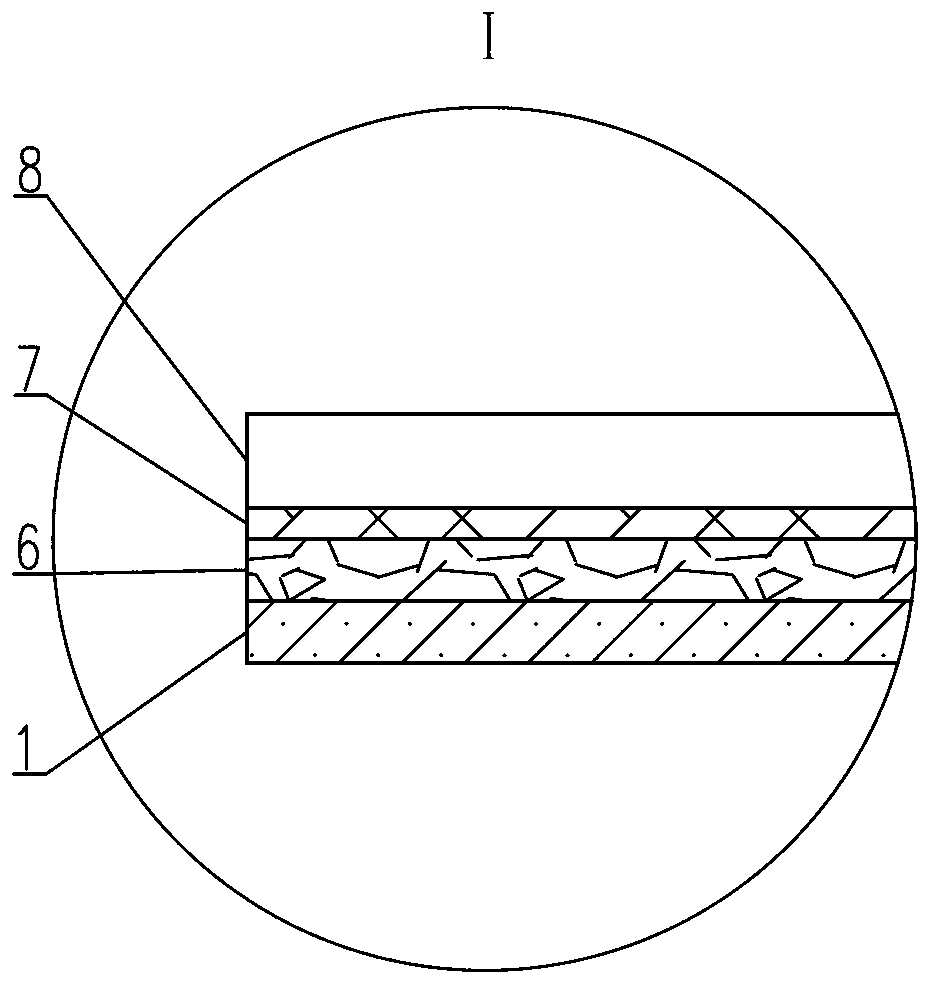

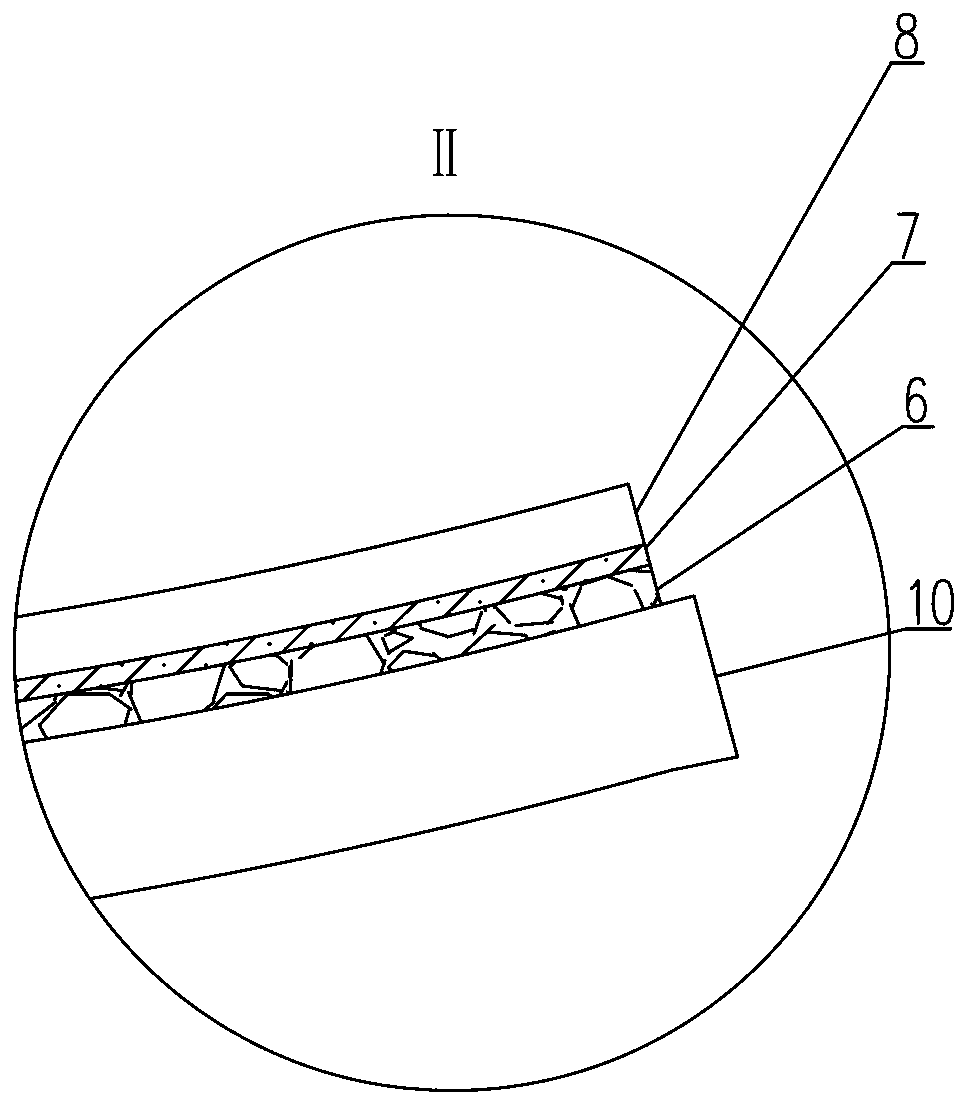

Bonding process of solar condenser lens assembly

InactiveCN102998773AAvoid breakageImprove impact resistanceSolar heating energyMountingsPaper recyclingBonding process

The invention discloses a bonding process of a solar condenser lens assembly. The bonding process comprises the following steps of enabling one ends of pressure-sensitive adhesive films to align with one ends of lenses, and bonding the painting surfaces of the lenses to the lower surfaces of the pressure-sensitive adhesive films; rotating a pressure-sensitive adhesive tape roller, utilizing an elastic push roller to push the pressure-sensitive adhesive films to the other ends of the lenses, and enabling a release paper recycling roller to drive release paper on the lower surfaces of the pressure-sensitive adhesive films to rotate; cutting and separating the pressure-sensitive adhesive films matched with the lenses according to the dimensions of cut lenses; respectively enabling a plurality of glass surfaces of the cut lenses to be adsorbed and flatly attached onto an adsorption surface of a convex die; removing the release paper on the upper surfaces of the pressure-sensitive adhesive films, and attaching the convex die adsorbing the plurality of cut lenses onto a back plate, wherein two ends of the convex die align with two ends of the back plate; and taking off the convex die, and utilizing the elastic push roller to gradually push the glass surfaces of the lenses to enable the upper surfaces of the pressure-sensitive adhesive films to completely contact with the bonding surface of the back plate. By means of the bonding process of the solar condenser lens assembly, the bonding effect is good, and the bonding performance is stable. Furthermore, the bonding process can be widely applied to the field of production of the solar condenser lens assembly.

