Patents

Literature

1558 results about "Paper cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A paper cut occurs when a piece of paper or other thin, sharp material slices a person's skin. Paper cuts, though named from paper, can also be caused by other thin, stiff materials. Although a loose paper sheet is usually too soft to cut, it can be very thin, being then able to exert high levels of pressure, enough to cut the skin. Paper cuts are most often caused by paper sheets that are strongly fastened together, because one single paper sheet might be dislocated from the rest. Thus all the other sheets are holding this dislocated sheet in position, and the very small part held away from the rest can be stiff enough to act as a razor. Paper cuts can be surprisingly painful as they can stimulate a large number of skin surface nociceptors in a very small area of the skin. Because the shallow cut does not bleed very much, the pain receptors are left open to the air, ensuring continued pain. However, the cut can also be very deep, in which case a puddle of blood pools around a longer gash. This is exacerbated by irritation caused by the fibers in the paper itself, which may be coated in chemicals such as bleach.

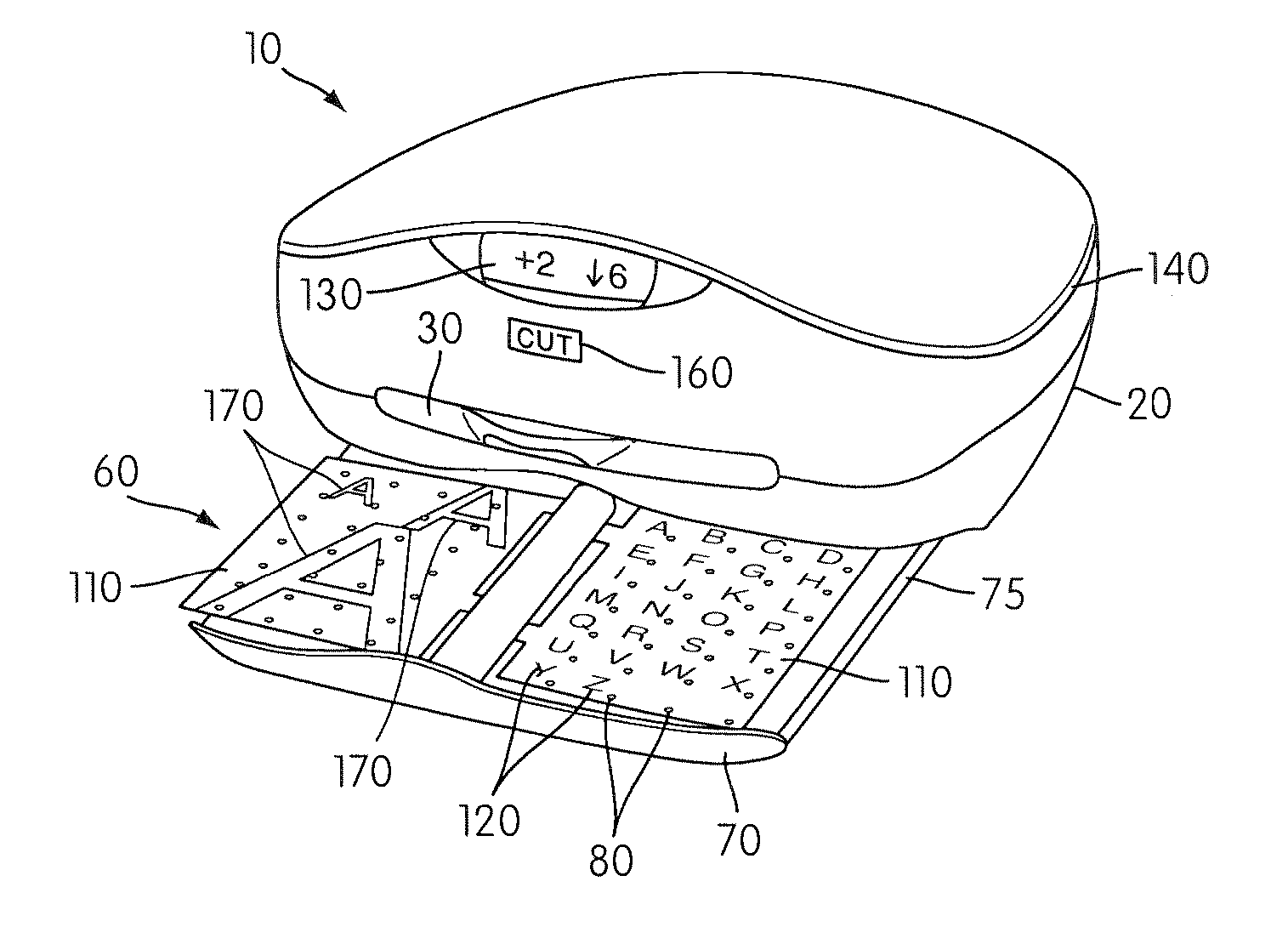

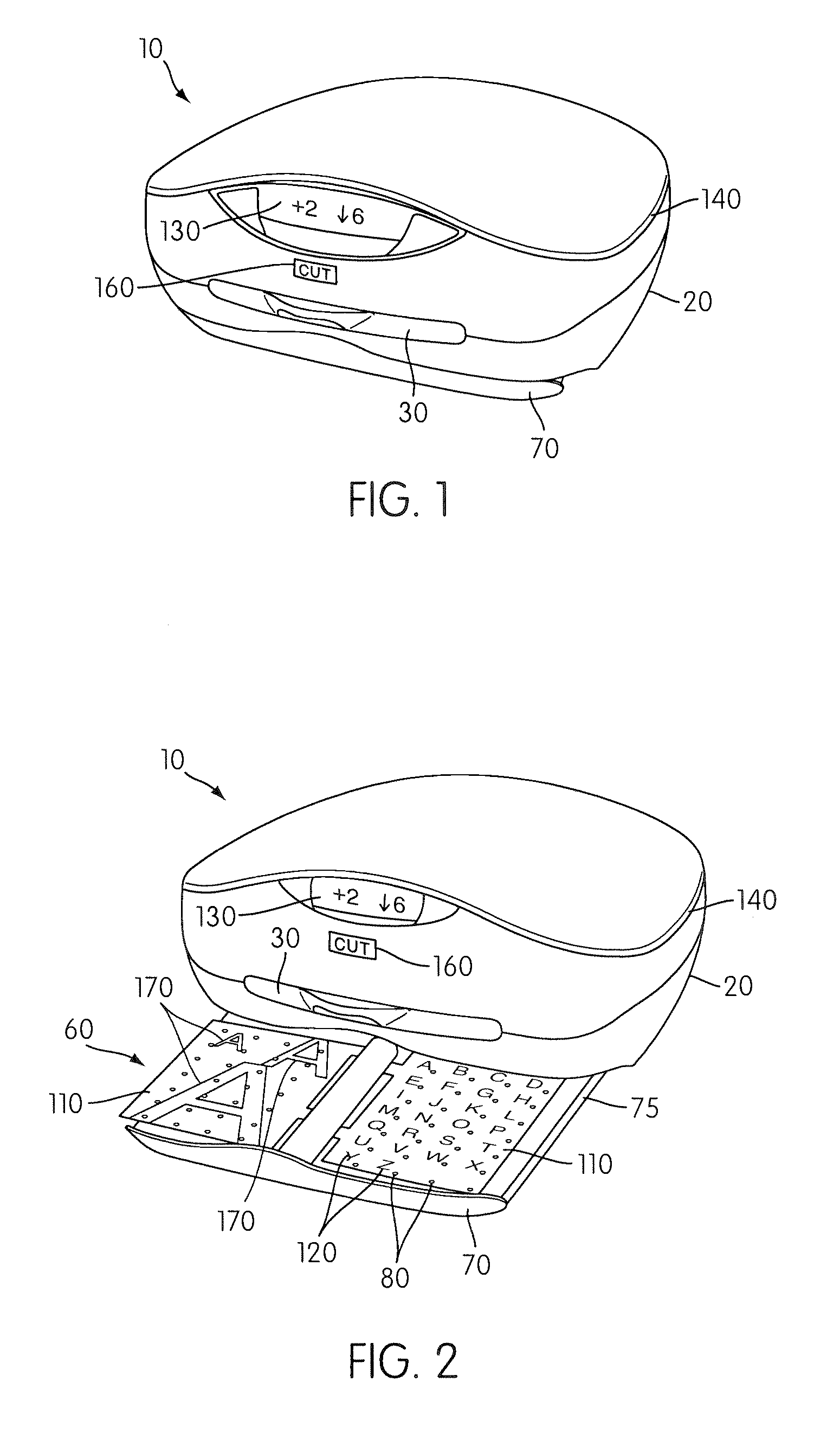

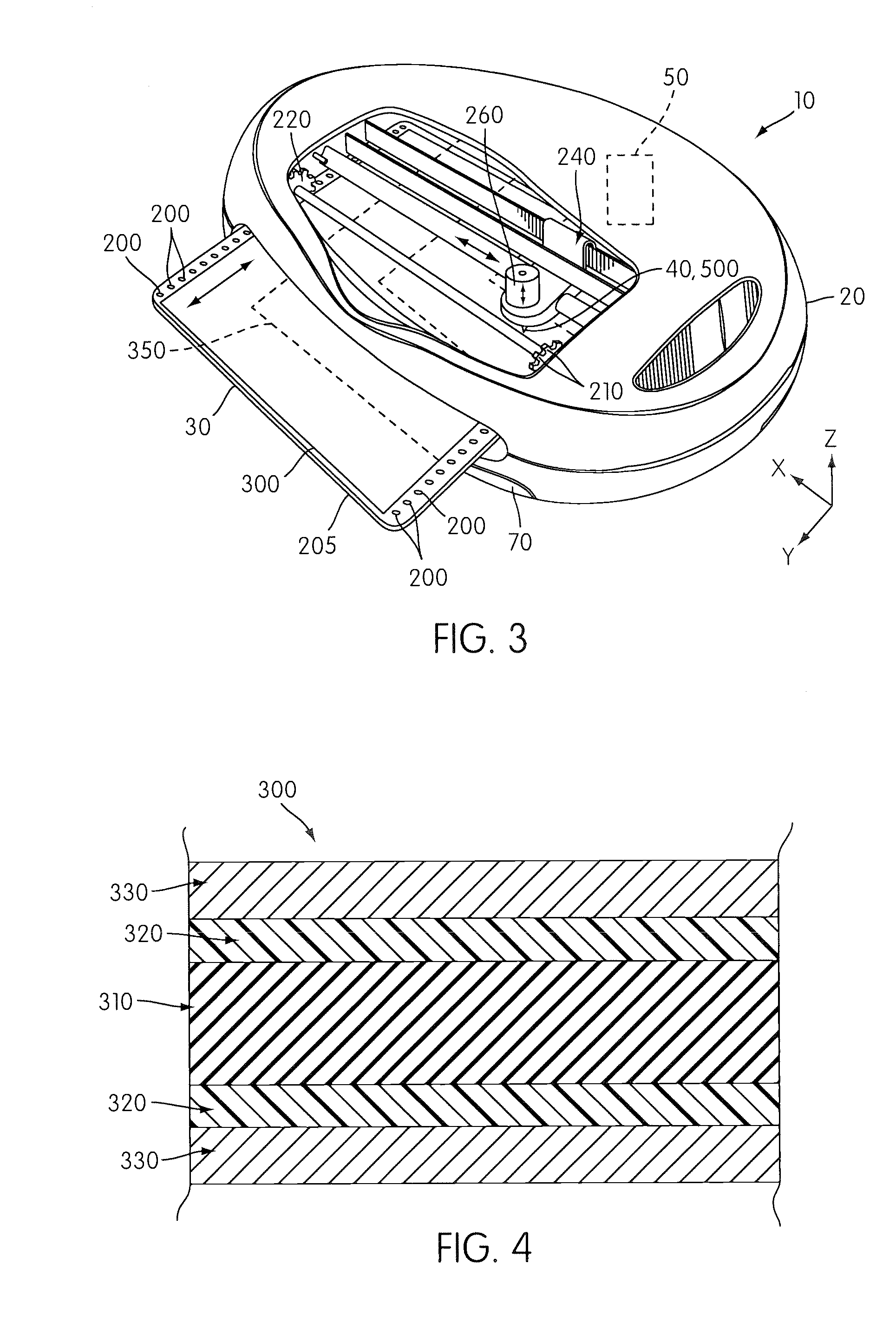

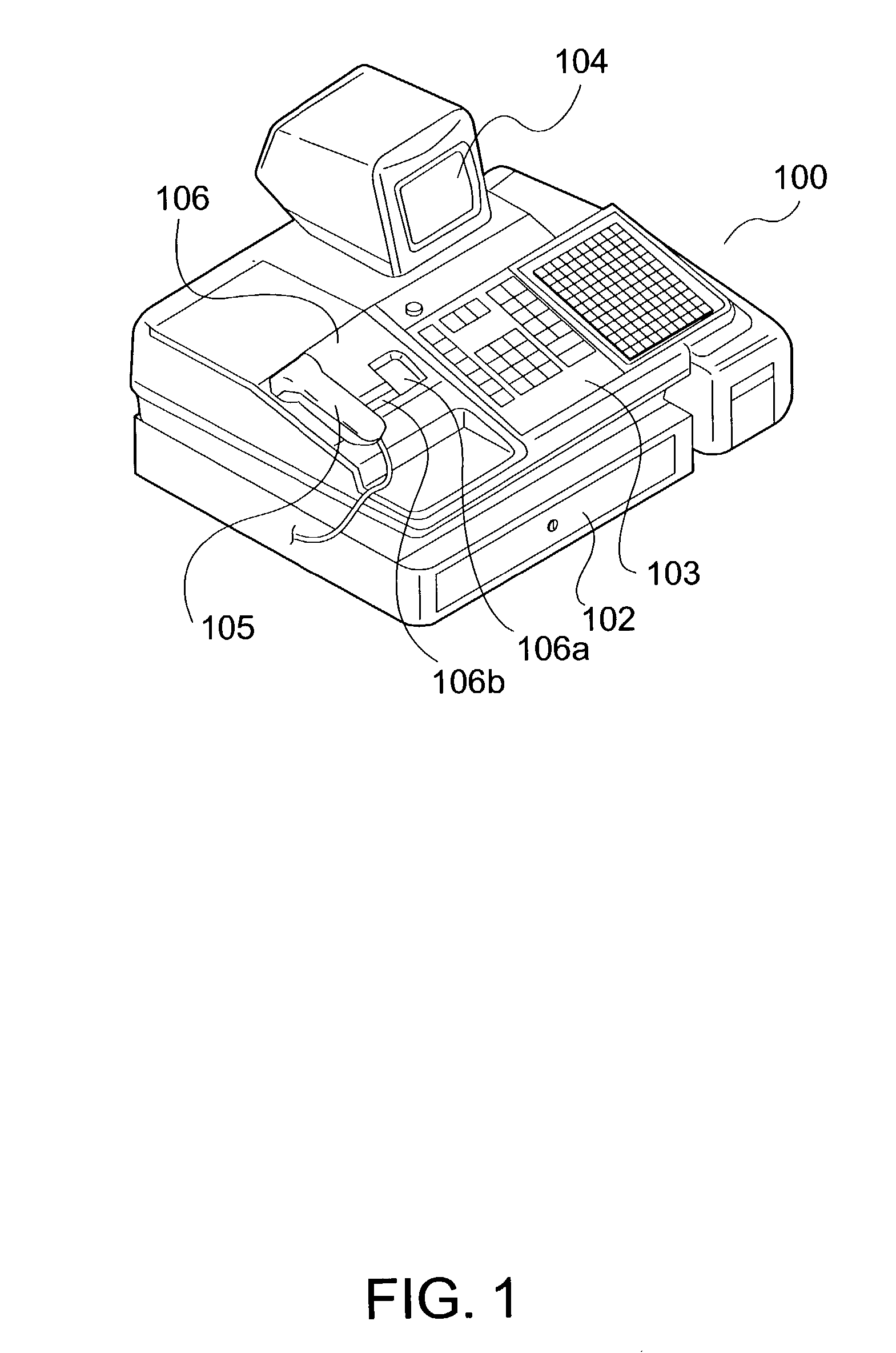

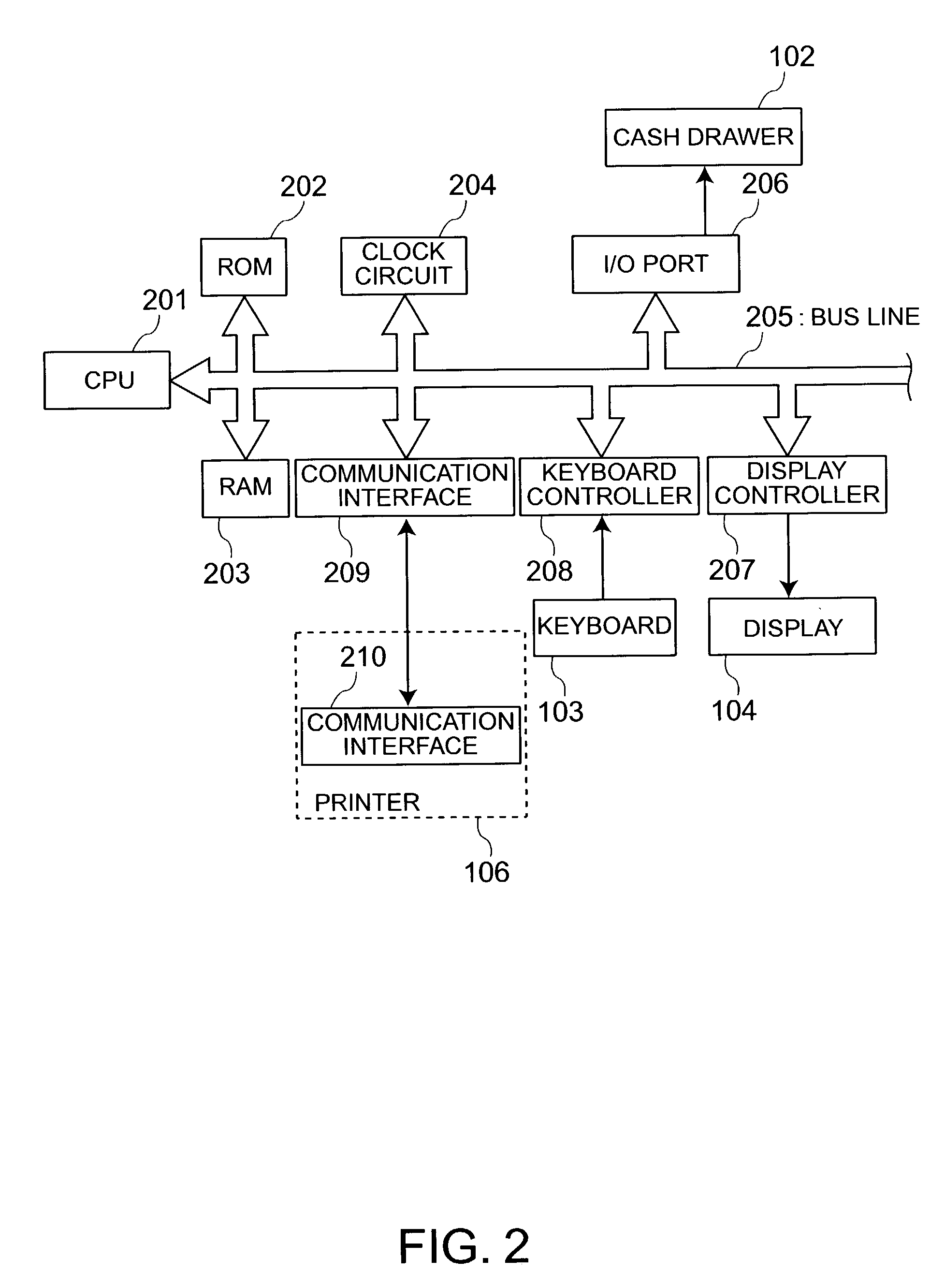

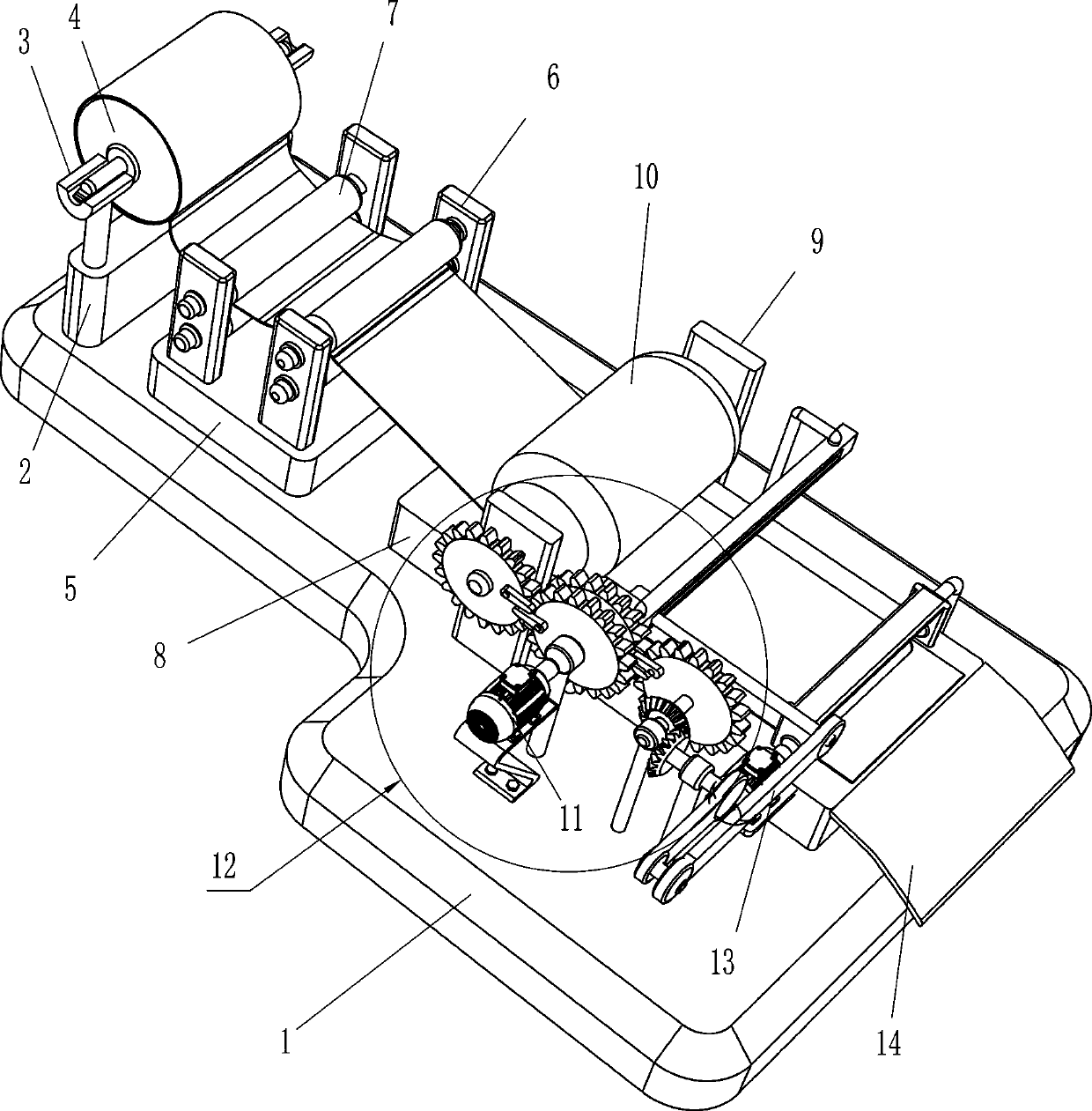

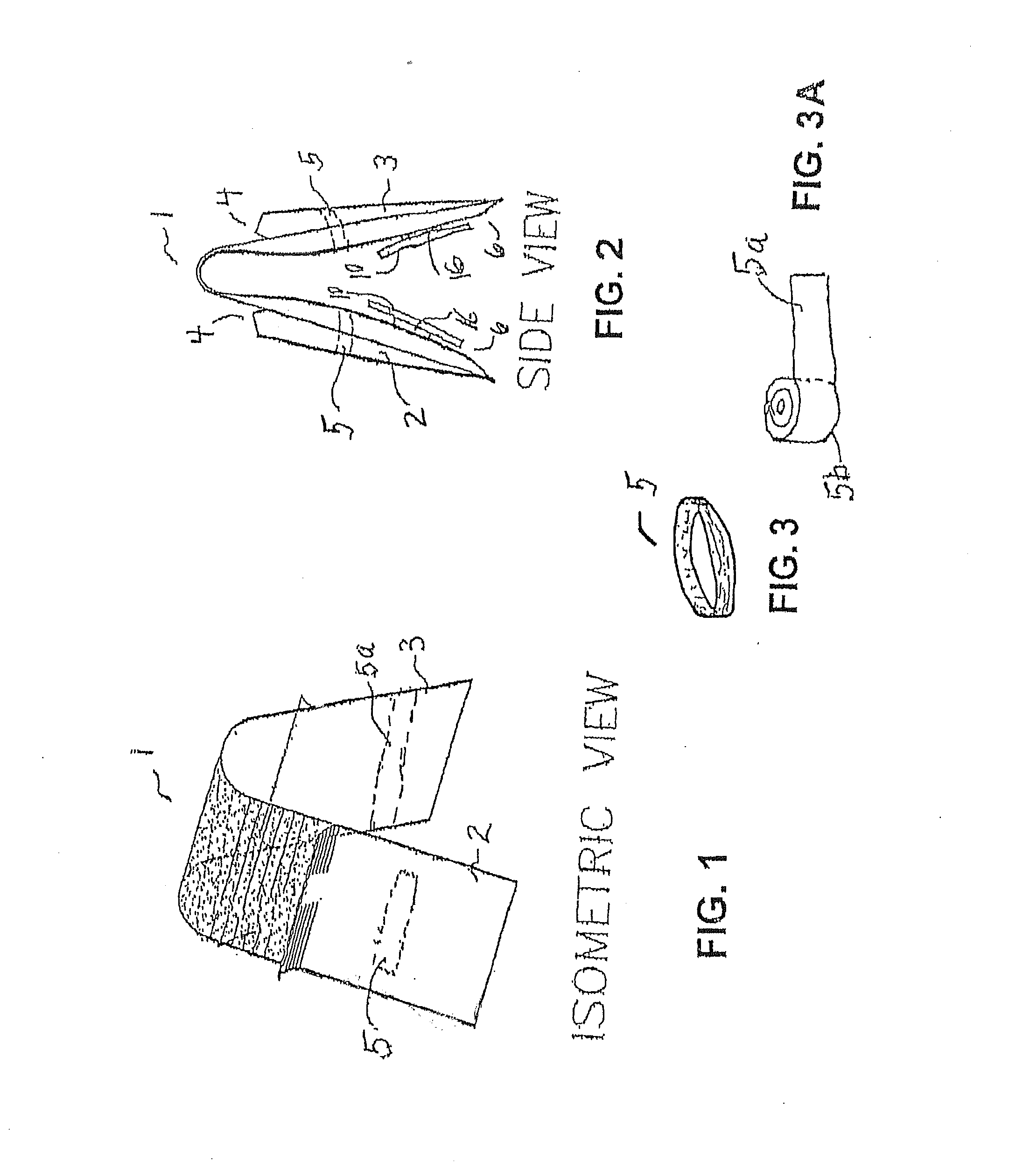

Automatic pattern making apparatus

InactiveUS20070227332A1Quickly and easily selectedQuick cutMetal working apparatusContainer making machineryEngineeringAdhesive

An automatic paper cutting apparatus includes an X-Y cutter, a cutter controller, and a pattern booklet. The pattern booklet includes a plurality of pattern identifiers and a memory device with cutting instructions for each of the identified patterns. The booklet removably mounts to the cutter controller so that an operator can select a pattern from the pattern booklet and have the memory device provide the corresponding set of cutting instructions to the cutter controller. The cutter controller uses the instructions to control the X-Y cutter and cut the desired pattern. A cutting platform of the X-Y cutter has a tacky adhesive that releaseably secures a work piece to the cutting platform during cutting operations. The cutting platform includes surface features that engage a spur gear. The cutter controller selectively rotates the spur gear to drive the cutting platform in the Y direction. The apparatus may use a journaling, embossing, perforating instrument instead of the cutter to make a pattern on the work piece.

