Patents

Literature

139results about How to "Good riveting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

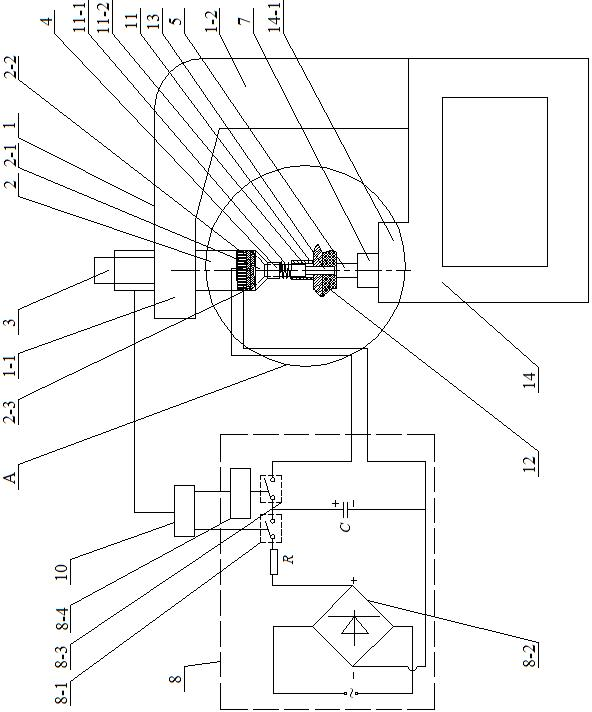

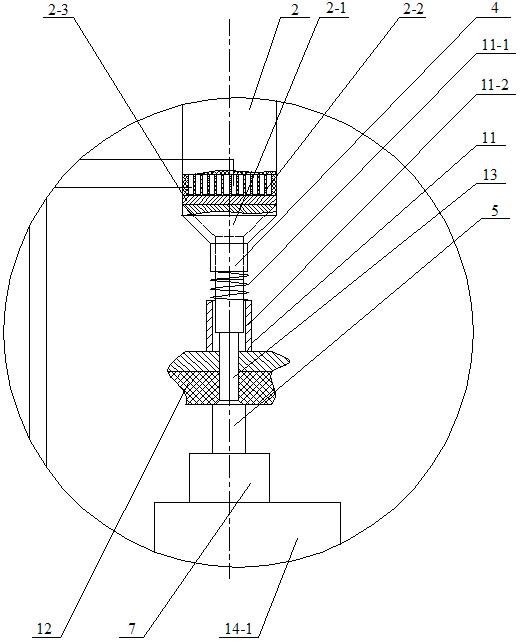

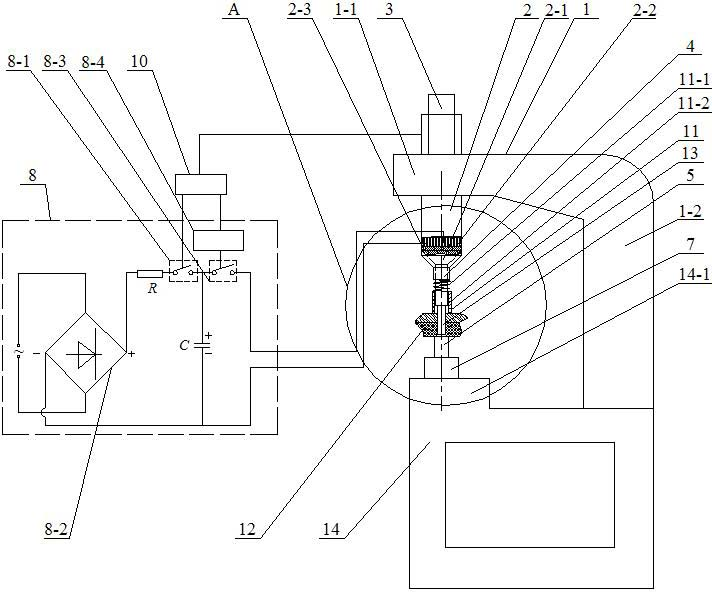

Electromagnetic riveting press suitable for large-diameter rivets and press riveting method thereof

InactiveCN101856713AImprove riveting quality stabilitySolve the strength problemVoltage pulseControl power

The invention discloses an electromagnetic riveting press suitable for large-diameter rivets and a press riveting method thereof, and relates to an electromagnetic riveting press and a press riveting method thereof. A composite structure is riveted by adopting the large-diameter rivets, and the problem of interference quantity and higher electromagnetic riveting requirement operation level are difficultly controlled by adopting hammer riveting and press riveting. An upper riveting die and a stress wave modulator of an electromagnetic riveting gun are jointed or manufactured into a whole; the electromagnetic riveting gun is arranged on a slipway on a horizontal arm; a riveting gun stroke control power source is connected with a control box; the control box is connected with a charge control signal input end of a low-voltage electromagnetic riveting device and a high-voltage pulse generator; the high-voltage pulse generator is connected with a discharge control signal input end of the low-voltage electromagnetic riveting device; positive and negative output ends of discharge signals are connected with two ends of a coil of the electromagnetic riveting gun; and the riveting gun stroke control power source drives the electromagnetic riveting gun to move downwards, a capacitor bank is charged and discharged, and a driving plate is subjected to the axial downward pulse loading effect so that an extended part of a nail bar forms an upset head. The electromagnetic riveting press is used for riveting structural members by the large-diameter rivets.

Owner:HARBIN INST OF TECH

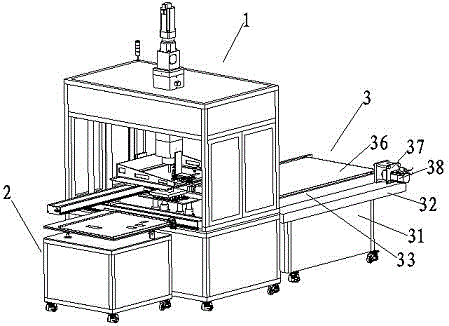

Riveting machine

The invention discloses a riveting machine which comprises a riveting mechanism fixed to the ground. The opposite outer side faces of the riveting mechanism are provided with a workpiece positioning mechanism and a discharging mechanism correspondingly. A workpiece is put into the workpiece positioning mechanism through manual work, and the workpiece positioning mechanism is used for positioning the workpiece; then the riveting mechanism sucks the workpiece and conducts riveting; and the workpiece is conveyed into the discharging mechanism by the riveting mechanism after riveting is completed. By means of the above manner, the riveting machine is convenient to operate, long in service life and capable of greatly improving the production efficiency.

