Patents

Literature

269results about How to "Deformation stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

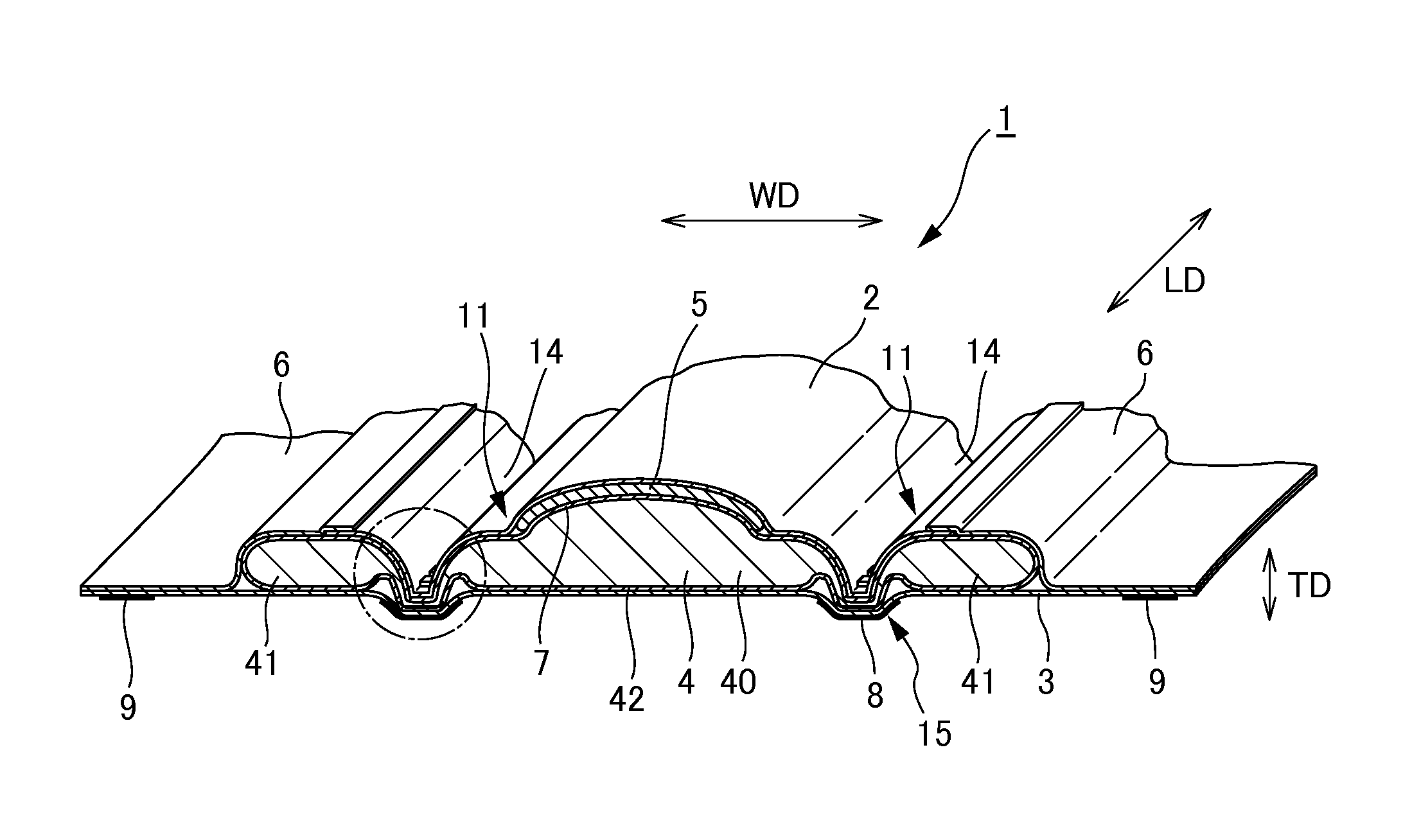

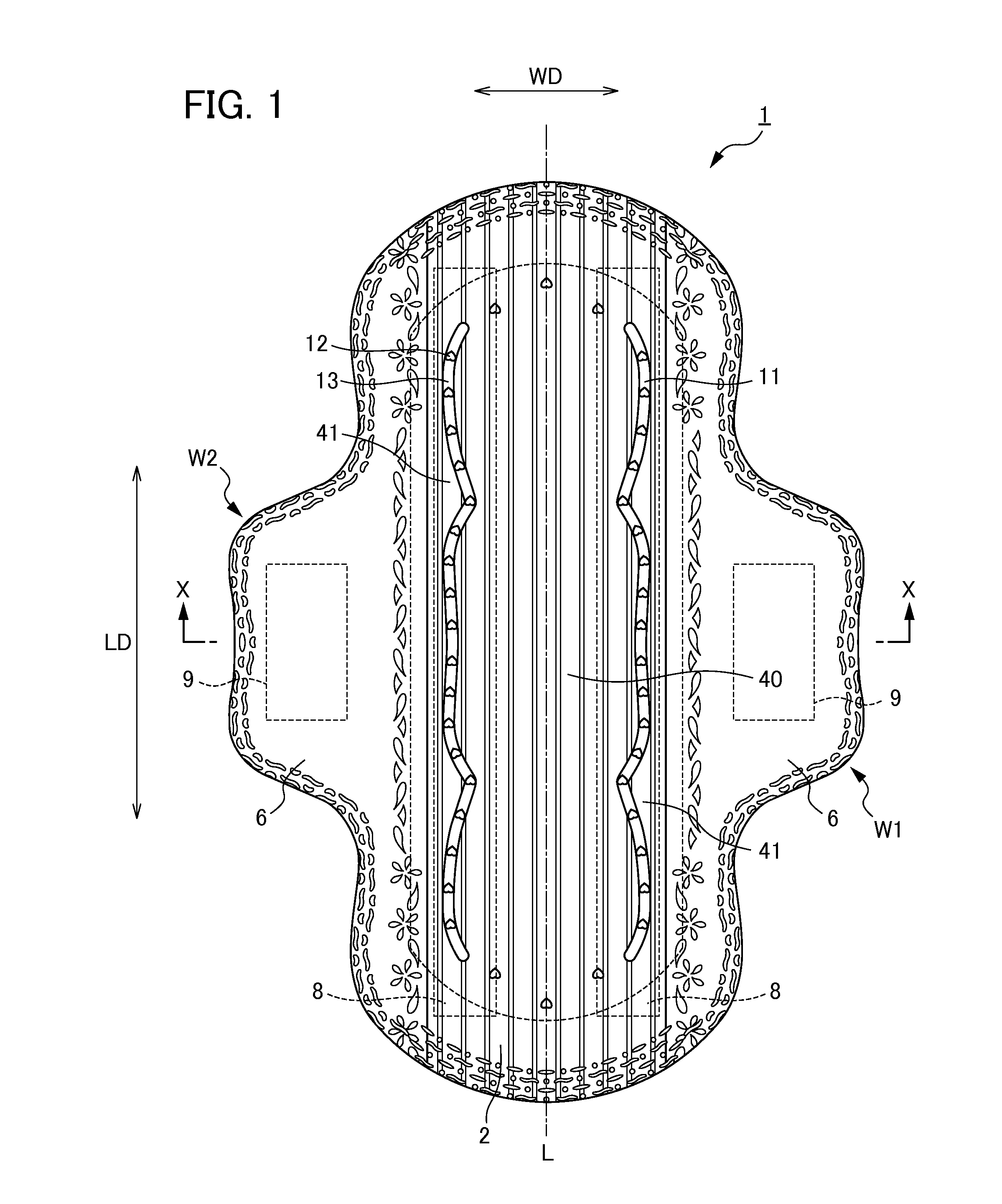

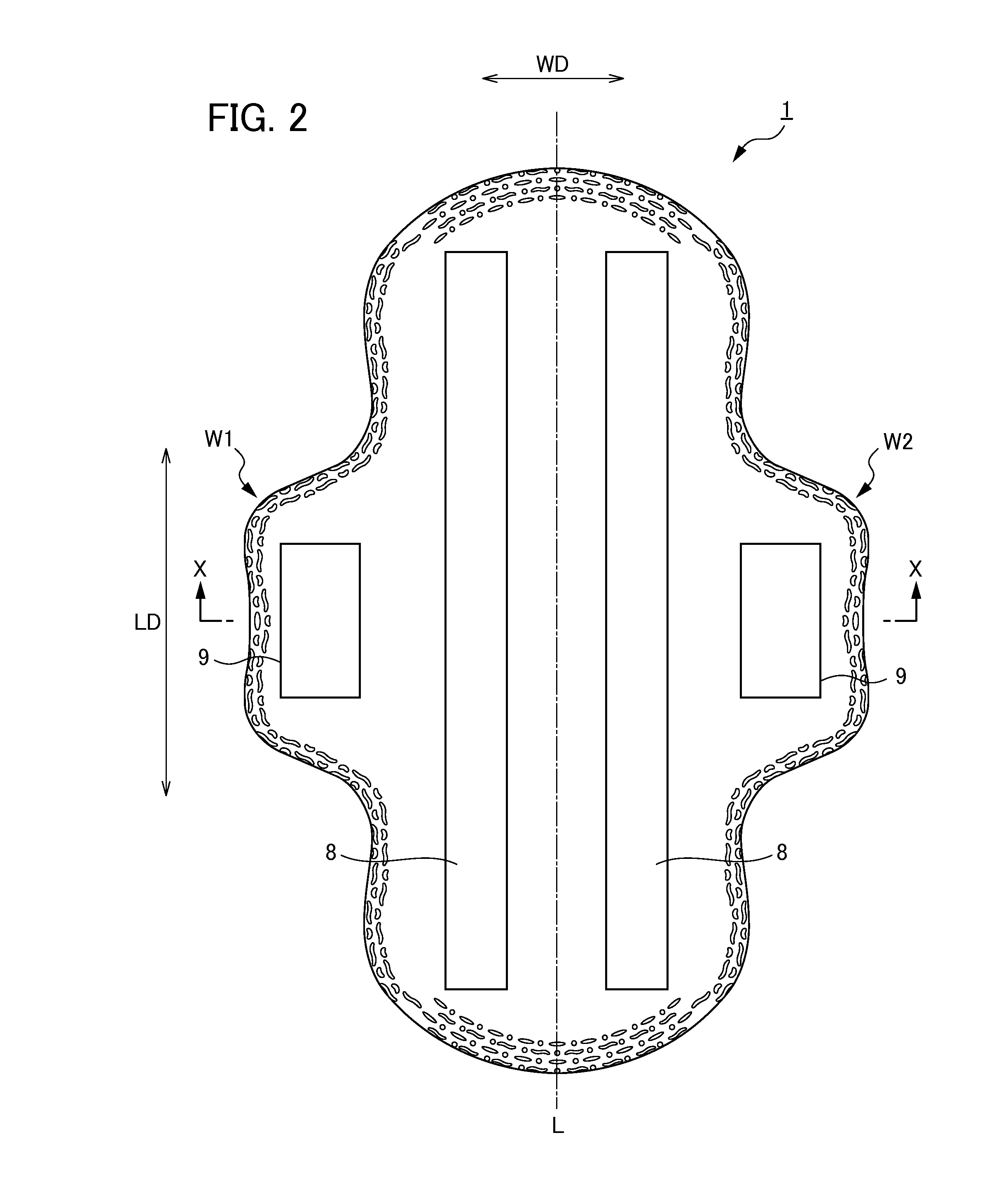

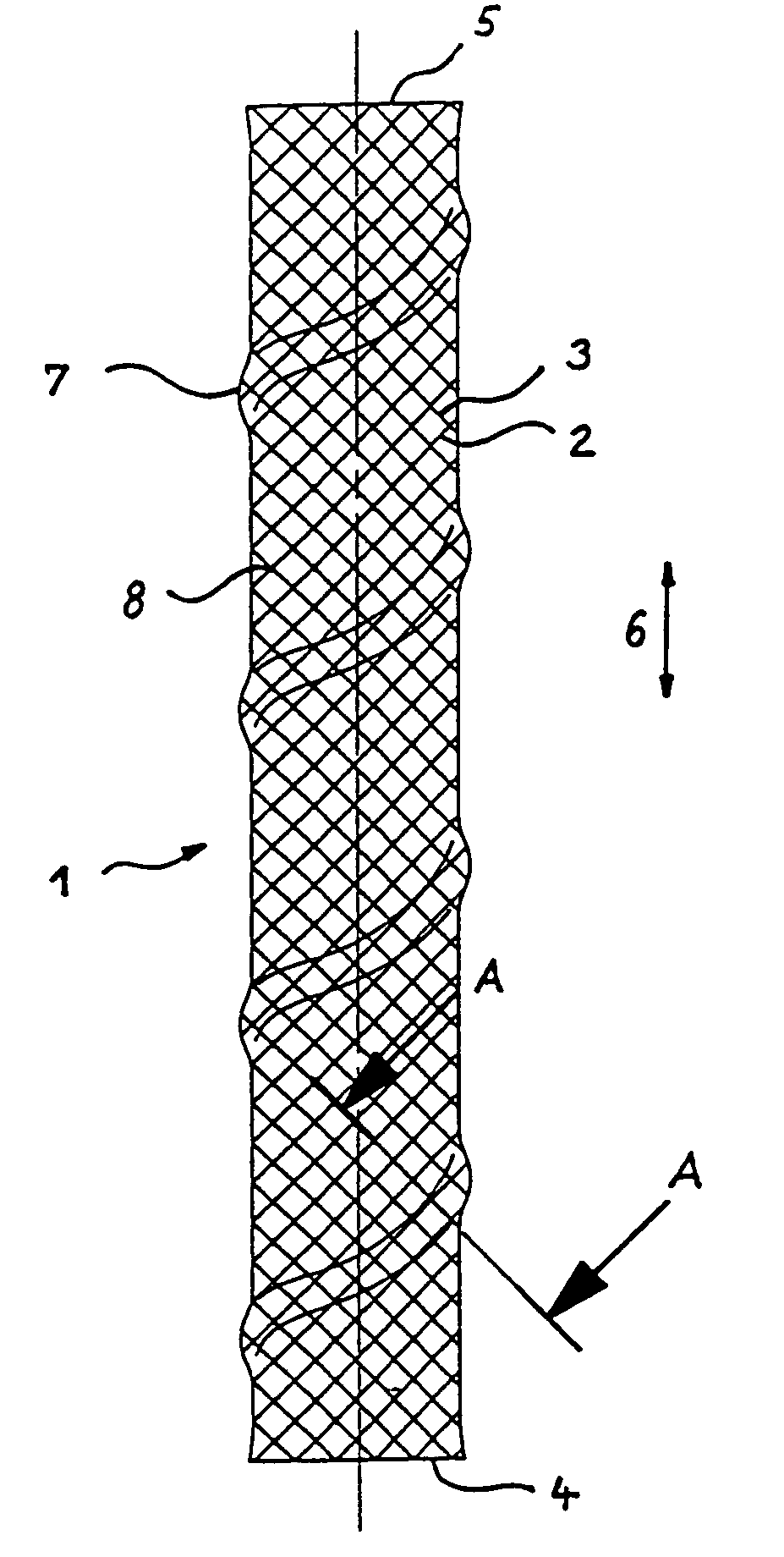

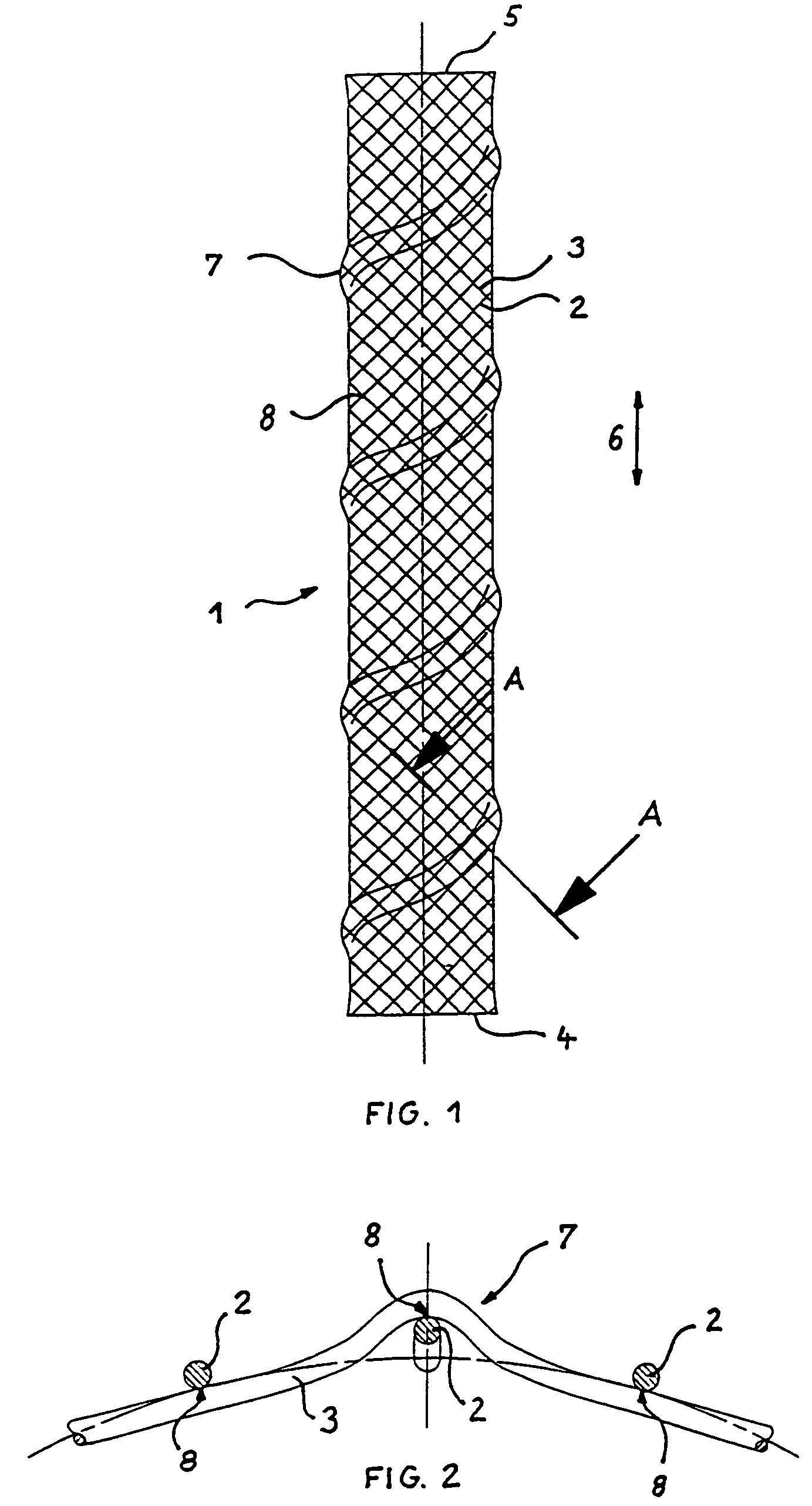

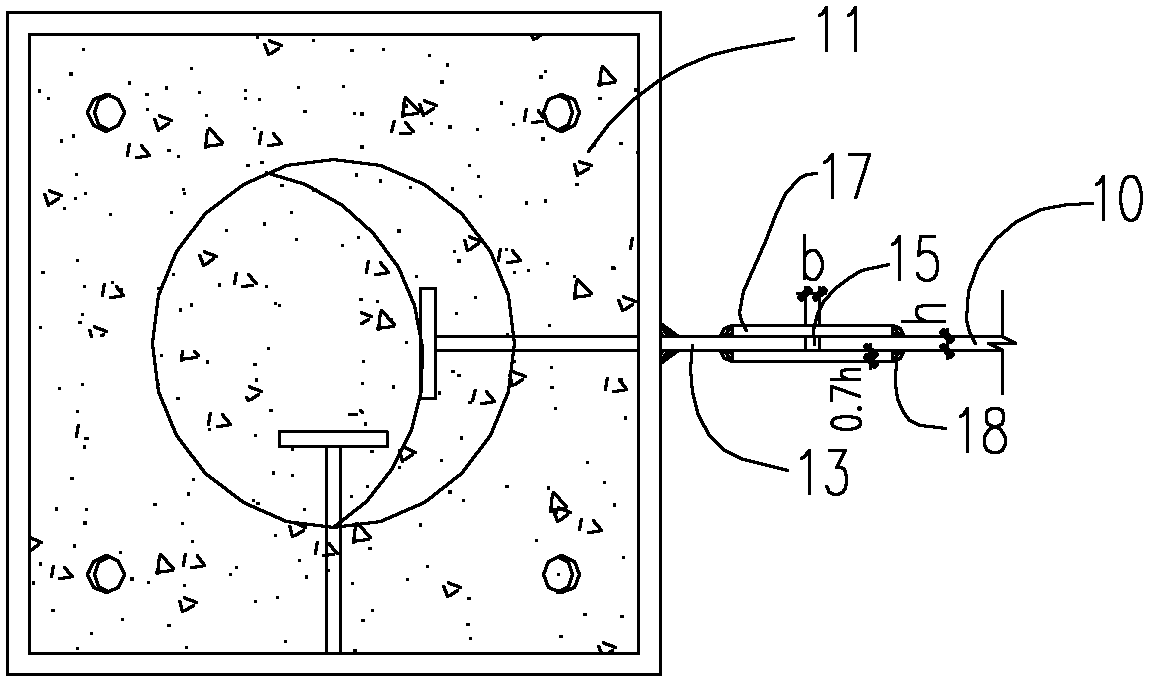

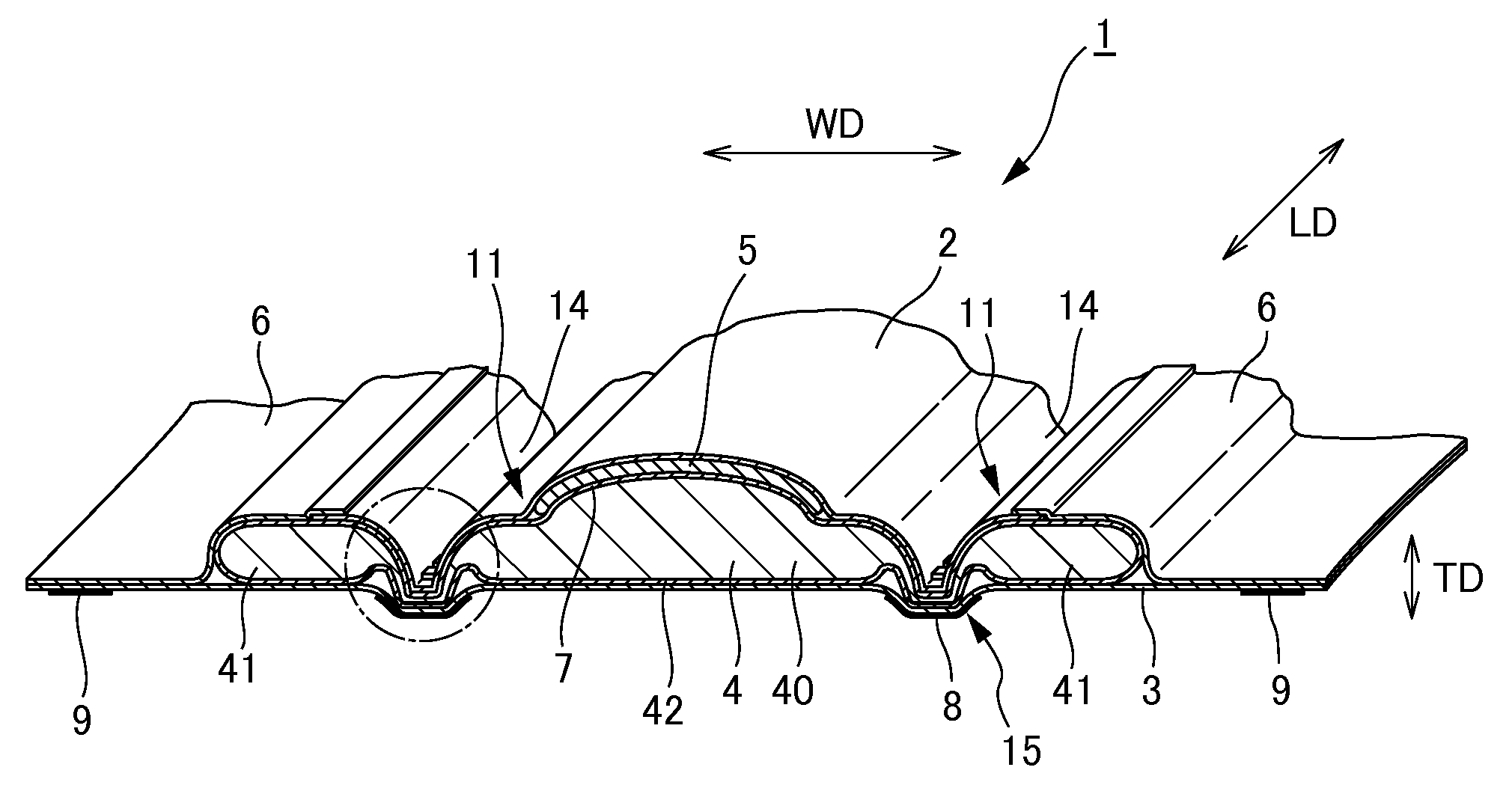

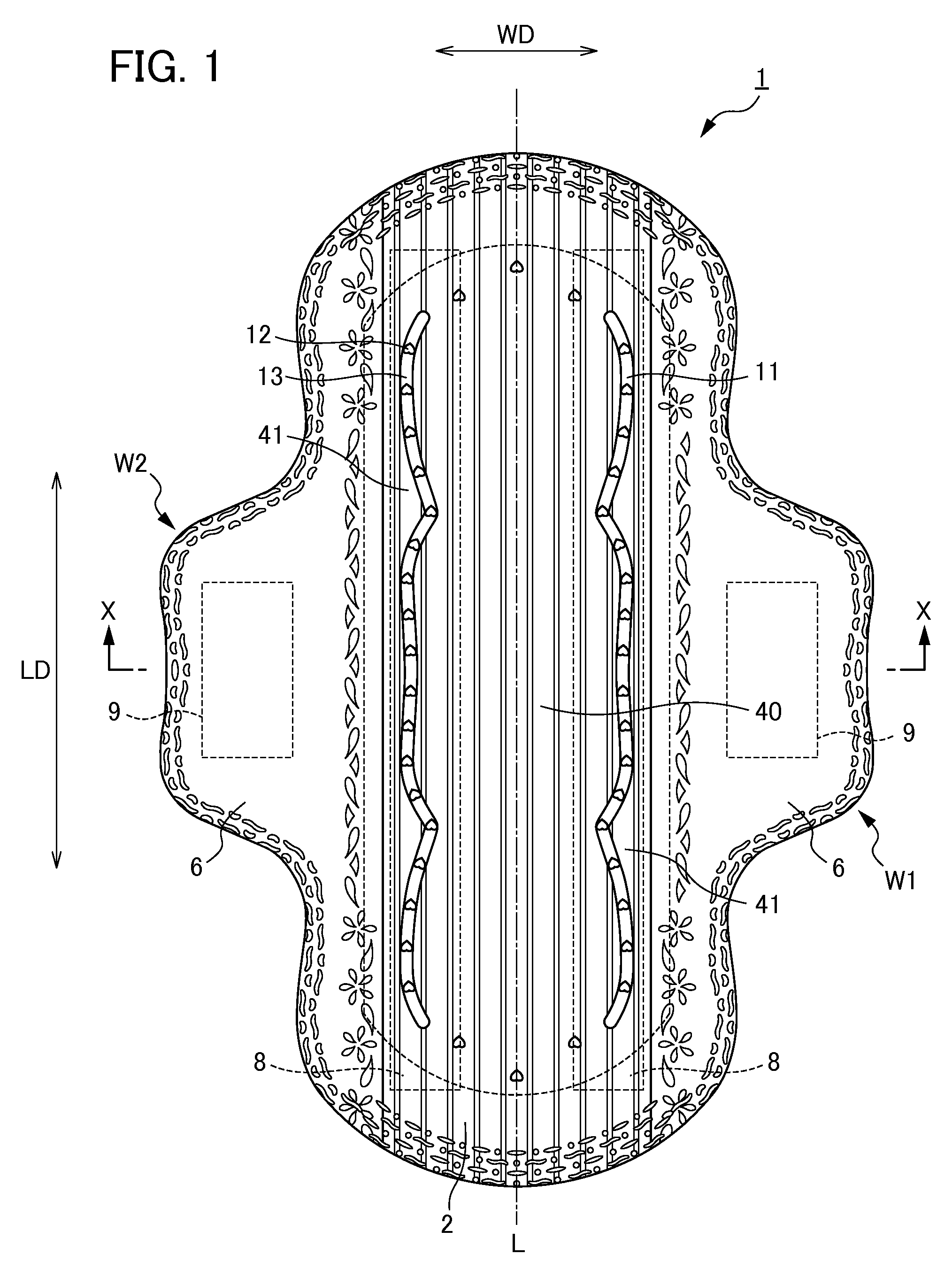

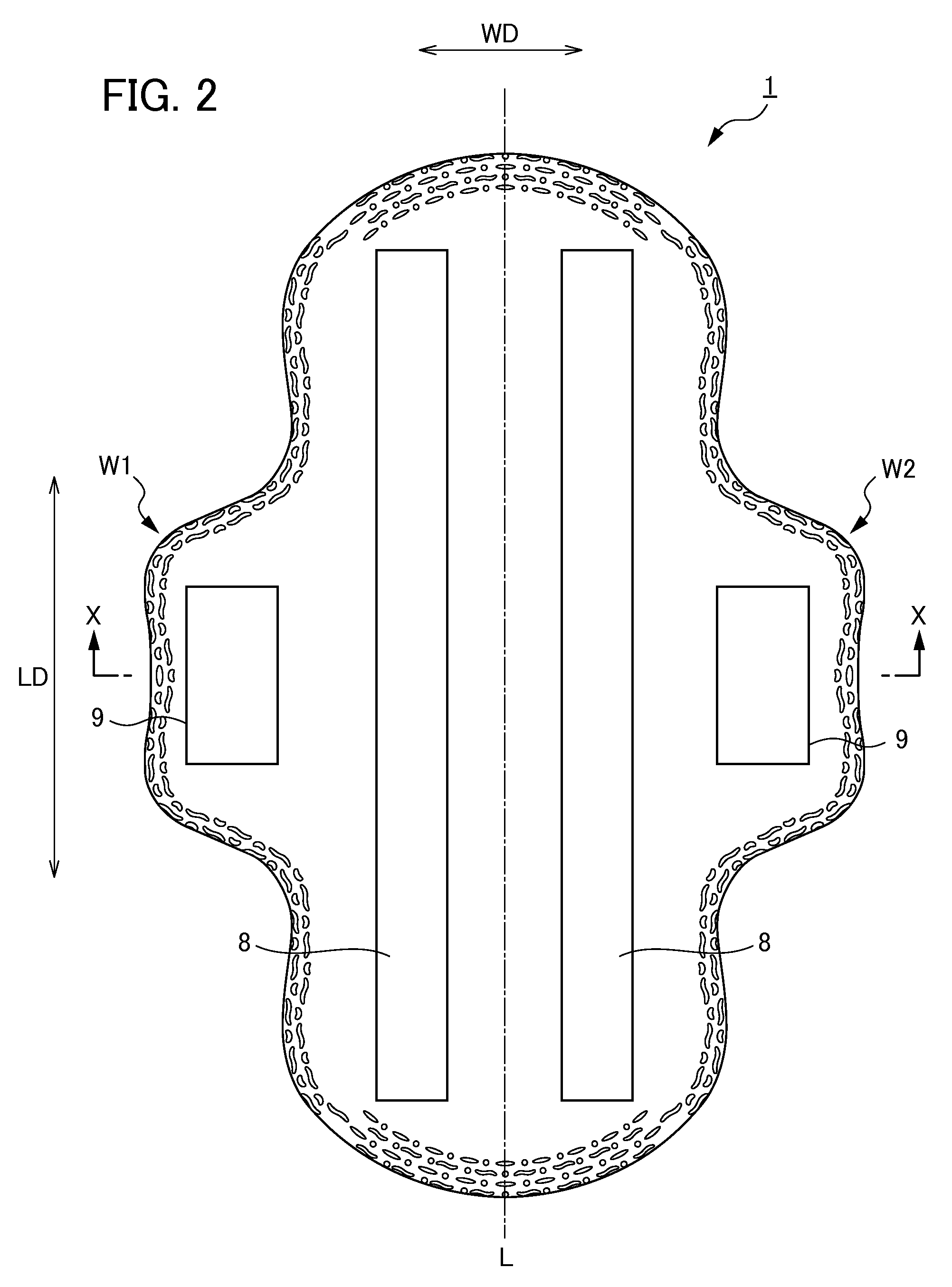

Absorbent article and manufacturing method thereof

InactiveUS20080119810A1Improve adhesionReduce leakageSanitary towelsBaby linensSkin contactBody fluid

An absorbent article is provided that improves adhesion to the skin and reduces leaks of bodily fluids by ensuring stable deformation thereof.An absorbent article has at least a portion thereof provided with a liquid-permeable top sheet disposed on a side of the absorbent article that contacts a wearer's skin; a liquid-impermeable back sheet disposed on a side of the absorbent article that contacts the wearer's clothing; and a liquid-retainable absorbent body disposed between the top sheet and the back sheet. The absorbent body has compressed channels formed into concave shapes in the side that contacts the wearer's skin at the side that contacts the wearer's body by compressing from the side that contacts the wearer's skin to the side that contacts the wearer's clothing; and spaces formed into convex shapes in the side that contacts the wearer's skin at the side that contacts the wearer's clothing by compressing from the side that contacts the wearer's clothing to the side that contacts the wearer's skin. The spaces are formed on both sides or on one side of channel backsides that are on an opposite side of the compressed portions on the side that contacts the wearer's skin.