Owner:ESSELTE LLC

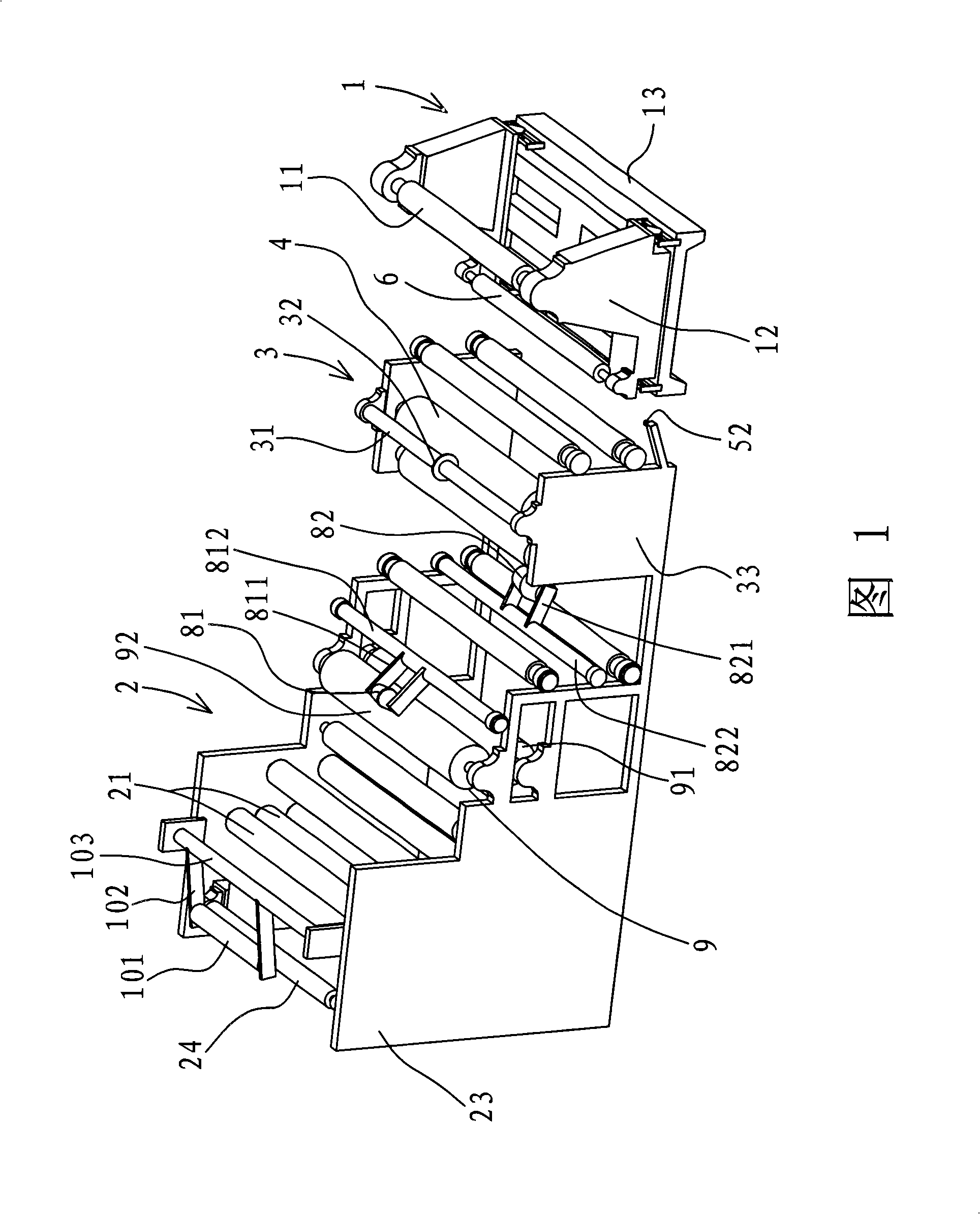

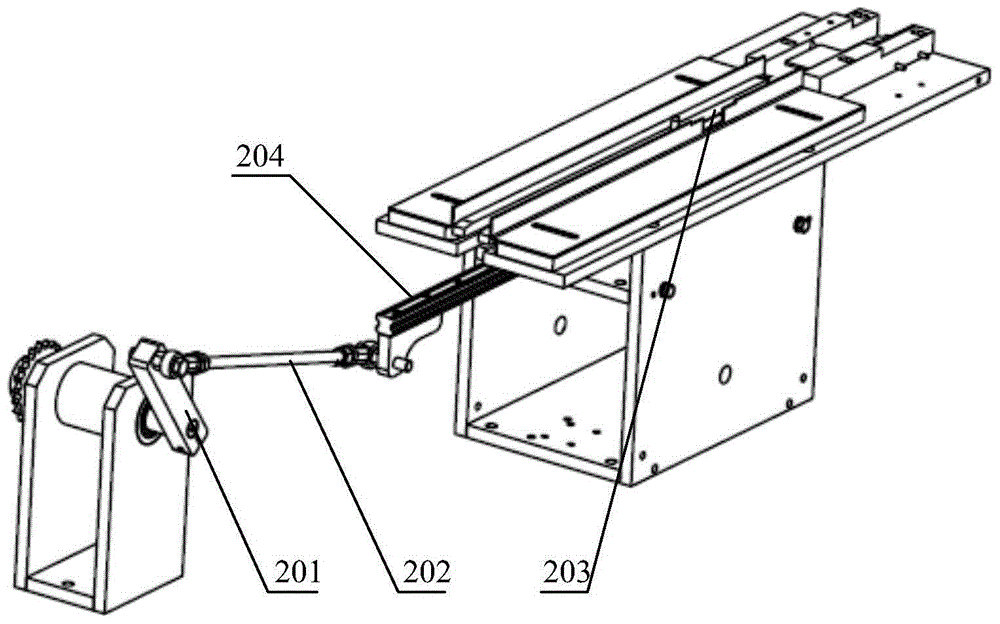

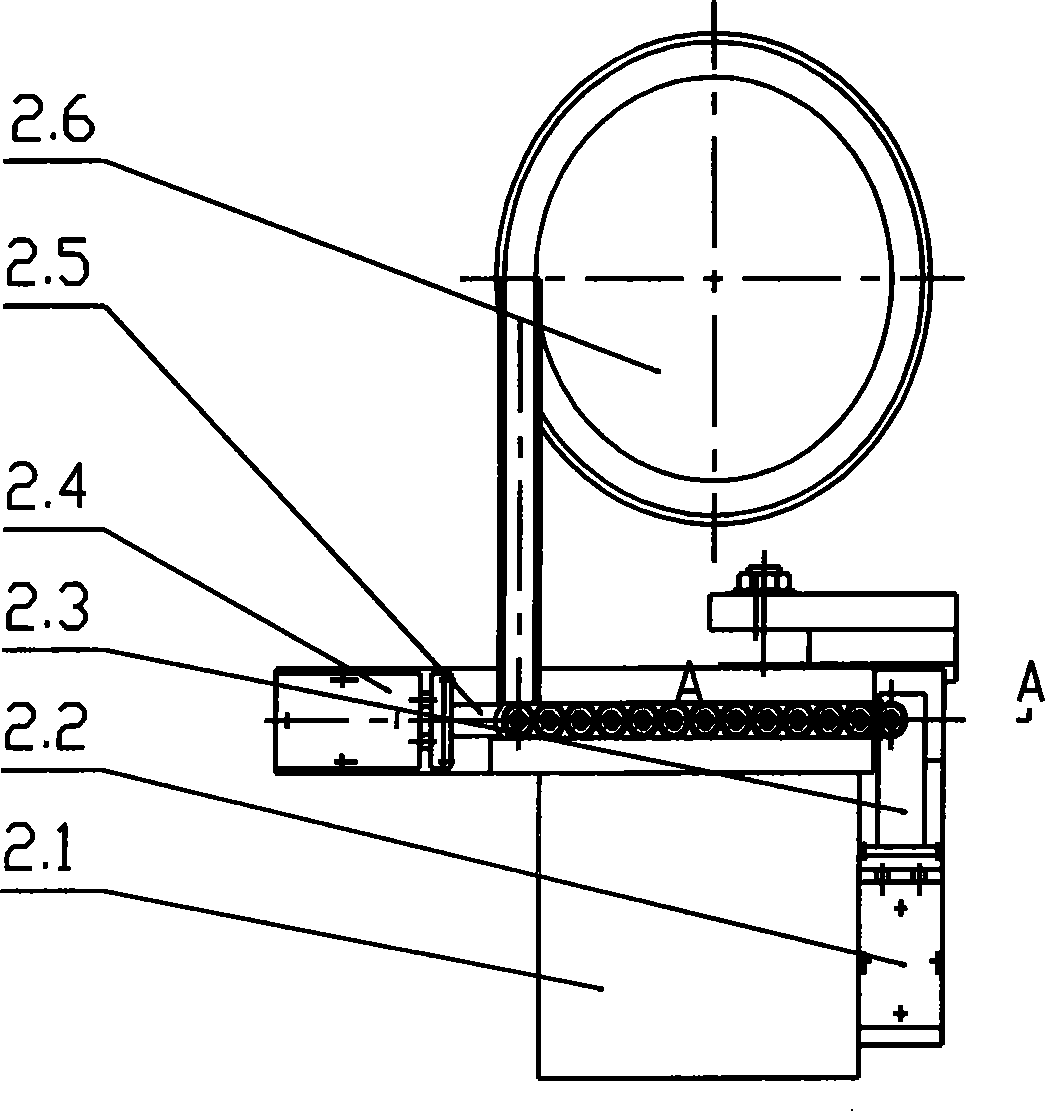

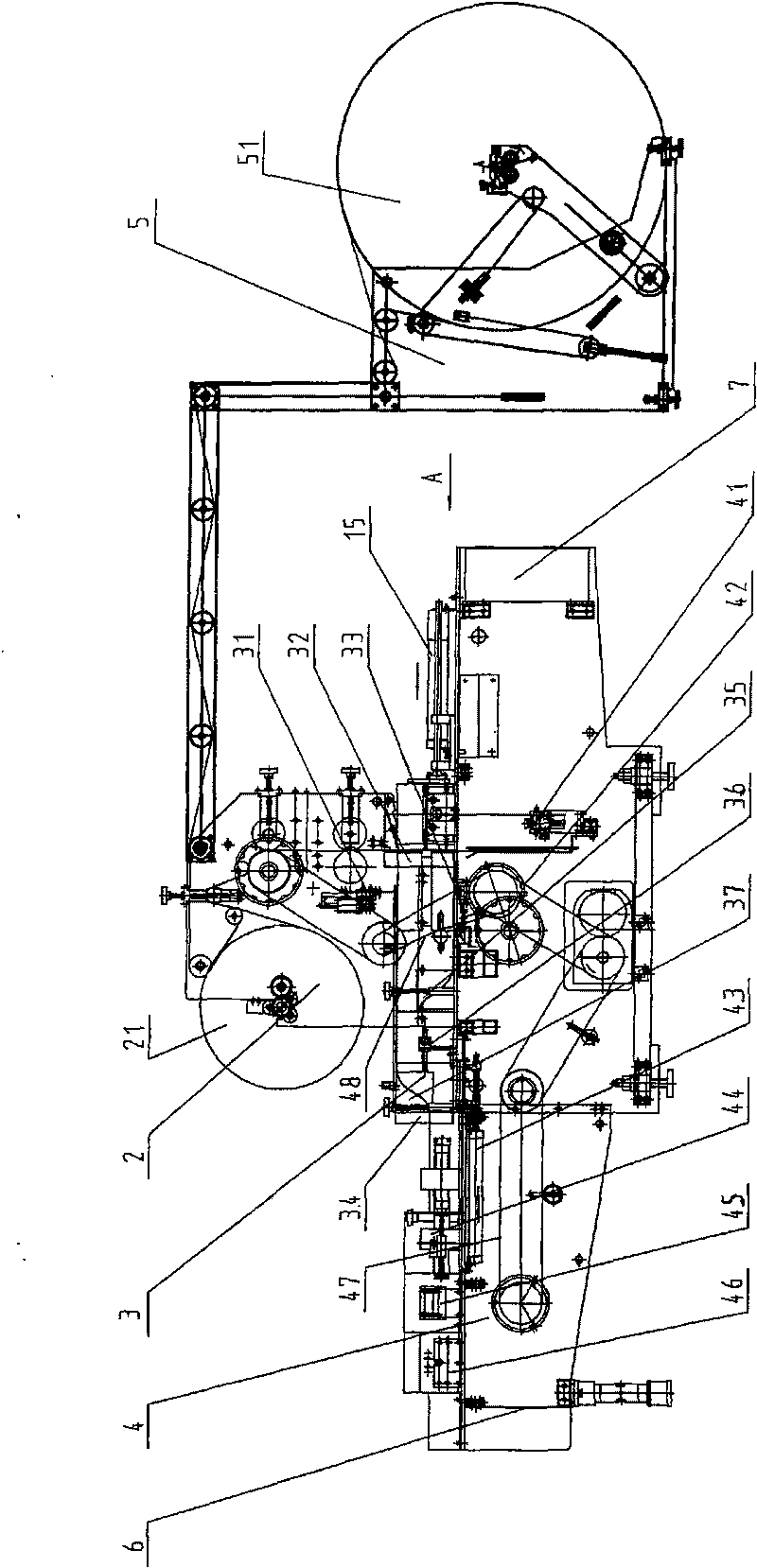

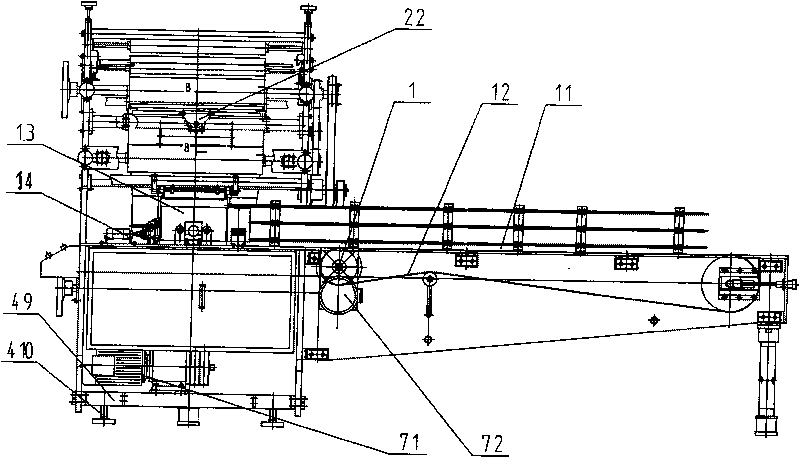

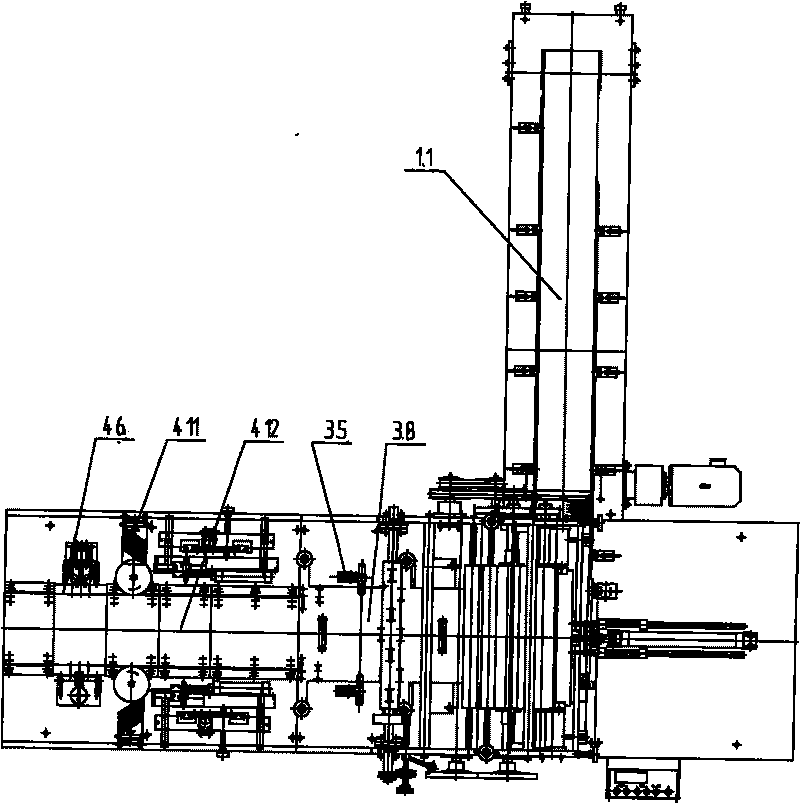

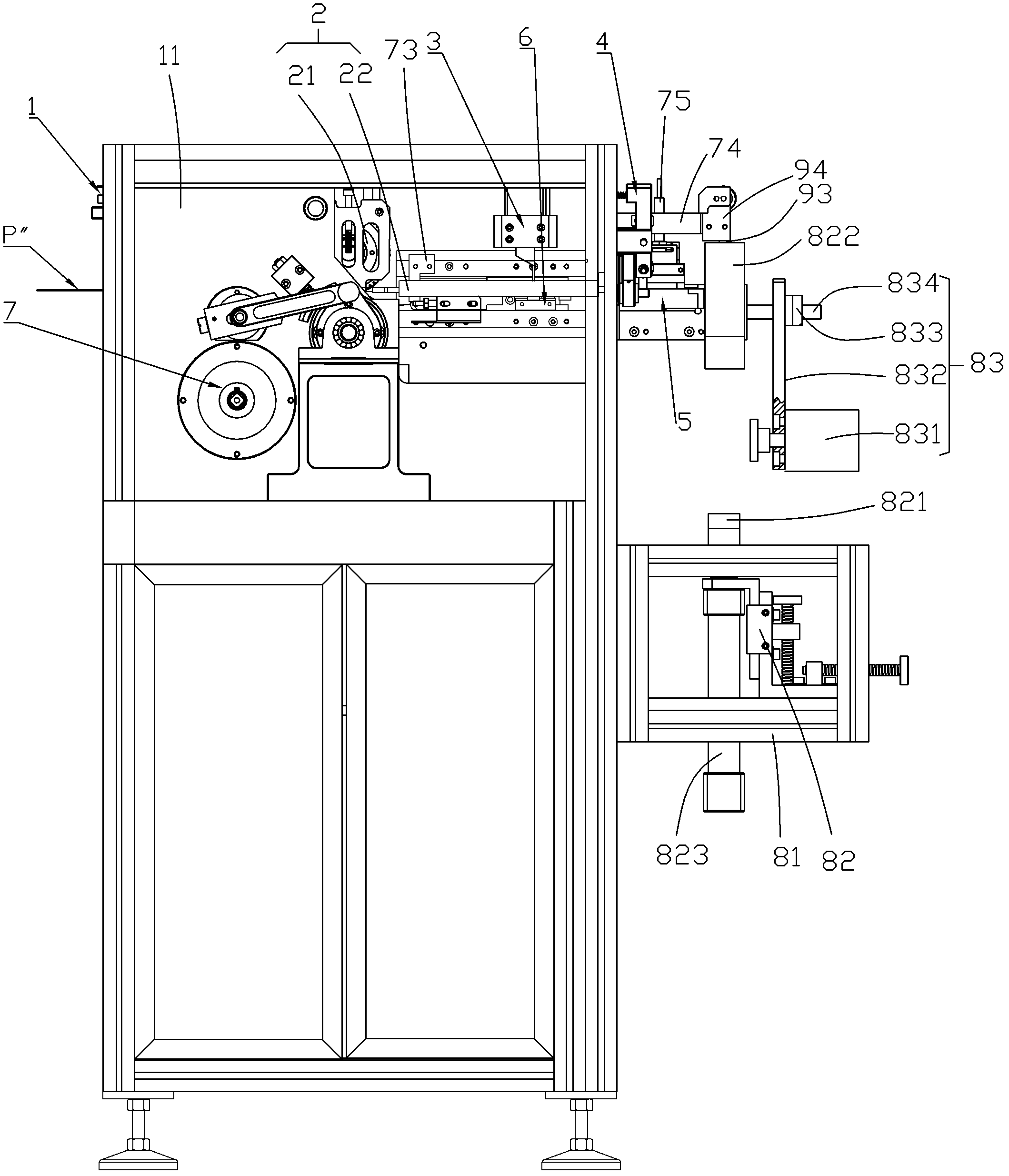

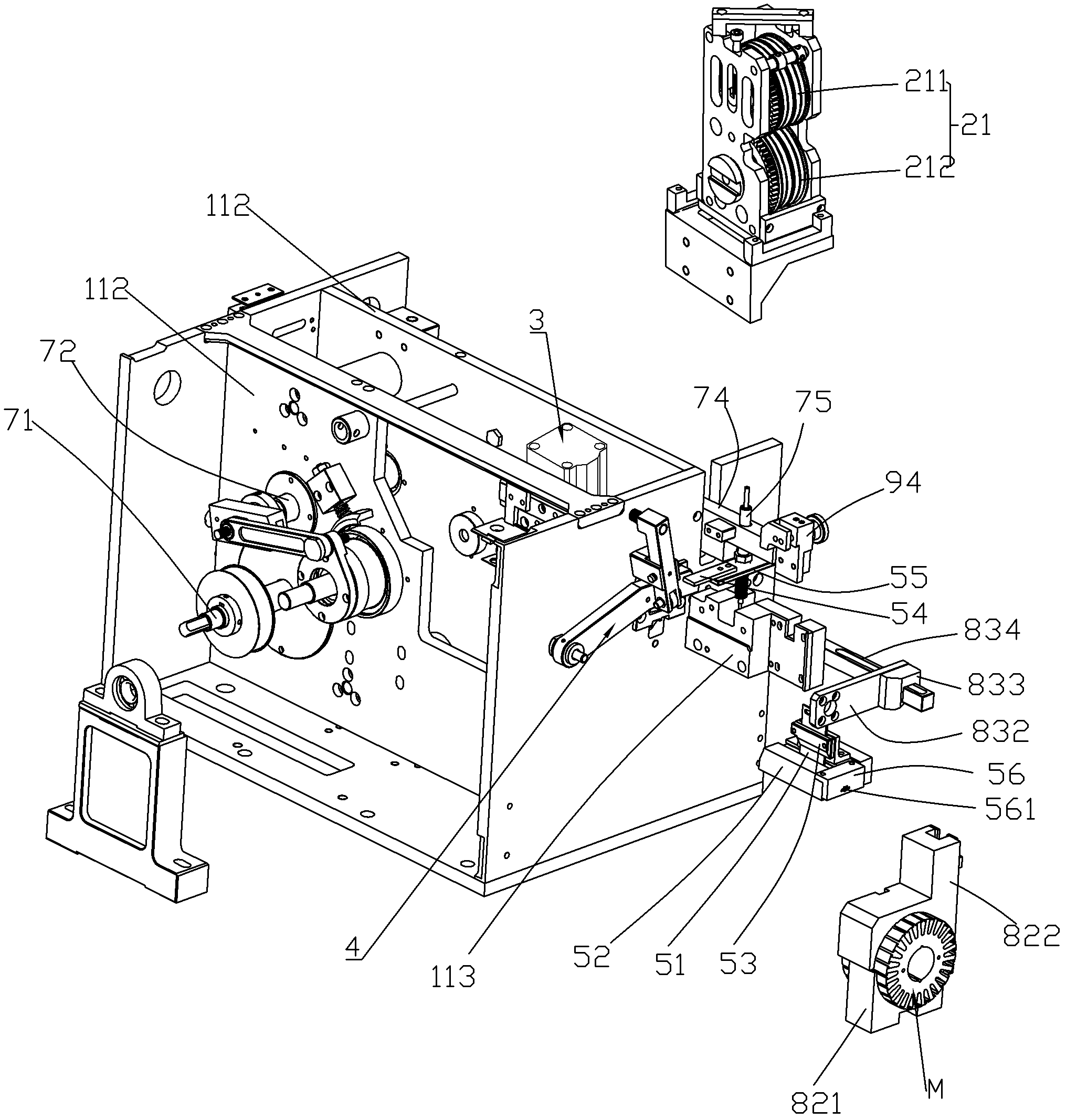

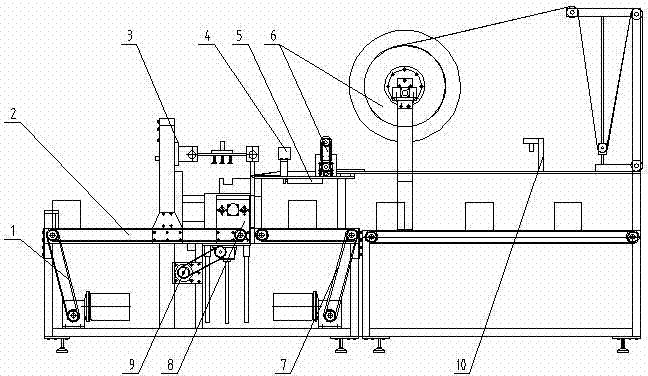

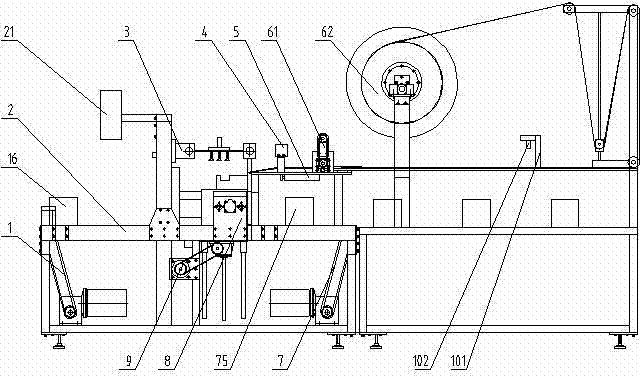

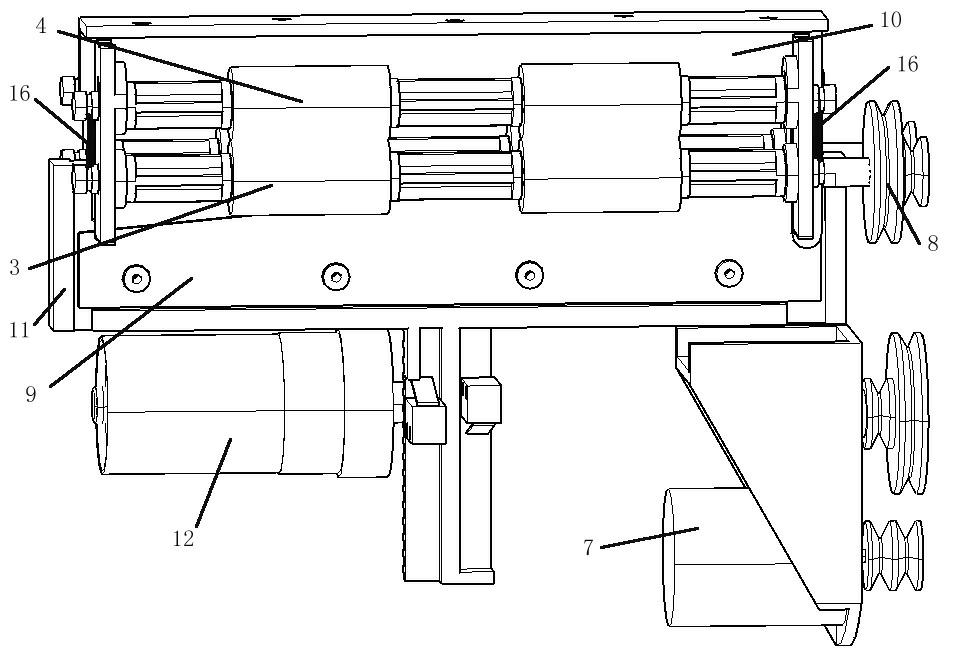

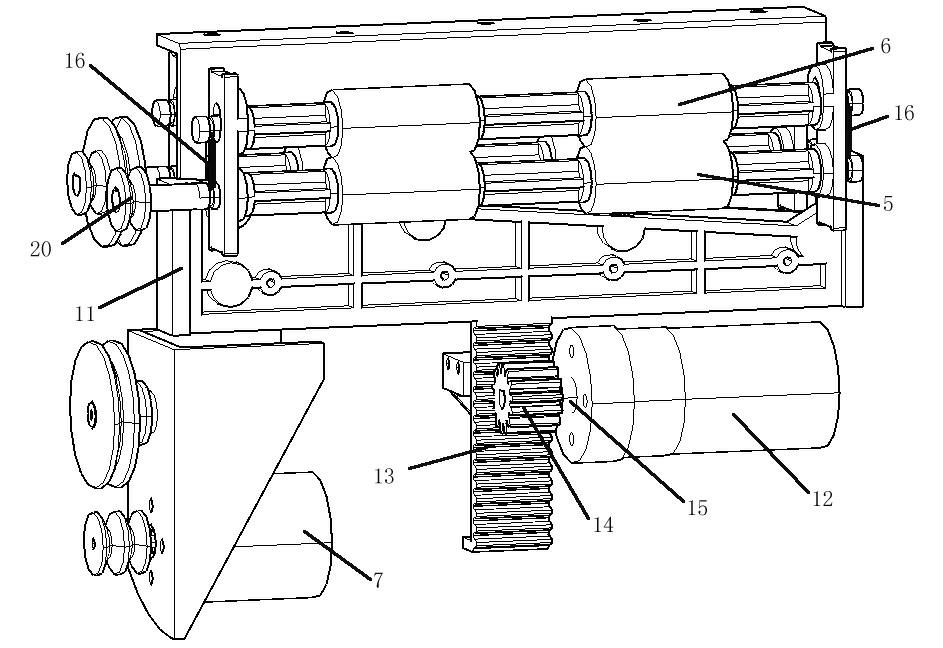

Splitting winding machine for base paper

ActiveCN101301969ACut evenlyOffset is automatically eliminatedMetal working apparatusArticle deliveryWinding machineEngineering

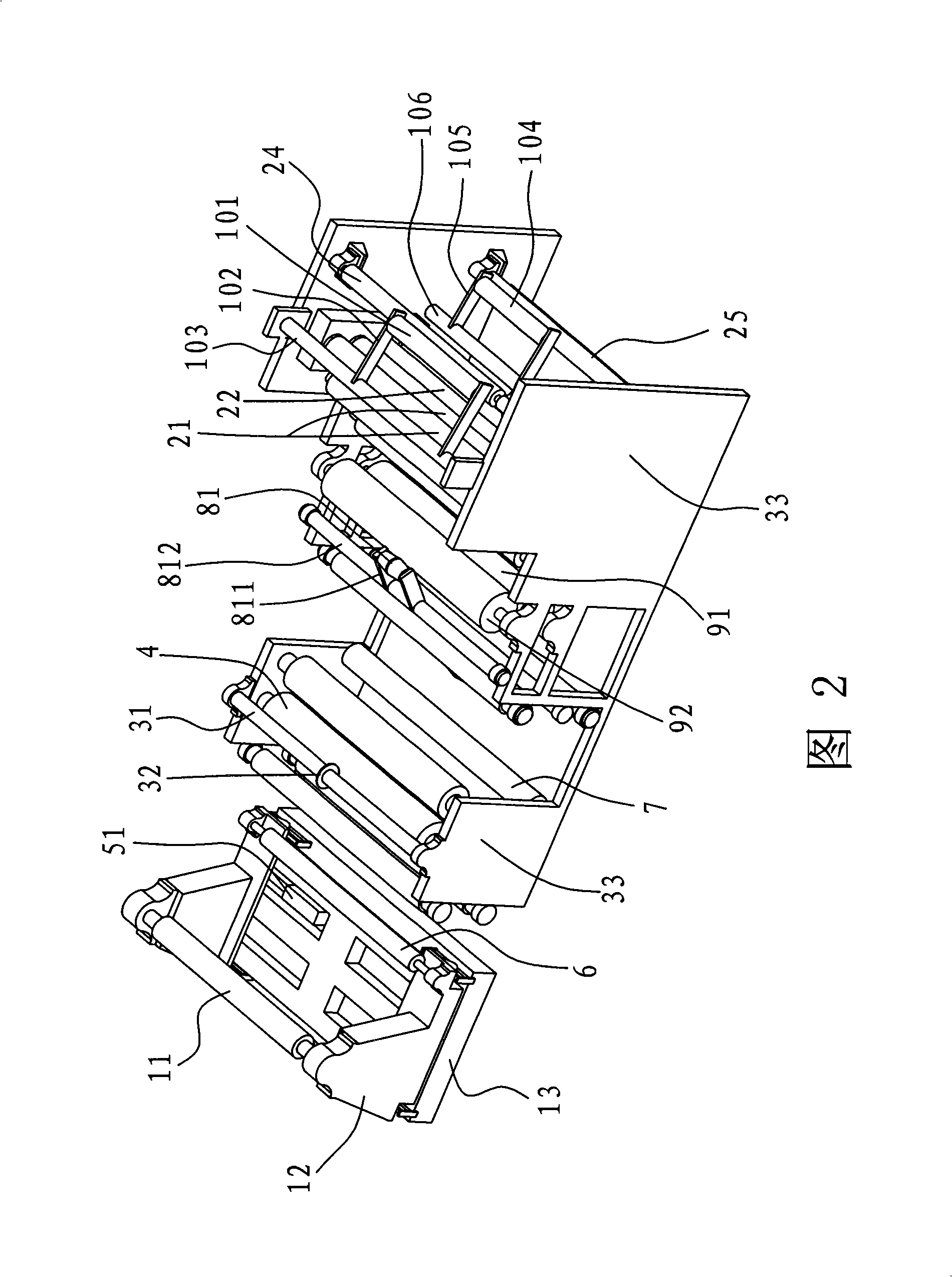

The invention relates to the decorative winding device technical field, in particular to a base paper cutting winding machine which comprises an unwinding device and a winding device. A cutting mechanism comprising a cutting roller and a cutting knife is arranged between the unwinding device and the winding device, the two ends of the cutting roller are movably arranged on a cutting bracket, and the cutting knife is coaxially arranged on the cutting roller. A driving roller is arranged right under the cutting roller, the two ends of the driving roller are movably arranged on the cutting bracket, and the cutting roller is respectively connected with the two ends of the driving roller by driving pairs. Two groups of guiding roller sets are arranged on the winding device, and the guiding roller sets are arranged on a winding frame. A first winding roller and a second winding roller are respectively arranged on the upper part and the lower part of the winding frame, and the first and the second winding rollers are respectively connected with a first driving mechanism and a second driving mechanism. By utilizing the cutting winding machine, cutting and winding works can be completed by one time, furthermore, the cutting is equal and the winding is neat, thus conserving manpower and cost.

Owner:东莞市华富立装饰建材有限公司

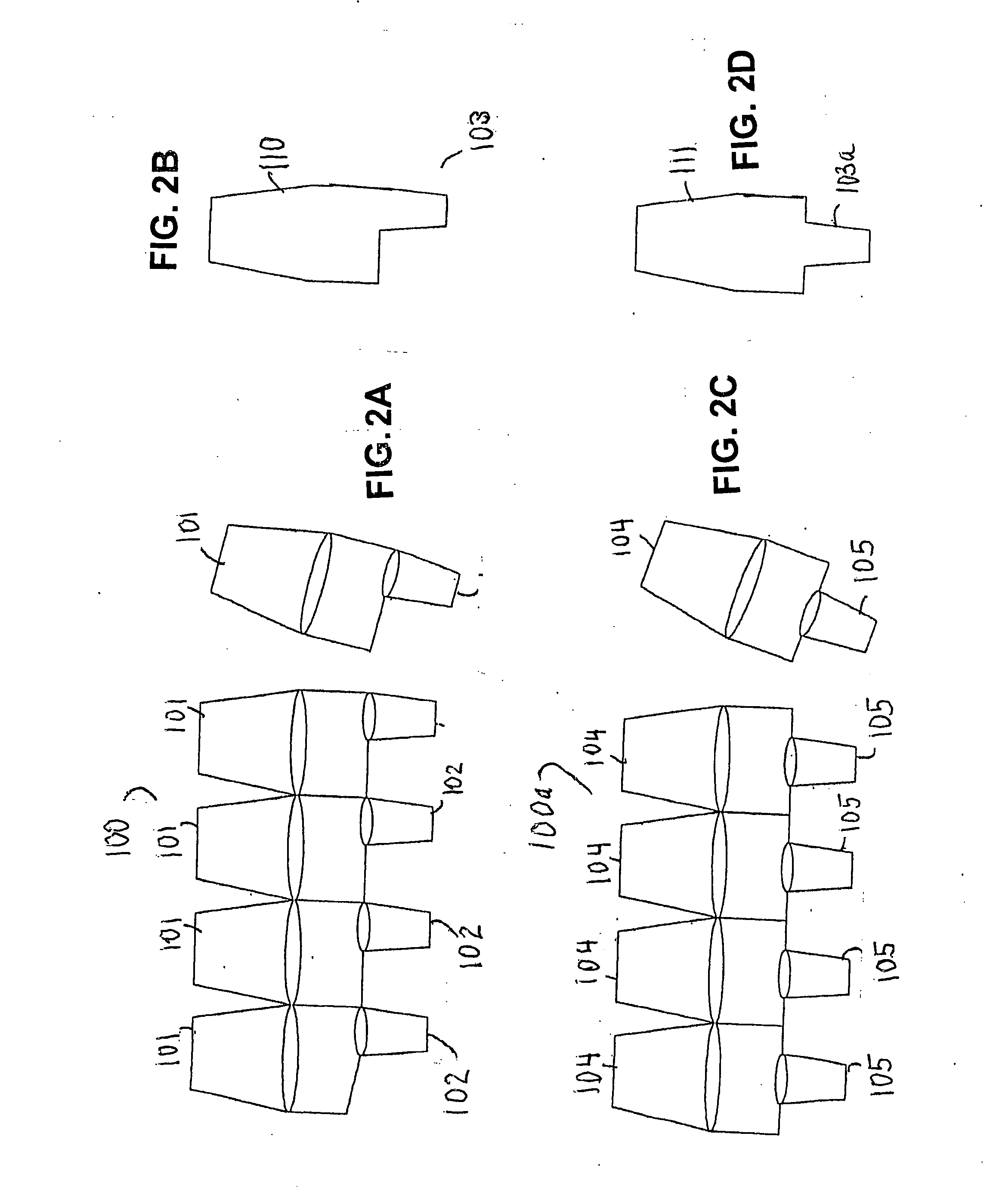

Method for registering sheets in a duplex reproduction machine for alleviating skew

ActiveUS6988725B2Reduce misalignmentMisalignment or “skew” between images is alleviatedRegistering devicesFunction indicatorsTrailing edgeReproduction