Owner:南通全昂等离子体科技有限公司

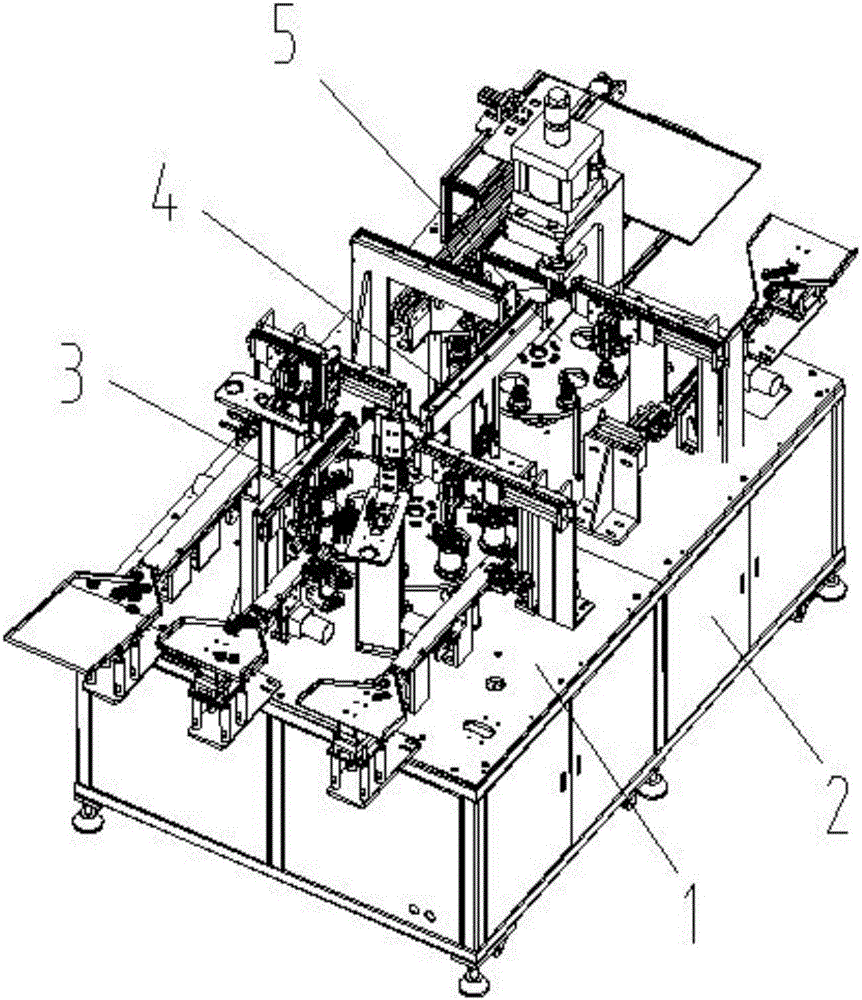

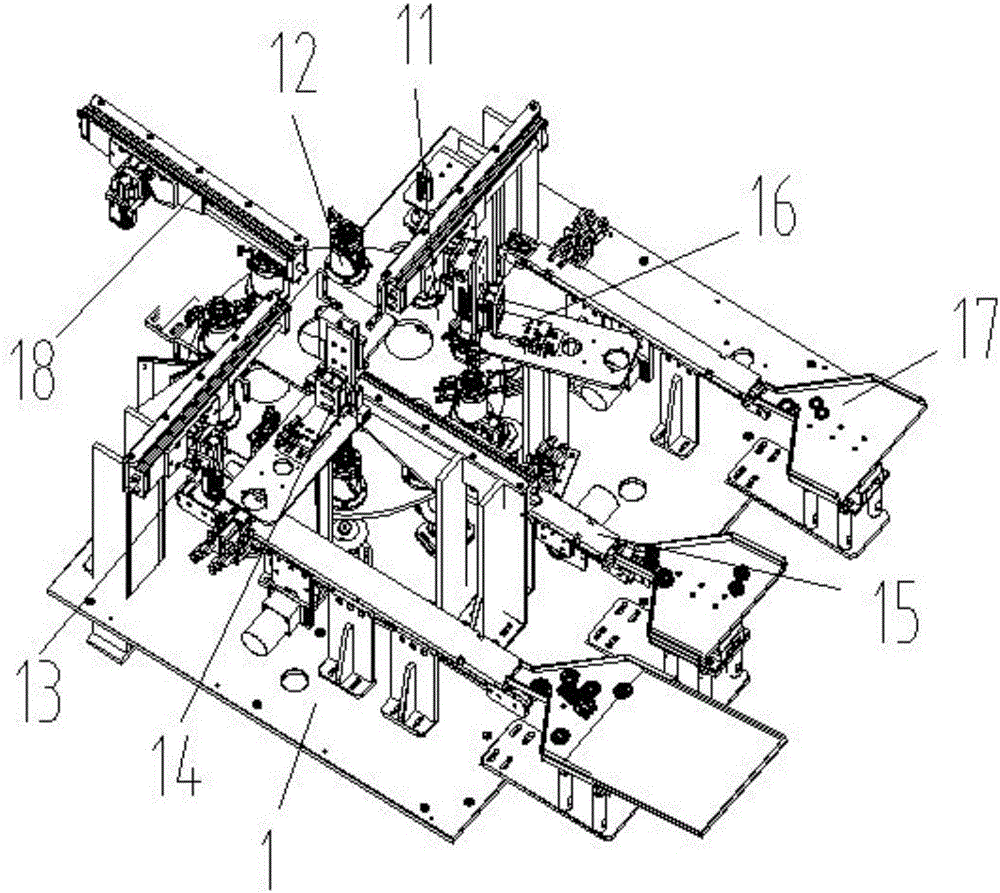

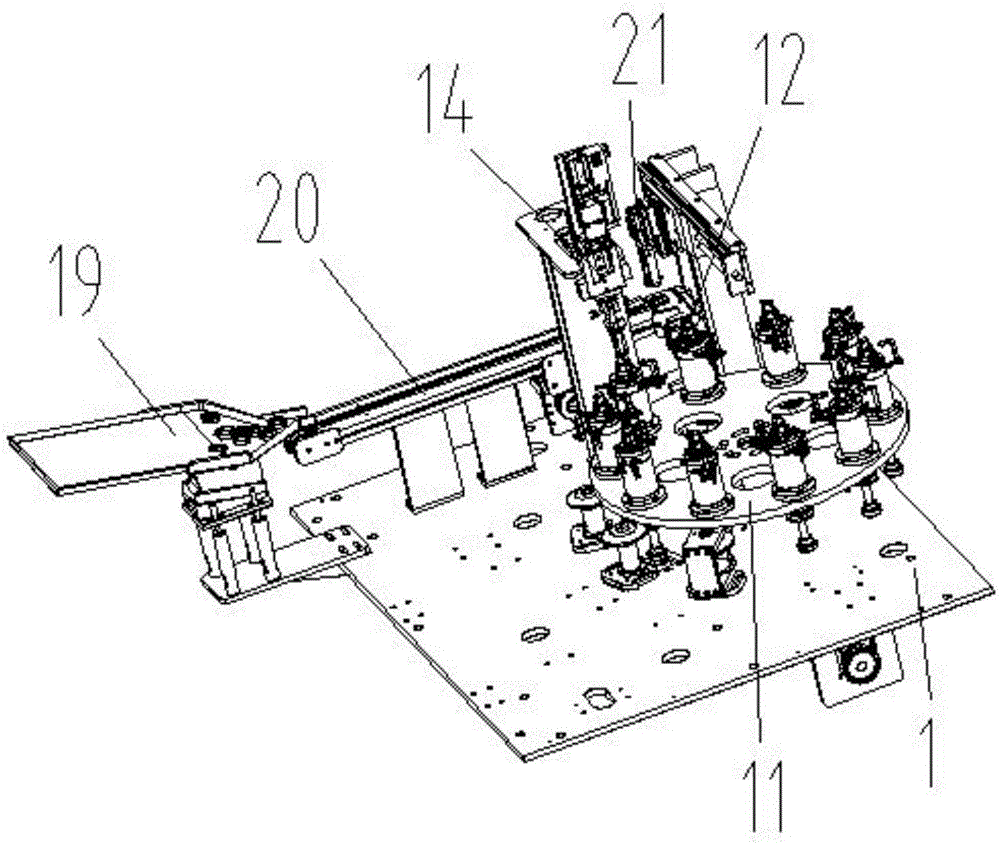

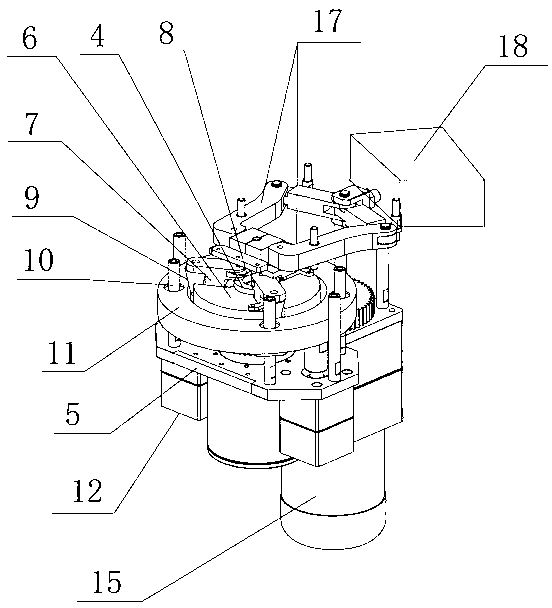

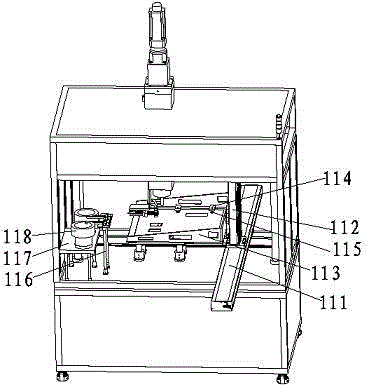

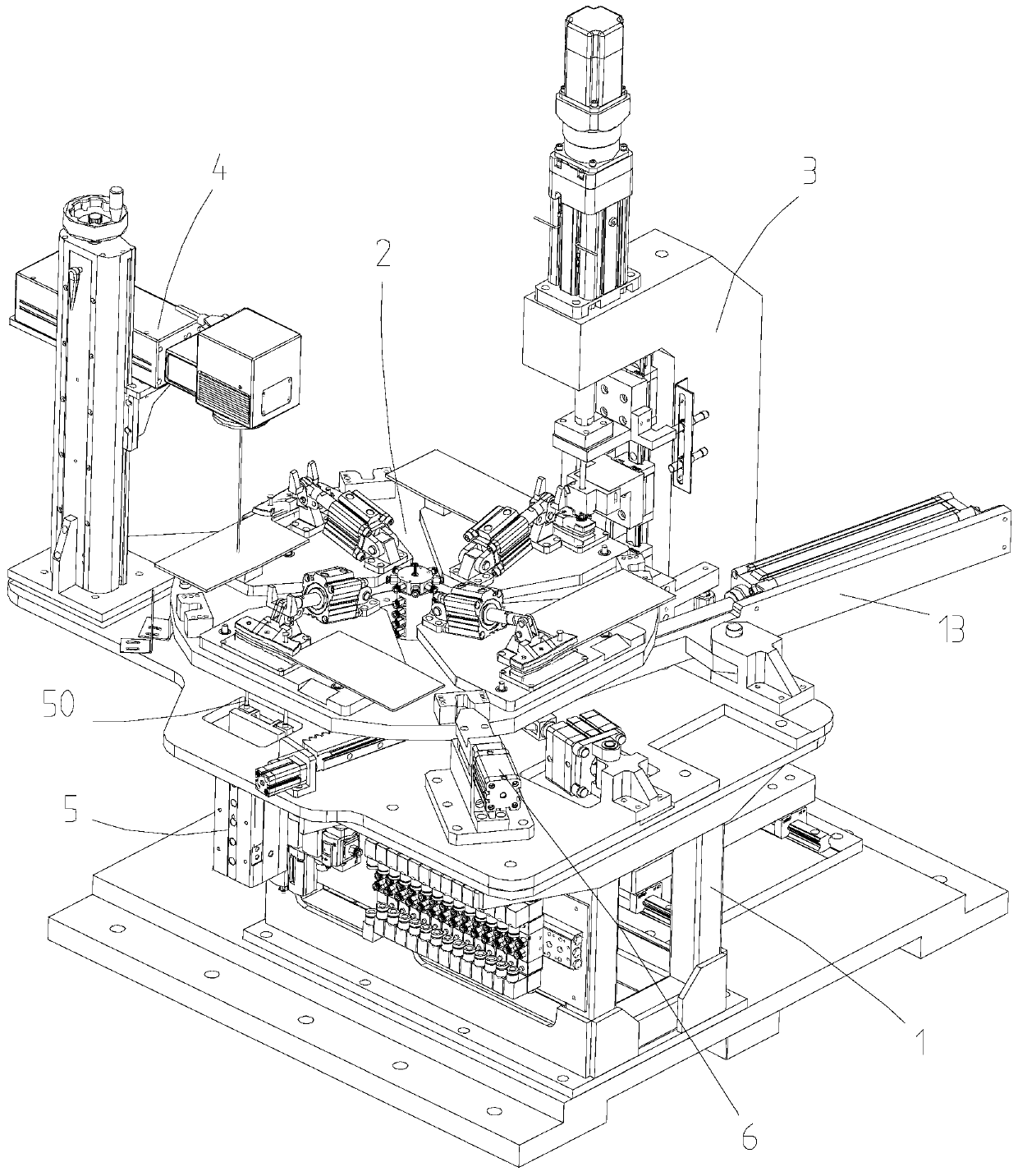

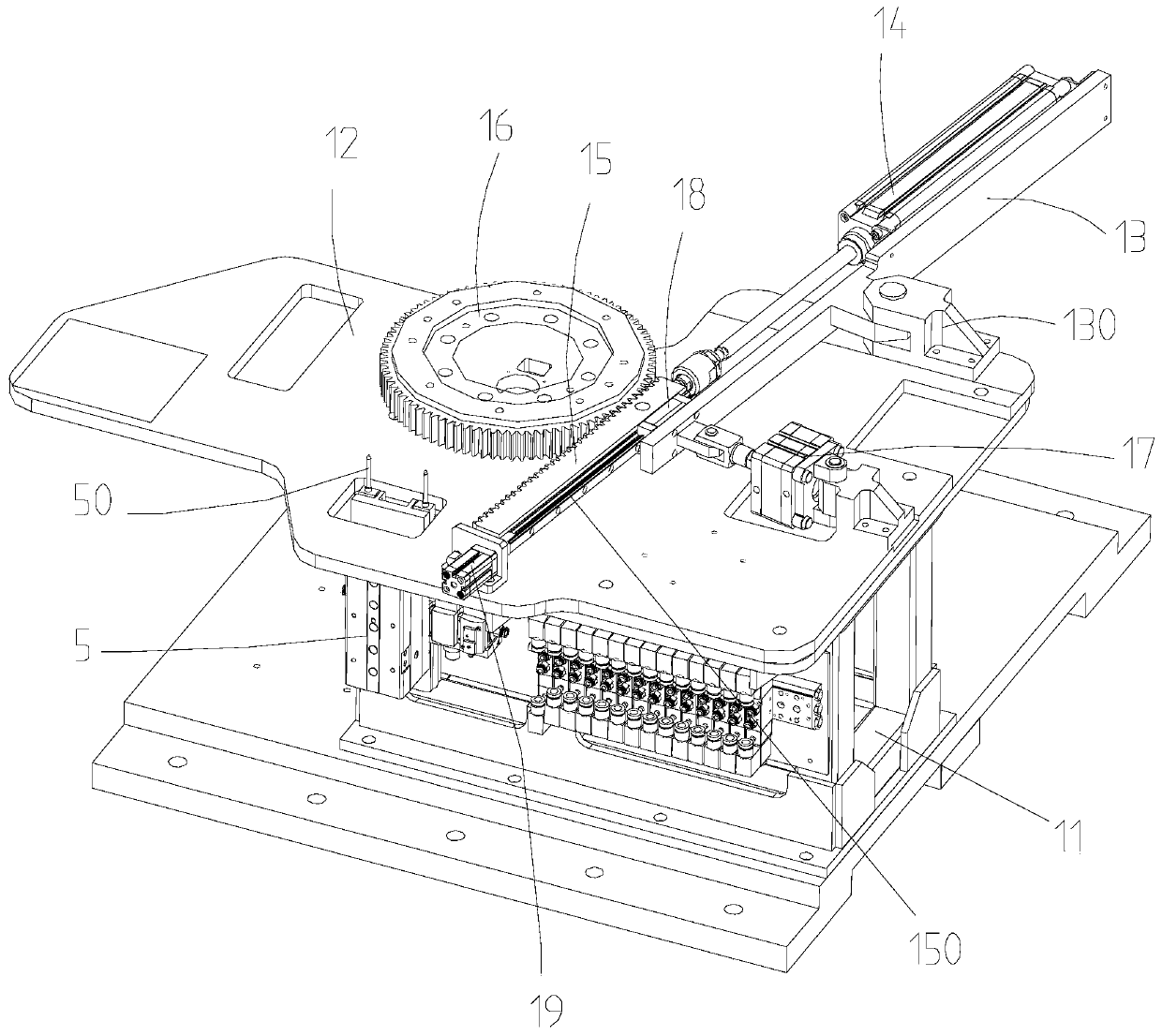

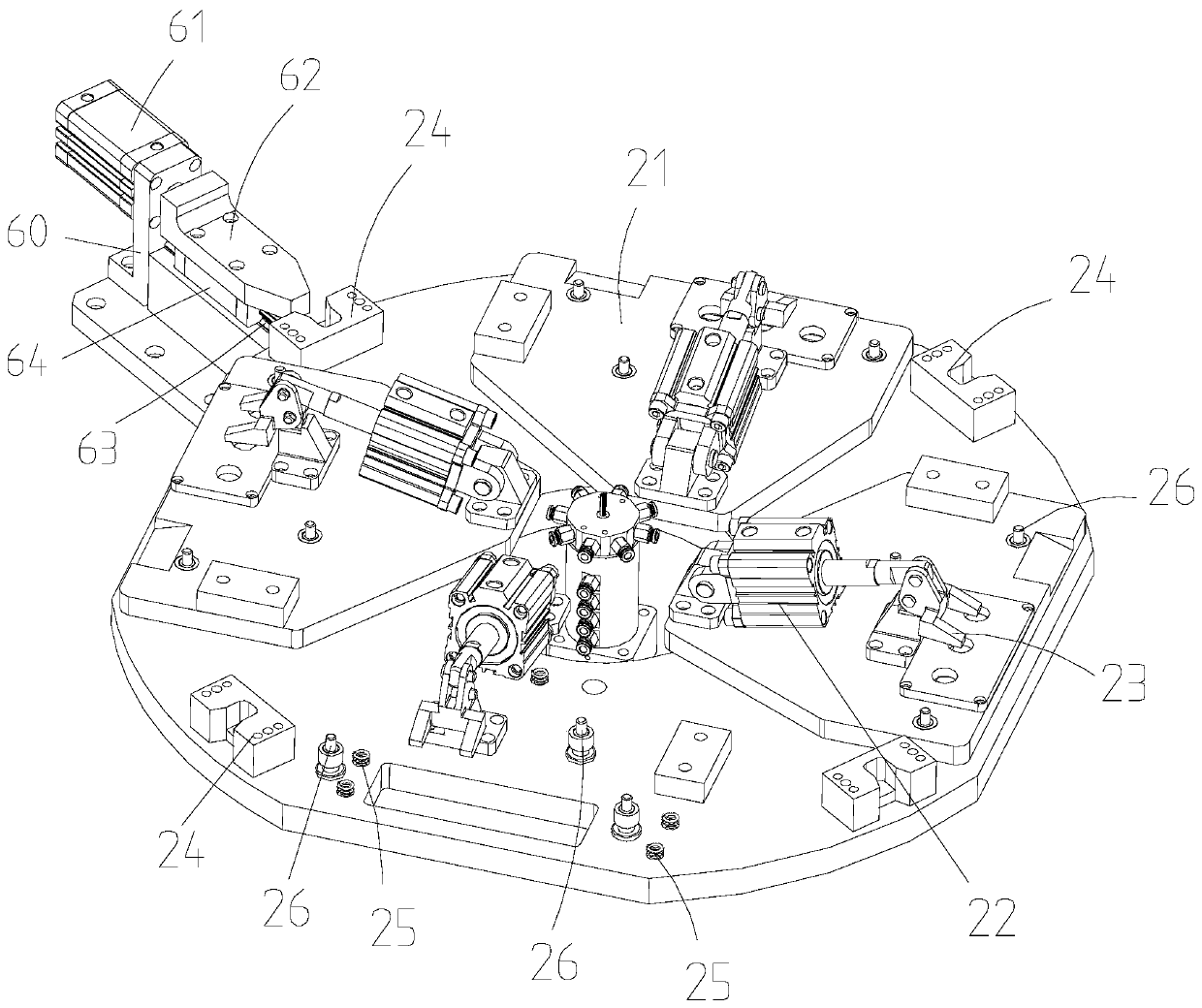

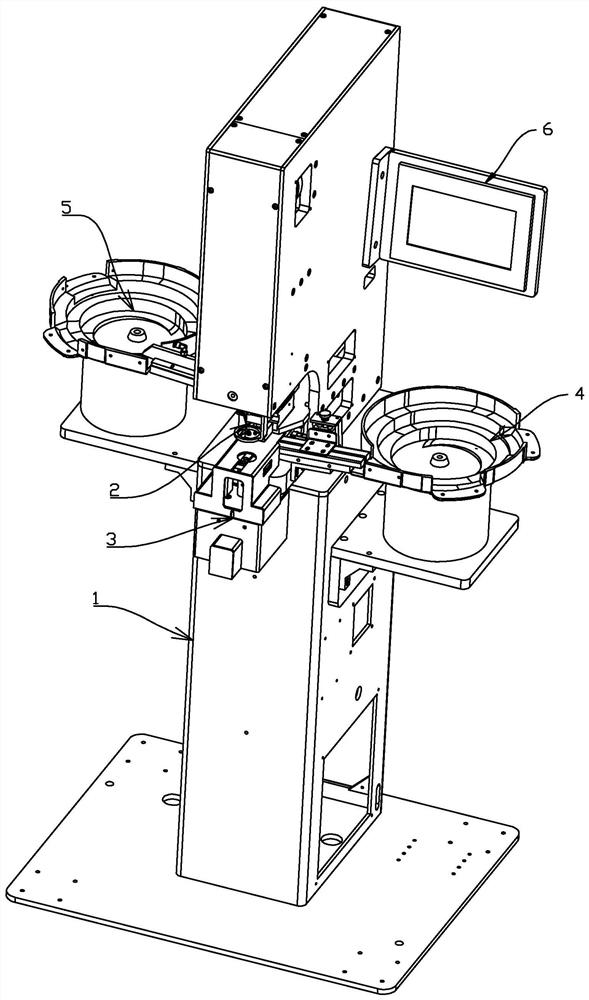

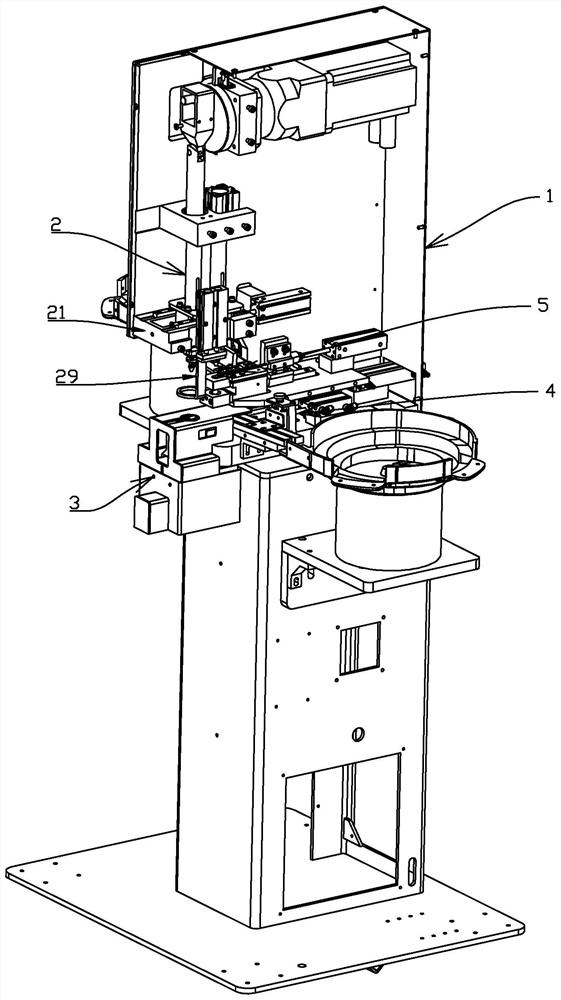

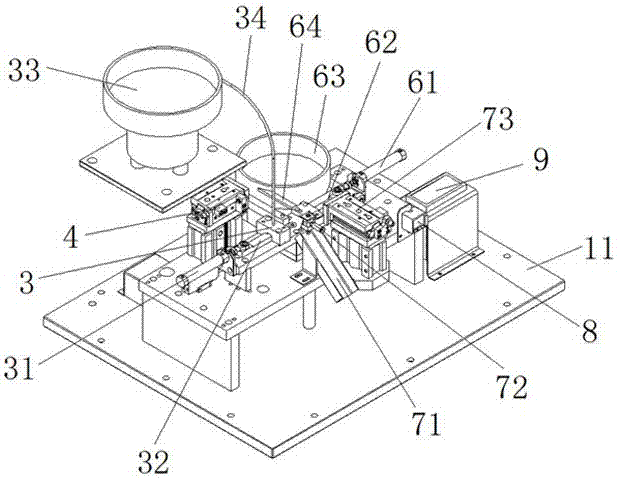

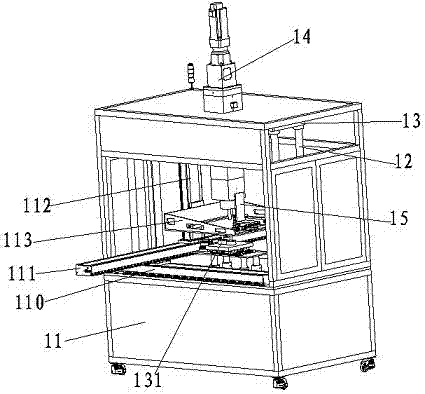

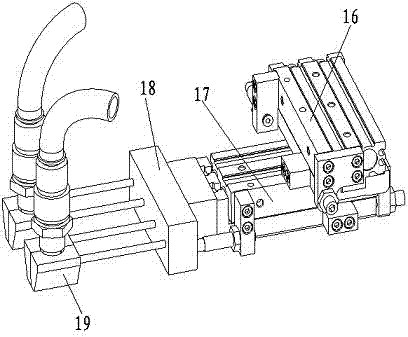

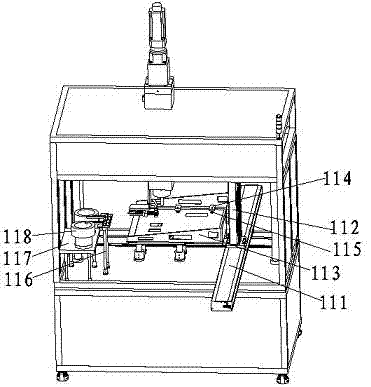

Automobile oil seal automatic glue dispensing and assembling machine

ActiveCN106733452AImprove assembly efficiencySimple structureLiquid surface applicatorsMaterial gluingDistribution controlEngineering

The invention relates to an automobile oil seal automatic glue dispensing and assembling machine. The automobile oil seal automatic glue dispensing and assembling machine comprises a machine frame and a power distribution control box. A glue dispensing assembling mechanism and a riveting assembling mechanism which are connected through a transferring device are arranged on the machine frame. The glue dispensing assembling mechanism comprises a glue dispensing rotary plate arranged on the machine frame. Glue dispensing carriers are evenly arranged on the glue dispensing rotary plate. A corrugated pipe base feeding device, a corrugated pipe base glue dispenser, a corrugated pipe assembly part feeding device, a corrugated pipe assembly part glue dispensing device and a graphite ring feeding device are arranged on the machine frame. The riveting assembling mechanism comprises a riveting rotary plate arranged on the machine frame. Riveting carriers are arranged on the riveting rotary plate. A detecting frame, a friction ring feeding device, a riveting device and a discharging device are arranged on the machine frame. Sealing of joints is completed through glue dispensing by the glue dispenser, assembled products on the glue dispensing rotary plate are conveyed to the riveting rotary plate through the transferring device to be subjected to automatic assembling and riveting with friction rings, and thus the assembling efficiency of automobile oil seals is greatly improved.

Owner:安徽鼎立智能制造股份有限公司

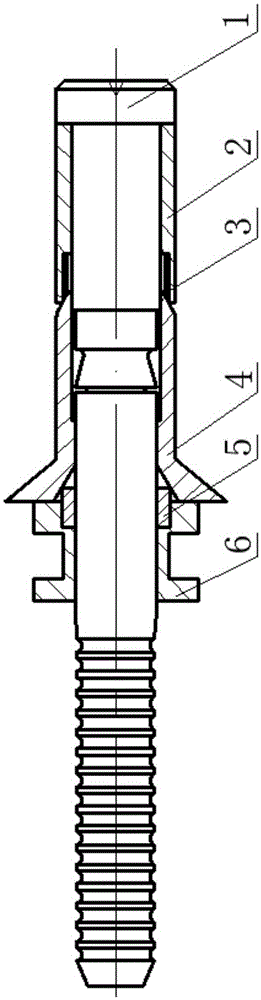

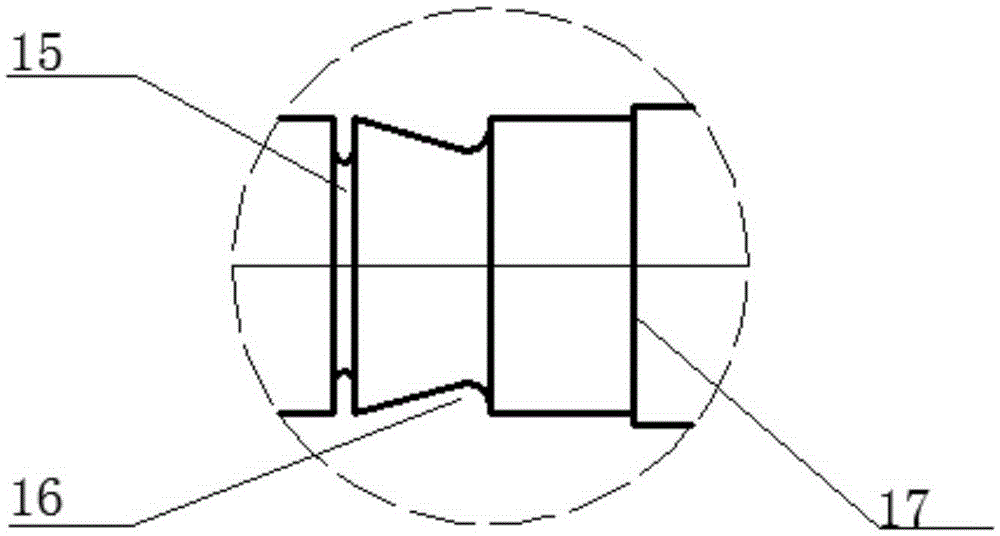

Pull rivet type self-plugging rivet

The invention provides a pull rivet type self-plugging rivet. The pull rivet type self-plugging rivet comprises a core rod, a tube body, a ring and a rivet body; the tube body, the ring and the rivet body are arranged on the outer side of the core rod in a sleeved mode in sequence; the core rod is composed of a head part and a rod part; the head part is provided with a stop block; the rod part is divided into three sections which include a section A connected with the head part, a section B in the middle and a section C which is provided with the free end; a neck breaking groove is formed between the section A and the section B; the tube body is hollow and cylindrical, a clamping shoulder A or a step A is disposed on the inner wall of the tube body; the section A of the core rod is sleeved with the tube body which is in clearance fit with the core rod; the ring is hollow and cylindrical and clamped at the clamping shoulder A or the step A inside the tube body; the rivet body is of a hollow structure, an outer chamfer structure is disposed at one end of the rivet body, and a protruding rivet cap is disposed on the outer wall of the other end of the rivet body. The pull rivet type self-plugging rivet has the beneficial effects that the structure is simple; installation and check are convenient; the structural strength is improved in a locking mode; deformation is not prone to occur; the riveting effect is better.