Owner:UNI CHARM CORP

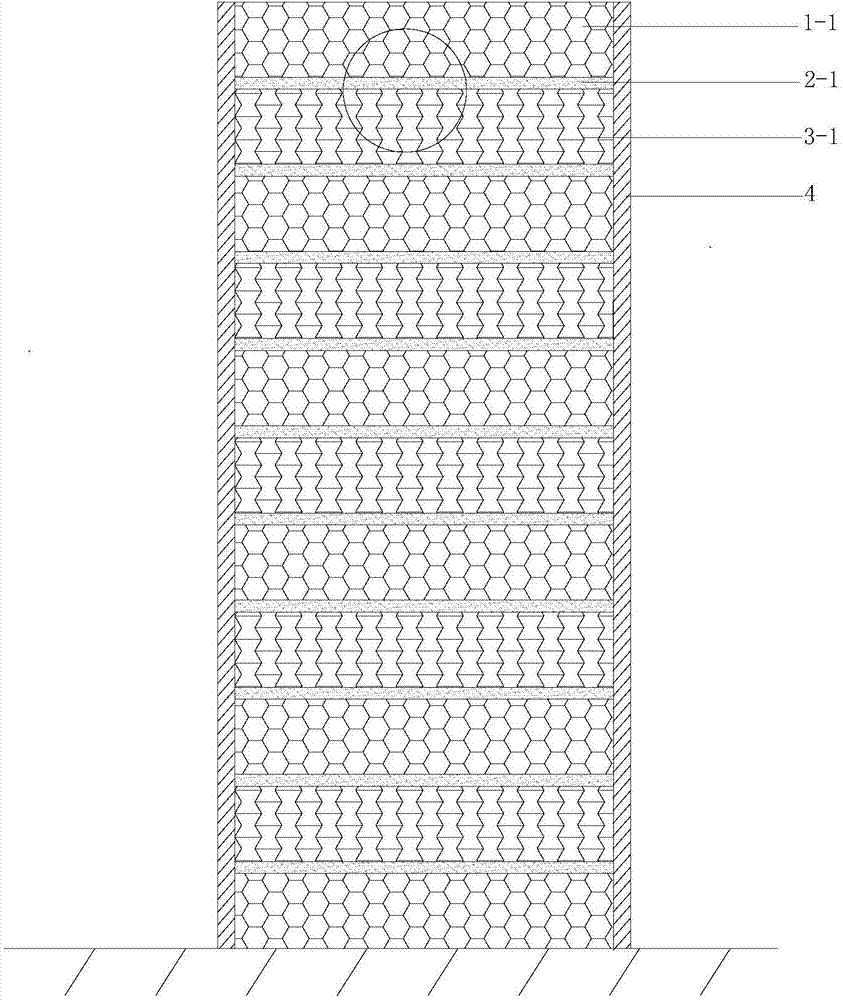

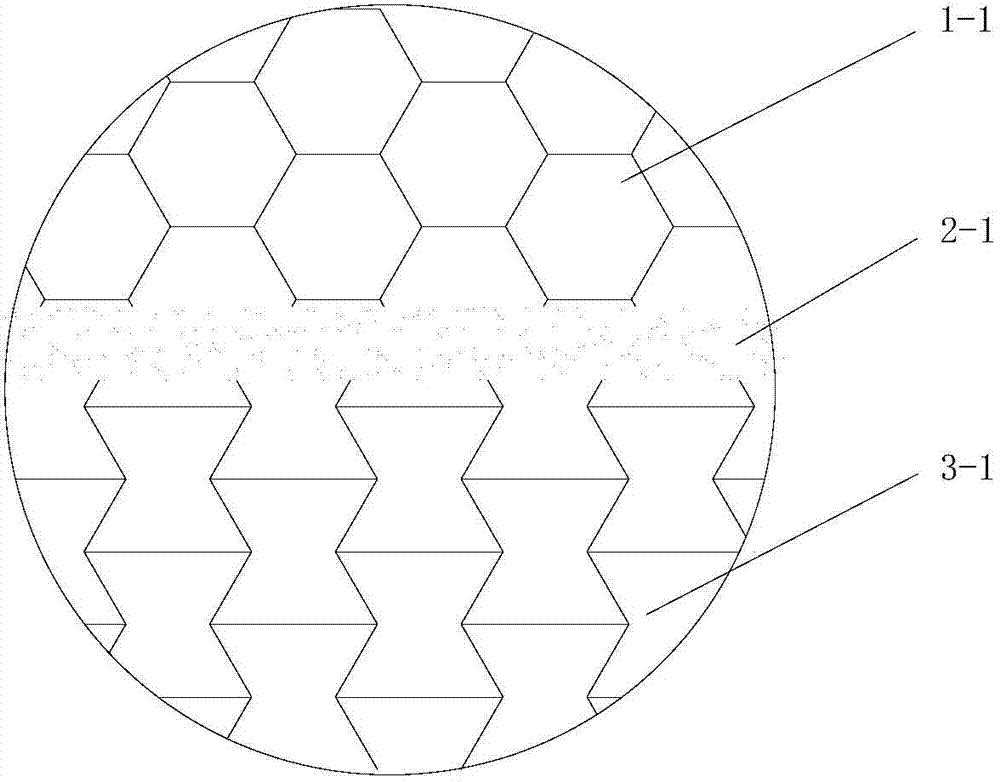

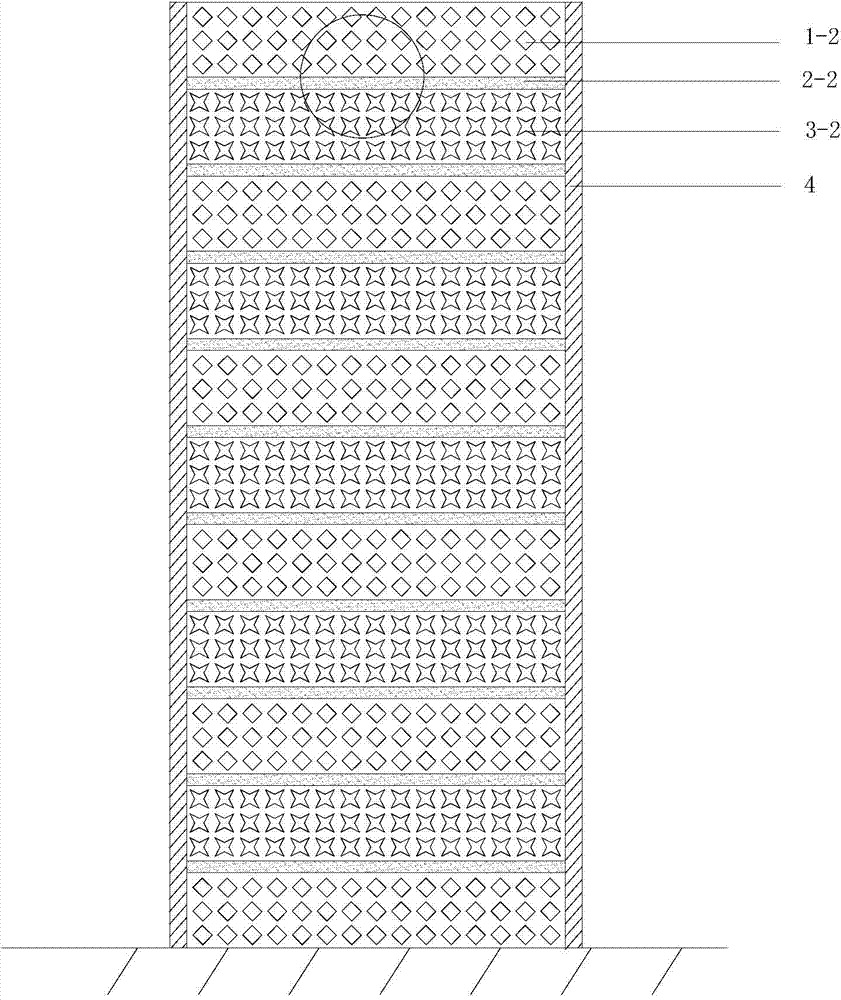

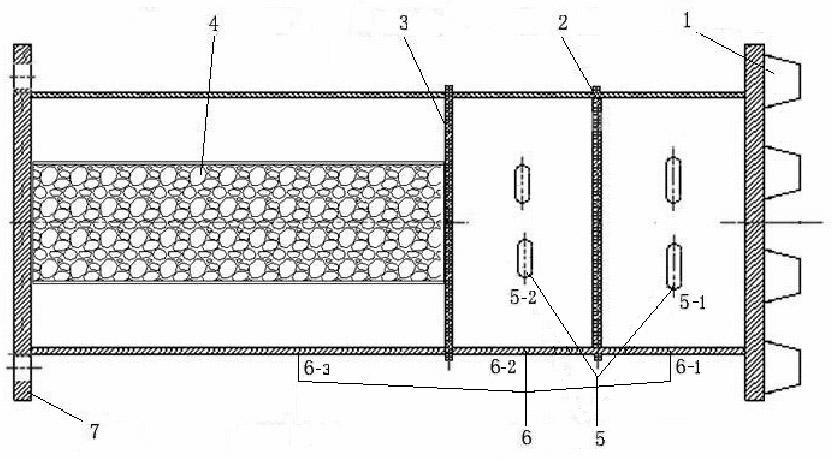

Buffering and energy absorbing structure

ActiveCN104763772ADeformation stableEnsure safetySpringsNon-rotating vibration suppressionHoneycombPeak value

The invention discloses a buffering and energy absorbing structure. The buffering and energy absorbing structure comprises a housing. The buffering and energy absorbing structure is a multi-layer metal grid structure or porous bubble structure filled in the housing; the metal grid structures or porous bubble structures of adjacent layers are lengthways alternatively overlapped in positive and negative poisson ratio; the metal grid structure in the positive poisson ratio is composed of a three-dimensional honeycomb grid structured formed by array type regular hexagonal pore grids; the metal grid structure in the negative poisson ratio is composed of a three-dimensional stretching and expanding grid structure formed by array type concave angle pore grids; the meshes of the porous bubble structure in the positive poisson ratio are of an array type rhombus structure; the meshes of the porous bubble structure in the negative rhombus structure are of an array type four-star shaped structure. Compared with the traditional buffering and energy absorbing structure, the buffering and energy absorbing structure can effectively reduce the peak value of the impact force, so that the whole energy absorbing process is stable, and as a result, the energy absorbing efficiency of the structure can be increased.

Owner:SOUTH CHINA UNIV OF TECH

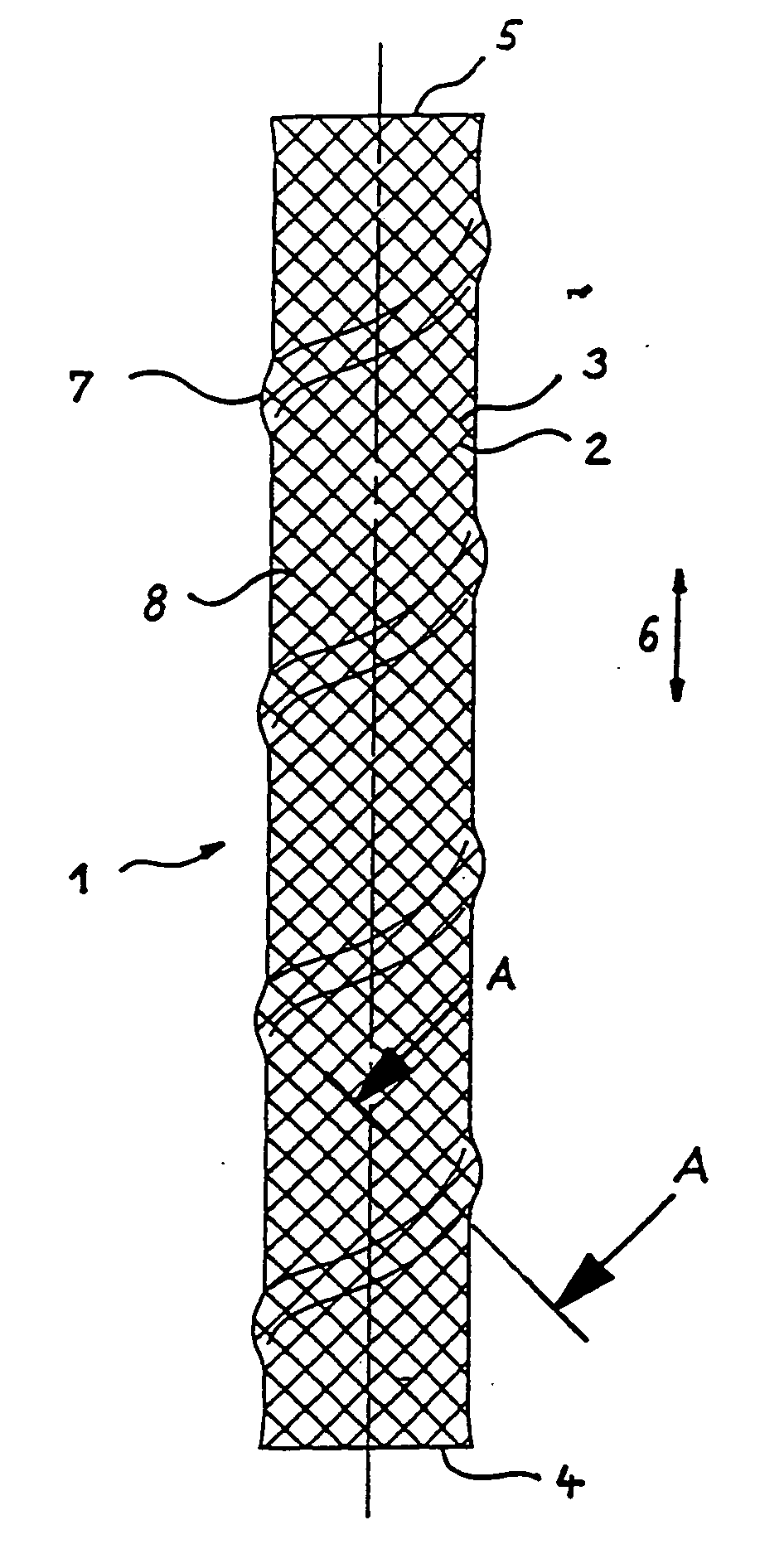

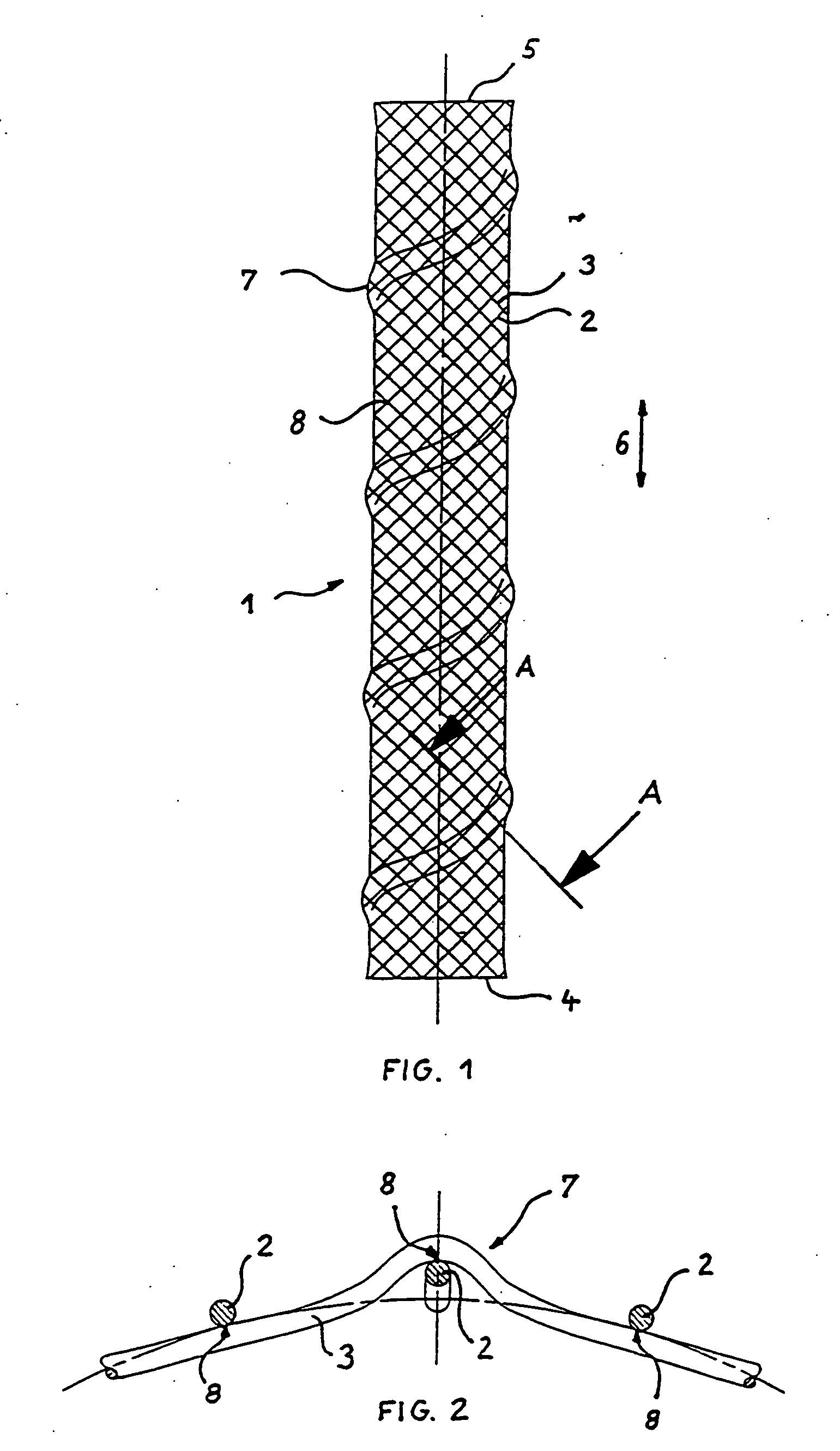

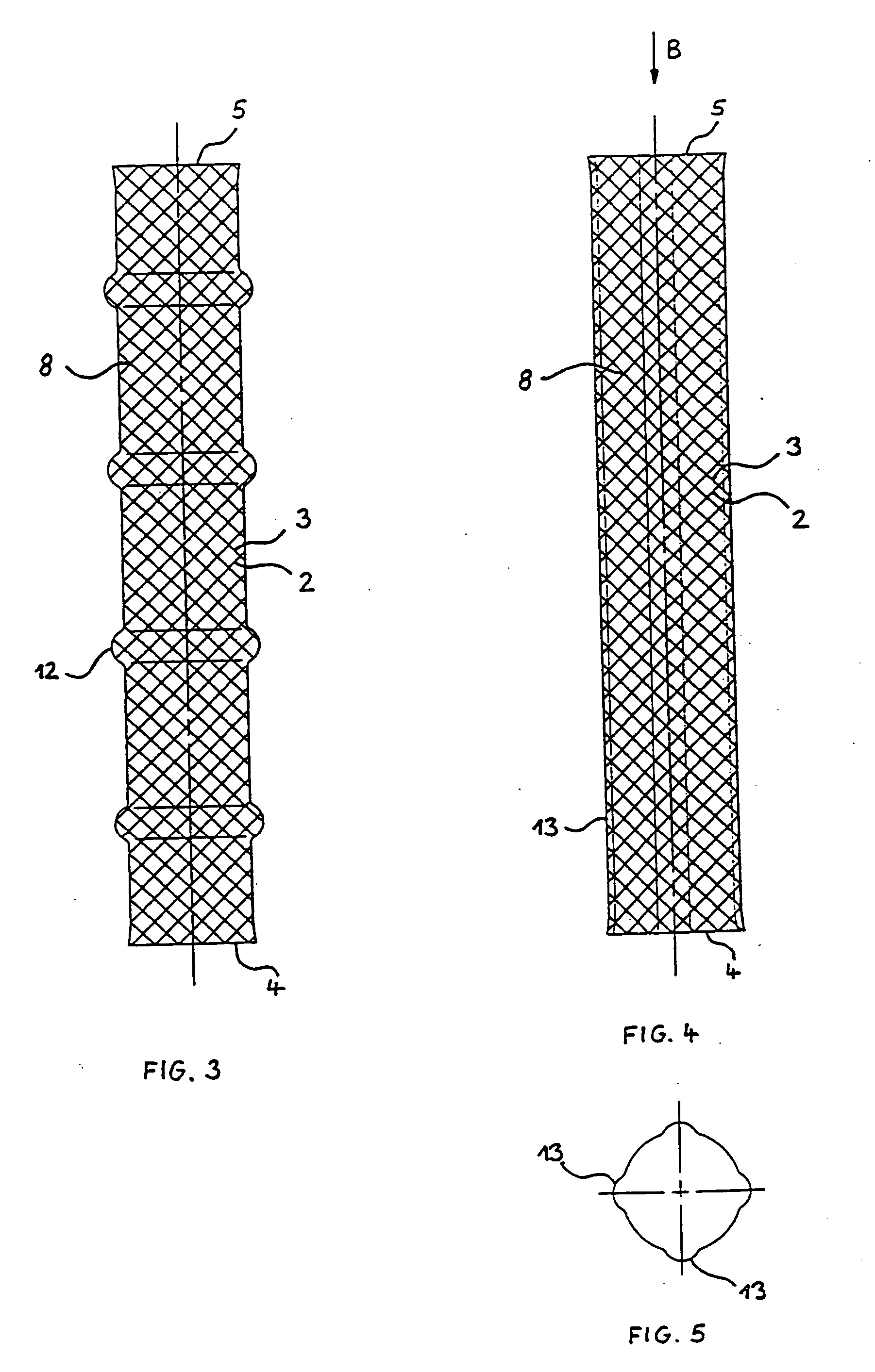

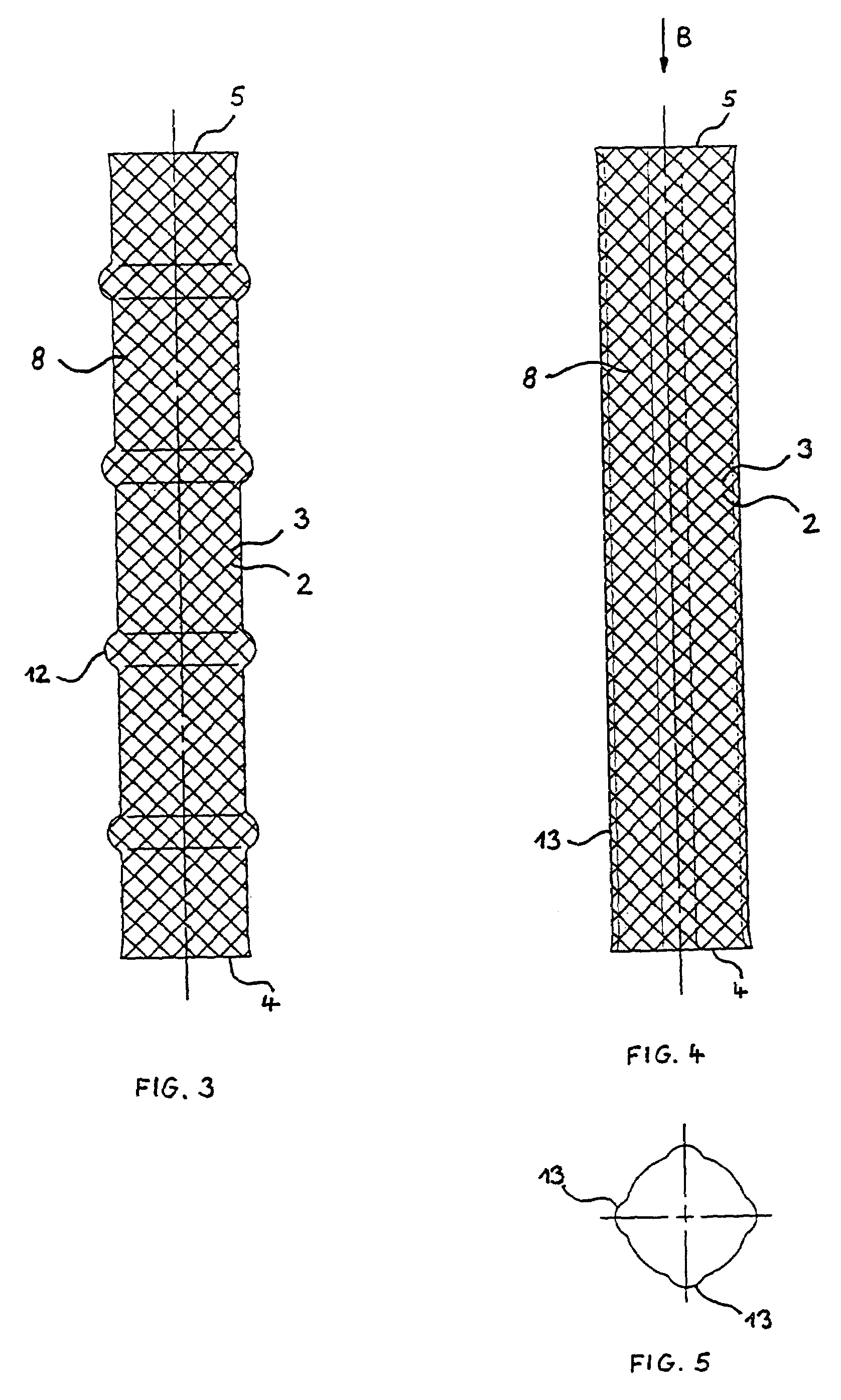

Braided stent

InactiveUS20070123969A1Less-shorteningEasy to manufactureStentsOrnamental textile articlesBraided stentInsertion stent

A stent for use in a body passageway includes a plurality of wires braided to form a self-expanding braided tubular structure. The braided wires form braiding angles along a length of the tubular structure. A portion of the wires are plastically deformed to reduce foreshortening of the braided structure.

Owner:BOSTON SCI CORP

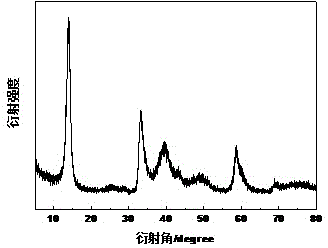

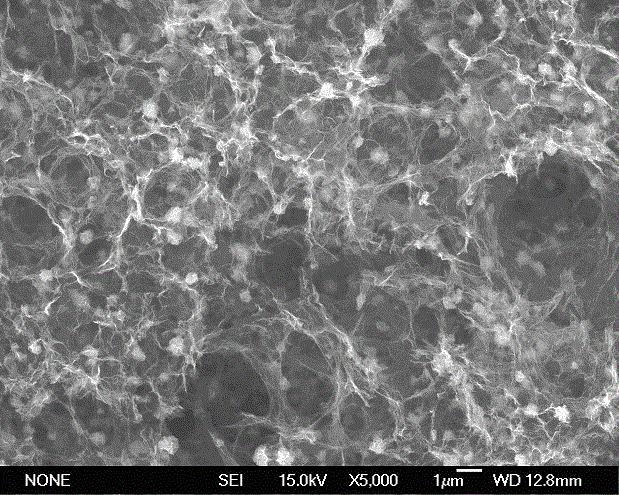

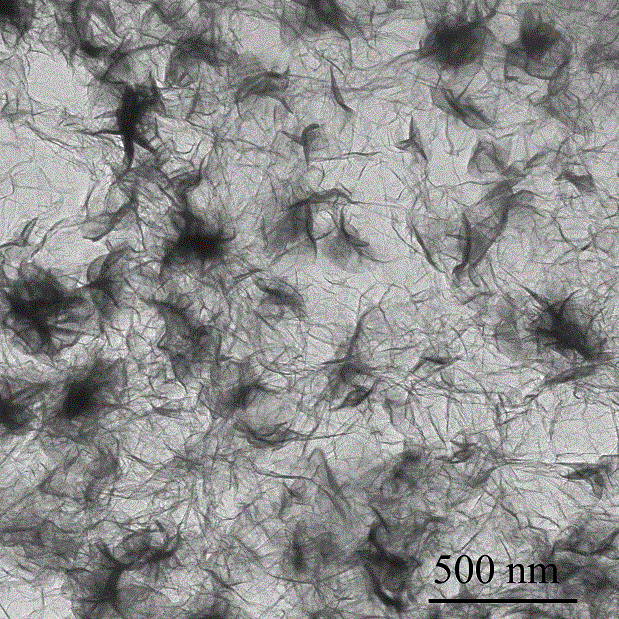

Flake MoS2/graphene composite aerogel and preparation method thereof

InactiveCN104600315AHigh electrical conductivityDeformation stableCell electrodesThioureaFreeze-drying

The invention relates to a flake MoS2 / graphene composite aerogel and a preparation method thereof and belongs to the technical field of anode materials of lithium ion batteries. The preparation method comprises the following steps: ultrasonically dispersing a certain quantity of graphene oxide solution into deionized water, adding a certain quantity of water-soluble molybdate and thiourea, then adding 0.1-3mL organic amine solution, taking out a cylindrical product after hydrothermal reaction at the temperature of 160-240 DEG C, freeze-drying, and then carrying out thermal treatment for 2h in the mixed atmosphere of argon and hydrogen at the temperature of 800 DEG C to obtain the flake MoS2 / graphene composite aerogel. According to the flake MoS2 / graphene composite aerogel and the preparation method thereof disclosed by the invention, thin layers of graphene are connected with one another in a staggering mode to form a three-dimensional ordered conductive network and form micron pore canals, MoS2 is uniformly dispersed on the ultra-large superficial area, and thus, the problems of volume expansion and crushing materials are effectively solved; meanwhile, the structure stability and the cycle performance of the flake MoS2 / graphene composite aerogel, serving as the anode material, are improved.