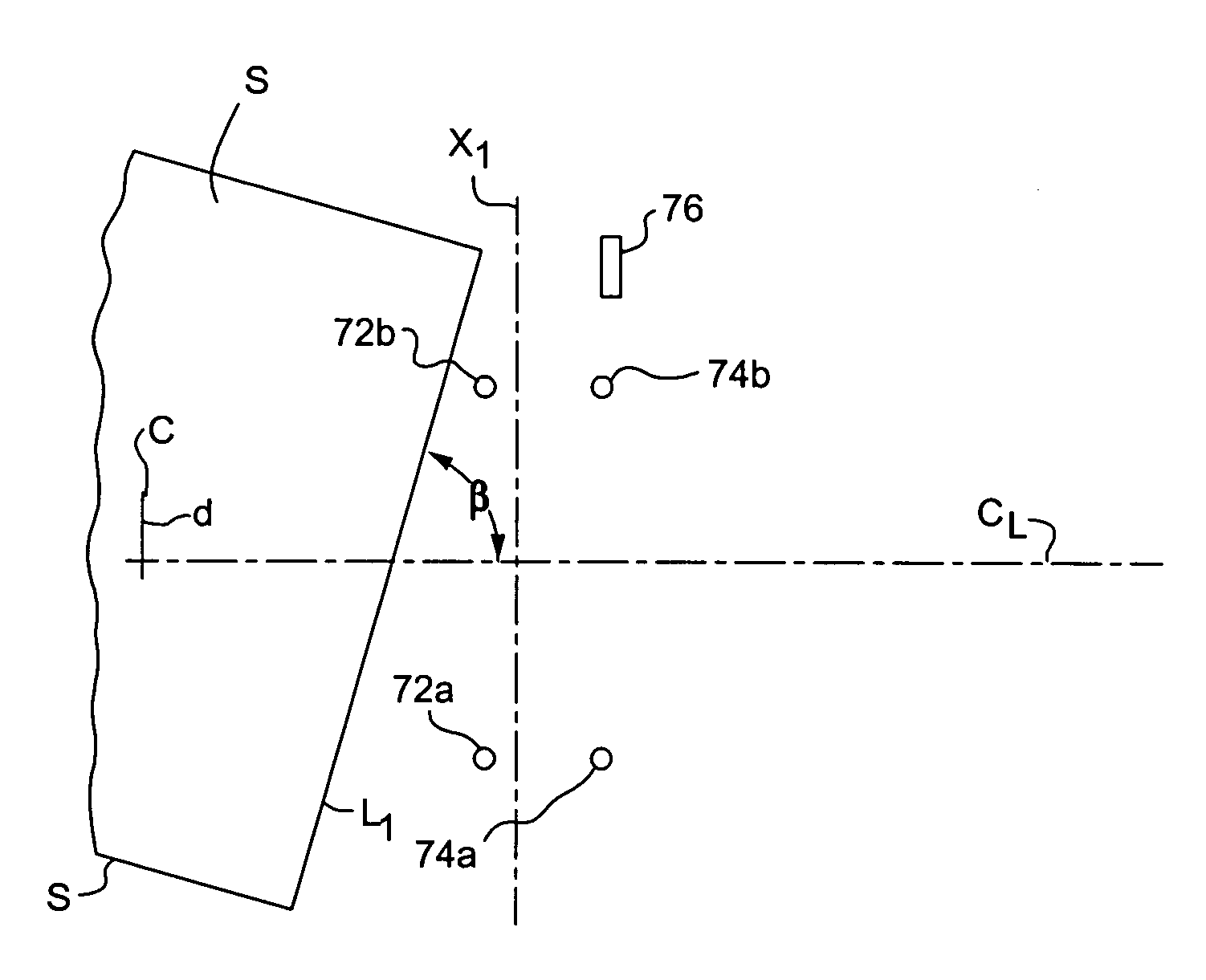

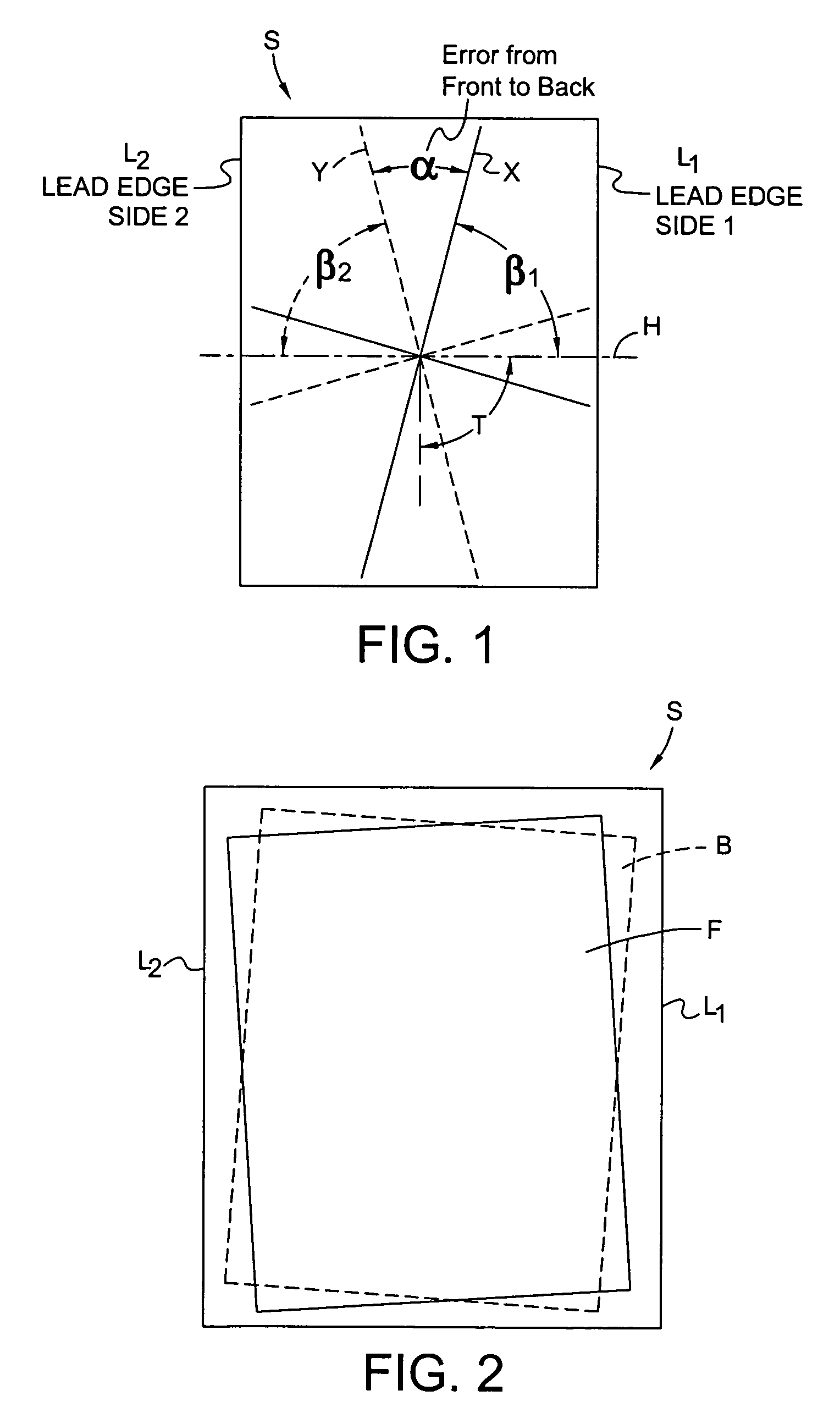

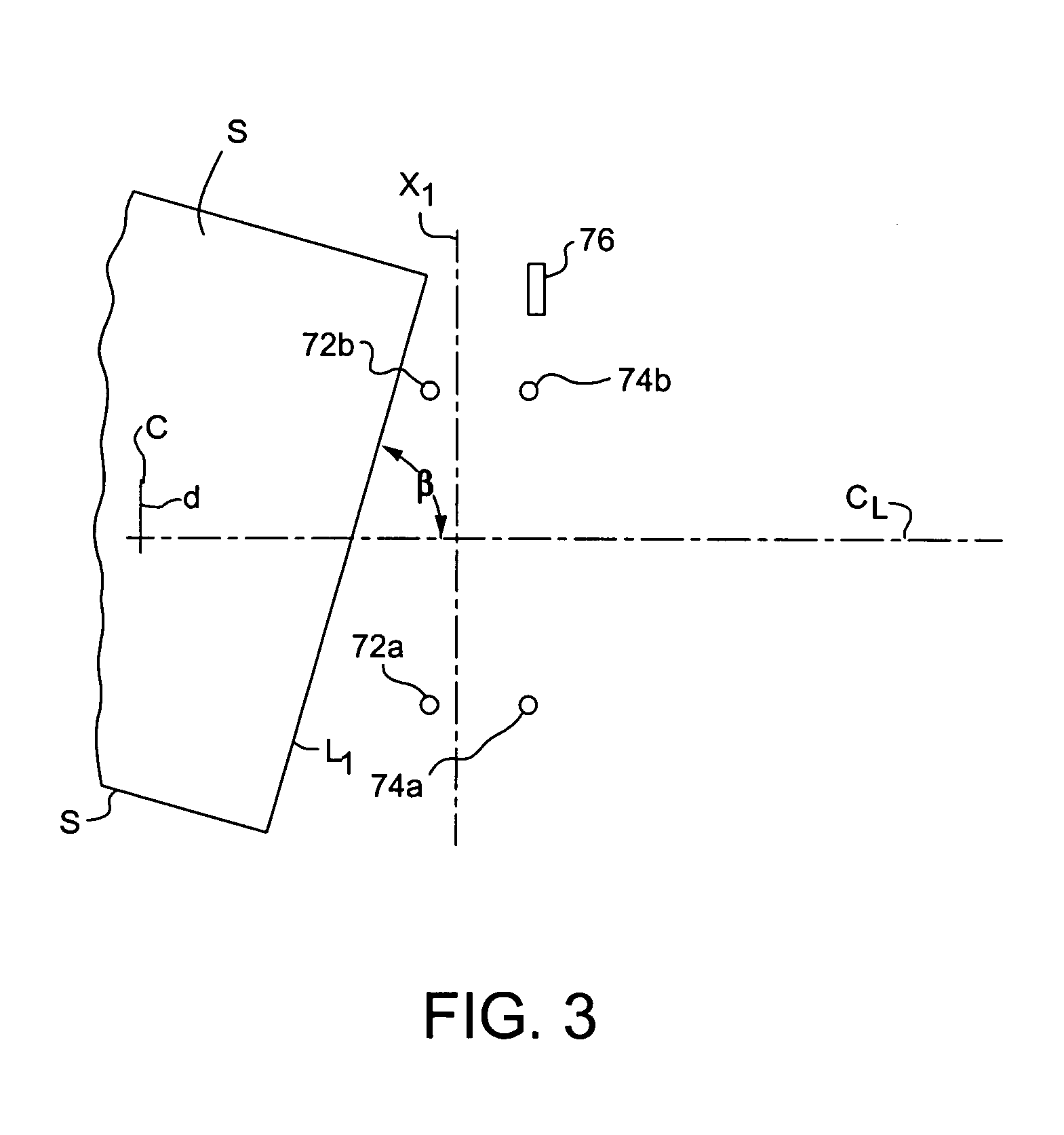

A method of registering a sheet in a duplex copier to alleviate the misalignment between the images copied on the front and back of the same sheet and to compensate for paper cut tolerances. The error angle of skew between a target angle, e.g. 90°, and the trailing edge of the sheet is measured and stored during a first pass. When the same sheet is fed through a second pass, the error angle is retrieved and the target angle is adjusted to compensate for the skew error of the first pass so that any misalignment between front and back images is substantially improved over systems that register images to the sheet without any knowledge of the location of the opposite side image.

Owner:HEIDELBERG DIGITAL +2

Sheet hole punching apparatus and sheet hole punching method

InactiveUS20070227324A1Reduce loadLarge storageThread cutting toolsThread cutting auxillary apparatusEngineeringCam

A cylindrical punch member equipped at the leading end thereof with a hole-punching blade is movably supported on a base frame in a hole-punching direction. A drive means is equipped that applies thrusting force to the punch member; a cam follower member disposed between the base frame and punch member engages a cam means disposed at either the base frame or punch member. An oblique cam surface inclined at a predetermined angle with regard to a hole-punching direction is equipped in cam means to give rotational drive force around an axis of rotation to the punch member that is moved in the hole-punching direction by the drive means. This configuration causes each of a plurality of cylindrical punch members to rotate around their axes of rotation when moved in a hole-punching direction by drive means thereby punching a hole in a sheet with a reduced shear force; the centrifugal force of that punch member rotation causing paper cutting debris to be scattered evenly under the punch member.

Owner:SEIKO CORP

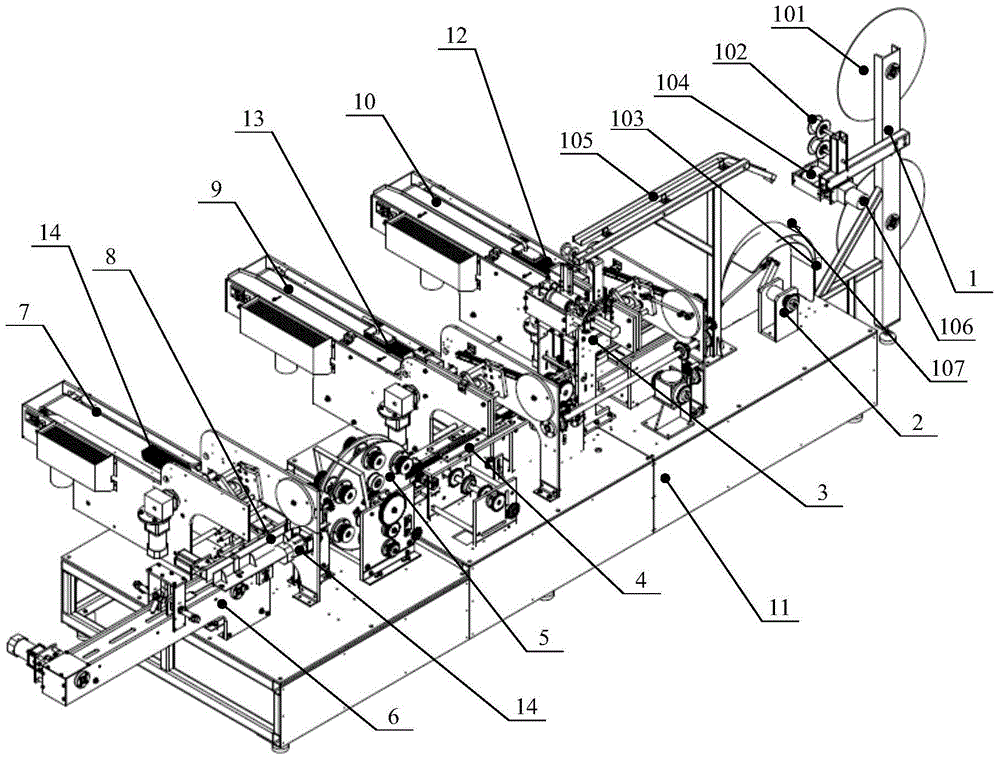

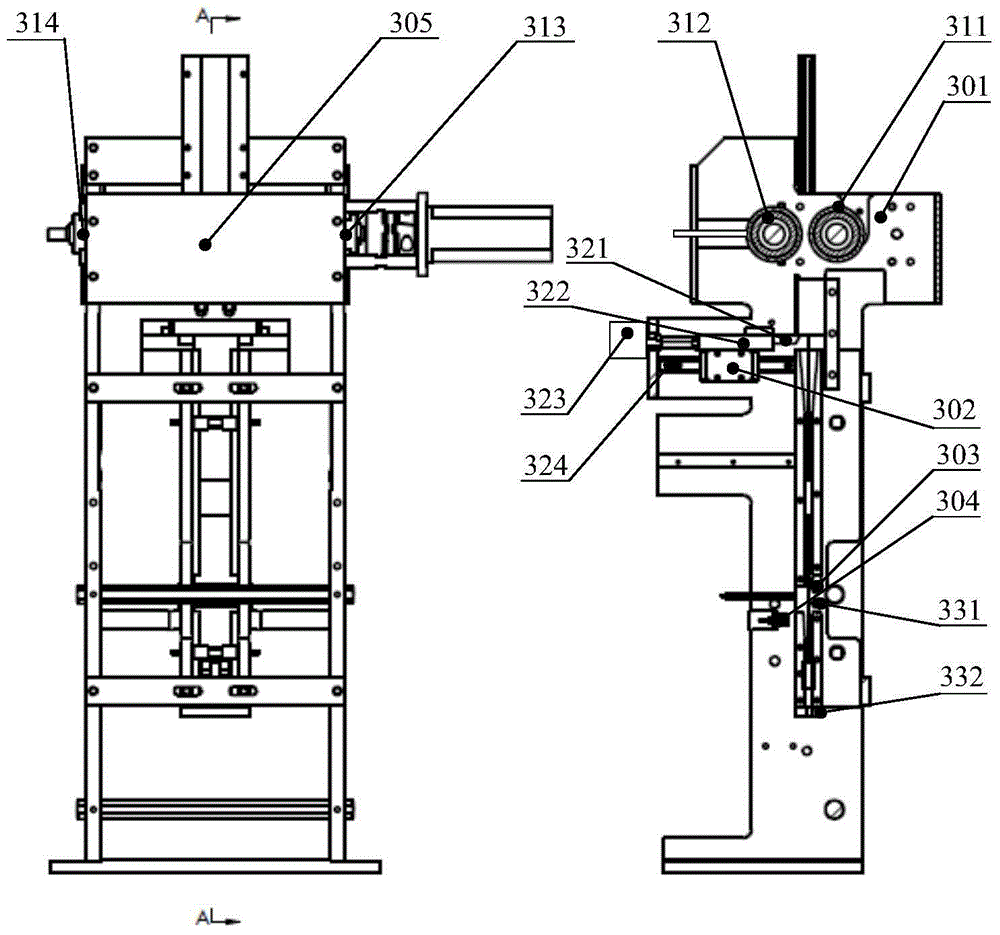

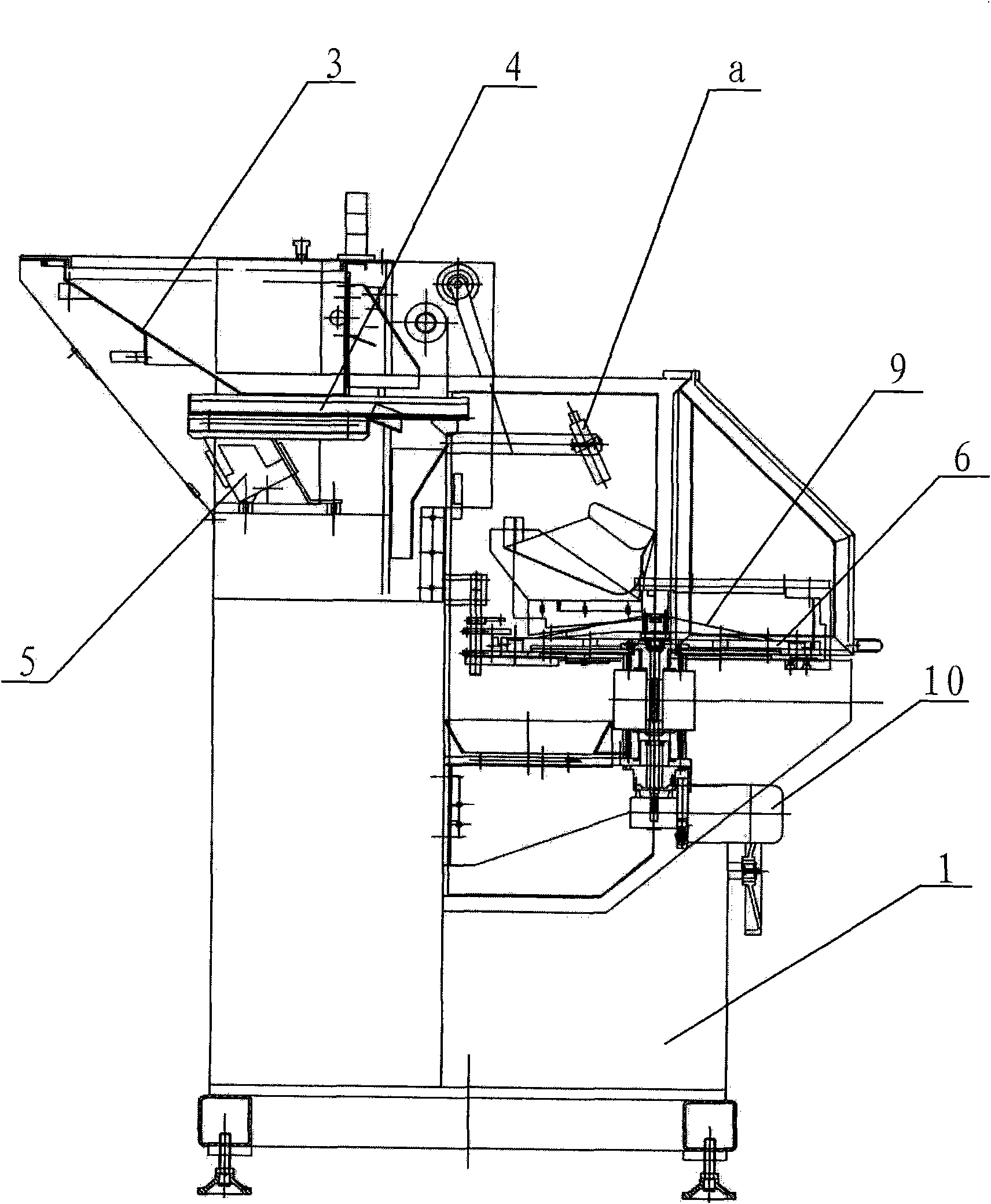

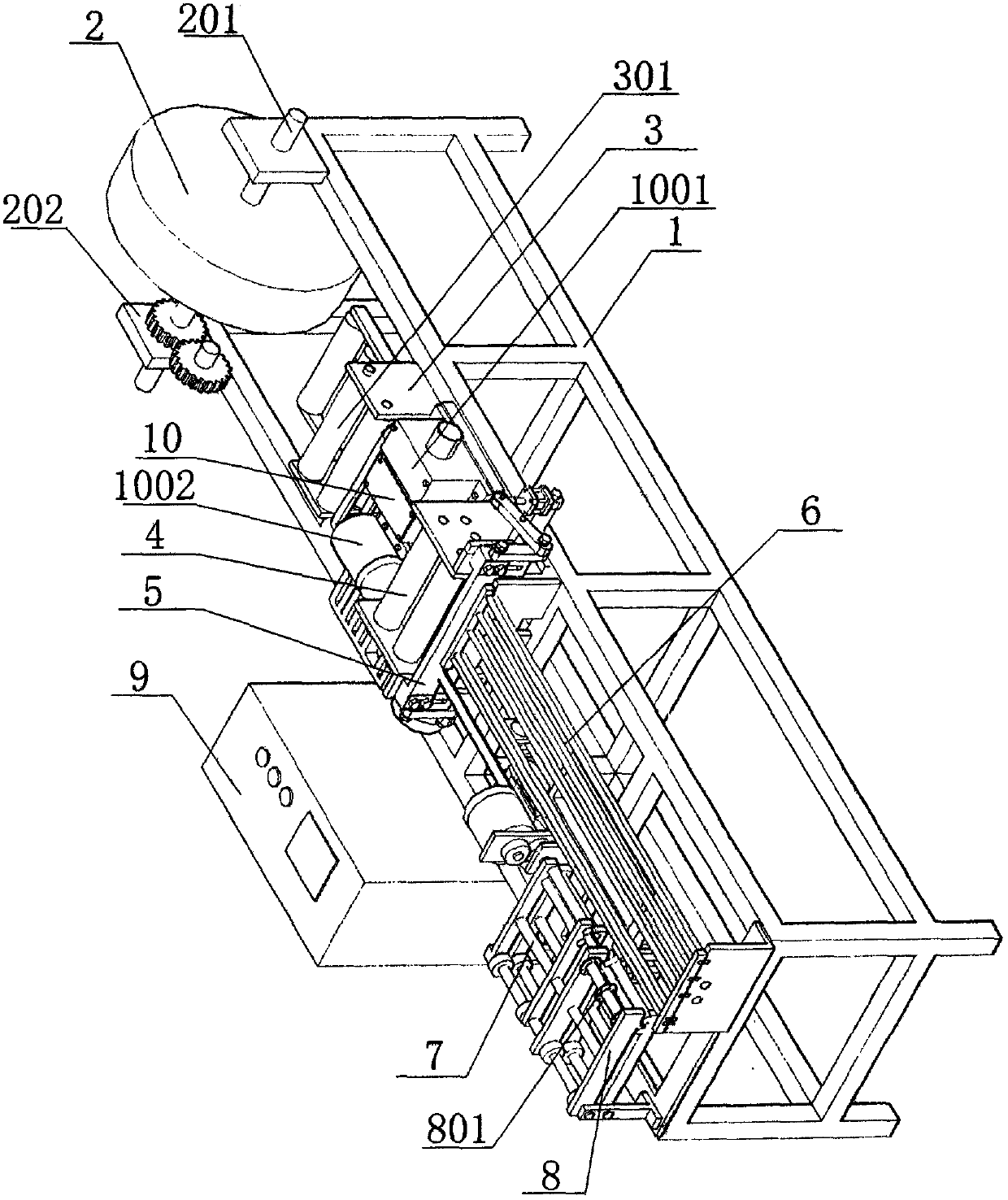

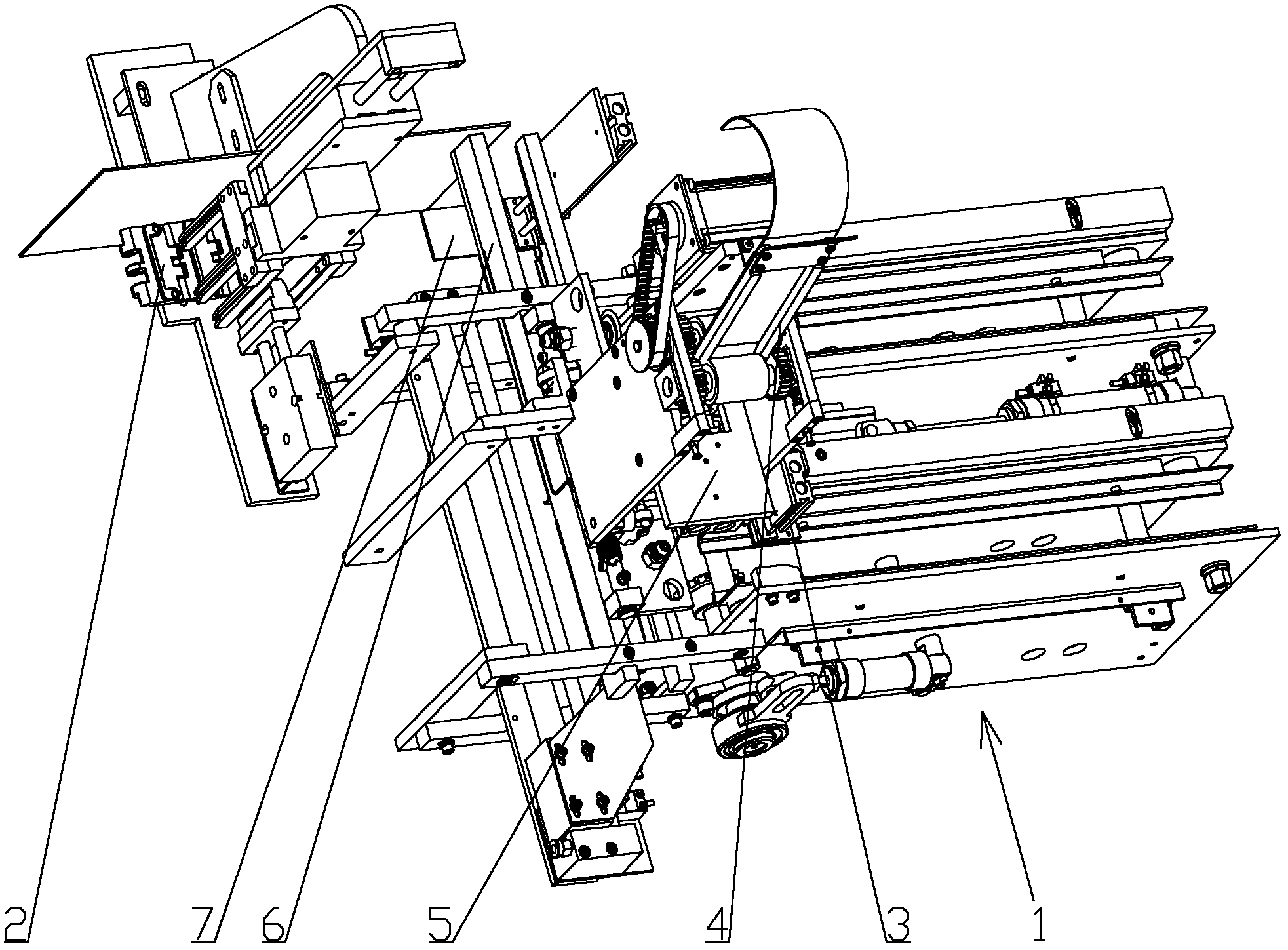

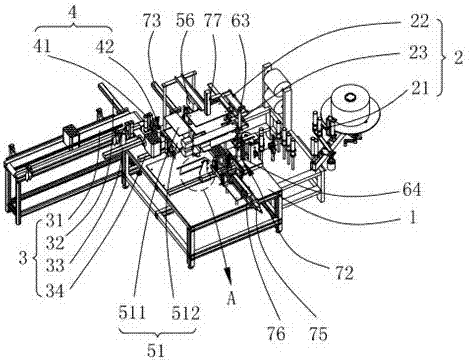

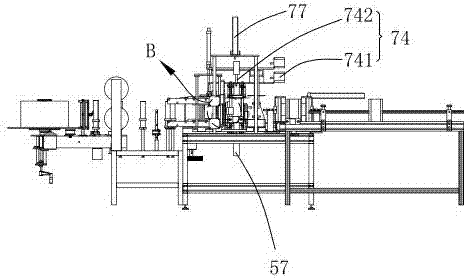

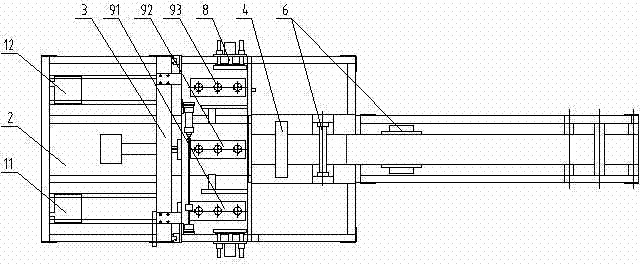

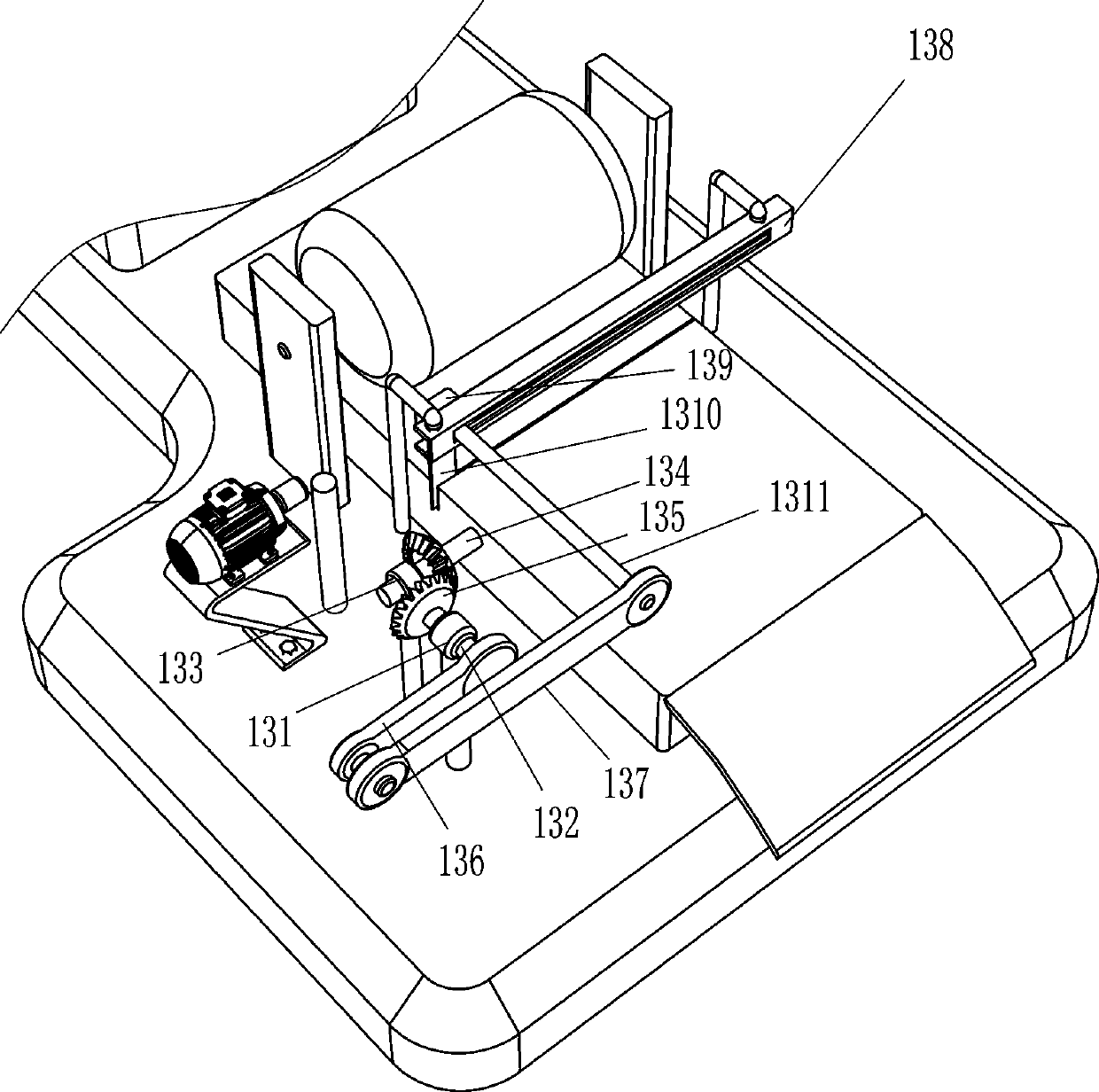

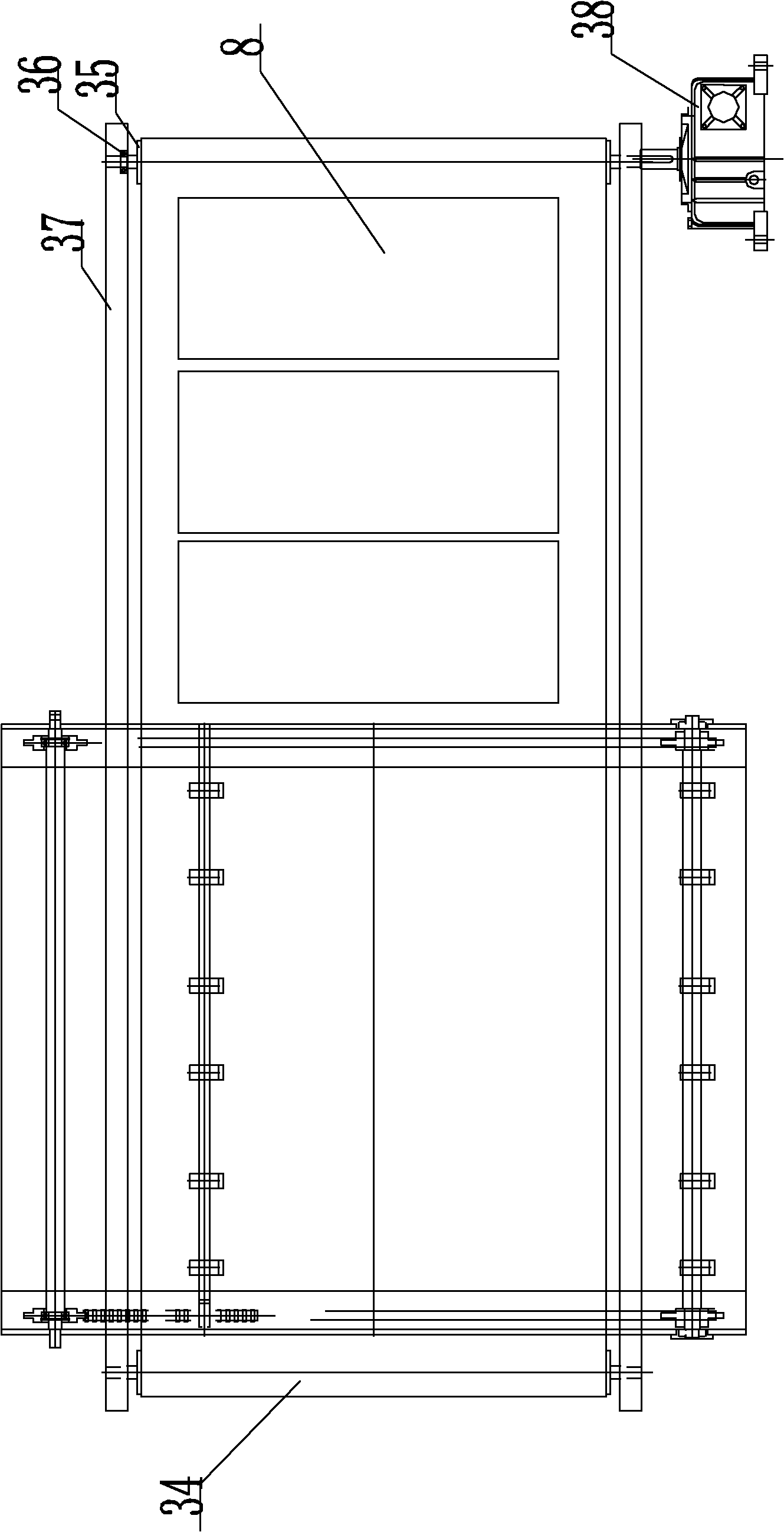

Full-automatic storage battery piece wrapping distribution machine

ActiveCN104681882ACompact structureReasonable structureFinal product manufactureLead-acid accumulators constructionPole pieceAssembly line

The invention provides a full-automatic storage battery piece wrapping distribution machine which comprises a paper cutting and wrapping piece mechanism, a rotary battery plate group piece laminating mechanism, a pole piece underfloor mechanism, a first feeding mechanism, a piece pushing mechanism, a partition paper transfer mechanism, a wrapping piece transfer mechanism, a second feeding mechanism, a pneumatic piece pushing mechanism, a third feeding mechanism and a frame, wherein the partition paper transfer mechanism, the piece pushing mechanism, the firs feeding mechanism, the paper cutting wrapping piece mechanism, the second feeding mechanism, the wrapping piece transfer mechanism, the rotary battery plate group piece laminating mechanism, the third feeding mechanism, the pneumatic piece pushing mechanism and the pole piece underfloor mechanism are sequentially arranged on the frame. The distribution machine provided by the invention can be used for achieving assembly line type production of wrapping pole pieces and automatically feeding, wrapping, laminating and discharging the pole pieces, so that the harm of lead dust is greatly reduced, the labor cost is lowered, the efficiency is improved, and the distribution machine is convenient to operate.

