Patents

Literature

1027results about "Conveyor wrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

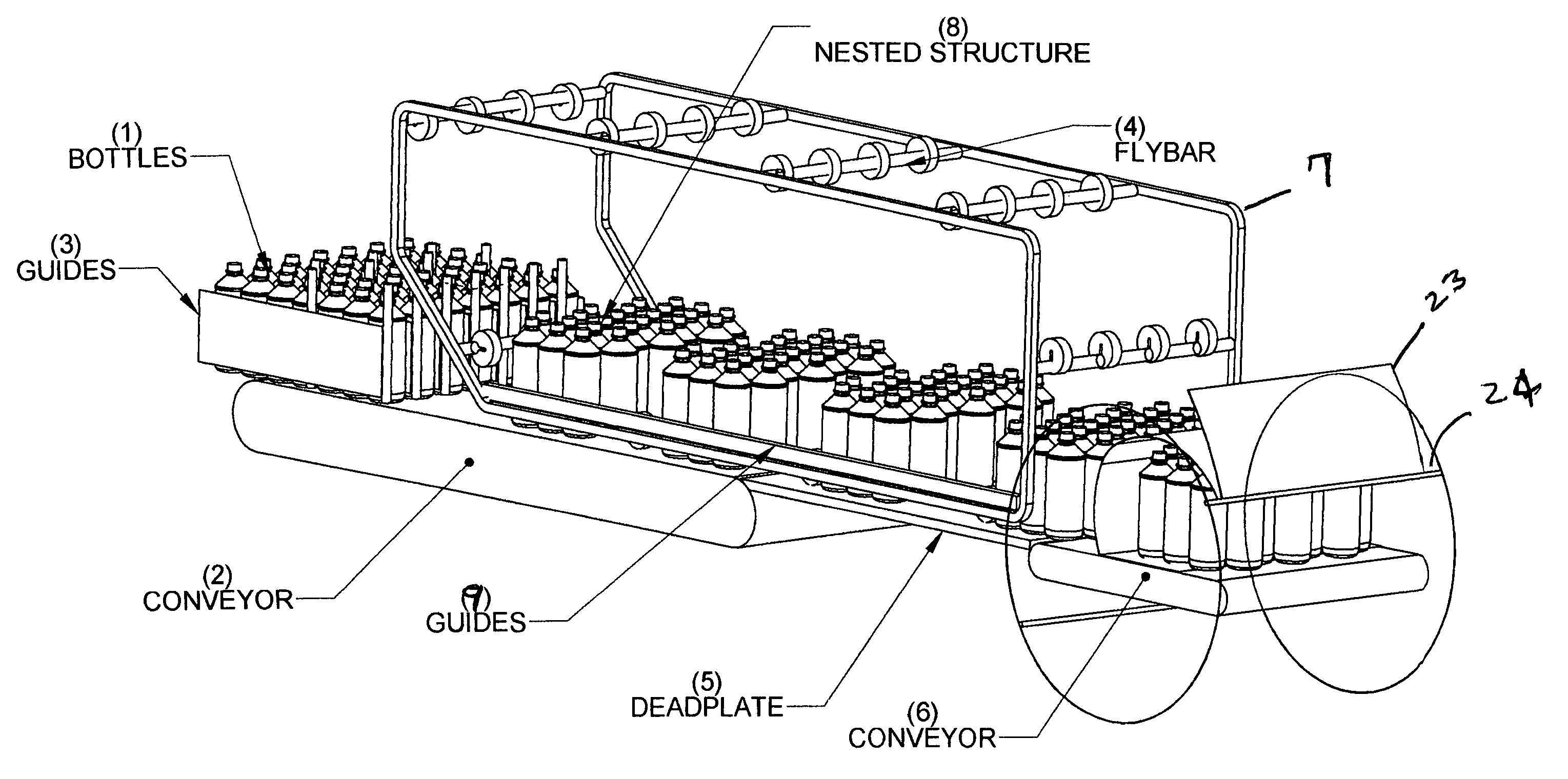

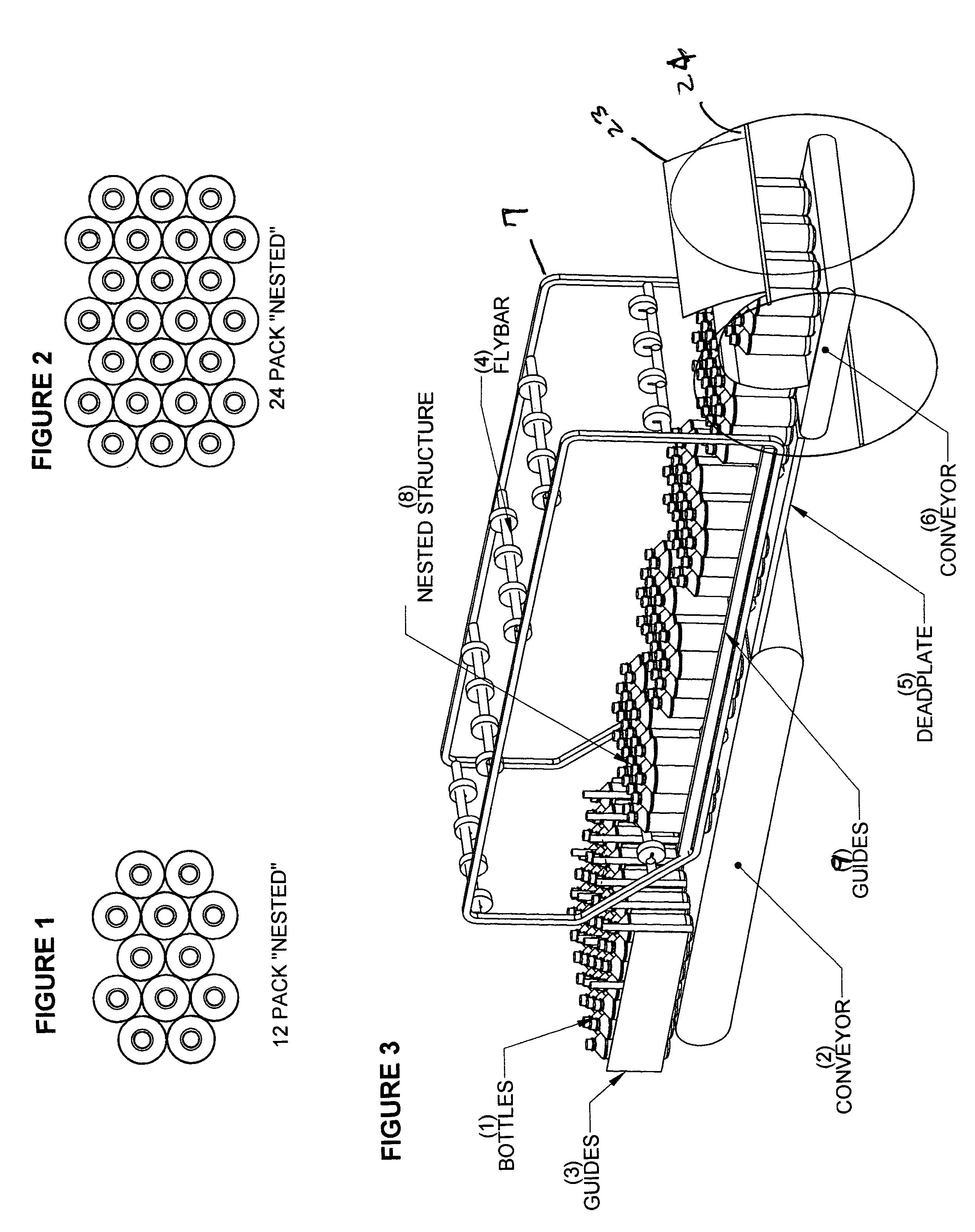

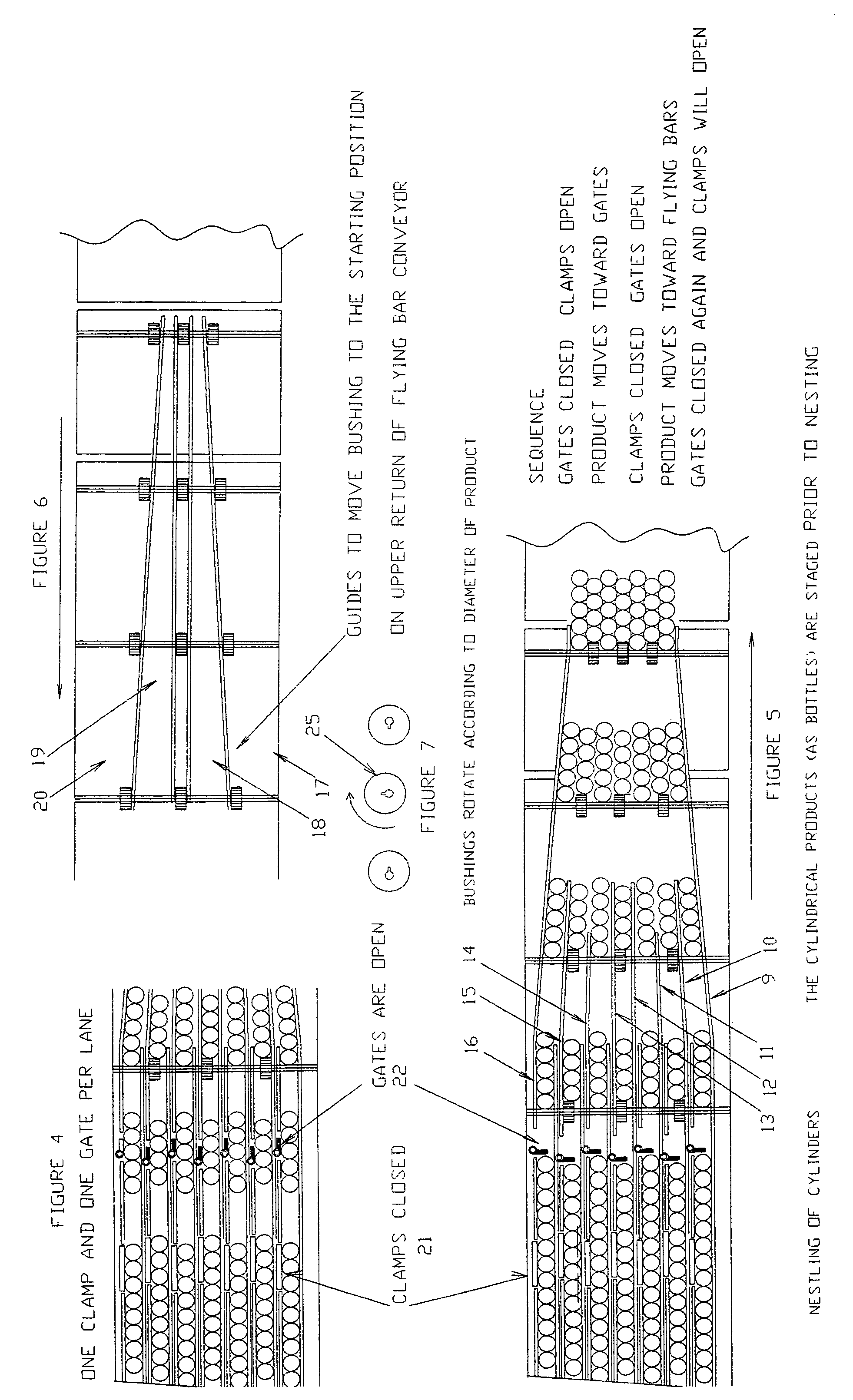

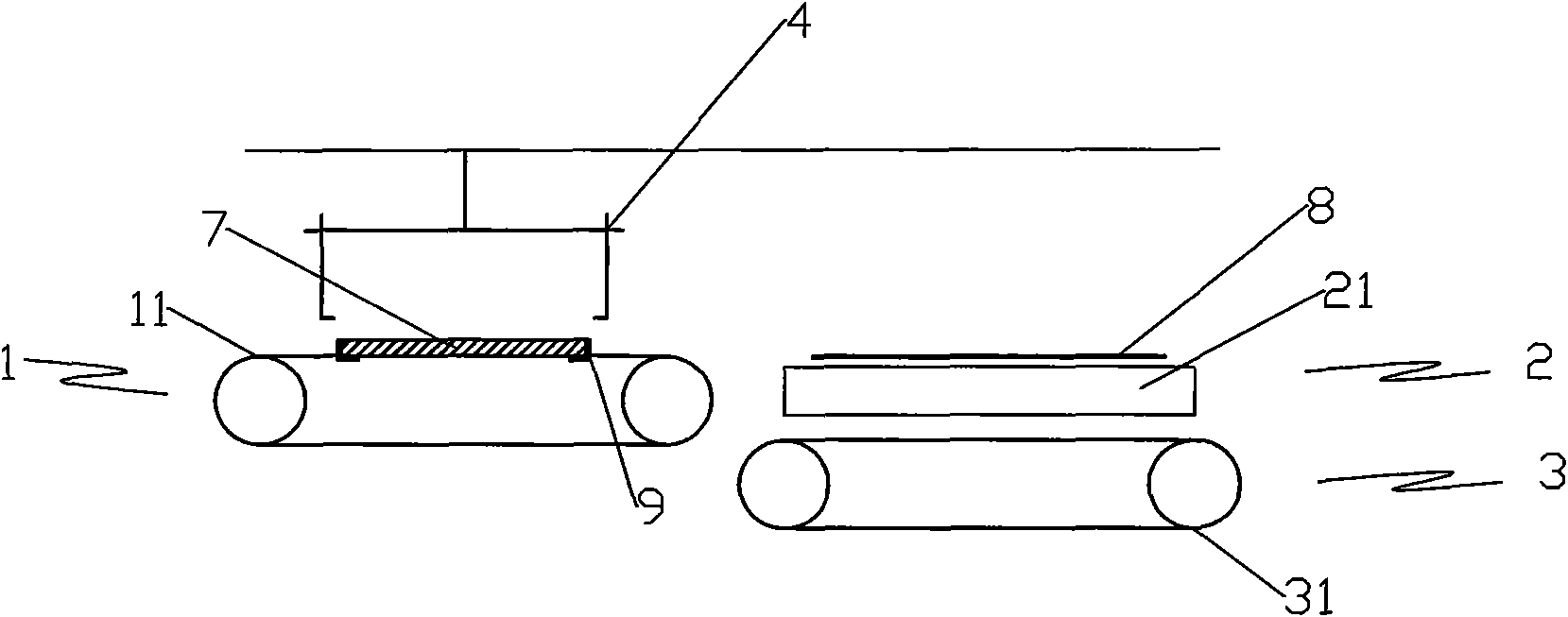

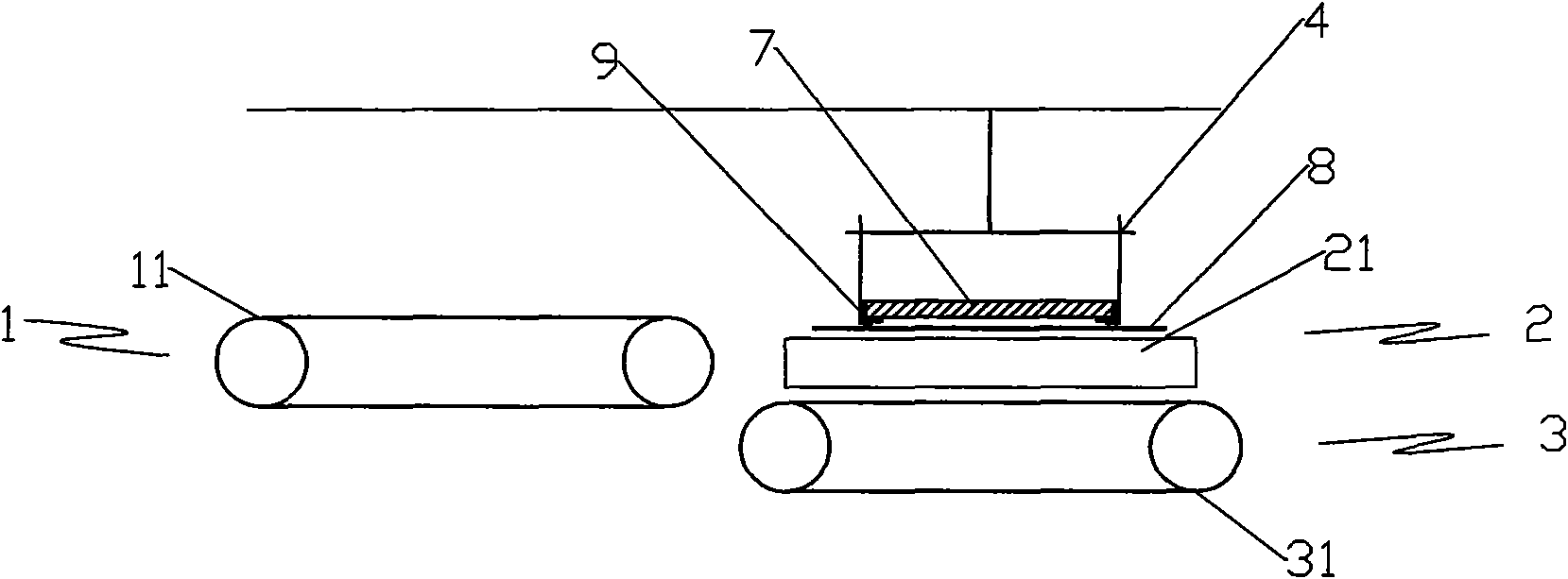

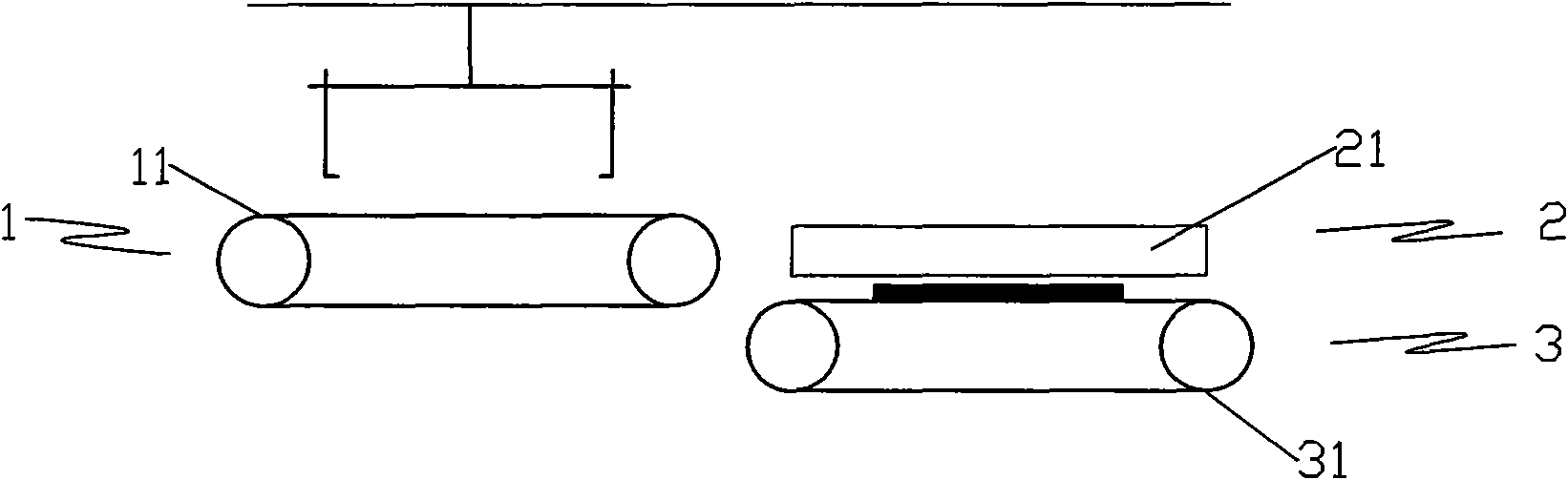

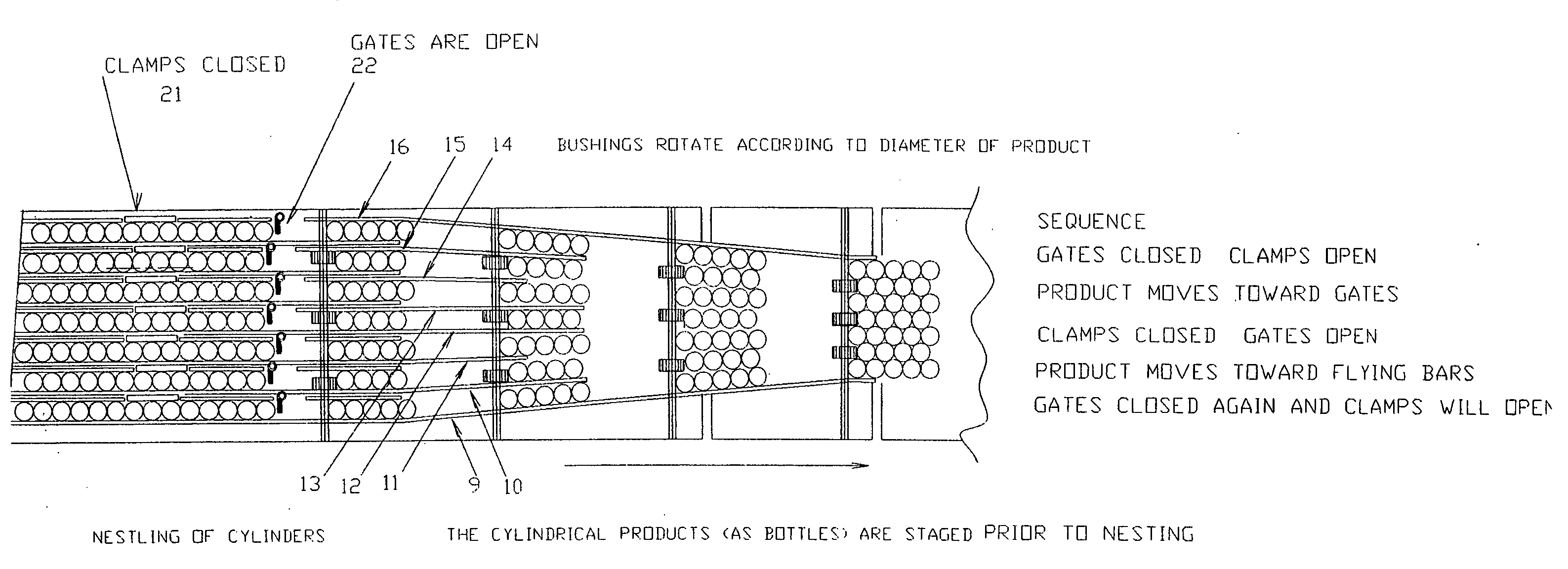

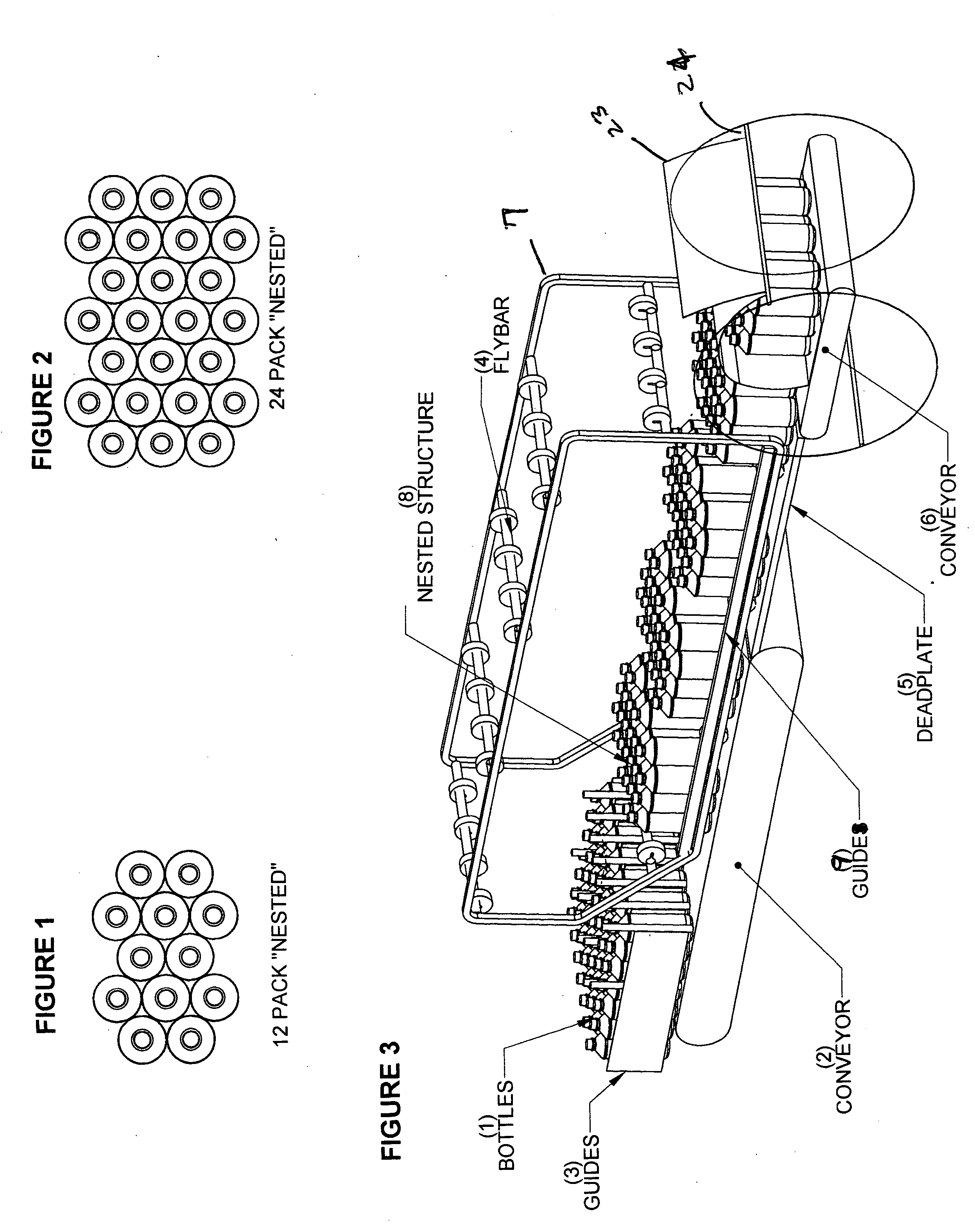

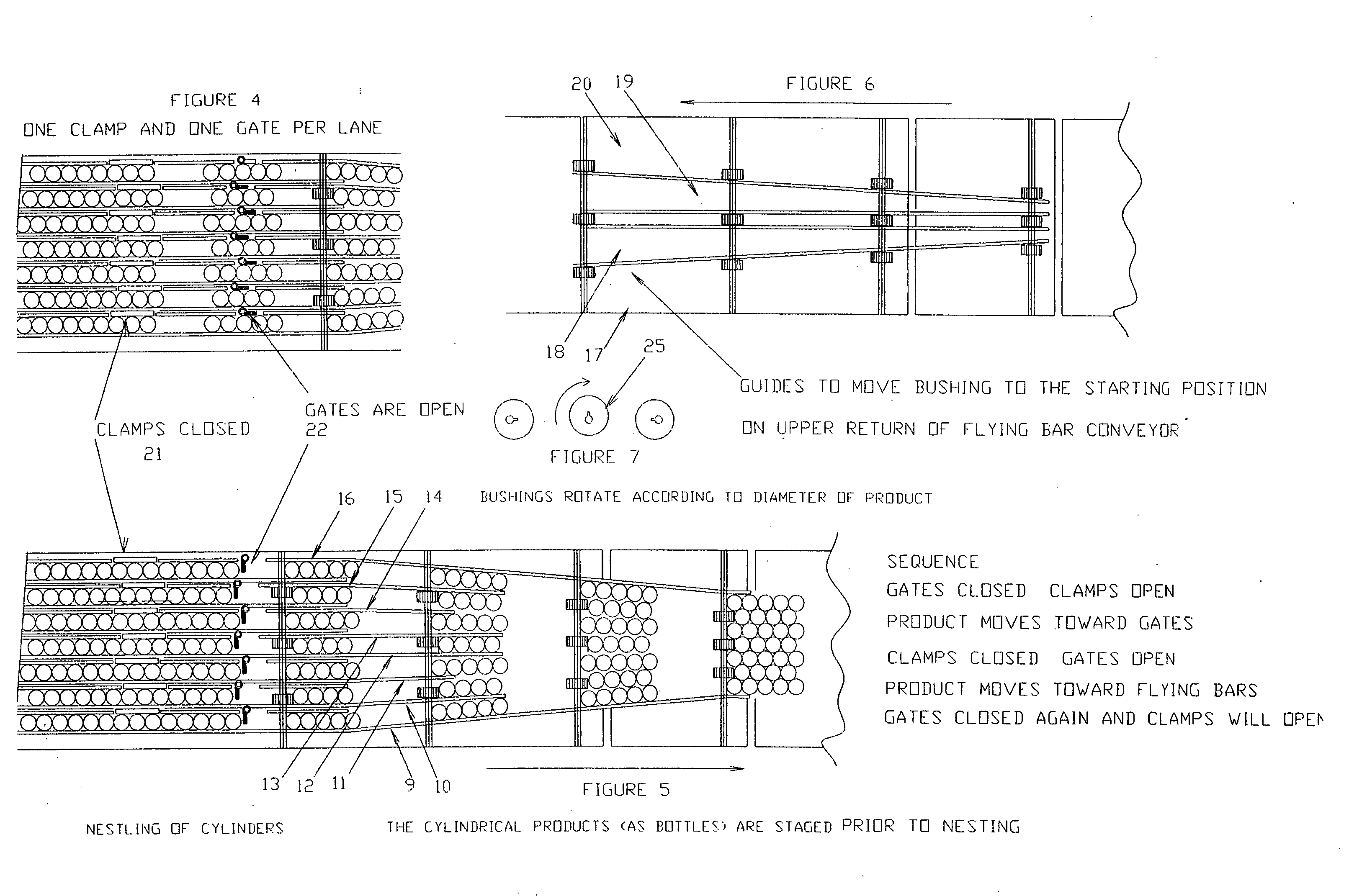

Apparatus for nesting bottles

The objective of this invention is to provide an apparatus for forming a stable arrangement of bottles so they can be moved on an inline conveyor system. This is accomplished by an apparatus for nesting bottles comprising a first conveyor having lanes of bottles, and a second conveyor, wherein a fixed number of bottles from each lane is released from each lane in a staggered arrangement to facilitate nesting of the released bottles and then pushing and guiding the released bottles from the first conveyor onto a second conveyor so that the bottles form a nested bundle.

Owner:CERF ALAIN

Repulpable container

A repulpable insulated container assembly having a container formed of paper such as corrugated cardboard or varying paper materials and defining an interior; and a repulpable insert placed within the interior of the container and formed of a first paper layer; and a paper fiber pad coupled to the first paper layer.

