Image forming apparatus

An image and paper technology, applied in the field of image forming devices, can solve the problems of damage to the printing surface, low work efficiency, inappropriateness, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, exemplary embodiments will be described with reference to the drawings. It should be added that the following descriptions of appropriate exemplary embodiments are basically just examples, and are not intended to limit the present invention, objects to which the present invention is applied, or uses thereof.

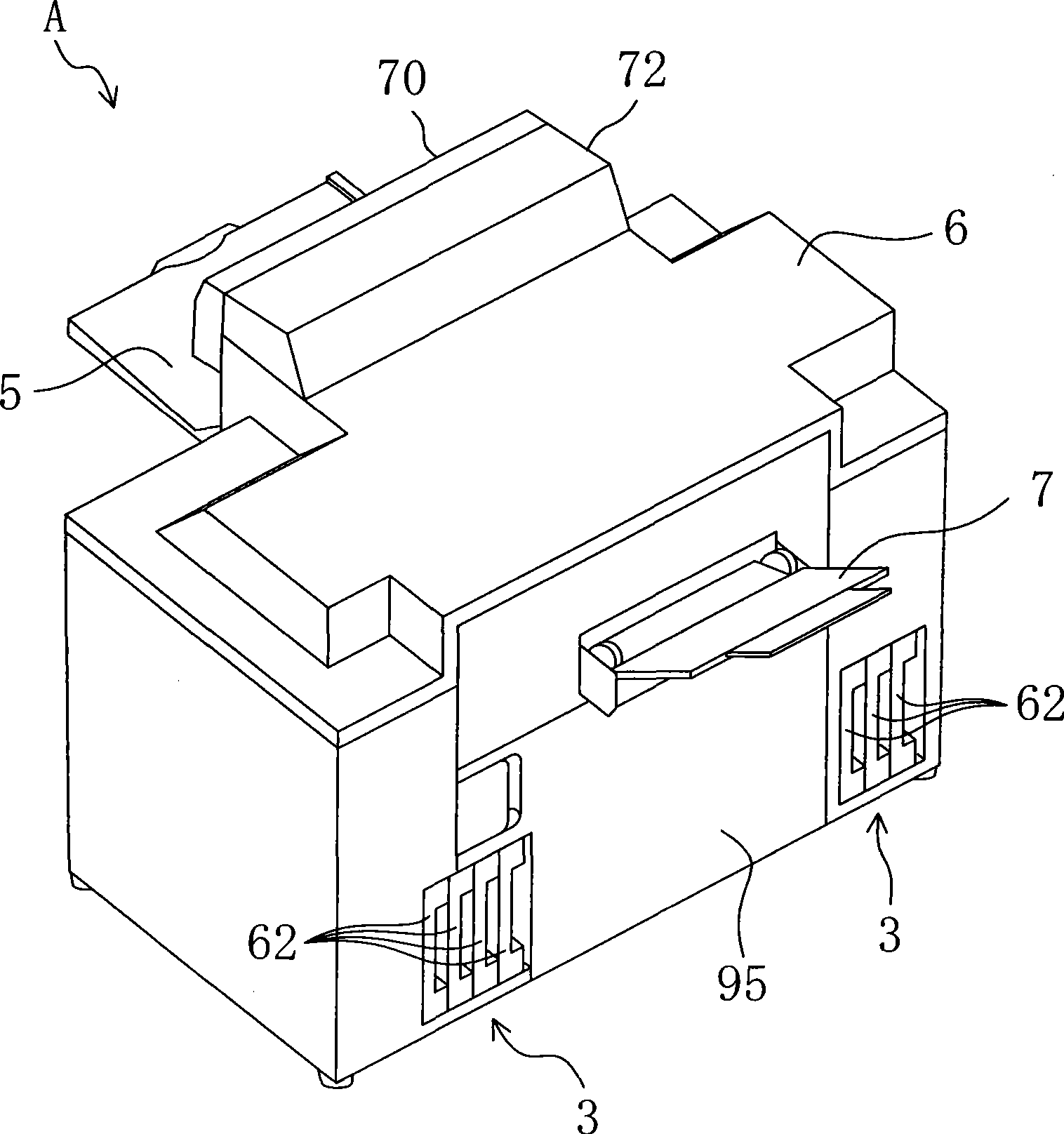

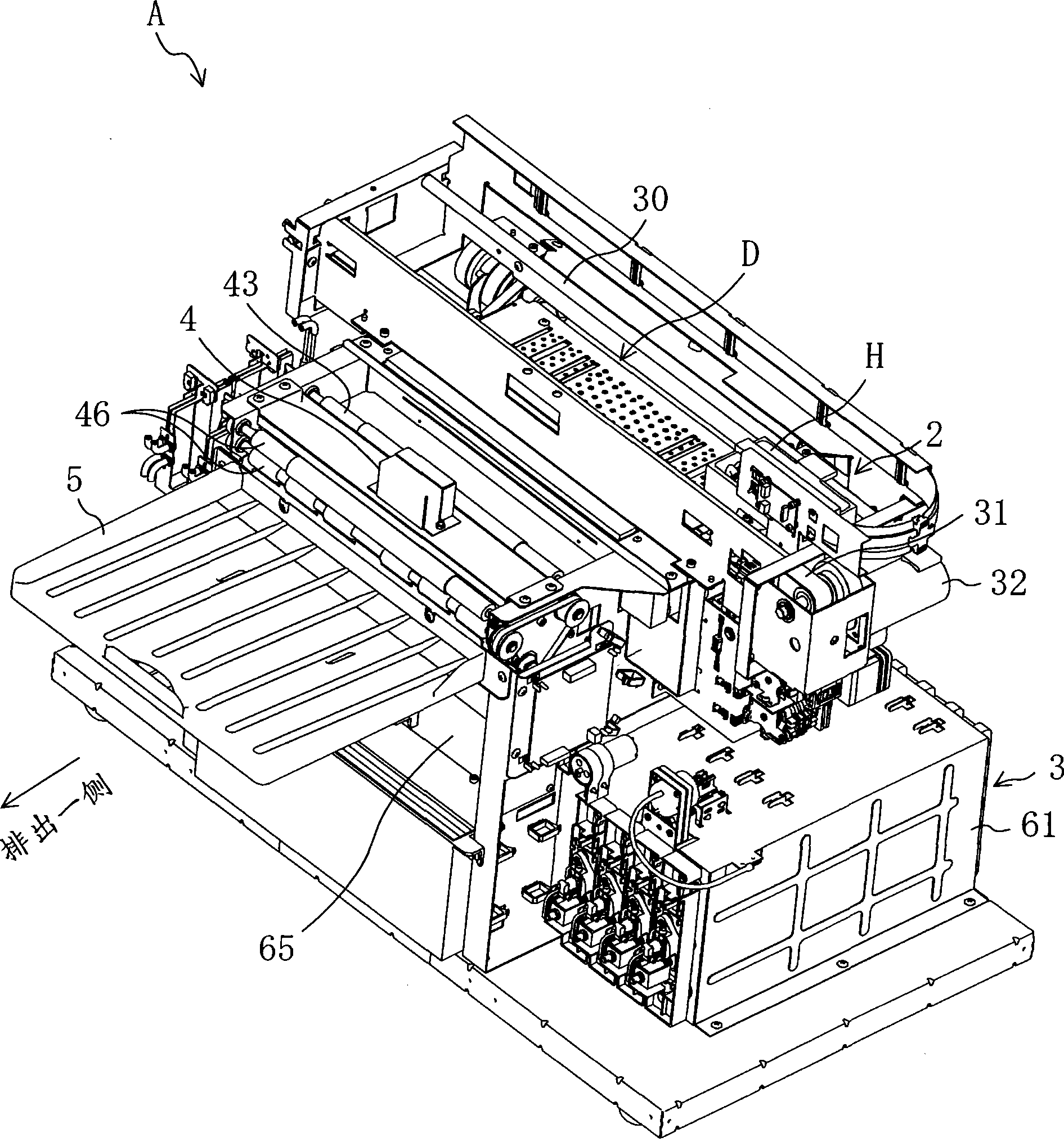

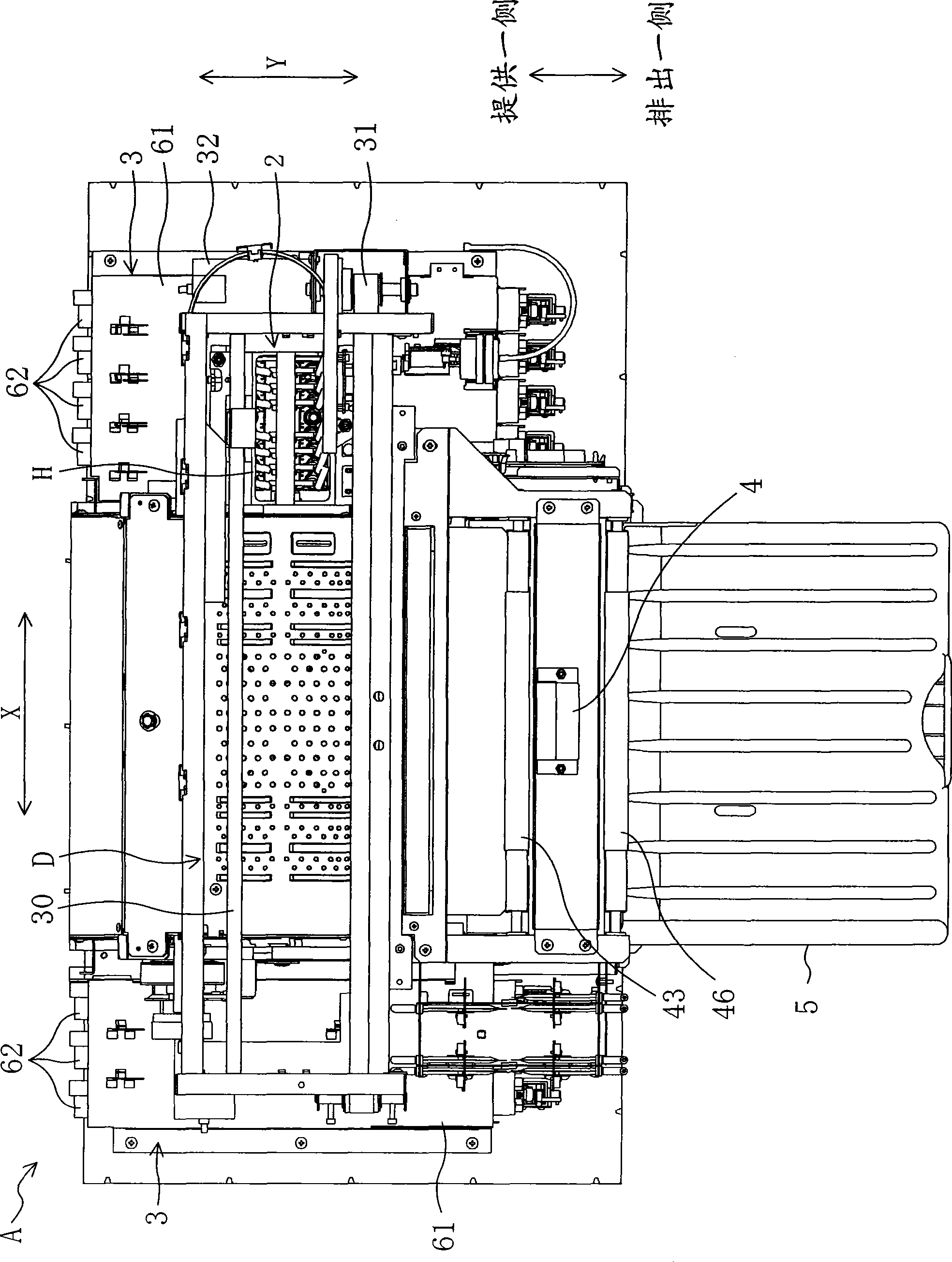

[0039] figure 1 The appearance of an inkjet printer A serving as an image forming apparatus according to an exemplary embodiment is shown, Figure 2 to Figure 5 The internal structure of inkjet printer A is shown. This inkjet printer A is used in a photo printing system, and prints on printing paper P1, P2 based on image data transmitted via a communication cable from a receiving block that acquires image data and performs necessary correction processing, for example. This inkjet printer A is configured to be able to perform automatic printing and manual paper feeding printing, and when performing automatic printing, pull out one end of a very long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com