Owner:FUJIAN JIANYANG YAHENG MACHINERY MFG

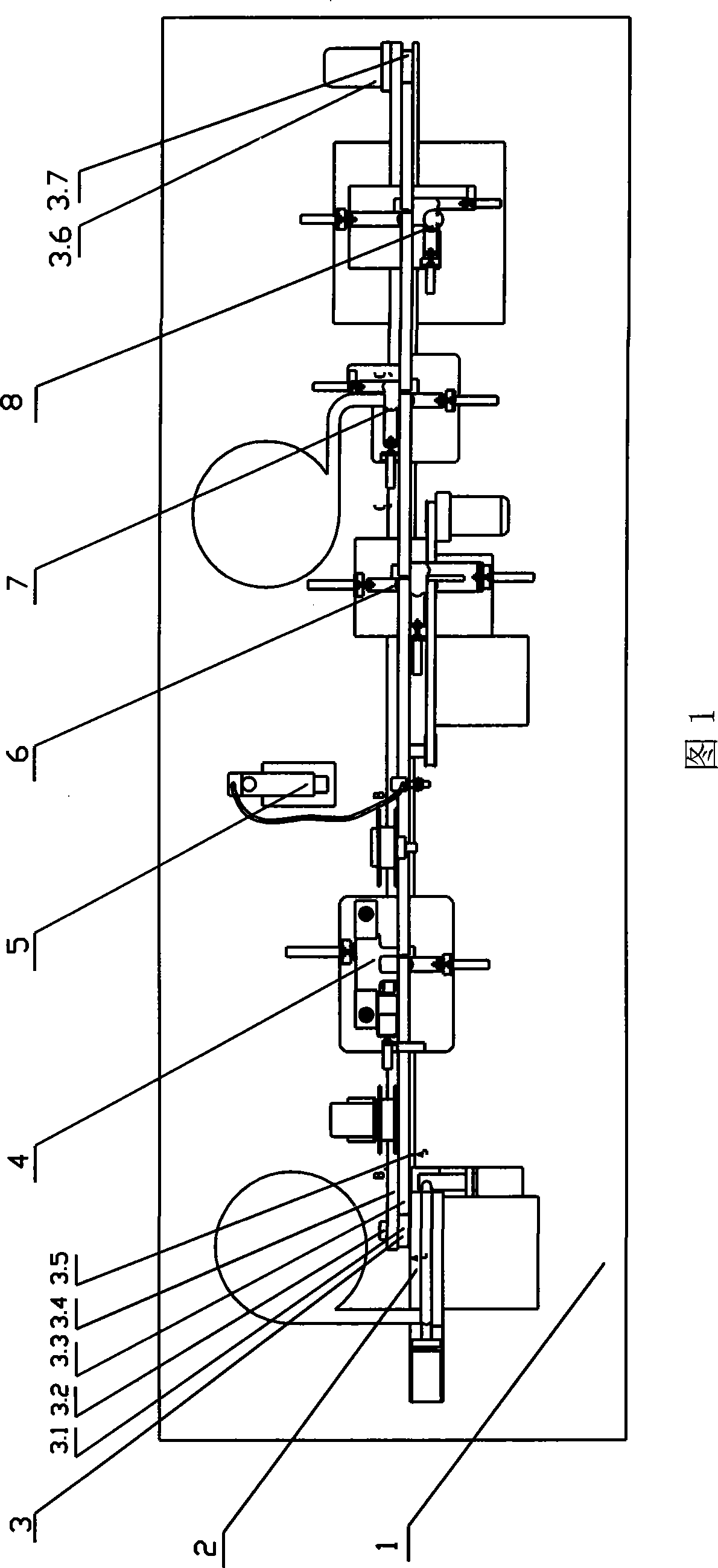

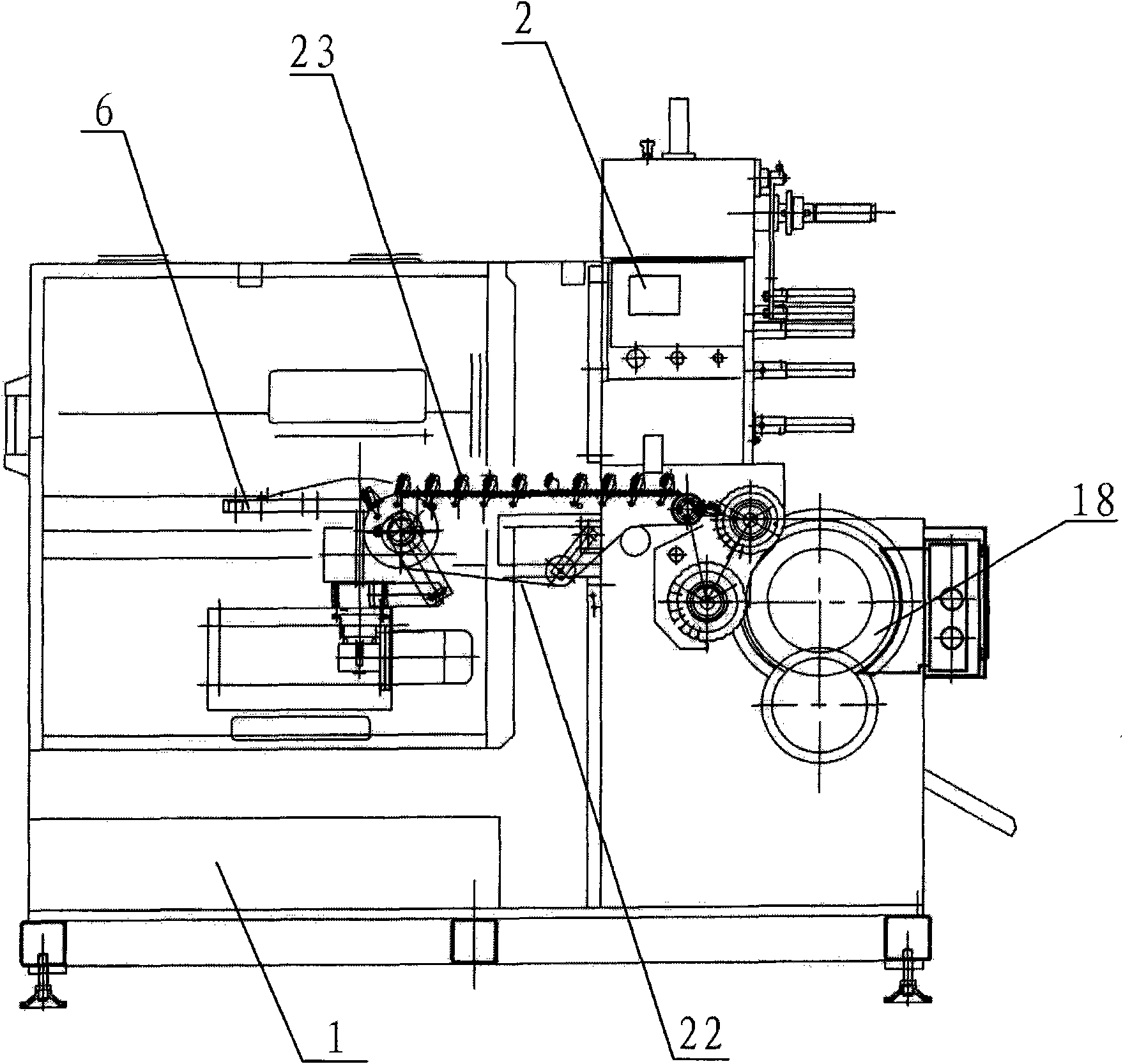

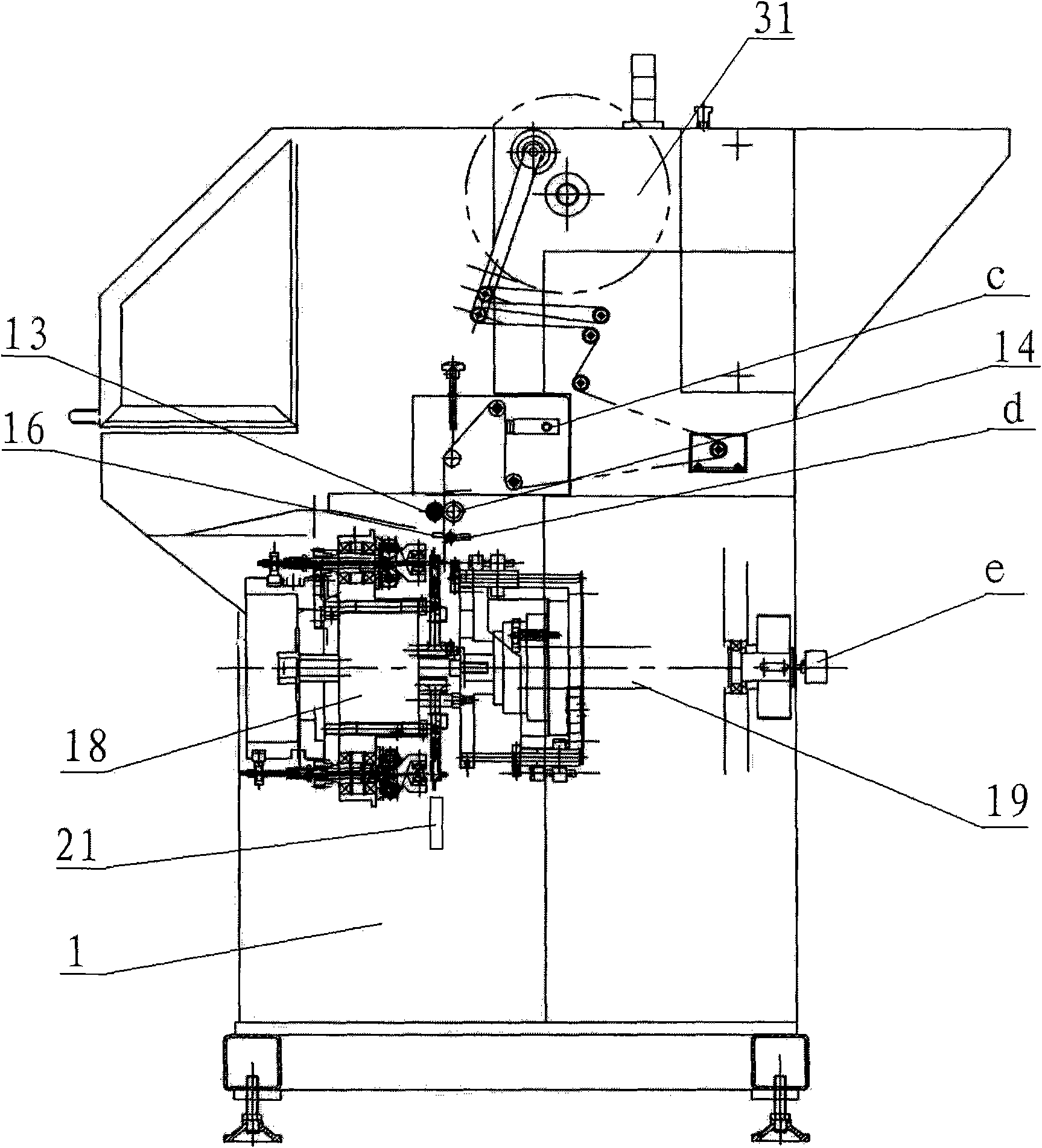

Button cell battery production line

InactiveCN101252194AAdvanced technologyEasy to controlFinal product manufactureNon-aqueous electrolyte cellsProduction lineLithium

The invention relates to a button cell production line, being characterized in comprising a rack component, a lithium chip loading mechanism, a paper cutting mechanism, a filling mechanism, a manganese chip loading mechanism, an anode case loading mechanism, a sealing mechanism, a main transmission mechanism, a pneumatic control system and an electrical apparatus control system as well as a control program; the rack component comprises a large worktable and a rack fastened on the lower surface of the large worktable, a lower base plate of the rack is arranged on a lower beam of the rack, a control cabinet is arranged on the upper part of the lower base plate of the rack; the lithium chip loading mechanism, the main transmission mechanism, the paper cutting mechanism, the filling mechanism, the manganese chip loading mechanism, the anode case loading mechanism and the sealing mechanism are arranged on the large worktable in turn; the pneumatic control system is arranged on the lower base plate of the rack; the electrical apparatus control system and the control program are arranged inside the control cabinet; a touch screen support is vertically arranged on the upper surface of the large worktable close to one end of the lithium chip loading mechanism.

Owner:TIANJIN POLYTECHNIC UNIV

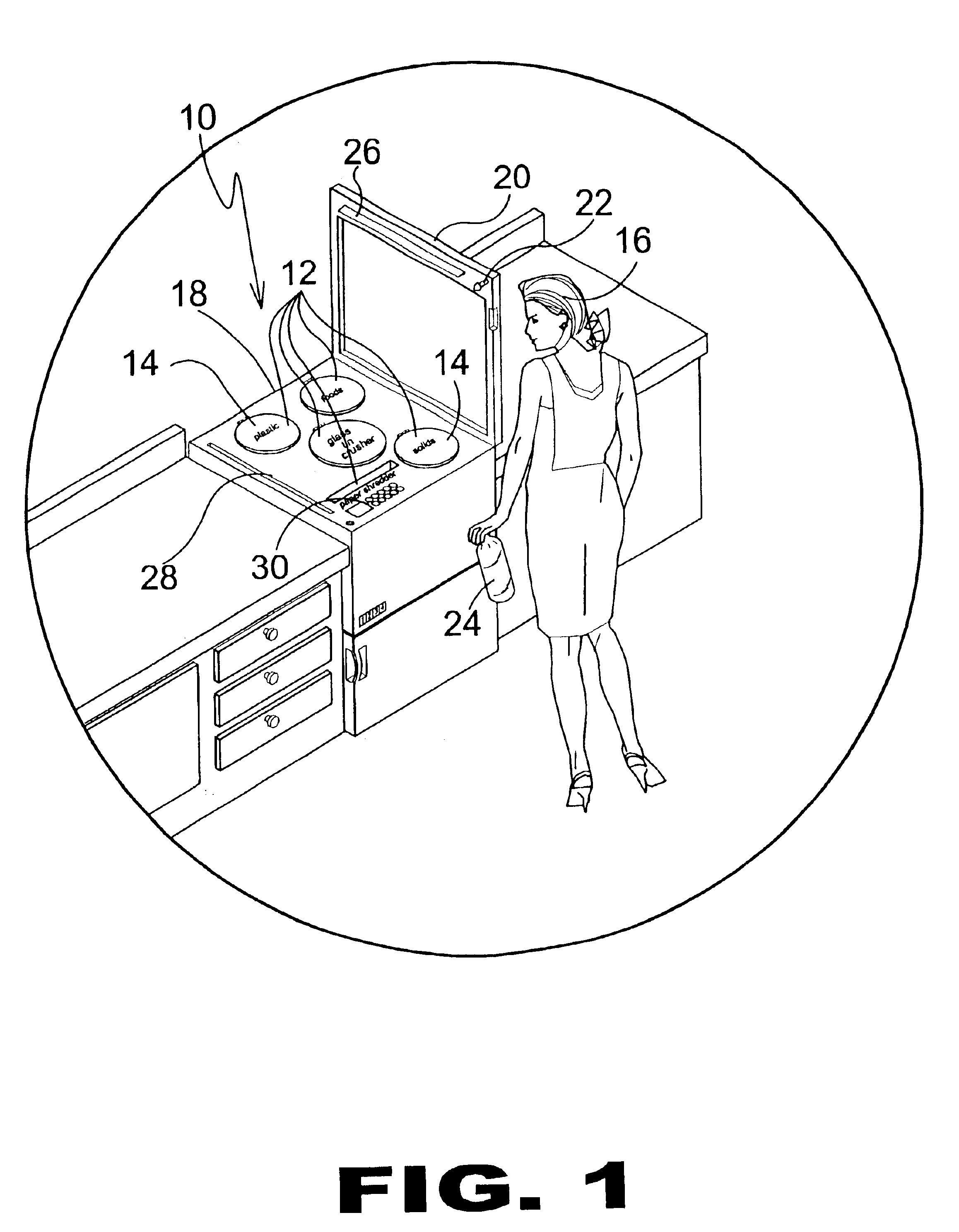

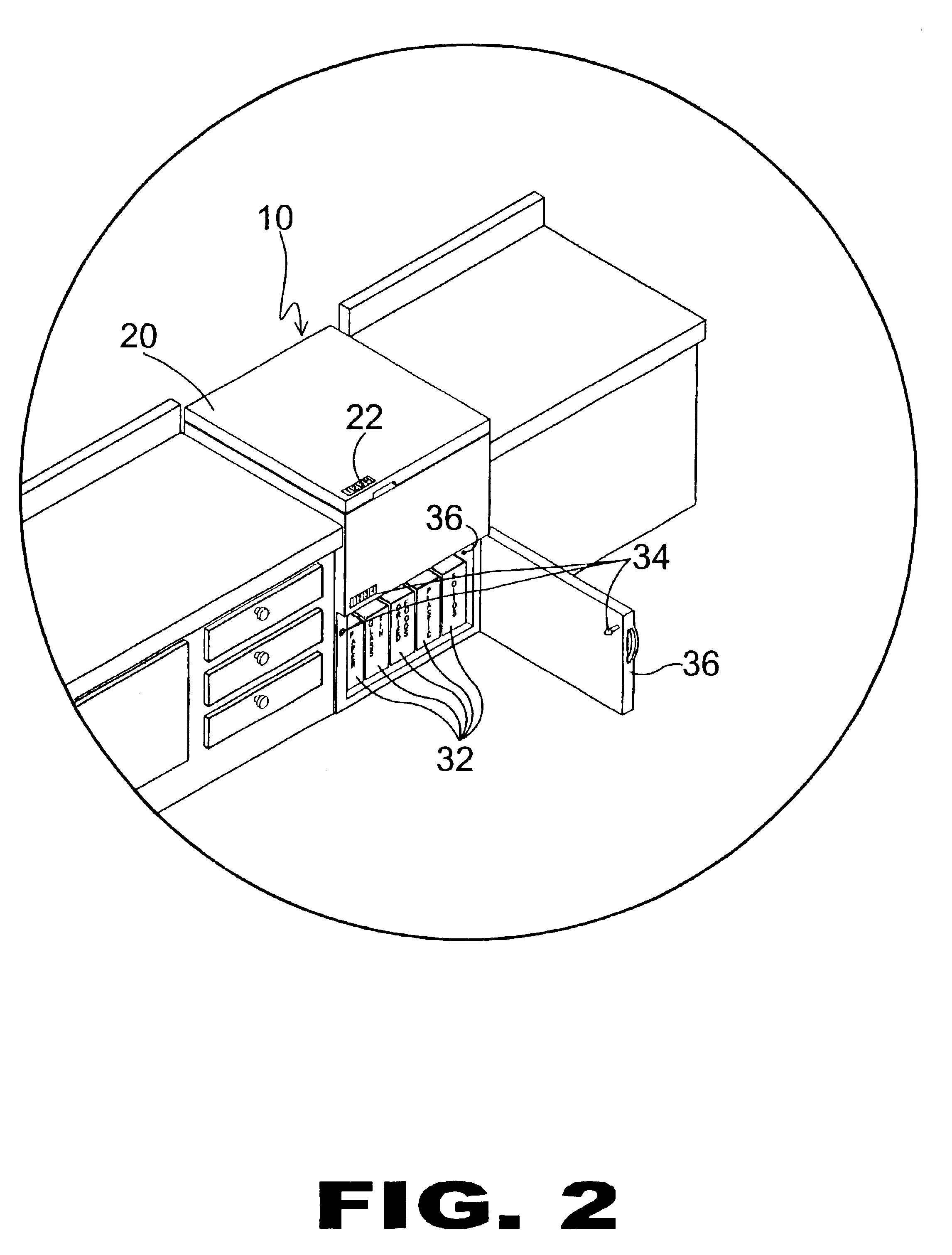

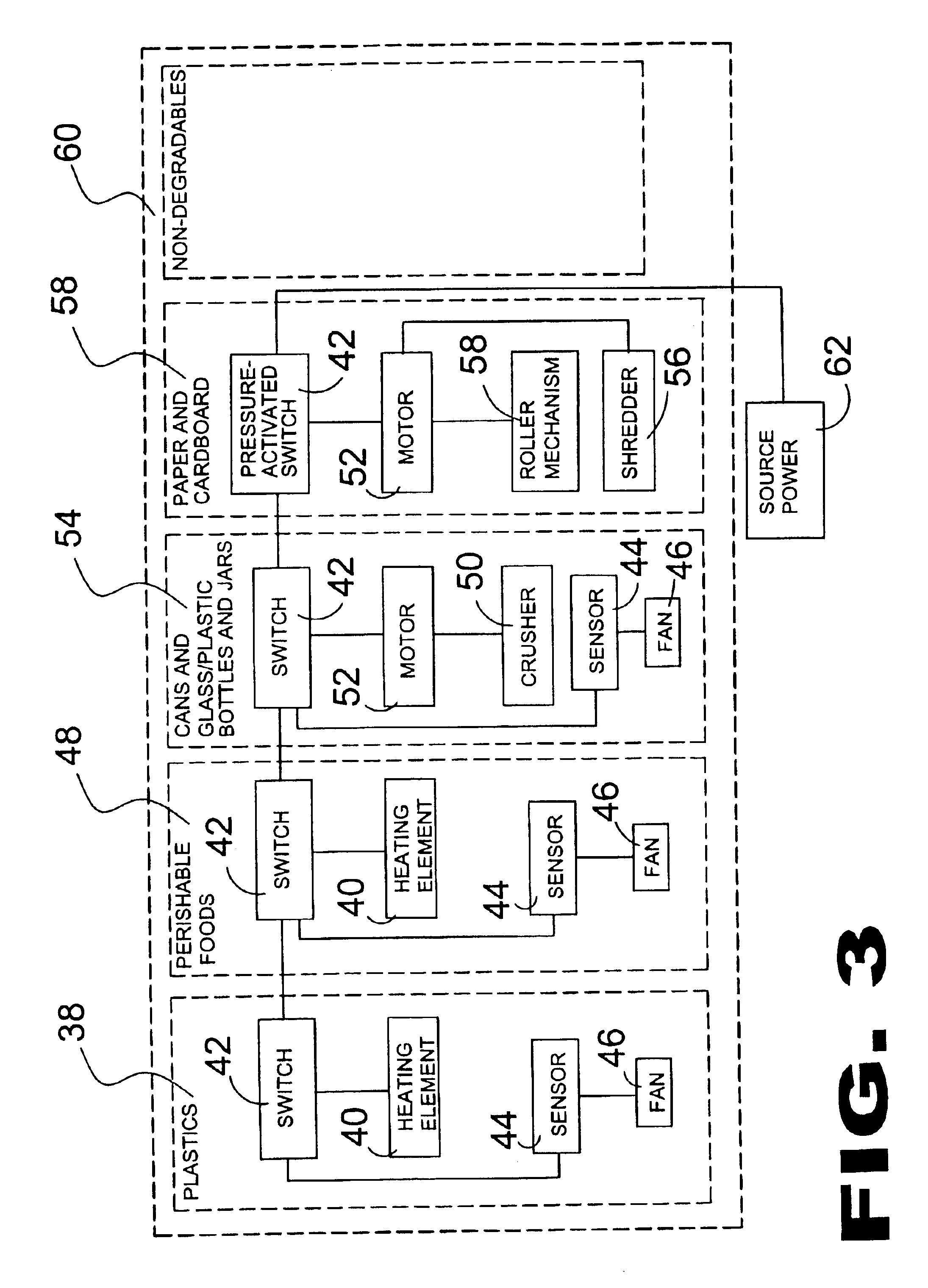

System for sorting and processing a plurality of types of solid waste products for recycling

InactiveUS6903142B1Reduce confusionLow costMechanical working/deformationSolid waste disposalCardboardWaste product

The present invention 10 discloses a trash and garbage processing device which may be sized to fit into a kitchen of a home or sized to be used in a multi-family dwelling. The present invention 10 has a plurality of sorting compartments 12 disposed on the top thereof for receiving various types of waste products. There is a compartment for shrinking and palletizing plastics, another compartment for shredding paper and cardboard 58, another compartment for perishable organic waste 48, a crushing compartment for crushing cans and glass / plastic products 54 and a disposal compartment 60 for non-degradable, solid waste such as bones and batteries. After the various types of waste materials are processed, they are transferred to a conduit to a recycling bin 32 for temporary storage and then thereafter removed from the recycling bin and transferred for final disposal. A paper cutting blade 26 is provided for cutting large pieces of cardboard or paper to proper size for placement into a paper shredding compartment 58. The individual openings 12 of the compartments have lids 14 thereon which have safety locks thereon 22 / 34 to prevent children from tampering therewith. A plastic handling compartment also may be coated with a non-stick material and the safety locks may use a touch digital keypad as commonly used. Further, the crusher unit may be equipped with a mechanism for determining the UPC codes of the materials.

Owner:STAUBER CHAIM M

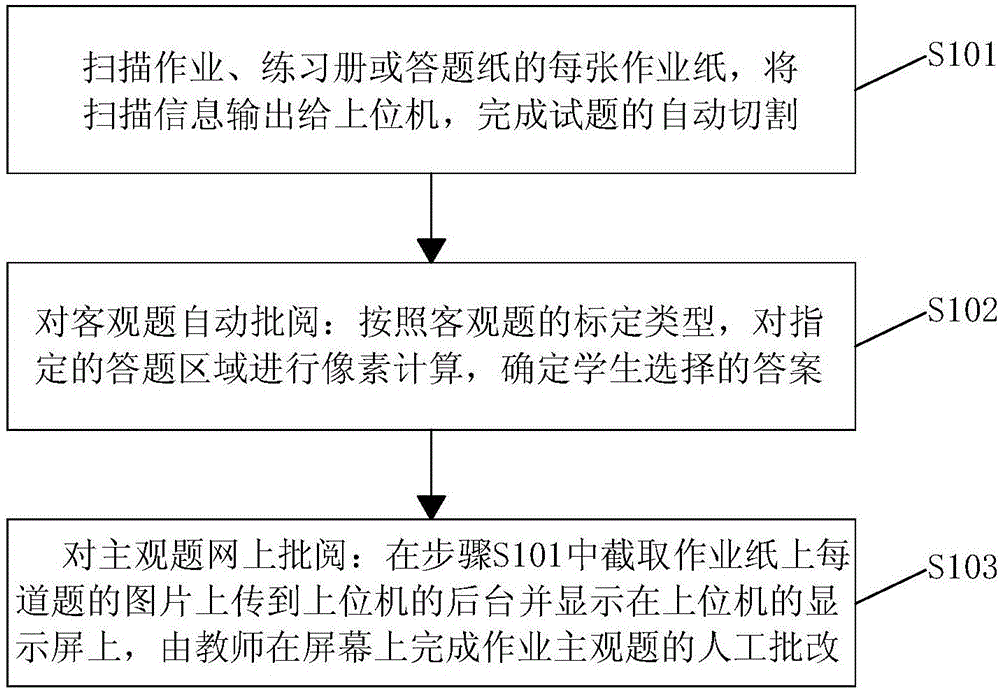

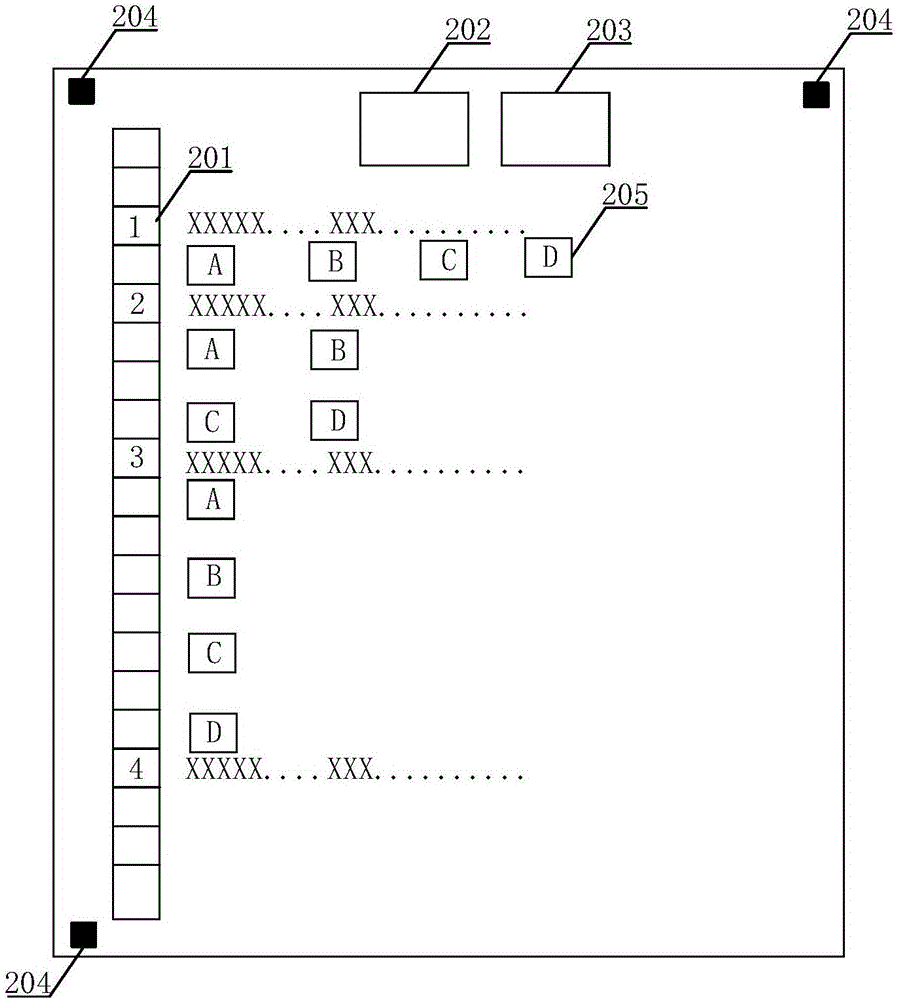

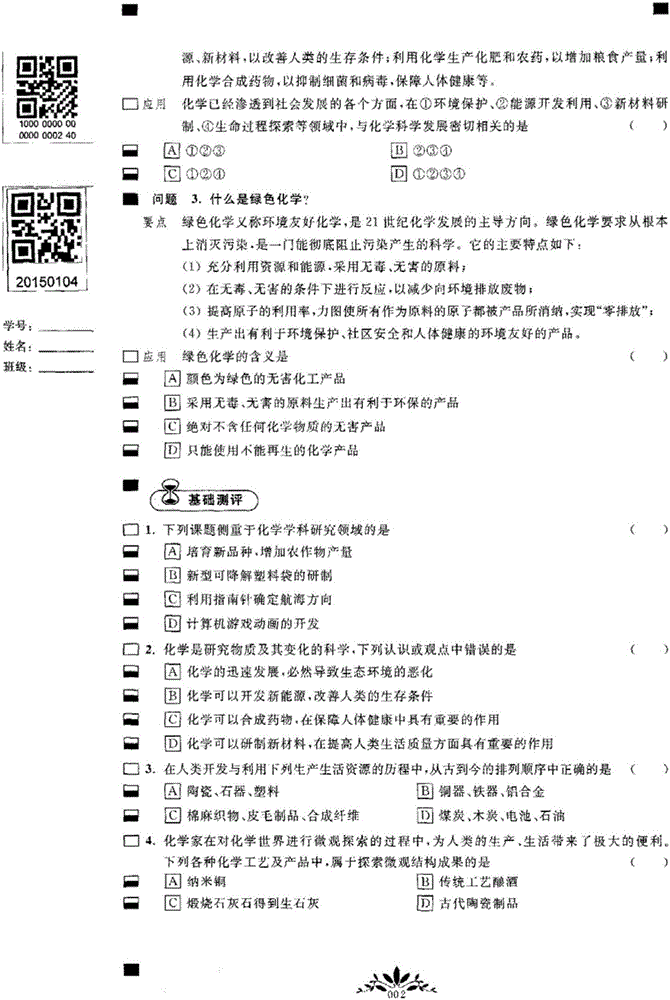

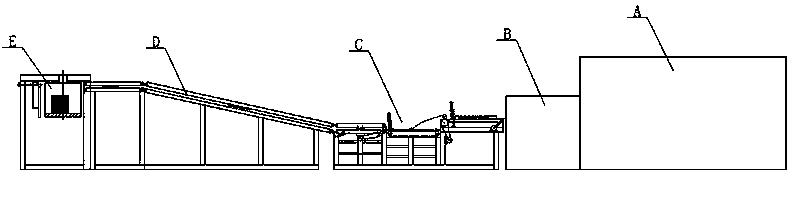

Automatic reading and amending method for homework and exercise books

InactiveCN106023698AAvoid misappropriationAvoid the situationElectrical appliancesTest questionComputer science

The invention discloses an automatic review method for homework and exercise books, comprising: S101 , scanning each work sheet of the homework, exercise book or answer sheet, outputting the scanned information to a host computer, and completing the automatic cutting of test questions. S102 , automatically reviewing the objective questions: according to the calibration type of the objective questions, pixel calculation is performed on the designated answering area to determine the answer selected by the student. S103, online review of subjective questions: in step S101, a picture of each question on the homework paper is intercepted and uploaded to the background of the host computer and displayed on the display screen of the host computer, and the teacher completes the manual correction of the subjective questions of the homework on the screen. The invention realizes automatic division of test questions, is suitable for various forms of homework and workbooks, and is stable and reliable; realizes automatic review of objective questions and online review of subjective questions, improves the efficiency of teachers' review of homework and workbooks, and avoids mistakes in test questions The occurrence of batch or missed batch is convenient and efficient; the cost is low, easy to implement, and suitable for promotion.