Owner:PRATT RETAIL SPECIALTIES LLC

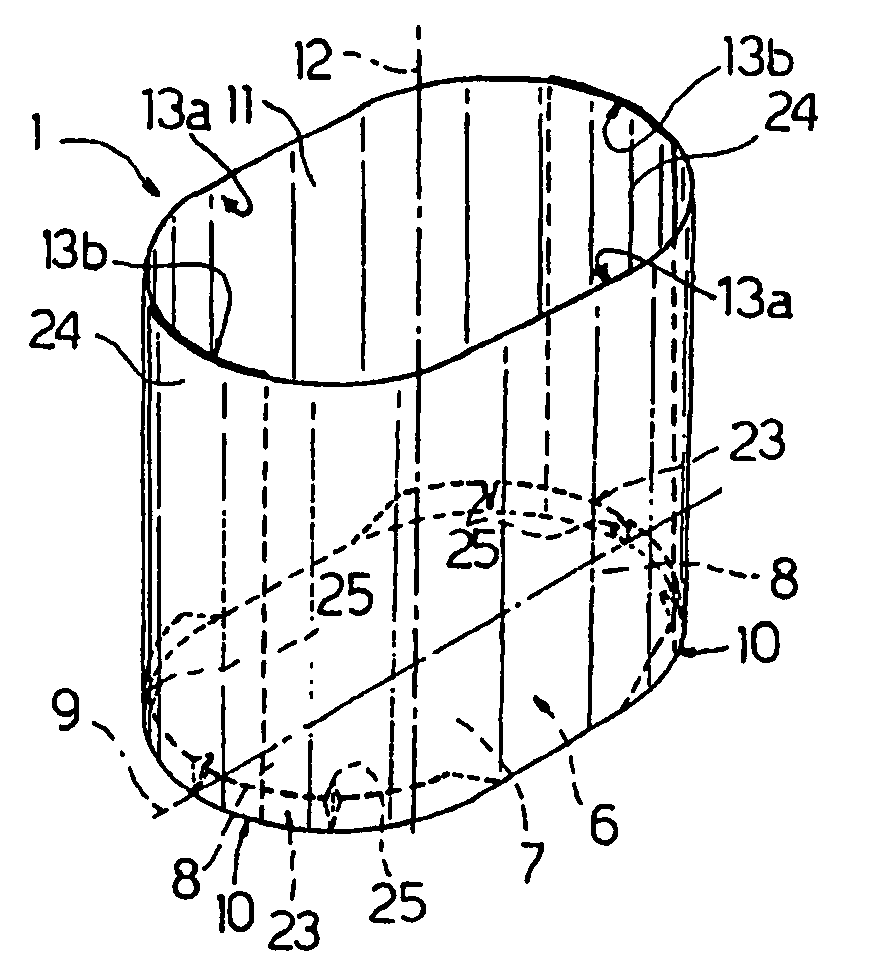

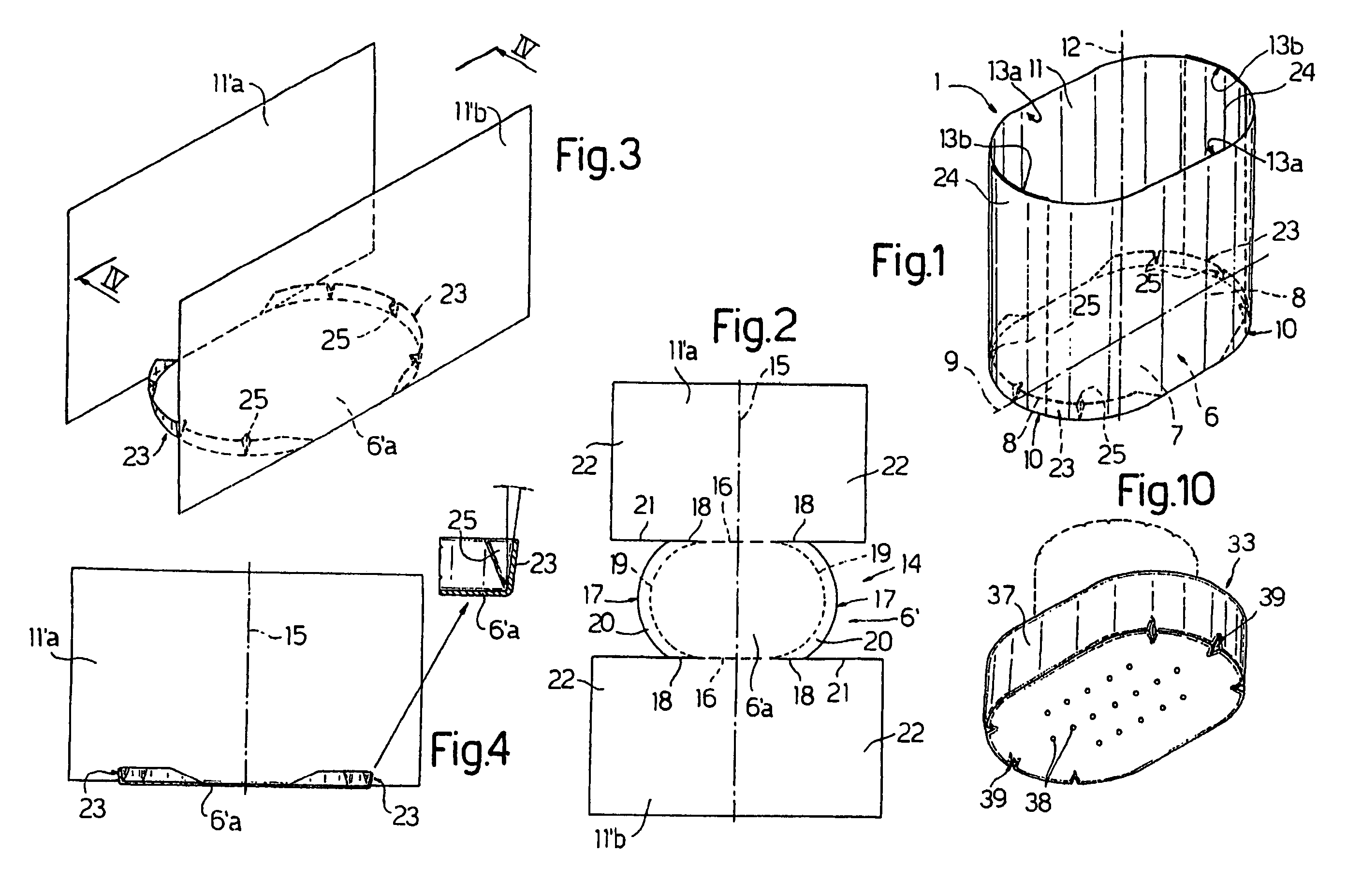

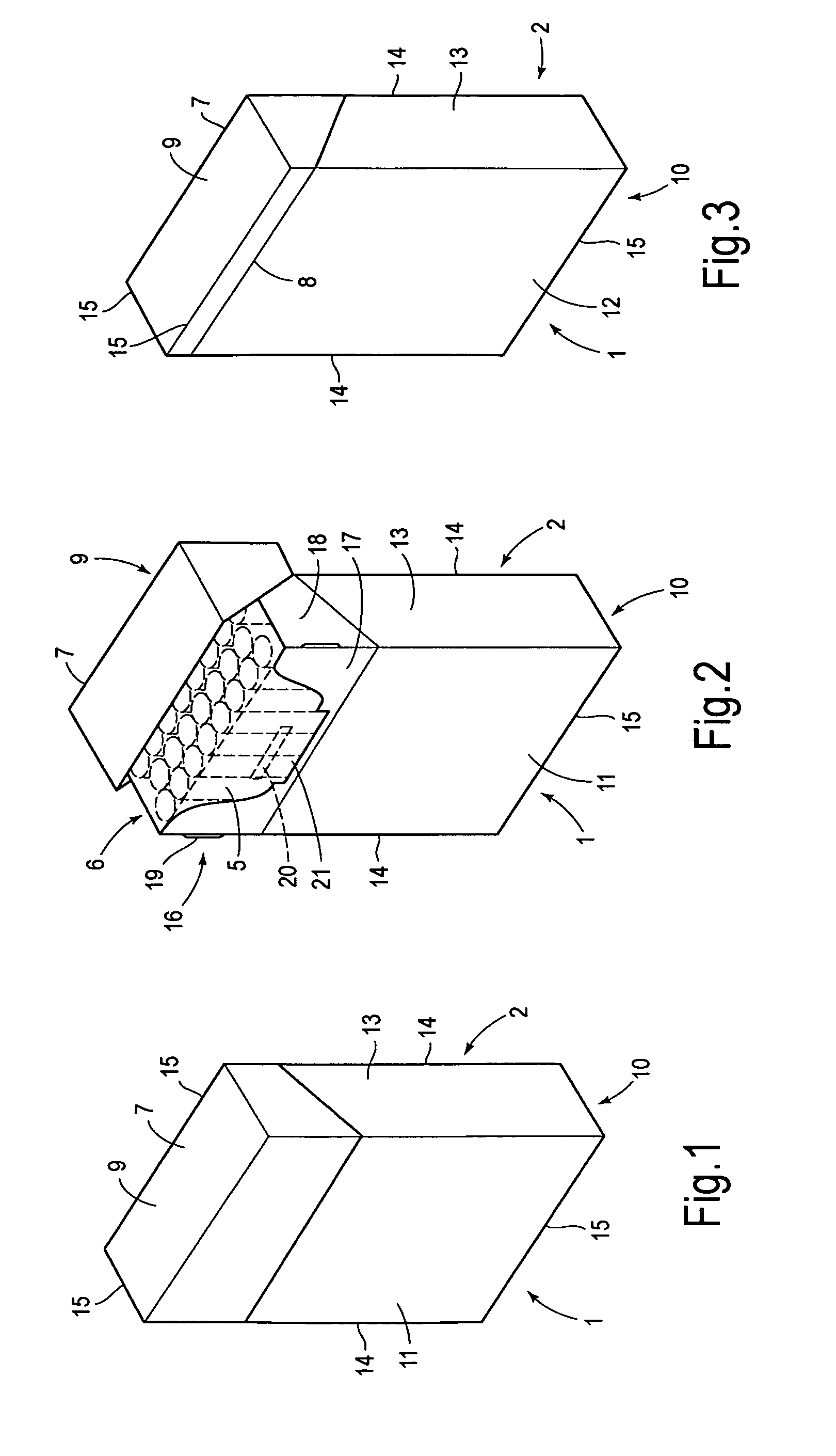

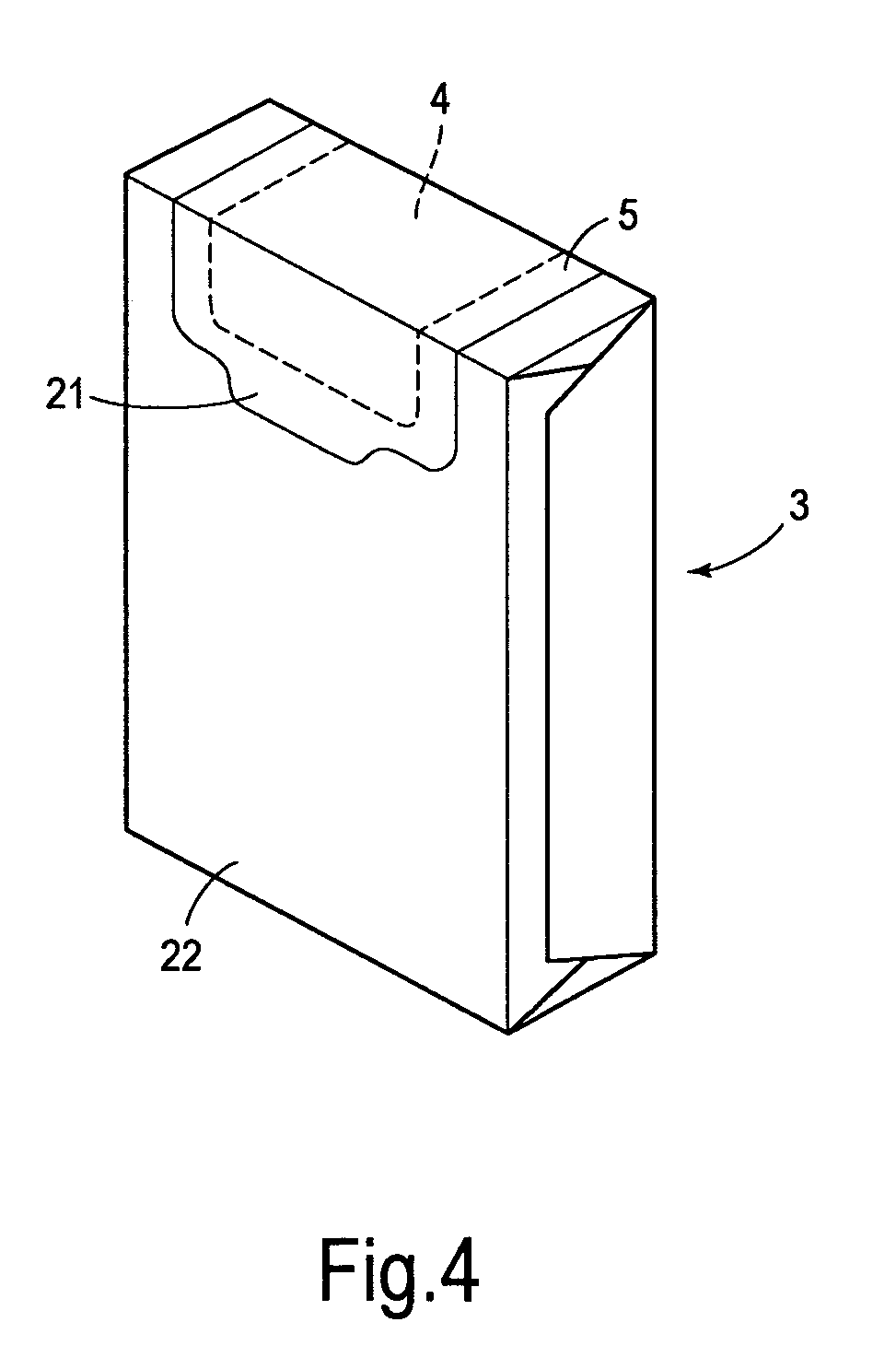

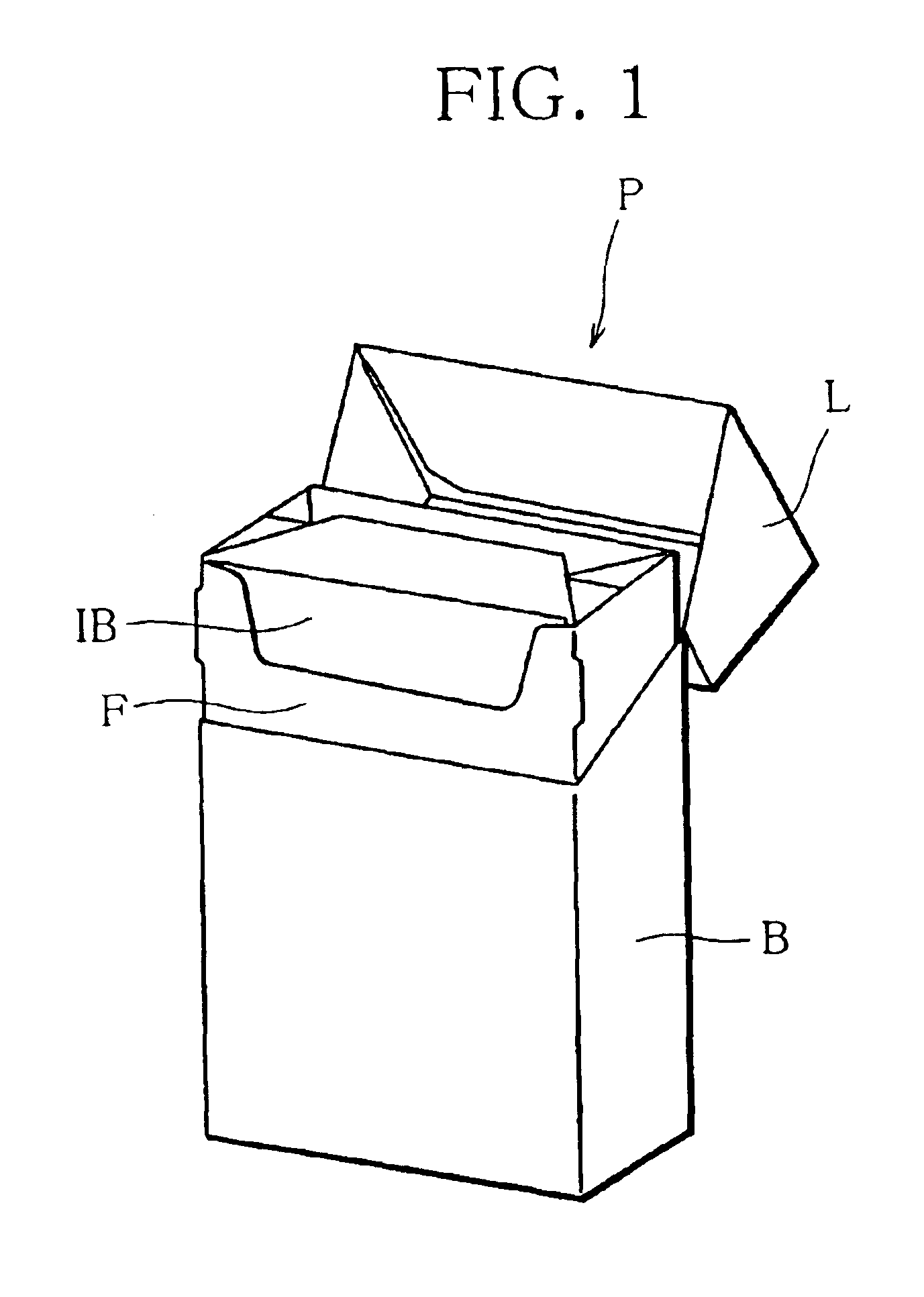

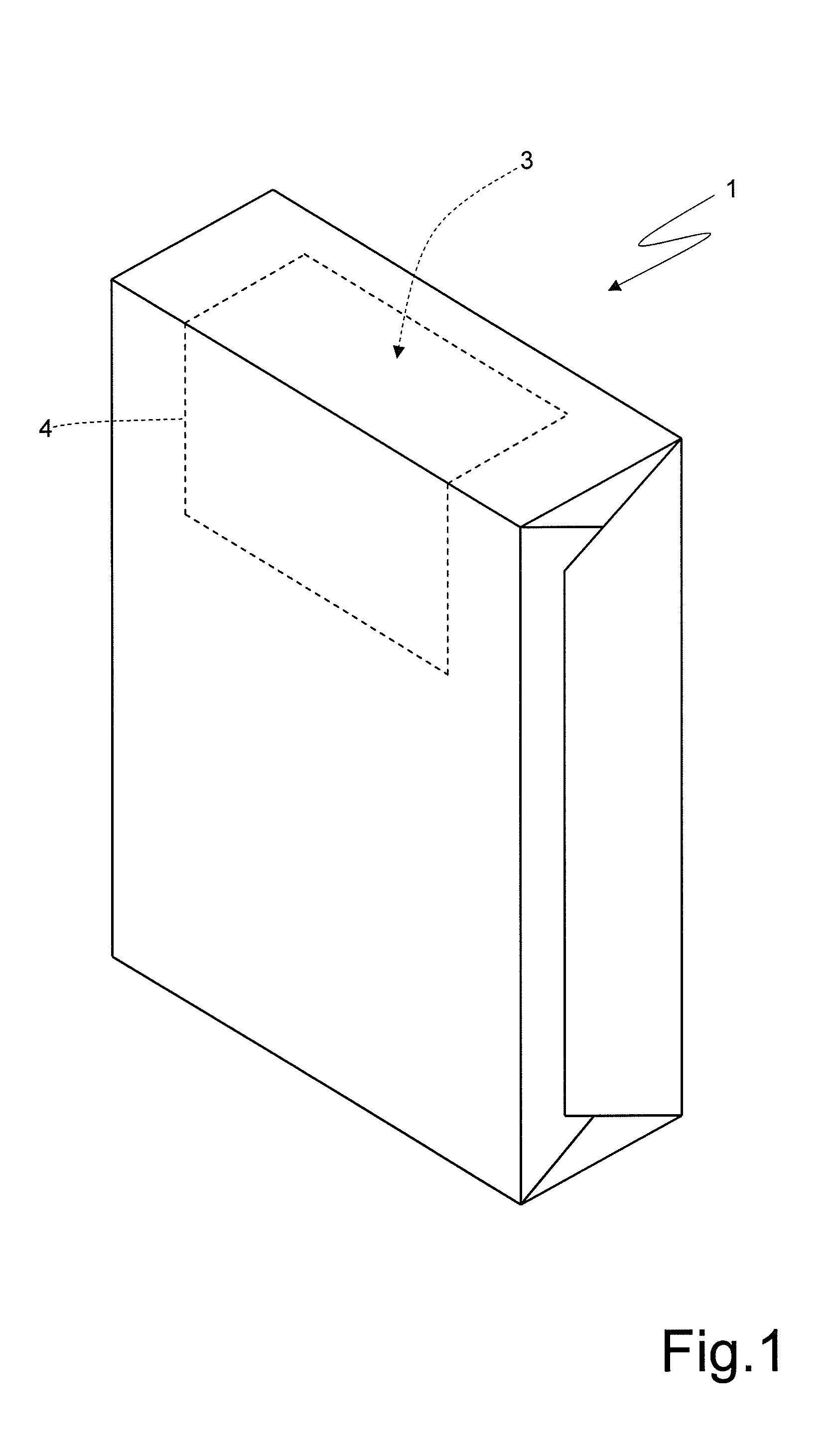

Rigid container for tobacco items and method of producing such a container

InactiveUS7318523B2Containers for flexible articlesBoxes/cartons making machineryEngineeringMechanical engineering

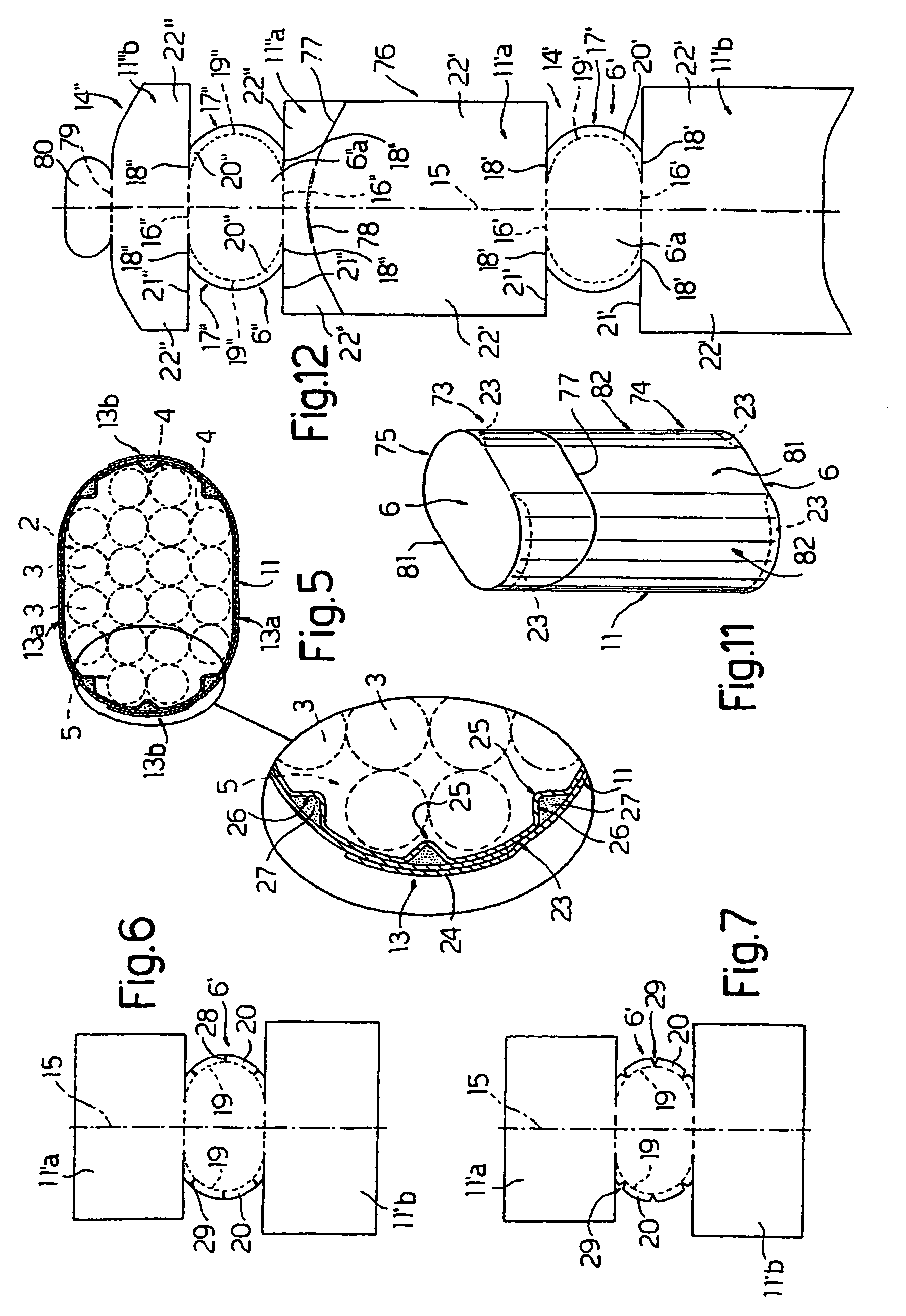

A rigid container for tobacco items, defined by a tubular lateral wall (11) and by at least one end wall (6), and wherein one of the two walls (6, 11) has at least one inwardly concave portion (13; 82; 91; 96; 102; 113), and the other wall has at least one flat portion (8; 114), which mates with the concave portion (13; 82; 91; 96; 102; 113) along a convex outer edge portion (10, 115) of its own, and is formed from a panel (6′; 6′, 6″; 121a, 122a) having a first portion (6′a; 6′a, 6″a; 128) corresponding to the flat portion (8; 114), and a peripheral second portion defined by at least one curved strip (20; 20′, 20″; 127) bounded internally by a curved crease line (19; 19′, 19″; 126) extending along the convex outer edge portion (10; 115); the strip (20, 20′, 20″; 127) being folded squarely, by drawing, to define a convex border (23; 129) extending along the convex outer edge portion (10; 115), and being made integral with an inner surface of the concave portion (13; 82; 91; 96; 102; 113).

Owner:GD SPA

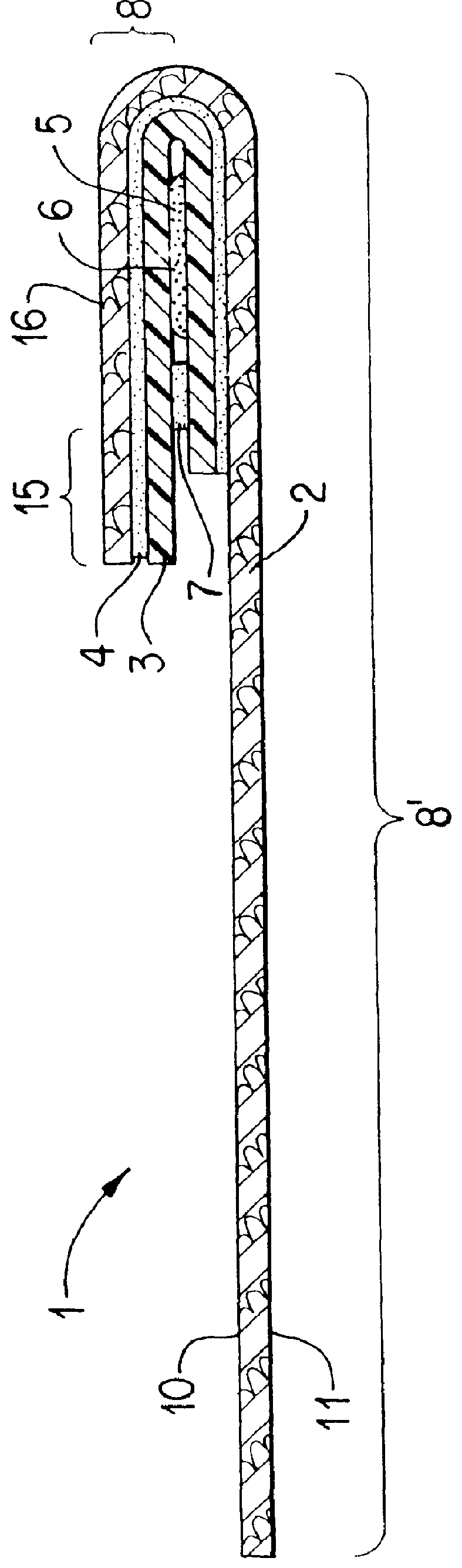

Method for making laminated page

A laminated page having a carrier sheet; two barrier plies, at least one of which is laminated to the carrier sheet; and sample material enclosed between the two barrier plies. The present invention also relates to a method of making the laminated page, including a mass manufacturing method in a single pass on a printing press.