Owner:AEROSPACE PRECISION PROD INC LTD

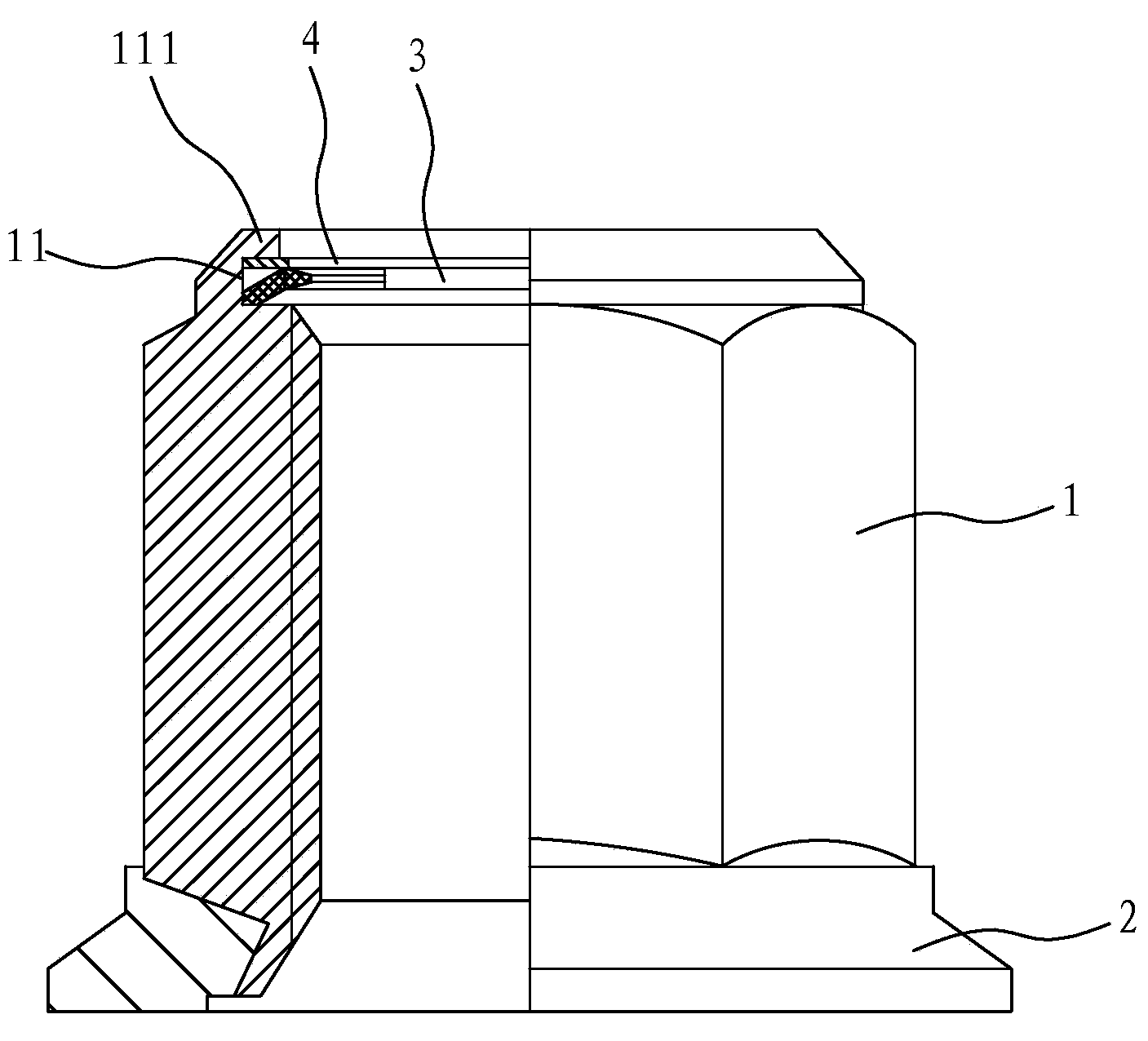

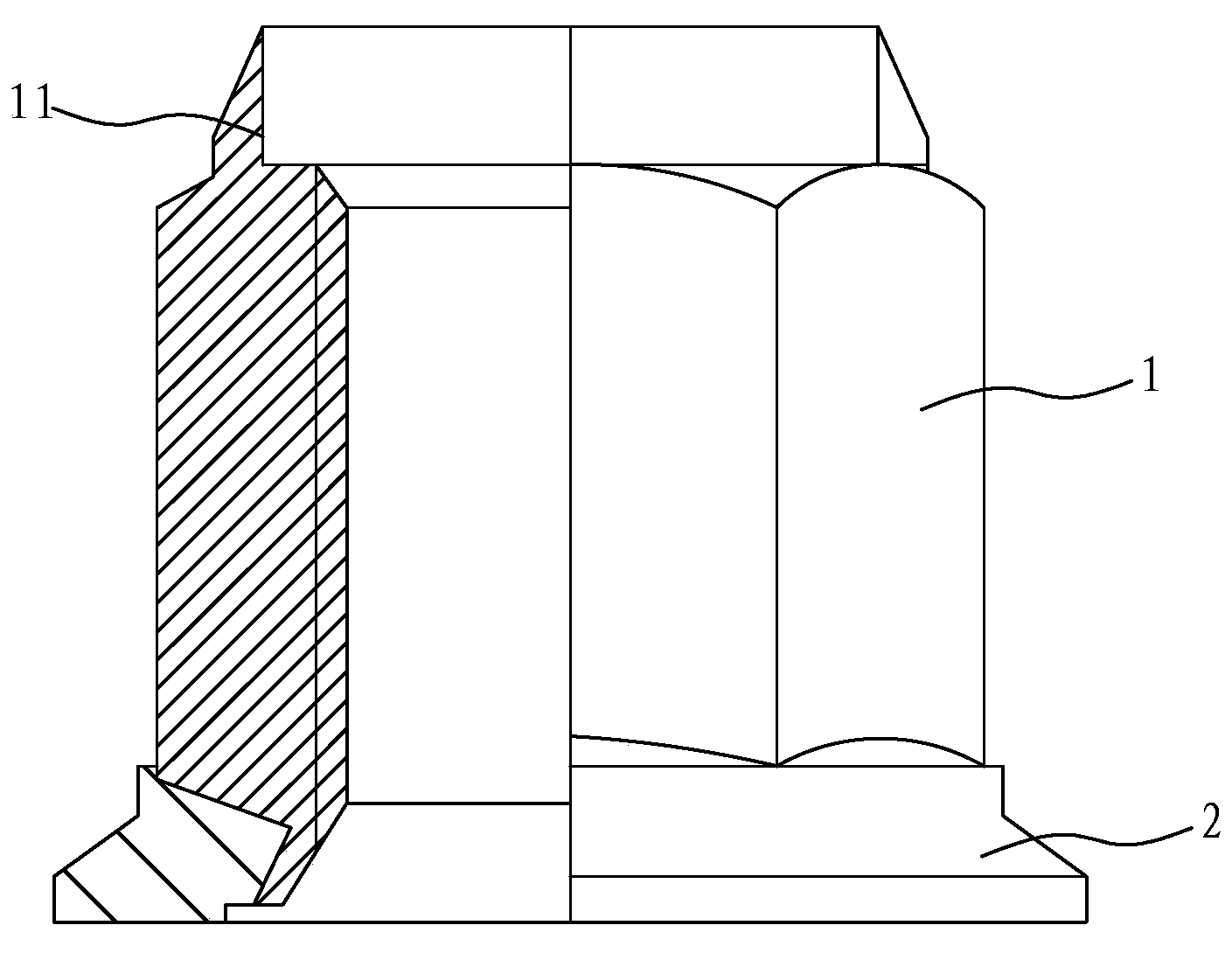

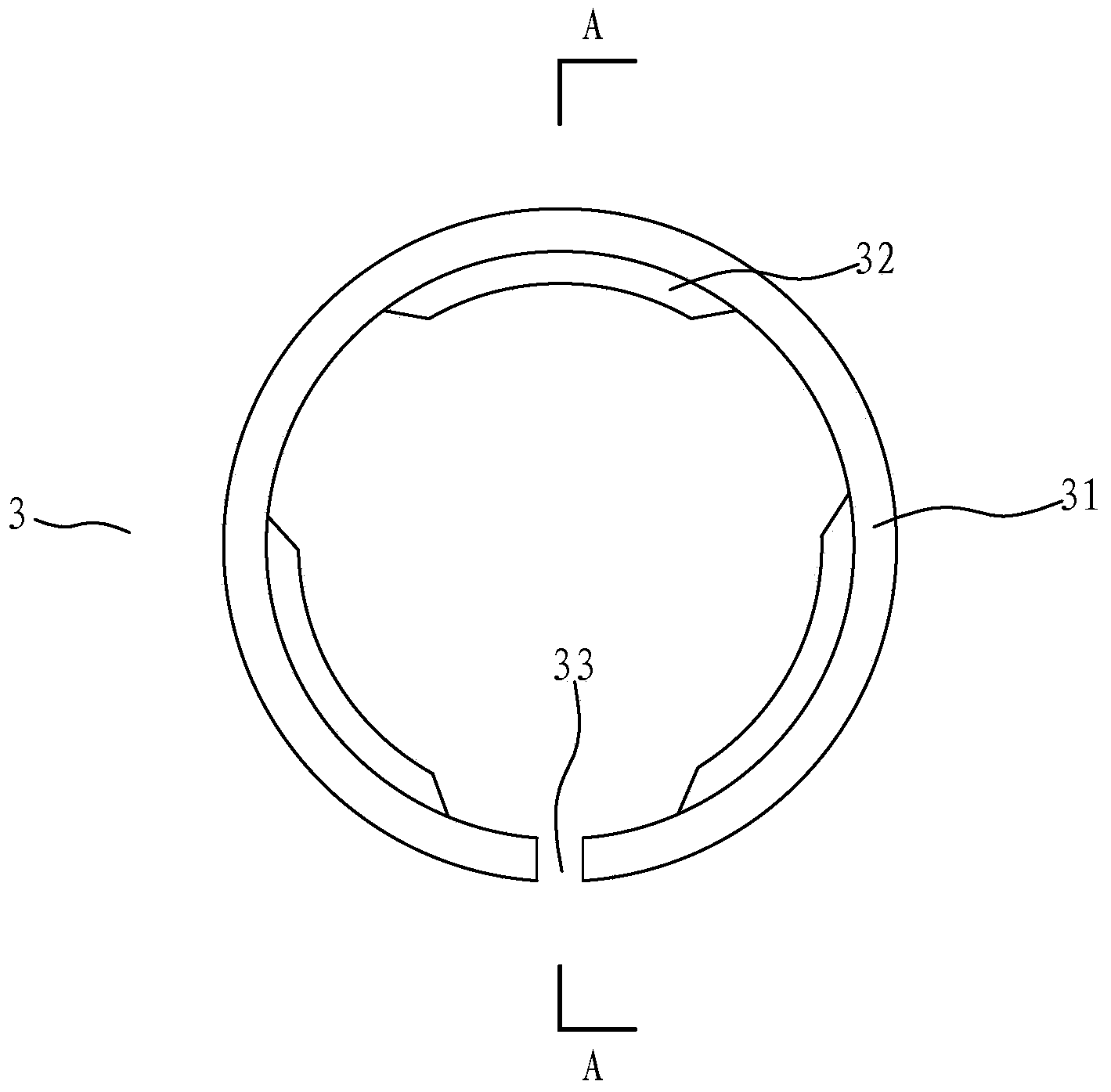

Anti-loose self-locking nut and production method thereof

The invention relates to the field of manufacturing of automobile parts, in particular to an anti-loose self-locking nut simple in structure, capable of effectively preventing the nut from falling off, convenient to mount and dismount and capable of being reused. The anti-loose self-locking nut comprises a nut body and a nut collar rotatably arranged at the lower end of the nut body, a threaded hole is penetratingly arranged in the middle of the nut body, a stepped groove is formed in the upper end of the nut body, a spring steel piece is placed in the stepped groove, a bending portion used for clamping the spring steel piece in the stepped groove is arranged on the upper portion of the stepped groove, the spring steel piece comprises an annular piece and more than two clamping pieces evenly arranged at the upper end of the annular piece and protruding along the radial direction, the annular piece is formed by a tilt surface rotating and scanning around the axis of the threaded hole, the clamping piece protrudes inwardly to extend into the threaded hole of the nut body, and the extending length of the clamping piece is located between the inner diameter and outer diameter of the threaded hole. The invention further comprises a production method of the anti-loose self-locking nut.

Owner:QUANZHOU JINQI MACHINERY PARTS

Riveting press for automobile automatic gear-shifting cable heads

InactiveCN103008482AImprove consistencyImprove the suppression effectEngineeringMechanical engineering

Owner:NINGBO AUTO CABLE CONTROLS

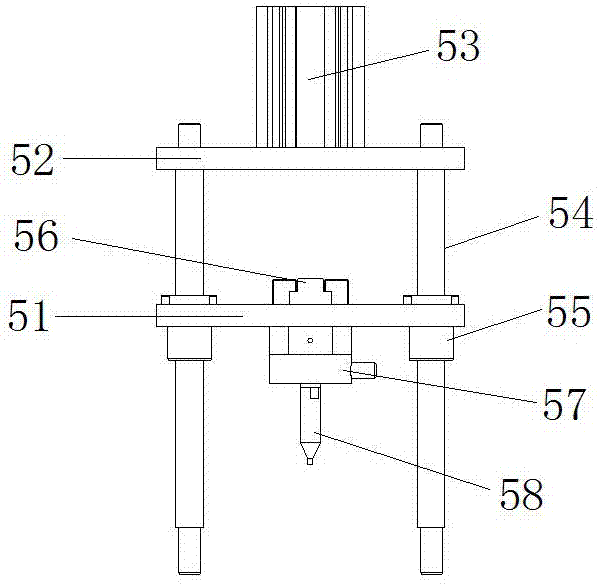

Riveting mechanism of riveting machine

The invention discloses a riveting mechanism of a riveting machine. The riveting mechanism of the riveting machine comprises a riveting rack. The two opposite sides of a worktable top of the riveting rack are each provided with two corresponding supporting pillars. A pressing machine fixing plate is fixed to the upper ends of the four supporting pillars. A longitudinal pressing machine is installed on the pressing machine fixing plate. The upper portion of the pressing machine penetrates the top face of the riveting rack, and the lower portion of the pressing machine penetrates the pressing machine fixing plate and is fixed to the vertical edge of an L-shaped air cylinder installation plate. A longitudinal displacement sliding table air cylinder is installed on the lower plane of the transverse edge of the L-shaped air cylinder installation plate. A rivet discharging sliding table air cylinder perpendicular to a sliding table of the displacement sliding table air cylinder is installed on the sliding table of the displacement sliding table air cylinder. The output end of a sliding table of the rivet discharging sliding table air cylinder is provided with a rivet discharging connecting block. The end face of the rivet discharging connecting block is provided with two pairs of rivet clamping claws through rivet discharging guide rods. By means of the above manner, the riveting mechanism is convenient to operate, long in service life and capable of greatly improving the production efficiency.

Owner:湖南哈工机器人研究院有限公司

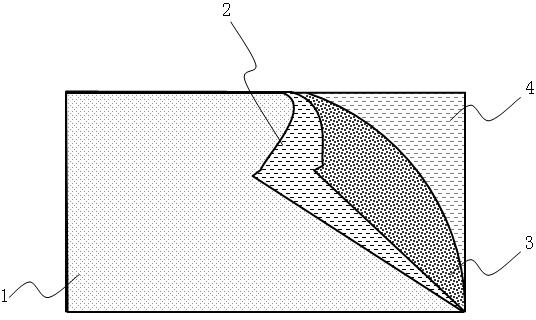

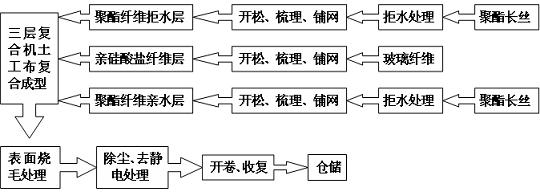

An anti-seepage geotextile for building surface gaps and its manufacturing method

ActiveCN102261081AGood riveting effectHigh strengthArtificial islandsUnderwater structuresGeotextilePolyester

The invention discloses an anti-leakage geotextile for a surface crack of a building and a manufacturing method thereof. The geotextile is a three-layer structure. The upper layer is of a water-repelling polyester filament material layer. The middle layer is of a silicate affinity fibre material layer. The lower layer is of a hydrophilic polyester filament material layer. The three layers are compounded into the geotextile in one manner of knitting, needling and spunlacing. A sintered layer formed by singeing is formed on at least one of upper and lower surfaces of the geotextile. The manufacturing method comprises the following steps of: preparing for materials; pre-treating; carding fibres of the three layers; laying a net; compounding and forming; singeing; post-treating; rolling; and storing. Different from the traditional product, the silicate affinity fibre layer tightly staggered with the polyester filament layer is additionally arranged; the silicate affinity fibre layer can be completely fused together with cement; and the geotextile disclosed by the invention can be widely applicable to national infrastructures and civil facilities.

Owner:上海名呈无纺布有限公司

Riveting stamping mechanism for pulley retaining rings

The invention discloses a stamping riveting mechanism for pulley retaining rings. The stamping riveting mechanism comprises a transmission shaft, a frame, two bearing boxes, a cam system, a rivet shank and a rivet holder. The bearing boxes are fixed at corresponding positions on the frame. Each bearing box is provided with a bearing inside. The transmission shaft is in interference fit with inner rings of the bearings. The cam system comprises a housing fixed on the frame and a cam fixedly connected to the transmission shaft. The rivet holder is fixedly connected to the frame. The rivet shank partly locates in the rivet holder. The axial direction of the rivet shank is along the radial direction of the cam. The stamping riveting mechanism is simple in structure, convenient to produce and use, effective in riveting and high in riveting efficiency.

Owner:CHENGDU SILVERTECH TIMING PULLEYS MFG

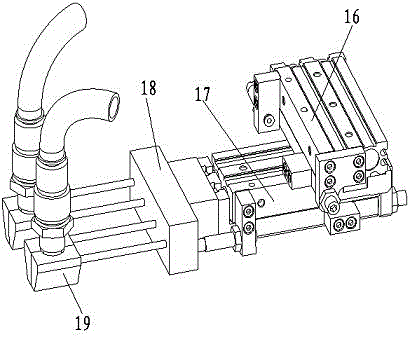

Titanium nail riveting device based on lateral ultrasonic energy field assistance and forming method thereof

The invention discloses a titanium nail riveting device based on lateral ultrasonic energy field assistance and a forming method thereof. The titanium nail riveting device comprises a rack used for supporting; a clamp tooling module used for fixing objects is erected at the top end of the rack; a vertical mounting frame is arranged at one side of the clamp tooling module; the bottom end of the vertical mounting frame is connected with the rack; and the vertical mounting frame is laterally provided with an ultrasonic assistant module. The titanium nail riveting device based on the lateral ultrasonic energy field assistance is scientific and reasonable in structure and safe and convenient to use; through laterally arranging the ultrasonic assistant module, an ultrasonic generator can work normally under the riveting force of a titanium rivet instead of being abnormal under the excessive riveting force, and the maximum riveting force can be increased up to 30 KN to improve the riveting quality; and the ultrasonic energy field assistant riveting is generated through the action of the ultrasonic assistant module, and the volume effect and the surface area effect under the ultrasonic energy field are fully utilized to reduce the deformation resistance during riveting, so that the uniformity of the interference amount of riveting is effectively improved, and the riveting quality is improved.