Owner:DALIAN GREAT OCEAN NEW ENERGY DEV

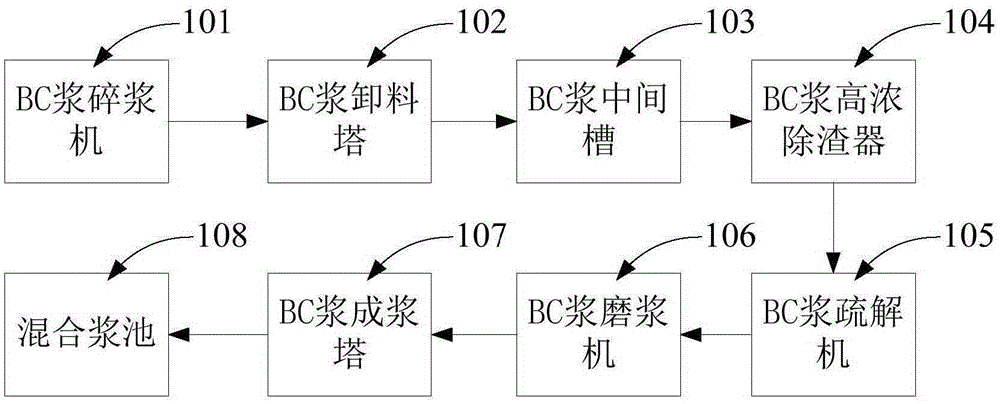

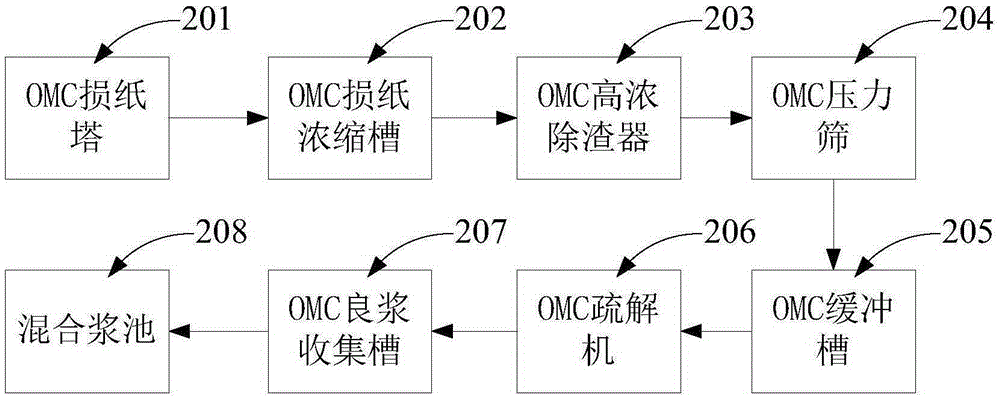

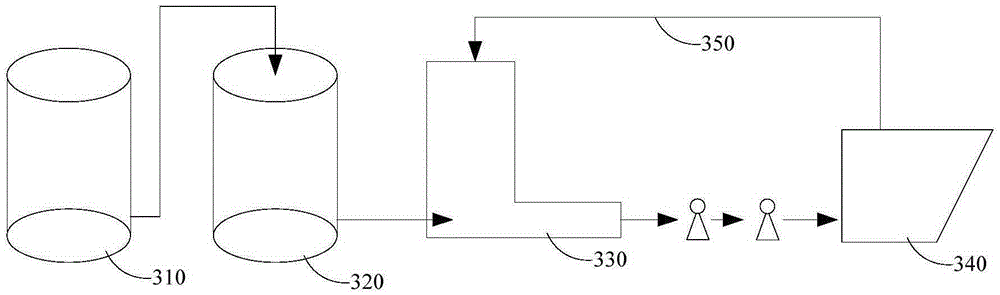

Paper machine system and negative ion control method thereof

InactiveCN105256647AImprove running performanceReduce productionDefoamers additionPaper/cardboardPaper recyclingWastewater systems