Owner:SHANGHAI UNIV

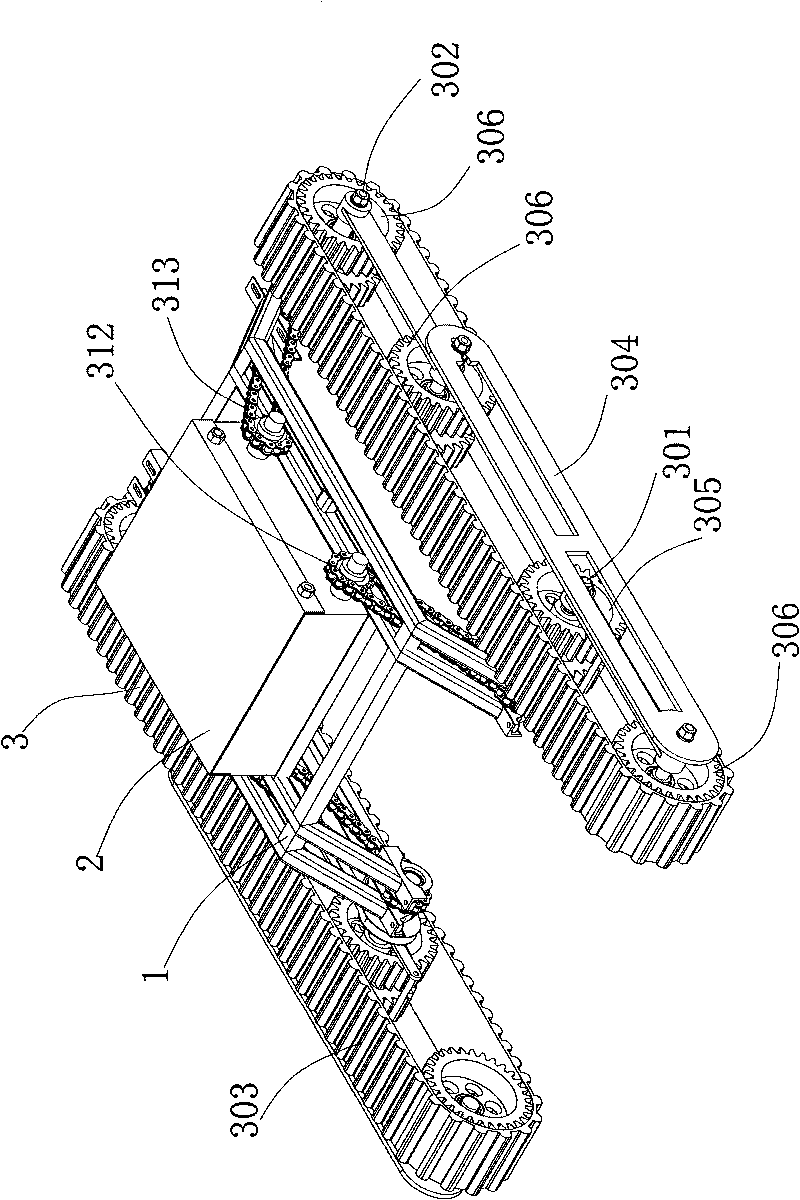

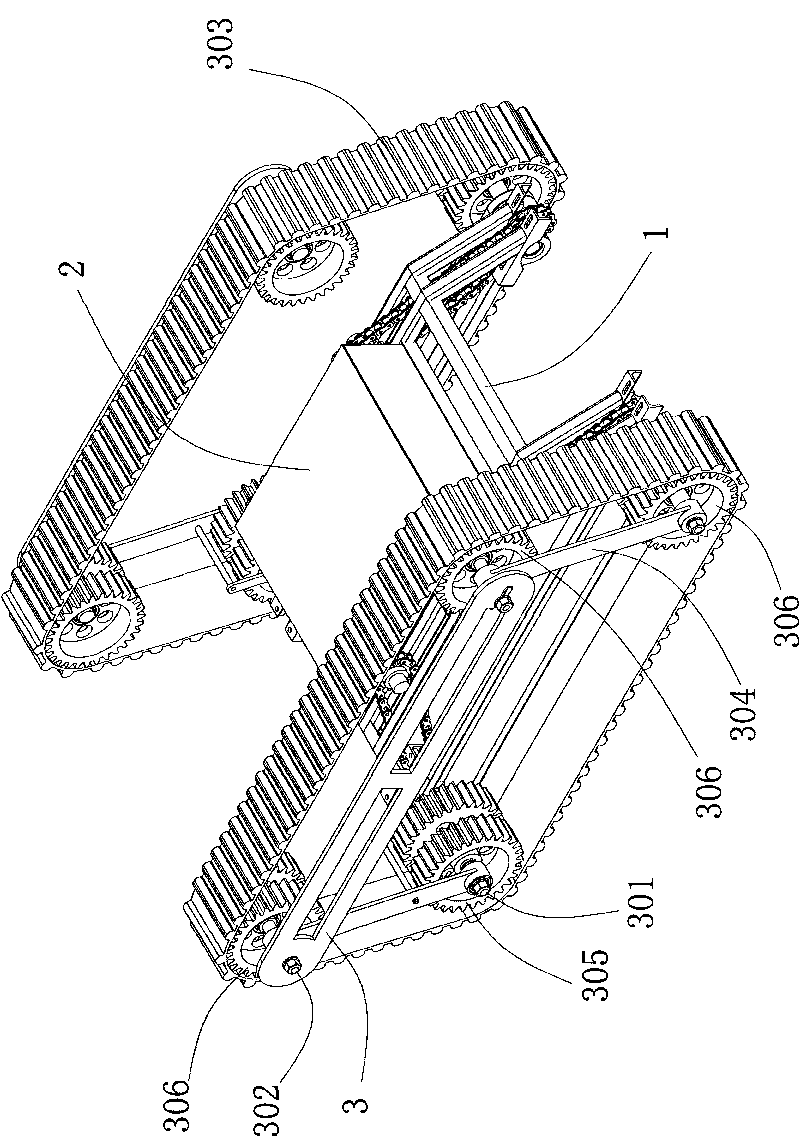

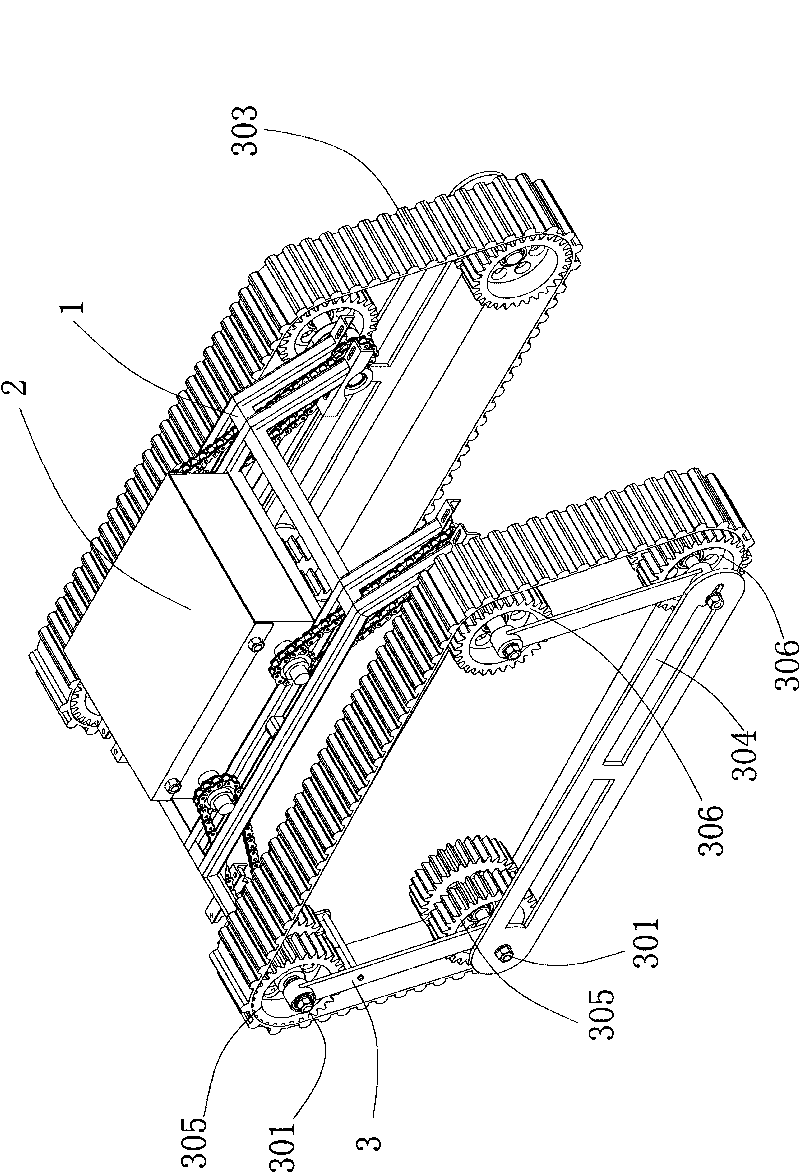

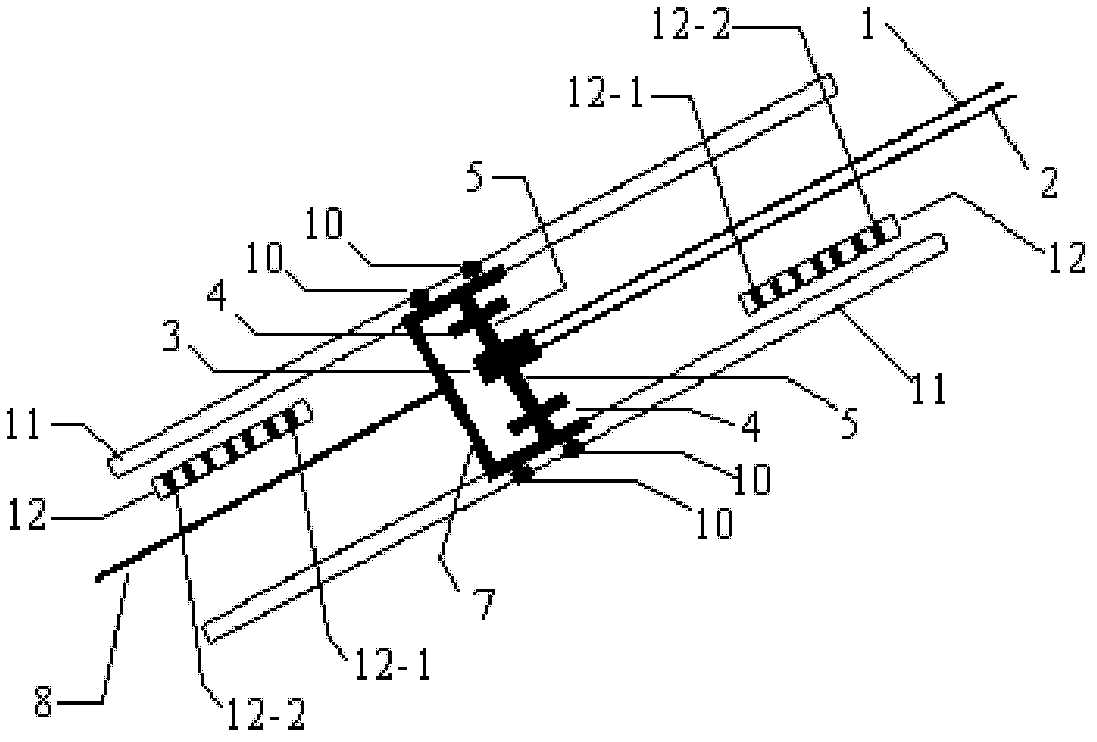

Deformed caterpillar robot

ActiveCN101734295AImprove obstacle-surpassing ability and smoothness of motionGood shock absorptionEndless track vehiclesFuselageDrive shaft

The invention discloses a deformed caterpillar robot which comprises a robot stand and a robot body, wherein robot body is installed on the robot stand; both sides of the robot stand are respectively provided with a set of deformed caterpillar running mechanism; each deformed caterpillar running mechanism comprises a traveling drive shaft, a caterpillar deformed drive shaft, a caterpillar and a deformed oscillating bar mechanism; each traveling drive shaft and each caterpillar deformed drive shaft are arranged on the robot stand in parallel; one end of each deformed oscillating bar mechanism is fixedly connected with each caterpillar deformed drive shaft, and the other end is supported on each traveling drive shaft by a bearing; a drive caterpillar wheel is installed on each traveling drive shaft; driven caterpillar wheels are both arranged on each caterpillar deformed drive shaft and each deformed oscillating bar mechanisms; and each drive caterpillar wheel and all driven caterpillar wheels are meshed with each caterpillar. The deformed caterpillar robot has steady running, high obstacle crossing and climbing capability, simple structure, stable working and reliable control.

Owner:NAT UNIV OF DEFENSE TECH

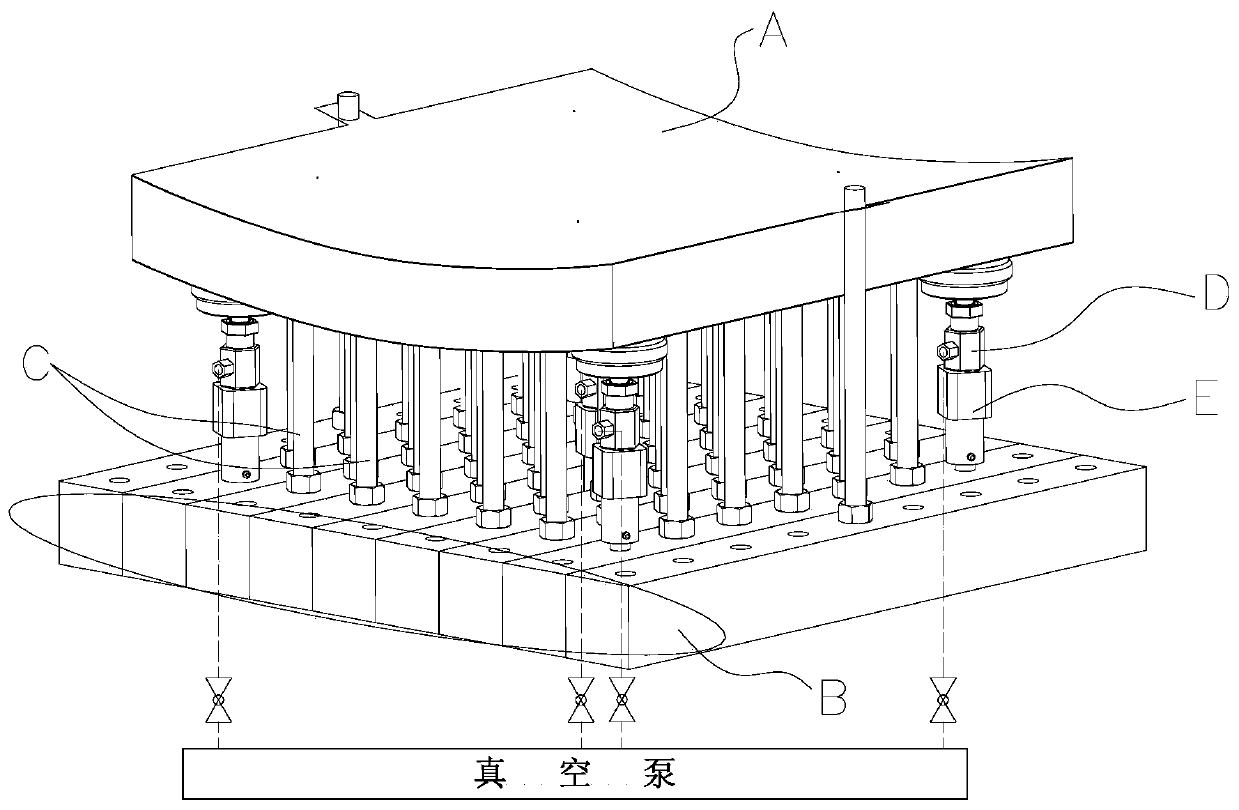

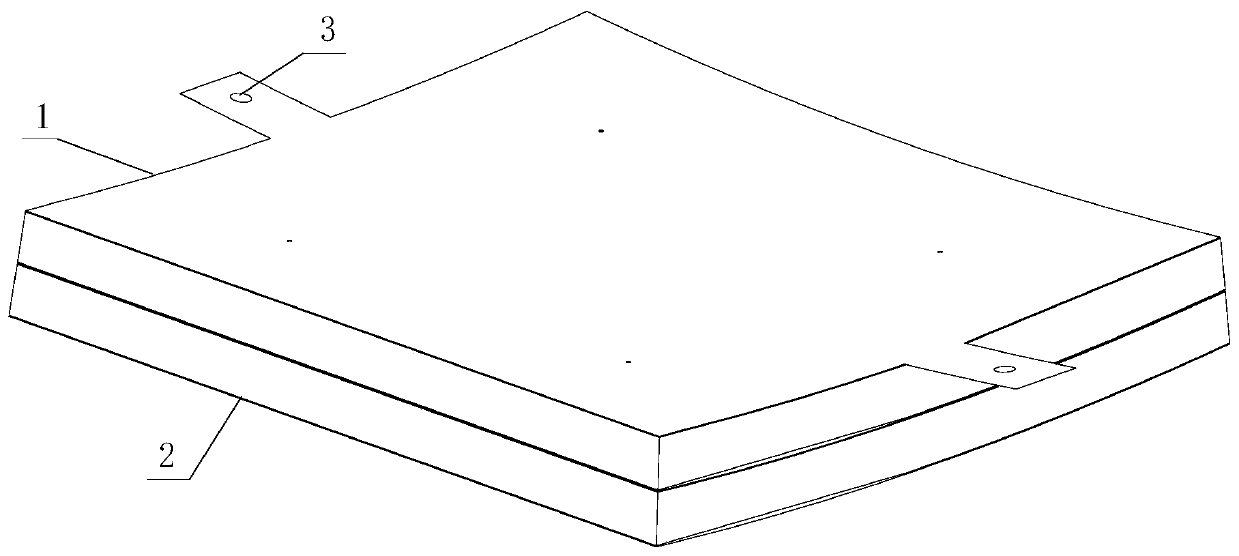

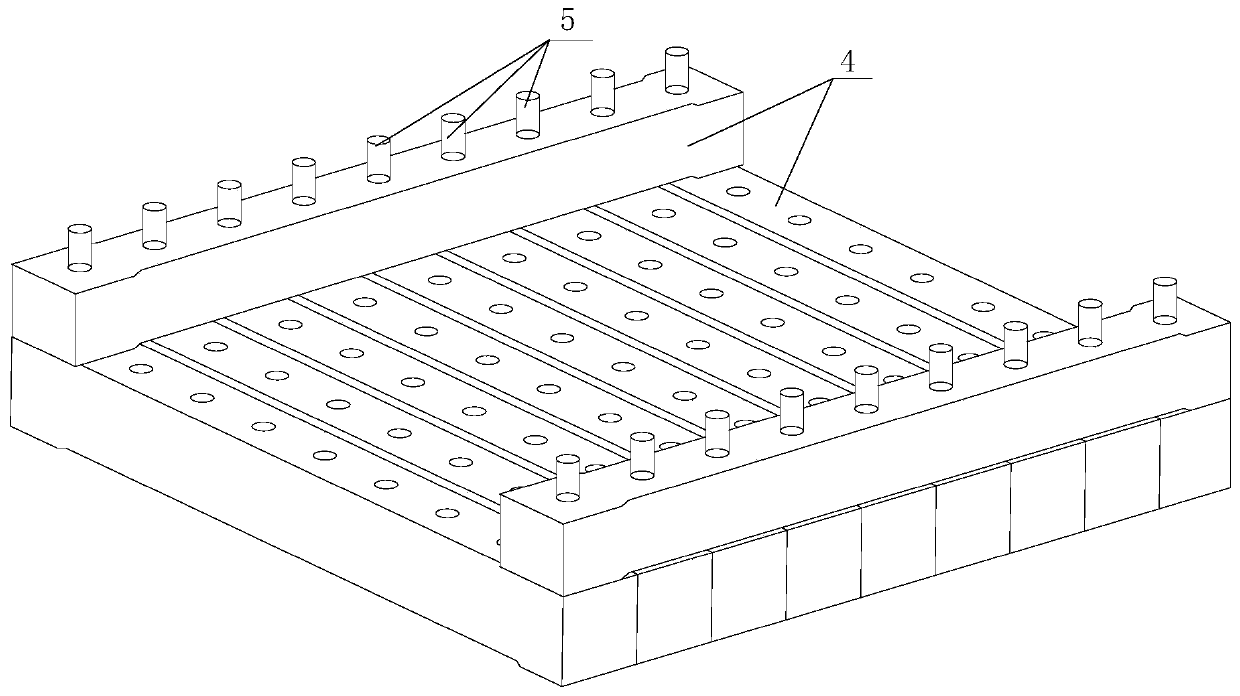

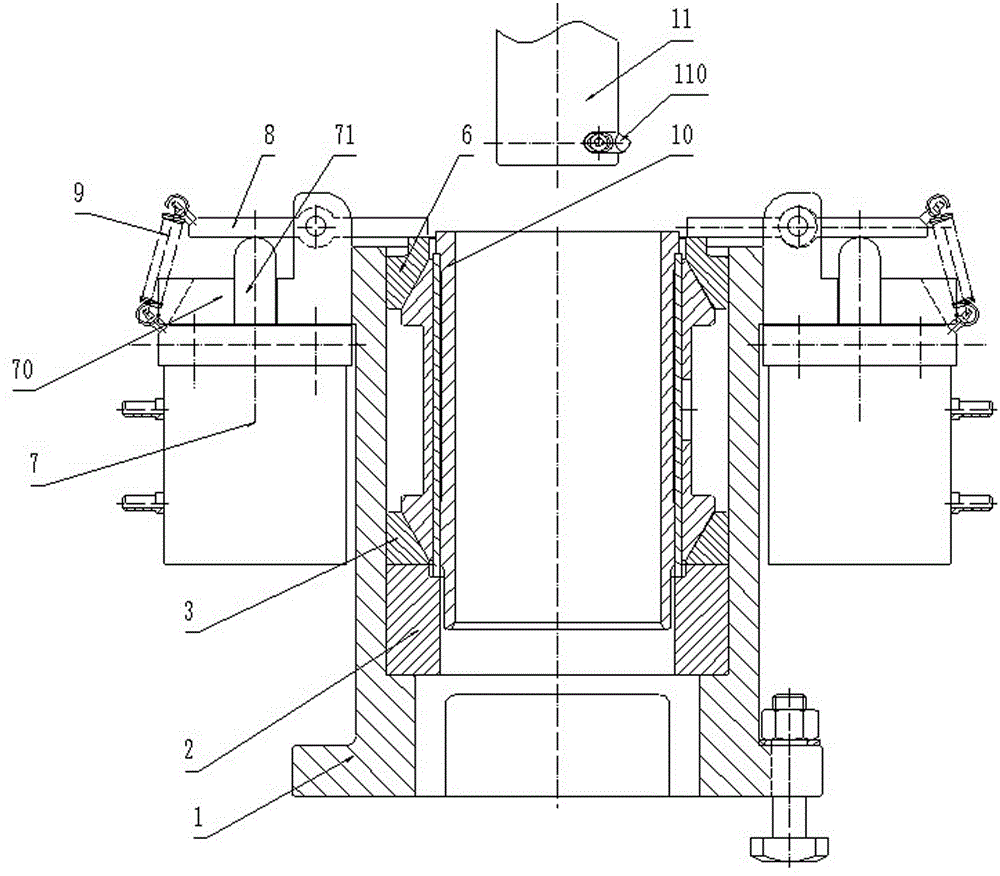

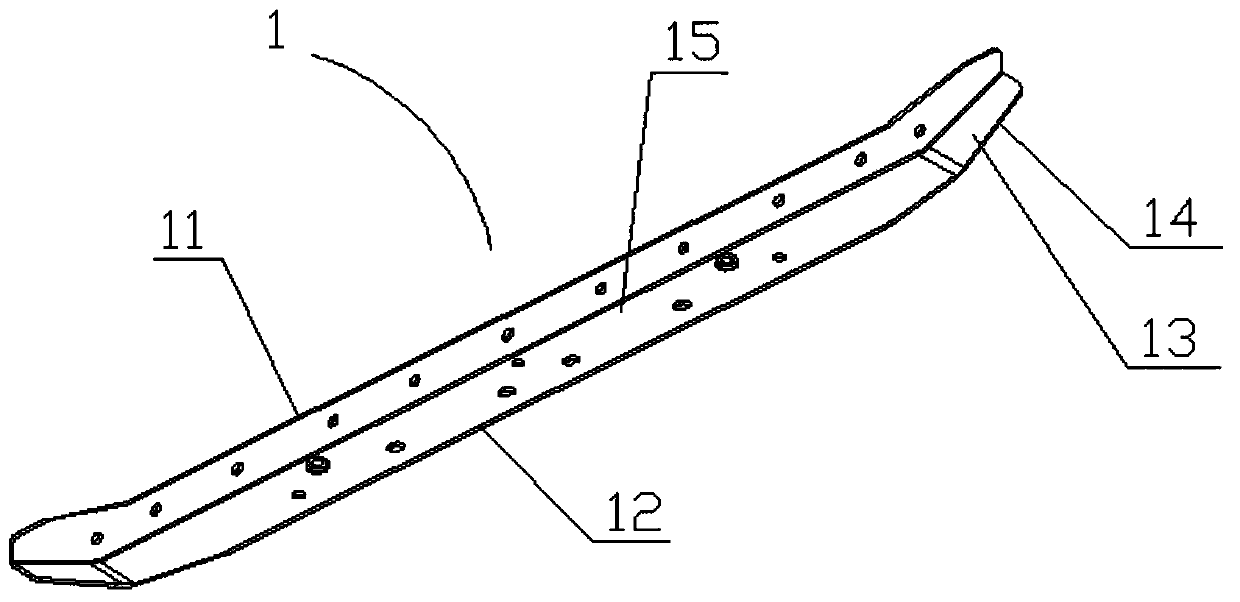

Multi-point-based large-curvature panel ultra-precision machining flexible clamping system

InactiveCN110142627AGuaranteed positioningDeformation stablePositioning apparatusMetal-working holdersEngineeringStability constraints

The invention discloses a multi-point-based large-curvature panel ultra-precision machining flexible clamping system. The system comprises a base, a height-adjustable nail column, a universal vacuum sucker and a transition connecting piece;the base takes stainless steel discrete spike strips with the same cross section and different lengths as a foundation, and the stainless steel discrete spike strips are reasonably combined and mechanical connected; the universal vacuum sucker can rotate in any direction within a 45-degree angle range; the bottom end of the height-adjustable nail column is provided with external threads so as to be installed in a nail hole of the base; and the transition connecting piece is composed of two parts, one part of the transition connecting piece is a sucker threaded sleeve, and the other part of the transition connecting piece is a nail column hole sleeve, and a hole which can be in clearance fit with the height-adjustable nail column is reserved in the center of the nail column hole sleeve. According to the flexible clamping system, concave discrete nail molds with different curvatures can be obtained by adjusting the height of the height-adjustable nail column and the vacuum sucker aiming at parts with different areas and panels with different curvatures, so that full positioning, stability constraint, micro deformation and flexible clamping of the parts with curved surfaces are realized.

Owner:BEIHANG UNIV

Stents with proximal and distal end elevations

InactiveUS7331990B2Improve a less-shortening stentAvoid deformationStentsOrnamental textile articlesMedicineMechanical stability

A prosthetic stent with a tubular wall having local inwardly or outwardly formed elevations. Stents having such elevations have a higher mechanical stability if bent according to the curvature of the body vessels to be supported or repaired. Also a method for manufacturing a stent with such elevations is described.

Owner:BOSTON SCI CORP

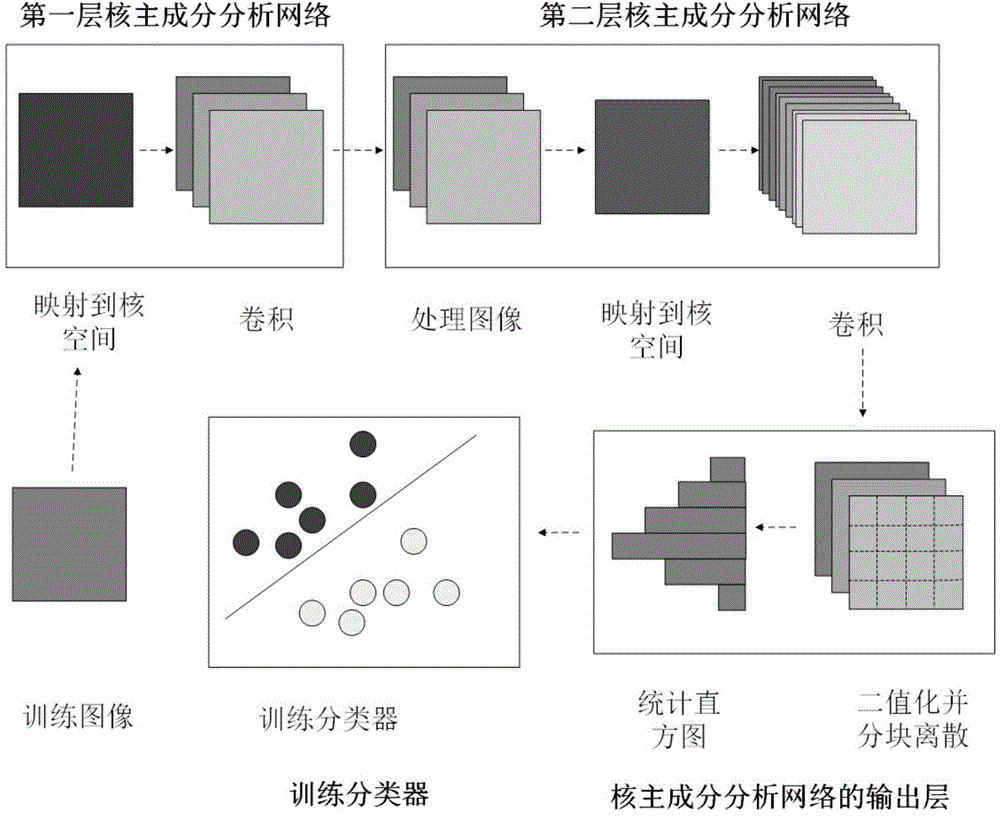

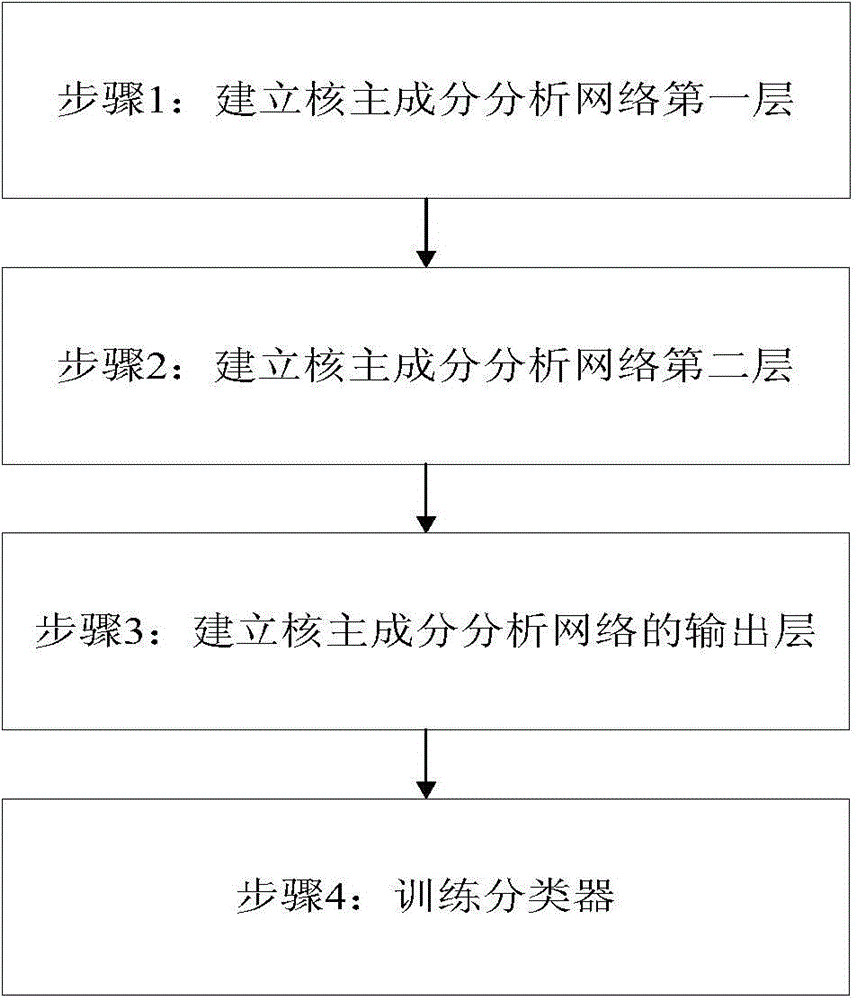

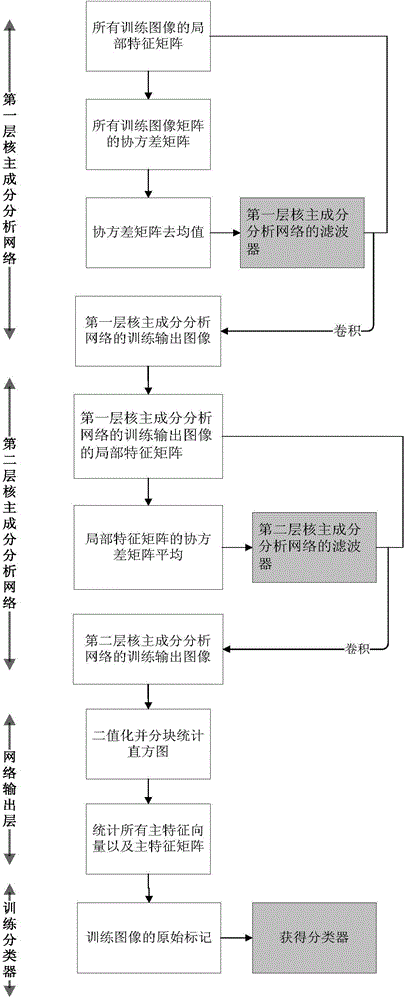

Image classification method based on kernel principal component analysis network

ActiveCN104573729AEfficient extractionDeformation stableCharacter and pattern recognitionKernel principal component analysisCharacteristic matrix

The invention discloses an image classification method based on a kernel principal component analysis network. The image classification method comprises the following steps that (1) a training image is input and pre-processed to obtain a local characteristic matrix of the training image; (2) the two-layer kernel principal component analysis network is built to obtain a main characteristic vector of the training image; (3) a classifier is trained by using the obtained main characteristic vector; for verifying the correctness of the classification, a kernel principal component analysis testing network is built to test a test image. According to the image classification method, through building the two-layer kernel principal component analysis network, the nonlinear characteristics of the image can be obtained, therefore, the description of the characteristics of the image is more precise, the classification is more accurate, and the accuracy is higher for image classification problems.