Owner:江苏航浦国创复材研究院有限公司

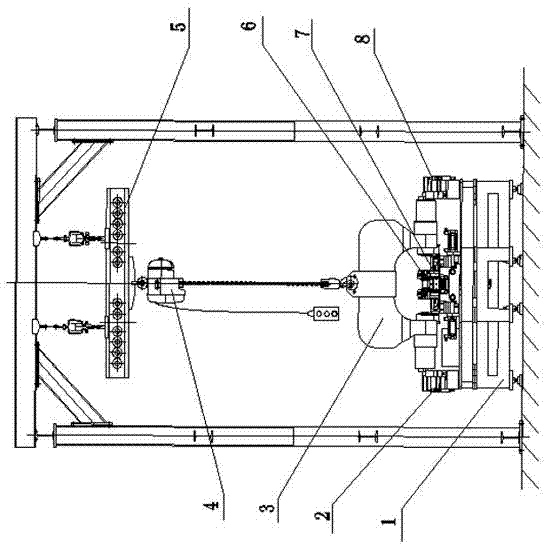

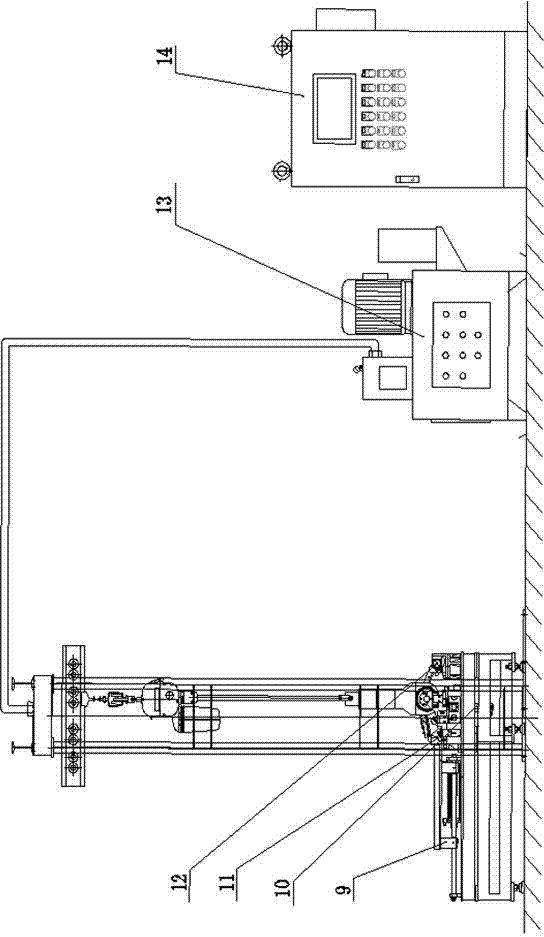

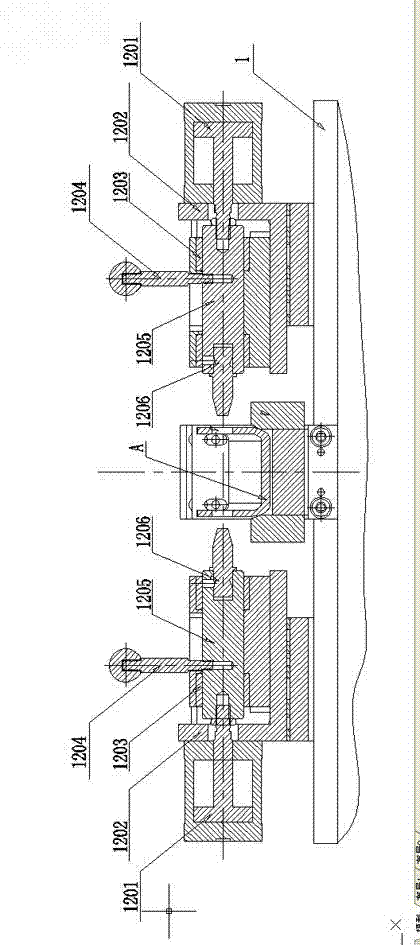

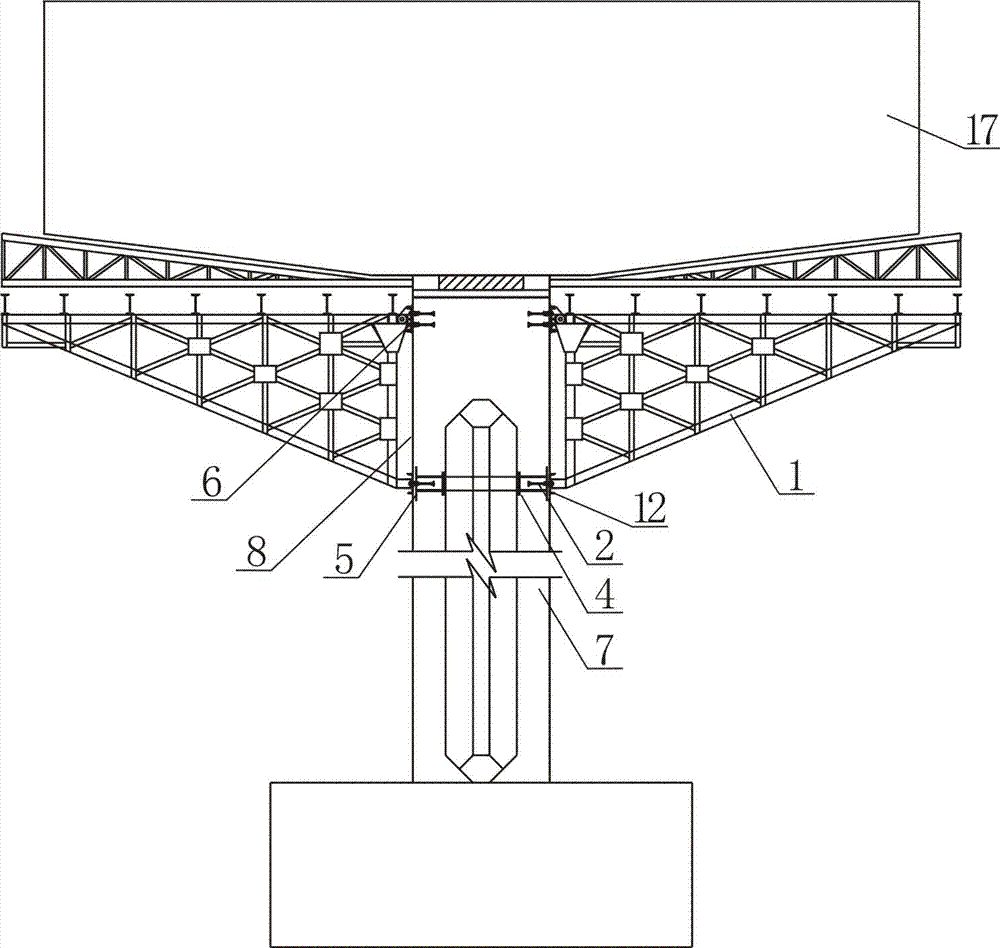

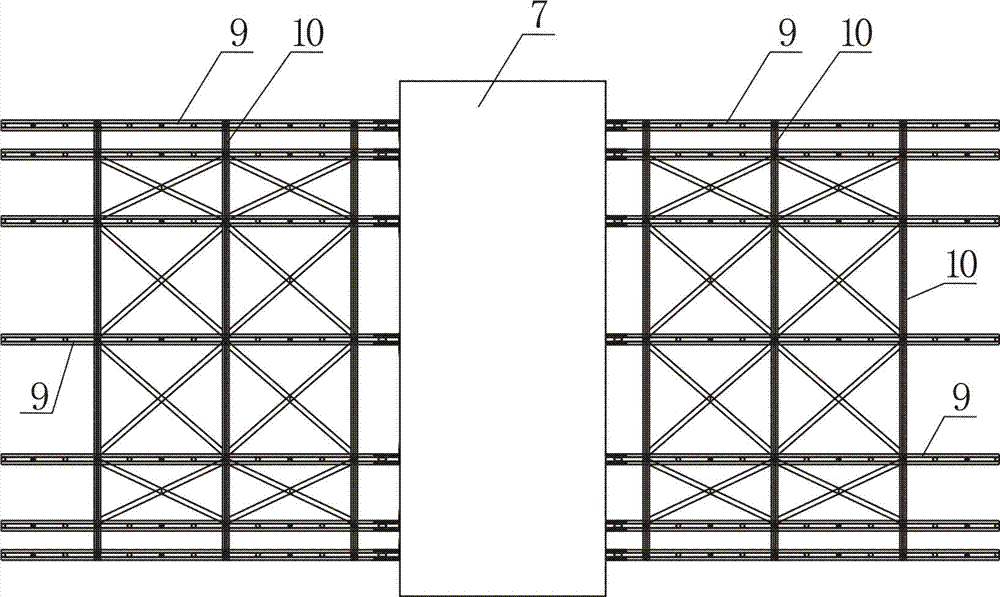

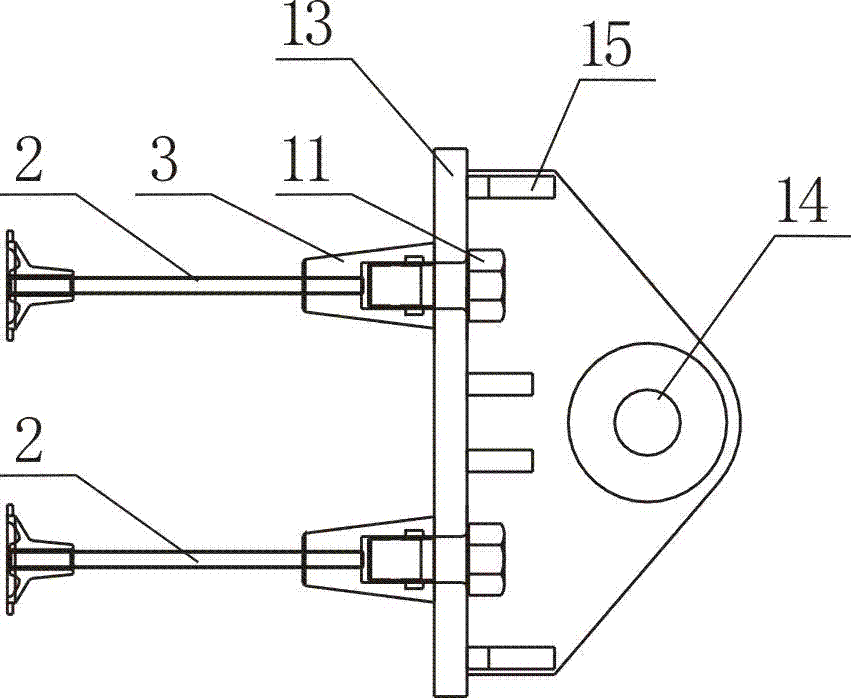

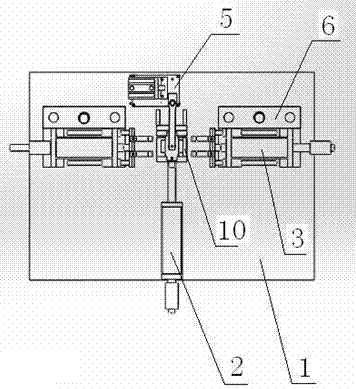

Bidirectional and synchronous riveting equipment of U-type section part

InactiveCN103586386ARealize two-way riveting functionSolve the disadvantages that the riveting function cannot be realizedPower stationElectrical control

The invention provides bidirectional and synchronous riveting equipment of a U-type section part. The bidirectional and synchronous riveting equipment of the U-type section part comprises a riveting clamp machine frame, a riveting clamp left locating base, a riveting clamp right locating base, a bidirectional hydraulic synchronous riveting clamp, an electric chain hoist, a KPK hanging steel frame, a part in-place detection mechanism, a pneumatic part combined loading pushing mechanism, a pneumatic compression resistance cushion block telescopic mechanism, a pneumatic telescopic locating protective mechanism, a pneumatic telescopic pin locating mechanism, a hydraulic power station and an electrical control system, wherein the hydraulic power station is a power source, and the electrical control system is a control part. The bidirectional and synchronous riveting equipment of the U-type section part is characterized in that the inner ends of rivets are located through the pneumatic compression resistance cushion block telescopic mechanism. According to the acting force and counter-acting force law, the bidirectional hydraulic synchronous riveting clamp is combined with a compression resistance cushion block in the middle of a U-type section cavity, the bidirectional riveting function of the U-type section part is achieved ingeniously, and the problem that the efficiency of a one-way riveting process of various U-type section parts is low is solved.

Owner:SHIYAN HANTANG ELECTROMECHANICAL ENG

Pressing rivet device for skylight support and guide way

The invention provides a pressing rivet device for a skylight support and a guide way. Two bilateral symmetry C-shaped bodies are arranged for pressing riveting, bottom plates which sliding columns penetrate are arranged at bottoms of the bodies, top plates with pressing blocks at bottoms vertically slide on the sliding columns, and air cylinders press transition plates to press the top plates. By means of the method for pressing and riveting parts to be pressed and riveted, bilateral symmetry positioning placing plates are placed on a track in the middle of the two bodies so as to place the parts, areas to be pressed and riveted of the parts are placed above pressing rivet blocks in the space of the positioning placing plates, thereby, the parts are merely required to be placed manually and then slide by the track to be pressed and riveted, human safety can be guaranteed, meanwhile, the producing efficiency is greatly increased, the bodies are arranged on slide ways and slideable left and right, and the positions of the bodies can be adjusted according to actual conditions so as to achieve optimal pressing rivet effect.

Owner:WUHU MOTIONTEC AUTOMOTIVE

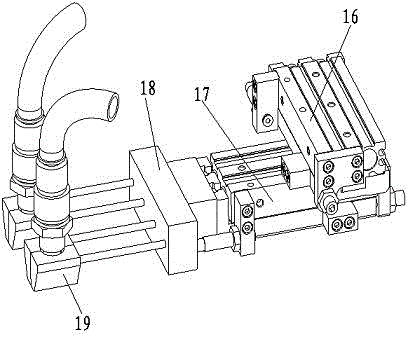

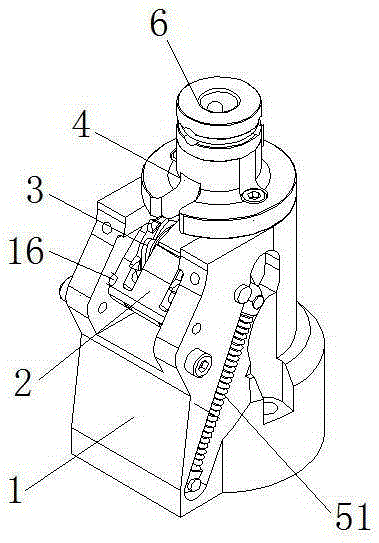

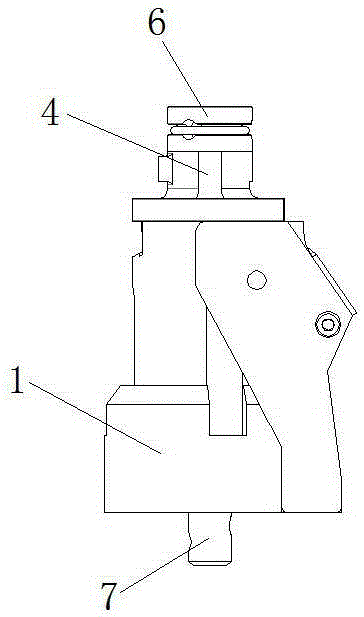

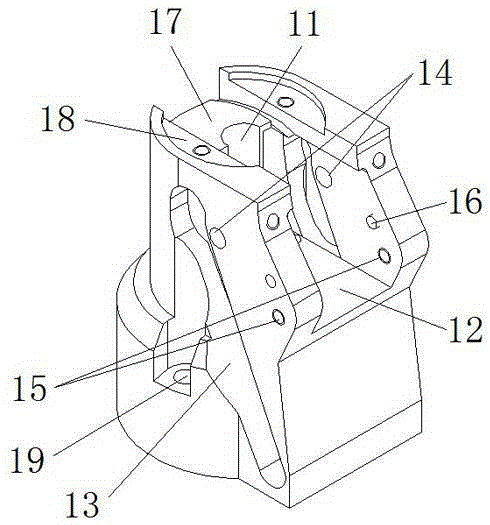

Pressing rivet feeding principle of full-automatic poking self-shooting riveting gun head

The invention discloses a pressing rivet feeding principle of a full-automatic poking self-shooting riveting gun head. The pressing rivet feeding principle comprises a gun head mounting base, a poking block, a ratchet wheel, a rivet guide base, a tension spring component, a rivet center positioning nozzle and a pressing rivet punching needle, wherein the pocking block is mounted in the gun head mounting base; the ratchet wheel is mounted on the poking block; the rivet guide base is mounted on the upper surface of the gun head mounting base; the rivet center positioning nozzle is mounted on the upper surface of the rivet guide base; and the pressing rivet punching needle penetrates through the gun head mounting base, the rivet guide base and the rivet center positioning nozzle in sequence. The pressing rivet feeding principle can use the pressing rivet power for finishing automatic rivet feeding and the pressing rivet processing, is simple in structure, convenient for maintenance and low in maintenance cost, can synchronously perform the feeding and the rivet pressing, has an automatic positioning function, enables the rivet feeding and the pressing and riveting fit to become precise, is excellent in rivet pressing effect, high in rivet pressing efficiency, high in automatic and intelligent operation degree and convenient for use, and satisfies the requirements of large-batch production, high efficiency and high quality in modern industrial development.

Owner:东莞市中特自动化科技有限公司

Climbing cone type triangular cantilever bracket

The invention discloses a climbing cone type triangular cantilever bracket which consists of a triangular bracket, a climbing cone bolt, a cone-shaped nut, a steel plate, a steel mesh and a permanent seat. The permanent seat is fixedly arranged on the side face of a pier body through match of a screw and the cone-shaped nut. The upper end on one side of the triangular bracket is hinged with the permanent seat while the lower end on another side is fixedly arranged on the side face of the pier body through the screw. The use level of materials of the whole bracket is small and the pier bodyloss rate is low, and the bracket can be repeatedly used, so that the construction cost is lowered. The bracket is in a split mounting type pin joint structure, so that the bracket is erected and detached in a short time and high is construction efficiency, and the process step transfer time can be shortened. The cone-shaped nut is adopted, so that the pier body can be repaired after the bracket is detached, the a pre-buried hole is small, the pier body is convenient to repair, and the shape of the pier body is less affected. Particularly, the steel plate and the steel mesh are pre-buried in the pier body, so that crack of the pier body bearing the bracket is effectively prevented, the anti-shearing force and anti-pressure ability of the pier body are improved, and meanwhile, the riveting property of the climbing cone bolt is further enhanced to provide the probability of supporting the cantilever of a cast-in-place box beam.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

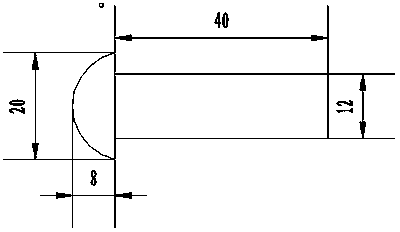

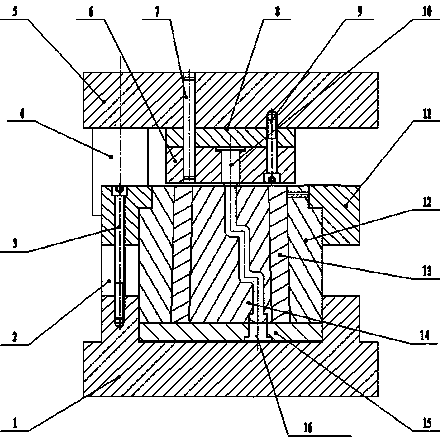

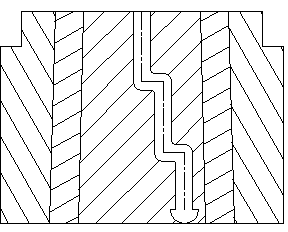

Extruding method and mould for high-strength low carbon steel round head rivet

The invention discloses a novel mould for preparing a high-strength low carbon steel material at a room temperature. The method is characterized in that: the mechanical property of low carbon steel is improved by fierce plastic deformation, wherein the adopted fierce plastic deformation device is an improved conventional ECAP technology mould, which can realize C route continuous ECAP extrusion, the female mould adopts a double-layer prestressed composite female mould structure, thus the mould material is effectively utilized, and the bearing performance is guaranteed at the same time. The method can effectively avoid the rupture of the female mould, prolongs the service life of mould, improves the efficiency of research or experiment, and saves the time and money.

Owner:SHANDONG JIANZHU UNIV

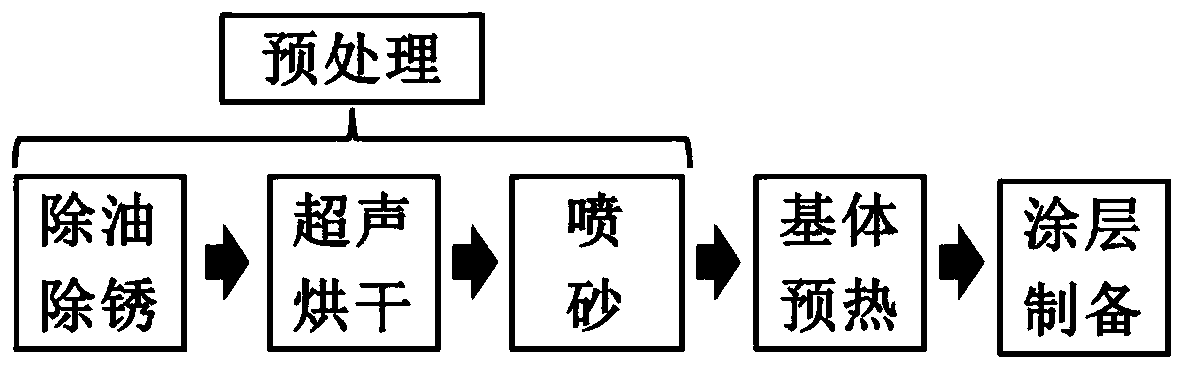

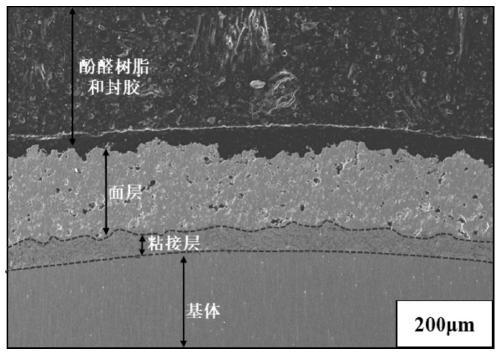

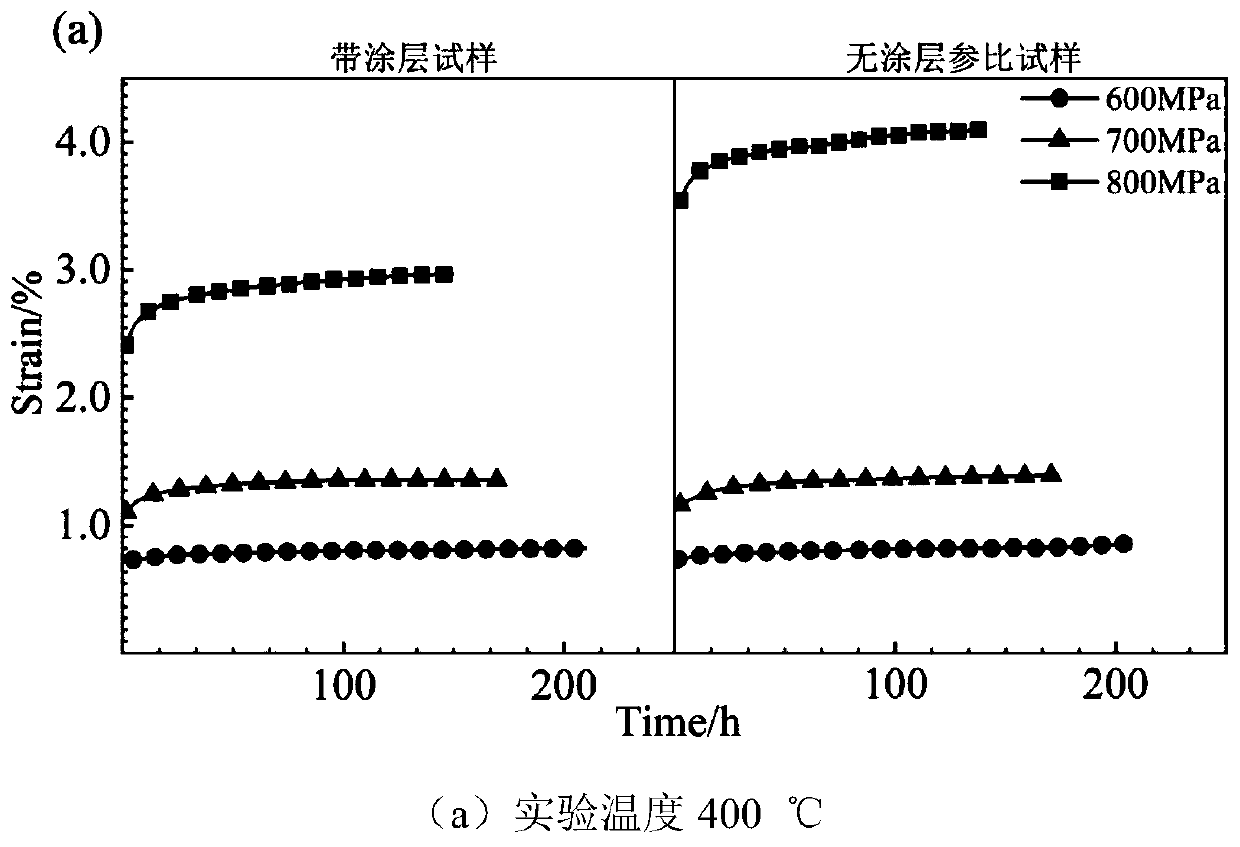

Method for improving high-temperature creep performance of titanium alloy substrate

ActiveCN111270191AGood insulationAntioxidant inhibitionMolten spray coatingThermal insulationMechanical properties of carbon nanotubes

The invention relates to a method for improving the high-temperature creep performance of a titanium alloy substrate. According to the method for improving the high-temperature creep performance of the titanium alloy substrate, the high-energy plasma spray-plating technology is used for preparing a nickel-based alloy bottom layer and a ceramic surface layer on the surface of a titanium alloy to obtain a thermal-barrier function layer with high bonding and no influence on the surface structure of the substrate. The process flow is controlled strictly with reasonable spray-plating process parameters, so that the porosity of a coating is controlled within a reasonable range, and the comprehensive mechanical properties are effectively improved. The deposited thermal barrier function layer caneffectively restrain the creep deformation of the titanium alloy substrate while effectively improving the high temperature oxidation resistance and thermal insulation performance of the titanium alloy, and the service life of the titanium alloy part is greatly prolonged.