The invention provides a negative ion control method of a paper machine system. The method comprises the step of adding a polymer of low molecular weight and high charge density into at least one of a mechanical pulp line, an off-machine coating (OMC) broken-paper recycling line and a paper machine wastewater circulation line of the paper machine system, so as to neutralize negative ions in a sizing agent. Through the paper machine system and the negative ion control method thereof, in the running process of a paper machine, the content of negative ions in the sizing agent is controlled in three points such as the mechanical pulp line (BC pulp line), the OMC broken-paper recycling line and the paper machine wastewater circulation line, so that the problem that the negative ion content is too high is solved in two manners of reducing the number of negative ions entering the system and treating the negative ions entering the system, not only can the content of negative ion garbage in a wastewater system of the paper machine be reduced effectively, and but also the requirement of positive ions is reduced. Moreover, cleaning of a wet part system can improve the stability of the wet part directly; furthermore, the running performance of the paper machine and the use efficiency of chemicals are improved, and the output of broken holes and broken paper in the running process of the paper machine is reduced.

Owner:GOLD EAST PAPER JIANGSU

Pulp manufacturing method of used paper recycling apparatus, pulp manufacturing device of used paper recycling apparatus, and used paper recycling apparatus

InactiveCN101798770ASmooth beatingEffective beatingPaper recyclingPulp beating/refining methodsManufacturing technologyPaper recycling

Owner:SEED RUBBER CO LTD

Enzymatic Treatment of Virgin Fiber and Recycled Paper to Reduce Residual Mineral Oil Levels for Paper Production

ActiveUS20150136343A1Good removal effectReduce changesFats/resins/pitch/waxes removal in pulpMicroorganism/enzyme additionFiberPaper recycling

Compositions comprising enzyme compositions are provided. Also provided are methods of treating virgin fiber and recycled wastepaper containing mineral oils using the compositions comprising enzyme compositions. The mineral oils generally originate from wastepapers with mineral oil based inks and certain other hydrocarbon-based chemistries used during the manufacturing, paperboard converting, and packaging process. The enzymes break down or modify mineral oils present in the fiber and paper, mobilize and liberate them from the fibers, and increase removal of mineral oils during paper recycling, pulping and papermaking processes. The method results in the break down or modification of mineral oil components in wastepaper, recycled pulp, and paper products by the enzyme compositions so that the mineral oils can be more efficiently detached and removed. The resulting pulp and paper has much reduced mineral oil concentration or less problematic forms of mineral oils and is beneficial for making food packaging paper products.

