Patents

Literature

690results about "Protective covers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

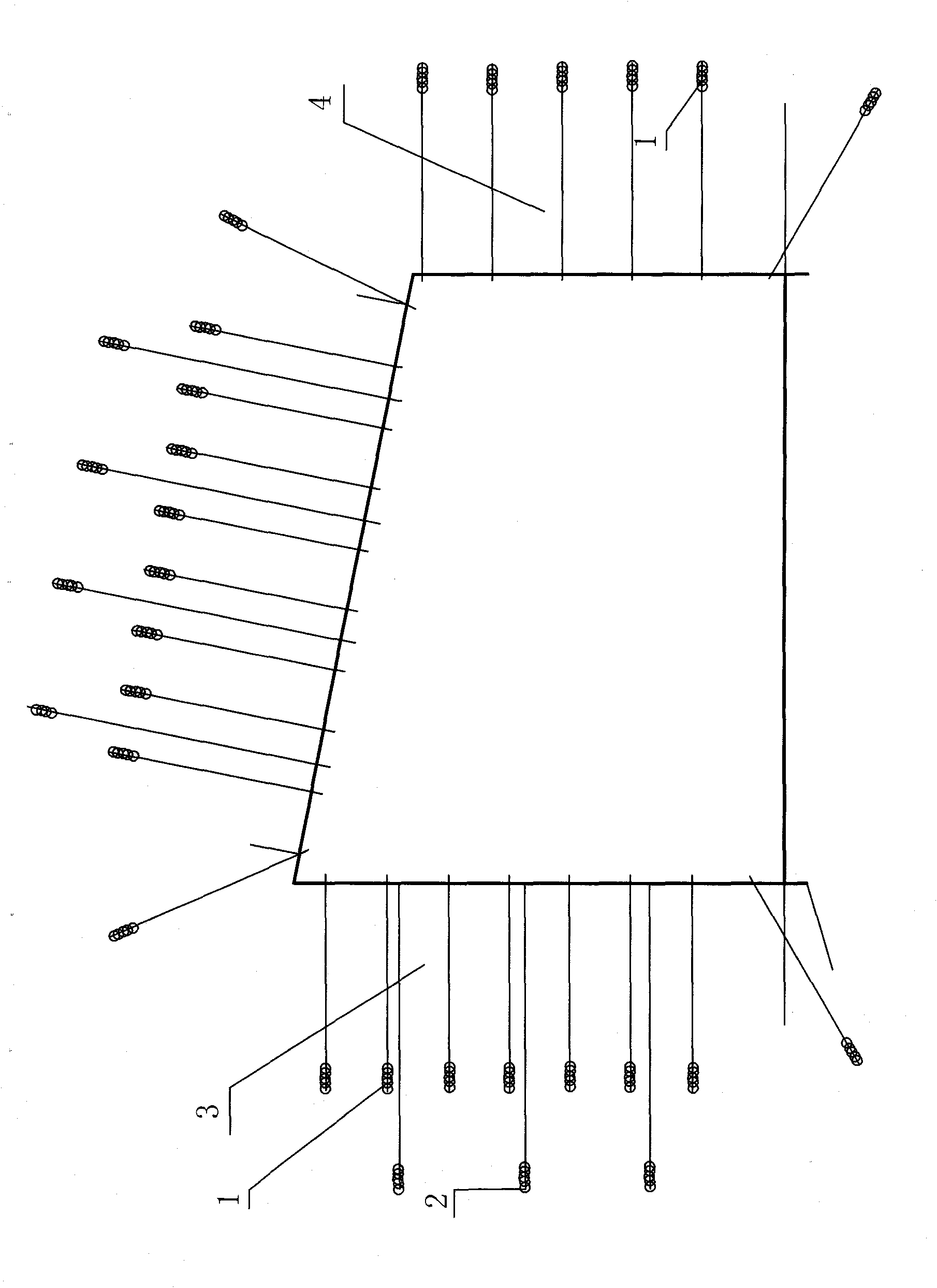

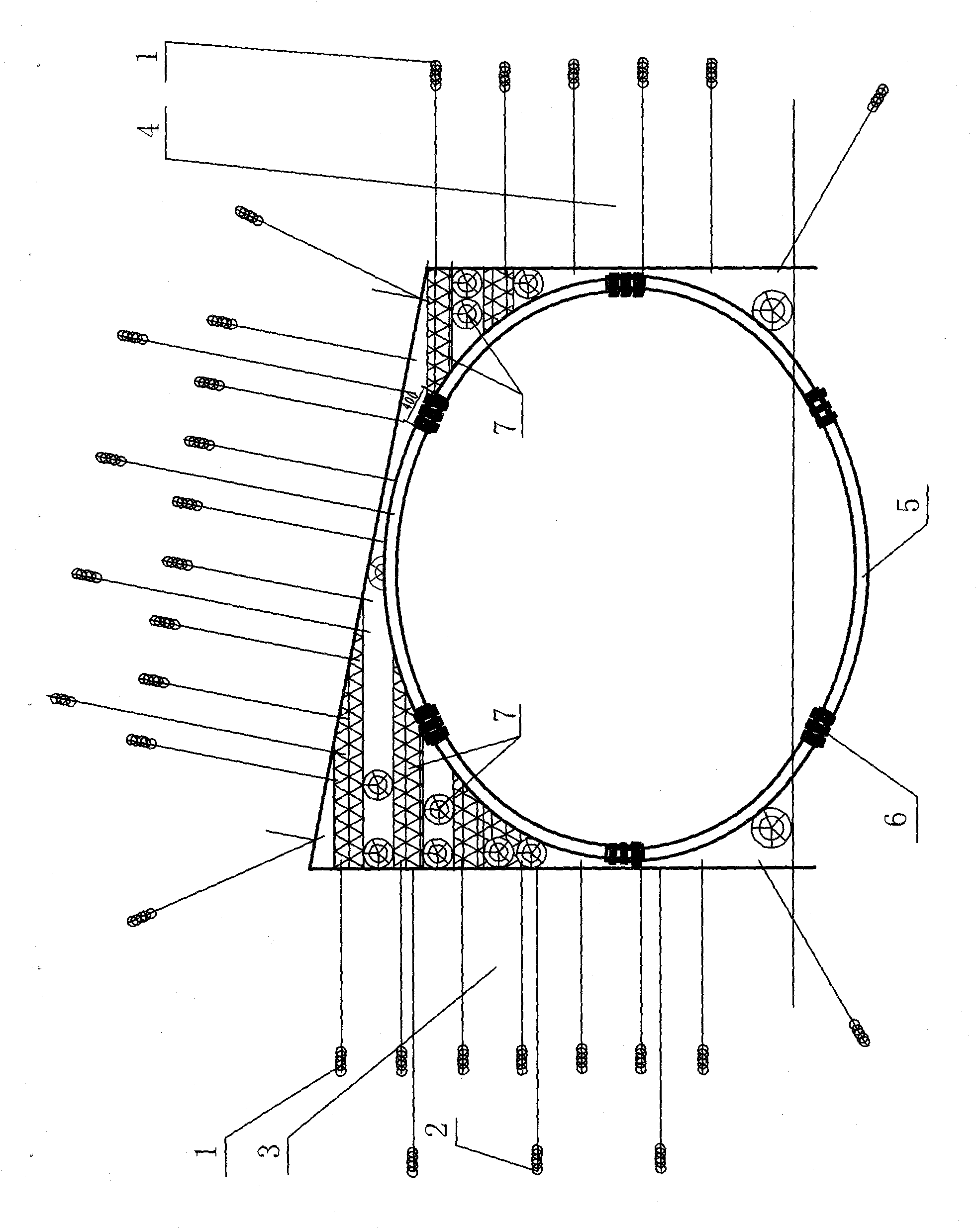

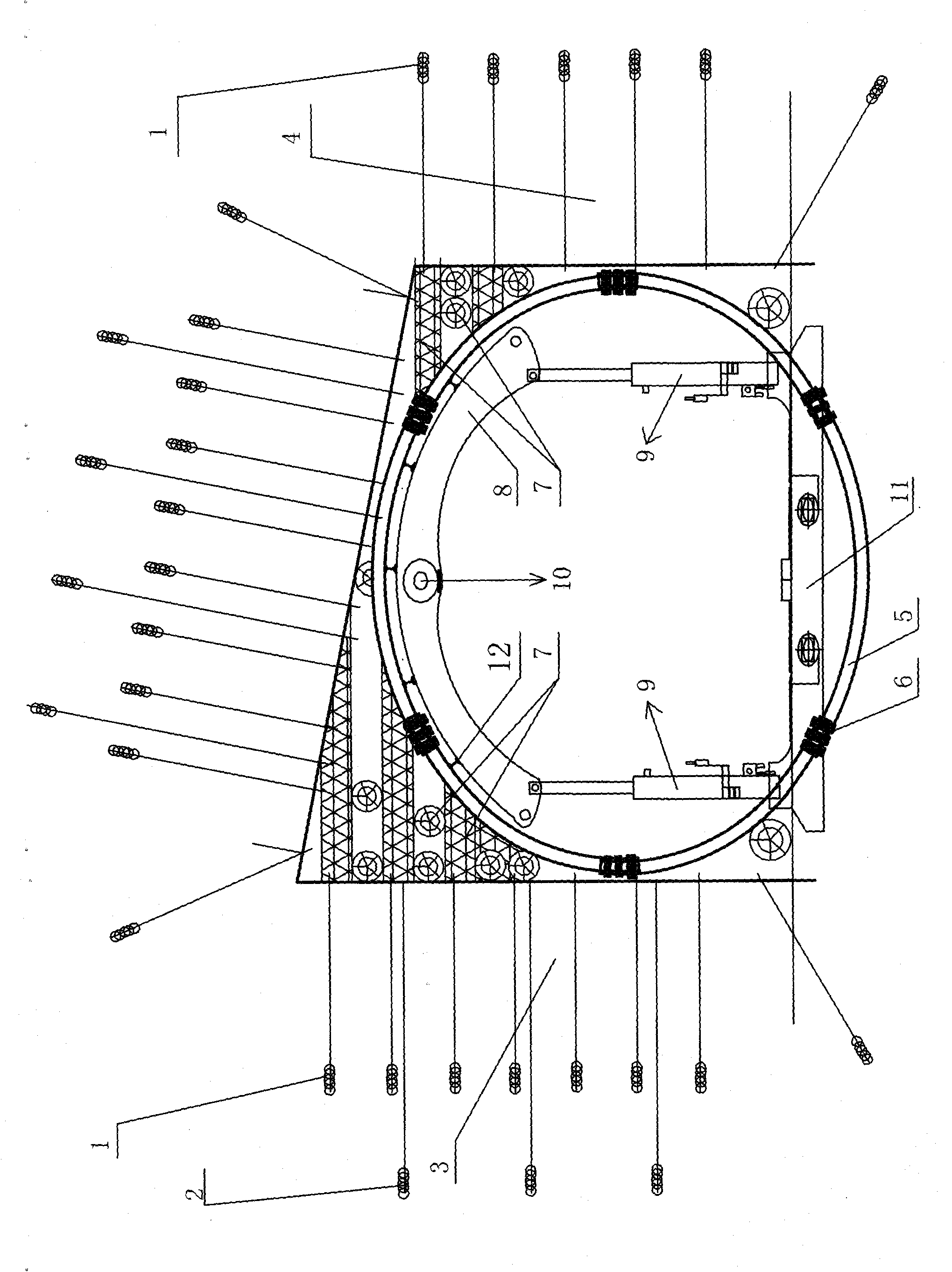

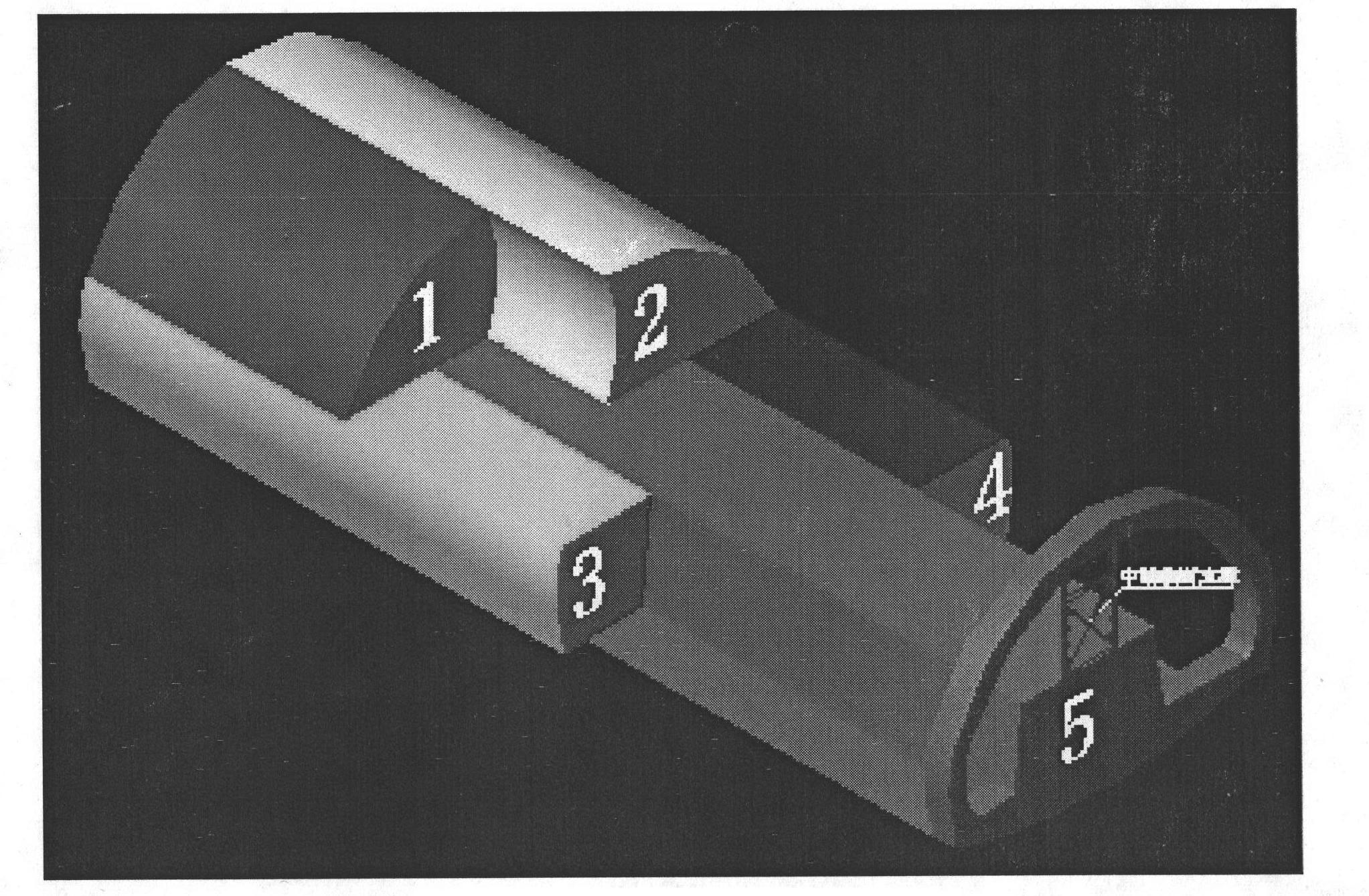

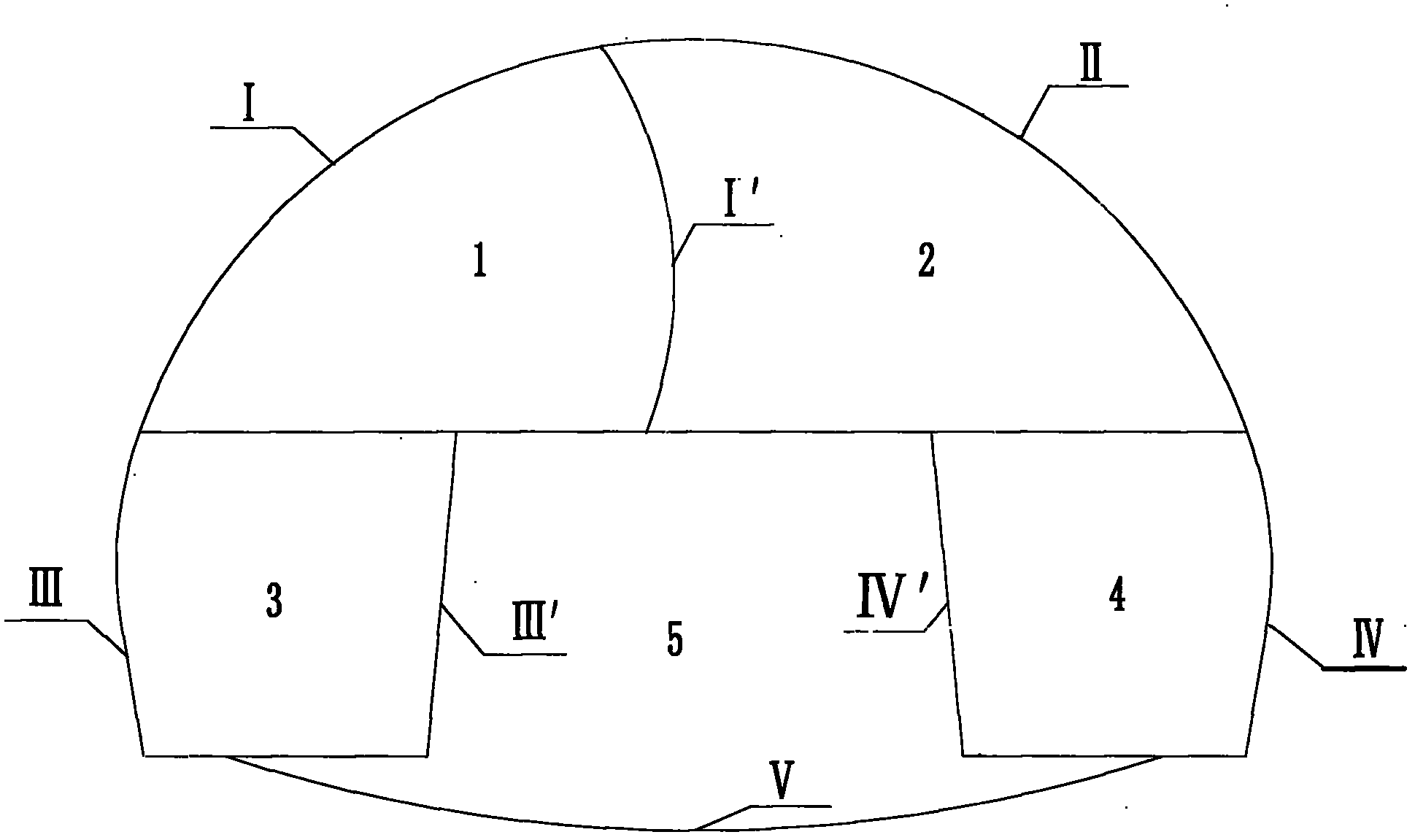

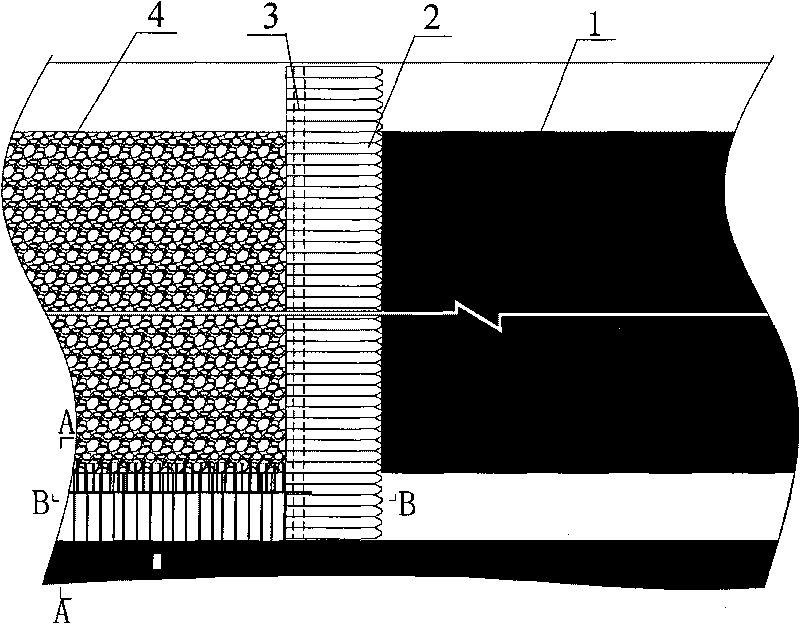

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

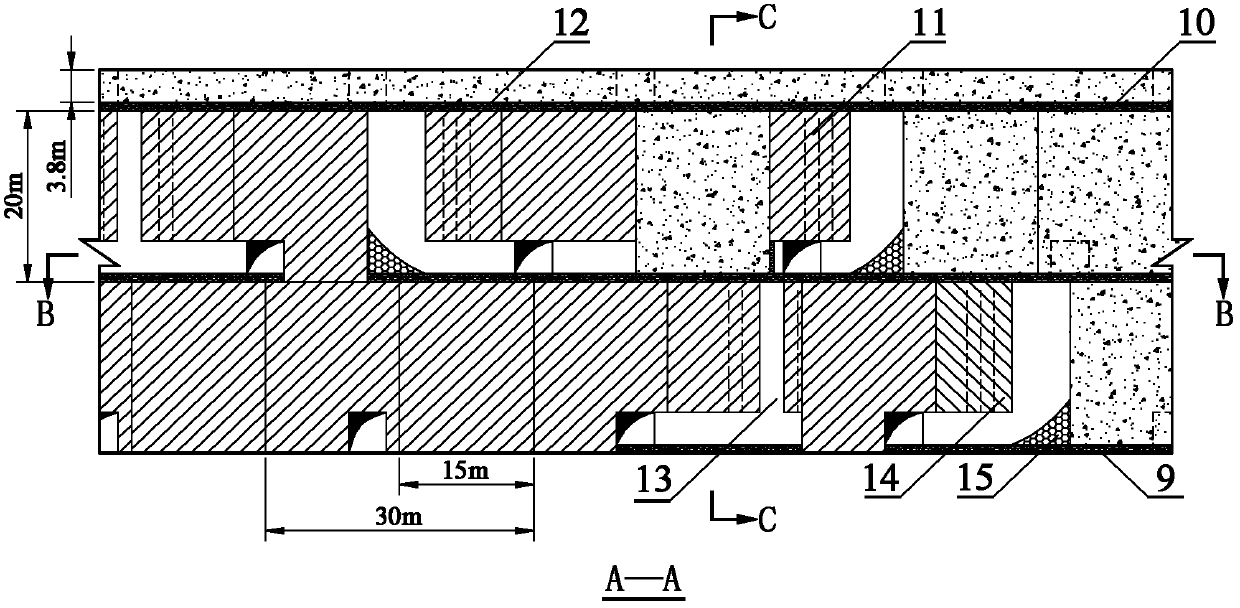

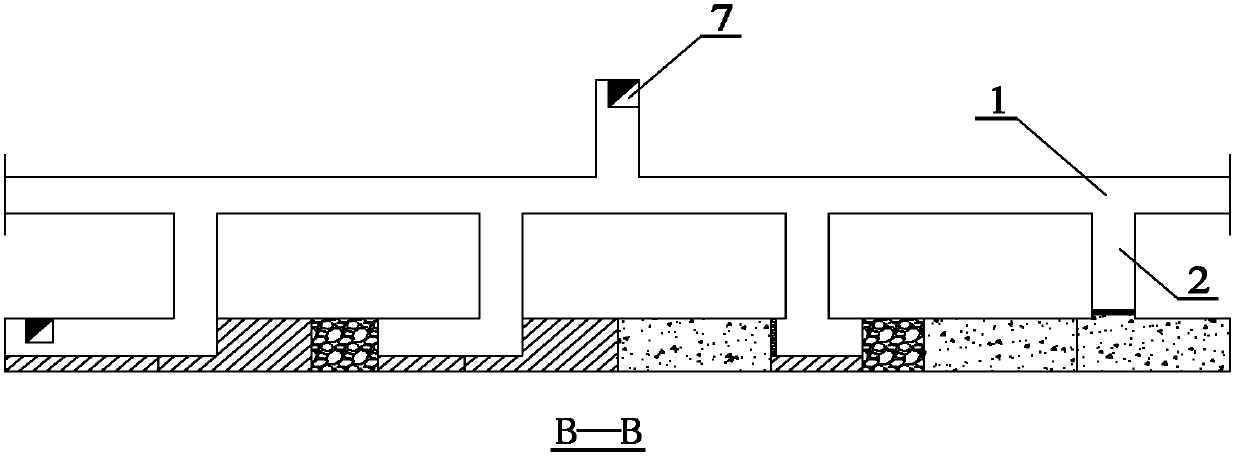

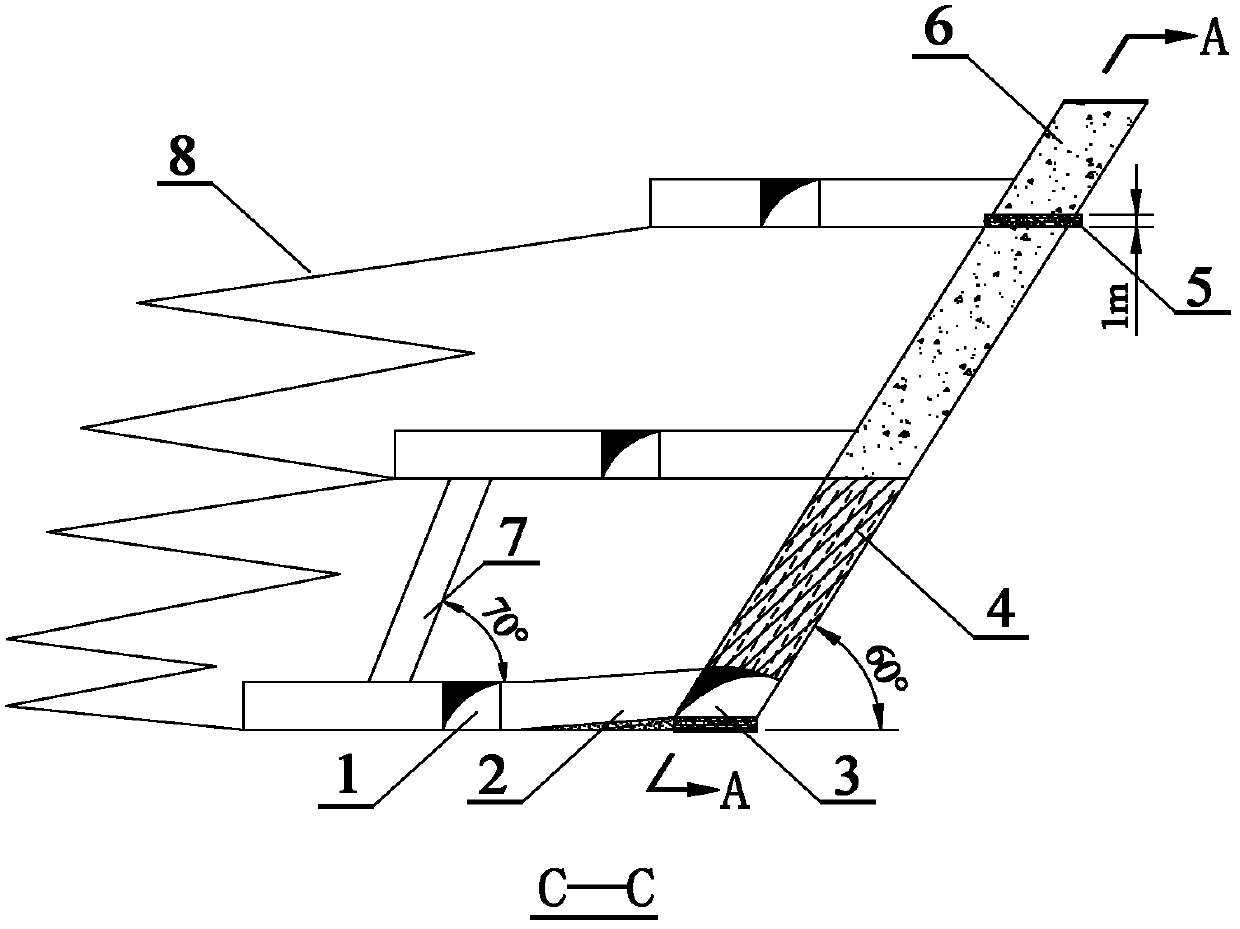

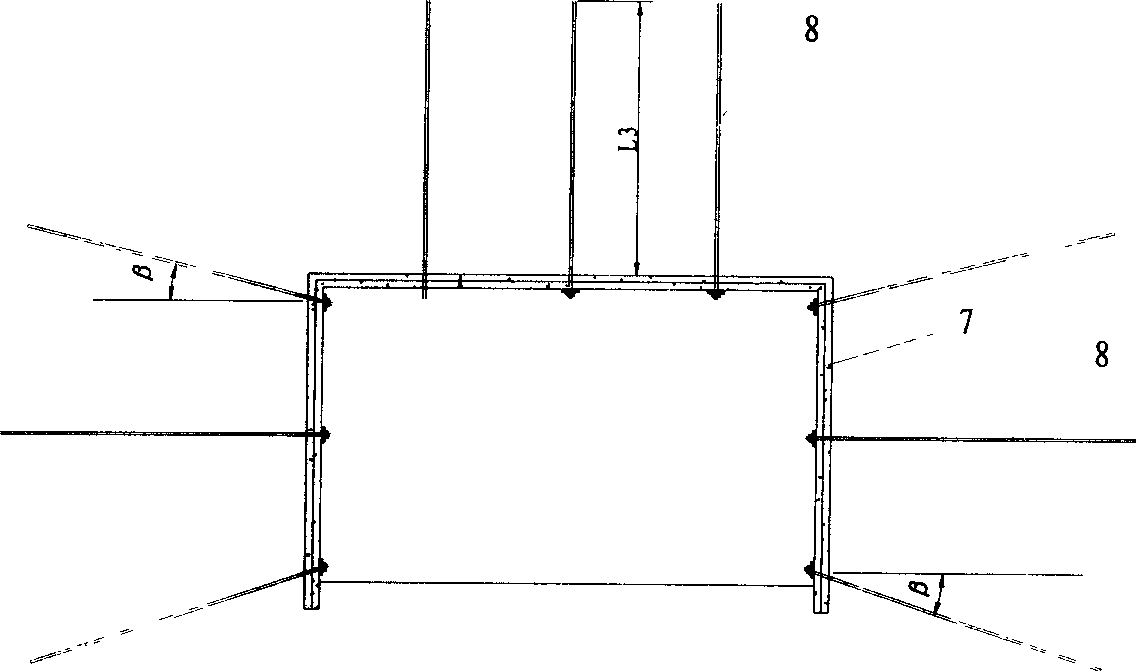

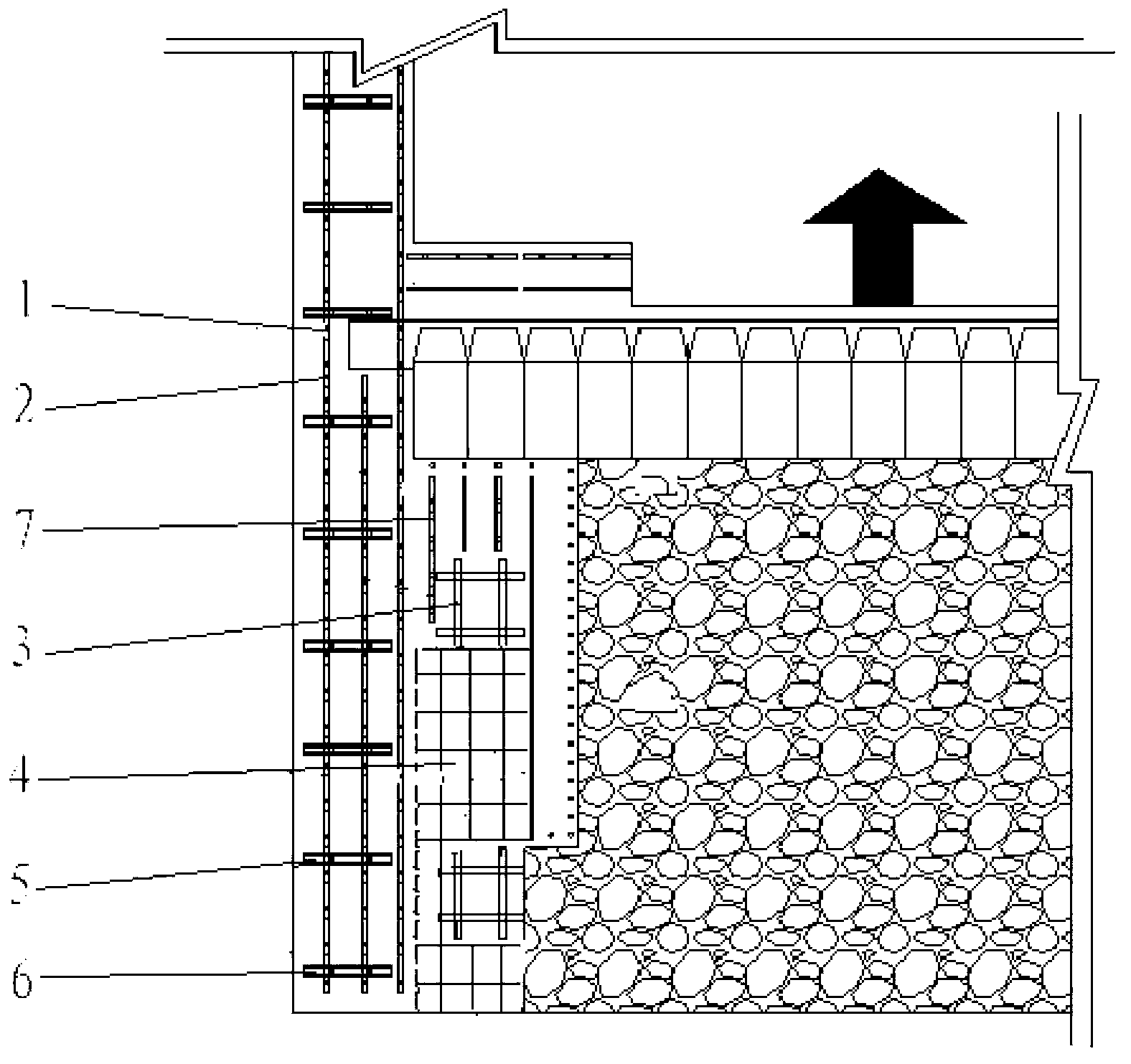

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

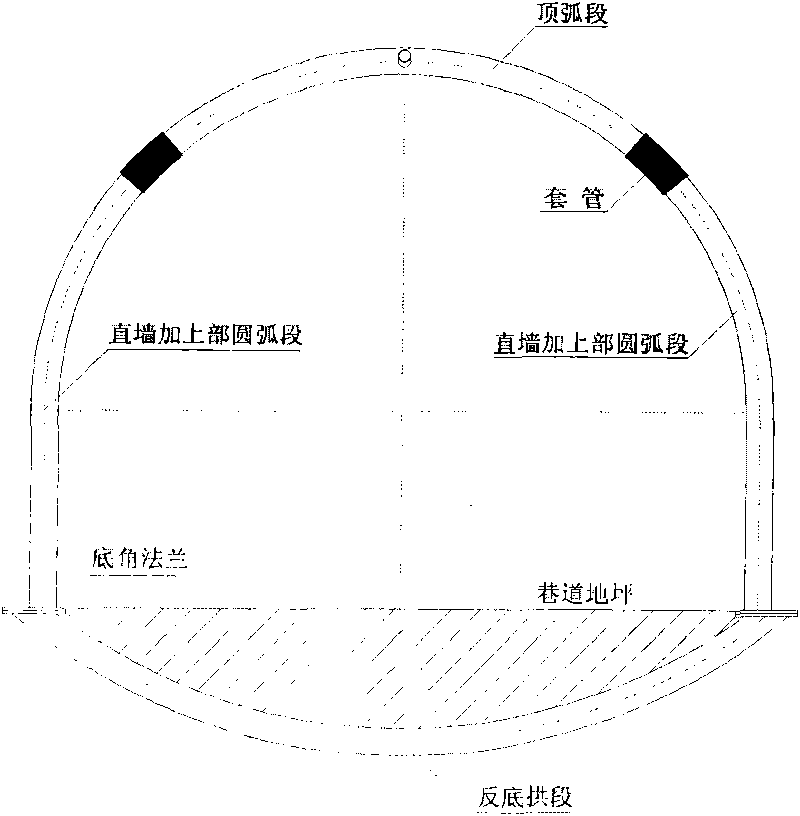

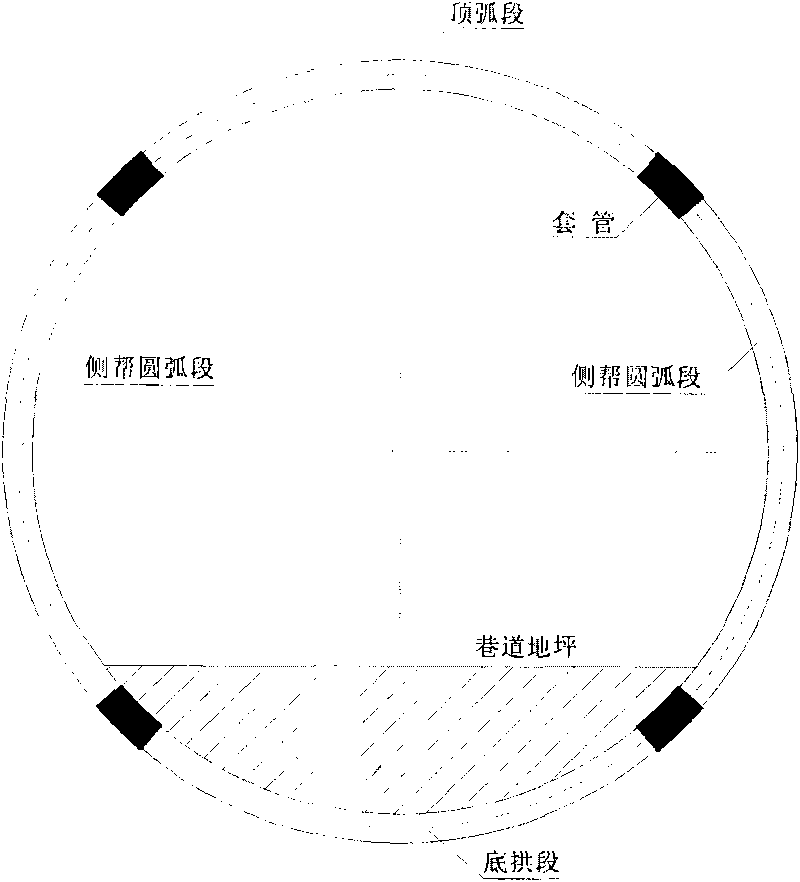

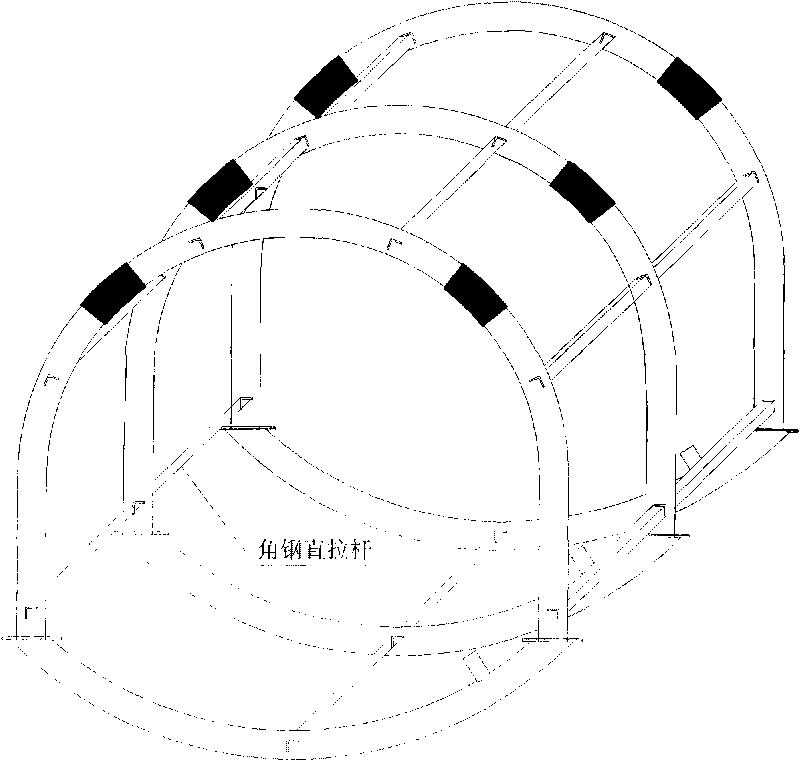

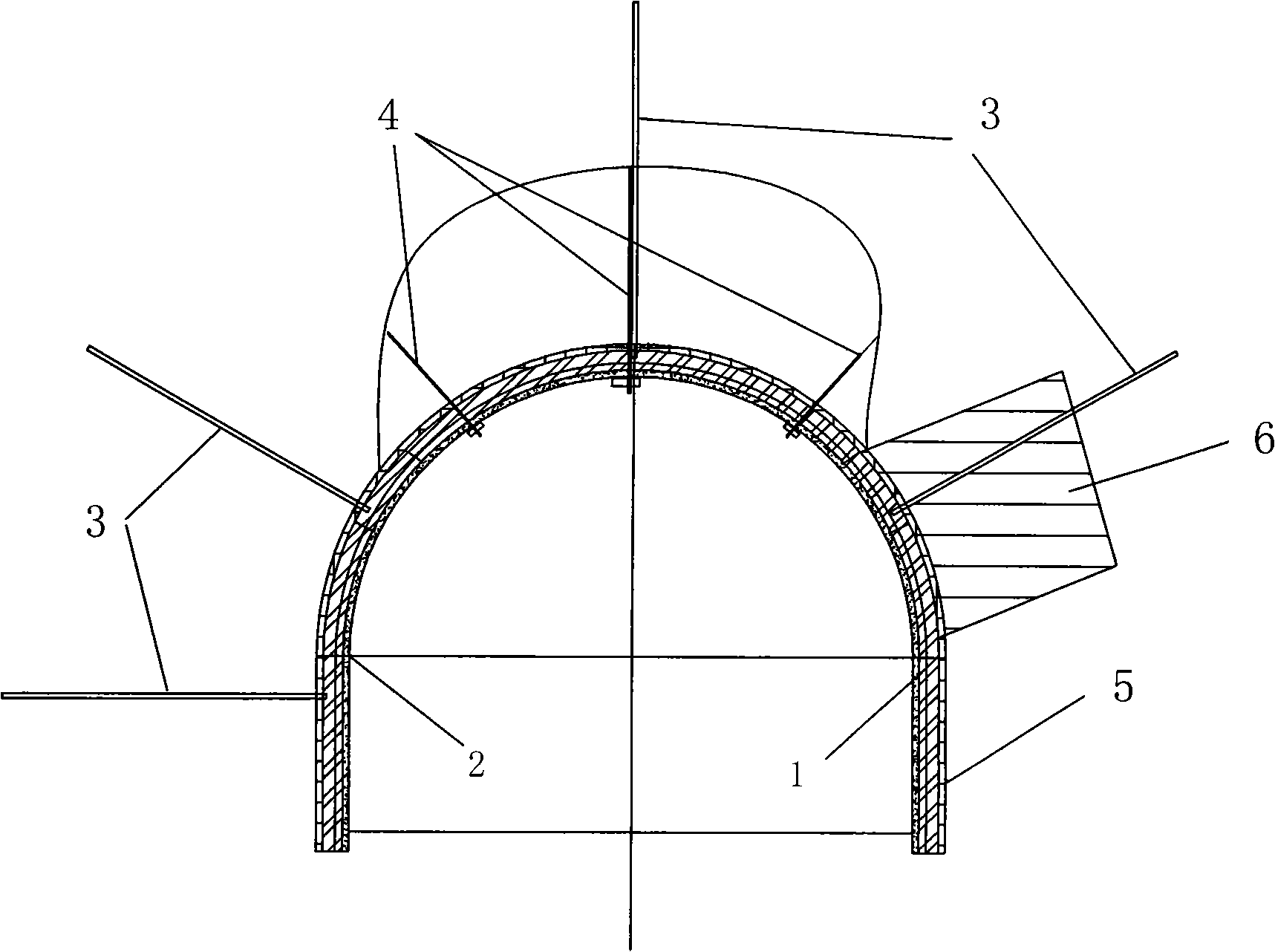

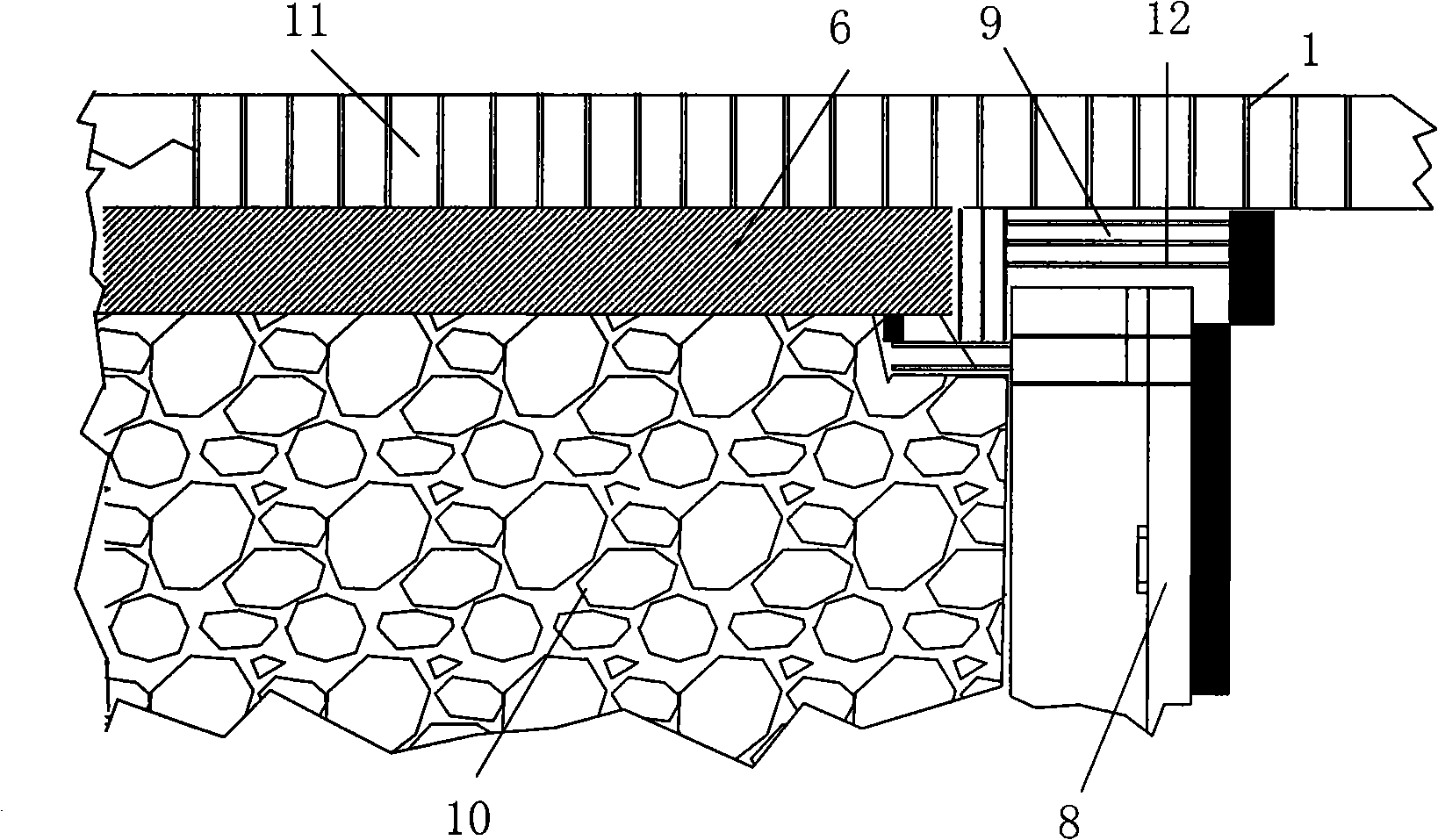

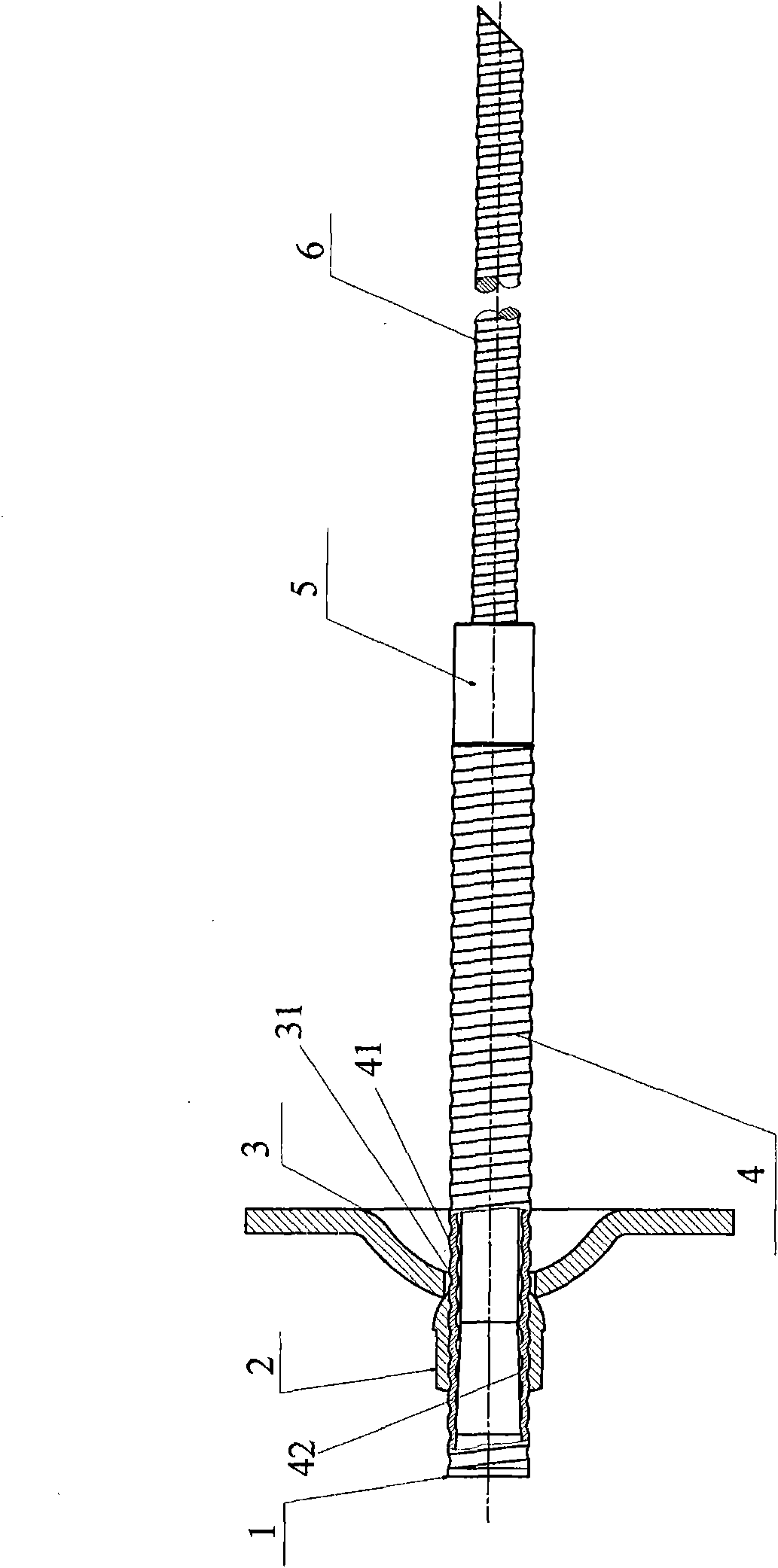

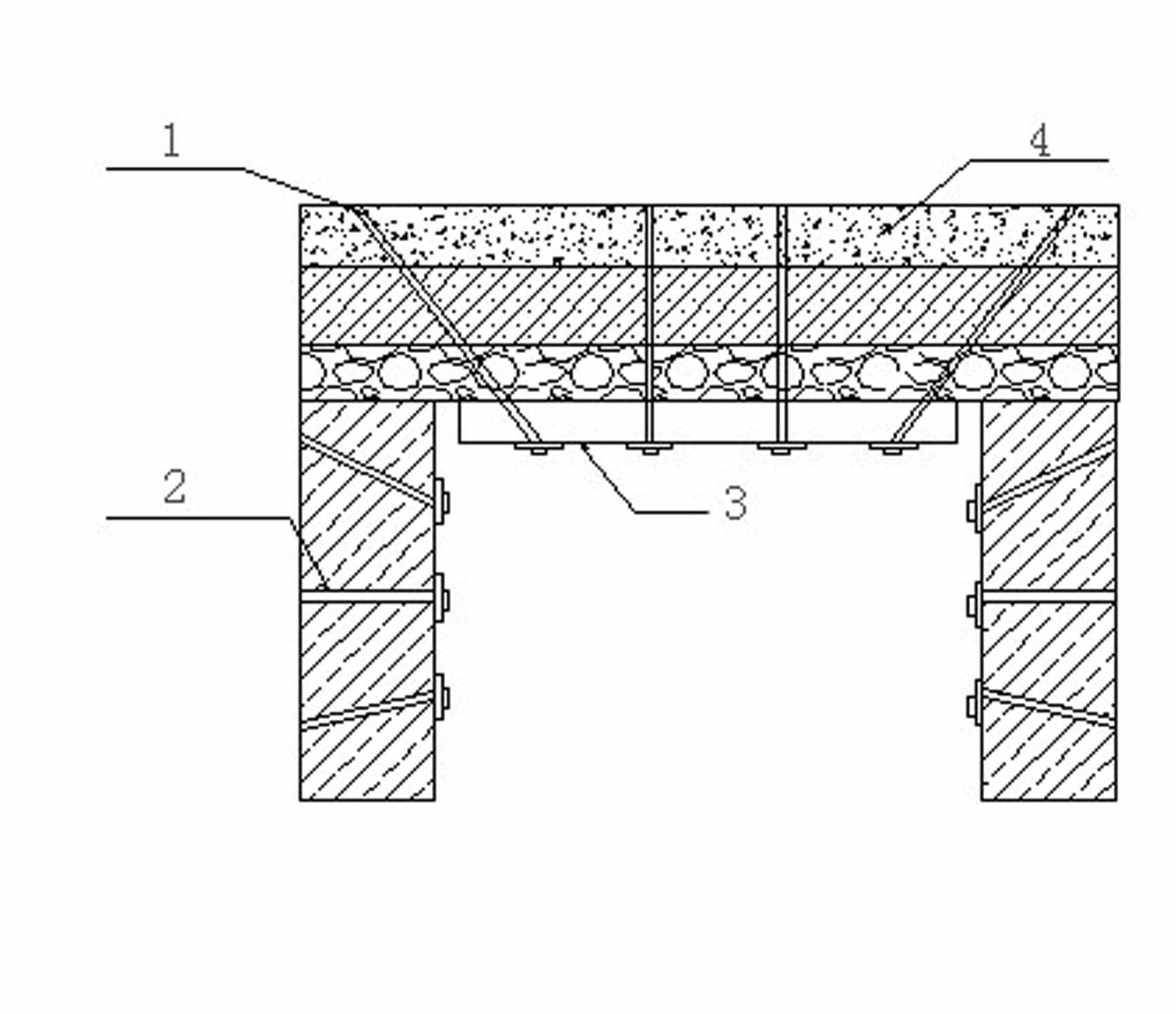

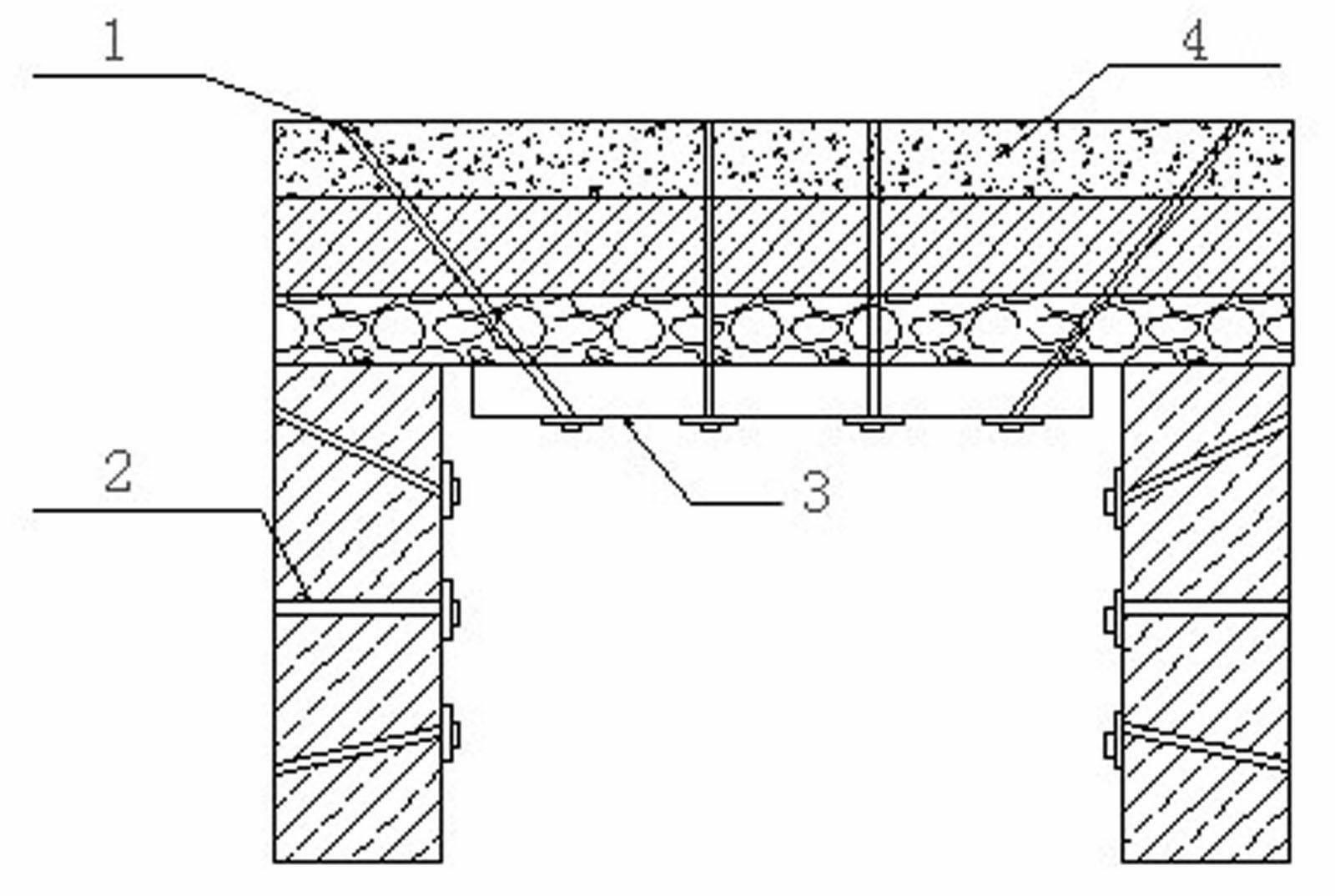

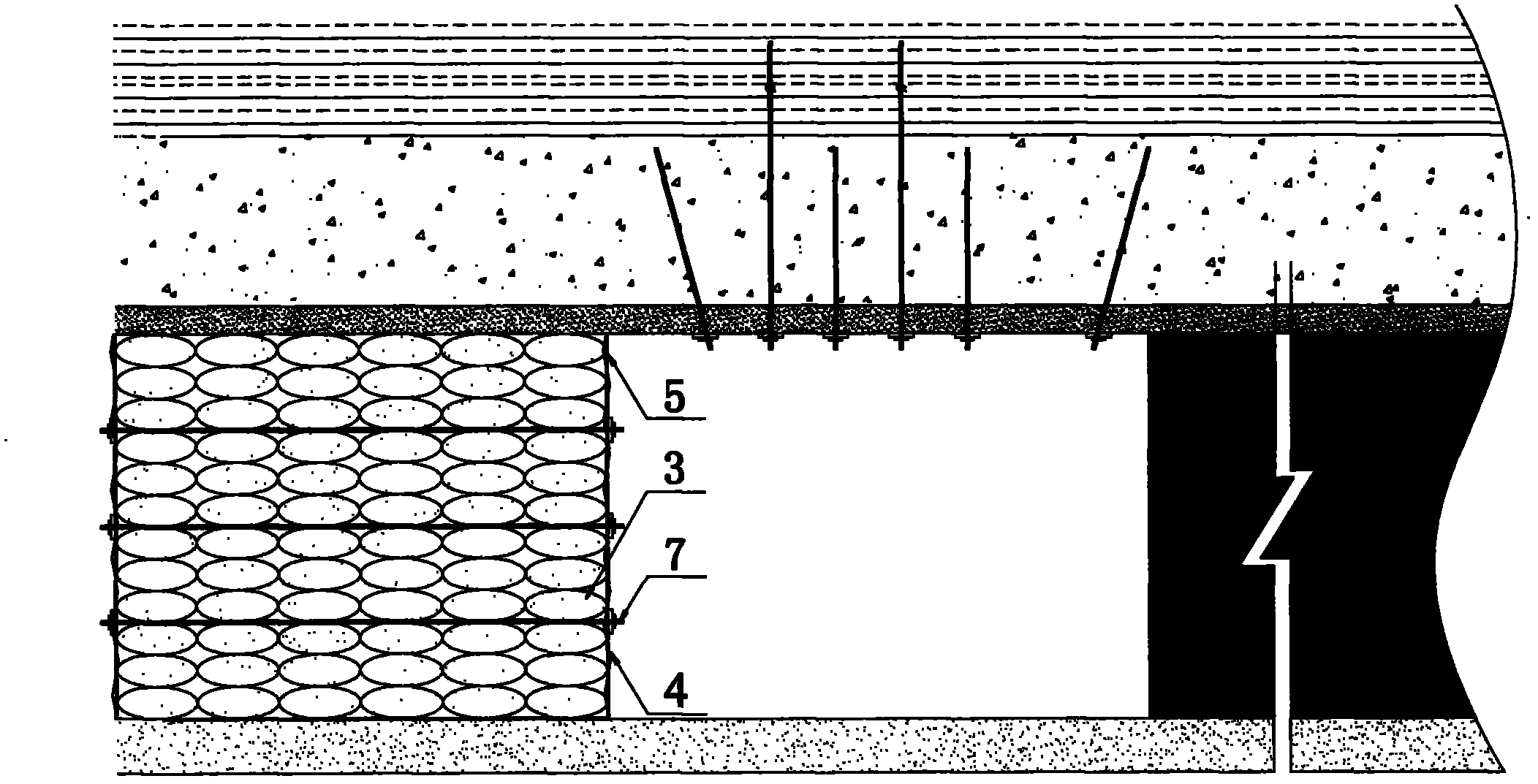

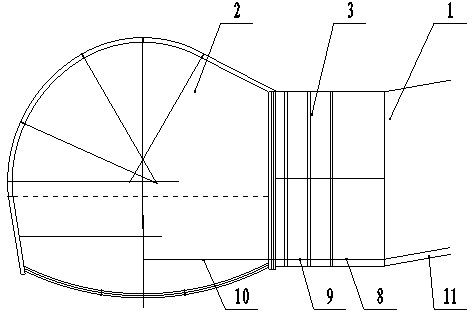

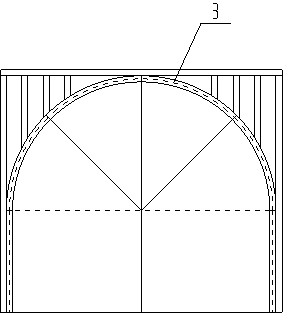

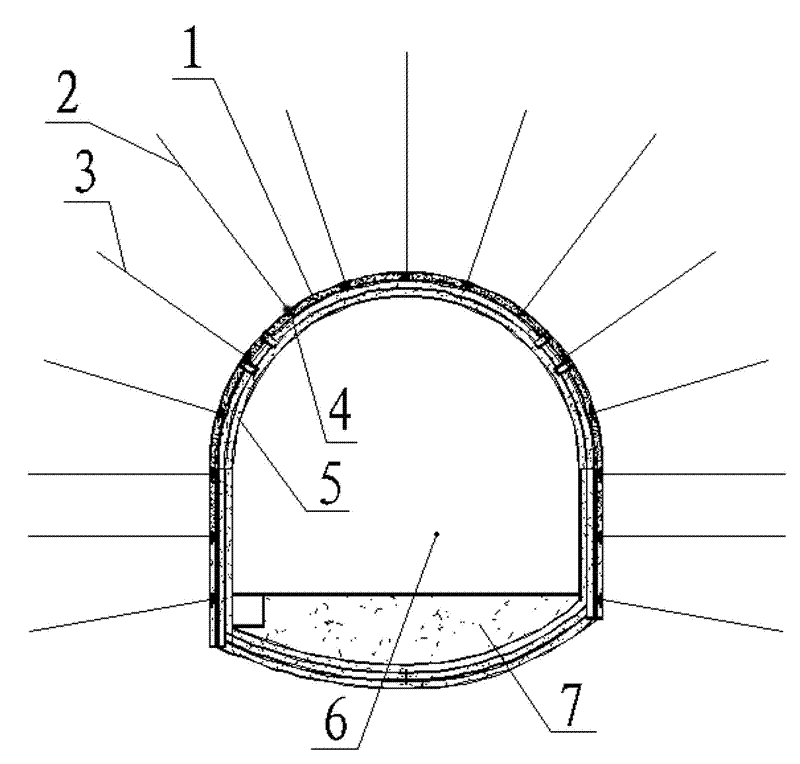

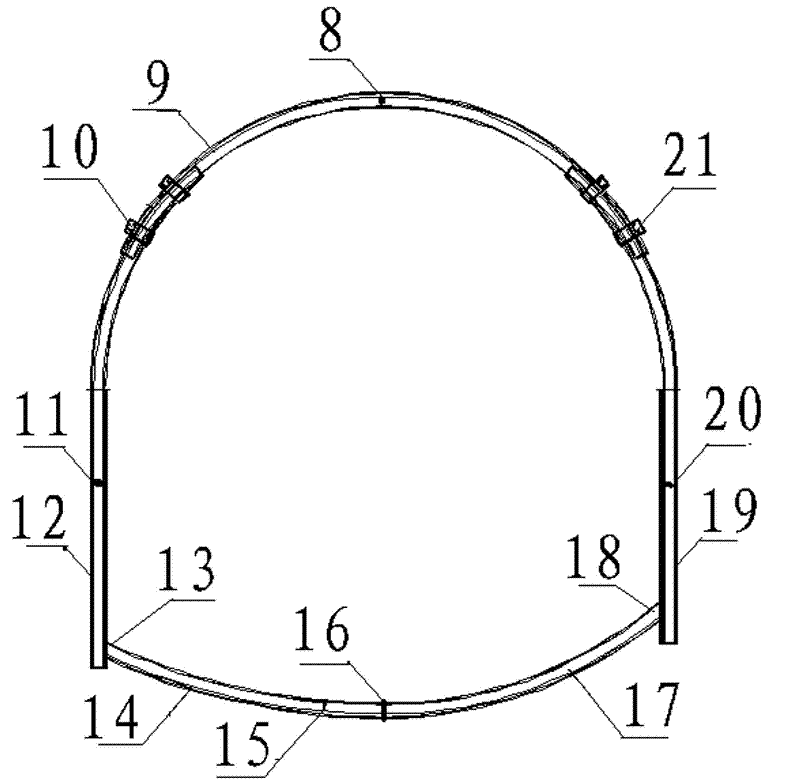

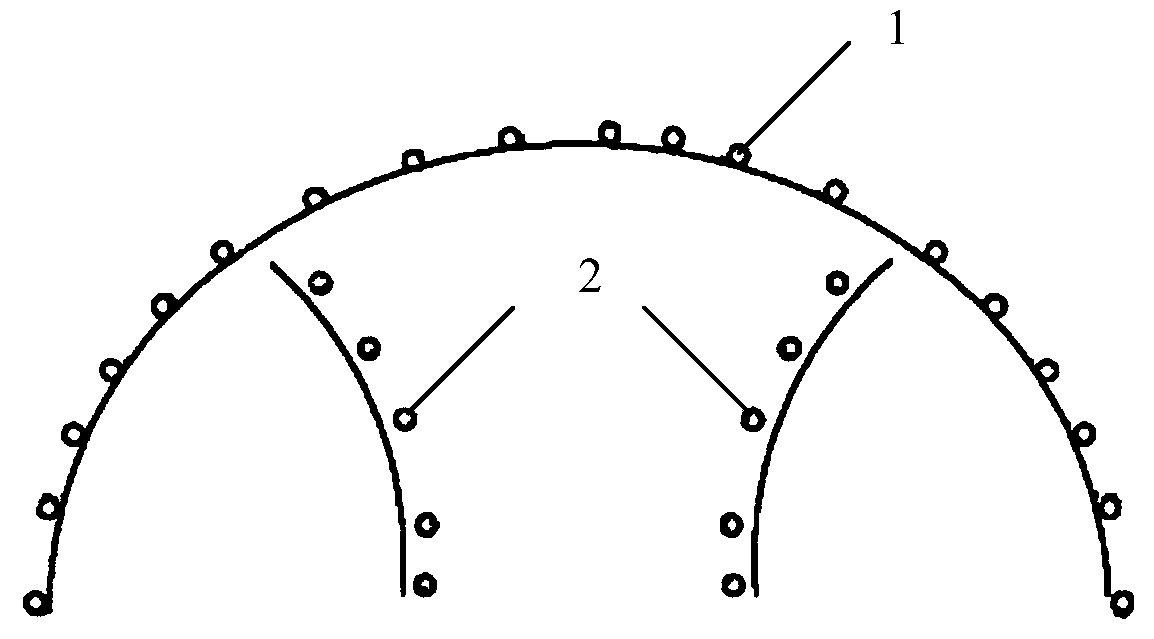

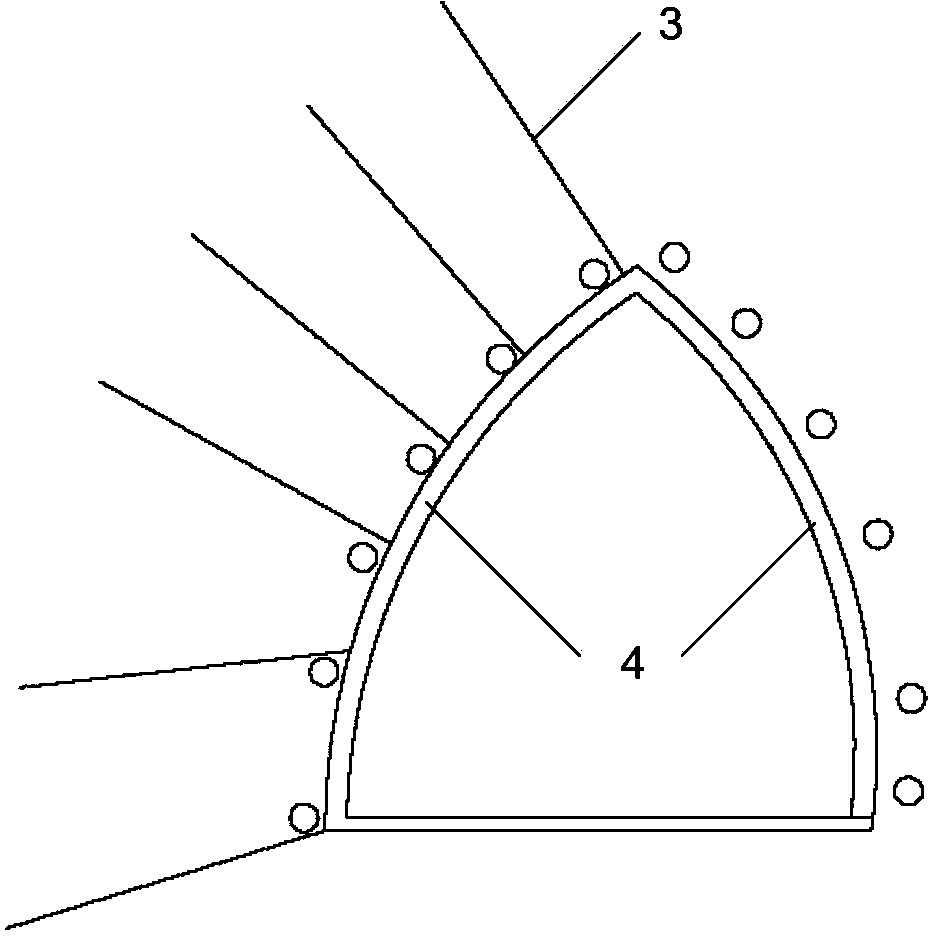

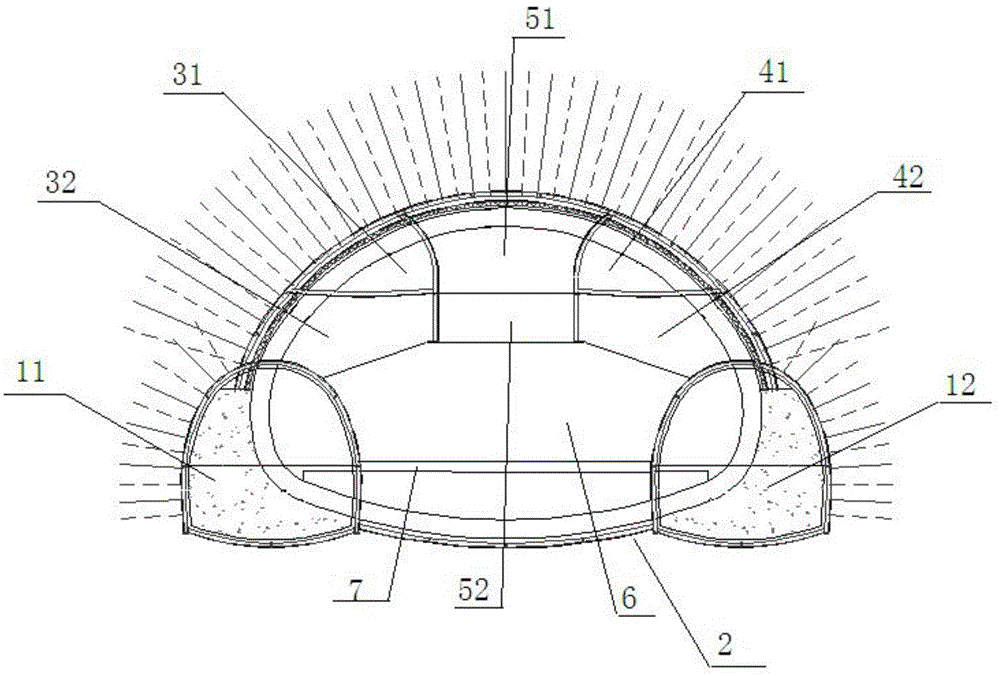

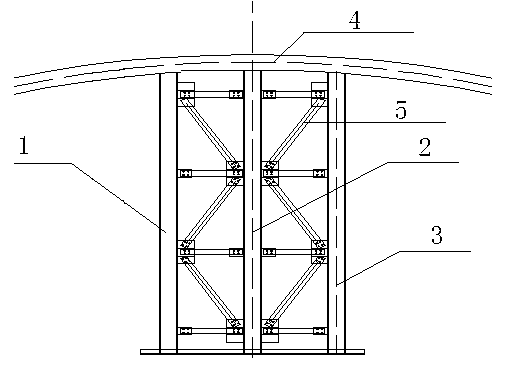

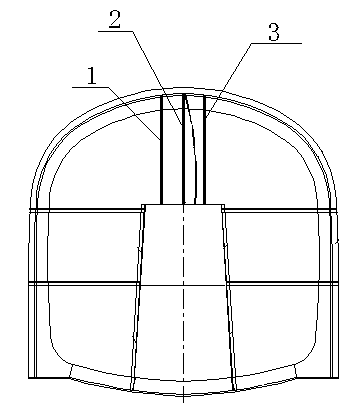

Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

InactiveCN101725362AControl deformationSimple structureProps/chocksAnchoring boltsSupporting systemHardness

The invention relates to a composite support device of a dynamic pressure softrock tunnel based on a steel pipe concrete bracket, which comprises a steel pipe concrete bracket, wherein a flexible pressure sharing and releasing layer is arranged between the steel pipe concrete bracket and supported surrounding rock. The