Owner:XI AN JIAOTONG UNIV

Rotated riveting device

The invention relates to a rotated riveting device, comprising a machine frame, a table board arranged in the middle of the machine frame, a lower supporting face arranged on the table board, the lower supporting face being provided with a dead plate and a supporting column, the supporting column being provided with an upper supporting face, a motor being arranged on the upper supporting face. The output end of the motor is connected with the head of rotated riveter. The lower equipment is connected with a cylinder via a spring and a guide column. The electricity box is arranged below the machine frame. The invention is simple in structure and by adopting rotated riveter head structure, has sound effect in riveting edges and improves working efficiency.

Owner:SUZHOU RISING AUTO PARTS

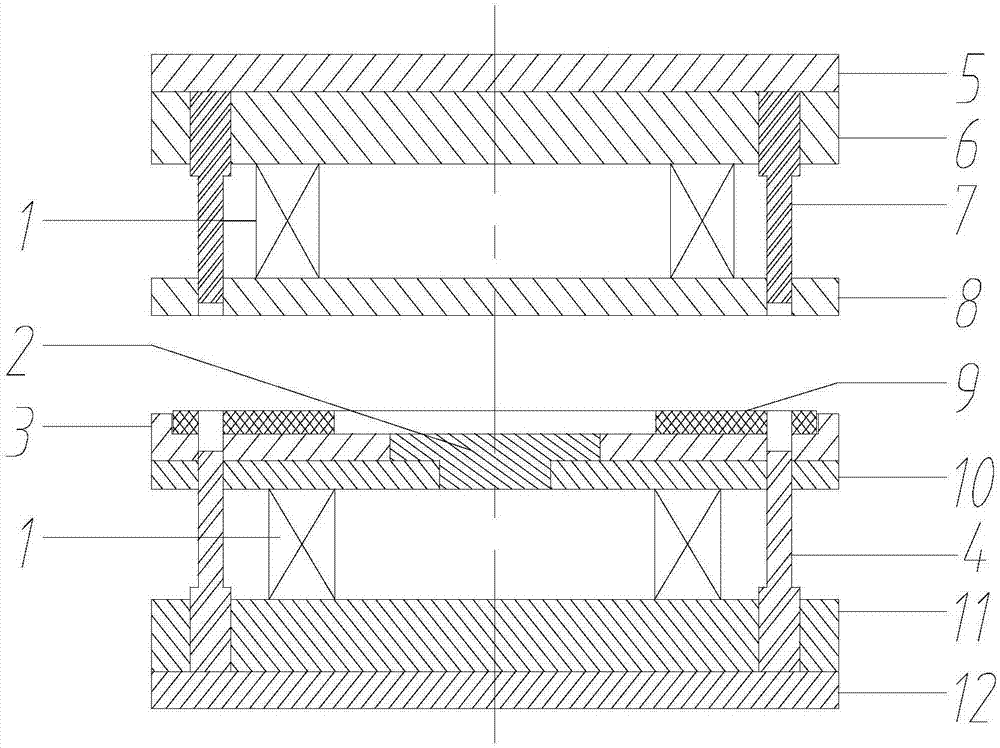

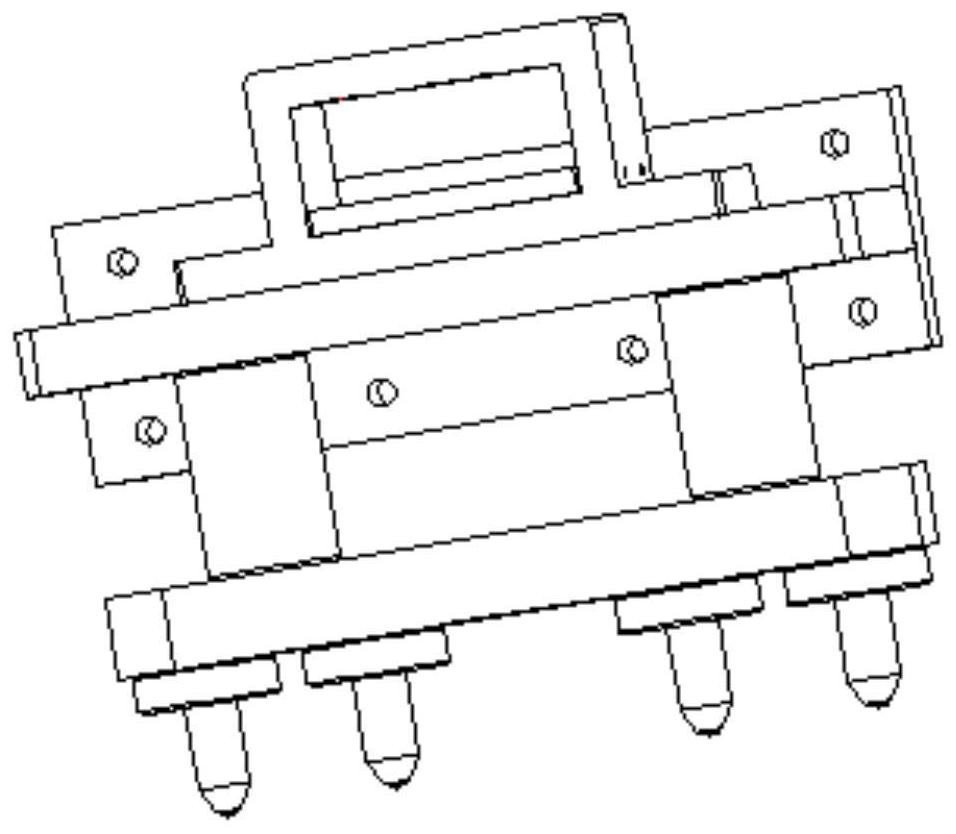

Clutch disc assembly friction plate riveting assembly mold

The invention discloses a clutch disc assembly friction plate riveting assembly mold. The mold comprises an upper mold and a lower mold matched with each other; when a friction plate is riveted and assembled, rivets are inserted in mounting holes of the friction plate and a waveform plate; then, the friction plate and the waveform plate are put on a tray to guarantee the mounting holes of the two to be corresponding to a first through hole and a second through hole; then, the upper mold is pressed downwards; in the downward pressing process, a rubber block is compressed, so that the lower end of an upper punch and the upper end of a lower punch are respectively contacted with two ends of the rivets; and the upper mold is continuously pressed down, so that the rivets are extruded by the upper punch and the lower punch for deformation to achieve the riveting effect, and the friction plate and the waveform plate are fixed as a whole. According to the model number and the shape of the friction plate, different trays only need to be replaced to achieve the purpose of riveting different friction plate products, and the production of a whole set of riveting assembly molds for different friction plate products is not needed, so that the generality of the friction plate assembly mold is improved, the cost is largely reduced, and the tray replacement is more convenient.

Owner:WUHU DAJIE CLUTCH

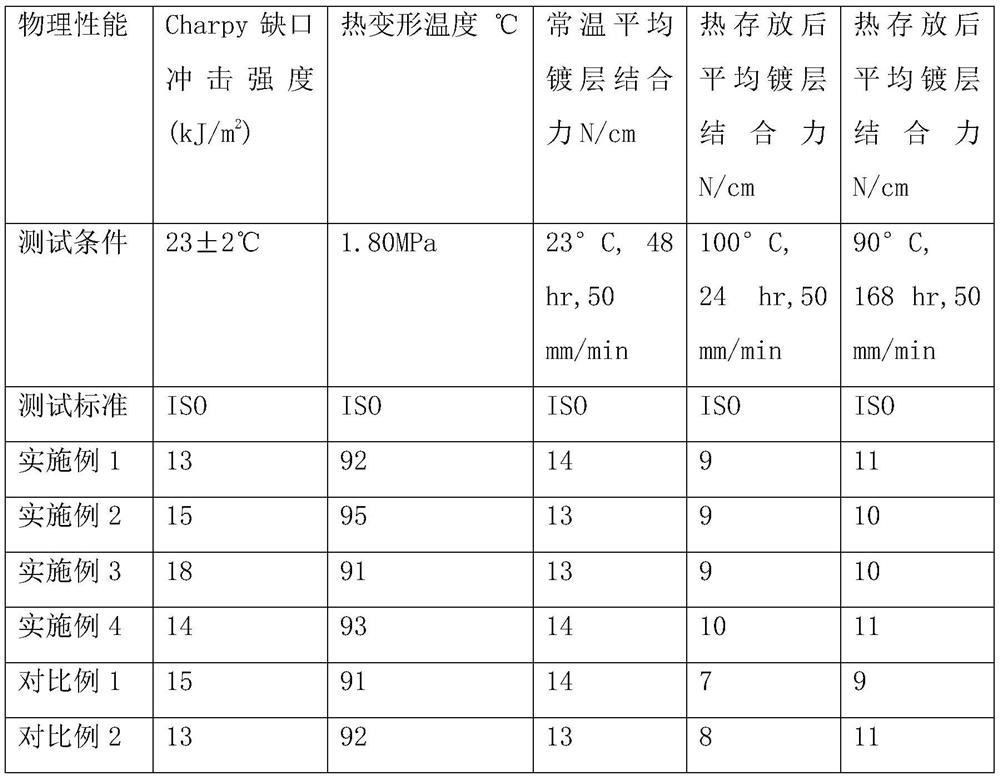

High-temperature-resistant electroplating-grade ABS resin and preparation method thereof

PendingCN111875897AGood high temperature resistanceExcellent plating adhesionComposite materialPolymer chemistry

The invention relates to high-temperature-resistant electroplating-grade ABS resin and a preparation method thereof. The high-temperature-resistant electroplating-grade ABS resin is prepared from thefollowing components in parts by weight: 10-20 parts of ABS resin, 25-35 parts of ABS high rubber powder, 40-55 parts of highly branched styrene-acrylonitrile copolymer, 10-15 parts of heat-resistantagent, 0.1-10 part of kaolin and 0.5-2 parts of other auxiliary agents. Compared with the prior art, the high-temperature-resistant electroplating-grade ABS resin is obtained by controlling the content of the ABS rubber, compounding the rubber with large and small particle sizes and introducing the kaolin filler. The high-temperature-resistant electroplating-grade ABS resin prepared by the methodhas excellent high-temperature resistance and electroplating binding force, and the failure probability of an electroplated part in a cold and hot alternating experiment is reduced, so that the use requirements of electroplating-grade ABS in the fields of automobiles, household appliances and machinery are met.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

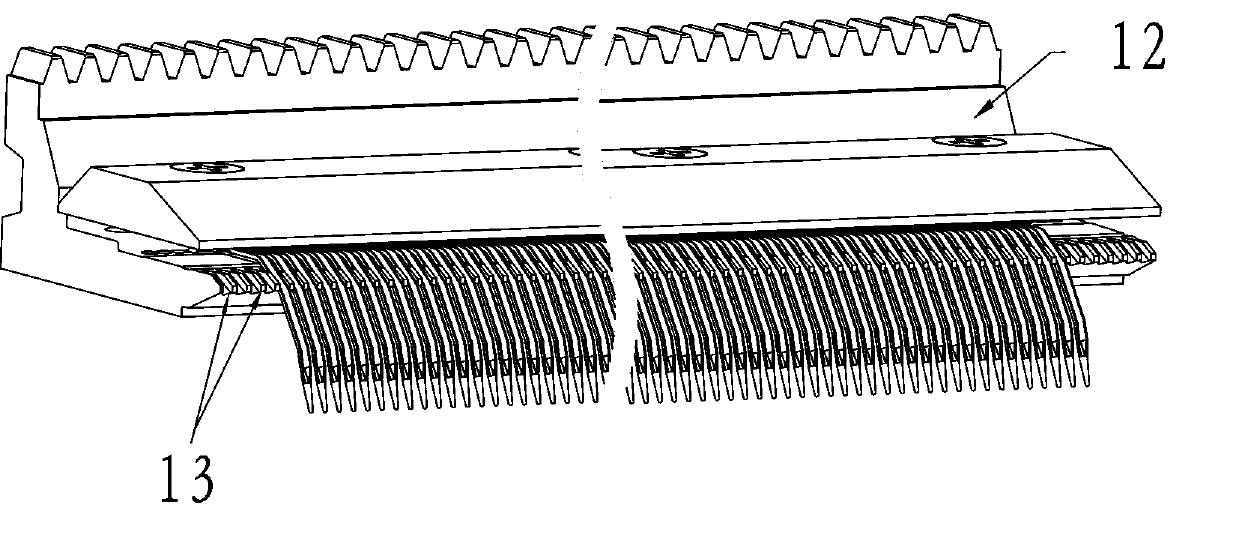

Rivet rolling device for collar suturing needle rake for knitting suturing machine

The invention discloses a rivet rolling device for a collar suturing needle rake for a knitting suturing machine. The rivet rolling device comprises a channel steel base, a channel steel boss, a plurality of needle rake locating pressure plates, two slide bars, a sliding seat, a roller bracket and a roller, wherein the channel steel boss is fixed on the channel steel base, the needle rake locating pressure plates are fixed on the channel steel boss, the two ends of each slide bar are both fixed on the channel steel base by virtue of a sliding seat baffle and then are together positioned in front of the channel steel boss, the bottom of each slide bar is provided with a plurality of slide bar supports, the sliding seat is sleeved on the two slide bars by virtue of two linear bearings, the roller bracket has a mounting hole and is fixed on one side of the sliding seat near the channel steel boss by virtue of screws, the mounting hole of the roller bracket is a long slotted hole, the roller is installed on the roller bracket, and a T-shaped handle is arranged above the sliding seat. With the adoption of the rivet rolling device, the riveting effect and the assembly efficiency of the collar suturing needle rake of the knitting suturing machine are both improved, and the manufacturing cost of the knitting suturing machine is lowered.