Owner:李铧

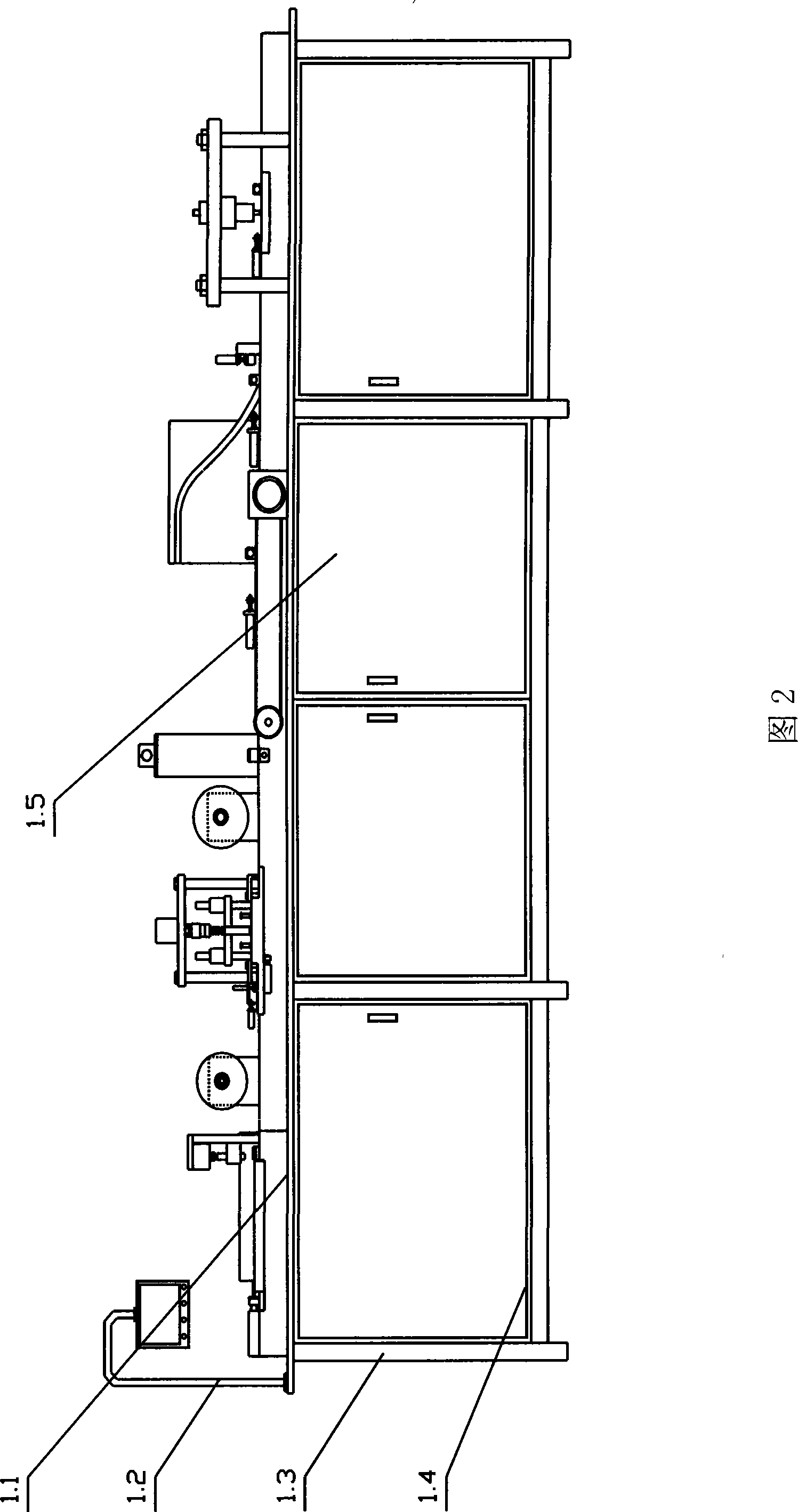

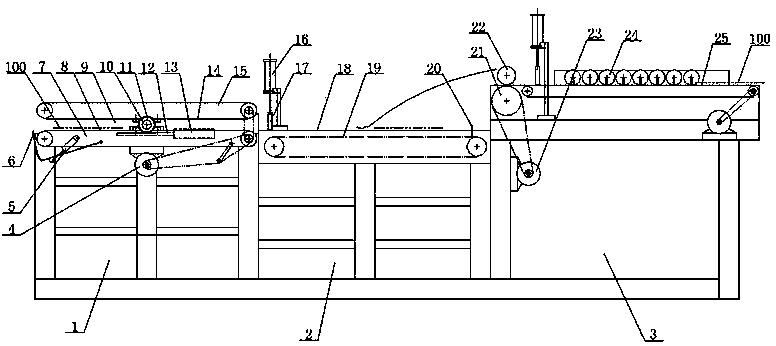

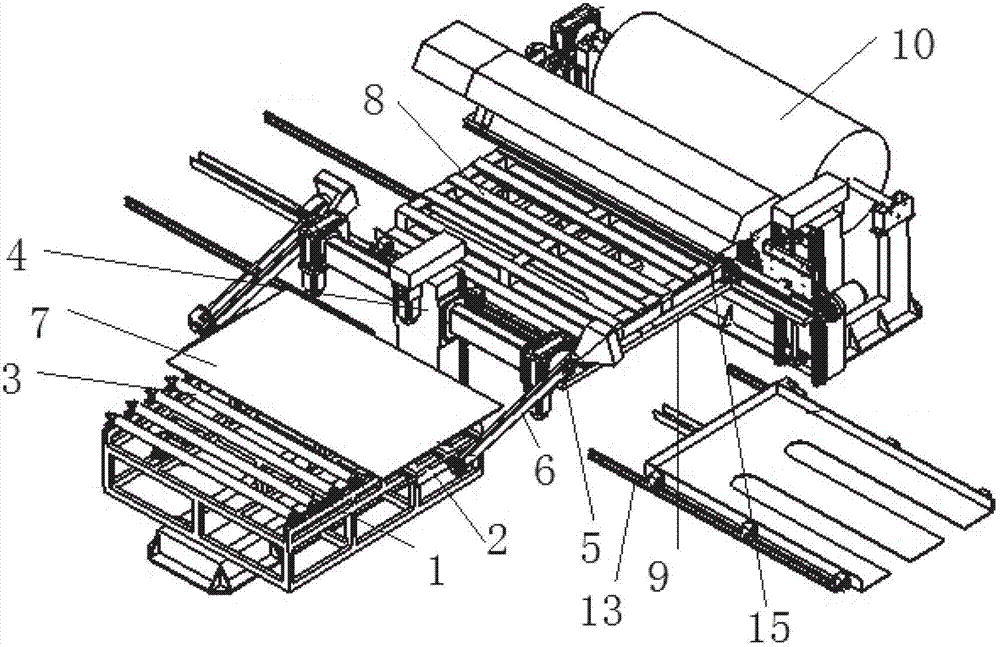

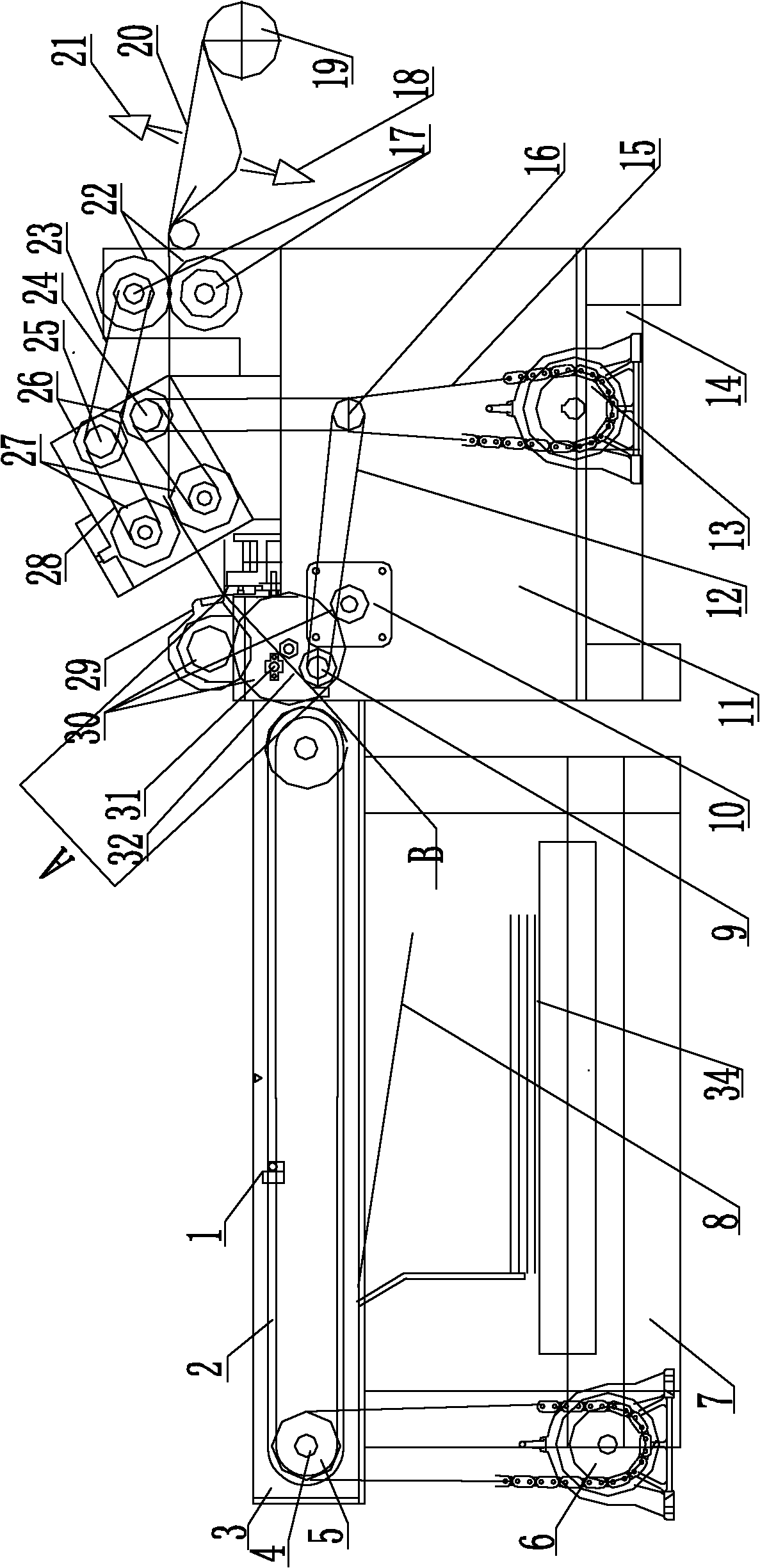

Compound hard paperboard production line with automatic overturning and paper collecting functions

InactiveCN104139999ARaise the output heightMeet the requirements of automatic stackingOverturning articlesPile receiversPaperboardManufacturing line

The invention discloses a compound hard paperboard production line with automatic overturning and paper collecting functions. The compound hard paperboard production line comprises a compound machine, a paper cutting machine, a paper feeding platform and a paper collecting table, and is characterized in that a paperboard overturning mechanism is arranged between the paper cutting machine and the paper feeding platform and comprises a paperboard overturning and conveying assembly, the paperboard overturning and conveying assembly comprises an overturning rack, an upper conveying belt, a lower conveying belt and a paper stop board, the overturning rack can perform 180-degree reciprocating overturning motion, the overturning of the overturning rack is pushed by an overturning pushing part, the upper conveying belt is arranged at the upper part of the overturning rack, the lower conveying belt is arranged at the lower part of the overturning rack, a material passing channel allowing stacked paperboards to pass is reserved between the upper conveying belt and the lower conveying belt, the paper stop board is movably arranged at an outlet of the material passing channel, and when the overturning rack performs forward turning action, the paper stop board blocks the outlet of the material passing channel. According to the compound hard paperboard production line with the automatic overturning and paper collecting functions, not only is automatic production of compound hard paperboards realized, but also the hard paperboards are automatically and flatly stacked and collected with high quality, the flatly stacked and collected hard paperboards can directly meet requirements of mechanical packaging, and the labor intensity of a worker is greatly reduced.

Owner:瑞安市荣庆包装机械厂

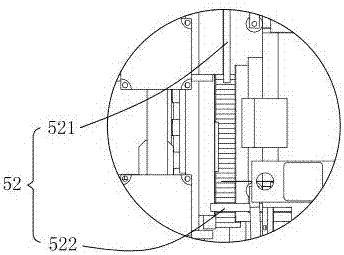

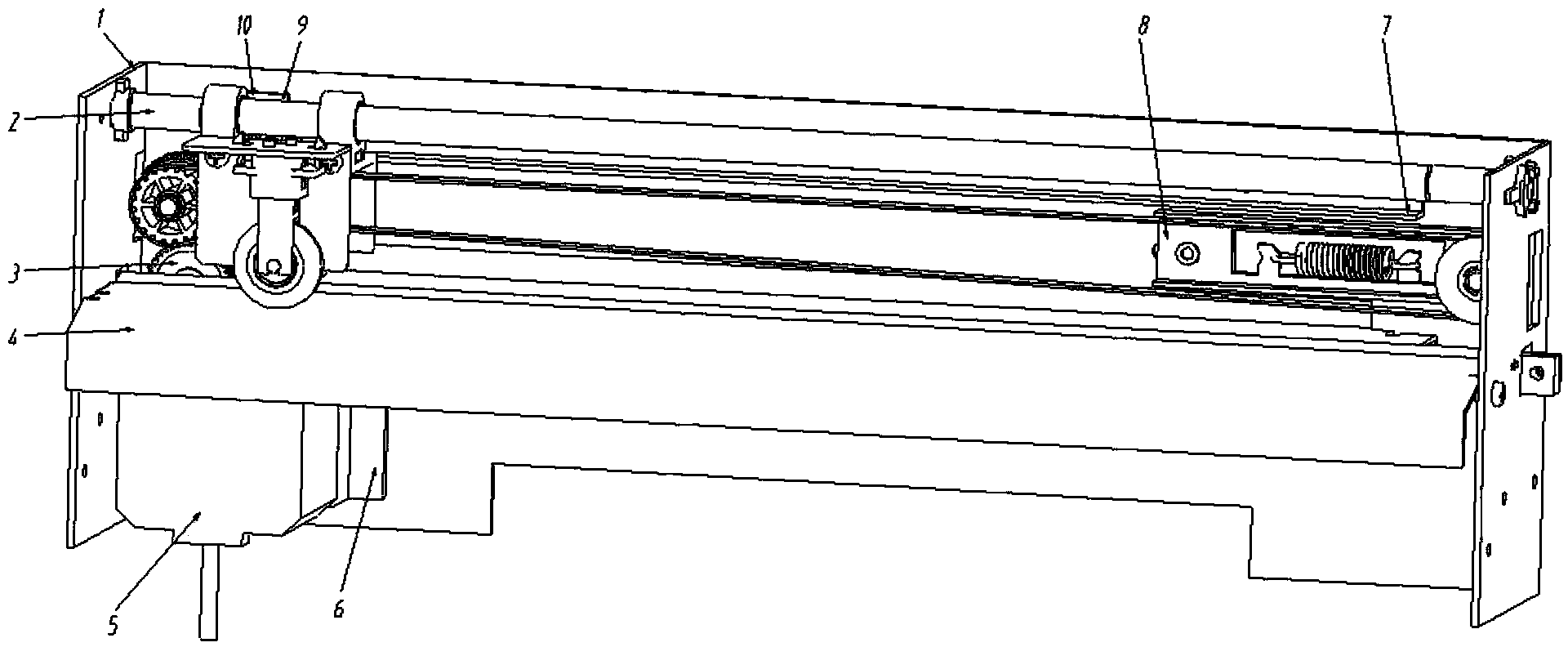

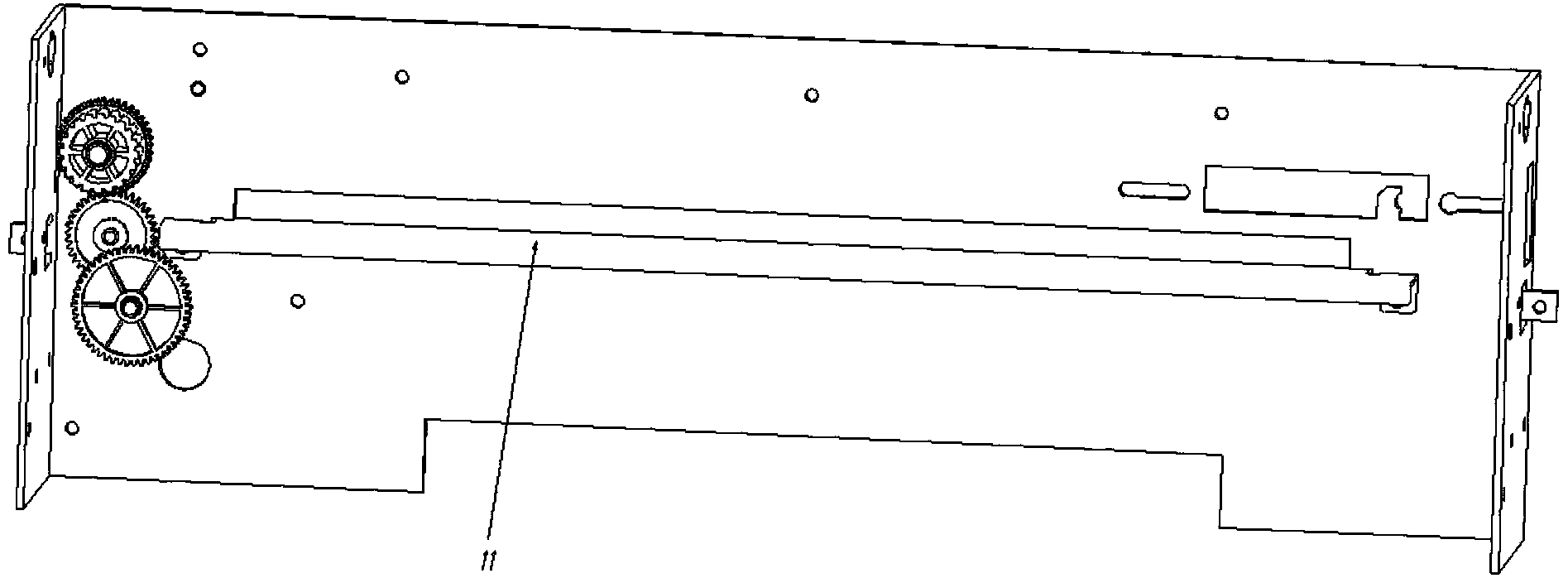

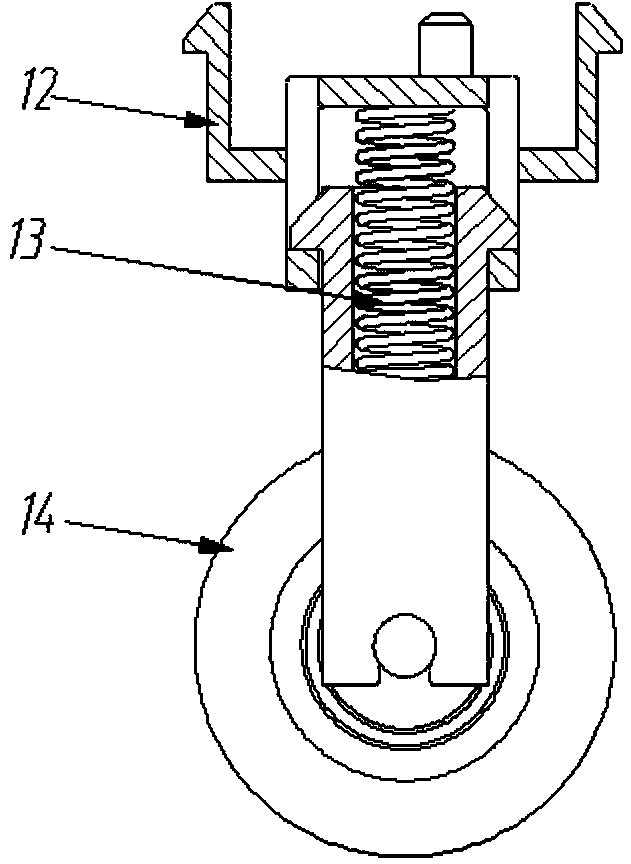

Intelligent horizontal type lollipop heat-seal kinking packaging system

ActiveCN101786508AGuaranteed to work in syncReduce labor intensityWrapper twisting/gatheringPackaging automatic controlControl systemElectric machinery

The invention relates to an intelligent horizontal type lollipop heat-seal kinking packaging system comprising a machine frame and a control system. The innovation of the packaging system is that a packaging machine further comprises an automatic lollipop dropping mechanism, a lollipop arranging mechanism, a paper conveying and cutting mechanism and a heat-seal packaging machine head. The automatic lollipop dropping mechanism uniformly conveys lollipops to the lollipop arranging mechanism, and a manipulator conveying mechanism conveys the lollipops which are well arranged to a heat-seal packaging kinking manipulator of the heat-seal packaging machine head; meanwhile, the paper conveying and cutting mechanism conveys lollipop paper required to be cut to the heat-seal packaging kinking manipulator of the heat-seal packaging machine head so as to carry out lollipop paper packaging without touching of operating personnel, which lowers the labor intensity and meets the sanitary requirements. In the whole process, a lollipop arranging disc of the lollipop arranging mechanism together with a rubber roller and a paper cutting roller in the paper conveying and cutting mechanism is respectively driven by a separate servo motor, the working condition of the servo motor is monitored instantly according to a photoelectric switch, a proximity switch, a photoelectric identifier and sensors like a rotary encoder with access of a control system in each mechanism, so as to ensure synchronous working of each mechanism, thereby ensuring the working efficiency.

Owner:NANTONG WEALTH MASCH TECH CO LTD

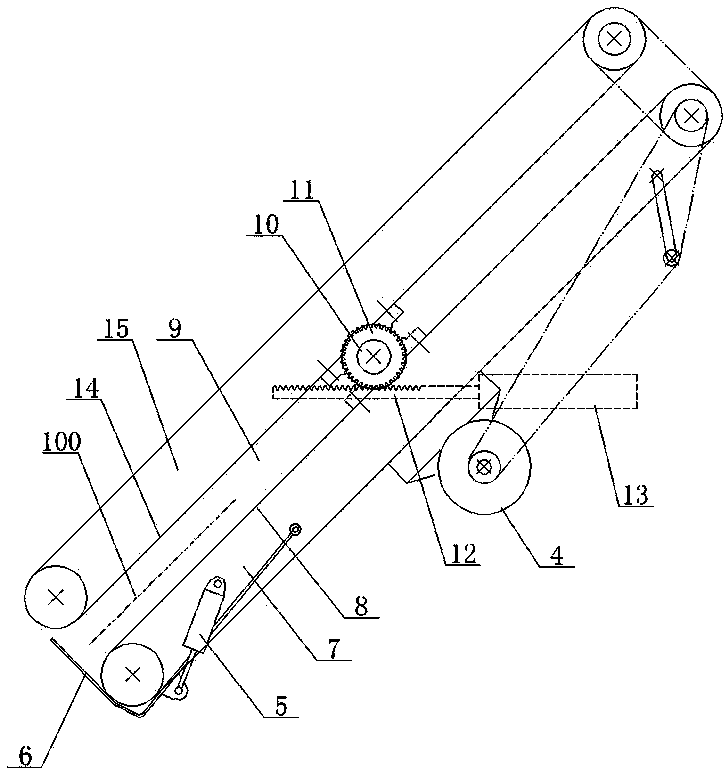

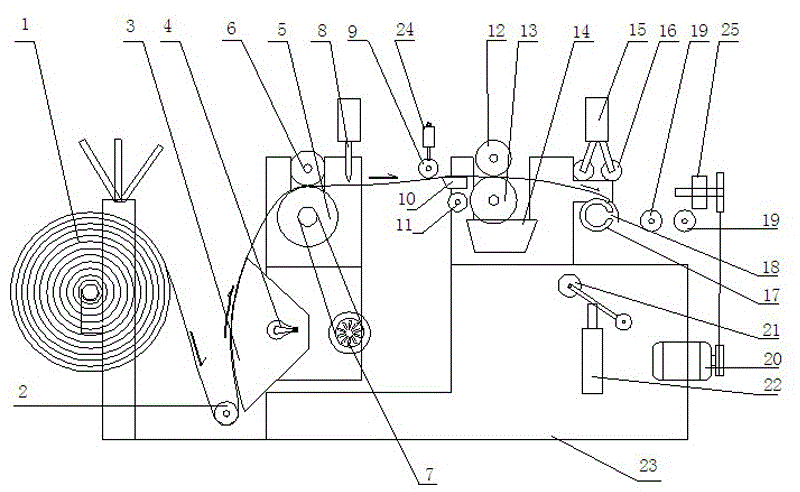

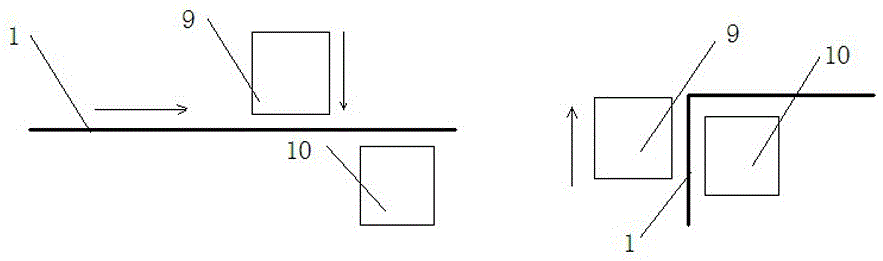

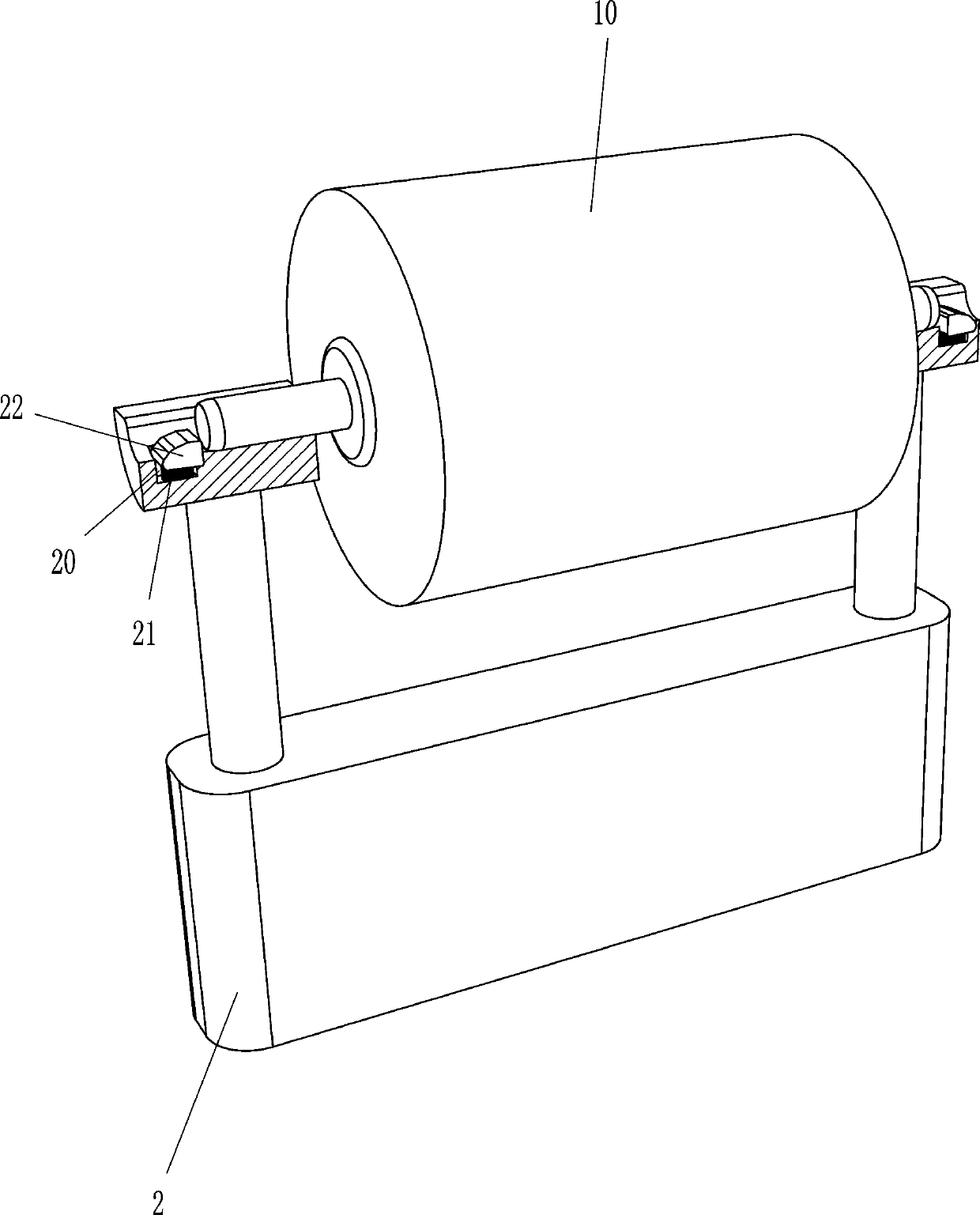

Flat paper tube reeling machine

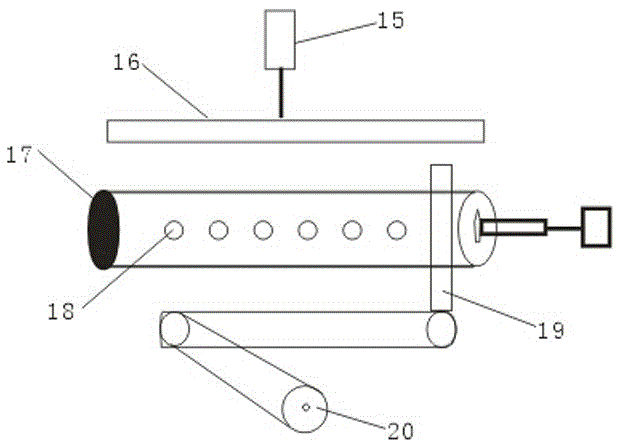

InactiveCN102774035AReduce thicknessExcellent adhesionPaper/cardboard wound articlesPulp and paper industryPaper cut

The invention discloses a flat paper tube reeling machine, comprising a rack, a paper placing device which is connected to the rack, a paper guiding device, a pasting device, a, paper cutting device, a paper feeding detaching device, a tube reeling device and a tube cutting device, wherein the pasting device comprises a sizing roller; a paper passing device is fixedly arranged between the pasting device and the paper cutting device; an paper inlet surface of the paper passing device and the top surface of the sizing roller are in a same plane; and an paper outlet surface of the paper passing device and a paper cutting surface of the paper cutting device are in a same plane. According to the flat paper tube reeling machine provided by the invention, the thickness of paper can be reduced; and during the tube reeling, the adherence force between two pieces of paper is increased, so that the paper tube quality is improved.

Owner:GUANGZHOU ZHONGSHI PACKAGE PROD

Automatic stacking paper-laying machine and paper laying method thereof

ActiveCN102862855AAdequate restGuaranteed aestheticsPile receiversArticle deliveryHigh volume manufacturingEngineering

The invention discloses an automatic stacking paper-laying machine which comprises a glass transiting mechanism, a glass overturn mechanism, a tray lifting mechanism, a glass tray, a paper cutting mechanism and a paper feeding mechanism. The glass transiting mechanism is arranged on one side of the glass overturn mechanism, and the glass tray is arranged on the other side of the glass overturn mechanism. The automatic stacking paper-laying machine with the structure has the advantages that paper can be automatically laid on glass; attractiveness of a whole stack of products can be guaranteed under the condition that the requirement on plate grabbing speed of a robot is met, so that a paper laying process is improved; labor is reduced, consistency and quality of the products are improved, the automatic stacking paper-laying machine is suitable for batch production, production cost is lowered, and production efficiency is improved; and the automatic stacking paper-laying machine is humanized, work intensity of staff is relieved, and industrial injury accidents can be reduced.