composite support device also comprises a surrounding rock grouting and reinforcing device, wherein the surrounding rock grouting and reinforcing device comprises a plurality of hollow surrounding rock grouting anchor rods, and the surrounding rock is grouted by the hollow anchor rods; after being injected with a concrete layer, the surrounding rock is covered by a flexible seal layer; and the steel pipe concrete bracket is provided with a vertical column shaped or Y-shaped or T-shaped high-strength steel pipe concrete strut. The high-strength steel pipe concrete bracket and the flexible pressure sharing and releasing layer are two necessary technologies; and the flexible seal layer, the surrounding rock grouting and reinforcement and the high-strength steel pipe concrete strut are three optional technologies. The flexible pressure sharing and releasing layer is combined with the steel pipe concrete bracket so that the whole support system combines hardness with softness, has simple structure, low cost and high support resistance and can effectively control the stability of large deformed tunnels of deep well softrock dynamic pressure, and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

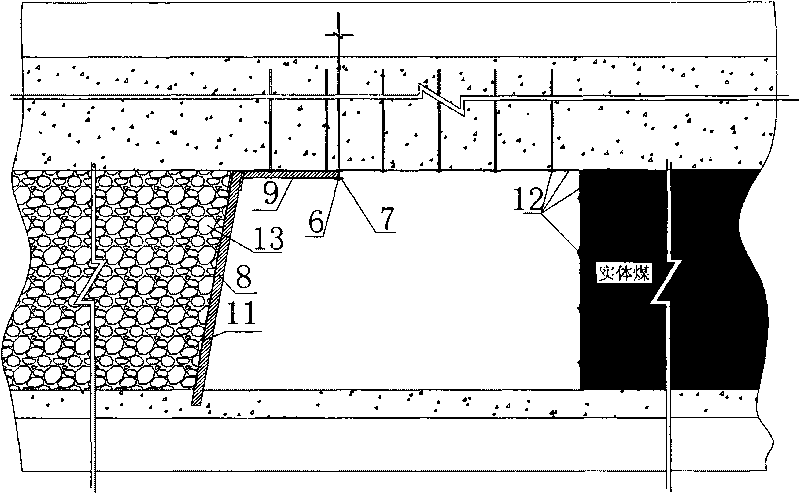

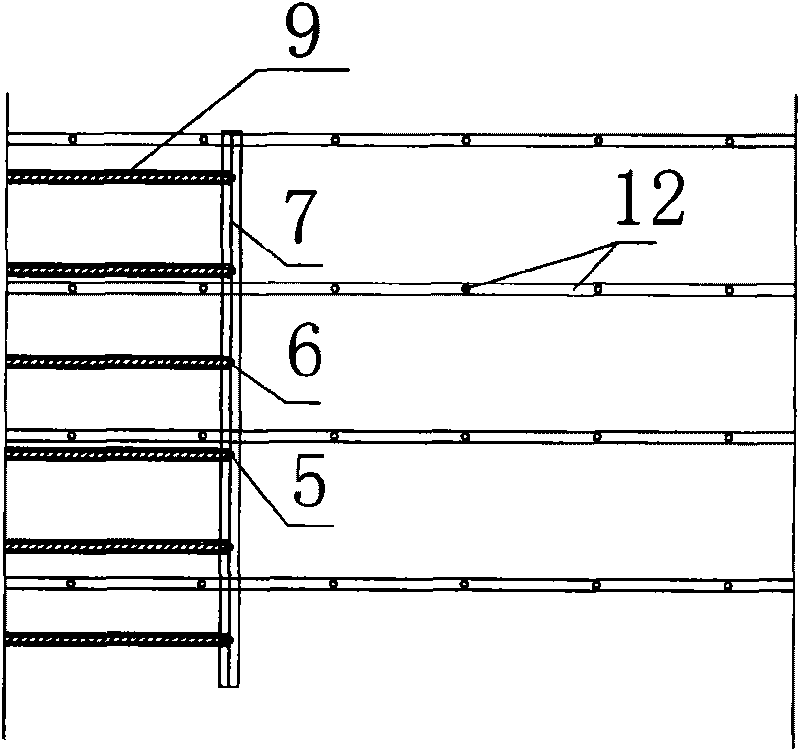

Goaf surrounding rock around gob-side supporting method under three soft geological condition

ActiveCN101280684ASolve support problemsPromote safe productionUnderground chambersTunnel liningEngineeringTechnical support

Disclosed is a method for retaining roadway and supporting the surrounding rock in goafs under geological condition, which is characterized by first reinforcing and retaining roadway for the first time, then constructing the exceeded roadway and finally constructing and retaining roadway for the second time. The method of the invention forms an effective supporting for the secondary retaining roadway along the