Owner:NINGBO CIXING

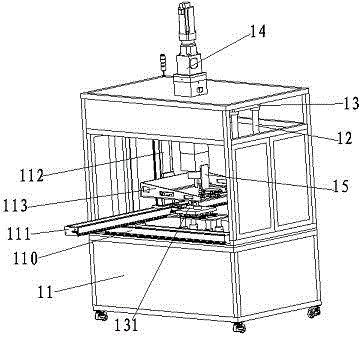

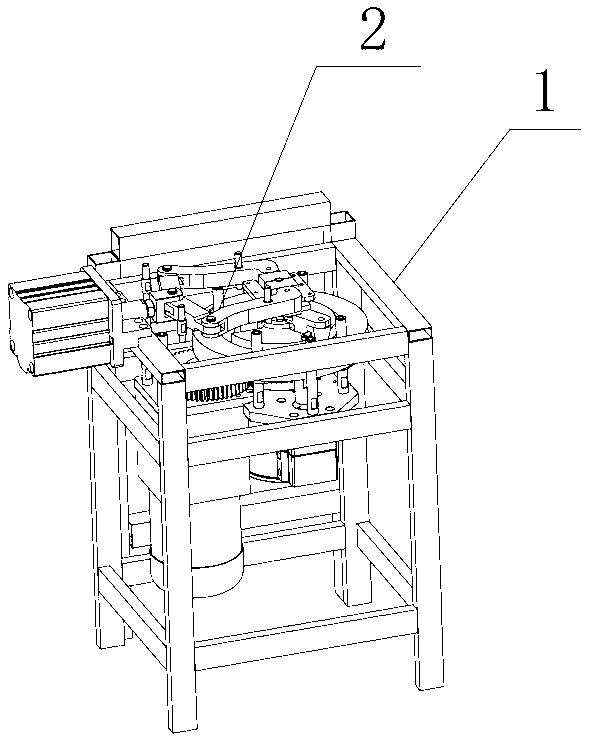

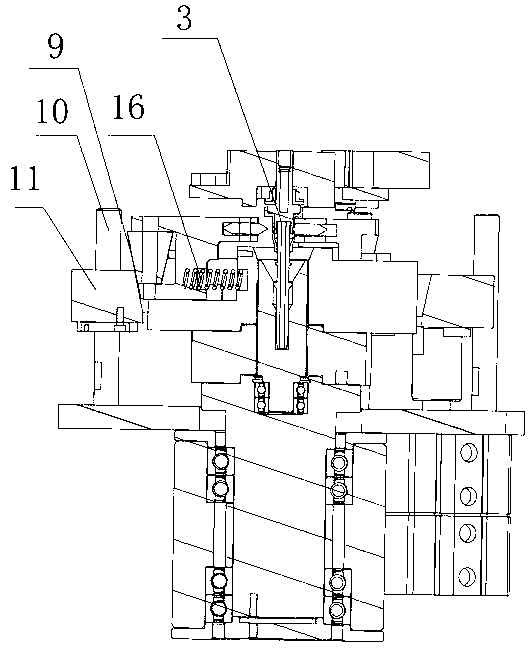

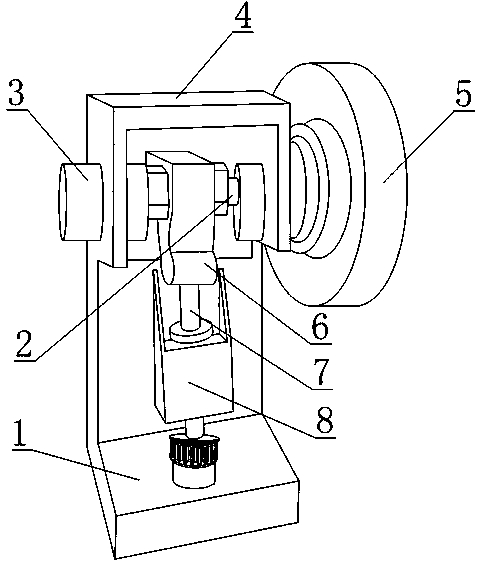

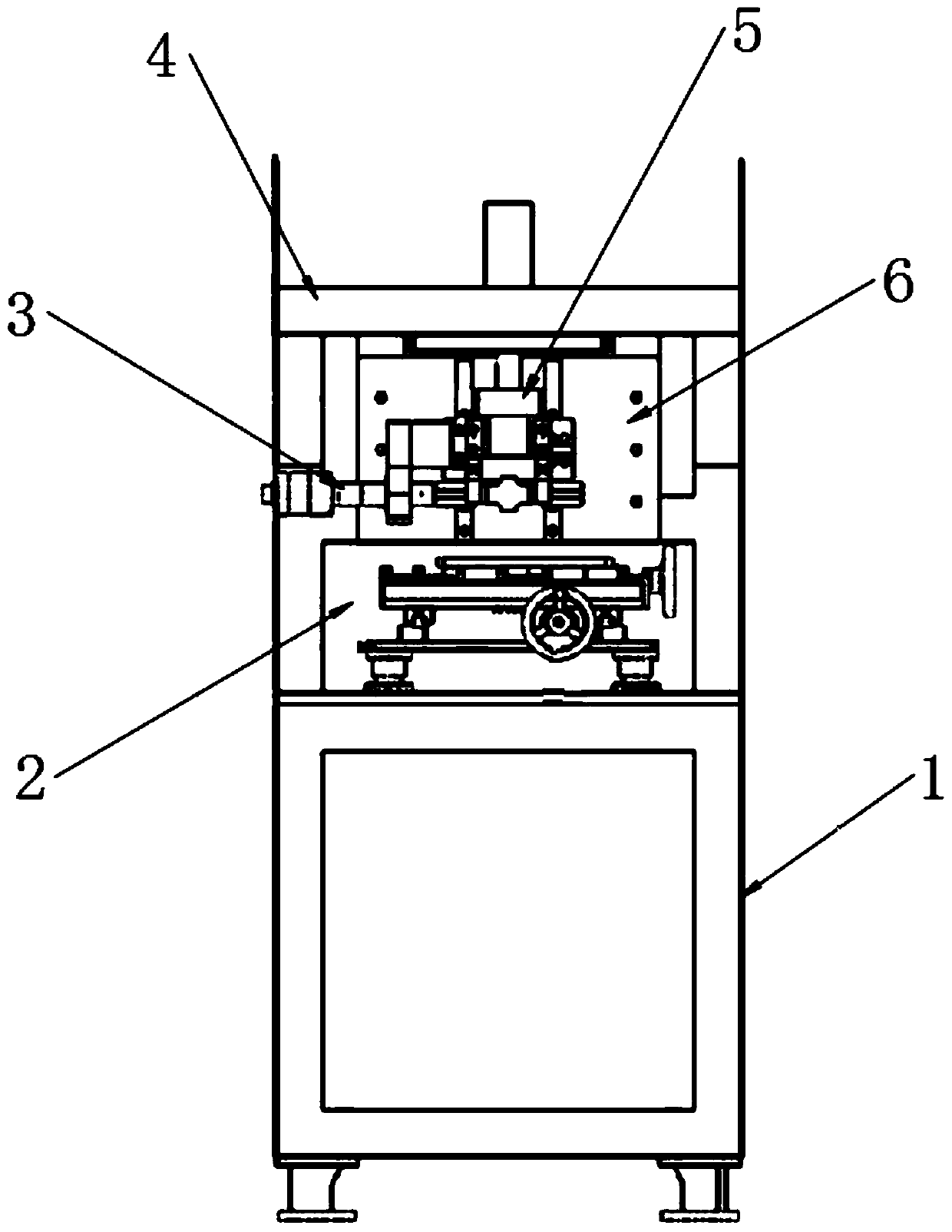

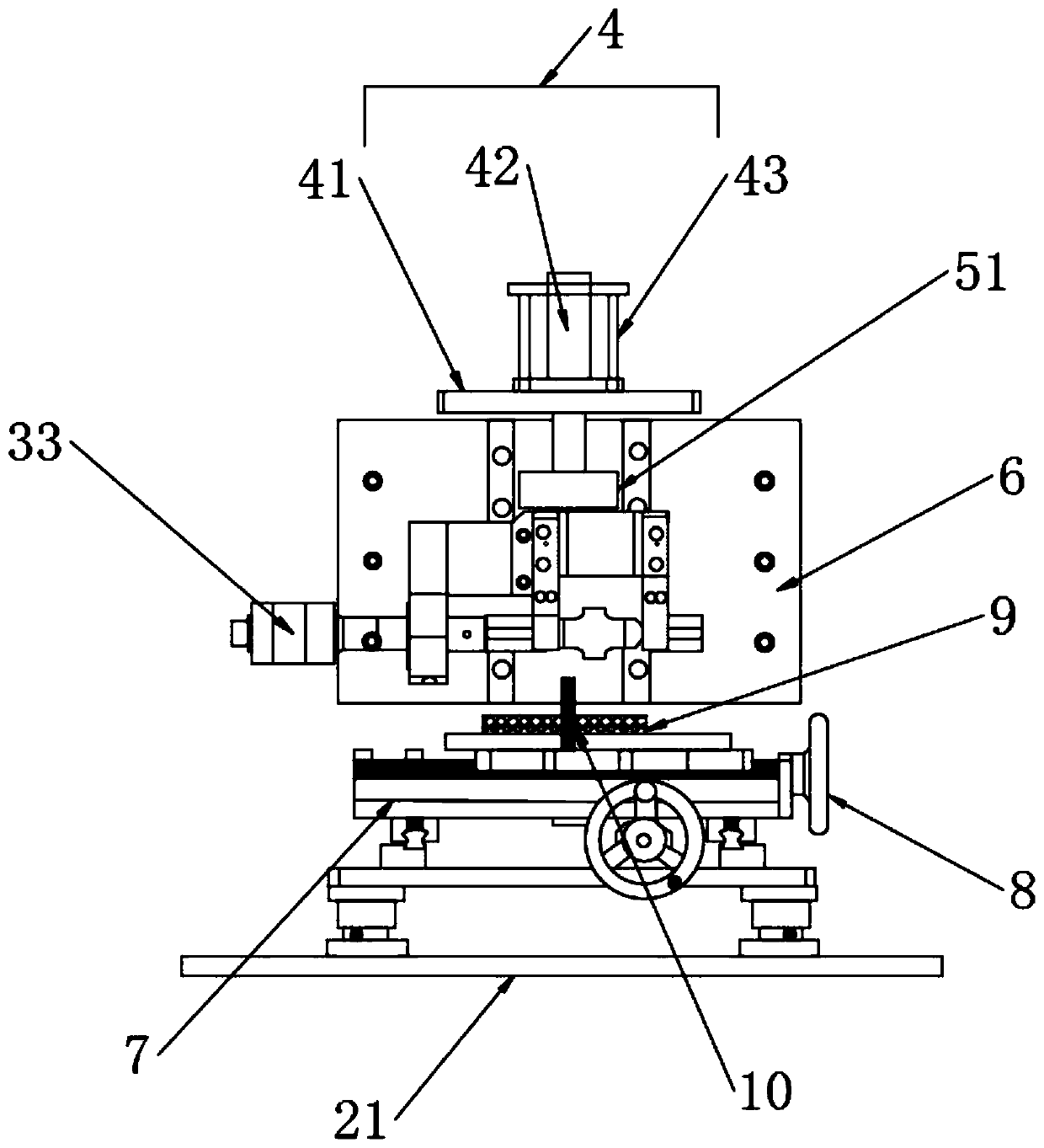

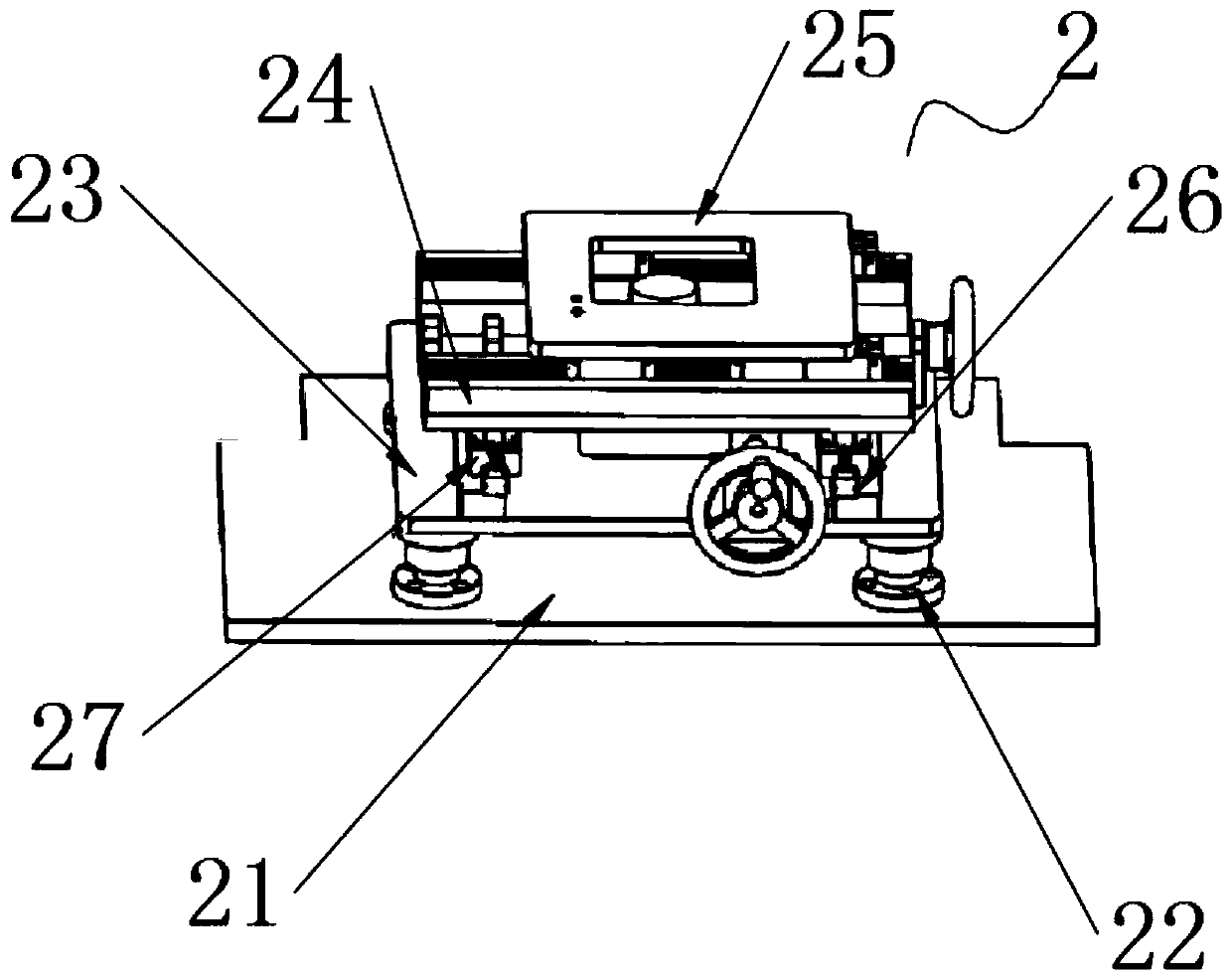

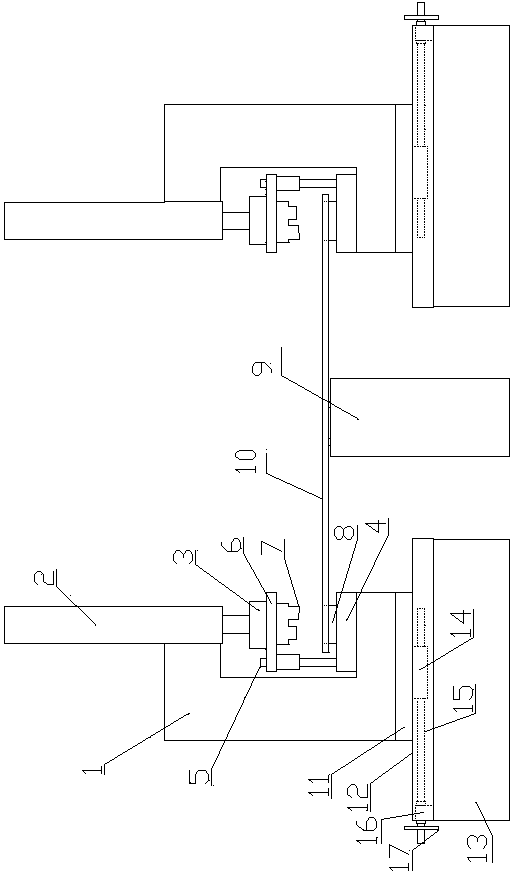

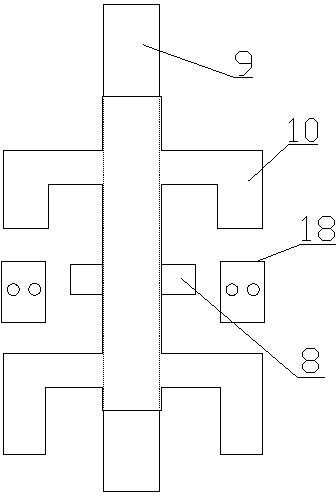

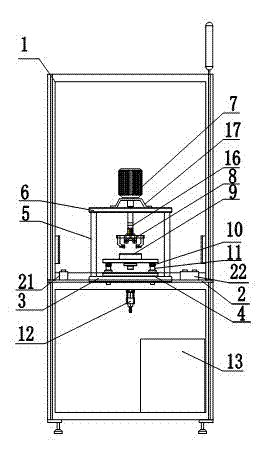

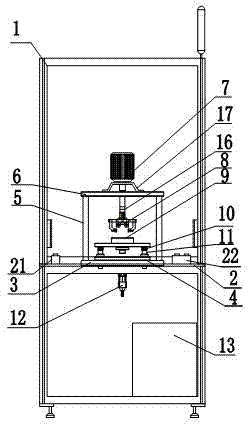

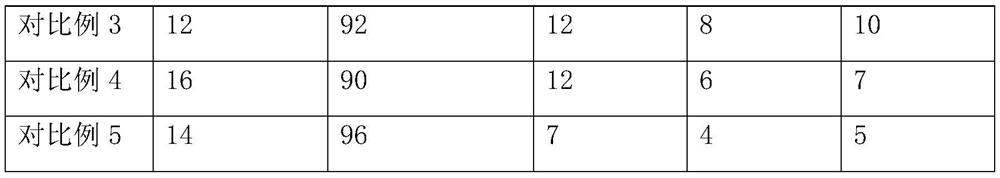

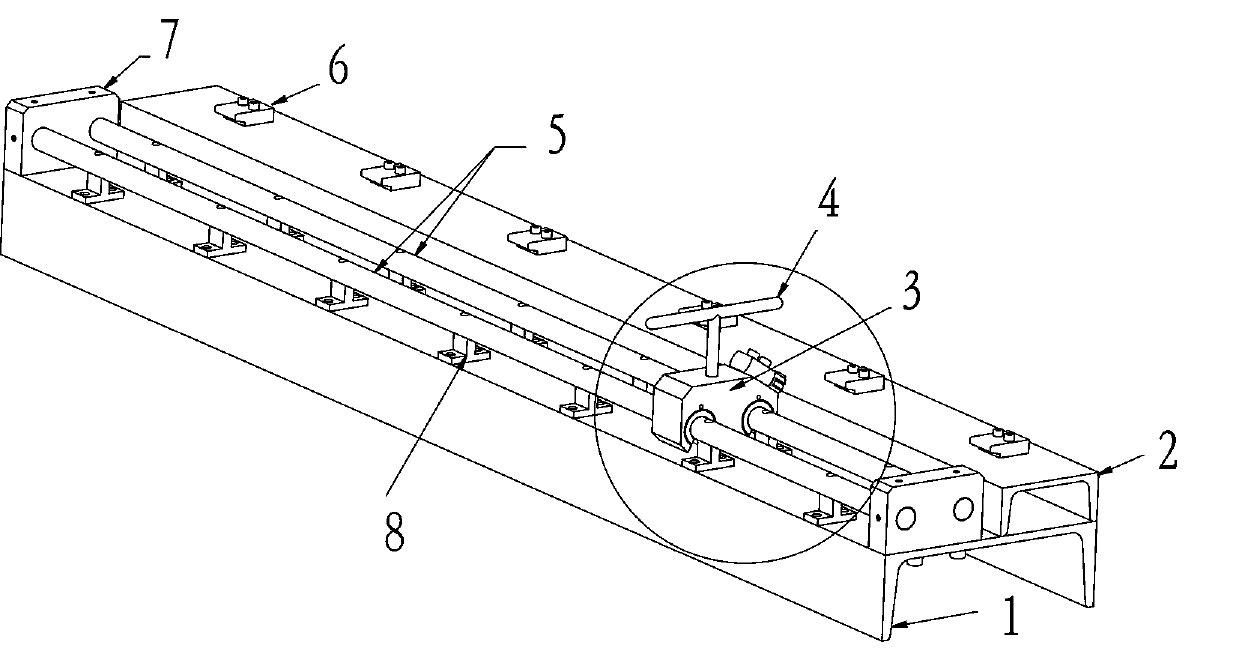

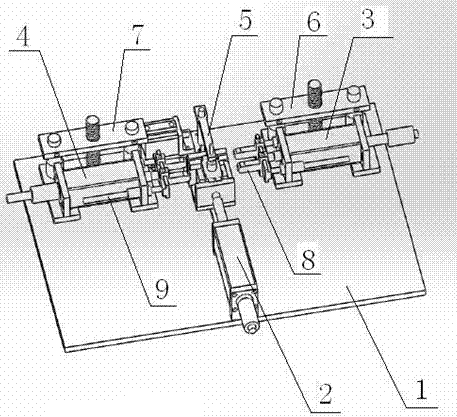

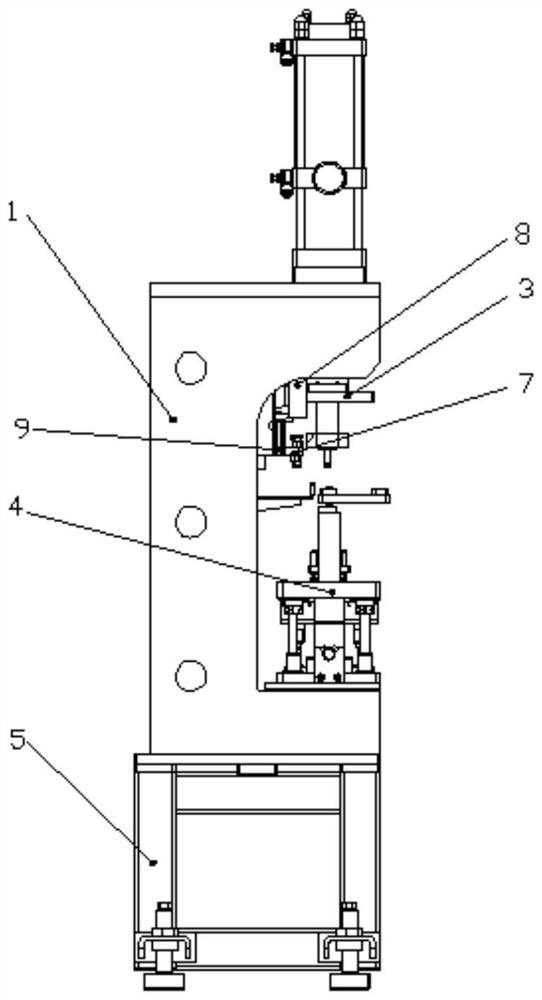

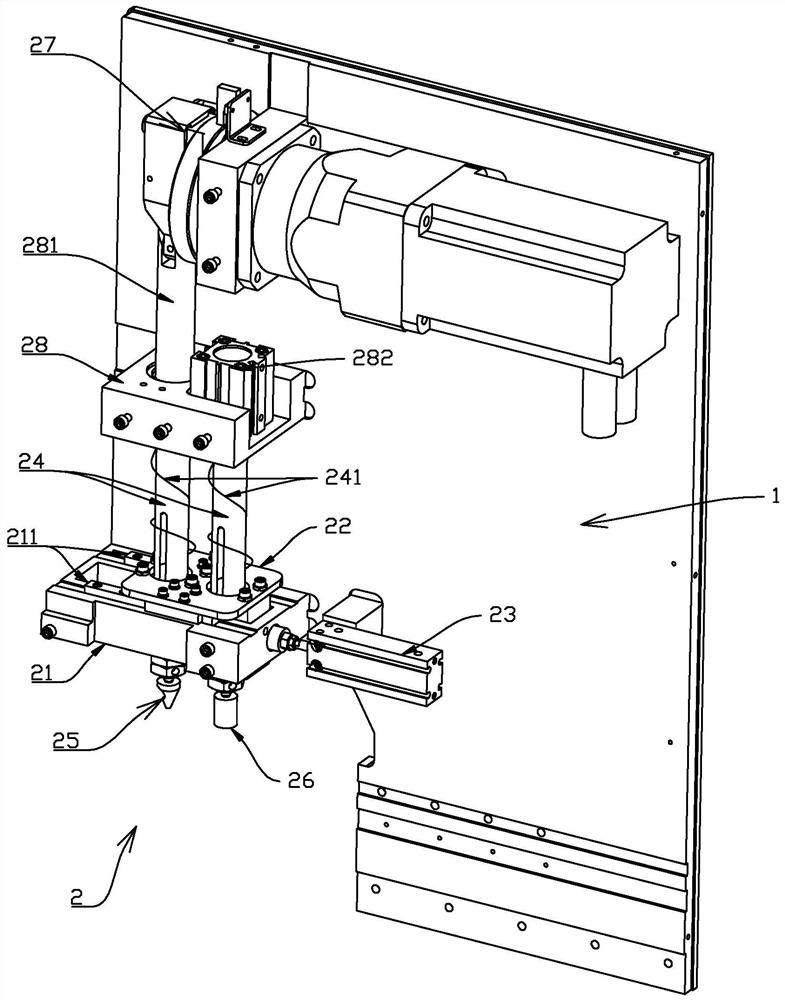

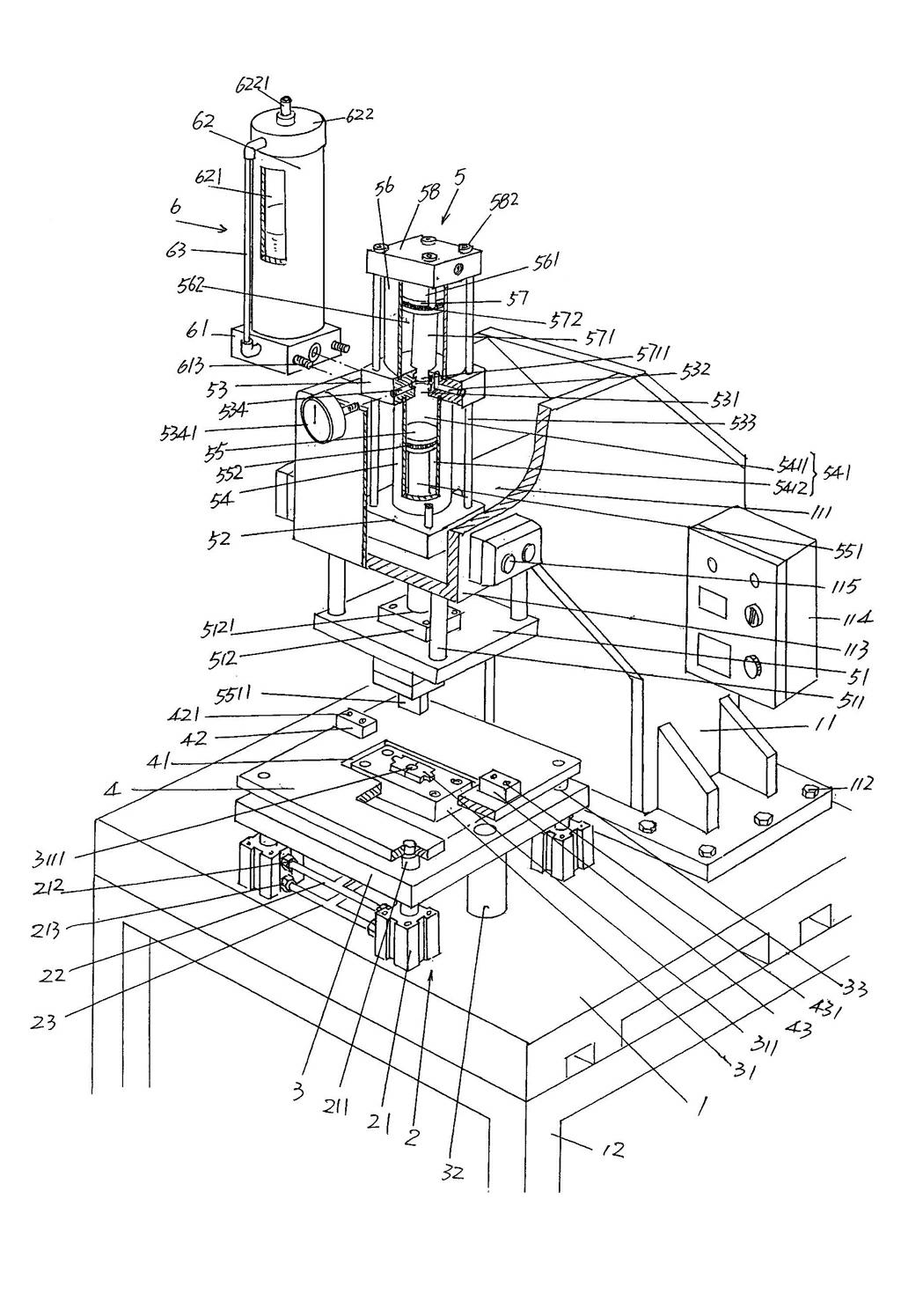

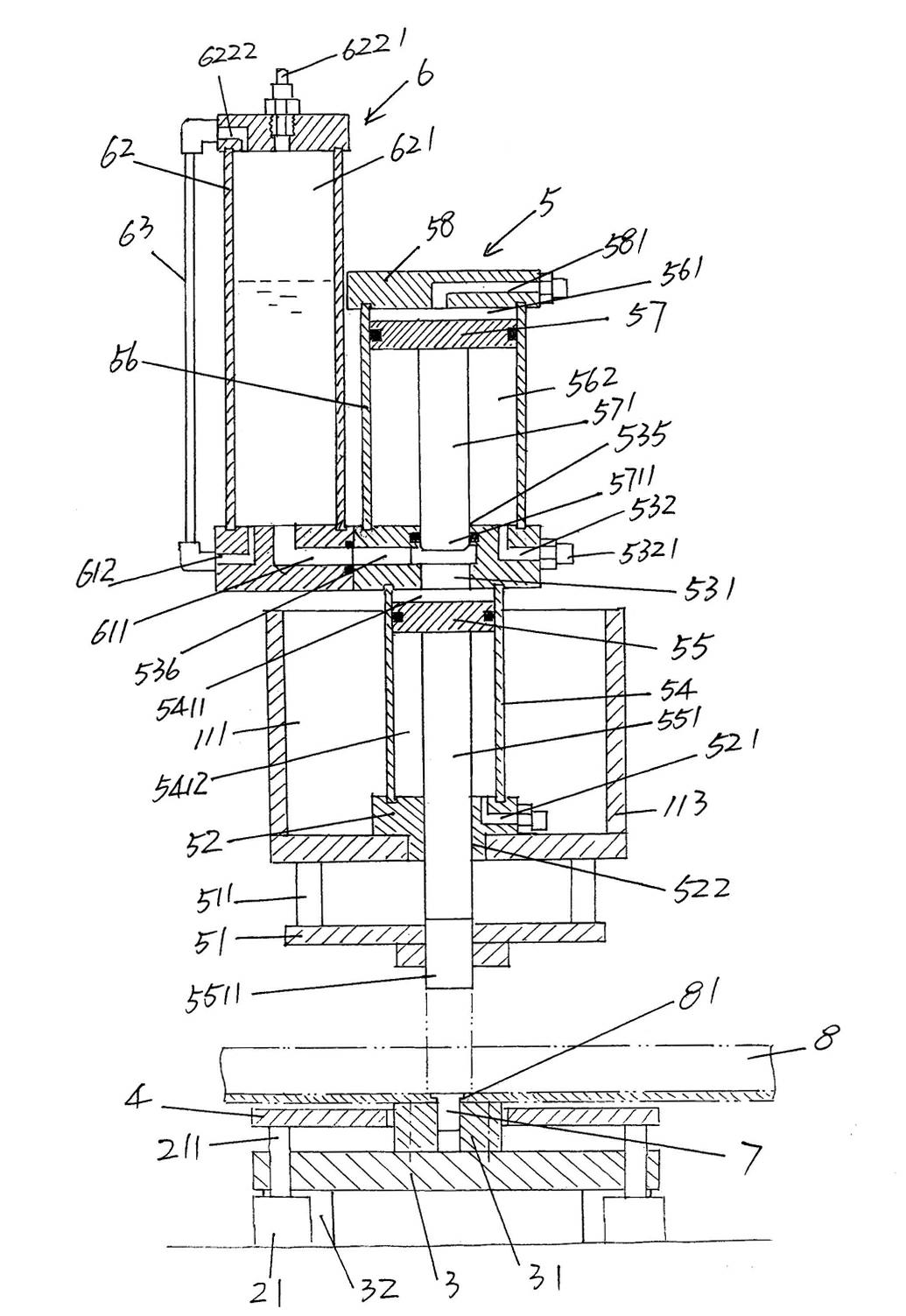

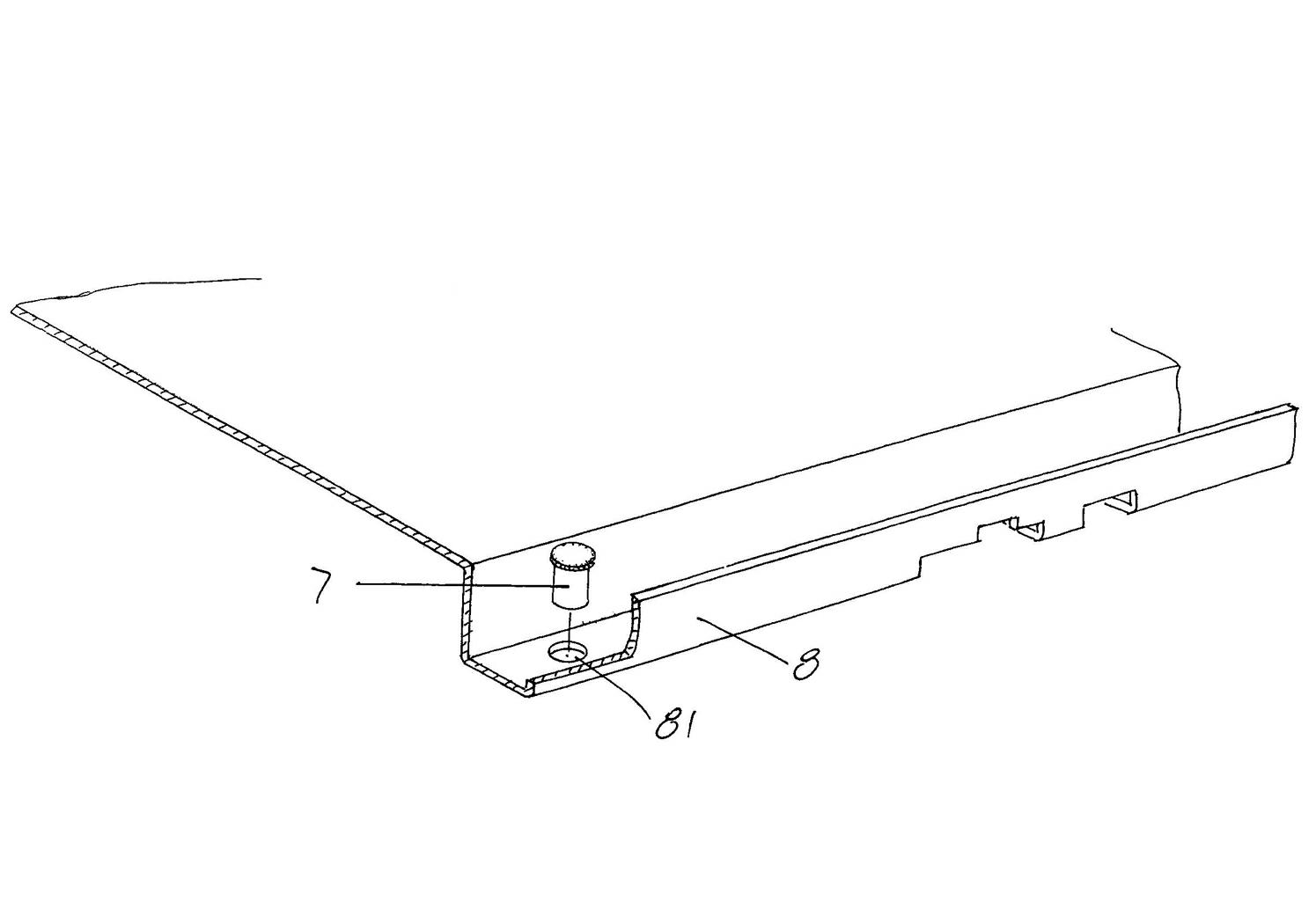

Automatic riveting device of transformer

InactiveCN103894499AGood riveting effectHigh degree of automationInductances/transformers/magnets manufactureTransformerFixed frame

The invention discloses an automatic riveting device of a transformer. The automatic riveting device comprises a bottom plate (1), a side fixing frame (2), a right riveting frame (3), a left riveting frame (4), an upper fixing frame (5) and a transformer installing base (10). The transformer installing base is fixed to the bottom plate. The upper fixing frame, the side fixing frame, the left riveting frame and the right riveting frame are located on the upper side, the lower side, the left side and the right side of the transformer installing base respectively. The upper fixing frame and the side fixing frame are fixed to the bottom plate, and the left riveting frame and the right riveting frame are fixed to the bottom plate through a left adjusting frame (7) and a right adjusting frame (6) respectively. The inner side of the left riveting frame and the inner side of the right riveting frame are respectively provided with a riveting head (8). The side fixing frame, the upper fixing frame, the left riveting frame and the right riveting frame are all connected with a controller. In the riveting process of an iron core outer housing, manual participation steps are fewer, after the transformer is manually placed on the transformer installing base, the controller controls the parts to fix and rivet the transformer, and the automation degree is high and the riveting effect is good in the whole process.

Owner:XUZHOU GLORIA TECH

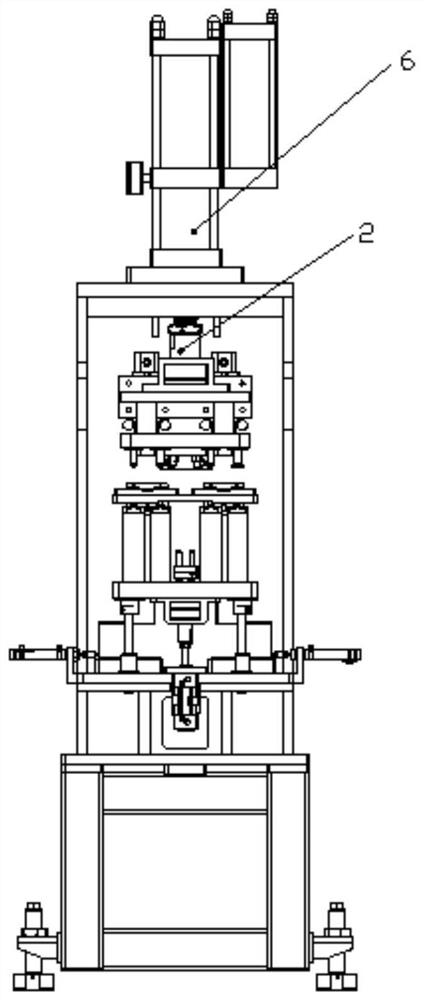

Equipment for riveting battery cover plate

ActiveCN112743030AQuality assuranceFlexible adjustment of riveting heightCell lids/coversStructural engineeringAir cylinder Press

The invention discloses equipment for riveting a battery cover plate. The equipment comprises a riveting support, a riveting rack table, a riveting pressing part and a riveting jacking part; the riveting support is fixed on the riveting rack table; the riveting pressing part is connected with the head of the riveting support; the riveting jacking part is connected with the table top of the riveting support; wherein the riveting pressing part comprises a gas-liquid pressure cylinder, a cylinder pressure head, a riveting pressure head assembly, a sliding block and a linear guide rail; The riveting jacking component comprises a jacking assembly; and the jacking assembly comprises a jacking bottom plate, a front air cylinder pressing head, a rear air cylinder pressing head, a jacking positioning plate, a front air cylinder floating connector base, a rear air cylinder floating connector base, four riveting jacking rods, a front jacking air cylinder, a rear jacking air cylinder and four bases. While the riveting quality is guaranteed, the application range is widened; and the riveting efficiency is improved.

Owner:马鞍山南实科技有限公司

Full-automatic labeling and riveting equipment

The invention discloses full-automatic labeling and riveting equipment. The full-automatic labeling and riveting equipment comprises a rotating base body, a rotating disc is rotatably connected with the rotating base body, the plane of the rotating disc is parallel to the horizontal plane, four positioning and clamping mechanisms are evenly distributed on the rotating disc in the circumferential direction of the rotating disc and correspond to a feeding station, a labeling station, a reverting station and a discharging station correspondingly, a labeling machine is arranged at the position, corresponding to the labeling station, of the rotating base body, a riveting machine is arranged at the position, corresponding to the riveting station, of the rotating base body, a through pin positioning cylinder is arranged at the position, corresponding to the feeding station, of the rotating base body in the vertical direction, two positioning pins are connected with the upper end of the through pin positioning cylinder, and the positioning pins can stretch into riveting holes in a cutter handle under the drive of the through pin positioning cylinder. According to the full-automatic labeling and riveting equipment, the full-automatic labeling and riveting process is achieved, the human participation does not need, and the whole work process can be completed after only one-time positioning.