Owner:AKI INC

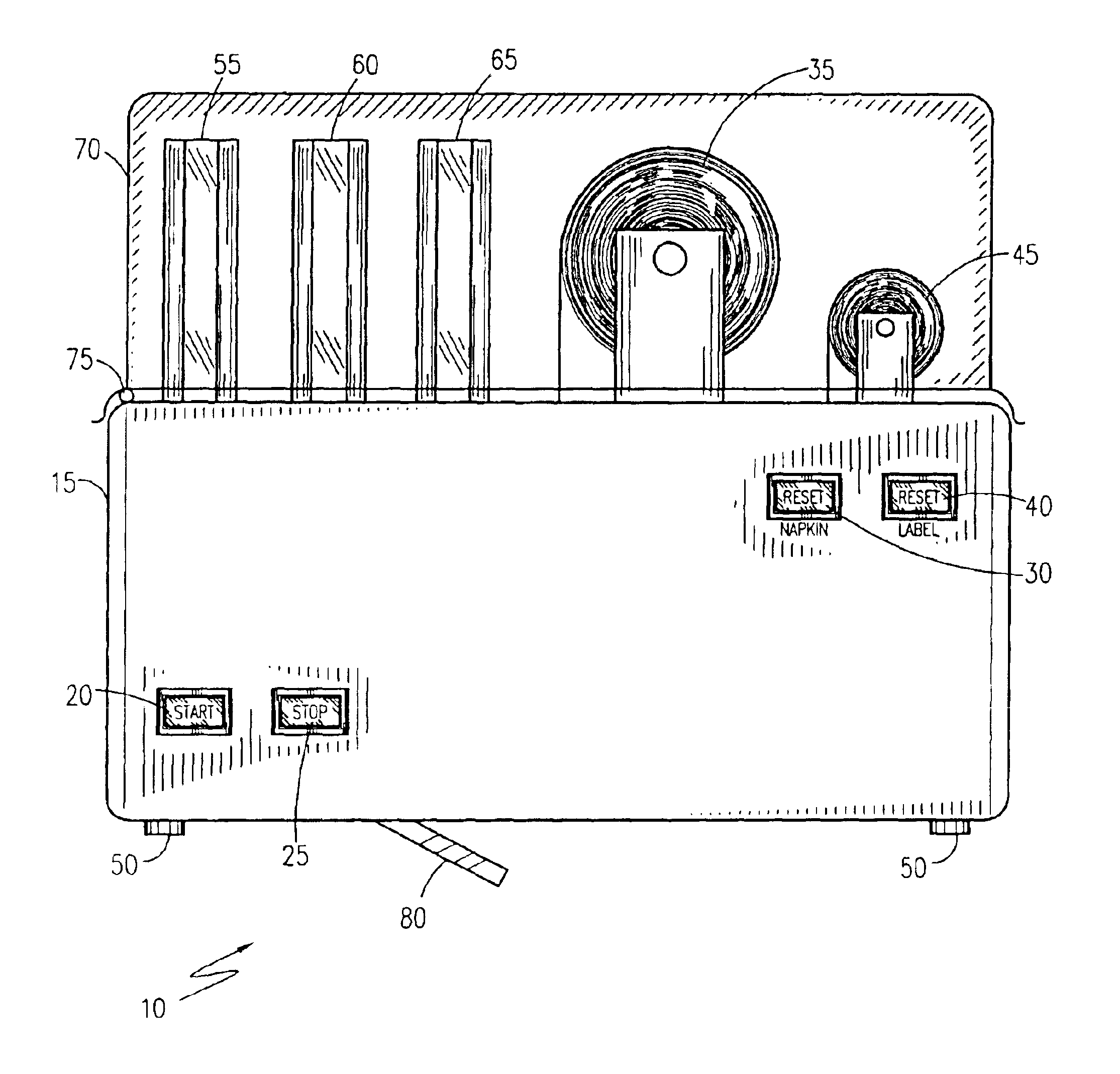

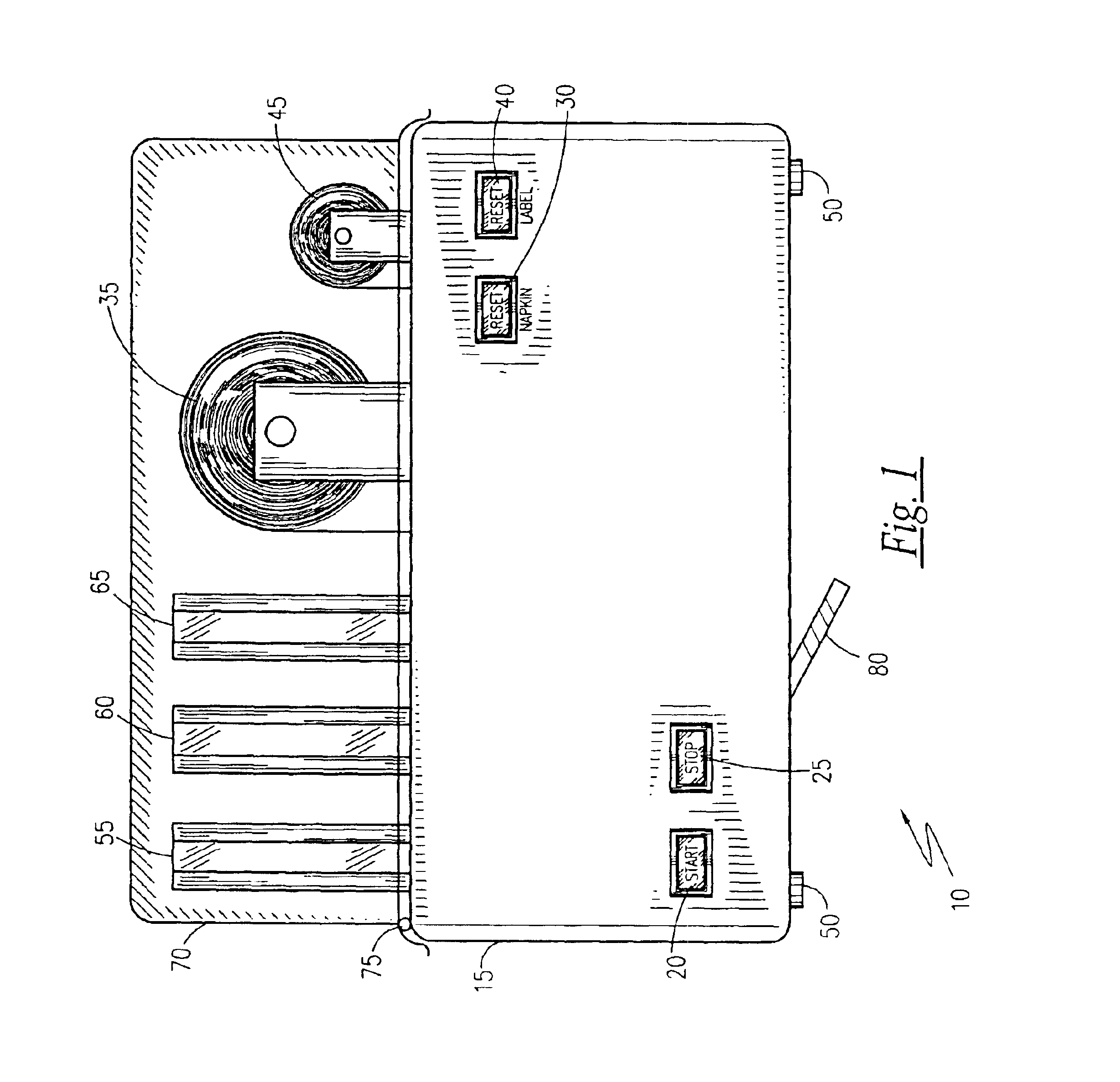

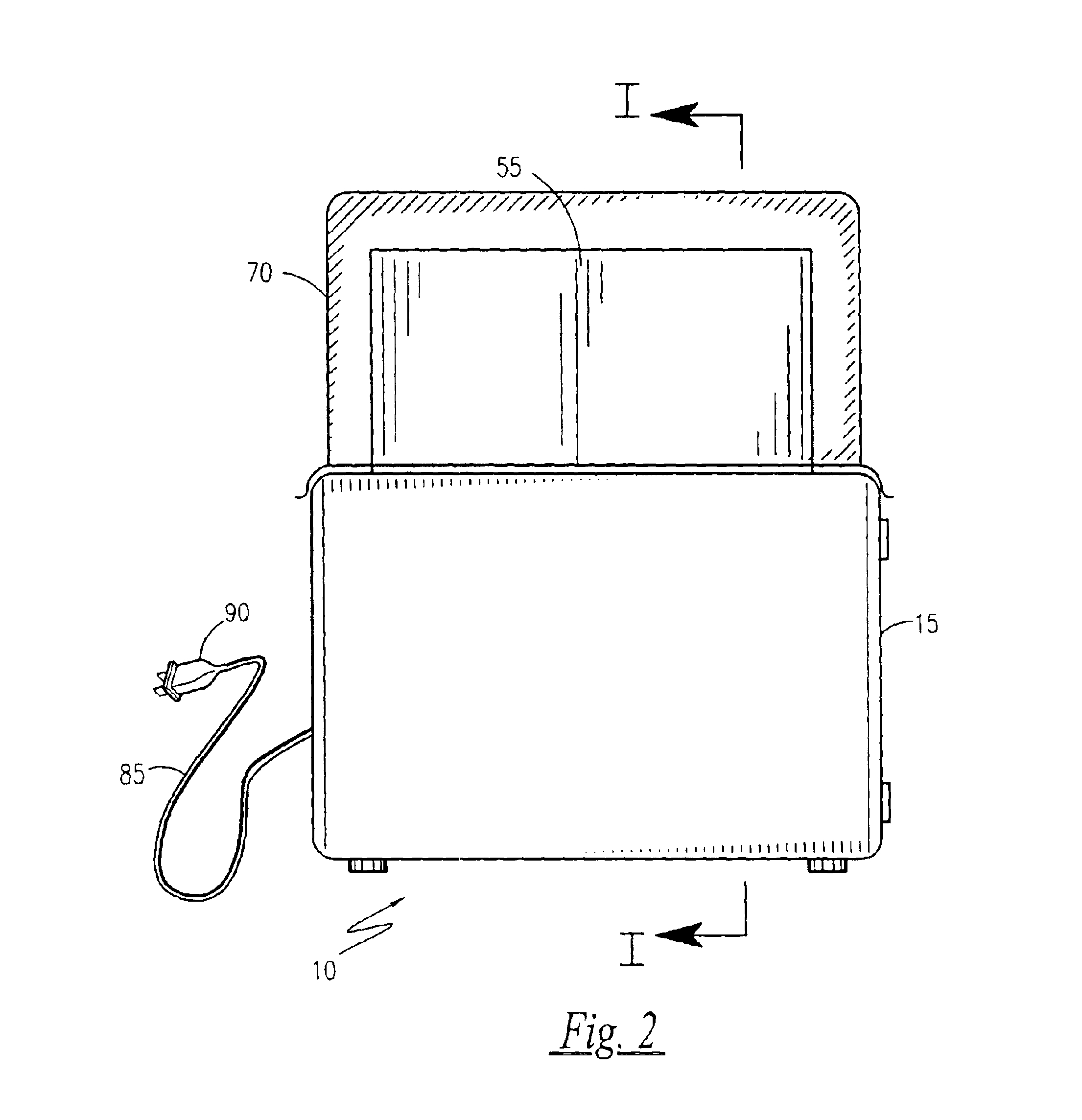

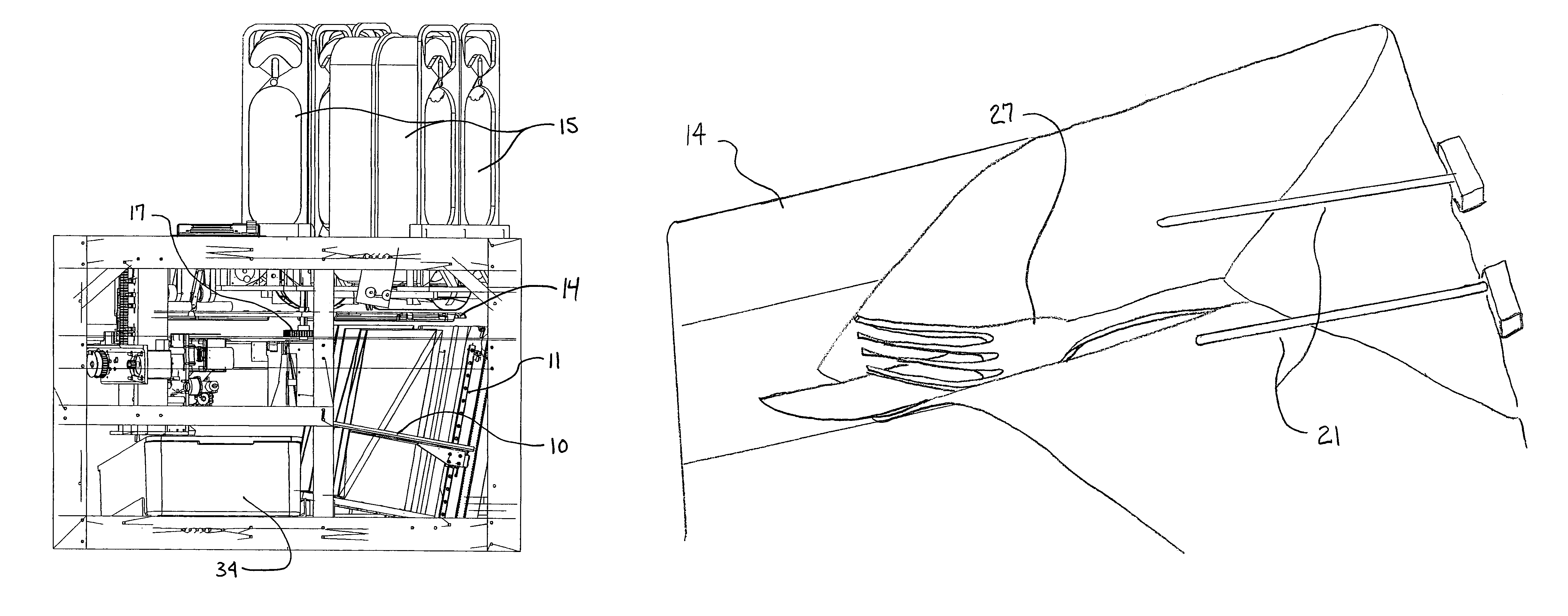

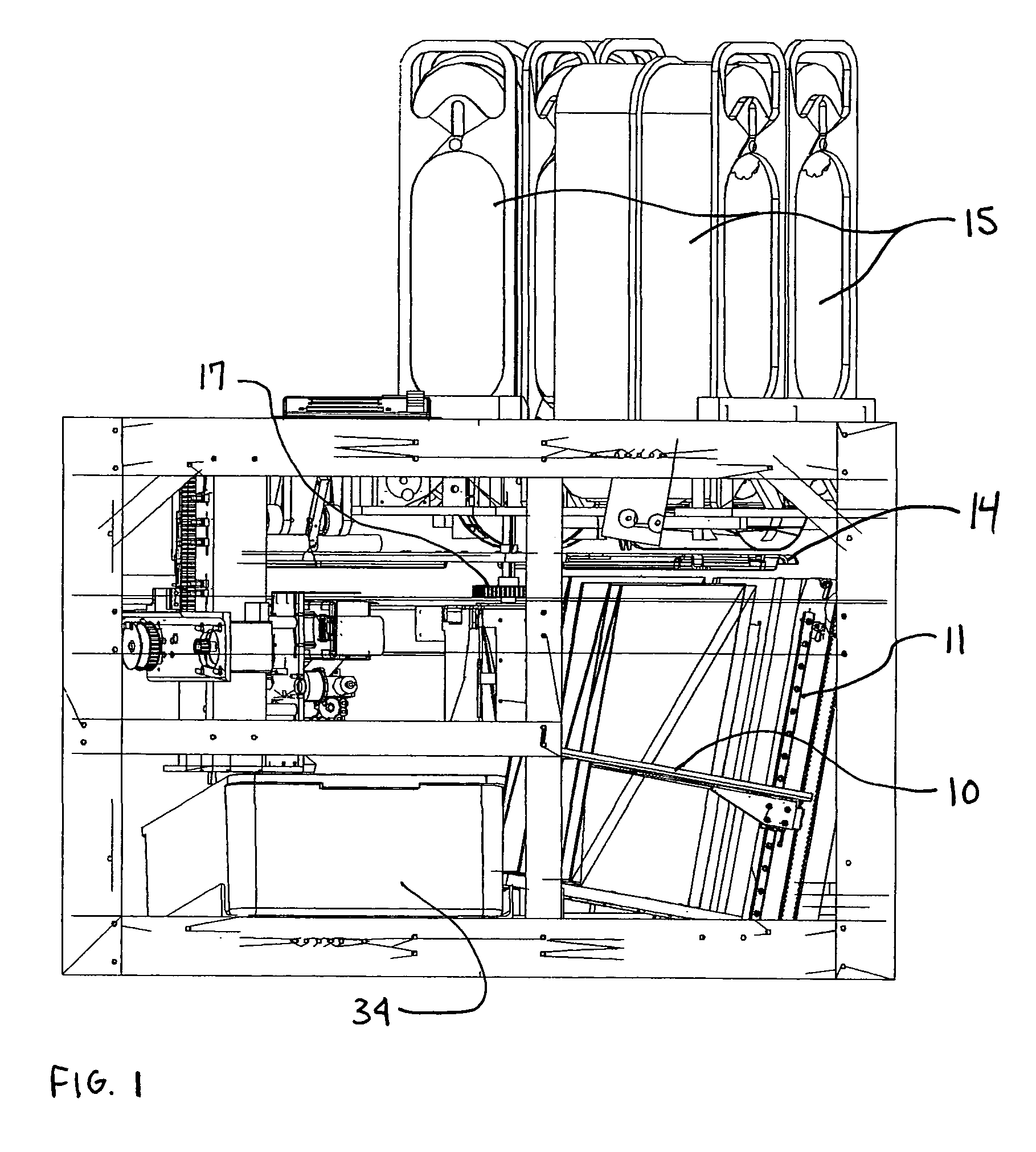

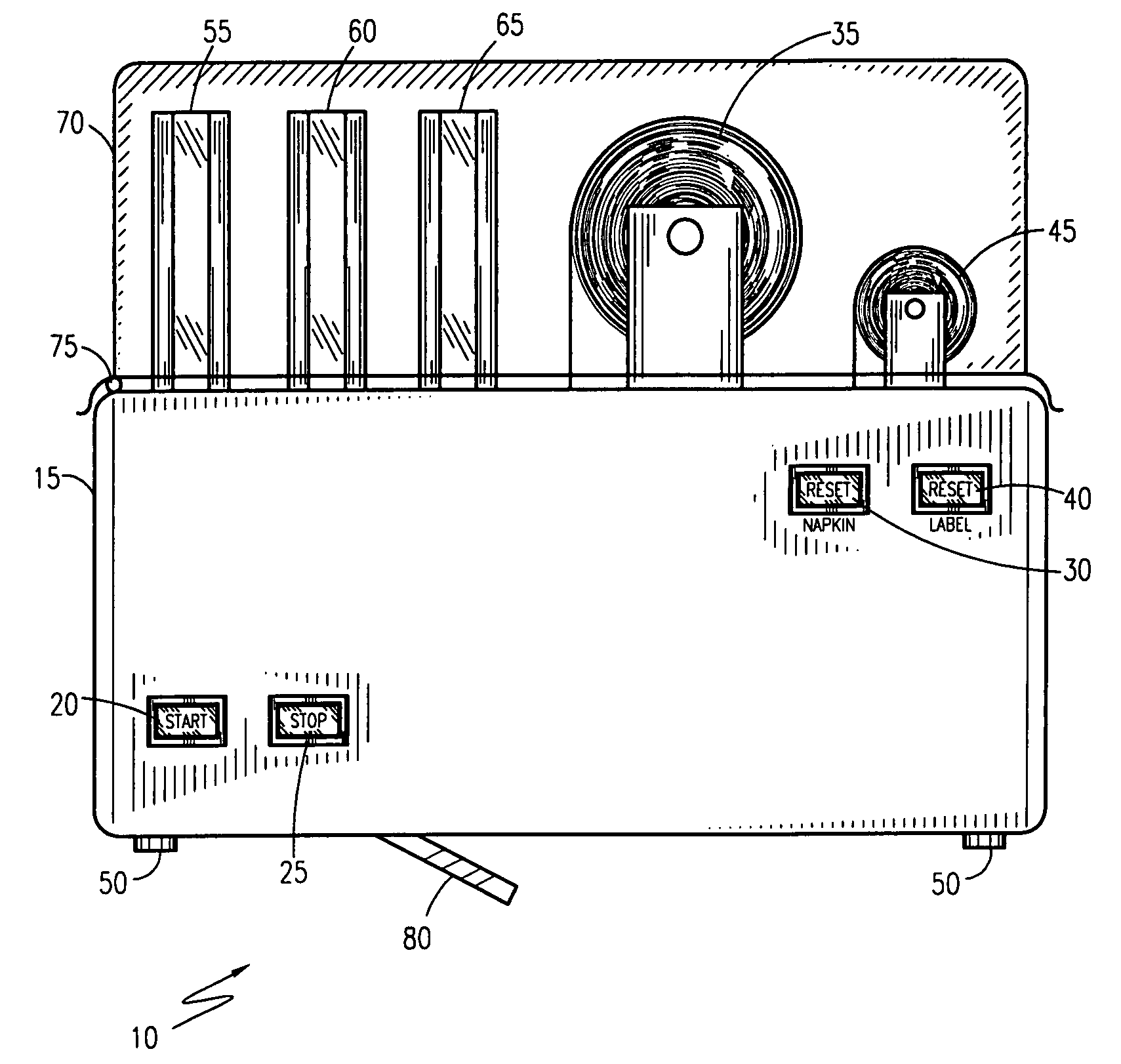

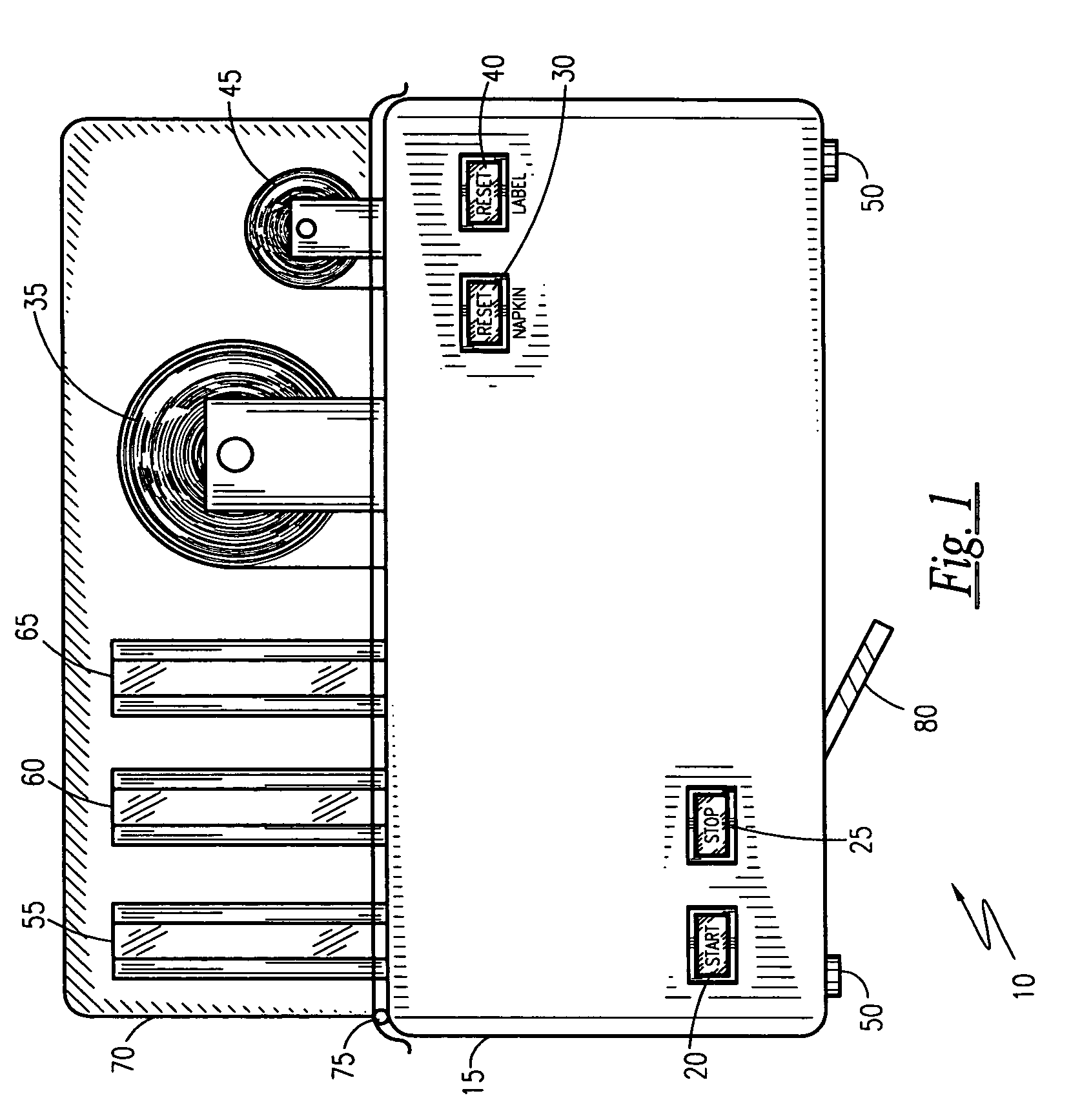

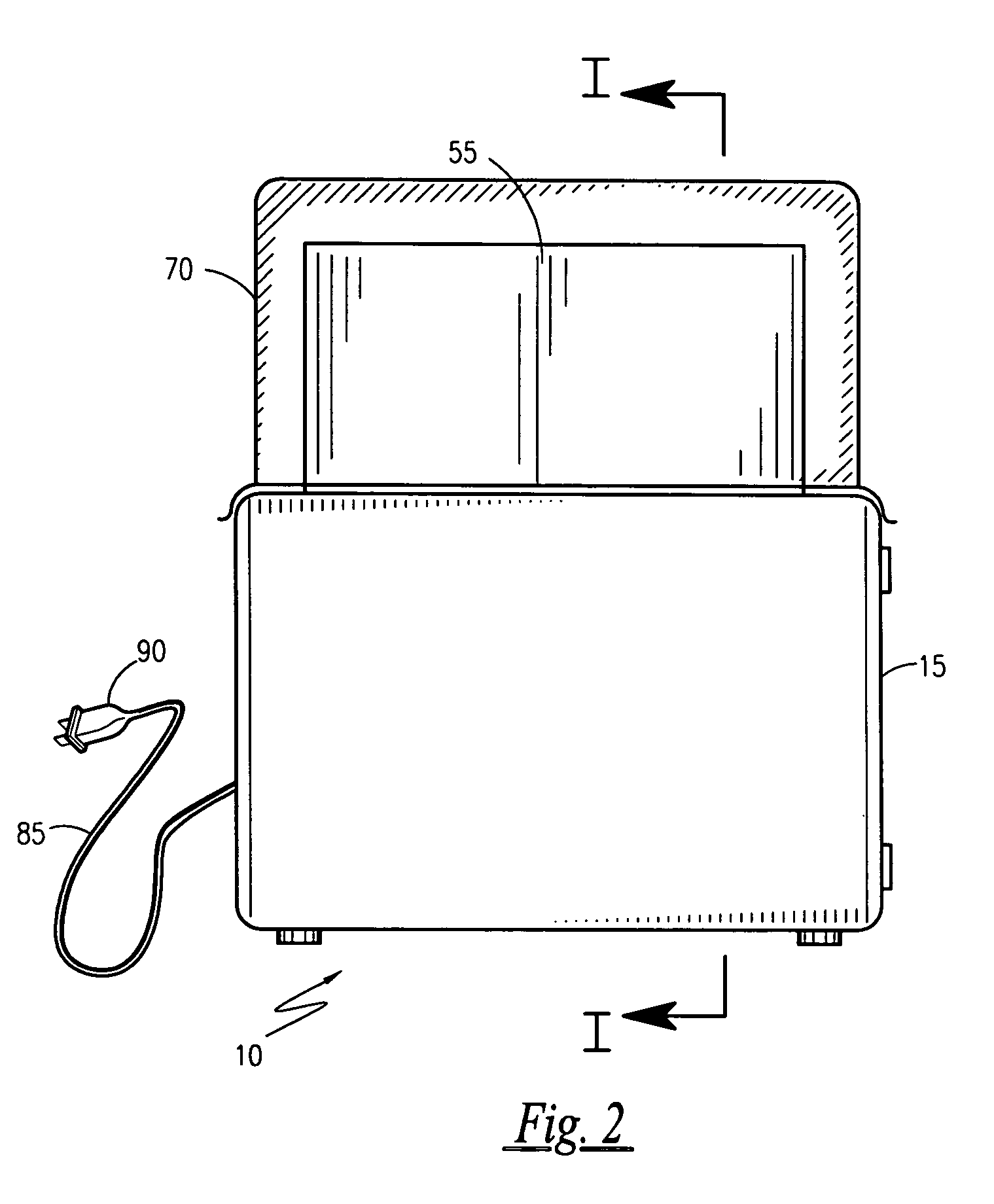

Automated flatware and napkin assembling apparatus

InactiveUS6837028B1Quickly and conveniently wrapLower Level RequirementsWrapper folding/bending apparatusConveyor wrappingPaper towelDirt

An apparatus that wraps dinner flatware in a paper napkin in an automated manner and secures it with a paper label is disclosed. The invention includes input hoppers for knives, forks, spoons, and napkins which are located on the front and top part of the unit. Additionally, a roll of paper napkins and a roll of securing paper labels are provided on top with their own automatic dispensing means. A plastic cover secures the entire top of the invention to protect it from dust and dirt as well as accidental contact during operation. Internal mechanisms then take one of each piece of flatware and fold and roll it in a napkin. The completed napkin unit then drops out the bottom of the invention, where it is collected for use. The invention is capable of processing up to 50 sets of flatware during one operating run. The use of the invention provides time and labor savings to restaurants and other eating establishments while producing rolled flatware secured in a paper napkin in fast and sanitary manner.

Owner:MIANO MARIO L +1

Apparatus and method for wrapping

Owner:RUBIN RICHARD HOWARD

Method of folding a sheet of packing material with an extraction opening about a group of cigarettes, and corresponding package of cigarettes

InactiveUS7827769B2Easy to implementContainers for flexible articlesPackage recyclingFilling materialsEngineering

Owner:GD SPA

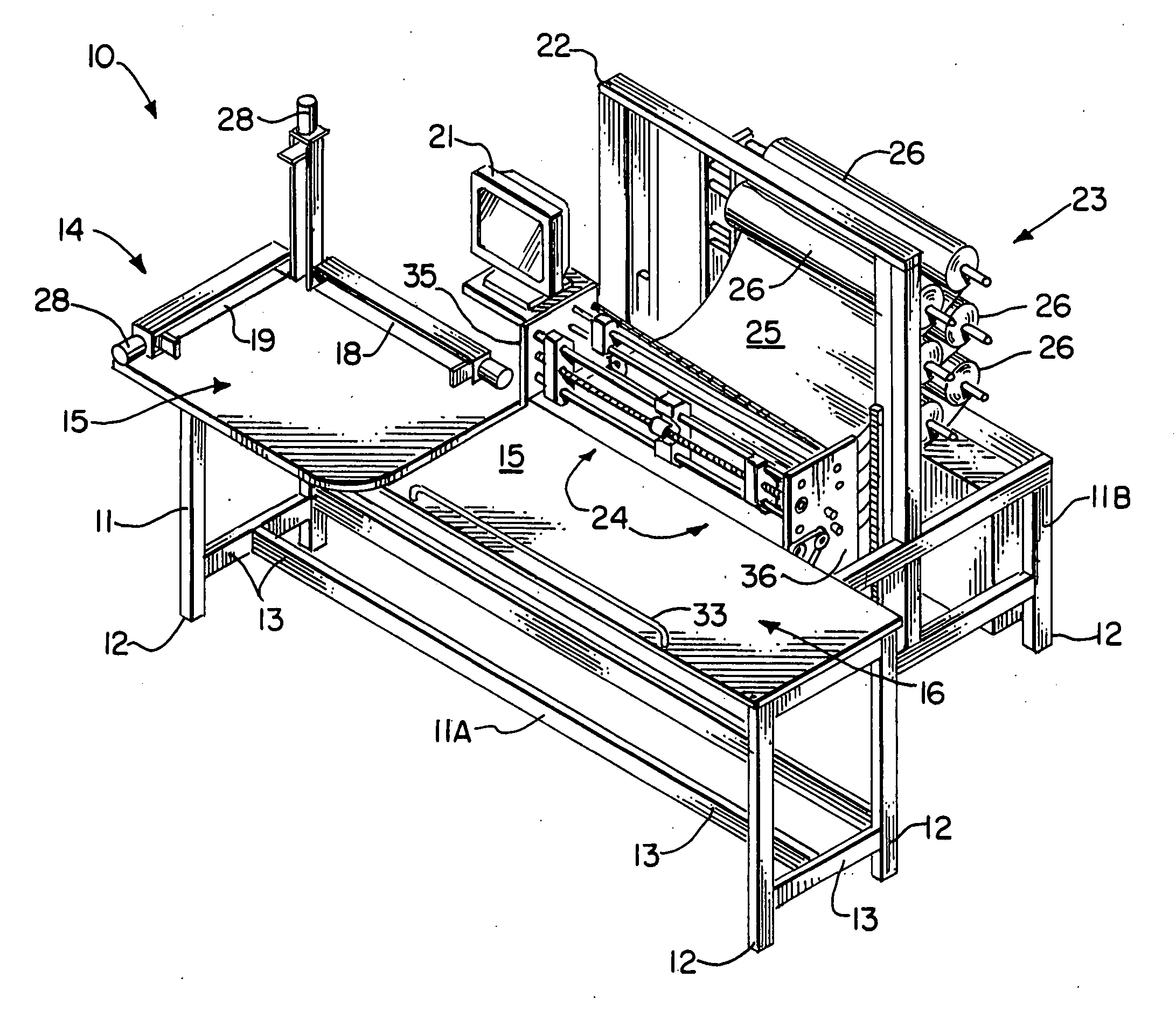

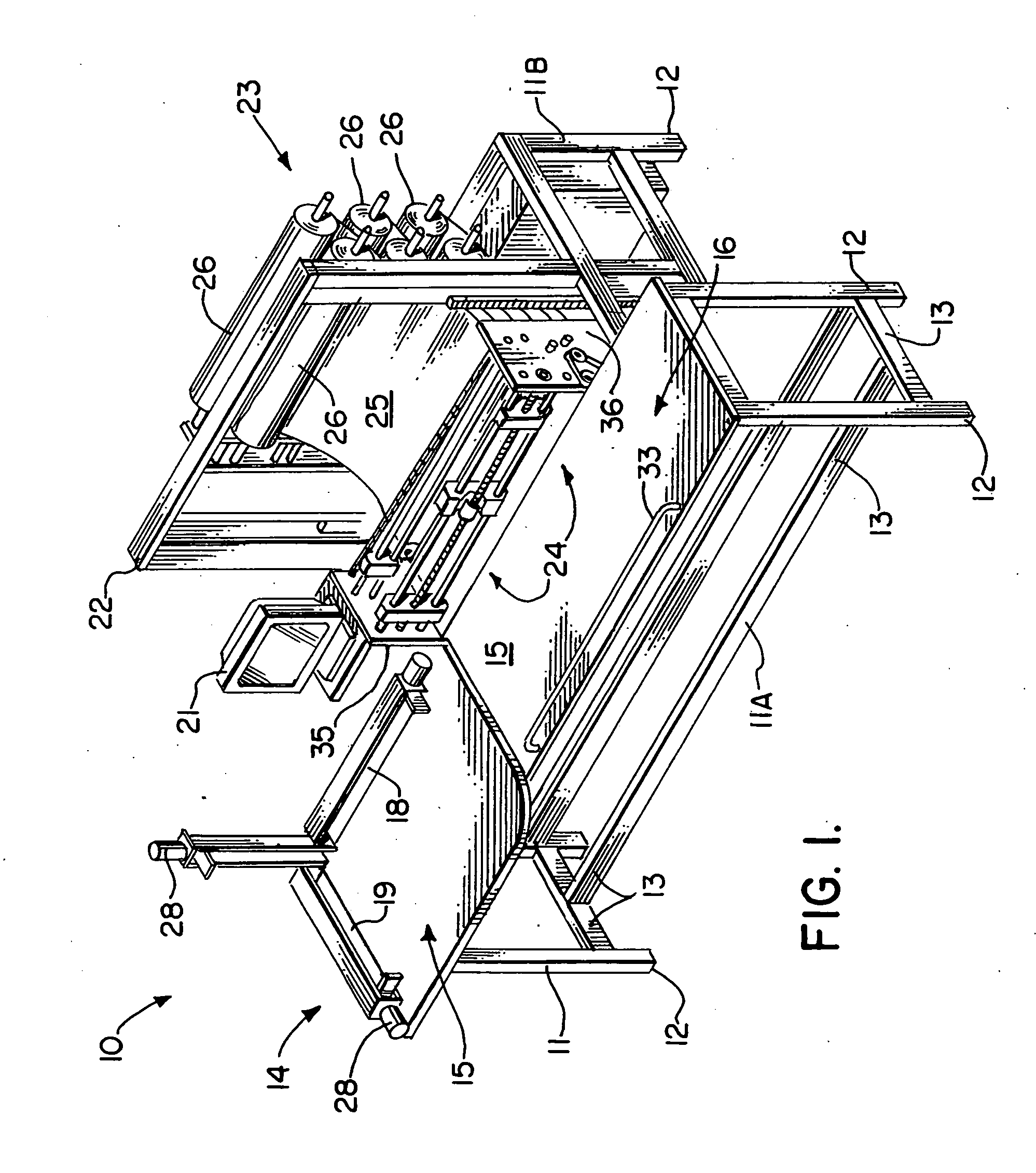

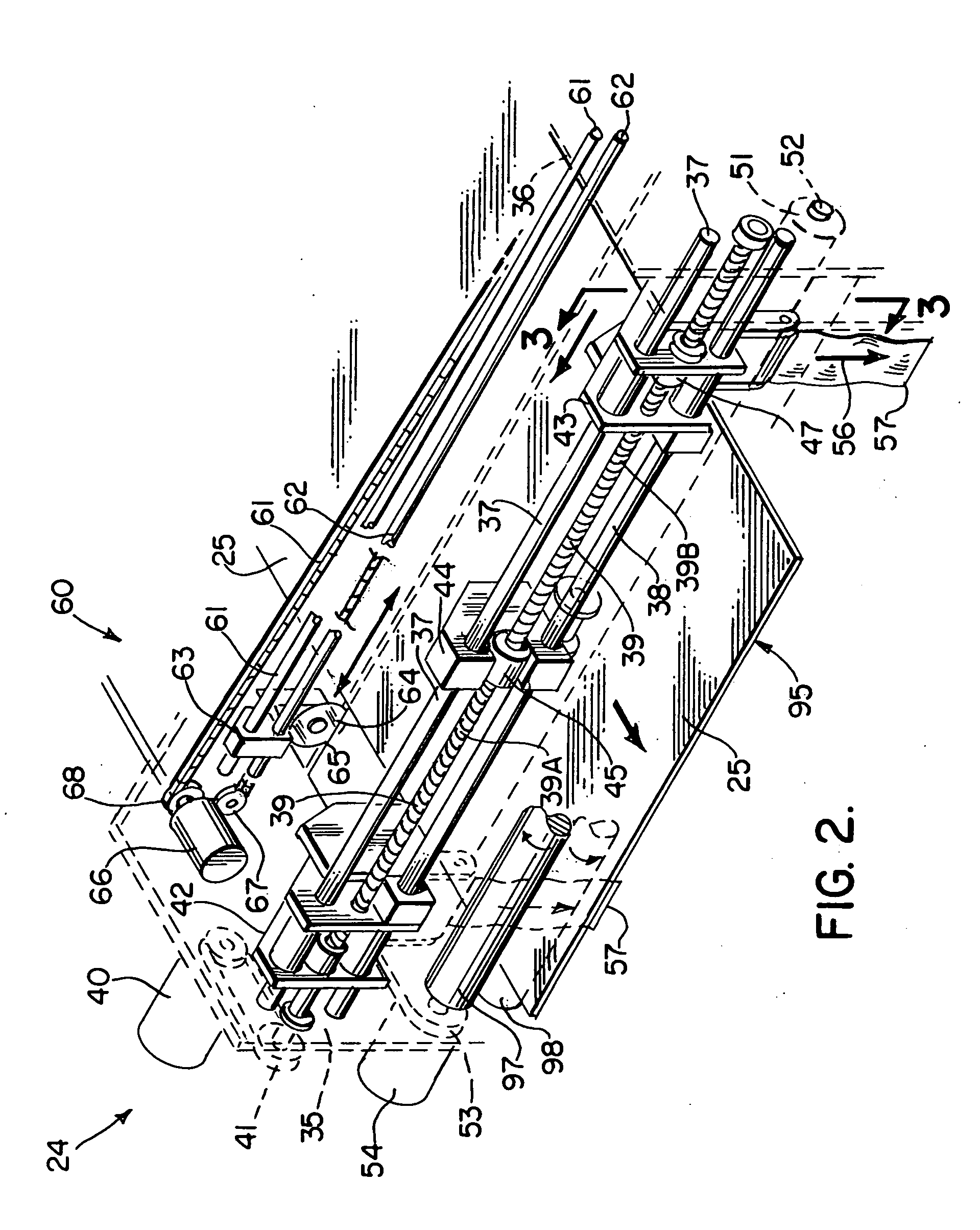

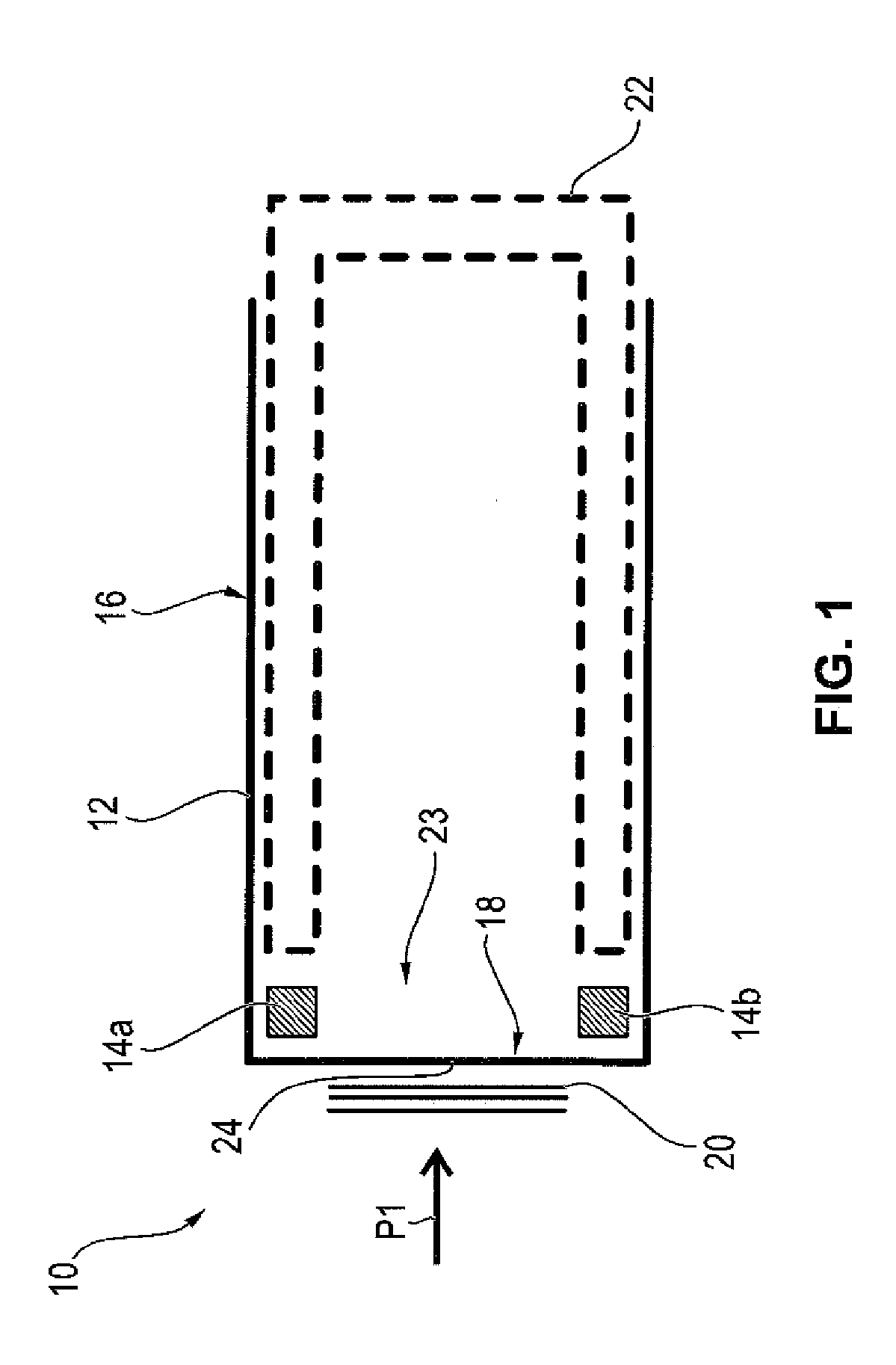

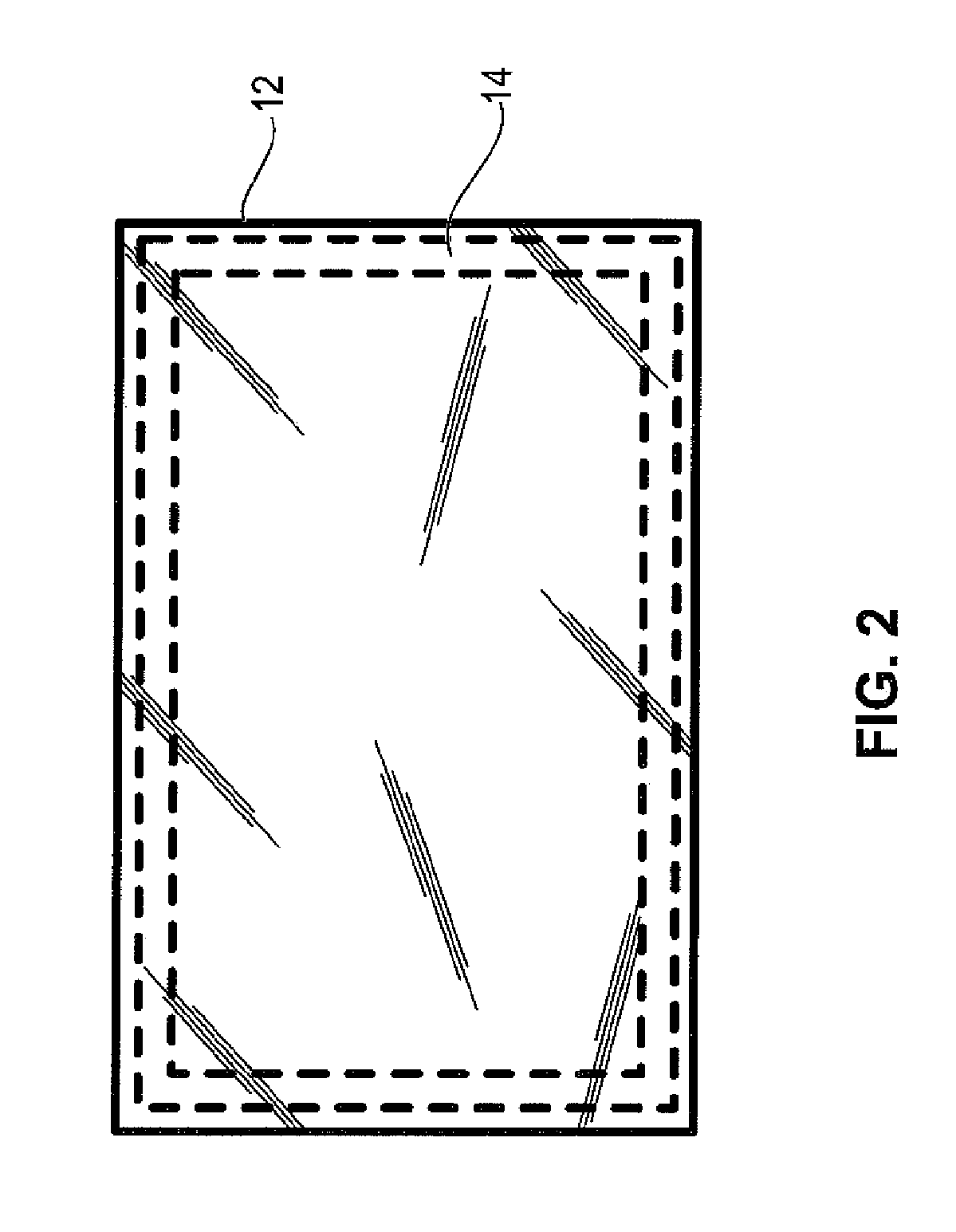

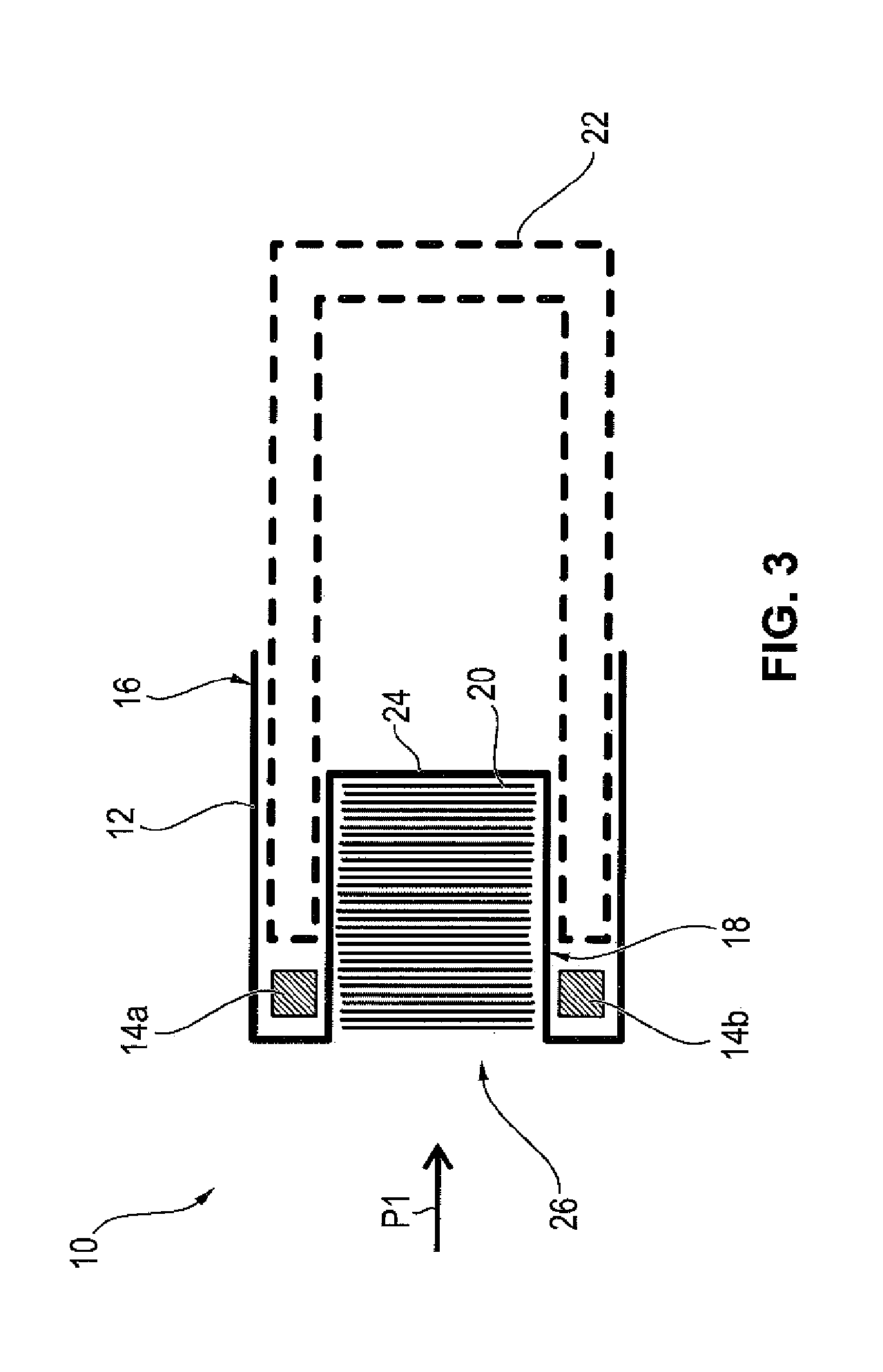

Package wrapping method and apparatus

InactiveUS20070289253A1Improve matchWrapper folding/bending apparatusWrapper supporting apparatusSemi automaticTrailing edge

A semi-automatic gift or package wrapping method and apparatus is disclosed. The apparatus includes a machine frame that provides a work surface with measuring and wrapping sections. A sheet feed and cutting mechanism feeds paper from a role in two steps with a time pause in between for enabling a user or operator to partially wrap the package with part of the first section of dispensed paper web. Thereafter, the second section of paper web is dispensed and the web cut transversely at a trailing edge. Multiple selectable supply rolls are optionally provided, or a single roll machine can be used. Longitudinal cutters trim the sides of the paper to obtain a custom desired width for the full cut sheet. A user interface display controls machine functions such as start, continue and sheeter. In the sheeter mode, a selected number of sheets of a selected size can be dispensed and cut for use at another workstation to warp other boxes of known uniform size (i.e. shirt boxes at a department store).