Owner:SOUTHEAST UNIV

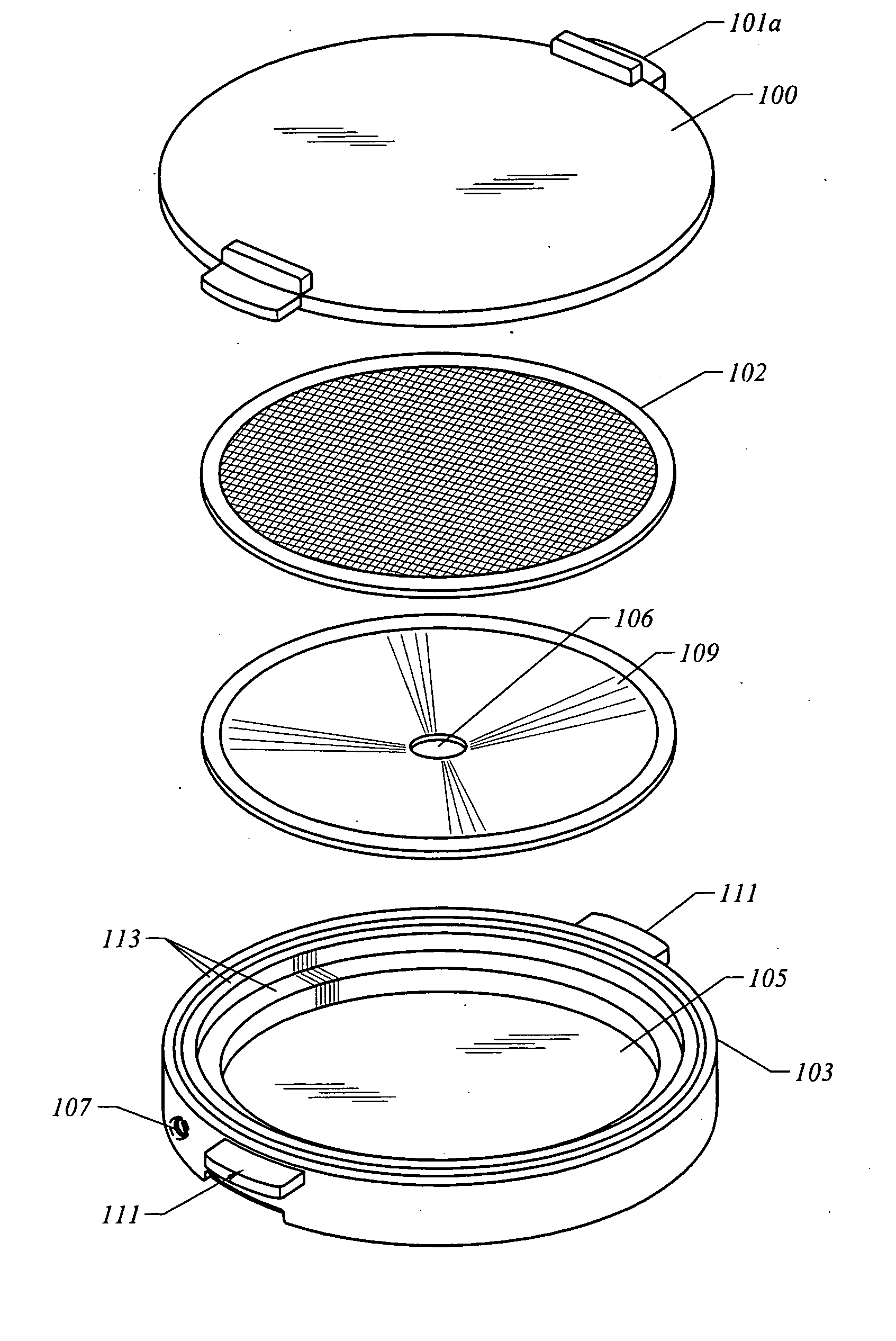

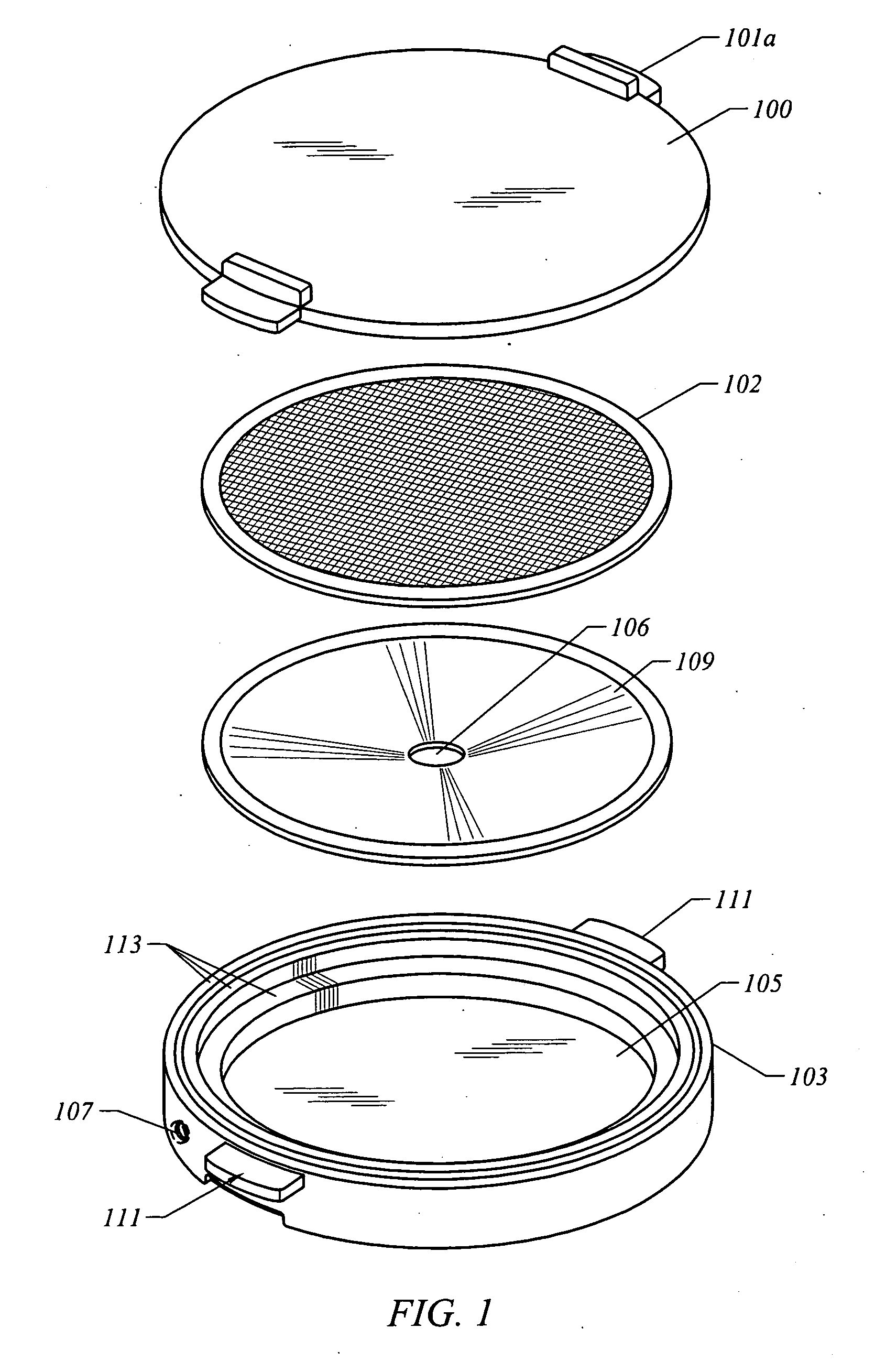

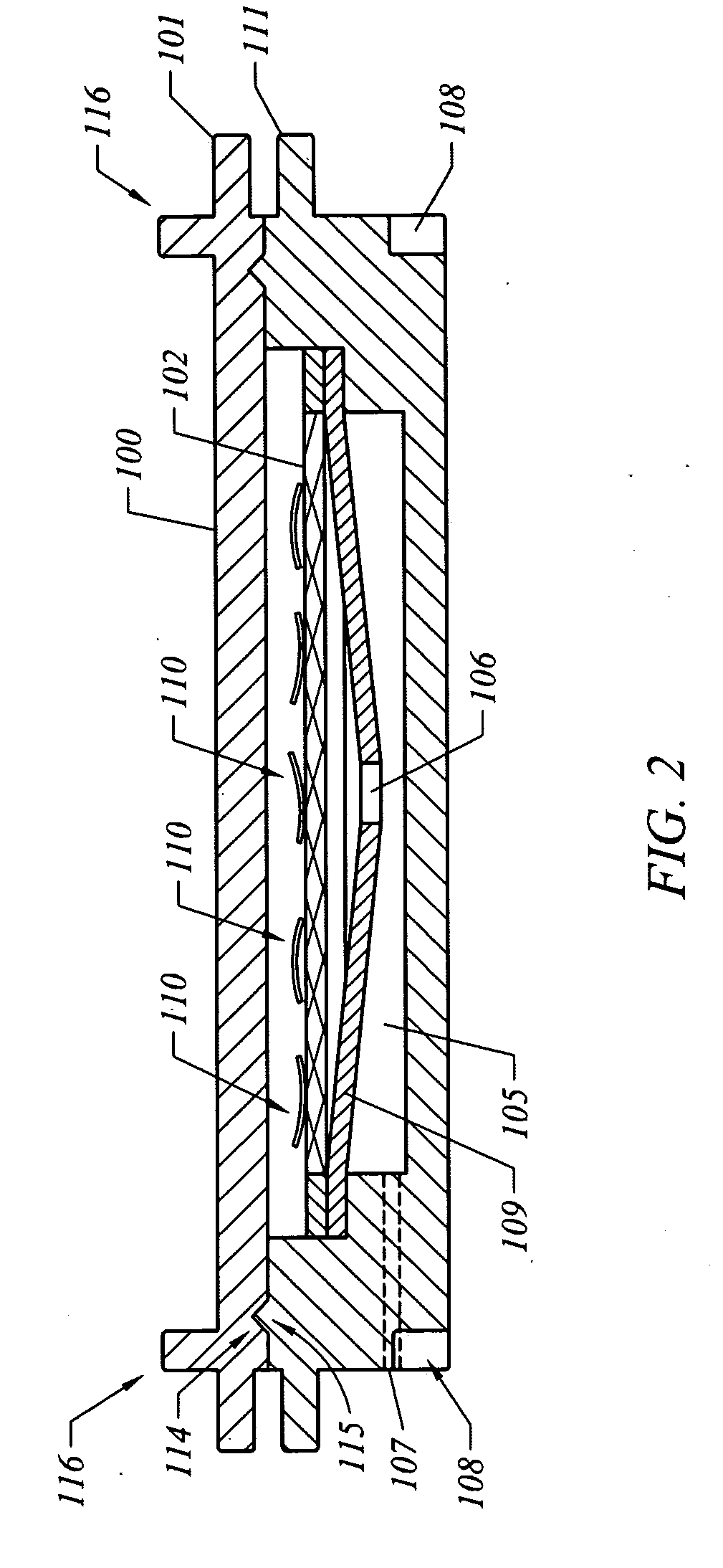

Cooking utensil for use in microwave oven

InactiveUS20070158339A1Easy to coverEasy to removeCooking vesselsMicrowave heatingMicrowave ovenEngineering

This invention relates to a cooking utensil, and more particularly, to an improved cooking utensil for use in cooking sliced pepperoni, salami or the like by microwave energy. The invention comprises a base that supports a cooking surface and lid, and collects the grease released during the cooking process.

Owner:BECKMAN PAUL

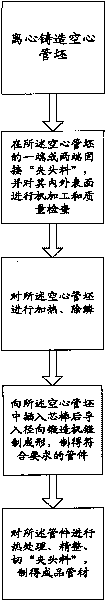

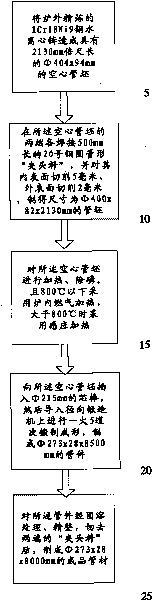

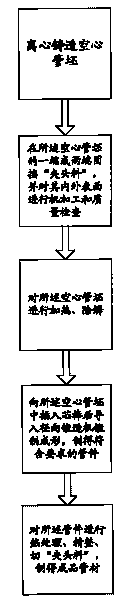

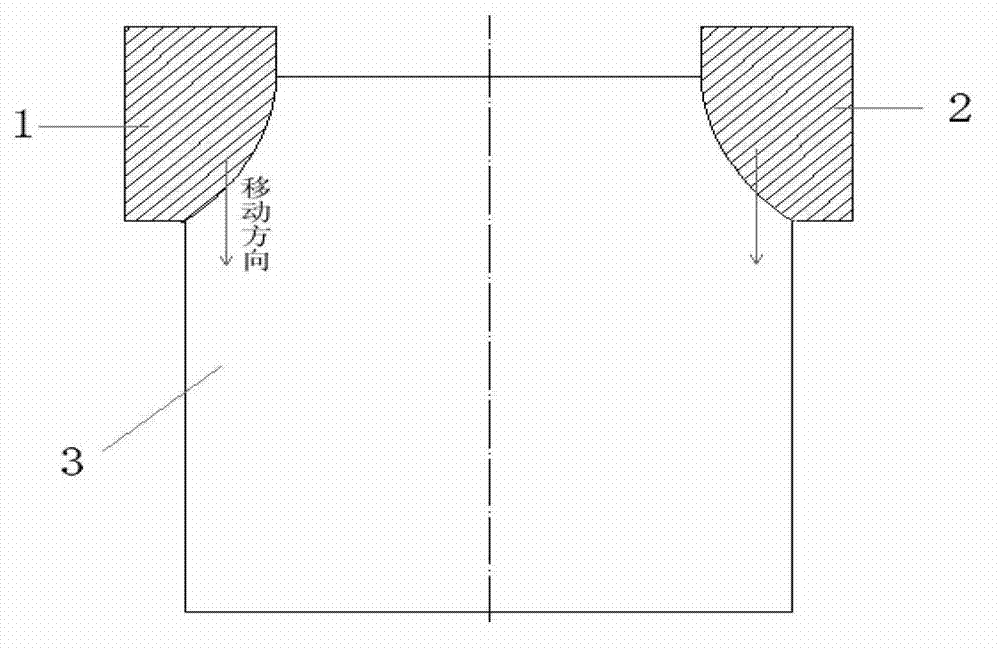

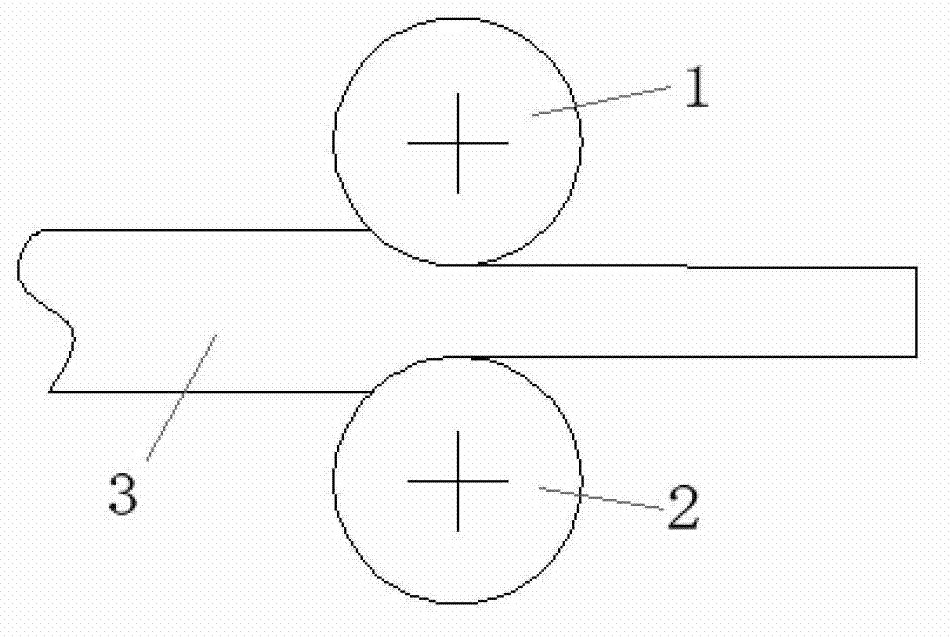

New method for producing medium and large caliber alloy steel seamless pipe by utilizing radial forging technology

The invention relates to a new method for producing medium and large caliber alloy steel seamless pipes by utilizing a radial forging technology, which comprises the following steps of: A. centrifugally casting a medium and large caliber hollow pipe blank through external refining molten steel; B. machining the internal and external surfaces of the medium and large caliber hollow pipe blank, fixedly connecting a carbon steel 'chuck material' at one end or both ends thereof and then carrying out quality inspection; C. heating and descaling the medium and large caliber hollow pipe blank; D. inserting a mandrel into the medium and large caliber hollow pipe blank and then leading into a radial forging machine for forging molding to manufacture a pipe of which the wall thickness, the diameter and the length meet requirements; and E. carrying out heat treatment, finishing and 'chuck materia' cutting for the pipe to manufacture a qualified finished product pipe. A technologic relation is established between high-quality centrifugal casting and radial forging with more ideal deforming state and tiny temperature drop by the method for the first time, thereby forming a new short-flow production process which has the advantages of energy saving, consumption reduction, high quality and economical efficiency and is used for producing alloy steel seamless pipes with large caliber, medium wall thickness and difficult deformation, and improving the product quality and the qualified rate; moreover, one end or both ends of the pipe blank is / are fixedly connected with the 'chuck material', thereby not only rapidly realizing stable deformation, but also reducing the remarkable difference of longitudinal temperature and dimensional precision of workpieces, lowering the consumption of an expensive alloy steel material and improving the yield of a finished product.

Owner:北京蓝海科融新技术有限公司

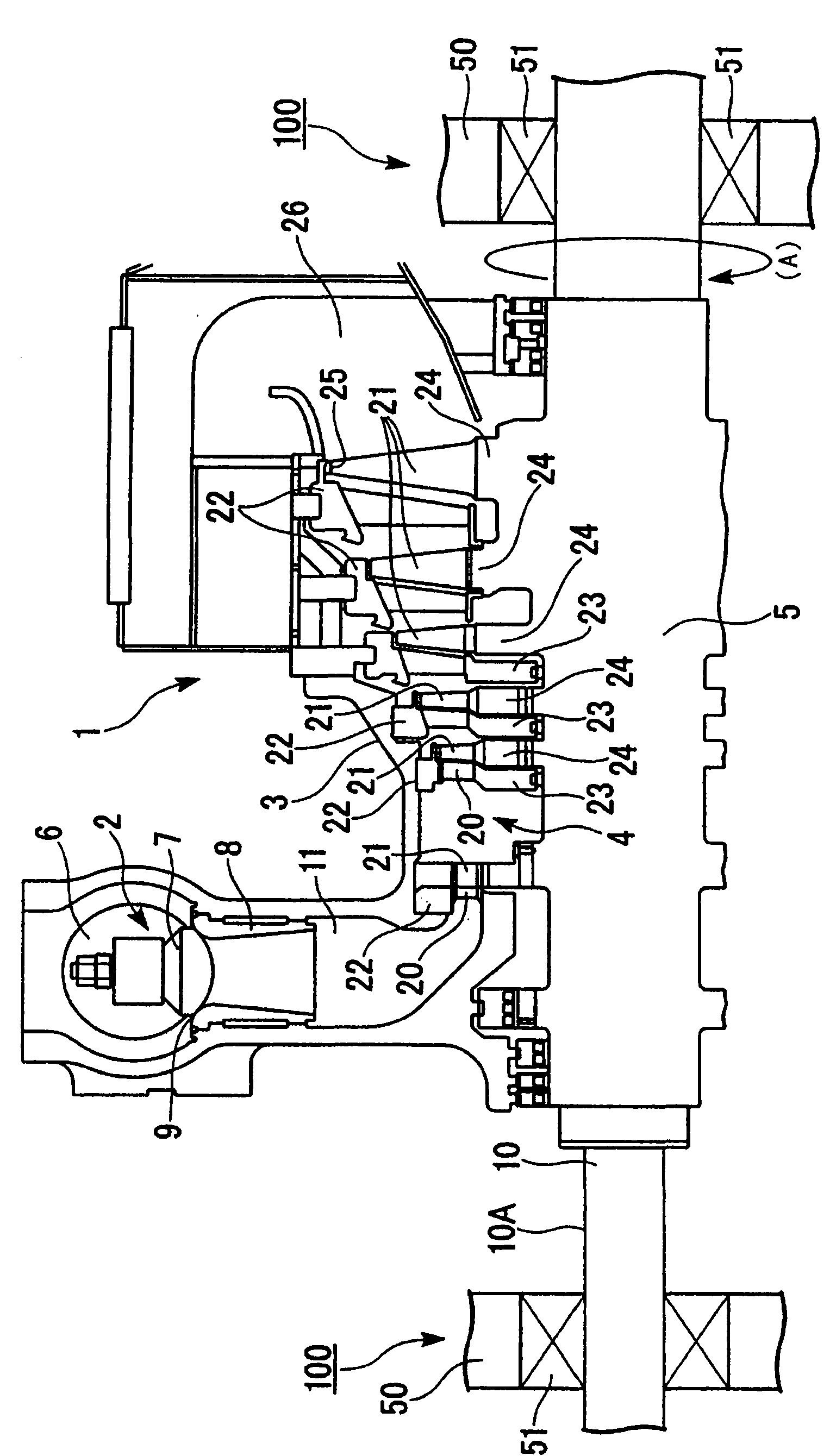

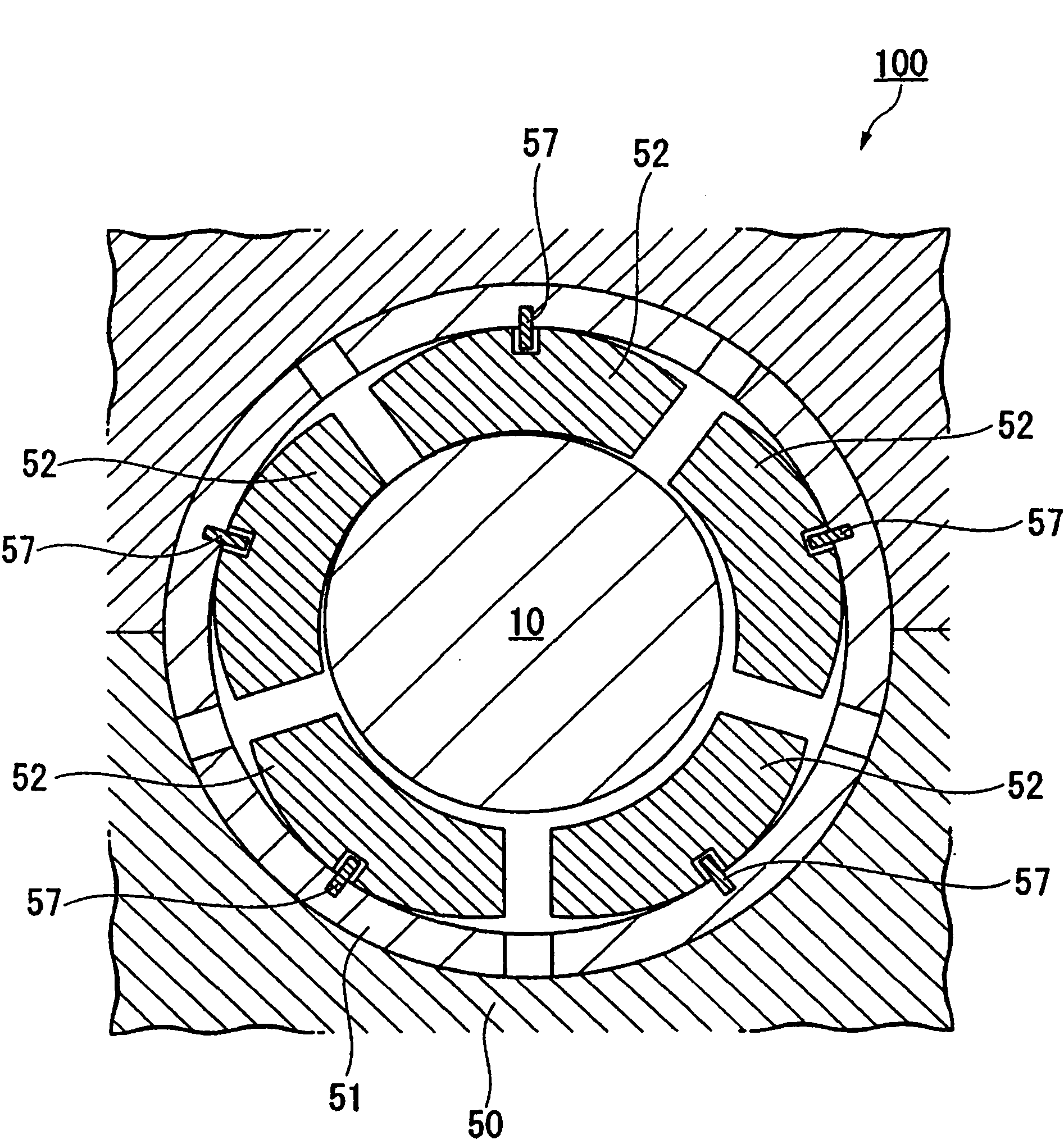

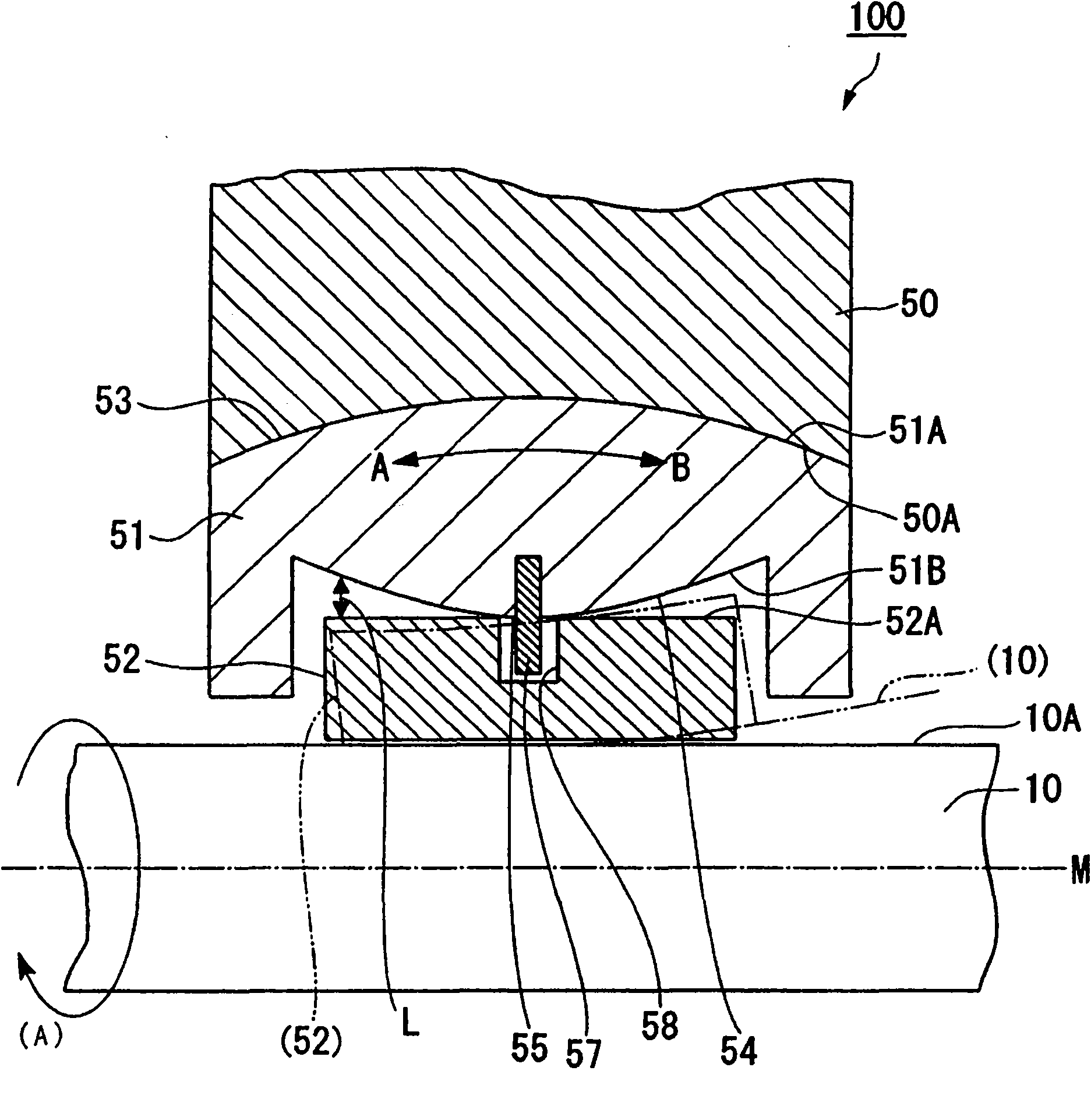

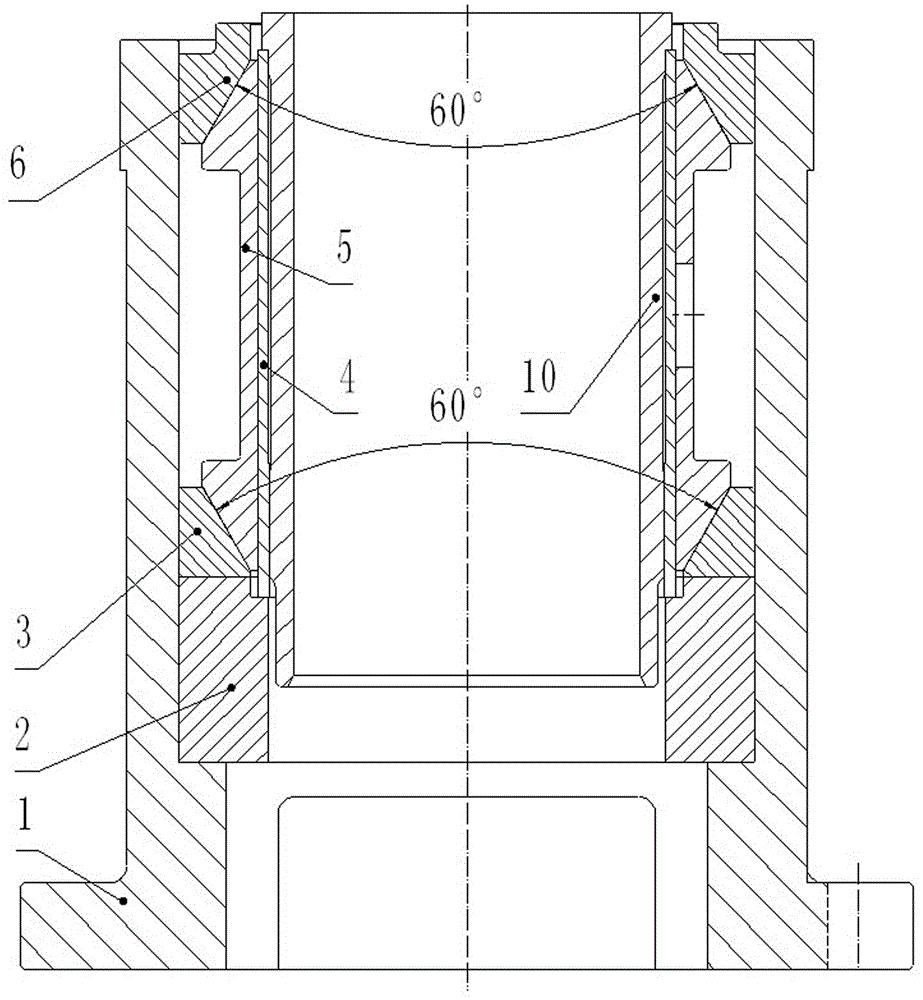

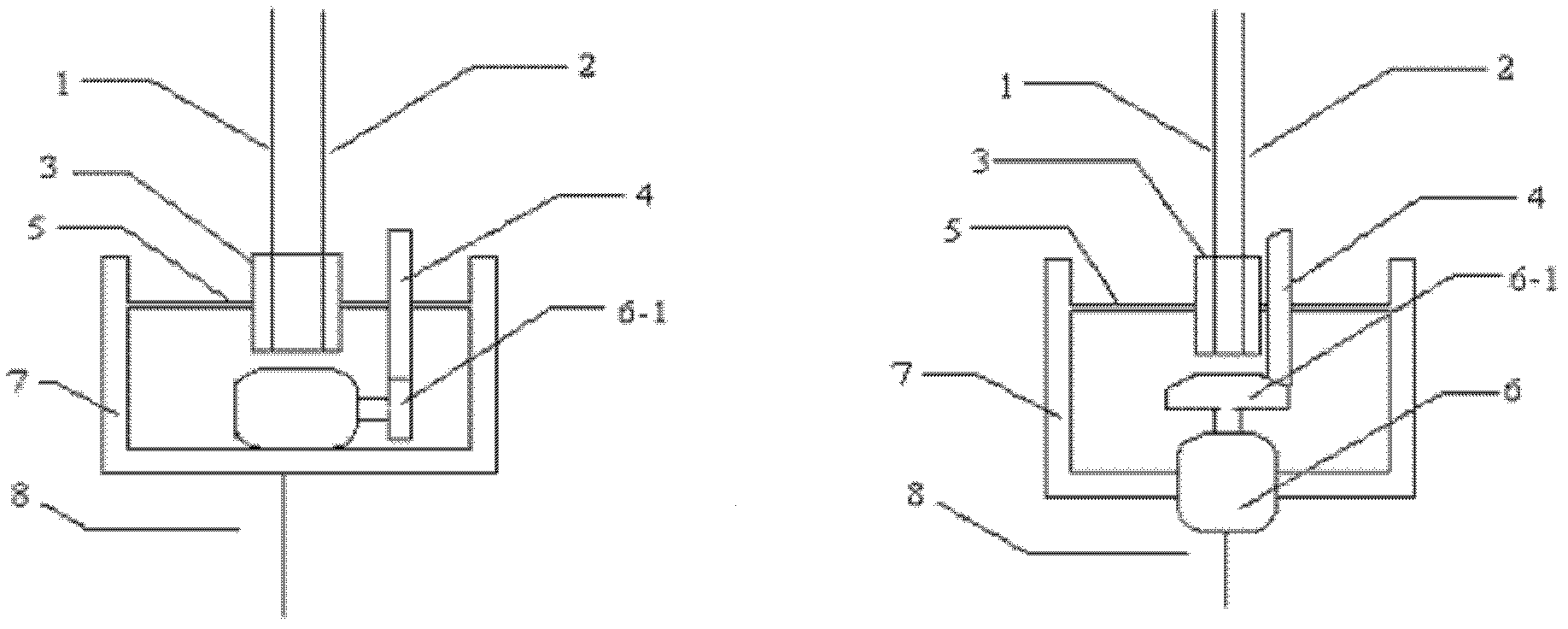

Bearing device and rotary machine

InactiveCN101932839ADeformation stableReliable deformationShaftsMachines/enginesEngineeringMechanical engineering