Owner:重庆合心智能科技有限公司

Multifunctional riveting machine

PendingCN112450531AImprove efficiencyControllable volumeClothes making applicancesElectric machineryMoving parts

The invention belongs to the technical field of garment processing equipment, and particularly relates to a multifunctional riveting machine which comprises a rack, a lower die mechanism, a lower button feeding mechanism, an upper button feeding mechanism and a punching and upper button taking mechanism are arranged on the rack, and the punching and upper button taking mechanism comprises a punching rod base, a punching rod sliding block, two punching rods and a punching rod moving part. The punching rod moving part is used for driving the punching rod sliding block to move between a first position and a second position; the lower ends of the two punching rods are provided with a punch assembly used for being matched with a punching frame and an upper riveting die used for being matched with a lower riveting die. And the punching rods realize punching through a punching rod driving device. The machine has the following advantages: 1) the machine is more stable and higher in efficiency;2) the cost of a cylinder is far less than that of a stepping motor; and 3) the structure is arranged in the rack, so that the volume is more controllable. In addition, the punching rod driving device can achieve the punching procedure and the riveting procedure at the same time, and the riveting efficiency and the riveting quality are greatly improved.

Owner:ZHEJIANG ZHONGSEN SEWING MACHINE

Gas-liquid pressurized riveting machine

InactiveCN102581200AEasy to replaceSimple structureMetal working apparatusEngineeringMechanical engineering

The invention relates to a gas-liquid pressurized riveting machine and belongs to the technical field of riveting machines. The gas-liquid pressurized riveting machine comprises an engine base platform, a pushing plate lifting mechanism, a die base, a pulverizing plate, an instant pressurized pressure-riveting mechanism and a pressurized oil supplying mechanism, wherein an engine base is fixedly arranged on one side of the upward surface of the engine base platform in a using state and forms an engine base cavity; the pushing plate lifting mechanism is arranged on the engine base platform; the die base is fixed on the engine base platform; the pulverizing plate corresponds to the upper part of the die base and is connected with the pushing plate lifting mechanism, and the center of the pulverizing plate is provided with a die abdicating cavity; the instant pressurized pressure-riveting mechanism is positioned in the engine base cavity, fixed with the engine base and is above the position corresponding to the die abdicating cavity; and the pressurized oil supplying mechanism is connected with the instant pressurized pressure-riveting mechanism and communicated with a hydraulic pressure oil path of the instant pressurized pressure-riveting mechanism, a die is fixedly arranged on the die base, and a die core is arranged on the die. The gas-liquid pressurized riveting machine has the advantages that the simplified structure enables that the operation and maintenance are more convenient; and the replacement of dies is convenient, is good for reflecting the stability of actions as well as saving energy sources, and can reflect an ideal pressure-riveting effect.

Owner:SOHBI CRAFT CHANGSHU

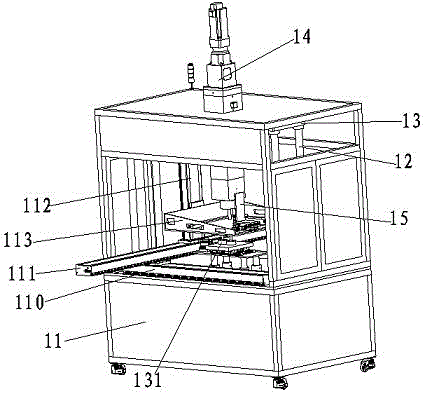

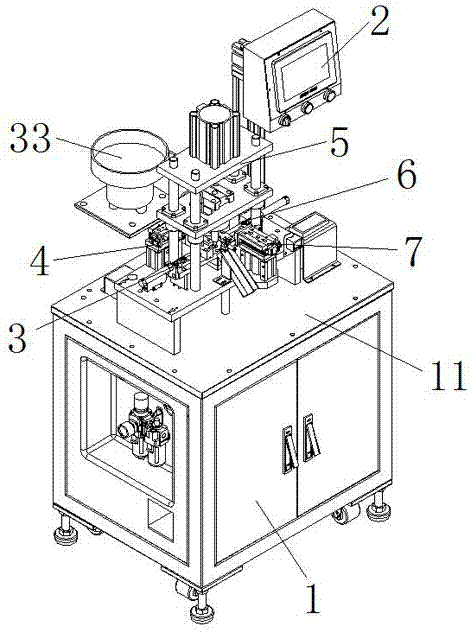

Machine for automatically combining and riveting gear shafts with gear plates in straight-line manner

A linear gear shaft and gear plate automatic combination riveting machine of the present invention includes a machine case, a machine table, a man-machine operation interface, a column gear feeding mechanism, a column gear stripping cylinder, a riveting combination mechanism, a piece gear feeding mechanism, and a finished product unloading mechanism. Feeding mechanism, pressure switch and pressure sensing display. The invention can realize a series of operations such as automatic feeding, automatic changing of the conveying direction of the workpiece, automatic positioning, automatic precise riveting, automatic material suction and unloading for the column gear and the plate gear. It not only has firm riveting, but also has high riveting efficiency. , high riveting precision and high production capacity, which also reduces the labor intensity and labor cost of workers, and ensures that the finished products riveted by it can reach a uniform standard. As a result, it has the problems of low riveting efficiency, poor riveting precision, inconsistent riveting pressure and difficulty in reaching uniform standards for riveted finished products.