Owner:ENZYMATIC DEINKING TECH LLC

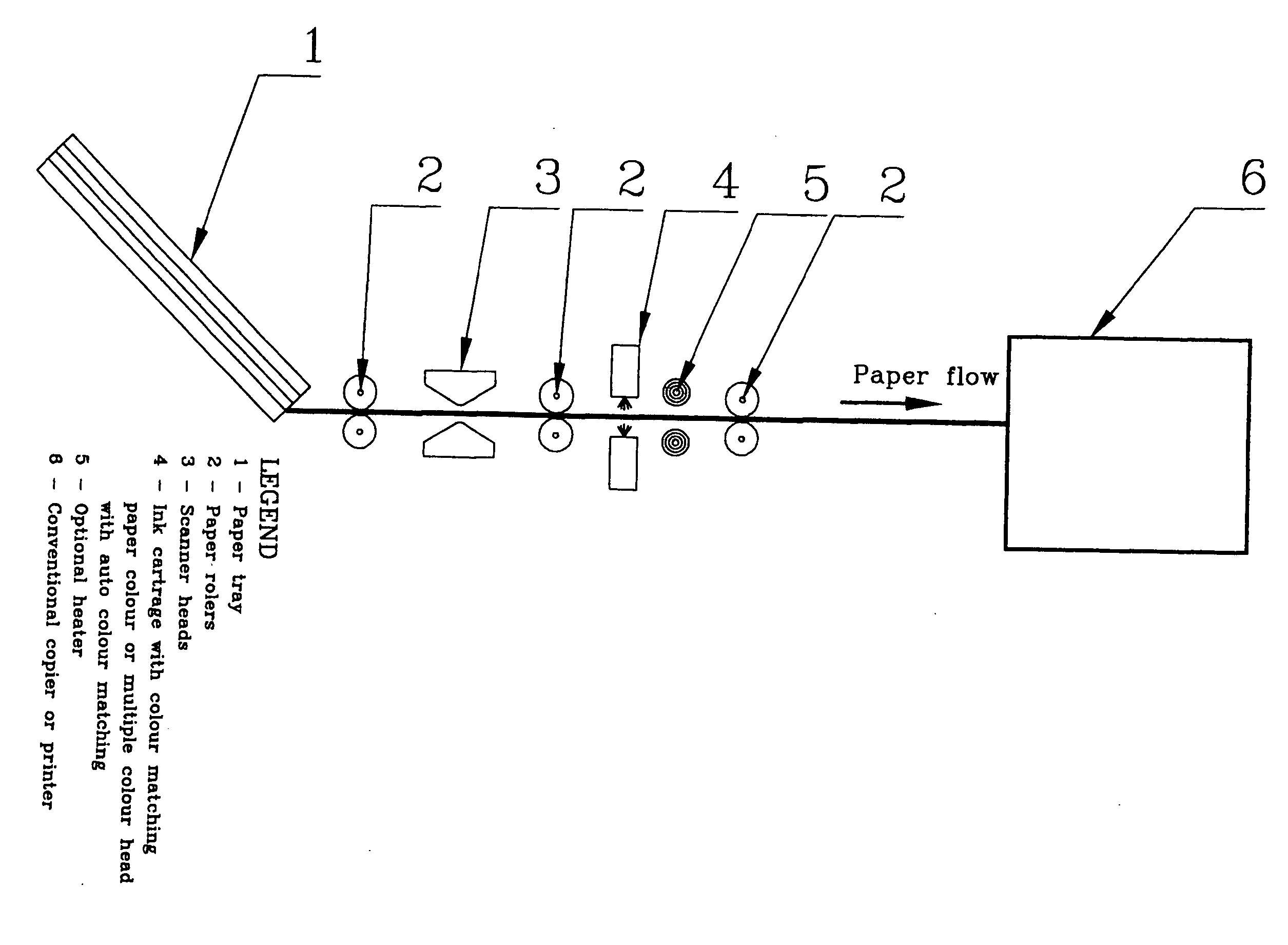

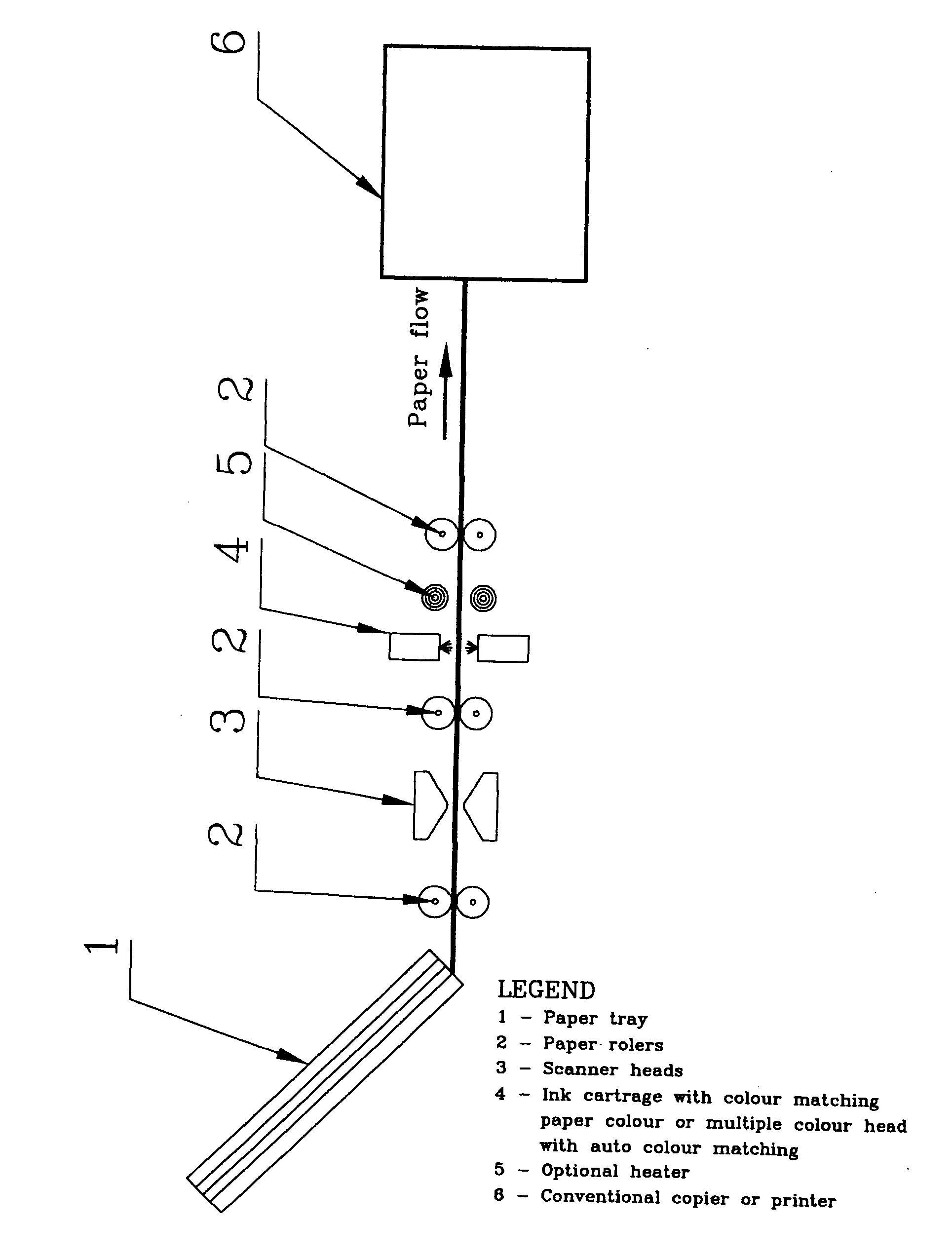

Print again assembly

InactiveUS20070132796A1New usageReduction in tree cuttingOther printing apparatusSystems designPaper recycling

An paper recycling and reclaiming system designed for paper copiers and printers or independent use. In one embodiment, the recycling paper system, will include the paper feeder, scanner, printer for same paper color printing (typically white) which could be externally or internally added to conventional copier or printer or used independently for general paper recycling and reclaiming.