goafs, thus overcoming the difficulty in supporting roadway in a condition of multi mining activities. The roadway is primarily guaranteed perfect during the mining period and the amount of shrinkage is in the allowed control range, thereby providing technical support and guarantee for smoothly realizing the Y-type ventilation of the working face with high content of methane and promoting the safety production in mine wells.

Owner:HUAINAN MINING IND GRP +2

Method for preventing and treating large deformation and collapse of softrock tunnel

ActiveCN101906977AImprove pullout resistanceGuaranteed stabilityUnderground chambersTunnel liningLarge deformationRock bolt

The invention relates to a method for preventing and treating large deformation and collapse of a softrock tunnel, which comprises the following steps: tunneling molding or enlarging a tunnel; primarily spraying the first layer of concrete, and hanging a side net and a top net at the first layer of concrete; arranging a constant-resistance large deformation rock bolt; multiply spraying the second layer of concrete; arranging a constant-resistance large deformation anchor cable on the top plate; digging and laying the first layer of base plate concrete; hanging a layer of backing screen on the first layer of base plate concrete, and arranging a base angle anchor rod at the base angle; laying the second layer of base plate concrete onto the grade level; setting a long-term ground pressure monitoring point, if the tunnel deforms to a certain preset valve, carrying out secondary support at the key position of the tunnel and carrying out pressurization and slip casting on surrounding rock. The invention can well ensure the stability of softrock tunnel under the condition of large deformation, in addition, the invention has the advantages of simple and practicable implement and lower cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