A bearing device has a bearing housing which is supported by a bearing base mounted to a body of a rotary machine having a rotating shaft and through which the rotating shaft penetrates, and also has pads arranged in the bearing housing so as to circumferentially surround the rotating shaft and rotatably supporting the rotating shaft. The contact surfaces between the outer peripheral surface of the bearing housing and the inner peripheral surface of the bearing base are convex curved surfaces protruding outward along the axis direction of the rotating shaft. The bearing housing is rockably supported by the bearing base via the contact surfaces, or the convex curved surfaces. At least either the inner peripheral surface of the bearing housing or the outer peripheral surface of the pads is a curved surface extending along the axis direction. The distance between the inner peripheral surface of the bearing housing and the outer peripheral surface of the pads gradually increases from the center toward the ends in the axis direction of the bearing housing.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

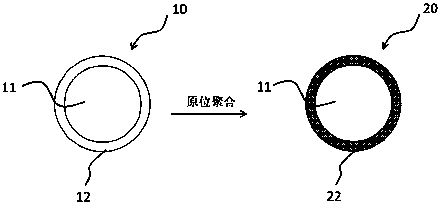

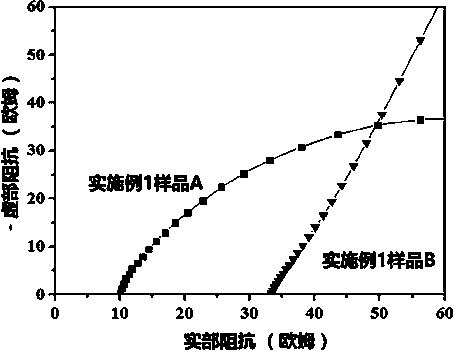

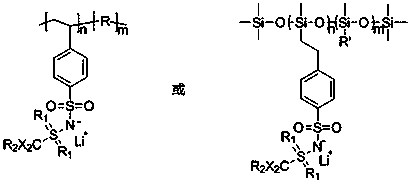

Positive electrode material with low internal resistance for solid state lithium battery and preparation method of positive electrode material

InactiveCN108232138ALower internal resistancePrevent interdiffusionCell electrodesSecondary cellsInternal resistanceConductive materials

The invention provides a positive electrode material with low internal resistance and particularly relates to a positive electrode material with low internal resistance for a solid state lithium battery and a preparation method of the positive electrode material. The positive electrode material with low internal resistance is prepared from a positive electrode active material core and a surface composite material layer covering the positive electrode active material core, wherein the surface composite material layer is mainly prepared from a nano long-range conducting material and a single ionconductor polymer material. The positive electrode material with low internal resistance, provided by the invention, has higher electronic conductivity and lithium ion conductivity and can effectively reduce the internal resistance of the solid state lithium battery; because the positive electrode active material core and the surface composite material layer have strong interaction, the phenomenaof granule cracking and grinding caused by volume deformation of the positive electrode active material core in repeated charging and discharging process can be effectively inhibited so as to ensurethe structural integrity of the positive electrode active material core and good interface stability; and furthermore, the technical scheme provided by the invention is simple and easy, low in production cost and suitable for performing large-scale production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

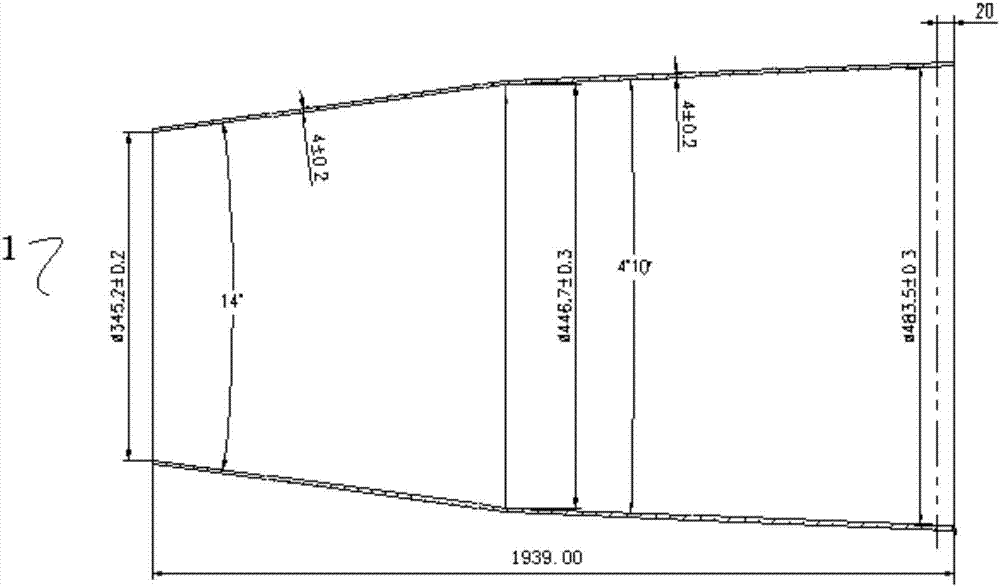

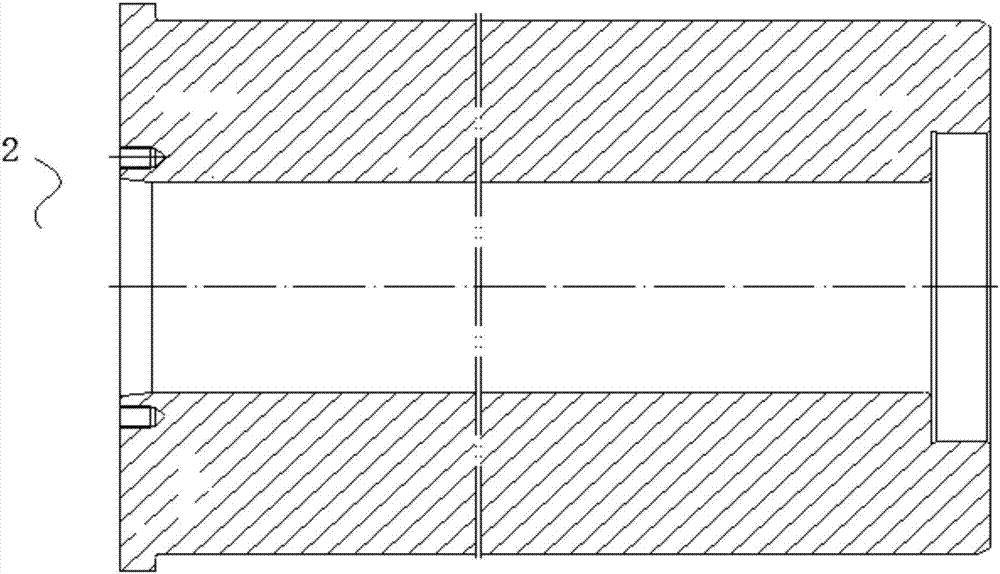

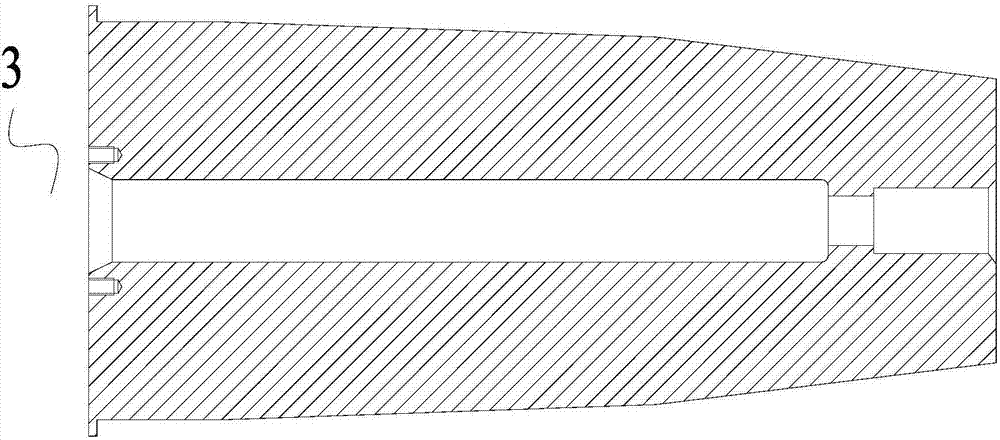

Spinning forming method for multi-angle tapered barrel body

The invention discloses a spinning forming method for a multi-angle tapered barrel body. The spinning forming method is characterized in that the multi-angle tapered barrel body is subjected to reversely compounded spinning forming, and two sections or multiple sections of the multi-angle tapered barrel body are integrally formed; compared with the conventional technological methods of part welding, machining and assembly welding forming, the spinning forming method has the advantages that processing efficiency is greatly improved, processing cost is greatly reduced, roundness requirements are met, and processing efficiency is effectively improved; and straight-side defects formed at longitudinal welding seam butt-joint parts of part welding forming are eliminated, and the problem that inner-profile circumferential welding seams at circumferential butt-joint welding seams are liable to sink is also eliminated, so that the integral processing precision, the appearance quality and the inner quality of the multi-angle tapered barrel body are effectively improved.

Owner:湖北三江航天江北机械工程有限公司

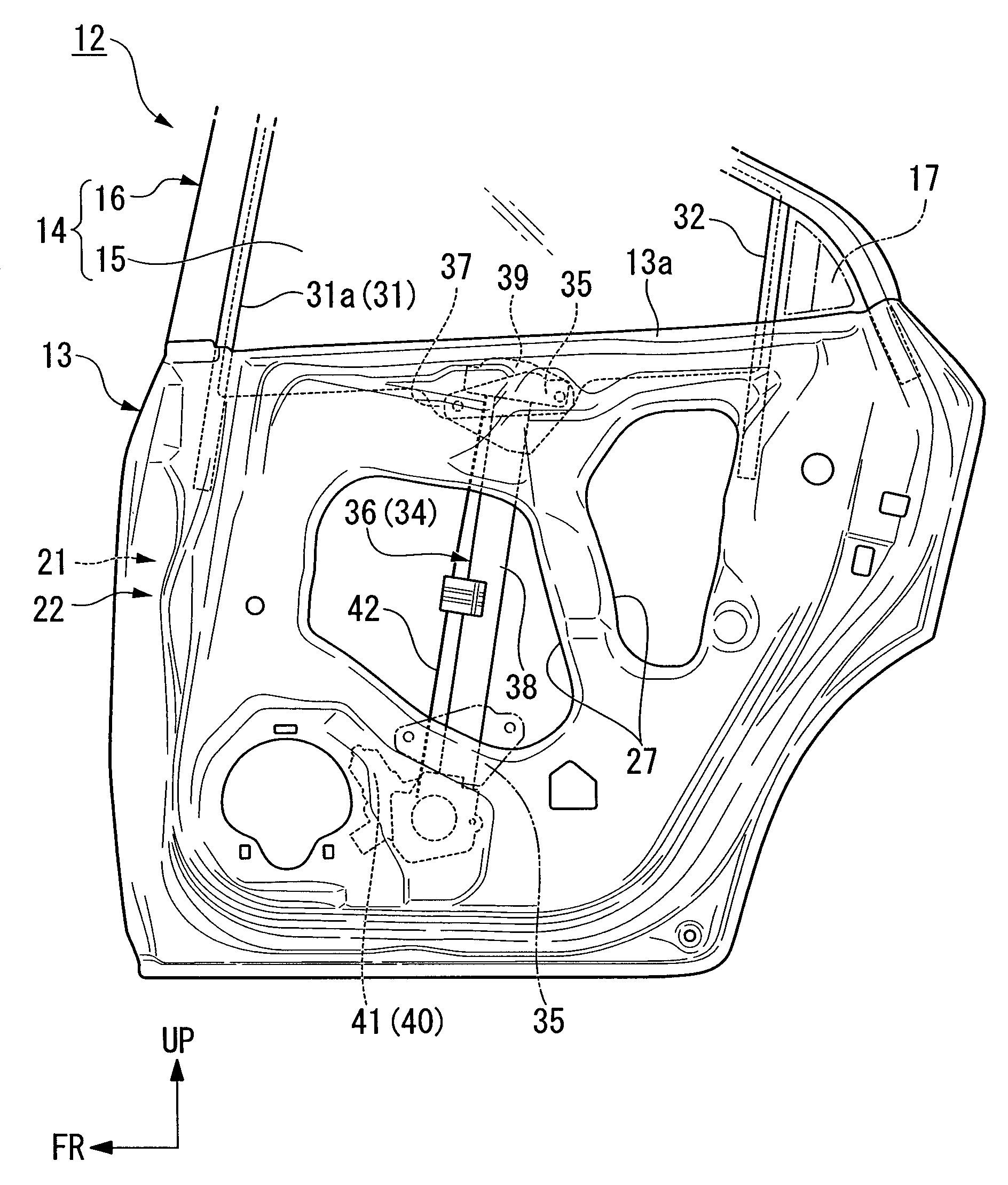

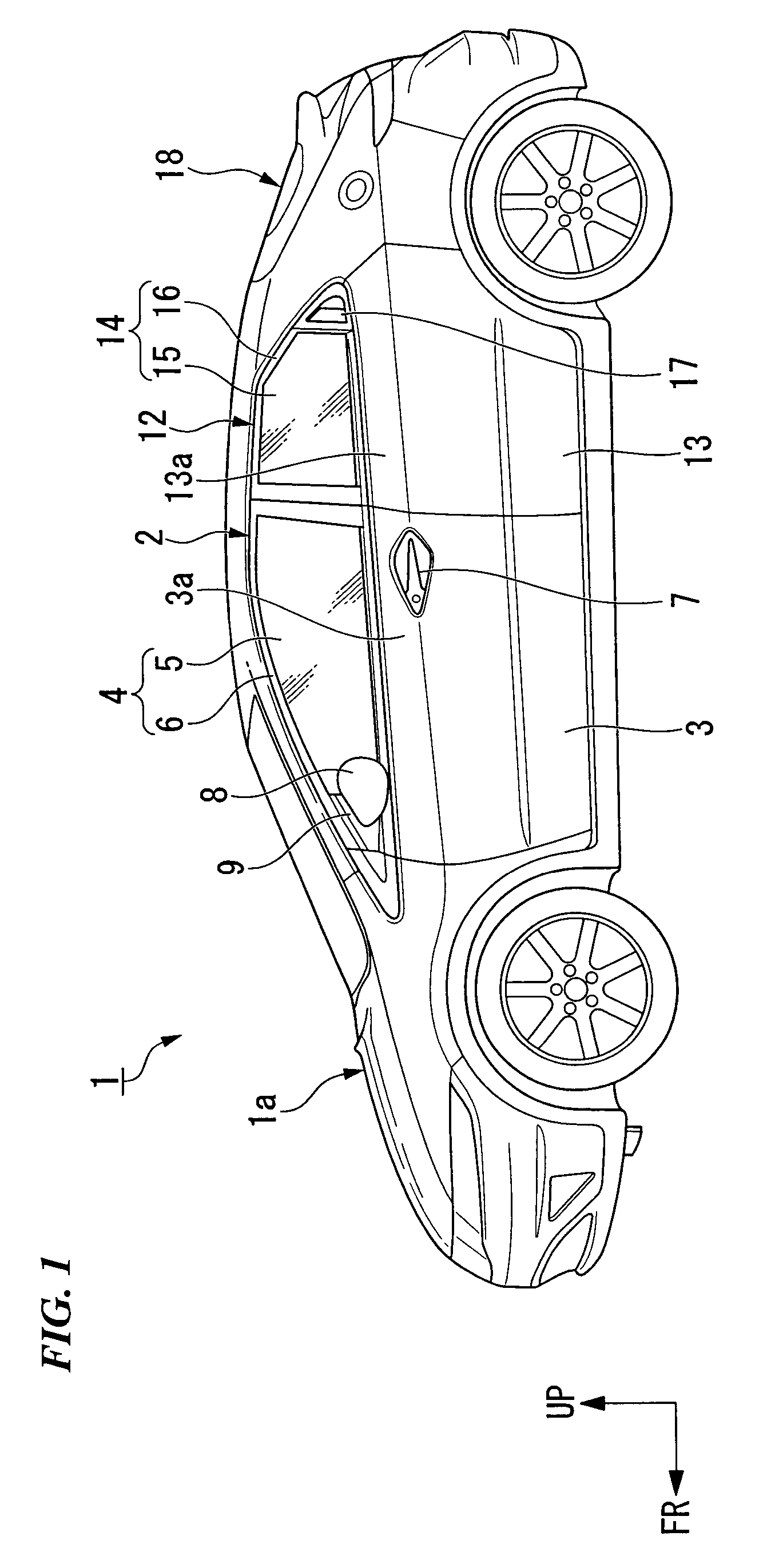

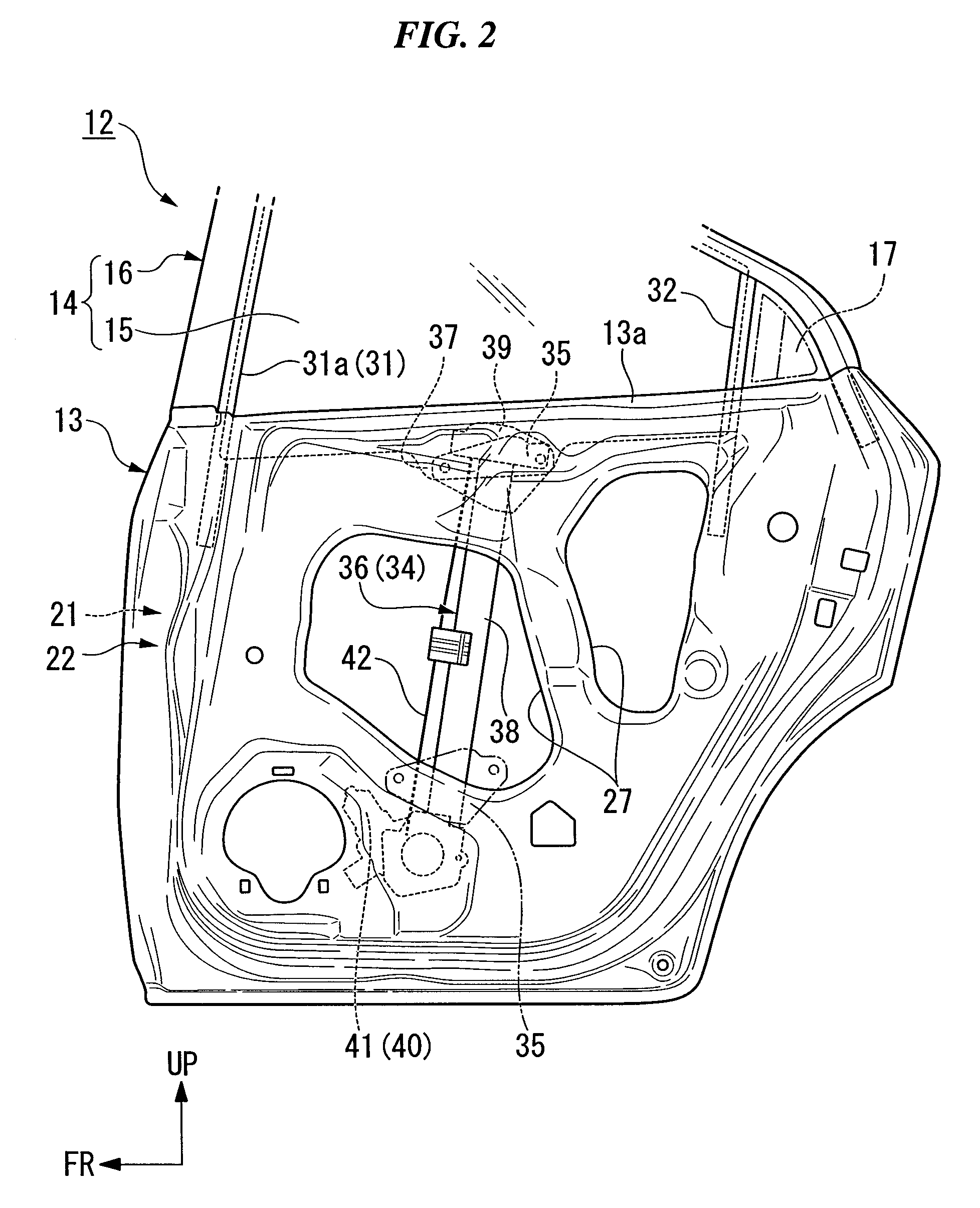

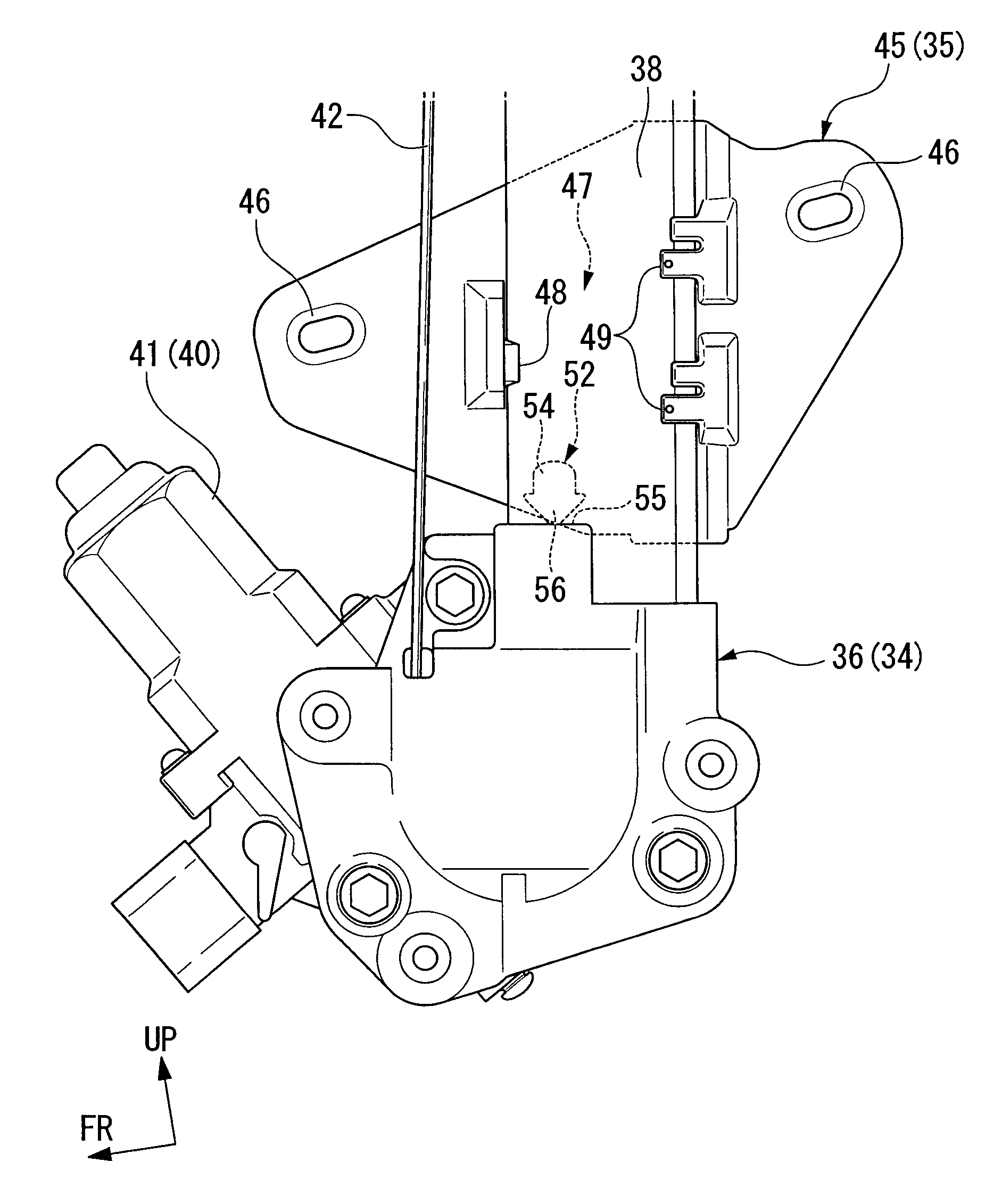

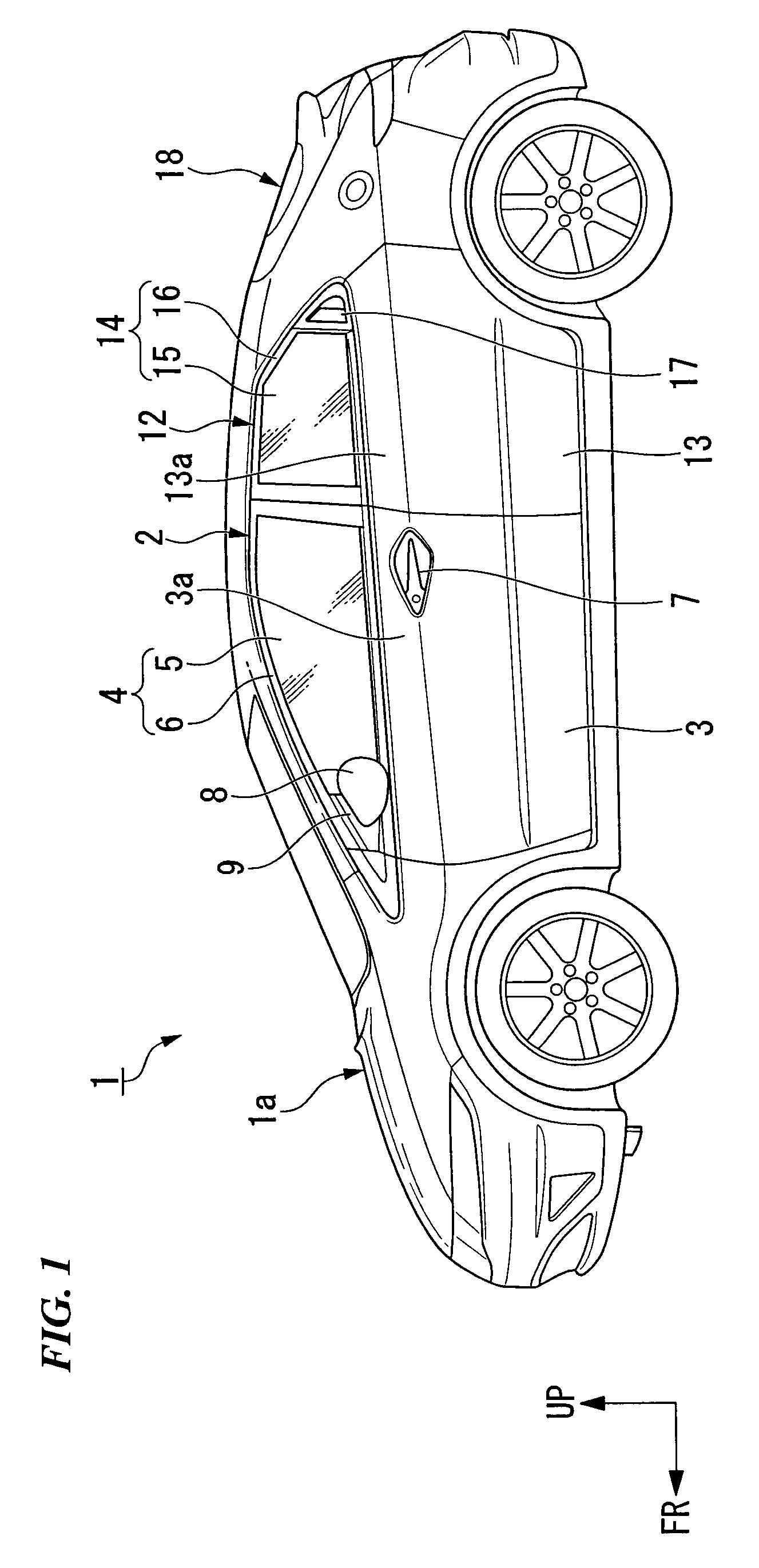

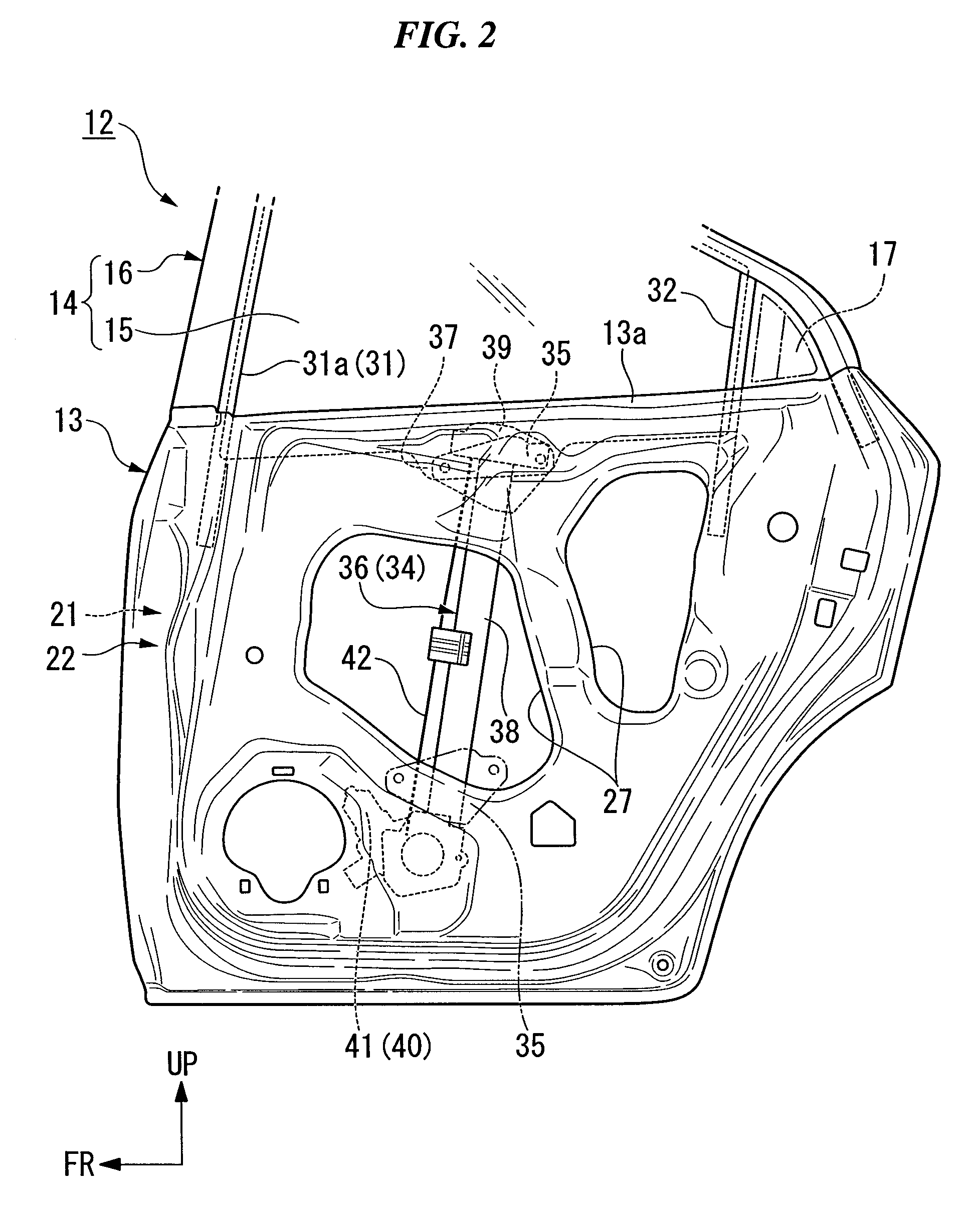

Elevating device for window glass

InactiveUS20070144073A1Prevent setting errorsAvoid knockingMan-operated mechanismPower-operated mechanismEngineeringElectrical and Electronics engineering