Owner:MET TECH CORP A CORP ORGANIZED UNDER THELAWS OF THE STATE OF MISSISSIPPI

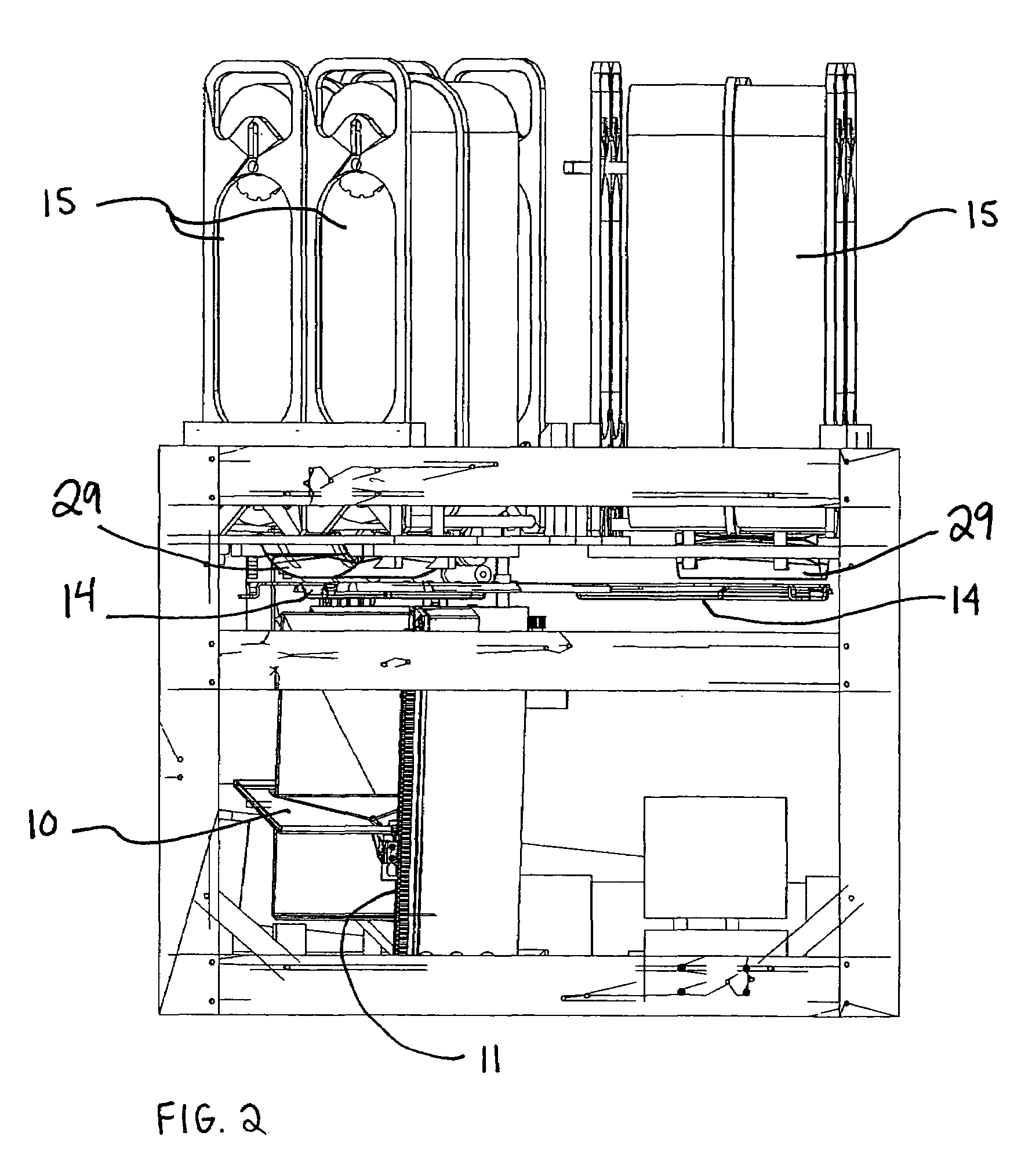

Silverware and napkin rolling apparatus

InactiveUS6976348B1Quickly and conveniently wrapReduce the amount requiredWrapper folding/bending apparatusConveyor wrappingPaper towelEngineering

Owner:MIANO MARIO L +1

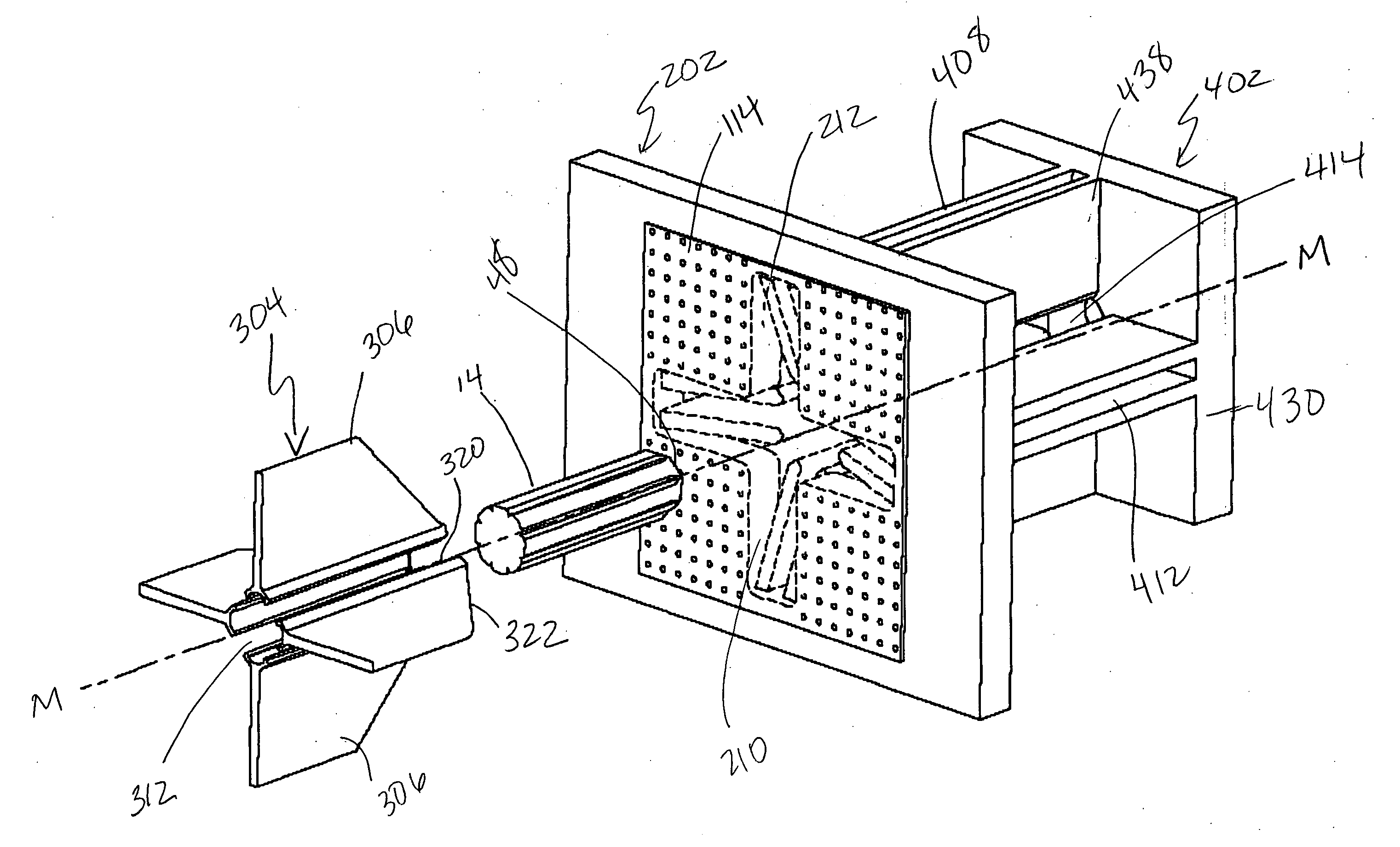

Intravaginal device with fluid transport plates

ActiveUS20070010388A1Increase contact areaReduce by-pass leakageMechanical working/deformationBox making operationsFluid transportRelative motion

An apparatus for producing an absorbent article includes a holding tool, a female tool disposed along a machine axis, and a male tool disposed along the machine axis. The holding tool has an aperture aligned along the machine axis and means for holding a flexible sheet across the aperture. The female tool has at least one folding element extending in a direction radially away from the machine axis, and the male tool has means for holding a fluid storage element and at least one pleating blade extending in a direction radially away from the machine axis. At least two of the holding tool, female tool, and male tool are capable of relative motion along the machine axis. Further the at least one pleating blade and of the male tool and the at least one folding element of the female tool are aligned to permit manipulation of the flexible sheet about the fluid storage element.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

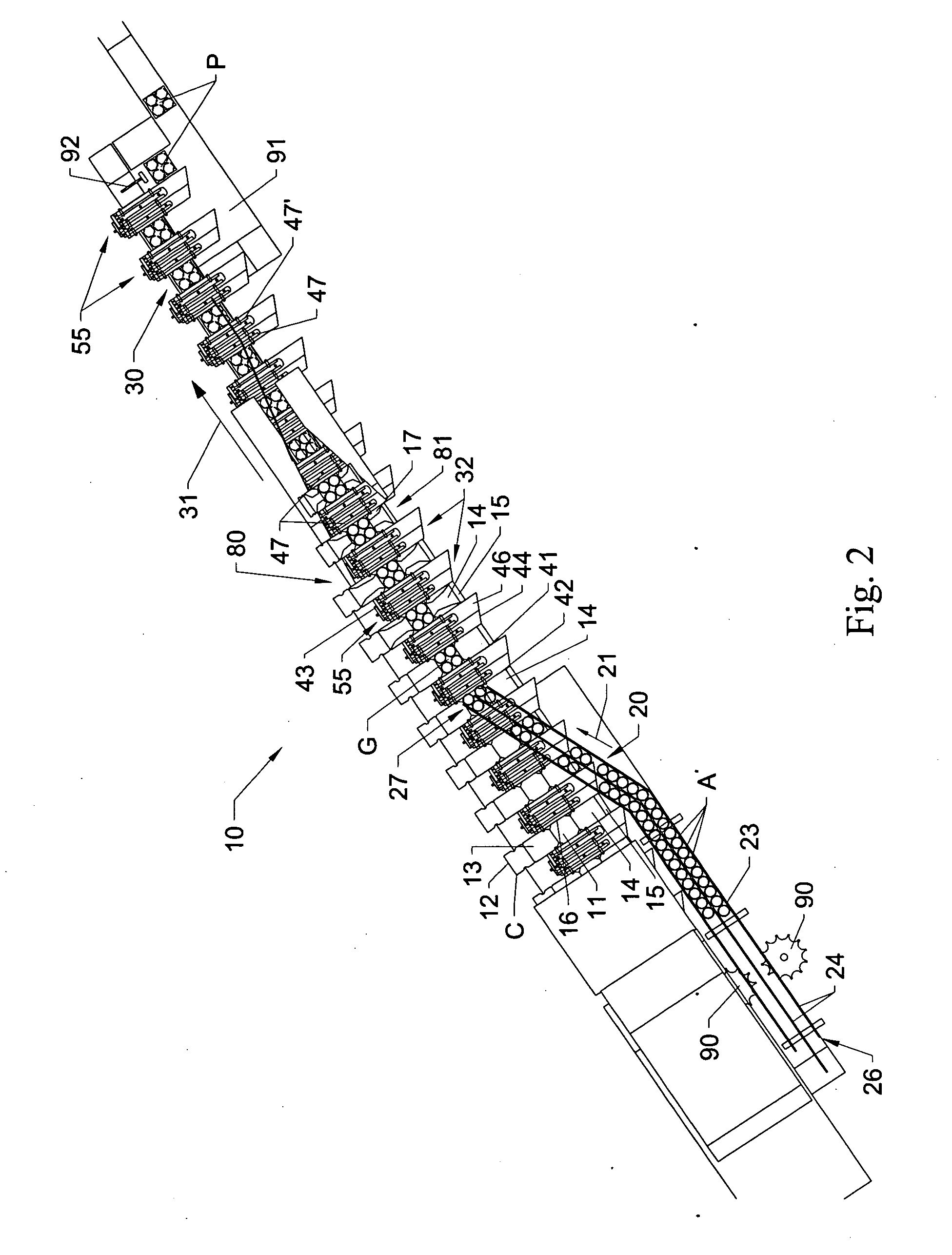

Method and unit for packing groups of products

InactiveUS20050005580A1Drawback can be obviatedPackaging cigaretteWrapper folding/bending apparatusMechanical engineeringPinch grip

A method and unit for packing groups of products, whereby each group is fed, at a loading station, to a respective radial first seat of a first wheel, together with a relative blank, which is first folded into a U and then completely about the relative group to form a packed group, which is transferred, at a transfer station, to a respective radial second seat of a second wheel, together with a relative sheet of overwrapping material, which is first folded into a U and then completely about the relative packed group to form an overwrapped group; the blank and the sheet of overwrapping material both being fed successively to a respective same gripper associated with the relative first seat and fitted to the first wheel, downstream from the first seat.

Owner:GD SPA

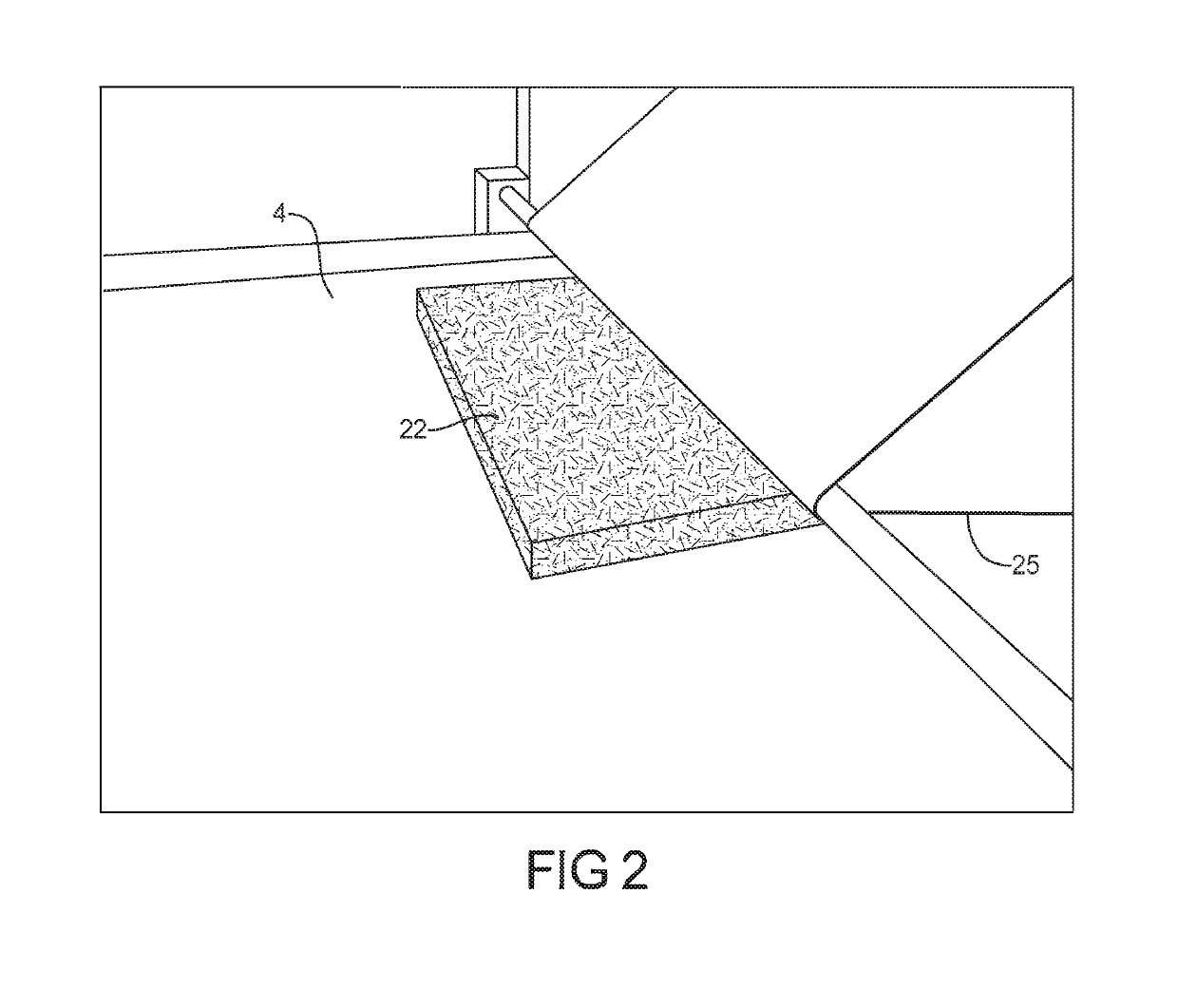

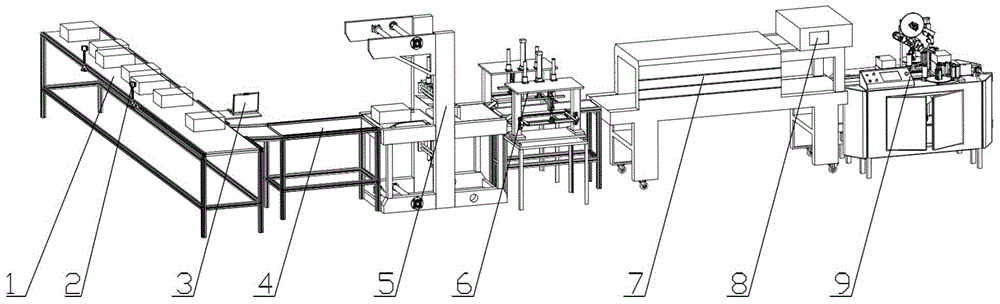

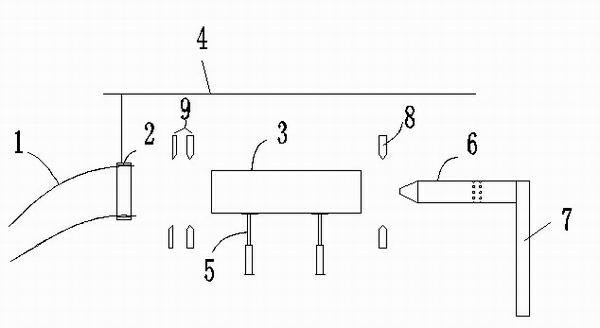

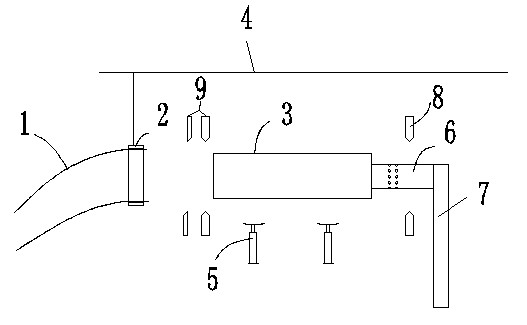

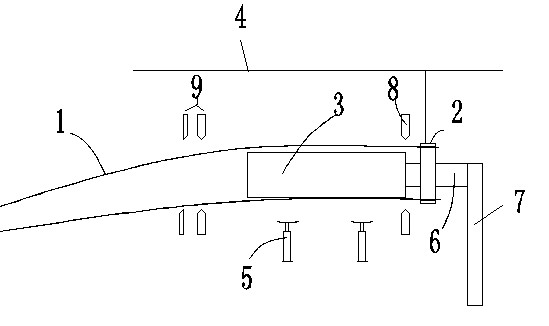

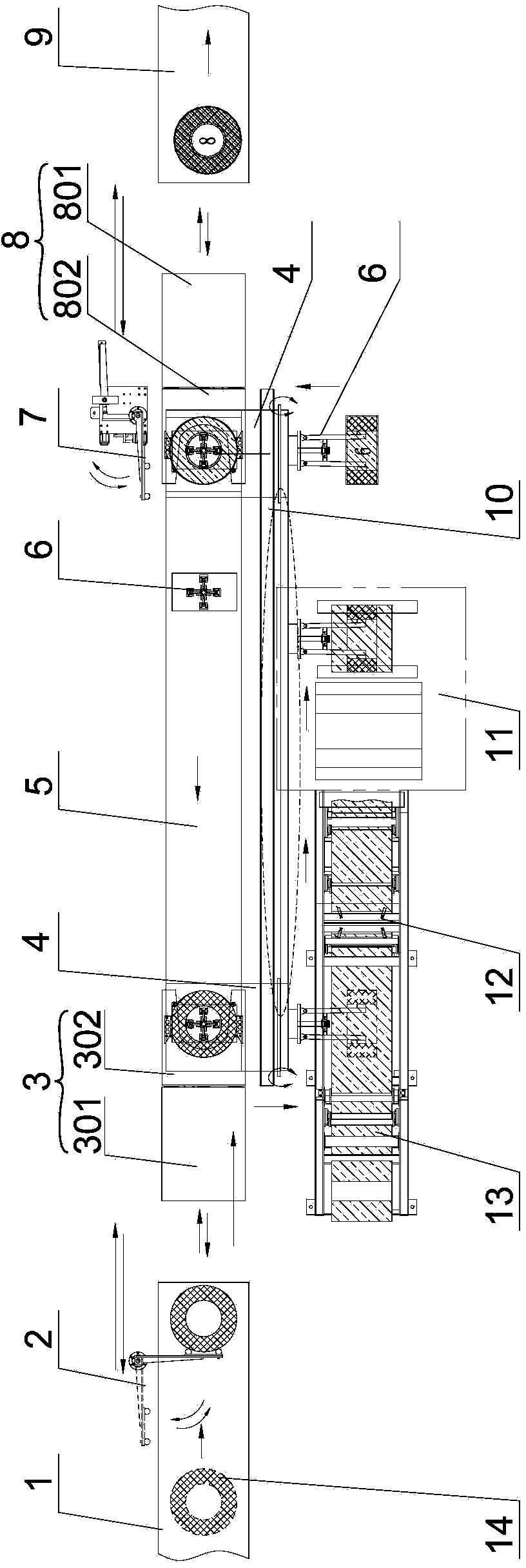

Packaging process and packaging equipment for large-specification ceramic tile

ActiveCN101992864AEnsure quality stabilityRealize automatic high speedWrapper folding/bending apparatusConveyor wrappingBrickEngineering

The invention discloses a packaging process and packaging equipment for a large-specification ceramic tile. Three independent working faces are included. The centering process, the alignment patting process and the corner wrapping process of a tile stack are finished on the first working face; the prepackaging location of the tile stack is finished on the second working face by using pre-placed box packaging paper; the tile pack packaging is finished in the process of the tile stack falling to the third working face; and finally, the outlet tiles of the tile pack are conveyed on the third working face. The packaging equipment comprises three working platforms, wherein the first working platform is provided with a centering mechanism, an alignment patting mechanism and a corner picking and placing mechanism; the second working platform is provided with a vertical packaging device; and the third working platform is arranged below the second working platform and is provided with an outlet tile conveying device. The invention adopts a brand-new packaging process flow and the packaging equipment with a brand-new layout to package the large-specification ceramic tile, makes the packaging speed greatly improved under the condition of ensuring the packaging quality stability and realizes automatic high-speed corner-wrapping packaging.

Owner:KEDA INDUSTRIAL GROUP CO LTD

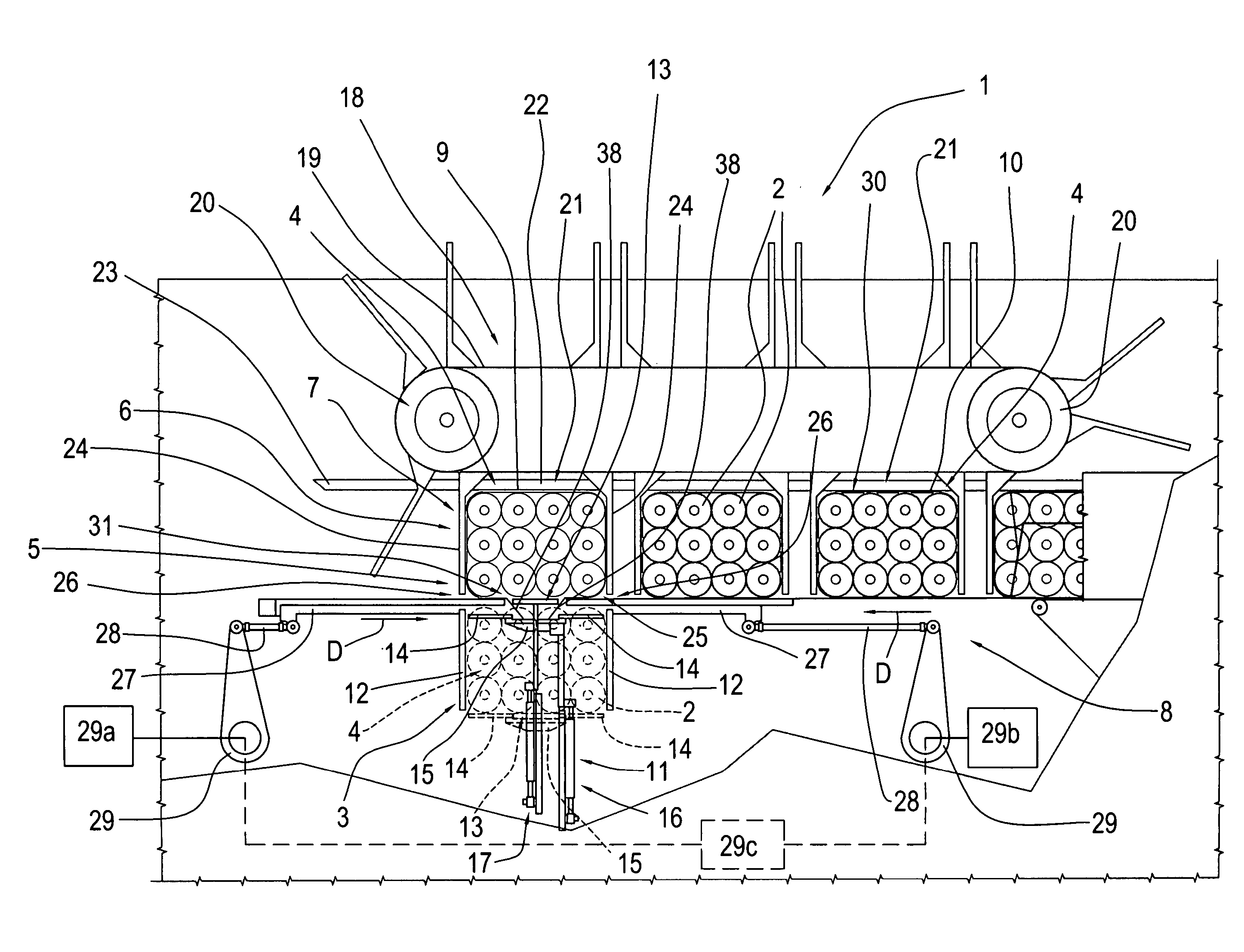

Apparatus for nesting bottles

The objective of this invention is to provide an apparatus for forming a stable arrangement of bottles so they can be moved on an inline conveyor system. This is accomplished by an apparatus for nesting bottles comprising a first conveyor having lanes of bottles, and a second conveyor, wherein a fixed number of bottles from each lane is released from each lane in a staggered arrangement to facilitate nesting of the released bottles and then pushing and guiding the released bottles from the first conveyor onto a second conveyor so that the bottles form a nested bundle.