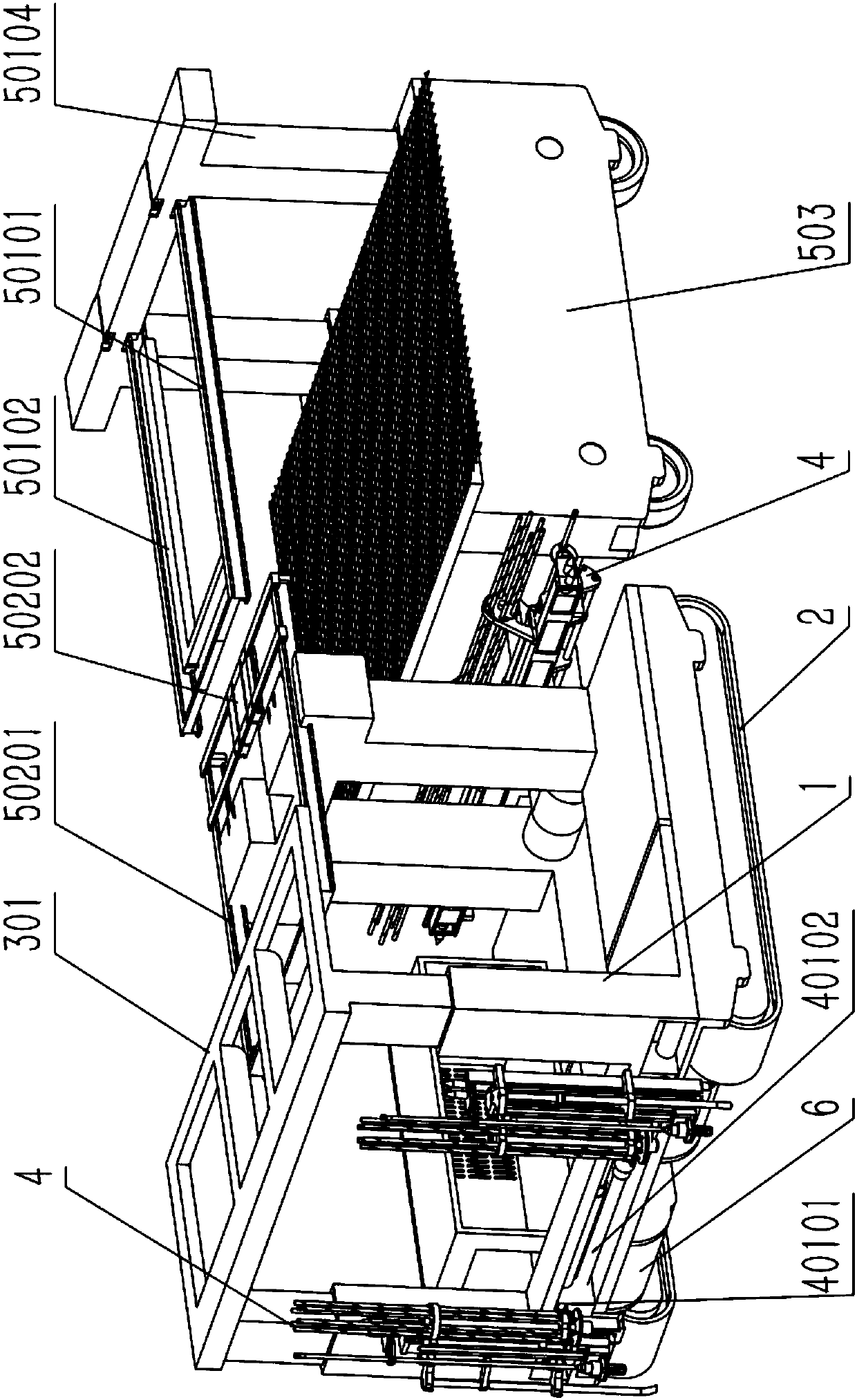

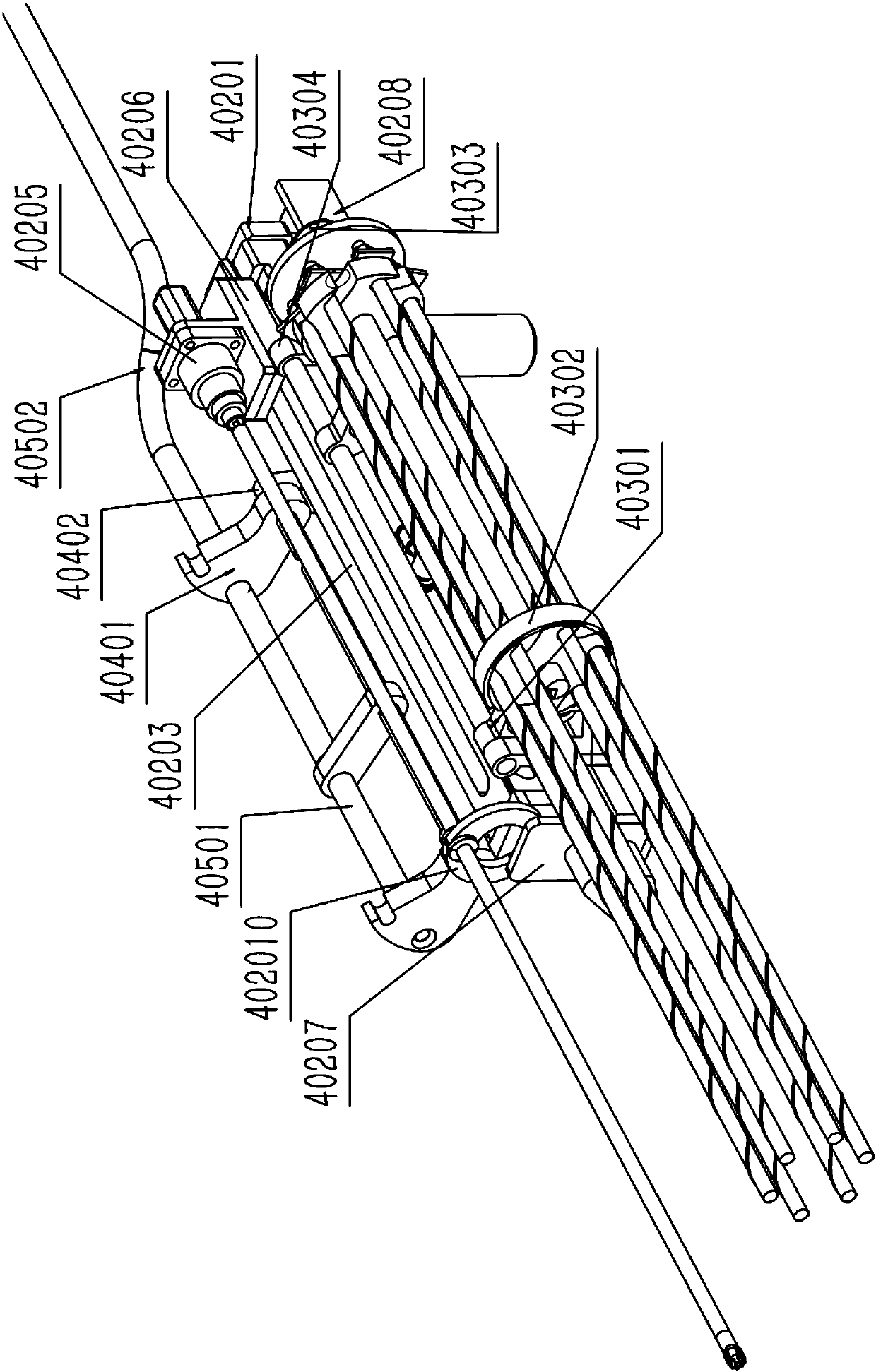

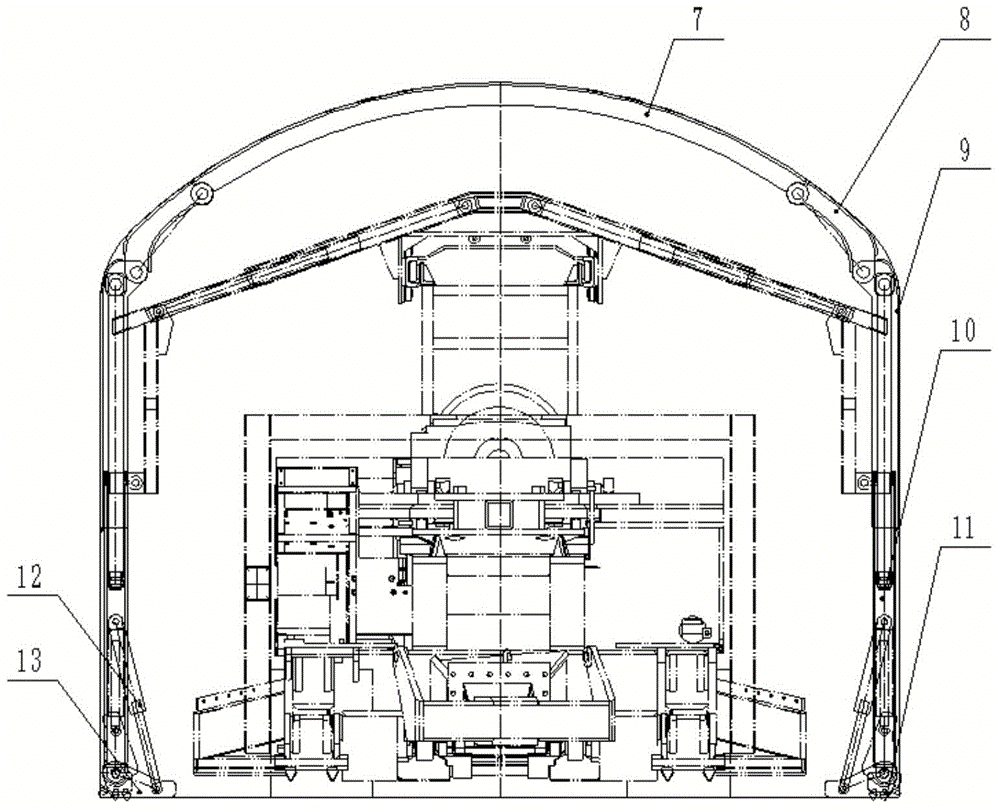

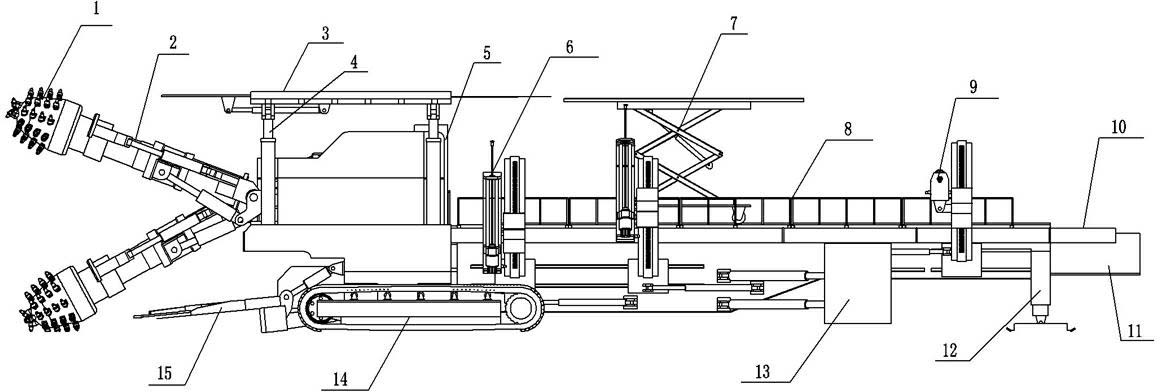

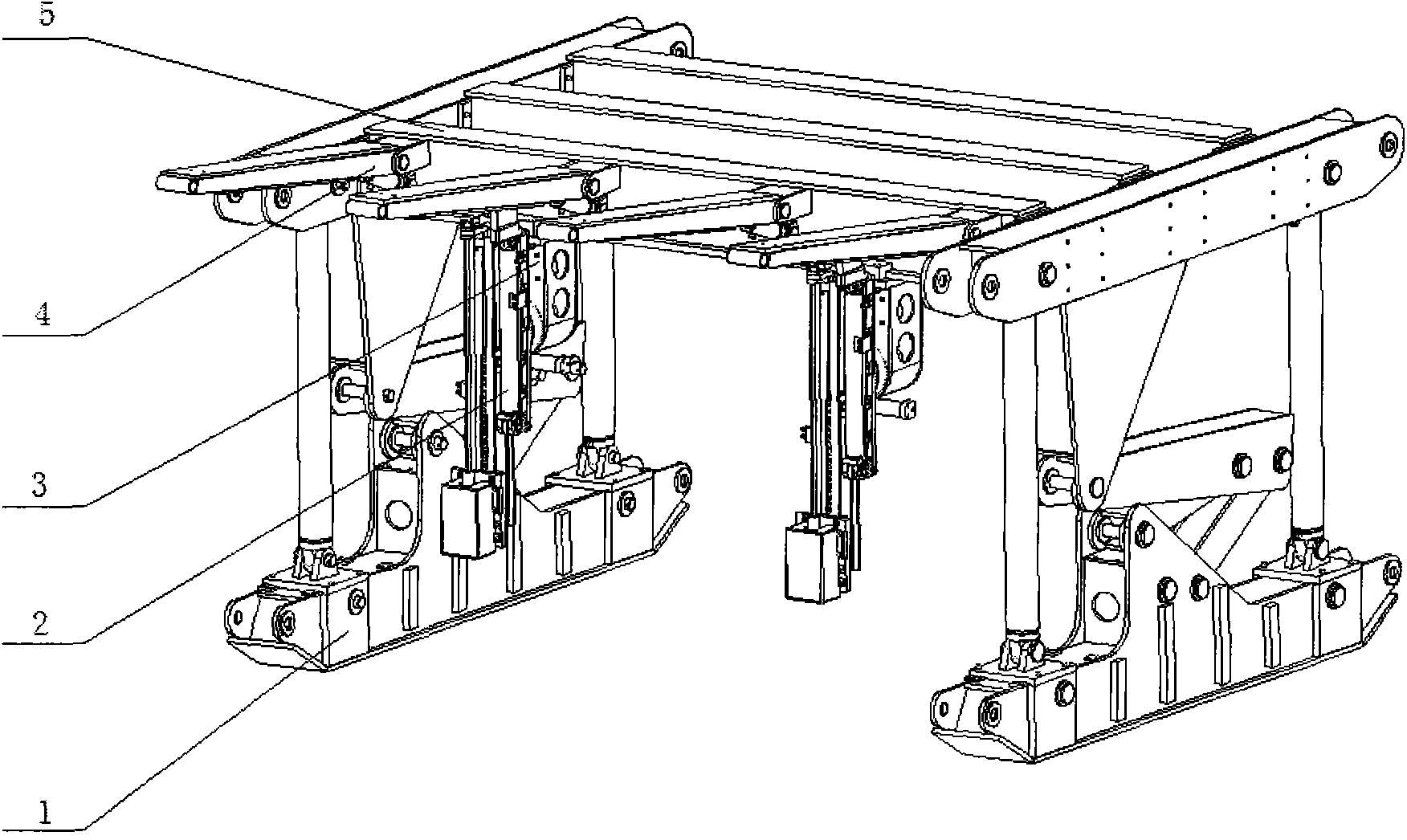

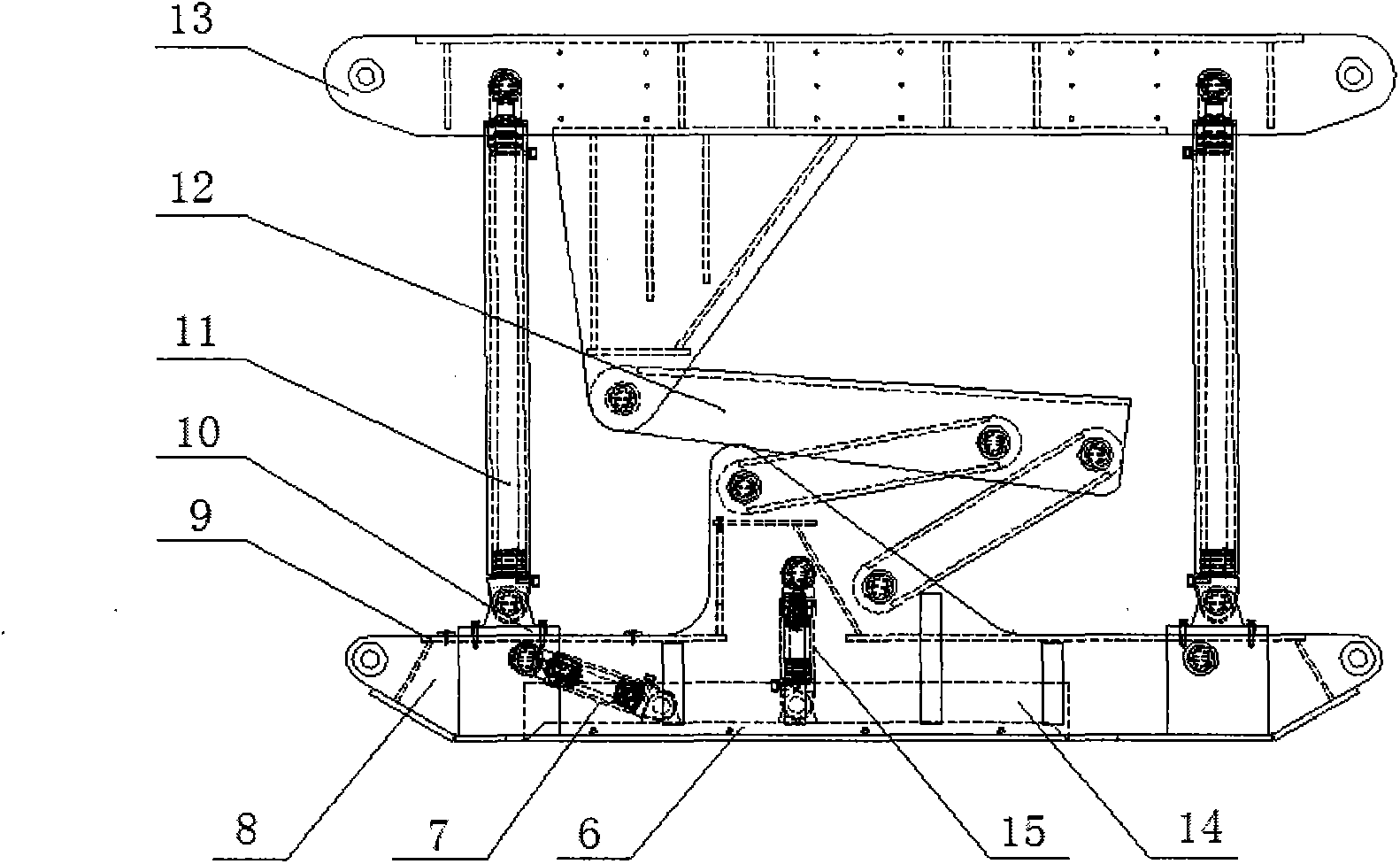

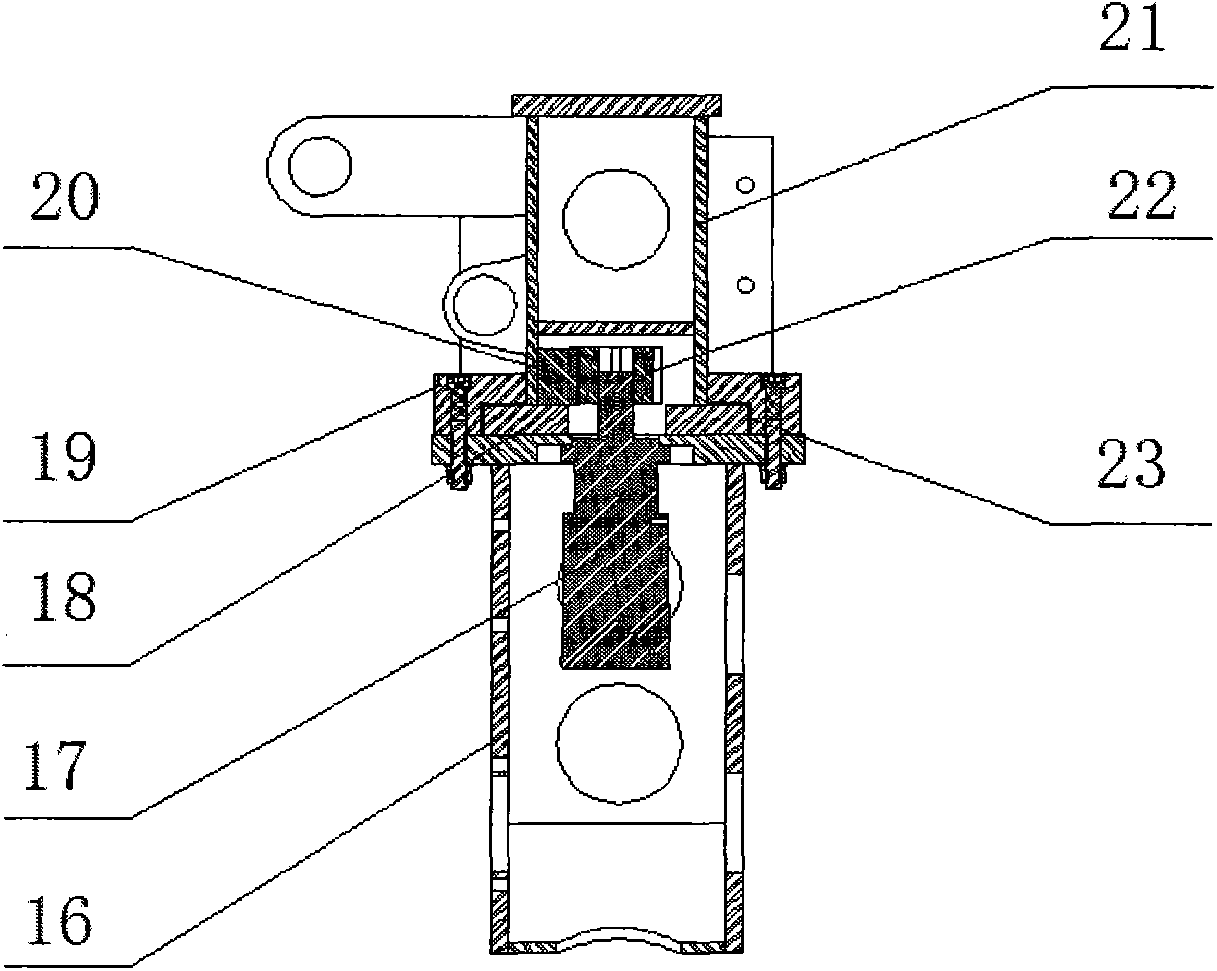

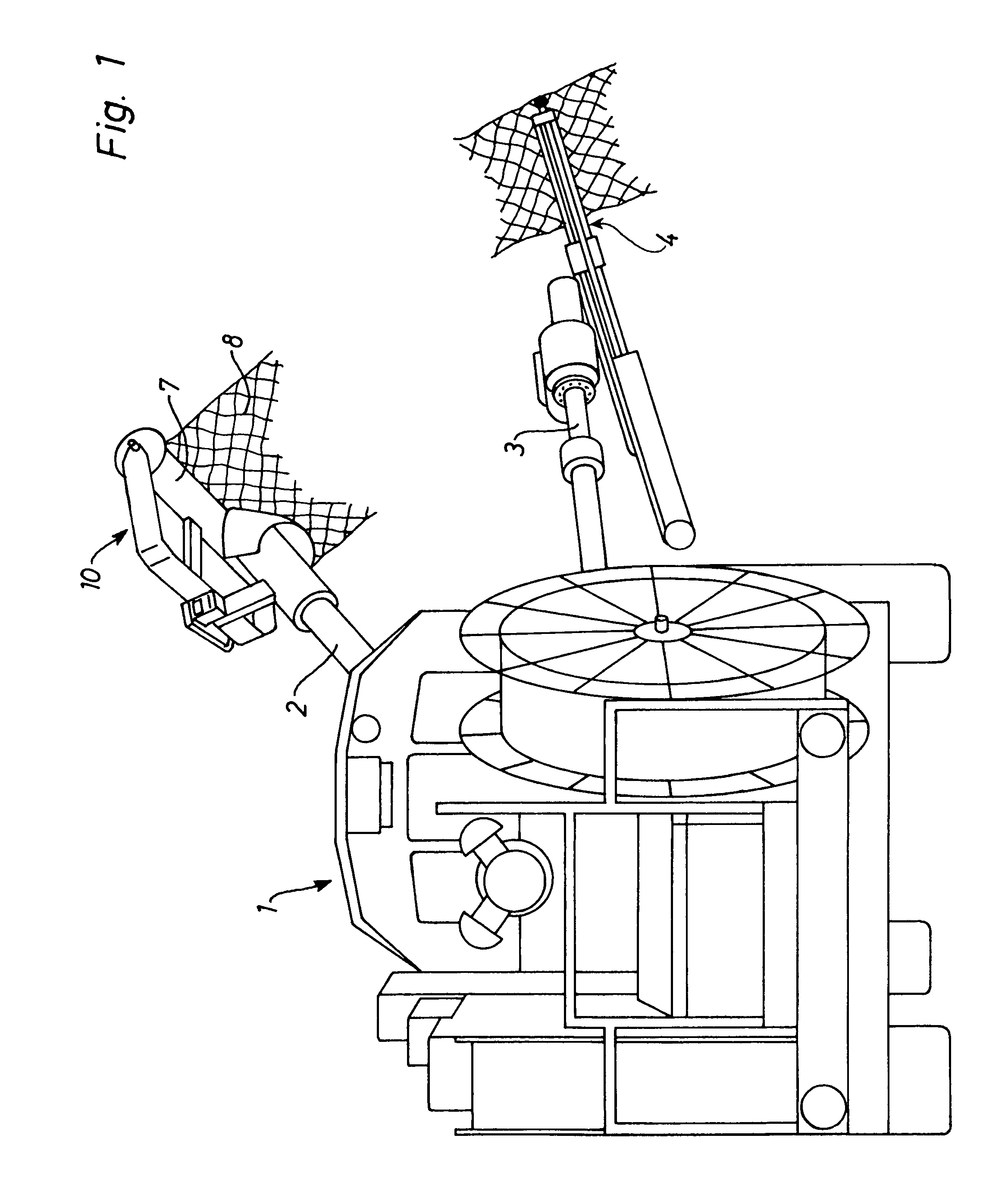

Fully automatic drilling anchor work vehicle

ActiveCN108104853AReduce volumeLess interferenceDrilling rodsConstructionsHydraulic cylinderEngineering

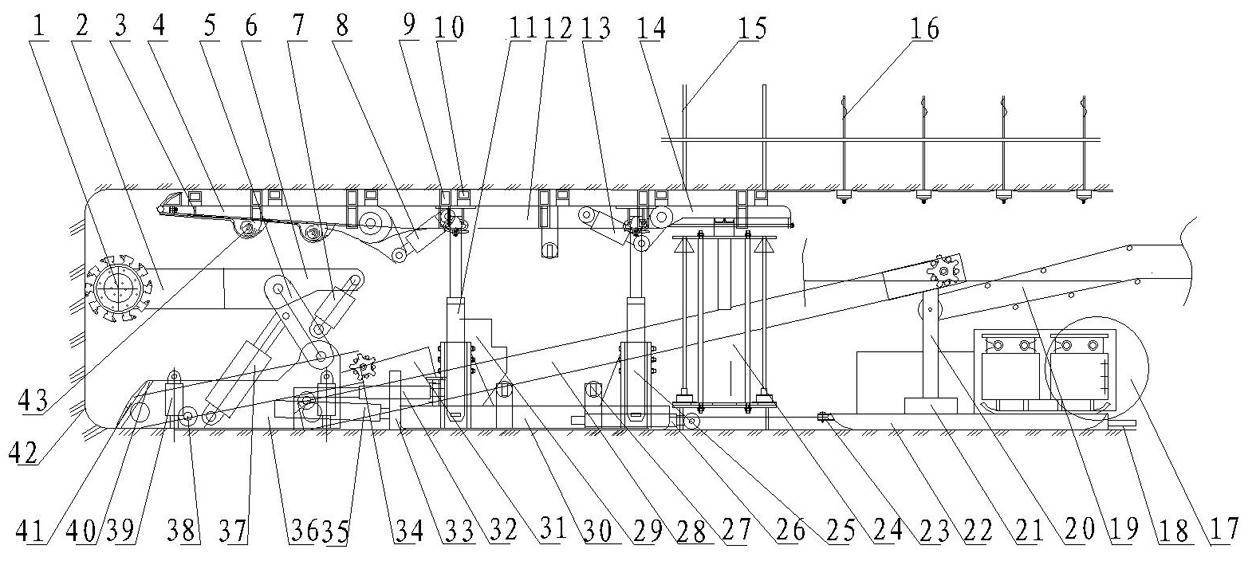

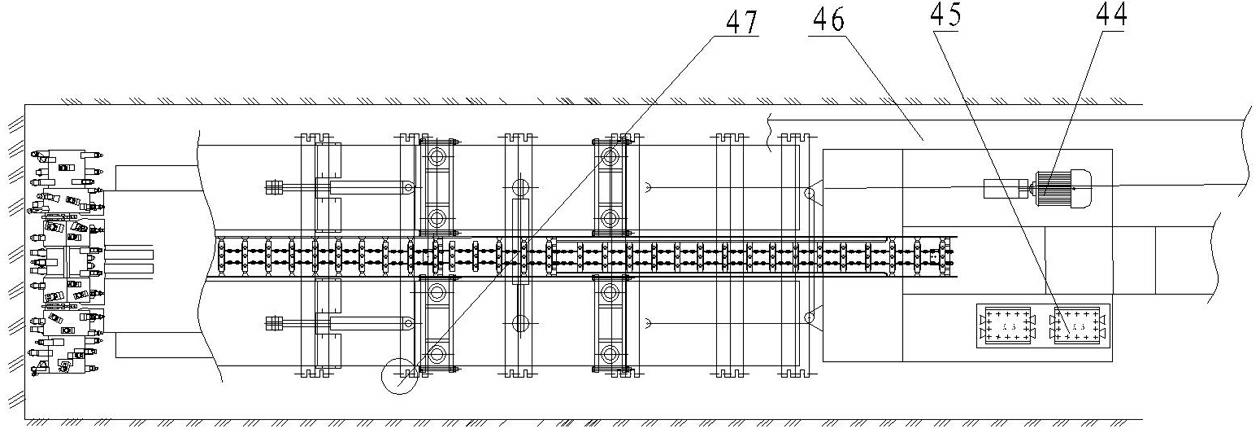

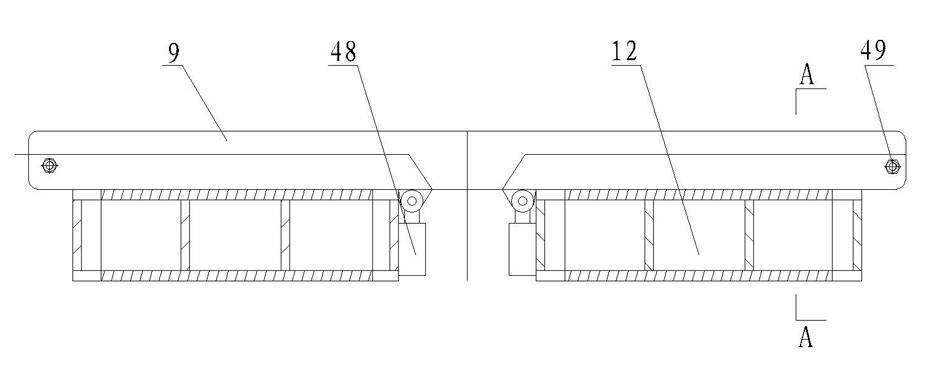

The invention discloses a fully automatic drilling anchor work vehicle integrating processes of anchor net paving, anchor hole drilling, anchoring agent injecting and installing of anchor bolt, and relates to the field of coal mine downhole tunnel support. The fully automatic drilling anchor work vehicle solves the existing problem of misalignment of digging and supporting caused by complicated process and low efficiency of tunnel support operation. The fully automatic drilling anchor work vehicle is characterized by comprising a vehicle body, a self-walking mechanism, a temporary support mechanism, an anchor drilling automation device, and an anchor net storing and a conveying mechanism. The anchor net is grabbed and conveyed to a temporary support frame by the anchor net conveying mechanism from an anchor net storage vehicle, and is supported by the temporary support frame to complete the anchor net laying work; and the anchor drilling automation device realizes the left-right and up-down displacement by the double-acting hydraulic cylinder in a car body sliding slot, and the rotation of the anchor drilling automation device is realized by a swing motor. According to the fully automatic drilling anchor work vehicle, the automatic laying of a back anchor net can be completed, mechanized support and automatic support of a top anchor rod and a side anchor rod can be realized, and the fully automatic drilling anchor work vehicle is matched with tunneling equipment to realize the parallel operation of digging and supporting anchor.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Unmanned roadway driving and anchoring all-in-one machine

InactiveCN104500086AImprove adjustabilityFlexible cuttingMine roof supportsTunnelsSupporting systemControl system

The invention discloses an unmanned roadway driving and anchoring all-in-one machine. The unmanned roadway driving and anchoring all-in-one machine comprises a driving system, a conveying system, a temporary support system, an anchoring system, a driving all-in-one machine water system, a sensing system and an electrical control system. A feed moving roller at the connection portion between a shovel of the driving system and the front end of the conveying system can prevent feed clogging at the shovel and the front end of a scraper conveyor. The temporary support system is uniform in supporting, can move relative to the driving and anchoring all-in-one machine to achieve no-deferring synchronization of driving, supporting and anchoring and can be adapted to the round, uprightly oval, approximately oval or rectangular cross section of a roadway to be applicable to driving and supporting operations of roadways of a variety of ground pressure and directions. The sensing system and the electrical control system of the driving and anchoring all-in-one machine can effectively collect and process information such as, light, distance, humidity and gas and the electrical control system performs automatic or remote manual analysis so as to achieve unattended operations in the working process and greatly improve the safety factor of the operations.