Owner:芜湖金三氏数控科技有限公司

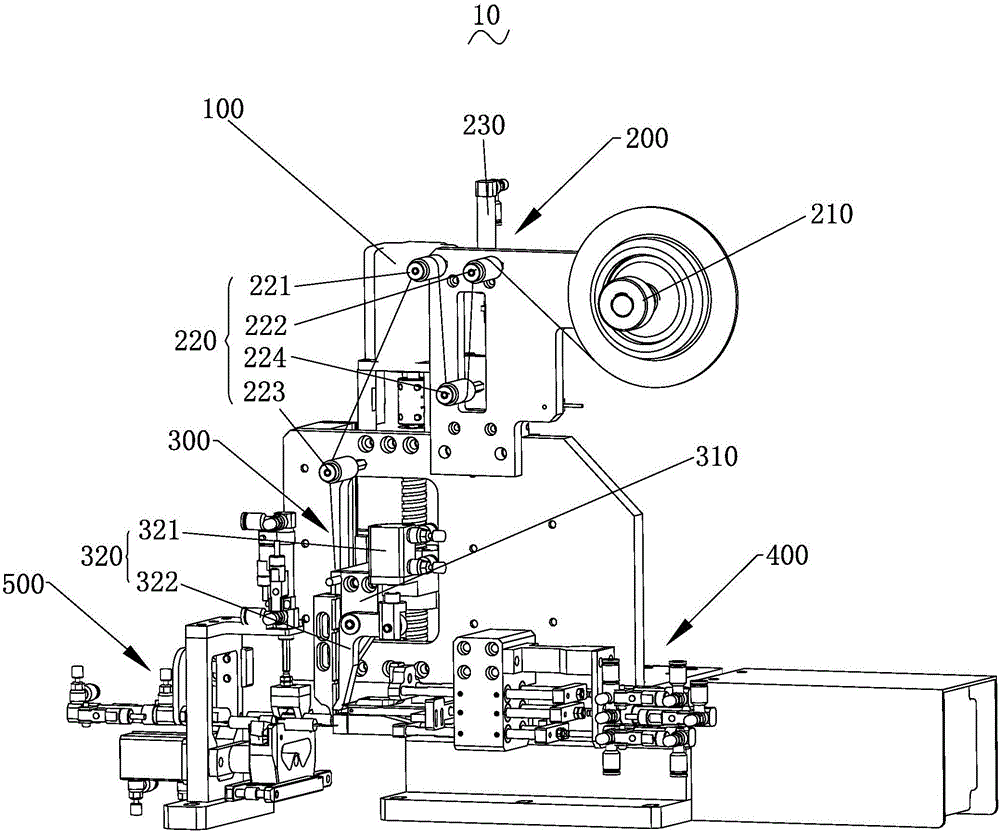

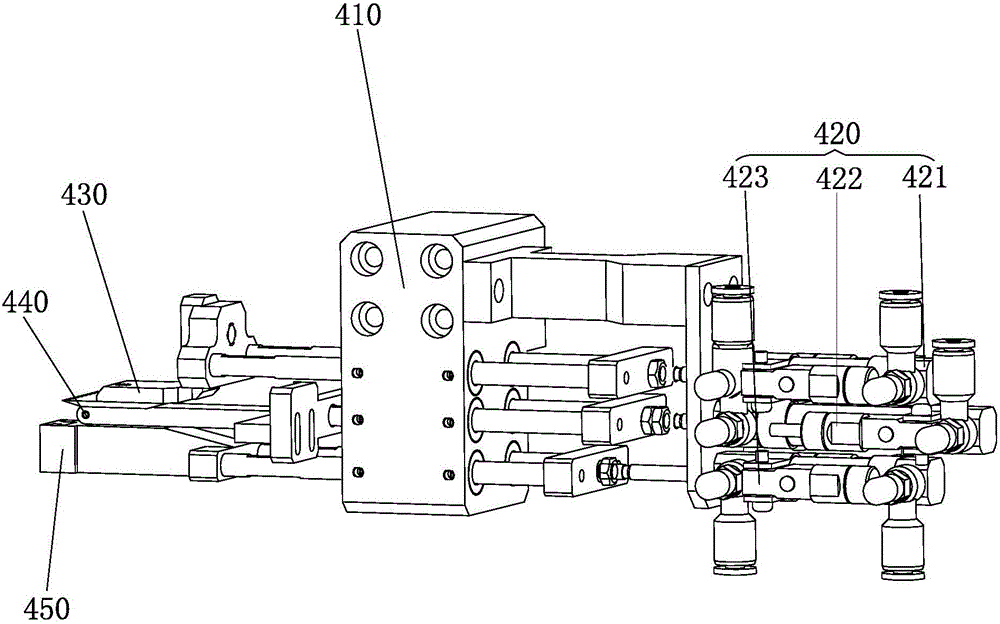

Battery gluing machine

ActiveCN105742684AEasy to operateReduce labor costsPrimary cell manufactureAssembling battery machinesPulp and paper industryPaper cut

The invention discloses a battery gluing machine. The battery gluing machine is characterized by comprising a rack, an adhesive paper feeding device, an adhesive paper transmitting device and an adhesive paper gluing device, wherein the adhesive paper feeding device, the adhesive paper transmitting device and adhesive paper gluing device are sequentially arranged on the rack, a battery placing device is further arranged on the rack and is used for fixing and placing a battery, the adhesive paper gluing device comprises a support block, a power driving part, an adhesive paper cutting part, an adhesive paper press part and an adhesive paper gluing part, the adhesive paper cutting part, the adhesive paper press part and the adhesive paper gluing part are sequentially and movably arranged on the support block, the power driving part is provided with a first driving air cylinder, a second driving air cylinder and a third driving air cylinder, the first driving air cylinder is in driving connection with the adhesive paper cutting part, the second driving air cylinder is in driving connection with the adhesive paper press part, and the third driving air cylinder is in driving connection with the adhesive paper gluing part. In the winding gluing machine disclosed by the invention, through mutual matching of all devices, automatic gluing operation on the battery is achieved, and the production efficiency is improved; and moreover, the whole structure is simple, 7-shaped or n-shaped gluing operation on different types of battery products can be achieved, and thus, the universality of the battery gluing machine is improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Firework coiling machine

ActiveCN106313638AReduce moistureReduce hardnessPaper/cardboard wound articlesFireworksFireworksPulp and paper industry

The invention discloses a firework coiling machine. The firework coiling machine comprises a paper feeding mechanism, a paper cutting mechanism, a coating mechanism, a coiling mechanism, a drum cutting mechanism and a drum receding mechanism, all of which are sequentially arranged on a rack. The firework coiling machine is characterized by further comprising a paper heating mechanism and a paper shaping mechanism, the paper heating mechanism is arranged at the front end of the paper feeding mechanism and comprises a driver with a heat source, and coiling paper is heated when conveyed to the paper feeding mechanism through the driver; and the paper shaping mechanism comprises an extrusion component and an extrusion face corresponding to the extraction component, the extrusion component moves towards the extrusion face, and the running coiling paper is shaped into an arc through the joint action of the extrusion component and the extrusion face. The firework coiling machine is simple in structure and convenient to use, the phenomenon of seam slippage of a paper drum is eradicated through the produced firework paper drum, the water content is extremely low, the production efficiency is improved, and the production cost is saved.

Owner:李金亮

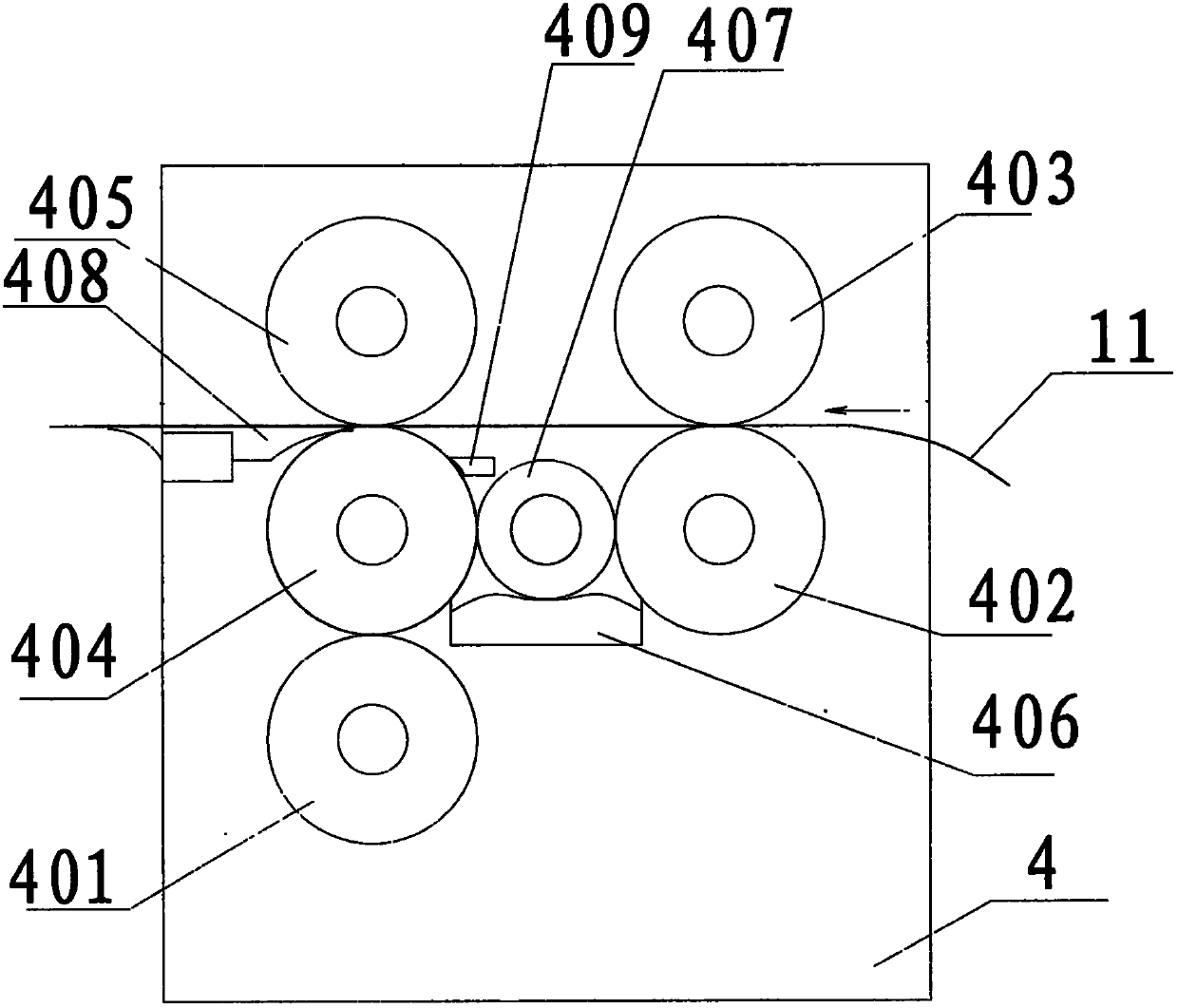

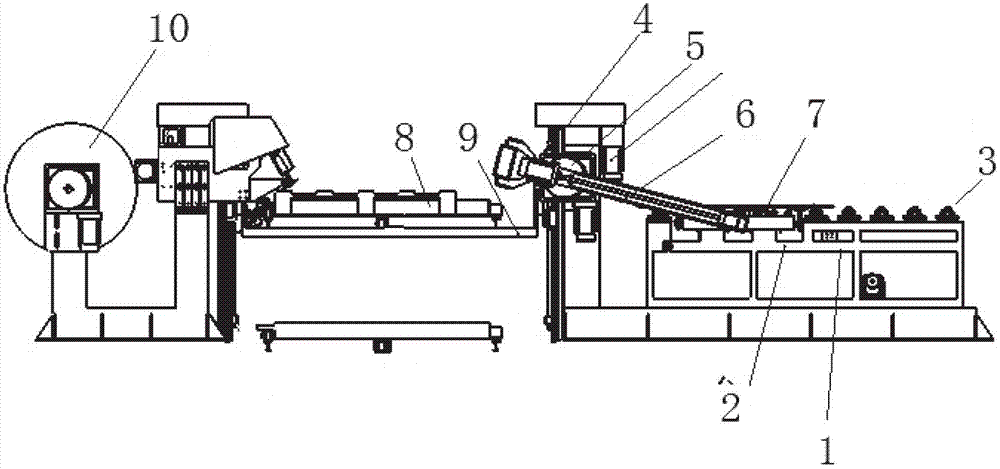

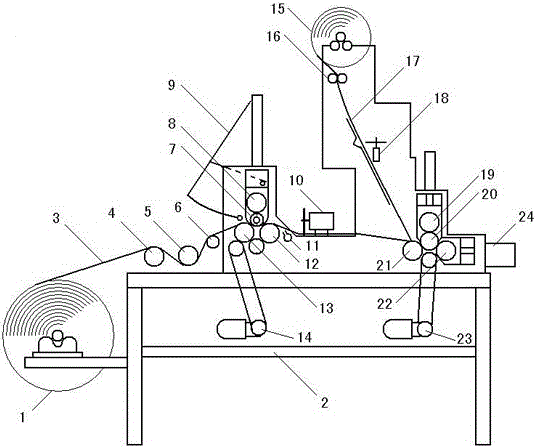

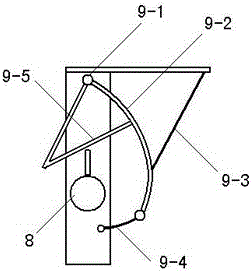

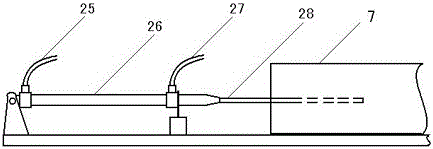

Slice packaging folding machine for storage battery electrode slices

ActiveCN102623741AReduce labor intensitySimple structureFinal product manufactureSecondary cells manufactureUltimate tensile strengthBattery electrode

The invention discloses a slice packaging folding machine for storage battery electrode slices, which comprises a conveying plate chain, a slice compressing mechanism, a paper feeding mechanism, a paper cutting mechanism, a slice packaging mechanism and a slice folding mechanism, wherein the slice compressing mechanism is arranged at the front end of the conveying plate chain, the paper feeding mechanism, the paper cutting mechanism, the slice packaging mechanism and the slice folding mechanism are arranged on the upper portion of the conveying plate chain, the rear end of the paper feeding mechanism is connected with the paper cutting mechanism, the rear end of the paper cutting mechanism is connected with the slice packaging mechanism, the rear end of the slice packaging mechanism is connected with the slice folding mechanism, and the direction of the slice packaging mechanism is consistent with the movement direction of the conveying plate chain. The slice packaging folding machine for storage battery electrode slices performs automatic whole production in the slice packaging folding process, the direction of the slice packaging mechanism is consistent with the movement direction of the conveying plate chain, the whole production process can be performed continuously, and all operations can be completed in the conveying process, so that production efficiency is improved, production cost is reduced, the structure of production equipment is optimized and labor intensity of workers is reduced.

Owner:CHANGXING KEWEI SOFTWARE TECH

Book packing machine

The invention relates to a book packing machine which comprises a transverse book conveying mechanism, a longitudinal book conveying mechanism, a paper conveying mechanism, a paper cutting mechanism, a beveling mechanism and a pasting, labeling and drying mechanism. The transverse book conveying mechanism is driven by a cam rack and simple and compact in structure, complicated movement requirements are easily met, various transmission ratios are easily designed, the longitudinal book conveying mechanism comprises a cam mechanism and a connecting rod slider mechanism and is easy to manufacture, large in bearing capacity and small in impact, the paper conveying mechanism and the paper cutting mechanism are compact, simple to machine, economical and easy to implement and assemble, working efficiency is improved by an upper edge and lower edge folding mechanism, a cam integrally appears quite compact owing to small rotating amplitude of the cam, the beveling mechanism is quite simple, easy to implement, low in manufacturing cost and high in cost performance, a cam rocker-slider mechanism can realize pasting, labeling, drying and secondary drying and is high in working efficiency and stable, the whole structure is complete and compact, and books can be rapidly packed.

Owner:苏州凯绚新科技有限公司

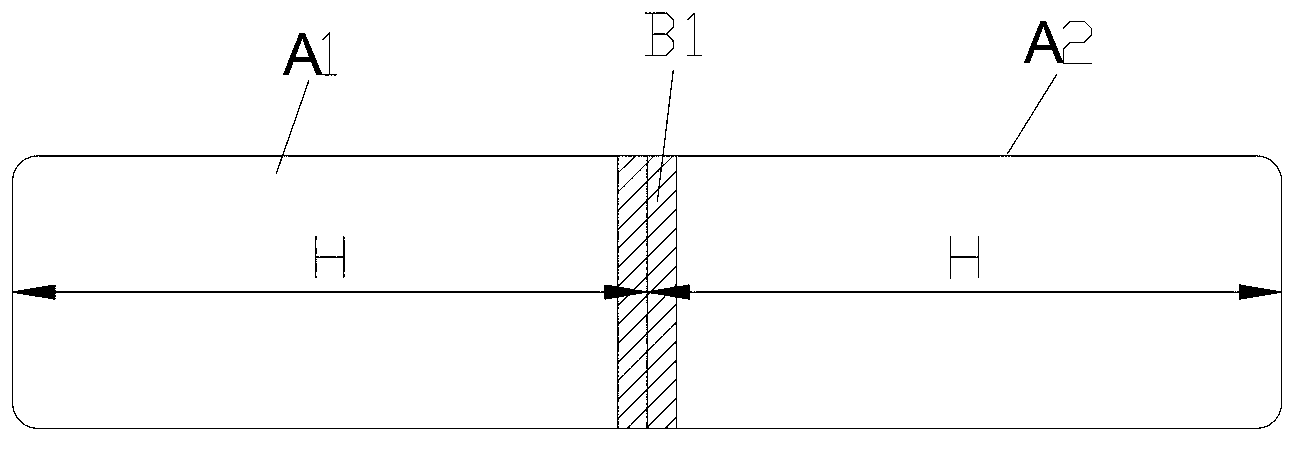

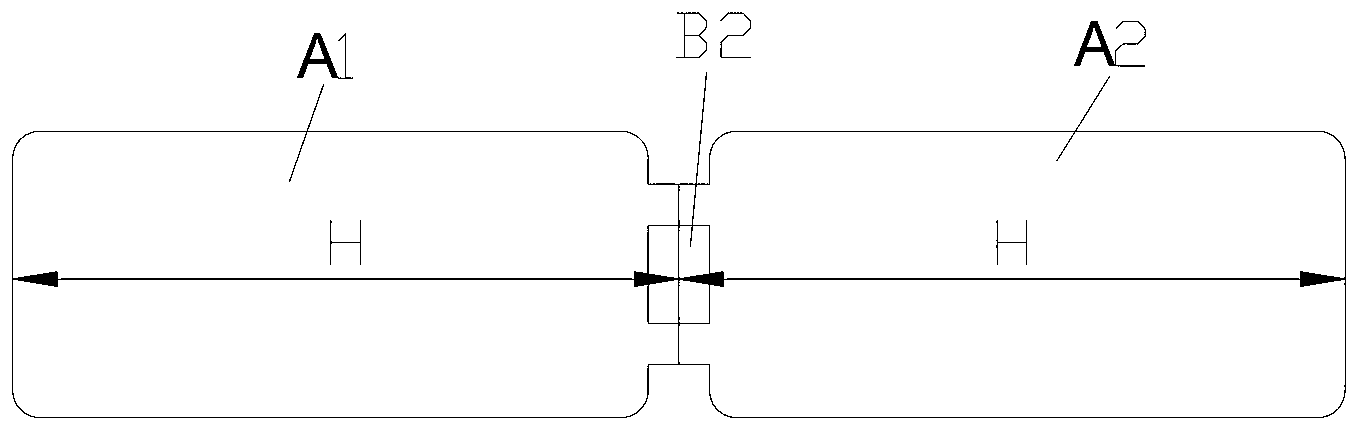

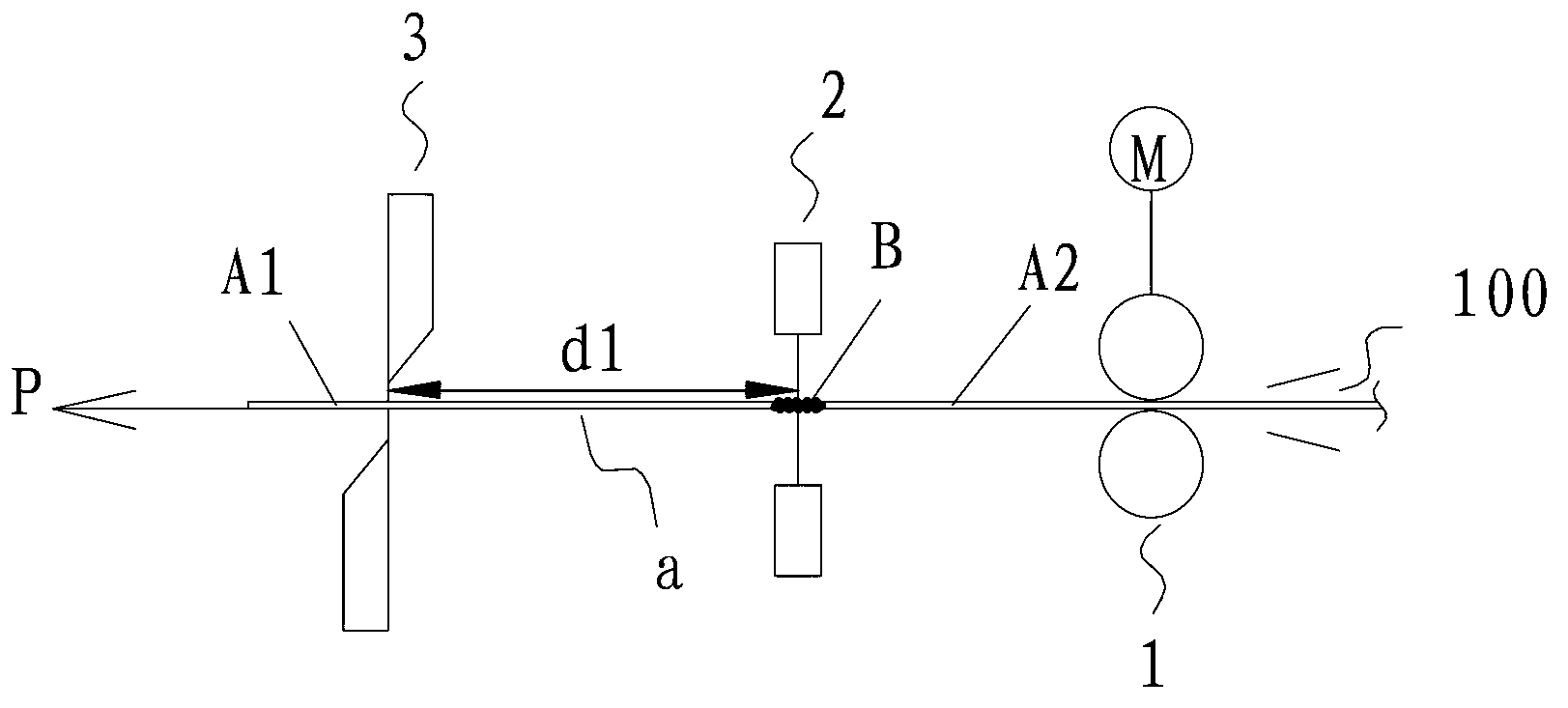

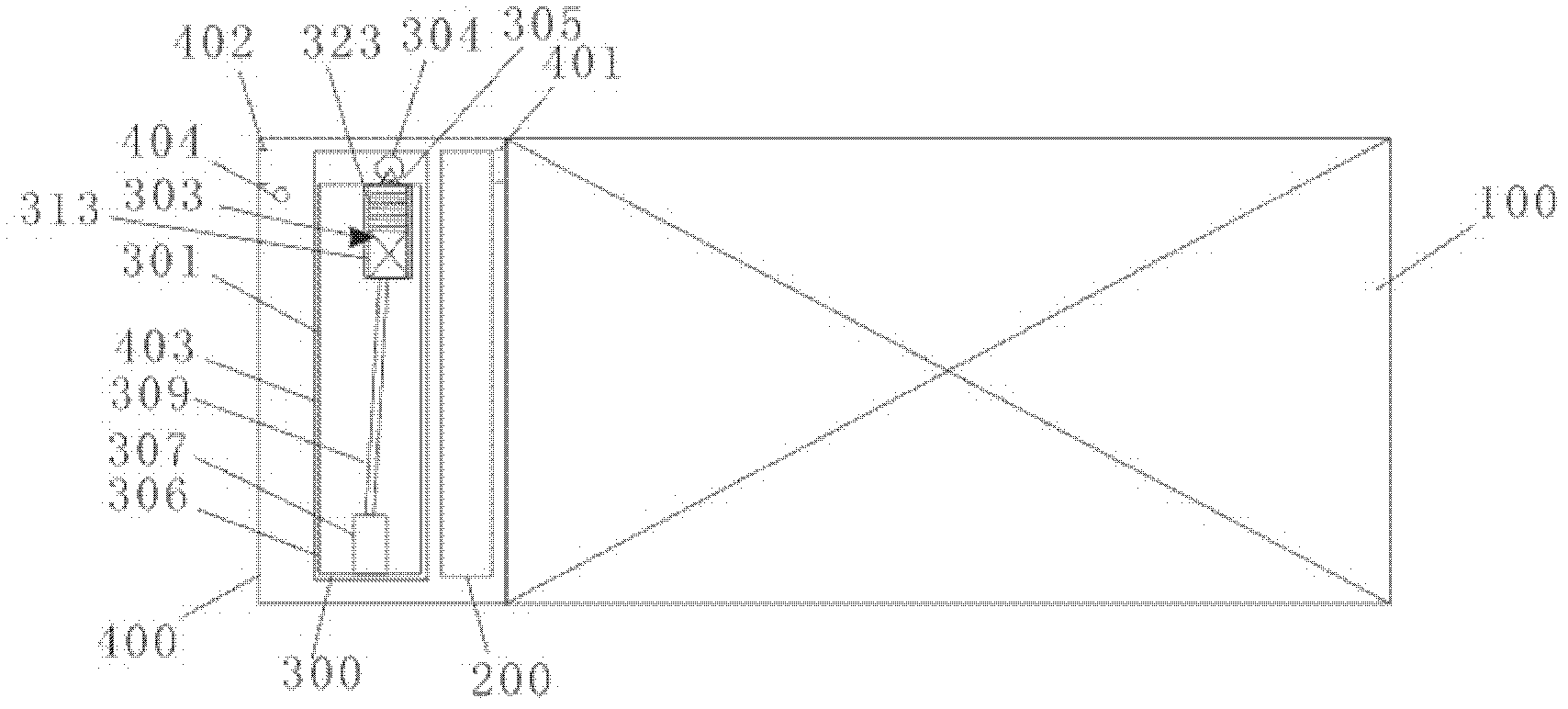

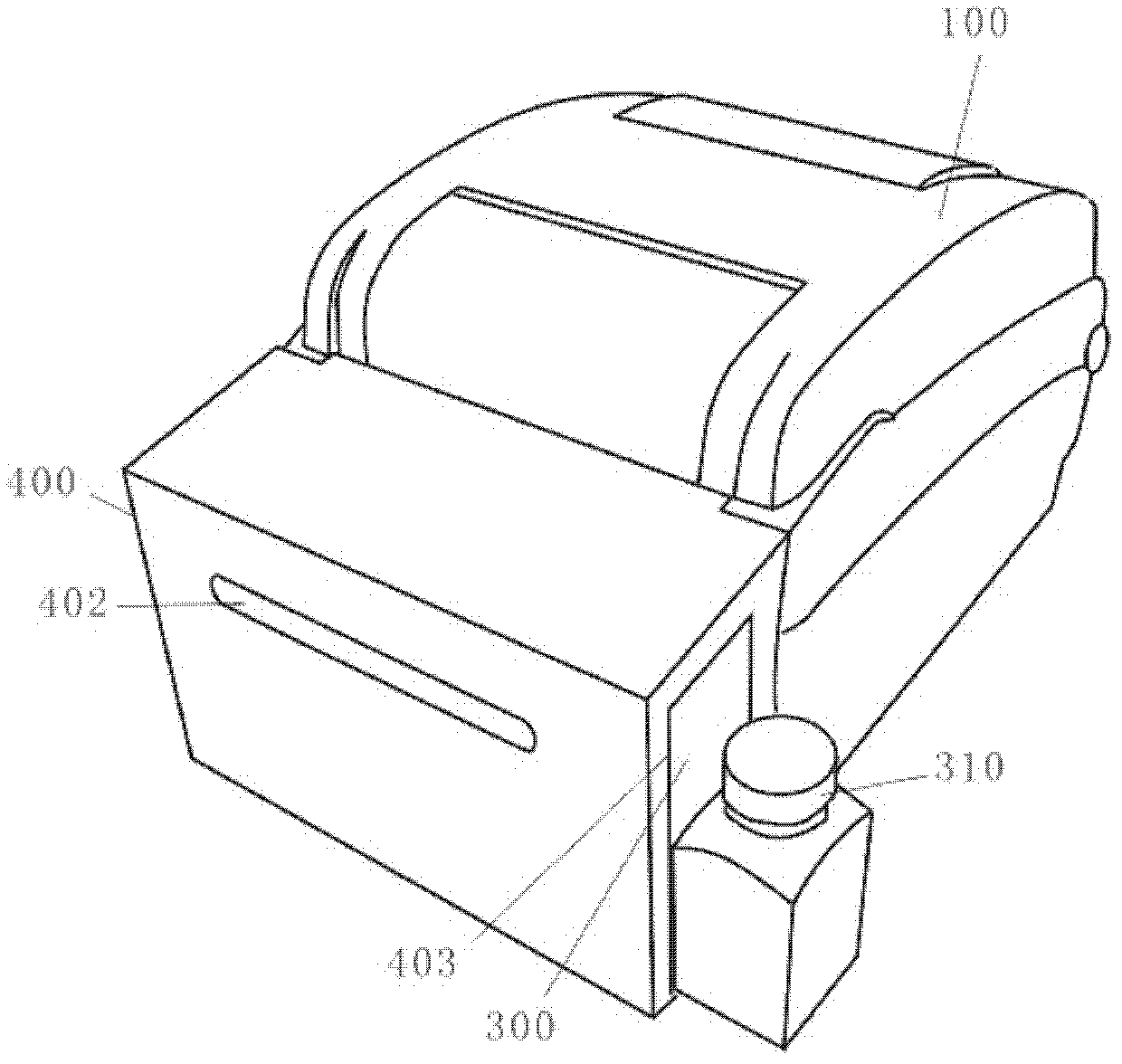

Receipt paper cutting control device and receipt drawing machine

ActiveCN103213410AAccurate paper cutting positionAccurate control of paper cutting positionOther printing apparatusDrive motorPaper sheet

The invention discloses a receipt paper cutting control device and a receipt drawing machine. The receipt paper cutting control device comprises an operation rail serving as a rail conveying receipt paper, and a drive motor used for driving the receipt paper to be conveyed along the operation rail. A first sensor, a cutter and a second sensor are sequentially arranged on the operation rail along the conveying direction of the receipt paper. Position arrangement of the first sensor and the second sensor meets the condition that (d1+d2)<=H, wherein H is the length of a receipt, d1 is the length of the operation rail between a detection position of the first sensor and a cutting position of the cutter, and d2 is the length of the operation rail between a cutting position of the cutter and a detection position of the second sensor. By means of the receipt paper cutting control device and the receipt drawing machine, the effect of precisely controlling a cutting position of the receipt is achieved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

Fireworks packaging equipment

The invention provides fireworks packaging equipment. The fireworks packaging equipment comprises a rack, a paper feeding device fixed on the rack, a molded fireworks barrel feeding device fixed on the rack, a gluing device fixed on the rack, a top and bottom poster paper gluing device, an adhesive tape feeding device and a peripheral poster paper gluing device, wherein the top and bottom poster paper gluing device comprises a paper receiving mechanism, a first paper cutting mechanism and a paper pressing mechanism; and the adhesive tape feeding device comprises a guide rail vertically fixed on the rack, an adhesive tape coil arranged on the guide rail, an adhesive tape pulling cylinder for driving the adhesive tape coil to slide downwards, a vacuum suction board arranged below the adhesive tape pulling cylinder and an adhesive tape pressing mechanism and an adhesive tape cutting mechanism which are fixed on one side of the bottom end of the guide rail. Compared with the prior art, the fireworks packaging equipment provided by the invention has the benefits as follows: through the coordination of the paper feeding device, the molded fireworks barrel feeding device, the gluing device, the top and bottom poster paper gluing device, the adhesive tape feeding device and the peripheral poster paper gluing device, the packaging of fireworks barrel by adopting the packaging paper is realized, the packaging speed is high, the production efficiency is high, and the human cost is reduced.