Owner:CERF ALAIN

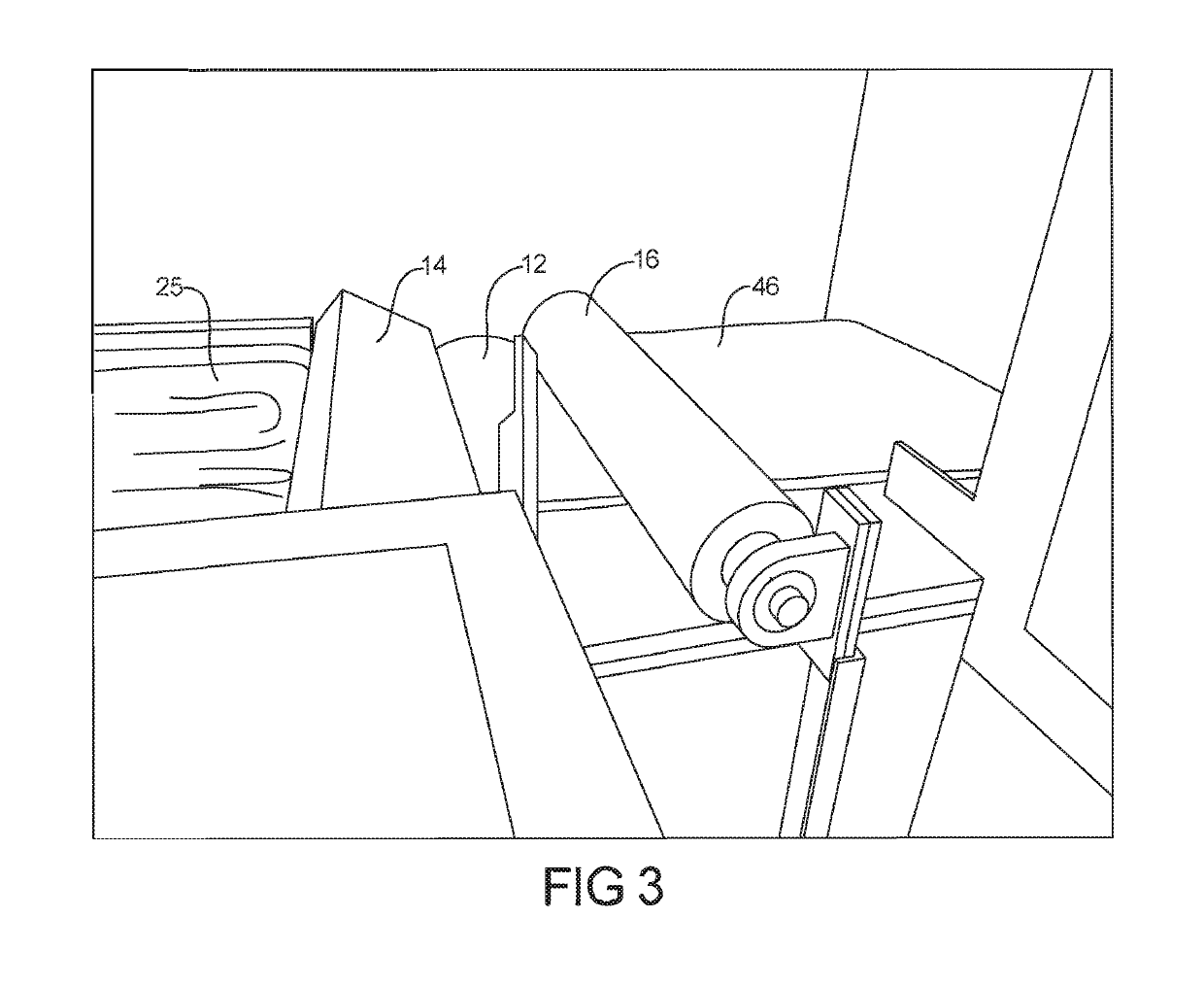

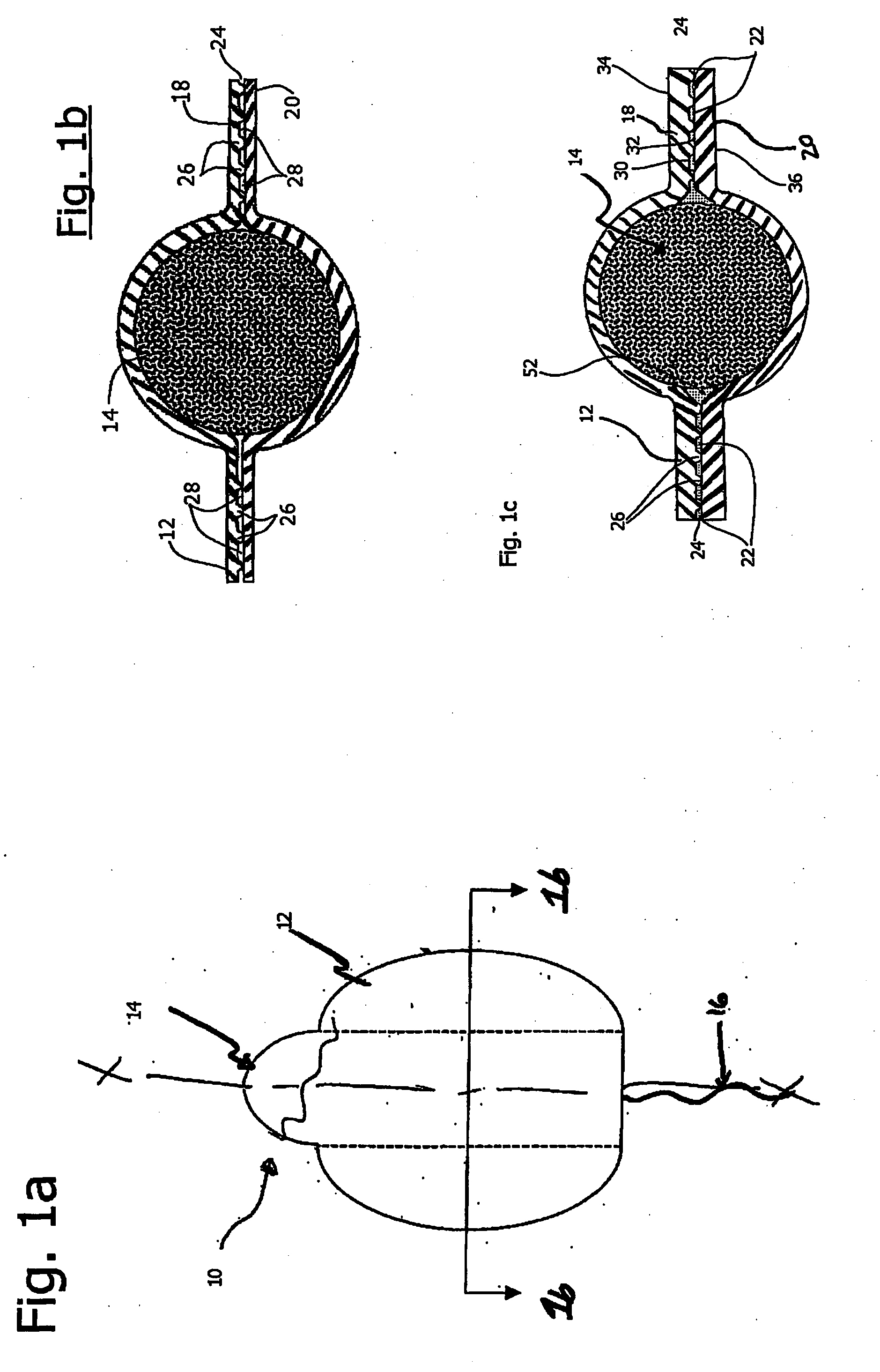

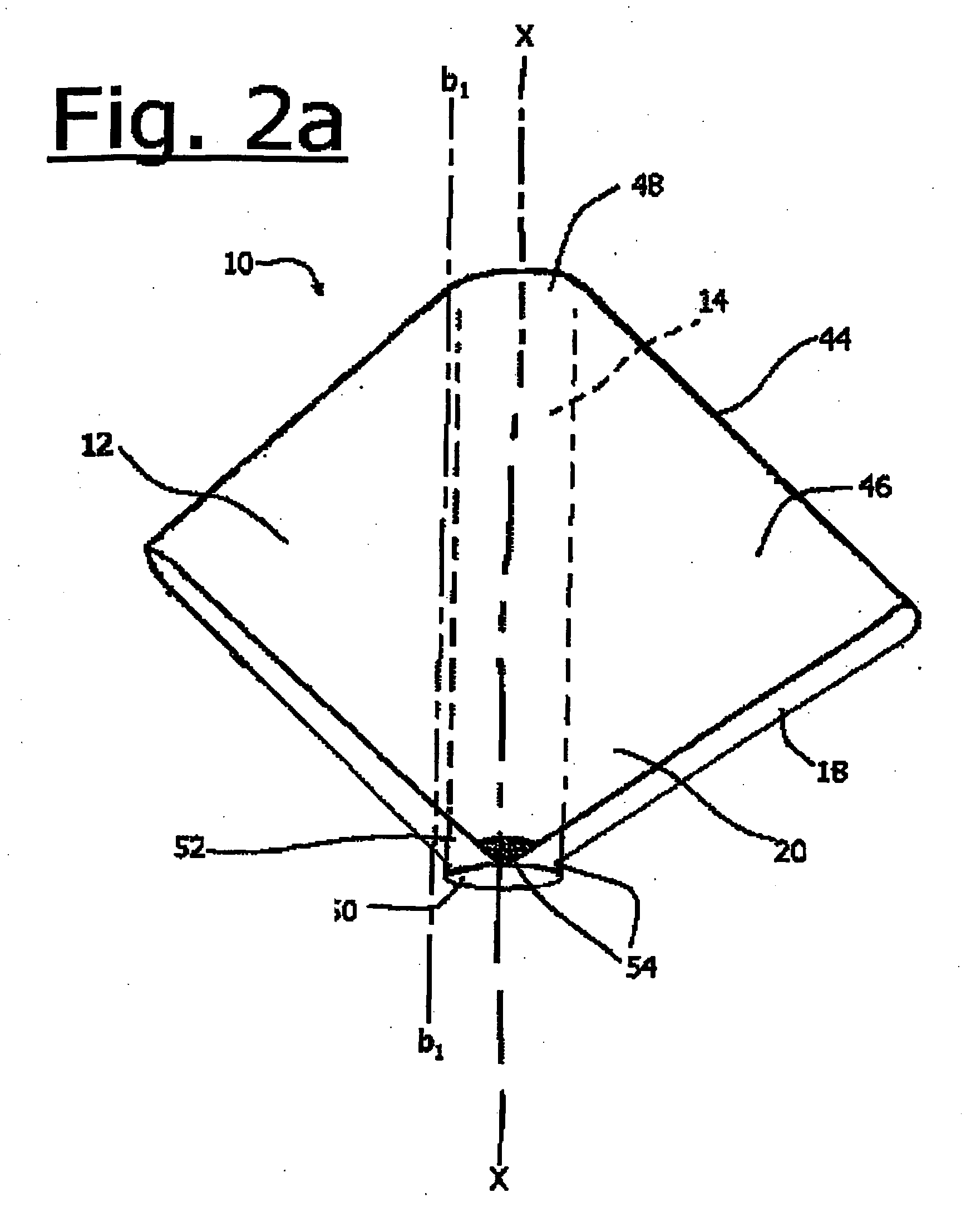

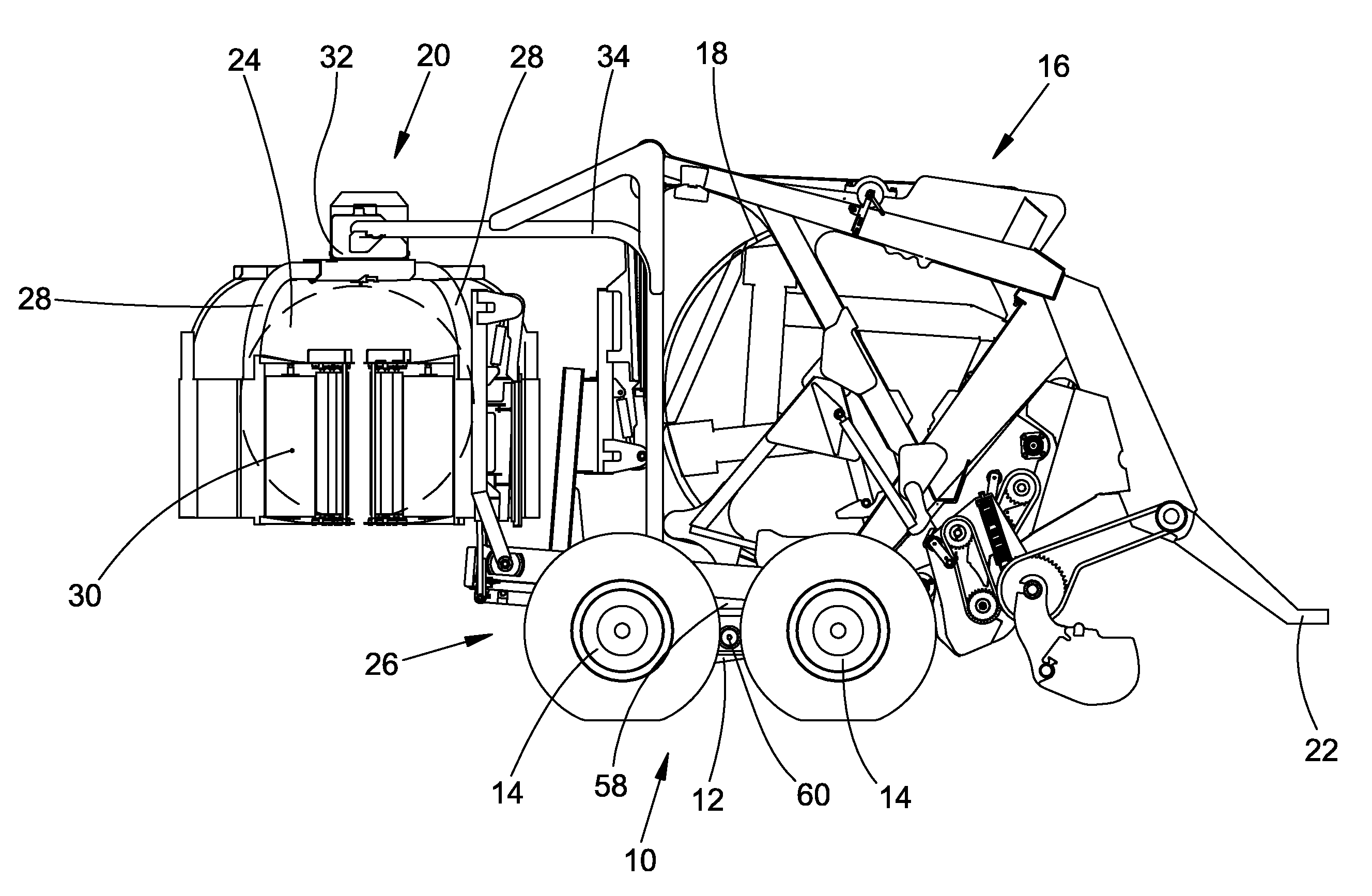

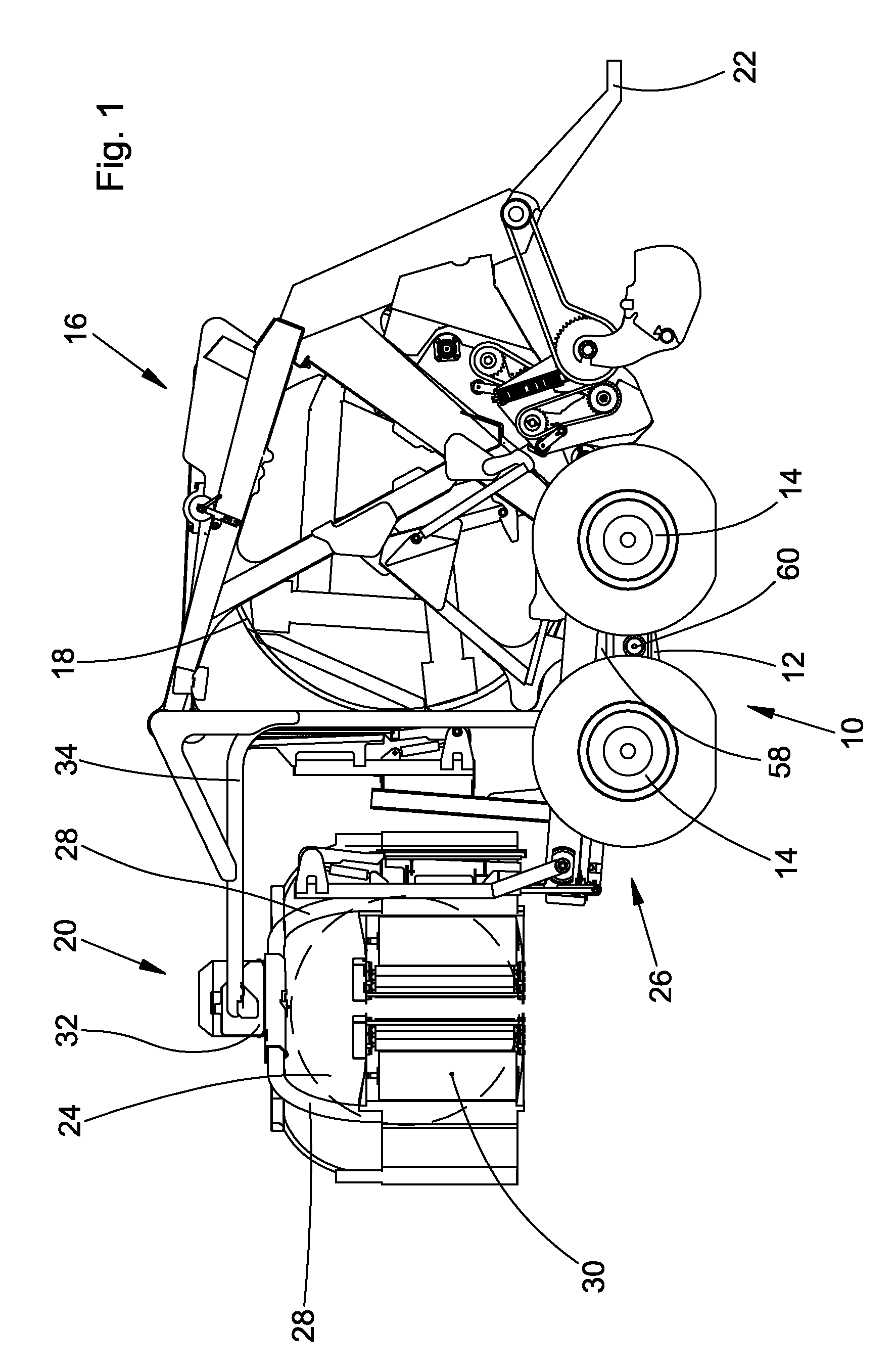

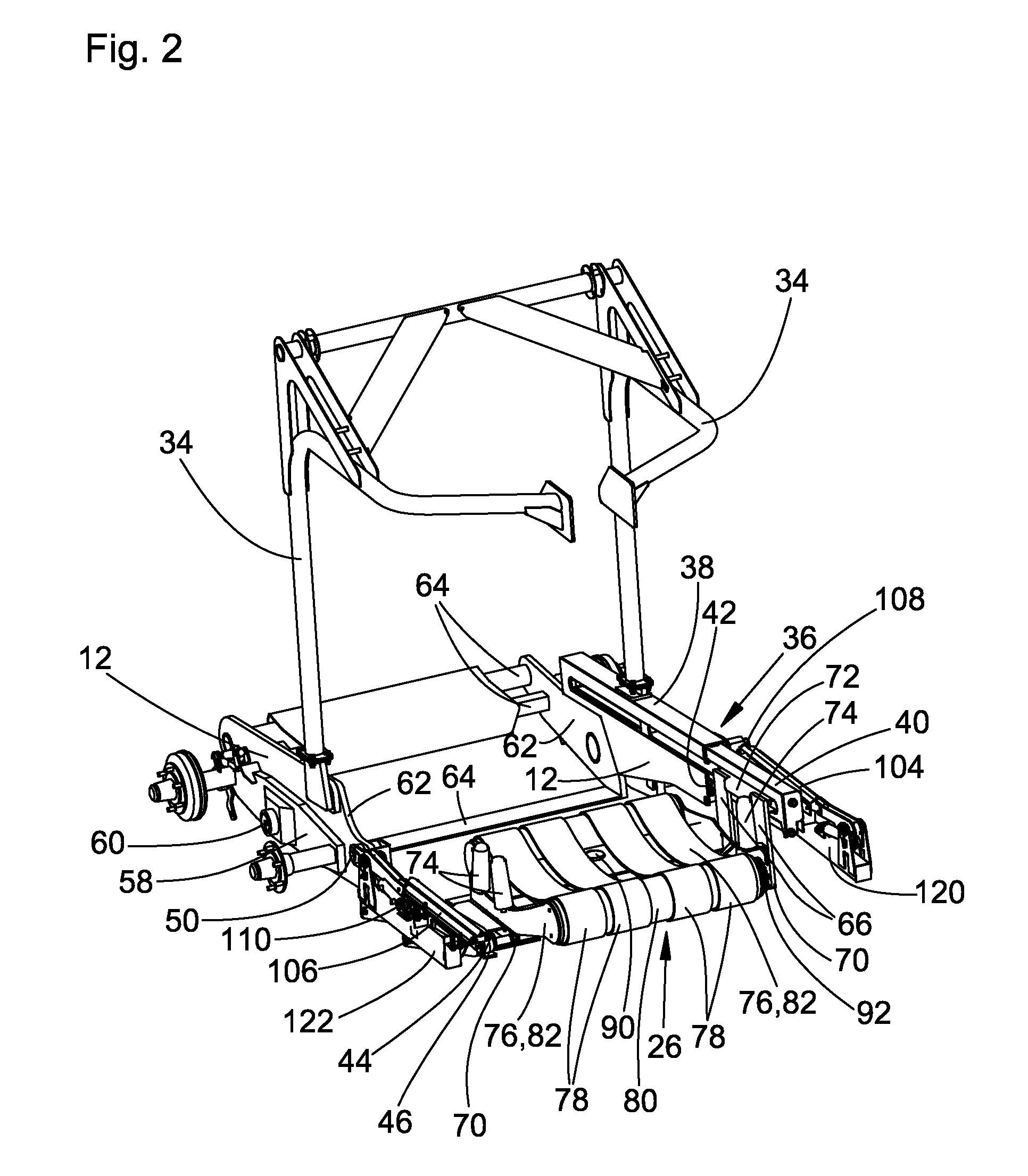

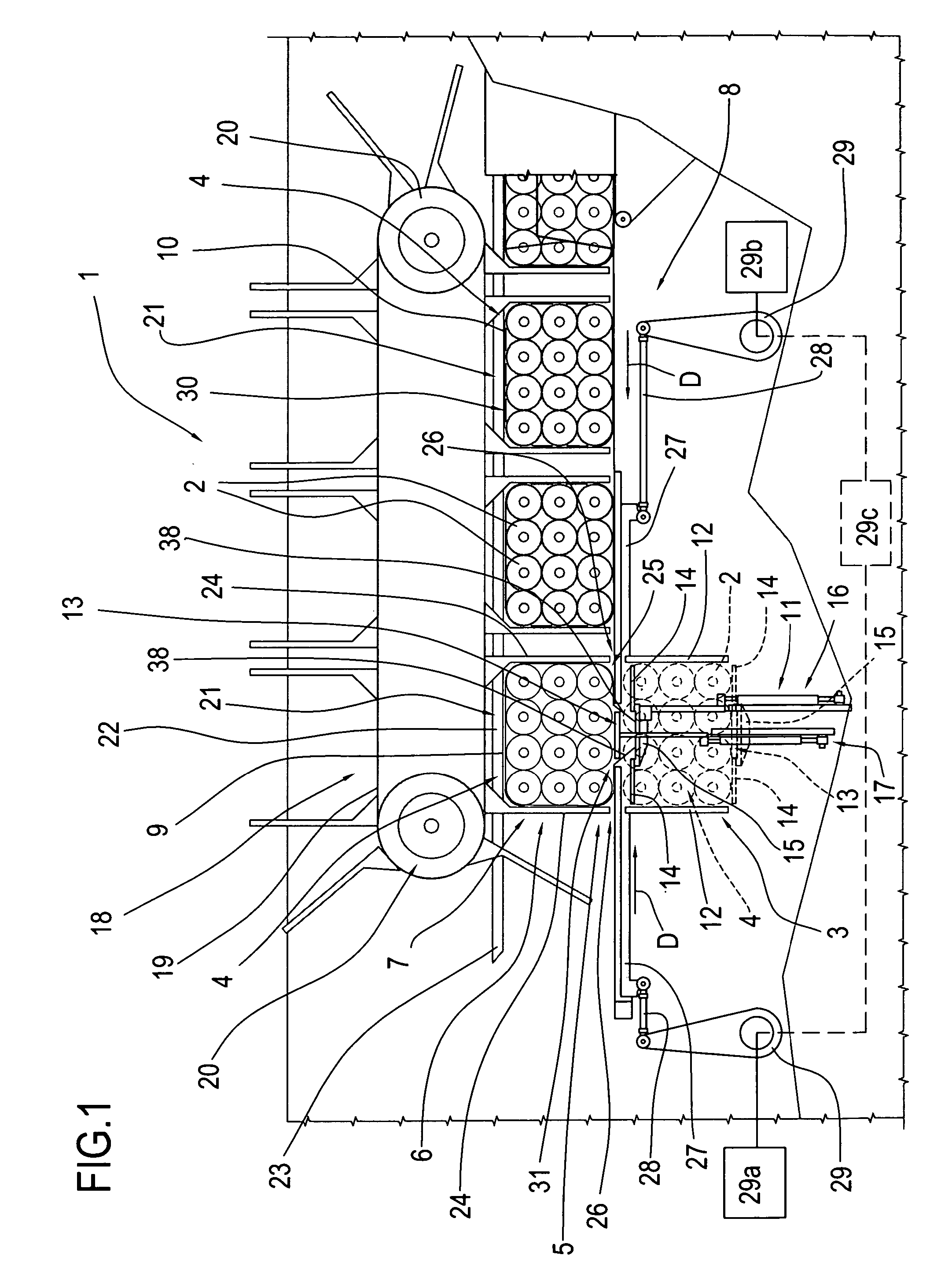

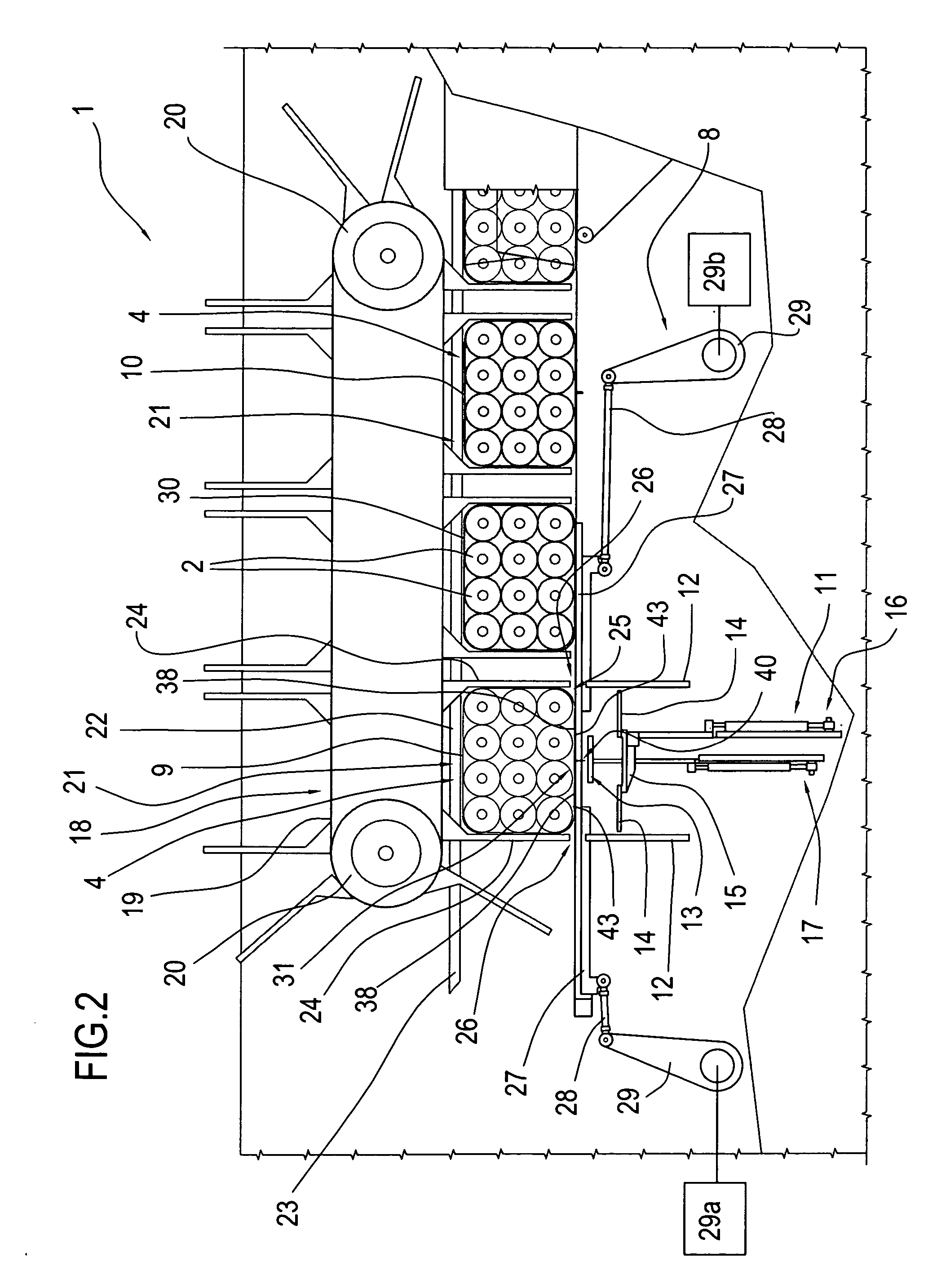

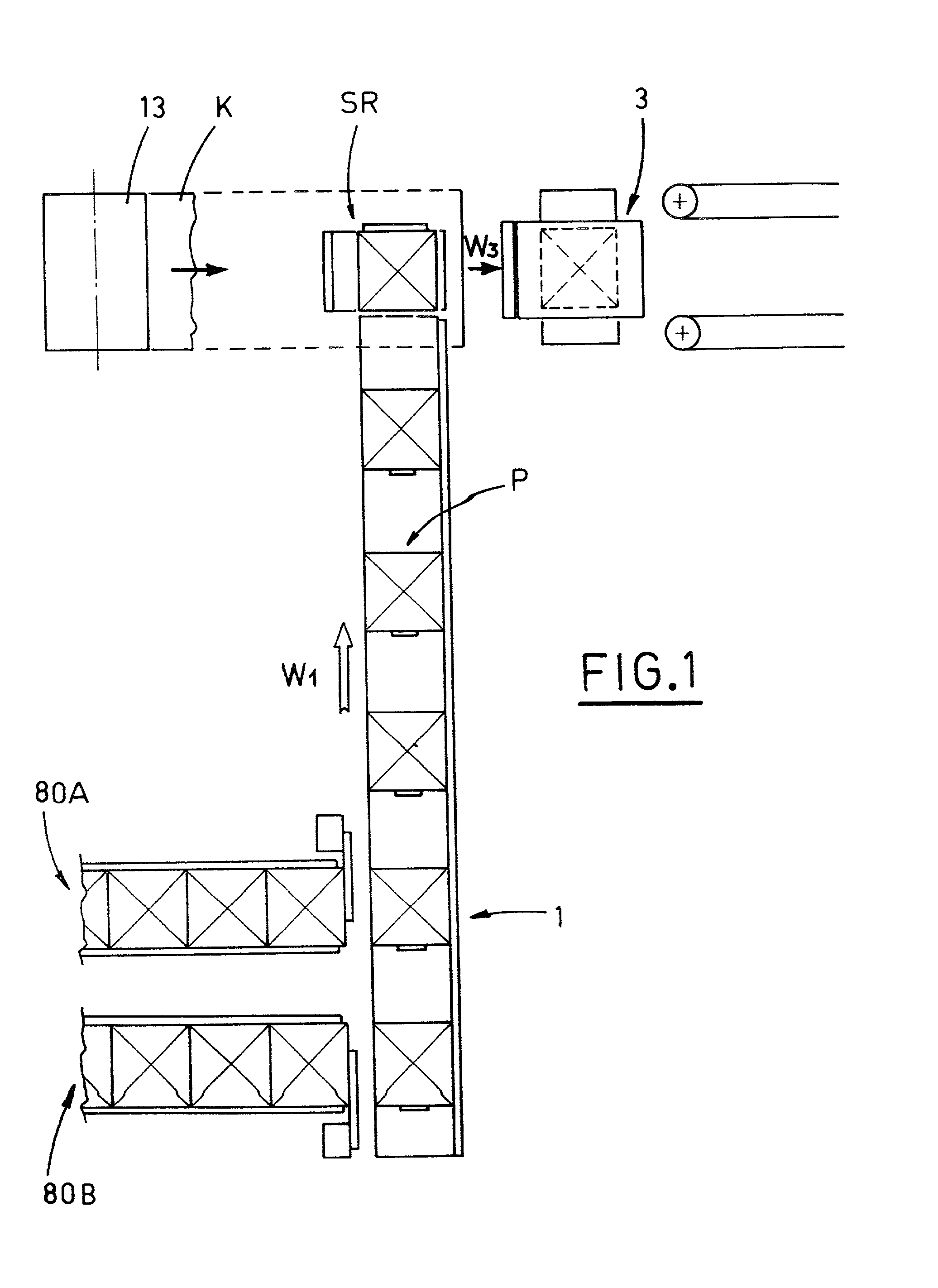

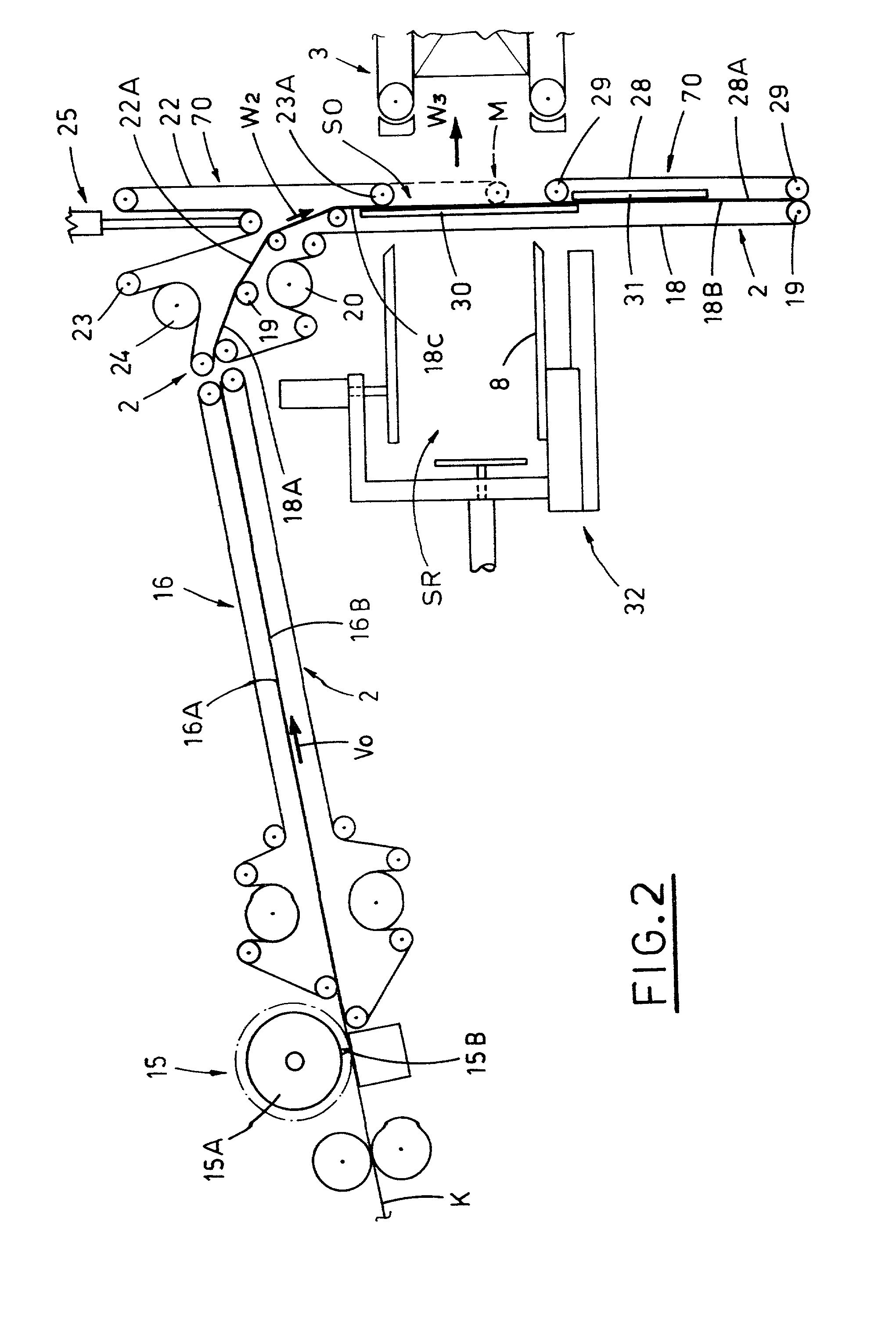

Baler and wrapper combination

ActiveUS20100024357A1Wrapping material feeding apparatusWrapper folding/bending apparatusEngineeringSheet material

A baler and wrapper combination comprises a baler, a bale wrapper, and a bale transport table. The bale transport table is movable between a bale receiving position at a bale output location of the baler, a wrapping position at which the wrapper can wrap a bale located upon the bale transport table with a sheet material, while movable bale support elements rotate the bale around its horizontal central axis, and a bale depositing position in which a wrapped bale can be deposited on the ground. The bale support elements are arranged to be moved in the bale depositing position into an orientation in which the bale is deposited on its flat end.

Owner:DEERE & CO

Packaging machine for packing rolls of paper and the like

ActiveUS20140260087A1Good riveting effectFilament handlingWrapper folding/bending apparatusEngineeringPackaging machine

A packaging machine including an insertion station for inserting the rolls in wrapping sheets; a feed path of the rolls; a conveyor for feeding the rolls along the feed path; and a folding station adapted to be equipped alternatively with different types of folding members, as a function of the type of pack to produce.

Owner:FABIO PERINI PACKAGING

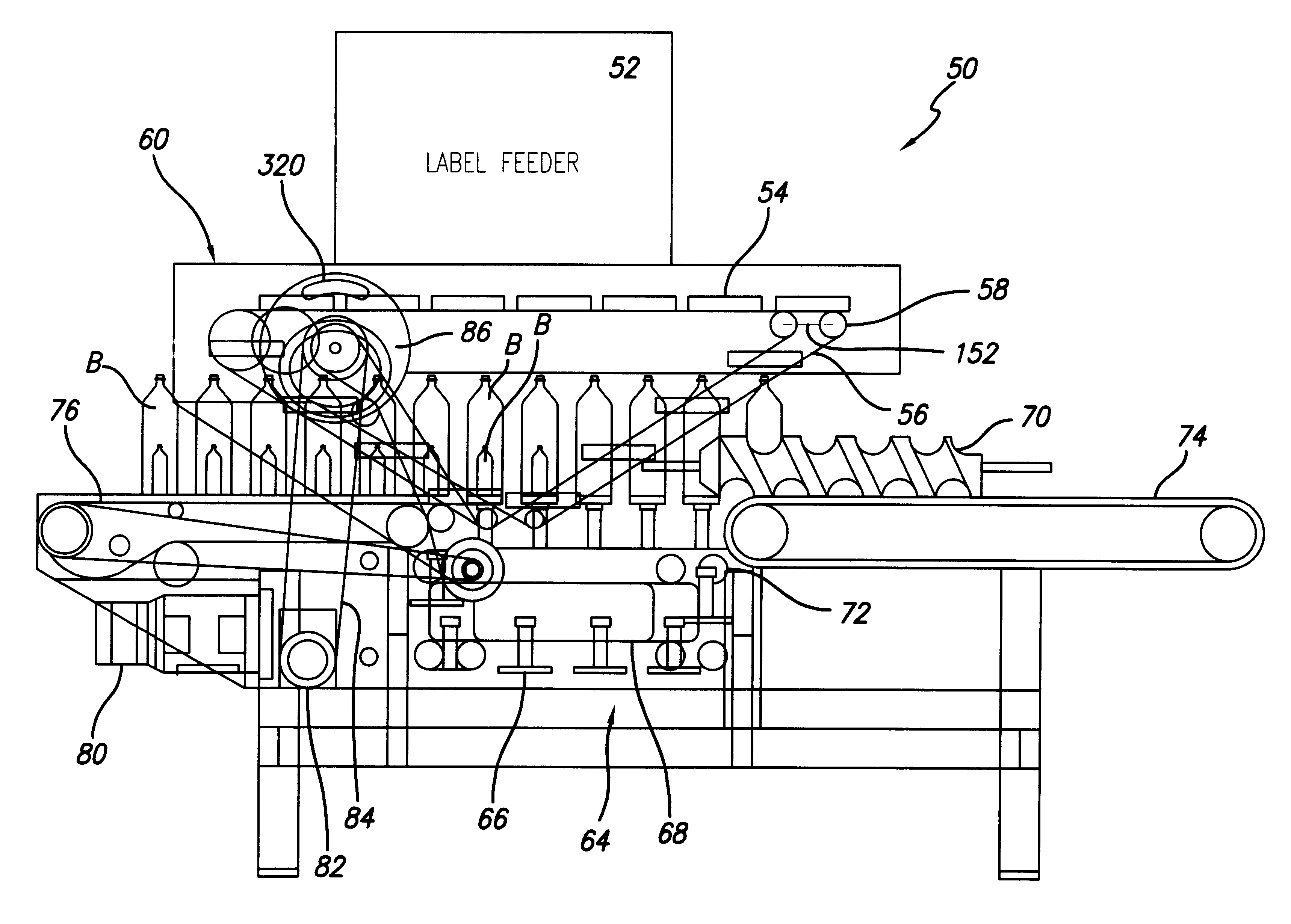

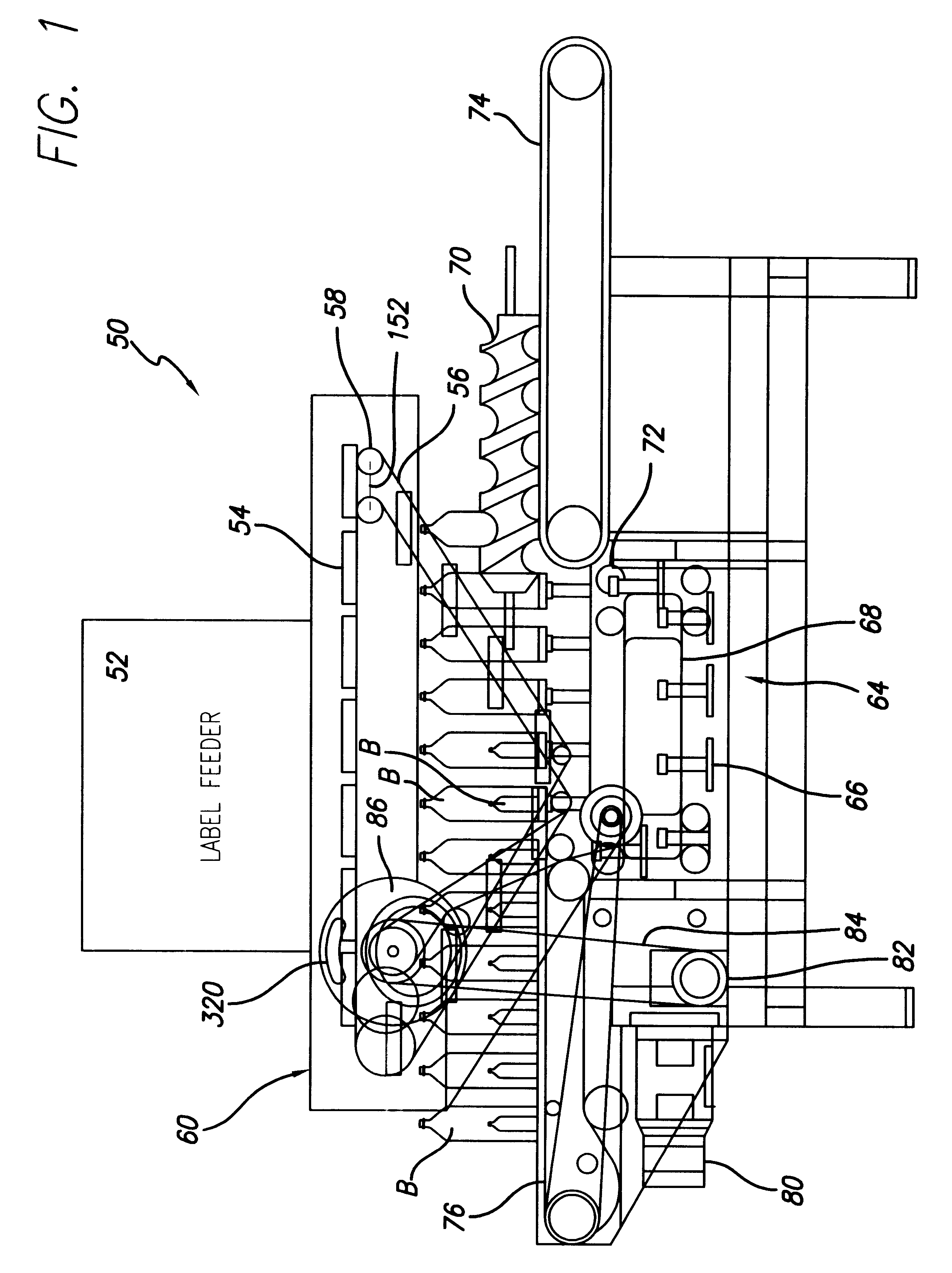

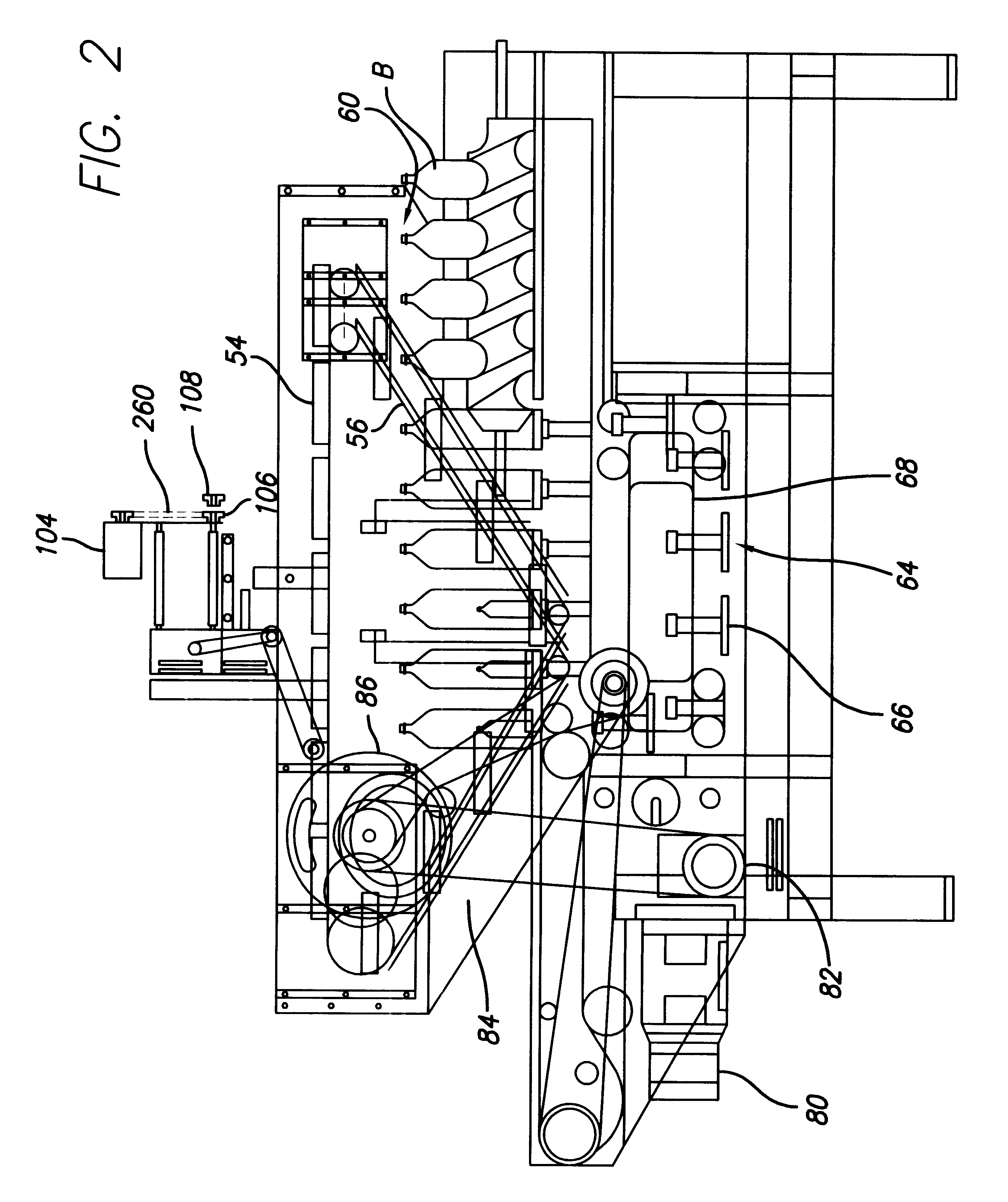

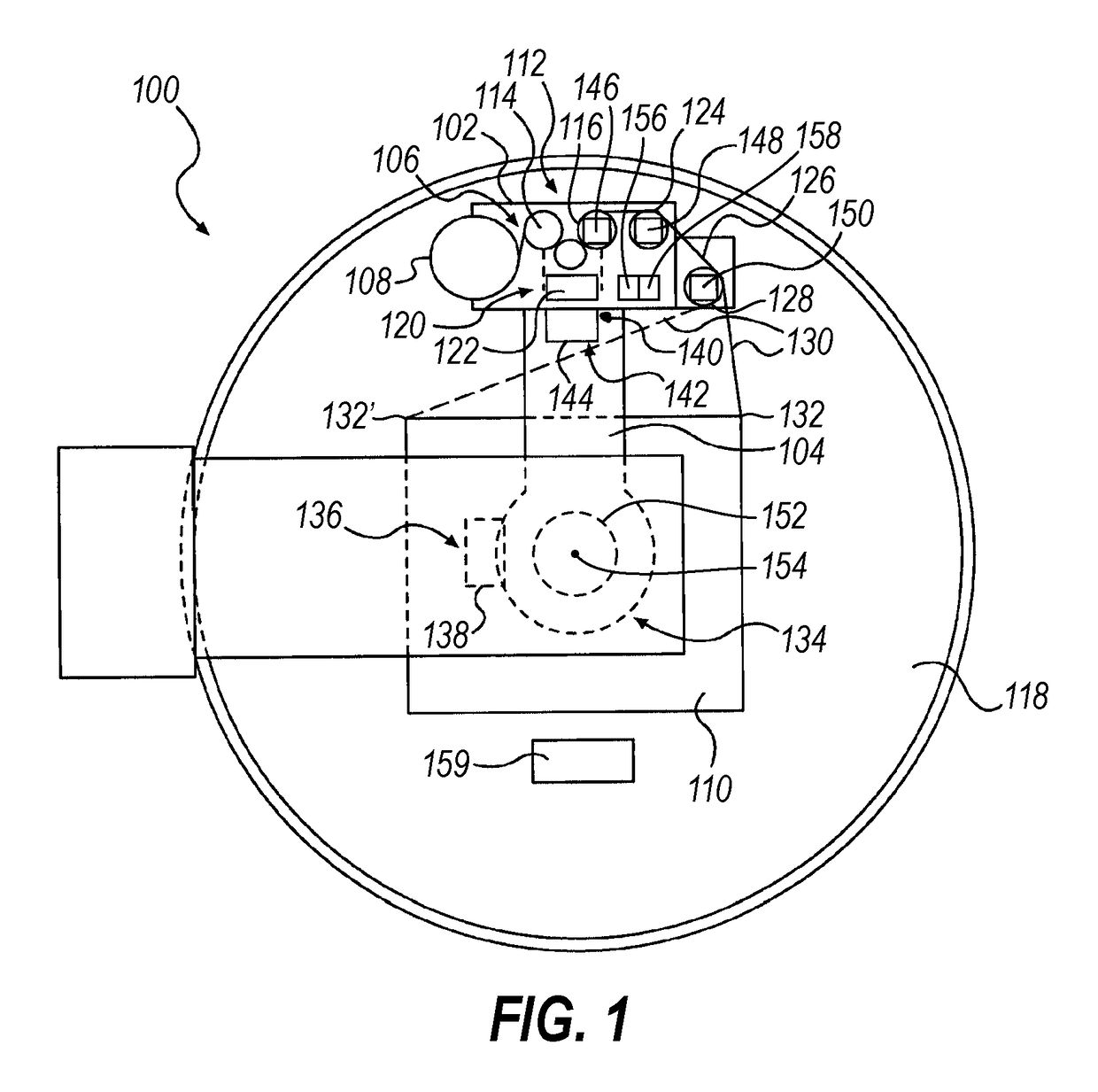

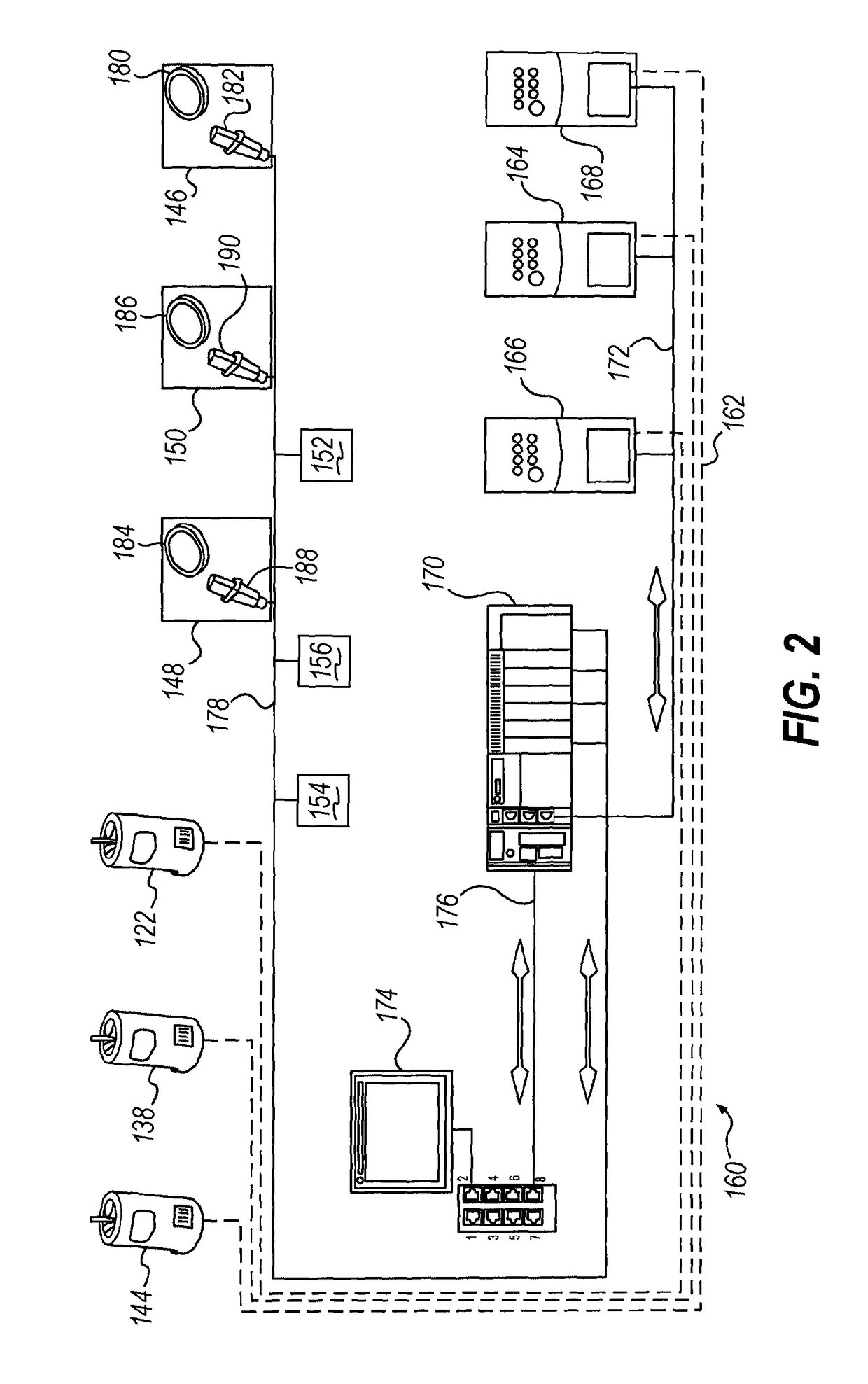

In-line continuous feed sleeve labeling machine and method

An in-line continuous feed sleeve labeling machine labels containers, such as beverage containers, in an in-line fashion maintaining the elevation of the containers during their linear transport. The in-line continuous feed sleeve labeling machine of the present invention receives bottles in flood feeder or linear fashion. A timing screw or the like properly separates, and both spatially and temporally disposes, the containers for sleeving. The timing screw propels the containers onto a pedestal system. The pedestals of the pedestal system maintain their horizontal nature due to offset pivotable attachments to the track system upon which they travel. In coordinated fashion with the travel of the pedestal system, iris carriers carrying sleeves upon articulating radial arms descend upon the bottles. Once the label sleeve has reached the appropriate point (generally adjacent to the central portion of the bottle), the iris carrier allows the label sleeve to engage the central portion of the bottle. Frictional attachment or otherwise allows the finger rods of the iris carrier to pull away from the sleeve as the iris carrier continues to descend down towards the pedestal. The sleeve then becomes attached to or engaged by the bottle until the finger rods of the iris carrier free themselves from the sleeve label. A container stabilizer may provide lateral bottle support and aid the ensleevement process. The finger rods then dilate to better disengage the bottle as the iris carrier ascends up and away from the bottle. The bottle is then transported to an exit conveyor having been properly sleeved, while the iris carrier returns to transport another sleeve.