Owner:HONDA MOTOR CO LTD

Mounting and constructing method for steel plate shear wall

ActiveCN102605962ADeformation stableNo local bucklingWallsBuilding material handlingSheet steelStructural load

The invention discloses a mounting and constructing method for a steel plate shear wall. The mounting and constructing method includes that steel tube border columns on two sides of the steel plate shear wall are mounted, during hoisting, the steel plate shear wall and the steel tube border columns are temporarily fixed via bolts, the mounting method is adopted repeatedly until all units of the steel plate shear wall are mounted, after all steel structural loads are added, double clamp plates on two sides of the steel plate shear wall are respectively welded with first attached plates, double clamp plates on the lower edge of the steel plate shear wall are welded with second attached plates on the upper flange of a border beam of a next unit, the temporarily fixed bolts are taken out after welding is finished, and construction is completed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

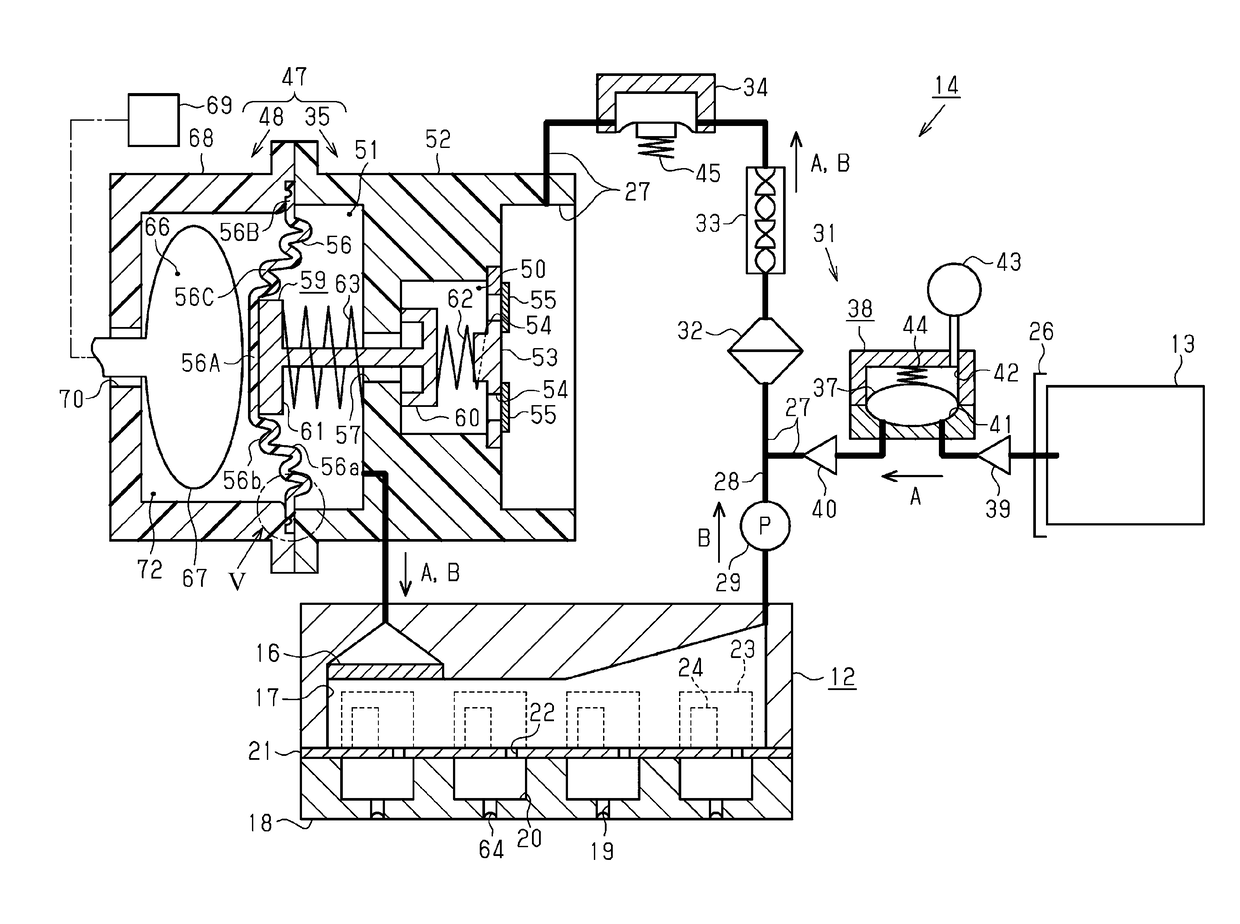

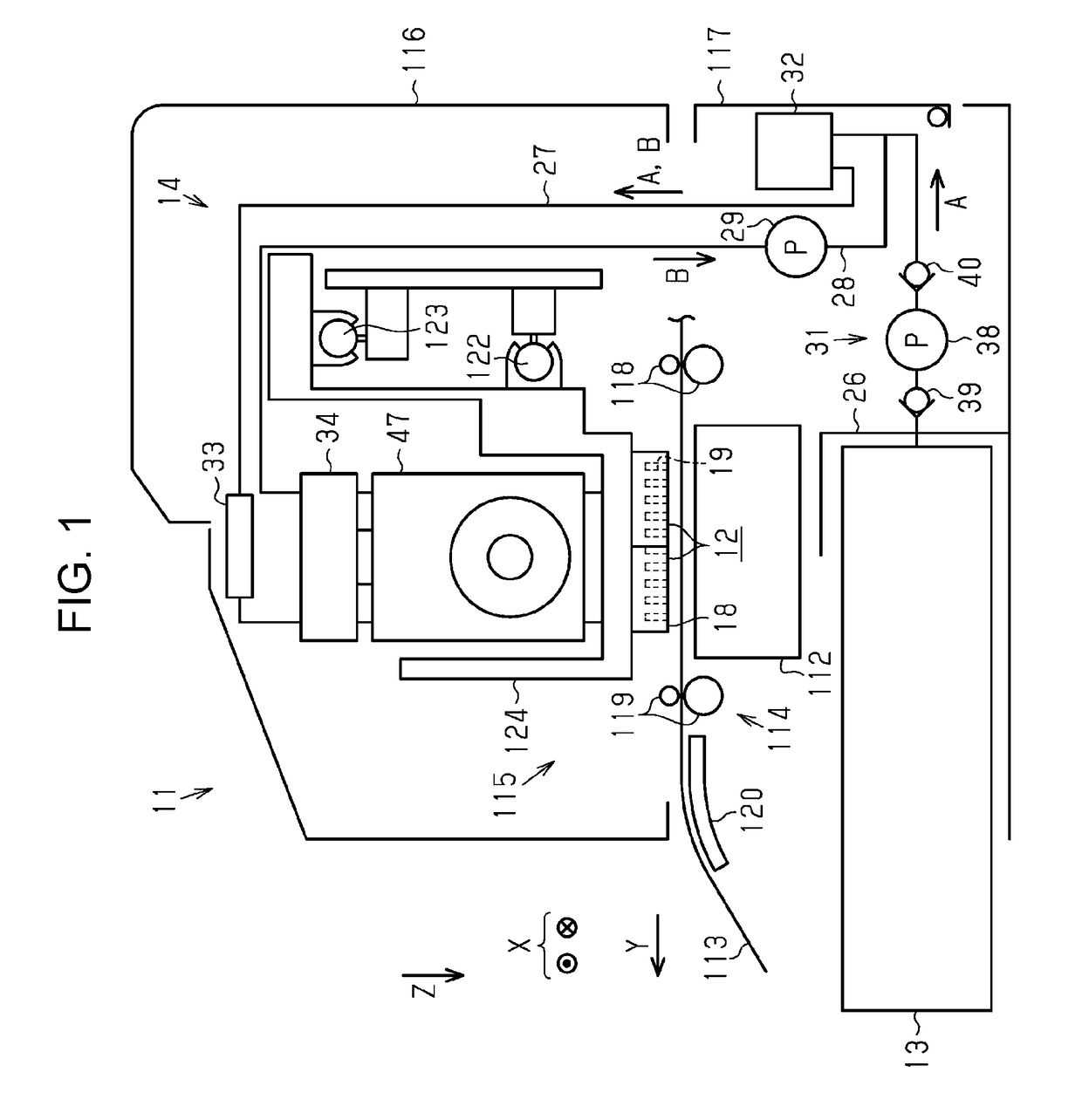

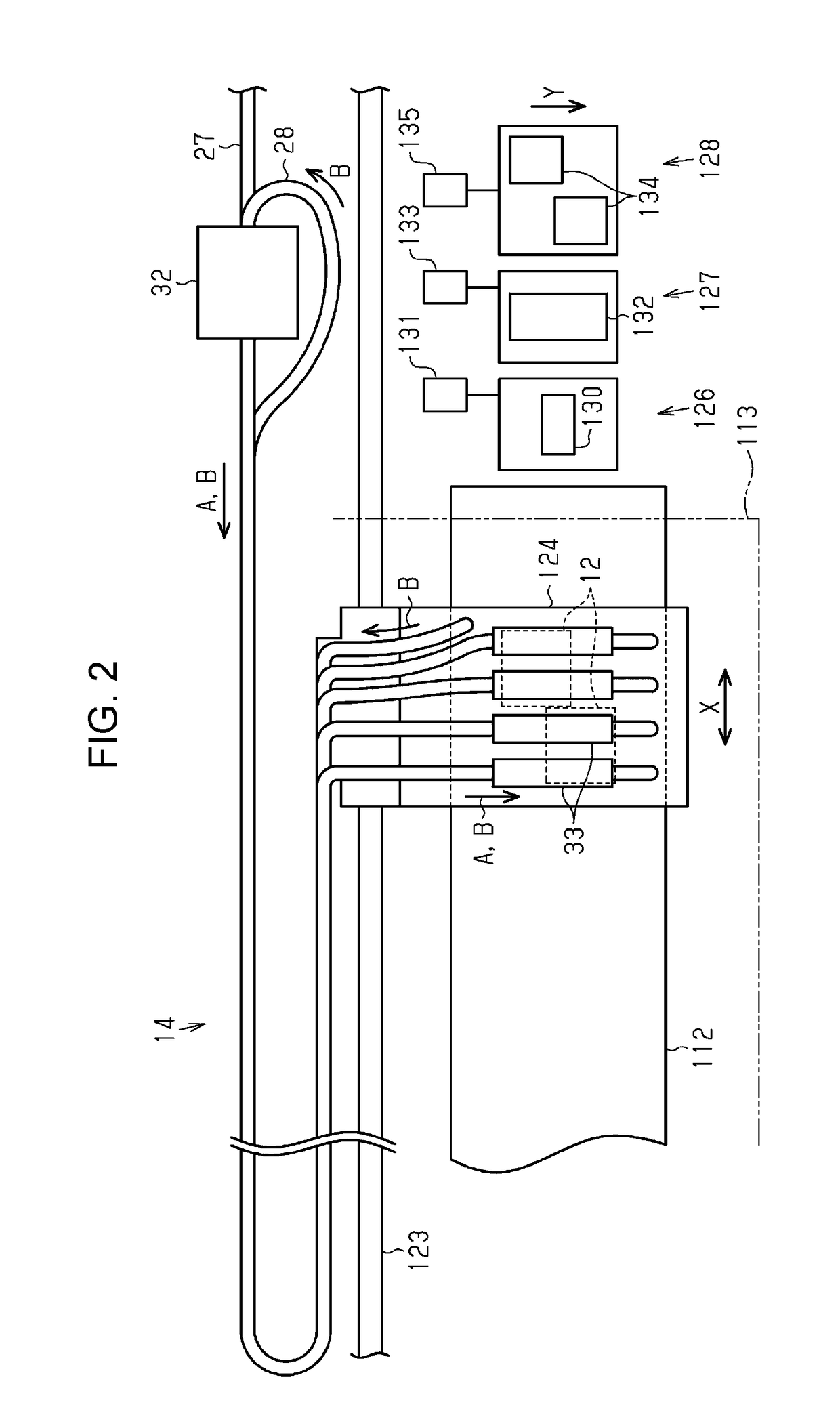

Liquid ejecting apparatus and pressure-regulating device

A liquid ejecting apparatus includes a pressure-regulating mechanism which is provided in a liquid supply path in which it is possible to supply liquid to a liquid ejecting unit, and includes a liquid accommodation part which can accommodate the liquid internally, and in which a volume of the liquid accommodation part is changed depending on displacing of a diaphragm section, in which the diaphragm section includes an annular corrugated portion formed in a sectional waveform shape which is deformed when the diaphragm section receives pressure.

Owner:SEIKO EPSON CORP

Elevating device for window glass

InactiveUS7765739B2Prevent setting errorsAvoid knockingMan-operated mechanismPower-operated mechanismEngineeringElectrical and Electronics engineering

Owner:HONDA MOTOR CO LTD

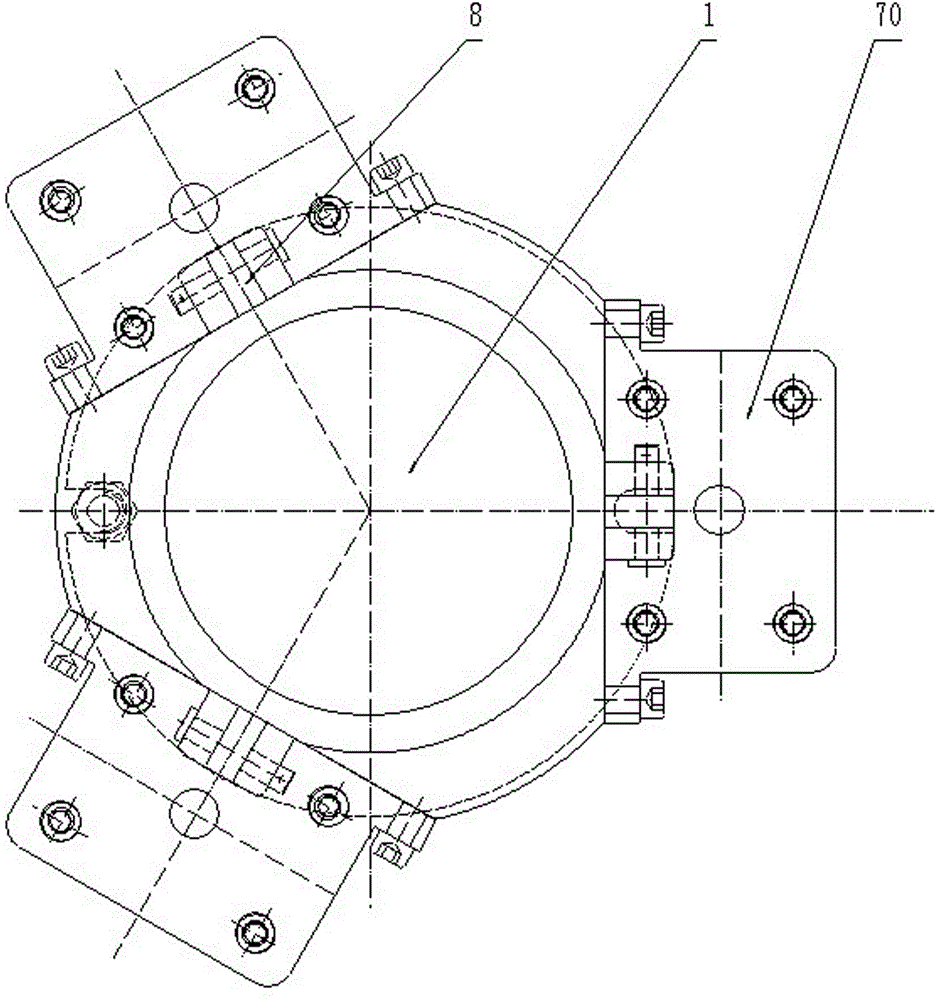

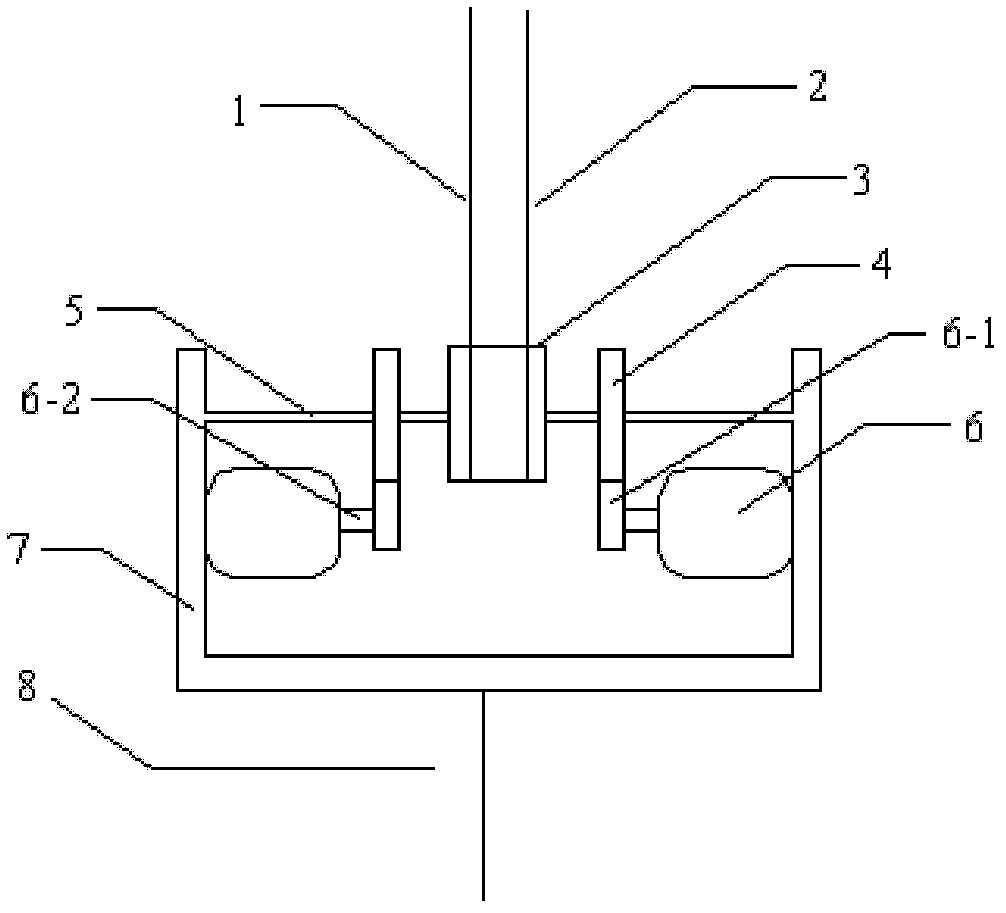

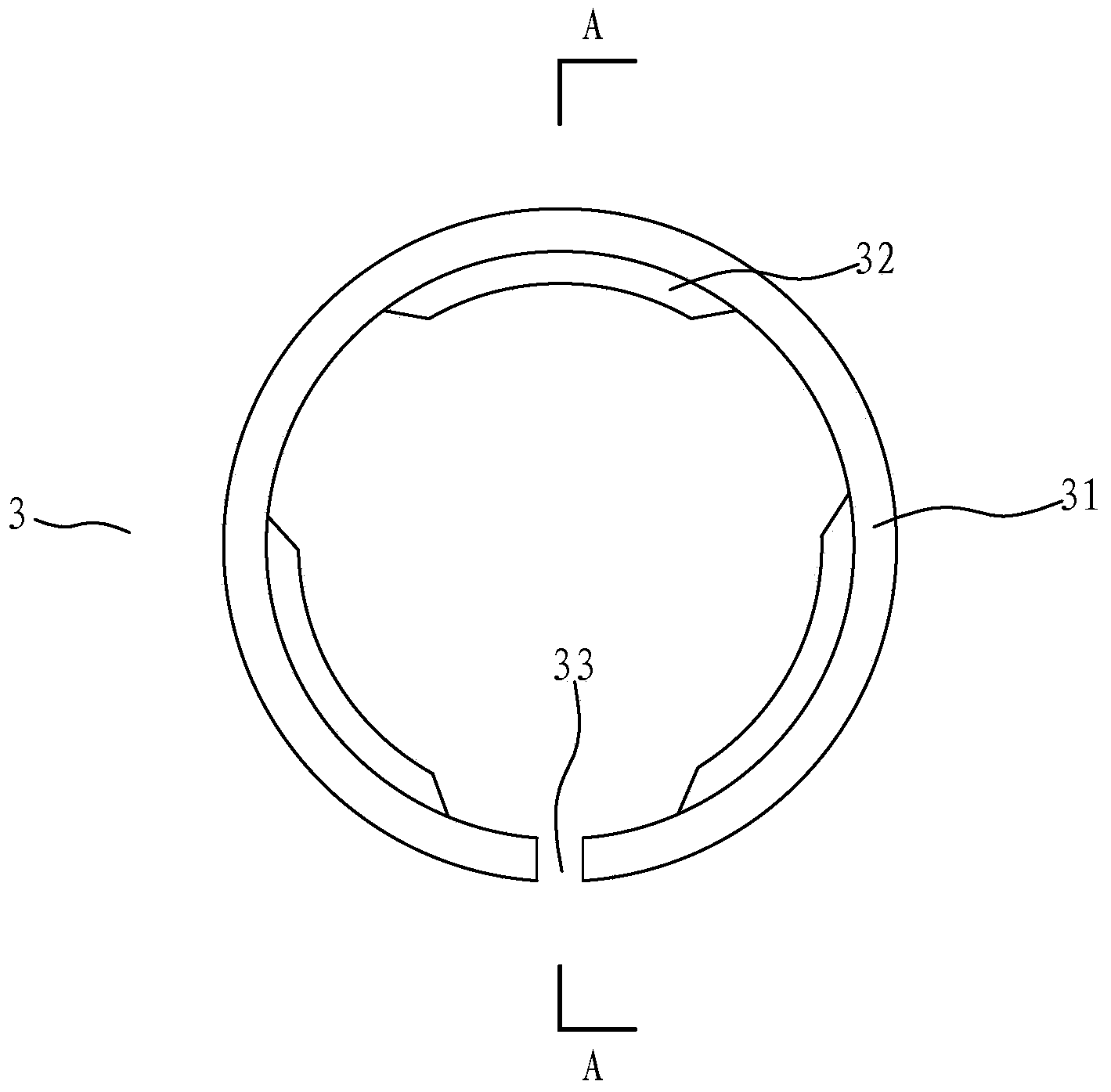

Air clamper for bore hole of thin-wall cylinder sleeve

InactiveCN104551780ANo deformationDeformation stableWork clamping meansPositioning apparatusPiston rodProcessing accuracy

The invention provides an air clamper for a bore hole of a thin-wall cylinder sleeve. The air clamper can steady and clamp the thin-wall cylinder sleeve, a workpiece is uniformly forced in the periphery direction, and deformation does not exist after the thin-wall cylinder sleeve is clamped, so that the processing accuracy is improved. The air clamper comprises a fixture body, wherein base plates are arranged at the bottom end of the inner cavity of the fixture body, lower taper sleeves with taper holes are arranged above the base plates, an elastic open sleeve and a spring sleeve are radially and successively arranged in the inner cavity of the fixture body above the lower taper sleeves, upper taper sleeves with the taper holes are arranged at the upper end of the spring sleeve, and the upper end and the lower end of the spring sleeve are respectively matched with conical surfaces of the upper taper sleeves and the conical surfaces of the lower taper sleeves; at least three sets of compressing devices are uniformly distributed in the periphery direction of the fixture body, and each compressing device comprises a cylinder and a cylinder seat arranged above the cylinder; and pressing arms are arranged on the cylinder seats through pin shafts, piston rods of the cylinders and the pressing arms are mounted in a matching manner, one ends of the pressing arms extend to the edge of the inner cavity of the fixture body, and stretching springs are arranged between the other ends of the pressing arms and the cylinder seats.