Owner:SHANXI DATONG UNIV

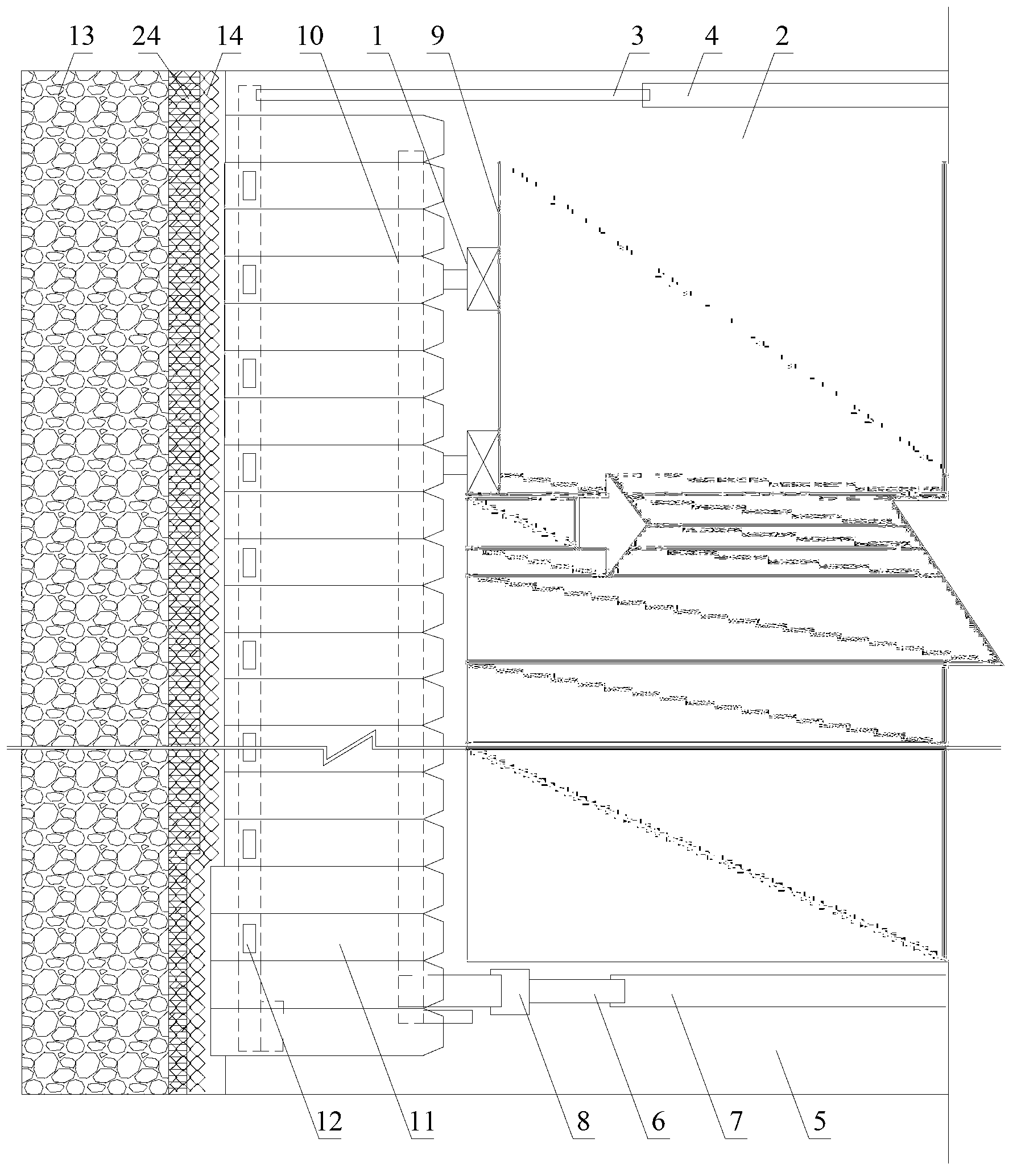

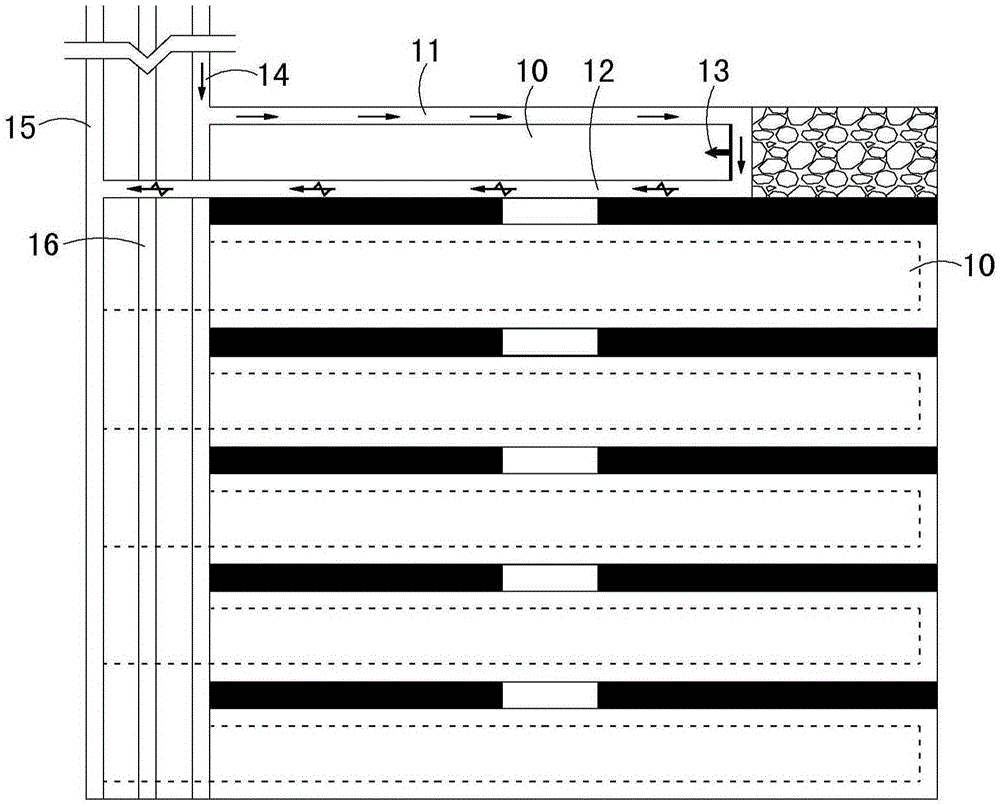

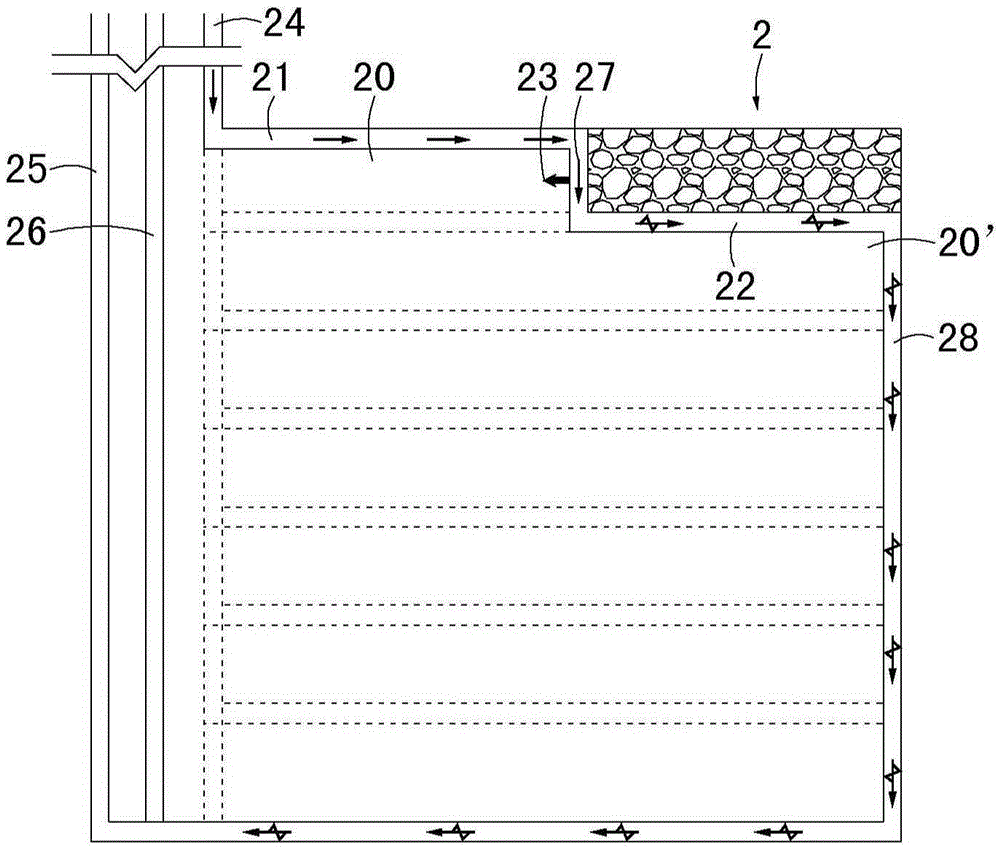

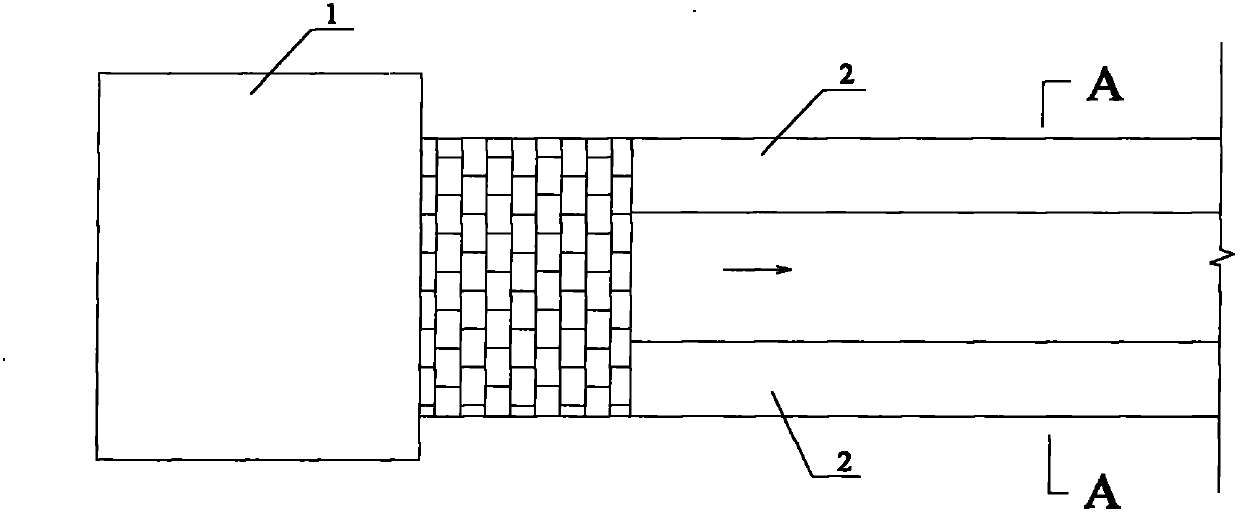

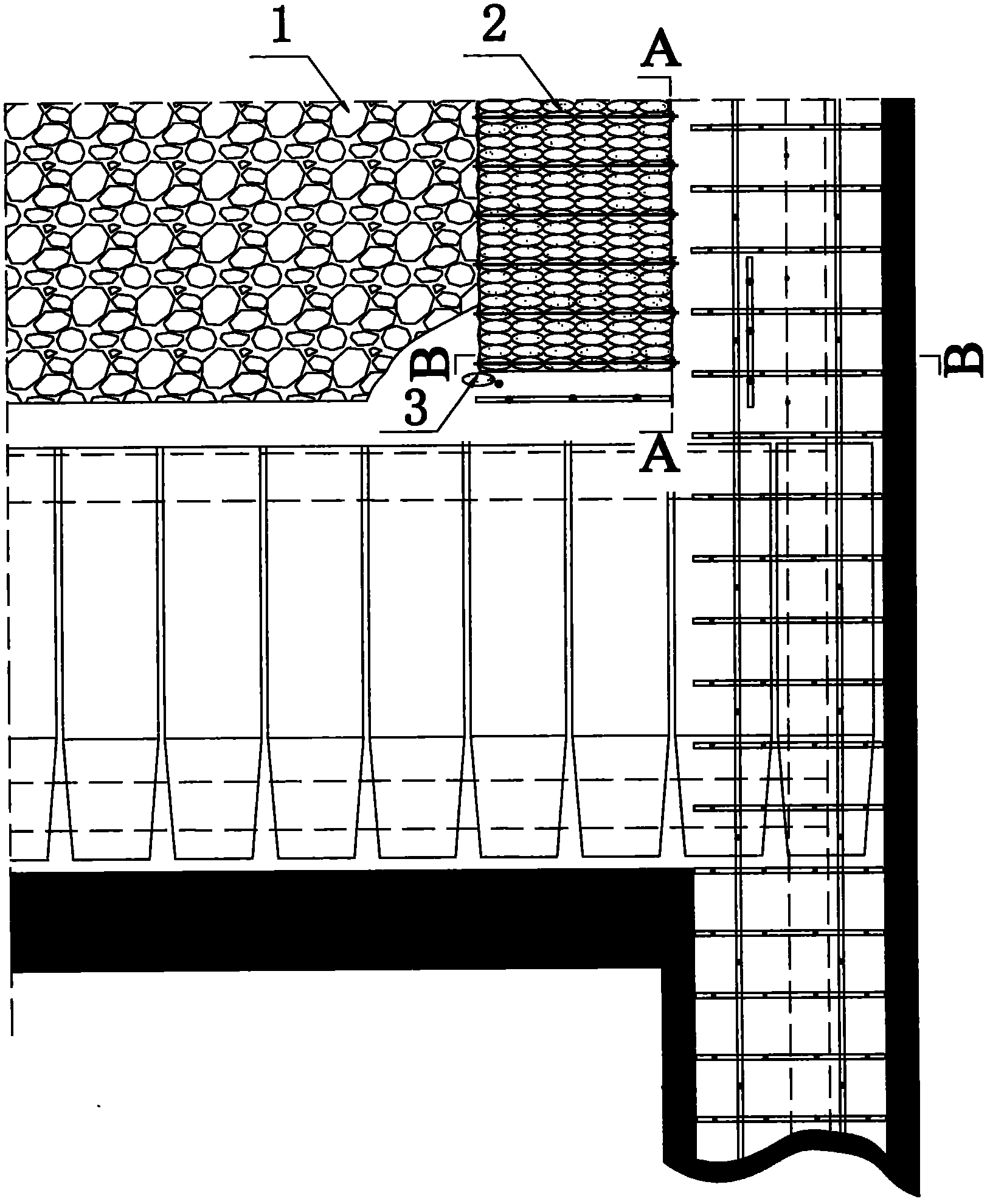

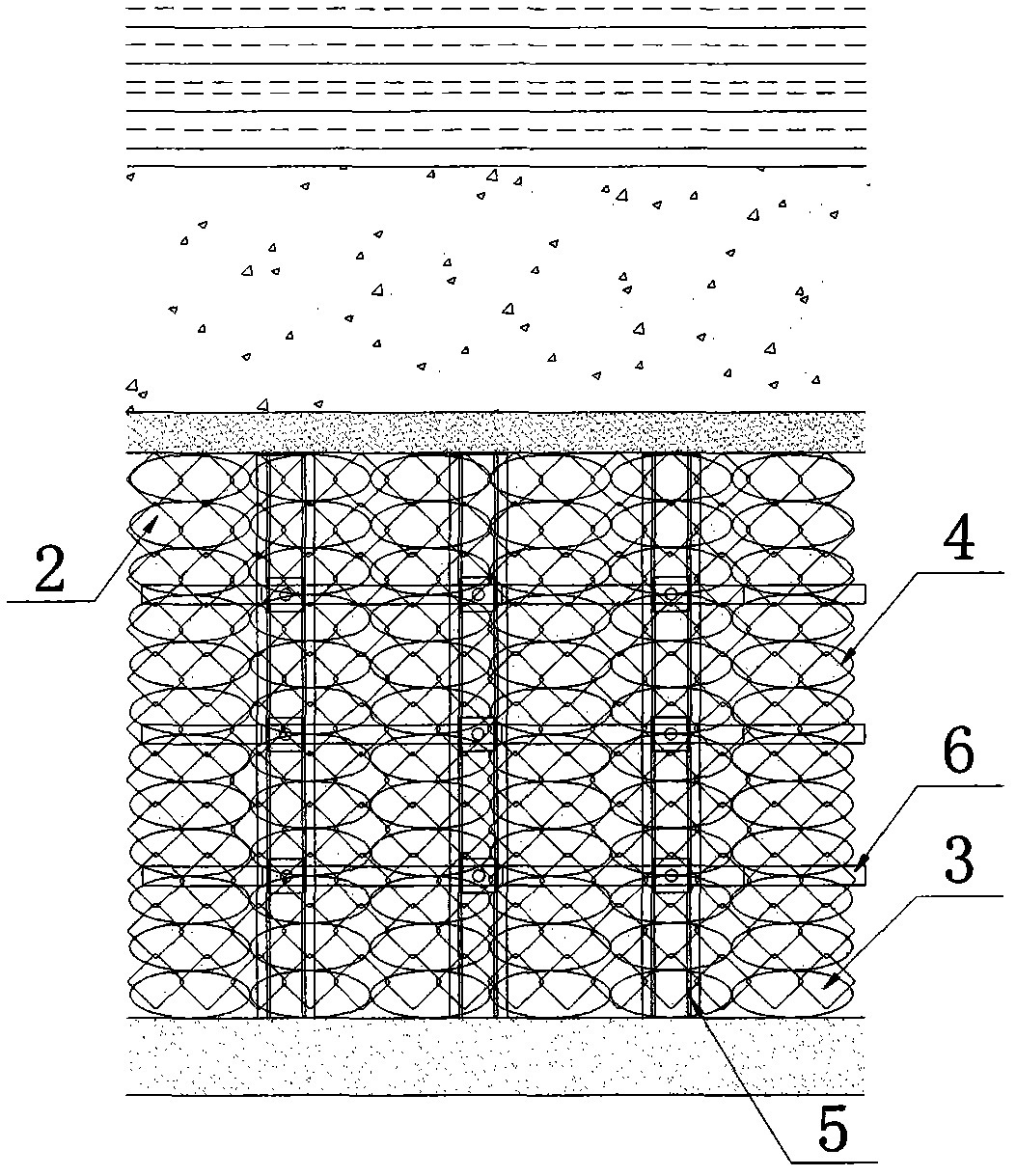

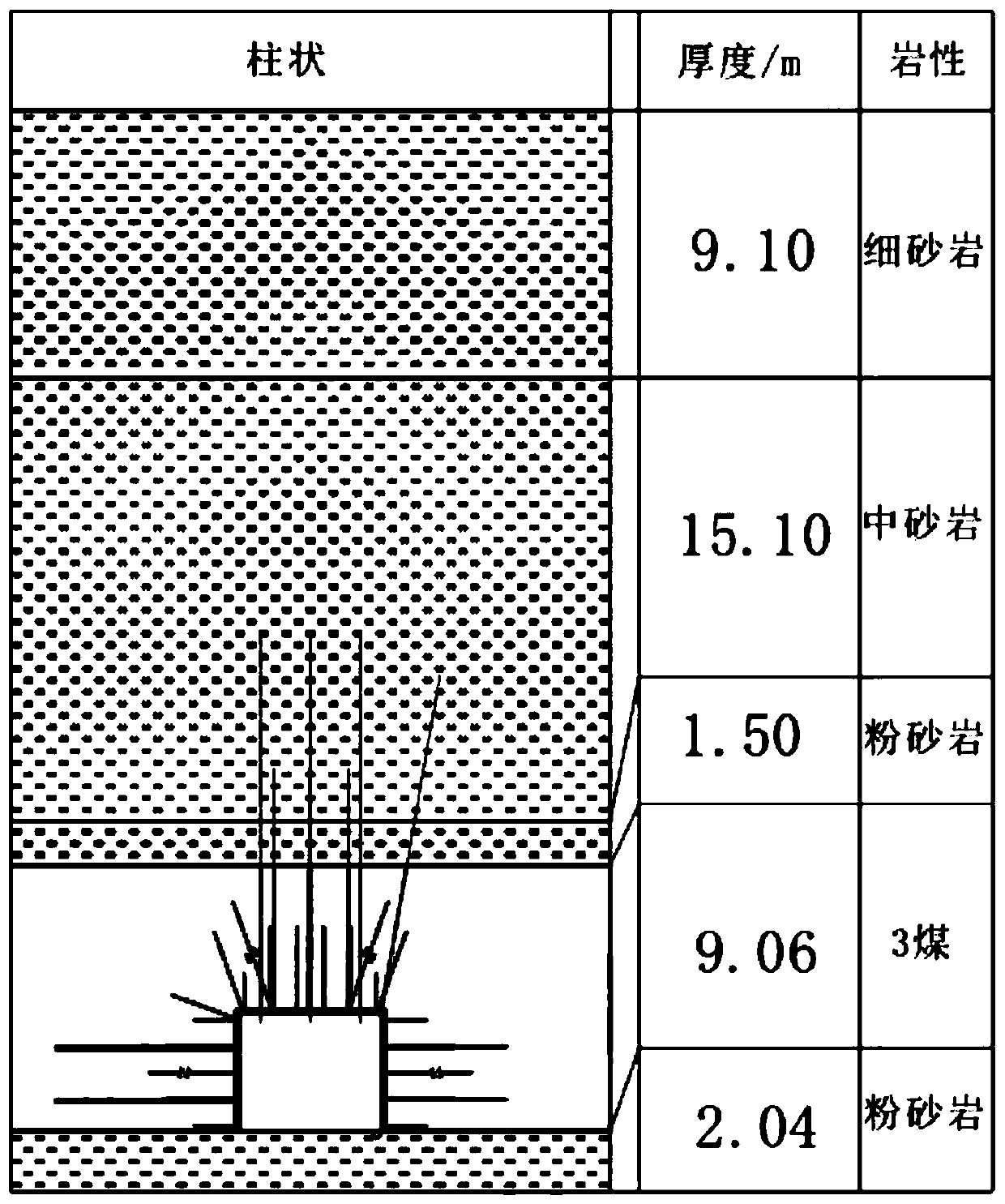

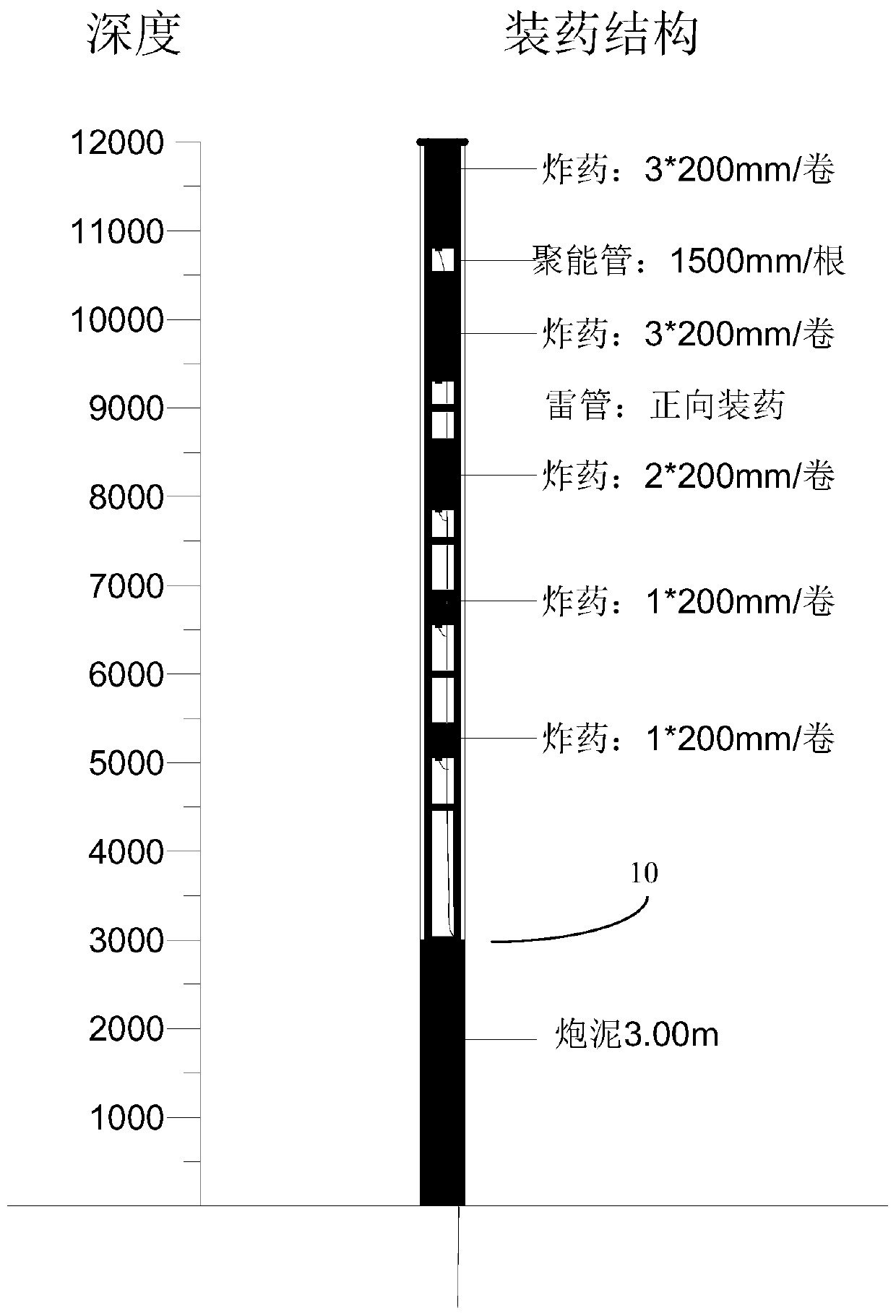

Inclined separated layer solid filling coal mining method for super thick coal seam

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

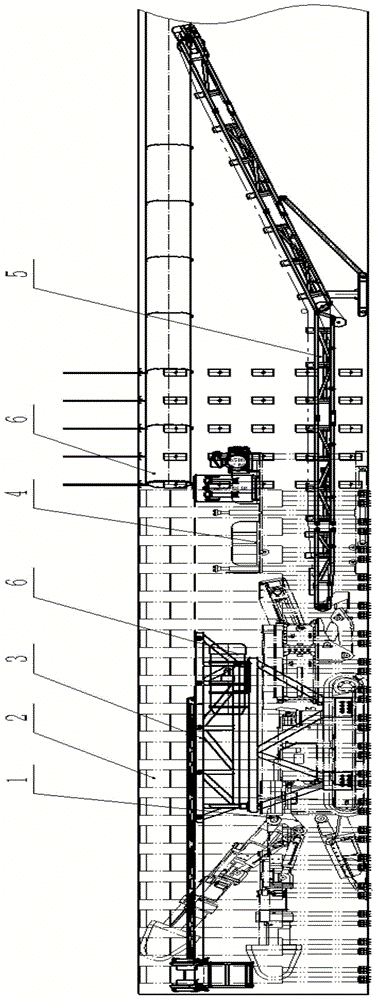

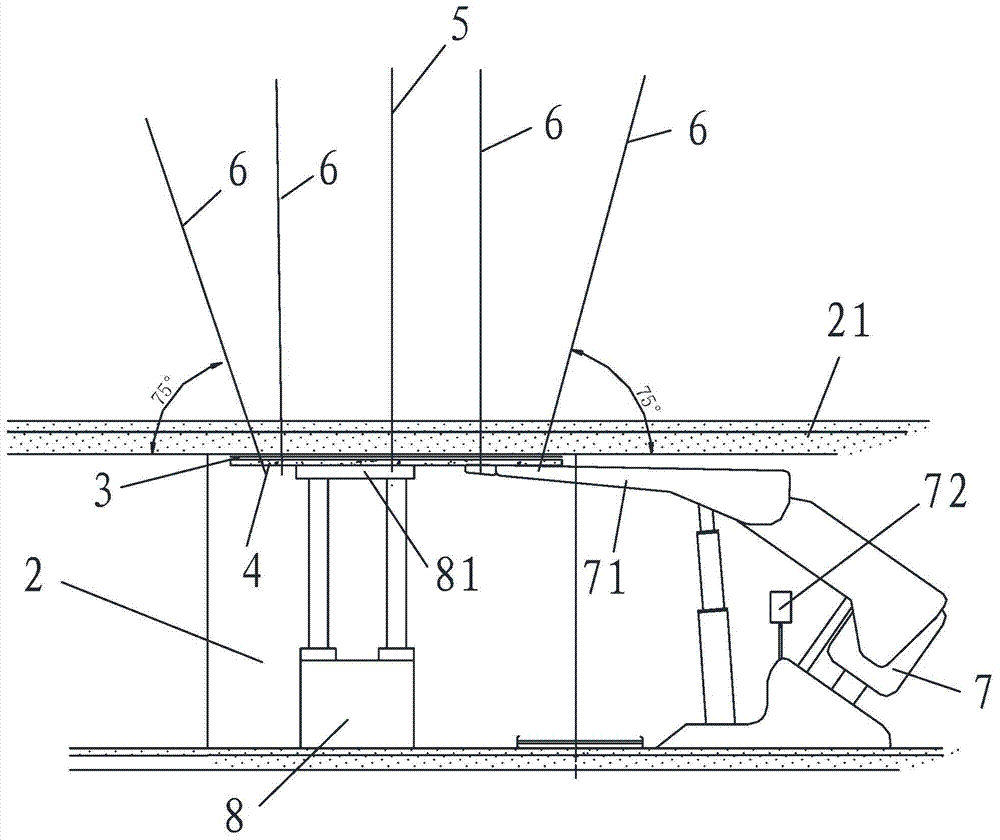

Process method and equipment for heading and anchoring parallel operation construction

ActiveCN104564050AImprove boot rateRaise the level of single advance in tunnelingSlitting machinesMine roof supportsComputer scienceBuilding construction

The invention discloses process method and equipment for heading and anchoring parallel operation construction. According to the process, a heading face is divided into a heading machine operation area and an anchoring support area, wherein the heading machine operation area ranges from a heading head to a heading machine tail, a heading machine post-anchoring operation range serves as the anchoring support area, the heading machine operation area and the anchoring support area are collectively called as a temporary support area, temporary support is carried out in the temporary support area by adopting folding telescopic laneway hydraulic support frames, and heading machine cutting and permanent support are parallelly operated; when the heading machine cutting and anchoring support are completed for one step pitch, the hydraulic support frames positioned on the tail ends of the temporary support area are withdrawn and carried to the heading head through an auxiliary support frame lifting and carrying device, and the hydraulic support frames are lifted to complete the temporary support so as to be subjected to heading and anchoring parallel operation in a next cycle. The heading and anchoring parallel operation construction comprises a heading machine, a plurality of laneway hydraulic support frames, the auxiliary support frame lifting and carrying device, an anchoring support operation platform, a machine back transportation system and a machine tracking ventilating dustproof facility.