Owner:AXON LLC

Method and system for packaging rolls of products

InactiveUS20050229546A1Simple and economical systemPaper article packagingWrapper folding/bending apparatusEngineeringMechanical engineering

A method and system for packaging rolls of products, in particular rolls of toilet and / or kitchen paper, in which a wrapping sheet is wrapped in a “U” shape around a group of products so that its two end flaps project from the group, each of the end flaps then being folded in an “L” shape so that one portion adheres to the group and the remaining end portion extends transversally to the group and adheres, at the point where they meet, to the end portion of the other flap; the flaps then being sealed to one another at their end portions to form a tubular wrapper.

Owner:TISSUE MACHINERY

Continuous motion packaging system

A continuous motion packaging system for packaging a series of articles in cartons as the cartons are moved along a carton conveyor. A series of selector wedges engage and form groups of articles received on the cartons, which are folded or wrapped about the articles as the cartons are moved forwardly along a packaging path.

Owner:GRAPHIC PACKAGING INT

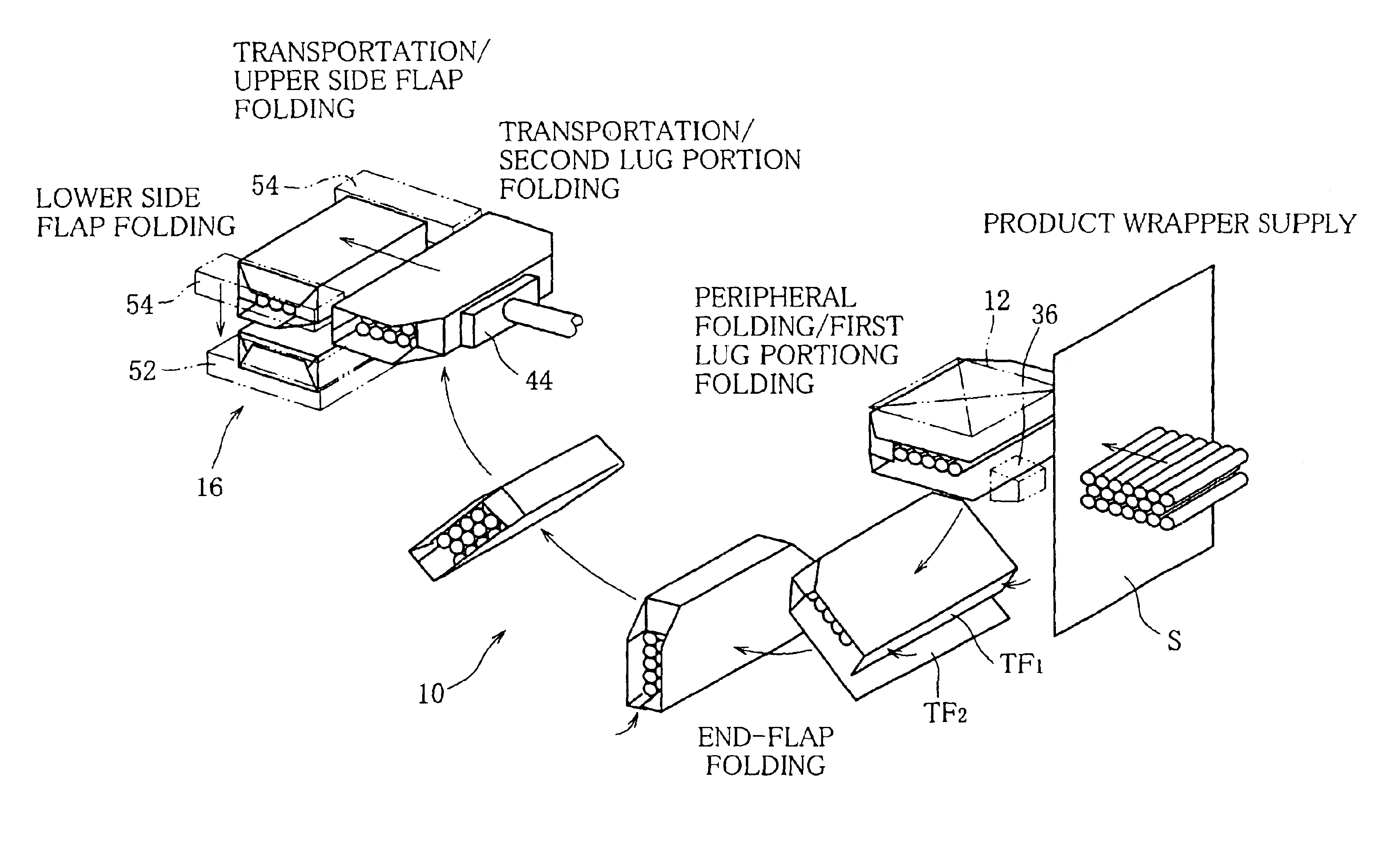

Packaging material folding device of packaging machine

InactiveUS6854243B2Stable and accurateReduce coefficient of frictionPackaging cigaretteWrapper folding/bending apparatusEngineeringTurret

A wrapper folding apparatus of a packaging machine has a second wheel (10) for use as a folding turret. The second wheel (10) is supplied with a cigarette bundle and an aluminized sheet (S) in an inlet position. As this is done, the aluminized sheet (S) is folded around the periphery of the cigarette bundle, and lug portions formed by the peripheral folding are folded by the use of primary lug folding guides (36). Since the lug protions are kept folded by the use of holding guides (38) thereafter, they cannot be freed until an outlet position is reached. When the cigarette bundle is discharged in the outlet position of the second wheel (10), the lug portions on the end-flap side are folded by the use of secondary lug folding guides (46). After the folding, side flaps continue to be folded without allowing the lug portions to be free.

Owner:JAPAN TOBACCO INC

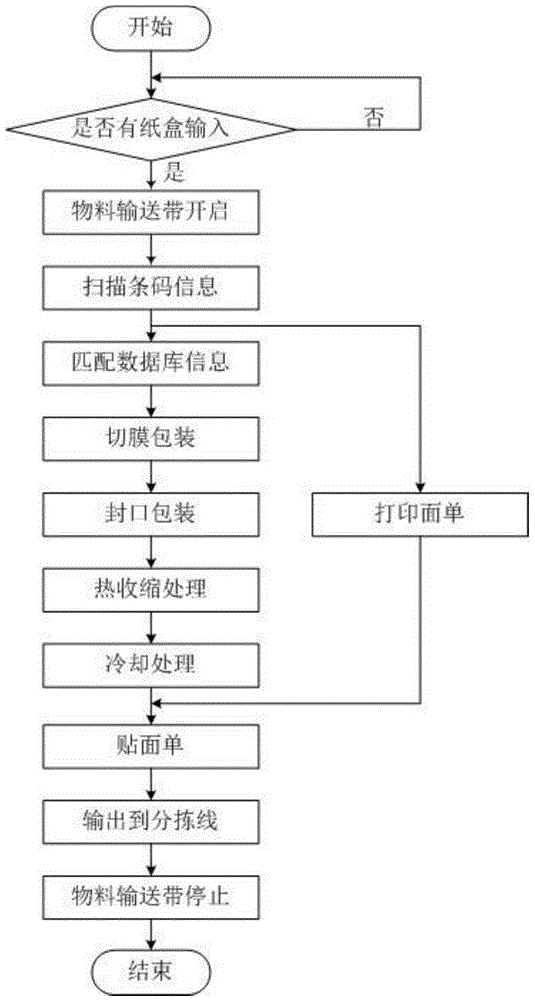

Novel automatic packing system and automatic packing method applied for electronic commerce and express delivery logistics industry

InactiveCN104890913AFully automatedReduce labor costsWrappers shrinkageConveyor wrappingLogistics managementPersonal computer

The invention provides a novel automatic packing system and a novel automatic packing method applied for electronic commerce and express delivery logistics industry. The packing system and the packing method are mainly provided for packing of paper boxes in electronic commerce and express delivery logistics industry. The packing system comprises a material conveyer belt, an industrial personal computer, a printer, a PLC, an infrared sensor, a film cutting machine, a sealing machine, a hot wind box, a cooling mechanism and a list pasting mechanism. The automatic packing method comprises steps of using transparent PE films as packing materials; scanning codes of paper boxes; matching information; sealing and packing four edges of each of the paper box; and performing thermal contraction, cooling and list pasting processes. Thus, automatic packing of the paper boxes is finished.

Owner:JIANGNAN UNIV

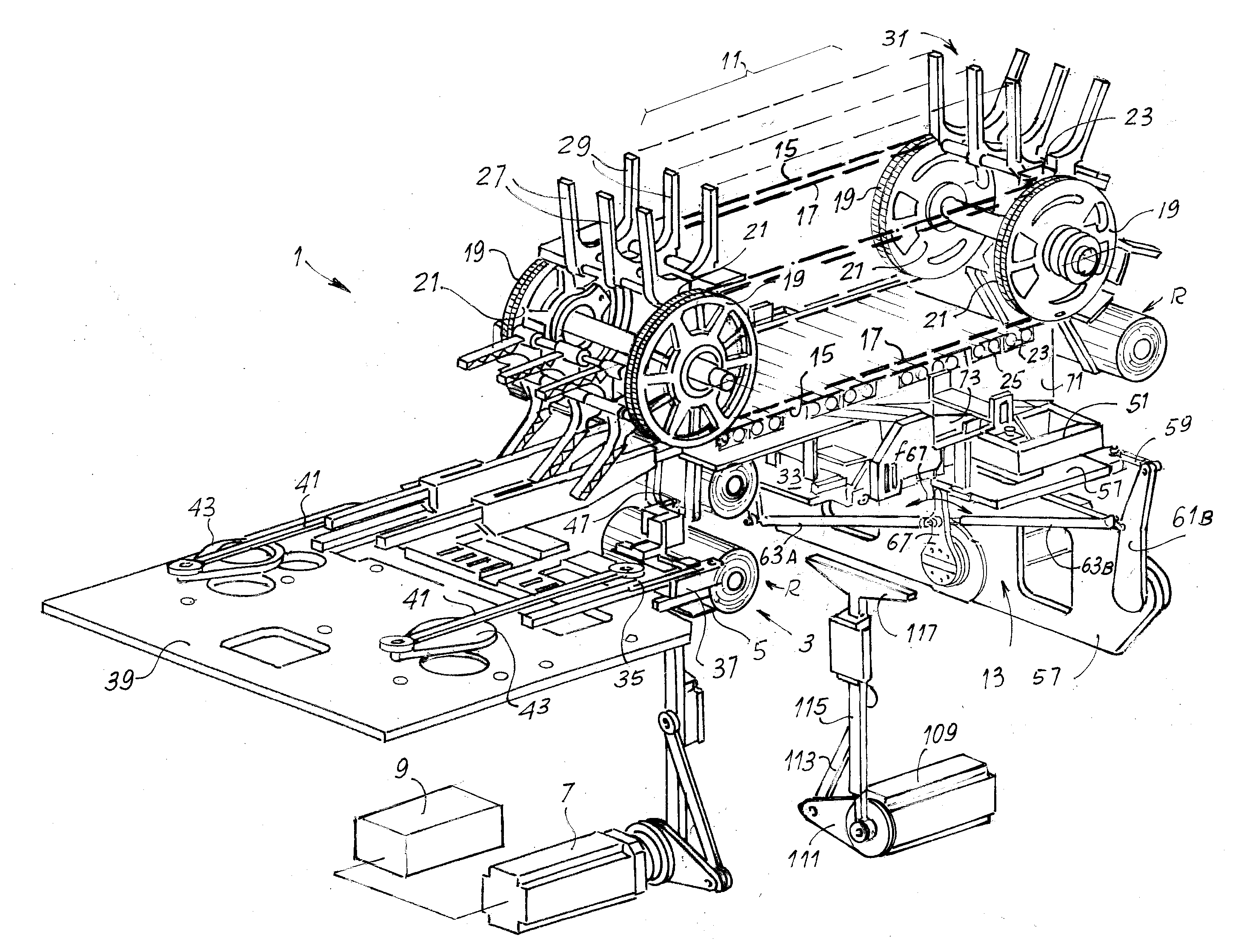

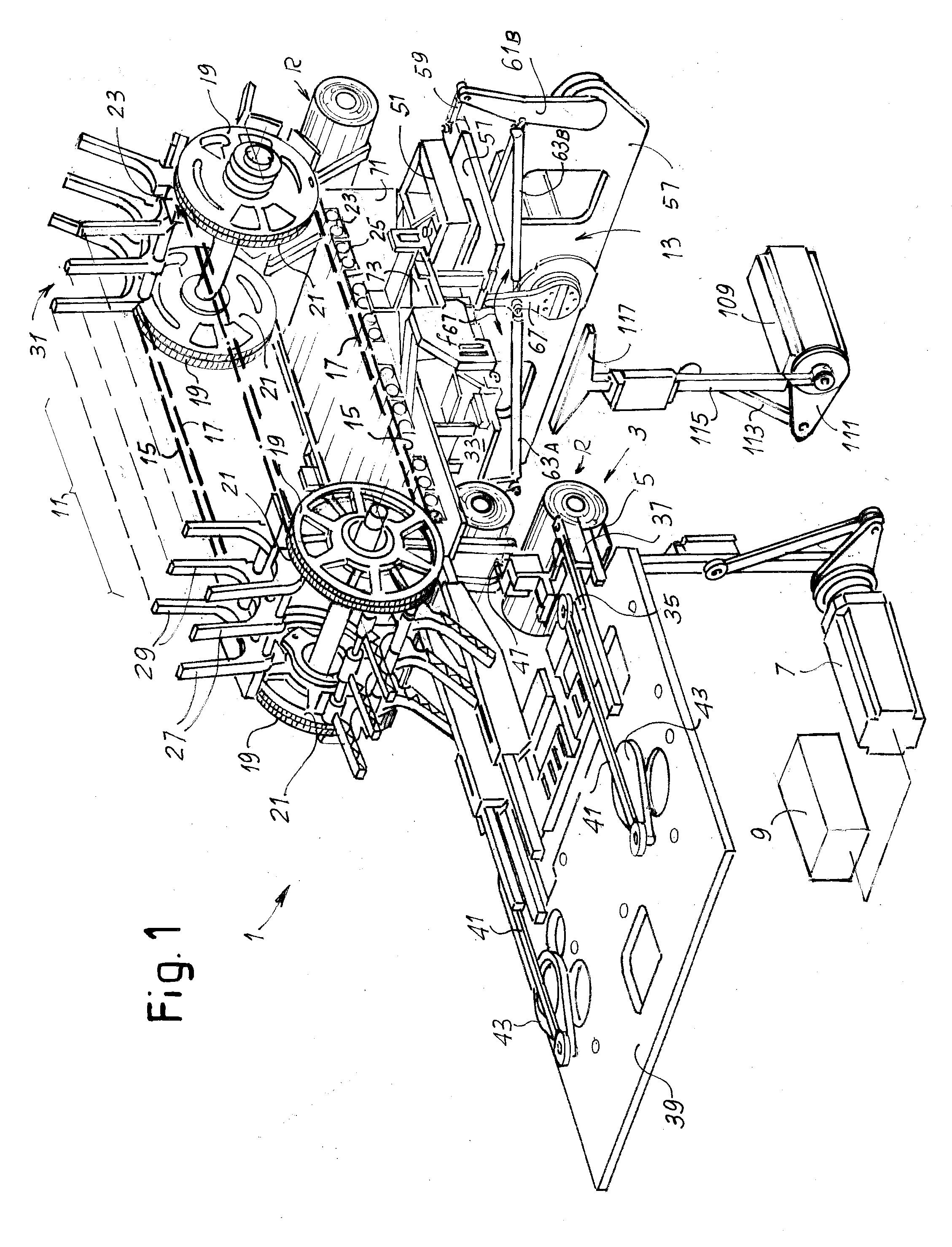

Machine for packaging stacks of multiply paper articles or the like into wrappings obtained from a wrapping sheet

InactiveUS20020073649A1Avoids curling and stretchingPaper article packagingWrapping material feeding apparatusEngineeringPaper sheet

In a machine for packaging stacks of multiply articles of paper into wrapping sheets, a first line conveys stacks of multiply articles of paper to a a wrapping station while a second feeds wrapping sheets to the wrapping station. Each sheet is kept vertically in a waiting position in the wrapping station until one stack is moved towards the sheet, so that the sheet gradually folds around the stack with overlapping parallel edges to be heat-welded. In the said second line there are first endless belts and second endless belts for a wrapping sheet received from conveying means situated upstream. The sheet is pulled up to the wrapping station and is clamped in the wait position by suction.

Owner:C G BRETTING MFG

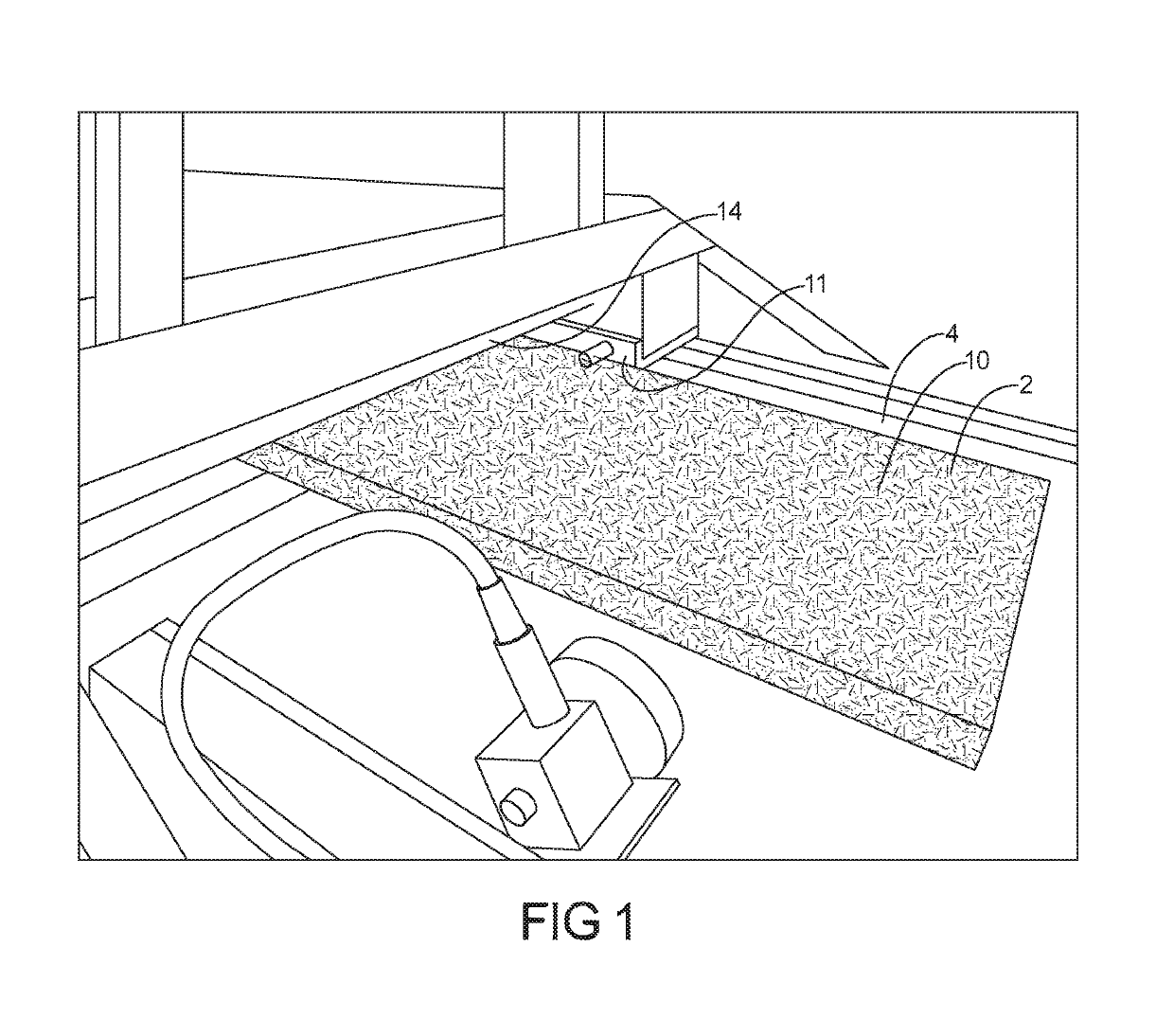

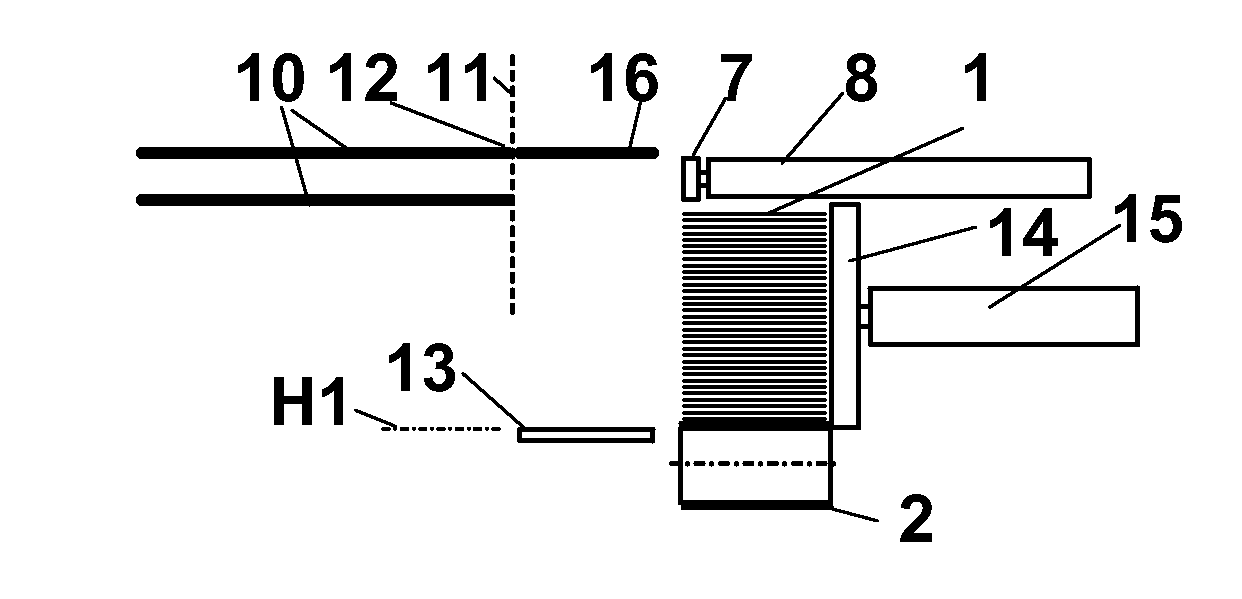

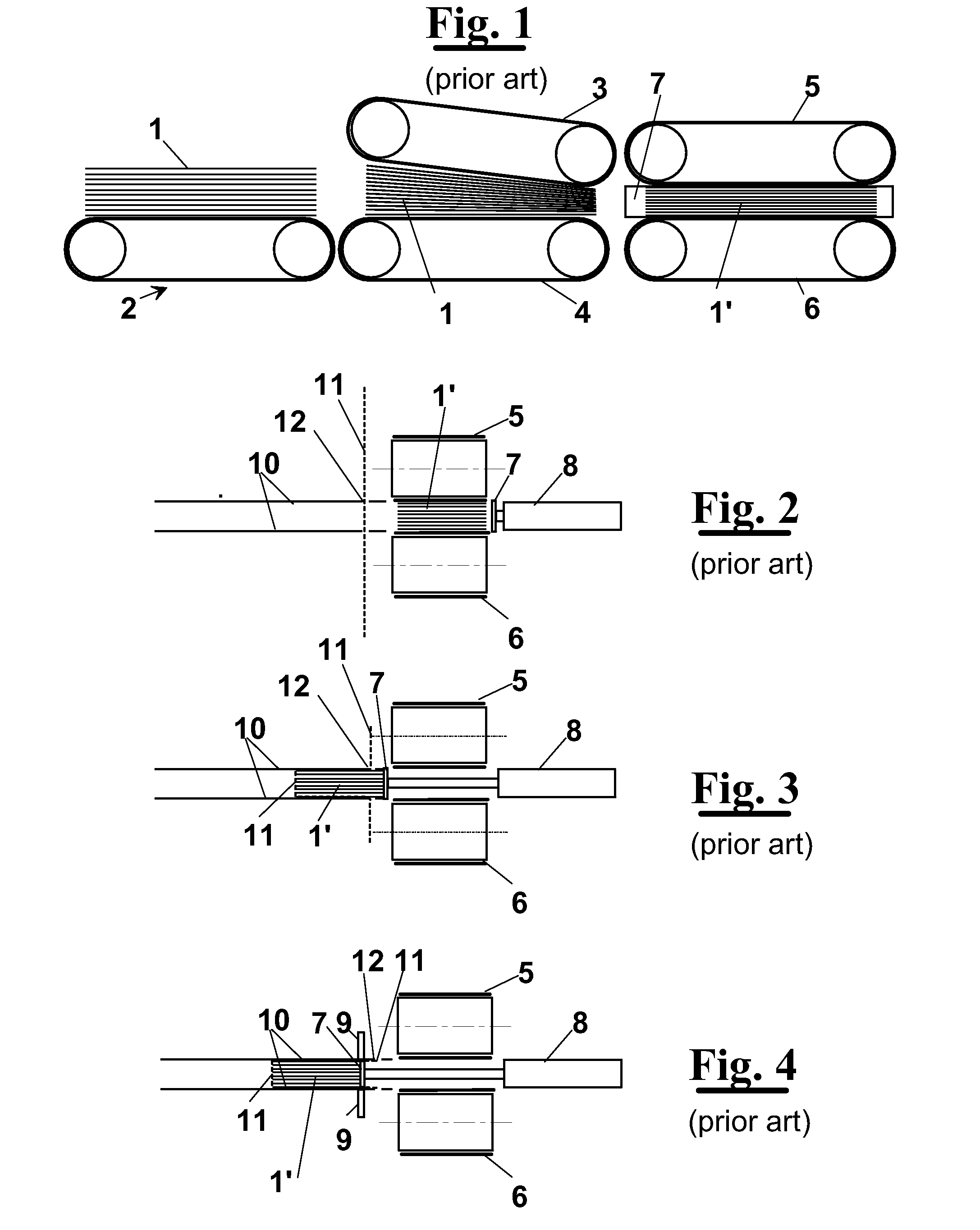

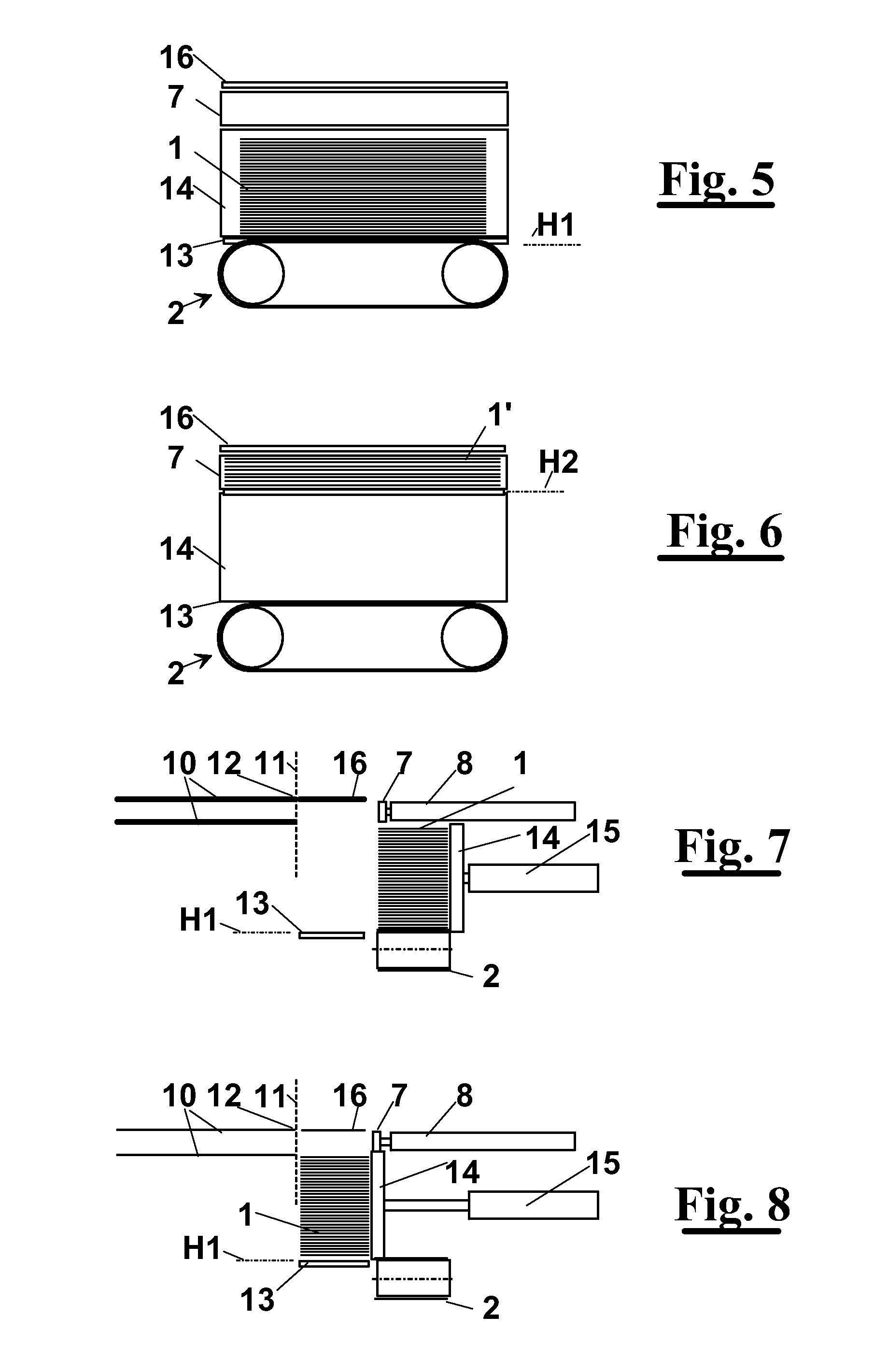

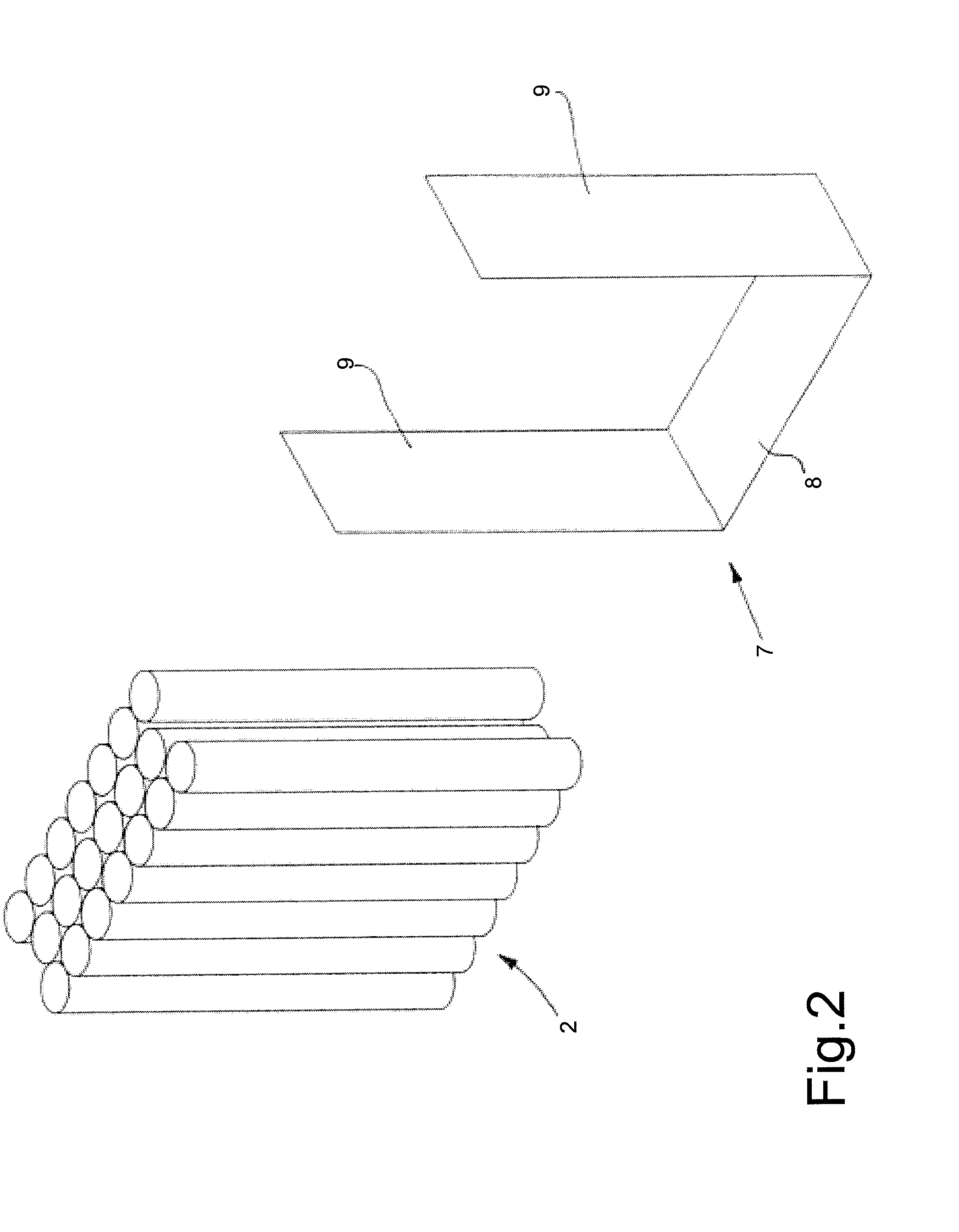

Banding machine for logs of sheet material

InactiveUS20070271872A1Improve productivityPaper article packagingWrapper folding/bending apparatusEngineeringSheet material

Banding machine for logs (1) of sheet material fed by a conveyor belt (2) to a packaging apparatus adapted to band it with a banding web (11) up to form a tubular wrapper around it. The packaging apparatus of the banding machine comprises a pusher (7) operated by an actuator (8), which pushes the log (1) in a channel (10) where a packaging sheet (11) is arranged stretched in front of the log, as an obstacle, along all the length of the machine through a passage (12). According to the invention, the conveyor belt (2) and the packaging apparatus (7) are arranged at different heights, respectively at a first and a second height (H1 and H2). Another pusher (14) can be provided, operated by a cylinder piston (15) at a first height (H1), in addition to the pusher (7) at the second height (H2), independent from each other. Furthermore, a lifting member (13) is provided, which receives the log (1) from the first pusher (14) and moves from the first height (H1) to the second height (H2). At its inlet in the banding machine the log (1) can be not compressed and is compressed up to reaching a compact shape indicated as (1′) when passing from the first height (H1) to the second height (H2). In particular, the lifting member (13) while lifting the log compresses at the same time the log (1) against a fixed wall (16), up to causing the log to achieve a compact configuration (1′).

Owner:MTC MACCINE TRASFORMAZIONE CARTA SRL

Method for automatically packaging tubular product

InactiveCN102180281AIncrease production capacityImplement packagingConveyor wrappingRod-shaped articlesProduction linePunching

The invention discloses a method for automatically packaging a tubular product. By steps of punching bags, installing tubes, inserting the tubes, lifting, wrapping the tubes, exchanging air, thermally encapsulating and cutting, emptying a position and the like, automation is realized in the whole process, complicated carrying work in manual packaging operation is avoided, production and working efficiency is improved, labor intensity of packaging is reduced, and production cost is lowered greatly; therefore, the method is matched with a tubular product extrusion production line, so that automatic continuous production and packaging of the tubular product can be realized.