Owner:浏阳大吉润华精密机械制造有限公司

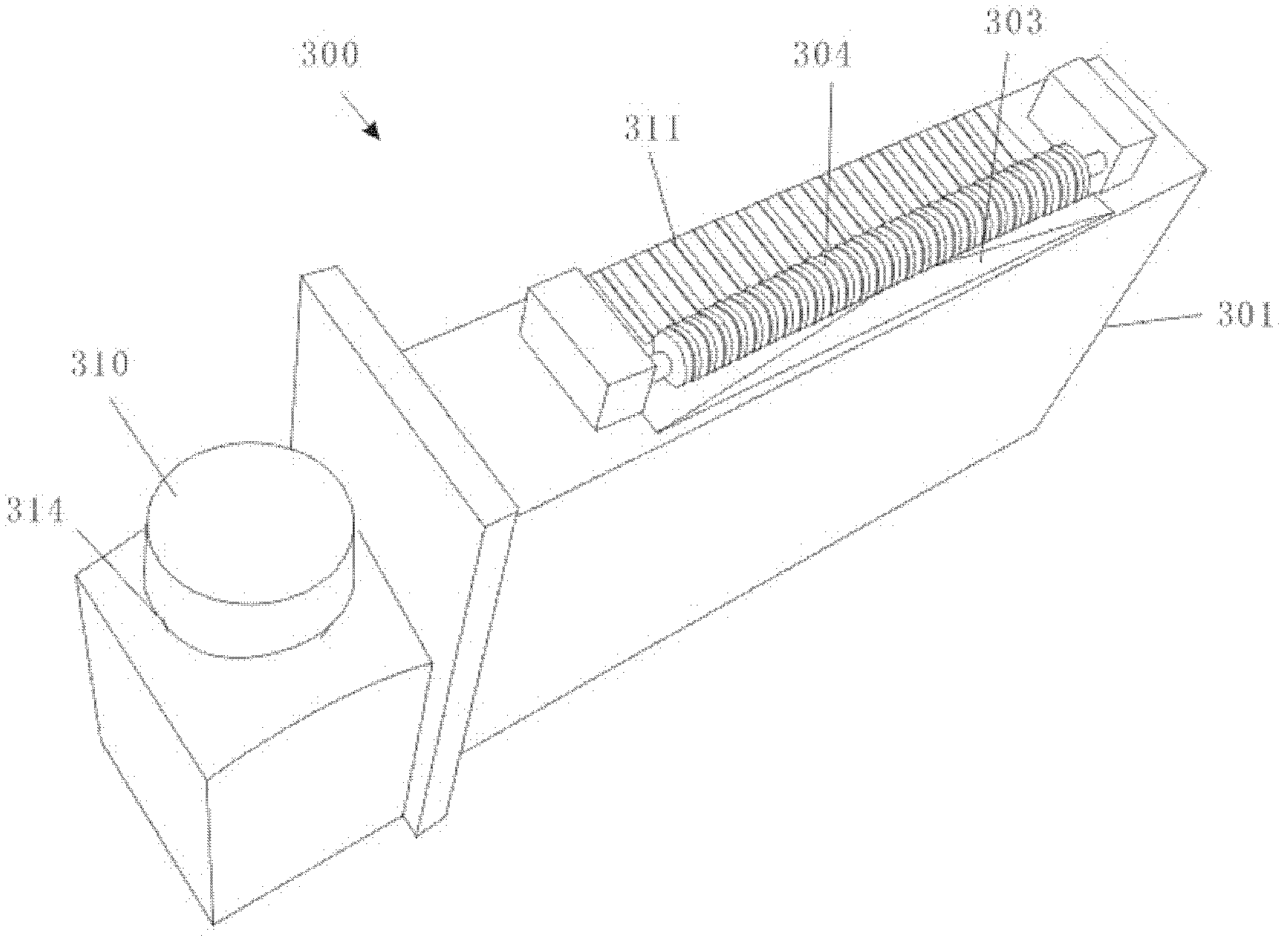

Hob type paper cutting device

ActiveCN104070841ASimple structureGood paper cutting reliabilityOther printing apparatusMetal working apparatusControl systemDrive motor

The invention discloses a paper cutting device, particularly relates to a hob type paper cutting device applied to a printer, and belongs to the field of computer communication technology. The hob type paper cutting device comprises a driving motor, a transmission mechanism, a rolling movable knife, a fixed knife, a holder, a paper pressing assembly, a guide support, a guide shaft, a guide plate, a position sensor, a tensioning support assembly, a control system and the like. The transmission mechanism transmits rotation movement of the driving motor to the rolling movable knife to perform automatic paper cutting. The hob type paper cutting device has the advantages that the hob type paper cutting device is modular in design manufacture, low in cost and convenient to maintain, assemble and disassemble; a pressure angle remains unchanged during paper cutting, so that paper is cut stably; a paper cutting assembly is simple in structure and good in paper cutting reliability.

Owner:NANJING FUJITSU ELECTRONICS INFORMATION TECH CO LTD

Book and periodical packaging machine

InactiveCN101723102AReduce labor intensityEasy to operateWrapper folding/bending apparatusConveyor wrappingPulp and paper industryPaper sheet

The invention discloses a book and periodical packaging machine which is characterized in that a mainframe is provided with a book sending channel, and the tail end of the book sending channel is provided with a book push position; the book push position is provided with a book push cylinder; and one side of the book push position is provided with a paper folding channel. The book and periodical packaging machine is provided with a paper feed mechanism, and the paper feed mechanism is provided with a paper cut device, wherein the tail end of the paper feed mechanism is arranged at the book push position. The paper folding channel is provided with a paper folding mechanism, the tail end of the paper folding channel is provided with a labeling channel, and the labeling channel is provided with a labeling mechanism. The book and periodical packaging machine has the advantages of simplicity, rapidness and easy operation and can lighten the labor intensity of workers and improve the book packaging quality and the book packaging speed.

Owner:SHANGHAI PURPLE MAGNA MACHINERY

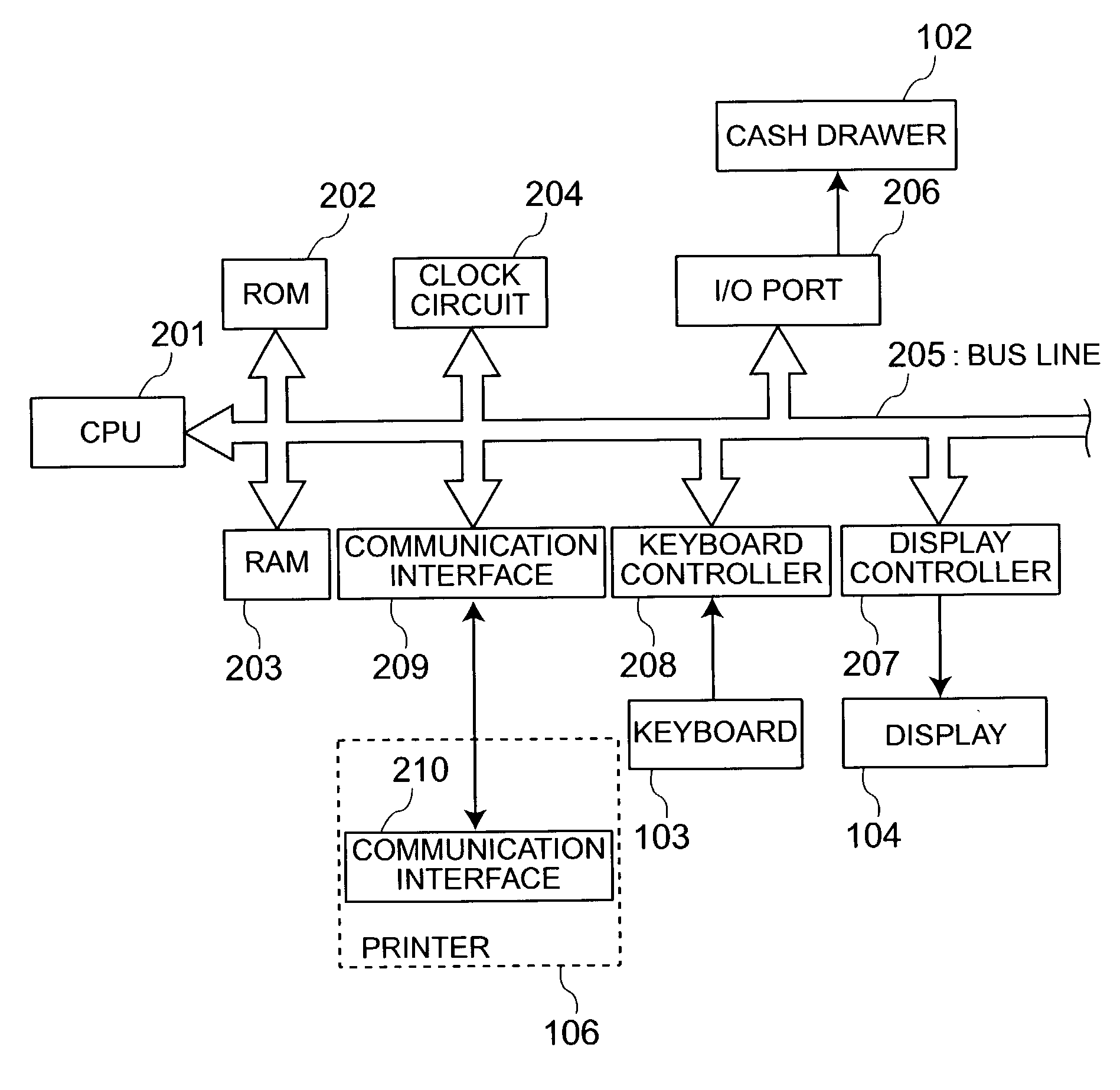

Printer driver, print control method and information recording medium

InactiveUS20020164185A1Character printing data arrangement from carrierError detection/correctionComputer printingProcess engineering

When printing a print document for which there is a print request from an application program, printing the one or plural print documents printed by page unit where a specific paper size is one page is controlled based on plural combinations of print paper feeding and cutting. When the page mode is the Form [No cut] mode, print image data is generated so that a paper feed is executed after completing printing one page (step S503); when the page mode is the Form [Cut] mode, print image data is generated so that a paper feed is executed after completing printing one page and a paper cut command is issued when paper feeding is completed (step S504); when the page mode is the Report [No cut] mode, print image data is generated so that a paper feed is executed after completing printing one print document (step S505); when the page mode is the Report [Cut] mode, print image data is generated so that a paper feed is executed after completing printing one print document and a paper cut command is issued when paper feeding is completed (step S506), and the page mode correspondence process ends.

Owner:SEIKO EPSON CORP

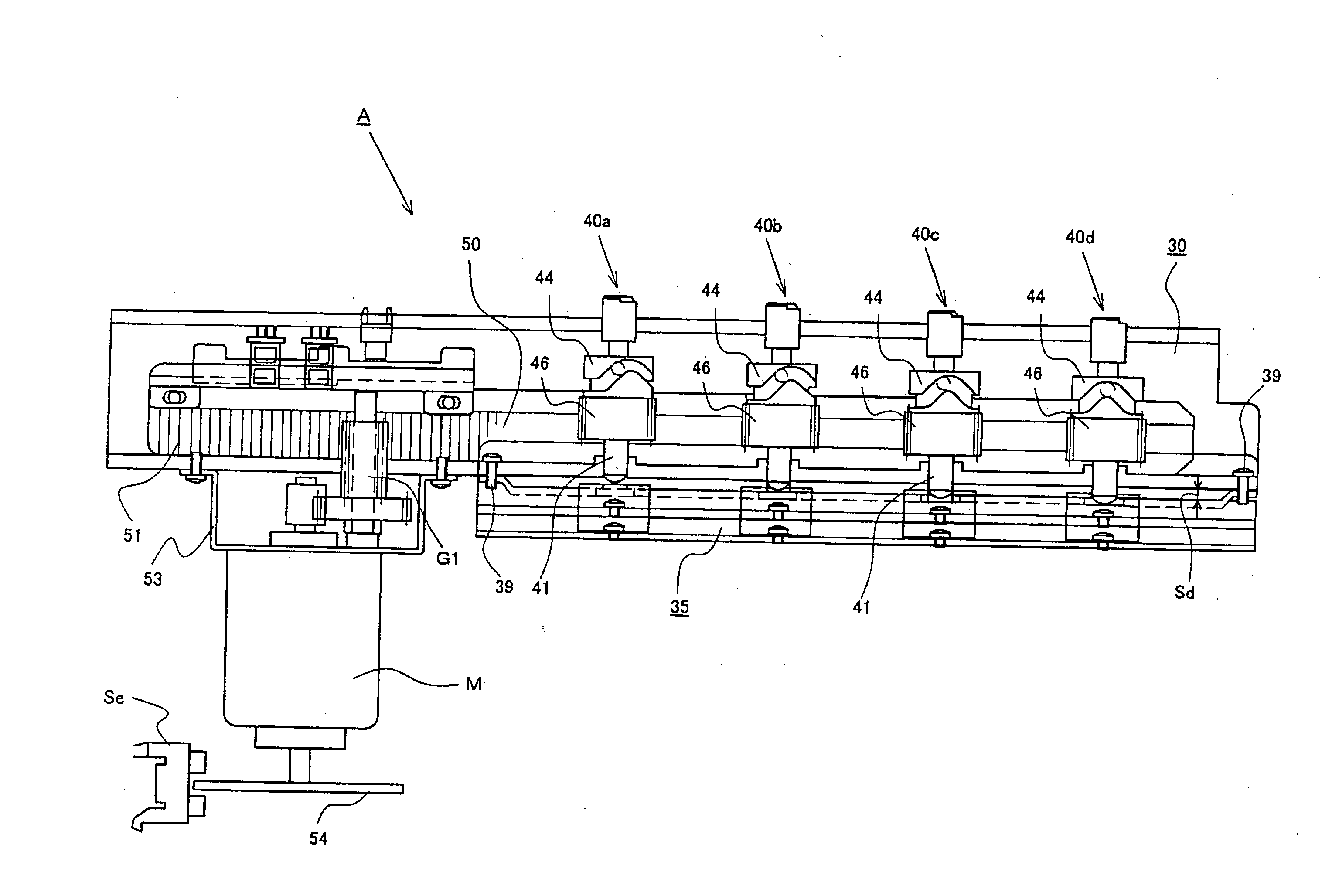

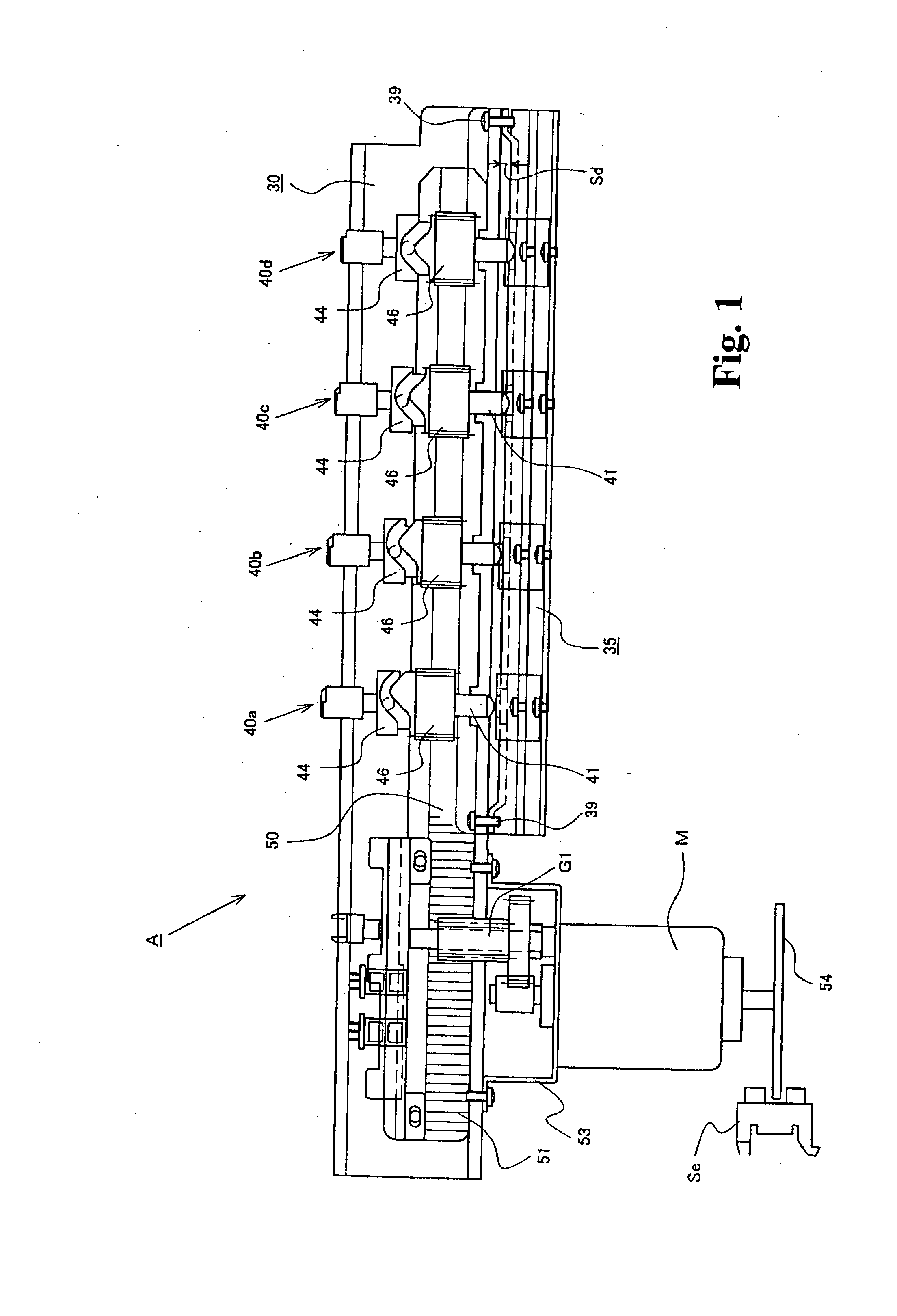

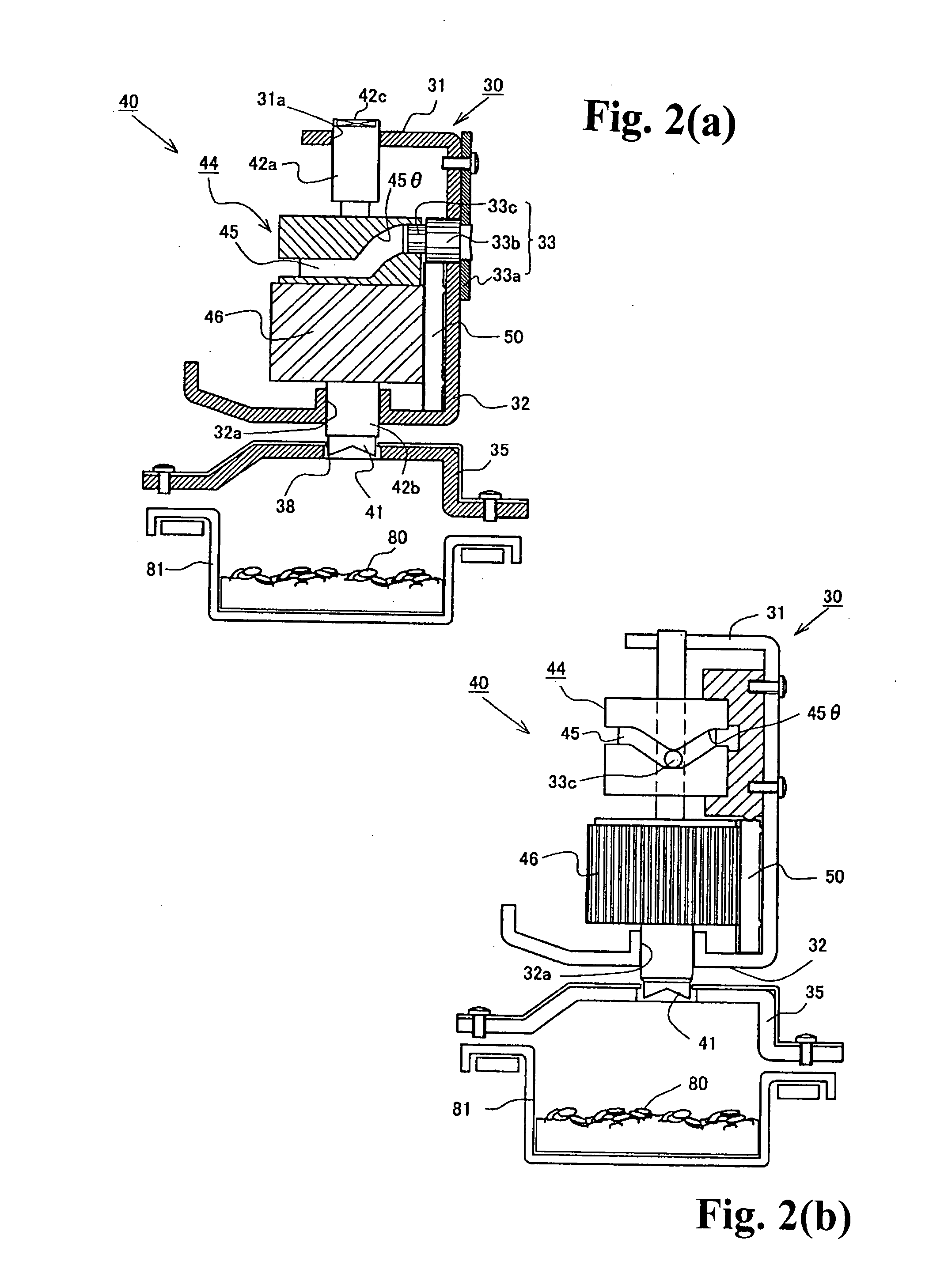

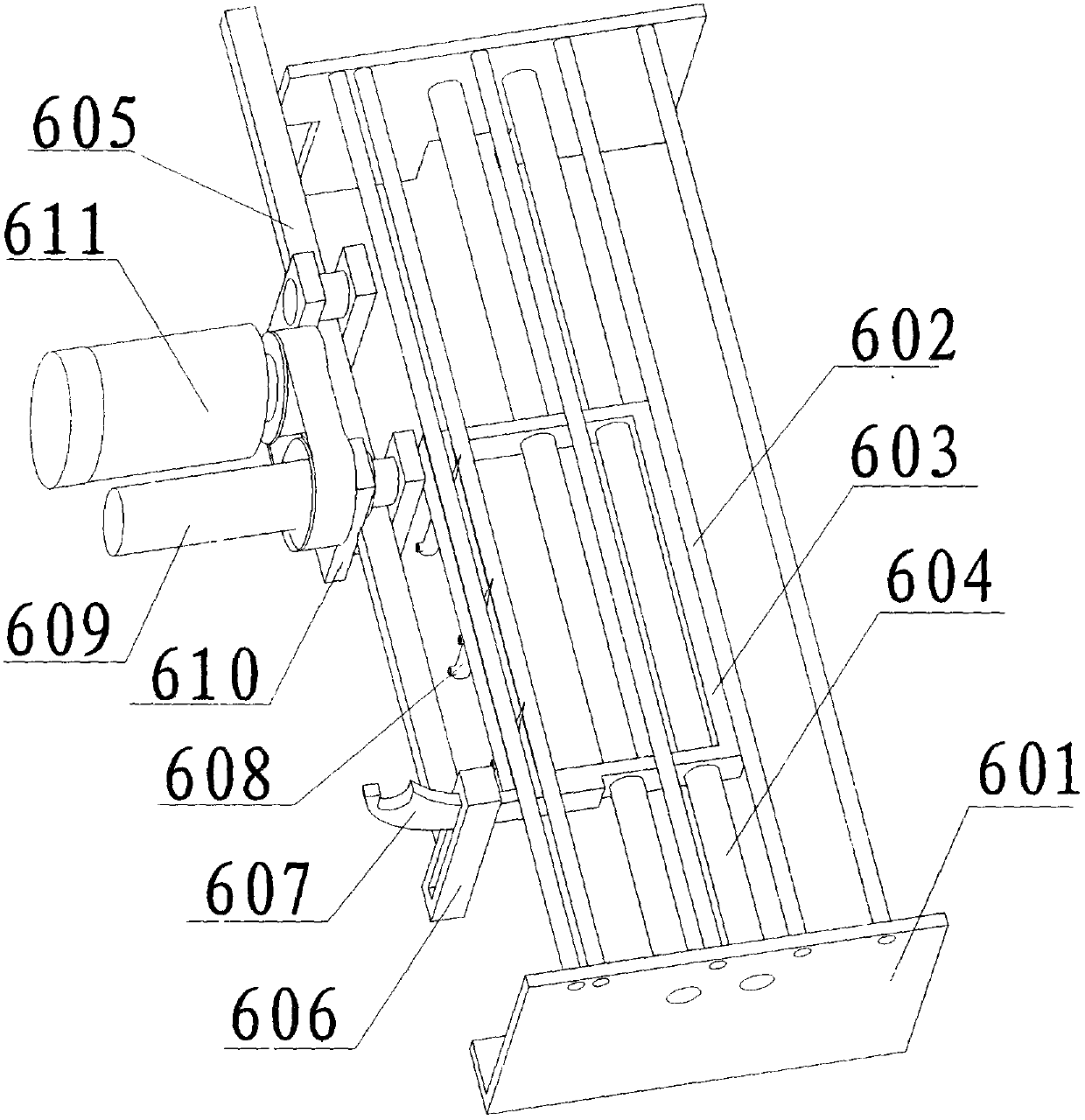

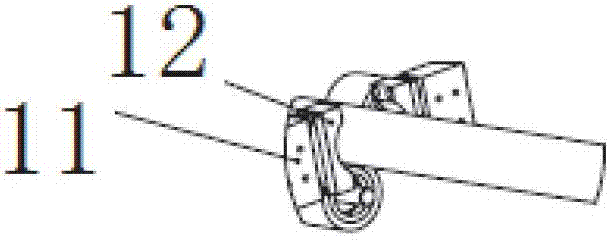

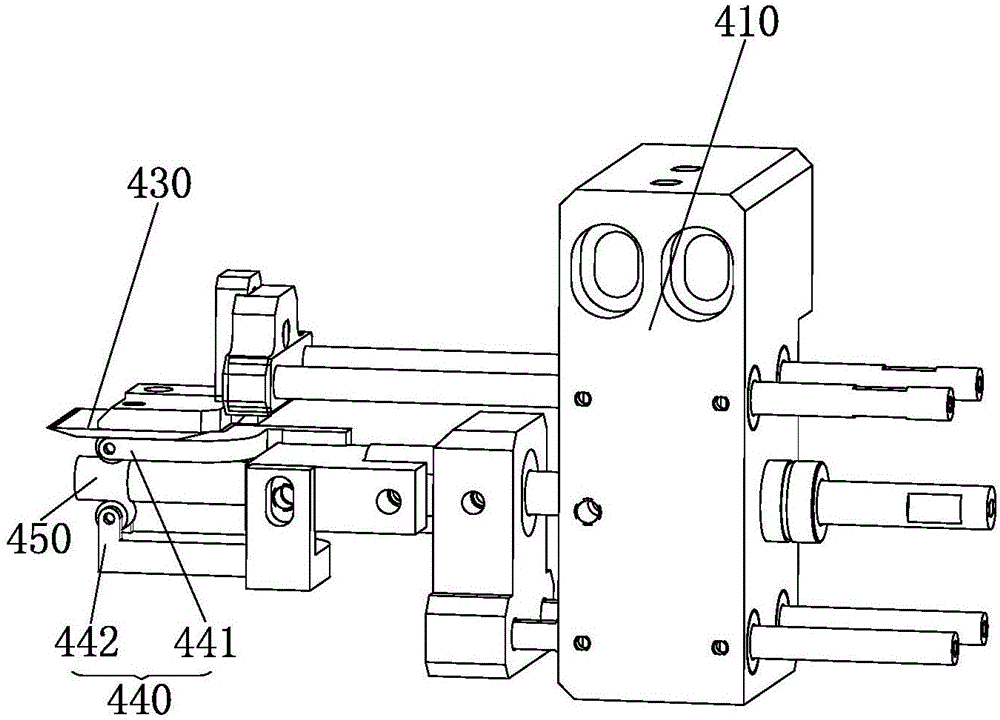

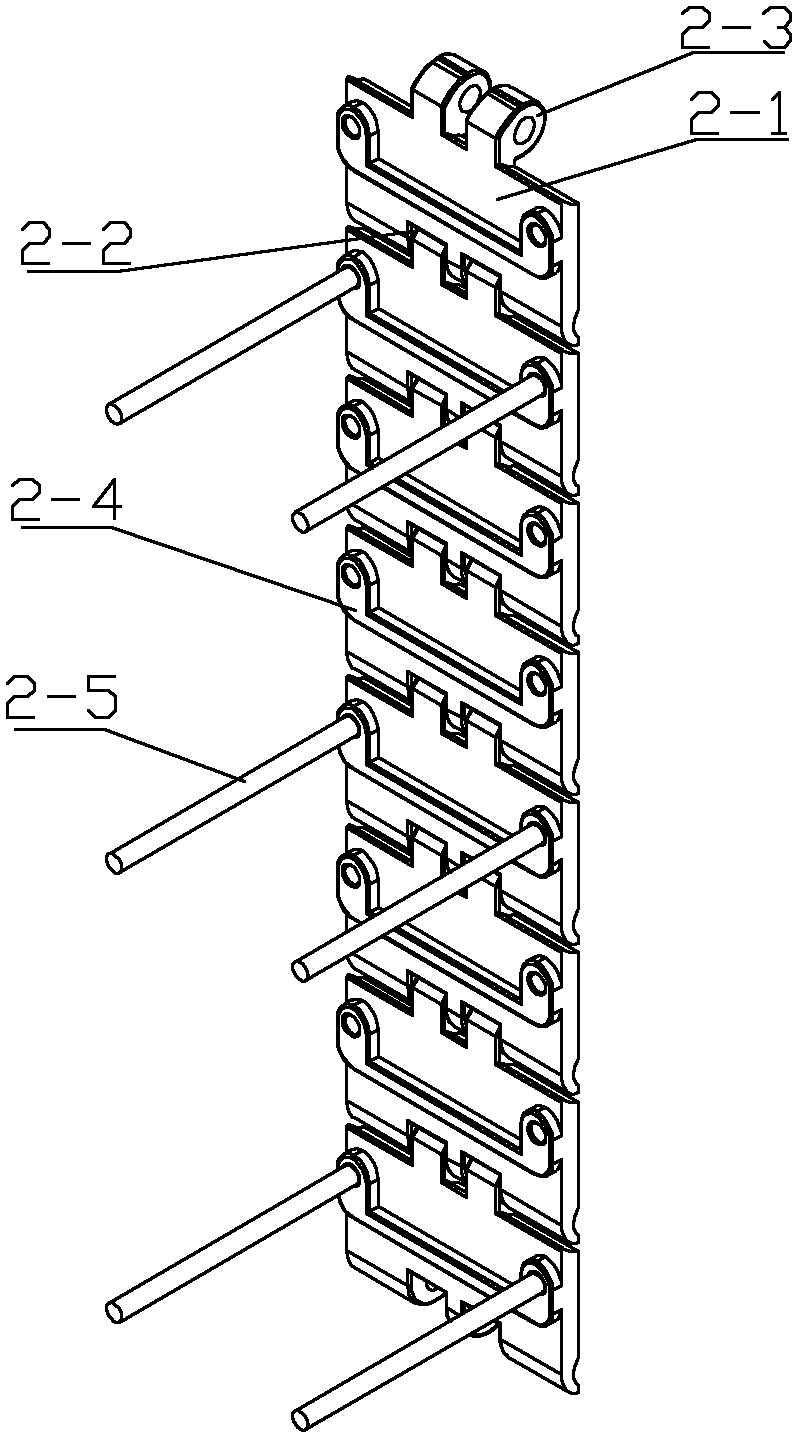

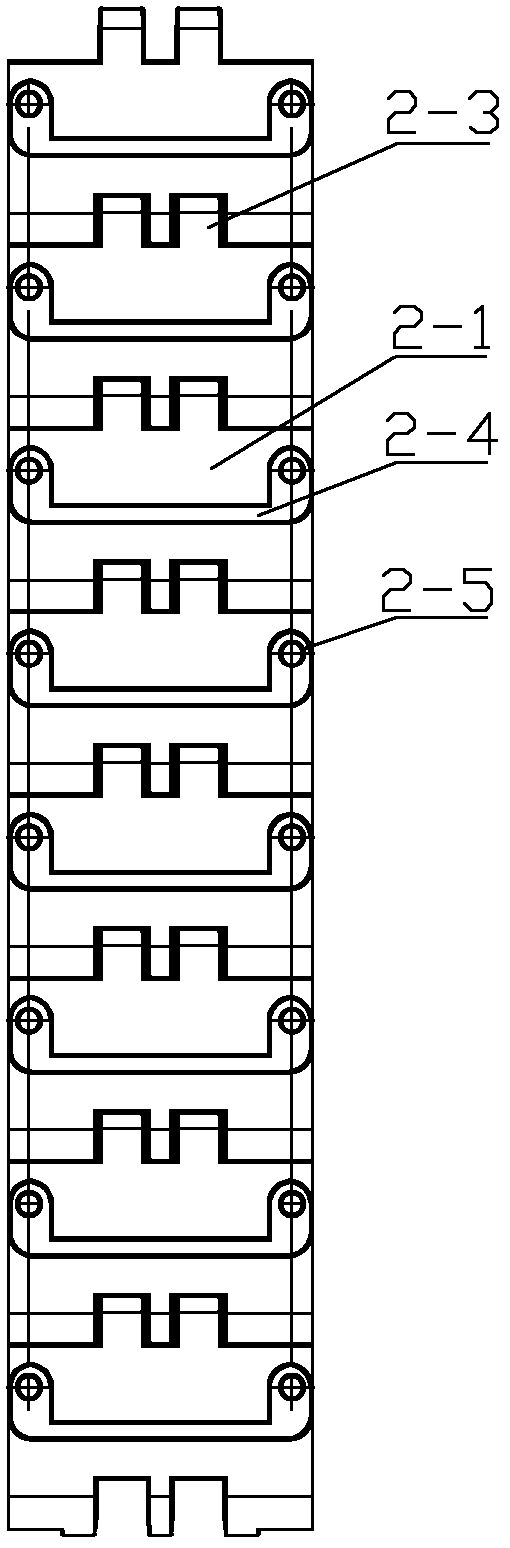

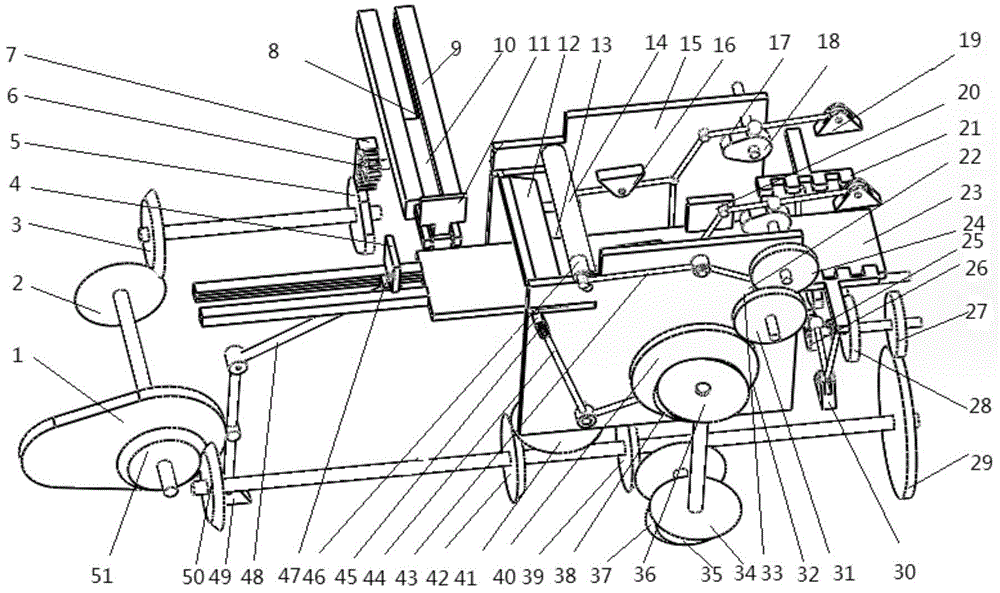

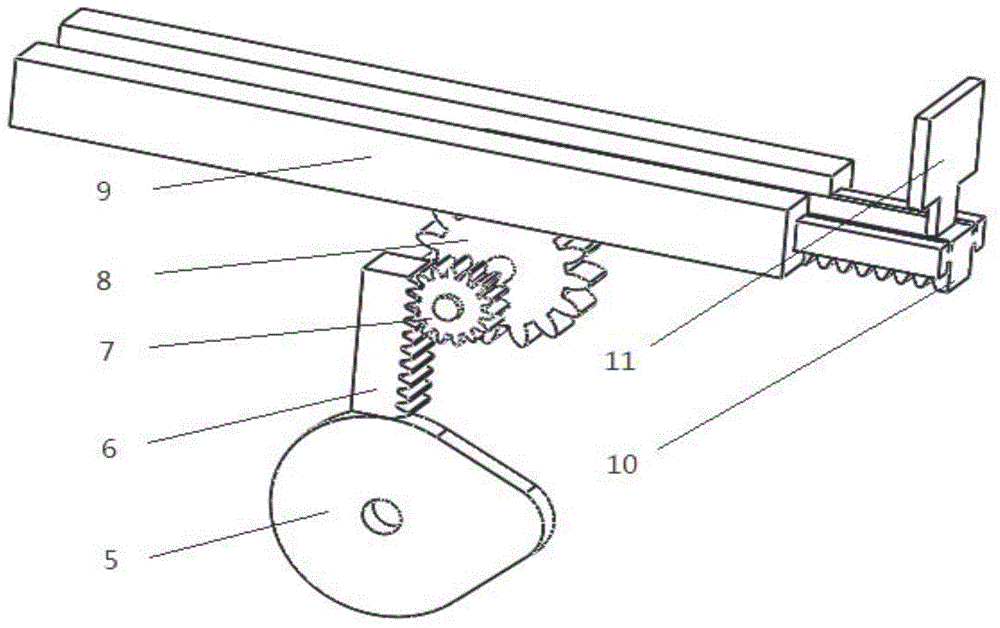

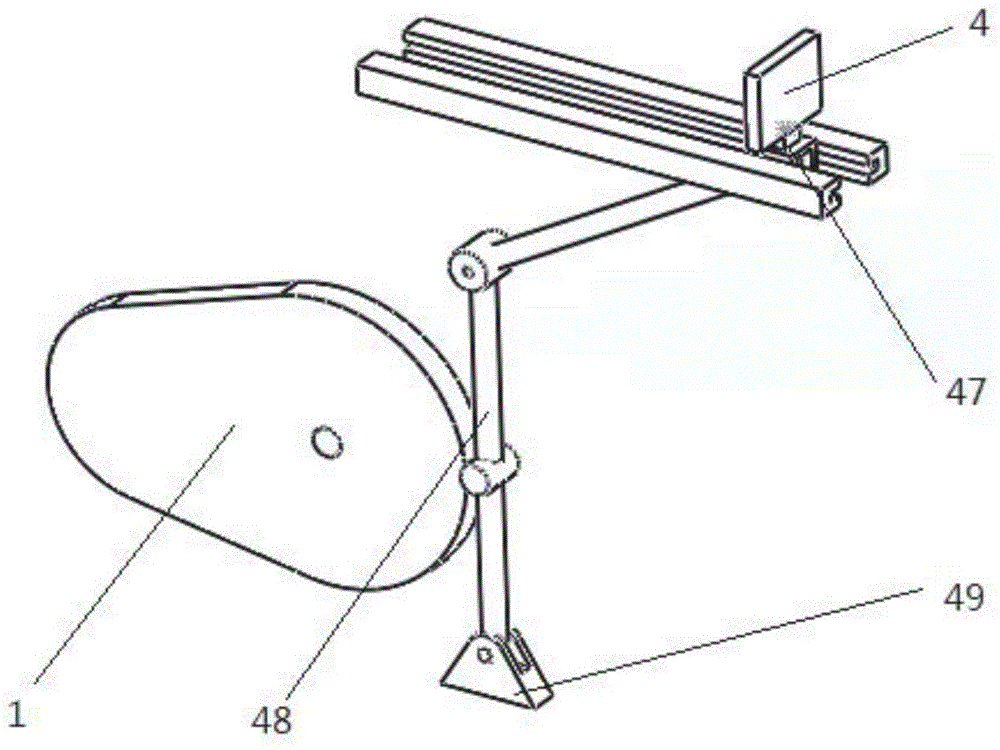

Rotor paper insertion equipment

ActiveCN102306987AImprove work efficiencyEasy to insertApplying solid insulationDrive shaftPaper tape

The invention relates to rotor paper insertion equipment. The equipment comprises: a drive unit, which is composed of a driving shaft and a driven shaft; a paper feeding device, which is used for conveying an insulation paper belt; a paper cutting device, which comprises a cutting knife that is used for cutting off the insulation paper belt; a paper folding moulding device, which is used for bending a piece of insulation paper to generate insulation papers and comprises a moulding knife and a moulding female die that is provided with a moulding groove; a paper insertion device, which includesa push rod that is used for inserting the bent and moulded insulation papers into a rotor; a rotor clamping device, which is installed near the side of the paper folding moulding device and is used for conveying and localizing the rotor; a rotor indexing device, which is arranged on the rotor clamping device and is used for carrying out rotary indexing on the rotor; and an insulation paper guiding head moulding device, which is slidely installed on a master box and is used for forming a guiding head at one end of one piece of insulation paper; besides, the insulation paper guiding head moulding device, the paper cutting device and the paper folding moulding device are successively installed on the rotor paper insertion equipment. According to the invention, a guide head can be formed on apiece of insulation paper, so that the paper insertion technology can be carried out smoothly.