Owner:郑东风 +1

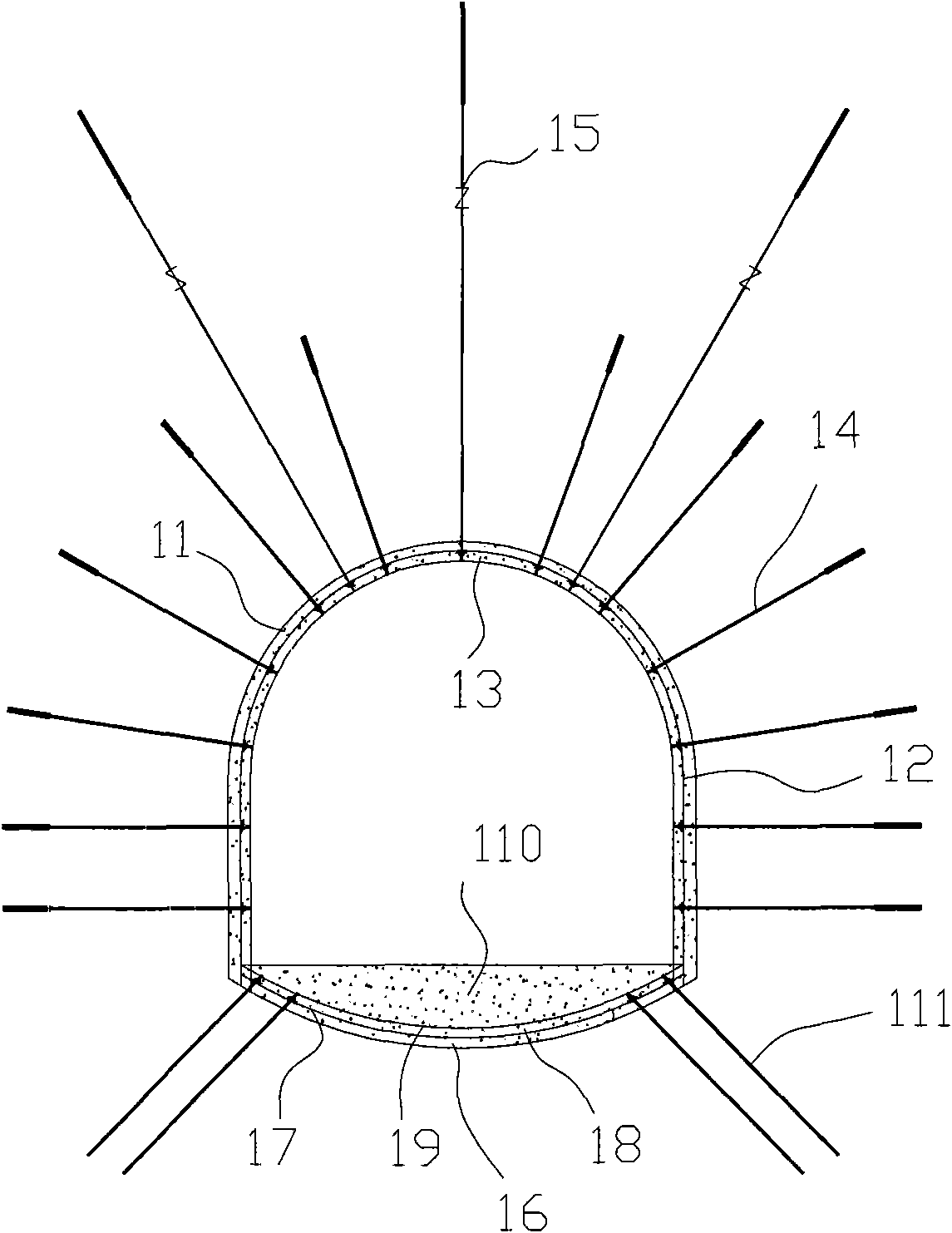

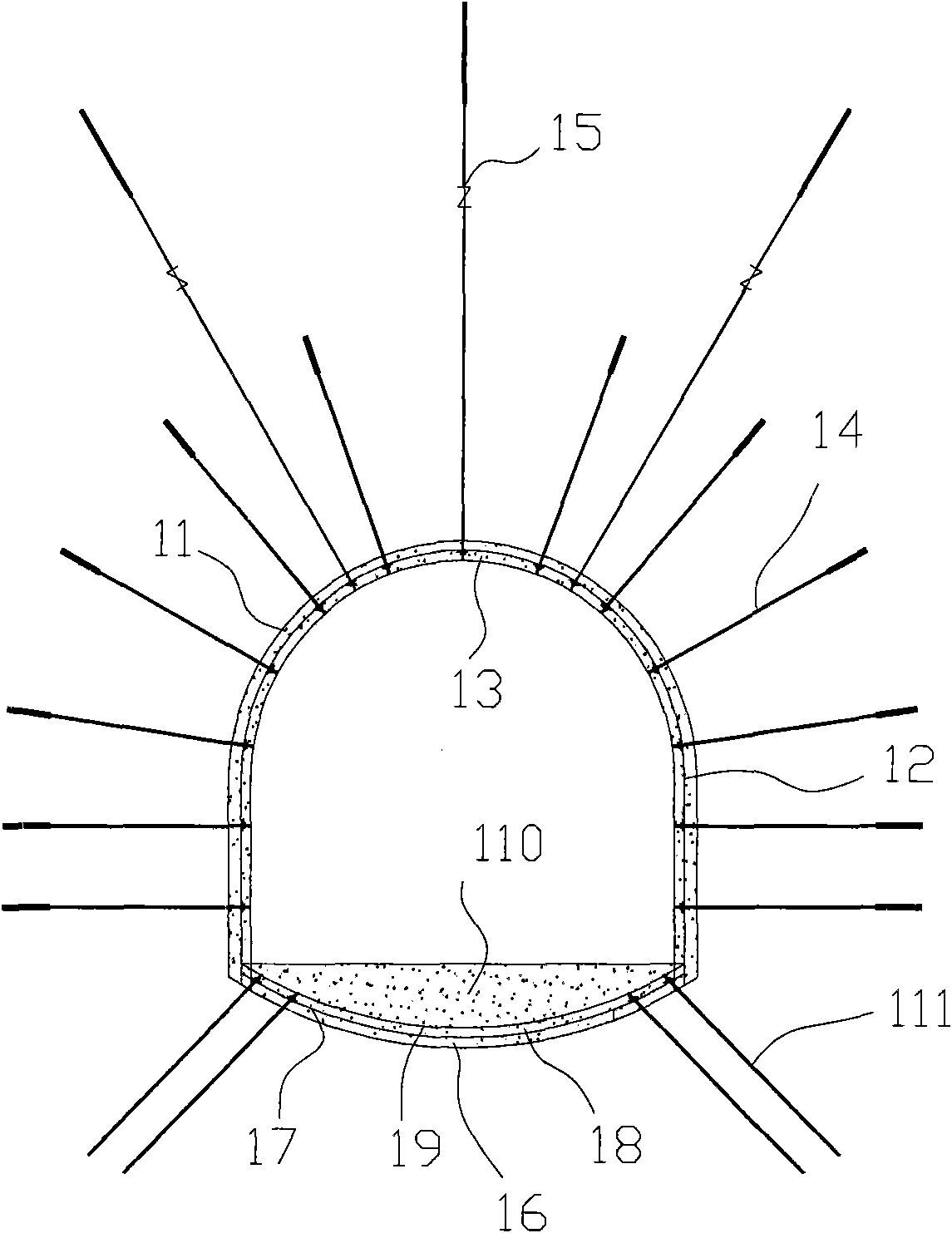

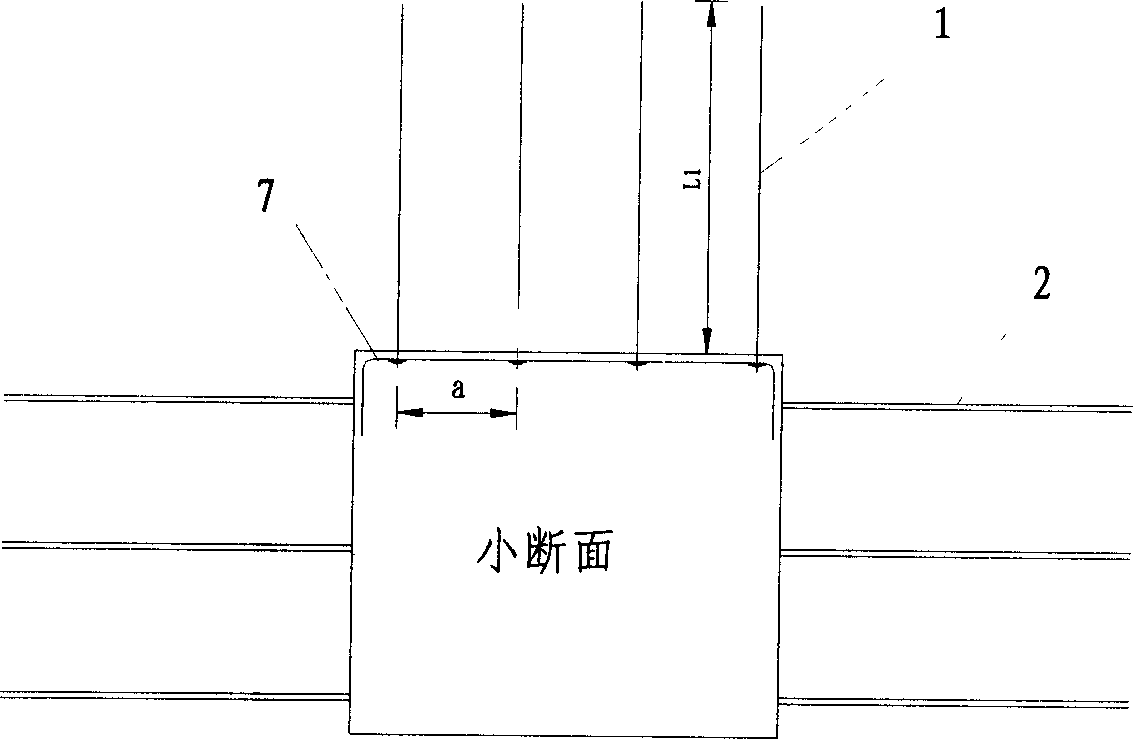

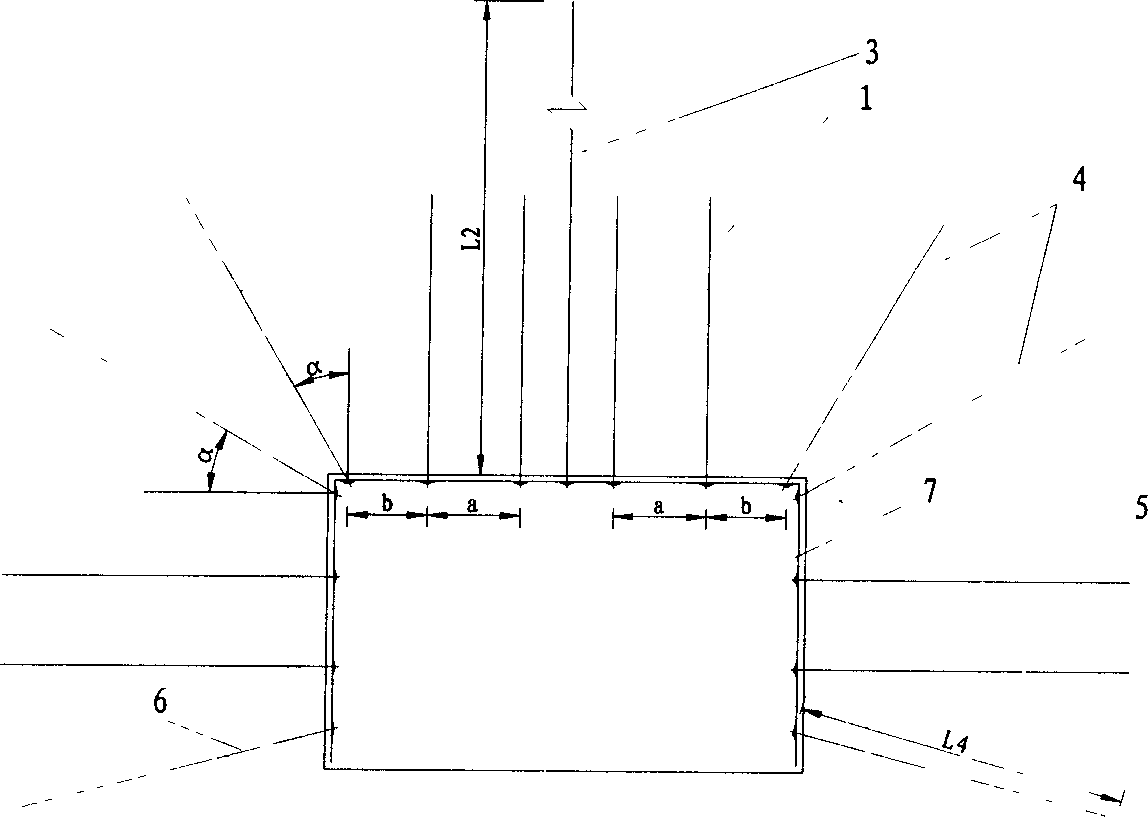

Three-anchor coupling supporting method for high stress tunnel break wall rock

InactiveCN1693670AEffective control of deformationEffective damage controlAnchoring boltsProtective coversStress concentrationEngineering

This invention is a three-anchor-coupling supporting method for high stress tunnel break wall rock. Small section digging is used, roof deformation is controlled by reinforce the support of roof plate to lighten the stress concentration of two sides coal bodies. Pressure relief holes that allow wall rock to deform and damage are drilled on both sides to release the high stress in wall rack, then construction of big brush and consolidation is done. Roof and bottom angles are reinforced support in stress releasing course to effectively control deformation and damage of tunnel roof for stabilizing wall rock. bolt-spray supports anchor cable consolidation and anchor inject support in coal road and soft rock supporting is combined as one piece. Its coupled relation is fully exerted and the support problem of conforming complicated area and deep buried high stress cracking wall rack or soft tunnel. Its stability is strong, operability is strong, it is safe and reliable can meet the stability needs of roadway in complicated conditions.

Owner:CHINA UNIV OF MINING & TECH

Comprehensive dredging machine

ActiveCN102155219AOvercome the disadvantages of not being able to drill holes and support at the same timeIncrease the speed of excavationMine roof supportsTunnelsPush and pullEngineering

The invention discloses a comprehensive dredging machine. The comprehensive dredging machine comprises a crawler-free type dredging machine, a hydraulic support, a drilling machine, a scraper conveyor, a runner and the like. The upper end of the hydraulic support is provided with a main top beam, a front canopy, a back canopy and a cross beam; the dredging machine is arranged on a foundation; thefront and rear ends of the foundation are provided with a slope regulation jack respectively; one end of a front pushing and pulling jack is connected with the foundation of the dredging machine, andthe other end of the front pushing and pulling jack is connected with the hydraulic support; the rear of the dredging machine is provided with a self-advancing jack, and two sides of the foundation are provided with a side push cylinder respectively; and the drilling machine is arranged below the main top beam or the back canopy; and the runner is arranged behind the hydraulic support and is connected with a rear push and pull jack arranged on the hydraulic support by an anchor chain and a pulley. The comprehensive dredging machine has the advantages of parallel operation of hole drilling andsupporting, and coal cutting of a development machine, a roadway turns flexibly, the turning radius is small, the turning speed is high, the tunneling speed is high, and the safety is guaranteed.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

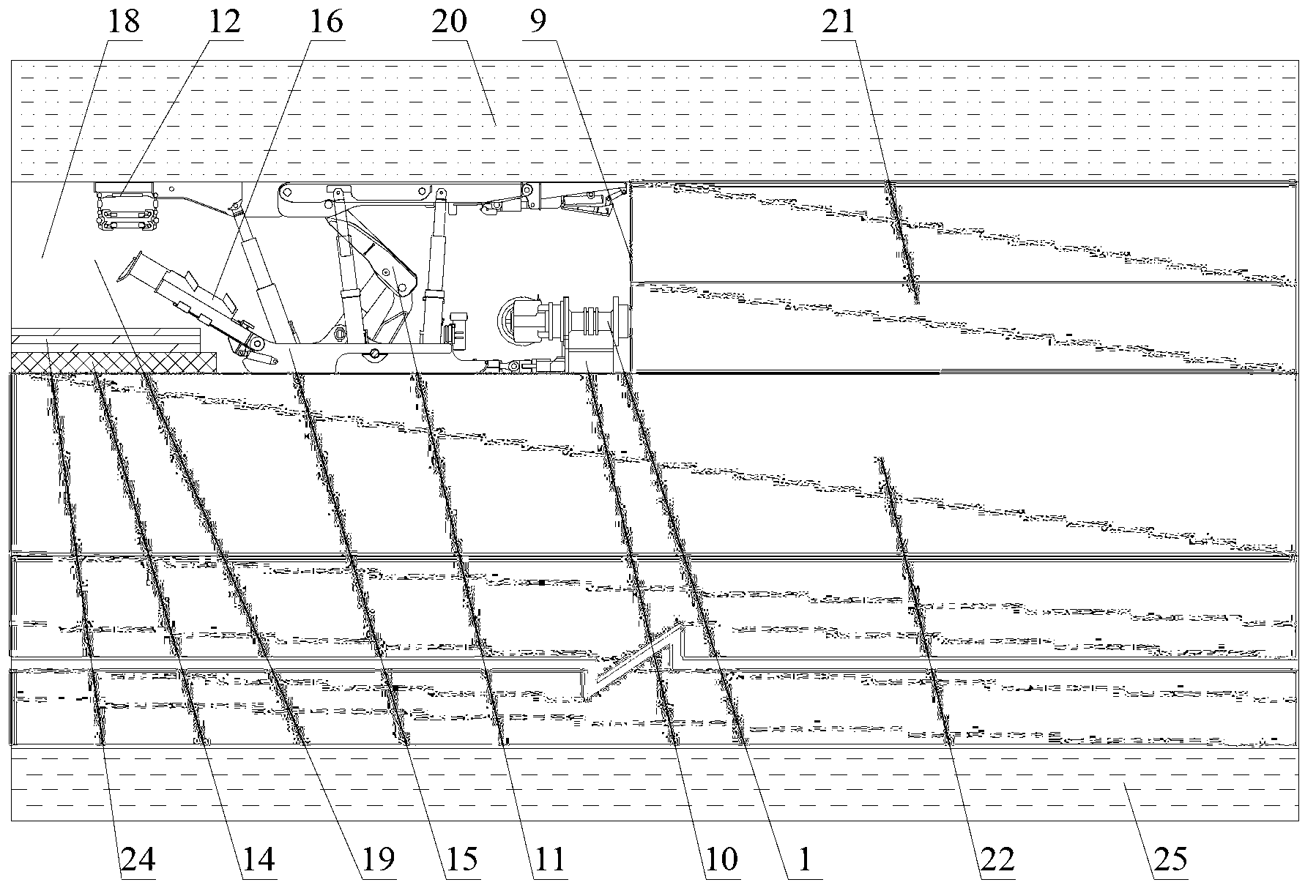

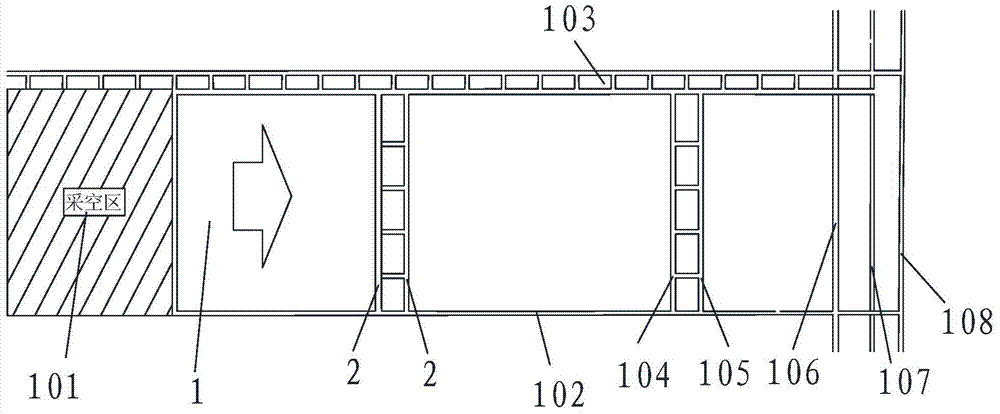

Longwall mining N00 construction method

ActiveCN105240013AGuaranteed ventilation effectSave resourcesUnderground miningTunnel/mines ventillationLongwall miningCoal pillar

The invention discloses a longwall mining N00 construction method, which is characterized in that roadway-free tunneling and coal-pillar-free mining are performed in N working faces of a bran-new panel; the whole panel is provided with an air return downhill passage, a belt downhill passage and a rail downhill passage; the air return downhill passage and the rail downhill passage are positioned at one end of the panel; and the belt downhill passage is communicated with the other end of the panel and is communicated with the air return downhill passage. The longwall mining N00 construction method has the advantages that the ventilation of the whole coal mining region can be ensured; during the mining of each working face in the panel, one part of a goaf is used for implementing roof cutting and pressure relief automatic roadway forming; any crossheading roadway does not need to be tunneled; and coal pillars do not need to be reserved, so that resources are saved, and the efficiency is improved.

Owner:何满潮

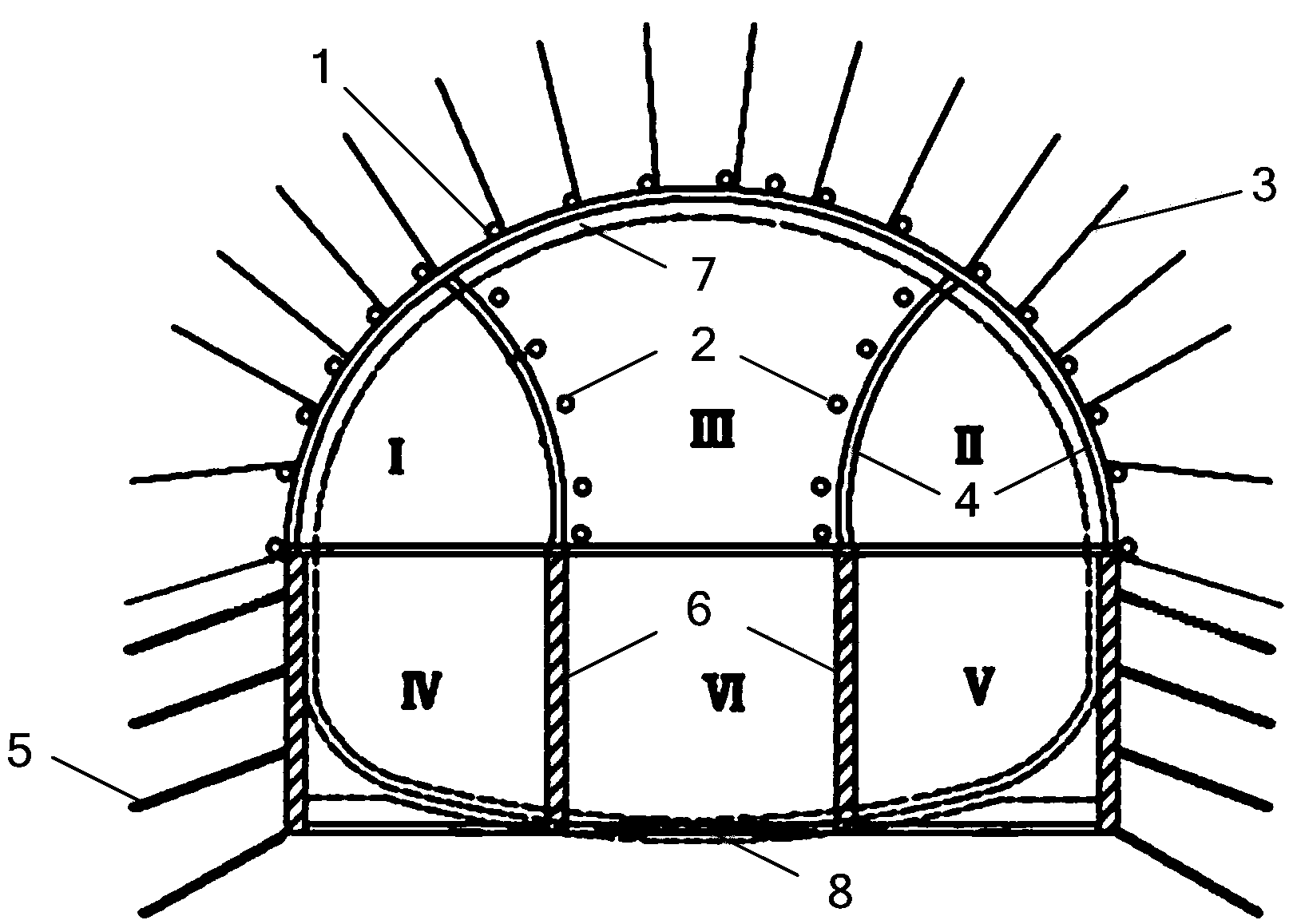

Construction method for compound construction of large-scale underground space structure by holes, groove and piles

InactiveCN102654055AReduce multiple perturbationsLow costUnderground chambersTunnel liningReinforced concretePilot hole

The invention relates to a construction method for compound construction of a large-scale underground space structure by holes, a groove and piles. The method comprises the following steps of: firstly building two or more than two pilot holes through an undercutting method or a shield method and other methods; then constructing support piles in the pilot holes, constructing a top groove in a construction vertical well, and constructing top longitudinal beams of the support piles in the pilot holes; completing the construction of a main reinforced concrete structure at the top to enable the support piles, the top longitudinal beams and the main reinforced concrete structure to form a whole; and then excavating oil among the pilot holes by adopting a shallow burying and undercutting method, and constructing an intermediate layer, the main reinforced concrete structure at the bottom and a sidewall once to form an integral underground space structure. The underground space structure constructed by the method disclosed by the invention has the advantages of clear stress, safety and high speed in construction, low engineering cost and higher effectiveness. The method disclosed by the invention can be used for constructing single-layer single-span, single-layer multi-span, multi-layer single-span, multi-layer multi-space and other underground space structures, and is particularly suitable for constructing underground large-span space structures.

Owner:乐贵平 +2

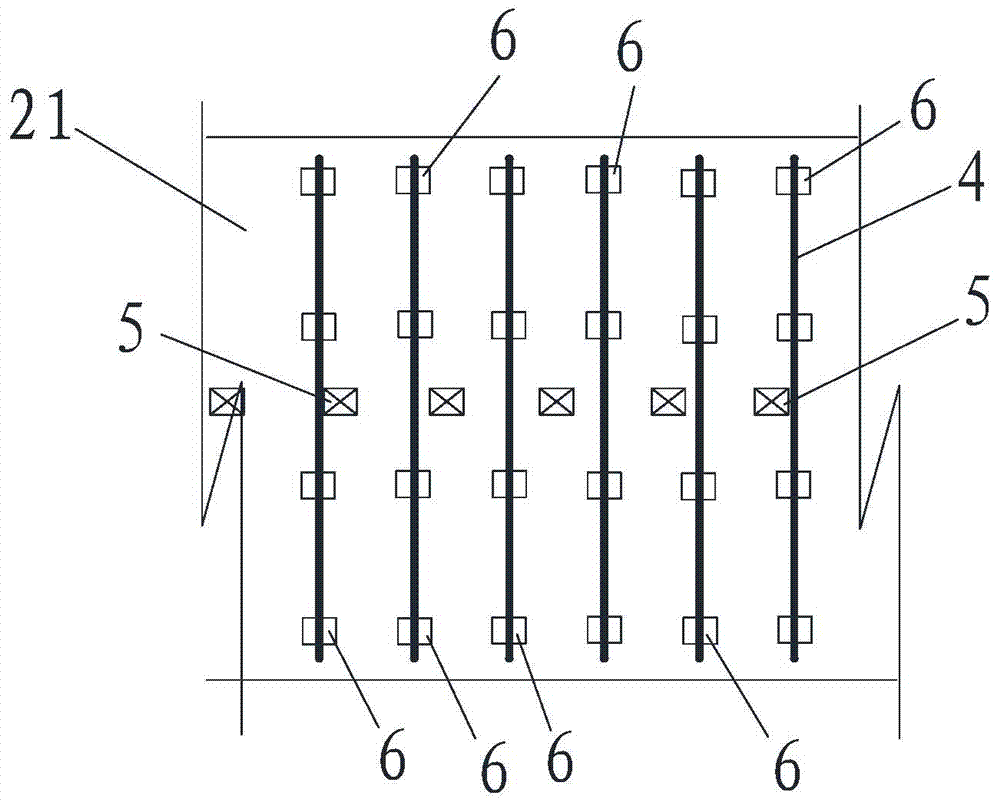

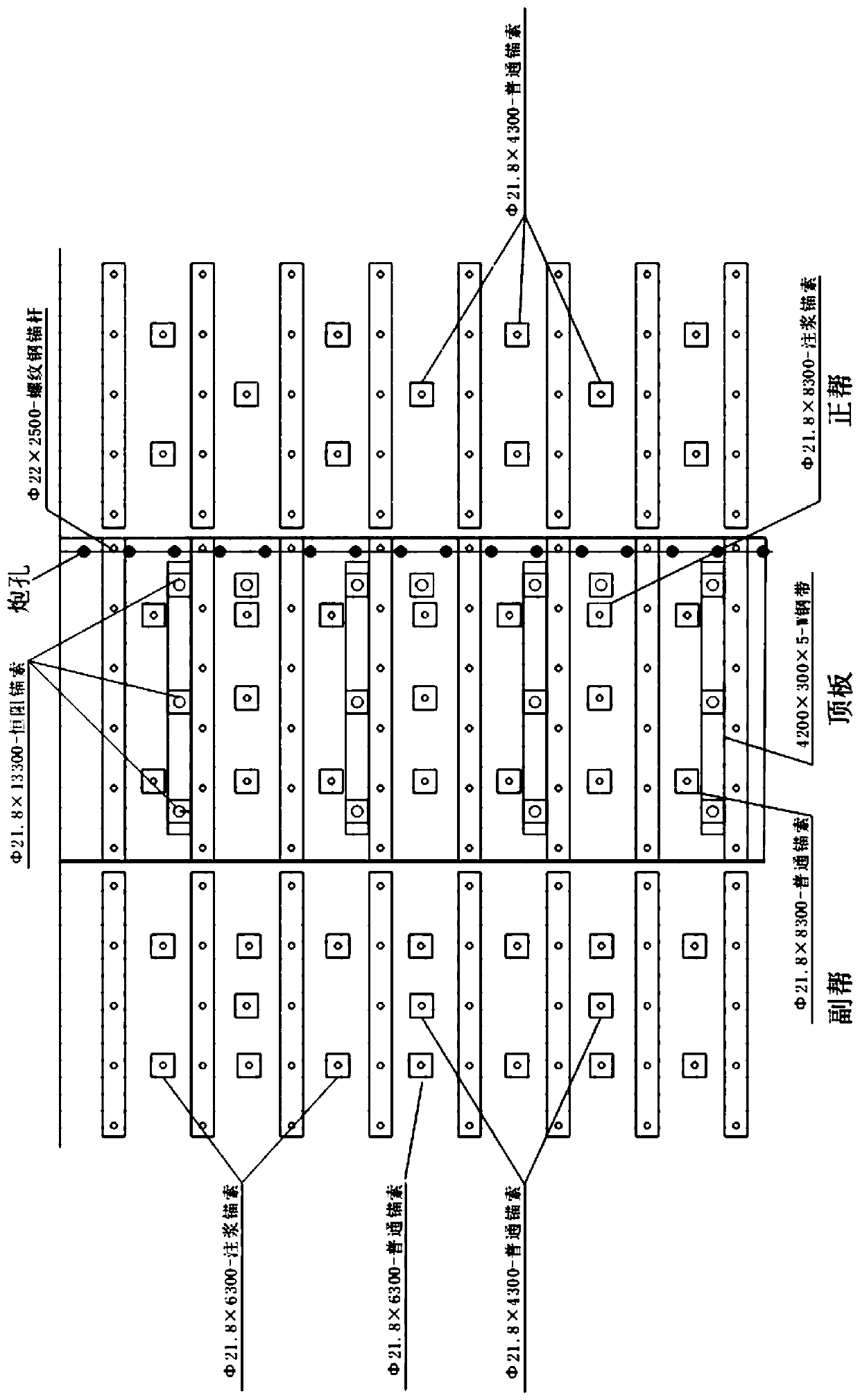

Supporting method of laneway under multiple goafs in ultra-close coal seam group

InactiveCN102425438ASolve the technical problems of roadway supportSolve support technical problemsAnchoring boltsProtective coversSocial benefitsEngineering

The invention specifically relates to a supporting method of a laneway under multiple goafs in an ultra-close coal seam group, which can be used for solving the problem of incomplete support of the laneway under the multiple goafs in the ultra-close coal seam group. The supporting method of the laneway under the multiple goafs in the ultra-close coal seam group comprises the following steps: performing preparation work, performing temporary supporting, laying a steel wire mesh, loading steel beams, mounting an anchor rod of a top plate, mounting the anchor rod of an upper part, mounting an anchor rope of the top plate and the like. By utilizing the effective supporting scheme according to the invention, the technical difficult problem of supporting the laneway under the multiple goafs in the ultra-close coal seam group in Datong mining area is solved, and the great safety economic effect and the great social benefits are achieved.

Owner:DATONG COAL MINE GRP

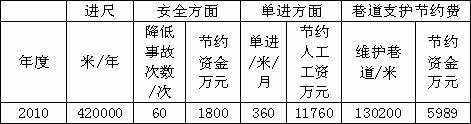

Impact-resistant combined anti-pressure supporting system

InactiveCN102182482AImprove efficiencyReduce maintenanceProps/chocksAnchoring boltsSupporting systemSocial benefits

The invention discloses an impact-resistant combined anti-pressure supporting system which is characterized by comprises a three-grade supporting system; and the impact-resistant combined anti-pressure supporting system has the advantages that: (1) by an optimized three-grade supporting manner, the maintenance amount of engineering roadways is reduced, the coal mining rate and the recovery ratio of a working face are increased, the safety coefficient is enlarged, and the comprehensive benefits of a mine are increased; (2) by applying a combined supporting system technology, the deformation of the roadway is effectively controlled when the working face is influenced by the ground pressure; and when the rock burst generates during production, the system plays a role of impact-resisting, realizes shrinkage and buffering changes and protects the safety of equipments and operators; and (3) according to the supporting system during recovery, dynamic alternatively circulative operation is realized, thus the purposes of resisting impaction, removing pressure and solving danger are realized, the construction process is simplified, various costs are saved, the quality is easy to control, the economic benefit is remarkable, the social benefit is also gained at the same time, and the competition among enterprises is improved.