Owner:罗飞龙

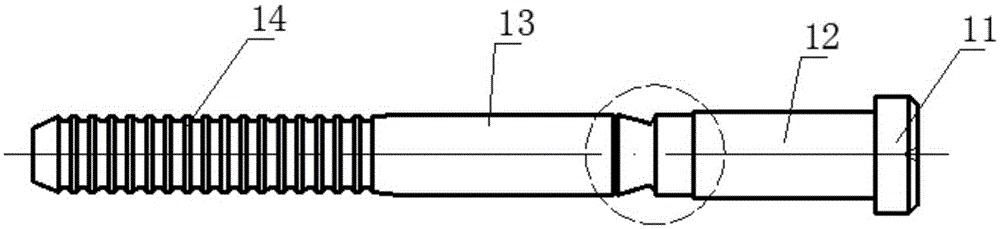

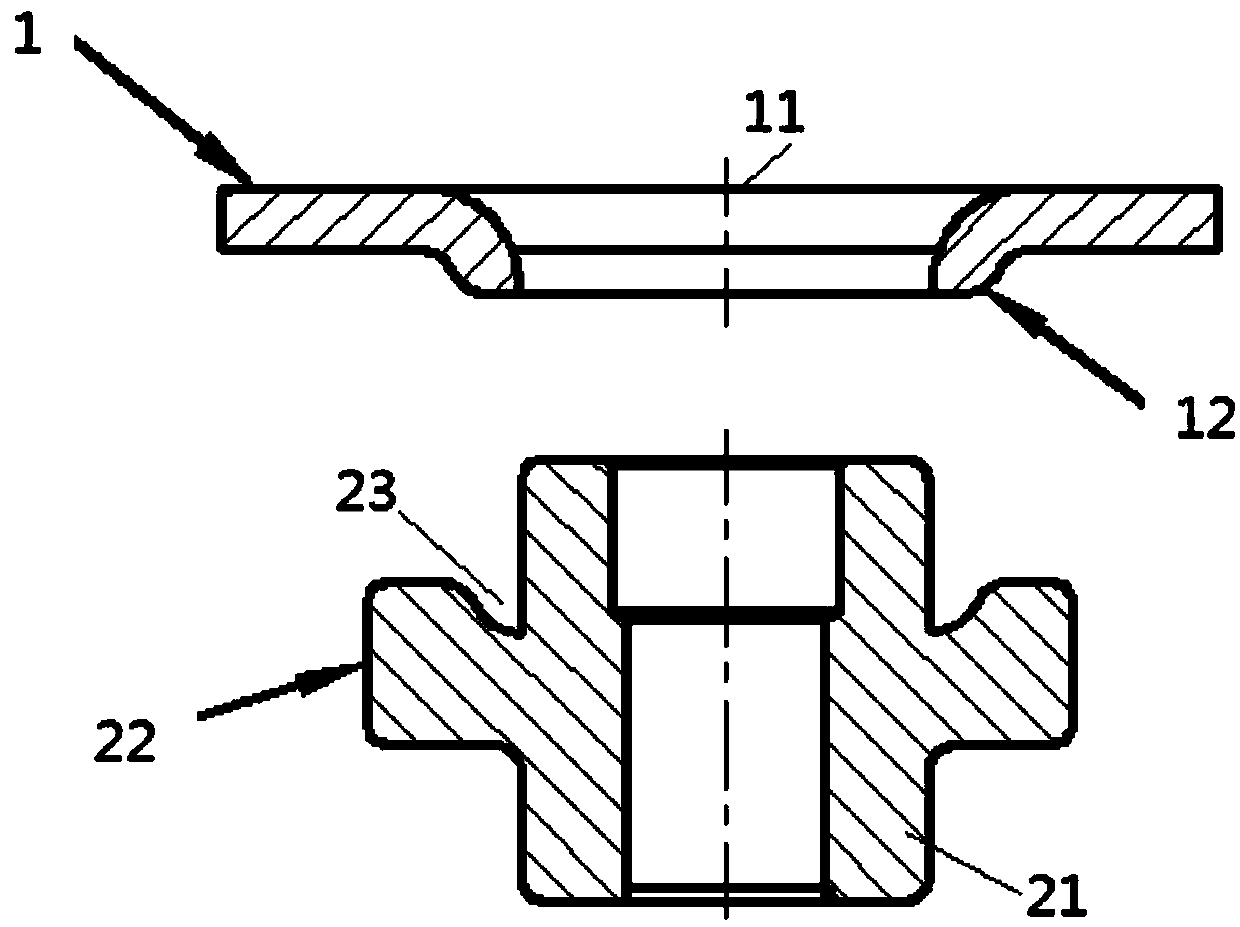

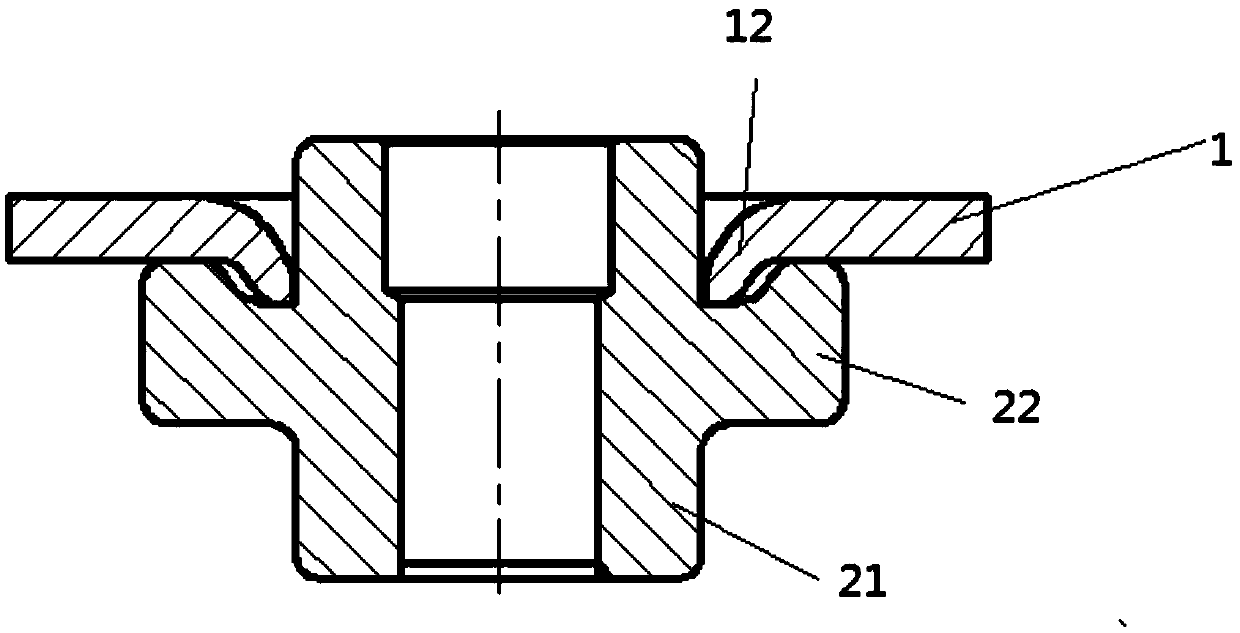

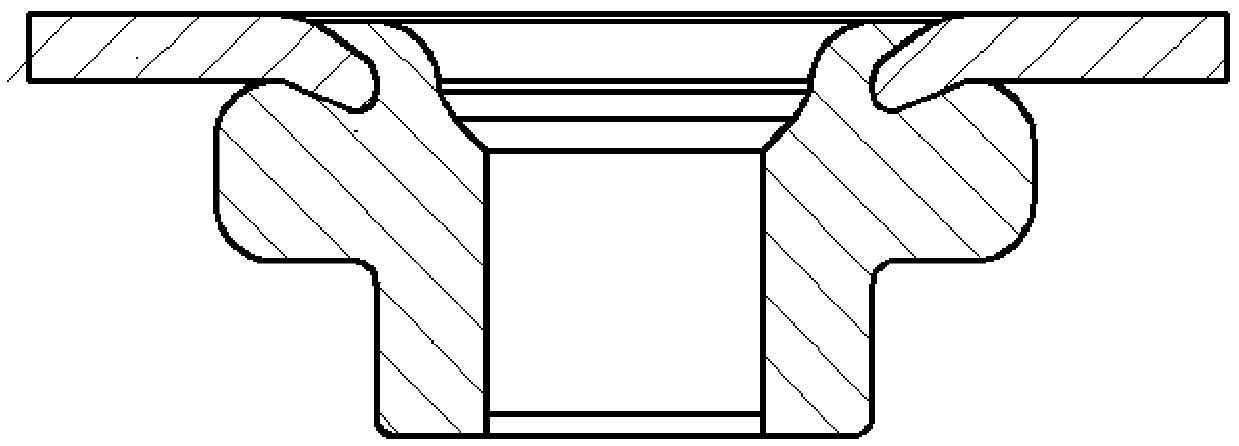

Technology for improving riveting performance of nut

The invention relates to a technology for improving riveting performance of a nut. The technology for improving the riveting performance of the nut comprises the following steps that (1) a pre-punchedhole (11) is pre-punched in a part to be riveted (1), and flanging is carried out on the periphery of the pre-punched hole (11) through flanging processes to form an arc-shaped flange (12) bent downwards; and (2) the riveting nut sleeves the part to be riveted (1) from the arc-shaped flange (12), and the riveting between the part and the riveting nut is completed through downward motion of an upper mould punch pin after positioning. Compared with the prior art, the stability of products is guaranteed, and the quality of the products is greatly improved.

Owner:SHANDONG AOLIN CAR FITTINGS

Riveting mechanism of riveting machine

The invention discloses a riveting mechanism of a riveting machine. The riveting mechanism of the riveting machine comprises a riveting rack. The two opposite sides of a worktable top of the riveting rack are each provided with two corresponding supporting pillars. A pressing machine fixing plate is fixed to the upper ends of the four supporting pillars. A longitudinal pressing machine is installed on the pressing machine fixing plate. The upper portion of the pressing machine penetrates the top face of the riveting rack, and the lower portion of the pressing machine penetrates the pressing machine fixing plate and is fixed to the vertical edge of an L-shaped air cylinder installation plate. A longitudinal displacement sliding table air cylinder is installed on the lower plane of the transverse edge of the L-shaped air cylinder installation plate. A rivet discharging sliding table air cylinder perpendicular to a sliding table of the displacement sliding table air cylinder is installed on the sliding table of the displacement sliding table air cylinder. The output end of a sliding table of the rivet discharging sliding table air cylinder is provided with a rivet discharging connecting block. The end face of the rivet discharging connecting block is provided with two pairs of rivet clamping claws through rivet discharging guide rods. By means of the above manner, the riveting mechanism is convenient to operate, long in service life and capable of greatly improving the production efficiency.

Owner:湖南哈工机器人研究院有限公司

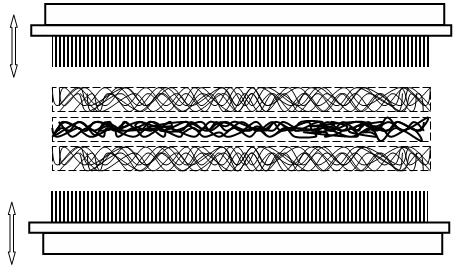

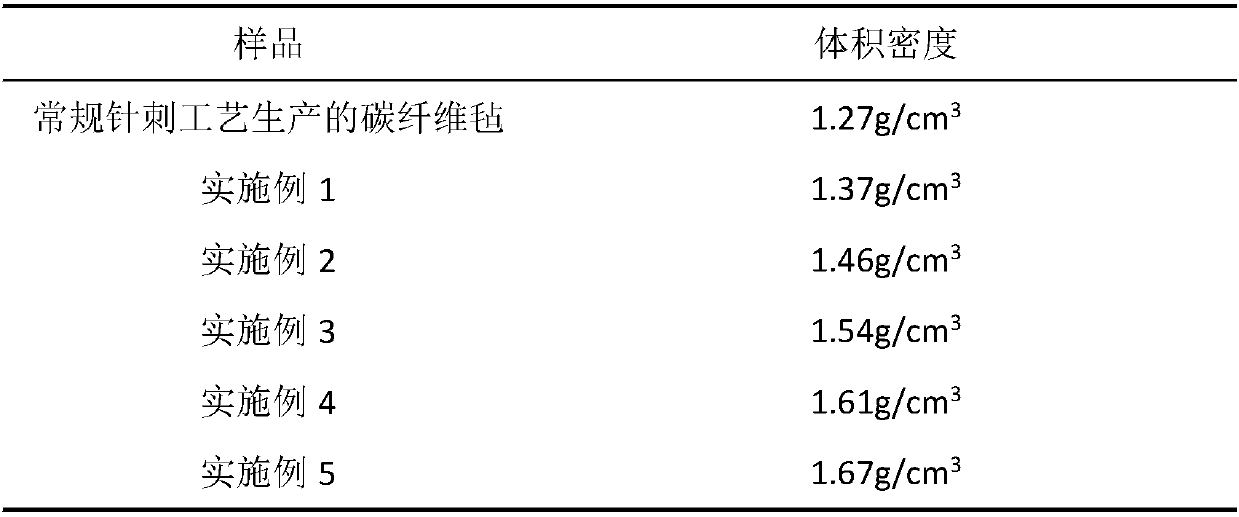

Method for improving carbon fiber felt needling efficiency

InactiveCN107558002AReduce voidsIncreased interlayer strengthNon-woven fabricsFiber bundleCarbon fibers

The invention relates to a method for improving the carbon fiber felt needling efficiency, and belongs to the technical field of textile processing. The method has the advantages that negative-pressure adsorption is carried out on fluffy carbon fiber nets under negative-pressure conditions in carbon fiber felt needling technologies when the carbon fiber nets which are already subjected to openingcarding and net laying are transmitted through the upper surfaces of needling tables, the adsorbed carbon fiber nets can be contracted towards negative-pressure running directions, and the contractedcarbon fiber nets are needled by needles of upper needling plates positioned above the needling tables while the carbon fiber nets are contracted; the fluffy carbon fiber nets are adsorbed and contracted under the negative pressures, accordingly, the carbon fiber nets can be densely woven, the needling frequencies can be reduced, and the carbon fiber felt needling efficiency can be improved; the problem of low carbon fiber net needling efficiency due to smooth surfaces of carbon fibers can be solved under the negative-pressure adsorption effects of the negative pressures on carbon fiber bundles, accordingly, carbon fiber felt needling effects can be enhanced, the quality of finished products can be improved, and the production cost can be reduced.

Owner:WUHAN TEXTILE UNIV

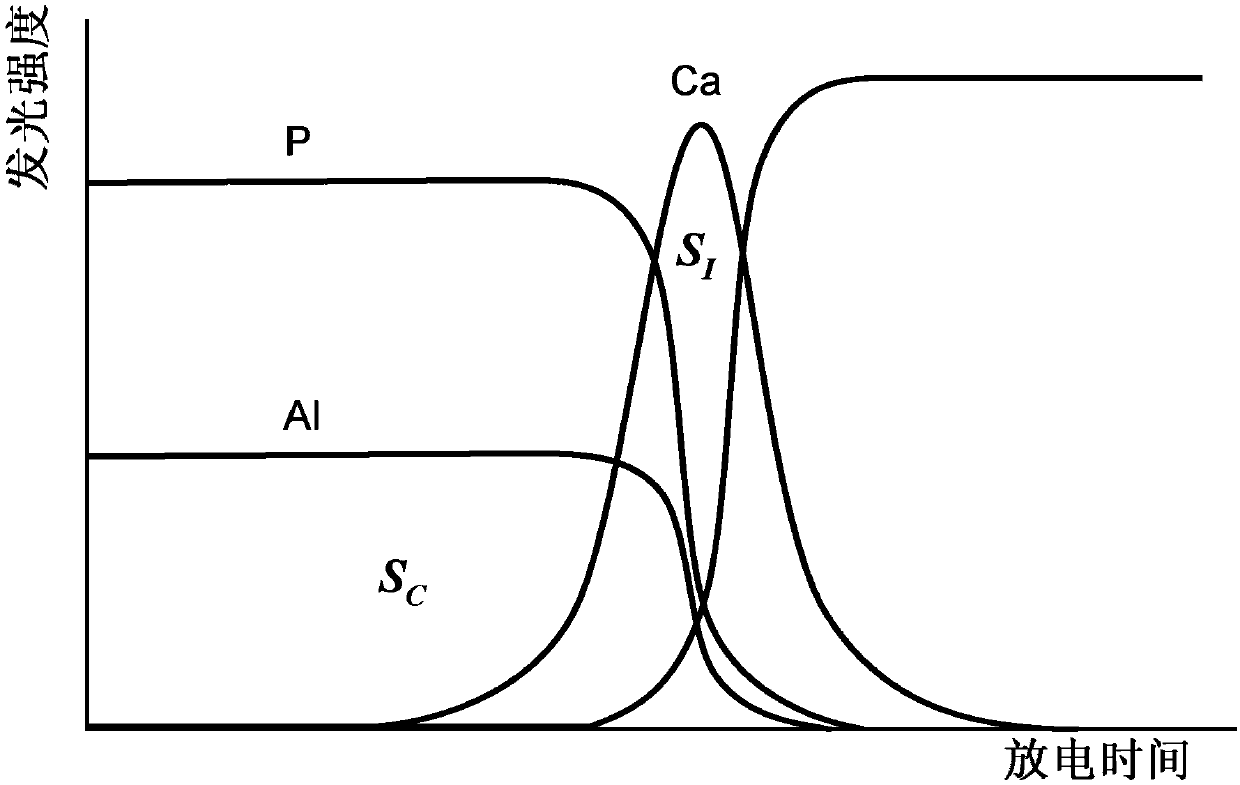

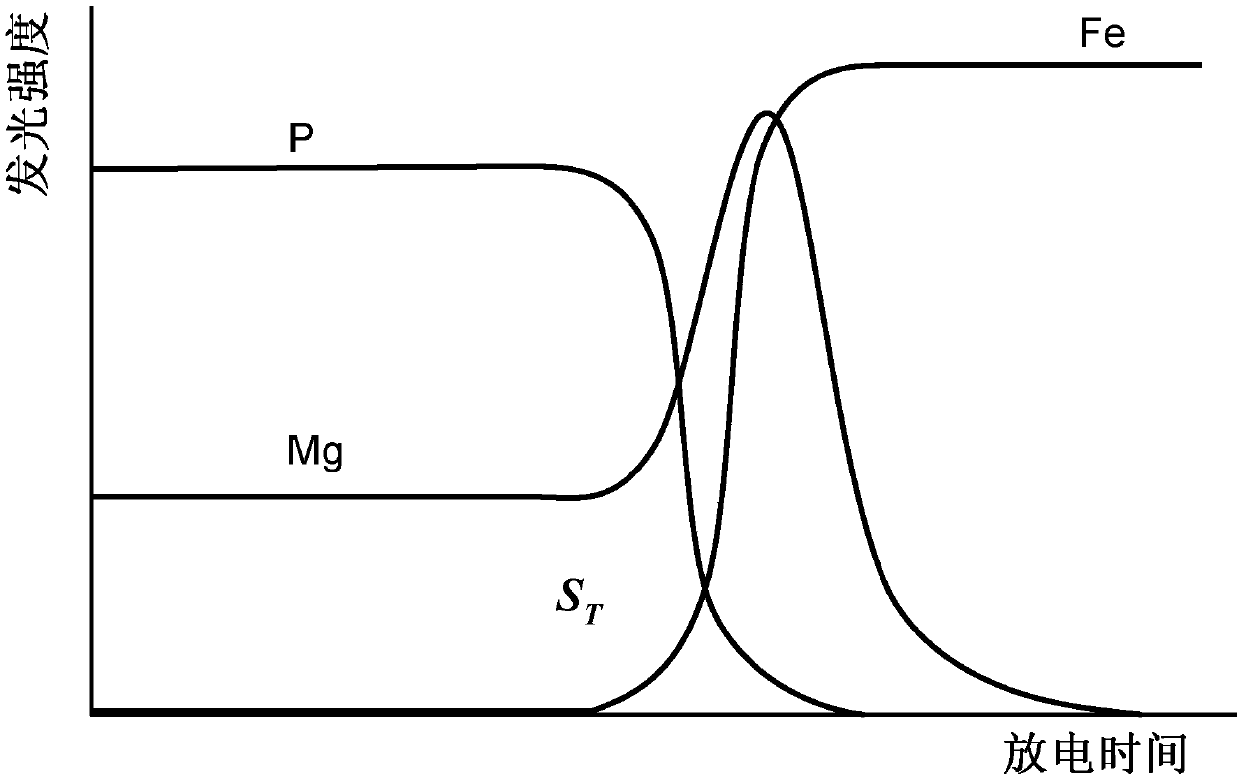

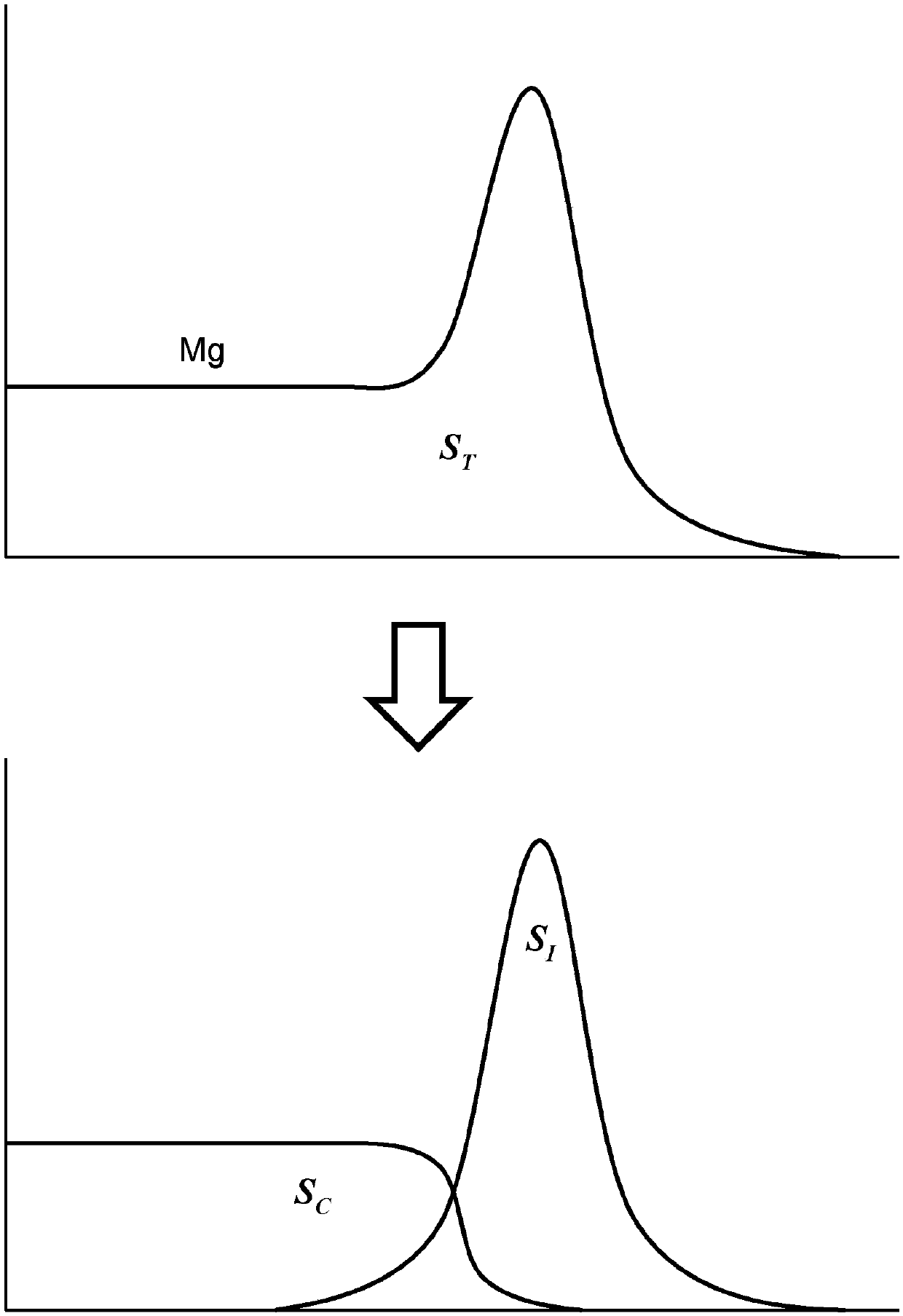

Insulating coating film for electromagnetic steel sheet

ActiveCN107614752AGood welding performanceGood riveting effectInorganic material magnetismFurnace typesDivalent metalPhosphate

Provided is an insulating coating film for an electromagnetic steel sheet, the coating film being formed on a surface of a base material of an electromagnetic steel sheet, wherein the insulating coating film contains a phosphate of at least one type of polyvalent metal selected from among Al, Zn, Mg and Ca, a divalent metal-concentrated layer is present at the interface between the insulating coating film and the surface of the base material, and the increase in concentration of the divalent metal in the concentrated layer is not less than 0.01 g / m<2> and less than 0.2 g / m<2>.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com