Owner:ANHUI WHITE RABBIT POWER

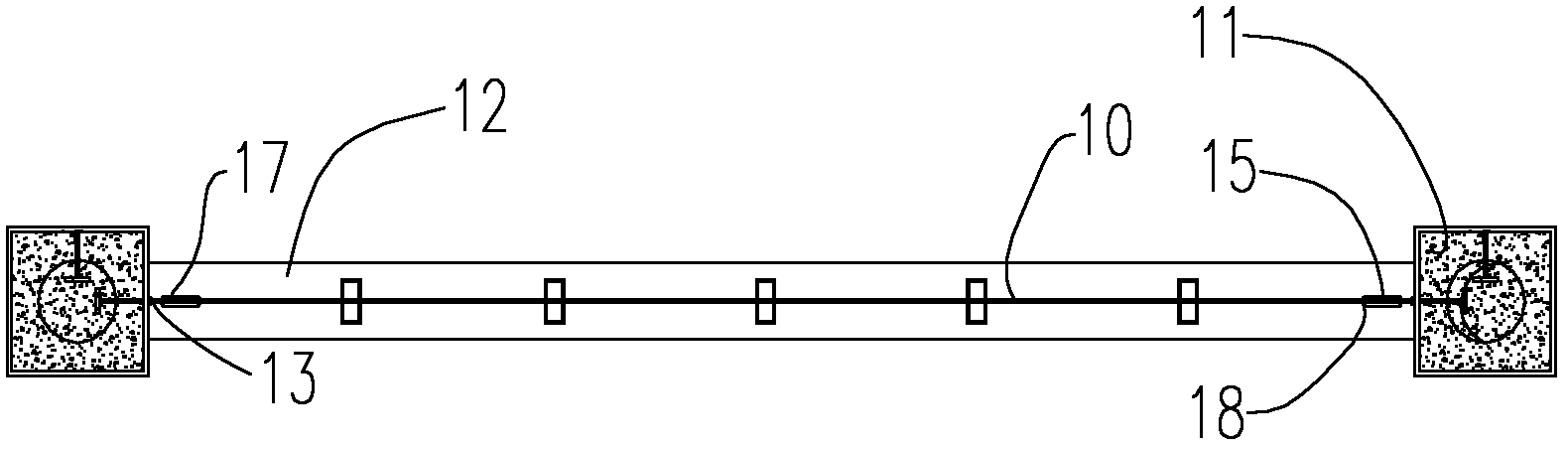

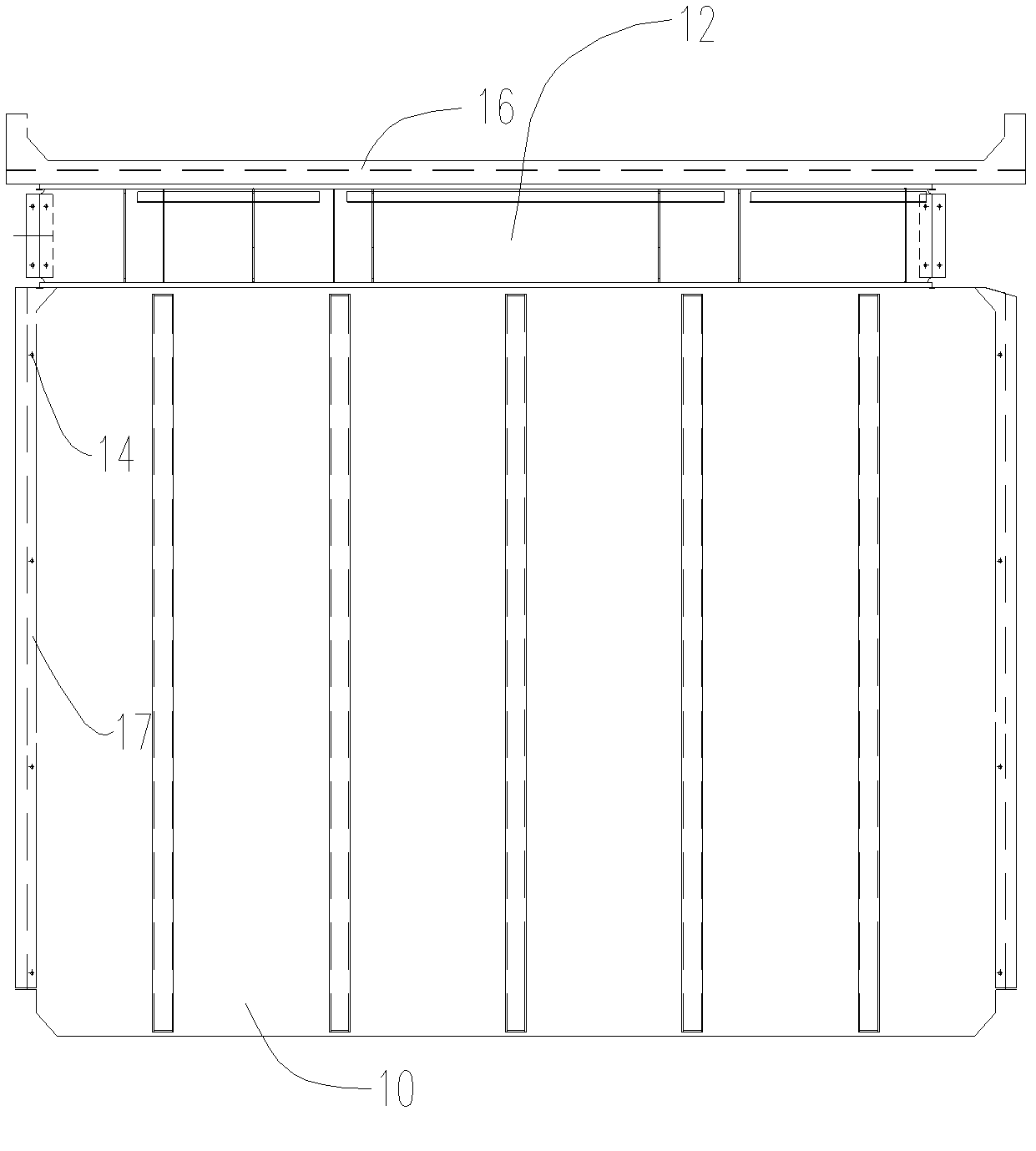

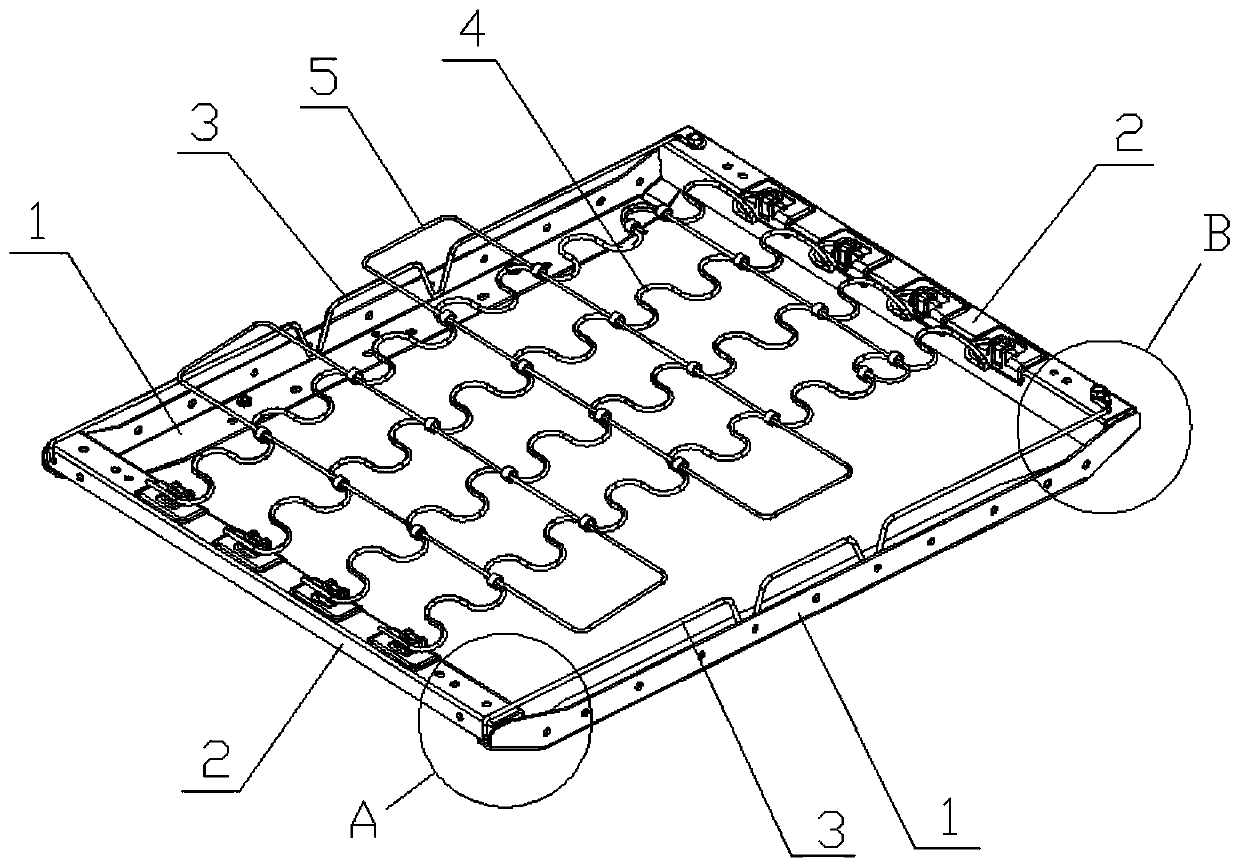

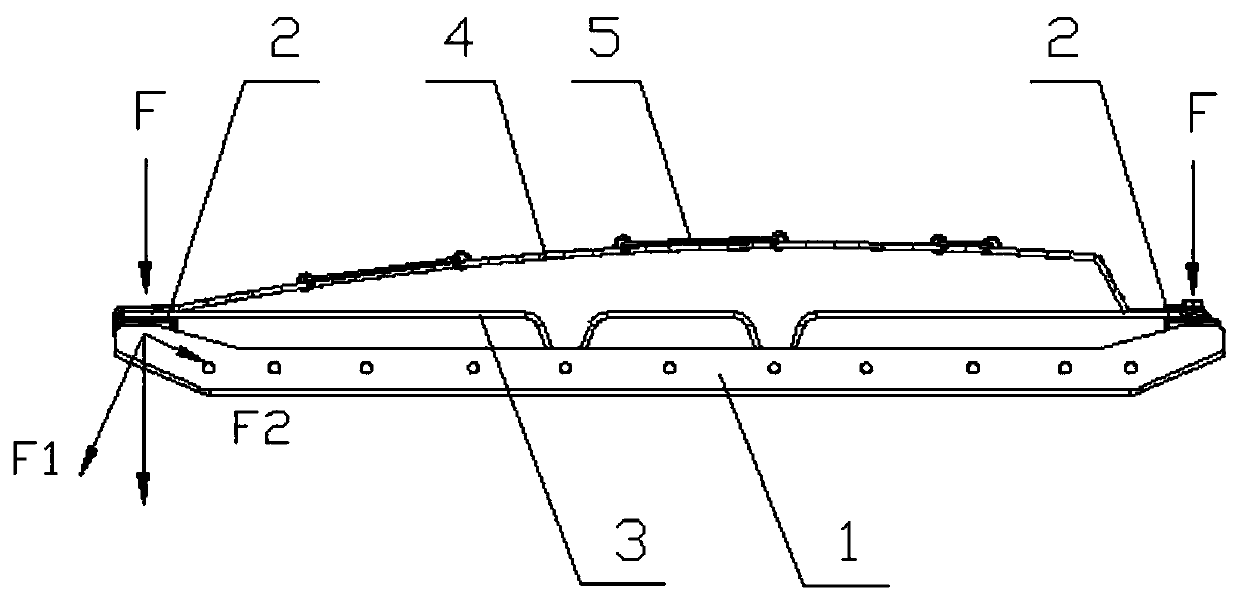

Sofa seat frame

InactiveCN110101245AGuaranteed support strengthIncrease productivitySpring mattressesEngineeringVertical path

The invention discloses a sofa seat frame, comprising a frame and several elastic members disposed in the frame. The frame comprises two symmetrically-disposed longitudinal beams and two crossbeams for connecting the two longitudinal beams. The cross section of the longitudinal beams is L-shaped and includes a vertical plate and a horizontal plate. The vertical plate and the horizontal plate forma placement cavity, and both ends of the horizontal plate in the length direction are bent towards the inner side of the placement cavity to form a folded edge. The two crossbeams are symmetrically disposed on folded edges at both ends of the longitudinal beams and located in the placement cavity. The sofa seat frame also comprises at least a supported beam, which is connected with the two crossbeams. In comparison with existing sofa seat frame structures, the invention has the following advantages: under the precondition of guaranteeing support strength of the seat frame, the production efficiency of components is improved, manufacturing materials are reduced, production cost is decreased, and complicated assembly process and required parts are simplified; and automation is easy to realize.

Owner:MAN WAH FURNITURE MFG HUIZHOU

Cable controller, kite, kite drive operating mechanism, kite power generator and automobile and boat wind-driving method

InactiveCN102602751ADeformation stableAvoid enteringFinal product manufactureWind motor combinationsNuclear powerWater reservoir

A cable controller, a kite, a kite drive operating mechanism, a kite power generator and an automobile and boat wind-driving method all relate to a counter-pulling cable controller and a completely-deformable double-cable kite which form a reciprocating discharging and collecting kite. The kite spreads to collect energy at a starting point and can flow to a finish point linearly, folds to discharge energy and backflows to the starting point linearly, and then re-spreads to collect energy to flow and draws a working machine round and round to run. The reciprocating discharging and collecting kite and the engine are combined to form a wind-kite power generator or a water-kite power generator, the same power generator can be pulled by hundreds of large-sized kites jointly, the maximum single-machine capacity of the two kinds of the power generators can reach or excess that of thermal-power generation and nuclear power. A pond energy storage power generation mechanism is a new combination of wind power generation and water power generation, river blocking and damming of water power generation are omitted, and electric quantity equal to that of larger power generation stations can be generated by low investment and small water reservoirs. The automobile and boat wind-driving method includes: utilizing trade-wind zones, westerlies and easterlies on the earth, and upper reverse wind and lower reverse wind of the stratosphere so that automobiles and boats can run with or against the wind and the crosswind.

Owner:罗琮贵

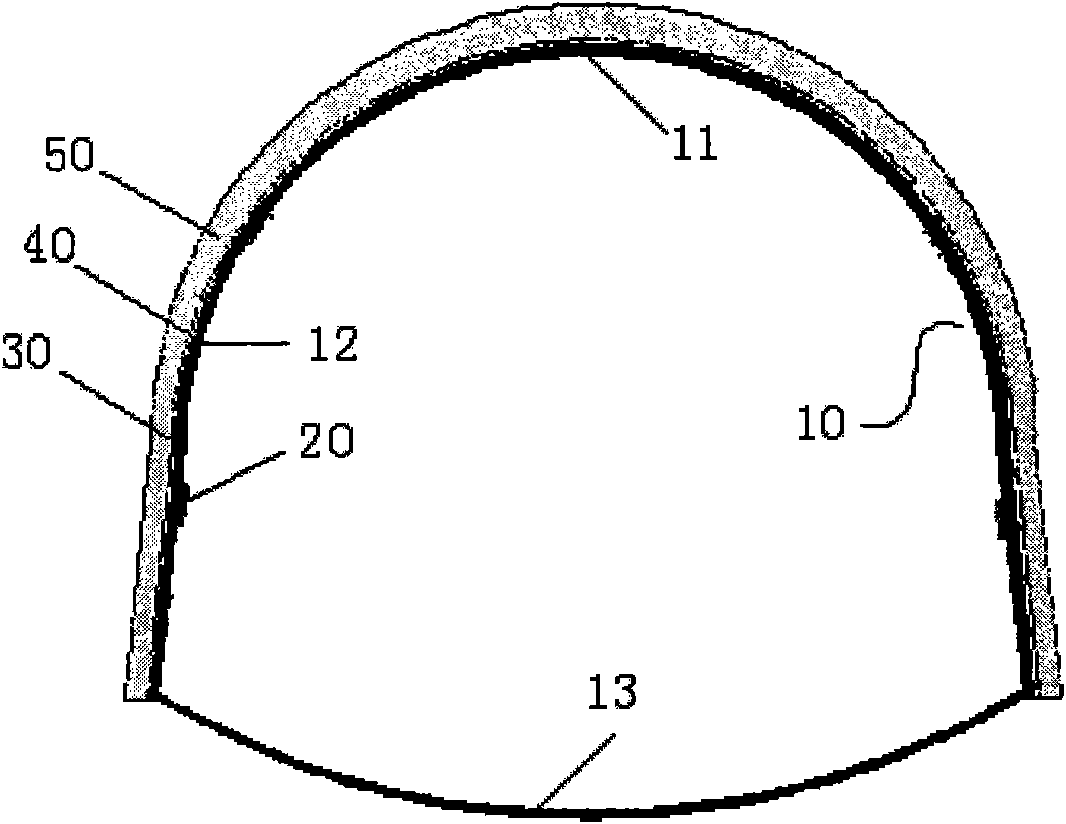

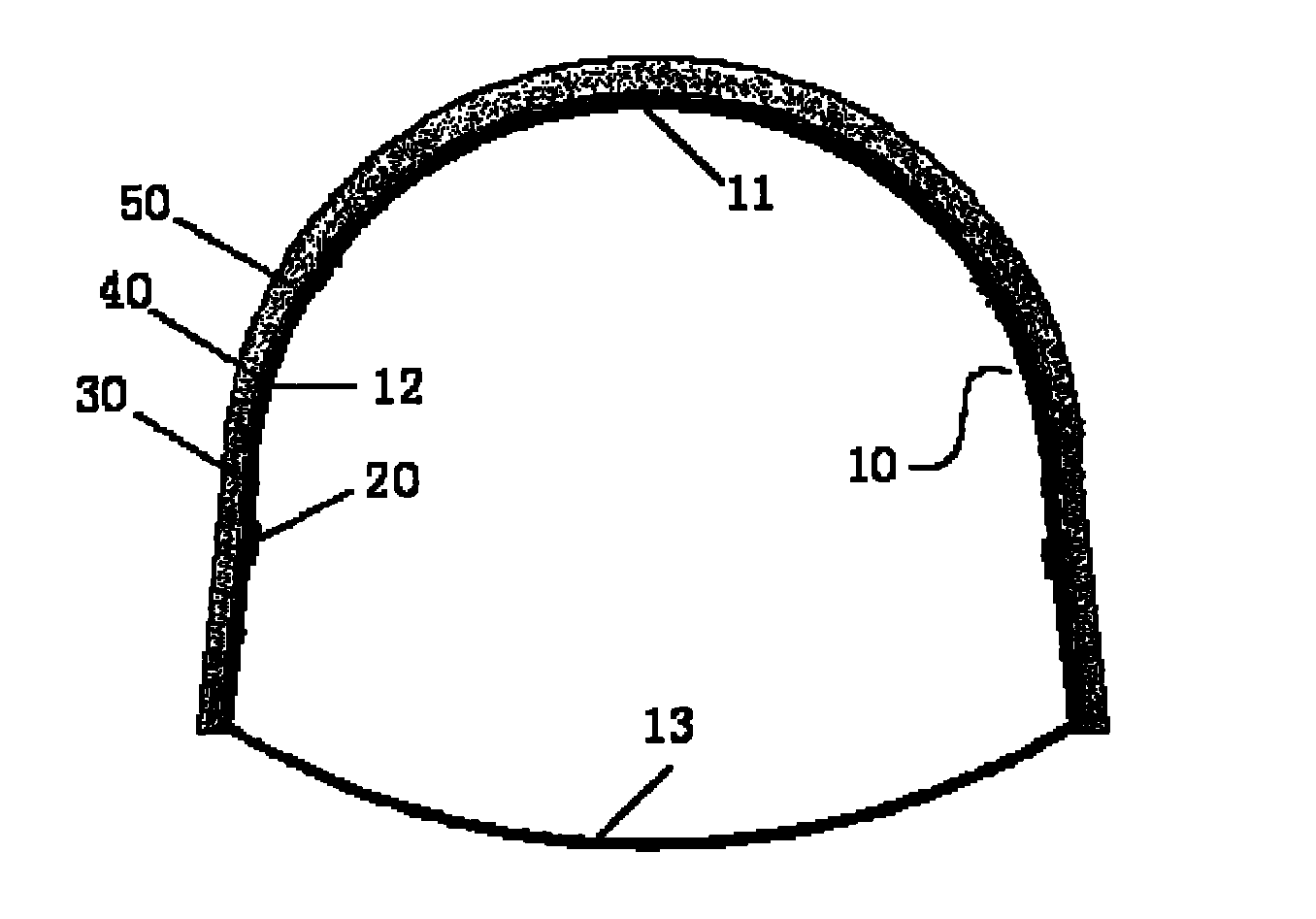

Method for supporting and protecting soft, collapsible and super thick coal seam tunnel based on filling behind support and device thereof

The invention discloses a method for supporting and protecting a soft, collapsible and super thick coal seam tunnel based on filling behind a support and a device thereof, relating to the supporting and protecting technology of the coal seam tunnel. The method comprises the following steps of: (1) the tunnel is supported and protected by a sealing retractable U-shaped steel support which consists of a top arch, a side wall and an inverted arch; (2) the inner wall of the side wall is provided with a waist beam; (3) the top arch and the outer wall of the side wall are suspended with a metal mesh; (4) the metal mesh is externally paved with a double resistance cloth; and (5) the outer side of the double resistance cloth is injected with a high-expansion chemical filling material behind the support. The device has the following structure: the waist beam (20), the sealing retractable U-shaped steel support (10), the metal mesh (30), the double resistance cloth (40) and the high-expansion chemical filling material (50) are sequentially connected with each other from the inside to the outside. The invention is suitable for supporting and protecting the super thick, soft and collapsible coal seam tunnel, and the landslide and soft tunnel.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

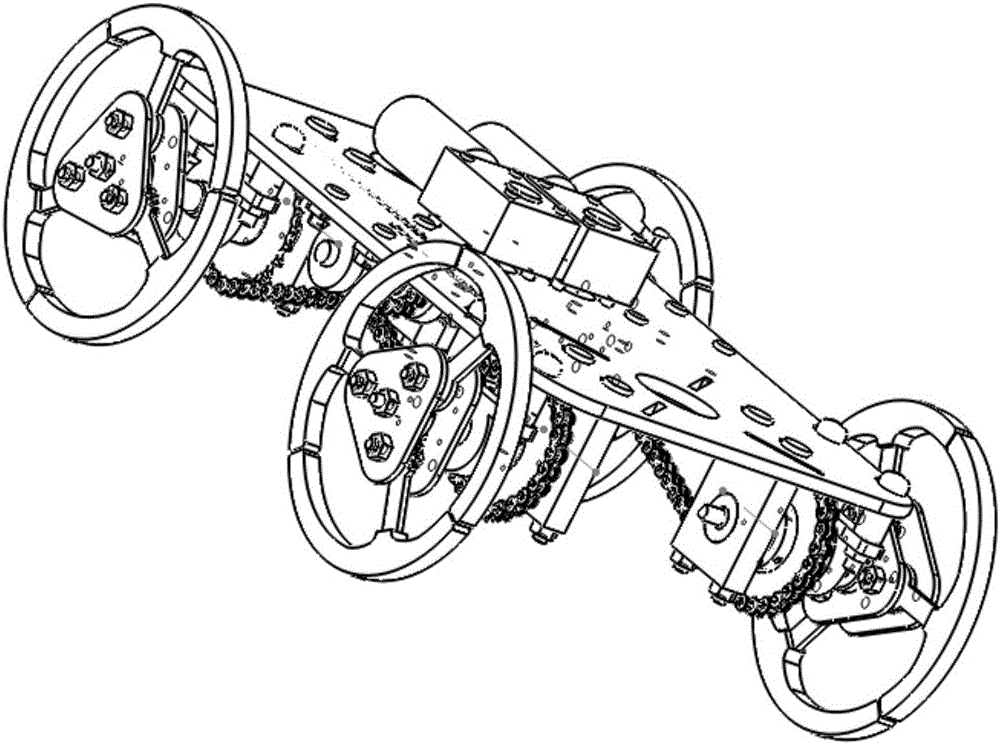

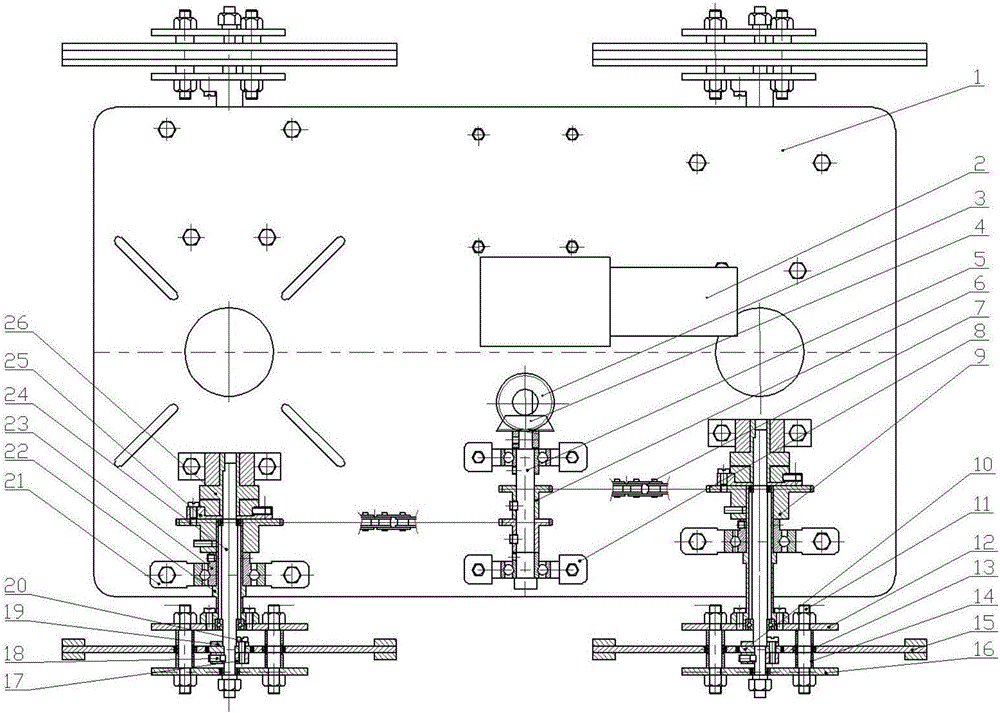

Stair climbing robot with planetary gear train

InactiveCN105857429ARealize separate controlDeformation stableVehiclesElectromagnetic clutchCoupling

The invention belongs to the field of mechanical-electrical integration, particularly relates to a stair climbing robot with a planetary gear train, and mainly solves the problems that a conventional stair climbing robot is low in transmission efficiency, difficult to deform, slow in movement, poor in structural stability and the like. The stair climbing robot with the planetary gear train comprises a transmission system, a changeover system and an executive system, wherein the transmission system comprises a left transmission group and a right transmission group, and the left transmission group and the right transmission group are in parallel and are symmetrically mounted by using a longitudinal center line as a symmetric center; the changeover system comprises four changeover groups, wherein the four changeover groups are separately arranged in four directions of a bottom plate, and each of the changeover groups consists of a sun gear shaft, a long sleeve, a shaft coupling, an electromagnetic clutch and a bearing; the executive system consists of four gear group systems, wherein each of the gear group systems comprises an inner triangle plate, an outer triangle plate, three planetary gear shafts, six planetary gear shaft sleeves, three planetary gear blades, a sun gear and a blade bearing.

Owner:ZHONGBEI UNIV

Ceramic clay material and ceramic product thereof

The invention discloses a ceramic clay material. The ceramic clay material comprises the following components in percentage by weight: 48%-55% of kaoline, 36%-42% of feldspar, 2%-4% of aluminum oxide, 3%-5% of talcum and 3%-6% of quartz. Compared with the prior art, the formula of the ceramic clay material disclosed by the invention is obtained by the applicant through a plurality of tests; each component in the formula is brought into play in a synergetic manner; particularly, 2%-4% of aluminum oxide is added to the formula; during product sintering, the contraction ratio control plays a key role, so that the sintered product is unlikely to deform; the sintering concentration ratio is controlled to be 14%-15%; and 3%-4% of talcum is added to the formula, so that the sintering temperature range of the product sintering can be expanded, and therefore, the yield of the product sintering is higher and the large-scale industrial production requirements are satisfied.

Owner:FUJIAN GUANFU IND CO LTD

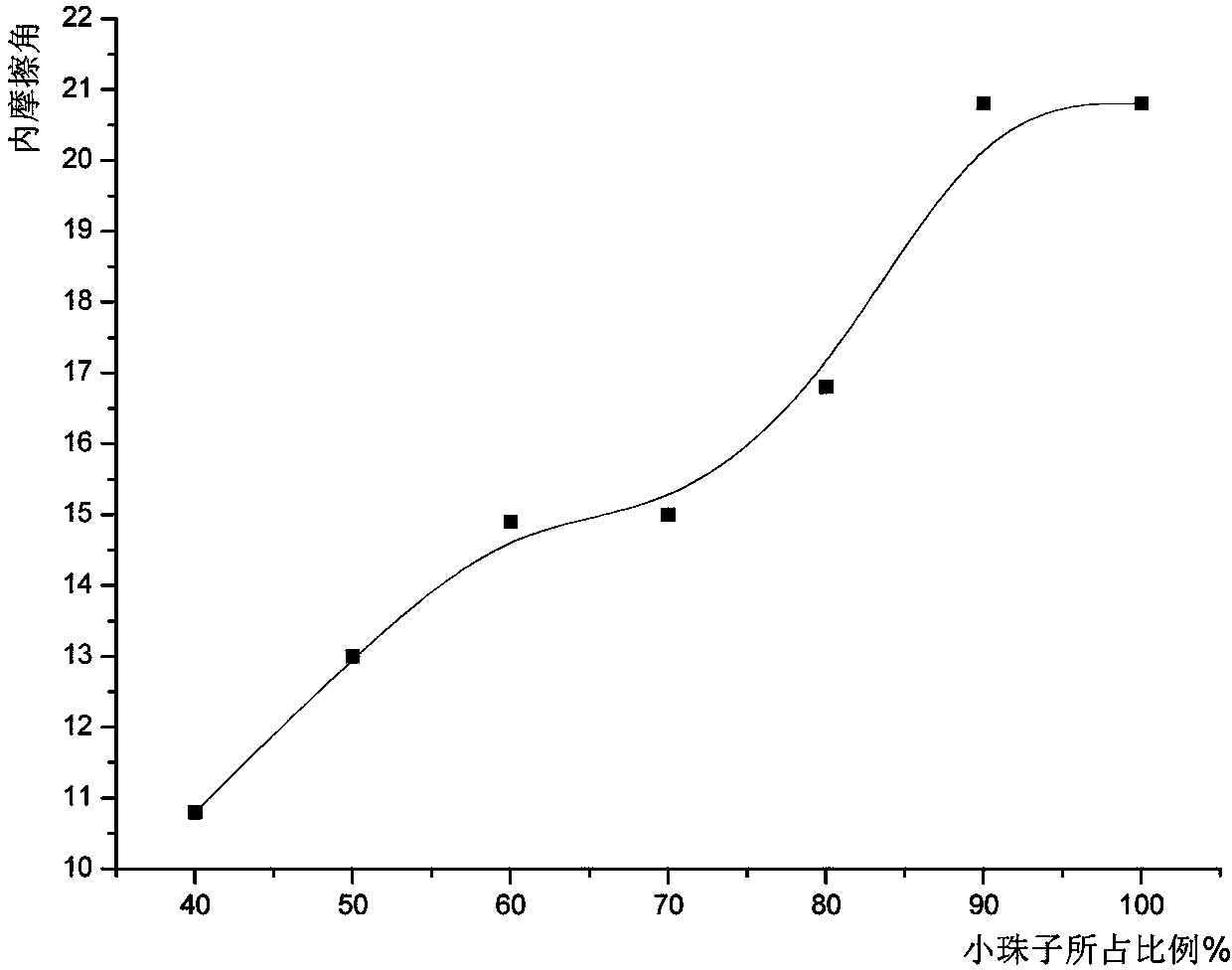

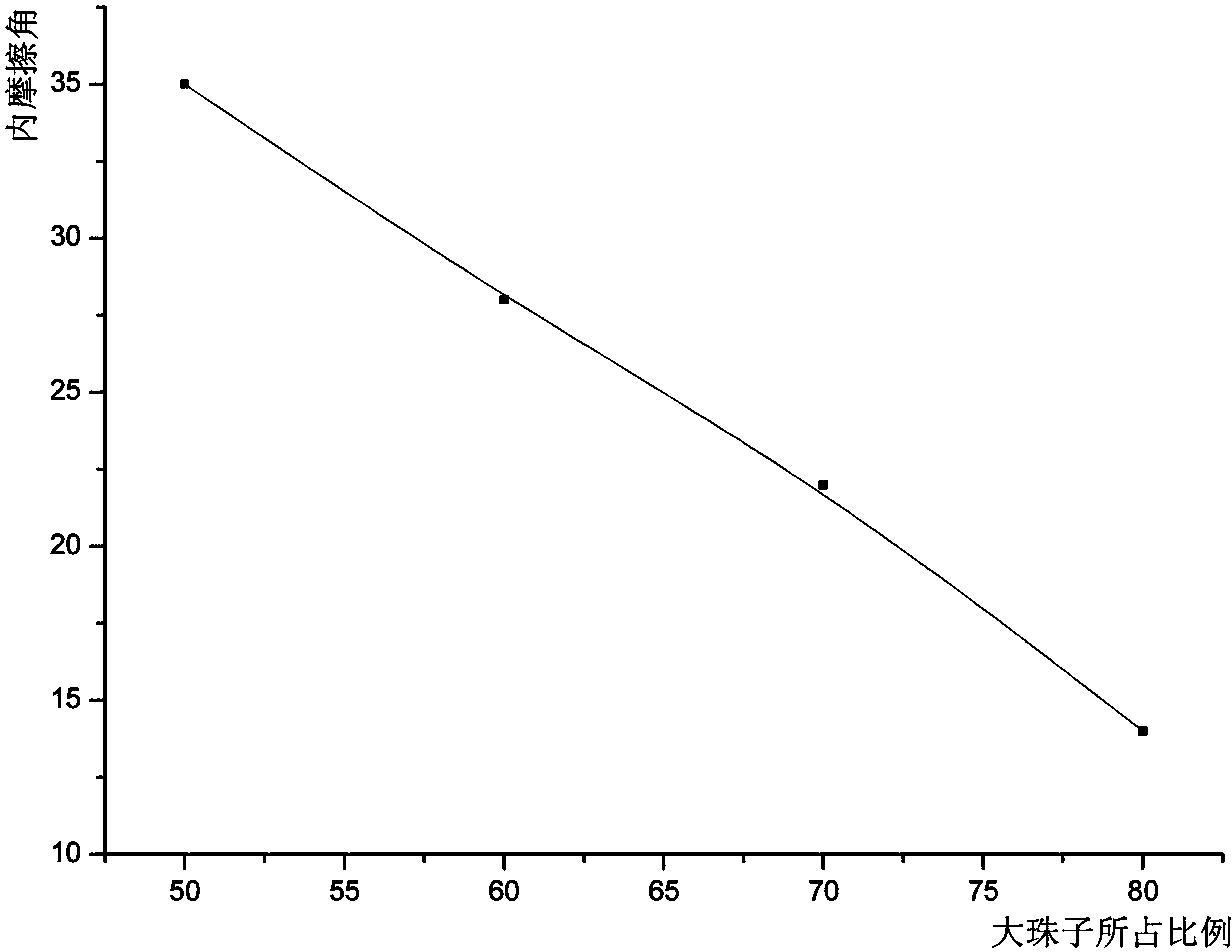

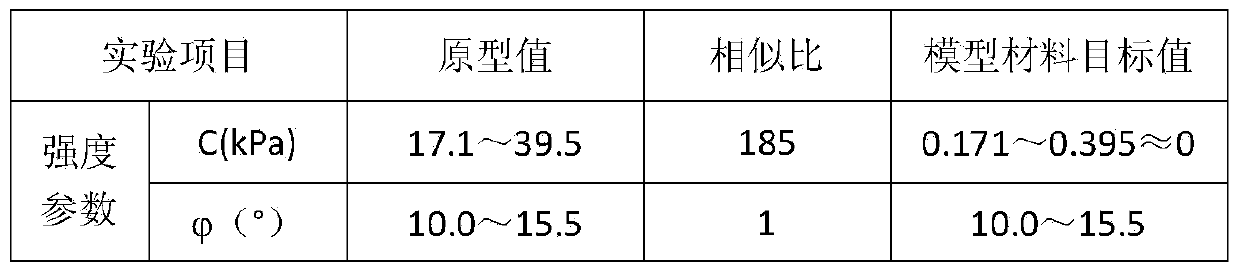

Slip zone similar material of landslide physical model, and preparation method thereof

InactiveCN103698189AStable mechanical propertiesGood similarityPreparing sample for investigationRiver sandPhysical model

The invention discloses a slip zone similar material of landslide physical model, and a preparation method thereof. The slip zone similar is prepared from a raw material of glass beads in different sizes, or, raw material of glass beads and river sand, a proper ratio is determined according to actual to-be-simulated landslide-slip zone prototype, a satisfactory slip zone similar material can be simulated, and the slip zone similar material satisfies that cohesive force and internal friction angle are similar as that of real slip zone. For the slip zone similar material provided by the invention, cohesive force can be conveniently regulated to be 0 by regulating volume of addition of the glass beads in different sizes and the sand river, and the internal friction angle can vary in a larger range, so that experiment needs of different landslide physical models can be satisfied. Moreover, the similar material has the advantages of abundant raw material source, simple preparation method, steady mechanical property, low cost, harmlessness to human body, and so on.