Owner:义马煤业集团股份有限公司跃进煤矿

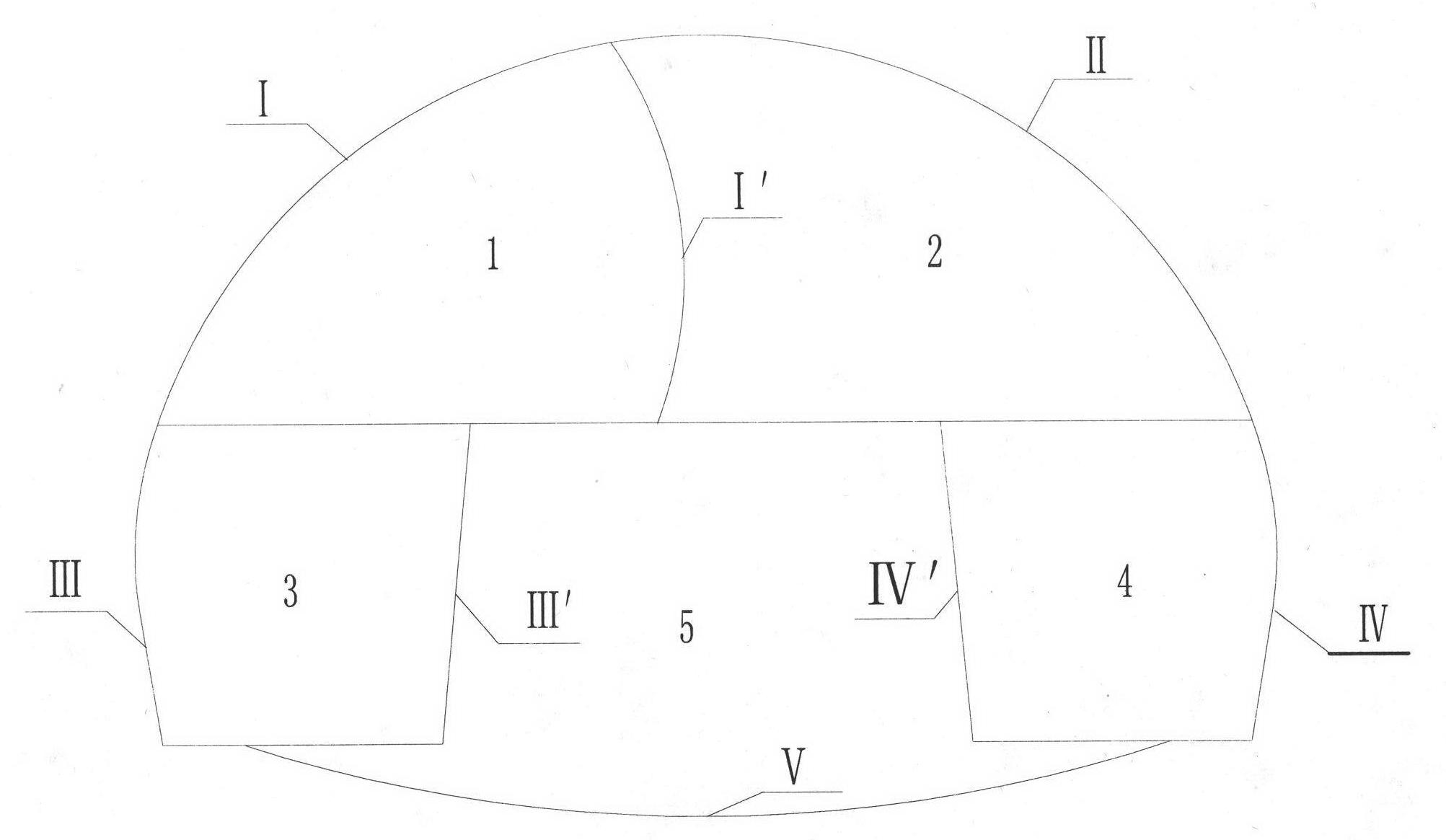

Urban shallow buried large-section tunnel five-step excavating method

InactiveCN102220868AReduce the number of explosionsImprove integrityBlastingTunnelsEngineeringBuilding construction

Owner:CHONGQING ZHONGHUAN CONSTR +1

A method of retaining entry along the goaf with solid filling coal mining and building gangue walls

InactiveCN102278140AAvoid lostImprove recovery rateMaterial fill-upAnchoring boltsSolid massMining engineering

The invention relates to a method of solid filling coal mining and building gangue walls along the goaf, which is to build a gangue wall on the side of the filling body in the goaf of the coal mining face, and pack the coal mine gangue into the gangue wall with woven bags or snakeskin bags. If it is full and built into a wall, the coal mine gangue can be directly filled with the gangue filling the coal mining face. Then, the gangue wall needs to be pre-prepared with single-layer metal mesh, "W"-shaped steel belt, ladder beam and double-ended threaded anchor rod. Tight support. As the working face continues to advance, this method can leave a complete gangue wall for the mining of the next working face. The roadway retaining method is simple and practical, has high support strength and low cost.

Owner:XUZHOU ZHONGKUANG BACKFILLING&MINING TECH CO LTD

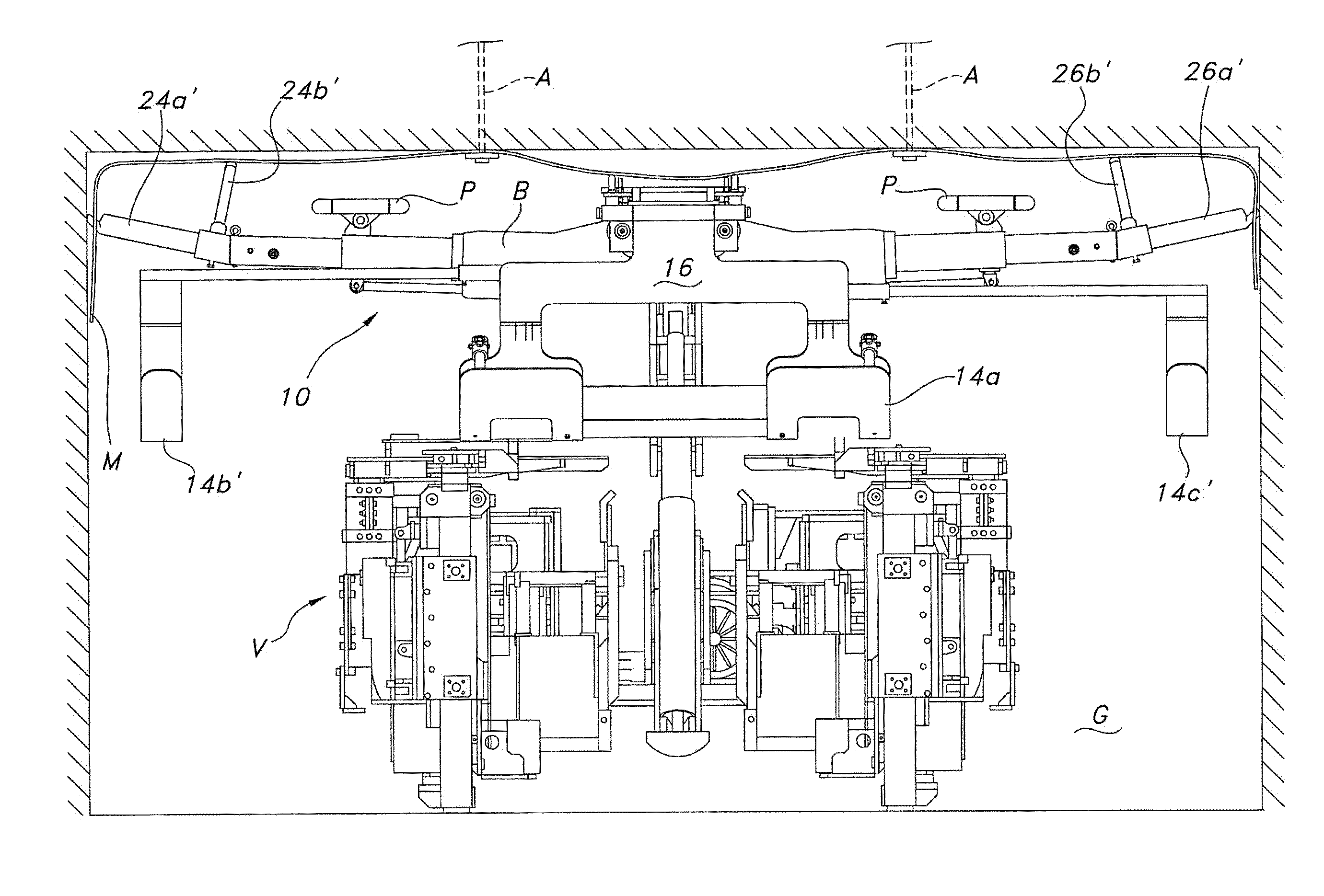

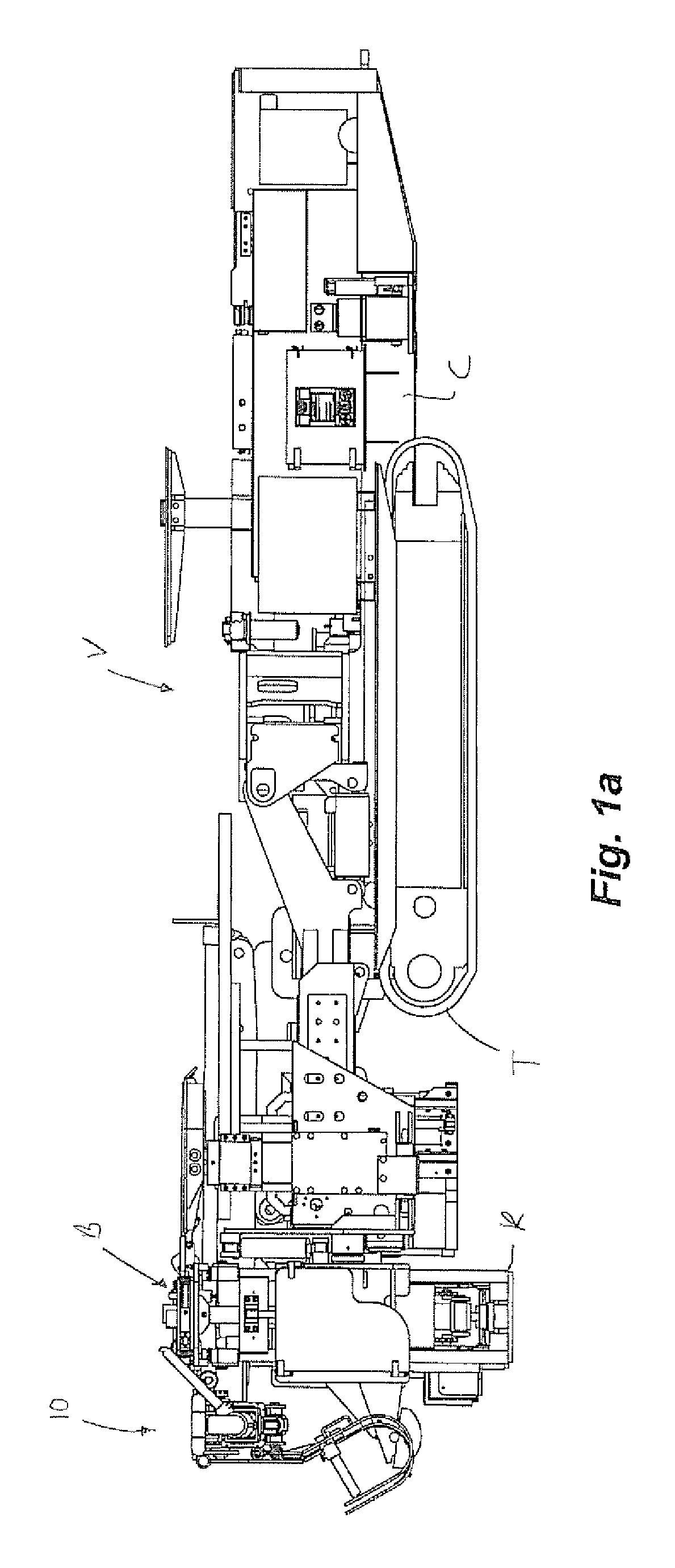

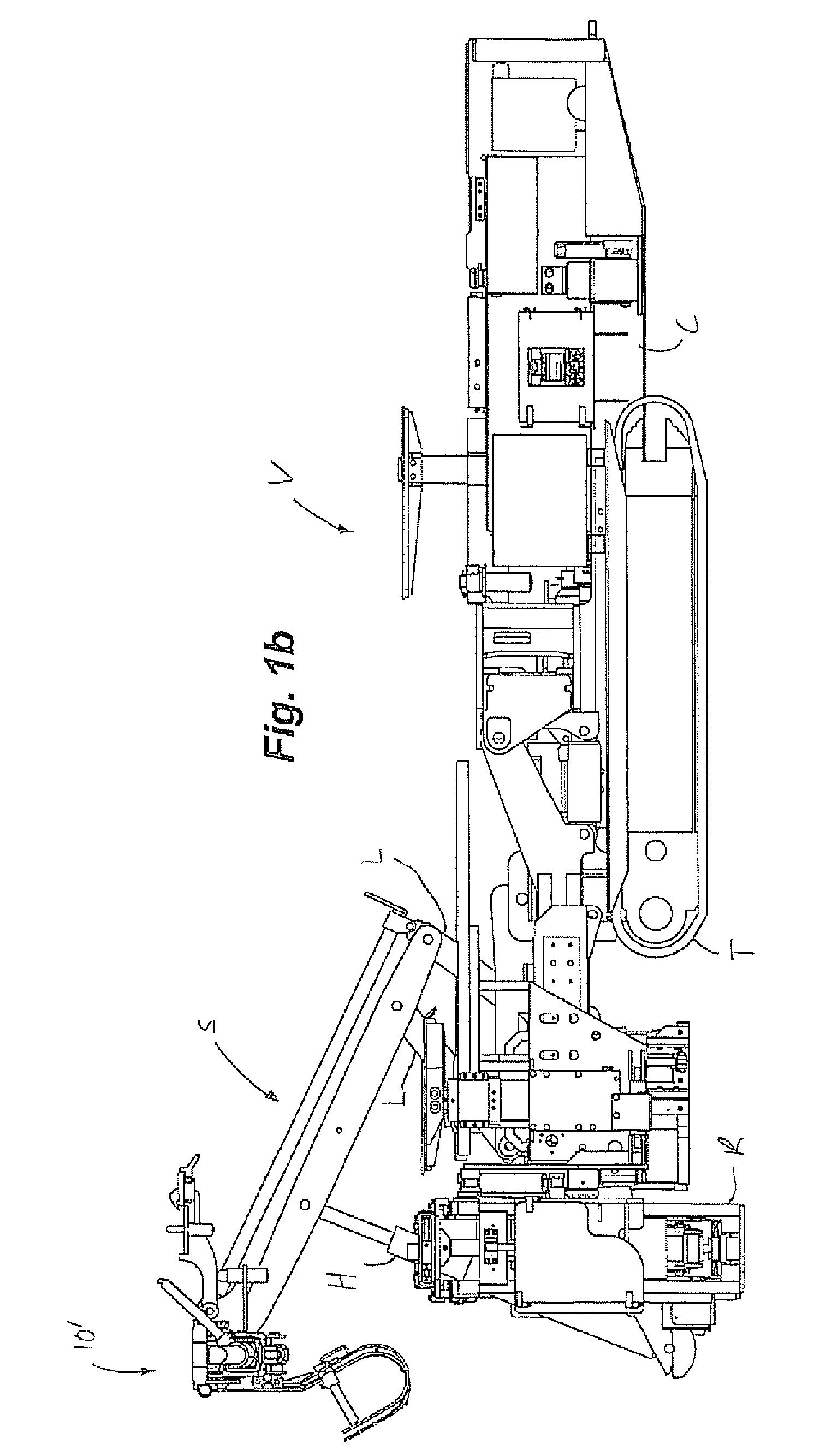

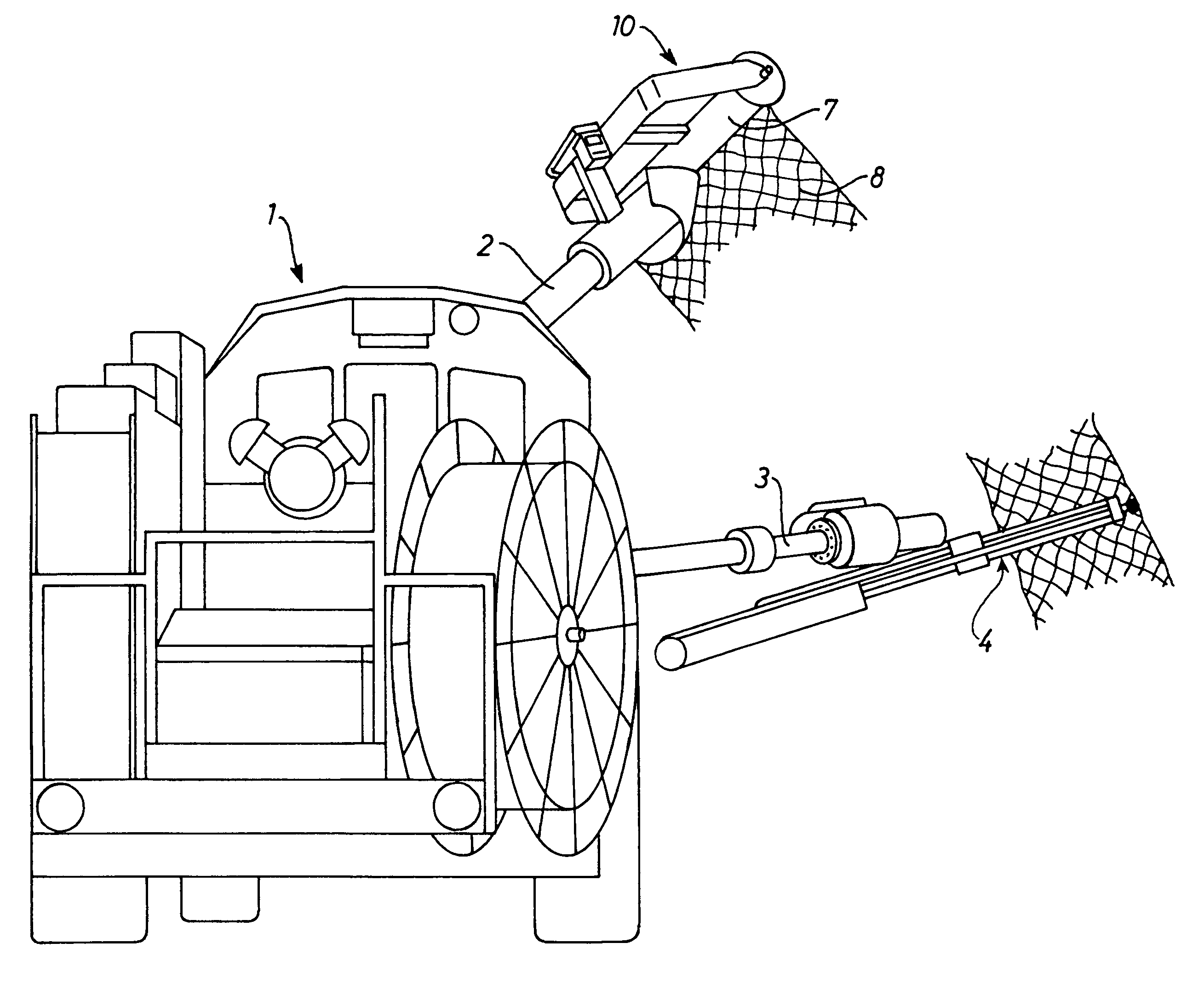

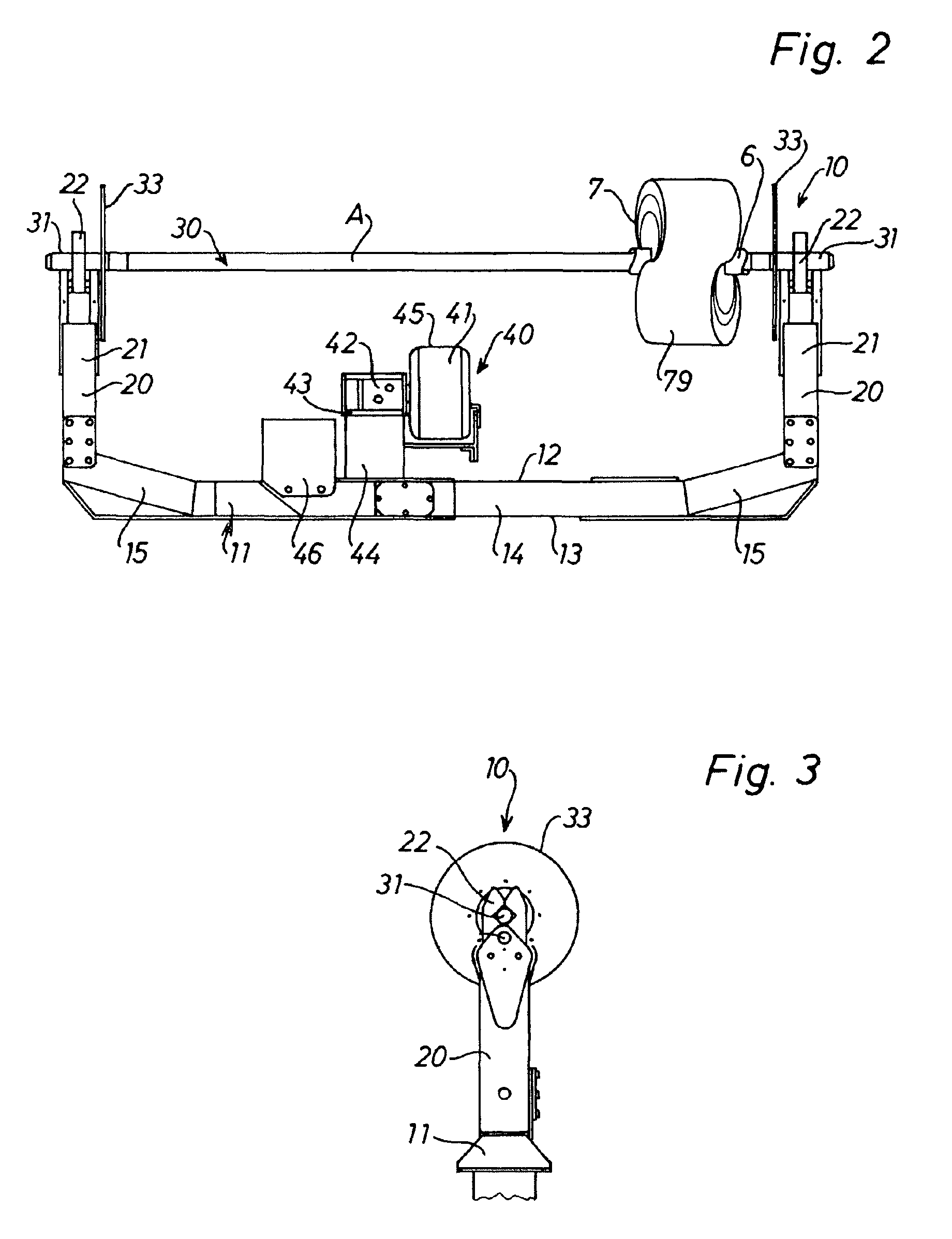

Mesh handling system for an underground mining machine and related methods

A system for handling a roll of mesh for application to one or more faces of an underground mine passage includes a dispenser for supporting the roll of mesh for application to at least one face of the mine passage, as well as at least one arm for supporting the mesh adjacent to the face upon being dispensed from the dispenser. The arm is capable of flexing in providing this support to provide tension to the mesh during the application from the roll to the at least one face of the mine passage. The dispenser may include a cradle for dispensing the mesh from the roll. The cradle may include a base for supporting the roll of mesh and at least one laterally extendable support for supporting a first lateral side of the roll of mesh. Related methods are also disclosed.

Owner:J H FLETCHER & CO INC

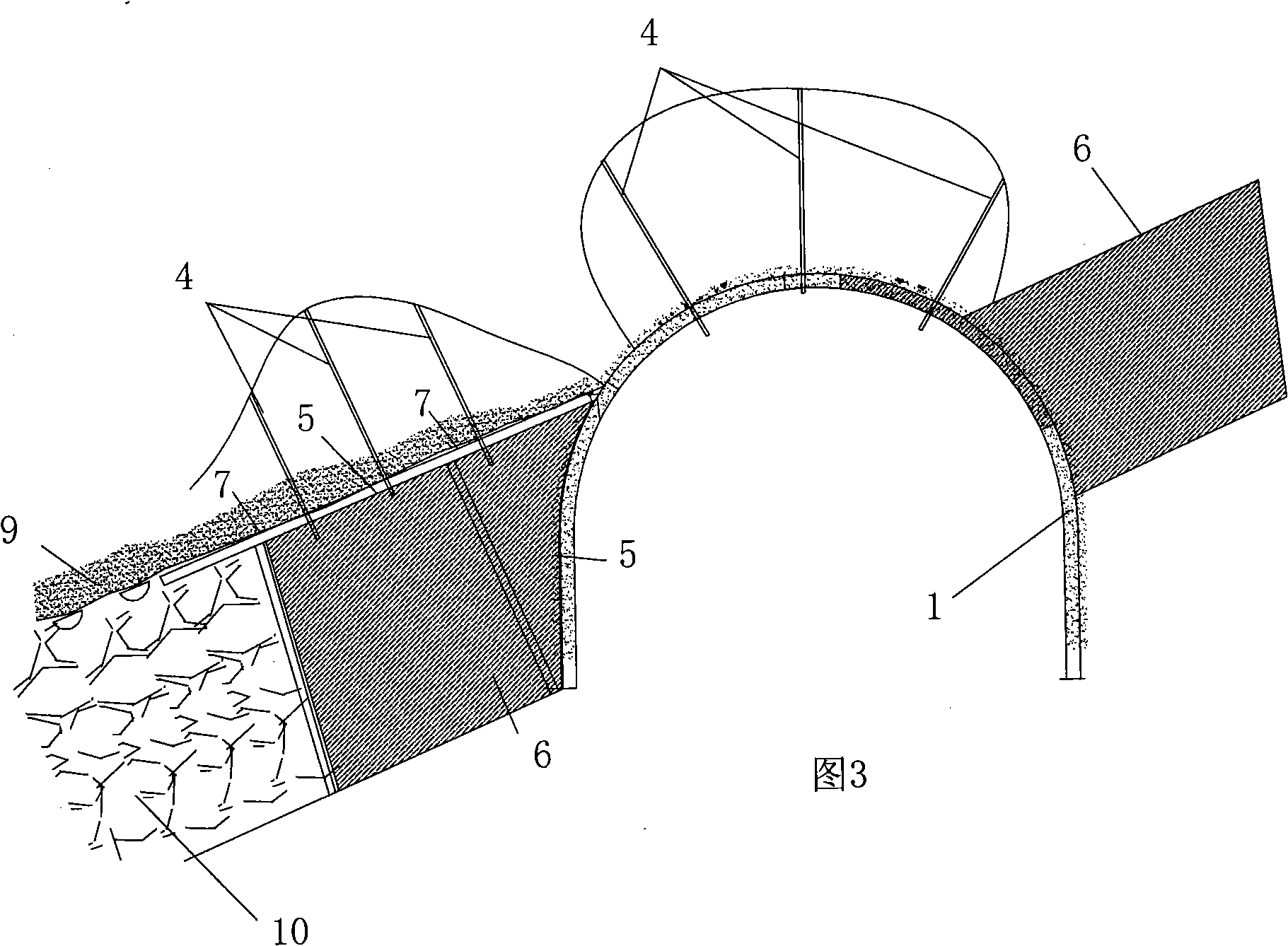

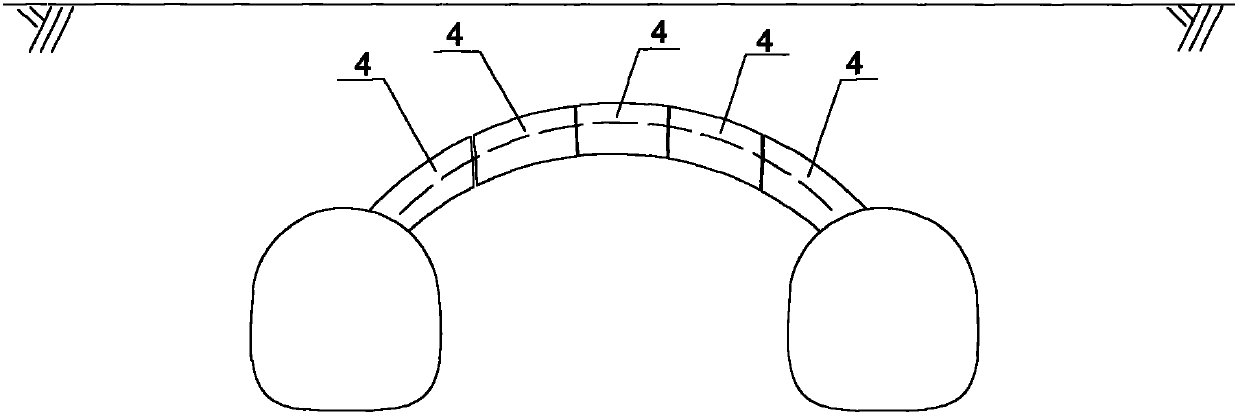

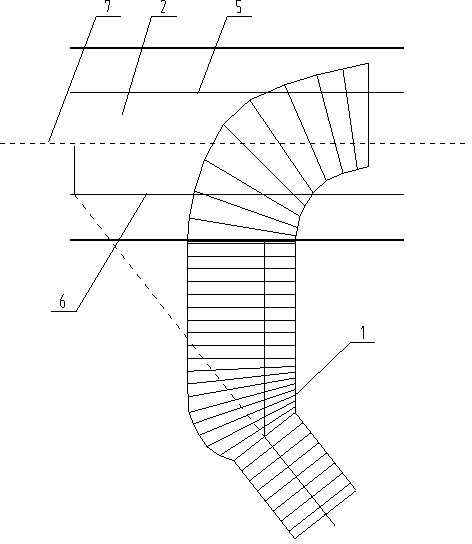

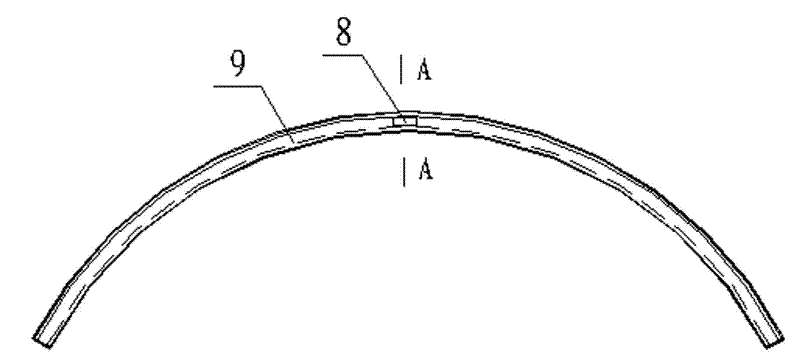

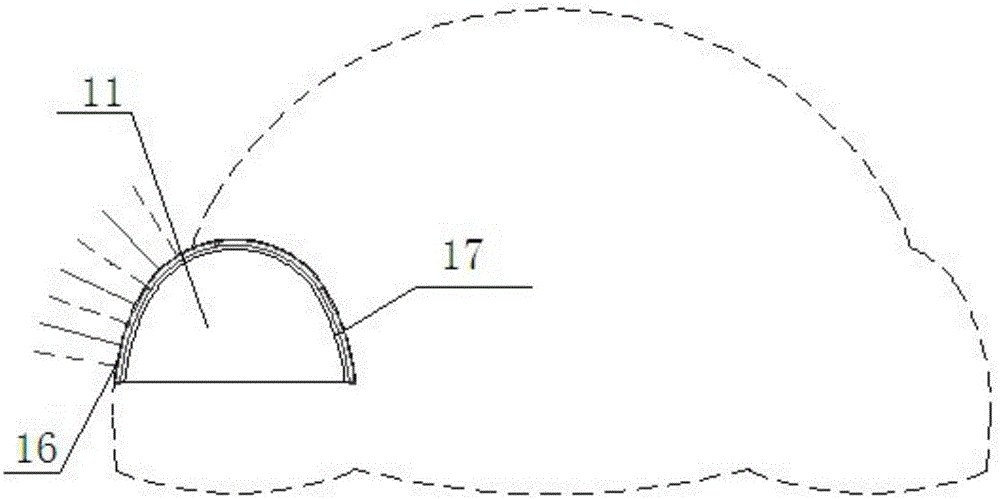

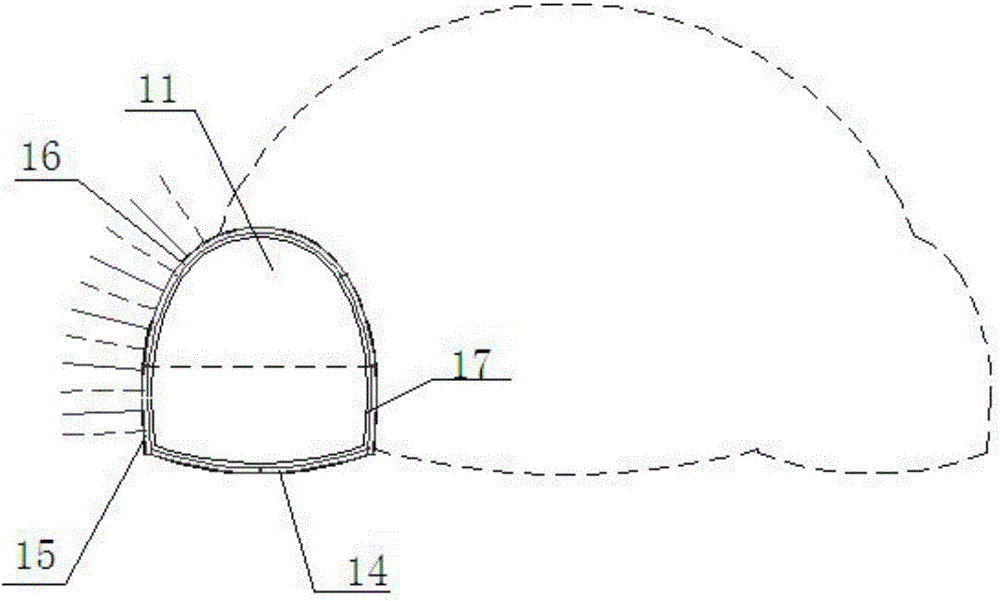

Oblique-crossing inclined shaft upper arc guide top brushing construction method for soft crushed rock layer

ActiveCN102587922AShorten the lengthOptimize the force structureUnderground chambersTunnel liningSteel frameEngineering

The invention relates to the field of inclined shaft top brushing, in particular to an oblique-crossing inclined shaft upper arc guide top brushing construction method for a soft crushed rock layer, and solves the problems of the existing inclined shaft top brushing construction adopting small pilot tunnel top brushing. The method comprises the following steps of: setting curve transition at the intersection of an inclined shaft and a front tunnel so that an inclined shaft mouth is orthogonal with the front tunnel; arranging a door-shaped steel frame support at the intersection, wherein a steel arch frame of the front tunnel is firmly connected with the door-shaped steel frame; arranging a cover arch support at the section close to the front tunnel and inclined shaft; additionally arranging an I-shaped steel cross arm on a bottom plate; performing top brushing by use of an upper arc guide within the front tunnel range, wherein the last arch frame of the upper arc guide is vertical to the line direction, and the arch top is level with the arch top of the front tunnel; performing expanded excavation along the cross section of the front tunnel, and constructing an upper guide primary support of the front tunnel; reversely dismantling the steel arch frame temporary supports of the upper arc guide one by one, and constructing an upper guide primary support of the front tunnel on the other side; and performing normal construction within the front tunnel range to finish the top brushing. Through the invention, the working efficiency is improved, the construction is accelerated, the safety risk is lowered, the inclined shaft top brushing construction is safely, quickly, perfectly and efficiently finished, and a good effect is obtained.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY +1

Gob-side entry retaining method of a solid filling coal mining half-section one-leg shed

InactiveCN101761338AAvoid lostImprove recovery rateUnderground miningSurface miningSolid massMining engineering

The invention relates to a gob-side entry retaining method of a solid filling coal mining half-section one-leg shed, which comprises the steps of supporting the coal side and the top plate of a roadway entity, filling a gob with a coal mining filling hydraulic support and a fill mining conveyor behind a filling coal mining working surface, and then fixing a row of H-shaped steel with an anchor rod and an anchor rope at the 1 / 3 point of the distance from an end top plate of the working surface to the gob; with the forward movement of one pace of the coal mining filling hydraulic support, a metal net is paved and side-wall I-beams are bridged firstly on the outer side of the gob; simultaneously, a metal net is paved within 1 / 3 of the distance from the top plate to the gob, and then a stull I-beam is bridged so as to form a reverse L-shaped one-leg shed steel structure support body; and with the forward movement of the coal mining filling hydraulic support, the side wall I-beams are connected and fixed via steel bars, and one-leg shed steel structure support bodies are connected into sheets which are matched with the support of the coal side and the top plate of a roadway entity to realize the gob-side entry retaining of a filling mining work surface mining roadway. The method is simple, has high support strength and low cost, is implemented easily and has high efficiency.

