A method of retaining entry along the goaf with solid filling coal mining and building gangue walls

A solid filling and filling coal mining technology, which is applied in the direction of filling, mining equipment, earthwork drilling and mining, etc., can solve the problems of loss of coal resources, complex construction technology, low work efficiency, etc., so as to alleviate the tension of connection and improve the recovery rate , The effect of saving excavation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

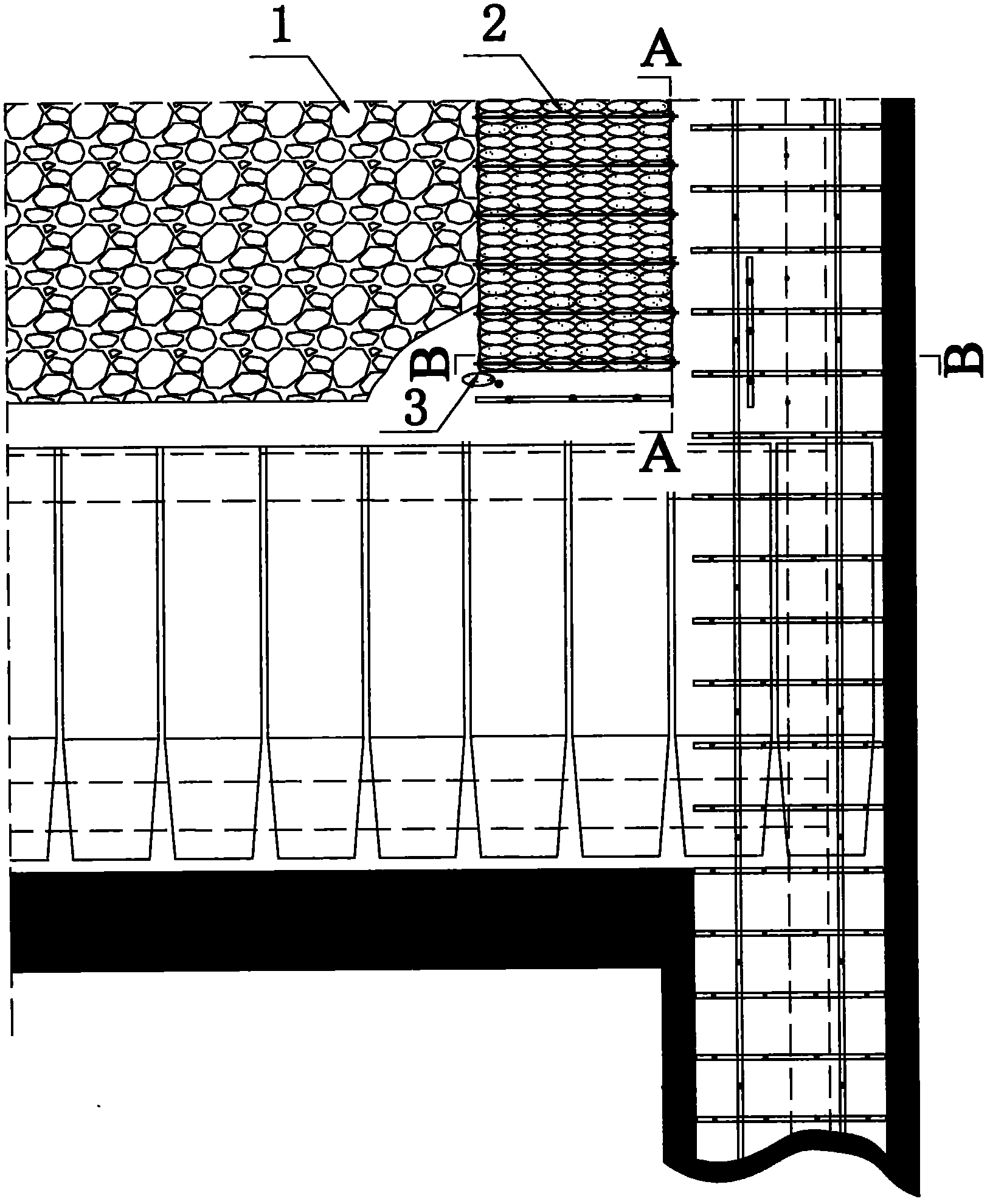

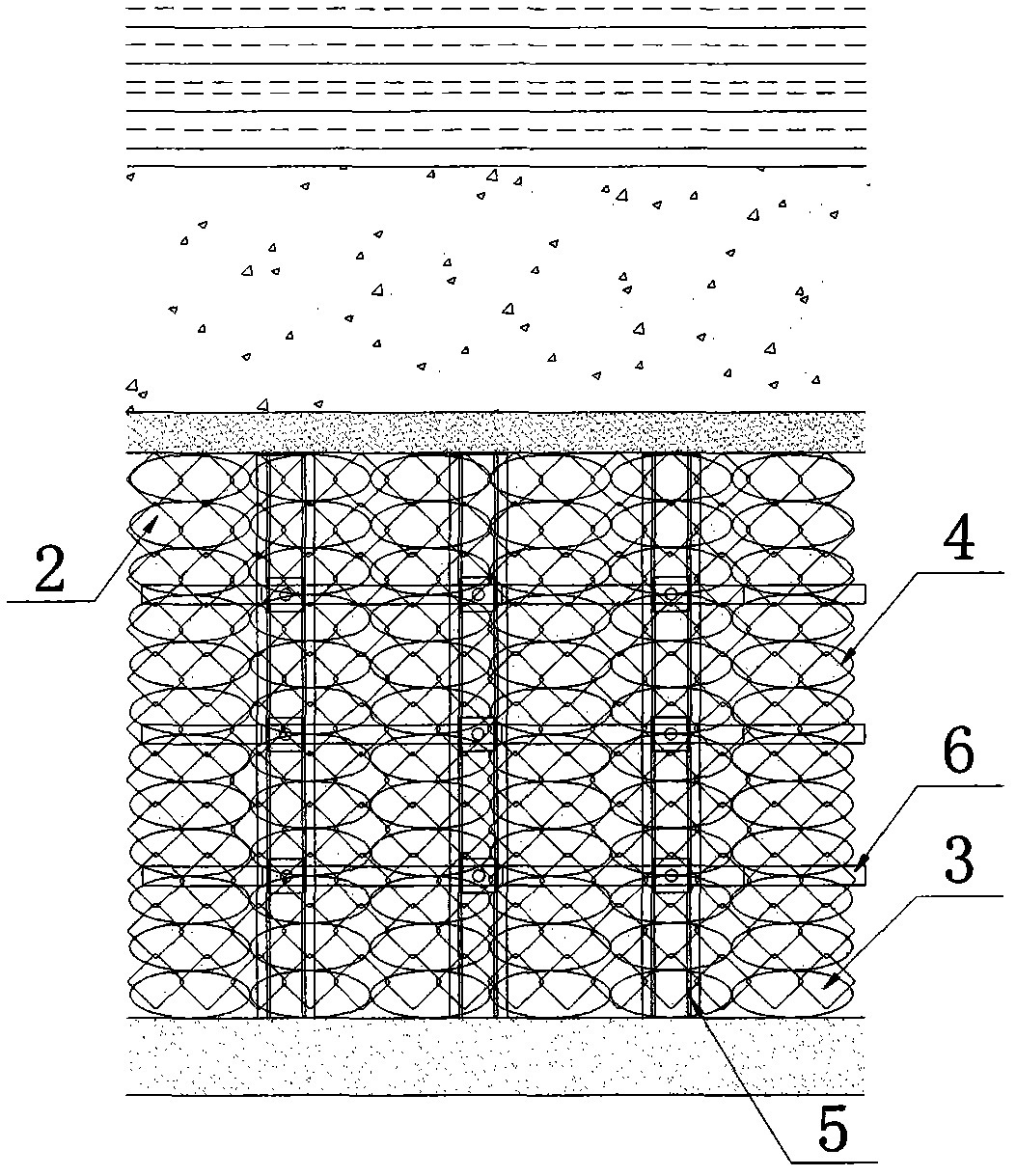

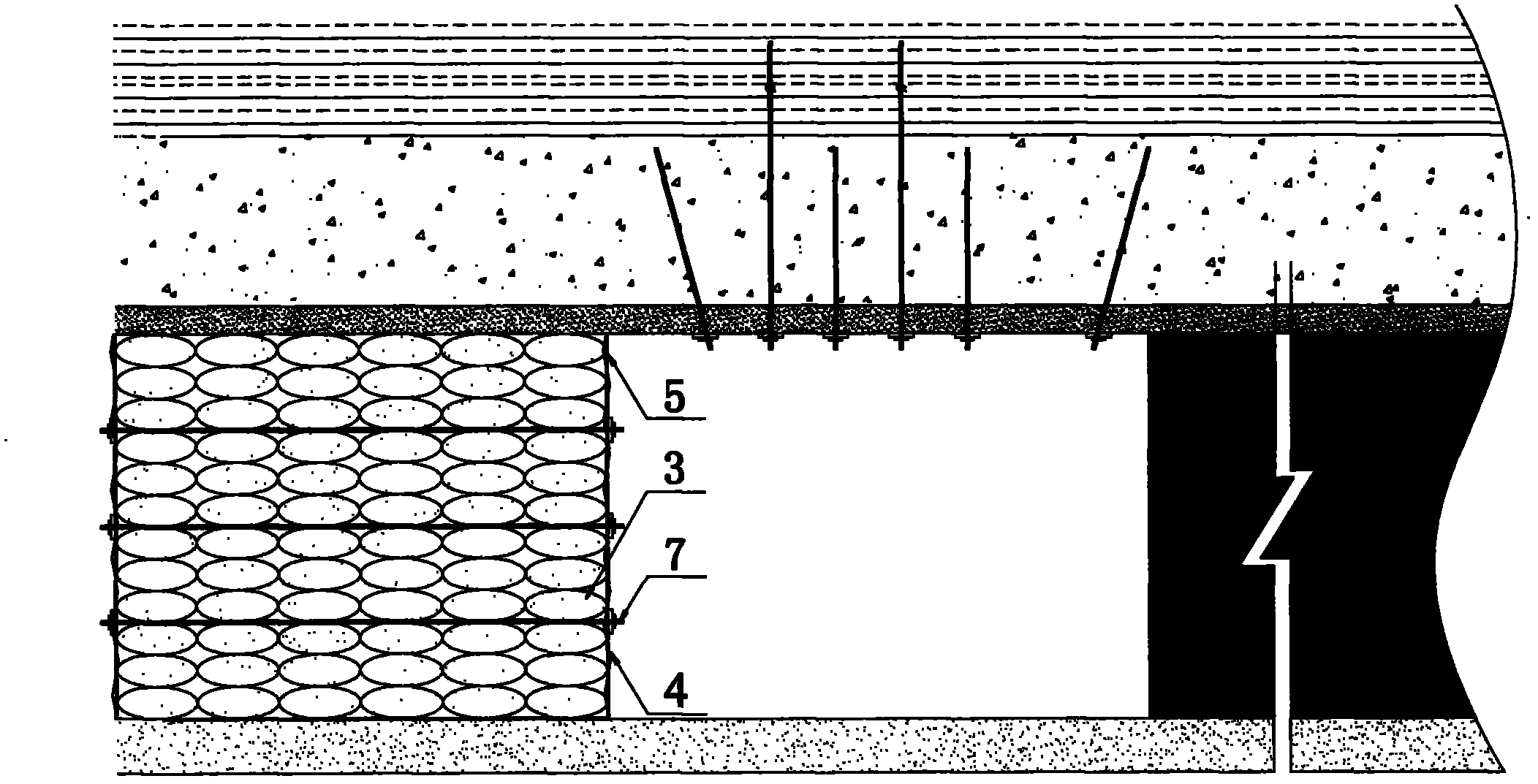

[0012] figure 1 Shown is a schematic diagram of the layout of the working face of the present invention. As the working face advances, a goaf is formed, and the gob is filled with gangue to form a goaf filling body 1, and then a side wall of the goaf filling body 1 is formed. Build the gangue wall 2, the width of the gangue wall 2 is 1.5m to 3m, the height of the gangue wall 2 is the same as the mining height of the working face; , the gangue packaging bag 3 used is a common woven bag or a snakeskin bag, and the coal mine gangue is directly filled with goaf with a uniform ratio, and the gangue particle size is less than 50mm; the support method of the gangue wall 2 is as follows: figure 2 As shown, single-layer metal mesh 4, "W"-shaped steel belt 5, ladder beam 6 and anchor rod 7 are used for combined reinforcement and support, and the row spacing between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com