Owner:CHINA THREE GORGES UNIV

Method for rolling large-sized fine grain magnesium alloy plate

InactiveCN102814325ADeformation stableRoll mill control devicesMetal rolling arrangementsProduction lineStrip mill

The invention discloses a method for rolling a large-sized fine grain magnesium alloy plate. The method comprises the following steps of: firstly, performing wide-direction compressive deformation on a plate blank on a production line to enable the plate blank to be reduced in width but increased in thickness; then, horizontally rotating the plate blank for 90 degrees; delivering the plate blank into a rolling mill along the wide direction to perform rolling elongation to enable the plate blank to be reduced in thickness and recovered to the original size in width; then, compressing along the long direction of the plate blank; horizontally rotating for 90 degrees; and then performing the rolling elongation. According to the method disclosed by the invention, as the elongation direction and the compression direction are opposite, but dependent variables are equal, the plate blank is unchanged in geometrical shape. The process of compression and rolling is repeated, so that a required dependent variable is obtained by the plate blank; crystalline grains are refined; and finally, the plate with the required specification is formed by rolling.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

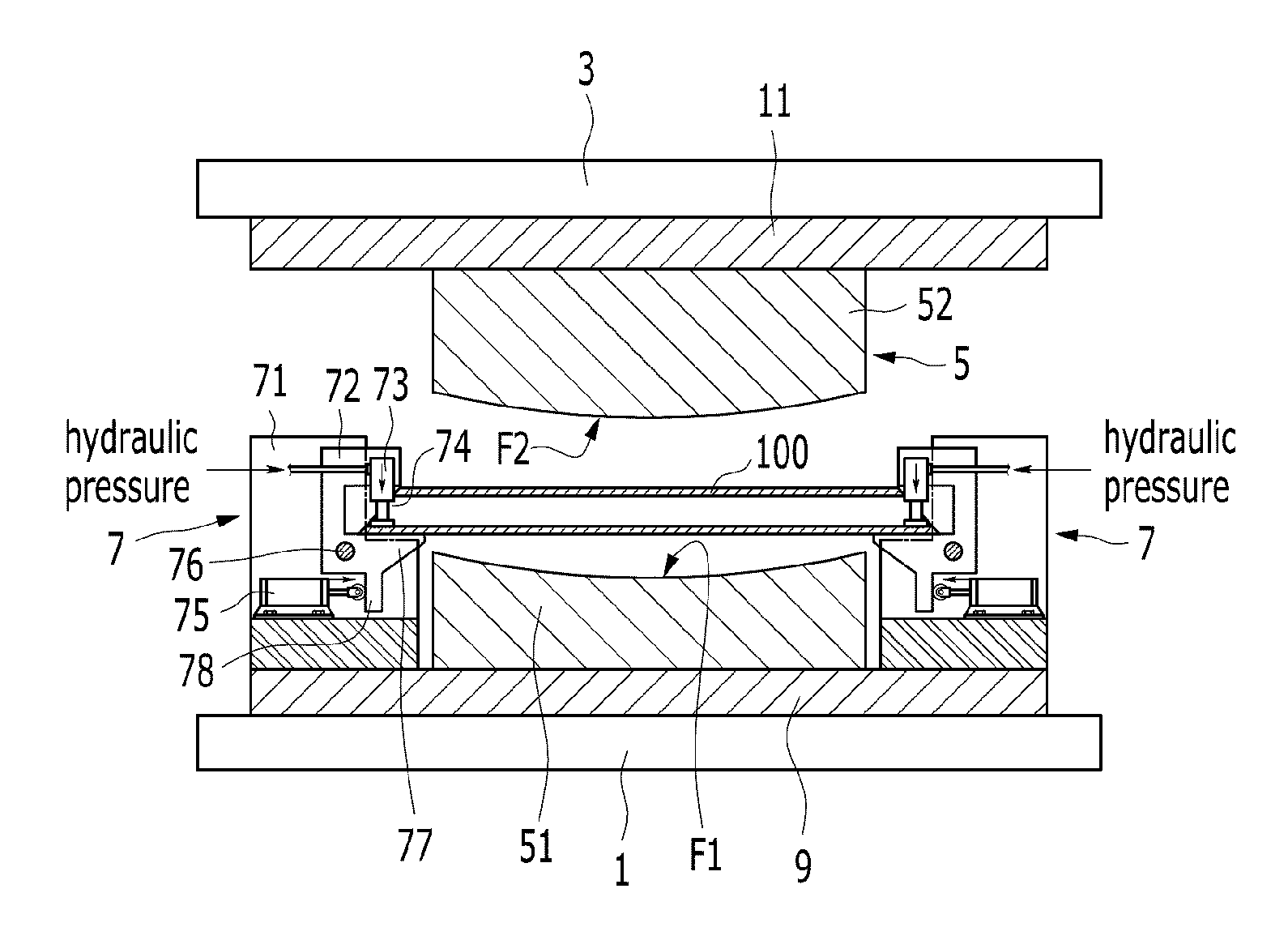

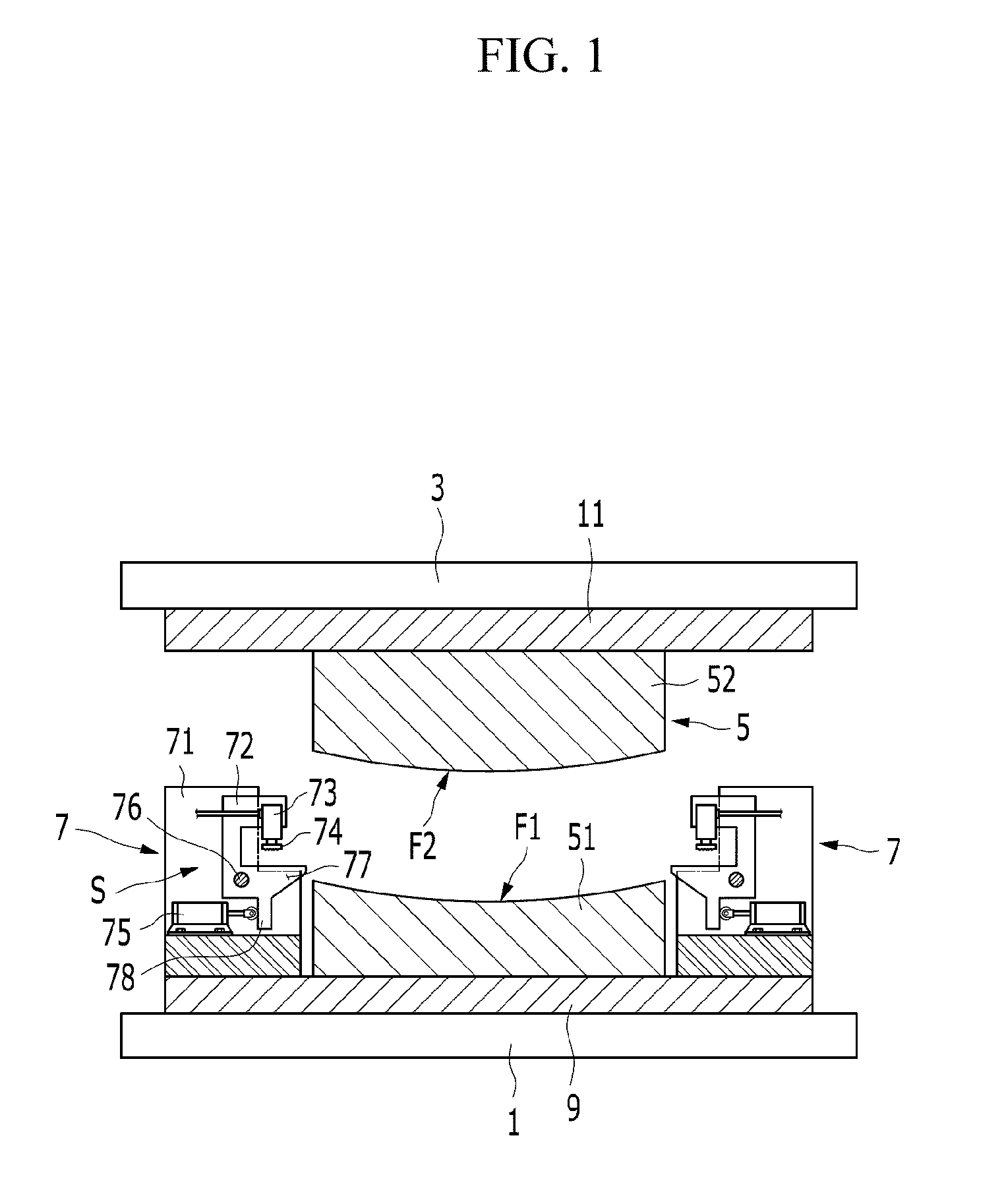

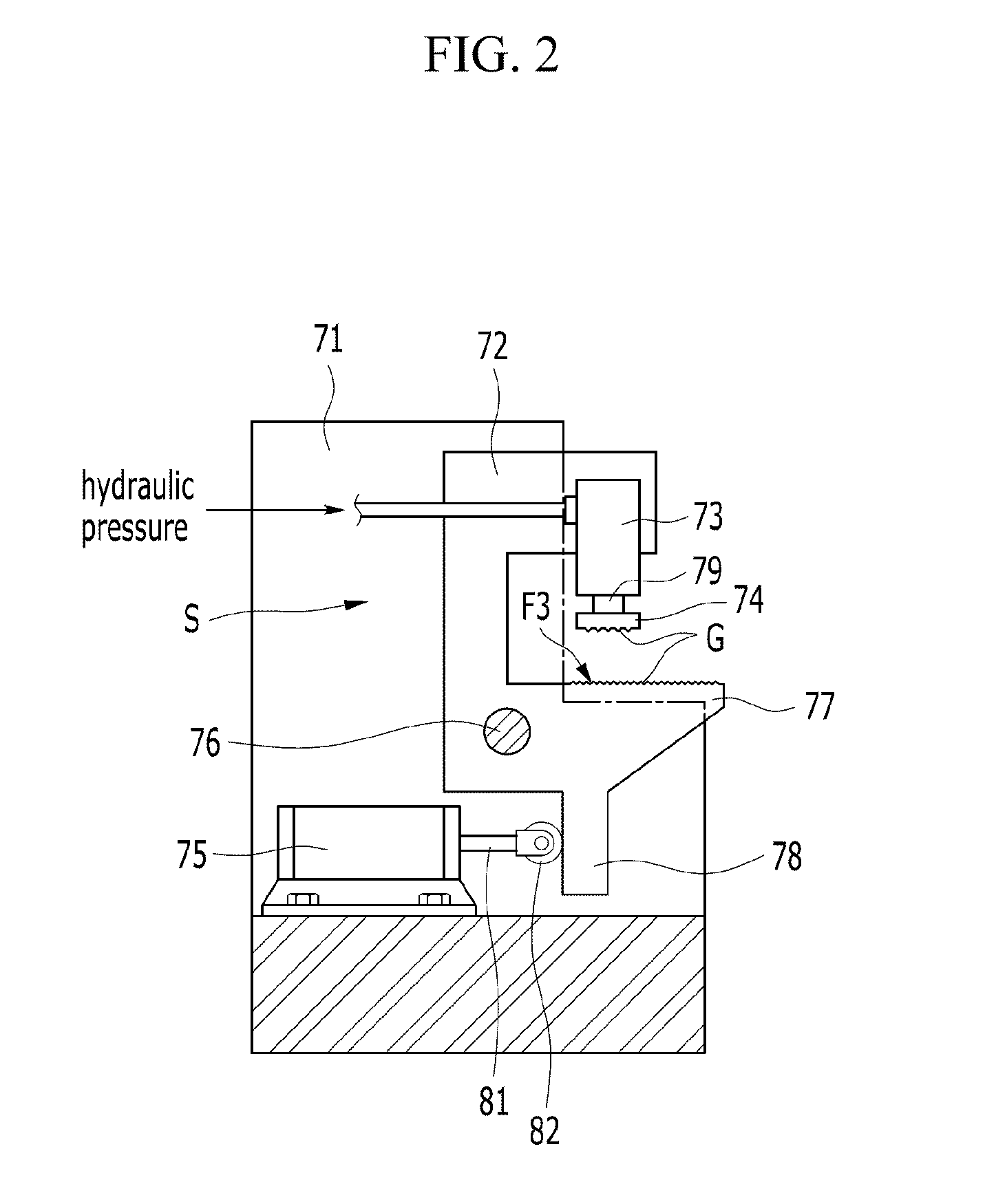

Bending press system

A bending press system is disclosed. The bending press system may include: a base; a slider disposed above the base and moving downwardly toward the base or moving upwardly from the base; a curvature die mounted at the base and the slider, and integrated by descent of the slider such that a pipe member inserted in the curvature die is formed to have a predetermined curvature; and a pair of clamping units disposed to be rotatable by a predetermined angle corresponding to the curvature die at both sides of the base, and clamping both end portions of the pipe member.

Owner:SUNG WOO HITECH

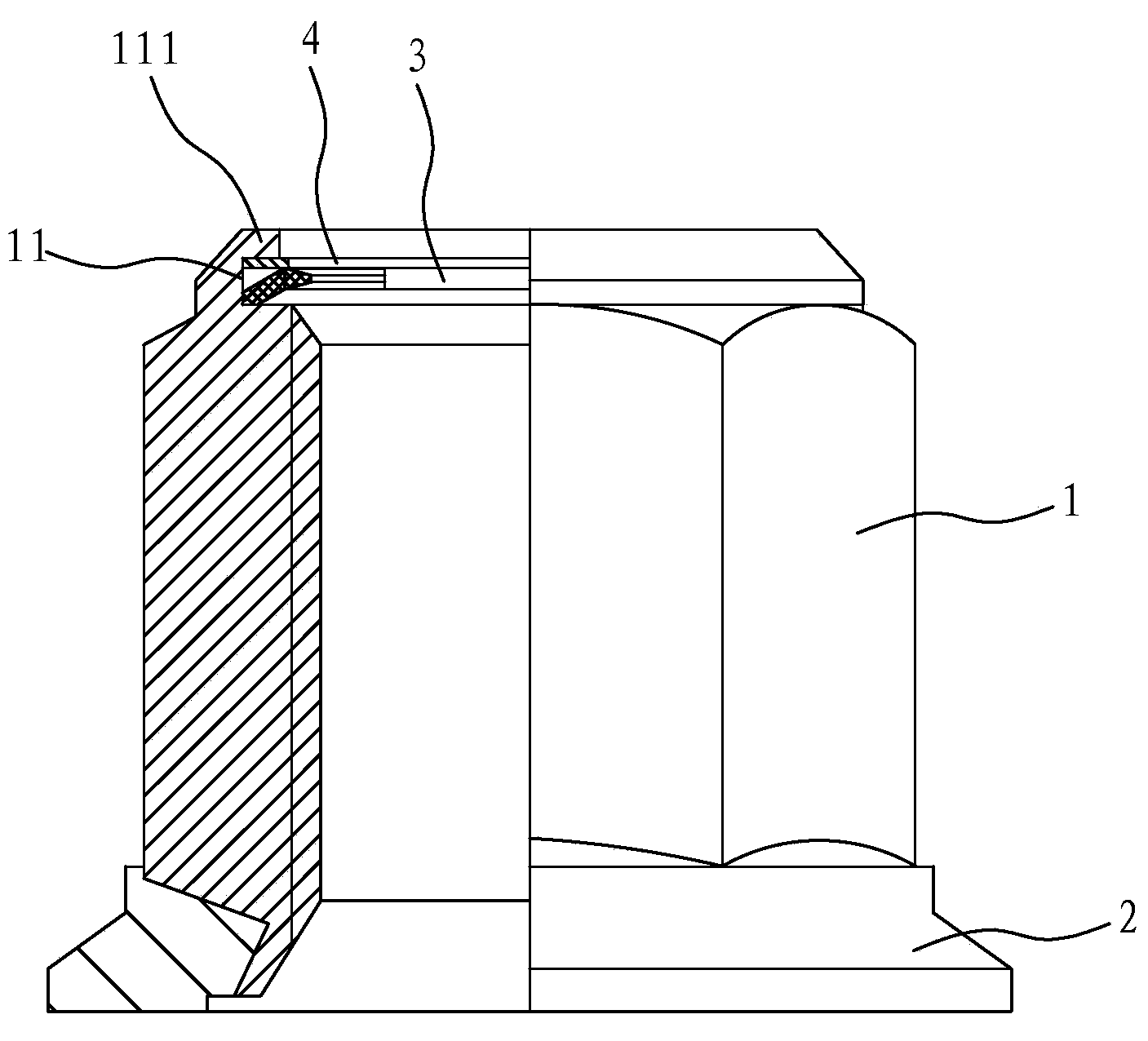

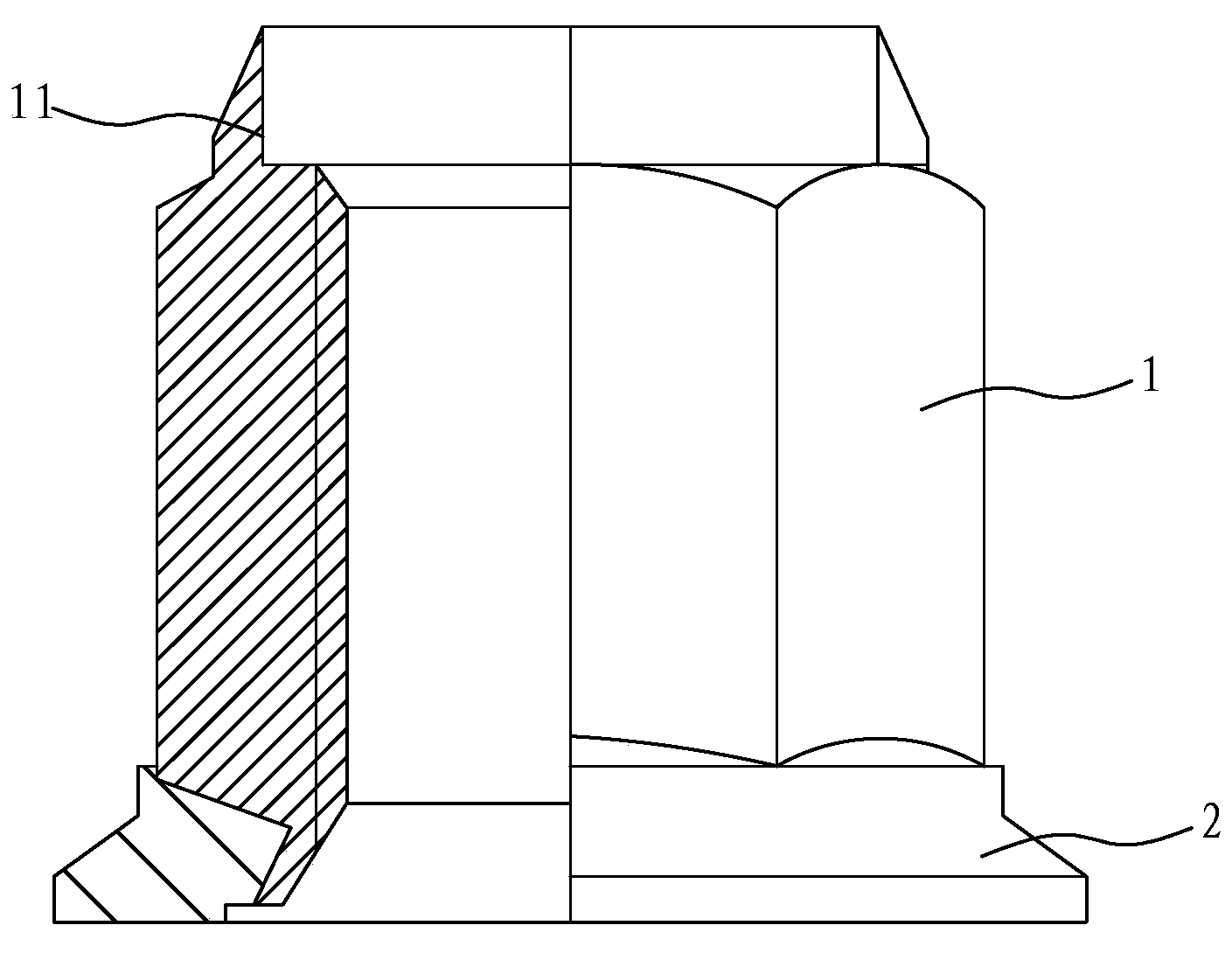

Anti-loose self-locking nut and production method thereof

The invention relates to the field of manufacturing of automobile parts, in particular to an anti-loose self-locking nut simple in structure, capable of effectively preventing the nut from falling off, convenient to mount and dismount and capable of being reused. The anti-loose self-locking nut comprises a nut body and a nut collar rotatably arranged at the lower end of the nut body, a threaded hole is penetratingly arranged in the middle of the nut body, a stepped groove is formed in the upper end of the nut body, a spring steel piece is placed in the stepped groove, a bending portion used for clamping the spring steel piece in the stepped groove is arranged on the upper portion of the stepped groove, the spring steel piece comprises an annular piece and more than two clamping pieces evenly arranged at the upper end of the annular piece and protruding along the radial direction, the annular piece is formed by a tilt surface rotating and scanning around the axis of the threaded hole, the clamping piece protrudes inwardly to extend into the threaded hole of the nut body, and the extending length of the clamping piece is located between the inner diameter and outer diameter of the threaded hole. The invention further comprises a production method of the anti-loose self-locking nut.

Owner:QUANZHOU JINQI MACHINERY PARTS

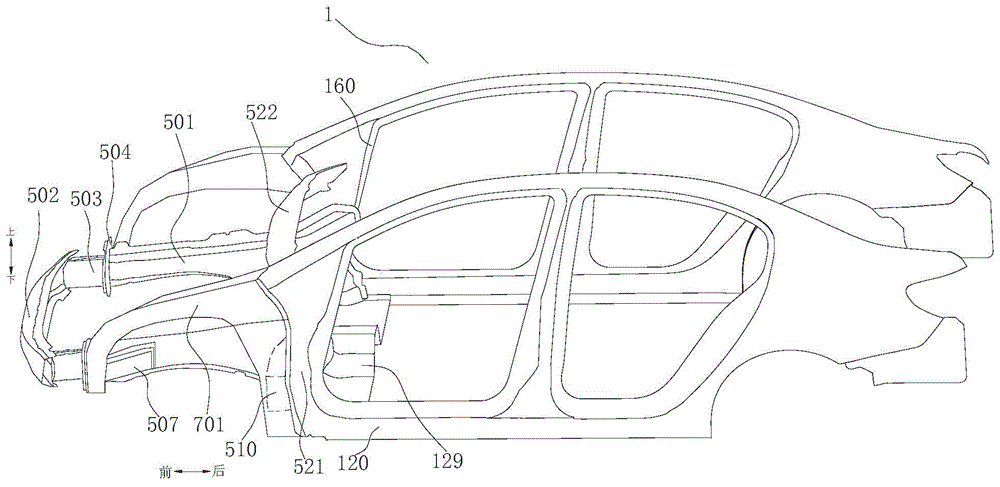

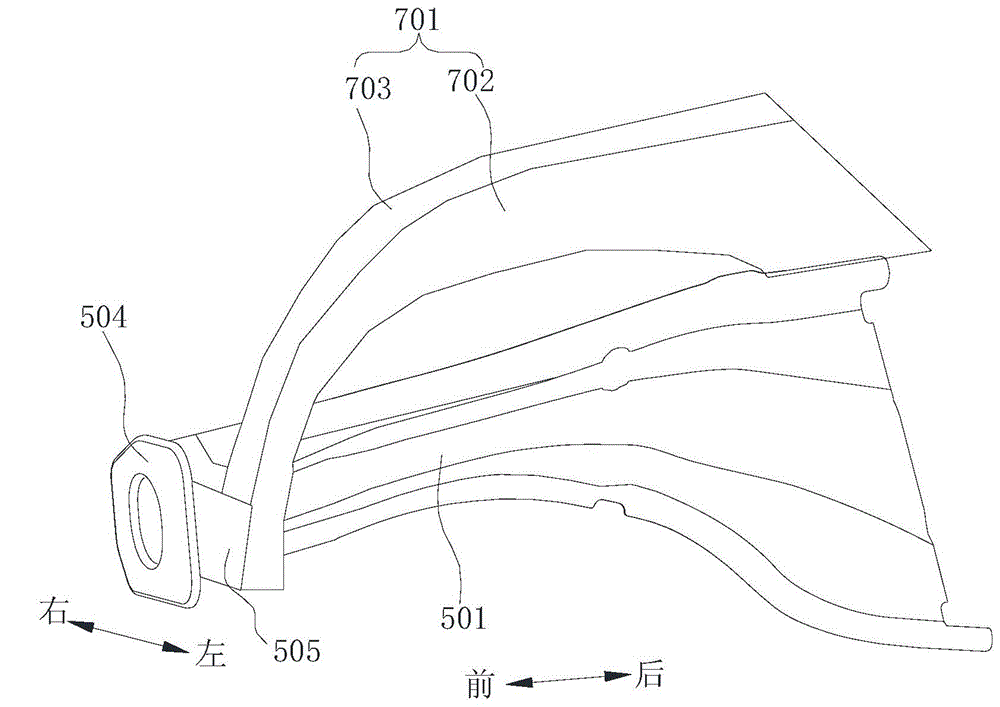

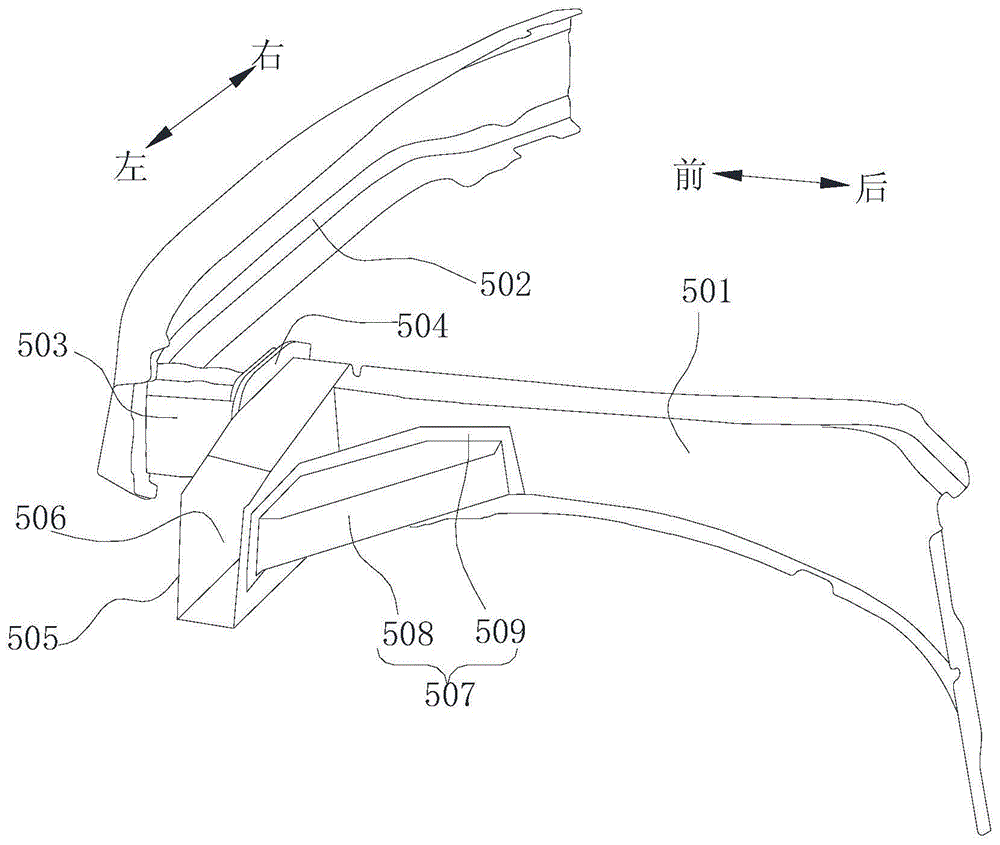

Vehicle body for vehicle and vehicle provided with vehicle body

The invention discloses a vehicle body for a vehicle and the vehicle provided with the vehicle body. The vehicle body for the vehicle comprises a floor, two side outer panels arranged on the left side and the right side of the floor respectively, a dash panel connected between the two side outer panels, A pillars arranged on inner sides of the two side outer panels and fixed with the corresponding side outer panels, two front longitudinal beams isolated in the transverse direction, a front-end anti-collision beam extending in the transverse direction, two front fender mounting beams and two front longitudinal beam reinforcing beams, wherein the rear end of each front longitudinal beam is fixed with the floor, the corresponding A pillar and the dash panel respectively; the front-end anti-collision beam is fixed to front ends of the two front longitudinal beams; the front end of each front fender mounting beam extends forwards to a corresponding front longitudinal beam fixing plate and fixed with the corresponding front longitudinal beam fixing plate, and the rear end of each front fender mounting beam extends backwards to the corresponding side outer panel and fixed with the corresponding side outer panel; each front longitudinal beam reinforcing beam is fixed with the corresponding front longitudinal beam fixing plate and the corresponding front longitudinal beam respectively to form a triangular structure.

Owner:GREAT WALL MOTOR CO LTD

Absorbent article with compressed channel portions

InactiveUS8998871B2Improve adhesionReduce leakageSanitary towelsBaby linensBody fluidBiomedical engineering

Owner:UNI CHARM CORP

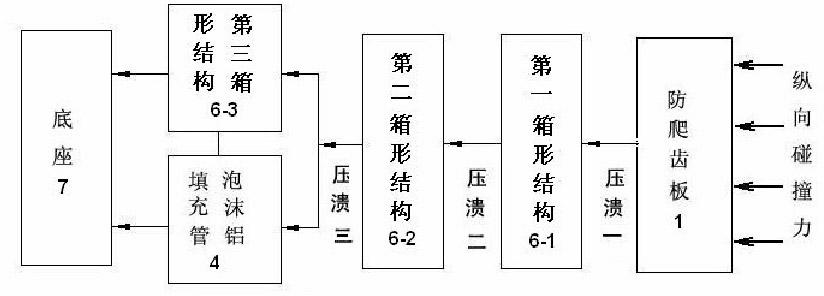

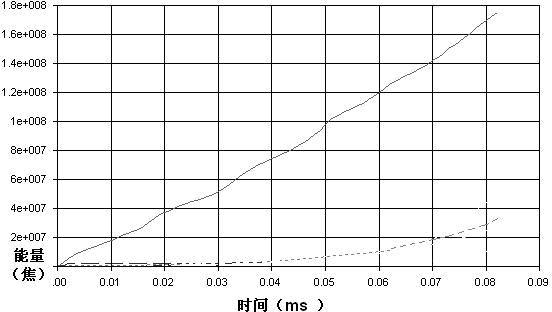

Energy-absorbing anticreeper of urban railway train

InactiveCN102358319AProtection Security RequirementsImprove protectionRailway wheel guards/bumpersRear-end collisionScientific management

The invention belongs to the safety research field of railway traffic vehicles, and particularly relates to an energy-absorbing anticreeper of an urban railway train. The energy-absorbing anticreeper of the urban railway train is composed of an anti-creeping toothed plate, a front baffle, a rear baffle, a foamed aluminum filling pipe, a cylindrical box body wall and a base. In the train collision (face-to-face collision or rear-end collision) accidents, large kinetic energy of the vehicle during the collision is consumed by the ordered large plastic deformation of a box body; and meanwhile, longitudinal collision force is reduced, and retarded velocity is lowered, thus the personnel safety of passengers, drivers and conductors are protected. From the two aspects of the scientific management of impact kinetic energy and the safety protection of passengers, the invention provides a novel energy-adsorbing device. The energy-absorbing anticreeper has the advantages of simple structure, big energy adsorption capacity, stable performances and good protection action on the passengers.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com