Owner:CHINA UNIV OF MINING & TECH

Abandoned roadway timbering device and construction method of fully mechanized coal mining face passed through abandoned roadway

ActiveCN103696788AReduce roof fall accidentsImprove support strengthUnderground miningSurface miningStructural engineeringCoal mining

The invention discloses an abandoned roadway timbering device which comprises a metal net, a steel belt, a protective net, timbering anchor ropes, hanging timbering anchor ropes, anchor rods and a hydraulic support. The steel belt is installed on a top plate of an abandoned roadway through multiple hanging timbering anchor ropes, the hanging timbering anchor ropes located at two ends of the steel belt and the top plate form an included angle alpha, the metal net is fixed under the top plate through the hanging timbering anchor ropes and the timbering anchor ropes, the steel belt is located under the metal net, multiple timbering anchor ropes are installed on the top plate located on a central line of the abandoned roadway, a hydraulic chock is located in the abandoned roadway, a top beam of the hydraulic chock abuts against the top plate, and the protective net is installed on the roadway side of the abandoned roadway through the anchor rods. The invention further discloses a construction method of a fully mechanized coal mining face passed through the abandoned roadway.

Owner:CHINA SHENHUA ENERGY CO LTD +1

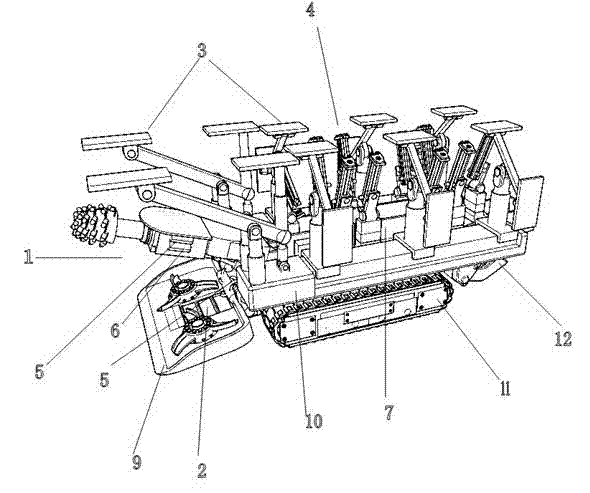

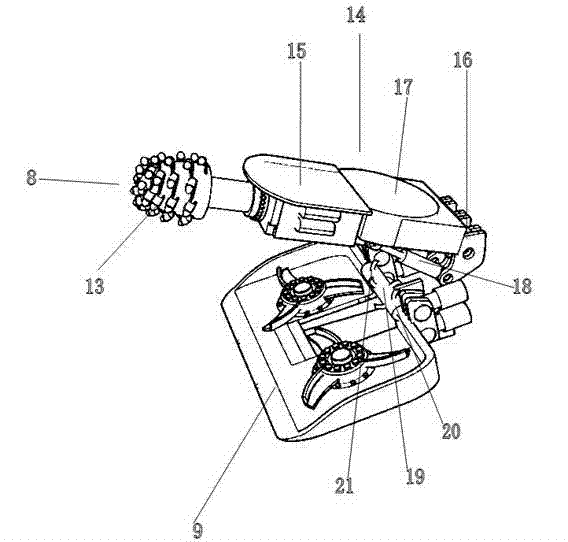

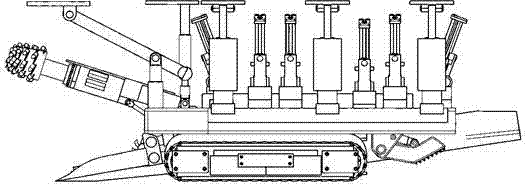

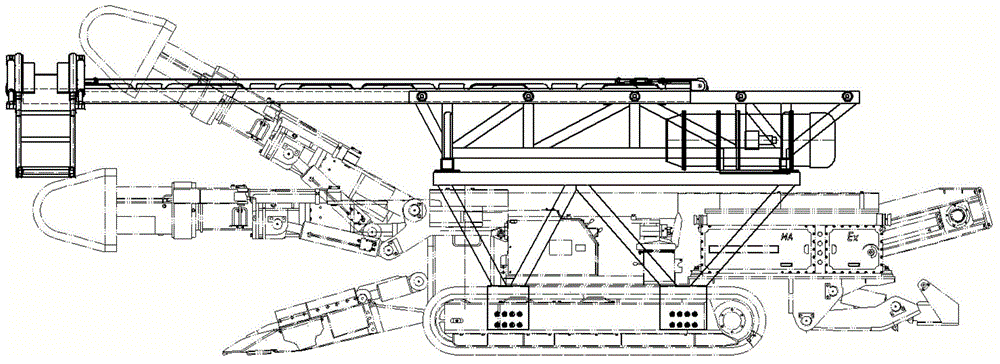

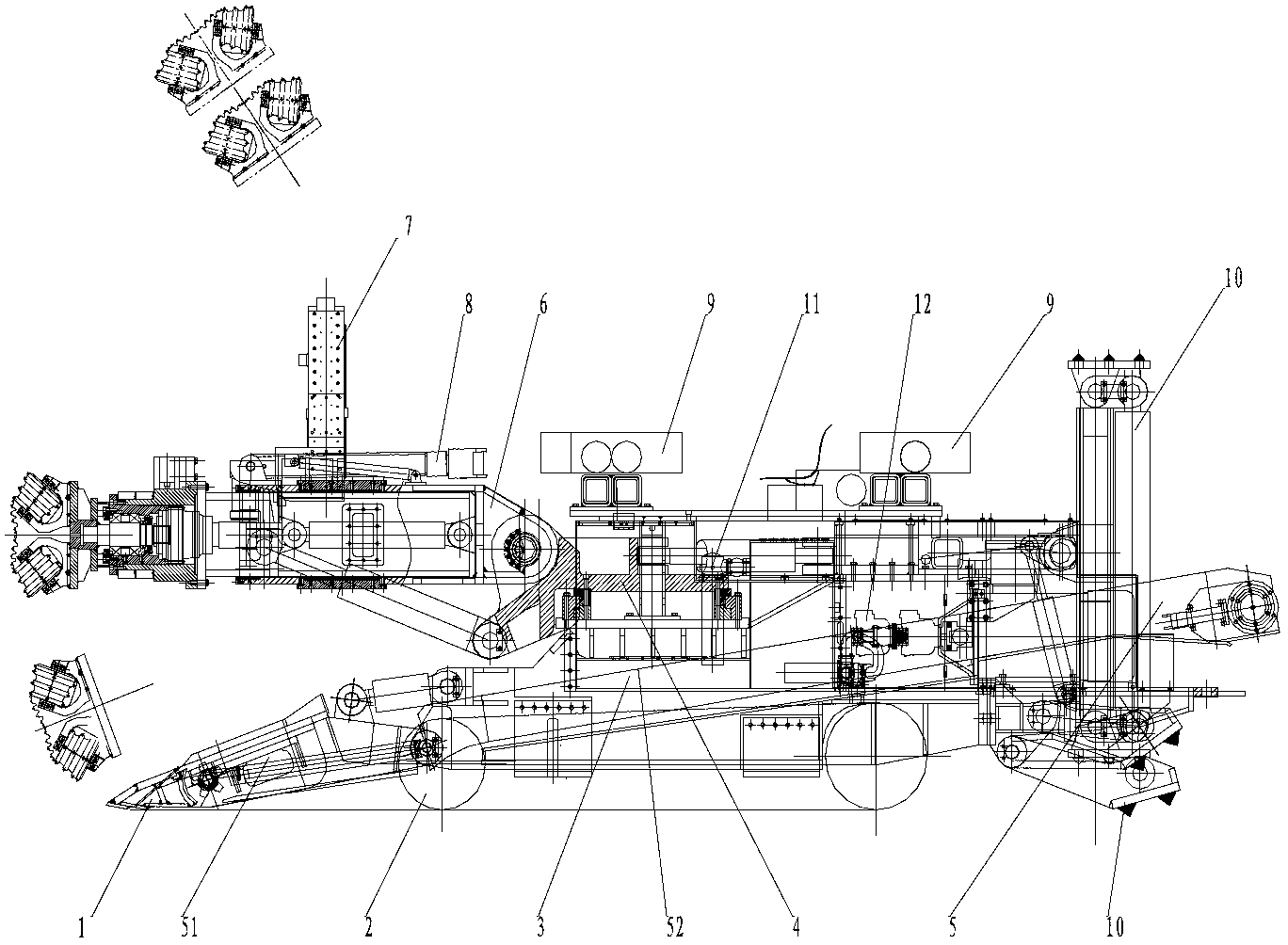

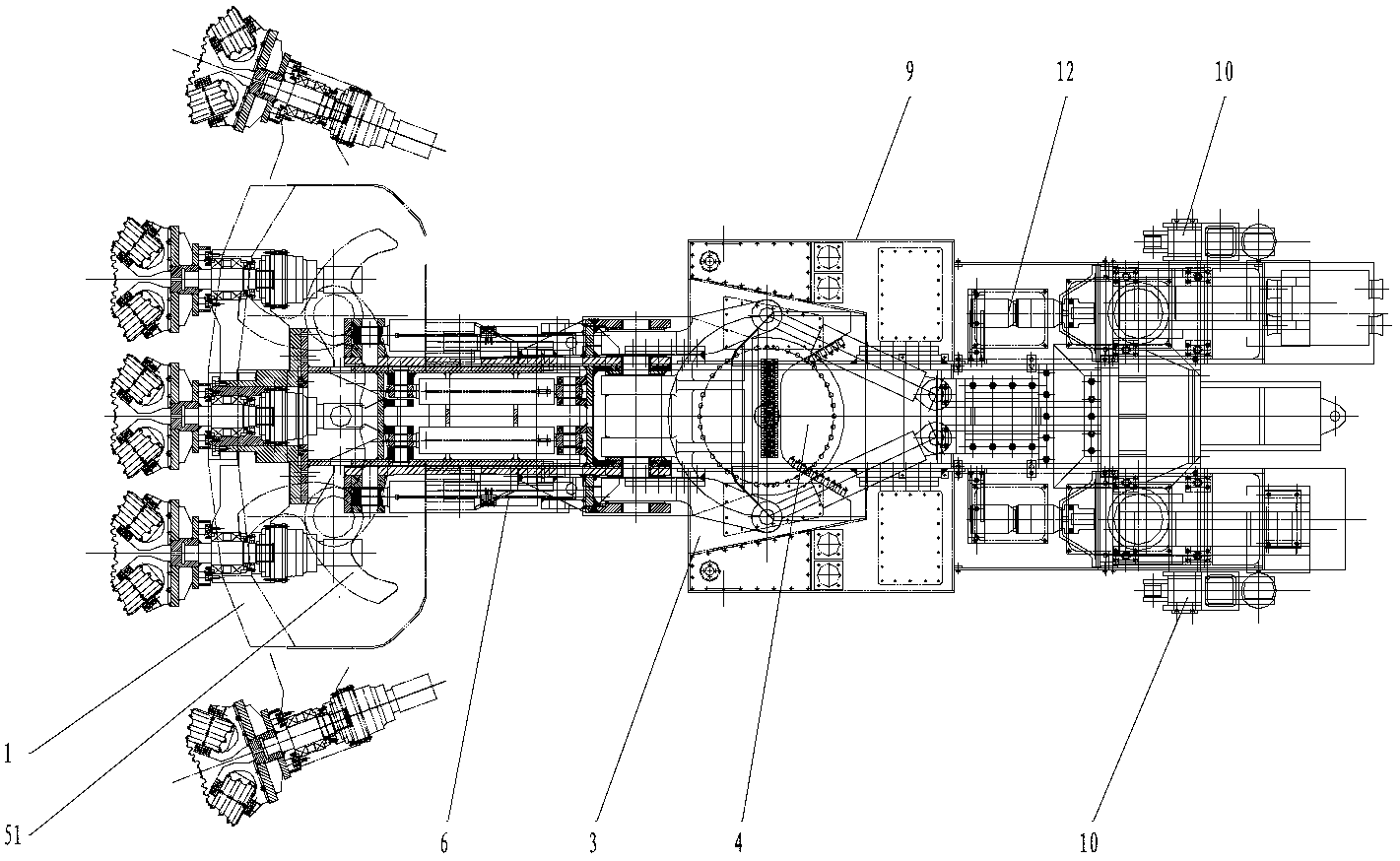

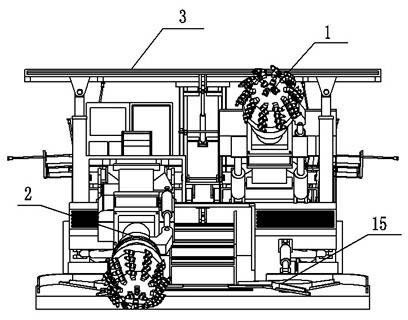

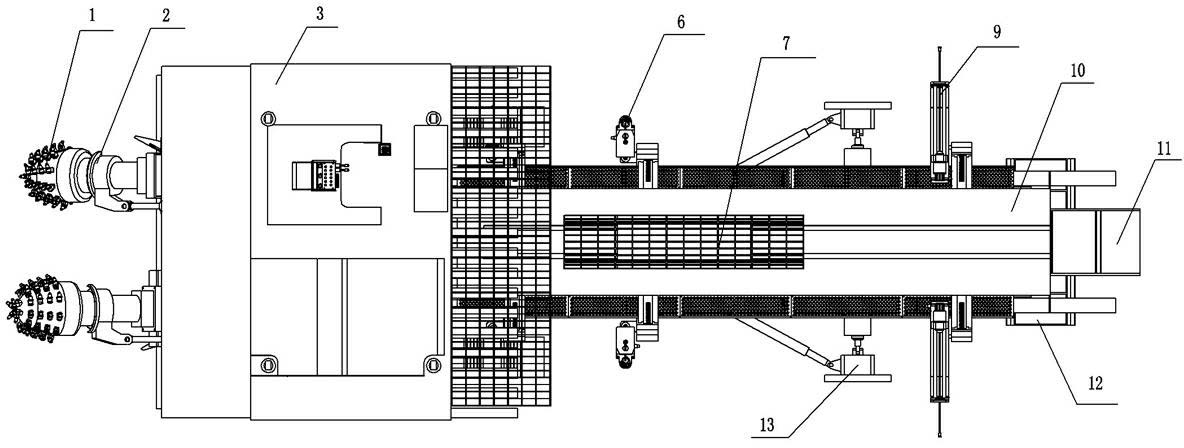

Comprehensive mechanization stone drift heading machine set

InactiveCN102704927AGuarantee the construction qualityReduce labor intensityMine roof supportsDriving meansControl systemEngineering

The invention relates to a comprehensive mechanization stone drift heading machine set, which comprises a shovel plate part, a caterpillar band travelling part, a rack, a belt conveying part, a flexible cutting part, a hydraulic drilling rig device, an advance support device, a hydraulic control system and an electric control system. The comprehensive mechanization stone drift heading machine set is characterized by also comprising a rotation part, two side supporting devices and top and bottom plate supporting devices. The comprehensive mechanization stone drift heading machine set disclosed by the invention is improved and perfected to enable the structure design to be more reasonable and compact, and the performances, such as working efficiency, stability, reliability, and safety of the set, are improved. Comprehensive mechanization construction equipment is provided for mine underground stone drift heading, and is especially adaptive to the underground stone drift mechanization operation and construction of various big, medium and small mines.

Owner:马晓山

Non-coal-pillar auto-roadway-forming mining method suitable for thick-seam fully mechanized top coal caving

ActiveCN110206542AConducive to collapseIncrease stressDisloding machinesUnderground miningPre crackingCoal pillar

The invention relates to the technical field of coal mine mining, in particular to a non-coal-pillar auto-roadway-forming mining method suitable for thick-seam fully mechanized top coal caving. The method includes the following steps that reinforcing and supporting are carried out on a roof and two walls of a roadway; roof cutting explosion is carried out to form a pre-cracking seam; a temporary supporting device in the roadway and a gangue blocking device are erected along a retained entry; coal caving is not performed within a preset distance to the working face end close to the entry retaining side; after the roadway is stabilized, the temporary supporting device in the roadway is removed, a goaf is closed, and the entry retaining is completed. The roof cutting explosion better facilitates collapsing of the rock stratum in the goaf, the stoping space can be well filled after the rock stratum in the seam is collapsed, a short arm beam structure is formed in the lateral direction of the entry-retaining roof, a long suspended roof formed in the goaf is avoided, and the surrounding rock stress of the gob-side entry is improved; coal caving is not performed within a certain range ofthe working face end of the entry retaining side, the filling effect of the empty area of the entry retaining side is further guaranteed, rotary sinking of basic top block bodies is effectively limited, and the influence on the entry retaining stability is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

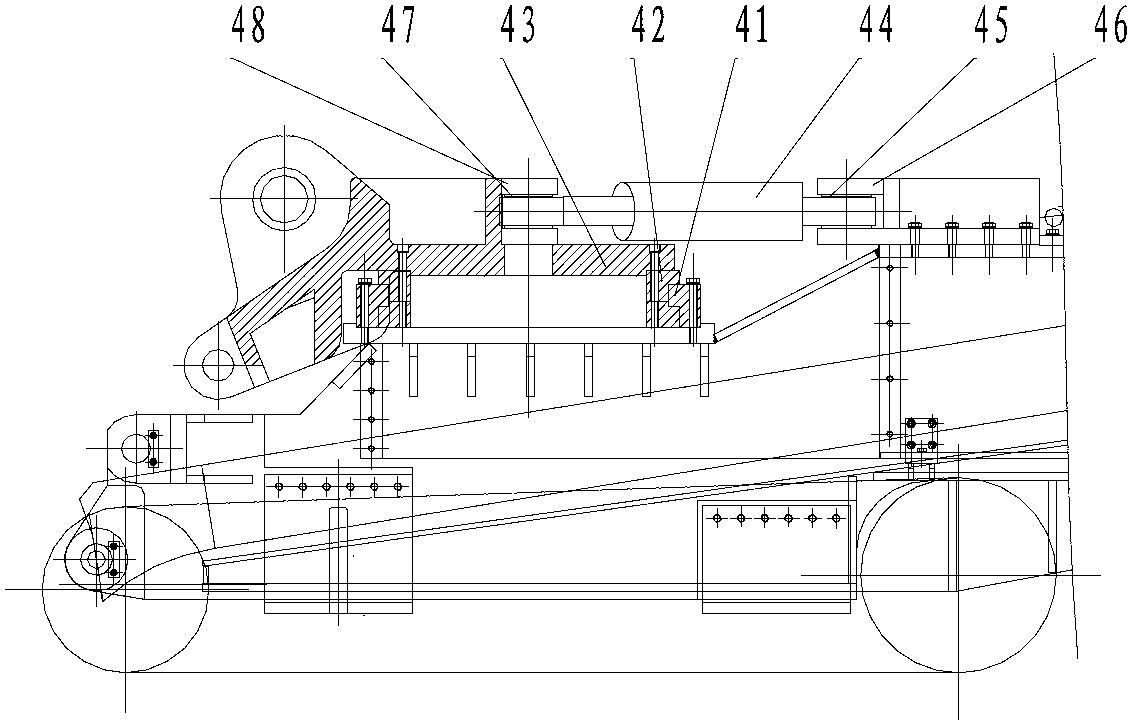

Double-cantilever hard rock coal roadway heading and anchoring device

ActiveCN102635353AImprove tunneling efficiencyImprove safety factorUnderground chambersTunnel liningControl systemDust control

The invention discloses a double-cantilever hard rock coal roadway heading and anchoring device which comprises a coal transporting device, a hydraulic system, an electrical control system, a dust removal system, a power system, a headstock, a cantilever cutting device, a crawler travel unit and a supporting platform, wherein the cantilever cutting device is connected to the front end of the headstock, the crawler travel unit is arranged below the headstock, and the supporting platform is hinged with the rear end of the headstock; the upper end of the headstock is provided with a temporary supporting device; the supporting platform is provided with a roof jumbolter and a side-wall jumbolter; and a mesh transporting car is also arranged on the supporting platform. In the double-cantilever hard rock coal roadway heading and anchoring device disclosed by the invention, a double-cantilever and double-cutting-head design is adopted, and a heading system and an anchoring system are organically combined together to carry out operations, thereby greatly improving the heading efficiency. The temporary supporting device is provided with a telescopic temporary support plate and a finger-shaped shield, so that the unsupported roof distance in a heading process is greatly shortened, the safe operation coefficient of the operating personnel is improved, and the safe production is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Supporting process in soft rock mine roadway rush through construction tunneling

The invention relates to a mine roadway tunneling process, in particular to a supporting process in soft rock mine roadway rush through construction tunneling. The problem that the supporting is failed due to roadway deformation caused by nonuniform pressure of a soft rock mine roadway is solved. The supporting process in the soft rock mine roadway rush through construction tunneling comprises the following steps of: after the mine roadway is tunneled, hanging a metal net on a roadway wall, driving an anchor cable and an anchor rod into the roadway wall for supporting, arranging a plurality of retractable metal supports to support the roadway, and finally spraying concrete; therefore, the problem that the supporting is failed due to roadway deformation caused by the nonuniform pressure of the soft rock mine roadway can be effectively solved; and after supporting, the stabilization time is long, and stability is high.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Large-span grotto excavation construction method

InactiveCN104047623AInitial support savingsLow costUnderground chambersTunnel liningBuilding construction

Owner:TONGJI UNIV

Self-propelled type temporary support and anchor support machine for coal mine roadway

InactiveCN103527228ASynchronous continuous workImprove labor efficiencyPropulsionAnchoring boltsUltimate tensile strengthContinuous operation

The invention provides a self-propelled type temporary support and anchor support machine for a coal mine roadway. The self-propelled type temporary support and anchor support machine for the coal mine roadway is mainly composed of a walking support module, a supporting cross beam module, a lead shield beam module, an anchor drilling machine module and a drilling machine walking module. The walking support module mainly comprises two walking supports which are parallel. The supporting transverse beam module comprises a main transverse beam and two auxiliary transverse beams; the main transverse beam and the auxiliary transverse beams are fixedly connected with the walking support module through bolts. The lead shield beam module comprises a lead shield beam and a hydraulic oil cylinder, the lead shield beam and the hydraulic oil cylinder are hinged through a pin shaft, and the lead shield beam module is connected with the main transverse beam through a pin shaft. The anchor drilling machine module is fixedly connected with the drilling machine walking module through bolts. The drilling machine walking module is installed on a guide rail of the main transverse beam through rail sliding blocks. According to the self-propelled type temporary support and anchor support machine for the coal mine roadway, synchronous and continuous operation of the fully-mechanized excavating work and support and anchor support work for the coal mine roadway can be achieved, the excavating efficiency for the coal mine roadway is improved, labor intensity is relieved, and safety of support and anchor support for the coal mine roadway is improved.

Owner:HUAINAN GUOLI HYDRAULIC MACHINERY MFG

Composite roof thin seam fully-mechanized coal mining face gob-side entry retaining method

InactiveCN103061806AEasy to withdrawConvenient retraction strutMaterial fill-upProps/chocksEngineeringMechanical engineering

Provided is a composite roof thin seam fully-mechanized coal mining face gob-side entry retaining method. An anchor cable beam strengthening support is repaired after a diamond net is hung on an advance face in a lane, the advance face is 1.6m, side opening is 6.0 in width, and a single prop is used for being matched with an articulated roof beam support after the diamond net is hung on a side opening section formed by side opening. A temporary support section is arranged beside the lane, a 4.5m long diamond net is hung on the temporary support section, and then the single prop is adopted to be matched with an articulated roof beam temporary support. When an erecting timber crib is filled beside the lane, a gangue bag is filled while withdrawing column beside the lane. The center of the timber crib is 1.85m away from a lateral column of a goaf close to a lane side, a distance between two adjacent timber cribs is 8.0m, the length of the timber cribs is 1.5m, the width of the timber cribs is 1.5m, the height of the timber cribs is equal to mining height of tail of a working face, and the position between the timber crib is filled by the gangue bags.

Owner:SHANDONG UNIV OF SCI & TECH

Method for constructing extra-large variable cross section tunnel

ActiveCN104653197AMeet complex force requirementsMeet the construction stability requirementsUnderground chambersTunnel liningSecondary layerSafety risk

The invention discloses a method for constructing an extra-large variable cross section tunnel. The method comprises the following steps: firstly excavating left pilot tunnels and timely constructing primary supports and temporary supports; packing large boot-shaped wall feet and constructing right pilot tunnels by the same process; excavating the upper half part of the left side of the main tunnel and timely constructing first-layer primary supports, temporary vertical braces and temporary inverted arches; excavating the lower half part and timely constructing first-layer primary supports and temporary vertical braces; constructing the upper half part of the right side of the main tunnel by the same process and excavating a middle arch part and timely constructing first-layer primary supports; constructing second-layer primary supports and removing the temporary braces and temporary inverted arches of the arch part; excavating a central part and timely constructing the primary supports of the inverted arches; removing the temporary supports of the left and right lower pilot tunnels, packing the secondary lining of the inverted arch, and filling the bottom of the tunnel; finally once packing the secondary lining of the arch wall by a model board trolley. According to the method, the safety risk for removing the temporary supports can be effectively reduced, the operation freedom degree is increased and the construction schedule is quickened.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Method and apparatus for lining tunnel walls or tunnel ceilings with protective nets

ActiveUS8662796B2Easy to operateWork process safetyUnderground chambersUnderground miningTunnel wallEngineering

Owner:GEOBRUGG AG +1

Combined steel temporary supporting excavation method for tunnel with extra-large section

InactiveCN102704939AImprove securitySpeed up excavationTunnelsProtective coversReinforced concreteRapid construction

The invention discloses a combined steel temporary supporting excavation method for a tunnel with an extra-large section. The combined steel temporary supporting excavation method comprises the following steps of: firstly excavating and supporting left and right upper pilot tunnels; secondly excavating and supporting left and right middle pilot tunnels, and left and right lower pilot tunnels, and excavating a pilot tunnel on the left lower part of the tunnel section; thirdly, setting temporary mid-partition supports and temporary steel supports for all parts; and finally, dismounting the temporary combined upright post steel supports of the left upper pilot tunnel and the right upper pilot tunnel, and pouring the second liner reinforced concrete, excavating core soil and carrying out inverted arch construction to the middle part of the tunnel. The combined steel temporary supporting excavation method uses a combined steel support to replace a temporary excavation method of the core soil, solves the technical difficulties that the excavation period is long, the construction quality cannot be ensured, the construction is difficult, and the like, and also solves the technical problems of ensuring the quick construction for the super-large section and the construction quality. A steel truss is used to replace the construction for the upper core soil, so that not only the construction safety of the tunnel can be improved, but also the tunnel excavation and the support speed can be quickened.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com