Owner:陈蕴

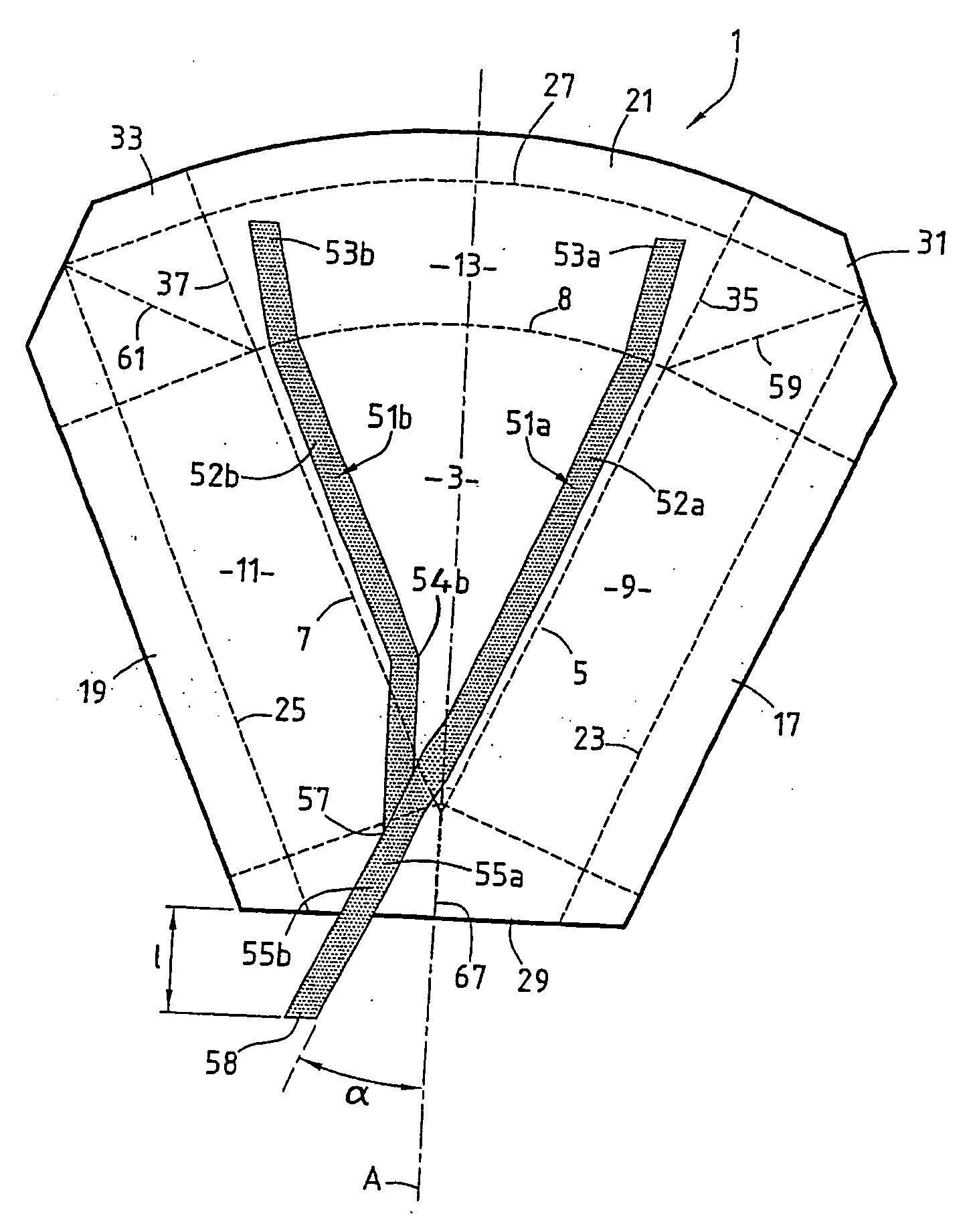

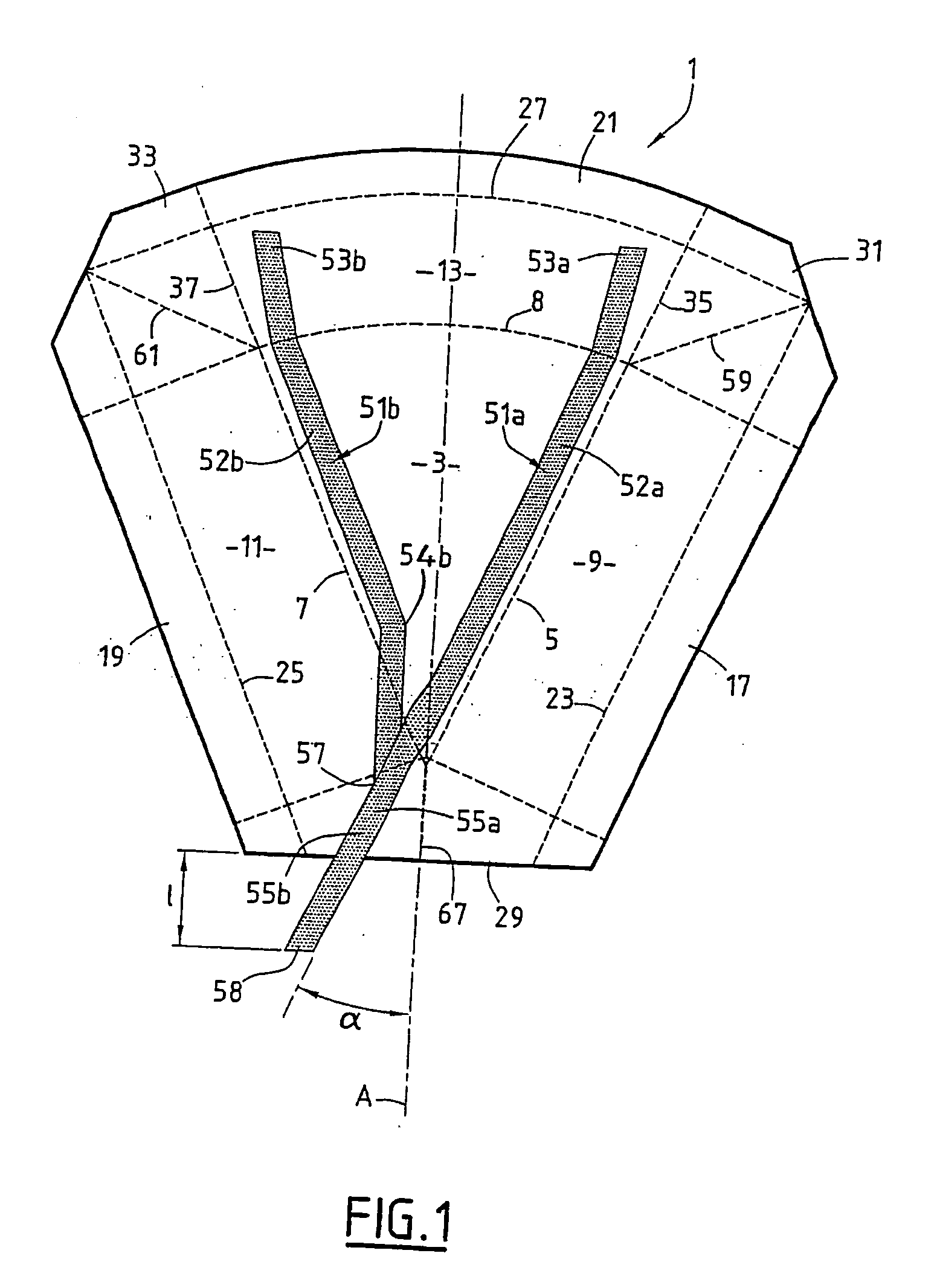

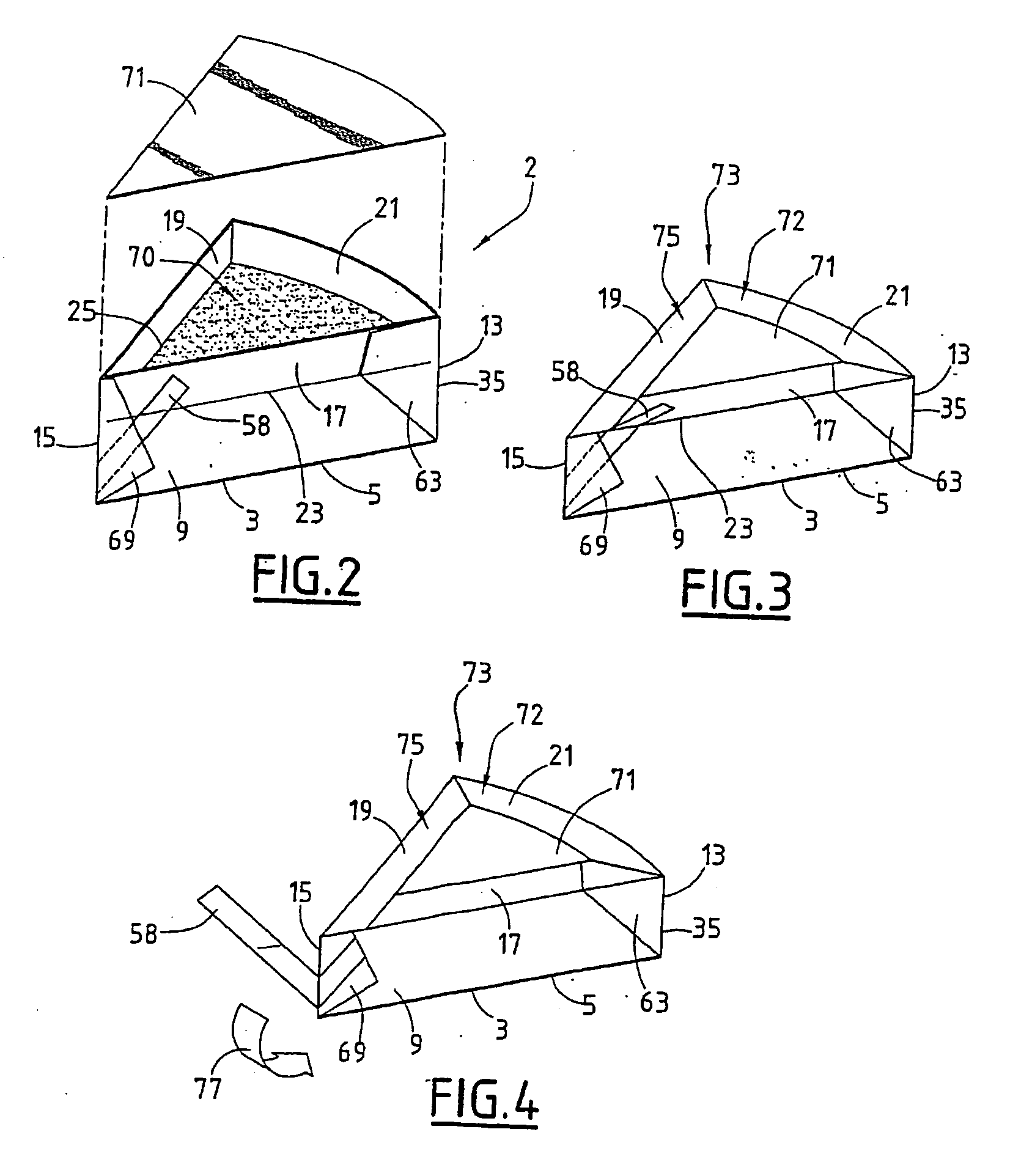

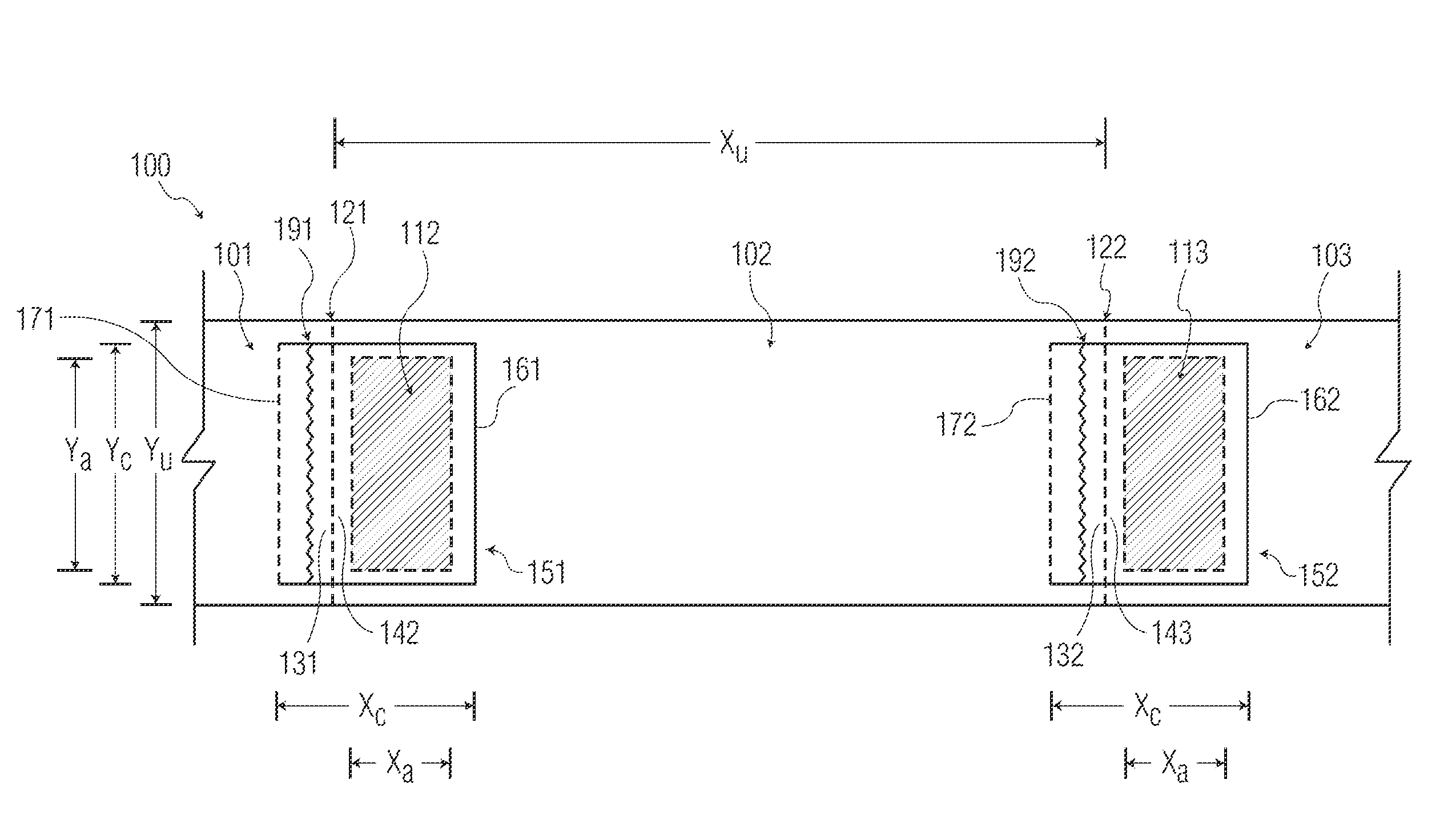

Element for producing a package for packaging a food product, corresponding package, assembly comprising such a package and a food product, cutting installation and method

InactiveUS20080276569A1Avoid hard activationReady-for-oven doughsPackaging cigaretteEngineeringFood products

The invention concerns an element including: 1 sheet (1) including an intermediate zone (29) located between two zones designed to form side walls (9, 11), the intermediate zone (29) being designed to form a flap folded along the tip against one first (9) of the side walls, and elements (51a, 51b) for guiding tears in the sheet (1) the elements forming a single pull tab (58) to cause tears, the pull tab (58) being, in the intermediate zone, spaced apart from the media axis (A) of the zone designed to form the base (3). The invention is, for example, applicable to packaging of melted cheese.

Owner:BEL

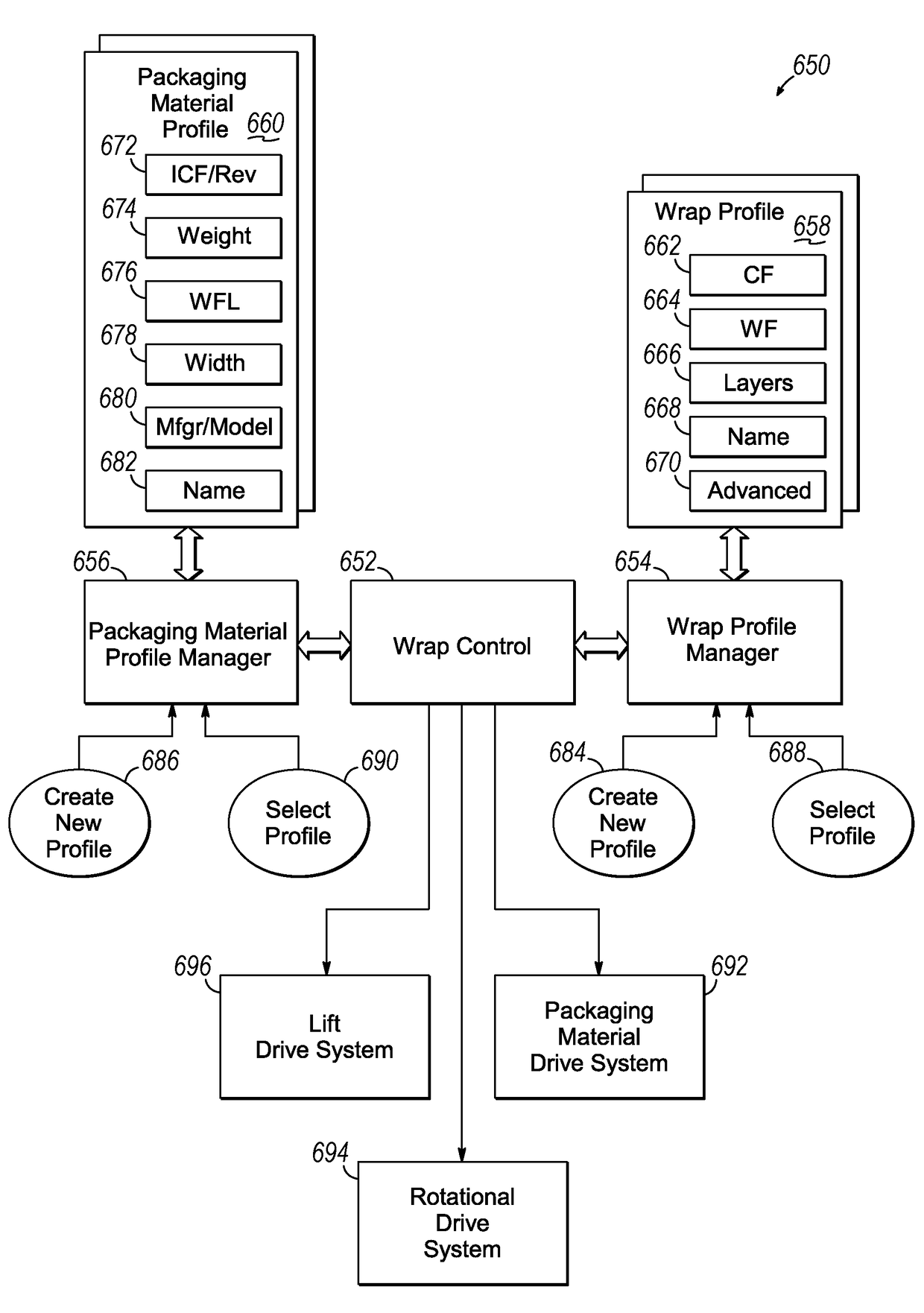

Containment force-based wrapping

ActiveUS9776748B2Reduce the amount requiredWeb rotation wrappingMultiple wrapper applicationControl systemUser input

Owner:LANTECH COM

Looped cable thermal shrinkage membrane packaging device and looped cable packaging method

The invention discloses a looped cable thermal shrinkage membrane packaging device. The looped cable thermal shrinkage membrane packaging device comprises a vertical plane horizontal movement platform and a grasping trolley used for fixing a looped cable, wherein the grasping trolley can be conveyed along the membrane packaging machining path of the looped cable on the vertical plane horizontal movement platform. The looped cable thermal shrinkage membrane packaging device further comprises a thermal shrinkage membrane take-up and pay-off system, a thermal shrinkage membrane cutting device and a drying oven in sequence in the moving direction of the looped cable, wherein the thermal shrinkage membrane take-up and pay-off system is used for conveying a thermal shrinkage membrane, the thermal shrinkage membrane cutting device is used for separating and bonding a packaged thermal shrinkage membrane, and the drying oven is used for forming the packaging membrane outside the looped cable in a thermal shrinkage mode. According to the looped cable thermal shrinkage membrane packaging device, the looped cable is fixed through the grasping trolley and moves along the membrane packaging machining path of the looped cable on the vertical plane horizontal movement platform, the looped cable passes the thermal shrinkage membrane take-up and pay-off system, the thermal shrinkage membrane cutting device and the drying oven in sequence, and the looped cable can be packaged. The whole process is carried out without manual winding, and the manual labor intensity is greatly reduced. The invention further discloses a looped cable packaging method based on the looped cable thermal shrinkage membrane packaging device.