Owner:JOVANOVIC ANNE +1

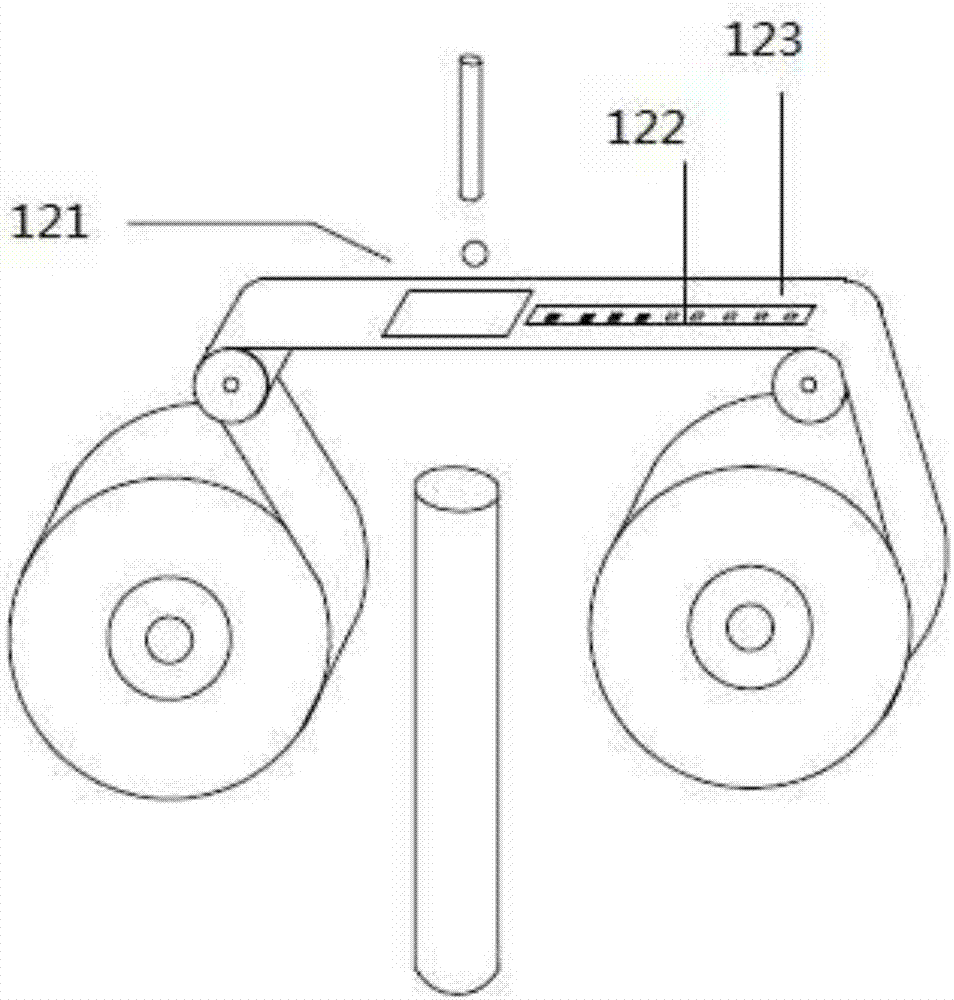

Pulp feeder for used paper recycling apparatus

InactiveCN102345239APrevent leakageImprove confidentialityPaper recyclingMachine wet endPaper recyclingPulp and paper industry

A pulp feeder capable of obtaining recycled paper of uniform texture, stable in the weight of the wet paper made on a mesh belt, in a very narrow used paper processing space of furniture size. A pulp feeding unit (pulp feeder) includes a retention unit disposed slidably on the upper side of an running mesh belt, for retaining a pulp suspension sent from a pulp manufacturing unit, and a paper making frame body for defining the supply width of the pulp suspension on the upper side of the mesh belt, in which the leading end position of this paper making frame body is provided with an overflow unit for keeping constant the water level of the pulp suspension retained in the retention unit. The pulp suspension supplied in the retention unit is retained to the water level defined the overflow unit, and is uniformly dispersed and supplied on the upper side of the mesh belt by cooperative action of this retention action and the running action of the mesh belt.

Owner:SEED RUBBER CO LTD

Test paper module

PendingCN107064132AReasonable structural designLow costMaterial analysis by observing effect on chemical indicatorPaper recyclingTest sample

A test strip module, comprising: a test strip storage bin, a test strip detection bin, a test strip recovery bin, a test strip supply device is arranged in the test strip storage bin, and a test strip recovery device is set in the test strip recovery bin; The test strip roll is arranged on the test strip supply device and is passed from the test strip storage bin through the test strip detection bin to be connected to the test strip recovery device arranged in the test strip recovery bin; the test strip detection bin is provided with a sample supply port, a waste Liquid collection port and sample detection window, wherein the sample supply port is used to provide the sample to the opposite test strip, the waste liquid collection port is used to recover excess waste samples, and the sample detection window is used for testing The sample testing instrument is used to test the test strip after carrying the sample.

Owner:易源易贝(北京)科技有限公司

Method for preparing hydrophobic paper

ActiveCN104120622ARaw materials are easy to getLow pricePaper coatingPhysical paper treatmentPolyolefinEmulsion

The invention discloses a method for preparing hydrophobic paper. The method comprises the following steps: firstly, grafting active monomer onto polyolefin through free radical polymerization reaction to obtain modified polyolefin; emulsifying the modified polyolefin to obtain modified polyolefin emulsion; finally uniformly mixing the modified polyolefin emulsion with paper coating to obtain composite emulsion, coating the paper by using the composite emulsion and drying to obtain the hydrophobic paper. The method disclosed by the invention has the advantages that on the premise that the existing paper producing processes are not changed, the hydrophobicity of the paper is increased; the using temperature range of the paper is broadened; the method is low in cost and good in controllability; the obtained paper is free of fluorosilicone chemical, easy and convenient in recovery processing and friendly to environment.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com