Owner:SHENZHEN JINMINJIANG RIVER MECHANICAL & ELECTRICAL EQUIP

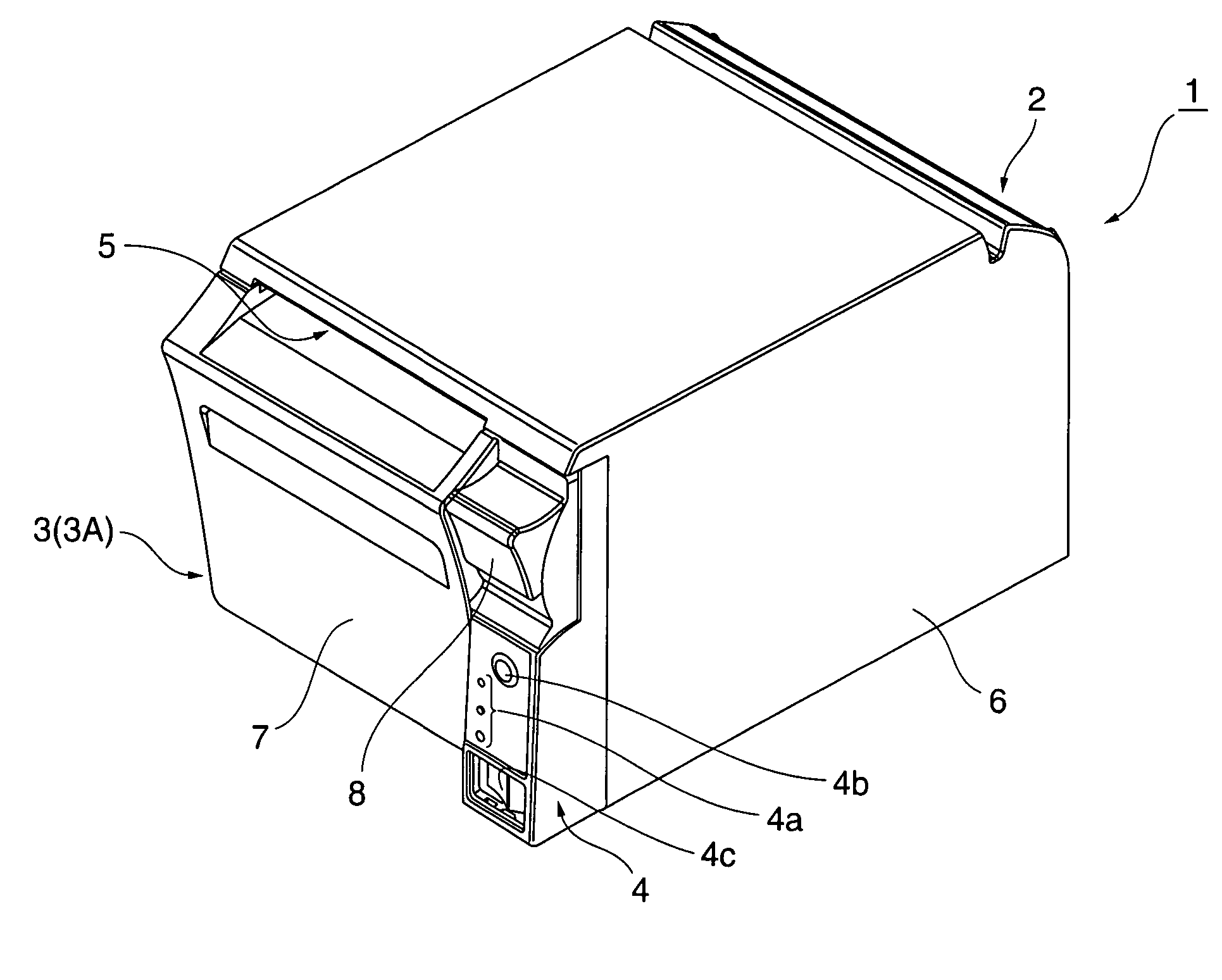

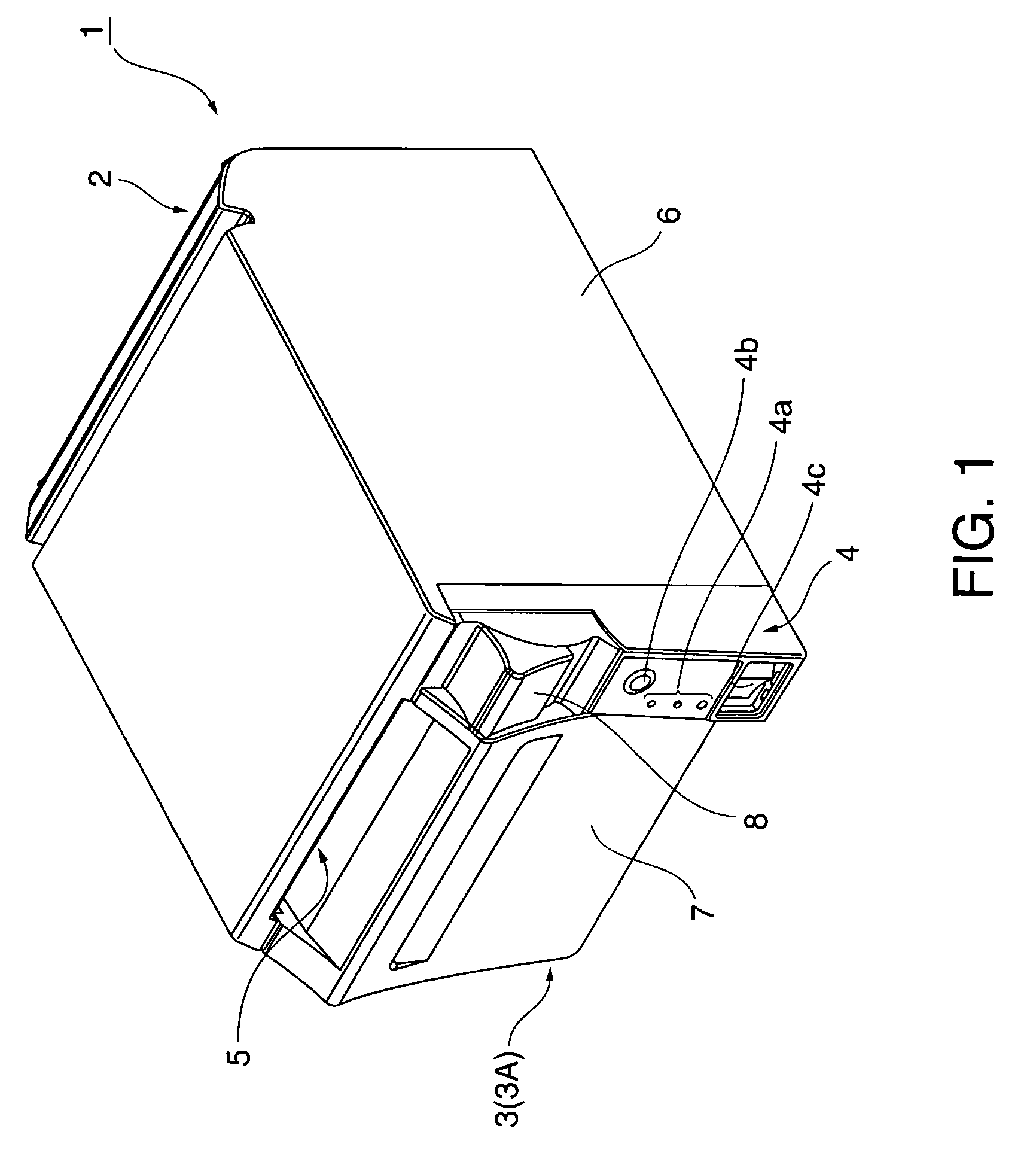

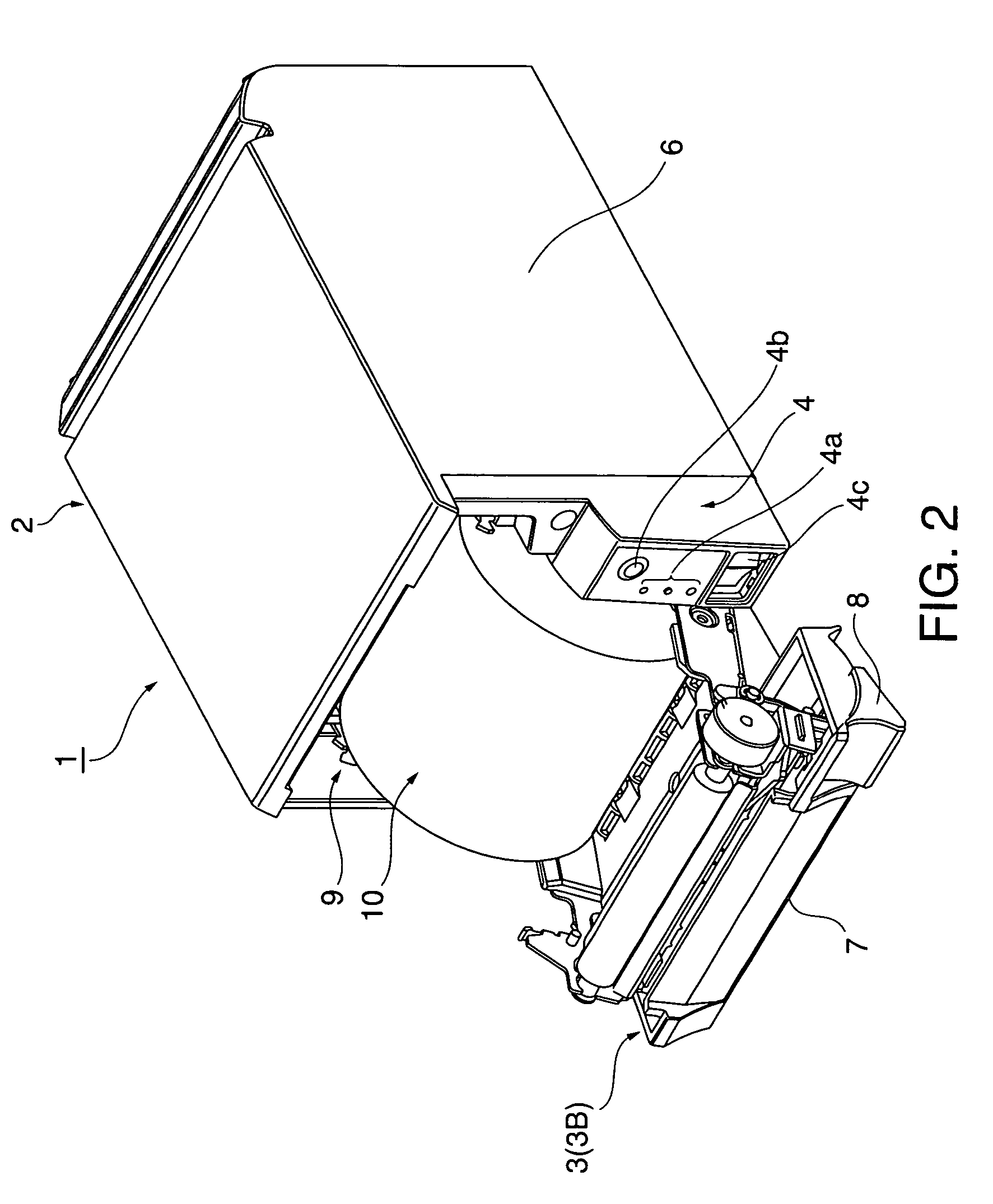

Paper cutting device and printer

InactiveUS7731437B2Increase in sizeSolve the lack of spaceStock shearing machinesOther printing apparatusPulp and paper industryKnife blades

A paper cutting device comprising a fixed blade, a movable blade, a movable blade drive mechanism for moving the movable blade, wherein the movable blade and the fixed blade are disposed in substantially perpendicular positions.

Owner:SEIKO EPSON CORP

Novel full-automatic numerical control board packaging machine

InactiveCN103794823ASimple structureOverall small sizeFinal product manufactureLead-acid accumulators constructionNumerical controlSmall footprint

The invention relates to a novel full-automatic numerical control board packaging machine which comprises a pole plate conveying device, a pole plate finishing device, a pole plate lifting device, a pole plate absorbing device, a clapboard paper conveying device, a clapboard paper cutting device, a board packaging device, a pole plate group conveying device and a stand, wherein the pole plate conveying device is arranged at the left lower part of the stand; the tail end of the pole plate conveying device is provided with the pole plate finishing device; the pole plate lifting device is arranged under the stand; the pole plate absorbing device is arranged above the pole plate lifting device; the clapboard paper conveying device is arranged at the right upper part of the stand; the tail end of the clapboard paper conveying device is provided with the clapboard paper cutting device and the board packaging device; the pole plate group conveying device is arranged just under the clapboard paper conveying device. The novel full-automatic numerical control board packaging machine not only is simple in structure, compact in volume and small in occupied land area and improves the environment of a workplace, but also greatly improves the board packaging efficiency and the board packaging quality.

Owner:浏阳市联创机械设备制造厂

Label paper cutting equipment

InactiveCN111590651AImplement automatic transferSave human effortMetal working apparatusStructural engineeringWorkbench

The invention relates to cutting equipment, in particular to label paper cutting equipment. The technical problem to be solved is to provide the label paper cutting equipment capable of automaticallyreleasing materials and automatically cutting. According to the technical scheme, the label paper cutting equipment comprises a bottom plate, a material rolling barrel, a mounting seat, a workbench, first bearing seats, a servo motor and an intermittent transmission mechanism, a fixing seat is arranged on the bottom plate, semi-ring placement blocks are symmetrically arranged on the fixing seat, the two semi-ring placement blocks are used for allowing the material rolling barrel to be placed, two mounting frames are symmetrically arranged on the bottom plate, two transmission rollers are rotationally arranged on the mounting frames at the same horizontal positions, the workbench is arranged on the other side of the bottom plate, the bottom plate is symmetrically provided with the first bearing seats with respect to the workbench, a rolling barrel is arranged between the two first bearing seats, and the servo motor is arranged at the position, close to the middle of the workbench, of the bottom plate. According to the label paper cutting equipment, the effects of automatic material releasing and automatic cutting are achieved.

Owner:廖裕兴

Fully-automatic bandage machine

InactiveCN105731136AIncrease productivityGuaranteed winding accuracyNon-adhesive dressingsWrapping material feeding apparatusPulp and paper industryFully automatic

The invention discloses a fully-automatic bandage machine, and relates to a sanitary material production machine. The fully-automatic bandage machine comprises a frame, an original cloth roll, a cloth rolling device, a cloth cutting device, a paper wrapping device, a paper cutting glue spray device, a power device and a program control device, wherein gauze wraps a spindle; the spindle is controlled by a telescopic device; the spindle is placed on an upper part between a roll making roller A and a roll making roller B; a pressure roller A is further arranged above a bandage roll A; the pressure roller A is connected with a roll pushing device through a shaft; the roll pushing device pushes the bandage roll A to a position behind a bandage roll B; the cloth cutting device is used for cutting the gauze; a paper roll is used for inserting the lower end of packaging paper into a cloth end of the bandage roll B through a paper supply device; the paper cutting glue spray device finishes paper cutting and glue spray, so that packaging of the bandage roll B is finished finally. The fully-automatic bandage machine has the beneficial effects that the average time in making one bandage roll is 22 seconds, and rolling, shaft extraction and paper wrapping are finished in a fully automatic way at one time; one person can operate and control two machines. The production efficiency is over three times compared with the prior art, and the labor cost is a quarter of the prior art.

Owner:HUAXIAN TIANHUA MECHANICAL EQUIP MFG CO LTD

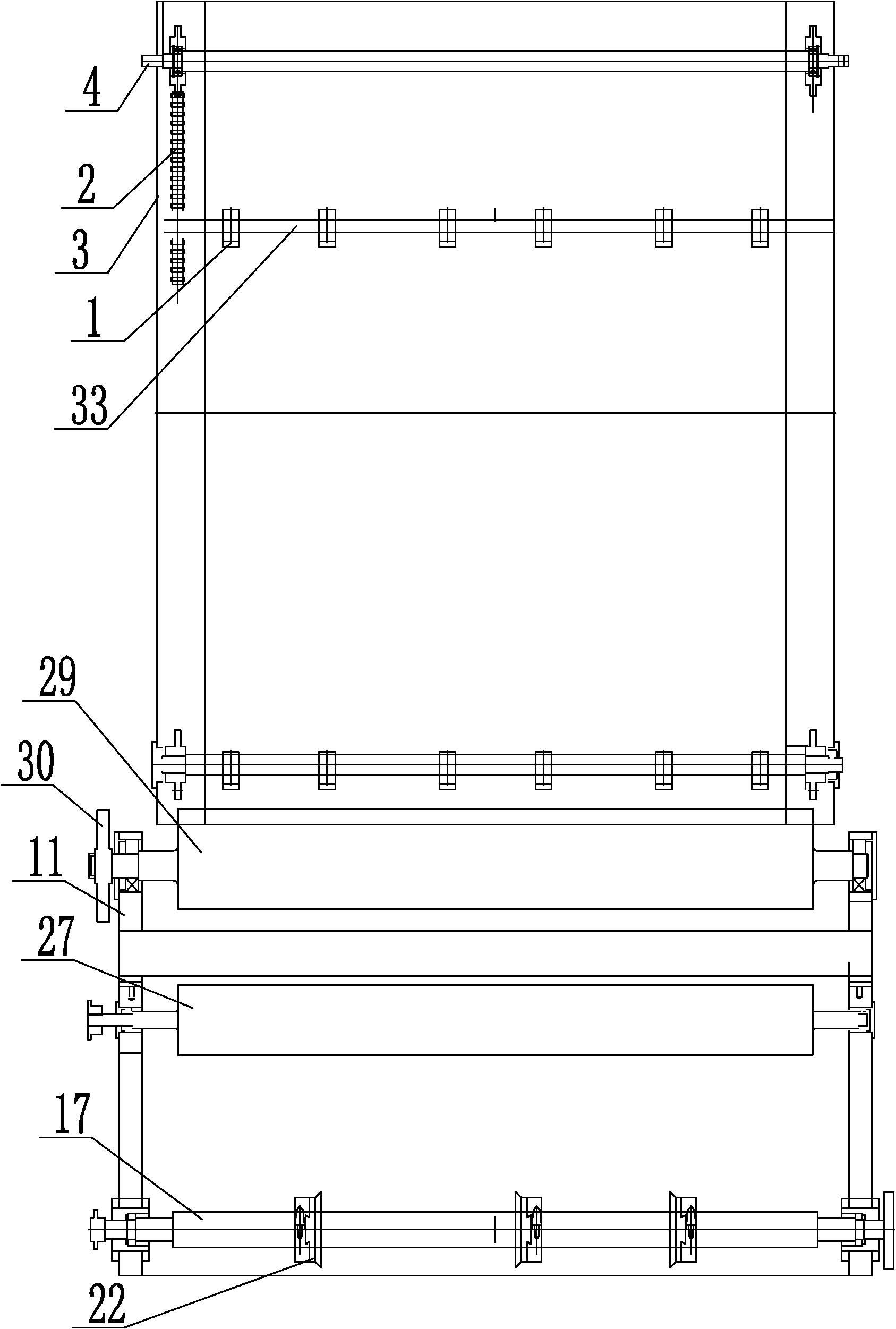

Paper cutting/receiving machine

InactiveCN102060205APrecise cut paper sizeNeatly stackedPile receiversArticle deliveryRolling paperLongitudinal splitting

The invention relates to a paper cutting / receiving machine, which comprises a paper conveying / cutting part, a paper receiving part and a transverse output belt (34), wherein the paper conveying / cutting part comprises a paper cutting foot (14), a paper cutting wallboard (11), a reversing gear (26), a paper drawing shaft (9), a paper pressing strip crossbar (31), a paper pressing strip (32), a round cutter (29), a round cutter gear (30), a servo motor (10), a reversing gear (26), a first short bridge axle (24), a second short bridge axle (25), a chain (28) with a paper conveying rubber roller, a bridge axle (16), a transmission bridge axle variable-frequency motor (13), a transmission paper drawing shaft chain (12), a longitudinal splitting cutter shaft (17), a longitudinal splitting cutter (22), a chain (23) with a longitudinal splitting cutter shaft, an upper photoelectric switch (21) and a lower photoelectric switch (18); and the paper receiving part comprises a paper receiving foot (7), a paper receiving wallboard (3), a seam (1), a seam mounting strip (33), a paper receiving chain (2), a paper receiving chain wheel shaft (4), a paper receiving chain wheel (5) and a transmission paper receiving shaft variable-frequency motor (6). Through the invention, the single-corrugated paper formed by a single-corrugated machine or roll paper is cut off and then automatically stacked.

Owner:赵祖良

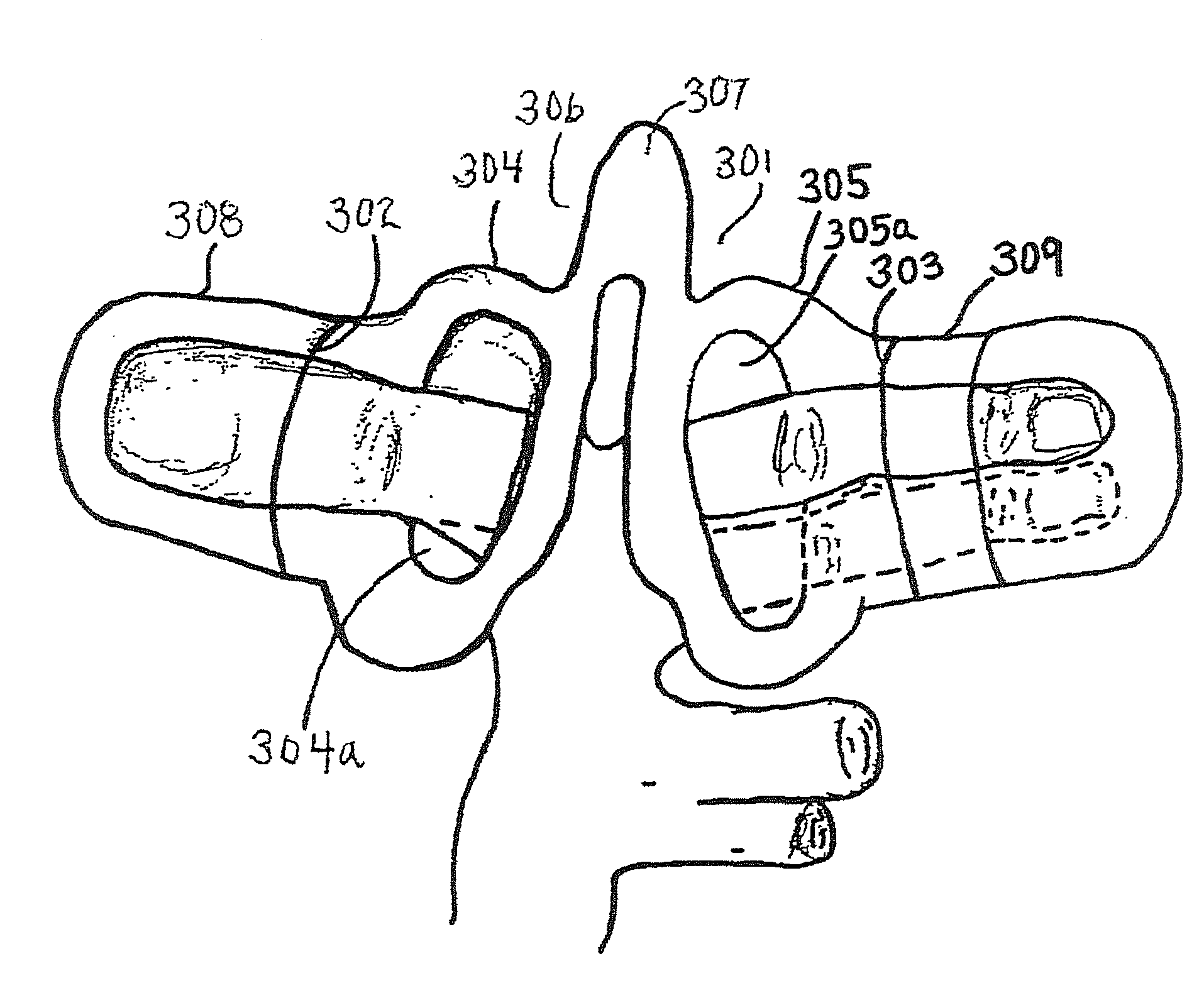

Disposable finger tongs for handling a food product

InactiveUS20160157647A1Improve grabbingReduced tearabilityFinger bandagesLifting devicesEngineeringFood contact

A disposal food handling finger tongs have finger pockets for grasping food. The pockets are connected by at least one connecting tab. At least one functional finger / thumb accommodation area is presented and at least one finger / thumb stability is optionally provided. The disposable tongs provide a triple protection to the user by providing soft irregular peripheral edges help prevent paper cuts. Also the central connecting tab between the two jaw pockets can be torn to separate the tongs into two tongs, so that the two food contact sides of the respective pockets can be folded against each other. Third, if both the front and back of pockets are messy, the clean central tab can be torn, and folded over the back and / or front of the messy pockets, thereby keeping the hands, fingers and / or thumb of the user clean during disposal.

Owner:RAMPERSAD KENRICK

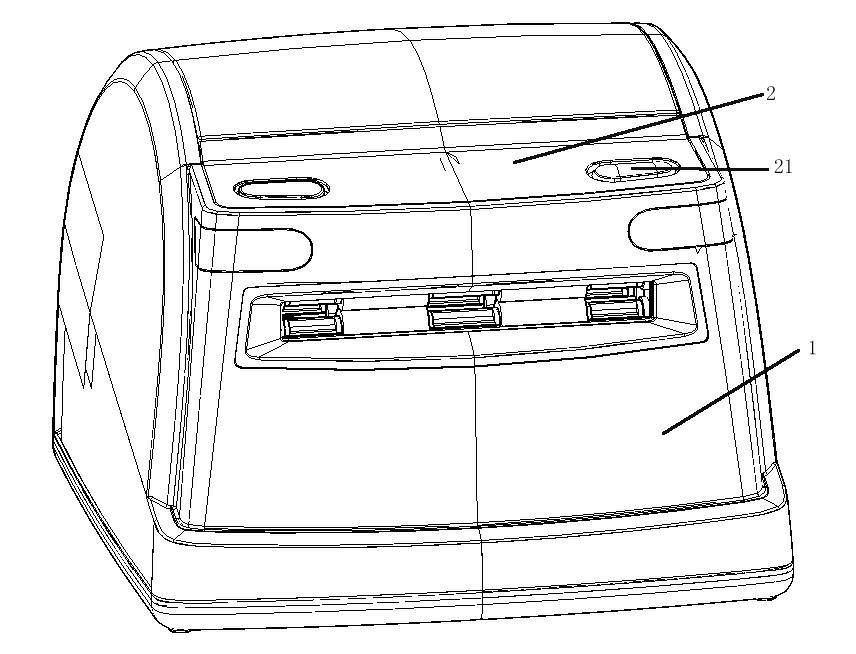

Dual-purpose intelligent facial tissue distributor

ActiveCN102525327AAvoid direct contact with paper towelsAvoid cross infectionDomestic applicationsPhysical medicine and rehabilitationPaper towel

The invention relates to a dual-purpose intelligent facial tissue distributor. The dual-purpose intelligent facial tissue distributor comprises a casing, a paper feeding mechanism, a paper cutting mechanism and a control circuit, wherein the paper feeding mechanism comprises a first paper feeding mechanism and a second paper feeding mechanism which are arranged in parallel; the paper cutting mechanism is positioned between the first paper feeding mechanism and the second paper feeding mechanism and comprises a moveable knife, a static knife, a knife rest and a driving shaft; the moveable knife is mounted on the knife rest; a plurality of spring holes are transversely formed at the upper end of the knife rest; springs are mounted in the spring holes and matched with the upper end of the moveable knife; more than one rack is fixedly connected below the knife rest; gears matched with the racks are arranged on the driving shaft; the driving shaft is driven by a moveable knife driving motor; and the casing is provided with a cover board. The dual-purpose intelligent facial tissue distributor overcomes the defects of a wall-mounted type intelligent facial tissue distributor, enlarges the using range, can automatically feed and cut paper, prevents hands from being directly contacted with the facial tissue, is convenient and sanitary to use, and avoids cross infection.

Owner:HANGZHOU GOLDEN KEY TECH

Portable printing machine for bottomless paper label

The invention discloses a portable printing machine for a bottomless paper label. The portable printing machine comprises a printing module and a paper cutting module positioned at the front part of the printing module. The portable printing machine is characterized in that a water coating module is also arranged in front of the paper cutting module and comprises a water tank and a water coating block which is positioned at the upper part inside the water tank and has water absorbing performance; the upper surface of the water coating block is exposed out of the upper surface of the water tank; a paper pressing member is arranged on the upper surface of the water tank, which is positioned above the water coating block; a clearance for allowing label paper to pass through is formed between the paper pressing member and the water coating block; a water trough is formed in the bottom in the water tank; and a water pump is arranged in the water trough and is connected to the water coating block through a water pipe. According to the portable printing machine for the bottomless paper label, which is disclosed by the invention, automatic water coating and cutting of a hydrophilic glue layer on the back side of the printed bottomless paper label are realized, the printing function, the water coating function and the cutting function are integrated, the convenience is brought to use of the bottomless paper label and the wide application of the bottomless paper label is facilitated.

Owner:MAXIM SMART MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com