Owner:HANGZHOU FUTONG ELECTRIC WIRE & CABLE

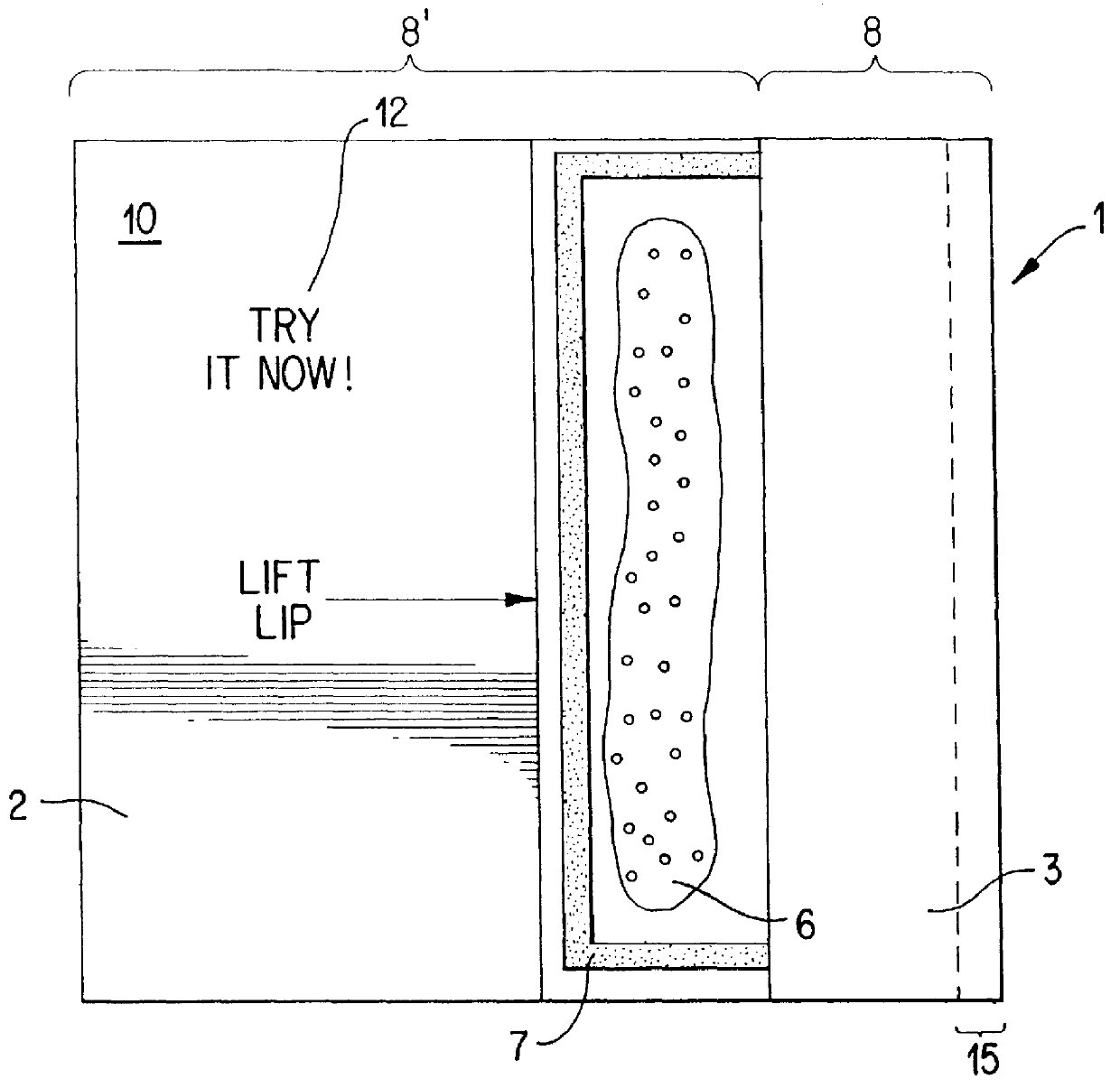

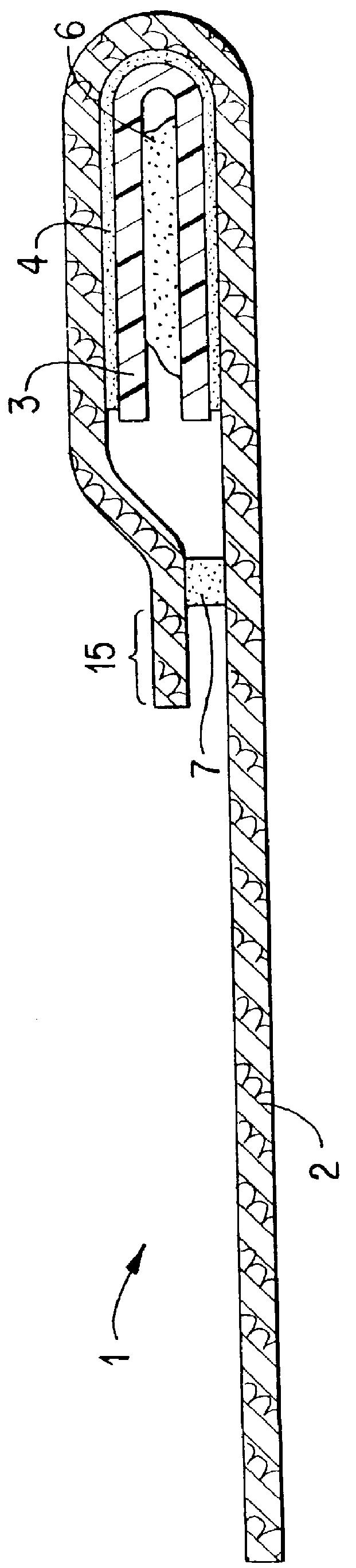

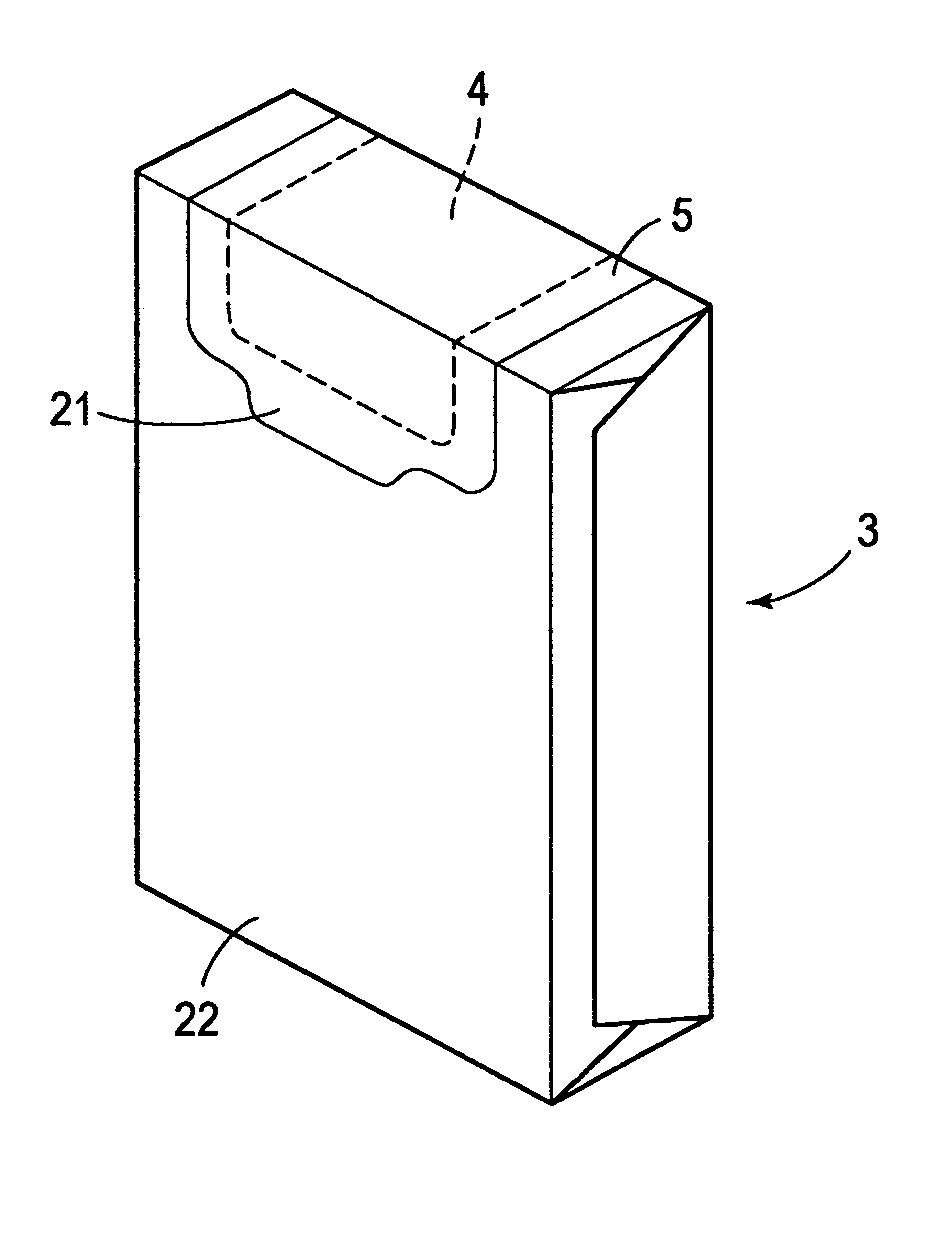

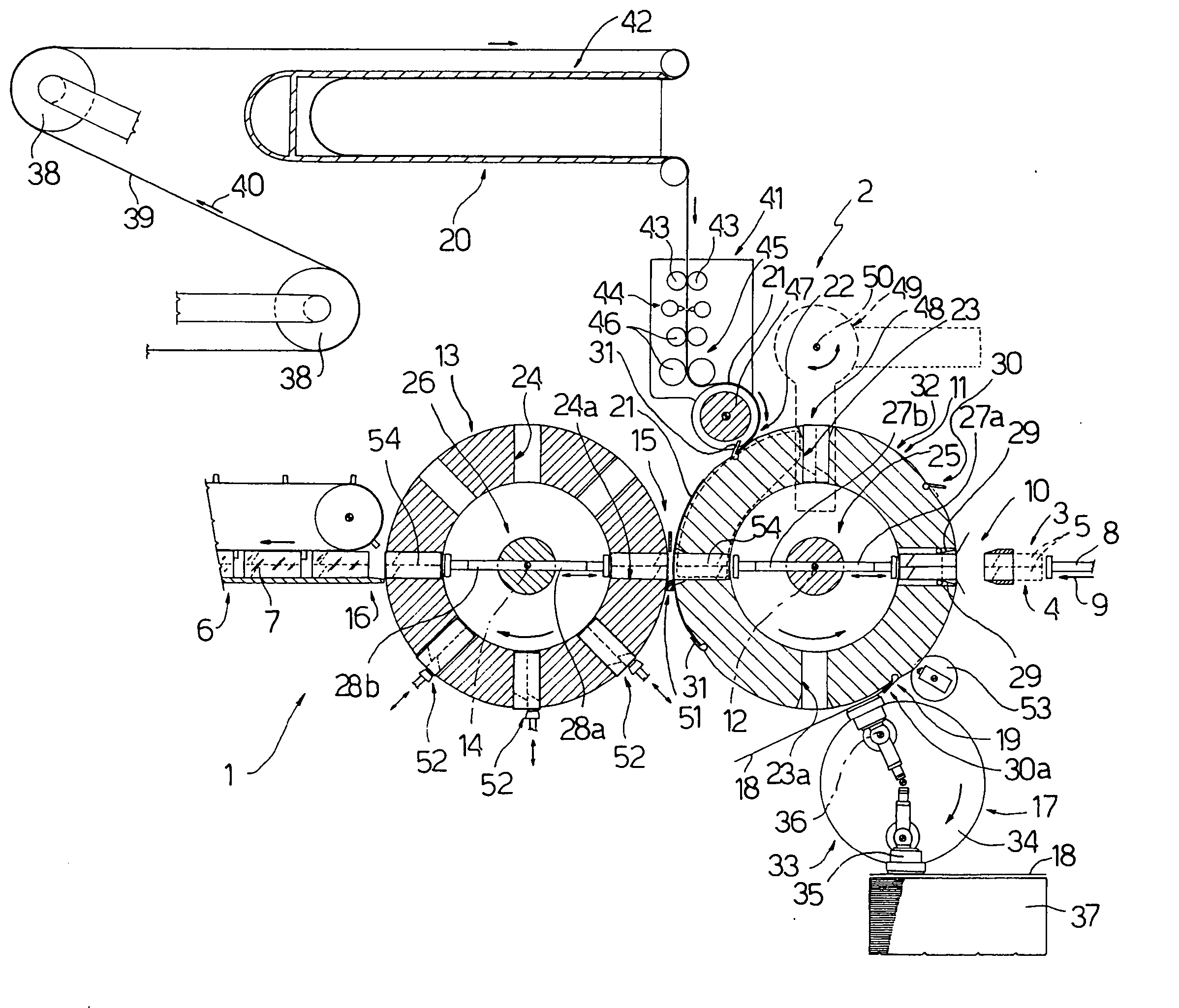

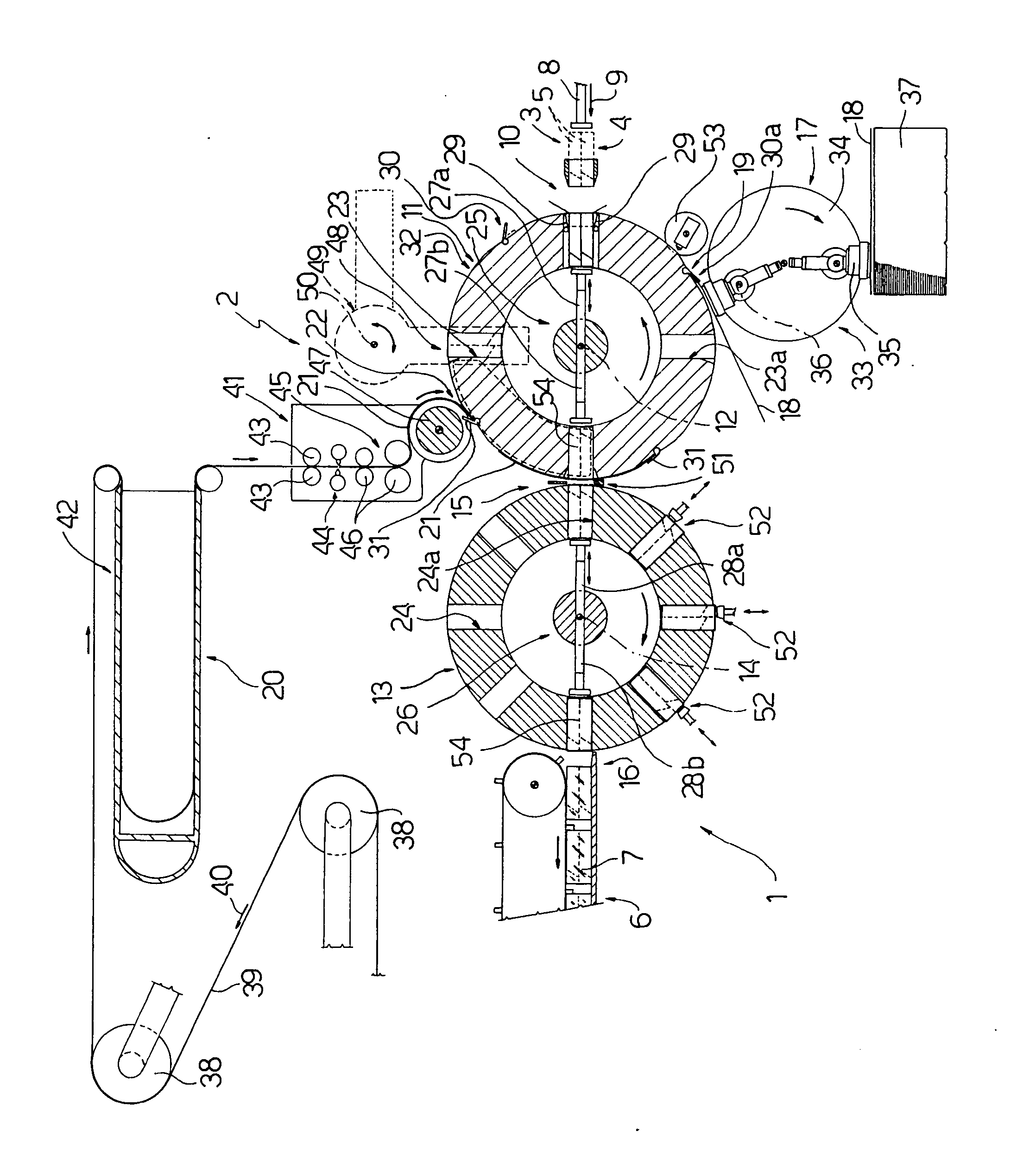

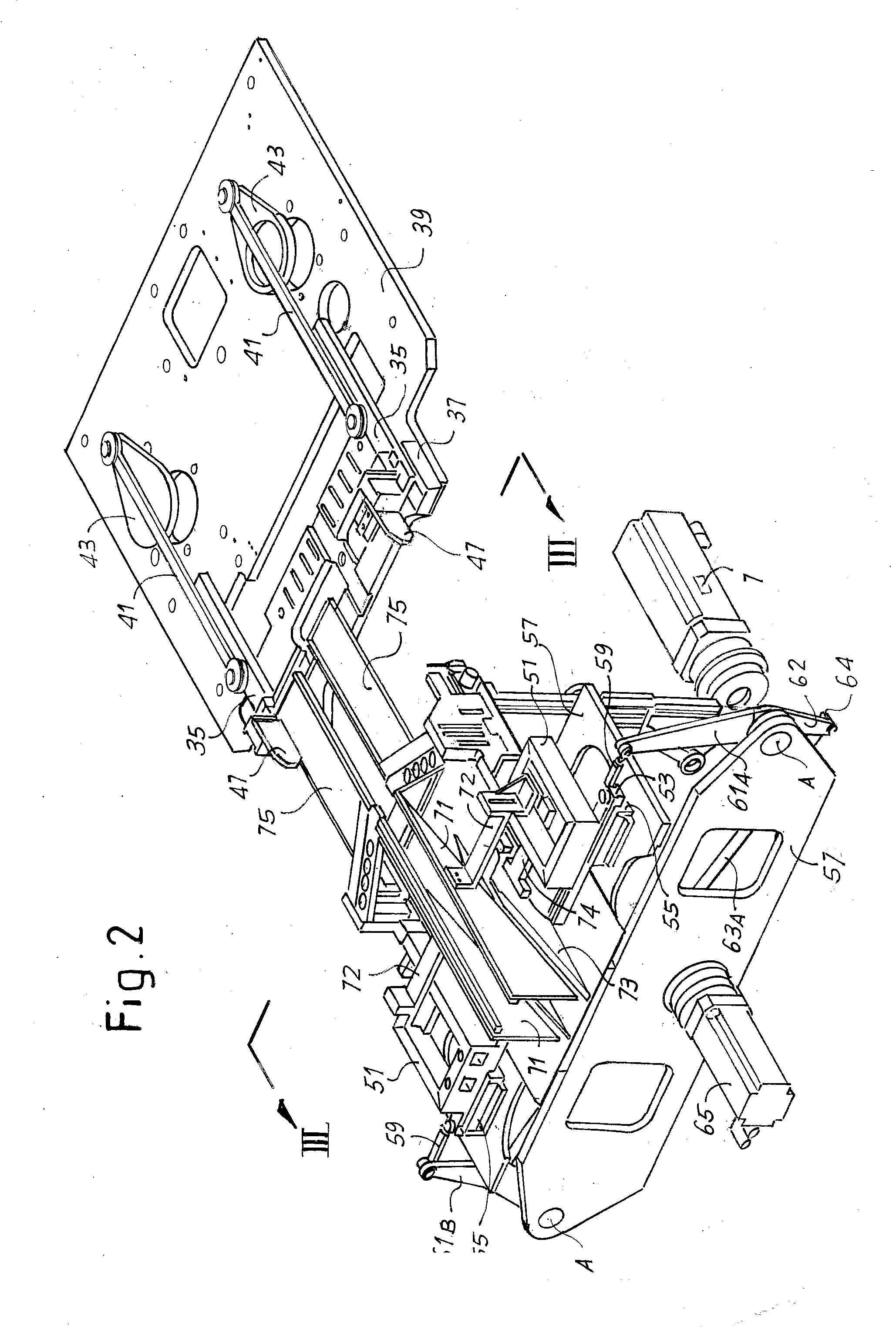

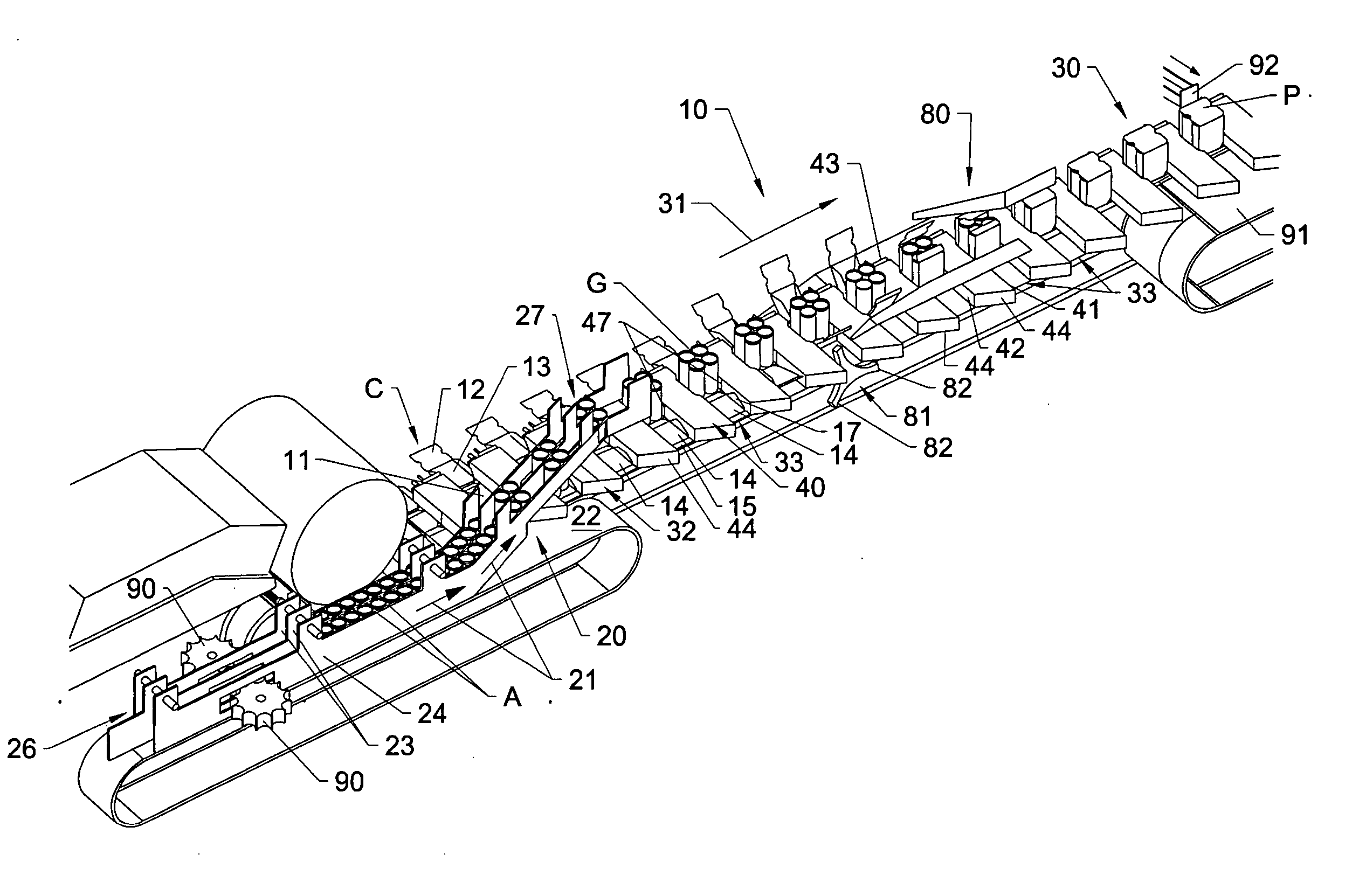

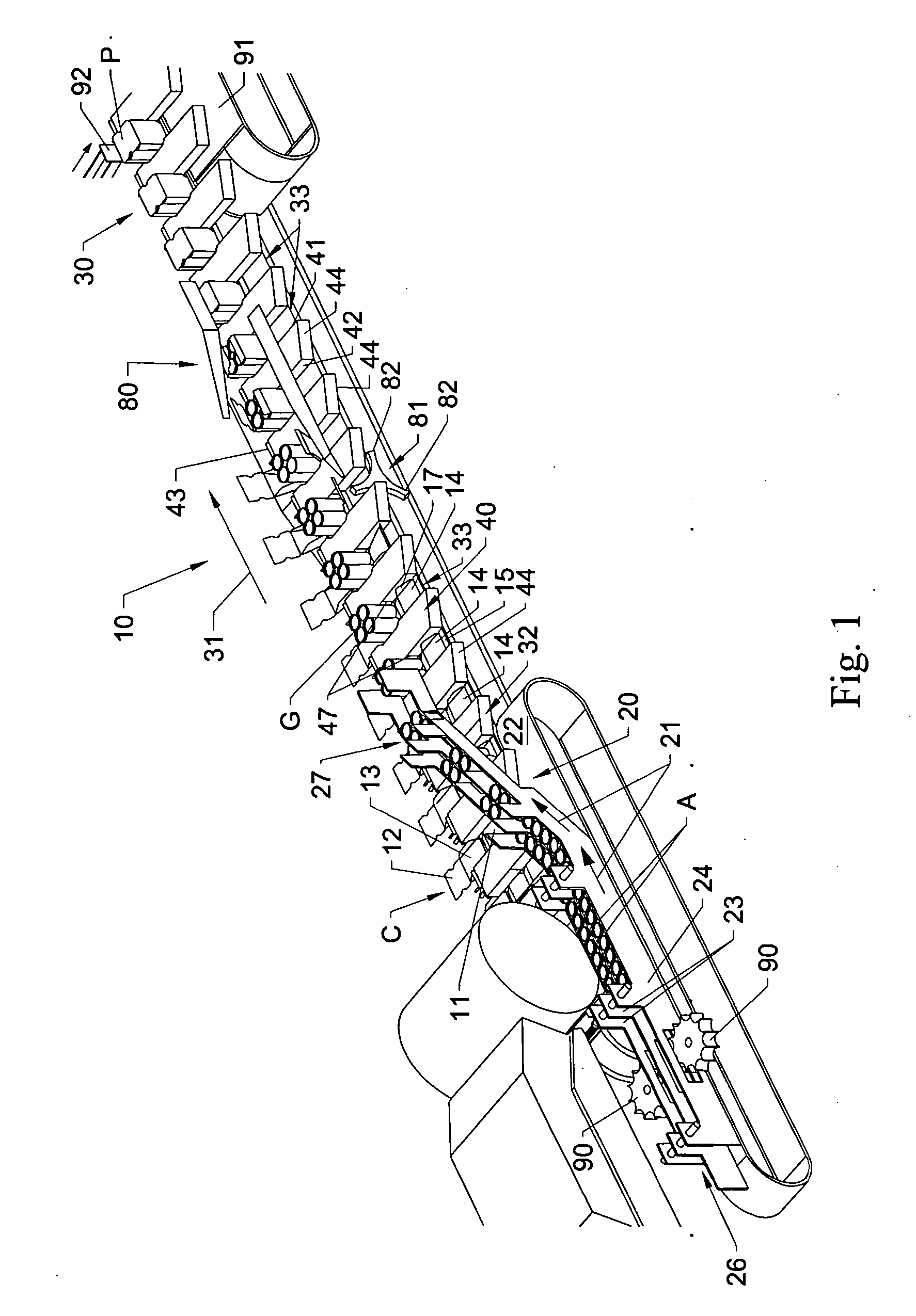

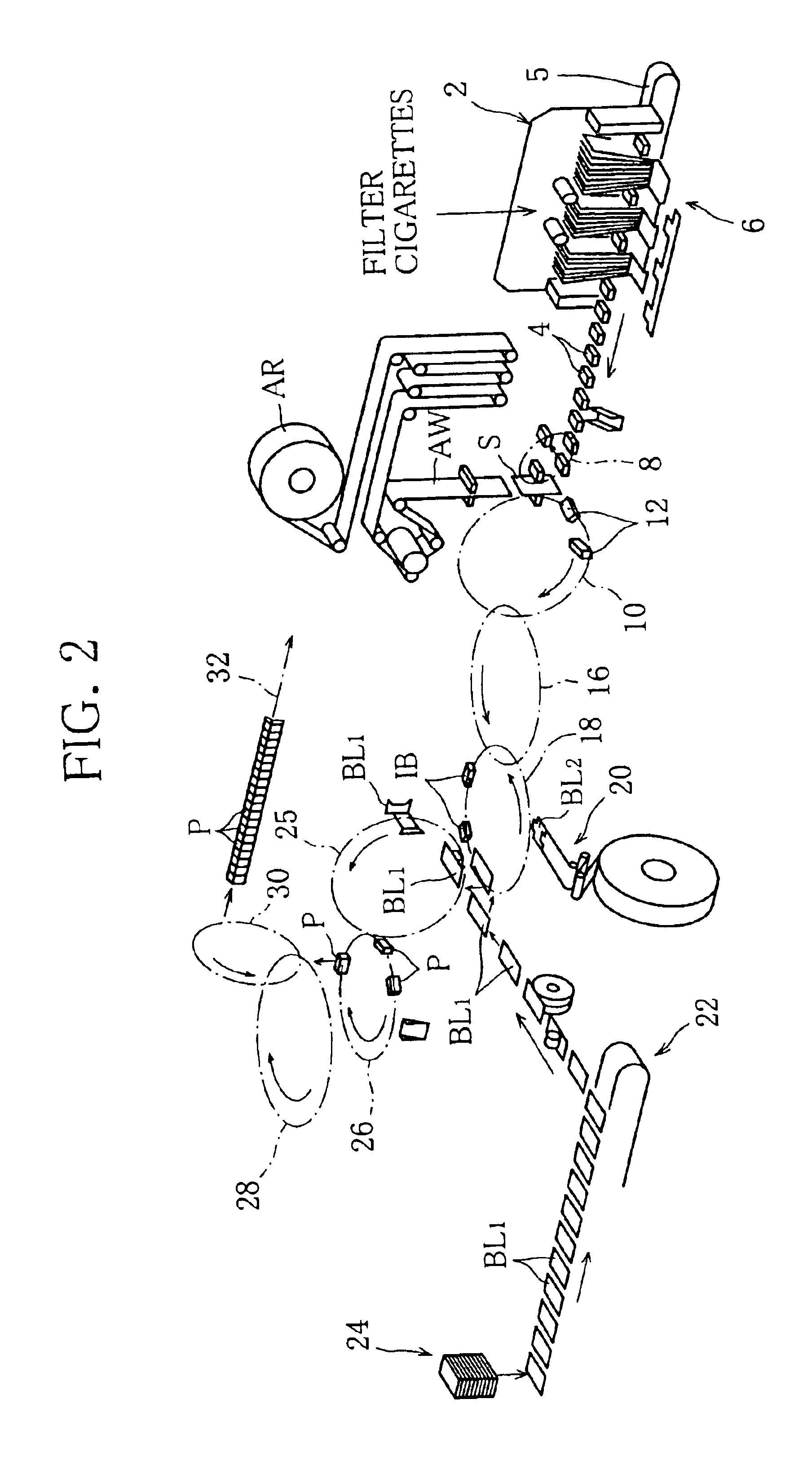

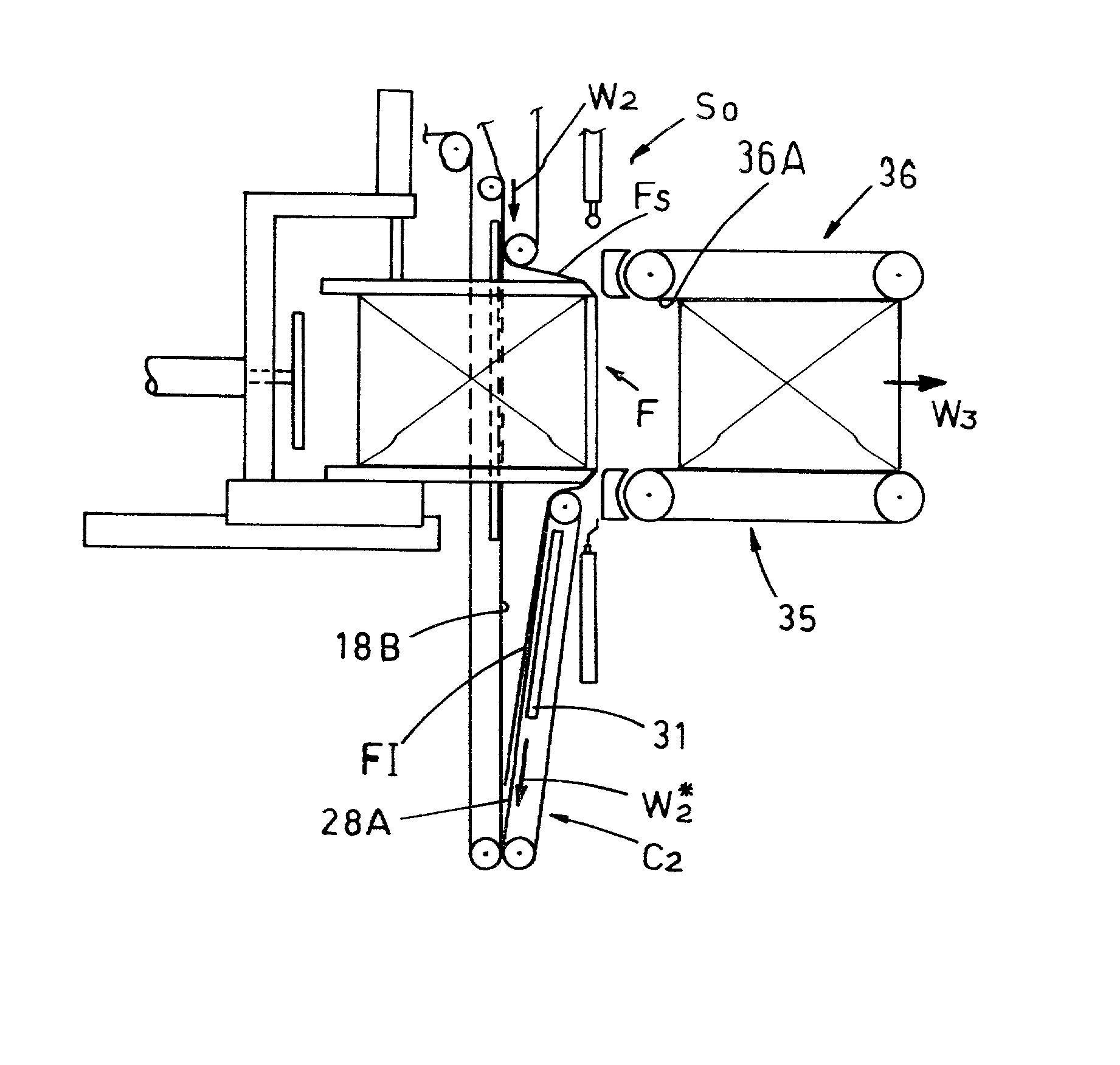

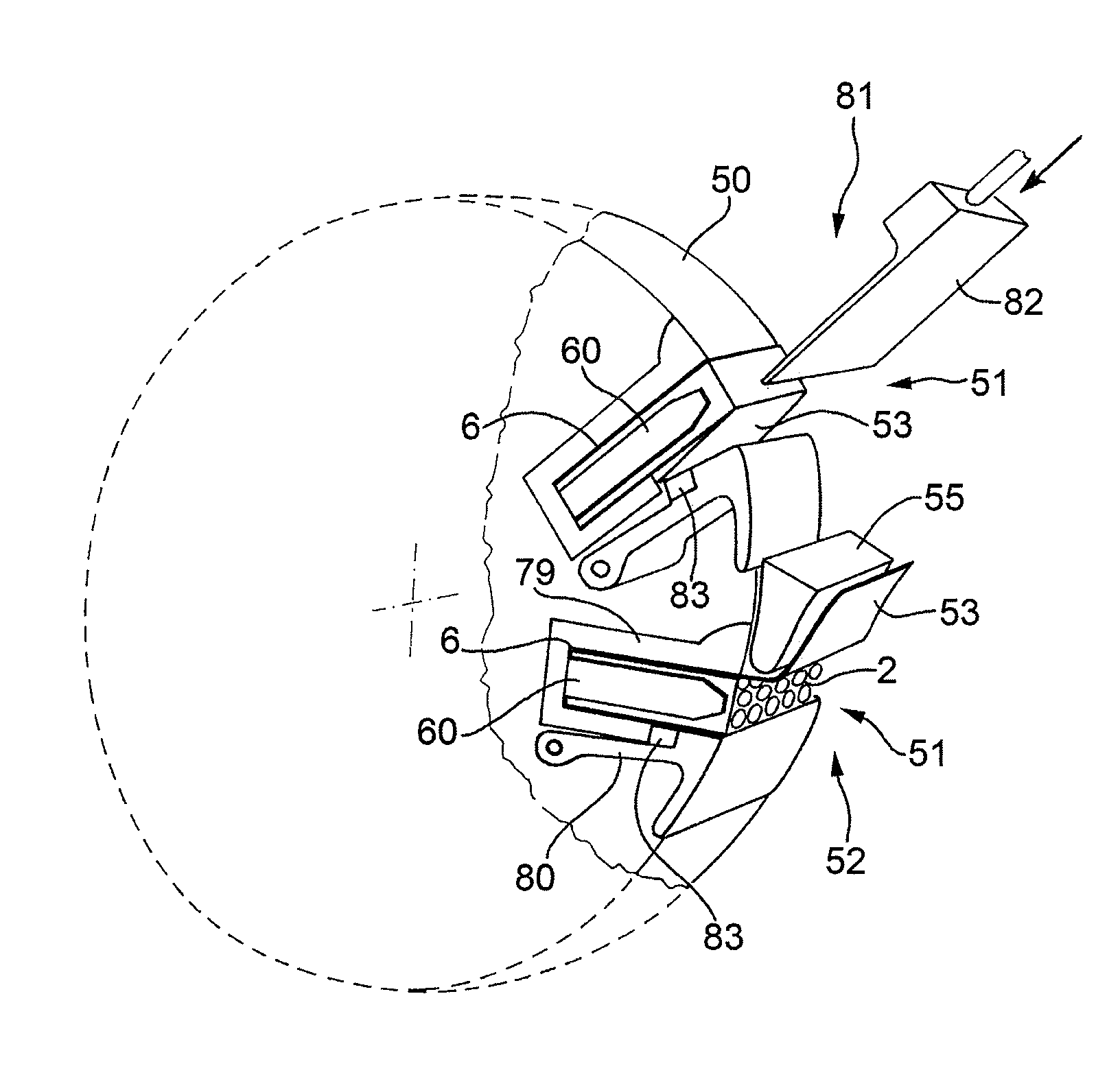

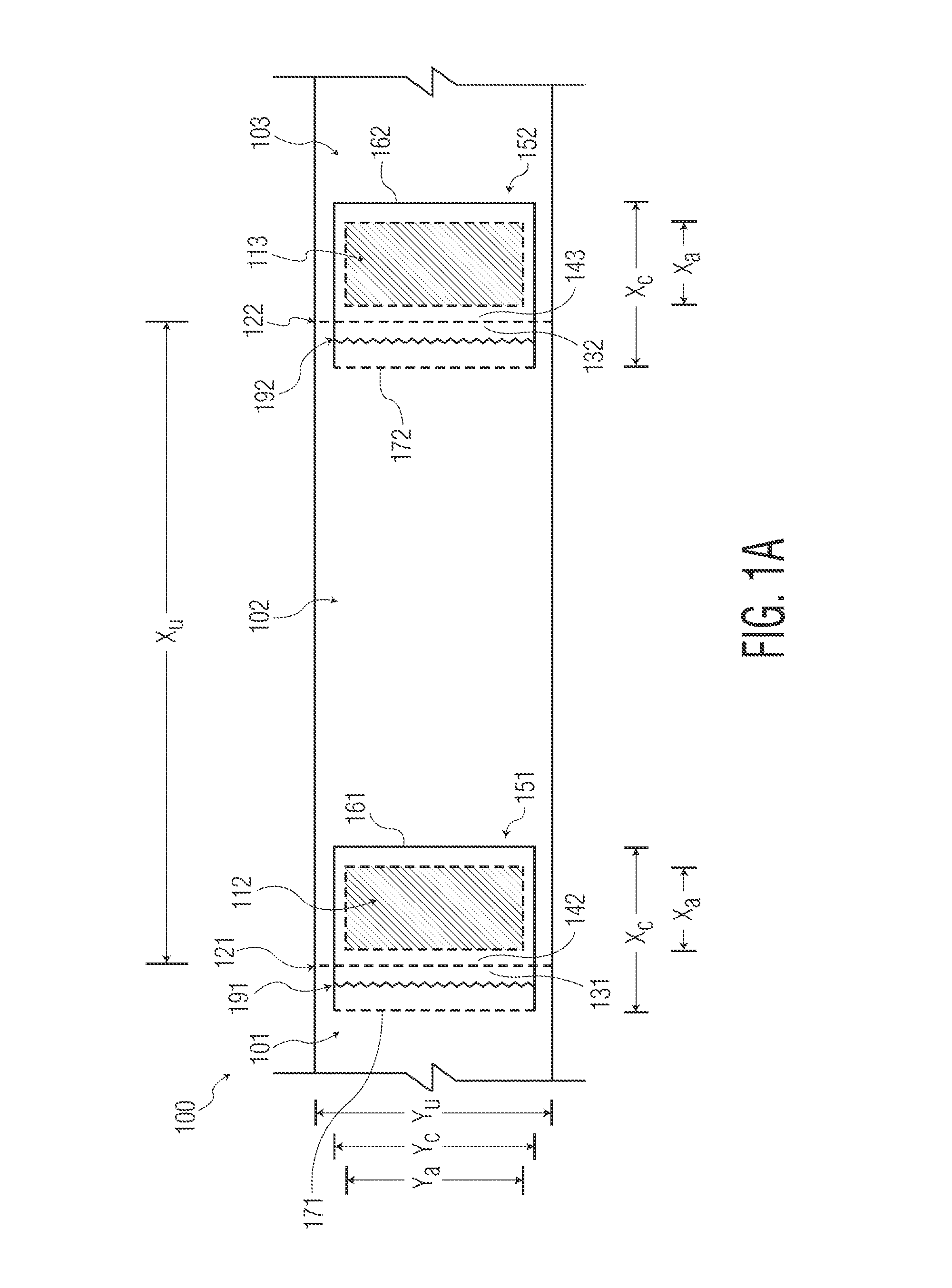

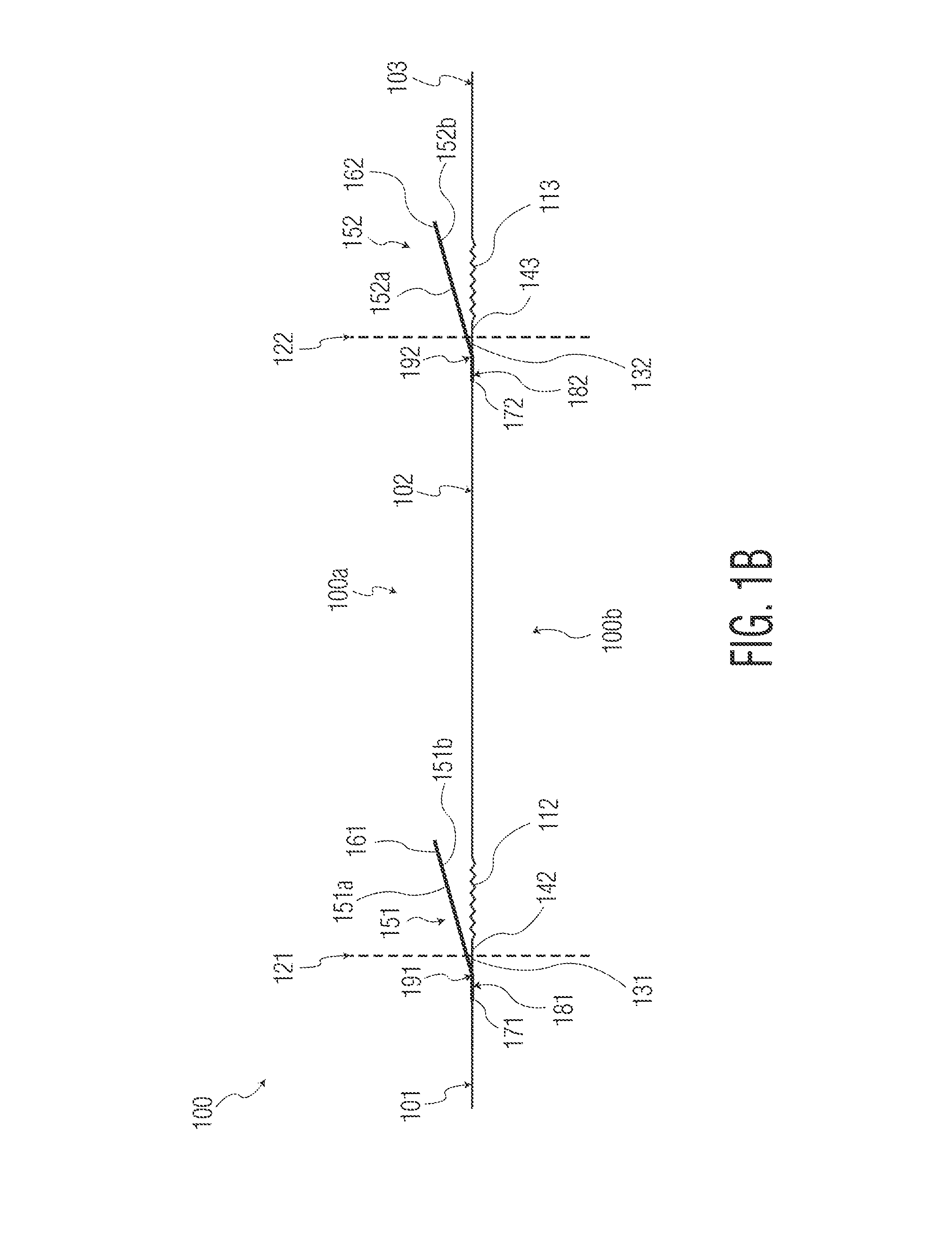

Wrapping method and unit for folding a sheet of wrapping material about a group of cigarettes

InactiveUS20090288371A1Cheap and easy to implementEliminate the aforementioned drawbacksPackaging cigaretteWrapper folding/bending apparatusStructural engineeringMechanical engineering

A wrapping method and unit for producing a package containing a group of cigarettes and having a cigarette extraction opening; a sheet of wrapping material, complete with the cigarette extraction opening, is fed into a pocket of a wrapping wheel so that the sheet of wrapping material folds into a U inside the pocket; then the group of cigarettes is fed into the pocket containing the U-folded sheet of wrapping material.

Owner:GD SPA

Hinged covering for adhesive surface

ActiveUS20140352263A1Improve functionalityImproves Structural IntegrityStampsFlexible coversLeading edgeEngineering

A wrapping material is provided comprising a plurality of wrapping units, each said wrapping unit having a leading edge at one of thereof and a tail edge at an opposing edge thereof, where each one of said plurality of wrapping units is serially connected to at least one other of said plurality of wrapping units at the corresponding leading edge, tail edge, or both. In a further embodiment, discrete adhesive areas are disposed on the first surface of said plurality of wrapping units. In a still further embodiment, the discrete adhesive areas are covered by a protective cover, wherein the protective cover is attached to the first surface of the next said serially connected wrapping unit.

Owner:TAMA PLASTIC IND

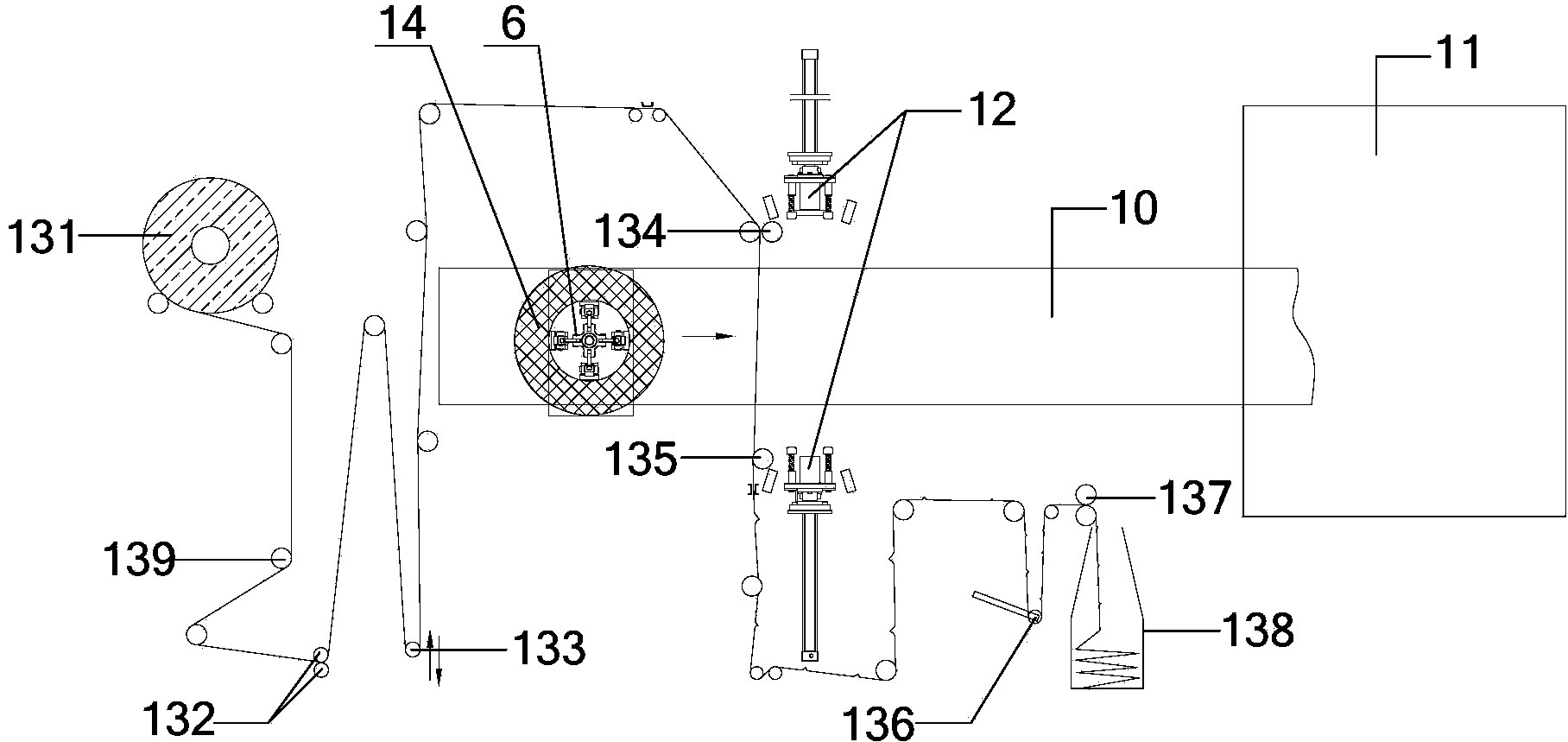

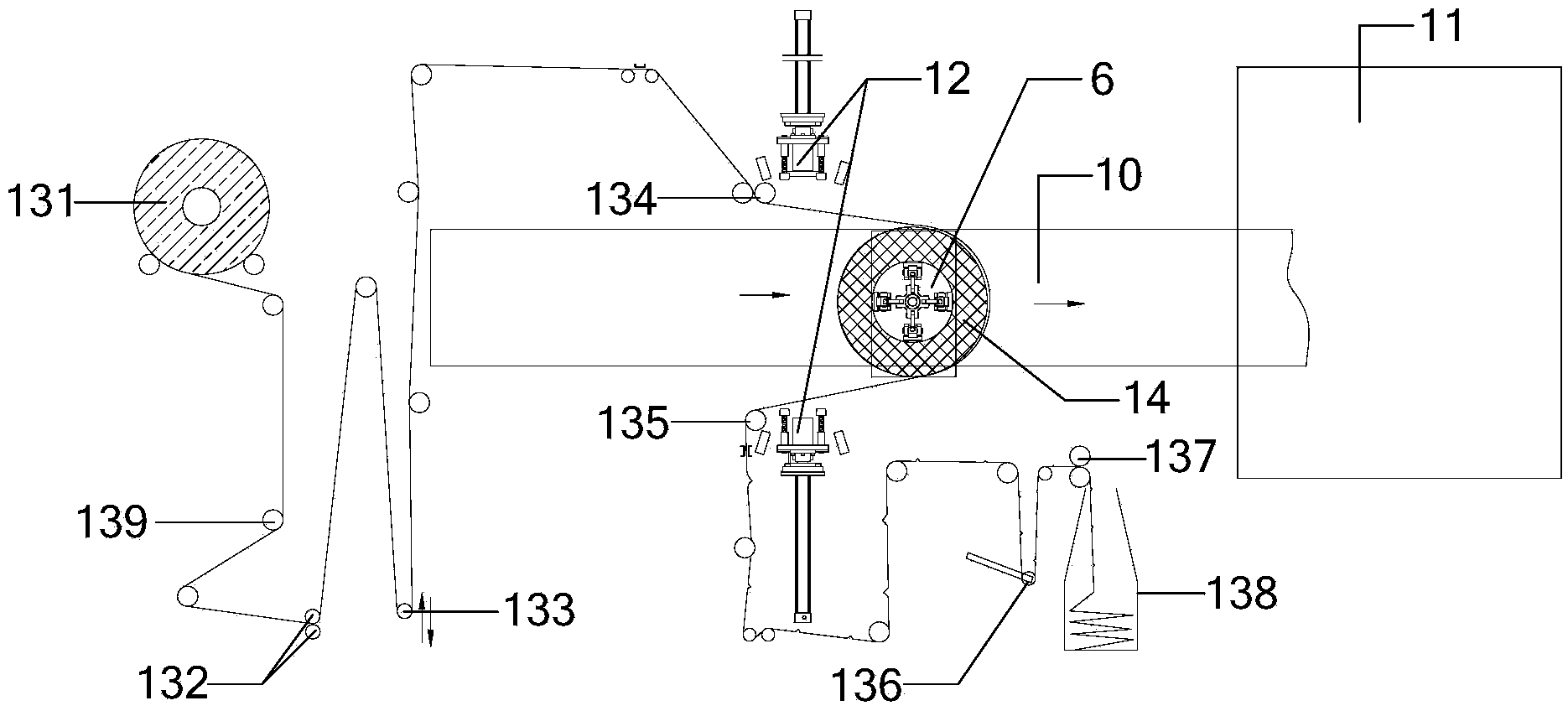

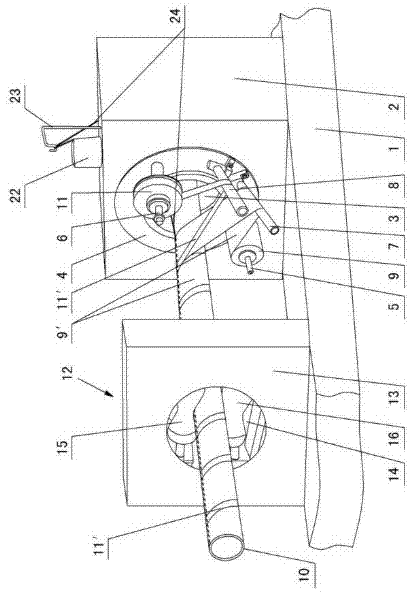

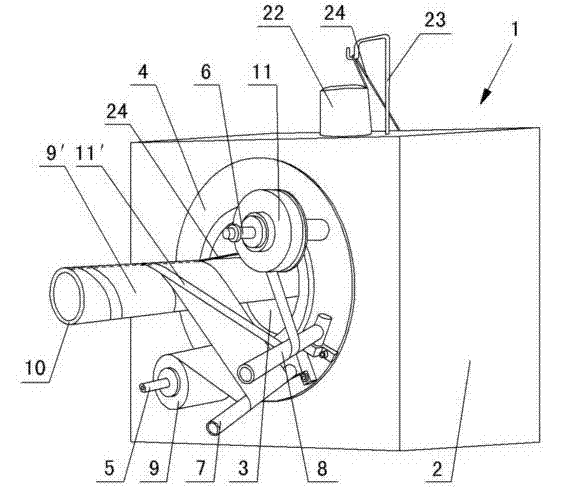

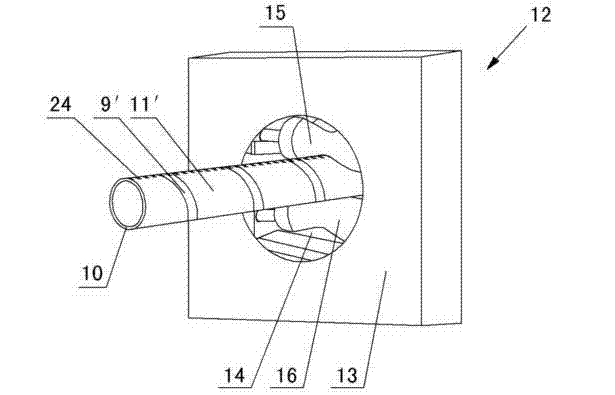

Automatic winding and packaging mechanism of plastic pipe protective film

The invention relates to an automatic winding and packaging mechanism of a plastic pipe protective film. The automatic winding and packaging mechanism comprises a conveyor seat connected with a plastic pipe manufacturing machine, wherein a plastic pipe produced from the manufacturing machine is arranged on the conveyor seat along the conveyor seat; and the automatic winding and packaging mechanism is characterized in that the automatic winding and packaging mechanism of the plastic pipe protective film is mounted on the conveyor seat, the automatic winding and packaging mechanism of the plastic pipe protective film comprises a packaging support mounted on the conveyor seat, wherein a plastic pipe conveying hole is formed at the center of the packaging support, a rotating disc is mounted at the front part of the packaging support, the rotating disc is driven by a power device to rotate, a protective film fixing rod, an adhesive tape fixing rod, a protective film winding rod and an adhesive tape winding rod are fixed in front of the rotating disc, a protective film coil is mounted on the protective film fixing rod, the protective film of the protective film coil is wound on the outer wall of the plastic pipe via the protective film winding rod, an adhesive tape coil is mounted on the adhesive tape fixing rod, and the reverse surface of an adhesive tape of the adhesive tape coil can enable the adhesive surface of the adhesive tape to be bound with the protective film wound on the outer wall of the plastic pipe via the adhesive tape winding rod.

Owner:YONGGAO CO LTD

Method for filling at least one thin-walled transport container with at least one valuable object and device for safekeeping at least one valuable object

ActiveUS20120167529A1Easy to closeEasy to fillPaper article packagingCoin/currency accepting devicesEngineeringThin walled

Owner:DIEBOLD NIXDORF SYST GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com